SECTION 6A2 - ENGINE MECHANI CAL -

V6 SUPERCHARGED ENGINE

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL INFORMATION

1.1 GENERAL DESCRIPTION

1.2 SYSTEM COMPONENTS

SUPERCHARGER ASSEMBLY

SUPERCHARGER DRIVE BELT TENSIONER

BALANCE SHAFT

CAMSHAFT SPROCKET

CRANKSHAFT BALANCER

ROCKER COVERS AND GASKETS

CONNECTING RODS

PISTONS AND PINS

CYLINDER HEADS AND GASKETS

FUEL INJECTORS

LOWER INTAKE MANIFOLD AND GASKETS

THROTTLE BODY ADAPTOR

FUEL RAIL

BYPASS VALVE ACTUATOR

BOOST CONTROL SOLENOID VALVE

WATER OUTLET HOSE AND RADIATOR

INLET PIPE

SUPERCHARGER DRIVE BELT IDLER

PULLEY AND BELT TENSIONER

FLEXPLATE

PCM CALIBRATION

HIGH TENSION LEADS

DIS COILS AND SPARK PLUGS

2. SERVICE OPERATIONS

2.1 SUPERCHARGER OIL LEVEL CHECK

2.2 SUPERCHARGER AND GASKET

REMOVE

REINSTALL

2.3 BYPASS SOLENOID HARNESS ASSEMBLY

REPLACE

2.4 THROTTLE BODY

REMOVE

REINSTALL

2.5 THROTTLE BODY ADAPTOR

REMOVE

REINSTALL

2.6 ENGINE VENTILATION SYSTEM

2.7 FUNCTIONAL CHECK OF CRANKCASE

VENTILATION VALVE

2.8 CRANKCASE VENTILATION VALVE

REPLACE

2.9 SUPERCHARGER DRIVE BELT

TENSION CHECK

INSPECT

REMOVE

REINSTALL

2.10 SUPERCHARGER DRIVE BELT TENSIONER

ASSEMBLY

REMOVE

REINSTALL

3. SPECIFICATIONS

4. TORQUE WRENCH SPECIFICATIONS

5. SPECIAL TOOLS

Techline

Techline

1. GENERAL INFORMA TION

A supercharged engine is available as an option on some MY 2003 VY and V2 Series model vehicles. The

superchar ged engi ne gives the benefit of muc h impr oved power and tor que at l arge throttle op enings e quiva lent to

having a lar ger c apacit y engin e. Fu el ec onomy is better tha n a larger capac it y en gine as the sup erchar ger b oost is

cut at low throttle openings, where the engine performs similarly to its normally aspirated counterpart. The

supercharger does not suffer from the lag that a turbocharger exhibits, and because of its more friendly

operating environment, it is more reliable than a turbocharger. For supercharger diagnosis, refer to

Section 6C2 POWERTRAIN MANAGEMENT – V6 S/C ENGINE in the MY 2003 VY and V2 Series Service

Information.

1.1 GENERAL DESCRIPTION

The supercharger is a positive d isplacement pum p that consists of t wo counter-rotating ro tors in a housi ng with an

inlet port and outlet port. The rot ors are designed with three lobes and a helical t wist. An air bypass circuit is built

into the housing.

Rotors in the supercharger are designed to run at a minimal clearance, not in contact with each other or the

housing. The rotors are timed to each other by a pair of precision spur gears which are pressed onto the rotor

shafts . The f orward end of the rotors ar e held in posit ion by deep groo ve ball bearings . The back end of the rotors

are supported by sealed roller bearings.

The gears and ball bearings are lubricated by a synthetic oil from the oil reservoir in the supercharger and do not

rely on eng ine oil f or lubr icatio n. The cov er on the su percharger c ontains the inp ut shaft which is sup ported by two

deep groove ball bearings and coupled at one end to the rotor drive gears. A pulley is pressed onto the other end of

the input shaft. The bearings for the input shaft are also lubricated by the synthetic oil.

Engine m echanical s ervice opera tions f or the V6 Sup ercharged en gine carr y over in general f rom those de scribed

for the non-supercharged V6 engine in Section 6 A1-1 ENGINE MECH ANIC AL – V6 ENGIN E.

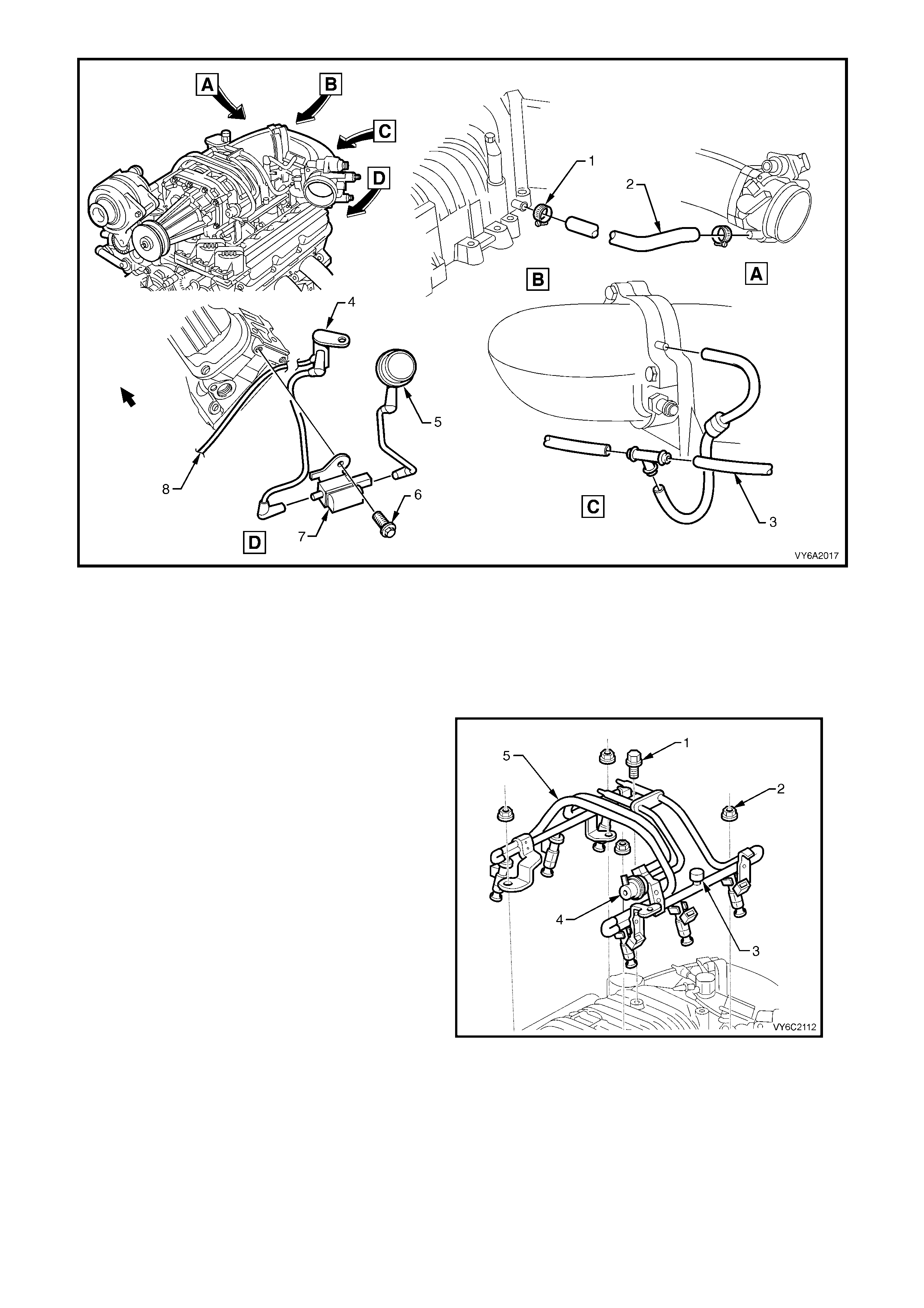

Figure 6A2-1

1.2 SYSTEM COMPONENTS

SU PE R C HAR G E R ASS E MB LY

The supercharger is designed to pump more air than the naturally aspirated engine would normally use. This air

creates a boost pressure in the intake manifold.

Maximum boost can range from 50 - 75 kPa. Since the supercharger is a positive displacement pump and is

directl y driven from the engine accessor y drive system, boost pressure is a vailable at all driving conditions. When

boost is n ot desired, suc h a s during idle a nd l ig ht thrott l e c r uising , the ex c ess air th at the s u perc har ger is producing

is recirculated via the bypass passage between the lower intake manifold and the supercharger inlet.

This bypass c ircuit is regu lated by a b ypass valve whi ch is s im ilar to a th rottle p late. T he b ypass v alve is con troll ed

by a vacuum actuator which is connected to the vacuum source between the throttle and the supercharger inlet.

Spring force from the actuator holds the valve closed to create boost and vacuum pulls the valve open when the

throttle closes.

The open bypass valve reduces pumping loss thereby increasing fuel efficiency. A PCM controlled solenoid valve is

used to reduce boost in the event of engine overheating as signalled by excessive coolant temperature.

For additional information on supercharger and boost control operation, refer to Section 6C2 POWERTRAIN

MANAGEMENT – V6 S/C ENGINE MY 2003 VY and V2 Series Service Information.

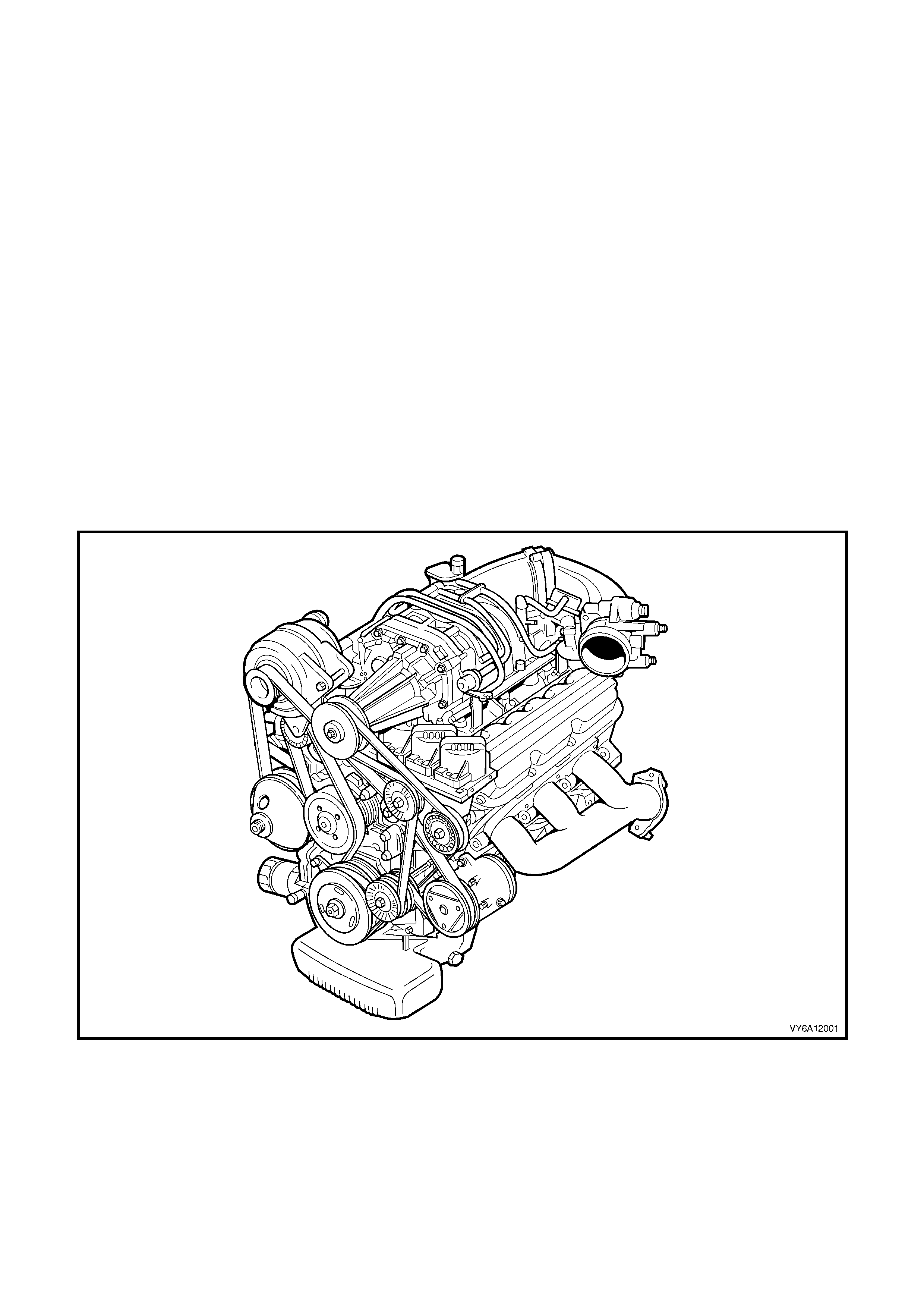

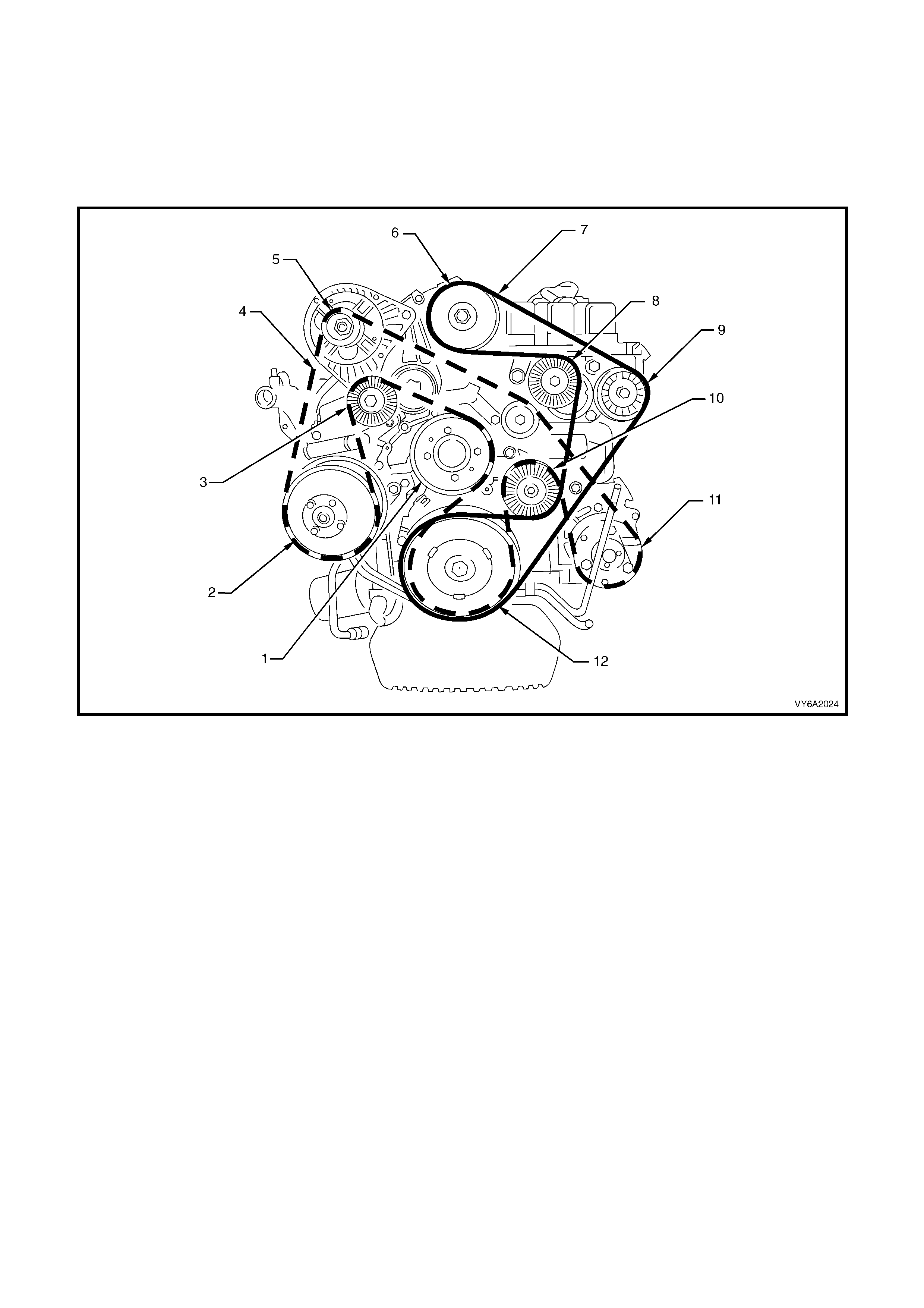

SUPERCHARGER DRIVE BELT TENSIONER

The supercharged engine uses two accessory

drive belts. The inner belt (9) drives the generator

(1), water pump (8), air conditioning compressor

(5) and power s teering pum p (7). The outer belt ( 3)

drives the supercharger (2). All belt driven

accessories are rigidly mounted to the engine.

Drive belt tension is maintained by the spring

loaded belt tens ioners (4 and 10). Eac h be lt has its

own tensioner.

A belt squeak when the engine is started or

stopped is normal and has no effect on belt

durability.

The drive belt tensioner can control belt tension

over a broad range of belt lengths due to

stretching; however, there are limits to the

tensioners ability to compensate. Using the

tensioner outside of its operating range can result

in poor tension control and/or damage to the

tensioner. The belt should be replaced when this

condition occurs.

Legend:

1. Generator

2. Supercharger

3. Supercharger Drive Belt (Outer)

4. Outer Drive Belt Tensioner Assembly

5. Air Conditioning Compressor

6. Crankshaft Balancer Assembly

7. Power Steering Pump Pulley

8. Coolant Pump

9. Accessory Drive Belt (Inner)

10. Inner Drive Belt Tensioner Assembly

Figure 6A2-2

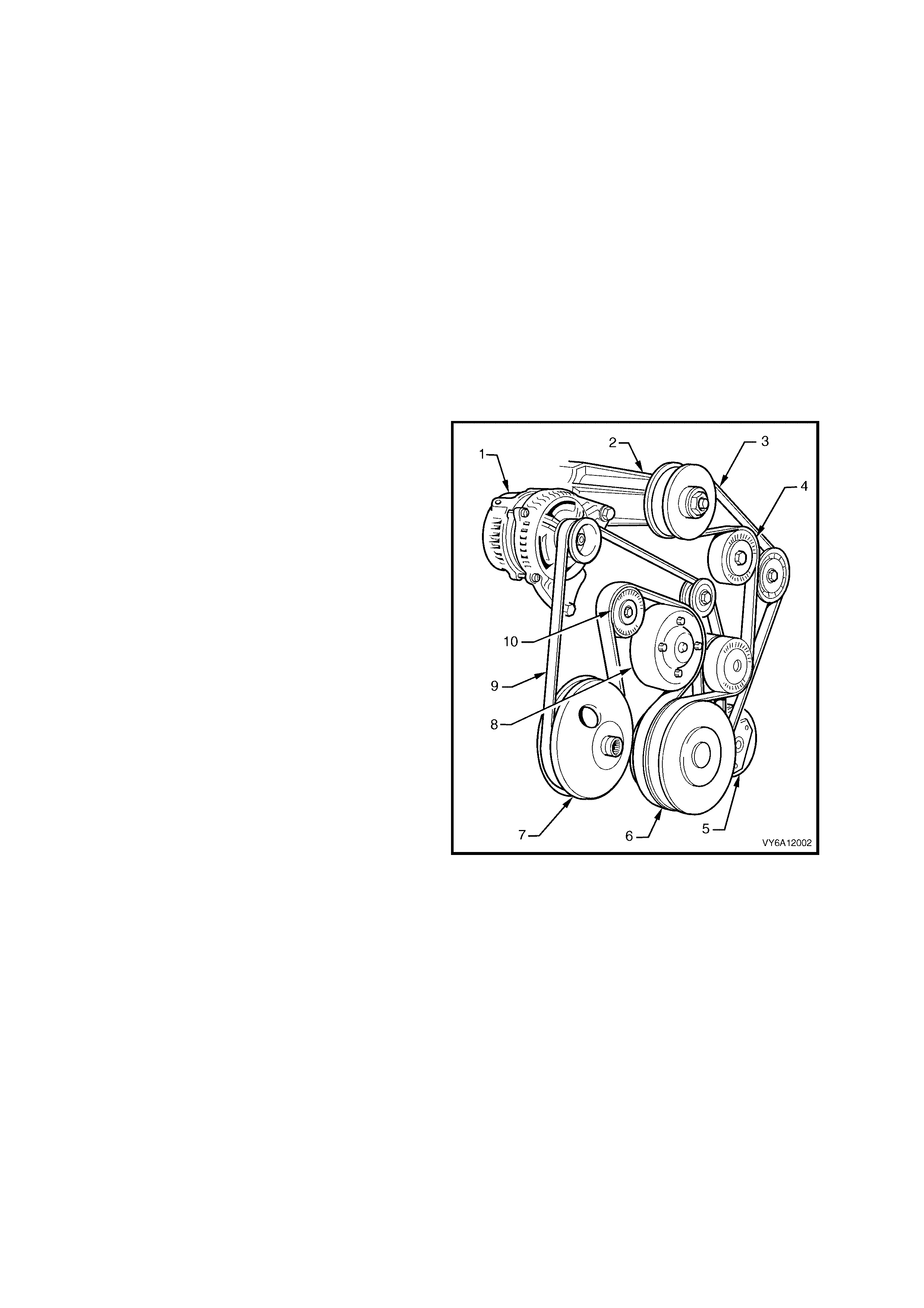

BALANCE SHAFT

The supercharged engine balance shaft has

revised balance specifications and can be

identified by the four lubrication holes (1) at the

rear bushing end of the shaft.

By contrast, the non-supercharged engine, can be

identif ied by the thre e holes (2) at the r ear bushing

end and the two groves (3).

Figure 6A2-3

CAMSHAFT SPROCKET

The camshaft sprocket (7) for the supercharged

engine can be identified by triangular holes while

the standard sprocket retains round holes.

Legend:

1. Balance Shaft Drive Gear

2. Timing Chain Assembly

3. Magnet Assembly

4. Dampener Assembly

5. Crankshaft Sprocket

6. Timing Marks

7. Camshaft Sprocket

8. Camshaft Sprocket Retaining Bolt

Figure 6A2-4

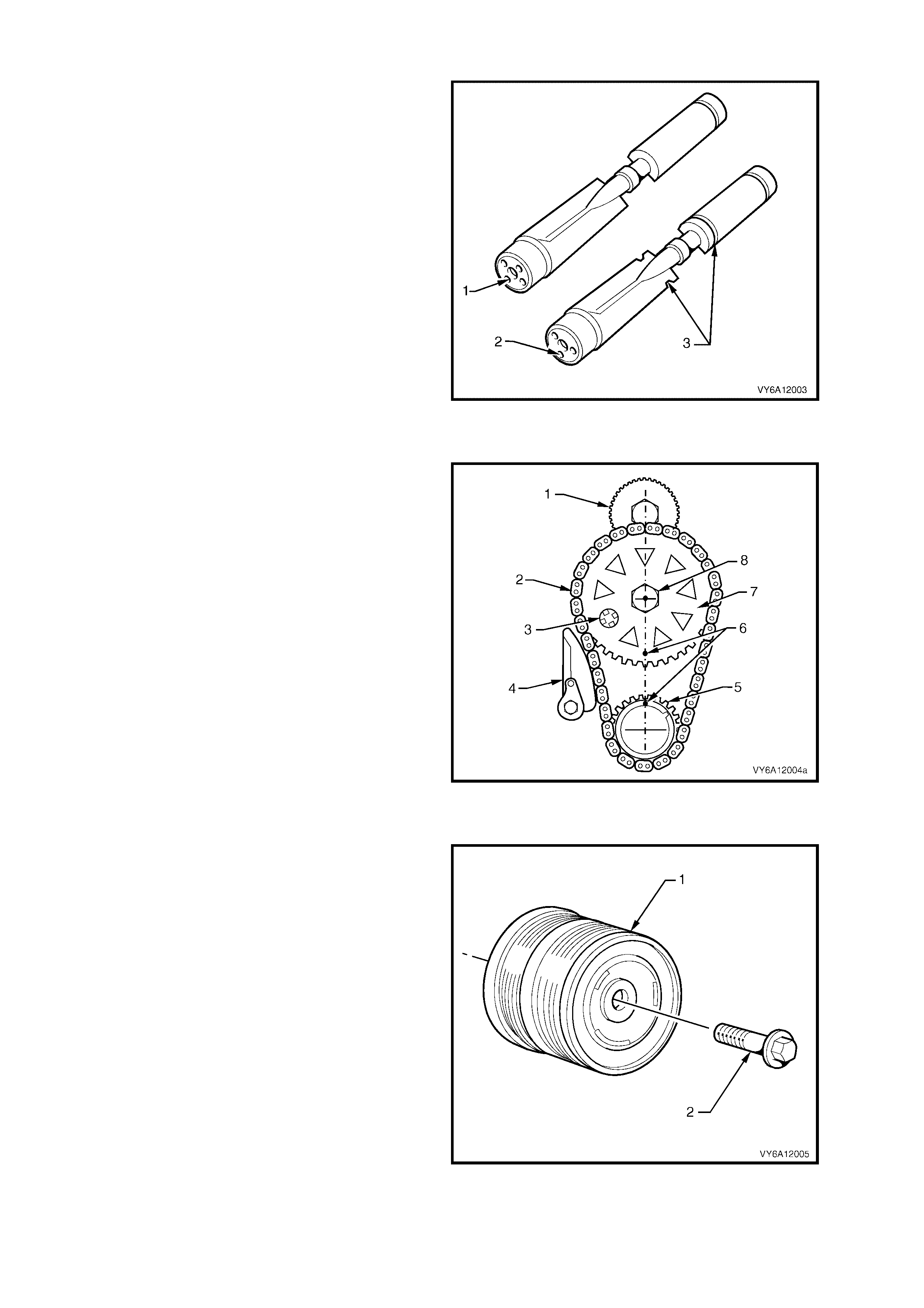

CRANKSHAFT BALANCER

The crankshaft balancer (1) is a twin track type

with balance compensation specifically for the

supercharged engine.

The balancer is secured to the end of the

crankshaft by a bolt (2).

Figure 6A2-5

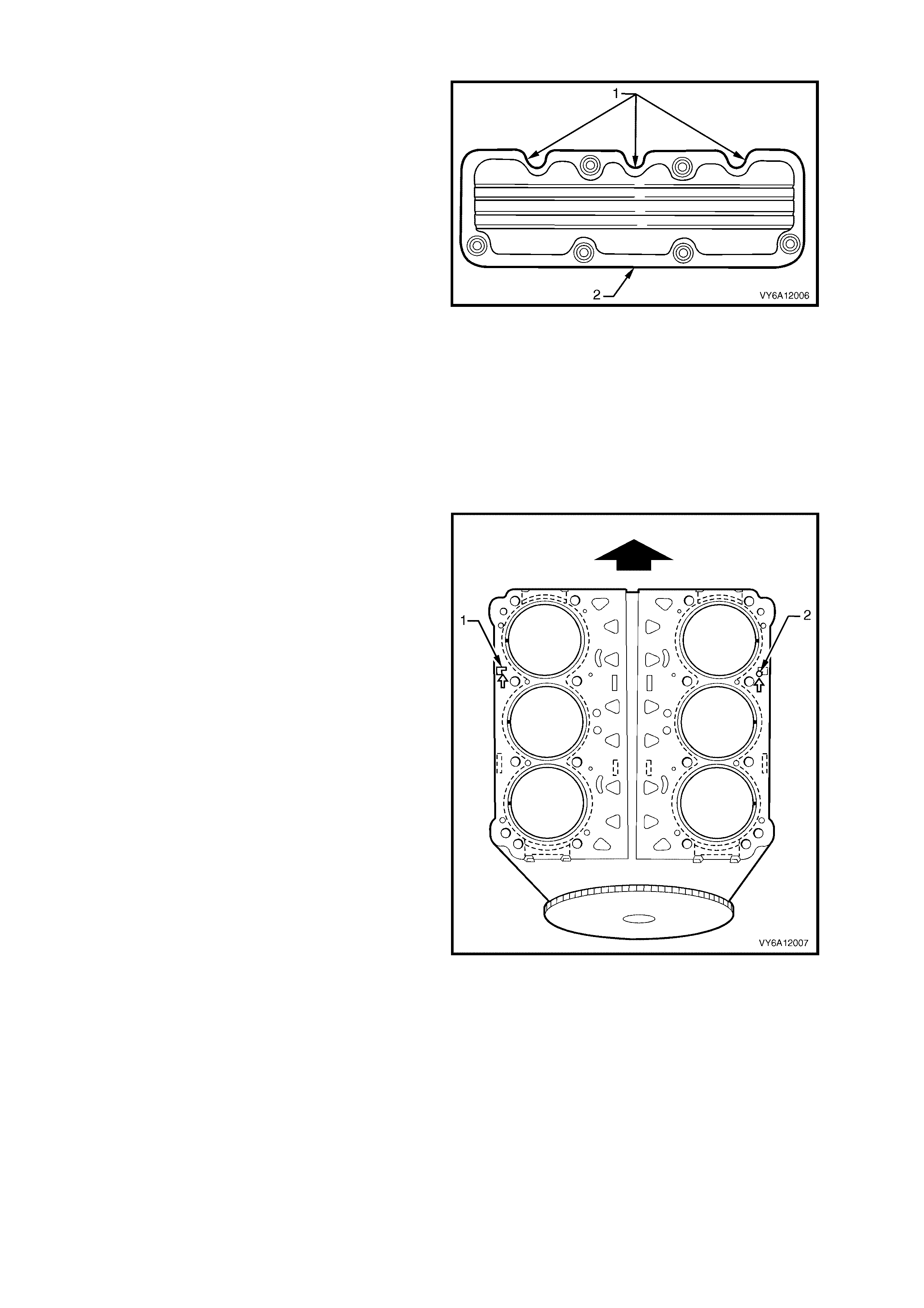

ROCKER COVERS & GASKETS

Rocker covers (2) and gaskets are modified with

cut outs (1) to suit relocation of the injectors in the

cylinder head inlet ports for the supercharged

engine.

Figure 6A2-6

CONNECTING RODS

The connecting rods have larger pin bush internal diameter and the big end/little end centre distance has been

revised.

PISTO NS AND PINS

Pistons and pins have been revised with a compression height of 30.6 mm and a larger floating piston pin of 23 mm

nominal diameter.

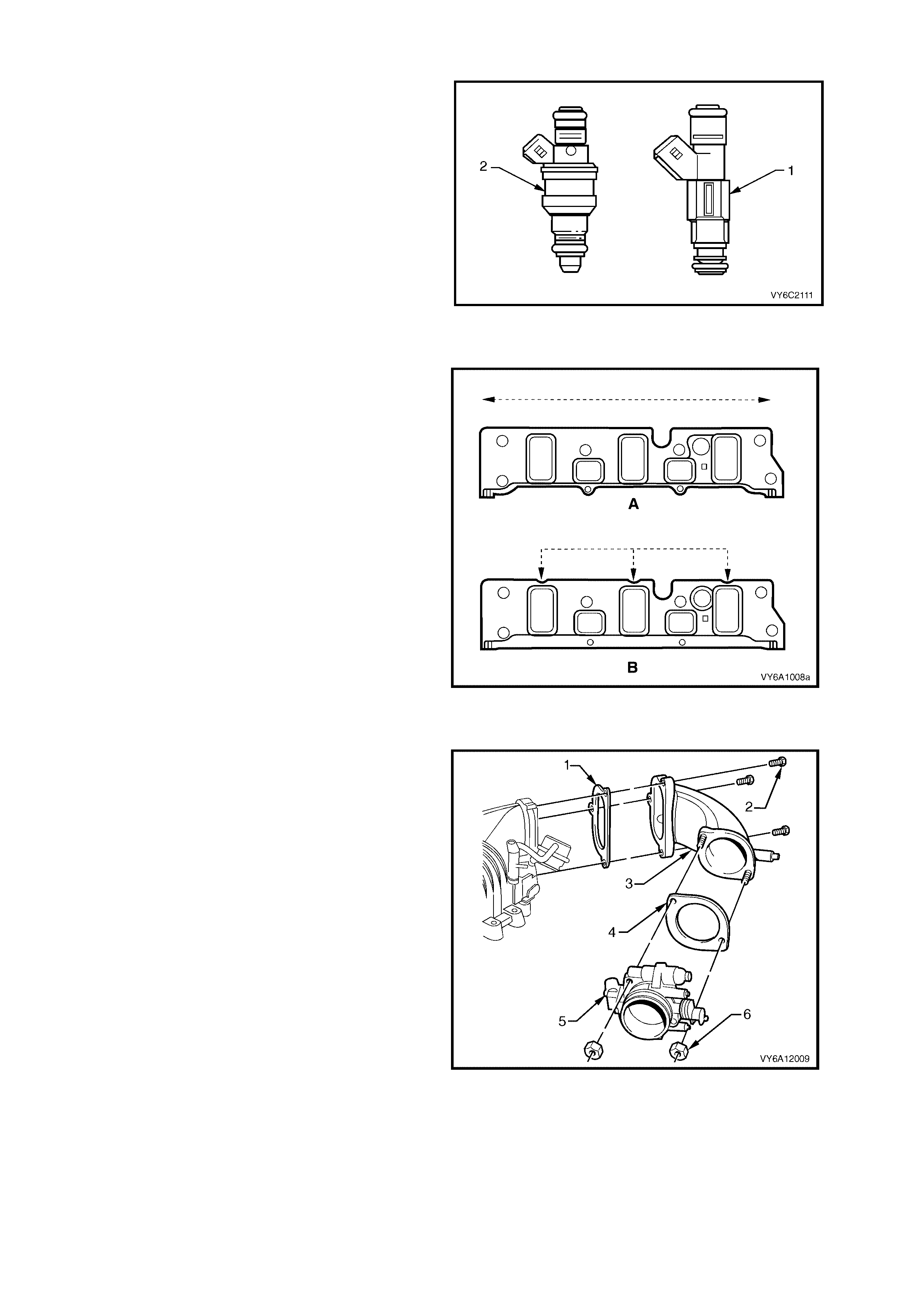

CYLINDER HEADS AND GASKETS

Cylinder heads have been machined for the

changed location of in-head fuel injectors. The

cylinder head gaskets feature revised material and

construction and are specific to each bank.

The arrows punched in each gasket must face the

engine front, as shown by the indicators, ‘1’ and ‘2’.

Figure 6A2-7

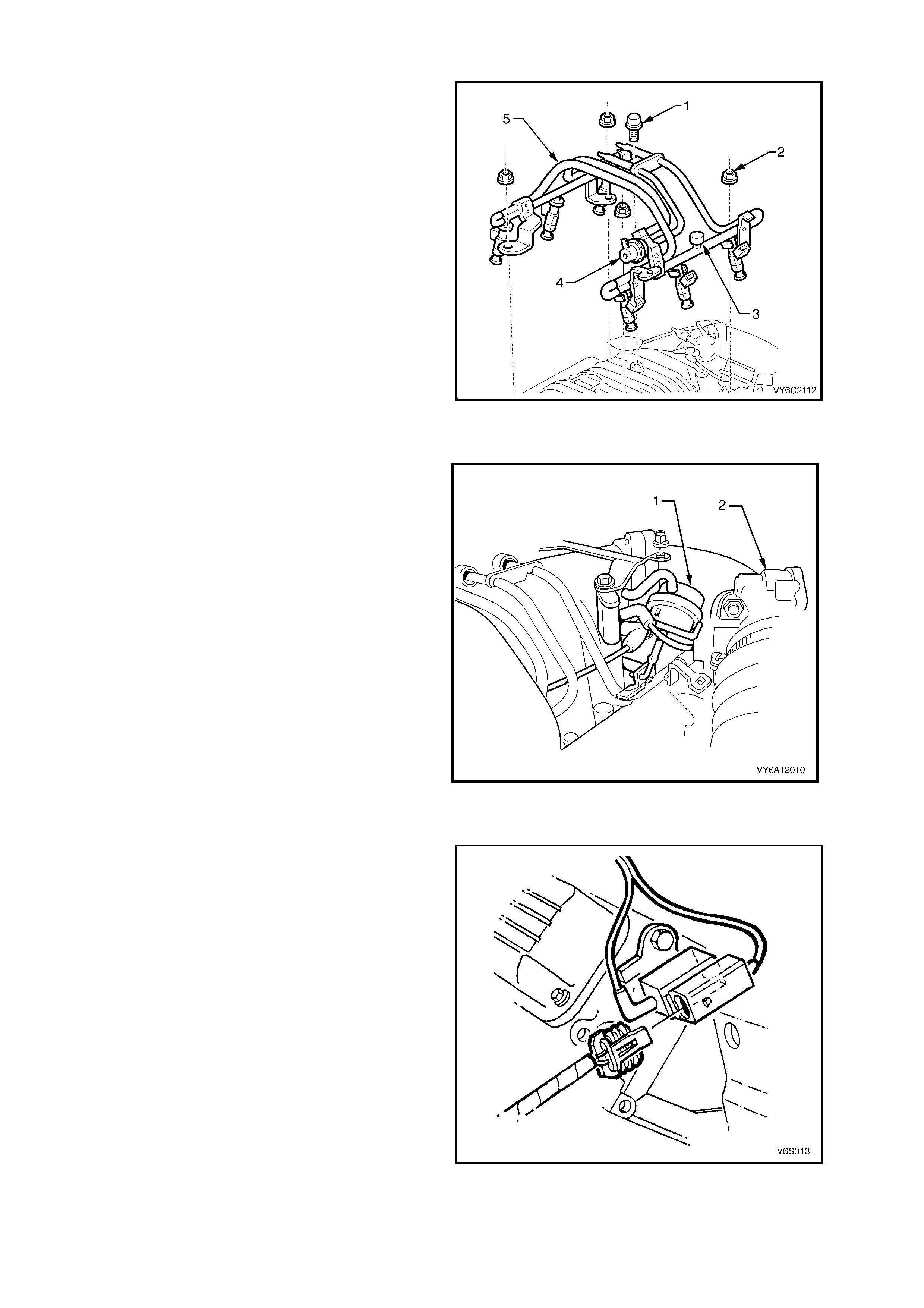

FUEL INJECTORS

Fuel injectors for the V6 Supercharged engine are

unique to this engine type and are of the high

capacity type.

Physically they are identified by (1), compared to

the naturally aspirated V6 i nj ec tor s (2) .

Figure 6A2-8

LOWER INTAKE MANIFOLD AND GASKETS

The lo wer int ake m anif old i s a machined alum inium

casting inc or por at ing th e lo wer s ect ion of the intake

ports, coolant and PCV passages. The top face is

machined flat to accommodate the supercharger

but, with the fuel injectors located in the cylinder

heads, cut-outs in view ‘B’ have b een incorporated

in the manifold gaskets for the injectors.

View ‘A’ shows the flat section on the non-

supercharged intake manifold.

Figure 6A2-9

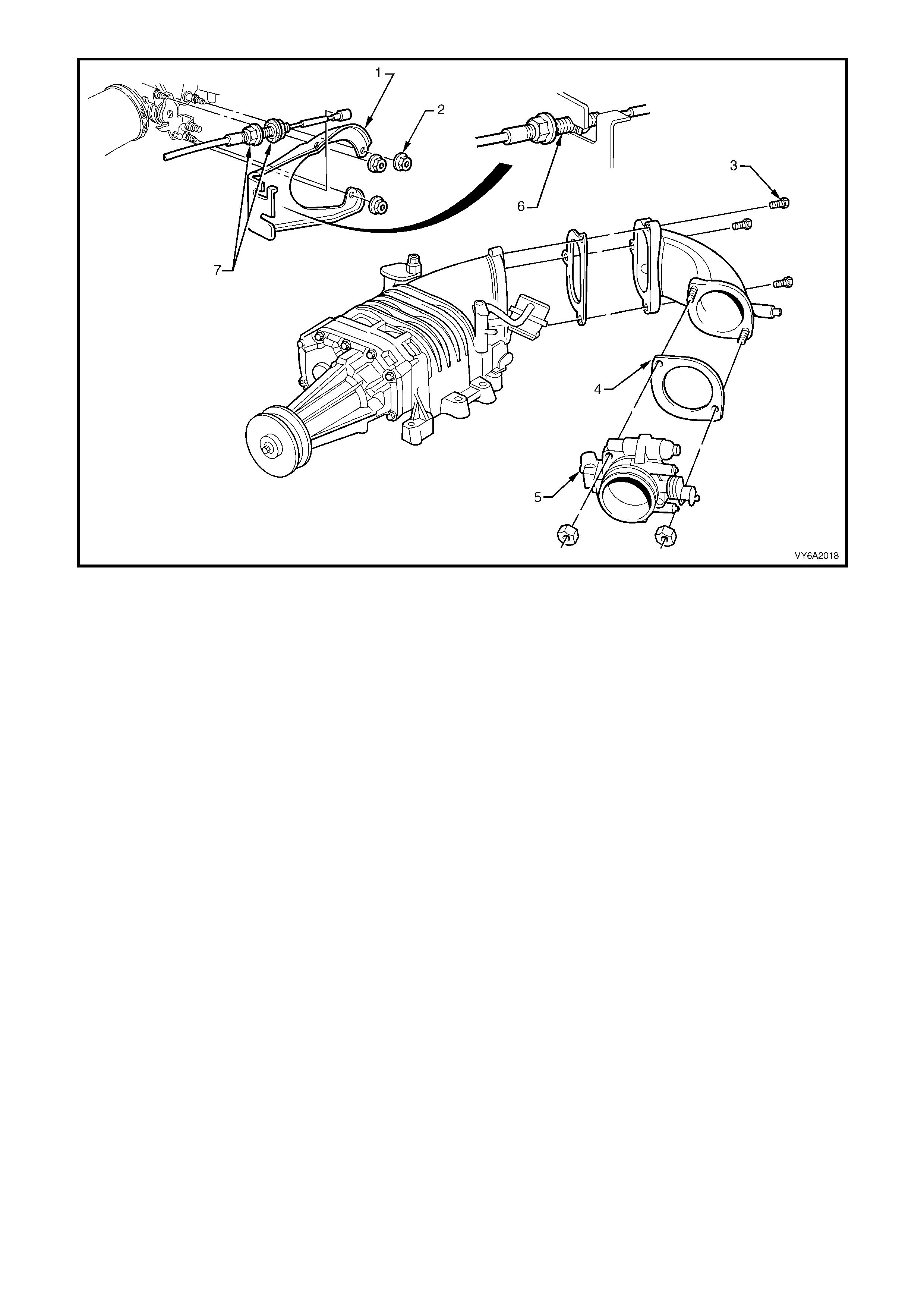

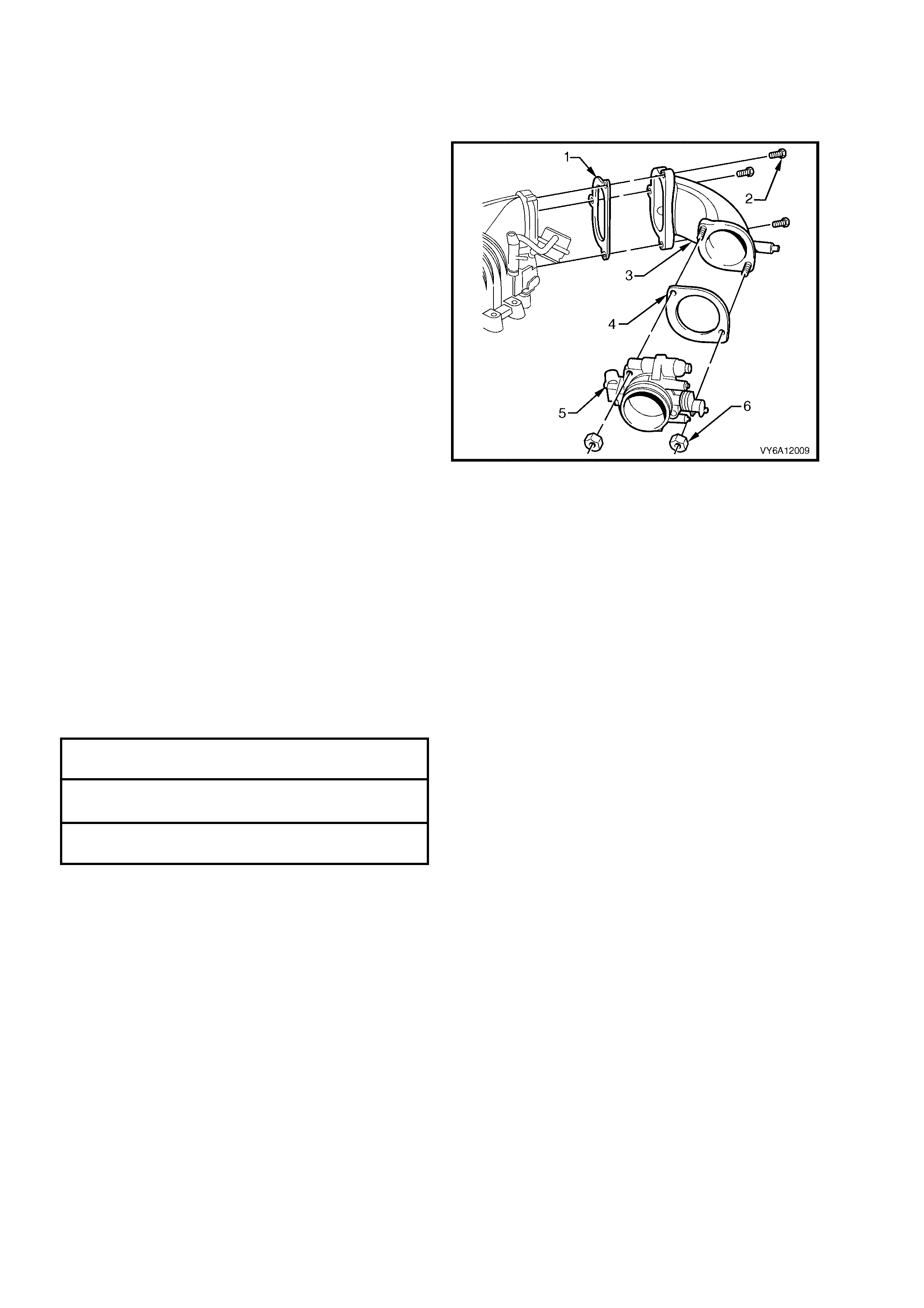

THROTTLE BODY ADAPTOR

The throttle b ody adaptor is a machined a luminium

casting which connects the remote throttle body to

the supercharger. The throttle body adaptor

includes br ak e boost er and heater vacuum nippl es,

cable bracket and mounting studs to suit the

superchar ger inlet.

Legend:

1. Adaptor Gasket

2. Bolts (3 places)

3. Throttle Body to Supercharger Adaptor

4. Throttle Body Gasket

5. Throttle Body Assembly

6. Nuts (2 places)

Figure 6A2-10

FUEL RAIL

The fuel rail assembly (5) is a steel tube type and

specif ic to t he su percharg ed en gine. Secur ed t o the

supercharger body with four nuts (2) and one bolt

(1), the fuel rail incorporates the fuel pressure

regulator (4) and a Schraeder valve (3) to enable

easy connection of a fuel pressure gauge. The fuel

pressure regulator (4) is not serviced separately

from the fuel rail.

Figure 6A2-11

BYPASS VALVE ACTUATOR

The supercharger bypass valve actuator (1)

operates a valve which can cut boost at idle or at

low throttle openings by diverting intake air around

the supercharger.

For additional information on bypass actuator

operation, refer to Section 6C2 POWERTRAIN

MANAGEMENT – V6 SUPERCHARGED

ENGINE in the MY 2003 V Y and V2 Ser ies Ser vice

Information.

Legend:

1. Supercharger Bypass Valve Actuator

2. Throttle Body

Figure 6A2-12

BOOST CONTROL SOLENOID VALVE

A boost control solenoid valve, located at the rear of

the left hand cylinder head is a PCM controlled

engine protec tion de vice which red uces boost in the

event of excessive coolant temperature.

Boost press ure is reduc ed by routing bo ost air from

the superch ar ger outlet v ia the sol eno id t o the lower

chamber of the bypass actuator, which then opens

the bypass valve.

NOTE: Electrical connection must always be

maintained to the boost control solenoid value as

no voltage will trigger boost reduction even under

normal coolant temperature operation.

Figure 6A2-13

WATER OUTLET HOSE AND RADIATOR INLET PIPE

The water outlet hose connects the thermostat hosing outlet port to the radiator inlet pipe to convey the engine

coolant f rom the bac k of the intak e manifold t o the radiat or inlet port. T he therm ostat housing c over is a m achined

aluminium casting which includes the cooling system bleeder valve. The therm ostat housing is located at the rear

of the intake manifold.

Figure 6A2-14

Legend

1. Radiator Inlet Pipe

2. Bolt

3. Coolant Outlet

4. Hose Clamps (2 places)

5. Coolant Outlet Hose

6. Plate

7. Nut

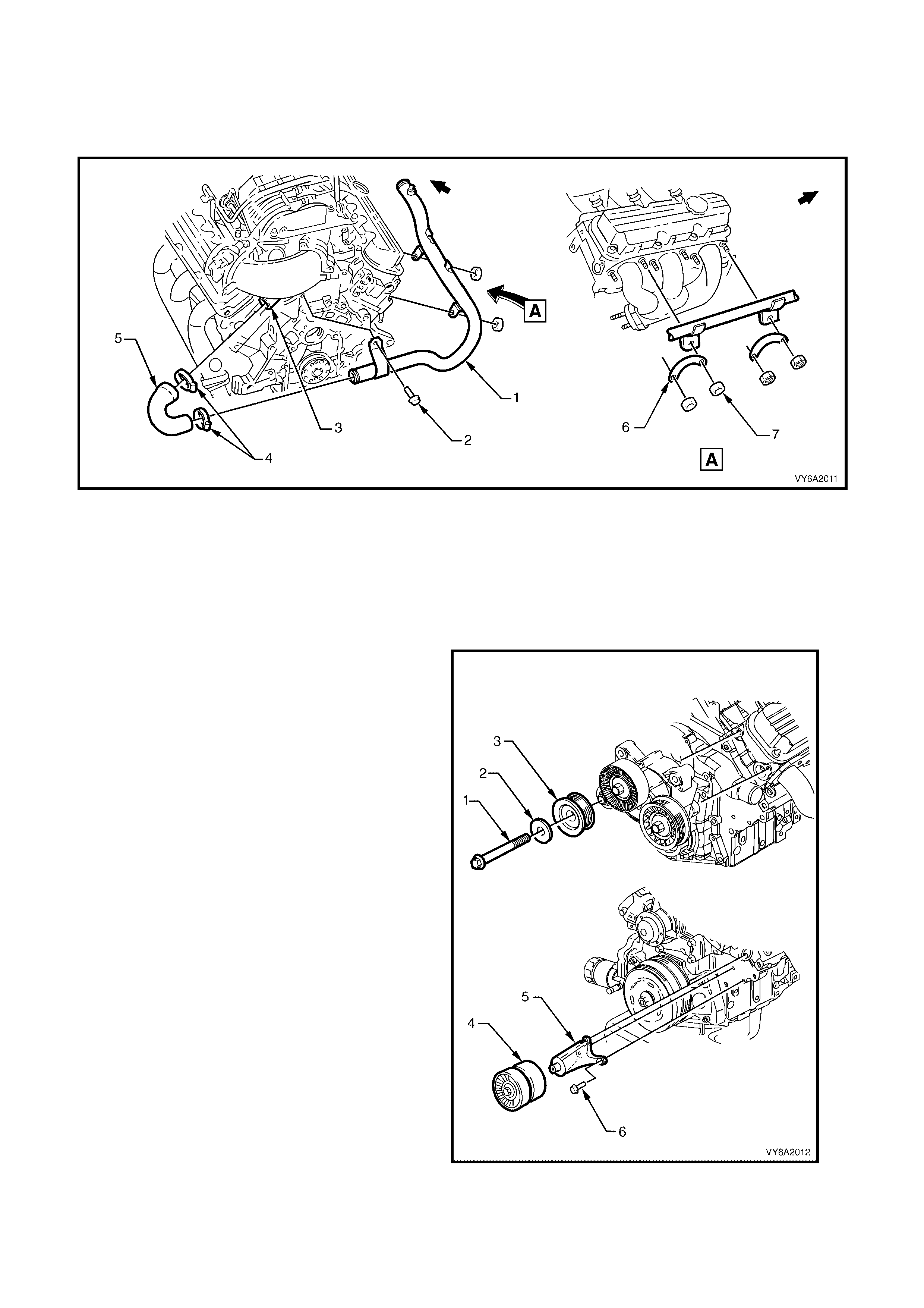

SUPERCHARGER DRIVE BELT IDLER PULLEY & BELT TENSIONER

There are two flat idler pulleys (4) for accessory

drive and supercharger drive, mounted on an

aluminium bracket (5) adjacent to the crankshaft

balancer and DIS coil pack.

Legend:

1. Bolt

2. Cover

3. Grooved Tensioner Pulley

4. Twin, Flat Idler Pulleys

5. Bracket

6. Bolt

Figure 6A2-15

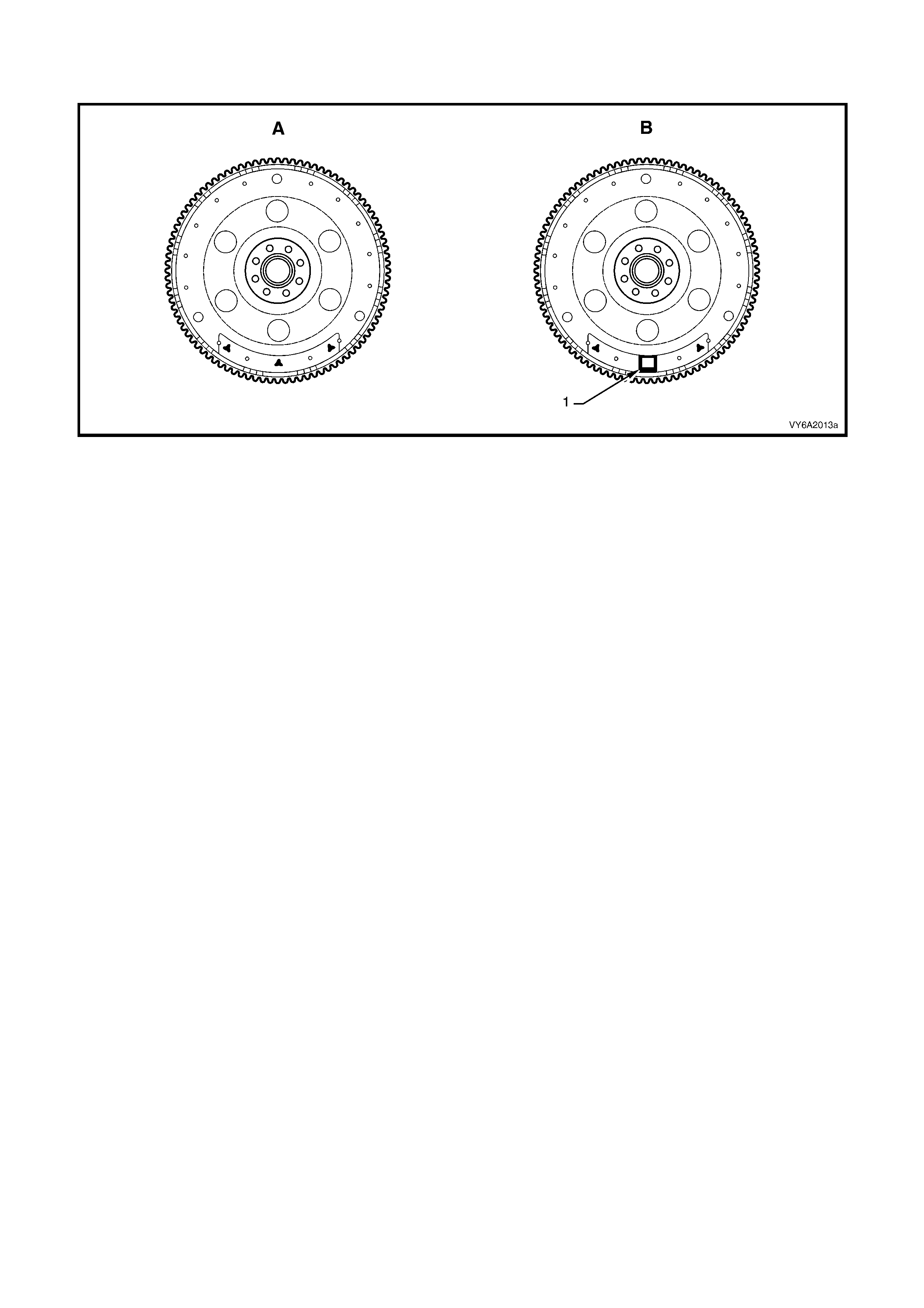

FLEXPLATE

The flexplate for the supercharged engine has revised balancing, as shown by ‘1’ in view ‘B’.

Figure 6A2-16

Legend

A V6 N on-Supercharg ed Engine

B V6 Supercharged Engine

1. V6 Supercharged Engine Balance Weight

PCM CALIBRATION

The supercharged engine PROM has revised calibration. For further information, refer to

Section 6C 2 POWERT RAIN M ANAGEMENT - V6 SUPERCH ARGED ENGINE in the M Y 2003 VY an d V2 Series

Service Information.

HIGH TENSION LEADS

The high tension leads are of low impedance for high energy coils with specific routing and retention. For high

tension lead routing, refer to Section 6C2-3 SERVICE OPERATIONS in Section 6C2 POWERTRAIN

MANAGEMENT - V6 SUPERCHARGED ENGINE in the MY 2003 VY and V2 Series Service Information.

DIS COILS & SPARK PLUGS

The coil and module assem bly is a Delco-high energy unit with specific bracketing. The spark plugs are a specific

heat range and design for the supercharged engine.

2. SERVICE OPERATIONS

LT Section No. – 00-375

2.1 SUPERCHARGER OIL LEVEL CHECK

NOTE: A small amount of oil weepage thro ugh the front seal, (behind the pulley) of the supercharger assembly is

normal. This oil weepage is caused by minute traces of oil escaping around the seal. A build up of airborne dust

can adhere to the thin oil film which causes oil weepage to appear worse than it really is. The supercharger

assembly should not be replaced due to weepage. If supercharger oil is visually dripping or puddling from the

supercharger front seal, the supercharger assembly will need to be replaced. Refer to

2.2 SUPERCHARGER AND GASKET in this Section.

CAUTION: Do not remove the oil plug when engine is warm. Engine should be cool to the touch.

Appro ximately 2 – 3 hours after running. Removing oil plug at warm engine temperatures can cause hot oil

to overflow. This could result in oil loss and possible personal injury.

Lubricant level is to be checked at the specified service intervals outlined in the MY 2003 VY and V2 Series,

Owner’s Handbook.

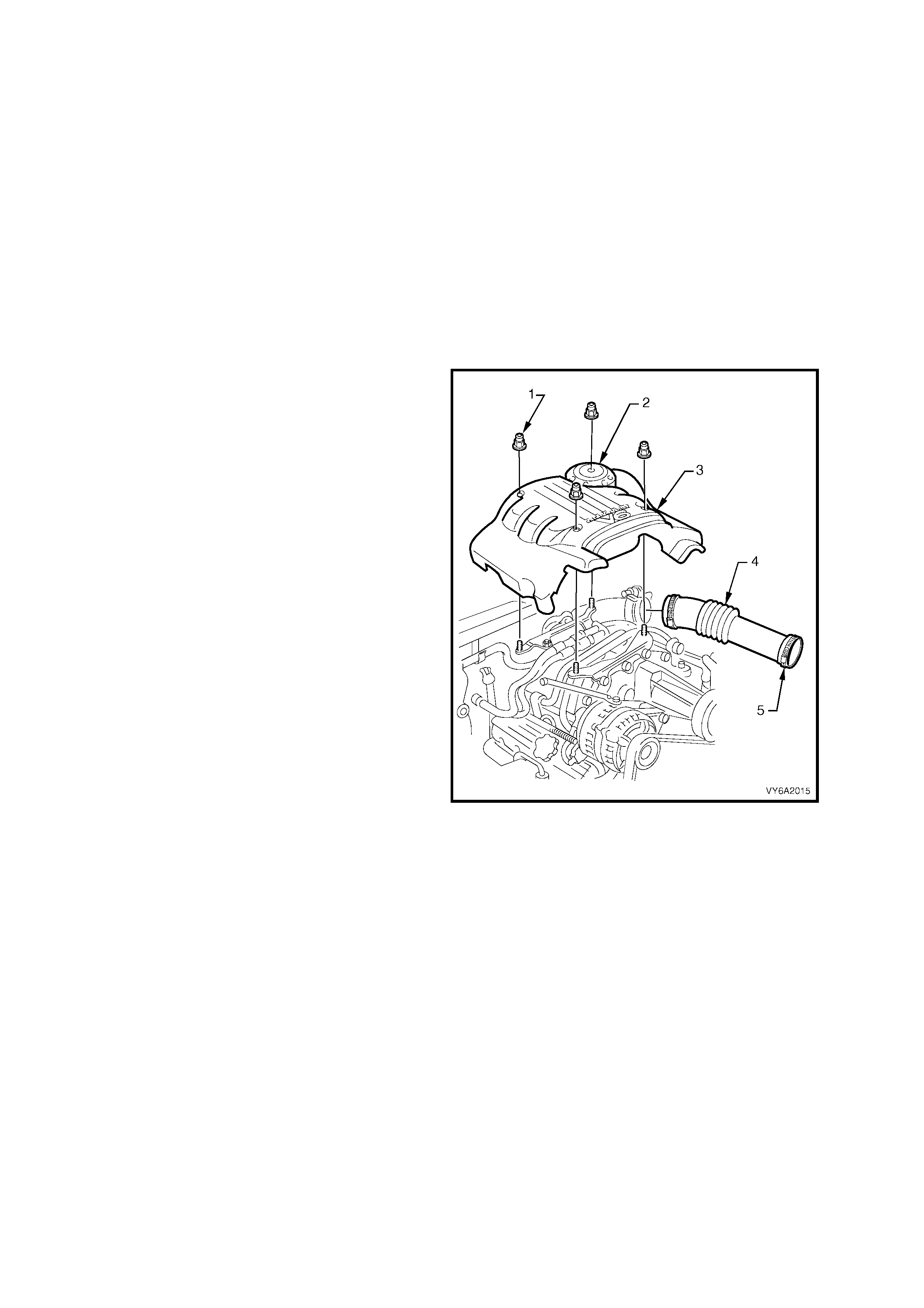

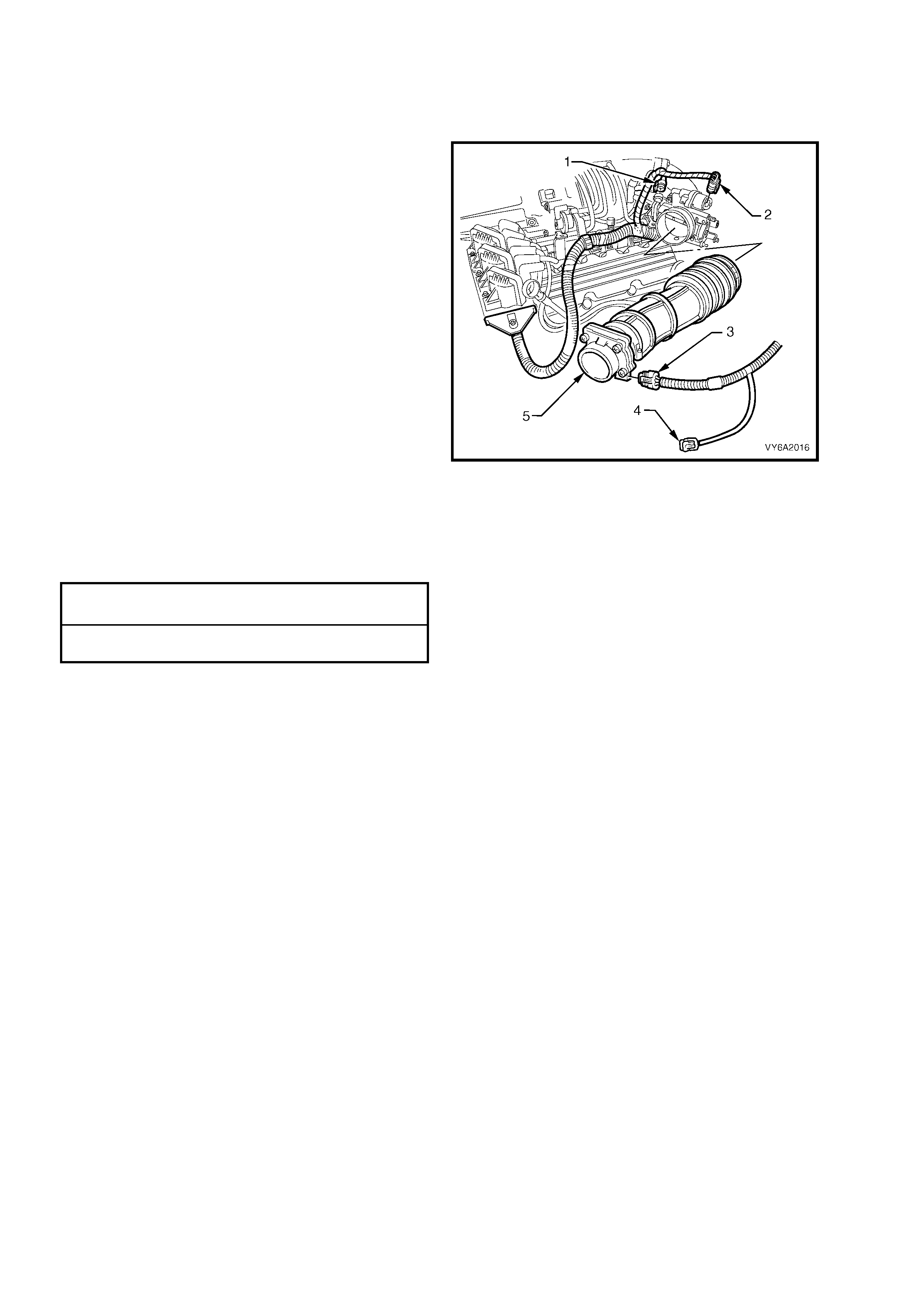

1. Remove the four dome nuts (1) securing the

engine dress cover assembly (3) to the

mounting br ack et studs , then rem ove th e cov er

assembly.

2. Loosen the two hose clamps (5), then remove

the air intake duct (4) from the mass air flow

sensor and thrott le body.

Figure 6A2-17

NOTE: To prevent contamination of the

superchar ger oil, cl ean the ar ea around the oi l filler

plug before removing.

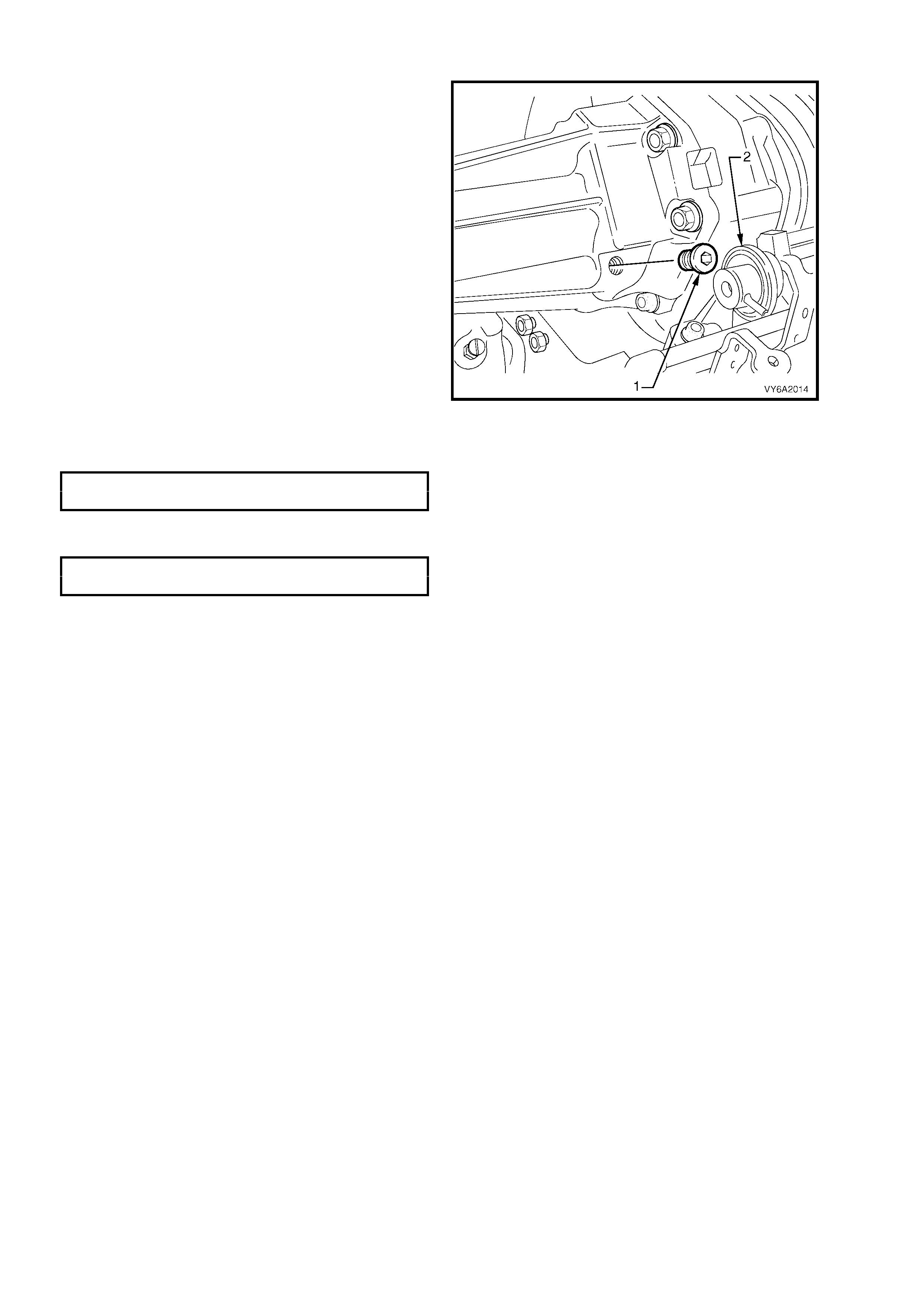

3. Using a 3/16 inch Allen key socket, remove

supercharger filler plug (1).

4. Check oil level, which should be maintained to

a level at the bottom of the threads in the oil

filler plug inspection hole in the supercharger

housing.

IMPORTANT: Do not us e petrole um bas ed oil. Use

only GM P/N 12345982 synthetic oil. Use of other

lubricant may cause supercharger failure.

Figure 6A2-18

5. Reins tall the o il filler plu g, ensuring s ealing cap O –ring is in p lace on plug. T ighten the f iller plug to th e correct

torque specification.

SUPERCHARGER OIL FILL ER

PLUG TORQUE SPECIFICATION 10 Nm

6. Reins tall engin e dress cover to the mounting br ackets, ensur ing that stud grom mets in the dress cover re main

in place. Tighten securing dome nuts to the correct torque specification.

ENGINE DRESS COVER DOME

NUT TORQUE SPECIFICATION 5 Nm

2.2 SUPERCHARGER AND GASKET

LT Section No. – 00-375

REMOVE

NOTE: Servicing of the supercharger unit itself is

limited to replacement only. No attempt should be

made to disassemble the supercharger as parts

damage may result.

1. Remove the four dome nuts (1) securing the

engine dress cover assembly (3) to the

mounting br ack et studs , then rem ove th e cov er

assembly.

2. Loosen the two hose clamps (5), then remove

the air intake duct (4) from the mass air flow

sensor and thrott le body.

Figure 6A2-19

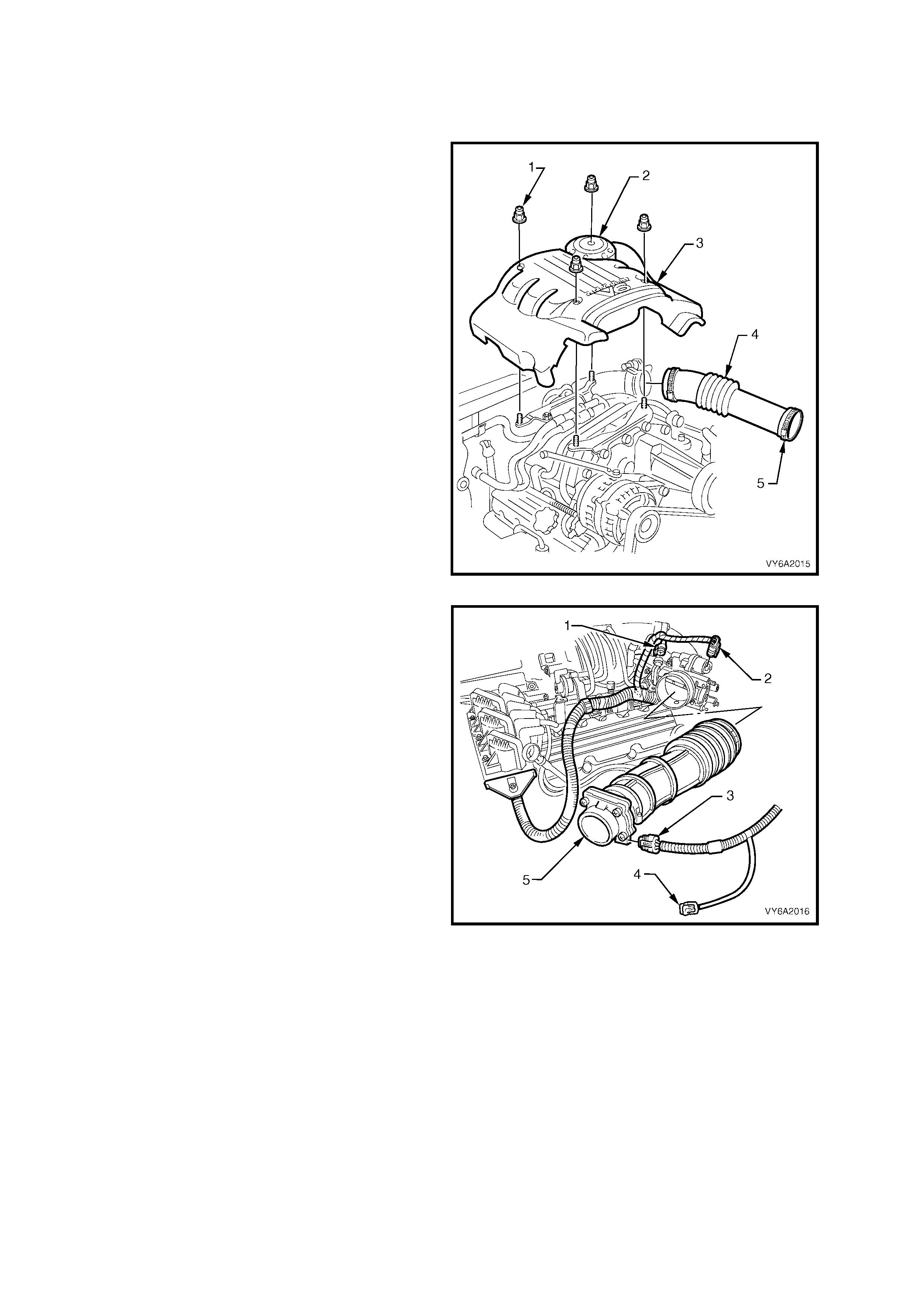

3. Disconnect the electrical connectors from the

TP sensor (1) IAC valve (2), MAF (3) and IAT

(4) sensors, then place harness to one side.

4. Rem ove the clamps securing air intake duct to

the throttle body and mass air flow sensor to

air filter, removing duct and sensor assembly.

Figure 6A2-20

5. Remove the screws securing rear dress cover

bracket and boost solenoid harness.

6. Disconnect supercharger vacuum connections

from heating/ventilation system (3), throttle

body (2), fuel pressure regulator, boost

solenoid harness and engine ventilation hose.

7. Remove bypass solenoid harness, refer to

2.3 BYPASS SOLENOID HARNESS

ASSEMBLY in this Section, and BYPASS

VALVE ACTUATOR in Section 6C2-3

POWERTRAIN MANAGEMENT – V6

SUPERCHARGED ENGINE in the MY 2003

VY and V2 Series Service Information.

Figure 6A2-21

Legend

1. Hose Clamp ( 2 places)

2. Hose – Throttle Body to Intake Manifold

3. Hoses – Heater Control, Vacuum Supply

4. Harness – Boost Control Solenoid

5. Bypass Actuator

6. Screw

7. Solenoid Valve – Boost Control

8. Hose – to Pressure Regulator

9. Depressurise the fuel rail, refer to

Section 6C2-3 SERVICE OPERATIONS in

Section 6C2 POWERTRAIN MANAGEMENT –

V6 SUPERCHARGED ENGINE in the MY 2003

VY and V2 Series Service Information and

disconnect the electrical connectors from

injectors.

10. Remove the generator support bracket.

11. Disconnect the fuel lines from the fuel rail

assembly and remove the fuel rail, refer to

Section 6C2-3 SERVICE OPERATIONS in

Section 6C2 POWERTRAIN MANAGEMENT –

V6 SUPERCHARGED ENGINE.

Legend:

1. Bolt

2. Nut (4 places)

3. Pressure Relief Schraeder Valve

4. Fuel Pressure Regulator

5. Fuel Rail

Figure 6A2-22

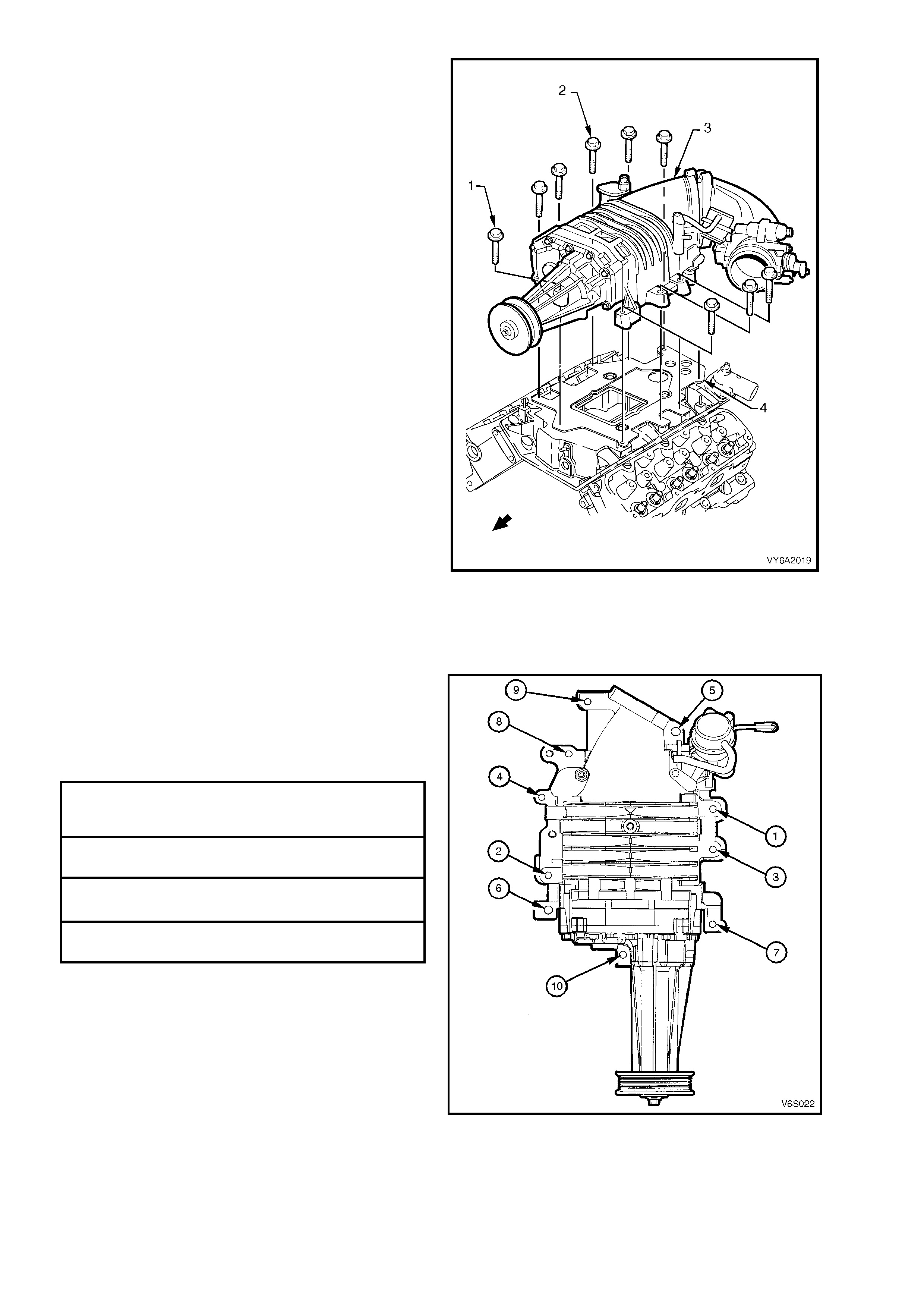

Figure 6A2-23

Legend

1. Mounting Bracket

2. Mounting Bracket Nuts (3 places)

3. Adaptor Assembly Attaching Bolts

4. Throttle Body to Adaptor Gasket

5. Throttle Body

6. Outer Throttle Cable Position

7. Throttle Cable Adjusting Nuts (Not to be removed)

8. Disconnect throttle cable and where fitted, the cruise control cable.

9. Remove throttle body from throttle body adaptor, refer to 2.4 THROTTLE BODY in this Section.

10. Remove the drive belt from supercharger

pulley, refer to 2.9 SUPERCHARGER DRIVE

BELT in this Section.

11. Remove supercharger to intake manifold bolts

(1 and 2), then remove the supercharger

assembly (3).

CAUTION: Do not place fingers or foreign

objects near supercharger vanes as personal

injury or damage to supercharger vanes can

result.

12. Remove supercharger gasket and O-rings (4).

Figure 6A1-24

REINST ALL

Installation of the supercharger is the reverse of

removal operations noting the following points:

1. Ensure that all mating surfaces are clean.

2. Sup ercharger to in take manifold g asket and O-

rings must be replaced.

3. The tightening sequence shown, and the

torque specification must be maintained.

SUPERCHARGER ATTACHING BOLT

TORQUE SPECIFICATION Stage 1 15 Nm

Stage 2 25 Nm

FUEL RAIL ATTACHING BOLT

TORQUE SPECIFICATION 25 Nm

FUEL RAIL ATTACHING NUT

TORQUE SPECIFICATION 10 Nm

ENGINE DRESS COVER NUT

TORQUE SPECIFICATION 5 Nm

Figure 6A2-25

2.3 BYPASS SOLENOID HARNESS ASSEMBLY

LT Section No. – 03-300

REPLACE

1. Ensure that the ignition switch is turned to the

OFF position.

2. Remove the four engine dress cover dome

nuts and remove the cover.

3. Rem ove the sc rews ( 3) sec uring the re ar dres s

cover bracket (4) and boost control solenoid

harness (2).

4. Disconnect vacuum connections from fuel

pressure regulator (6) and bypass solenoid (5).

5. Reinstallation is the reverse of the above

removal operations, apart from tightening all

fasteners to the correct torque specifications.

ENGINE DRESS COVER

BRACKET BOLT/NUT

TORQUE SPECIFICATION 18 Nm

ENGINE DRESS COVER NUT

TORQUE SPECIFICATION 5 Nm

Legend:

1. Supercharger Assembly

2. Boost Control Solenoid Harness

3. Screw (2 places)

4. Engine Dress Cover, Rear Mounting Bracket

5. Vacuum Connection to Boost Control Solenoid

6. Fuel Pressure Regulator

Figure 6A2-26

2.4 THROTTLE BODY

LT Section No. – 03-300

REMOVE

1. Ensure that the ignition switch is turned to the

OFF position.

2. Disconnect the electrical connectors from the

TP sensor (1) IAC valve (2), MAF (3) and IAT

(4) sensors, then place harness to one side.

3. Rem ove the clamps securing air intake duct to

the throttle body and mass air flow sensor to

air filter, removing duct and sensor assembly.

4. Remove the t wo nuts s ec ur ing t he t hr ott le body

assembly to the throttle body adaptor and

remove the assembly.

Figure 6A2-27

REINST ALL

Apart from a requirement to tighten fasteners to the

correct torque specifications, reinstallation is the

reverse to removal operations.

THROTTLE BODY NUT

TORQUE SPECIFICATION 18 Nm

ENGINE DRESS COVER NUT

TORQUE SPECIFICATION 5 Nm

2.5 THROTTLE BODY ADAPTOR

LT Section No. – 03-300

REMOVE

1. Ensure that the ignition switch is turned to the

OFF position.

2. Remove the four engine dress cover dome

nuts and remove the cover.

3. Remove the throttle body (5), refer to

2.4 THROTTLE BODY in this Section.

4. Remove the bypass solenoid harness and

bypass valve actuator, refer to 2.3 BYPASS

SOLENOID HARNESS ASSEMBLY in this

Section.

5. Disconnect the vacuum lines from the throttle

body adaptor.

6. Rem ove the b olts ( 2) sec uring the thr ottle b od y

adaptor (3) to the supercharger.

7. Remove the adaptor to supercharger gasket

(1) and discard.

Figure 6A2-28

REINST ALL

1. Apart from a requirement to tighten fasteners

to the correct torque specifications,

reinstallation is the reverse to removal

operations, except for the following:

a. Ensure bypass valve actuator preload is

adjusted correctly. Refer 6.5 BY-PASS

VALVE ACTUATOR, in Section 6C2-3

SERVICE OPERATIONS, in the MY 2003

VY and V2 Series Service Information.

b. Ensure all vacuum lines are connected

correctly.

THROTTLE BODY ADAPTOR

BOLT TORQUE SPECIFICATION 25 Nm

THROTTLE BODY NUT

TORQUE SPECIFICATION 18 Nm

ENGINE DRESS COVER NUT

TORQUE SPECIFICATION 5 Nm

2.6 ENGINE VENTILATION SYSTEM

The engine ventilation system, utilises engine vacuum to draw blow-by gasses into the combustion chambers

where they are recycled through the combustion process. The ventilation system should be checked at the

specified time or distance intervals in the MY 2003 VY and V2 Series, Owner’s Handbook.

2.7 FUNCTIONAL CHECK OF CRANKC ASE VE NTILATION VALVE

If an engine is idling rough, check for a clogged crankcase ventilation valve. Replace as required using the

follo wing proc ed ur e:

1. Remove crankcase ventilation valve from rear of supercharger, refer to 2.8 CRANKCASE VENTILATION

VALVE in this Section.

2. Shake valve and listen for the rattle of needle inside valve. If valve does not rattle, replace valve.

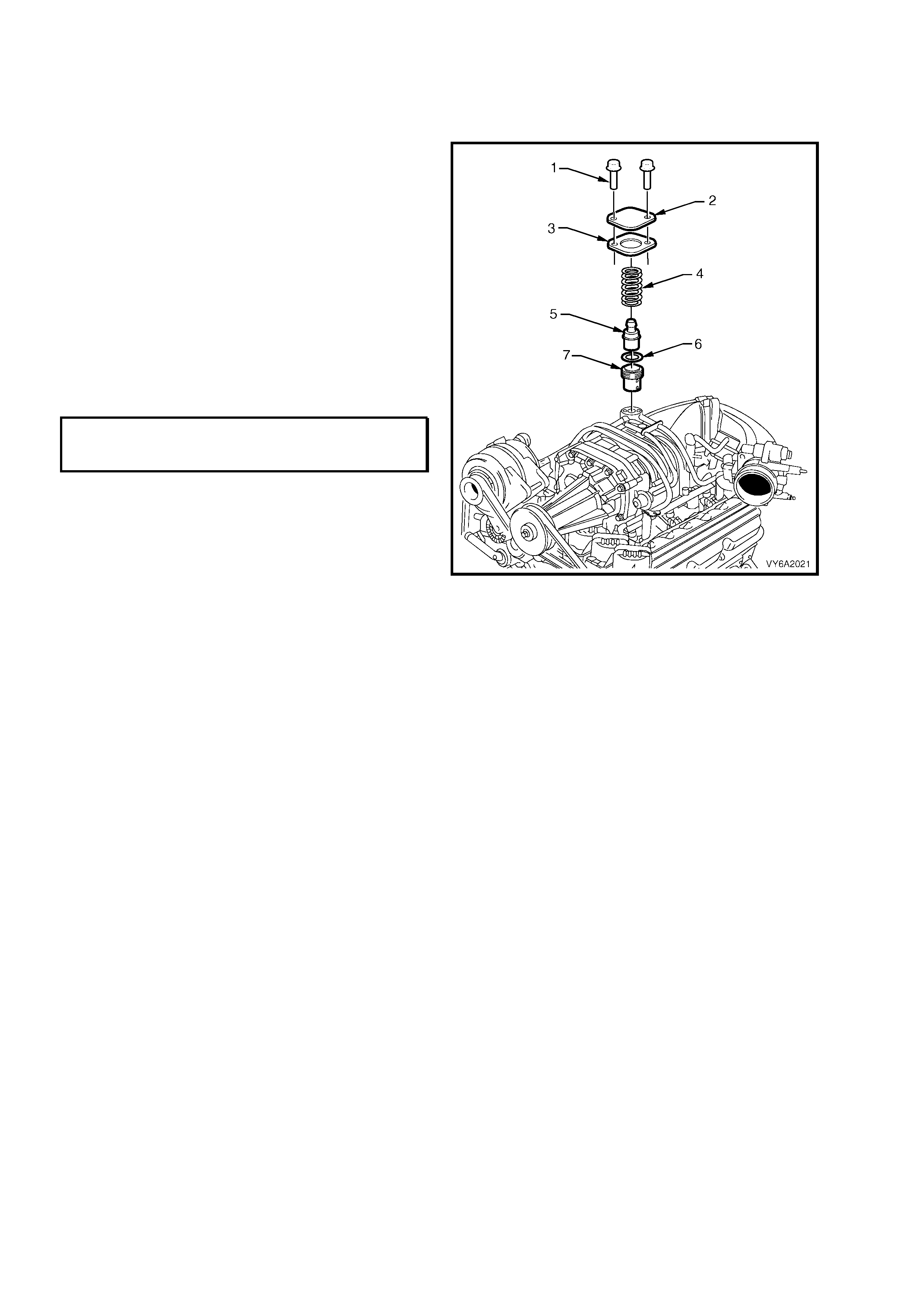

2.8 CRANKCASE VENTILATION VALVE

LT Section No. – 00-249

REPLACE

1. Remove the four engine dress cover dome

nuts and remove the cover.

2. Hold down the crankcase ventilation valve

cover (2) and remove the two cover retainer

screws (1).

3. Remove the crankcase ventilation valve cover

(2), gasket (3), crankcase ventilation valve (5),

spring (4) O-ring (6) and oil separation

baffle (7).

4. Reverse r em oval op eration s using new O -rin gs

and gasket, as necessary and tightening

fasteners to the specified torque specification.

NOTE: The holes in the oil separatio n baffle are to

be aligned at 90° to the engine centreline

CRANKCASE VENTILATION VALVE

COVER SCREW

TORQUE SPECIFICATION 5.0 Nm

Figure 6A2-29

2.9 SUPERCH ARGER DRIVE BE LT

LT Section No. – 01-003

TENSION CHECK

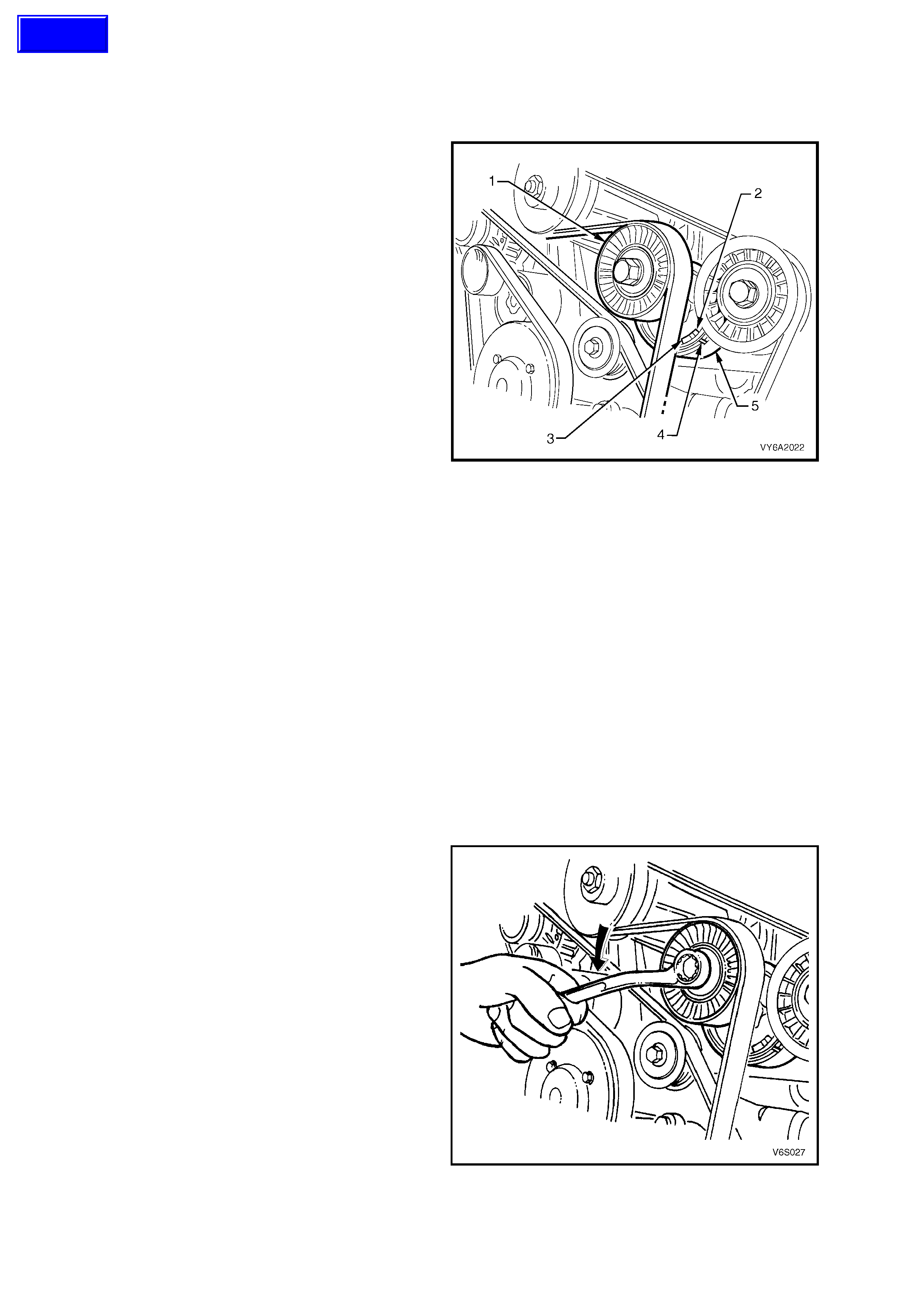

1. Inspect tensioner markings to see if belt is

within operating limits. Replace belt if

excessively worn or outside the tensioner

operating range.

2. Run th e e ngi ne unt il warmed up. S witc h e ngi ne

off and read belt tension with Belt tensioner

tool BT3373-F placed between the

supercharger and upper idler pulley (bold

arrow). Remove tension gauge.

NOTE: Before carrying out drive belt tension,

check the calibration of Tool No. BT3373-F.

3. Run the e ngine again, allowing the drive belt to

stabilis e for 15 s econds. T urn engine off . Then,

using a 15 mm ring spanner, apply clockwise

force (tighten) to tensioner pulley (1) bolt.

Remove ring spanner and immediately take a

tension reading with Tool No. BT3373-F

without disturbing the belt tensioner assembly.

4. Using a 15 mm ring spanner, apply an anti-

clockwise force to tensioner pulley (1) bolt and

raise pulley to 'belt install' position. Slowly

lower pulley to 'at rest' position and take a

tension reading without disturbing belt

tensioner position. Recor d reading and rem ove

tool.

5. Average the three readings (add them

together, then divide by three). If the average

of the three readings is lower than 250 N and

the belt is within tensioner operating range,

replace be lt tens io ner.

Figure 6A2-30

Legend:

1. Tensioner Pulley

2. Minimum Tension Limit

3. Maximum Tension Limit

4. Indicator

5. Spring Loaded Tension Arm

INSPECT

This process is the same as that detailed for

the inner accessory drive belt. Refer to

2.7 DRIVE BELT, in Section 6A1-1 ENGINE

MECHANIC AL – V6 ENGI NE.

REMOVE

1. Disconnect the negative cable from the battery

terminal.

2. Remove the four engine dress cover dome

nuts and remove the cover.

3. Using a 15 mm ring spanner on supercharger

drive belt tensioner pulley pivot bolt, rotate

tensioner pulley assembly anti-clockwise and

remove drive belt from supercharger. Release

tensioner pulley assembly and remove drive

belt from remaining drive pulleys.

Figure 6A2-31

Techline

REINST ALL

1. Inspect dr ive belt c ondit ion, which is the sam e proc ess as that detailed f or the in ner acces sor y drive belt. Ref er

to 2.7 DRIVE BELT, in Section 6A1-1 ENGINE MECHANICAL – V6 ENGINE.

NOTE: Ensure drive belt ribs are aligned into all pulleys and crankshaft balancer drive belt grooves.

2. Us ing a 15 mm ring spanner , rotate super charger driv e belt tensi oner pulle y ant i-clockwise a nd feed dri ve b elt

over supercharger pulley. Return tensioner to its normal position.

3. Reconnect battery ground cable, start engine and check drive belt operation.

Figure 6A2-32

Legend

1. Coolant Pump

2. Power Steering Pump Pulley

3. Inner Drive Belt Tensioner Pulley

4. Generator

5. Inner Drive Belt

6. Supercharger

7. Outer Drive Belt

8. Outer Drive Belt Tensioner Pulley

9. Outer Drive Belt, Upper Idler Pulley

10. Outer Drive Belt, Lower Idler Pulley

11. Air Conditioning Compressor Pulley

12. Crankshaft Balancer Pulley

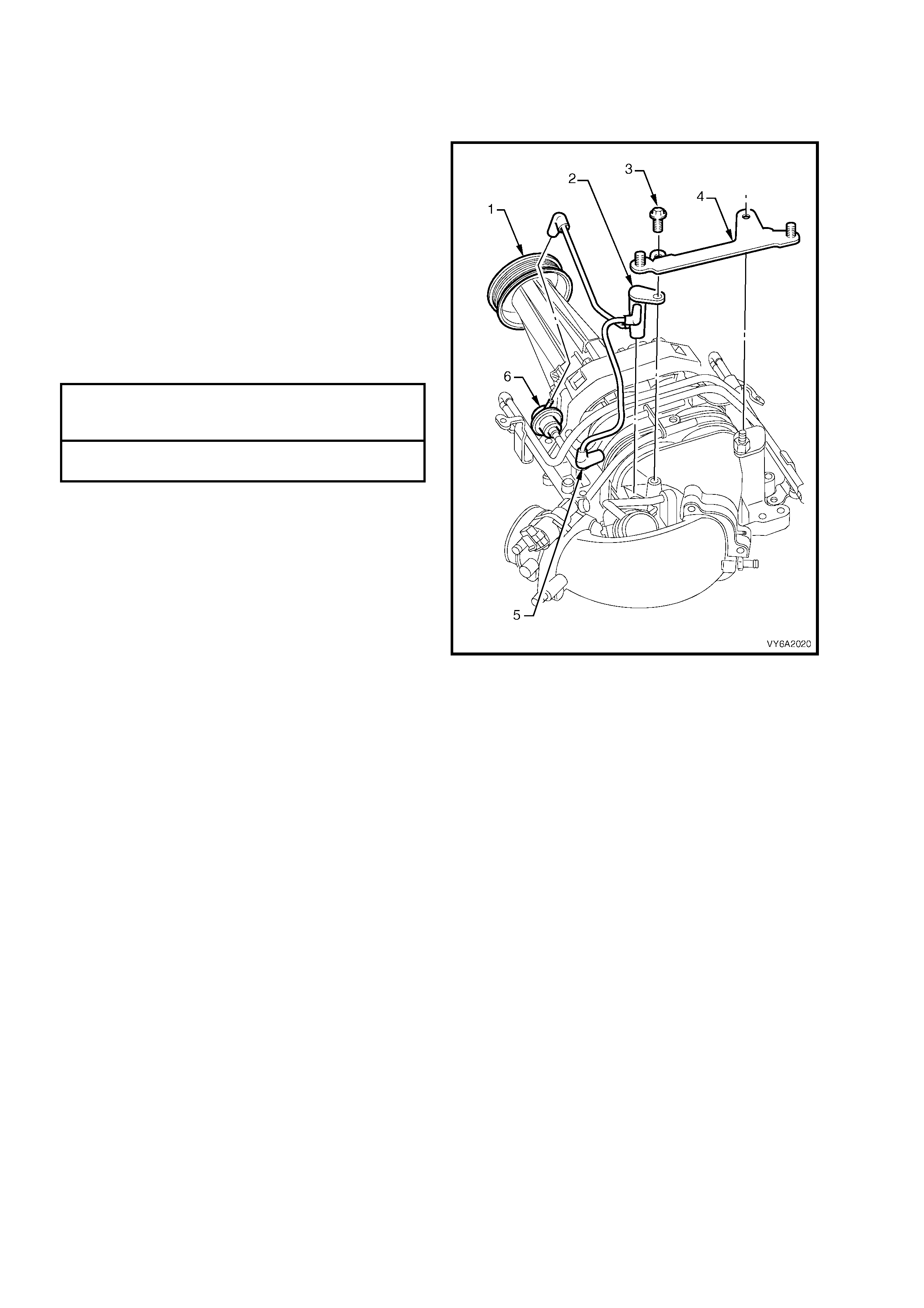

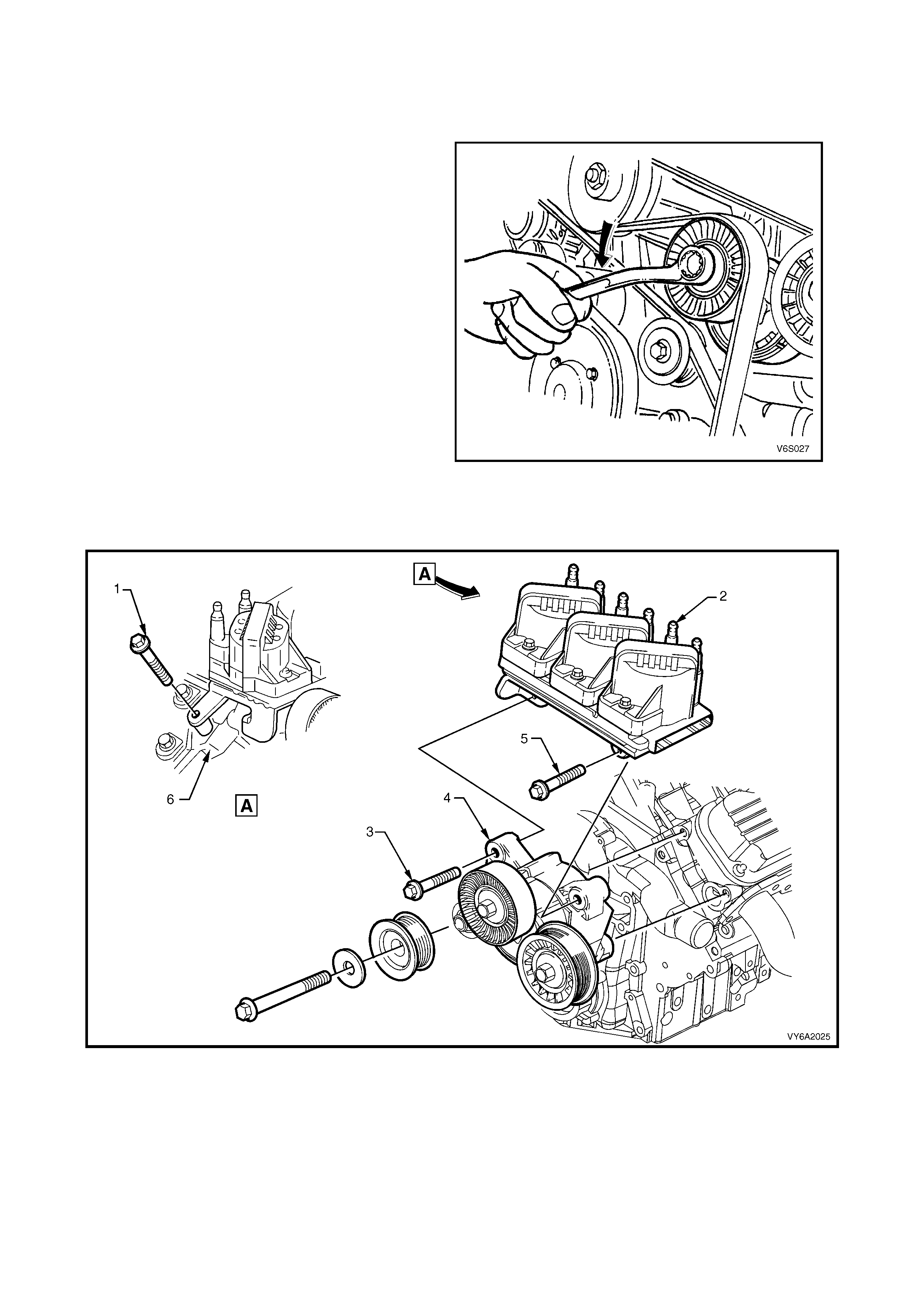

2.10 SUPERCHARGER DRIVE BELT TENSIONER ASSEMBLY

LT Section No. – 01-030

REMOVE

1. Disconnect the ground cable from the battery

terminal.

2. Rem ove the f our engi ne dr ess c over dom e nuts

and remove the cover.

3. Using a 15 mm ring spanner on supercharger

drive belt tensioner pulley pivot bolt, rotate

tensioner pulley assembly anti-clockwise and

remove drive belt from supercharger. Release

tensioner pulley assembly and remove drive

belt from remaining drive pulleys.

Figure 6A2-33

4. Remove the bolts securing the coil pack to the drive belt tensioner assembly.

5. Remove the bolts securing the drive belt tensioner assembly to the cylinder head.

NOTE: If the drive belt tension pulley is to be removed, the securing bolt has a left hand thread.

Figure 6A2-34

Legend

1. Bolt – Ignition Module Mounting Bracket

2. Ignition Module, Coil and Bracket Assembly

3. Bolt – Ignition Module and Drive Belt Tensioner

4. Drive Belt Tensioner Bracket Assembly

5. Bolt – Ignition Module and Drive Belt Tensioner

6. Le ft Hand Cylinder Head

REINST ALL

1. Ensure all fasteners are tightened to the correct torque specification, refer to 4. TORQUE WRENCH

SPECIFICATIONS in this Se ct ion .

NOTE: The DIS module and coil assembly attaching bolts must be tightened in the sequence ‘A’, ‘B’ and ‘C’ as

indicated in Figure 6A2-34.

2. Start engine and check drive belt operation.

3. SPECIFICATIONS

NOTE: Refer to Section 6A1-1 ENGINE MECHANICAL – V6 ENGINE for specifications not quoted here.

GENERAL

Engine Type............................................................... 90 degree V6 supercharged, OHV

Piston Displacement (Nominal).................................. 3791 cm3

Compression Ratio..................................................... 8.5:1

Number of Cylinders .................................................. 6

Bore x Stroke - mm .................................................... 96.5 X 86.3

Taxable HP RAC or SAE ........................................... 34

Power DIN @ RPM .................................................... 171 kW @ 5,200 rpm

Torque DIN @ RPM................................................... 375 Nm @ 3,000 rpm

4. TORQUE WRENCH SPECIFIC ATIONS

NOTE: Refer to Section 6A1-1 ENGINE MECHANICAL – V6 ENGINE for specifications not quoted here.

Nm

Boost reduction solenoid bolt................................................ 35

Bypass actuator solenoid valve attaching bolts.................... 35

Bypass harness attaching bolt.............................................. 18

Bypass valve actuator attaching bolts .................................. 26

Crankshaft balancer attaching bolt....................................... 300

Crankcase ventilation valve cover retainer screws............... 5

DIS Module attaching bolts (in sequence)............................ 45

Engine dress cover attaching nut ......................................... 5

Engine dress cover bracket attaching bolt/nut...................... 18

Fuel rail attaching bolt........................................................... 25

Fuel rail attaching nut ........................................................... 10

Radiator inlet pip e attac hin g bolt .......................................... 25

Supercharger attaching bolts (in sequence) – Stage 1....... 15

– Stage 2....... 25

Supercharger drive belt tensioner attaching bolt.................. 45

Supercharger drive belt tensioner pulley bolt....................... 45

Supercharger drive belt idler pulley bolt ............................... 50

Supercharger drive belt idler pulley bracket bolt .................. 30

Supercharger oil filler plug.................................................... 10

Throttle bod y adaptor attac hin g bolts ................................... 25

Throttle body attaching nuts ................................................. 18

Thermostat housing water outlet hose clamp....................... 3

Throttle body to intake manifold hose clamp........................ 3

Throttle cable adjusting nuts................................................. 3