SECTION 6C2-2A - DIAGNOSTIC TABLES -

V6 SUPERCHARGED ENGINE

IMPORTANT

Before p erf orming any Service O p eratio n o r ot her p rocedu re describ ed in th is Sect ion , refer t o Sect ion 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

SYSTEM COMPONENT LOCATIONS

PCM WIRING DIAGRAMS

POWERTRAIN CONTROL MODULE CONNECTOR IDENTIFICATION

PCM CONNECTOR TERMINAL VOLTAGES WITH EXPLANATIONS

PCM ENGINE AND TRANSMISSION DIAGNOSTIC TROUBLE CODES

4L60-E TRANSMISSION FLUID CHECKING PROCEDURE

TABLE A- V6 S/C PCM - ON BOARD DIAGNOSTIC (OBD) SYSTEM CHECK

TABLE A-1 V6 S/C PCM - NO "CHECK POWERTRAIN" MALFUNCTION INDICATOR LAMP (MIL)

TABLE A-2 V6 S/C PCM - NO SERIAL DATA

TABLE A-3. 1 V6 S/C PCM - ENGINE CRANKS BUT WILL NOT RUN

TABLE A-3. 2 V6 S/C PCM - ENGINE CRANKS BUT WILL NOT RUN

TABLE A-3. 3 V6 S/C PCM - ENGINE CRANKS BUT WILL NOT RUN

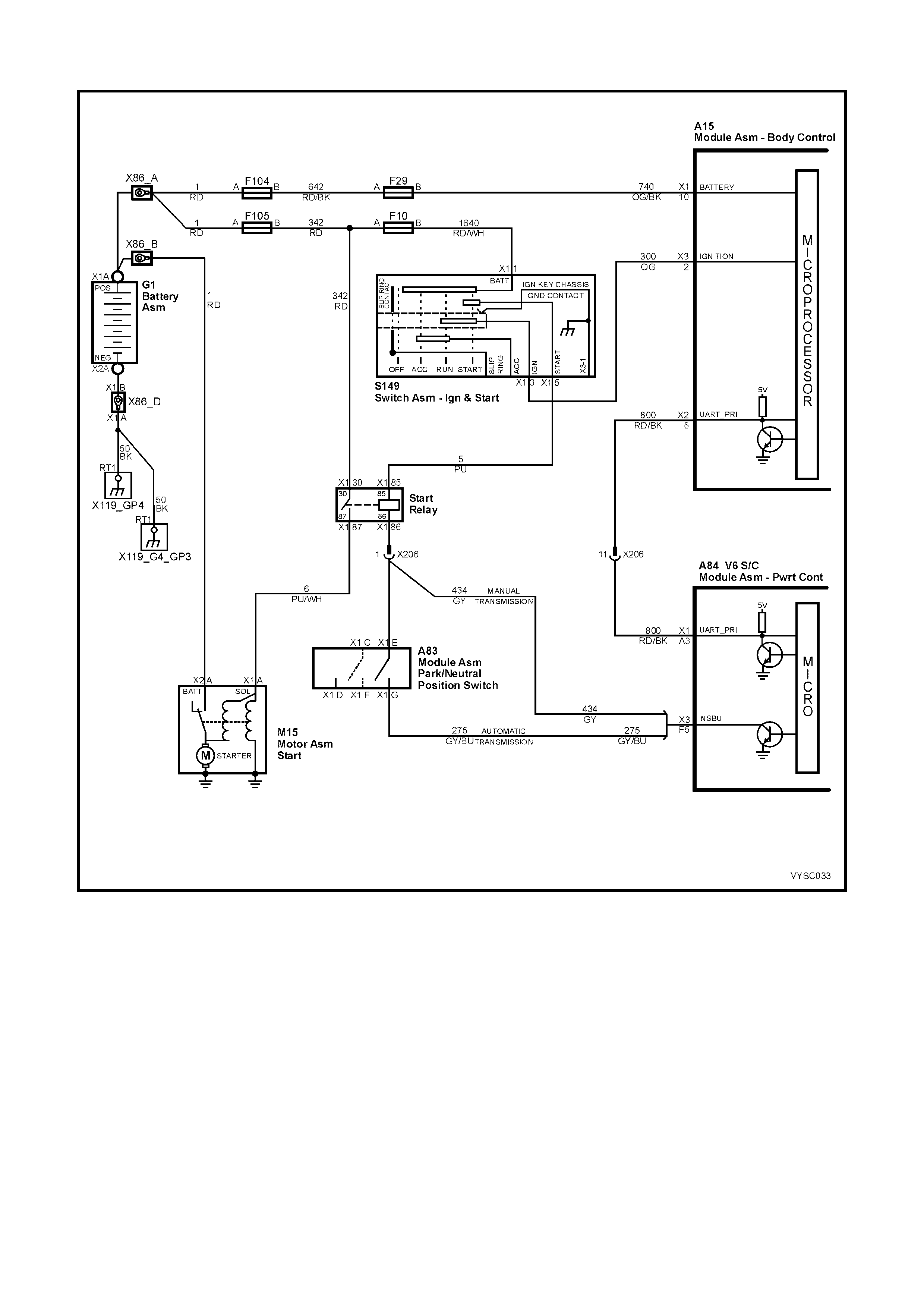

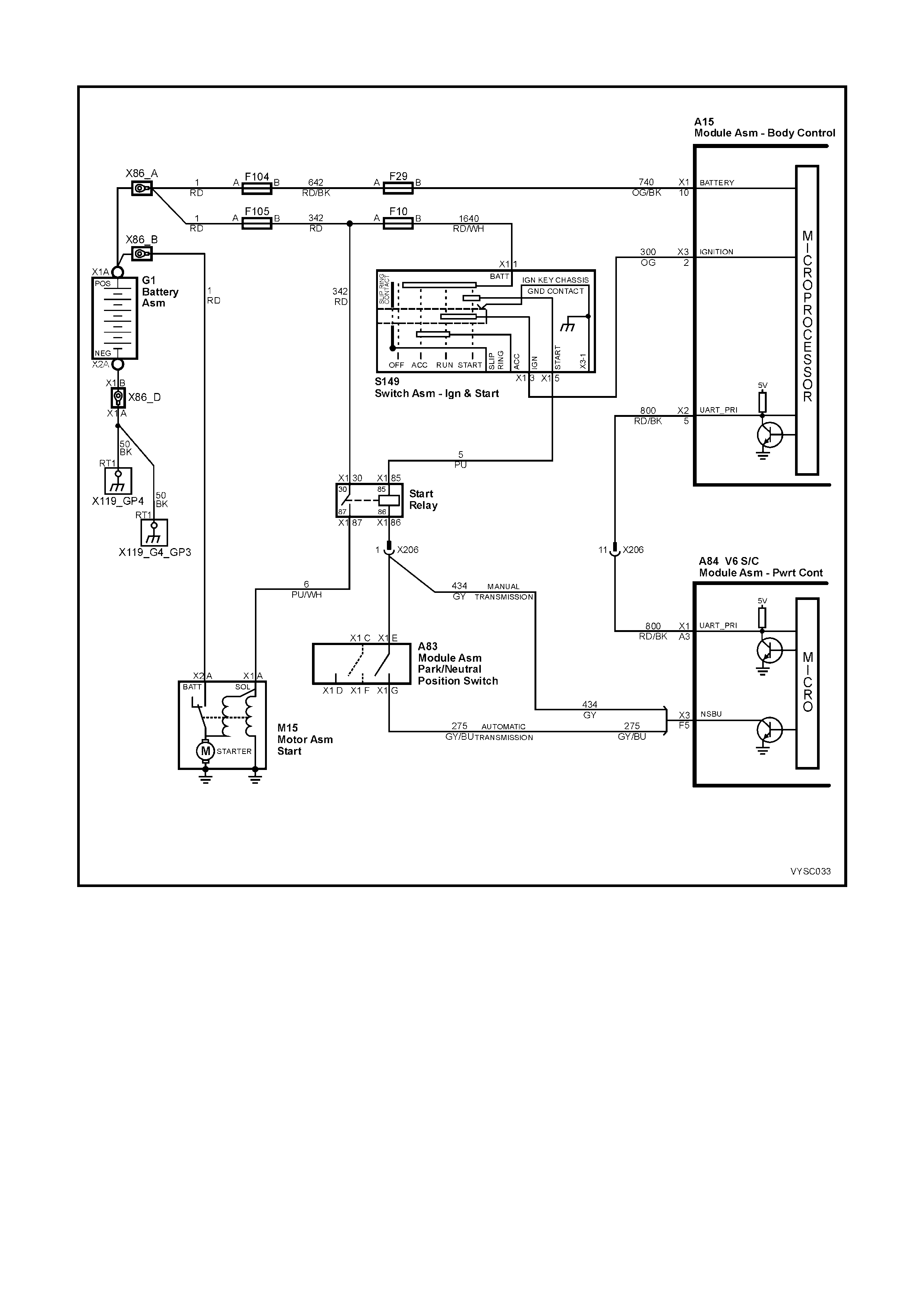

TABLE A-4. 0 V6 S/C PCM - STARTER CRANKING CIRCUIT

TABLE A-4.1 V6 S/C PCM - FUEL PUMP ELECTRICAL CIRCUIT

TABLE A-4.2 V6 S/C PCM - FUEL DELIVERY SYSTEM

TABLE A-4.3 V6 S/C PCM - FUEL DELIVERY SYSTEM

TABLE A-4.4 V6 S/C PCM - FUEL DELIVERY SYSTEM

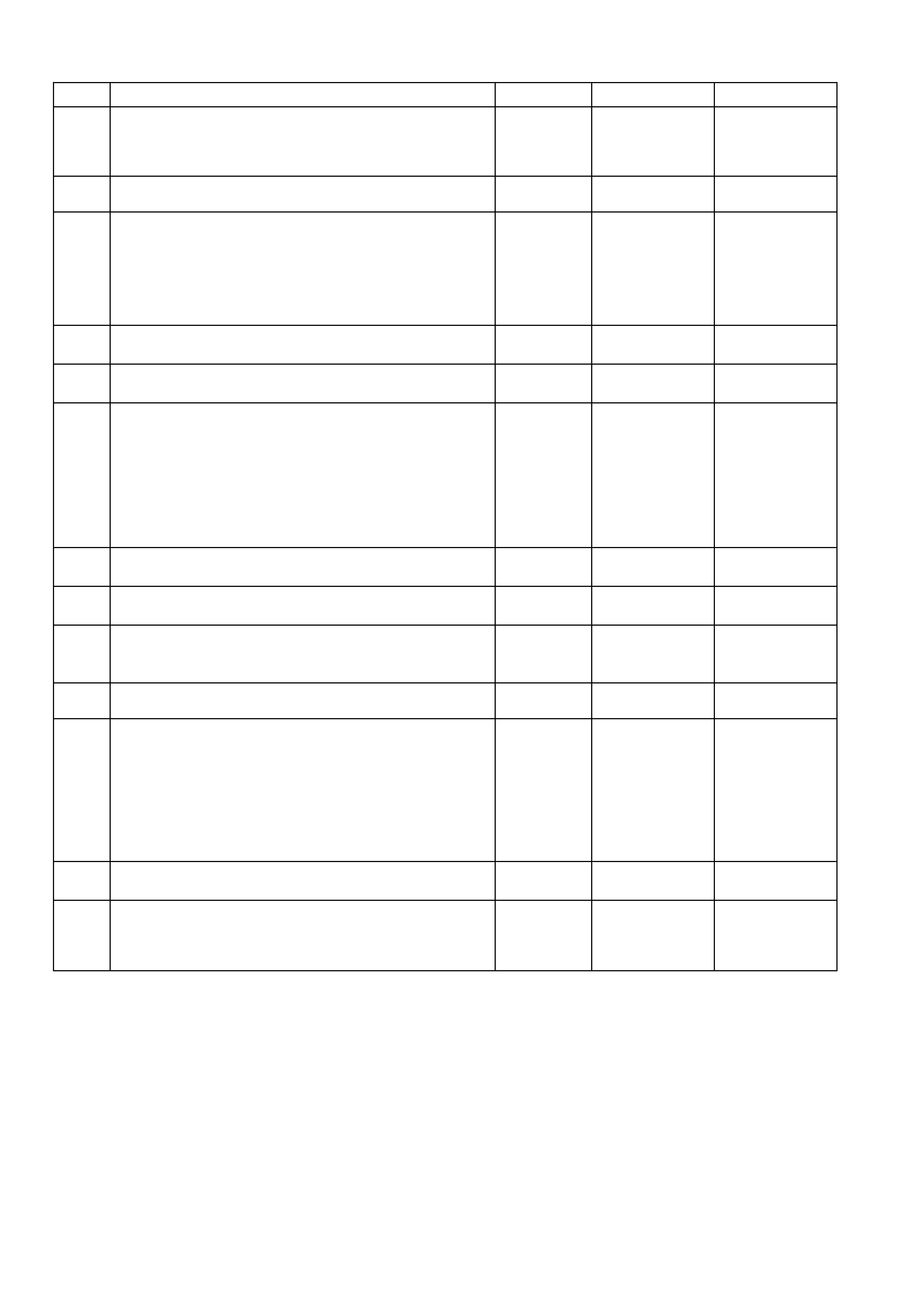

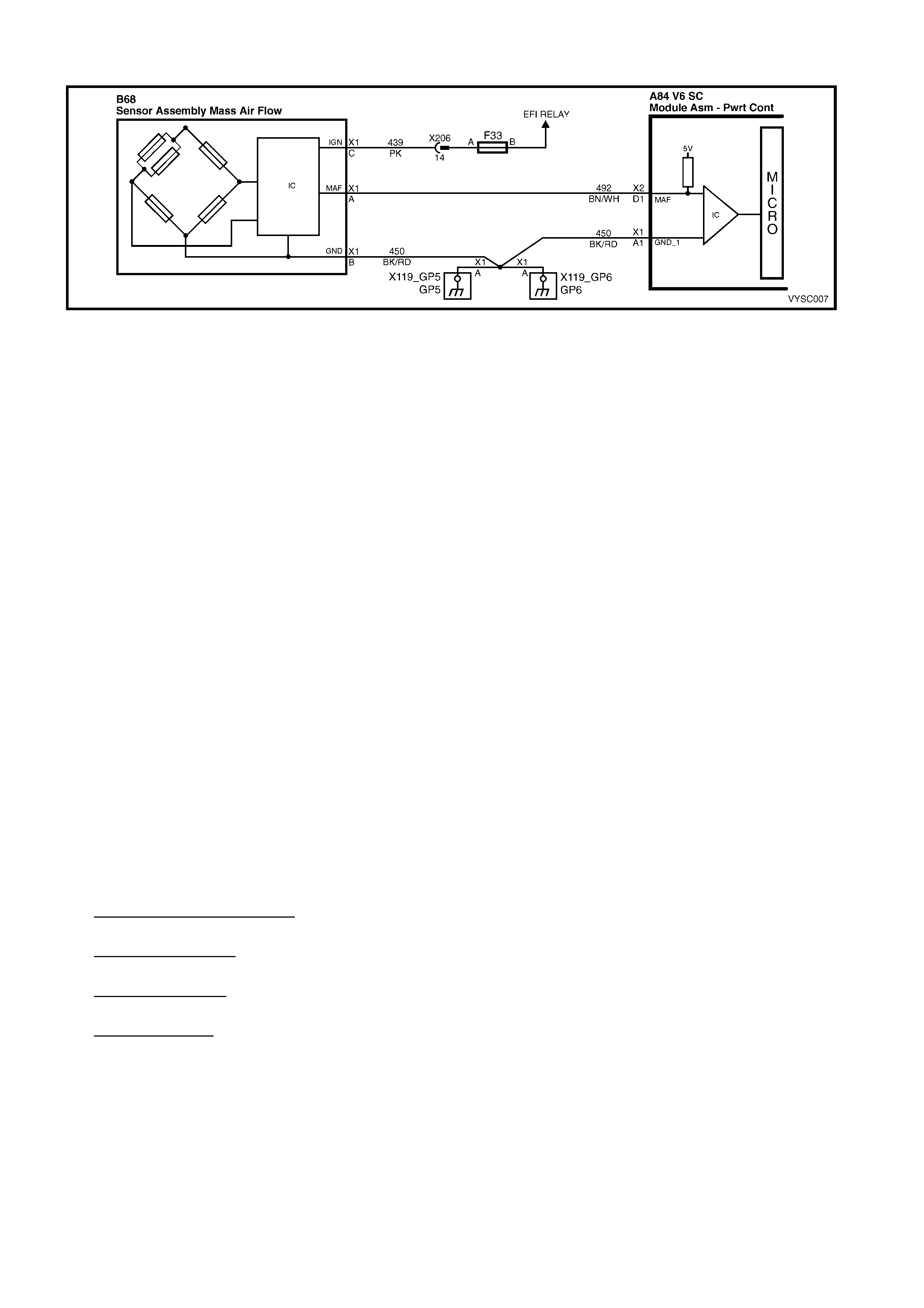

TABLE A-6. 1 V6 S/C PCM - MAF SENSOR OUTPUT CHECK

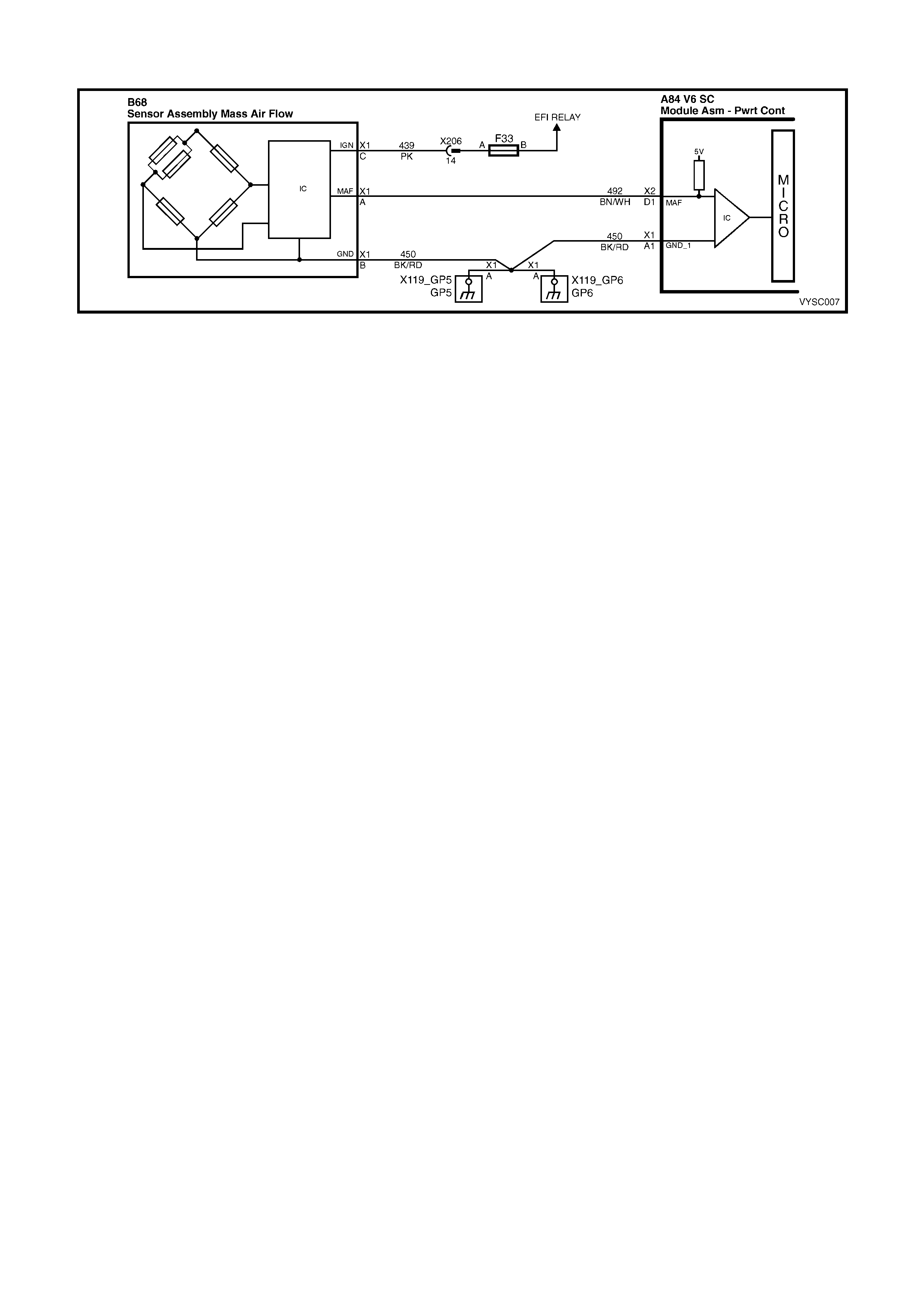

TABLE A-6. 2 V6 S/C PCM - TP SENSOR OUTPUT CHECK

TABLE A-6.3 V6 S/C PCM - OXYGEN SENSOR CHECK

TABLE A-6.3-A V6 S/C PCM - ENGINE OXYGEN SENSOR HEATER CHECK

TABLE A-6. 4 V6 S/C PCM - CANISTER PURGE SOLENOID CHECK

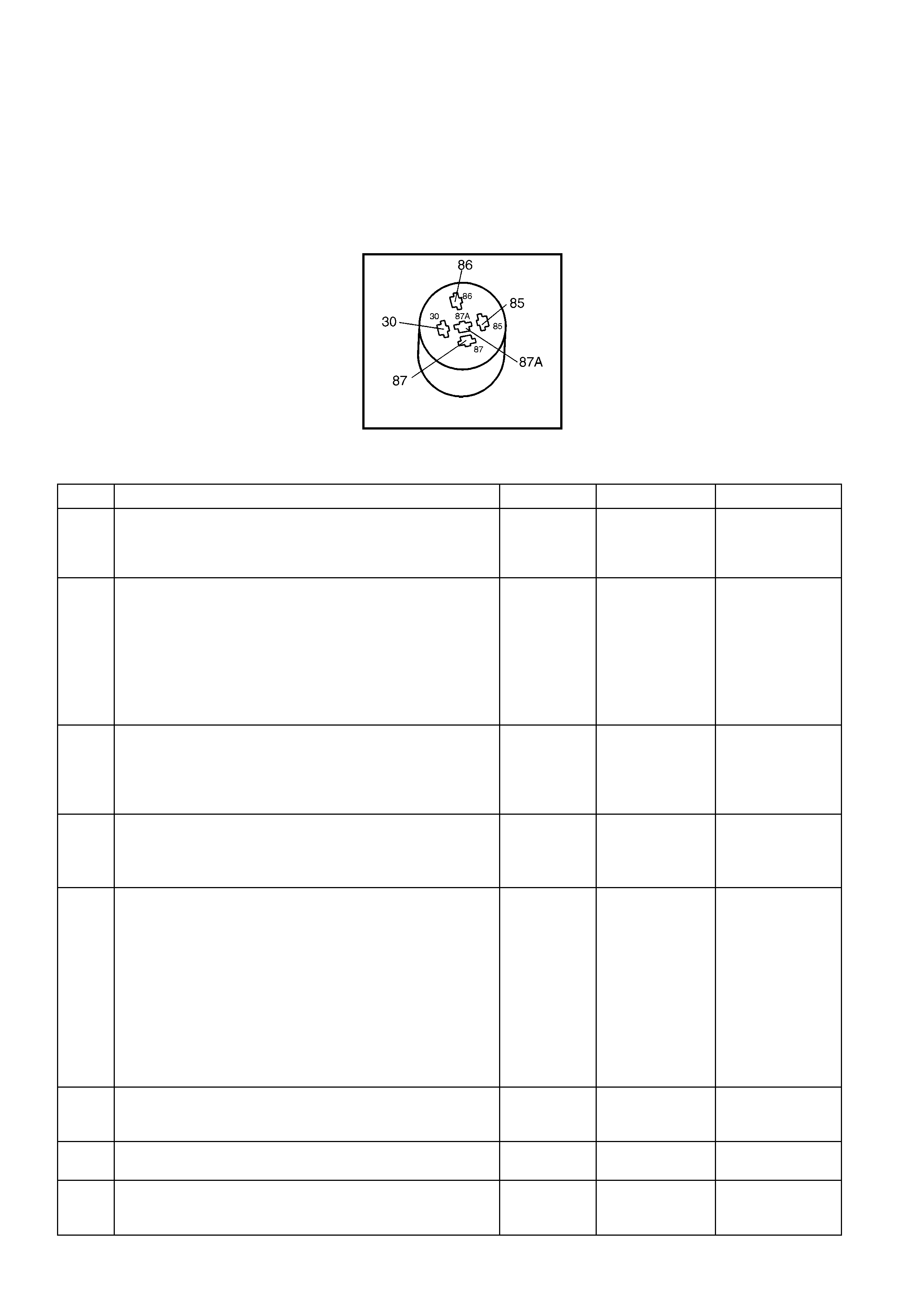

TABLE A-6.5 V6 S/C PCM - EFI RELAY DIAGNOSIS

TABLE A-7.1 V6 S/C PCM - IDLE AIR CONTROL (IAC) SYSTEM

TABLE A-7.2 V6 S/C PCM - IDLE AIR CONTROL (IAC) SYSTEM

TABLE A-8.1 V6 S/C PCM - DIRECT IGNITION SYSTEM (DIS) CHECK

TABLE A-8.2 V6 S/C PCM - DIRECT IGNITION SYSTEM (DIS) CHECK

TABLE A-11.1 V6 S/C PCM - A/C CLUTCH CONTROL (HVAC CLIMATE CONTROL)

TABLE A-11.3 V6 S/C PCM - A/C CLUTCH CONTROL WITH OCCUPANT CLIMATE CONTROL (OCC)

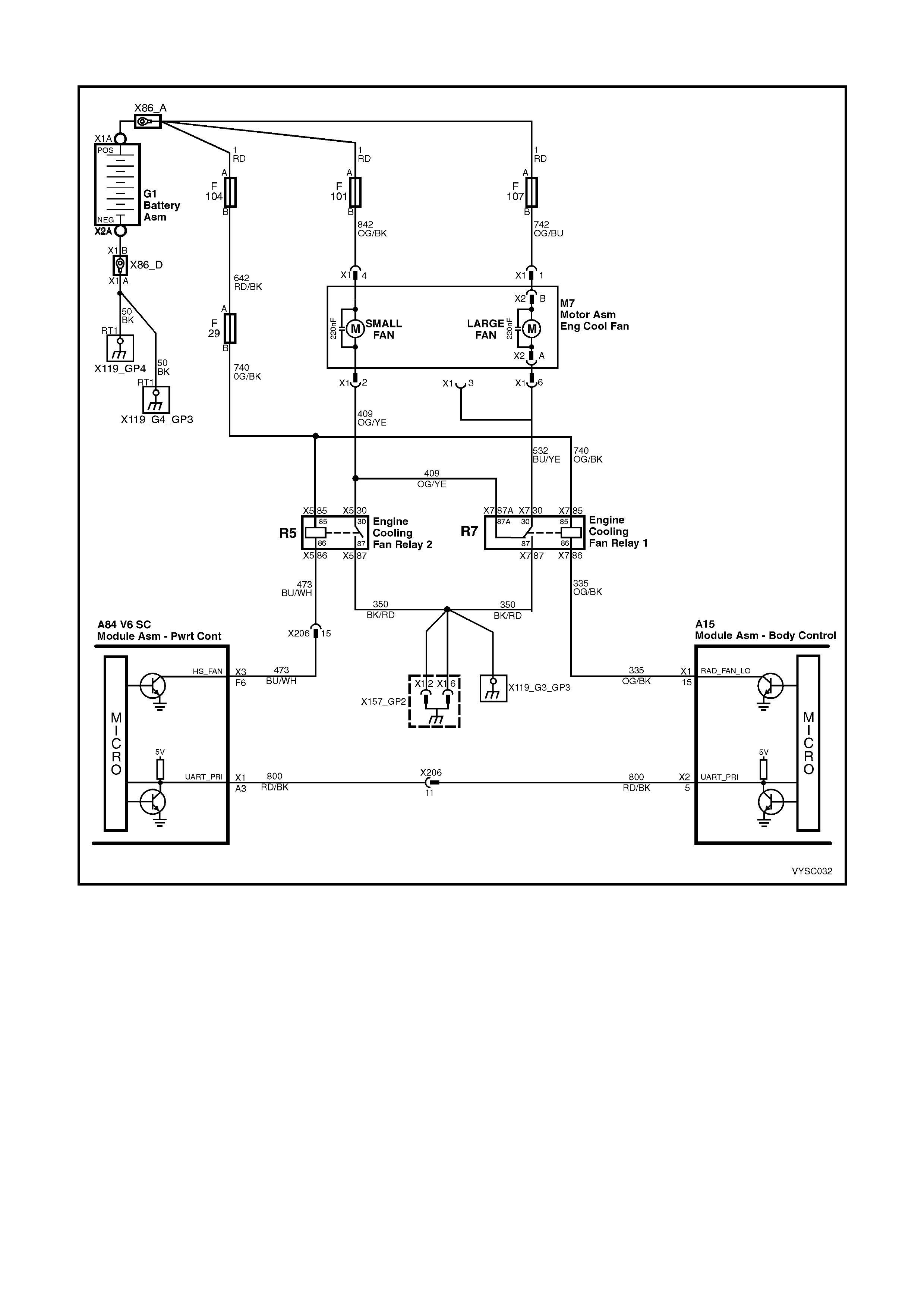

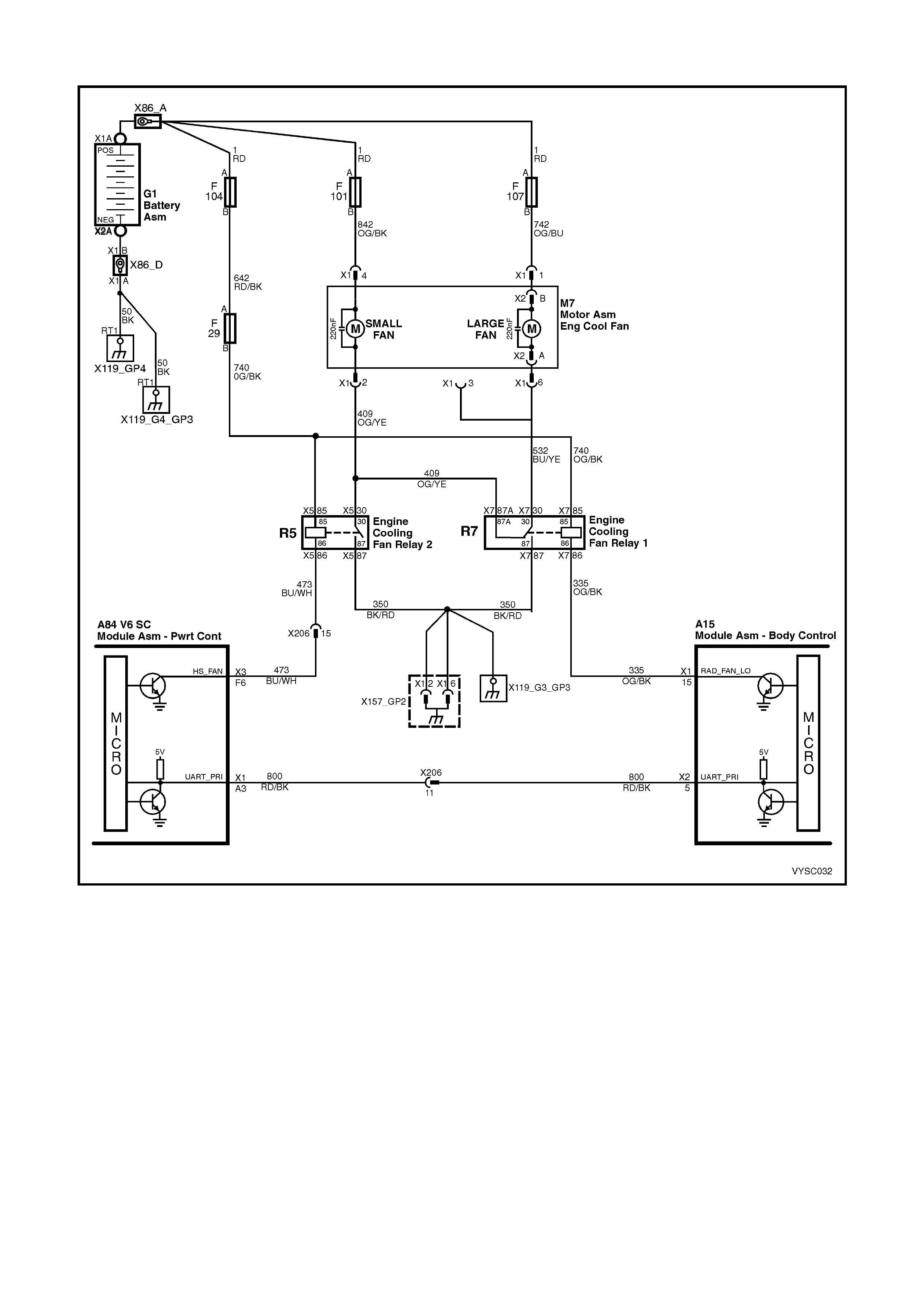

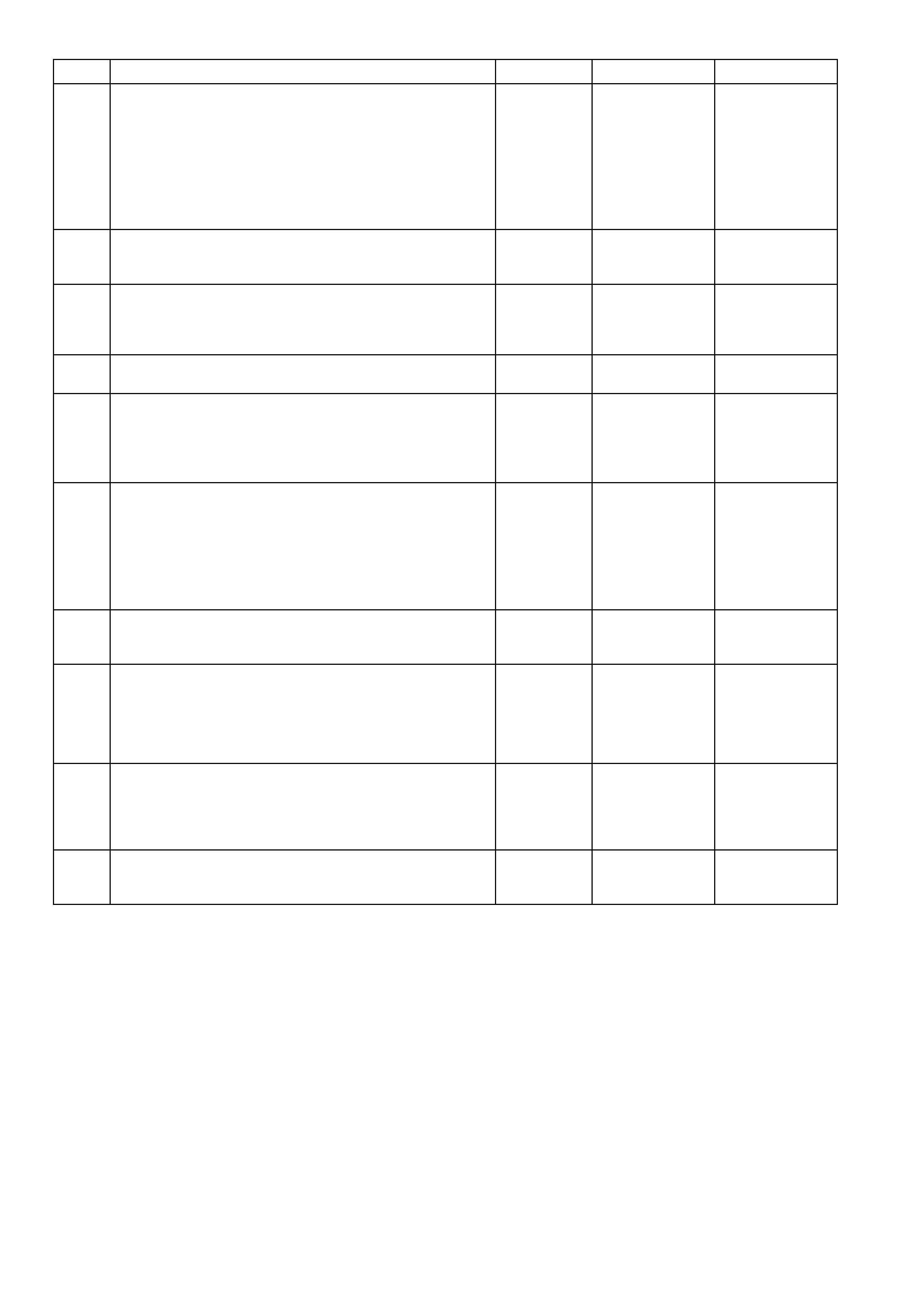

TABLE A-12.1 V6 S/C PCM - ELECTRIC FAN CONTROL

TABLE A-12.2 V6 S/C PCM - ELECTRIC FAN CONTROL

TABLE A-13 V6 S/C PCM - RESTRICTED EXHAUST CHECK

DTC 13 V6 S/C PCM - RIGHT HAND OXYGEN SENSOR (HO2S) INSUFFICIENT ACTIVITY

DTC 14 V6 S/C PCM - ENGINE COOLANT TEMPERATURE (ECT) SENSOR LOW VOLTAGE

DTC 15 V6 S/C PCM - ENGINE COOLANT TEMPERATURE (ECT) SENSOR HIGH VOLTAGE

DTC 16 V6 S/C PCM - ENGINE COOLANT TEMPERATURE (ECT) SENSOR UNSTABLE)

DTC 17 V6 S/C PCM - PCM ERROR - ECT CIRCUIT

DTC 19 V6 S/C PCM - THROTTLE POSITION (TP) SENSOR CIRCUIT INSUFFICIENT ACTIVITY

DTC 21 V6 S/C PCM - THROTTLE POSITION (TP) SENSOR CIRCUIT HIGH VOLTAGE

DTC 22 V6 S/C PCM - THROTTLE POSITION (TP) SENSOR CIRCUIT LOW VOLTAGE

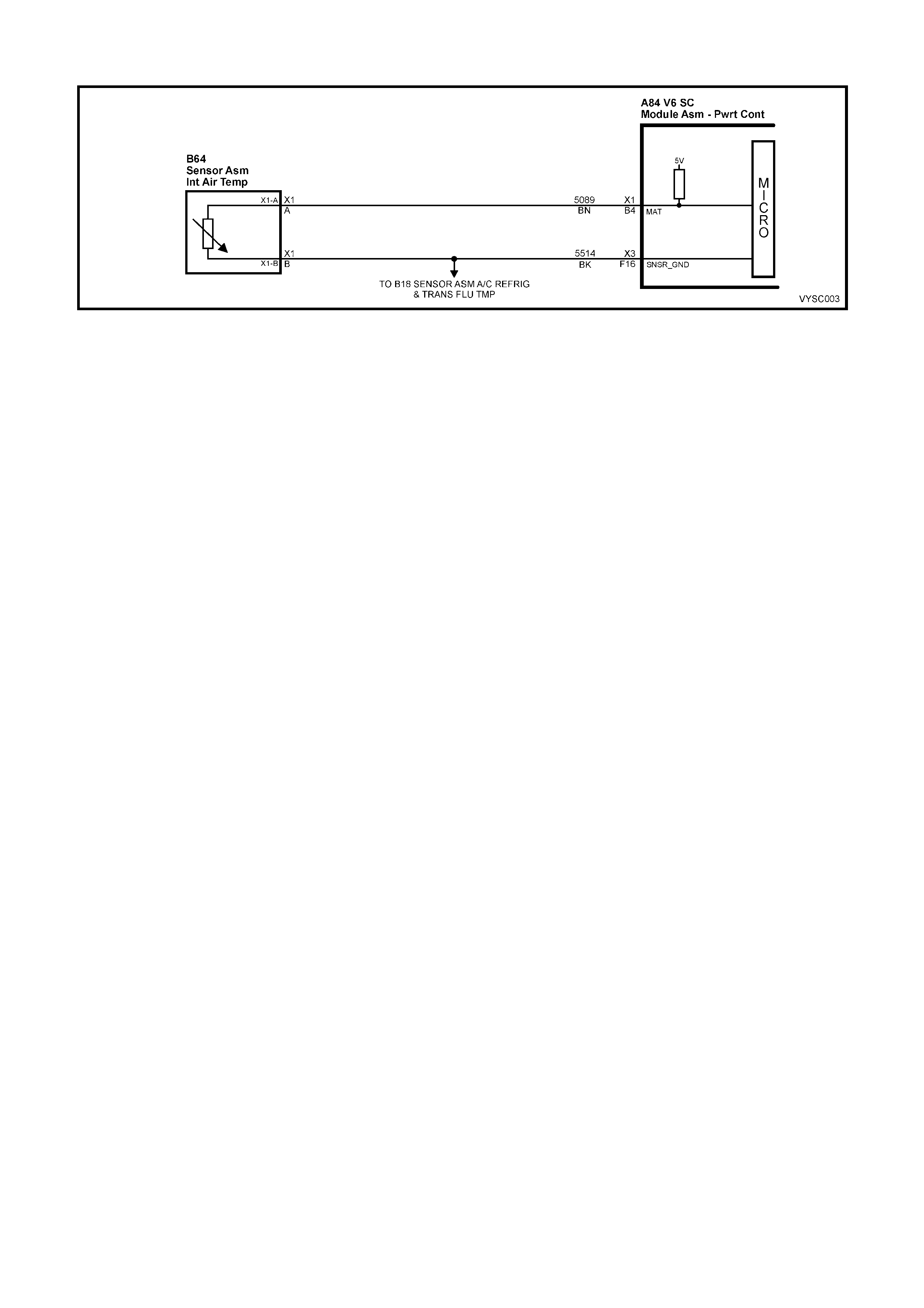

DTC 23 V6 S/C PCM - INTAKE AIR TEMPERATURE (IAT) SENSOR CIRCUIT HIGH VOLTAGE

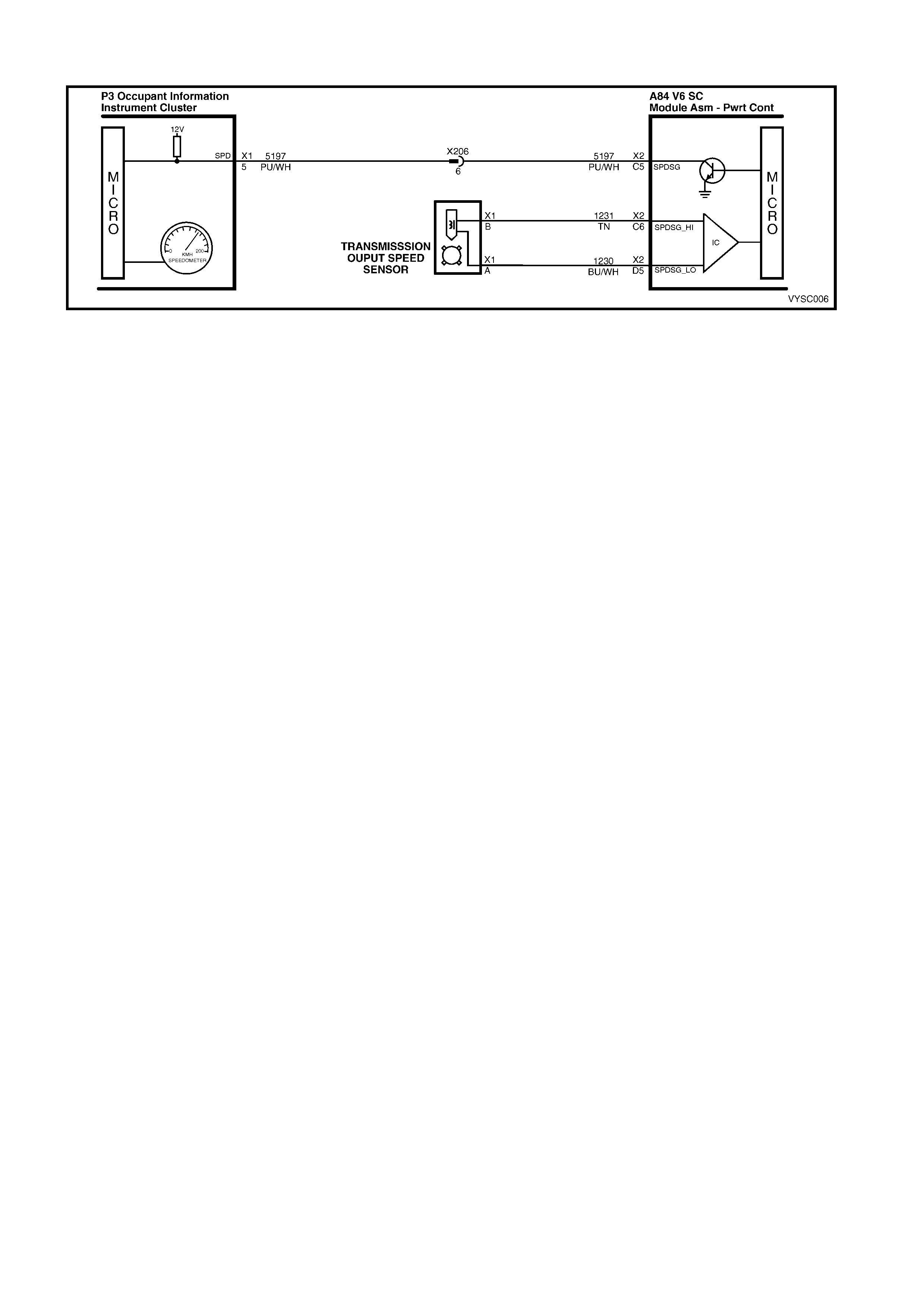

DTC 24 V6 S/C PCM - VEHICLE SPEED SENSOR (VSS) CIRCUIT LOW VOLTAGE

DTC 25 V6 S/C PCM - INTAKE AIR TEMPERATURE (IAT) SENSOR CIRCUIT LOW VOLTAGE

DTC 26 V6 S/C PCM - INTAKE AIR TEMPERATURE (IAT) SENSOR UNSTABLE)

DTC 28 V6 S/C PCM - TRANSMISSION FLUID PRESSURE (TFP) MANUAL VALVE POSITION

SWITCH CIRCUIT

DTC 31 V6 S/C PCM - THEFT DETERRENT SIGNAL MISSING

DTC 32 V6 S/C PCM - MASS AIR FLOW (MAF) OUT OF RANGE

DTC 35 V6 S/C PCM - IDLE SPEED LOW

DTC 36 V6 S/C PCM – VACUUM LEAK

DTC 41 V6 S/C PCM - ELECTRONIC SPARK TIMING (EST) – OUTPUT CIRCUIT FAULT

DTC 42 V6 S/C PCM - IGNITION BYPASS CIRCUIT FAULT

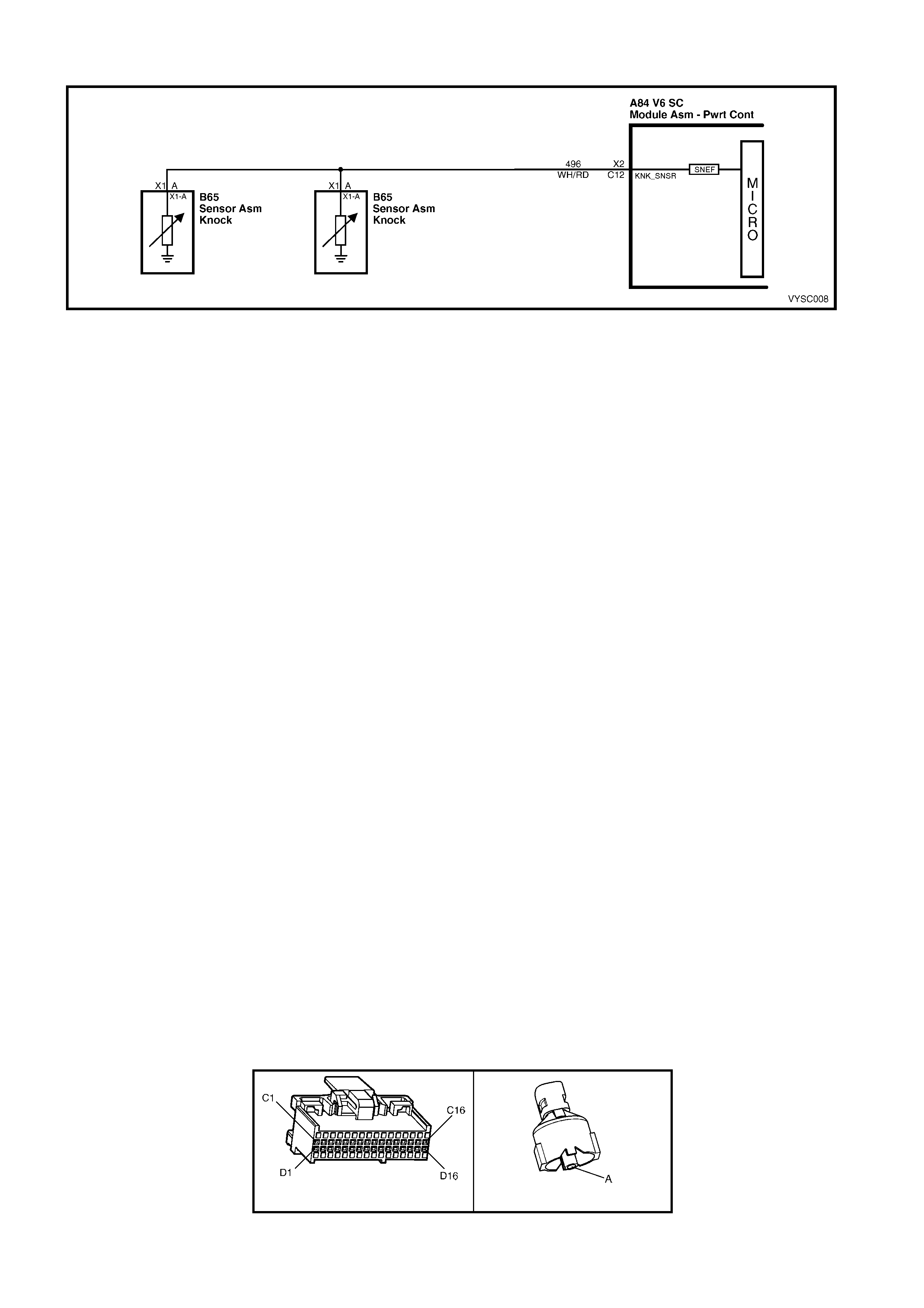

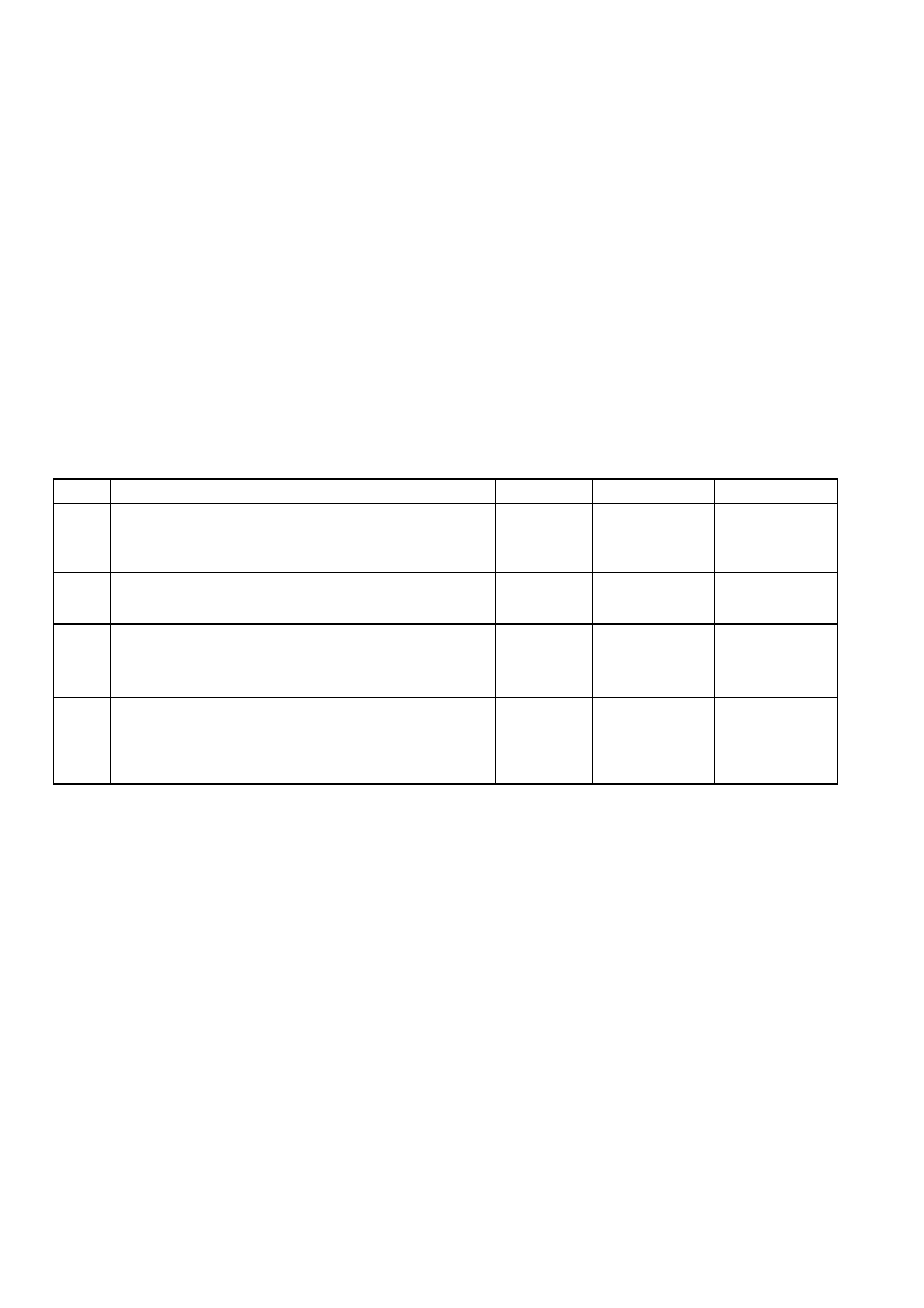

DTC 43 V6 S/C PCM - KNOCK SENSOR CIRCUIT FAULT

DTC 44 V6 S/C PCM - RIGHT HAND HEATED OXYGEN SENSOR (HO2S) LOW VOLTAGE

DTC 45 V6 S/C PCM - RIGHT HAND HEATED OXYGEN SENSOR (HO2S) HIGH VOLTAGE

DTC 46 V6 S/C PCM - NO REFERENCE PULSES WHILE CRANKING

DTC 47 V6 S/C PCM - 18 X REFERENCE SIGNAL MISSING

DTC 48 V6 S/C PCM - CAMSHAFT POSITION SENSOR CIRCUIT LOW VOLTAGE

DTC 49 V6 S/C PCM - CAMSHAFT POSITION SENSOR PERFORMANCE

DTC 51 V6 S/C PCM – POWERTRAIN CONTROL MODULE (PCM) M EMORY

DTC 52 V6 S/C PCM - SYSTEM VOLTAGE TOO HIGH (LONG TIME)

DTC 53 V6 S/C PCM - SYSTEM VOLTAGE TOO HIGH

DTC 54 V6 S/C PCM - SYSTEM VOLTAGE UNSTABLE

DTC 55 V6 S/C PCM - PCM - ANALOGUE – DIGITAL (A/D) CONVERSION ERROR

DTC 56 V6 S/C PCM - LEAN CONDITION UNDER LOAD

DTC 57 V6 S/C PCM - INJECTOR VOLTAGE MONITOR FAULT

DTC 58 V6 S/C PCM - TRANSMISSION FLUID TEMPERATURE (TFT) SENSOR – LOW INPUT

DTC 59 V6 S/C PCM - TRANSMISSION FLUID TEMPERATURE (TFT) SENSOR HIGH INPUT

DTC 63 V6 S/C PCM - LEFT HAND OXYGEN SENSOR (HO2S) INSUFFICIENT ACTIVITY

DTC 64 V6 S/C PCM - LEFT HAND HEATED OXYGEN SENSOR (HO2S) LOW VOLTAGE

DTC 65 V6 S/C PCM - LEFT HAND HEATED OXYGEN SENSOR (HO2S) HIGH VOLTAGE

DTC 66 V6 S/C PCM - 3-2 SHIFT SOLENOID CIRCUIT ELECTRICAL

DTC 67 V6 S/C PCM - TORQUE CONVERTER CLUTCH (TCC) ENABLE SOLENOID CIRCUIT ELECTRICAL

DTC 69 V6 S/C PCM - TORQUE CONVERTER CLUTCH (TCC) SYSTEM STUCK ON

DTC 72 V6 S/C PCM - TRANSMISSION OUTPUT SPEED LOSS

DTC 73 V6 S/C PCM - PRESSURE CONTROL (PC) SOLENOID CIRCUIT ELECTRICAL

DTC 75 V6 S/C PCM - SYSTEM VOLTAGE LOW

DTC 76 V6 S/C PCM - SHORT TERM FUEL TRIM (STFT) DELTA HIGH

DTC 78 V6 S/C PCM - LONG TERM FUEL TRIM (LTFT) DELTA HIGH

DTC 79 V6 S/C PCM - TRANSMISSION FLUID OVER-TEMPERATURE

DTC 81 V6 S/C PCM - 2-3 SHIFT SOLENOID ‘B’ ELECTRICAL CIRCUIT ELECTRICAL FAULT

DTC 82 V6 S/C PCM - 1-2 SHIFT SOLENOID ‘A’ ELECTRICAL CIRCUIT FAULT

DTC 83 V6 S/C PCM - TORQUE CONVERTER CLUTCH (TCC) PULSE WIDTH M ODULATION (PWM)

SOLENOID CIRCUIT FAULT

DTC 85 V6 S/C PCM - TRANSMISSION SLIPPING

DTC 91 V6 S/C PCM - QDSM (QUAD DRIVER SURFACE MODULE) CIRCUIT

DTC 92 V6 S/C PCM - LOW SPEED FAN – NO BCM RESPONSE

DTC 93 V6 S/C PCM - KNOCK SENSOR SYSTEM

DTC 95 V6 S/C PCM - REQUESTED TORQUE OUT-OF-RANGE

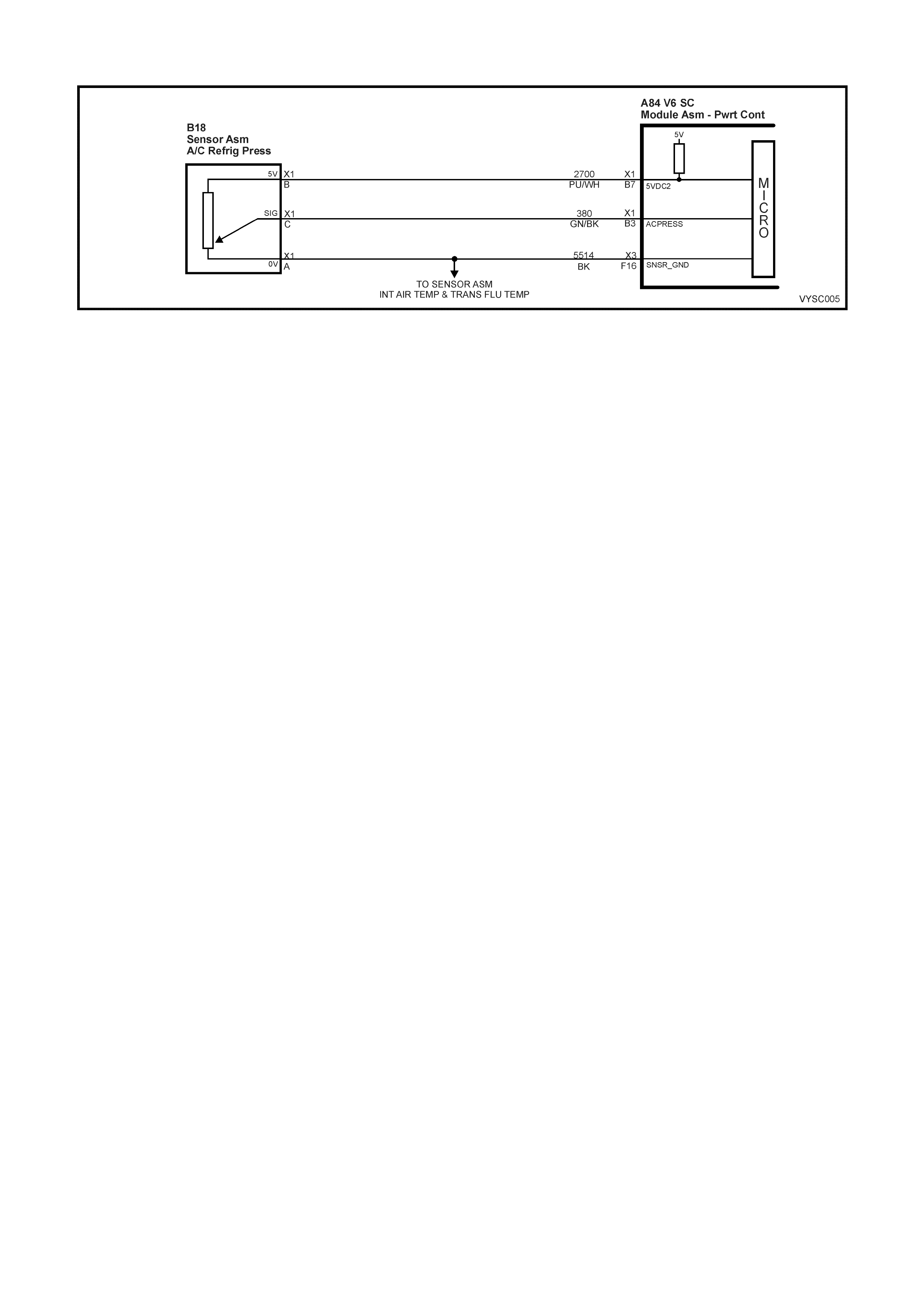

DTC 96 V6 S/C PCM - A/C REFRIGERANT PRESSURE SENSOR CIRCUIT FAULT

DTC 97 V6 S/C PCM - EVAP PURGE SOLENOID CONTROL CIRCUIT FAULT

SYSTEM COMPONENT LOCATIONS

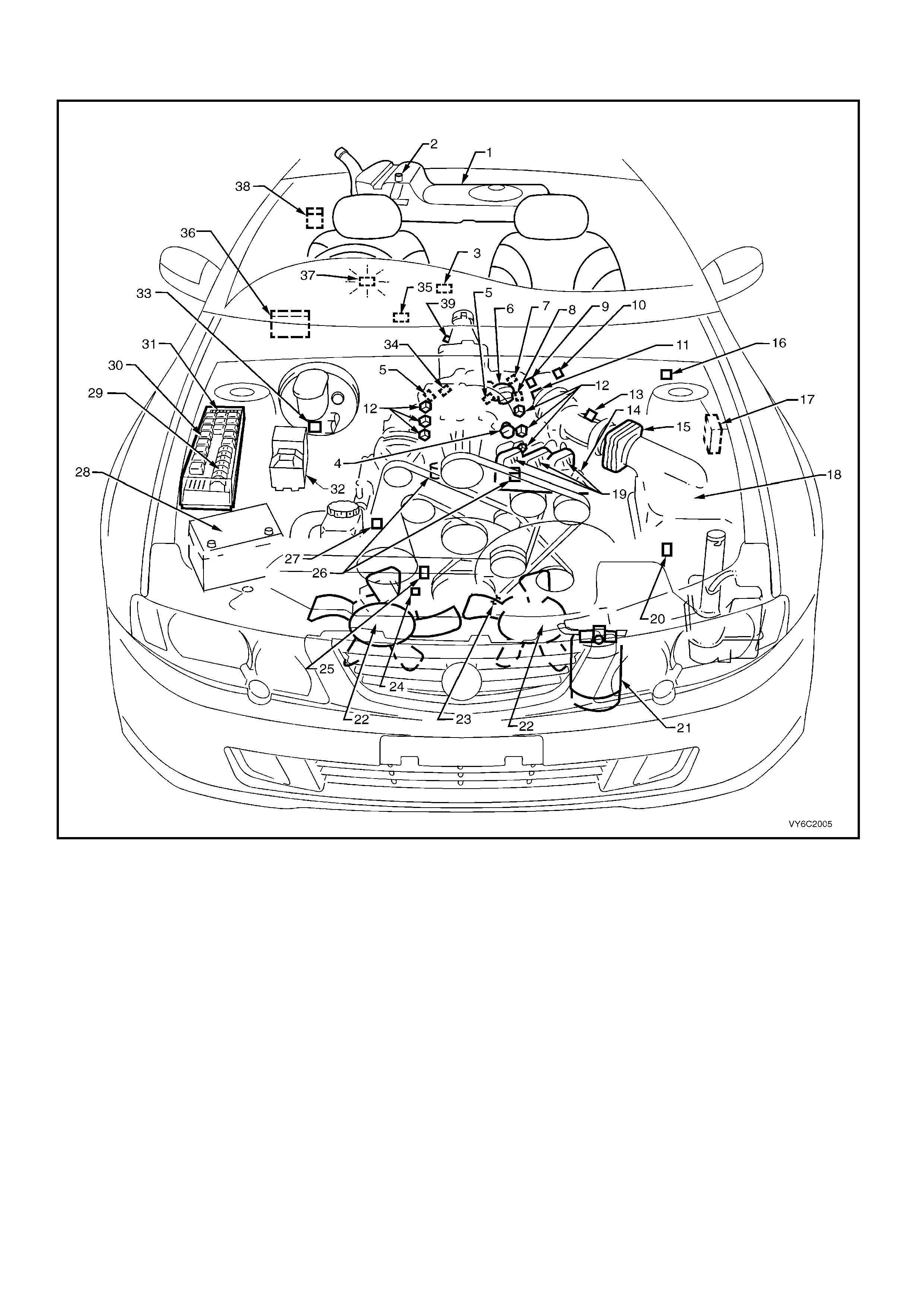

Figure 6C2-2A-1 – V6 Supercharged Engine Compartment Component Locations

Legend

1. Fuel Tank

2. Fuel Pump (Inside Fuel Tank)

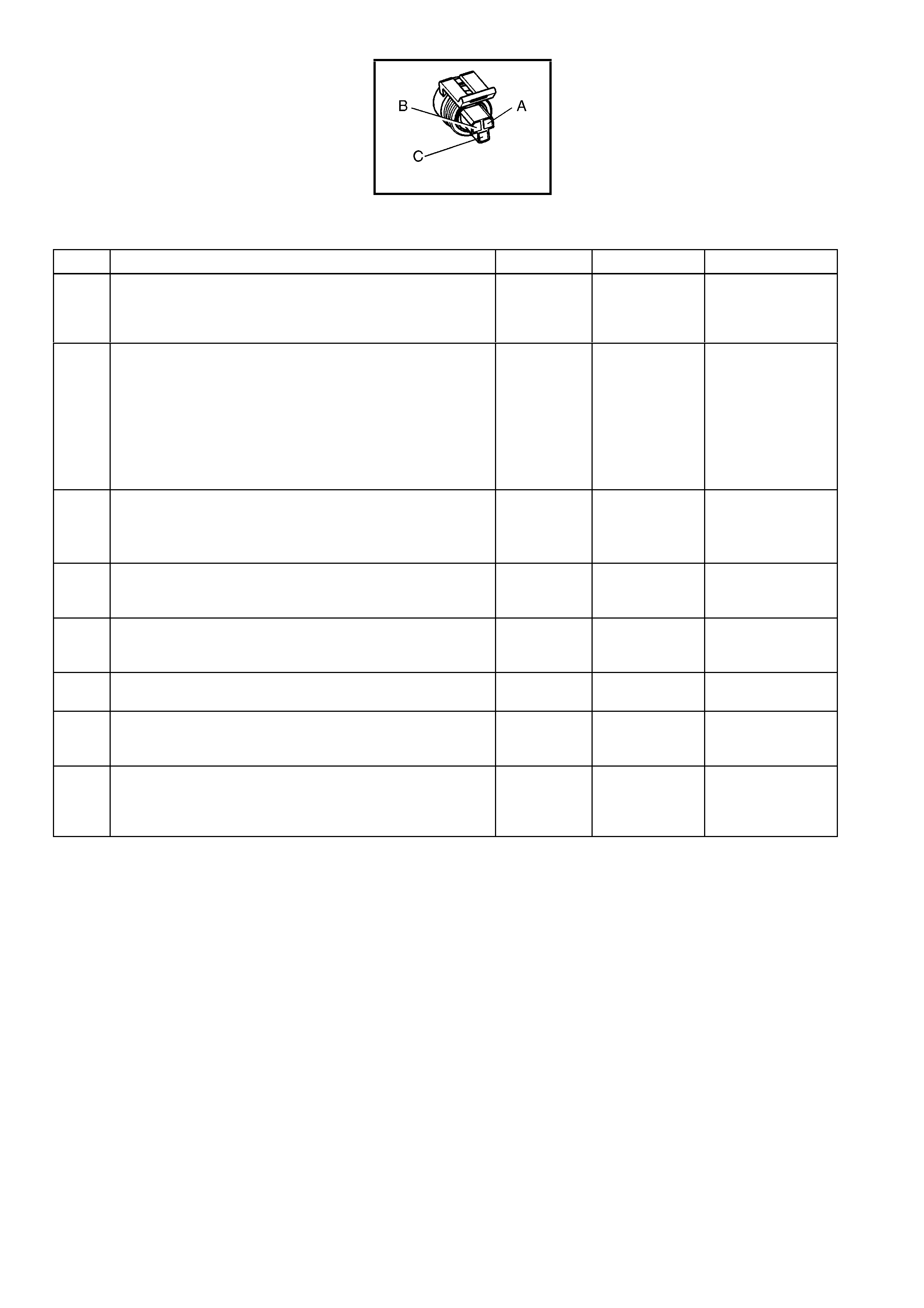

3. OCC In-Car Air Temperature Sensor

4. Fuel Pressure Regulator

5. Heated Exhaust Gas Oxygen (HO2S) Sensor (Two)

6. Bypass Valve Actuator

7. Engine Coolant Temperature (ECT) Sensor

8. Boost Control Solenoid

9. Throttle Position (TP) Sensor

10. Idle Air Control (IAC) Valve

11. Engine Harness (PCM) Ground (Two Terminals)

12. Fuel Injectors

13. Intake Air Temperature (IAT) Sensor

14. DIS Module

15. Mass Air Flow (MAF) Sensor

16. Tachometer Lead

17. Powertrain Control Module (PCM) (Inside Vehicle)

18. Air Cleaner

19. Ignition Coils

20. A/C Refrigerant Pressure Sensor

21. A/C Accumulator

22. Engine Cooling Fans (Two)

23. Crankshaft Position (CKP) Sensor

24. Oil Pressure Switch

25. Camshaft Position (CMP) Sensor

26. Detonation Knock Sensors (KS) (Two)

27. Engine Harness (PCM) Ground (Two Terminals)

28. Battery

29. Engine Compartment Fusible Links

30. Engine Compartment Relays

31. Engine Compartment Fuses

32. Anti-Lock Braking System (ABS)

33. Brake Hydraulic Failure Switch

34. EVAP Canister Purge Solenoid

35. Diagnostic Link Connector (DLC)

36. Body Control Module (BCM)

37. Check Powertrain Malfunction Indicator Lamp (MIL)

38. Fuel Pump Control Module (Rear Compartment)

39. Vehicle Speed Sensor (VSS)

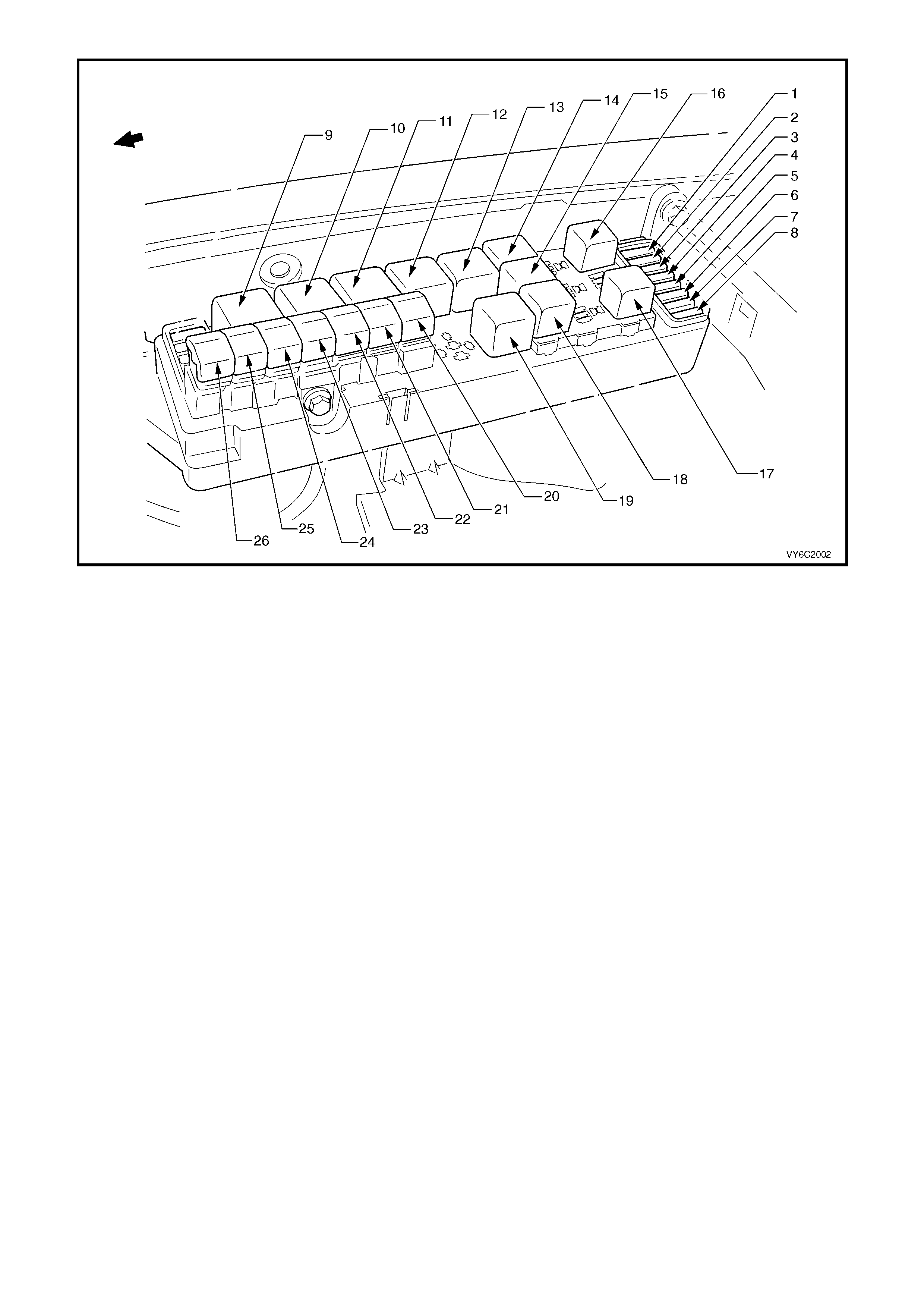

Figure 6C2-2A-2 – Engine Compartment Fuse/Relay/Fusible Link Locations

Legend

Fuses

1. Fuel Pump Fuse – F28

2. Engine Control / BCM – F29

3. RH Headlamps – F30

4. LH Headlamps – F31

5. Automatic Transmission – F32

6. Engine Sensors – F33

7. Injectors / Ignition – F34

8. Injectors / Ignition – F35

Relays

9. Start – X1

10. Blower Fan – X2

11. Headlamp (High Beam) – X3

12. Engine Control (EFI) – X4

13. Engine Cooling Fan (High Speed) – X5

14. Horn – X8

15. A/C Compressor – X11

16. Fog Lamp – X10

17. Fuel Pump – X16

18. Headlamp (Low Beam) – X14

19. Engine Cooling Fan (Low Speed) – X7

Fusible Links

20. Engine Cooling Fan LT – F101 (30A)

21. Blower Fan – F106 (60A)

22. Main – F105 (60A)

23. Engine – F104 (60A)

24. A.B.S. – F103 (60A)

25. Lighting – F102 (60A)

26. Engine Cooling Fan RT – F107 (30A)

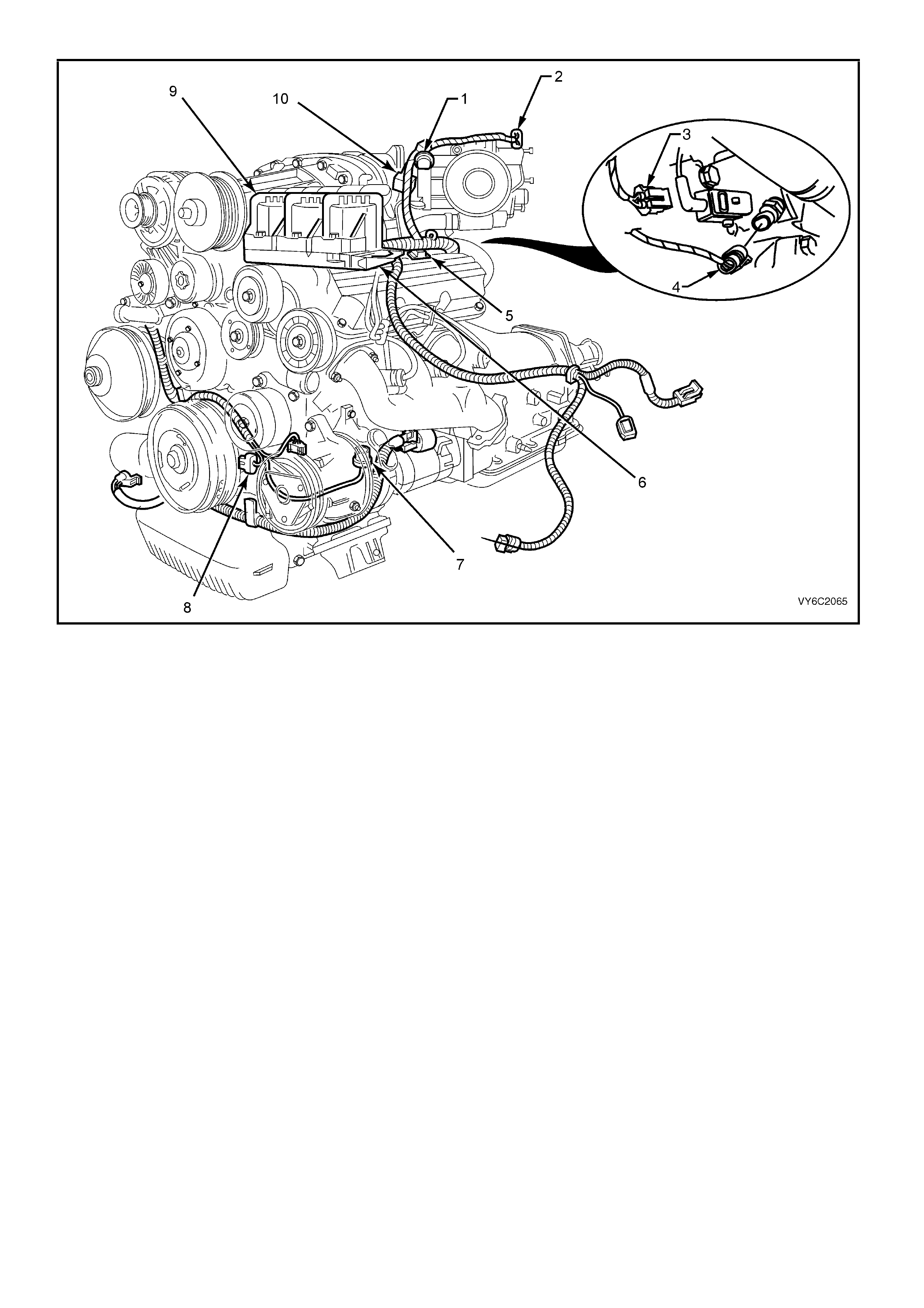

Figure 6C2-2A-3 – V6 Supercharged Engine Component Locations

Legend

1. Throttle Position (TP) Sensor

2. Idle Air Control Valve (IAC)

3. Boost Control Solenoid Valve

4. Engine Coolant Temperature (ECT) Sensor

5. Injectors

6. Direct Ignition System Module

7. L.H. Knock Sensor (KS)

8. Crankshaft Position (CKP) Sensor

9. Ignition Coils (3 places)

10. Bypass Valve Actuator

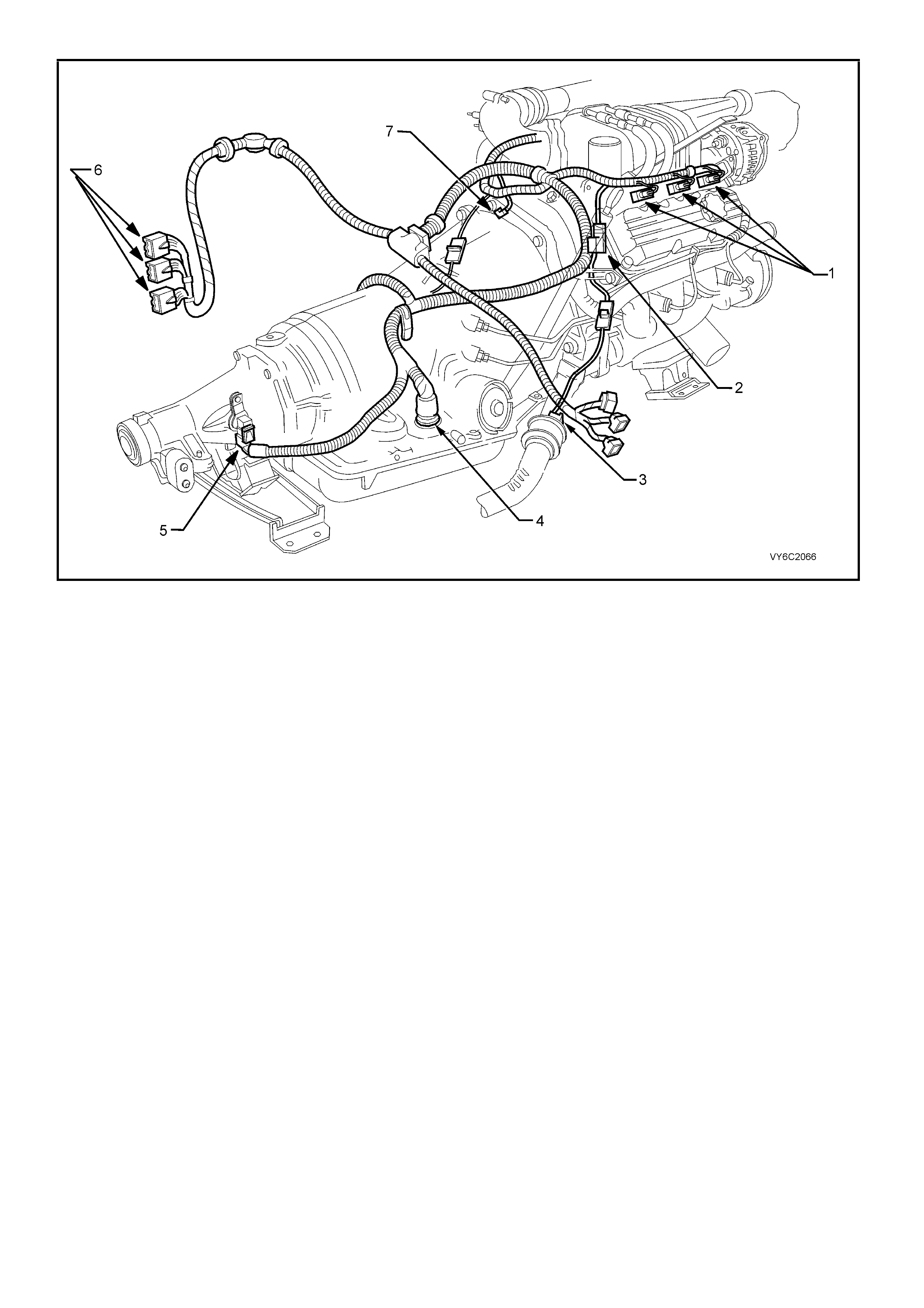

Figure 6C2-2A-4 – V6 Supercharged Engine Component Locations

Legend

1. Injectors

2. Canister Purge Solenoid

3. R.H. Heated Oxygen (HO2S) Sensor

4. Transmission Pass-Through Connector

5. Vehicle Speed Sensor (VSS) (Automatic Trans)

6. PCM Connectors

7. Engine Harness Ground

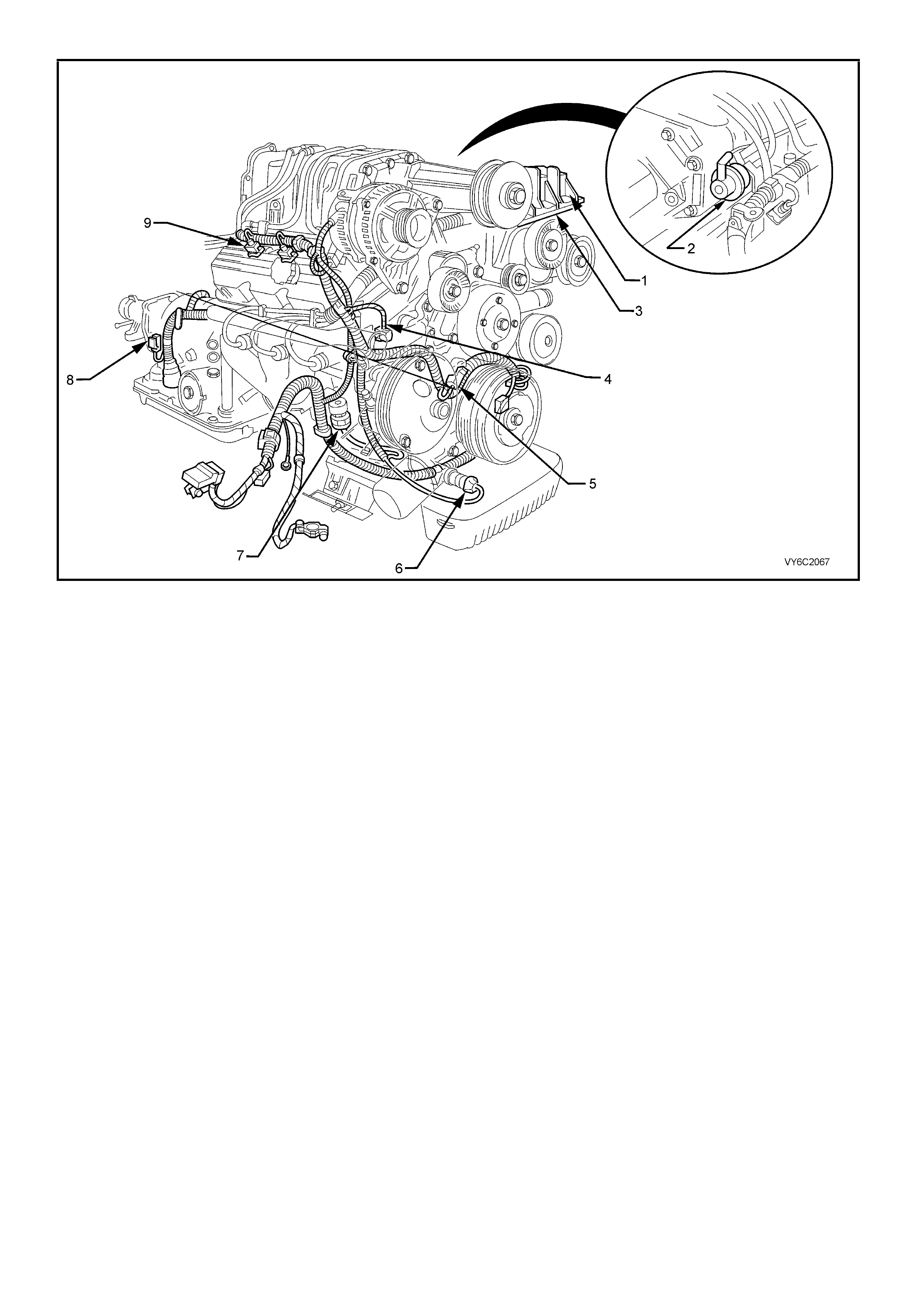

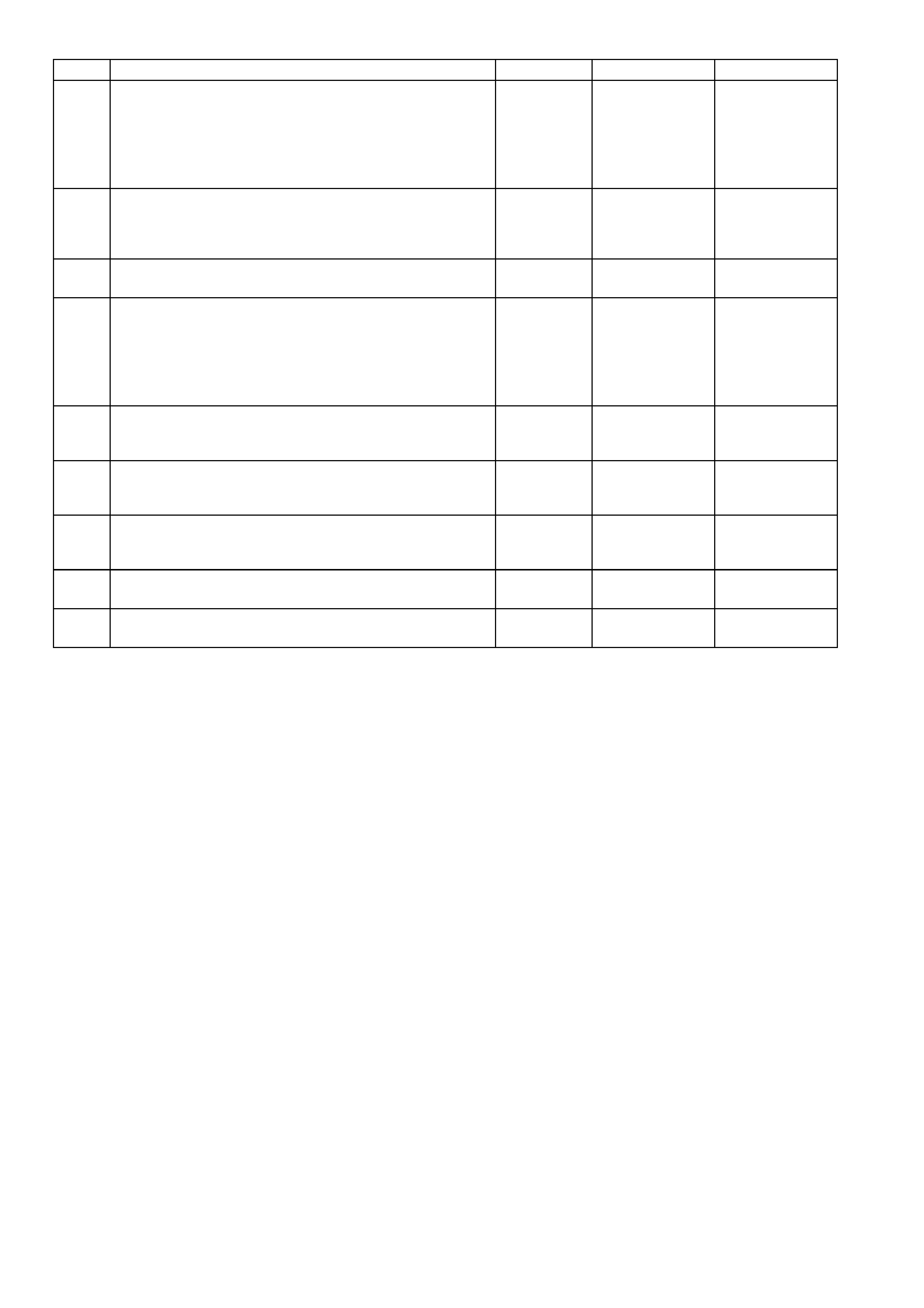

Figure 6C2-2A-5 – V6 Supercharged Engine Component Locations

Legend

1. Ignition Coils (3 places)

2. Fuel Pressure Regulator

3. Direct Ignition System Module

4. Engine Harness Ground

5. Camshaft Position (CMP) Sensor

6. Oil Pressure Switch

7. R.H. Knock Sensor (KS)

8. Vehicle Speed Sensor (VSS) – Automatic Transmission

9. Injectors (3 places)

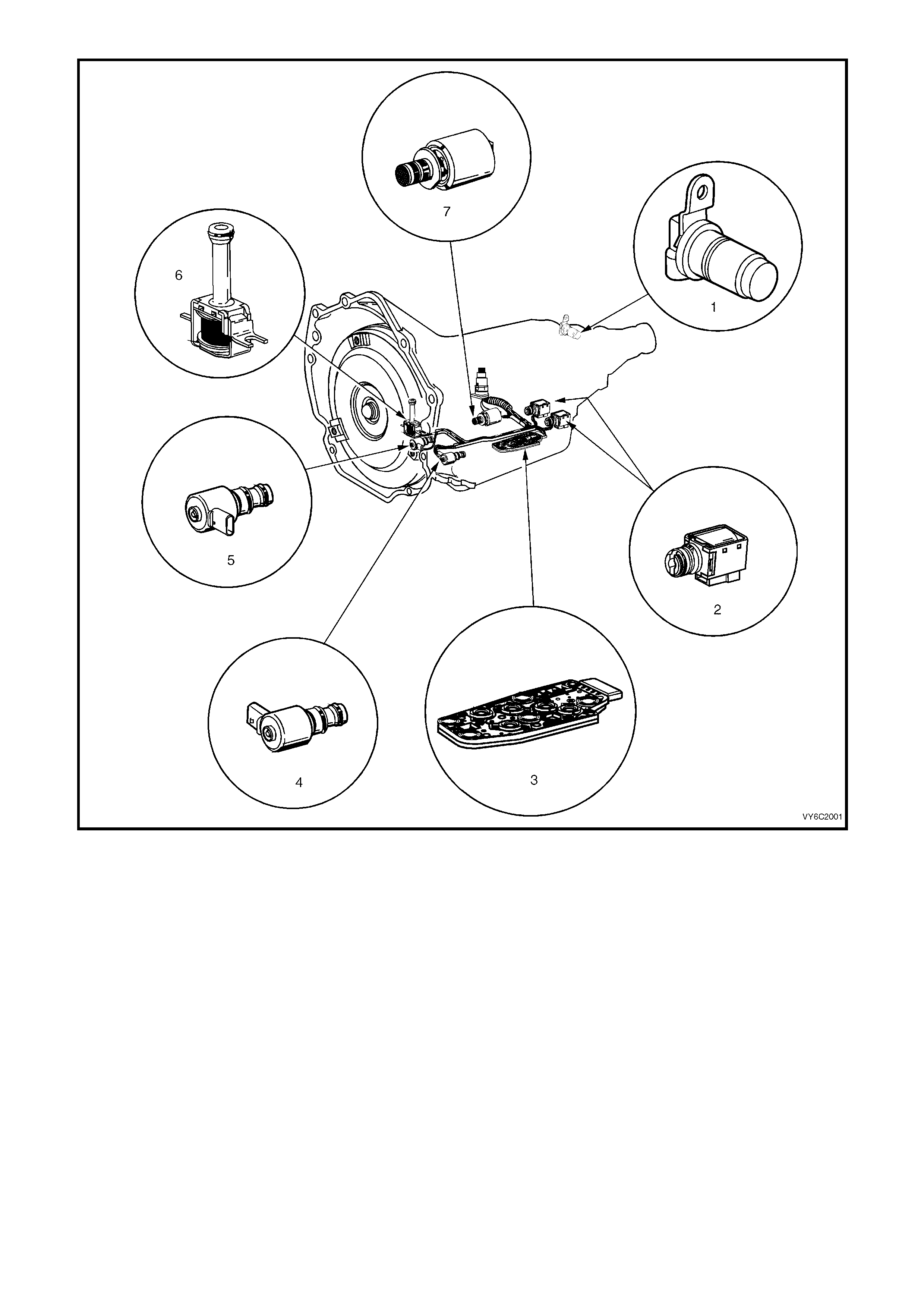

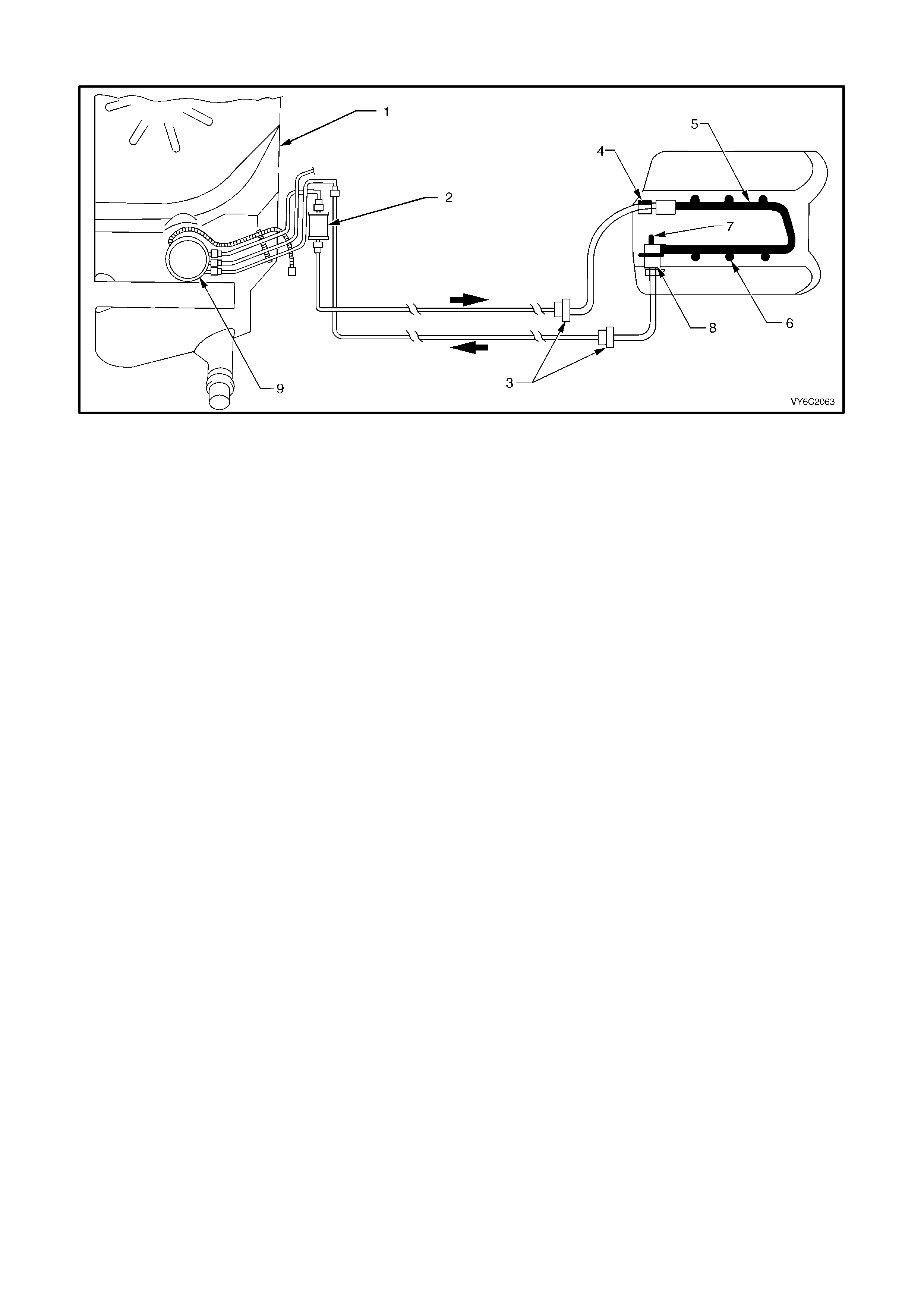

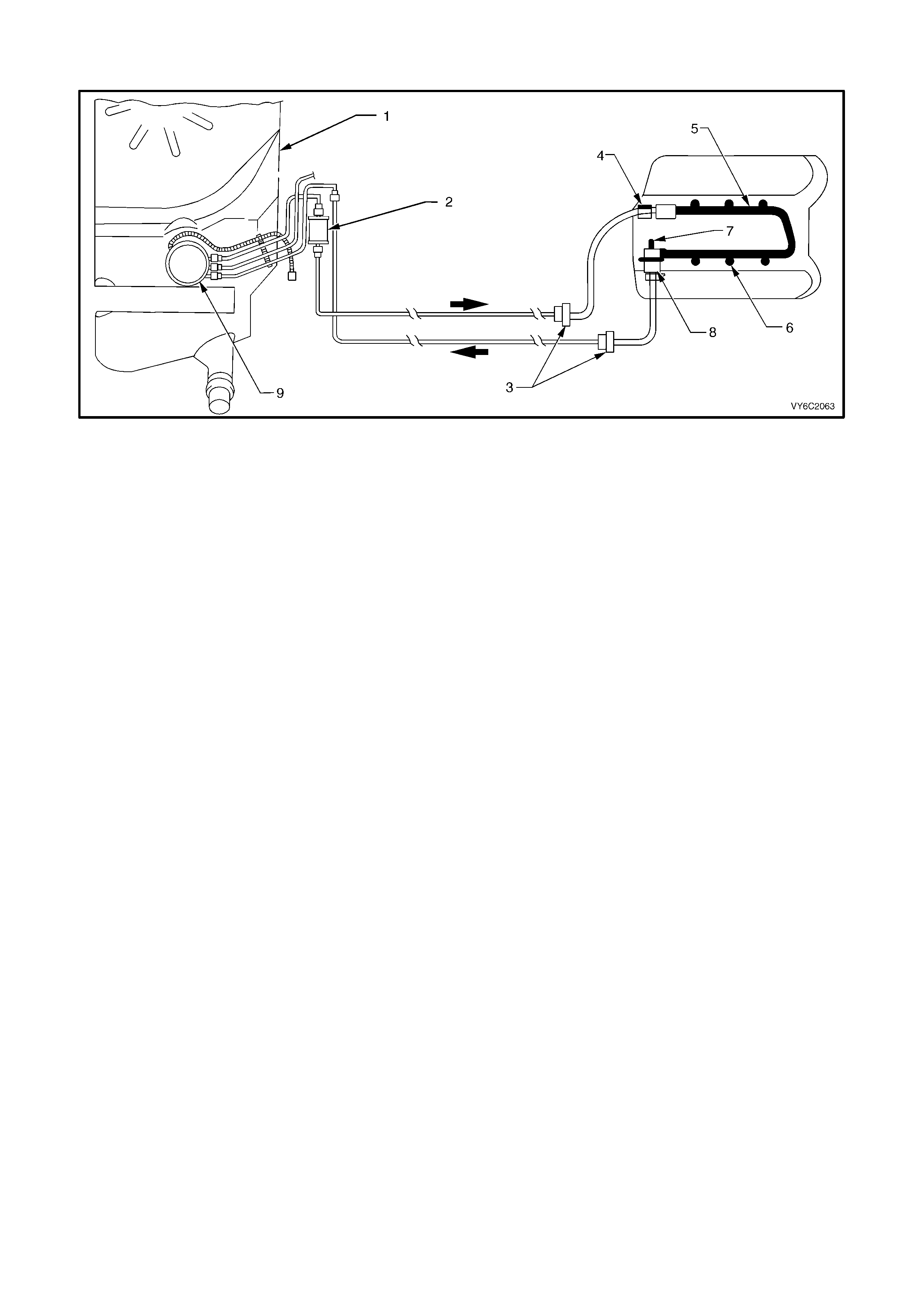

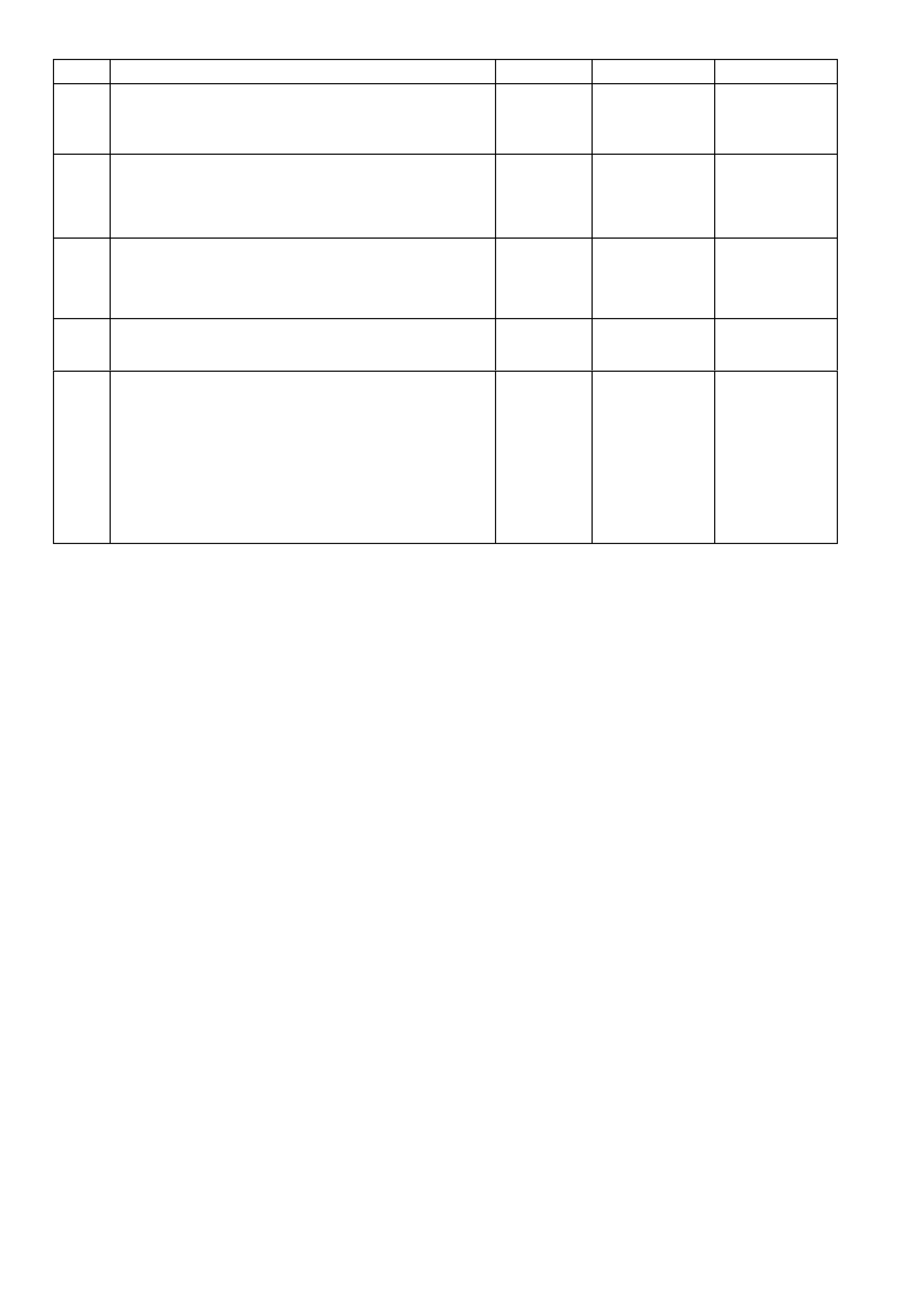

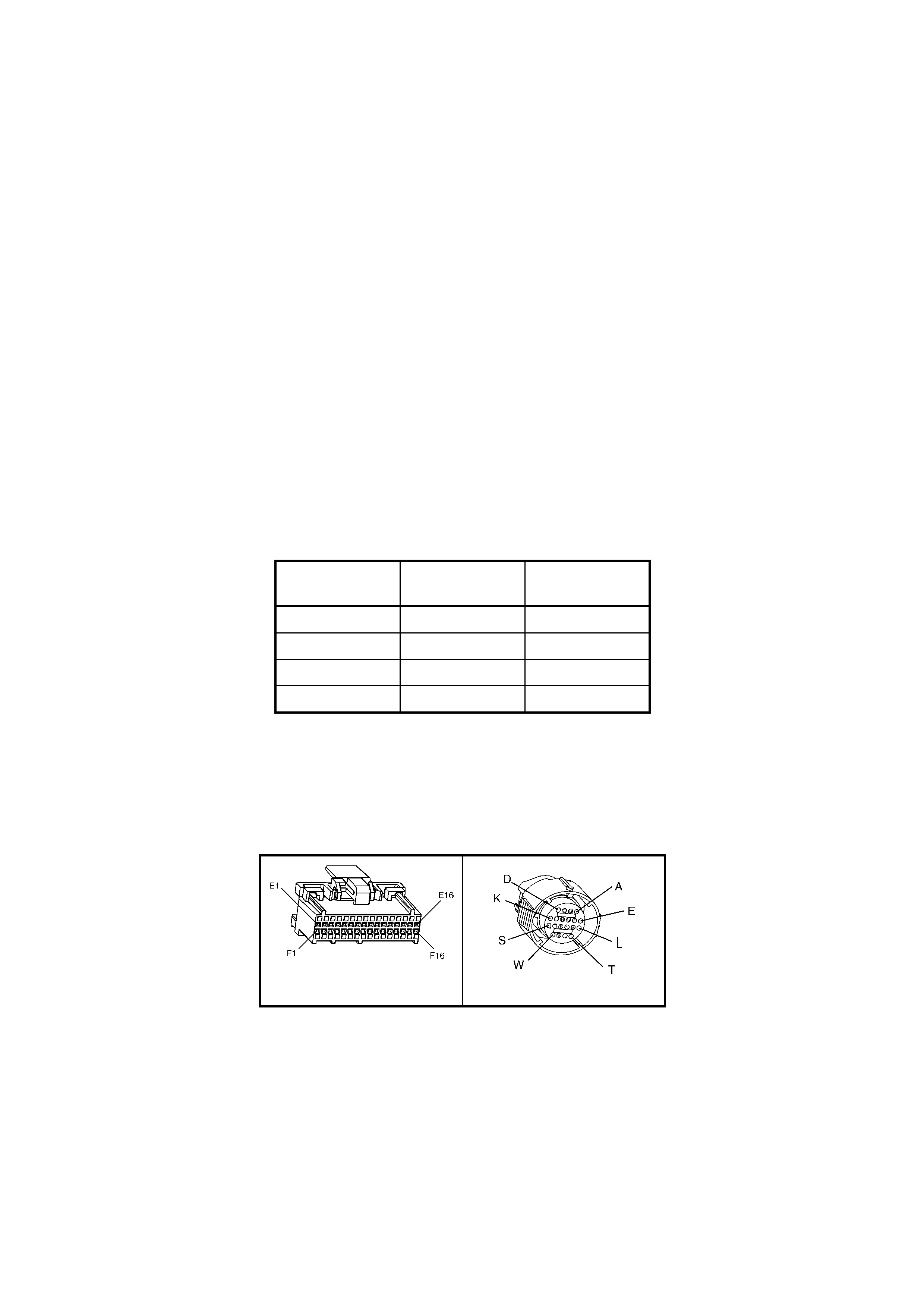

Figure 6C2-2A-6 – V6 Supercharged Engine, Automatic Transmission,

Internal Electronic Component Locations

Legend

1. Vehicle Speed Sensor

2. 1-2 Shift Solenoid A and 2-3 Shift Solenoid B

3. Automatic Transmission Fluid Pressure (TFP) Manual

Valve Position Switch

4. 3-2 Downshift Control Solenoid

5. Torque Converter Clutch Pulse Width Modulation

(TCC PWM) Solenoid Valve

6. Torque Converter Clutch (TCC) Solenoid Valve

7. Pressure Control Solenoid (PCS) Valve

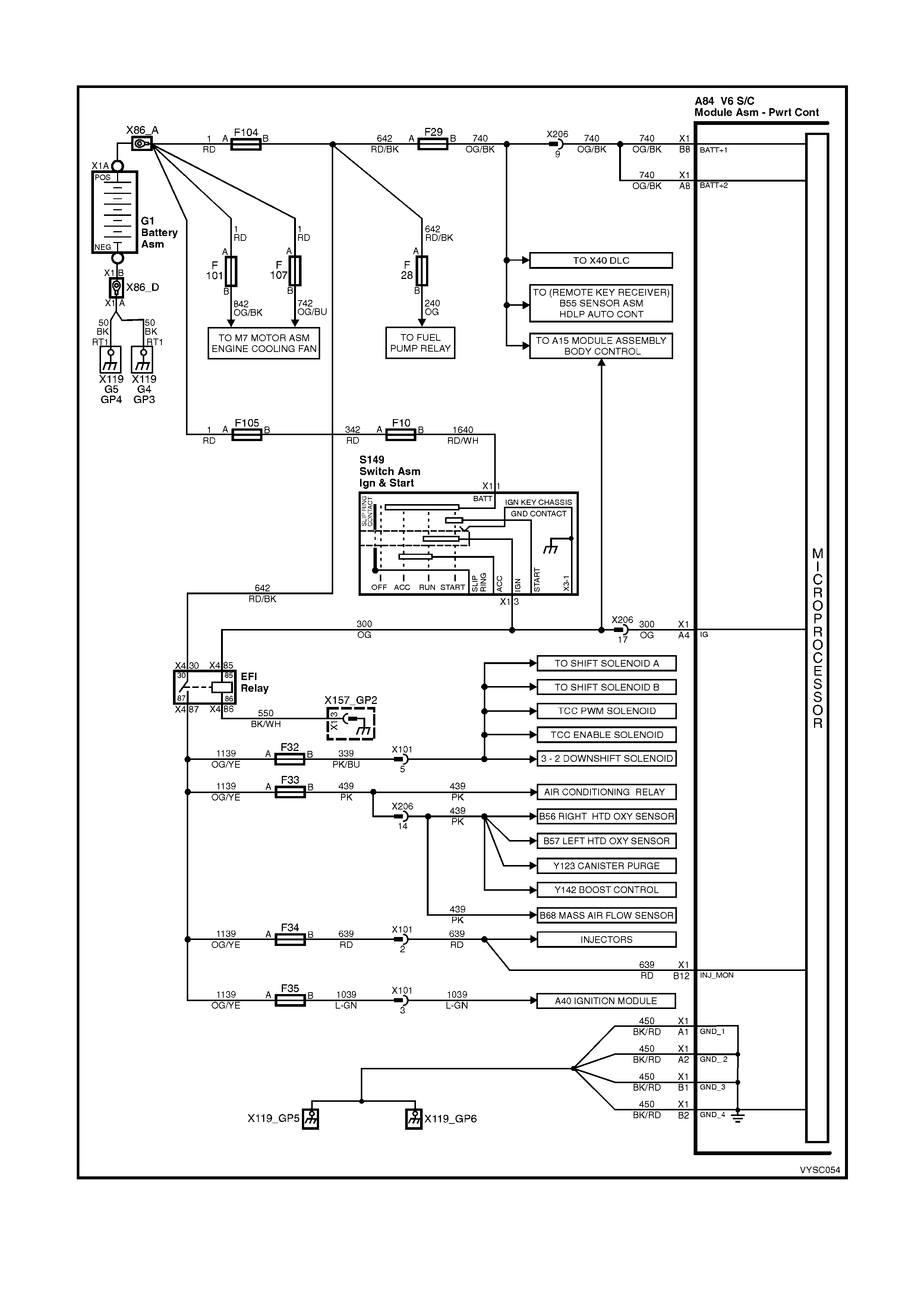

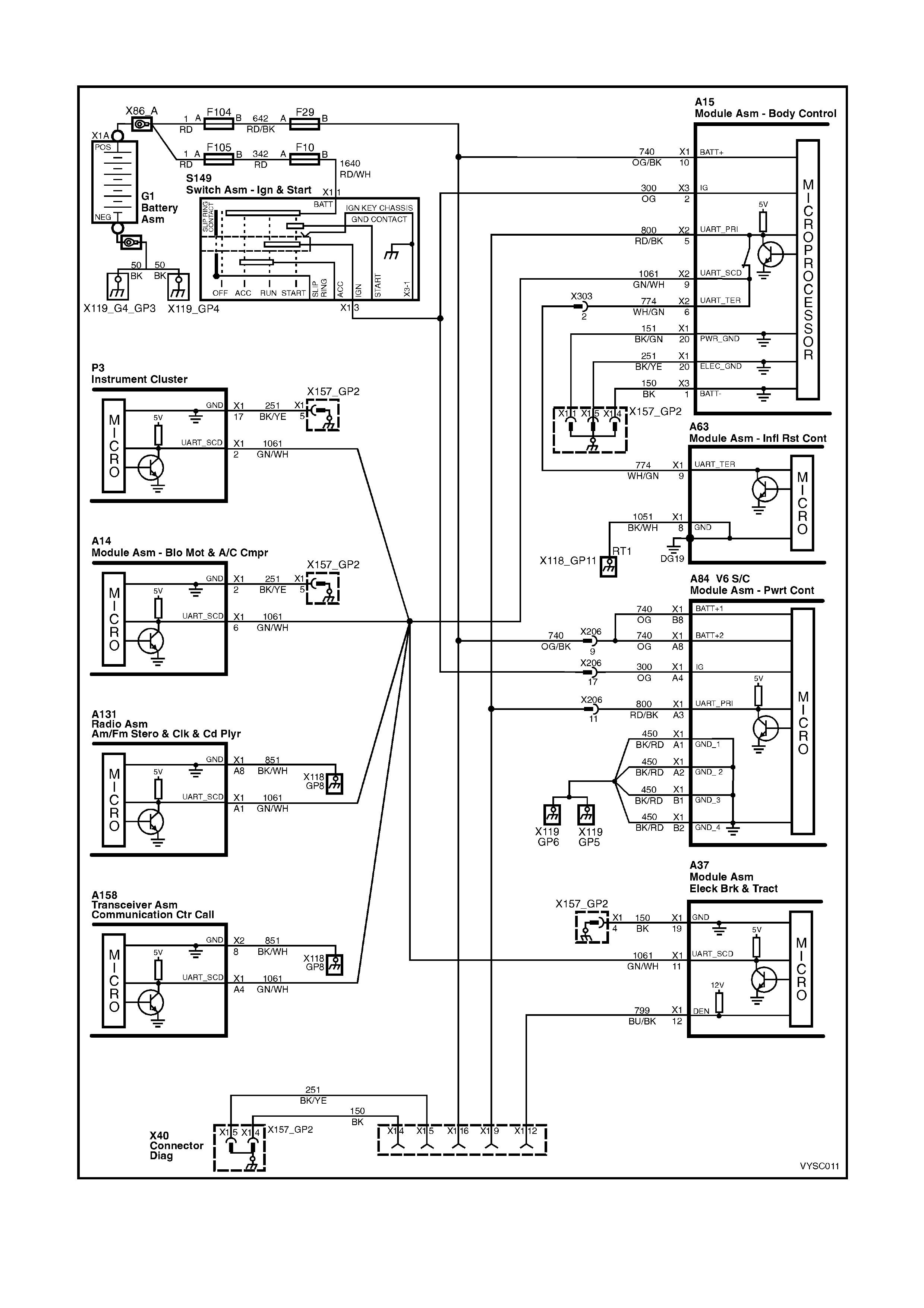

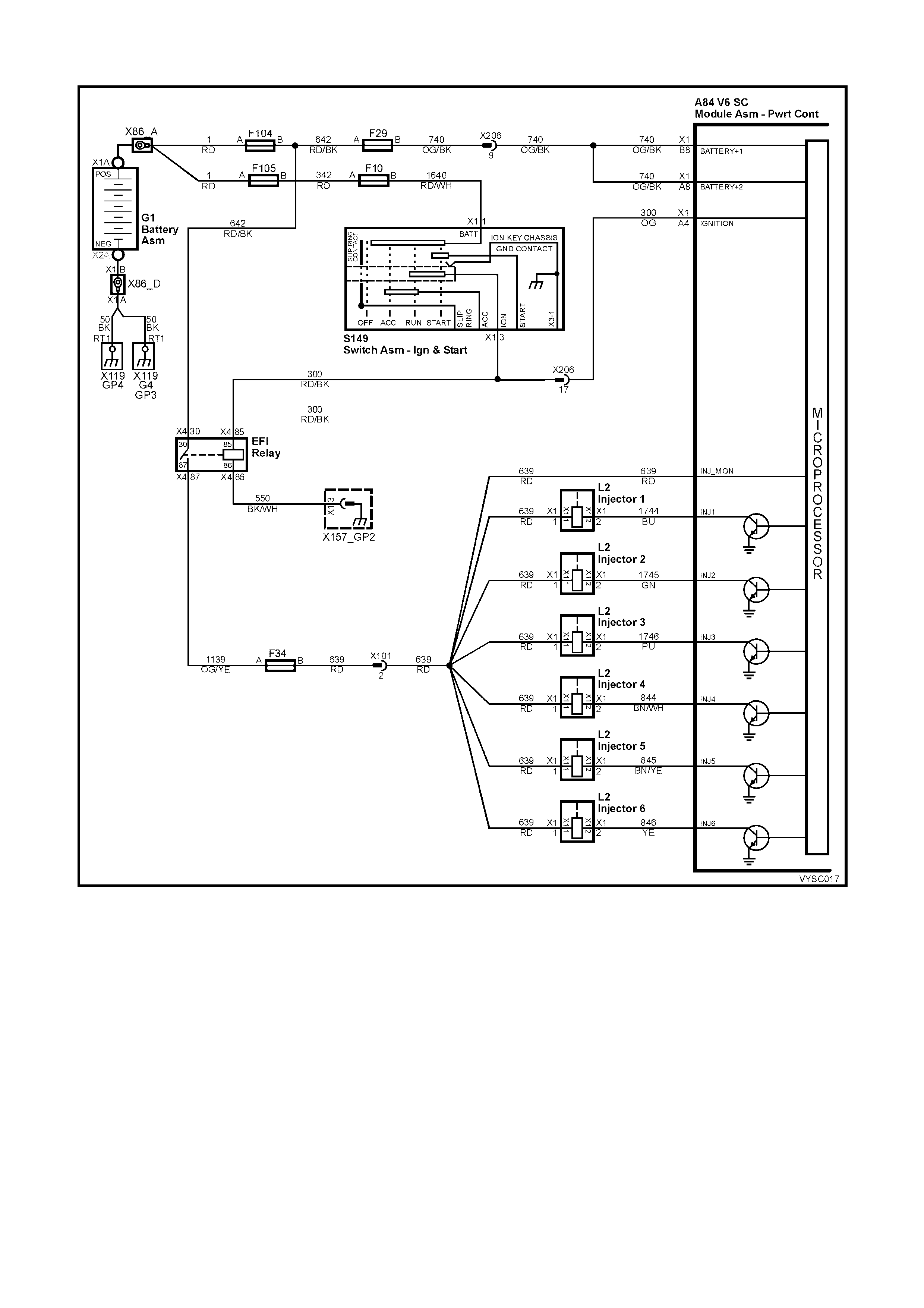

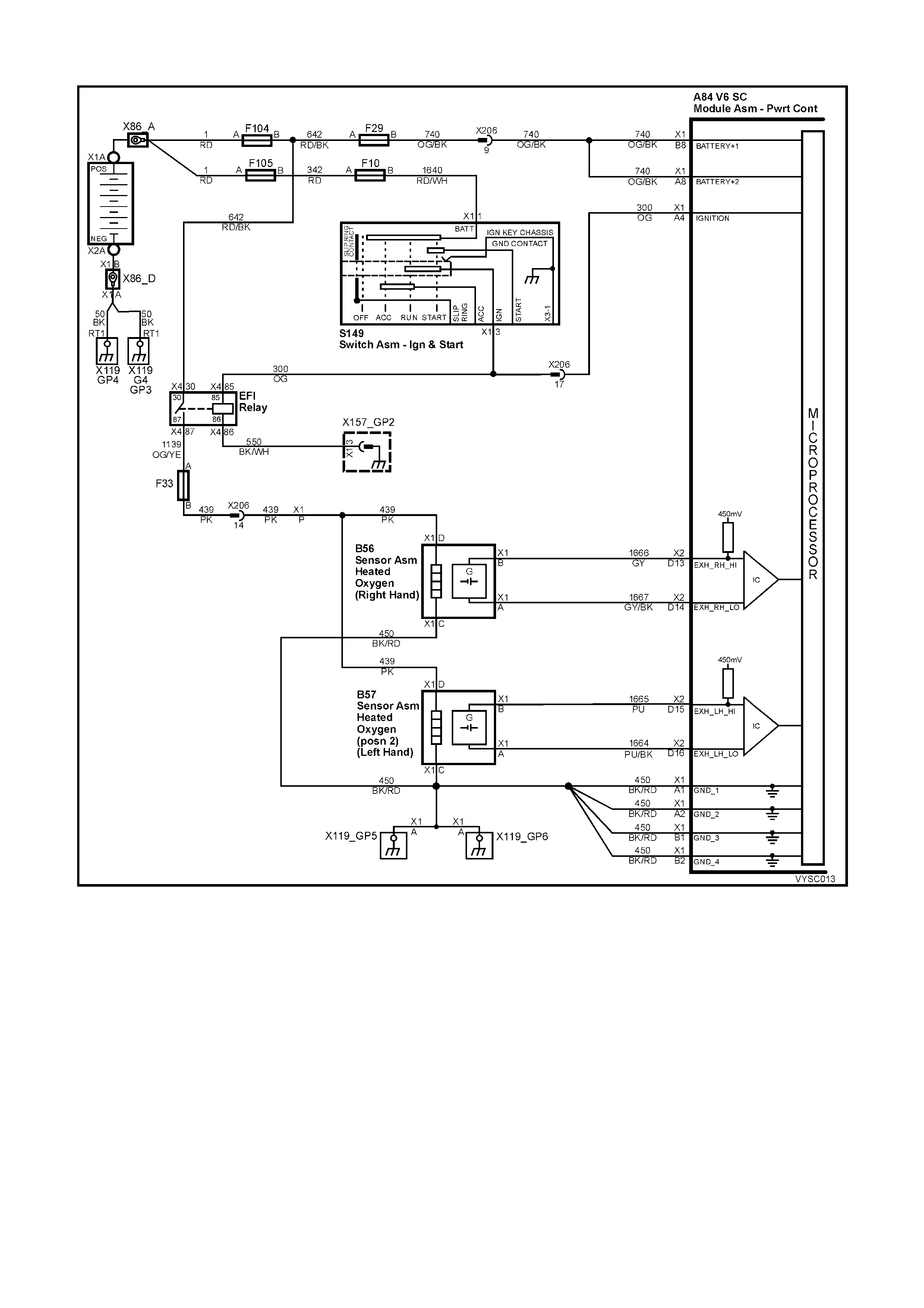

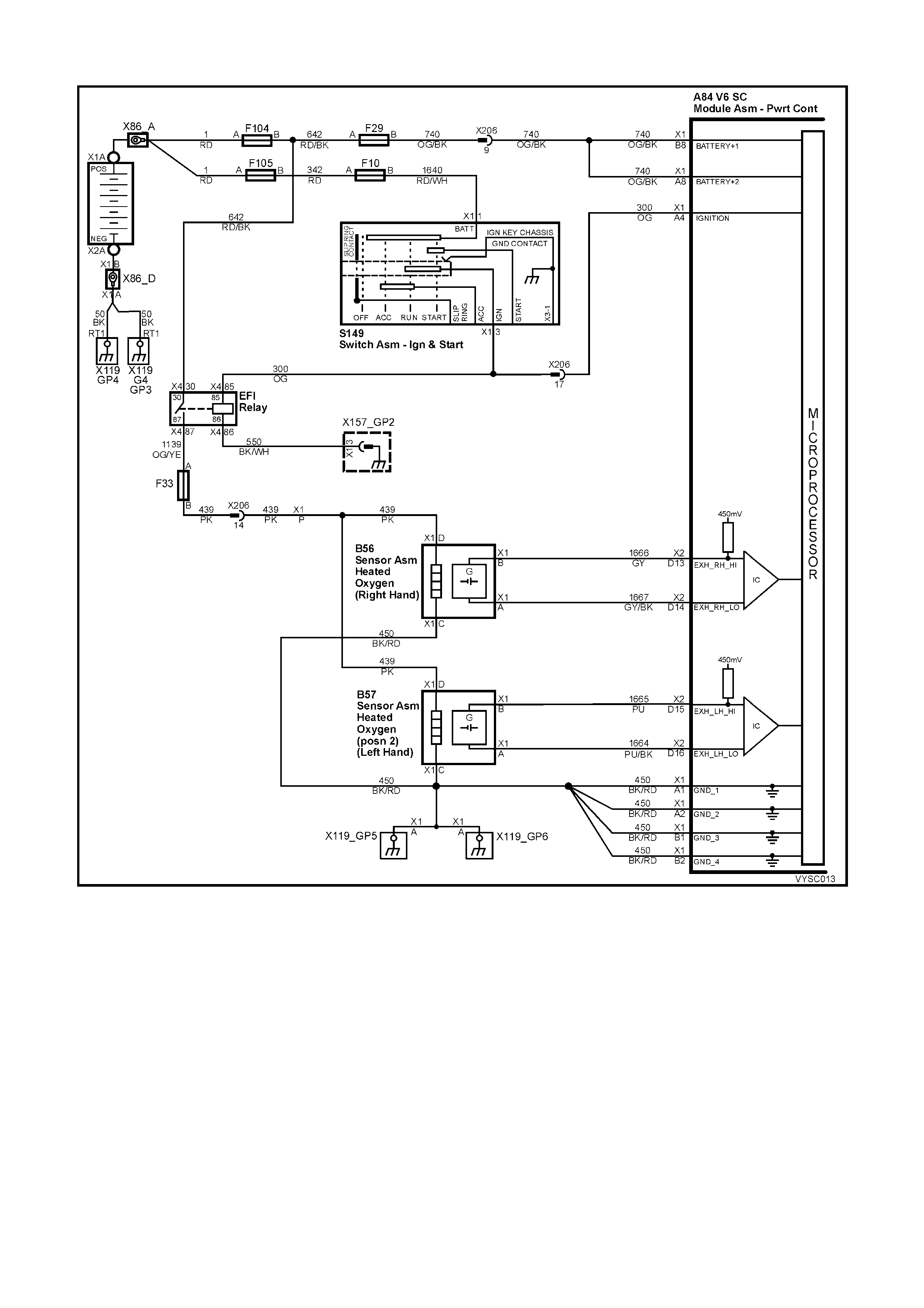

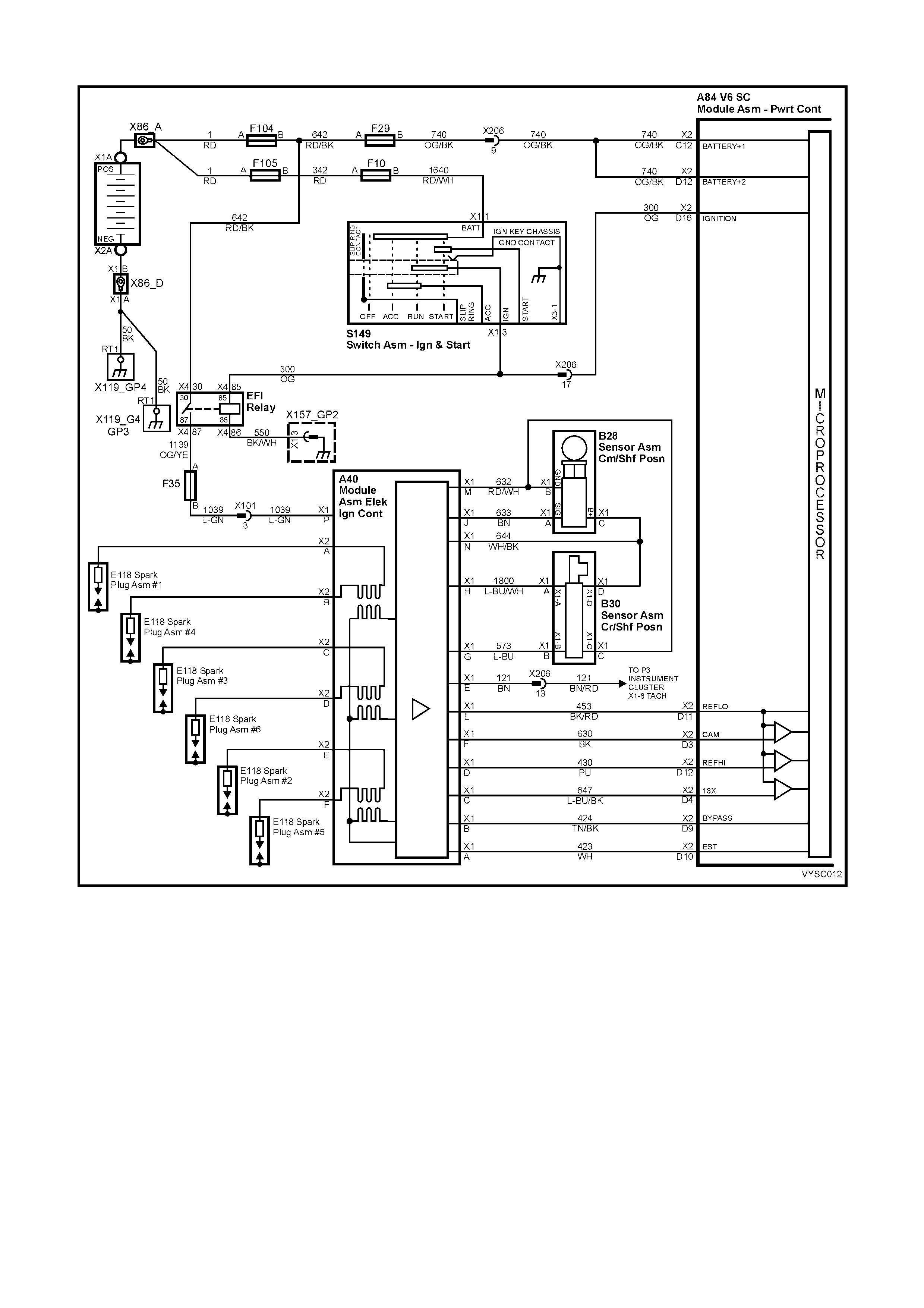

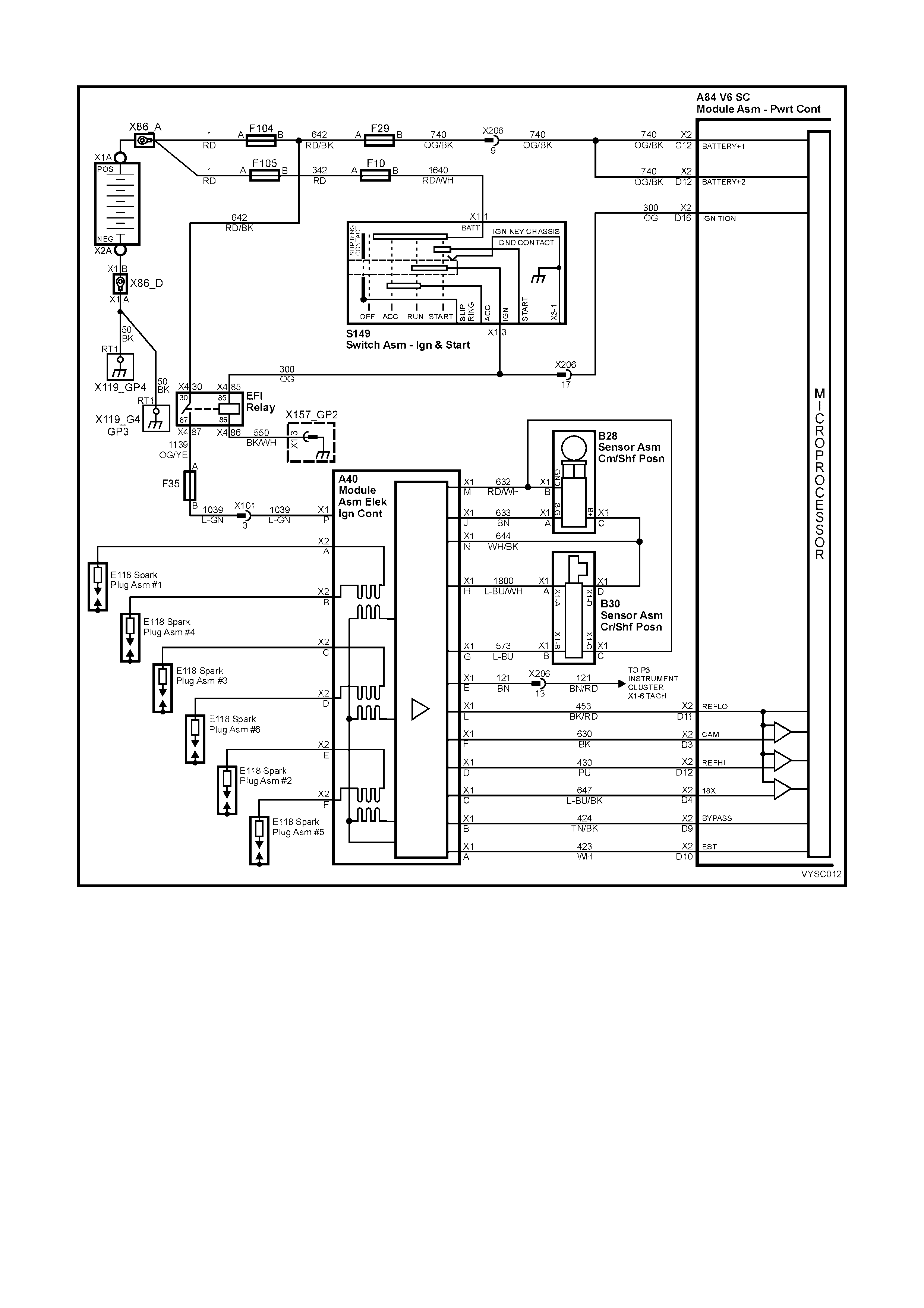

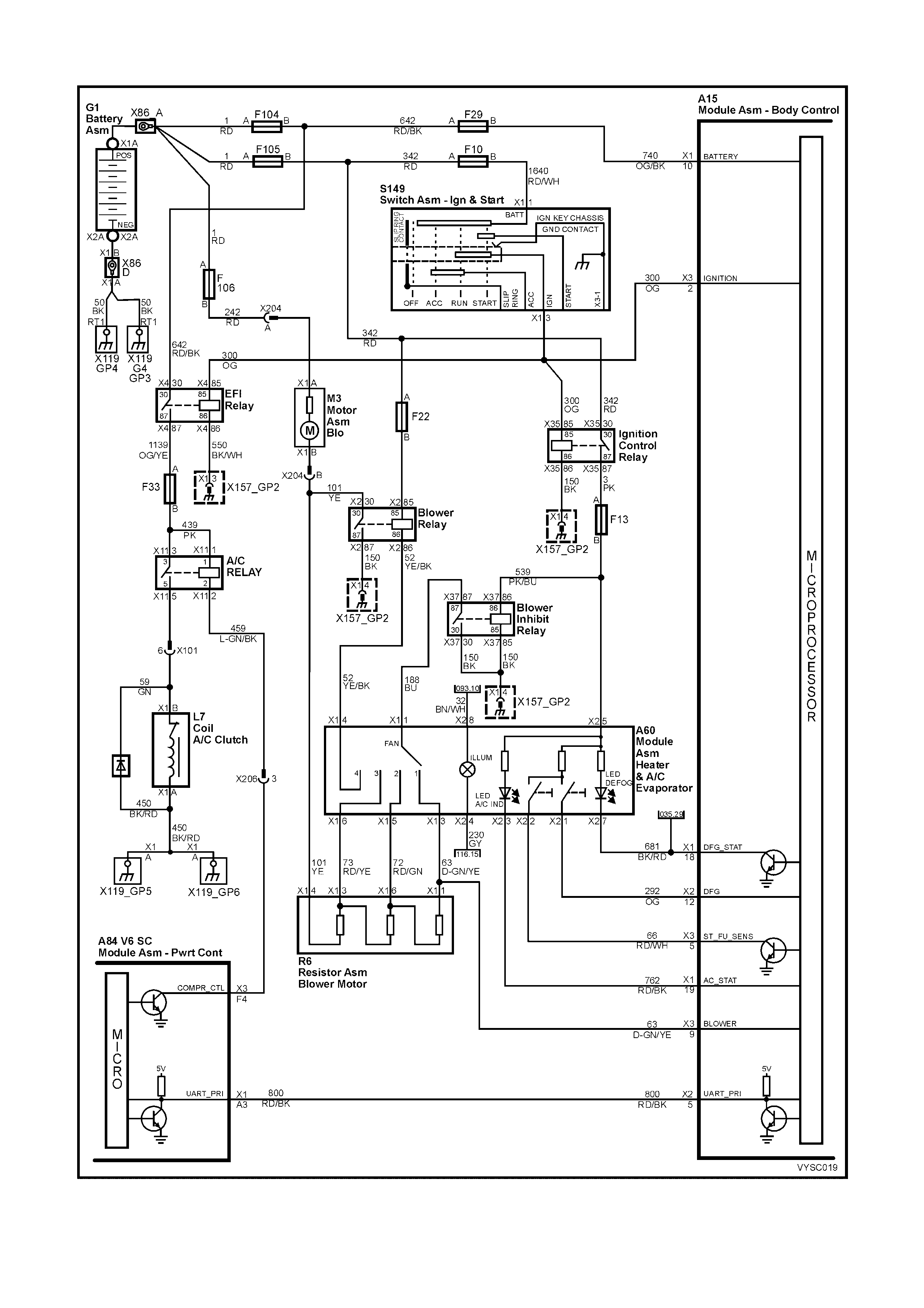

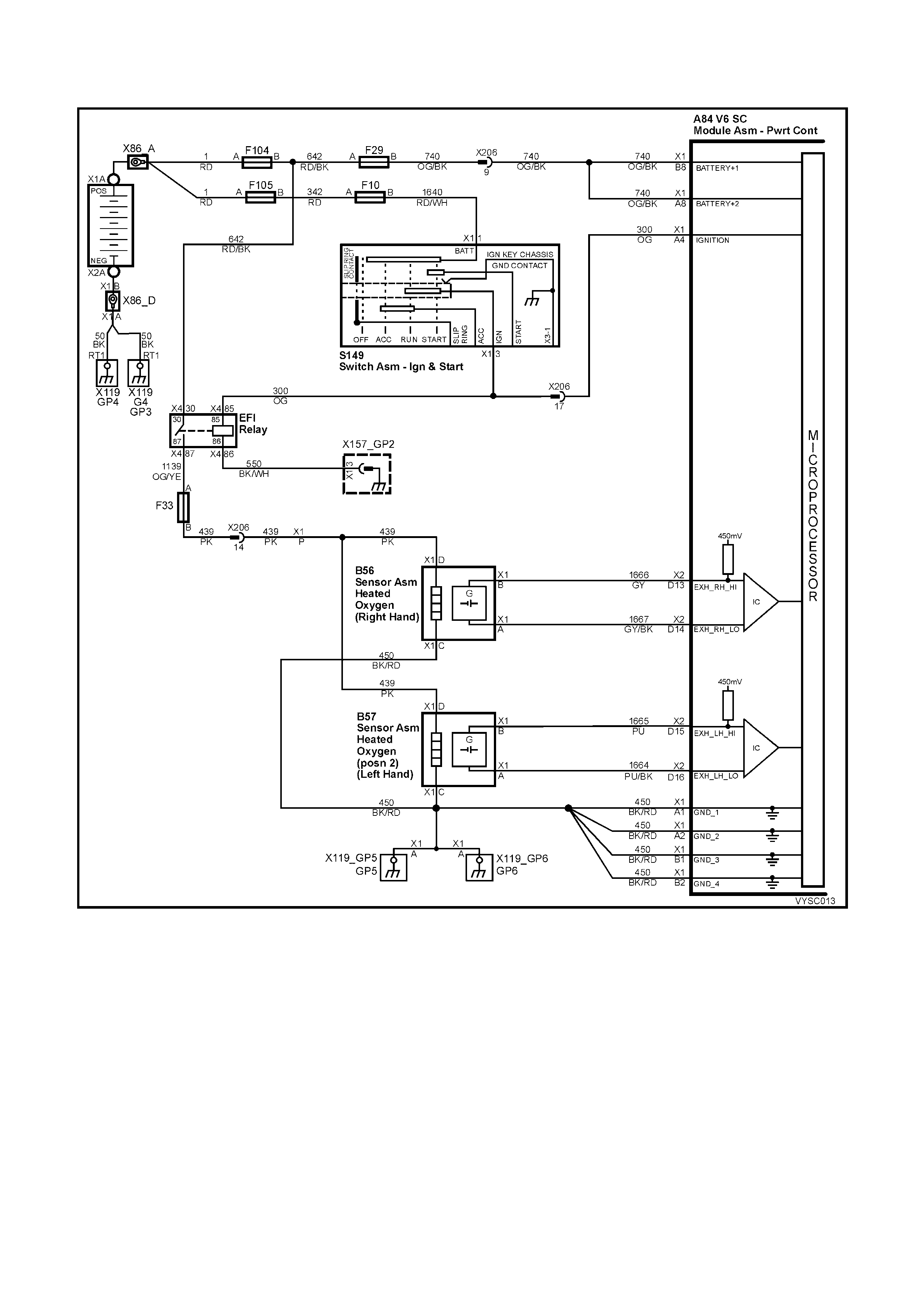

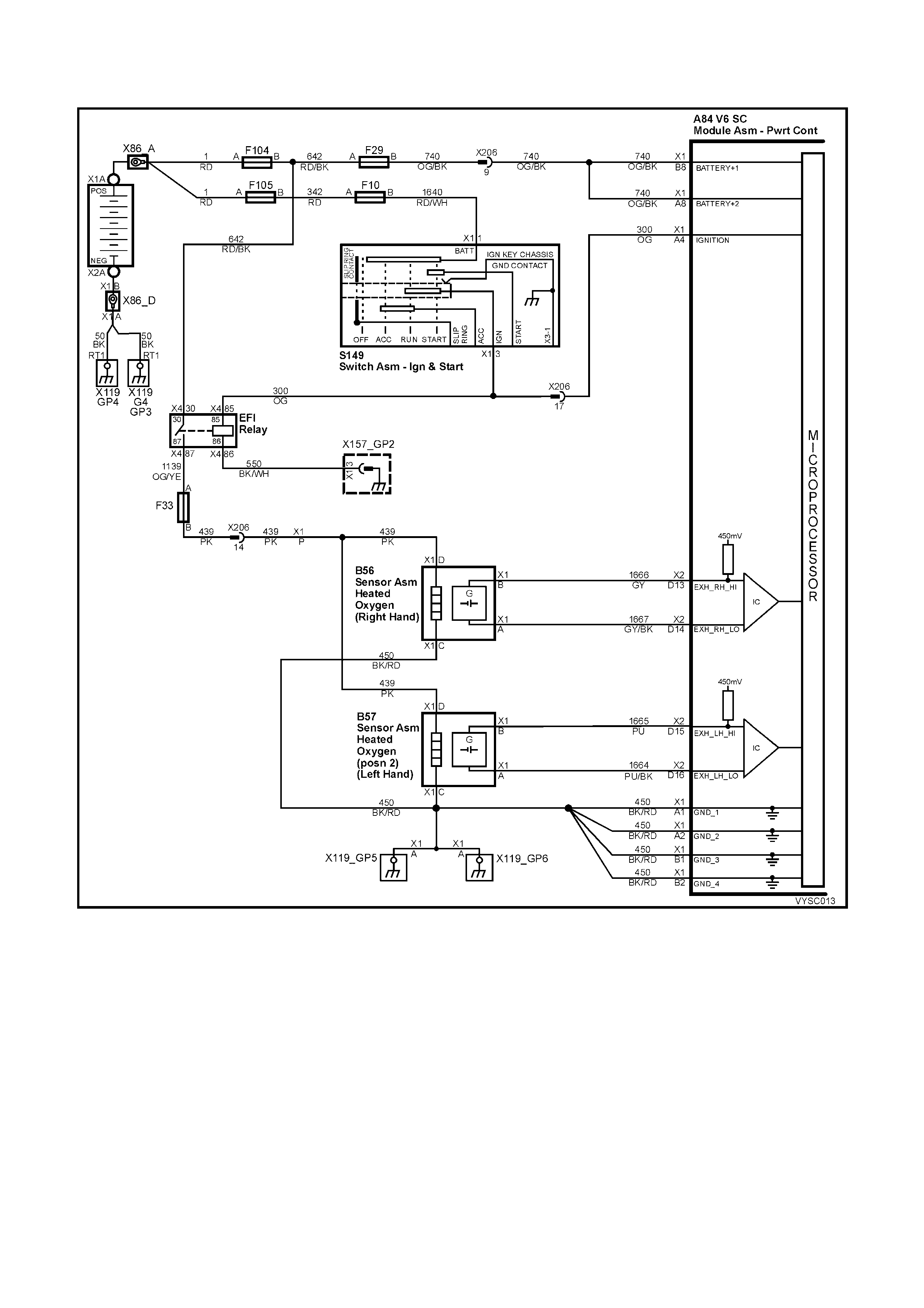

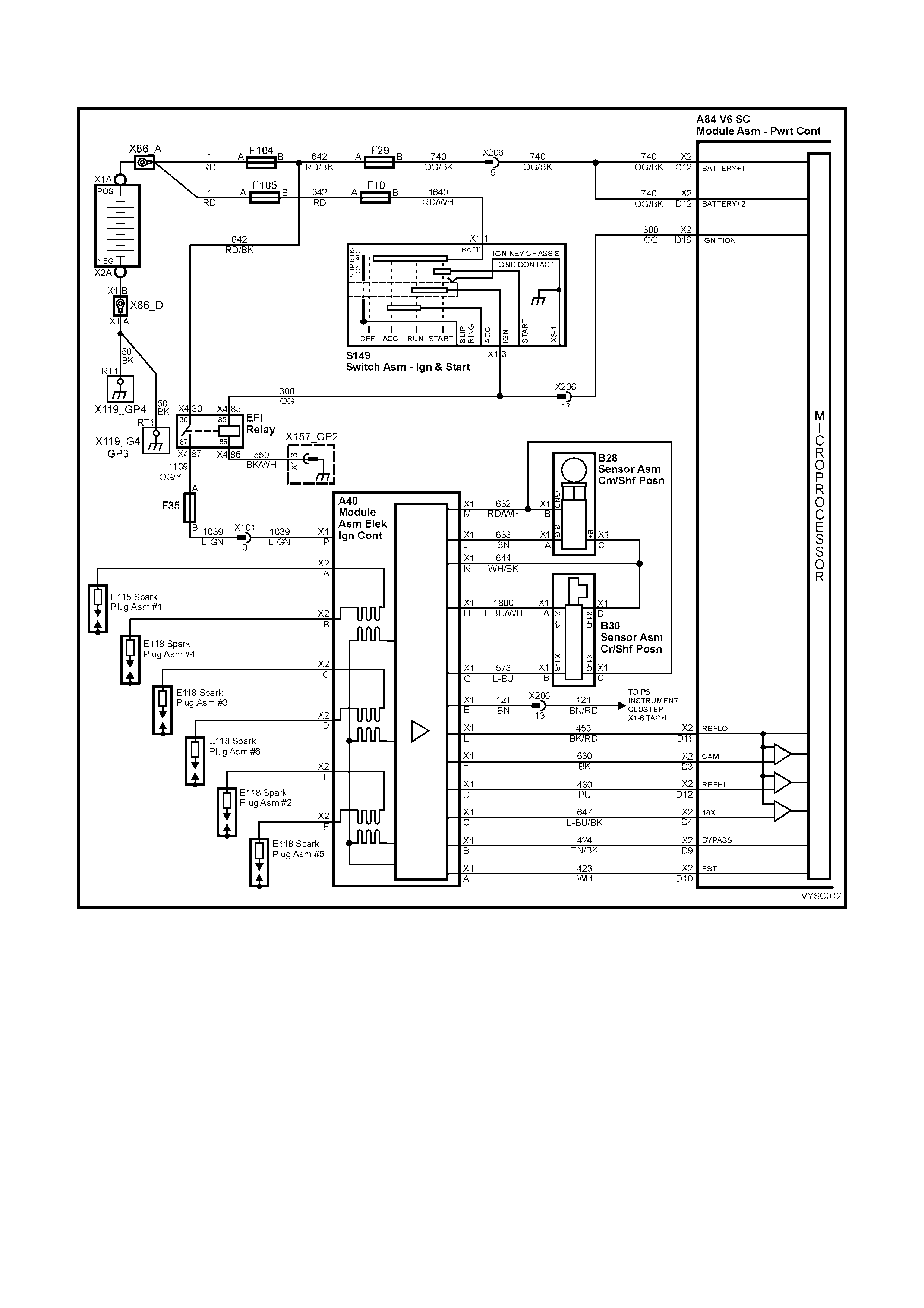

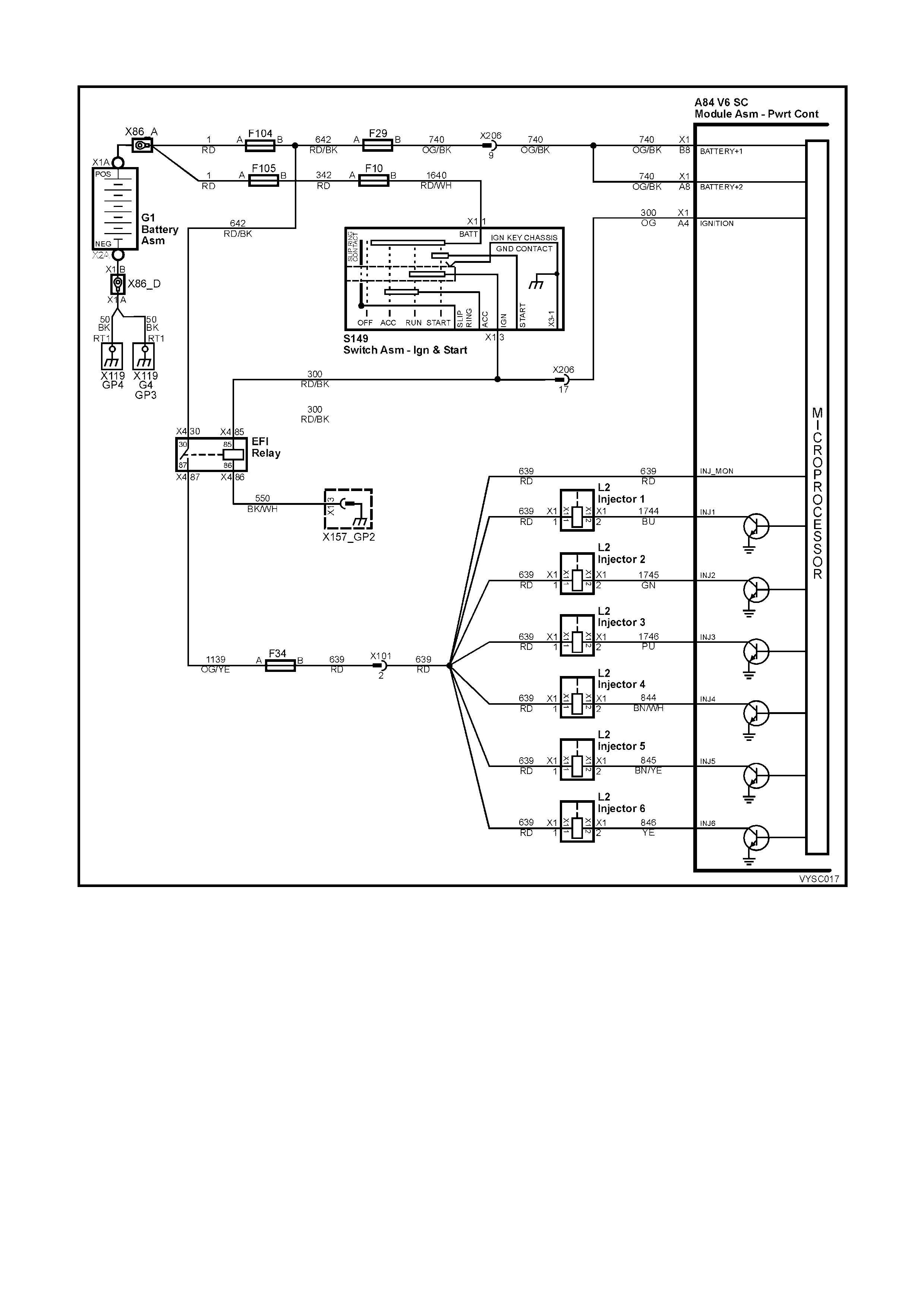

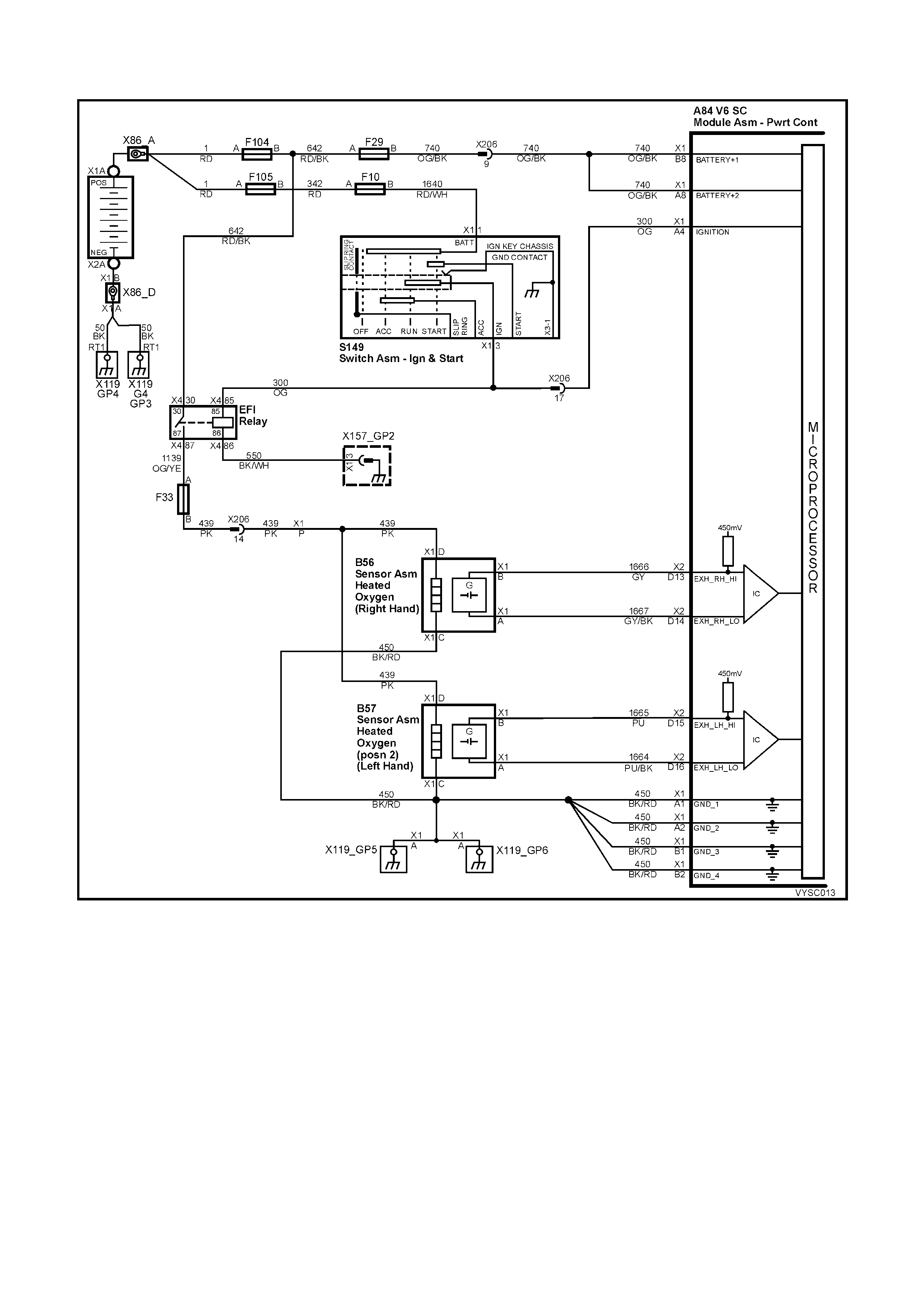

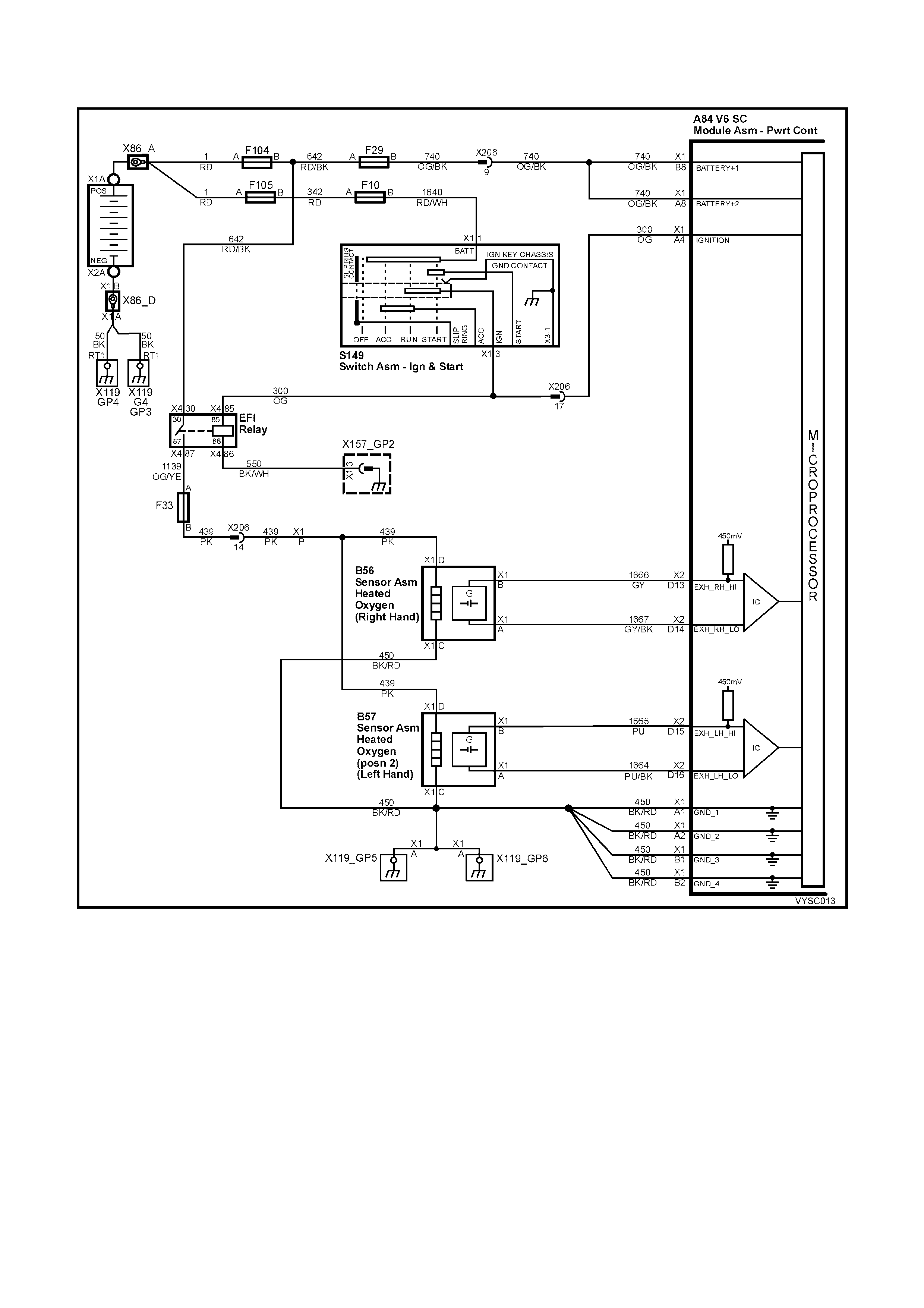

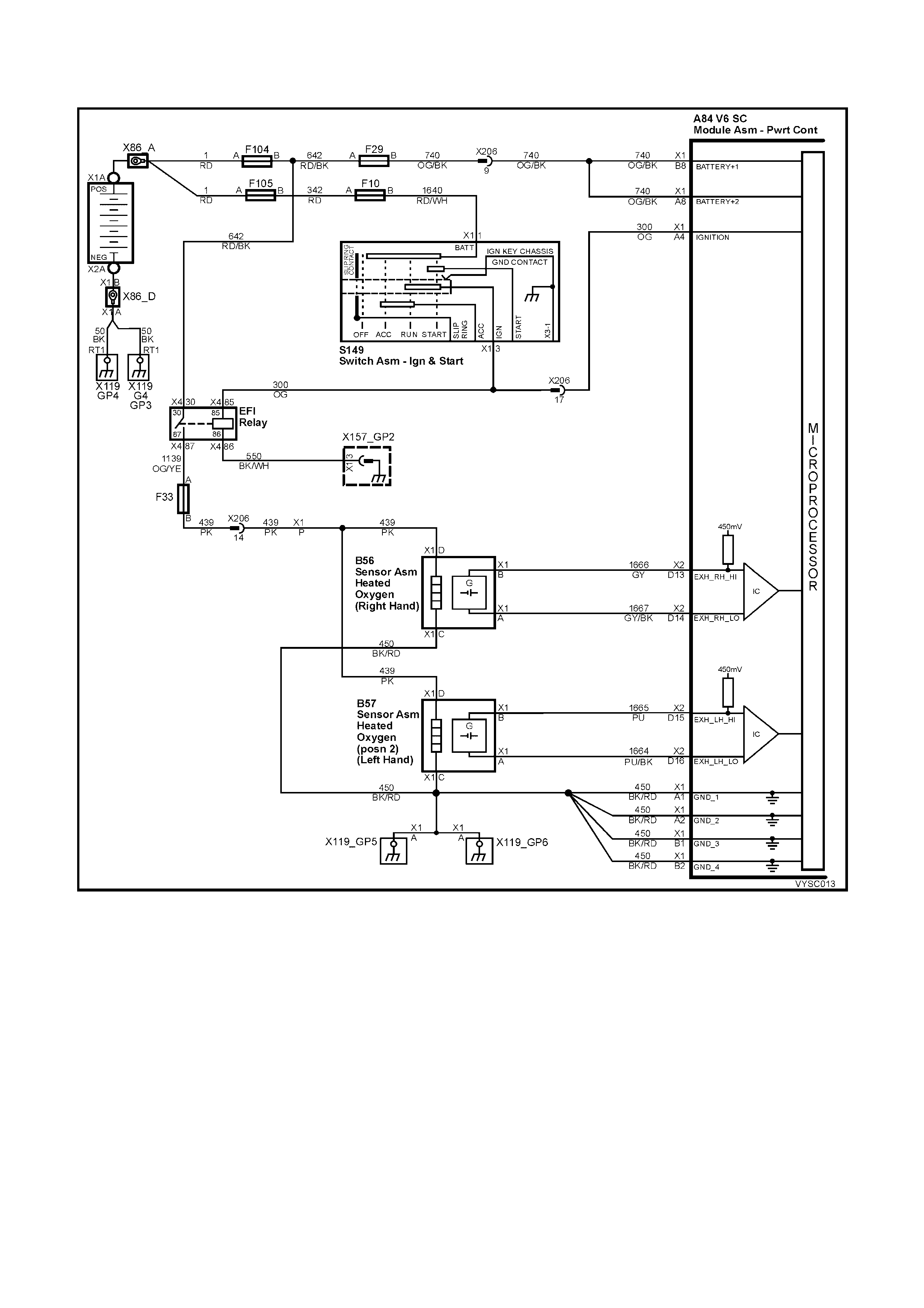

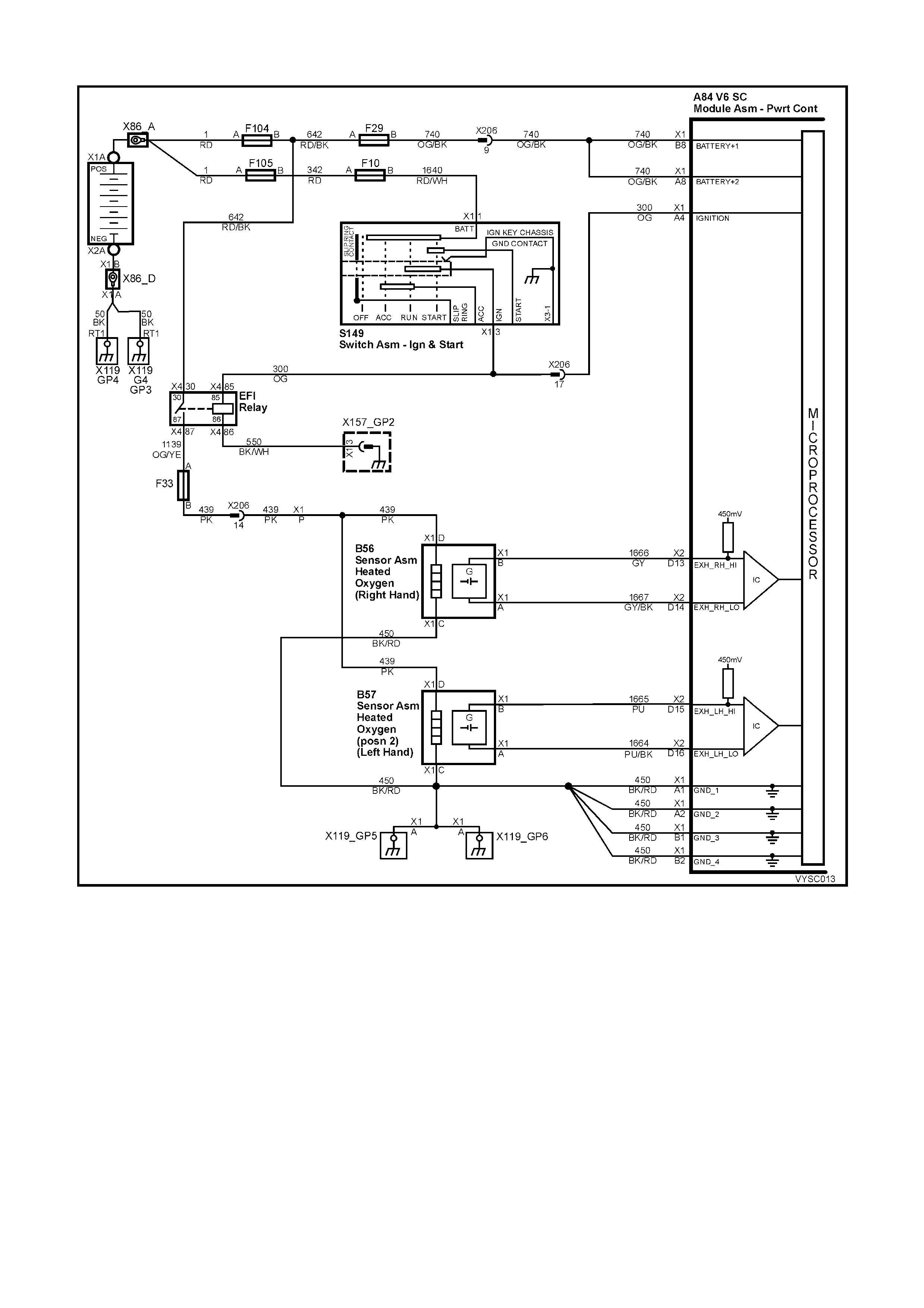

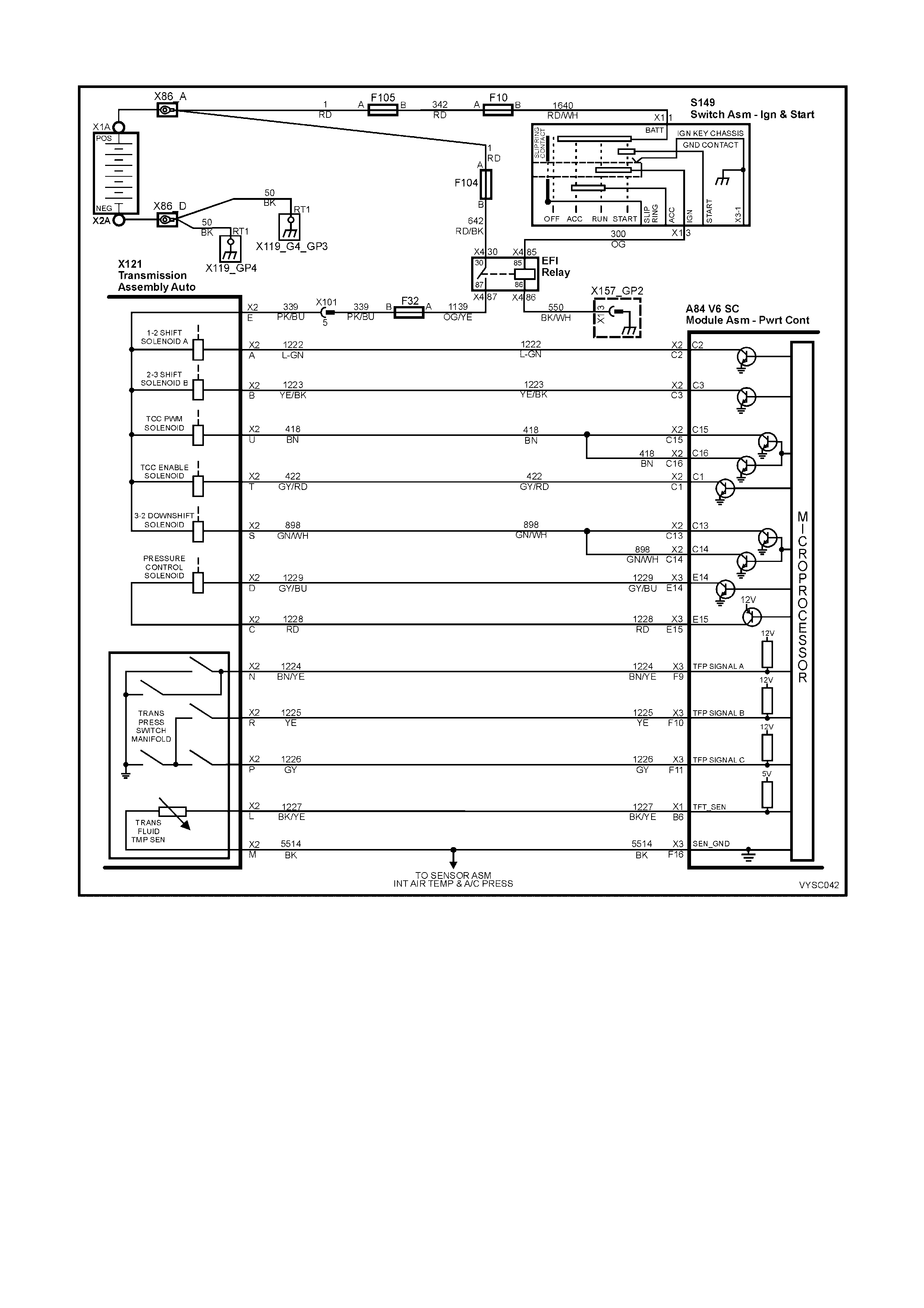

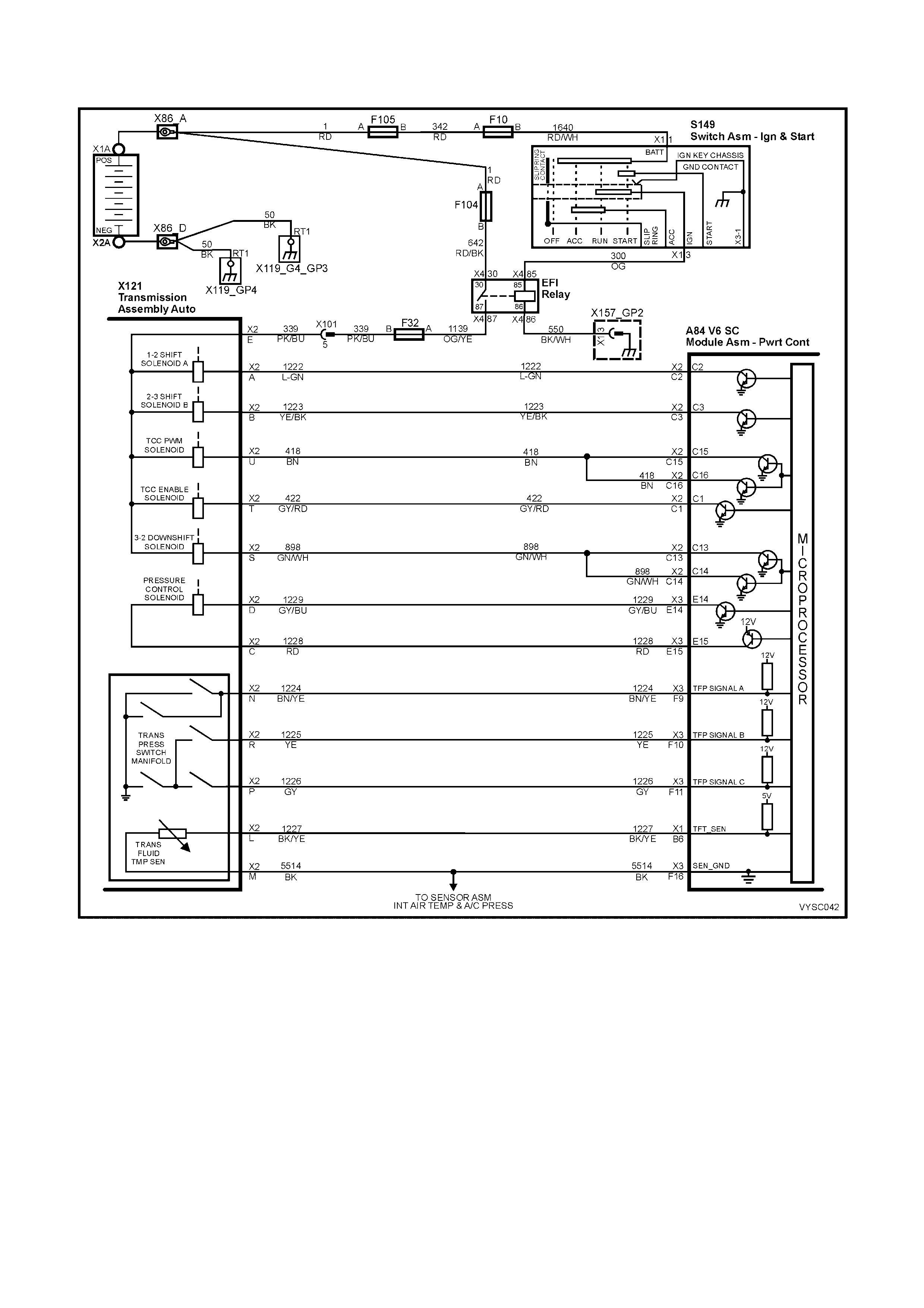

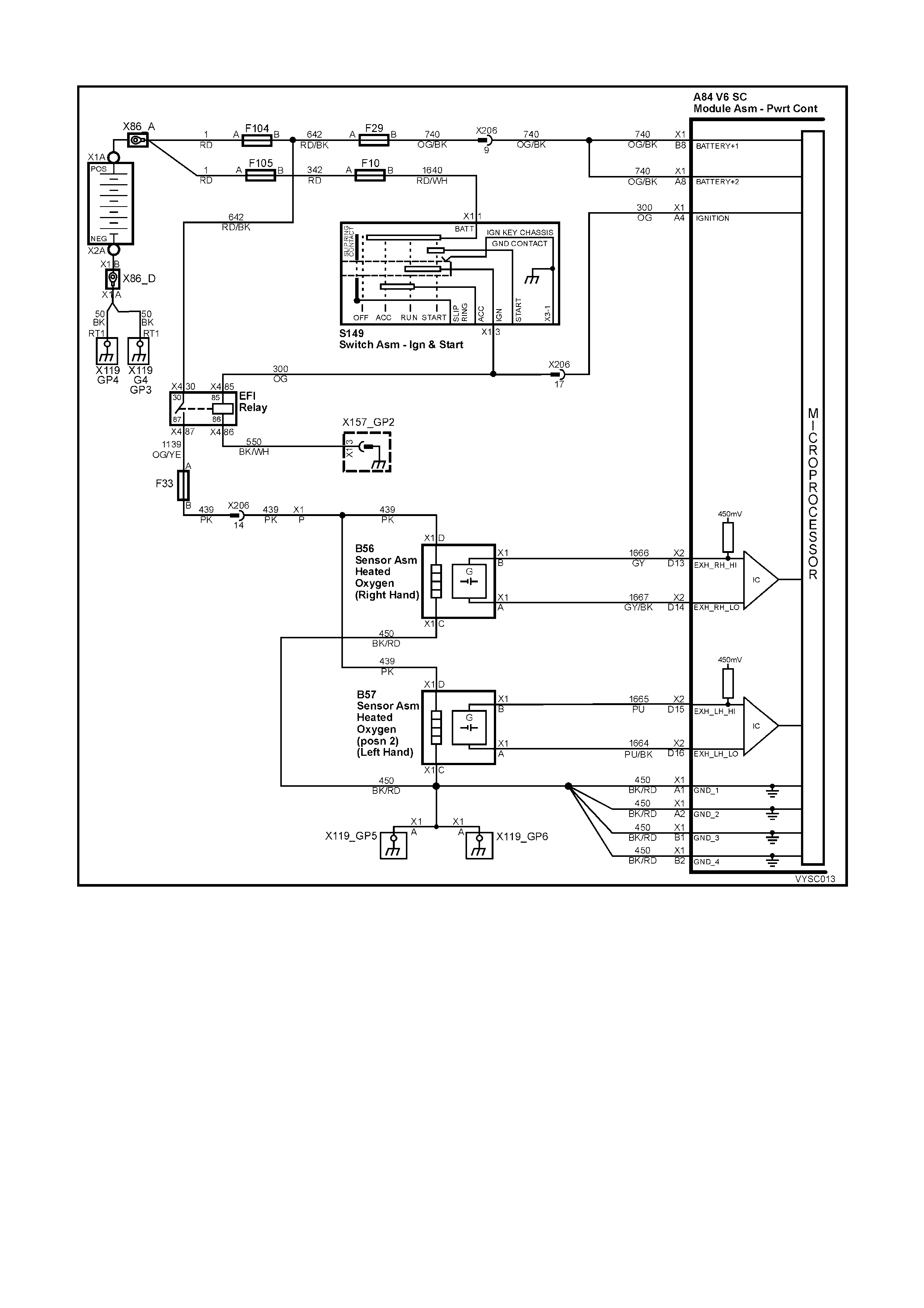

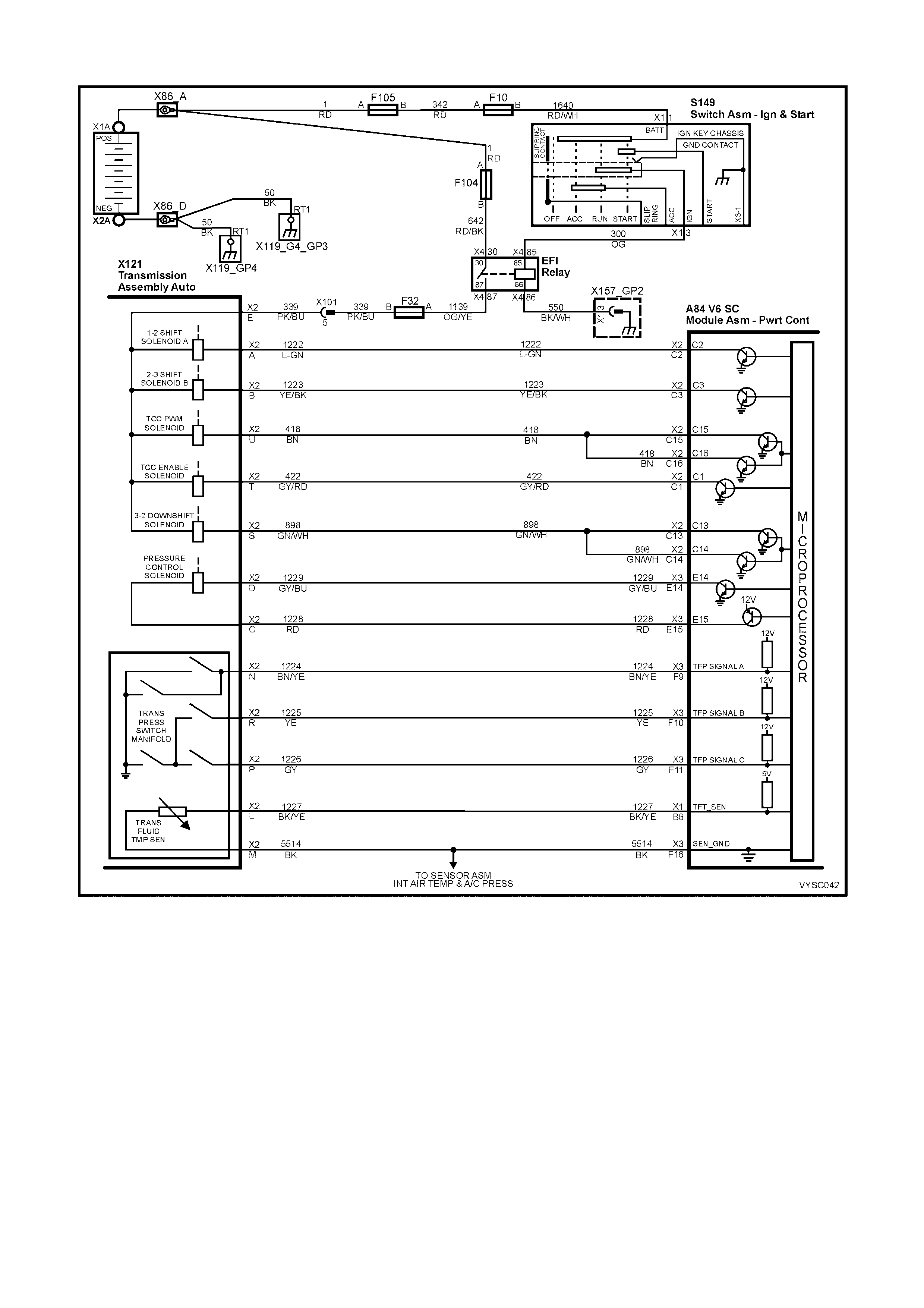

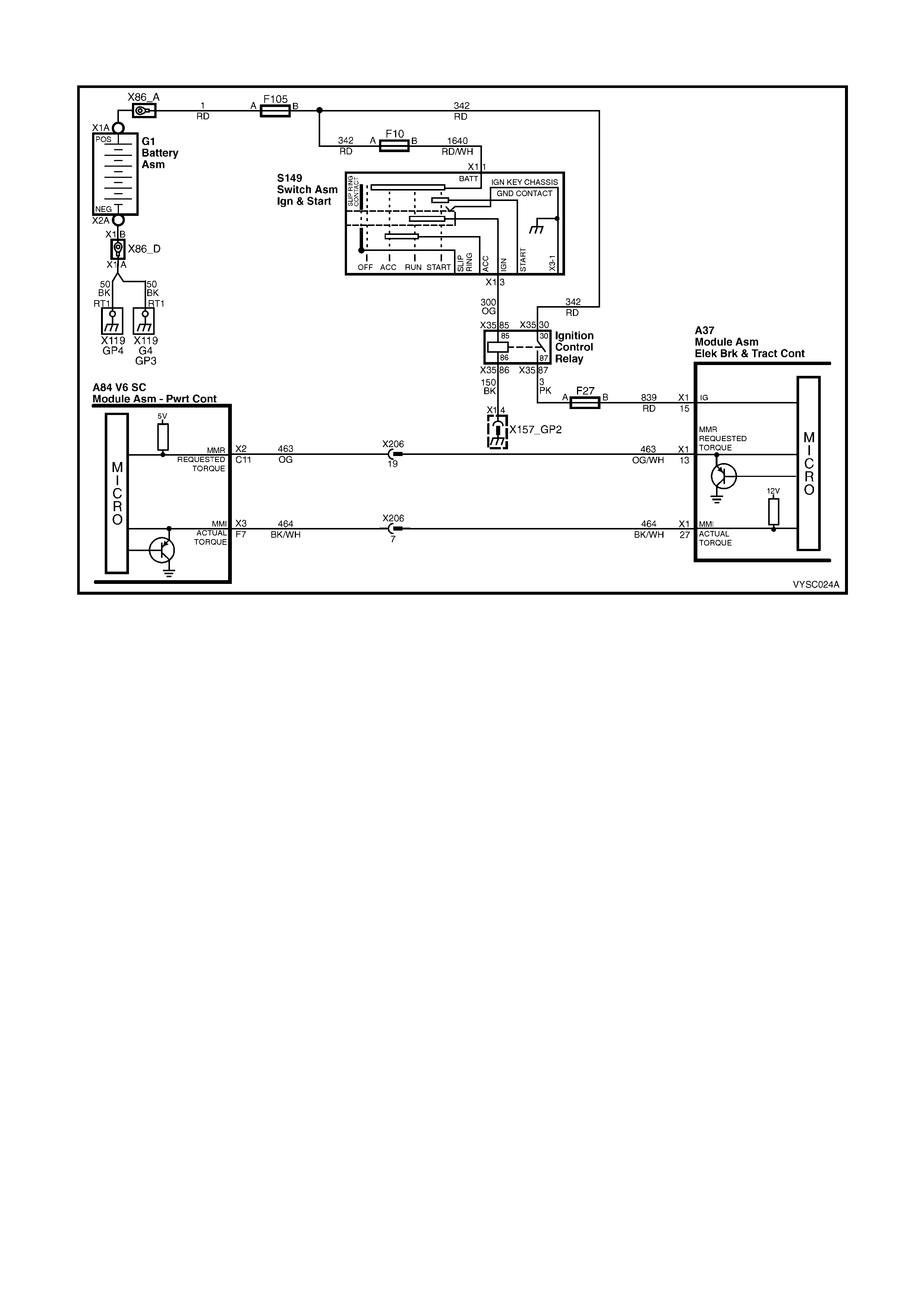

PCM WIRING DIAGRAMS

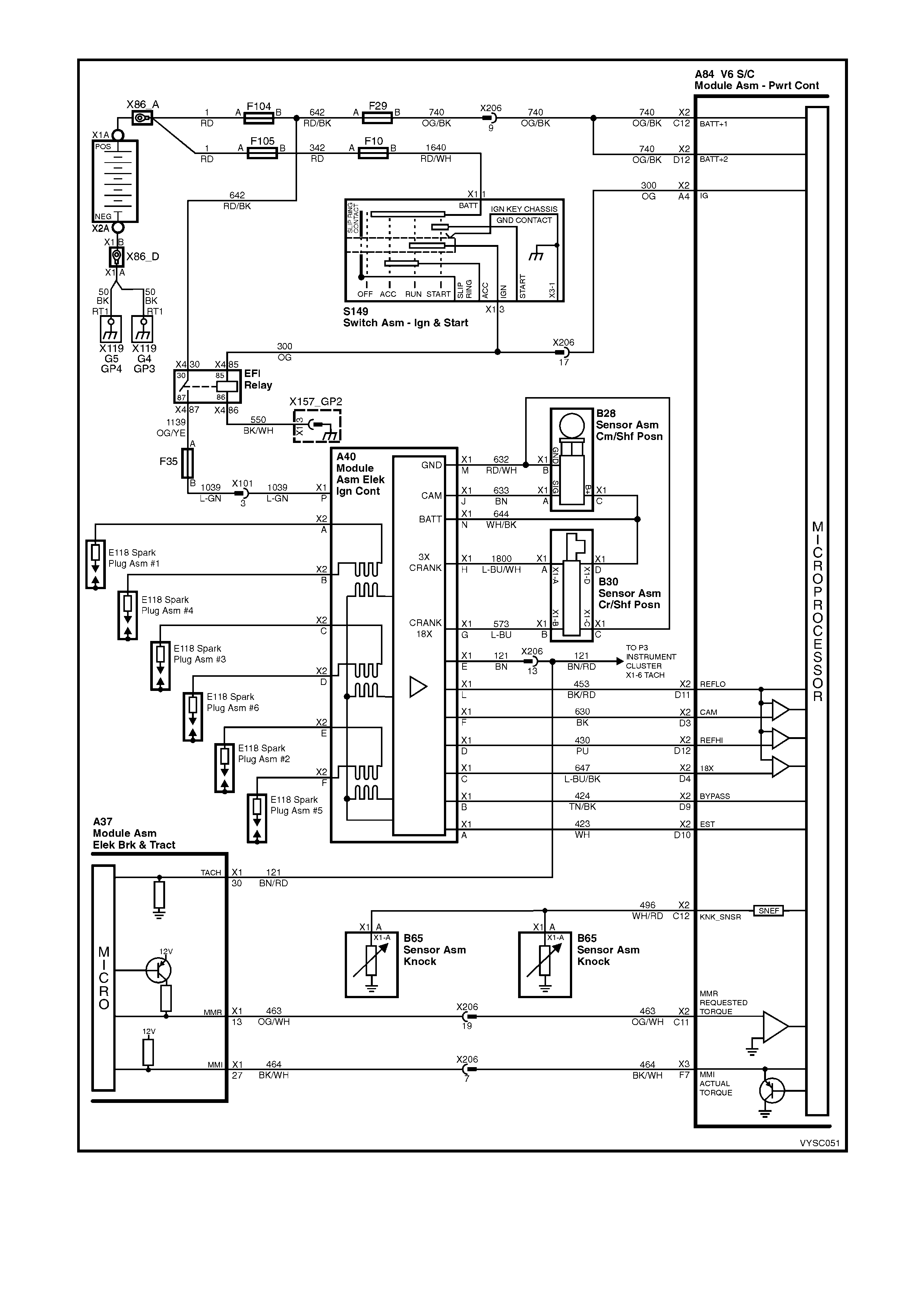

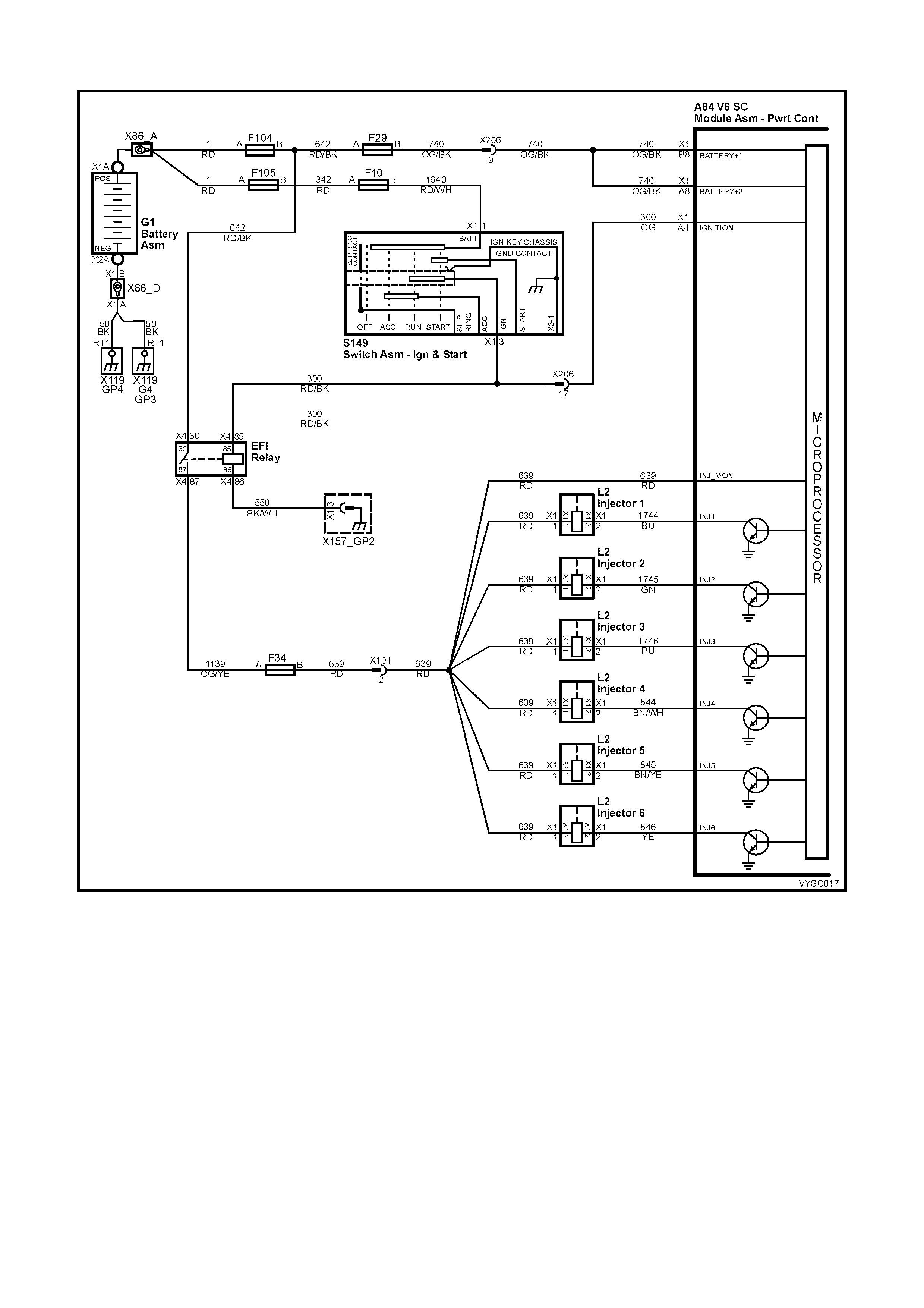

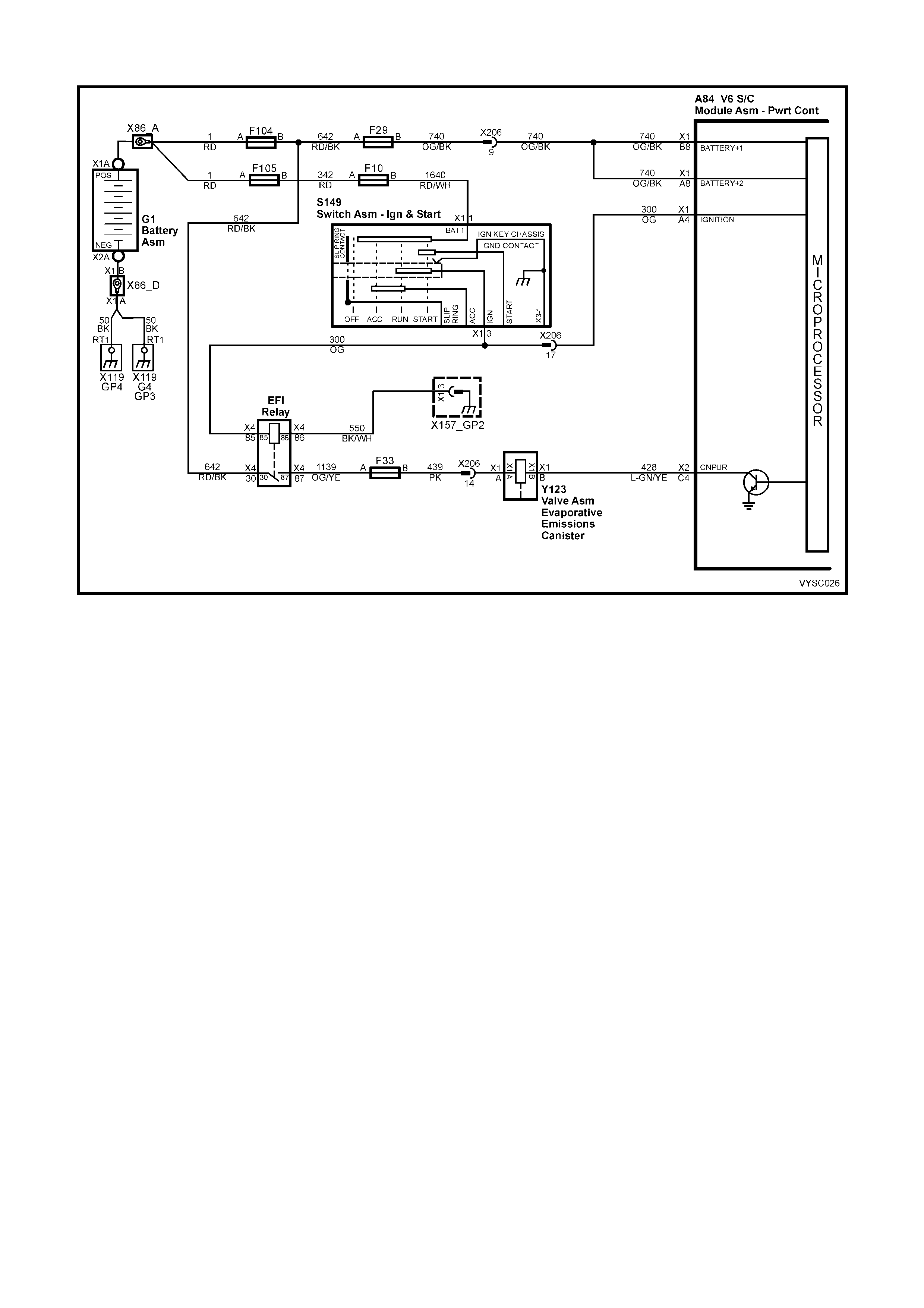

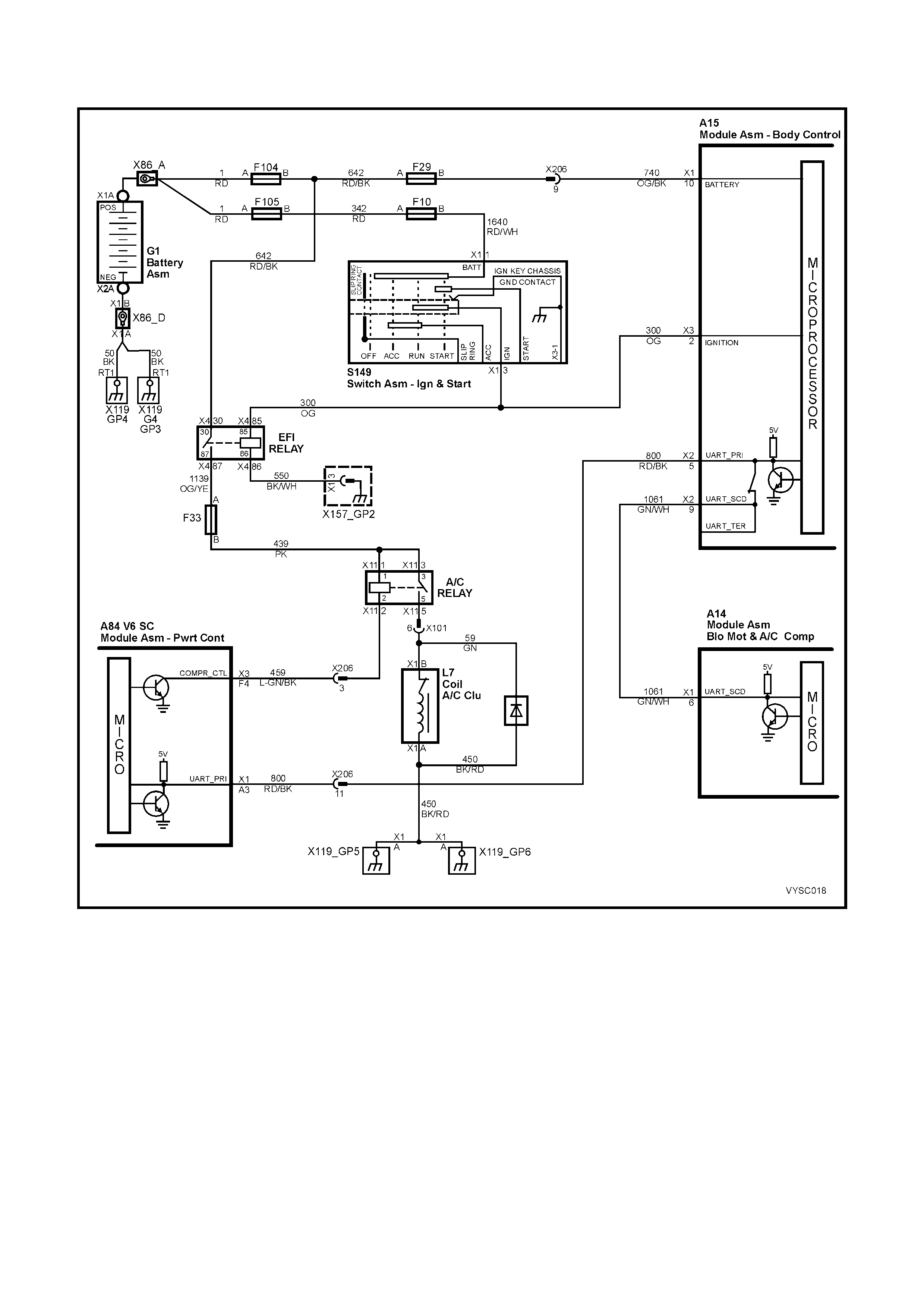

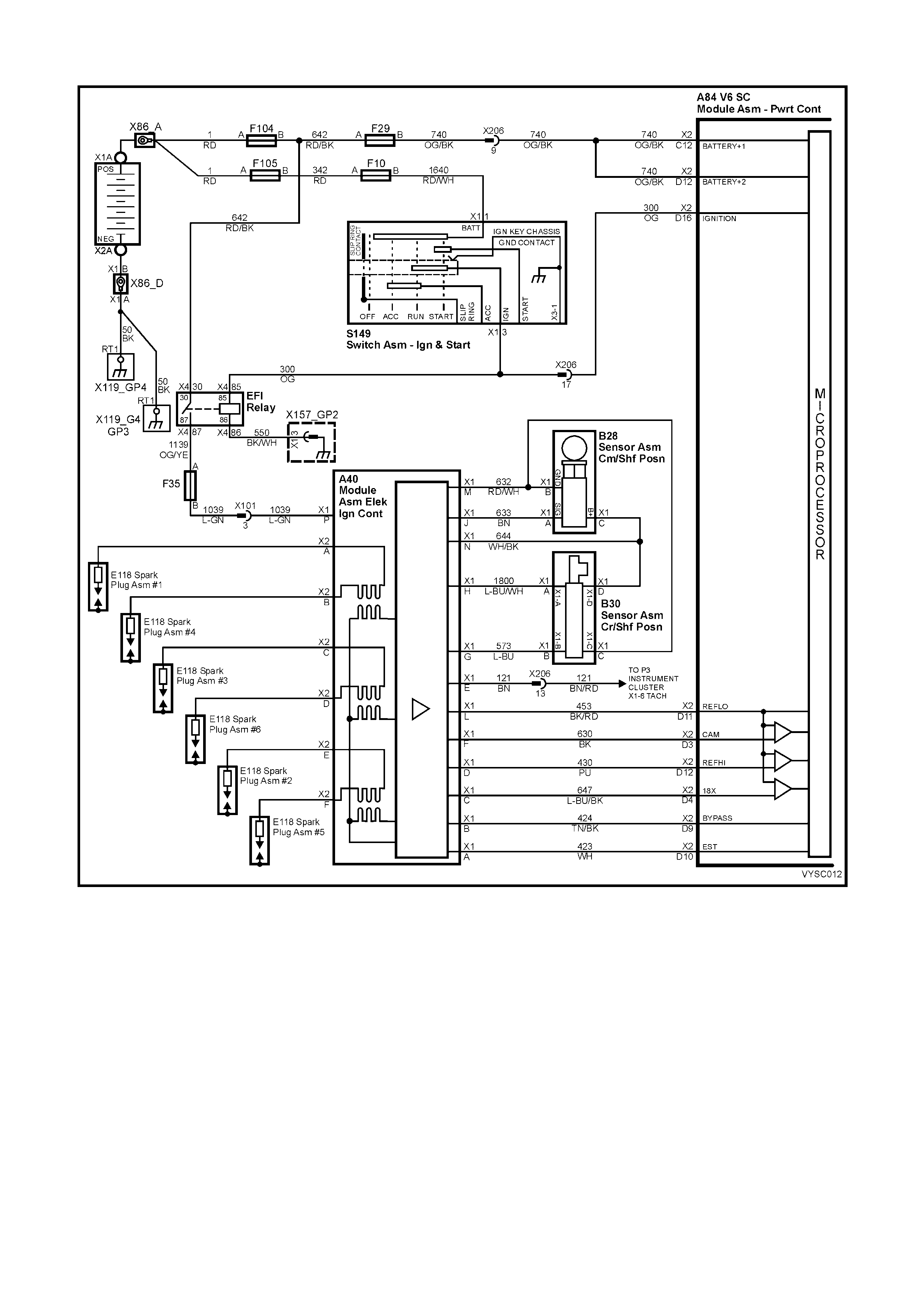

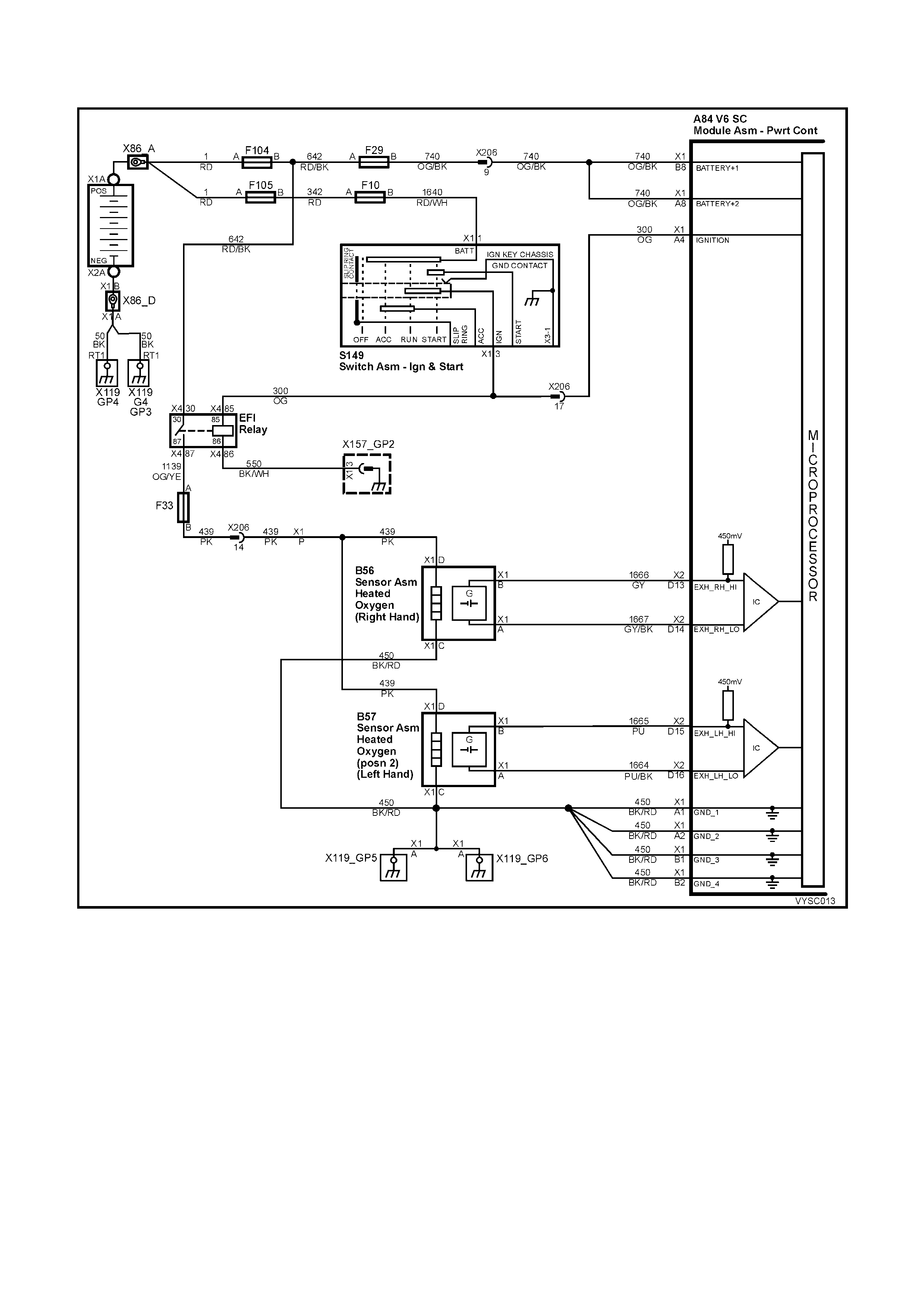

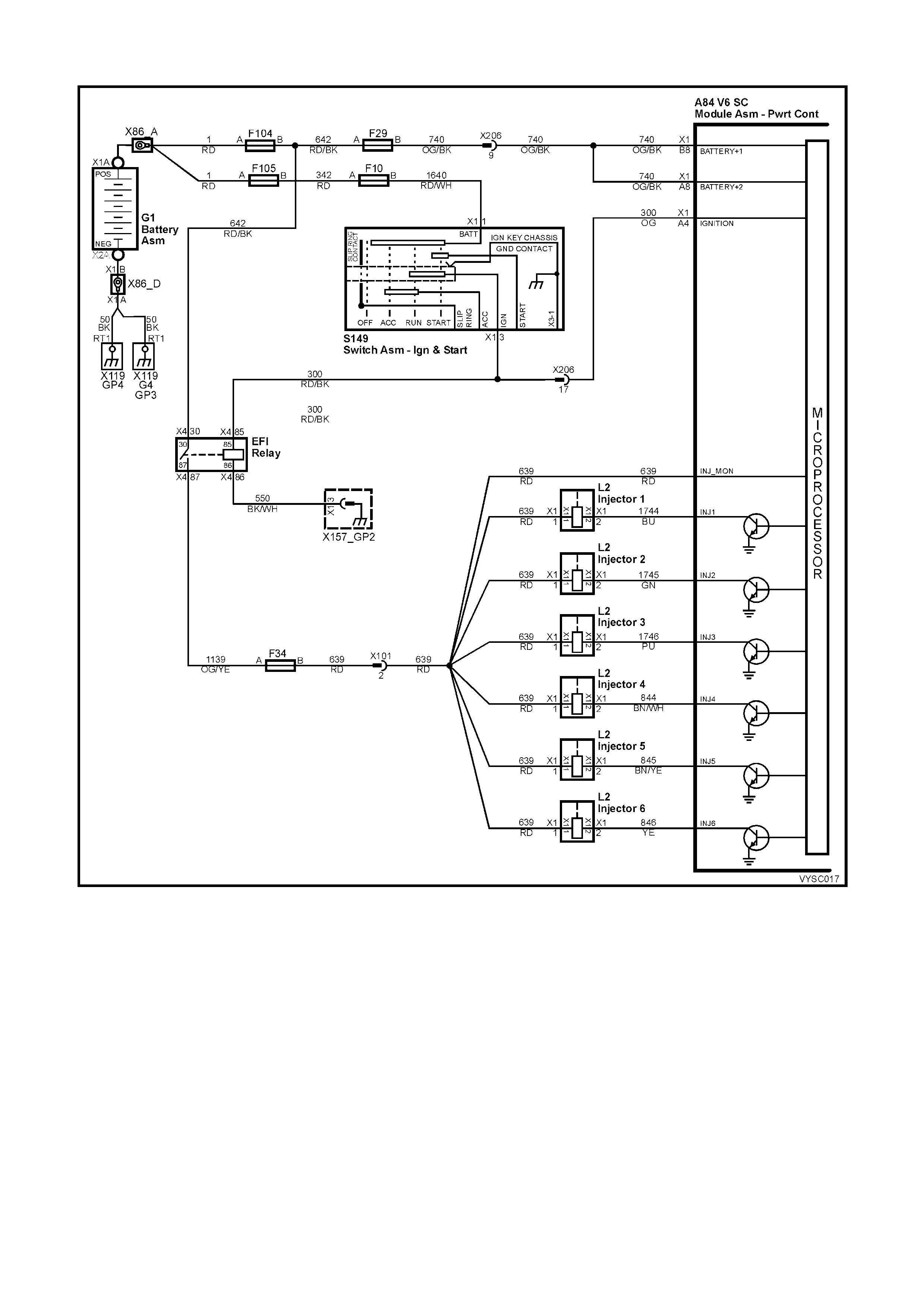

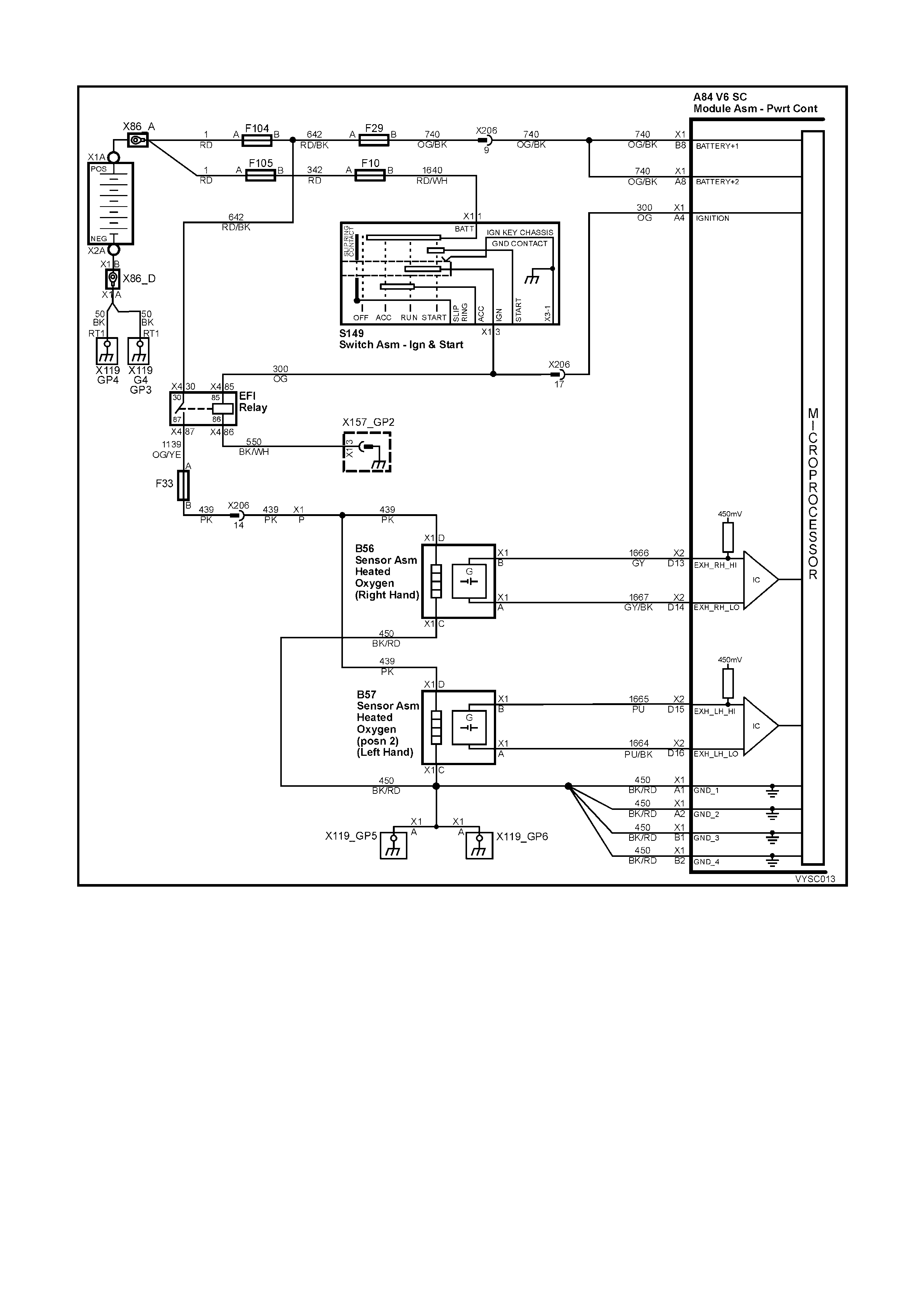

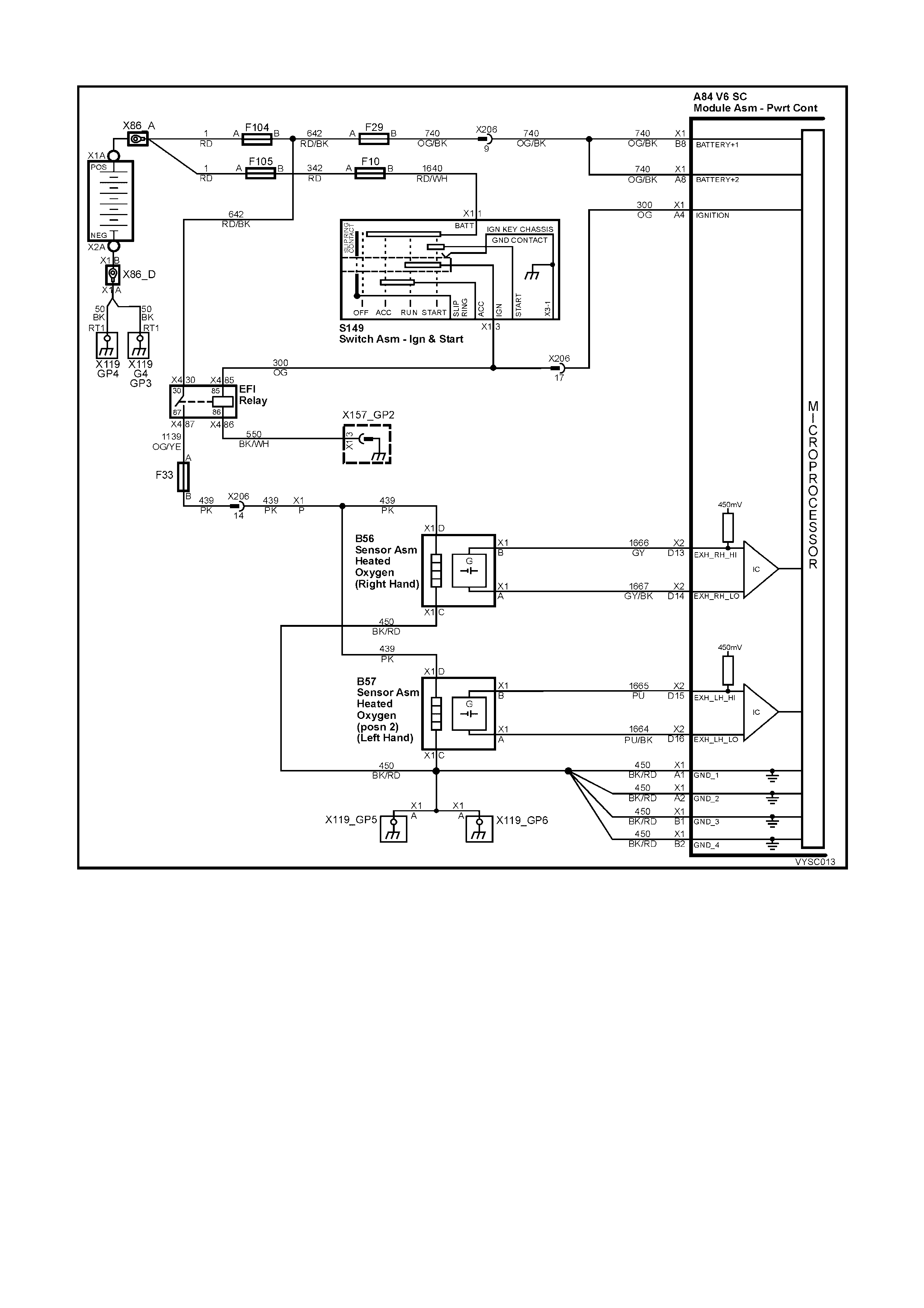

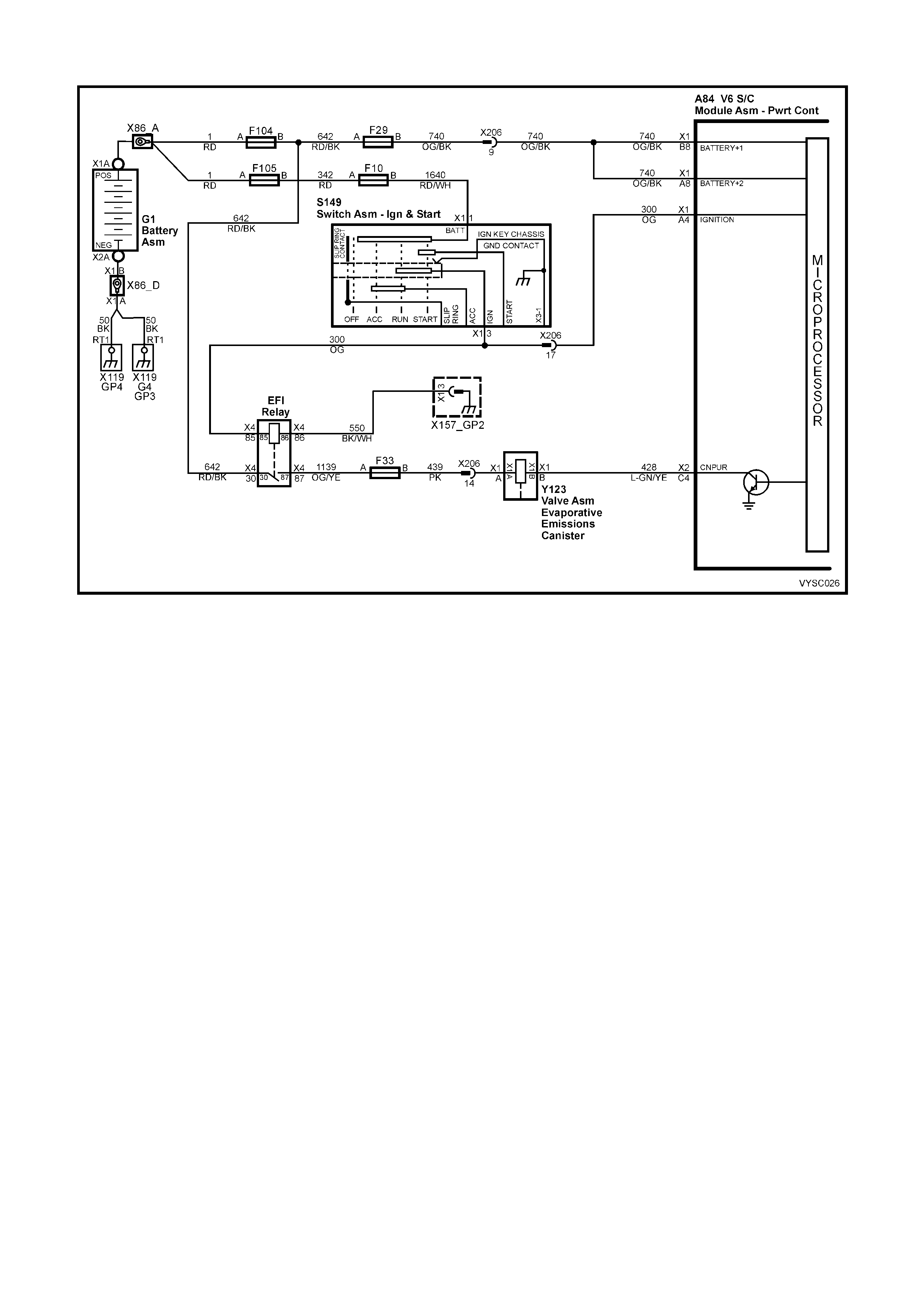

Figure 6C1-2A-7 – PCM Wiring Diagram (1 of 8) V6 Supercharged Engine – Fuse & Power Circuits

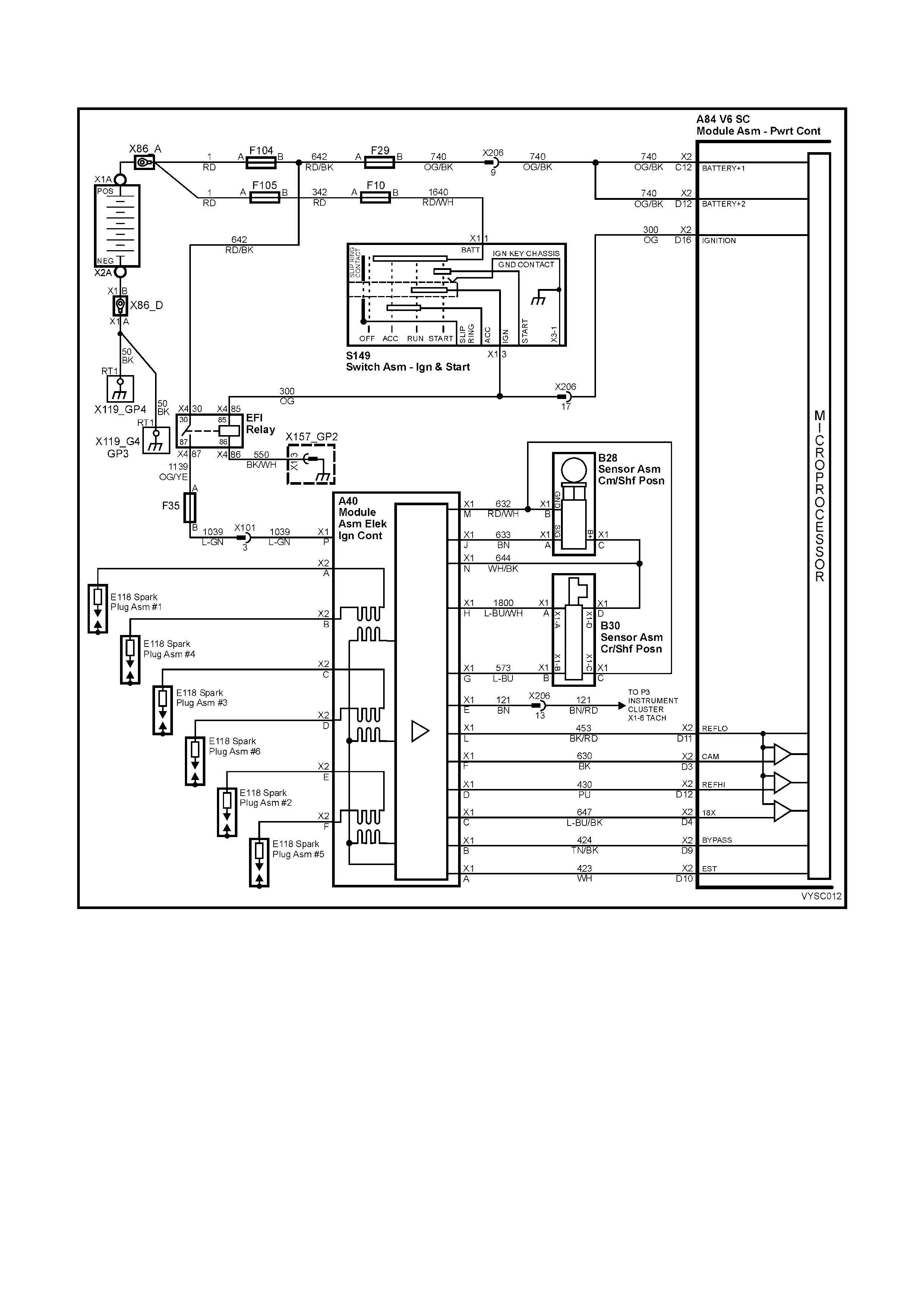

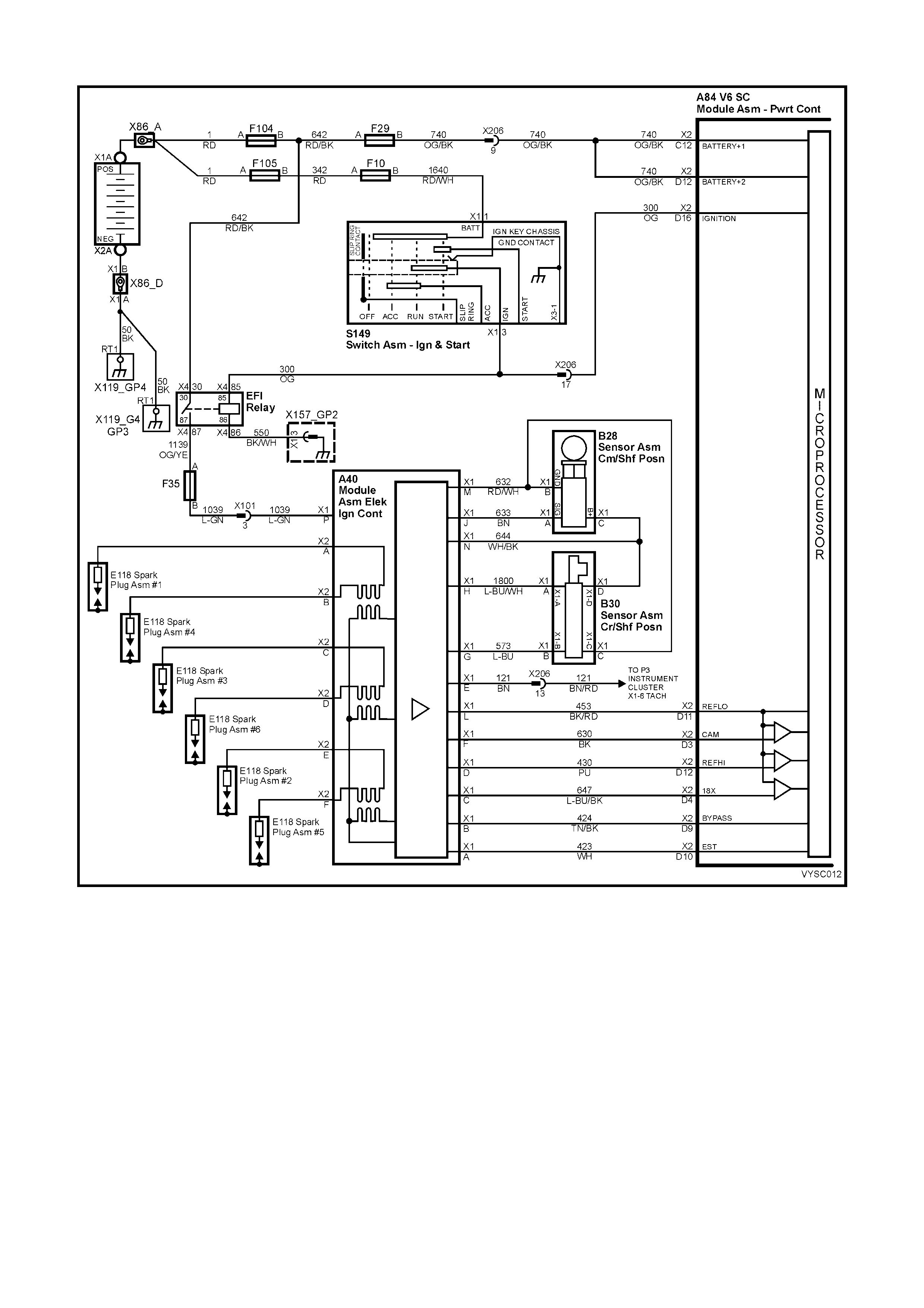

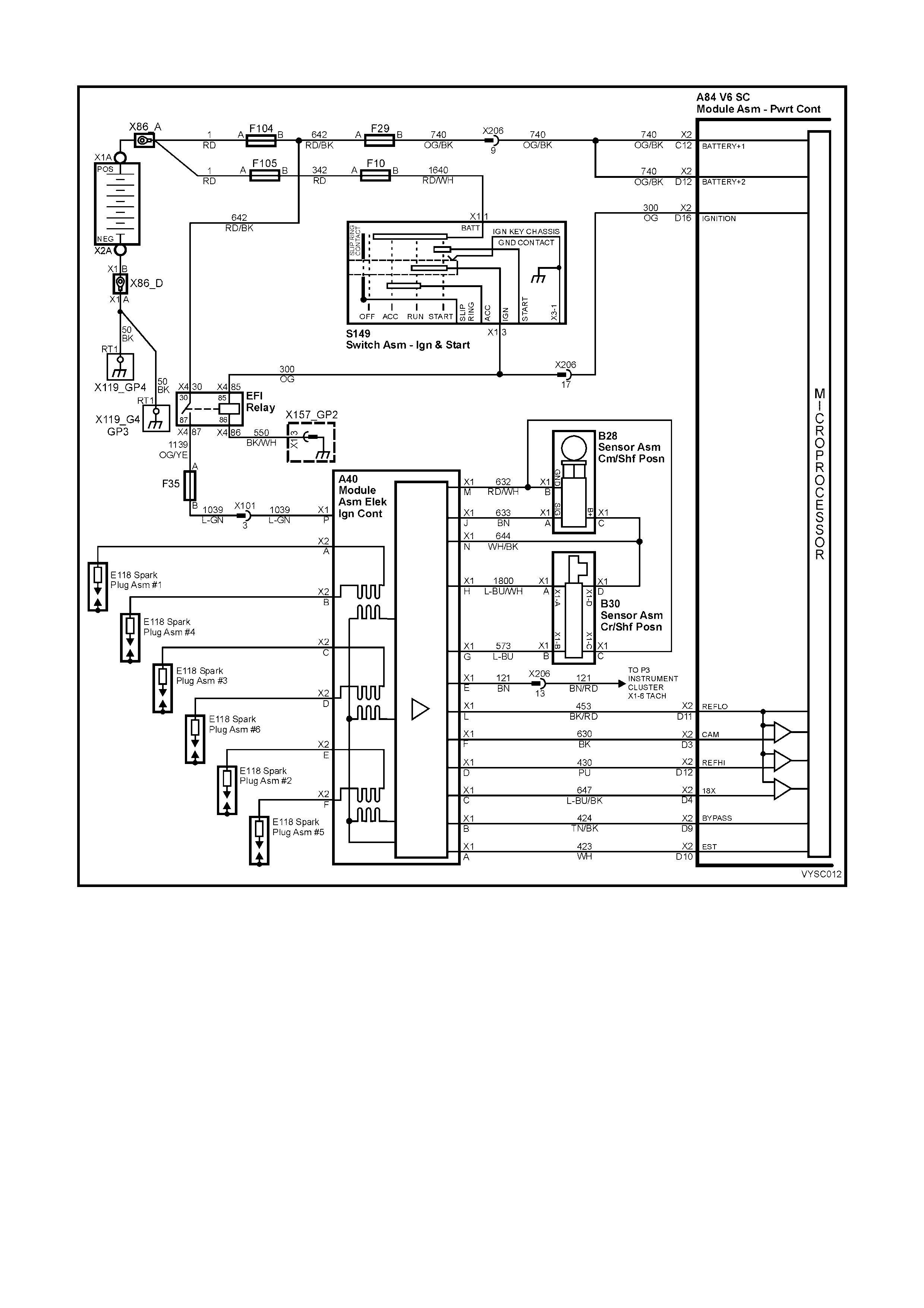

Figure 6C1-2A-8 – PCM Wiring Diagram (2 of 8) V6 Supercharged Engine Application – DIS Ignition System

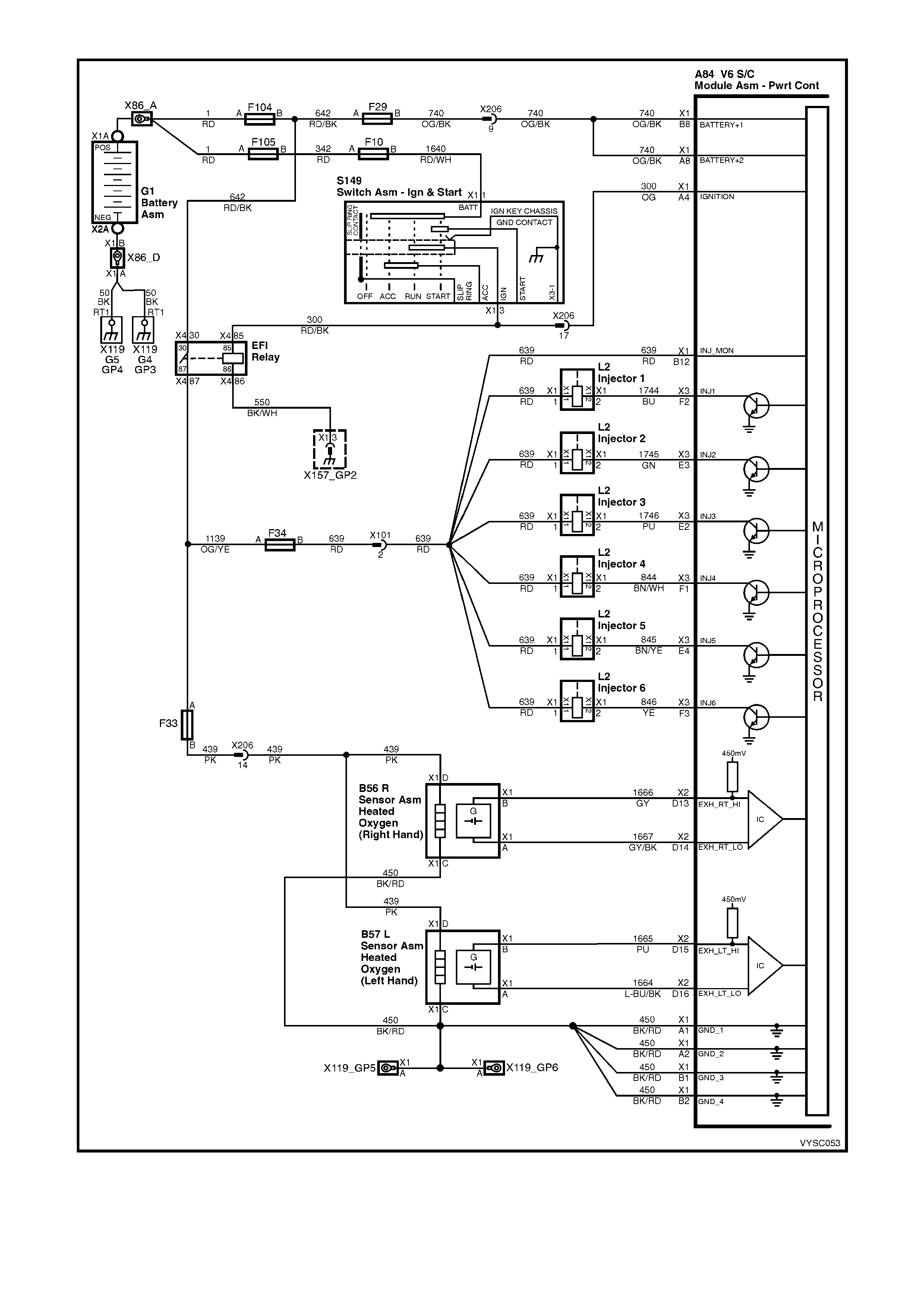

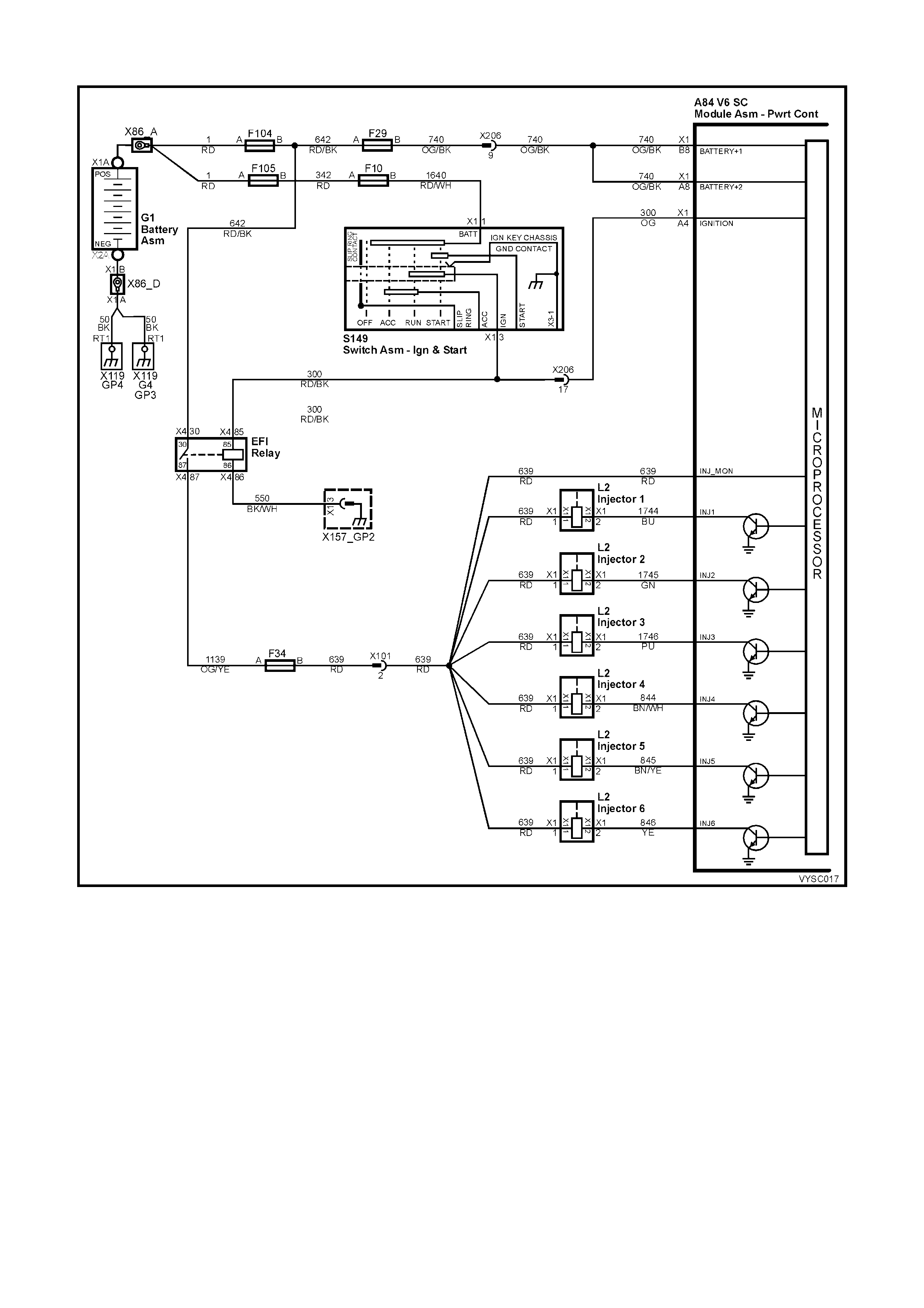

Figure 6C1-2A-9 – PCM Wiring Diagram (3 of 8 ) V6 Supercharged Engine Application – Fuel System Circuits

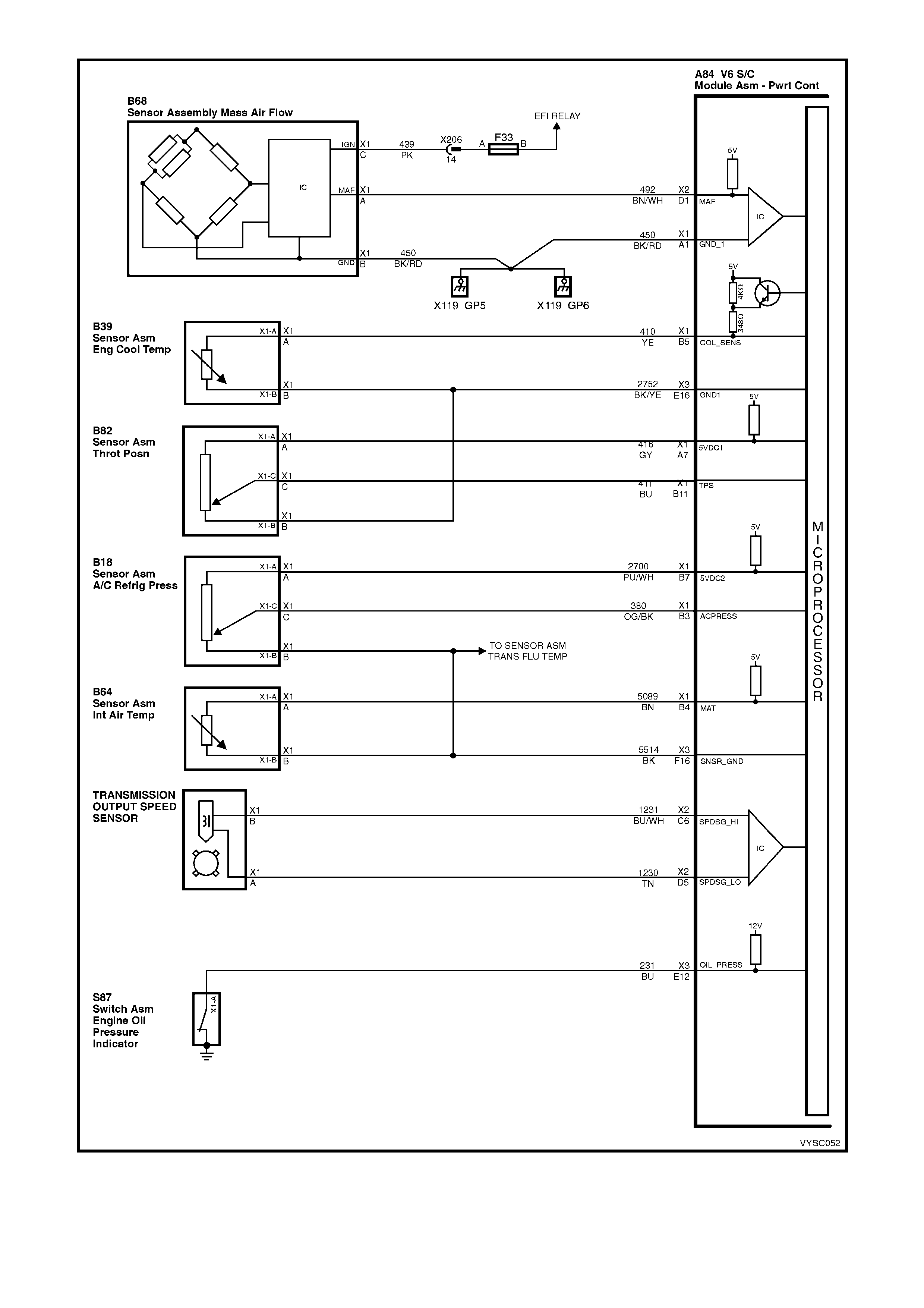

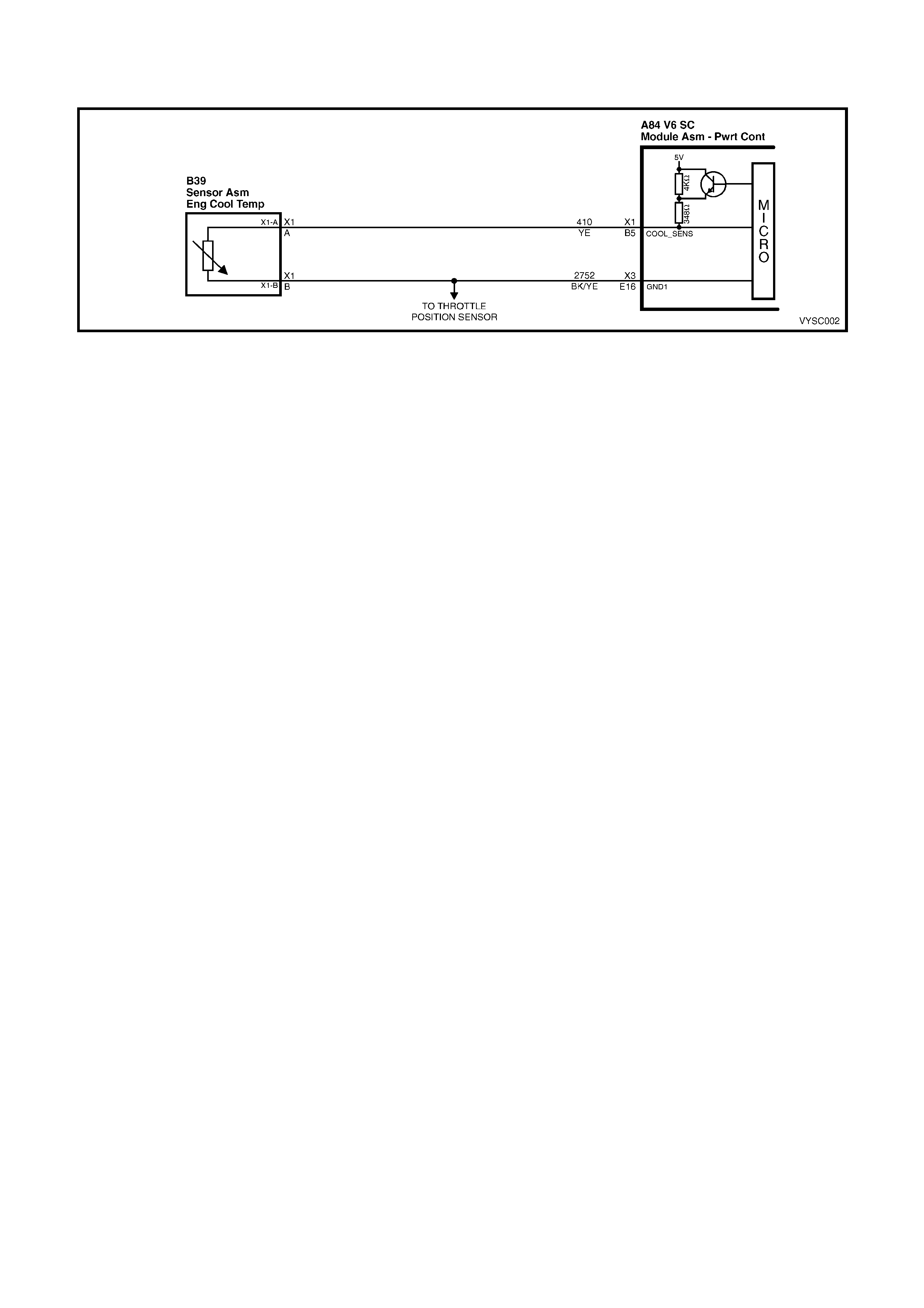

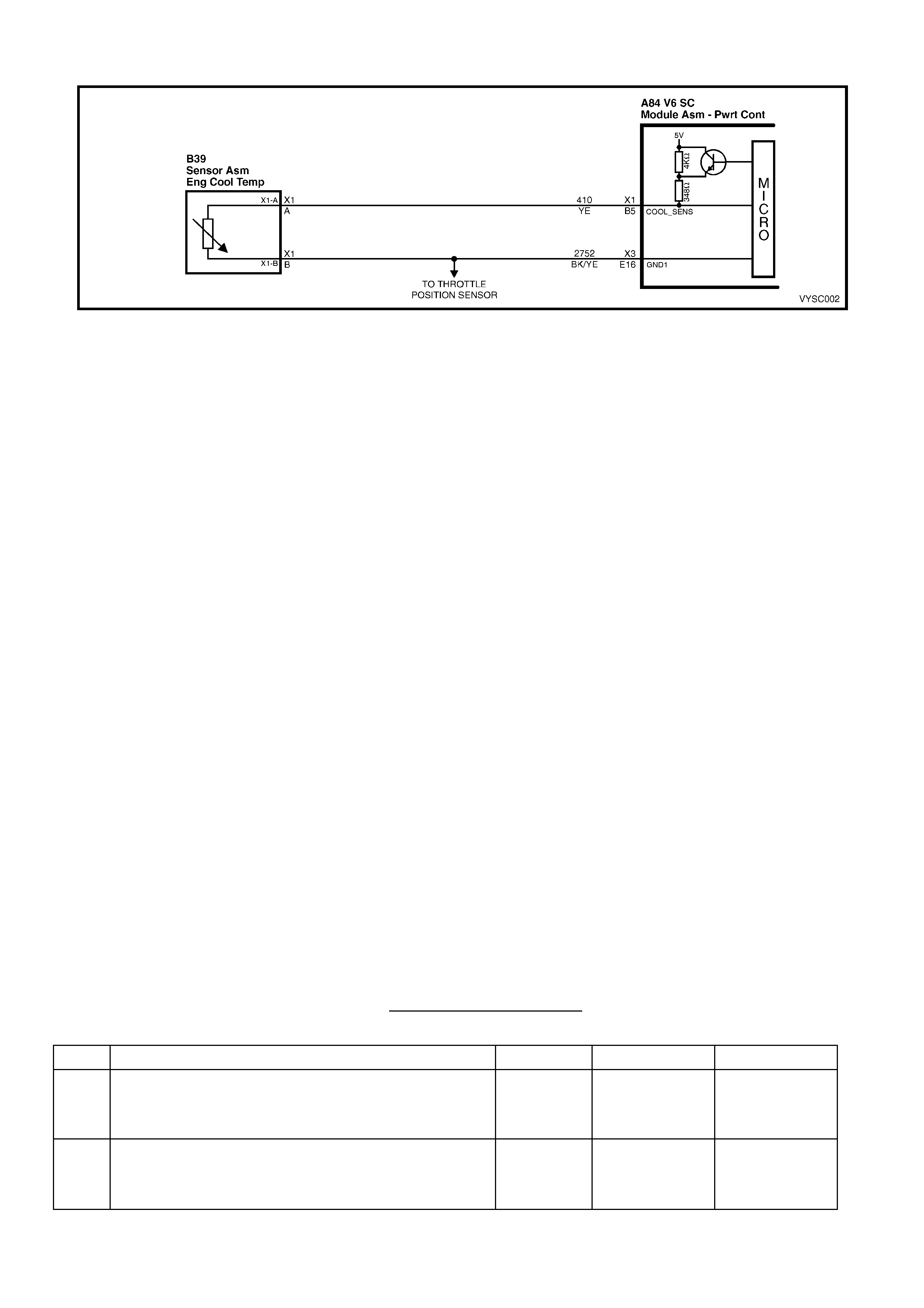

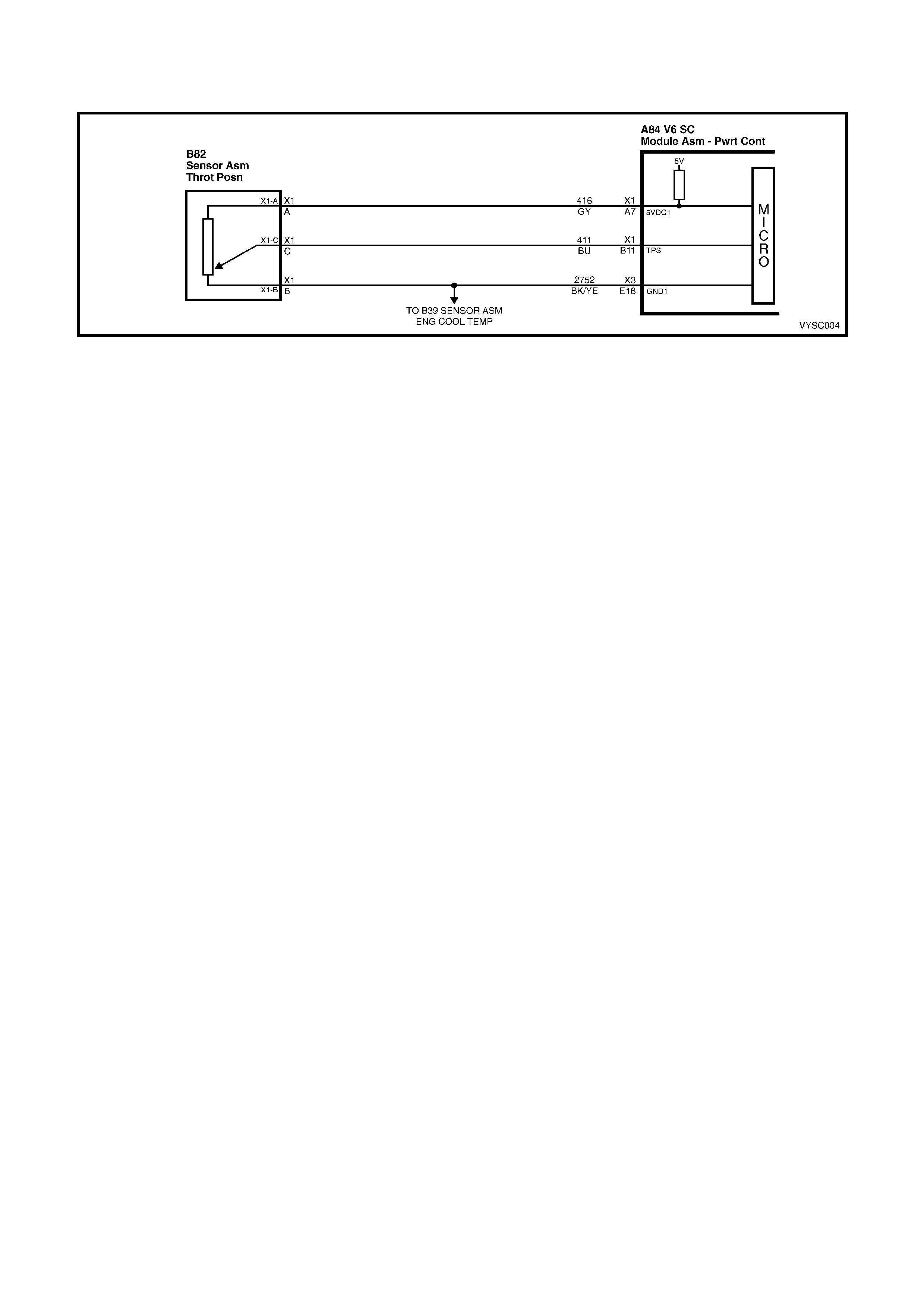

Figure 6C1-2A-10 – PCM Wiring Diagram (4 of 8) V6 Supercharged Engine Application – Sensor Input Circuits

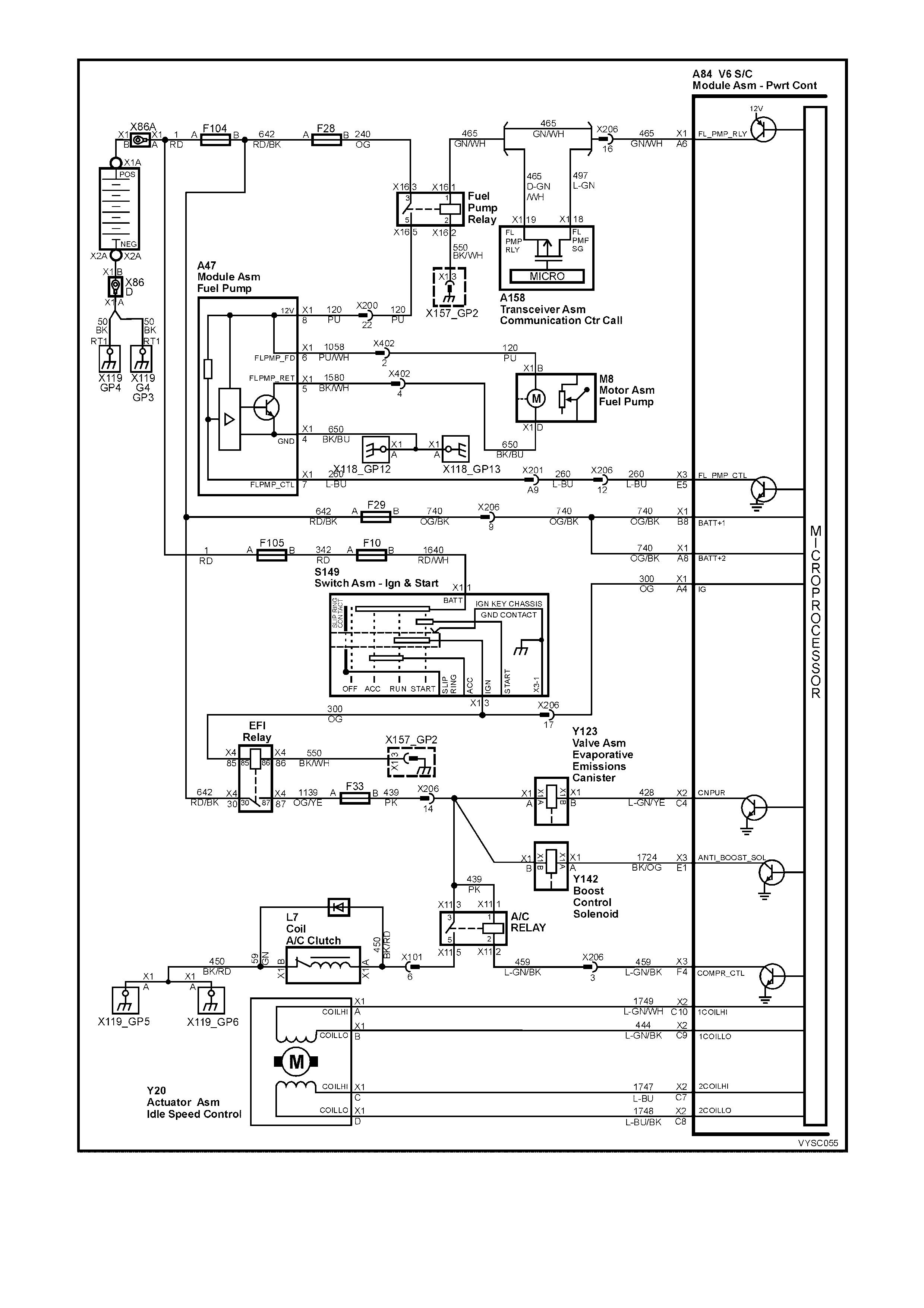

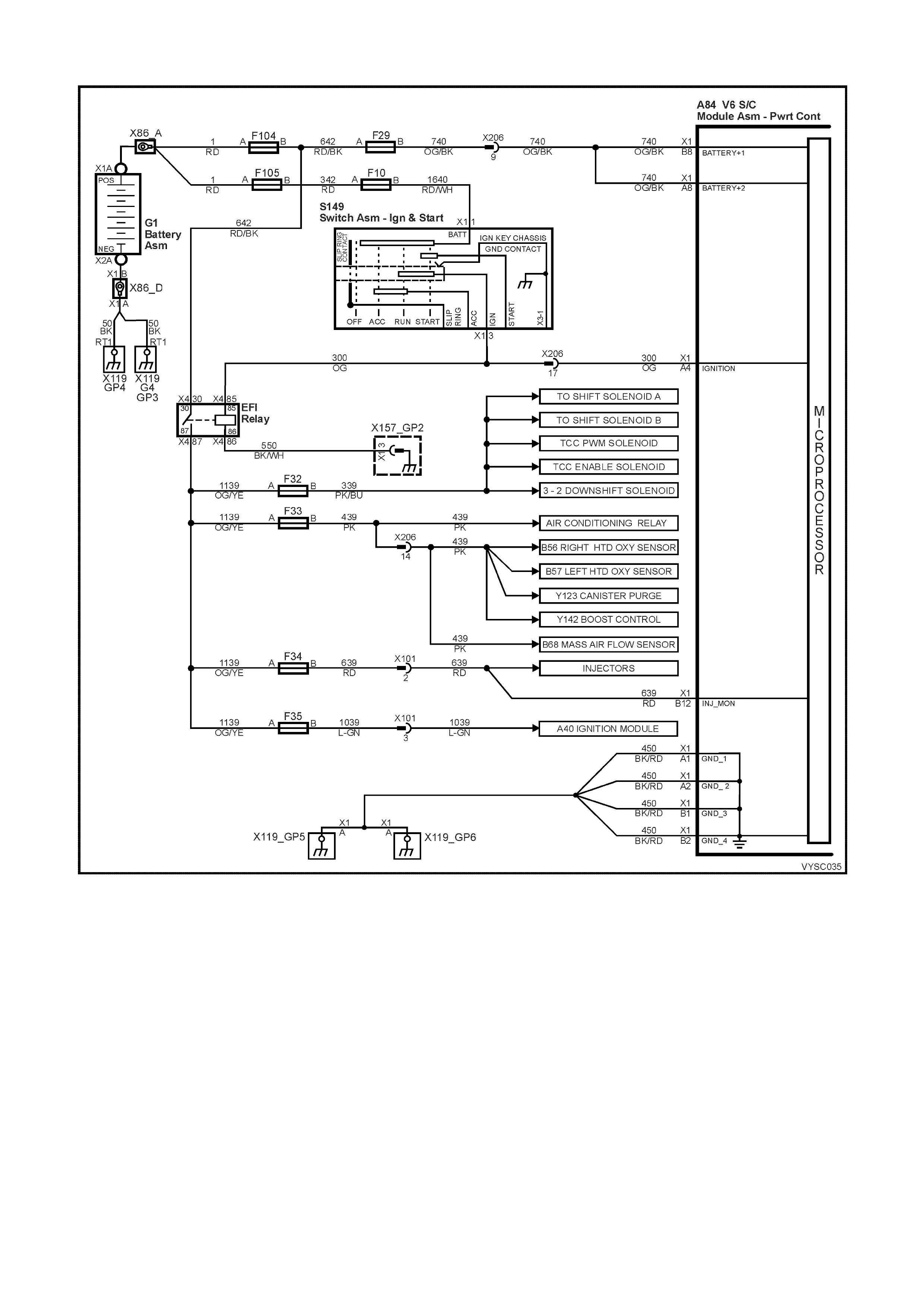

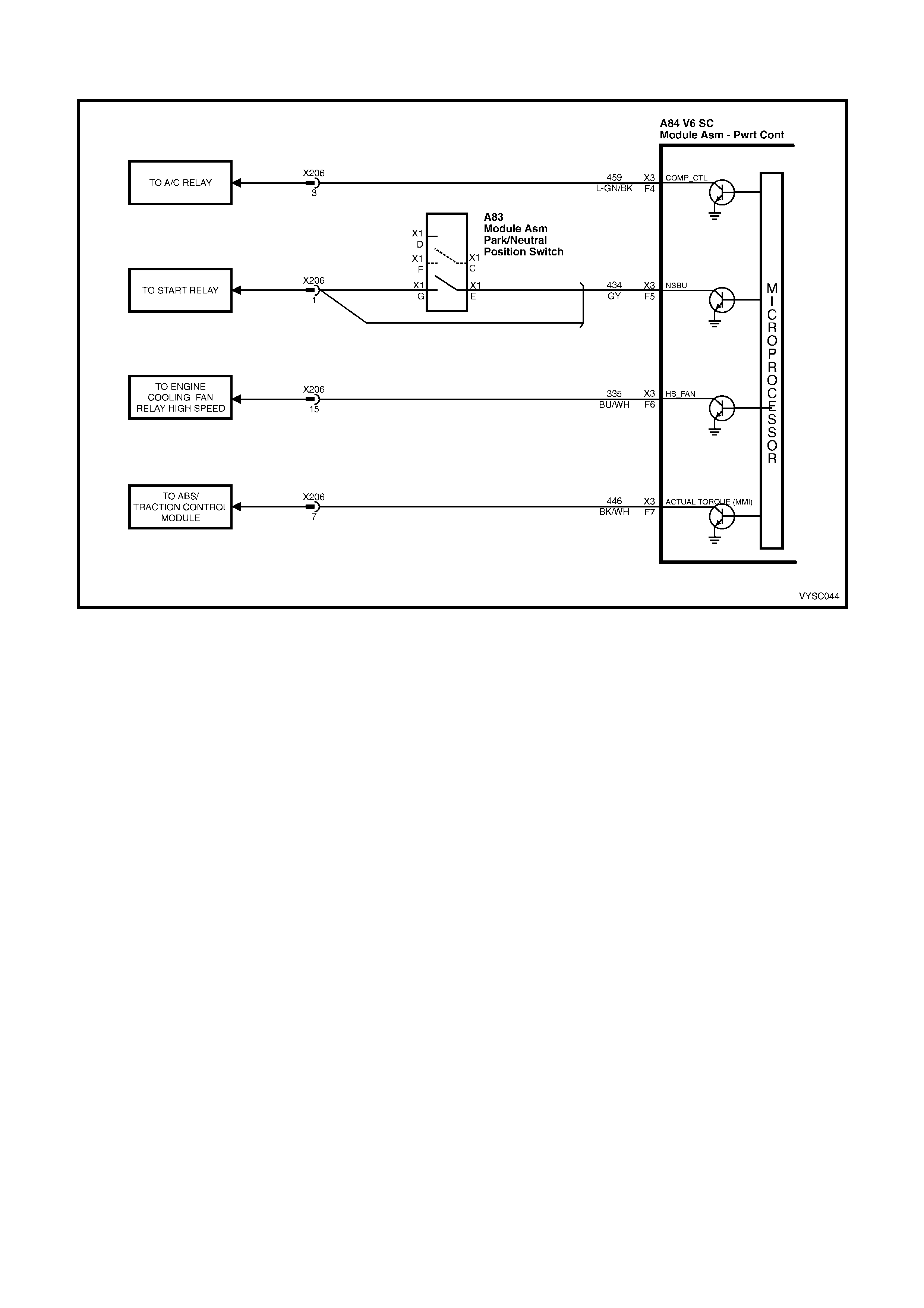

Figure 6C1-2A-11 PCM Wiring Diagram (5 of 8) V6 Supercharged Engine Application – Control Circuits

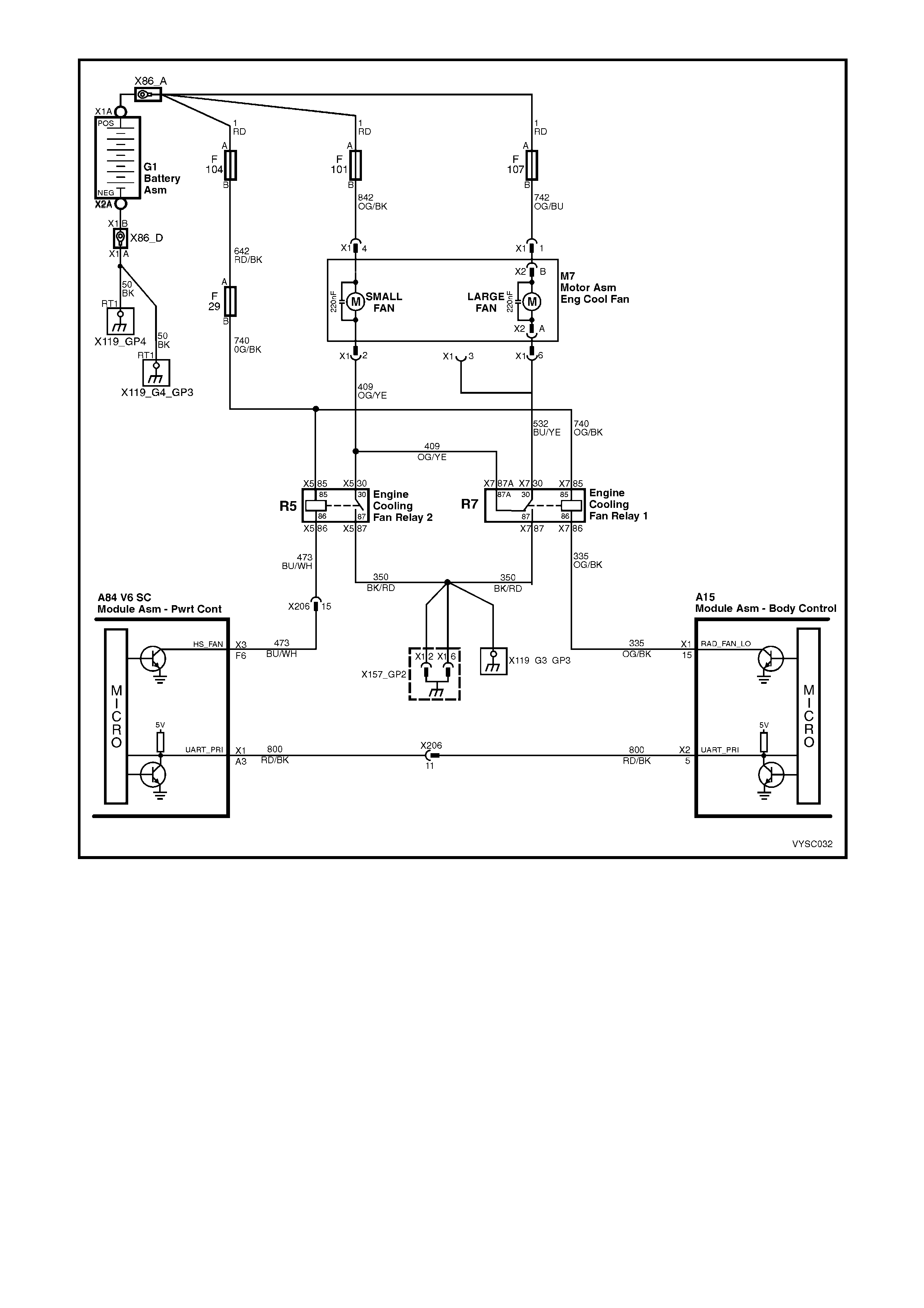

Figure 6C1-2A-12 PCM Wiring Diagram (6 of 8) V6 Supercharged Engine Application – Cooling System Control

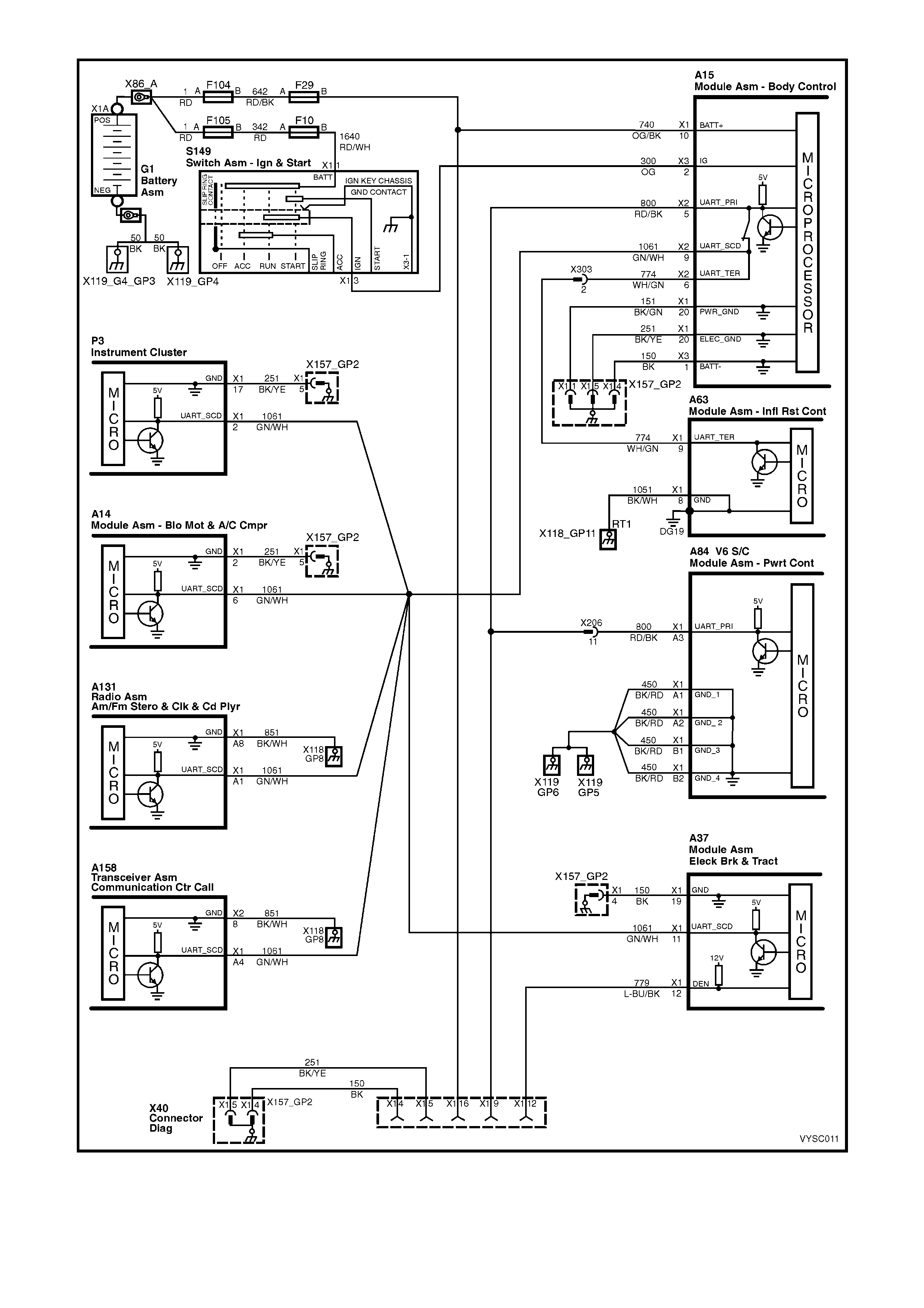

Figure 6C1-2A-13 PCM Wiring Diagram (7 of 8) V6 Supercharged Engine Application – Serial Data Circuits

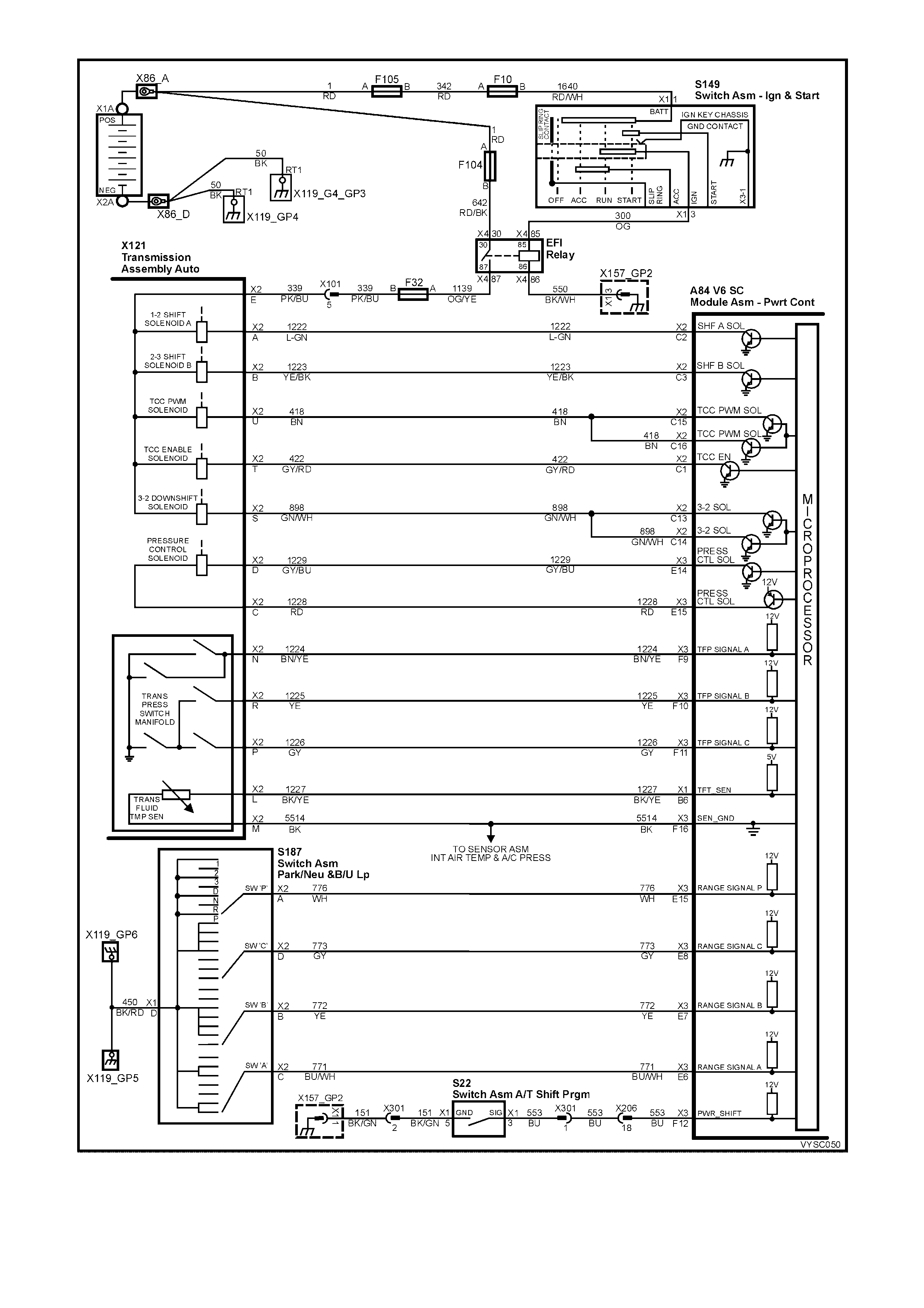

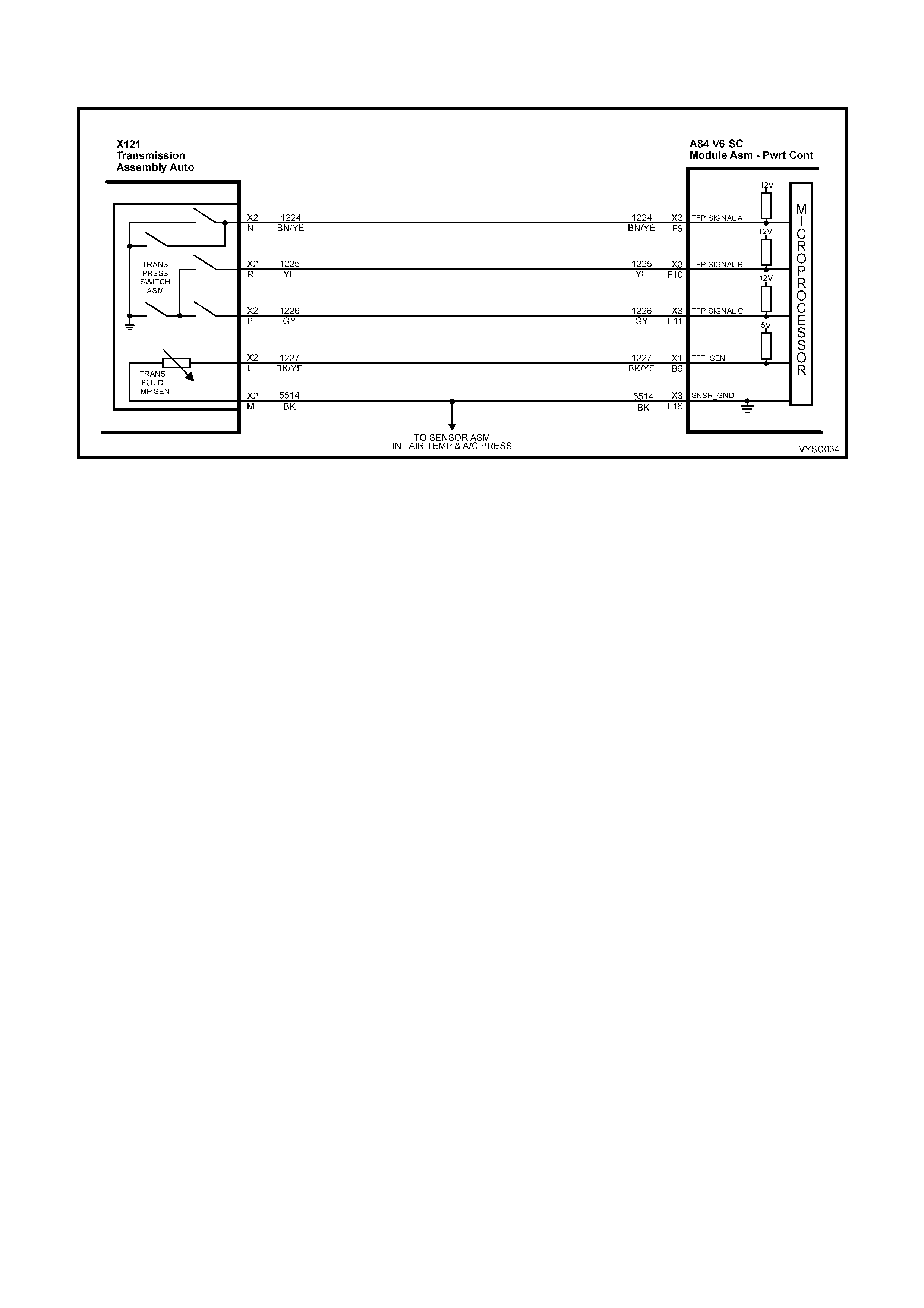

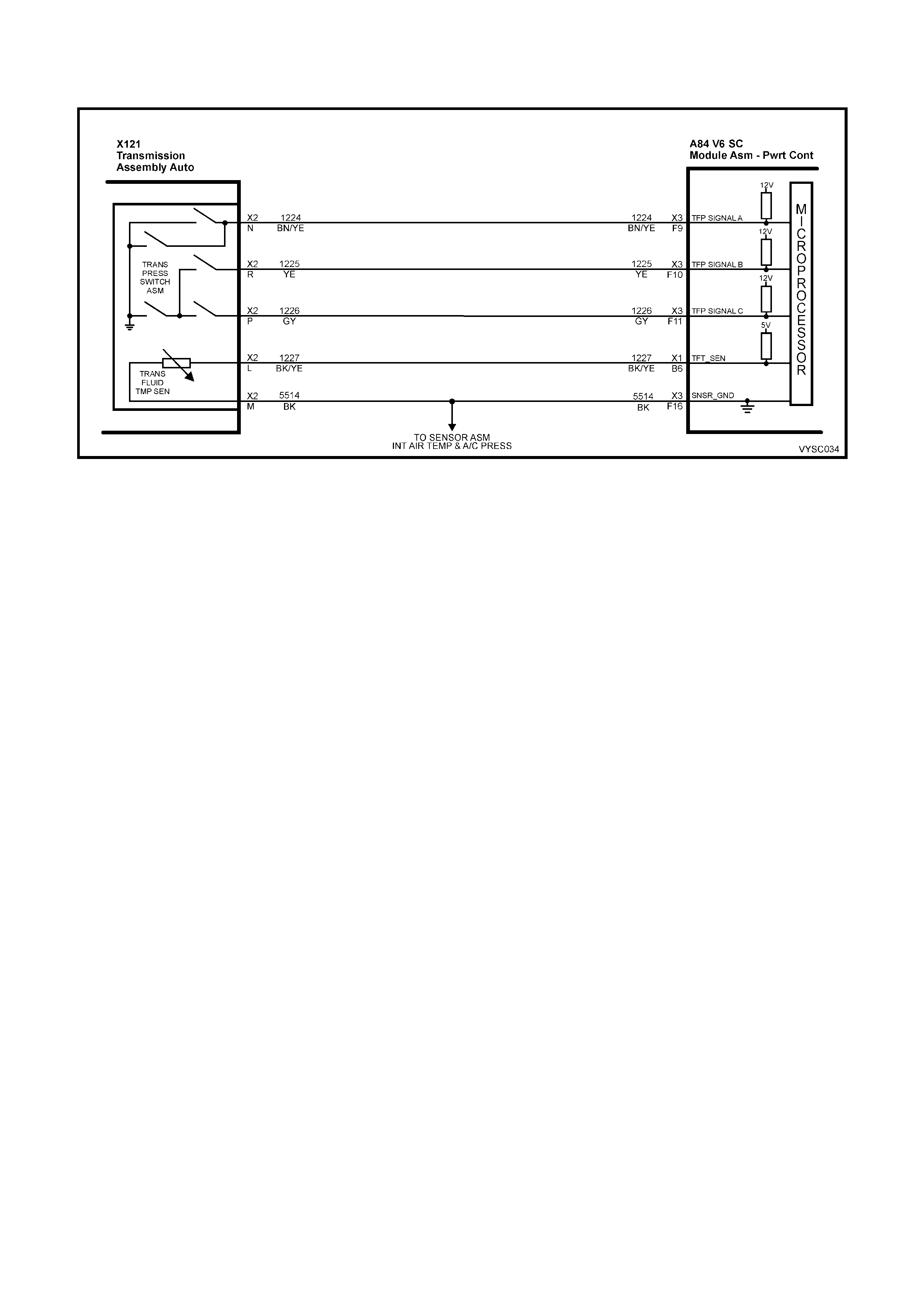

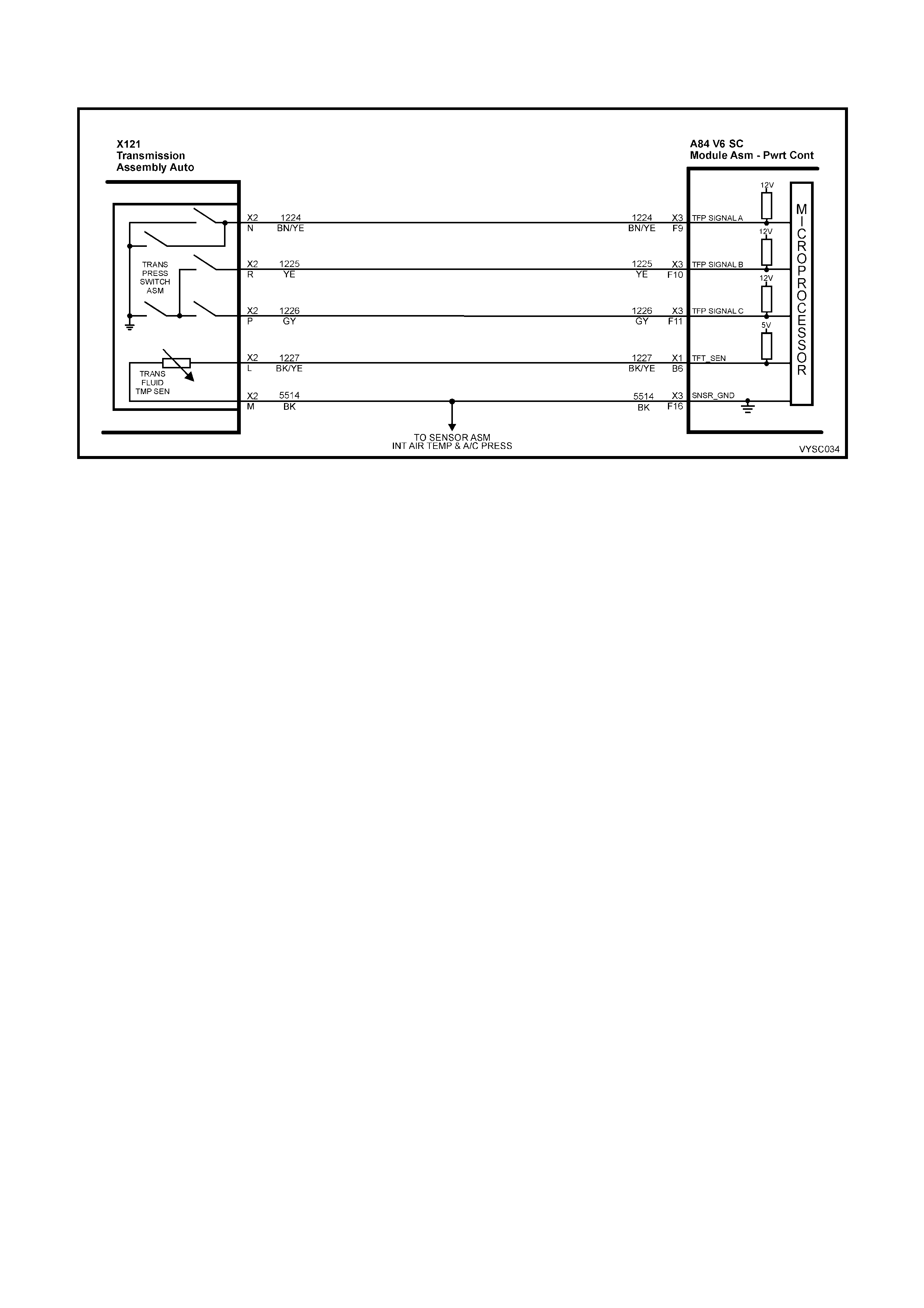

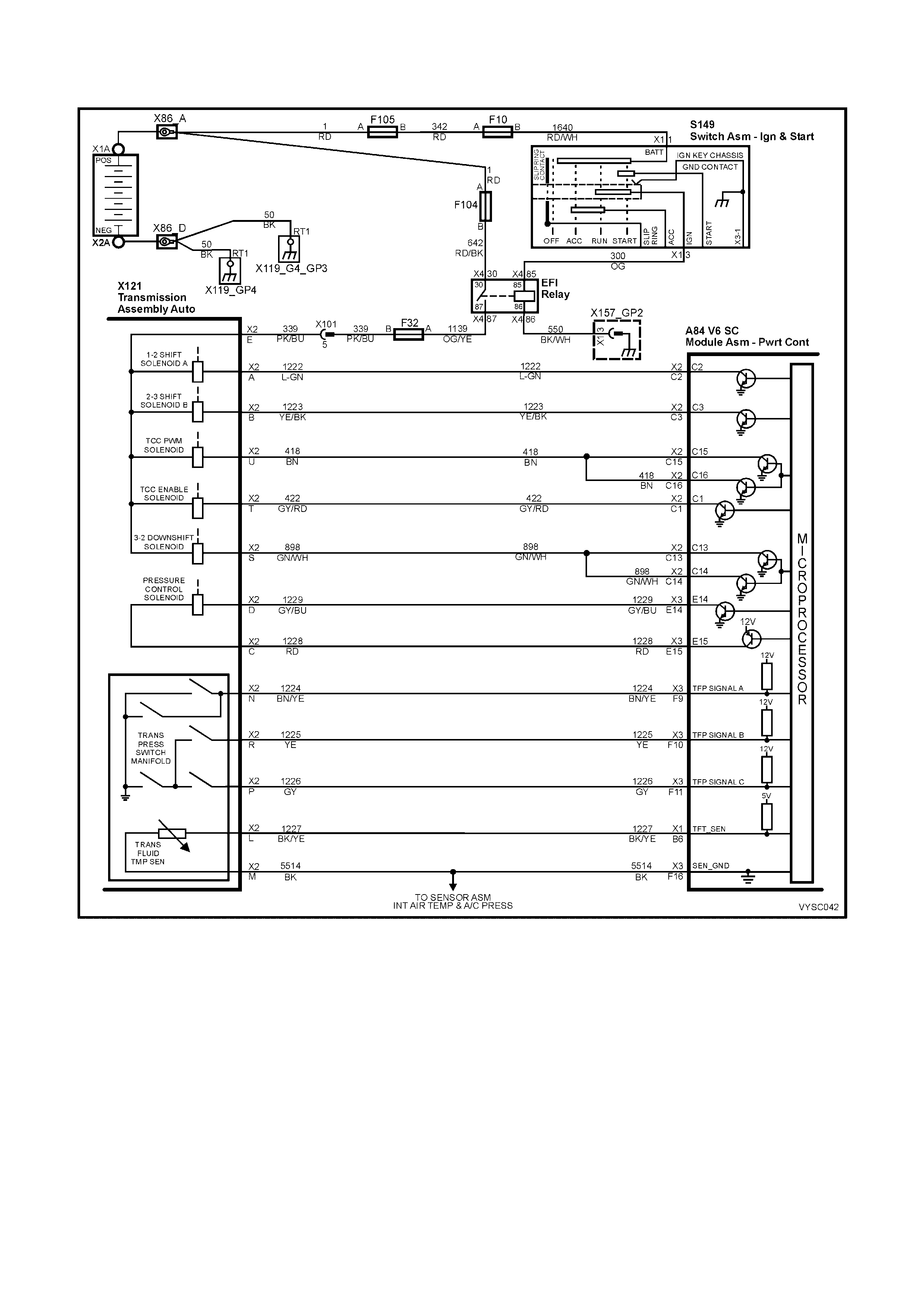

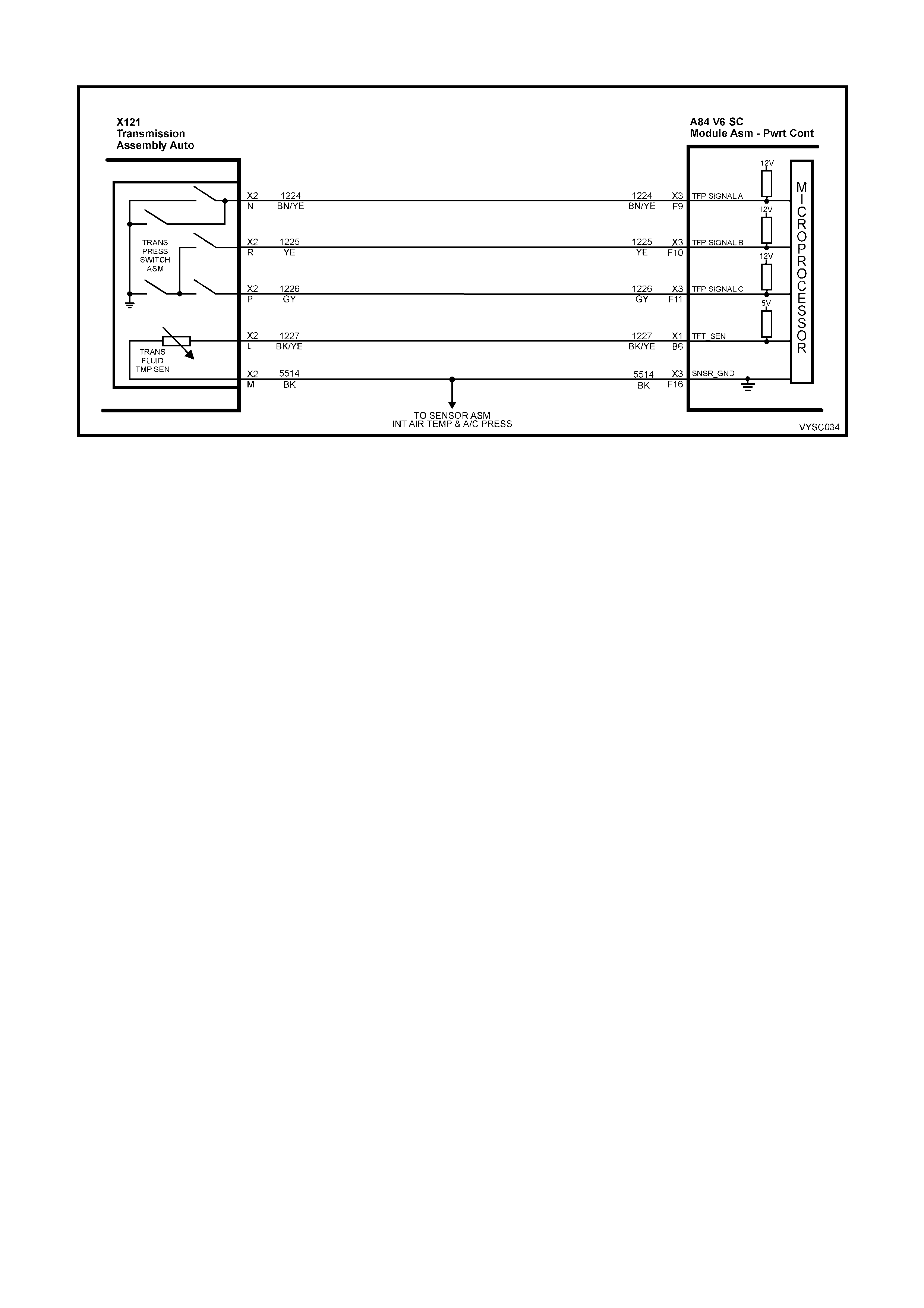

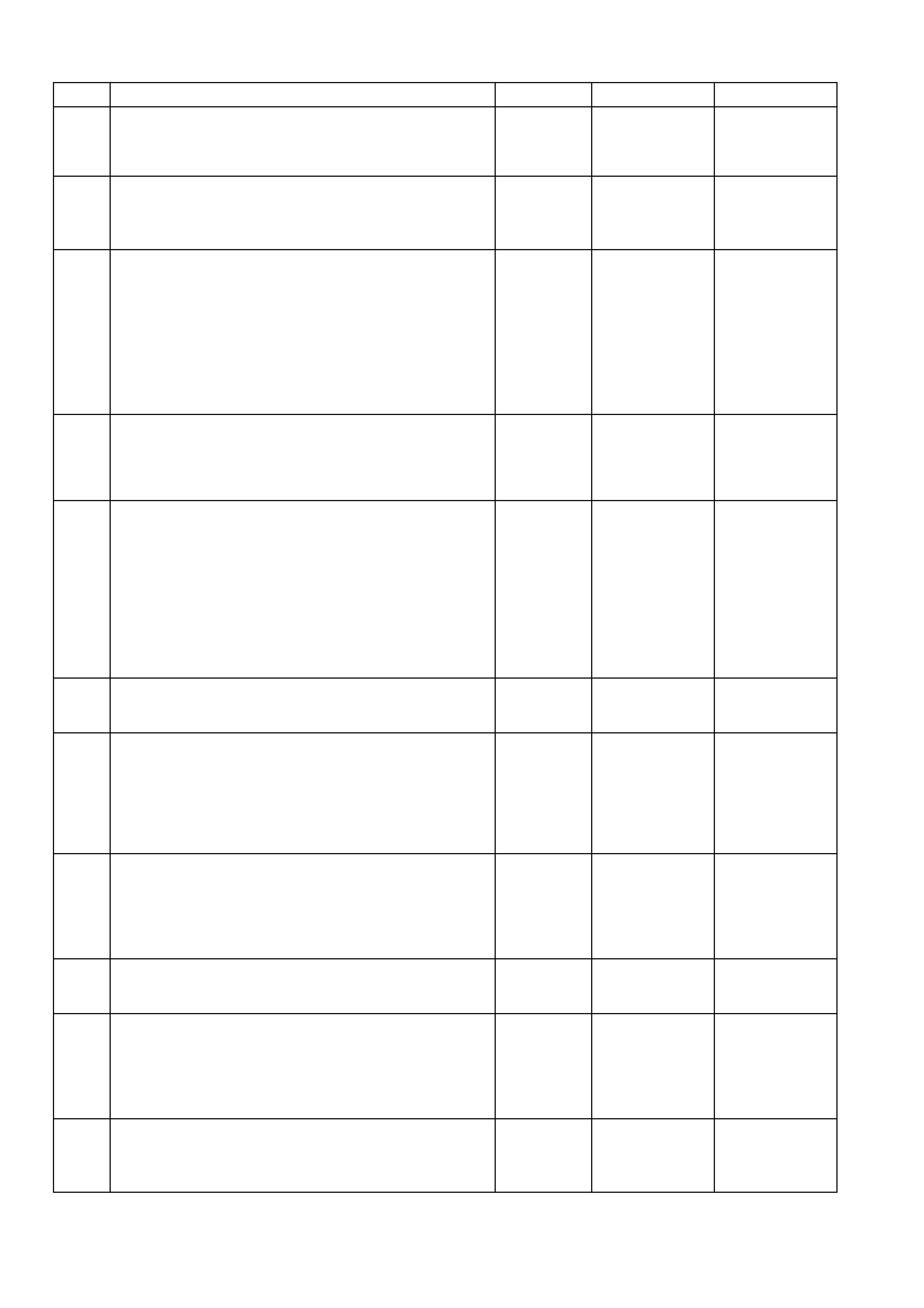

Figure 6C1-2A-14 PCM Wiring Diagram (8 of 8) V6 Supercharged Engine Application –

Automatic Transmission Circuits

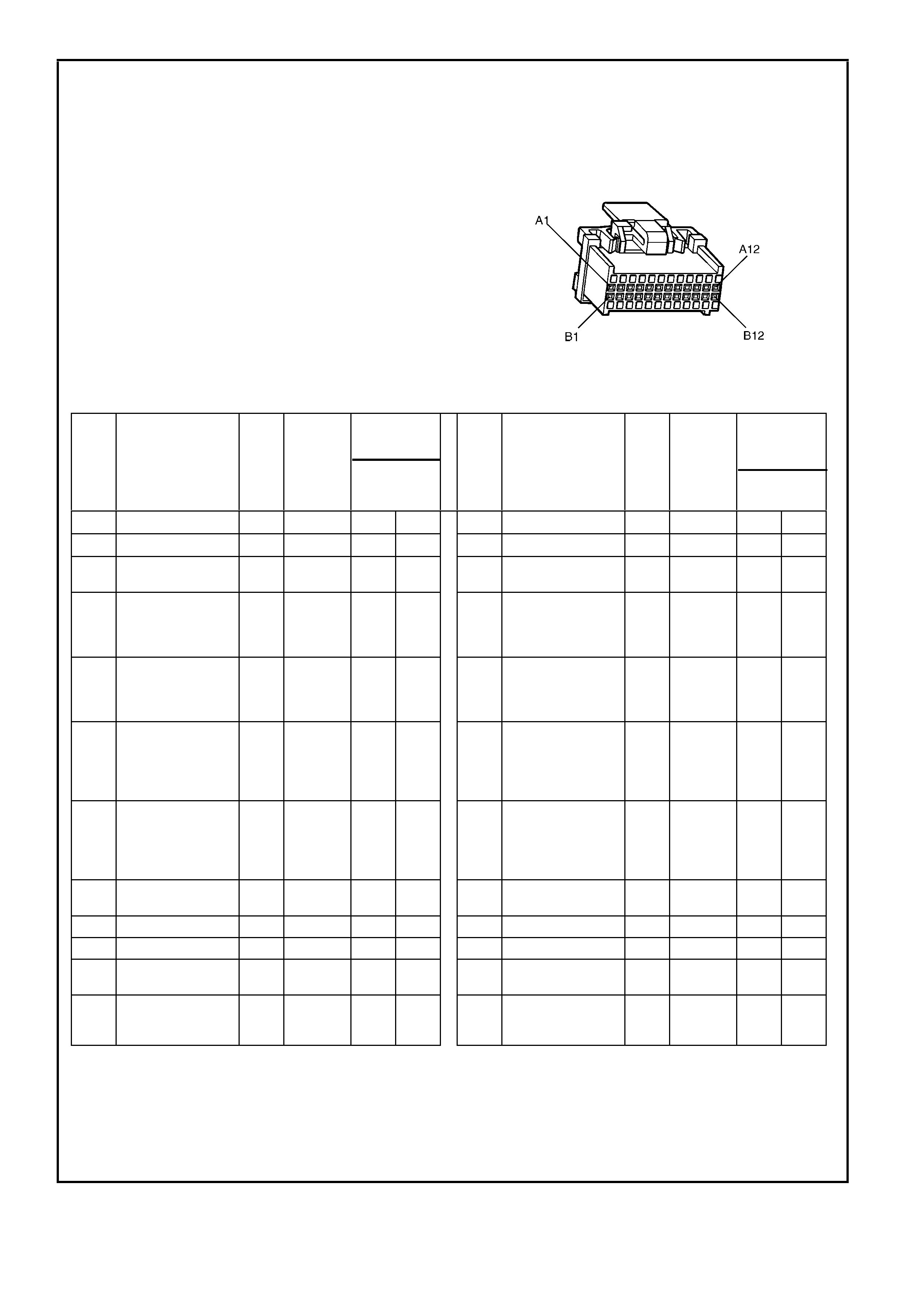

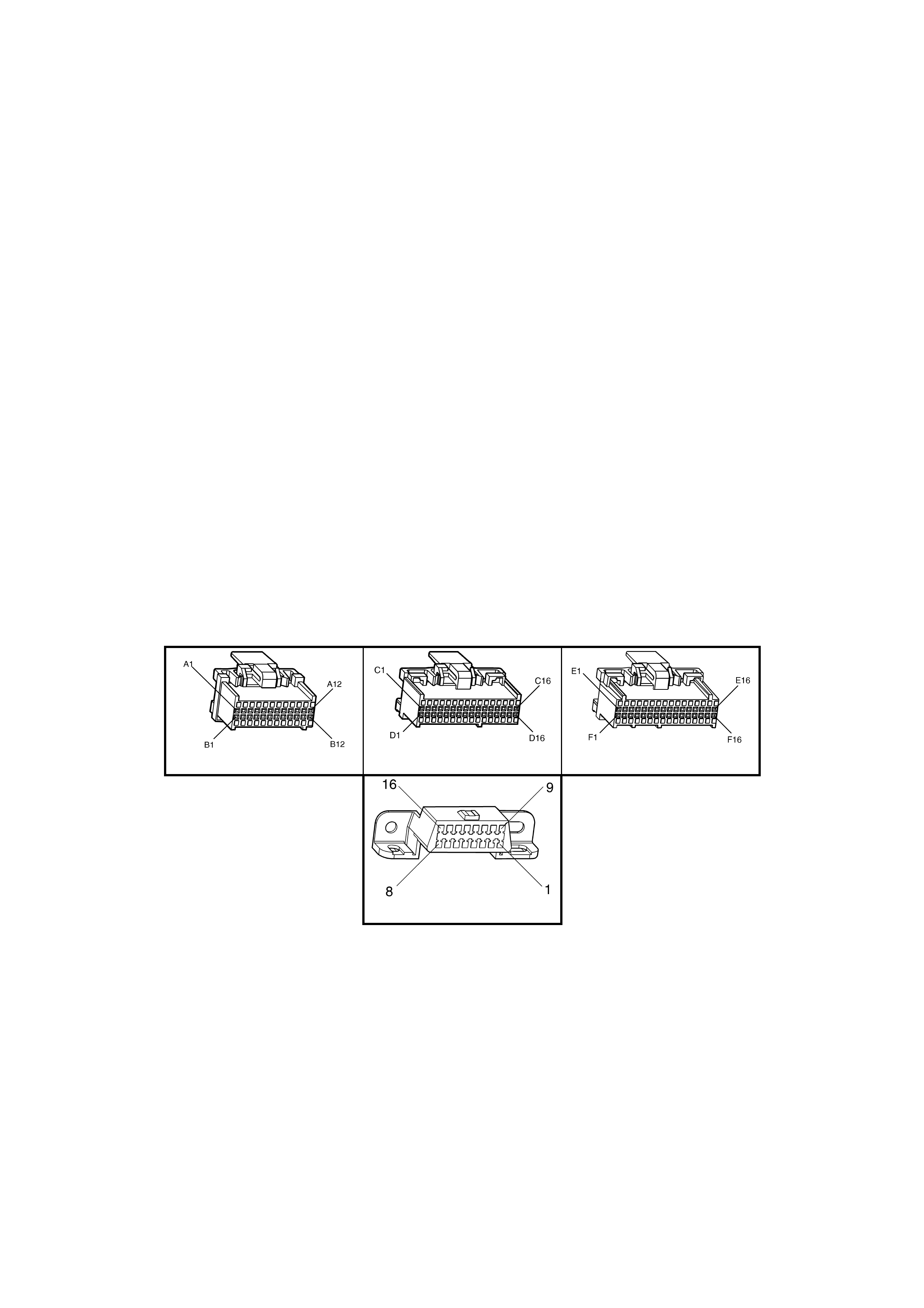

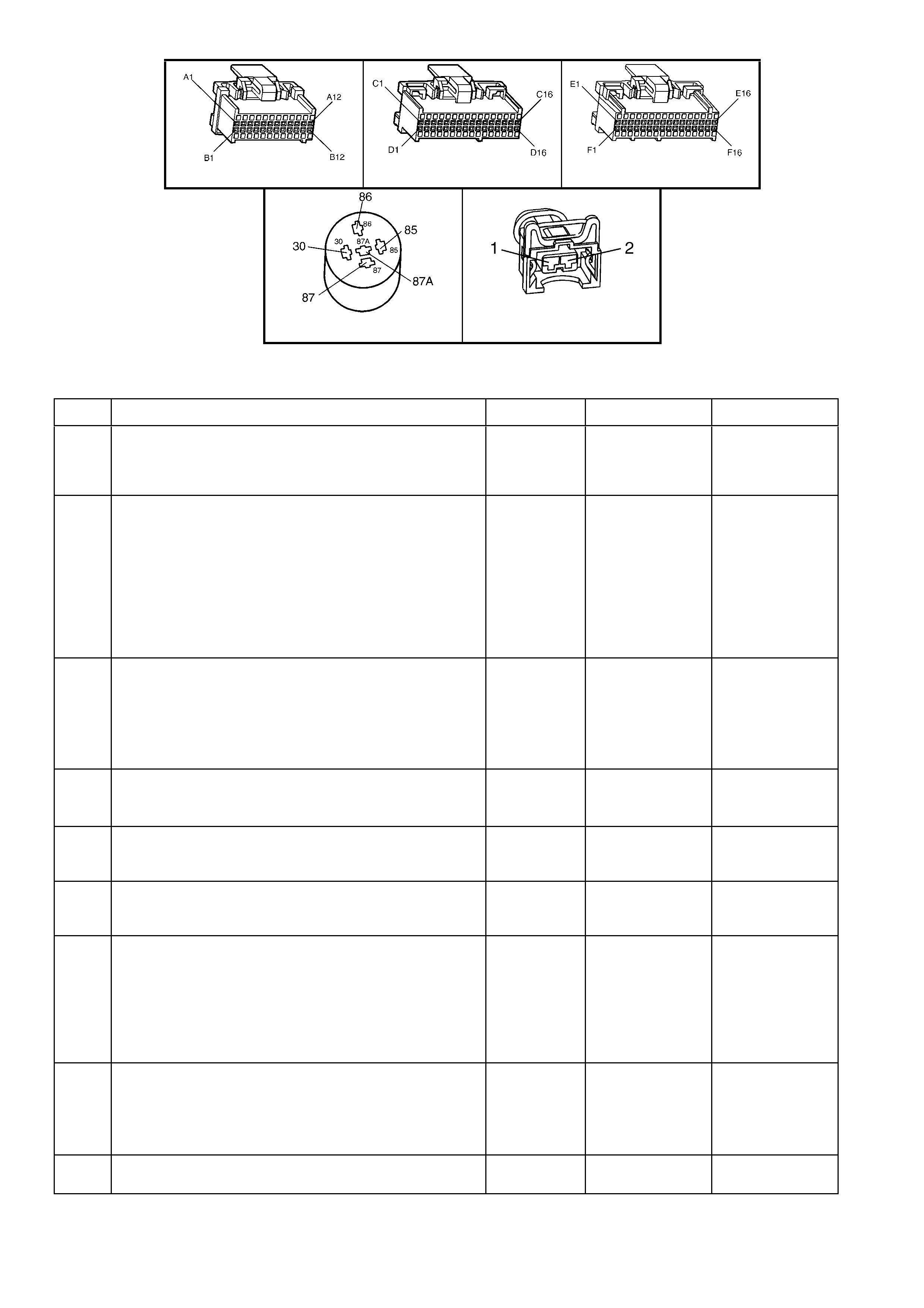

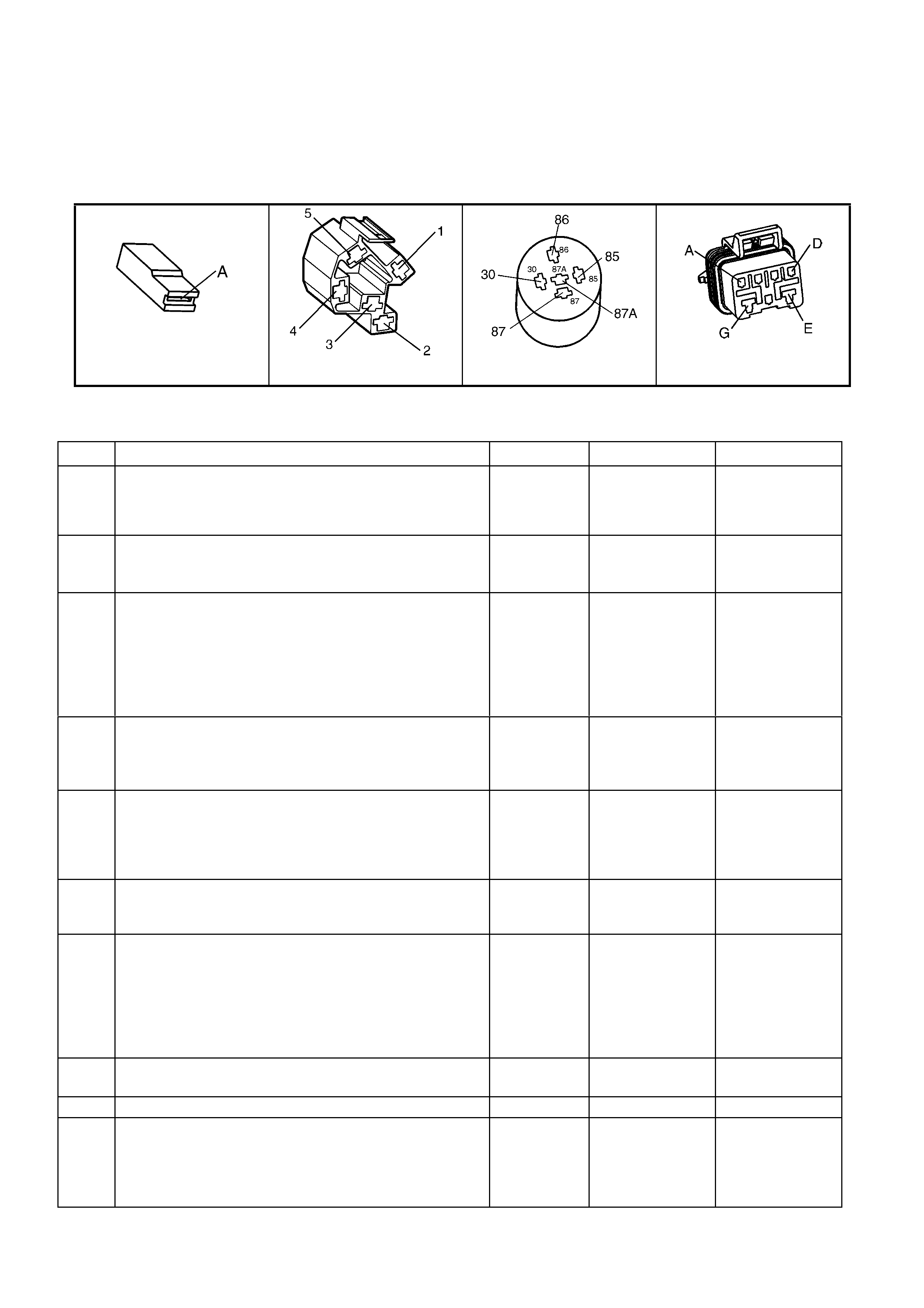

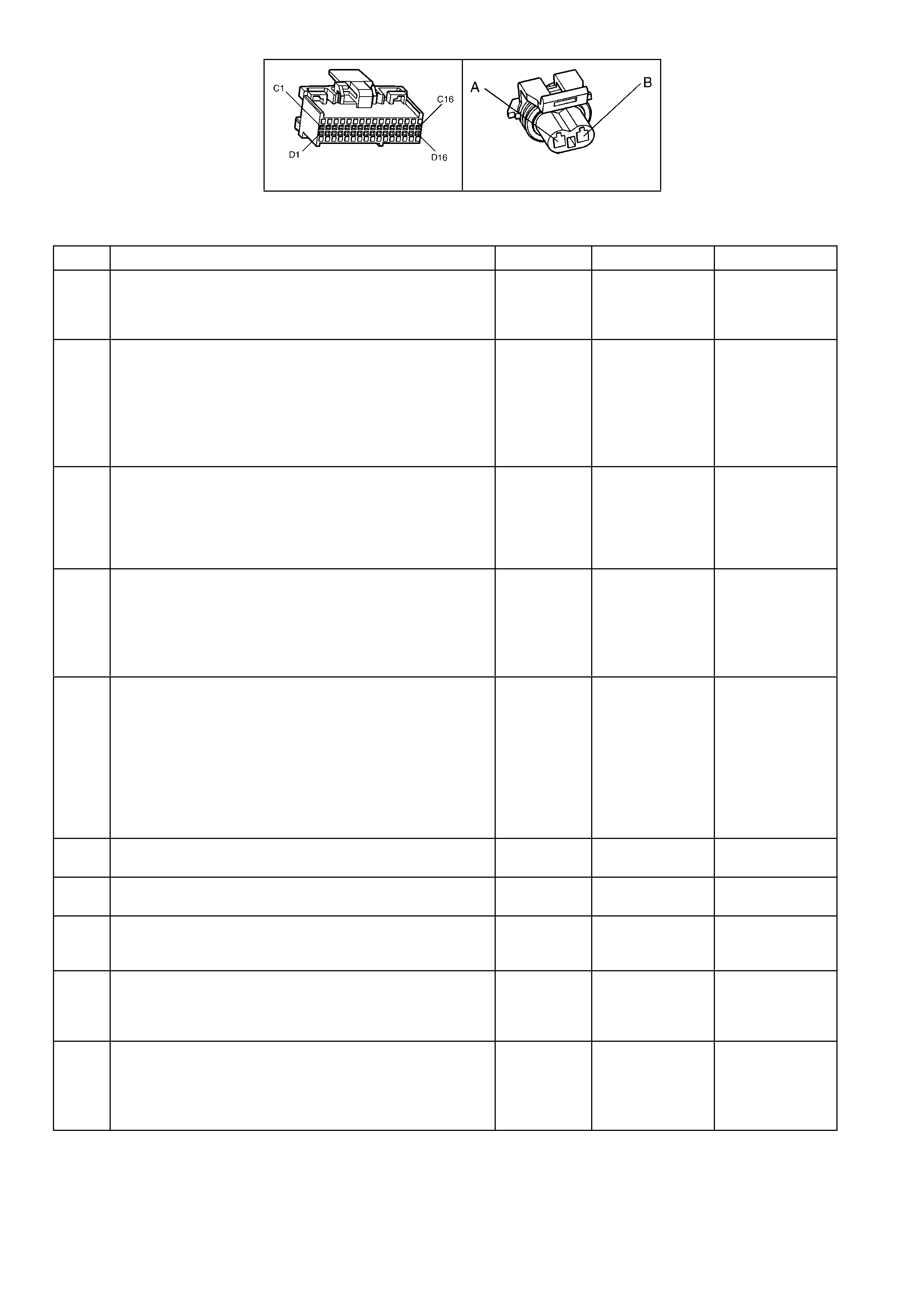

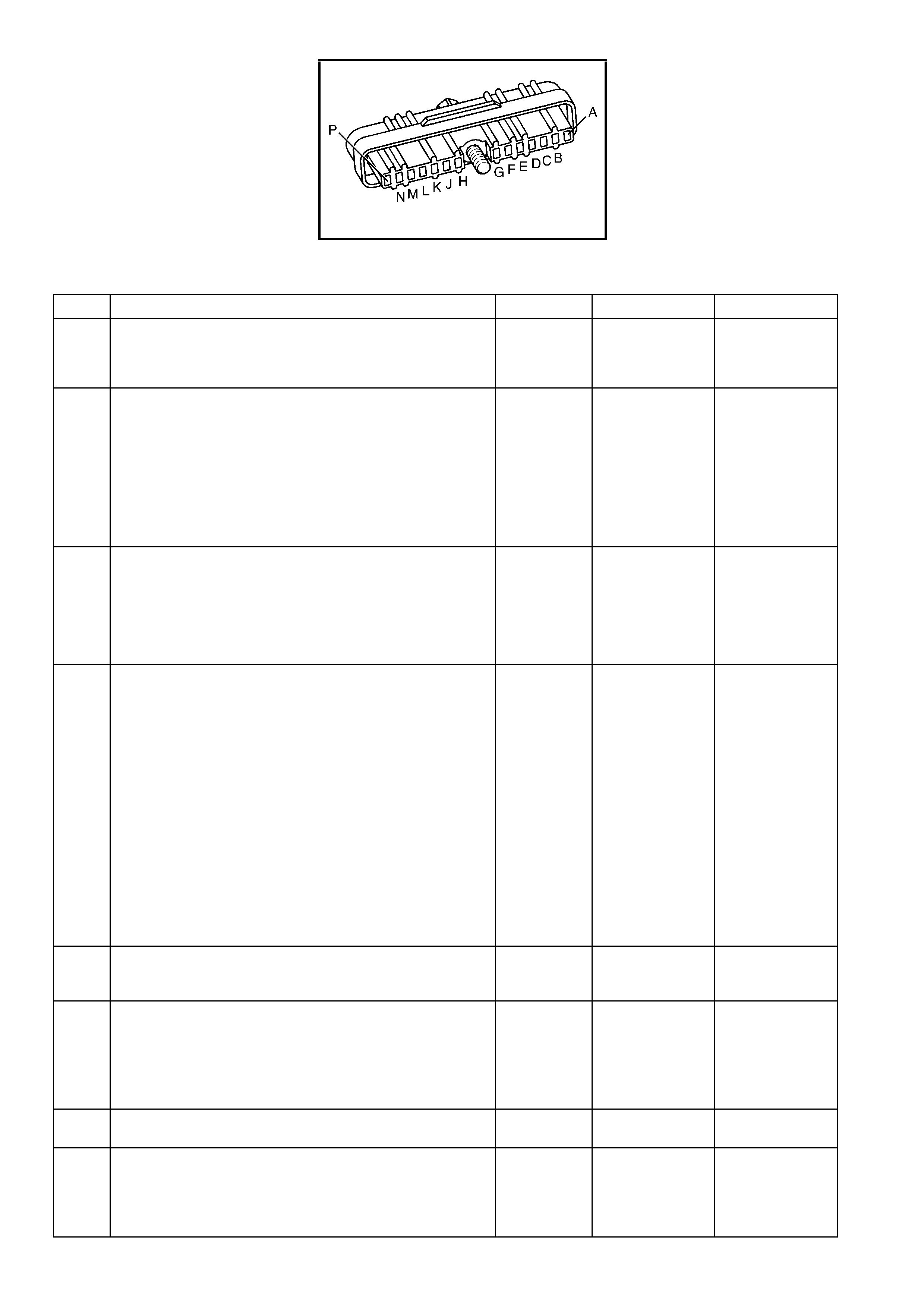

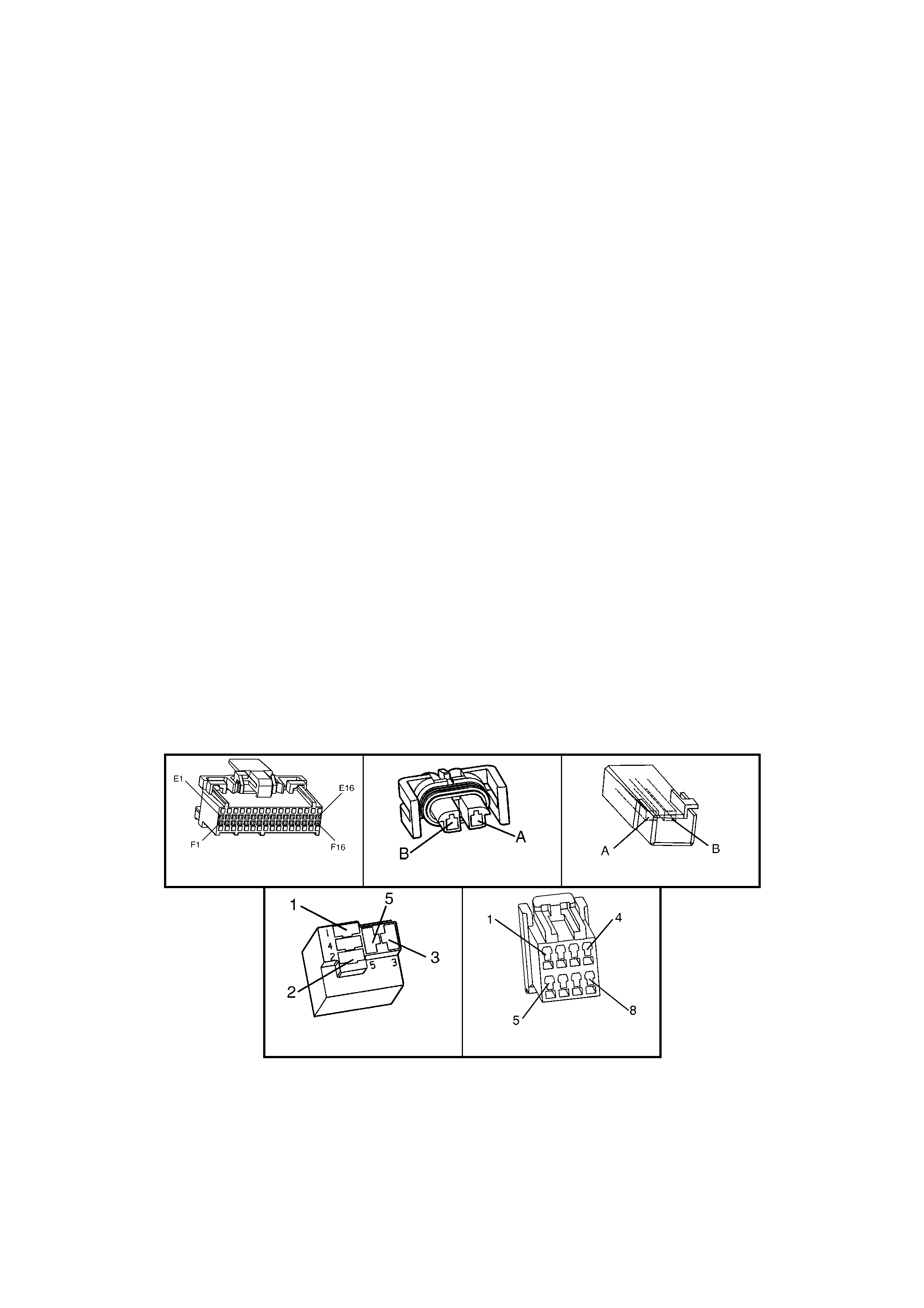

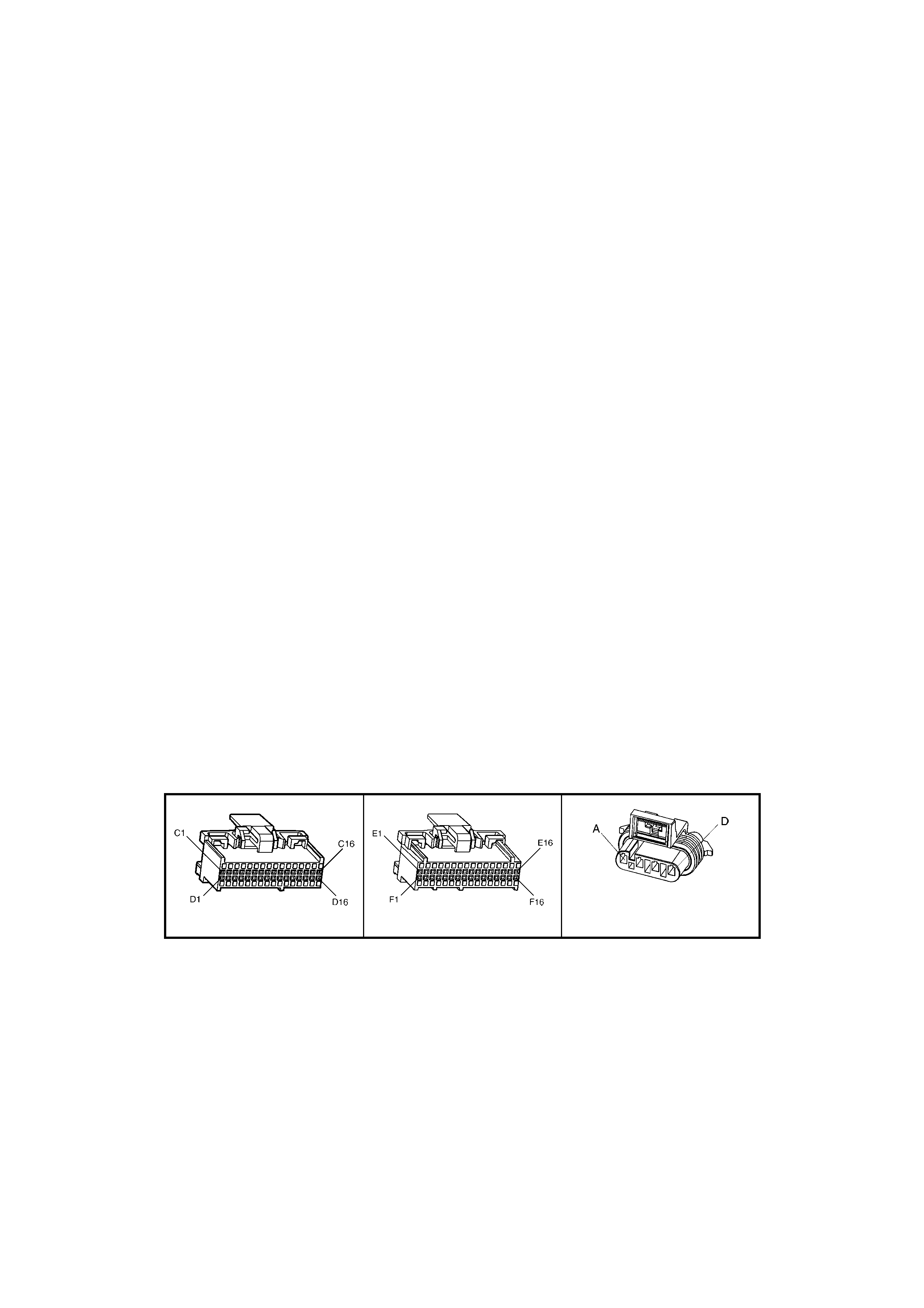

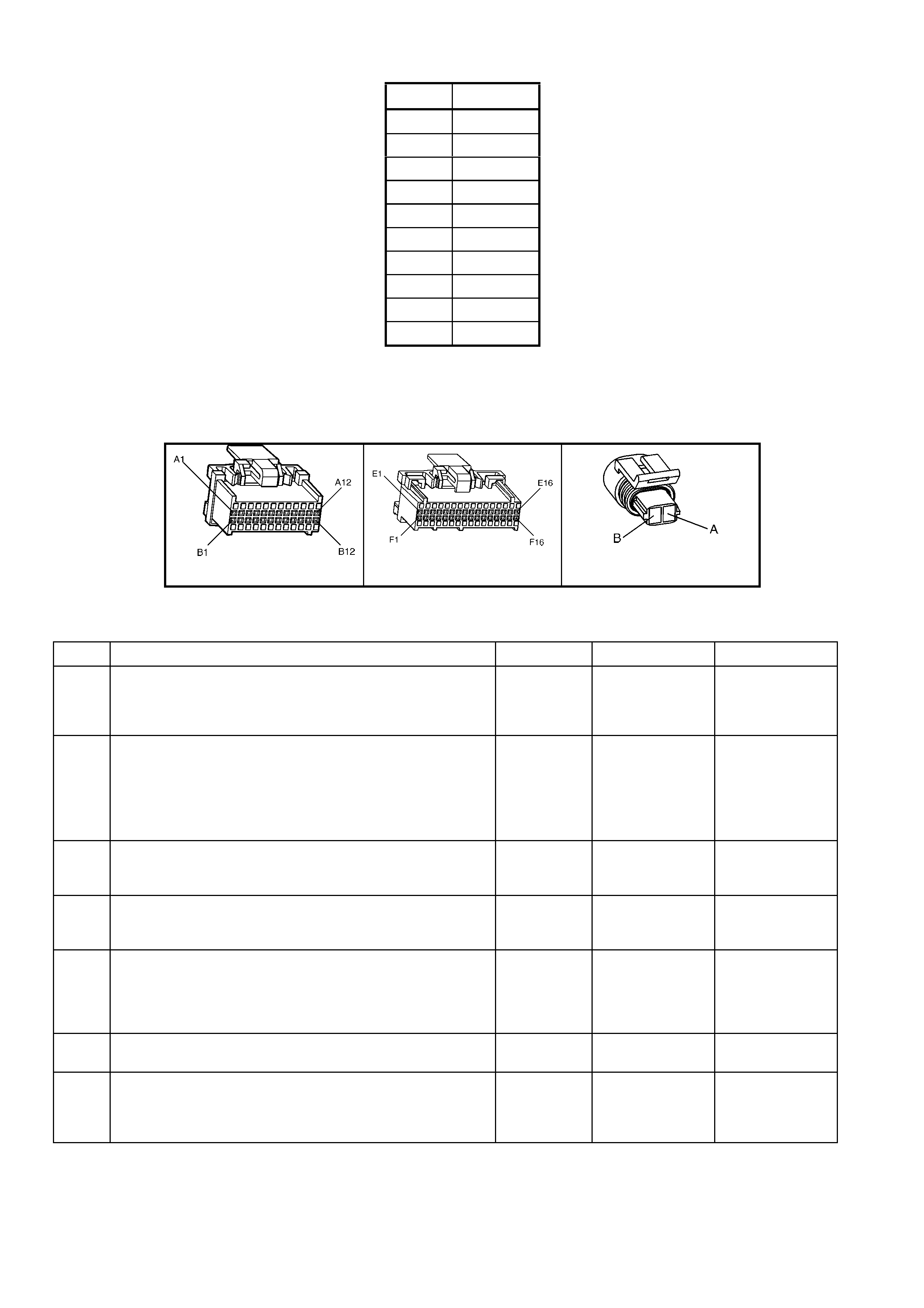

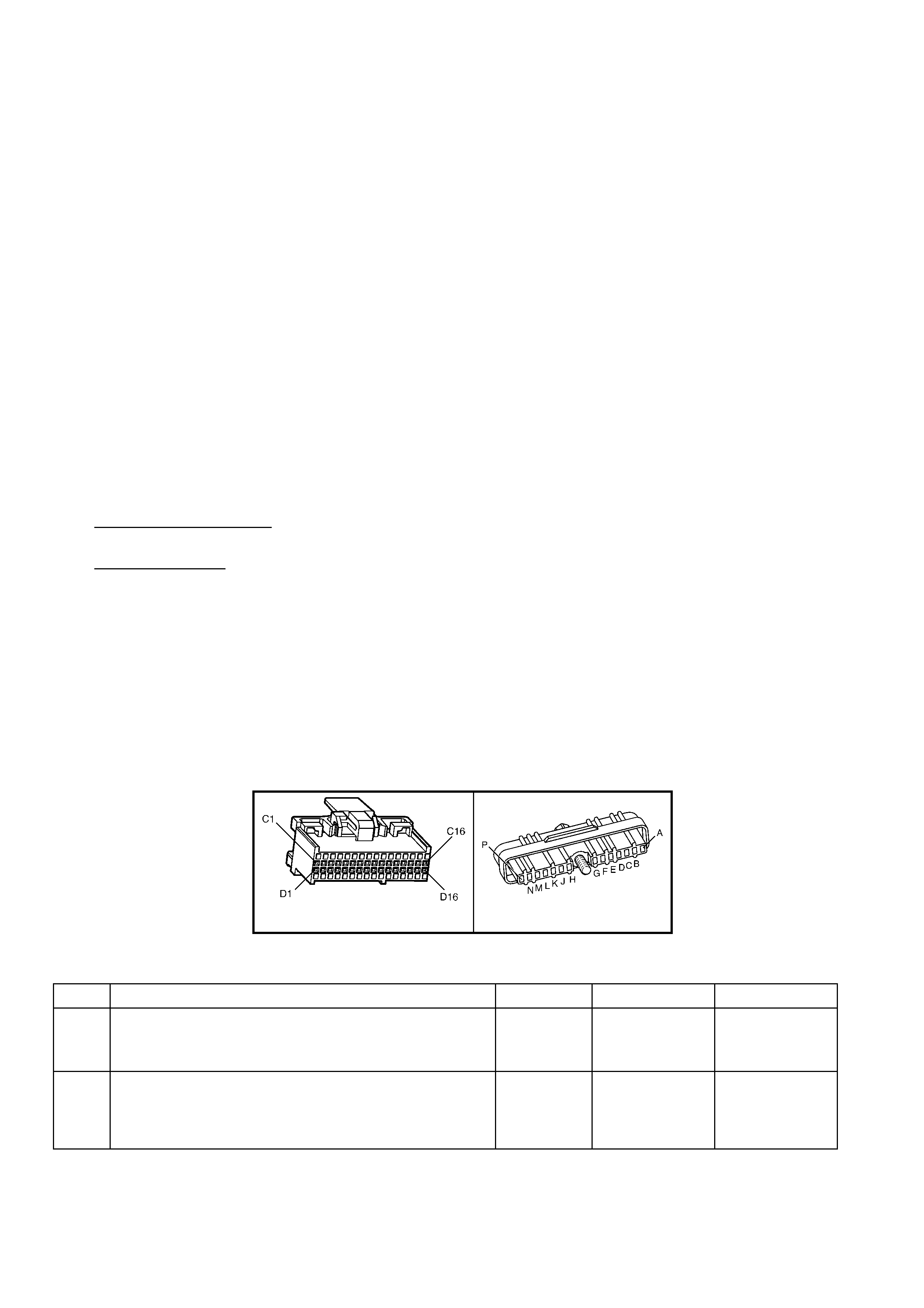

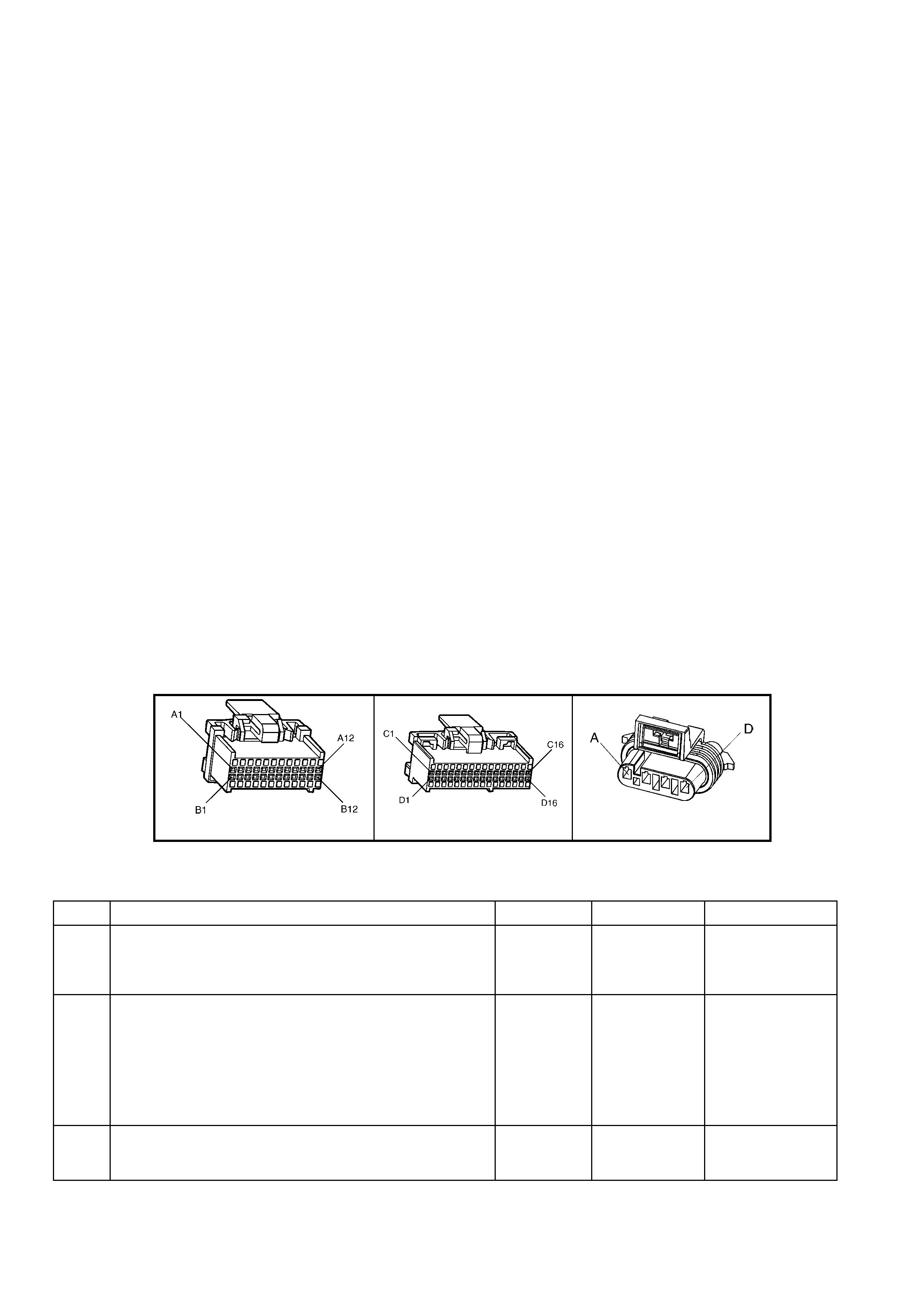

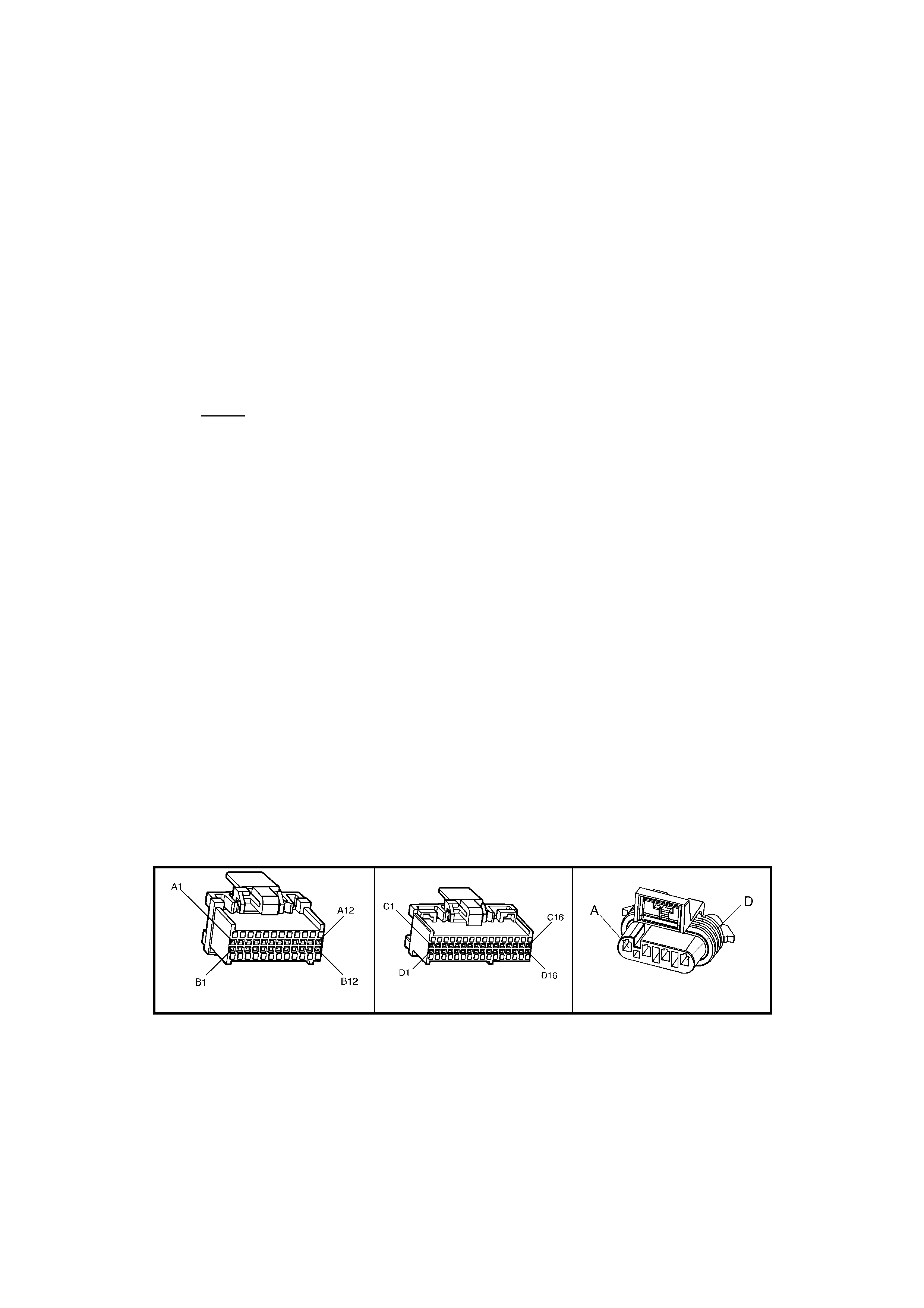

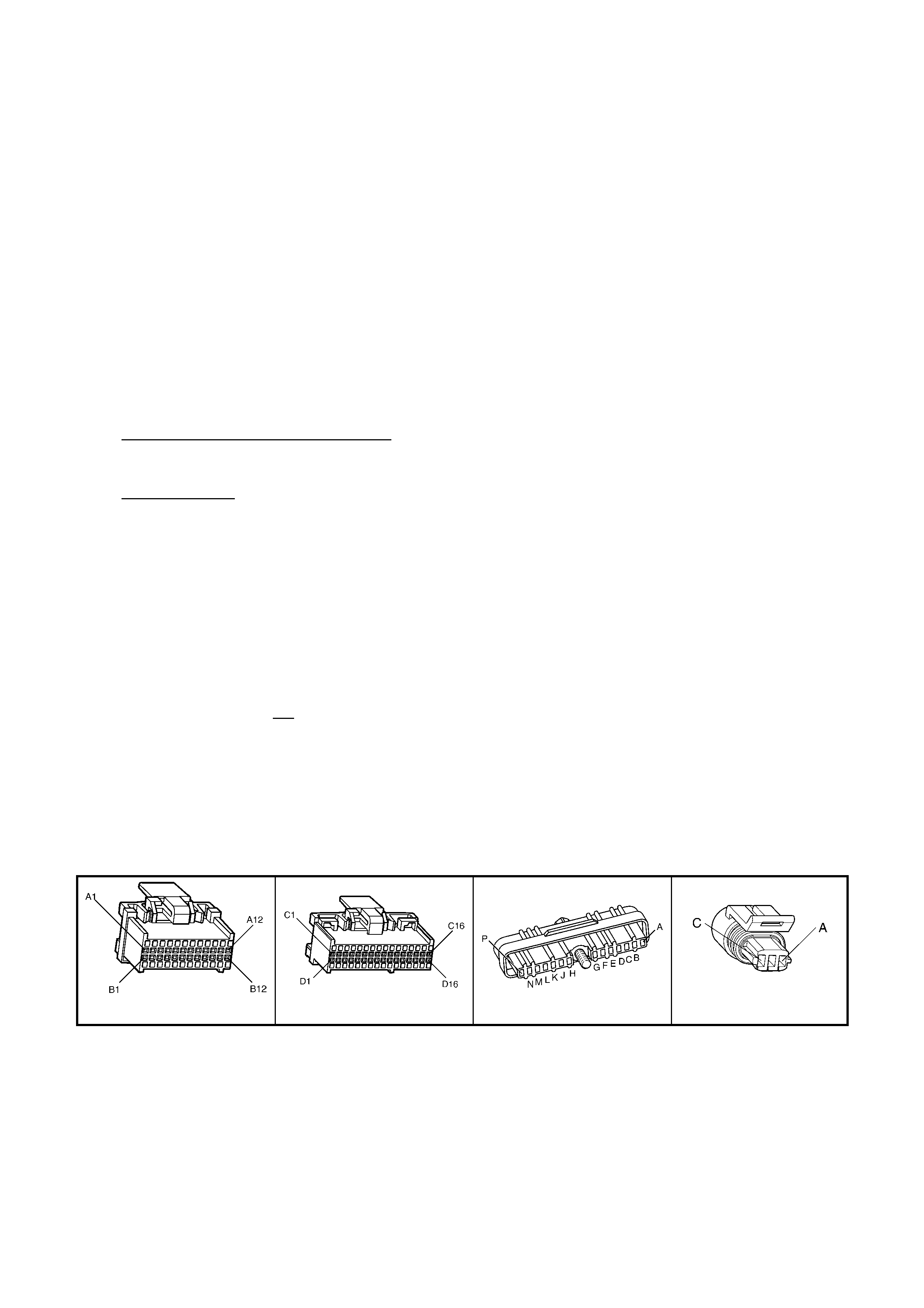

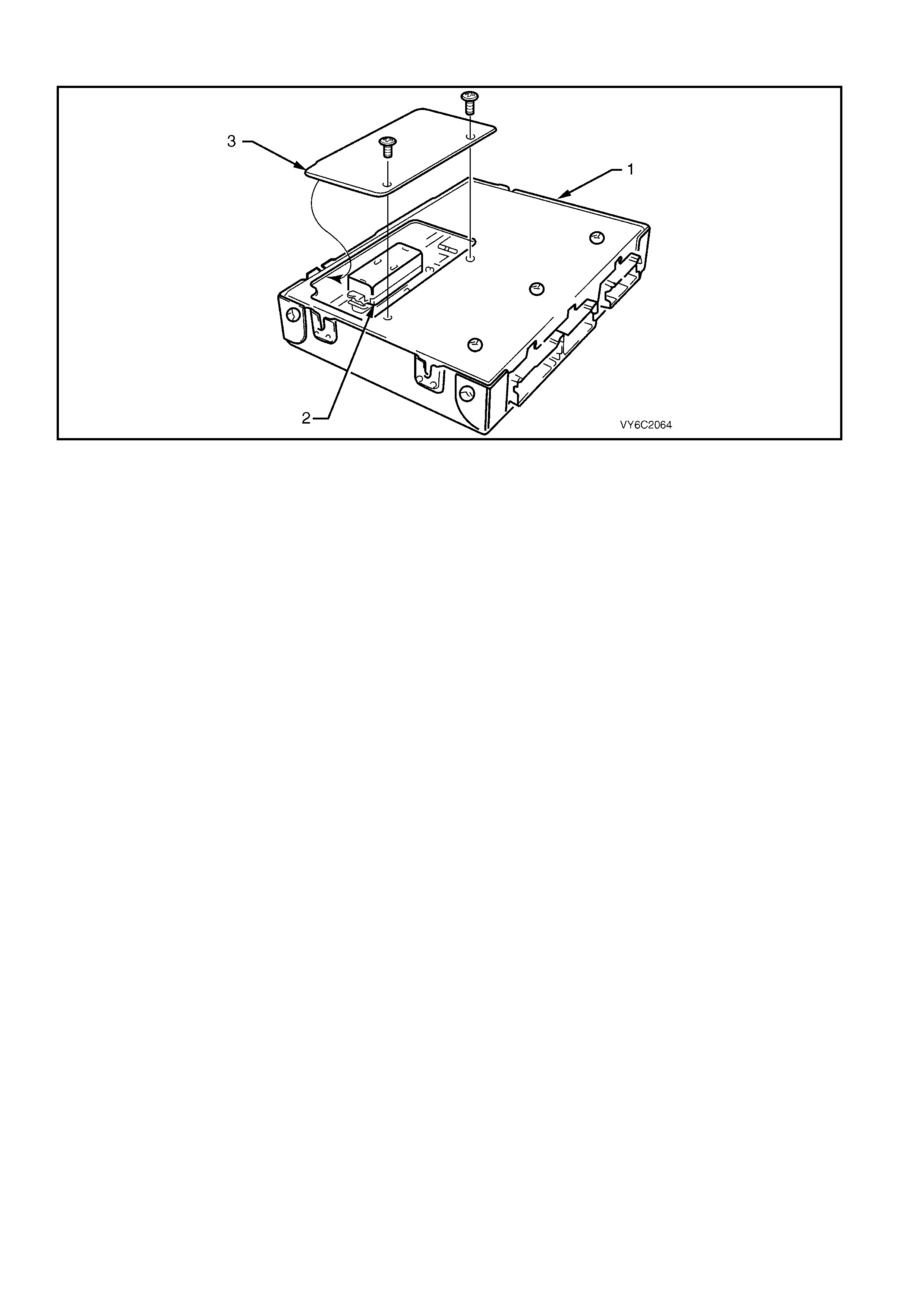

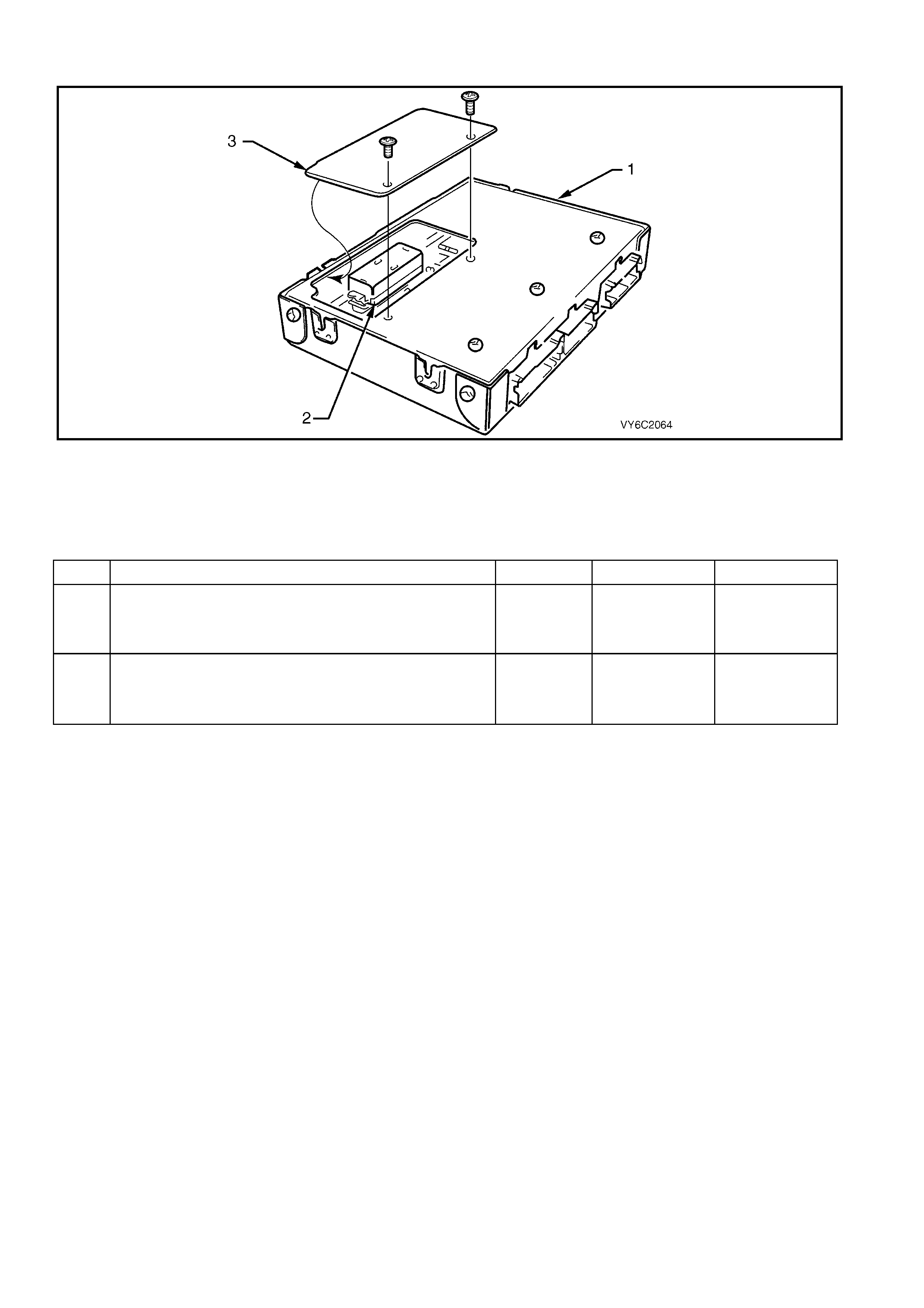

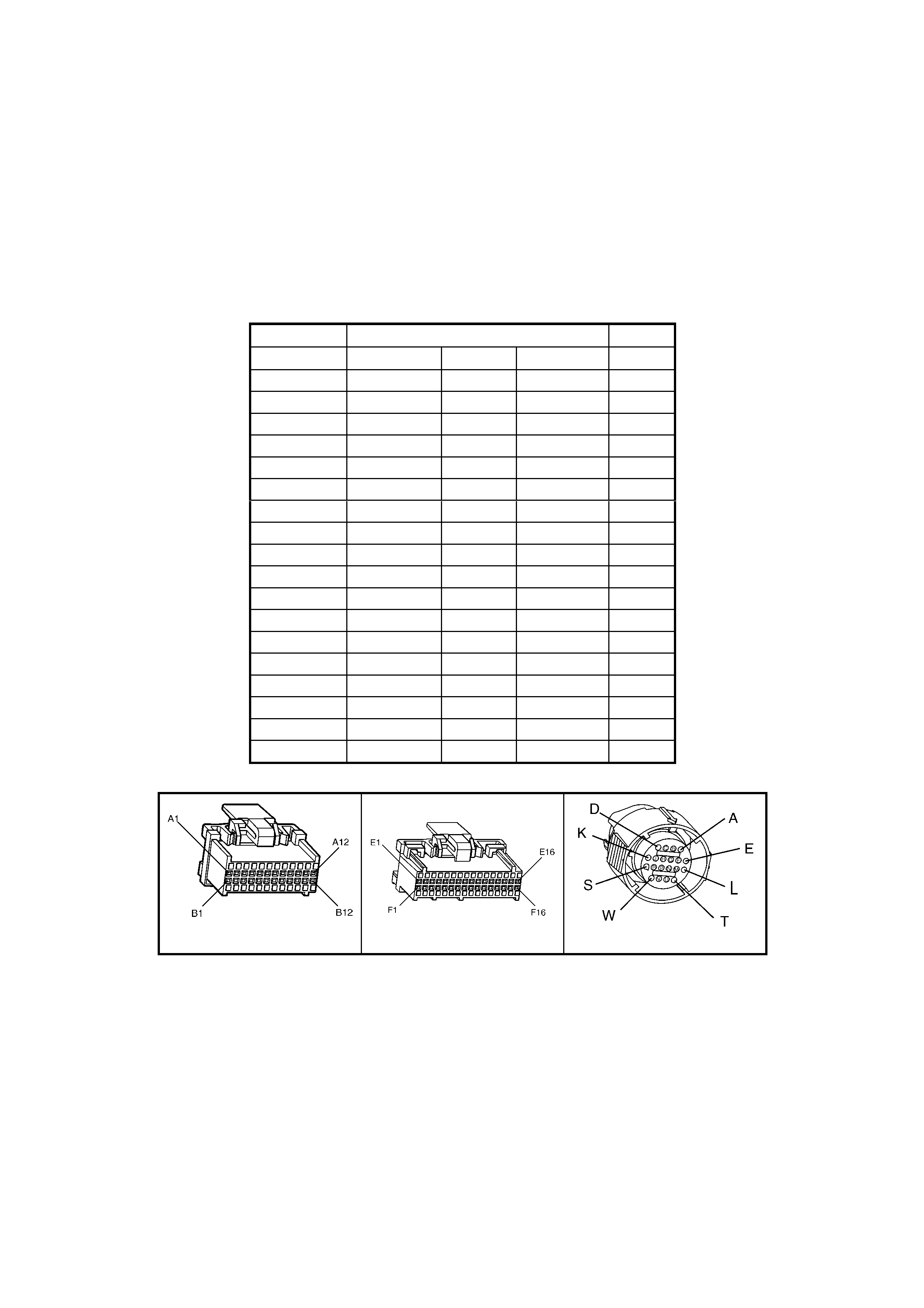

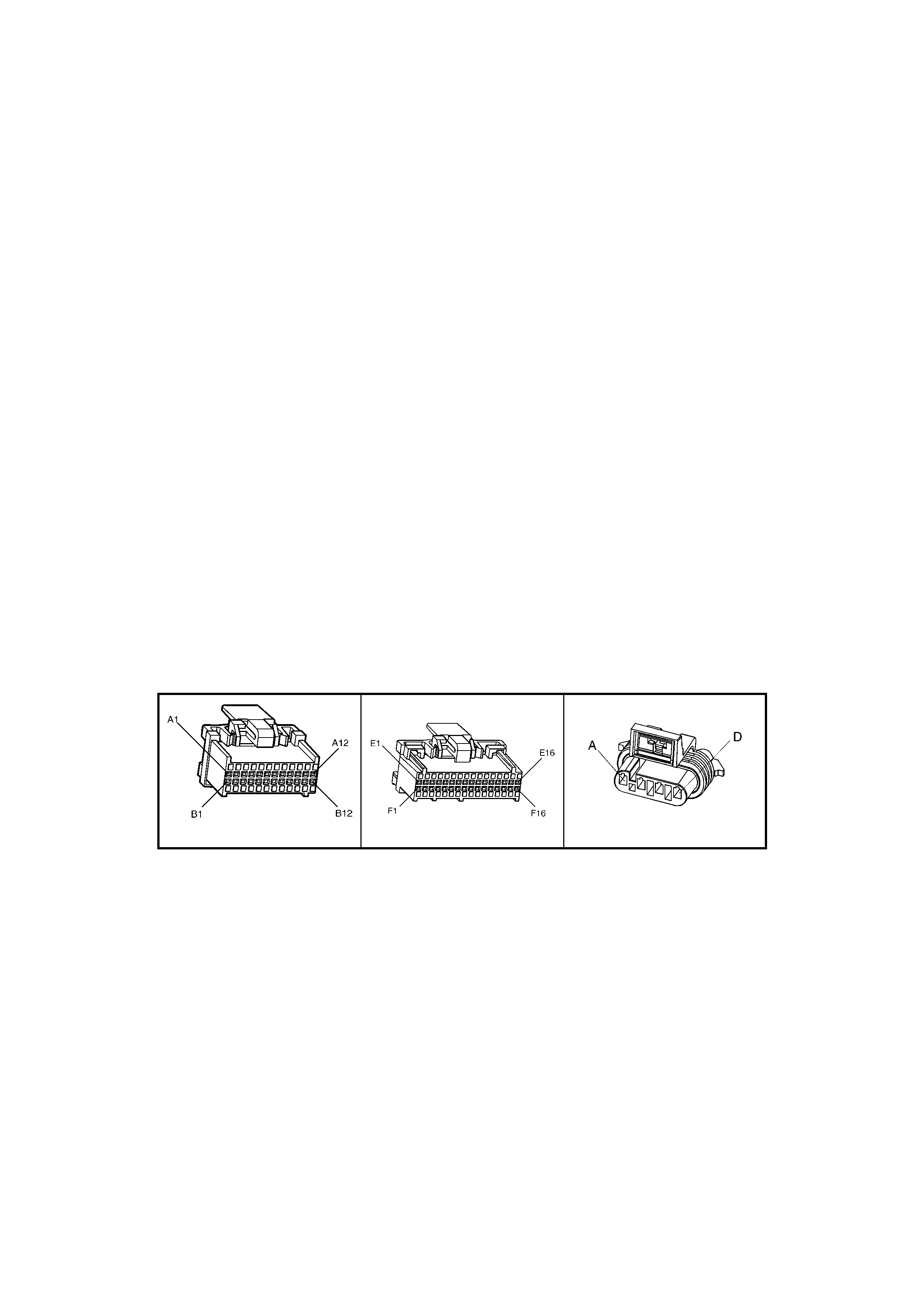

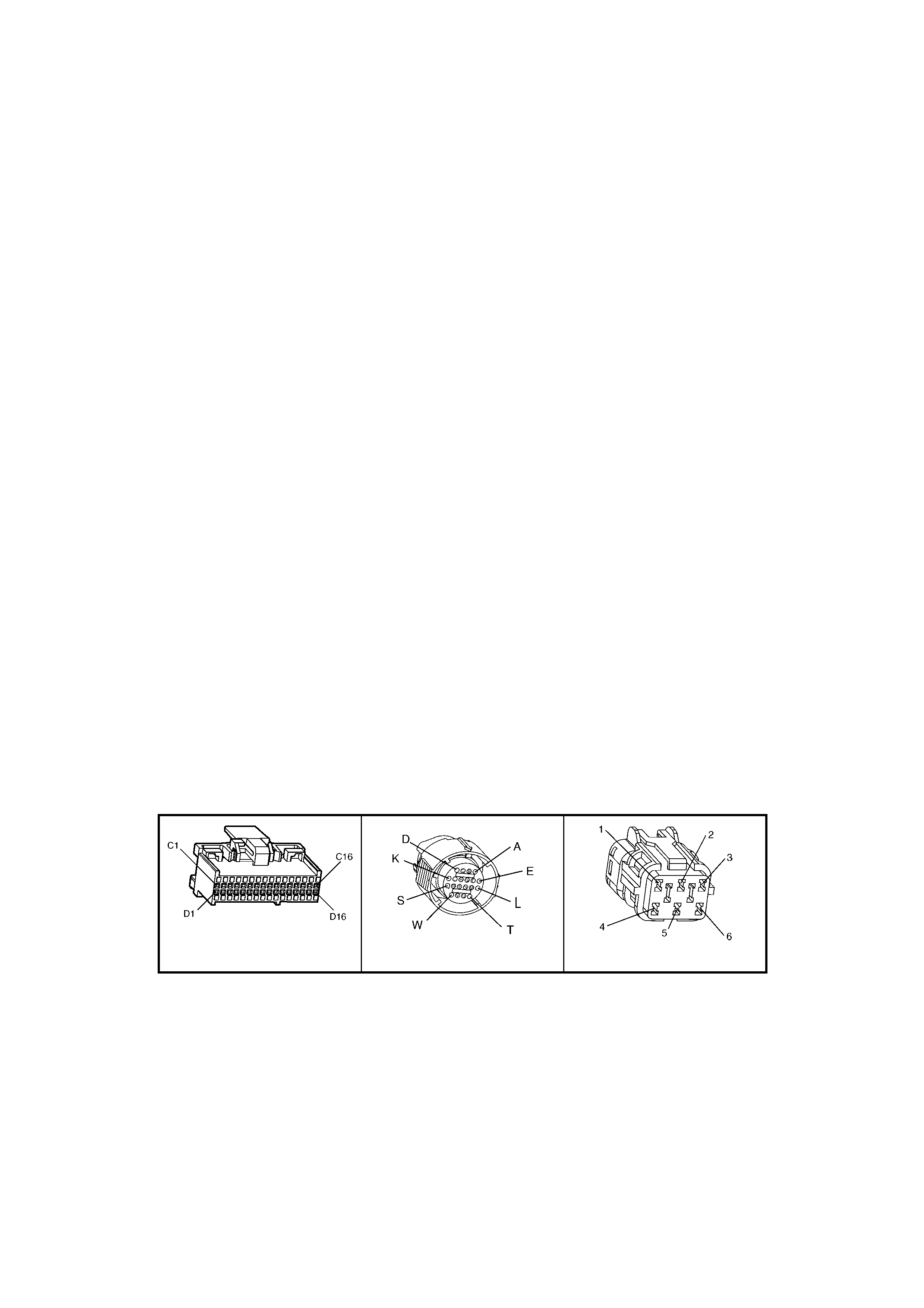

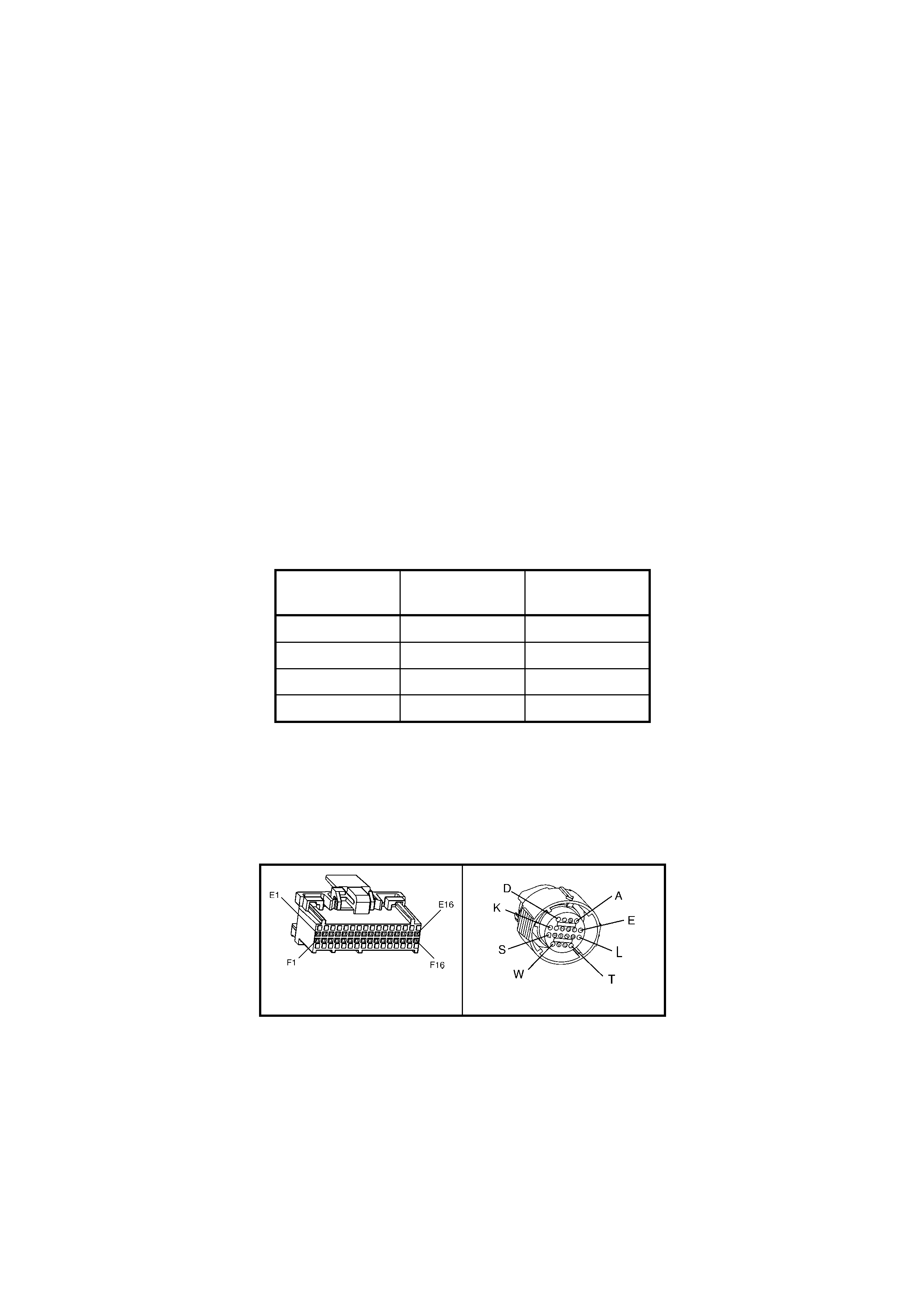

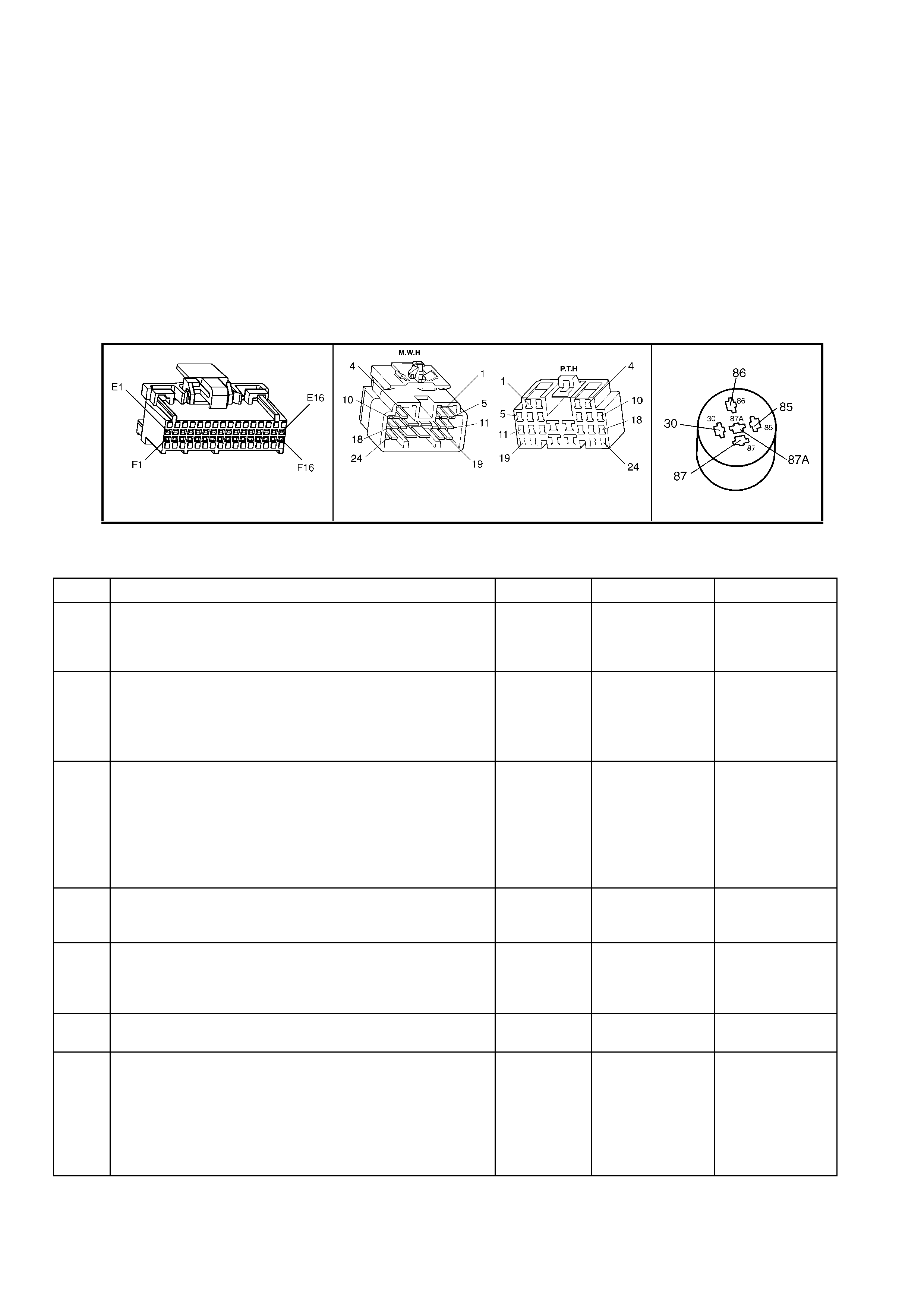

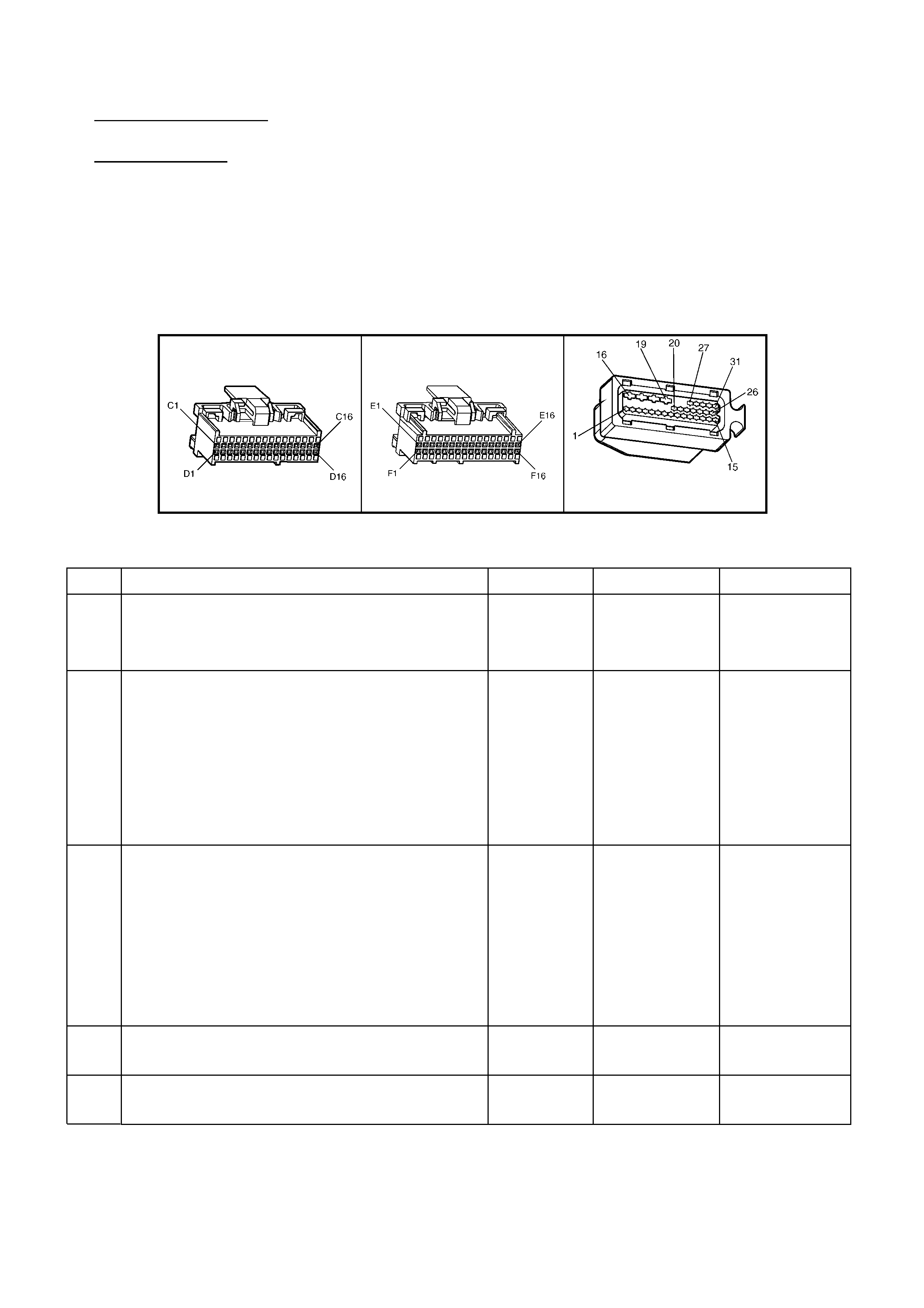

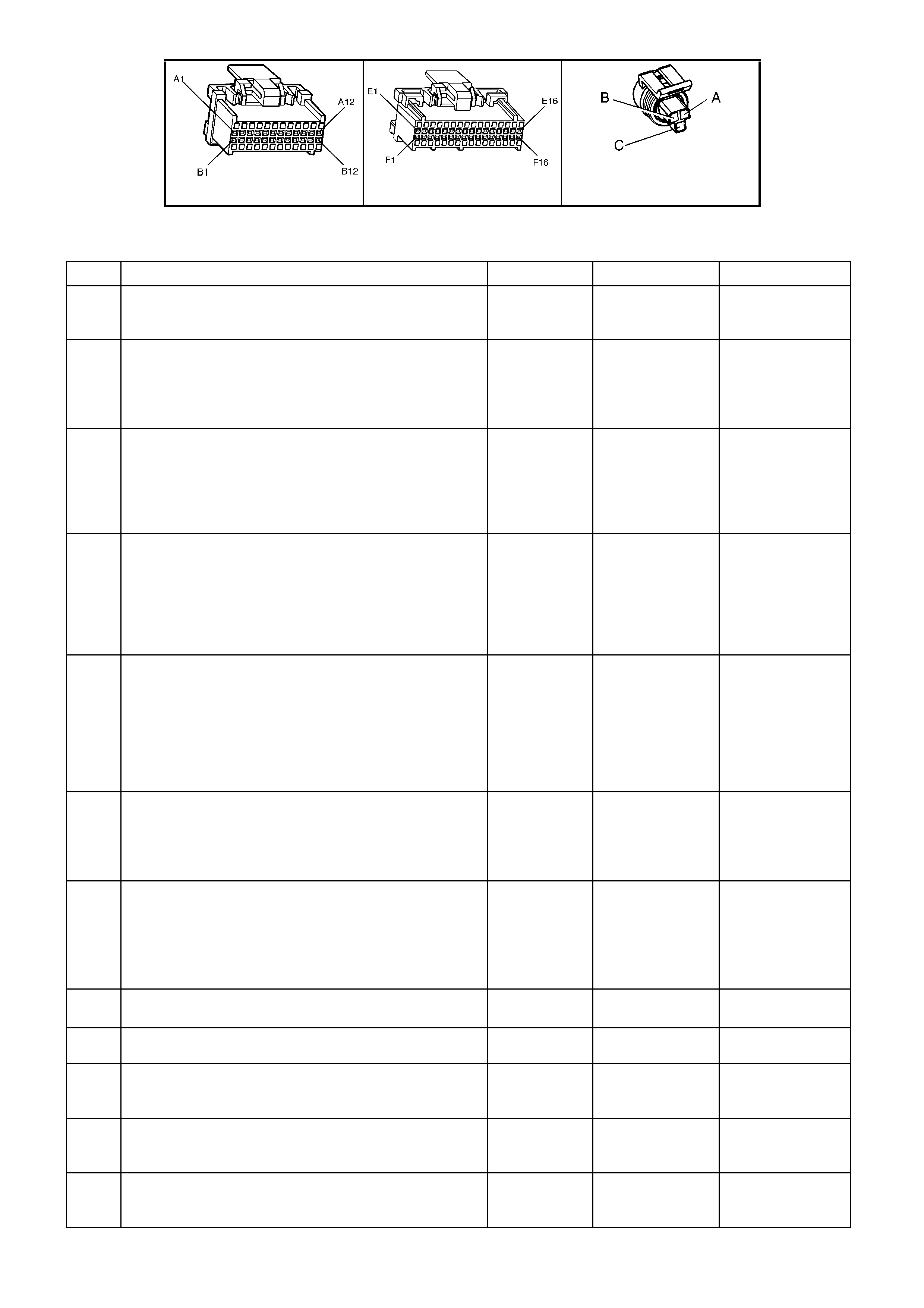

POWERTRAIN CONTROL MODULE CONNECTOR IDENTIFICATION

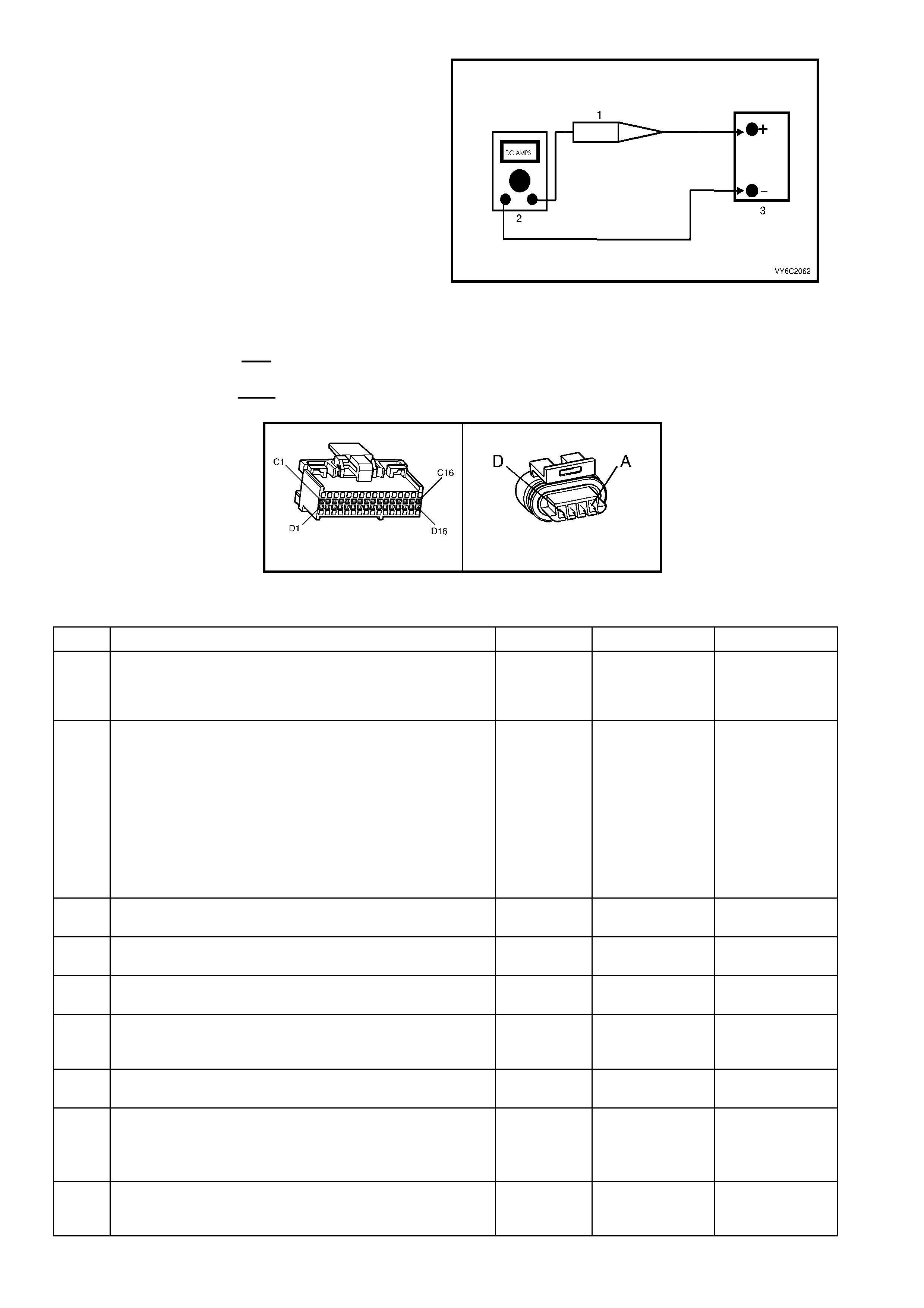

This Powertrain Control Module Voltage Table is for use with a digital voltmeter to further aid in diagnosis.

Connect the Black (–) probe to a good chassis ground, and backprobe the powertrain control module terminal

with the Red ( +) pr obe. T hese voltages were derived fr om a k nown good vehicle. The voltages you get m ay vary

due to low battery charge or other reasons, but they should be very close.

THE FOLLOWING CONDITIONS MUST BE MET BEFORE TESTING:

• Engine and Transmission at operating

temperature

• Closed Loop

• Engine idling (for "Engine Run" column)

• Diagnostic "Test" terminal not grounded

• Tech 2 scan tool not installed

• Accessories "OFF"

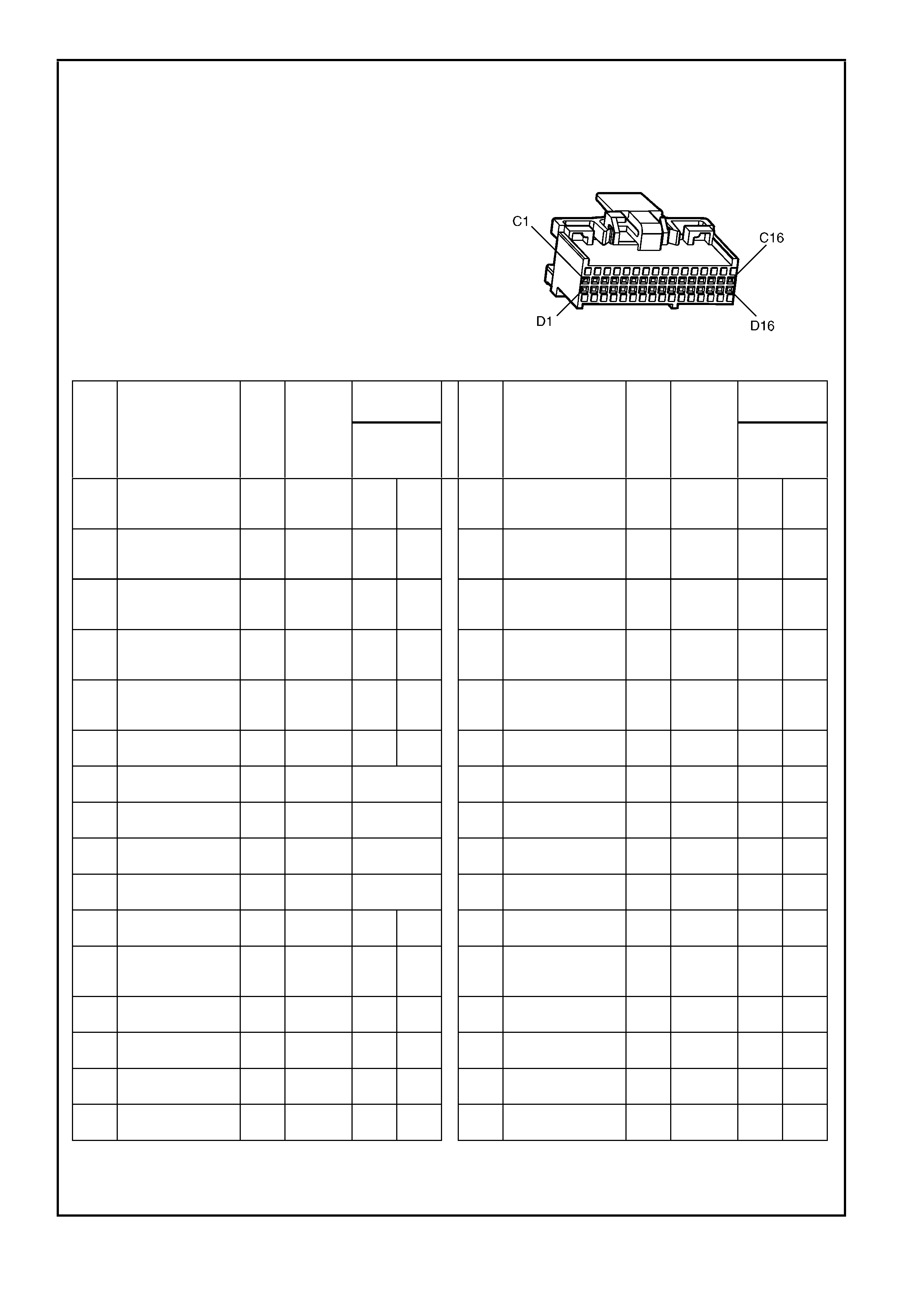

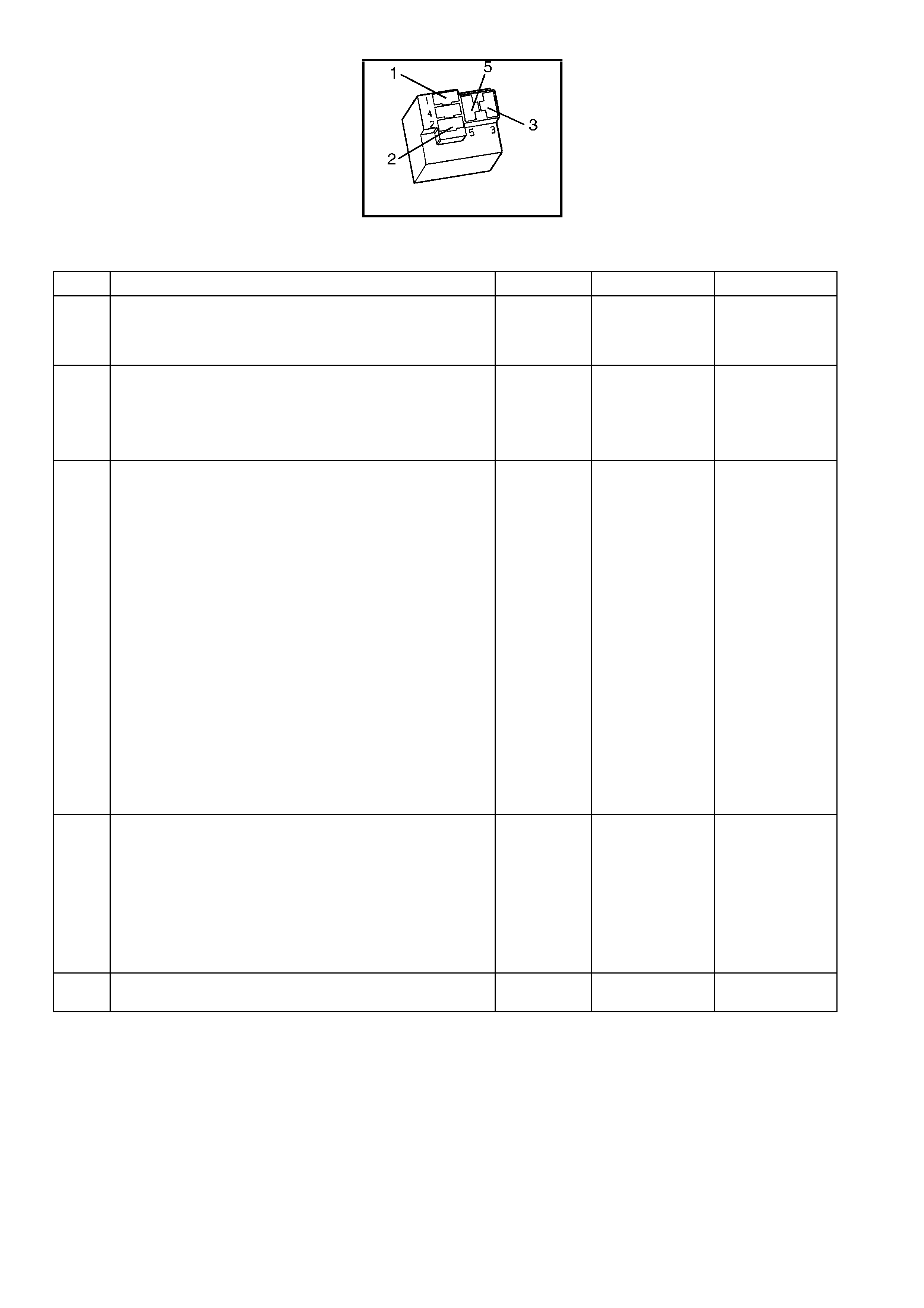

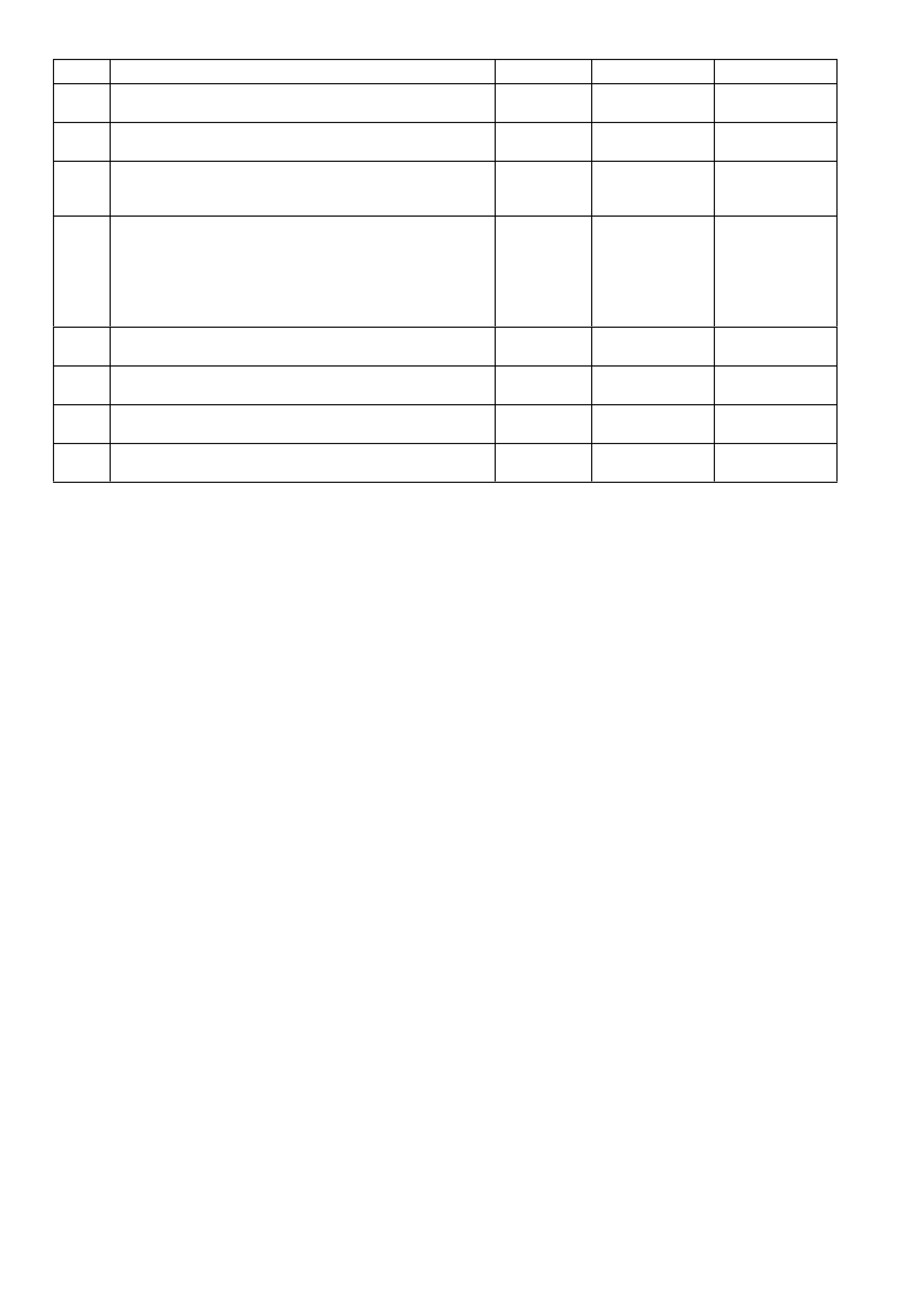

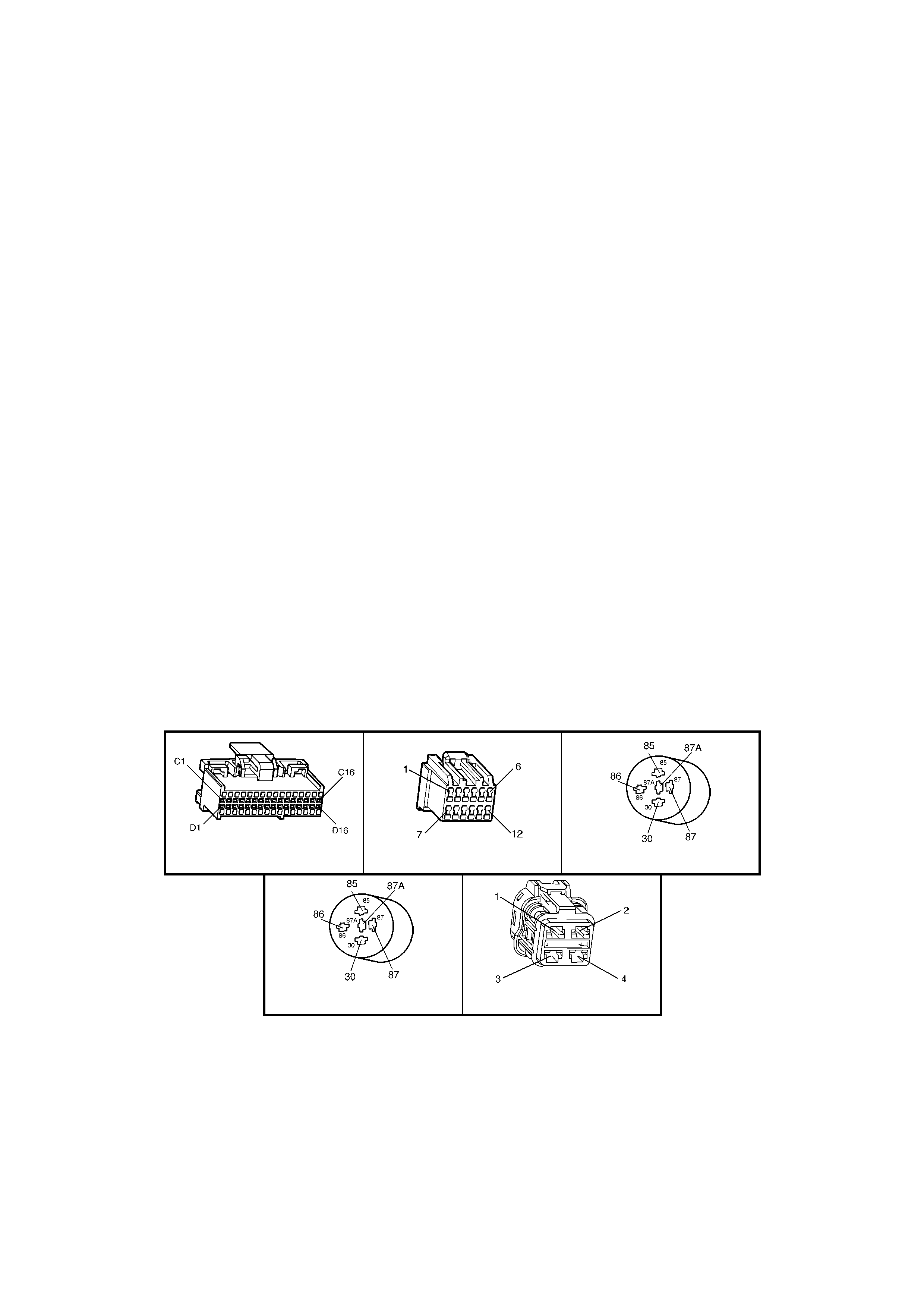

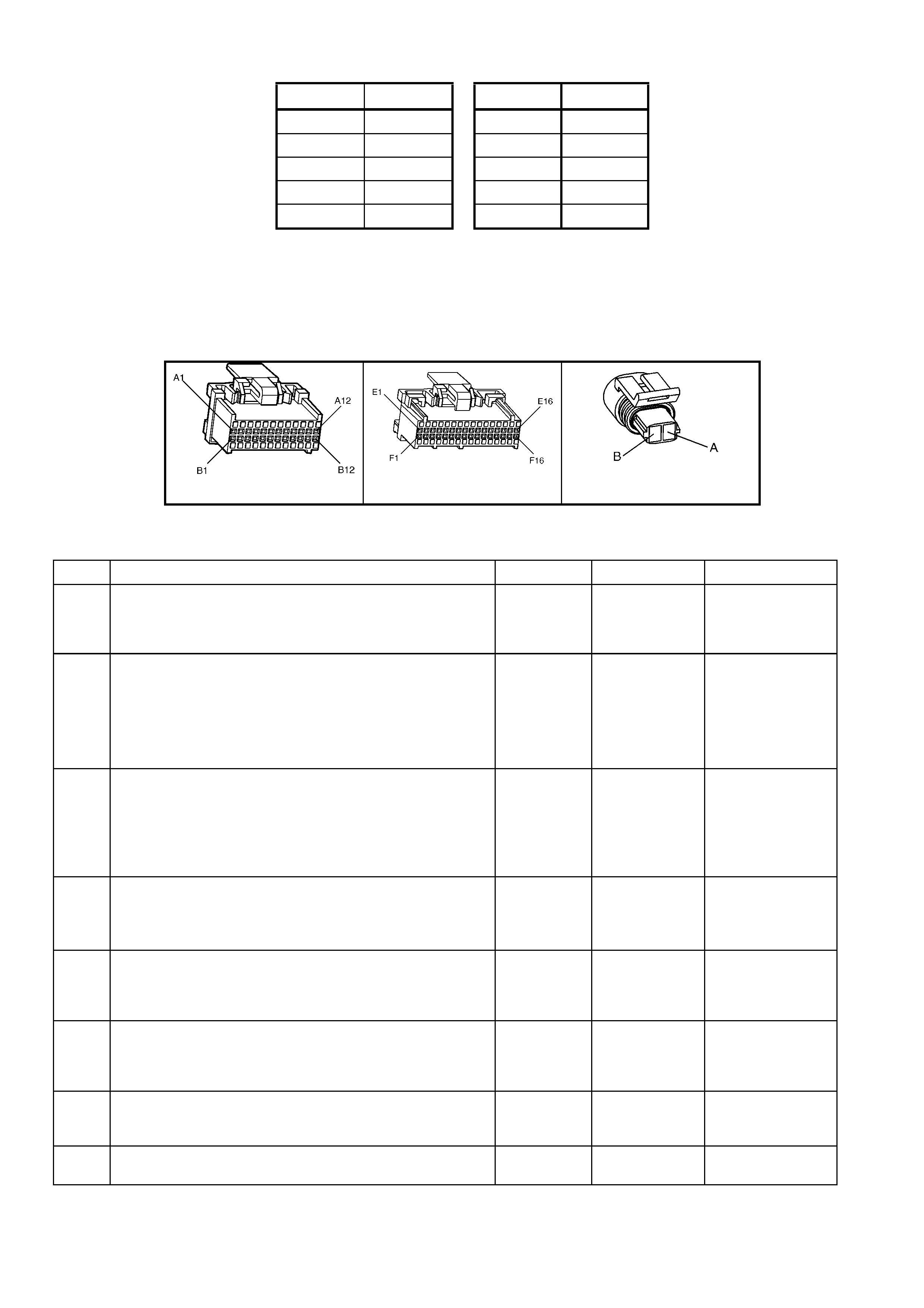

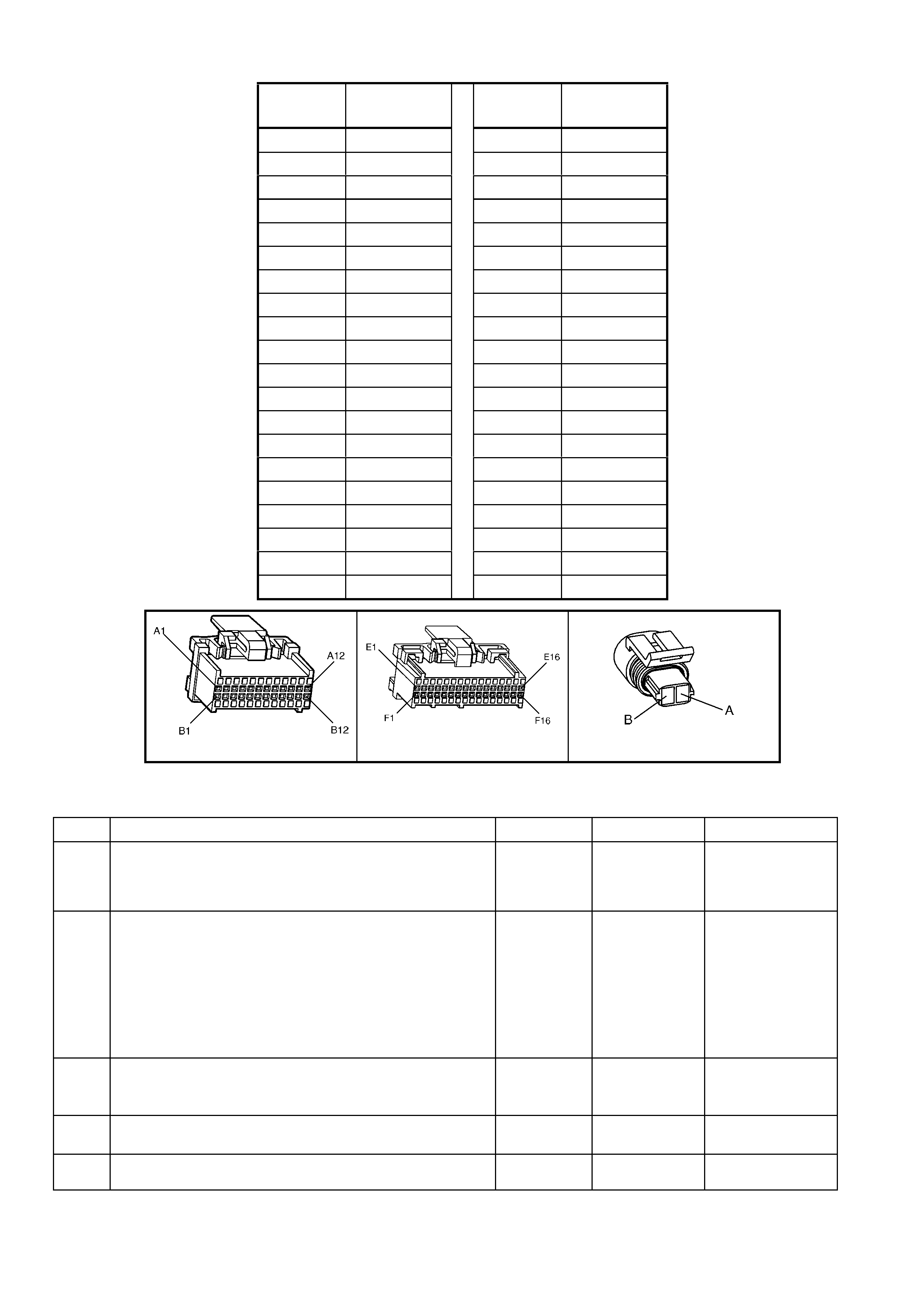

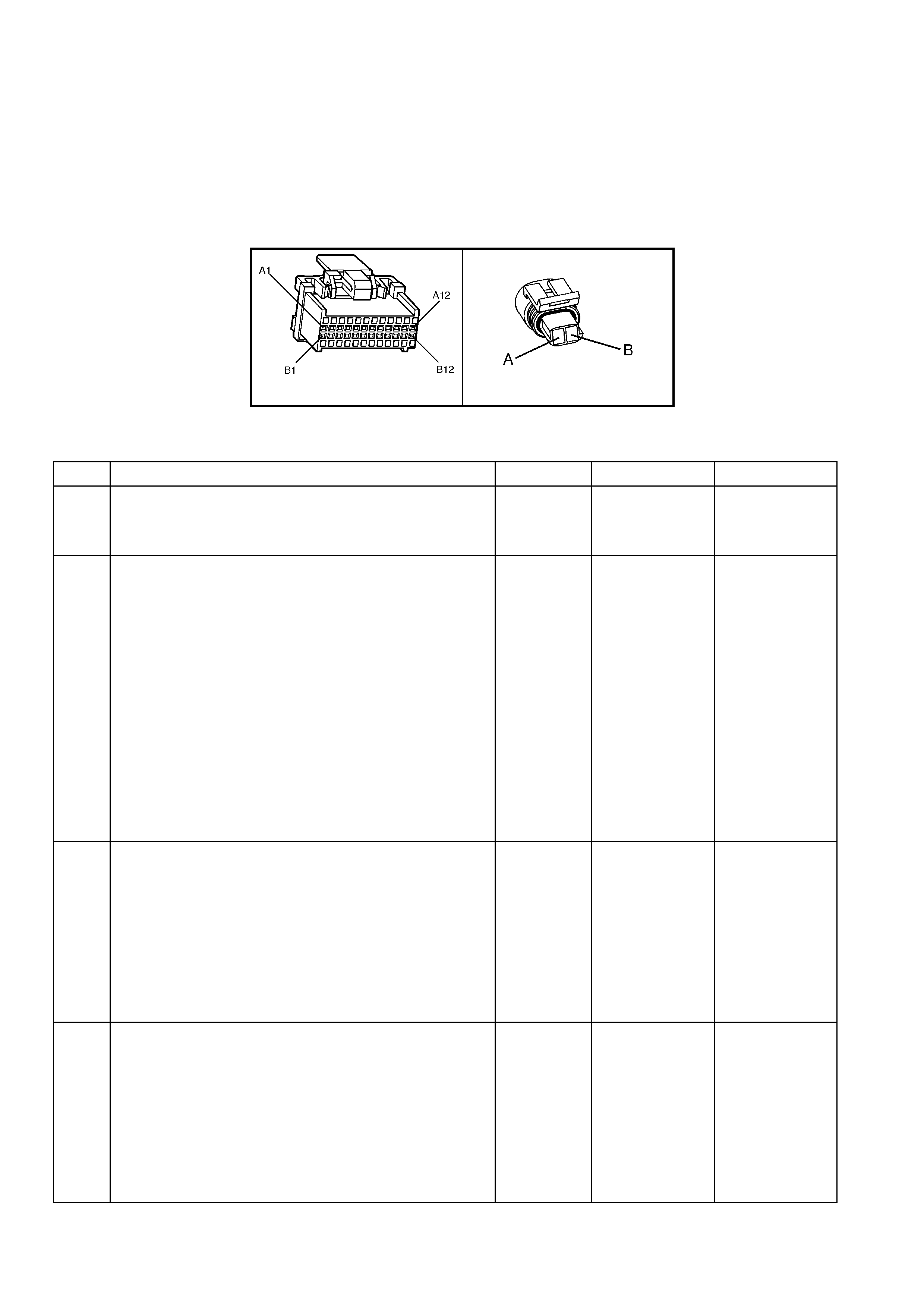

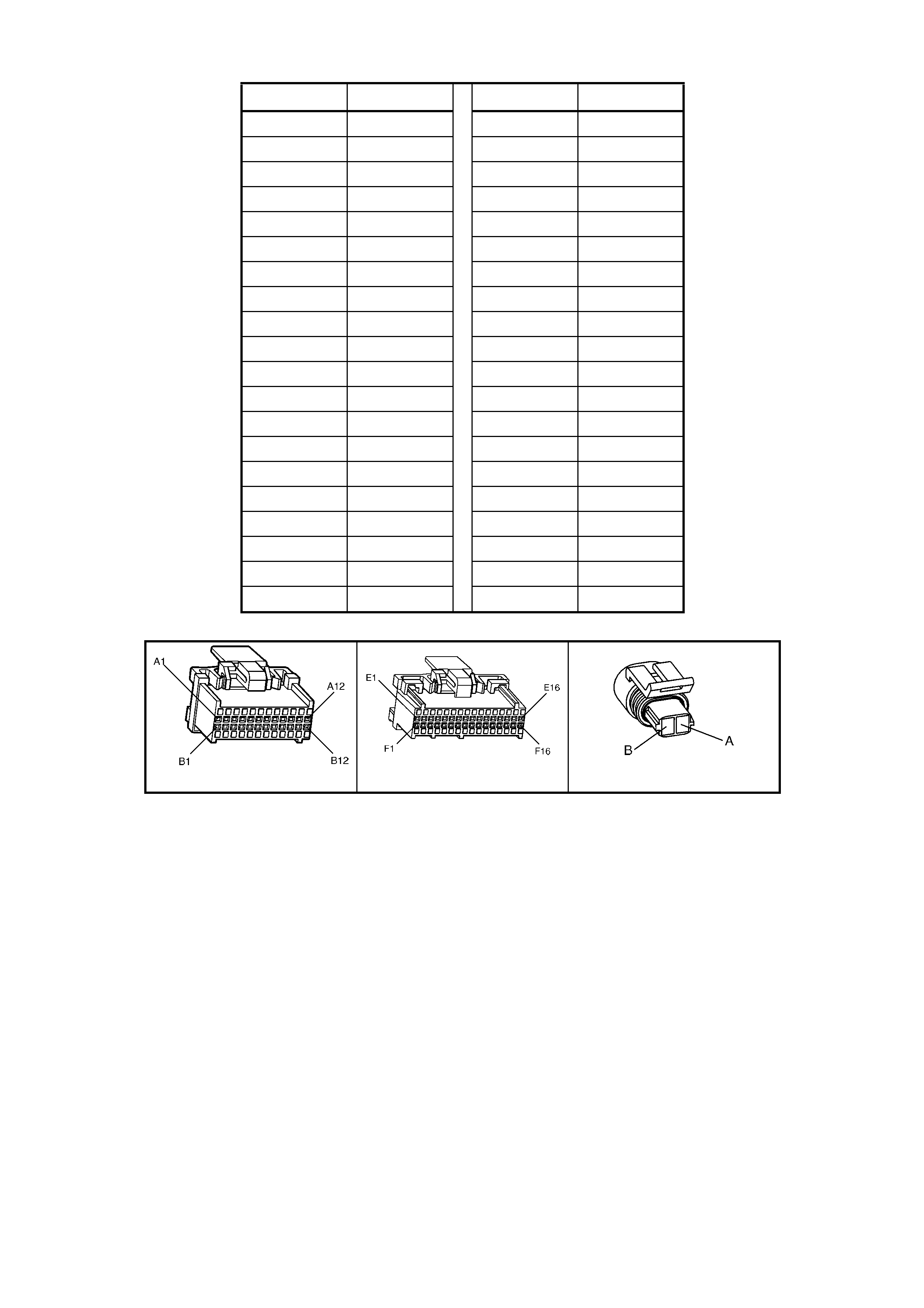

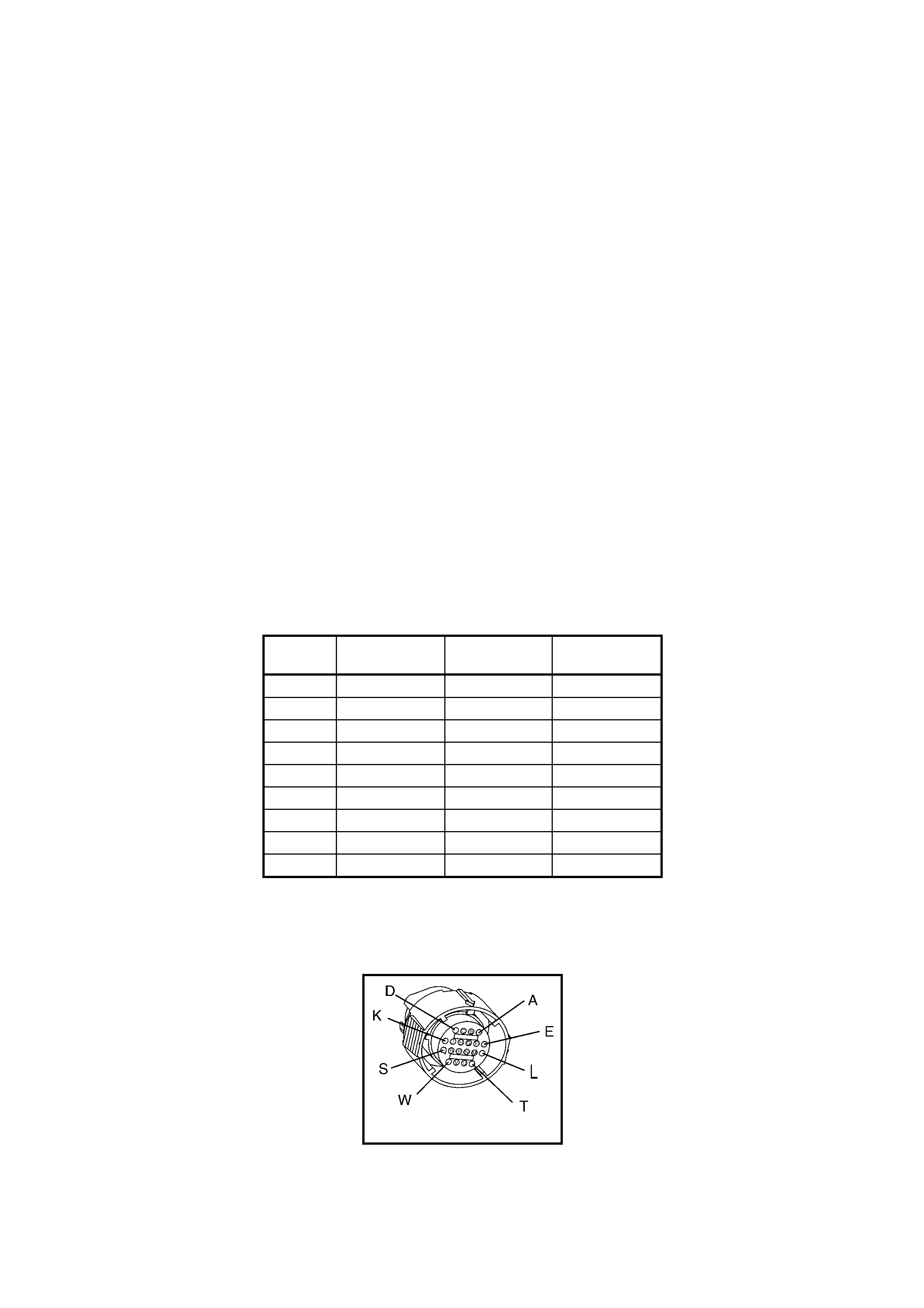

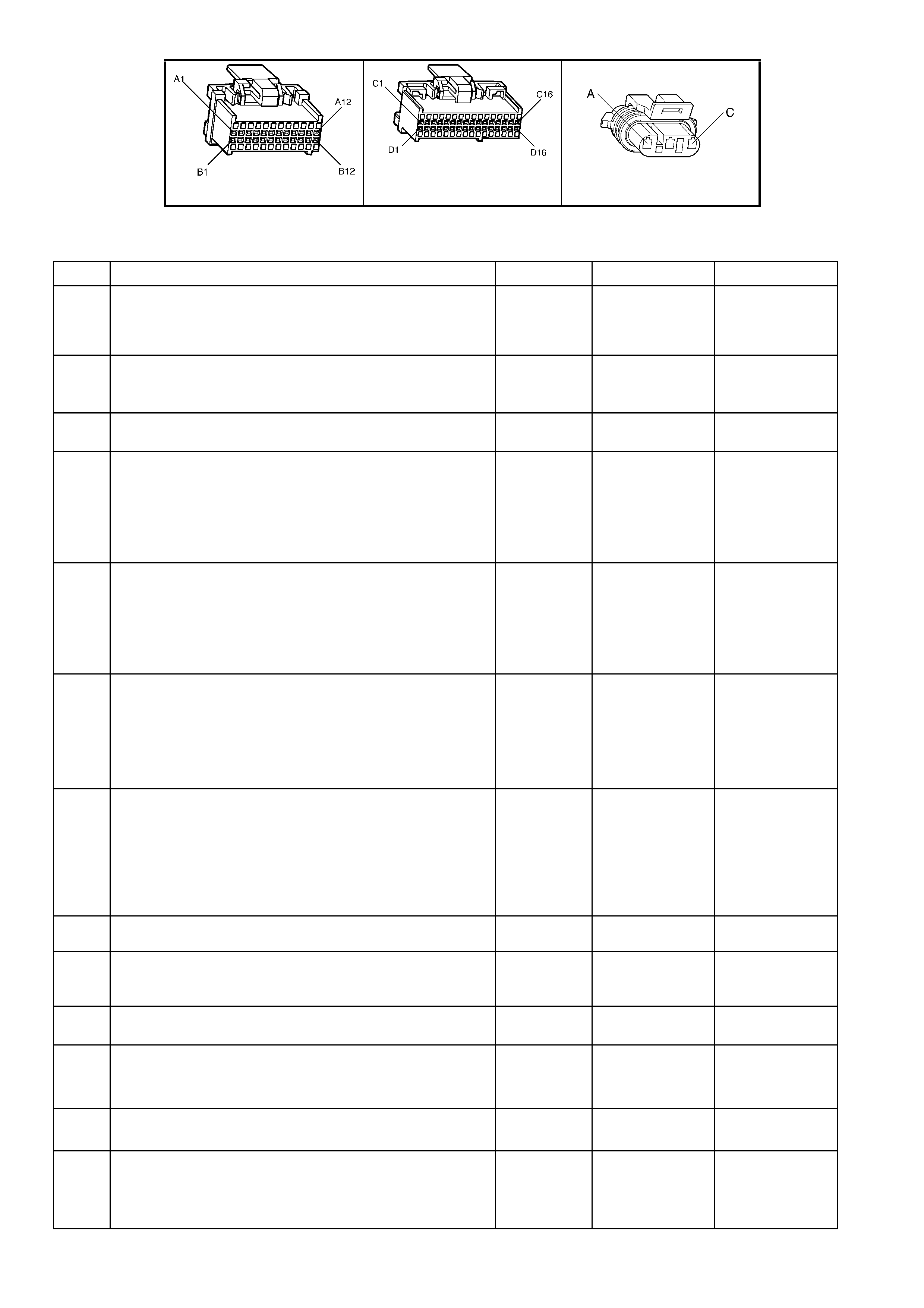

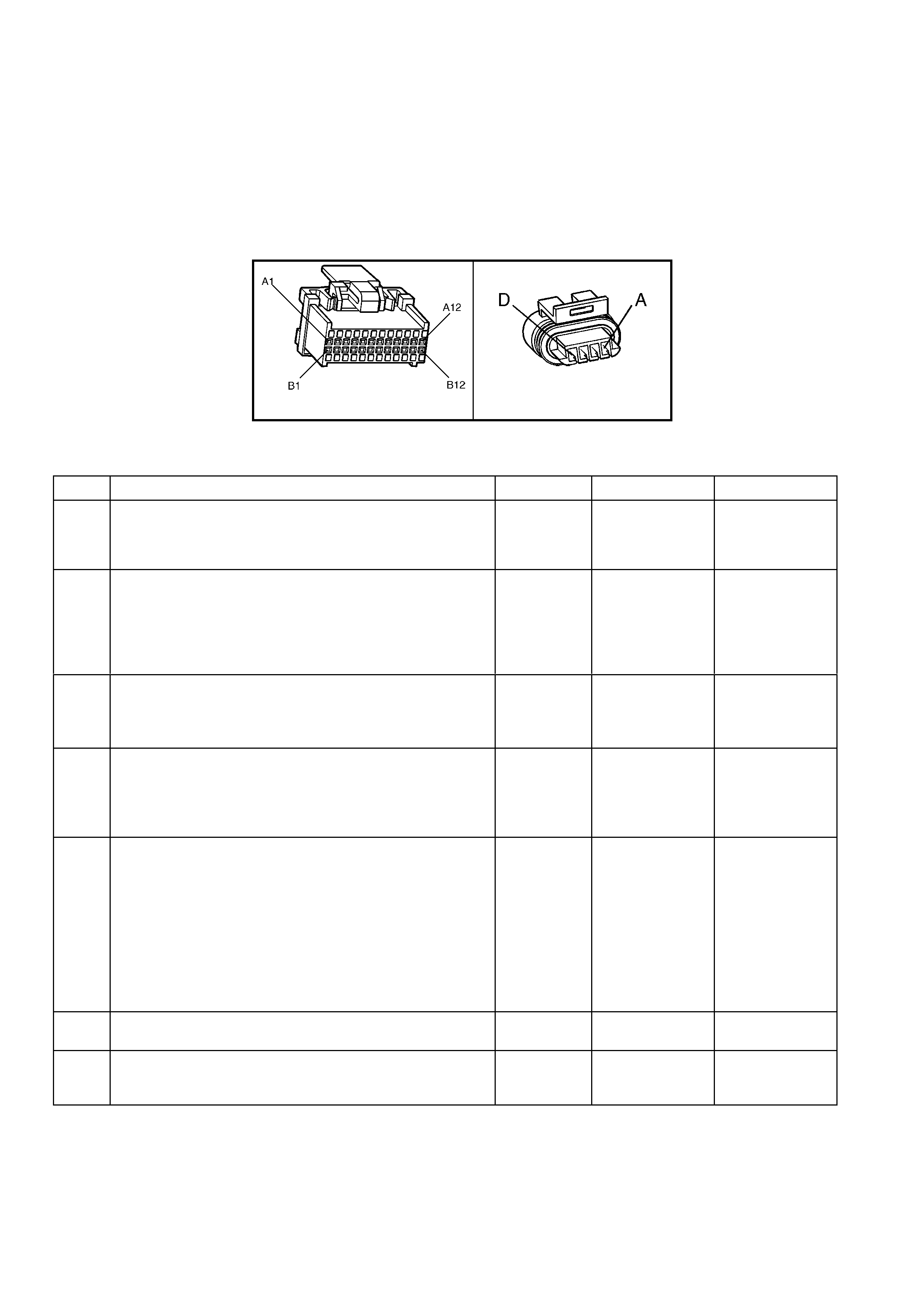

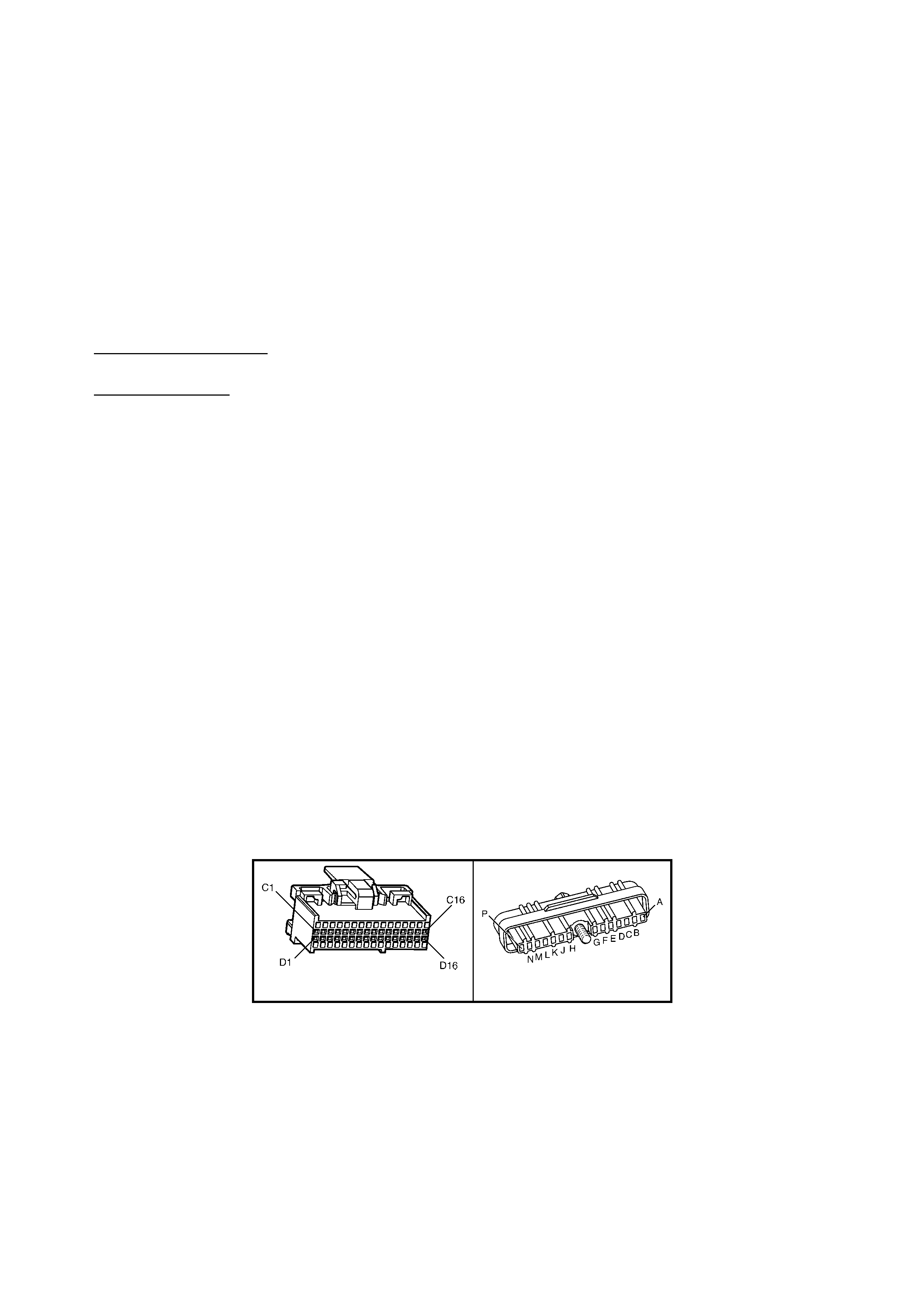

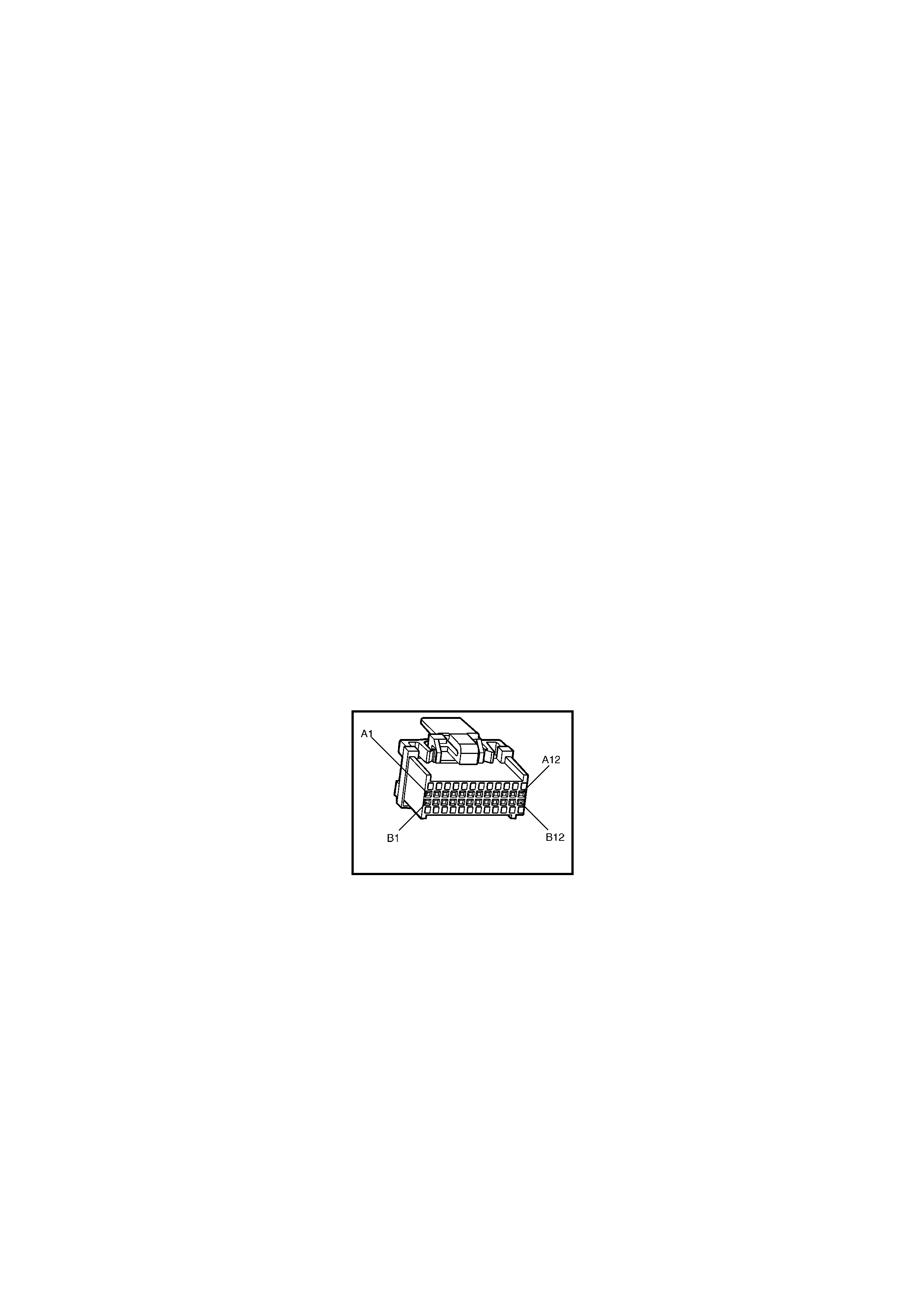

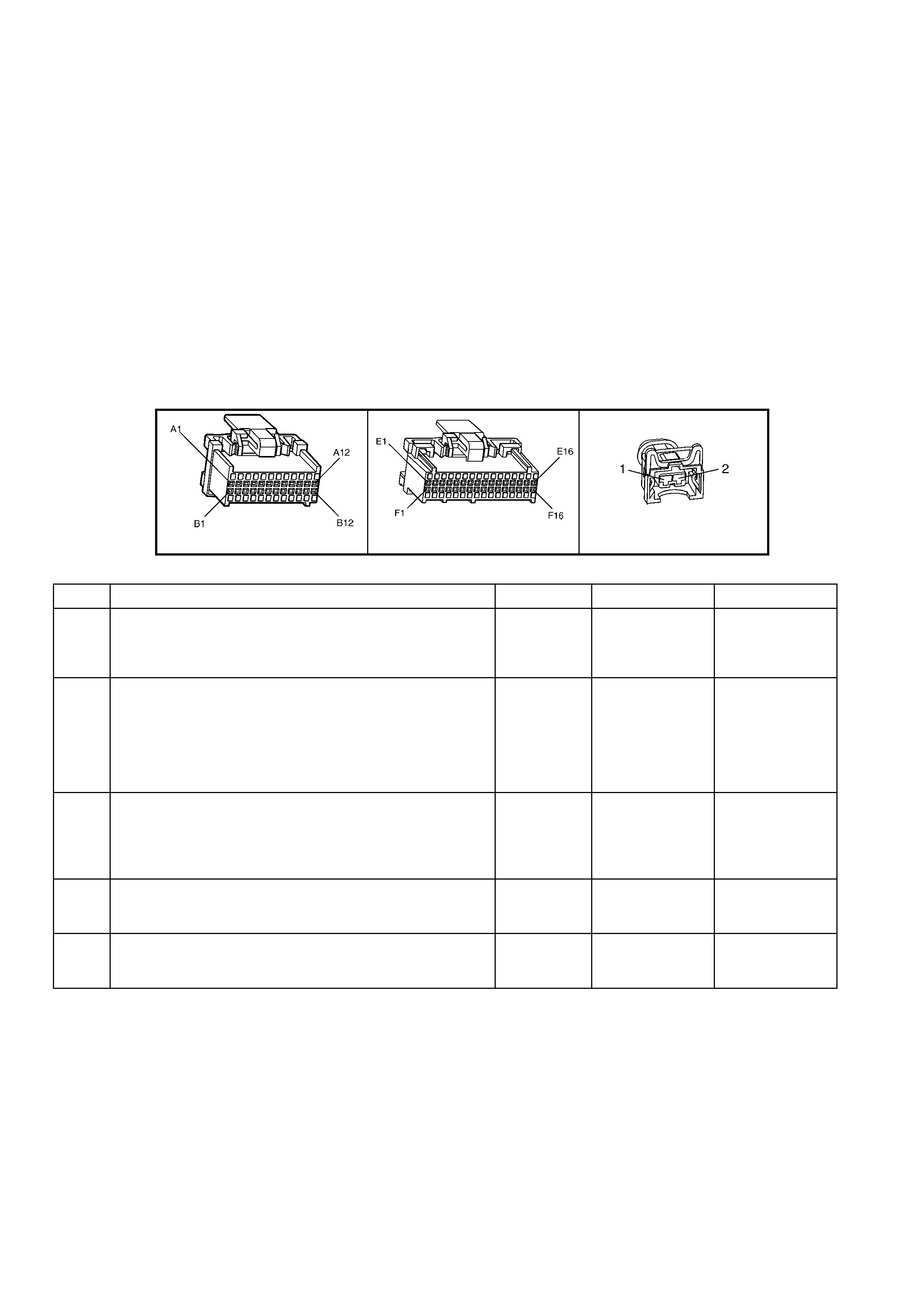

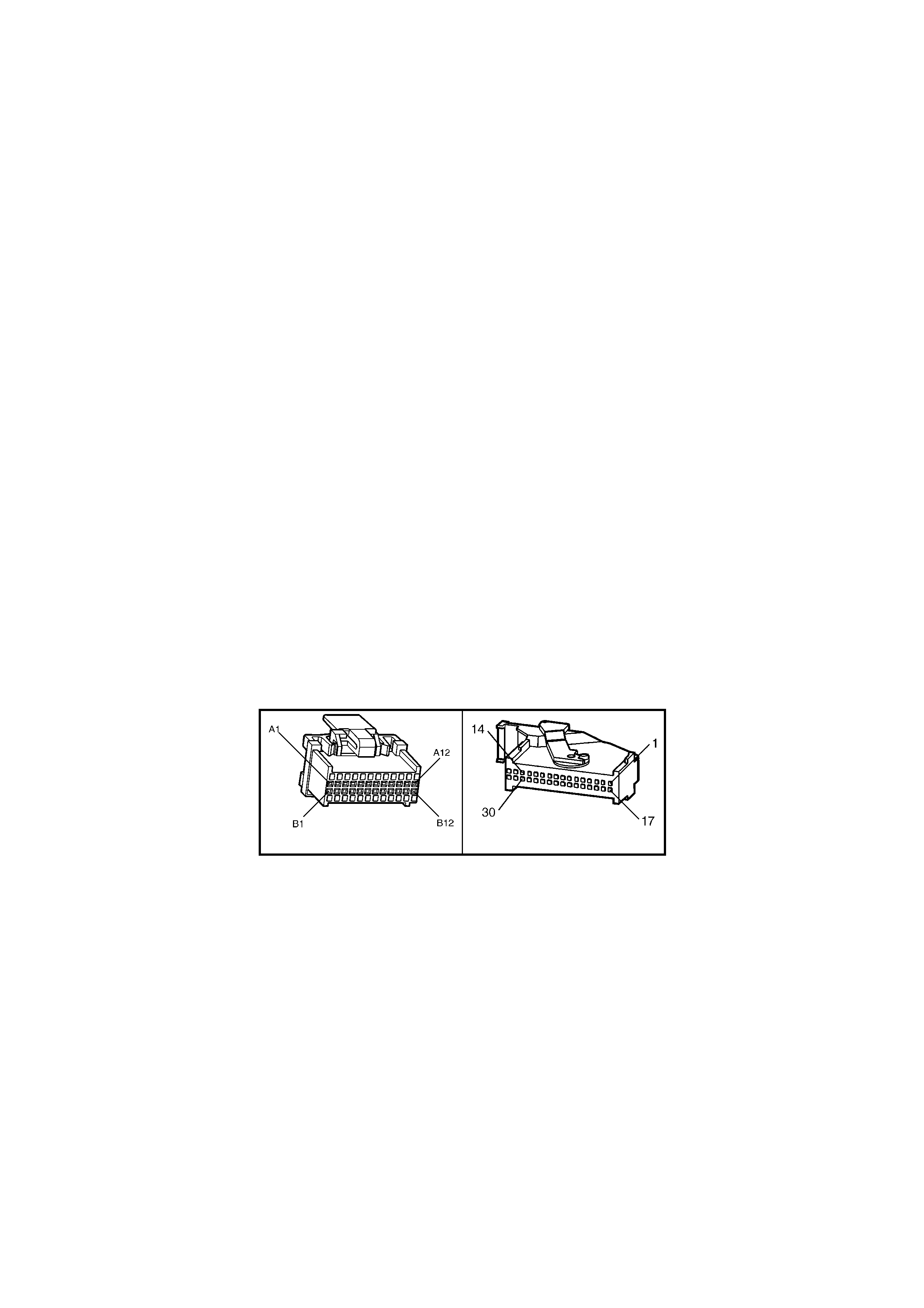

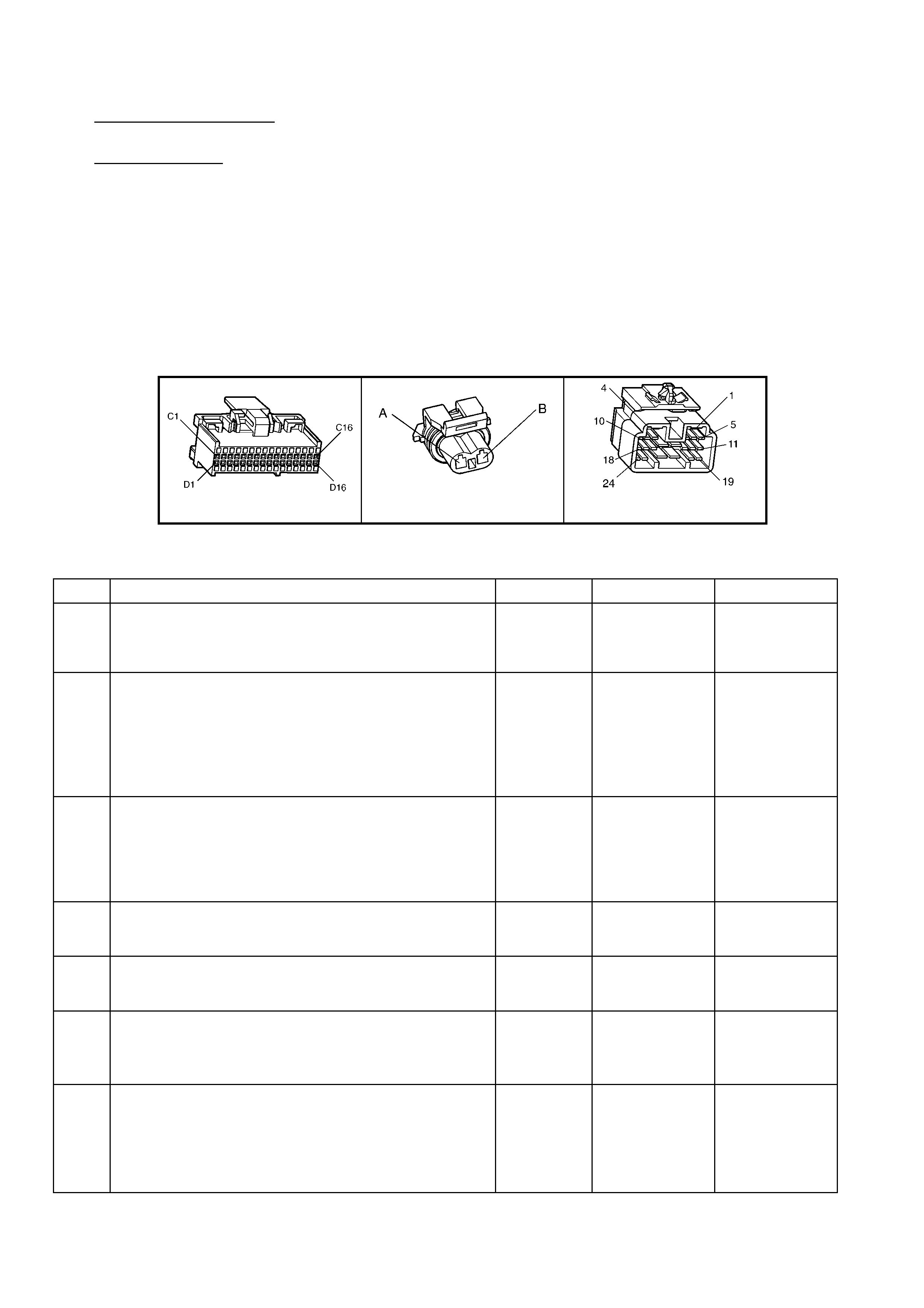

A84 S/C V6 – X1

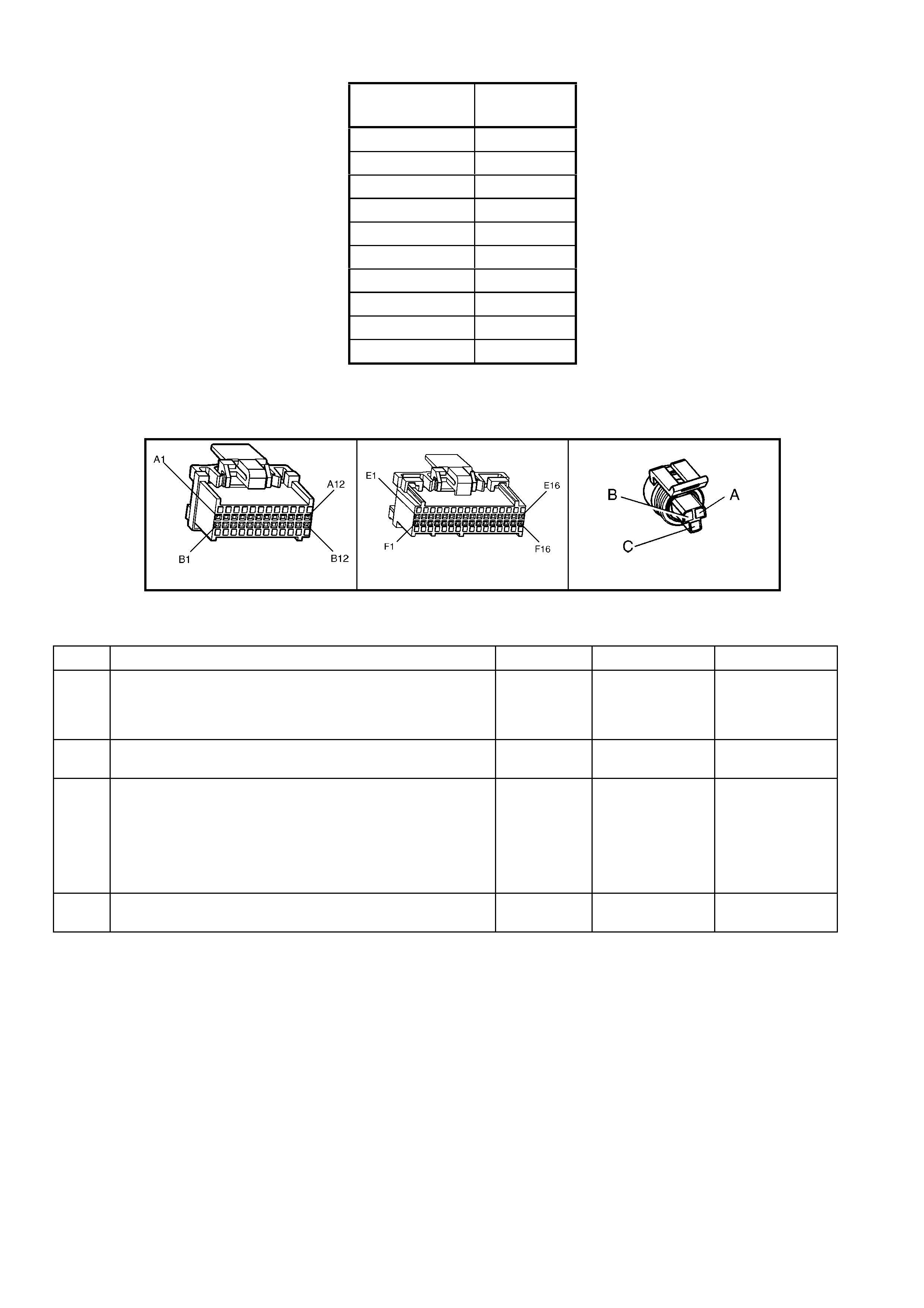

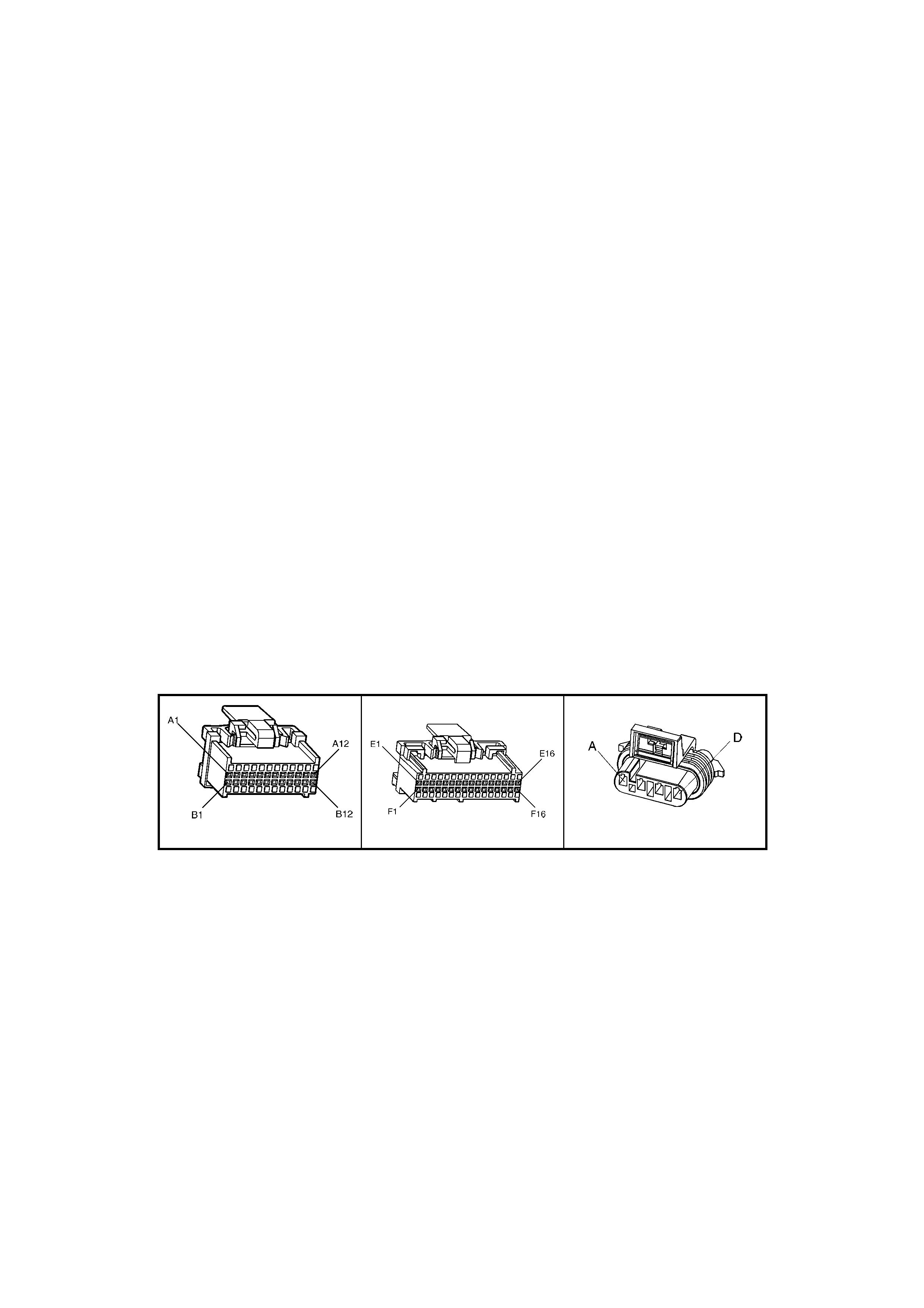

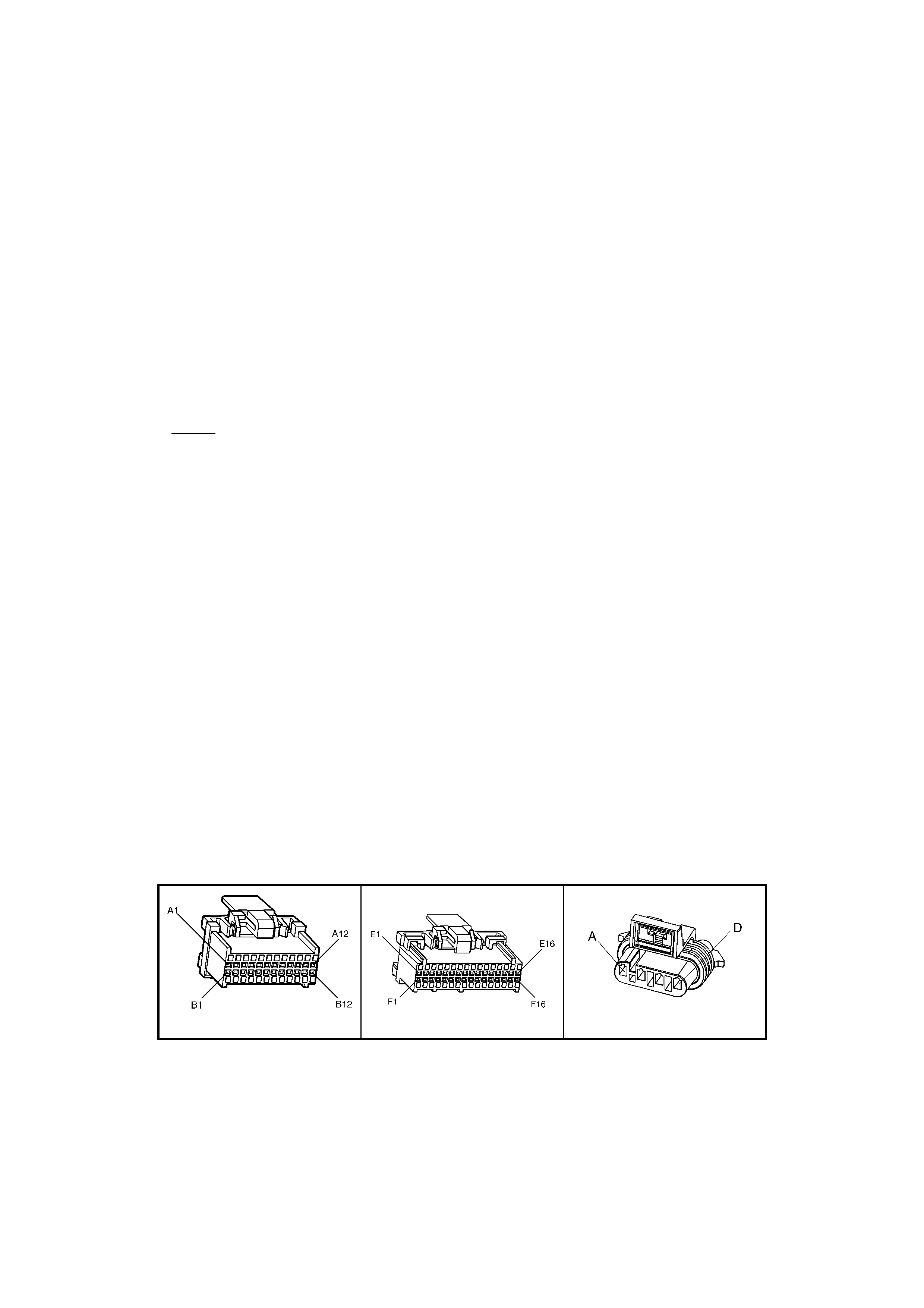

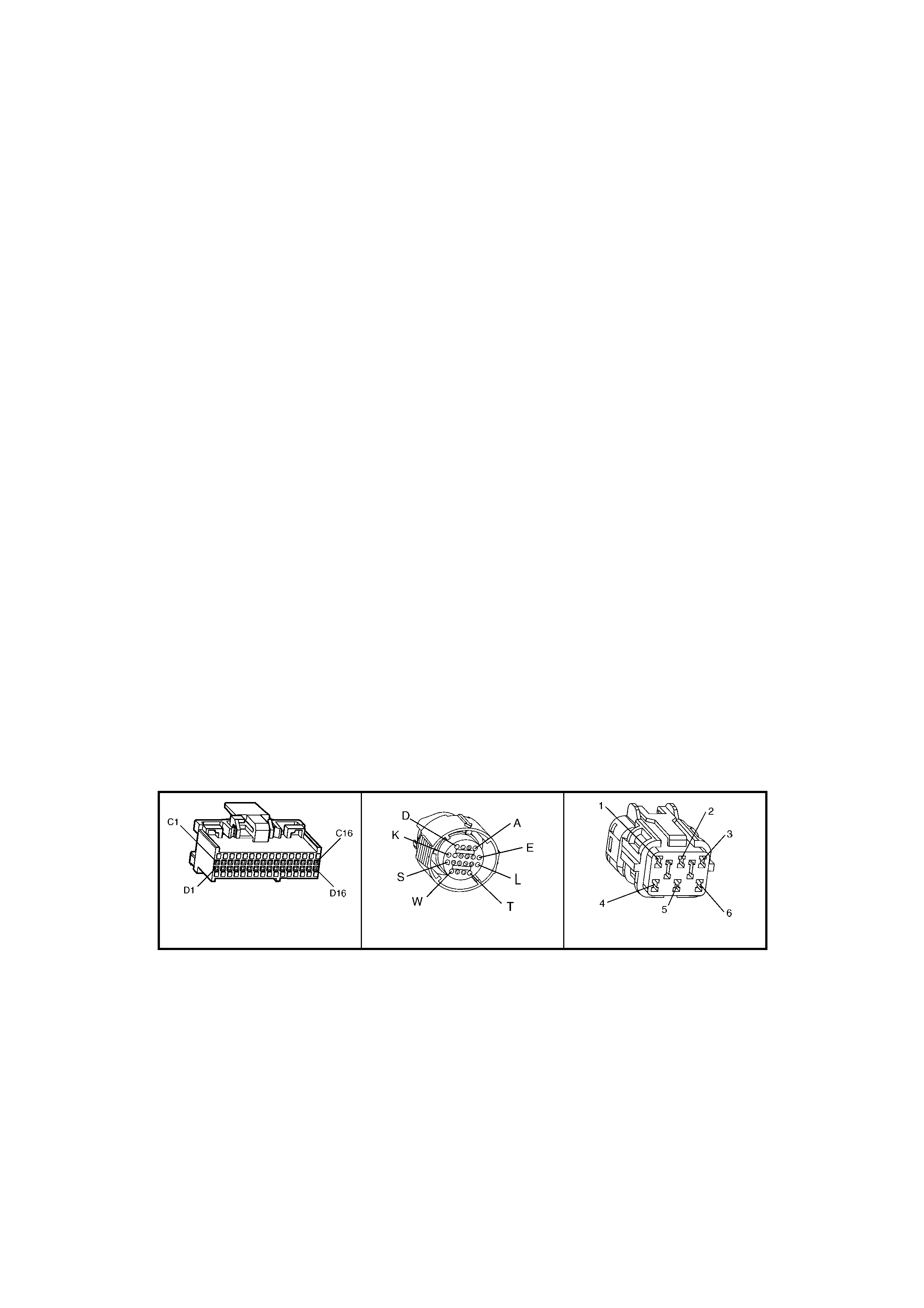

BACKPROBING VIE W OF PINK PCM CONNECTOR – A84 S/C V6 – X1

Figure 6C1-2A 15 – PCM Connector Terminal End View (1 of 3)

Pin

Pin Funct i on

CKT

#

Wire

Colour

Ign

"ON"

Eng

Run

Pin

Pin Funct i on

CKT

#

Wire

Colour

Ign

"ON"

Eng

Run

A1 SYSTEM GROUND 450 BK/RD -

--

- -

--

- B1 SYSTEM GROUND 450 BK/RD -

--

- -

--

-

A2 SYSTEM GROUND 450 BK/RD -

--

- -

--

- B2 SYSTEM GROUND 450 BK/RD -

--

- -

--

-

A3 PRIMARY SERIAL

DATA 800 RD/BK 2.5 to

3.5 2.5 t o

3.5 B3 A/C PRESSURE

SENSOR SIGNAL 380 OG/BK 1 to 2 1 to 2

A4 FUSED IGNITION

FEED 300 OG 12 13 B4 INTAKE AIR

TEMPERATURE

(IAT) SENSOR

SIGNAL

5089 BN (3) (3)

A5 NOT USED – – – – B5 ENGINE COOLANT

TEMPERATURE

(ECT) SENSOR

SIGNAL

410 YE (3) (3)

A6 FUEL PUMP

RELAY CONT ROL 465 GN/WH (1) 13 B6 TRANSMISSION

FLUID

TEMPERATURE

(TFT) SENSOR

SIGNAL

1227 BK/YE (3) (3)

A7 TP SENSOR

5 VOLT

REFERENCE

416 GY 5 5 B7 A/C

REFRIGERANT

PRESSURE

SENSOR 5 VOLT

REFERENCE

2700 PU/WH 5 5

A8 BATTERY

VOLTAGE FEED 740 OG/BK 12 13 B8 BATTERY

VOLTAGE FEED 740 OG/BK 12 12

A9 NOT USED – – – – B9 NOT USED – – – –

A10 NOT USED – – – – B10 NOT USED – – – –

A11 NOT USED – – – – B11 TP SENSOR

SIGNAL 411 BU (5) (5)

A12 NOT USED – – – – B12 INJECTOR

VOLTAGE

MONITOR LINE

639 RD 12 13

(1) Battery voltage first 2 seconds.

(3) Varies with temperature.

(5) 0.25 – 1.25 volts measured between terminals "B11" and "B1" or about 4.0 volts at wide open throttle.

(6) Varies with altitude.

-

--

- Less than 0.50 volts

Normal

Voltages Normal

Voltages

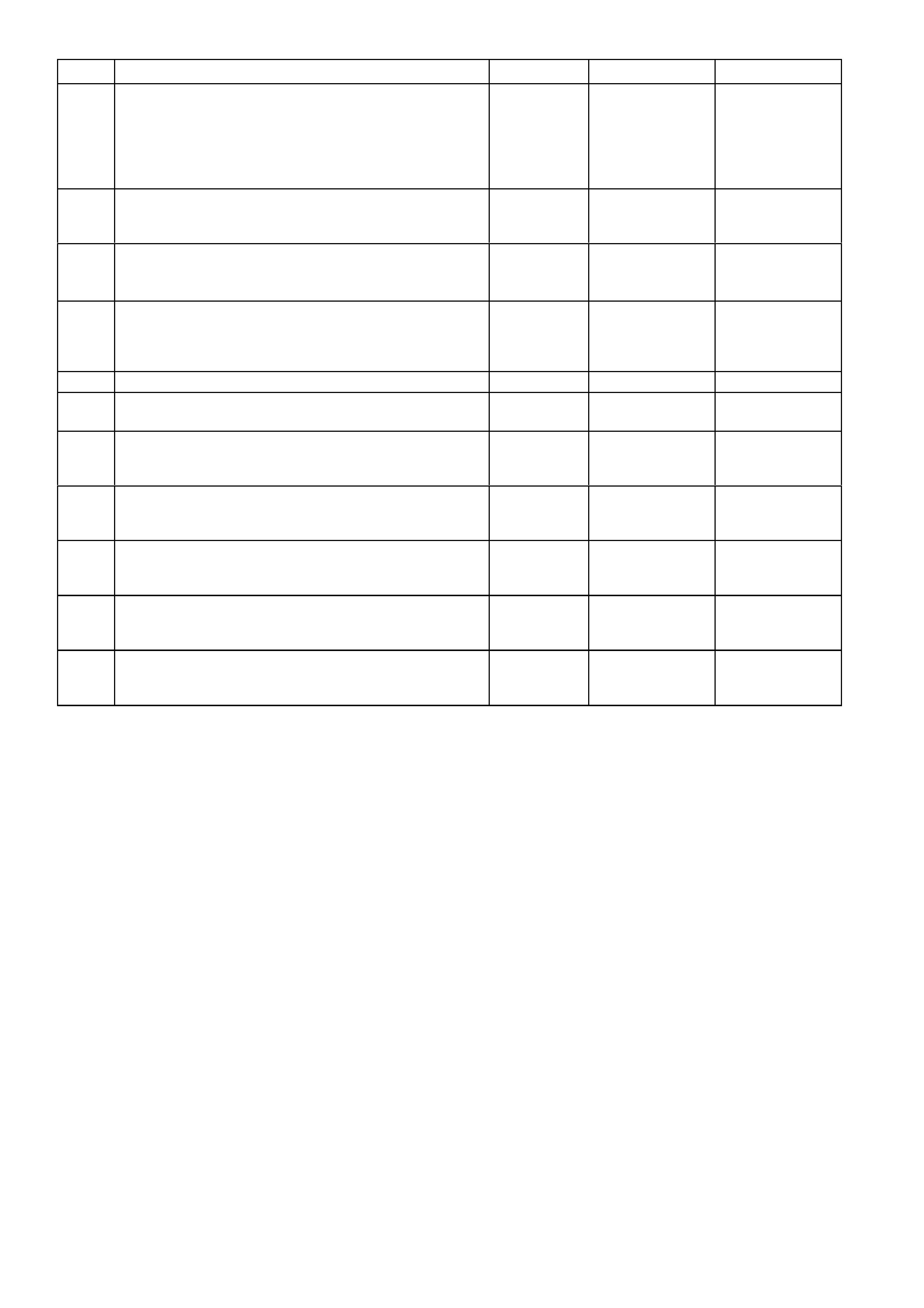

POWERTRAIN CONTROL MODULE CONNECTOR IDENTIFICATION

This Powertrain Control Module Voltage Table is for use with a digital voltmeter to further aid in diagnosis.

Connect the Black (–) probe to a good chassis ground, and backprobe the powertrain control module terminal

with the Red ( +) pr obe. These voltages were derived from a known good vehicle. The voltages you get may vary

due to low battery charge or other reasons, but they should be very close.

THE FOLLOWING CONDITIONS MUST BE MET BEFORE TESTING:

• Engine and Transmission at operating

temperature

• Closed Loop

• Engine idling (for "Engine Run" column)

• Diagnostic "Test" terminal not grounded

• Tech 2 scan tool not installed

• Accessories "OFF"

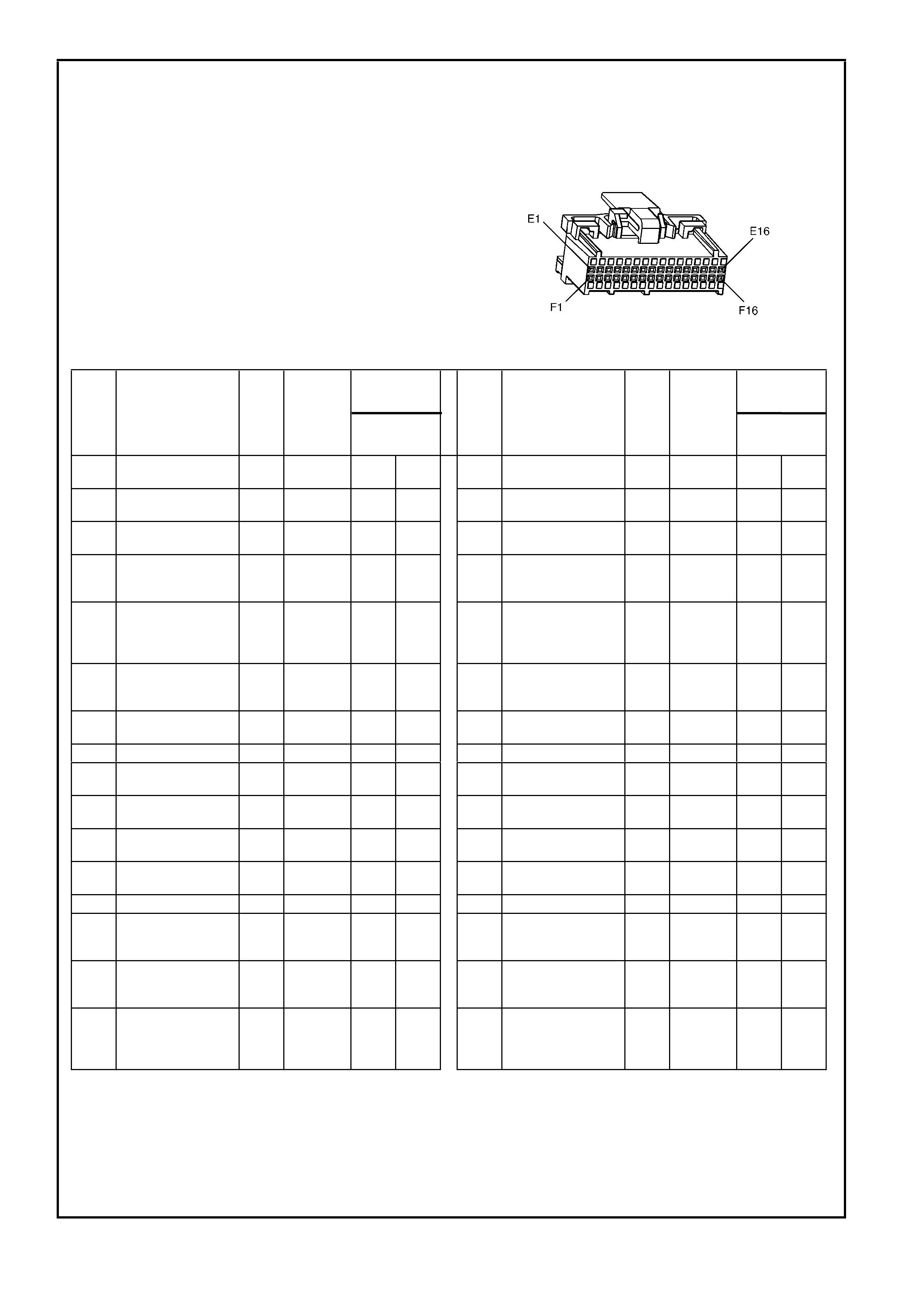

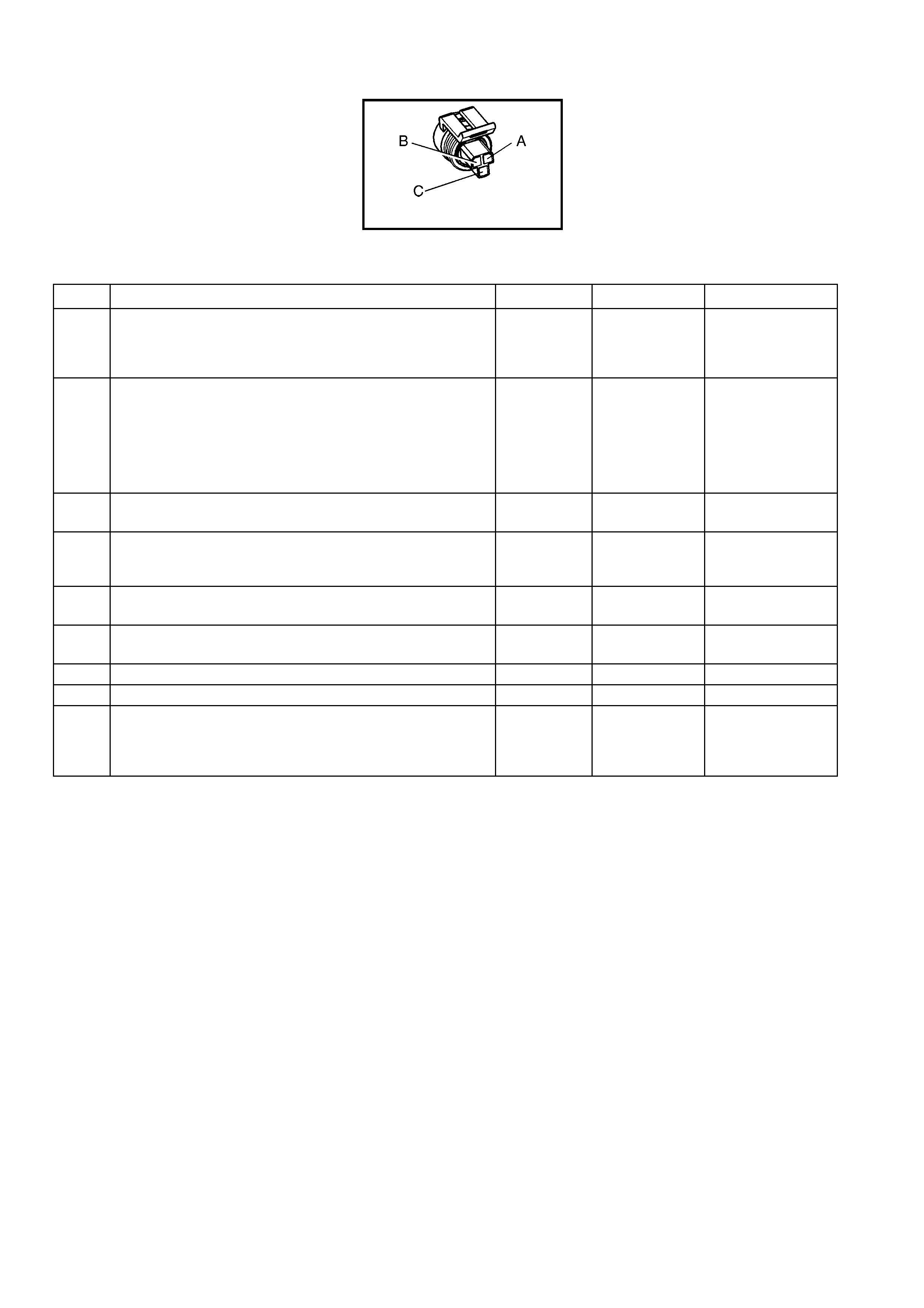

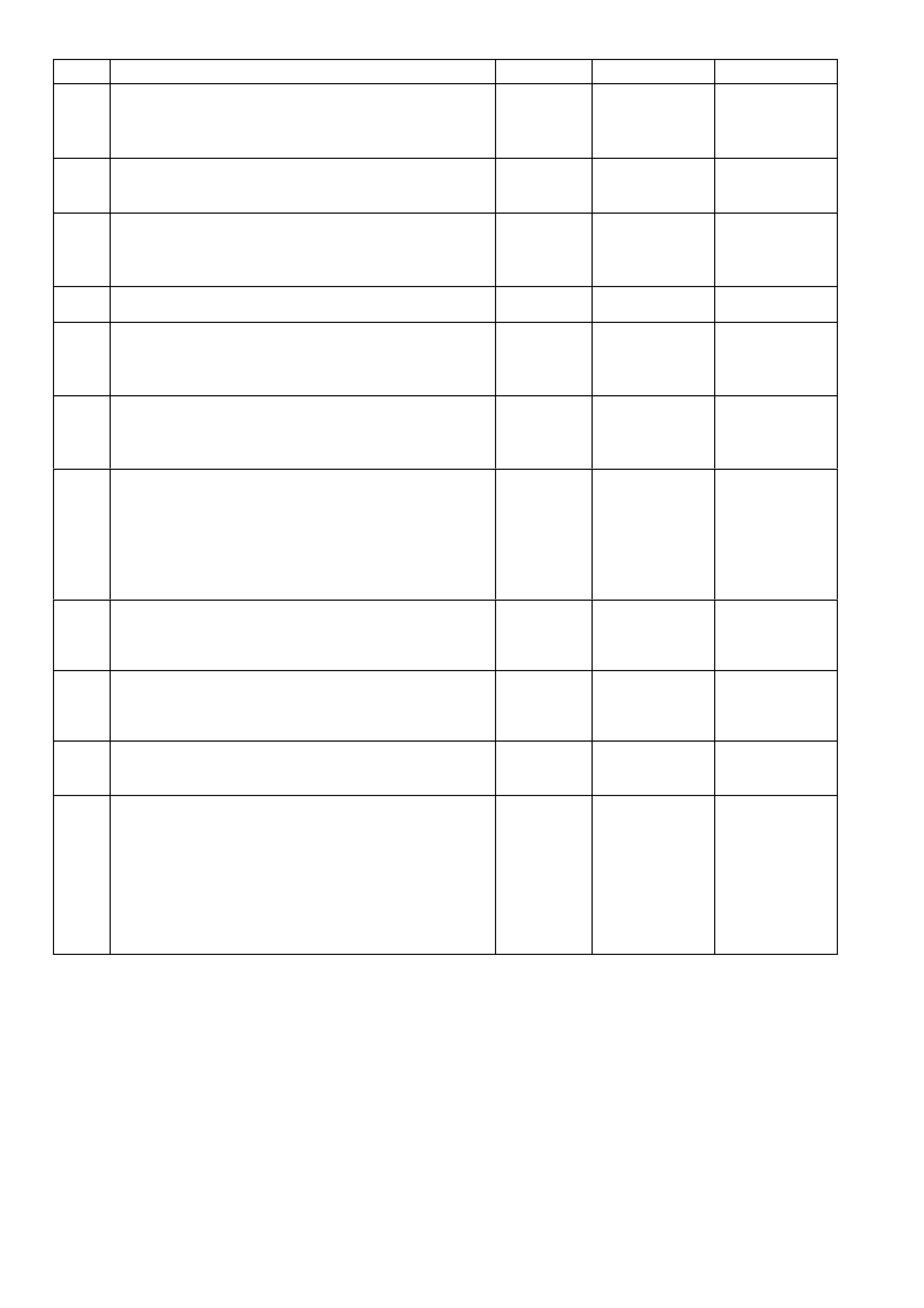

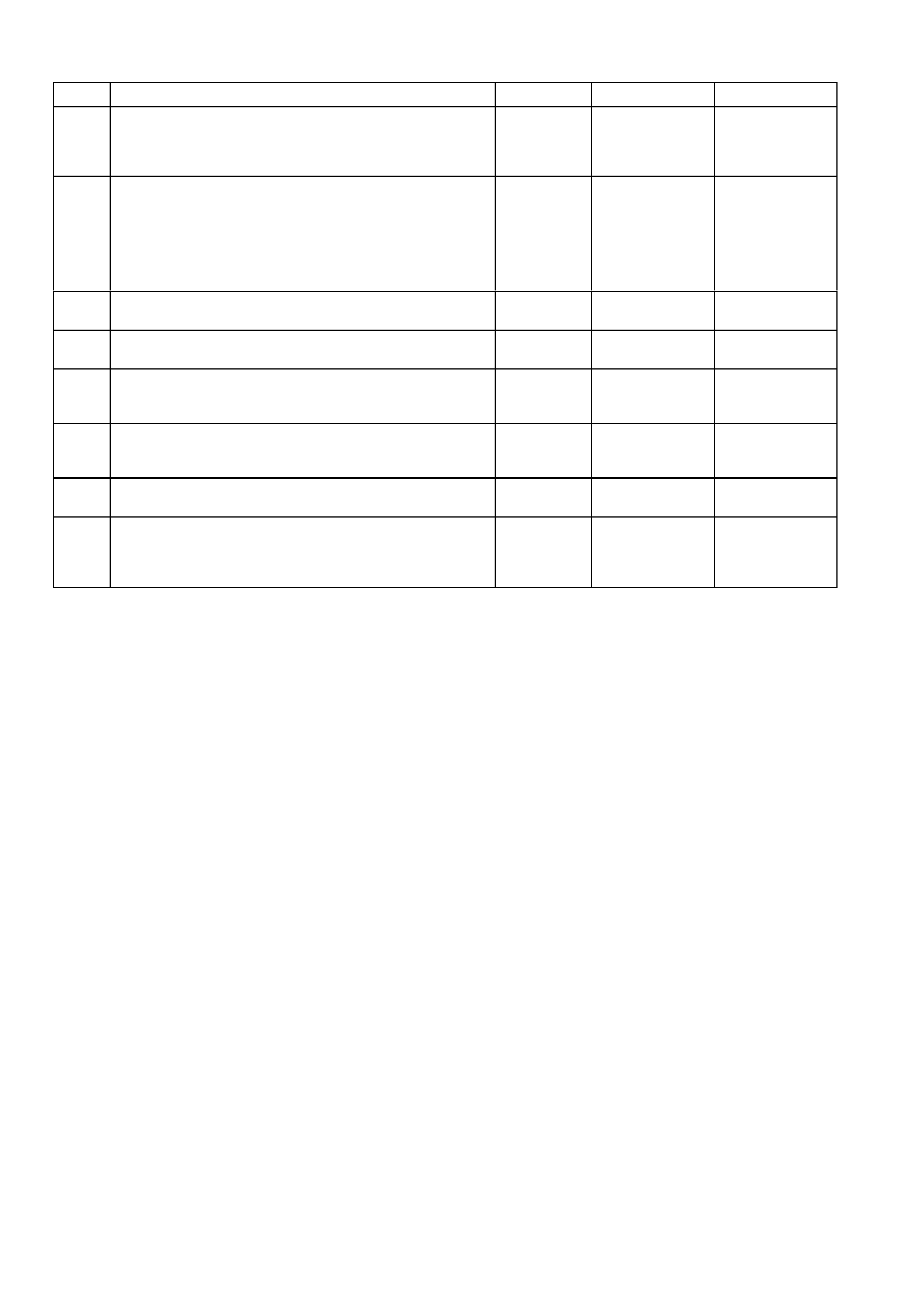

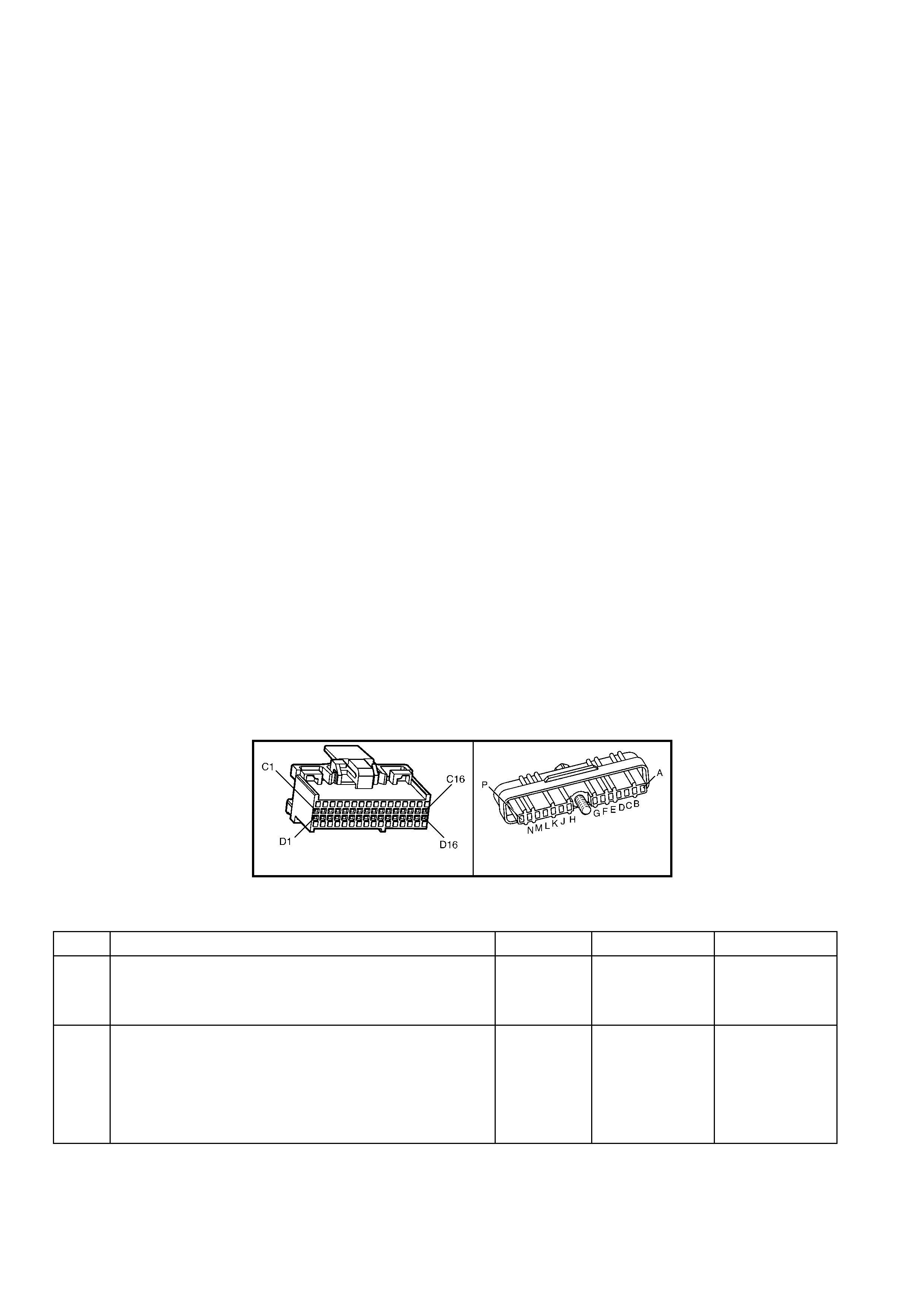

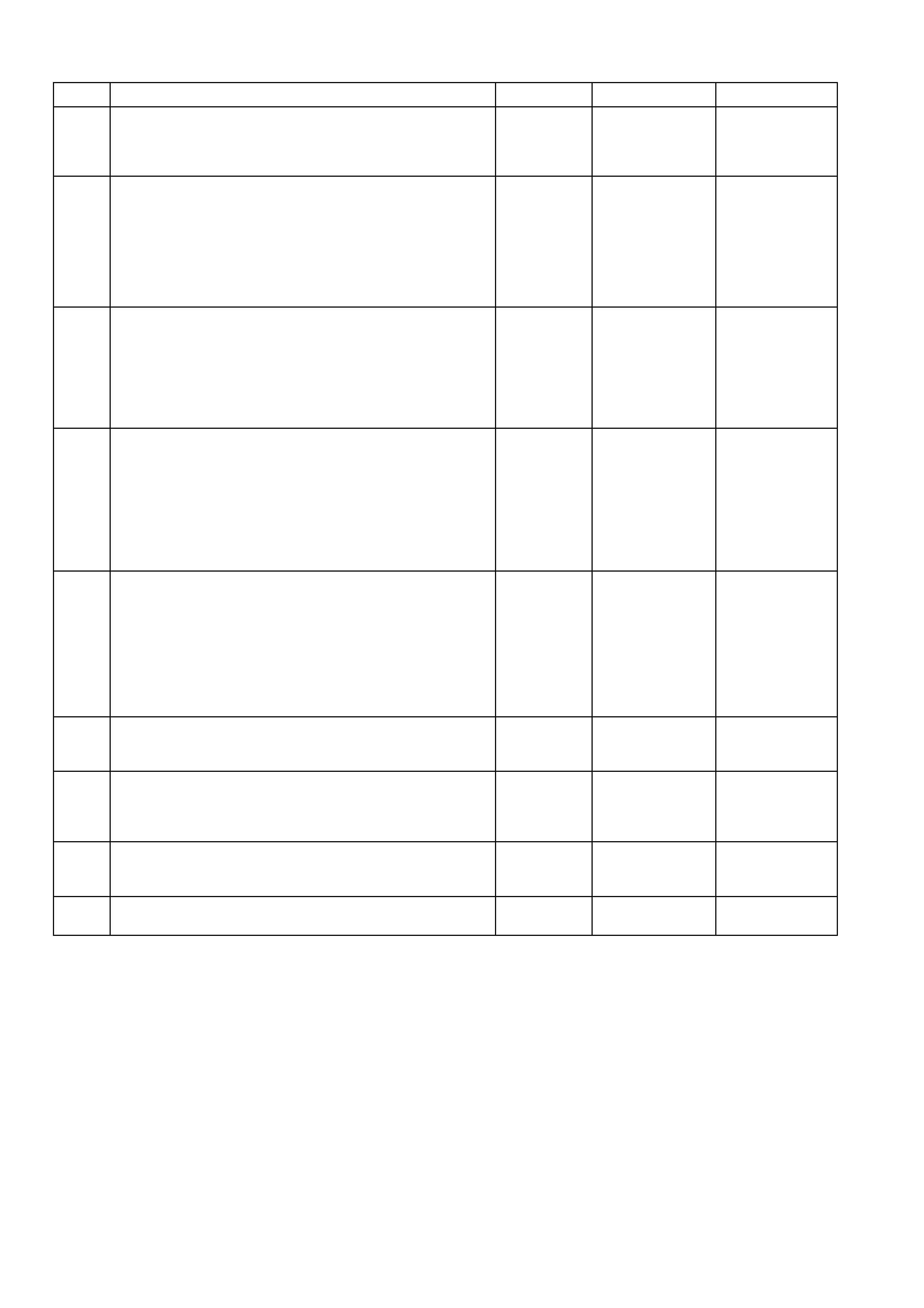

A84 S/C V6 – X2

BACKPROBING VIE W OF PINK PCM CONNECTOR – A84 S/C V6 – X2

Figure 6C1-2A-16 – PCM Connector Terminal End View (2 of 3)

Pin

Pin Funct i on

CKT

#

Wire

Colour

Ign

"ON"

Eng

Run

Pin

Pin Funct i on

CKT

#

Wire

Colour

Ign

"ON"

Eng

Run

C1 TCC "ON-OFF"

SOLENOID

CONTROL

422 GY/ RD 12 13 D1 MASS AI R FLOW

(MAF) SENS OR

INPUT SIGNAL

492 BN/WH 4.8 4.2

C2 1-2 SHIFT

SOLENOID

CONTROL

1222 L-GN 12 -

--

- D2 NOT USED – – – –

C3 2-3 SHIFT

SOLENOID

CONTROL

1223 YE/BK 12 -

--

- D3 CAMSHAFT

POSITION (CMP)

SENSOR INPUT

630 BK 4.8 4.0

C4 CANISTER PURGE

SOLENOID 428 L-GN/YE 12 13 D4 CRANKSHAFT 18X

SIGNAL 647 L-BU/BK 5

or

0

2.0

to

3.0

C5 VEHICLE SPEED

OUTPUT TO

SPEEDOMETER

5197 PU/WH 0.1

OR

12

0.1

OR

13

D5 VEHICLE SPEED

SENSOR SIGNAL

LOW

1230 TN -

--

- -

--

-

C6 VEHICLE SPEED

SIGNAL HIGH 1231 BU/WH -

--

- -

--

- D6 NOT USED – – – –

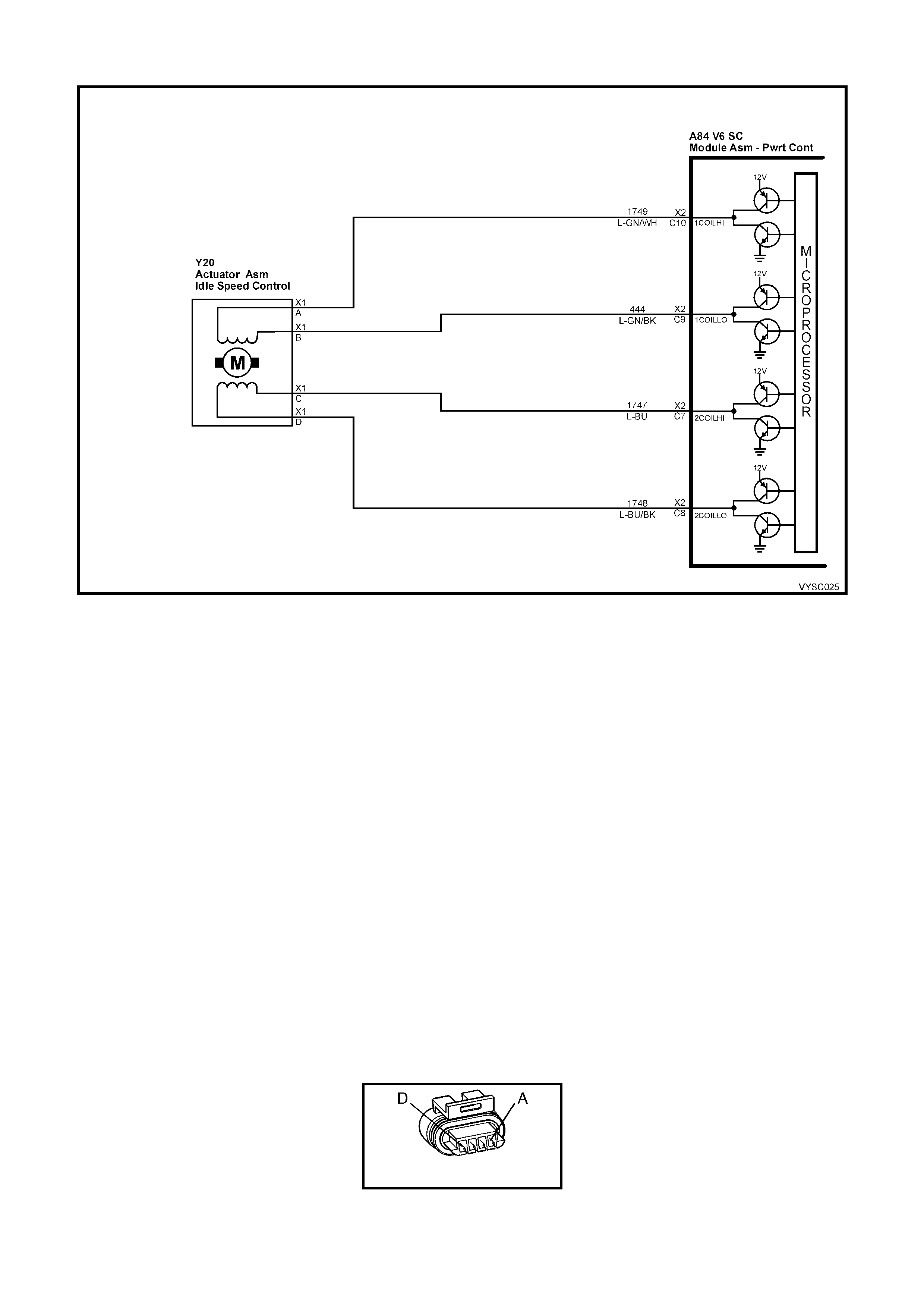

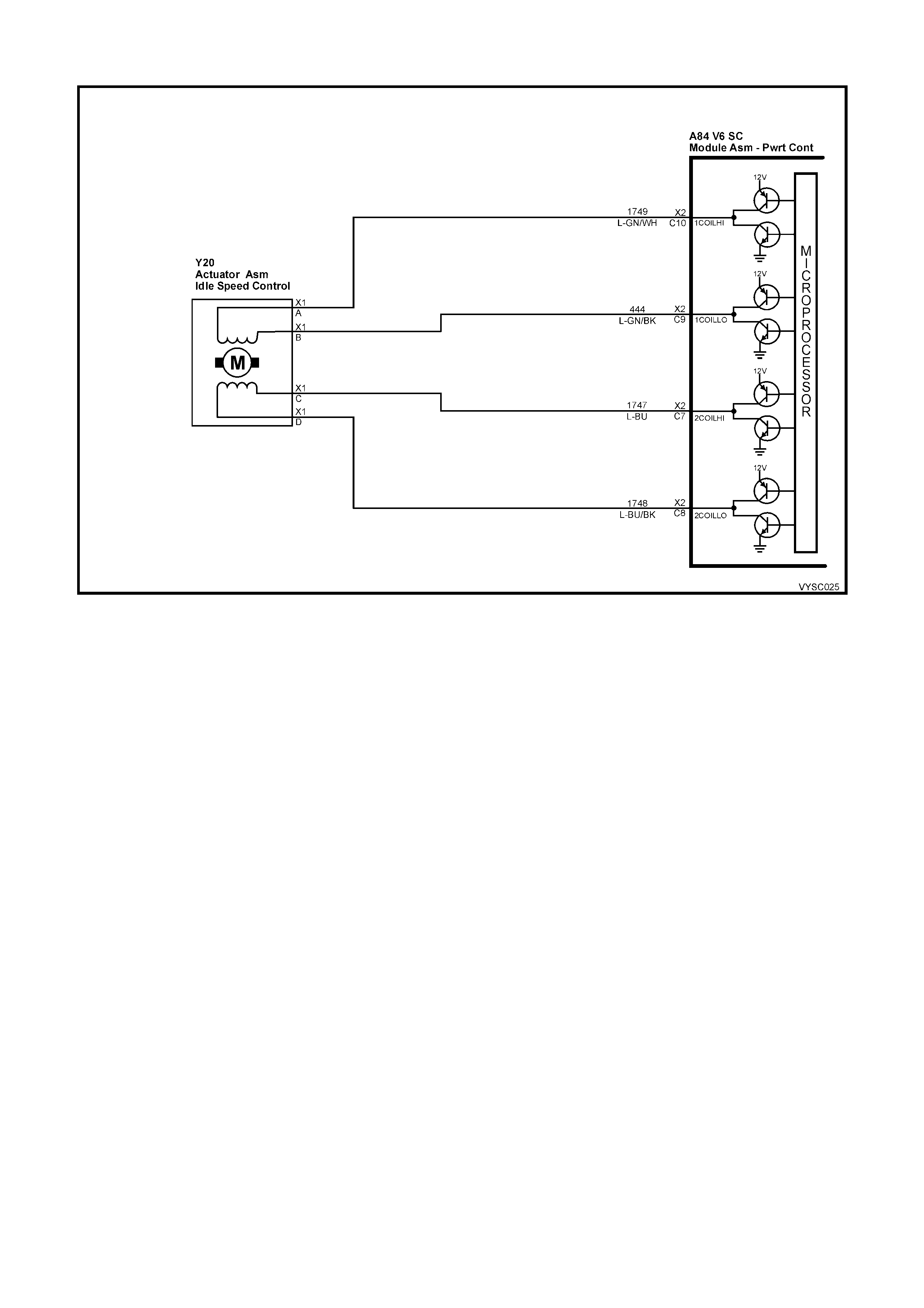

C7 IAC 2 COIL ‘ HI ’ 1747 L-BU/WH NOT

USEABLE D7 NOT USED – – – –

C8 IAC 2 COIL ‘ LO’ 1748 L-B U/BK NOT

USEABLE D8 NOT USED – – – –

C9 IAC 1 COIL ‘ LO’ 444 L-GN/BK NOT

USEABLE D9 BYPASS

CONTROL 424 TN/BK 0 4.7

C10 IAC 1 COIL ‘ HI ’ 1749 L-GN/WH NOT

USEABLE D10 EST OUTPUT 423 WH 0 2.0

C11 TORQUE

REQUEST 463 OG/WH 4-5 4-5 D11 CRANKSHAFT

REFERE NCE LOW 453 BK/RD -

--

- -

--

-

C12 KNOCK SENSOR

(ESC) SIGNAL

INPUT

496 WH/RD 1.3

mV

AC

19

mV

AC

D12 CRANKSHAFT

REFERE NCE HIGH 430 PU 4.8 2.3

C13 3-2 CONTROL

SOLENOID 898 GN/WH 12 -

--

- D13 RH OXYGEN

SENSOR SIGNAL 1666 GY 450

mV (4)

C14 3-2 CONTROL

FEEDBACK 898 GN/WH 12 -

--

- D14 RH OXYGEN

SENSOR GROUND 1667 GY/BK -

--

- -

--

-

C15 TCC PWM

FEEDBACK 418 BN 12 13 D15 LH OXYGEN

SENSOR SIGNAL 1665 PU 450

mV (4)

C16 TCC SOLENOID

PWM CONTROL 418 BN 12 13 D16 LH OXYGEN

SENSOR GROUND 1664 L-BU/BK -

--

- -

--

-

(4) The voltage should vary between 100 mV - 1000 mV.

-

--

- Less than 0.50 volts

Normal

Voltages Normal

Voltages

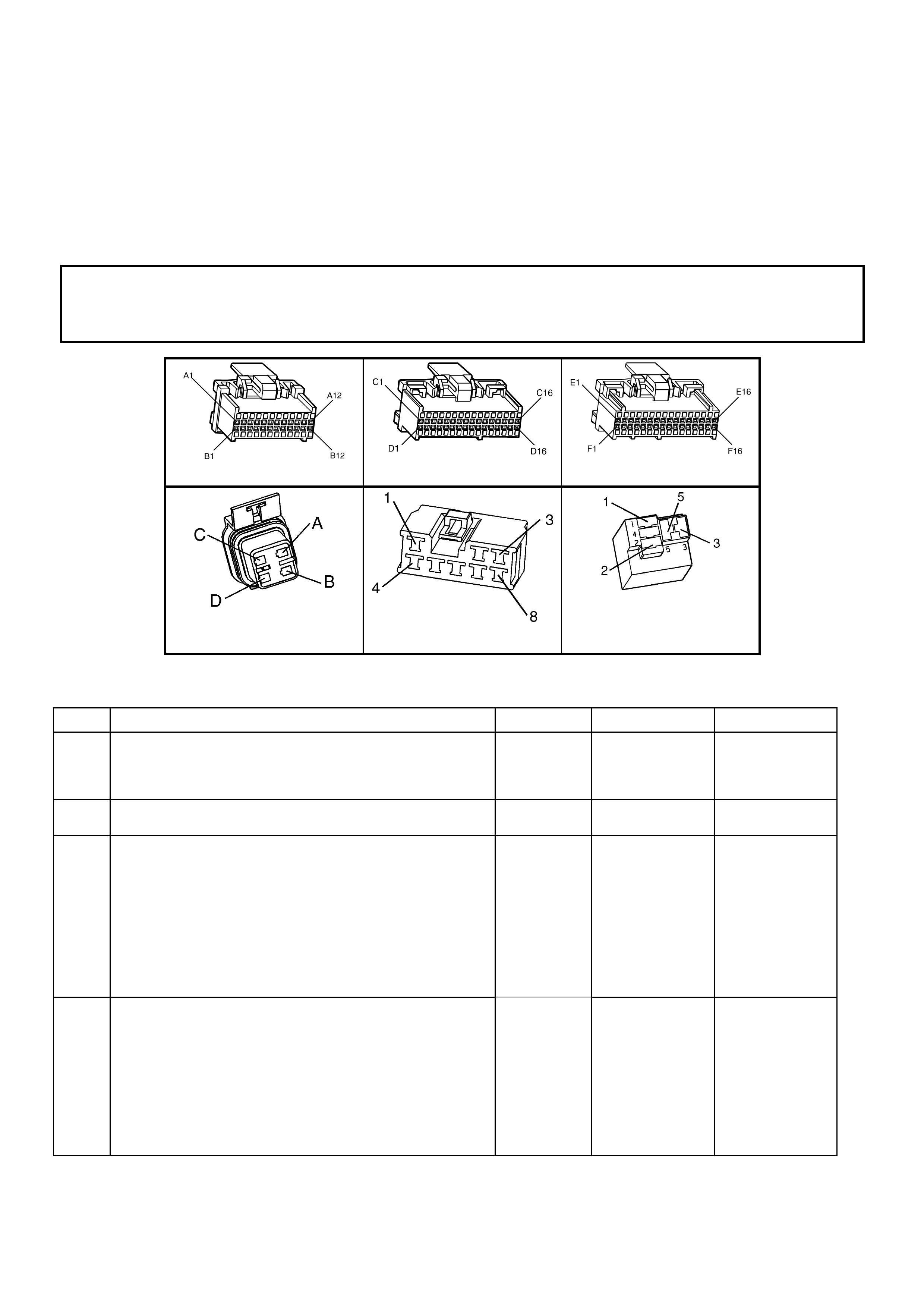

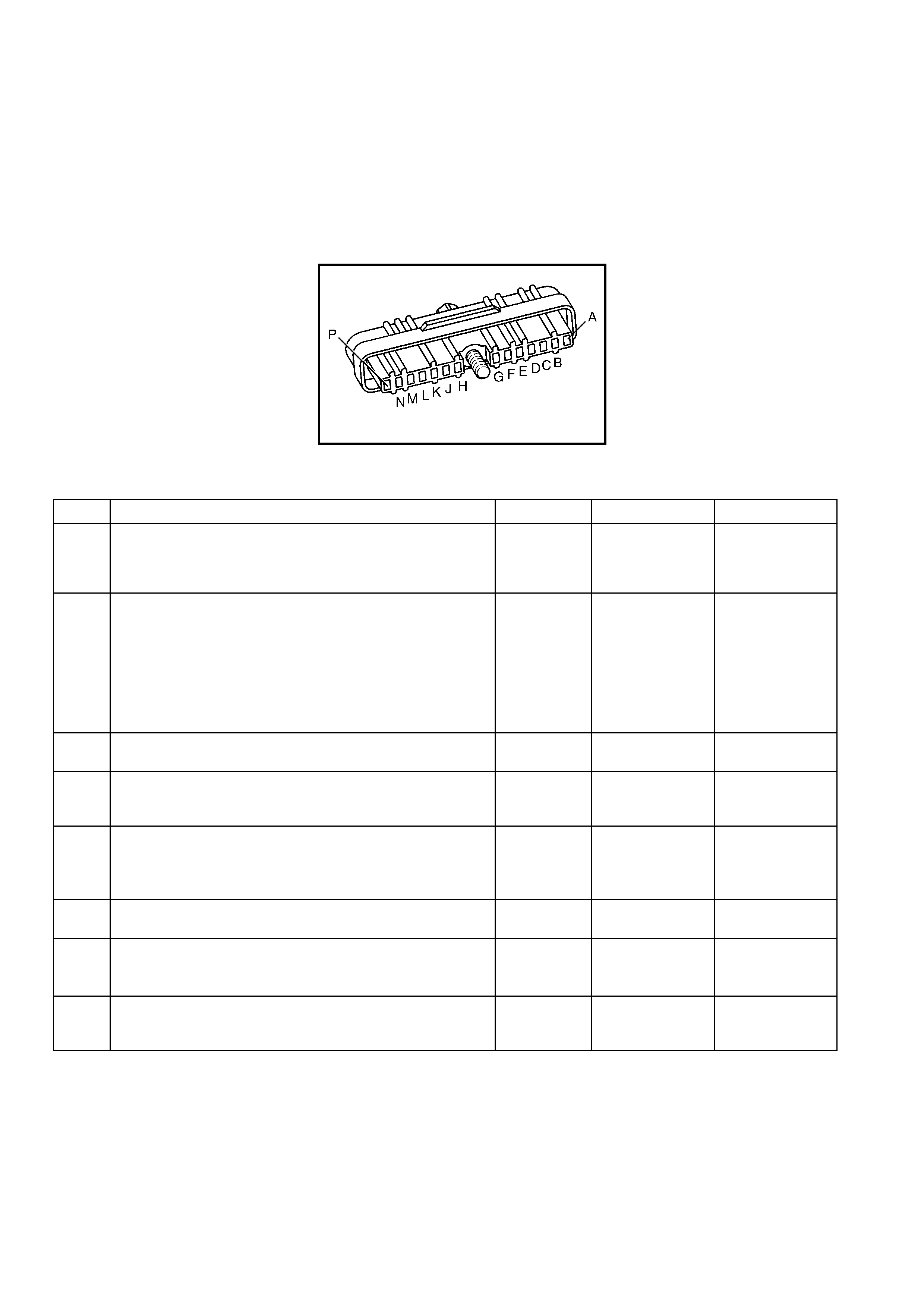

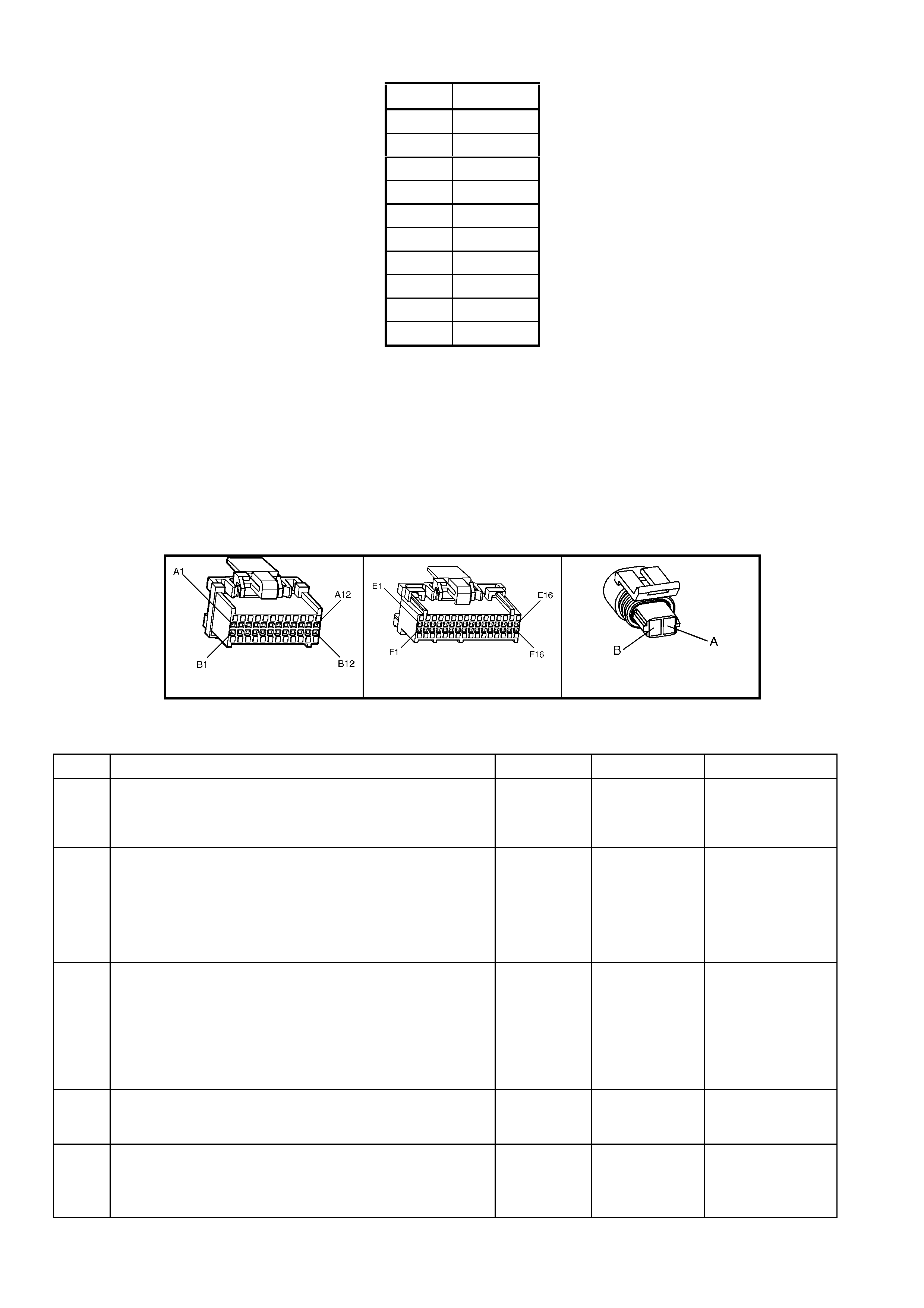

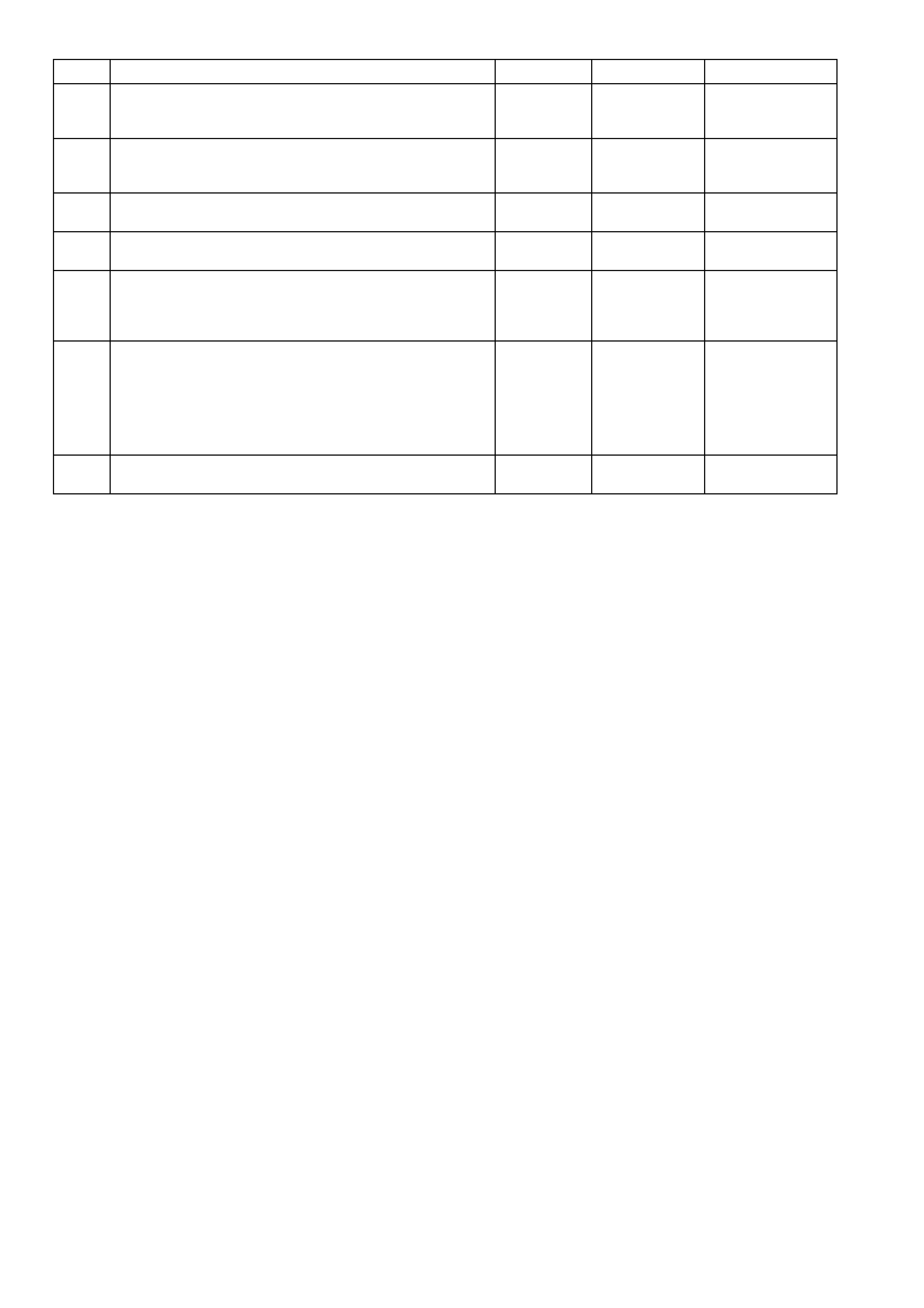

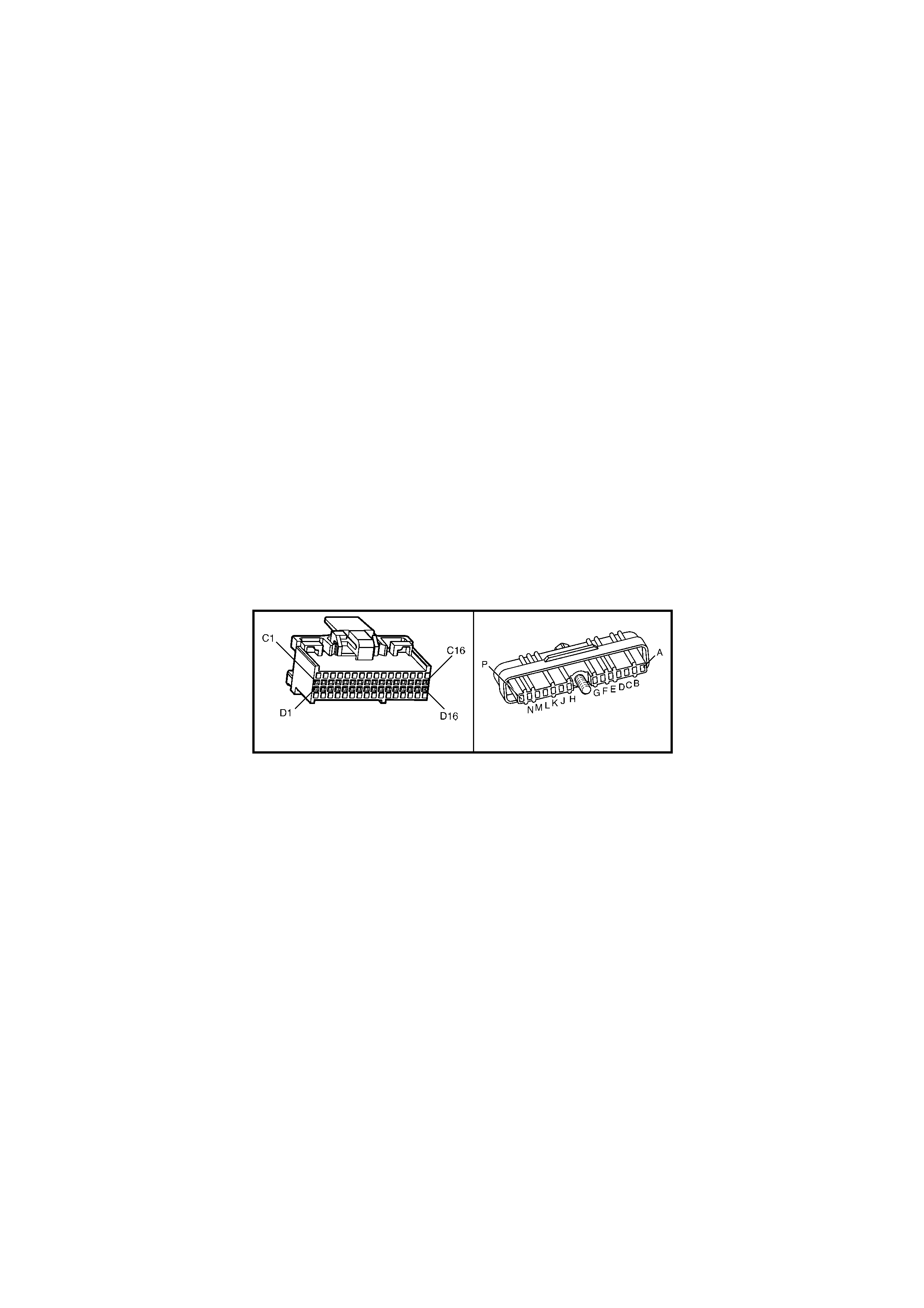

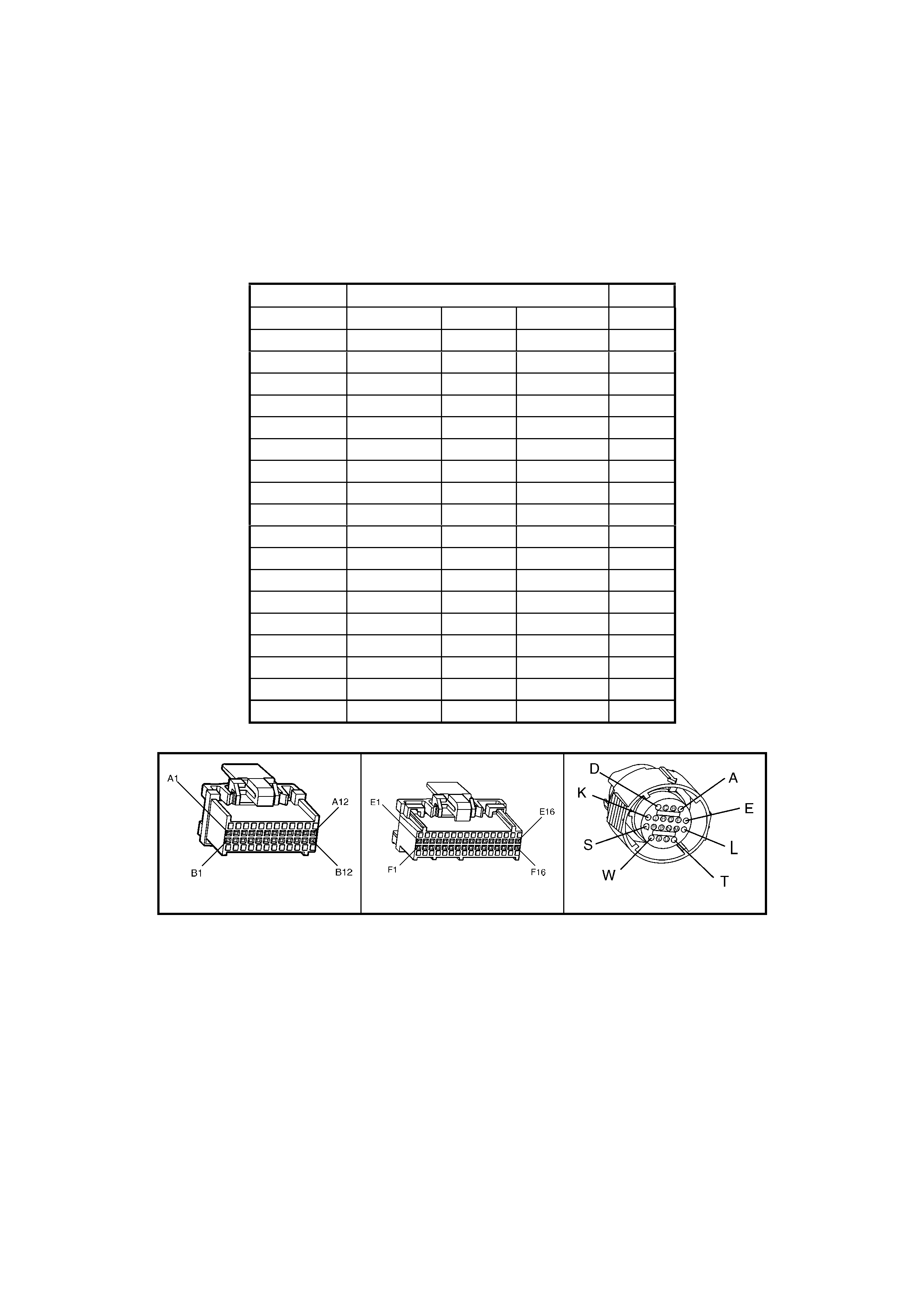

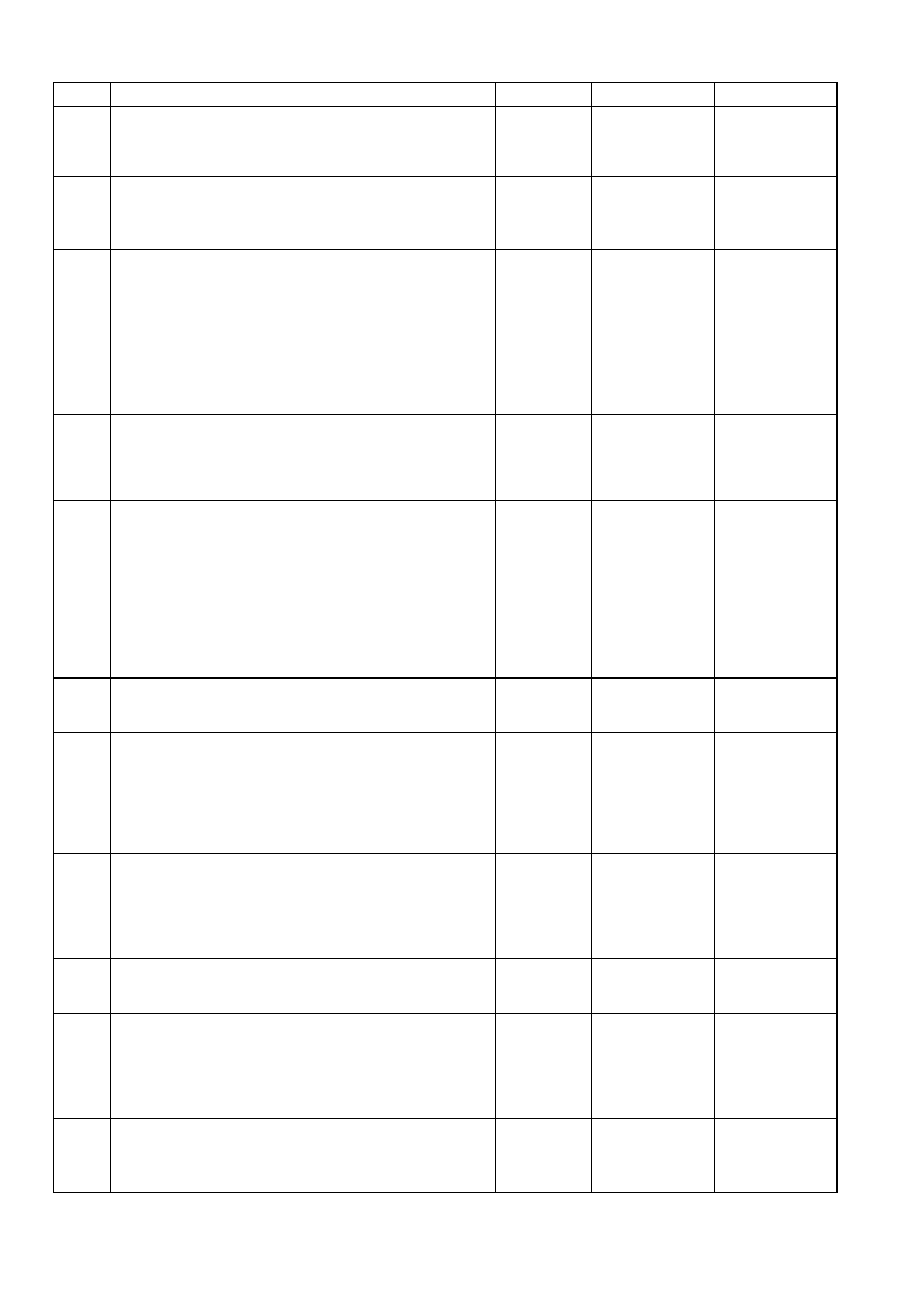

POWERTRAIN CONTROL MODULE CONNECTOR IDENTIFICATION

This Powertrain Control Module Voltage Table is for use with a digital voltmeter to further aid in diagnosis.

Connect the Black (–) probe to a good chassis ground, and backprobe the powertrain control module terminal

with the Red ( +) pr obe. These voltages were derived from a known good vehicle. The voltages you get may vary

due to low battery charge or other reasons, but they should be very close.

THE FOLLOWING CONDITIONS MUST BE MET BEFORE TESTING:

• Engine and Transmission at operating

temperature

• Closed Loop

• Engine idling (for "Engine Run" column)

• Diagnostic "Test" terminal not grounded

• Tech 2 scan tool not installed

• Accessories "OFF"

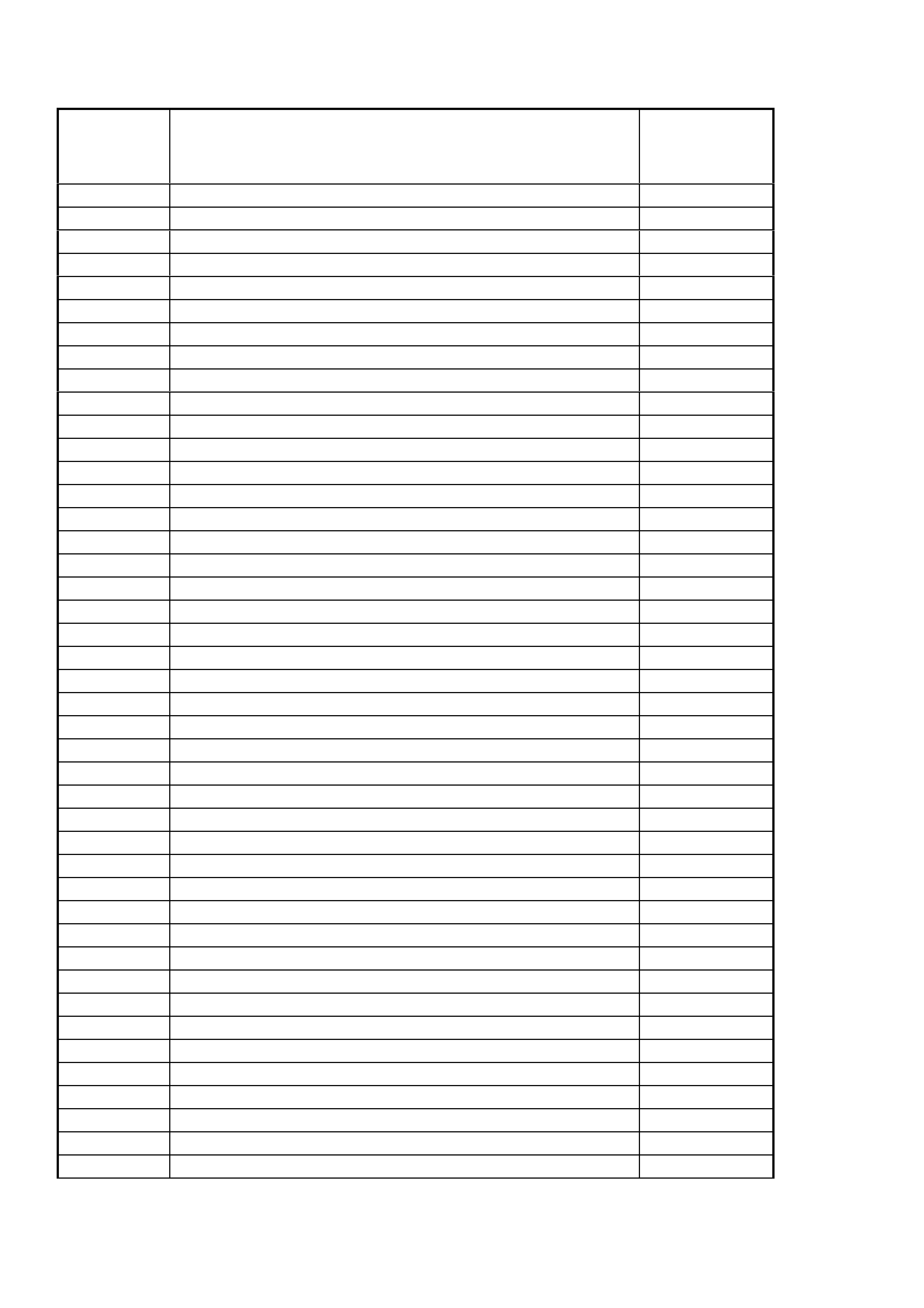

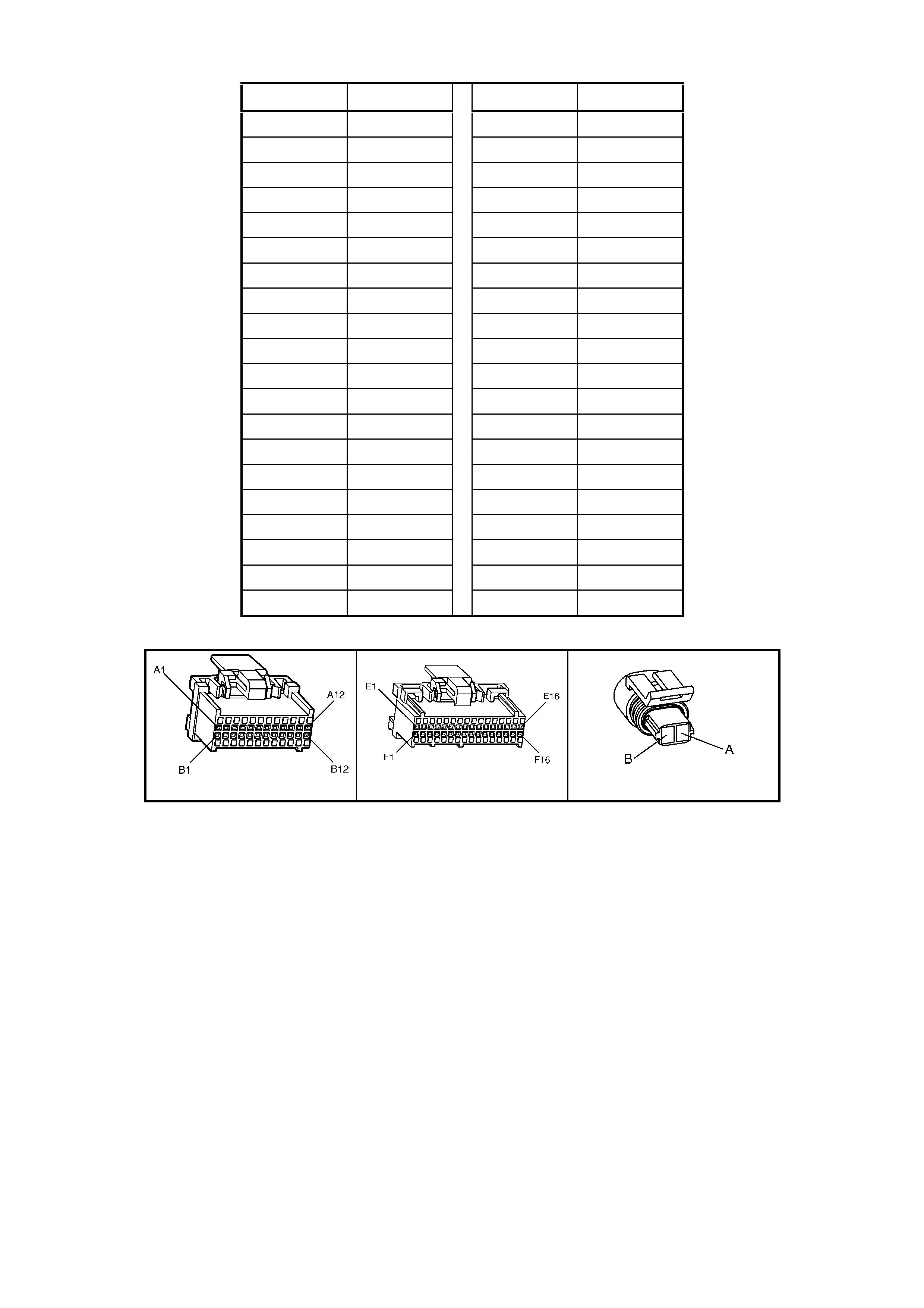

A84 S/C V6 – X3

BACKPROBING VIE W OF BLUE PCM CONNECTOR – A84 S/C V6 – X3

Figure 6C1-2A 17 – PCM Connector Terminal End View (3 of 3)

Pin

Pin Funct i on

CKT

#

Wire

Colour

Ign

"ON"

Eng

Run

Pin

Pin Funct i on

CKT

#

Wire

Colour

Ign

"ON"

Eng

Run

E1 BOOST CONTROL

SOLENOID 1724 BK/OG 12 -

--

- F1 FUEL INJECTOR

#4 CONTROL 844 BN/WH 12 13

E2 FUEL INJECTOR

#3 CONTROL 1746 PU 12 13 F2 FUE L INJECTOR

#1 CONTROL 1744 BU 12 12

E3 FUEL INJECTOR

#2 CONTROL 1745 GN 12 13 F3 FUEL INJE CTOR

#6 CONTROL 846 YE 12 13

E4 FUEL INJECTOR

#5 CONTROL 845 BN/YE 12 13 F4 AIR

CONDITIONING

RELAY CONT ROL

459 L-GN/BK 12 (2)

E5 FUEL PUMP

CONTROL

MODULE (PWM)

DRIVER

260 L-BU -

--

--

--

- 3.0

to

3.4 V

F5 START RELAY

CONTROL 434

or

275

GY

or

GY/BU

-

--

- -

--

-

E6 PRNDL "A" 771 BU/WH -

--

- -

--

- F6 ENGINE COOLING

FAN RELA Y HIGH

SPEED CONTROL

473 BU/WH 12 (7)

E7 PRNDL "B" 772 YE 12 13 F7 TORQUE

ACHIEVED (MMI) 464 BK/WH 0.9 3-6

E8 PRNDL "C" 773 GY 12 13 F8 NOT-USED – – – –

E9 NOT USED – – – – F9 RANGE SIGNAL

"A" 1224 BN/YE 12 13

E10 NOT-USED – – – – F10 RANGE SIGNAL

"B" 1225 YE 0 0

E11 NOT USED – – – – F11 RANGE SIGNAL

"C" 1226 GY 12 13

E12 OIL PRESSURE

INPUT SIGNAL 231 BU * 13 F12 POWER/ECONOM

Y SWITCH INPUT 553 BU (6) (6)

E13 NOT USED – – – – F13 NOT USED – – – –

E14 PRESSURE

CONTROL

SOLENOID LOW

1229 GY/BU -

--

- 6.8

to

7.8

F14 NOT USED – – – –

E15 PRESSURE

CONTROL

SOLENOID HIGH

1228 RD -

--

- 1.3

to

1.5

F15 PRNDL "P" 776 WH -

--

- -

--

-

E16 ECT/TP SENSOR

SENSOR GROUND 2752 BK/YE -

--

- -

--

- F16 IAT, TFT, A/C

REFRIGERANT

PRESSURE

SENSOR GROUND

5514 BK -

--

- -

--

-

(2) With air conditioning "ON" 0 volts, with air conditioning "OFF" 13 volts.

(3) 12 volts while engine is cranking.

(6) W hen Power/Economy switch is depressed, voltage will quickly change from 12 to 0 volts then back

to 12 volts.

(7) With engine cooling fan "ON" 0 volts, with engine cooling fan "OFF" 13 volts.

-

--

- Less than 0.50 volts.

-

--

--

--

- 9 – 10 volts for 2 seconds

Normal

Voltages Normal

Voltages

PCM CONNECTOR TERMINAL VOLTAGES WITH EXPLANATIONS

A1 - SYSTEM GROUND

A2 - SYSTEM GROUND

These terminals should have zero volts. They are connected directly to the engine ground.

A3 - PRIMARY SERIAL DATA

This is a serial bus that connects the PCM, BCM, A.B.S./T.C.S., OCC, INSTRUMENT S and SIR. T he T ech 2 sc an

tool can "talk" to each of these modules by sending a message to a controller and asking only it to respond. The

communication rate is at 8192 baud. The normal voltage on this circuit is about 5 volts, but with serial data

communication occurring, the voltage will vary and if read with a DMM may read about 2.5 volts

A4 - IGNITION SWITCH INPUT SIGNAL

This is the "turn on" s ignal to the PCM from the ignition s witch circ uit. It is not the "power supply" to the PCM, it only

tells the PCM that the ignition switch is "ON." The voltage should equal the battery voltage when the key is in either

the `run' or ‘crank' position.

A5 - NOT USED

A6 - FUEL PUMP (FP) RELAY CONTROL

Turning the ignition "O N" c aus es the PCM to ener gis e (+12V) the F uel Pump Relay. If no crank s haf t refer enc e input

pulses are received, the PCM turns "OFF" the relay. As soon as the PCM receives crankshaft reference input

pulses, the PCM will turn the Fuel Pump Relay on again.

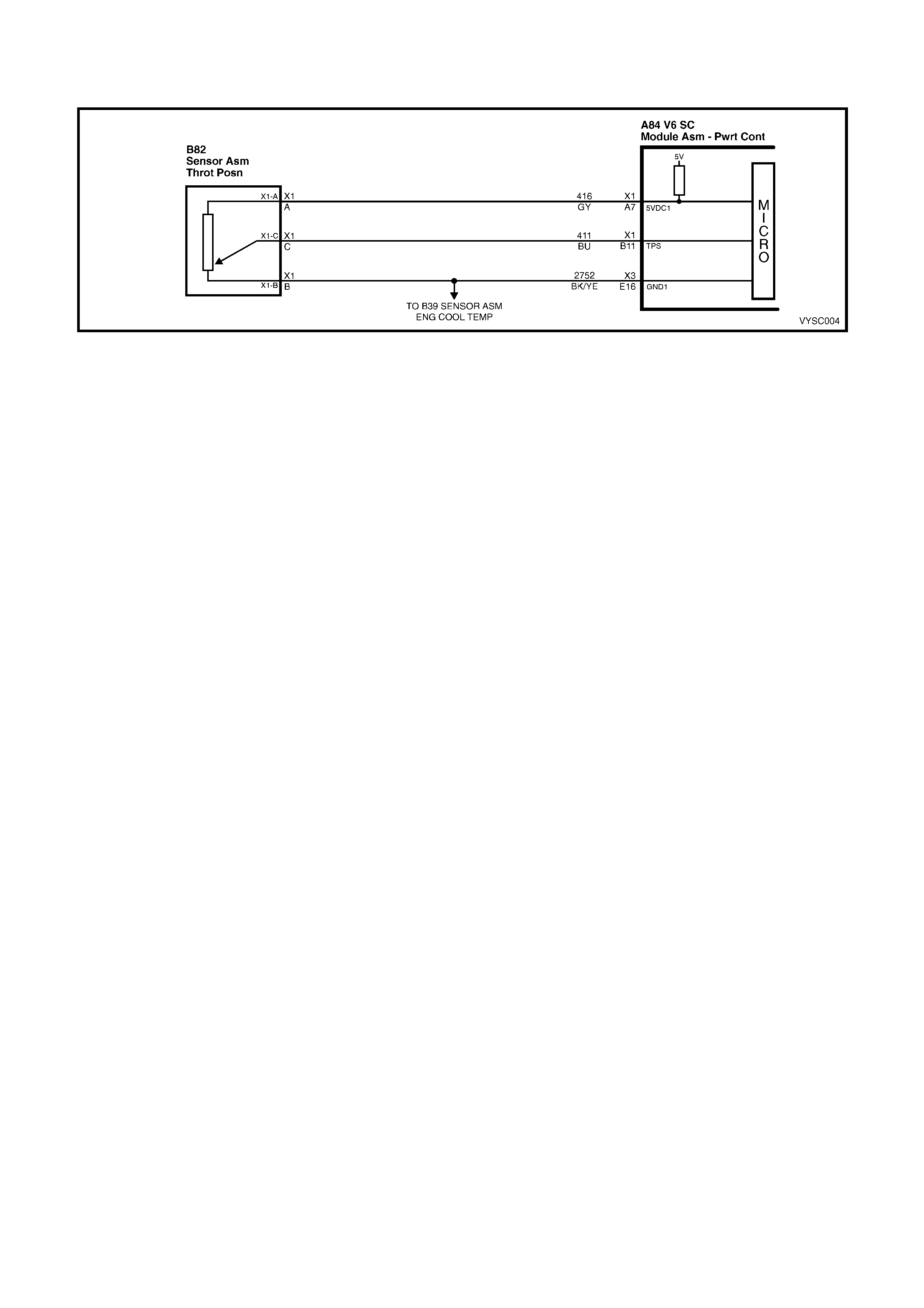

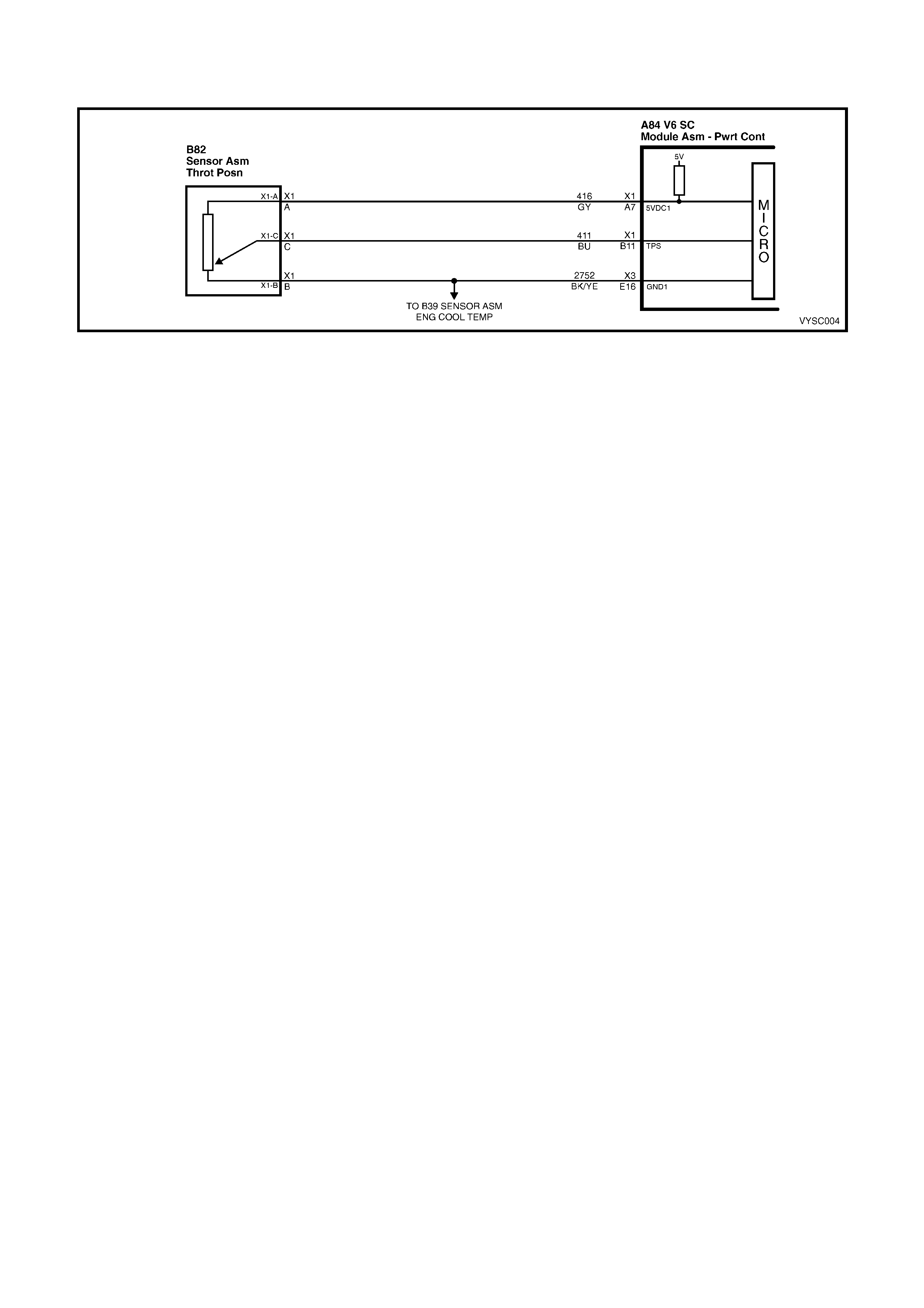

A7 - THROTTLE POSITION (TP) SENSOR REFERENCE VOLTAGE

This voltage should always be 5 volts anytime the ignition is "ON." It is a regulated voltage output from the PCM,

and supplies 5 volts to the TP sensor.

A8 - BATTERY VOLTAGE FEED – HOT AT ALL TIMES

This supplies the PCM with full- time +12 volts . It s tays hot even when the ignition is turned off . It receives its voltage

through the "ENGINE" fuse F29. This PCM terminal could be called the power supply and "MEMORY" terminal.

A9 - NOT USED

A10 - NOT USED

A11 - NOT USED

A12 - NOT USED

B1 - SYSTEM GROUND

B2 - SYSTEM GROUND

These terminals should have zero volts. They are connected directly to the engine ground.

B3 - A/C REFRIGERANT PRESSURE SENSOR INPUT SIGNAL

The signal that is sent from the pressure Sensor to the PCM indicates to the PCM what the A/C pressure is at.

Depending on the A/C pressure, this signal will indicate to the PCM if A/C pressure is too low or too high.

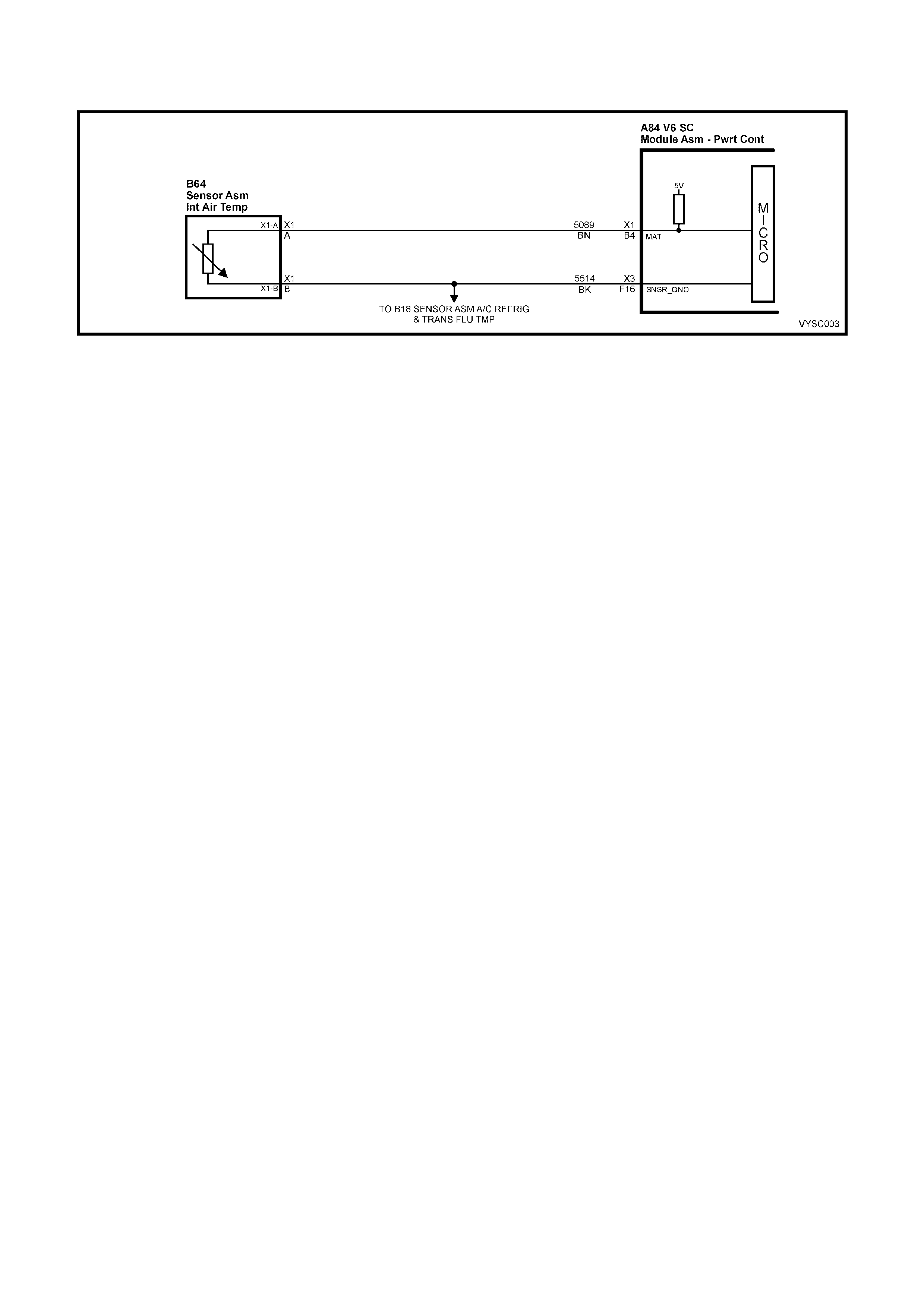

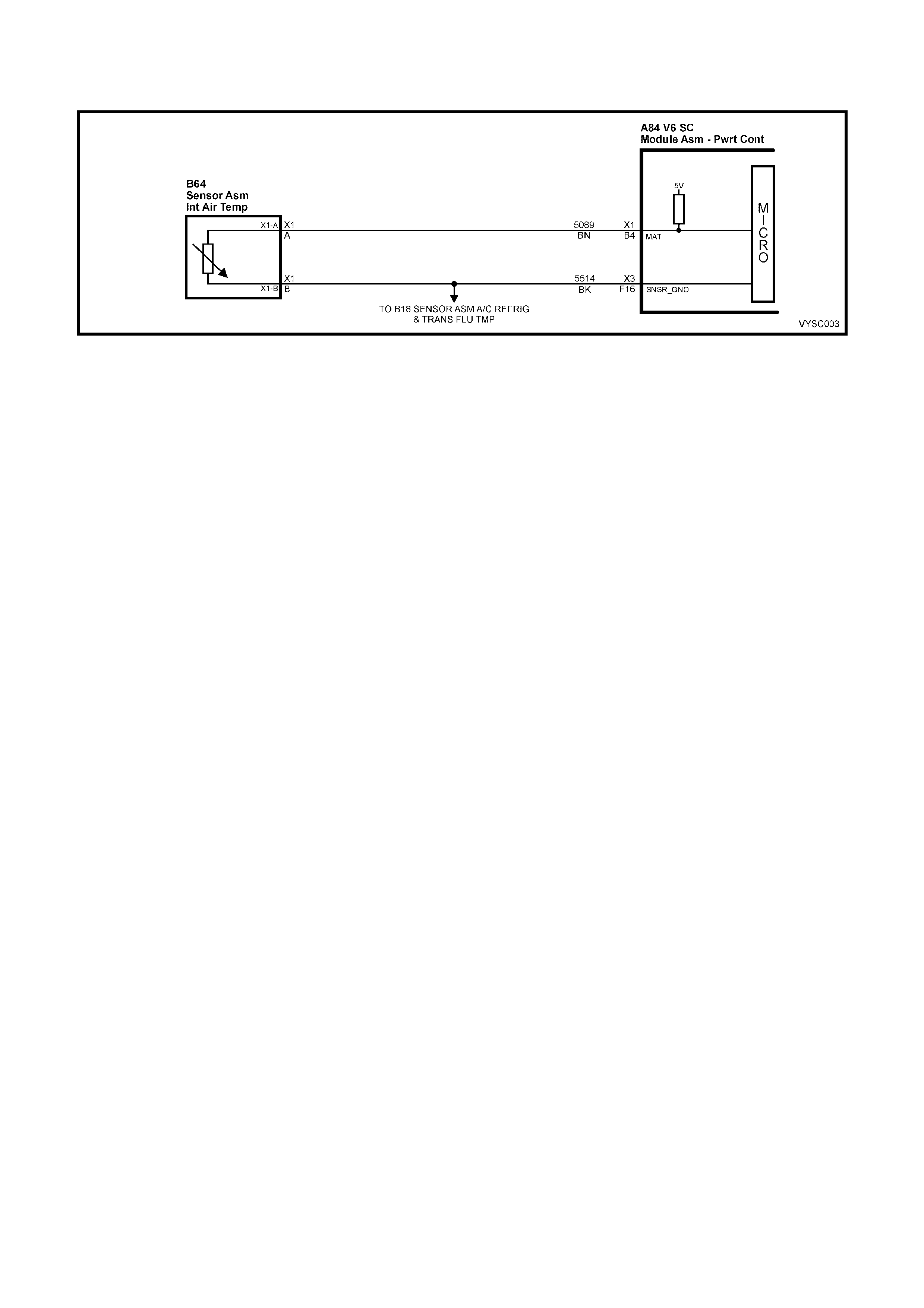

B4 - INTAKE AIR TEMPERATURE (IAT) INPUT SIGNAL

The PCM sends a 5 volt signal voltage to the IAT sensor, which is a temperature - variable-resistor called a

thermistor. The sensor is also connected to ground, and will alter the signal voltage according to incoming air

temperature. As the air temperature increases, the voltage seen on this terminal decreases. At 0 degrees C, the

voltage will be above 4 volts. At normal operating temperature (10 degrees C to 80 degrees C) the voltage will be

less than 4 volts.

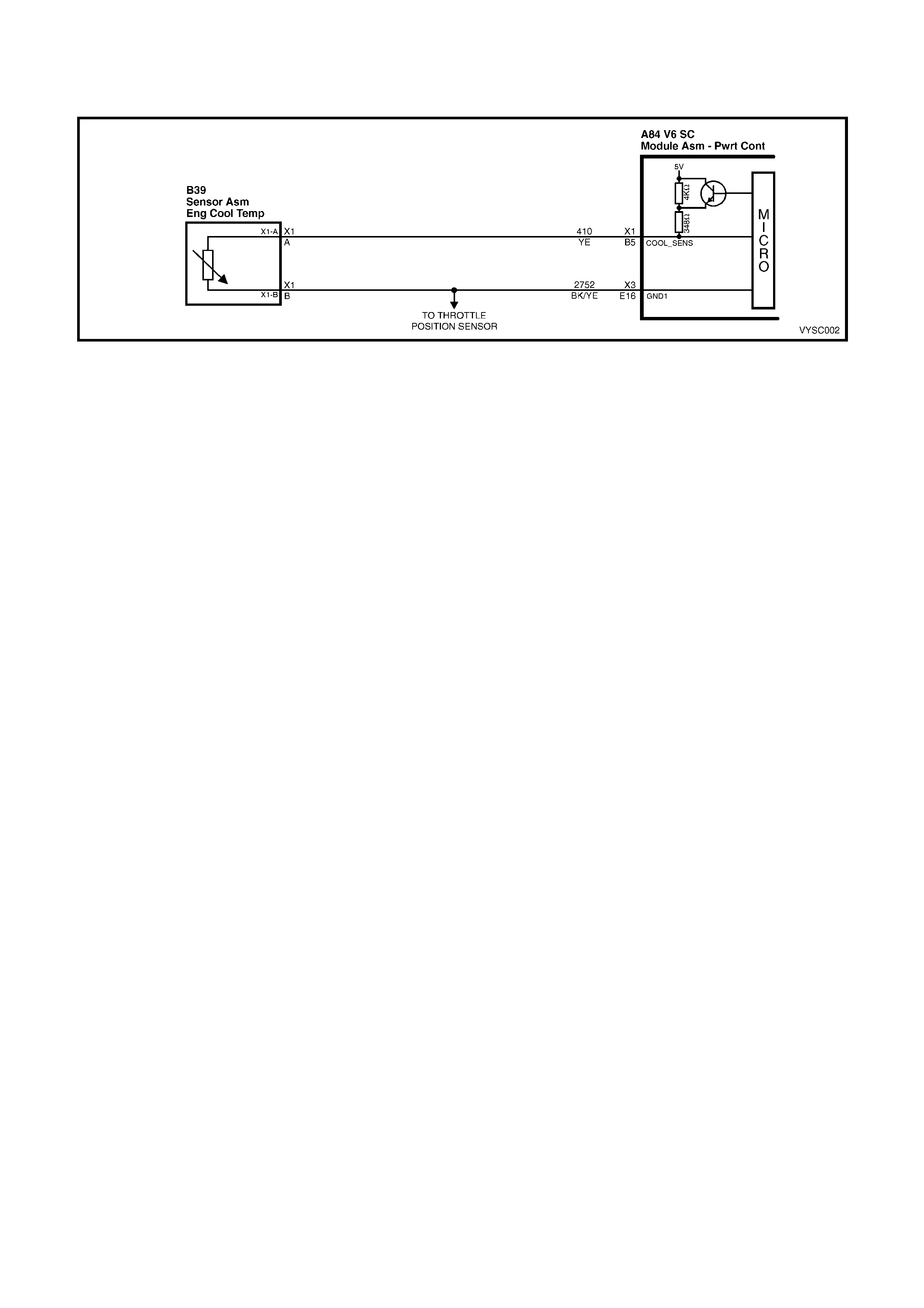

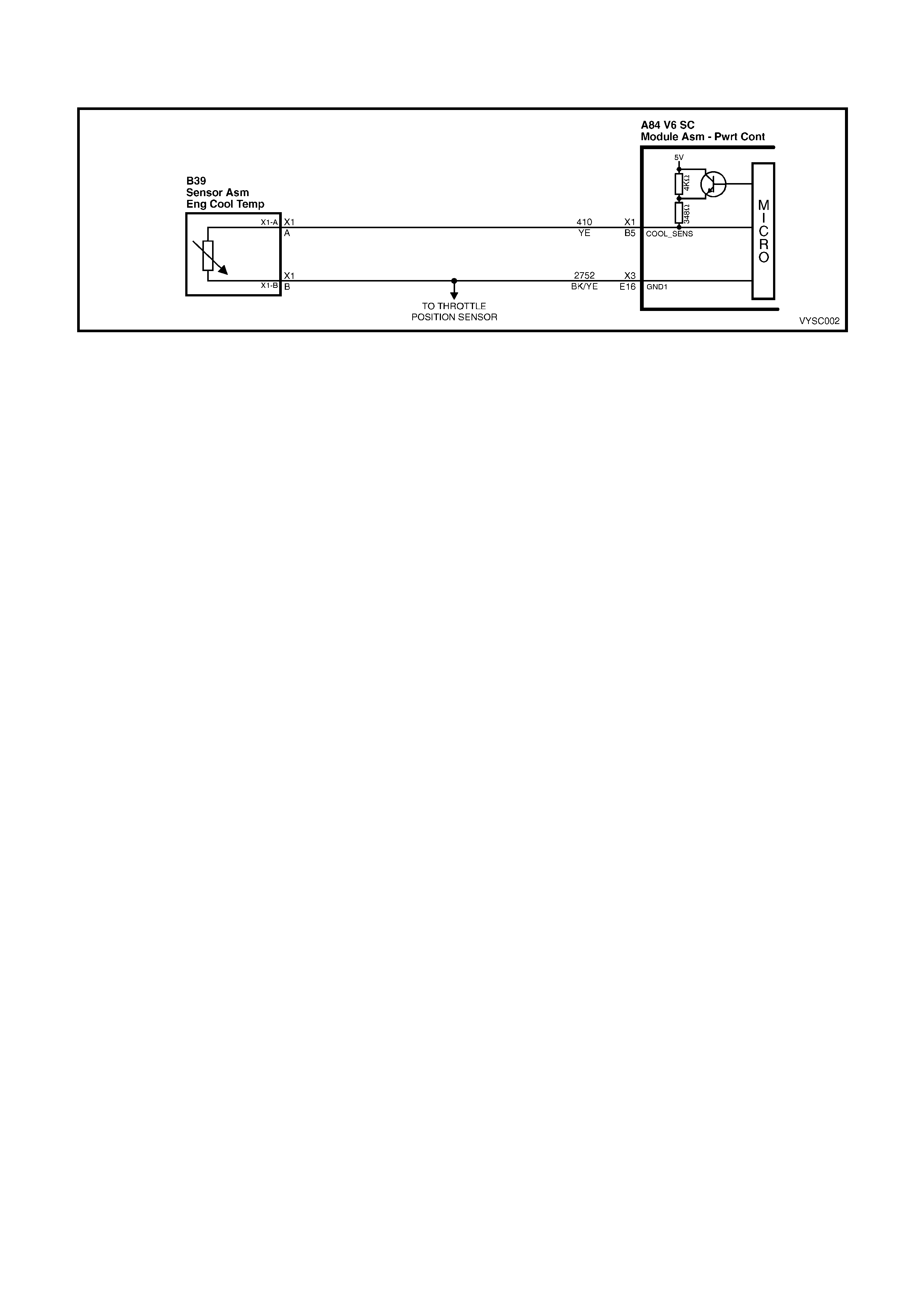

B5 - ENGINE COOLANT TEMPERATURE (ECT) INPUT SIGNAL

The PCM sends a 5 volt signal voltage out to the engine coolant temperature sensor, which is a temperature-

variable-resistor called thermistor. The sensor, being also connected to ground, will alter the voltage according to

engine coolant temperature. As the engine coolant temperature increases, the voltage seen on terminal B5

decreases. At 0 degrees C engine coolant temperature the voltage will be above 4 volts. At normal operating

temperature (85 degrees C to 100 degrees C) the voltage will be less than 2 volts.

B6 - TRANSMISSION FLUID TEMPERATURE (TFT) INPUT SIGNAL (AUTO TRANS ONLY)

The PCM sends a 5 volt signal voltage out to the transmission fluid temperature sensor, which is a temperature-

variable-resistor called thermistor. The sensor, being also connected to ground, will alter the voltage according to

transmission fluid temperature. As the fluid temperature increases, the voltage seen on terminal B6 will decrease.

B7 - A/C PRESSURE SENSOR REFERENCE VOLTAGE

This voltage should always be 5 volts anytime the ignition is "ON." It is a regulated voltage output from the PCM,

and supplies 5 volts to the A/C Pressure Sensor.

B8 - BATTERY VOLTAGE FEED – HOT AT ALL TIMES

This supplies the PCM with full- time +12 volts . It s tays hot even when the ignition is turned off . It receives its voltage

through the "ENGINE" fuse F29. This PCM terminal could be called the power supply and "MEMORY" terminal.

B9 - NOT USED

B10 - NOT USED

B11 - THROTTLE POSITION (TP) SENSOR SIGNAL

The TP sensor input voltage, which follows actual throttle changes, is variable from 0 to 5 volts. Typically the voltage

is less than 1 volt at idle, and 4 to 5 volts at wide-open throttle.

B12 - INJECTOR CIRCUIT VOLTAGE MONITOR INPUT SIGNAL

The inj ector voltage m onitor line is used s o that the PCM will know the exact voltage the fuel injectors are operating

at. This voltage signal is used to modify the fuel injector pulse width calculation.

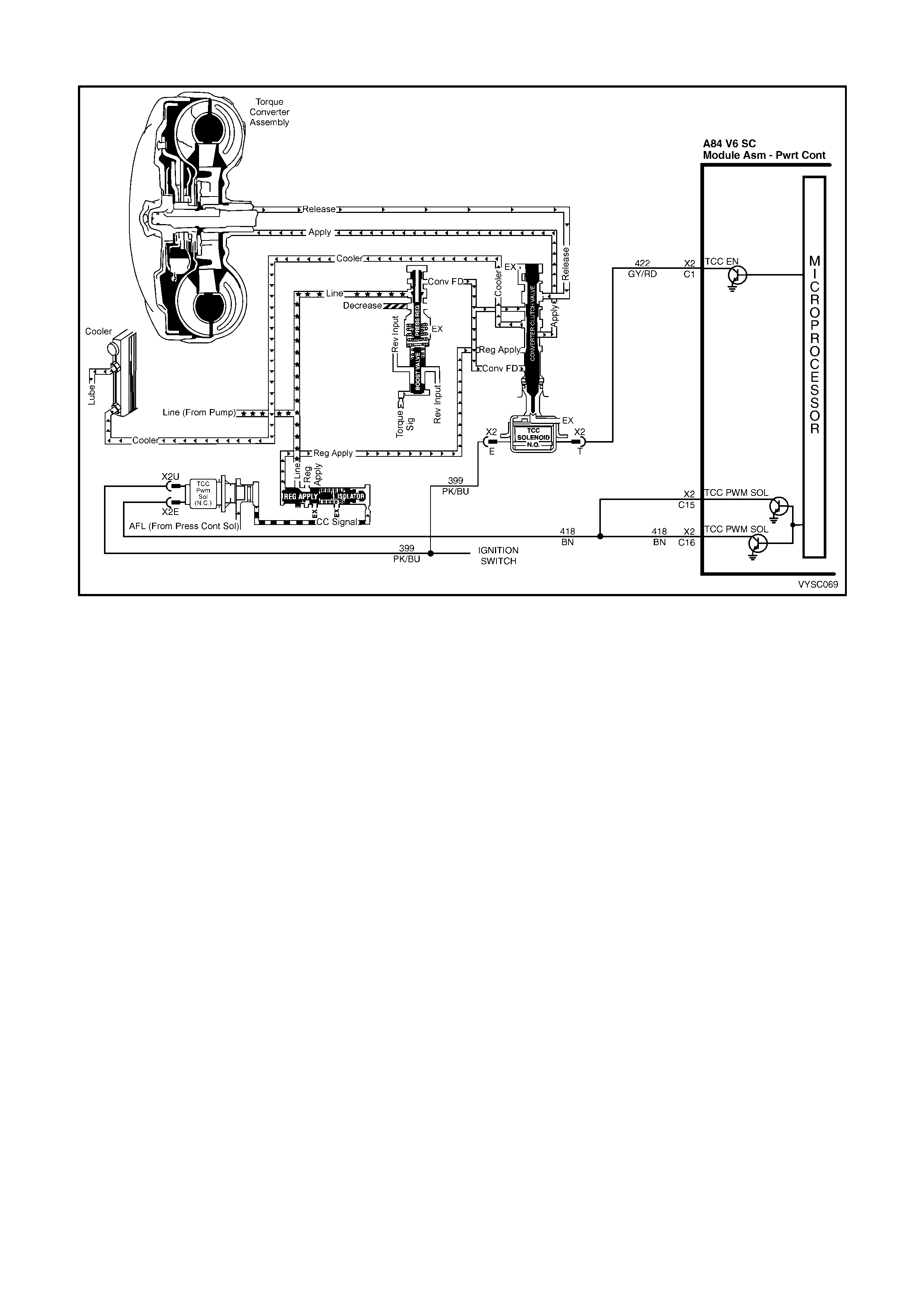

C1 - TORQUE CONVERTER CLUTCH ENABLE SOLENOID CONTROL (AUTO TRANS ONLY)

The PCM is used to either open or provide a path to ground for the torque converter solenoid. When the PCM

provides a path to ground, the TCC solenoid is cons idered ON and voltage should be near 0 volts. T he PCM uses

both the TCC enable s olenoid and the TCC "PWM" solenoid to c ontrol the torque converter clutch. (See TCC PW M

solenoid, terminal C16)

C2 - 1-2 SHIFT SOLENOID ‘A’ CONTROL (AUTO TRANS ONLY)

The PCM is used to either open or provide a path to ground for the 1-2 shift solenoid. When the PCM provides a

path to ground, the 1-2 shift solenoid is considered "ON" and the voltage should read 0 volts.

C3 - 2-3 SHIFT SOLENOID ‘B’ CONTROL (AUTO TRANS ONLY)

The PCM is used to either open or provide a path to ground for the 2-3 shift solenoid. When the PCM provides a

path to ground, the 2-3 shift solenoid is considered "ON" and the voltage should read 0 volts.

C4 - CANISTER PURGE SOLENOID CONTROL

The PCM operates a normally closed solenoid valve, which controls vacuum to purge the evaporative emissions

storage canister of stored fuel vapours. The PCM turns "ON" the pulse width modulated control of the purge

solenoid, to control purging of the stored vapours. If the PCM is not energising the purge solenoid, the voltage

meas ured at this ter m inal should equal battery voltage. If the PCM is c ontrolling the solenoid, the measured voltage

will be between battery voltage and 0.50 volts.

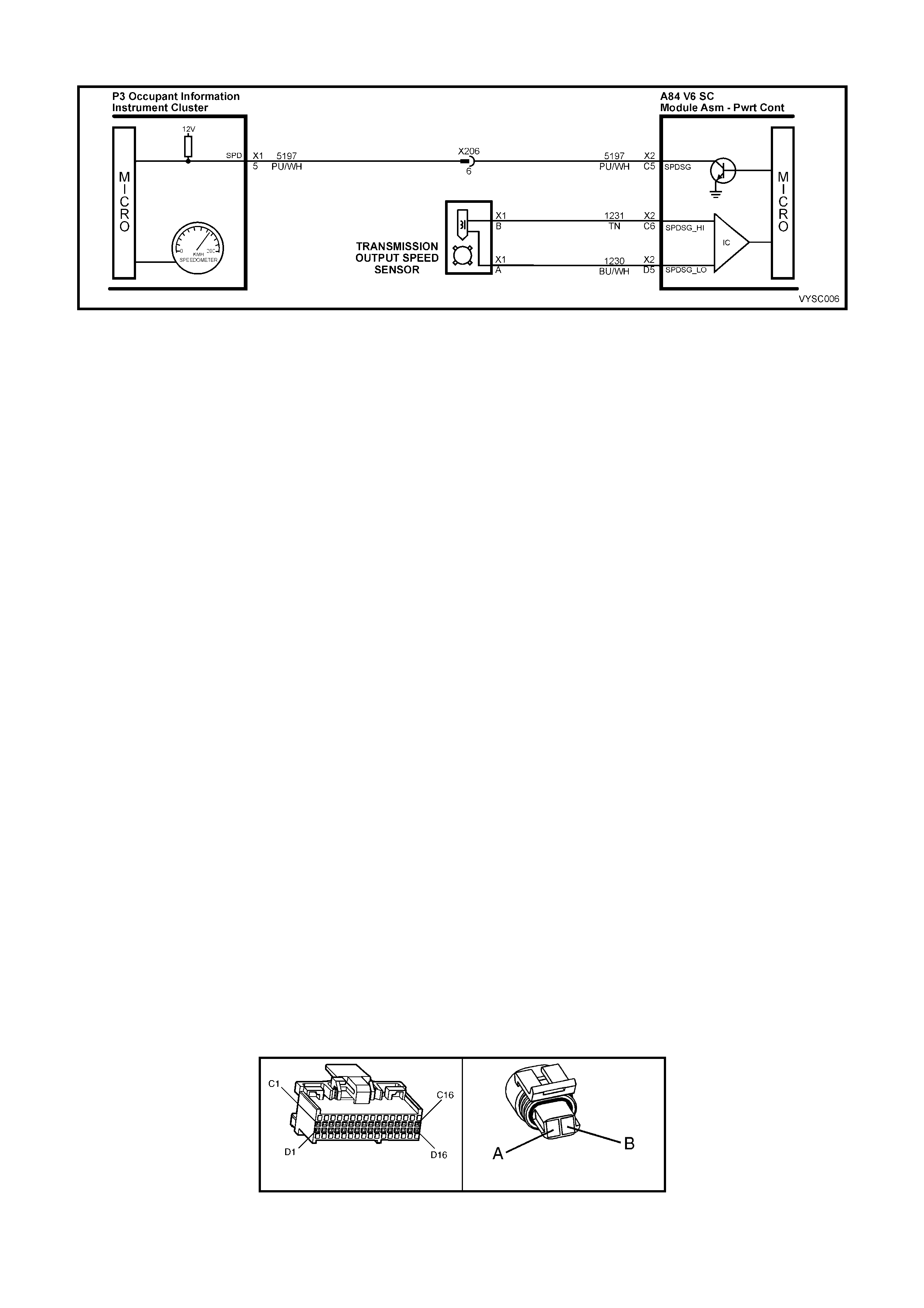

C5 - VEHICLE SPEED OUTPUT

The PCM alternately grounds this signal, in pulses, when it rec eives a vehicle speed signal fr om the vehicle speed

sensor in the transmission. This pulsing action takes place about 6,250 times per kilometre. The control modules

calculate vehicle speed based on the time between pulses (frequency).

C6 - VEHICLE SPEED SENSOR - OUTPUT SHAFT SPEED INPUT SIGNAL HIGH

The transmission has an output shaft speed sensor used by the PCM to calculate vehicle speed, and to help

determ ine various autom atic transm ission shif ting functions . It is a m agnetic inductive sens or that generates an AC

voltage signal sent to the PCM. If measured with the digital AC voltmeter, no voltage will appear until the output

shaft begins turning.

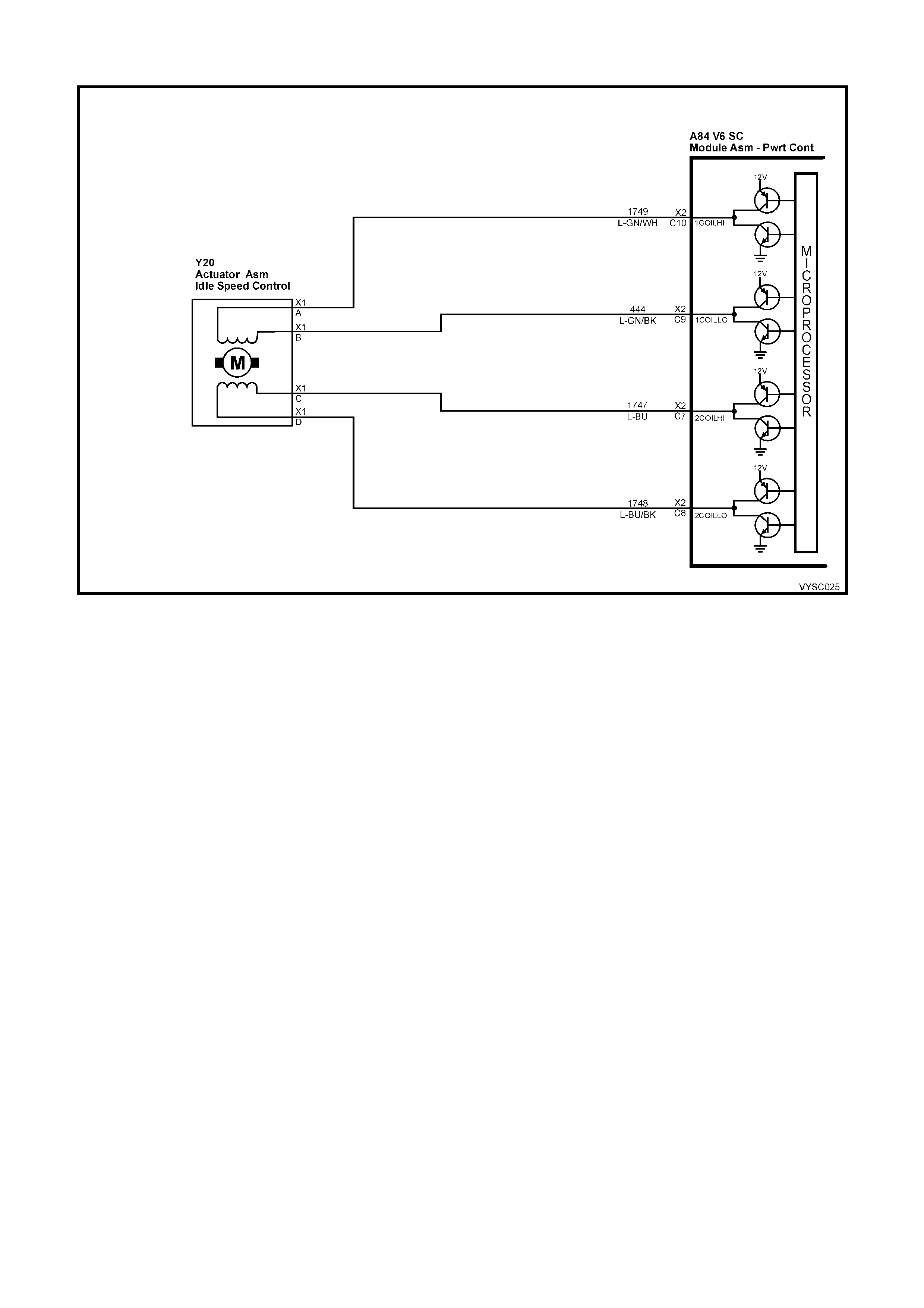

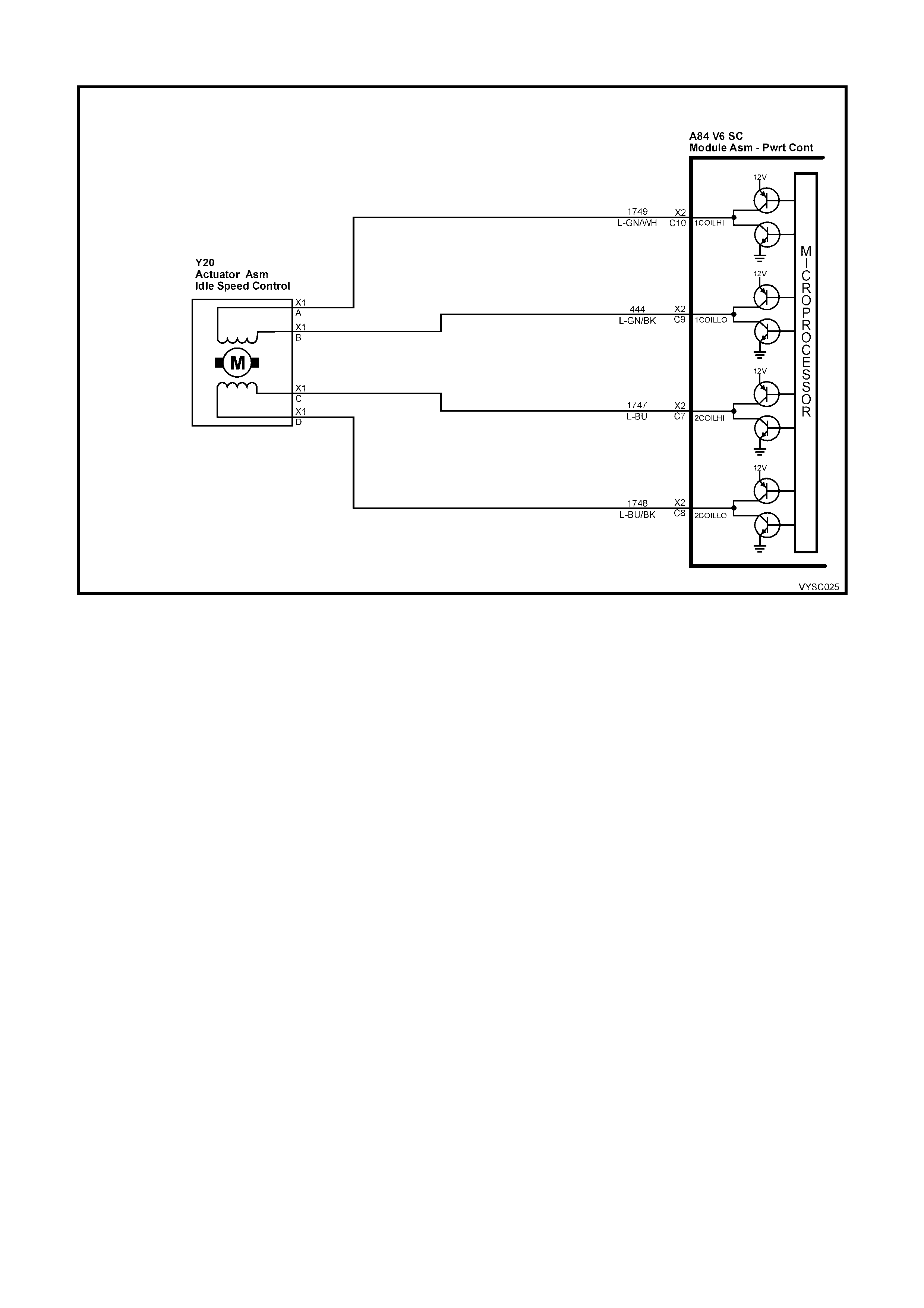

C7 - IDLE AIR CONTROL (IAC)

C8 - IDLE AIR CONTROL (IAC)

C9 - IDLE AIR CONTROL (IAC)

C10 - IDLE AIR CONTROL (IAC)

These terminals connect the Idle Air Control valve, located on the throttle body, to the PCM. It is difficult to predict

what the voltage will be, and the measurement is unusable for any service procedures.

C11 - TRACTION CONTROL (TORQUE REQUESTED)

The A.B.S./T.C.S. module will send a Nm signal to the PCM when torque reduction is requested from the

A.B.S./T.C.S. module for traction control. This Nm signal should match closely with Torque Achieved Nm signal,

when traction control is being requested.

C12 – ELECTRONIC SPARK CONTROL (ESC) "KNOCK" INPUT SIGNAL

The Electronic Spark Control "knock" sensors detect when detonation is occurring in the combustion chambers.

W hen detected, the PCM will reduce the am ount of spar k advance being delivered on the EST output circuit to the

ignition module.

C13 - 3-2 DOWNSHIFT CONTROL SOLENOID CONTROL (AUTO TRANS ONLY)

The 3-2 control solenoid is a norm ally closed, solenoid us ed to control the 3- 2 downshift. T he solenoid is constantly

fed 12 volts and PCM controls the length of time the path to ground for the electrical circuit is closed.

C14 - 3-2 SHIFT SOLENOID FEEDBACK (AUTO TRANS ONLY)

The 3-2 Shift solenoid is a normally closed solenoid used to control the 3-2 downshift. The solenoid is constantly fed

12 volts and PCM controls the length of time the path to ground for the electrical circuit is closed. The PCM does

this to pr ovide a s mooth 3-2 downshif t. If the PCM s ens es an inc or rec t voltage on this c irc uit when controlling the 3-

2 downshift solenoid (i.e. – zero volts with the solenoid OFF, or 12 volts with the solenoid ON) a DT C code 66 will

set.

C15 - T ORQUE CONVERTER CLUT CH - PULSE WIDTH M ODULATED APPLY SOLENOID FEEDBACK (AUTO

TRANS ONLY)

The PCM us es the puls e width m odulated TCC apply solenoid to smoothly engage the torque converter clutch, after

the TCC "ON-OFF" solenoid is energised. By varying the duty cycle pulse width modulation, the PCM can slowly

engage the torque converter clutch, allowing very smooth TCC engagement. If the PCM senses an incorrect voltage

on this circuit when controlling the TCC PWM solenoid (i.e. zero volts with the solenoid OFF, or 12 volts with the

solenoid ON ) a DTC code 83 will set.

C16 - TORQUE CONVERTER CLUTCH - PULSE WIDTH MODULATED APPLY SOLENOID CONTROL (AUTO

TRANS ONLY)

The PCM us es the puls e width m odulated TCC apply solenoid to smoothly engage the torque converter clutch, after

the TCC "ON-OFF" solenoid is energised. By varying the duty cycle pulse width modulation, the PCM can slowly

engage the torque converter clutch, allowing very smooth TCC engagement.

D1 - MASS AIR FLOW (MAF) INPUT SIGNAL

The PCM supplies a 5-volt signal voltage to the mass air flow sensor on this circuit. The mass air flow sensor

pulses the 5-volt signal to ground. These ground pulses occur at a very fast rate - from less than 500 per second

(500 Hz) with no airflow through the sensor, to upwards of many thousands of pulses per second at high air flow

rates suc h as during ac c eleration. If measur ed, the voltage seen will be between 0.5 and 4.5 volts, depending on air

flow through the sensor.

D2 - NOT USED

D3 - CAMSHAFT POSITION INPUT SIGNAL

This signal is used by the PCM to "sequence" the energising of the fuel injectors, similar to the firing order of an

engine. This allows the PCM to operate the fuel injectors in a "sequential fuel injection" mode. The camshaft

position sensor is actually wired to the ignition module. The ignition module sends one pulse per every two

crankshaft revolutions to the PCM to determine actual camshaft position, and thus, engine cycle sequence.

D4 - CRANKSHAFT 18X INPUT SIGNAL

The 18X crank s haft ref erenc e input signal is us ed to very accurately control EST spark timing at low engine speeds

- below 1200 RPM. Below 1,200 RPM, the PCM monitors the 18X signal to control spark timing. At engine s peeds

above 1,200 RPM, the PCM uses the crankshaft reference input signal to control spark timing. (See crankshaft

reference terminal D12).

D5 - VEHICLE SPEED SENSOR - OUTPUT SHAFT SPEED INPUT SIGNAL LOW

The transmission has an output shaft speed sensor used by the PCM to calculate vehicle speed, and to help

determ ine various autom atic transm ission shif ting functions . It is a m agnetic inductive sens or that generates an AC

voltage signal sent to the PCM. If measured with the digital AC voltmeter, no voltage will appear until the output

shaft begins turning.

D6 - NOT USED

D7 - NOT USED

D8 - NOT USED

D9 - IGNITION MODULE BYPASS CONTROL (IGNITION SYSTEM MODE CONTROL)

With ignition "ON" and engine not running this term inal will have very low voltage. As soon as the PCM sees engine

RPM of more than 450 RPM (Electronic Spark Timing "run" threshold) the PCM turns on 5 volts to the Ignition

Module Bypass Control circuit, causing the ignition module to allow the PCM to control the ignition system.

D10 - ELECTRONIC SPARK TIMING (EST) OUTPUT

This terminal will have very low voltage with the ignition "ON" but engine not running. With the engine running at

idle, the voltage should be slightly more than 1 volt. As the engine RPM goes up, this voltage will increase.

D11 - CRANKSHAFT REFERENCE INPUT SIGNAL LOW

This terminal should always be zero volts. It is connected through the ignition module to engine ground.

D12 - CRANKSHAFT REFERENCE INPUT SIGNAL HIGH

This term inal could be called the "tacho" input. It provides the PCM with RPM and crank shaft position information.

W ith ignition "ON" but engine not running, the voltage will be either high or low, depending on crankshaft position.

As the crank s haft tur ns, the voltage will be an average of the two readings. The PCM uses this signal to contr ol fuel

injection, and spark timing with engine speeds above 1,200 RPM. (See 18X crankshaft reference terminal D4).

D13 - OXYGEN SENSOR INPUT SIGNAL (RIGHT BANK)

W ith ignition "ON" and engine not running, the voltage should be 350 - 450 millivolts (0.350 - 0.450 volts). This is

the PCM-supplied 02 circuit "bias" voltage. With the engine running and after the 02 sensor is hot, the voltage

should be rapidly changing, som ewher e between 10 - 1000 m illivolts (0.010 - 1.000 volt, with the PCM operating in

closed loop).

D14 - OXYGEN SENSOR GROUND (RIGHT BANK)

This term inal should have zero volts. It is connected directly to the engine ground. This term inal grounds the PCM

circuitry for the O2 voltage monitor inside the PCM.

D15 - OXYGEN SENSOR INPUT SIGNAL (LEFT BANK

W ith ignition "ON" and engine not running, the voltage should be 350 - 450 millivolts (0.350 - 0.450 volts). This is

the PCM-supplied 02 circuit "bias" voltage. With the engine running and after the 02 sensor is hot, the voltage

should be rapidly changing, som ewher e between 10 - 1000 m illivolts (0.010 - 1.000 volt, with the PCM operating in

closed loop).

D16 - OXYGEN SENSOR GROUND (LEFT BANK)

This term inal should have zero volts. It is connected directly to the engine ground. This term inal grounds the PCM

circuitry for the O2 voltage monitor inside the PCM.

E1 - BOOST CONTROL SOLENOID

The PCM operates a normally closed solenoid valve, which controls vacuum to the By-Pass Valve Actuator. The

PCM turns "ON" the s olenoid , to allow vacuum to the By-Pass Valve Actuator , to c lose the By-Pass valve and allow

full boost. If the PCM is not energising the boost solenoid, the voltage measured at this terminal should equal

battery voltage. If the PCM is controlling the solenoid, the measured voltage will be between battery voltage and

0.50 volts.

E2 - FUEL INJECTOR 3 - CONTROL

E3 - FUEL INJECTOR 2 - CONTROL

E4 - FUEL INJECTOR 5 - CONTROL

The voltage seen at these terminals actually comes through the injectors, which are connected to +12 volts. W ith

the engine not running, the voltage seen would be battery voltage. With the engine running at idle, the charging

system increases the voltage slightly, so this voltage will increase. With higher engine RPM or more engine load,

the resulting increase in injector pulse frequency or injector pulse width will cause this voltage to appear slightly

less.

E5 - FUEL PUMP CONTROL MODULE

A duty c ycle ground signal on this cir cuit var ies depending on engine load. Under nor mal driving c onditions , the duty

cycle ground signal supplied f rom the PCM to the Fuel Pum p Control Module (term inal 7 of the Fuel Pum p Control

Module) is at 67% duty cycle. This 67% duty cycle runs the Fuel Pump at a lower f uel f low rate. When the vehicle is

in a heavy engine load condition, the PCM will switch from 67% duty cycle to 100% duty cycle. This will cause the

Fuel Pump to operate at a high fuel flow rate to compensate for the higher engine load condition. This change in

duty cycles does not change the fuel system operating fuel pressure, but changes the fuel flow rate.

E6 - PRNDL A

E7 - PRNDL B

E8 - PRNDL C

Thes e circuits along with PCM circuit F15 indic ate to the PCM what transmiss ion gear the driver has selected. The

PCM will then send a com mand via the ser ial data line to the ins trument panel clus ter (sm art cluster) to indicate to

the driver what gear has been selected.

E9 – NOT USED

E10 - NOT USED

E11 - NOT USED

E12 - OIL PRESSURE SWITCH

This is a ground input to the PCM from the Oil Pressure Switch indicating proper oil pressure when the engine is

running. If oil pr essure is lost while the engine is r unning, the switch will close its contacts and the ground signal to

the PCM will be seen. W hen the PCM sees this ground signal, the PCM will command the oil pressure icon in the

Instrument MFD to be activated, via a serial data normal mode message.

E13 - NOT USED

E14 - TRANSMISSION PRESSURE CONTROL

SOLENOID (PCS) – LOW (AUTO TRANS ONLY)

The 4L60-E automatic transmission uses an electrical solenoid to control hydraulic pressure inside the

transmission. This electrical solenoid allows the PCM to control "line pressure", similar to other automatic

transm issions that use a "throttle valve" cable or vacuum modulator. The duty cycle, and amount of current flow to

the PCS, are both controlled by the PCM. By monitoring this line, the PCM can determine if the commanded

amperage has gone to the PCS and returned to the PCM.

E15 - TRANSMISSION FLUID PRESSURE CONTROL SOLENOID (PCS) – HIGH (AUTO TRANS ONLY)

The duty cycle, and am ount of c urrent flow to the PCS, are c ontrolled by the PCM. T his circ uit is the B+ supply line

from the PCM to the PCS. The duty cycle and amperage are controlled by the PCM.

E16 - ENGINE COOLANT TEMPERATURE and THROTTLE POSITION SENSOR GROUND

This terminal should be zero volts. It is connected through the PCM circuitry to engine ground.

F1 - FUEL INJECTOR 4 - CONTROL

F2 - FUEL INJECTOR 1 - CONTROL

F3 - FUEL INJECTOR 6 - CONTROL

The voltage seen at these terminals actually comes through the injectors, which are connected to +12 volts. W ith

the engine not running, the voltage seen would be battery voltage. With the engine running at idle, the charging

system increases the voltage slightly, so this voltage will increase. With higher engine RPM or more engine load,

the resulting increase in injector pulse frequency or injector pulse width will cause this voltage to appear slightly

less.

F4 -AIR CONDITIONING RELAY CONTROL

When the A/C is requested, the BCM or the OCC module, will communicate to the PCM via the serial data line,

requesting A/C. The PCM supplies the ground path on this terminal to energise the A/C control relay. The voltage

will be less than 1 volt when the PCM energises the relay and battery voltage, when the relay is commanded OFF.

F5 - START RELAY CONTROL

W hen the PCM receives the proper T heft Deterrent signal, the PCM will supply a ground signal to the Start Relay.

This will allow the vehicle to start. If an impr oper Thef t Deterr ent s ignal is s ens ed by the PCM, then the PCM will not

supply a ground signal to the Start Relay. This will prevent the starter motor from operating.

F6 - ENGINE COOLING FAN - HIGH SPEED RELAY CONTROL

This terminal will have battery voltage until the PCM energises the high speed cooling fan relay by supplying the

ground; then it will be close to zero. The input that causes the PCM to energise the high speed fan relay is the

engine coolant temperature sensor or the A/C pressure sensor. The PCM will also energise the high speed fan relay

in the Diagnostic Mode - i.e., ignition "ON," engine stopped, and DLC diagnostic "test" enable terminal grounded.

Refer engine fan TABLE A-12 in this Section for further explanation. (The Body Control Module operates the cooling

fan low speed relay).

F7 - TRACTION CONTROL (TORQUE ACHIEVED)

The PCM sends a Nm signal to the A.B.S./T.C.S. module on the actual torque circuit informing the A.B.S./T.C.S.

module of response made to the desired torque Nm signal. This Nm signal should match closely with the

Requested Torque Nm signal during a traction control event. A problem with the delivered torque circuit should

cause an A.B.S./T.C.S. DTC to set, and traction control to be disabled.

F8 – NOT USED

F9 - RANGE SIGNAL A INPUT SIGNAL (AUTO TRANS ONLY)

F10 - RANGE SIGNAL B INPUT SIGNA L (AUTO TRANS ONLY)

F11 - RANGE SIGNAL C INPUT SIGNA L (AUTO TRANS ONLY)

Range signal "A", "B" and "C". The PCM sends out a buffered 12 volt signal to the transmission fluid pressure

manual valve position s witc h assem bly ( TFP), loc ated in the automatic transm ission valve body. T he 12 volt signal

must pass through either a normally open or normally closed switch to reach ground. When the switches are closed,

the signal should be near 0 volts. The PCM monitors the status of these signals to determine which position the

manual valve has actually been moved to.

F12 -POWER / ECONOMY INPUT SIGNAL (AUTO TRANS ONLY)

The PCM sends a signal of about 12 volts, and monitors the status of this circuit. In the ECONOMY position the

switch is open, the PCM voltage s tatus s ignal remains high – about 12 volts, and the PCM does not allow shif t point

changes. When the transmission switch is pressed to the POWER position the switch is momentarily closed and

the PCM voltage status s ignal is mom entarily pulled low. The PCM s enses the m omentary voltage signal drop and

enables power mode s hifting. T he PCM rem embers this status and will only enable Economy Mode if the switch is

depressed again.

F13 - NOT USED

F14 - NOT USED

F15 - PRNDL

This circuit, along with PCM circuits E6, E7 and E8, indicate to the PCM what transmission gear the driver has

selected. T he PCM will then send a com mand via the s erial data line to the instr ument panel cluster (sm art cluster)

to indicate to the driver what gear has been selected.

F16 - INTAKE AIR TEMPERATURE / TRANSMISSION FLUID TEMPERATURE / A/C PRESSURE SENSOR

GROUND CIRCUIT

This terminal should be zero volts. It is connected through the PCM circuitry to engine ground.

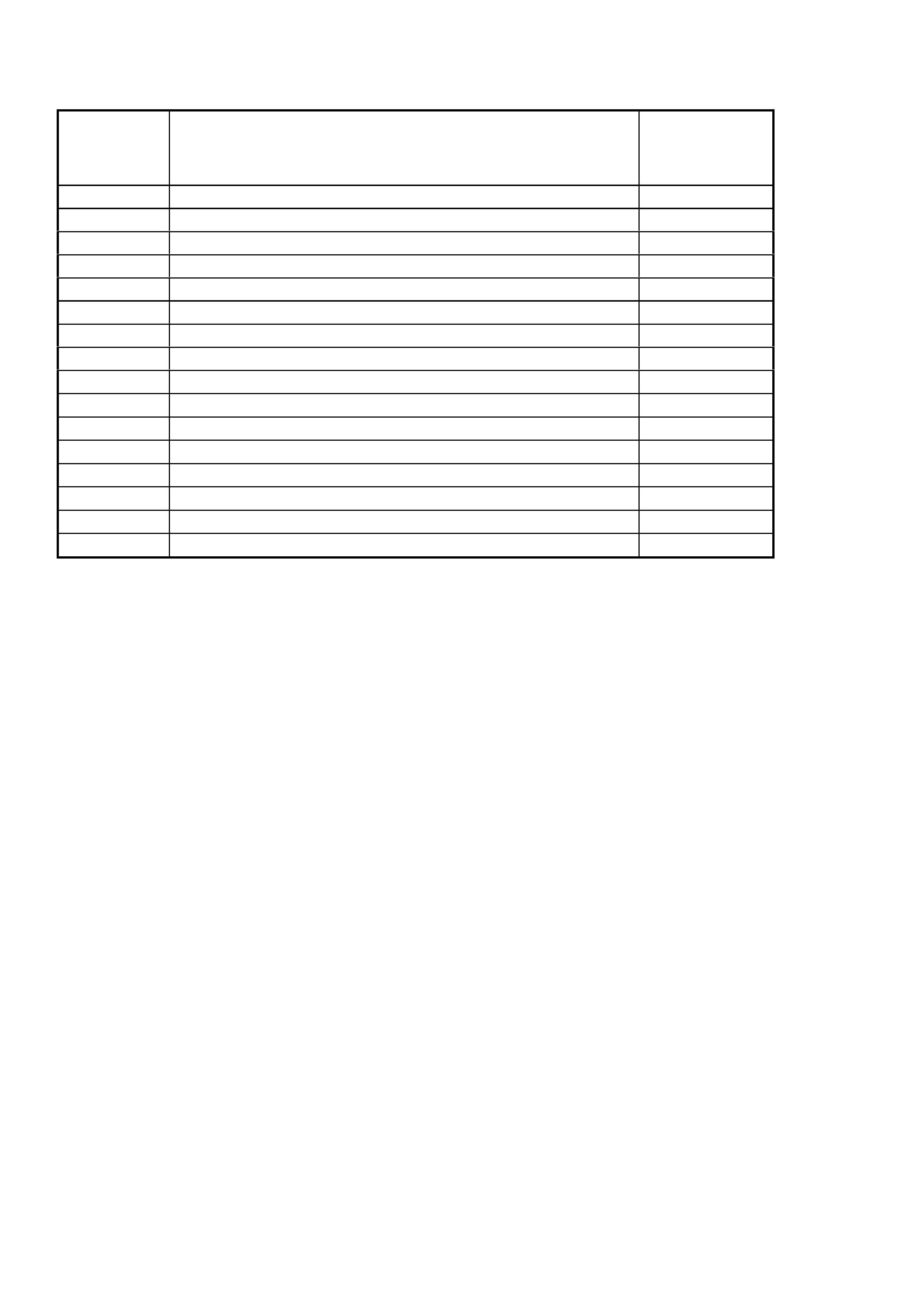

PCM V6 SUPERCHARGED ENGINE AND TRANSMISSION DIAG NOSTIC

TROUBLE CODES (DTC)

DTC DESCRIPTION

ILLUMINATE

"CHECK

POWERTRAIN"

LAMP

12 No revolutions per minute signal - normal when engine is not running No

13 Right Hand Heated Oxygen Sensor (HO2S) Insufficient Activity Yes

14 Engine Coolant Temperature ECT - Signal Voltage Low Yes

15 Engine Coolant Temperature ECT - Signal Voltage High Yes

16 Engine Coolant Temperature ECT – Sensor Unstable No

17 PCM Error - ECT Circuit No

19 Throttle Position (TP) Sensor Circuit Insufficient Activity Yes

21 Throttle Position (TP) Sensor Circuit High Voltage Yes

22 Throttle Position (TP) Sensor Circuit Low Voltage Yes

23 Intake Air Temperature (IAT) Sensor Circuit High Voltage No

24 Vehicle Speed Sensor (VSS) Circuit Low Voltage Yes

25 Intake Air Temperature (IAT) Sensor Circuit Low Voltage No

26 Intake Air Temperature (IAT) Sensor Unstable No

28 Transmission Fluid Pressure (TFP) Manual Valve Position Switch Circuit Yes

31 Theft Deterrent Signal Missing Yes

32 Mass Air Flow (MAF) Out Of Range Yes

35 Idle Speed Low No

36 Idle Speed High No

41 Ignition Electronic Spark Timing (EST) Output Circuit Fault Yes

42 Ignition Bypass Circuit Fault Yes

43 Knock Sensor Circuit Fault No

44 Right Hand Heated Oxygen Sensor (HO2S) Low Voltage Yes

45 Right Hand Heated Oxygen Sensor (HO2S) High Voltage Yes

46 No Crankshaft Reference Pulses W hile Cranking Yes

47 18X Reference Signal Missing No

48 Camshaft Position Sensor Circuit Low Voltage No

49 Camshaft Position Sensor Circuit Performance No

51 PROM Error Yes

52 System Voltage Too High (Long Time) Yes

53 System Voltage Too High Yes

54 System Voltage Unstable Yes

55 PCM – Analogue/Digital (A/D) Conversion Error Yes

56 Lean Condition Under Load (Supercharged Engine Only) Yes

57 Injector Voltage Monitor Fault No

58 Transmission Fluid Temperature (TFT) Sensor Circuit - Low Input No

59 Transmission Fluid Temperature (TFT) Sensor Circuit - High Input No

63 Left Hand Heated Oxygen Sensor (HO2S) Insufficient Activity Yes

64 Left Hand Heated Oxygen Sensor (HO2S) Low Voltage Yes

65 Left Hand Heated Oxygen Sensor (HO2S) High Voltage Yes

66 3-2 Shift Solenoid Circuit Electrical Yes

67 Torque Converter Clutch (TCC) Enable Solenoid Circuit Electrical Yes

69 Torque Converter Clutch (TCC) System Stuck On No

72 Transmission Output Speed Loss No

PCM V6 SUPERCHARGED ENGINE AND TRANSMISSION DIAGNOSTIC TROUBLE CODES (DTC) (Cont)

DTC DESCRIPTION

ILLUMINATE

"CHECK

POWERTRAIN"

LAMP

73 Pressure Control (PC) Solenoid Circuit Electrical No

75 System Voltage Low Yes

76 Short Term Fuel Trim (STFT) Delta High No

78 Long Term Fuel Trim (LTFT) Delta High No

79 Transmission Fluid Over-temperature Yes

81 2-3 Shift Solenoid ‘B’ Circuit - Fault Yes

82 1-2 Shift Solenoid ‘A’ Circuit - Fault Yes

83 Torque Converter Clutch Pulse Width Modulation Solenoid Circuit - Fault No

85 Transmission Slipping No

91 QDSM (Quad Driver Surface Module) Circuit No

92 Low Speed Fan No BCM Response No

93 SNEF Circuit Fault No

94 Not Used with the V6 Supercharged Engine –

95 Requested Torque Out Of Range Yes

96 A/C Pressure Sensor Fault No

97 Canister Purge Circuit Fault No

4L60-E TRANSMISSION FLUID CHECKING PROCEDURE

GENERAL INFORMATION

W hen adding or changing the transm ission fluid, us e only Dexron® III. Ref er to the MY2003 Owner's Handbook for

the recommended servicing intervals.

Because this transmission fluid changes colour and smell very easily in its life, these indicators should not

necessarily be relied upon to diagnose either transmission internal condition or fluid deterioration.

The Fluid Chec king Procedure s hows that a dar k brown fluid colour , coupled with a delayed shift pattern, m ay only

indicate that the fluid requires replacement and alone, is not a definite indication of a potential transmission failure.

NOTE: Do not overf ill the transmis sion. Overfilling will cause f oaming of the f luid, loss of f luid, shift com plaints and

possible damage to the transmission.

TRANSMISSION FLUID COLOUR

Transmission fluid colour when new and unused, is red. A red dye is added so that it can be distinguished from

other oils and lubricants. The red dye is not an indicator of fluid quality and is not permanent. As the vehicle is

driven, the transmission fluid will quickly begin to look darker in colour. The colour will then appear light brown. A

DARK brown colour with a distinctively burnt odour MAY indicate fluid deterioration and a need for the fluid to be

changed.

TRANSMISSION FLUID CHECKING PROCEDURE

1. Start the engine and drive vehicle for a maximum of 24 km, or until the transmission normal operating

temperature is reached.

NOTE: As temperature greatly affects transmission fluid levels, this operation must only be carried out when the

transm ission is at norm al operating tem perature (82 – 94° C) . If the vehicle is not at nor mal operating tem perature,

and the proper checking procedures are not followed, the result could be a false reading of the fluid level on the

dipstick.

2. Park vehicle on level ground.

3. Move gear selector to 'PARK' position.

4. Apply park brake.

5. Let engine idle for 3 minutes with accessories turned off.

6. Locate red coloured dipstick in the engine compartment, lift the locking lever, remove the dipstick and check

fluid colour, condition and level.

7. If the fluid level is low, add only enough DEXRONâ III to bring the level into the "HOT" area.

NOTE: Inaccurate fluid level readings will result if checked immediately after the vehicle has been operated under

any or all of the following conditions:

a. In high ambient temperatures above 32° C.

b. At sustained high speeds.

c. In heavy city traffic during hot weather.

d. Towing

e. In commercial use (e.g. taxi).

If the vehicle has been operated under these conditions , switch the engine off and allow the vehicle to 'cool' for

approximately thirty minutes. After cool-down period, re-start the vehicle and continue from step 2.

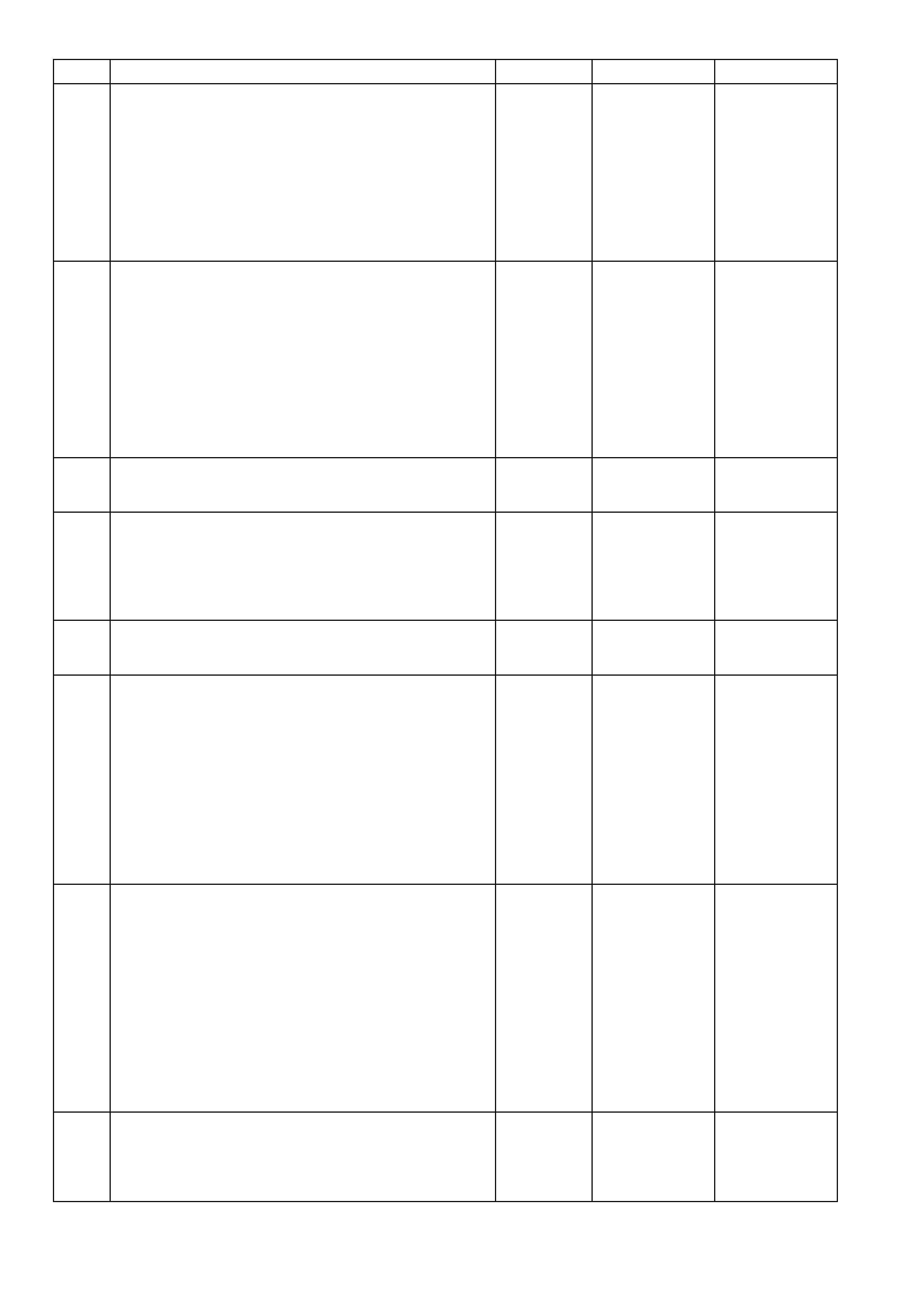

4L60-E AUTOMATIC TRANSMISSION FLUID CHECKING PROCEDURE

STEP ACTION VALUE YES NO

1. Check the fluid colour.

Is the fluid colour red? Go to Step 2 Go to Step 11

2. Is the fluid level satisfactory? Go to Step 20 Go to Step 3

3. Check the fluid.

Is the fluid foamy? Go to Step 8 Go to Step 4

4. Check the fluid level. The proper fluid level should be in

the middle of the X-hatch.

Is the level high?

Go to Step 9 Go to Step 5

5. Fluid will be low.

Add fluid to the proper fluid level.

Is the fluid level satisfactory?

Go to Step 6 Go to Step 1

6. Check for external leaks.

Were any leaks present? Go to Step 7 Go to Step 20

7. Correct the fluid leak condition.

Is action complete? Go to Step 20

8. Is the fluid level too high? Go to Step 9 Go to Step 10

9. Remove excess fluid to adjust to the proper fluid level.

Is action complete? Go to Step 20

10. 1. Check for contaminants in the fluid.

2. Drain the fluid to determine the source of the

contamination.

Is action complete?

Go to Step 15

11. Is the fluid colour non-transparent pink? Go to Step 12 Go to Step 13

12. Replace the cooler.

Is action complete? Go to Step 15

13. The fluid colour should be light brown. Transmission fluid

may turn dark with normal use. This does not always

indicate oxidation or contamination.

Is the fluid colour light brown?

Go to Step 14 Go to Step 1

14. Drain the fluid to determine if the fluid is contaminated.

A very small amount of material in the bottom of the pan

is a normal condition, but large pieces of metal or other

material in the bottom of the pan requires a transmission

overhaul.

Was the fluid contaminated?

Go to Step 15 Go to Step 18

15. Overhaul the transmission. Refer to Section 7C5, UNIT

REPAIR in the MY 2003 VY and V2 Series Service

Information.

Is action complete?

Go to Step 16

16. Flush the cooler.

Is action complete? Go to Step 17

17. Add new fluid.

Is action complete? Go to Step 19

18. Change the fluid and filter.

Is action complete? Go to Step 19

19. Is the fluid level satisfactory, If not, correct as necessary.

Is action complete? Go to Step 20

20. Refer to 4L60-E Transmission Functional Test

Procedure, in Section 7C3, HYDRAULIC/MECHANICAL

DIAGNOSIS, in the MY 2003 VY and V2 Series Service

Information.

Is action complete?

Fluid Checking

Procedure

Completed

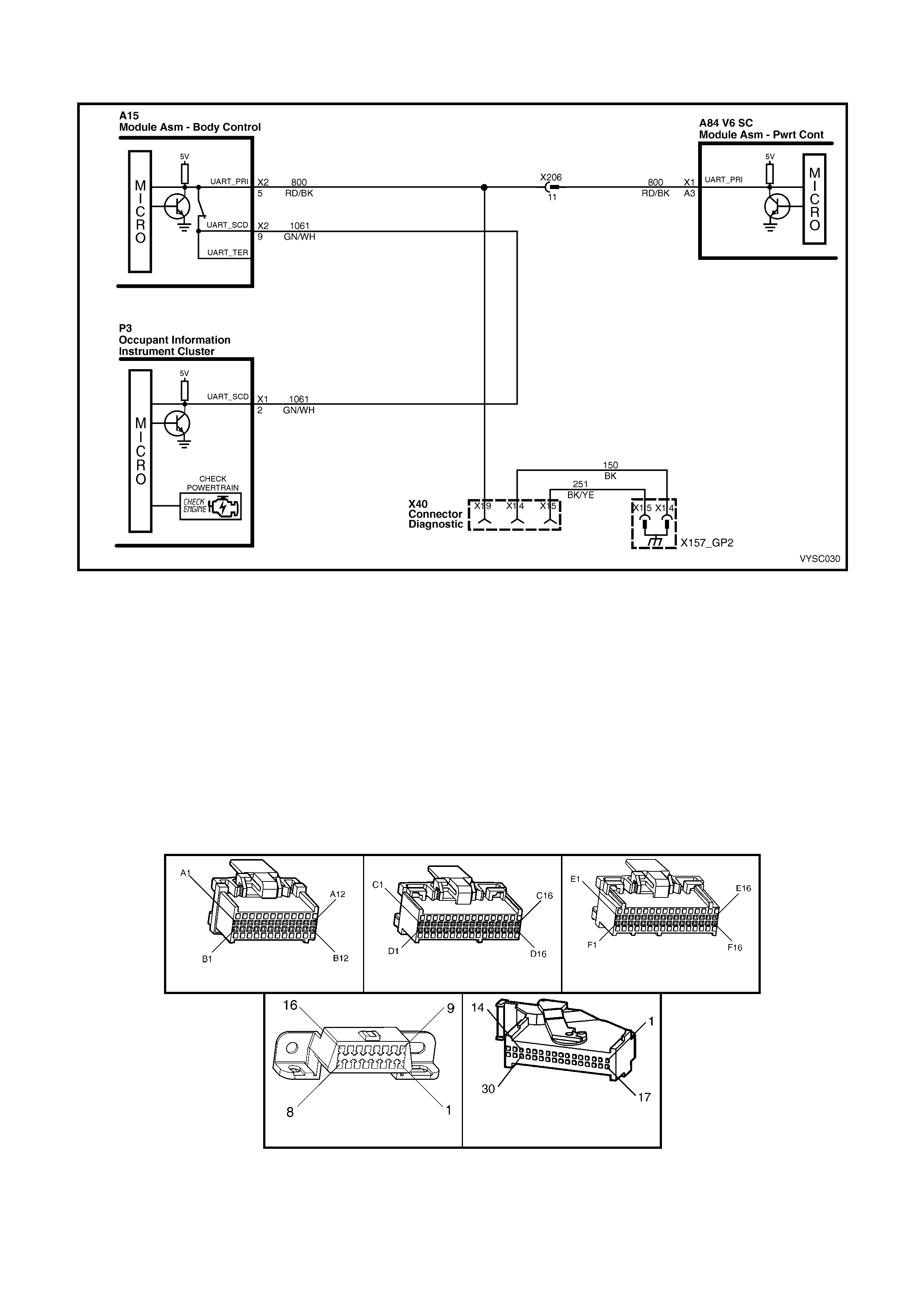

TABLE A V6 S/C PCM – ON-BOARD DIAGNOSTIC (OBD) SYSTEM CHECK

Figure 6C2-2A-18 – Check Powertrain Malfunction Indicator Lamp Circuit

CIRCUIT DESCRIPTION:

The On-Board Diagnostic System Check is an organised approach in identifying a problem created by a powertrain

control system malfunction. It must be the starting point for any driveability complaint diagnosis, because it directs

the service technician to the next logical step in diagnosing the complaint. Understanding the Table and using it

correctly will reduce diagnostic time and prevent the unnecessary replacement of good parts.

TEST DESCRIPTION:

NOTE: Number(s) below refer to the step number(s) on the diagnostic table.

1. Confirms TECH 2 operation and that Tech 2 is being powered up.

2. This check is used to establish if the PCM can supply serial data for Tech 2 use. If the PCM is capable of

communicating serial data to Tech 2, the PCM power supply, ground and the serial data line are OK. If Tech 2

displays “Incorrect Selection or Unknown Software” check that you have selected the correct Model Year,

Vehicle Type and Engine. If these selections where correct, check that the PCM has the correct software

loaded from TIS 2000 Service Programming System.

3. This check is to see if there is a Theft Deterrent DTC stored. If the PCM has not received a valid theft deterrent

signal from the BCM a DTC 31 should set, this may be the cause of a ‘no crank’ condition.

4. This test determines if the vehicle is able to crank. If the vehicle will not crank, refer to Table A-4.0 to diagnose

the starter cranking circuit.

5. This test determines if any DTC’s are stored in the PCM memory. To determine if a DTC is current, select DTC

History and refer to “Ignition Cycles Since”.

6. This test is used to determine the cause of a "Cranks But Will Not Run," although the PCM is powered up, a

"Cranks But Will Not Run" symptom could exist because of a PCM problem or the vehicle electrical system.

7. Look at all the parameters to determine if one is not in a normal state with just the ignition "ON" and engine

stopped. For example, look at the ECT value to see if the value is shifted above or below where it should be. If

so, refer "Diagnostic Aid Table" on DTC 14.

8. Look at all the parameters to determine that all values are within typical ranges for normal operating

temperatures at idle. Keep in mind that a basic engine problem may alter sensor value.

DIAGNOSTIC AIDS:

If the Serial Data circuit is shorted to voltage or ground or open, the vehicle will not crank. Check Serial Data circuit

from PCM to BCM, and from BCM to all other controllers.

X40 P3

Figure 6C2-2A-19

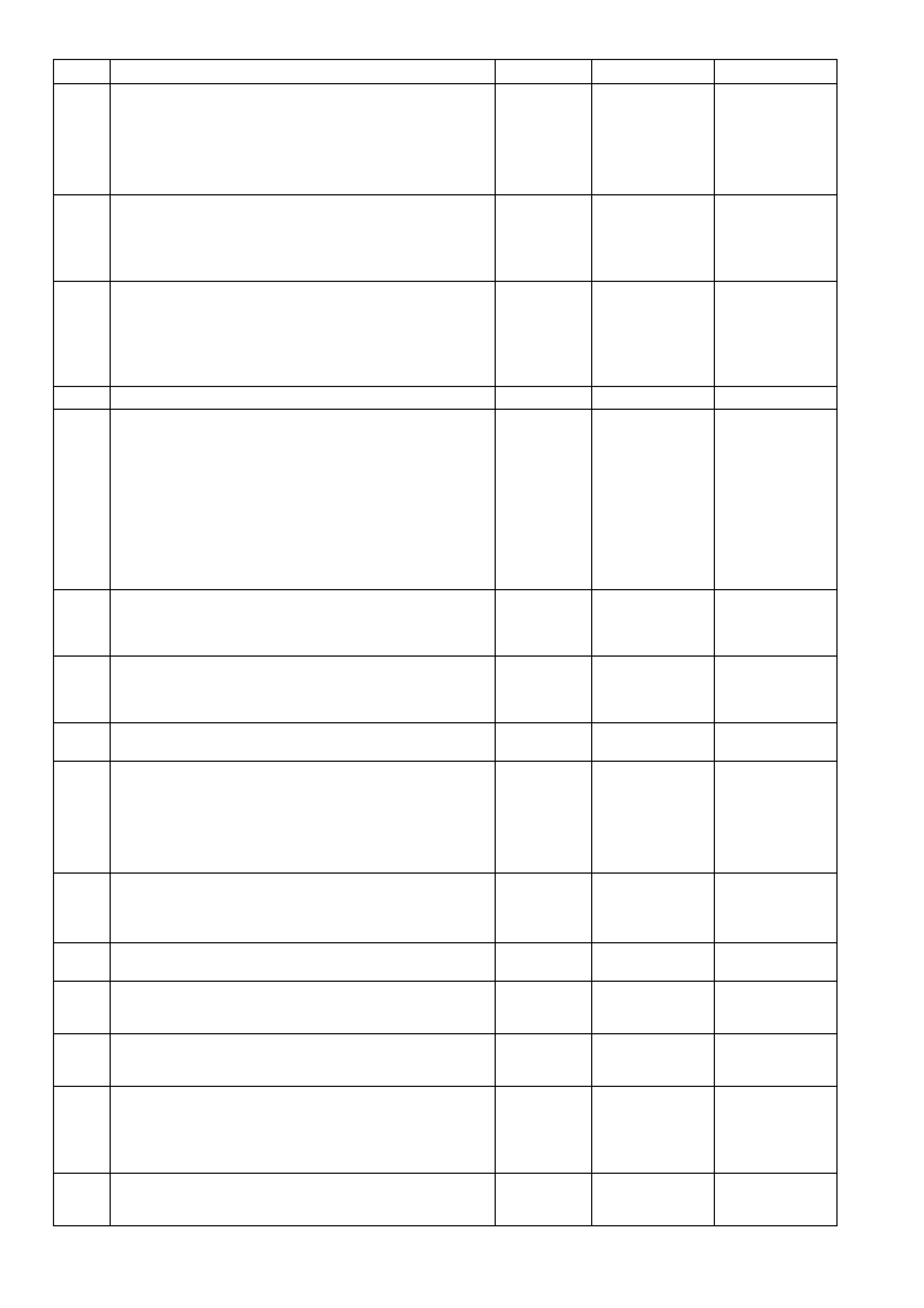

TABLE A V6 S/C PCM – ON-BOARD DIAGNOSTIC (OBD) SYSTEM CHECK

STEP ACTION VALUE YES NO

1. 1. Turn ignition off, install Tech 2 to DLC, turn ignition

on and turn on TECH 2.

Does Tech 2 power up and display the title display

screen?

Go to Step 2 Refer TECH 2

Diagnosis,

Section 0C

TECH 2 in this

Service

Information.

2. 1. Install Tech 2 to Data Link Connector (DLC).

2. Select V6 Engine.

Does Tech 2 display Identification Data?

Go to Step 3 Go to Table A-2

in this Section

3. 1. Ignition "ON".

2. Using Tech 2, check for DTC 31.

Is DTC 31 set?

Go to DTC 31

Table

Go to Step 4

4. Does engine crank?

Go to Step 5 Go to

Table A-4.0

5. 1. Using Tech 2, select Current DTC(s).

Are any Diagnostic Trouble Codes displayed?

Refer to

Applicable DTC

Table.

Start with lowest

DTC

Go to Step 6

6. Does engine start and continue to run?

Go to Step 7 Go to

Table A-3.1

7. 1. Ignition "ON", engine "STOPPED".

2. Compare Tech 2 data with typical values shown on

scan data page.

Are values normal or within typical ranges?

Go to Step 8 Refer to

indicated

"Component(s) –

System" checks

in this Section.

8. 1. Run engine until normal operating temperature is

reached.

2. Run engine at 1500 revolutions per minute for 2

minutes, then idle engine.

3. Compare Tech 2 with typical values shown on Scan

Data page in this Section.

Are values normal or within typical ranges?

Refer to 6C2-2B

SYMPTOMS

Refer to

indicated

"Component(s) –

System "checks

in this Section.

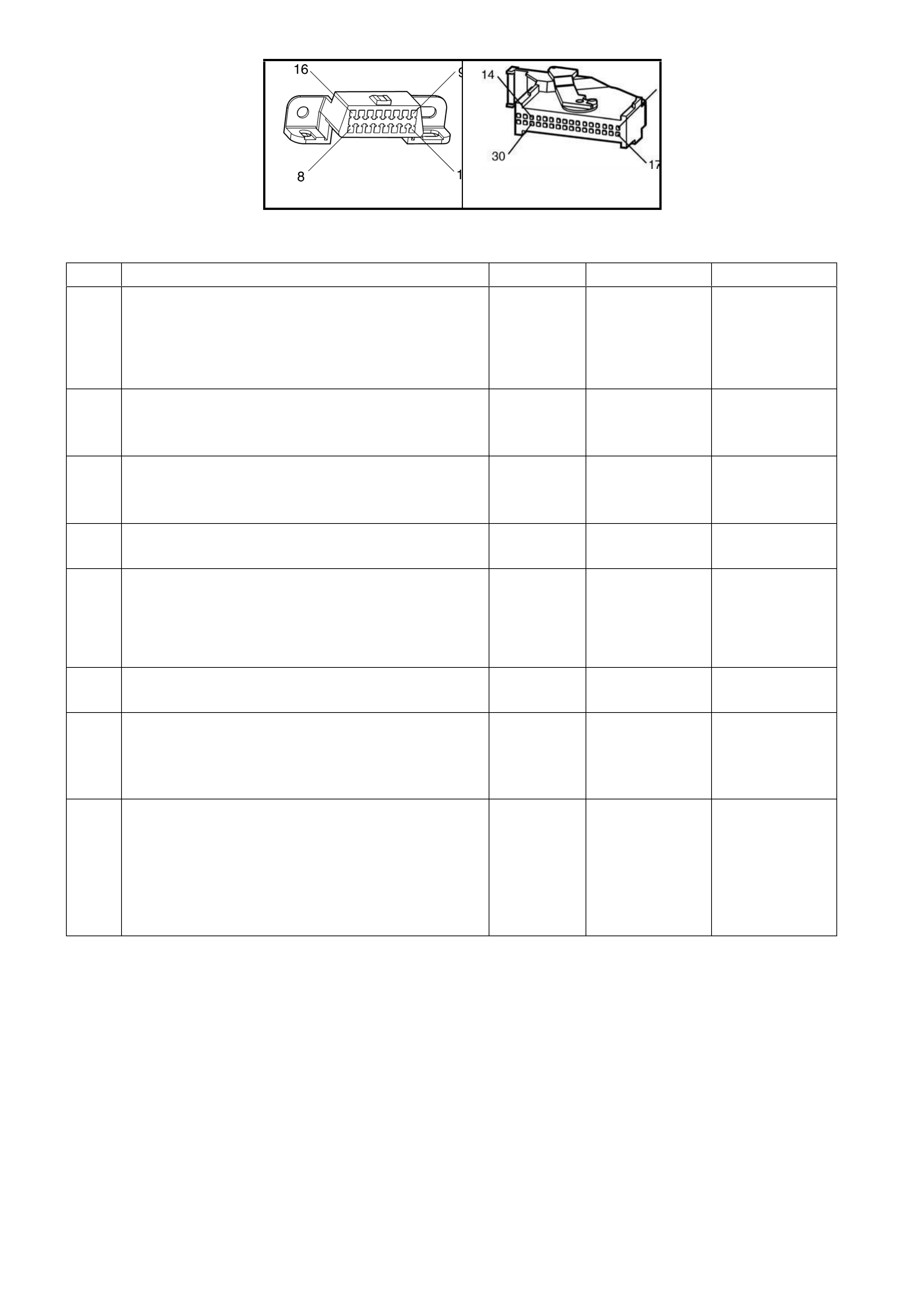

TABLE A-1 V6 S/C PCM –

NO CHECK POWE RTRAIN MALFUNCTION INDICATOR LAMP (MIL)

Figure 6C2-2A-20 – Check Powertrain Malfunction Indicator Lamp Circuit

CIRCUIT DESCRIPTION:

The Powertrain Control Module (PCM) controls the lamp via serial data communication to the Instrument on the

serial data circuit. When the PCM determ ines that the Check Powertrain MIL s hould be "ON", the PCM will send a

mes sage to the instrum ents via the serial data c ircuit norm al mode m es sage, reques ting the Check Powertrain MIL

"ON”. The Instrument will then activate the Check Powertrain MIL.

TEST DESCRIPTION:

NOTE: Number(s) below refer to step number(s) on the diagnostic table.

2. This test confirms that the Instrument MFD has passed its system check.

3. Disconnecting the Mass Air Flow Sensor should cause DTC 32 to set and the PCM to command the Check

Powertrain Lamp “ON” via the serial data normal mode message. If the DTC does not set then the internal

diagnostics of the PCM are not functioning correctly.

4. This test checks that the serial data normal mode message displays "ON" when the DTC sets.

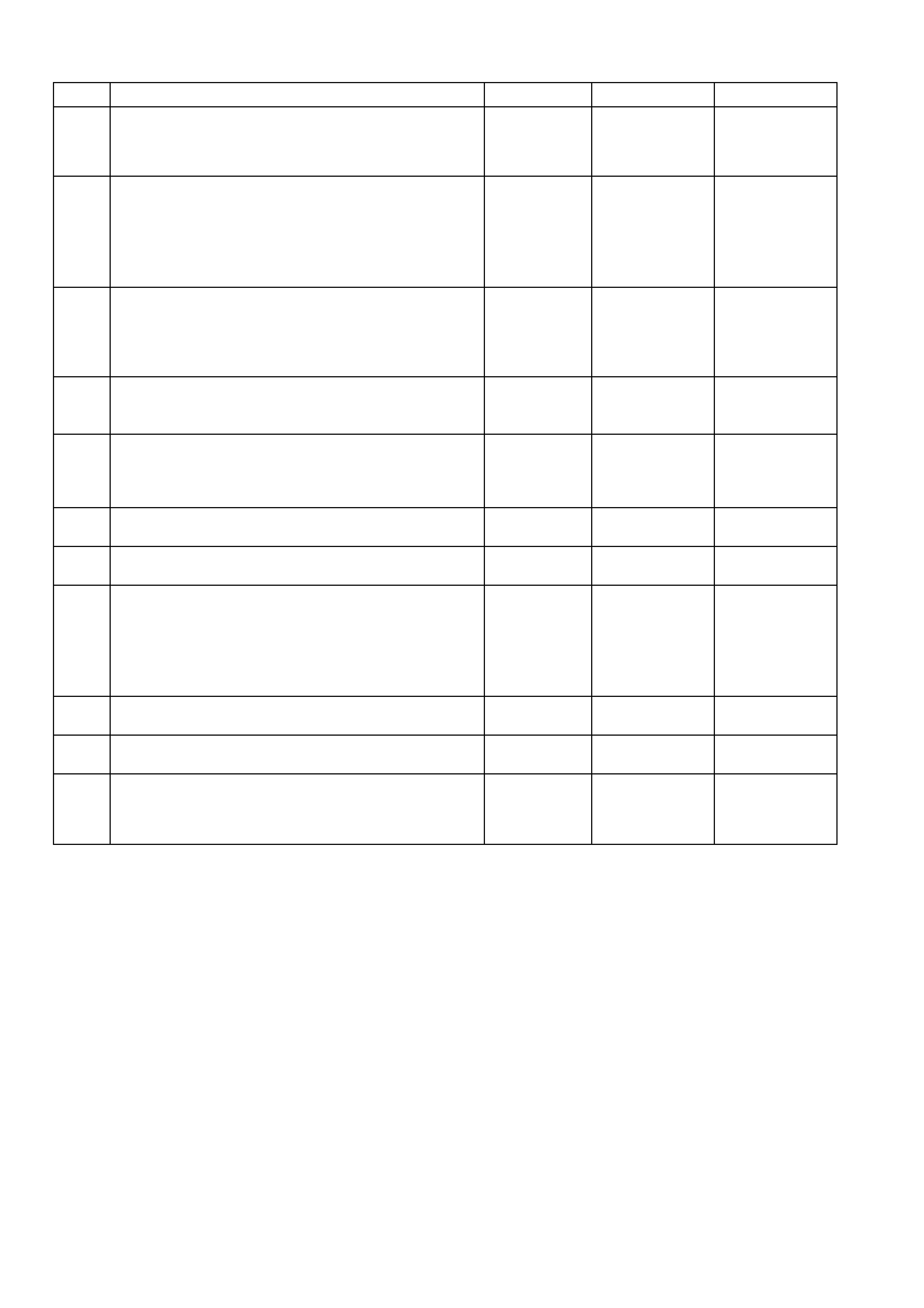

A84 V6 S/C – X1 A84 V6 S/C – X2 A84 V6 S/C – X3

X40 P3

Figure 6C2-2A-21

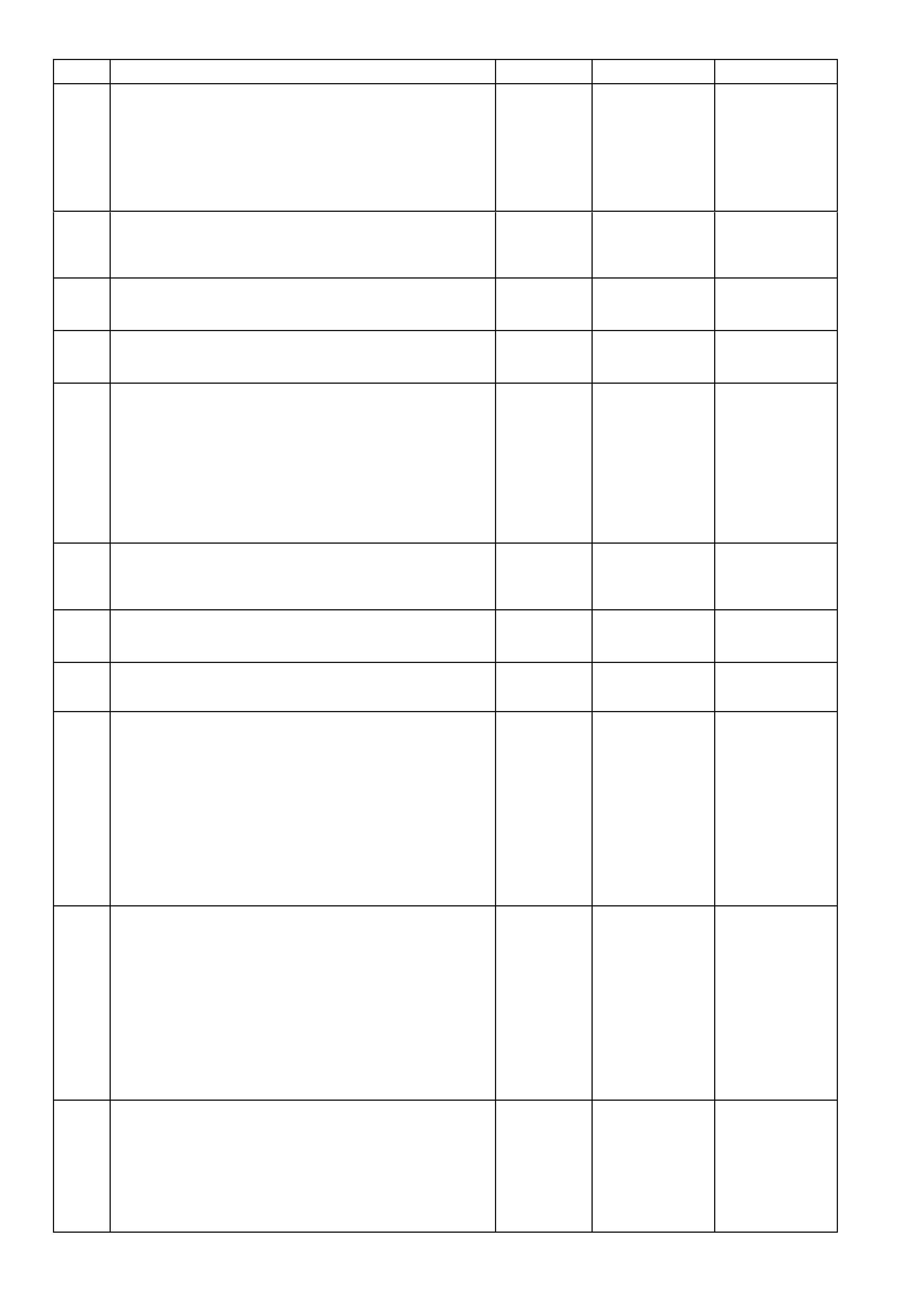

TABLE A-1 V6 S/C PCM – NO "CHECK POWERTRAIN" MALFUNCTION INDICATOR LAMP (MIL)

STEP ACTION VALUE YES NO

1. Was the "On-Board Diagnostic" (OBD) System Check

performed? Go to Step 2 Go to

OBD System

Check

in this Section/

2. 1. Turn the ignition "ON".

2. Observe the Instrument Multi Function Display

(MFD).

Does the MFD display "OK!" once the “System Check”

is completed?

Go to Step 3 Refer

Section 12C

in this Service

Information

3. 1. Disconnect the Mass Air Flow Sensor connector

B68.

2. Start the engine and allow to idle for 20 seconds.

Does the MFD display the "Check Powertrain MIL"?

Check

Powertrain MIL

is operating

correctly

Go to Step 4

4. 1. Connect Tech 2 to the DLC.

2. With Tech 2 connected, select F0: Normal Mode.

3. With the Mass Air Flow Sensor connector B68 still

disconnected.

4. Start the engine and monitor the "Normal Mode"

data display.

Does the "Normal Mode" display "Check Powertrain

Lamp" display "ON"?

Refer

Section 12C

in this Service

Information

Go to Step 5.

5. 1. Replace PCM. Refer to Section 6C2-3 Service

Operations, for PCM Security Link procedure

Is action complete?

Verify Repair

TABLE A-2 V6 S/C PCM – NO SERIAL DATA

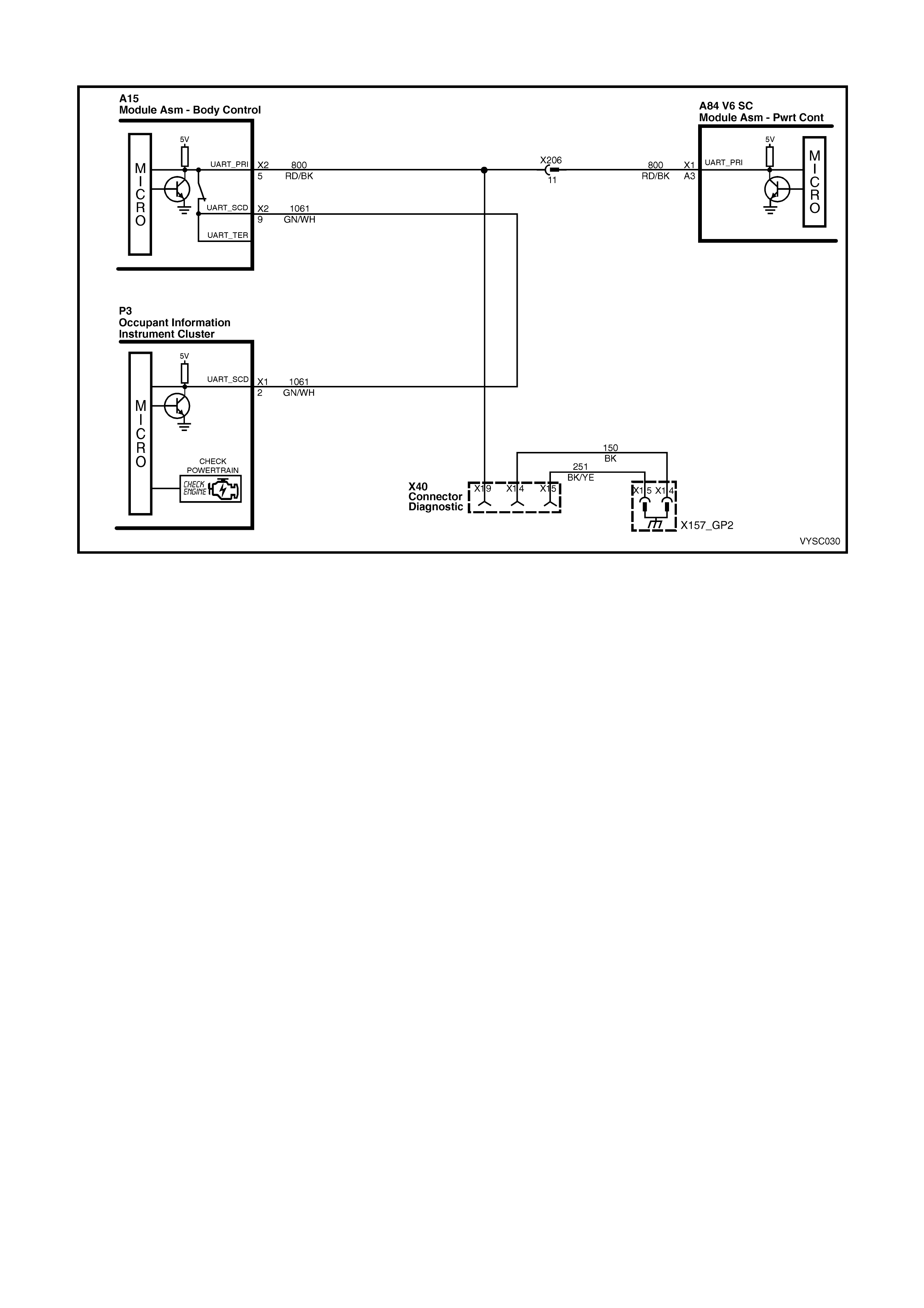

Figure 6C2-2A-22 – Serial Data Circuit

CIRCUIT DESCRIPTION:

The VY and V2 series of vehicles use a “Bus Master” communication system, where the BCM is the bus master.

The BCM periodically polls (surveys) each control module on the bus (serial data circuit) and requests status data.

The control modules connected via the serial data circuit are the (PCM, BCM, A.B.S./T.C.S. module, OCC module,

SDM, instrument and Telematics Module, Tech 2 communicates with these modules via the serial data circuit and

DLC terminal 9. Any one of these modules could cause a fault on the serial data line. This fault could result in the

scan tool not being able to display serial data. If there is no serial data the instrument will display “Service Error

Contact Dealer” and Tech 2 will not be able to communicate with any of the control modules.

TEST DESCRIPTION:

NOTE: The number(s) below refer to the step number(s) on the diagnostic table.

2. This step checks to see if Tech 2 will communicate with the PCM.

3. This step checks to see if Tech 2 will communicate with the BCM.

4. Using a Digital Multi Meter (DMM), there should be 3 to 4.5 volts at the DLC terminal 9. If the voltage is higher

or lower, serial communication will be affected. This serial data circuit is also connected to several other

modules. A problem with any one of these other modules, may cause a serial data communication malfunction.

5. If the voltage at DLC terminal 9 is at or above 5 volts the serial data circuit is shorted to voltage. If the voltage is

0 volts the serial data circuit may be open or shorted to ground.

6. This step checks the PCM power supply circuit 740. There should be battery voltage at these terminal at all

times.

7. This step checks the PCM ignition circuit 300. There should be battery voltage at this terminal when the ignition

is on.

8. This step checks the continuity of the four PCM ground circuits. All four ground circuits should be checked for

continuity.

9. If the voltage at DLC terminal 9 is at or above 5 volts the serial data circuit is shorted to voltage. If the voltage is

0 volts the serial data circuit may be open or shorted to ground.

DIAGNOSTIC AIDS:

If there is a fault with the serial data circuit, it could be caused by one or more of the several modules connected to

this serial data circuit. Isolate the fault by disconnecting each controller (one at a time), until the serial data

communication is restored.

A84 V6 S/C – X1 A84 V6 S/C – X2 A84 V6 S/C – X3

X40

Figure 6C2-2A-23

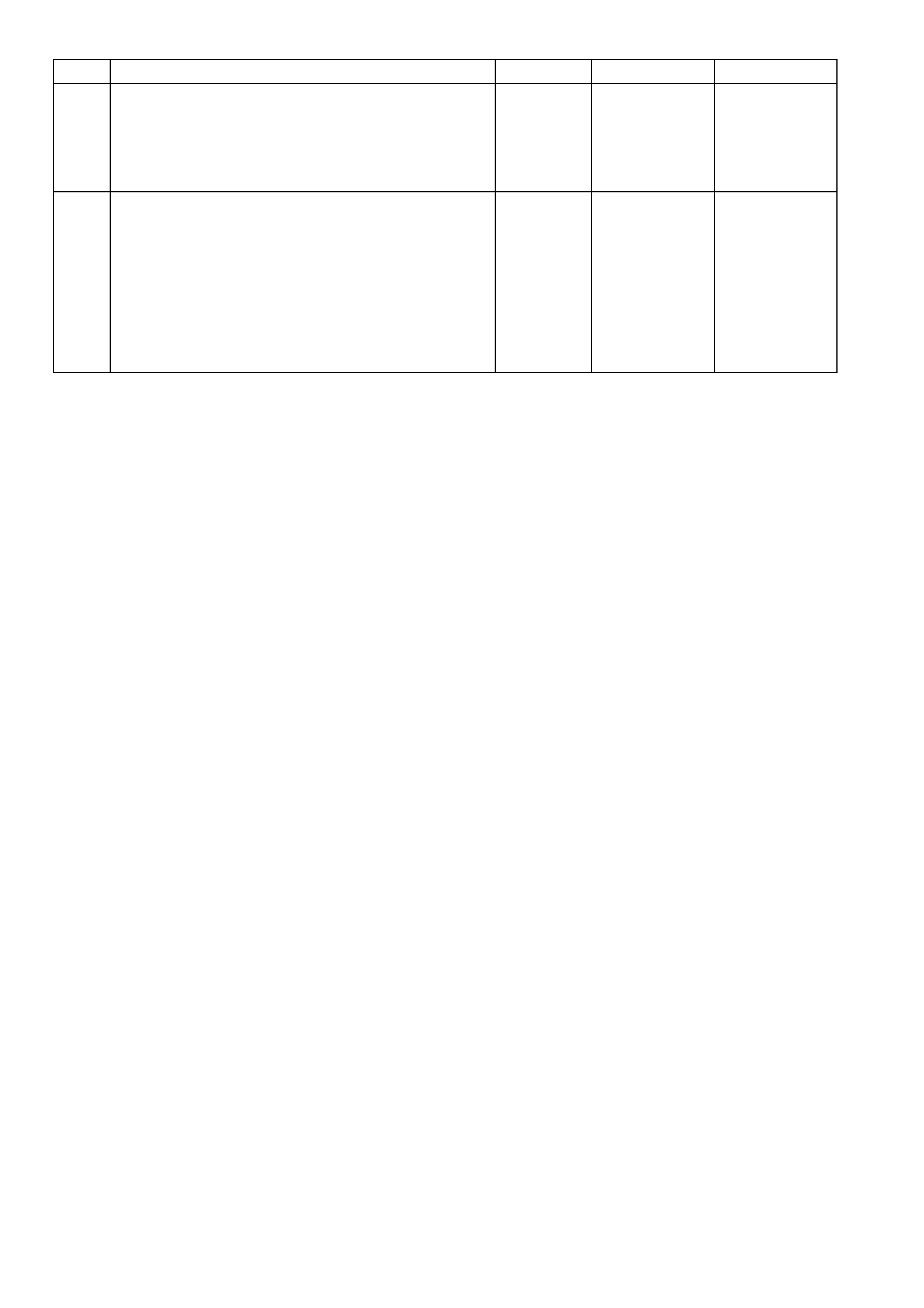

TABLE A-2 V6 S/C PCM – NO SERIAL DATA

STEP ACTION VALUE YES NO

1. Was the "On-Board Diagnostic" (OBD) System Check

performed?

Go to Step 2 Go to

OBD System

Check

2. 1. Connect Tech 2 to DLC.

2. Ignition "ON", engine stopped.

Does Tech 2 display PCM serial data?

No trouble found Go to Step 3

3. 1. Connect Tech 2 to DLC.

2. Ignition "ON", engine stopped.

Does Tech 2 display BCM serial data?

Go to step 6 Go to Step 4

4. 1. Ignition "ON", engine stopped.

2. Using DMM, probe DLC terminal 9 with DMM

connected to ground.

Does DMM display voltage varying between the

specified value?

3 – 4.5 volts Go to Step 15 Go to Step 5

5. Is voltage steady at or above the specified value? 5 volts Go to Step 10 Go to Step 11

6. 1. Ignition "ON", engine stopped.

2. Using DMM, check for voltage at PCM power

supply circuit 740 terminals X1-A8 and X1-B8.

Does DMM display the specified value at both

terminals?

B+ Go to Step 7 Go to Step 12

7. 1. Ignition "ON", engine stopped.

2. Using DMM, check for voltage at PCM ignition

supply circuit 300 terminal X1-A4.

Does DMM display the specified value?

B+ Go to Step 8 Go to Step 13

8. 1. Using DMM, check continuity of the four PCM

ground circuits 450, between PCM terminals

X1-A1, X1-A2, X1-B1 & X1-B2 and a known good

ground.

Do all four ground circuits have continuity?

Go to Step 9 Go to Step 14

9. Check for open in the serial data circuit 800 between

the PCM and the DLC.

Is the circuit open?

Verify Repair Go to step 16

10. Repair short to voltage on the serial data circuit.

NOTE: Ensure that none of the other modules on the

serial data circuit are causing this voltage problem.

Unplug each module one at a time to isolate short to

voltage.

Is action complete?

Verify Repair

11. Repair short to ground or open in the serial data line.

NOTE: Ensure that none of the other modules on the

serial data circuit are causing this voltage problem.

Unplug each module one at a time to isolate short to

ground.

Was a problem found?

Verify Repair Go to Step 16

12. Repair open in PCM power suppy circuit 740.

Was a problem found?

Verify Repair

13. Repair open in PCM ignition circuit 300.

Was a problem found?

Verify Repair

14. Repair open in PCM ground circuit 450.

Was a problem found?

Verify Repair

15. 1. Refer to BCM No Serial Data diagnostics in Section

12J BCM in this Service Information.

Is action complete?

Verify Repair

16. 1. Replace PCM. Refer to 6C1-3 Service Operations,

for PCM Security Link procedure

Is action complete?

Verify Repair

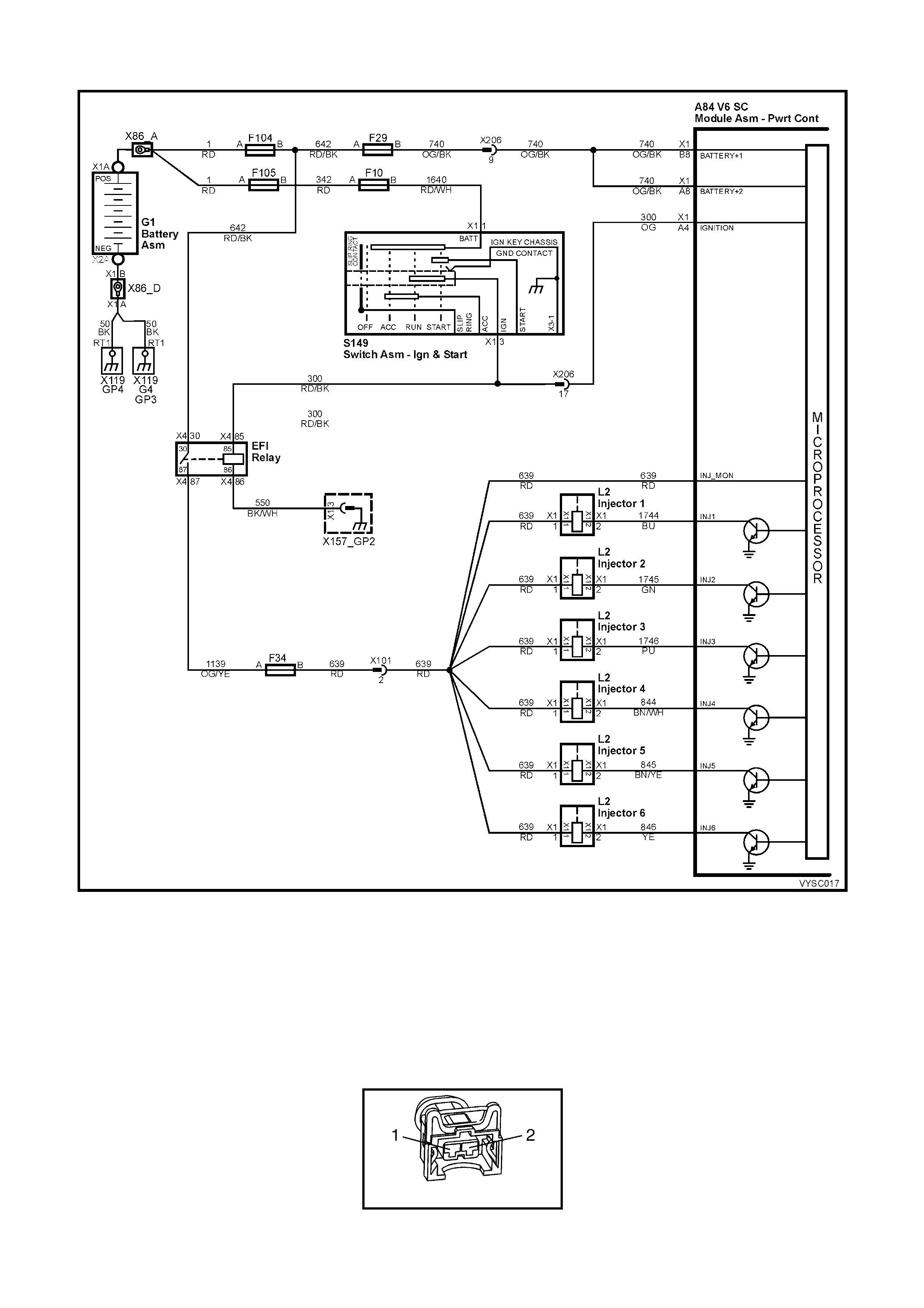

TABLE A-3 .1 V6 S/ C PCM – ENGINE CRANKS BUT WILL NOT RUN

Figure 6C2A-2-24 – Fuel Injector Circuit

CIRCUIT DESCRIPTION:

This is the first of several diagnostic tables that m ust be followed in an orderly, progressive fashion in order to find

the cause of a no-start. These tables assume an adequate supply of good quality fuel is in the fuel tank, that the

cranking motor circuit is in good working order, and that the engine will crank with adequate RPM. These tables

also assume that no Diagnos tic T rouble Code (DT C) 31 or 46 is s et in the PCM m em ory, as determined by the On-

Board Diagnostic System Check. The On-Board Diagnostic System Check is always the beginning point for all

diagnostic procedures.

TEST DESCRIPTION:

NOTE: Number(s) below refer to step number(s) on the diagnostic table.

1. The PCM must be operable. The On-Board Diagnostic System Check will prove that. There are few chances

that the PCM itself would cause a no-start, but the On-Board Diagnostic System Check will uncover any

problems in the PCM power and ground circuitry.

4. This checks for a short to ground on the injector control circuit. If this were to occur, the engine would be

extremely flooded, since the injectors would be "ON" continuously, and would inject fuel any time there is fuel

pressure.

5. Any time the PCM has been "OFF" for at least 10 seconds, it should energise the Fuel Pump Relay for 2

seconds af ter the ignition is tur ned "ON." If the engine is not c r ank ed, the PCM should turn the relay "OFF" after

2 seconds . Proper operation of the Fuel Pum p elec trical c ircuit would be noted here by the test light being "ON"

for 2 seconds after the ignition switch is turned to the "ON" position. After 2 seconds, the test light should go

"OFF."

6. Note that this check is for sufficient voltage at the spark plug wire. If, for some reason, the spark plug electrodes

were wet with fuel (engine flooded), this could cause a no-start. However, a "flooded" engine is a symptom of

some other problem. There is no normal condition that should ever be able to "flood" the engine.

NOTE: Use Tool ST 125 spark checker or equivalent. An ST 125 requires about 25,000 volts (25 kilovolts, or 25

kV) to "s park ". Do not use a s park plug in open air grounded to the engine as an indication of suff icient "spar k ".

Only a few kilovolts are required to jump the gap of a spark plug outside of the engine, and that would be an

inadequate test of the ignition coil output ability.

7. This is a quick c heck of the fuel s yst em. The appropriate plac e to install the press ure gauge is at the Schr ader

valve test point on the left hand side, fuel rail, using fuel pressure adaptor, Tool AU 453 with fuel pressure

gauge Tool AU 338.

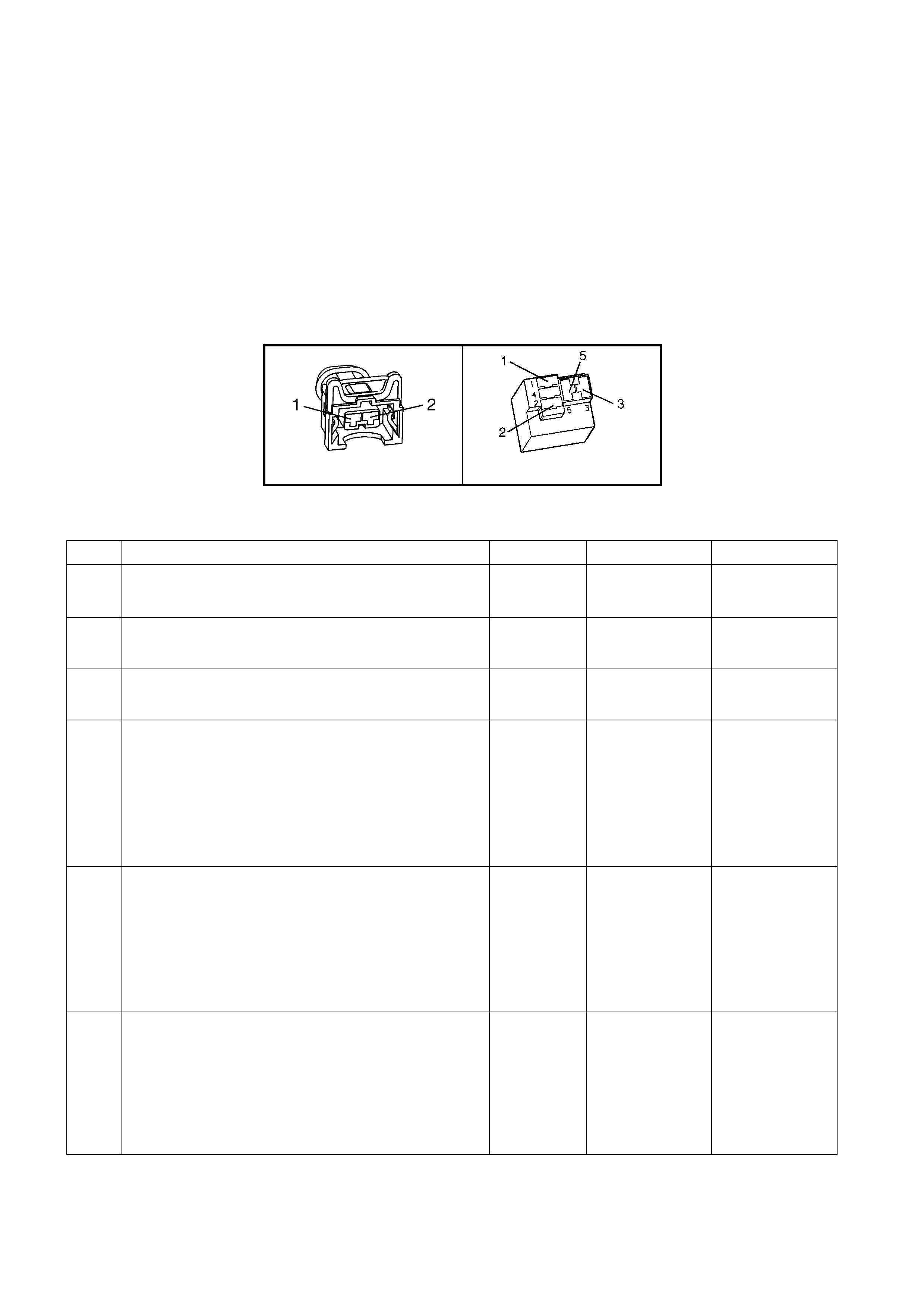

L2 X 16 (PART OF X100)

Figure 6C2-2A-25

TABLE A-3.1 V6 S/C PCM ENGINE CRANKS BUT WILL NOT RUN

STEP ACTION VALUE YES NO

1. Was the "On-Board Diagnostic" (OBD) System Check

performed? Go to Step 2. Go to OBD

System Check

in this Section.

2. Is DTC 31 present ?

Go to DTC 31

Table in this

Section.

Go to Step 3

3. Is DTC 46 present ?

Go to DTC 46

Table in this

Section.

Go to Step 4

4. 1. Check fuel tank quantity.

2. Disconnect ALL injector electrical connectors.

3. Connect test light between the terminals of each

injector harness connector.

• Be very careful not to short across the

terminals, or to engine ground.

4. Switch ignition "ON", while noting the test light.

Is light "OFF" ?

Go to Step 5 Go to Step 8

5. 1. Ignition "OFF".

2. Backprobe Fuel Pump Control Module A47

connector, terminal X1-6 with a test light connected

to ground.

3. Ignition "ON".

4. Using TECH 2 scan tool, select “Fuel Pump”.

5. Activate Fuel Pump.

Is test light "ON"?

Go to Step 6 Go to

Table A-4.1-1 in

this Section.

6. 1. Ignition "OFF".

2. Remove the spark plug leads from two spark plugs.

3. Connect ST 125 spark checker (refer NOTE #6

above) to each spark plug lead and check for spark

activity, while cranking the engine.

4. Check both wires. A few sparks and then nothing is

considered no spark.

Was there spark on both wires?

Go to Step 7 Go to

Table A-8.1 in

this Section.

STEP ACTION VALUE YES NO

7. 1. Ignition "OFF".

2. Reconnect both spark plug leads to spark plugs.

3. Reconnect all injector electrical connectors.

4. Remove Fuel Pump Relay R16 from underhood

electrical centre in the engine compartment and

crank engine for 15 seconds to relieve any residual

fuel pressure.

5. Ignition "OFF," connect Fuel Pressure Gauge.

6. Reinstall Fuel Pump Relay.

7. Turn the ignition “ON” and observe fuel pressure.

8. Pressure should be within the value, and not

continue to drop after pump stops running.

Is fuel pressure at or between the specified value and

holding steady?

290 to 410

kPa Go to

Table A-3.2 in

this Section.

Go to

Table A-4.3 in

this Section.

8. 1. Check for short to ground on Injector Circuit.

Was Injector Circuit shorted to ground ? Verify Repair Go to Step 9

9. 1. Replace PCM. Refer to Section 6C2–3 SERVICE

OPERATIONS, for the PCM Security Link

procedure.

Is action complete?

Verify Repair –

TABLE A-3 .2 V6 S/ C PCM – ENGINE CRANKS BUT WILL NOT RUN

Figure 6C2-2A-26 – Fuel Injector Circuit

TEST DESCRIPTION:

NOTE: Number(s) below refer to step number(s) on the diagnostic table.

6. "ST EADY LIGHT" indicates the PCM is continuously supplying the ground path on the injector circuit. It is not a

harness problem at this point; that would have been in Table A-3.1. This may destroy an injector, as they are

designed to be energised in short pulses and may not withstand 100% "ON" time. If any injector checks less

than 11.4 ohms, it could be the cause of the defective PCM. The PCM can be damaged when it attempts to

energise the injector circuit with a very-low-resistance load. Normal injector resistance is approximately 12.2

ohms at 20 degrees C per individual injector.

L2

Figure 6C2-2A-27

TABLE A-3.2 V6 S/C PCM – ENGINE CRANKS BUT WILL NOT RUN

STEP ACTION VALUE YES NO

1. Was the "On-Board Diagnostic" (OBD) System Check

performed? Go to Step 2. Go to

OBD

System Check

in this Section.

2. From Table A-3.1.

1. Ignition "OFF".

2. With all injectors disconnected, connect test light

across both harness terminals of one injector

connector.

Be very careful to not short across the terminals, or

to engine ground.

3. Have a helper crank the engine while you closely

observe the test light.

4. Test light should blink while cranking, indicating

electrical injector pulses are present. Repeat this

test for all injectors.

Did test light blink while cranking ?

Go to Step 3 If there was no

blinking light, Go

to Table 3.3 in

this Section.

----------------------

If the test light

was on steady

(no blinking light)

Go to Step 6.

3. 1. Check the remaining 5 injector connectors for

blinking test light, as described in step 2.

Did all the remaining injector connectors blink the test

light?

Go to Step 4 Go to Step 5

4. At this stage, the fuel control system, fuel delivery

system, and ignition system are OK.

Check For:

• Fouled spark plugs.

• Proper MAF sensor operation. If engine will start with

MAF sensor electrical connector disconnected, refer

Table A-6.1 in this Section.

• Proper TP sensor circuit operation. Use Tech 2 scan

tool to monitor TP sensor signal. If voltage is over

1.25 volts with throttle closed, refer Table A-6.2 in

this Section.

• Restricted exhaust system. Loosen front pipe from

exhaust manifold(s). If the engine will start, refer

Table A-13 in this Section.

• Improper engine coolant temperature (ECT) sensor

resistance. Refer DTC 14 Diagnostic Aids in this

Section to check resistance of ECT sensor.

• Water or foreign material in fuel, or incorrect fuel.

• Spark plug wires crossed.

• Camshaft timing chain.

• Inadequate engine compression.

Is action complete?

Verify Repair

5. 1. Repair open in injector power circuit or injector

circuit to connector that did not blink the test light.

Is action complete ?

Verify Repair

6. 1. Check for a short to ground in injector circuit that

caused test light to stay "ON" steady.

Was a problem found?

Verify Repair Go to Step 7

7. 1. Check resistance across each injector. Each injector

should be between the specified value.

Is each injector at the value ?

11.4 - 12.6

ohms Go to step 8 Go to step 9

8. 1. Replace PCM. Refer to Section 6C1-3 SERVICE

OPERATIONS in this Section, for PCM Security Link

procedure.

Is action complete?

Verify Repair

9. 1. Replace any injector that did not measure within the

specified value.

2. Retest beginning at Step 2.

Is action complete?

11.4 – 12.6

ohms Verify Repair

TABLE A-3 .3 V6 S/ C PCM – ENGINE CRANKS BUT WILL NOT RUN

Figure 6C2-2A-28 – Fuel Injector Circuit

TEST DESCRIPTION:

NOTE: Number(s) below refer to step number(s) on the diagnostic table.

2. “NO LIGHT” indicates no PCM control of the injector. Fuse F34 supplies +12 volts to the injectors. Probe both

terminals of one injector connector with a test light to ground. There should be a light on only one terminal,

confirming ignition voltage to one terminal, but not both.

3. T he PCM inject or control c ircuit m ay be open. Reconnec t the injectors. Using a tes t light connected to ground,

check for a light at the PCM connec tor terminals . A light at this point indicates that inject or control circuit is not

“open.” T he voltage to light that test light com es fr om circ uit 639 (Red wire), through the injector windings, and

continues through the injector control circuit to PCM connector terminals.

7. There is no ter minal identif ic ation on the relay connector s ocket, but the relay itself has terminal num ber s . Mak e

certain the correct relay connector socket terminal (NOT the relay) is being probed.

A84 V6 S/C – X1 A84 V6 S/C – X2 A84 V6 S/C – X3

X4 (Part of X100) L2

Figure 6C2-2A-29

TABLE A-3.3 V6 S/C PCM – ENGINE CRANKS BUT WILL NOT RUN

STEP ACTION VALUE YES NO

1. Was the "On-Board Diagnostic" (OBD) System Check”

performed? Go to Step 2. Go to

OBD

System Check

in this Section.

2. 1. Ignition "OFF"

2. Disconnect injector connectors. From Table A-3.2 –

No Light

3. Ignition "ON," engine stopped.

4. Probe each terminal of each injector harness

connector with a test light to ground.

Is the test light "ON" at only one terminal for each

injector?

Go to Step 3 If the test light

was" ON" at both

terminals, repair

short to voltage

on injector

circuit.

----------------------

If there was no

light "ON", Go to

Step 7

3. 1. Ignition "OFF".

2. Reconnect injectors.

3. Ignition "ON".

4. Backprobe PCM injector control terminals with a test

light connected to ground.

Is test light "ON" at each terminal?

Go to Step 4 Go to Step 12

4. 1. Ignition "ON".

2. Using Tech 2, monitor TP sensor signal voltage.

Is voltage less than value?

1.25 volts Go to Step 5 Go to

Table A-6.2 in

this Section.

5. 1. Check for faulty crankshaft reference High signal

input to PCM connector terminal.

Was a problem found?

Verify Repair Go to Step 6

6. 1. Replace PCM. Refer to 6C1-3 SERVICE

OPERATIONS, for PCM Security Link procedure.

Is action complete?

Verify Repair –