SECTION 6C2-1 - GENERAL INFORMATION –

V6 SUPERCHARGED ENGINE

IMPORTANT

Before perfo rming any Service Operat ion or oth er procedure described in this Section , refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1 GENERAL DESCRIPTION

1.1 POWERTRAIN CONTROL MODULE (PCM)

PCM SECURITY LINK

PROM

PCM MEMORY FUNCTIONS

1.2 ENGINE INFORMATION SENSORS

AND SIGNALS

CAMSHAFT POSITION SENSOR

ENGINE COOLANT TEMPERATURE (ECT)

SENSOR

EXHAUST GAS OXYGEN SENSOR

INTAKE AIR TEMPERATURE (IAT) SENSOR

MASS AIR FLOW (MAF) SENSOR

THROTTLE POSITION (TP) SENSOR

VEHICLE SPEED SENSOR (VSS)

A/C REQUEST SIGNAL

BATTERY VOLTAGE

CRANKSHAFT REFERENCE SIGNAL

ENGINE COOLING FAN SIGNAL

TRANSMISSION POWER/ECONOMY SWITCH

THEFT DETERRENT INPUT SIGNAL

OIL PRESSURE SWITCH

1.3 AUTOMATIC TRANSMISSION INFORMATION

SENSORS AND SIGNALS

1-2 (A) AND 2-3 (B) SHIFT SOLENOID VALVES

3-2 CONTROL SOLENOID VALVE

TRANSMISSION PRESSURE CONTROL

SOLENOID

TORQUE CONVERTER CLUTCH SOLENOID

VALVE

TORQUE CONVERTER CLUTCH PWM

SOLENOID VALVE

TRANSMISSION FLUID PRESSURE (TFP)

MANUAL VALVE POSITION SWITCH

VEHICLE SPEED SENSOR

AUTOMATIC TRANSMISSION FLUID

TEMPERATURE SENSOR

TRANSMISSION PASS-THROUGH CONNECTOR

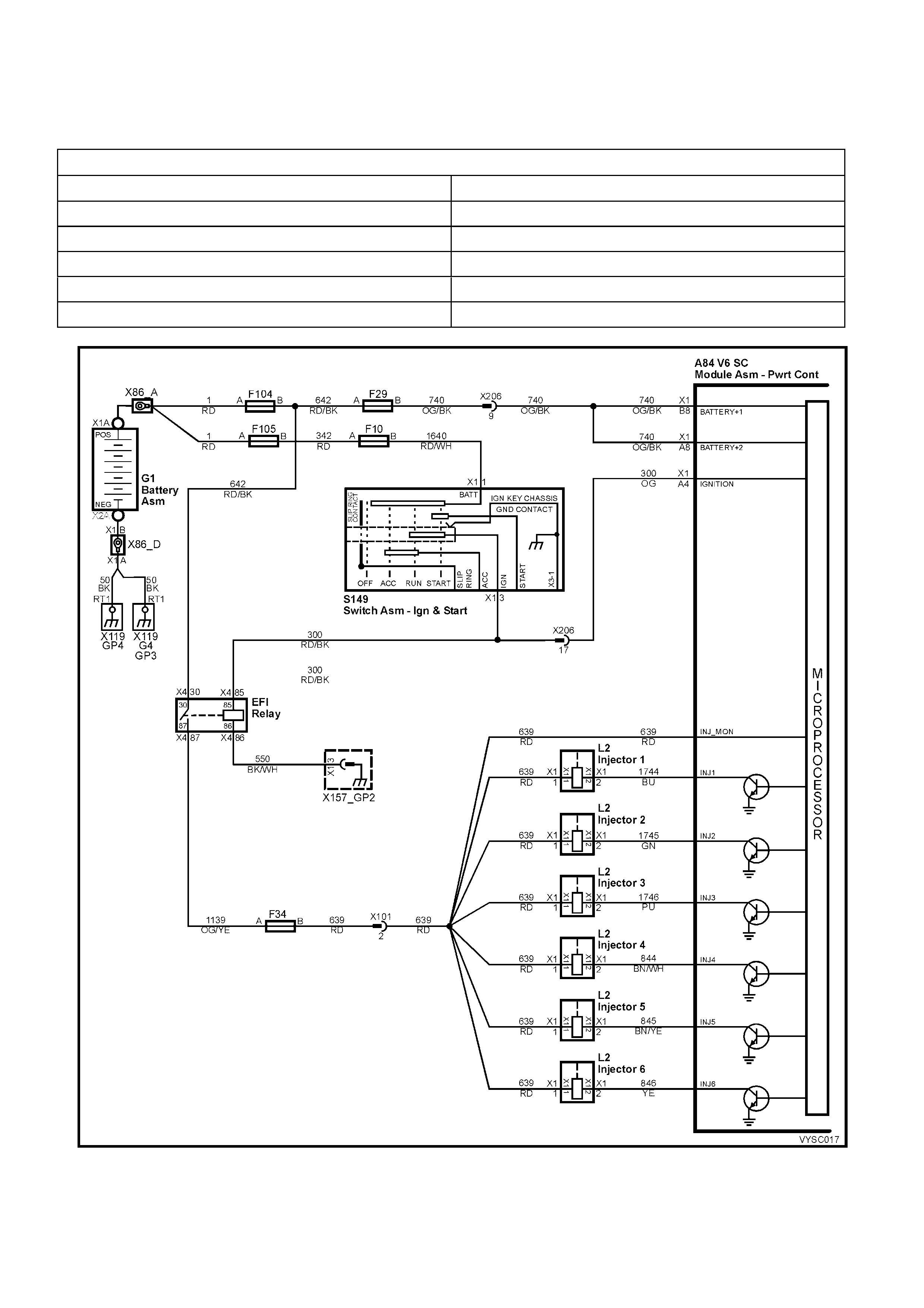

1.4 FUEL CONTROL SYSTEM

PURPOSE

FUNCTION

MASS AIR FLOW SYSTEM

MODES OF OPERATION

CAMSHAFT POSITION SENSOR

SHORT TERM FUEL TRIM

LONG TERM FUEL TRIM

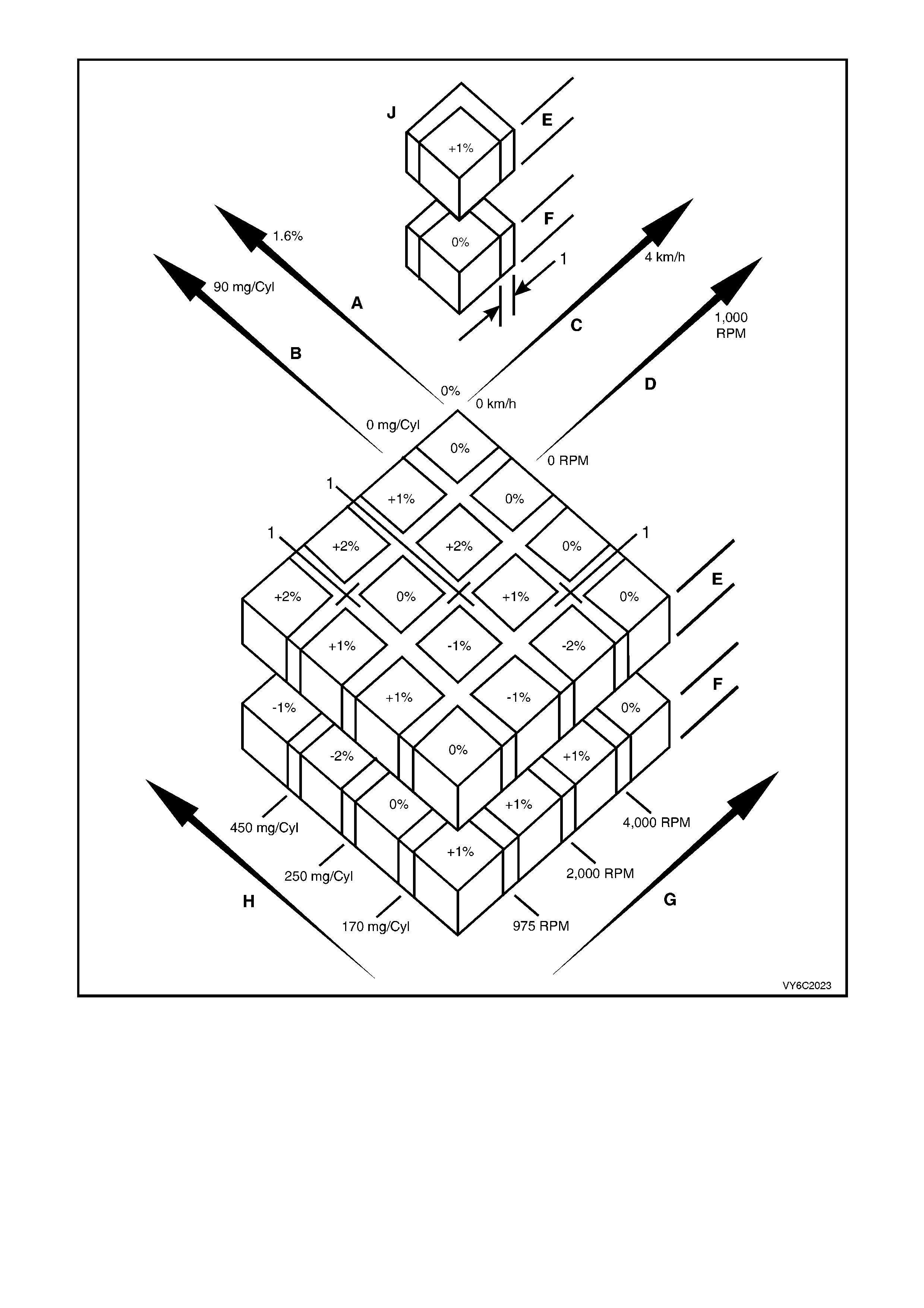

LONG TERM FUEL TRIM CELLS

BASIC FUEL SYSTEM OPERATION

SYSTEM COMPONENTS

1.5 IDLE AIR CONTROL (IAC) VALVE

1.6 DIRECT IGNITION SYSTEM (DIS)

PURPOSE

OPERATION

SYSTEM COMPONENTS

DIRECT IGNITION SYSTEM (DIS)

NOTEWORTHY INFORMATION

1.7 ELECTRONIC SPARK TIMING (EST)

HOW DTC 41 AND 42 ARE DETERMINED

RESULTS OF INCORRECT OPERATION

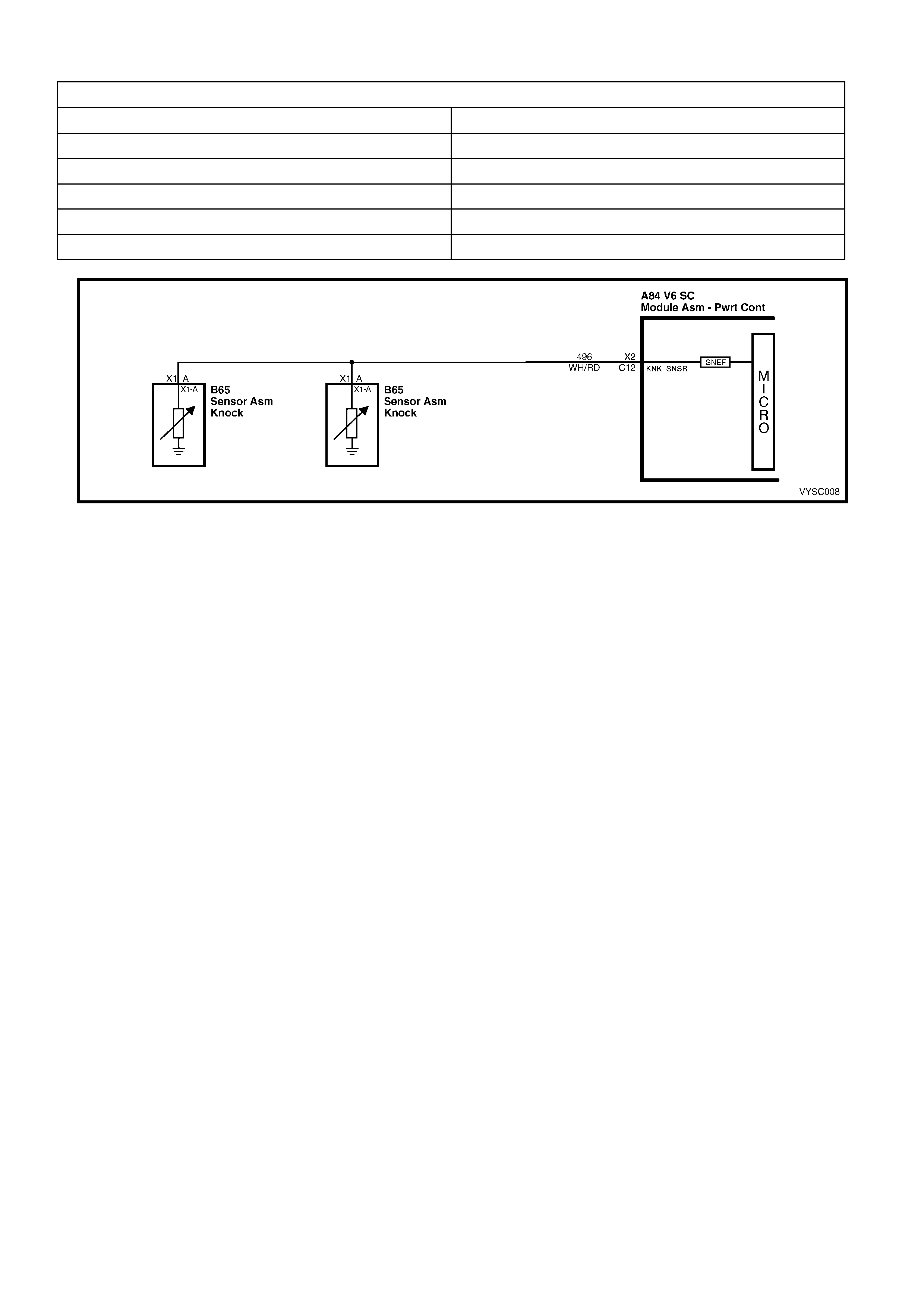

1.8 ELECTRONIC SPARK CONTROL (ESC) SYSTEM

PURPOSE

OPERATION

1.9 EVAPORATIVE EMISSION CONTROL

RESULTS OF INCORRECT OPERATION

1.10 ELECTRIC COOLING FAN

ENGINE COOLING FAN LOW SPEED

ENGINE COOLING FAN HIGH SPEED

1.11 A/C CLUTCH CONTROL

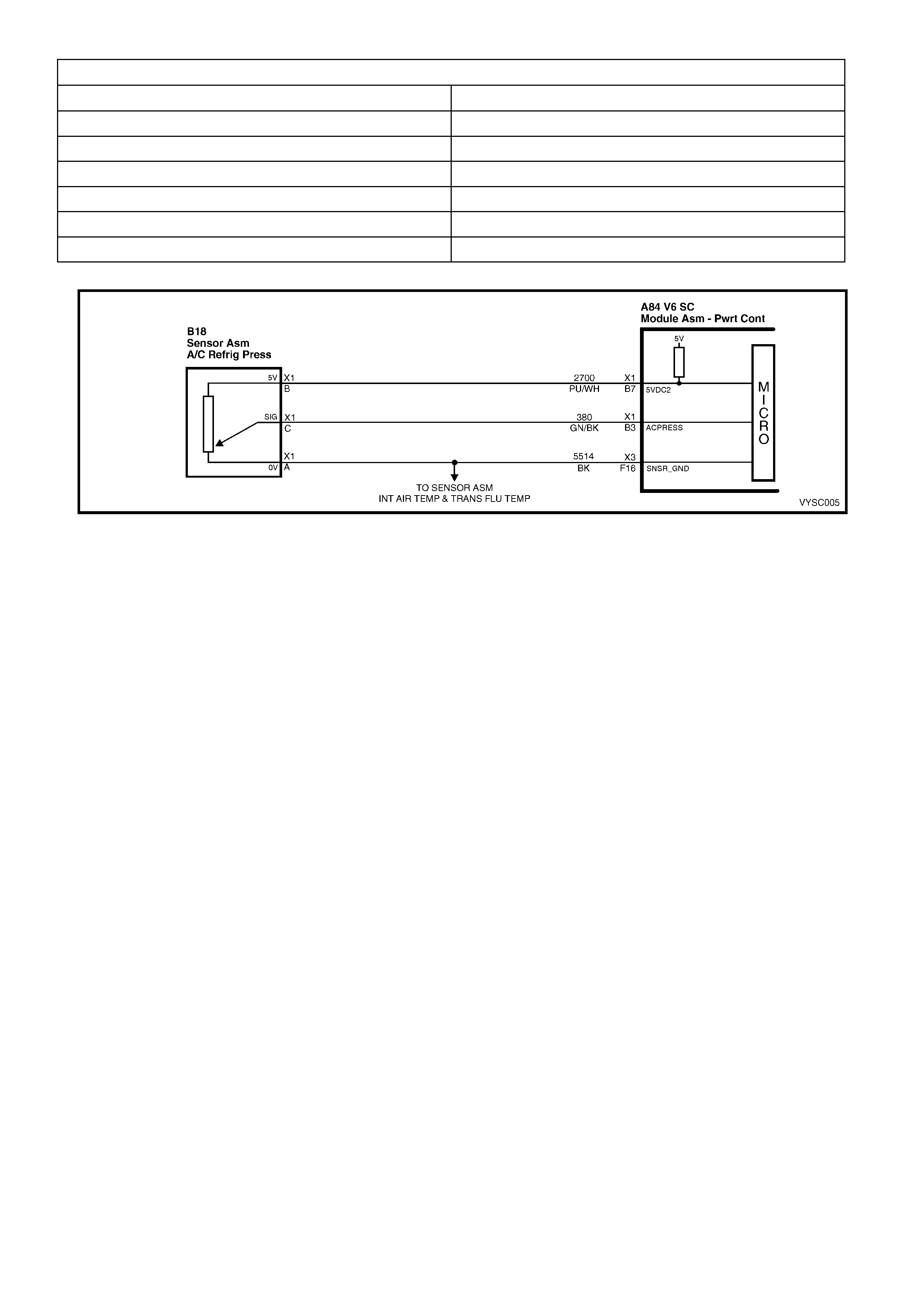

1.12 A/C REFRIGERANT PRESSURE SENSOR

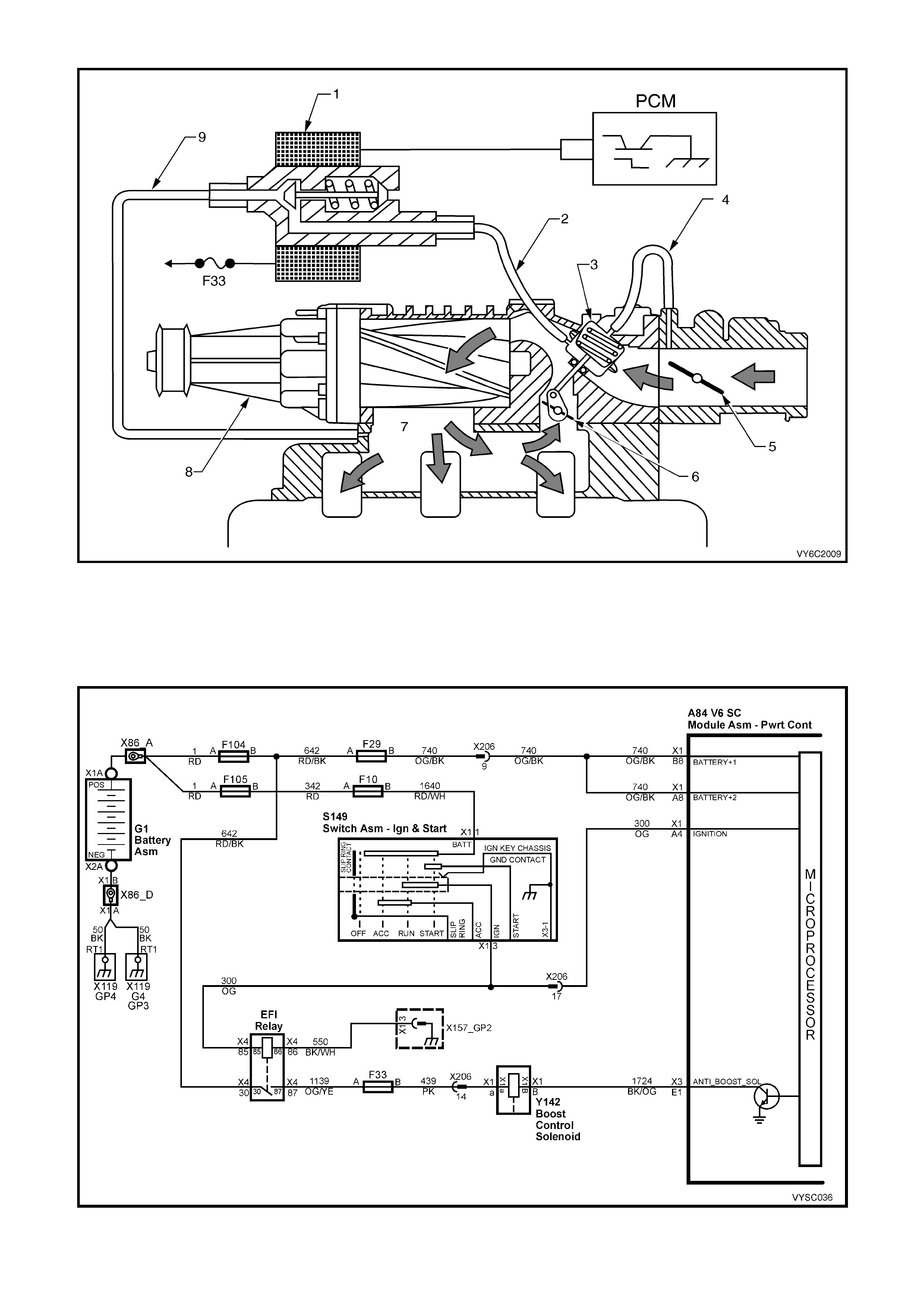

1.13 SUPERCHARGER SYSTEM

DESCRIPTION

SUPERCHARGER OPERATION

BOOST CONTROL

OPERATION

RESULTS OF INCORRECT OPERATION

DIAGNOSIS

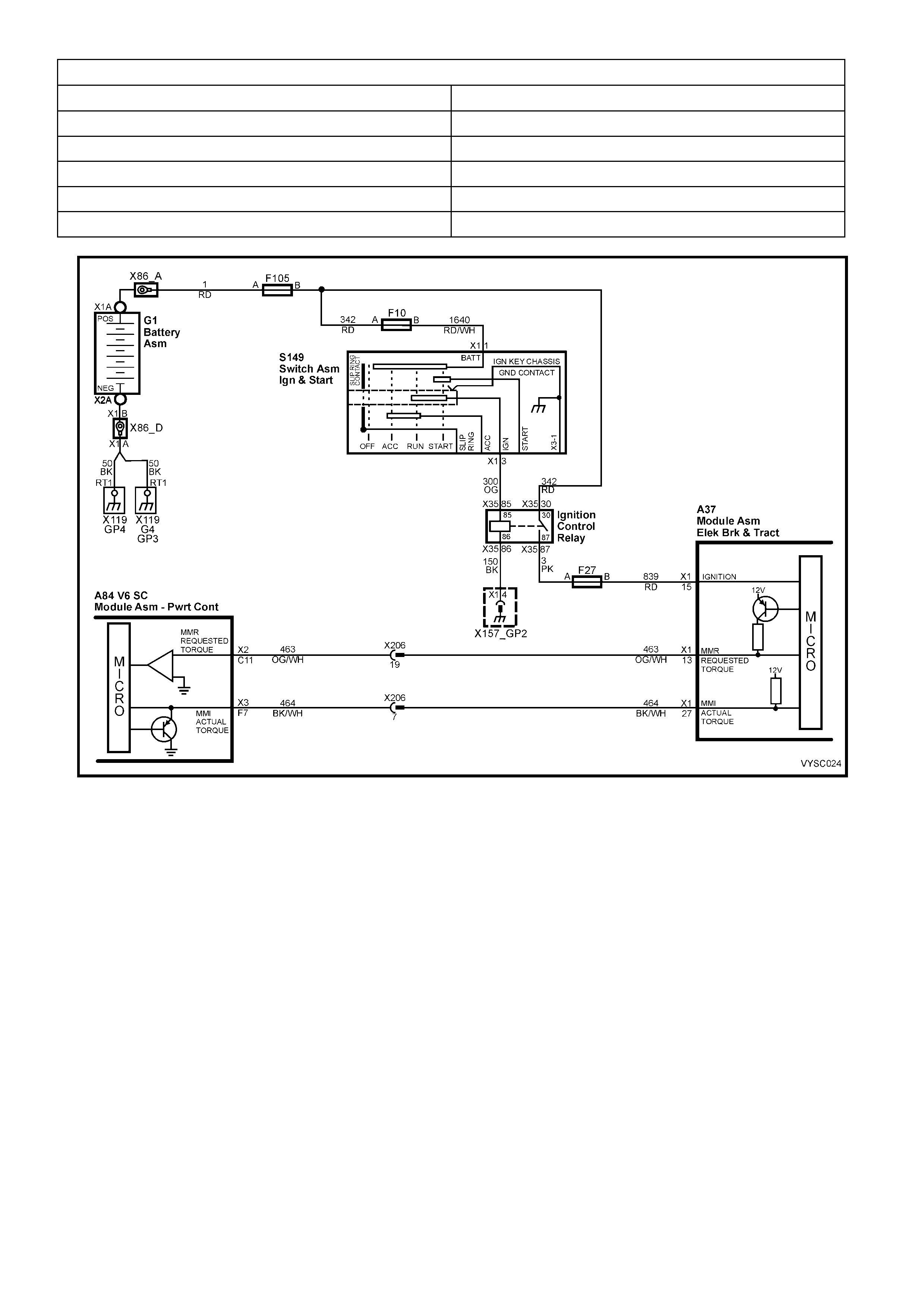

1.14 ANTILOCK BRAKING SYSTEM / TRACTION

CONTROL SYSTEM

PURPOSE

1.15 ABBREVIATIONS AND GLOSSARY OF TERMS

Techline

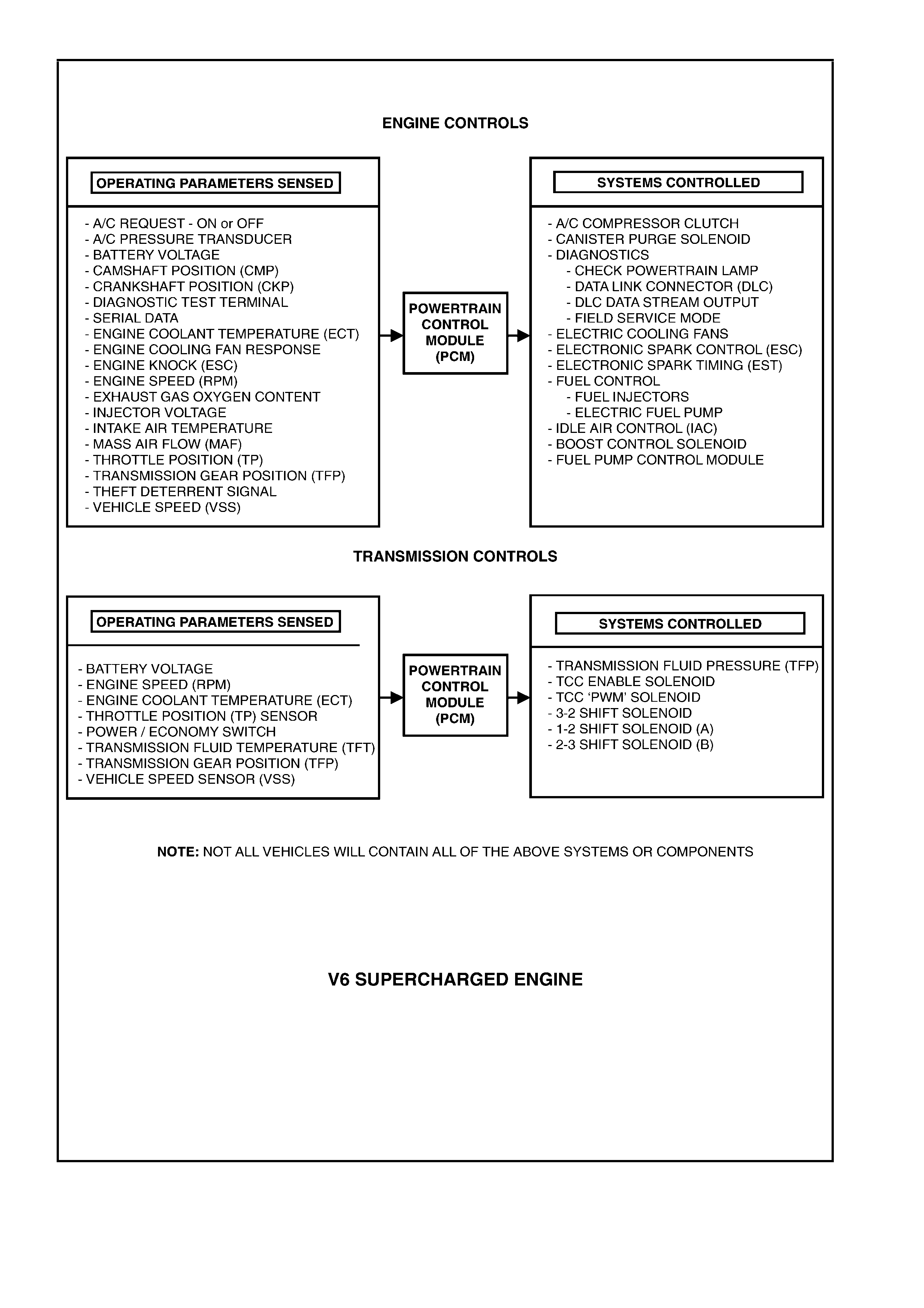

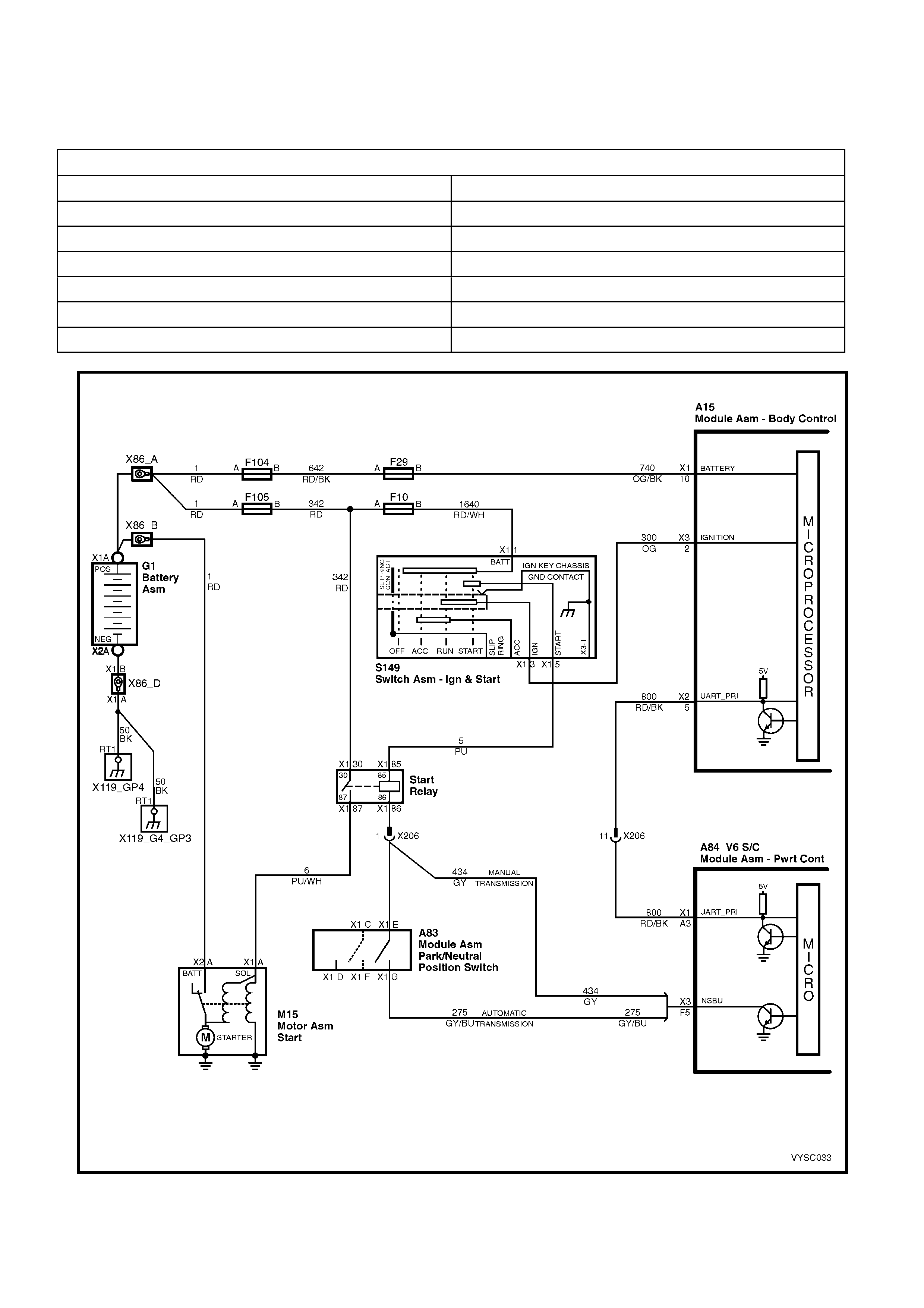

1. GENERAL DESCRI PTI O N

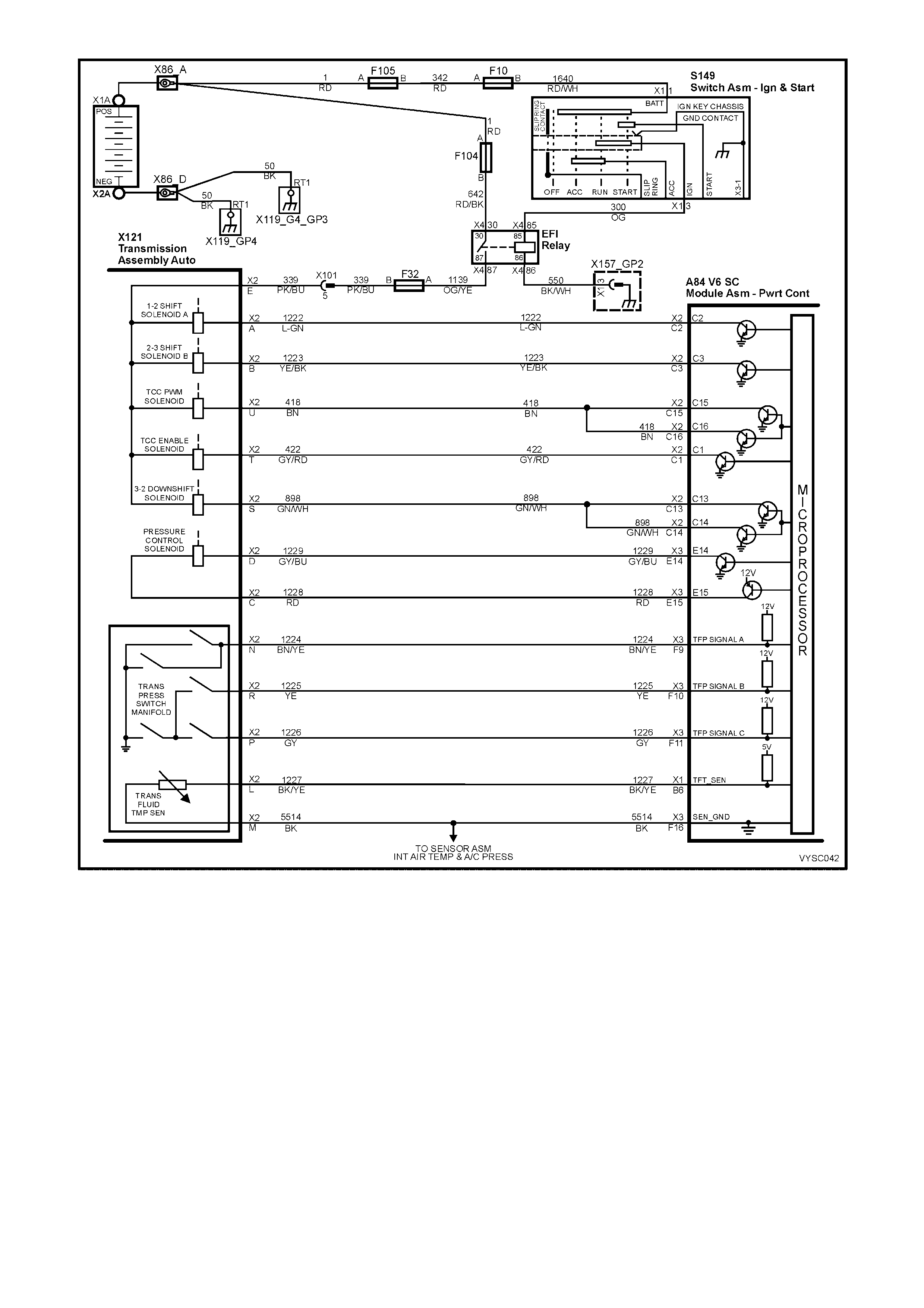

This engine, with an autom atic tr ans miss ion, uses a Powertrain Contr ol Module ( PCM) to c ontrol ex haus t emiss ions

while maintaining excellent driveability and fuel economy. The PCM maintains a desired air/fuel ratio of precisely

14.7 to 1 by m onitoring electrical signals f rom dual oxygen sensors m ounted in the exhaust stream and optimising

the amount of fuel flow from the injectors. This method of "feed back" fuel control is called CLOSED LOOP.

In addition to fuel control, the PCM also controls ignition dwell and timing, idle speed, electric engine cooling fan,

electric fuel pum p, ins tr ument "Chec k Powertr ain" Malf unc tion Indic ator ( MIL) and, on vehicles so equipped, the A/C

compressor clutch. The PCM controls the automatic transmission functions and also interfaces through the serial

data line with other vehicle control or information modules, such as the Instrument, Body Control Module (BCM),

ABS/TCS m odule, OCC m odule and SIR m odule. Figure 6C2-1-1 c ontains a list of the various operating conditions

sensed by the PCM on the left, and the various systems controlled, on the right. Details of basic operation,

diagnosis, and service are covered in this Section.

The PCM has a built-in diagnostic system that recognises and identifies possible operational problems and alerts

the driver by activating the "Check Powertr ain" Malfunc tion Indicator Lam p ( MIL) on the instr um ent panel. If the MIL

is activated while driving, it does not m ean that the engine s hould be stopped im m ediately, but the cause of the MIL

being activated should be chec k ed as soon as is reas onably possible. The PCM has built- in back up sys tem s that in

all but the most severe failures will allow the vehicle to operate in a near normal manner until repairs can be made.

Below the instrum ent panel and the steer ing colum n is a Data Link Connector (DLC) which is used by the ass em bly

plant for a c omputer "c hec k-out" of the s ystem. This c onnec tor is us ed in s ervic e together with the Tec h 2 scan tool,

to help diagnose the system. Refer to Section 6C2-2, DIAGNOSIS for further details.

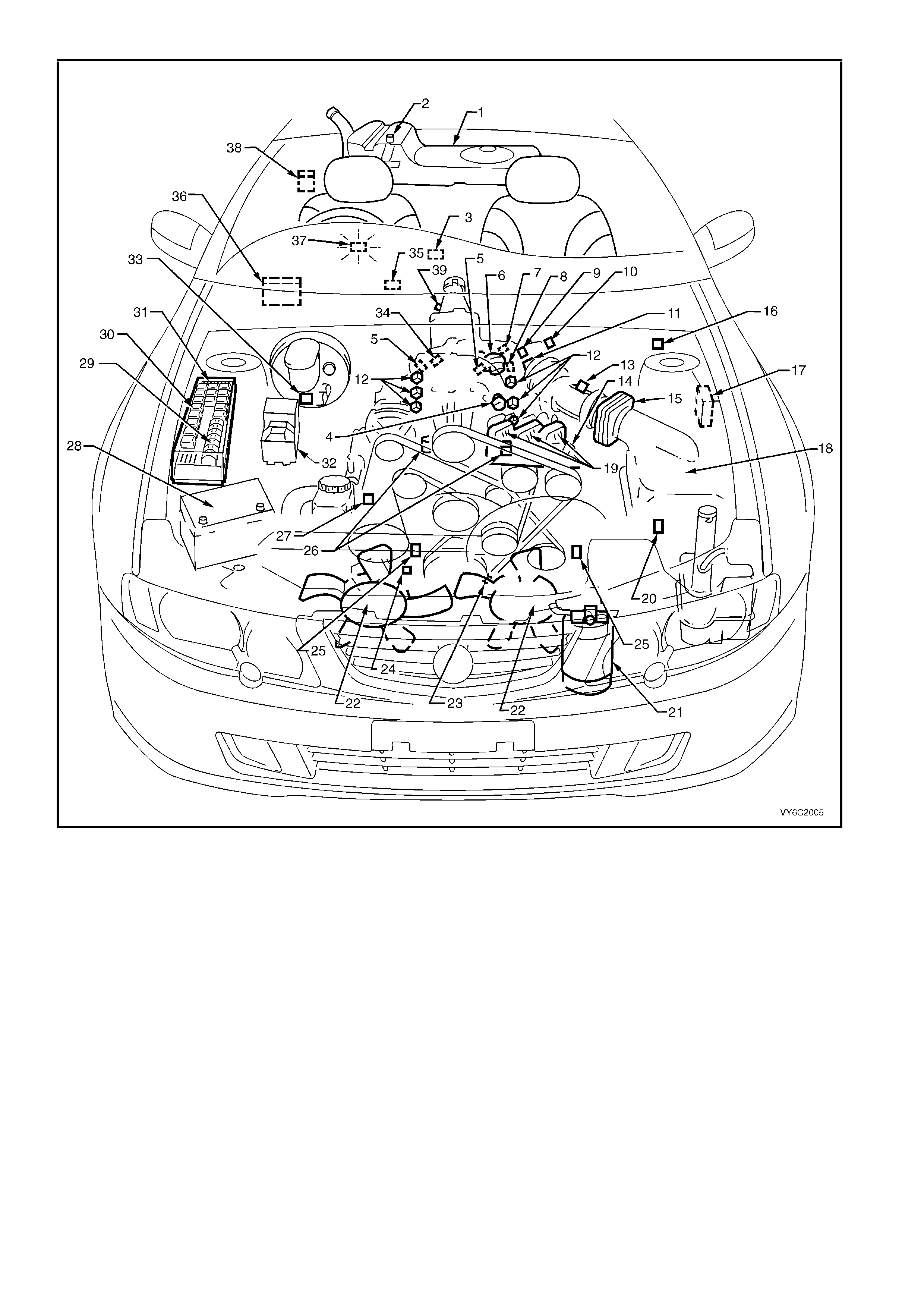

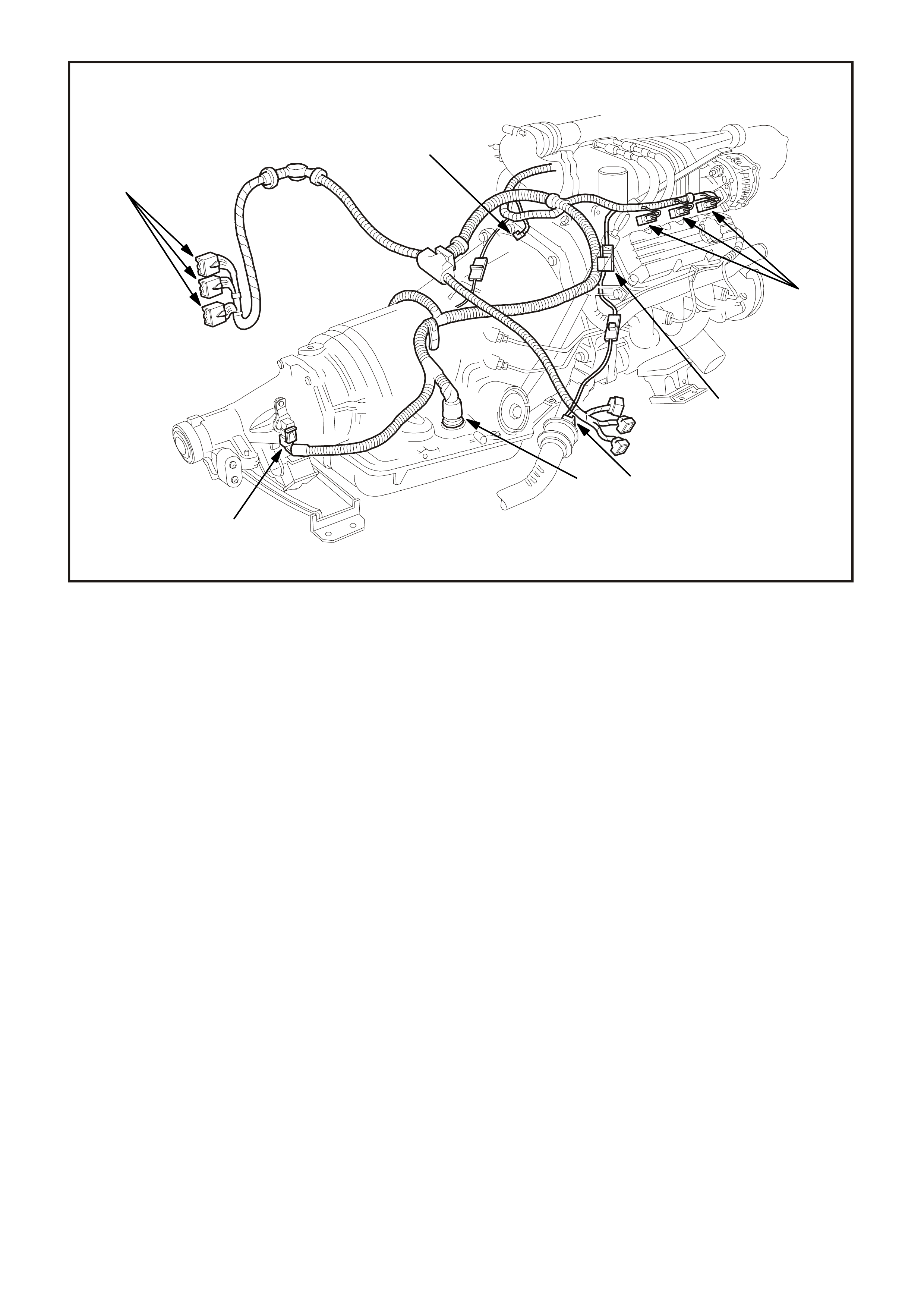

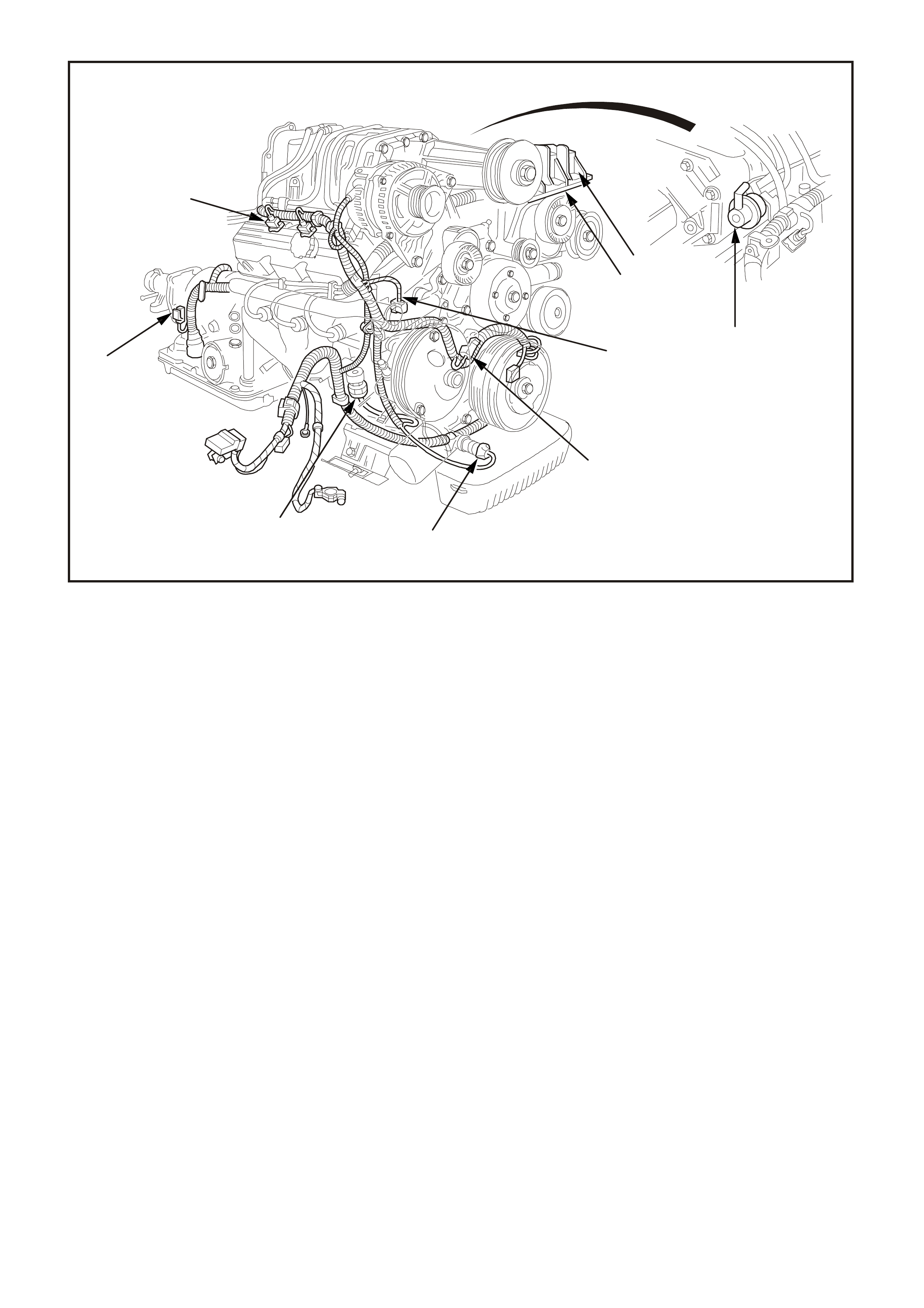

The locations of the engine management components of the system are shown in the following Figure 6C2-1-2

through 6C2-1-6.

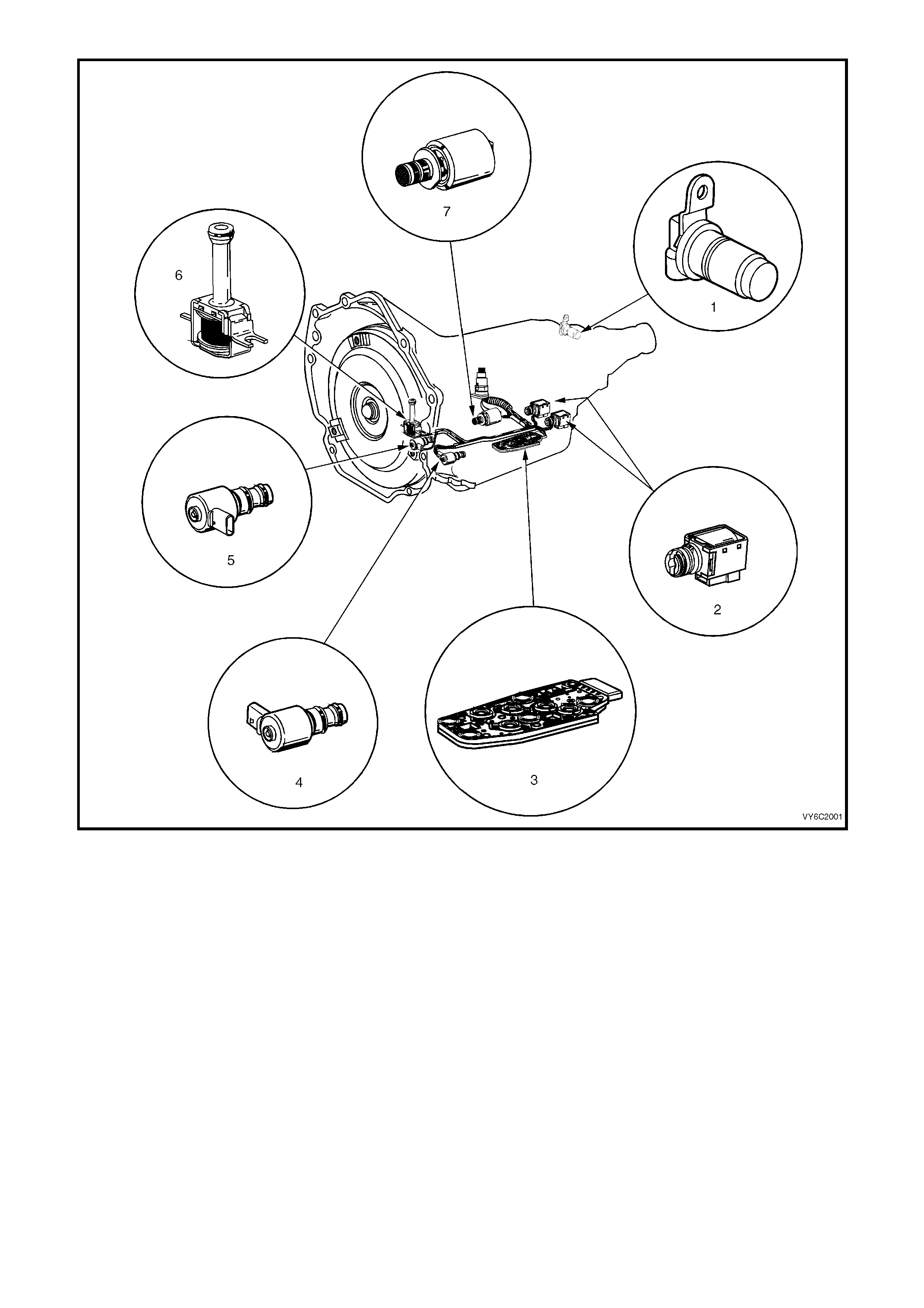

For the automatic tr ansmis sion management system c omponents and their locations , r ef er to F igure 6C2- 1-7 in this

Section.

Figure 6C2-1-1 V6 Supercharged Engine Powertrain Control Module Systems

Figure 6C2-1-2 – V6 Supercharged Engine Compartment Component Locations

Legend

1. Fuel Tank

2. Fuel Pump (Inside Fuel Tank)

3. ECC In-Car Air Temperature Sensor

4. Fuel Pressure Regulator

5. Heated Exhaust Gas Oxygen (HO2S) Sensor (Two)

6. Bypass Valve Actuator

7. Engine Coolant Temperature (ECT) Sensor

8. Boost Control Solenoid

9. Throttle Position (TP) Sensor

10. Idle Air Control (IAC) Valve

11. Engine Harness (PCM) Ground (Two Terminals)

12. Fuel Injectors

13. Intake Air Temperature (IAT) Sensor

14. DIS Module

15. Mass Air Flow (MAF) Sensor

16. Tachometer Lead

17. Powertrain Control Module (PCM) (Inside Vehicle)

18. Air Cleaner

19. Ignition Coils

20. A/C Refrigerant Pressure Sensor

21. A/C Accumulator

22. Engine Cooling Fans (Two)

23. Crankshaft Position (CKP) Sensor

24. Oil Pressure Switch

25. Camshaft Position (CMP) Sensors

26. Detonation Knock Sensors (KS) (Two)

27. Engine Harness (PCM) Ground (Two Terminals)

28. Battery

29. Engine Compartment Fusible Links

30. Engine Compartment Relays

31. Engine Compartment Fuses

32. Anti-Lock Braking System (ABS)

33. Brake Hydraulic Failure Switch

34. EVAP Canister Purge Solenoid

35. Diagnostic Link Connector (DLC)

36. Body Control Module (BCM)

37. Check Powertrain Malfunction Indicator Lamp (MIL)

38. Fuel Pump Control Module (Rear Compartment)

39. Vehicle Speed Sensor (VSS)

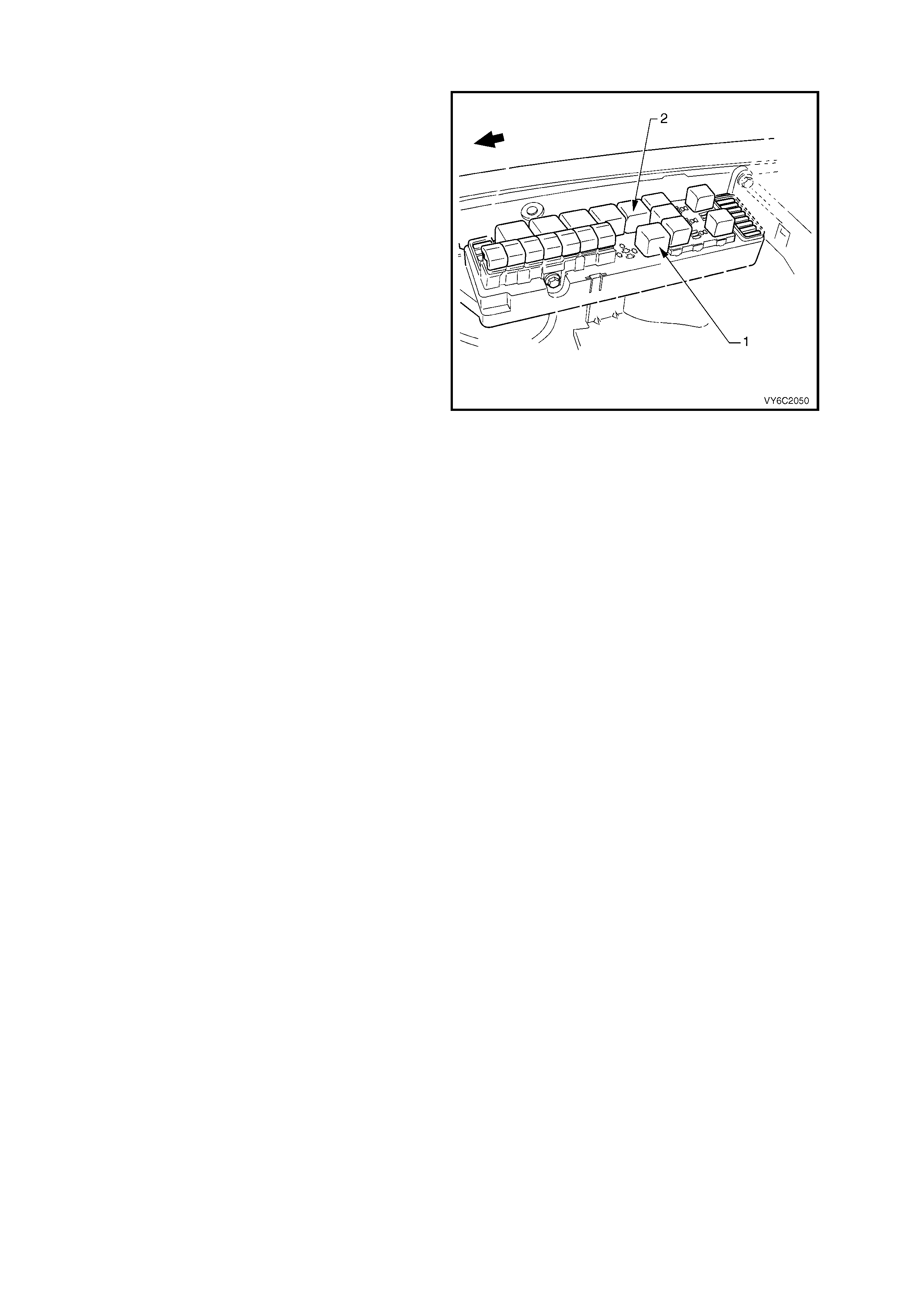

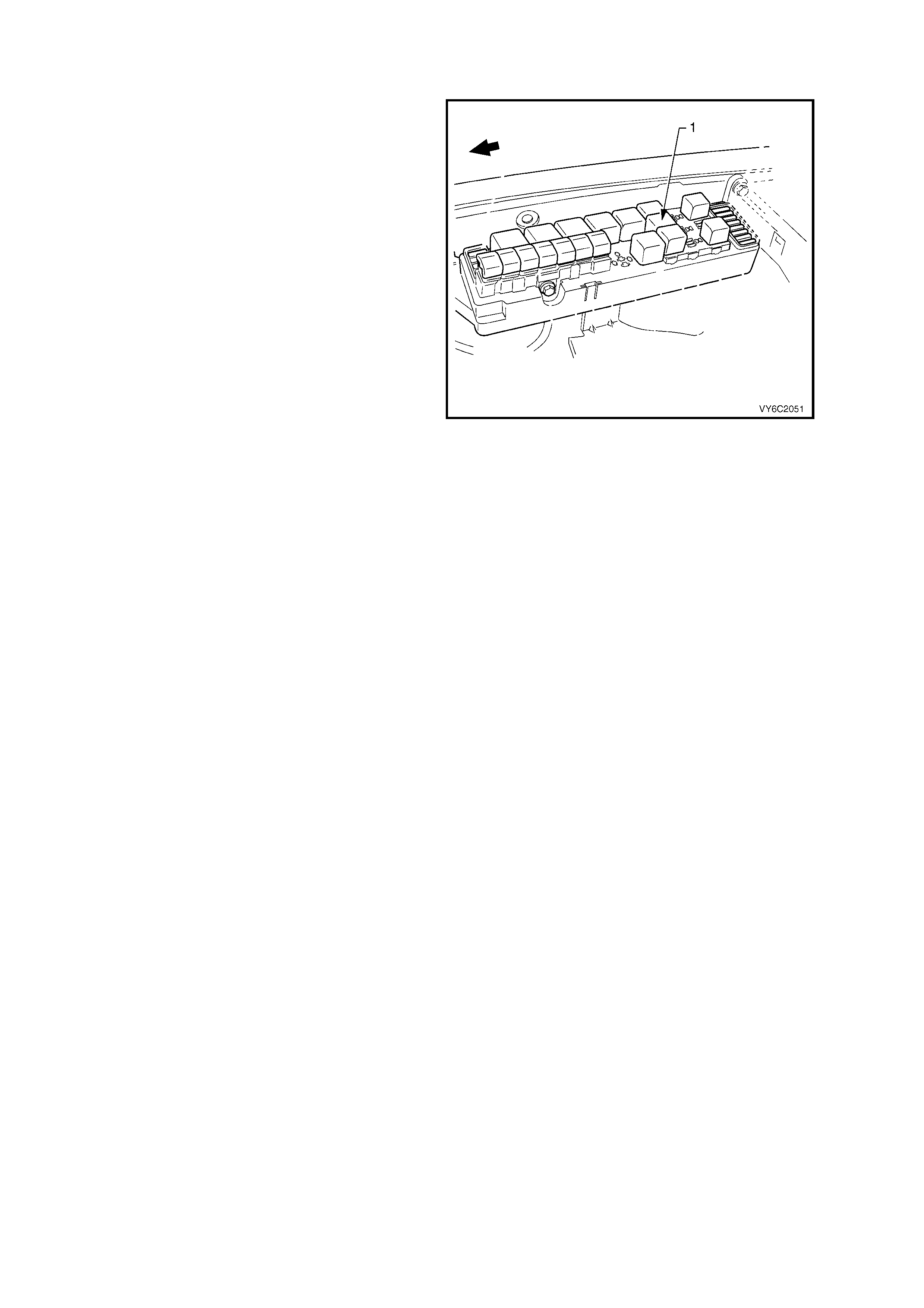

Figure 6C2-1-3 – Engine Compartment Fuse/Relay/Fusible Link Locations

Legend

Fuses

1. Fuel Pump Fuse – F28

2. Engine Control / BCM – F29

3. RH Headlamps – F30

4. LH Headlamps – F31

5. Automatic Transmission – F32

6. Engine Sensors – F33

7. Injectors / Ignition – F34

8. Injectors / Ignition – F35

Relays

9. Start – X1

10. Blower Fan – X2

11. Headlamp (High Beam) – X3

12. Engine Control (EFI) – X4

13. Engine Cooling Fan (High Speed) – X5

14. Horn – X8

15. A/C Compressor – X11

16. Fog Lamp – X10

17. Fuel Pump – X16

18. Headlamp (Low Beam) – X14

19. Engine Cooling Fan (Low Speed) – X7

Fusible Links

20. Engine Cooling Fan LT (F101 (30A)

21. Blower Fan – F106 (60A)

22. Main – F105 (60A)

23. Engine – F104 (60A)

24. A.B.S. – F103 (60A)

25. Lighting – F102 (60A)

26. Engine Cooling Fan RT (F107 (30A)

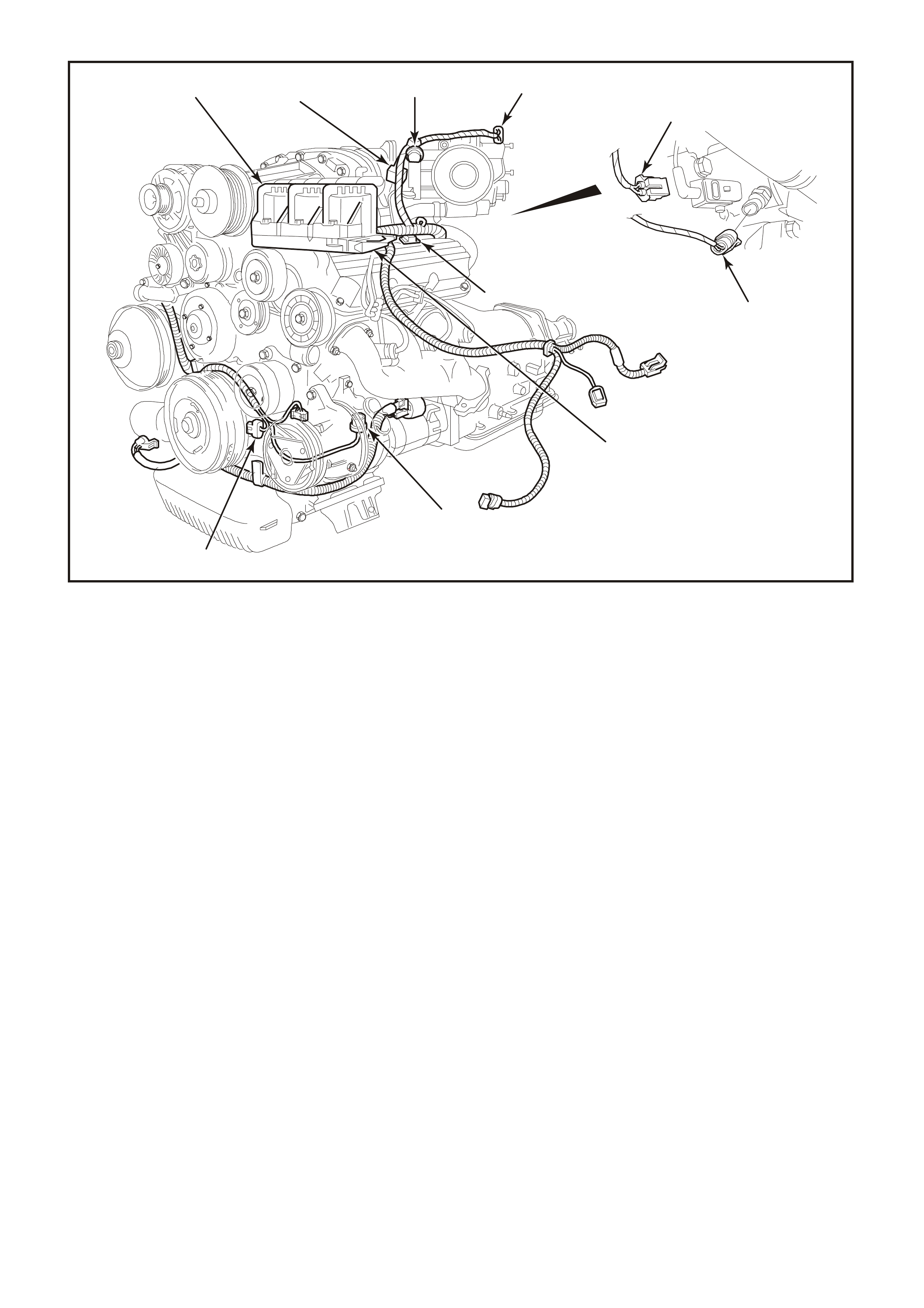

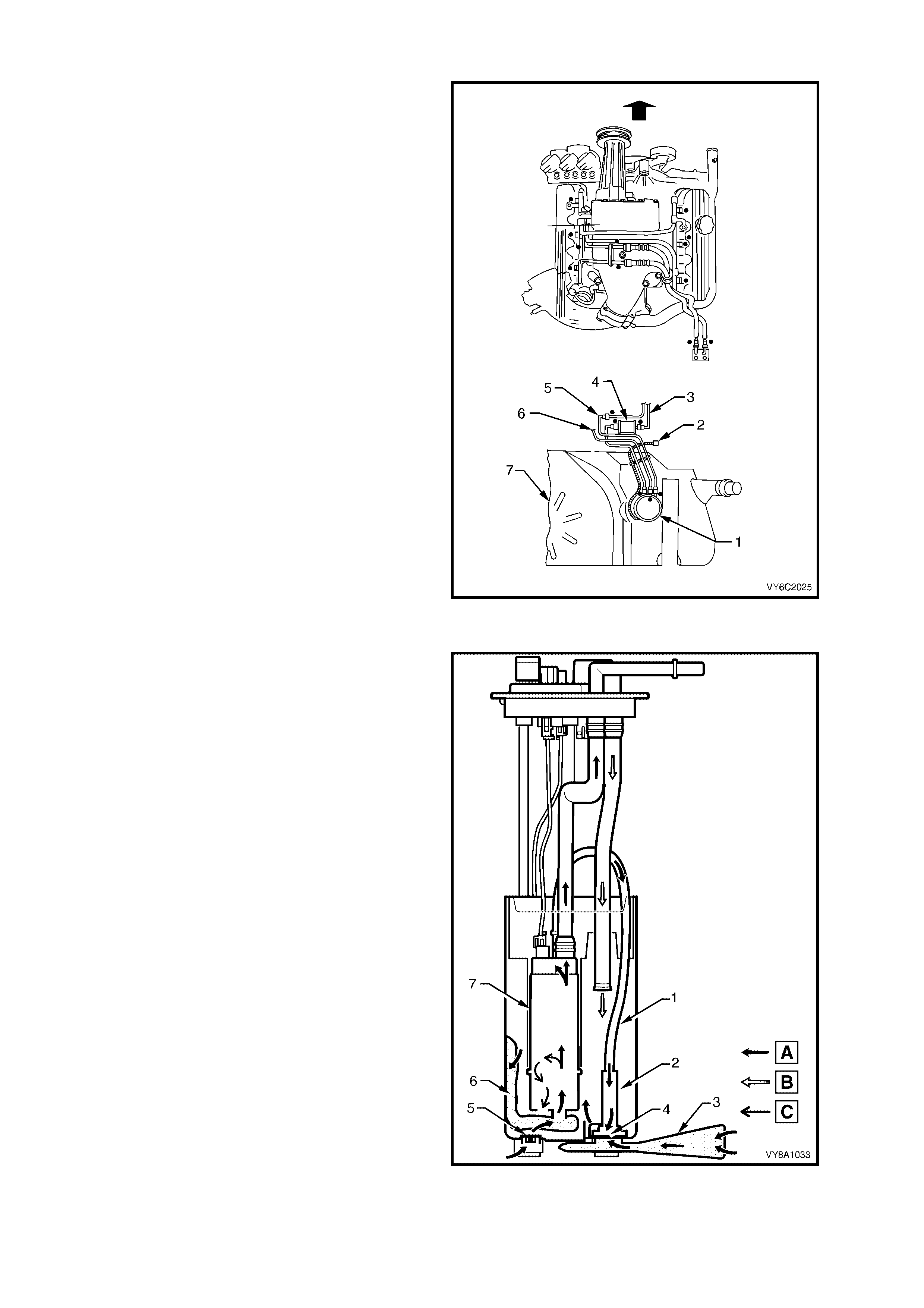

Figure 6C2-1-4 – V6 Supercharged Engine Component Locations

Legend

1. Throttle Position (TP) Sensor

2. Idle Air Control Valve (IAC)

3. Boost Control Solenoid Valve

4. Engine Coolant Temperature (ECT) Sensor

5. Injectors

6. Direct Ignition System Module

7. L.H. Knock Sensor (KS)

8. Crankshaft Position (CKP) Sensor

9. Ignition Coils (3 places)

10. Bypass Valve Actuator

910

5

8

7

4197

6

12

3

4

Figure 6C2-1-5 – V6 Supercharged Engine Component Locations

Legend

1. Injectors

2. Canister Purge Solenoid

3. R.H. Heated Oxygen (HO2S) Sensor

4. Transmission Pass-Through Connector

5. Vehicle Speed Sensor (VSS) (Automatic Trans)

6. PCM Connectors

7. Engine Harness Ground

6

7

4199

1

2

3

4

5

Figure 6C2-1-6 – V6 Supercharged Engine Component Locations

Legend

1. Ignition Coils (3 places)

2. Fuel Pressure Regulator

3. Direct Ignition System Module

4. Engine Harness Ground

5. Camshaft Position (CMP) Sensor

6. Oil Pressure Switch

7. R.H. Knock Sensor (KS)

8. Vehicle Speed Sensor (VSS) Automatic Trans)

9. Injectors (3 places)

9

8

76

4201

5

4

31

2

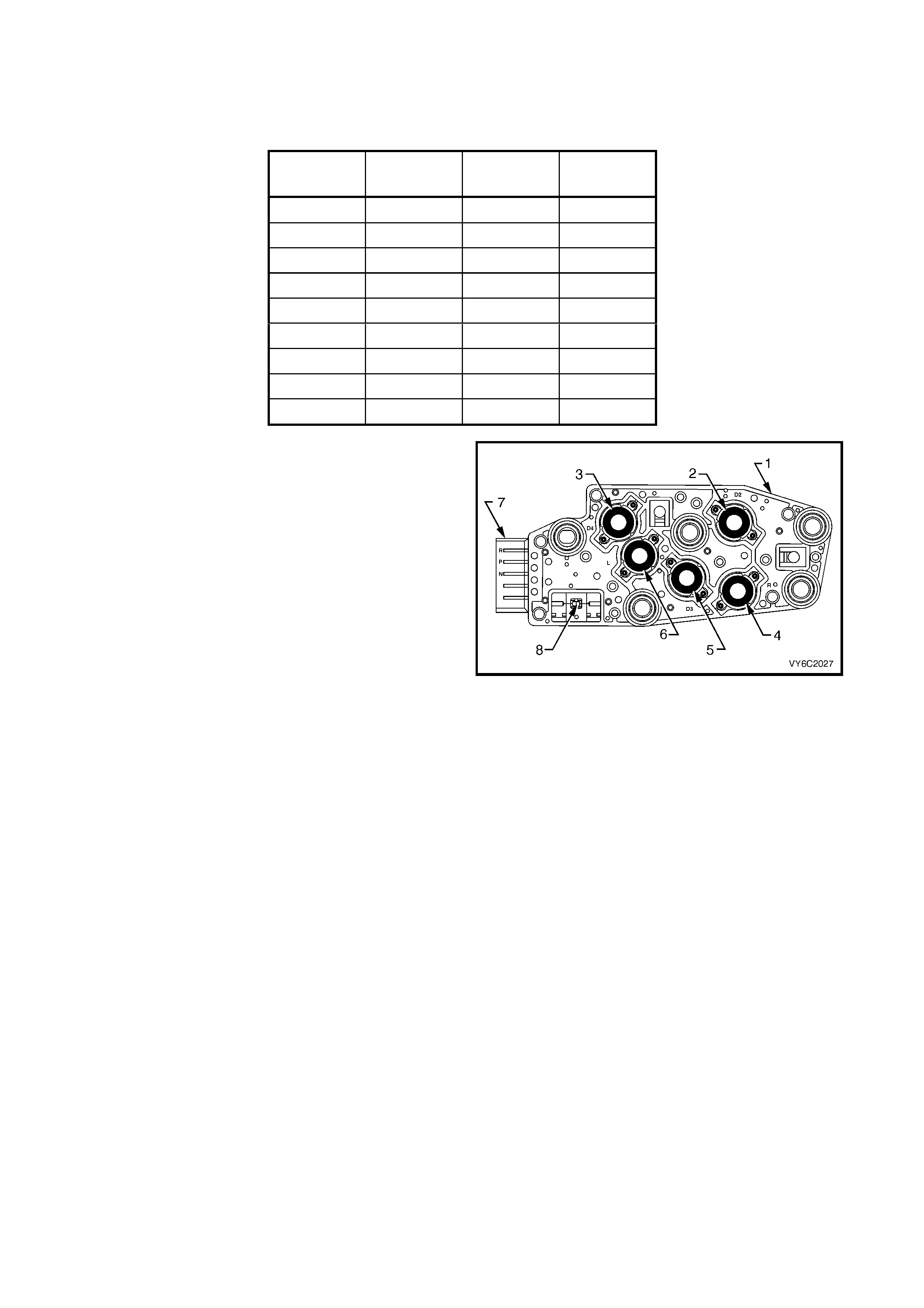

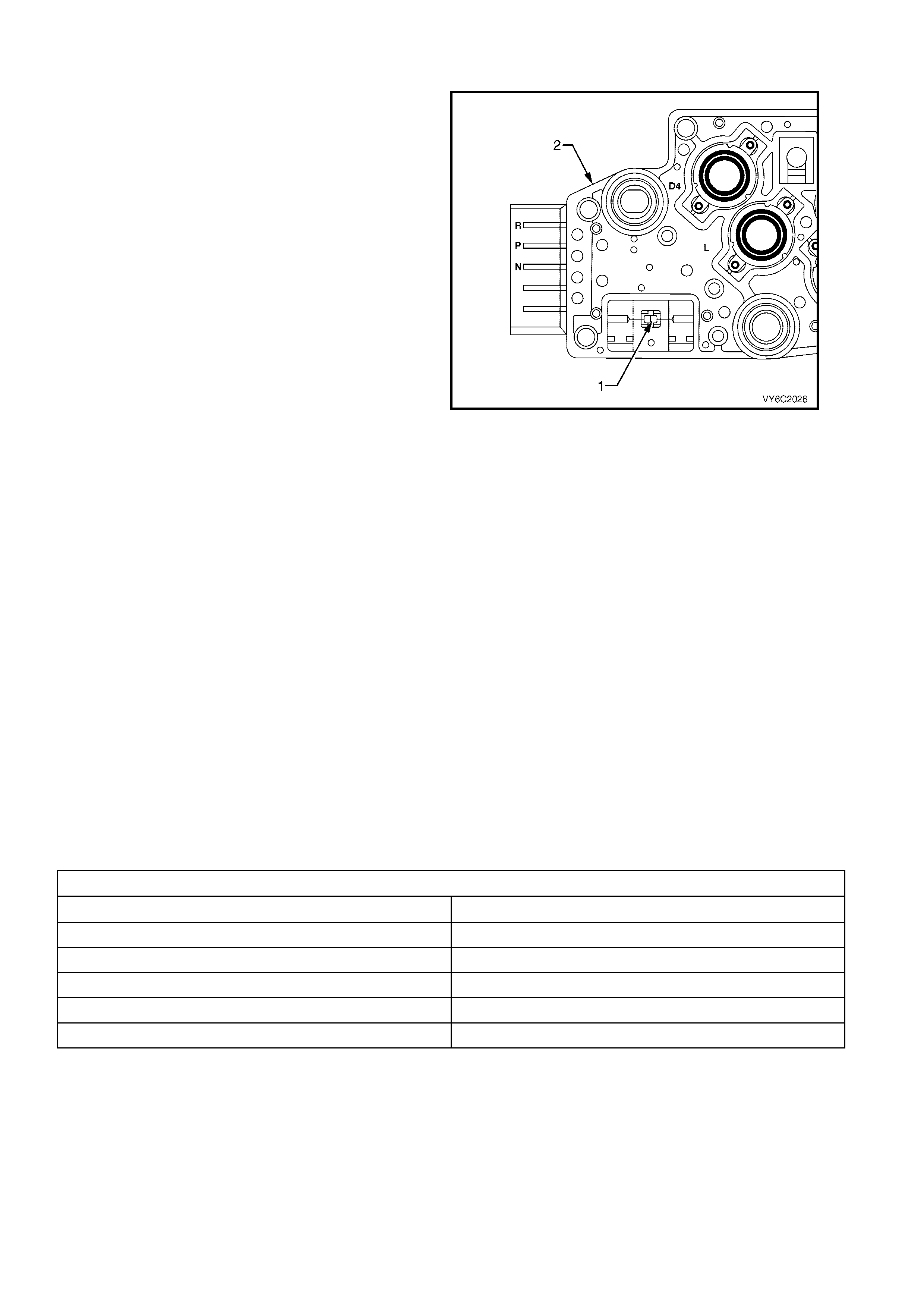

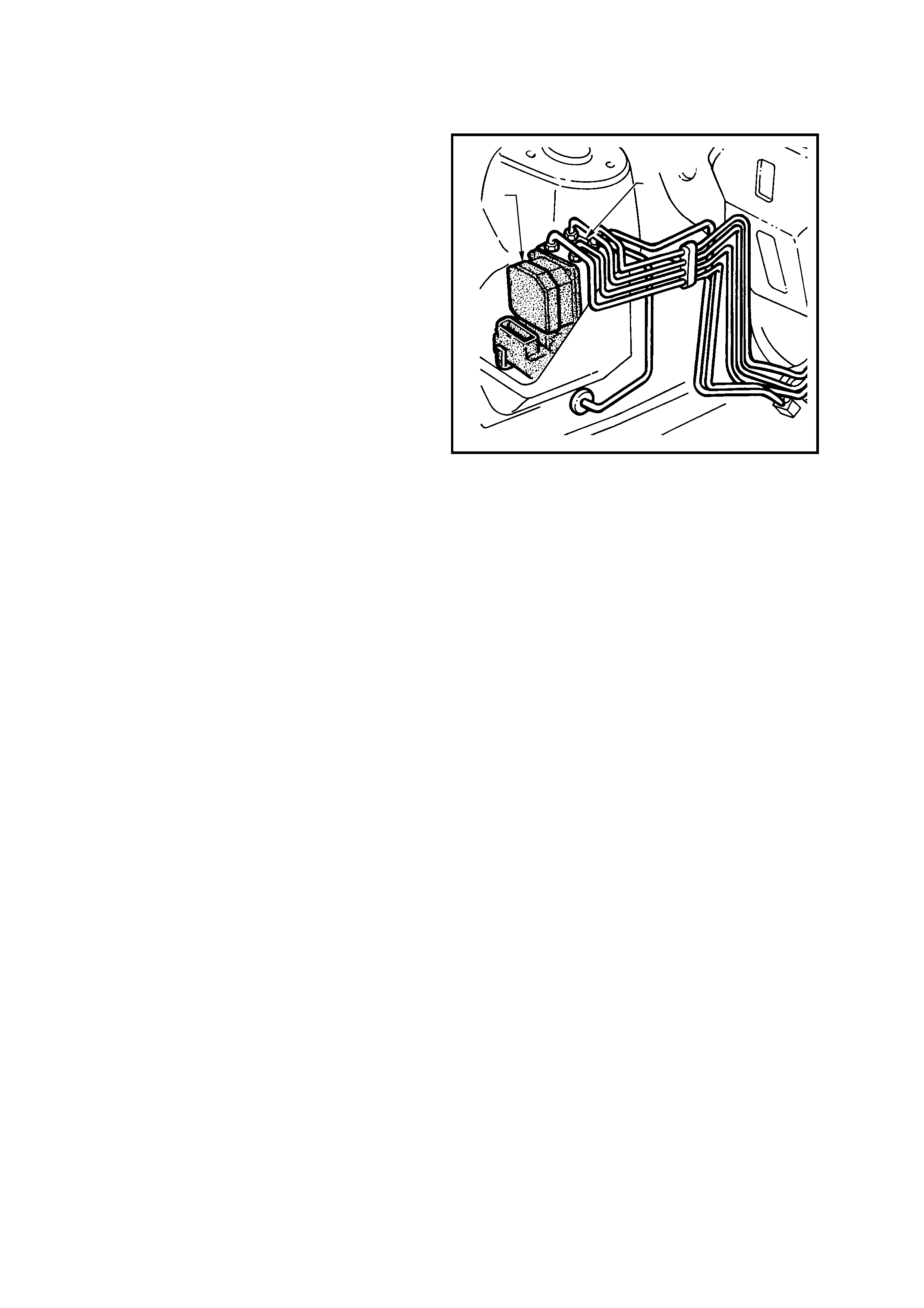

Figure 6C2-1-7 – V6 Supercharged Engine, Automatic Transmission, Internal Electronic Component Locations

Legend

1. Vehicle Speed Sensor

2. 1-2 Shift Solenoid A and 2-3 Shift Solenoid B

3. Automatic Transmission Fluid Pressure (TFP)

Manual Valve Position Switch

4. 3-2 Downshift Control Solenoid

5. Torque Converter Clutch Pulse Width Modulation (TCC

PWM) Solenoid Valve

6. Torque Converter Clutch (TCC) Solenoid Valve

7. Pressure Control Solenoid (PCS) Valve

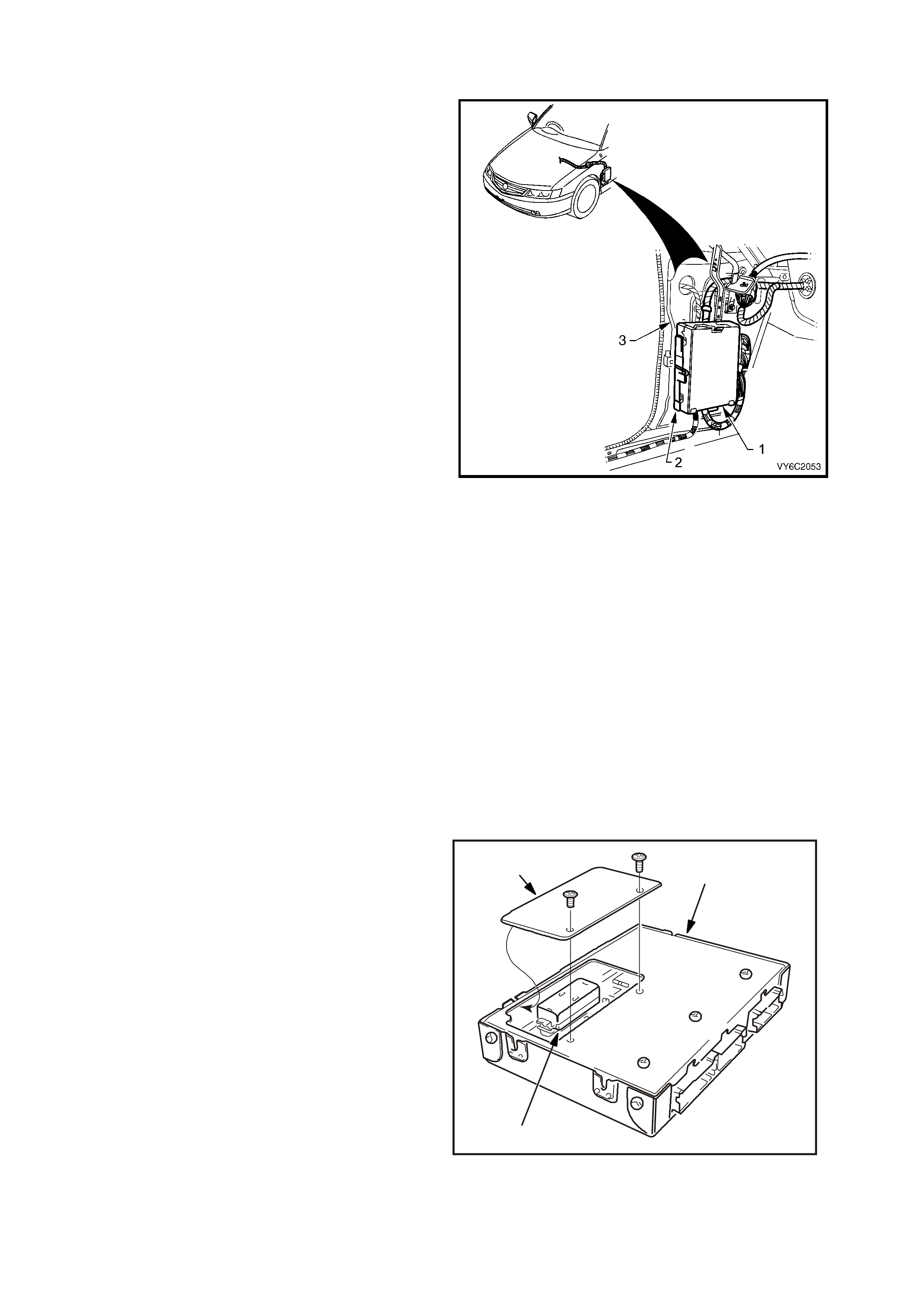

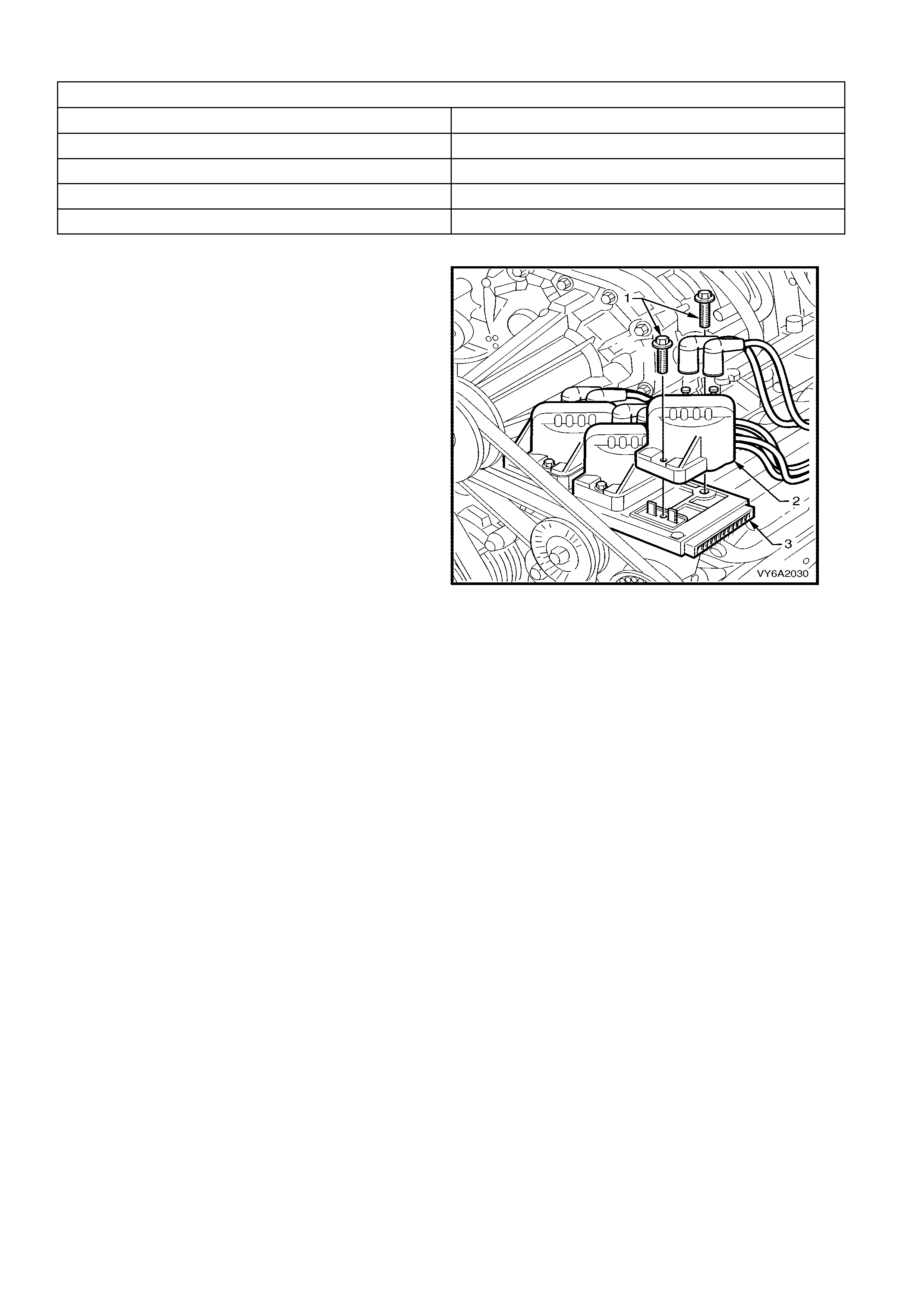

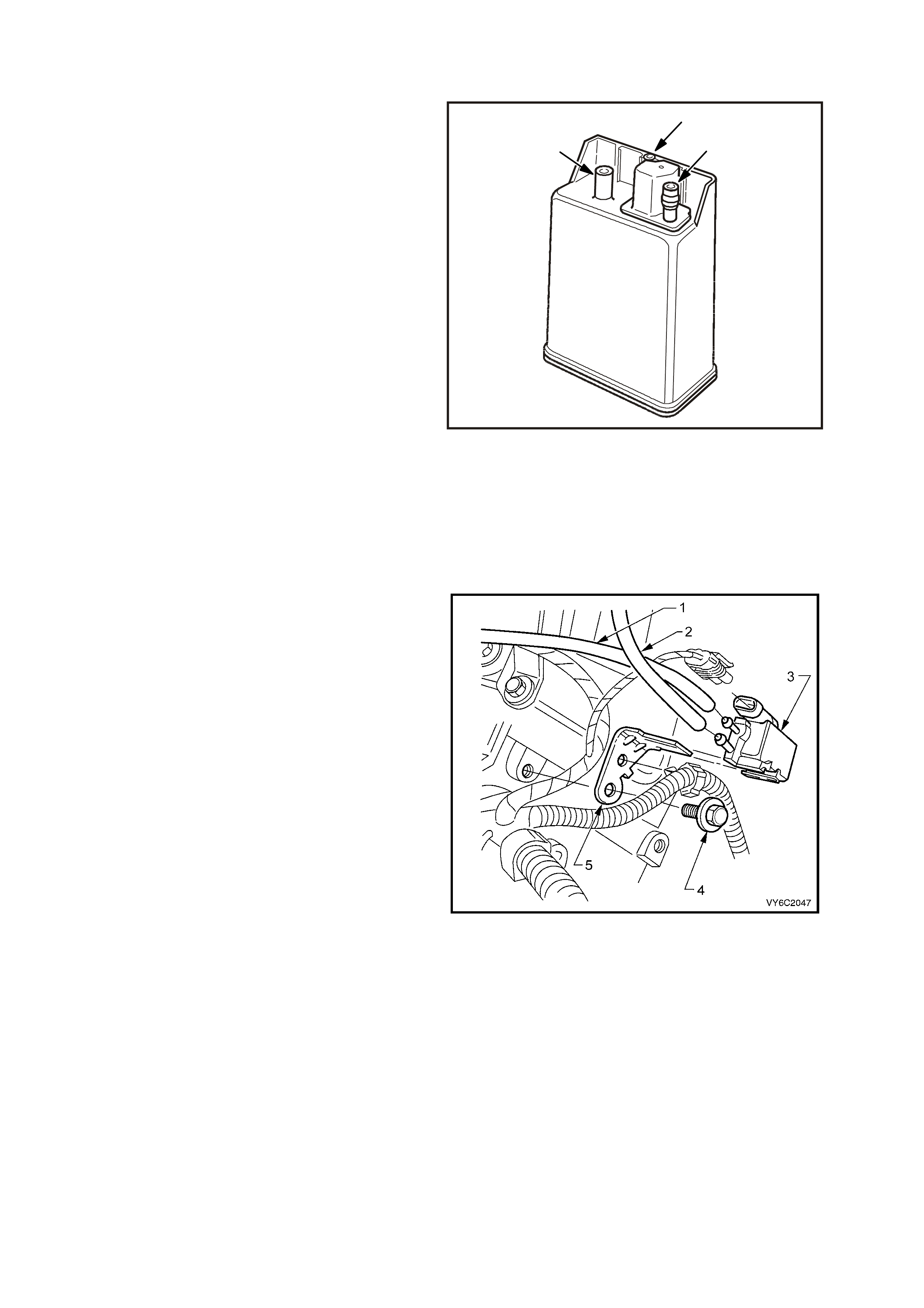

1.1 POWERTRAIN CONTROL MODULE

The Powertrain Control Module (PCM) (1) is

mounted to a bracket (2), located behind the front

left hand cowl trim panel (3) and is the control

centre of the engine and transmission management

systems. It constantly monitors information from

various sensors, and controls the systems that

affect exhaust emissions and vehicle performance.

The PCM performs the diagnostic function of the

system. It can recognise operational problems,

alert the driver through a

"Check Powertrain" Malfunction Indicator

Lamp (MIL) display and store a diagnostic code(s)

that will identify problem areas to aid the

technician in making repairs. Refer to

Section 6C2-2 DIAGNOSIS for more information

on using the diagnostic functions of the PCM.

The PCM s upplies either a buff ered 5 or 12 volts to

power various sensors or switches. This is done

through resistances in the PCM which are so high

in value that a test light will not light when

connected to the circuit.

In some cases, even an ordinary voltmeter will not

give an accurate reading because the meter's

internal resistance is too low.

NOTE: A 10 Megohm input impedance digital

voltmeter is required to assure accurate voltage

readings.

Figure 6C2-1-8 – Powertrain Control Module Location

The PCM c ontrols output c irc uits suc h as the inj ec tors , IAC, and var ious r elays, etc. by controlling the ground circuit

through transistors or a device located in the PCM called a "Quad-Driver" module (QDM). Two exceptions to this

are the fuel pump relay control circuit and the automatic transmission Pressure Control Solenoid (PCS).

The fuel pump relay is the only PCM controlled circuit where the PCM controls the +12 volts sent to the coil of the

relay. The ground side of the f uel pump relay coil is connected to engine ground. T he PCM supplies current to the

PCS and monitors how much current returns to the PCM on a separate terminal.

PCM SECURITY LINK

Once the PCM and/or BCM have been r eplaced, the new PCM and/or BCM mus t be s ecur ity linked to each other. If

this procedure is not performed, the vehicle will not crank. Refer 2.1 POWERTRAIN CONTROL MODULE, PCM

SECURITY LINK, in Section 6C2-3 SERVICE OPERATIONS.

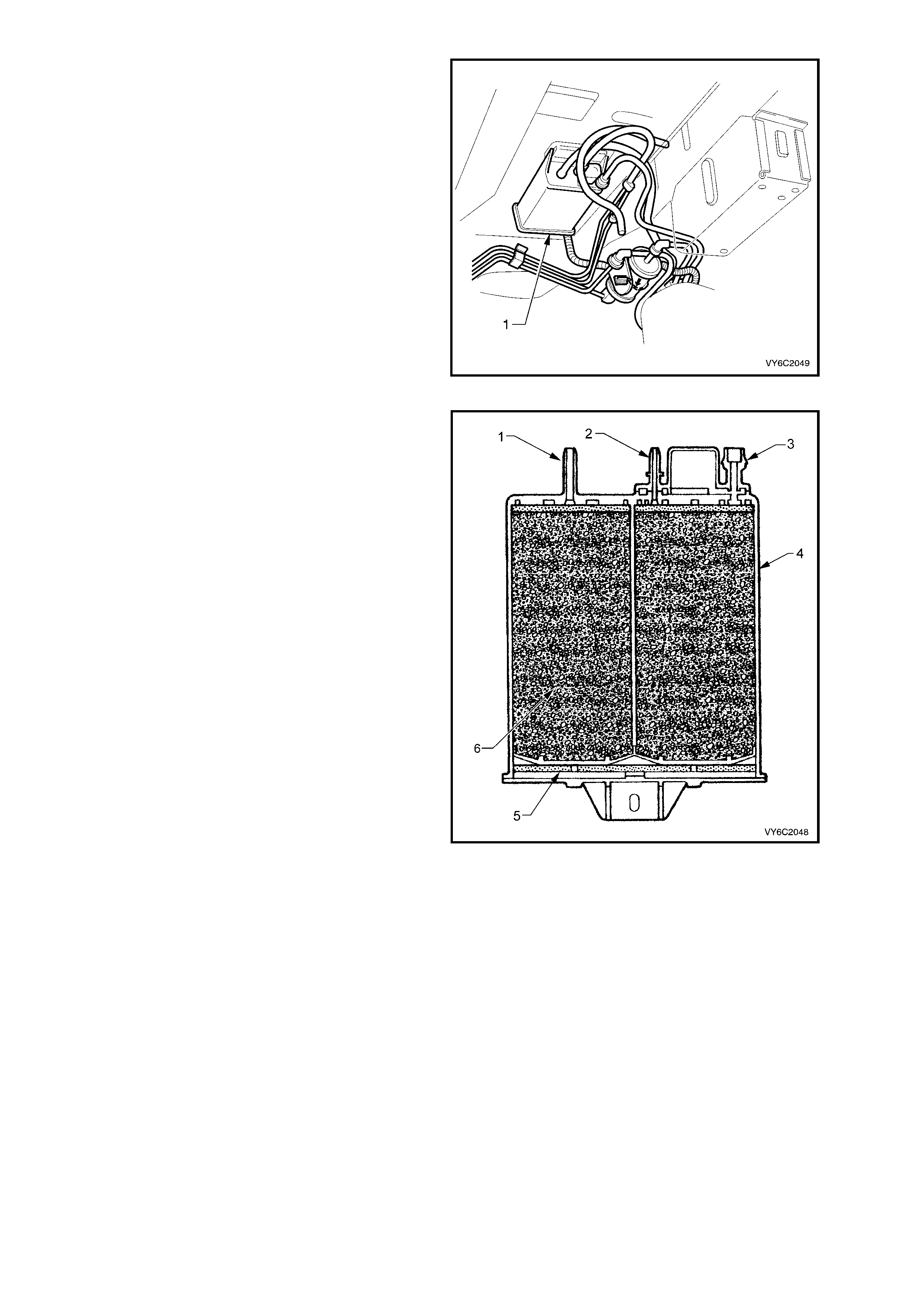

PROGRAMMABLE READ ONLY MEMORY (PRO M)

To allow one model of PCM to be used for many

diff erent vehicles, a device called a PRO M is used.

The PROM is located inside the PCM and has

information on the vehicle's weight, engine,

transmission, axle ratio and several other factors.

While one PCM part number m ay be used by many

different vehicles, a PROM is specific. For this

reason, it is ver y im portant to chec k the latest parts

catalogue and Technical Information Bulletins for

the correct part number when replacing a PROM.

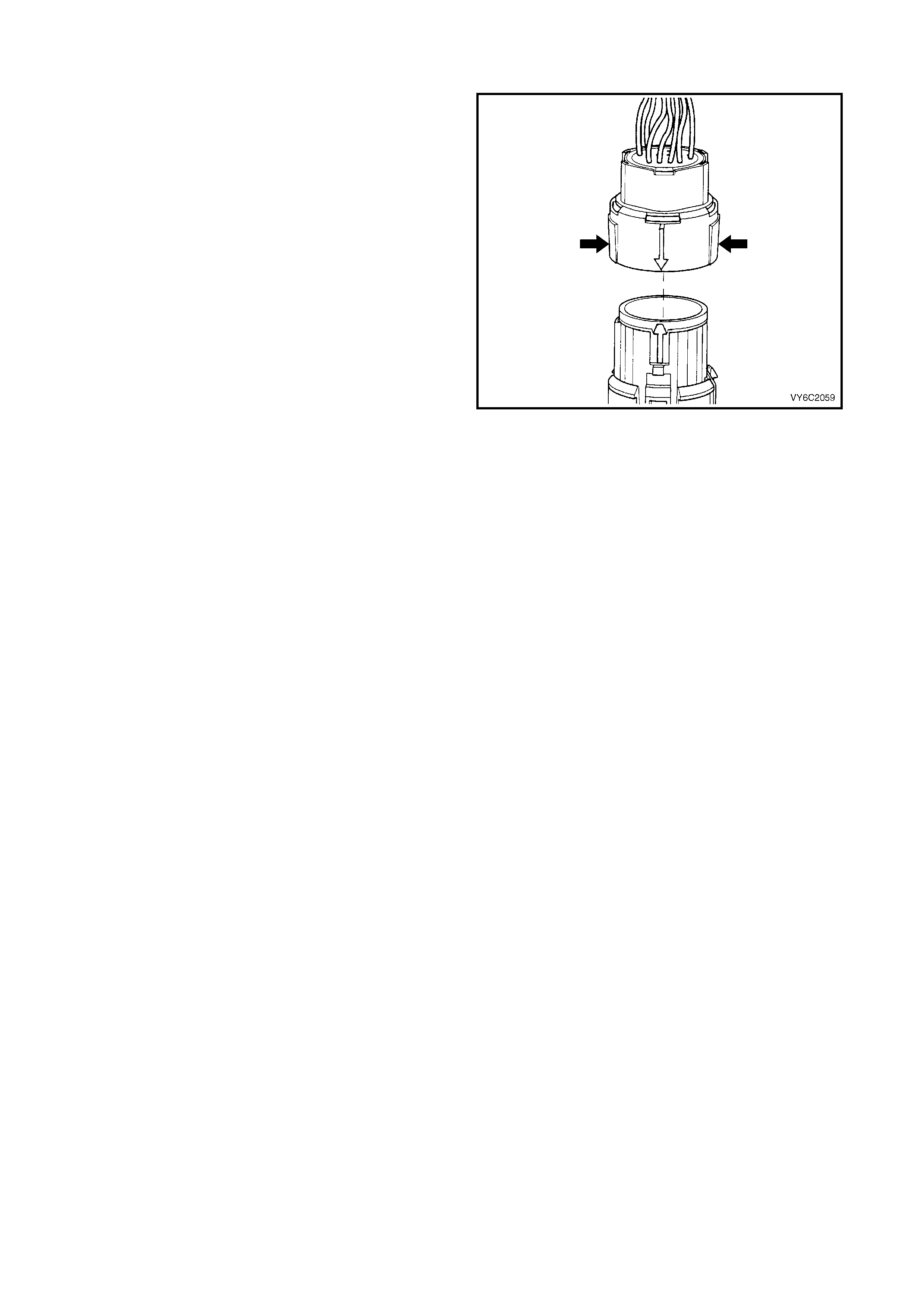

A replacement PCM (called a controller) (1) is

supplied without a PROM (2). After removing the

cover (3), the PROM from the old PCM must be

carefully removed and installed in the new PCM.

For details, refer Section 6C2-3 SERVICE

OPERA TIONS in this Service Information.

3

4204

2

1

Figure 6C2-1-9 – PROM Location

PCM MEMORY FUNCTIONS

There are three types of memory storage within the PCM: RAM, EPROM and EEPROM.

RAM

Random Access Memory (RAM) is the microprocessor "scratch pad." The processor can write into, or read from

this memory as needed. This memory is volatile and needs a constant supply of voltage to be retained. If the

voltage is lost, the memory is lost.

EPROM

Erasable Programmable Read Only Memory (EPROM) is the portion of the PCM which means that the program can

be erased. This is also the portion of the PCM that contains software and the different engine and transmission

calibration inform ation that is specific to year, model and em issions. This memory is erased by exposing it to high

intensity ultra violet radiation for several minutes.

The service Programmable Read Only Memory (PROM) which is used by technicians in the field to update

calibrations in the PCM is actually an EPROM. T he service PROM is removable f rom the PCM. The PROM should

be retained with the vehicle following PCM replacement.

EEPROM

Electrically Erasable Programmable Read Only Memory (EEPROM) is the portion of the PCM that means the

program can only be erased electronically. This type of memory cannot be erased by disconnecting the vehicle's

battery. The only way to erase this type of memor y is by a spec ial elec tronic tool, s uch as the Tech 2 s c an tool. This

type of m emory is used to store the Diagnostic Trouble Codes (DT C). DTC history data is stored in EEPROM and

will be saved even after the vehicle's battery has been disconnected. For this reason, the only way that the DTC

history data can be cleared is with the Tech 2 scan tool.

1.2 ENGINE INFORMATION SENSORS AND SIGNALS

CAMSHA FT POSITION SENSOR (CMP)

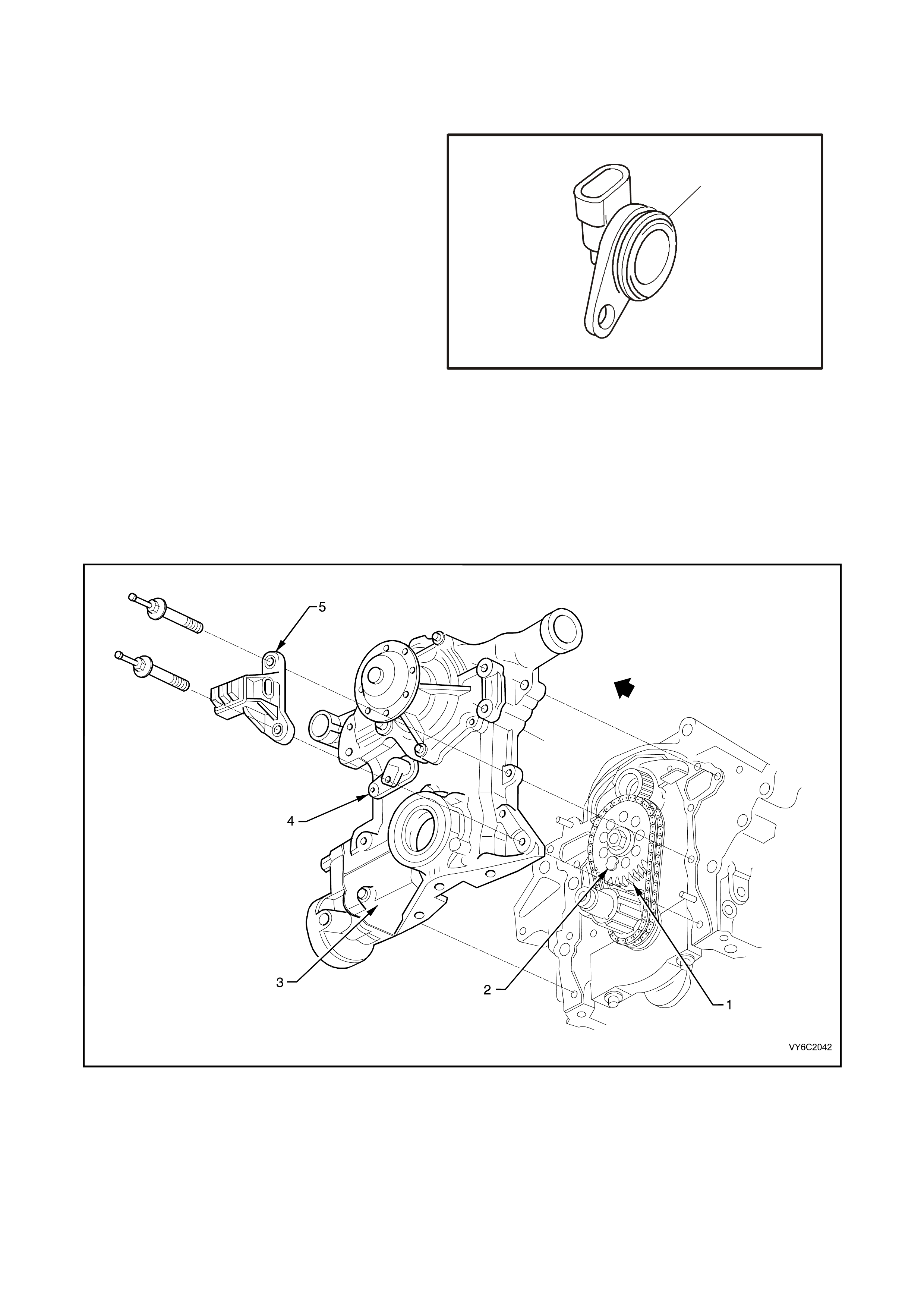

The camshaft position (CMP) sensor (1) is located

in the engine front cover, behind and below the

water pump, near the camshaft sprocket.

As the cam shaf t spr ock et turns, a m agnet mounted

on it activates the Hall Ef f ec t s witch in the c amshaft

position sensor (1). When the Hall Effect switch is

activated, it ground's the signal line to the DIS

module, pulling the camshaft position signal line's

applied voltage low. This is interpreted as a

camshaft position signal (Synchronisation Pulse).

Because of the way the signal is created by the

camshaft position sensor, the signal circuit is

always either at a high or low voltage (digital

signal).

While the camshaft sprocket continues to turn, the

Hall Eff ect switch turns "OFF" as the m agnetic f ield

passes the camshaft position sensor, resulting in

one signal each time the camshaft makes one

revolution.

The camshaft position signal, which actually

represents camshaft position due to the sensor's

mounting location, is used by the PCM to properly

time its sequential fuel injection operation.

1

4205

Figure 6C2-1-10 – Camshaft Position (CMP) Sensor

Figure 6C2-1-11 – Camshaft and Crankshaft Position Sensor Locations

Legend

1. Camshaft Sprocket

2. Magnetic Interrupter

3. Front Cover

4. Camshaft Position (CMP) Sensor

5. Crankshaft Position (CKP) Sensor

Camshaft Position Signal

The PCM uses the cam shaft position signal to determine the position of the No. 1 piston on its power strok e. This

signal is used by the PCM to calculate sequential f uel inj ec tion oper ation. If the c amshaft position s ignal is los t while

the engine is running, the fuel injection mode will be based on the last fuel injection pulse, and the engine will

continue to run. The engine can be restarted and will run in sequential mode, even though the fault is present.

When the camshaft position signal is not received by the PCM, DTC 48 will be set.

If the PCM sees an incorrect number of pulses on the Camshaft Position PCM input circuit, DTC 49 will set.

If either of thes e DTC's ar e s et, the f uel system will rem ain in sequential fuel injection mode. However, the PCM has

a one in six chance of sequencing the injectors at the ideal time in the engine cycle.

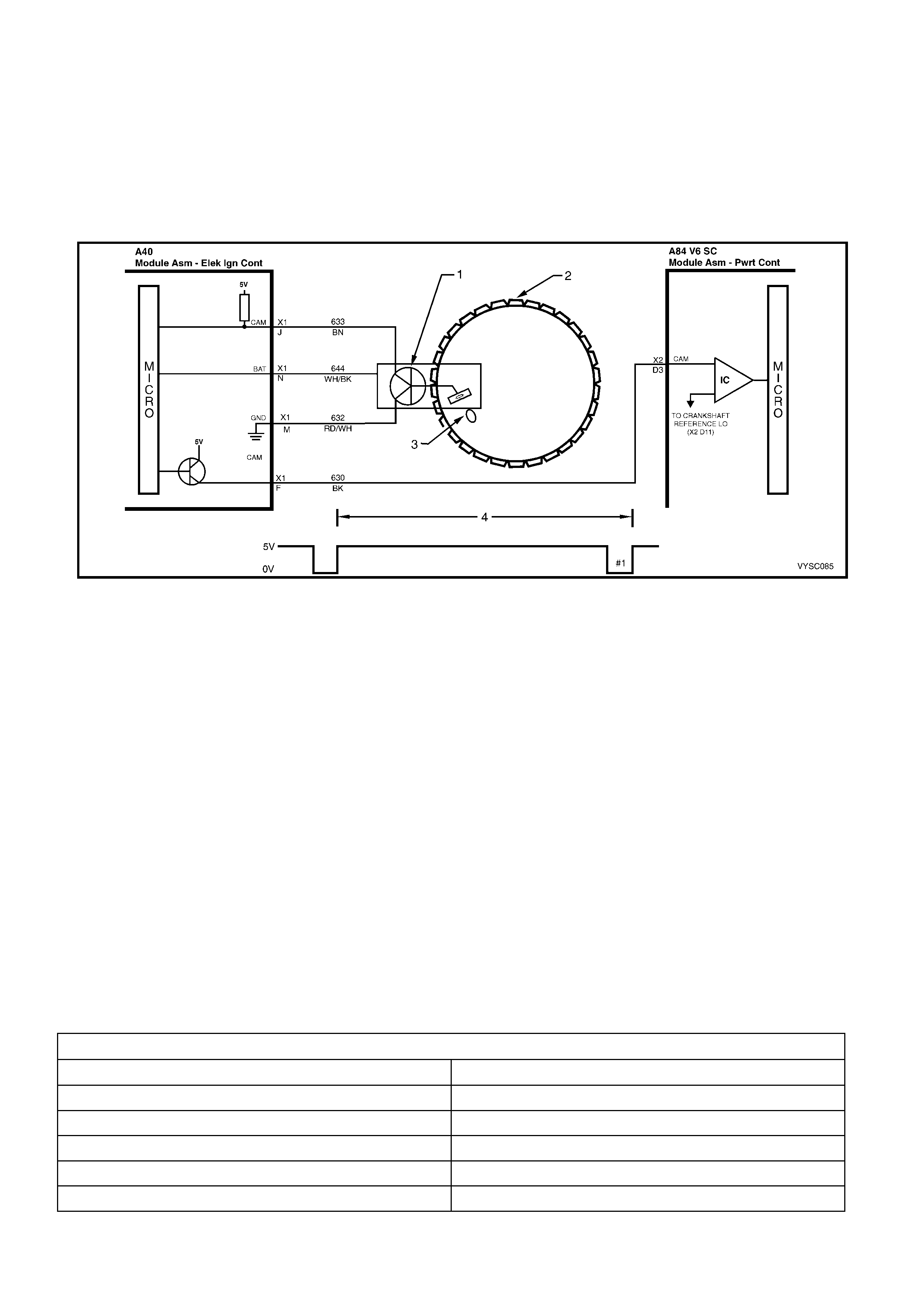

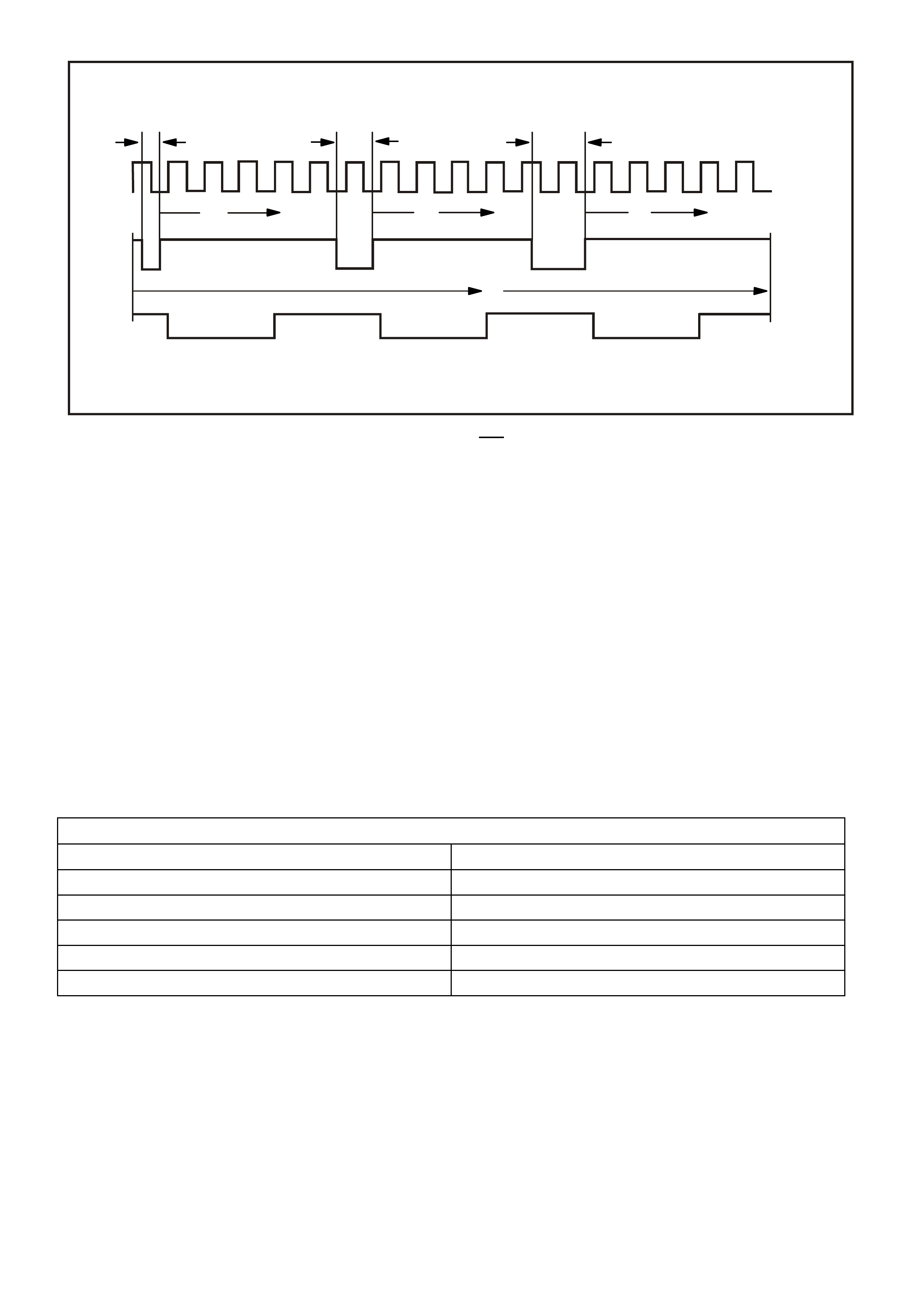

Figure 6C2-1-12 – Camshaft Position Signal

Legend

1. Camshaft Position (CMP) Sensor

2. Camshaft Gear 3. Magnetic Interrupter

4. Camshaft Position Signal = One Camshaft Rotation

The Camshaft Position signal is a normally high signal that will go low for 60° once every 720° of crankshaft

rotation. T he timing of the cams haft signal is not c ritical sinc e it only provides inform ation to the PCM for sequential

fuelling.

DTC 48 (Camshaft Position Sensor Circuit Low Voltage) will set if:

• The engine is running.

• The PCM detects the Camshaft Position sensor signal is low when the signal should be high for 5.0 seconds.

• The PCM will not illuminate the Check Powertrain MIL.

DTC 49 (Camshaft Position Sensor Circuit Performance) will set if:

• The engine is running.

• An incorrect number of crankshaft reference pulses have been received since the previous camshaft position

signal.

• The PCM will not illuminate the Check Powertrain MIL.

Default Value

If either DTC is set, the PCM will determine the fuel injection sequence based on the last fuel injection pulse

received. In the calculated SFI mode, the engine continues to start and run. However, with the fault present, only a 1

in 6 chance of the correct injection sequence exists.

Recovery will occur on the next ignition cycle.

DTC 48 AND 49 HISTORY DATA

PARAMETER PARAMETER

ENGINE SPEED BATTERY VOLTAGE

TIME FROM START REFERENCE VOLTAGE

TIMES OCCURRED VEHICLE SPEED

IGNITION CYCLES INJECTOR VOLTAGE

COOLANT TEMPERATURE

Figure 6C2-1-13 – Camshaft Position Signal

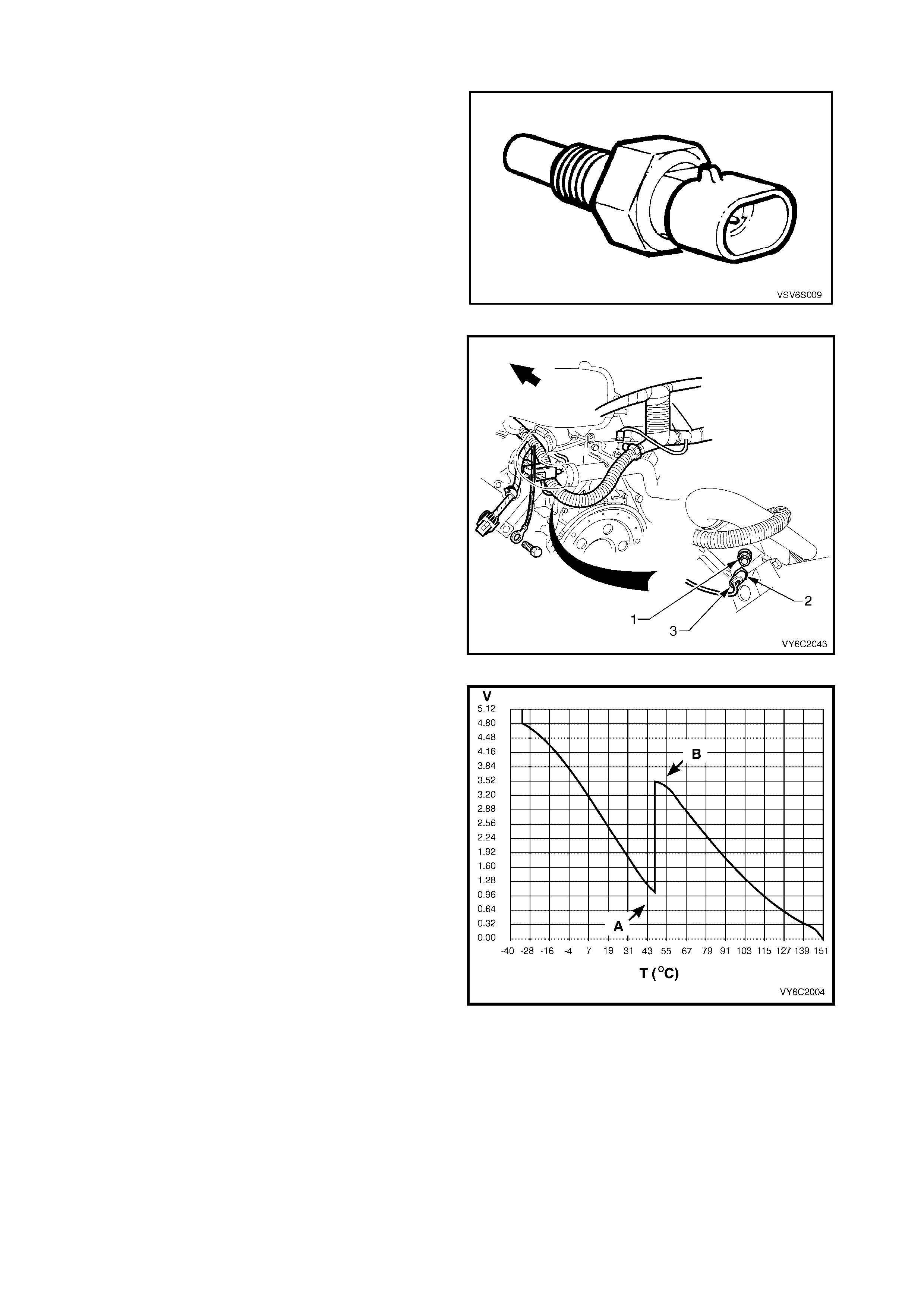

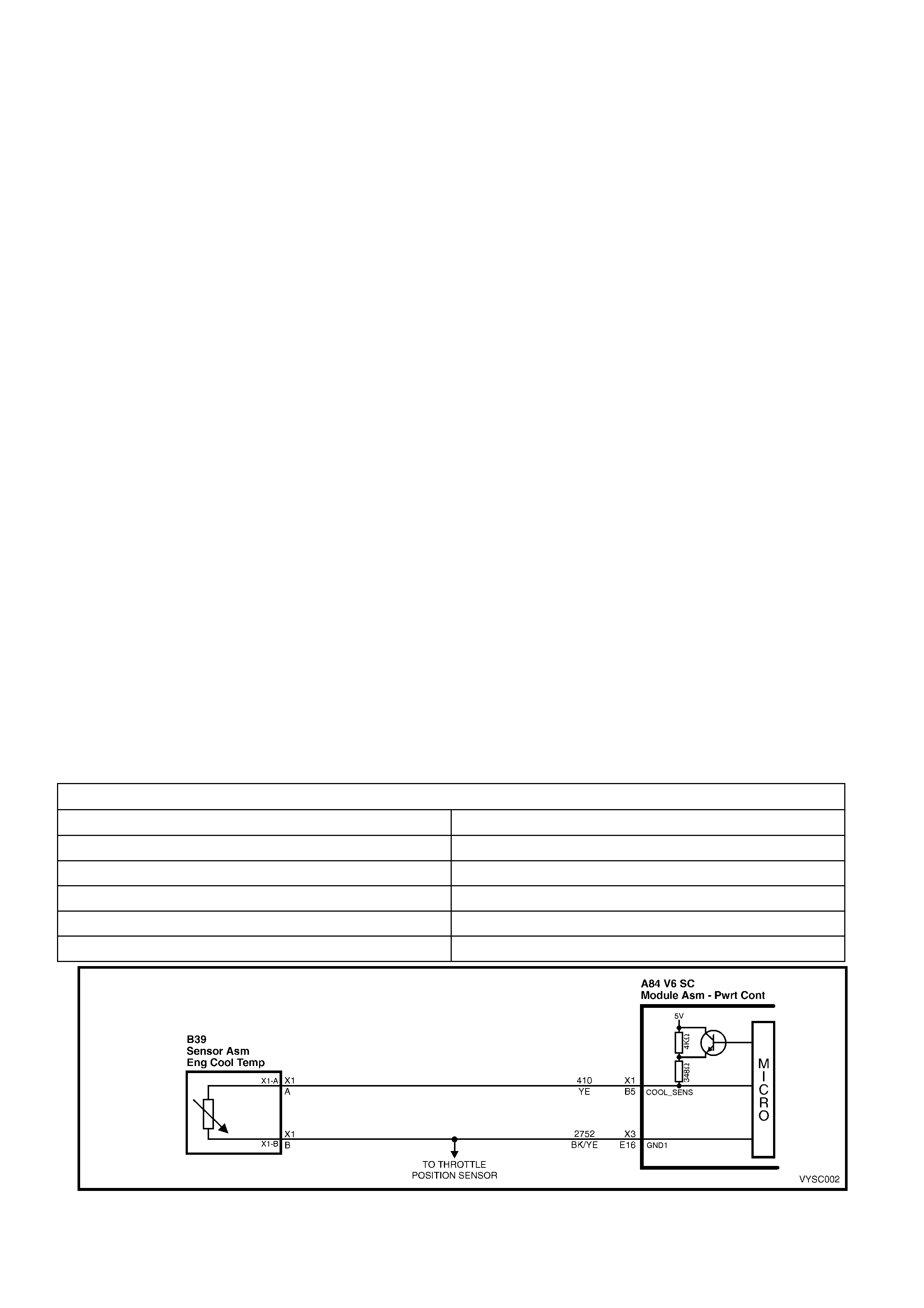

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

The Engine Coolant Temperature (ECT) sensor is a

thermistor (a resistor that changes value based on

temperature) mounted in the engine coolant stream

and is used by the PCM and other control modules

via the serial data bus f or engine coolant temperature

information. Low engine coolant temperature

produces a high sensor resistance (28,939 ohms at -

20° C) while high engine coolant temperature causes

low sensor resistance (180 ohms at 100° C).

Figure 6C2-1-14 – ECT Sensor

The Engine Coolant Temperature sensor location on

the V6 Supercharged engine is at the rear of the

engine.

Legend

1. Engine Coolant Temperature (ECT) Sensor

2. Locking Tang

3. Wiring Harness Connector

Figure 6C2-1-15 – ECT Sensor Location

The PCM supplies a 5 Volt signal to the engine

coolant tem per ature ( ECT) s ensor, either through two

resistors in series or through just one of these two

resistors. When the engine coolant is cold, the PCM

monitors the sensor voltage through two resistors in

series with one another and then switches one

resistor out of the circuit at approx imately 50° C. This

switching is shown by points ‘A’ (sensor just below

50° C) and point ‘B’ (sensor just above 50° C).

The circuit voltage will vary depending on the

resistance of the engine coolant temperature sensor.

The circuit voltage will be close to the 5 volt level

when the sensor is cold, and will decrease as the

sensor warms. Engine coolant temperature affects

most systems controlled by the PCM.

A failure in the engine coolant temperature sensor

circuit should set either DTC 14 or DTC 15.

An interm ittent open or a short f ailure should s et DTC

16.

W hile the circuit voltage will change at approximately

50° C, the Tech 2 scan tool will still read the correct

temperature value and will not suddenly jump (as

indicated f rom points ‘A’ to ‘B’). A failur e in one of the

two resistors should set DTC 17.

Figure 6C2-1-16 – ECT Temperature (T) vs Voltage (V)

DTC 14 (Engine Coolant Temperature (ECT) Sensor Low Voltage) will set if:

• Engine run time is longer than 10 seconds.

• The ECT sensor signal indicates an engine coolant temperature greater than 134°C.

• Above conditions present for at least 10 seconds.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

DTC 15 (Engine Coolant Temperature (ECT) Sensor High Voltage) will set if:

• Engine run time is longer than 10 seconds.

• The ECT sensor signal indicates an engine coolant temperature less than -30°C.

• Above conditions present for at least 1 second.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

DTC 16 (Engine Coolant Temperature (ECT) Signal Voltage Unstable) will set if:

• Engine run time is longer than 10 seconds.

• The ECT sensor reading changes more than 400 mV in 200 milliseconds.

• The PCM will not illuminate the Malfunction Indicator Lamp (MIL).

DTC 17 (Engine Coolant Temperature (ECT) pull-up Resistor Failure) will set if:

• Engine run time is longer than 10 seconds.

• The pull-up resistor inside the PCM switches and there is less than a 60mV change in the engine coolant

temperature signal.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

Default Value

When an ECT sensor circuit fault is detected, and current, the PCM will substitute a coolant temperature default

value. The PCM arr ives at this def ault, or s ubstitute value, by switching to a star ting point, then counting upwards to

95° C at a rate of 11 degrees per minute.

The starting point is the present temperature indication from the Intake Air Temperature (IAT) Sensor.

NOTE: W hen a DTC 14, 15, 16 or 17 is current, the PCM will turn on the electric engine cooling fan(s). This is a

FAIL-SAFE action by the PCM to prevent a possible engine overheat condition, since these DTC’s indicate an

unknown actual engine coolant temperature.

If the ECT s ens or c irc uit opens with the ignition off , the PCM will interpret - 30° C and deliver enough f uel to s tar t the

engine at this temperature. If the actual ambient temperature is above 0°C, the engine may flood and not start

unless CLEAR FLOOD MODE is used by fully depressing the accelerator while cranking. In the CLEAR FLOOD

MODE the injectors pulse width is set to zero milliseconds.

Recovery

Recovery will occur when the PCM sees a valid condition.

DTC 14, 15, 16 AND 17 HISTORY DATA

PARAMETER PARAMETER

ENGINE SPEED IAT SENSOR

TIME FROM START INTAKE AIR TEMPERATURE

TIMES OCCURRED BATTERY VOLTAGE

IGNITION CYCLES REFERENCE VOLTS

ECT SENSOR

Figure 6C2-1-17 ECT Sensor Circuit

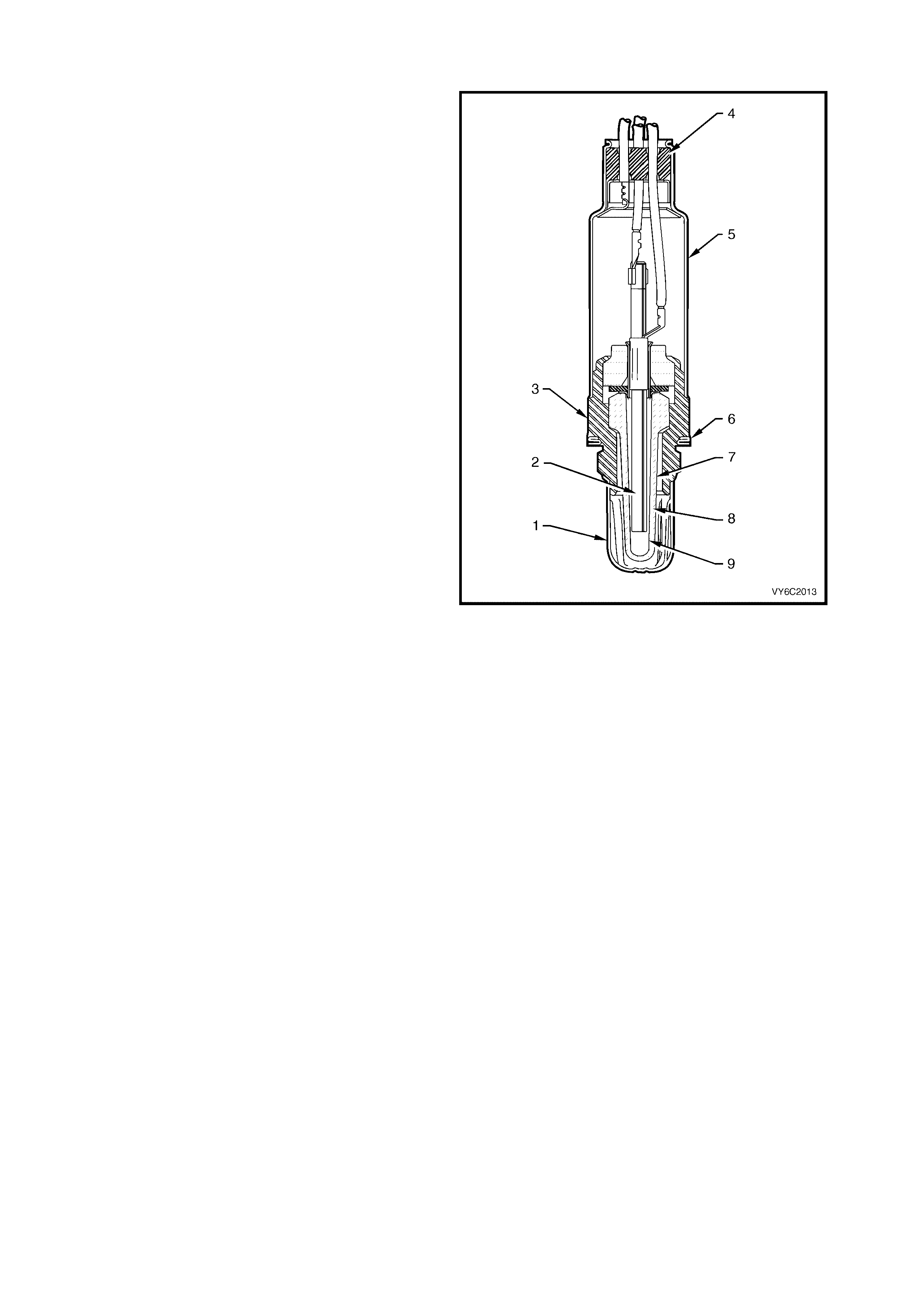

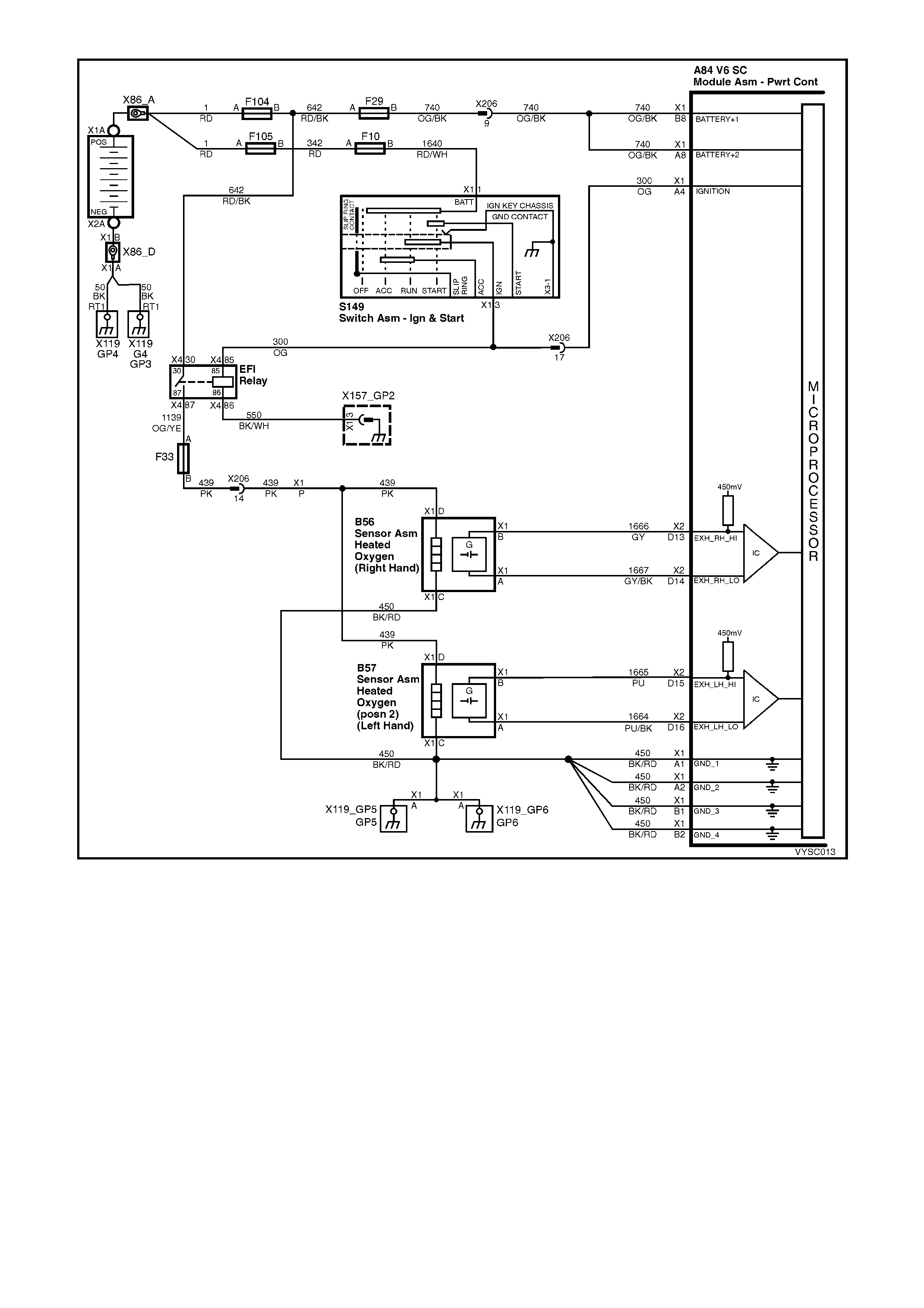

EXHAUST GAS OXYGEN SENSOR

The exhaust gas oxygen sensors are the key to

fuel control. The PCM uses information from the

oxygen sensors to precisely fine-tune its fuel

injector pulse width calculations, based on the

unused, "left-over" oxygen content in the exhaust.

The V6 Supercharged engine uses two heated

oxygen sensors, with one oxygen sensor located in

each exhaust pipe. This is done so that the PCM

can better control the engine's fuelling

requirements. These heated oxygen sensors have

an internal heater element (2) that is used to heat

the Zirconia element (8) faster inside the sensors,

thereby decreasing the amount of time the fuel

control system needs before running in closed loop

fuel control.

These oxygen sensors have a zirconia element (8)

that, when heated to temperatures above 360° C,

produce voltages based on the amount of oxygen

content s urr ounding the tip, as compar ed to oxygen

in the atmosphere.

The s ensor is m ounted in the exhaust pipe with the

sensing portion exposed to the exhaust gas

stream. When the sensor has reached an operating

temperature of more than 360° C, it acts as a

voltage generator, producing a rapidly changing

voltage of between 10 - 1000 millivolts.

Legend:

1. Lower Shield

2. Heater Element

3. Body

4. Lead Seal

5. Upper Shield

6. Seal Gasket

7. Outer Electrode and Protective Coating

8. Zirconia Element

9. Inner Electrode

Figure 6C2-1-18 Four Wire Heated Oxygen Sensor

This voltage output is dependent upon the oxygen content in the exhaust gas, as compared to the sensor's

atmospheric oxygen reference cavity. The reference cavity of this heated oxygen sensor is exposed to the

atmos pher e by the air that pas s es between the wire strands and ins ulation. T he s ignal and heater leads us ed of the

heated oxygen sensor are of the s tranded type that have small s paces between the wire strands and the insulation.

Thes e spaces allow a satisfac tory am ount of air to pass thr ough the lead to m aintain an adequate air referenc e f or

the sensor.

IMPORTANT: Under no circumstances are the wiring harness connectors associated with the heated oxygen

sensor circuits to be sealed in any way, by using grease or other substance. To do so, would result in an inadequate

supply of referenc e air to be able to r eac h the atmospher ic r ef er ence c avity of each sens or, r es ulting in a DTC to be

set. If a f lexible s ealant is used (i.e. gr ease), then this would be drawn into the sensor cavity, poisoning the s ensor,

resulting in a premature failure. Also, should connector damage be evident, then the sensor and lead must be

replaced, as soldering of the wiring would also negate the ‘breathing’ capability of the sensor wiring.

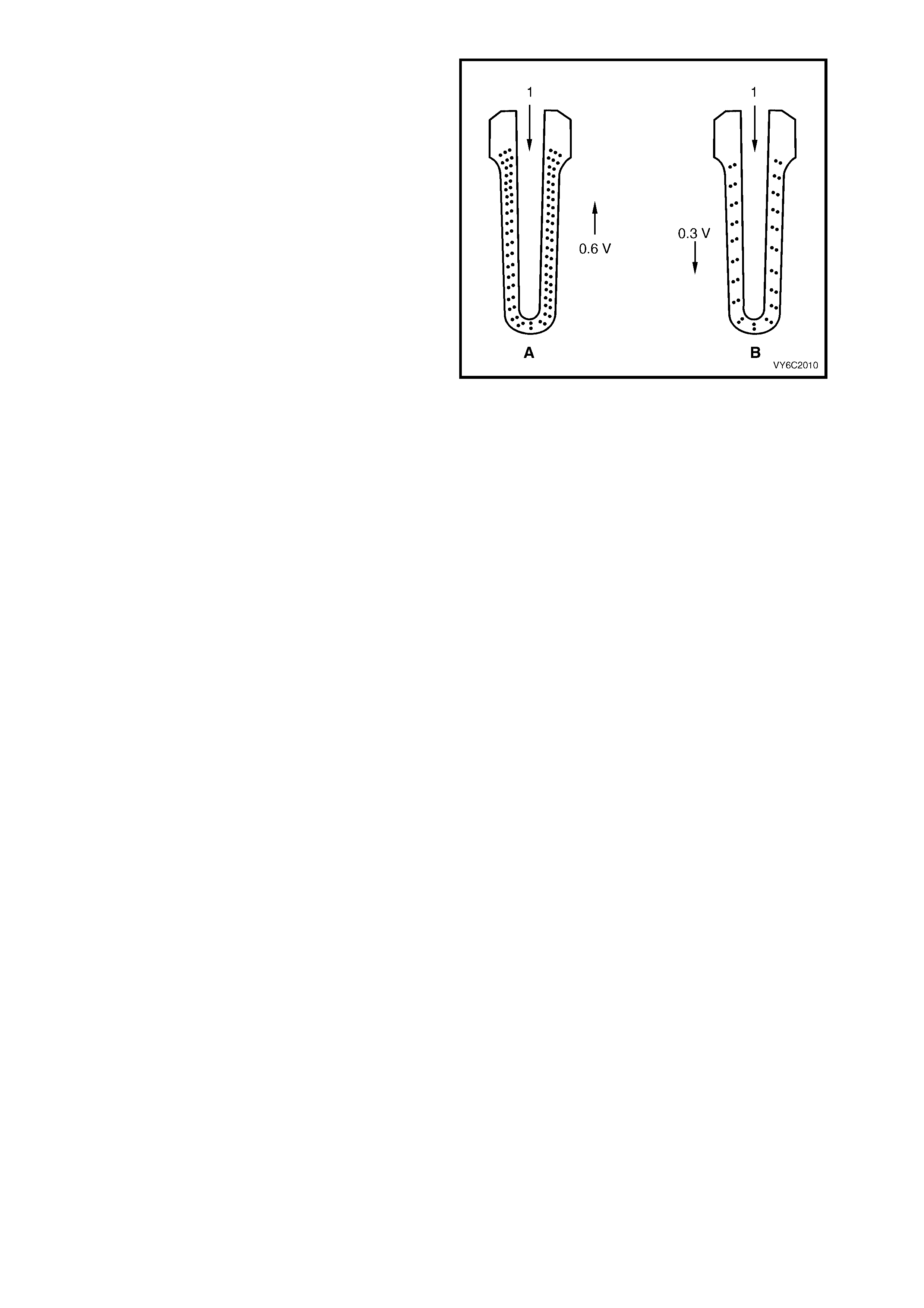

When the sensor is cold, it produces either no voltage, or an unusable, slowly changing one. Also when cold, its

internal electric al r es istanc e is ex tremely high - many million ohms . The PCM always supplies a steady 450 millivolt,

very low current, "bias" voltage to the oxygen sensor circuit. When the sensor is cold and not producing any voltage,

the PCM "detec ts " only this s teady bias voltage. As the sens or begins heating, its internal r es istanc e dec reas es and

it begins producing a rapidly changing voltage that will overshadow the PCM's supplied steady bias voltage.

When the PCM "detects" the changing voltage, it

knows the oxygen sensor is hot and its output

voltage can be used for "fine-tuning" the fuel

injector puls e width. T he PCM monitors the oxygen

sensor's "changing voltage" for going above and

below a mid-range voltage band (approximately

300 - 600 m illivolts ), to help decide when to operate

in the closed-loop mode. (refer "B’ (Ready Test),

Figure 6C2-1-21.)

When the fuel system is correctly operating in the

closed-loop mode, the oxygen sensor voltage

output will change rapidly, several times per

second, going above and below a rich/lean band.

The PCM monitors the changing voltage, and

decides the needed fuel mixture correction. (refer

"A’ (Normal, Closed-Loop Operation), Figure 6C2-

20).

An open s ensor s ignal circuit or gr ound circuit, or a

defective, contaminated, or cold sensor could

cause the voltage to stay within a 350-550 millivolt

band too long, keeping the fuel control system in

open-loop and setting either DTC 13 or DTC 63.

Legend:

A. More Conduction (Exhaust Gas with 0% Oxygen)

B. Less Conduction (Exhaust Gas with 2% Oxygen)

1. Atmospheric Reference Cavity

Figure 6C2-1-19 Oxygen Sensor Zirconia Element

If the PCM monitors a low voltage for too long (indicating a "lean" exhaust), either DTC 44 or DTC 64 will set.

If the PCM m onitors a high oxygen sensor c ircuit voltage for too long ( indicating a "rich" exhaus t), either DTC 45 or

DTC 65 will set.

Response Time

Not only is it necessary for the oxygen sensor to produce a voltage signal for rich or lean exhaust, it is also

impor tant to r espond quic kly to changes. The PCM s ens es the r es ponse times and dis plays this on the Tech 2 scan

tool as the "rich-lean status" and as "cross counts". If the oxygen sensor responds slowly, the customer may

complain of poor fuel economy, rough idle or lack of performance. It may also set false PCM DTC’s because the

PCM uses oxygen sensor voltages for system checks.

Oxygen Sensor Contaminants

Carbon

Black carbon or soot deposits result from over-rich air/fuel mixtures. However, carbon does not harm an oxygen

sensor. Deposits can be burned off in the vehicle by running it at least part throttle for two minutes.

Silica

Certain RTV silicone gasket materials give off vapour as they cure that may contaminate the oxygen sensor. This

contamination is usually caused by the vapours being pulled from the PCV system, into the combustion chamber

and passed on to the exhaust system. The sand like particles from the RTV silica embed in the molecules of the

oxygen sensor element and plug up the surface. W ith the outside of the oxygen sensor element not able to sense

all of the oxygen in the exhaust s ystem it results in "lazy" oxygen sensor res ponse and engine control. The ox ygen

sensor will have a whitish appearance on the outside if it has been contaminated.

There is also a possibility of silica contamination caused by silicone in the fuel. Some oil companies have used

silicone to raise the octane rating of their fuel. Careless fuel handling practices with transport containers can result

in unacceptable concentrations of silicone in the fuel at the pump.

There is also a possibility of silica contamination caused by silicon in lubricants used to install vacuum hoses on

fittings. Do not use silicone sealers on gaskets or exhaust joints.

Lead

Lead glazing of the sensors can be introduced when regular, or leaded fuel is burned. Fuel containing large

amounts of methanol will also result in lead contamination.

The methanol dissolves the terne coating of the fuel tank, which introduces lead into the fuel system, and into the

exhaust after combustion. It is difficult to detect lead contamination by visual inspection.

Other Substances

Oil deposits will ultimately prevent oxygen sensor operation. The sensor will have a dark brown appearance.

Causes of high oil consumption should be checked.

The additives in ethylene glycol can also af fec t oxygen sensor perf orm anc e. This produces a whitish appearance. If

antifreeze enters the exhaust system, you will likely encounter other, more obvious, symptoms of cooling system

trouble. If for example the engine had a head gasket failure where coolant did enter the combustion chamber it

would be a good idea to check the oxygen sensor operation after the head gasket was repaired.

Multiple Failures

Leaded fuel, silic a contam ination f rom uncur ed, low-grade (unapproved) RTV s ealant, and high oil consum ption are

possible causes.

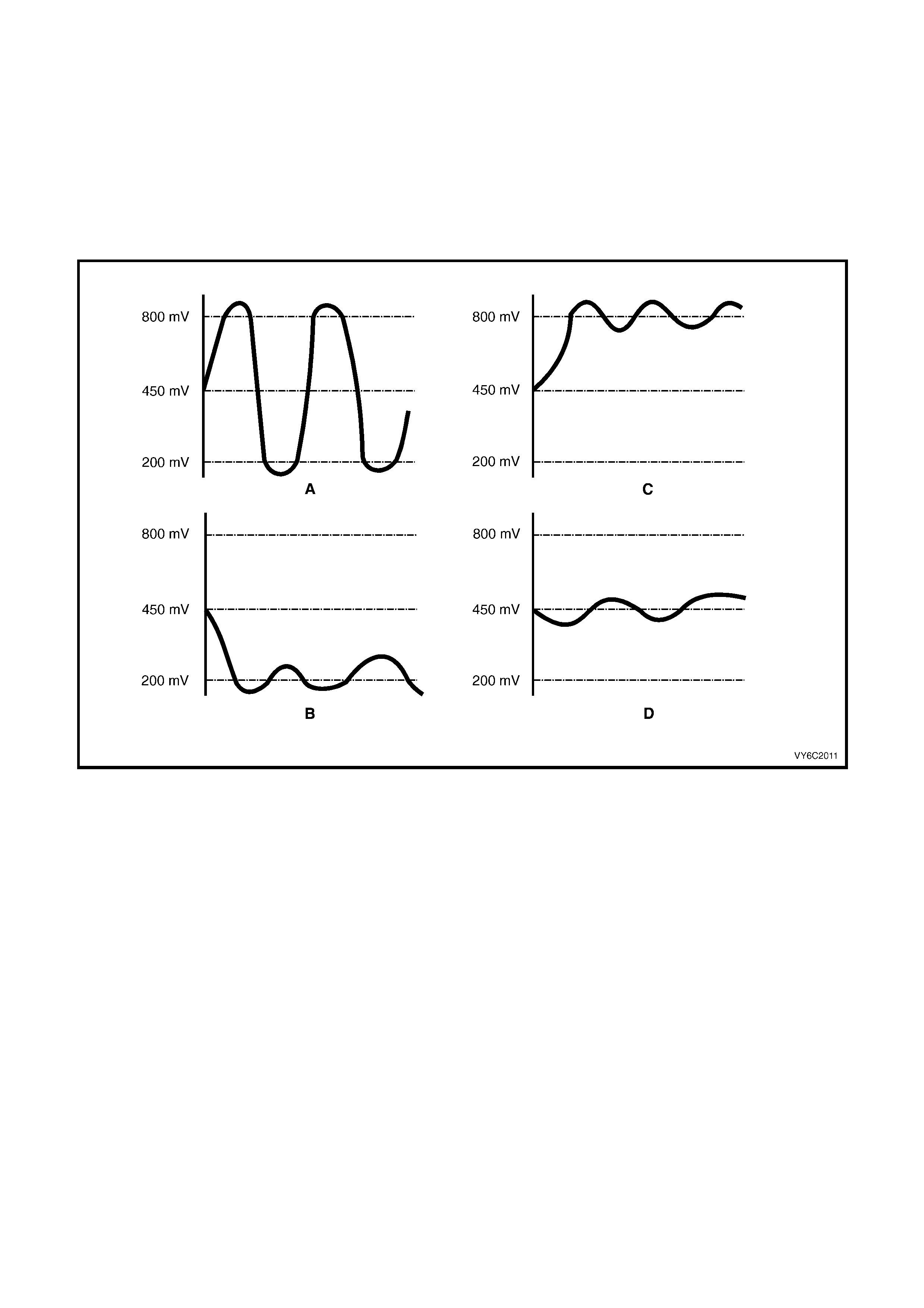

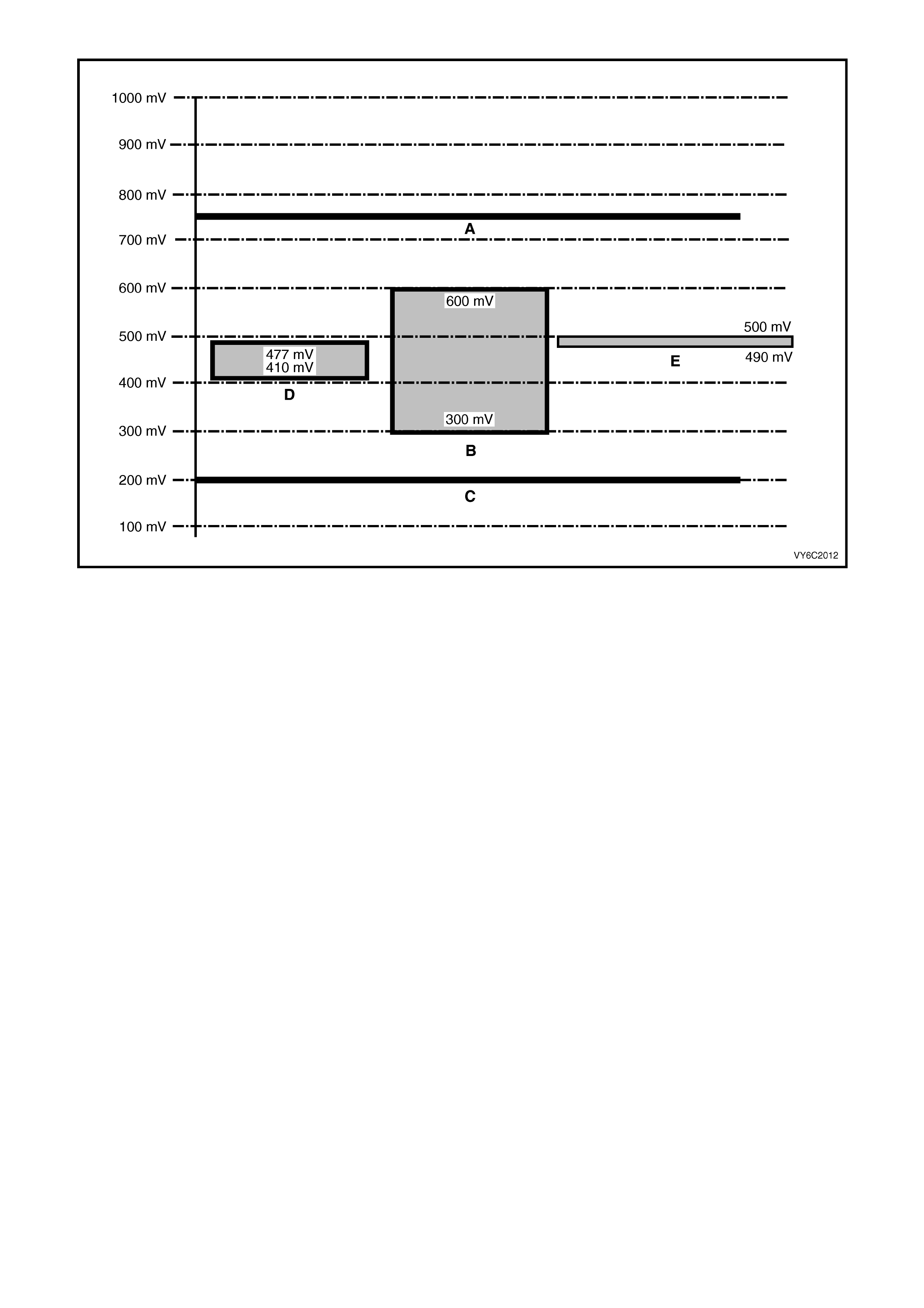

Figure 6C2-20 Oxygen Sensor Voltage Curves

Legend

A. Normal, Closed Loop Operation

B. Lean – Below 200 mV for too long in Closed Loop (DTC 44 or 64 Will Set)

C. Rich – Above 780 mV for too long in Closed Loop (DTC 45 or 65 Will Set).

D. Between 410 – 477 mV Too Long (DTC 13 or 63 Will Set).

800 mV – Rich

450 mV – PCM O2 Reference Signal

200 mV – Lean

Figure 6C2-1-21 Normal Oxygen Sensor Voltages, and Abnormal Trends

Legend

A. More than 780 mV for Too Long (plus other parameters). (DTC 45 or 65 Will Set)

B. “Ready” Test

C. Less than 200 mV for Too Long (plus other parameters). (DTC 44 or 64 Will Set)

D. Between 410 and 477 mV (DTC 13 or 63 Will Set)

E. Rich-Lean Band at a Hot Idle (between 490 and 500 mV)

DTC 13 (RH Oxygen Sensor Insufficient Activity) will set if:

• No TP Sensor DTC’s are set.

• The ECT sensor is more than 85°C.

• TP Sensor voltage indicates the throttle is open more than 15%.

• RH O2S voltage stays between 410-477 millivolts.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

DTC 44 (RH Oxygen Sensor Lean Exhaust Indicated) will set if:

• No IAT Sensor DTC’s are set.

• RH O2S signal voltage remains below 200 millivolts for 46 seconds.

• The system is in “Closed Loop”.

• IAT Sensor is below 75°C.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

DTC 45 (RH Oxygen Sensor Rich Exhaust Indicated) will set if:

• No TP Sensor DTC’s are set.

• RH O2S signal voltage remains above 780 millivolts for 40 seconds.

• The system is in “Closed Loop”.

• Throttle angle is between 9% and 30%.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

Default Value

Once an O2S DTC is set and current, the PCM will operate the fuel system in the “Open Loop” mode.

Recovery

Recovery will occur when the PCM sees a valid condition.

DTC 13, 44, AND 45 HISTORY DATA

PARAMETER PARAMETER

ENGINE SPEED MASS AIR FLOW

TIME FROM START R.H SHORT TERM FUEL TRIM

TIMES OCCURRED R.H LONG TERM FUEL TRIM

IGNITION CYCLES THROTTLE ANGLE

R.H O2 SENSOR

DTC 63 (LH Oxygen Sensor Insufficient Activity) will set if:

• No TP Sensor DTC’s are set.

• The ECT sensor is more than 85°C.

• TP Sensor voltage indicates the throttle is open more than 15%.

• LH O2S voltage stays between 410-477 millivolts.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

DTC 64 (LH Oxygen Sensor Lean Exhaust Indicated) will set if:

• No IAT Sensor DTC’s are set.

• LH O2S signal voltage remains below 200 millivolts for 46 seconds.

• The system is in “Closed Loop”.

• IAT Sensor is below 75°C.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

DTC 65 (LH Oxygen Sensor Rich Exhaust Indicated) will set if:

• No TP Sensor DTC’s are set.

• LH O2S signal voltage remains above 780 millivolts for 40 seconds.

• The system is in “Closed Loop”.

• Throttle angle is between 9% and 30%.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

Default Value

Once an O2S DTC is set, and current, the PCM will operate the fuel system in the “Open Loop” mode.

Recovery

Recovery will occur when the PCM sees a valid condition.

DTC 63, 64, AND 65 HISTORY DATA

PARAMETER PARAMETER

ENGINE SPEED L.H O2 SENSOR

TIME FROM START MASS AIR FLOW

TIMES OCCURRED L.H STFT

IGNITION CYCLES L.H LTFT

COOLANT TEMPERATURE THROTTLE ANGLE

Figure 6C2-1-22 V6 Supercharged Engine Four Wire Oxygen Sensor Circuit

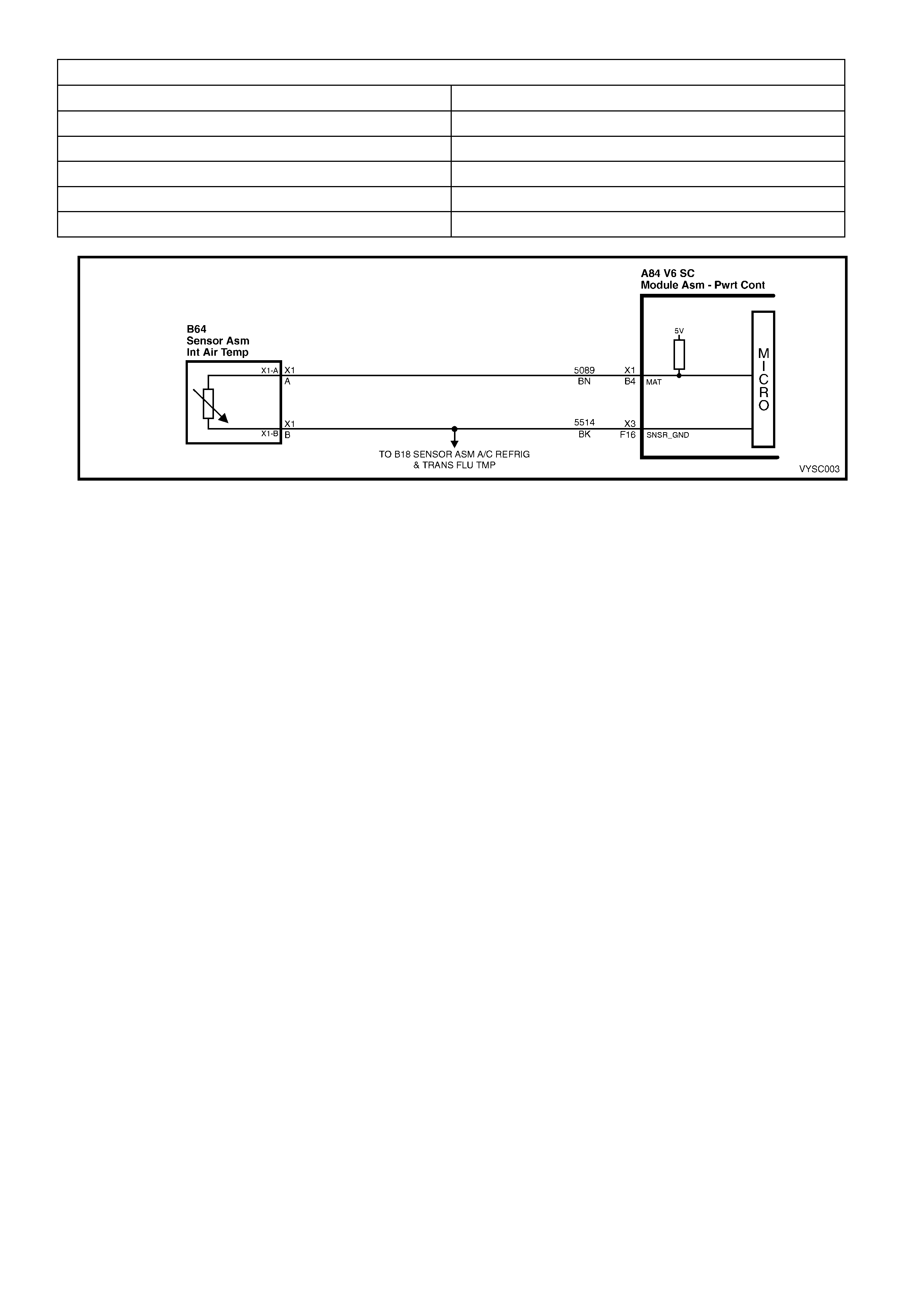

INTAKE AIR TEMPERATURE (IAT) SENSOR

The Intake Air Temperature (IAT) sensor is a thermistor (a resistor that changes resistance with changes in

temperature) mounted in the air cleaner housing of the intake system. Low intake air temperature produces high

resistanc e in the sensor (100,866 ohm s at -40° C), while high intake air tem perature caus es low sensor resistanc e

(78 ohms at 130° C).

The PCM:

1. Supplies a 5 volt signal voltage to the sensor through a resistor in the PCM, and

2. Monitors the intake air temperature circuit voltage, which will change when connected to the intake air

temperature sensor.

The circuit voltage will vary depending on the resistance of the IAT sensor. The voltage will be close to the 5 volt

level when the sensor is cold, and will decrease as the sensor warms.

The input intake air temperature signal voltage is used by the PCM to assist in calculating the fuel injector pulse

width.

A failure in the IAT sensor circuit should set either DTC 23 or 25.

An intermittent or unstable voltage in the IAT sensor circuit should set DTC 26.

Figure 6C2-1-23 – IAT Sensor & Location

Legend

1. Wiring Harness Connector

2. Air Cleaner Upper Housing

3. Mating Tang

4. Retainer

5. IAT Sensor

DTC 23 (Intake Air Temperature Sensor Signal Voltage High) will set if:

• IAT Sensor signal voltage is more than 4.9 volts, indicating an intake air temperature below –36°C for more

than one second.

• The PCM will not illuminate the Malfunction Indicator Lamp (MIL).

DTC 25 (Intake Air Temperature Sensor Signal Voltage low) will set if:

• IAT Sens or signal voltage is les s than 0.3 volts , indicating an intake air tem perature above 147°C for m or e than

one second.

• The PCM will not illuminate the Malfunction Indicator Lamp (MIL).

DTC 26 (Intake Air Temperature Sensor Unstable Voltage) will set if:

• Engine run time is longer than 10 seconds.

• IAT Sensor reading changes more than 140 millivolts in 100 milliseconds

• The PCM will not illuminate the Malfunction Indicator Lamp (MIL).

Default Value

Once an IAT DTC is set and current, the PCM will substitute an IAT value of 25°C.

Recovery

Recovery will occur when the PCM sees a valid condition.

DTC 23, 25 AND 26 HISTORY DATA

PARAMETER PARAMETER

ENGINE SPEED ECT SENSOR

TIME FROM START IAT SENSOR

TIMES OCCURRED BATTERY VOLTAGE

IGNITION CYCLES REFERENCE VOLTS

COOLANT TEMPERATURE

Figure 6C2-1-24 IAT Sensor Circuit

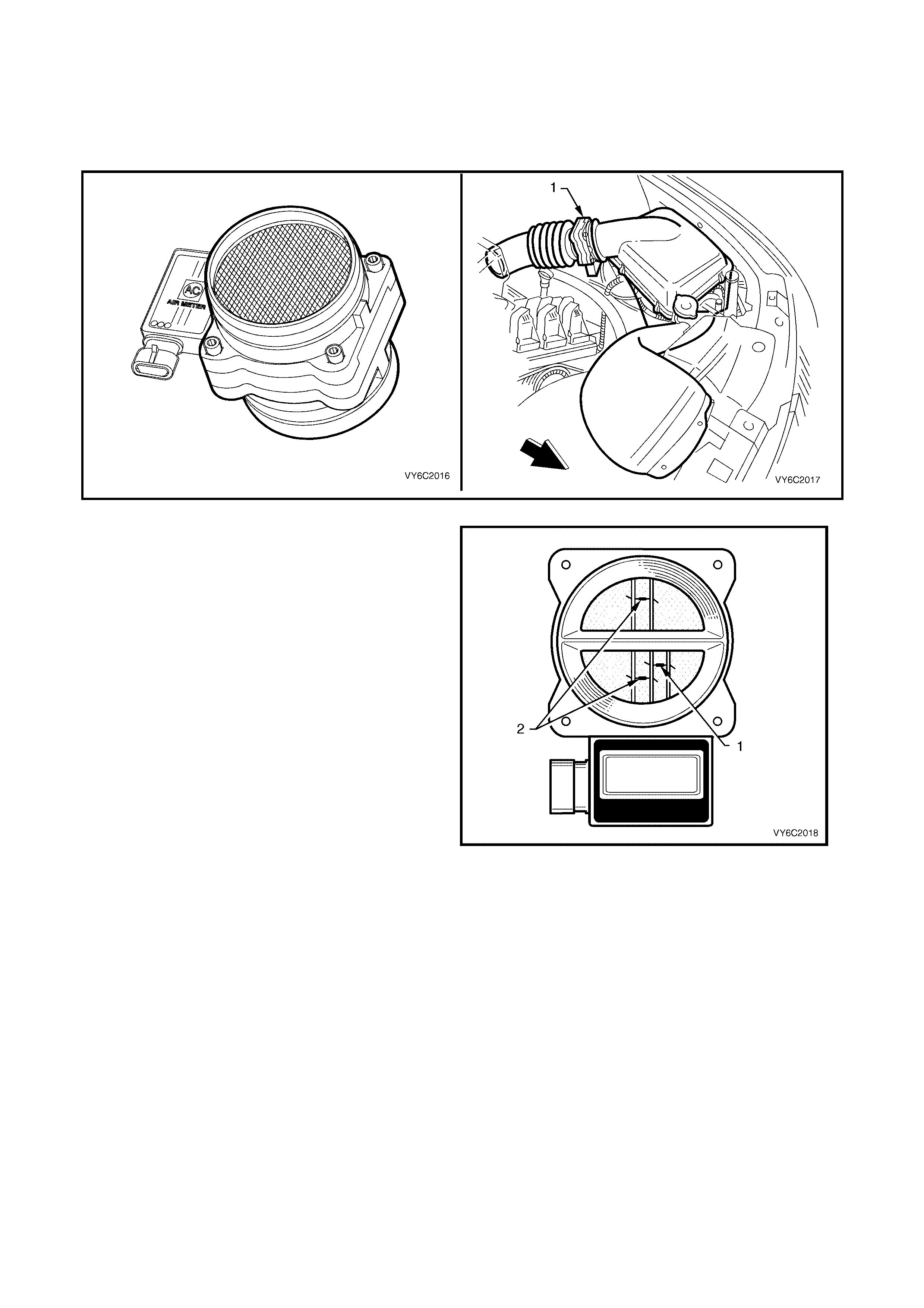

MASS AIR FLOW (MAF) SENSOR

The Mass Air Flow (MAF) sensor (1) used on this engine, utilises a heated element type of operation. A heated

element in the MAF is placed in the air flow str eam of the engine intak e s ystem. T he heating elem ent is m aintained

at a constant temperature differential above the air temperature. The amount of electrical current required to

maintain the heated elem ent at the proper temperature is a direct function of the mass flow rate of the air past the

heated element.

Figure 6C2-1-25 – Mass Air Flow Sensor & Location

Three sensing elements are used in this system.

One senses ambient air temperature (1) and uses

two calibratable resistors (2) to establish a voltage

that is always a function of ambient temperature.

This am bient sensor is m ounted in the lower half of

the sensor housing. The other two sensing

elements are heated to a predetermined

temperature that is significantly above ambient air

temperature.

The two heated elements (2) are connected

electric ally in par allel and m ounted direct ly in the air

flow stream of the sensor housing. One element is

in the top and the other elem ent is in the bottom of

the sensor housing. This is done so that the air

meter is less sensitive to upstream ducting

configurations that could skew the flow of air

through the housing.

As air passes over the heated elements during

engine operation they begin to cool. By measuring

the amount of elec tr ical c ur rent r equir ed to maintain

the heated elements at the predetermined

temperature above ambient temperature the mass

air flow rate can be determined.

Once the mass air flow sensor has developed an

internal signal related to the mass air flow rate, it

must send this information to the PCM. In order to

preserve the accuracy and resolution of the small

voltage signal in the mass air flow sensor, it is

converted to a frequency signal by a voltage

oscillator and sent to the PCM.

Figure 6C2-1-26 Sensing Elements

Figure 6C2-1-27 – MAF Sensor Simplified Schematic

The s ignal that is s ent f r om the mass air flow sensor is s ent in the f orm of a frequenc y output. A large quantity of air

passing through the sensor (such as when accelerating) will be indicated as a high frequency output. A small

quantity of air pass ing through the sens or will be indicated as a low fr equency output (such as when decelerating or

at idle). T he Tec h 2 scan tool dis plays MAF sensor inf orm ation in f requenc y, in grams per second (calc ulated in mg

per cylinder). At idle, the readings should be low and increase with engine RPM.

As the PCM r ec eives this f r equenc y signal from the Mass Air F low sensor , it s earc hes its pr e- progr ammed tables of

information to determine the pulse width of the fuel injectors required to match the Mass Air Flow signal.

If a problem occurs in the Mass Air Flow sensor circuit, after a period of time, the PCM will store a DTC in its

memory. The PCM will turn "ON" the "Check Powertrain" Malfunction indicator Lamp (MIL) indicating there is a

problem. If this occurs, the PCM will calculate a "substitute" Mass Air Flow signal based on engine speed and

Throttle Position (TP) sensor signal.

No field service adjustment is necessary or possible with this Mass Air Flow sensor.

A failure in the Mass Air Flow sensor circuit should set DTC 32.

Remember, this DTC indicates a failure in the circuit, so proper use of the diagnostic Table will lead to either

repairing a wiring problem or replacing the MAF Sensor, to properly repair a problem.

The Mas s Air Flow sensor identification is m ade up

of four number groups:

Legend:

1. Year

2. Julian Date (Day of the Year)

3. Last Four Digits of Part Number.

4. Flow Stand Number.

Figure 6C2-1-28 – Mass Air Flow Sensor Identification

DTC 32 (Mass Air Flow System Performance) will set if:

• The engine is running.

• No MAF Signal for over two seconds.

• Above conditions present for at least 10 seconds.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

Default Value

W hen a MAF sens or or circuit f ault is detected, and current, the PCM will subs titute a MAF sensor value based on

RPM, throttle angle and IAC position.

Recovery

Recovery will occur when the PCM sees a valid condition.

DTC 32 HISTORY DATA

PARAMETER PARAMETER

ENGINE SPEED R.H O2 SENSOR

TIME FROM START MASS AIR FLOW

TIMES OCCURRED R.H STFT

IGNITION CYCLES R.H LTFT

COOLANT TEMPERATURE THROTTLE ANGLE

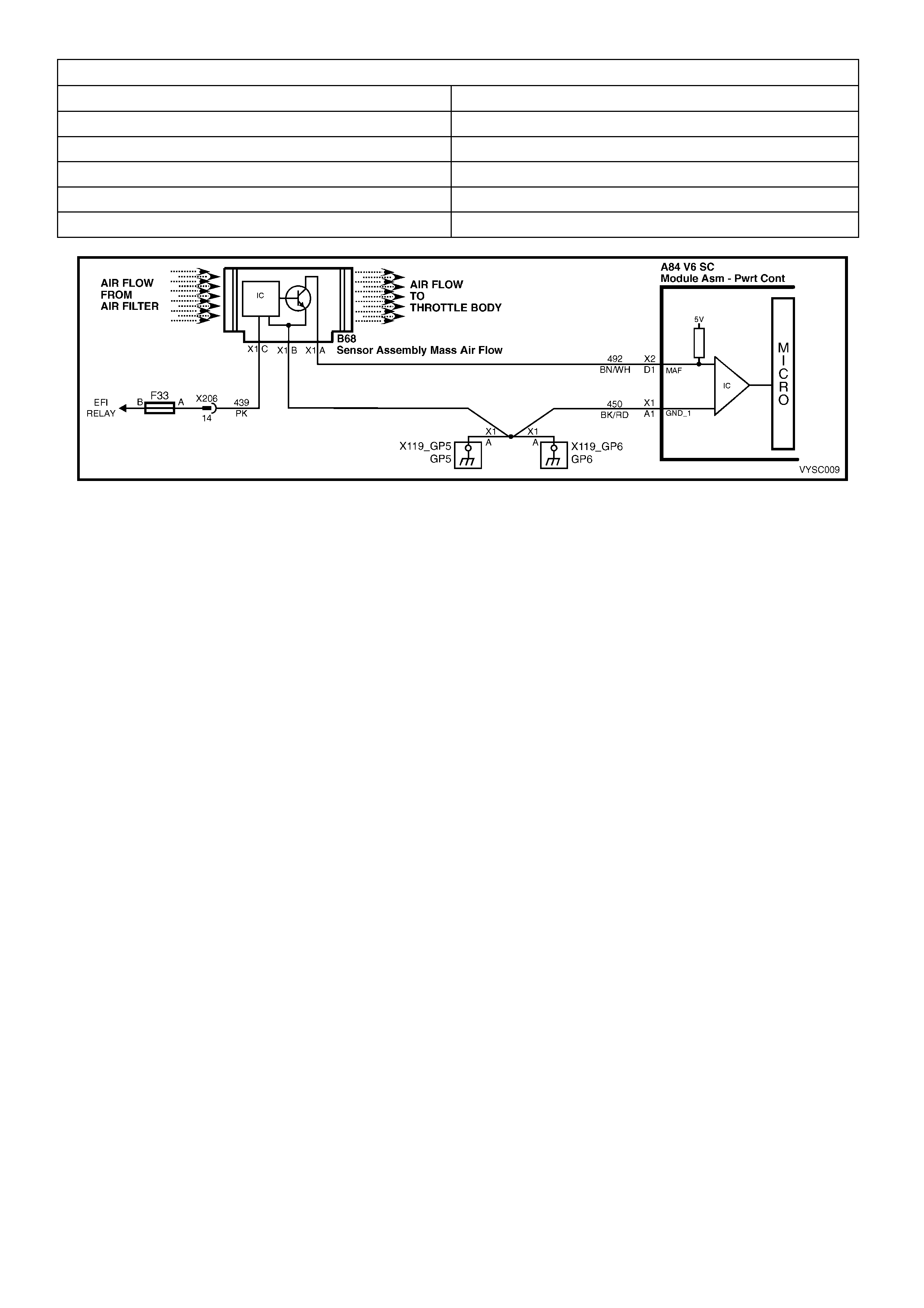

Figure 6C2-1-29 – MAF Sensor Circuit

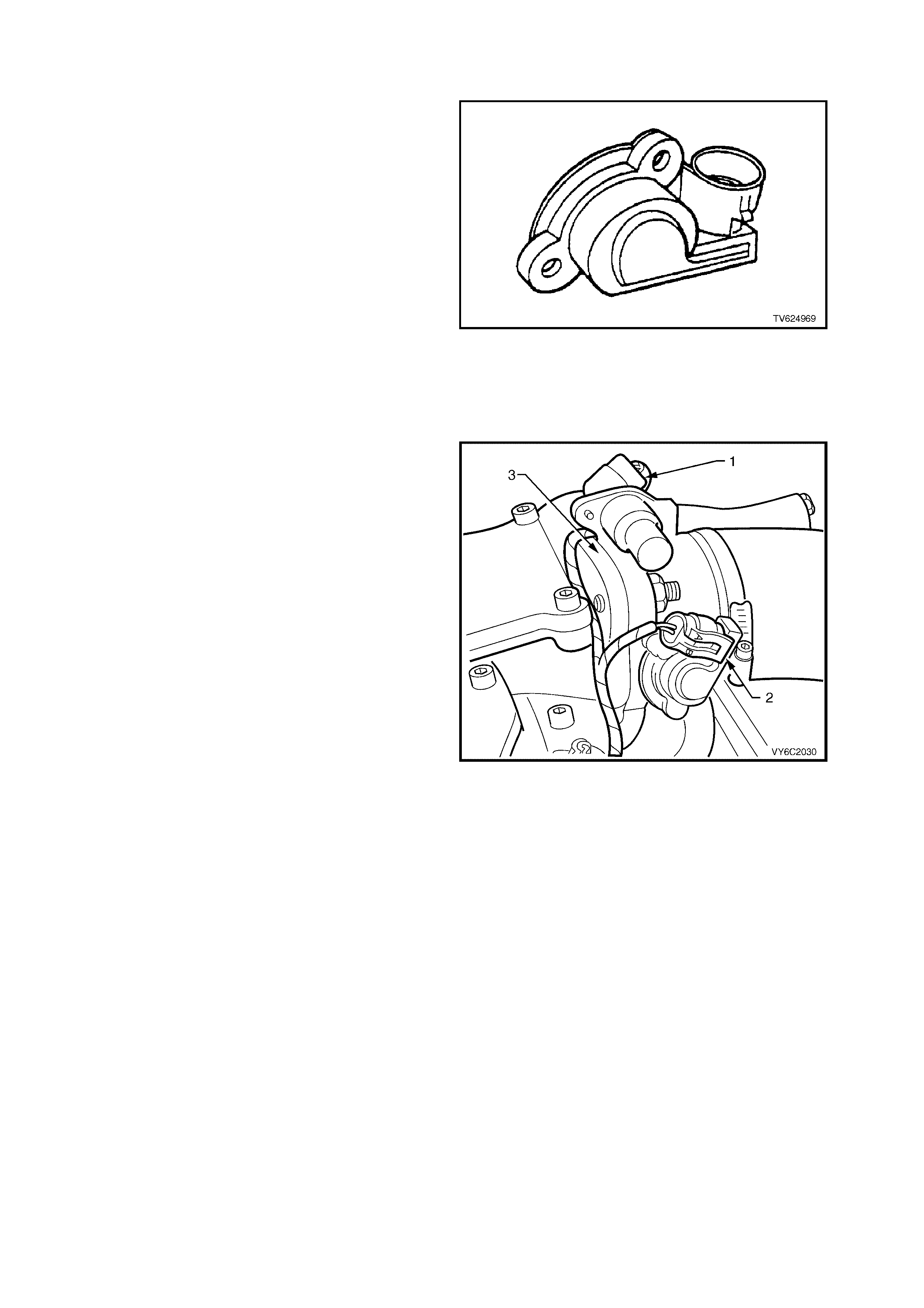

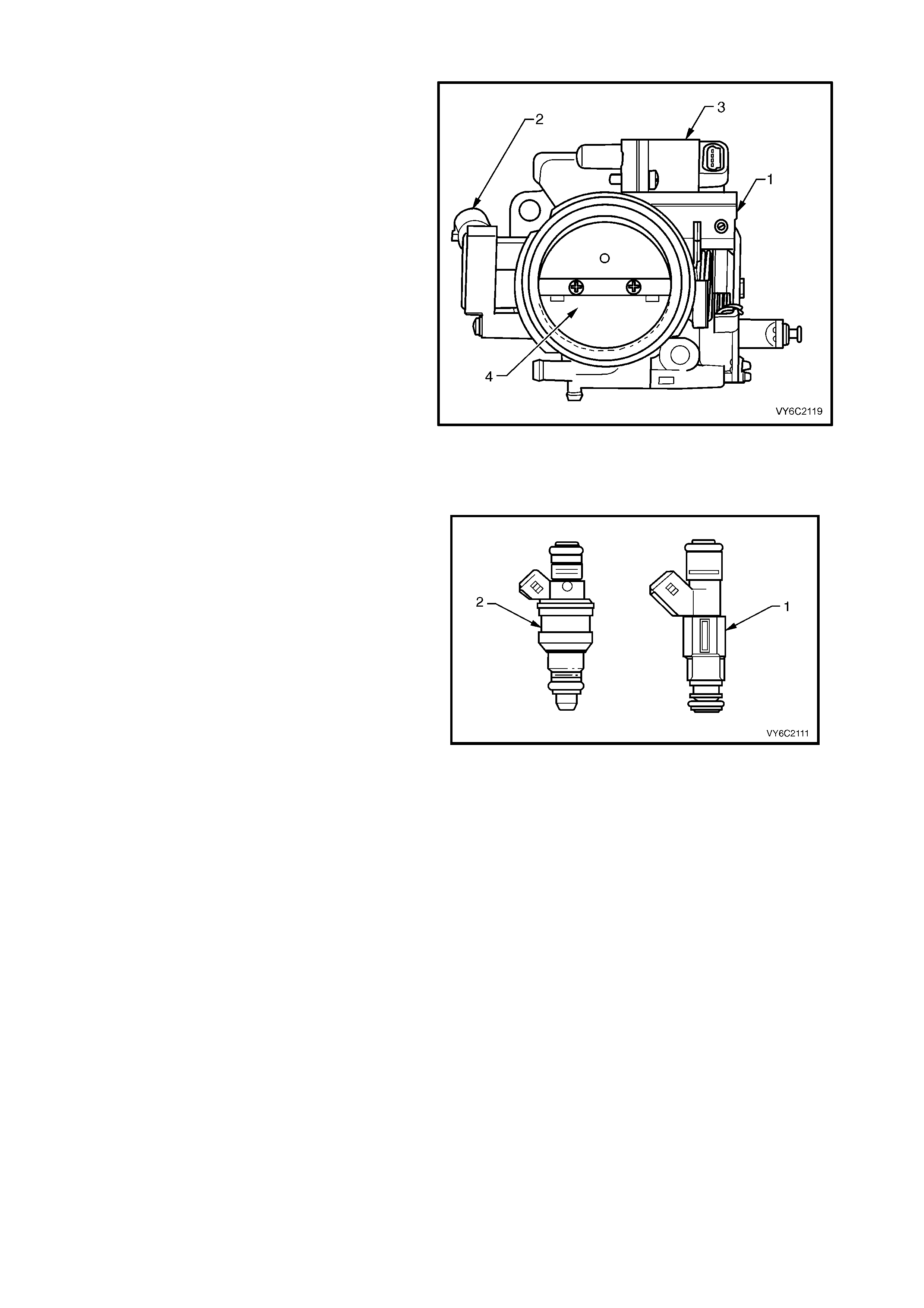

THROTTLE POSITION (TP) SENSOR

The Throttle Position (TP) sensor is connected to

the throttle shaft on the throttle body unit. It is a

potentiometer with one end connected to 5 volts

from the PCM and the other end to PCM ground. A

third wire connects from a sliding contact in the T P

sensor to the PCM allowing the PCM to measure

the voltage from the TP sensor.

As the throttle is m oved (ac celerator pedal moved) ,

the output of the TP sensor changes. At a closed

throttle position, the output of the TP sensor is

below 1.25V. As the throttle valve opens, the output

increases so that, at wide-open throttle (W OT ), the

output voltage should be about 4 volts.

By monitoring the output voltage from the TP

sensor, the PCM c an determ ine fuel delivery based

on throttle valve angle (driver demand). A broken or

loose TP sensor can cause intermittent bursts of

fuel from the injectors, and an unstable idle,

because the PCM interprets the throttle is moving.

Figure 6C2-1-30 – TP Sensor

The TP s ensor (2) is not adjustable and there is no

set value for voltage at closed throttle, becaus e the

actual voltage at closed throttle can vary from

vehicle to vehicle due to tolerances. The PCM has

a special progr am built into it that can adjus t for the

tolerances in the TP sensor voltage reading at idle.

The PCM us es the r eading at c losed thr ottle idle for

the zero reading (0% throttle) so no adjustment is

necessary. Even if the TP sensor voltage reading

was to be changed by; tampering, throttle body

coking, sticking cable or any other reason, the TP

sensor will s till be 0%. The PCM will learn what the

closed throttle value is every time the throttle

comes back to closed throttle. The new closed

throttle value will be used by the PCM and no

driveability complaint will be present because the

PCM learned a new setting.

A failure in the TP sensor circuit should set either

DTC 21 or 22. If the internal spring in the TP

sensor s hould fail, the T P sens or will be stuck high.

A sticking TP sensor should set DTC 19.

Legend

1. Idle Air Control (IAC) Valve

2. Throttle Position (TP) Sensor

3. Throttle Body

Figure 6C2-1-31 – TP Sensor Location

DTC 19 (Throttle Position Sensor Stuck) will set if:

• The TP Sensor indicated percentage of opening is greater than the RPM that can be reached with a Mass Air

Flow of less than 301 mg/cyl.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

DTC 21 (Throttle Position Sensor Signal Voltage High) will set if:

• The TP Sensor voltage between the PCM TP Sensor signal terminal and the TP Sensor ground terminal is

greater than 4.9 volts for more than two seconds.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

DTC 22 (Throttle Position Sensor Signal Voltage Low) will set if:

• The T P Sensor voltage between the PCM TP Sensor s ignal term inal and the T P Sensor ground term inal is less

than 0.2 volts for more than two seconds.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

Default Value

Once a TP Sensor DTC is set, and current, the PCM will substitute a TP Sensor value based on Idle Air Control

Valve position and Mass Air Flow.

Recovery

Recovery will occur when the PCM sees a valid condition.

DTC 19, 21, AND 22 HISTORY DATA

PARAMETER PARAMETER

ENGINE SPEED TP SIGNAL

TIME FROM START MASS AIR FLOW

TIMES OCCURRED R.H LTFT

IGNITION CYCLES BATTERY VOLTAGE

COOLANT TEMPERATURE REFERENCE VOLTS

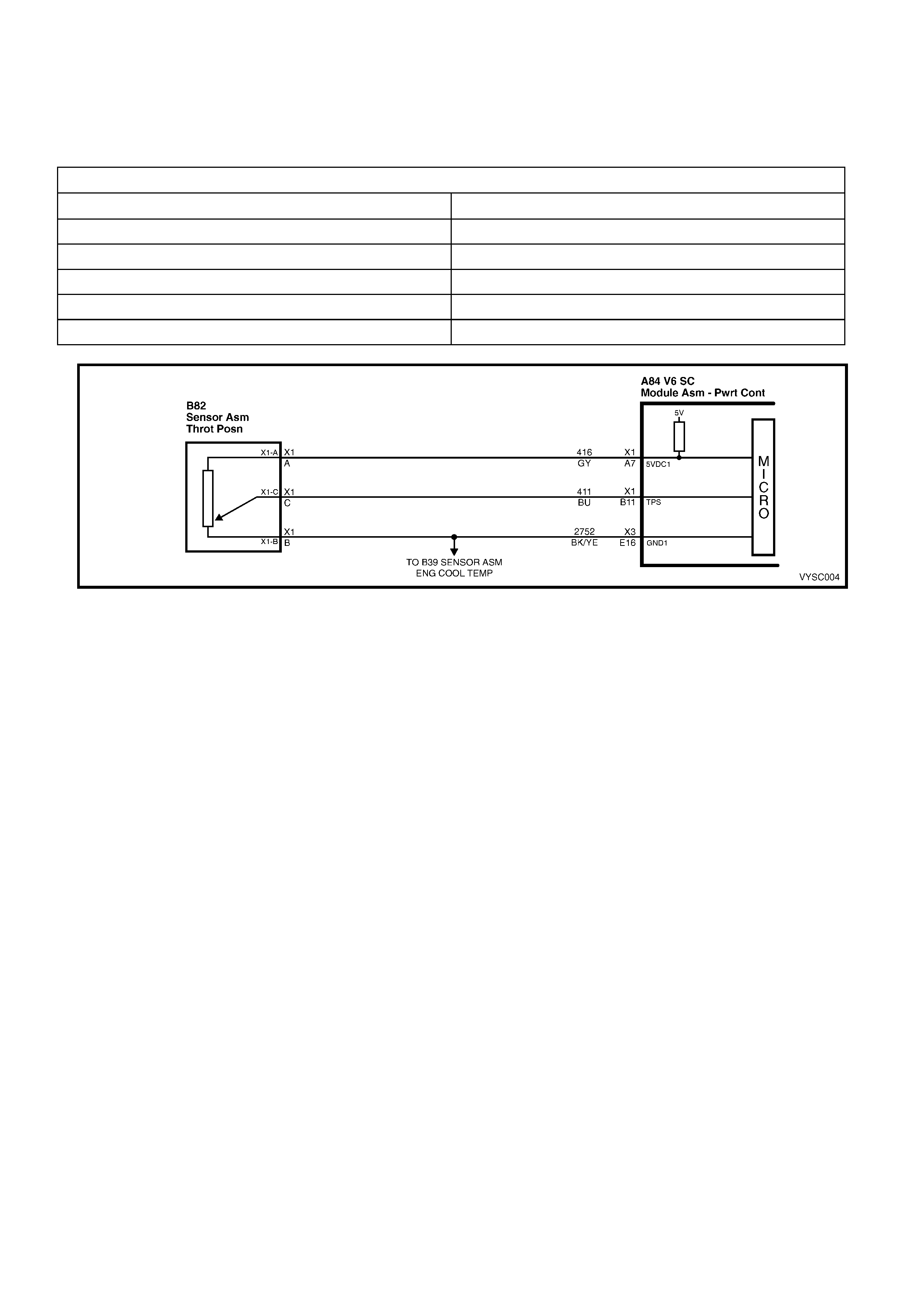

Figure 6C2-1-32 – TP Sensor Circuit

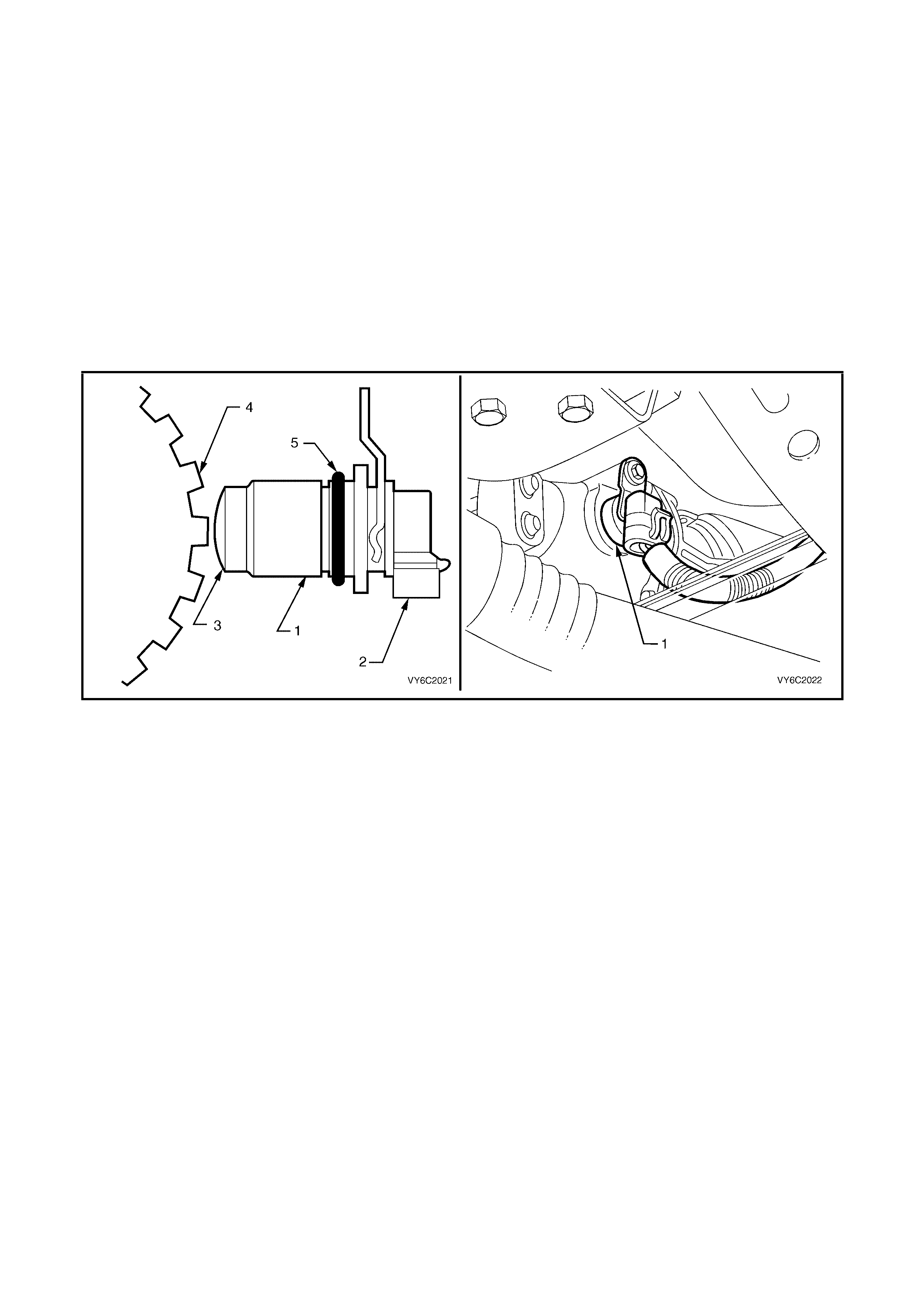

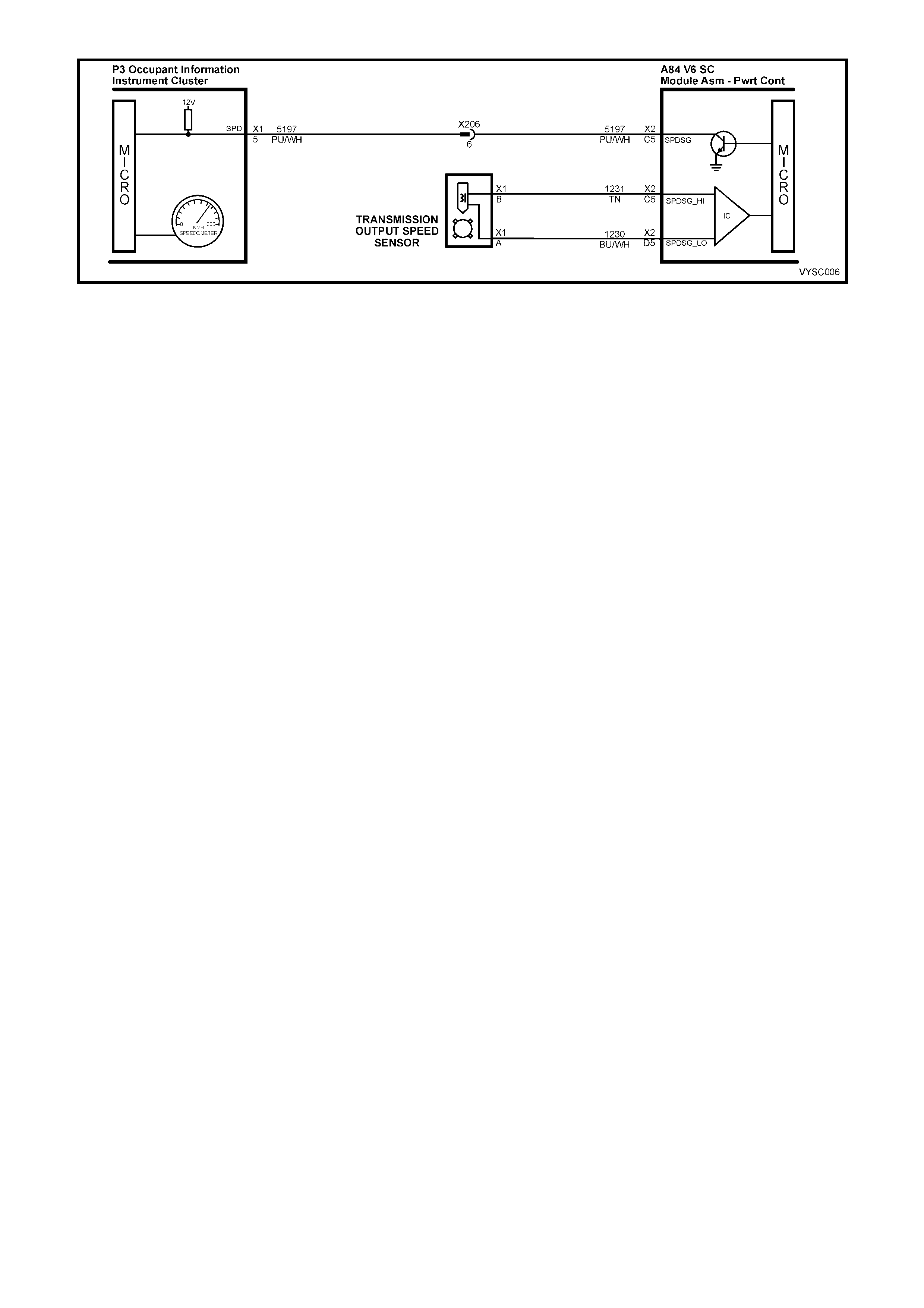

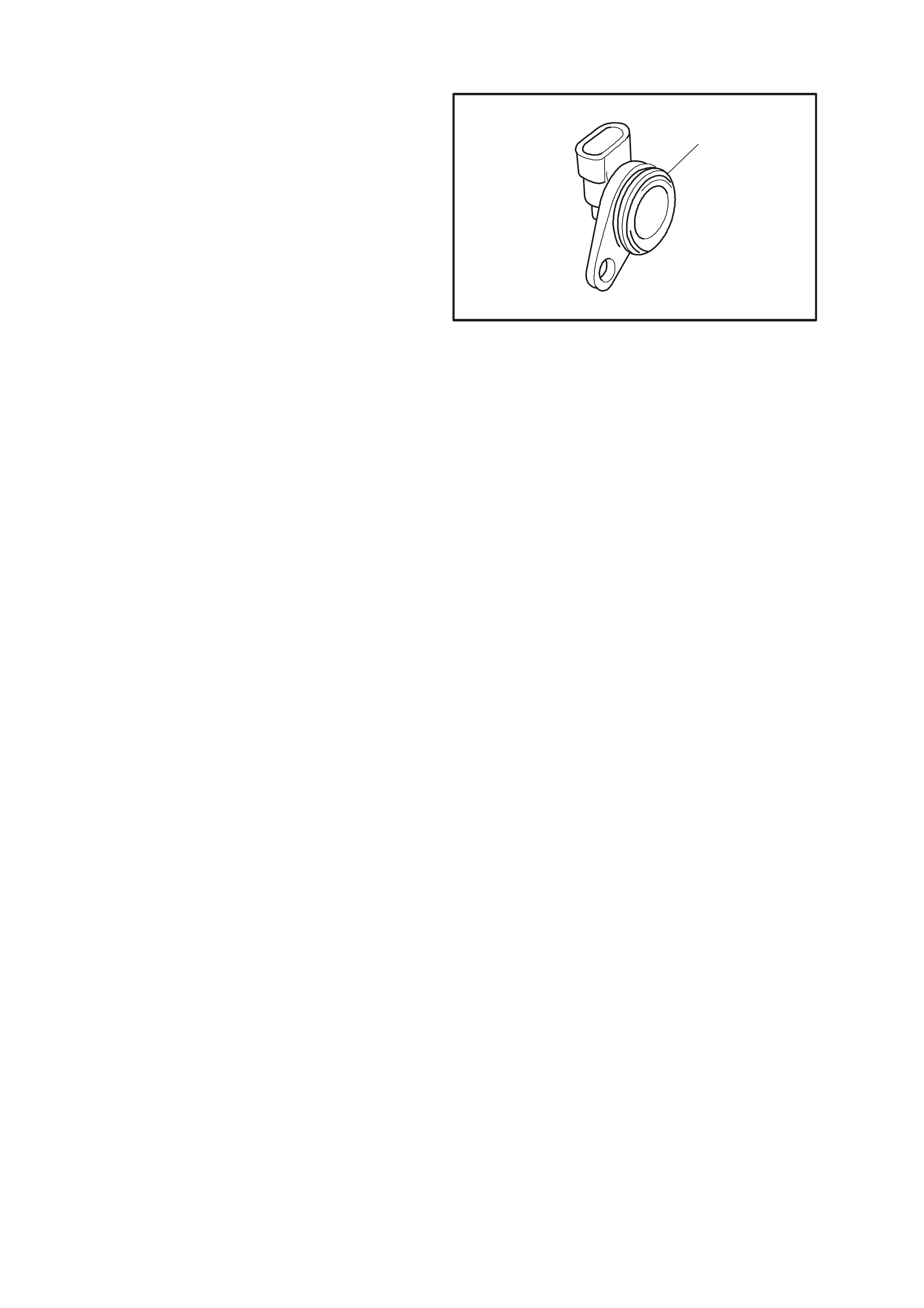

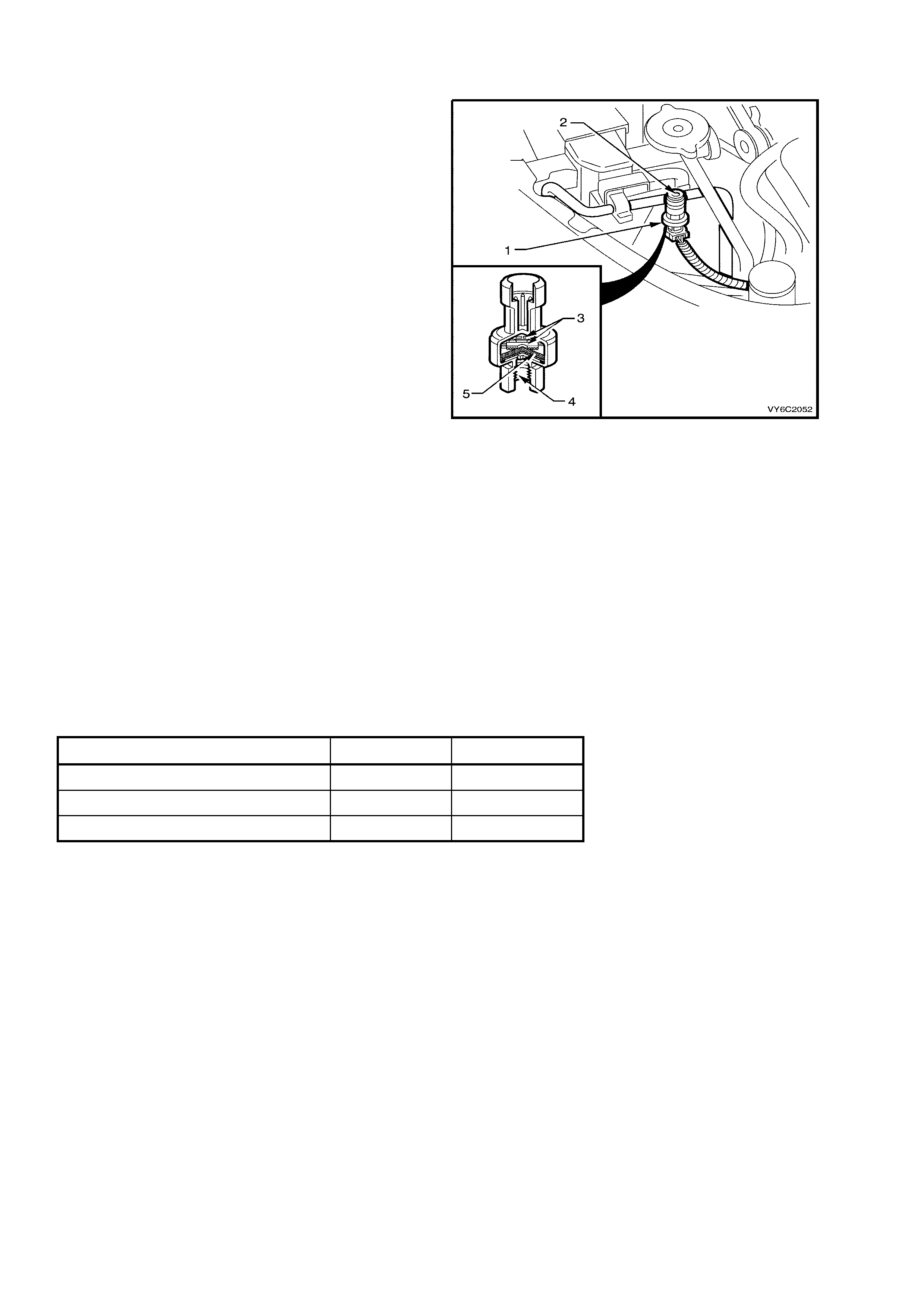

VEHICLE SPEED SENSOR (VSS)

The VSS (1) provides an indication of road speed to the PCM. The sensor is mounted in the extension housing of

the transmission and is an inductive pick-up or pulse generator, which generates an AC voltage at a varying

frequency. The frequency will change with a change in output shaft speed. The PCM uses this signal for internal

processing and to also generate a vehicle speed signal for use by other control modules

The PCM als o uses inf orm ation f rom the VSS f or IAC valve operation and some of the engine fuelling modes. If the

PCM receives no pulses on the vehicle speed sensor input while certain conditions exist, DTC 24 will be set.

DTC 24 will set if a fault exists in the vehicle speed sensor circuit when the vehicle is accelerated, and the VSS

signal is constant, or not pulsing. The DTC will set and a default value will be substituted by the PCM. As long as

the fault remains and the diagnostic trouble code is set. If the fault is removed, norm al operation will resume after

the next ignition cycle.

The vehicle speed sensor contains a coil that has a continuous magnetic field, generated by the magnetic pick-up

(3). A voltage signal is induced in the vehicle speed sensor by teeth on the output shaft (4) that rotate past the

sensor and br eak the m agnetic field. Each break in the field sends an electr ical pulse from the electrical connector

(2) and wiring harness, to the PCM.

The O-ring (5), prevents transmission fluid from leaking externally.

Figure 6C2-1-33 – Vehicle Speed Sensor & Location

Legend

1. Vehicle Speed Sensor

2. Electrical Connector

3. Magnetic Pickup

4. Rotor

5. O-Ring

This voltage output will vary with transmission output shaft speed from a minimum of 0.5 volts AC at 100 RPM to

more than 100 volts AC at 8000 RPM with no load on the circuit on the vehicle, with the engine at 4,000 RPM in

fourth gear the voltage will be approximately 10-12 volts AC.

The PCM uses speed information from this sensor to determine the following:

• Vehicle speed.

• Control shift points (Auto Trans).

• Calculate transmission slip (Auto Trans).

• Engine fuelling modes.

DTC 24 will set if a f ault ex is ts in the vehicle s peed s ensor c irc uit indic ating the vehicle is not moving. As the vehicle

is accelerated, the PCM shifts the transmission to second gear at approximately 3,000 RPM. If the vehicle speed

signal is still not pres ent while in second gear, the DT C is set, the transm iss ion will have maxim um line pressure in

2nd gear only and have no TCC. A default value will be substituted by the PCM.

DTC 72 will set if there is an intermittent failure in the VSS circuit while the vehicle is moving. As long as the fault

remains and DTC 72 is set, the PCM will have maximum line pressure and 3rd gear only. If the fault is removed,

normal operation will resume after the next ignition cycle.

DTC 24 (Vehicle Speed Sensor Circuit Low Voltage) will set if:

• The transmission is not in Park or Neutral.

• The engine speed is greater than 3000 RPM.

• The TP Sensor angle is between 10% and 99%.

• The VSS indicates an output shaft speed of less than 3 km/h for 3 seconds.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

Default Value

When the DTC sets, the PCM will command second gear only, maximum line pressure, freeze shift adapts from

being updated and inhibit TCC engagement.

Recovery

Recovery will occur when the PCM sees a valid condition.

DTC 24 HISTORY DATA

PARAMETER PARAMETER

ENGINE SPEED THROTTLE ANGLE

TIME FROM START TFT

TIMES OCCURRED MASS AIR FLOW

IGNITION CYCLES COMMANDED GEAR

COOLANT TEMPERATURE VEHICLE SPEED

DTC 72 (Output Speed Loss) will set if:

• The transmission is not in Park or Neutral.

• Two succes sive speed readings have a dif ference of m ore than 1000 RPM in any drive range (differ ence must

be more than 2048 RPM in park or neutral). This test checks the vehicle speed sensor signal to the PCM.

• The PCM will not illuminate the Malfunction Indicator Lamp (MIL).

Default Value

When Diagnostic Trouble Code 72 is set, the transmission will have maximum line pressure and command 3rd gear

only. If DTC 72 is set while in 4th gear, the vehicle will stay in 4th gear. However, as the vehicle is coasting to a

stop, the transmission will downshift normally from 4 to 3. Once the downshift into 3rd gear has occurred, the

vehicle will stay in 3rd gear.

Recovery

Recovery will occur when the PCM sees a valid condition.

DTC 72 HISTORY DATA

PARAMETER PARAMETER

ENGINE SPEED TRANSMISSION SLIP SPEED

TIME FROM START TFT

TIMES OCCURRED THROTTLE ANGLE

IGNITION CYCLES VEHICLE SPEED

COOLANT TEMPERATURE COMMANDED GEAR

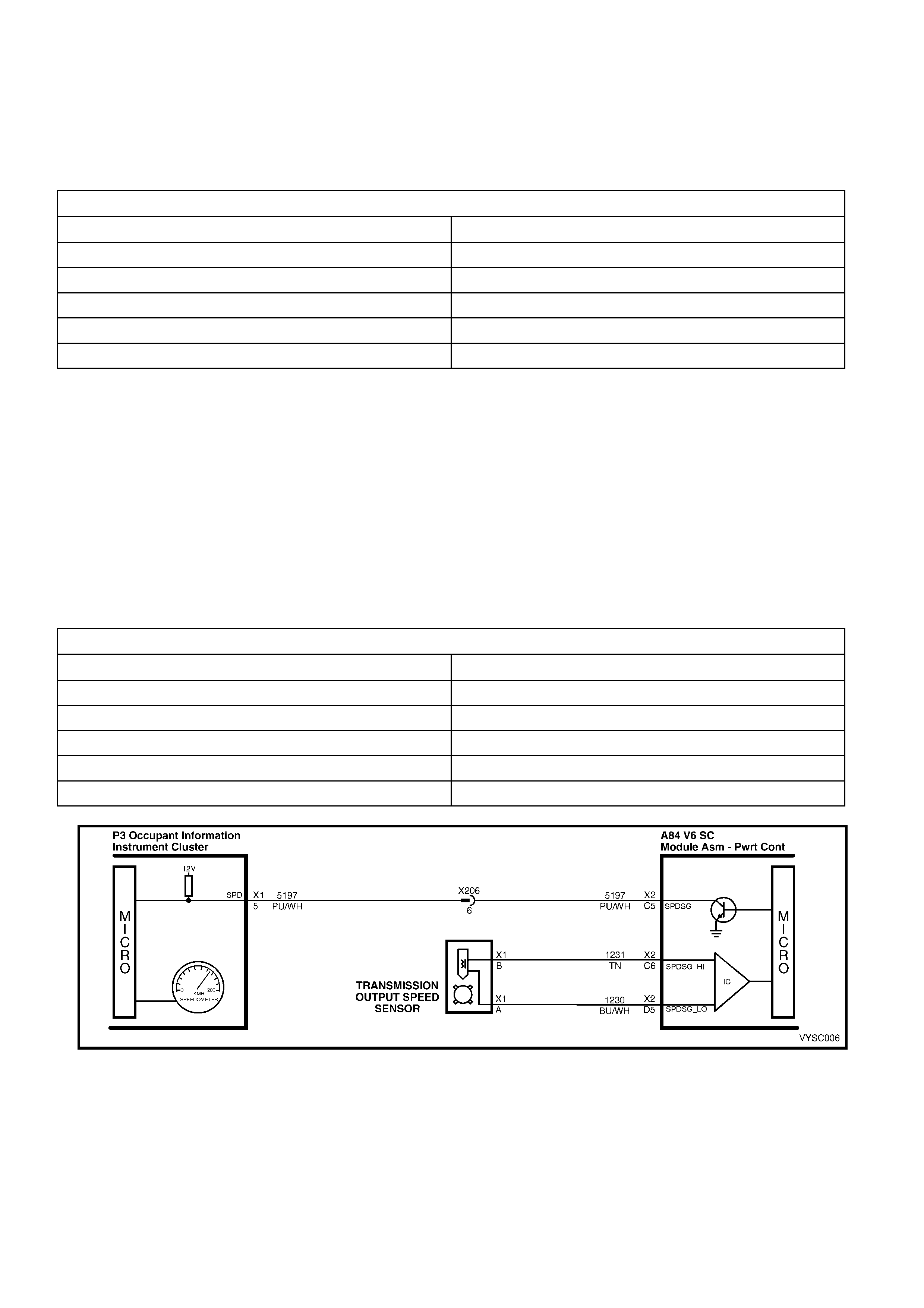

Figure 6C2-1-34 VSS Circuit

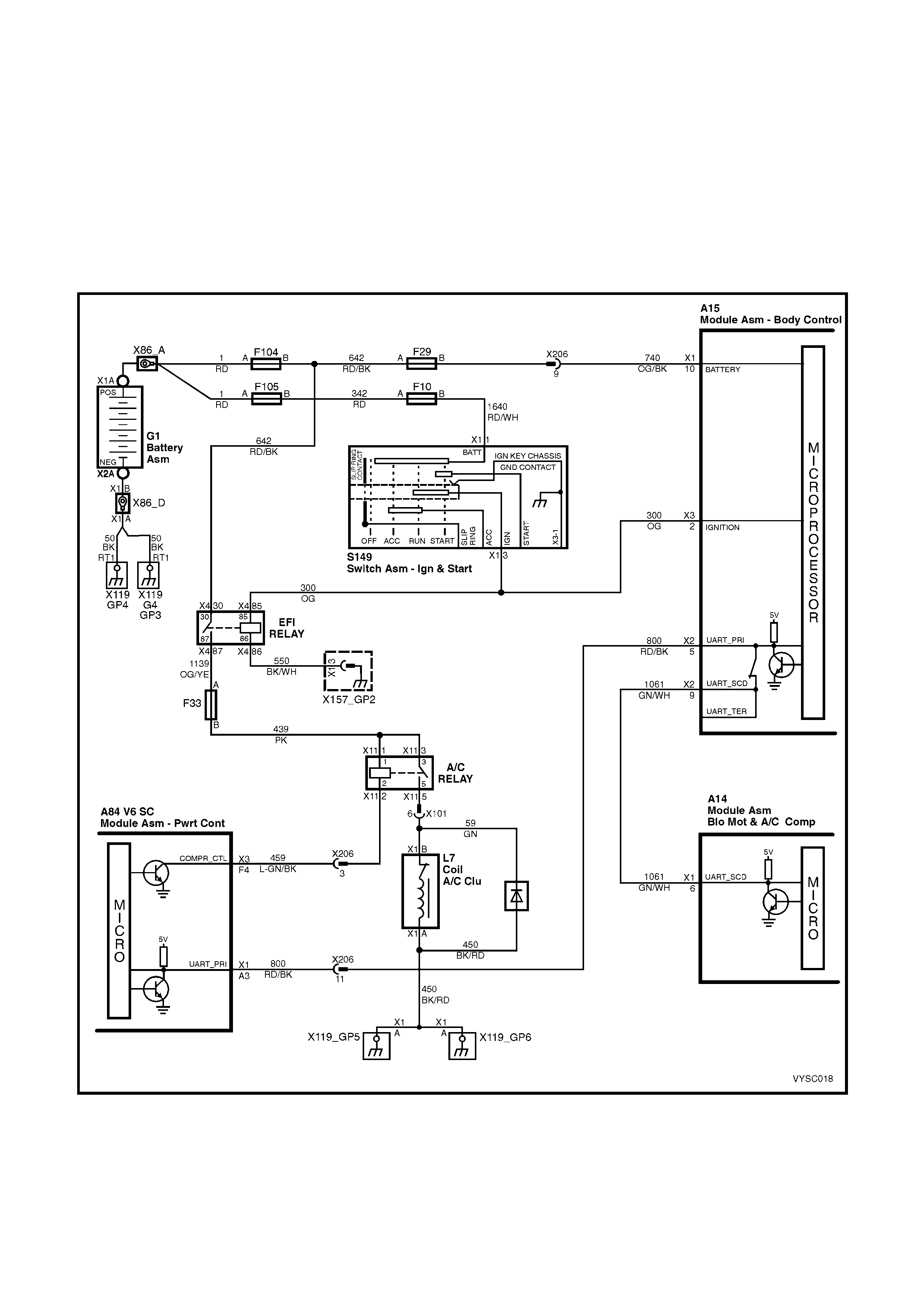

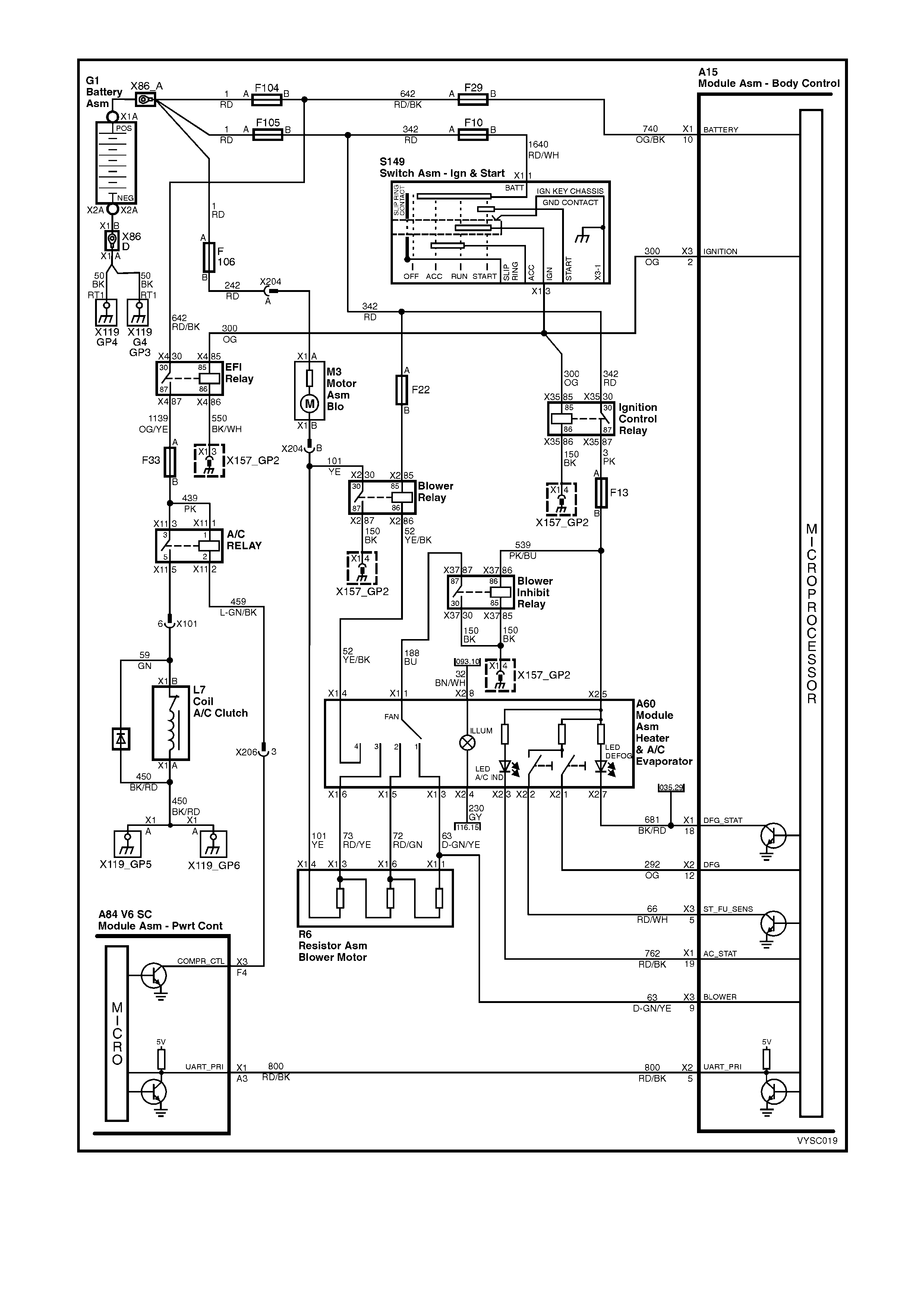

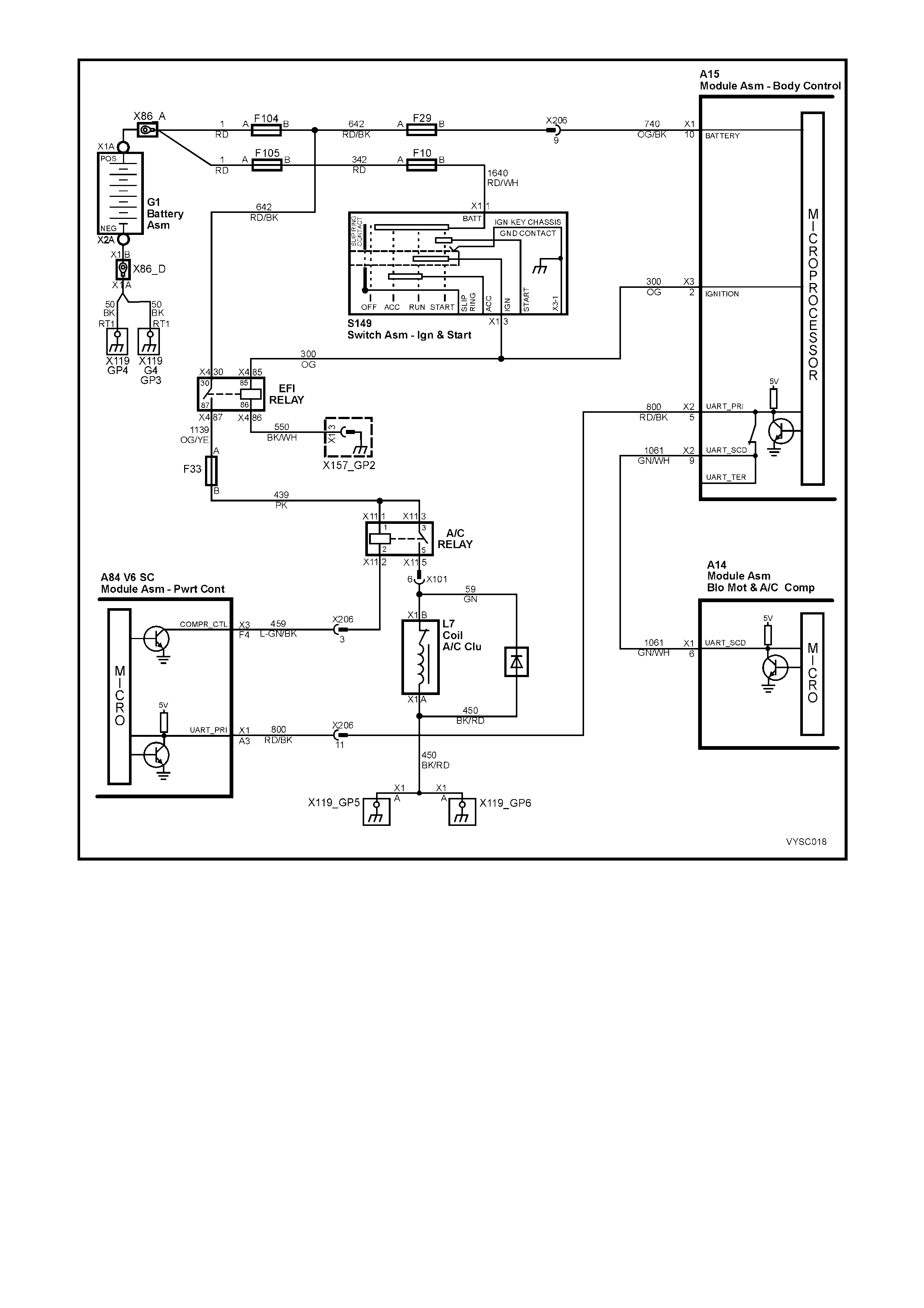

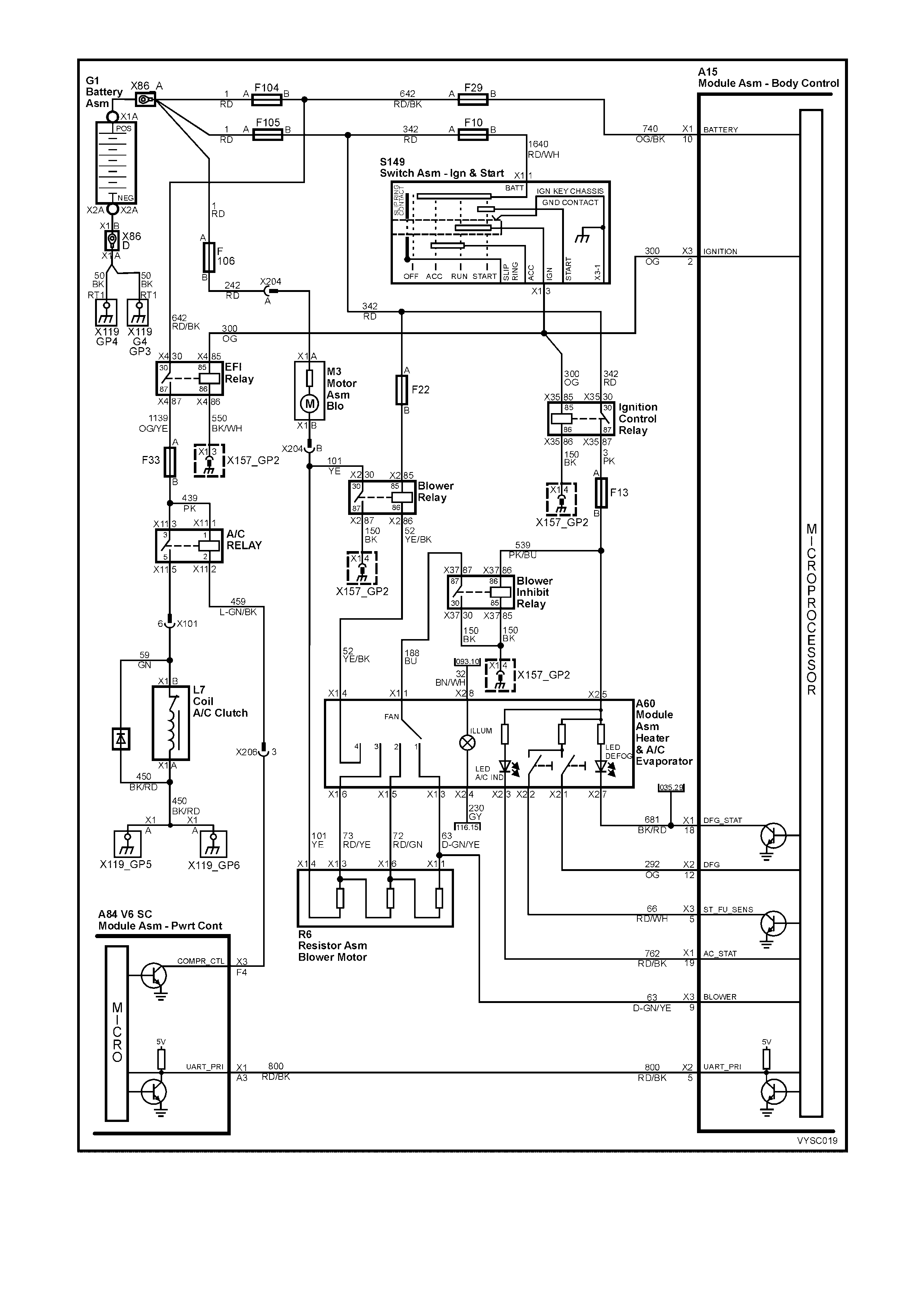

A/C REQUEST SIGNAL

If the vehicle is equipped with HVAC Occupant Clim ate Control (Auto A/C), the HVAC control m odule receives the

command to switch the A/C on and sends this as an A/C request to the PCM, via the serial data bus.

W hen A/C is reques ted from the dash master A/C switch, the A/C request signal is sent to the BCM. T he BCM will

then send a command via the serial data line to the PCM. The PCM will then supply a ground signal to the A/C

compressor relay, to energise the A/C compressor. There are no PCM DTC(s) associated with this A/C Request

Signal. Refer to Section 6C2-2A DIAGNOSTIC TABLES, table A-11.1 or A 11.3 for A/C system diagnosis.

The PCM uses this serial data command to:

1. Adjust the Idle Air Control (IAC) position to compensate for the additional load placed on the engine by the air

conditioning compressor, and then

2. Energises the A/C compressor relay, to operate the A/C compressor.

Figure 6C2-1-35 HVAC Occupant Climate Control (Automatic A/C)

Figure 6C2-1-36 A/C Request Signal Circuit – HVAC Climate Control (Manual A/C)

BATTERY VOLTAGE

The PCM continually monitors battery voltage. W hen the battery voltage is low, the ignition system may deliver a

weak spark and the injector mechanical movement takes longer to open the injector. The Powertrain Control

Module will compensate by:

1. Increasing the ignition coil dwell time if the battery voltage is less than 12 Volts.

2. Increasing the engine idle RPM if battery voltage drops below 10 Volts.

3. Increasing the injector pulse width if the battery voltage drops below 10 Volts.

W ith vehicles equipped with the V6 Supercharged engine and autom atic trans miss ion, Diagnostic T rouble Code 52

will set when the engine is running and the voltage at PCM terminal “X1 A4” is above 16 Volts for 109 minutes.

Diagnostic Trouble Code (DTC) 53 will set when the ignition is “ON'' and PCM terminal “X1 A4'' voltage is more than

19.5 Volts for about 2 seconds.

Diagnostic Trouble Code (DTC) 54 will set when the ignition is “ON'' and PCM terminal “X1 A4'' voltage changed

more than 2.5 volts in 100 milliseconds.

Diagnostic Tr ouble Code (DT C) 75 will set when the ignition is “ ON'' and PCM ter m inal “X 1 A4'' voltage is les s than

8.6 Volts for about 4 seconds. Minimum voltage allowed for Diagnostic Trouble Code 75 to set is on a graduated

scale and will change with the temperature. Minimum voltage at –40 ° C is 7.3 Volts, minim um voltage at 90° C is

8.6 Volts, minimum voltage at 152 ° C is 11.4 Volts.

DTC 52 (System Voltage Too High – Long Time) will set if:

• The engine is running and the PCM ignition voltage is greater than 16 volts for more than 109 minutes.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

Default Value

During the time fault is present, the pressure control solenoid is turned "OFF", the transmission shifts immediately to

3rd gear and TCC operation is inhibited.

Recovery

Recovery will occur when the PCM sees a valid condition.

DTC 53 (System Voltage High) will set if:

• Ignition is on.

• Voltage at PCM ignition feed terminal is more than 19.5 volts for more than 2 seconds.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

Default Value

During the time fault is present, the PCM will turn all transmission output devices off and freeze shift adapts from

being updated.

Recovery

Recovery will occur when the PCM sees a valid condition.

DTC 54 (System Voltage Unstable) will set if:

• Ignition is on.

• System voltage changes more than 2.5 volts in 100 milliseconds.

• Above conditions present for at least 10 seconds.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

Default Value

There are no default values.

Recovery

Recovery will occur when the PCM sees a valid condition.

DTC 75 (System Voltage Low) will set if:

• The system voltage is less than 7.3 volts with the TFT at –40° C.

Or:

• The system voltage is less than 10 volts with the TFT at 151° C.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

Default Value

When DTC 75 sets, the PCM will turn off all transmission output devices and freezes shift adapts from being

updated. T he PCM will also adjust ignition timing and adj ust injector puls e width to com pensate for the low voltage

condition.

Recovery

Recovery will occur when the PCM sees a valid condition.

DTC 52, 53, 54 AND 75 HISTORY DATA

PARAMETER PARAMETER

ENGINE SPEED ECT SENSOR

TIME FROM START IAT SENSOR

TIMES OCCURRED BATTERY VOLTAGE

IGNITION CYCLES REFERENCE VOLTS

COOLANT TEMPERATURE

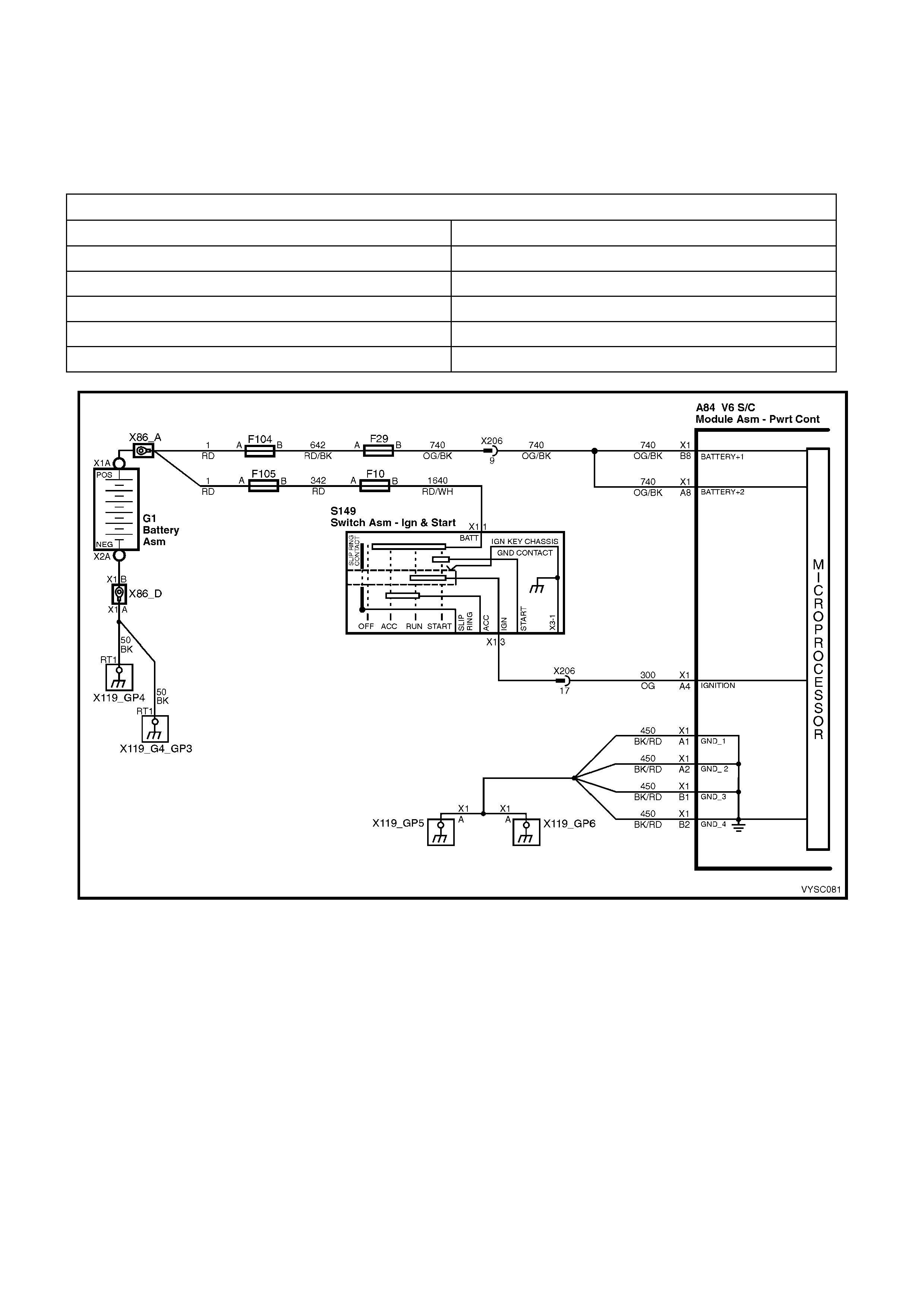

Figure 6C2-1-37 PCM Battery Feed

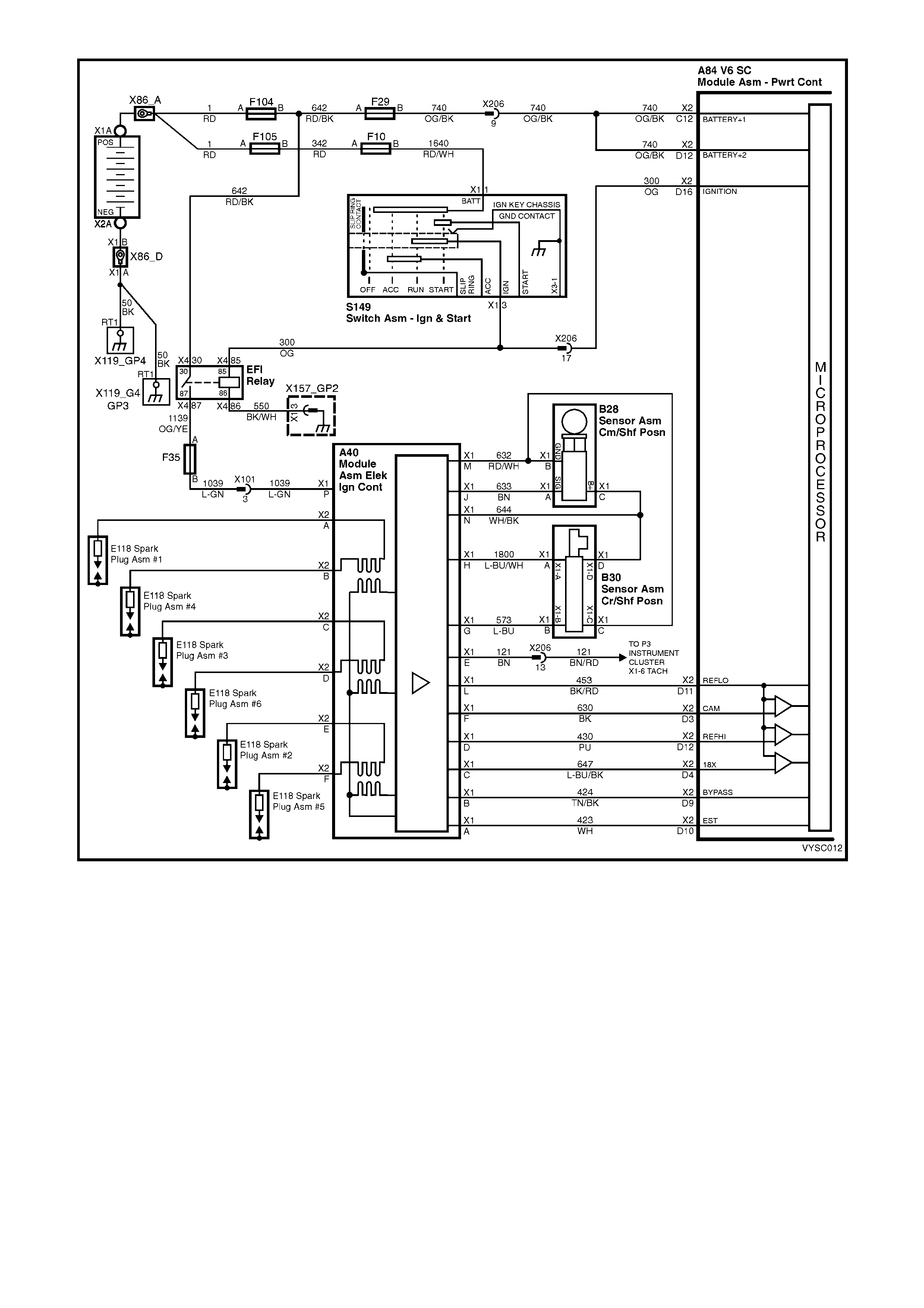

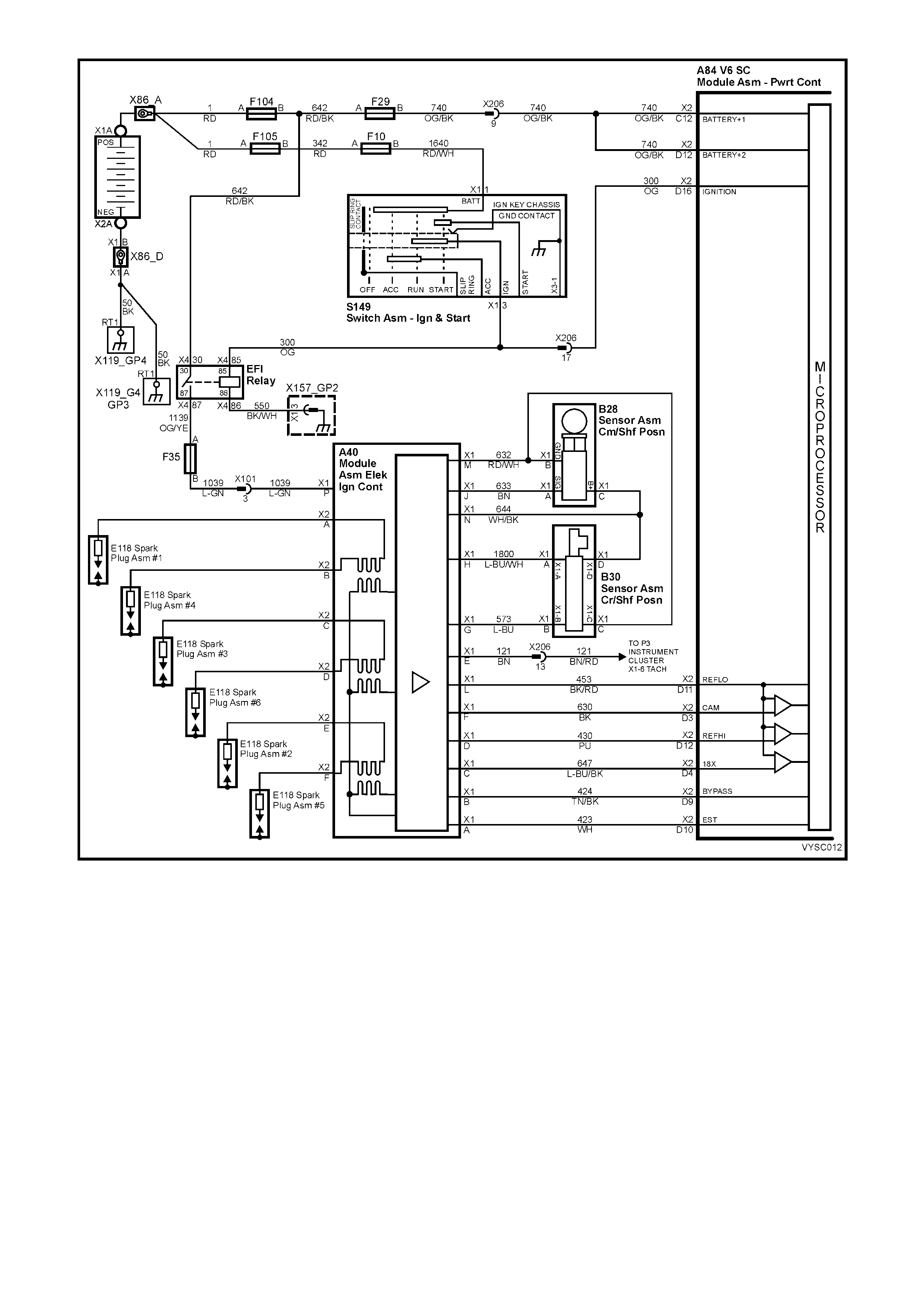

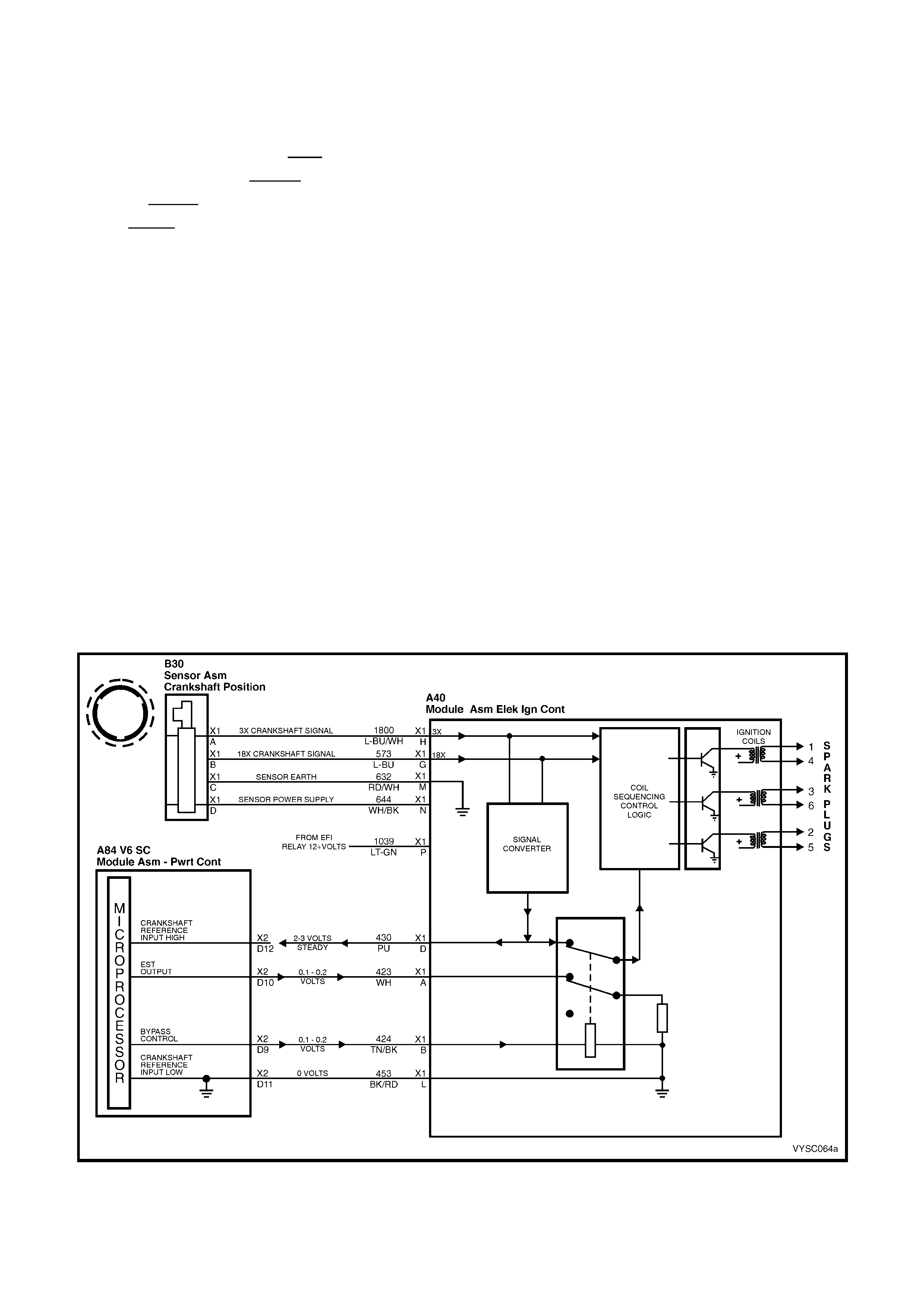

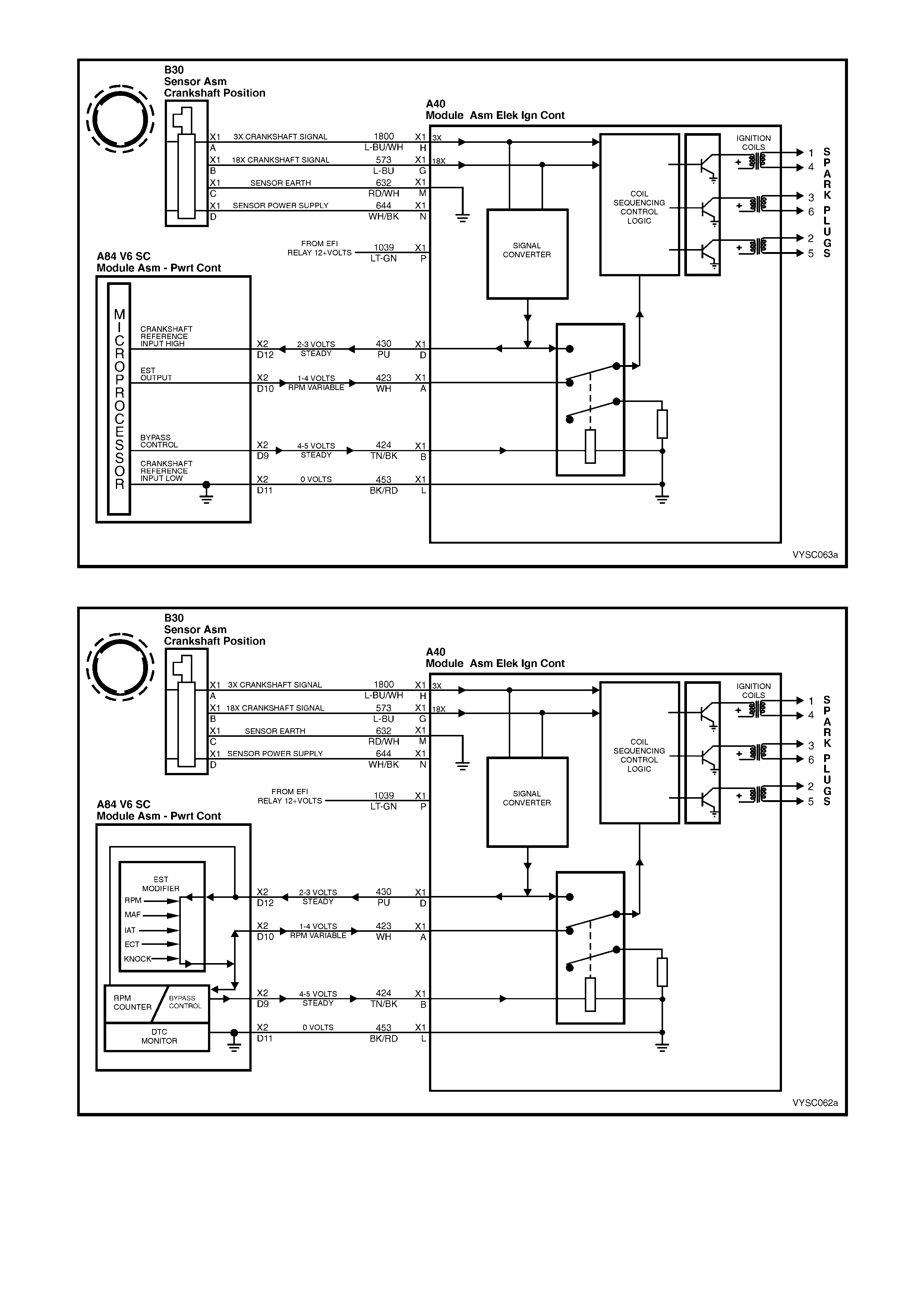

CRANKSHAFT REFERENCE SIGNAL

The Direct Ignition System (DIS) sends this signal to the PCM to tell it engine RPM and crankshaft position. This

signal is a repeating s eries of low voltage electr ical pulses generated by the ignition module. T he PCM initiates fuel

injector pulses based upon receiving these crankshaft reference signal pulses. If the PCM's MAF sensor input

detects manifold vacuum and the ignition voltage input detects less than 11 volts and there are no crankshaft

reference input pulses, a DTC 46 will set.

This engine also uses the cam shaf t position s ensor s ignal to synchronise the fuel injector circuits for sequential fuel

injection. The PCM also uses these reference pulses for Electronic Spark Timing (EST) operation.

For a full description of the ignition system operation Refer to 1.6 DIRECT IGNITION SYSTEM (DIS) in this Section.

DTC 46 (No Reference Pulses While Cranking) will set if:

• MAF DTC is not set.

• Battery voltage is at or below 11 volts.

• MAF sensor input is above 2048 Hz.

• No DIS reference input pulses at PCM.

• Conditions exist for more than 2 seconds.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

Default Value

There are no def ault values f or the Crank shaft Reference Signal. This DTC is intended to help in diagnosing a no-

start condition.

Recovery

Recovery will occur when the PCM sees a valid condition.

DTC 46 HISTORY DATA

PARAMETER PARAMETER

ENGINE SPEED REFERENCE VOLTS

TIME FROM START MASS AIR FLOW

TIMES OCCURRED CAM SIGNAL

IGNITION CYCLES FUELLING MODE

COOLANT TEMPERATURE FUEL PUMP RELAY

BATTERY VOLTAGE

Figure 6C2-1-38 Crankshaft Reference Signal

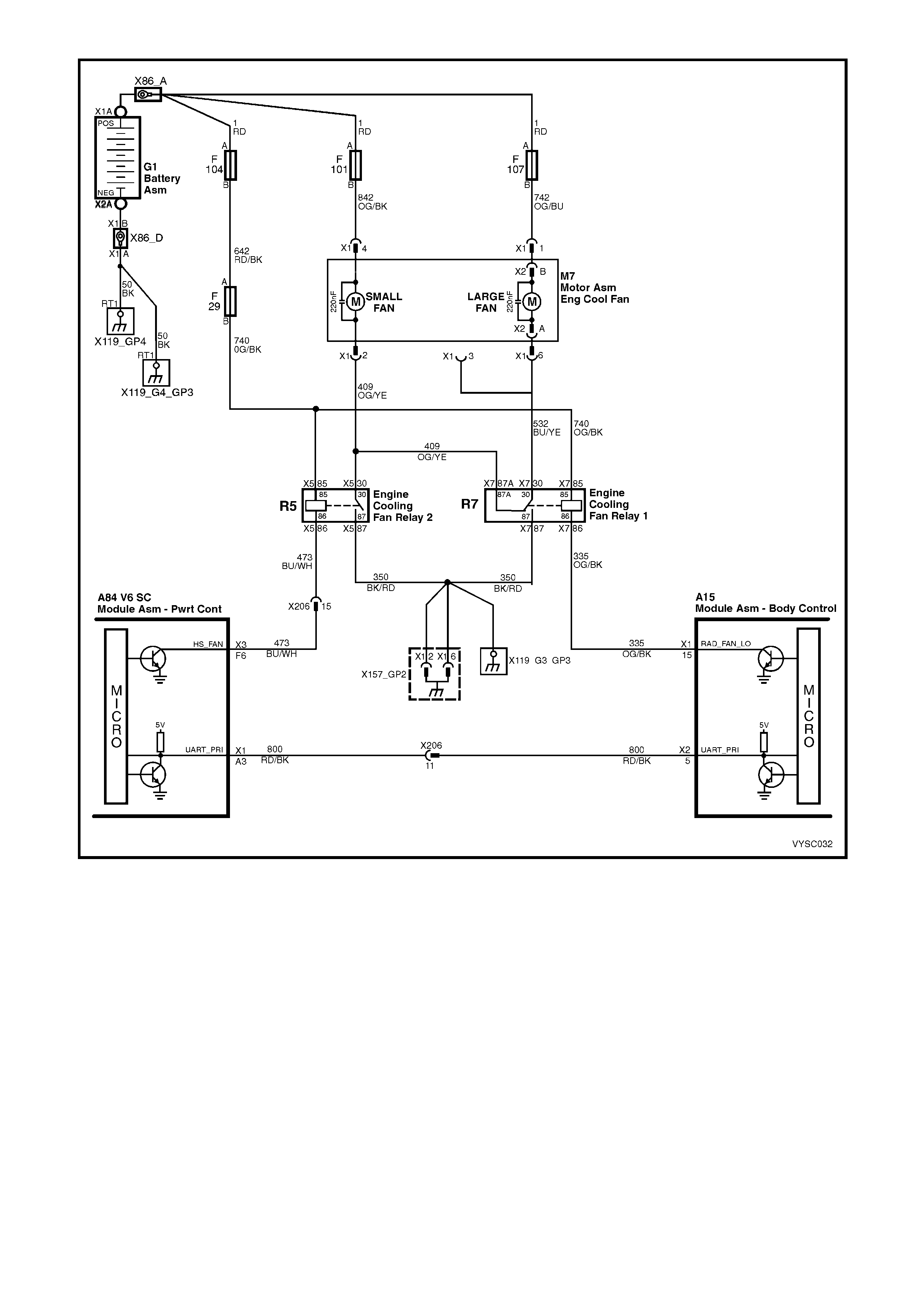

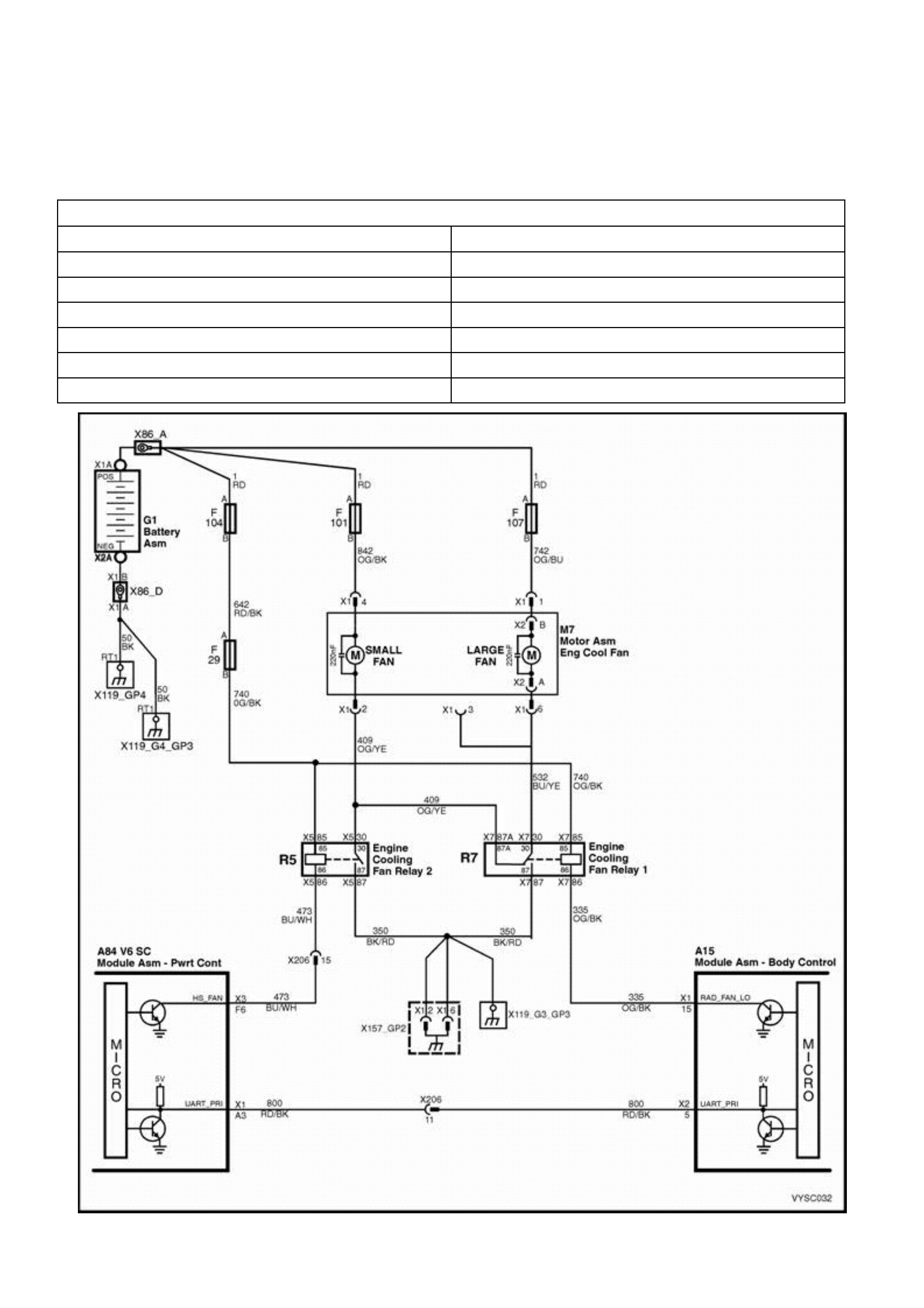

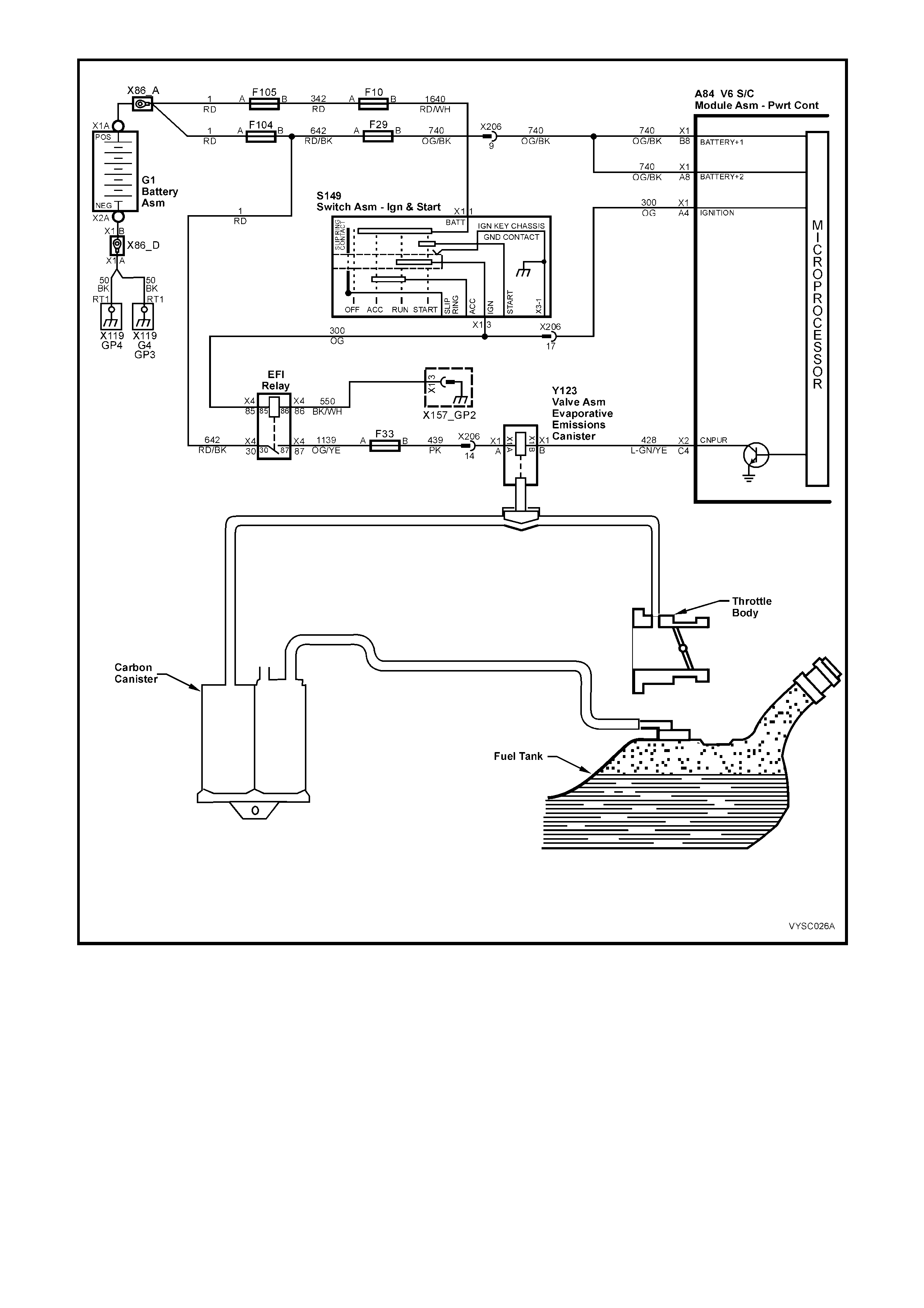

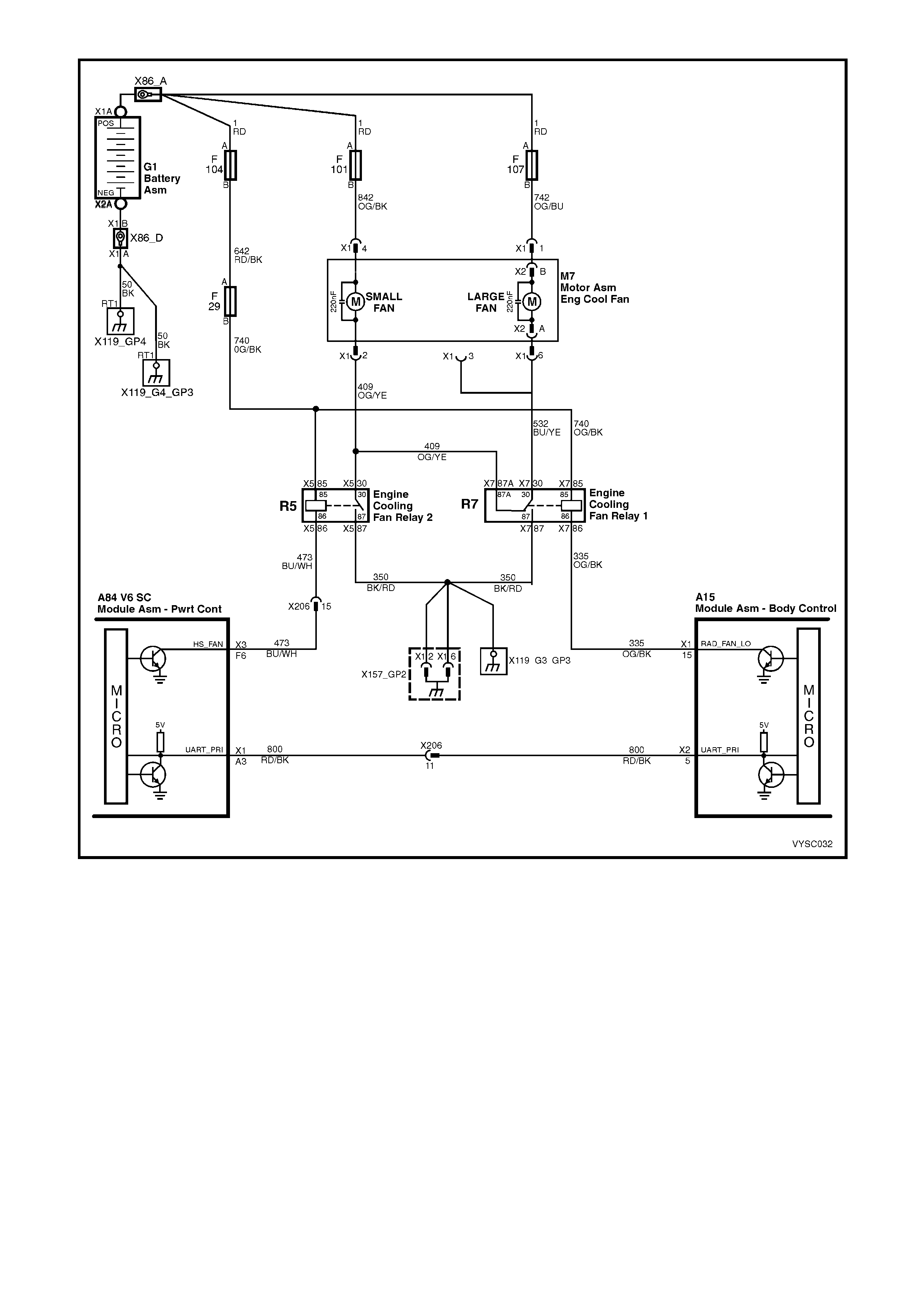

ENGINE COOLI NG FAN SIGNAL

(Low Speed Operation)

The engine cooling low speed fan is enabled when the low speed relay is energised by the BCM. The PCM will

request the BCM to turn the low speed engine cooling fan relay on or off, via the serial data bus normal mode

message. After the PCM requests a change in the engine cooling fan low speed relay, the BCM will send a

response message back to the PCM via the serial data bus normal mode message confirming it received the

request. A failure in the response communication will set a DTC 92.

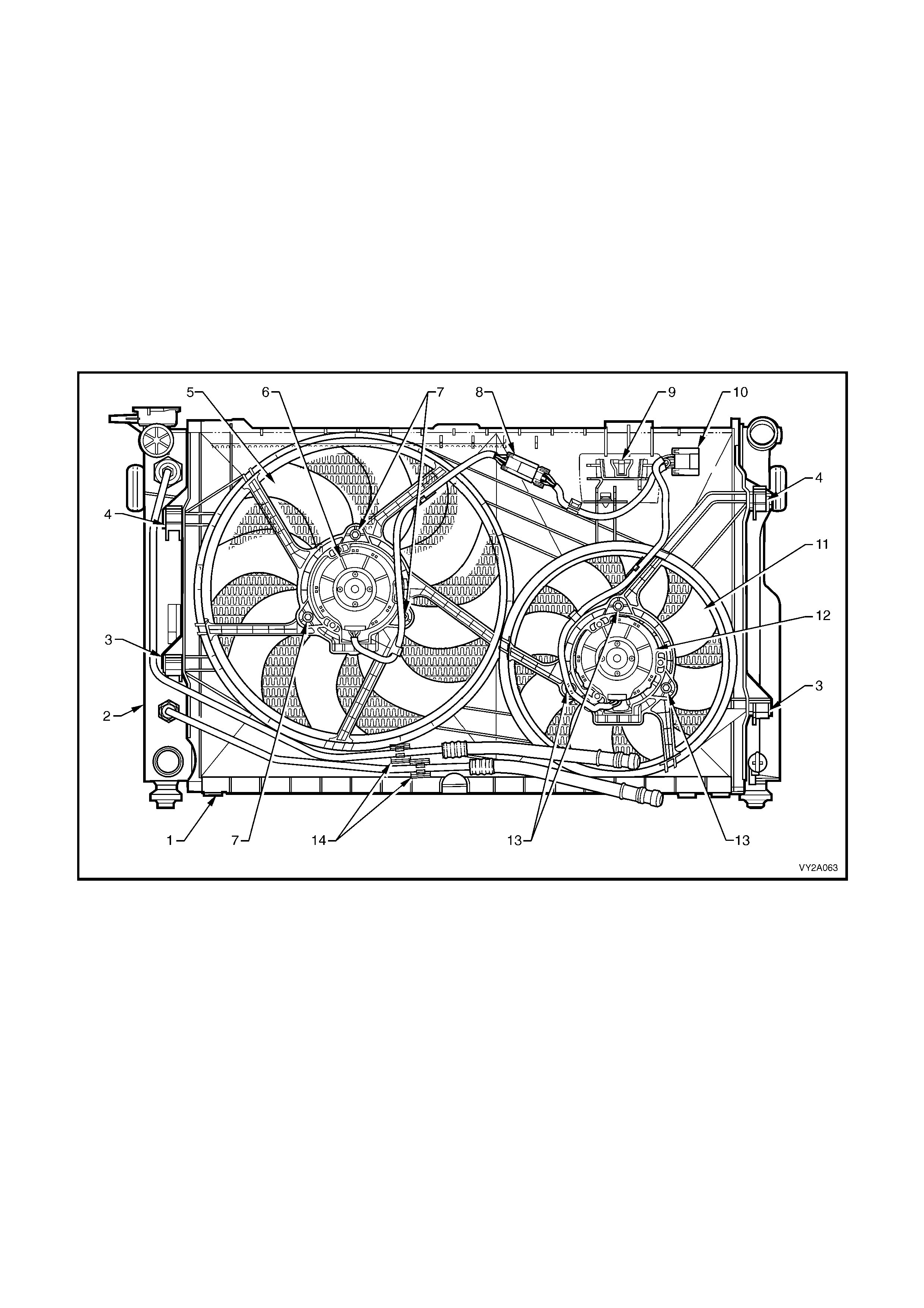

There are also two (2) suppression capacitors incorporated into the fan motor wiring circuits. These suppression

capacitors help eliminate fan motor noise through the radio speakers. If these capacitors are open, then noise will

be present through the radio speakers. If shorted to ground, the fan motors could continuously run, or the fuse or

fusible link could fail.

DTC 92 (Low Speed Fan No BCM Response) will set if:

• Engine is idling.

• The PCM sends a request to the BCM to turn on the engine cooling fan low speed relay via the serial data

normal mode message and the BCM does not send a message back to the PCM.

• The PCM will not illuminate the Malfunction Indicator Lamp (MIL).

Default Value

Once DTC 92 is set, the PCM will energise the engine cooling fan high speed relay.

Recovery

Recovery will occur on the next ignition cycle.

DTC 92 HISTORY DATA

PARAMETER PARAMETER

ENGINE SPEED REFERENCE VOLTS

TIME FROM START MASS AIR FLOW

TIMES OCCURRED CAM SIGNAL

IGNITION CYCLES FUELLING MODE

COOLANT TEMPERATURE FUEL PUMP RELAY

BATTERY VOLTAGE

Figure 6C2-1-39 Engine Cooling Fan Signal Engine Cooling Fan – Low Speed

High Speed Operation

The engine cooling fan high speed is controlled by the PCM based on input from the Engine Coolant T emperature

Sensor (ECT). The PCM will only turn "ON" the engine cooling fan high speed if the engine cooling low speed fan

has been "ON" for 2 seconds and the following conditions are satisfied.

• There is a BCM message response fault which will cause a DTC 92.

• An engine coolant temperature sensor failure is detected, such as DTC 14, 15, 16, 17 or 91.

• Coolant temperature greater than 107° C.

• If the fan low speed was "OFF" when the criteria was met to turn the fan high speed "ON", the fan high speed

will come "ON" 5 seconds after the fan low speed is turned "ON".

• The high speed engine cooling fan relay can also be enabled by the A/C Refrigerant Pressure Sensor input.

The PCM will enable the high speed cooling fan, if the A/C system pressure becomes too high.

There are also two (2) suppression capacitors incorporated into the fan motor wiring circuits. These suppression

capacitors help eliminate fan motor noise through the radio speakers. If these capacitors are open, then noise will

be pres ent through the r adio speakers. Is shorted to ground, the fan m otors could continuous ly run, or the f use or

fusible link could fail.

DTC 91 Quad Driver Module (QDSM) will set if:

• Engine run time is longer than 10 seconds.

• A/C is requested ON.

• The PCM recognises a QDSM malfunction.

• Above conditions present for at least 10 seconds.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

DTC 91 HISTORY DATA

PARAMETER PARAMETER

ENGINE SPEED REFERENCE VOLTS

TIME FROM START A/C RELAY

TIMES OCCURRED STARTER RELAY

IGNITION CYCLES PURGE PWM

COOLANT TEMPERATURE HIGH SPEED FAN

BATTERY VOLTAGE ACTUAL TORQUE

Figure 6C2-1-40 Engine Cooling Fan Signal – High Speed

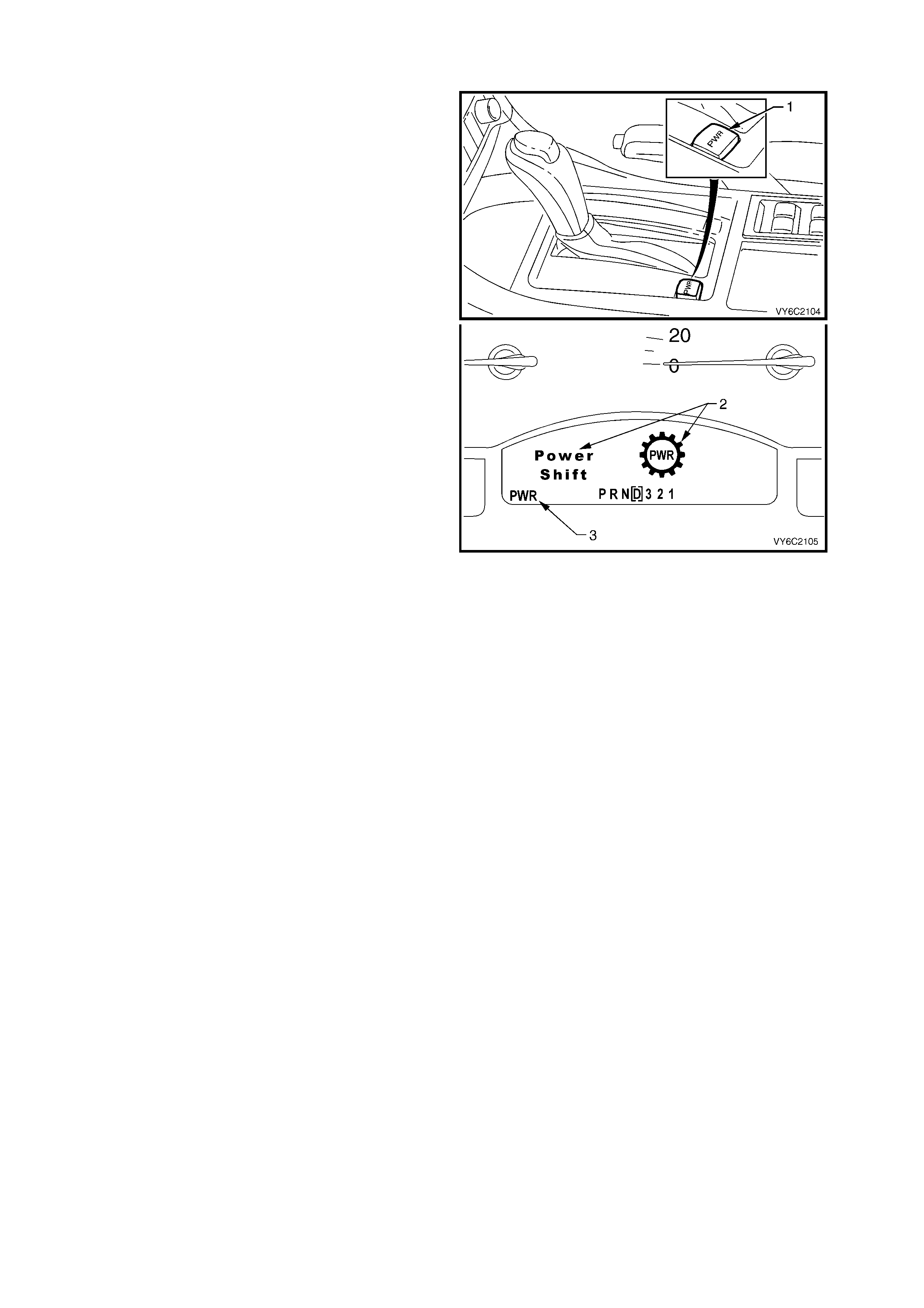

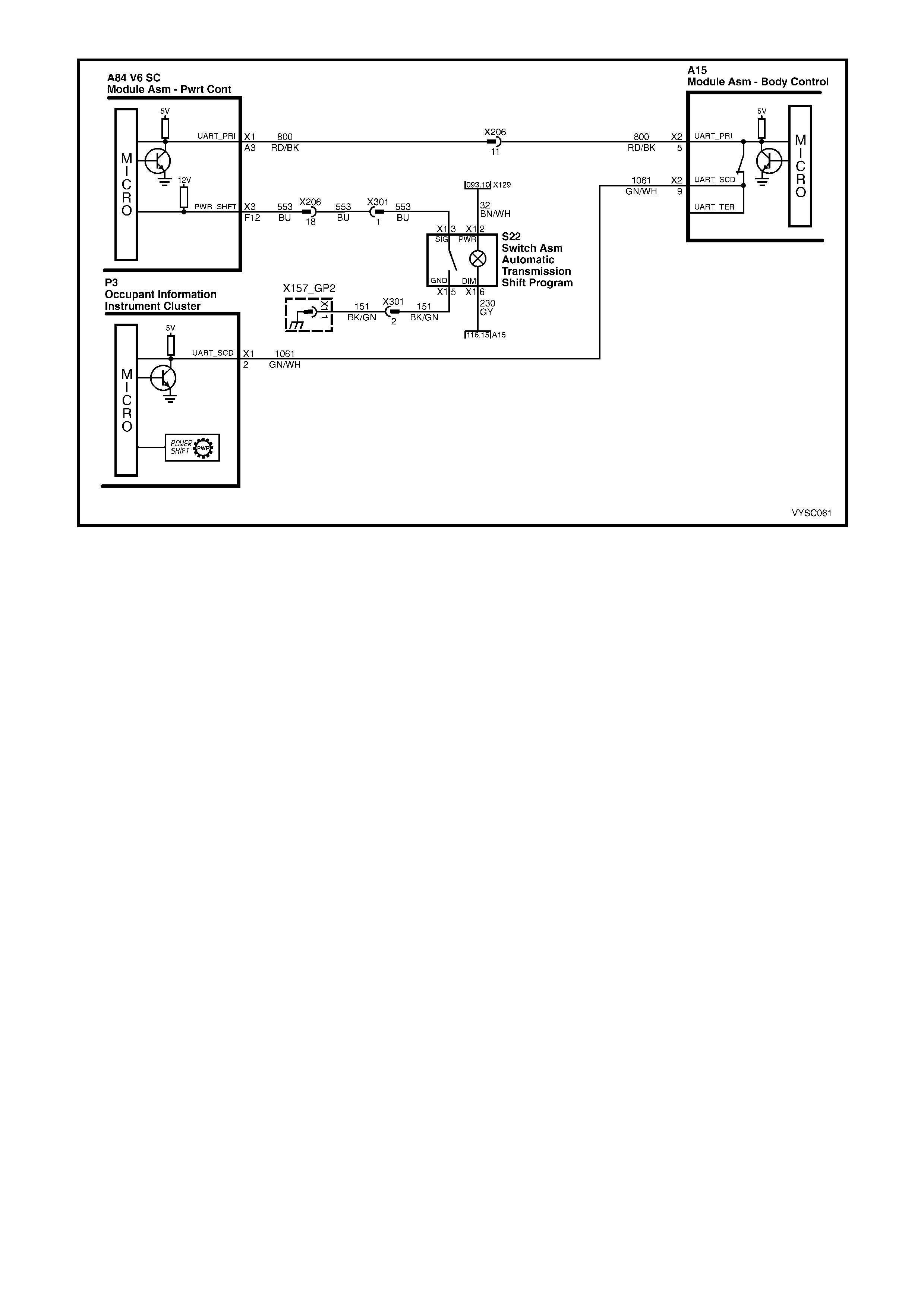

TRANSMISSION POWER/ECONOMY SWITCH

The Power/Economy switch (1) is used to modify

upshifts and shift times. The driver can select either

Economy or Power mode with the switch (1)

located in the centre console.

An animated icon in the instrument cluster Multi

Function Display (MFD) (2) is activated for 2

seconds and then changes to a highlighted “PW R”

icon (3), to remind the driver that the ‘Power Shift’

mode is enabled.

The PCM provides a voltage signal of about 12

volts, and monitors the status of this circuit. In the

Econom y position, the switch is open and the PCM

voltage status signal remains high, about 12 volts.

The PCM does not allow shift point changes in the

economy mode. When the transmission switch is

pressed to the Power position the switch is

momentarily closed and the PCM voltage status

signal is mom entarily pulled low, to about 0.5 volts.

The PCM senses this m omentary voltage drop and

enables Power m ode (alternate shif t pattern tables)

to be utilised.

In the Power mode, the T CC can be applied in 3rd

and 4th gears. When the TCC is applied in 3rd

gear it will stay applied until the normal 4th gear

upshift criteria is m et. W hen the 3-4 ups hift occ urs,

the TCC will be released momentarily. Also, in the

Power mode while in D gear select position, the

PCM will delay the 1-2 and 2-3 shift while under

light throttle. The shift patterns will be the same in

the Econom y and Power m odes if the TP sensor is

between 80% – 100%.

The power mode should be used when towing, as

applying the TCC in 3rd and 4th gear reduces

slippage in the TCC and thus reduces heat build

up.

In cr uise mode oper ation, when the driver activates

the cruise control, the power icon “PWR” and

power mode will be deactivated (if vehicle was in

power mode) and a CRUISE ACTIVE icon will be

displayed in the instrument cluster MFD. The

transmission shift pattern will then switch to cruise

shift pattern.

Figure 6C2-1-41 Transmission Power/Economy Switch

When in cruise mode the PCM will modify the transmission calibration so that transmission shift activity is reduced.

When the key is turned ON, the PCM shift mode is set to the last mode that was previously selected

(Power/Economy). The cruise control is set to OFF at every key ON cycle.

For replacement of the Power/Economy switch, Refer to Section 7C4 AUTOMATIC TRANSMISSION – ON

VEHICLE SERVICE in MY 2003 VY and V2 Series Service Information.

Figure 6C2-1-42 Transmission Power/Economy Switch Wiring

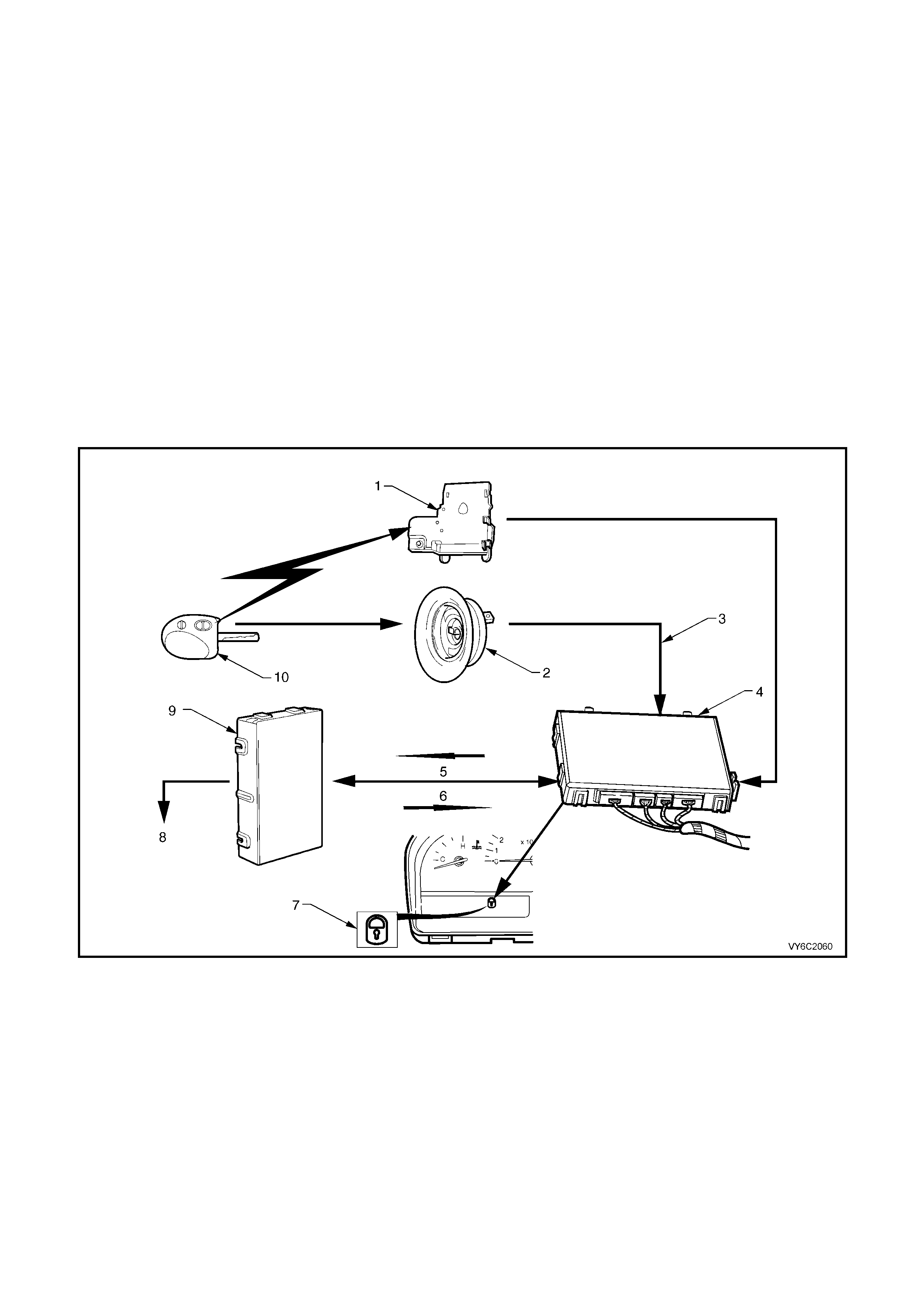

THEFT DETERRENT INPUT

W hen the ignition switch is turned to the “ON” pos ition, the BCM polls the PCM and sends an encr ypted BCM / k ey

security code. The security code is received by the BCM, via the remote key reader (slip ring) or via the remote

receiver in the event of no slip ring communication.

The PCM compares the received security code with its stored security code and if m atched, the PCM will continue

to enable injector fuelling and engine crank.

The PCM will return a Valid Code mes s age (O K TO START ), which tells the BCM to jump fr om the short loop mode

to the long loop mode.

When the ignition switch is turned from the OFF position to the ON position, the BCM will communicate with the

PCM for anti-theft purposes. If the BCM does not receive the message OK TO START from the PCM within 0.5

seconds of the ignition being switched on, the auxiliary bus is isolated via switching within the BCM.

The isolation of the auxiliary data bus during this period eliminates the possibility of a device failure other than the

BCM or PCM causing a problem on the bus and inhibiting anti-theft communications.

This period is known as “Short Loop Time”, and continues until the PCM responds with an acknowledgment or a

maximum of 5 seconds, after which the BCM will switch to the standard poling sequence.

Following successful anti-theft communications, the BCM begins sequential poling of devices on the bus and

normal system operation is established.

DTC 31 will set when the PCM at ignition ON sends 20 messages to the BCM and does not receive a valid theft

deterrent message.

Figure 6C2-1-43 Theft Deterrent System

Legend

1. Remote Receiver Module

2. Remote Coded Key Reader Assembly

3. Code From Remote Coded Key

4. BCM

5. Security Code

6. OK To Start

7. Theft Deterrent Alert Indicator LED (LHS of Instrument)

8. Enable Or Disable Fuel System Control And Starter Motor

9. Powertrain Control Module (PCM)

10. Remote Coded Key

DTC 31 (Theft Deterrent Signal Missing) will set if:

• The ignition is on.

• The PCM sends 20 messages to the BCM and does not receive a valid theft deterrent message.

• Conditions present for at least 10 seconds.

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

Default Values

There is no default value for DTC 31, the engine will not start if DTC 31 is current.

Recovery

Recovery will occur when the PCM sees a valid condition.

DTC 31 HISTORY DATA

PARAMETER PARAMETER

ENGINE SPEED REFERENCE VOLTS

TIME FROM START MASS AIR FLOW

TIMES OCCURRED CAM SIGNAL

IGNITION CYCLES FUELING MODE

COOLANT TEMPERATURE FUEL PUMP RELAY

BATTERY VOLTAGE

Figure 6C2-1-44 Theft Deterrent Serial Data Circuit

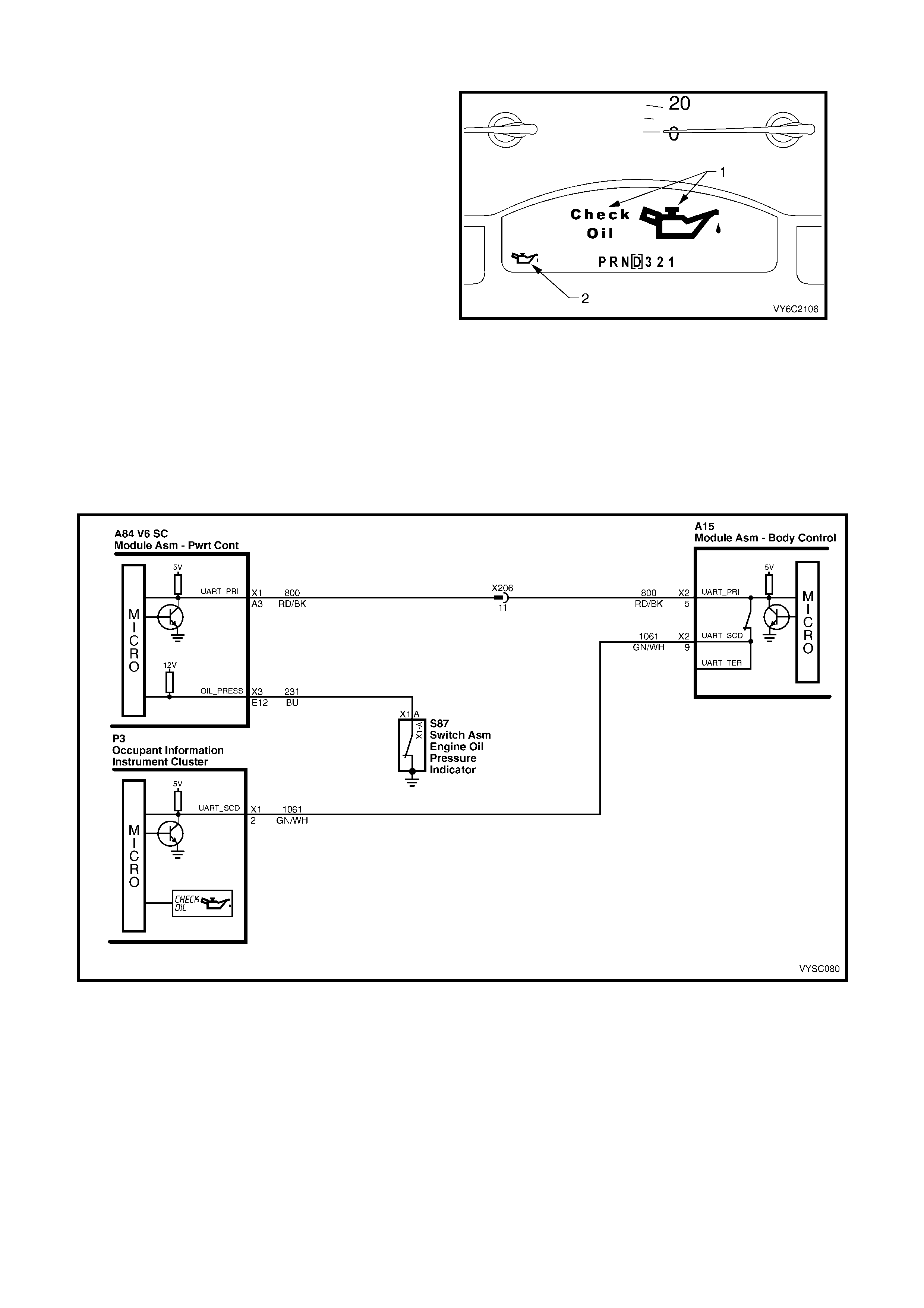

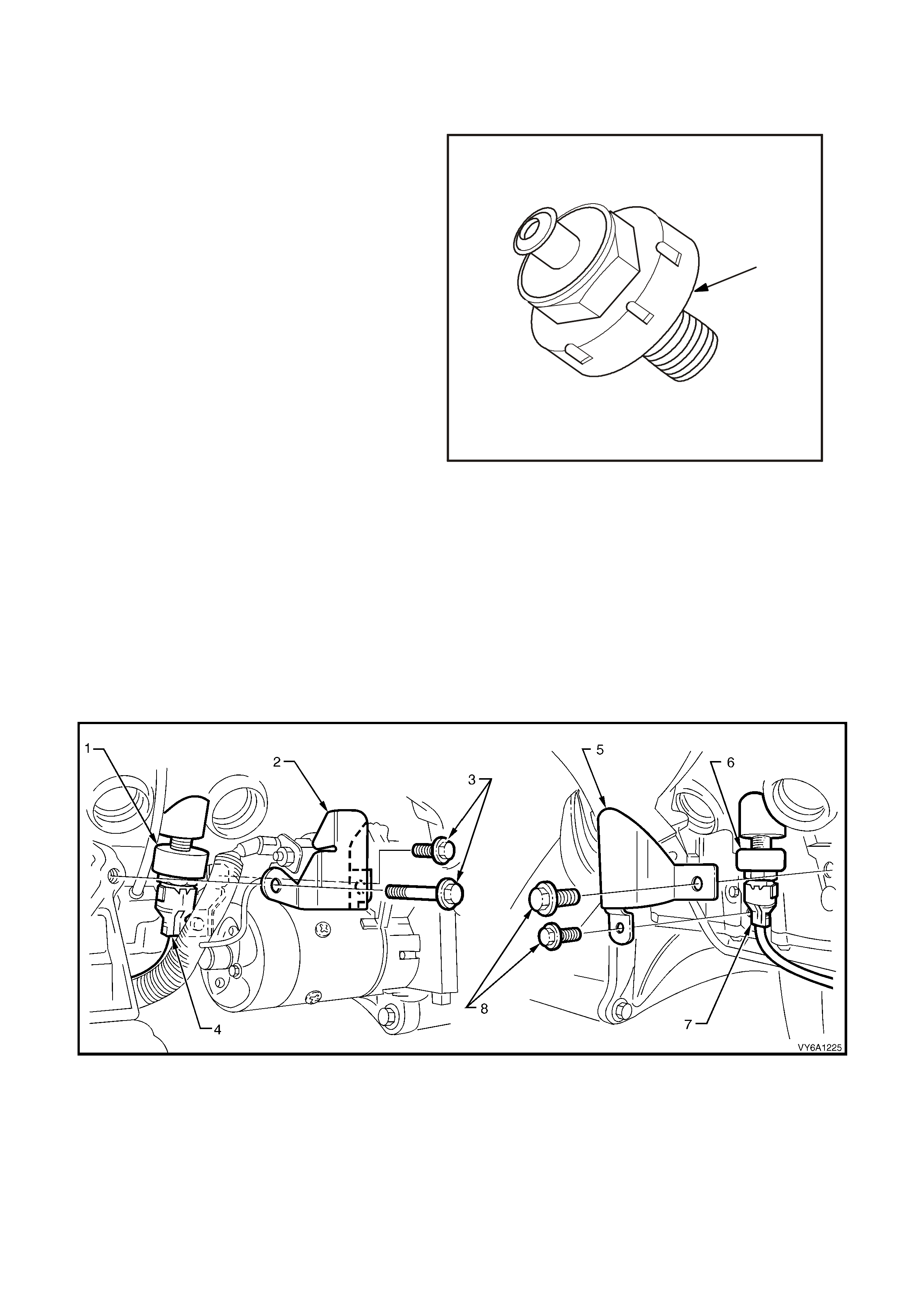

OIL PRESSURE SWITCH

The instruments receive oil pressure switch status

information from the PCM via the serial data bus

normal mode message. The PCM monitors the

voltage at terminal X3 E12 to determine the status

of the oil pressure switch. When the oil pressure

switch is open the voltage at X3 E12 will be 12

volts, when the switch closes the voltage at

terminal X3 E12 will be pulled low, less than 0.2

volts via circuit 231 ( Blue wire) and the oil pressur e

switch.

This low voltage is seen by the PCM as an oil

pressur e s witch clos ed input signal. When the PCM

sees this low voltage at terminal X3 E12 the PCM

will command the instruments to activate the oil

pressure warning icon (1), in the MFD. The large

icon and message then revert to the smaller icon

(2). When the PCM sees a high voltage at ter minal

X3 E12 the PCM will command the instruments to

deactivate the oil pressure warning icon, via the

serial data bus normal mode message.

There are no PCM trouble codes for this oil

pressure switch.

Figure 6C2-1-45 – Oil Pressure Warning Lamp

Figure 6C2-1-46 – Oil Pressure Warning Lamp

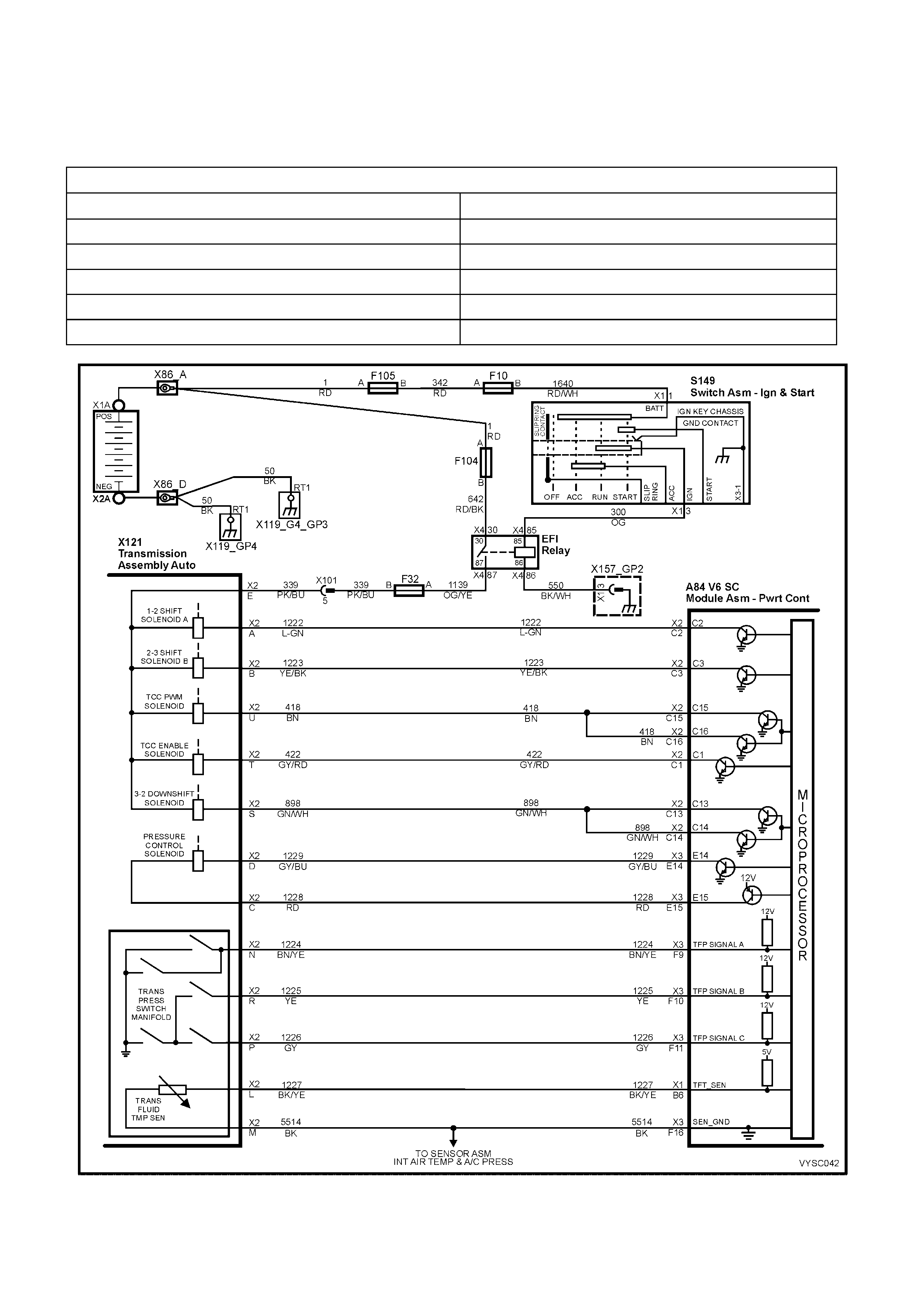

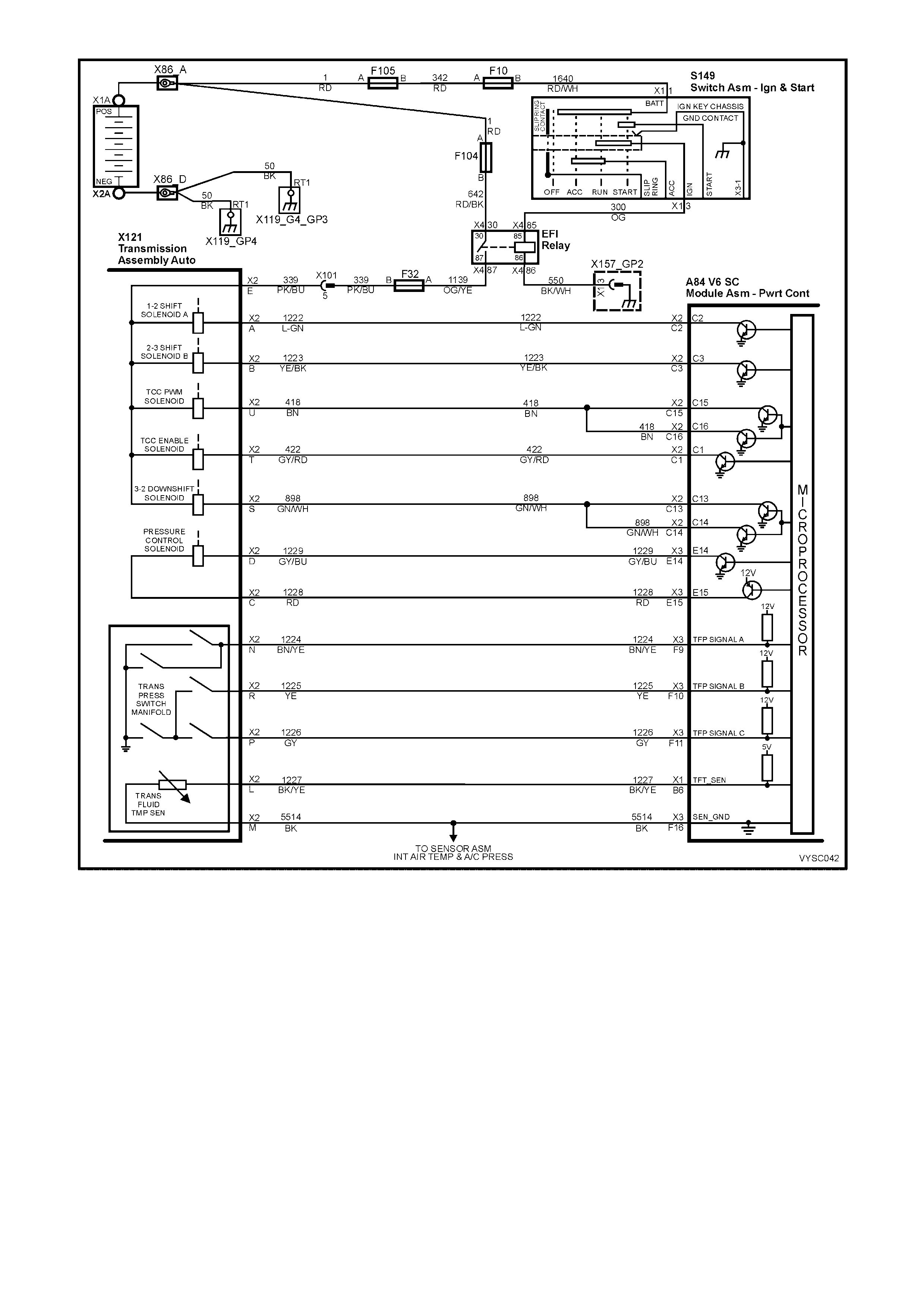

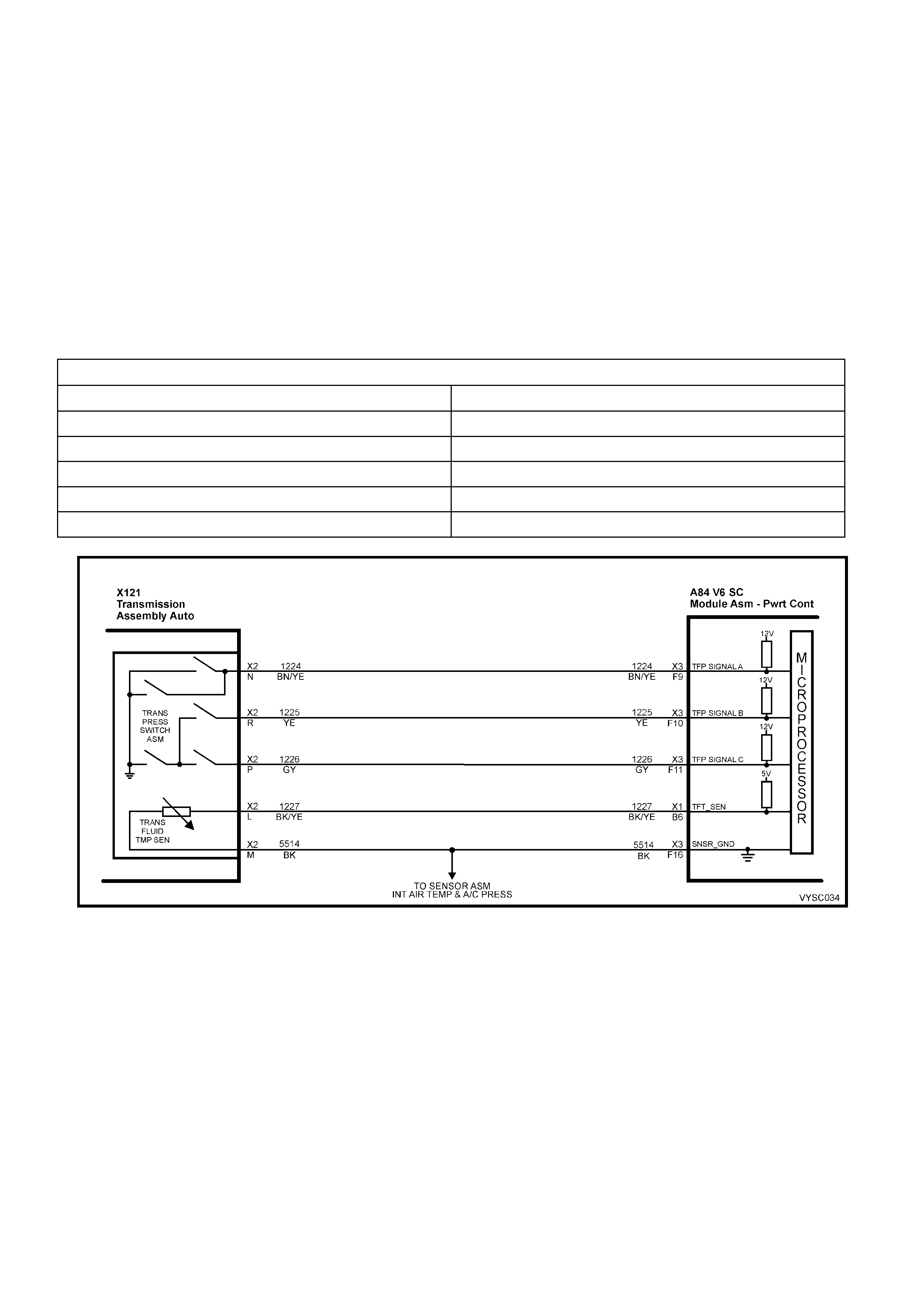

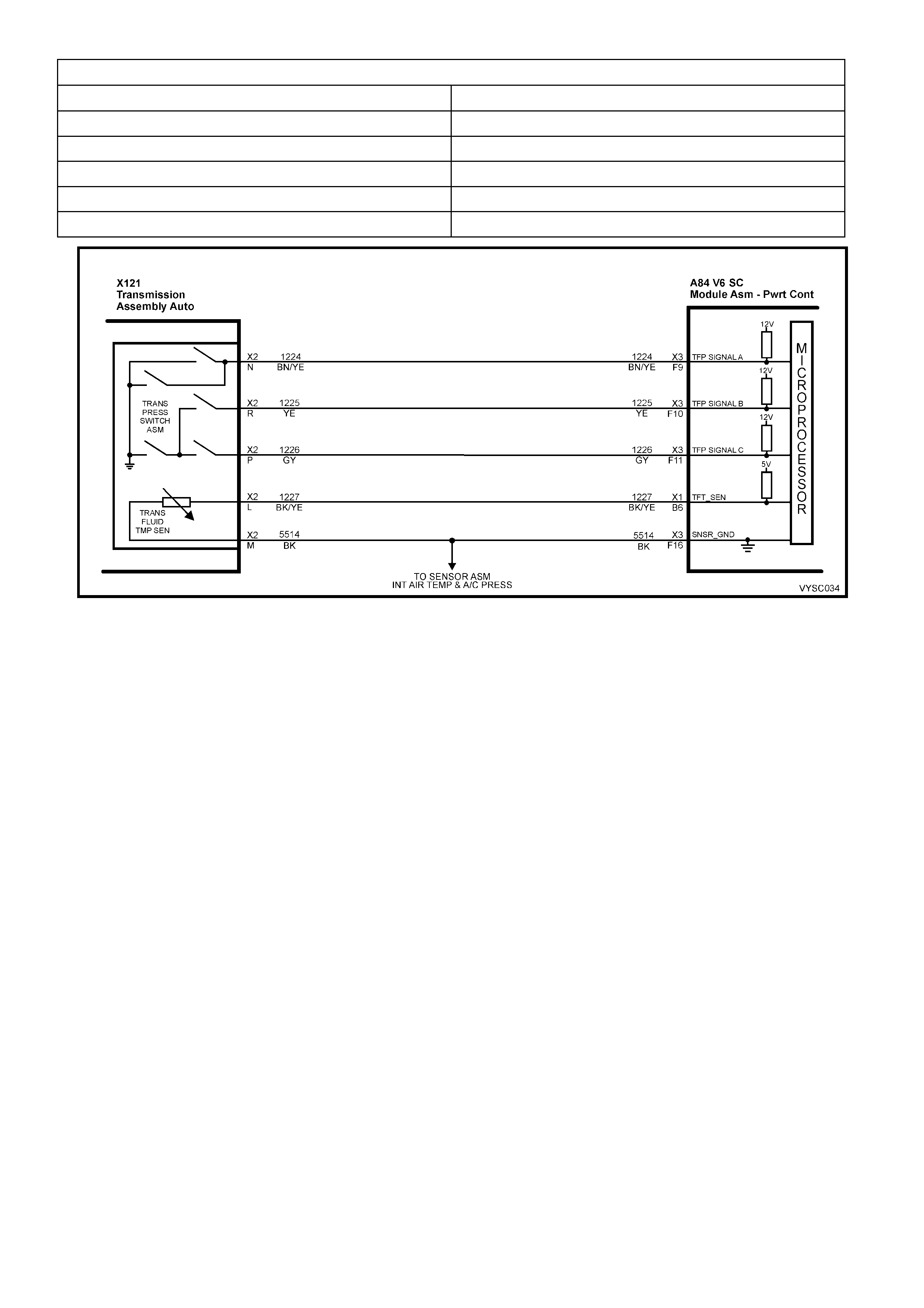

1.3 AUTOMATIC TRANSMISSION INFORMATION SENSORS & SIGNALS

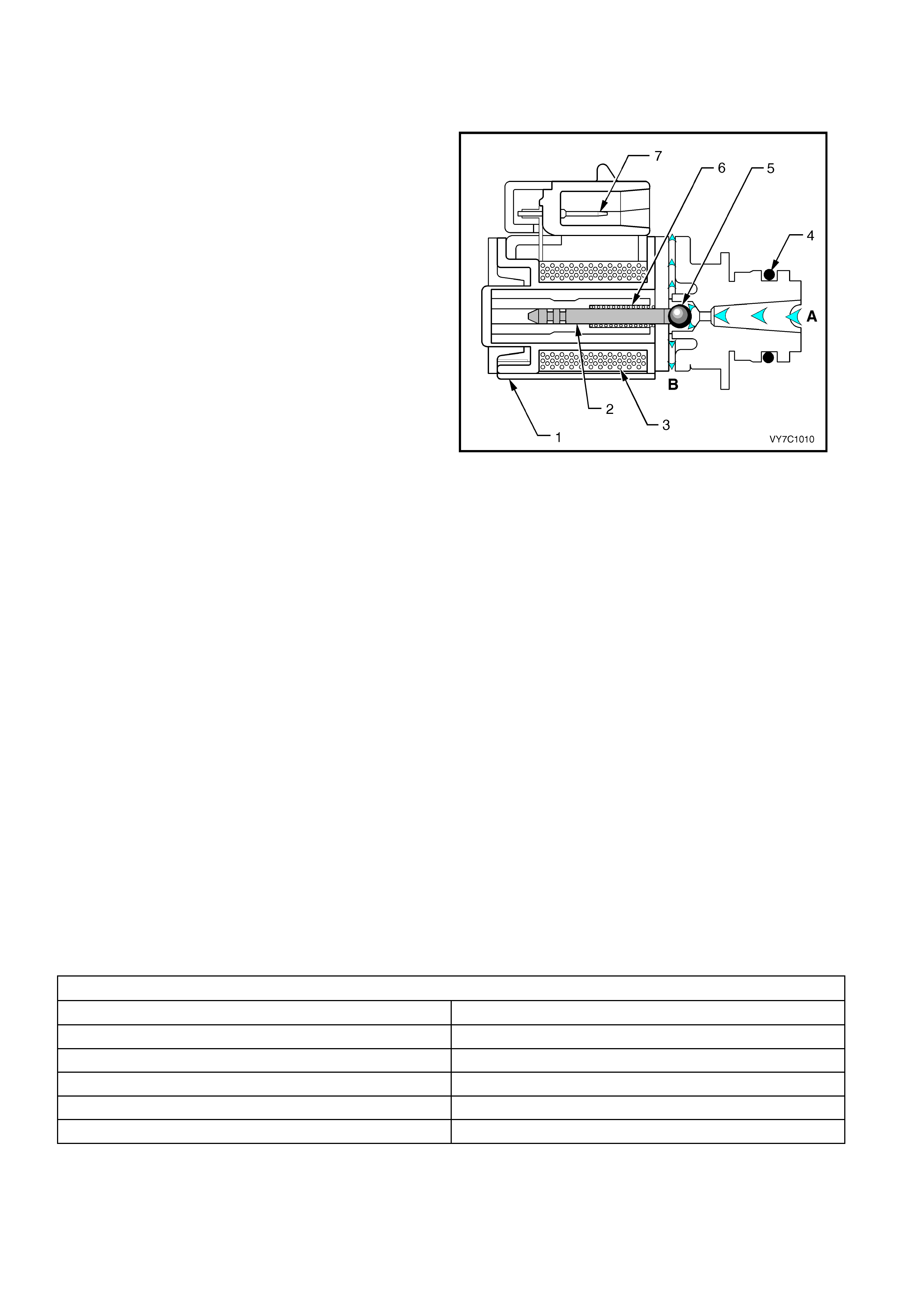

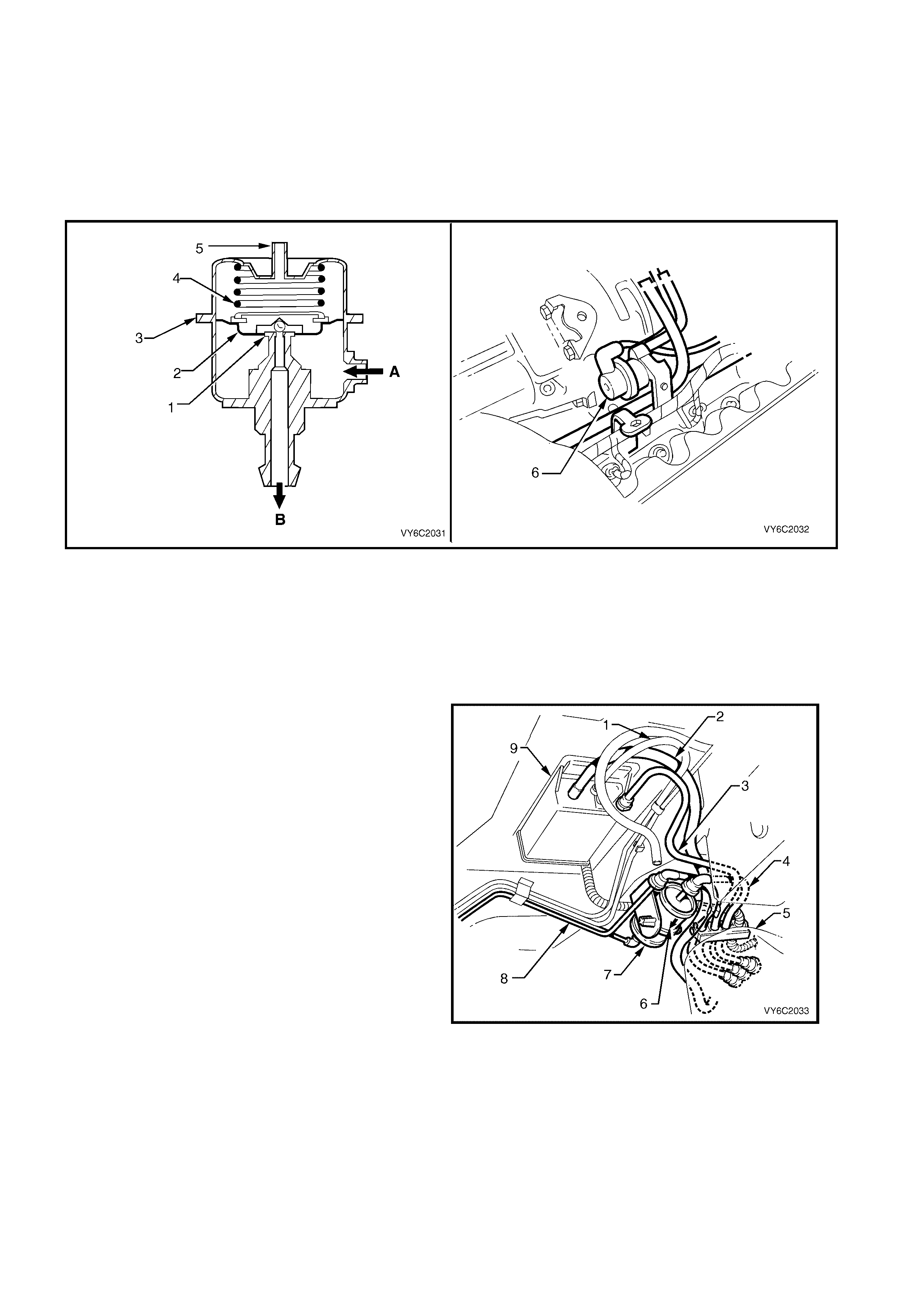

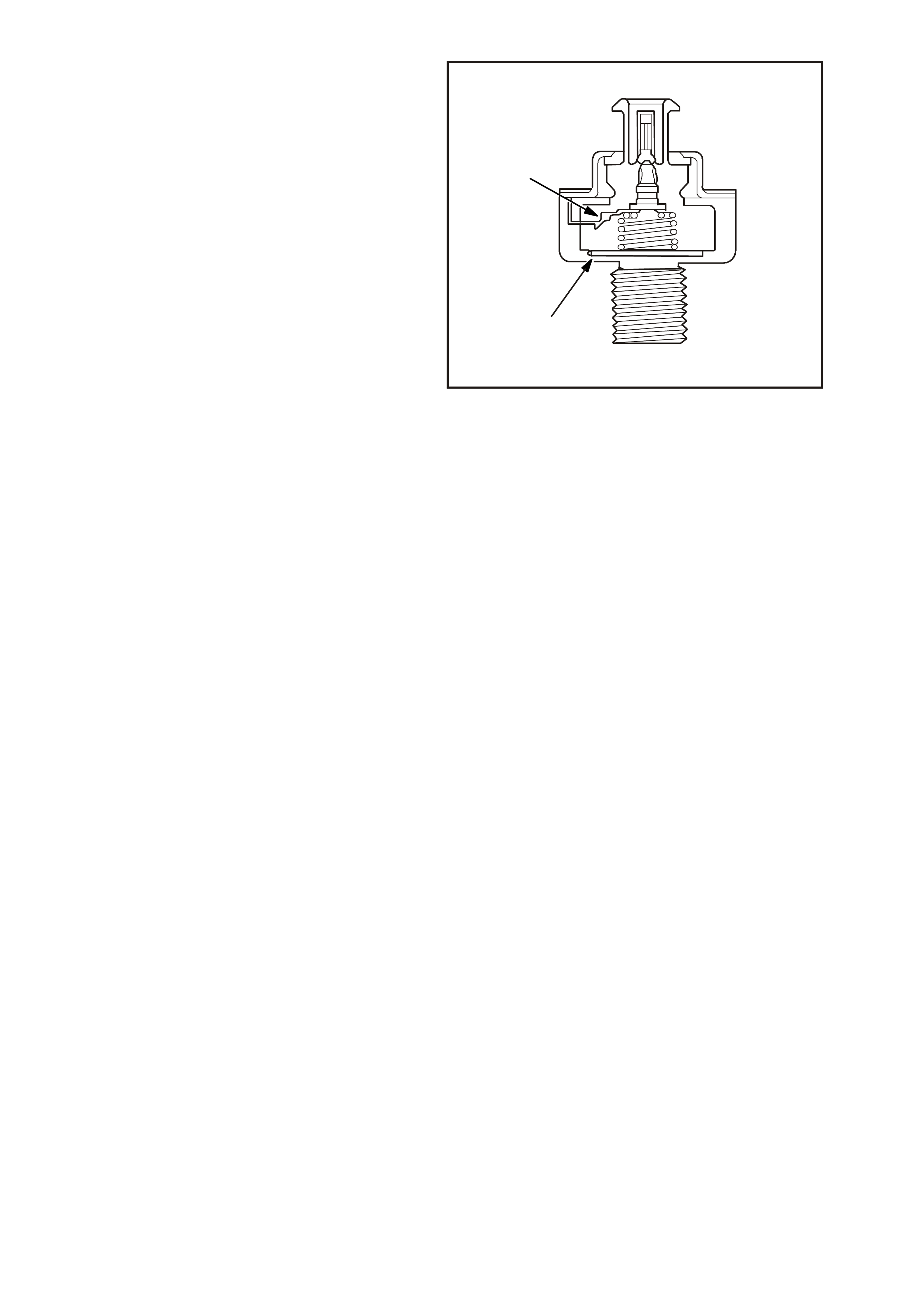

1-2 (A) AND 2-3 (B) SHIFT SOLENOID VA LVES

IMPORTANT: The shift solenoid valve resistance

should measure 19-24 ohms minimum when

measured at 20° C. The shift solenoid current flow

should not exceed 0.75 amps. The shift solenoid

should energise at a voltage of 7.5 volts or more

(m eas ured ac r oss the ter minals) . The shif t solenoid

should de-energise when the voltage is one volt or

less.

If both solenoids lose power, third gear only results.

The 1-2 and 2-3 shif t solenoid valves (also c alled A

and B solenoids) are identical devices that control

the movement of the 1-2 and 2-3 shift valves (the

3-4 shift valve is not directly controlled by a shift

solenoid). The solenoids are normally open

exhaust valves that work in four combinations to

shift the transmission into different gears.

The PCM energises each solenoid by grounding

the solenoid through an internal quad driver. This

sends current through the coil winding in the

solenoid and moves the internal plunger out of the

exhaust position. When ON, the solenoid redirects

fluid to move a shift valve.

IMPORTANT: The manual valve hydraulically can

override the shift solenoids. Only in D4 do the shift

solenoid states totally determine what gear the

transmission is in. In the other manual valve

positions, the transmission shifts hydraulically and

the shift solenoid states CATCH UP when the

throttle position and the vehicle speed fall into the

correct ranges.

Diagnostic trouble codes 81 and 82 indicate shift

solenoid circuit voltage faults.

The PCM-controlled shift solenoids eliminate the

need for T V and governor pres sures to control shif t

valve operation.

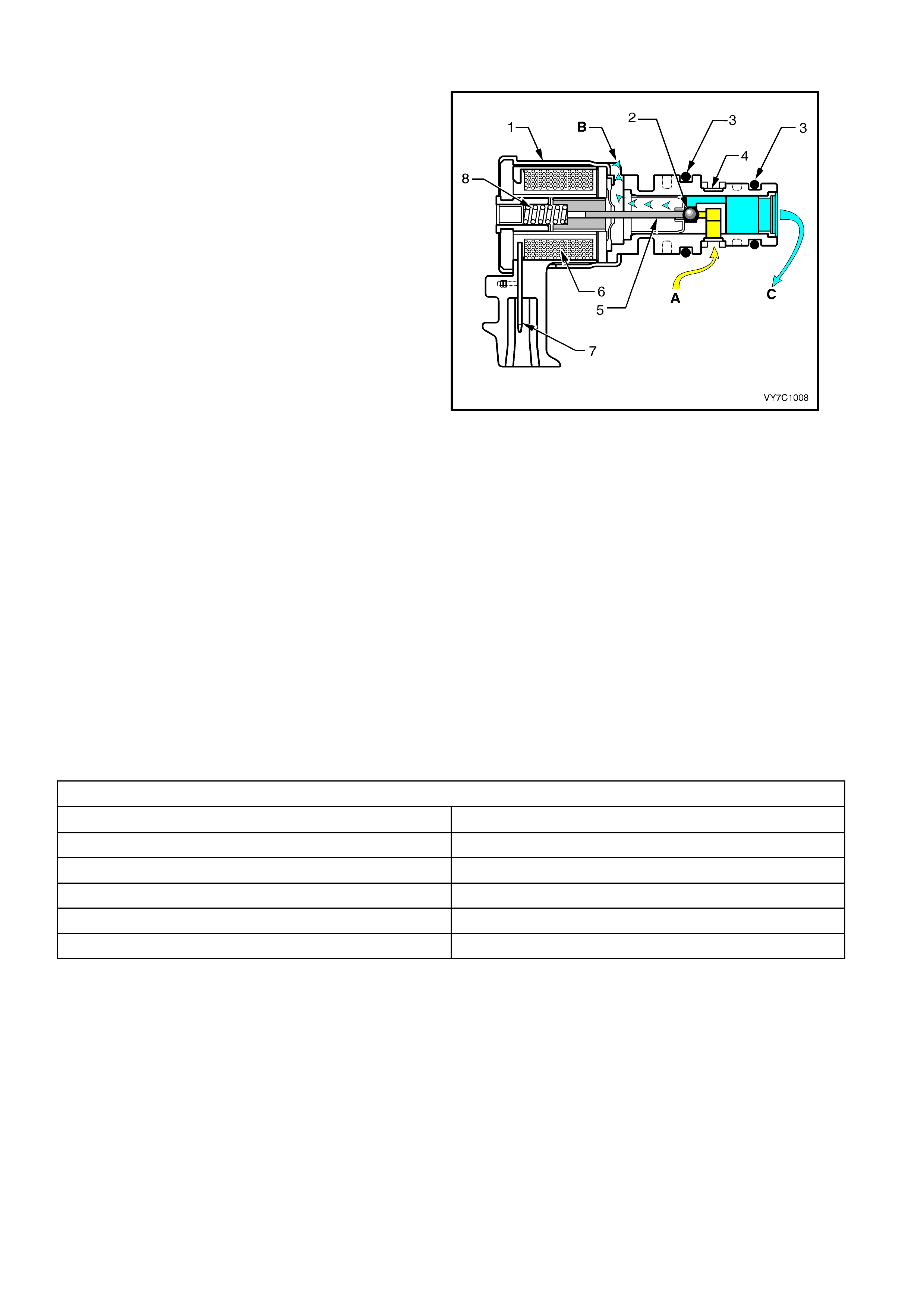

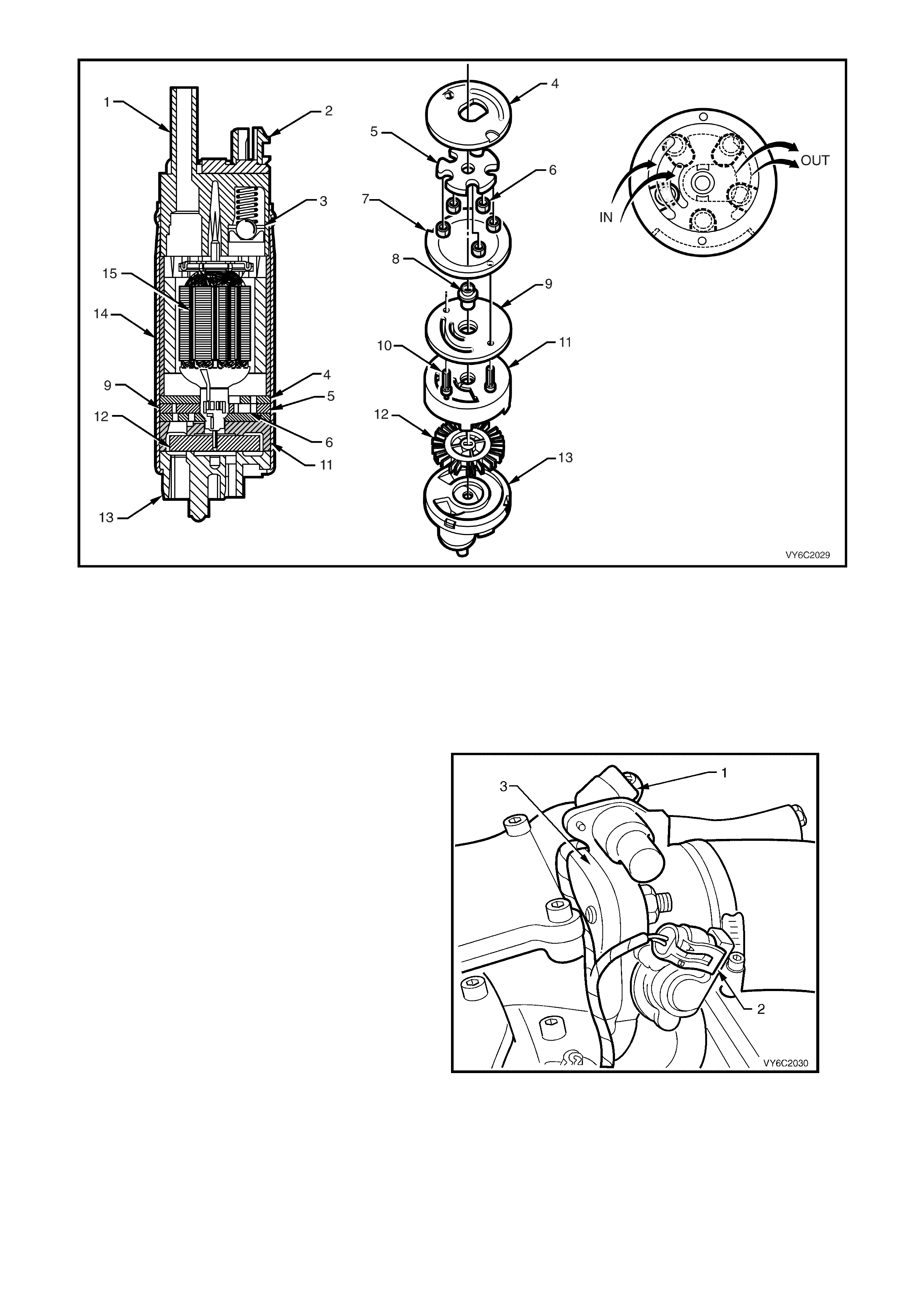

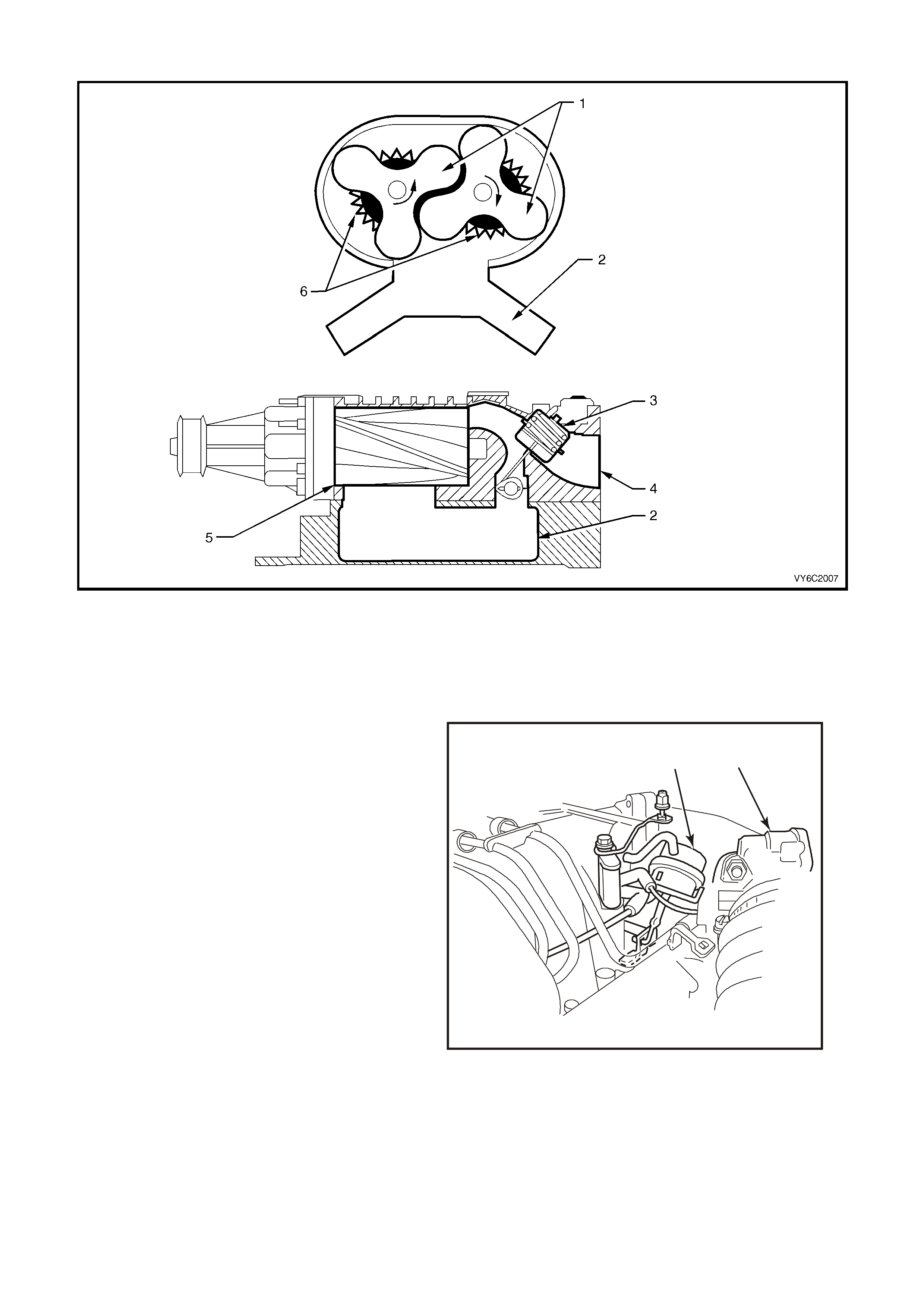

Figure 6C2-1-47 Shift Solenoid

Legend

A Signal Fluid 4 O-Ring

B Exhaust 5 Metering Ball

1 Frame 6 Spring

2 Plunger 7 Connector Terminal

3 Coil Assembly

DTC 81 (2-3 Shift Solenoid Circuit Electrical) will set if:

• The PCM commands the solenoid ON and the voltage input remains high (B+).

• The PCM commands the solenoid OFF and the voltage input remains low (0volts)

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

Default Values

When this DTC sets, the PCM will command D2 line pressure, the PCM will inhibit 3-2 downshift if the vehicle

speed is greater than 48 km/h and the PCM will also freeze shift adapts from being updated.

Recovery

Recovery will occur when the PCM sees a valid condition.

DTC 81 HISTORY DATA

PARAMETER PARAMETER

ENGINE SPEED TCC SOLENOID

TIME FROM START THROTTLE ANGLE

TIMES OCCURRED VEHICLE SPEED

IGNITION CYCLES COMMANDED GEAR

COOLANT TEMPERATURE

DTC 82 (1-2 Shift Solenoid Circuit Electrical) will set if:

• The PCM commands the solenoid ON and the voltage input remains high (B+).

• The PCM commands the solenoid OFF and the voltage input remains low (0volts)

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

Default Values

When this DTC sets, the PCM will command 3rd gear only, command maximum line pressure, inhibit TCC

engagement and will freeze shift adapts from being updated.

Recovery

Recovery will occur when the PCM sees a valid condition.

DTC 82 HISTORY DATA

PARAMETER PARAMETER

ENGINE SPEED 2-3 SHIFT SOLENOID

TIME FROM START THROTTLE ANGLE

TIMES OCCURRED VEHICLE SPEED

IGNITION CYCLES COMMANDED GEAR

COOLANT TEMPERATURE

Figure 6C2-1-48 – Transmission Solenoid Circuits

3-2 CONTROL SOLENOID VALVE

IMPORTANT: The 3–2 control solenoid valve

resistance should be a m inim um of 20–24 ohms at

20°C.

The 3-2 control solenoid valve is an ON/OFF

solenoid that is used in order to improve the 3–2

downshift. The solenoid regulates the release of

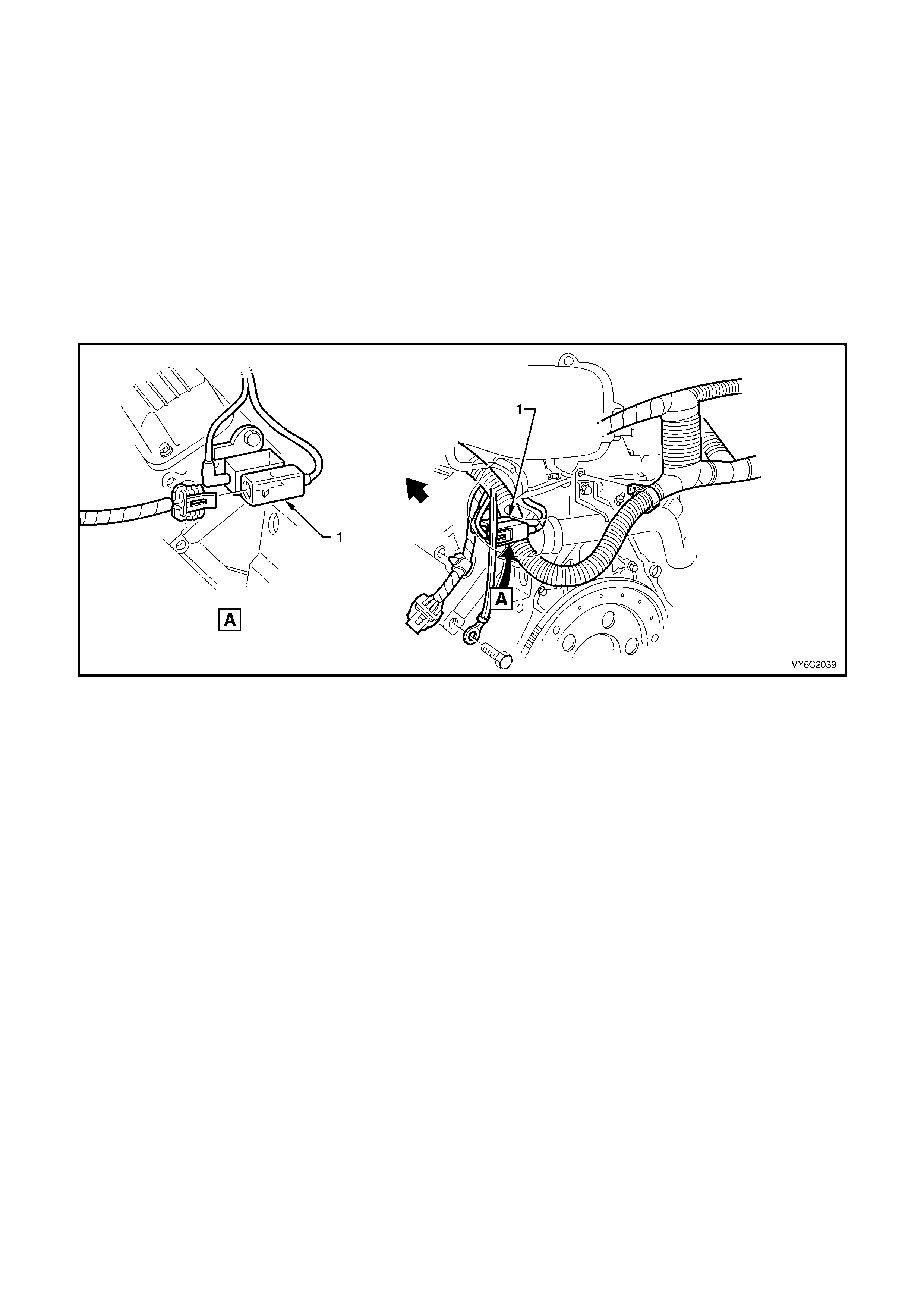

the 3–4 clutch and the 2–4 band apply.

If a voltage fault is detected in the 3–2 control

solenoid circuit, diagnostic trouble code 66 will set.

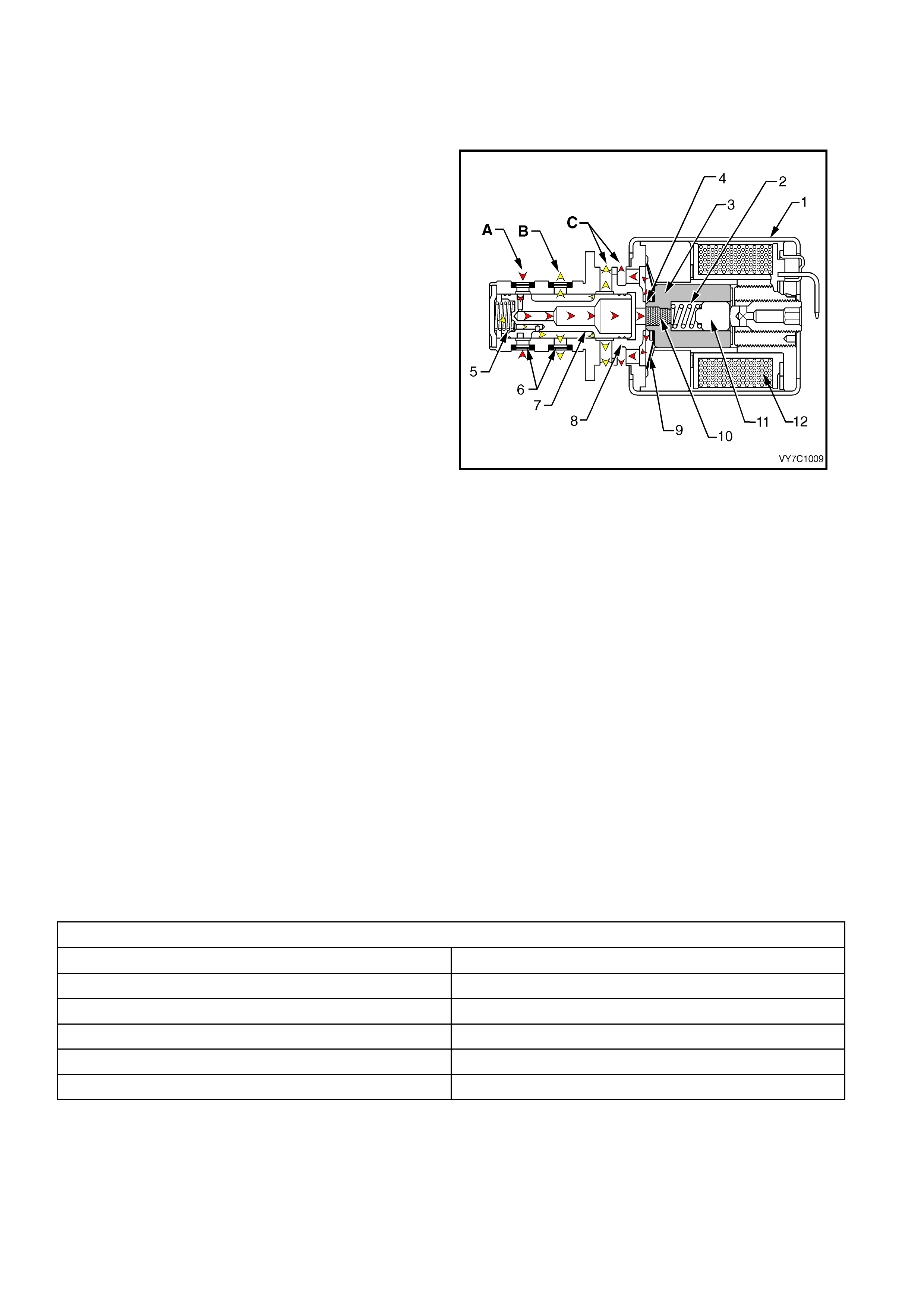

Figure 6c2-1-49 – 3-2 Control Solenoid

Legend

A Pressure Supply (AFL) 4. Filter Screen

B Exhaust 5 Plunger

C Pressure Control (3-2 Signal 6 Coil Assembly

1 Housing 7 Connector Terminal

2 Metering Ball 8 Spring

3 O-Ring

DTC 66 (3-2 Control Solenoid Circuit Electrical) will set if:

• The PCM commands the solenoid ON and the voltage input remains high (B+).

• The PCM commands the solenoid OFF and the voltage input remains low (0 volts).

• The PCM will illuminate the Malfunction Indicator Lamp (MIL).

Default Values

When this DTC sets, the PCM will command a soft landing to 3rd gear, inhibit TCC engagement, command

maximum line pressure, inhibit 4th gear if the transmission is in hot mode and freeze shift adapts from being

updated.

Recovery

Recovery will occur when the PCM sees a valid condition.

DTC 66 HISTORY DATA

PARAMETER PARAMETER

ENGINE SPEED TFT

TIME FROM START THROTTLE ANGLE

TIMES OCCURRED VEHICLE SPEED

IGNITION CYCLES COMMANDED GEAR

COOLANT TEMPERATURE

Figure 6C2-1-50 – Transmission Solenoid Circuits

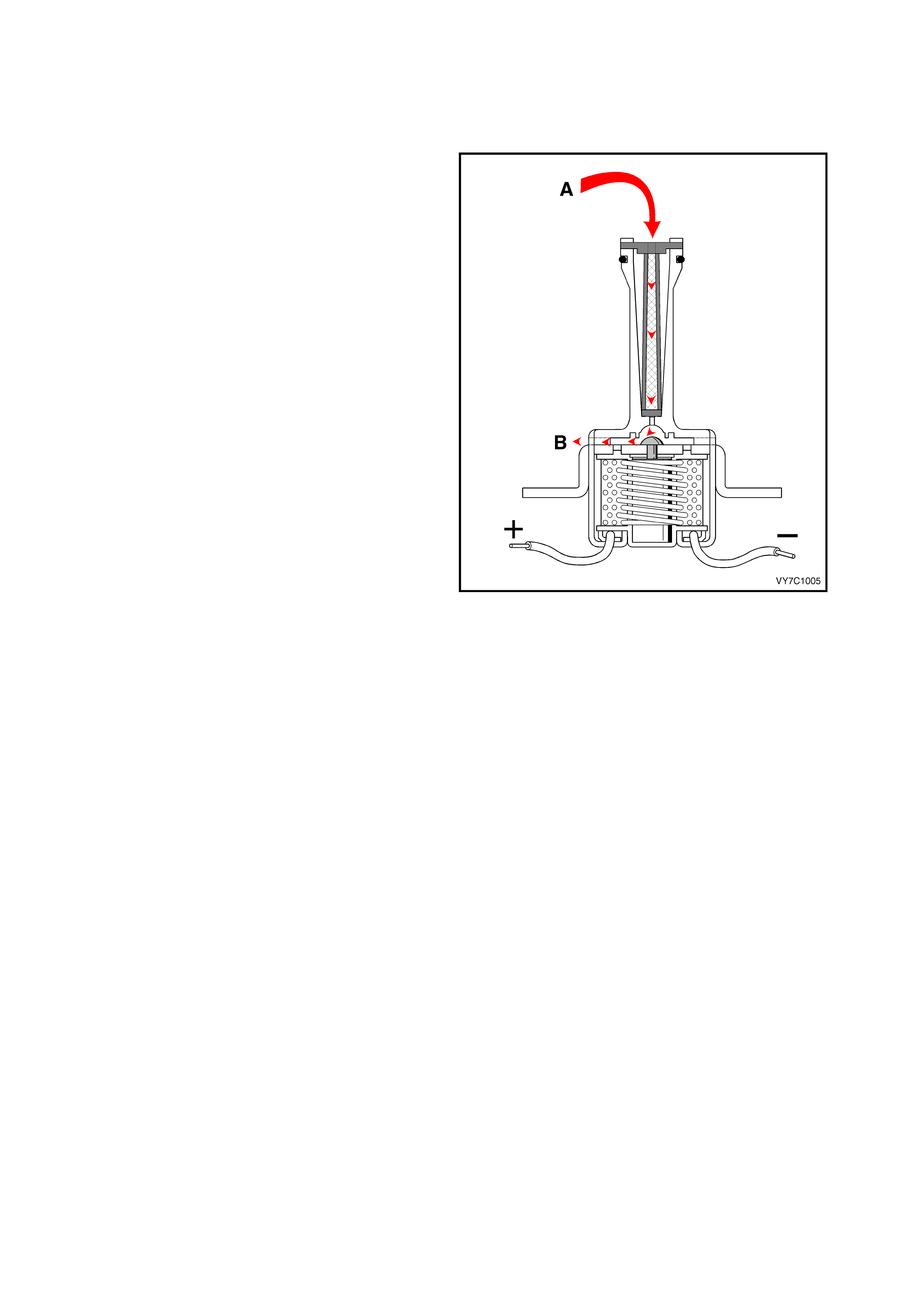

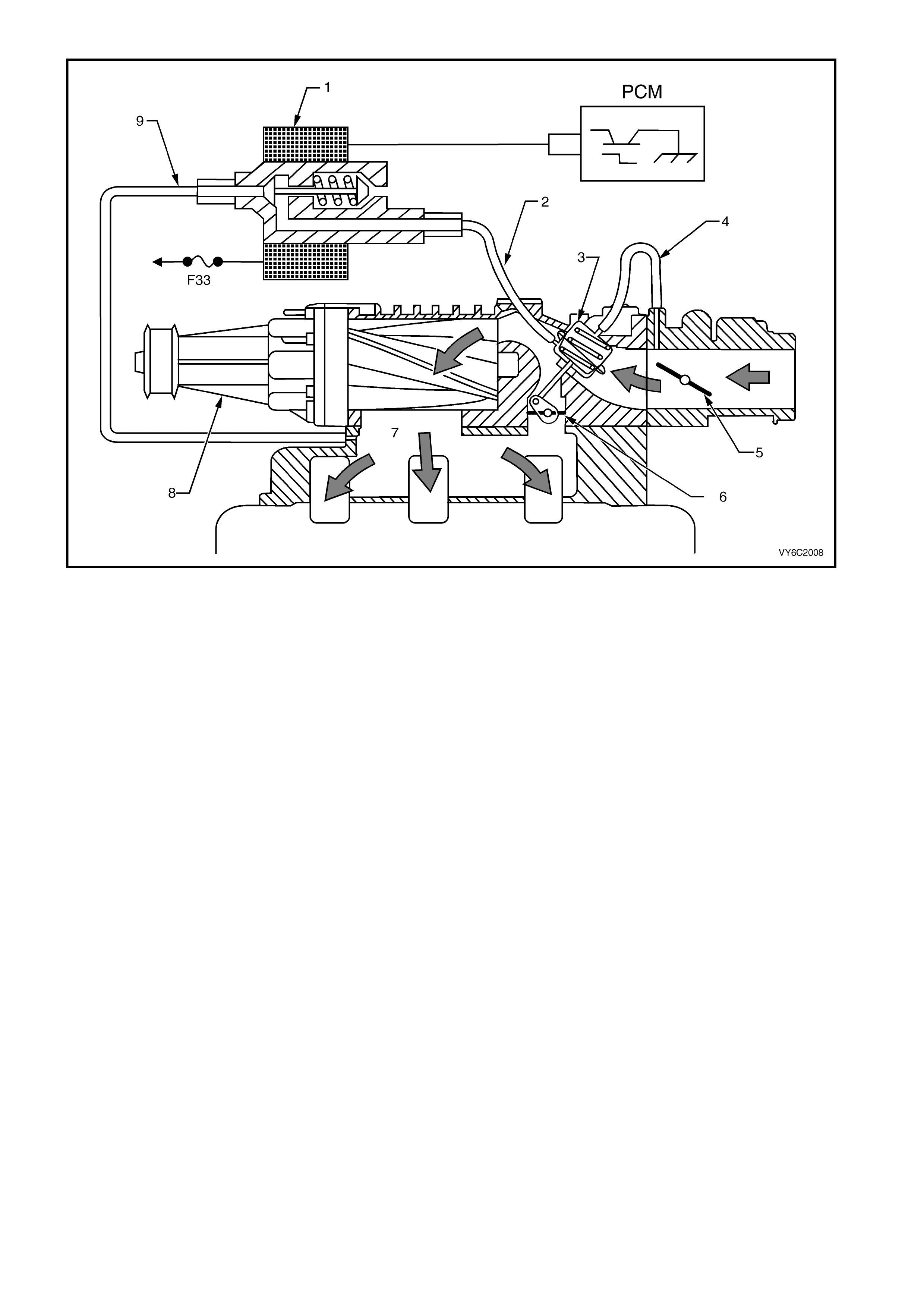

TRANSMISSION PRESSURE CONTROL SOLENOID

IMPORTANT: Transmission pressure control

solenoid resistance should measure 3-5 ohms when

measured at 20°C.

The transmission pressure control solenoid is an

electronic pressure regulator that controls pressure

based on the current flow through its coil winding.

The magnetic field produced by the coil moves the

solenoid's internal valve, which varies pressure to

the pressure regulator valve.

The PCM controls the pressure control solenoid by

commanding current between 100 and 1100

milliamps. This changes the duty cycle of the

solenoid, which can range between 5 percent and

95 percent (typically less than 60 percent). 1100

milliamps corresponds to minimum line pressure,

and 100 milliamps corresponds to maximum line

pressure (if the solenoid loses power, the

transmission defaults to maximum line pressure).

The PCM commands the line pressure values,

using inputs such as the throttle position sensor.

The pressure control solenoid takes the place of

the throttle valve or the vacuum m odulator that was

used on the past model transmissions.

If the duty cycle drops below 5 percent or rises

above 95 percent, DTC 73 will set.

Figure 6C2-1-51 – Pressure Control Solenoid Valve

Legend

A Actuator Feed Limit Fluid 6. Filter Screens

B Torque Signal Fluid 7. Spool Valve

C Exhaust 8. Spool Valve Sleeve

1. Frame 9. Damper Spring

2. Spring 10. Restrictor

3. Armature 11. Push Rod

4. Variable Bleed Orifice 12. Coil Assembly

5. Spool Valve Spring

DTC 73 (PC Solenoid Circuit Electrical) will set if:

• No DTC 75 is set.

• The system voltage is between 10 and 16 volts.

• The engine is running.

• The PC solenoid valve duty cyc le reaches its high lim it (appr oximately 95%) or low lim it (approxim ately 0%) for

200 milliseconds.

• The PCM will not illuminate the Malfunction Indicator Lamp (MIL).

Default Values

When this DTC sets, the PCM will command the PC solenoid valve OFF and freeze shift adapts from being

updated.

Recovery

Recovery will occur when the PCM sees a valid condition.

DTC 73 HISTORY DATA

PARAMETER PARAMETER

ENGINE SPEED COMMANDED PCS

TIME FROM START ACTUAL PCS

TIMES OCCURRED THROTTLE ANGLE

IGNITION CYCLES VEHICLE SPEED

COOLANT TEMPERATURE COMMANDED GEAR

Figure 6C2-1-52 Transmission Solenoid Circuits

TORQUE CONVERTER CLUTCH SOLENOID VALVE

IMPORTANT: T he T CC s olenoid r esis tanc e should

be 21 – 26 ohms minimum when measured at

20° C.

There are two DTC’s associated with the TCC

solenoid. T he f irs t DT C is 67, TCC enable solenoid.

DTC 67 is designed to detect a fault in the TCC

enable solenoid electrical circuit. While DTC 67 is

set, the PCM will inhibit 4th gear if the trans mis sion

is in hot m ode, and no TCC operation. T he second

DTC associated with the TCC enable solenoid is

DTC 69, TCC stuck on. DTC 69 is designed to

detect a TCC enable solenoid that does not

disengage. It does this by monitoring engine RPM

when the TCC is commanded off. If the engine

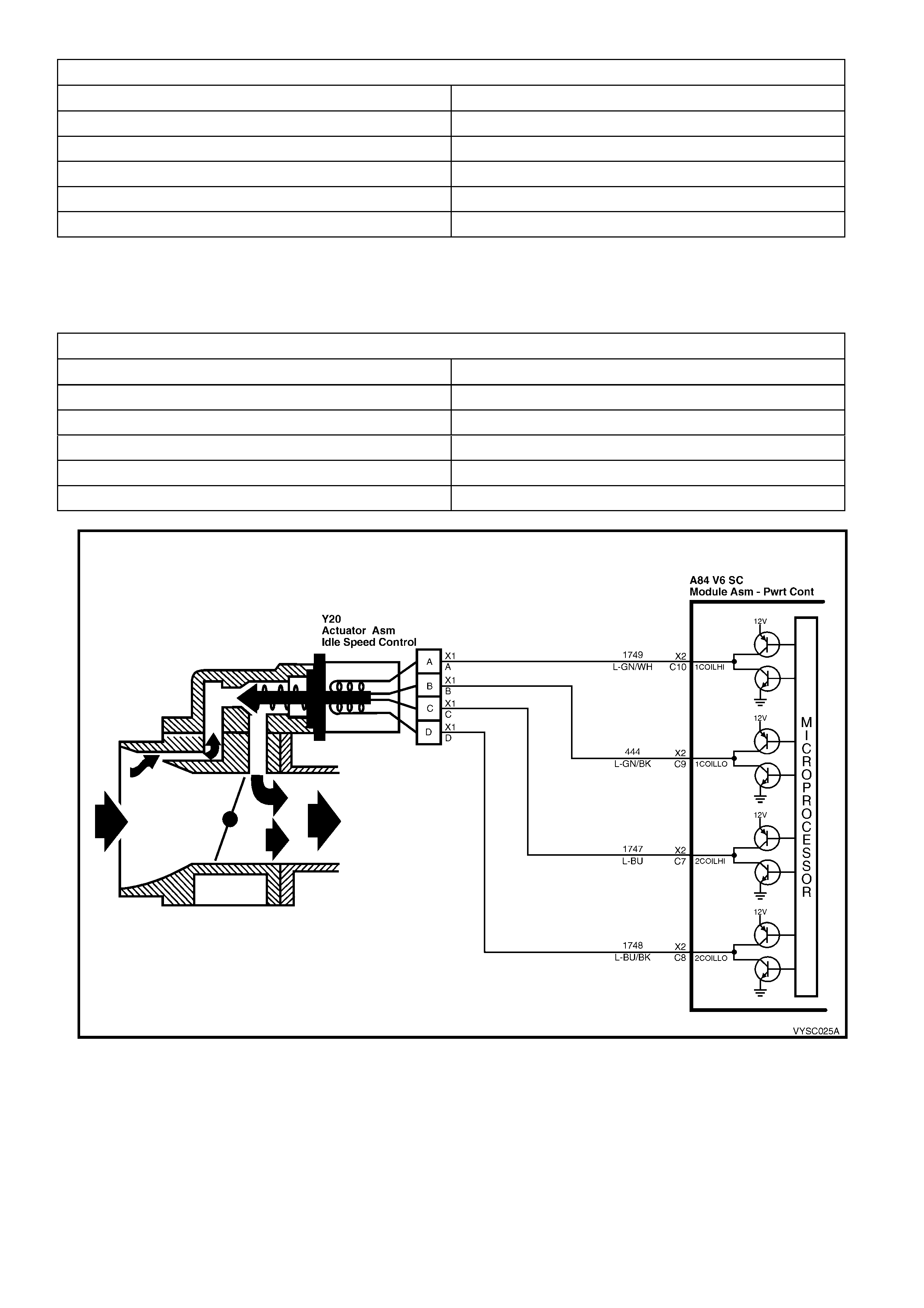

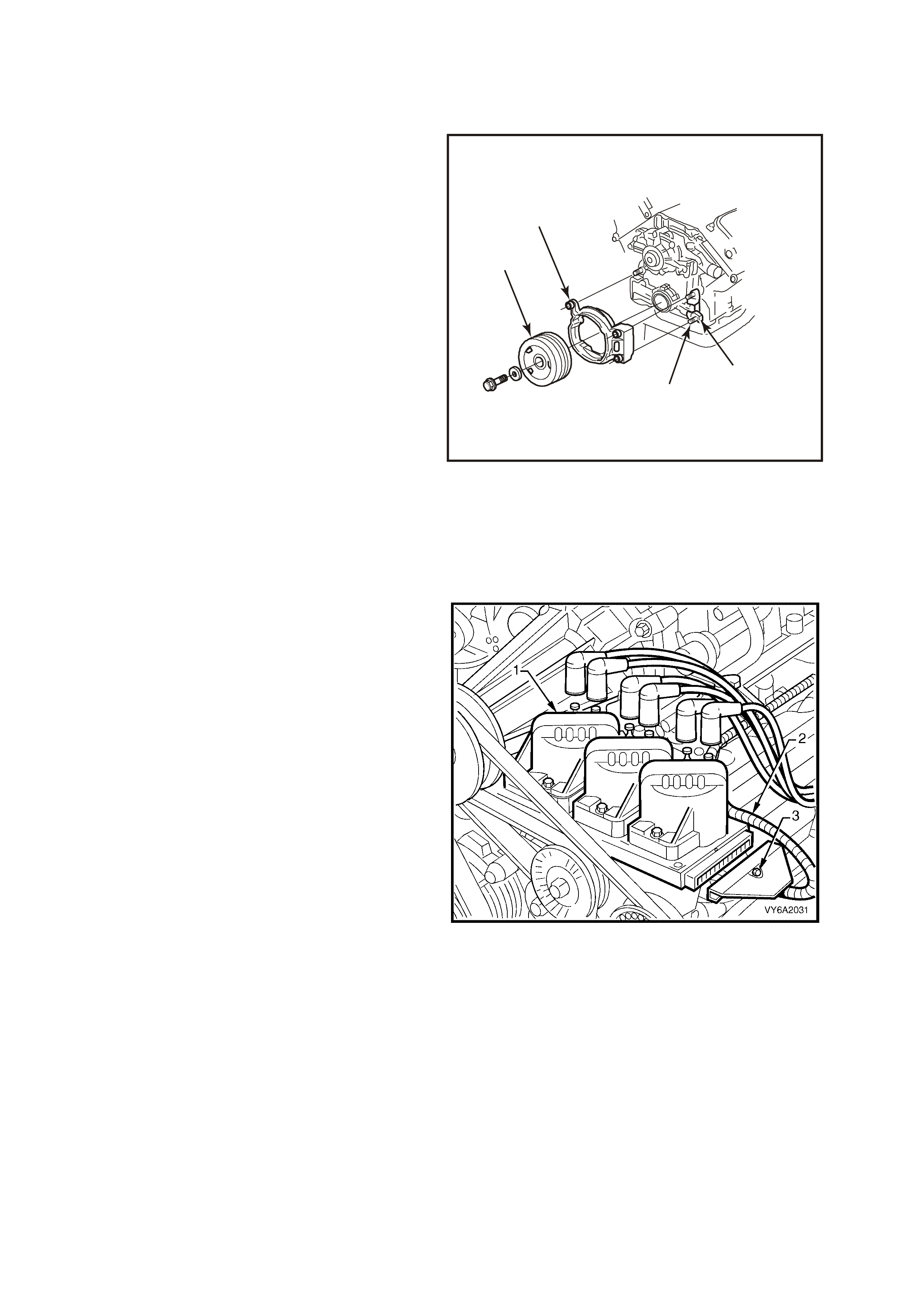

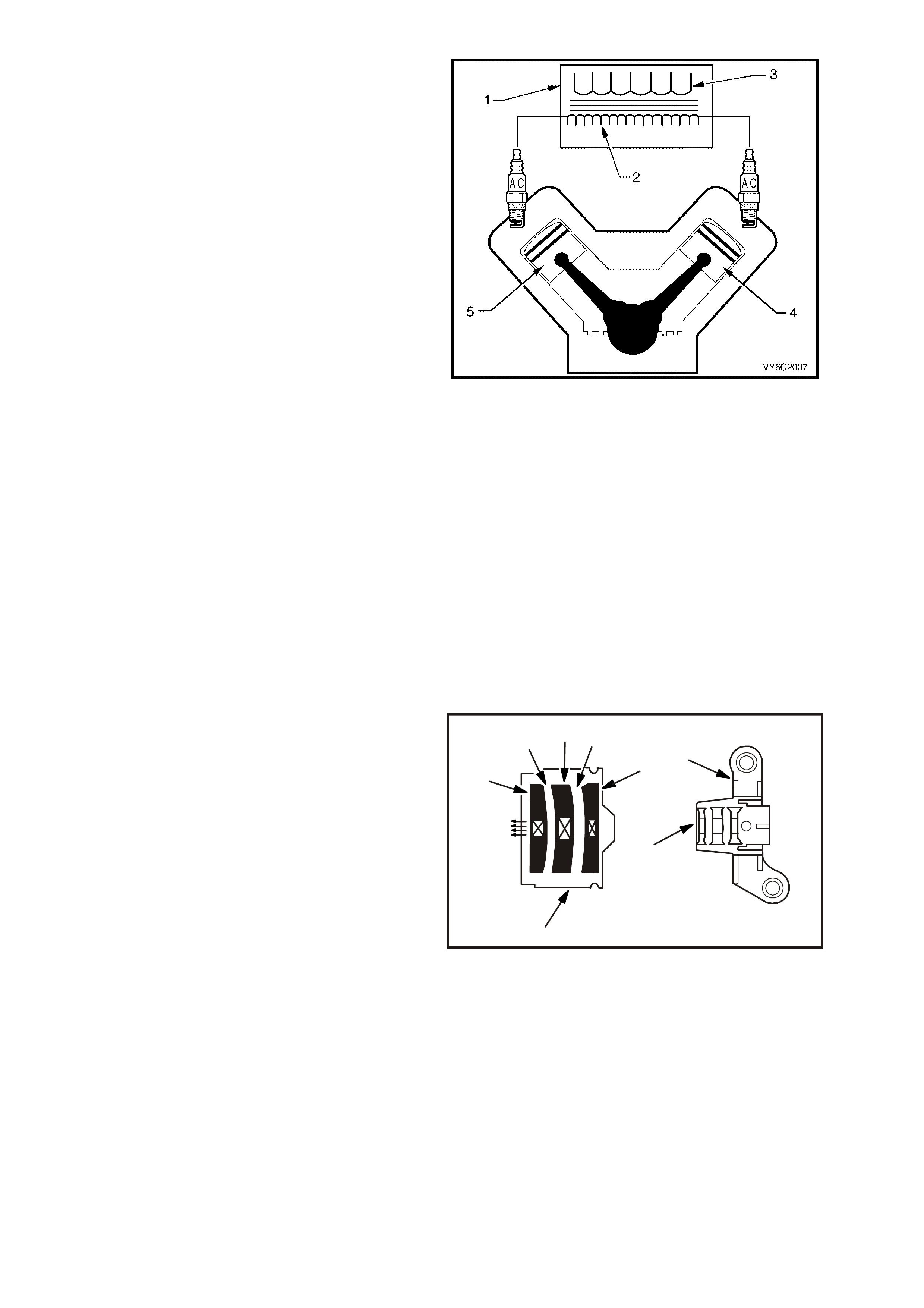

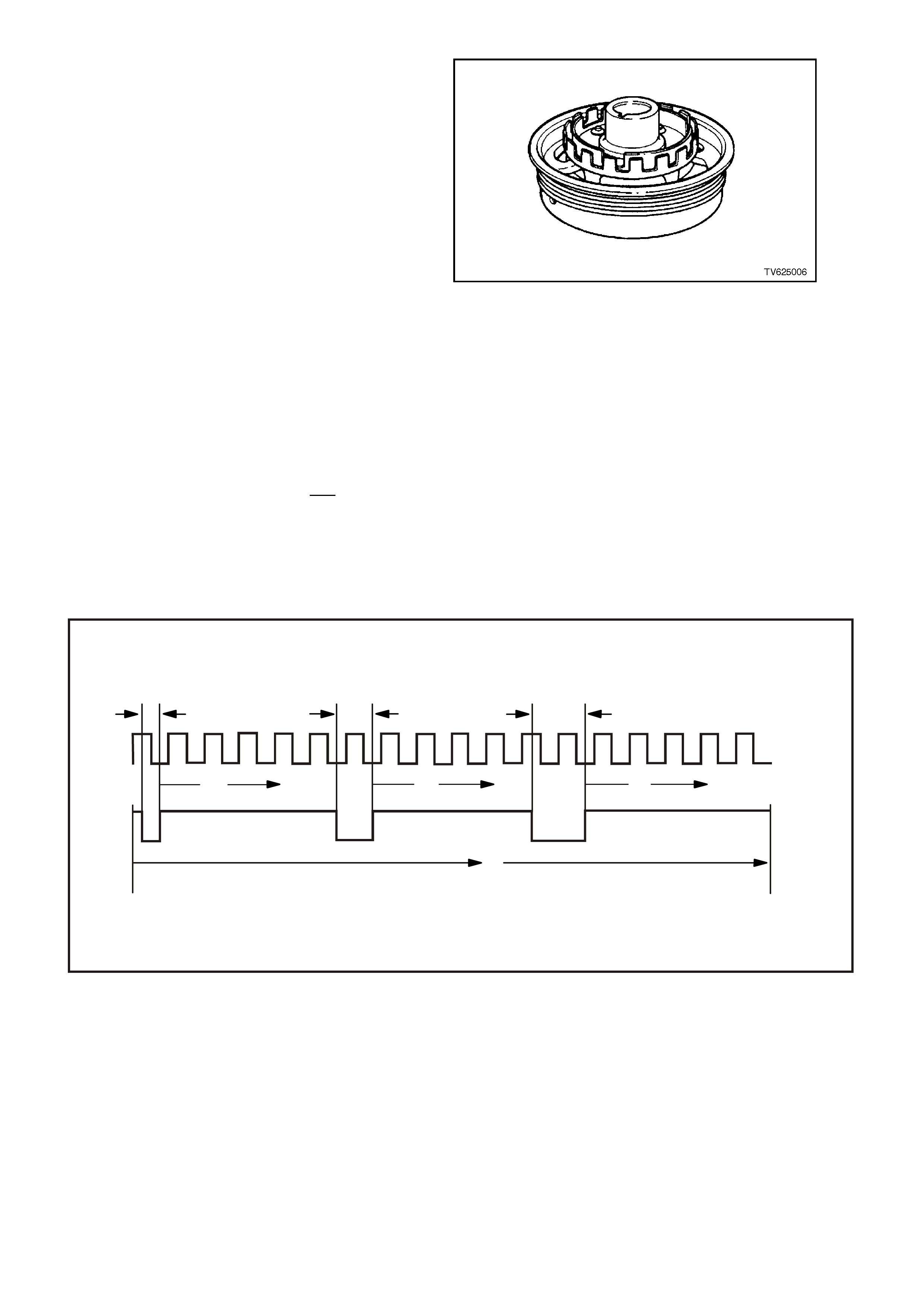

speed does not rise when the TCC solenoid is