SECTION 6C1-3 - SERVICE OPERATIONS - V6 ENGINE

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1. GENERAL DESCRIPTION

1.1 SERVICE PRECAUTIONS

2. ELECTRONIC CONTROL

2.1 POWERTRAIN CONTROL MODULE

PCM REPLACEMENT/PROGRAMMING

REMOVE

REINSTALL

SERVICE PROGRAMMING

PCM SECURITY LINK

FUNCTIONAL CHECK

2.2 CAMSHAFT POSITION SENSOR

REMOVE

REINSTALL

2.3 ENGINE COOLANT TEMPERATURE (ECT)

SENSOR

REMOVE

REINSTALL

2.4 INTAKE AIR TEMPERATURE (IAT) SENSOR

REMOVE

REINSTALL

2.5 MASS AIR FLOW (MAF) SENSOR

REMOVE

REINSTALL

2.6 OXYGEN SENSOR

REMOVE

REINSTALL

2.7 THROTTLE POSITION (TP) SENSOR

REMOVE

REINSTALL

2.8 VEHICLE SPEED SENSOR

REMOVE

REINSTALL

3. FUEL CONTROL SYSTEM

3.1 FUEL PUMP RELAY

FUEL PRESSURE RELIEF PROCEDURE

3.2 THROTTLE STOP SCREW- RESET

PROCEDURE

CHECK OR RESET

3.3 MODULAR FUEL SENDER ASSEMBLY

REMOVE

REINSTALL

FUEL STRAINER AND FUEL LEVEL SENSOR)

FUEL PUMP ASSEMBLY

3.4 FUEL SYSTEM PRESSURE TEST

MEASURE

3.5 FUEL FILTER

REMOVE

REINSTALL

3.6 LEAK TESTING

3.7 FUEL PRESSURE REGULATOR

REMOVE

REINSTALL

3.8 FUEL RAIL AND INJECTORS

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

3.9 AIR CLEANER ASSEMBLY

REMOVE

REINSTALL

3.10 THROTTLE CABLE

REMOVE

REINSTALL

ADJUST

3.11 THROTTLE BODY

REMOVE

CLEAN

THROTTLE BODY CLEANING PROCEDURE

REINSTALL

THROTTLE BODY IAC VALVE COUNT

CHECKING PROCEDURE

3.12 FUEL RAIL AND INJECTORS

3.13 IDLE AIR CONTROL VALVE

REMOVE

CLEAN

REINSTALL

3.14 THROTTLE PEDAL ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

4. DIRECT IGNITION SYSTEM (DIS)

4.1 GENERAL SERVICE INFORMATION

TIMING ADJUSTMENT

CHECK EST SPARK TIMING OPERATION

4.2 IGNITION COIL/S

REMOVE

RESISTANCE TESTS

REINSTALL

4.3 DIS MODULE

REMOVE

REINSTALL

4.4 CRANKSHAFT (CKP) SENSOR

REMOVE

REINSTALL

4.5 KNOCK SENSORS

CHECKING KNOCK SENSOR OPERATION

REMOVE

REINSTALL

4.6 SPARK PLUG LEADS

REMOVE

SPARK PLUG LEAD BENCH TESTS

REINSTALL

4.7 SPARK PLUGS

REMOVE

CLEANING AND INSPECTION

REINSTALL

SPARK PLUG DIAGNOSIS

ANALYSIS OF SPARK PLUG CONDITION

5. AUTOMATIC TRANSMISSION

SERVICE OPERATIONS AND COMPONENTS

6. MISCELLANEOUS SYSTEMS

6.1 EVAPORATIVE EMISSION CONTROL CANISTER

6.2 CANISTER PURGE SOLENOID

REPLACE

6.3 EXHAUST GAS RECIRCULATION (EGR) VALVE

REMOVE

REINSTALL

6.4 A/C REFRIGERANT PRESSURE SENSOR

REPLACE

Techline

Techline

1. GENERAL DESCRIPTION

This Section describes the proper service procedures to repair components of the Powertrain Management

System , used with th e V6 engine. Emphasis is placed on the proper pr ocedures and repair of components related

to this specific system.

1.1 SERVICE PRECAUTIONS

The following requirements must be observed when working on vehicles:

1. Before removing any PCM system component, disconnect the battery ground lead.

2. Never start the engine without the battery being solidly connected.

3. Never disconnect the battery from the on board electrical system while the engine is running.

4. When charging the battery, disconnect it from the vehicle's electrical system.

5. Never subject the PCM to temperatures above 80° C; i.e. paint oven. Always remove PCM first if this

temperature is to be exceeded.

6. Ensure that all cable harness plugs are connected solidly and that battery terminals are thoroughly clean.

7. The engine management system harness connectors are designed to fit in only one way; there are indexing

tabs and slots on both halves of the connector. Forcing the co nnector into place is not necessar y if it is be ing

installed with the proper orientation. Failure to take care to match the indexing tabs and slots to ensure the

connector is being installed correctly can cause damage to the connector, the module, or other vehicle

components or s ystem s .

8. Never connect or disconnect a cable harness plugs at the PCM when the ignition is switched "ON."

9. Before attempting any electric arc welding on the vehicle, disconnect the battery leads and the PCM

connectors.

10. When steam cleaning engines, do not direct the steam cleaning nozzle at PCM system components. If this

happens, corrosion of the terminals can take place.

11. Use only the test equipment specified in the diagnostic Tables, since other test equipment may either give

incorrect results or damage good components.

12. All vol tag e meas urements using a vo ltmeter mus t us e a dig ital voltmeter with an inter na l impedance r at in g of at

least 10 million ohms per volt (10 megohm/volt).

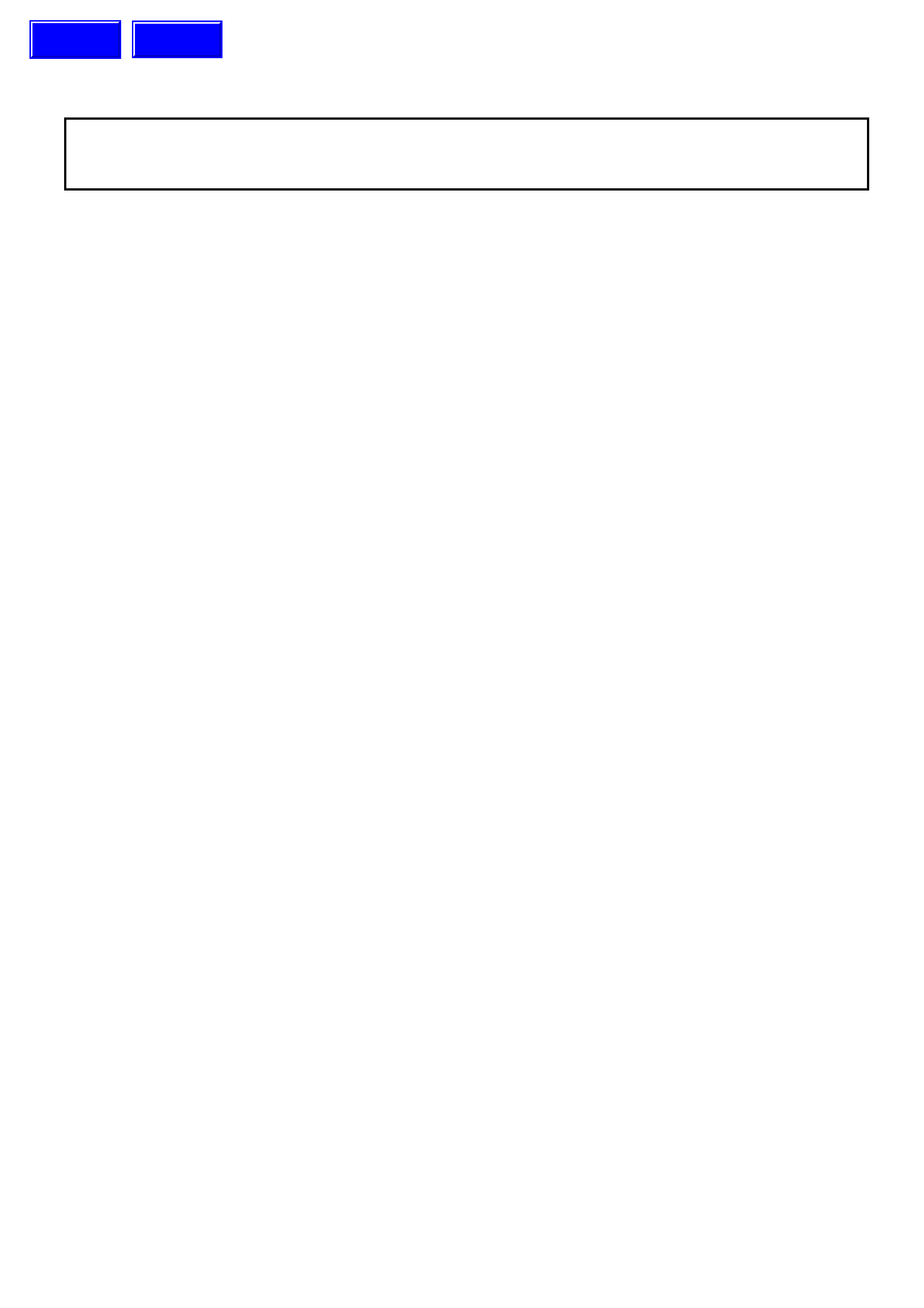

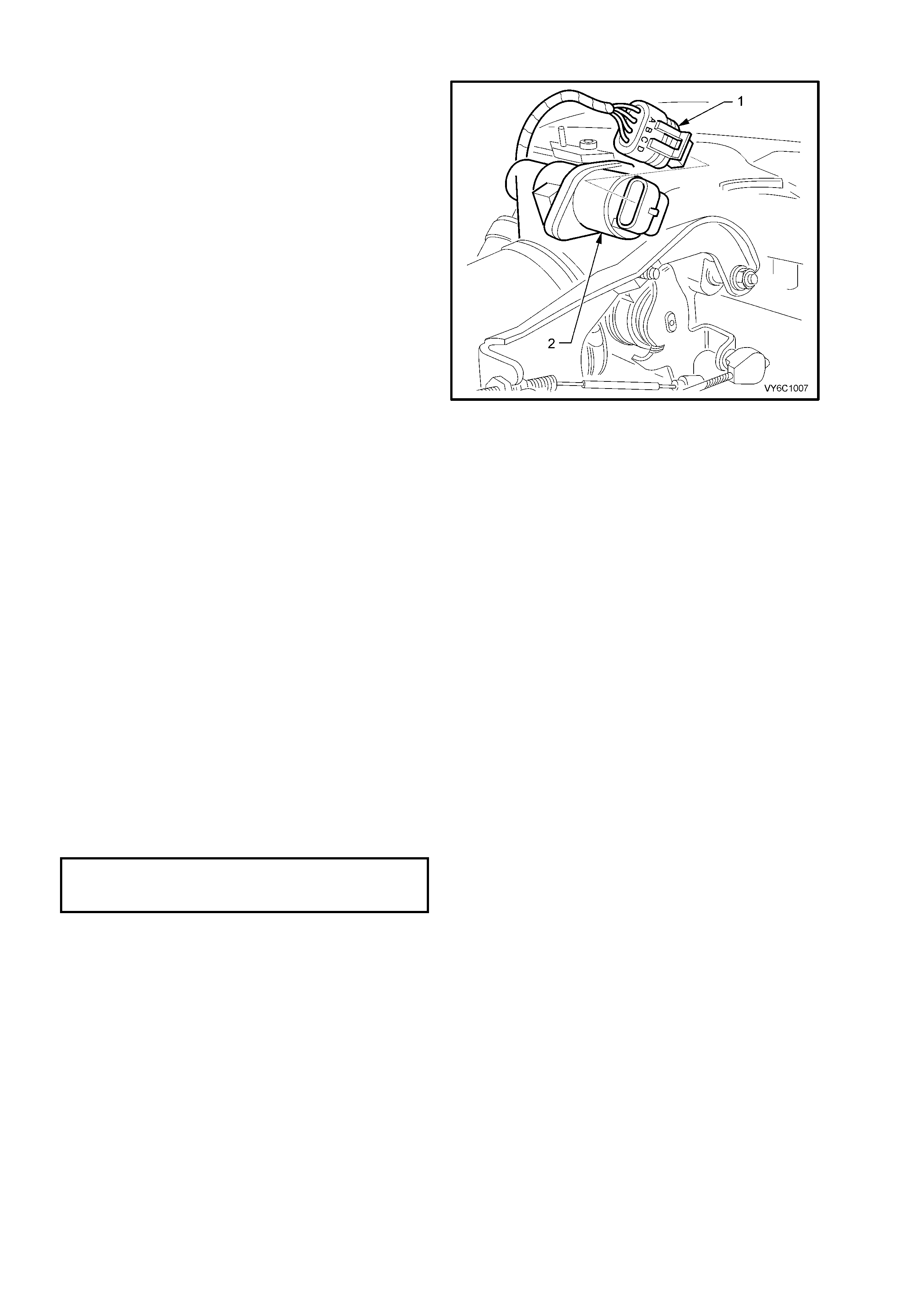

13. When a test light ( 1) is s pec ified, a " low-p ower"

test light must be used. Do not use a high –

wattage test light. While a particular brand of

test ligh t is no t sug geste d, a sim ple t est o n an y

test light will ensure it to be OK for PCM c ircuit

testing. Connect an accurate (2) Ammeter

(such as a high-impedance digital multimeter)

in series with the test light being tested, and

power the test light-ammeter circuit with the

ve hicle battery (3).

If the am meter indicat es less tha n 0.3 Am p current

flow (300 mA), the test light is OK to use.

If the ammeter indicates more than 0.3 Amp

current flow (or 300 mA), the test light is NOT OK

to use.

Figure 6C2-3-1

14. When fasteners are removed, always reinstall them at the same location from which they were removed. If a

fastener needs to be replaced, use the correct part number fastener for that application. If the correct part

number fastener is not available, a fastener of equal size and strength (or stronger) may be used. Fasteners

that are not to be re-used, or those requiring thread locking compound will be identified. The correct torque

value must be used when installing fasteners that require it. If the above conditions are not followed, parts or

system damage could result.

2. ELECTRONIC CONTROL

2.1 POWERTRAIN CONTROL MODULE

LT Section No. – 02-245

PCM REPLACEMENT/ PROGRAMMING

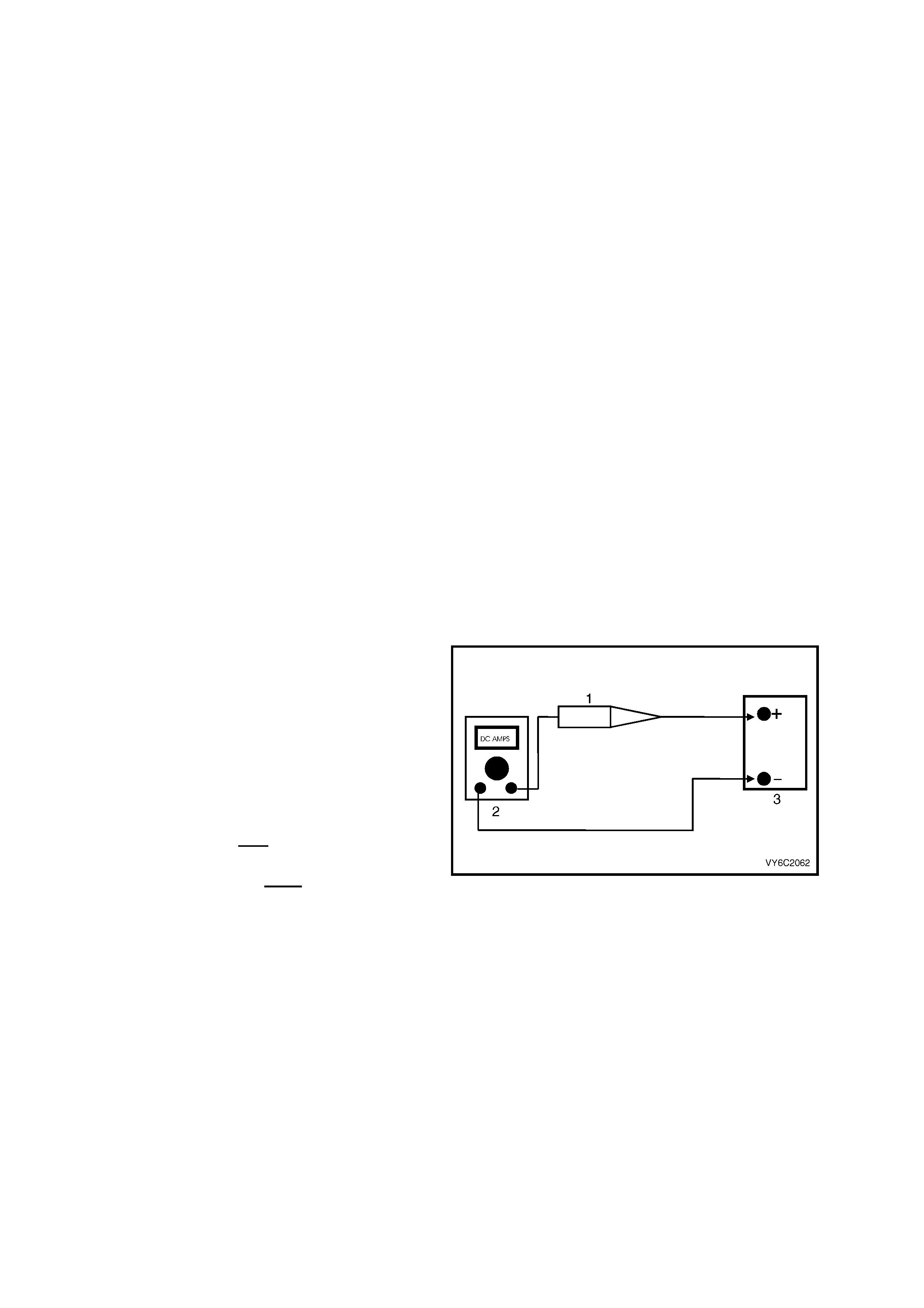

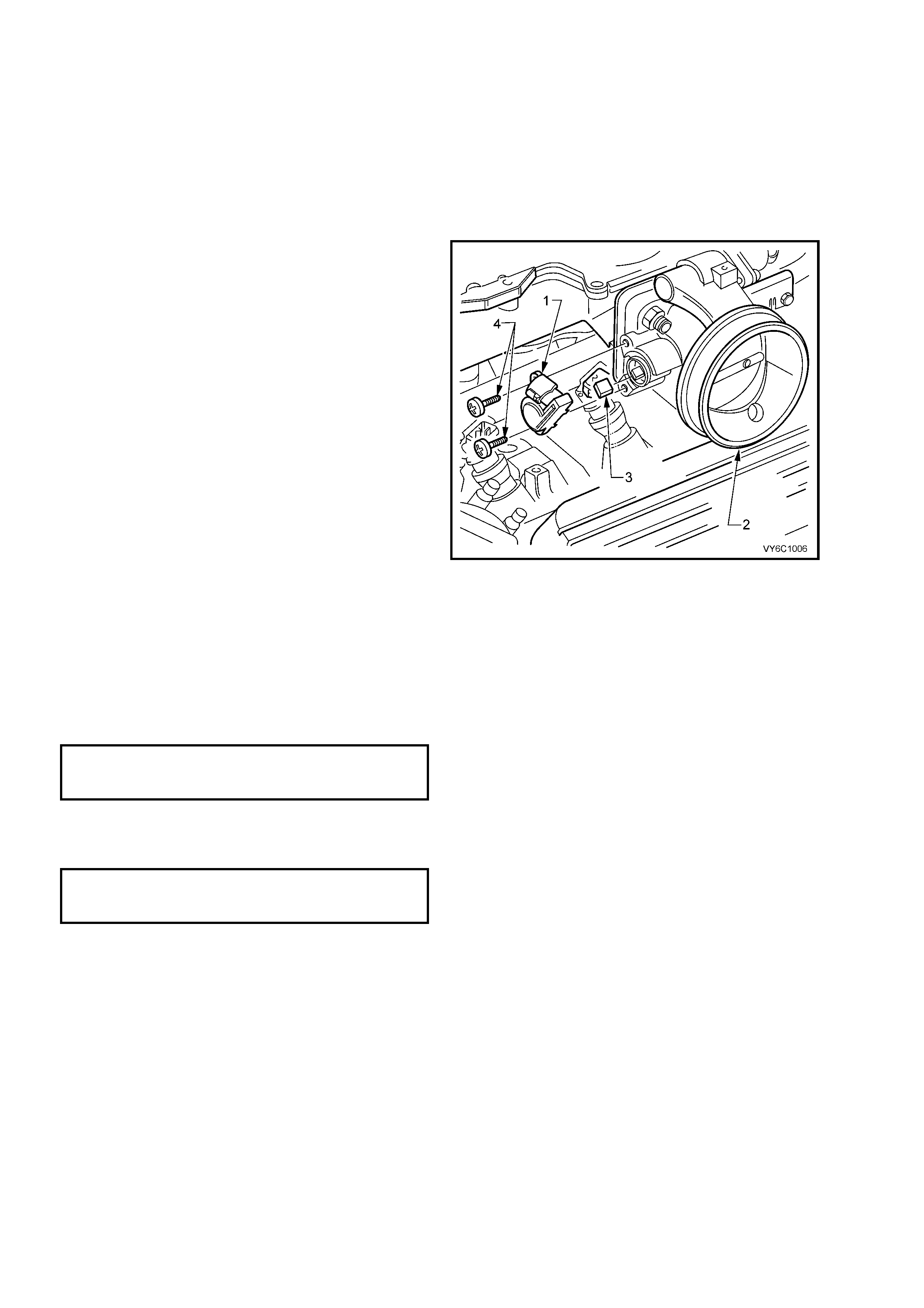

Service of the PCM (1) should normally consist of

either replacement of the PCM or EEPROM (flash

memory) programming. If the diagnostic

procedures call for the PCM to be replaced, the

PCM should be first checked to ensure it is the

correct part. If it is, remove the faulty PCM and

insta ll the ne w PCM .

NOTE 1: The replacement PCM EEPROM will not

be programmed.

NOTE 2: DT C P0601 indic ates the E EPRO M is not

programmed or has malfunctioned. Refer to

Service Programming in this Section for

programming procedures.

IMPORTANT: The following operations must be

carried out whenever the PCM is replaced:

• The EEPROM must be programmed.

• The Functional Check must be performed

(described later in this Section).

IMPORTANT: W henever the PCM is disconnected

or loses power:

• The Functional Check must be performed

(also described later in this Section).

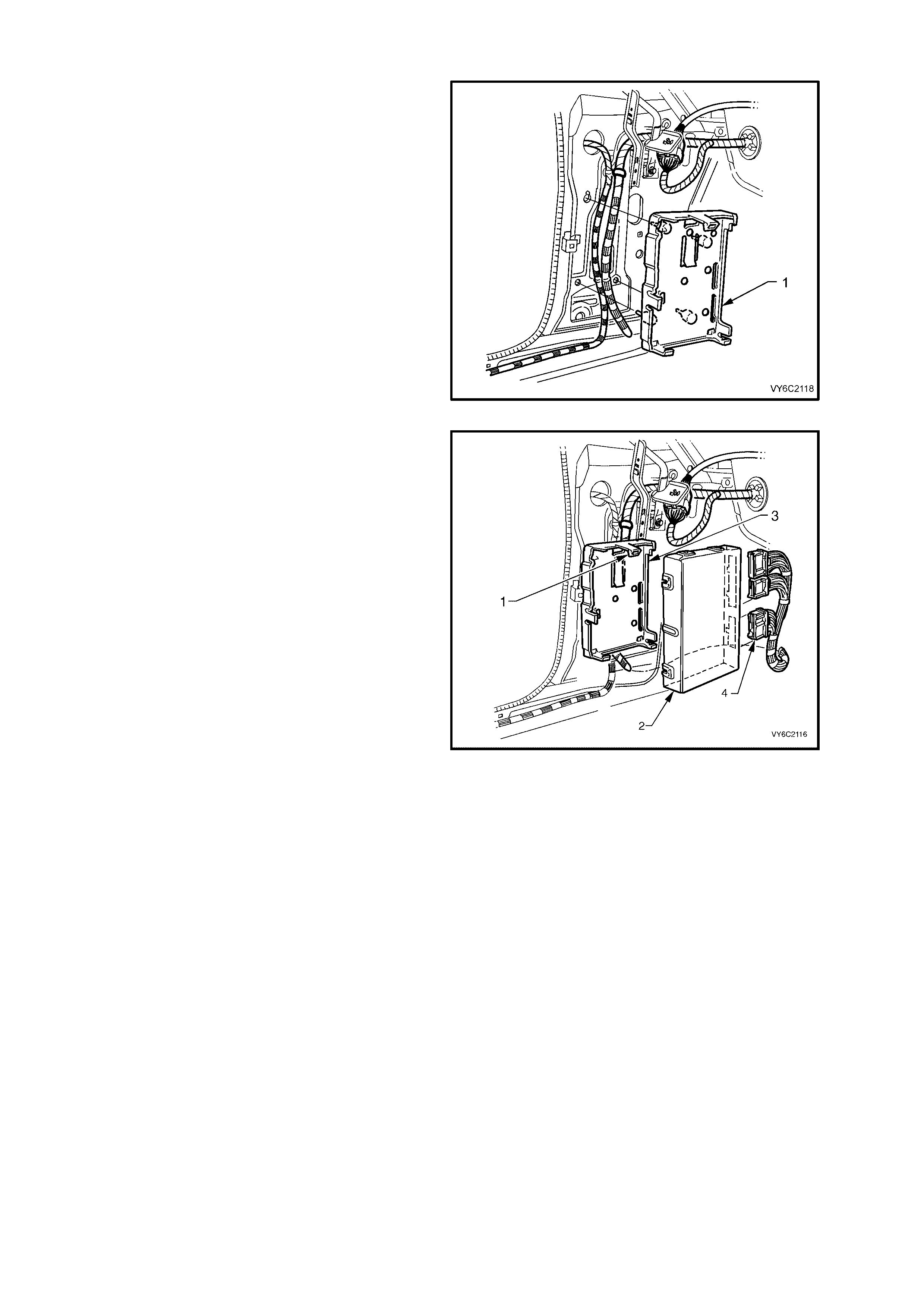

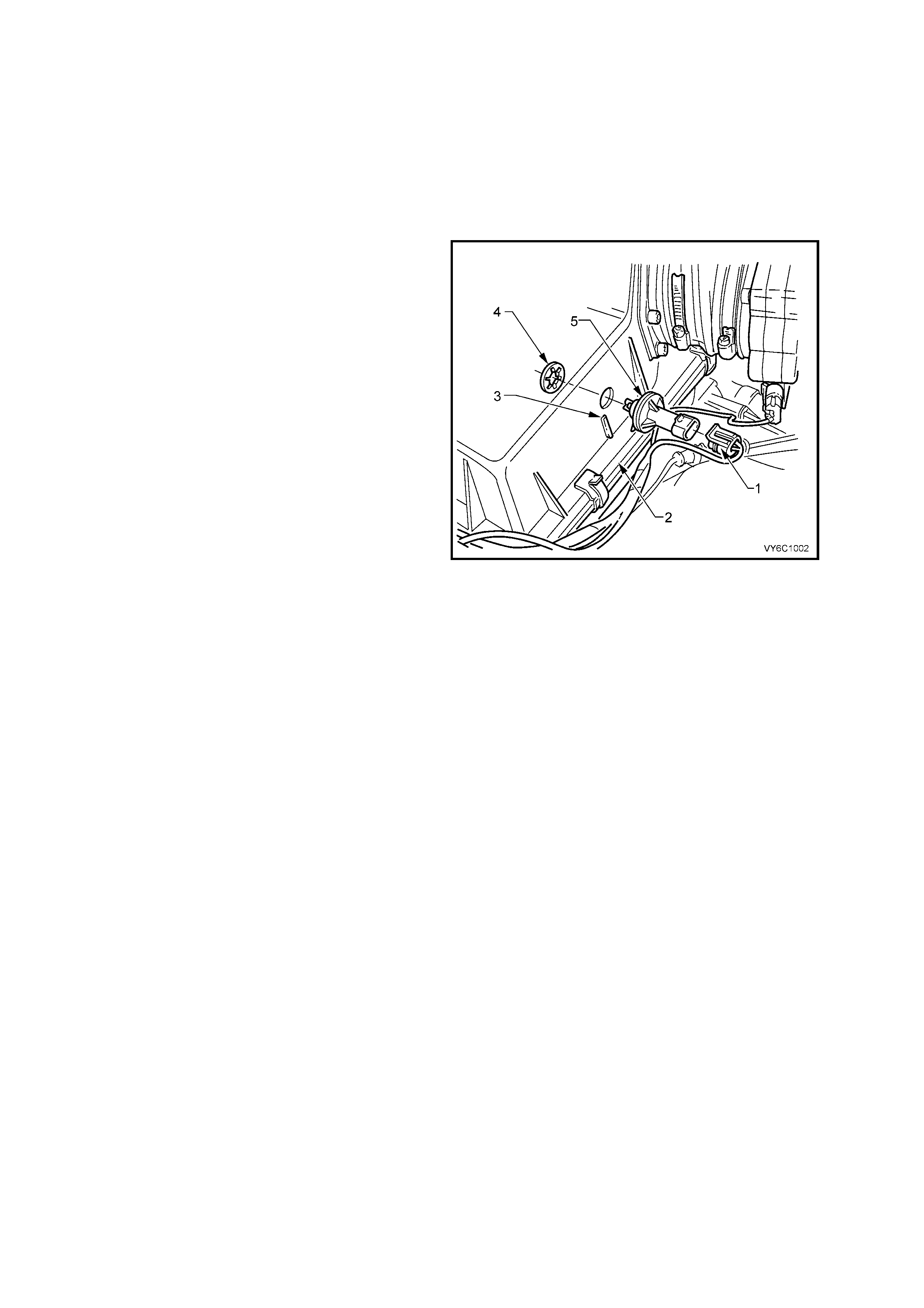

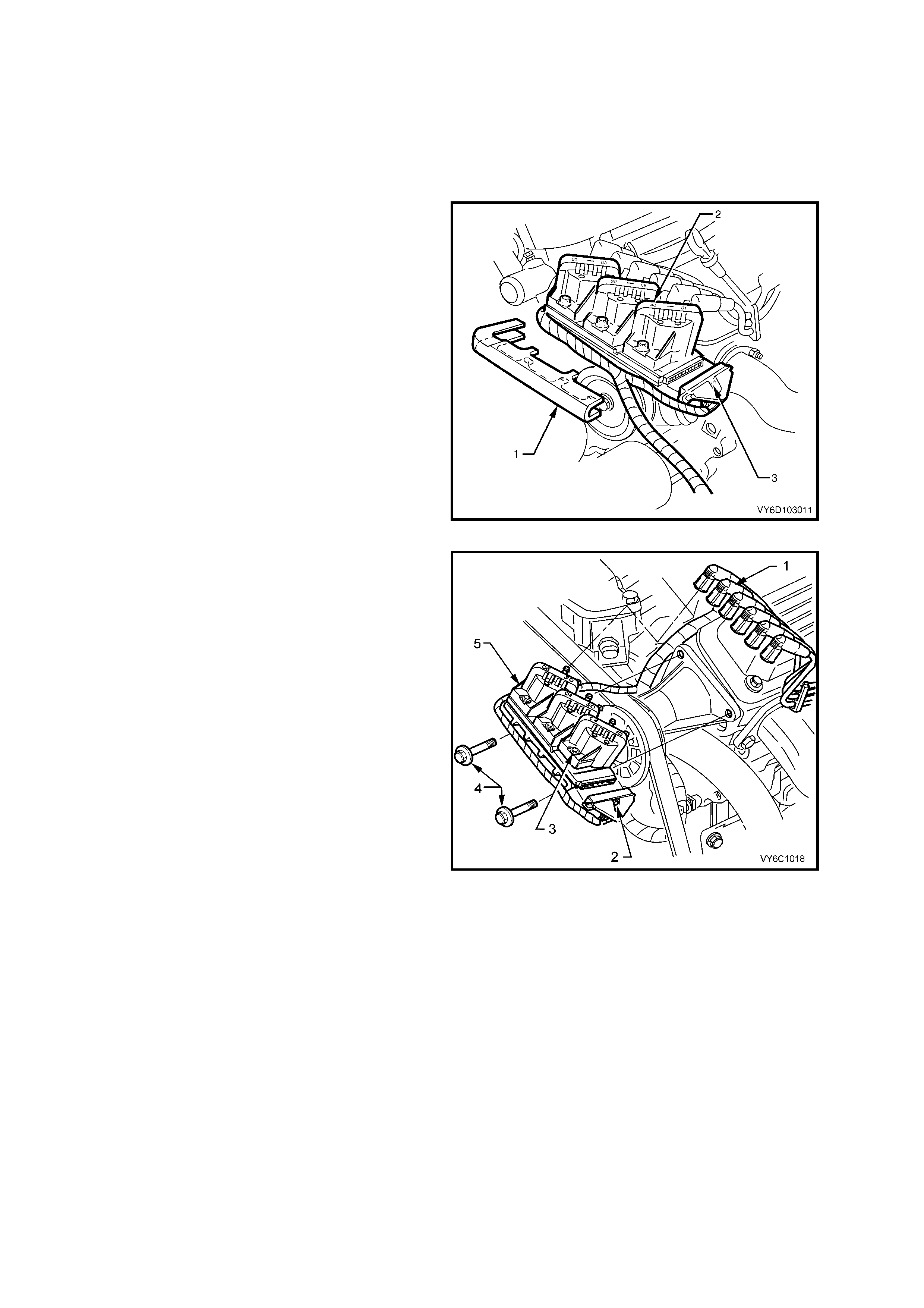

Legend:

1. Powertrain Control Module (PCM)

2. PCM Mounting Bracket

3. Left Hand Front Shroud Panel

Figure 6C1-3-2 – PCM Location

NOTE 1: To prevent internal PCM damage, the

ignition must be OFF when disconnecting or

reconnecting power to the PCM.

NOTE 2: The PCM (1) and mounting bracket are

located un der the left ha nd front shr oud panel trim ,

as shown.

Figure 6C1-3-3 – PCM Mounting

Techline

REMOVE

IMPORTANT: Remove any debris from the PCM connector surfaces before servicing the PCM.

NOTE: Do not touch the connector pins or soldered components on the circuit board. Otherwise possible

electrostatic discharge damage to the PCM could occur.

1. Disconnect battery ground lead.

IMPORTANT: Disconnection of the battery affects certain vehicle electronic systems. Refer to Section 00 CAUTIONS, 5.

Battery Disconnection Procedures before disconnecting the battery.

2. Remove left hand front shroud panel lower trim assembly (cowl panel trim), refer to

Section 1A3, INSTRUMENT PANEL and CONSOLE in the MY 2003 VY and V2 Series Service Information.

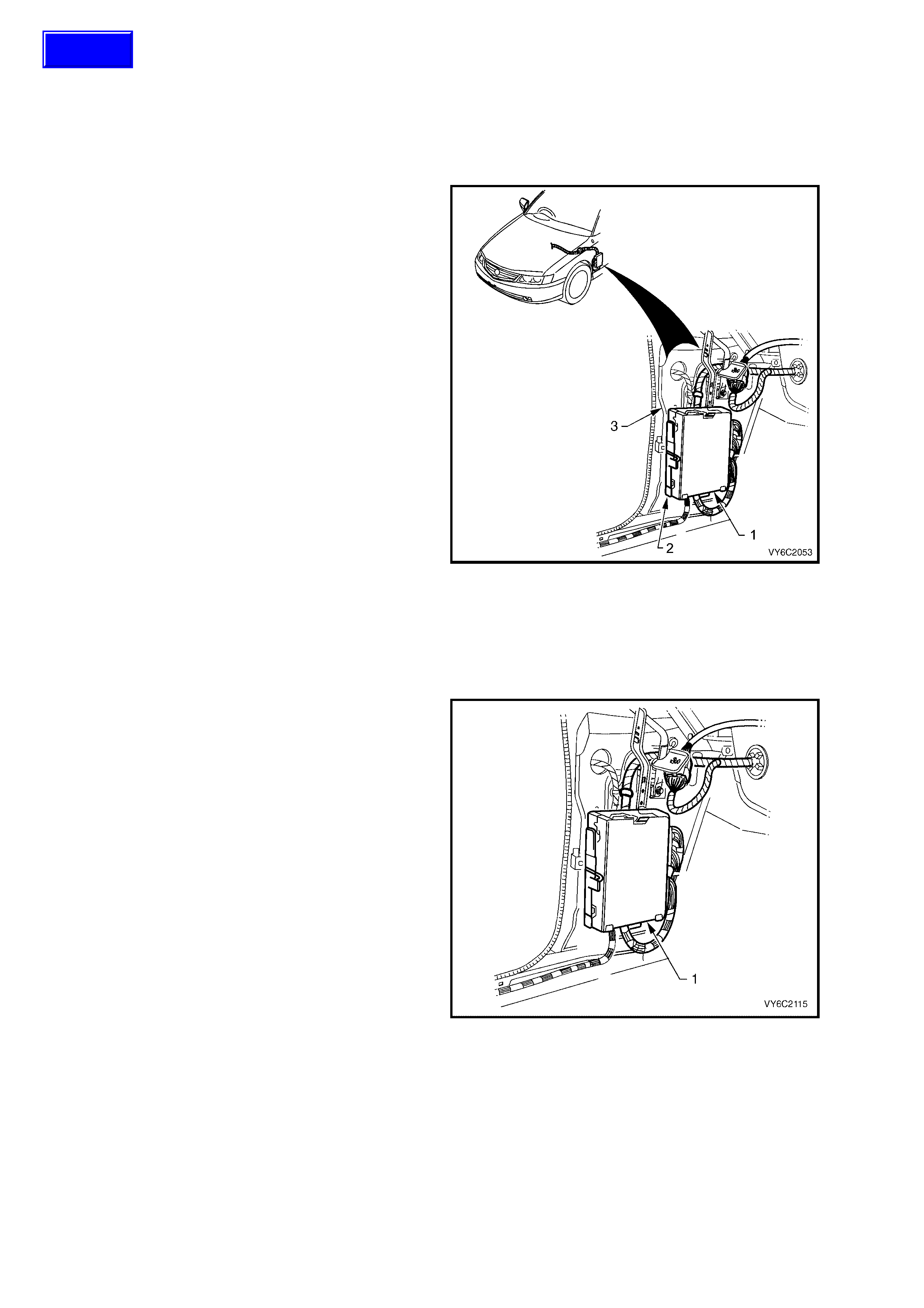

3. Lift up mounting bracket to PCM upper

retaining tang (1), pull PCM (2) out at the top

then up, to remove it from the mounting

bracket (3).

4. Remove wiring harness connectors (4) from

PCM, then remove the PCM (2) from the

vehicle.

IMPORTANT: The replacement PCM EEPROM

will not be programmed.

Figure 6C1-3-4 – PCM Removal

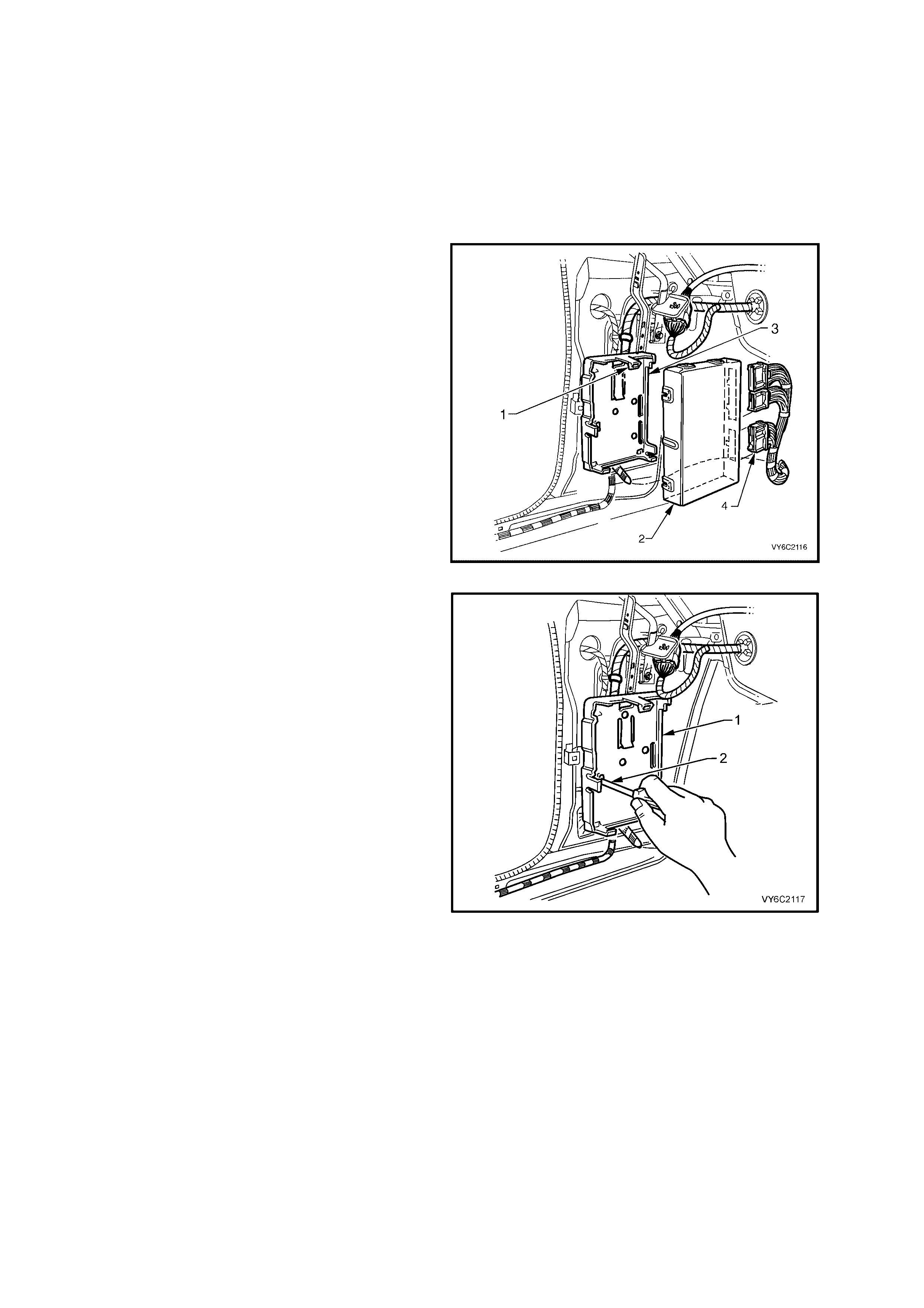

5. If required, remove PCM mounting bracket (1)

by inserting a screwdriver (2) into the retaining

tang slot, lever screwdriver to release tang.

Pull bracket out then down to release from the

cowl panel.

Figure 6C1-3-5 – PCM Mounting Bracket Removal

REINST ALL

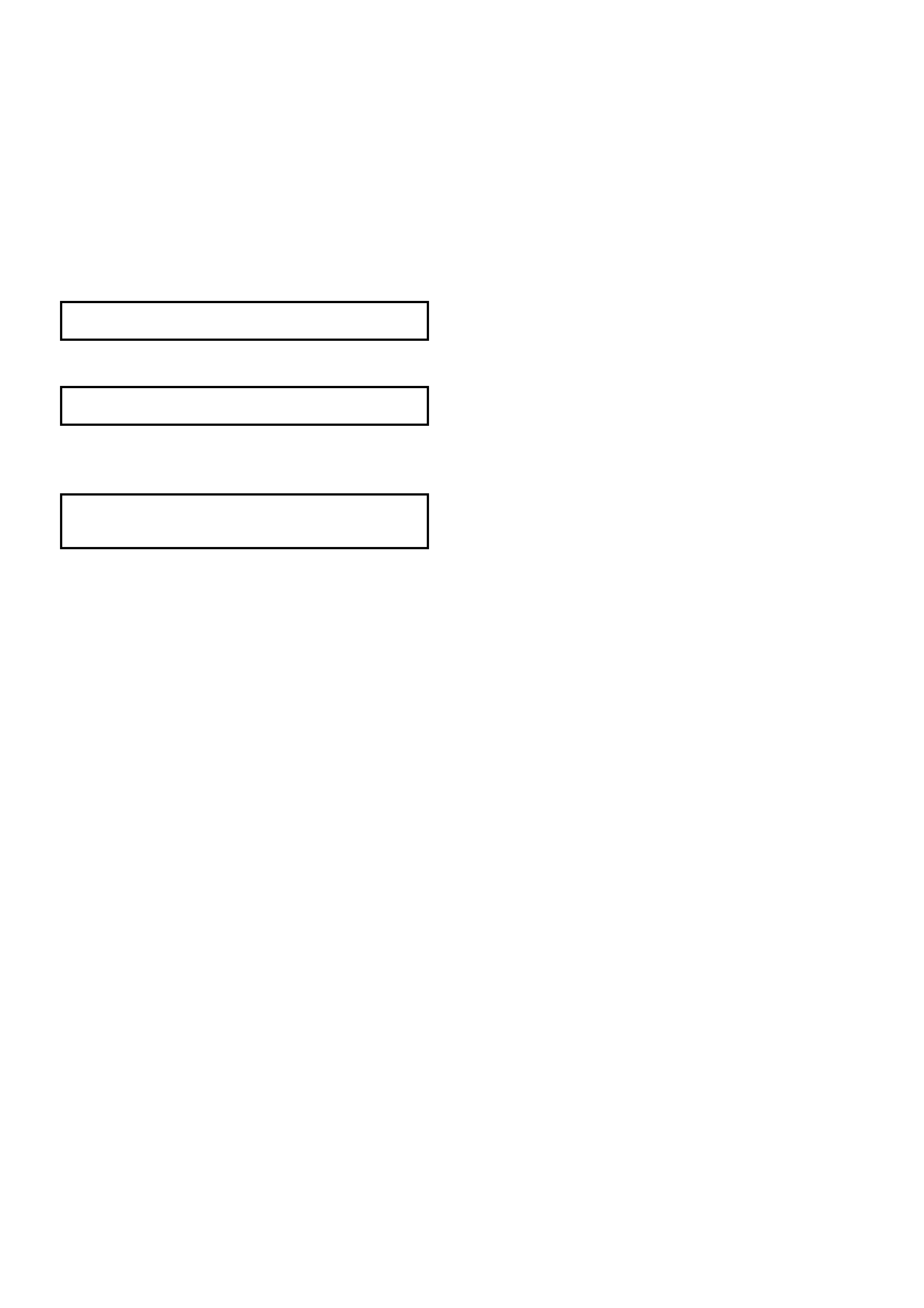

1. If removed, r eins tal l PC M mounting brac ket (1) ,

engaging bracket leg into slotted hole in cowl

panel. Lift up bracket and engage bracket

lower retainers and retaining tang into cowl

panel.

Figure 6C1-3-6 – PCM Mounting Bracket Reinstallation

2. Reconnect wiring harness connectors (4) to

PCM.

3. Assemble PCM (2) into mounting bracket (3),

ensurin g wiring harness is r outed in f ront of the

mounting bracket.

4. Reinstall cowl panel trim, Refer to

Section 1A3, INSTRUMENT PANEL AND

CONSOLE.

5. Reconnect batter y ground l ead.

6. Perform Service Programming if the PCM

was replaced with a new unit, refer to

Service Programming in this Section.

Otherwise start the vehicle and allow to idle.

Check vehicle for correct operation.

Figure 6C1-3-7 – PCM Mounting Bracket Reinstallation

SERVIC E PRO GRAMMING

NOTE: Follow th e program ming instru ctions c omplete ly an d do n ot ke y OFF dur ing progr am ming unles s ins tr uc ted.

If the key is turned OFF during programming, possible PCM damage may occur.

IMPORTANT: Do not disconnect Tech 2 during each programming step.

1. Ensure that the following conditions have been met, before starting this process:

a. The battery is fully charged, but not charging during programming.

b. The ignition is ON.

c. Ensure that all PCM connections are OK.

2. Connect Tech 2 to the vehicle and select Service Programming System (SPS) / Request Info and follow

instructions.

3. Connect Tech 2 to a PC with the Technical Information System (TIS) installed and download latest software

matching the vehicle. Refer to TIS terminal/equipment user instructions.

4. Connect Tech 2 to the vehicle again and select Service Programming System (SPS) / Program ECU.

5. If the PCM fails to program, proceed as follows:

a. Ensure that all PCM connections are OK.

b. Attempt to re-program the PCM. If the PCM still cannot be programmed correctly, replace the PCM and

program it according to this procedure.

IMPORTANT: O nce the ne w PCM has been pr ogram m ed, it m ust be Securit y Linked. Ref er to PCM Security Link

for linking procedure. If updating calibrations to the vehicle’s existing PCM hardware, no linking procedure is

necessary.

PCM SECURITY LINK

Once the PCM an d or BCM h ave been replace d, the ne w PCM and /or BCM must be securit y linked t o each ot her.

If this procedure is not performed, the vehicle will not crank.

PCM to BCM Link ing Proce dur e

Connect Tech 2 to DL C an d s elect “D iag nos tic / (3) 20 03 V Y C om modore / Body / Body Contro l M odu le / Securit y /

BCM Link to PCM” and follow Tech 2 instructions.

For additional information regarding Tech 2 and Tech 2 test modes (including this linking procedure), refer to

Tech 2 Diagnosis for BCM, in Section 12J BCM.

NOTE: If this vehicle is als o fitted with LPG, ref er to Section 8A2 LPG SY STEM , after the PCM is r eplaced and/or

reprogrammed for the LPG setup procedure. This must be performed whenever the PCM is replaced or

reprogrammed.

FUNCTIONAL CHECK

1. Clear the Diagnostic Trouble Codes (DTCs).

2. Perform the Powertrain OBD System Check.

3. Start the engine and idle for one minute.

4. Use Tech 2 to check for DTCs.

2.2 CAMSHAFT POSITION SENSOR

LT Section No. – 02-200

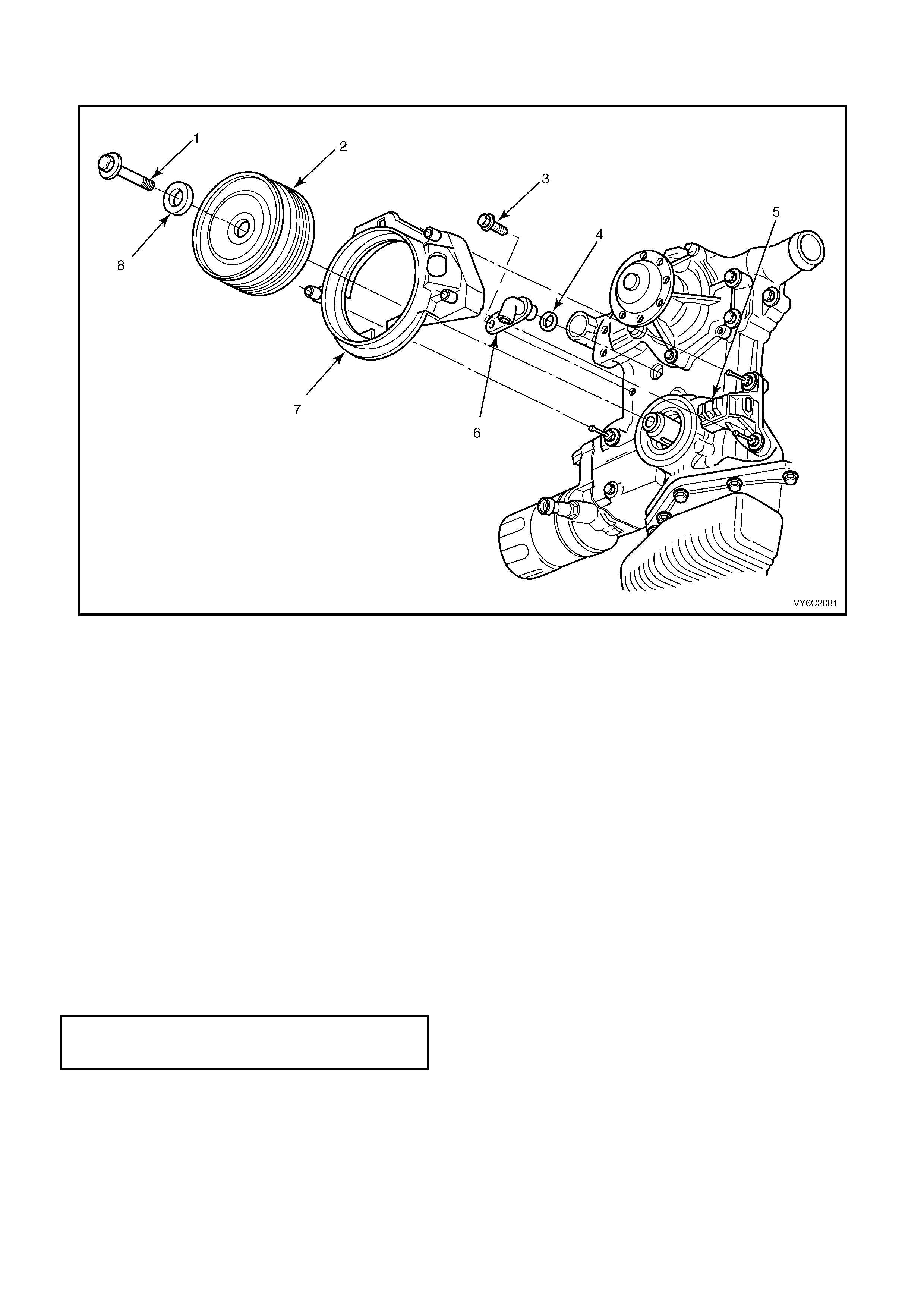

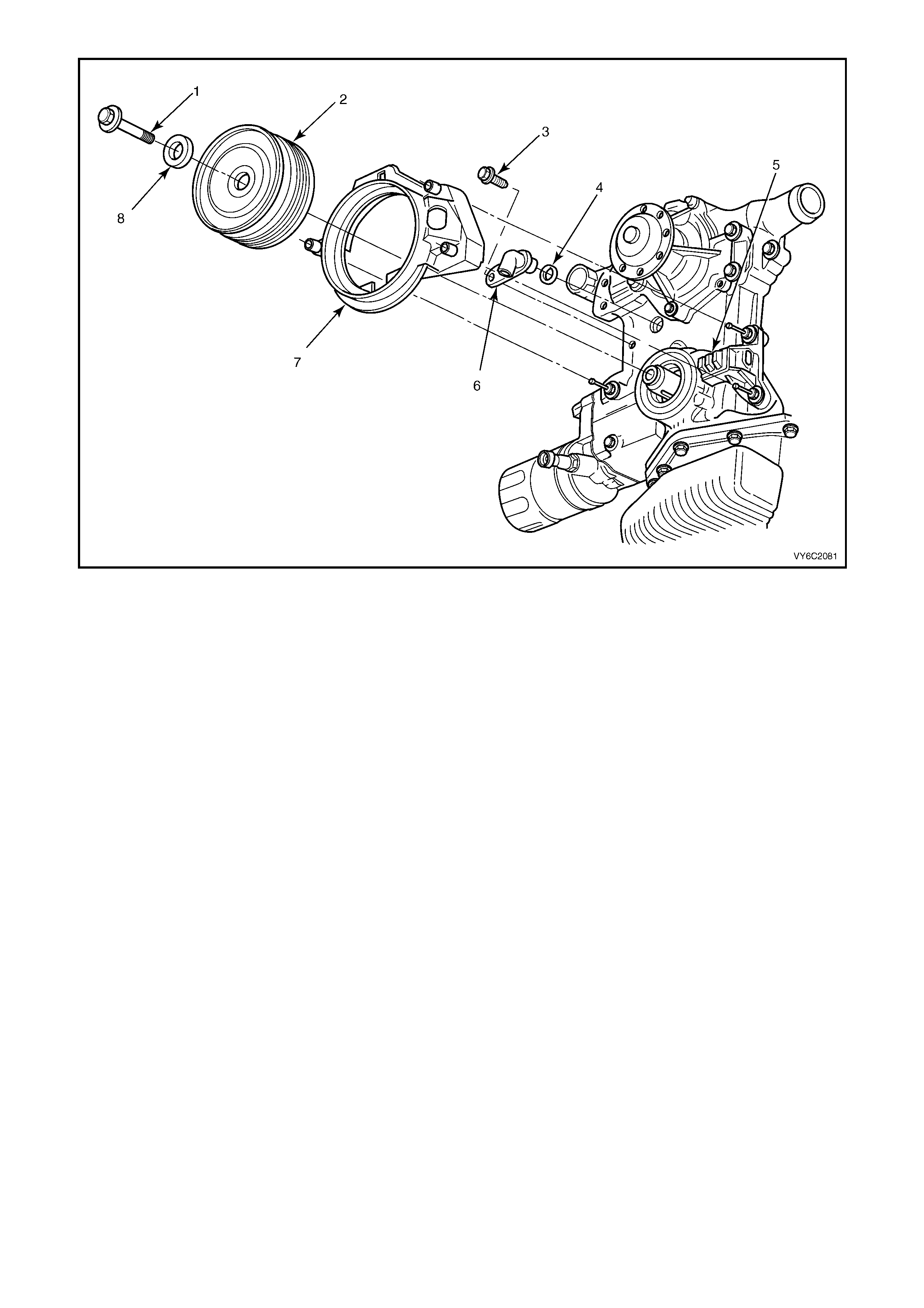

Figure 6C1-3-8 – Camshaft/Crankshaft Position Sensors

Legend

1. Bolt

2. Balancer - Crankshaft

3. Screw – Camshaft Sensor Retaining

4. O-Ring

5. Sensor – Crankshaft Position

6. Sensor – Camshaft

7. Shield – Crankshaft Position Sensor

8. Bolt

REMOVE

1. Disconnect battery ground lead.

IMPORTANT: Disconnection of the battery affects certain vehicle electronic systems. Refer to Section 00 CAUTIONS, 5.

Battery Disconnection Procedures before disconnecting the battery.

2. Lift up retaining tang and disconnect wiring harness connector from camshaft position sensor (6).

3. Remove camshaft position sensor to front cover retaining screw (3).

4. Remove camshaft position sensor and O-ring (4) from front cover.

REINST ALL

1. Apply light engine oil to O-ring (4) on new camshaft position sensor (6).

2. Assemble camshaft position sensor (6) into front cover hole.

3. Install camshaft position sensor (6) to front cover retaining bolt (3) and tighten to the correct torque

specification.

CAMSHAFT POSITION SENSOR

RETAINING SCREW

TORQUE SPECIFICATION 11 Nm

4. Reconnect wiring harness connector to camshaft position sensor (6).

5. Reconnect batter y ground l ead.

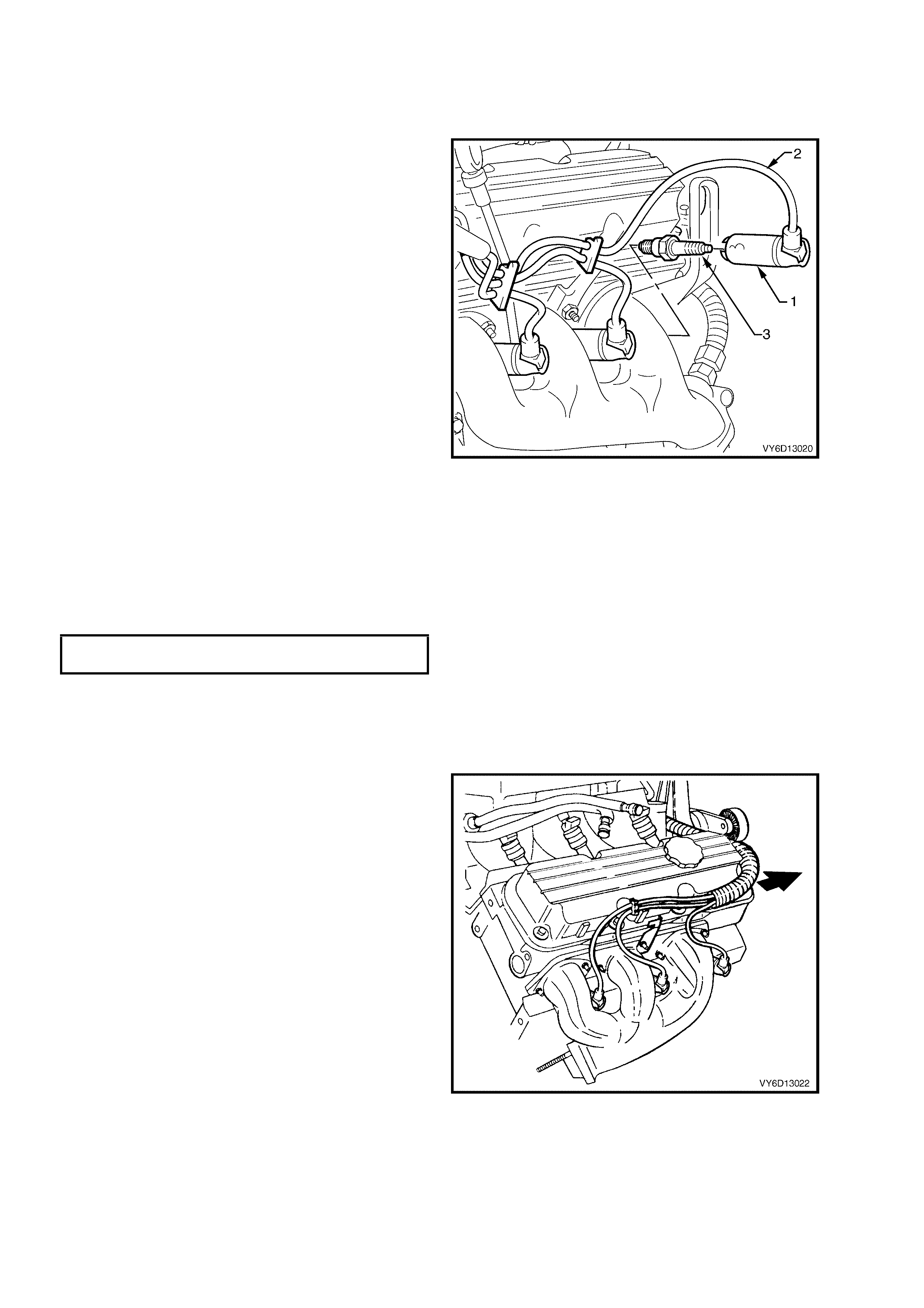

2.3 ENGINE COOLANT TEMPERATURE (ECT) SENSOR

LT Section No. – 02-000

IMPORTANT: Care must be taken when handling the PCM engine coolant sensor. Damage to the sensor will affect

the operation of the engine management system. Ensure that the correct sensor is located before service is

attempted. The ECT sensor is located in the front of the intake manifold below the engine thermostat housing

(Refer to Figure 6C1-3- 1 0).

NOTE: The Engine C oolant Temperature (ECT ) sensor (2) is installed in to a "wet" engine coolant passage (in the

intake m anifold, b elow t he ther m ostat housing) . Drain t he engin e coola nt befor e removing the E CT sensor from the

engine. Position a coolant drain pan appropriately, then loosen lower radiator hose at the radiator to drain the

coolant.

REMOVE

1. Disconnect battery ground lead.

IMPORTANT: Disconnection of the battery affects certain vehicle electronic systems. Refer to Section 00

CAUTIONS, 5. Battery Disconnection Procedures before disconnecting the battery.

2. De-pressurise engine cooling system by removing the radiator cap in two stages.

CAUTION: Do not remove radiator cap while the engine coolant temperature is above 50°

°°

° C.

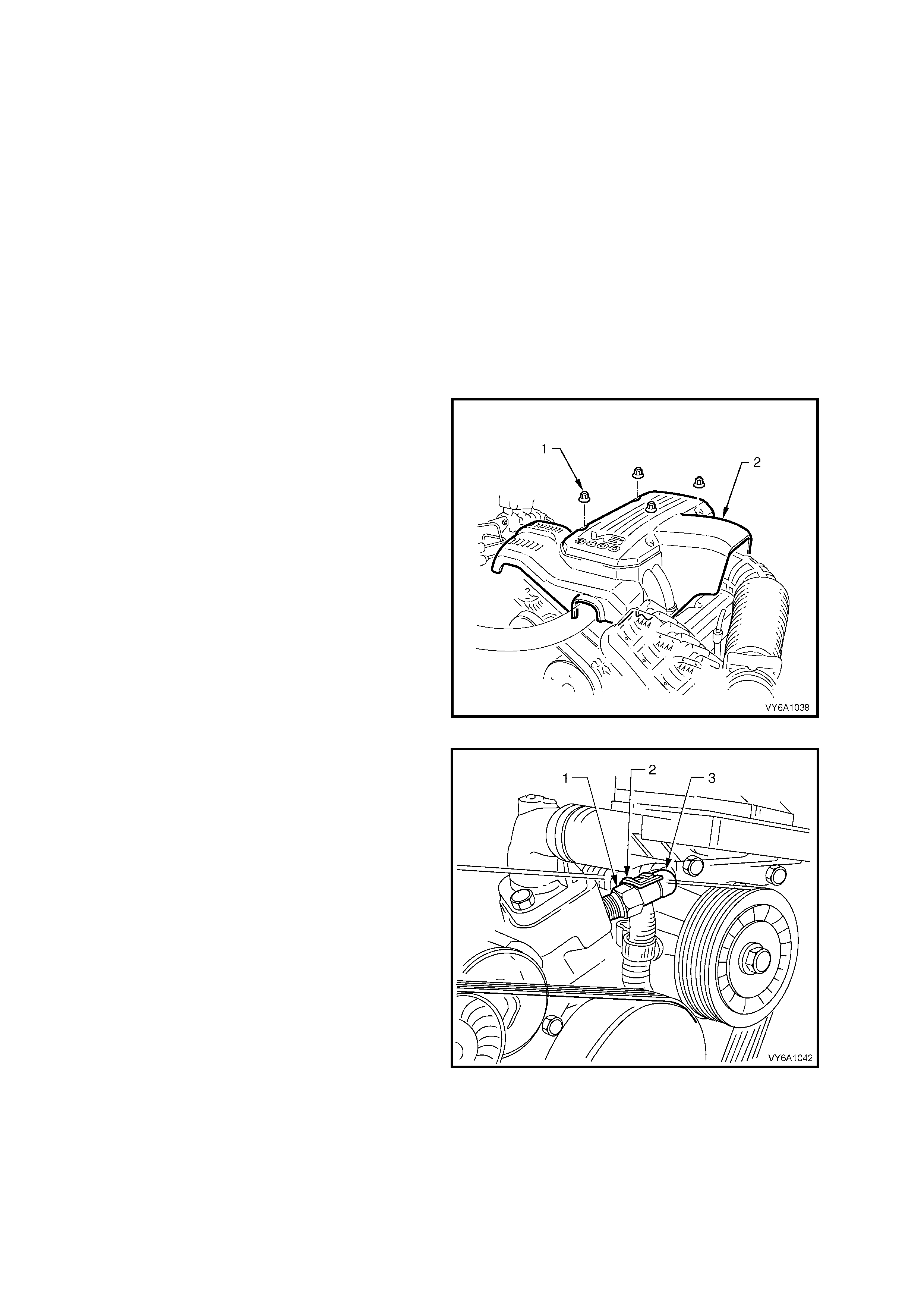

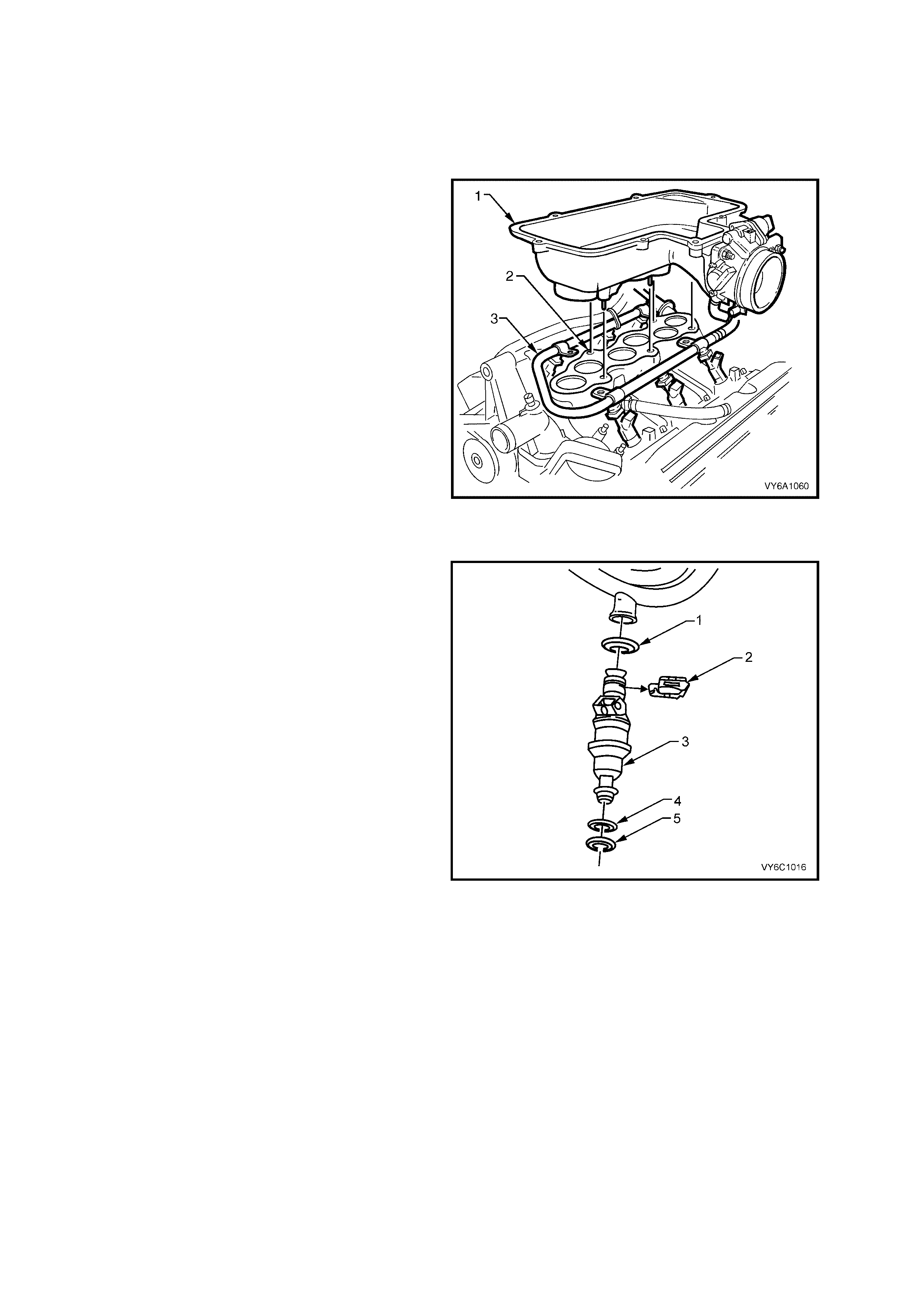

3. Remove four dome nuts (1) securing the

engine dress cover assembly (2) to the intake

manifold studs, then remove the cover

assembly.

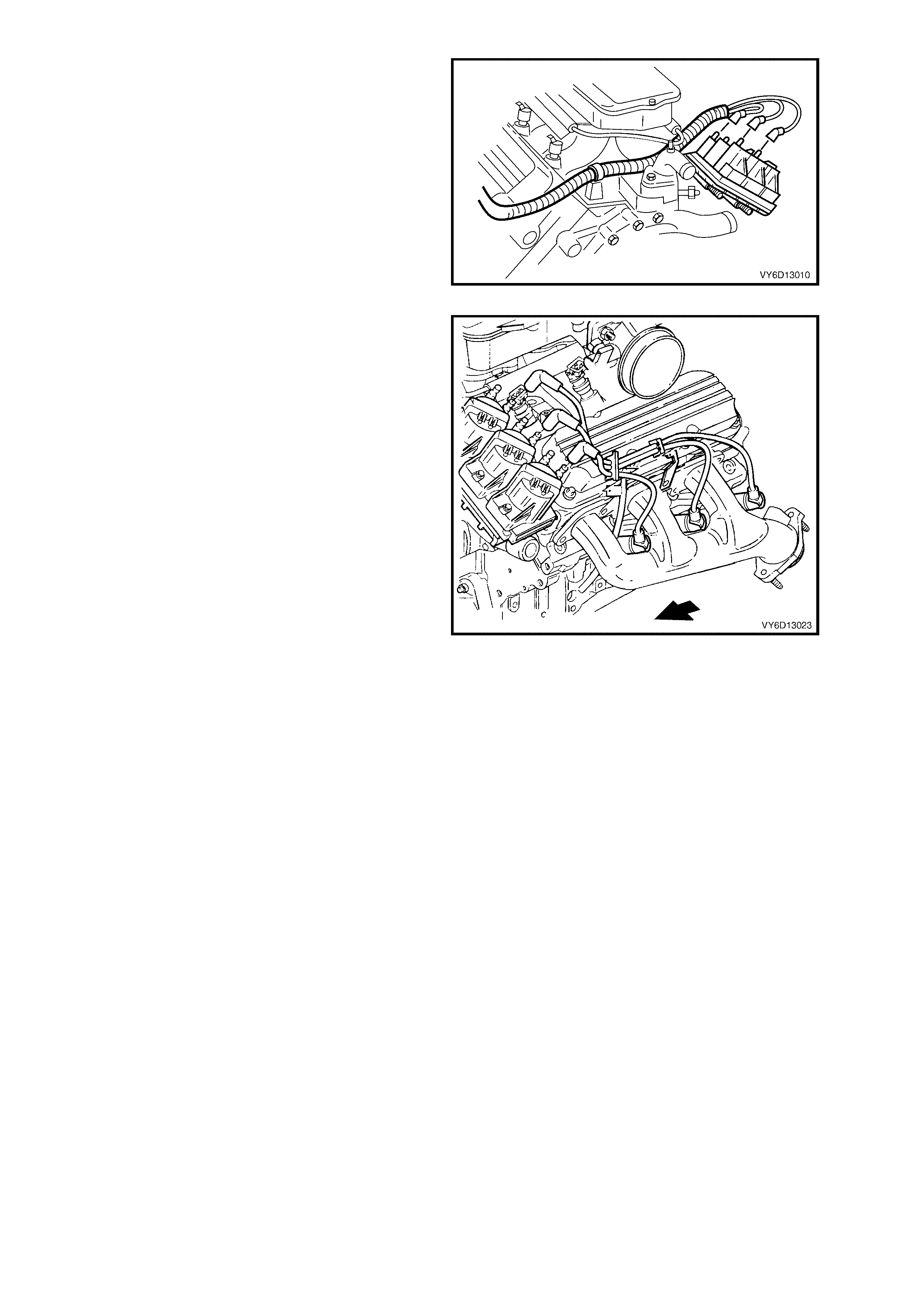

Figure 6C1-3-9 – Engine Dress Cover - V6 Engine

4. Place a suitable coolant drain pan under the

vehicle, then loosen lower radiator hose at the

radiator to drain the engine coolant.

5. Lift up retaining tang (2) and disconnect wiring

harness connector (3) from ECT sensor (1). Lift

connector up away from sensor.

6. Carefully move powertrain wiring harness

down und er the ECT sens or to allow acc ess to

the sensor.

7. Using a 19 mm ring spanner, carefully loosen

and remove PCM, ECT sensor.

Figure 6C1-3-10 – ECT Sensor Location

REINST ALL

1. Apply Loctite 242 (GM Specification 998 5283) sealant to the cleaned sensor threads.

2. Install ECT sensor into intake manifold and tighten to the correct torque specification.

ECT SENSOR TO INTAKE MANIFOLD

TORQUE SPECIFICATION 18 Nm

3. Reconnect wiring harness connector onto ECT sensor.

NOTE: Recheck that wiring harness connector and harness are correctly positioned. The accessory drive belt

passes ver y close to the tem perature sensor conn ector. Futur e damage to the harness could occur if not cor rectly

positioned now.

4. Reconnect batter y ground l ead.

5. Refill the engine coolant system, Refer to Section 6B1, ENGINE COOLING - V6 ENGINE .

6. Reinstall engine dress cover to the intake manifold, ensuring that stud grommets in dress cover remain in

place. Tighten securing dome nuts to the correct torque specification.

ENGINE DRESS COVER TO INTAKE

MANIFOLD DOME NUT

TORQUE SPECIFICATION 5 Nm

2.4 INTAKE AIR TEMP ERATURE (IAT) SENSOR

LT Section No. – 03-250

IMPORTANT: Care must be taken when handling the IAT Sensor. Damage to the IAT Sensor will affect proper

operation of the fuel control system.

REMOVE

1. Disconnect battery ground lead.

IMPORTANT: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00 CAUTIONS, 5. Battery Disconnection Procedures before disconnecting the battery.

2. Lift up tang on IAT sensor wiring harness

connector (1) and pull connector from

sensor (5).

3. Loosen intake air duct adaptor clamp that is

located closest to air cleaner assembly.

4. Disconnect air duct, with mass air flow sensor

attached, from air cleaner upper housing.

5. Unclip 5 retaining clips holding the air cleaner

upper housing (2) in place.

6. Separate the upper and lower air cleaner

housings.

IMPORTANT: Air filter should remain in the lower

housing.

7. Remove air cleaner upper housing and place

on bench.

8. Using a pair of side cutters, cut across the IAT

sensor retainer (4) to remove it. Once

removed, discard retainer.

9. Pull out IAT sensor (5) from air cleaner upper

housing.

Figure 6C1-3-11 – IAT Sensor Removal

REINST ALL

1. Push new IAT s ensor (5) into air clea ner up per housin g (2) , with triangular ta ng o n the mounting f lan ge loc ati ng

on the mating rib (3) of the air cleaner upper housing.

2. Position the upper air cleaner housing assembly, with the IAT sensor on the work bench, pushing up into the

air cleaner upper housing.

3. Position new retainer (4) onto IAT sensor and then using a 20 m m socket, push the retainer full y onto the IAT

sensor.

4. Assemble the air filter element into the air cleaner upper housing and place the upper housing onto the air

cleaner lower air cleaner housing, ensuring that air filter element remains in position.

5. Snap 5 retainer clips up into place over the top of the air cleaner upper housing.

6. Reconnect wiring harness connector (1) to IAT sensor (5).

7. Carefully assemble intake air duct and mass air flow sensor onto air cleaner upper housing.

NOTE: Align notch on air cleaner housing adaptor with notch in air duct adaptor and notch in clamp.

8. Tighten air duct clamp securely.

9. Check that mass air flow sensor wiring harness connector has remained firmly in place.

2.5 MASS AIR FLOW (MAF) SENSOR

LT Section No. – 02-000

NOTE: Care must be taken when handling MAF sensor. Damage to MAF sensor will affect proper operation of

PCM control.

REMOVE

1. Disconnect battery ground lead.

IMPORTANT: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00 CAUTIONS, 5. Battery Disconnection Procedures before disconnecting the battery.

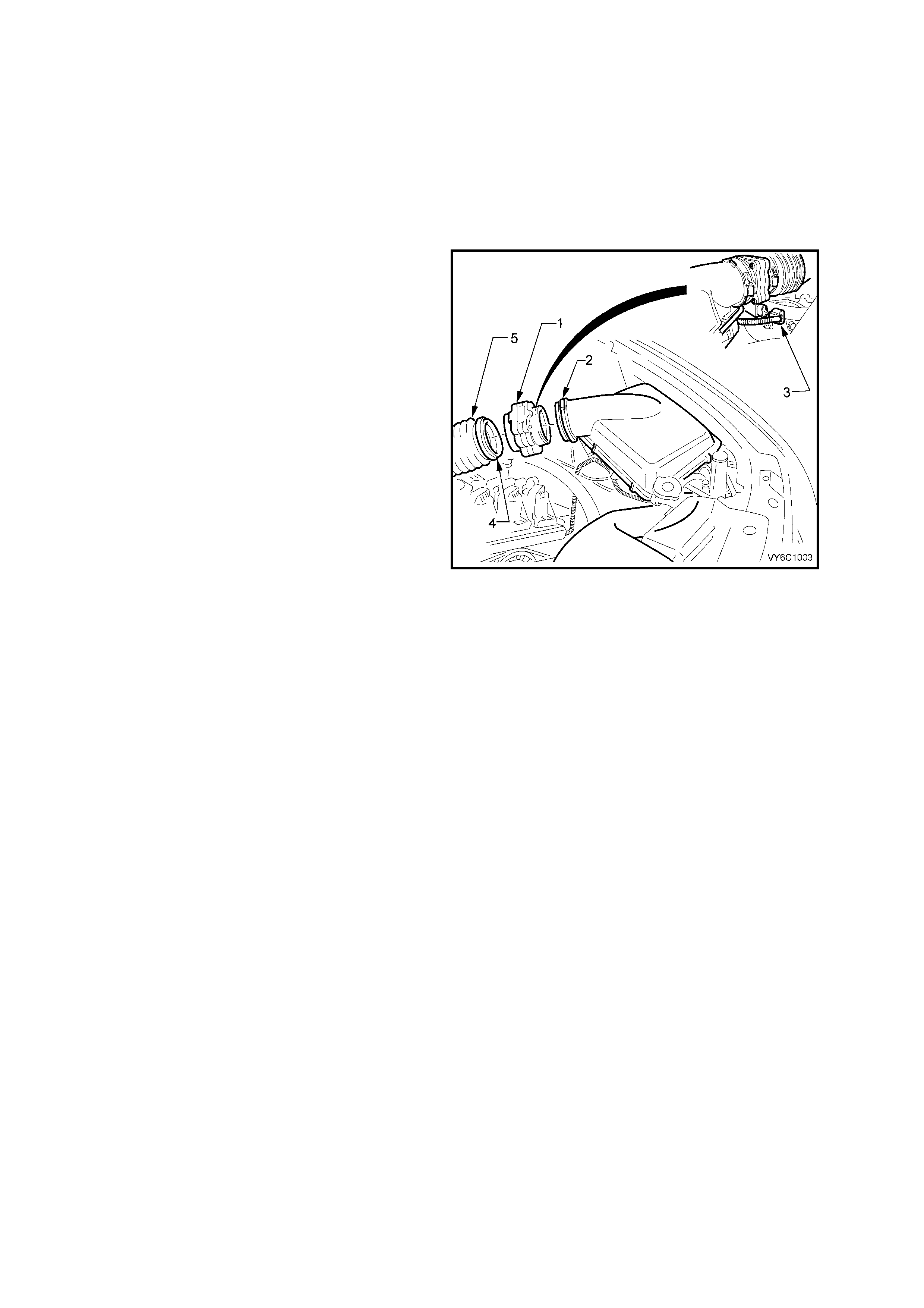

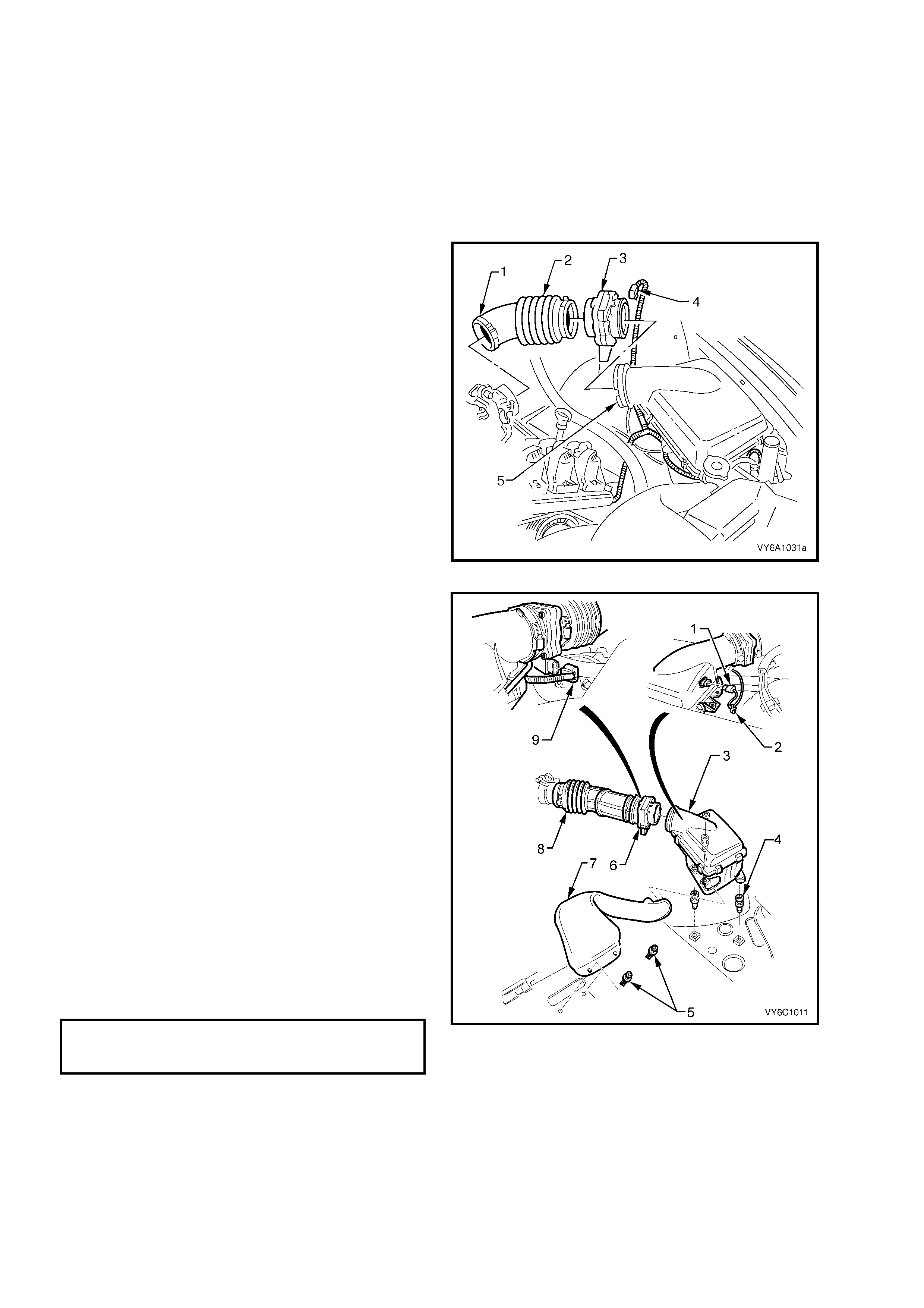

2. Lift up tang on MAF sensor wiring harness

connector (3) and pull connector from

sensor (1).

3. Loosen clamp on air duct adaptor (2), closest

to MAF sensor (1).

4. Loosen clamp (4) on air duct (5) at MAF sensor

(1) and pull back air duct (5) from sensor.

IMPORTANT: Air duct adaptor (between the air

cleaner and MAF sensor), both clamps, air duct

and MAF sensor itself, all have locating notches.

5. Remove MAF sensor (1) from air duct

adaptor (5).

REINST ALL

1. Reinstall MAF sensor (1) into air duct adaptor

(5) and air duct, aligning all notches.

2. Reinstall clamps, aligning notches, tighten

clamps securely.

3. Reconnect MAF sensor wiring harness

connector (3). Reconnect battery ground lead.

4. Start vehicle and check for air leaks.

Figure 6C1-3-12 – MAF Sensor Removal

2.6 OXYGEN SENSOR

LT Section No. – 00-450

NOTE 1: The oxygen sensor uses a permanently attached pigtail and connector. This pigtail should not be

rem oved from the ox ygen sens or. Damage or r emova l of the pigta il or connector will affec t proper operation of the

oxygen sensor.

NOTE 2:Take care when handling the oxygen sensor. The in-line electrical connector and louvred end must be

kept free of grease, dirt or other contaminants. Avoid using any cleaning solvents. Do not drop or roughly handle

the oxygen sensor.

NOTE 3: The ox ygen sens or m ay be diff icult to remove when e ngine temper ature is below 60 ° Celsius. Excessive

force may damage threads in the exhaust pipe or sensor.

NOTE 4: Under no c ircumstances ar e the wiring harnes s connectors as sociated with the ox ygen sens or circuits to

be sealed in any way, by using grease or other substance. To do so, would result in an inadequate supply of

refer ence air to be able t o reach the atm ospheric reference c avity of eac h sensor, res ulting in a DTC to be s et. If a

flexible sealant is used (i.e. grease), then this would be drawn into the sensor cavity, poisoning the sensor,

resulting in a premature failure. Also, should connector damage be evident, then the sensor and lead must be

replace d, as soldering of the wiri ng wou ld also neg ate the ‘br eat hi ng ’ capa bility of the sensor wiri ng.

REMOVE

1. Disconnect battery ground lead.

IMPORTANT: Disconnection of the battery affects

certain vehicle electronic systems. Refer to

Section 00 CAUTIONS, 5. Battery

Disconnection Procedures before disconnecting

the battery.

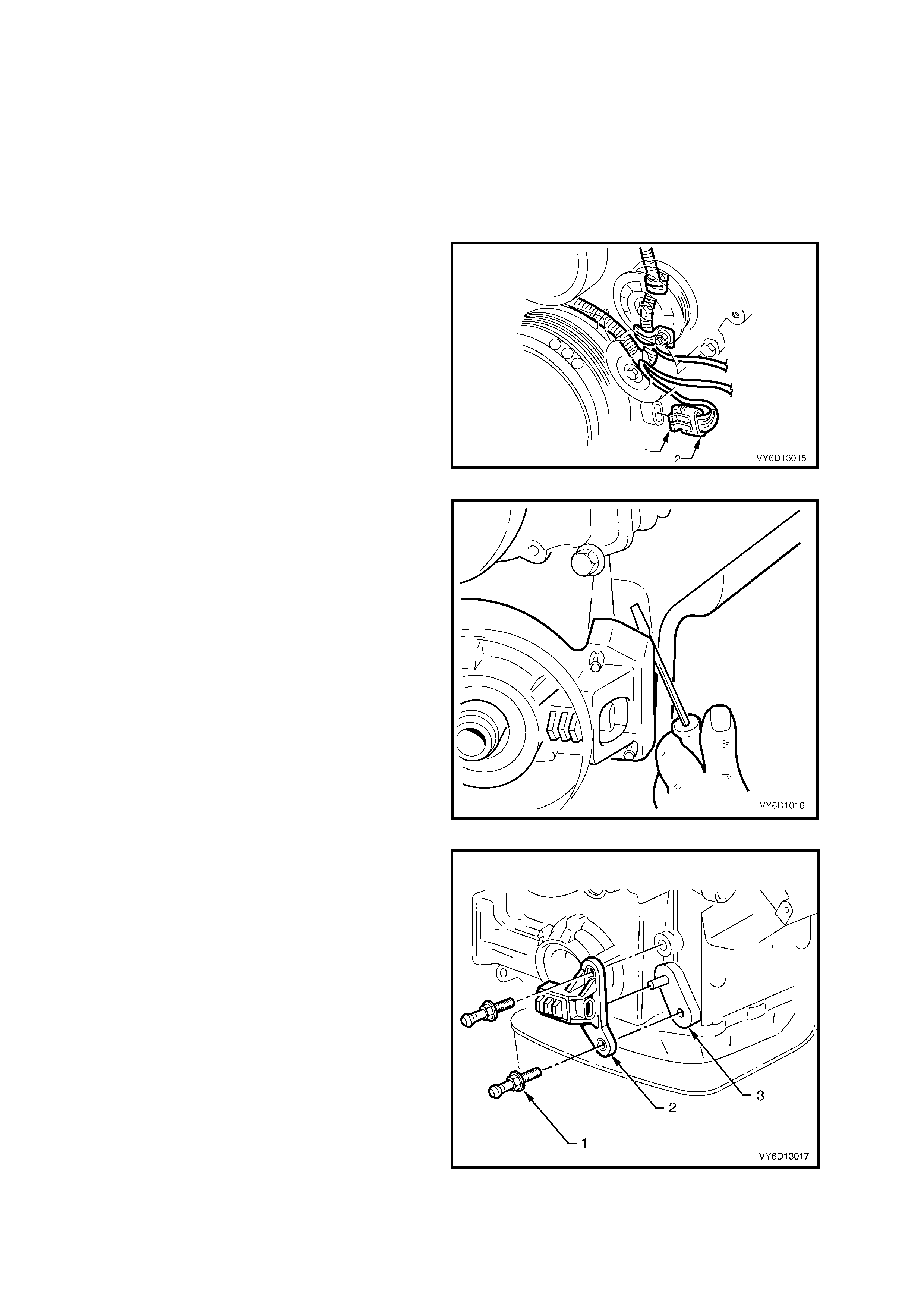

2. Lift up retaining tang on oxygen sensor wiring

harness connector (1) and pull connector from

sensor pigtail connector.

For RH sensor, the connector (1) is located at

the rear of the RH cylinder head and is

accessed from the rear of the engine

compartment. The sensor pigtail leads are

further retained by a c lip attac hed to the torque

converter housing (automatic transmission).

For LH sensor (refer Figure 6C3-1-14), the

connector is located at the rear of the LH

cylinder head and is accessed from the rear of

the engine compartment.

3. Raise vehicle and support on safety stands.

Refer to Section 0A GENERAL

INFORMATION in the MY 2003 VY and V2

Series Service Information, for the location of

jacking and support points.

4. Carefully unscrew oxygen sensor (2) from

exhaust pipe referring to the ‘NOTES’ above.

NOTE: While the RHD vehicle arrangement is

shown, the LHD is similar.

Figure 6C1-3-13 – RH Sensor Location

REINST ALL

NOTE 1: A special anti-s eize c ompound is us ed o n

the oxygen sensor threads. The compound

consists of a liquid graphite and very small glass

beads. The graphite will burn away, but the glass

beads will remain, making the sensor easier to

remove.

NOTE 2: Genuine replacement sensors will

already have the compound applied to the threads.

If a sensor is removed from an engine, and, if for

any reason it is to be reinstalled, the threads

MUST have the specified anti-seize compound

applied before reinstallation.

NOTE: Specified anti-seize compound is available

from authorised Parts Outlets as part number

5613695.

1. If necessary, coat the cleaned oxygen sensor

threads with the specified anti-seize

compound.

2. Install oxygen sensor (2) into exhaust pipe and

tighten to the correct torque specification.

EXHAUST GAS OXYGEN SENSOR

TORQUE SPECIFICATION 45 Nm

3. Remove safety stands and lower the vehicle.

4. Reconnect oxygen sensor wiring harness

connector (1).

IMPORTANT: Ensure that the RH sensor pigtail

leads are retained by a clip attached to the torque

converter housing (refer Figure 6C1-3-13).

5. Reconnect batter y ground l ead.

Figure 6C1-3-14 – LH Sensor Location

2.7 THROTTLE POSITION (TP) SENSOR

LT Section No.– 03-300

REMOVE

1. Disconnect battery ground lead.

IMPORTANT: Disconnection of the battery affects certain vehicle electronic systems. Refer to Section 00

CAUTIONS, 5. Battery Disconnection Procedures before disconnecting the battery.

2. Remove four dome nuts securing the engine dress cover assembly to the intake manifold studs, then remove

the cover assembly . Refer to Figu re 6C1-3-9.

3. Lift up retaining tang on TP sensor wiring

harness connector and pull connector from

sensor (1).

4. Remove the two TP sensor to throttle body

attaching screws (4).

5. Remove sensor (1) from throttle body (2)

taking care not to lose the drive adaptor (3).

IMPORTANT: The "drive adaptor" (3) is a plastic

cover th at loose ly slid es ov er the end of the thr ottle

shaft, on the TP sensor side of the throttle body. It

is captured when the TP sensor is in position on

the throttle body. The drive adaptor could fall from

the throttle shaft after the TP sensor is removed.

Ensure that the drive adaptor is not lost.

Figure 6c1-3-15 – TP Sensor Removal

REINST ALL

1. Check that the drive adaptor (3) is in place on the throttle valve shaft, refer to the previous ‘IMPORTANT’

statement relating to the drive adaptor.

2. With throttle va lve i n the no rmall y closed i dl e pos i tio n, i nst all TP sens or ( 1) on to t hrottl e v al ve shaf t an d thr ot tle

body at a position 30° clockwise past throttle body attaching screw holes.

3. Rotate TP sensor anti-clockwise on throttle body, and install TP sensor attaching screws and tighten to the

correct torque specification.

TP SENS O R TO TH R OTTL E B ODY

ATTACHING SCREW

TORQUE SPECIFICATION 1.2 Nm

4. Reconnect TP sensor wiring harness connector.

5. Reinstall engine dress cover to the intake manifold, ensuring that stud grommets in the dress cover remain in

place . Tighten securing dome nuts to the correct torque specification.

ENGINE DRESS COVER TO INTAKE

MANIFOLD DOME NUT

TORQUE SPECIFICATION 5 Nm

6. Reconnect batter y ground l ead.

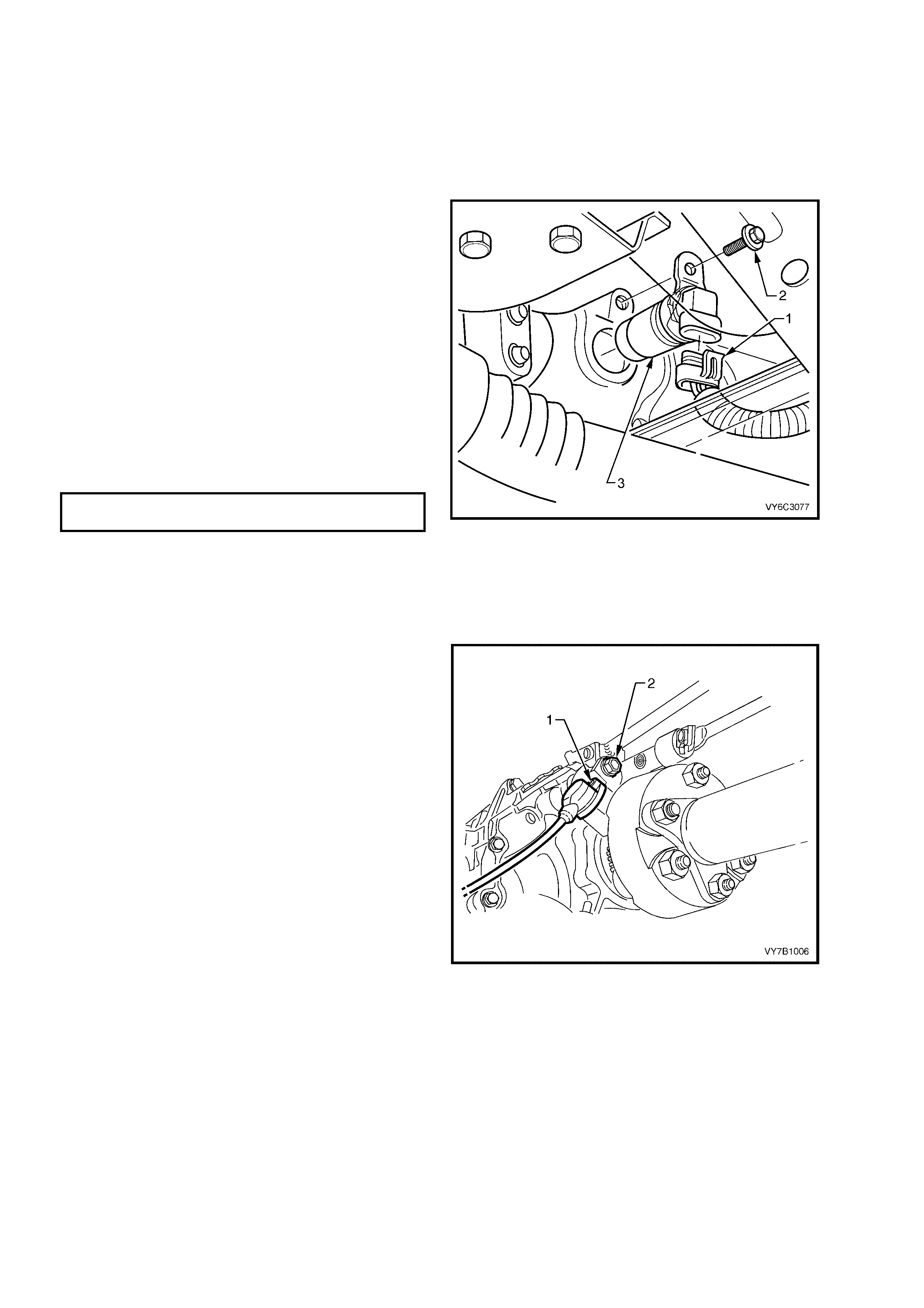

2.8 VEHICLE SPEED SENSOR

LT Section No.– 04-075

REMOVE

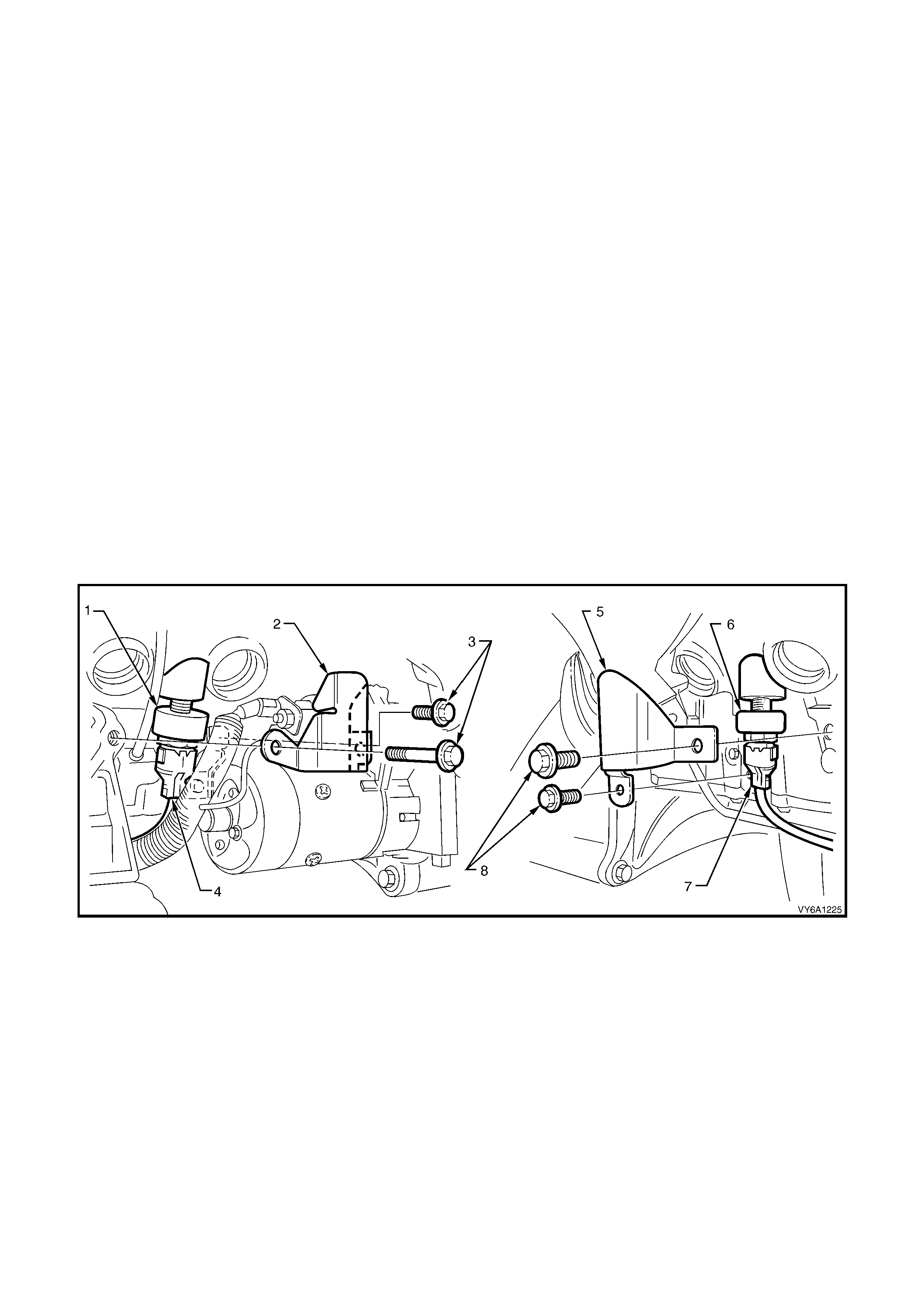

Automatic Transmission

1. Raise rear of vehic le an d suppor t on saf ety st ands. R ef er to Section 0 A GENERAL INFORM ATION in t he M Y

2003 VY and V2 Series Service Information, for the location of jacking and support points.

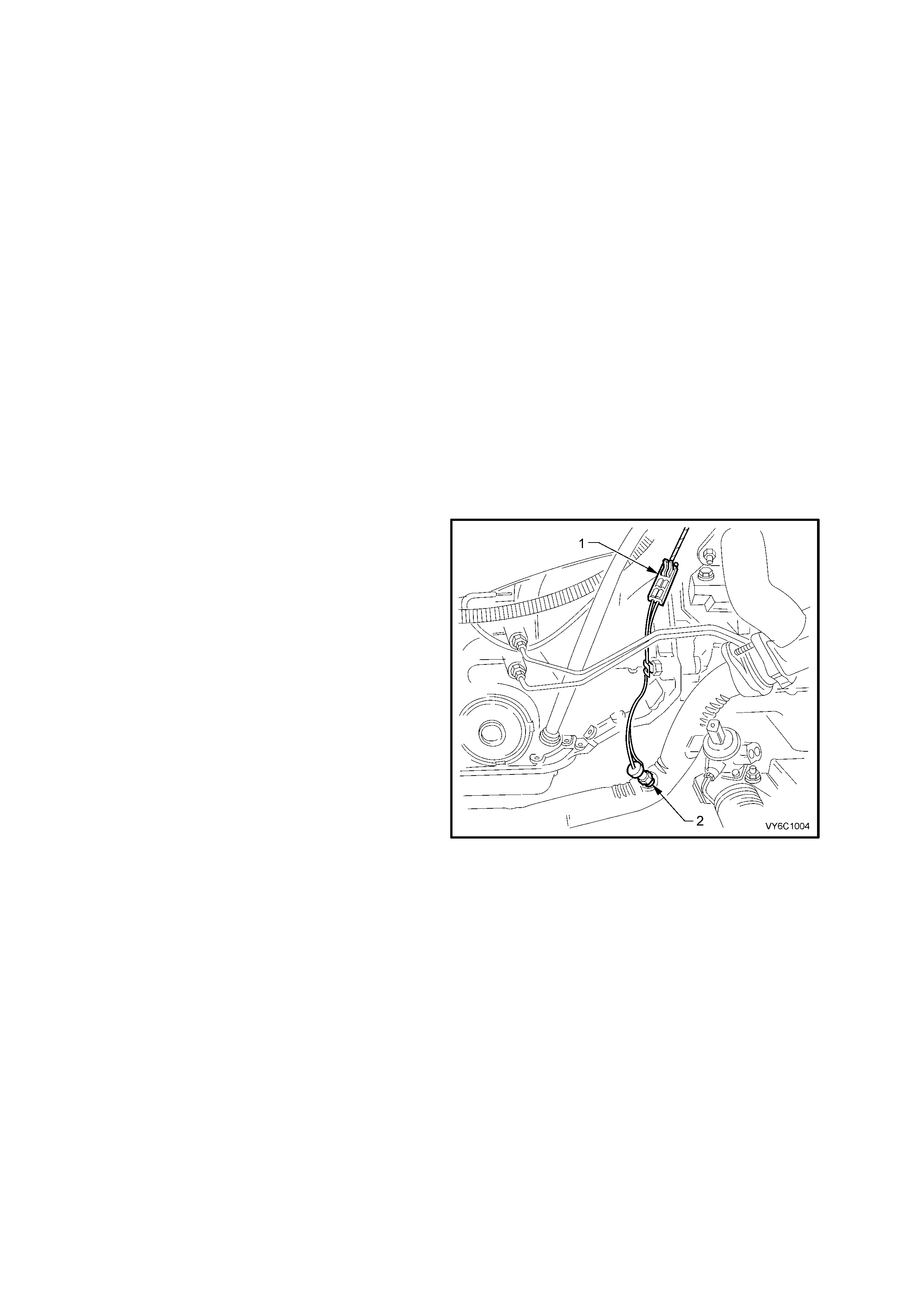

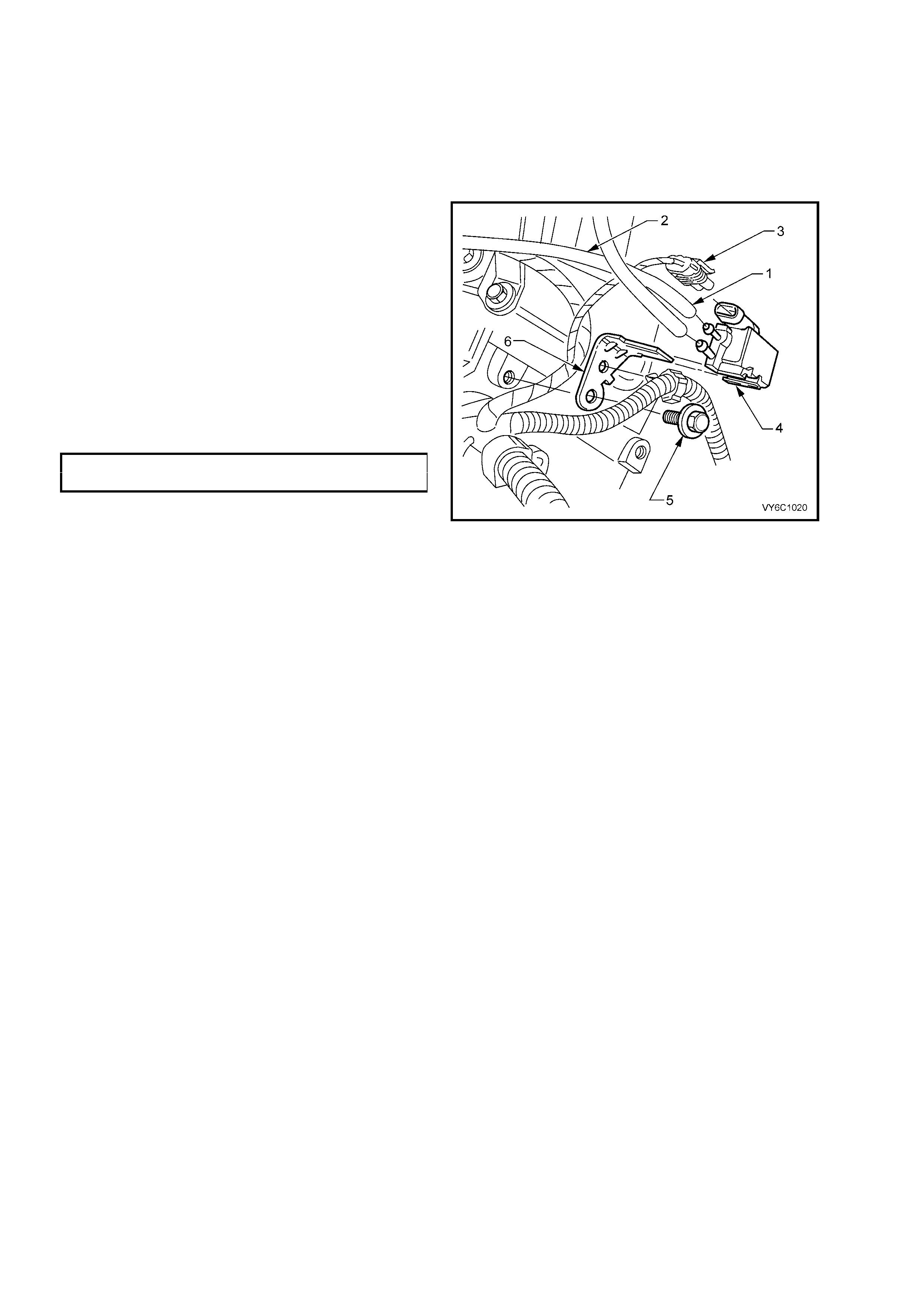

2. Lift up tang on VSS wiring harness connector

(1) and pull connector from VSS (3).

3. Remove VSS to transmission extension

housing screw (2).

4. Remove VSS and O-ring seal from extension

housing by slowly prying out sensor with a flat

screwdriver.

REINST ALL

1. Coat the VSS O-ring seal with a thin film of

transmission fluid.

2. Install new VSS and O-ring into transmission

extension housing.

3. Reinstall retaining screw (2) and tighten to the

correct torque specification.

VSS RETAINING BOLT

TORQUE SPECIFICATION 11 Nm

4. Reconnect wiring harness connector (2) to

VSS (3).

5. Remove safety stands and lower vehicle.

Figure 6C1-3-16 – VSS Location Automatic Transmission

Manual Transmission

For vehicle speed sensor removal and

reinstallation, Refer to 3.2 Speed Sensor and/or

Bracket, in Section 7B1 MANUAL

TRANSMI SSIO N – V6 EN GI NE.

Figure 7C1-3-17 VSS Location Manual Transmission

3. FUEL CONTROL SYSTEM

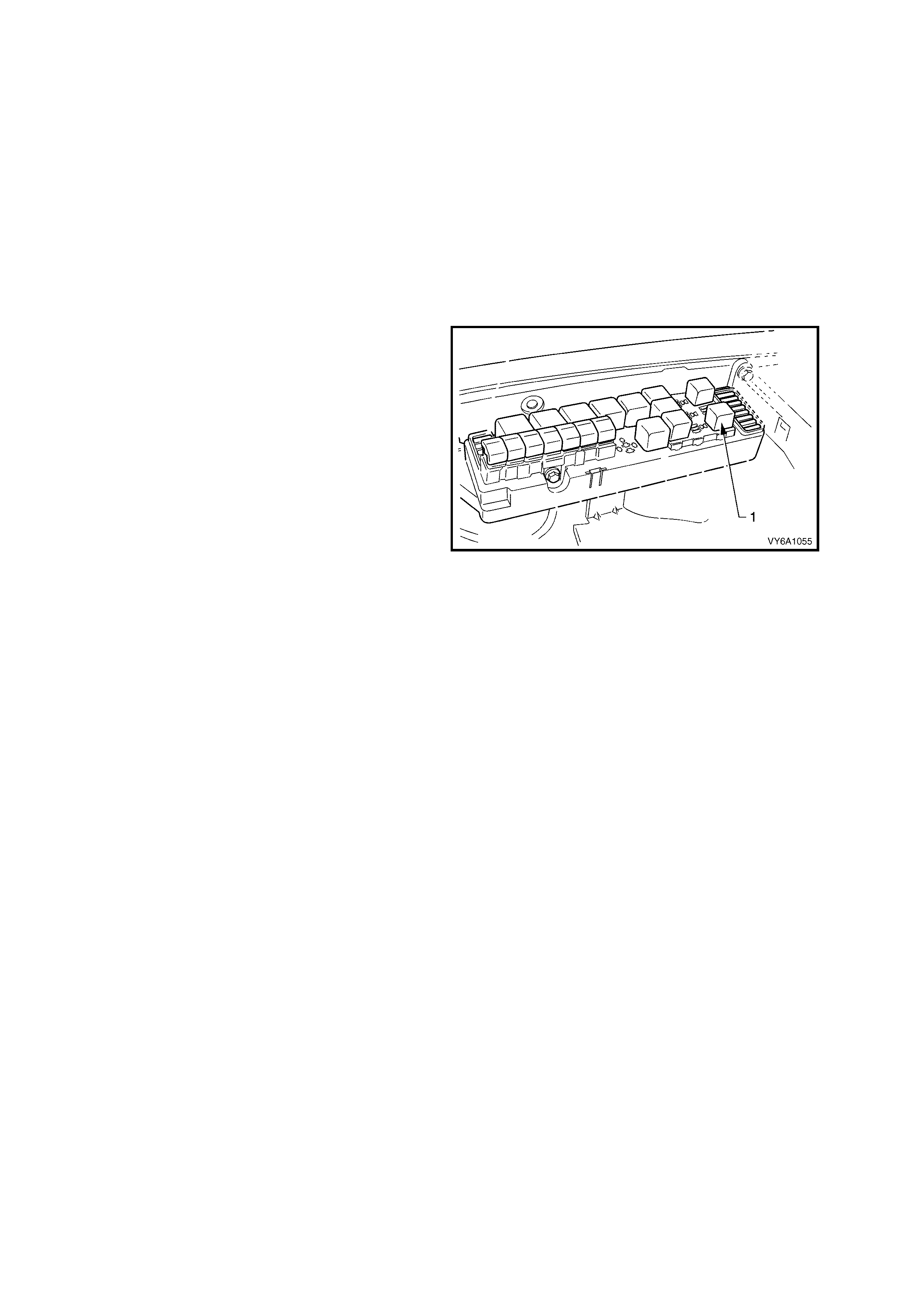

3.1 FUEL PUMP RELAY

LT Section No.– 02-250

The fuel pump relay (1) is located in the underhood fuse and relay centre, in the engine compartment. The relay

centre is posit ioned for ward of the righ t sid e strut t ower . Other t han c heck ing for loose c onnec tors, the onl y s ervice

possible is replacement.

FUEL PRESSURE RELIEF PROCEDURE

CAUTION: Unless this procedure is carried out

before servicing fuel lines or connections, fuel

spray into the engine compartment could

occur!

1. Remove Fuel Pump Relay (1) from the

underhood fuse and relay centre.

2. With throttle closed, crank engine – engine

ma y start and idle u ntil f uel suppl y rem aining in

fuel line is exhausted. When engine stops,

engage starter again for 10 seconds to ensure

dissipation of any remaining pressure.

3. Reinstall fuel pump relay (1).

Figure 6C1-3-18 – Fuel Pump Relay Location

3.2 THROTTLE STOP SCREW – RESET PROCEDURE

IMPORTANT: Engine idle for the V6 engine must

be checked every 80,000 km. If the IAC

valve counts are greater than 25 at idle, the

throttle body must be removed and cleaned. Refer

to ‘Throttle Body Cleaning Procedure’ in

3.11 THROTTLE BODY, in this Section for the

procedure.

The throttle stop screw (1) controls the minimum

throttle opening (nominal "Closed Throttle"

position). It i s preset at th e factor y and must no t

be reset unless:

a. The screw position is known to have been

tampered with, or;

b. Clearly instructed to do so by a diagnostic

table.

NOTE 1: Engine idle speed, which will vary with

engine temperature, is PCM controlled and is not

adjustable.

NOTE 2: T he PCM con troll ed idle sp eed (IAC) and

throttle stop screw setting (rpm) ARE NOT THE

SAME!

The throttle stop screw setting (RPM) m ust always

be less than the PCM controlled idle speed, and is

check ed only after tem porarily disabling the PCM's

method of controlling idle speed (i.e. the Idle Air

Control system). The throttle stop screw setting is

the least lik ely cause of an abnorm al idle conditi on,

therefore resetting the screw should only be

considered as a last resort. An incorrect setting is

likely to cause a deterioration in idle stability.

Figure 6C1-3-19 Throttle Stop Screw Location

IMPORTANT: Before any adjustments are made,

ensure that no vacuum leaks exist. Check all

vacuum hoses, MAF air ducts, intake manifold

gasket, throttle body-to-manifold attachment, and

any vacuum-operated devices. The engine must

be at normal operating temperature before any

checking or resetting is attempted.

WITH THIS ENGINE CONTROL SYSTEM, ANY

VACUUM LEAK WILL RESULT IN A

LOW/ROUGH IDLE SPEED.

CHECK OR RESET

IMPORTANT: Before performing this procedure,

carry out the On-Board Diagnostic System Check.

Refer to Section 6C1-2A DIAGNOSTIC TABLES,

in this Section.

1. Before performing steps 3 to 10 of this

procedure, ensure that the IAC system is

functioning properly. Refer diagnostic

TABLE A-7.1 (IAC system check) in Section

6C1-2A, DIAGNOSTIC TABLES - V6 ENGINE

in this Section, and work through to the "NO

TROUBLE FOUND - IAC OK", step before

proceeding.

2. Engine must be at normal operating

temperature (above 90° C), preferable

achieved by driving for at least 15 minutes,

before continuing.

3. Set parking brake and block drive wheels.

Ensure transmission is in ‘Park' (automatic

transmission) or Neutral (manual

transmission).

4. Remove four dome nuts securing the engine

dress cover assembly to the intake manifold

studs, l ift off and s et the c o ver assembl y to on e

side.

5. Verify that t he t hr ott le c ab le and t hrottle linkage

are not binding. The throttle lever attached to

the throttl e butterfly shaft m ust be able to open

fully, and shut fully and freely every time the

accelerator pedal is full y depressed and slowly

released.

Figure 6C1-3-20 – IAC Valve Harness Removed

NOTE: Refer to THROTTLE CABLE – Adjust in this Section if throttle cable adjustment is required.

6. Install Tech 2 and select Miscellaneous tests, IAC System, Base Idle.

7. Ignition “ON”, engine running.

NOTE: If the engine has completed less than 3,000 km, do not reset the throttle stop screw unless the RPM is

above 600 rpm. Otherwise, RPM should be 500 – 600 rpm. If a reset is necessary, adjust throttle stop screw to

obtain an engine speed of 450 - 550 rpm.

8. Using Tech 2, activate the Base Idle test and follow the Tech 2 instructions.

9. Adjust the base idle screw to obtain engine idle speed of 450-550 rpm.

10. Reinstall engine dress cover to the intake manifold, ensuring that stud grommets in the dress cover remain in

place. Tighten securing dome nuts to the correct torque specification.

ENGINE DRESS COVER TO INTAKE

MANIFOLD DOME NUT

TORQUE SPECIFICATION 5 Nm

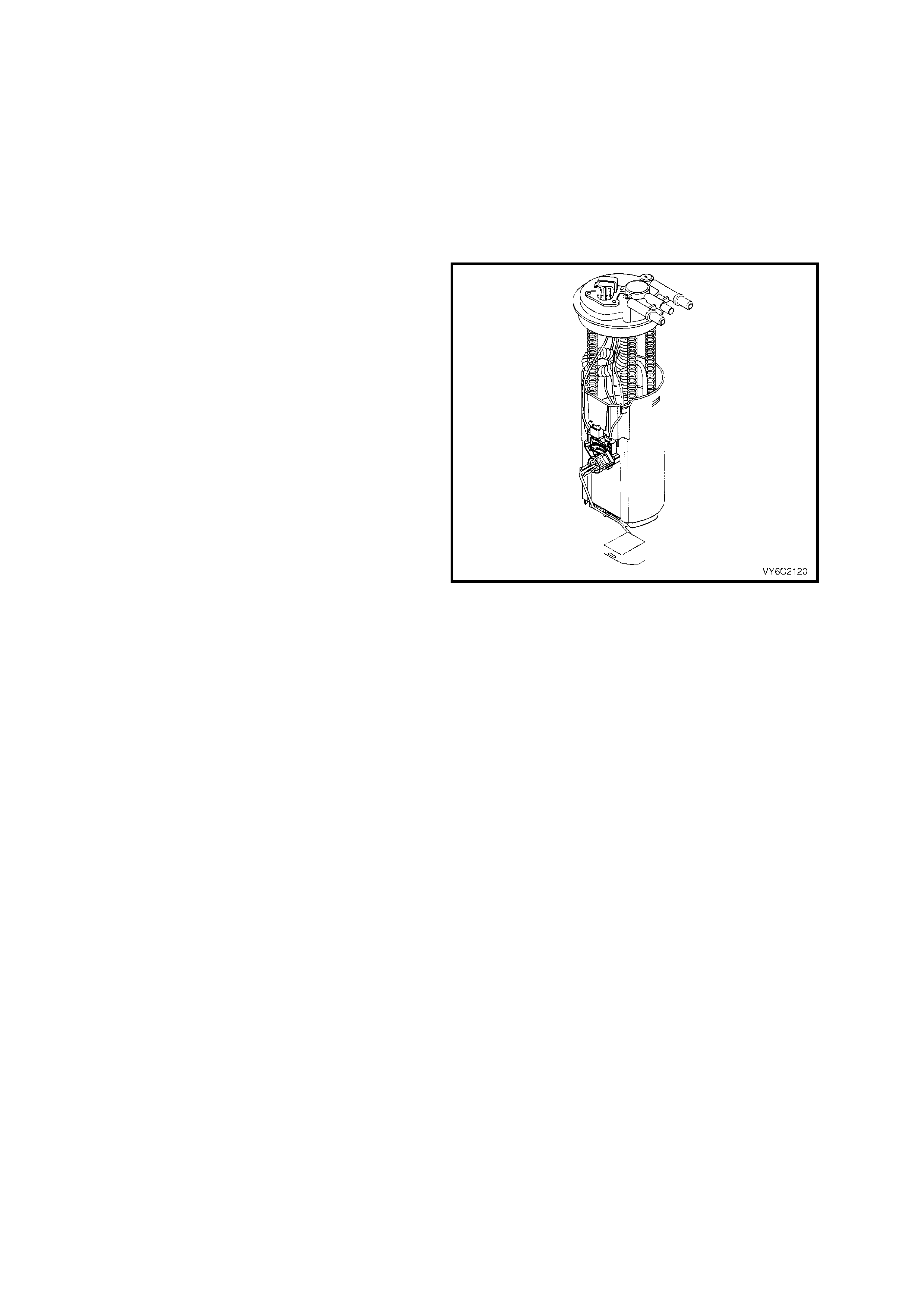

3.3 MODULAR FUEL SENDER ASSEMBLY

LT Section No.– 03-074

REMOVE

NOTE: Do not handle the modular fuel sender assembly by the fuel pipes.

1. Relieve the f uel system pressur e. Refer to the ‘Fuel Pressur e Relief Proc edure’ in 3.1 FUEL PUM P REL AY, in

this Section.

2. Dis c onnect batter y ground l ead.

IMPORTANT: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00 CAUTIONS, 5. Battery Disconnection Procedures before disc onn e c ting the batt ery.

3. Remove fuel tank, Refer to Section 8A, FUEL

TANK.

4. Remove the modular fuel sender retaining ring

using the J 39765 Fuel Sender Locknut

Wrench.

CAUTION: When removing the modular fuel

sender assembly from the fuel tank, the

reservo ir buck et on the fuel send er as sembl y is

full of fuel. The modular fuel sender assembly

must be tipped slightly during removal in order

to avoid damage to the float. Place any

remaining fuel into an approved container once

the modular fuel sender assembly is removed

from the fuel tank.

IMPORTANT: The modular fuel sender assembly

will spring-up when the locking ring is removed.

5. Pull the modular fuel sender straight up while

draining the fuel from the reservoir.

6. Clean the fuel sender assembly O-ring sealing

surface.

7. Inspect the fuel sender assembly O-ring

sealing surface.

Figure 6C1-3-21 – Modular Sender Assembly

REINST ALL

IMPORTANT: Always replace the fuel sender O-ring when reinstalling the fuel sender assembly.

1. Position the new fuel sender assembly O-ring on the fuel tank, after lubricating with some commercially

available, rubber grease.

IMPORTANT: Car e should be taken not to fold over or twist the f uel pum p strainer when install ing the fuel sender

assem bly, as th is will res trict fuel f low. Also, as sure that the f uel pum p strainer does not interfer e with full travel of

float arm.

2. Reins tall the f uel sender as sembly and the fuel se nder assem bly retainer r ing using the J 39765 Fuel Sender

Locknut Wrench.

3. Reinstall fuel tank, Refer to Section 8A FUEL TANK.

4. Rec onn ec t batter y ground l ead.

5. Inspect system for leaks.

FUEL STRAINER AND FUEL LEVEL SENSOR

NOTE: T he fuel s trainer is not s er viced s eparat ely. Sh ould th e strai ner b ecom e clogge d or dam aged, the c om plete

modular fuel sender assembly must be replaced.

FUEL PUMP ASSEMBLY

NOTE: The f uel pump is not s erviced separa tely. If the f uel pump is f ound to be fault y, then the c omplete m odular

fuel sender assembly must be replaced.

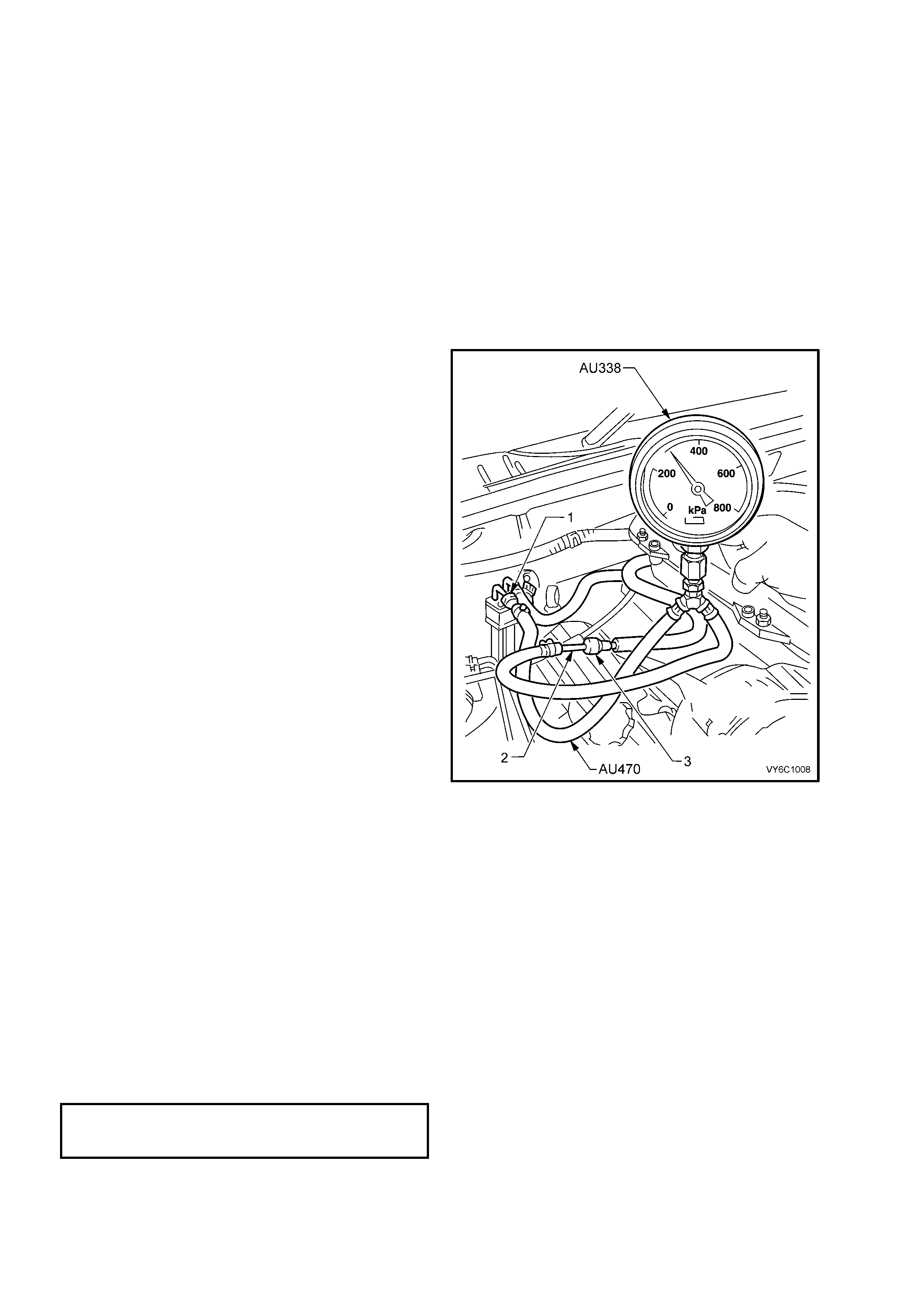

3.4 FUEL SYSTEM PRESSURE TEST

A Fuel S ystem Pr ess ur e Test is par t of s everal of the Diagnostic T ables an d S ymp tom check s . To perf orm this tes t,

follow this procedure:

CAUTION: To reduce the risk of fire or personal injury, it is necessary to relieve fuel system pressure

before performing this test. See Fuel Pressure Relief Procedure in 3.1 FUEL PUMP RELAY, " in this

Section.

IMPORTANT: At no time must the fuel intake hose or return line hose be clamped or kinked, as this will cause a

permanent deformation of the inner hose section and will result in restricted fuel flow.

1. Relieve fuel pressure as described in Fuel Pressure Relief Procedure in 3.1 FUEL PUMP RELAY, in this

Section. Turn ignition OFF.

2. Remove f our dome nuts s e c uring the en gi ne dres s c over as sembl y to the intake manif old, lif t off and s et t o on e

side.

3. Open Tool No. 7370 and install over fuel inlet line.

4. Close 7370 and pull into fuel line quick connect to release it from the fuel inlet line, pull back on quick connect.

IMPORTANT: Before conducting step 5, inspect

adaptor tube (2) on fuel pressure gauge hose

(AU470) to ensure that it is free from any damage

or burrs. This is necessary to ensure that the tube

does not damage the sealing ring in the quick

connect fitting (3). If the sealing ring becomes

damaged, f uel le akage will occ ur.

5. Install fuel pressure gauge AU338 (also

released as SD28018) & hose AU4570 (also

released as SD28057) fitted with Coupler

212157 (1) and tube 216812 (2) in the

pressure line, between the fuel inlet line and

the fuel inlet hose quick connect (3).

NOTE: The fuel pressure gauge hose assembly

AU470 is comprised of the following:

212157 Coupler (1)

216812 Adaptor Tube (2)

SD28057 Hose Assembly

MEASURE

1. Using Tech 2, enable fuel pump so that the fuel

pump can pressurise the system.

2. Fuel gauge reading should be 270 – 350 kPa.

If not, refer to Diagnostic TABLE A-4.1 in

Section 6C1-2A, DIAGNOSTIC TABLES, in

this Section.

3. Relieve fuel pressure as described in

3.1, FUEL PUMP RELAY - FUEL

PRESSURE RELIEF PROCEDURE, in this

Section.

4. Remove fuel pressure gauge and adaptor.

5. Reinstall fuel line.

6. Check for fuel leaks as described in

3.0, FUEL CONTROL SYSTEM, 3.6 LEAK

TESTING, in this Section.

Figure 6C1-3-22 – Fuel Pressure Gauge Set-Up

7. Reinst all engine dress cover, ensuring that t he

four stud grommets in the cover, remain in

place. Secure with the four decorative nuts,

tightened to the correct torque specification.

ENGINE DRESS COVER

DECORATIVE NOT

TORQUE SPECIFICATION 5 Nm

3.5 FUEL FILTER

LT Section No.– 03-075

REMOVE

1. Relieve fuel pressure as described in 3.1, FUEL PUMP RELAY, Fuel Pressure Relief Procedure in this

Section.

2. Dis c onnect batter y ground l ead.

IMPORTANT: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00 CAUTIONS, 5. Battery Disconnection Procedures before disconnecting the battery.

3. Raise rear of vehic le and support on safet y stands, ref er to Section 0 A, GENERAL INFORM AT ION in the MY

2003 VY and V2 Series Service Information.

4. Place a drain tray beneath fuel filter.

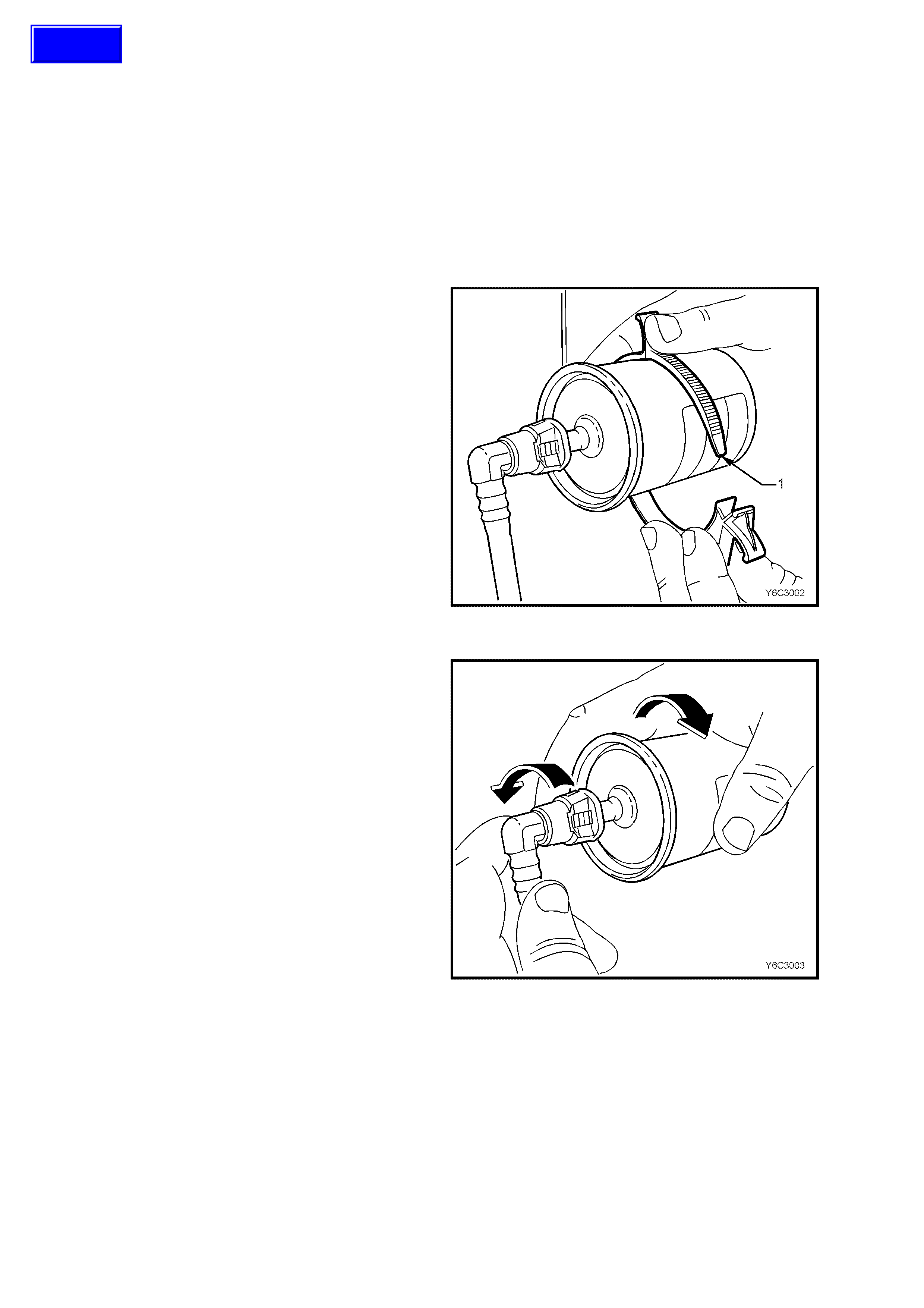

5. Remove the fuel filter from the retaining

bracket (1) with the fuel lines still connected to

the fuel filter to allow easier access.

Figure 6C1-3-23 – Releasing Filter From Retaining Strap

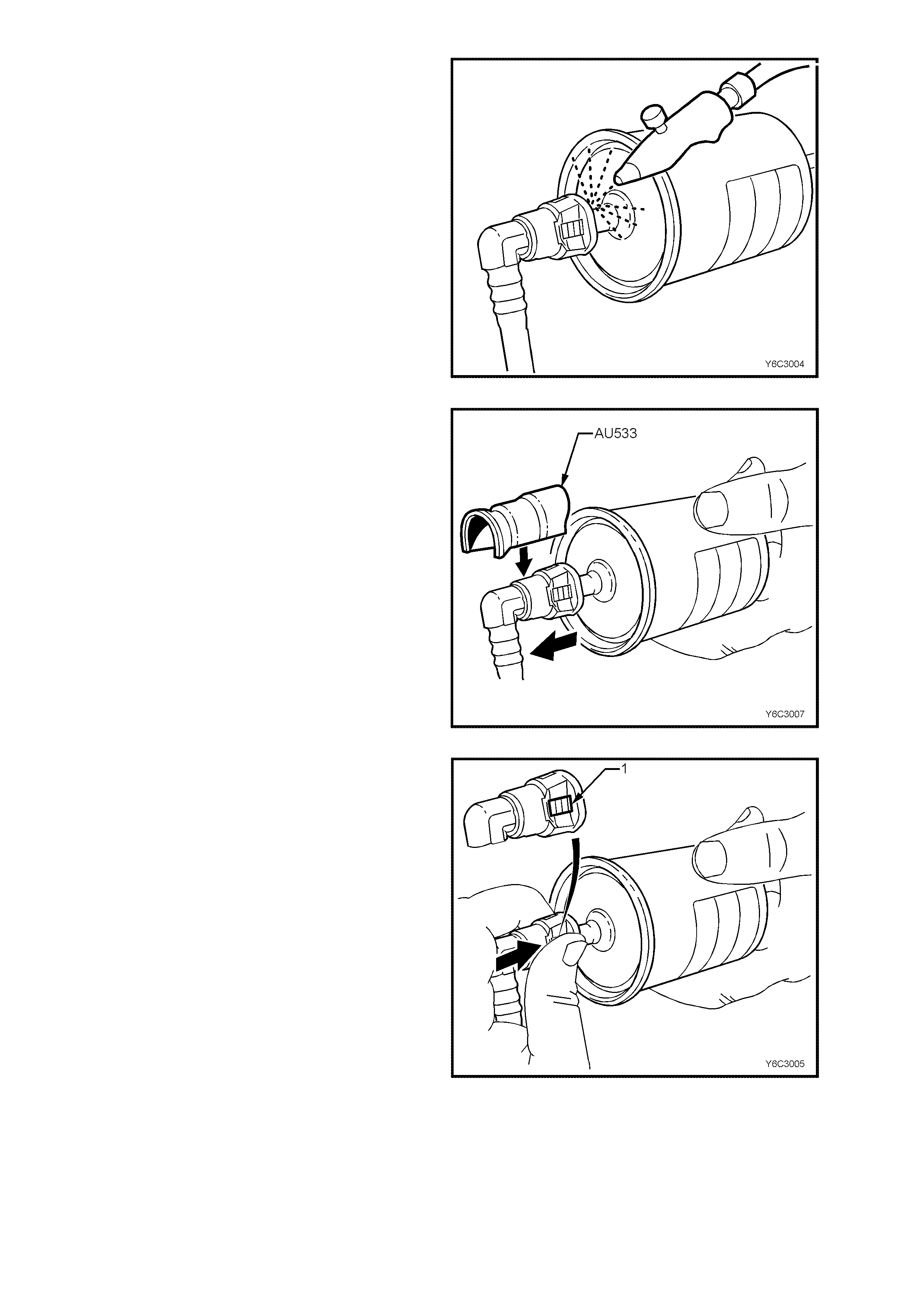

Quick Connect Fittings (Plastic Collar)

6. Grasp the quick-connect fittings on each side

of the fuel filter. Twist the female connectors

1/4 turn in each directio n in order to loos e n any

dirt within the quic k-connec t fittin g.

Figure 6C1-3-24 – Rotating Quick Connect Fitting

Techline

7. Using compressed air, blow any dirt out of the

quick-connect fitting to aid the release of any

tension or binding on the release tabs .

CAUTION: Wear safety glasses when using

compressed air, in order to prevent eye injury.

Figure 6C1-3-25 – Clearing Debris

8. Use Tool No. AU533 to squeeze the release

tabs, by pushing down on the quick connect

fitting. This action compresses both release

tabs. With AU533 in place, push the

connection together to release tension on the

locking tabs and then pull to separate the two

components. Repeat this operation for the

second connection, to release the fuel filter.

NOTE: Tool No AU533 is available in two pipe

sizes; Red for 5/16” and Blue for 3/8”. Only the

blue (3/8”) tool is required for this operation.

9. Remove fuel filter from vehicle and discard

safely, remembering that some fuel will still

remain in the filter.

Figure 6C1-3-26 – Releasing Quick Connect Fitting

If Tool No. AU533 is not available, an alternative

method of removing the filter, is as follows:

10. Hold the f uel filter f irm ly in one h and to sup port

the filter.

11. Using your o ther hand, grasp one of the quick -

connect fittings and squeeze the plastic

retainer release tabs (1) on each side of the

fitting whi le pushing the fitti ng firmly toward the

fuel filter to release any tension on the release

tabs.

Figure 6C1-3-27 – Releasing Quick Connect Fitting

12. With the tension release tabs still held in the

squeezed position, move the complete quick-

connect fitting away from the fuel filter to

separate the connector fitting from the fuel

filter.

13. App ly the sam e m ethod from steps 10 to 12 for

the remaining quick-connect fitting.

Figure 6C1-3-28 – Separating Quick Connect Fitting

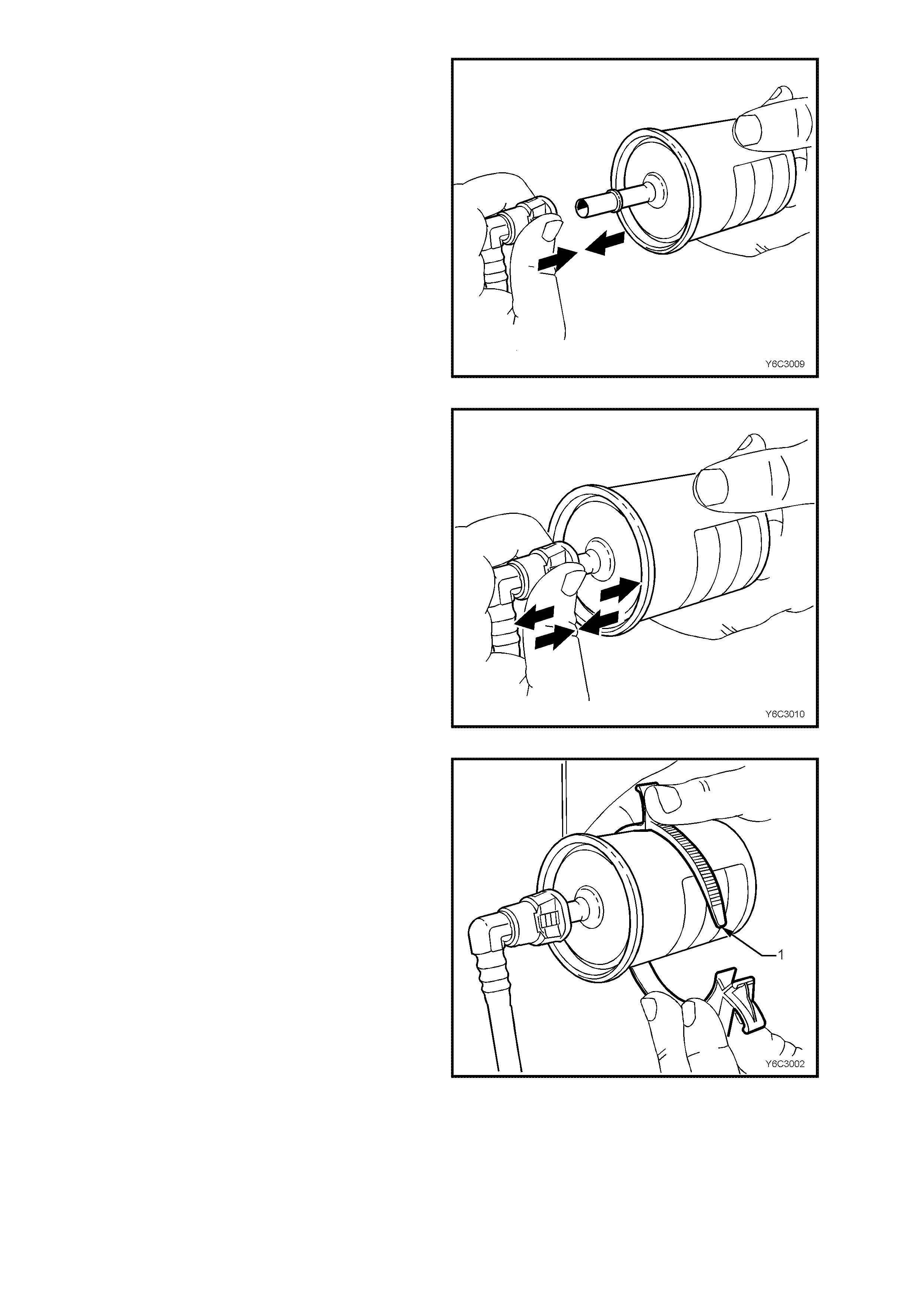

REINST ALL

IMPORTANT: The fuel filter must be installed with

the flow arrow (6) on its body pointing in the same

direction as the fuel flow to the front of the vehicle.

Legend:

1 Evaporative Emission Charcoal Canister

2 Fuel Tank Vapour Purge Line

3 Atmospheric Line

4 Fuel Vapour Inlet Line

5 Fuel Feed from Modular Fuel Sender

6 Filter Fuel Flow Arrow

7 Fuel Filter.

8 Fuel Return Line to Fuel Tank.

Figure 6C1-3-29 – Fuel Filter Installation

IMPORTANT: In or der t o r educ e t he ris k of fir e and

personal injury, before connecting fuel filter quick-

connect fittings, always apply a few drops of clean

engine oil to the male ends of the fuel filter. This

will ensure proper reconnection and prevent a

possible fuel leak.

During normal operation, the O-ring located in the

fem ale connec tor will s wel l and ma y prevent proper

reconnection if not lubr icated.

1. Apply a few drops of clean engine oil to each

male fuel filter end.

Figure 6C2-3-30 – Lubricating Fittings

2. Push both th e quic k -conne ct f itting a nd the fuel

filter together, causing the retaining tabs to

snap into place. Apply this method to both

ends of the fuel filter and the respective quick-

connect fittings.

Figure 6C1-3-31 – Installing Quick Connect

3. Once installed, pull and push on both the

quick-connect fitting and the fuel filter in order

to make sure the connection is secure. Apply

this method to each end of the fuel filter and

the respective quick-connect fittings.

Figure 6C1-3-32 – Testing Quick Connect Security

4. Re-install the fuel filter to the retaining bracket

(1).

5. Conn ec t battery ground lead.

6. Check for fuel leaks, refer to 3.6 LEAK

TESTING in this Section.

7. Remove safety stands and lower vehicle.

Figure 6C1-3-33 – Installing Filter Retainer

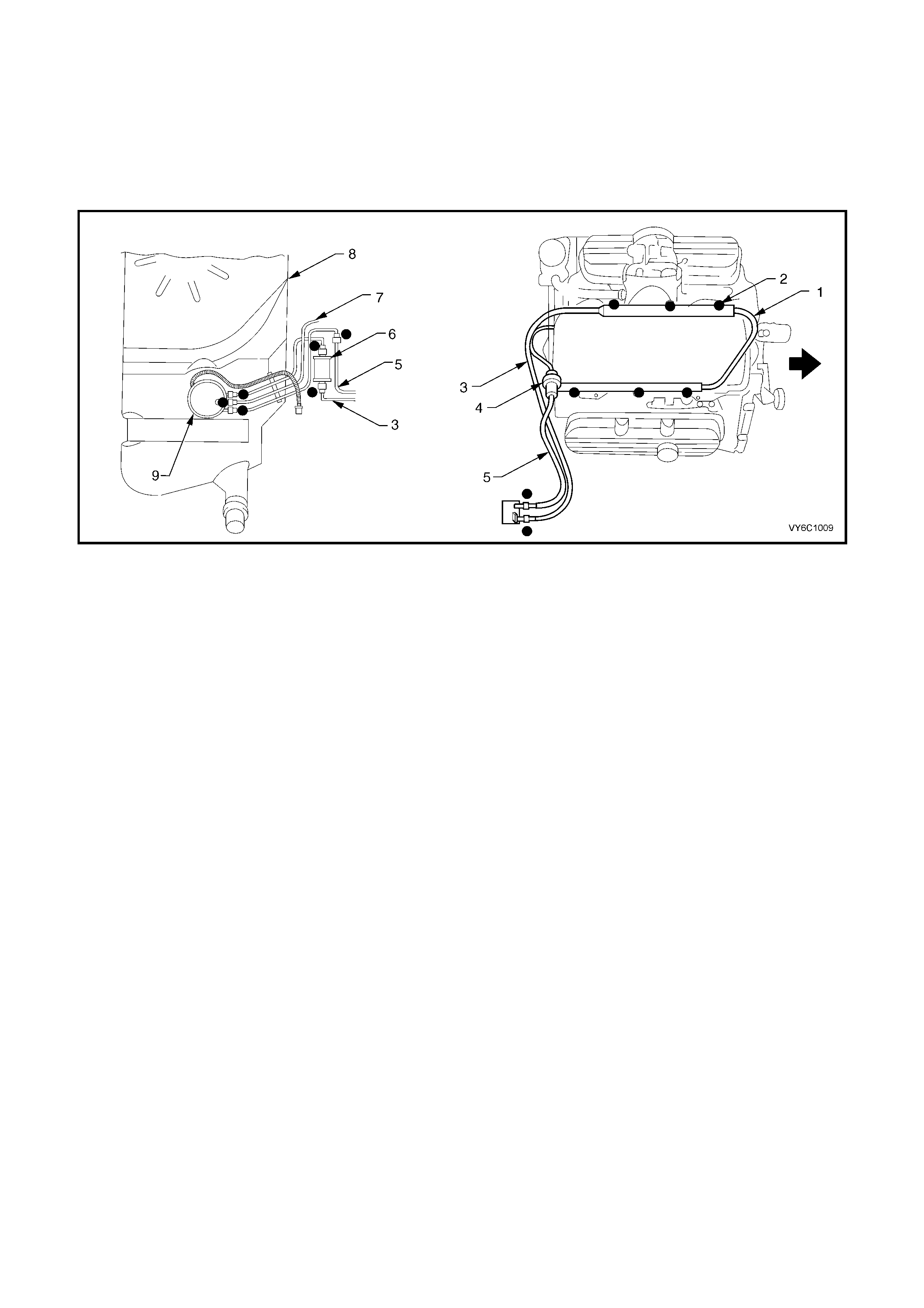

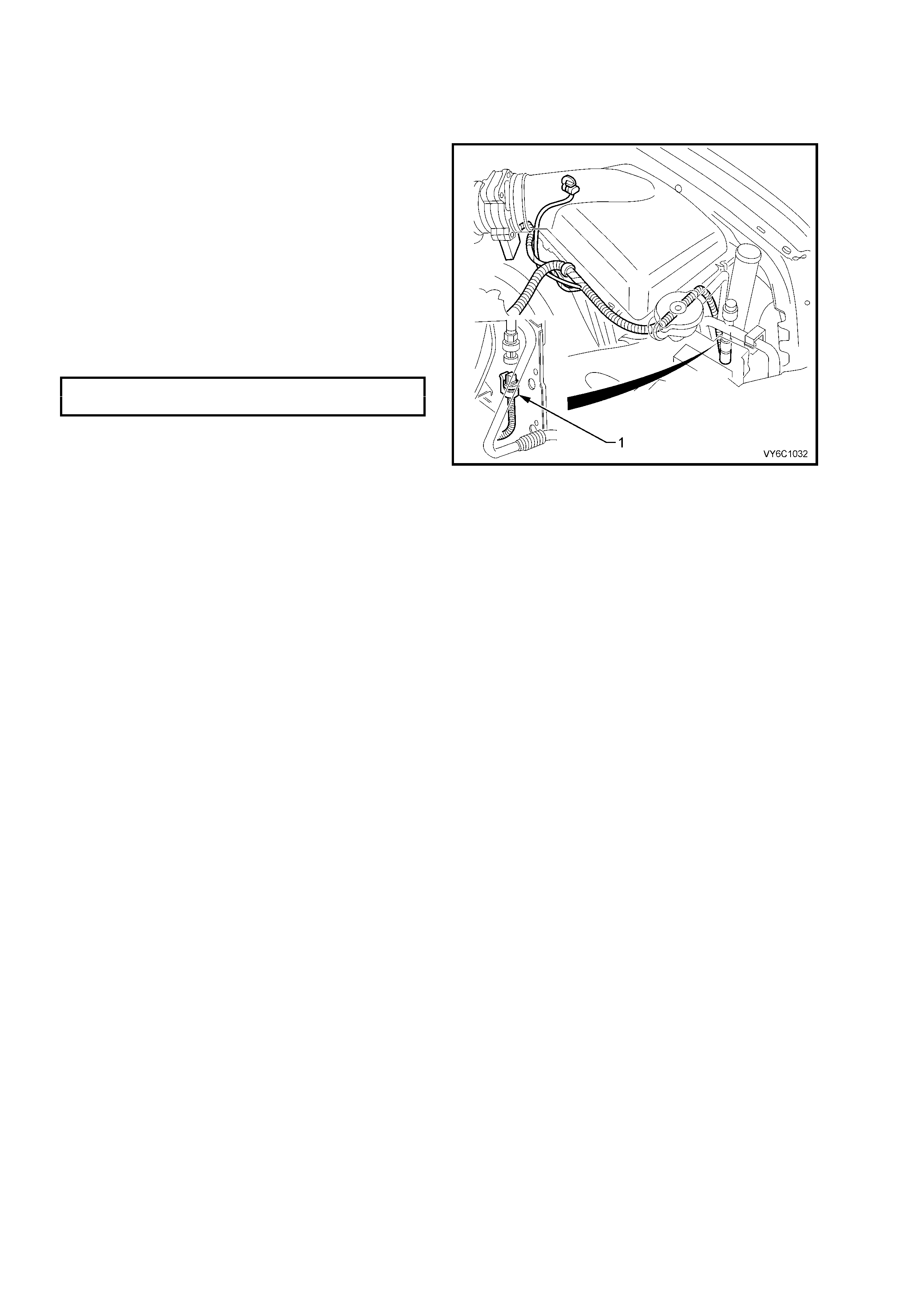

3.6 LEAK TESTING

IMPORTANT: Following the installation of any fuel system component, and prior to starting the engine, the fuel

system must be checked for leaks, using the following procedure:

1. Check to ensure that there is a sufficient level of fuel in the fuel tank.

2. Install T ech 2 to the vehic le and sel ect "Ou tput T est" f or "Fuel Pum p." Ena bling t he output tes t will activate the

fuel pump to pressurise the fuel system.

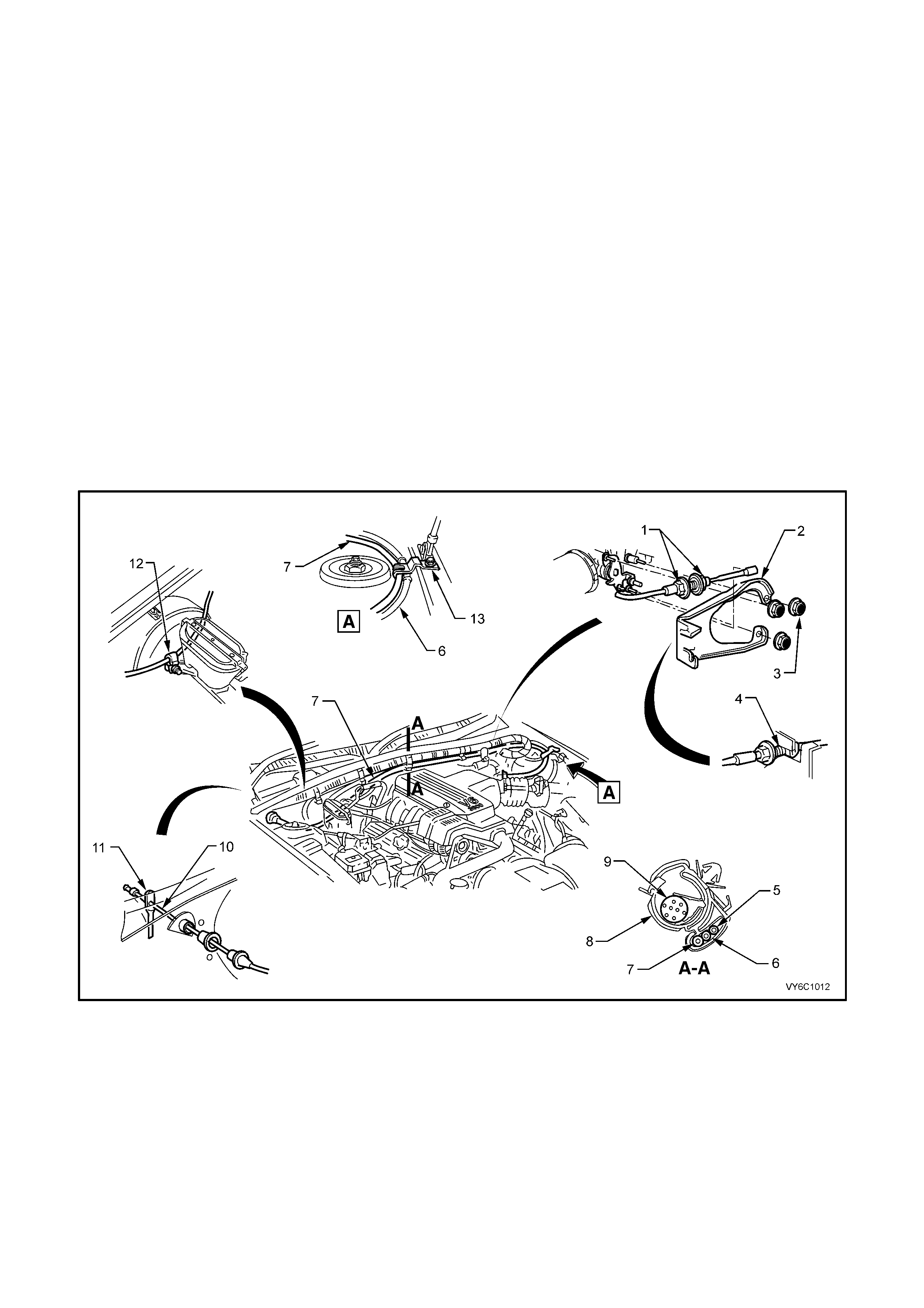

3. Check fuel system for leaks, particularly at points marked (l) in Figure 6C1-3-34.

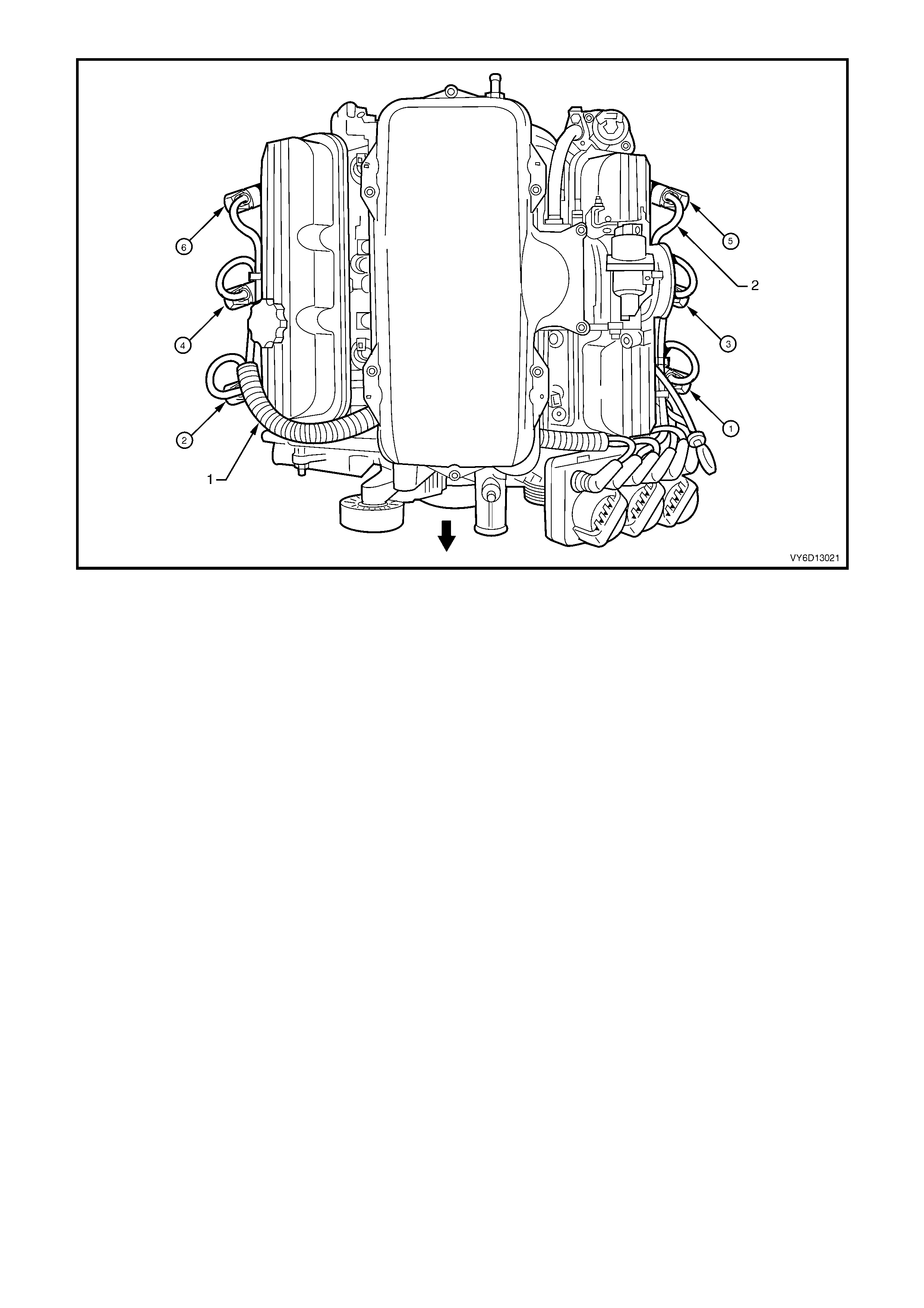

Figure 6C1-3-34 – Leak Testing V6 Engine

Legend

1. Fuel Rail

2. Fuel Injector (6 places)

3. Fuel Feed

4. Fuel Pressure Regulator

5. Fuel Return

6. Fuel Filter

7. Fuel Tank Vapour Line

8. Fuel tank

9. Modular Fuel Sender Assembly

3.7 FUEL PRESSURE REGULATOR

LT Section No.– 03-375

NOTE 1: Compressed air must never be used to test or clean a fuel pressure regulator, as damage to the

regulator may result.

NOTE 2: To prevent damage to the fuel pressure regulator, do not immerse in solvent.

REMOVE

1. Relieve fuel pressure as described in Fuel Pressure Relief Procedure, in 3.1 FUEL PUMP RELAY, in this

Section.

2. Dis c onnect batter y ground l ead.

IMPORTANT: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00 CAUTIONS, 5. Battery Disconnection Procedures before disconnecting the battery.

3. Remove four dome nuts securing the engine dress cover assembly to the intake manifold studs, then remove

the cover assembly. Refer Figure 6C1-3-9 in this Sec t ion.

4. Remove fuel rail assembly, refer to 3.8, FUEL RAIL, in this Section.

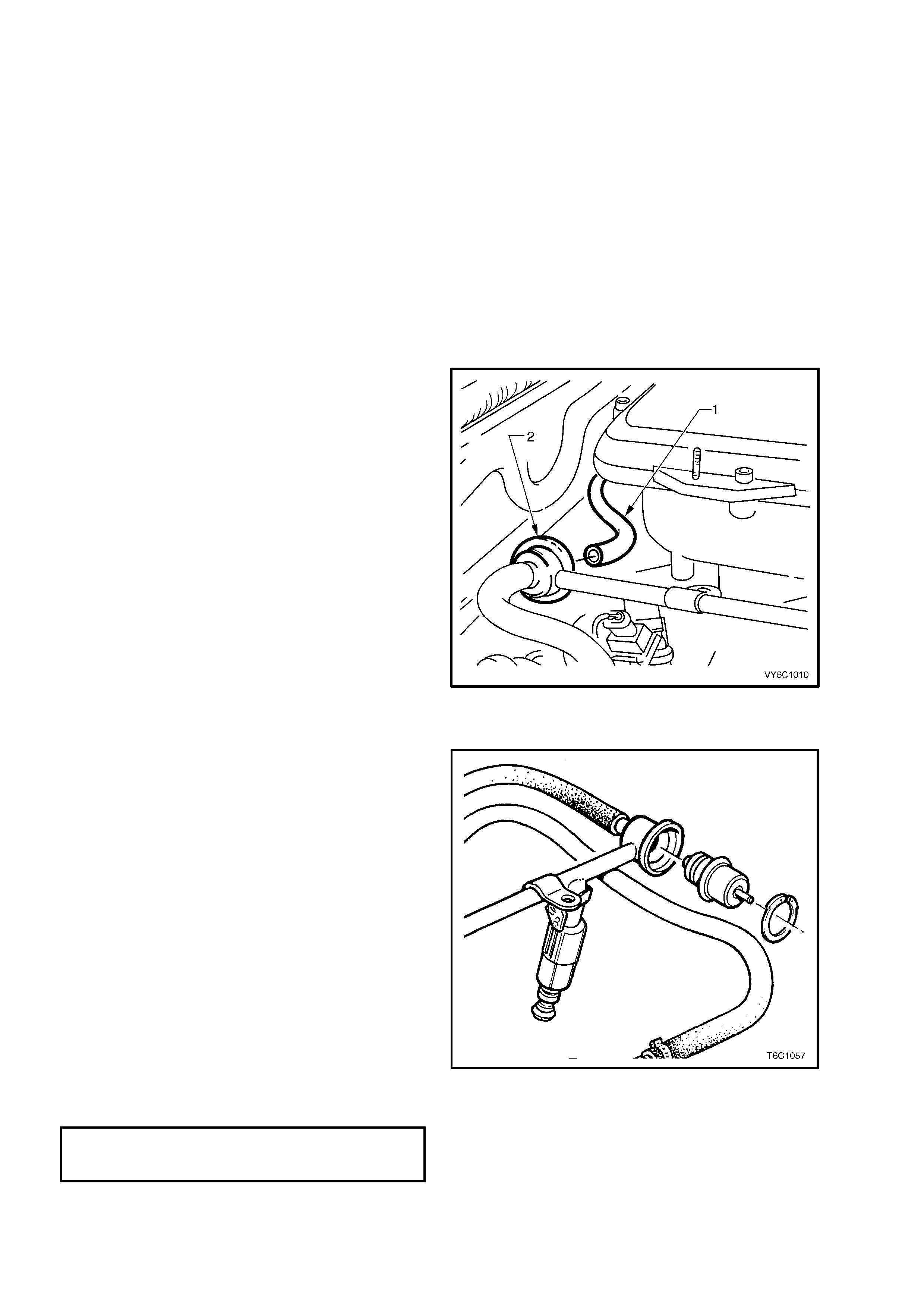

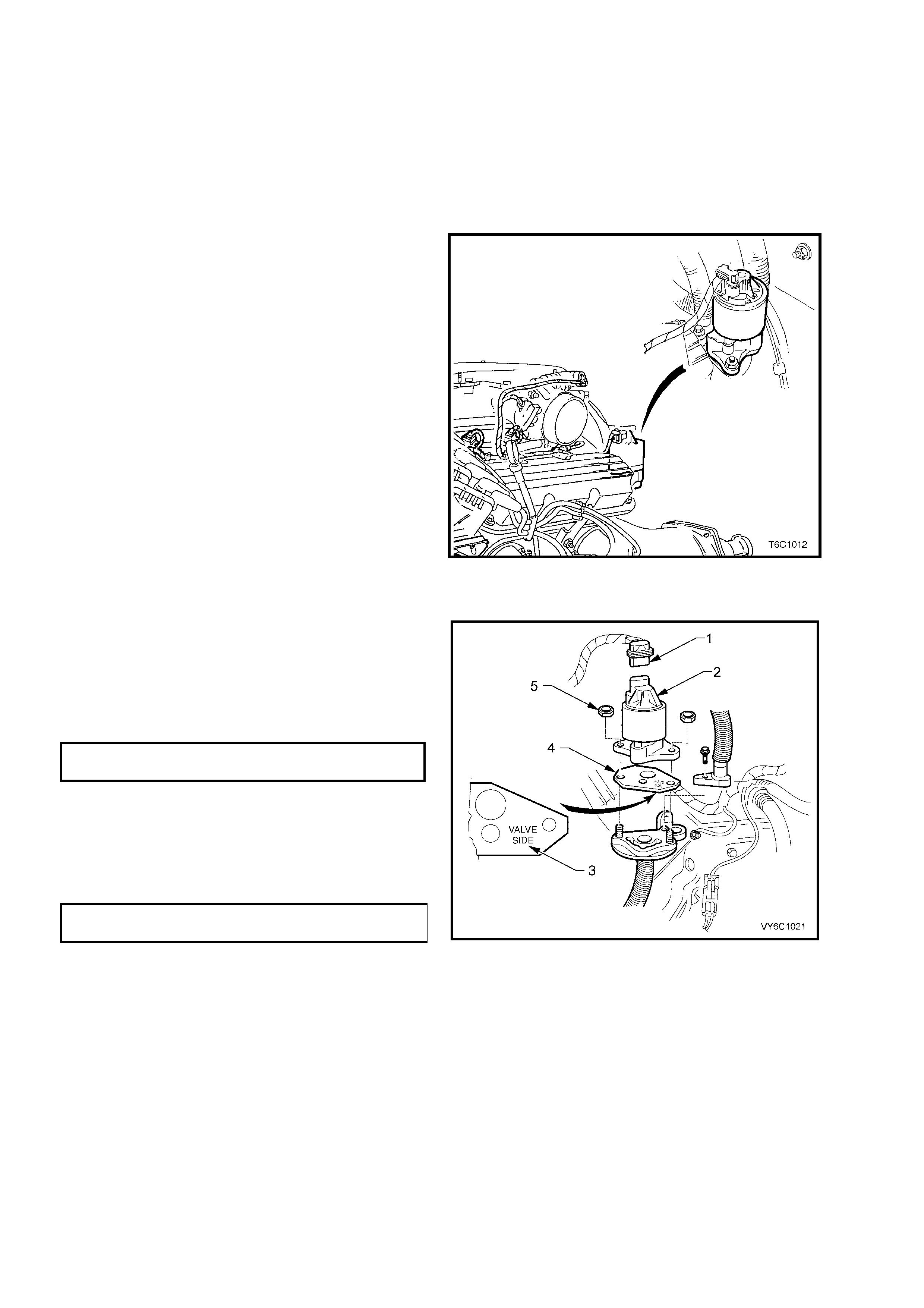

5. Disconnect vacuum hose (1) from fuel

pressure regulator (2).

6. Clean any dirt from the fuel pressure regulator

retaining ring.

7. Using suitable snap ring pliers, remove snap

ring from fuel pressure regulator.

8. Using a sh op towel to c atch an y spilled f uel, lift

and twist the fue l pressure regulator in order to

remove the fuel pressure regulator from the

fuel pressure regulator housing.

9. Cover the fuel pressure regulator housing to

prevent contamination from entering the fuel

system.

Figure 6C1-3-35 – Fuel Pressure Regulator Location

REINST ALL

1. If a new fuel pressure regulator is not being

installed, fit new O-rings to the fuel pressure

regulator and lightly lubricate the O-rings with

clean engin e oil.

2. Reinstall the fuel pressure regulator in the fuel

pressure regulator housing.

3. Reinstall the retaining circlip to the fuel

pressure regulator using suitable pliers.

4. Reinstall the fuel rail. refer to 3.8 FUEL RAIL,

in this Section.

5. Reinstall the vacuum hose to the fuel pressure

regulator.

6. Rec onn ec t batter y ground l ead.

7. Check for fuel leaks as described in

3.6 LEAK TESTING in this Section.

8. Reinstall engine dress cover to the intake

manif old, ensurin g that stu d gromm ets in dres s

cover remain in place. Tighten securing dome

nuts to the correct torque specification.

ENGINE DRESS COVER TO INTAKE

MANIFOLD DOME NUT

TORQUE SPECIFICATION 5 Nm

Figure 6C1-3-36 Fuel Pressure Regulator

3.8 FUEL RAIL AND INJECTORS

LT Section No.– 03-375

NOTE: The fuel inlet hose, return hose and the fuel rail are a complete assembly. No components are serviced

separately.

REMOVE

IMPORTANT: The fuel rail and injectors (3) are

attached to the bottom of the two-piece air inlet

plenum (1). T he top of the air inlet plen um m ust be

rem oved to ga in ac c ess to the bo lts th at s ecur e th e

inlet plenum (1) to the lower intake manifold (2).

For the procedure to remove both the upper inlet

plenum and the f uel rail/i njector ass embl y (3), refer

to 2.10 UPPER INTAKE MANIFOLD, in Section

6A1, ENGINE MECHANICAL – V6 ENGINE.

IMPORTANT: Following the removal of the upper

inlet plenum (1) and the fuel rail/injector assembly

(3), place a clean piece of cardboard over the

intake manifold (or plug all open ports with clean

workshop rag), to prevent foreign objects from

entering the exposed intake manifold ports.

Figure 6C1-3-37

DISASSEMBLE

1. Remove injector retaining clip/s (2). Withdraw

injector/s (3) from fuel rail.

NOTE 1: When servicing the fuel rail assembly,

precautions m ust be taken to pr event d irt and other

contaminants from entering the fuel passages. It is

recommended that fittings be capped, and holes

plugged, during servicing.

NOTE 2: Any time the fuel system is opened for

service, the O-ring seals used with related

component(s) should be replaced, including those

used between the air inlet plenum and intake

manifold, and between the plenum and it's cover.

REASSEMBLE

1. Coat NEW O-rings (1 & 5) with clean engine

oil, then install to each removed injector.

2. Reinstall removed injector/s to the fuel rail,

securing with injector retaining clip/s (2).

3. If removed, reinstall the pressure regulator to

fuel rail.

REINSTALL

Reinstal l the fuel rail/i njector assem bly to the l ower

intake manifold, then reinstall the upper air inlet

plenum and cover. Refer to 2.10 UPPER INTAKE

MANIFOLD, in Section 6A1, ENGINE

MECHANIC AL – V6 ENGI NE.

Figure 6C1-3-38 – Fuel Injector Removal

3.9 AIR CLEANER ASSEMBLY

LT Section No.– 03-250

REMOVE

1. Dis c onnect batter y ground l ead.

IMPORTANT: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00 CAUTIONS, 5. Battery Disconnection Procedures before disconnecting the battery.

2. Remove four dome nuts securing the engine dress cover assembly to the intake manifold studs, then remove

the cover assembly. Refer Figure 6C1-3-9 in this Sec t ion.

3. Disconnect the mass air flow sensor wiring

harness connector (4) from the sensor.

4. Loosen the air f low duct rubber boot clam ps at

the throttle body (1) and air cleaner housing

(5).

5. Rem ove the air f low duct (2) and m ass air f low

sensor assembly (3) and carefully set to one

side.

Figure 6C3-3-39

6. Pull up retaining tang on IAT sensor wiring

harness connector and pull connector from

sensor (1).

7. Unclip five clips holding the air cleaner upper

housing (3) in place.

8. Remove air cleaner upper housing (3) and air

cleaner element assembly.

9. Remove three studs (4) securing air cleaner

lower housing to fender inner panel insulators.

10. Disengage air cleaner cold air intake duct

assembly (7) from lower housing, after

removing the two scrivets (5).

11. Remove the lower air cleaner housing

grommets from the retaining screw heads (4),

then remove from the vehicle.

REINST ALL

1. Reassemble air cleaner lower housing on to

mounting insulators, engaging with the intake

duct assembly (7).

2. Reinstall securing studs (4) (if removed) and

tighten to the correct torque specification.

AIR CLEANER LOWER

HOUSING SECURING STUD

TORQUE SPECIFICATION 10 Nm

3. Secure the cold air intake duct assembly ( 7) by

reinstalling the two scrivets.

Figure 6C1-3-40 – Air Cleaner Housing Removal

4. Reas s emble the a ir c leaner element int o th e air c lean er upp er ho us in g ( 3) and pl a c e the up per h ousi ng ont o

the air cleaner lower housing, ensuring that air filter element remains in position.

5. Snap 5 retainer clips up into place to secure the air cleaner upper housing (3).

6. Reconnect wiring harness connector to IAT sensor (1).

7. Carefully reinstall the air flow duct (8) and mass air flow sensor assembly (6) to the throttle body and air cleaner

upper hous ing (3).

IMPORTANT: Align notch on air cleaner housing adaptor with notch in air duct adaptor and notch in clamp.

8. Tighten air duct clamp securely.

9. Reinstall the mass air flow sensor wiring harness connector (9) to the sensor.

10. Reinstall engine dress cover to the intake manifold, ensuring that stud grommets in dress cover remain in

place. Tighten securing dome nuts to the correct torque specification.

ENGINE DRESS COVER TO INTAKE

MANIFOLD DOME NUT

TORQUE SPECIFICATION 5 Nm

11. Reconnec t batter y ground l ead.

3.10 THROTTLE CABLE

LT Section No.– 03-325

REMOVE

1. Remove four dome nuts securing the engine dress cover assembly to the intake manifold studs, lift off and

remove the cover assembly. Refer to Figure 6C1-3-9.

2. Loosen outer cable lock nuts at throttle body mounting bracket.

NOTE: Do not detach adjusting nuts from cable.

3. Remove inner cable from throttle body linkage.

4. Disconnect outer cable from mounting bracket.

5. Remove instrument panel lower right side trim assembly retainers and lower trim, Refer to

Section 1A3, INSTRUM ENT PANEL.

6. Disconnect inner cable plastic spacer from throttle pedal lever.

7. Withdraw cable assembly from engine compartment.

REINST ALL

1. Reassemble outer cable into dash panel.

2. Attach inner cable to throttle pedal lever.

3. Reinstall outer cable to mounting bracket.

4. Attach inner cable to throttle body linkage.

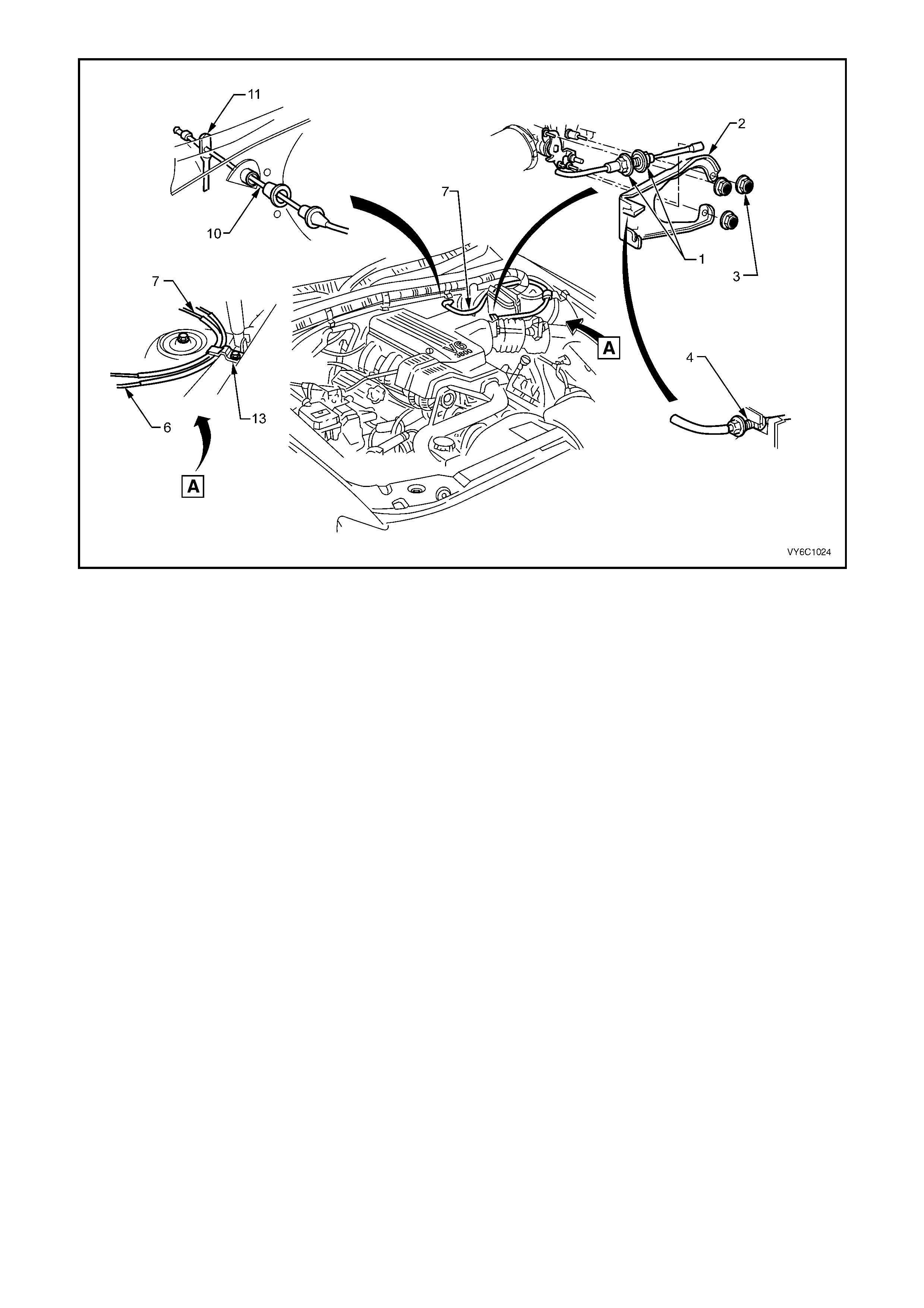

Figure 6C1-3-41 – Throttle Cable V6 Engine – RHD

Legend

1. Nuts – Outer Cable Adjusting

2. Bracket – Throttle Cable

3. Nut – Mounting Bracket (3 places)

4. Circular Hole – Outer Cable Locating

5. Hose – Rear Washer Hose (Wagon)

6. Cable – Cruise Control

7. Cable – Throttle

8. Clip – Wiring Harness Retaining

9. Harness – Powertrain Wiring

10. Cable – Inner Throttle

11. Lever – Throttle Pedal

12. Clip – Throttle Cable Routing

13. Clip – Cable securing

Figure 6C1-3-42 – Throttle Cable V6 Engine – LHD

Legend

1. Nuts – Outer Cable Adjusting

2. Bracket – Throttle Cable

3. Nut – Mounting Bracket (3 places)

4. Circular Hole – Outer Cable Locating

5. Cable – Cruise Control

6. Cable – Throttle

7. Cable – Inner Throttle

8. Lever – Throttle Pedal

9. Clip – Cable securing

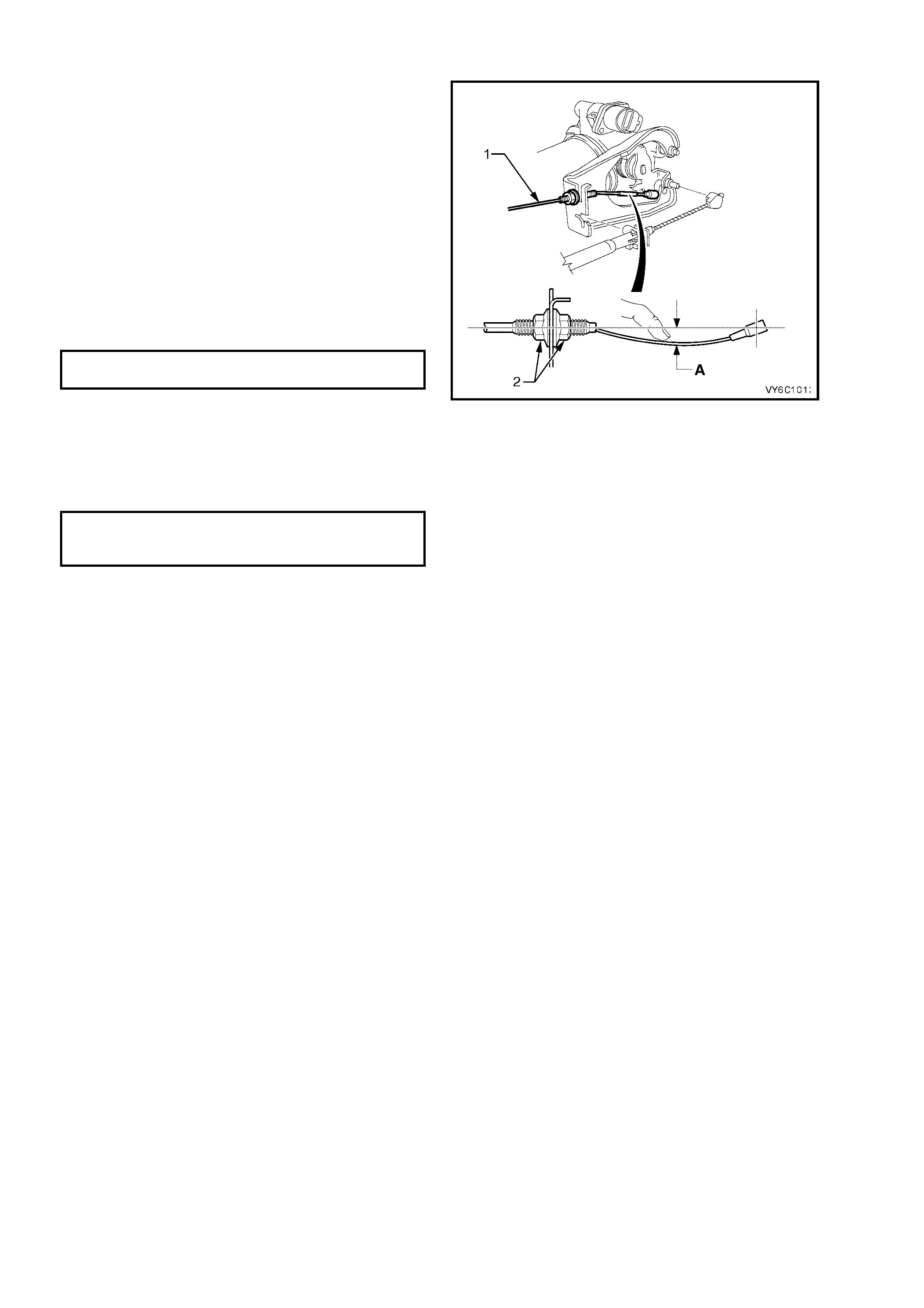

ADJUST

1. Remove instrument panel lower right side

trim (if not already removed, Refer to

Section 1A3, INSTRUMENT PANEL AND

CONSOLE.

2. Ensure throttle pedal is free to move from

closed to fully open position. Check that throttle

pedal comes to rest at the correct closed

throttle position (against pedal stop).

3. Adjust outer cable lock nuts (2) so that inner

cable length has a deflection of 10 – 15 mm

(‘A’), without moving throttle linkage from idle

stop.

4. Tighten cable lock nuts (2) to the correct torque

specification.

THROTTLE CABLE OUTER CABLE

LOCK NUT TORQUE SPECIFICATION 5 Nm

5. Check for Wide Open Throttle (WOT) and

smooth operation of throttle pedal.

6. Reinstall engine dress cover to the intake

manif old, ensurin g that stu d gromm ets in dres s

cover remain in place. Tighten securing dome

nuts to the correct torque specification.

ENGINE DRESS COVER TO INTAKE

MANIFOLD DOME NUT

TORQUE SPECIFICATION 5 Nm

7. Refit instrument panel lower right side trim,

Refer to Section 1A3, INSTRUMENT PANEL

& CONSOLE.

Figure 6C1-3-43 – Throttle Cable Adjustment

3.11 THROTTLE BODY

LT Section No.– 03-300

REMOVE

1. Dis c onnect batter y ground l ead.

IMPORTANT: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00 CAUTIONS, 5. Battery Disconnection Procedures before disconnecting the battery.

2. Remove four dome nuts securing the engine dress cover assembly to the intake manifold studs, lift off and

remove the cover assembly. Refer to Figure 6C1-3-9.

3. Disconnect wiring harness connectors from IAC valve and TP sensor.

4. Loosen air duct clamp at throttle body and mass air flow sensor.

5. Remove air flow duct from the vehicle.

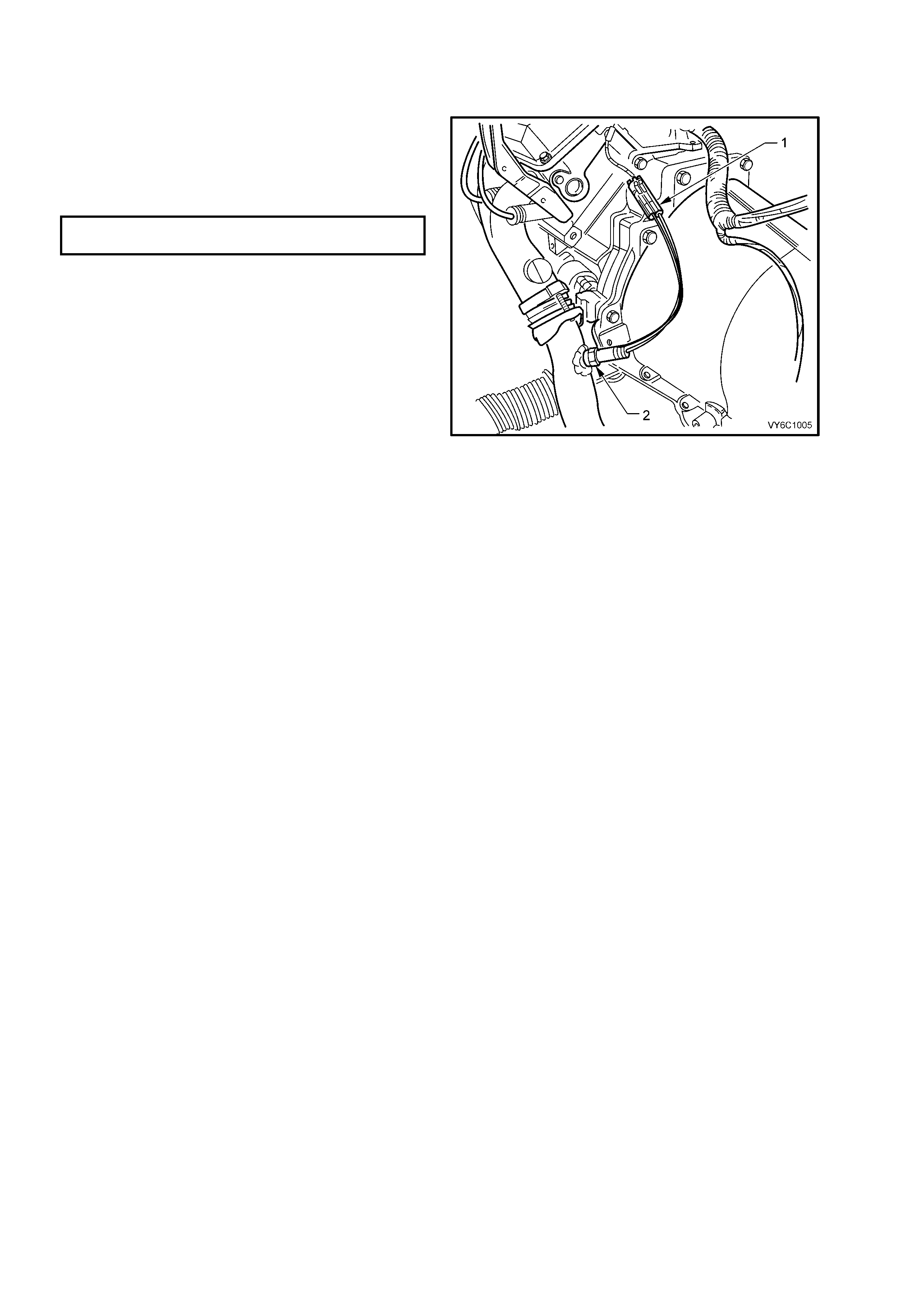

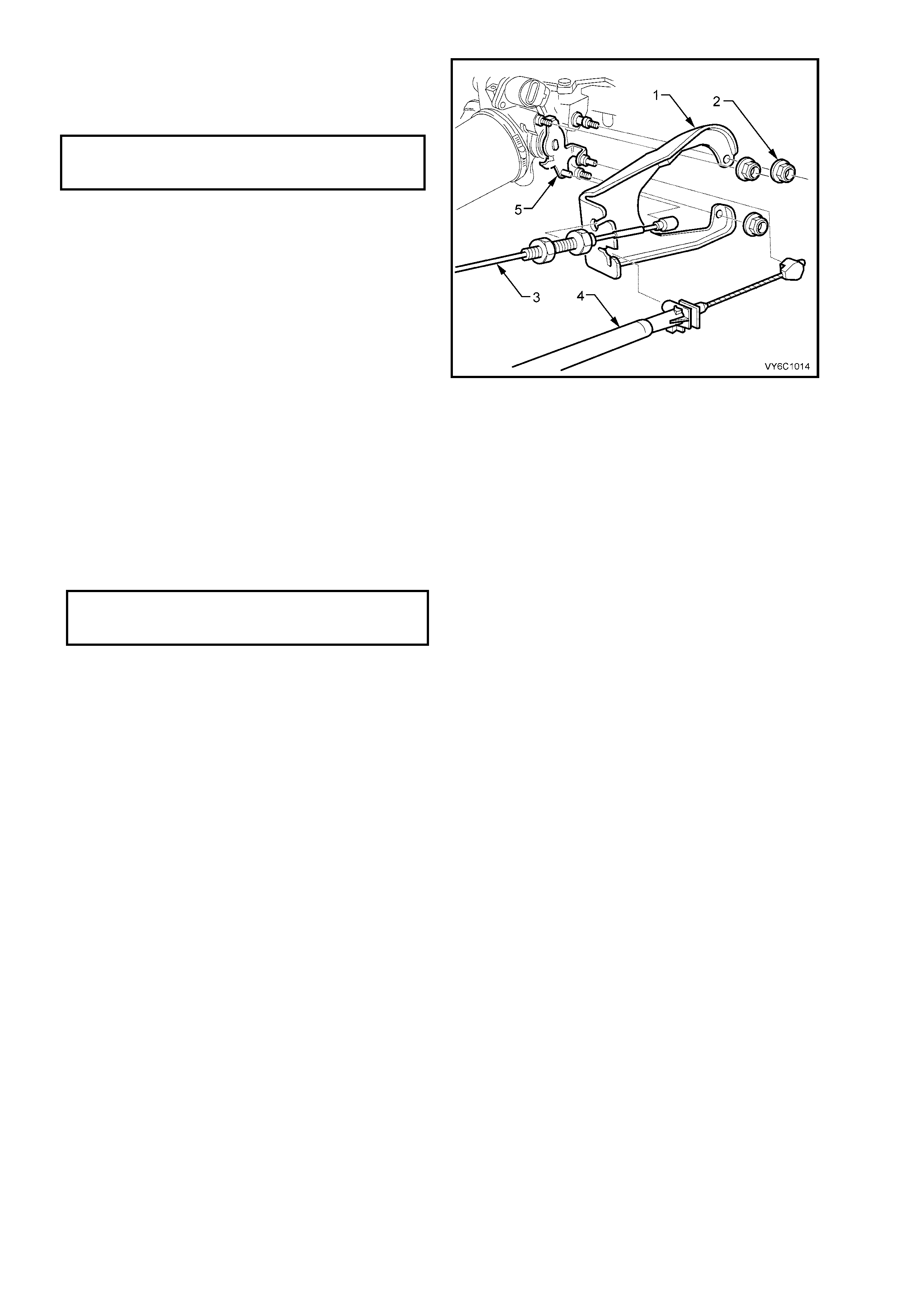

6. Disconnect throttle cable (3) from the throttle

body linkage (5).

7. If vehicle is fitted with cruise control, remove

cruise control cable (4) from throttle body

linkage.

8. Remove throttle cable mounting bracket

attaching nuts (2).

Figure 6C1-3-44 – Throttle Cable Mounting Bracket

9. Loosen the hose clamps (1) and remove

engine positive crankcase ventilation hose (2)

from throttle body union.

10. Remove canister purge hose from throttle

body.

11. Remove throttle body to intake manifold

attaching nuts (3).

12. Remove throttle body (4) and gasket (5) from

the intake m anif old.

Figure 6C1-3-45 – Throttle Body Removal

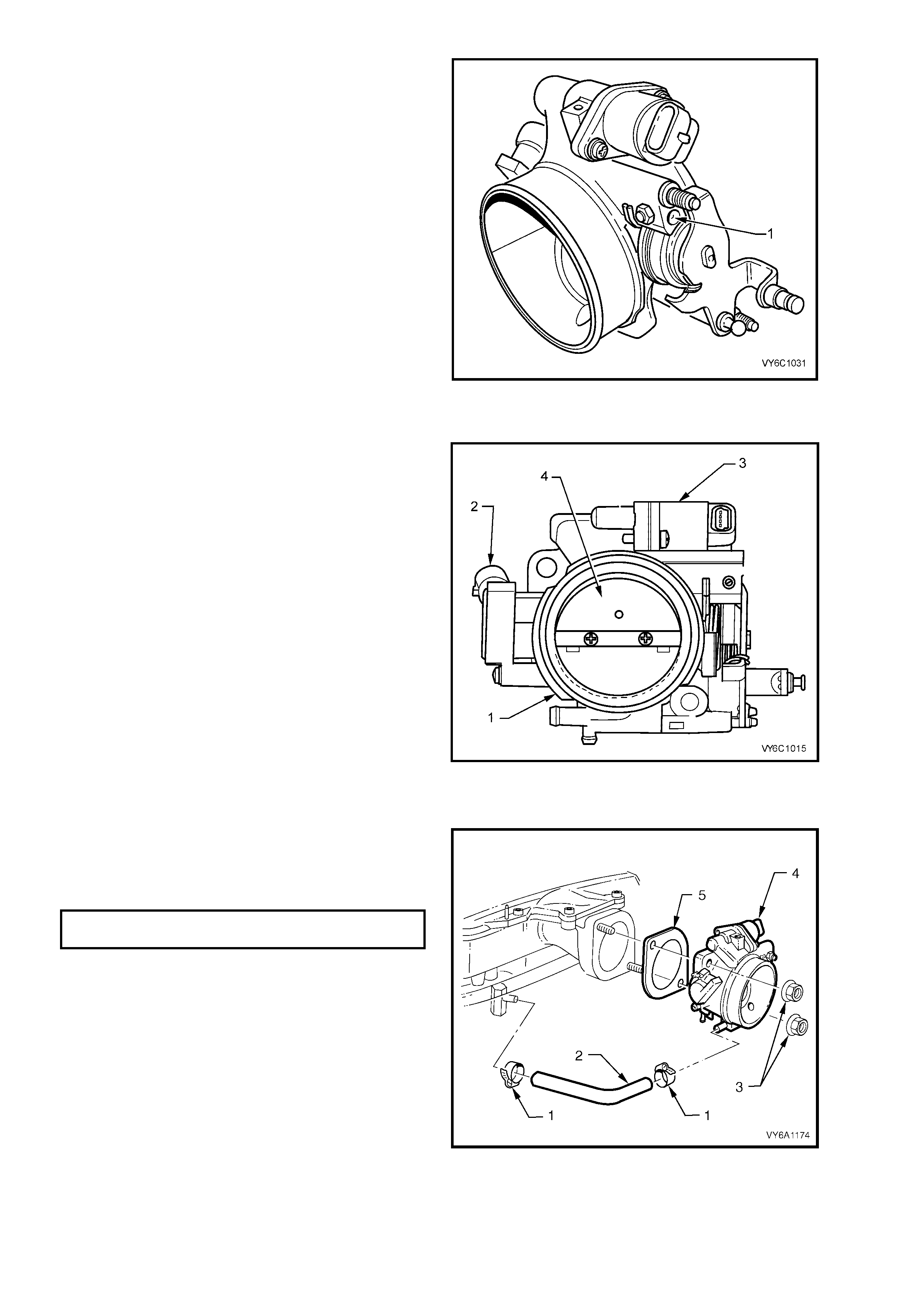

CLEAN

Gasket surfaces on throttle body and manifold.

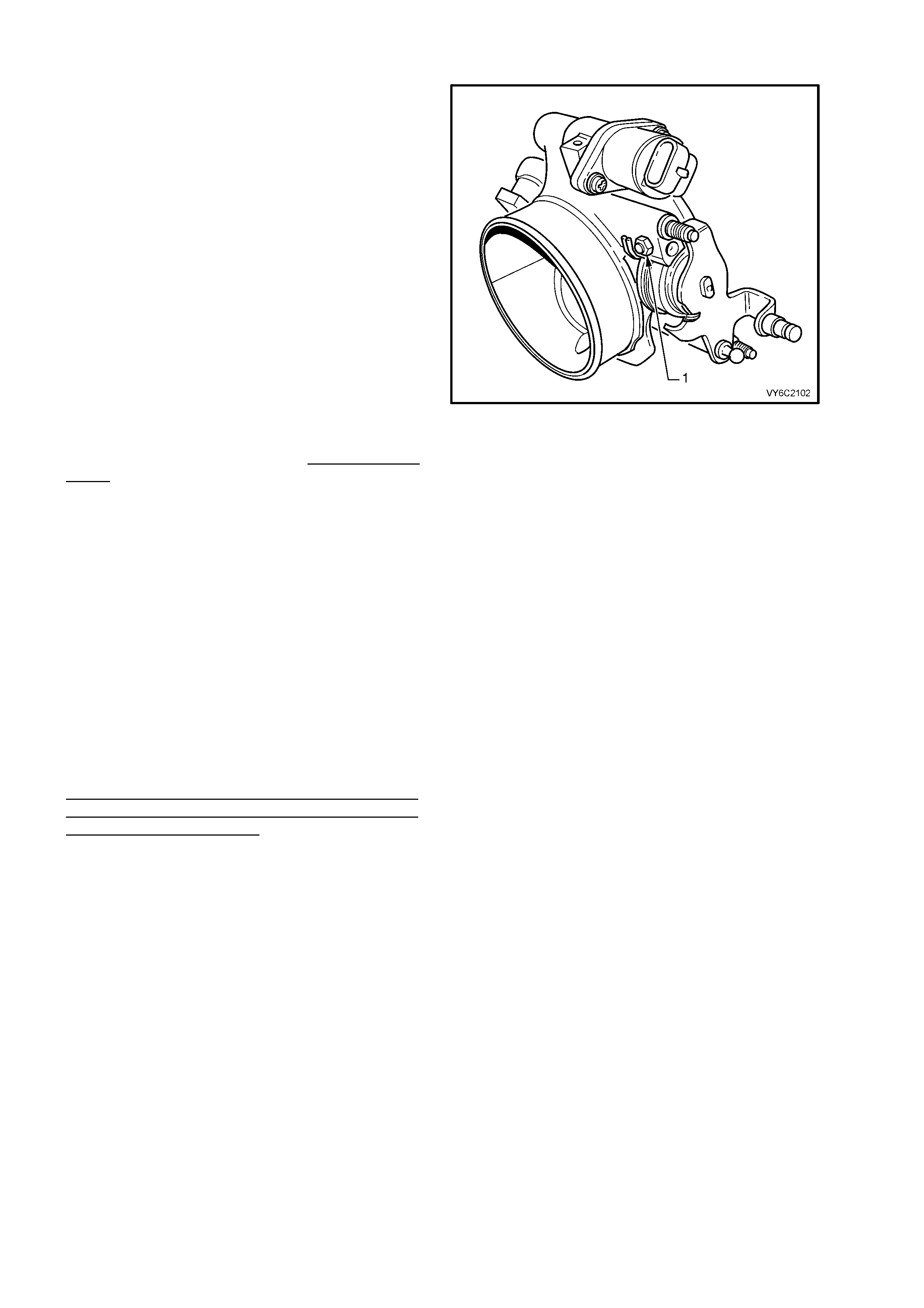

IMPORTANT: If reusing the old throttle body, the

Throttle Body Cleaning Procedure must be

completed before reinstalling.

NOTE: There are specific t hrottle body assemblies

for vehicles with automatic and manual

transmissions. If replacing a throttle body, ensure

that the correct type is fitted.

For example f or ve hic les wi th manual tr ansmis sion,

identification is by a drill point marking (1) on the

throttle body.

Figure 6C1-3-46

THROTTLE BODY CLEANING PROCEDURE

1. Remove throttle body (1) from vehicle.

2. Remove the TP sensor (2) and IAC valve (3)

from the throttle body.

3. Using an approved injector cleaner, clean the

carbon build up around the pintle of the IAC

valve (3).

4. On the throttle body, clean the carbo n build up

around the IAC air port, throttle body bore and

throttle blade (4).

5. Reinstall TP sensor (2) to throttle body.

6. Reinstall IAC valve (3) to throttle body.

7. Continue with the reinstallation of the throttle

body (1) to the engine.

Figure 6C1-3-47 – Throttle Body Cleaning

REINST ALL

1. Instal l thrott le bod y gask et (5) and thrott le b od y

(4) to intake manifold.

2. Install throttle body attaching nuts (3) and

tighten to the correct torque specification.

THROTTLE BODY ATTACHING

NUTS TORQUE SPECIFICATION 15 – 20 Nm

3. Reinst all canister purge control hose to throttle

body.

4. Reinstall engine positive crankcase ventilation

(PCV) hose (2) to throttle body and intake

manifold. Tighten both PCV hose clamps (1)

securely.

5. Reinstall wiring harness connectors to IAC

valve and TP Sensor.

6. Reinstall throttle cable mounting bracket

attaching nut.

Figure 6C1-3-48 – Throttle Body Installation

7. Reinstall cable mounting bracket (1) to the

throttle body, reinstall the three mounting

nuts (2), tightening to the correct torque

specification.

THROTTLE CABLE MOUNTING

BRACKET ATTACHING NUT

TORQUE SPECIFICATION 10 Nm

8. Reinstall throttle cable (3) to throttle body

linkage (5), then reinstall t he outer ca ble to the

bracket (1).

9. Reinstall cruise control cable (4) (if fitted) to

throttle body linkage.

10. Reinstall air duct onto throttle body and mass

air flow sensor, align clamp and air duct

locating notches. Tighten air duct clamp at

throttle body securely.

11. Reconnec t batter y ground l ead.

12. Start engine then listen for air leaks.

13. Check throttle cable adjustment, refer Throttle

Cable Adjust, in 3.10, THROTTLE CABLE, in

this Section.

14. Check cruise control cable adjustment, Refer

to Section 12E, CRUISE C ONTROL.

15. Reinstall engine dress cover to the intake

manifold, ensuring that stud grommets in the

dress cover remain in place. Tighten securing

dome nuts to the correct torque specification.

Figure 6C1-3-49

ENGINE DRESS COVER SECURING

DOME NUT TO INTAKE MANIFOLD

TORQUE SPECIFICATION 5 Nm

THROTTLE BODY IAC VALVE COUNT CHECKING PROCEDURE

1. Start engine and run to normal operating temperature (85° C).

2. Transmission in Park or Neutral.

3. Turn off all accessories (A/C, radio etc.).

4. Install Tech 2 and display Engine Data.

5. Confirm the IAC valve counts are at 25 counts or less at idle.

6. If the counts are not at 15 or less, refer to 3.2 THROTT LE STOP SCREW RESET PROCEDURE if the screw

has been tampered with. If the Throttle Stop Screw has not been tampered with, replace the throttle body.

3.13 IDLE AIR CONTROL VALVE

LT Section No.– 03-300

REMOVE

1. Disconnect battery ground lead.

IMPORTANT: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00 CAUTIONS, 5. Battery Disconnection Procedures before disconnecting the battery.

2. Remove four dome nuts securing the engine dress cover assembly to the intake manifold studs, lift off and

remove the cover assembly.

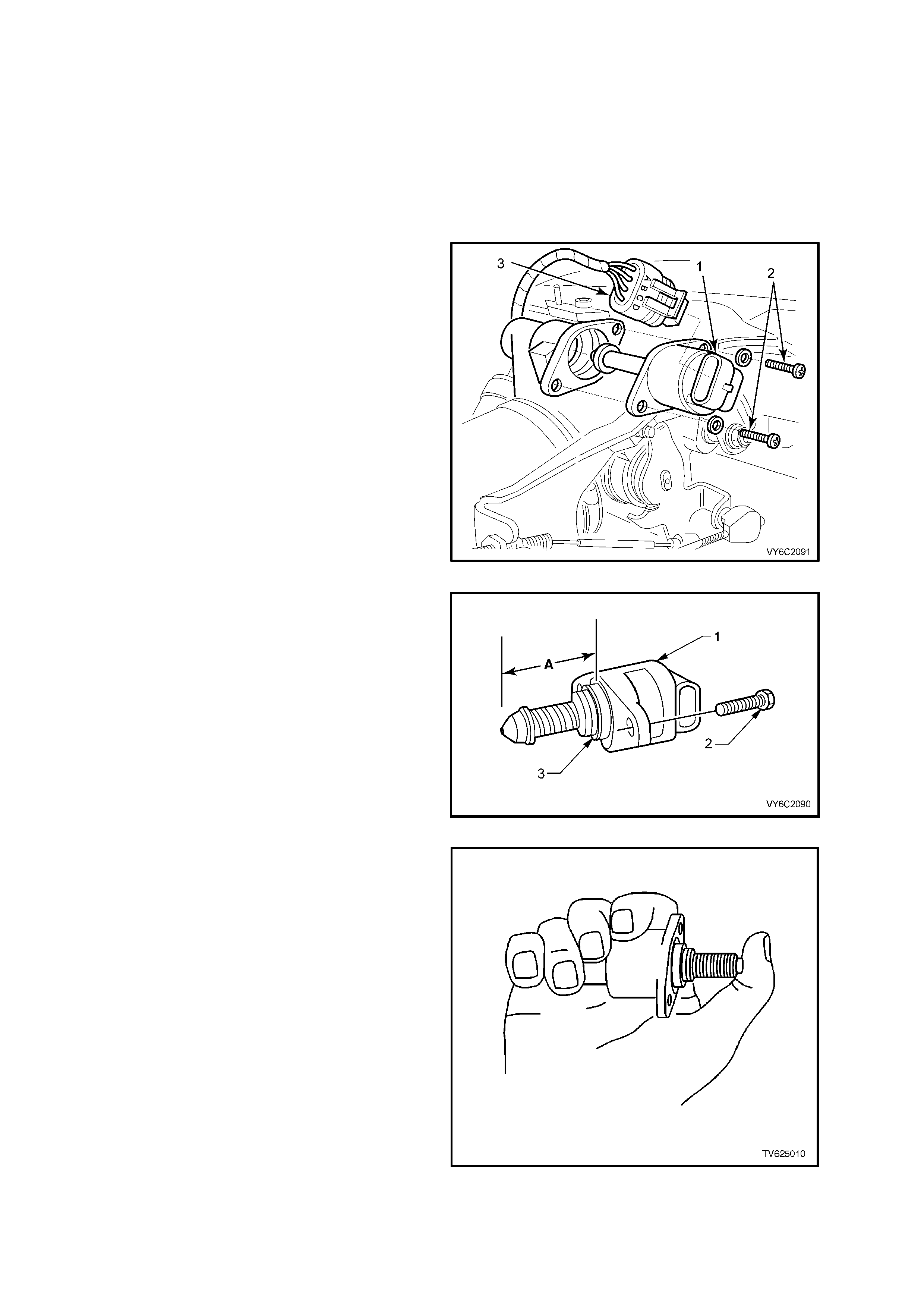

3. Lift up retaining tang on IAC valve wiring

harness connector (3) and pull connector from

valve.

4. Remove IAC valve to throttle body attaching

screws (2).

5. Remove IAC valve (1) from throttle body.

CLEAN

IAC valve sealing surfaces on throttle body, to

assure proper seal of O-ring and contact of IAC

valve flange.

IMPORTANT: When installing a new IAC valve, be

sure it has the correct part number. Check the

current release of the PartFinder® CD ROM.

Figure 6C1-3-50 – IAC Valve Removal

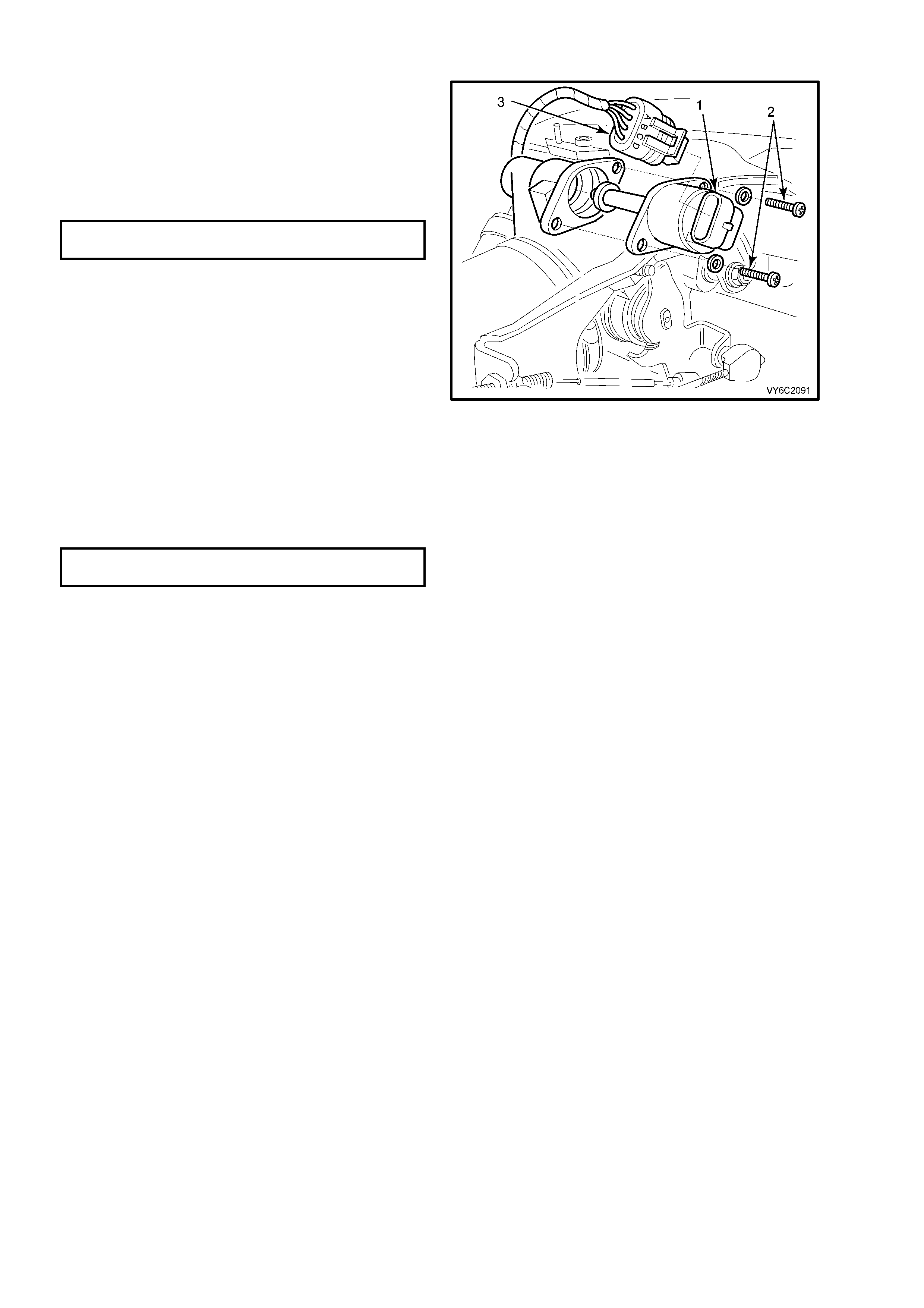

IMPORTANT: Before installing a new IAC valve,

measure distance "A" between tip of valve pintle

and the flange mounting surface (3). If it is greater

than 28 mm, it m us t be reduc ed to prevent d amage

to the valve when it is installed.

Figure 6C1-3-51 – IAC Measured Distance

6. To reduce the length of the pintle, exert firm

pressure on valve pintle to retract it. (A slight

side-to-side movement may be helpful).

Figure 6C1-3-52 – IAC Retraction Method

REINST ALL

1. Lubr icate IAC valv e O-ring with li ght engine oil.

If necessary, install on to valve assembly.

2. Reinstall IAC valve (1) into throttle body with

wiring harness connector (3) facing up, as

shown.

3. Reinstall IAC valve attaching screws (2) and

tighten to the correct torque specification.

IAC VALVE TO THROTTLE BODY

SCREW TORQUE SPECIFICATION 1.5 Nm

4. Rec onnect IAC val ve wiring harn ess connect or

(3).

5. Rec onn ec t batter y ground l ead.

6. If required, clear any DTCs using Tech 2.

7. Start engine, and allow engine to run for 5

seconds then turn engine "OFF" to "reset" the

IAC valve.

OR

Using Tech 2, select “IAC RESET” to reset the

IAC valve.

8. Reinstall engine dress cover to the intake

manifold, ensuring that stud grommets in the

dress cover remain in place. Tighten securing

dome nuts to the correct torque specification.

ENGINE DRESS COVER NUT

TORQUE SPECIFICATION 5 Nm

Figure 6C1-3-53– Idle Air Control Valve Reinstallation

3.14. THROTTLE PEDAL ASSEMBLY

GENERAL DESCRIPTION

This Section describes the servicing procedures for the throttle pedal assemblies fitted with the moulded plastic pad

or the alloy pad.

Althou gh there are obvi ous dif f erences between the t wo st yles of p edal pads, the ser vice pr ocedur es are the sam e

for both options. For the purposes of service information, only the alloy pedal pad is shown.

NOTE: There are differences in the throttle cable adjustment procedures for the various engines available. The

procedure described in this Section for servicing the throttle pedal assembly does not require the throttle cable

adjustment to be altered. However, if throttle cable adjustment is required, refer to the correct Section for the

appropriate engine option.

REMOVE

1. Remove the instrument panel lower right

side trim, refer Section 1A3, INSTRUMENT

PANEL in the MY2003 VY and V2 Series

Service Information.

2. Pull the throttle cable and the plastic retainer

free of the pedal ar m and then s lide the c able

through the slot in the pedal arm.

3. Remove the four nuts (1) securing the pedal

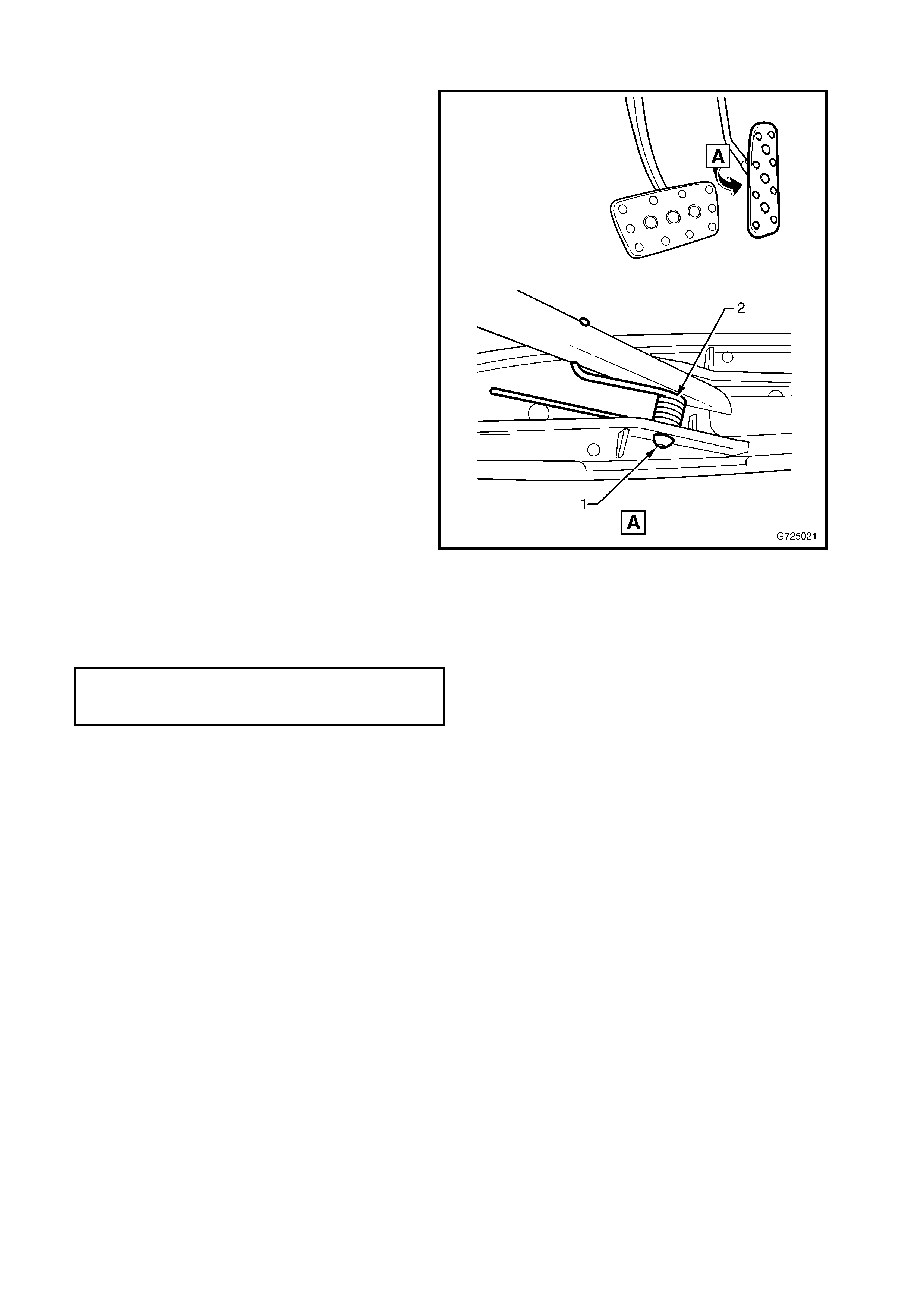

assembly to the dash panel bracket and

remove from the mounting studs.

Figure 6C1-3-54

DISASSEMBLE

1. Using a vice, lay the pedal assembly over on

its side to gain access to the roll pin (1)

securing the ped al pad to the shaf t.

2. Us ing a suit able si ze pin p unc h tap the rol l pin

(1) out of the pedal pad and the assembly,

remove the roll pin and return spring, taking

note of the position of the return spring. (2).

Figure 6C1-3-55

REASSEMBLE

1. Position the throttle pedal pad and return

spring into the correct position as shown.

2. Using a s uitable p in punch, tap the roll pin (1)

in until it is even with the pedal pad housing

on both sides.

3. Ensur e the pedal pad is f ree to swivel and th e

return spr ing has been s eated into the correct

position shown.

Figure 6C1-3-56

REINST ALL

Installation throttle pedal assembly is in the reverse of the removal process noting the following:

1. Tighten the four nuts to the specified torque.

2. Before starting the engine ensure the throttle pedal assembly is free from any restrictions and check throttle

operatio n. If required, adj ust the throttle c able, for V6 engine ref er to 3.10 THROT TLE CABLE – ADJUST , for

V6 S/C eng ine refer to Section 6C2-3, 3.10 THROTTLE CABLE – ADJUST, or for GEN III V8 engin e refer to

Section 6C3-3, 3.4 THROTTLE CABLE ADJUSTMENT – ALL.

3. Reinstall the instrument panel lower right side trim, refer Section 1A3, INSTRUMENT PANEL in the MY2003

VY and V2 Series Service Information.

THROTTLE PEDAL ASSEMBLY

ATTACHING NUT

TORQUE SPECIFICATION 20.0 – 25.0 Nm

4. DIRECT IGNITION SYSTEM

4.1 GENERAL SERVICE INFORMATION

TIMING ADJUSTMENT

The Direc t Ignition S ystem ( DIS) system fully contro ls the spark tim ing. No adjust ment for s park timing is pr ovided.

There are no timing marks on the crankshaft balancer or engine.

CHECKING EST SPARK TIMING OPERATION

The PCM will force the Electronic Spark Timing (EST) spark advance to 10 degrees BTDC when Tech 2 is used,

and By-Pass mode is selected. To check for EST operation, run the engine with the throttle fixed at a steady

1,600 – 1,800 rpm, then enter the "By-Pass" mode of operation, using Tech 2. If the engine speed changes

(drops), EST spark timing is operating. An EST system fault will set a DTC. Use proper DTC Table in

Section 6C1-2A DIAGNOST IC TABLES, to correctly diagnosis the system.

4.2 IGNITION COIL/S

LT Section No.– 02-235

REMOVE

1. Dis c onnect batter y ground l ead.

IMPORTANT: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00 CAUTIONS, 5. Battery Disconnection Procedures before disconnecting the battery.

2. Remove spark plug leads (3) from coil towers,

noting lead numbering with reference to coil

tower numbers.

IMPORTANT: Sli ght l y twis t s park plug leads bef or e

removing from coil towers

IMPORTANT: All spark plug leads and coil

terminals are numbered to correspond to the

cylinder numbering. On service replacement coils

the cylinder numbering does not appear on top of

any coil assembly, refer to cylinder numbering on

the module.

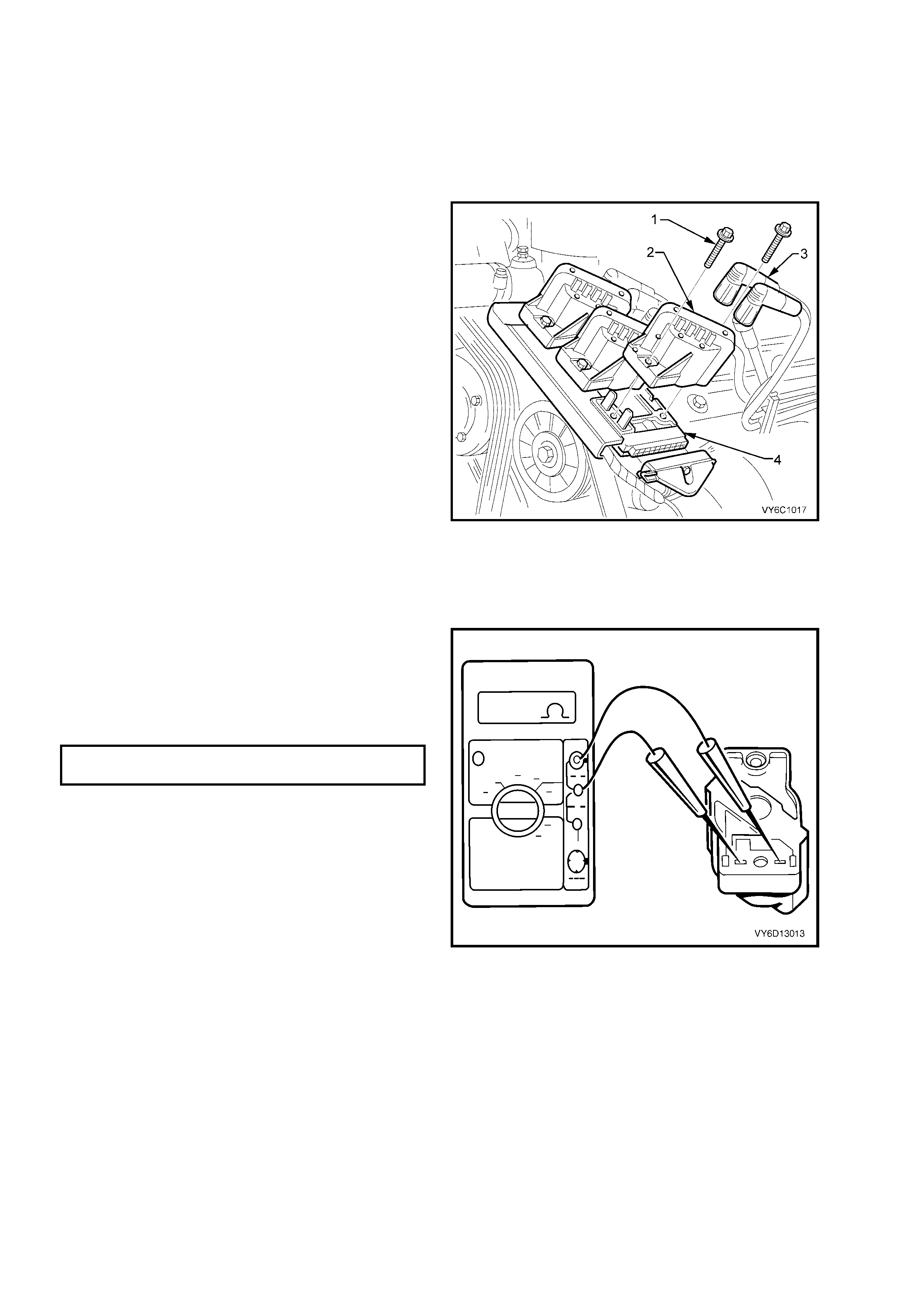

3. Remove screws (1) securing coil(s) to module

and mounting plate (4).

4. Pull coil/s (2) from module (4), taking care not

to bend module terminals.

5. Repeat ste ps 2 to 4 inclusi ve for an y addition al

coils that are to be removed.

Figure 6C1-3-57 – Ignition Coils To Module

RESISTANCE TEST

1. Visually inspect each coil for any signs of

damage or spark tracking.

2. Using a Digital Multimeter (DMM) set to

resistance, measure the coil primary winding

resistance by probing into terminals from the

underside of the coil assembly.

3. Compare the resistance reading to the

specification.

IGNITION COIL PRIMARY WINDING

RESISTANCE SPECIFICATION 0.3 – 1.5 Ω

4. Replace a ny coil that is da maged, s hows signs

of spark tracking or is outside the specified

resistance range.

NOTE: Som e DMM lead pr obes m y be too lar ge to

contact the primary winding connections inside the

coil housing. If this is the case, then use a suit able

size test terminal from J35616-A Connector Test

Adaptor Kit.

Figure 6C1-3-58 – Testing Coil Primary Windings

5. To check the secondary winding resistance of

the coil, turn the coil over and measure the

resistance between the two high tension

terminals, as shown.

6. Compare the reading to the specification.

IGNITION COIL SECONDARY WINDING

RESISTANCE SPECIFICATION 5,000 – 7,000 Ω

7. Replace any coil assembly that is not within

specification.

Figure 6C1-3-59 – Testing Coil Secondary Windings

REINST ALL

1. Reinstall coil/s (2) onto module (4), aligning

module terminals with mating slots on

underside of coil.

2. Reins t al l c oi l sec uri ng s c rews ( 1) a nd t ig hten to

the correct torque specification.

DIS COIL TO MOUNTING PL ATE

SCREW TORQUE SPECIFICATION 5 Nm

3. Reconnect spark plug leads (3) to coil

term inals, ensuring correct lead to coi l term inal

relationship.

4. Reconnect battery ground lead, start engine

and ensure eng ine operate s corr ectl y.

Figure 6C1-3-60 – Ignition Coils To Module

4.3 DIS MODULE

LT Section No.– 02-235

REMOVE

1. Dis c onnect batter y ground l ead.

IMPORTANT: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00 CAUTIONS, 5. Battery Disconnection Procedures before disconnecting the battery.

2. From beneath powertrain harness retainer (1)

at front of gently pull down on the retainer

lower locating tangs and pull retainer (1) from

coil and module assembly (2).

3. Loosen screw (3) attaching 14-pin wiring

harness connector to coil and module

assem bly (2), until the c onnector can be p ulled

from module.

4.

Figure 6C1-3-61 Removing Module Electrical Connector

5. Remove all spark plug leads (1) from the coil

towers, taking particular note of the lead

numbering with reference to the coil tower

markings.

NOTE 1: Slightly twist spark plug leads to break

the seal, before removing from coil towers

NOTE 2: All spark plug leads and ignition coil

terminals are numbered to correspond to the

cylinder numbering. On service replacement

ignition coils, the cylinder numbering does not

appear on top of any coil assembly, so refer to

cylinder numbering on t he module.

6. Rem ove two bolts ( 4) securing the DIS m odule

and coil assembly, to the left hand cylinder

head. Carefully place the DIS module and coil

assembly to one side.

7. Remove the two screws (3) securing the three

ignition coils (5) from the DIS module. Refer to

4.2 IGNITION COIL/S, in this Section.

8. Rem ove the co ils from the m odule, taking car e

not to bend the module terminals.

9. Remove the ignition module assembly from he

module mounting plate.

Figure 6C1-3-62 – Ignition Module Removed

REINST ALL

1. When replacing module assembly, remove module to coil terminal and 14 pin wiring harness connector

terminal seals from original module. Install seals onto new module, taking care not to damage seals. If any

seal(s) is damaged in any way, install new seal(s).

2. Place coils onto module, aligning module terminals with mating slots on underside of coil. Refer to

4.2 IGNITION COIL/S, Reinstall, in this Section.

3. Reinstall the ignition module assembly to the mounting plate, locating raised lugs on both coil and module

together.

NOTE: The lugs on the underside of the module will only mate with the mounting plate holes in one way only to

ensure correct assembly relationship.

4. Reinstall screws (3) securing coils and module to the mounting plate and tighten to the correct torque

specification.

DIS COIL TO MOUNTING PL ATE

SCREW TORQUE SPECIFICATION 5 Nm

5. Reins t al l DI S module and c oil as sembl y to the lef t h an d cylinder h ead, s ecur in g with t he t w o retainin g b olts a nd

tightening to the correct torque specification.

DIS MODULE AND COIL ASSEMBLY

BOLT TORQUE SPECIFICATION 45 Nm

6. Reconnect spark plug leads (1) to coil terminals, ensuring correct lead to coil terminal relationship.

7. Reconnect 14-pin wiring harness connector to module assembly and tighten attaching bolt (2) to the correct

torque specification.

WIRING HARNESS CONNECTOR

TO DIS MODULE SCREW

TORQUE SPECIFICATION 1.0 Nm

8. Snap powertrain wiring harness retainer onto coil and module assembly and it's mounting plate.

9. Rec onn ec t batter y ground l ead.

10. Start engine and ensure engine operates correctly.

4.4 CRANKSHAFT (CKP) SENSOR

LT Section No.– 02-000

REMOVE

1. Dis c onnect batter y ground l ead.

IMPORTANT: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00 CAUTIONS, 5. Battery Disconnection Procedures before disconnecting the battery.

2. Remove crankshaft balancer. Refer to 2.19 CRANKSHAFT BALANCER, in Section 6A1, ENGINE

MECHANICAL - V6 ENGINE.

3. Lift up retaining tang on crankshaft sensor

engine wiring harness connector and pull

connector from sensor assembly.

Figure 6C1-3-63 – CKP Sensor Connector Removal

4. Rem ove the s ensor shie ld by car efull y leveri ng

each corner from the front cover using a

screwdriver or s imilar lever . Move the sh ield to

and fro until it comes clear. Set the shield to

one side.

Figure 6C1-3-64 – CKP Sensor Shield Removal

5. Remove the studs (1) attaching the sensor (2)

to the front cover (3).

6. Remove the sensor (2) from the front plate.

Figure 6C1-3-65 – Removing the CKP Sensor

REINST ALL

1. Clea n the threads of the studs and , using a suita ble tap, clean s ealer from the sensor m ounting threa ds in the

cylinder bl oc k.

2. Reinstall the crankshaft sensor onto the front cover dowel pin.

3. Apply Loctite 242 or equivalent to the cleaned CKP sensor retaining studs, reinstall to the front cover and

tighten to the correct torque specification.

CKP SENSOR TO FRONT COVER

STUD TORQUE SPECIFICATION 25 Nm

4. Reins tall the se nsor shield onto the front co ver studs, ens uring that the sh ield retain ers are full y engaged ov er

the stud ends. Gently tap fully home, using a plastic faced hammer.

5. Reinstall the wiring harness connector to the sensor, ensuring that the locking tang is engaged and that the

harness is routed correctly.

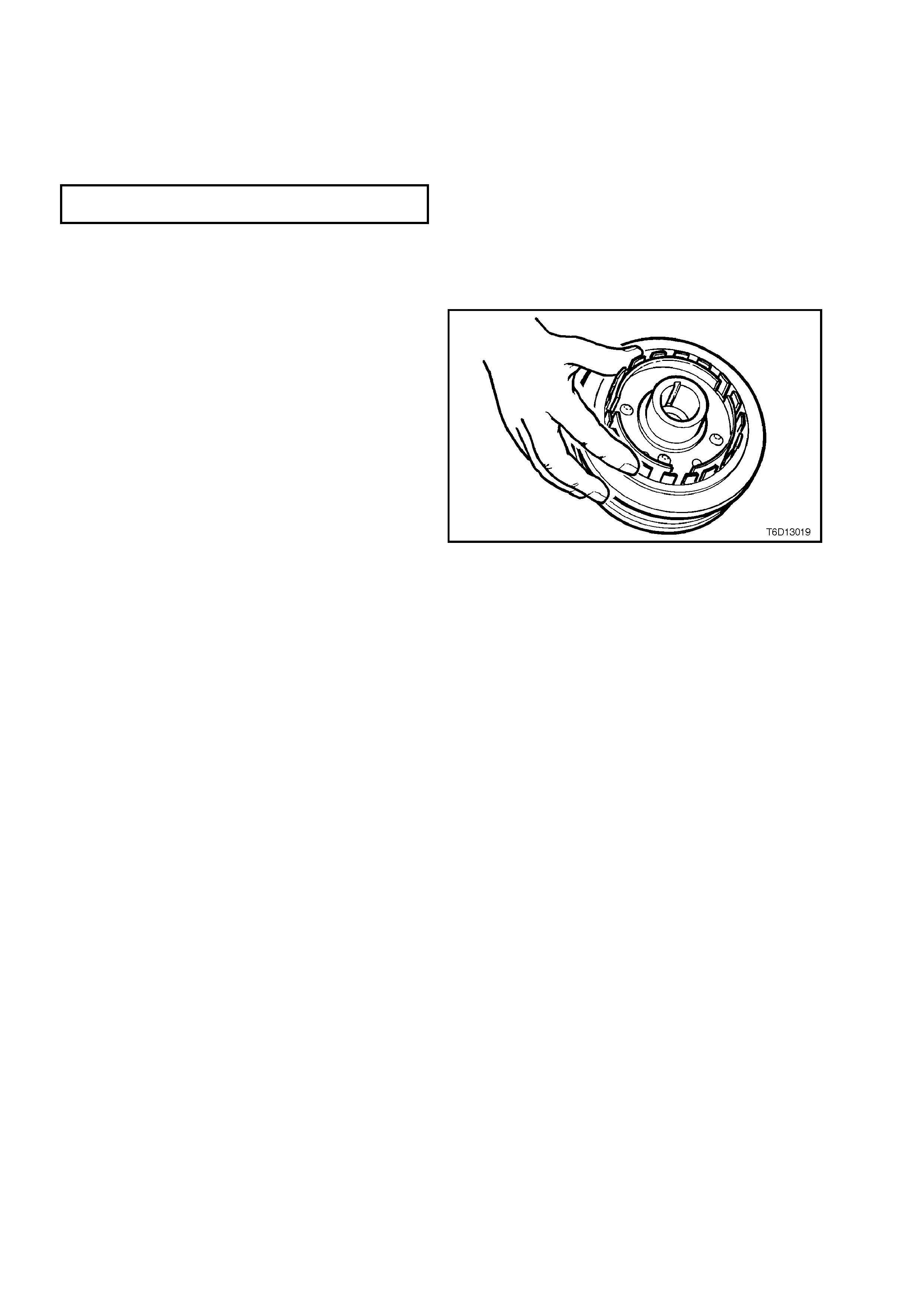

6. Visually inspect the interrupter rings for any

damage or distortion.

NOTE: Replace the crankshaft pulley if any

damage or distortion is noticed. Do not attempt to

repair any damage.

Figure 6C1-3-66 – Inspect Crankshaft Pulley Rings

7. Reinstall the crankshaft pulley. Refer to

2.19 CRANKSHAFT BALANCER, in Section

6A1, ENGINE MECHAN IC AL - V6 ENGINE.

NOTE: Do not install the drive belt at this stage.

8. Rotate the crankshaft to check that the

interrupter rings do not contact the sensor.

9. Replace the balancer assembly if the

interrupter rings contact the sensor at any

point. This indicates that the interrupter rings

have excessive runou t.

10. Reinstall the engine drive belt. Refer to

2.7 ENGINE DRIVE BELT, in Section 6A1

ENGINE MECH ANIC AL – V6 ENG IN E.

11. Refit the battery ground lead.

12. Start the engine and check for correct engine

operation.

Figure 6C1-3-67 – Camshaft/Crankshaft Position Sensors

Legend

1. Crankshaft Balancer Retaining Bolt

2. Crankshaft Balancer

3. Screw _ Camshaft Sensor Retaining

4. O-Ring – Camshaft Sensor Sealing

5. Sensor – Crankshaft Position

6. Sensor – Camshaft Position

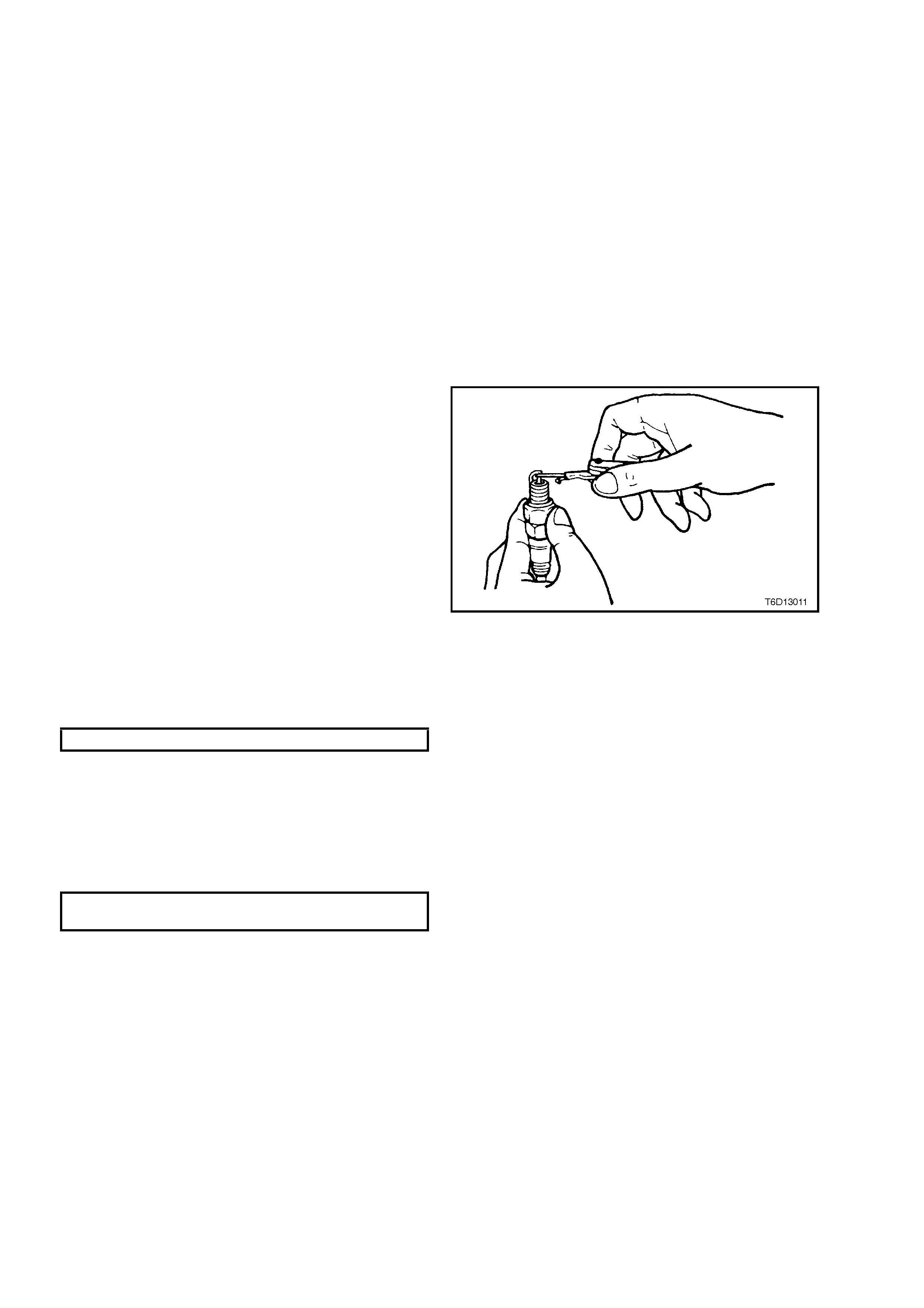

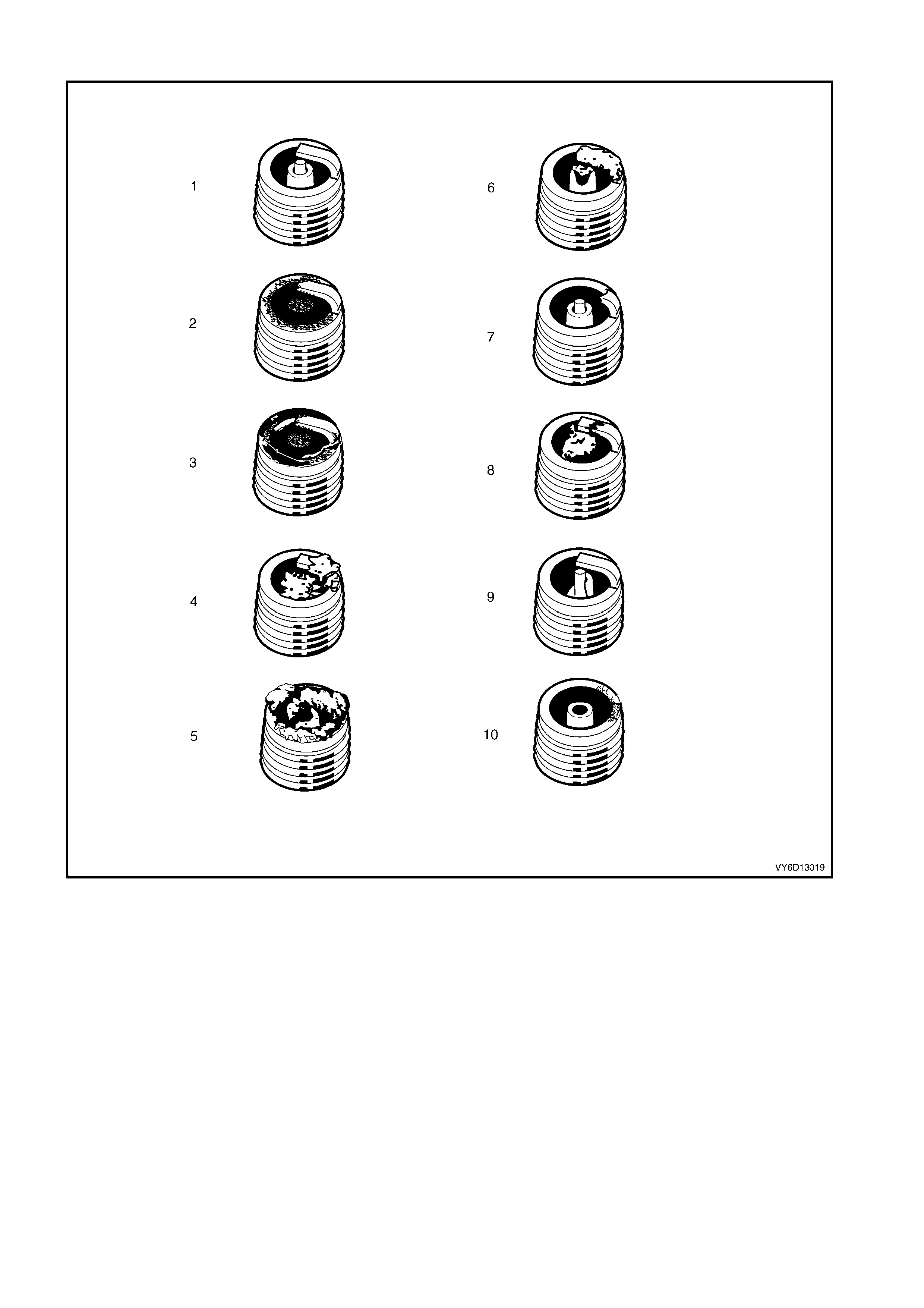

7. Shield – Crankshaft Sensor