SECTION 6C1-2 - DIAGNOSIS – V6 ENGINE

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL DESCRIPTION

1.1 DIAGNOSTIC PRECAUTIONS

1.2 BLOCKING DRIVE WHEELS

1.3 VISUAL/PHYSICAL INSPECTION

1.4 BASIC KNOWLEDGE AND TOOLS

REQUIRED

1.5 ELECTROSTATIC DISCHARGE DAMAGE

1.6 DIAGNOSTIC INFORMATION

SELF DIAGNOSTICS

CHECK POWERTRAIN MALFUNCTION

INDICATOR LAMP (MIL)

INTERMITTENT CHECK POWERTRAIN

(MIL)

DATA LINK CONNECTOR (DLC)

2. STRATEGY BASED DIAGNOSTICS

3. DIAGNOSTIC TROUBLE CO DES

CURRENT DIAGNOSTIC TROUBLE

CODES

HISTORY DIAGNOSTIC TROUBLE CODE

HOW DTC HISTORY WORKS

HOW TO USE DTC HISTORY CODE

INFORMATION

READING DTCS

CLEARING DTCS

CLEARING DTC HISTORY

IGNITION CYCLE DEFAULT

PCM SLEEP TEST

PCM LEARNING ABILITY

TRANSMISSION ADAPT FUNCTION

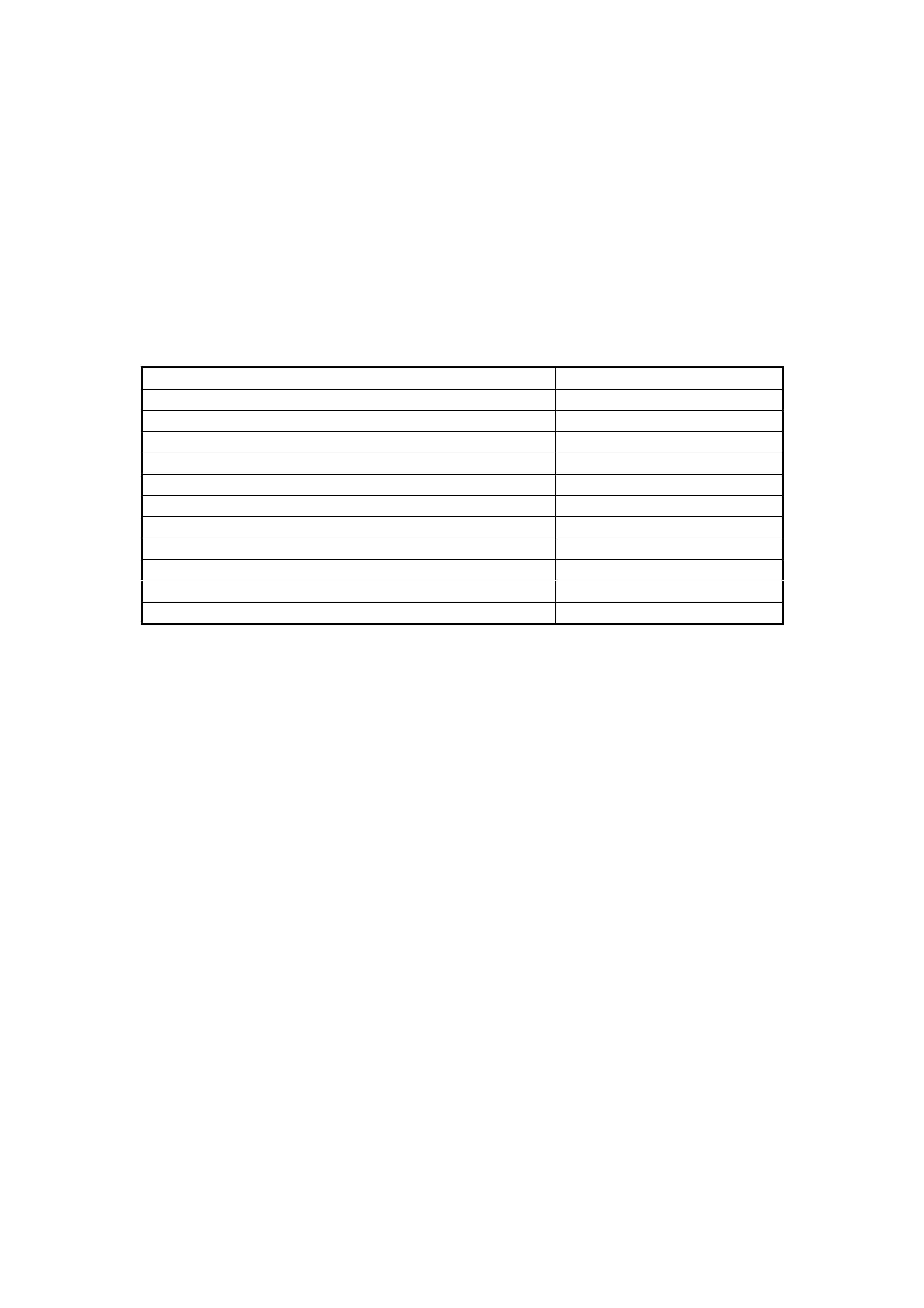

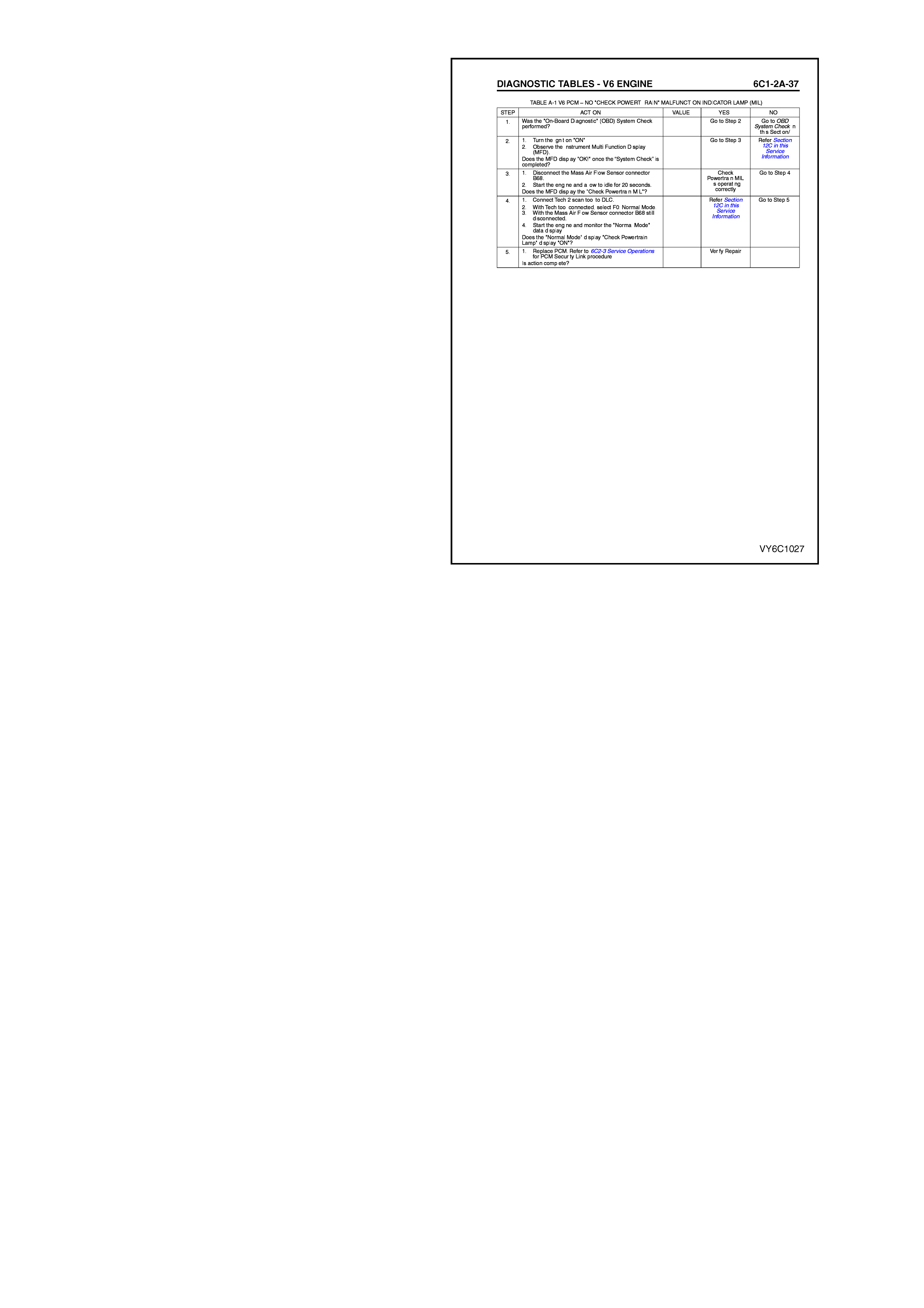

4. TABLE A – V6 ENGINE PCM

ON-BOARD DIAGNOSTIC (OBD)

SYSTEM CHECK

5. POWERTRAIN OBD SYSTEM CHECK

DLC TECH 2

TECH 2 EXPLANATION

5.1 TECH 2 USES - POWERTRAIN CONTROL

MODULE (PCM)

MODE F0: NORMAL MODE

MODE F1: DIAGNOSTIC TROUBLE CODES

MODE F2: DATA DISPLAY

MODE F3: SNAPSHOT

MODE F4: MISC. TESTS

MODE F5: FUNCTION TESTS

MODE F6: STALL DATA

MODE F7: SPECIAL FUNCTIONS

TECH 2: USE WITH INTERMITTENT FAULTS

TECH 2: LIMITATIONS

5.2 TECH 2: PCM NORMAL MODE

TECH 2: PCM NORMAL MODE DESCRIPTIONS

5.3 TECH 2: ENGINE DATA

TECH 2: ENGINE DATA DESCRIPTIONS

5.4 TECH 2: AUTOMATIC TRANSMISSION DATA

TECH 2: AUTOMATIC TRANSMISSION

DATA DESCRIPTIONS

6. DIAGNOSTIC TABLES

6.1 INTRODUCTION

6.2 WRITING THE REPAIR ORDER

6.3 QUESTIONS

"WHO"? QUESTIONS

"WHAT"? QUESTIONS

"WHEN"? QUESTIONS

"WHERE"? QUESTIONS

"HOW"? QUESTIONS

SUMMARY

VERIFYING THE COMPLAINT

CALIBRATIONS

1. GENERAL DESCRIPTION

This is where to start all driveability and emissions diagnosis, once you read and understand Section 6C1-1

GENERAL INFORMATION in this Section. The beginning of Section 6C1-2A contains reference material such as

wiring di agrams, c ontrol modu le terminal e nd views, and engi ne component locations. Rem ember, this inform ation

is for ref erenc e only and is not intended to be us e d as a s tart to di agn os is . A lways start diag nos is on the pag e titl e d

“Powertra in OBD System Check”. This c heck verif ies that the diag nos tic c irc uits a re oper ati ng pro per ly, then directs

you to the correct Service Information location for specific diagnosis.

If the init ia l s teps in the Po wer tr ain O BD System Chec k reveal a prob lem, or if the engi ne d oes not s tart, you wil l be

using one or more tables in Sect ion 6C1-2A in this Se ction for diagnos is. The Powertr ain OBD System Check will

send you to the correct table. These tables follow the Powertrain OBD System Check and problems that prevent

the engine from starting.

If the Powertrain OBD System Check shows that diagnostic trouble codes have been stored, proceed to the

appropriate Diagnostic Trouble Code (DTC) diagnosis pages. If more than one diagnostic trouble code has been

stored, always start diagnostic trouble code diagnosis with the lowest diagnostic trouble code number and work

upward. Diagnostic trouble code diagnosis pages start immediately after the diagnosis tables in Section 6C1-2A.

1. 1 DIAGNOSTIC PRECAUTIONS

THE FOLLOWING REQUIREMENTS MUST BE OBSERVED WHEN WORKING ON VEHICLES.

1. Before removing any PCM system component, disconnect the battery ground lead.

2. Never start the engine without the battery being solidly connected.

3. Never separate the battery from the on board electrical system while the engine is running.

4. When charging the battery, disconnect the battery from the vehicle's electrical system.

5. Never subject the PCM to temperatures above 80° C i.e. paint oven. Always remove control unit first if this

temperature is to be exceeded.

6. Ensure that all cable harness plugs are connected solidly and that battery terminals are thoroughly clean.

7. The powertrain management system harness connectors are designed to fit in only one way; there are indexing

tabs and slots on both halves of the connector. Forcing the co nnector into place is not necessar y if it is being

installed with the proper orientation. Failure to take care to match the indexing tabs and slots to ensure the

connector is being installed correctly can cause damage to the connector, the module, or other vehicle

components or s ystem s .

8. Never connect or disconnect a PCM wiring harness connector when the ignition is switched ON.

9. Before attempting any electric Arc welding on the vehicle, disconnect the battery leads and the PCM

connectors.

10. When steam cleaning engines, do not direct the steam cleaning nozzle at PCM system components. If this

happens, corrosion of the terminals can take place.

11. Use only the test equipment specified in the diagnostic tables, since other test equipment may either give

incorrect results or damage good components.

12. For all voltage measurements using a voltmeter, a digital multimeter with an internal impedance rating of at

least 10 million ohms per volt (10 megohms) such as the DMM J 39200, must be used .

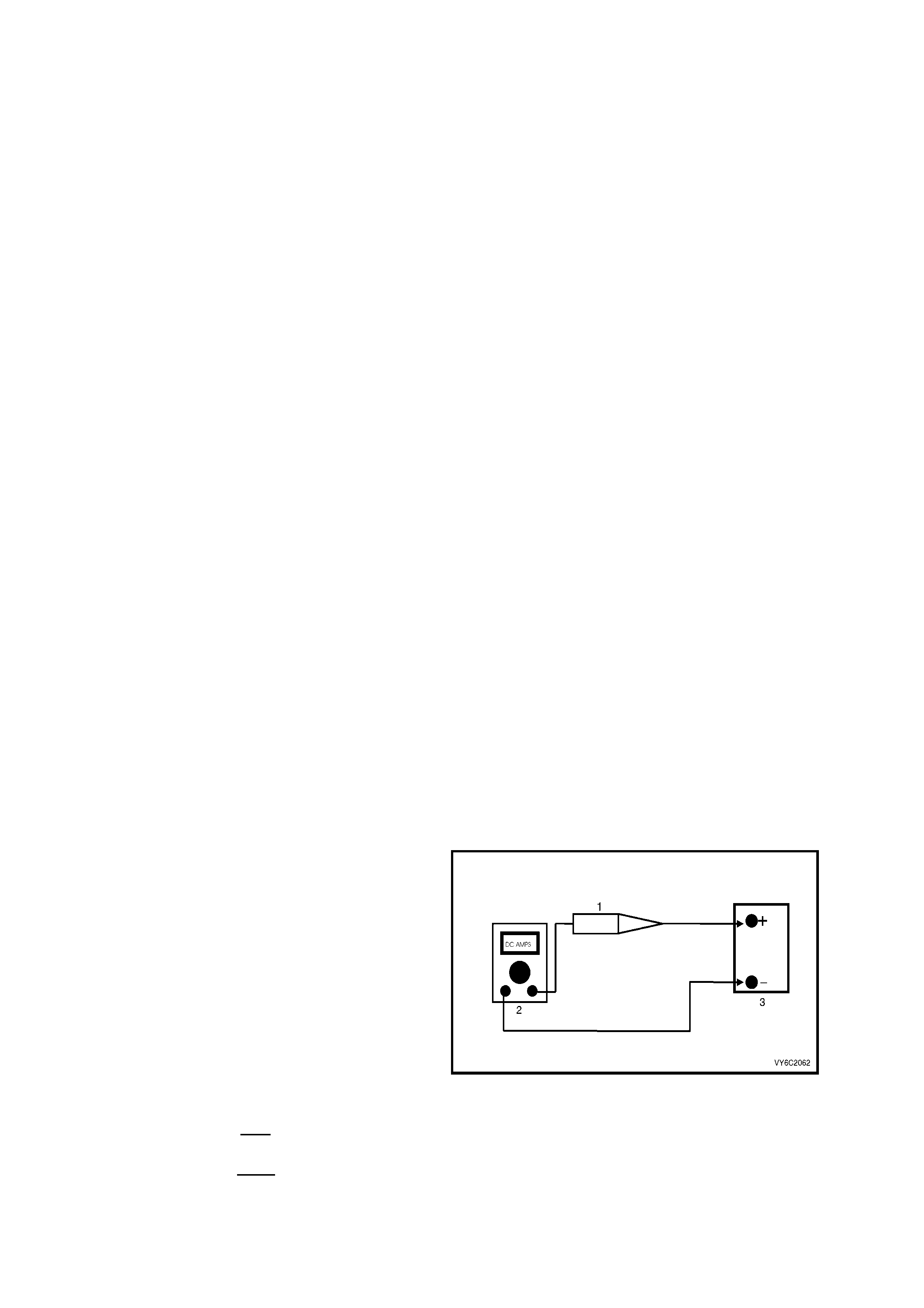

13. When a test light is specified, a "low-power"

test light must be used. Do not use a high -

wattage test light. While a particular brand of

test ligh t is no t sug geste d, a sim ple t est o n an y

test light will ensure it to be OK for PCM c ircuit

testing. Connect an accurate ammeter (such

as the high-impedance digital multimeter) in

series with the test light being tested, and

power the test light-ammeter circuit with the

vehicle battery.

Legend:

1. Test Lamp

2. Digital Multimeter, Set to DC Amps

3. 12 Volt Battery

If the ammeter indicates less than 0.3 A (300 mA)

current flow, the test light is OK to use.

If the am meter in dic at es more than 0.3 A (300 mA)

current flow, the test light is NOT OK to use.

Figure 6C1-2-1

1.2 BLOCKING DRIVE WHEELS

The vehicle drive wheels should always be chocked and the parking brake firmly applied while checking any

system.

1.3 VISUAL/PHYSICAL INSPECTION

A careful visual and physical inspection must be performed as part of any diagnostic procedure. This can often lead

to fixing a problem without further steps. Inspect all the wires in the engine compartment for bad connections,

burned or chafed spots, pinched wires, or contact with sharp edges or hot exhaust manifolds. Check beneath the

air cleaner, the compressor, the generator, etc. This visual/physical inspection is very important. The inspection

must be done carefully and thoroughly.

1.4 BASIC KNOWLEDGE AND TOOLS REQUIRED

To use this service manual most effectively, a general understanding of basic electrical circuits and circuit testing

tools is required. You should be familiar with wiring diagrams, the meaning of voltage, ohms, amps, the basic

theories of electricity, and understand what happens in an open or shorted circuit.

To perform system diagnosis, the following tools are required.

• A Tech 2

• A test light

• A digital multimeter with 10 megohms impedance

• A vacuum gauge

• A fuel pressure gauge and suitable fittings

• Fuel injec tor co il/ ba lanc e te s ter

• IAC motor analyser

Familiarise yourself with the tools and their uses before attempting diagnosis. Special tools that are required for

system service and the ones described above are illustrated in Section 6 SPECIAL TOOLS, at the end of this

Section.

1.5 ELECTROSTATIC DISCHARGE DAMAGE

Electronic components used to control the systems are often designed to carry very low voltage. They are very

susceptib le to dam age caus ed by electr ostatic dis charge. It is possib le for less than 100 vo lts of s tatic electr icit y to

cause damage to some electronic components.

By comparison, it takes as much as 4,000 volts for a person to even feel the zap of a static discharge.

There ar e several wa ys for a person to bec ome staticall y charged. T he mos t common methods of charging are by

fric tion and b y induction. An ex am ple of c harging by fr iction is a pers on slidi ng ac ross a car seat, in which a charge

of as much as 25,000 volts can build.

Charging by induction occurs when a person with well-insulated shoes stands near a highly charged object and

mom entarily touches ground. Charges of the sam e polarity are drained of f, leaving the person high ly char ged with

the opposite polarity. Static charges of either type can cause damage, therefore, use care when handling and

testing the electronic components.

NOTE: To prevent possible Electrostatic Discharge damage:

Do Not touch the PCM connector pins or soldered components on the PCM circuit board.

1.6 DIAGNOSTIC INFORMATION

The diagnostic tables and functional checks in this manual are designed to locate a faulty circuit or component

through logic based on the process of elimination. The tables are prepared with the understanding that the vehicle:

Functioned correctly at the time of assembly.

There are no multiple faults.

The problem currently exists.

The PCM per f orms a c ontin ual self- diagn os is on ce rta i n c ontr ol f unc tions . This dia gnos tic c ap abi lity is suppor t ed by

the diagnostic procedures. The PCM indicates the source of a fault through the use of Diagnostic Trouble Codes

(DT Cs). The DT Cs are two dig it codes. When a fault is detec ted b y the PCM, a d iagnost ic troub le code will set and

the Check Powertrain Malfunction Indicator Lamp (MIL) indicator may be activated.

SELF-DIAGNOSTICS

The PCM performs system self diagnostics. The PCM can detect and often isolate system faults. When a fault is

detected, th e PCM sets a DTC that repr esents the area of the f ault. The PC M may or m ay not turn ON the "Check

Powertrain" Malfunction Indicator Lam p (MIL).

CHECK POWERTRAIN MALFUNCTION INDICATOR LAMP (MIL)

The instruments receive Check Powertrain MIL

information from the PCM via the serial data bus

normal mode message.

The PCM will command the MIL ON, when a DTC

has been set and the DTC requires the icon to be

activated in the instrument Multi Function Display

(MFD).

If the instruments do not receive a normal mode

message from the PCM, the MIL will be activated

continuously. When the MIL remains activated

when the engine is running, or when a fault is

suspected due to a driveability or emissions

problem, perform the “On-Board Diagnostic

System Check". Refer to POWERTRAIN OBD

SYSTEM CHECK in this Section. These checks

will help ide ntif y faults whic h ma y not be detected if

other diagnostics are performed.

Figure 6C1-2-2 – Malfunction Indicator Lamp (MIL) Symbol

INTERMITTENT CHECK POWERTRAIN MALFUNCTION INDICATOR LAMP (MIL)

In the case of an "intermittent" problem, the Check Powertrain MIL may be activated for ten seconds and then

disappear . The corr esponding D iagnostic Trouble Co de will be store d. The DT C will rem ain stored unt il the batter y

voltage to t he PCM has b een disconnec ted or unti l it is erased us ing Tech 2. W hen unexpecte d diagnostic t rouble

codes appear, chances are that these diagnostic trouble codes were set by an intermittent fault.

An intermittent DTC may not re-set. If an intermittent fault occurs, do not use a Diagnostic Trouble Code Table.

Consult the "Diagnostic Aids" on the facing page. The diagnostic table corresponds to the intermittent diagnostic

trouble code.

Section 6C1-2B , SYMPTOM S also covers the topic of "In termittents." A physic al inspect ion of the ap plicable sub-

system most often will resolve the problem. Tech 2 also has several features which can help in diagnosing

interm ittent pr ob lems.

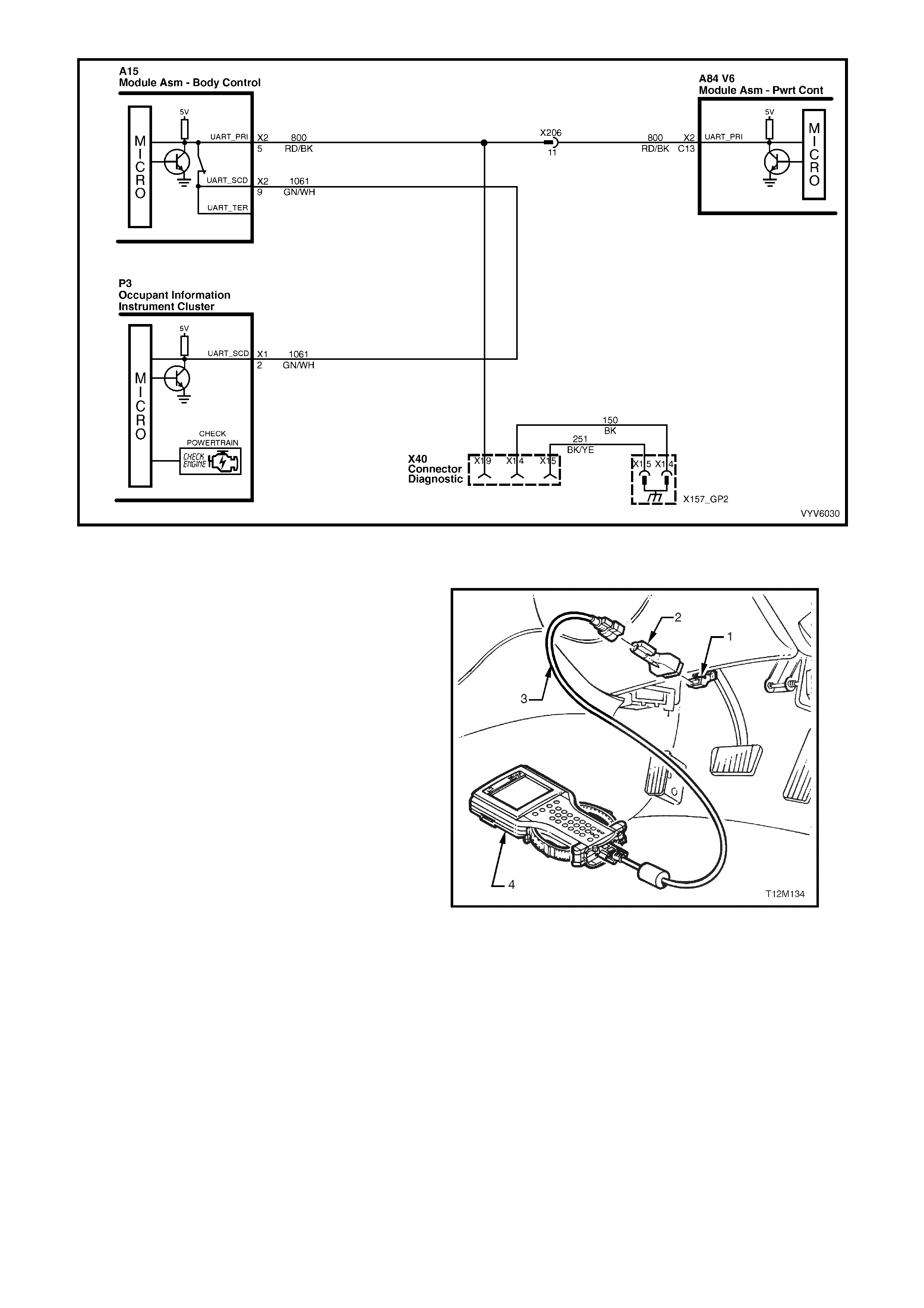

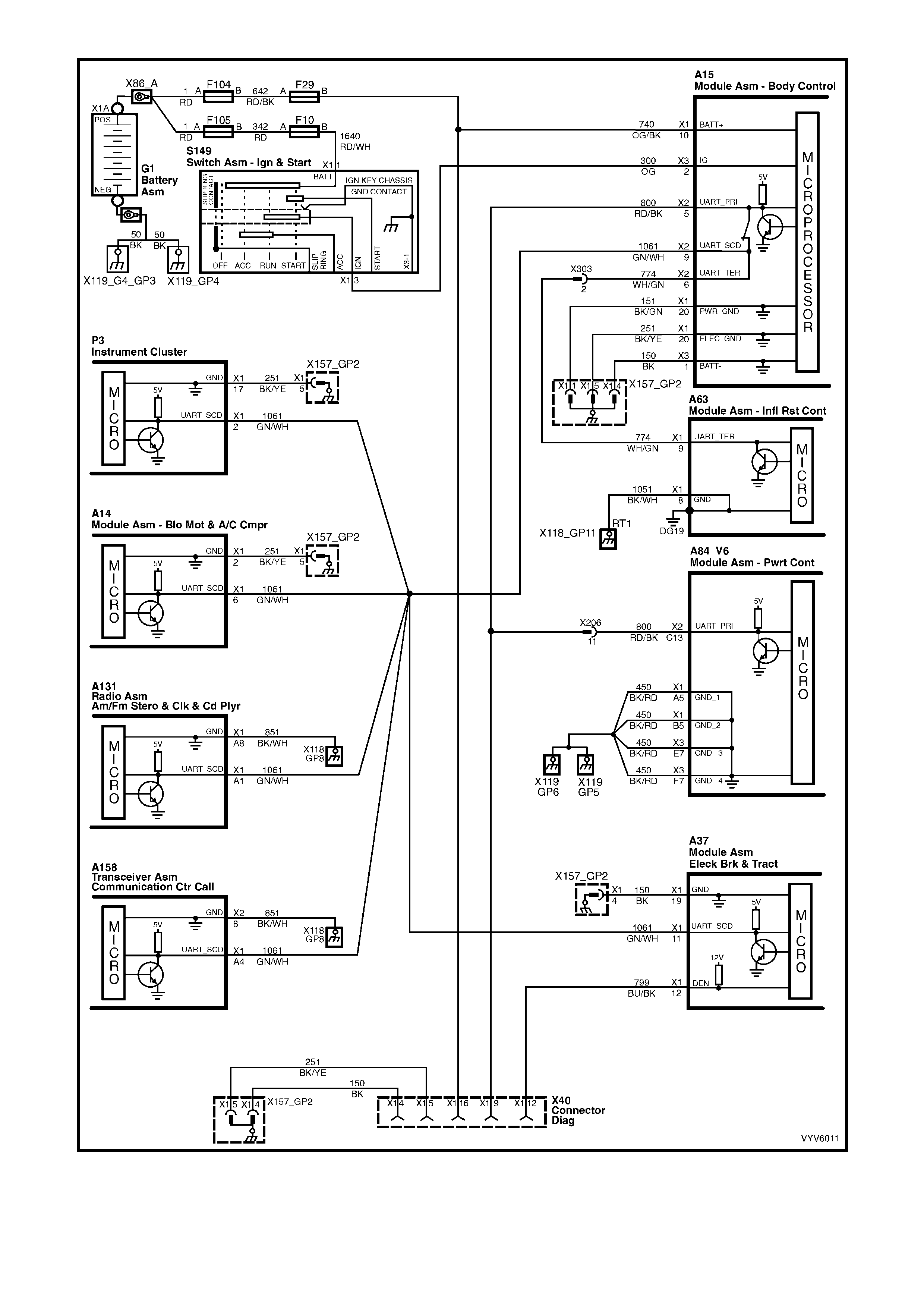

Figure 6C1-2-3 – Check Powertrain MIL Circuit

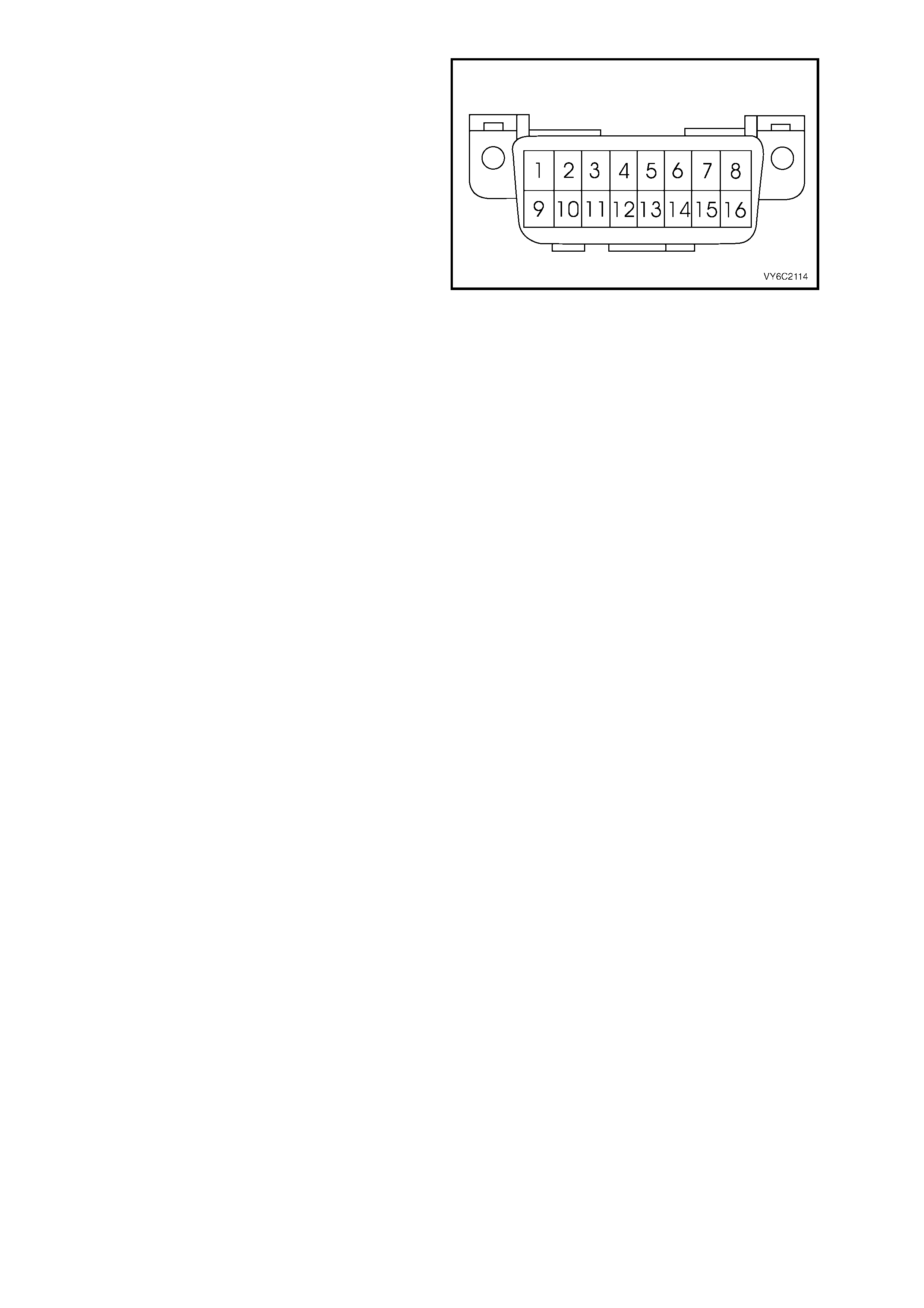

DA TA LINK CONNECTOR (DLC)

The DLC is a standardised 16 way connector

located below the instrument panel and close to

the steering column.

Legend:

1. Data Link Connector (DLC)

2. DLC Adaptor

3. DLC Cable

4. Tech 2

Figure 6C1-2-4 – Data Link Connector (DLC) Location

• Pin 2 is the Class II serial data circuit that is

only used in GEN III V8 engine applications.

This circuit is used to comm unicate only to the

GEN III V8, PCM.

• Pin 4 is the ground circuit for Tech 2, while Pin

5 is an auxil iary groun d, that should be used to

ground the Diagnostic Test Enable Circuits,

where used.

• The DLC p in 9 is the prim ary UART serial dat a

circuit. Tech 2 uses this circuit to read serial

data information from the PCM, BCM,

Instruments, Occupant Climate Control,

Supplemental Inflatable Restraint System and

the ABS/TCS Control Modules.

• The DLC pin 12 is the ABS/TCS Diagnostic

Tes t Enable circuit. T his circuit when jum pered

to DLC pin 5 will cause the ABS/TCS Control

Module to enter the Diagnos tic Mode and flash

out ABS/TCS diagnostic trouble codes.

• The DLC is designe d to provi de batter y voltage

to pin 16 from fuse F29. This circuit is used to

power Tech 2.

Figure 6C1-2-5 Data Link Connector (DLC)

Figure 6C1-2-6 – Data Link Connector Circuits

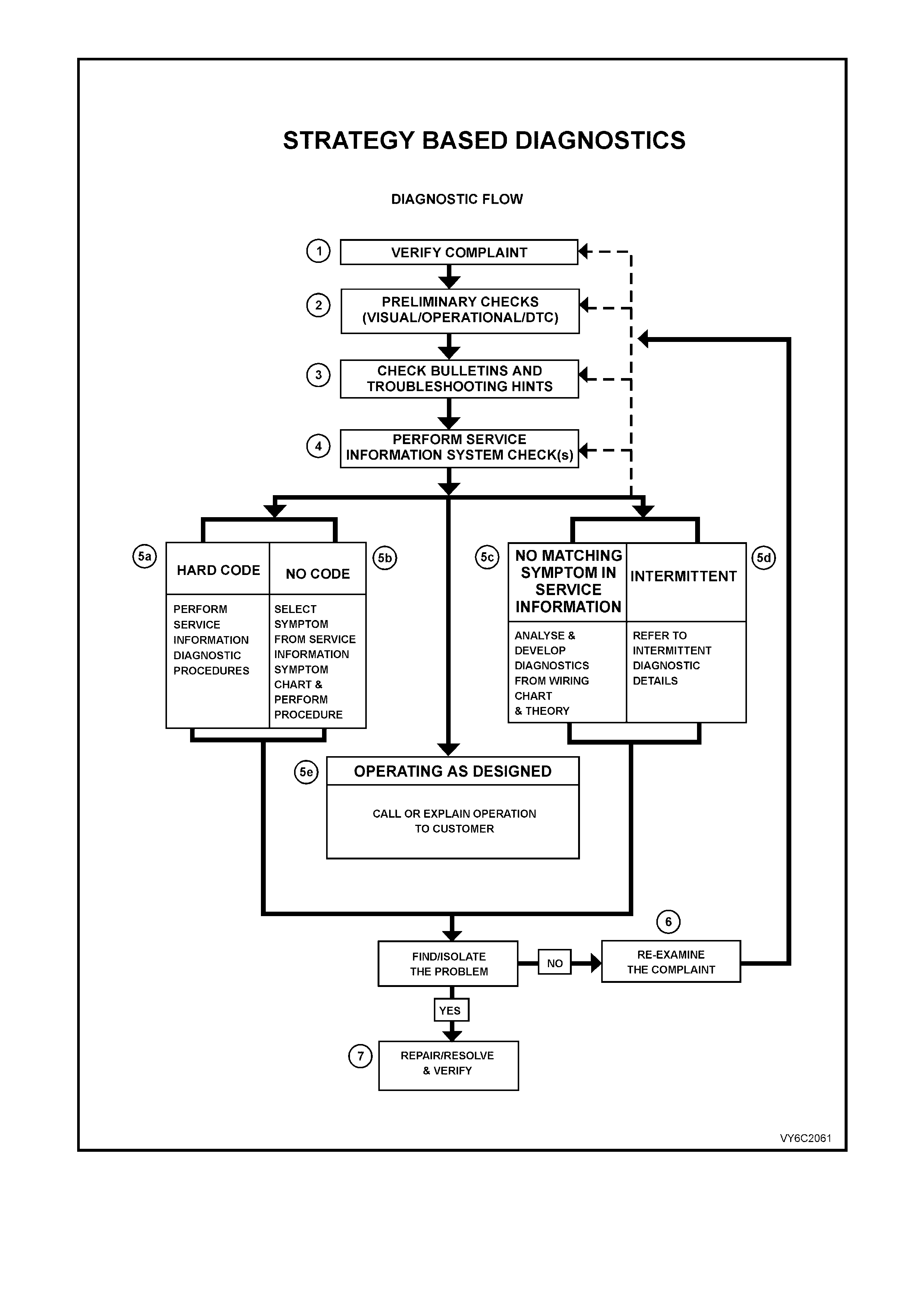

2. STRATEGY BASED DIAGNOSTICS

The strategy based diagnostic is a uniform approach to repair all Electrical/Electronic systems. The diagnostic flow

can always be used to resolve an Electrical/Electronic system problem and is a starting point when repairs are

necessary. The steps below are defined to instruct the technician how to proceed with a diagnostic. Steps below

also refer to step numbers found on the Strategy Based Diagnostic table.

1. Verify the Customer Concern: To verify the customer concern, the technician should know the normal

operation of the system.

2. Preliminary Check: Conduct a thorough visual and operational inspection, review the service history, detect

unusual sounds or odours, and gather diagnostic trouble code information to achieve effective repair.

3. Service Information (Manual) System Check(s): System checks verify proper operation of the system. This

will lead the technician in an organised approach to diagnostics.

4. Check Bulletins and Other Service Information: This should include Dealer letters, Service Techlines and

Service Training publications.

5. Service Diagnostics (Paper/Electronic)

5a DTC Stored: Follow the designed DTC table exactly to make an effective repair.

5b Symptom, No DTC: Select the symptom from the symptom tables and follow the diagnostic

paths or suggestions to complete the repair, or refer to the applicable component/system checks in

Section 6C1-2C FUNCTION AL CHECKS, in this Section.

5c No Published Diagnostics: Analyse the complaint and develop a plan for diagnostics. Utilise the wiring

diagrams and theory of operation.

Call Technical Assistance for similar cases where repair history may be available. Combine Technician

knowledge with efficient use of the available service information.

5d Intermittent: Conditions that are not always present are intermittent. T o resolve intermittents, perform the

following steps:

5d.1 Observe history DTCs, DTC modes.

5d.2 Evaluate the symptoms and conditions described by the customer.

5d.3 Use a check sheet or other method to identify the circuit or electrical system component.

5d.4 Follow the suggestions for intermittent diagnosis found in the service documentation.

The Tech 2 and DMM have data capturing capabilities that can assist in detection of intermittents.

5e Vehicle Operates As Designed/No T rouble Found: This condition exists when the vehicle is found to be

operatin g nor mally. T he co ndition des c ribe d by the cu stomer m a y be norm al. Verif y agains t an oth er veh icl e

that is operating normally. The condition may be interm ittent. Contact Technical Assistance if the concern

is common. Verify the complaint under the conditions described by the customer before releasing the

vehicle.

6. Re-examine the Concern: When the complaint cannot be successfully found or isolated, a re-evaluation is

necessary. The complaint should be re-verified and could be intermittent or normal as per step 5c or 5d.

7. Repair and Verification Tests: After isolatin g the caus e, the repair s hould be m ade. Then val idate for proper

operatio n and verif y that the s ymptom has bee n corrected. T his m ay involve roa d testing or other m ethods to

verify the complaint has been resolved under the following conditions:

• Conditions noted by the customer.

• If a DTC was diagnosed, verify a repair by duplicating conditions for setting the DTC.

Figure 6C1-2-7 – Strategy Based Diagnostic Table

3. DIAGNOSTIC TROUBLE CODES

CURRENT DIAGNOSTIC TROUBLE CODES

A current diagnostic trouble code is one that is set in the vehicle at this time. The diagnostic trouble code can be

displa yed on T ech 2 b y pressing the a ppropr iate butt on at the a ppro priate m enu. When the diagnostic tr oubl e code

is disp la yed, a code desc riptor will a lso b e liste d on T ec h 2 scr een. Use of the proper diagnos tic trouble cod e table

will find the cause of the problem.

HISTORY DIAGNOSTIC TROUBLE CODE

A history Diagn ostic Trouble Cod e ( DTC) is on e th at was a cur r ent troub le c ode at s ome point prev io us l y, however ,

the fault that caused the diagnostic trouble code to be logged is no longer present. The way to identify whether a

DTC is current or history is to look at the DTC history information parameter "IGN CYCLES". If the number is ‘0’,

the DTC is current, any other num ber means it's a hist ory DT C. . The diagn ostic trouble code c an be displayed on

Tech 2 b y press ing th e proper button at the appropr iat e m enu. Use of th e diag nos tic troub le co de tab les to f ind the

cause of the problem for the history diagnostic trouble code may lead to replacement of good components.

W henever a h istor y code is s et Refer to Sect ion 6 C1- 2B SYM PT OM S and also look at the "D ia gnost ic Aids " lis ted

on the dia gnost ic trou ble codes fac ing page f or c riteri a to set th e DT C. Histor y diagnos tic tr ouble codes are usuall y

caused by intermittent conditions.

HOW DTC HISTORY WORKS

When a DTC is set, up to eleven (11) parameters will always be stored with it. The first four (4) parameters are:

1. "Engine speed" - RPM when DTC set .

2. "Time from start" - how long the engine had been running when the DTC set.

3. Times occurred, - number (#) of DTC occurrences.

4. "Ignition cy cles" - since DTC last appeared.

Depending upon the DTC, up to 7 additional param eters that are related t o this specific DT Cs are also stored, for

example, if DTC P0123 TP sensor circuit high voltage was set, the variable parameters would be: TPS signal, ECT,

Fuel, MAF, Battery Voltage, Reference Voltage and RH LTFT.

HOW TO USE DTC HISTORY CODE INFORMATION

Based upon this information stored in DTC history, the Technician can obtain the DTC criteria when the DTC set

and should be able to get the DTC to become current again by repeating the criteria.

READING DTC'S

The provision for communicating with the PCM is the Data Link Connector (DLC). It is attached to the instrument

panel lower trim, directly beneath the steering column. It is used in the assembly plant to receive information in

checking that the engine and transmission are operating properly before they leave the plant. The diagnostic

trouble code(s) stored in the PCM's memory can only be read by using Tech 2, (a handheld diagnostic scanner

plugged into the DLC).

NOTE: For MY2003 vehicles, there is no flash code capability for powertrain DTCs. Grounding the Diagnostic

Enable circuit (DLC pin #6) will not cause the Check Powertrain MIL to flash diagnostic information.

CLEARING DTCS

To c lear th e c urr ent d iag no s tic trouble c ode f r om the memor y of the PC M, eit her to det er mine if the malf unc tion wil l

occur again or because repair has been completed, the PCM power feed must be disconnected for at least thirty

(30) seconds. The PCM power feed can be disconnected by turning the ignition "OFF" and disconnecting the

negative battery terminal or by removing fuse F29. Tech 2 has a special mode that must be used to clear both

history and current diagnostic trouble codes.

NOTE: To prevent PCM damage, the ignition must be "OFF" when disconnecting or reconnecting PCM power.

CLEARING DTC HISTORY

Tec h 2 is the on l y tool cap able of clear ing the DT C hi stor y. Disconnec ting th e b atter y or rem ovin g fus e F29 wil l not

erase DTC history. Tech 2 sends a special message into the PCM to erase this memory.

PCM SLEEP TEST

After the ignition switch is turned "OFF," the PCM will continue to operate for several seconds. During this shut

down, the PC M will return the IAC back to a position to be used on th e next startup, de-e nergise all the s olenoids

and relays, then the PCM will "go to sleep". The PCM can be checked for this sleep test by monitoring how long

Tech 2 will display updated data before the sleep m ode is activated. Once activated, the PCM will no longer send

out serial data and Tech 2 will display ‘DLC DATA LOST’.

PCM LEARNING ABILITY

The PCM has a "learning" ability which allows it to make corrections for minor variations in the engine or

transmission system to improve driveability.

TR ANSM ISSION ADAPT FUNCTION

The HYDRA-MATIC 4L60-E uses a feedback line pressure control system which has the ability to adapt the

system's line pressure to compensate for normal wear of clutch fibre plates, seals, springs, etc. This "learning"

feature is similar to what is used for engine fuel control, short term fuel correction, long term fuel trim.

The HYDRA-MATIC 4L60-E transmission only uses the adapt function for the 1-2 upshift. The PCM monitors

engine speed to determine if the shift is occurring too fast (harsh) or too slow (soft) and adjusts the pressure control

solenoid to maintain t he corr ect shift feel. T he line pres sure can adapt t o values rang ing from 35 kPa below, to 70

kPa above normal line pressure.

If the batt er y is disc onn ec te d, to cl ear d iag nostic tr o uble c odes or for other r e pair, the " le ar ning " pr oces s res et s and

begins aga in. A c hange m ay be n oted in t he veh icle's perform anc e. To "teac h" the ve hicle, r eset th e IAC va lve and

ensure that the engine is at operating temperature. The vehicle should be driven at part throttle, with moderate

acceleration and idle conditions until normal performance returns.

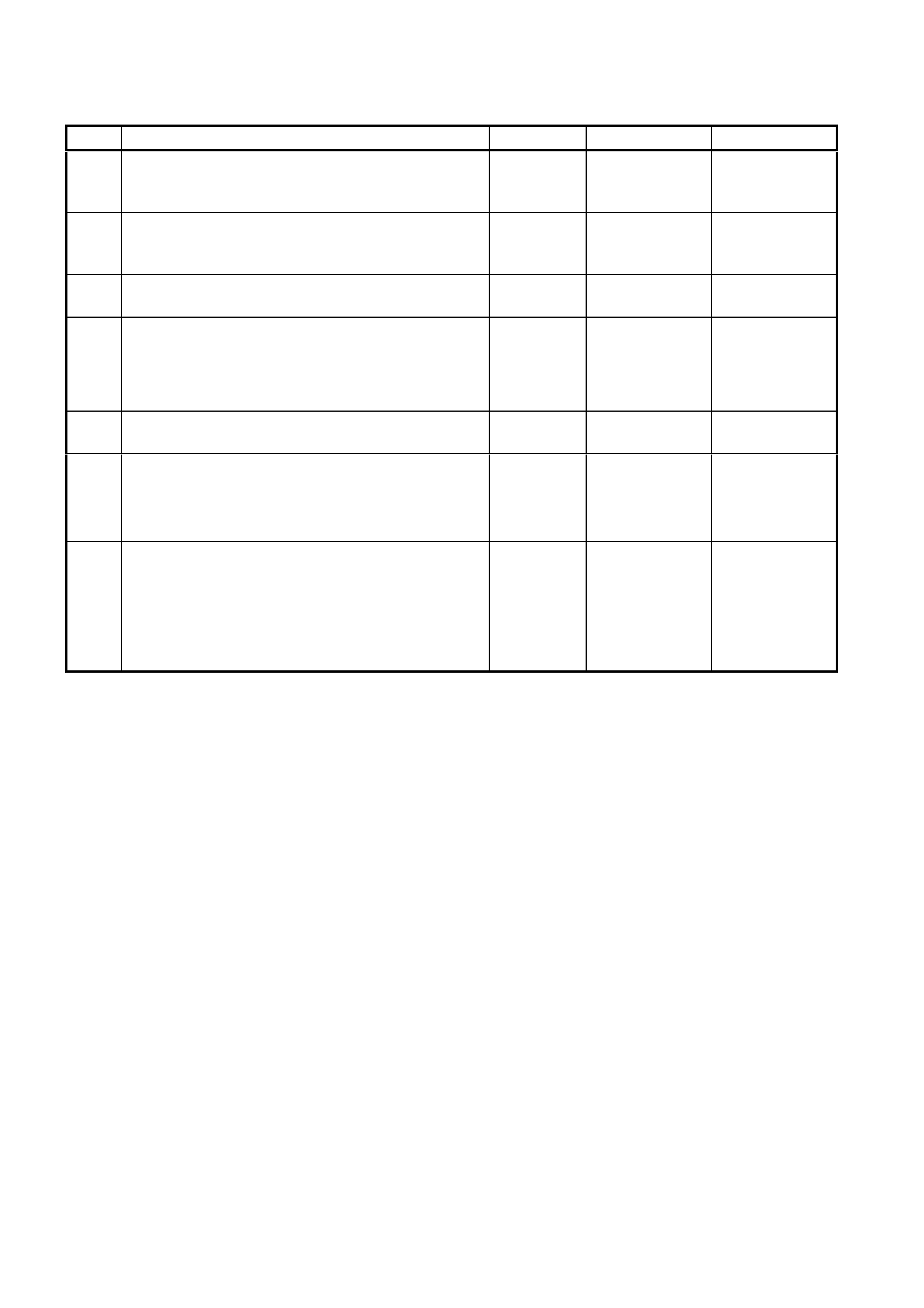

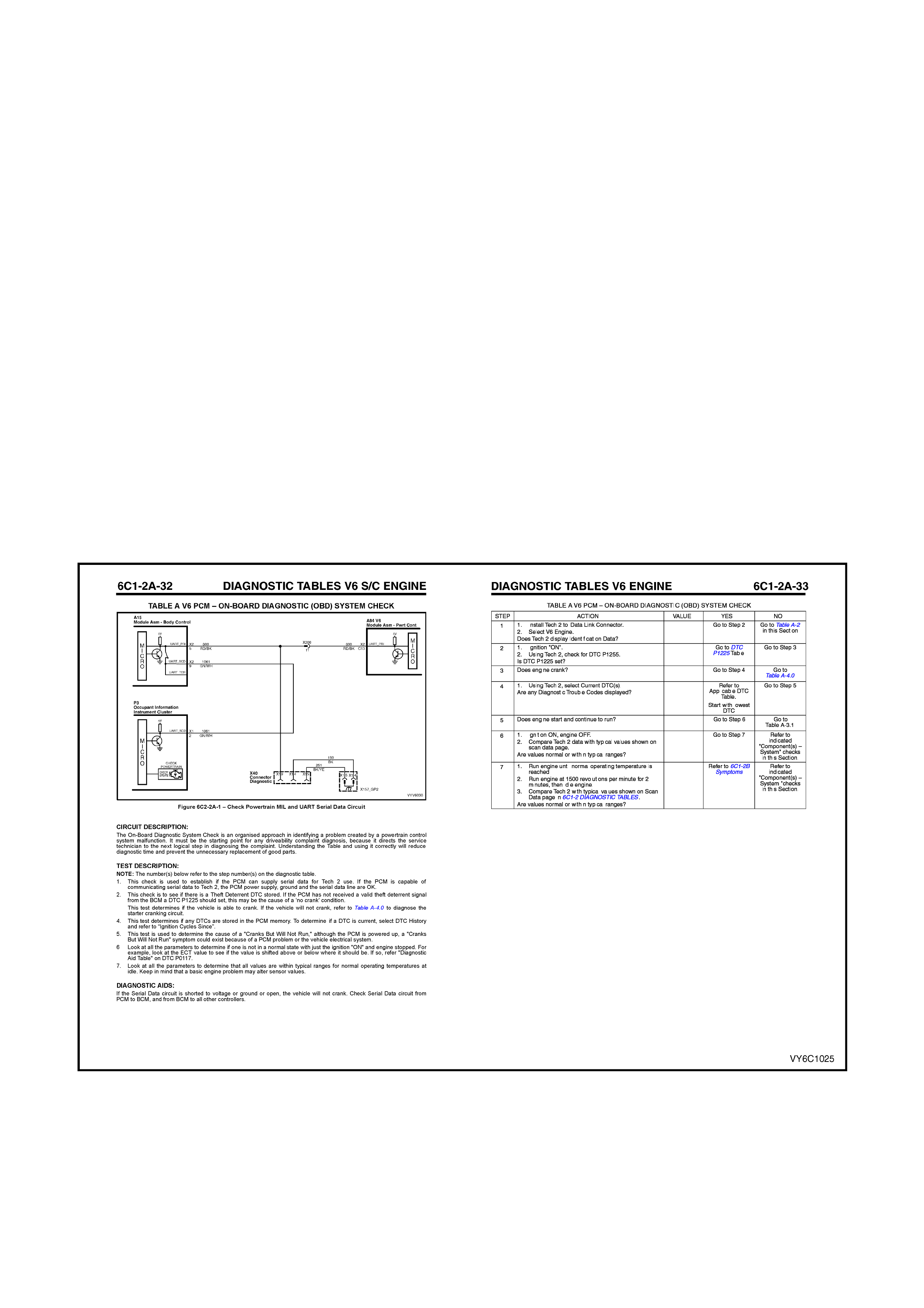

4. TABLE A V6 ENGINE PCM

ON-BOARD DIAGNOSTIC (OBD) SYSTEM CHECK

STEP ACTION VALUE YES NO

1. 1. Install Tech 2 to Data Link Connector.

2. Select V6 Engine.

Does Tech 2 display Identification Data?

Go to Step 2 Go to Table A-2

in this Section

2. 1. Ignition "ON".

2. Using Tech 2, check for DTC P1255.

Is DTC 31 set?

Go to DTC

P1255 Table Go to Step 3

3. Does engine crank?

Go to Step 4 Go to

Table A-4.0

4. 1. Using Tech 2, select Current DTC(s).

Are any Diagnostic Trouble Codes displayed?

Refer to

Applicable DTC

Table.

Start with lowest

DTC

Go to Step 5

5. Does engine start and continue to run?

Go to Step 6 Go to

Table A-3.1

6. 1. Ignition "ON", engine "STOPPED".

2. Compare Tech 2 data with typical values shown on

Scan Data page.

Are values normal or within typical ranges?

Go to Step 7 Refer to

indicated

"Component(s) –

System" ch ec ks

in this Section.

7. 1. Run engine until normal operating temperature is

reached.

2. Run engine at 1500 revolutions per minute for 2

minutes, then idle engine.

3. Compare Tech 2 data with typical values shown on

Scan Data page in this Section.

Are values normal or within typical ranges?

Refer to

Section 6C1-2B

SYMPTOMS.

Refer to

indicated

"Component(s) –

System "checks

in this Section.

Figure 6C1-2-8 – Example of On-Board Diagnostic System Check

5. POWERTRAIN OBD SYSTEM CHECK

After the visual and physical underhood inspection, the Powertrain OBD System Check is the starting point for all

diagnostic procedures or finding the cause of an emissions test failure.

All diagnostic procedures must always begin with the Powertrain OBD System Check.

Diagnostic procedures must begin with the Powertrain OBD System Check, which represents an organised

approach for identifying system problems.

The POW ERTRAIN OBD SYSTEM CHECK m akes an initial check of the system , then will direct th e technician to

other tabl es in this Vol ume. It m ust be used as a star ting point for all procedures . The entire Volume is set up in a

specif ic order , that is, the P OW ERTRAIN O BD S YSTEM CH ECK wi ll lea d the tec hnic ian t o other ta bles , and those

tables may lead to still other tables. THE SEQUENCE MUST BE FOLLOWED. The engine/transmission control

system uses many input signals and controls many output functions. If the correct diagnostic sequence is not

followed, incorrect diagnosis and replacement of serviceable parts may happen.

Diagnostic tables incor porat e diagnosis pr ocedures using T ech 2 where possib le. This Tech 2 is a sm all hand-held

computer in itself. Its job is to give information to a technician about what is happening in the powertrain

management system.

The Data Link Connector (DLC) is used by the as sembl y plant to perf orm end of line tests. T his c onnector c an also

be used by the Technician to monitor certain inputs and output as seen by the electronic control module. Tech 2

reads and displays the information (serial data) supplied to the data link connector from the Powertrain Control

Module (PCM).

The correct procedure to diagnose a problem is to follow three basic steps:

1. Are the On-Board Diagnostics working?: This is determined by performing the Powertrain OBD System

Check. Since this is the starting point for the diagnostic procedures or finding the cause of a failure, always

begin here.

If the On-Board Diagn os tics ar en't working, t he Po wertrain OBD S ystem Chec k will l ea d to a d iag nostic t ab le in

this Volume to correct the problem. If the On-Board Diagnostics are working correctly, the next step is:

2. Is there a Diagnostic Trouble Code stored?: If a diagnostic trouble code is stored, go directly to the

numbered diagnostic trouble code table in Section 6C1-2A DIAGNOSTIC TABLES. This will determ ine if the

fault is still present. If no diagnostic trouble code is stored, then:

3. Observe Serial Data transmitted by the PCM: This involves reading the information available on the Serial

Data Stream with Tech 2. Inf ormation on this tool and the m eaning of the var ious displa ys can be found i n the

succeeding paragraphs. Typical data readings under a particular operating condition can be found on the "Tech

2 Scan Tool Data" page.

DLC TECH 2

The PCM can communicate a variety of information through DLC connector. This data is transmitted at a high

frequency which requires Tech 2 for interpretation.

TECH 2 EXPLANATION

To ex plain how Tec h 2 works , think for a minute abo ut how a tel evision work s. A televis ion is an el ectronic d evice

that rec eives and proc es ses inf ormation, a nd s ends o ut i nf ormation i n a f or m that can be un der stood b y the pers on

watching it. The television receives a signal (from a transmitting station) that is not useable to the person.

The television processes it, then sends the signal to a screen. The person can then see the information that the

televis ion transm itting station s ent out. Tech 2 is like the televis ion because it a lso proces ses inform ation, sent to it

by the PCM.

The information is sent out of the PCM to the Data Link Connector (DLC) serial data line. Tech 2 plugs into the

Data Link Connector (DLC) , and the inform ation is sent to the tool on its cable. Tech 2 processes the inform ation,

and "sends" the signal to the Tech 2 display screen.

Just like a television, you can select which "station" that you want to see. The difference is instead of seeing the

picture on a television, you "see" the display screen, and the "stations" that you can select on Tech 2 are the

different input and output signals that are being processed by the PCM.

Tec h 2 has the ability to se nd messages back to the PCM to do dif ferent things s uch as switch outp uts "OFF" and

"ON." This allows the Technician to control the PCM but this control only lasts as long as Tech 2 is connected to

the DLC.

5.1 TECH 2 US ES - POWERTRAIN CONTRO L MODULE (PCM)

Tech 2 is a useful and quick way of com paring operating parameters of a poorly operating engine or transmission

with a known good one. For example, a sensor may shift its value but not set a DTC. Comparison with a known

good vehicle may uncover this problem.

Tec h 2 allows a q uick c heck of s ensors and s witches whic h are i nputs to th e PCM. The PC M in the vehicle, sends

out information to Tech 2 at a very fast rate, and the display on Tech 2 can update quicker than a digital multimeter.

Tec h 2 allows the Tec hnician to manipula te wiring har nesses or components under the vehic le while obser ving the

Tech 2 readout. This can help in locating intermittent connections.

After you enter the c orrect vehicle inf ormation, the f irst display on Tech 2 will as k for what type of s ystem to select

from.

The following is a list of systems the Tech 2 will display:

F0: Engine

F1: Tr ansmission

F2: Chassis

F3: Body

F4: Vehicle DTC Check

After selecting “F0: Engine”, Tech 2 will display:

V6

V8 GEN III

Once the correct engine has been selected, Tech 2 will now have seven test modes for diagnosis and service of

the PCM system. The seven test modes are as follows:

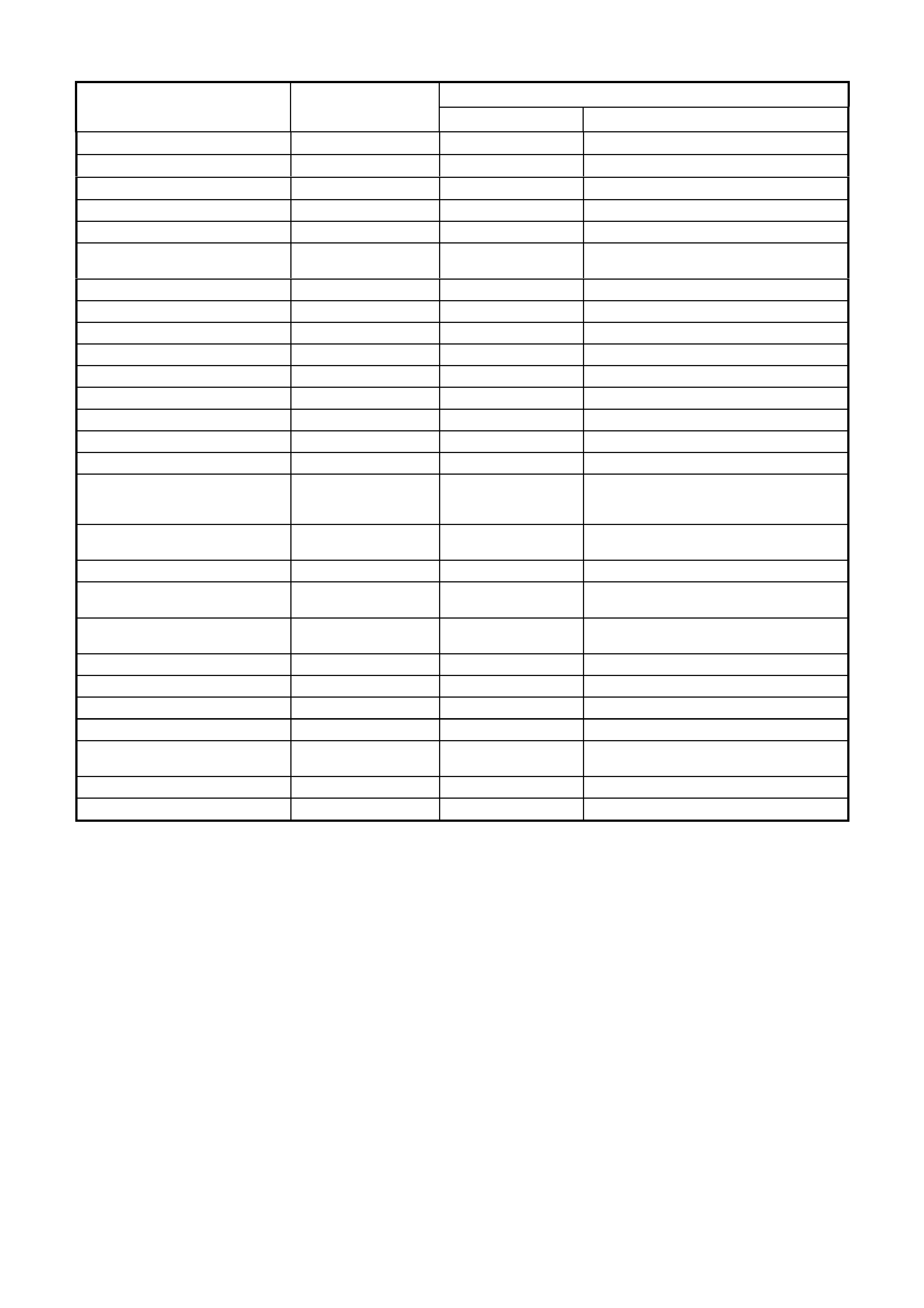

MODE F0: NORMAL MODE

In this mode, Tech 2 will display various engine and transmission data and vehicle information.

The following PCM Normal Mode controller usage table, indicates specific Control Modules using the PCM supplied

report status information:

PCM Normal Mode Controller Usage Table

PCM Normal Mode Parameters Used by:

Tech 2 String BCM INST ECC ABS/ETC SRS Audio

Engine Speed √

√√

√

Coolant Temperature √

√√

√ √

√√

√

Intake Air Temperature

Vehicl e Speed √

√√

√ √

√√

√

√

√√

√

A/C Clutch

A/C Pre s su r e √

√√

√

Low Speed Fan Request √

√√

√

Low Fan Run ON √

√√

√

Theft Status √

√√

√

PCM DTC Status √

√√

√

Check Powertrain MIL √

√√

√

MFD Message √

√√

√

Fuel Used √

√√

√

Fuel Flow Rate (Instantaneous) √

√√

√

Engine Type √

√√

√

Transmission Coding

Fuel Type √

√√

√ √

√√

√

Engine Oil Change

Transmission Oil Change

Shift Patte r n √

√√

√

Torque Multiplier

√

√√

√

High Coolant Temperature

Oil Pressur e Sw itch √

√√

√

PRNDL Switch √

√√

√

Commanded Gear √

√√

√

PCM Chime √

√√

√

Table 6C1-2-1

MODE F1: DIAGNOSTIC TROUBLE CODES

In this test mode, DTCs stored by the PCM may be displayed or cleared. When entering this mode there are four

modes: F0. Read Current DTC

F1. Read History DTC

F2: Clear Current DTC

F3: Clear History DTC

MODE F2: DATA DISPLAY

In this test mode, Tech 2 continuously monitors system data, such as: engine speed data, engine coolant

temperature, etc. When entering this mode, there are three modes;

F0: All Data – Displays all engine input and output data.

F1: Inputs – Displays all input data to the PCM.

F2: Outputs – Displays all output data from the PCM.

MODE F3: SNAPSHOT

In this test mode, Tech 2 captures data before and after a snapshot triggering condition which may or may not set a

DTC.

MODE F4: MISCELLANEOUS TESTS

In this test mode, Tech 2 performs PCM software override commands, to help in problem isolation during

diagnostics.

F0: OUTPUT TESTS

F0: Fuel Pump

F1: A/C Clutch

F2: Check Powertrain Lamp

F3: High Fan

F4: Canister Purge

F5: Starter Relay

F1: IAC SYSTEM

F0: RPM Control: used to control engine RPM from 600 RPM to 1675 RPM.

F1: IAC Control: Used to control IAC steps from 0 to 255 in 25 step increments.

F2: IAC Reset: used to reset IAC if the IAC is lost or if IAC has been replaced.

F3: Base Idle: used to set the engine to base idle.

F2: EGR CONTROL

This test will allo w for control of the EGR by increments of 10% to decrease or in crease EGR flow up to 100% on

time.

F3: RESET CELLS

Resets all LT Fuel Trim values to 0%

F4: BYPA SS SPARK

With the engine running, this command turns the bypass control circuit, ON and OFF.

F5: A/F RATIO

With the engine running, forces air fuel ratio from 11.7 to 17.7.

F6: LPG FCV TEST

This test will allow for control of the FCV by increments of 7% to decrease or increase FCV flow up to 100% on

time.

F7: LPG ENABLE TEST

Used to command the LPG enable circuit on and off.

MODE F5: FUNCTION TESTS

This mode performs functional tests on the PCM system which help verify proper operation. In this mode, fault

conditions are automatically logged by Tech 2.

Tech 2 also has the ability to send commands to the PCM, instructing the PCM to perform various functions or

tasks. This provides a quick way to determine if a device is operational or not.

In the F5 mode, the following tests can be performed:

F0: IAC Circuit

Designed to conf irm that the IAC motor functions O K and is not losi ng track of position. Moni tor the engine

speed. Repeatedly cycles the IAC motor in and out and then monitors the engine speed. If OK, then

ignition "OFF" and start repeatedly, then stabilise. If the value of final RPM – initial RPM is greater than a

calibrated threshold, then the IAC circuit has failed.

F1: O2 Sensor

Designed t o confirm ox ygen sensor is funct ioning OK and not bi ased or s low respond ing. Mon itors ox ygen

sensor voltages and cross counts when in "Closed Loop" and forces rich/lean "Open Loop" operation.

F2: Power Balance

Designed to identify low power output from individual cylinders. Automatically cycles each injector "OFF"

then "ON" while monitoring and recording the RPM drop for each cylinder.

F3: Wiring Harness

Designed to confirm no intermittent open or short circuits exist in selected circuits. Engine is at idle in "N".

The Technician should wriggle powertrain harness. Tech 2 monitors inputs that should remain relatively

static at idle such as: ECT, IAT, TP Sensor, VSS, CAM signal present, 18X signal present, EST lines,

injector vo lta ge monitor, ba ttery and ignit io n. If disc ontinuity occur s , T ec h 2 logs the f ailur e an d prompts the

Technician to check the appropriate circuit.

F4: Low Fan

Designed to confirm that the PCM will send a command to the BCM to turn "ON" the low speed fan.

F5: LPG Setup

This is used to lock the vehicle in a fixed state in order for the LPG fuel system mixture adjustment screw to

be adjus ted. The PC M will s et the f oll o wing to a pr e d etermined s ett ing i n or der f or the adj ustment s cr ew t o

be adjusted:

Fixed Spark

IAC Fixed to 800 RPM

Fixed FCV to 40%

MODE F6: STALL DA TA

Designed to capture nine (9) particular data values, when the engine is in a stall condition. This is very similar to

DTC History mode. The PCM will store the first stall condition values, then count the number of stalls after the first.

NOTE: Stall data will be erased from the PCM memory whenever DTC HISTORY DATA is cleared.

TECH 2: Stall Data

SCAN POSITION UNITS DISPLAYED

Engine Speed RPM

Time Fro m Start Time

Times Occurred Number

Igniti on Cycles Number

Coolant Temperature Degrees

Idle Air Contr o l STEPS

Vehicl e Speed km/h

Battery Voltage Volts

Throttle Position Sensor 0-100%

A/C Request No/Yes

Fuel Petrol / L PG

TECH 2: USE WITH INTERMITTENT FAULTS

Tec h 2 allows m anipu lat io n of wiring harness es or c o mponents und er th e bonnet with the engi ne not runnin g, wh il e

observing the Tech 2 readout.

Tec h 2 can be plugge d in and obs erve d while dri ving the v ehicle und er the cond ition when the "C heck Powe rtrain"

MIL turns ON mom entarily or when the eng ine driveab ility is m omentaril y poor. If the problem seems to be relat ed

to certain parameters that can be checked on Tech 2, they should be checked while driving the vehicle. If there

does not s eem to be an y connection bet ween the problem and an y specif ic circuit, T ech 2 can be use d to m onitor

each parameter, watching for a period of time to see if there is any change in the readings that indicates an

intermittent condition.

Tec h 2 can capture and s to r e data when the pr o blem occ urs , s o it can be played back at a s lower rate to d ete rmine

what happened to the system. This is called the "SNAPSHOT" mode.

Tech 2 is an easy way to compare the operating parameters of a poorly operating engine with those of a known

good one. F or ex ample, a sensor ma y shift in value but not s e t a DTC. Com par ing the s ensor 's r e adi ngs with t hos e

of a known good vehicle may uncover the problem.

Tec h 2 saves tim e in diag no sis and h elps to prevent t he replac em ent of s ervicea ble par ts. T he ke y to using Tec h 2

successfully is the Technician's ability to understand the system being diagnosed, as well as understanding the

Tech 2 operation and limitations. The Technician should read the Tech 2 Operator’s Manual to become familiar

with the Tech 2 operation.

With an understanding of the data which the tool displays, and knowledge of the circuits involved, Tech 2 can be

very useful in obta in ing info rmation which wou ld be m or e diff icult or imposs ible to obta in with other equi pment.

Tec h 2 does not m ake the use of diagnos tic tables unnec essar y, nor can it in dica te exactl y where a pr oblem is in a

particular circuit. Diagnostic Tables incorporate diagnosis procedures that require the use of Tech 2.

TECH 2: LIMITATIONS

Tech 2 must receive a signal from the PCM in order to display any useable information. If the PCM sends no

signals to the DLC, or the c onnection to Tech 2 is defectiv e, Tech 2 will onl y dis play, "W AITING FOR DATA - NO

DATA RECEIVED FROM PCM." The Powertrain OBD System Check instructs the Technician what to do if this

happens.

Tec h 2 has a few limitatio n s. If Tech 2 is dis p laying a PCM "o utpu t" funct ion, it di s plays onl y the com mand g iven by

the PCM. That does not mean that the desired action took place. This is similar to the automatic transmission

dashboar d gearshif t indicat or. Just bec ause the gearshif t P R N D L poin ter indic ates the trans mis sion is in DRIV E

does not mean that the transmission is actually in that gear. To be sure, you must check the linkage and

adjustment at the transmission.

When using Tech 2 to observe one of the PCM "output" functions, such as an idle air control motor, or a TCC

solenoid, the Technician must not assume that the ‘indicated’ is the same as the ‘actual’. If Tech 2 is displaying

TCC s olenoid as be ing "O N," but the wire to power it is discon nected or defecti ve, the PCM in s ome ca ses has no

way of knowing it. The display may indicate the command is "ON," but the device may not be operating!

Tec h 2 saves tim e in diag no sis and h elps to prevent t he replac em ent of s ervicea ble par ts. T he ke y to using Tec h 2

successfully for diagnosis is the Technician's ability to understand the system being diagnosed, as well as an

understanding of Tech 2's limitations.

W ith an understan ding of the data that T ech 2 displa ys, and knowledge of the circuits in volved, Tec h 2 is useful in

obtaining inf or mation whic h is diff ic ult or im pos s ible to re trie ve with oth er m ethods .

Remember, Tech 2 does NOT make using diagnostic tables unnecessary, nor can it tell you exactly where a

problem is in a circuit. Most diagnostic tables incorporate diagnosis procedures that require the use of Tech 2.

5.2 TECH 2: PCM NORMAL MODE

The Tech 2 ‘Normal Mode’ in the table may be used for comparison if a status report is being sent from the PCM:

1. After completing the Powertrain OBD System Check.

2. Finding the on-board diagnostics are functioning properly and

3. No diagnostic DTCs are displayed.

IMPORTANT: A Tech 2 that displays faulty data should not be used and the problem should be reported to

the manufacturer. The use of a faulty Tech 2 can result in misdiagnosis and unnecessary parts

replacement.

Only the parameters listed are used in this Section for diagnosis. For more description on the values and use of

Tec h 2 to di agn ose P C M in puts, ref er to th e ap pl ic ab le dia gnosis tab le in Section 6C1-2A DI AGNOST IC TABLES.

If all values are within the range illustrated, refer to Section 6C1-2B SYMPTOMS.

Test Description: The number(s) below refer to the number(s) on the Tech 2., ‘PCM Normal Mode’ table header.

1. DATA PARAMETER:– Tech 2 can display nine (9) data parameters at any one time. The down arrow button

will scroll down through all of the data parameters one at a time. After the last data parameter is displayed,

pressing the down arrow button again, will display the fist data parameter, once again.

2. UNITS DISPLAYED are th e ways/units that each par ameter will be displayed, w hich is the value that is being

sensed or being is sued b y the PCM.

3. TYPICAL DATA VALUE is separated into two parts. These displayed values are typical of a normally operating

vehicle . T he ‘IGNITION O N ’ c omparis on should be performed f irs t as this may lea d to a quick identificati on of a

failure. T he ‘ENGIN E RUN NING’ data s hould be com pared to th e ‘IGNIT ION ON ’ data as a diagn ostic c heck to

make sure the component or system is operating properly.

4. IGNITION ON values are the typical values that should be seen on Tech 2 with the ignition ON and engine

stopped. T emperature sensors should be com pared to the actual tem peratures (e.g. coolant, air, transmission

fluid) b y allowing the sens or to coo l overnig ht and the n com paring their valu es. A diff erence of 3-5° C f rom the

actual temperature may indicate a problem with the sensor. Use the diagnostic aids table for that sensor to

compare the resistance to temperature values.

5. ENGINE RUNNING typical data values are an average of display values recorded from a normally operating

vehicles at normal operating temperature. They are intended to represent what a normally functioning system

would typically display.

TECH 2: PCM NORMAL MODE

TYPICAL DATA V ALUE S

DATA POSITION Q UNITS DISPLAYED R IGNITION ON T ENGINE RUNNING U

Engine Speed RPM 0 RPM 600 – 650 RPM (± 50 RPM In Drive)

Coolant Temperature ° C Varies Varies

Intake Air Temperature ° C Varies Varies

Vehicl e Speed km/h 0 0

A/C Clutch On /Off Off Off

A/C Pressure kPa 896 kPa 400 – 1000 kPa A/C Off

500 – 1900 kPa A/C On

Low Speed Fan Request On / Off OFF OFF

Low Fan Run on Yes / No NO NO

Theft Status No Start / Start START START

PCM DTC Stat us No DTC / DTC Set No DTC(s) No DTC(s )

Check Powertrain Lamp Off/On On Off

MFD Message Yes/No No No

Fuel Used L 00.00 Varies

LPG Used L Varies

Fuel Flow Rate L/Hour 00.00 Varies

Engine Type V6, V8,

V6 Supercharged,

GEN III V8 V6 V6

Transmissi on Codi ng Manual Trans.

Automatic Trans. Manual Trans.

Automatic Trans. Manual Trans.

Automatic Trans.

Fuel Type Petrol / LPG Petrol Petrol

Engine Oil Change Okay /

Service Requi red Okay Okay

Transmission Oil Change Okay /

Service Requi red Okay Okay

Shift Pattern Power/Economy Economy Economy

Torque Multiplier Ratio 0 13

High Coolant Temperature Yes/No No No

Oil Pressure Switch Off/On Off Off

PRNDL Switc h Invalid / P,R,N,D,3,2,1 Invalid or Gear

Selected Invalid or Gear Selected

Commanded Gear 1, 2, 3, 4 1 Gear 1 Gear

PCM Chime Yes/No Yes Yes

Table 2

TECH 2: PCM NORMAL MODE DESCRIPTIONS

A list of explanations for each data message displayed on Tech 2 is listed below. This information will assist in

diagnosi ng emiss ion or dr i v eab ility problems . The dis pl a ys can be vi e wed whi le th e veh icl e is bei ng dri ve n. R efer to

“Powert rain OBD S ystem Check” for additional information.

ENGINE SPEED: Tech 2 Displays a range of 0 to 9999 RPM

The engine speed is computed by the PCM from the crankshaft reference input. It should remain close to desired

idle speed under various engine loads with engine idling.

COOLANT TEMPERATURE: Tech 2 Displays a range of -39° C to 140° C

The Engine Coolant T emperature (ECT) sensor is mounted in the c ylinder head of the left bank . The PCM apples

5.0 volts to the ECT sensor circuit. The sensor is a thermistor which changes internal resistance as temperature

changes. W hen the s ensor is co ld (in terna l res istanc e hig h), th e PCM m onitors a high s igna l vo ltage and in ter prets

the voltage as a cold engine. As the sensor warms (internal resistance decreases), the voltage signal decreases

and the PCM interpr ets the lo wer vo lta ge as a warm engin e.

INTAKE AIR TEMPERATURE: Tech 2 Displays a range of -40° C to 148° C

The Intake Air Temperature (IAT) sensor is mounted in the rear of the upper air cleaner housing and senses the

temperature of the incoming air. The PCM apples 5.0 volts to the IAT sensor circuit. The sensor is a thermistor

which ch anges inter nal res istance as tem perature cha nges. W hen the se nsor is c old (int ernal res istance h igh), the

PCM monitors a high signal voltage and interprets the voltage as cold intake air. As the sensor warms (internal

resistance decreases), the voltage signal decreases and the PCM interprets the lower voltage as warm intake air.

VEHICLE SPEED: Tech 2 Displays a range of 0 to 255 km/h

The vehicle speed sensor signal is converted into km/h for display.

A/C CLUTCH: Tech 2 Displays "ON" or "OFF"

Represents the commanded state of the A/C clutch control relay. Clutch should be engaged when ON is displayed.

A/C PRESSURE: Tech 2 Displays a range of 0 to 3195 kPa

The kPa displayed indicates that the PCM is monitoring an A/C Refrigerant Pressure signal voltage which is too

high or too low to allow the A/C compressor clutch to engage.

LOW SPEED FAN REQUEST: Tech 2 Displays "ON" or "OFF

Indicates if the engine cooling fan low speed relay has been commanded ON or OFF.

LOW FAN RUN ON: Tech 2 Displays "NO" or "YES"

This indicates if the PCM is requesting the BCM to turn the Low Speed Fan ON at key OFF.

THEFT STATUS: Tech 2 Displays "NO START" or "START"

Indicates the status of the Theft Deterrent System.

PCM DTC STATUS: Tech 2 Displays "NO DTC(s)" or “DTC SET”

Indicates if a DTC is set. This does not indicate what DTC is set, just informs that DTCs are or are not set.

CHECK POWERTRA IN MALFUNCTION INDICATOR LAMP (MIL): Tech 2 Displays "OFF" or "ON"

Indicated if the instrument panel Malfunction Indicator Lamp is ON or OFF.

MULTI-FUNCTION DISPLAY MESSAGE: Tech 2 displays either Yes or No

The PCM can send extra messages to the Instrument, Multi-Function Display (MFD).

FUEL USED: Tech 2 Displays a range of 0 to 1000 Litres

When the key is turned ON, and the engine is running, the PCM will calculate ‘Fuel Used’ during each ignition

cycle.

LPG USED: Tech 2 Displays a range of 0 to 1000 Litres

When the vehicle is equipped with this fuel type, and the engine is running, the PCM will calculate ‘Fuel Used’

during each ignition cycle.

FUEL FLOW RATE: Tech 2 Displays a range of 0 to 100 litres

Indicates fuel consumption per litres per hour.

ENGINE TYPE: Tech 2 Displays Engine Type

The Tech 2 uses this information for proper Tech 2 software.

TRANSMISSION CODING: Tech 2 Displays “MANUAL” or “AUTOMATIC”

The Tech 2 uses this information for proper Tech 2 software.

FUEL TYPE: Tech 2 Displays “PETROL” or “LPG”

The scan tool will display what fuel type the PCM software is set up for.

ENGINE OIL CHANGE: The Tech 2 Displays “OKAY” or “SERVICE REQUESTED”

The scan tool will display the status of the engine oil change condition. This display is currently not in use.

TRANSMISSION OIL CHANGE: The Tech 2 Displays “OKAY” or “SERVICE REQUESTED”

The scan tool will display the status of the transmission oil change condition. This display is currently not in use.

SHIFT PATTERN: Tech 2 Displays “ECONOMY” or “POWER”

This display shows the state of the POWER/ECONOMY switch.

TORQUE MULTIPLIER: Tech 2 Displays a range of 0 to 13

The display shows a calculated value derived from the Transmission Slip and Commanded Gear values. The

calcula ted va lue is used b y the ABS/ ET C m odule.

HIGH COOLANT TEMPERATURE: Tech 2 Displays "NO" or "YES"

This is an indication to the PCM that the engine is running hot.

LOW COOLANT LEVEL: Tech 2 Displays "NO" or "YES"

This is an indicat ion to the PCM th at the coo lant le vel i s low, and th e PCM wil l turn on the Lo w Coo lant lam p. (O nly

with GEN III V8 Engine).

OIL PRESSURE SWITCH: Tech 2 Displays "OFF" or "ON"

This is an indica tion to t he PCM if the oil pres sure is high or low. If the o il pressur e is lo w, the PCM will activ ate a

“Check Oil” icon in the Instrument Multi-Function Display (MFD).

PRNDL SWITCH: Tech 2 Displays “INVALID” or “P, R, N, D, 3, 2, 1”

This displa ys if th e veh icle i s not e quippe d with a PRN DL s witch (IN VALID) , or if equ ipped, indicat es what g ear the

driver has selected.

COMMANDED GEAR: Tech 2 Displays “1, 2, 3, 4”

The gear that the PCM is commanding the transmission to be in. In PARK, the Tech 2 will display "1", the

commanded state of the shift.

PCM CHIME: Tech 2 Displays "NO" or "YES"

This is a indication to the instrument panel allowing the instrument panel to chime if a problem or fault is detected.

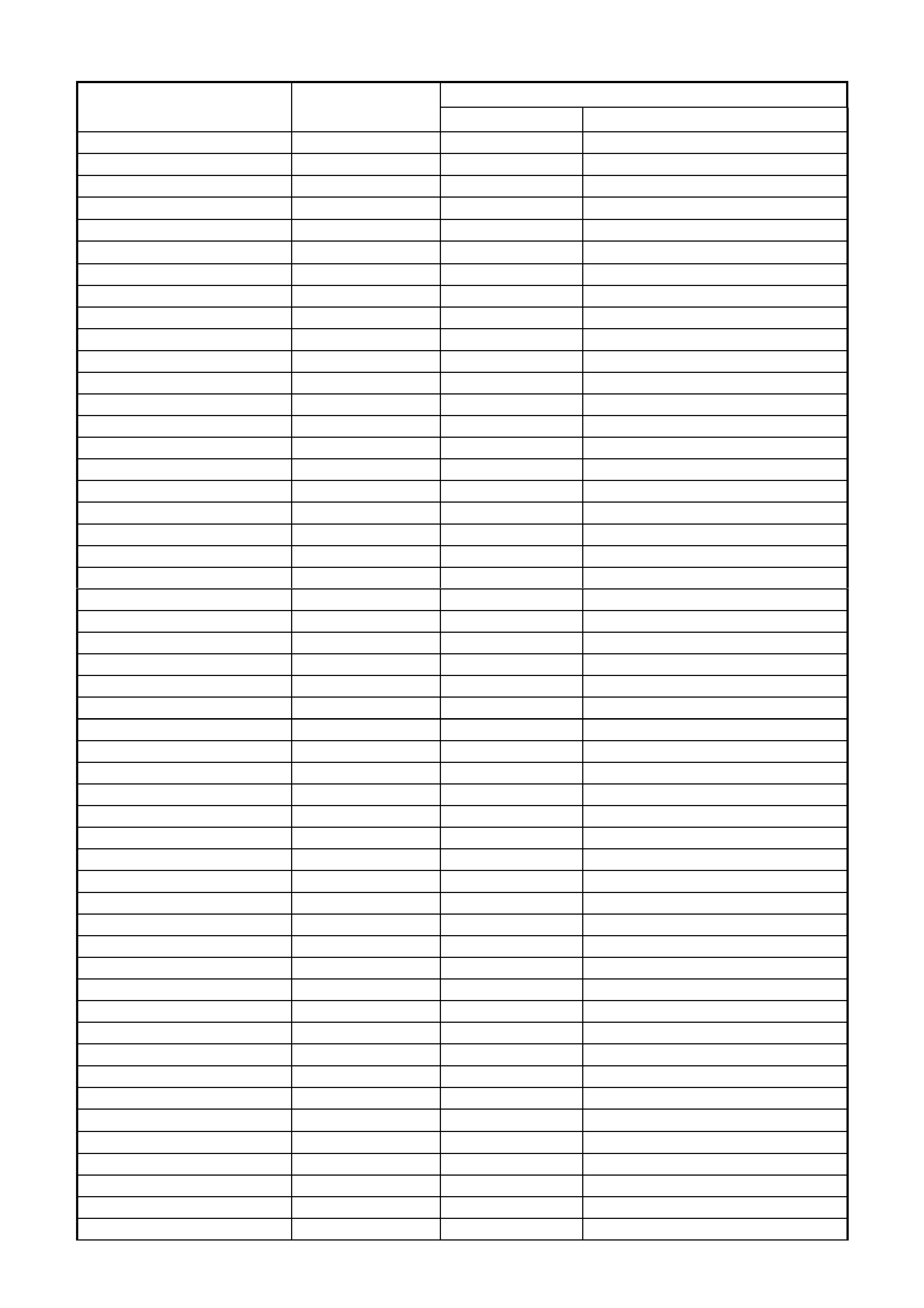

5.3 TECH 2: ENGINE DATA DISPLAY – ALL DATA

The Tech 2 Engine Data listed in the following table may only be used for comparison:

1. After completing the Powertrain OBD System Check.

2. Finding the on-boar d dia gn os tic s are func tio ning properly and

3. No diagnostic DTCs are displayed.

A TECH 2 THAT DISPLAYS FAULTY DATA SHOULD NOT BE USED, AND THE PROBLEM SHOULD BE

REPORTED TO THE MANUFACTURER. THE USE OF A FAULTY TECH 2 CAN RESULT IN MISDIAGNOSIS

AND UNNECESSARY PARTS REPLACEMENT.

Only the parameter s lis ted ar e used in this Vo lume f or diagnosis . F or mor e desc r iption on th e va lues and use of the

Tech 2 to diagnosis PCM inputs, refer to the applicable diagnosis table in S ectio n 6C1-2A DIAGNOST IC T ABLES.

If all values are within the range illustrated, refer to Section 6C1-2B SYMPTOMS.

Test Description: The number(s) below refer to the number(s) on the ‘Tech 2 Engine Data Display’ table.

1. DATA PARAMETER:– Tech 2 can display nine (9) data parameters at any one time. The down arrow button

will scroll down through all of the data parameters one at a time. After the last data parameter is displayed,

pressing the down arrow button again, will display the fist data parameter, once again.

2. UNITS DISPLAYED are th e ways/units that each par ameter will be displayed, w hich is the value that is being

sensed or being is sued b y the PCM.

3. TYPICAL DATA VALUE is separated into two parts. These displayed values are typical of a normally operating

vehicle . T he ‘IGNITION O N ’ c omparis on should be performed f irs t as this may lea d to a quick identificati on of a

failure. T he ‘ENGIN E RUN NING’ data s hould be com pared to th e ‘IGNIT ION ON ’ data as a diagn ostic c heck to

make sure the component or system is operating properly.

4. IGNITION ON values are the typical values that should be seen on Tech 2 with the ignition ON and engine

stopped. T emperature sensors should be com pared to the actual tem peratures (e.g. coolant, air, transmission

fluid) b y allowing the sens or to coo l overnig ht and the n com paring their valu es. A diff erence of 3-5° C f rom the

actual temperature may indicate a problem with the sensor. Use the diagnostic aids table for that sensor to

compare the resistance to temperature values.

5. ENGINE RUNNING typical data values are an average of display values recorded from a normally operating

vehicles at normal operating temperature. They are intended to represent what a normally functioning system

would typically display.

TECH 2: ENGINE DATA DISPLAY

TYPICAL DATA V ALUE S

DATA PARAMETER Q UNITS DISPLAYED R IGNITION ON T ENGINE RUNNING U

Engine Speed RPM 0 RPM 735

Desired Idl e Speed RPM 0 RPM 725

ECT Sensor Volts Varies 1.92 volts

Coolant Temperat ure degrees C Varies 92° C

IAT Sensor Volts Varies 2.29 – Varies

Intake Air Temperature degrees C Varies 31° C – Varies

MAF Sensor Hz 0 Hz 2200 – 2500 Hz

Mass Air Flow gram/sec 0 g/s 4 – 9 g/s

Mass Air Flow Per Cylinder milligram/sec 0.0 mg/s 135 to 150 mg/s

TPS Signal Volts 0.57 V 0.57 V

Throttle Angle 0-100 % 0 % 0 %

Right O2 Sensor Ready Yes/No No Yes

Left O2 Sensor Ready Yes/No No Yes

Right 02 Sensor mV 447 mV 100 – 1000 mV and Varying

Left O2 Sensor mV 447 mV 100 – 1000 mV and Varying

Right Short Term Fuel Trim + 100% to –100% +0% + 0% +10% to –10%

Left Short Term Fuel Trim + 100% to –100% +0% + 0% +10% to –10%

Right Long Term Fuel Trim + 100% to – 100 % + 0 % + 0 % + 10% to – 10%

Left Long Term Fuel Trim + 100% to – 100 % + 0 % + 0 % + 10% to – 10%

LTFT Enabled Yes / No No Yes

Fuelling Mode Open/ Closed Loop Open Loop Closed Loop

LTFT Cell Cell # 0 0

Right O2 Status Rich / Lean Lean Rich/Lean and Varying

Left O2 Status Rich / Lean Lean Rich/Lean and Varying

Right O2 Cross Counts Counts 0 0 -– 10

Left O2 Cross Counts Counts 0 0 -– 10

STFT Delta 0 – 100 % 0 % Varies

LTFT Delta 0 – 100 % 0 % Varies

Decelerati on Fuel Cutoff No/Yes No No

Injector Puls Width ms 27.5 ms 3.25 ms

Injector V olt age Volts 11.4 V 14.0 V

Air / Fuel Ratio % 0. 0 : 1 14.7 : 1

Canister Purge PWM % 0 % 0% – 10 %

EGR Position Commanded % 0% 0%

EGR Position Feedback % 0% 0%

EGR Pintle Sensor Volts 0.6 V 0.6 V

Battery Voltage Volts 11.3 V 14.0 V

Reference Volts Volts 4. 99 V 5.0 volts

3X SIGNAL Missing / Present Missing Present

18X Signal Missing / Present Missing Present

Cam Signal Missing / Present Missing Present

Idle Air Control Steps 169 Steps 22 Steps

Litres Per Hour Litres/ Hour 00.00 1 - 2 L/Hour

Idle RPM Variat i on RPM 0 RP M 100 RPM

Spark Mode Bypass/EST Bypass EST

Spark Advance Degrees BTDC 14 ° BTDC + 20° CA

Knock Signal Cyl i nder 1 None/Knock Detect ed None None

Knock Signal Cyl i nder 2 None/Knock Detect ed None None

Knock Signal Cyl i nder 3 None/Knock Detect ed None None

Knock Signal Cyl i nder 4 None/Knock Detect ed None None

Knock Signal Cyl i nder 5 None/Knock Detect ed None None

TYPICAL DATA V ALUE S

DATA PARAMETER Q UNITS DISPLAYED R IGNITION ON T ENGINE RUNNING U

Knock Signal Cyl i nder 6 None/Knock Detect ed None None

Knock Signal Any Cylinder None/Knock Detected None None

Knock Ret ard Yes/No No No

Knock Ret ard Cylinder 1 # of Degrees 0 ° 0 °

Knock Ret ard Cylinder 2 # of Degrees 0 ° 0 °

Knock Ret ard Cylinder 3 # of Degrees 0 ° 0 °

Knock Ret ard Cylinder 4 # of Degrees 0 ° 0 °

Knock Ret ard Cylinder 5 # of Degrees 0 ° 0 °

Knock Ret ard Cylinder 6 # of Degrees 0 ° 0 °

TCC Solenoid On / Off Off Off

Vehicl e Speed km/h 0 km/h 0 km/ h

A/C Request On /Off Off On/Off

A/C Clutch On /Off Off On/Off

A/C Pressure Sensor Volts 1 – 2 V 1 – 2 V

A/C Pressure kPa 352 kPa 600 – 700 kPa A/C Off

800 – 1000 kPa A/C On

High Speed Fan On / Off Off Off

Low Speed Fan Request On / Off Off On/Off

Theft Status No Start/Start Start Start

Starter Relay Off/On On Off

Fuel Pump Relay On / Off Off On

Crank Time Seconds 0.0 sec 0.3 s ec

DTC Status No DTC / DT C Set No DTC(s) No DTC(s)

Time From Start Time 0:00:00 Varies

Check Powertrain Lamp Off/0n Off Off

Requested Torque Nm 214 Nm 476 Nm

(will decrease with engine load)

Actual Torque Nm 0 Nm 15 – 30 Nm

(will closely follow requested torque once

engine load is detected)

Low Oil Pressure No/Yes Yes No

-

--

- LPG Swi tch Off/On Off Off

-

--

- LPG Fuel Enabled No/Yes No No

-

--

- Fuel Petrol / L PG Petrol Petrol

-

--

- LPG Fuel Control Valve 0 – 100 % 0% 0%

-

--

- LPG Mode Enabled No/Yes No No

-

--

- LPG Low Petrol Cutout No/Yes No No

-

--

- LPG Smart Solenoid Enabled No/Yes No No

-

--

- These data displays only apply to those vehicles equipped with Liquefied Petroleum Gas (LPG) fuel.

TECH 2: ENGINE DATA DESCRIPTIONS

A list of explanations for each data m essage displayed on T ech 2 begins as f ollows. This inform ation will assist in

track ing down em iss ion or driv eabil it y problem s, s ince the disp la ys can be viewe d while th e vehic le is be ing driven.

Refer to the "On-Board Diagnostic System Check" for additional information.

ENGINE SPEED - Range 0-9999 RPM - Engine speed is computed by the PCM from the fuel control reference

input. It should remain close to desired idle under various engine loads with engine idling.

DESIRED IDL E - Range 0- 3175 R PM - The idle s peed that is c omm anded b y the PCM. The PC M will c om pensate

for various engine loads to keep the engine at the desired idle speed.

ECT SENSOR VOLTS/ENG COOLANT TEMP - Range –40°

°°

° to 151°

°°

° C/ 0 – 5 VOLTS - The Engine Coolant

Tem perature (ECT) sens or is mounted in the in let manifold a nd sends engi ne temperatur e information to the PCM

applies 5 volts to the coolant temperature sensor circuit. The sensor is a thermistor which changes internal

resistance as temperature changes. When the sensor is cold (internal resistance high), the PCM monitors a high

signal vol tag e whic h it inter p rets as a cold engin e. As the sens or war ms (internal r esis tanc e decr eas es) , the v olta ge

signal will increase, the voltage signal will decrease and the PCM will interpret the lower voltage as a warm engine.

IAT SENSOR VOLTS/IAT - Range -40°

°°

° to 151 °

°°

° C – The PCM converts the res istanc e of the intake air temperatur e

sensor to d egrees. Intak e Air Te mp (IAT) is used by the PC M to adjust fuel deliver y and spark tim ing accordin g to

incoming air density.

M AF SENSOR FREQUENCY - Range 0-10,192 Hz - The s ignal that is sent fr om the Mas s Air Flo w (MAF) s ensor

to the PC M is in the f orm of a f requenc y outp ut. This freque nc y output c hanges a s the d em and of engi ne air intak e

changes.

MASS AIR FLOW - Range 0-246 grams/sec. - The Mass Air Flow (MAF) sensor measures the change in the

intake air flow which results from engine load and speed changes. As intake air flow increases, the air in the inlet

manifold also increases and addition fuel is required.

MASS AIR FLOW/CYL - Range 0-1000 mg/S. - Calculated air flow per each cylinder.

TPS SIGNAL - Range 0 to 5.10 Volts - Used by the PCM to determine the amount of throttle demanded by the

driver. Should read 0.25 - 1.25 volt at idle to above 4 volts at wide open throttle.

TPS ANGL E - Range 0-100% - Com puted b y the PCM f rom TP s ensor voltag e (T hrottle Position) should r ead 0%

at idle, 100% at Wide Open Throttle (WOT).

RH/LH OXYGEN SENSOR RE ADY - Tech 2 Displays "YES" or "NO". Indica tes if the 02 sensors have reached

operating temperature.

RH/LH OXYGEN SENSOR - Range 0-1192 - Represents the exhaust sensor output voltage. Should fluctuate

constant ly withi n a r ange b etween 1 00 m V (Lea n exh aust) an d 1000 m V (R ich e xhaus t) whe n operat ing i n " Closed

Loop".

ST FUEL TRIM R/L - Range -100% -0% -+ 100% - Short Term F uel Trim repr esents a s hort-term correc tion to fuel

deliver y b y the PCM in res ponse to the amount of time the oxygen sensor voltage spends above or belo w the 450

mV thr es hold. If the oxygen s ens or v olt age has mainly been be lo w 45 0 mV, ind ica ting a lea n a ir /f uel mixtur e, STFT

will increase to tell the PCM to reduce fuel delivery to compensate for the indicated rich condition. Under certain

conditions such as extended idle and high ambient temperatures, canister purge may cause STFT to read less than

–10%.

LT F UEL TRIM R/L -100% - 0% - +100 % – LT FT is derive d b y the PCM from the ST FT value and is used f or long-

term correction of fuel delivery. A value of 0% indicates that fuel delivery requires no compensation to maintain a

14.7:1 air/fuel rat io. A valu e be low 0 % m eans th at the fuel syst em has been ric h and fuel deli ver y is be ing r educed

(decreas ed injector pulse width) to m aintain a 1 4.7 to 1 A/F rati o. A value abov e 0% indicates that a lean c onditio n

exists and the PCM has been compensating by adding fuel (increased injector pulse width). LTFT tends to follow

STFT, a value of less than -10% due to canister purge at idle should not be considered unusual.

LTFT EN ABLE - T ech 2 D ispla ys "Y ES" o r "NO ". - The Long T erm Fuel T rim is enable b y the PCM when a lon g

term fuel correction is required. A YES indicates that the LTFT is enabled, a NO indicates that is not.

FUELLING MO DE - Tech 2 Displays "O PEN" o r "CLOSED " - "Close d Loop" d ispla yed indicat es that the PCM is

controlling fuel delivery according to oxygen sensor voltage. In "Open Loop", the PCM ignores the oxygen sensor

voltage and bases the amount of fuel to be delivered on TP Sensor, coolant and IAT sensor inputs only. "Closed

Loop" operation should begin when the 02 sensor be comes active, engine coolant tem perature exceeds 50° C for

more than 30 seconds and the PCM has seen a RPM of 1200 or greater for 10 seconds. At extremely high

temperature or when towing a trailer, it is possible for the system to remain in "Open Loop" operation to control

catalytic converter temperatures.

LONG TERM FUEL TRIM CELL (LTFT CELL) - Range 0-34 - LTFT cell is dependent upon engine speed and

m ass air f low readi ngs and canis ter pur ge. A plot of RPM vs MAF is brok en int o 34 cel ls. LT FT cell indic ate s wh ich

cell is curr ently active.

RH/LH 02 ST ATUS - Tech 2 Displays "RICH" or "LEAN" - Indicates whether exhaust ox ygen sensor voltage is

above (r ich) or be low ( lean) the 45 0 m V ox ygen sensor threshol d volt age. Sh ould change c onstant l y indicat ing tha t

the PCM is controlling the air/fuel mixture properly.

RH/LH O2 CROSS CNTS - Range 0-255 - The number of times the oxygen sensor voltage crosses over the

rich/lean threshold during a two second interval.

STFT /LTFT DELT A - Range 0-100 %. - T he diff erence ( Delta) in % of the ST FT/LT FT counts f rom eac h bank . This

value is used by the PCM to determine bank to bank fuel trim balance.

DECEL FUEL CUTOFF - Tech 2 Displays "YES" or "NO" - Yes displayed indicates that the PCM has detected

conditions appropr iate to operate in deceleration fuel m ode. The PCM will command deceleration fuel mode when

a sudden dec reas e in t hr ott le pos i tio n has be en det ec t ed while th e ve hicle is trav e ll ing o ver a c erta in k m/h. While in

decelerati on fuel mode, t he PCM will d ecrease the am ount of fuel del ivered by en tering open loop and decreas ing

the injector pulse width.

INJ. PULSE WIDTH TIME - Range 0.0 - 999.9 ms. - The "ON" time of the injector as determined by the PCM.

INJECTOR VOLTAGE - Range 0 - 14.0 Volts. System voltage monitoring

AIR/FUEL RATIO - Range 0.00 : 99.99 - The reading reflects the commanded value. This should be at or near

14.7. A lower number indicates a richer commanded air fuel mixture while a higher number indicates a leaner

mixture.

PURGE PW M - Ran ge 0 - 100% - A proport ional sign al used to contr ol EV AP Canister Purge func tion. 0% implies

the valve is commanded fully closed, while 100% implies that the value is fully open.

EGR POSITION COMMANDED - Range 0 - 100% - Represents the EGR pintle position that the PCM is

commanding. Desired EGR position should stay close to EGR Pintle Position.

EGR POSITION FEEDBACK - Range 0% - 100% - Represents the actual position of the EGR pintle in percent.

0% displayed indicates a fully extended pintle (EGR valve closed).

EGR PINTLE SENSOR - Range 0.0 - 5.0 Volts - Repr esents the v oltage that th e PCM uses to de termine weathe r

or not the EGR valve is fully closed (0% pintle position).

BATTERY VOLTAGE - Range 0-25.5 volts - This represents the system voltage measured by the PCM at its

ignition No. 1 feed.

REFERENCE VOLTS - Range 0-5.10 Volts - Indicates the voltage that is supplied to various sensors from the

PCM.

3X SIGNAL - Range Missing or Present - Signal indicates crankshaft position for correct ignition coil sequencing.

18X SIGNAL - Range Missing or Present – Signal indicates the position of the crankshaft within the 3X cycle.

CAM SIGNAL - Range Missing or Present - Signal sent to the PCM by the Cam Sensor. This indicates

movement of the camshaft. This signal is used by the PCM to indicate if the engine is running.

IAC POSITION - Range 0-255 Counts - Displays the commanded position of the idle air control pintle in counts.

The higher the number of counts, the greater the commanded idle speed. Idle air control should respond fairly

quickly to changes in engine load to maintain desired idle RPM.

LITRES Per Hour - Range 0-100 - Indicates fuel consumption per litres per hour.

IDLE RPM VARIANT - Range 0-9999 RPM - Indicates the variation in RPM between sampling's of the engine

speed.

SPARK MODE - Tech 2 displays "BYPASS" or "EST" - Indicates what mode of ignition timing the vehicle is

operating under.

SPARK ADVANCE - Range –90°

°°

° to +90°

°°

° – This is a display of the spark advance (EST) calculation which the

PCM is programming into the ignition system. It computes the desired spark advance using data such as engine

temperature, rpm, load, vehicle speed, and operating mode.

KNOCK SIGNAL CYLINDER (1 THROUGH 6) - Tech 2 Displays NONE or knock detected – This signal

indicates what cylinder is knocking.

KNOCK SIGNAL - Tech 2 Displays "KNOCK" or "NONE" – Indicates whether or not a knock signal is being

detected by the PCM. Should read "NONE" at idle.

KNOCK RETARD - Range 0°

°°

° - 90°

°°

° – Indicates the amount of spark advance the PCM is removing from EST in

response to the Knock sensor (ESC) signal. Should read 0 degrees at idle.

KNOCK RETARD CYLINDER (1 THROUGH 6) - Range 0°

°°

° – 90°

°°

° – Indicates the amount of spark advance the

PCM is removing from each cylinder in response to the Knock sensor (ESC) signal. Should read 0° at idle.

TCC SOLENOID - Tech 2 Displays "ON" or "OFF". - Indicates if the transmission TCC Solenoid is comm anded

the TCC ON or OFF.

VEHICLE SPEED - Range 0-255 km/h - The vehicle speed sensor signal is converted into kph and mph for

display.

A/C REQU EST - Tech 2 Disp lays "Y ES" o r "NO" - Repres ents the s tate of the A/C r equest s erial data in put f rom

the BCM.

A/C CLUTCH - Tech 2 Displays "ON" or "OFF" - Represents the commanded state of the A/C clutch control

relay. Clutch should be engaged when "ON" is displayed.

A/C PR ESSUR E - T ech 2 Disp lays 0. 0 – 5.10 Volts - Repres ents the A /C ref rig erant press ure Sensor signal. T he

amount of pressure indicates the amount of load that the A/C compressor is placing on the engine.

The PCM uses this information to adjust idle speed and to control the cooling fan.

A/C PRESSURE - Range 0 - 3195 kPa - The kPa displayed indicates that the PCM is monitoring an A/C

Refrigerant Pressure signal voltage which is too high or too low to allow the A/C compressor clutch to engage.

HIGH SPEED FAN - Tech 2 Displays "ON" or "OFF - Indicates if the engine cooling fan high speed relay has

been commanded ON or OFF.

LOW SPEED FAN REQUEST - Tech 2 Displays "ON" or "OFF - Indicates if the engine cooling fan low speed

relay has been commanded ON or OFF.

THEFT STATUS - Tech 2 Displays "NO START" or "START". - Indicates the status of the Theft Deterrent

System.

ST ARTER REL AY - Tech 2 Displays "OF F" or "ON" - If Tec h 2 indicates ON, then the veh icle will start. As long

as the Theft Deterrent System is working properly, Tech 2 should indicate "ON"

FUEL PUMP RELAY - Tech 2 Displays "ON" or "OFF. - Indicates if the Fuel Pump is ON or OFF.

CRANK TIME - Range 0 - 99.9 Seconds. - Indicates the duration of the engine crank time.

DTC STATUS - Tech 2 Displays "NO DTC(s)" or DTC SET - Indicates if a DTC is set. This does not indicate what

DTC is set, just informs that DTC are or are not set.

TIM E FROM START - T ech 2 Displa ys 0:00:00. - Indicates the ho urs, m inutes and sec onds t he engine has been

running.

CHECK POWERT RAIN MALFUNCT ION INDICATOR L AMP (M IL) - Tech 2 Displays "OFF" or "ON" - Indicated

if the instrument panel Malfunction Indicator Lamp is "ON", or "OFF".

REQUESTED T ORQUE - T ech 2 Displays 0 - 2 15 N m of T orque - In dic at es what Nm torqu e s i gna l t he A BS/T C S

module is sending to the PCM.

ACTUAL TO RQUE - T ech 2 Displa ys 0 - 2 15 Nm of T o rqu e - Indic ates the PC M Nm torque r espons e back to the

ABS/ETC module.

LOW OIL PRESSURE - Tech 2 Displays "NO" or "YES" - Indicated if the PCM is detecting a low oil pressure

signal.

LPG SWITCH - Tech 2 Displays "OFF" or "ON" - Indicates which mode the driver has selected, Petrol or LPG

mode.

LPG FUEL ENABLE - Tech 2 Displays "NO" or "YES" Indicates if the PCM is capable of operating in LPG

mode..

FUEL - Tech 2 Displays Petrol or LPG - Indicates what type of fuelling mode the Vehicle is currently operating

under.

LPG FUEL CONTROL VALVE – Range 0% - 100% Represents the actual position of the FCV in percent. 0%

displayed indicates the FCV is OFF. 100% indicated the FCV is fully ON.

LPG MODE ENABLE – Tech 2 Displays "NO" or "YES" This indicates if the LPG mode has been selected.

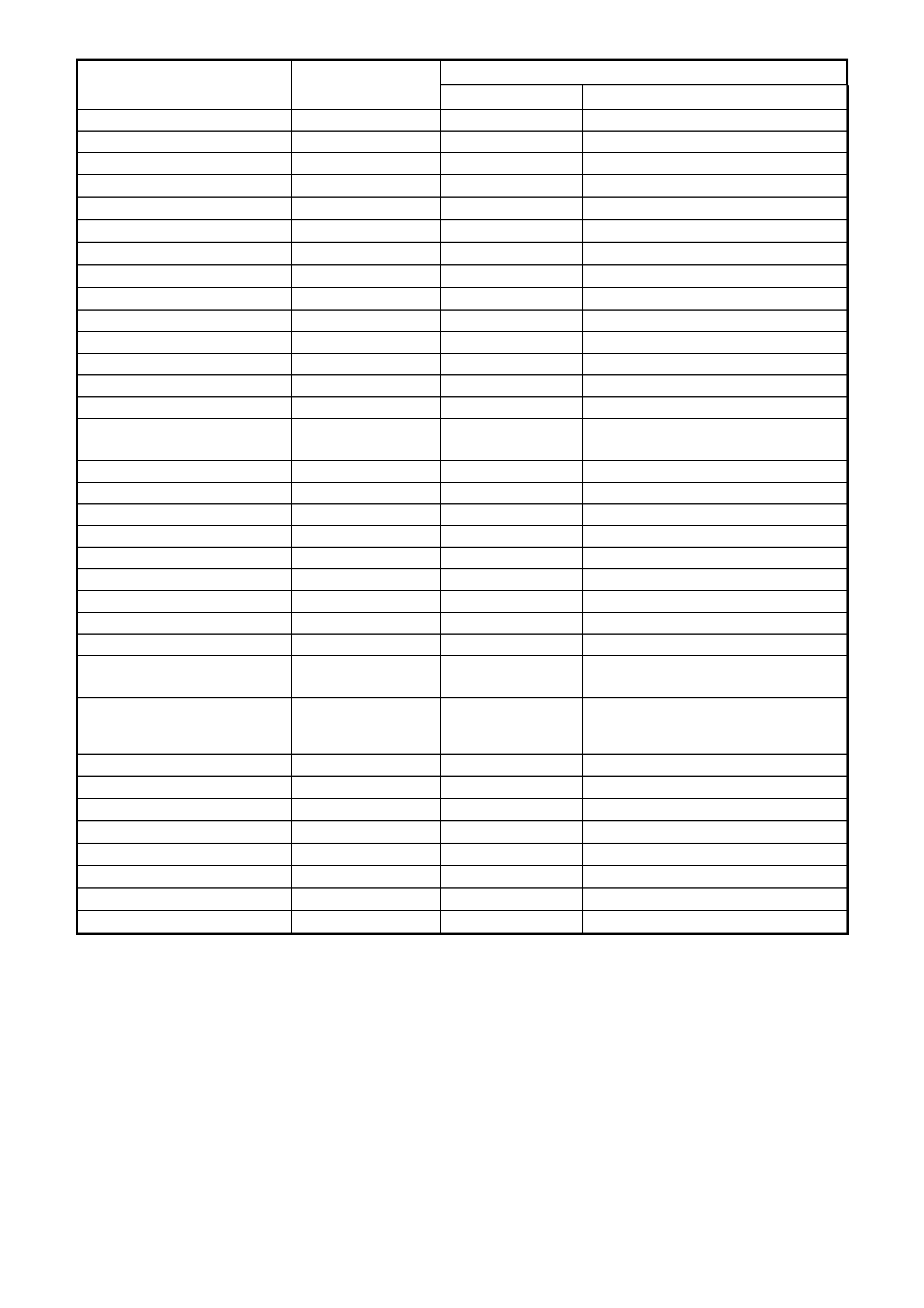

5.4 TECH 2: AUTOMATIC TRANSMISSION DATA

The Tech 2 scan data listed in the following table may be used for comparison:

1. After completing the Powertrain OBD System Check.

2. Finding the on-boar d dia gn os tic s are func tio ning properly and

3. No diagnostic DTCs are displayed.

A TECH 2 THAT DISPLAYS FAULTY DATA SHOULD NOT BE USED, AND THE PROBLEM SHOULD BE

REPORTED TO THE MANUFACTURER. THE USE OF A FAULTY TECH 2 CAN RESULT IN MISDIAGNOSIS

AND UNNECESSARY PARTS REPLACEMENT.

Only the parameter s lis ted ar e used in this Vo lume f or diagnosis . F or mor e desc r iption on th e va lues and use of the

Tech 2 to diagnosis PCM inputs, refer to the applicable diagnosis table in S ectio n 6C1-2A DIAGNOST IC T ABLES.

If all values are within the range illustrated, refer to Section 6C1-2B SYMPTOMS.

Test Description: The number(s) below refer to the number(s) on the ‘Tech 2 Transmission Data Display’ table.

1. DATA PARAMETER:– Tech 2 can display nine (9) data parameters at any one time. The down arrow button

will scroll down through all of the data parameters one at a time. After the last data parameter is displayed,

pressing the down arrow button again, will display the fist data parameter, once again.

2. UNITS DISPLAYED are th e ways/units that each par ameter will be displayed, w hich is the value that is being

sensed or being is sued b y the PCM.

3. TYPICAL DATA VALUE is separated into two parts. These displayed values are typical of a normally operating

vehicle . T he ‘IGNITION O N ’ c omparis on should be performed f irs t as this may lea d to a quick identificati on of a

failure. T he ‘ENGIN E RUN NING’ data s hould be com pared to th e ‘IGNIT ION ON ’ data as a diagn ostic c heck to

make sure the component or system is operating properly.

4. IGNITION ON values are the typical values that should be seen on Tech 2 with the ignition ON and engine

stopped. T emperature sensors should be com pared to the actual tem peratures (e.g. coolant, air, transmission

fluid) b y allowing the sens or to coo l overnig ht and the n com paring their valu es. A diff erence of 3-5° C f rom the

actual temperature may indicate a problem with the sensor. Use the diagnostic aids table for that sensor to

compare the resistance to temperature values.

5. ENGINE RUNNING typical data values are an average of display values recorded from a normally operating

vehicles at normal operating temperature. They are intended to represent what a normally functioning system

would typically display.

TECH 2 TRANSMISSION DATA DISPLAY – ALL DATA

TYPICAL DATA VALUE S

SS

S

DATA PARAMETER Q

QQ

Q UNITS DISPLAYED

R

RR

R IGNITION "ON"

T

TT

T ENGINE RUNNING U

UU

U

Engine Speed RPM 0 RPM ± 100 RPM FROM DESIRED RPM

(± 50 RPM IN DRIVE)

Vehicl e Speed km/h 0 0

TPS Signal Volts 0.25V – 1.25V 0. 25V – 1.25V

Throttle Angle % 0% 0%

ECT Sensor Volts 1.9 V

(Varies) 1.9 V

(Varies)

Coolant Temperature ° C +96° C

(Varies) +96° C

(Varies)

TFT Sensor Volts 2.8 V

(Varies) 2.8 V

(Varies)

Transmission Fluid Temperat ure ° C 96° C

(Varies) 96° C

(Varies)

TFP Switch A 0V - 12V 12 V 12 V

TFP Switch B 0V -12 V 0 V 0 V

TFP Switch C 0V - 12V 12 V 12 V

TFP Gear P/ N R, D, 3, 2, 1 P/N P/N

PRNDL Switc h Invalid / P,R,N,D,3,2,1 Invalid or Gear

Selected P/N

Transmission Range (TR) Park/Neutral

Reverse, Drive 4, O/D,

Drive 3, Drive 2, Drive 1 Park/Neutral -P-

TR Switch P Open 12 V/Closed 0V Closed 0V Closed 0V

TR Switch A Open 12 V/Closed 0V Closed 0V Closed 0V

TR Switch B Open 12 V/Closed 0V Closed 0V Open 12V

TYPICAL DATA VALUE S

SS

S

DATA PARAMETER Q

QQ

Q UNITS DISPLAYED

R

RR

R IGNITION "ON"

T

TT

T ENGINE RUNNING U

UU

U

TR Switch C Open 12 V/Closed 0V Closed 0V Open 12V

1 - 2 Shift Solenoid A On/Off Off On

2 - 3 Shift Solenoid B On/Off On On

1 - 2 Shift Solenoid A Feedback On/Off Off On

2 - 3 Shift Solenoid B Feedback On/Off On On

1 - 2 Shift Time Sec 0. 00 0.00

2 - 3 Shift Time Sec 0. 00 0.00

Commanded. PCS Millia mps 0 mA 957 mA

Actual PCS Milliamps 0 mA 957 mA

PCS Duty Cycle % 0 % 55 to 75 %

TCC Solenoid On/Off Off Off

TCC PWM Solenoid % 0% 0%

TCC Solenoid Feedback On/Off Off Off

Transmission Slip Speed RPM 0 +700 to 800 RPM