SECTION 6B2 - ENGINE COOLING -

V6 SUPERCHARGED ENGINE

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL INFORMATION

2. SERVICE OPERATIONS

2.1 SERVICE NOTES

2.2 COOLANT MAINTENANCE

TOPPING UP THE COOLING SYSTEM

2.3 DRAINING AND FILLING COOLING SYSTEM

DRAINING THE COOLING SYSTEM

REFILLING AND BLEEDING THE COOLING SYSTEM

2.4 COOLING SYSTEM HOSES

SOME SERVICE NOTES

2.5 THERMOSTAT

REMOVE

REINSTALL

2.6 RADIATOR INLET PIPE

REMOVE

REINSTALL

3. SPECIFICATIONS

4. TORQUE WRENCH SPECIFICATIONS

5. SPECIAL TOOLS

1. GENERAL INFORMA TION

The cooling system for MY 2003 VY and V2 Series vehicles, fitted with the V6 Supercharged engine differs from

naturally aspirated V6 eng i nes with re vise d p lum bing and additiona l ble eder po in ts.

The radiator and fan module has been completely re-designed and, in this respect, is the same as the standard

assem bly fitted to V6 e ngined ve hicles, wit h automatic transm ission. T herefore, f or all service operatio ns related to

the radiator and/or cooling fans, refer to Section 6B1 ENGINE COOLING – V6 ENGINE.

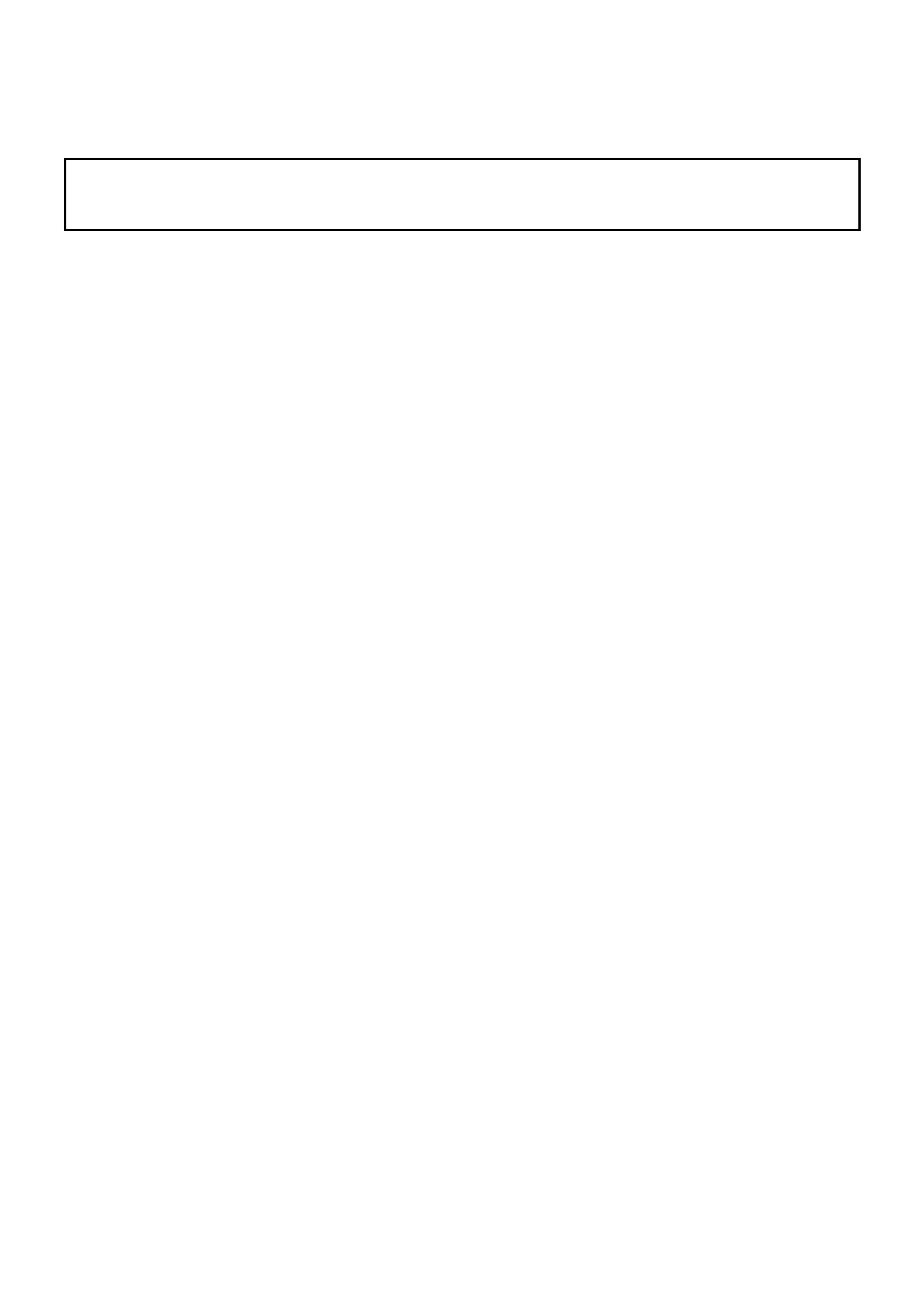

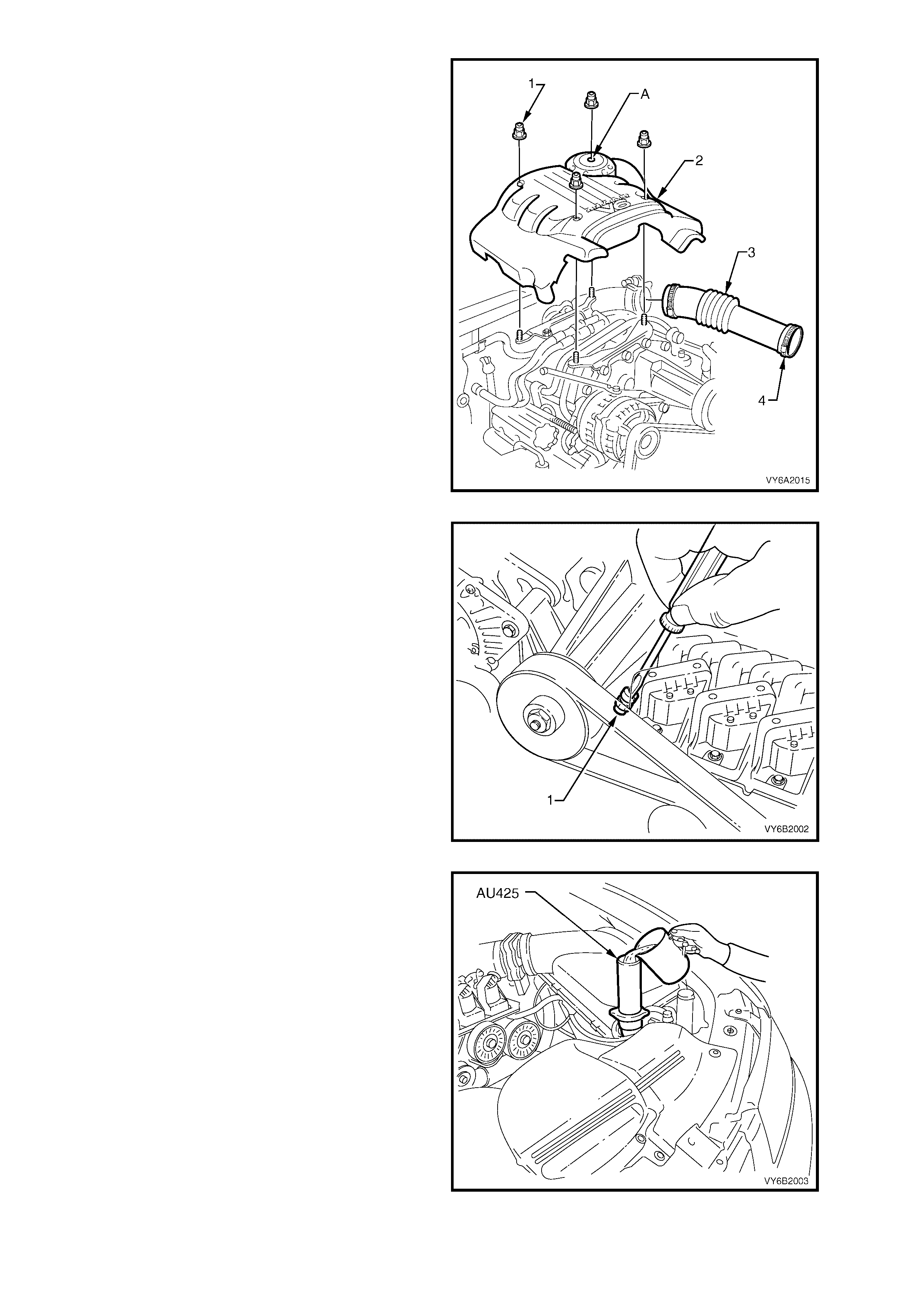

Figure 6B2-1

Legend:

1. Thermostat Cover Bleeder Screw

2. Radiator Inlet Pipe Bleeder Screw

3. Coolant Bypass Housing Bleeder Screw

2. SERVICE OPERATIONS

Cooling system service operations carry over in general from those described in Section 6B1-1 ENGINE

COOLING - V6 ENGINE, except for the following operations.

2.1 SERVICE NOTES

1. Before removing the radiator cap, allow the engine to cool, then place a shop rag over the radiator cap and

then slowly turn the cap anti-clock wise, without pressing down until the cap reac hes the first 'stop'. T his is the

pressur e relief st op, which will al low any rem aining pres sure within the s ystem to es cape. Then pr ess down on

cap and continue to rotate it anti-clockwise until it can be removed.

2. The vehicle is fitted with radiator electric cooling fans. W hen working around the engine com partment with the

engine running or with the ignition 'ON', keep clear of the fan as it may start operating without warning.

3. The cooling system requires little care except for maintaining the coolant to the correct level in the recovery

reservoir and periodic servicing at the time or distance intervals as outlined in the MY 2003 VY and V2 Series

Owner's Handbook.

Periodic servicing includes:

a. Checking coolant level, refer 3.3 CHEC KING AND FILLING COOLING SYSTEM in Section 6B1 ENGIN E

COOLING – V6 ENGINE.

b. Checking coolant concentration, refer 3.2 COOL ANT M AINTEN ANCE – Testing Coolant Concentration

in Section 6B1 ENGINE COOLING – V6 ENGINE.

c. Pressure test cooling system and radiator cap, refer 3.7 PRESSURE TESTING in Section 6B1 ENGINE

COOLING – V6 ENGINE.

d. Tighten hose clamps and inspect all hoses, refer 3.6 COOLANT HOSES in Section 6B1 ENGINE

COOLING – V6 ENGINE. Replace hoses if swollen or deteriorated.

CAUTION: Always wear protective safety glasses when working with spring type hose clamps.

Failure to do so could result in eye injury.

e. Clean out cooling system, refer 3.4 CLEANING COOLING SYSTEM – COOLING SYSTEM FLUSH, in

Section 6B1 ENGINE COOLING – V6 ENGINE and refill cooling system, refer 3.3 CHECKING AND

FILLING COOLING SYSTEM in Section 6B1 ENGINE COOLING – V6 ENGINE.

4. To reduce environm ental impact and m aintenance cost, whenever the coolant is drained f rom any engine, the

service records are to be checked to determine when the coolant was last changed. If more than six months life

is left before the next coolant change, then the following procedure is to be followed:

a. When draining the coolant from the engine, use a clean container of at least 12 litres capacit y and ensure

that the coolant is not contaminated in the draining process.

b. After repairs have been completed, refill the engine cooling system with the drained coolant.

c. Top up as required, using a 50/50 m ix of clean water and the recomm ended coolant, which is either ‘Ne w

Formula Long Life All Seasons Coolant’ or DEX-COOL® coolant (to GM 6277M Specification). Refer to

3.2 COOLANT MAINTENANCE and 3.3 CHECKING AND FILLING COOLING SYSTEM in Section 6B1

ENGINE COOLING – V6 ENGINE, for the necessary procedures and further information.

2.2 COOLANT MAINTENANCE

IMPORTANT: Do not mix different types of anti-freeze or corrosion inhibitors as they may be incompatible. If a

different type has been used in the cooling system, flush the system with clean water, refer 3.4 CLEANING

COOLING SYSTEM – COOLING SYSTEM FLUSH in Section 6B1 ENGINE COOLING – V6 ENGINE and refill

cooling system with the correct coolant, refer 3.3 CHECKING AND FILLING COOLING SYSTEM in Section 6B1

ENGINE COOL ING – V6 ENGINE.

The cooling system is designed to use a coolant (a mixture of ethylene glycol antifreeze with added corrosion

inhibitors, and water), rather than plain water. The use of glycol also raises the boiling point and increases the

cooling s ystem efficienc y. For this r eason, it is of the utm ost impor tance to m aintain the c orrect concentra tion leve l

of ethylene glycol in the cooling system.

Addition of plain water into the cooling system when 'topping-up' may dilute the coolant mixture to a point where the

antifreeze/anti-boil and corrosion inhibitor properties of ethylene glycol become ineffective.

The coolant should comprise of a mixture 50% ethylene glycol antifreeze/inhibitor with 50% clear, clean water.

Ethylene glycol conforming to the correct specification is either named 'New Formula Long Life All Seasons

Coolant' or, DEX-COOL ® and are both available in a number of different quantities. Check the current release of

PartFinder® for specific details.

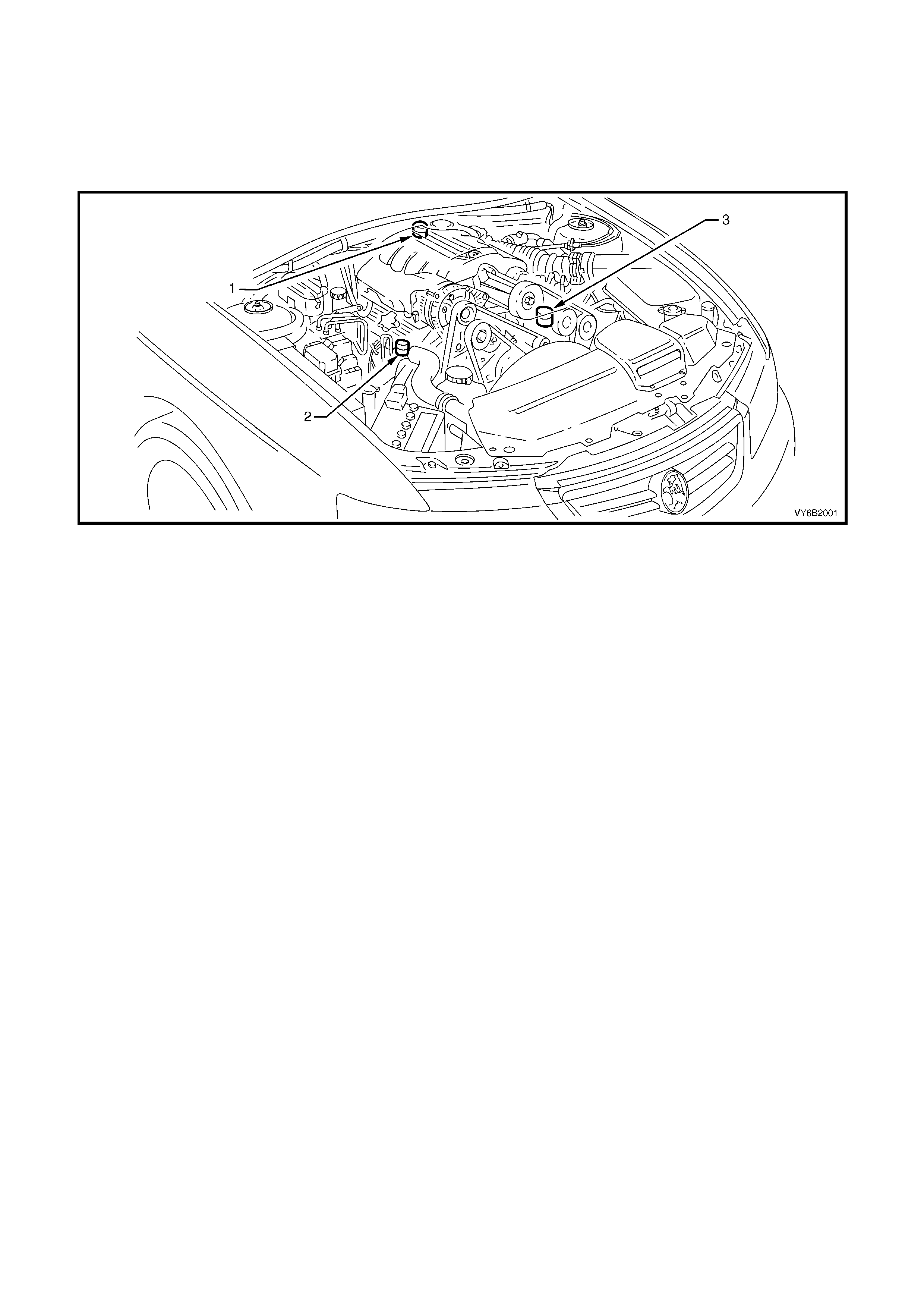

TOPPING UP THE COOLING SYSTEM

Under normal operating conditions, the cooling

system should not be topped up at the radiator

filler. The level can be checked at the coolant

recovery reservoir, and coolant (in the correct

concentration with clear, clean water) added as

necessary to bring the level to between the

indicator arrows (‘A’) on the coolant recovery

reservoir dipst ic k when the engine is col d.

Figure 6B1-2

2.3 DRAINING AND FILLING COOLING SYSTEM

During any service operation that requires the cooling system to be partly or completely drained, the following

instructions must be followed.

DRAINING COOLING SYSTEM

CAUTION: To avoid serious personal injury, never remove the radiator cap or open the air vent valve on the

coolant outlet when the engine is hot, even if the cooling system should require filling. Sudden release of

cooling system pressure is very dangerous.

1. Before removing the radiator cap, allow the engine to cool, then place a shop rag over the radiator cap and

then slowly turn the cap anti-clock wise, without pressing down until the cap reac hes the first 'stop'. T his is the

pressur e relief st op, which will al low any rem aining pres sure within the s ystem to es cape. Then pr ess down on

cap and continue to rotate it anti-clockwise until it can be removed.

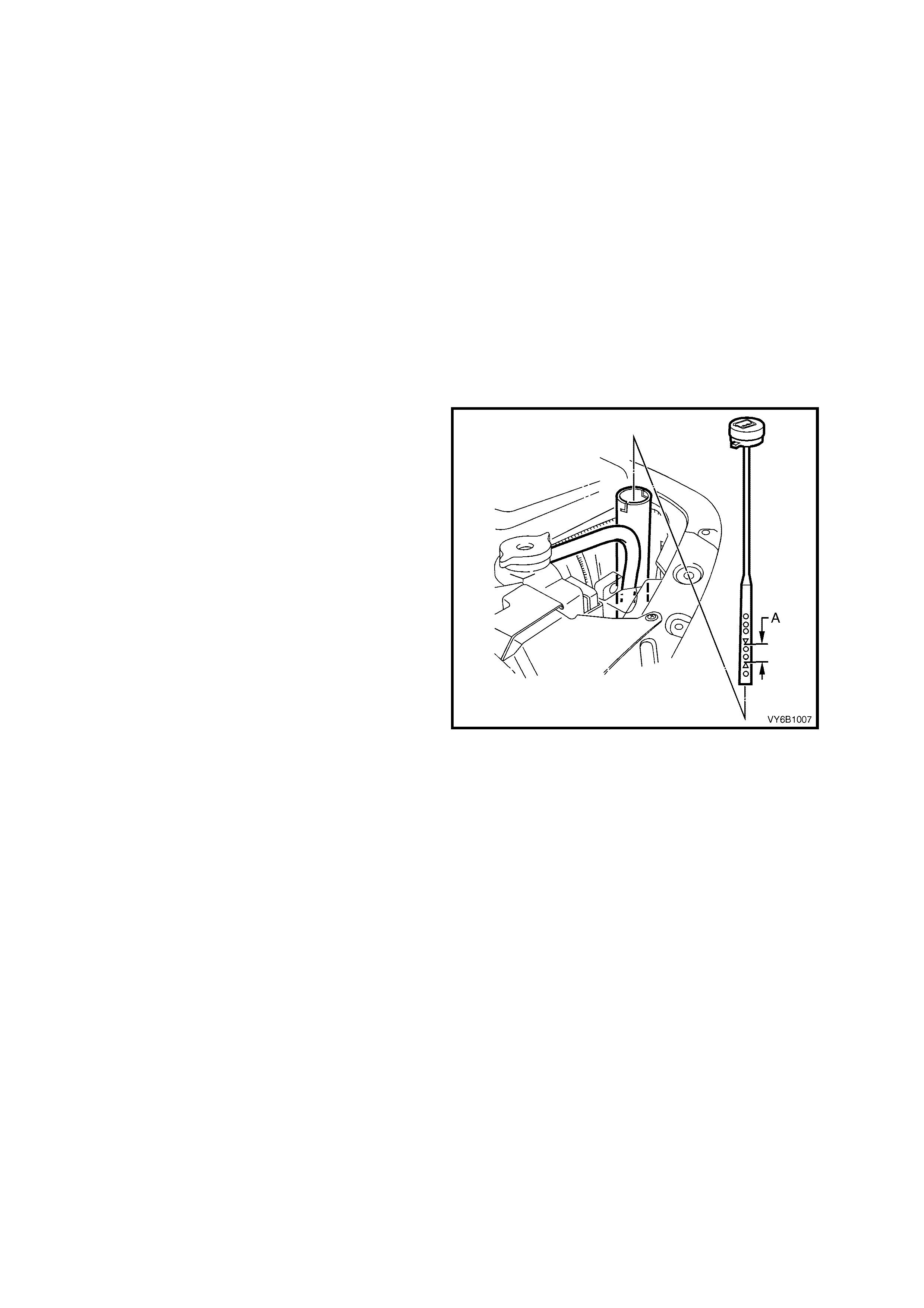

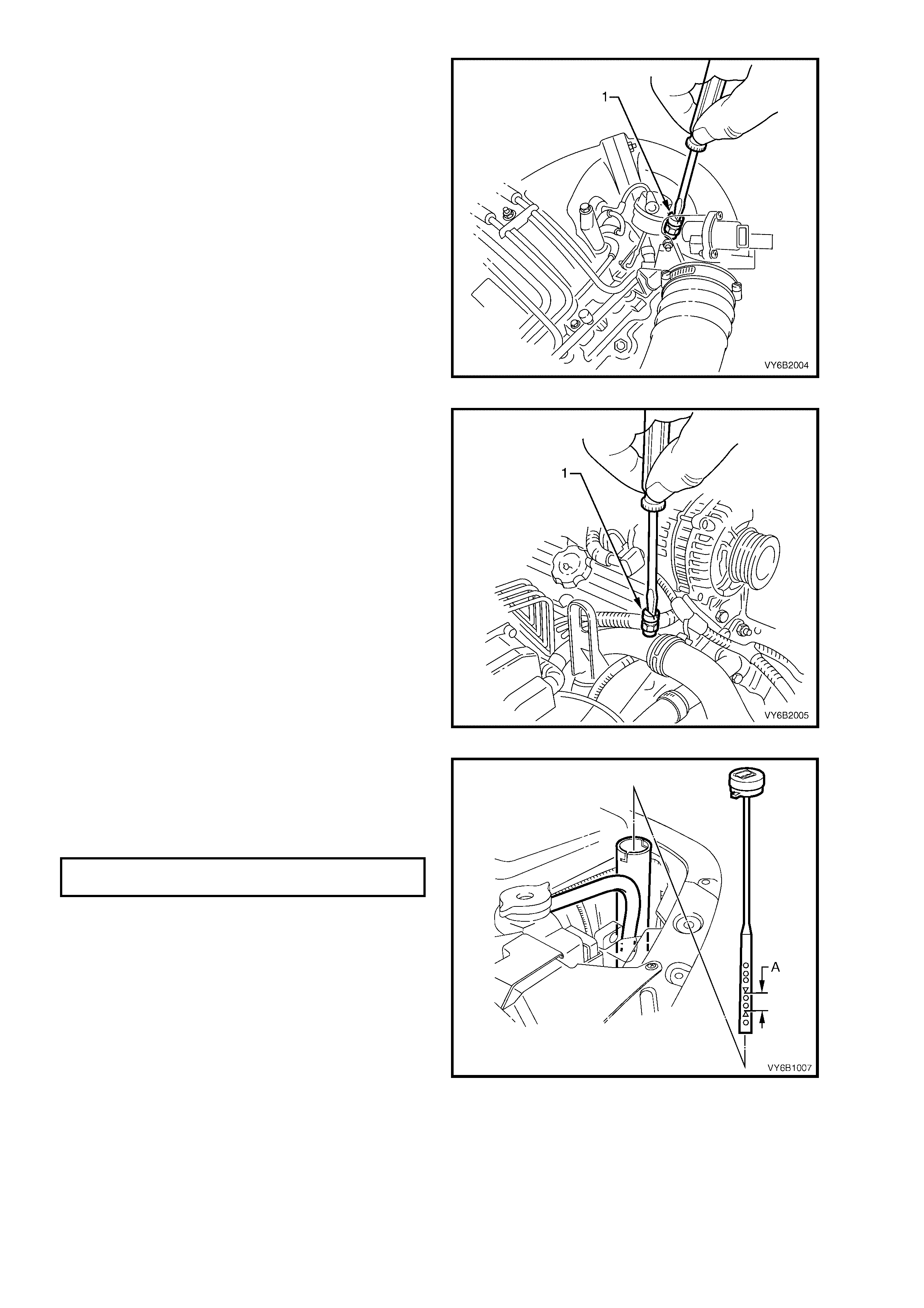

2. Place a clean drain tray capable of collecting

12 litres of coolant, under the front of the

vehicle.

IMPORTANT: Refer Note 4 in 2.1 SERVICE

NOTES, in this Section.

3. Disconnect the lower radiator hose at the

radiator end (1) and drain coolant into

container.

NOTE: Should the total cooling system require

draining, remove both knock sensors. Refer

3.4 CLEANING COOLING SYSTEM in

Section 6B1 ENGINE COOLING – V6 ENGINE.

Figure 6B2-3

REFILLING AND BLEEDING THE COOLING SYSTEM

The following procedure requires the use of Tool No. AU 425 to fill the cooling system.

1. Set heater control to maximum.

2. Mix a coolant mixture consisting 50% ethylene glycol antifreeze/inhibitor with 50% clear, clean water.

NOTE 1: Ethylene glycol conforming to the correct specification is either named 'New Formula Long Life All

Seasons Coolant' or, DEX-COOL® and are both available in a number of different quantities. Check the current

release of PartFinder® for specific details. As either of these coolants may be specified, refer to the MY 2003 VY

and V2 Series Owner’s Handbook to ensure that the correct type is used.

NOTE 2: Do not mix different types of anti-freeze or corrosion inhibitors as they may be incompatible. If

a different type has been used in the cooling system, flush the system with clean water, refer to

3.4 CLEANING COOLING SYSTEM in Section 6B1 ENGINE COOLING – V6 ENGINE.

3. If cooling system was completely drained, add a pack of pellets (three pellets) P/N M40124 to cooling system

by disconn ecting radiator upper h ose from engine coolant outlet and placing pellets inside radiator hose. Refit

hose to coolant outlet and tighten hose clamp.

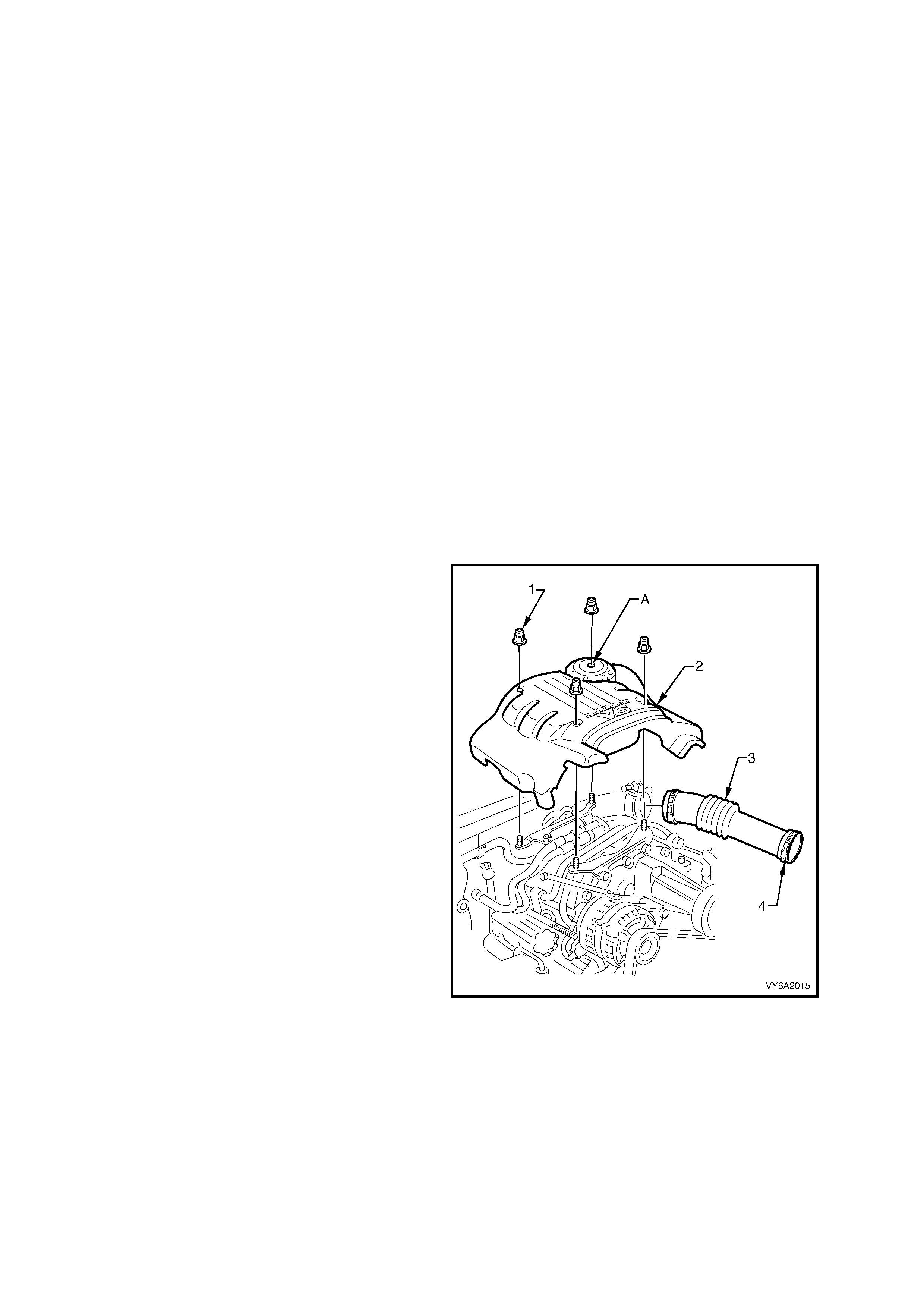

4. Remove the four engine dress cover dome

nuts (1), then remove the cover (2).

5. Remove radiator cap and install Tool No.

AU425 to radiator filler neck.

Figure 6B1-4

NOTE: Commence bleeding the cooling system

using the air vent bleeder screw (1) located in the

water bypass housing.

6. Using a screwdriver, open air vent bleeder

screw (1) at water bypass housing.

Figure 6B2-5

7. Fill cooling system using coolant mixture via

Tool No. AU 425 until coolant flows from air

vent bleeder screw at water bypass housing

and all air is expelled. Close air vent bleeder

screw.

Figure 6B2-6

8. Cont inue bleed ing cool ing s ystem from air vent

bleeder ( 1) loc at ed in ther mostat hous ing c ove r

until indications of air stop. Close air vent

bleeder screw.

Figure 6B2-7

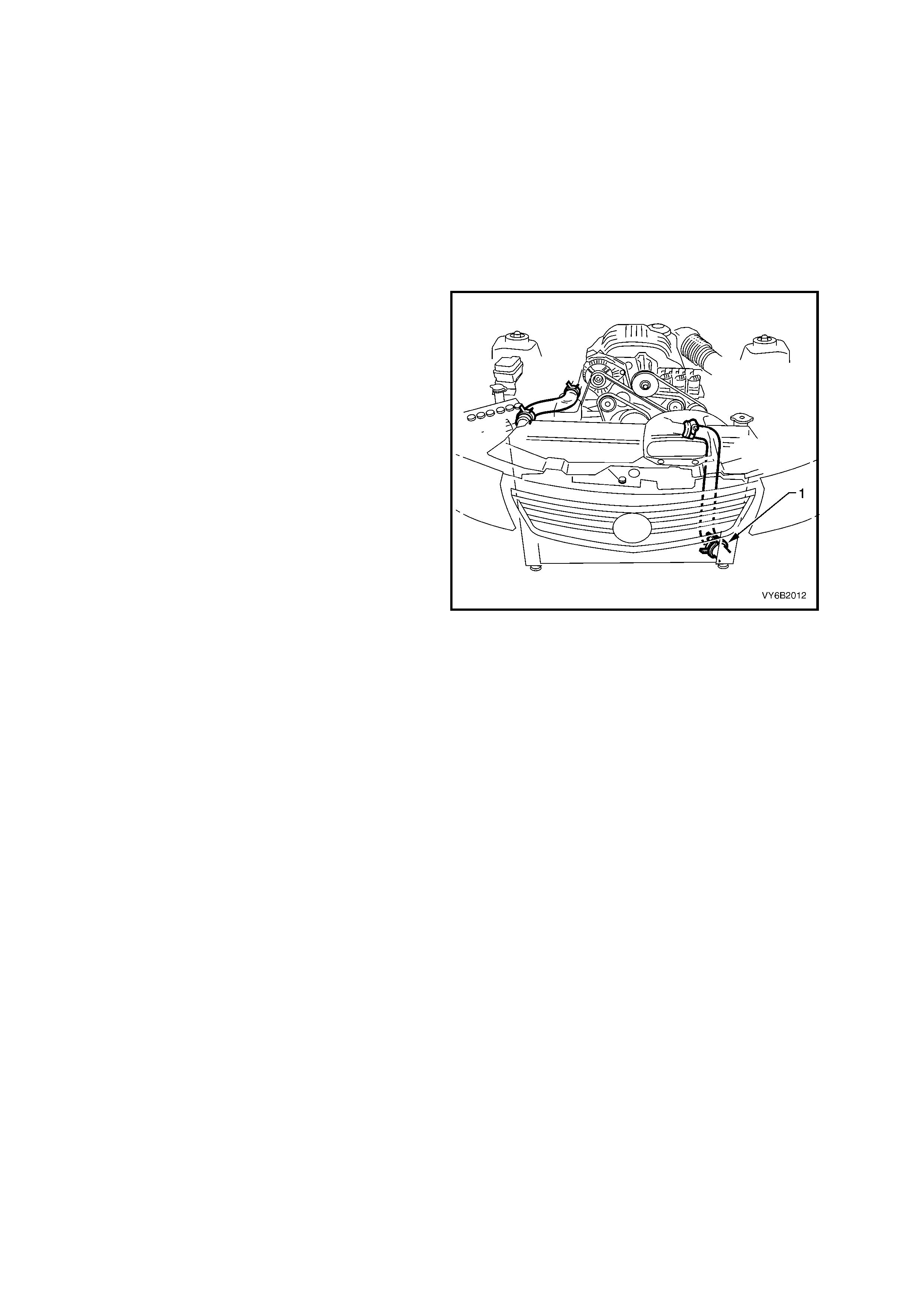

9. Comm ence bleeding system from radiator inlet

pipe air vent bleeder screw (1) until indications

of air stop. Close air vent bleeder screw.

Repeat operations 6 to 9 until all air is

exhausted from cooling system.

Figure 6B2-8

10. Ensure air vent bleeder screws are closed,

then remove AU425 from radiator.

11. Reinstall the engine dress cover and retain

with the four decorative nuts, tightened to the

correct torque specification.

ENGINE DRESS COVER NUT

TORQUE SPECIFICATION 5 Nm

NOTE: Use the hole at the left rear of the dress

cover (‘A’) to assist in aligning the mounting studs

with the cover holes. Refer to Figure 6B2-4.

12. If necessary, remove coolant dipstick from

recovery tank and fill tank to between the

indicator arrows (‘A’), then refit recovery tank

dipstick.

13. Pressure test cooling system, refer to

3.7 PRESSURE TESTING in Section 6B1

ENGINE COOL ING – V6 ENGINE.

14. Refit radiator cap.

Figure 6B2-9

15. Start engine and run at idle until operating temperature is reached (thermostat is open).

16. Repeat bleeding procedure as outlined in steps 6-9 until all air is exhausted from cooling system.

17. Top up cooling system using coolant mixture as described in step 2 and refit radiator cap.

18. Check coolant concentration. Refer to Testing Coolant Concentration, in 3.2 COOLANT MAINTENANCE,

Section 6B1 ENGINE COOLING – V6 ENGINE.

2.4 COOLING SYSTEM HOSES

LT Section No. – 01-160

SOME SERVICE NOTES:

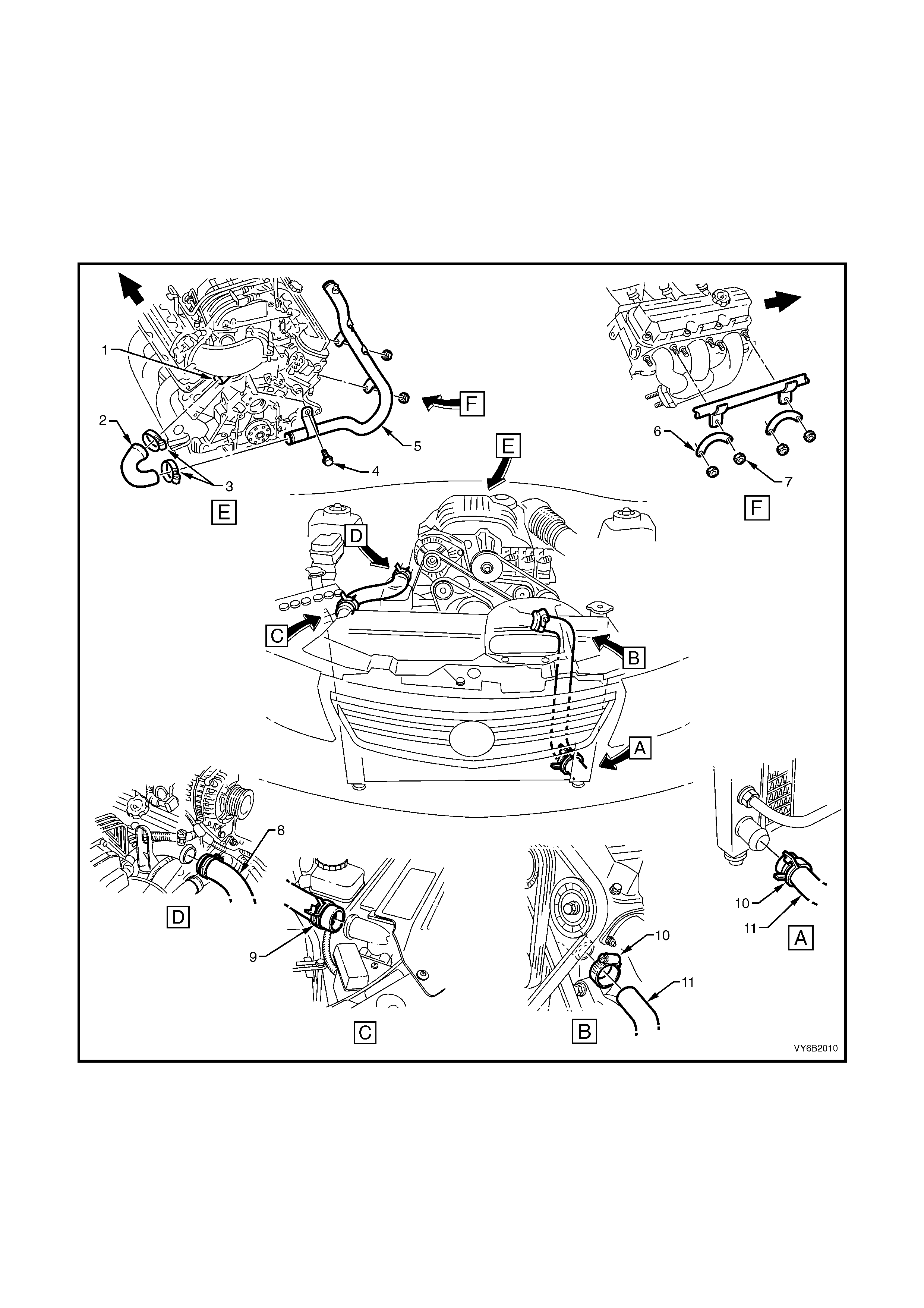

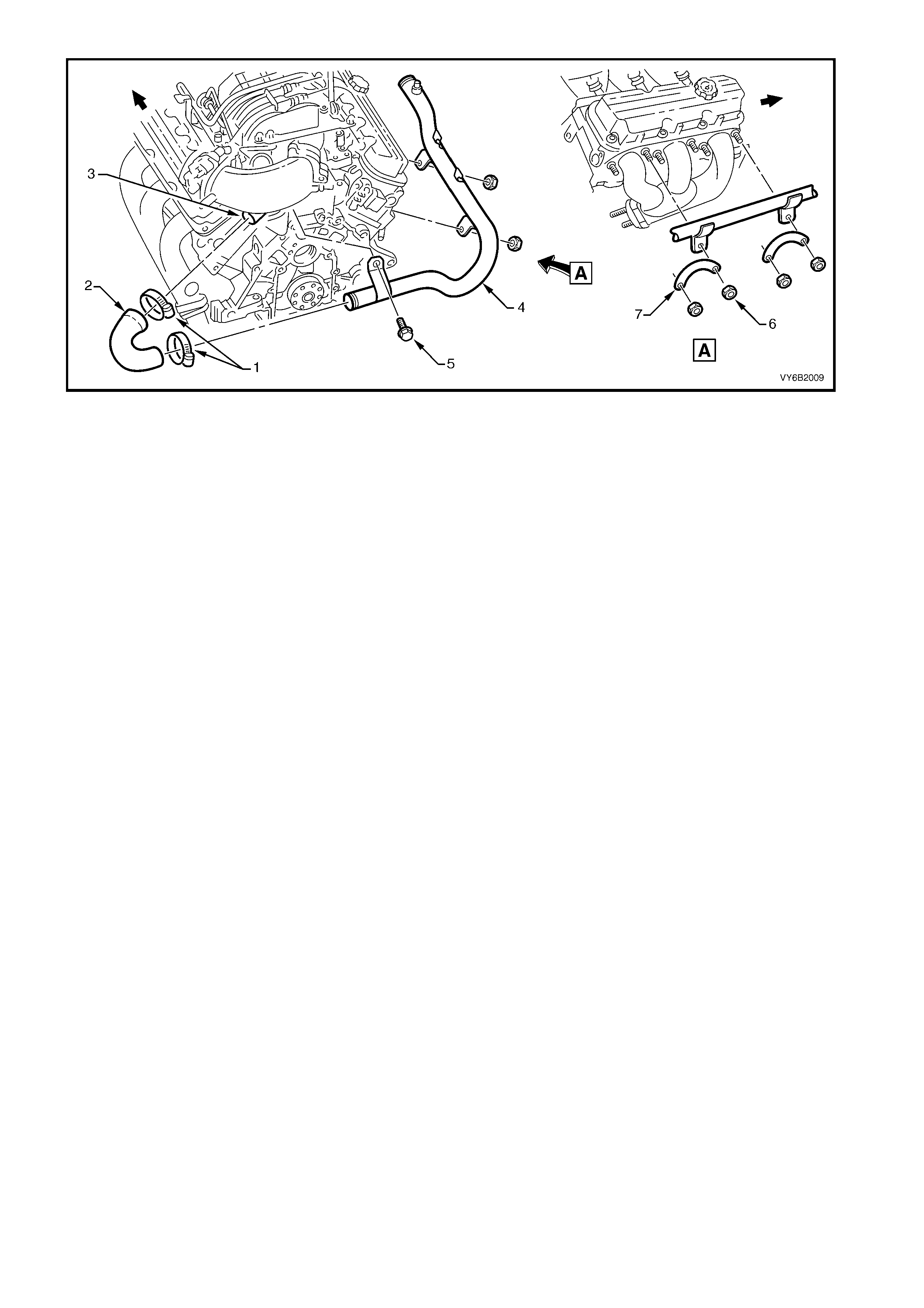

1. Coolant hoses are installed as shown in the following illustration.

2. Hose connections should be thoroughly cleaned before installing any new hose.

3. Following hose/s installation, always refill the cooling system with the correct type and concentration of

coolant. Refer to 2.3 DRAINING AND FILLING COOLING SYSTEM, in this Section.

CAUTION: Always wear protective safety glasses when working with spring type hose clamps. Failure to

do so could result in eye injury.

Figure 6B2-10

Legend

1. Coolant Outlet

2. Coolant Outlet Hose

3. Hose Clamps

4. Screw

5. Radiator Inlet Pipe

6. Plate

7. Plate Nut

8. Radiator Inlet Hose

9. Radiator Inlet Hose Clamps (2 places)

10. Radiator Outlet Hose Clamps (2 places)

11. Radiator Outlet Hose

2.5 THERMOSTAT

LT Section No. – 00-350

REMOVE

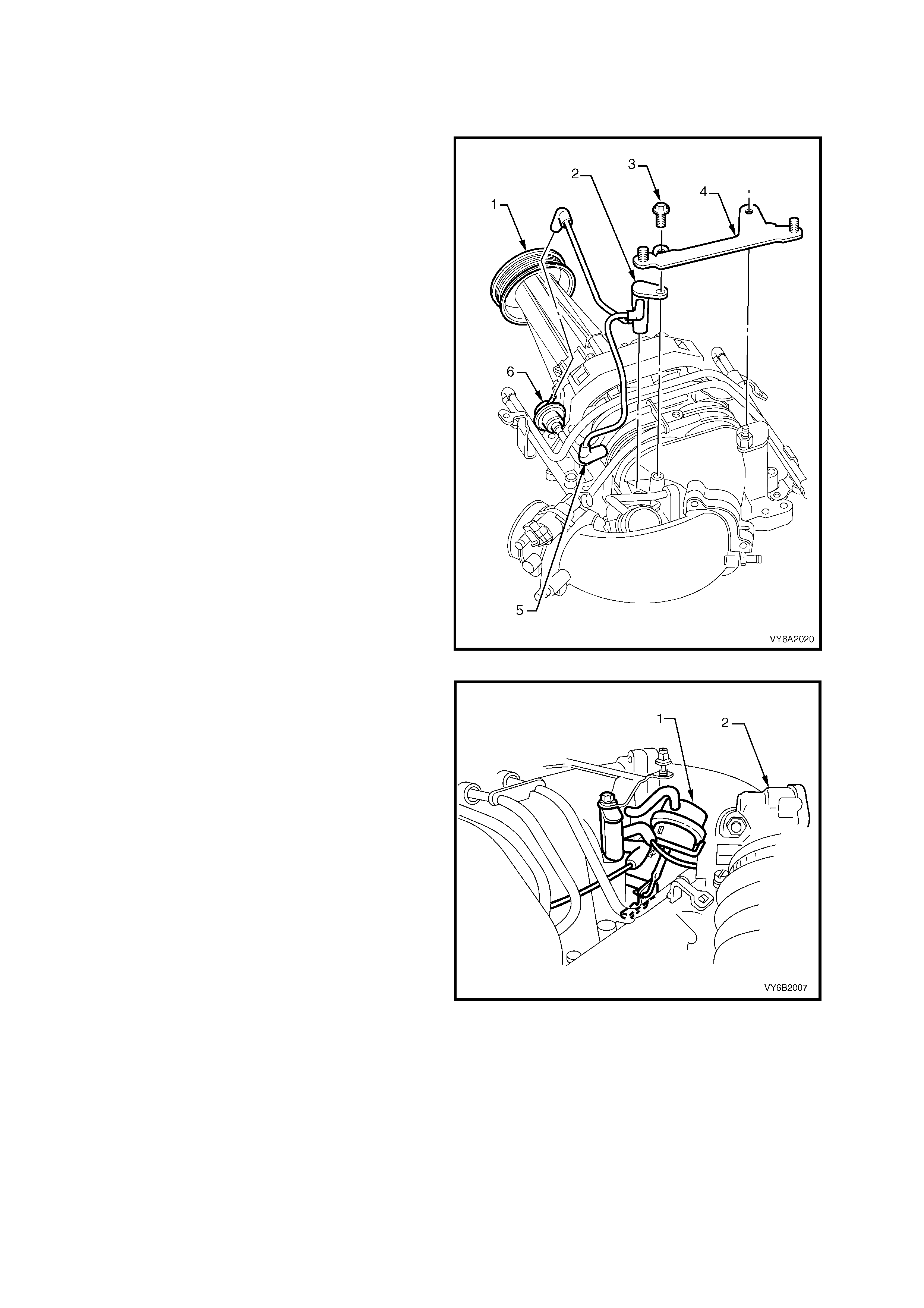

1. Remove the four engine dress cover dome

nuts and remove the cover.

2. Remove 2 b olts (3) securing rear engine cover

bracket assembly (4) and remove bracket.

3. Tag and disconnect vacuum connections from

fuel pressure regulator (6) and bypass

solenoid, lift out the boost control solenoid

harness assembly (5).

Legend:

1. Supercharger Assembly

2. Boost Control Solenoid Harness

3. Screw (2 places)

4. Engine Dress Cover, Rear Mounting Bracket

5. Vacuum Connection to Boost Control Solenoid

6. Fuel Pressure Regulator

Figure 6B2-11

4. Remove bolts attaching bypass valve actuator

(1) and swing actuator to one side to gain

access to thermostat front bolt.

5. Remove air intake duct, throttle body (2) and

throttle cable mounting bracket, refer to

Section 6A2 ENGINE MECHANICAL – V6

SUPERCHARGED ENGINE.

6. Remove the water outlet hose from the

thermostat housing cover.

Figure 6B2-12

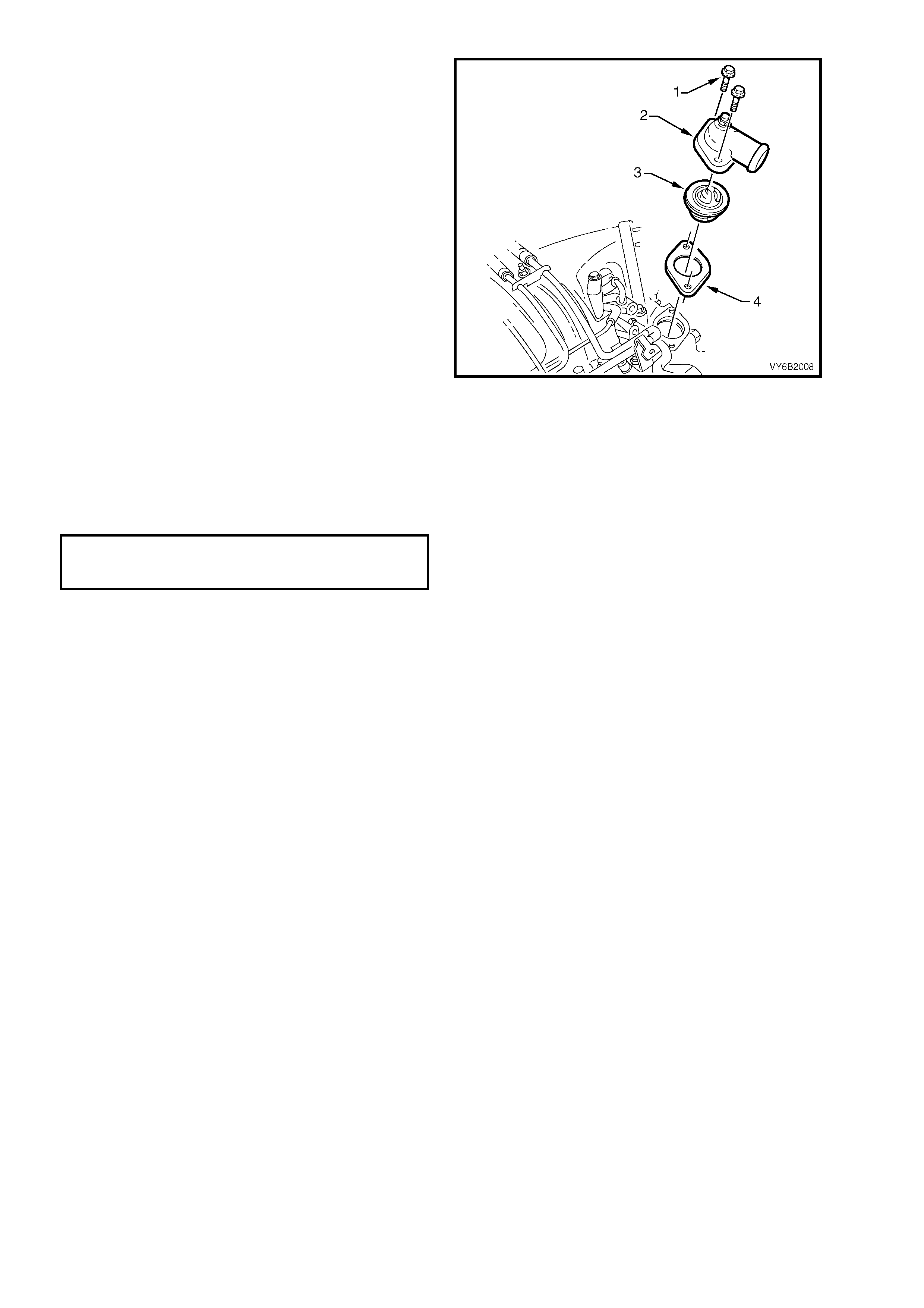

7. Remove the two screws (1) securing the

thermostat housing cover (2), remove cover,

thermostat (3) and gasket (4), discarding the

rem oved gask et. T he rear bolt c an be rem oved

by reaching around from behind supercharger

(using short open-ended spanner) and the front

bolt removed by using a socket ratchet with

extension. The wiring harness located in front

of the rear firewall, ma y need to b e temporaril y

shifted in order to gain access to rear bolt.

Figure 6B2-13

REINST ALL

Reinstallation of the thermostat is the reverse of

removal procedures noting the following.

1. Ensure all gasket surfaces are clean.

2. Tighten th ermostat hous ing c over s c rews ( 1) to

the correct torque specification

THERMOSTAT HOUSING

COVER SCREWS

TORQUE SPECIFICATION 28 Nm

3. Ensure the cooling system is bled correctly,

refer to 2.3 CHECKING AND FILLING

COOLING SYSTEM in this Section.

4. If the wiring harness was moved during

removal, reposition to original location.

2.6 RADIATOR INLET PIPE

LT Section No. – 01-160

REMOVE

1. Disconnect the negative cable from the

battery.

IMPORTANT: Disconnection of the battery affects

certain vehicle electronic systems. Refer to Section 00

CAUTIONS, 5. BATTERY DISCONNECTION

PROCEDURES before disconnecting the battery.

CAUTION: To avoid serious personal injury,

never remove the radiator cap or open the air

vent valve on the coolant outlet when the

engine is hot, even if the cooling system

should require filling. Sudden release of

cooling system pressure is very dangerous.

2. Before removing the radiator cap, allow the

engine to cool, then place a shop rag over the

radiator cap and then slowly turn the cap anti-

clockwise, without pressing down until the cap

reaches the first 'stop'. This is the pressure

relief stop, which will allow any remaining

pressure within the system to escape. Then

press down on cap and continue to rotate it

anti-clockwise until it can be removed.

3. Drain coolant. Refer 2.3 DRAINING AND

FILLING COOLING SYSTEM, in this Section.

4. Remove the four engine dress cover dome

nuts (1) and remove the cover (2).

Figure 6B1-14

5. Remove the coolant outlet hose from the

radiator inlet pipe.

6. Disconnect the wiring harness from the

retainer brackets on the radiator inlet pipe.

7. Remove the screws securing the radiator inlet

pipe to the engine assembly removing the

pipe.

Figure 6B2-15

Legend

1. Clamps

2. Coolant Outlet Hose

3. Coolant Outlet

4. Radiator Inlet Pipe

5. Screw

6. Plate Nut

7. Plate

REINST ALL

Reinstallation of the radiator inlet pipe is the reverse of removal operations noting the following points.

1. Use the hole at the left rear of the dress cover (‘A’) to assist in aligning the mounting studs with the cover holes.

Refer to Figure 6B2-14.

2. Ensure the cooling system is bled correctly, refer to 2.3 CHECKING AND FILLING COOLING SYSTEM in this

Section.

3. Tighten all fasteners to the correct torque specification. Refer 4. TORQUE SPECIFICATIONS in this Section,

for details.

3. SPECIFICATIONS

GENERAL

Radiator cap pressure rating................................... 135 kPa

Cooling system capacity ......................................... 12 Litres

Coolant corrosion inhibitor ...................................... 'New Formula Long Life All Seasons Coolant' or;

DEX-COOL® (depending on vehicle specification)

THERMOSTAT

Type ........................................................................ Power element (wax pellet)

Start to open............................................................ 89° – 93° C

Fully open at............................................................ 106° C max

WATER PUMP

Type ........................................................................ Centrifugal

Drive........................................................................ V-belt

Bearing type............................................................ Double Row Ball Bearin g

RADIATOR

Core type................................................................. Aluminium crossflow core

Overall width (including side tanks) ........................ 826 mm

Core width............................................................... 675 mm

Overall height.......................................................... 507 mm

Core height.............................................................. 430.5 mm

Core thickness ........................................................ 16 mm

Plastic tanks............................................................ Nylon 6,6

RADIATOR HOSE S

Lower

Number and type ............................................... One, Moulded

Inside diameter .................................................. 38.5 mm

Upper

Number and type ............................................... One, Moulded

Inside diameter .................................................. 34.0

RIGHT ENGINE COOLING FAN

Number of blades.................................................... 8

Spacing ................................................................... Symmetrical

Material.................................................................... Polypropylene (20% glass filled)

Diameter.................................................................. 268 mm

Electric motor drive ................................................. 120 Watts (nominal)

LEFT ENGINE COOLING FAN

Number of blades.................................................... 8

Spacing ................................................................... Symmetrical

Material.................................................................... Polypropylene (20% glass filled)

Diameter.................................................................. 370 mm

Electric motor drive ................................................. 160 Watts (nominal)

4. TORQUE WRENCH SPECIFIC ATIONS

Nm

Thermostat housing cover retaining bolts............................. 28

Radiator inlet pipe retaining nuts and screw......................... 25

Coolant Hose Clam ps........................................................... 3

Engine dress cover attaching nut ......................................... 5

Rear engine cover bracket assembly securing bolts............ 18

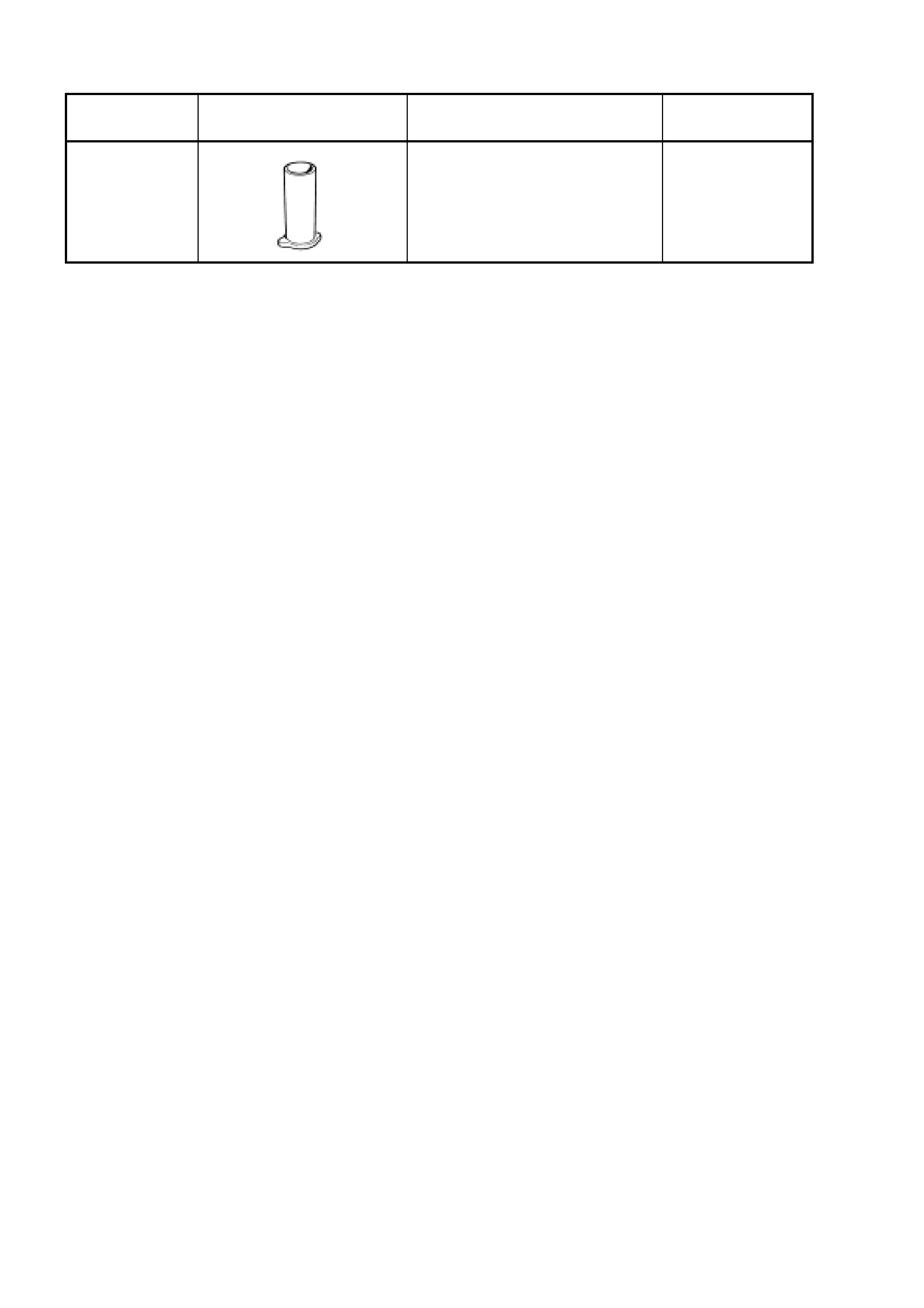

5. SPECIAL TOOLS

TOOL

NUMBER ILLUSTRATION DESCRIPTION CLASSIFICATION

AU425 COOLING SYSTEM FILLER

TUBE

Previously released

Mandatory