SECTION 6B1 - ENGINE COOLING – V6 ENGINE

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL DESCRIPTION

2. GENERAL INFORMATION

2.1 RADIATOR

2.2 COOLING FANS – STANDARD SPECIFICATION

GENERAL DESCRIPTION

OPERATION

2.3 COOLING FANS – HIGH PO WER

SPECIFICATION

GENERAL DESCRIPTION

OPERATION

2.4 COOLING SYSTEM COMPONENTS

3. SERVICE OPERATIONS

3.1 SERVICE NOTES

3.2 COOLANT MAINTENANCE

TOPPING UP THE COOLING SYSTEM

TESTING COOLANT CONCENTRATION

3.3 CHECKING AND FILLING COOLING SYSTEM

FILLING COOLING SYSTEM WITH TOOL

AU425

FILLING COOLING SYSTEM WITHOUT

TOOL AU425

3.4 CLEANING COOLING SYSTEM

COOLING SYSTEM FLUSH

3.5 DRIVE BELT TENSION

3.6 COOLANT HOSES

3.7 PRESSURE TESTING

RADIATOR CAP TESTING

COOLING SYSTEM PRESSURE TESTING

3.8 THERMOSTAT

REMOVE

TEST

REINSTALL

3.9 COOLANT RECOVERY RESERVOIR

REMOVE

INSPECT

REINSTALL

3.10 AIR BAFFLE

REPLACE

3.11 COOLANT PUMP

REMOVE

REINSTALL

3.12 COOLING FAN AND SHROUD ASSEMBLY

REMOVE

REINSTALL

DISASSEMBLE

REASSEMBLE

3.13 FLEXIBLE TRANSMISSION COOLER HOSE

REPLACE

3.14 RADIATOR

REMOVE

REINSTALL

RADIATOR REPAIR PROCEDURE

4. ENGINE COOLING SYSTEM DIAGNOSIS

5. SPECIFICATIONS

6. TORQUE WRENCH SPECIFICATIONS

7. SPECIAL TOOLS

1. GENERAL DESCRIPTION

The cooling system for MY 2003 VY and V2 Series models with the V6 engine has been completely re-designed.

With the standard system, two, single speed electric cooling fans are mounted on the shroud, that is attached

behind the radiator. When operating on stage 1, only the right (smaller) fan motor is enabled. When stage 2 is

required, the left (larger) fan is also activated. For stage 1 then, only one fan m otor is operational but for stage 2,

both fan motors operate.

Dependent on vehicle specification, a high power cooling fan arrangement may be fitted to the vehicle. In this

situation, while the fan diameters are the same, each fan motor is dual speed and has a different power rating. Both

fan motors fitted, operate either on low speed (1st stage) or high speed (2nd stage).

Regardless of the system f itted, operat ion of the coolin g fans is depende nt on engine coolan t temperature, ve hicle

speed, A/C request (where fitted) and A/C system pressure. Refer to Section 6C1-1 POWERTRAIN

MANAGEMENT - V6 ENGINE in the MY 2003 VY and V2 Series Service Information for further information.

Also dependent on vehicle specification, is the t ype of coolant used. As requirements can change, always ref er to

the MY 2003 VY and V2 Series Owners Handbook for specific information regarding the particular vehicle being

serviced. As both coolant types are discussed in this Section, refer to the coolant applicable.

2 GENERAL INFORM ATION

2.1 RADIATOR

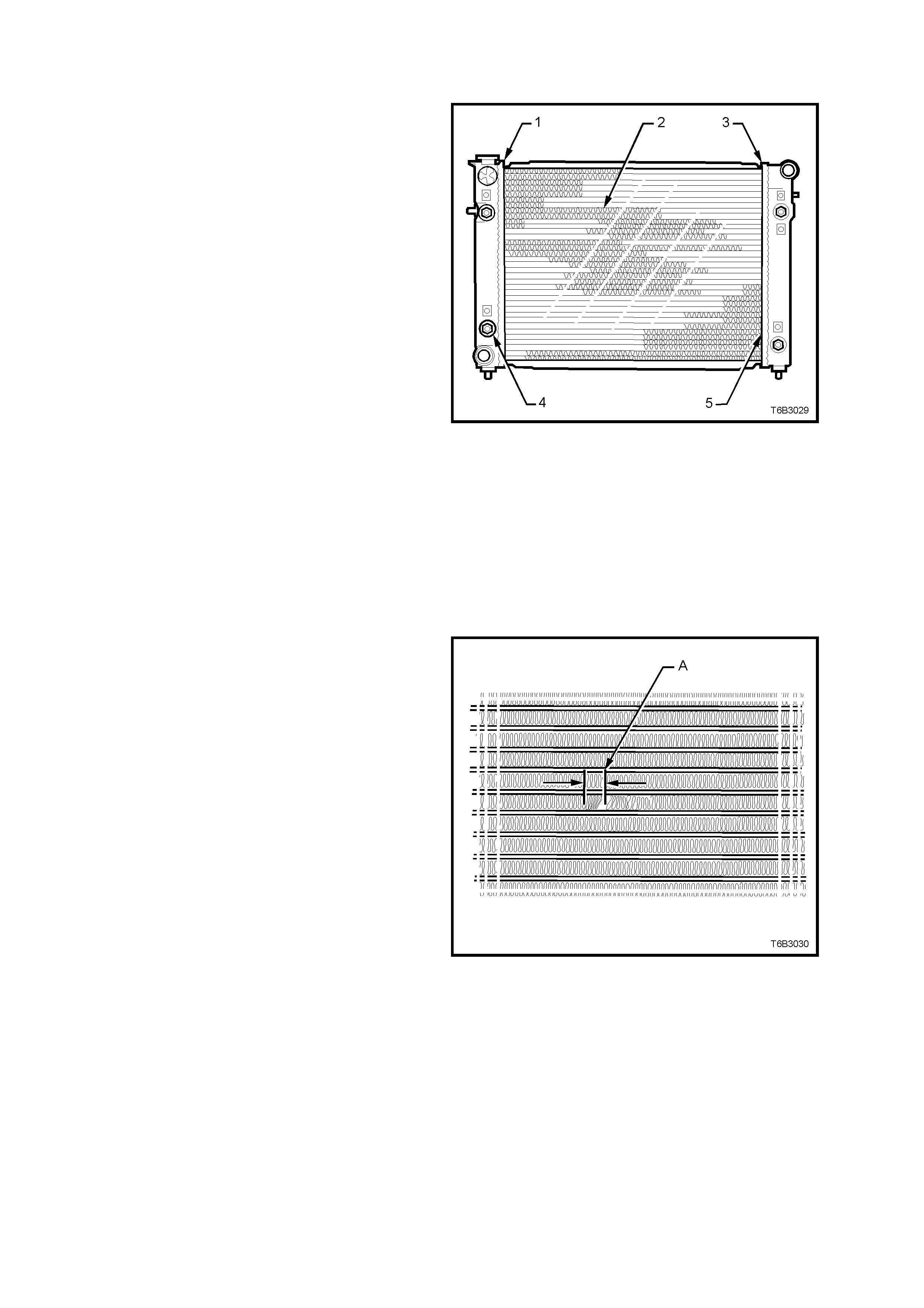

The radiat or util ises an al um inium cor e and is of the cros s-flow design, with a r adiator ca p locate d on the lef t hand

side tank. Plastic side tanks are attached to the core by the use of clinch tabs. The clinch tabs are formed as part of

the core assembly.

A high temperature rubber seal is used to seal the mating surface between the core and each side tank. The

seal(s) must be replaced any time the side tank is removed from the core.

IMPORTANT: T he radiator c ore side tank s or transm ission oi l coo ler CANNO T be r eplaced s epar atel y. If there is a

fault with any of these components, the radiator assembly must be replaced. Small core repairs may be made,

using an Aluminised Silicon based liquid repair agent, refer to 3.14 RADIATOR - RADIATOR REPAIR

PROCEDURE in this Section.

For ve hicl es with a utomatic trans miss ion, a tra ns mis sion oil cool er is loc at ed in th e left hand s id e r ad iat or tan k. The

cooler p ipes from and to the transm ission ar e connected to th e oil coo ler flexib le hoses b y means of quick connec t

fittings.

When air conditioning is fitted, the air conditioning condenser is mounted, by means of clips and brackets, to the

front of the radiator. The air conditioning receiver drier also forms a part of the complete assembly.

Pegs are attached to the lower frame and the upper area of each side tank. These pegs are used to support the

radiator in four rubber mounts. The assembly is held in position by two spring clips at the upper mounting locations.

2.2 COOLING FANS – STANDARD SPECIFICATION

GENERA L DESCRIPTION

Two, si ngle speed, en gine cooling f an m otors are used. T he smaller , right fan is 268 mm in diameter with a m otor

rated at 120 Watts, while the larger, left fan is 370 mm in diameter with a motor power rating of 160 Watts.

With 12 volts applied and the fans mounted to the radiator with a condenser fitted, the operating speeds are:

Stage 1 Stage 2

Large Fan 1,900 ± 150

rpm 1,900 ± 150

rpm

Small Fan Inoperati ve 2,350 ± 150

rpm

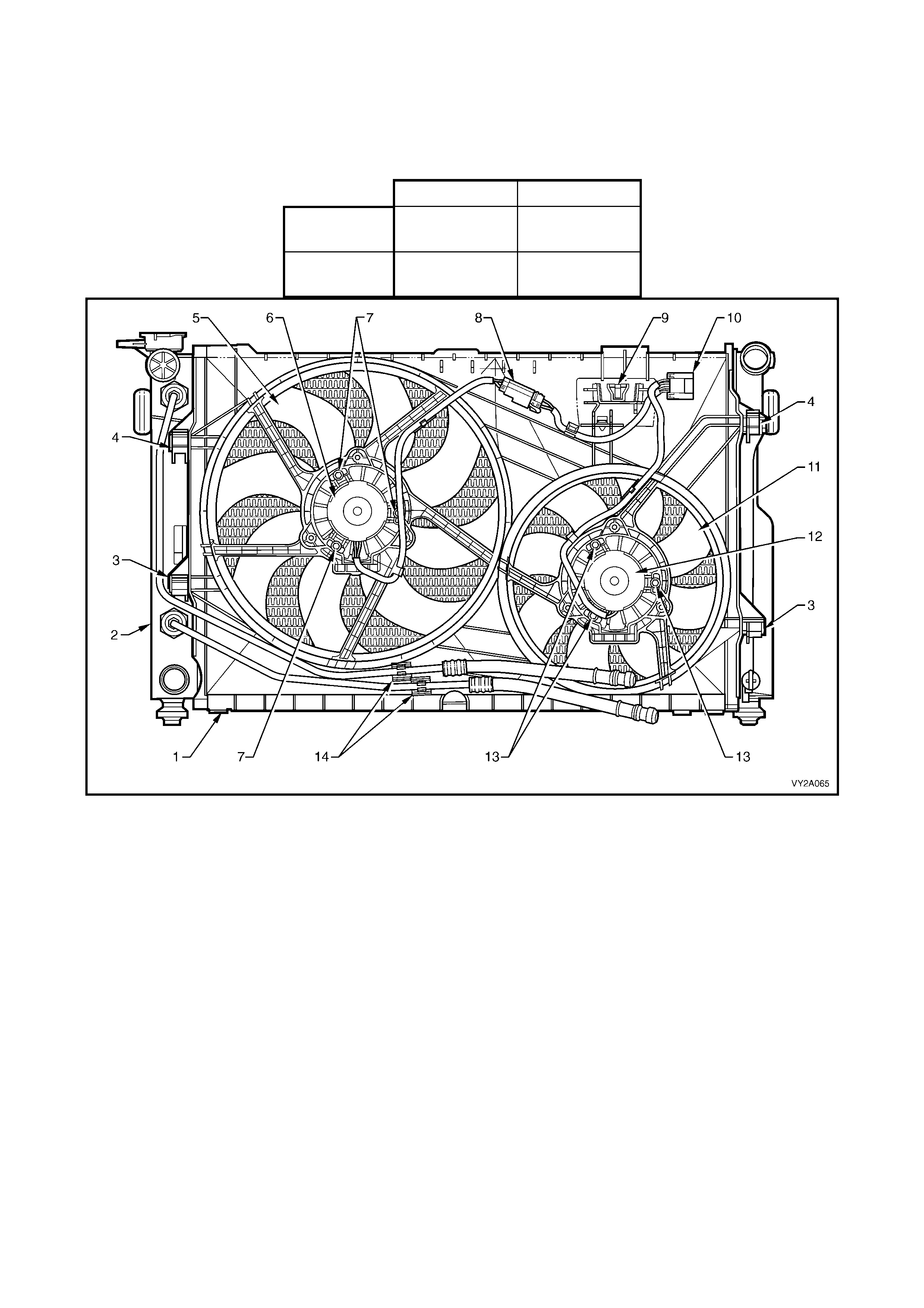

Figure 6B1-1 – Cooling Fans, V6 Engine Standard Specification

Legend

1. Fan Shroud

2. Radiator

3. Fan Shroud Lower Support

4. Fan Shroud Upper Support/Locking Retainer

5. Large, Left Fan – 8 Blade, 370 mm Diameter

6. Left Fan Motor – 160 Watt, Single Speed

7. Left Fan Motor Securing Screws (3 places)

8. Left Fan Motor Harness Connector (2 terminal)

9. Power Steering Reservoir Mount

10. Left and Right Fan Motor Harness Connector (4 terminal)

11. Small, Right Fan – 8 Blade, 268 mm Diameter

12. Right Fan Motor – 120 Watt, Single Speed

13. Right Fan Motor Securing Screws (3 places)

14. Automatic Transmission Cooling Line Retaining Clips

OPERATION

On MY 2 003 VY a nd V2 S eries m odels with V6 engi nes and s tandard s pecific ation fan m otors, eac h of the engine

cooling fan motors has two terminals; one positive and one negative. The positive terminals are permanently

connected to battery voltage, via fusible links F101 (large fan) and F107 (small fan).

W hen the negat ive t erm inal is co nnecte d to groun d

through engine cooling fan relay 1 (R7), the large

cooling fan (left) will operate. When the negative

terminal is connected to earth via the engine

cooling fan relay 2 (R5), both cooling fans will

operate.

The large (left) cooling fan operation is enabled

when the engine cooling f an relay 1 (located in the

underhood electrical centre) is energised by the

Body Contr ol Mo du le (BCM ) , via a r equest f r om the

Powertrain Control Module (PCM). The PCM will

request low speed fan enable or disable, via the

serial data Normal Mode Message to the BCM on

circuit 800 (Red/Black wire). After the PCM

requests a change in the state of the engine

cooling fan relay 1 (i.e. OFF to ON or ON to OFF),

the BCM will sen d a serial data respons e m essage

back to the PCM confirming it received the

message.

Should a response from the BCM fail to occur, a

PCM DTC P1064, will set.

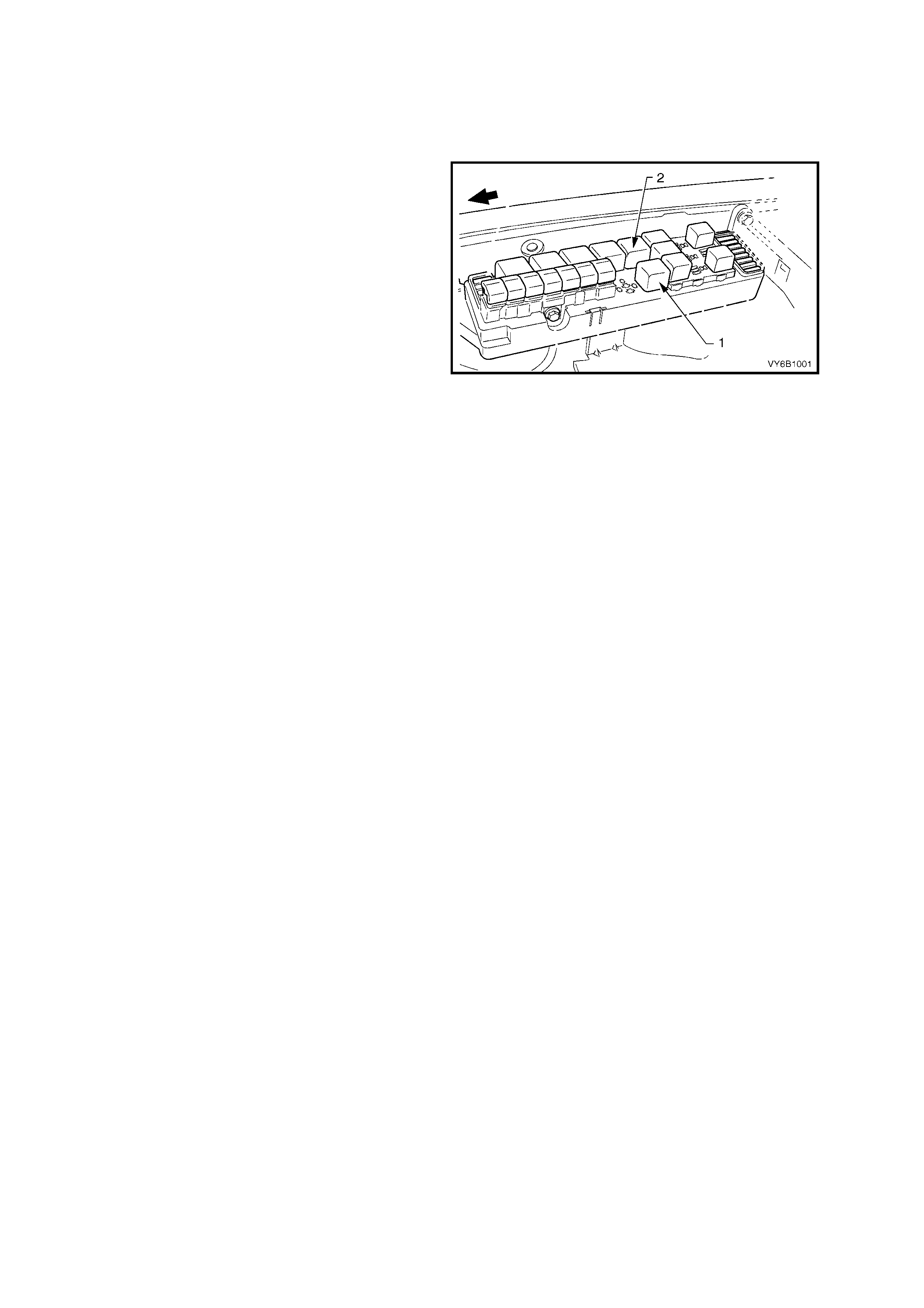

Figure 6B1-2 – Underhood Fuse & Relay Centre

The PCM d etermines whe n to enable t he engine co oling fan rela y 1, bas ed on inputs f rom the A/C re quest signal,

Engine Coolant Temperature (ECT) sensor and the Vehicle Speed Sensor (VSS).

There are also suppression capacitors incorporated into the fan motor, located on the brush holders. These

suppression capacitors help eliminate fan motor noise through the radio speakers. As these capacitors are not

serviced separately, should a problem occur with either capacitor, then the motor assembly must be replaced.

Stage One Fan Operation

1. The engine cooling fan relay 1 will be turned ON when:

• Air conditioning request indicated (YES) and the vehicle speed is less than 30 km/h or:

• Air conditioning pressure is greater than 1,500 kPa or:

• Coolant temperature is greater than 104° C or:

• An engine coolant temperature sensor failure is detected by the PCM, refer to

Section 6C1 POWERTRAIN MANAGEMENT – V6 ENGINE for additional information.

• When the ignition switch is turned from ON to OFF and the engine coolant temperature is above 117° C,

the BCM will continue to energise the engine cooling fan micro relay 1 for approximately four minutes.

2. The PCM will reques t the BCM to s witch of f the engine coo ling fan r elay 1 when th e following c onditions h ave

been met:

• Air conditioning request not indicated (NO) and the coolant temperature is less than 99° C or:

• Air co nditioning r equest indic ated (YES) with pres sure less than 1,170 k Pa, vehicle sp eed greater t han 5 0

km/h and coolant temperature less than 99° C.

Stage Two Fan Operation

The PCM determines when to enable the engine cooling fan relay 2, based on inputs from the ECT sensor.

1. The engine coolin g fan relay 2 will be turne d ON if the engine coolin g fan relay 1 has be en energised for one

second and the following conditions have been met:

• If there is a BCM message response fault, setting a DTC P1064 or:

• An engine coolant temperature sensor failure is detected by the PCM, refer to

Section 6C1 POWERTRAIN MANAGEMENT – V6 ENGINE for additional information or:

• Engine coolant temperature is above 108° C or:

• Air conditioning pressure is greater than 2,000 kPa.

NOTE: If the lar g e en gi ne cooling f an is of f when th e cr iteri a f o r tur n ing the s mall e ngine c o ol ing f an on ar e f irst

met, the small engine cooling fan will turn on 5 seconds after the large engine cooling fan is switched on.

2. If both the large and small cooling fans are enabled, the PCM will turn the small cooling fan OFF when:

• The engine coolant temperature is less than 103° C and:

• Air conditioning request is not indicated (NO) or:

• Air conditioning request is indicated (YES) and the pressure is less than 1,500 kPa.

2.3 COOLING FANS – HIGH POWER SPECIFICATION

GENERA L DESCRIPTION

Some MY 2003 VY and V2 Ser ies vehicl e specific ations m ay require the fitm ent of a high power ver sion of the t wo

fans. When this is the c as e , t wo, double s p eed, en gi n e c oo lin g f an motors ar e f itt ed. T he s mall, ri ght f an is 2 68 mm

in diam eter and has a m otor rated at 18 0 W atts, while the left f an is 370 mm in diameter with a motor power rating

of 220 Watts.

While both the standard a nd high power assemblies have the sam e diameter fans, the power rating of the electric

motors, changes and can be seen visually by the larger diameter motor for the high power assemblies.

With 12 volts applied and the fans mounted to the radiator with a condenser fitted, the operating speeds are:

Stage 1 Stage 2

Large Fan 2,000 ± 150

rpm 2,300 ± 150

rpm

Small Fan 2,350 ± 150

rpm 2,700 ± 150

rpm

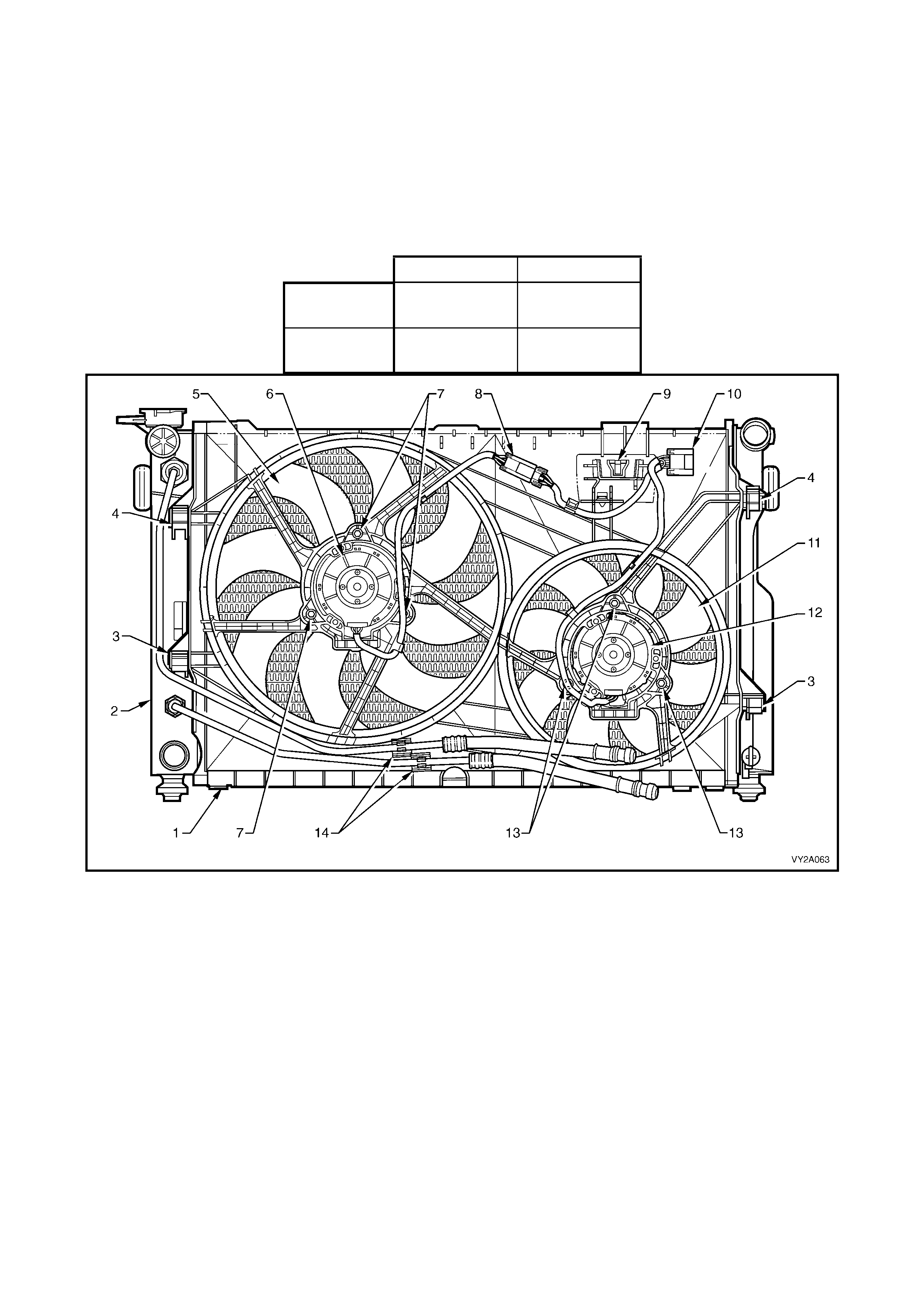

Figure 6B1-3 – Cooling Fans, V6 Engine High Power Specification

Legend

1. Fan Shroud

2. Radiator

3. Fan Shroud Lower Support

4. Fan Shroud Upper Support/Locking Retainer

5. Large, Left Fan – 8 Blade, 370 mm Diameter

6. Large, Left Fan Motor – 220 Watt, Double Speed

7. Large, Left Fan Motor Securing Screws (3 places)

8. Left Fan Motor Harness Connector (3 terminal)

9. Power Steering Reservoir Mount

10. Left and Right Fan Motor Harness Connector (5

terminal)

11. Small, Right Fan – 8 Blade, 268 mm Diameter

12. Small, Right Fan Motor – 180 Watt, Double Speed

13. Small, Right Fan Motor Securing Screws (3 places)

14. Automatic Transmission Cooling Line Retaining Clips

OPERATION

The electrical circuitry for the high power specification cooling fans is completely different to that used for the

standard specification system. Each high power fan m otor has three wires; One wire (Orange/Blue), is connected

to the battery via fusible links F101 or F107, a Low/High speed negative wire (Blue/Yellow), is grounded by the

engine coo li ng f an r elay 1 and a third , Hig h s peed n eg ati ve wire (O ra n ge Yello w) i s grounded by the eng in e c ool ing

fan relay 2. Both fusible links and the two relays are located in the underhood electrical centre.

The fan motors are also connected electrically, as follows;

• The Low/Hi gh speed nega tive wir es from each motor go thr ough the rad iator fan c onnector s eparatel y and are

spliced together in the main wiring harness before reaching engine cooling fan relay 1.

• The High speed wires from each m otor are spliced together before the radiator fan connector and go through

the connector as one circuit, to engine cooling fan relay 2.

When the High/Low negative terminal from each

motor is connected to ground via engine cooling

fan relay 1, both cooling fans will operate at stage

1 (Large f an at 2, 00 0 ± 150 rpm, Small fan at 2,350

± 150 rpm). With engine cooling fan relay 1 still

activated, when the high speed negative terminal

from eac h motor is c onnected to gro und via eng ine

cooling fan relay 2, both fans operate at stage 2

(Large fan at 2,300 rpm ± 150 rpm, Small fan at

2,700 ± 150 rpm). .

Stage 1 cooling fan operation is enabled when the

engine cooling fan micro relay 1 (located in the

underhood electrical centre) is energised by the

Body Contr ol Mo du le (BCM ) , via a r equest f r om the

Powertrain Control Module (PCM).

The PCM will request stage 1 enable or disable,

via the serial data Normal Mode Message to the

BCM on circui t 800 (Red/Black wire).

Figure 6B1-4 – Underhood Fuse & Relay Centre

After the PCM reques ts a change in the state of the low sp eed rela y ( i.e. OFF to ON or ON to OFF), the BCM will

send a serial data response message back to the PCM confirming it received the message. Should a response

from the BCM fail to occur, a PCM DTC P1064, will set.

The PCM determines when to enable stage 1, based on inputs from the A/C request signal, Engine Coolant

Temperature (ECT) sensor and the Vehicle Speed Sensor (VSS).

There are also suppression capacitors incorporated into the fan motor, located on the brush holders. These

suppression capacitors help eliminate fan motor noise through the radio speakers. As these capacitors are not

serviced separately, should a problem occur with either capacitor, then the motor assembly must be replaced.

Stage One Fan Operation

1. The cooling fan relay 1 will be turned ON when:

• Air conditioning request indicated (YES) and the vehicle speed is less than 30 km/h or:

• Air conditioning pressure is greater than 1,500 kPa or:

• Coolant temperature is greater than 104° C or:

• An engine coolant temperature sensor failure is detected by the PCM, refer to

Section 6C1 POWERTRAIN MANAGEMENT – V6 ENGINE for additional information.

• When the ignition switch is turned from ON to OFF and the engine coolant temperature is above 117° C,

the BCM will continue to energise engine cooling fan micro relay 1 for approximately four minutes.

2. The PCM will requ es t the B CM to s witc h of f engine c o oli ng f an re lay 1 when the fo llo wing c ond it ions ha ve b e en

met:

• Air conditioning request not indicated (NO) and the coolant temperature is less than 99° C or:

• Air co nditioning r equest indic ated (YES) with pres sure less than 1,170 k Pa, vehicle sp eed greater t han 5 0

km/h and coolant temperature less than 99° C.

Stage Two Fan Operation

The PCM determines when to enable the engine cooling fan relay 2, based on inputs from the ECT sensor.

1. Engine cooling fan relay 2 will be turned ON if the engine cooling fan relay 1 has been energised for one

second and the following conditions have been met:

• If there is a BCM message response fault, setting a PCM DTC P1064 or:

• An engine coolant temperature sensor failure is detected by the PCM, refer to

Section 6C1 POWERTRAIN MANAGEMENT – V6 ENGINE for additional information or:

• Engine coolant temperature is above 108° C or:

• Air conditioning pressure is greater than 2,000 kPa.

2. If stage 2 has been enabled, the PCM will revert to stage 1 operation when:

• The engine coolant temperature is less than 103° C and:

• Air conditioning request is not indicated (NO) or:

• Air conditioning request is indicated (YES) and the pressure is less than 1,500 kPa.

2.4 COOLING SYSTEM COMPONENTS

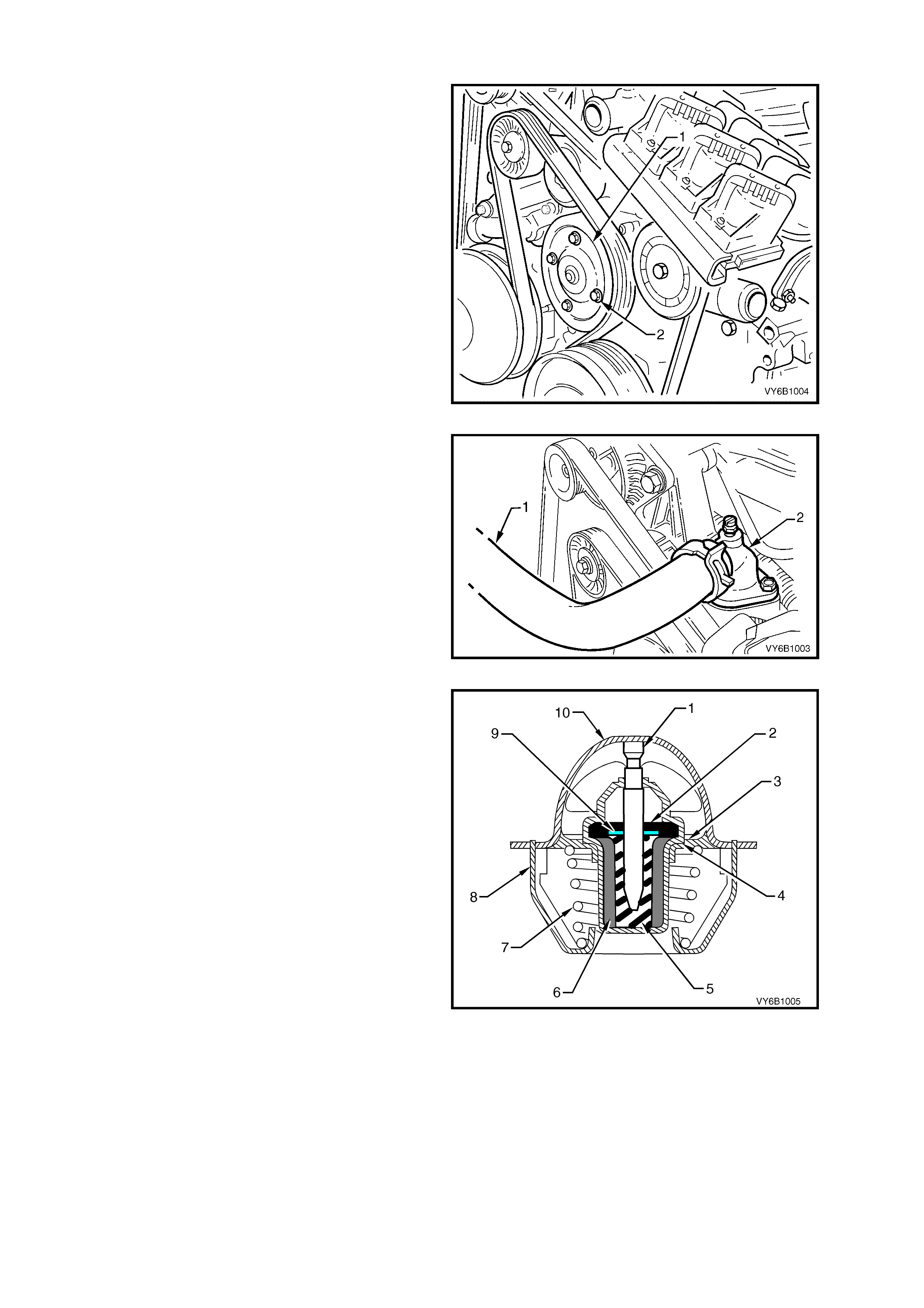

The coolant pump (1) is mounted to the engine

front cover and is driven by the multi-ribbed drive

belt, turning the pump pulley, bolted (2) to the

coolant pump flange. Coolant passes through the

engine from the coolant pump inlet at the engine

front c over and exits via th e ther mos tat and coolant

outlet at the front of the intake manifold.

Figure 6B1-5

The coolant outlet (2) is located at the front of the

intake manifold.

The thermostat is housed between the coolant

outlet and the intake manifold.

Figure 6B1-6

A wax pellet type therm ostat is used in the coolant

outlet passage to control the flow of coolant,

providing fast engine warm up and regulating

coolant temperature. The wax pellet or power

element in the thermostat, expands when heated

and contracts when cooled. The wax pellet is

connected through a piston to a valve and when

the pellet is heated, pressure is exerted against a

metal valve which is forced to open.

As the pellet is cooled, the contraction allows a

spring to close the valve. Thus, the valve remains

closed while the coolant is cold, preventing

circulation of coolant through the radiator, but

allowing the coolant to circulate throughout the

engine to warm it quickly and evenly.

As the engine becomes warm, the pellet expands

and the th erm os tat opens, perm itting the coo lant to

flow through to the radiator where heat is

transferred to the surrounding air, through the

radiator walls .

This opening and closing of the thermostat valve

permits enough coolant to enter the radiator to

keep the engine within specified temperature limits.

Legend

Figure 6B1-7

1. Piston

2. Flange Seal

3. Valve Seat

4. Valve

5. Rubber Diaphragm

6. Wax Pellet

7. Spring

8. Frame

9. Teflon Seal

10. Flange

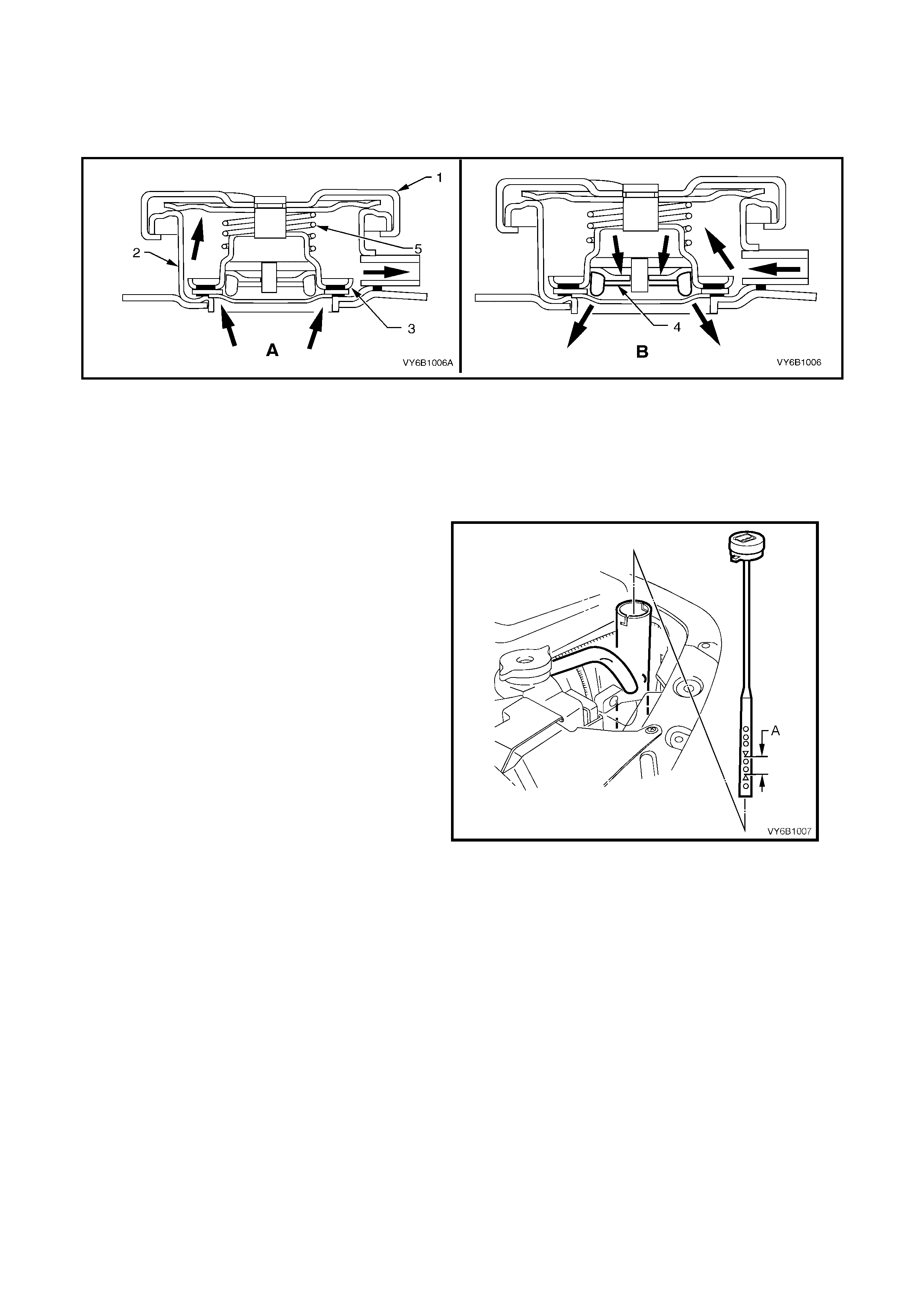

A radiator cap (1), fitted to the radiator filler neck (2), causes the cooling system to operate at higher than

atmospheric pressure. The higher pressure, raises the boiling point of the coolant, resulting in increased engine

cooling efficiency. The radiator cap contains a pressure valve (3) and a vacuum (atmospheric) valve (4).

Referring to view ‘A’, The pressure valve is held against its seat by a spring (5), which determines the maximum

operating pressure of the cooling system (135 kPa for V6 engine).

Figure 6B1-8

Referring to view ‘B’, The vacuum valve (4) is held against its seat by a light spring (not illustrated) and opens

during cool down because of the drop in pressure with contraction of the coolant volume. This pressure drop over-

comes the spring force and the valve is opened, preventing the radiator hoses from collapsing. In addition, coolant

can also flow back into the cooling system, from the coolant reservoir, while this valve is open.

NOTE: Should the radiator pressure cap require replacement, only fit the correct pressure rating cap for this

engine. Refer to the current release of PartFinder® for this information.

The coolant is maintained at the ideal level in the

radiator by the radiator cap and the coolant

recovery reservoir, resulting in increased cooling

efficiency.

The c oolant r ec ov ery reser vo ir is loc a ted on t he lef t

hand fr ont of the e ng ine c o mpartm ent, bet ween th e

radiator support panel and air cleaner assembly.

The coolant recovery reservoir is connected to the

radiator overflow connection by a hose.

As the engine temperature rises, the coolant is

heated and expands. The fluid displaced by

expansion f lows from the radiator into the recover y

reservoir.

When the engine is turned 'OFF', the coolant

contracts as it cools. Coolant is then drawn back

into the radiator through the radiator cap

atmospheric valve.

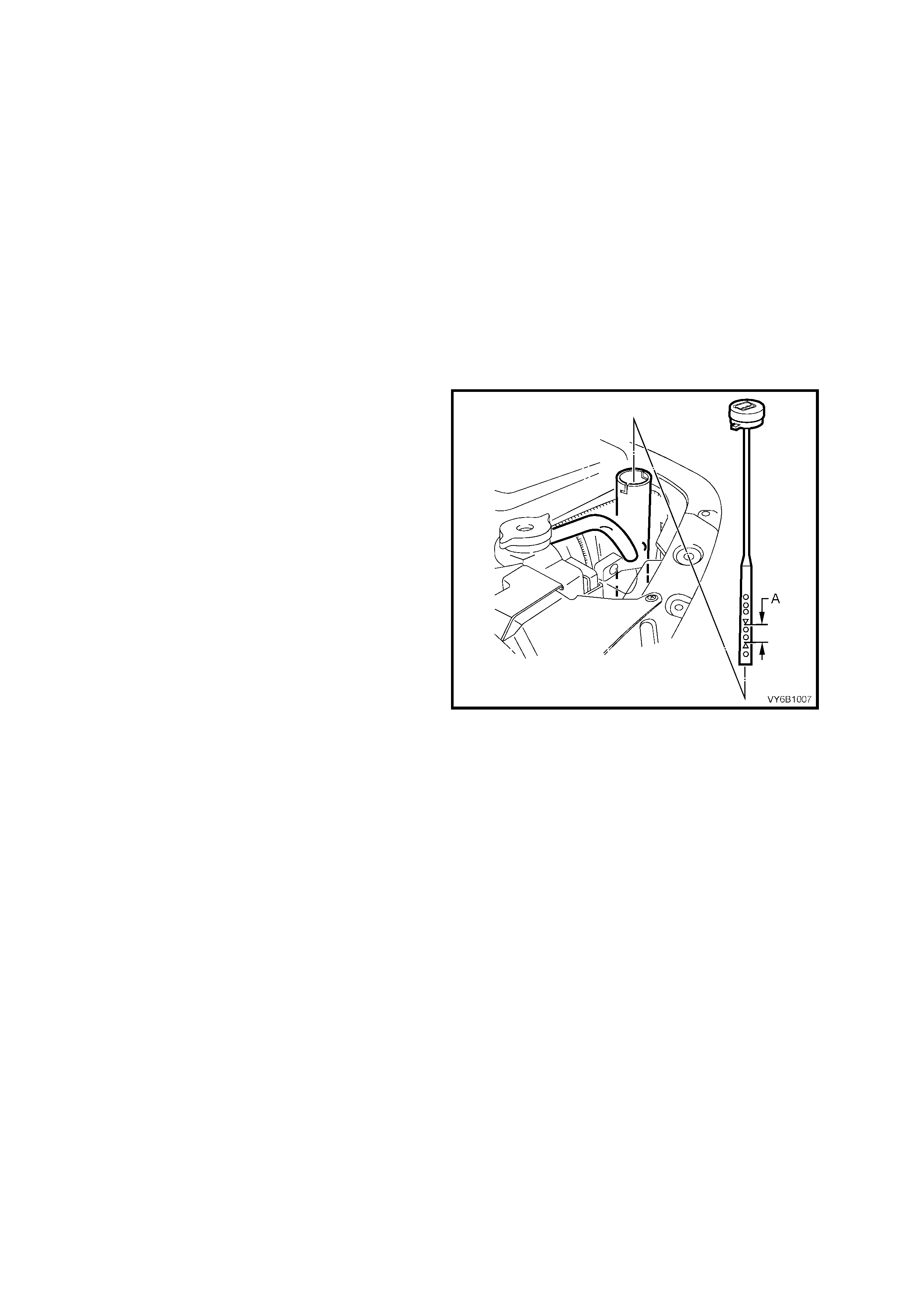

Coolant level should be maintained between

indicator arrows (‘A’) on the coolant recovery

reservoir di ps tic k when the eng ine is cold.

Figure 6B1-9

The cooling system is designed to use a coolant (a mixture of ethylene glycol antifreeze and corrosion inhibitors

and water), rather than plain water to maintain the integrity of the cooling system, and to prevent oxidation

occurring within the engine.

NOTE: Some MY 2003 VY and V2 Series vehicle mark ets may call for an alternative coolant, known as exte nded

life anti-freeze coolant, conforming to GM6277M. If in doubt regarding the correct coolant to be used, refer to the

MY 2003 VY and V2 Series Owner’s Handbook.

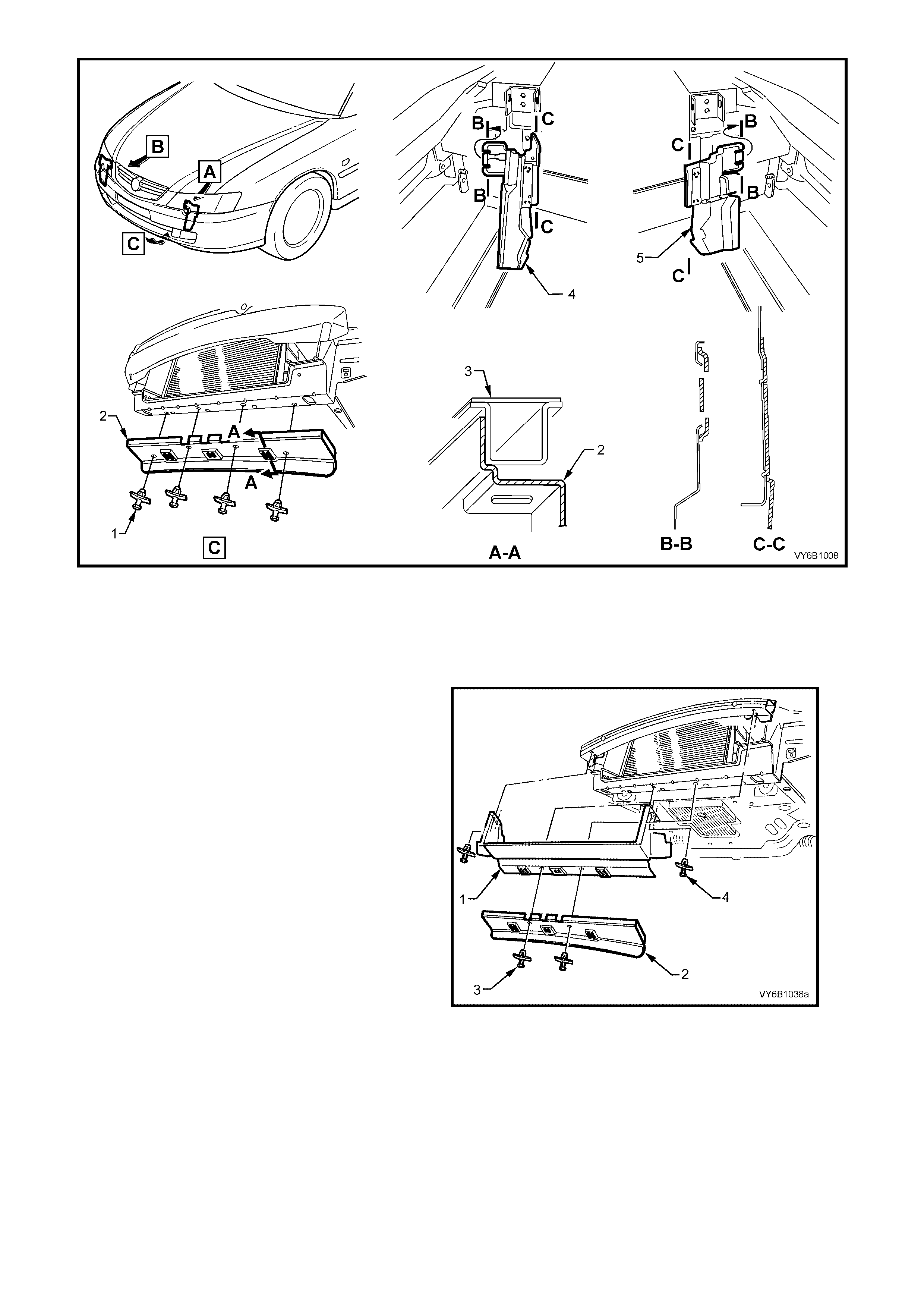

An air baffle and side chutes are fitted to the front end of the vehicle to direct and promote air flow through the

radiator to provide maximum cooling. With ‘S’ pack series vehicles (except Utility), a front duct is fitted that is in

addition to the air baffle, refer to Figure 6B1-11 for details.

The purpose of the air baffle is to create a low pressure area behind the radiator whilst the vehicle is at speed.

This enables additional air flow through the radiator core to maintain the desired engine cooling.

The air baf f le or side c hute s s hould ne ver be r em oved unl ess f or s ervice work. If either the a ir baff le or sid e c hutes

are damaged, this will reduce the cooling system efficiency, and therefore they must be replaced.

Figure 6B1-10

Legend

1. Plastic Fastener ( 4 places

2. Lower Air chute Baffle 3. Front Crossmember

4. Right Side Air chute

5. Left Side Air chute

‘S’ pack vehicles (except Utility) have a front air

duct (1) fitted, in addition to the lower air chute

baffle (2), to concentrate more air flow through the

radiator core.

The two central ‘scrivets’ (3), secure both the air

duct and the lower air chute baffle to the front

crossmember, while the two outer scrivets (4)

attach the air duct to the front upper panel

assembly.

Figure 6B1-11

An upper radiator shroud (4) is fitted between the

upper radiator support panel and the radiator

assembly, to minimise the recirculation of hot air

from the rear of the radiator back over the core.

The shroud (4) is held in place by four plastic

‘scrivet' fasteners (3) and by two locating tabs (5).

A inlet air duct (2) is mounted to the shroud with

two plastic fasteners (1)

Figure 6B1-12

A coolant tem perature s ensor ( 1) is mounted in th e

front of the intake manifold. The coolant

temperature sensor is used in conjunction with the

instrument panel temperature gauge. The coolant

temperature sensor generates a signal which is

used by the engine management PCM/BCM for

calculation of the various engine management

functions.

Figure 6B1-1 3 shows the wirin g harness conn ector

(3) installed to the sensor (1) and retained in

position by the locking tang 2.

Figure 6B1-13

3. SERVICE OPERATIONS

3.1 SERVICE NOTES

CAUTION: TO AVOID SE RIOUS PER SON AL INJU RY, NEVER REMOVE T HE R ADIATOR C AP OR OP EN THE

AIR VENT VALVE ON THE COOLANT OUTLET WHEN THE ENGINE IS HOT, EVEN IF THE COOLING

SYSTEM SHOULD REQUIRE FILLING. SUDDEN RELEASE OF COOLING SYSTEM PRESSURE IS VERY

DANGEROUS.

1. Before removing the radiator cap, allow the engine to cool, then place a shop rag over the radiator cap and

then slowly turn the cap anti-clock wise, without pressing down until t he cap reaches the first 'stop'. This is the

pressur e relief stop, which will al low any rem aining pr essure within the s ystem to escape. T hen press down on

cap and continue to rotate it anti-clockwise until it can be removed.

2. The vehicle is fitted with radiator electric cooling f ans. W hen working around the engine com partment with the

engine ru nning or with the ignit ion 'ON', k eep clear of the f an as the lar ge (or bot h) ma y start operating without

warning.

3. The cooling system requires little care except for maintaining the coolant to the correct level in the recovery

reservoir an d periodic servicing at the time or distance intervals as outlined in the MY 2003 VY and V2 Series

Owner's Handbook.

Periodic servicing includes

a. Checking coolant level, refer to 3.3 CHECKING AND FILLING COOLING SYSTEM this Section.

b. Checking coolant concentration, refer to 3.2 COOLANT MAINTENANCE - TESTING COOLANT

CONCENTRATION this Section.

c. Pressure test cooling system and radiator cap, refer to 3.7 PRESSURE TEST ING in this Section.

d. Tighten h ose clam ps and inspec t all hoses , refer to 3. 6 COOL ANT HOS ES in this Section. Re place hose s

if swollen or deteriorated.

CAUTION: Always wear protective safety glasses when working with spring type hose clamps.

Failure to do so could result in eye injury.

e. Clean out cooling system, refer to 3.4 CLEANING COOLING SYSTEM - COOLING SYSTEM FLUSH, in

this Section and refill cooling system, refer to 3.3 CHECKING AND FILLING COOLING SYSTEM in this

Section.

4. To reduce environmental im pact and maintenance cost, whene ver the coolant is drained f rom an y eng ine, the

service records are to be checked to determine when the coolant was last changed. If more than six months life

is left before the next coolant change, then the following procedure is to be followed:

a. When drai ning the cool ant fr om the en gine, use a clean co ntainer of at least 1 2 litres ca pacity and ensure

that the coolant is not contaminated in the draining process.

b. After repairs have been completed, refill the engine cooling system with the drained coolant.

c. Top up as required , using a 50/50 m ix of clean water and the recommended coola nt, which is either ‘New

Formula Long Life All Seasons Coolant’ (to HN2043 Specification or equivalent) or extended life

anti-freeze coolant, conforming to GM6277M. Refer to 3.2 COOLANT MAINTENANCE and

2.3 CHECKING AND FILLING COOLING SYSTEM in this Section, for the necessary procedures and

further information.

3.2 COOLANT MAINTENANCE

IMPORTANT: Do not mix different types of anti-freeze or corrosion inhibitors as they may be incompatible. If a

different type has been used in the cooling system, flush the system with clean water, refer to

3.4 CLEANING COOLING SYSTEM - COOLING SYSTEM FLUSH in this Section and refill cooling system with the

correct coolant, refer to 3.3 CHECKING AND FILLING COOLING SYSTEM in this Section.

The cooling system is designed to use a coolant (a mixture of ethylene glycol antifreeze with added corrosion

inhibitors, and water), rather than plain water. The use of glycol also raises the boiling point and increases the

cooling system efficiency. For this reason, it is of the utmost importance that the correct concentration level of

ethylene glycol in the cooling system is maintained.

Addition of plain water into the cooling system when 'topping-up' may dilute the coolant mixture to a point where the

antifreeze/anti-boil and corrosion inhibitor properties of ethylene glycol become ineffective.

The coolant should comprise of a mixture 50% ethylene glycol antifreeze/inhibitor with 50% clear, clean water.

Ethylene glycol conforming to the correct specification is either named 'New Formula Long Life All Seasons

Coolant' (to HN2043 Specification or equivalent) or, extended life anti-freeze coolant, conforming to GM6277M,

both available in a number of different quantities. Check the current release of PartFinder® for specific details.

TOPPING UP THE COOLING SYSTEM

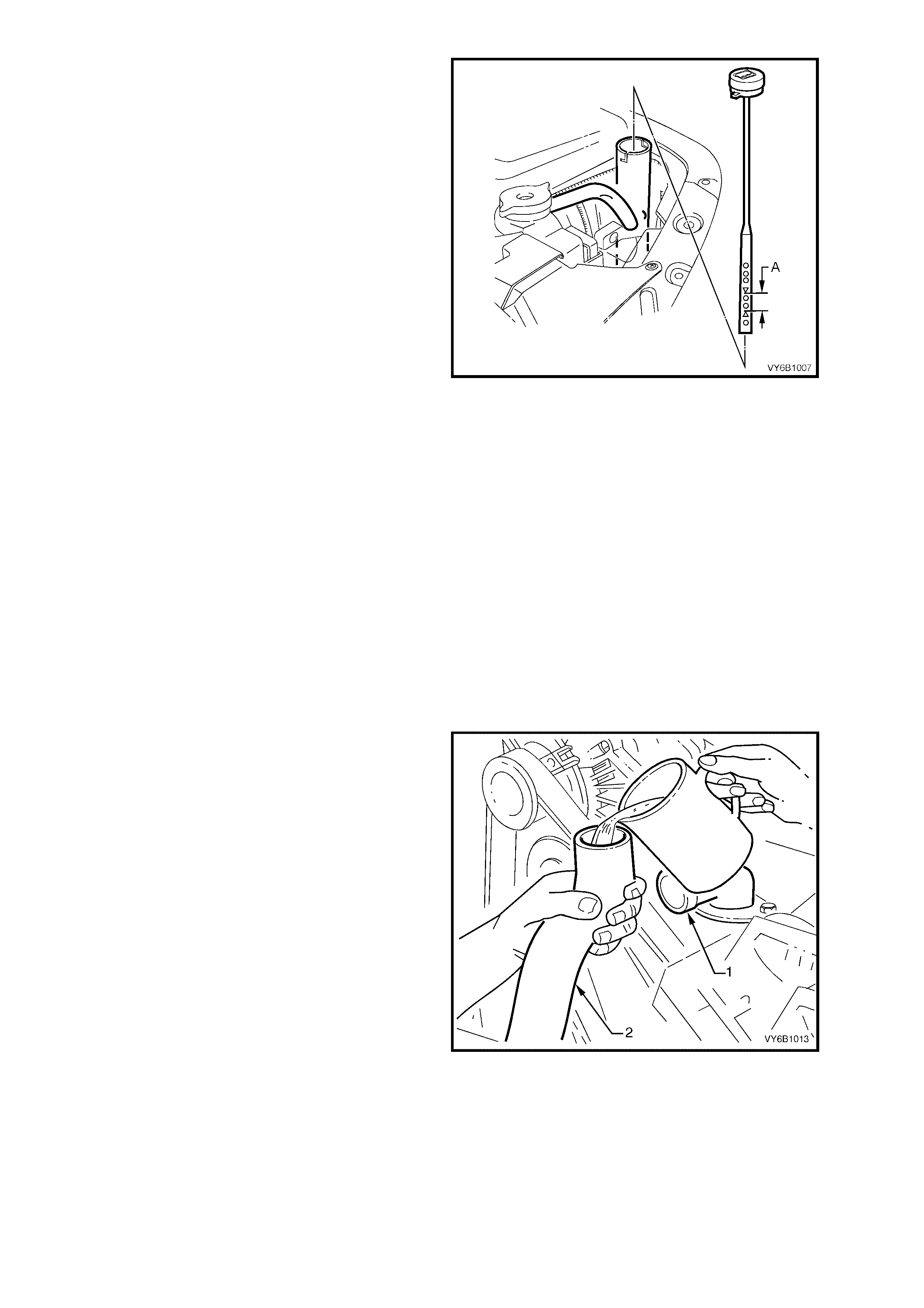

Under normal operating conditions, the cooling

system should not be topped up at the radiator filler

cap. The level can be checked at the coolant

recovery reservoir, and coolant (in the correct

concentration with clear, clean water) added as

necessary to bring the level to between the

indicator arrows (‘A’) on the coolant recovery

reservoir di ps tic k when the eng ine is cold.

Figure 6B1-14

TESTING COOLANT CONCENTRATION

To ensure the specified ethylene glycol concentration is maintained in the engine coolant, the coolant concentration

must be checked at the time or distance intervals outlined in the MY 2003 VY and V2 Series Owner's Handbook.

NOTE 1: W hile a number of coolant concentrat ion m easuring devices are availab le, the two pref erred types ar e as

described.

NOTE 2: The procedures detailed, apply to either coolant type used.

Method 1 - Refractometer

NOTE 1: Coolant tester, Tool No. J 26568, automatically compensates for temperature.

NOTE 2: Ensure that the eyepiece of the tester is free of coolant before looking through it.

NOTE 3: Before each use, swing back the plastic cover at the slanted end of the coolant tester, exposing the

measuring window and the bottom of the plastic cover. Carefully wipe the measuring window dry with a tissue or

clean, soft cloth. Close the plastic cover.

1. Check the calibration of the coolant tester as follows:

a. Place a few drops of distilled water (between 21 – 29° C) onto the measuring window, then close the

plastic cover.

b. Point the tester toward any light source, look into the eyepiece and check that the indicated reading is zero.

If not, then re-calibrate the tester as detailed at the end of this Test Method; CALIBRATING THE TESTER.

2. Release the tip of the bulb pump from under

the refractometer body. It is not necessary to

remove the complete pump from the tool.

3. Carefully remove the radiator cap.

CAUTION: Refer to 3.1 SERVICE NOTES in

this Section, for important safety items.

4. Insert the tube of the pump into the coolant,

then press the bulb to obtain a sample.

5. Bend the tube around and insert the end into

the cover plate opening.

6. Press the pump bulb to deposit a few drops of

coolant onto the measuring surface. Do not

open the plastic cover when taking readings,

as moisture evaporation will change the

reading obta ined.

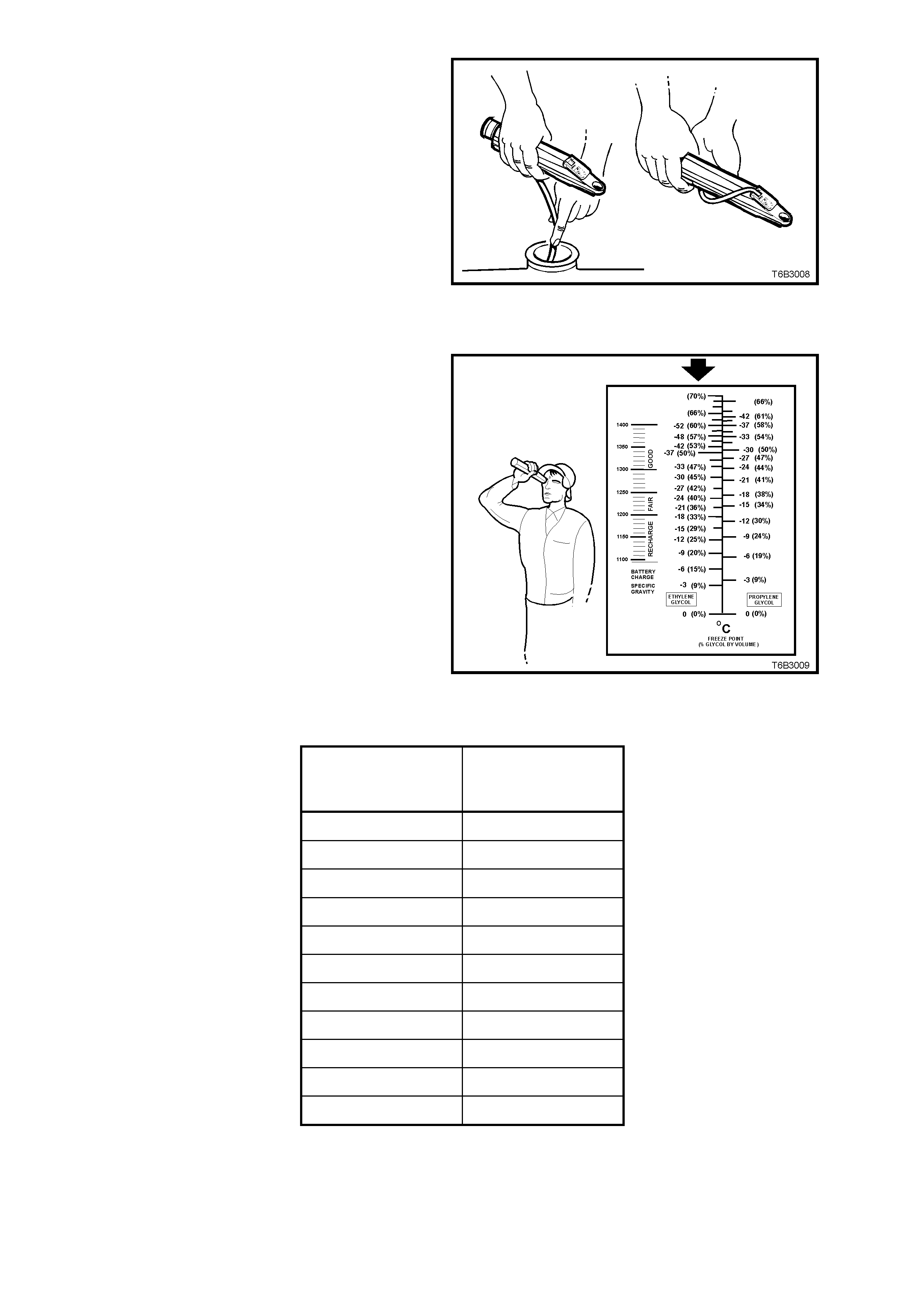

Figure 6B1-15

7. Point the coolant tester toward any light

source, looking into the eyepiece.

a. The coolant protection reading is at the

point where the dividing line between the

light and dark, crosses the scale.

b. The scale for ethylene glycol (bold arrow)

is the reference scale for either 'New

Formula Long Life All Seasons' (to

HN2043 Specification or equivalent) or

extended life anti-freeze coolant,

conforming to GM6277M.

NOTE: The temperature scale is reversed from

that of a conventional thermometer. Below zero

readings are on the upper half of the scale.

8. A reading between -30 and -52° C

(corresponding to a coolant concentration

between 45 - 60%), is satisfactory for the V6

engine cooling system.

Figure 6B13-16

CONCENTRATION

READING % LITRES OF

COOLANT TO BE

ADDED

0 6.0

5 5.7

10 5.3

15 4.9

20 4.5

25 4.0

30 3.4

35 2.8

40 2.0

45 1.1

50 0

Table 1

NOTE: If the reading is not clear, then properly

clean and dr y the m easuring sur face, then conduct

another test. Also ensure that there is sufficient

fluid on the measuring prism.

2. If the reading shows that the concentration

level of the coolant is inadequate, refer to the

previous table to determine the amount of

coolant that needs to be added to the coolant

reservoir tank.

3. Start and run the e ngine until n ormal operat ing

temperature is reached, to allow the added

coolant to be distributed throughout the engine

cooling system.

Figure 6B3-17

Calibrating the Tester

While the coolant tester calibration is checked at manufacture, if the calibration check detailed in Step 1 of this

method shows that the instrument is not reading correctly, then conduct the following re-calibration procedure;

1. Remove the sealant covering the adjustment screw on the underneath of the tester.

2. With a distilled water sample on the measuring surface, carefully adjust the screw until a zero reading is

obtained.

NOTE: DO NOT completely remove the screw.

3. After re-calibration, reseal the screw with a small amount of silicone sealant.

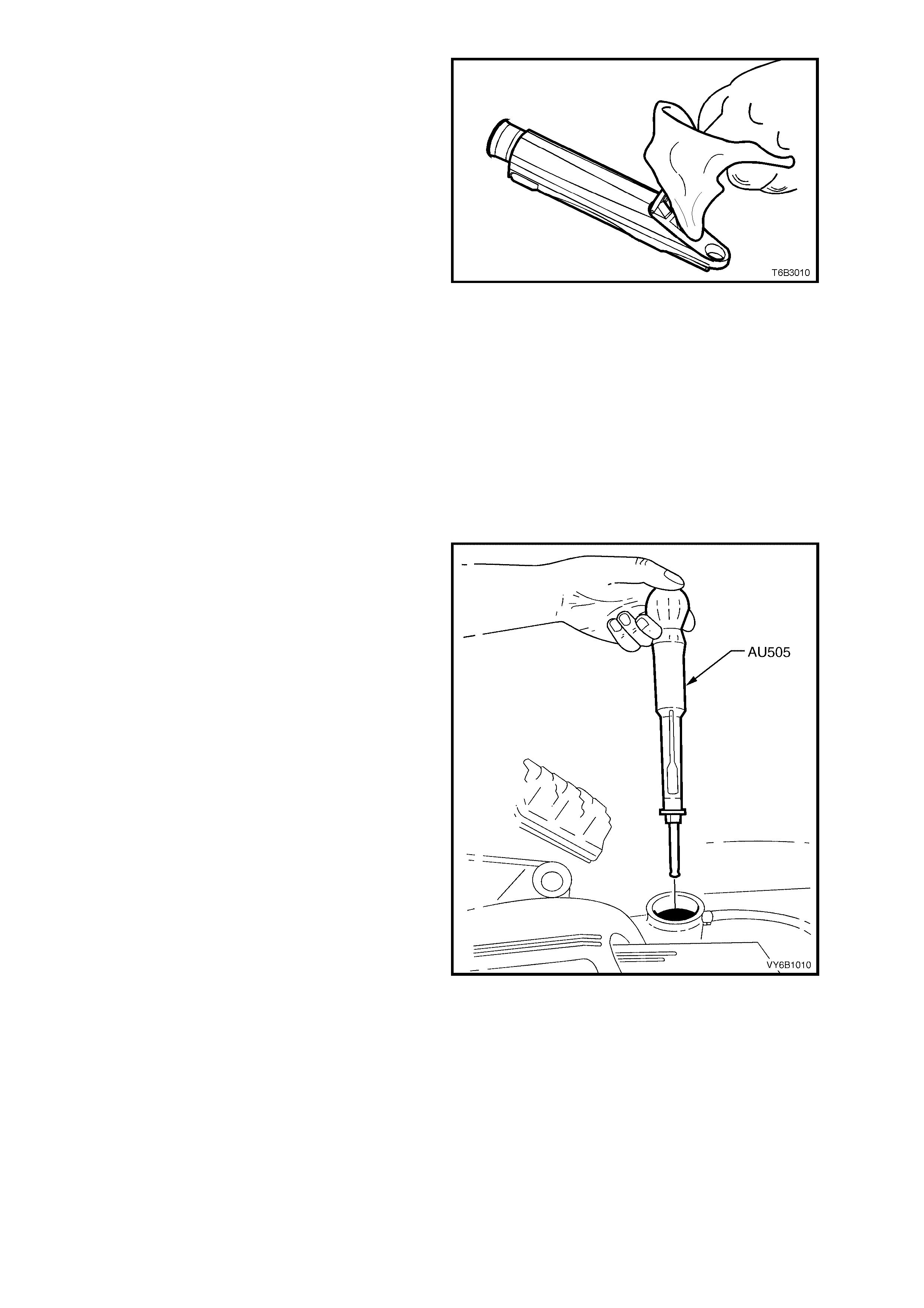

Method 2: – Hydrometer

1. The cooling system should be at or close to ambient temperature.

2. Carefully remove the radiator pressure cap

from the radiator and, while holding the rubber

bulb squeezed, insert nozzle of coolant tester

hydrometer, Tool No. AU505 into coolant.

Releasing the rubber bulb will then draw

sufficient coolant into the tester to float

hydrometer bulb freely.

3. Hold tester at eye level and read scale on

hydrometer bulb at coolant level.

The reading shows the percentage of ethylene

glycol antifreeze contained in the engine

coolant.

4. The hydrometer reading should show 50% if

the coolant concentration is correct.

If a reading of less than 50% is achieved, the

cooling system requires topping up with either

'New Formula Long Life All Seasons Coolant'

(to HN2043 Specification or equivalent) or

extended life anti- free ze coolant, c onform ing to

GM6277M.

Refer to the chart shown for the previous

method to determine how much coolant

additive of either type is required to be added

to the cooling system to bring the coolant to the

specified concentration.

5. Drain suf ficient quantit y of coola nt from coolin g

system to allow top-up with coolant additive,

then add the required amount of the correct

additive. Reinstall pressure cap to the radiator.

6. Start and run the e ngine until n ormal operat ing

temperature is reached. This will allow the

added coolant to be distributed throughout the

engine cooling system.

Figure 6B3-18

3.3 CHECKING AND FILLING COOLING SYSTEM

During any service operation that requires the cooling system to be partly or completely drained, the following

instructions must be followed when refilling the cooling system, to ensure that all air is bleed from system.

FILLING COOLING SYSTEM WITH TOOL AU425

The f ollowing proce dure re quires the us e of T ool No. AU425 to f ill the c ooling s ystem . An alternative procedur e for

filling the cooling system is also given, should Tool No. AU425 not be available.

1. Set heater control to maximum.

2. Make up a mixture consisting 50% of either 'New Formula Long Life All Seasons Coolant' (to HN2043

Specification or equivalent) (or extended life anti-freeze coolant, conforming to GM6277M) with 50% clear,

clean water.

IMPORTANT: Do not mix different types of anti-freeze or corrosion inhibitors as they may be incompatible.

Always check which coolant is to be added to the particular vehicle being serviced. If a different type has

been used in the cooling system (or is added accidentally), flush the system with clean water, refer to

3.4 CLEANING COOLING SYSTEM - COOLING SYSTEM FLUSH in this Section.

3. If the cooling system was completely drained, add a pack of pellets (three pellets), P/N M40124 to cooling

system by disconnecting radiator upper hose from engine coolant outlet and placing pellets inside radiator

hose. If cooling system was only partially drained, add one pellet for every four litres of coolant replaced.

IMPORTANT: Pellets are not to be used when the specified coolant is extended life anti-freeze coolant,

conforming to GM6277M.

CAUTION: Always wear protective safety glasses when working with spring type hose clamps. Failure

to do so could result in eye injury.

Refit hose to coolant outlet and tighten hose clamp.

4. Remove radiator cap and install Tool No. AU425 to radiator filler neck.

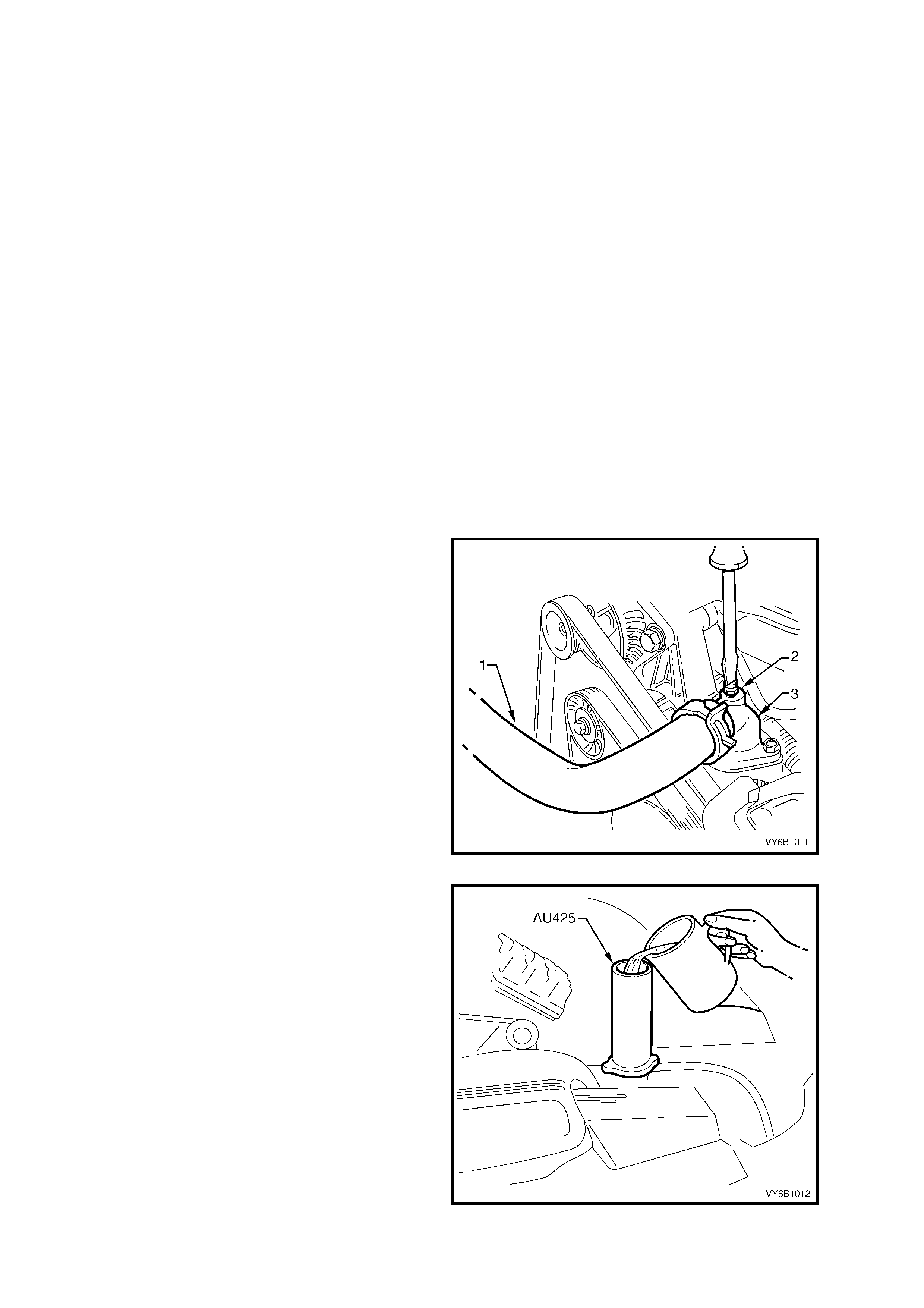

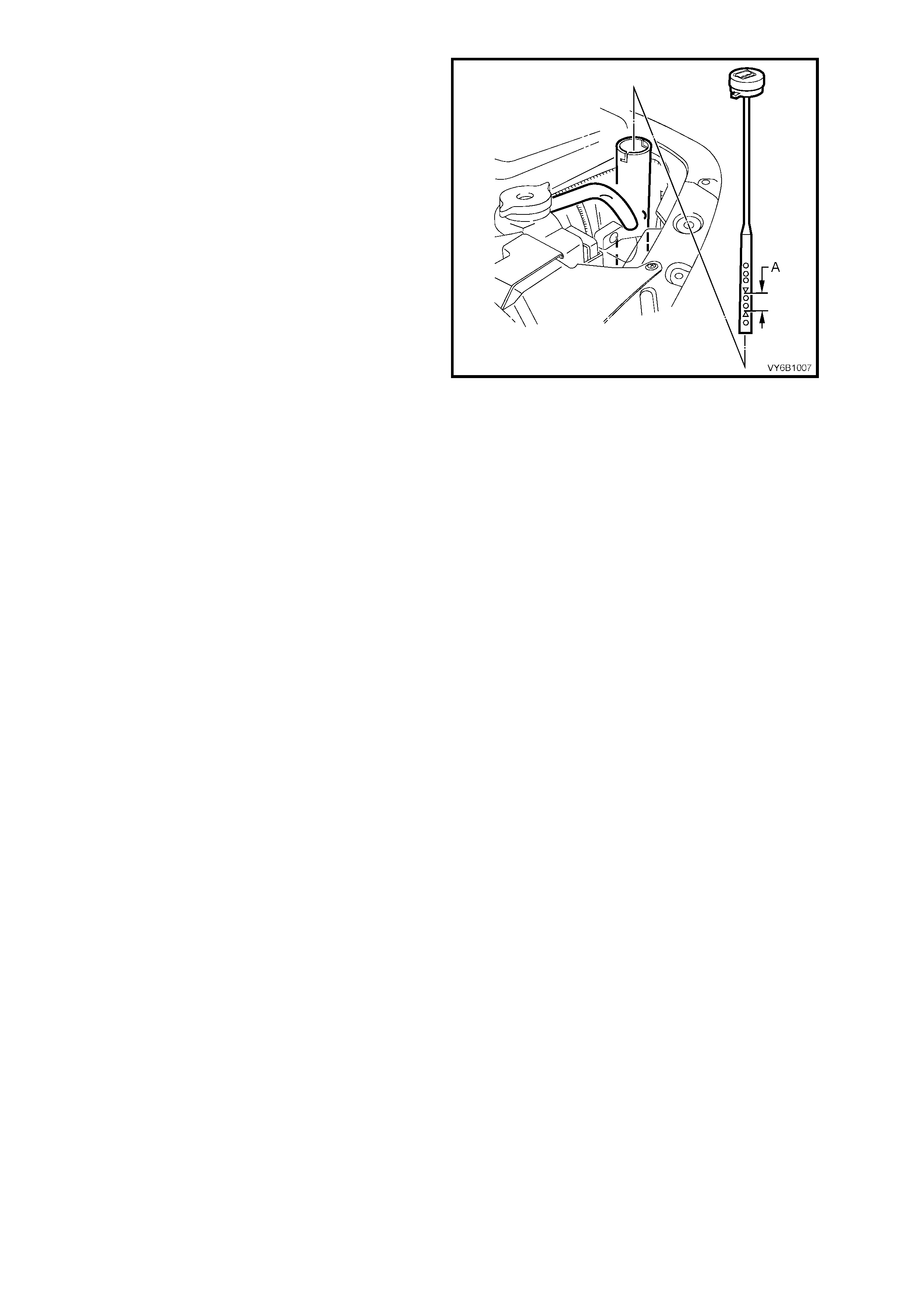

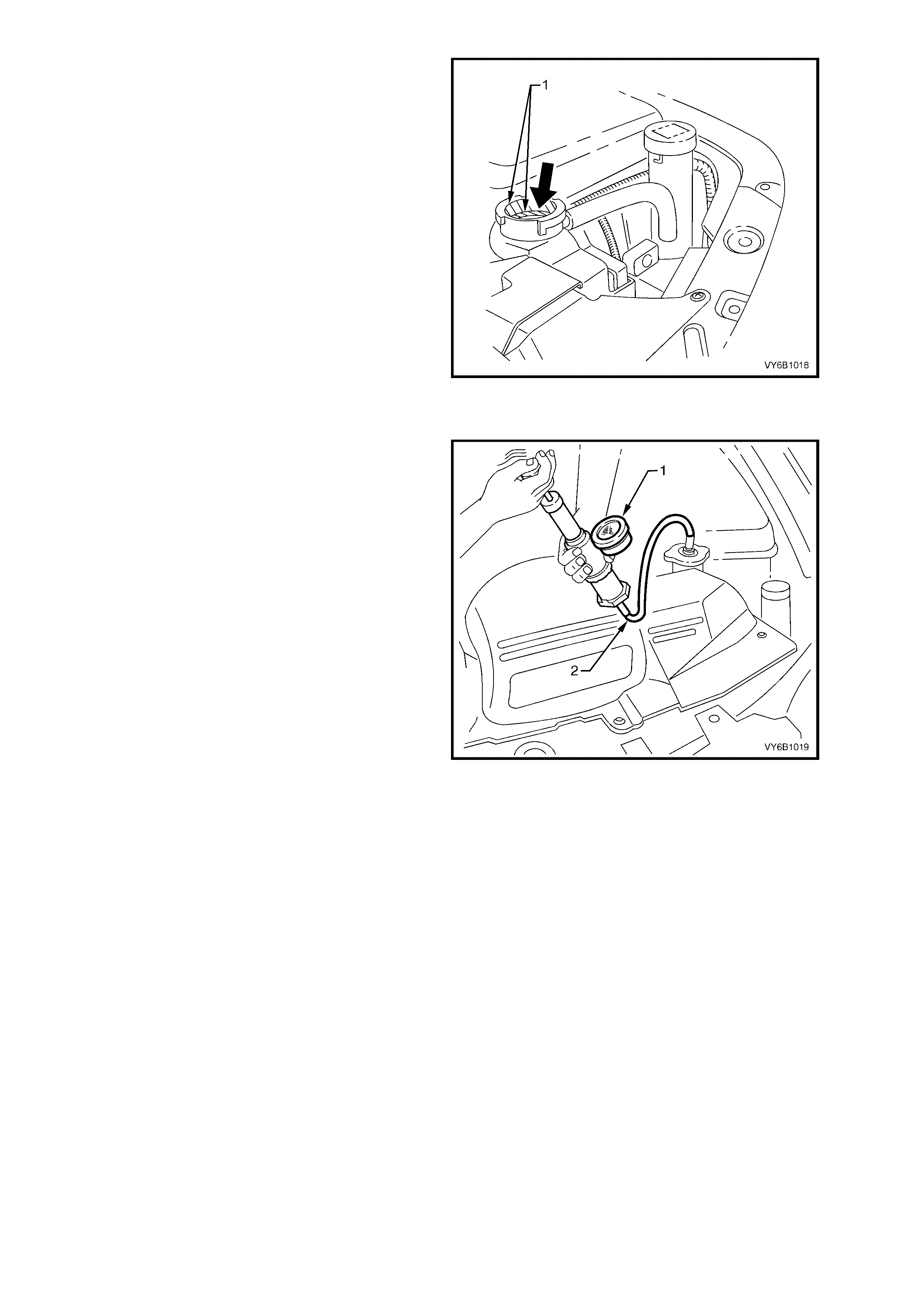

5. Using a screwdriver, open air vent valve (2) at

coolant outlet (3), to which is fitted the top

radiator hose (1).

Figure 6B1-19

6. Fill cooling system using coolant mixture via

Tool No. AU425 until coolant flows from air

vent opening and all air is expelled.

7. Close air vent valve and remove AU425 from

radiator.

Figure 6B1-20

8. If necessary, remove cap from coolant

recovery reservoir and fill to between the

indicator arrows (‘A’) on the coolant recovery

reservoir di ps tic k when the eng ine is cold.

Figure 6B1-21

9. Pressure test cooling system, refer to 3.7 PRESSURE TESTING in this Section.

10. Refit radiator cap.

FILLING COOLING SYSTEM WITHOUT TOOL AU425

Should Tool No. AU425 not be available, an alternative method of filling the cooling system is detailed next.

1. Set heater control to maximum.

2. Make up a mixture consisting 50% of either 'New Formula Long Life All Seasons Coolant' (to HN2043

Specification or equivalent) (or extended life anti-freeze coolant, conforming to GM6277M) with 50% clear,

clean water.

IMPORTANT: Do not m ix diff erent types of ant i-fr eeze or cor rosion inhibit ors as the y may be inc ompatib le. Alwa ys

check which coolant is to be added to the particular vehicle being serviced. If a different type has been used

in the cooling system (or is added accidentally), flush the system with clean water, refer to

3.4 CLEANING COOLING SYSTEM - COOLING SYSTEM FLUSH in this Section.

3. Remove radiator cap and fill cooling system with as much coolant mixture as possible.

4. Replace radiator cap.

5. Loosen radiator upper hose clamp at coolant

outlet (1) and remove hose (2) from engine

coolant outlet.

CAUTION: Always wear protective safety

glasses when working with spring type hose

clamps. Failure to do so could result in eye

injury.

6. Holding disconnected end of radiator upper

hose (2) upward, fill cooling system using

coolant mixture via open end of radiator upper

hose until coolant starts to flow from coolant

outlet (1).

Figure 6B1-22

7. If cooling system was completely drained, add a pack of pellets (three pellets), P/N M40124 b y placing pellets

inside rad iator hose. If cooling system was onl y partially drained, add one pellet for every four litres of coolant

replaced.

IMPORTANT: Do not use the pack of pellets, if the specified coolant is extended life anti-freeze coolant,

conforming to GM6277M.

8. Quickly install radiator upper hose onto engine coolant outlet, ensuring that neither the pellets nor a large

amount of coolant is spilled. Reinstall hose clamp at coolant outlet connection.

9. Pressure test cooling system, refer to 3.7 PRESSURE TESTING in this Section.

10. Remove cap from recovery reservoir and fill

with coolant to a level approximately 25 mm

ABOVE the indicator arrows (‘A’) on the

coolant recovery reservoir dipstick, refit

dipstick.

NOTE: This condition only applies when the

cooling s ystem is first being filled af ter a maj or loss

of coolant. The level of coolant in the reservoir will

then drop, once the engine is started and normal

operating temperature is reached. The coolant

level sh ould then be m aint ained at the c orrect le vel

(between the two dipstick arrows (‘A’).

Figure 6B1-23

3.4 CLEANING COOLING SYSTEM

A cleaning solution should be used to loosen the rust and scale before performing a cooling system flush. Use

radiator cleaner, such as M39304 (500 ml). Follow the instructions on the container.

COOLING SYSTEM FLUSH

IMPORTANT: This operation should only be carried out when the engine and radiator are at ambient temperature.

NOTE: When using specialised cooling system flushing equipment, connect in accordance with the manufactures

recommendations.

CAUTION: Apply air pressure gradually as the radiator will only withstand a maximum pressure of 150 kPa.

1. Place drain tray beneath vehicle.

2. Remove coolant outlet and thermostat from front of intake manifold, refer to 3.8 THERMOSTAT – REMOVE in

this Section. Refit coolant outlet (without thermostat).

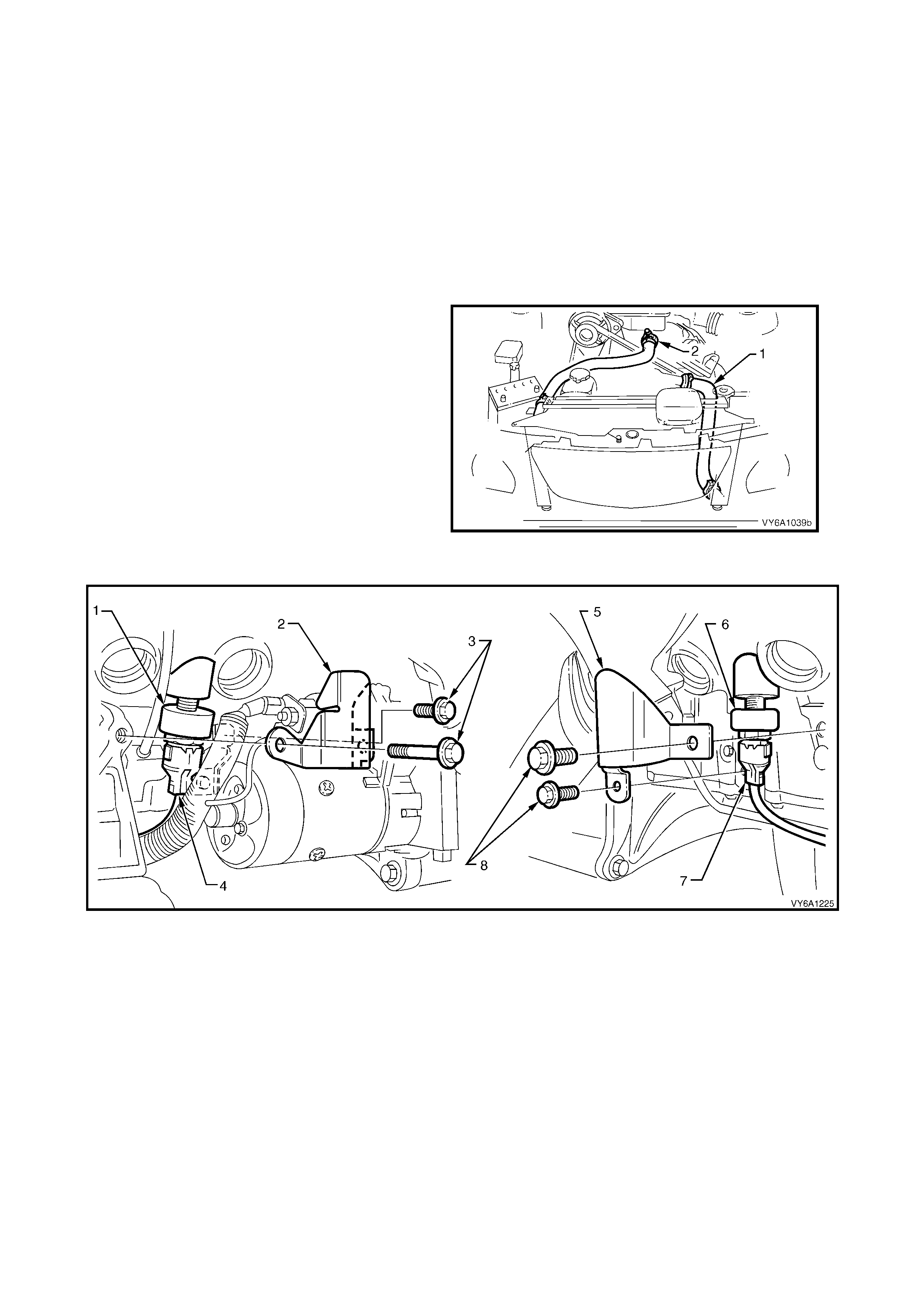

3. Remove radiator lower hose (1) at the engine

front cover connection.

4. Remove radiator upper hose (2) at radiator

connection.

CAUTION: Always wear protective safety

glasses when working with spring type hose

clamps. Failure to do so could result in eye

injury.

Figure 6B1-24

5. Referring to Figure 6B1-24, remove both knock sensors (1 & 6) from each side of cylinder block.

Figure 6B1-25

Legend

1. Lef t Hand Kn ock Senso r

2. Knock Sensor Shield LHS

3. Attaching Bolts

4. Wiring Harness Connector

5. Knock Sensor Shield RHS.

6. Right Hand Knock Sensor

7. Wiring Harness Connector

8. Attaching Bolts

6. Place coolant hose into upper radiator hose fitting, turn on water pressure and flush until water coming from

radiator lower hose connection (front cover) is clear.

7. Place coolant hose into front cover radiator lower hose connection and flush, until water coming from upper

hose is clear.

8. Place coolant hose into radiator lower hose fitting and flush out radiator in reverse direction of normal coolant

flow, until water coming from radiator upper hose connection is clear.

9. Remove coolant recovery reservoir, refer to 3.9 COOLANT RECOVERY RESERVOIR - REMOVE in this

Section. Flush out reservoir with clean water.

10. With cooling system flushed clean, refit all cooling system components. For reinstallation of thermostat and

coolant outlet housing, refer to 3.8 THERMOSTAT - REINSTALL in this Section.

NOTE: If reinstalling original knock sensor, use a wire brush to clean thread sealant residue from the sensors.

Then apply a light coating of thread sealant such as Loctite 24 2 or equivalent to the threads of the k nock sensors

and tighten to t he correct torque specification. If a new sensor is f itted, do not apply sealant to thre ads as threads

are coated with a sealant during manufacture. Applying additional sealant will affect the sensor's ability to detect

engine knock.

KNOCK SENSOR

TORQUE SPECIFICATION 20 Nm

11. Fill cooling system with coolant to the correct concentration level, refer to 3.3 CHECKING AND FILLING

COOLING SYSTEM and pressure test system, refer to 3.7 PRES SURE TEST ING in this Section.

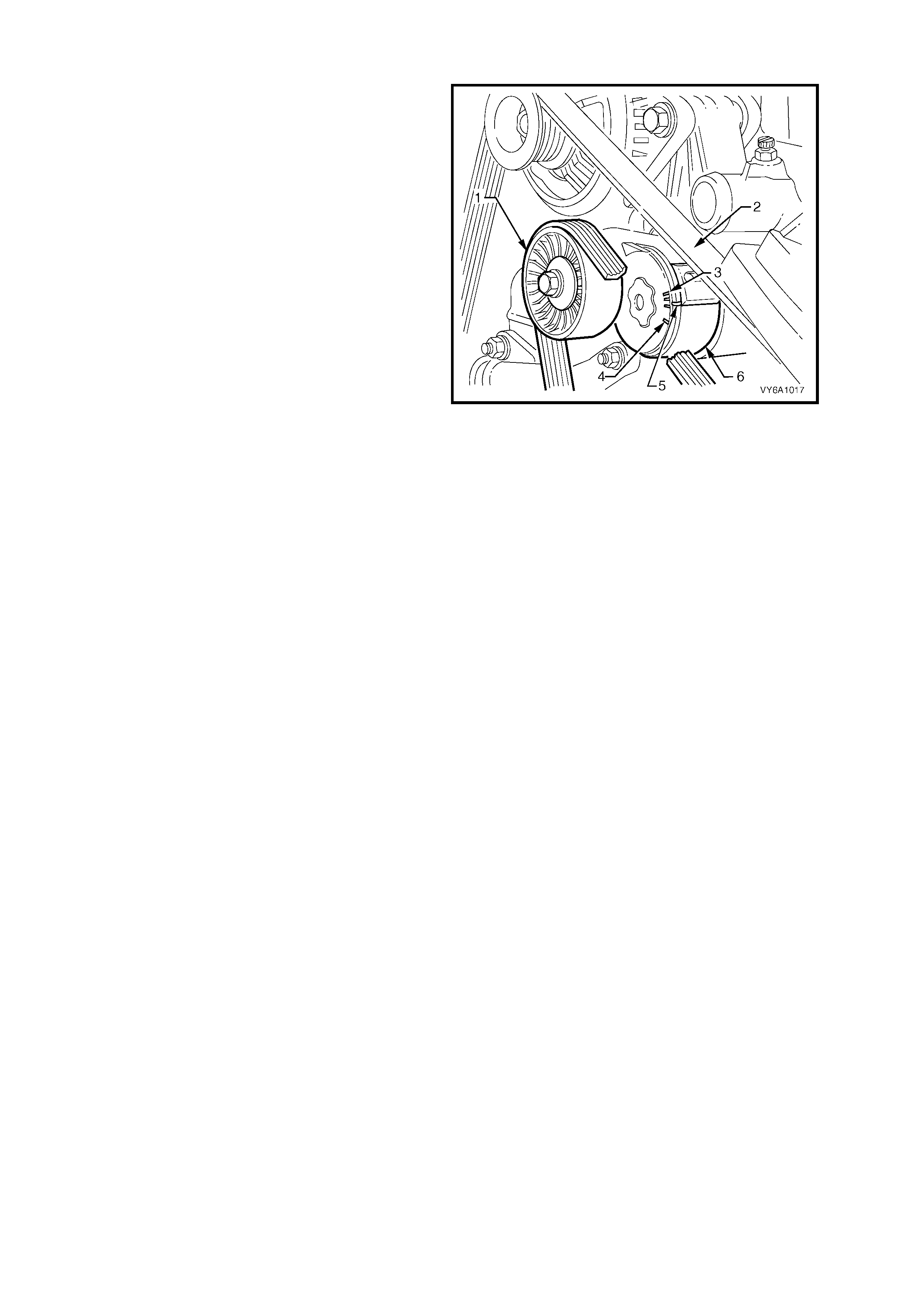

3.5 DRIVE BE LT TENSION

Drive belt tension is provided by an automatic

tensioner as sembl y. The tens ion er is an idler pul ley

mounted on a s pring- load ed arm that m aintains th e

drive belt at the proper tension, without imposing

undue loads on the various components.

Throughout its functional travel, the tensioner

mechanis m will m aintain correc t belt tension, usin g

a pulley (1) mounted to a spring loaded arm (6),

that compensating for increases in belt wear and

stretch.

W hen the indicator poin ter (5) on the tension er has

reached minimum tension range (4), the tensioner

has reached the full extent of its travel and

replacement of the belt (2) is necessary.

The maximum tension range is shown as (3).

When the indicator pointer on the tensioner has

reached m inimum tension r ange, the tension er has

reached the full extent of its travel and belt

replacement is necessary.

Drive belt tension can be checked using Tool No.

BT3373-F, refer to Section 6A1-1 ENGINE

MECHANICAL - V6 ENGINE in the MY 2003 VY

and V2 Series Ser v ice Infor mation.

Figure 6B1-26

3.6 COOLANT HOSES

LT Section No. – 01-160

Coolant hoses are installed as shown in the f ollowing illustrations, taking note that there are a number of variants,

depend ing on a specif ic ve hic le spec if ic ation.

Hose connections should be thoroughly cleaned before installing any new hose.

After all hoses are fitted, always refill the cooling system with correct concentration of coolant, refer to

3.3 CHECKING AND FILLING COOLING SYSTEM and pressure test cooling system, refer to

3.7 PRESSURE T EST ING in this Section.

CAUTION: Always wear protective safety glasses when working with spring type hose clamps. Failure to

do so could result in eye injury.

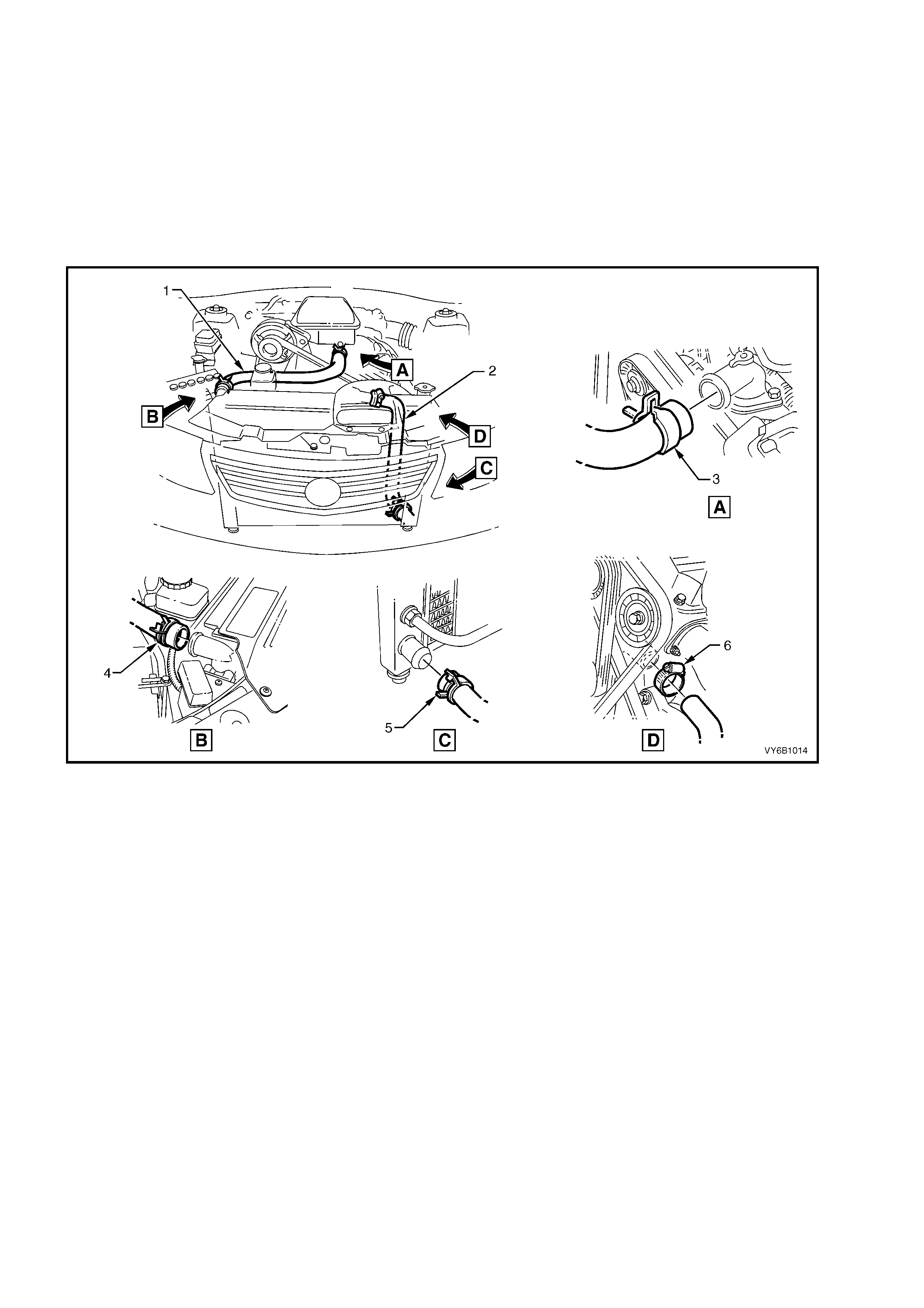

Figure 6B1-27

Legend

1. Radiator Hose – Upper

2. Radiator Hose – Lower

3. Hose Clamp – Upper Hose to Engine Outlet

4. Hose Clamp – Upper Hose to Radiator Inlet

5. Hose Clamp – Lower Hose to Radiator Outlet

6. Hose Clamp – Lower Hose to Engine Front Cover

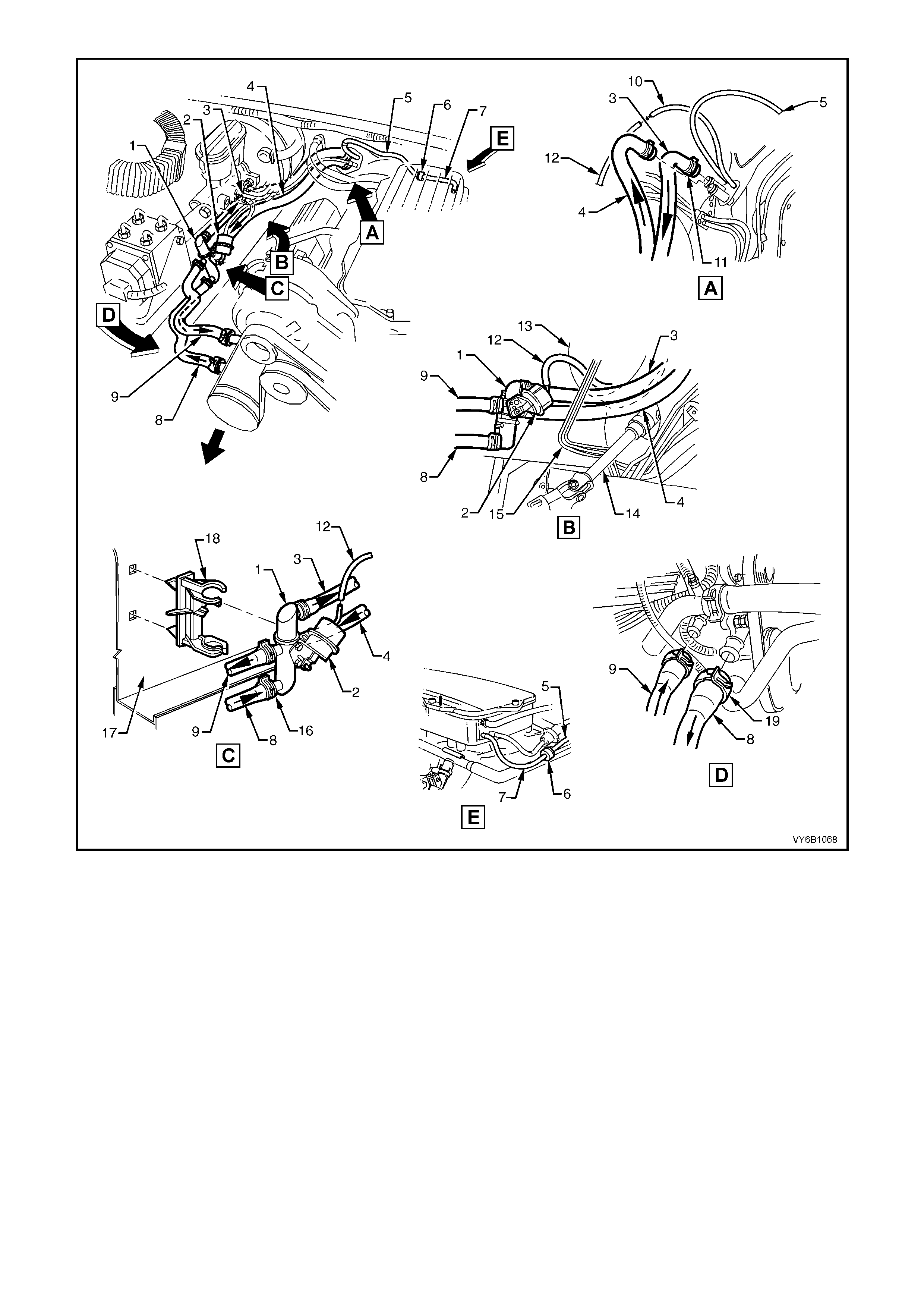

Figure 6B1-28 – Coolant and Vacuum Hose Routing – V6 RHD

Legend

1. Heater Coolant Valve

2. Coolant Valve Actuator

3. Heater Hose to Cabin

4. Heater Hose from Cabin

5. Vacuum Hose – HVAC Supply

6. One-Way Check Valve

7. Vacuum Hose to Intake Manifold

8. Heater Hose to Engine

9. Heater Hose from Engine

10. Vacuum Hose from Internal Control

11. Heater Core Hose Clamps (2 places)

12. Vacuum Hose – Coolant Valve Actuator

13. Brake Booster

14. Steering Shaft

15. Brake Hydraulic Pipes

16. Coolant Valve Hose Clamps (4 places)

17. Wheel House RHS

18. Mounting Clip for Heater Coolant Valve

19. Hose Clamps to Engine (2 places)

NOTE: Heater and vacuum hoses to be routed under brake hydraulic pipes. Refer view B

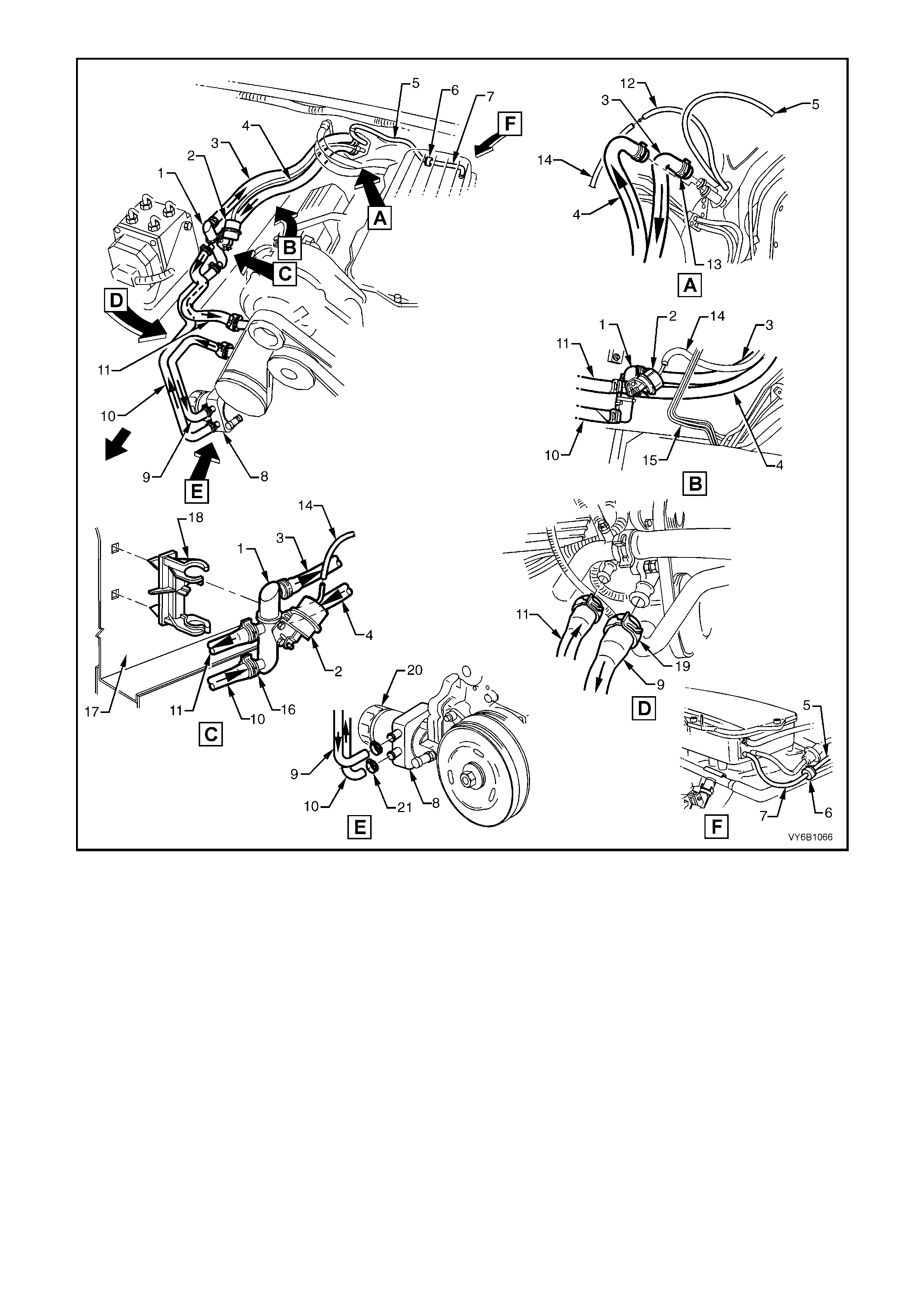

Figure 6B1-29 – Coolant and Vacuum Hose Routing – V6 LHD With Oil Cooler

Legend

1. Heater Coolant Valve

2. Coolant Valve Actuator

3. Heater Hose to Cabin

4. Heater Hose from Cabin

5. Vacuum Hose – HVAC Supply

6. One-Way Check Valve

7. Vacuum Hose to Intake Manifold

8. Engine Oil Cooler

9. Heater Hose – Engine

10. Heater Hose – Oil Cooler

11. Heater Hose from Engine

12. Vacuum Hose from Internal Control

13. Heater Hose Clamps (2 places)

14. Vacuum Hose – Coolant Valve Actuator

15. Brake Hydraulic Pipes

16. Coolant Valve Hose Clamps (4 places)

17. Wheel House RHS

18. Mounting Clip for Heater Coolant Valve

19. Hose Clamps to Engine (2 places)

20. Engine Oil Filter

21. Hose Clamps – Oil Cooler (2 places)

NOTE: Heater and vacuum hoses to be routed under brake hydraulic pipes. Refer view B

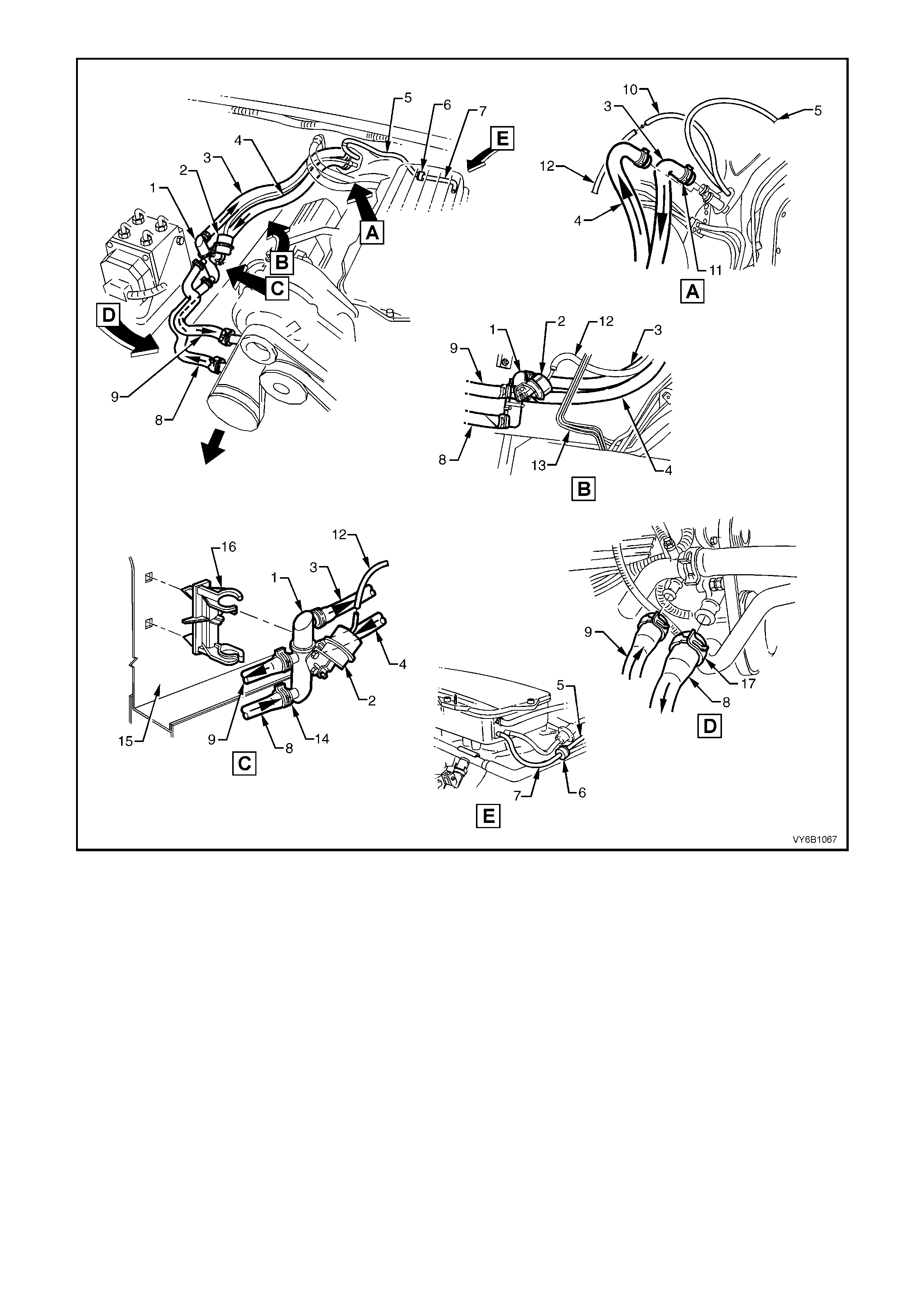

Figure 6B1-30 – Coolant and Vacuum Hose Routing – V6 LHD – Without Oil Cooler

Legend

1. Heater Coolant Valve

2. Coolant Valve Actuator

3. Heater Hose to Cabin

4. Heater Hose from Cabin

5. Vacuum Hose – HVAC Supply

6. One-Way Check Valve

7. Vacuum Hose to Intake Manifold

8. Heater Hose to Engine

9. Heater Hose from Engine

10. Vacuum Hose from Internal Control

11. Heater Core Hose Clamps (2 places)

12. Vacuum Hose – Coolant Valve Actuator

13. Brake Hydraulic Pipes

14. Coolant Valve Hose Clamps (4 places)

15. Wheel House RHS

16. Mounting Clip for Heater Coolant Valve

17. Hose Clamps to Engine (2 places)

NOTE: Heater and vacuum hoses to be routed under brake pipes. Refer View B.

3.7 PRESSURE TESTING

RADIATOR CAP TESTING

1. Allow engine to cool to ambient temperature

(less than 50° C), then remove radiator cap.

CAUTION: Do not remove radiator cap while the

engine coolant temperature is above 50°

°°

° C, as

personal injury may result.

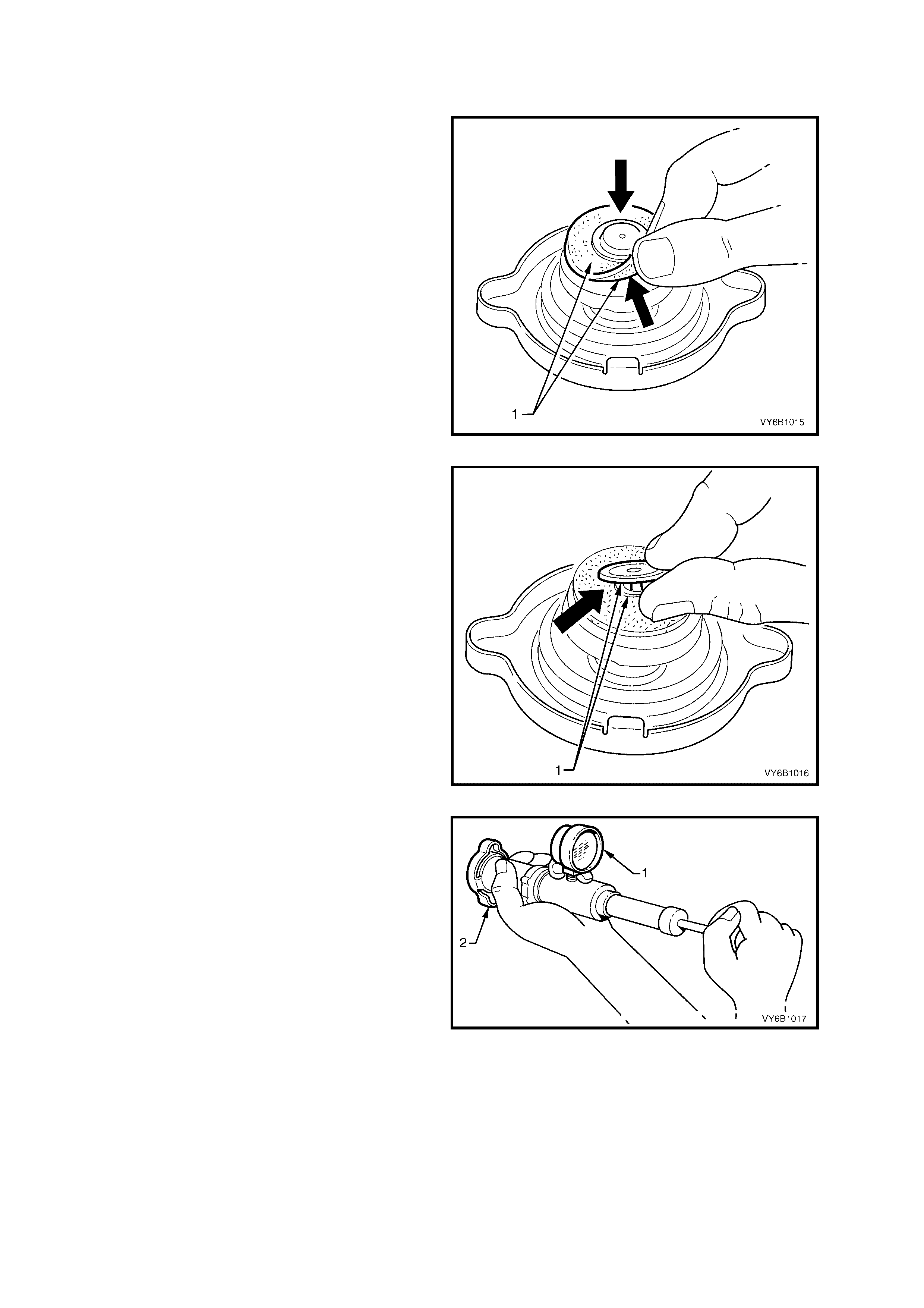

2. Clean both sid es ( 1) of radiator c ap g asket with

a wet cloth.

NOTE: Use only water to wet cleaning cloth.

Figure 6B1-31

3. Lift centre valve and clean gasket area under

valve (1).

Figure 6A1-1-32

4. Attach radiator cap (2) to a commercially

available cooling system pressure tester (1).

Slowly pressurise cap to 120 – 150 kPa. The

cap is serviceable if it unloads slightly above

this pressure range and holds pressure at 120

kPa. Should cap fail to reach or hold the

specified pressure, replace cap.

Figure 6B1-33

5. Pr ior t o reins talli ng radiat or cap ensur e radi ator

filler neck cap seating surface (1) is clean and

free from obstruction.

Figure 6A1-1-34

COOLING SYSTEM PRESSURE TESTING

1. Allow engine to cool to ambient temperature

(less than 50° C), then remove radiator cap.

CAUTION: Do not remove radiator cap while the

engine coolant temperature is above 50°

°°

° C, as

personal injury may result.

2. Ensure coolant level is correct.

3. Connect a commercially available cooling

system pr es sur e tes ter ( 1) to r adiator f il ler nec k

by using the hose supplied (2) or other

arrangement and using compressed air, blow

dry any spilled coolant around radiator filler

neck. Pressurise cooling system to 120–150

kPa and check for leaks at the following points:

a. All hoses and hose connections.

b. Overflow hose connection at radiator.

c. Radiator seams and core.

d. Corroded or faulty engine welch plugs or drain

plugs.

e. Coolant pump and gask et.

f. Vehicle heater system.

g. Check engine oil dipstick for evidence of

engine oil cont aminatio n wi th coolant .

4. If pressure will not hold, there is a leak in the

cooling system. Repair as necessary.

Figure 6B1-35

3.8 THERMOSTAT

LT Section No. – 00-350

REMOVE

1. Allow the engine to cool to an ambient

temperature (less than 50° C), then remove

radiator cap.

CAUTION: Do not remove radiator cap while the

engine coolant temperature is above 50°

°°

° C, as

personal injury may result.

2. Remove engine decorative cover.

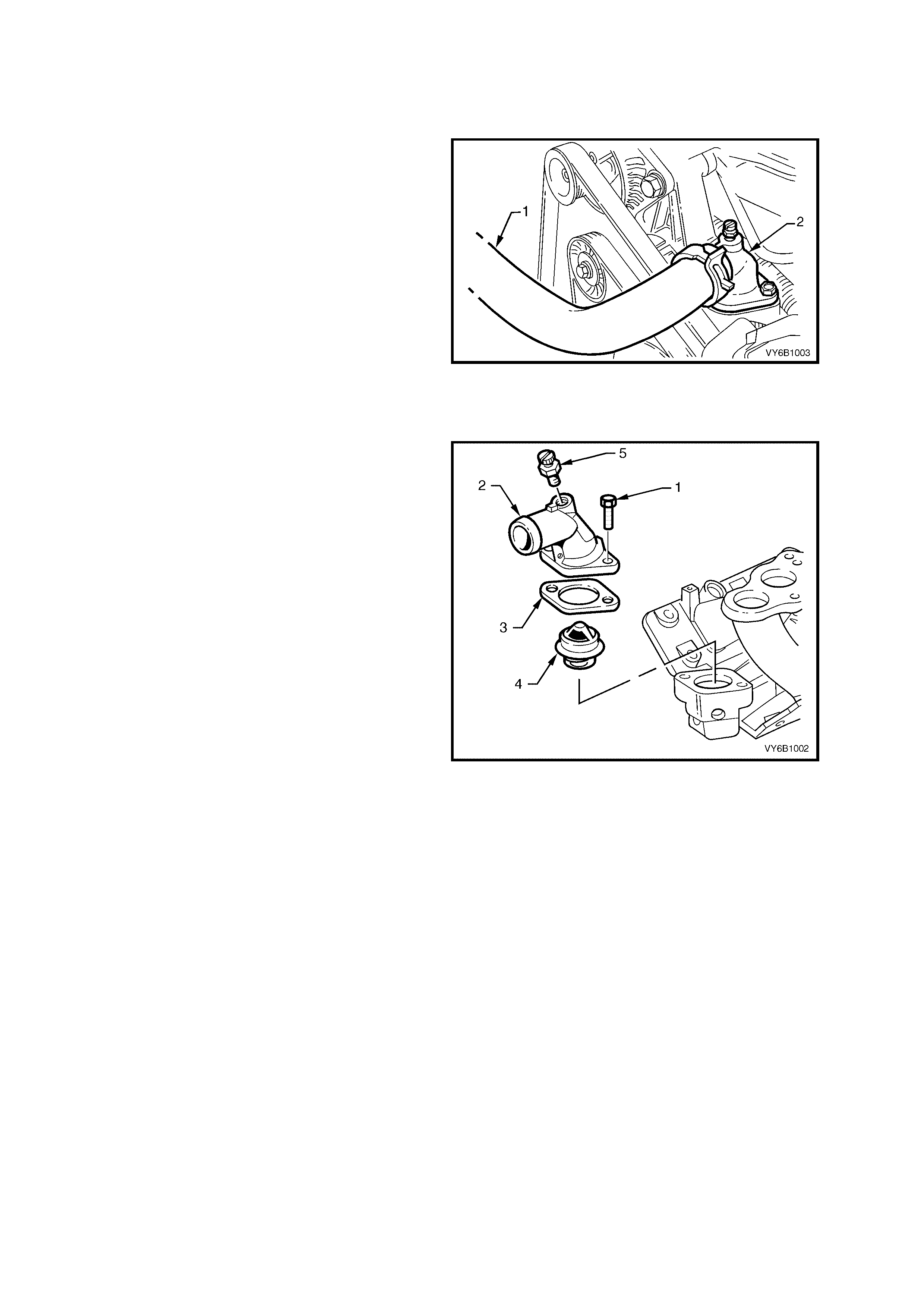

3. Disconnect radiator upper hose (1) from

coolant outlet (2) at front of intake manifold.

CAUTION: Always wear protective safety

glasses when working with spring type hose

clamps. Failure to do so could result in eye

injury.

Figure 6B1-36

4. Remove coolant outlet to inlet manifold

attaching bolts (1). If Required remove the

bleeder screw and lock nut (5).

5. Pull coolant outlet (2) from intake manifold,

remove and discard gasket (3).

6. Remove thermostat (4) from intake manifold.

Figure 6B1-37

TEST

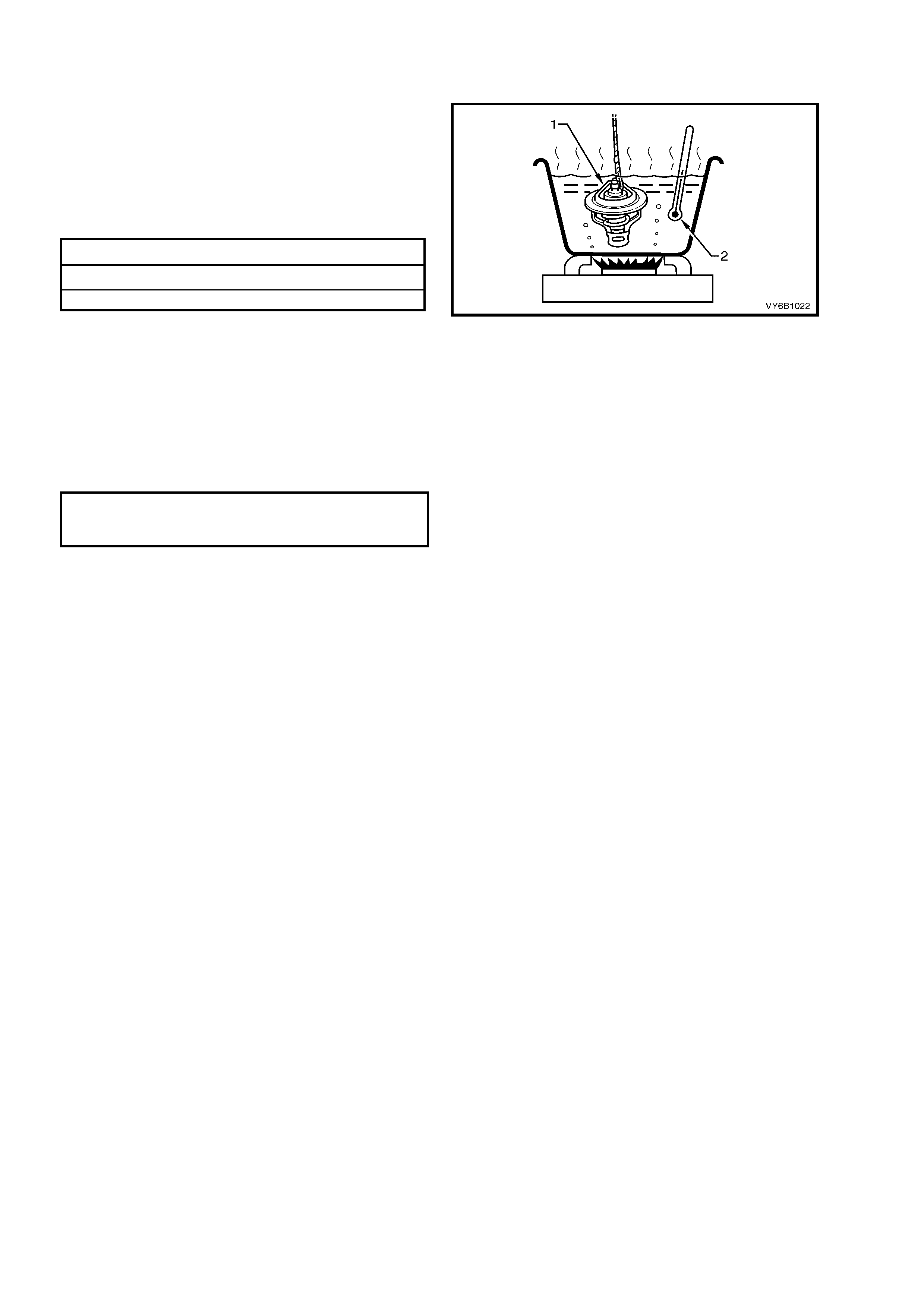

1. Suspend thermostat (1) and a suitable thermometer (2) in a container of 50/50 glycol/water.

2. Heat container until thermostat (1) begins to

open. Agitate solution to ensure uniform

temperature. Note temperature (2) and ensure

thermostat opens within specified temperature

range.

3. Replace thermostat if it does not meet these

operating conditions.

Thermostat Opening Specifications

OPENING TEMPERATURE RANGE 89 – 93° C

FULLY OPEN TEMPERATURE 106° C

IMPORTANT: Neither the thermostat (1) nor the

thermometer (2) should rest on the bottom of the

container because of uneven conce ntration of heat

at this point when the container is heated.

Figure 6B1-38

REINST ALL

1. Reinstall thermostat, new gasket and coolant outlet into inlet manifold.

2. Reinstall coolant outlet to intake manifold attaching bolts and tighten to the correct torque specification.

COOLANT OUTLE T TO I NTAKE

MANIFOLD ATTACHING BOLT

TORQUE SPECIFICATION 28 Nm

3. Refit radiator upper hose and clamp to outlet housing.

4. Refill cooling system, refer to 3.3 CHECKING AND FILLING COOLING SYSTEM in this Section.

5. Check for cooling system leaks, refer to 3.7 PRES SUR E TESTING in this Section.

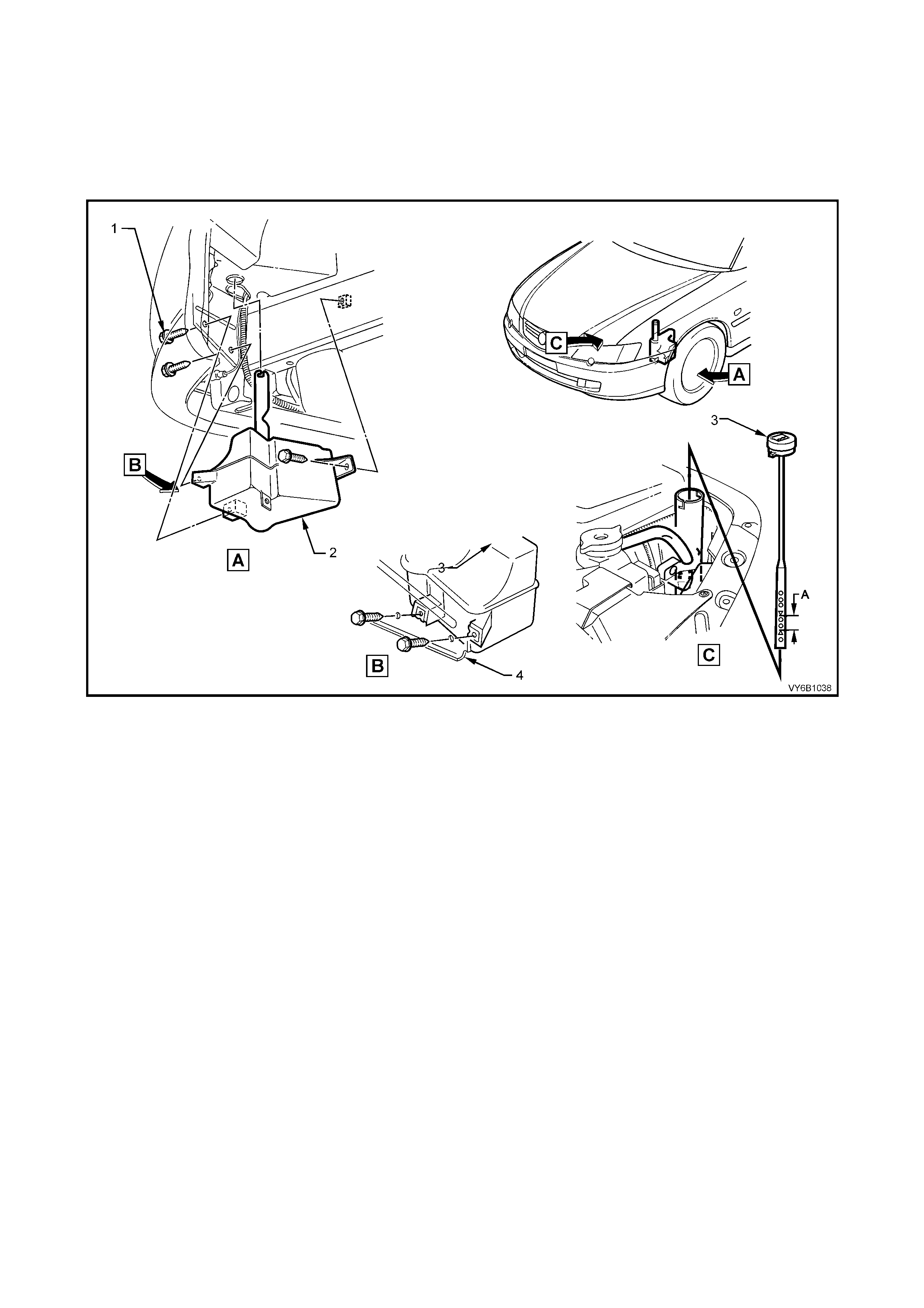

3.9 COOLANT RECOVERY RESERVOIR

LT SECTION NO. – 01-140

REMOVE

1. Remove the radiator overflow hose from the radiator assembly neck and remove the reservoir tube from the

reservoir body assembly (twist and pull).

2. Remove reservoir assembly attaching screws, remove rese rvoir assembly from the veh icle.

Figure 6B1-39

Legend

1. Screw (3 places)

2. Reservoir 3. Reinstall dipstick and rotate to eth right toe retain

4. Console Front Panel

INSPECT

1. Drain contents from reservoir assembly.

2. Clean reservoir ass embl y with water and dry using co mpress ed air.

3. Check reservoir and assembly for damage, e.g. abrasions, cracks, or distortion. Replace if required.

REINST ALL

Reinstallation of the reservoir assembly is the reverse of removal procedures, noting the following points:

1. Refill cooling recovery reservoir and cooling system with the correct concentration of coolant, refer to

3.3 CHECKING AND FILLING COOLING SYSTEM in this Section.

2. Check cooling system for leaks.

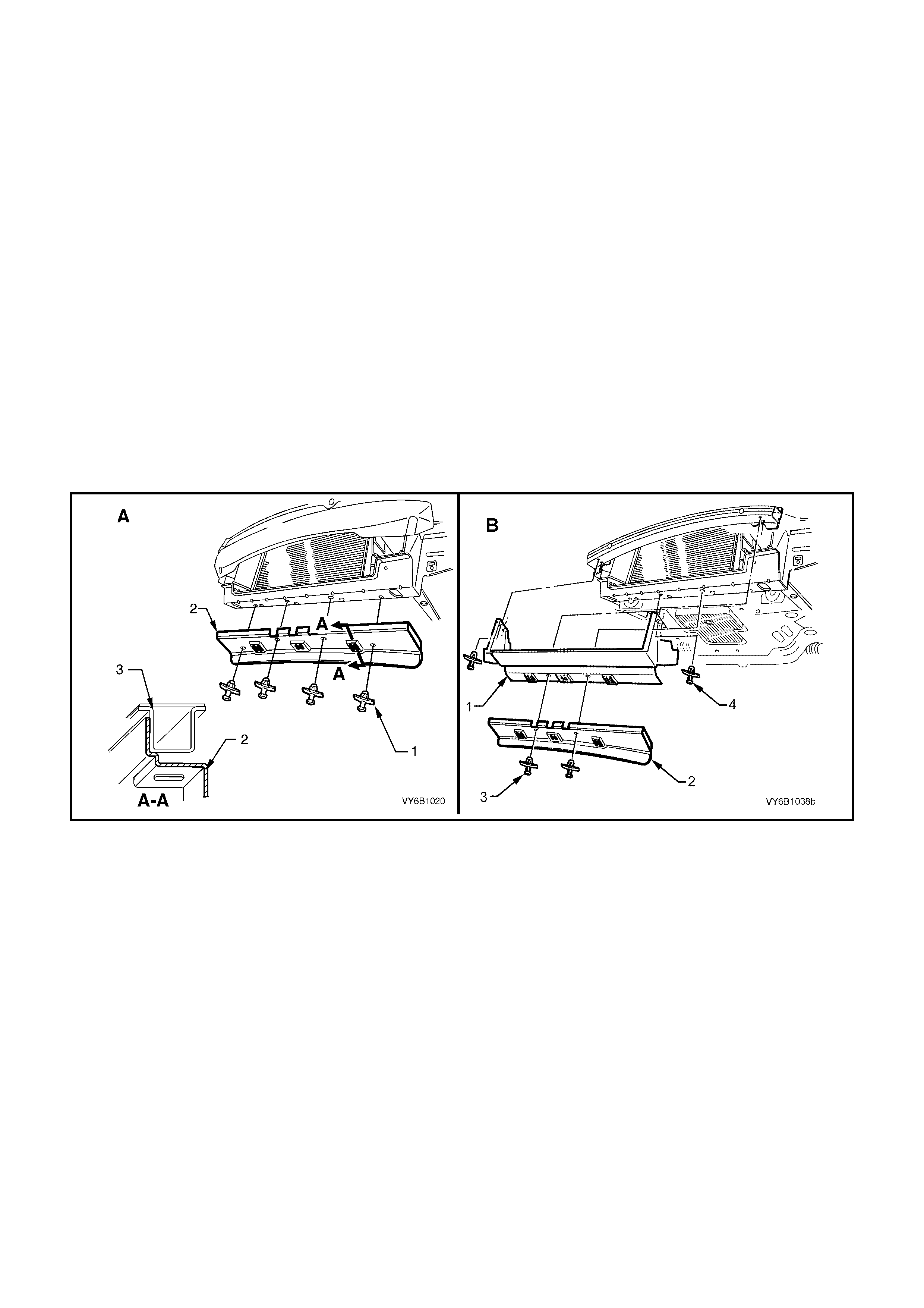

3.10 AI R BAFFLE

LT Section No. –

REPLACE

1. Raise front of ve hic l e a nd s uppor t on s af et y sta nds . R ef er to Section 0 A GENERAL INFORMATION in the MY

2003 VY and V2 Series Service Information, for the location of jacking and support points.

All Models Except ‘S’ Pack (View ‘A’)

2. Remove lower front baffle (2) to crossmember fasteners (1) (four places), slide the front air chute baffle (1)

forward to release the tangs, then remove from the vehicle.

‘S’ Pack Models, Except Utility (View ‘B’)

3. Remove the front bumper bar, refer to Section 1D BUMPER BARS.

NOTE: W hile the air duc t c an be rem oved without f irst rem oving t he bumper bar, ex cess ive distor tion of the duct is

required, both on removal and reinstallation. Also the reinstallation of the two upper scrivets is extremely difficult.

4. Remove the two scrivet fasteners (3) securing both the lower front baffle (2) and the duct (1) to the front

suspension crossmember, then remove the lower front baffle from the vehicle.

5. Rem ove the t wo scrivet fastener s (4) sec uring t he air duc t (1), to th e front u pper pane l assem bly, then r emove

the duct from the vehicle.

6. Reinstallation is the reverse to removal procedures.

NOTE 1: Do not overtighten any of the fasteners.

In Figure 6B1-40, view ‘A’ shows the standard air baffle, while view ‘B’ shows the ‘S’ pack arrangement (except

Utility).

Figure 6B1-40

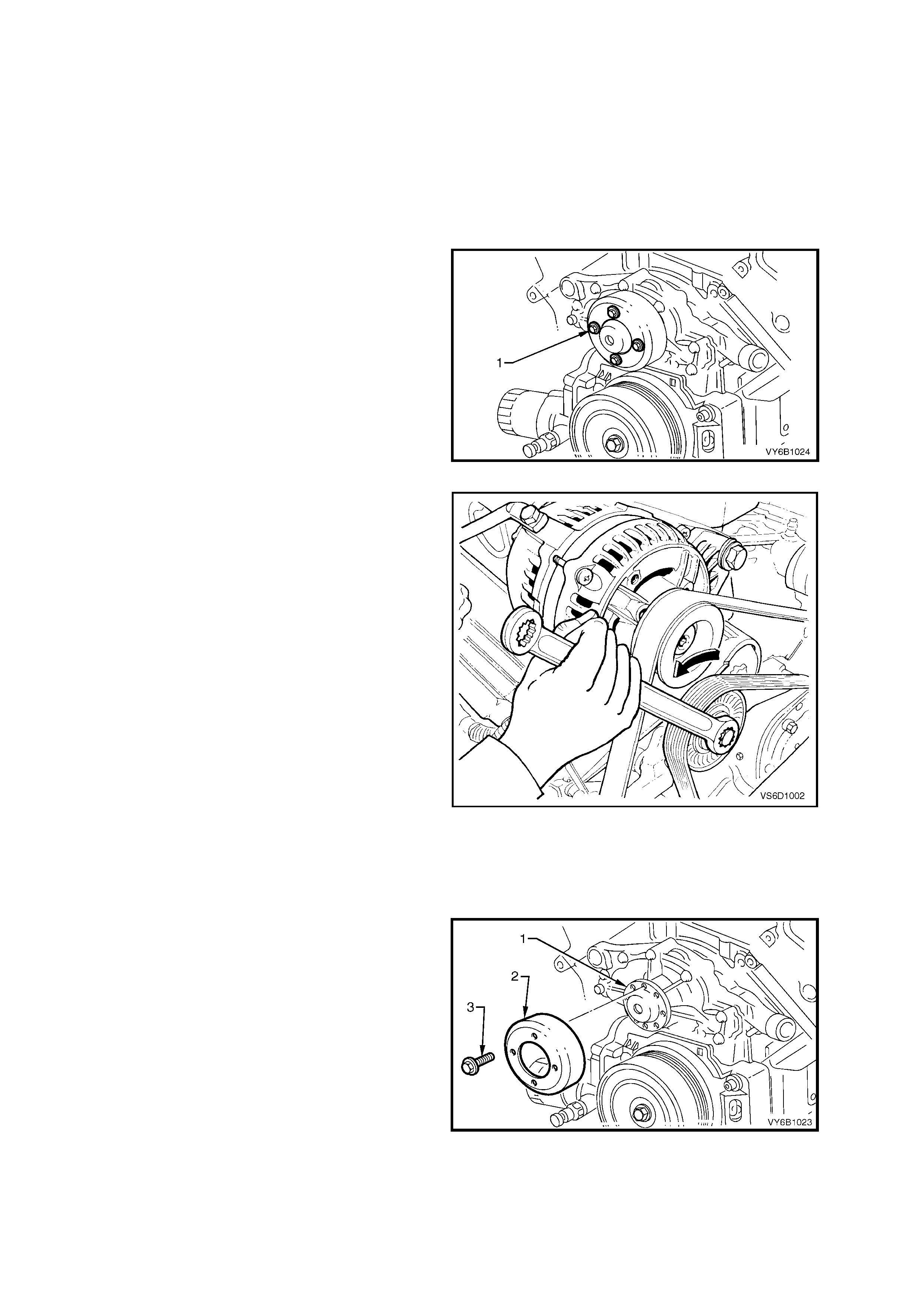

3.11 COOLANT PUMP

LT Section No. – 00-325

REMOVE

NOTE: The coolant pump cannot be disassembled and therefore can only be replaced as an assembly.

1. Allow engine to cool to ambient temperature (less than 50° C), then remove radiator cap.

CAUTION: Do not remove radiator cap while the engine coolant temperature is above 50°

°°

° C, as personal

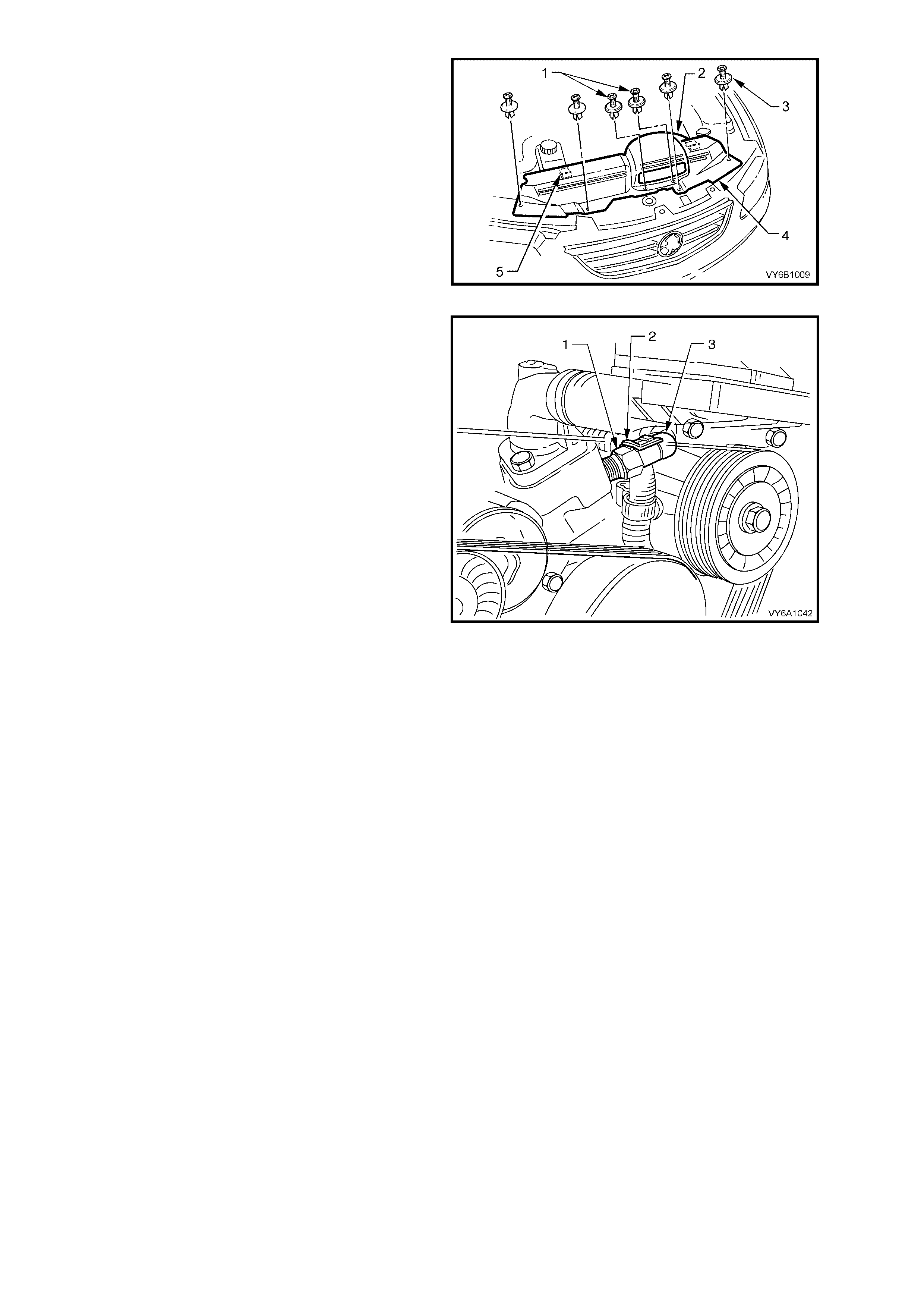

injury may result.

2. Disconnect battery ground lead.

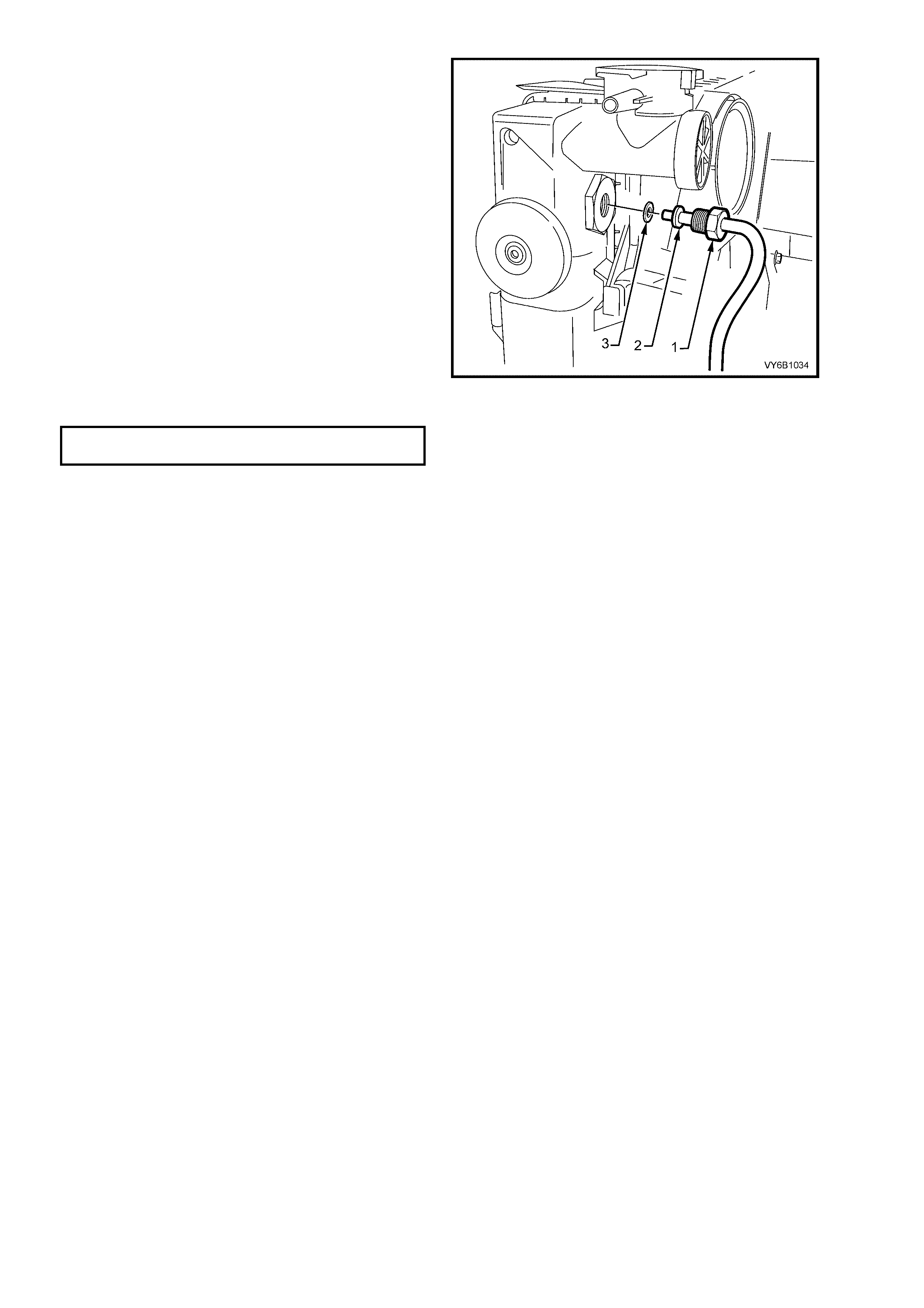

3. Loosen coolant pump pulley to hub bolts (1).

NOTE: While the view shows the drive belt

removed, it will be easier to loosen the four pulley

bolts, with the belt installed.

Figure 6B1-41

4. Using an 15 mm ring spanner on drive belt

tensioner pulley pivot bolt, rotate tensioner

pulley assembly anti-clockwise (arrow) and

remove drive belt from coolant pump pulley.

Figure 6B1-42

5. Remove radiator lower hose clamp at engine front cover connection, disconnect hose from front cover and

allow coolant to drain into a suitable splash tray.

CAUTION: Always wear protective safety glasses when working with spring type hose clamps. Failure to

do so could result in eye injury.

6. Remove coolant pump pulley (2) to hub (1)

attaching bo lts ( 3), then re move pulley fr om the

pulley.

Figure 6B1-43

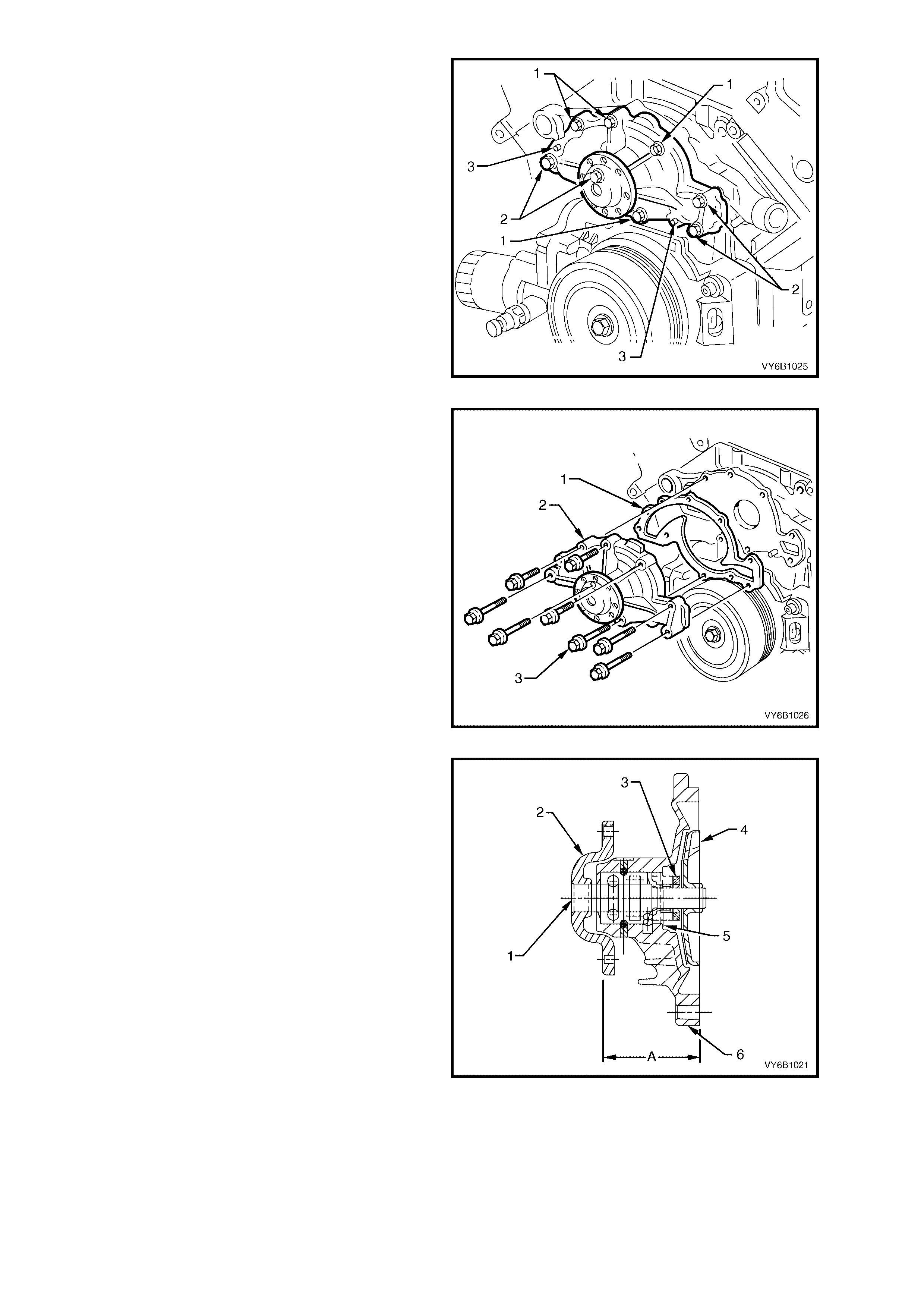

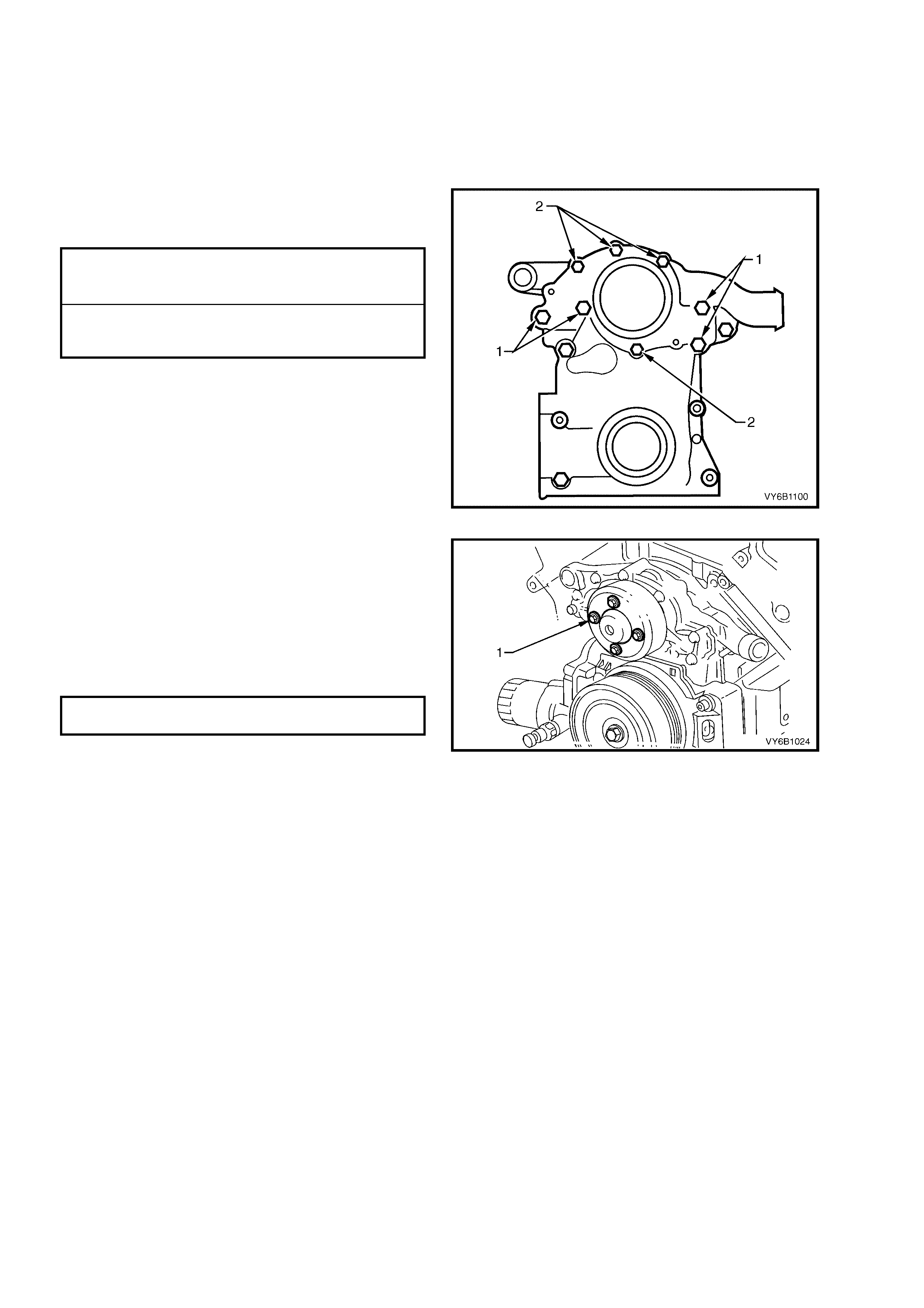

7. Remove coolant pump to front cover (1) and

cylinder block (2) attaching bolts.

NOTE: The coolant pump is located by two dowel

pins (3).

Figure 6B1-44

8. Using a soft faced hammer, lightly tap coolant

pump housing to separate it from front cover.

9. Remove coolant pump to front cover gasket

and discard.

Figure 6B1-45

10. Check coolant pump bearing for excessive

end-play, or rough operation by rotating

bearing pulley hub. Replace coolant pump if

faulty.

Legend:

1 Shaft and Bearing Assembly

2 Coolant Pump Hub

3 Seal Assembly

4 Impeller (Installed from 0.38 mm Proud to 0.13

mm Below Housing)

5 Seal Flange Seats Against this Surface

6 Coolant Pump Housing

A Hub Flange to rear of Pump Housing, 54.7 ±

0.25 mm

Figure 6B1-46

REINST ALL

1. Ensure that coolant pump and front cover mating surfaces are clean and dry.

2. Reinstall new gasket to front cover dowel pins.

3. Clean threads of coolant pump to front cover and cylinder block attaching bolts. Coat threads of bolts with

Loctite 242 sealant or equivalent.

NOTE: Do not apply sealant to the first 1-2 threads of each bolt.

4. Reinstall coolant pump and attaching bolts.

Tighten all bolts to the correct torque

specification.

COOLANT PUMP TO

CYLINDER BLOCK BOLT (‘1’)

TORQUE SPECIFICATION 30 Nm

COOLANT PUMP TO

FRONT COVER BOLT (‘2’)

TORQUE SPECIFICATION 10 Nm

Figure 6B1-47

5. Reinstall coolant pump pulley and attaching

bolts (1).

6. Reinstall drive belt (reverse to removal

procedures) and ensure that drive belt is

aligned with all accessory pulleys and

crankshaft balancer drive belt grooves.

7. Tighten cool ant pump pulle y attach ing bolts (1)

to the correct torque specification.

COOLANT PUMP PULLEY TO HUB

BOLT TORQUE SPECIFICATION 14 Nm

8. Refit radiator lower hose and clamp to front

cover connection.

9. Refill cooling system, refer to 3.3 CHECKING

AND FILLING COOLING SYSTEM in this

Section.

10. Check for coolant leaks, refer to

3.7 PRESSURE T EST ING in this Section.

11. Reconn ec t batter y ground l ead.

Figure 6B1-48

3.12 COOLING FAN AND SHROUD ASSEMBLY

LT Section No. – 01-105

REMOVE

1. Disconnect battery ground lead.

IMPORTANT: Disconnection of the battery affects certain vehicle electronic systems. Refer to Section 00

CAUTIONS, 5. Battery Disconnection Procedures before disconnecting the battery.

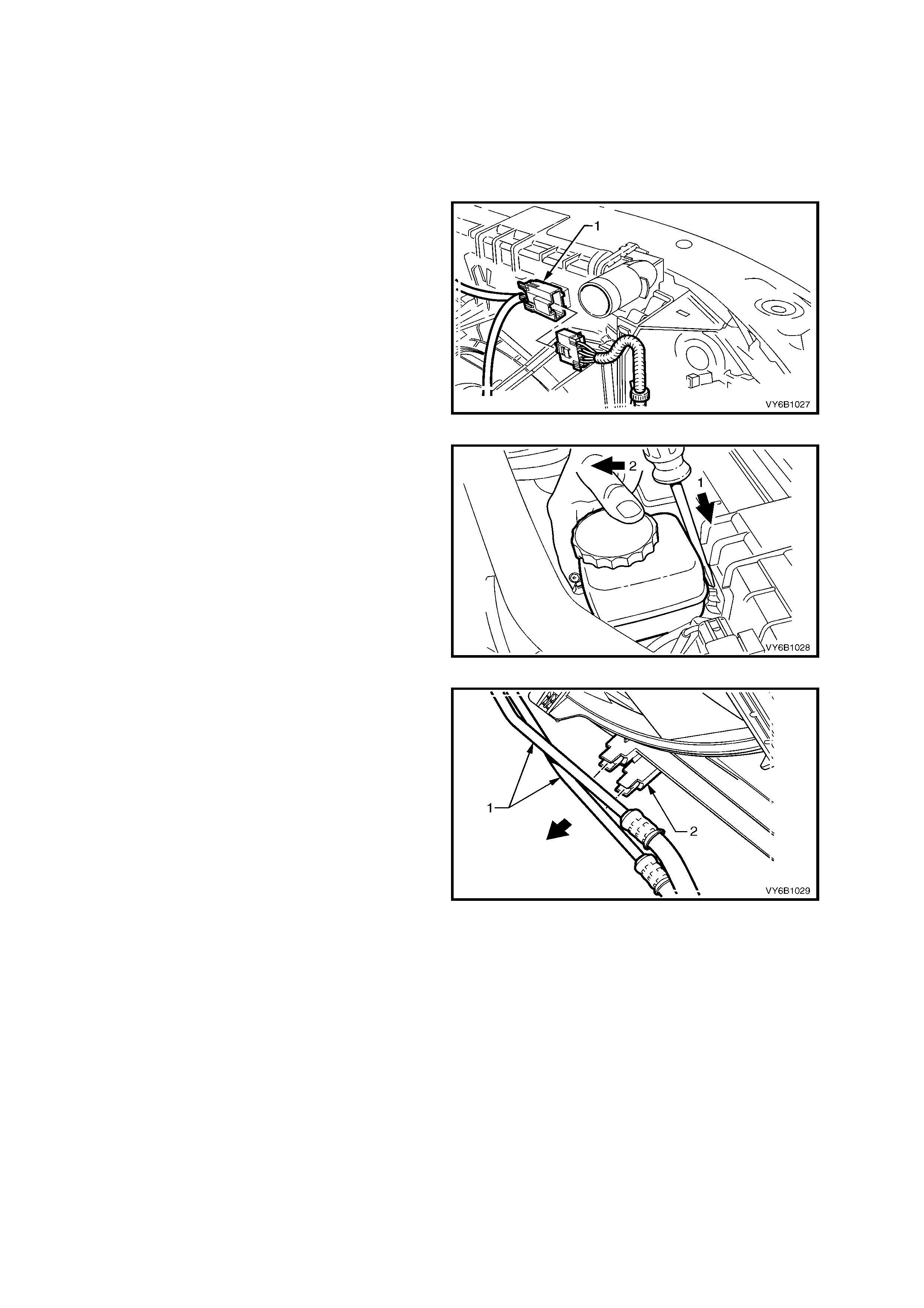

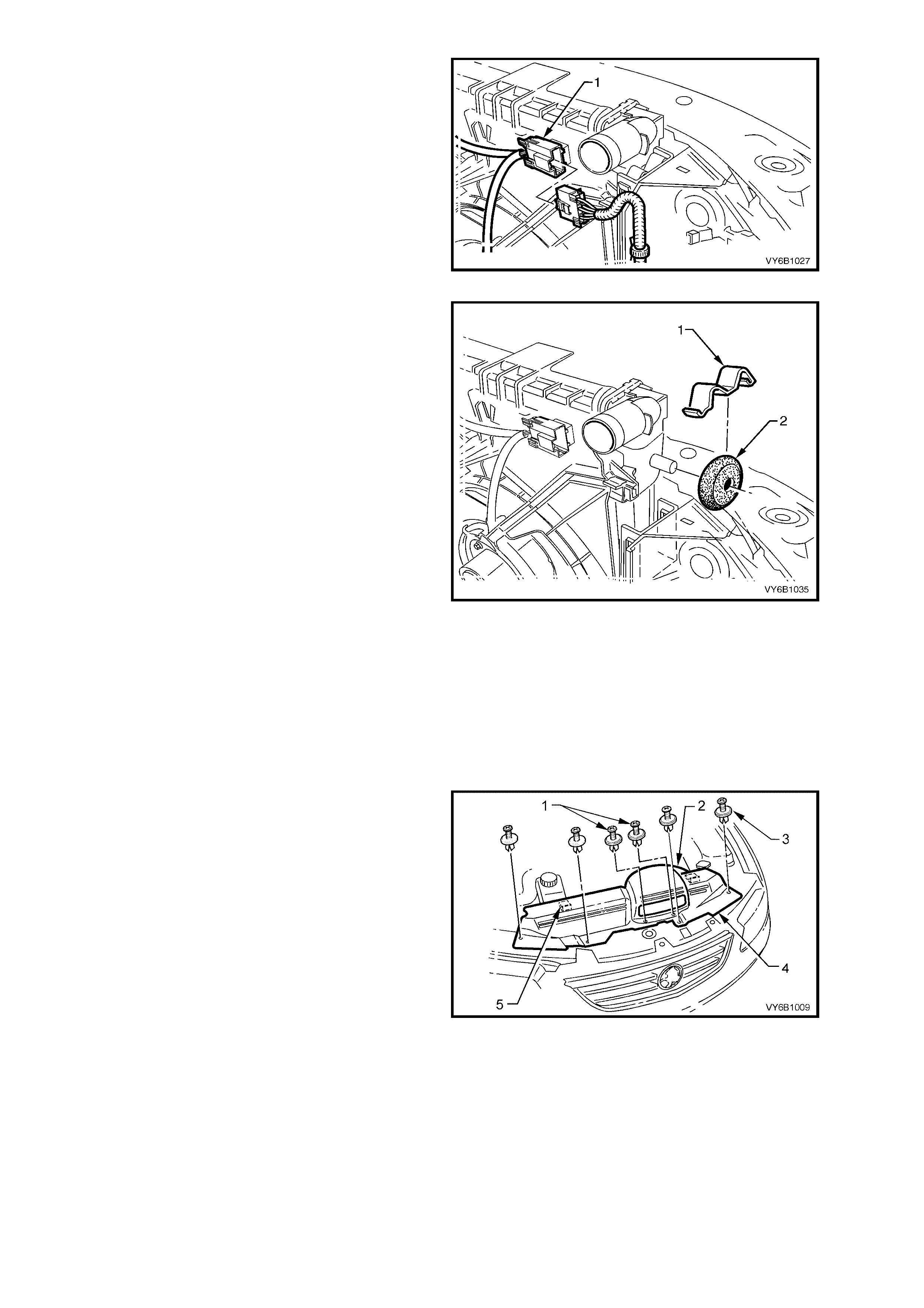

2. Depress tang on main wiring harness to

cooling fan motor wiring harness connector

and separate connector.

Figure 6B1-49

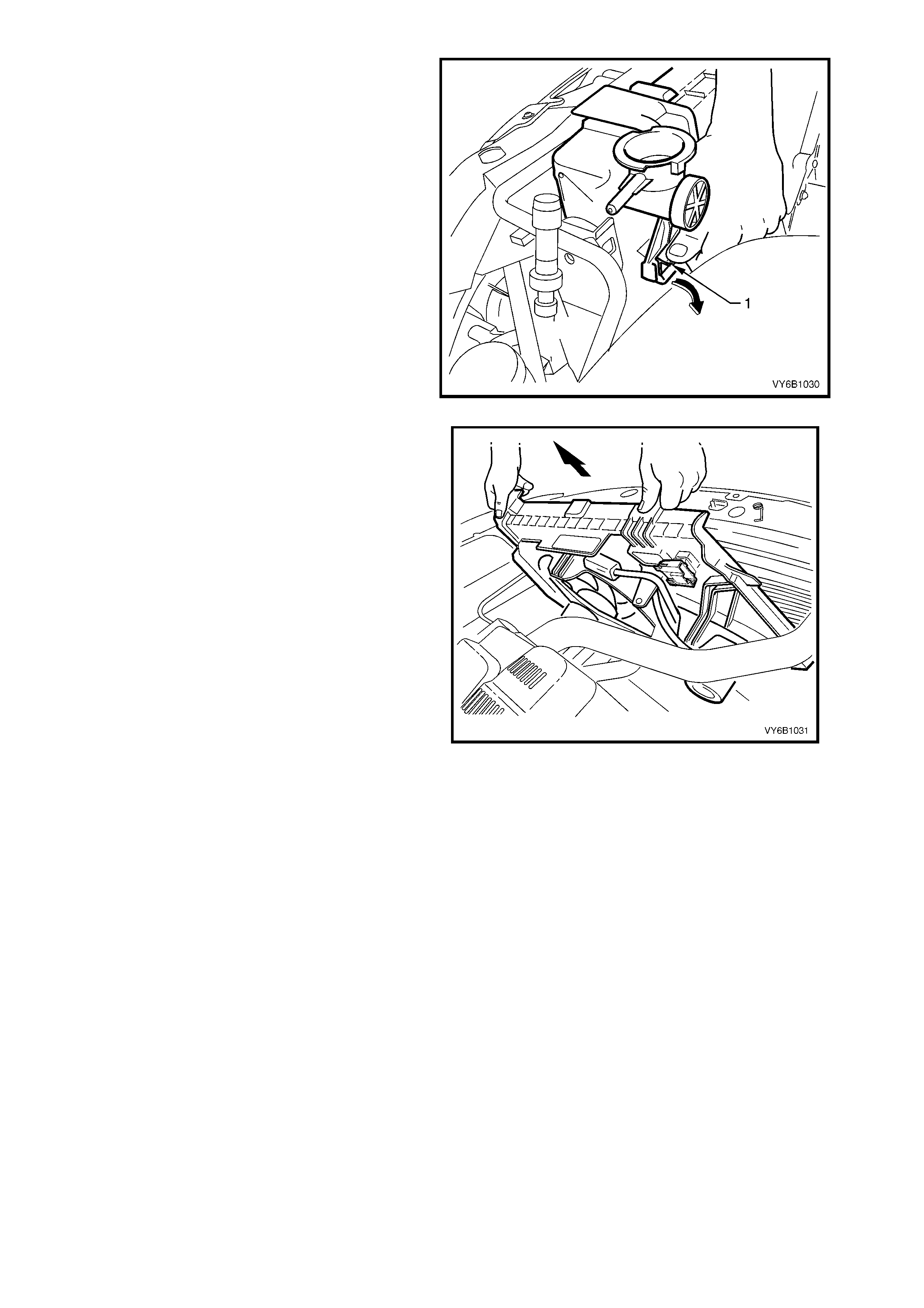

3. Remove the power steering pump reservoir

from its clip on the radiator shroud, using a

screwdriver to lever the clip lock, enabling

removal of the reservoir. Lay the reservoir and

hoses to one side.

Figure 6B1-50

4. Release each of the automatic transmission

cooling p ip es ( if f itted) from the integral cl ips o n

the fan shroud.

Figure 6B1-51

5. Release the fan shroud to radiator clips by

holding one of the lugs (1) out with the fingers

of one hand while lifting the shroud with the

other. Repeat this operation to release the

second side.

Figure 6B1-52

6. Lift the fans and shroud assembly from the

engine bay.

IMPORTANT: Do not lift the assembly clear by

lifting on the fan rings, as this will bend the fan

motor shaft and create an unnecessary vibration.

Figure 6B1-53

REINST ALL

Reinstallation of the cooling fan and shroud assembly is the reverse of removal procedures, noting the following

points:

1. Ensure that fan and shroud assembly to radiator attaching clips are fully engaged.

2. Ensure that both automatic transmission cooling pipes (if fitted) are reinstalled to the shroud clips.

3. Check cooling fan operation, refer to Section 6C1 POWERTRAIN - V6 ENGINE. Also check rotation

direction of cooling fans.

DISASSEMBLE

1. Remove cooling fan and shroud assembly as previously described.

IMPORTANT: Neither fan (2) is to be separated

from its fan motor. The assembly is carefully

balanced during manufacture and, duplicating this

balance on reassembly, is not possible.

1. Remove the m otor as sembly wiring harnes s (1)

from the integral clips that form a part of the

shroud (3).

NOTE: Separate the intermediate wiring harness

connector (5).

2. Remove screws (4) attaching the motor

assem bly (to the shr oud (3), then r emove each

motor, fan and wiring (2) assembly from the

shroud (3).

Figure 6B1-54

REASSEMBLE

Reassembly is the reverse of disassembly procedures, noting the following points:

1. After r einstalling the f an motor and f an assem bly to t he shroud, reins tall and t ighten motor to s hroud attac hing

screws securely but do not over-tighten.

2. Reinstall motor wiring harness to shroud attaching clips. Reinstall the intermediate connector.

3. Reinstall cooling fan and shroud assembly to the radiator, as previously described.

3.13 FLEXIBLE TRANSMISSION COOLER HOSE

LT Section No. – 04-150

REPLACE

NOTE: The flexible hoses are not serviced separately. Therefore, should a hose require replacement, then the

hose and radiator to hose cooler pipe assembly must be fitted.

1. Place a drip tray beneath the engine and radiator section.

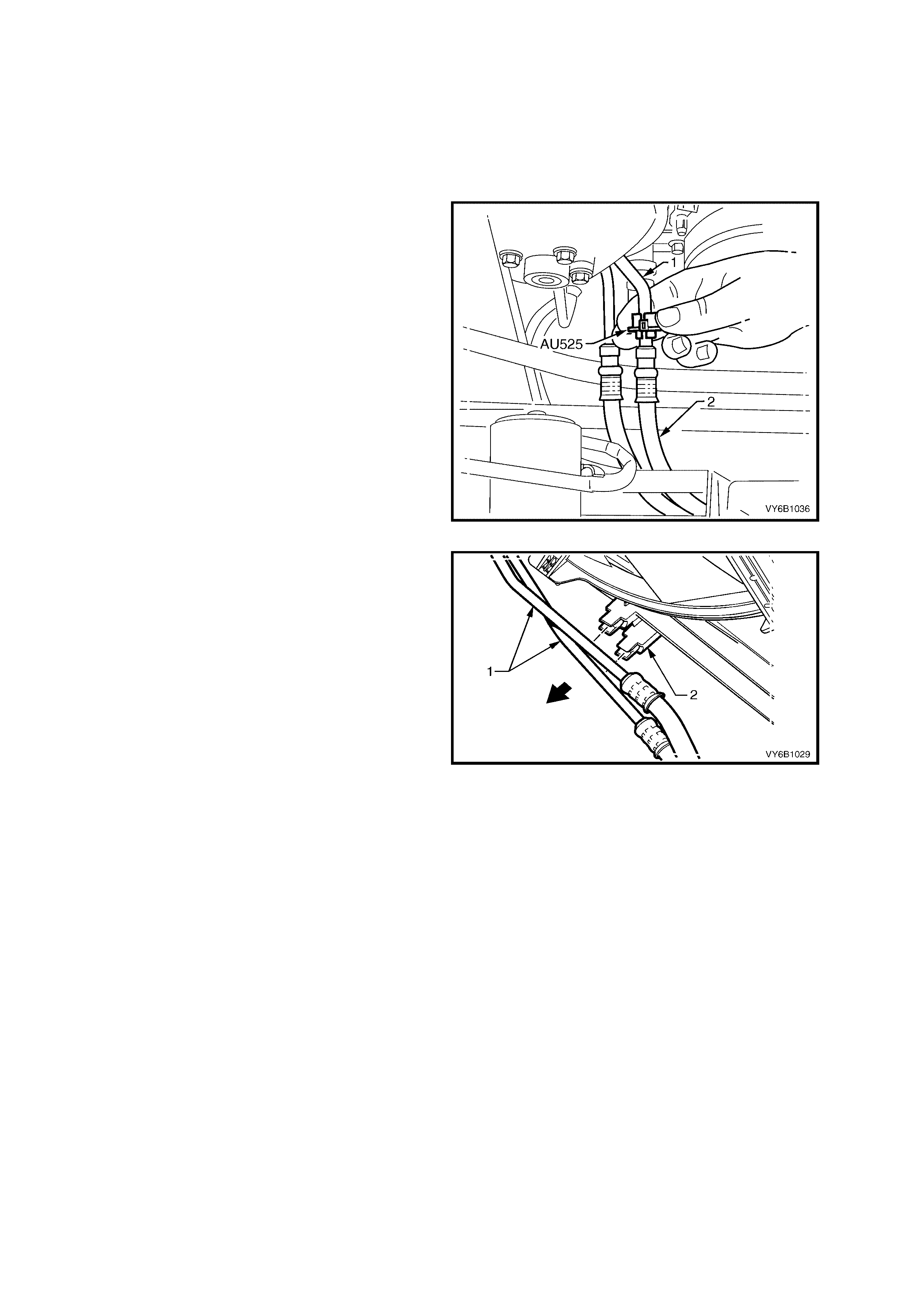

2. Disconnect the transm ission cooler p ipe/s from

the flexible hose/s, using Tool No. AU525:

a. Open release tool AU525, then close and

clip around the pipe to be disconnected.

b. While hold ing t he flex ibl e h ose (2) with one

hand, push the tool into connection, to

release, then pull back on the pipe (or

hose).

c. Repeat for the second fitting, if required.

Plug both pipe openings and hoses to minimise

fluid loss and prevent foreign matter entry.

Figure 6B1-55

3. Release each of the automatic transmission

cooling p ipe/s (1) fr om the integral c lip/s on the

fan shroud (2).

Figure 6B1-56

4. Us ing a s uita ble s et span ner , loosen th e cooler

pipe tube nut (1), then remove, taking care not

to lose the sealing washer (3). Plug both open

ends to prevent fluid loss and/or dirt entry.

IMPORTANT: W hen carrying out this operation on

LHD V6 engined vehicles with automatic

transmission, a back-up spanner must be used on

the larger cooler, flare nut fitting to prevent it from

loosening.

5. Repeat for the second pipe/hose assembly.

6. Before reinstalling each pipe (2) to the cooler,

carefully inspect the pipe sealing washer (3). If

the centre, silicone portion shows signs of

distress or damage, it must be replaced.

7. Remove the plugging from the pipe and fittings,

fit the sealing washer (3) to the cleaned pipe

(2) and reinstall into the cooler.

8. Reinstall the tube nut (1) and tighten to the

correct torque specification.

COOLER PIPE TUBE NUT

TORQUE SPECIFICATION 25 Nm

NOTE: On LHD V6 engined vehicles with

automatic transmission, always use a back-up

spanner to prevent the turning of the fluid cooler

flare nut fitting.

9. Check the transmission fluid level. Refer to

2.1 FLUID LEVEL CHECK, in S ectio n 7C4 A/T

ON-VEHICLE SERVICING.

Figure 6B1-57

3.14 RADIATOR

LT Section No. – 01-105

REMOVE

1. Allow engine to cool to ambient temperature (less than 50° C), then remove radiator cap.

CAUTION: Do not remove radiator cap while the engine coolant temperature is above 50°

°°

° C, as personal

injury may result.

2. Disconnect battery ground lead.

IMPORTANT: Disconnection of the battery affects certain vehicle electronic systems. Refer to Section 00

CAUTIONS, 5. Battery Disconnection Procedures before disconnecting the battery.

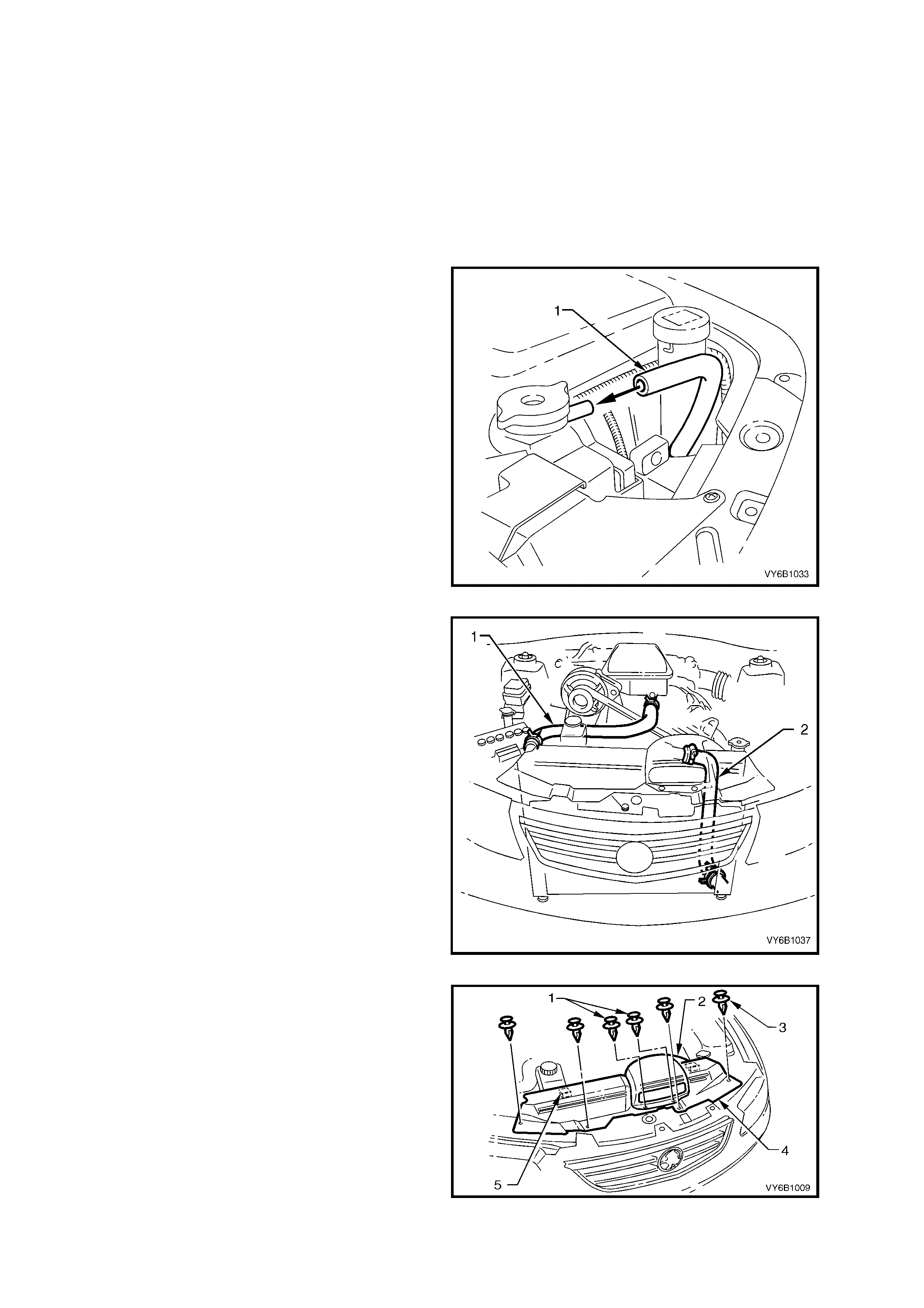

3. Remove coolant overflow hose (1) from

radiator filler neck connection.

Figure 6B1-58

4. Remove radiator lower hose (2) from radiator

connection, allowing the coolant to drain into a

suitable sized and clean drain tray.

IMPORTANT: Refer to ITEM NO. 4 in 3.1

SERVICE NOTES in this Section regarding the

collection of the drained coolant.

CAUTION: Always wear protective safety

glasses when working with spring type hose

clamps. Failure to do so could result in eye

injury.

5. Remove radiator upper hose (1) from radiator.

Figure 6B1-59

6. Remove the cold air intake duct and radiator

upper shroud retainers (1 and 2). Remove the

cold air intake duct (2), then disengage the

shroud locating tabs (5) by pulling the shroud

(4) towards front of vehicle, prior to removal.

7. If fitted with air conditioning, disconnect the

retainer clip securing the high pressure air

conditioning pipe to the top of the front upper

panel assembly on the left hand side.

Figure 6B1-60

NOTE: If fitted with a ir conditioning, the condenser

must be separated from the radiator assembly.

This action will allow the radiator removal without

having to open any refrigerant lines.

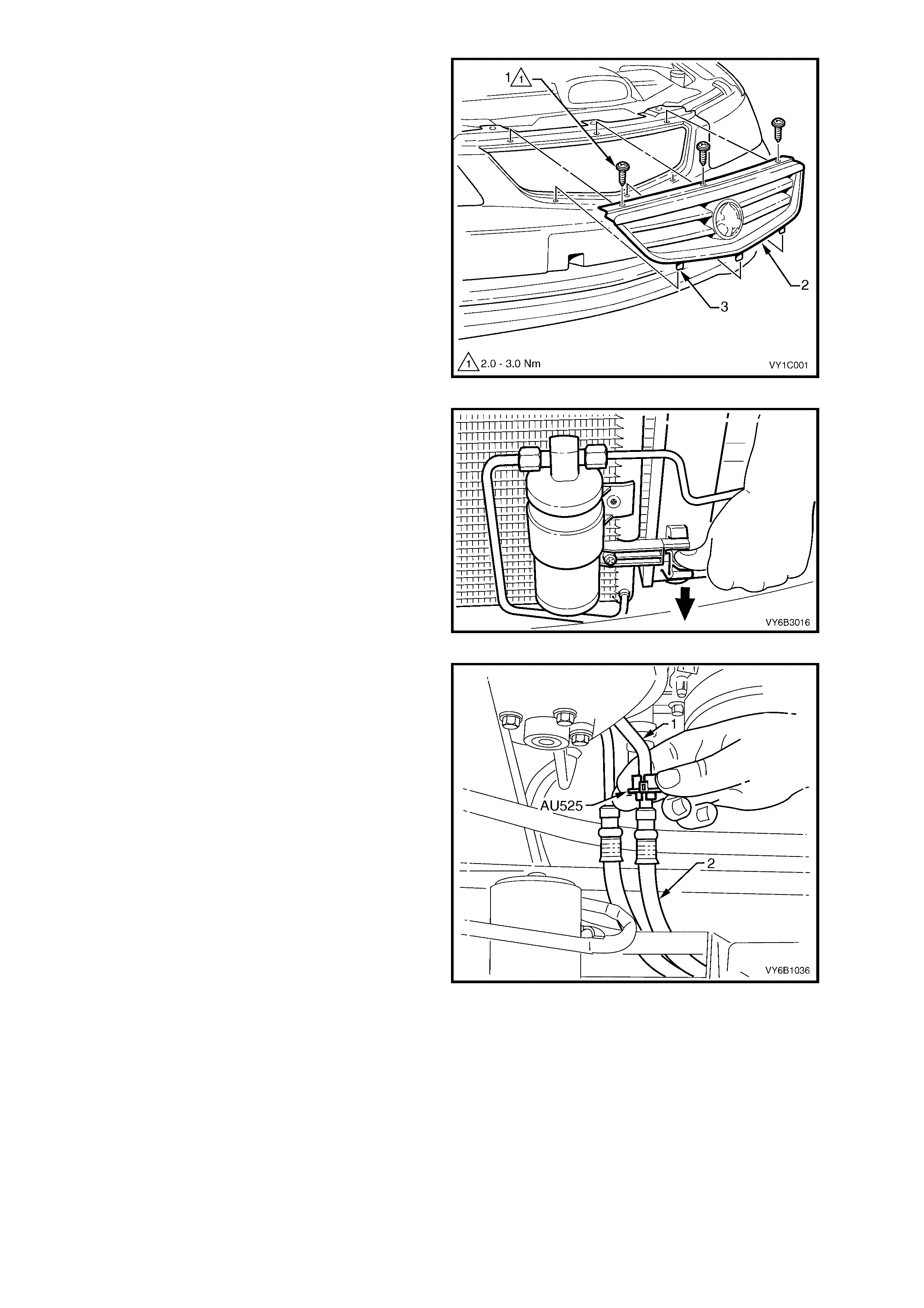

8. Remove the three screws (1) attaching the

radiator grille assembly (2) to the bumper

fascia.

9. Tilt the top of the grille assembly forward

slightly and lift it out of the bumper fascia to

release the three pins (3) along the lower edge.

NOTE: The grille on ‘S’ Sedan and ‘SS’ model

vehicles is s ecured i n a si m ilar m anner but ha s two

lugs on the lower edge rather than three pins.

Figure 6B1-61

10. Working through the grille opening, release

one of the clips securing the condenser to the

radiator (bold arro w). Do th is by pres sing down

on the lug with the fingers of one hand, while

lifting the condenser assembly with the other.

Repeat for the other side.

11. Once released, pull the condenser assembly

forward to clear the radiator mounting lugs.

Figure 6B1-62

12. If vehicle is equipped with an automatic

transmission, disconnect the transmission oil

cooler line quick connect fittings, using Tool

No. AU525:

a. Open release tool AU525, then close and

clip around the pipe to be disconnected.

b. While hold ing t he flex ibl e h ose (2) with one

hand, push the tool into connection, to

release, then pull back on the pipe.

NOTE: If Tool No. AU525 is not available, the

cooler pipes can be disconnected from the cooler,

in the left side radiator tank. Refer to

3.13 FLEXIBLE TRANSMISSION COOLER

HOSE, in this Section, for important information

regarding this procedure.

c. Plu g all op enings to m inim ise fluid loss and

prevent dirt entry.

Figure 6B1-63

13. Depress tang on main wiring harness to

cooling fan motor wiring harness connector (1)

and separate connector.

Figure 6B1-64

14. Using a screwdriver, compress and lever out

radiator retaining clips (1) from radiator upper

mounting brackets.

15. Lift radiator upwards out of lower insulators

and remove radiator from vehicle.

IMPORTANT: If removing the fan and shroud as

an assembly to the radiator, do not use the fan

outer rings, as lifting devices, as this will bend the

fan motor shafts causing unnecessary vibration,

when the vehicl e is pl aced bac k in service.

16. Remove upper (2) and lower insulators from

the radiator.

17. If required, separate the fan and shroud

assembly from the radiator by releasing the

two locking tangs at the upper locations, then

slide the fan shroud up and clear from the

radiator.

Figure 6B1-65

REINST ALL

Reinstallation of the radiator is the reverse of removal procedures, noting the following points:

1. Before ins talling radiator , inspect cor e to ensure that there is no for eign matter in core f ins. Clean out bet ween

core fins with compressed air, blowing from rear to front.

2. Ensure that radiator lower mounting pins are correctly located in lower insulators.

3. Ensure that upper insulators are installed on upper mounting pins and radiator retainers are installed.

4. Reinstall radiator upper shroud (4) by first

locating each of the two locating tabs (5), then

securing with four plastic ‘scrivet’ fasteners (3).

5. Reinstall the cold air intake duct to the lower

air cleaner body, securing with two plastic

fasteners (1).

Figure 6B1-66

6. Refill cooling system, refer to 3.3 CHECKING

AND FILLING COOLING SYSTEM in this

Section.

7. Check for coolant leaks, refer to

3.7 PRESSURE T EST ING in this Section.

8. Check cooling fan operation, refer to

Section 6C1 POWERTRAIN MANAGEMENT

- V6 ENGINE, including fan rotation direction.

RADIATOR REPAIR PROCEDURE

Repairable Leaks

There are two types of leaks that can be repaired

on the aluminium-plastic radiator; core leaks and

automatic transmission oil cooler seal leaks. Leaks

in the plastic tanks or the seals between the side

tanks and the headers cannot be repaired,

therefore the radiator must be replaced.

Core leaks may occur in a tube or in the joints

between the tubes and the headers. Seal leaks

may occur in the joints between the plastic tanks

and the headers or in the joints between the oil

cooler fittings and the tank (vehicles with automatic

transmission).

While some leaks can be repaired while the

radiator is installed in the vehicle, it is strongly

recommended that the radiator is first removed

from the vehicle.

Legend:

1. Side Tank Seal

2. Core Tubes

3. Side Tank Seal

4. Oil Cooler Pipe Fittings

5. Joint Between Tube and Header

NOTE: Minor damage to tubes, or tube to header

joint (holes up to 1mm diameter max.) can be

repaired. Core replacement is necessary if damage

is any greater.

Figure 6B1-67

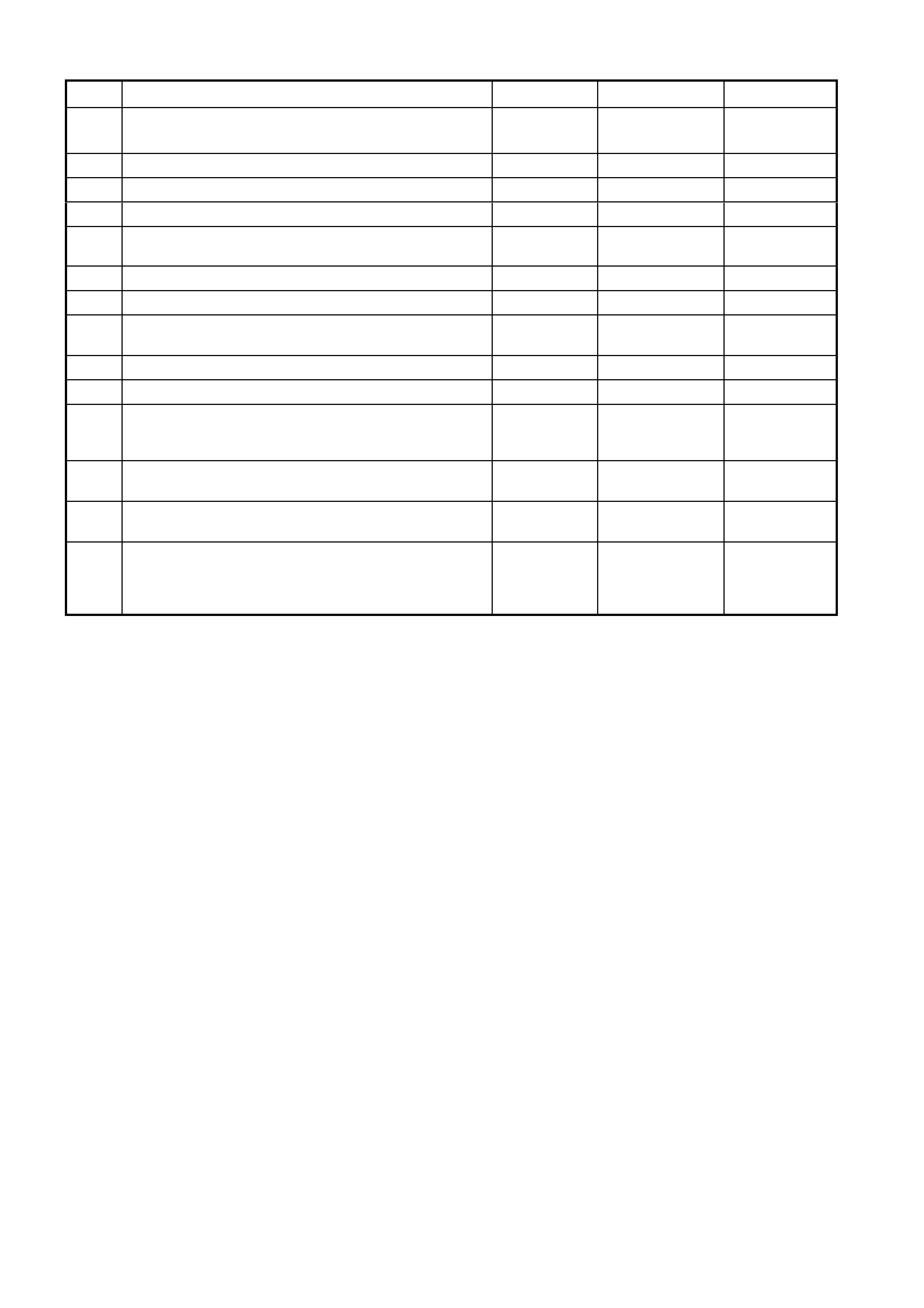

Repair Method

Repairs to the aluminium radiator core should only

be made using the recommended 'Aluminised

Silicon' based liquid repair agent, in accordance

with the recommended procedure outlined in

GENERAL CORE REPAIR in this Section. Refer to

the current PartFinder® for Aluminised Silicon base

liquid part number.

For damaged areas that are between the cooling

fins, it may be necessary to remove some of the

fins. Do not remove more fins than is necessary.

Usually 6 mm (distance ‘A’) beyond the leak or

damage area, up to a maximum of 25 mm of total

fin material, is enough to make an effective repair.

Figure 6B1-68

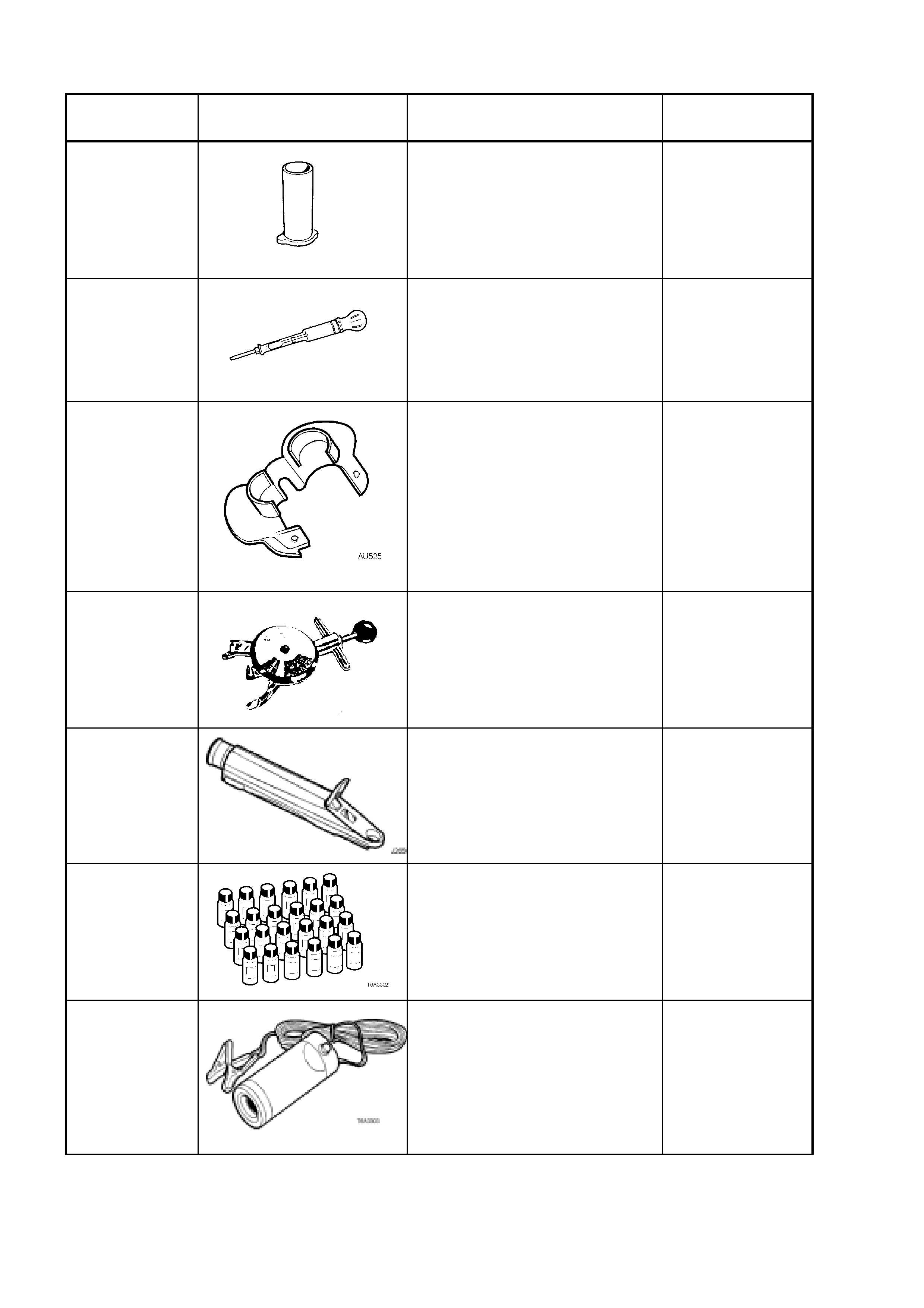

Tube Blocking

If a tube is severely damaged, it can be blocked

off.

NOTE: Do not block off more than two tubes in a

radiator. Blocking off more than two tubes will

reduce the cooling capacity of the system.

The tube should be cut off 6 mm from the header

and pinched shut before it is cleaned and sealed,

refer to GENERAL CORE REPAIR in this Section.

Figure 6B1-69

Header Repair

If the header or a tube near the header requires a repair, the side tank does not have to be removed.

General Core Repair

The need for careful preparation of the surface in the repair area cannot be over-emphasised. If the leak area

surface is not clean, the repair material will not adhere to the surface.

1. Remove and drain radiator, refer to 3.14 RADIATOR - REMOVE in this Section.

2. If necessary, carefully cut away fins to expose the damaged area.

NOTE: Do not cut away more than 25 mm total fin material.

3. Clean away dirt etc. with water. Dry the affected area using hot air from a hair drier.

NOTE: Do not apply flame to dry damaged area.

4. Clean affected area with petrol to remove any traces of oil.

5. Thoroughly stir contents of repair agent.

NOTE: In cases of extended shelf life, the silicon in solution may separate from the thinner base. Should this

occur, mix contents well until agent is again homogeneous.

6. Apply repair agent sparingly to damaged area. Do not apply excessive amount, as this will cause blockage of

the radiator tube.

NOTE: Use a clean, dry wooden applicator to 'DRIP' agent onto damaged area of radiator.

7. Allow radi ator t o s tan d i n a c lean, dr y ar ea f or a minimum of 3 hour s ( at ambient t emperatur e of 20 - 3 0 °C) with

adequate ventilation.

NOTE: Do not apply heat or flame to promote drying.

8. Refit radiator, refer to 3.14 RADIATOR - REINSTALL in this Section.

Transmission Oil Cooler L eak Test

If the transmission oil cooler is suspected of leaking oil, test it before the radiator is replaced, as follows:

1. Disconnect oil cooler pipes at the flexible hose connections. Refer to

3.13 FLEXIBLE TRANSMISSION COOLER HOSE, in this Section.

2. Plug one of the connections, using a blocked pipe fitting and attach an air supply to the other flexible hose.

3. Remove radiator cap and check that the coolant is filled to the radiator cap filler neck.

4. APPLY AIR PRESSURE GRADUALLY, increasing up to an absolute maximum of 103 kPa. If bubbles appear

in radiator neck, the oil cooler is leaking and the radiator assembly must be replaced.

4. ENGINE COOLING SYSTEM DIAGNOSIS

1. POOR HEATER OPERATION

Little or no heat coming from the heater, especially at idle, could be an indication of a cooling system problem.

As the c oolant lev el begins to get lower than norm al, air enter s the s ystem to replace the mis sing coolant. The

heater core is one of the highest parts of the cooling system and therefore, the first area to lose coolant.

At first, with a small amount of coolant loss, lack of heat will be most noticeable at idle. As driving speed

increases, the engine pumps more coolant and more heat is now able to pass through the heater core.

If coolant level drops even lower, heater operation will become less effective, even during normal driving.

Cooling and engine systems can be adversely affected if problem is not corrected.

2. LEAKING CYLINDER HEAD GASKET

Combus tion gas es leak ing pas t the cylinder he ad gas k et c an pres sur ise the c ool in g s ystem, f orc ing c oolan t o ut

of the system and into the coolant recovery reservoir.

Indications are air bubbles in the coolant or an overflow condition of the recovery reservoir.

3. QUESTION THE CUSTOMER

To avoid needless tim e and cost in di agnosing co oling system complaints , the custom er should be questi oned

about driving conditions that place abnormal loads on the cooling system.

1. IS OVERHEATING OCCURRING AFTER PROLONGED IDLE, IN GEAR, WITH AIR CONDITIONING

SYSTEM OPERATING?

If answer is YES - instruct owner on driving techniques that would avoid overheating such as:-

a. Idle in ne utral as m uch as pos sible – inc rease engine rpm to get hig her air flo w (due to an increase in

voltage to the fan) and coolant flow through radiator.

b. Turn air conditioning system off during extended idling periods if overheating is indicated on

temperature gauge. Further diagnostic checks should not be required.

2. IS OVERHEATING OCCURRING AFTER PROLONGED DRIVING IN SLOW CITY TRAFFIC, TRAFFIC

JAMS, PARADES, ETC?

If answer is YES, explain driving technique to the customer, that would avoid overheating – same as for

prolonged idle - No.1. Further diagnostic checks should not be required.

4. DIAGNOSTIC CHART

If none of the above conditions apply, refer to the following Diagnosis Chart.

To effectively use this chart, question the customer to determine which of the following three categories apply to the

complaint:-

A. IF COMPLAINT IS HOT INDICATION ON TEMPERATURE GAUGE.

Was temperature reading accompanied by boiling? If answer is YES, go to overheating on diagnosis chart. If

answer is NO, check temperature gauge and sender.

B. IF COMPLAINT IS BOILING - go to overheating on diagnosis chart.

C. IF COMPLAINT IS COOLANT LOSS.

Determine if customer is filling the system correctly.

If incorrect filling is not the problem, go to coolant loss in the diagnosis chart.

WARNING: THE COOLING SYSTEM IS DESIGNED TO OPERATE AT 120-150 kPa AND TEMPERATURES

NOT EXCEEDING 130°

°°

° C.

Refer to the WARNING in 3.1 SERVICE NOTES in this Section before removing the radiator cap or servicing the

system.