SECTION 6C3-1 - GENERAL INFORMATION –

GEN III V8 ENGINE

IMPORTANT:

Before perfo rming any Service Operat ion or oth er procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1 GENERAL DESCRIPTION

1.1 POWERTRAIN CONTROL MODULE (PCM))

PCM POWER SUPPLIES

PCM FIVE VOLT REFERENCE CIRCUITS

SERIAL DATA COMMUNICATIONS

DIAGNOSTIC INFORMATION

RECORDING TEST RESULTS (DIAGNOSTIC

EXECUTIVE)

PCM PROGRAMMING

PCM/PIM/BCM SECURITY LINK

PCM MEMORY FUNCTIONS

1.2 POWERTRAIN INTERFACE MODULE (PIM)

PIM DIAGNOSTIC TROUBLE CODES

STARTER RELAY

1.3 ENGINE INFORMATION SENSORS

AND SIGNALS

ENGINE COOLANT TEMPERATURE

(ECT) SENSOR

ENGINE COOLANT LEVEL SWITCH

MASS AIR FLOW (MAF) SENSOR

INTAKE AIR TEMPERATURE (IAT) SENSOR

MANIFOLD ABSOLUTE PRESSURE

(MAP) SENSOR

SPEED DENSITY SYSTEM

HEATED OXYGEN SENSORS (HO2S)

THROTTLE POSITION (TP) SENSOR

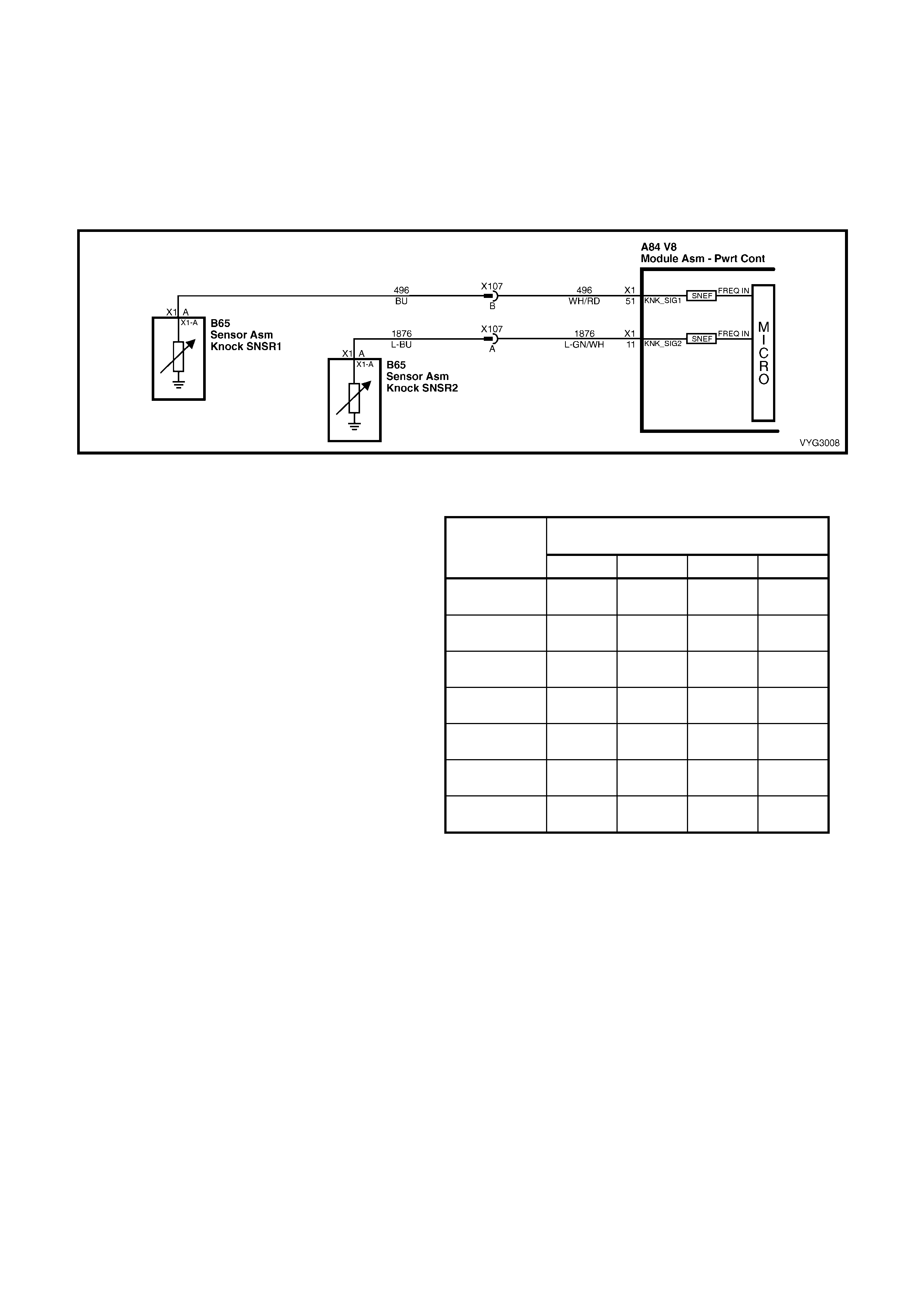

KNOCK SENSOR (KS)

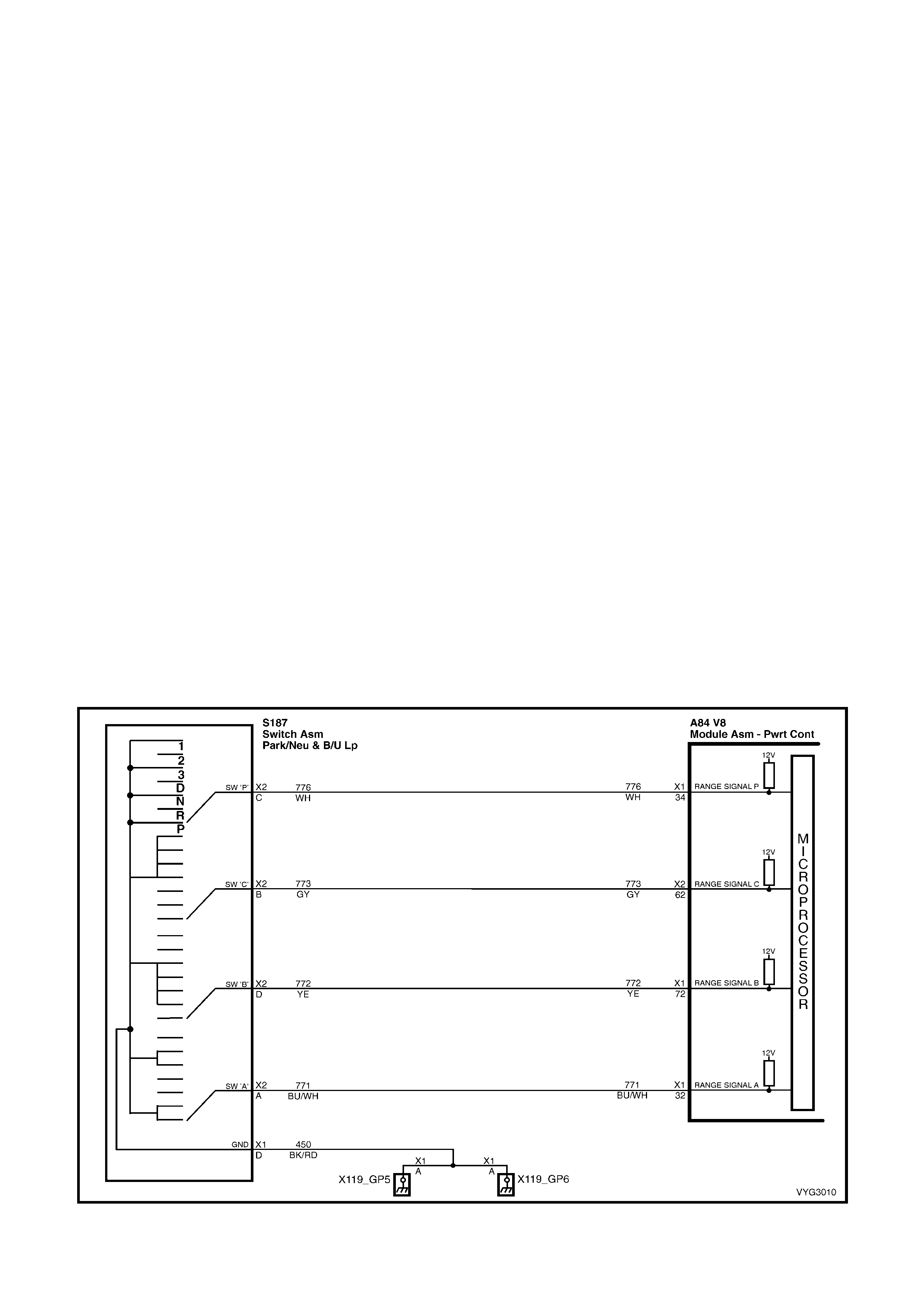

PARK, REVERSE, NEUTRAL, DRIVE, LOW

(PRNDL) SWITCH

A/C REQUEST SIGNAL AND A/C CLUTCH

CONTROL WITH OCC

A/C REQUEST SIGNAL AND A/C CLUTCH

CONTROL WITHOUT OCC

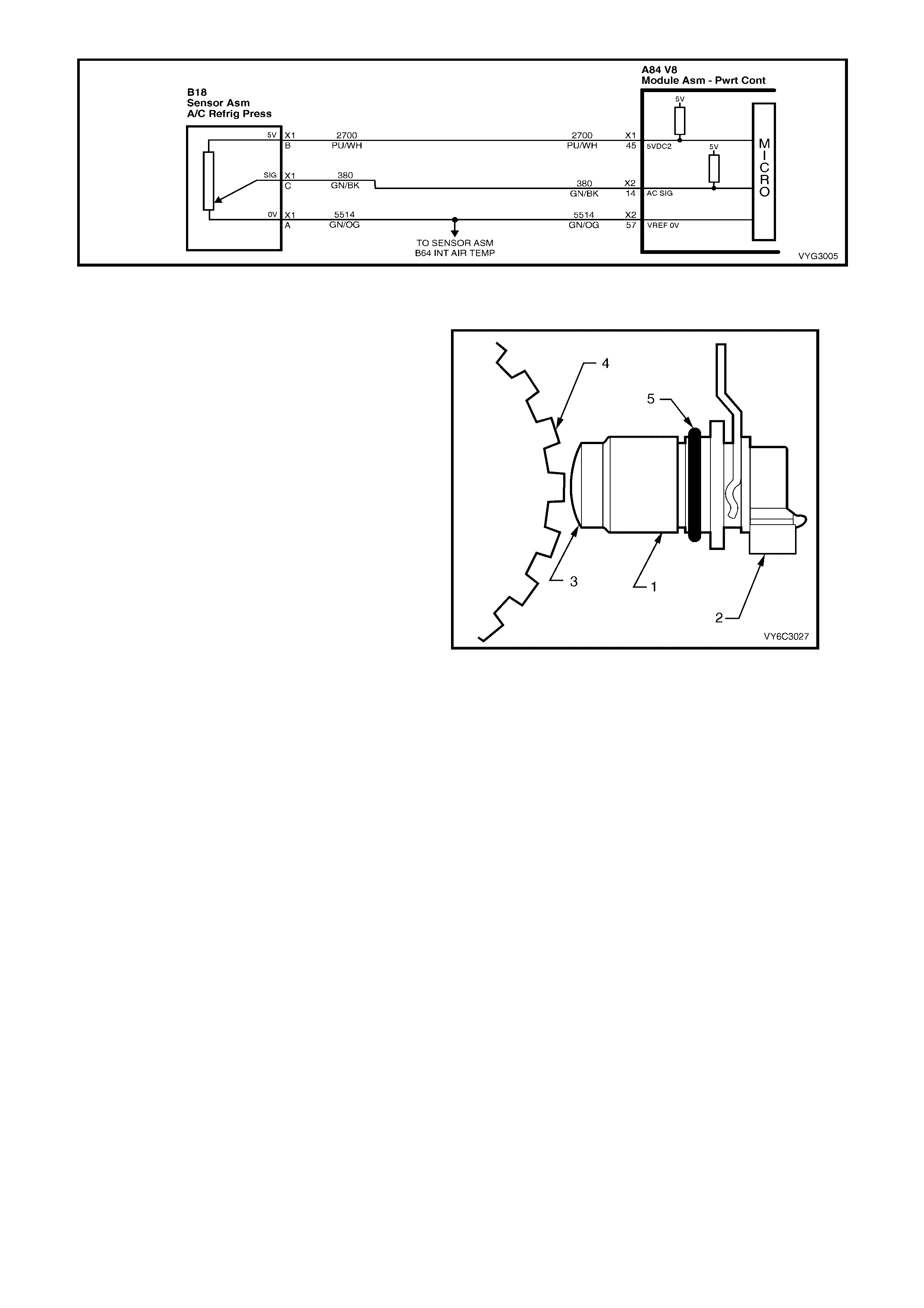

A/C REFRIGERANT PRESSURE SENSOR

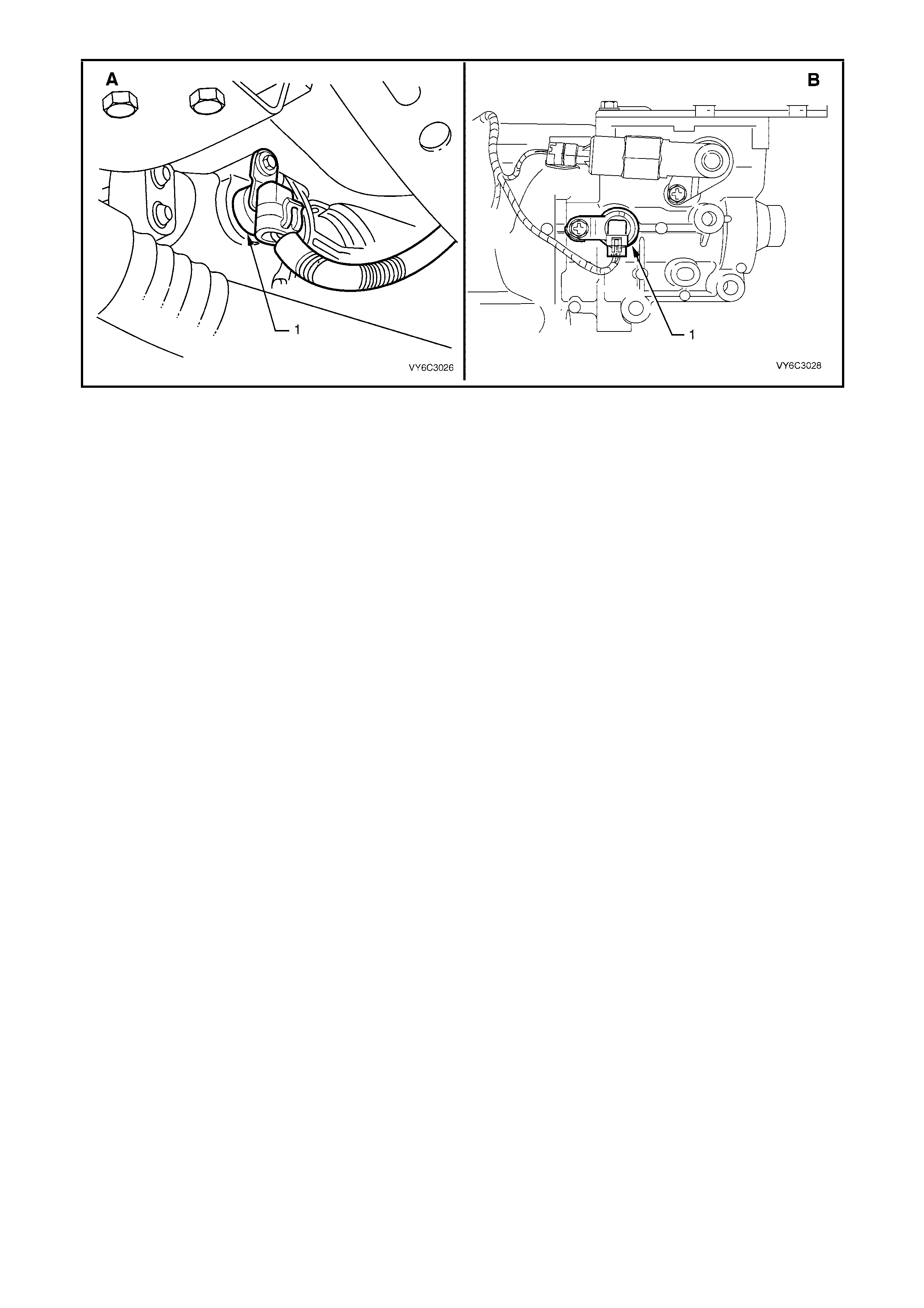

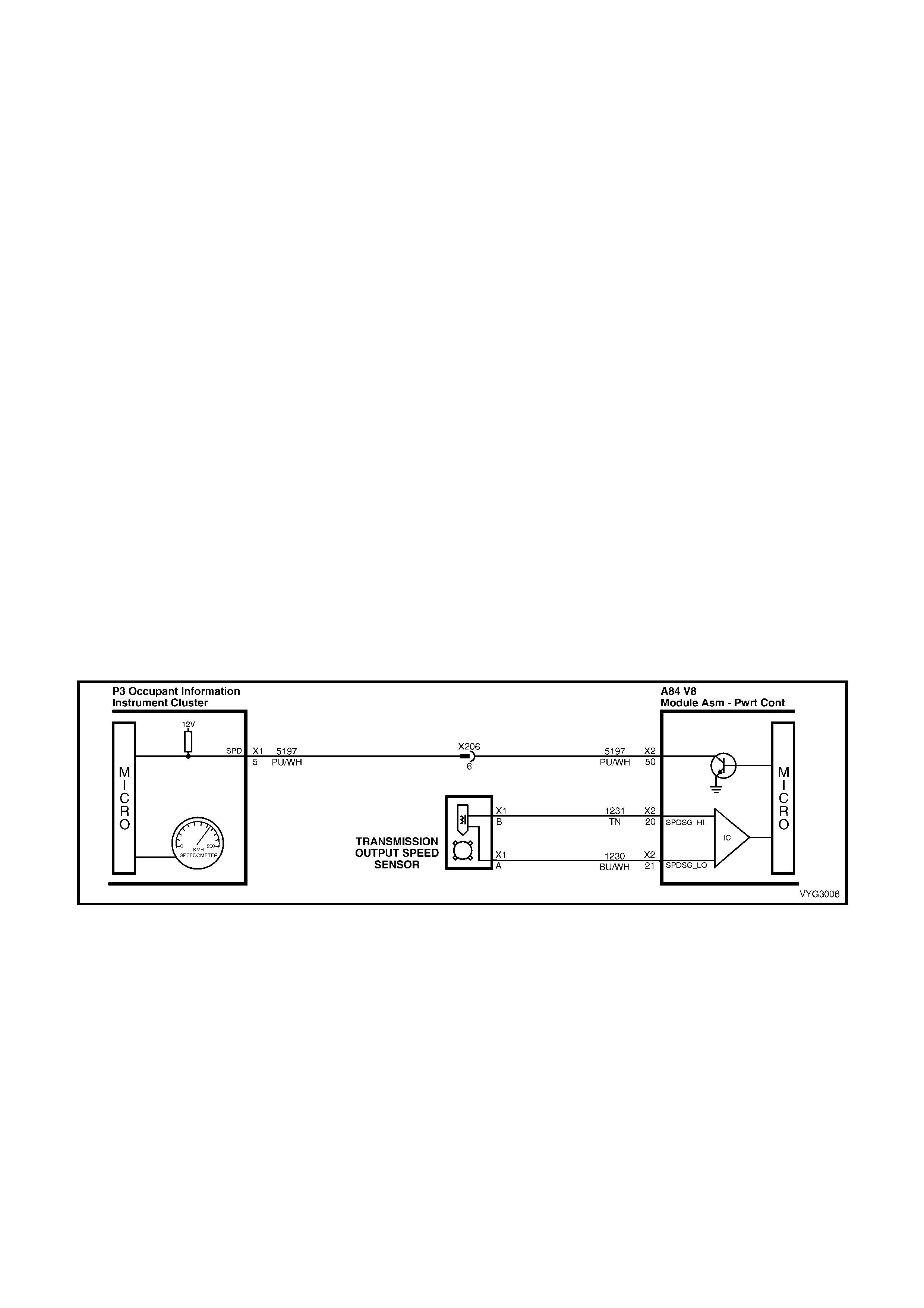

VEHICLE SPEED SENSOR (VSS)

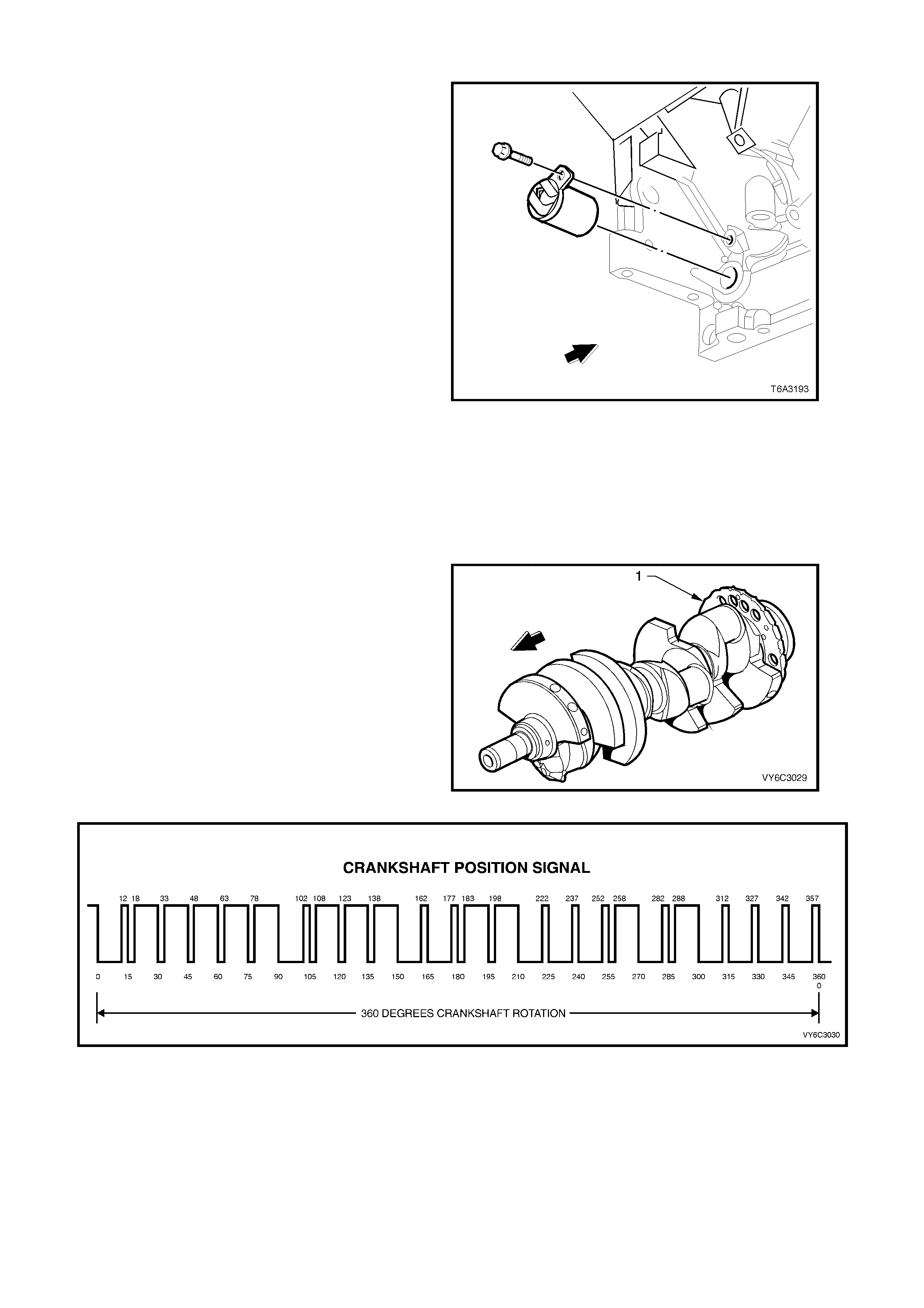

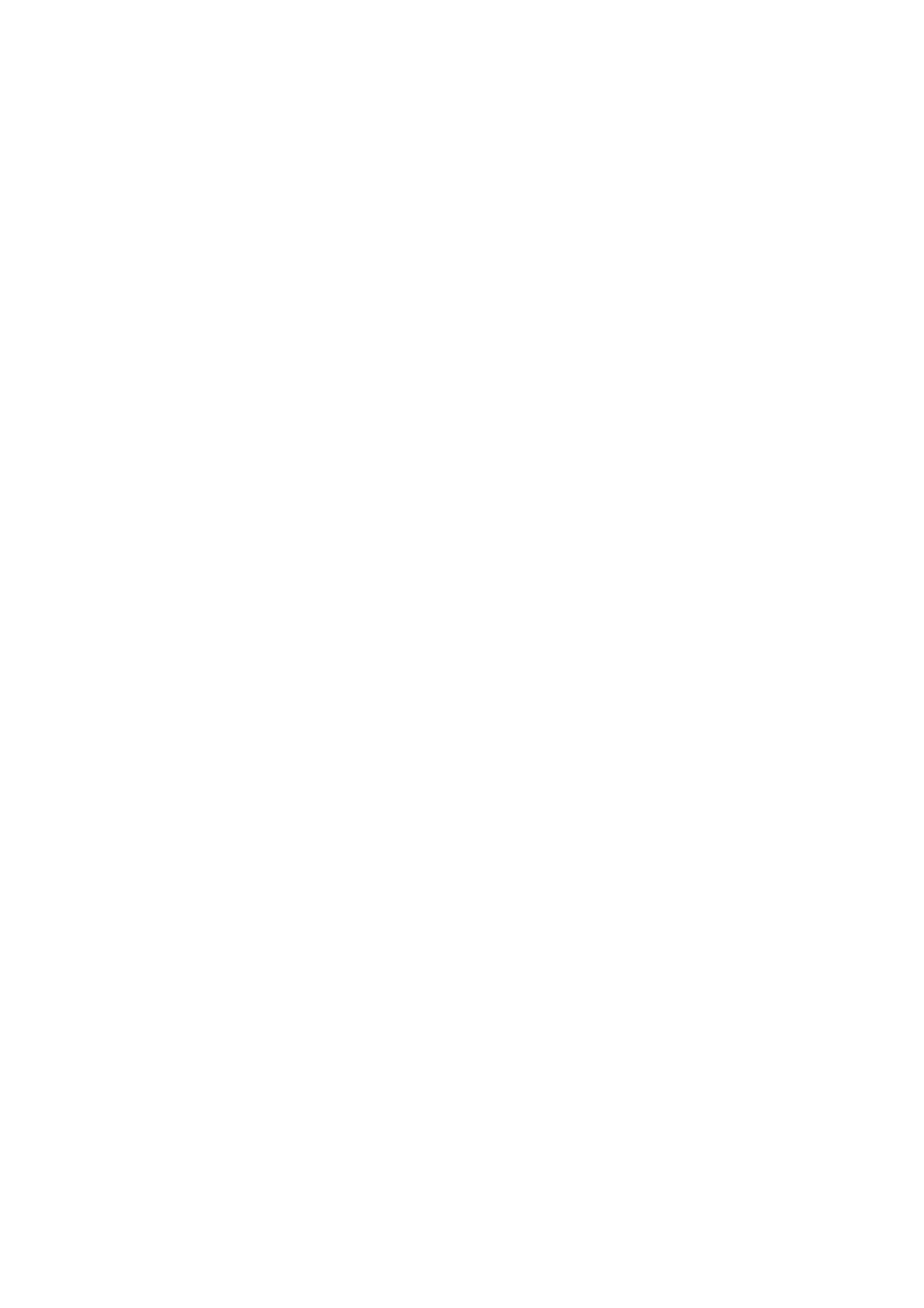

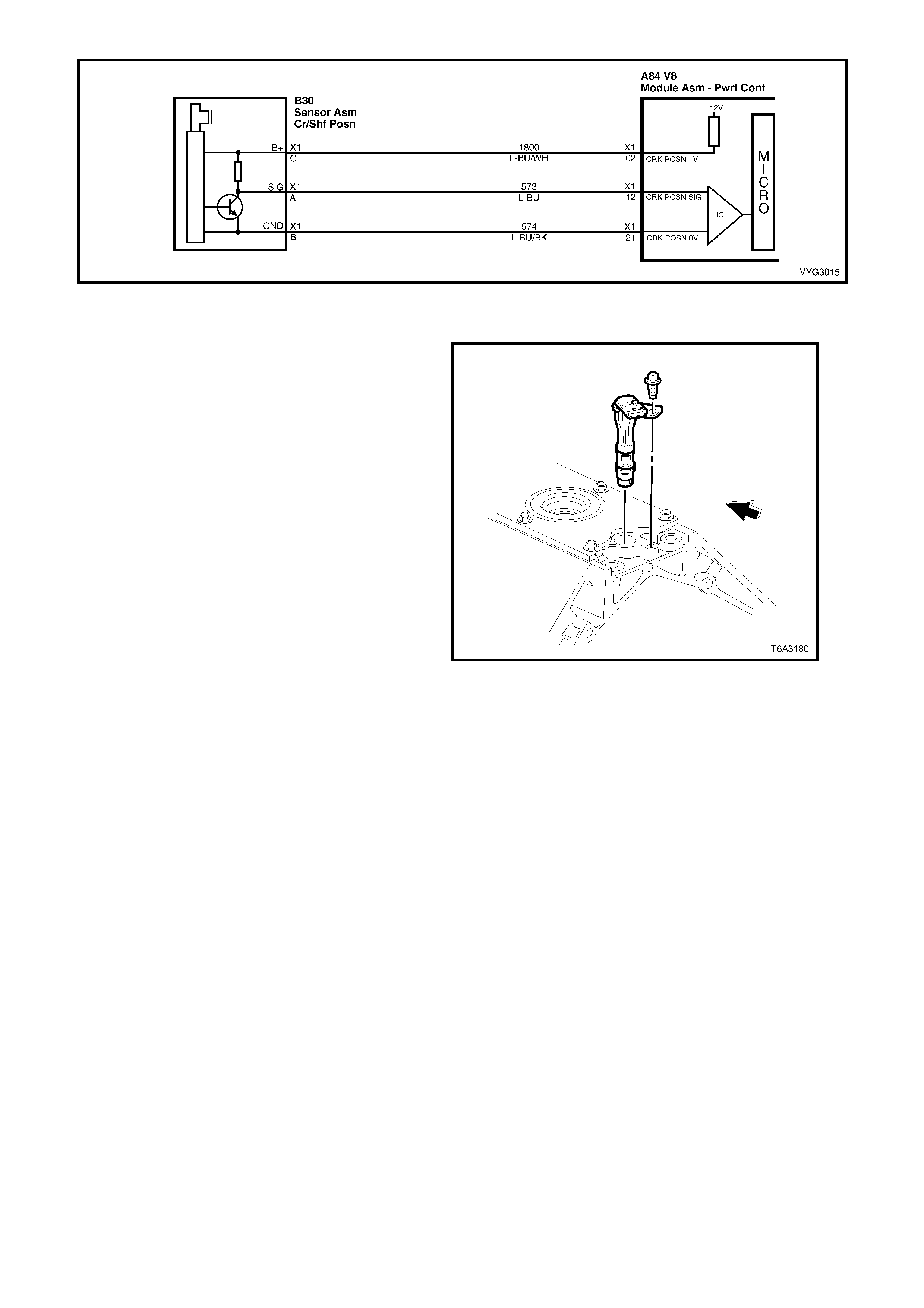

CRANKSHAFT POSITION (CKP) SENSOR

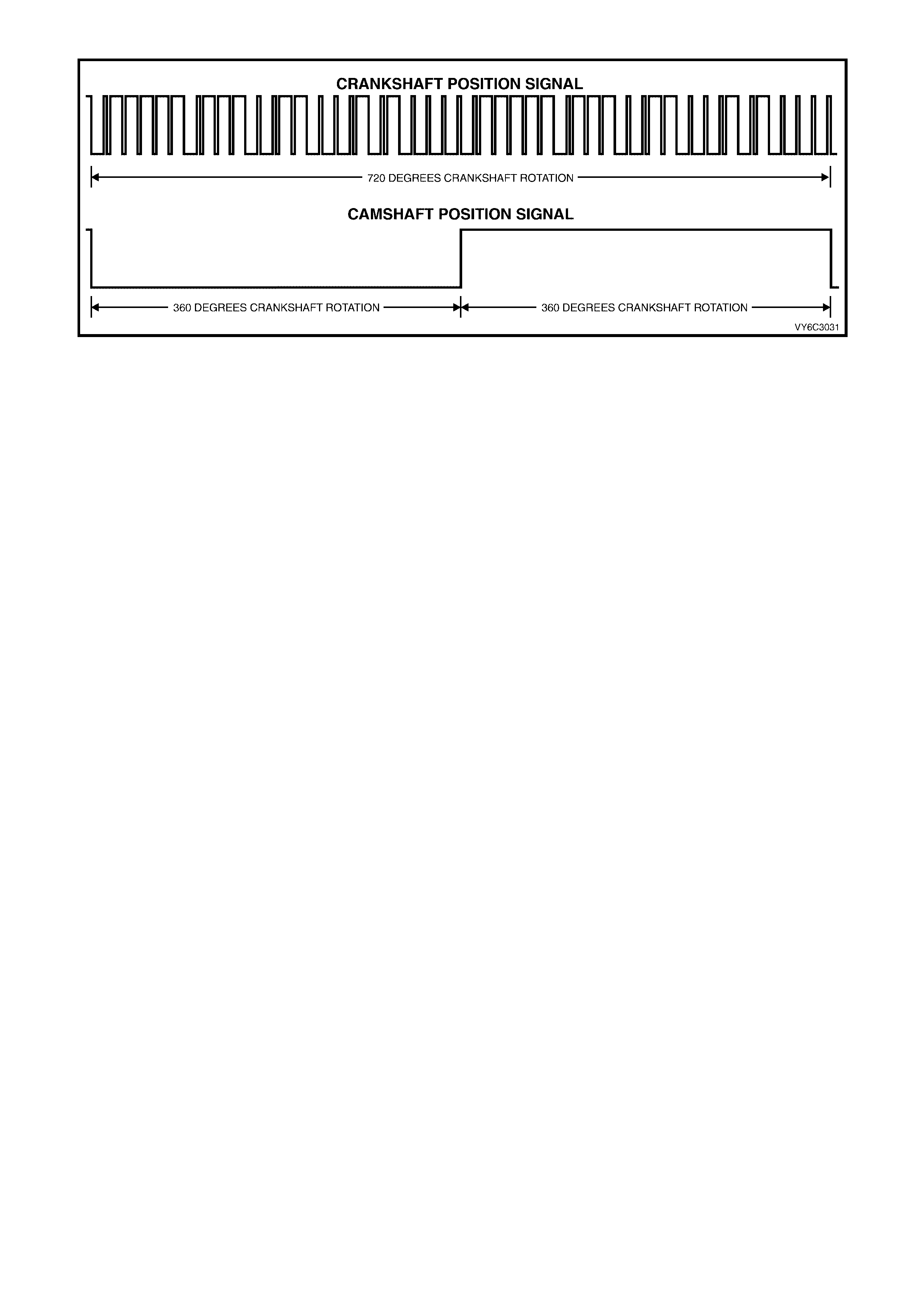

CAMSHAFT POSITION (CMP) SENSOR

BATTERY VOLTAGE

TRANSMISSION POWER/ECONOMY SWITCH

THEFT DETERRENT SYSTEM

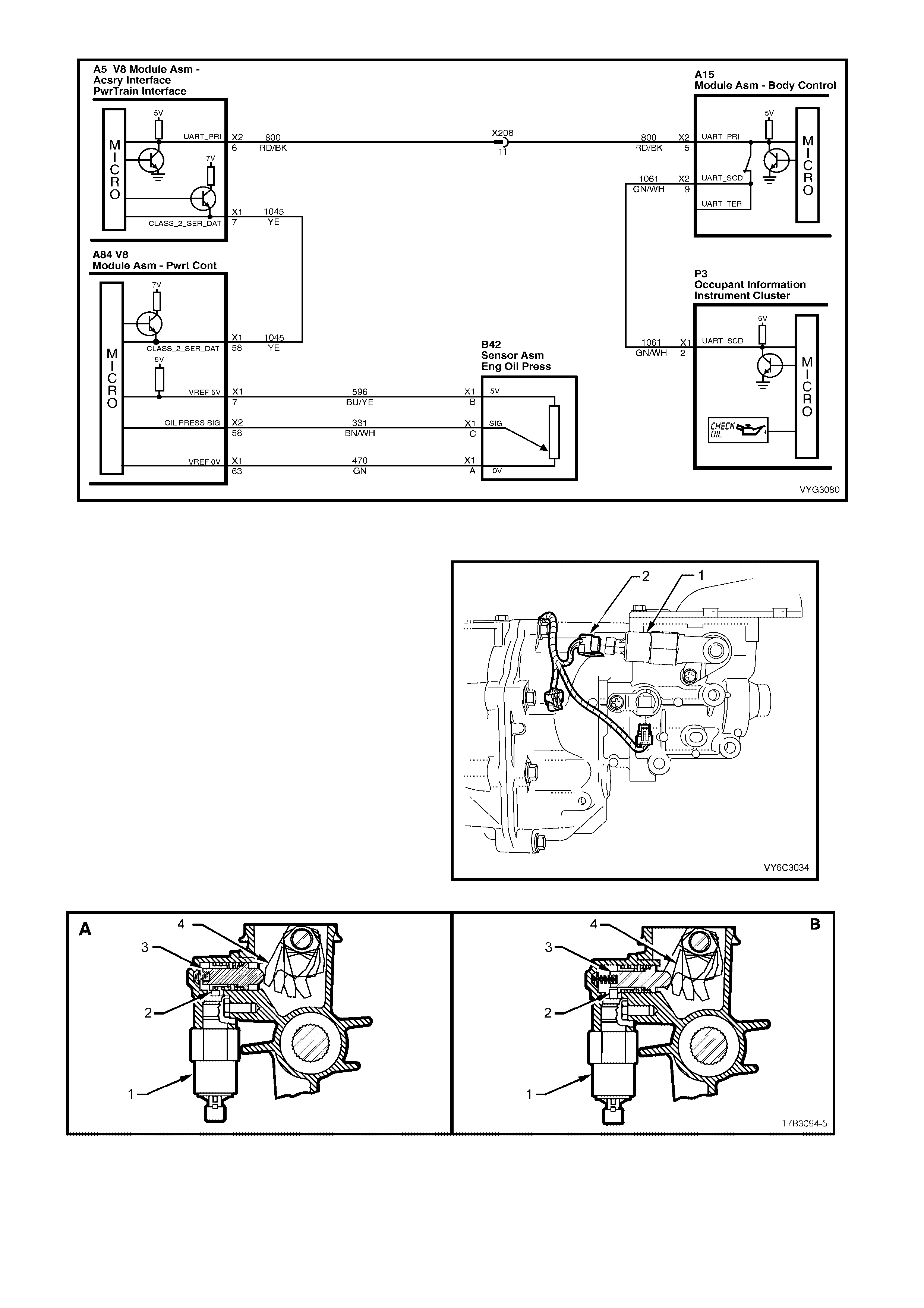

ENGINE OIL PRESSURE SENSOR

MANUAL TRANSMISSION REVERSE

INHIBIT SOLENOID

BRAKE PEDAL SWITCHES

1.4 FUEL CONTROL SYSTEM

SYSTEM OVERVIEW

COMPONENTS

FUEL METERING MODES OF OPERATION

FUEL METERING SYSTEM COMPONENT

DESCRIPTION

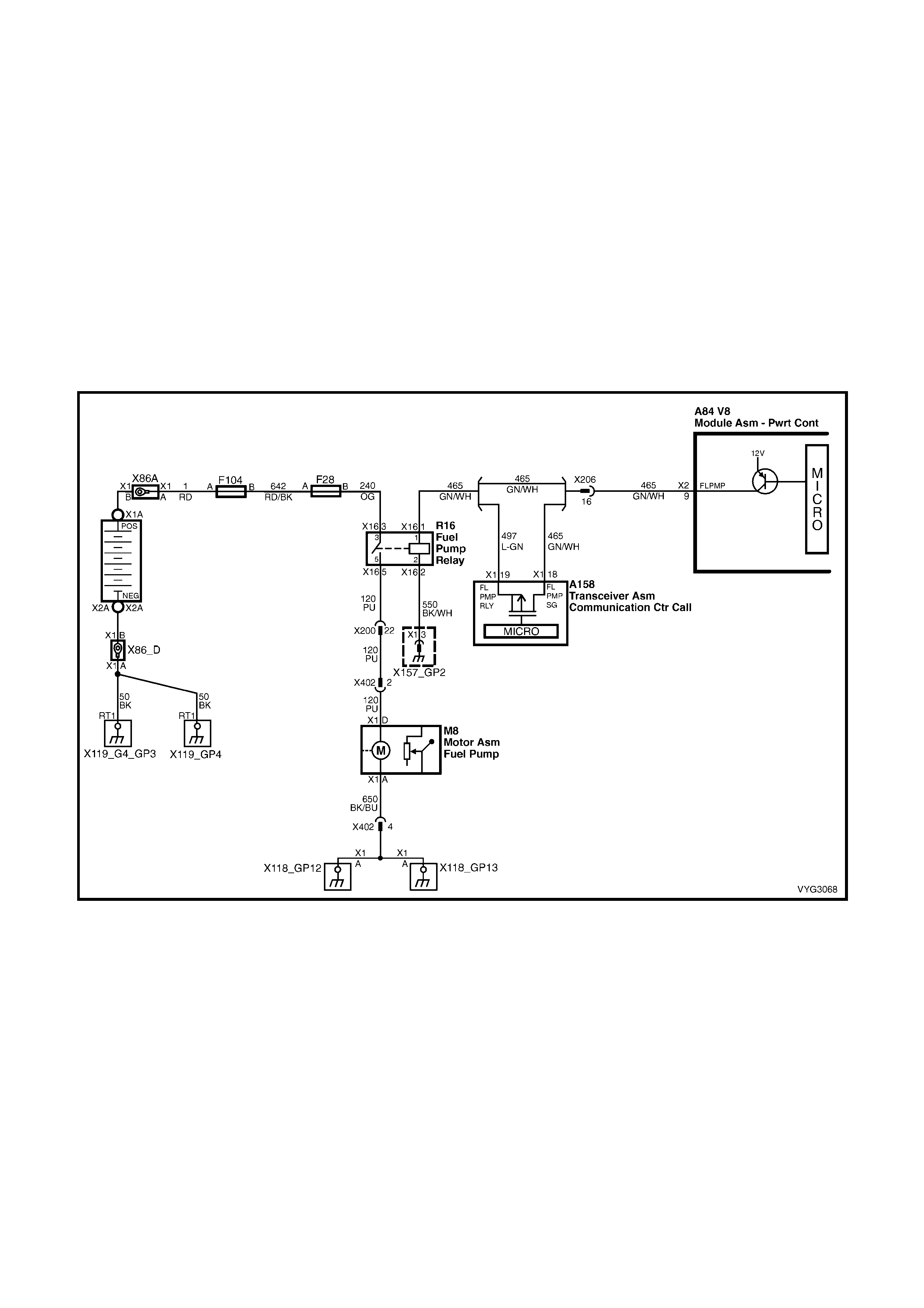

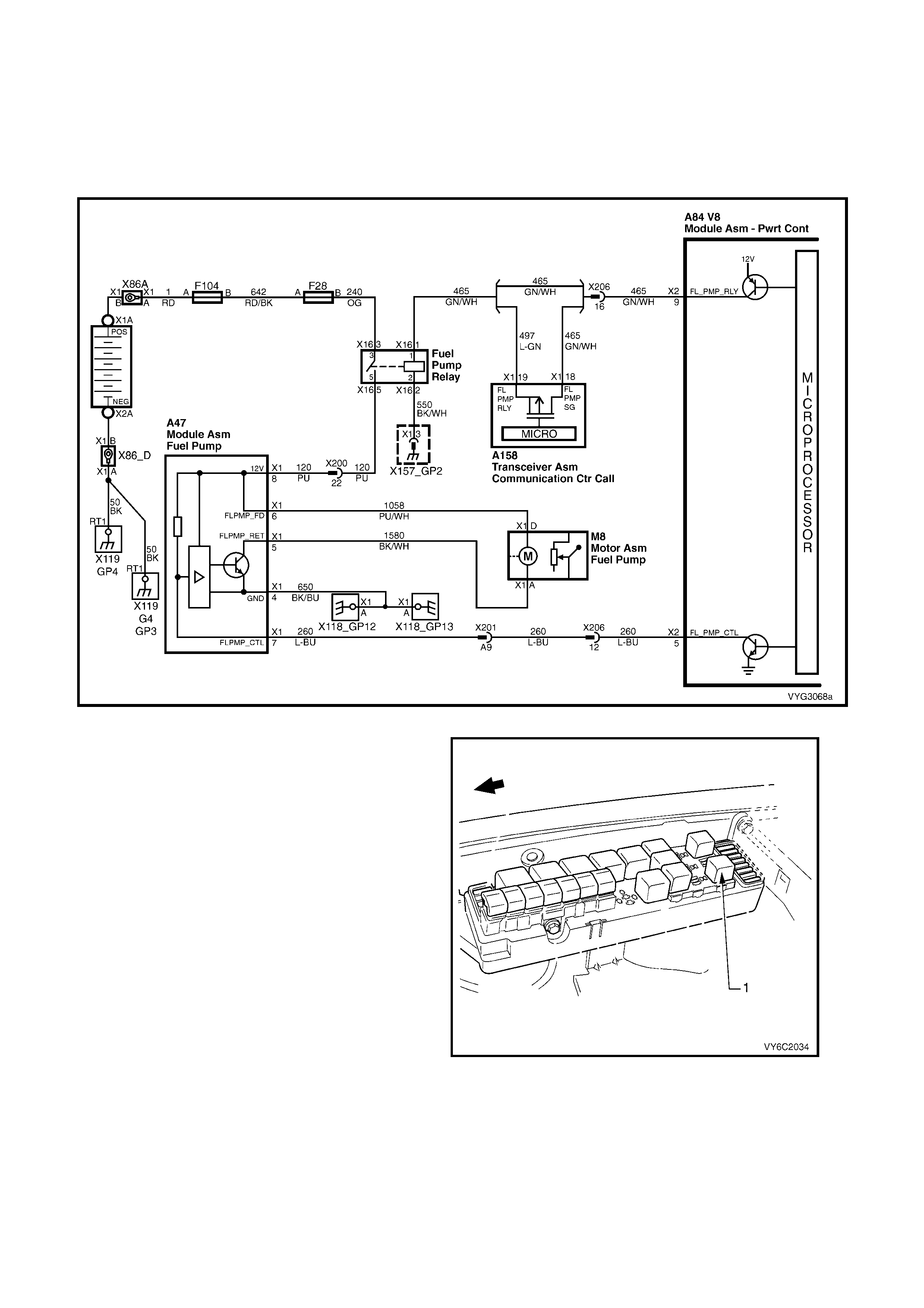

FUEL PUMP ELECTRICAL CIRCUITS FOR

UTILITY WITH GEN III V8 ENGINE

1.5 IDLE AIR CONTROL (IAC) VALVE

IDLE AIR CONTROL VALVE POSITION RESET

1.6 ELECTRONIC IGNITION SYSTEM

IGNITION SYSTEM OVERVIEW

COMPONENTS

CIRCUITS AFFECTING IGNITION CONTROL

RESULTS OF INCORRECT OPERATION

NOTEWORTHY IGNITION INFORMATION

1.7 CRANKCASE VENTILATION SYSTEM

RESULTS OF INCORRECT OPERATION

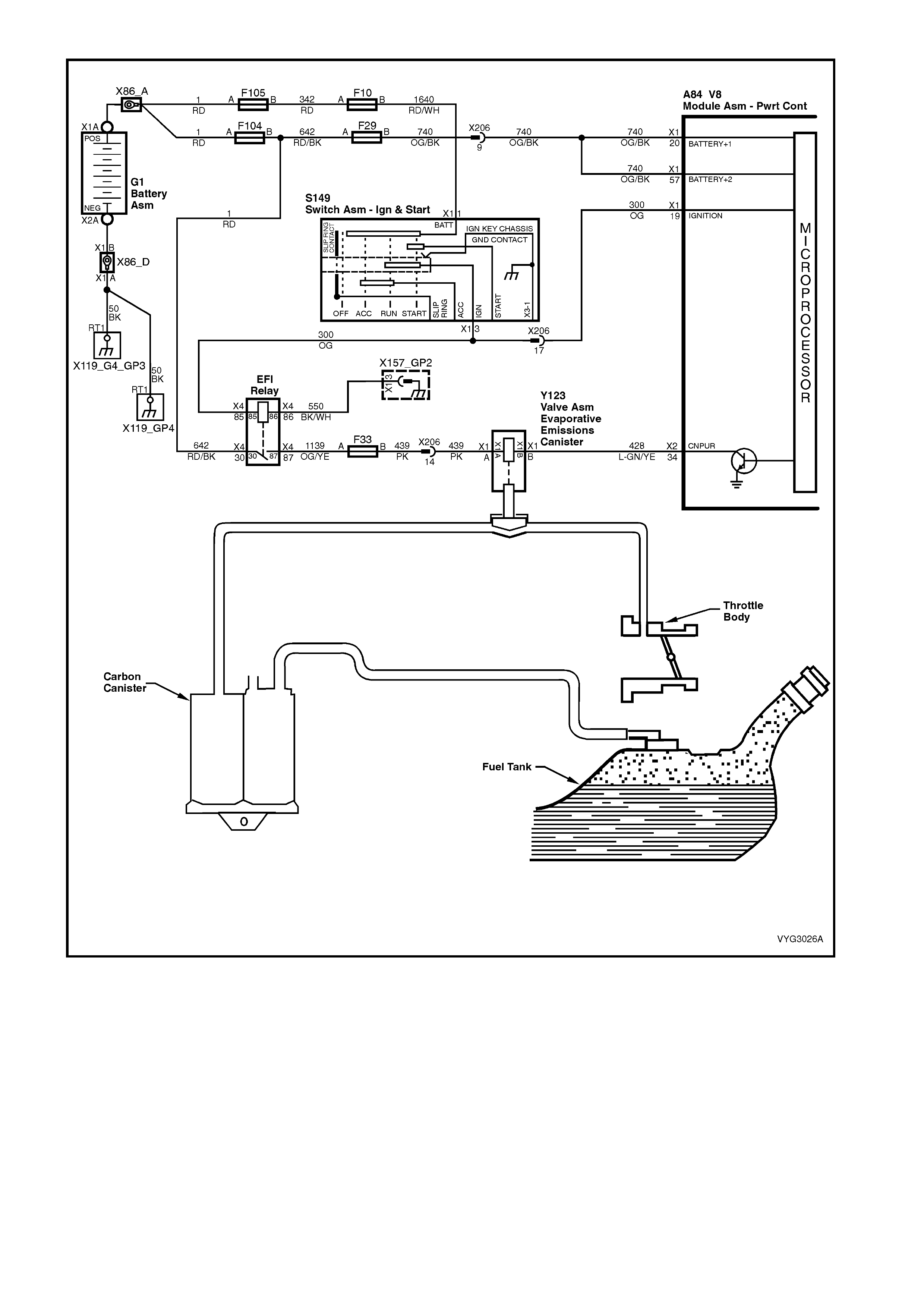

1.8 EVAPORATIVE EMISSION CONTROL

RESULTS OF INCORRECT OPERATION

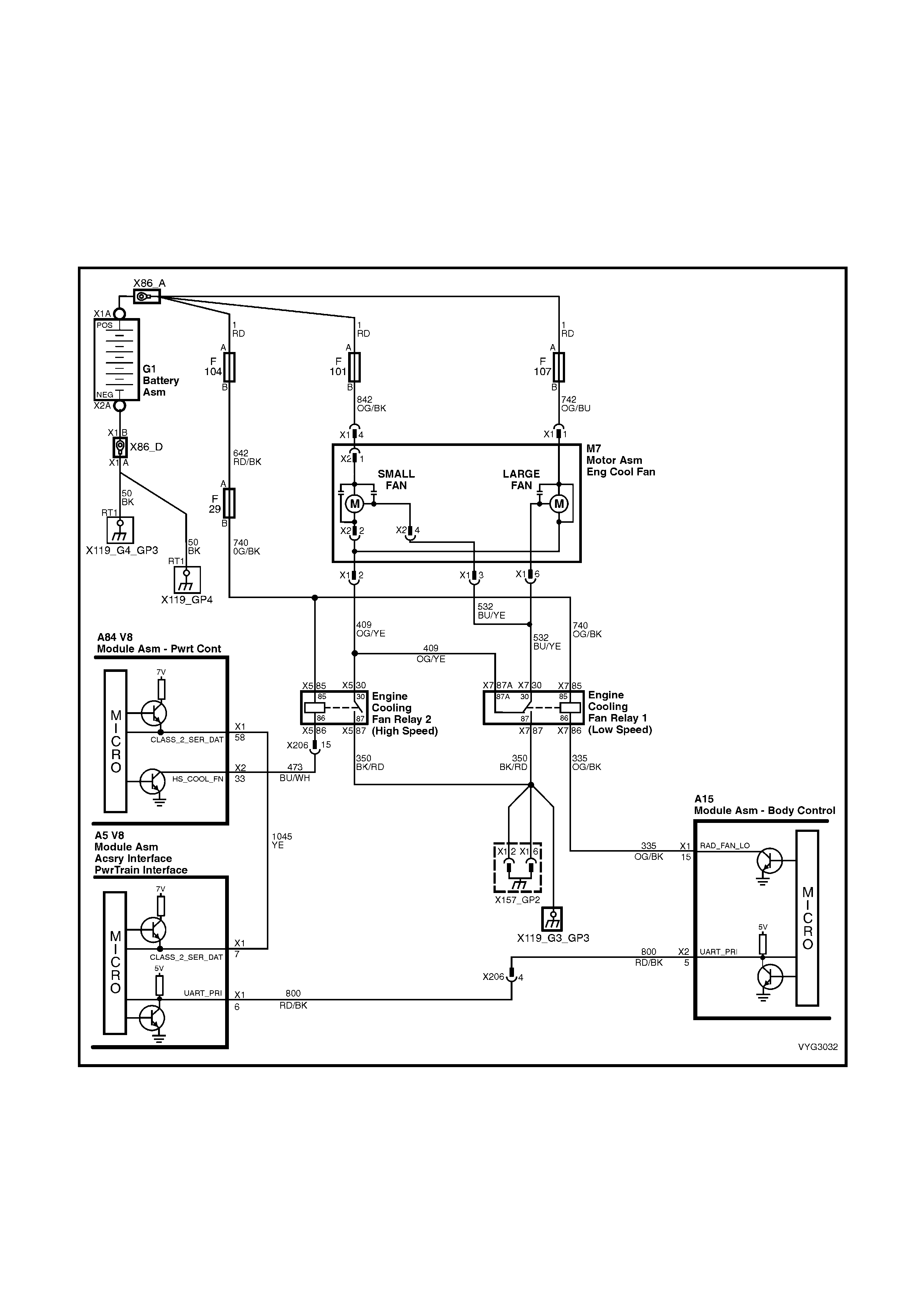

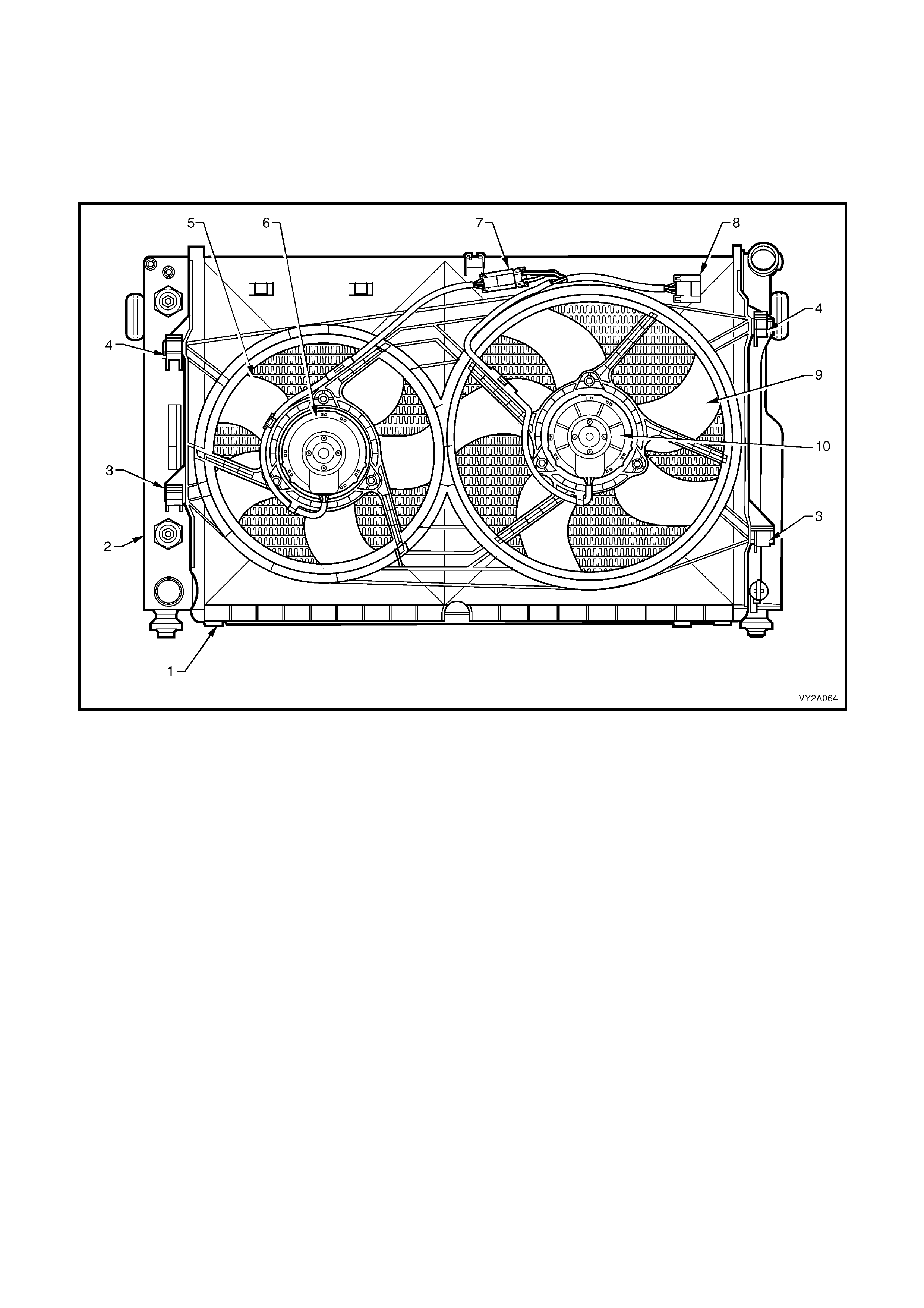

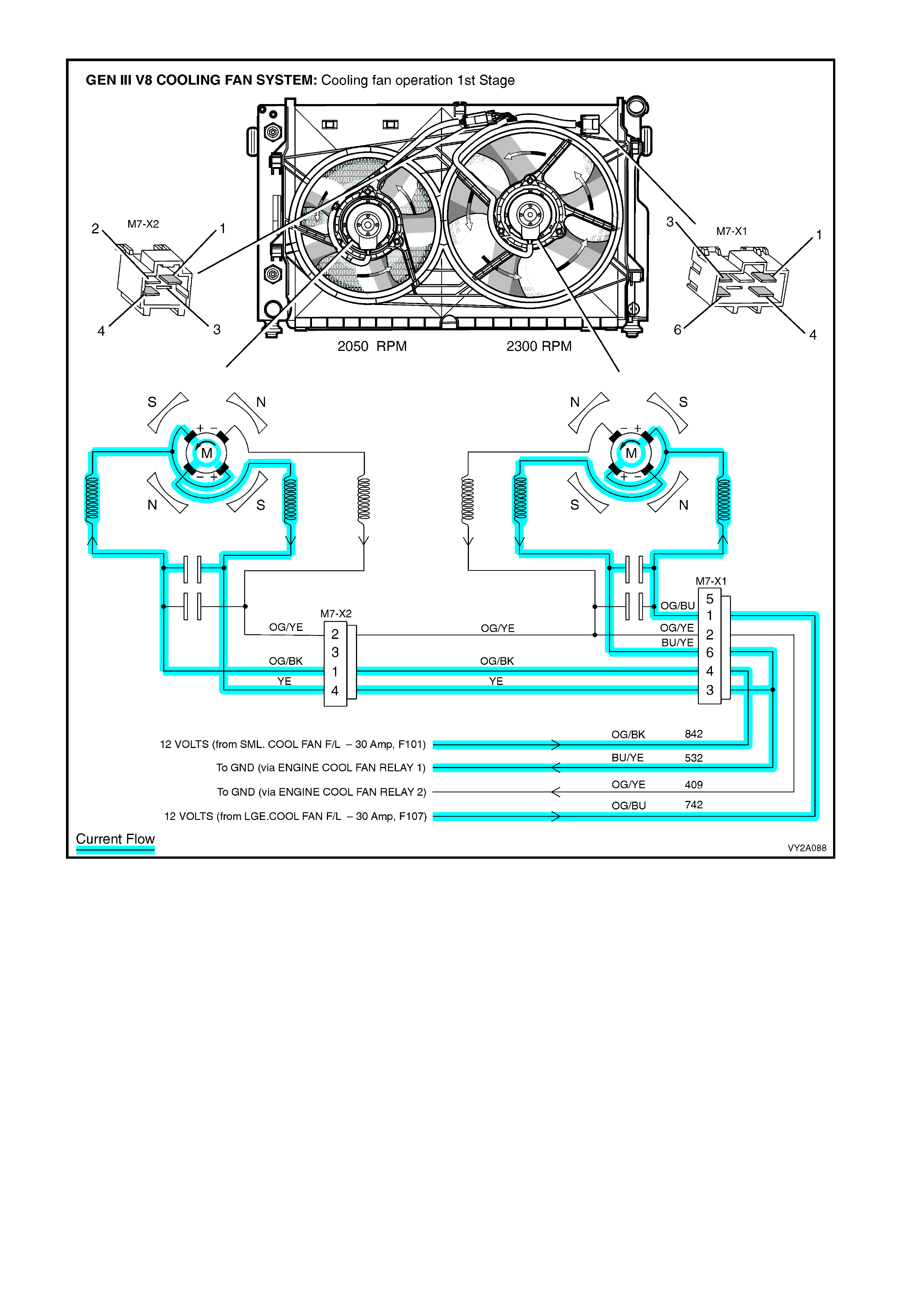

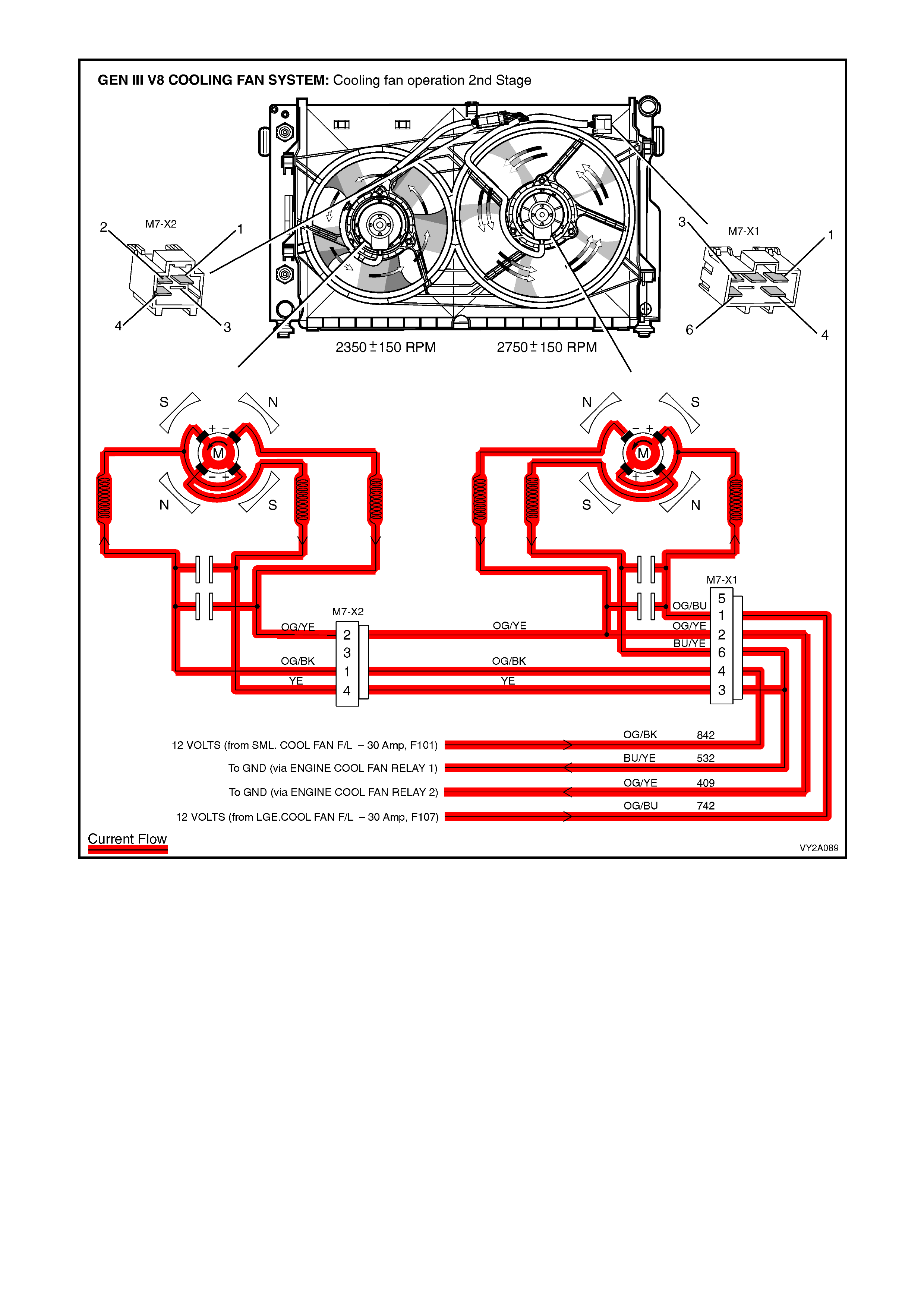

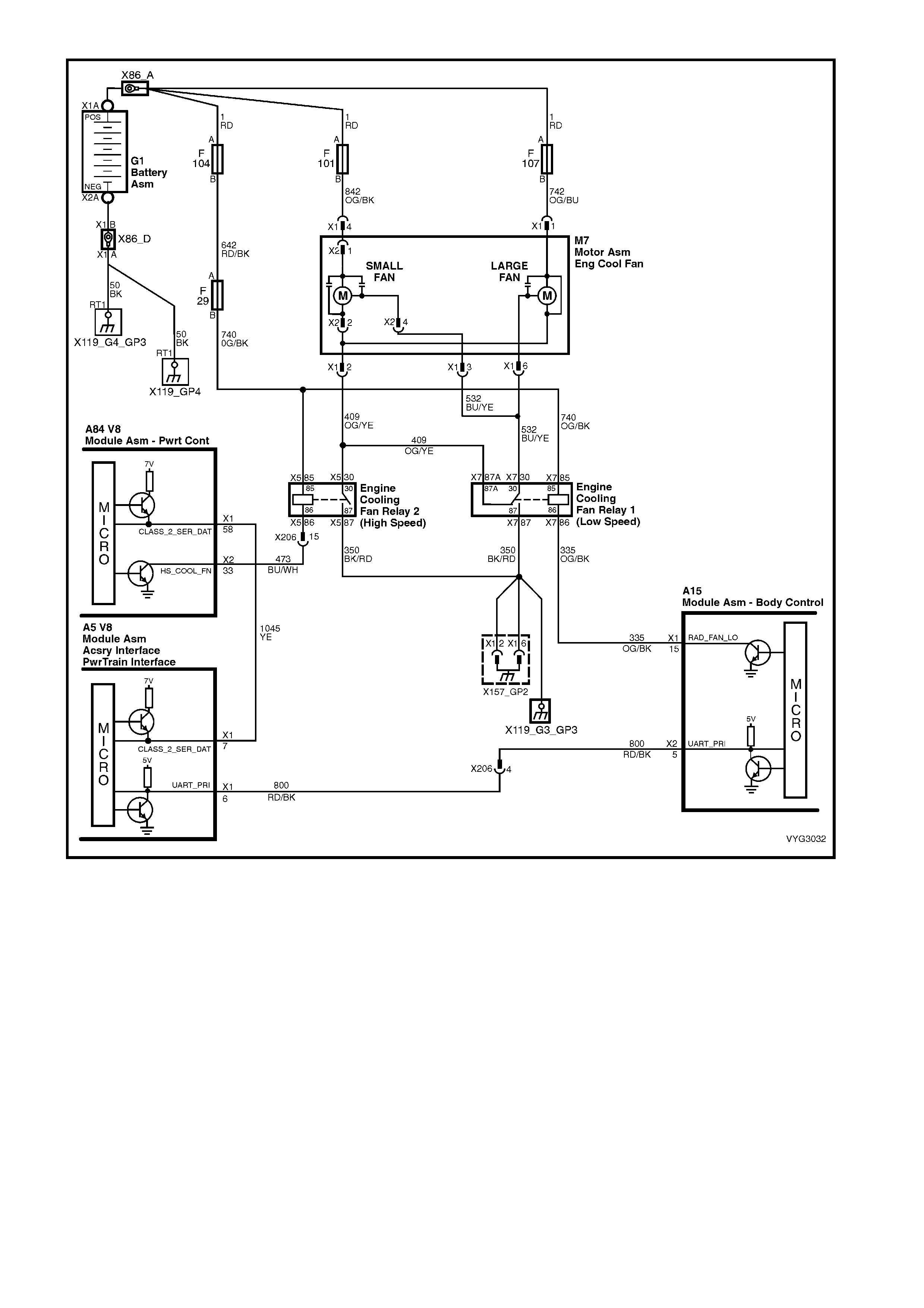

1.9 ELECTRIC COOLING FANS

OPERATION

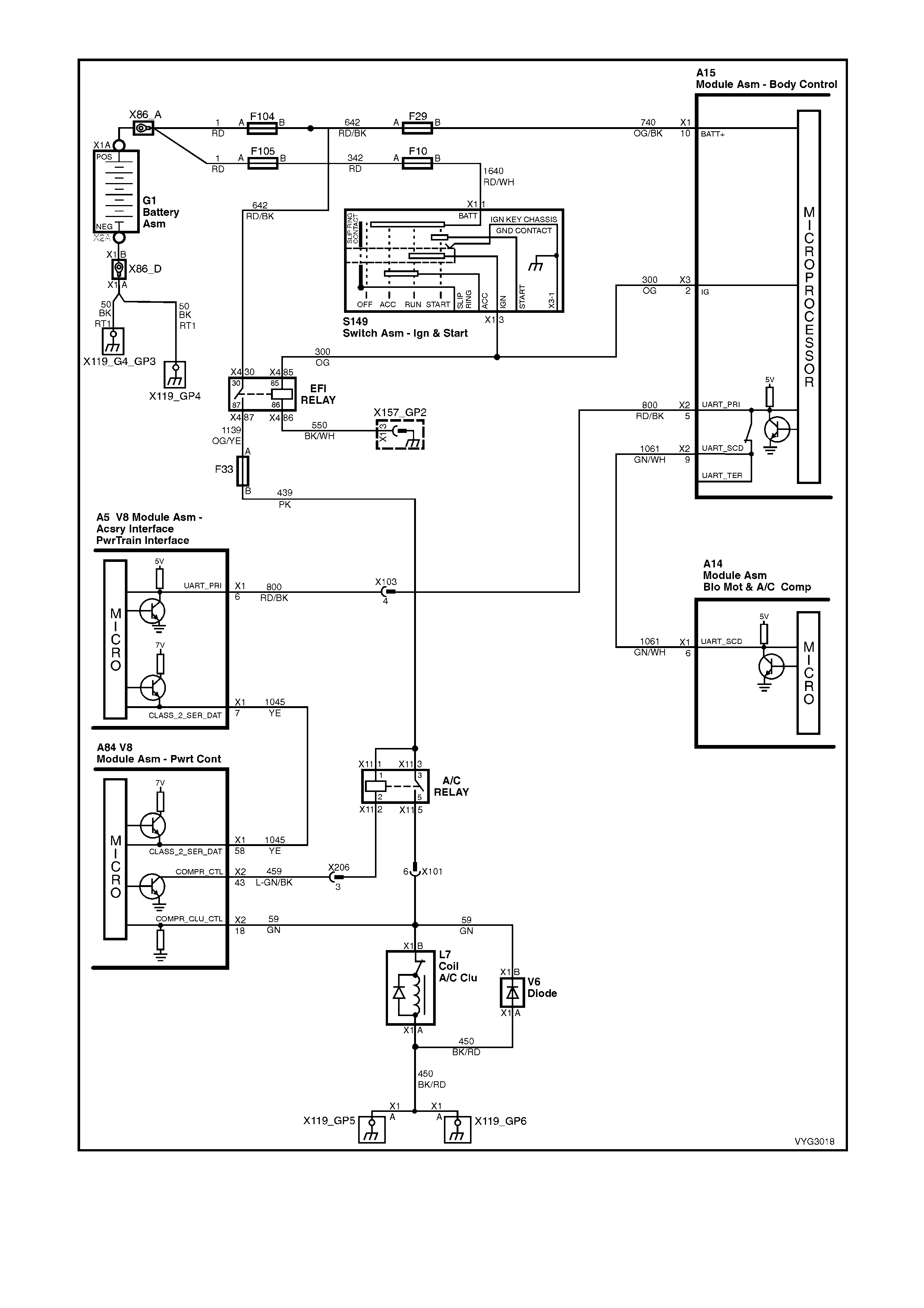

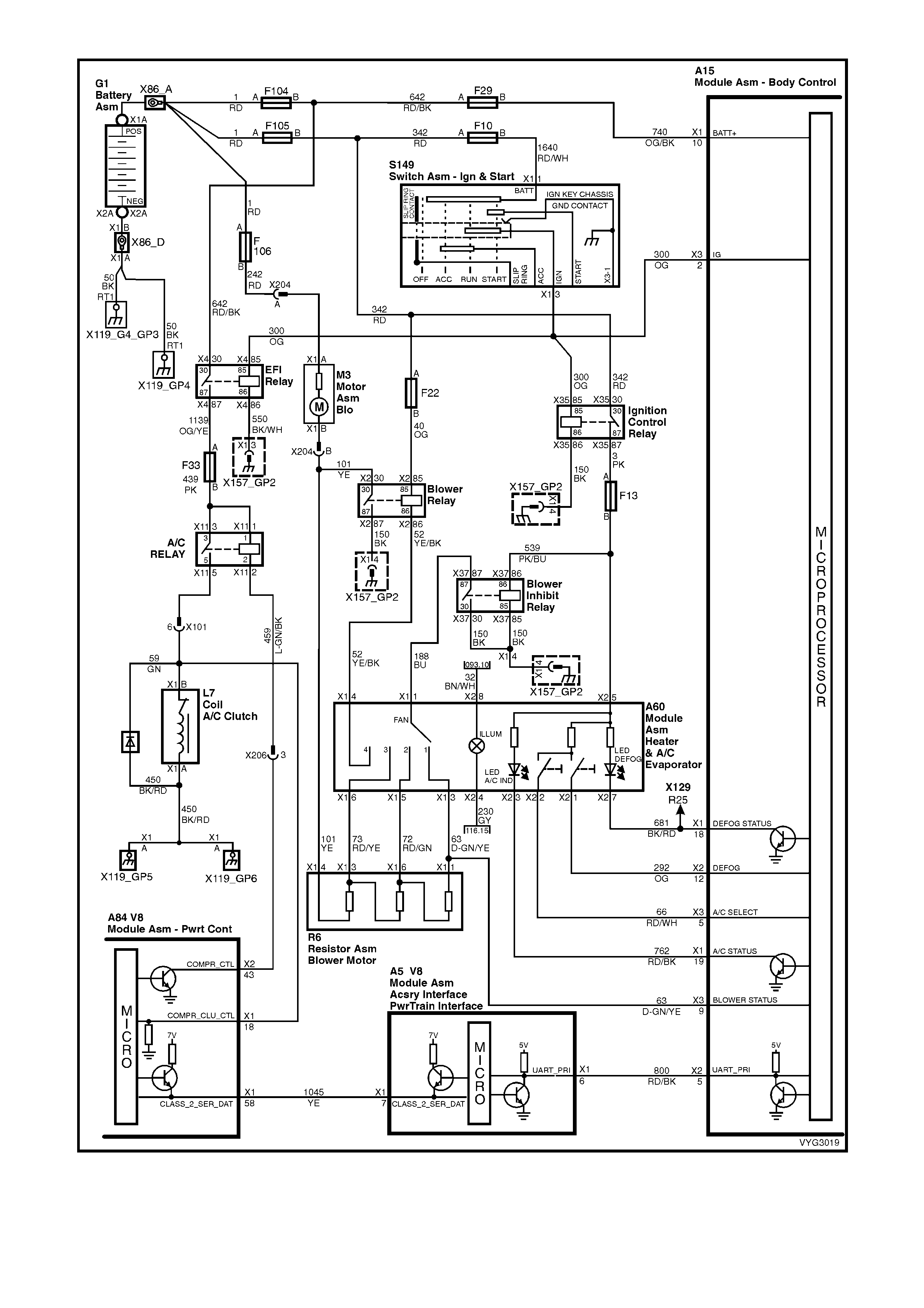

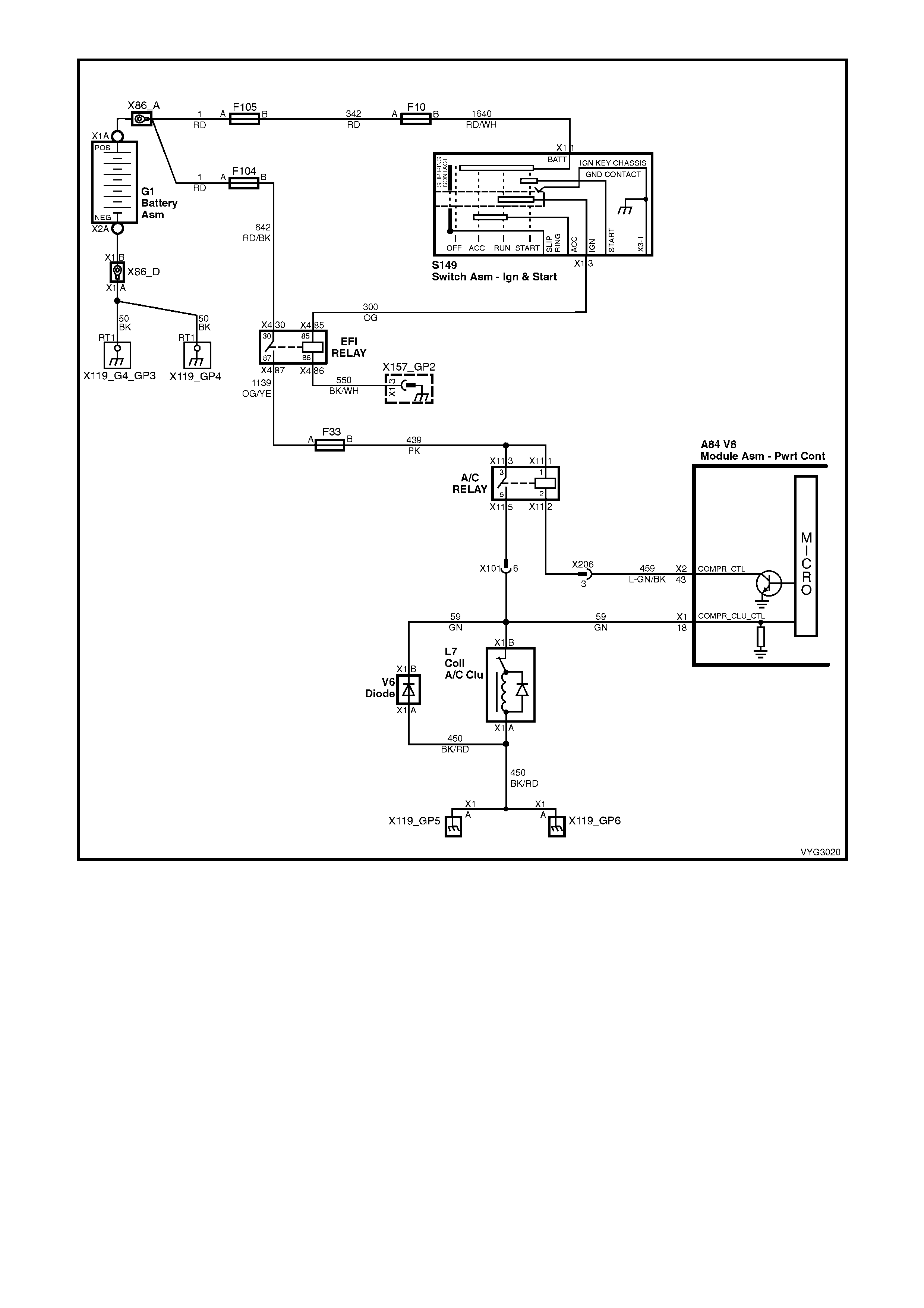

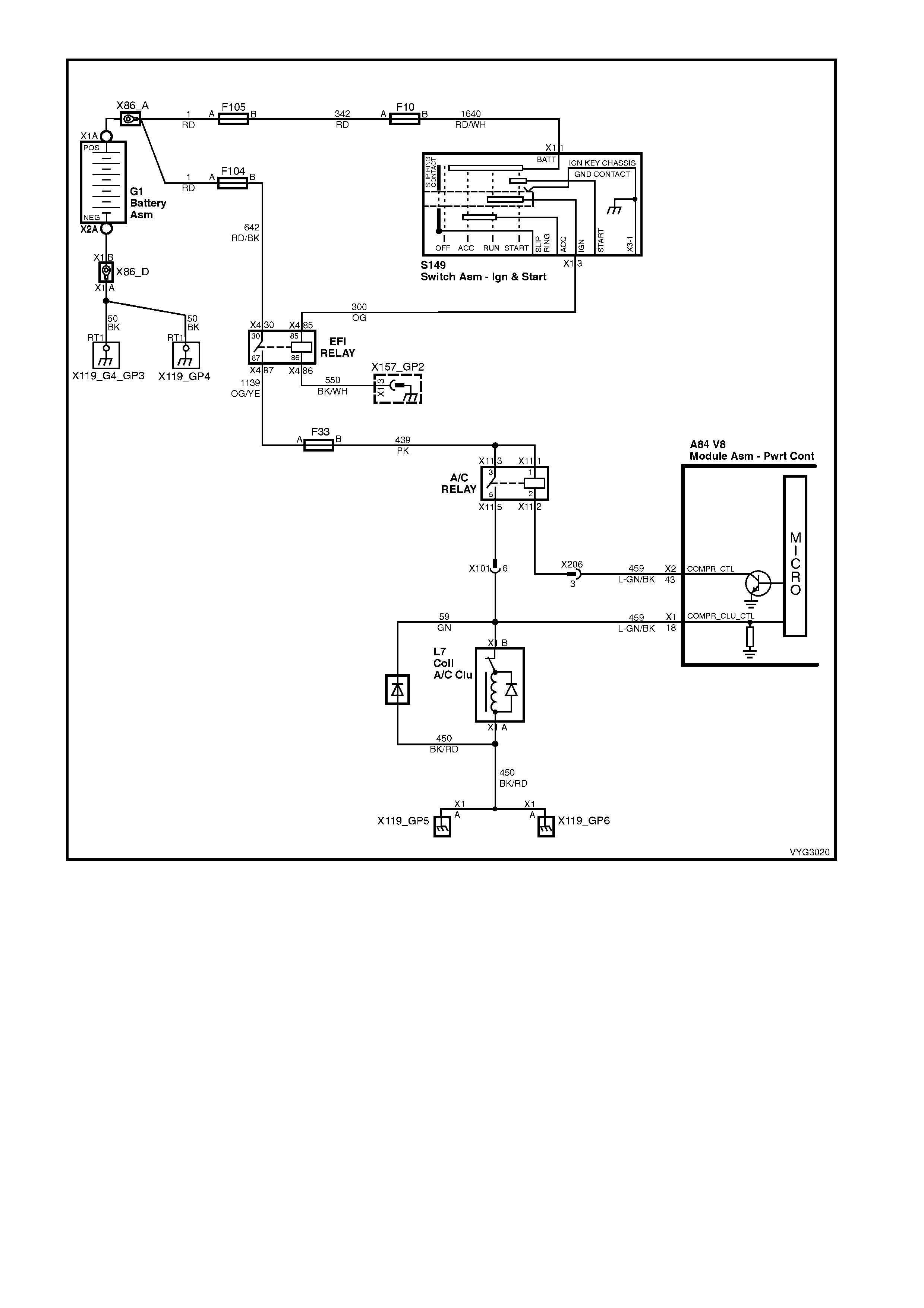

1.10 A/C CLUTCH CONTROL

OCC SYSTEM

STANDARD A/C SYSTEM

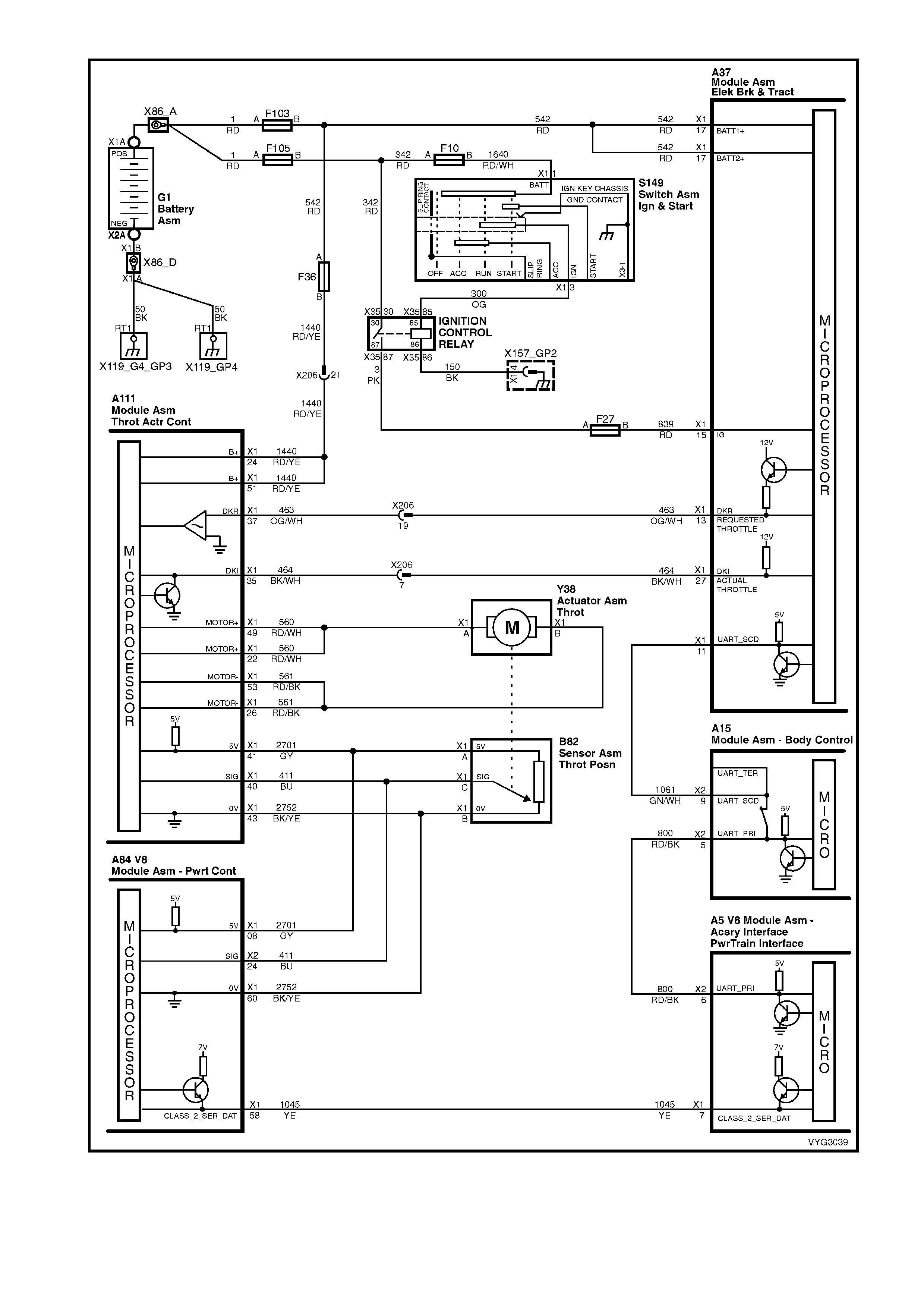

1.11 ELECTRONIC TRACTION CONTROL

ENGINE SPARK AND THROTTLE POSITION

INTERVENTION

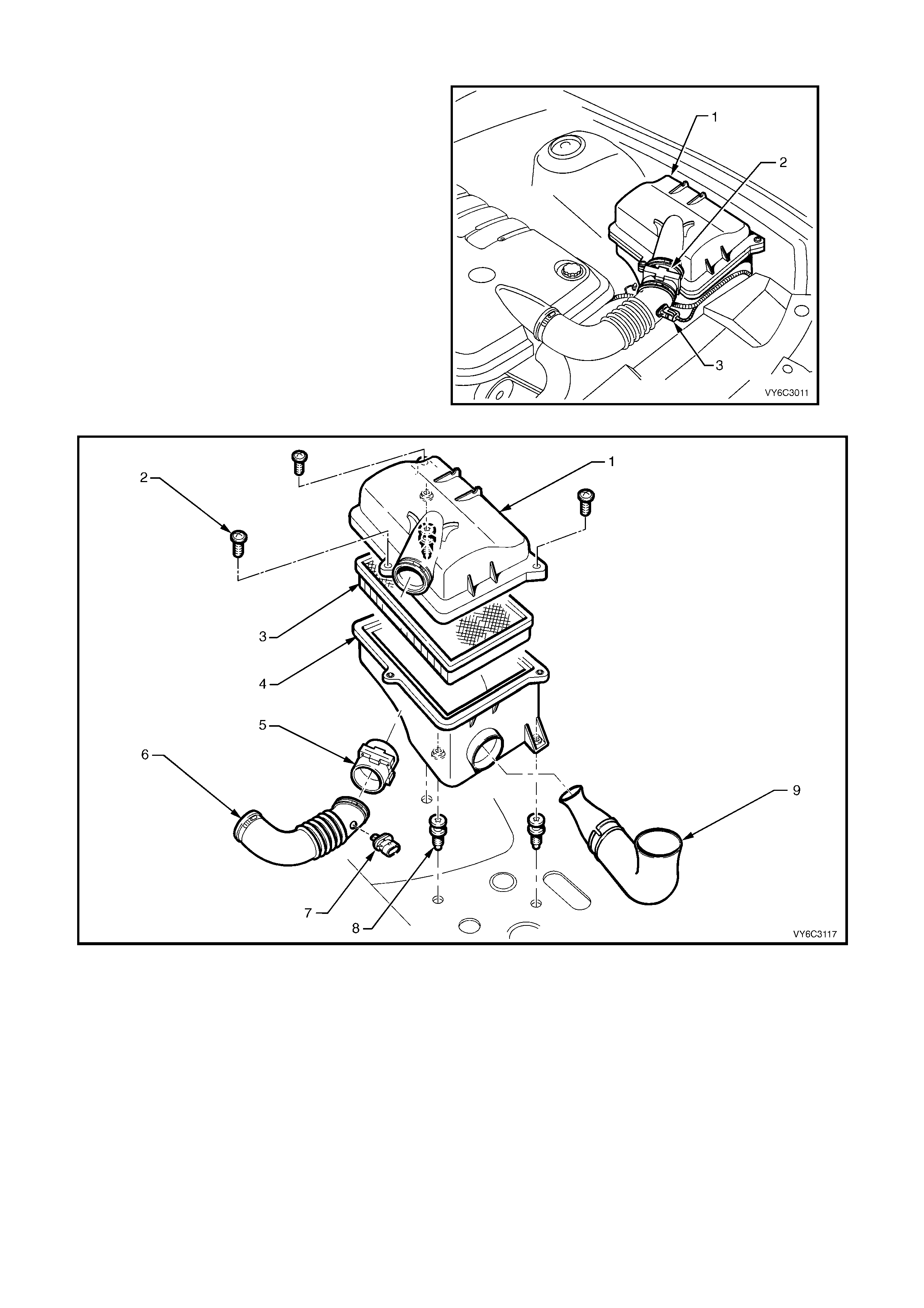

1.12 AIR INTAKE SYSTEM

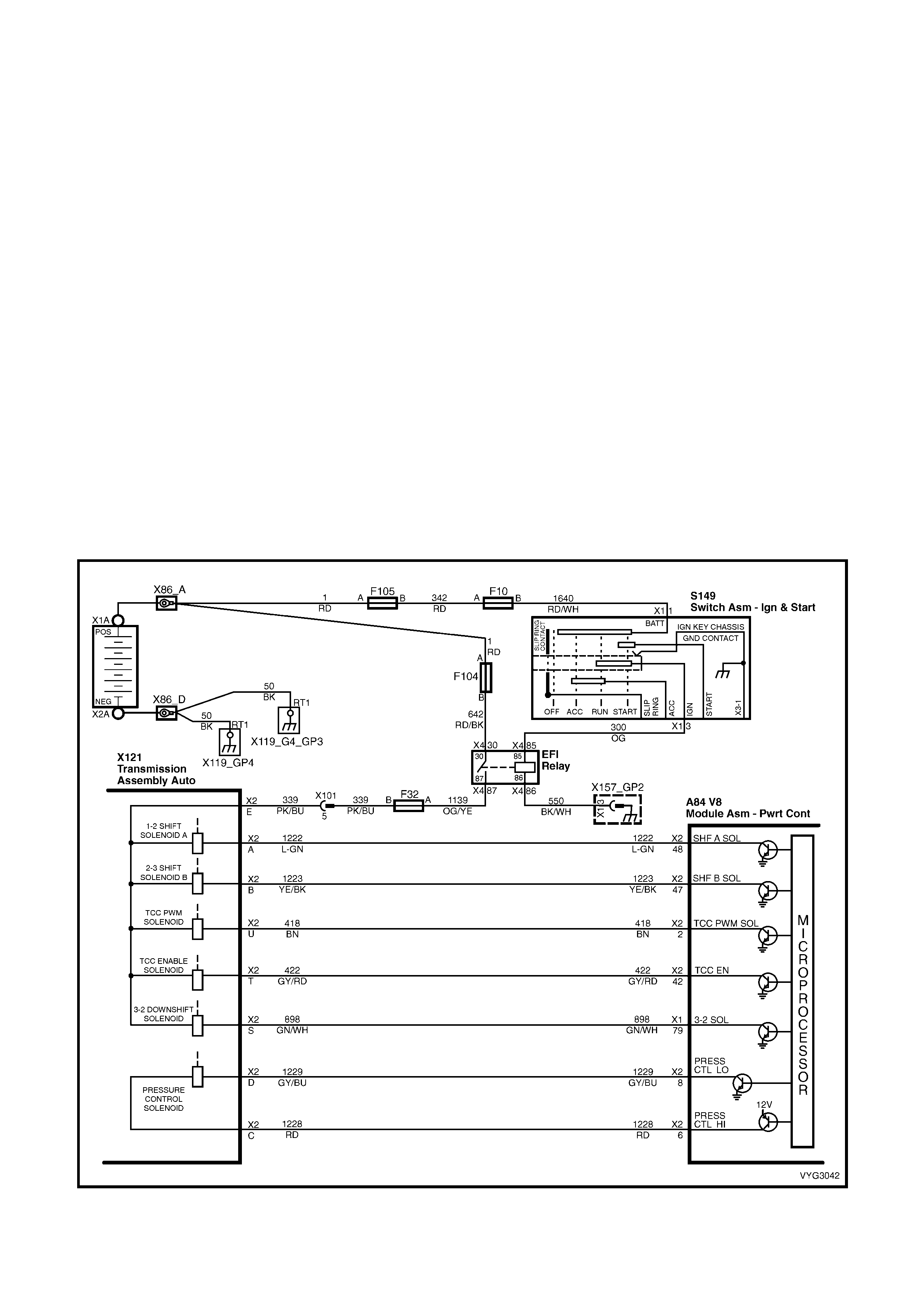

1.13 AUTOMATIC TRANSMISSION SENSORS

AND SIGNALS

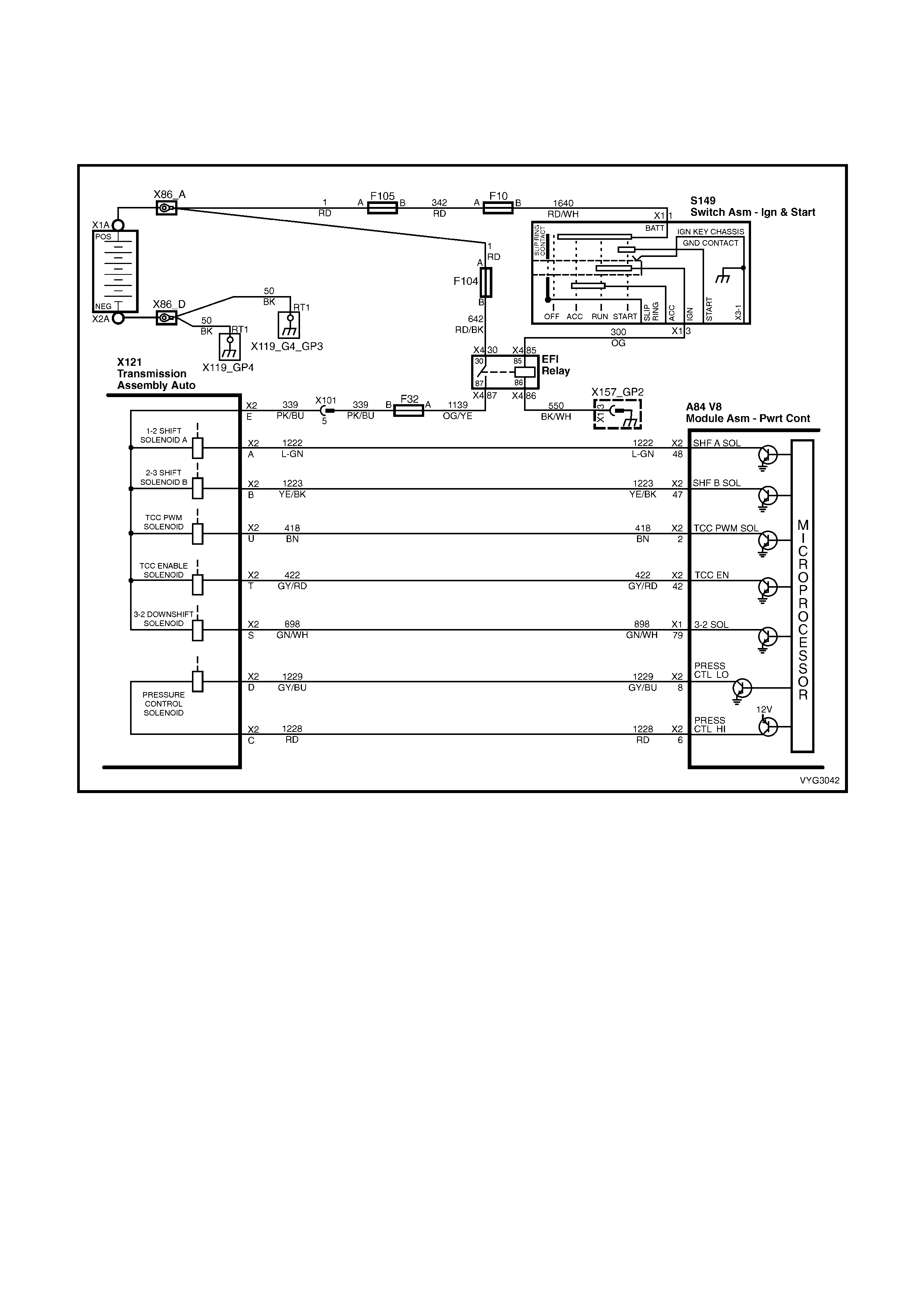

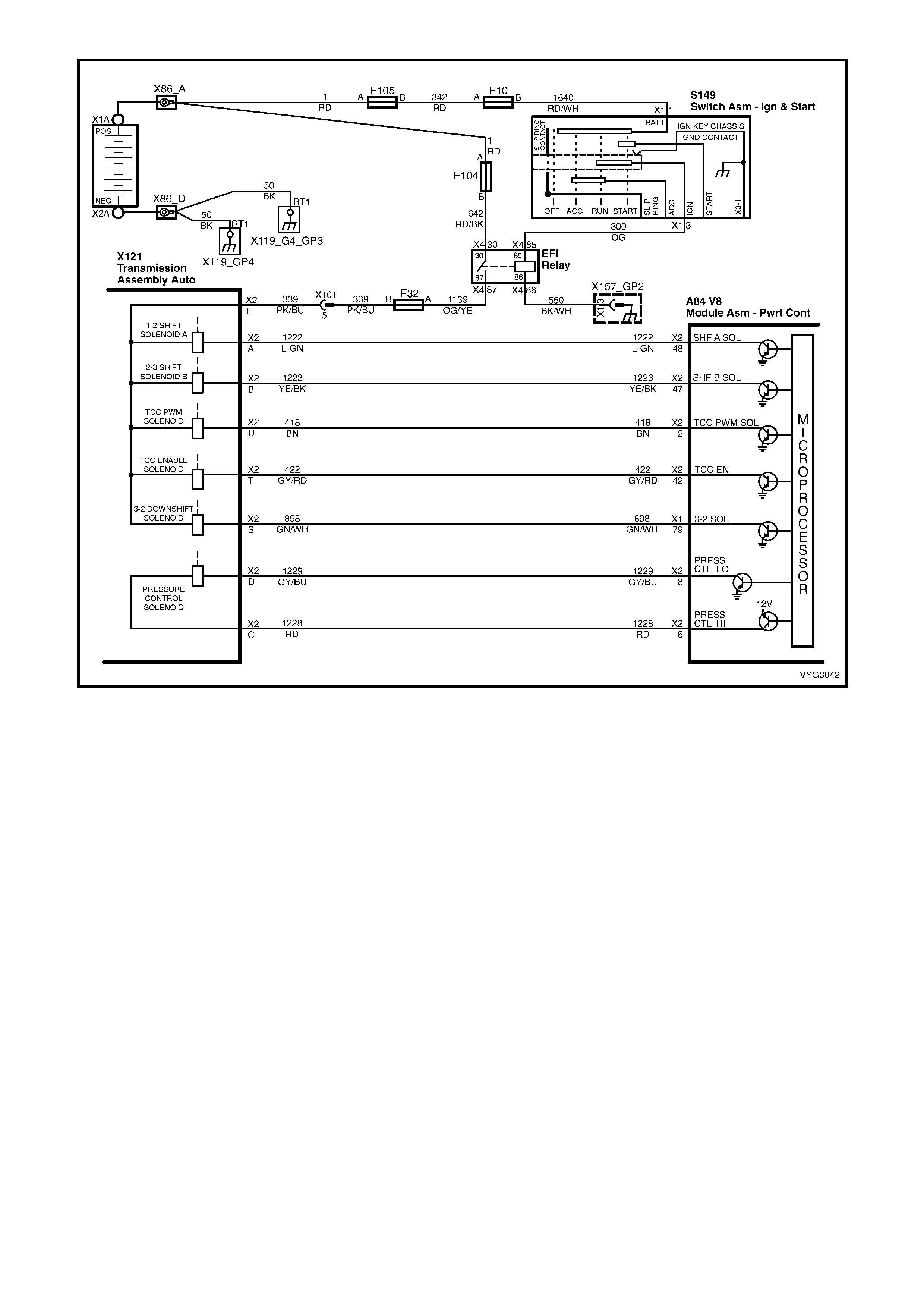

1-2 (A) AND 2-3 (B) SHIFT SOLENOID VALVES

3-2 SHIFT SOLENOID VALVE

TRANSMISSION PRESSURE CONTROL

SOLENOID

TORQUE CONVERTER CLUTCH SOLENOID

VALVE

TORQUE CONVERTER CLUTCH PWM

SOLENOID VALVE

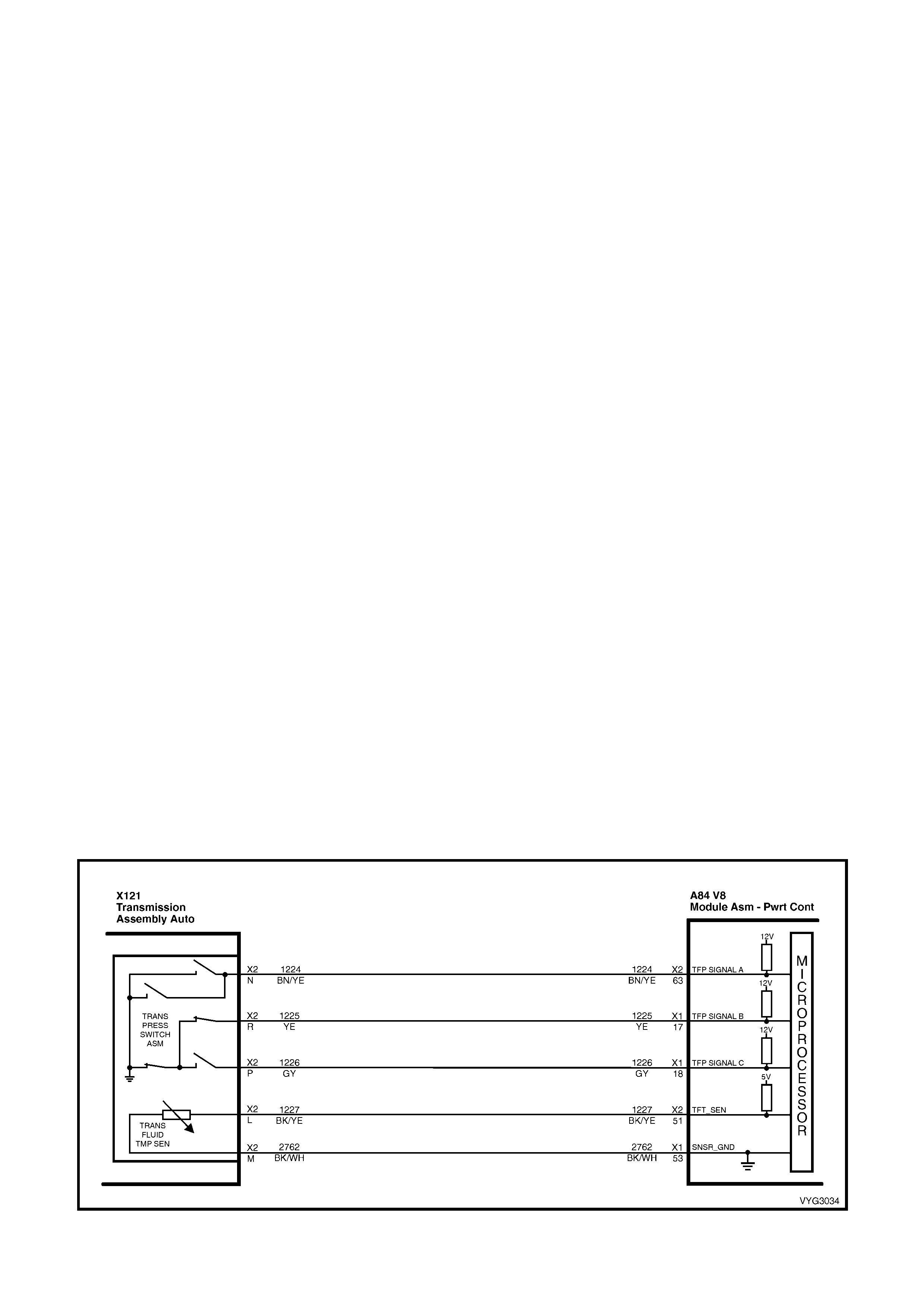

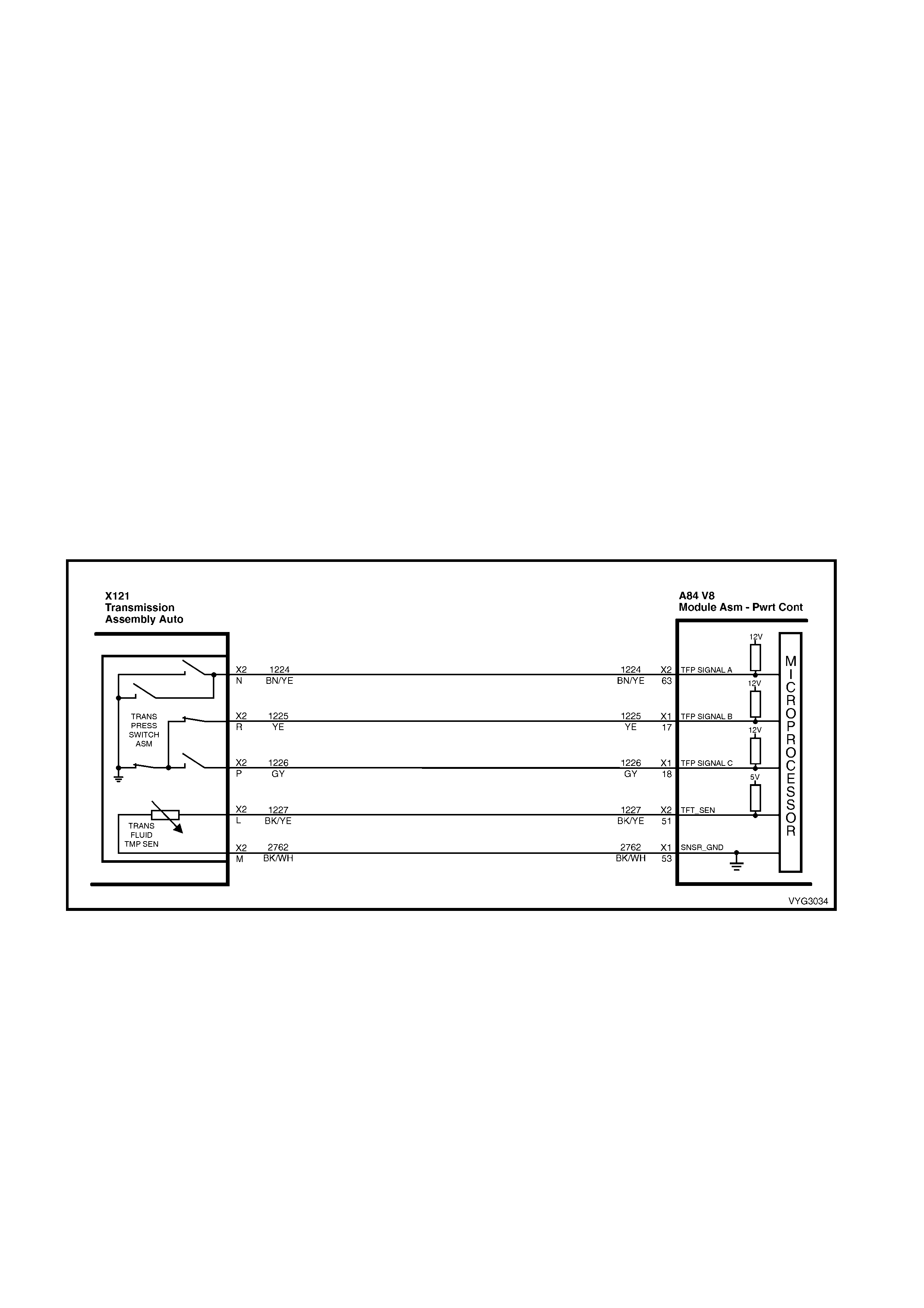

TRANSMISSION FLUID PRESSURE (TFP)

MANUAL VALVE POSITION SWITCH

VEHICLE SPEED SENSOR

AUTOMATIC TRANSMISSION FLUID

TEMPERATURE SENSOR

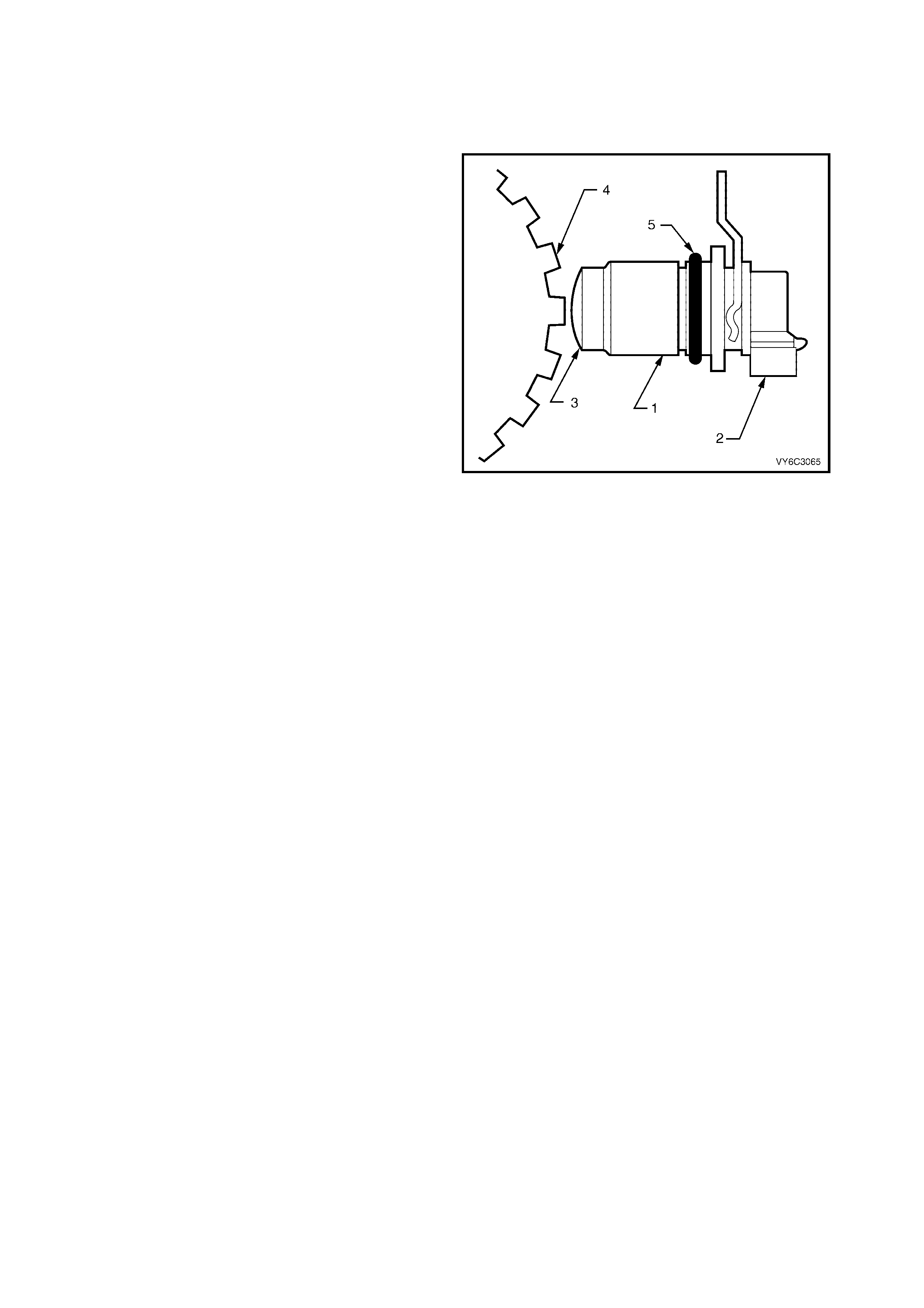

ELECTRICAL CONNECTOR

1.14 ABBREVIATIONS AND GLOSSARY OF TERMS

Techline

1. GENERAL DESCRI PTI O N

The engine used in this vehicle uses a Powertrain Control Module (PCM) to control exhaust emissions while

maintaining excellent driveability and fuel econom y. The PCM m aintains a desired air/f uel ratio at precisely 14.7 to

1. To m aintain a 14.7 to 1 air f uel ratio the PCM monitor s the output signal from two ox ygen sensors . The PCM will

either add or subtr act f uel pulses bas ed on the oxygen sensors output signal. T his m ethod of f eed back fuel c ontrol

is called CLOSED LOOP.

In addition to fuel control, the PCM also controls the following systems.

• The Ignition Dwell

• The Ignition Timing

• The Idle Speed

• The Engine Electric Cooling Fans

• The Fuel Pump

• The Instrument Panel Check Powertrain Malfunction Indicator Lamp (MIL) icon.

• The A/C Compressor Clutch

• The Automatic Transmission Functions

• The Manual Transmission Reverse Inhibit

• Theft Deterrent

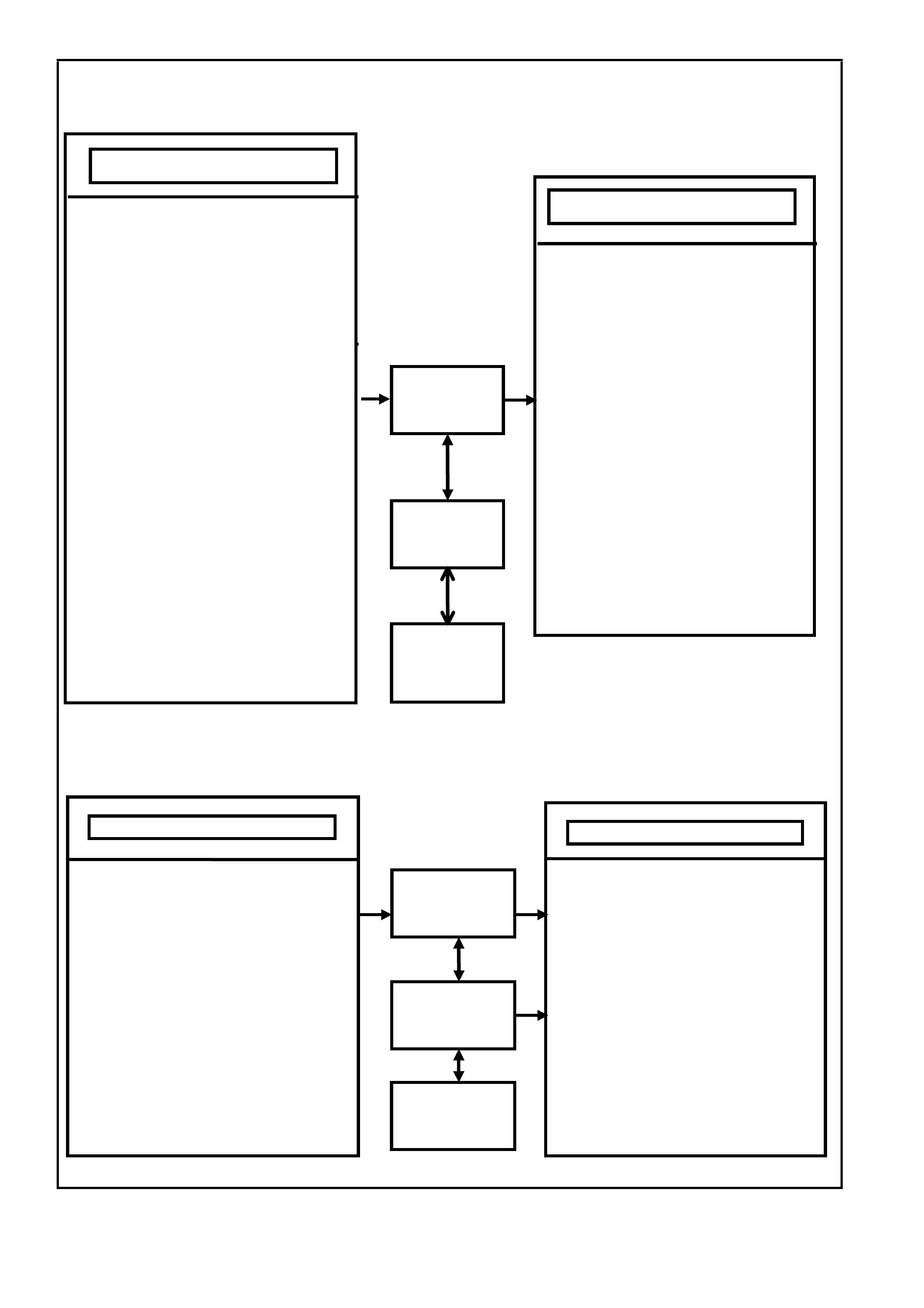

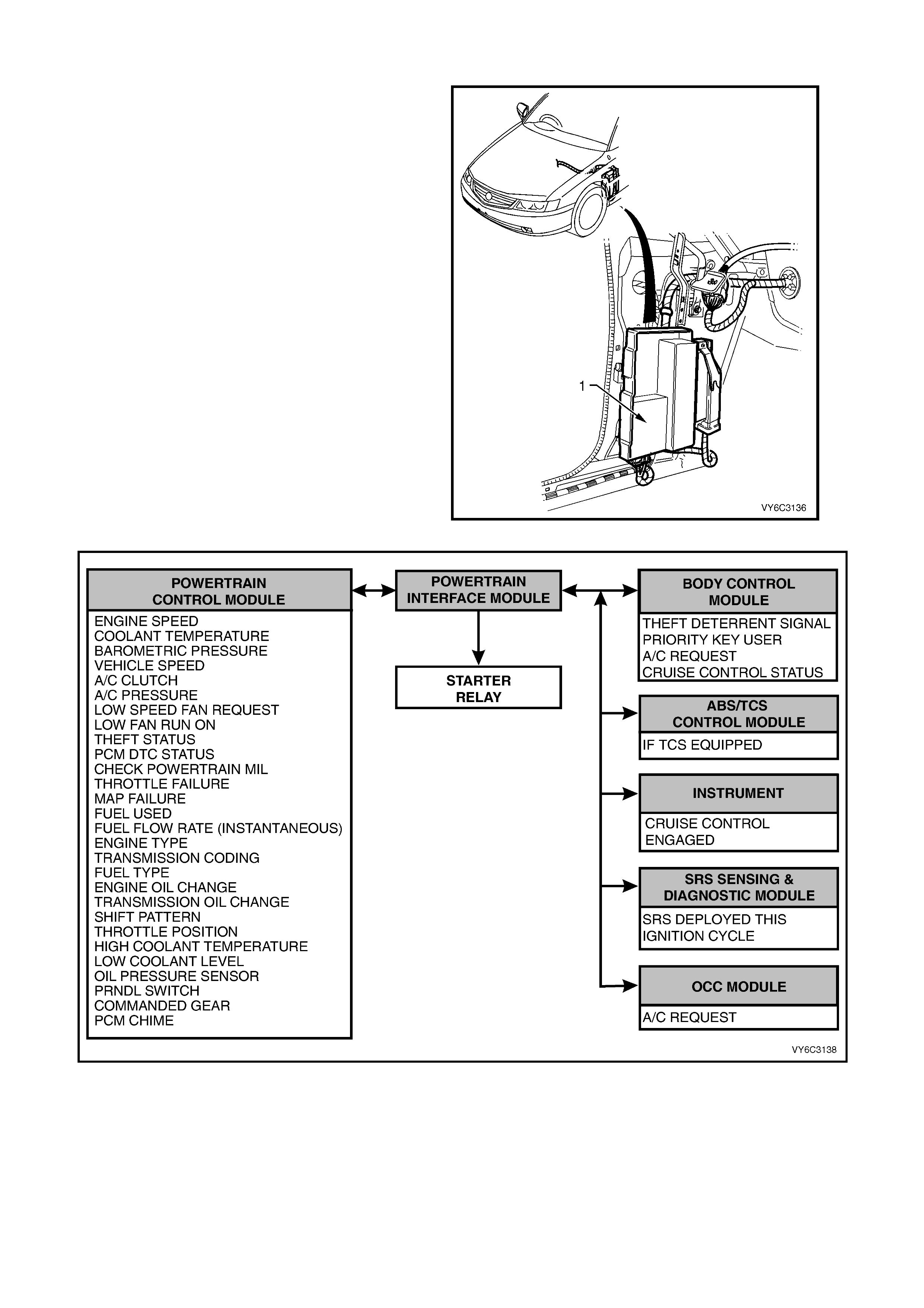

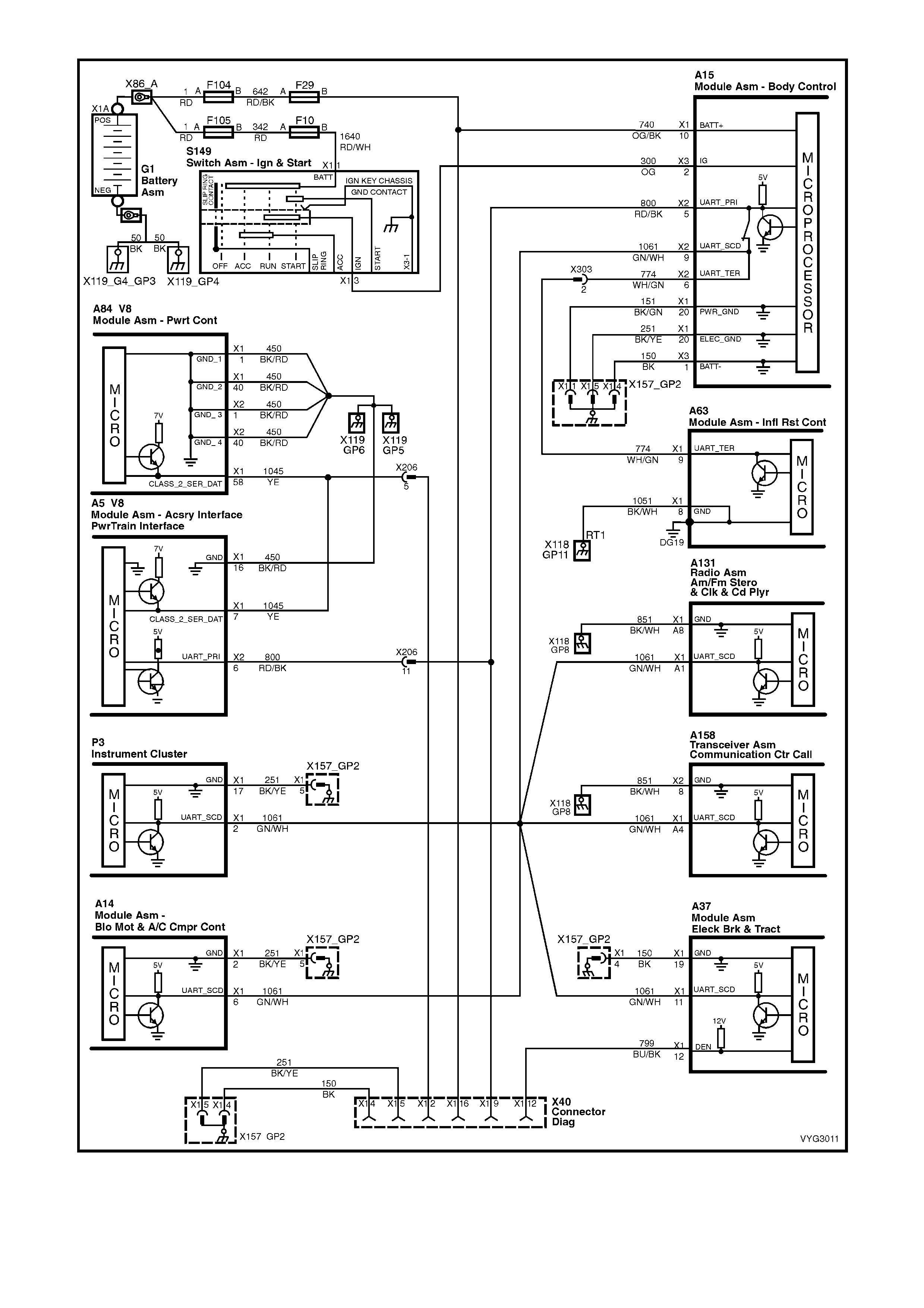

The PCM also interfaces with other vehicle control modules, such as the Powertrain Interface Module (PIM),

Instruments, and Body Control Module (BCM). The following diagram contains a list of the various operating

conditions sensed by the PCM, and the various systems controlled. Details of basic operation, diagnosis, and

service are covered in this Section.

The PCM has a built-in diagnostic system that identifies operational pr oblems and alerts the driver by activating the

Check Powertrain Malfunction Indicator Lamp (MIL) icon in the instrument panel. If the lamp is activated while

driving, it does not m ean that the engine should be stopped imm ediately, but the cause of the activation should be

checked as soon as is reasonably possible. The PCM has built in back-up systems that in all but the most severe

faults will allow the vehicle to operate in a near normal manner until repairs can be made.

Below the instrument panel is a Data Link Connector (DLC) which is used by the assembly plant for a computer

check-out of the powertrain management system. The DLC is also used in service to help diagnose the system

using Tech 2. Refer to Section 6C3-2, DIAGNOSIS for further details.

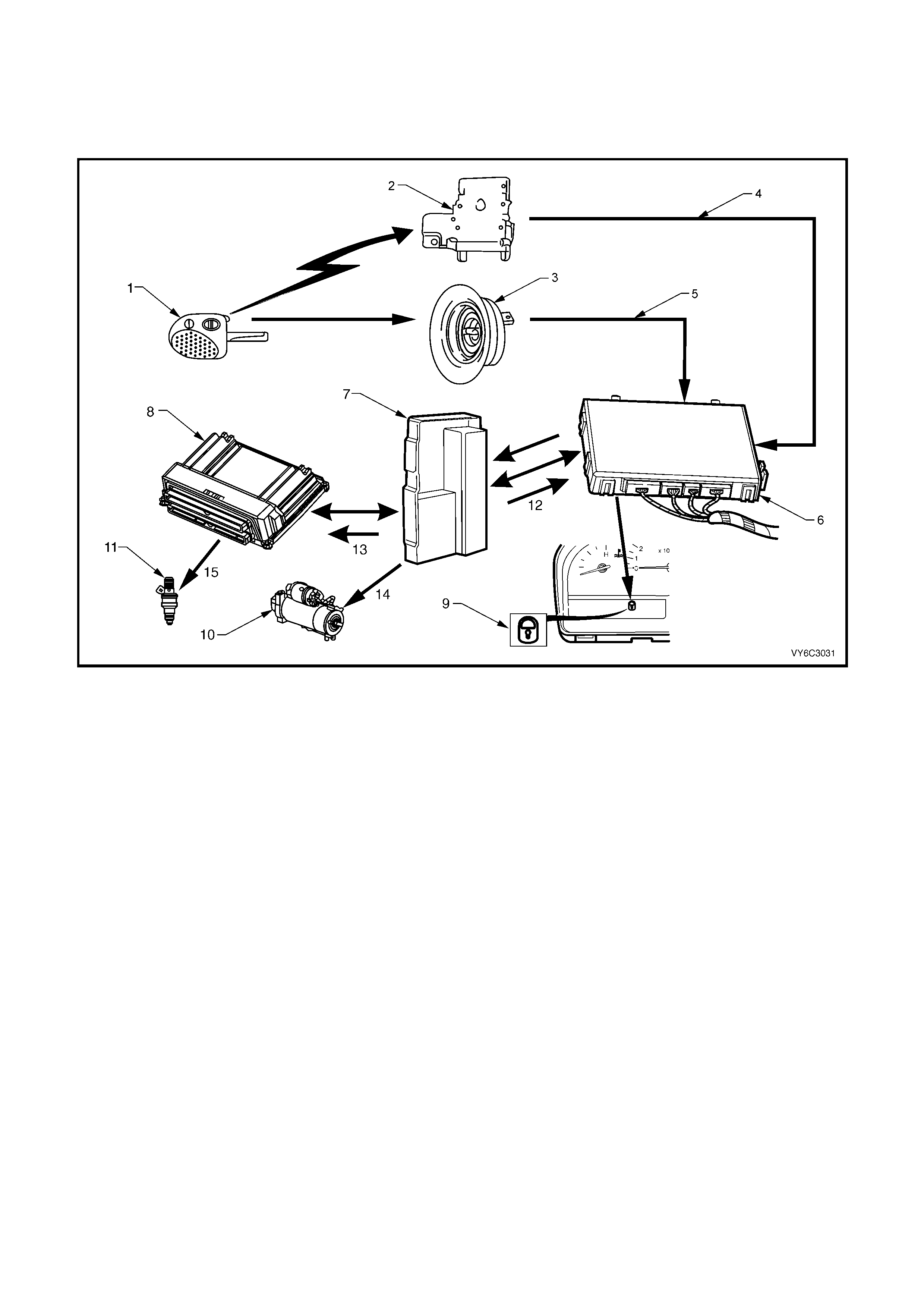

The locations of the Engine Management System (EMS) components are shown in Figures 6C3-1-2 through

6C3-1-5.

For the Transmission Management System components and their locations, refer to Figure 6C3-1-6 in this Section.

Engine Controls

transmission controls

NOTE: Some parameters may travel through one or more controllers for input or output controls.

Figure 6C3-1-1 – PCM Operating Conditions Sensed and Systems Controlled

• A/C Pressure Sensor

• A/C Request "ON" or "OFF"

• Battery Voltage

• Camshaft Position (CMP)

• Crankshaft Position (CKP)

• DLC Data Stream Input

• Engine Coolant Level Switch

• Engine Coolant Temperature (ECT)

• Engine Cooling Fan Response

• Engine Knock (KS)

• Engine Speed (RPM)

• Exhaust Gas Oxygen Content

• Intake Air Temperature (IAT)

• Mass Air Flow (MAF)

• Manifold Absolute Pressure (MAP)

• Oil Pressure Sensor

• Spark Retard Signal

• Stop Lamp Switch

• Throttle Position (TP)

• Transmission Gear Position (TFP)

• Theft Deterrent Signal

• Vehicle Speed (VSS)

POWERTRAIN

CONTROL

MODULE (PCM)

• Air Conditioning Compressor Clutch

• Canister Purge Solenoid

• Diagnostics

• - Malfunction Indicator Lamp (MIL)

• - DLC Data Stream Output

• - Field Service Mode

• Electric Engine Cooling Fans

• Electronic Spark Control (ESC)

• Electronic Spark Timing (EST)

• Fuel Control

- Fuel Injectors

- Fuel Pump

• Idle Air Control

• Torque Management

• Battery Voltage

• Power/Economy Switch

• Engine Speed (RPM)

• Engine Coolant Temperature (ECT)

• Stop Lamp Switch

• Throttle Position (TP Sensor)

• Transmission Fluid Temperature (TFT)

• Transmission Gear Position (TFP)

• Vehicle Speed Sensor (VSS)

• Pressure Control Solenoid (PCS)

• Transmission Fluid Pressure (TFP)

Switch Assembly

• TCC Enable Solenoid

• TCC PW M Solenoid

• 3-2 Shift Solenoid

• 1-2 Shift Solenoid – ‘A’

• 2-3 Shift Solenoid – ‘B’

• Diagnostics

• - Malfunction Indicator Lamp (MIL)

• - DLC Data Stream Output

• Manual Transmission Reverse

Inhibit

POWERTRAIN

CONTROL

MODULE (PCM)

OPERATING PARAMETERS SENSED SYSTEM CONTROLLED

POWERTRAIN

INTERFACE

MODUL E (P IM)

POWERTRAIN

INTERFACE

MODULE (PIM)

BODY

CONTROL

MODUL E (B C M)

BODY

CONTROL

MODULE (BCM)

OPERATING PARAMETERS SENSED

SYSTEMS CONTROLLED

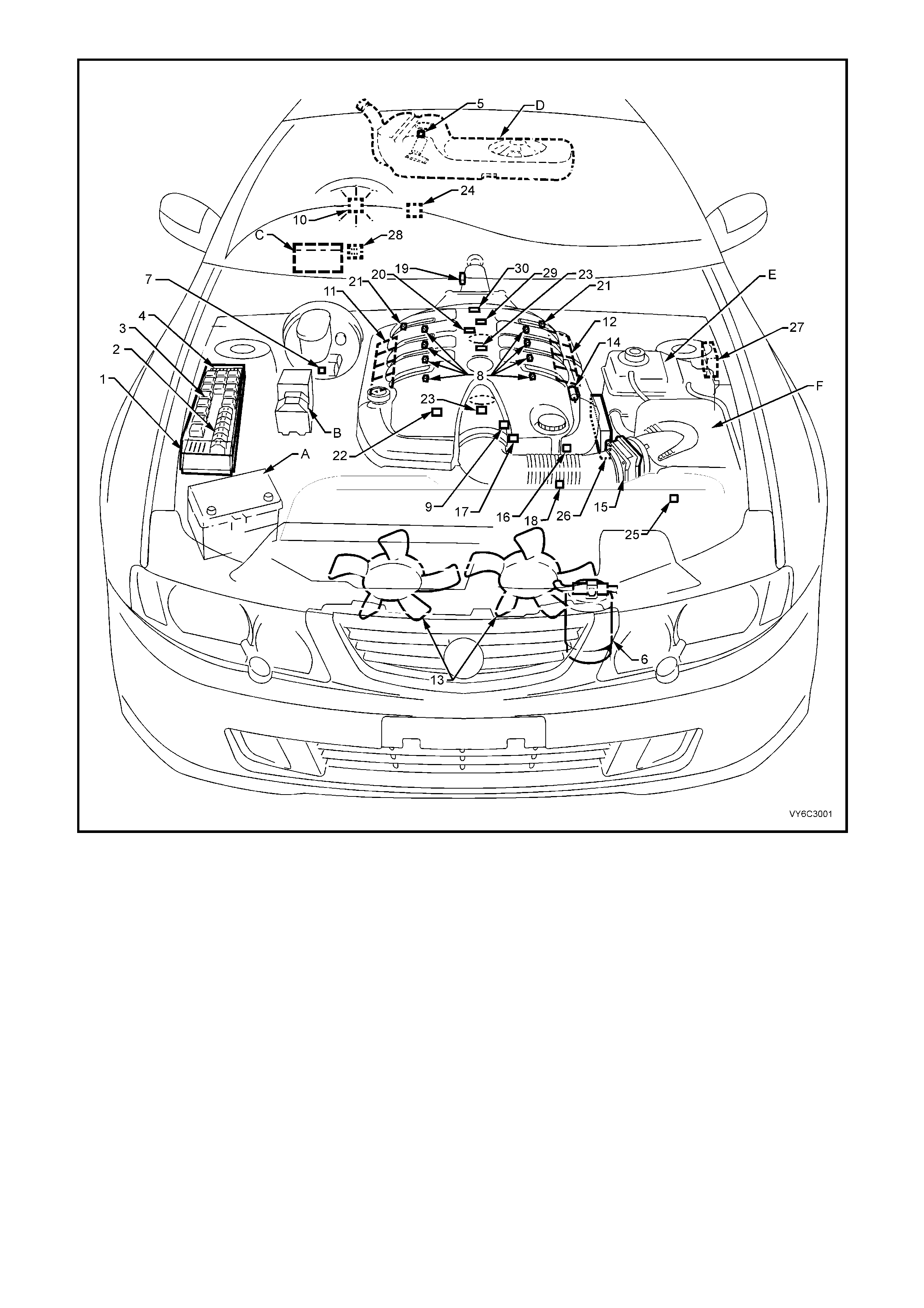

Figure 6C3-1-2 – Component Locations – GEN III V8 Engine RHD (LHD Similar)

Legend

1. Underhood Electrical Centre

2. Fusible Links

3. Relays – Mini & Micro

4. Underhood Fuses

5. Fuel Pressure Regulator (in Fuel Tank)

6. A/C Accumulator Tank

7. Brake Hydraulic Failure Switch

8. Fuel Injectors (8)

9. Idle Air Control (IAC) Valve

10. Check Powertrain Malfunction Indicator Lamp

(MIL)

11. Ignition Coil/Module Right Bank

12. Ignition Coil/Module Left Bank

13. Engine Cooling Fans (2)

14. Canister Purge Solenoid

15. Mass Air Flow (MAF) Sensor

16. Engine Coolant Temperature (ECT) Sensor

17. Throttle Position (TP) Sensor

18. Intake Air Temperature (IAT) Sensor

19. Vehicle Speed Sensor (VSS)

20. Camshaft Position (CMP) Sensor

21. Heated Oxygen (HO2S) Sensor (2)

22. Crankshaft Position (CKP) Sensor

23. Knock Sensors (KS) (2)

24. OCC In - Car Air Temperature Sensor

25. A/C Refrigerant Pressure Sensor

26. Powertrain Control Module (PCM)

27. Powertrain Interface Module (PIM) - Inside vehicle

behind left kick panel

28. Diagnostic Link Connector (DLC)

29. Oil Pressure Sensor

30. Manifold Absolute Pressure (MAP) Sensor

A Battery

B A.B.S./T.C.S. Module

C BCM

D Fuel Tank

E Surge Tank (With Low Coolant Level Switch)

F Air Cleaner

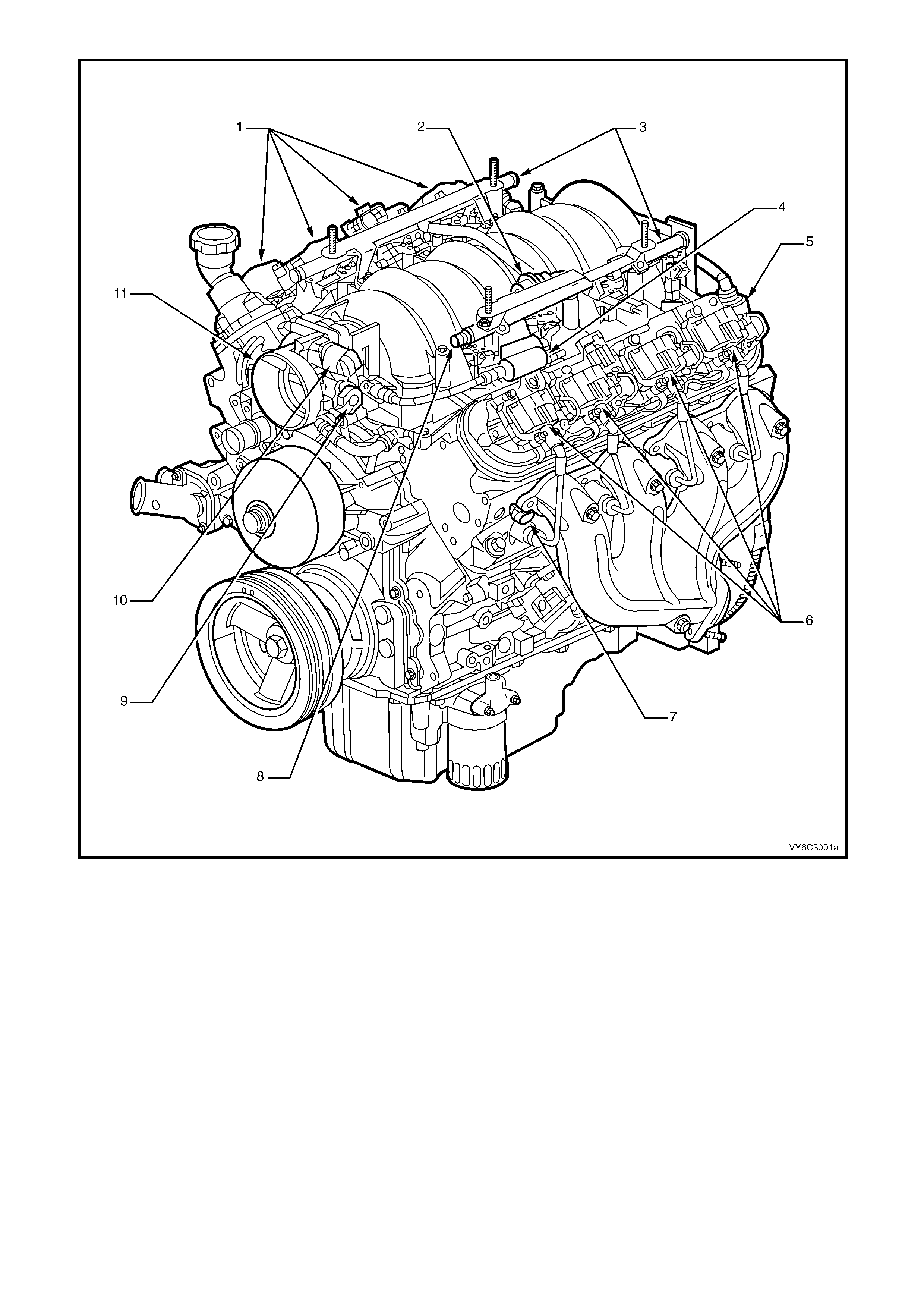

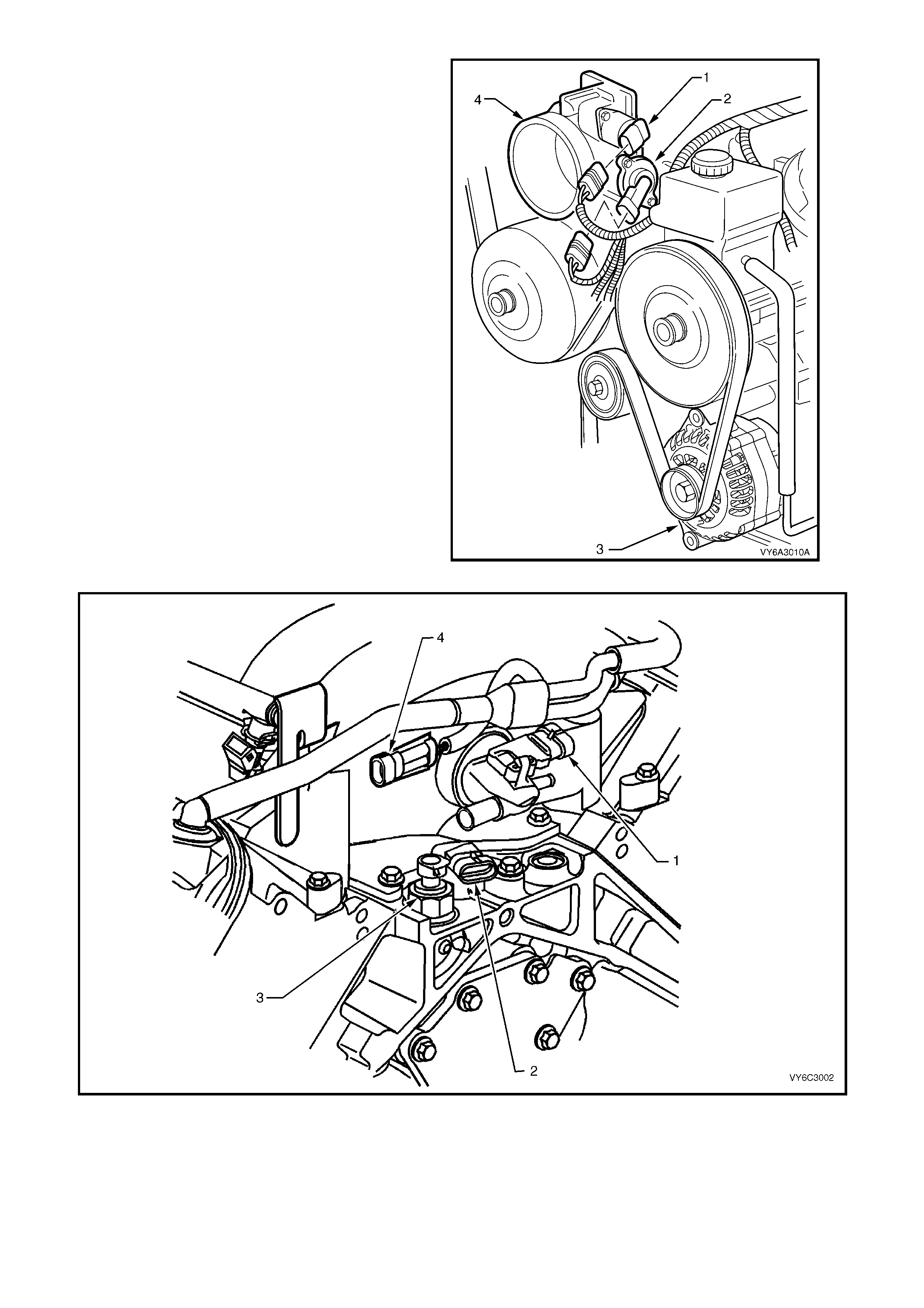

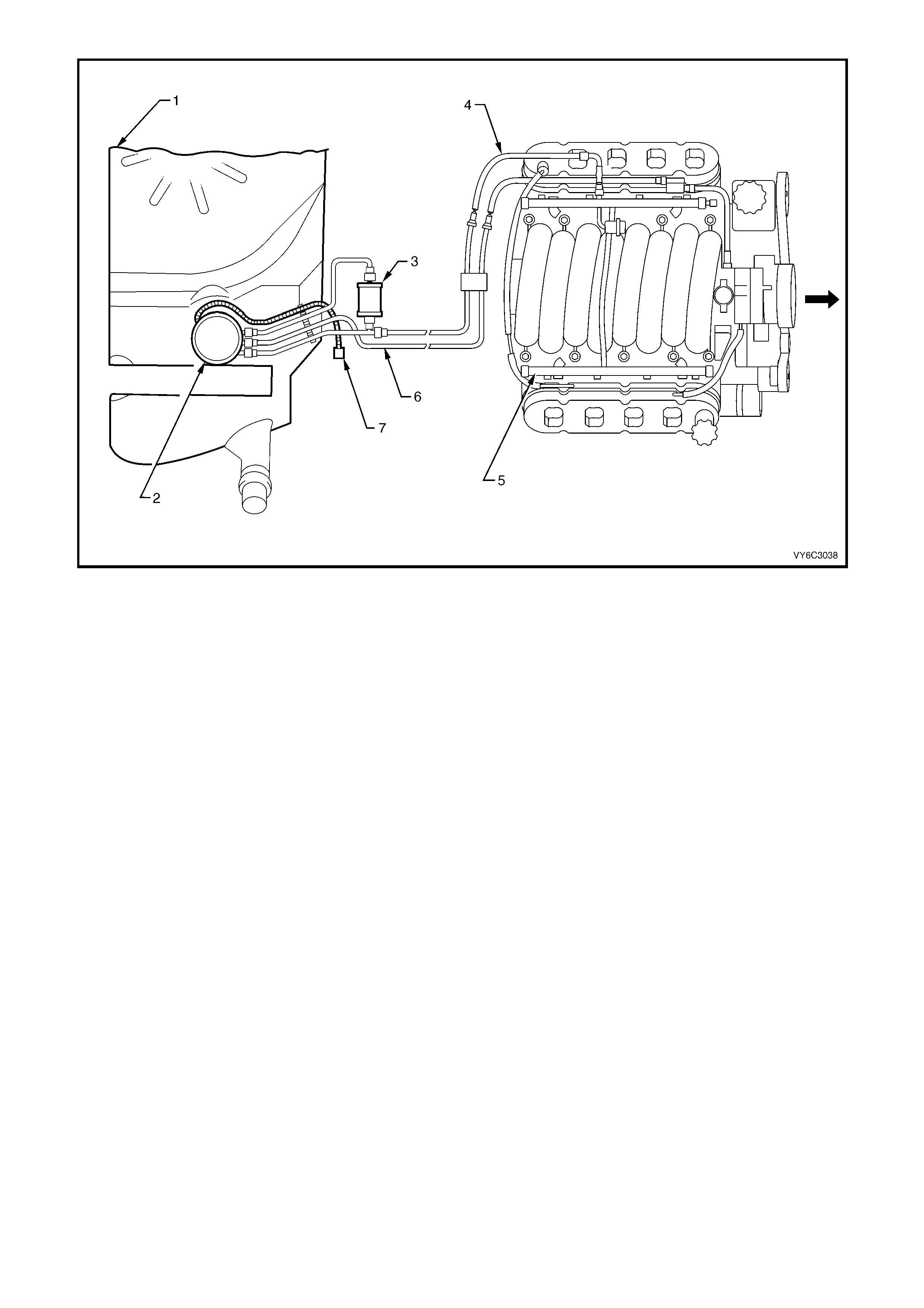

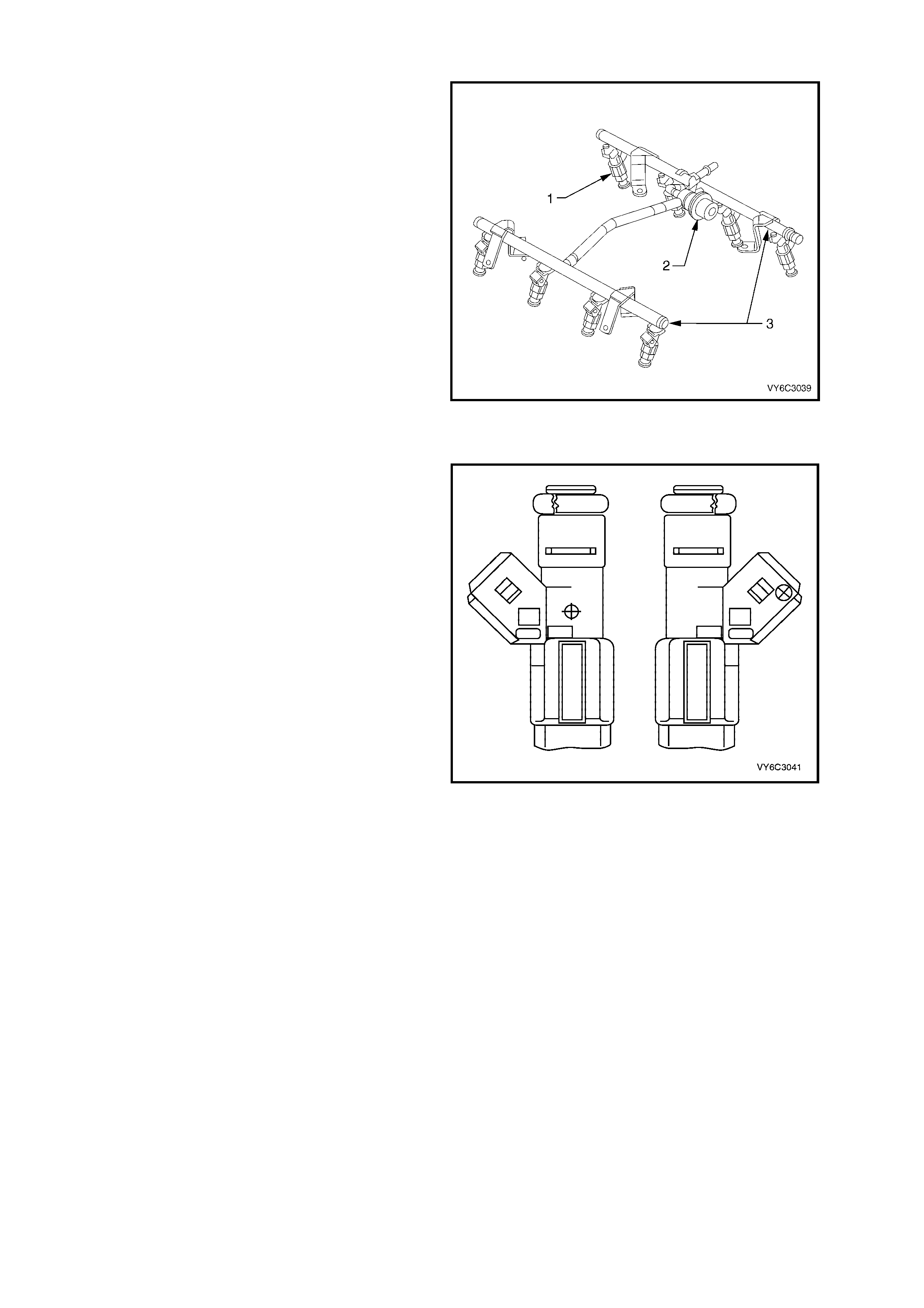

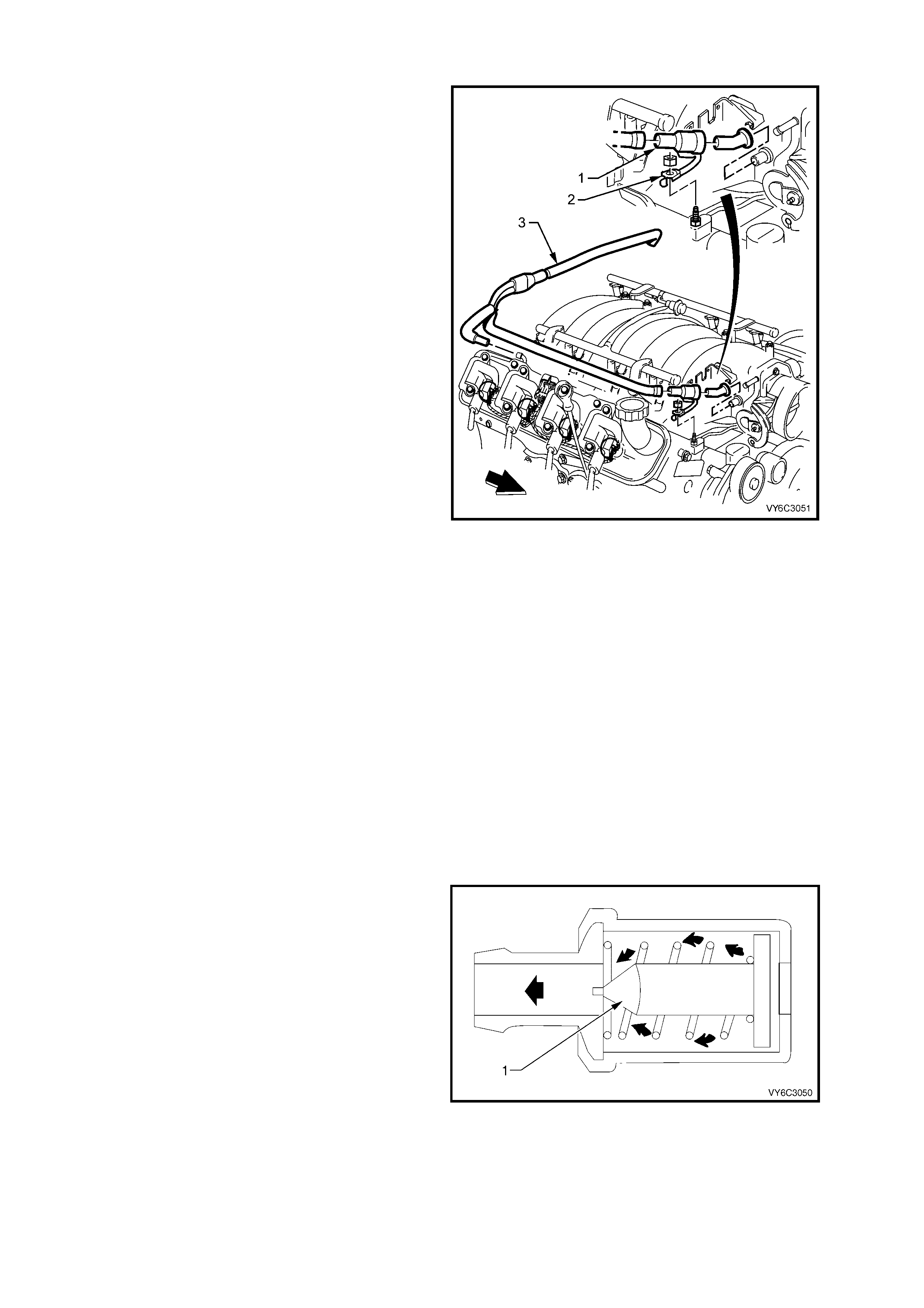

Figure 6C3-1-3 GEN III V8 Engine View Left-Hand Side

Legend

1. Right-Hand Ignition Coils/Modules

2. Fuel Pulse Dampener

3. Fuel Rail with Injectors

4. Evaporative Canister Purge Solenoid

5. Crankcase Vent

6. Left-Hand Ignition Coils/Modules

7. Engine Coolant Temperature (ECT) Sensor

8. Fuel Pressure Gauge Test Connector

9. Throttle Position (TP) Sensor

10. Idle Air Control (IAC) Valve

11. Throttle Body

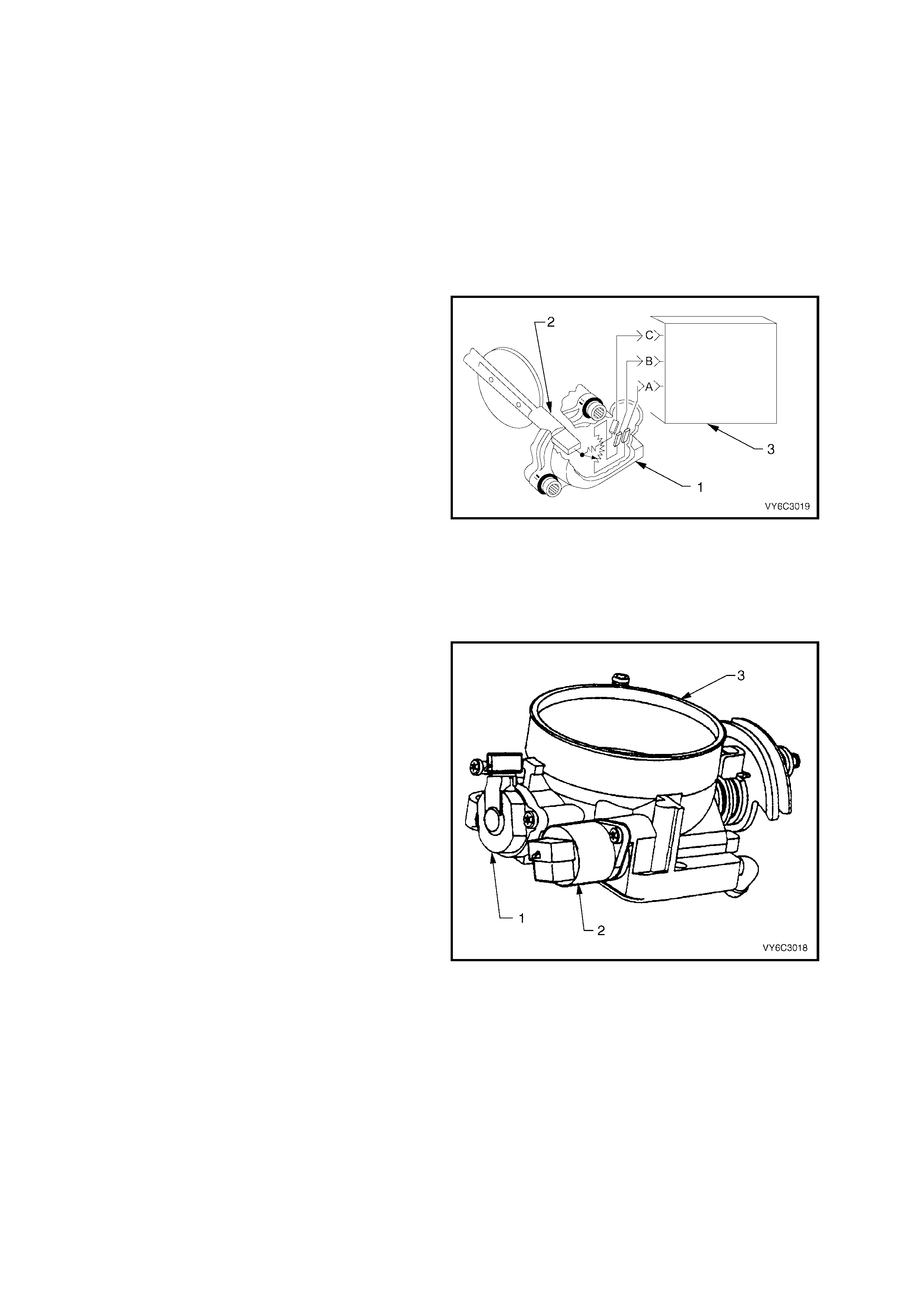

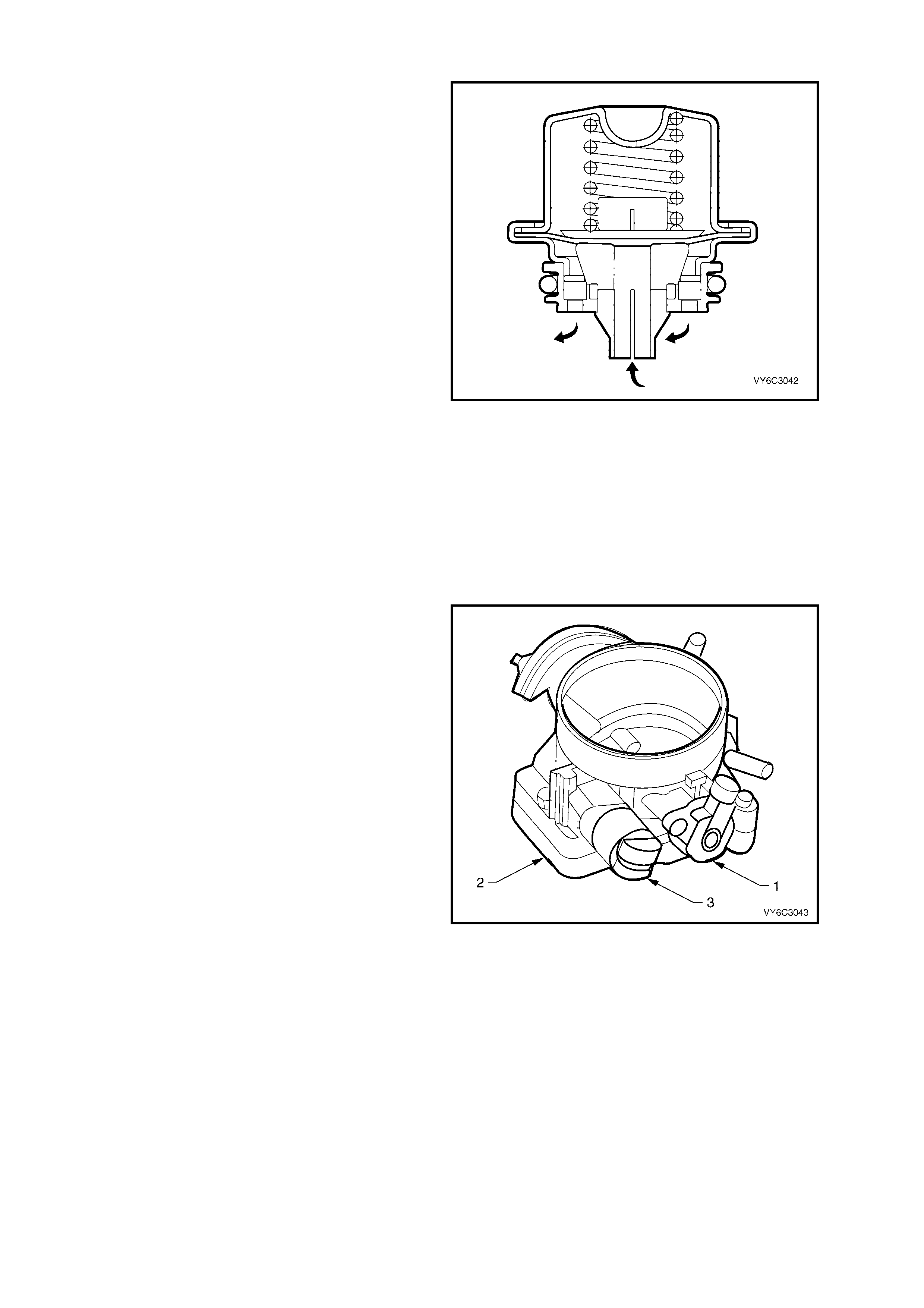

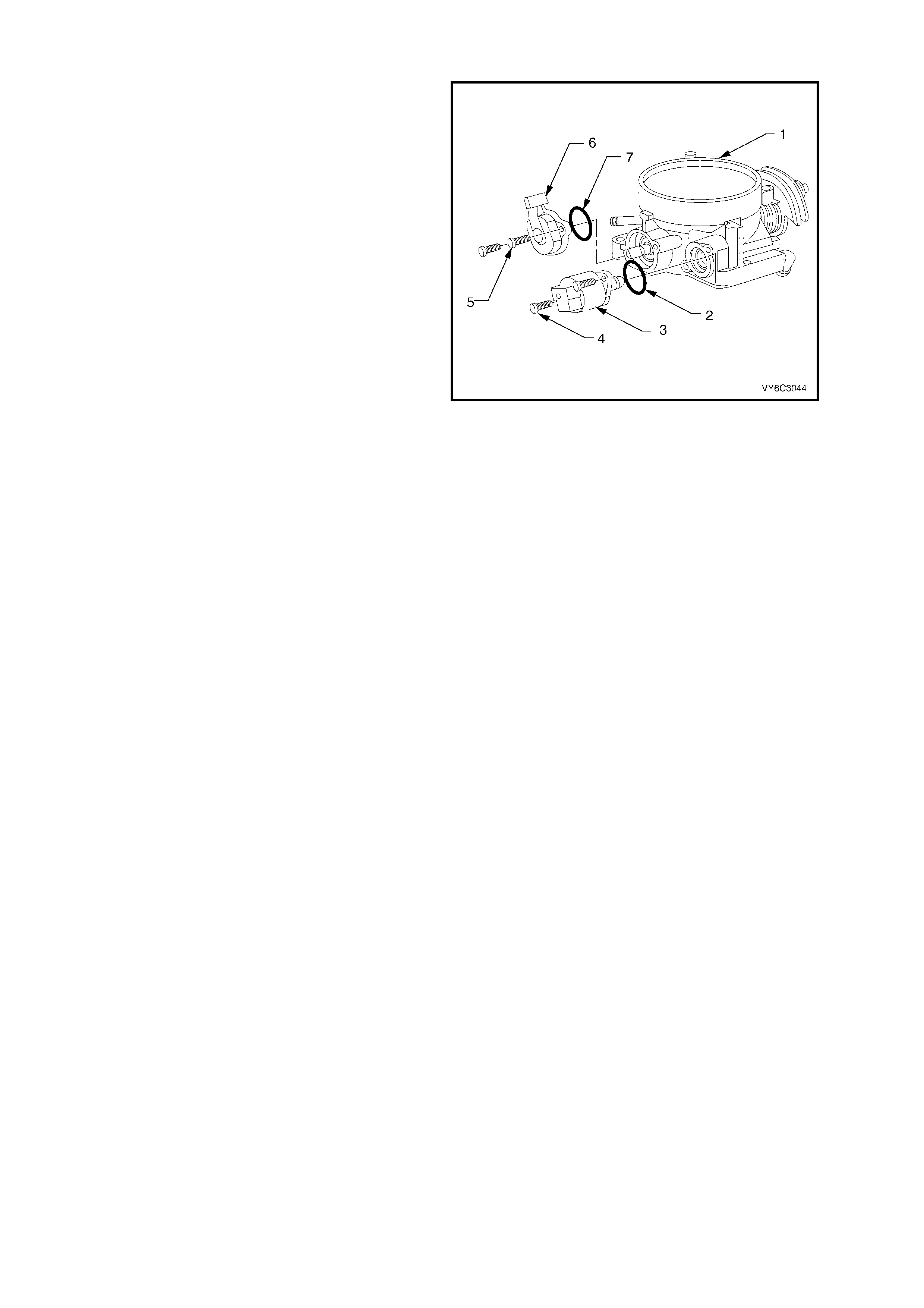

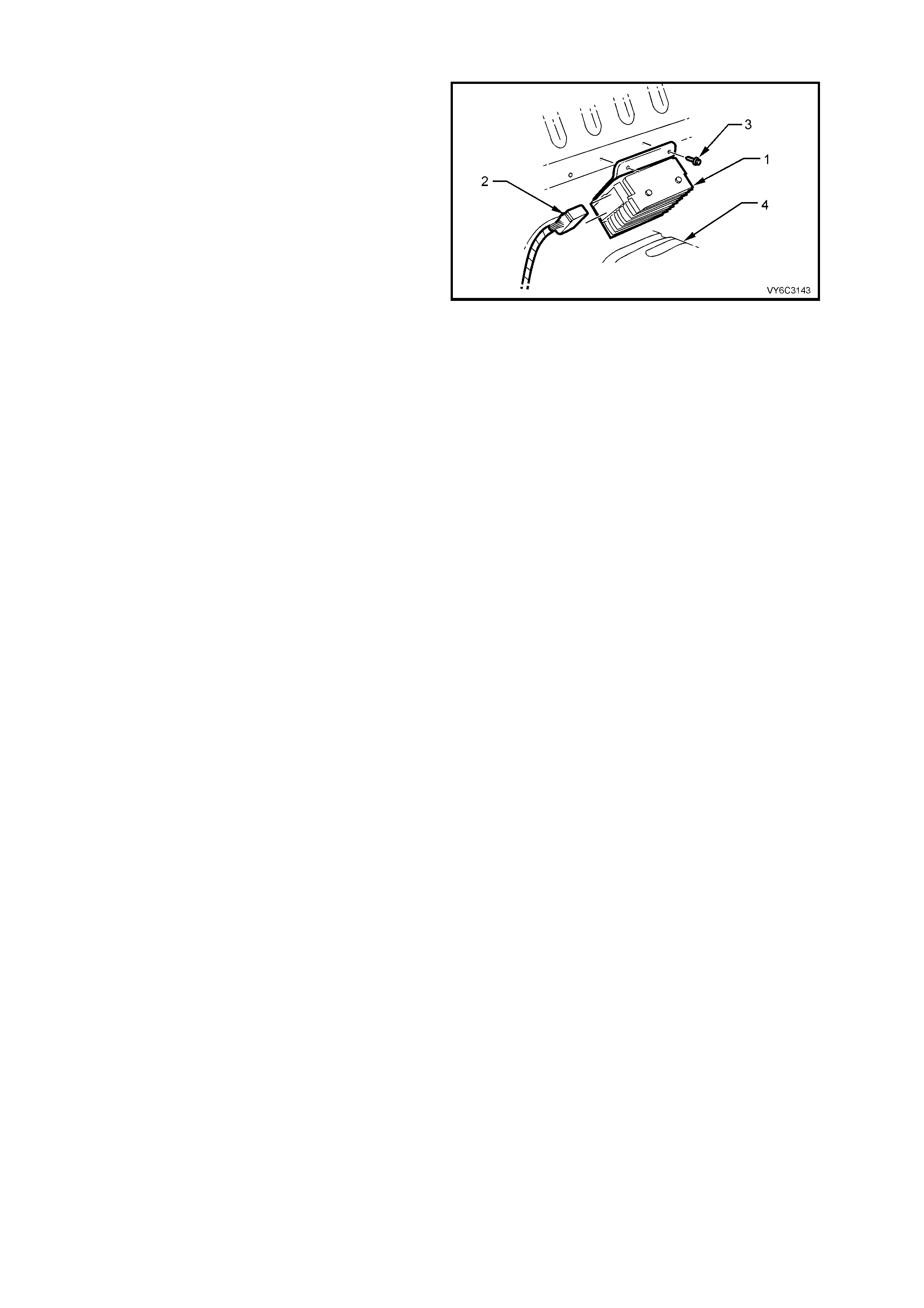

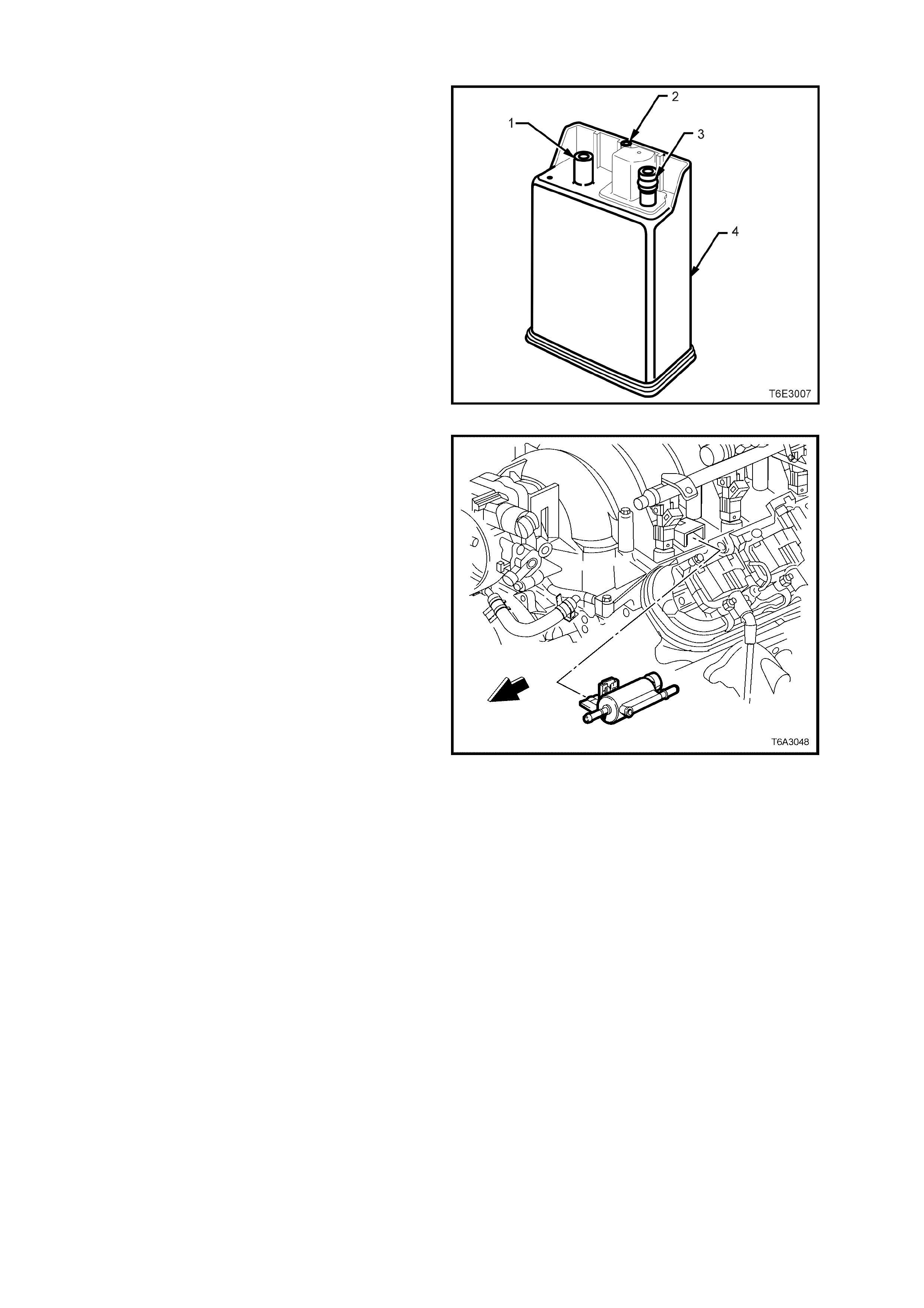

Legend

1. Idle Air Control (IAC) Valve

2. Throttle Position (TP) Sensor

3. Generator

4. Throttle Body

Figure 6C3-1-4 – GEN III V8 Engine Front View

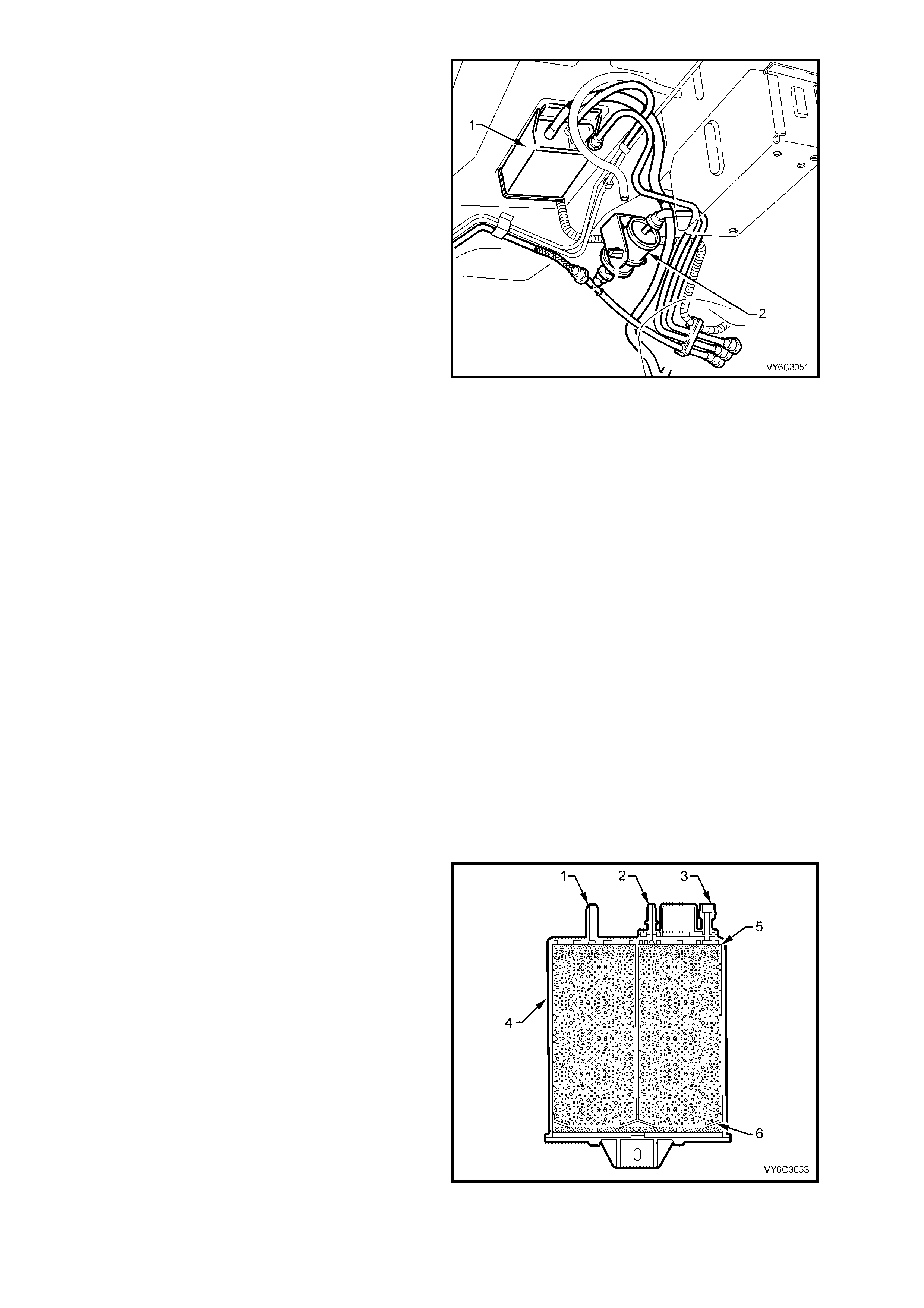

Figure 6C3-1-5 GEN III V8 Engine Rear View

Legend

1. Manifold Absolute Pressure (MAP) Sensor

2. Camshaft Position (CMP) Sensor 3. Oil Pressure Sensor

4. Connector to Knock Sensor Jumper Harness

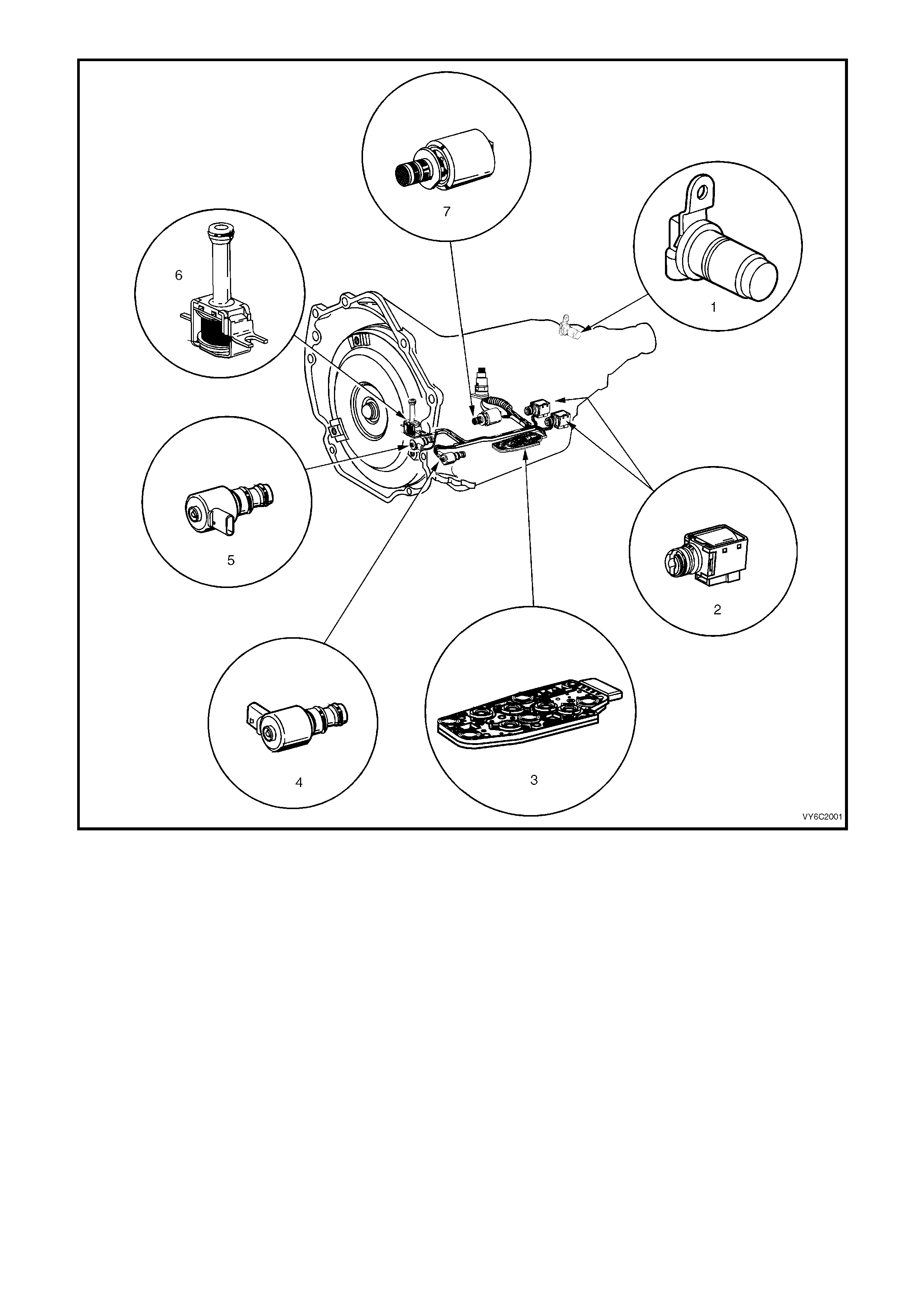

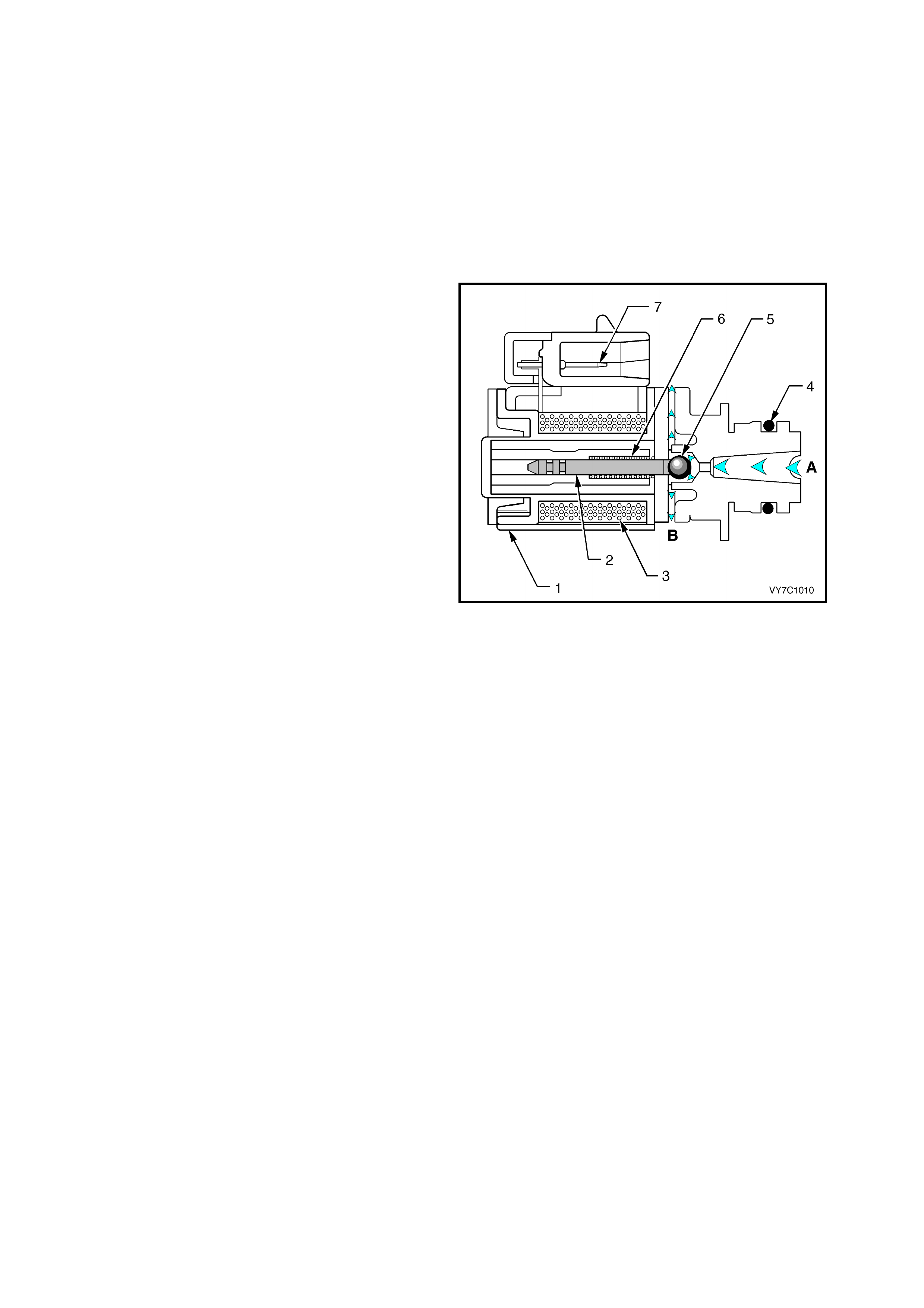

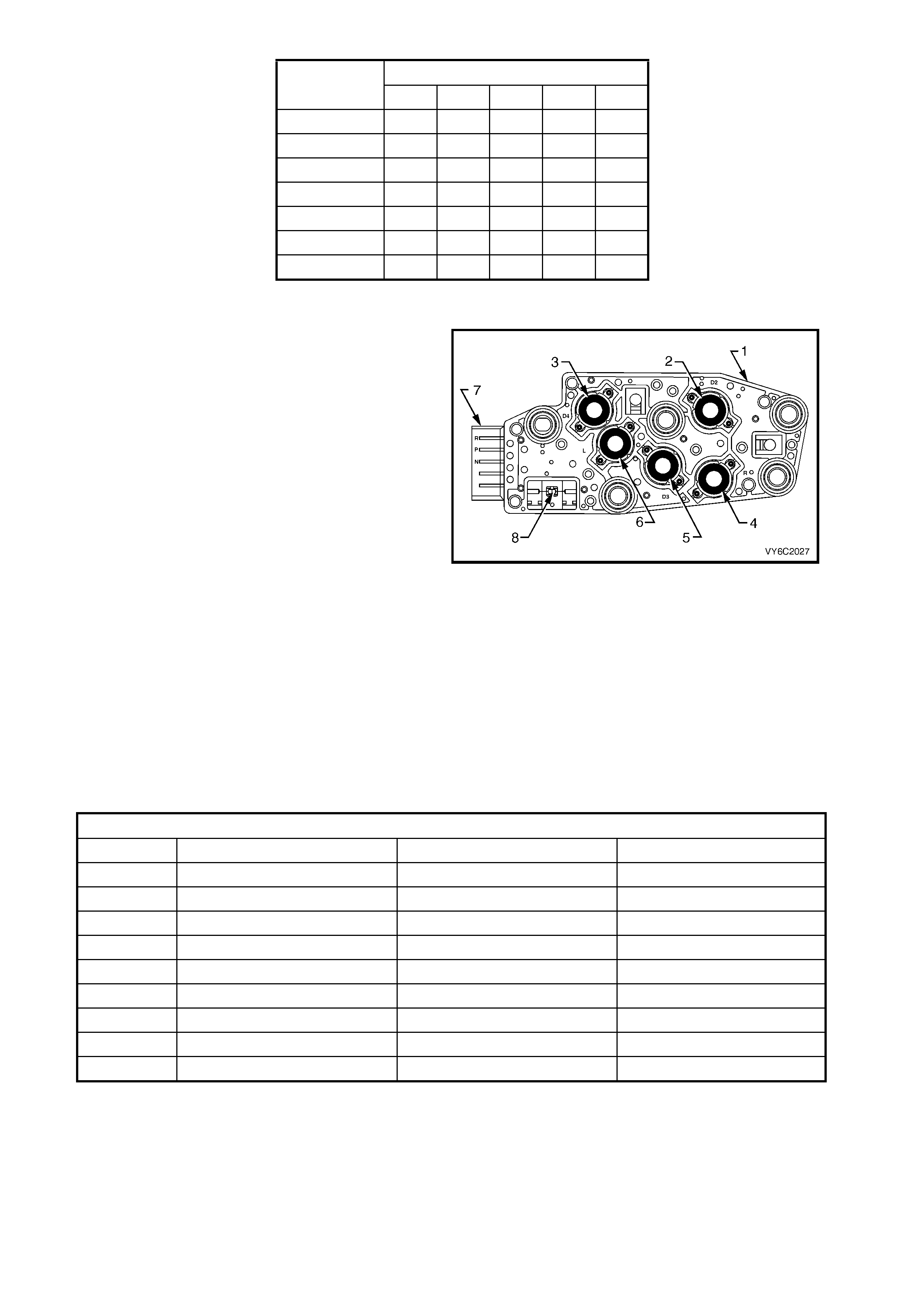

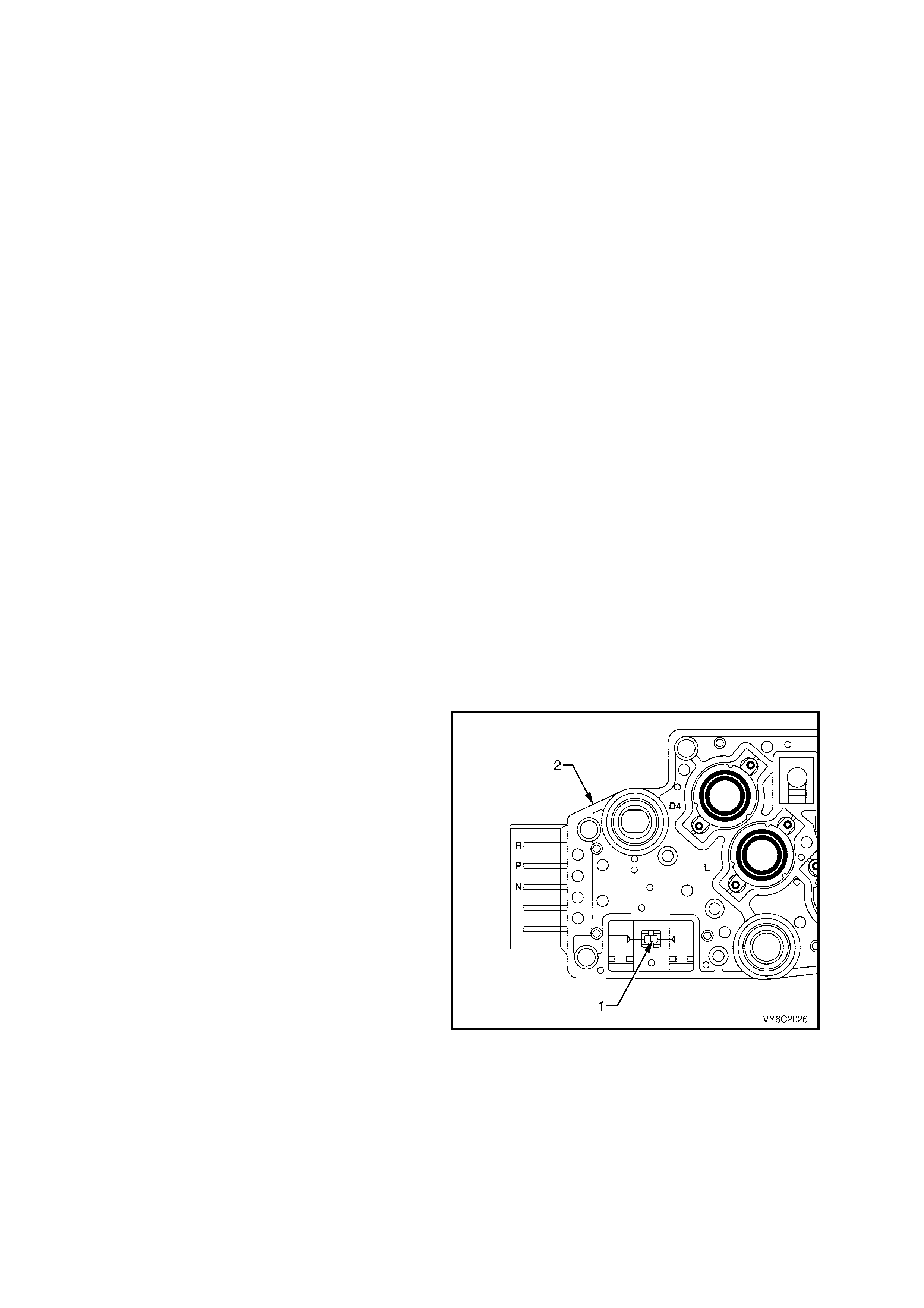

Figure 6C3-1-6 Automatic Transmission Internal Electronic Component Locations

Legend

1. Vehicle Speed Sensor

2. 1-2 Shift Solenoid ‘A’ and 2-3 Shift Solenoid ‘B’

3. Automatic Transmission Fluid Pressure (TFP) Manual

Valve Position Switch

4. 3-2 Downshift Control Solenoid

5. Torque Converter Clutch Pulse Width Modulation

(TCC PWM) Solenoid Valve

6. Torque Converter Clutch (TCC) Solenoid Valve

7. Pressure Control Solenoid (PCS) Valve

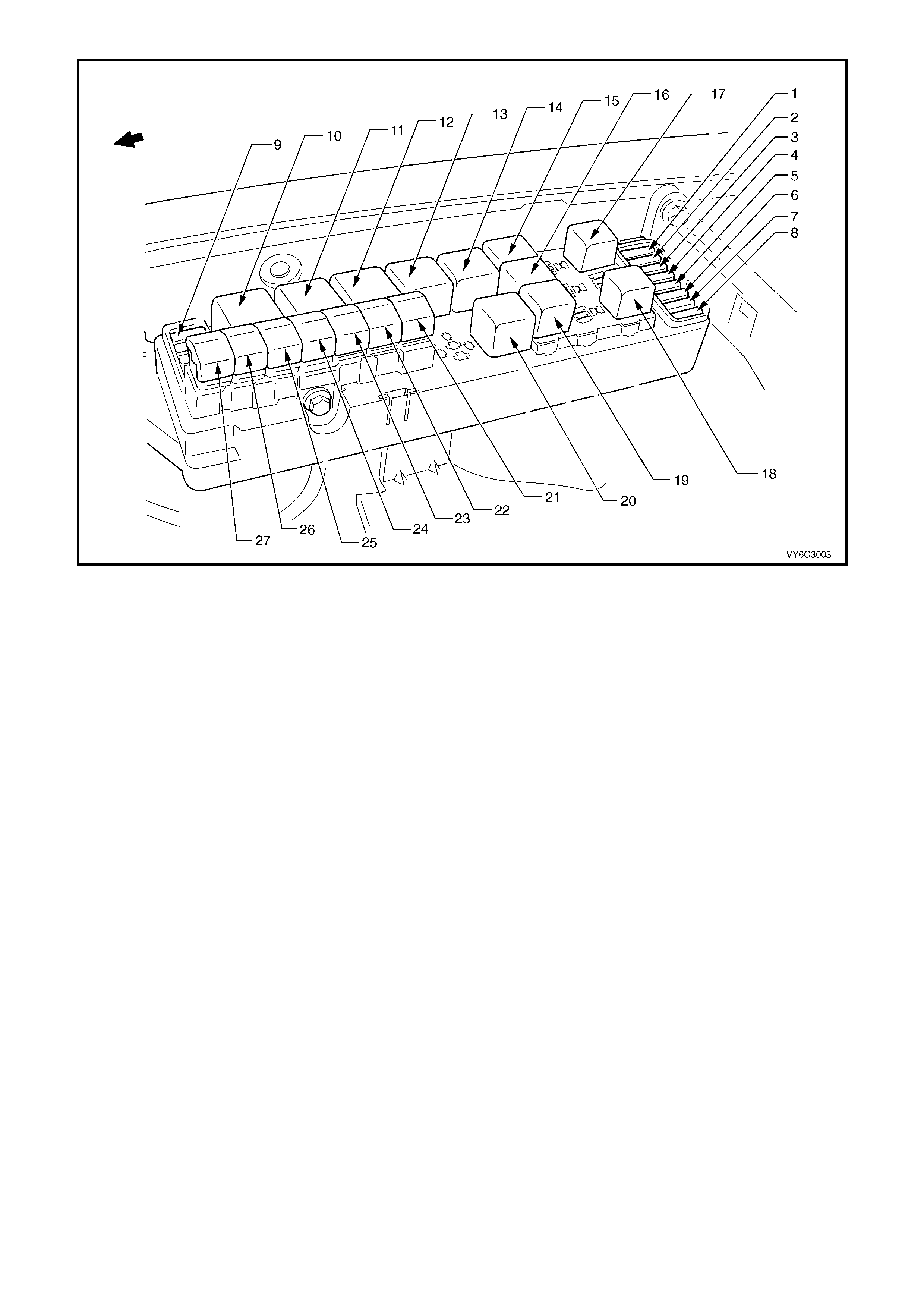

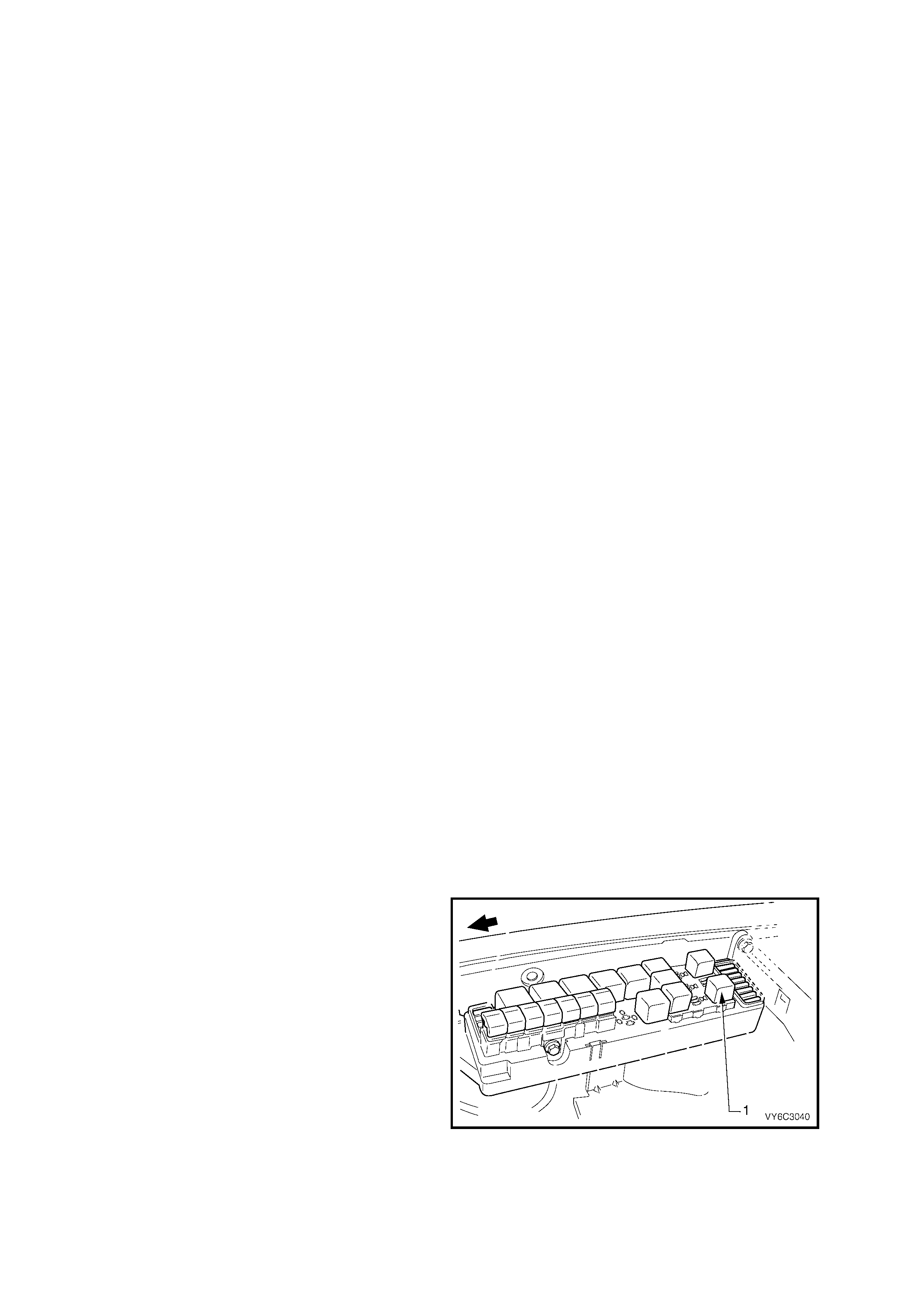

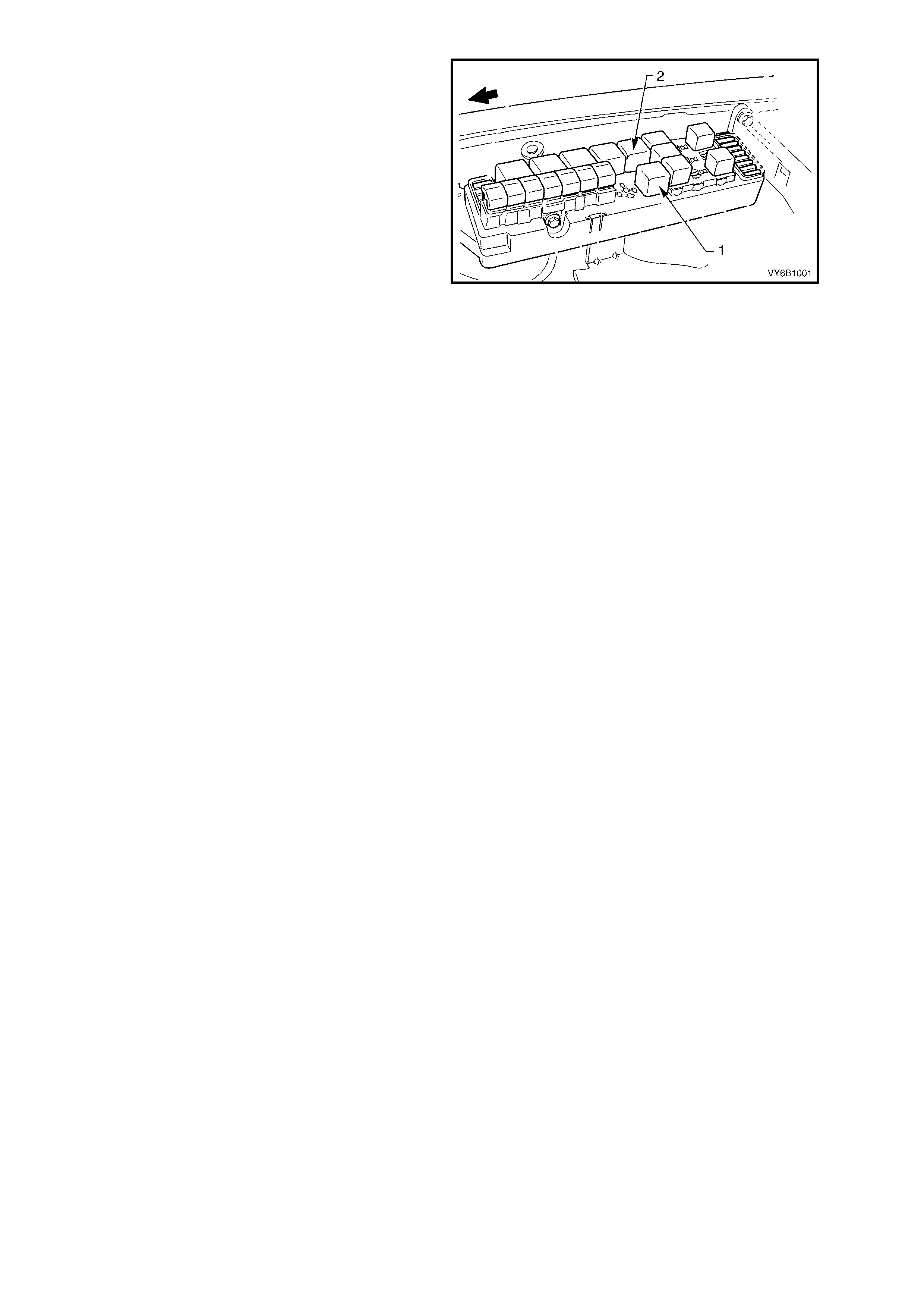

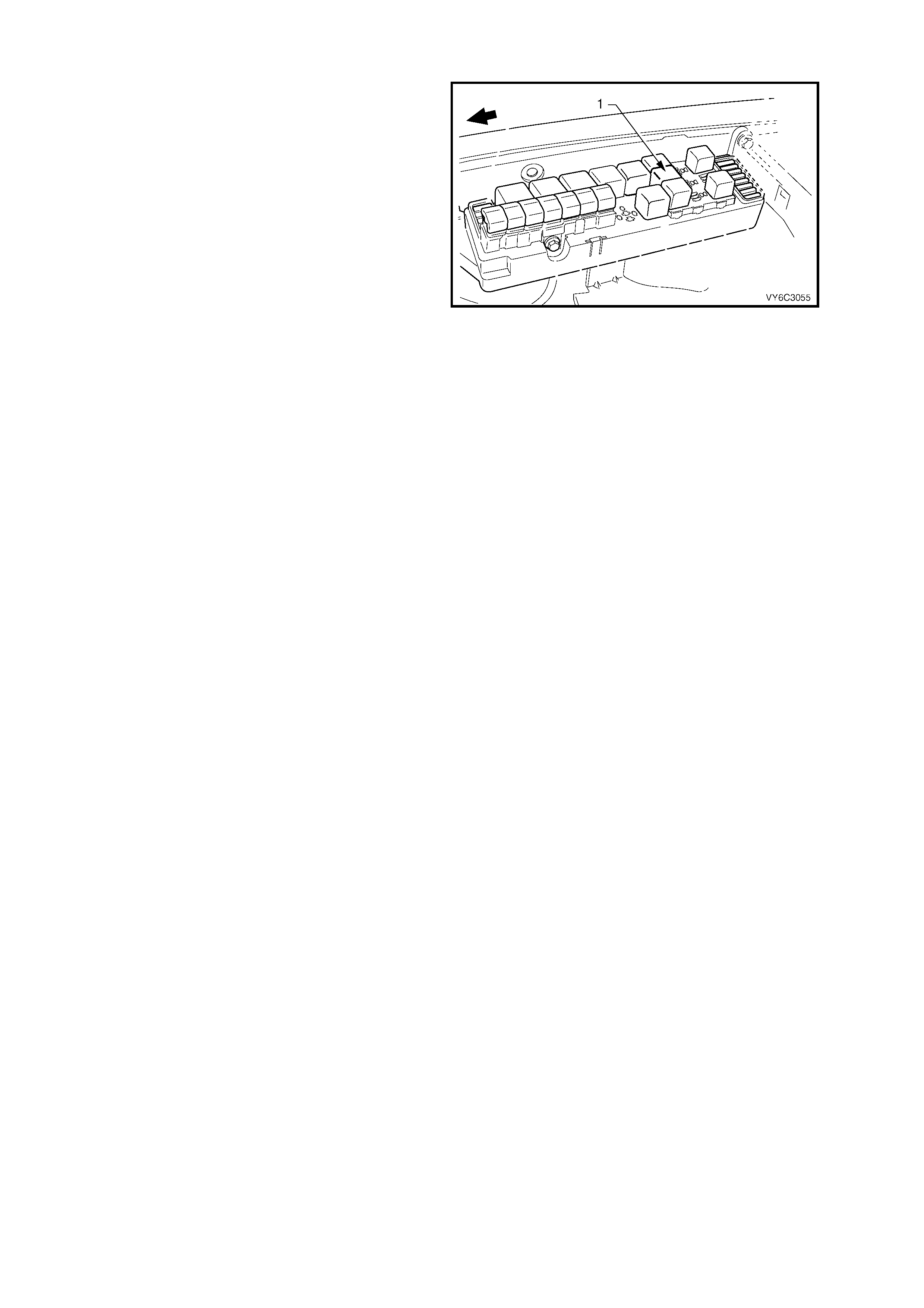

Figure 6C2-1-7 – Engine Compartment Fuse/Relay/Fusible Link Locations

Legend

Fuses

1. Fuel Pump Fuse – F28

2. Engine Control / BCM – F29

3. RH Headlamps – F30

4. LH Headlamps – F31

5. Automatic Transmission – F32

6. Engine Sensors – F33

7. Injectors / Ignition – F34

8. Injectors / Ignition – F35

9. Throttle Relaxer Module – F36

Relays

10. Start – R1

11. Blower Fan – R2

12. Headlamp (High Beam) – R3

13. Engine Control (EFI) – R4

14. Engine Cooling Fan Relay 2 – (High Speed) – R5

15. Horn – R8

16. A/C Compressor – R11

17. Fog Lamp – R10

18. Fuel Pump – R16

19. Headlamp (Low Beam) – R14

20. Engine Cooling Fan Relay 1 – (Low Speed) – R7

Fusible Links

21. Engine Cooling Fan (Large) – F107 (30A)

22. Blower Fan – F106 (60A)

23. Main – F105 (60A)

24. Engine – F104 (60A)

25. ABS – F103 (60A)

26. Lighting – F102 (60A)

27. Engine Cooling Fan (Small) – F101 (30A)

1.1 POWERTRAIN CONTROL MODULE (PCM)

The Powertr ain Control Module ( PCM), is located in

the engine compartment. The PCM is the control

centre of the vehicle. It controls the following:

• Fuel metering system.

• Transmission shifting.

• Ignition timing.

• Knock control.

• Evaporative Emission Control System (EECS)

Purge.

• Cooling fans.

• A/C system.

• Malfunction Indicator Lamp (MIL)

• Theft Deterrent (Injector control).

The PCM constantly monitors the information from

various sensors, and controls the systems that

affect vehicle performance. The PCM also

perfor ms a diagnos tic function of the system . It can

recognise operational problems. The PCM also

alerts the driver through the Malfunction Indicator

Lamp (MIL) via the Class II serial data

communication line to the Powertrain Interface

Module (PIM). This is where the PIM converts the

Class II serial data communication to Universal

Asynchronous Receiving/Transmitting (UART).

This UART serial data communication is then sent

from the PIM to the Instrument panel cluster, via

the Serial data Bus. When the PCM detects a

malfunction, it stores a Diagnostic Trouble Code

(DTC).

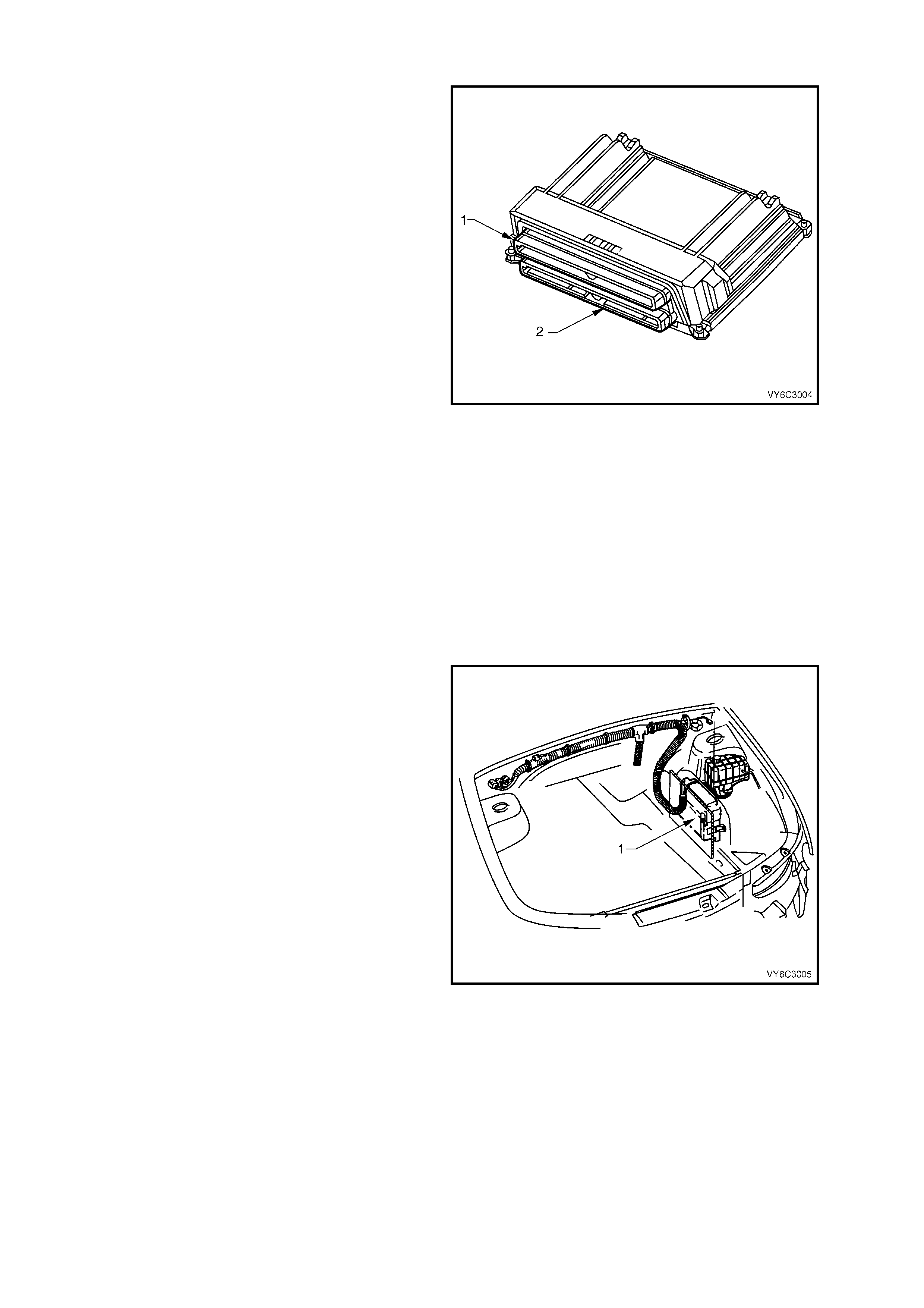

Figure 6C3-1-8 – Powertrain Control Module

Legend:

1. Connector A84 X1 – BLUE

2. Connector A84 X2 – RED

A stored DTC will identify the problem areas. This

will assist the Technician in making repairs.

The PCM supplies either 5.0 or 12.0 volts to power

various sensors or switches. This is done through

resistanc e in the PCM. The resistanc e is so high in

value that a test lamp will not illuminate when

connected to the circuit. In some cases, even an

ordinary shop voltmeter will not give an accurate

reading because its resistance is too low.

Therefore, a digital multimeter (DMM) (J 39200)

with at least 10 megohms input impedance is

required to ensure accurate voltage readings.

The PCM controls output circuits such as the

injector s, IAC, cooling fan relays, etc. by controlling

the ground or circuits through transistors or a

device called a “Driver” in the PCM. The two

exceptions to this are the fuel pump relay control

circuit and the automatic transmission pressure

control solenoid (PCS). The fuel pump relay is the

only PCM c ontrolled circ uit where the PCM controls

the +12 volts sent to the coil of the relay. The

ground side of the f uel pump relay coil is connected

to engine ground. The PCM supplies current to the

PCS and m onitors how muc h current retur ns to the

PCM on a separate terminal. The PCM also

receives and transmits serial data via the

Powertrain Interface Module (PIM) and the serial

data bus.

Figure 6C3-1-9 – Powertrain Control Module

Legend:

1. Powertrain Control Module (PCM) Location

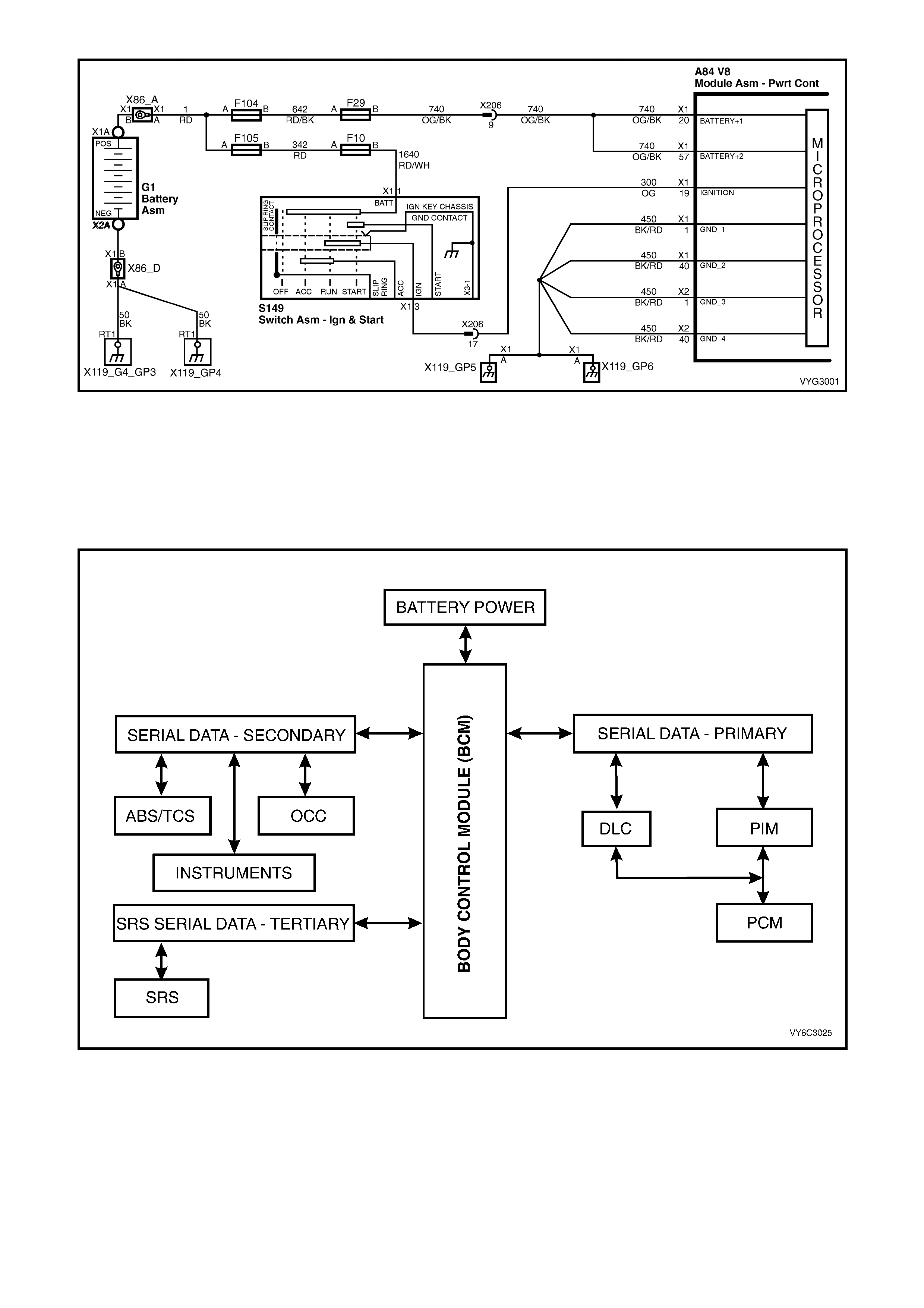

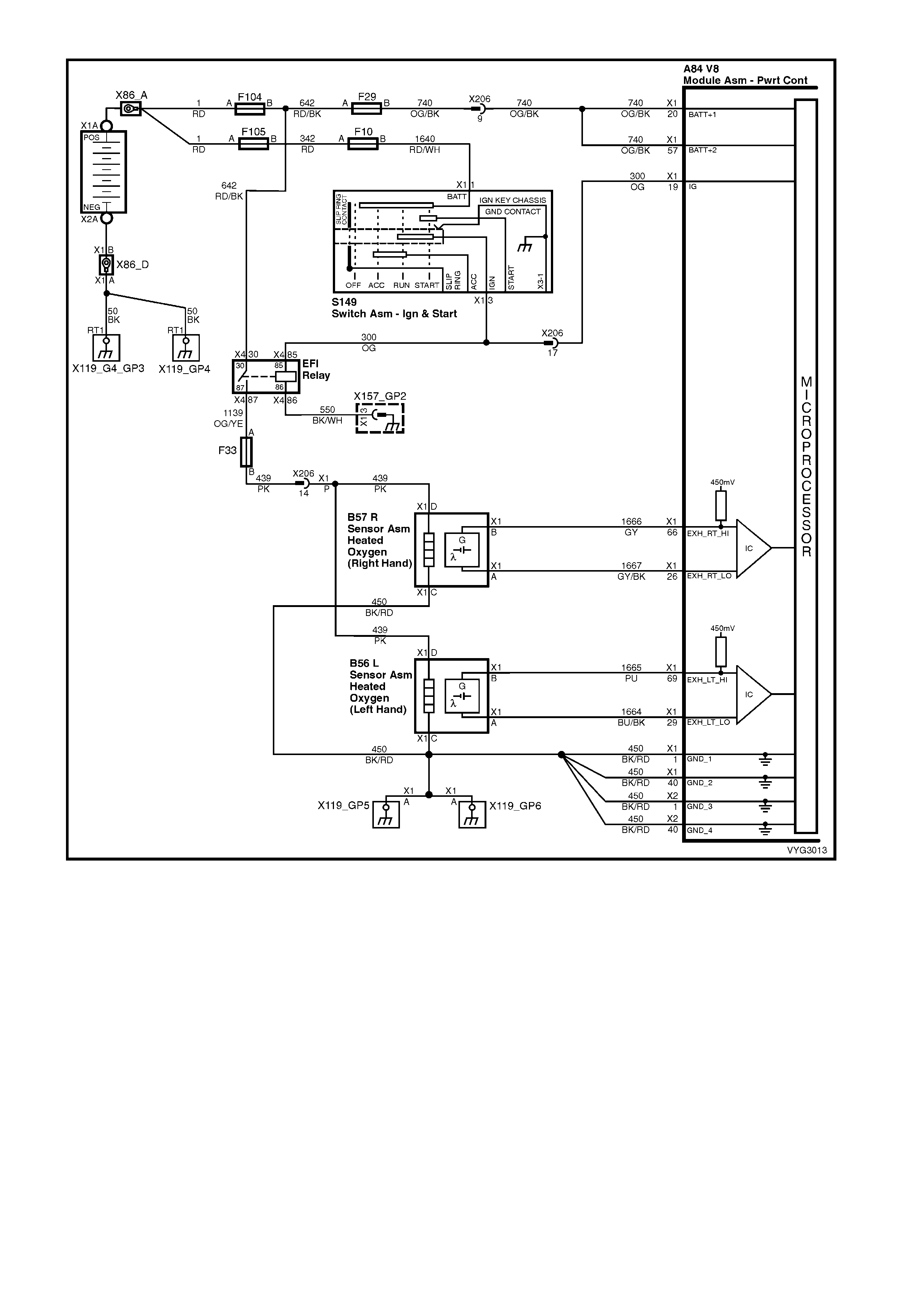

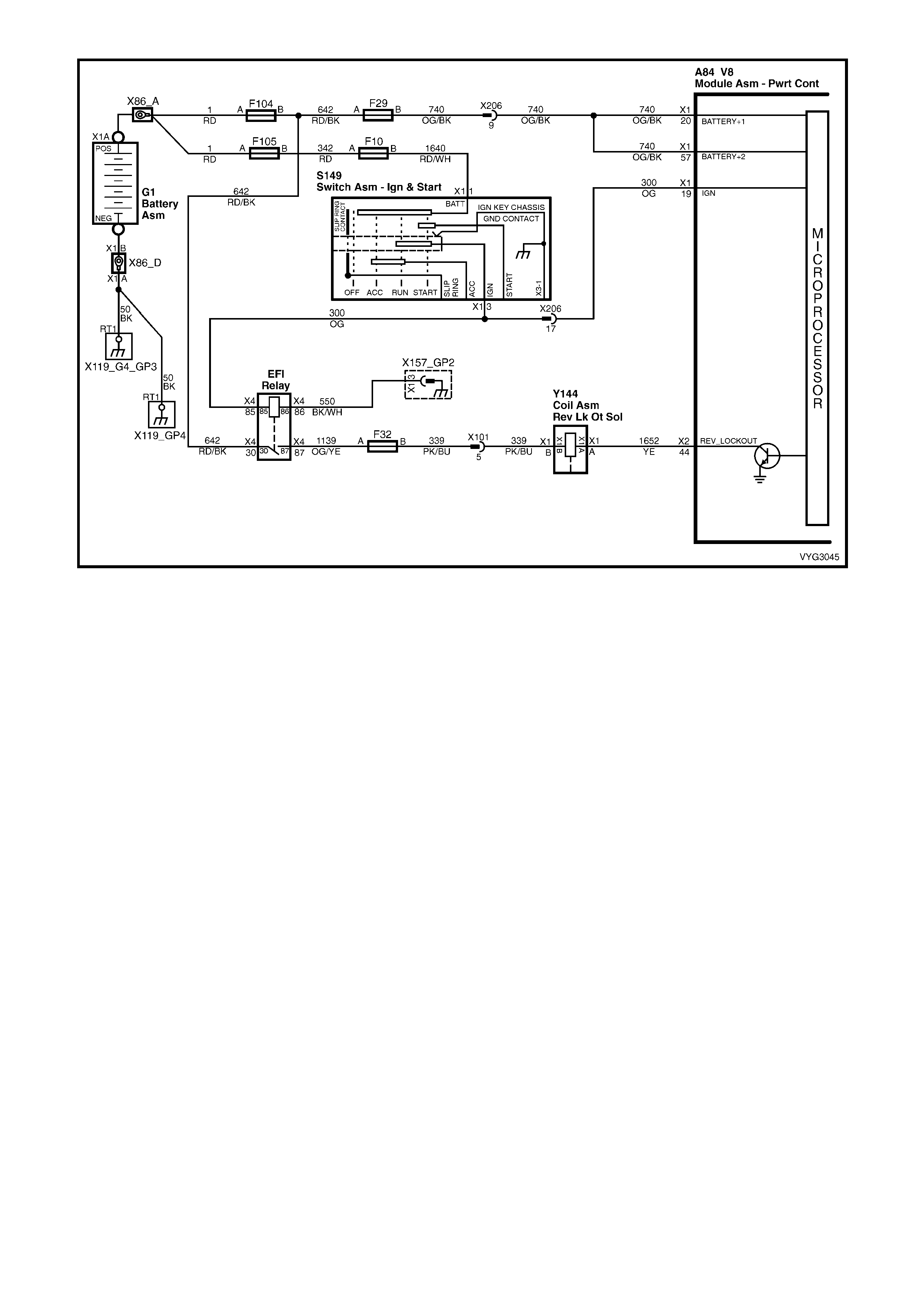

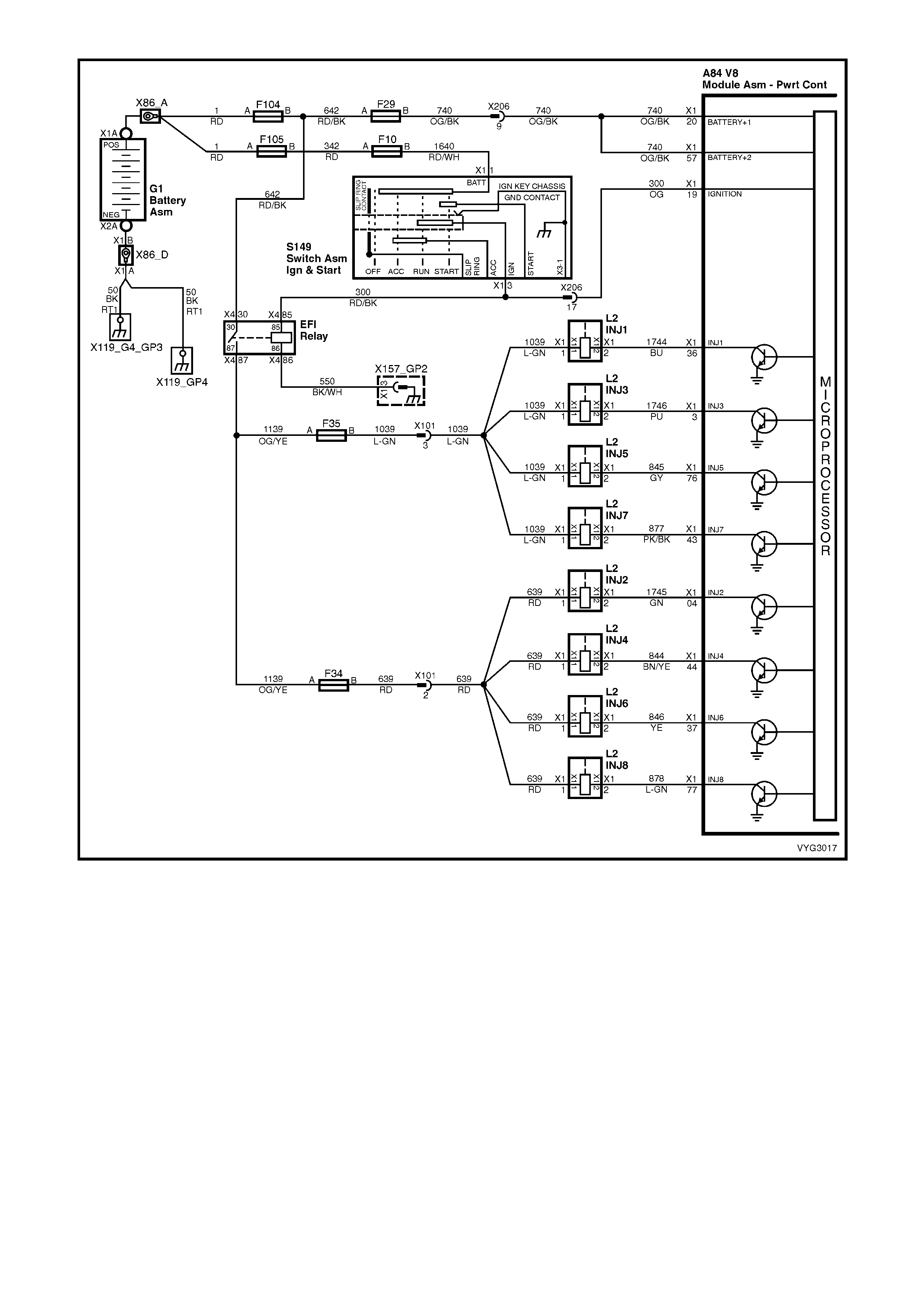

PCM POWER SUPPLIES

Battery voltage is applied to PCM terminals X 1-20 and X 1- 57 at all times via f us e F 29 and ignition voltage is applied

to PCM terminal X1-19 via fuse F10 whenever the ignition switch is in the ON or START position. The PCM is

grounded from terminals X1-01, X1-40, X2-01, and X2-40 to ground points X119 at the Rear Left and Front Right

sides of the engine block.

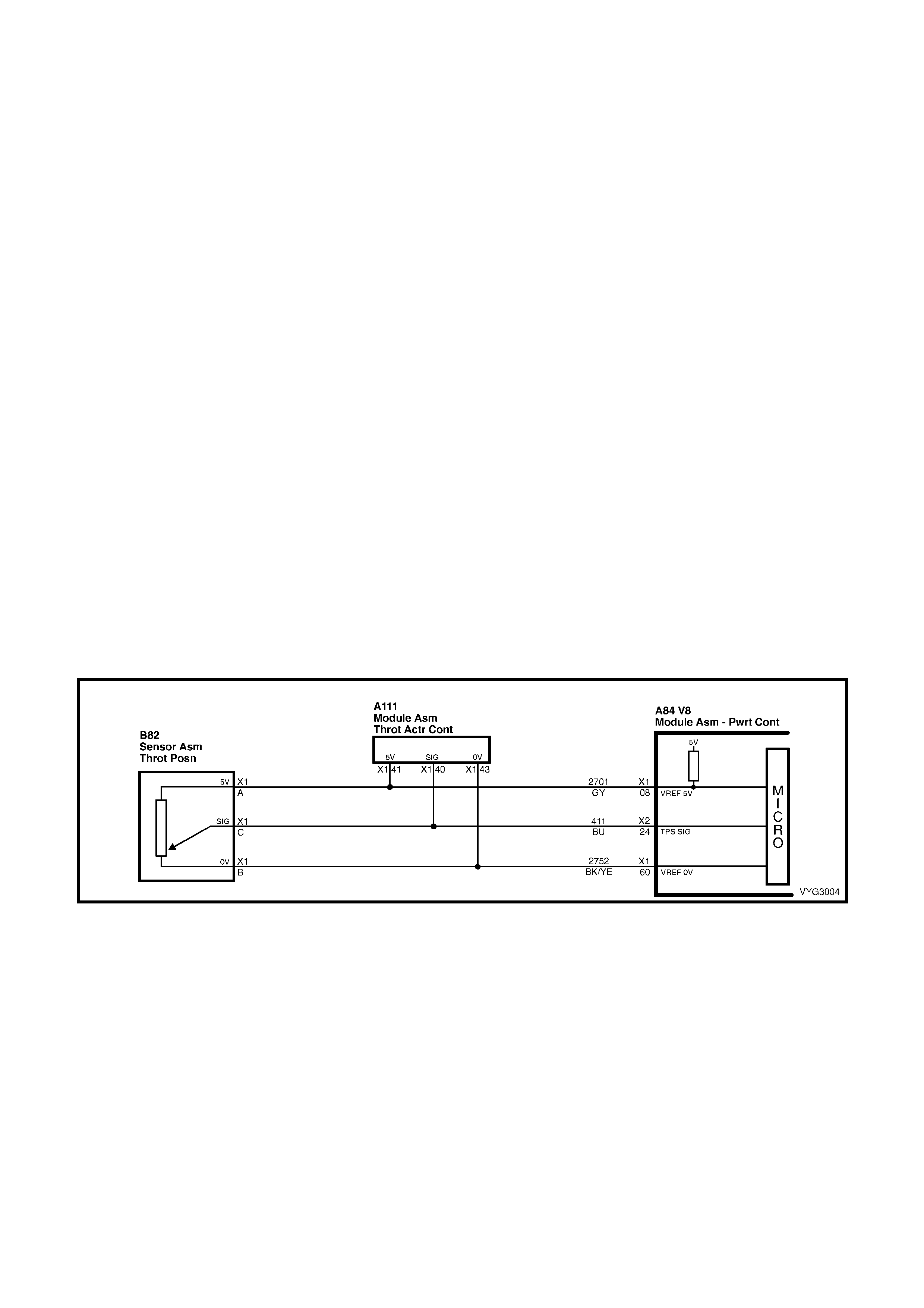

PCM FIVE VOLT REFERENCE CIRCUITS

The PCM has two, five volt reference circuits. The five volt reference circuit number one supplies five volts to the

following sensors:

• The Throttle Position (TP) Sensor

• The Manifold Absolute Pressure (MAP) Sensor

• Oil Pressure Sensor

The five volt reference circuit number two, supplies five volts to the following sensor:

• The A/C Pressure Sensor

The PCM monitors the voltage on the 5.0 volt reference circuit. The following DTCs will set if the voltage is out of

range.

A failure in a five volt reference circuit will set either DTC P1635 or P1639.

DTC P1635 FIVE VOLT REFERENCE #1 CIRCUIT

Conditions for running DTC P1635

• The ignition is on.

Conditions for setting DTC P1635

• The five volt reference #1 circuit is out of range.

• All of the above conditions are present for greater than 2 seconds.

Action taken when DTC P1635 Sets

• The PCM activates the Malfunction Indicator Lamp (MIL) when the diagnostic runs and fails.

• The PCM records the operating conditions at the time the diagnostic fails. The PCM stores this information in

the Freeze Frame/Failure Records.

Conditions for clearing the Malfunction Indicator Lamp (MIL) and DTC P1635

• The PCM deactivates the Malfunction Indicator Lamp (MIL) after one ignition cycle that the diagnostic runs and

does not fail.

• A last test failed (Current DTC) clears when the diagnostic runs and does not fail.

DTC P1639 FIVE VOLT REFERENCE #2 CIRCUIT

Conditions for running DTC P1639

• The ignition is on.

Conditions for setting DTC P1639

• The five volt reference #2 circuit is out of range.

• All of the above conditions are present for greater than 2 seconds.

Action taken when DTC P1639 Sets

• The PCM activates the Malfunction Indicator Lamp (MIL) when the diagnostic runs and fails.

• The PCM records the operating conditions at the time the diagnostic fails. The PCM stores this information in

the Freeze Frame/Failure Records.

Conditions for clearing the Malfunction Indicator Lamp (MIL) and DTC P1639

• The PCM deactivates the Malfunction Indicator Lamp (MIL) after one ignition cycle that the diagnostic runs and

does not fail.

• A last test failed (Current DTC) clears when the diagnostic runs and does not fail.

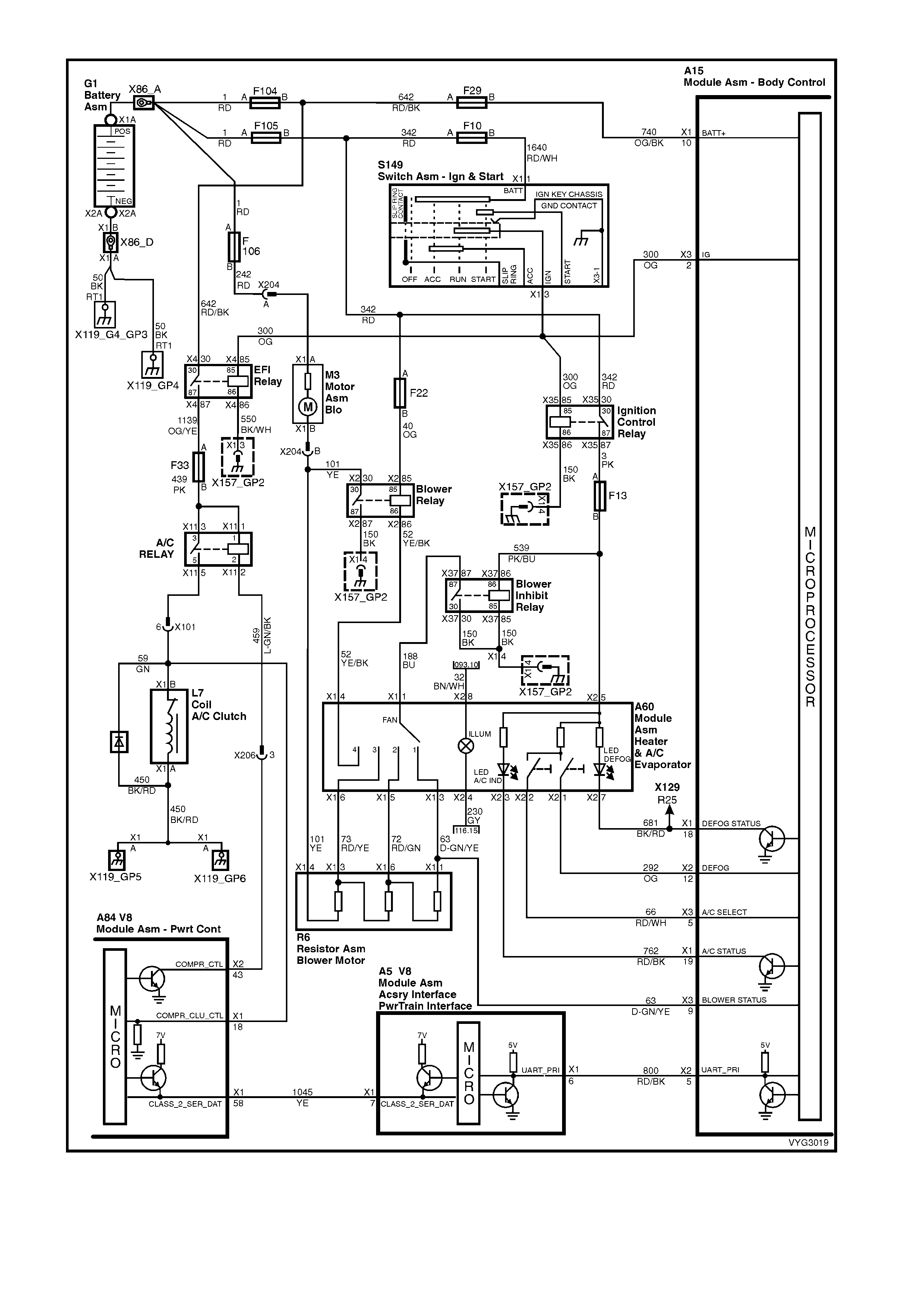

Figure 6C3-1-10 – PCM Battery, Ignition and Ground Circuits

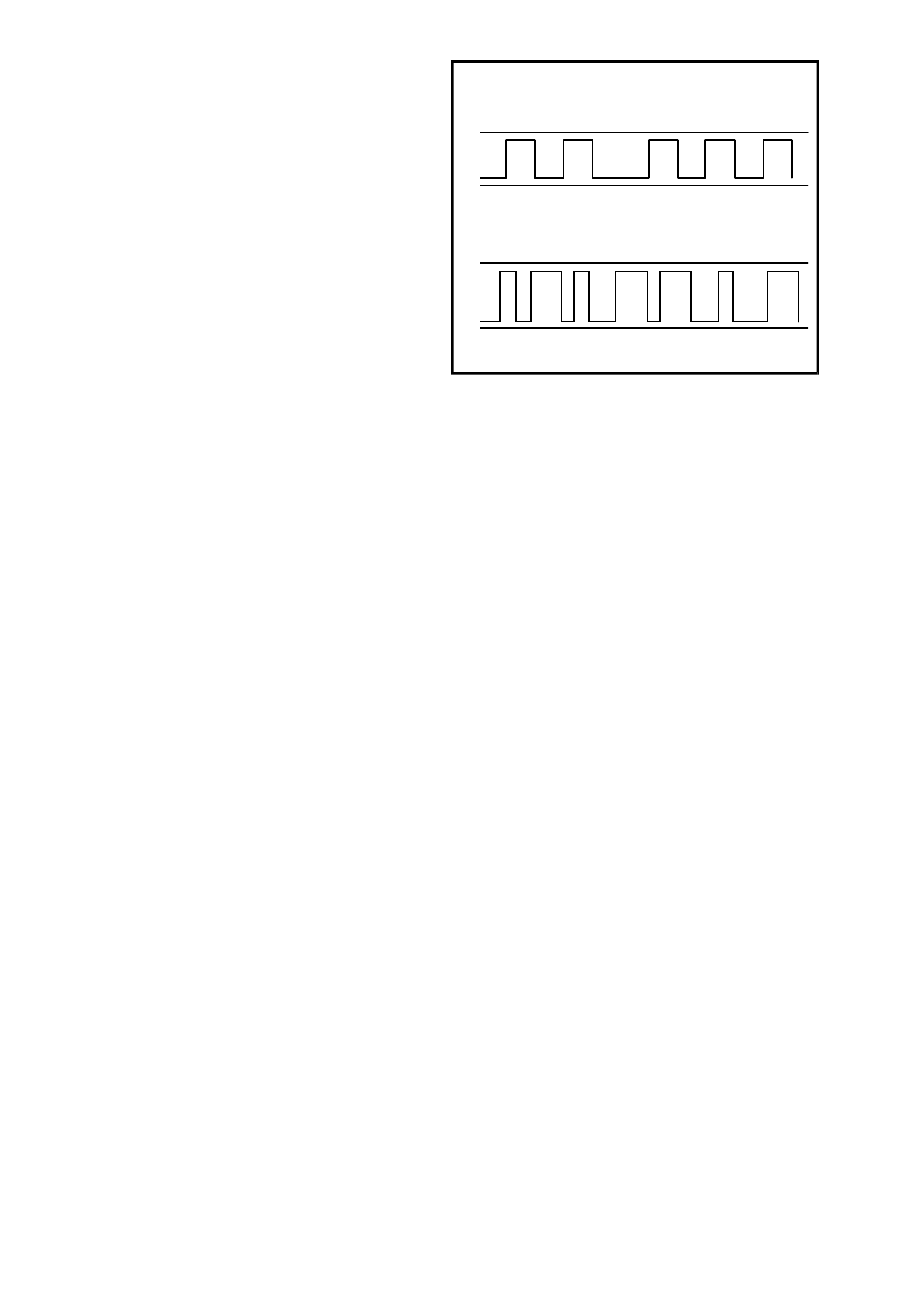

SERIAL DA TA COMMUNICATION

Various devices; system control modules of the vehicle, as well as TECH 2 communicate with each other. The

communication between control m odules and communication with the TECH 2 diagnostic scan tool is achieved on

the ser ial comm unication lines using serial data. Serial data transf ers infor mation in a linear f ashion - over a single

line, one bit at a tim e. The ser ial data line is r eferr ed to as the ‘data bus’. Ex cluding the GEN III V8 PCM, all c ontrol

modules communicating on the data bus communicate using UART communication.

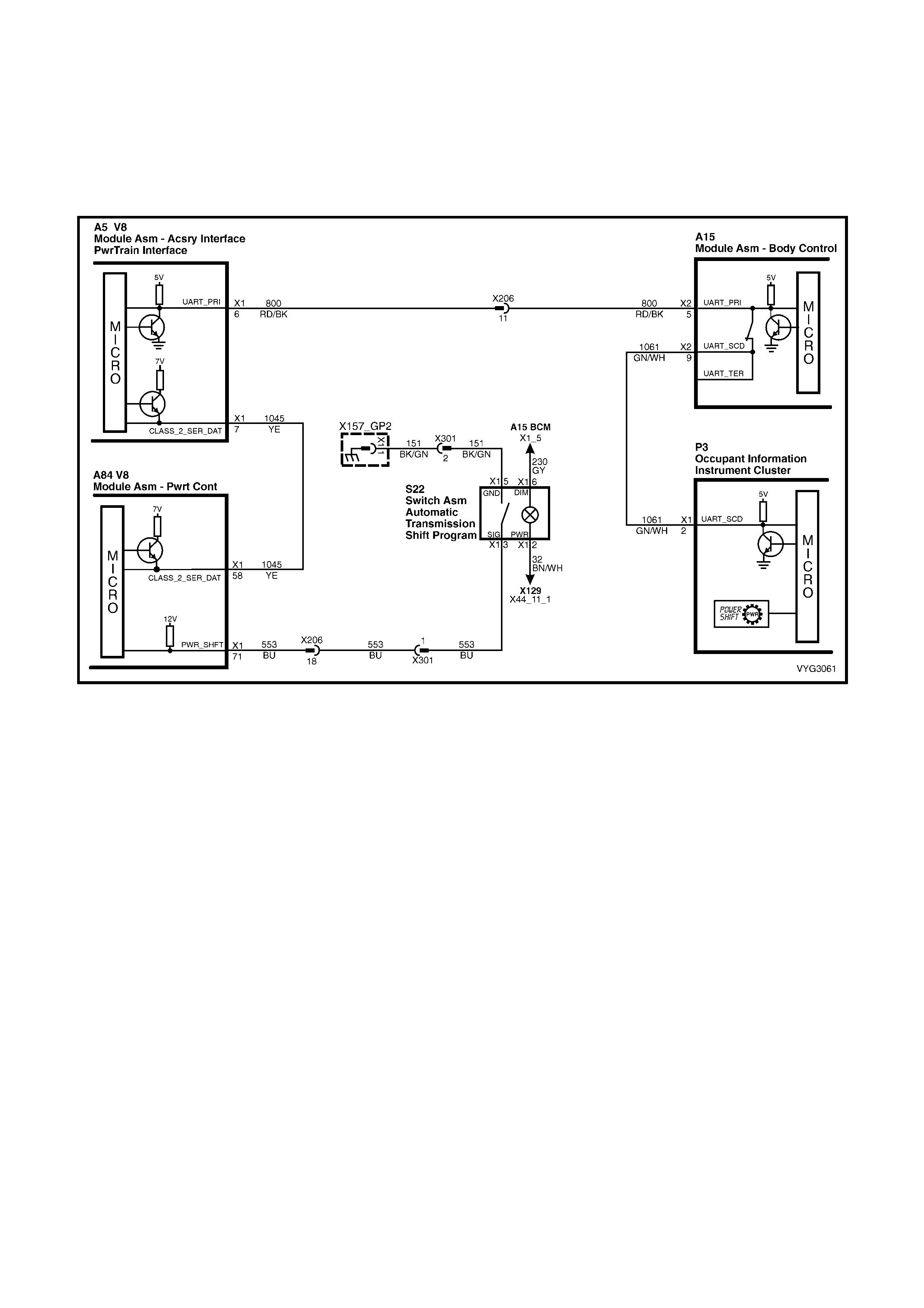

Figure 6C3-1-11 – System Overview - Serial Communication

UART is a 5 volt data line that toggles the voltage to ground (0 volts) at a fixed bit pulse width during

communication. UART transmits data at the rate of 8.2 kilobits per second (8192 bits/sec). With UART

communication, when there is no communication on the data line, the system voltage will be 5 volts.

The GEN III V8 PCM us es Class 2 comm unication.

This type of communication toggles the data line

from 0 volts to 7 volts at either a s hor t or long puls e

width at a rate of 10.4 kilobits per second

(average). With Class 2 communication, when

there is no communication on the data line, the

system voltage will be 0 volts.

As the ‘Class 2’ communication is different to

UART (different languages), communication

between the modules is incom patible, and as such,

requires a Powertrain Interface Module (PIM) to

convert Class 2 communication into UART, and

UART into Class 2 (a translator).

TECH 2 is able to communicate with both UART

and Class 2 control modules.

On all MY 2003 VY and V2 Series models, the

BCM is the Bus Master of the serial data

com munication system. The BCM periodically polls

(surveys) each device on the data bus and

requests status data.

T212J1012

11

0

1

00

1

0

1

0

5V

0V

UART

CLASS 2

11 1

111

000 0

000

7V

0V

Figure 6C3-1-12 – Serial Data Digital Wave Form

On vehicles fitted with a GEN III V8, the devices (control modules) the BCM polls are:

• Powertrain Interface Module (PIM).

• Instrument cluster (INS).

• Antilock Brake/Traction Control System (ABS/TCS) Module.

• Supplemental Restraint System (SRS) Sensing and Diagnostic Module (SDM).

• Occupant Climate Control (OCC) Module.

• TECH 2.

The data provided by each device may be utilised by any device connected to the bus.

Each device has a unique response Message Identifier Word (MIW) for ease of identification.

The bus master ( BCM) polls each device with a serial data m essage which includes that devic es MIW . The device

responds by putting a s erial data m ess age onto the bus which inc ludes its MIW and data, of which is retrieved and

utilised by any device requiring it.

The BCM polls each device for a status update, once every 300 milliseconds. The exception to this being the PIM

(GEN III V8) which is polled twice every 300 milliseconds. The PIM will construct a serial data message from

inform ation requested from the PCM via the Class 2 com munic ation. This cons tructed serial data m essage is then

placed on the serial data bus.

When the ignition switch is turned from the OFF position to the ON position, the BCM will communicate with the

PCM via the PIM for theft deterrent purposes. If the BCM does not receive an OK TO START message from the

PIM within 0.5 seconds of ignition on, the auxiliary data bus is isolated via switching from the BCM.

The isolation of the auxiliary data bus during this period eliminates the possibility of a device failure other than the

BCM, or PIM, causing a problem on the serial data bus and inhibiting theft deterrent communications.

This period (short loop time) continues until the PIM responds with an acknowledgment or for a maximum of five

seconds after which the BCM will switch to the standard polling sequence and a no start condition will occur.

Following succ essful theft deterrent com munica tions, the BCM begins sequential polling of devices on the bus and

normal system operation is established.

When the ignition switch is in the OFF position, the BCM continues to poll, allowing for TECH 2 communications

and external control of the bus prior to the ignition being switched on.

DIAGNOSTIC INFORMATION

The Diagnos tic Tables (Section 6C3-2A) and Functional Check s (Section 6C3-2C) in this Service Infor mation, are

designed to locate a faulty circuit or component through logic based on the process of elimination. These tables

have been prepared with the understanding that the vehicle:

• Functioned correctly at the time of assembly.

• There are no multiple faults.

• The problem currently exists.

The PCM perf orms a continual self-diagnosis on certain control functions. The PCM indicates the source of a fault

through the use of Diagnostic Trouble Codes (DTCs). The DTCs are four digit codes (P0XXX or P1XXX). W hen a

fault is detected by the PCM, a DTC will be set and stored in the memory of the PCM and the Check Powertrain

Malfunction Indicator Lamp (MIL) may be activated.

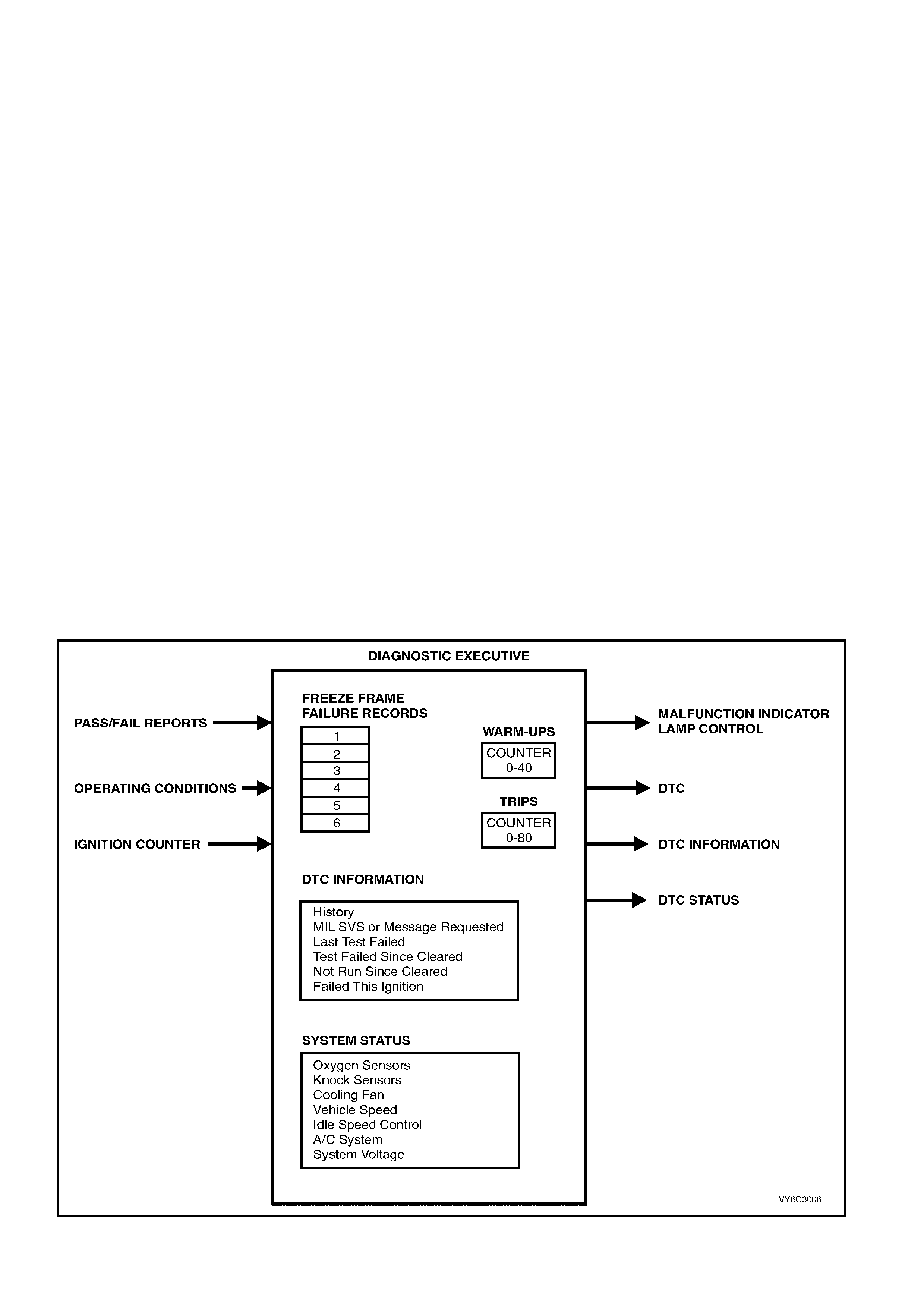

RECORDING TEST RESULTS (DIAGNOSTIC EXECUTIVE)

The Diagnostic Exec utive is a unique s egment of the PCM s oftware which is designed to c o-ordinate and prioritise

the diagnostic procedures as well as define the protocol for recording and displaying their results. The main

responsibilities of the Diagnostic Executive are:

• DTC Information

DTC Information indicates the status of the diagnostic testing for a specific DTC. It contains information on pass

/ fail status of the test, when the diagnostic test failed and if the DTC is requesting the activation of the

Malfunction Indicator Lamp (MIL).

• Freeze Frame / Failure Records

Freeze fram e / failur e records ar e stored any time a diagnostic tes t fails. T he PCM has the ability to store up to

six freeze frame / failure records. W hen a diagnostic test fails, records are stored in the first fail position. If a

different diagnostic test fails, a second fail record position. Additional failed diagnostic tests for different DTCs

also store fail records until the fail record memory is full. The PCM has the ability to store six freeze frame /

failure r eco rds , if mor e than s ix DTC f reeze f r ame / f ailure r ec ords ar e st ored, the f ail r ec ords ar e replac ed on a

first in, first out basis.

The freeze frame / failure records data list has 32 parameters for data capture. W hen a DTC is set, the PCM

will capture all 32 parameters at the time the DTC is logged.

In addition to the regular data list parameters found in the freeze frame / failure records data list, there is

additional information available about the DTC diagnostics:

• First Odometer - Vehicle kilometre value when the DTC failure first recorded.

• Last Odometer - Vehicle kilometre value when the DTC fail is recorded.

• Fail Counter - Number of ignition cycles with failure (DTC was set).

• Pass Counter - Number of ignition cycles with diagnostic passes (DTC was not set again).

• Not Run Counter - Number of ignition cycles without diagnostic run (DTC conditions were not tested).

• System Status

T he System Status (I/M Flag) stores inf orm ation on which diagnostics have run. If a s ystem diagnostic has run,

the system status flag (yes/no) will be set.

• Warm-Up Cycles

Records the number of warm-up cycles that have been achieved since the DTC was set

Figure 6C3-1-13 – Diagnostic Executive

TECH 2 SCAN TOOL: FREEZE FRAME / FAILURE RECORDS DA TA DISPLAY

SCAN POSITION Q UNITS DISPLAYED R DATA VALUE S

Engine Speed rpm Varies

Desired Idl e Speed rpm Varies

Eng. Coolant Temp (ECT) Degrees C Varies

Start Up E CT Degrees C Varies

Throttle P osition 0 – 100% 0 – 100%

Engine Load % %

Baro kPa kPa

Baro Sensor Volts Volts Volts

MAP Sensor kPa kPa

MAP Sensor Volts Volts Volts

Mass Air Fl ow gram /sec gram /sec

Fuel Syst em St atus Open Loop/Closed Loop Open Loop/Closed Loop

Left Short Term Fuel Trim (Bank 1) % +20% to –20%

Right Short Term Fuel Trim (Bank 2) % +20% to –20%

Left Long Term Fuel Trim (Bank 1) % +20% to –20%

Right Long Term Fuel Tri m (Bank 2) % +20% to –20%

inject i on pul se bank 1 ms ms

inject i on pul se bank 2 ms ms

Air Fuel Rati o Ratio 14.7:1

Transm i ssion Range Park, Reverse, Neutral ,

Drive , Drive 3, Dri ve 2, Dri ve 1, Invalid Park, Reverse, Neutral ,

Drive, Drive 3, Dri ve 2, Dri ve 1, Invalid

Current Gear 1,2,3,4 1,2,3,4

A/T Output Speed (Auto Trans ) rpm rpm

TCC Brake Switch ON / OFF ON / OFF

TCC Solenoid ON / OFF ON / OFF

TCC PWM ON / OFF ON / OFF

Vehicl e S peed km /h km /h

Time From Start Time 0:00:00

First Odometer km km

Last Odometer km km

Fail Counter # #

Pass Count er # #

Not Ran Counter # #

PCM PROGRAMMING

The PCM for this vehicle application does not

contain a removable PROM, instead it uses an

EEPROM (Flash Memory) which is non removable.

From the factory, the PCM is programmed with the

proper calibrations for vehicle operation. In the

event that the PCM is replaced, or an updated

calibration is required to correct a vehicle's

operating condition, the new PCM or the new

calibration will require the use of the Tech 2 scan

tool for down loading to the EEPROM (Flash

Memory). Down loading is accomplished through

the vehicle Data Link Connector (DLC) using the

Tech 2 scan tool.

The service replacement PCM EEPROM (Flash

Memory) will not be programm ed. DTC P0601 and

P0602 indicates the Flash Memory is not

programmed or has malfunctioned.

NOTE: The PCM used in this vehicle application is

not interchangeable with any other V8 GEN III

program. Only the PCM part number for this vehicle

must be used.

Refer to Section 6C3-3 SERVICE OPERATIONS

for this service programming procedure.

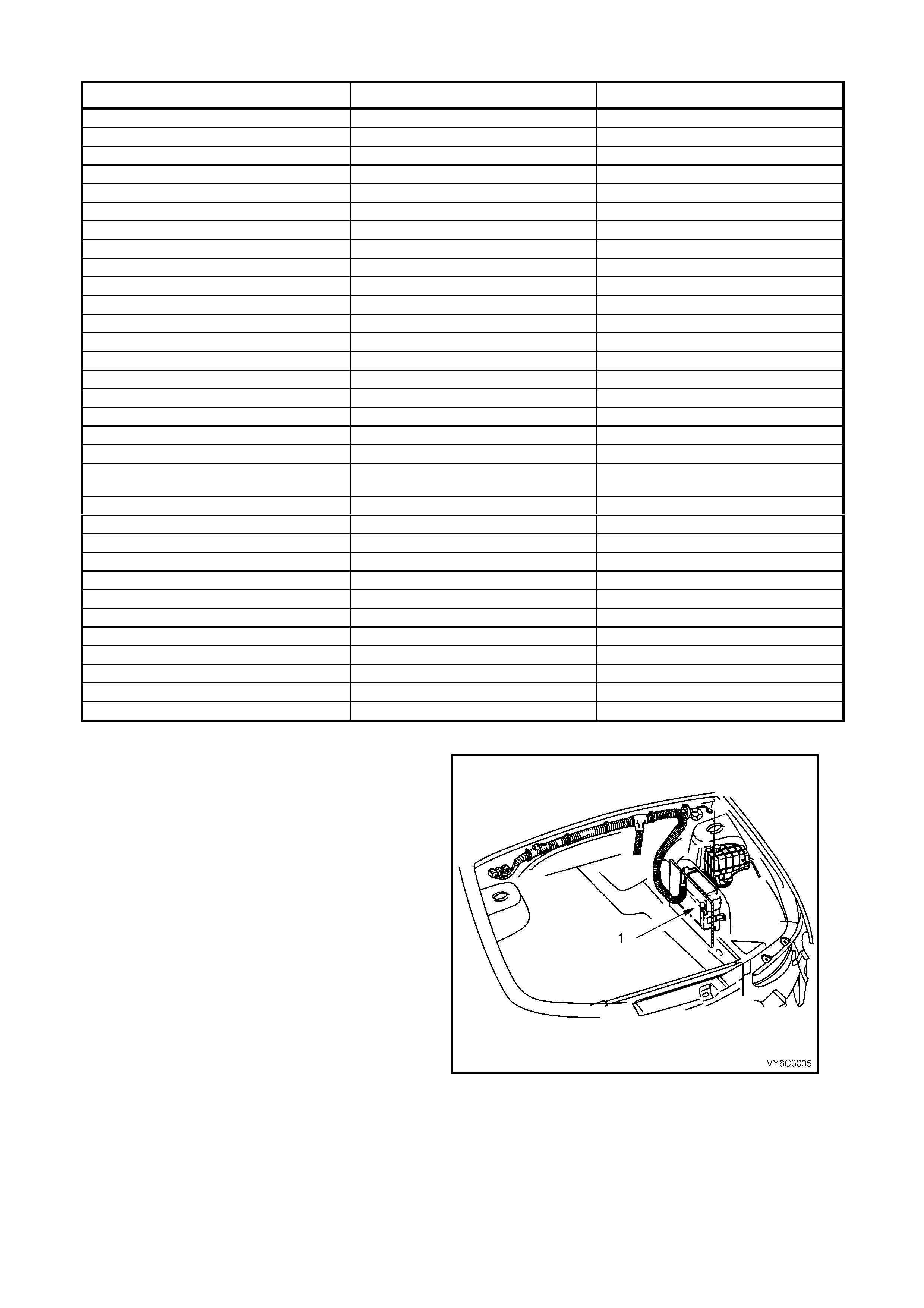

Figure 6C3-1-14 – Powertrain Control Module Location

Legend:

1. Powertrain Control Module (PCM)

DTC P0601 POWERTRAIN CONTROL MODULE (PCM) MEMORY

Conditions for running DTC P0601

• The ignition switch is in the crank position or the run position.

Conditions for setting DTC P0601

• The PCM is unable to correctly read data from the EEPROM (flash memory).

Action taken when DTC P0601 Sets

• The PCM activates the Malfunction Indicator Lamp (MIL) when the diagnostic runs and fails.

• The PCM records the operating conditions at the time the diagnostic fails. The PCM stores this information in

the Freeze Frame/Failure Records.

Conditions for clearing the Malfunction Indicator Lamp (MIL) and DTC P0601

• A last test failed (Current DTC) clears when the diagnostic runs and does not fail.

• A History DTC clears after forty consecutive warm-up cycles, if this or any other emission related diagnostic

does not report any failures.

• Use Tech 2 in order to clear the MIL/DTC.

DTC P0602 POWERTRAIN CONTROL MODULE (PCM) NOT PROGRAMMED

Conditions for running DTC P0602

• The ignition switch is in the run position.

Conditions for setting DTC P0602

• No software data is present in the PCM.

Action taken when DTC P0602 Sets

• The PCM activates the Malfunction Indicator Lamp (MIL) when the diagnostic runs and fails.

• The PCM records the operating conditions at the time the diagnostic fails. The PCM stores this information in

the Freeze Frame/Failure Records.

Conditions for clearing the Malfunction Indicator Lamp (MIL) and DTC P0602

• A last test failed (Current DTC) clears when the diagnostic runs and does not fail.

• A History DTC clears after forty consecutive warm-up cycles, if this or any other emission related diagnostic

does not report any failures.

• Use Tech 2 to clear the MIL/DTC.

PCM/PIM/BCM SECURITY LINK

Once the PCM, PIM and or BCM have been replaced, the new module(s) must be security linked to each other

using the Tech 2 and TIS. If the procedure is not performed, the engine will not crank or run.

For more detail on this linking procedure, refer to TECH 2 DIAGNOSIS FOR BCM in Section 12J BCM. The

procedure, is to be performed as follows:

• Connect TECH 2 to DLC and select:

• Diagnostic / (3) 2003 / VY Commodore / Body / Body Control Module / Security / BCM Link to PCM/PIM.

• The procedure ‘BCM Link to PCM/PIM’ will first ask to select the installed engine. If GEN III V8 is selected, a

TIS Enable Programming approval is required.

• Connect TECH 2 to a T IS terminal and s elec t ”Enable Pr ogramming”. After returning to the vehicle, again selec t

the linking procedure. The BCM is linked first, followed by the PIM and finally, the PCM – PIM linking is

performed automatically.

For additional information regarding TECH 2 and TECH 2 test modes (including this linking procedure), refer to

TECH 2 DIAGNOSIS FOR BCM in Section 12J BCM in the MY 2003 VY and V2 Series Service Information.

PCM MEMORY FUNCTIONS

The following list contains the two types of memory within the PCM.

• RAM

• EEPROM (Flash Memory)

RAM

Random Ac cess Mem ory (RAM) is the m icroproc essor sc ratch pad. T he processor can write into, or read f rom this

memory as needed. This memory is volatile and needs a constant supply of B+ voltage to be retained. If the B+

voltage is lost, the memory is lost.

EEPROM (FLASH MEMORY)

A new Service Programming System (SPS) has been incorporated with this GEN III PCM. This SPS enables

technicians to directly update the data stored in the Powertrain Control Module (PCM). The part of the PCM which

contains the specific calibration data for a particular vehicle and engine combination is commonly referred to as the

EEPROM. EEPROM is an acronym for Electrically Erasable Programmable Read Only Memory. In effect, the data

in the memory matches the PCM to the vehicle to provide optimum performance, driveability and emissions control.

Sometimes EEPROM data is updated to modify engine operations. For example, the EEPROM calibration data may

be changed to adjust ignition timing in order to eliminate a potential detonation condition or improve idle quality .

Before the SPS was implemented, the procedure for updating EEPROM data was to simply replace the PCM

EEPROM unit.

The relative ease of changing engine data has led to increased use of aftermarket EEPROMs designed to enhance

performance. Unfortunately, such “HOT” EEPROMs often cause engine emissions to exceed regulated standards.

In such instances, installation of an aftermarket EEPROM is considered tampering. Governing bodies ruled that

emission-related control modules must be tamper resistant. These tamper-resistant EEPROMs are soldered in

place as an integral part of the PCM. Updating the EEPROM data is accomplished through flash programming.

Flash programming refers to the SPS used to transfer (or download) PCM data from a computer terminal and

compact disk-read only memory (CD-ROM) to the vehicle’s PCM. The system is designed so that the vehicle

verification procedures are required to eliminate EEPROM tampering that could increase engine emission levels.

There are three main flash programming techniques listed below:

1. Direct Programming (Pass Through)

This is where the vehicle’s Data Link Connector (DLC) is connected directly to a computer terminal. On screen

directions are then followed for downloading.

2. Remote Programming

Reprogramming information is downloaded from a computer terminal to Tech 2. Tech 2 is then connected to the

vehicle’s Data Link Connector (DLC). On screen directions are then followed for downloading.

3. Off-Board Programming

The off-board programming method is used when a re-programmable PCM must be programmed separate from

the vehicle. For example, an independent repair facility may find it necessary to replace a faulty PCM. On flash

programming equipped vehicles, the replacement PCM must be programmed with data for the specific Vehicle

Identification Number (VIN) or the vehicle may not operate properly.

1.2 POWERTRAIN INTERFACE MODULE (PIM)

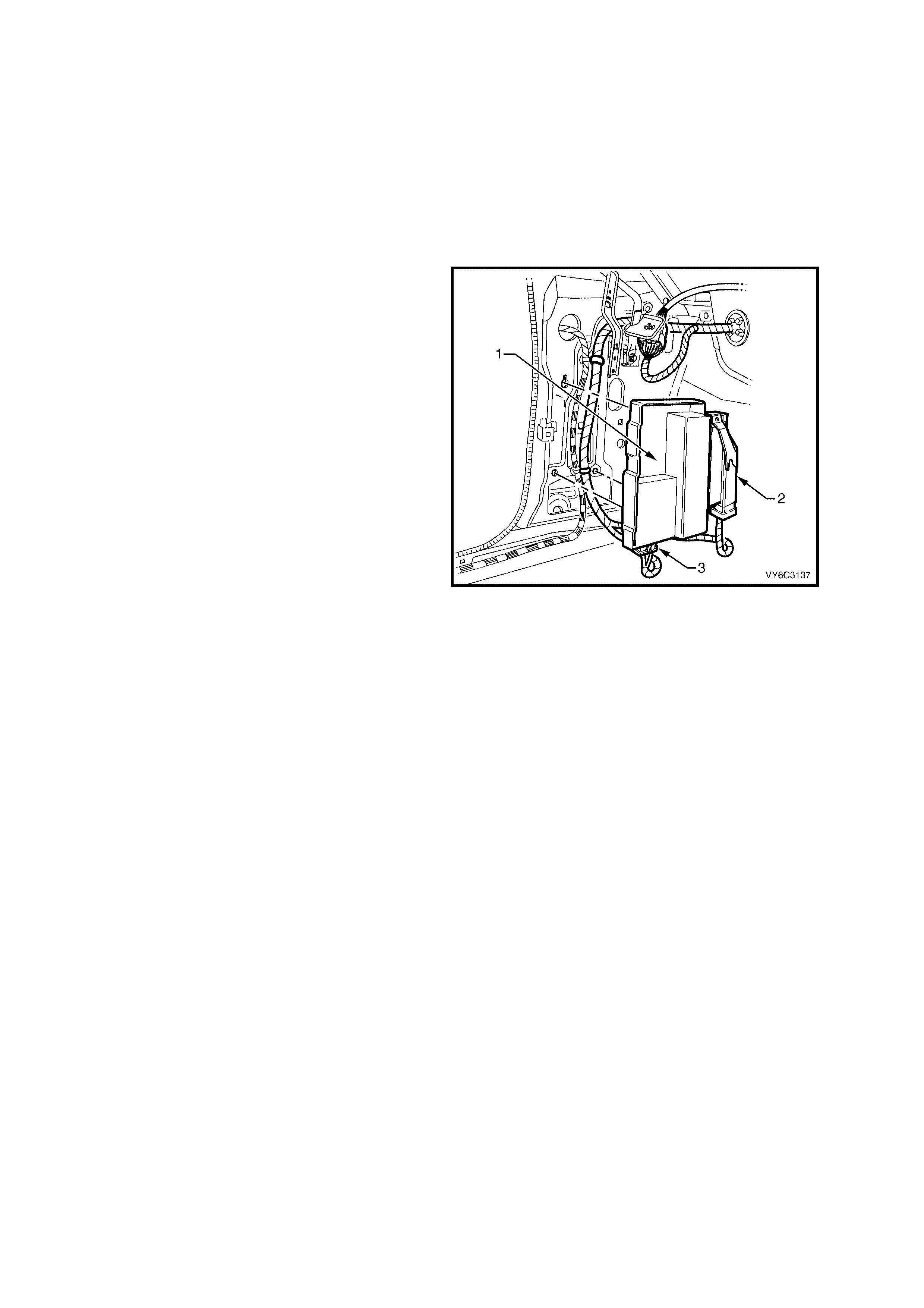

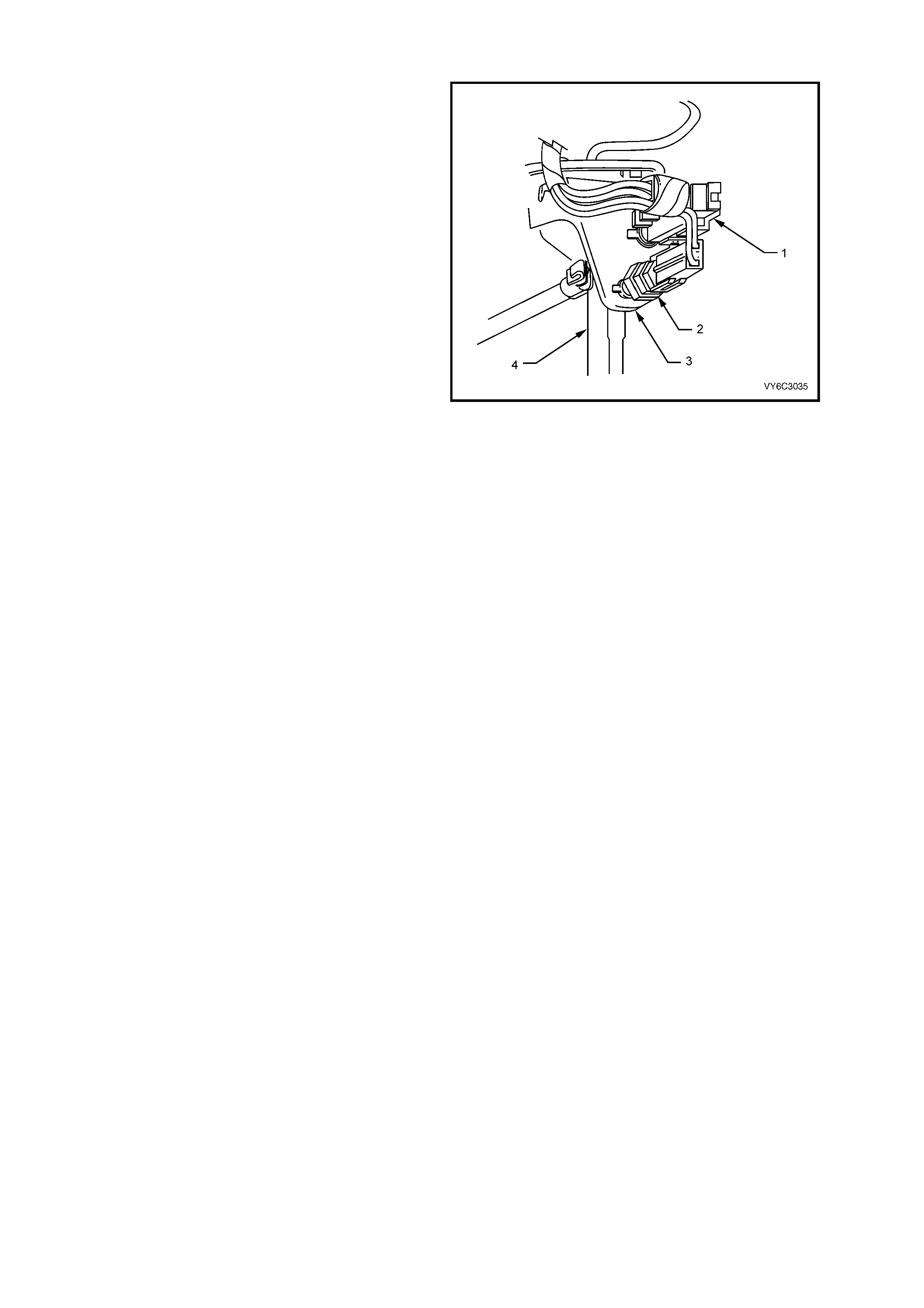

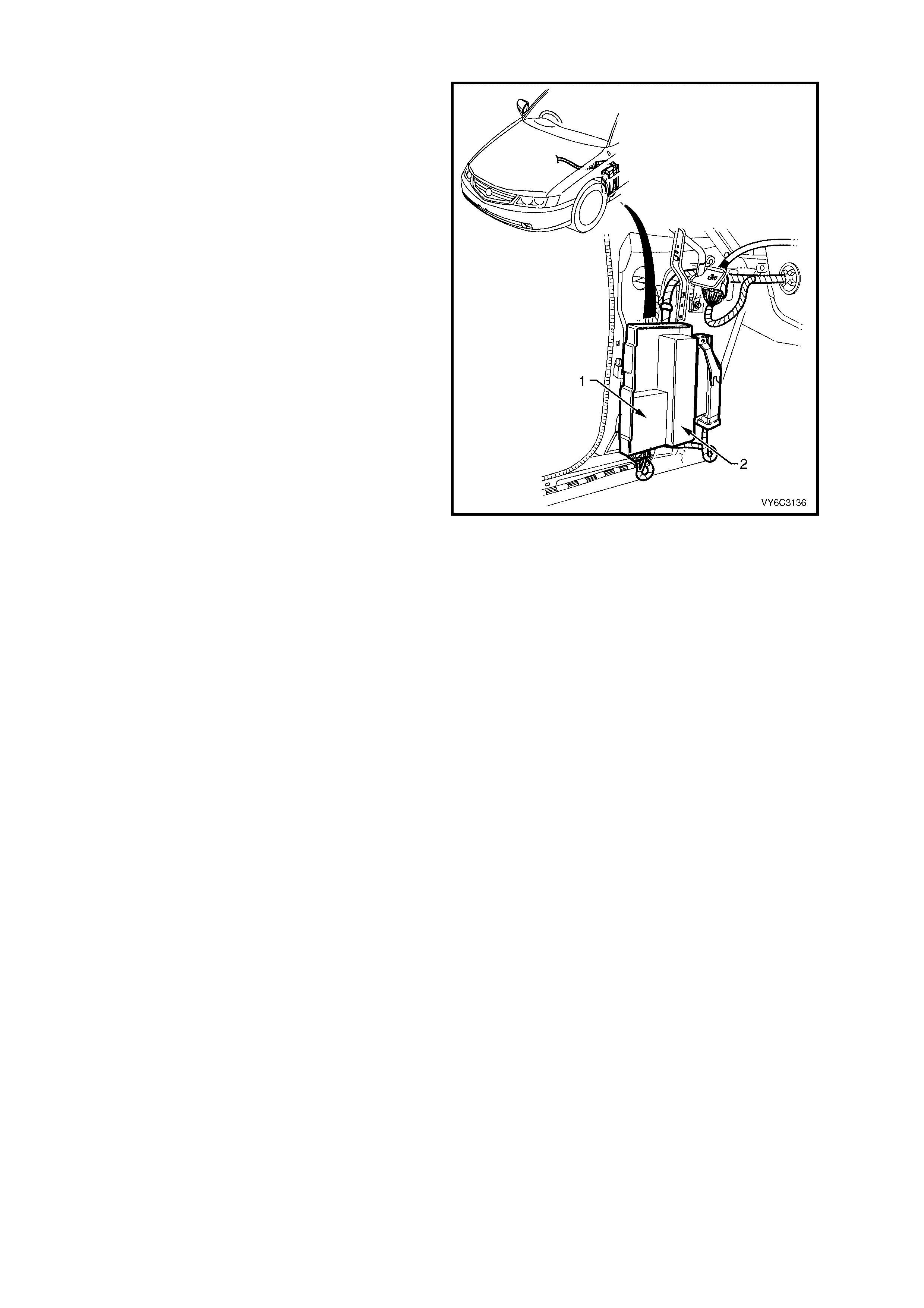

The Powertrain Interface Module (PIM) (1), is

located in the passenger compartment behind the

left kick panel. The PIM (1) acts as a

communication translator between the PCM and

other control modules that use a different serial

data protocol. The GEN III V8 PCM uses Class II

serial data to communicate, while other control

modules in the vehicle are designed to transmit

serial data via the conventional Universal

Asynchronous Receive and Transmit (UART)

protocol.

Since these two types of serial data are not

compatible, the PIM is required to transmit data in

either dire ction between the PCM and other control

modules. The PIM will interpret the serial data

inform ation and tr anslate UART to Class II or Class

II to UART to support the appropriate vehicle

control module operation. The PIM is also used to

control the operation of the starter relay.

Figure 6C3-1-15 – PIM Location

Figure 6C3-1-16 – PIM Communication

PIM DIAGNOSTIC TROUBLE CODES

A PIM m alfunction m ay af fect vehicle operation and m ay interrupt starter motor operation. For PIM diagnosis refer

to Section 6C3-2A DIAGNOSTIC TABLES in this Section, for PIM DTC diagnosis. There are four (4) PIM DTCs

that will set. Each of these DTCs have corresponding diagnostic tables.

The PIM does not have the memory to store any DTC information, so only a current DTC, using Tech 2, can be

displayed. Once the fault is corrected, the DTC is no longer active.

DTC DTC DESCRIPTION

B2002 Low Speed Fan No BCM Response

B2006 No Serial Data From PCM

B2007 Starter Relay Voltage High

B2009 EEPROM Checksum Error

There are twenty (20) other PIM DTCs that will also set whenever DTC B2006 sets. These DTCs indicate the loss

of part of the Class II serial data. If there is a problem with the Class II serial data circuit, and the PIM does not

receive any of this information, a DTC B2006 will set. The Powertrain On Board Diagnostic (OBD) System Check

will identify a problem with the serial data circuit or other circuits, and direct the Technician in the proper direction for

diagnosis. As ther e are no PIM DT C tables ass ociated with these twenty (20) PIM DTCs, always diagnose the PCM

first.

DTC DTC DESCRIPTION

B2017 No Throttle Position Sensor (TPS) Information

B2018 No A/C Clutch Information

B2019 No Engine Speed Information

B2020 No Vehicle Speed Information

B2021 No Commanded Gear Information

B2022 No Transmission Type

B2023 No Low Speed Fan Run On Information

B2024 No Low Speed Fan Request Information

B2025 No Engine Coolant Temp (ECT) Information

B2026 No Fuel Flow Rate Information

B2027 No Fuel Used Counter Information

B2028 No A/C Pressure Information

B2029 No PRNDL Information

B2030 No Engine Oil Information

B2031 No Oil Pressure Information

B2032 No Shift Information

B2033 No Malfunction Indicator Lamp (MIL) Information

B2034 No Low Coolant Level Information

B2035 No Barometric Pressure Information

B2036 No PCM Information

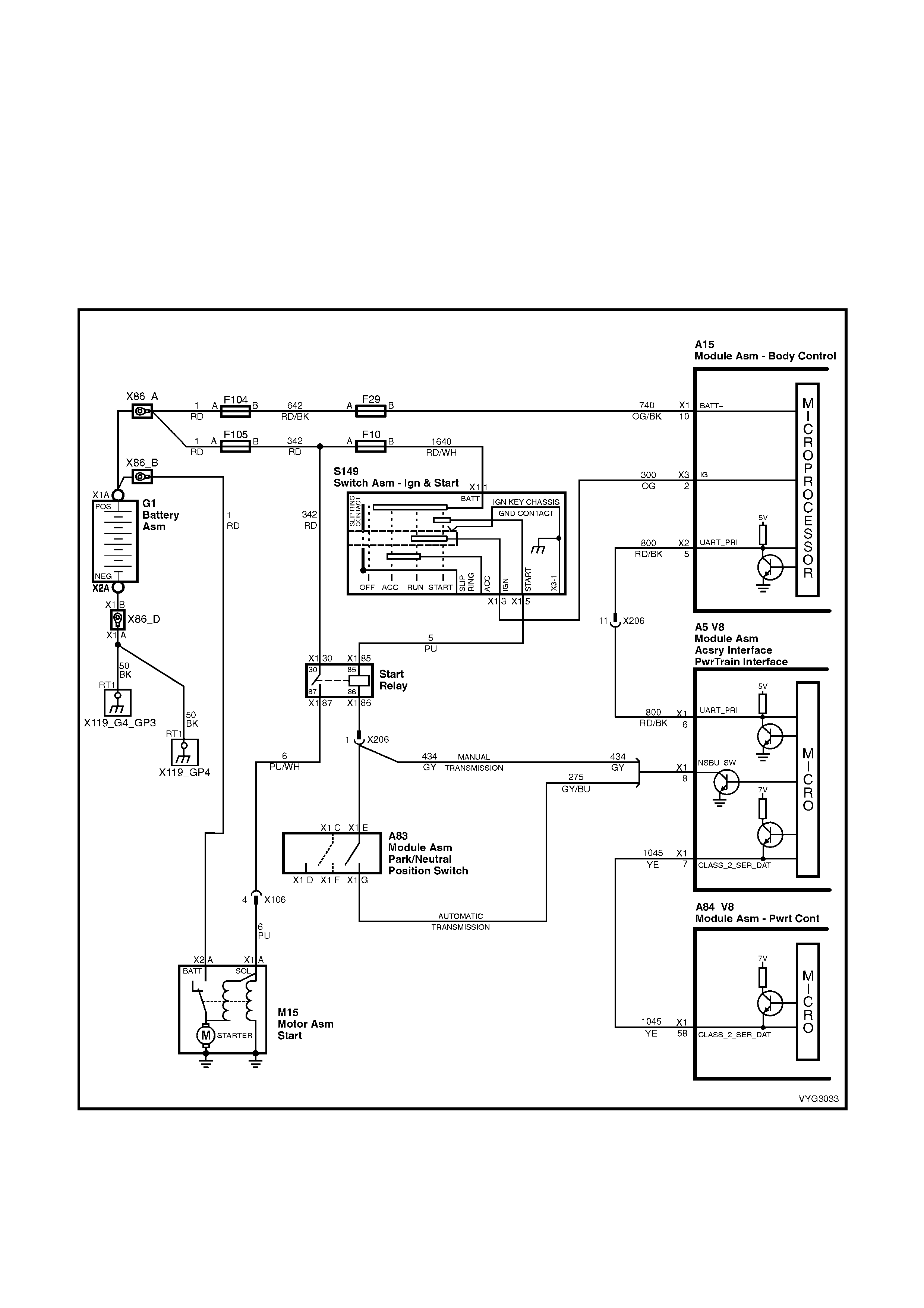

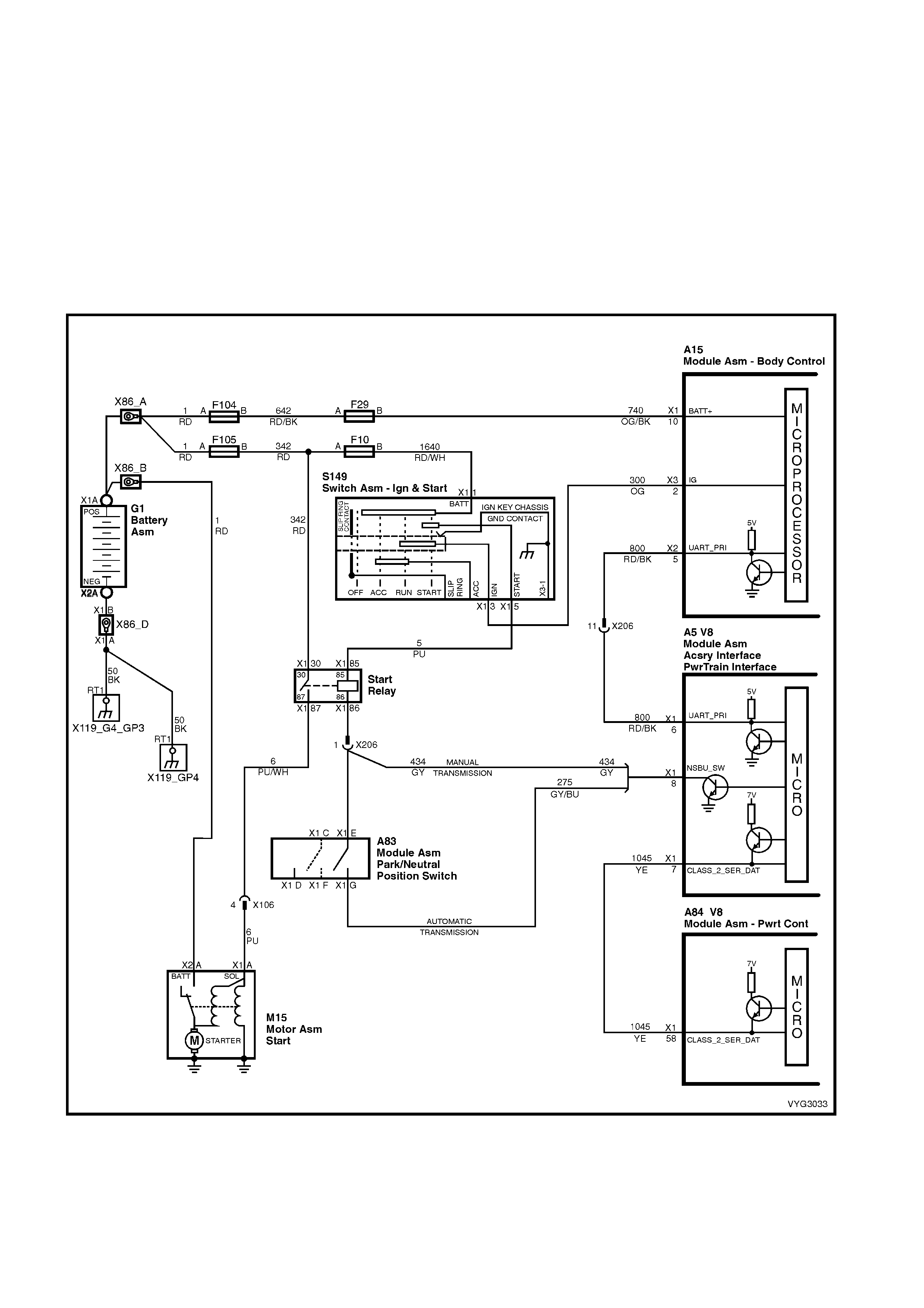

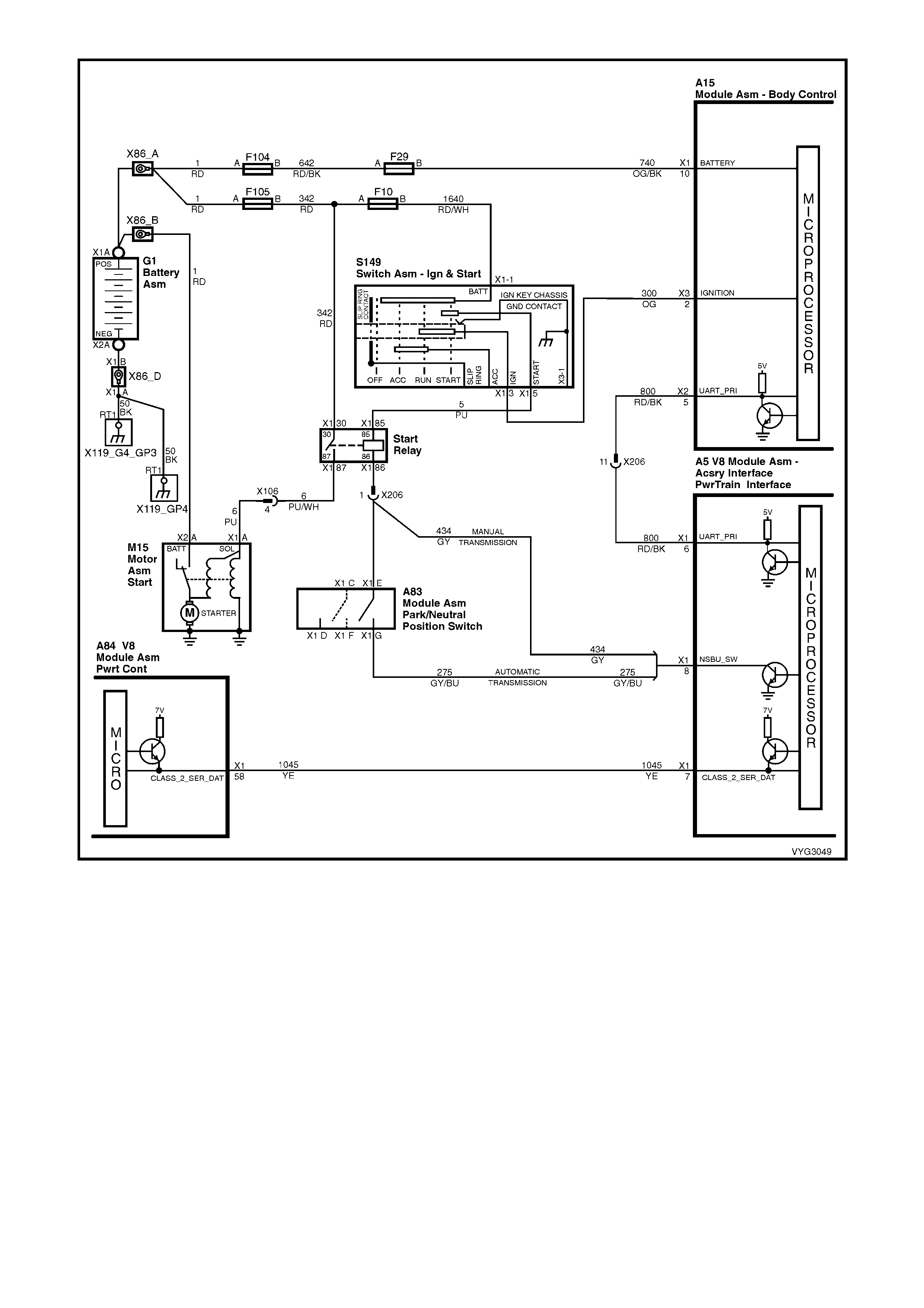

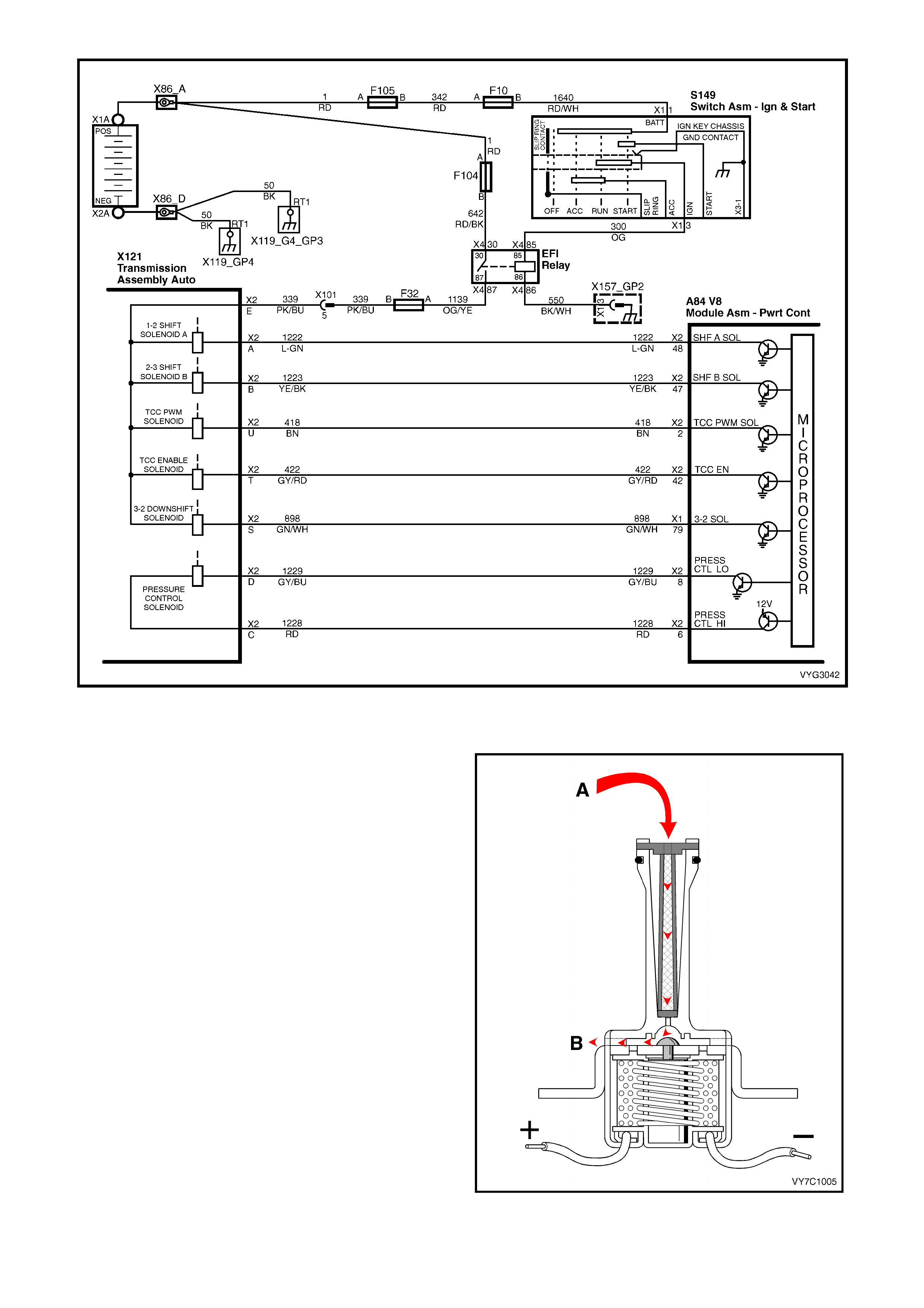

STARTER RELAY

The PIM als o c ontrols the oper ation of the s tarter r elay. When the ignition s witch is turned to on, the PIM will enable

the starter relay for one second, if the PIM does not receive the correct theft deterrent signal from the BCM it will

disable the starter relay. If the PIM receives the correct signal from the BCM, it will continue to enable the start relay.

Once the engine has started and the engine speed is above 500 RPM the PIM will disable the starter relay,

preventing starter engagement while the engine is running.

If the ser ial data bus between the BCM and the PIM should fail ( no polling from the BCM f or m or e than 10 minutes)

after suc cess ful thef t deterrent c om m unications , the PIM will allow subsequent starts , however there will be a crank

delay of one second. If the PIM receives valid communication, normal operation will resume.

If the Class II serial data bus between the PIM and the PCM should fail (no communications for 20 seconds) after

successful theft deterrent communications, the PCM will allow subsequent starts, however there will be a crank

delay of one second. If communications between the PCM and the PIM are re-established, normal operation will

resume.

Figure 6C3-1-17 – Starter Circuit

DTC B2002 LOW SPEED FAN NO BCM RESPONSE

Conditions for running DTC B2002

• The ignition is ON.

Conditions for setting DTC B2002

• The PIM sends a Low Speed request signal to the BCM , with no response back from the BCM.

Action taken when DTC B2002 Sets

• The PIM will display the DTC only when current.

Conditions for clearing DTC B2002

• A current DTC will clear when the PIM receives a Low Speed Fan Response from the BCM.

Figure 6C3-1-18 – Cooling Fan Circuit

DTC B2006 NO SERIAL DATA FROM PCM

Conditions for running DTC B2006

• The ignition switch is on.

• The ignition voltage is between 5.0 and 17 volts.

Conditions for setting DTC B2006

• PIM does not receive any serial data communication from the PCM.

Action taken when DTC B2006 Sets

• The PIM will display the DTC only when current.

Conditions for clearing DTC B2006

• A current DTC will clear when the PIM receives serial data from the PCM.

Figure 6C3-1-19 – Serial Data Circuit

DTC B2007 STA RTER RELAY VOLTAGE HIGH

Conditions for running DTC B2007

• The ignition switch is in the crank position.

• The ignition voltage is between 5.0 and 17 volts.

Conditions for setting DTC B2007

• PIM detects high voltage on the starter relay control circuit.

Action taken when DTC B2007 Sets

• The PIM will display the DTC only when current.

• The Malfunction Indicator Lamp (MIL) (MIL) will not illuminate.

Conditions for clearing DTC B2007

• A current DTC will clear when the PIM no longer detects a high voltage on the starter relay circuit.

Figure 6C3-1-20 – Starter Relay Circuit

DTC B2009 PIM EEPROM CHECKSUM ERROR

Conditions for running DTC B2009

• The ignition switch is in the crank position or run position.

Conditions for setting DTC B2009

• The PIM is unable to correctly read data from its memory.

Action taken when DTC B2009 Sets

• The PIM will display the DTC only when current.

Conditions for clearing DTC B2009

• A current DTC will clear when the PIM is able to correctly read data.

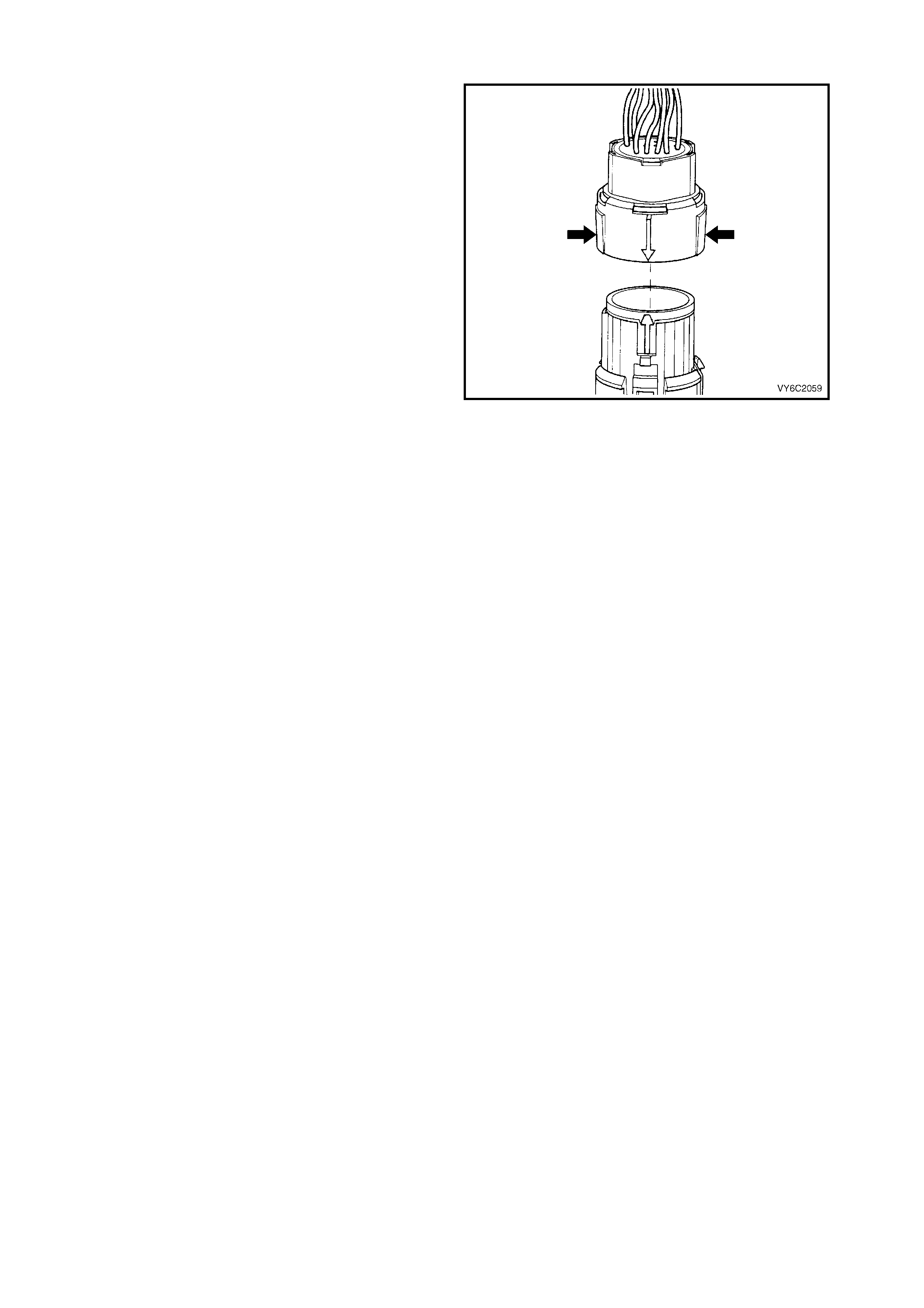

The only action taken if DTC B2009 is set, is to

replace the PIM (1) assembly.

Legend:

1. Powertrain Interface Module (PIM)

2. Throttle Relaxer Control Module

3. PIM W i ring Harness Connector

Figure 6C3-1-21 – Powertrain Interface Module (PIM)

1.3 ENGINE INFORMATION SENSORS AND SIGNALS

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

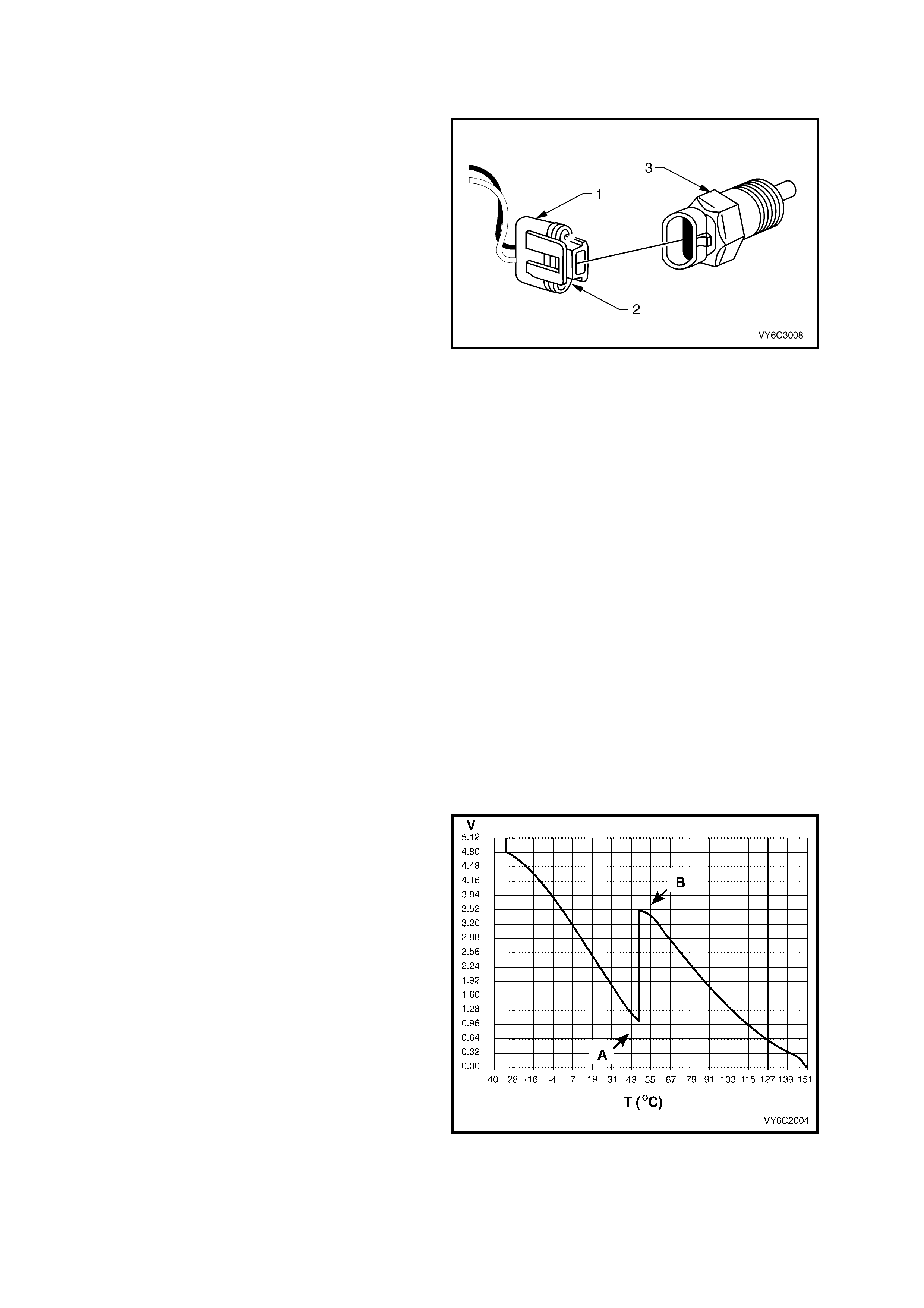

The Engine Coolant Tem peratur e (ECT) s ensor (3)

is a thermistor, (a resistor that changes value

based on temperature) mounted in the engine

coolant stream. Low engine coolant temperature

produces a high s ensor res istance (29 kilohm s at –

20° C) while high engine coolant temperature

causes low sensor resistance (180 ohms at 100°

C).

The PCM supplies a 5 volt signal voltage to the

sensor through an internal resistor network and

monitors the circuit voltage, which will change when

connected to the sensor.

The circuit voltage will vary depending on the

resistance of the coolant temperature sensor. The

circuit voltage will be close to the 5 volt level when

the sensor is cold, and will decrease as the sensor

warms. Engine coolant temperature affects most

systems controlled by the PCM.

The PCM uses a dual pull up resistor network to

increase the r esolution through the entire operating

range of engine coolant temperature. When the

coolant temperature is less than 51° C both the 4K

and 348 ohm res istors are used ( point ‘A’ in Figure

6C3-1-23). W hen the coolant temperature reaches

51° C, the PCM switches a short across the 4K

resistor and only the 348 ohm resistor is used

(point ‘B’ in Figure 6C3-1-23).

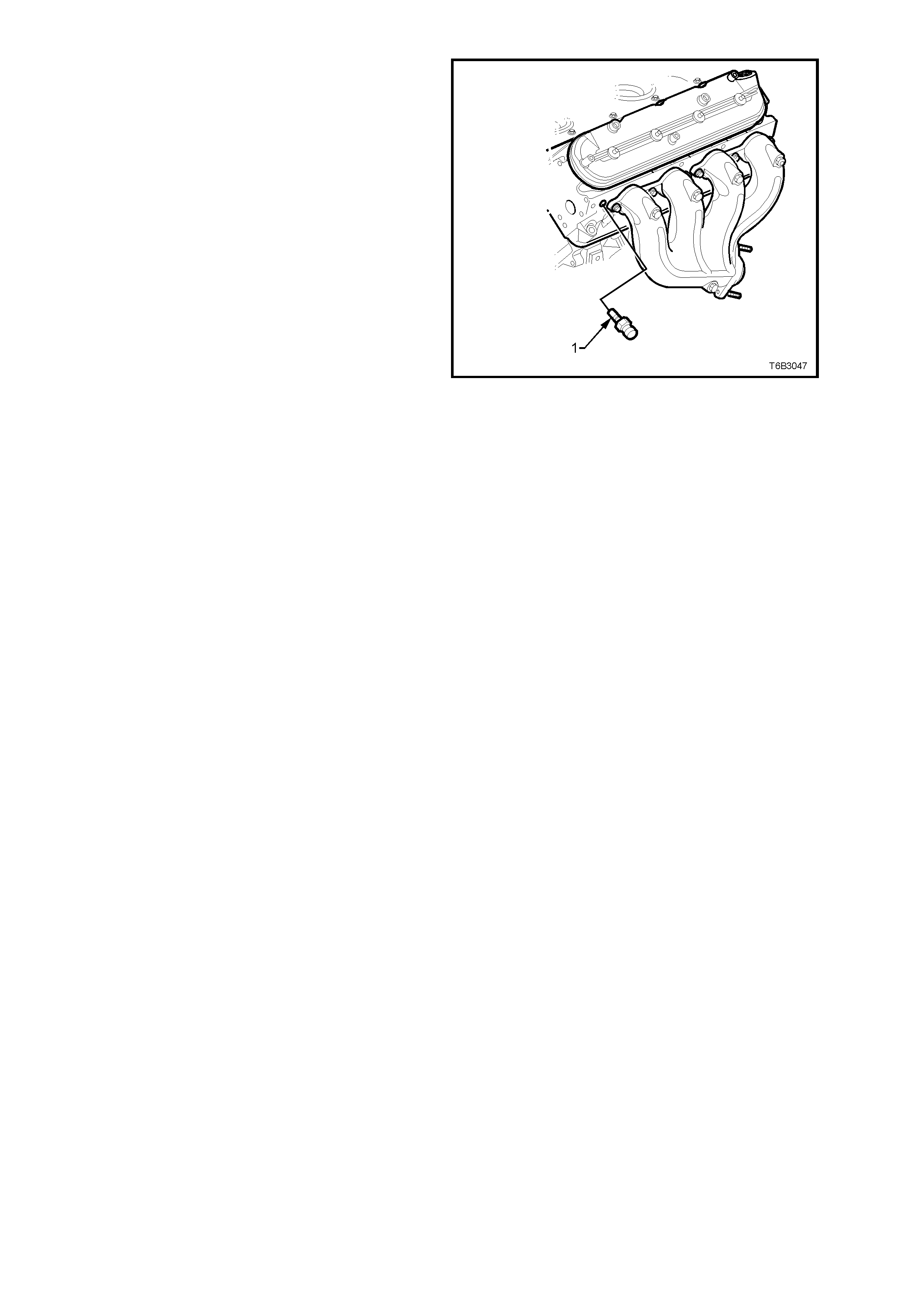

Figure 6C3-1-22

Engine Coolant Temperature (ECT) Sensor

Legend:

1. ECT Electrical Connector

2. Connector Tab

3. Engine Coolant Temperature (ECT) Sensor

As the engine warms, the sensor resistance

becomes less and the voltage at the PCM coolant

temperature sensor signal terminal should

decrease from approximately 4.5 volts when cold

to 0.9 volts at 51° C. At this temperature the PCM

switches the short across the 4k resistor, the

voltage will then rise to 3.5 volts. The voltage will

again decrease as the coolant temperature

increases until at normal engine operating

temperature (95° C), the voltage should be less

than 2.0 volts.

The following DTCs will set when the PCM detects

a malfunction in the engine coolant temperature

sensor circuit:

• DTC P0117: ECT Sensor Circuit Low Voltage.

• DTC P0118: ECT Sensor Circuit High Voltage.

• DTC P0125: ECT Excessive Time to Closed

Loop Fuel Control.

• DTC P1114: ECT Sensor Circuit Intermittent

Low Voltage.

• DTC P1115: ECT Sensor Circuit Intermittent

High Voltage.

• DTC P1258: Engine Coolant Over Temp Fuel

Disable

Figure 6C3-1-23 – ECT Temperature vs Voltage

Section 6C3-2C FUNCTIONAL CHECKS, contains

a table to check for sensor resistance values

relative to temperature.

Figure 6C3- 1-shows the ECT s ensor loc ation in the

left hand cylinder head.

Figure 6C3-1-24

Engine Coolant Temperature (ECT) Sensor Location

DTC P0117 ENGINE COOLANT TEMPERATURE SENSOR CIRCUIT LOW VOLTAGE

Conditions for running DTC P0117

• The engine run time is greater than 10 seconds.

Conditions for setting DTC P0117

• The engine coolant temperature is greater than 139°C.

• All conditions met for at least 45 seconds.

Action taken when DTC P0117 Sets

• The PCM activates the Malfunction Indicator Lamp (MIL) when the diagnostic runs and fails.

• The PCM will substitute a coolant temperature default value.

The PCM arrives at this default value, by using current intake air temperature, then counting upward to 116°C at

a rate of approximately 7 degrees per minute.

• The PCM will turn on the electric engine cooling fans. This is a FAIL-SAFE action by the PCM to prevent a

possible engine overheat condition, since the DTC indicates an unknown actual coolant temperature.

• The PCM records the operating conditions at the time the diagnostic fails. The PCM stores this information in

the Freeze Frame/Failure Records.

Conditions for clearing the Malfunction Indicator Lamp (MIL) and DTC P0117

• The PCM deactivates the Malfunction Indicator Lamp (MIL) when the diagnostic runs and does not fail.

• A last test failed (current DTC) clears when the diagnostic runs and does not fail.

DTC P0118 ENGINE COOLANT TEMPERATURE SENSOR CIRCUIT HIGH VOLTAGE

Conditions for running DTC P0118

• The engine run time is greater than 10 seconds.

Conditions for setting DTC P0118

• The engine coolant temperature is less than –38.9° C.

• All conditions met for at least 45 seconds.

Action taken when DTC P0118 Sets

• The PCM activates the Malfunction Indicator Lamp (MIL) when the diagnostic runs and fails.

• The PCM will substitute a coolant temperature default value.

The PCM arr ives at this default value, by using current intak e air temperatur e, then counting upward to 116° C

at a rate of approximately 7° C per minute.

• The PCM will turn on the electric engine cooling fans. This is a FAIL-SAFE action by the PCM to prevent a

possible engine overheat condition, since the DTC indicates an unknown actual coolant temperature.

• The PCM records the operating conditions at the time the diagnostic fails. The PCM stores this information in

the Freeze Frame/Failure Records.

Conditions for clearing the Malfunction Indicator Lamp (MIL) and DTC P0118

• The PCM deactivates the Malfunction Indicator Lamp (MIL) when the diagnostic runs and does not fail.

• A last test failed (current DTC) clears when the diagnostic runs and does not fail.

DTC P0125 ENGINE COOLANT TEMPERATURE SENSOR EXCESS TIME TO CLOSED LOOP FUEL CONTROL

Conditions for running DTC P0125

• DTCs P0112, P0113, P0117, P0118 are not set.

• The engine is running.

• The engine coolant temperature is between -36° C and 40° C at engine start-up.

• The intake air temperature is greater than –7° C.

• The vehicle speed is greater than 1.6 km/h.

Conditions for setting DTC P0125

• The closed loop coolant temperature of 34° C is not reached within a predetermined time. The maximum

allowable time depends on the start-up coolant temperature and the amount of airflow into the engine. The

range for the time is from 2 minutes and 20 seconds to 22 minutes and 30 seconds.

Action taken when DTC P0125 Sets

• The PCM stores the DTC information into memory when the diagnostic runs and fails.

• The Malfunction Indicator Lamp (MIL) will not be activated.

• The PCM records the operating conditions at the time the diagnostic fails. The PCM stores this information in

the Freeze Frame/Failure Records.

Conditions for clearing the Malfunction Indicator Lamp (MIL) and DTC P0125

• A last test failed (current DTC) clears when the diagnostic runs and does not fail.

DTC P1114 ENGINE COOLANT TEMPERATURE SENSOR CIRCUIT INTERMITTENT LOW VOLTAGE

Conditions for running DTC P1114

• The engine run time is greater than 10 seconds.

Conditions for setting DTC P1114

• The engine coolant temperature is greater than 139° C for at least one second.

Action taken when DTC P1114 Sets

• The PCM stores the DTC information into memory when the diagnostic runs and fails.

• The Malfunction Indicator Lamp (MIL) will not be activated.

• The PCM records the operating conditions at the time the diagnostic fails. The PCM stores this information in

the Freeze Frame/Failure Records.

Conditions for clearing the Malfunction Indicator Lamp (MIL) and DTC P1114

• A last test failed (current DTC) clears when the diagnostic runs and does not fail.

DTC P1115 ENGINE COOLANT TEMPERA TURE SENSOR CIRCUIT INTERMITTENT HIGH VOLTAGE

Conditions for running DTC P1115

• The engine run time is greater than 60 seconds.

Conditions for setting DTC P1115

• The engine coolant temperature is less than –35°C for at least one second.

Action taken when DTC P1115 Sets

• The PCM stores the DTC information into memory when the diagnostic runs and fails.

• The Malfunction Indicator Lamp (MIL) will not be activated.

• The PCM records the operating conditions at the time the diagnostic fails. The PCM stores this information in

the Freeze Frame/Failure Records.

Conditions for clearing the Malfunction Indicator Lamp (MIL) and DTC P1115

• A last test failed (current DTC) clears when the diagnostic runs and does not fail.

DTC P1258 ENGINE COOLANT OVER TEMP FUEL DISABLED

Conditions for running DTC P1258

• DTCs P0117, P0118, are not set.

• The engine is running.

Conditions for setting DTC P1258

• The engine coolant temperature is greater than 132° C.

• The above conditions present for greater than 10 seconds.

Action taken when DTC P1258 Sets

• The PCM will randomly disable several injectors.

• The PCM activates the Malfunction Indicator Lamp (MIL) when the diagnostic runs and fails.

• The PCM records the operating conditions at the time the diagnostic fails. The PCM stores this information in

the Freeze Frame/Failure Records.

Conditions for clearing the Malfunction Indicator Lamp (MIL) and DTC P1258

• The PCM deactivates the Malfunction Indicator Lamp (MIL) when the diagnostic runs and does not fail.

• A last test failed (current DTC) clears when the diagnostic runs and does not fail.

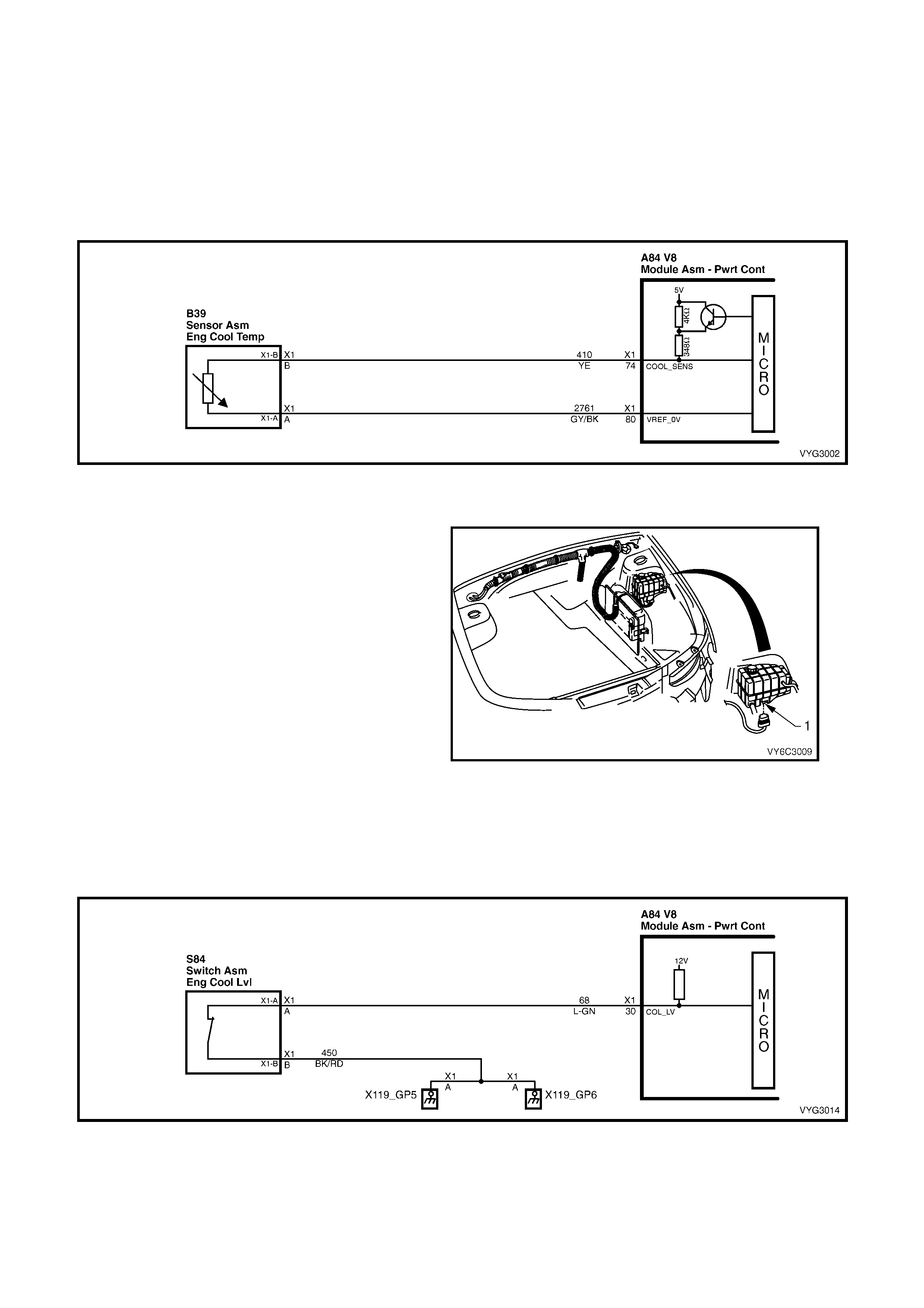

Figure 6C3-1-25 – Engine Coolant Temperature (ECT) Sensor Circuit

ENGINE COOLANT LEVEL SWITCH

The engine coolant level switch is a reed switch

and is used to inform the PCM when the coolant

level is at a calibrated low level. When the engine

coolant is at norm al operating level, the float inside

the surge tank will rise, the magnet in the float will

cause the reed s witc h contacts to close, pulling the

PCM supplied voltage low. When the coolant level

is low, the f loat will fall, the r eed s witch c ontac ts will

open, causing the PCM voltage signal to go high.

The PCM will then send a serial data message to

the instrument cluster instructing the instrument

panel cluster to activate the Low Coolant warning

lamp icon.

For diagnosis of the engine coolant level switch,

refer to Section 6C3-2C FUNCTIONAL CHECKS.

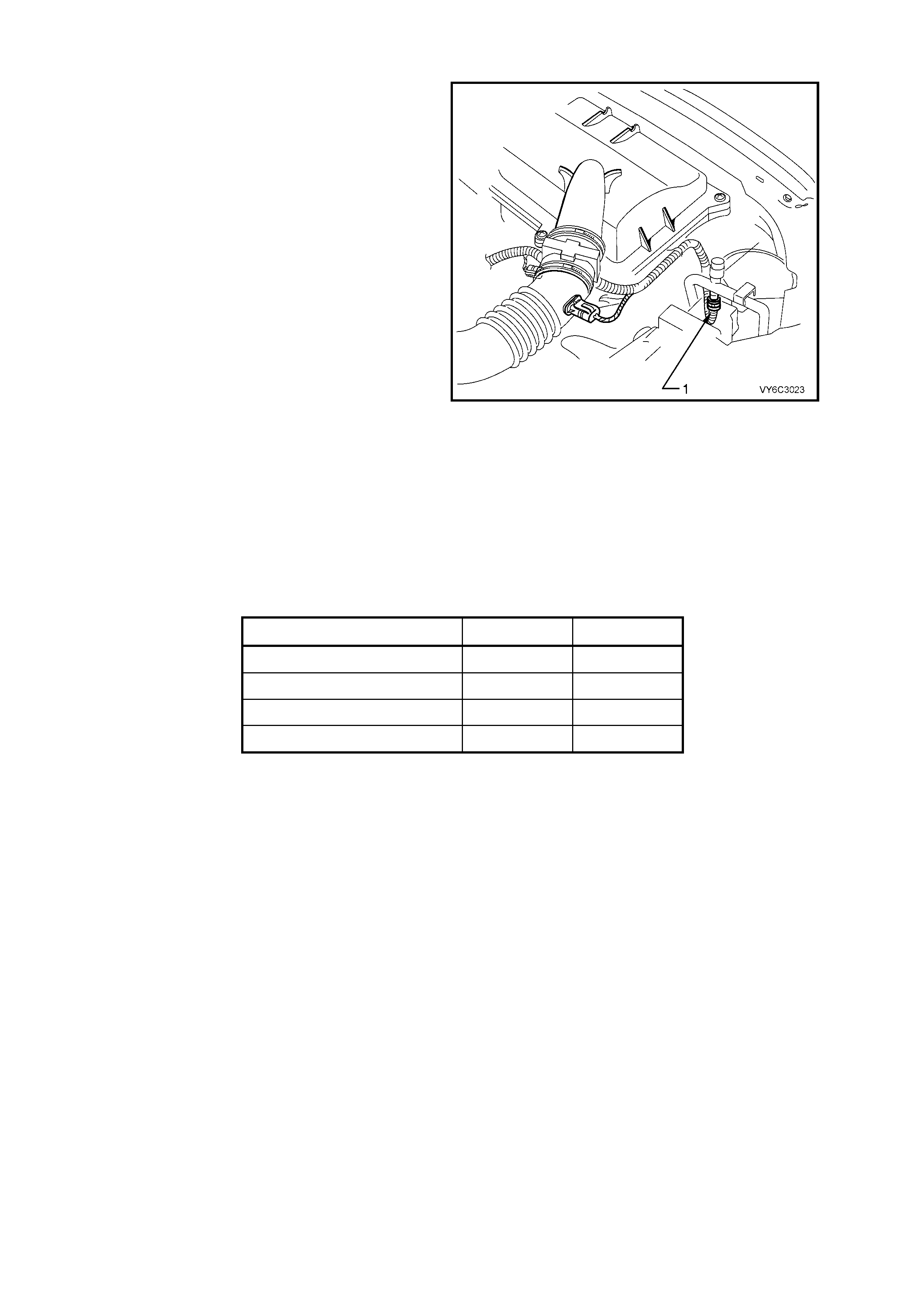

The engine coolant level switch is located in the

coolant s urge tank. T he engine coolant level switch

is serviceable only by replacing the surge tank.

Refer to Section 6B3 ENGINE COOLING, GEN III

V8 ENGINE, for surge tank replacement.

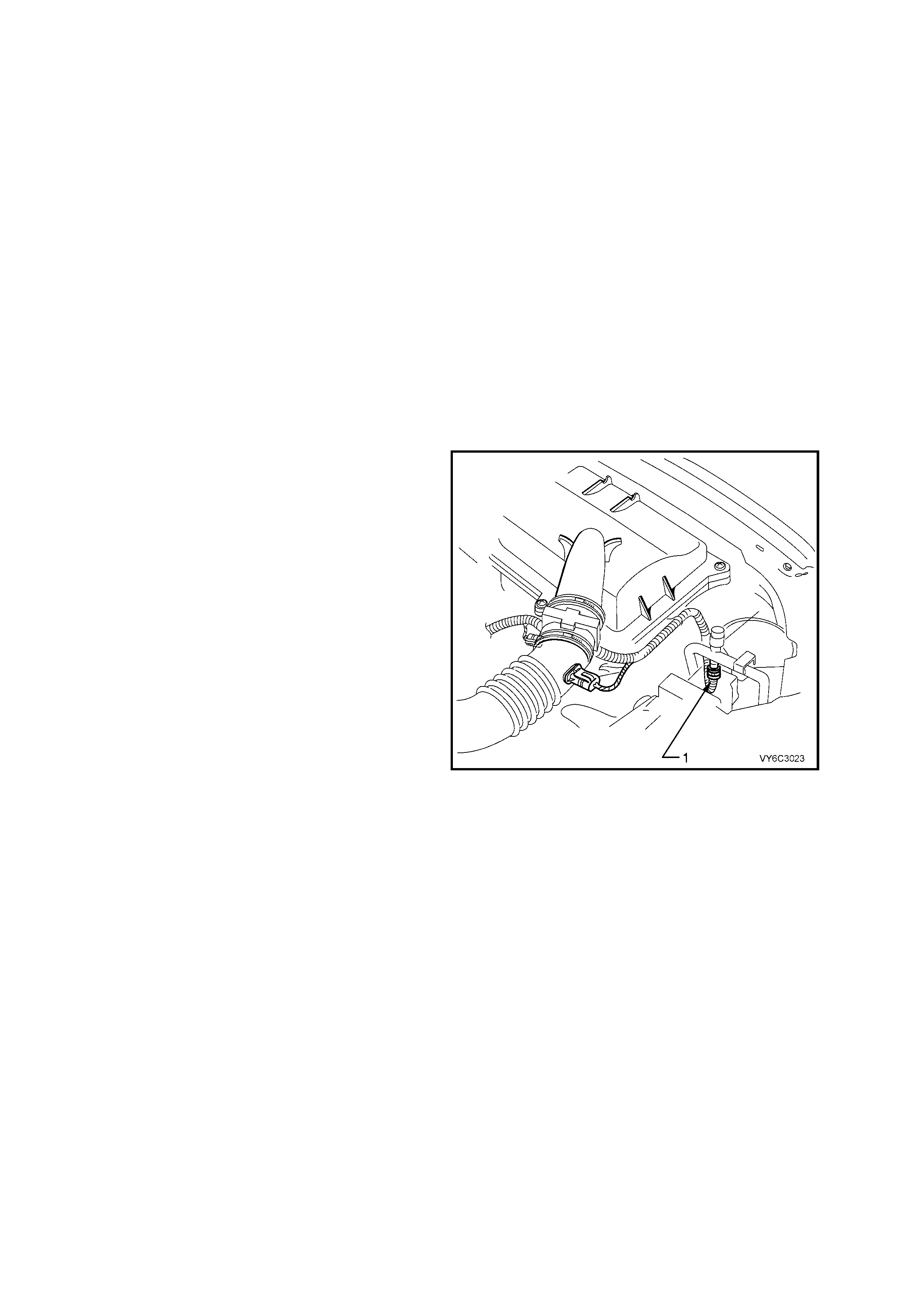

Figure 6C3-1-26 – Coolant Level Switch Location

Figure 6C3-1-27 – Engine Coolant Level Switch Circuit

MASS AIR FLOW (MAF) SENSOR

The Mass Air Flow (MAF) sensor utilises a heated

element type of operation. Heated elements in the

MAF are plac ed in the air f low stream of the engine

intake system. The heating elements are

maintained at a constant temperature differential

above the air temperature.

The amount of elec tric al power requir ed to maintain

the heated element at the proper temperature is a

direct function of the mass flow rate of the air past

the heated elements.

The following DTCs are set when the PCM detects

a malfunction in the MAF sensor circuit:

• DTC P0101: Mass Air Flow System

Performance.

• DTC P0102: MAF Sensor Circuit Low

Frequency.

• DTC P0103: MAF Sensor Circuit High

Frequency.

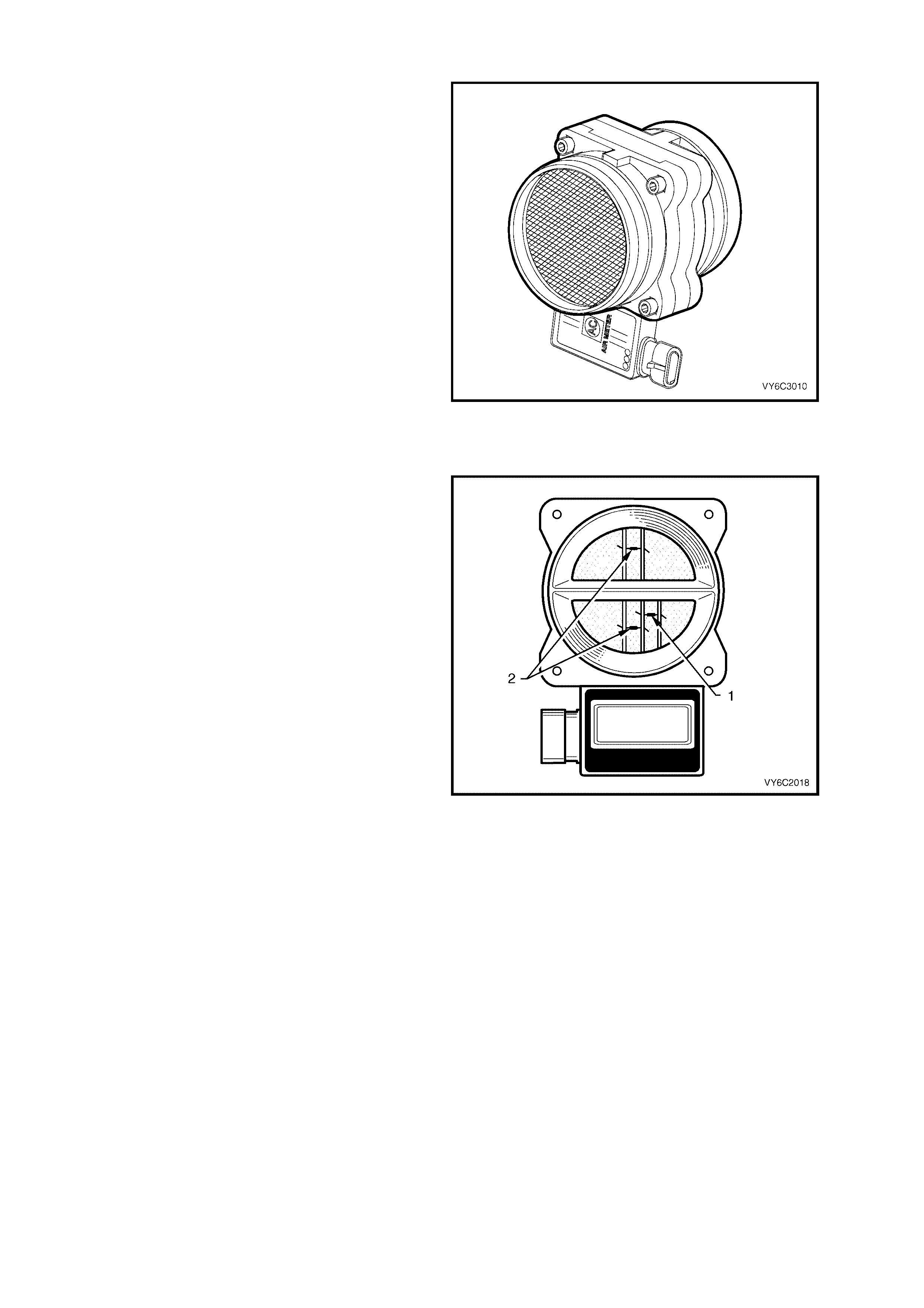

Figure 6C3-1-28 – Mass Air Flow (MAF) Sensor

Three sensing elements are used in this system.

One senses ambient air temperature (1) and uses

two calibrated resis tor s to es tablis h a voltage that is

always a function of ambient temperature. This

ambient sensor is mounted in the lower half of the

sensor housing.

The other two sens ing elem ents (2) are heated to a

predetermined temperature that is significantly

above ambient air temperature. The two heated

elements are connected electrically in parallel and

mounted directly in the air flow stream of the

sensor housing.

One sensor is in the top and the other sensor is in

the bottom of the sensor housing. This is done so

that the air meter is less sensitive to upstream

ducting configurations that could skew the flow of

air through the housing.

As air passes over the heated elements during

engine operation they begin to cool. By measuring

the amount of electrical power required to maintain

the heated elements at the predetermined

temperature above ambient temperature the mass

air flow rate can be determined.

Once the mass air flow sensor has developed an

internal signal related to the mass air flow rate, it

must send this information to the PCM.

Figure 6C3-1-29 – MAP Sensor Elements

In order to preserve the accuracy and resolution of

the sm all voltage s ignal in the mass air flow sensor,

it is converted to a frequency signal by a voltage

oscillator and sent to the PCM.

The s ignal that is sent from the MAF sensor is sent

in the form of a frequency output. A large quantity

of air passing through the sensor (such as when

accelerating) will be indicated as a high frequency

output. A small quantity of air passing through the

sensor will be indicated as a low frequency output

(such as when decelerating or at idle). The Tech 2

scan tool displays MAF sensor information in

frequency, and in grams per second. At idle the

readings should be low and increase with engine

RPM.

If a problem occurs in the MAF sensor circuit, the

PCM will store a DTC in its memory. The PCM will

activate the Malfunction Indicator Lamp (MIL),

indicating there is a problem. If this occurs, the

PCM will calculate a subs titute mass air flow signal

based on speed density; i.e. RPM, MAP and IAT.

No field service adjustment is necessary or

possible with this MAF sensor.

Legend:

1. Air Cleaner Housing

2. Mass Air Flow (MAF) Sensor

3. Intake Air Temperature (IAT) Sensor.

Figure 6C3-1-30 – MAF Sensor Location

The Mas s Air Flow sensor identification is m ade up

of four number groups:

Legend:

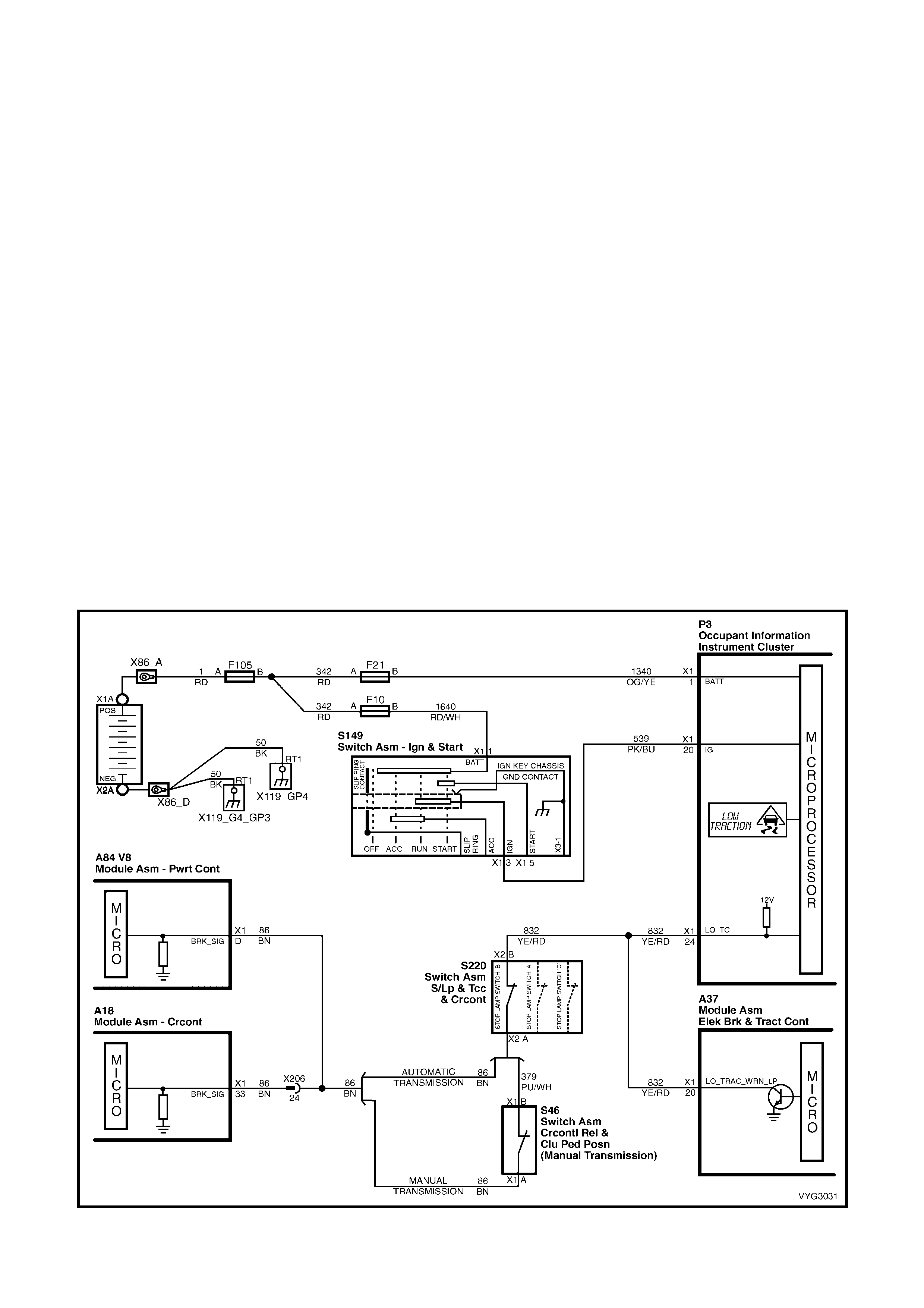

1. Year

2. Julian Date (Day of the Year)

3. Last Four Digits of Part Number

4. Flow Stand Number

Figure 6C3-1-31 – MAF Sensor Identification

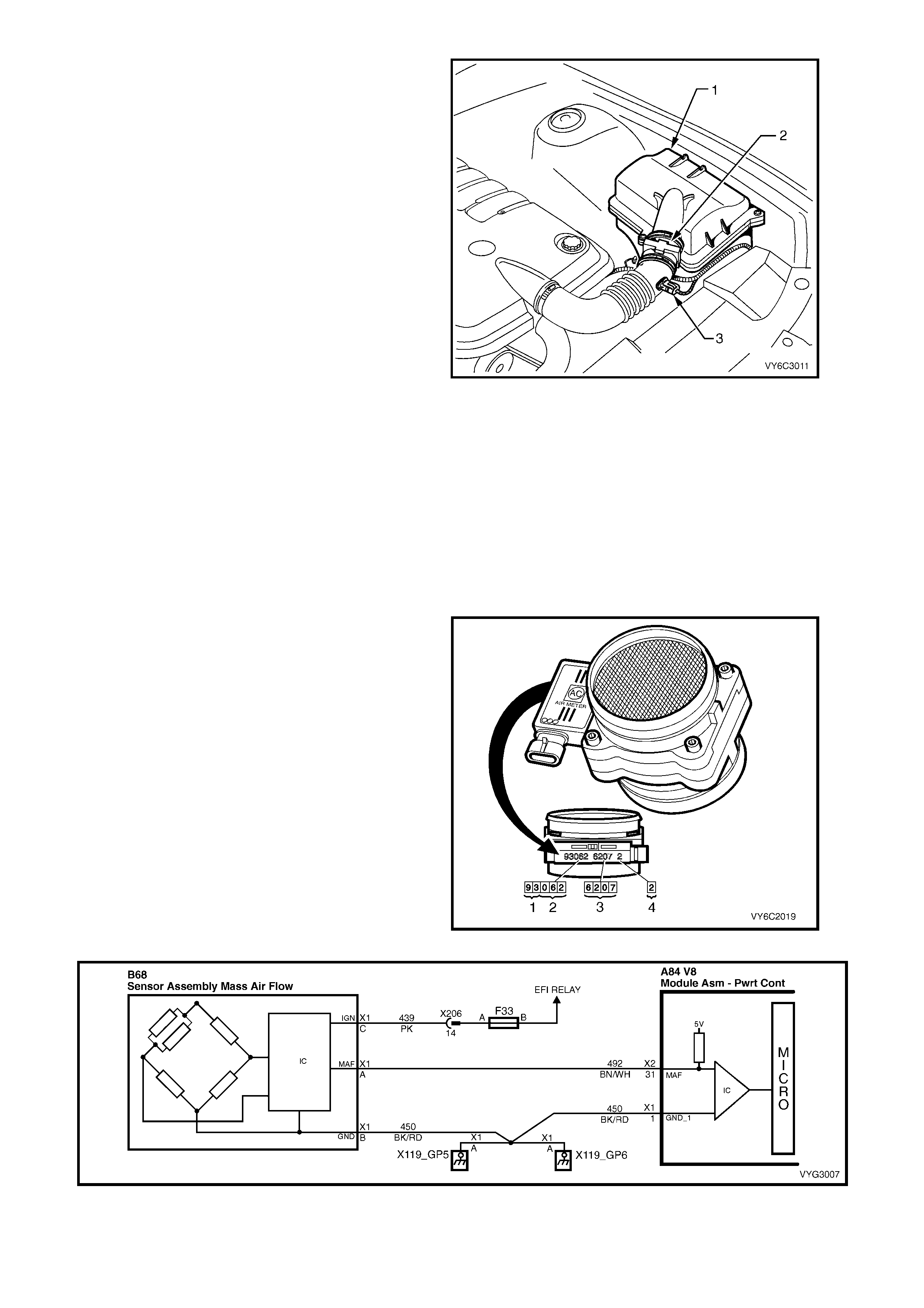

Figure 6C3-1-32 – MAF Sensor Simplified Schematic Circuit

DTC P0101 MASS AIR FLOW SYSTEM PERFORMANCE

Conditions for running DTC P0101

• DTCs P0102, P0103, P0107, P0108, P0121, P0122, P0123 are not set.

• The engine is running.

• The throttle position angle is less than 50% and the engine vacuum (BARO-MAP) is greater than 65 kPa.

• The system voltage is greater than 11 volts but less than 16 volts.

• The change in throttle position is less than 3%.

• All above conditions stable for two seconds.

Conditions for setting DTC P0101

• The MAF frequency is 50% different from the speed density calculation.

• The conditions met for at least five seconds.

Action taken when DTC P0101 Sets

• The PCM activates the Malfunction Indicator Lamp (MIL) when the diagnostic runs and fails.

• The PCM records the operating conditions at the time the diagnostic fails. The PCM stores this information in

the Freeze Frame/Failure Records.

• The PCM utilises speed density (RPM, MAP, IAT) for fuel management.

Conditions for clearing the Malfunction Indicator Lamp (MIL) and DTC P0101

• The PCM deactivates the Malfunction Indicator Lamp (MIL) after one ignition cycle that the diagnostic runs and

does not fail.

• A last test failed (current DTC) clears when the diagnostic runs and does not fail.

DTC P0102 MASS AIR FLOW SENSOR CIRCUIT LOW FREQUENCY

Conditions for running DTC P0102

• The engine speed is greater than 300 RPM.

• The system voltage is at least 11 volts.

Conditions for setting DTC P0102

• The MAF frequency is 50% different from the speed density calculation.

• The conditions met for at least five seconds.

Action taken when DTC P0102 Sets

• The PCM activates the Malfunction Indicator Lamp (MIL) when the diagnostic runs and fails.

• The PCM utilises speed density (RPM, MAP, IAT) for fuel management.

• The PCM records the operating conditions at the time the diagnostic fails. The PCM stores this information in

the Freeze Frame/Failure Records.

• The PCM utilises speed density (RPM, MAP, IAT) for fuel management.

Conditions for clearing the Malfunction Indicator Lamp (MIL) and DTC P0102

• The PCM deactivtes the Malfunction Indicator Lamp (MIL) after one ignition cycle that the diagnostic runs and

does not fail.

• A last test failed (current DTC) clears when the diagnostic runs and does not fail.

DTC P0103 MASS AIR FLOW SENSOR CIRCUIT HIGH FREQUENCY

Conditions for running DTC P0103

• The engine speed is greater than 300 RPM.

• The system voltage is at least 11 volts.

Conditions for setting DTC P0103

• The MAF frequency is greater than 11,250 Hz.

• The conditions met for at least one seconds.

Action taken when DTC P0103 Sets

• The PCM activates the Malfunction Indicator Lamp (MIL) when the diagnostic runs and fails.

• The PCM utilises speed density (RPM, MAP, IAT) for fuel management.

• The PCM records the operating conditions at the time the diagnostic fails. The PCM stores this information in

the Freeze Frame/Failure Records.

Conditions for clearing the Malfunction Indicator Lamp (MIL) and DTC P0103

• The PCM deactivates the Malfunction Indicator Lamp (MIL) after one ignition cycle that the diagnostic runs and

does not fail.

• A last test failed (current DTC) clears when the diagnostic runs and does not fail.

Figure 6C3-1-33 – Mass Air Flow Sensor Circuit

INTAKE AIR TEMPERATURE (IAT) SENSOR

The Intake Air Temperature (IAT) sensor is a

thermistor, (a resistor that changes resistance with

changes in temperature) mounted in the air intake

duct, after the Mass Air Flow (MAF) sensor. Low

intake air temperature produces high resistance in

the sensor, approximately 101k ohms at -40°C,

while high intake air temperature causes low

sensor resistance, approximately 80 ohms at

130°C.

The PCM:

1. Supplies a 5 volt signal voltage to the sensor

through a resistor in the PCM, and

2. Monitors the intake air temperature circuit

voltage, which will change when connected to

the intake air temperature sensor.

The circuit voltage will vary depending on the

resistance of the IAT sensor. The voltage will be

close to the 5 volt level when the sensor is cold,

and will decrease as the sensor warms.

The IAT sensor signal voltage is used by the PCM

to assist in calculating the fuel injector pulse width,

idle speed, canister purge and electronic spark

timing.

Figure 6C3-1-34 – Intake Air Temperature (IAT) Sensor

The following DTCs are set if the PCM detects a

malfunction in the IAT sensor circuit:

• DTC P0112: IAT Sensor Circuit Low Voltage.

• DTC P0113: IAT Sensor Circuit High Voltage.

• DTC P1111: IAT Sensor Circuit Intermittent High

Voltage.

• DTC P1112: IAT Sensor Circuit Intermittent Low

Voltage.

Legend:

1. Air Cleaner Housing

2. Mass Air Flow (MAF) Sensor

3. Intake Air Temperature (IAT) Sensor.

Figure 6C3-1-35

Intake Air Temperature (IAT) Sensor Location

DTC P0112 INTAKE AIR TEMPERATURE SENSOR CIRCUIT LOW VOLTAGE

Conditions for running DTC P0112

• DTC(s) P0101, P0102, P0103, P0117, P0118, are not set.

• The engine run time is greater than 30 seconds.

• The vehicle speed is less than 40 km/h.

Conditions for setting DTC P0112

• The Intake Air Temperature is greater than 139° C.

• The conditions met for at least 20 seconds.

Action taken when DTC P0112 Sets

• The PCM stores the DTC information into memory when the diagnostic runs and fails.

• The Malfunction Indicator Lamp (MIL) will not be activated.

• The PCM will substitute a default Intake Air Temperature value of 25° C.

• The PCM records the operating conditions at the time the diagnostic fails. The PCM stores this information in

the Freeze Frame/Failure Records.

Conditions for clearing the Malfunction Indicator Lamp (MIL) and DTC P0112

• A last test failed (current DTC) clears when the diagnostic runs and does not fail.

DTC P0113 INTAKE AIR TEMPERATURE SENSOR CIRCUIT HIGH VOLTAGE

Conditions for running DTC P0113

• DTC(s) P0101, P0102, P0103, P0117, P0118, are not set.

• The engine run time is greater than 100 seconds.

• The engine coolant temperature is greater than 0° C.

• The vehicle speed is less than 11 km/h.

Conditions for setting DTC P0113

• The Intake Air Temperature is at or below –35° C.

• The conditions met for at least 20 seconds.

Action taken when DTC P0113 Sets

• The PCM stores the DTC information into memory when the diagnostic runs and fails.

• The Malfunction Indicator Lamp (MIL) will not be activated.

• The PCM will substitute a default Intake Air Temperature value of 25° C.

• The PCM records the operating conditions at the time the diagnostic fails. The PCM stores this information in

the Freeze Frame/Failure Records.

Conditions for clearing the Malfunction Indicator Lamp (MIL) and DTC P0113

• A last test failed (current DTC) clears when the diagnostic runs and does not fail.

DTC P1111 INTAKE AIR TEMPERATURE SENSOR CIRCUIT INTERMITTENT HIGH VOLTAGE

Conditions for running DTC P1111

• DTC(s) P0101, P0102, P0103, P0117, P0118, are not set.

• The engine run time is greater than 100 seconds.

• The engine coolant temperature is greater than 0° C.

• The vehicle speed is less than 11 km/h.

• The Mass Air Flow is less than 15 g/s.

Conditions for setting DTC P1111

• The Intake Air Temperature is at or below –35° C.

• The conditions present for 0.3 seconds.

Action taken when DTC P1111 Sets

• The PCM stores the DTC information into memory when the diagnostic runs and fails.

• The Malfunction Indicator Lamp (MIL) will not be activated.

• The PCM will substitute a default Intake Air Temperature value of 25° C.

• The PCM records the operating conditions at the time the diagnostic fails. The PCM stores this information in

the Freeze Frame/Failure Records.

Conditions for clearing the Malfunction Indicator Lamp (MIL) and DTC P1111

• A last test failed (current DTC) clears when the diagnostic runs and does not fail.

DTC P1112 INTAKE AIR TEMPERATURE SENSOR CIRCUIT INTERMITTENT LOW VOLTAGE

Conditions for running DTC P1112

• DTC(s) P0101, P0102, P0103, P0117, P0118, are not set.

• The engine run time is greater than 30 seconds.

• The vehicle speed is less than 40 km/h.

Conditions for setting DTC P1112

• The Intake Air Temperature is at or above 139° C.

• The conditions present for 0.3 seconds.

Action taken when DTC P1112 Sets

• The PCM stores the DTC information into memory when the diagnostic runs and fails.

• The Malfunction Indicator Lamp (MIL) will not be activated.

• The PCM will substitute a default Intake Air Temperature value of 25° C.

• The PCM records the operating conditions at the time the diagnostic fails. The PCM stores this information in

the Freeze Frame/Failure Records.

Conditions for clearing the Malfunction Indicator Lamp (MIL) and DTC P1112

• A last test failed (current DTC) clears when the diagnostic runs and does not fail.

Figure 6C3-1-36 – Intake Air Temperature Sensor Circuit

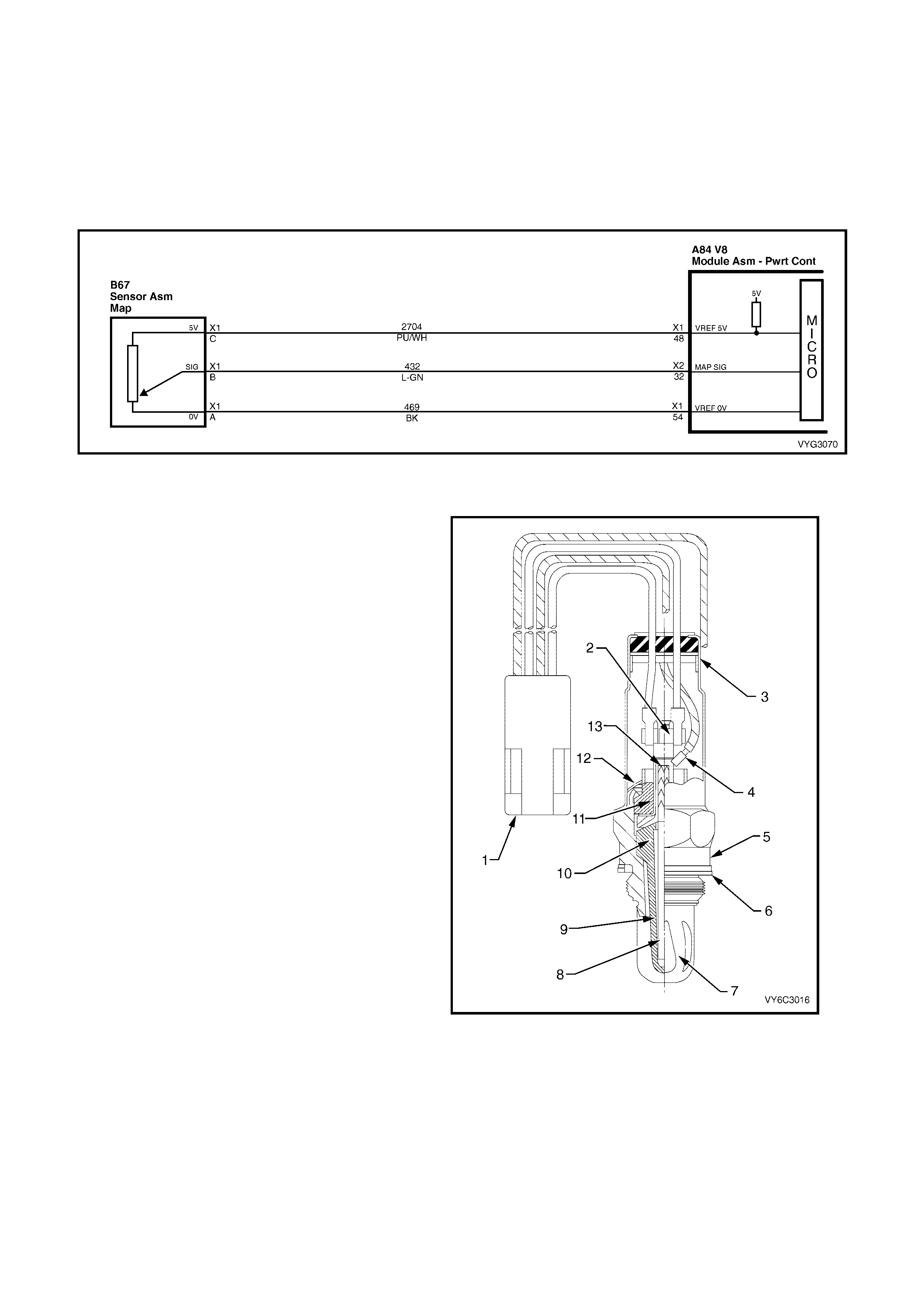

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

The Manifold Absolute Pressure (MAP) sensor

measures the changes in the intake manifold

pressure which result from engine load (intake

manifold vacuum) and RPM changes and converts

these into a voltage output.

The c ontrol module s ends a 5-volt supply voltage to

the MAP sensor. As the manifold pressure

changes, the output voltage of the sensor also

changes. By monitoring the sensor output voltage,

the control module knows the manifold pressure.

A closed throttle during engine coast down would

produce a relatively low MAP output, while a wide

open throttle would produce a high output. This

high output is produced because the pressure

inside the manifold is the same as outside the

manifold during wide open throttle, so it measures

100% of outside air pressure (atmospheric

pressure). The MAP sensor is also used, to

measure barometric pressure, allowing the control

module to m ak e adjustm ents f or differ ent operating

altitudes.

With the engine running, the MAP output voltage

signal should vary from about 1.0 to 1.5 volts at

idle, to about 4.0 to 4.5 volts at wide open throttle.

This MAP output voltage signal is sent to the

control module MAP sensor input signal terminal.

With ignition on and engine stopped, the manifold

pressure is equal to atmospheric (or barometric)

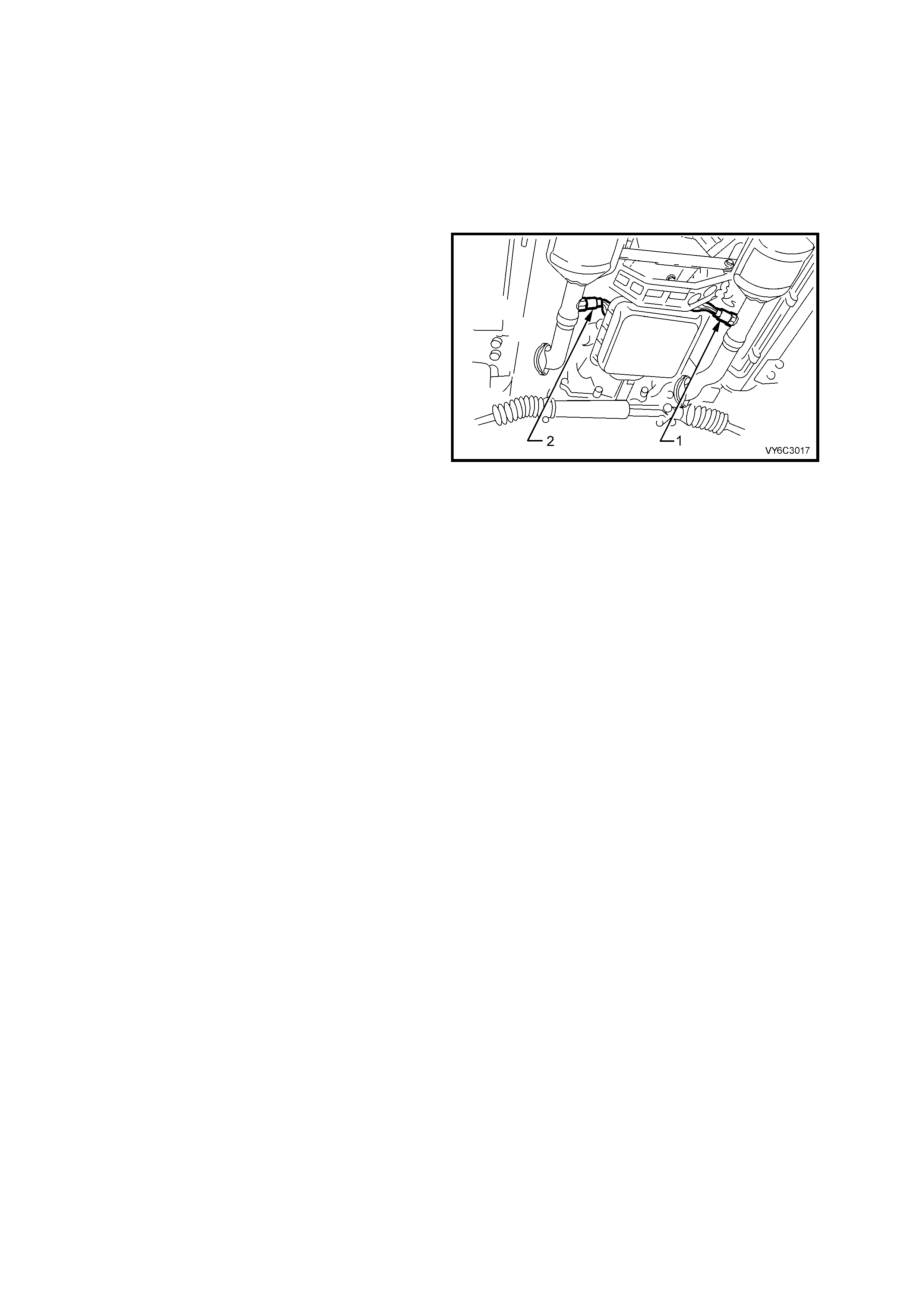

pressure and the signal voltage output will be high,

close to 5 volts at s ea level. T his voltage is us ed by

the PCM as an indication of engine load and the

atmospheric pressure, referred to as BARO.

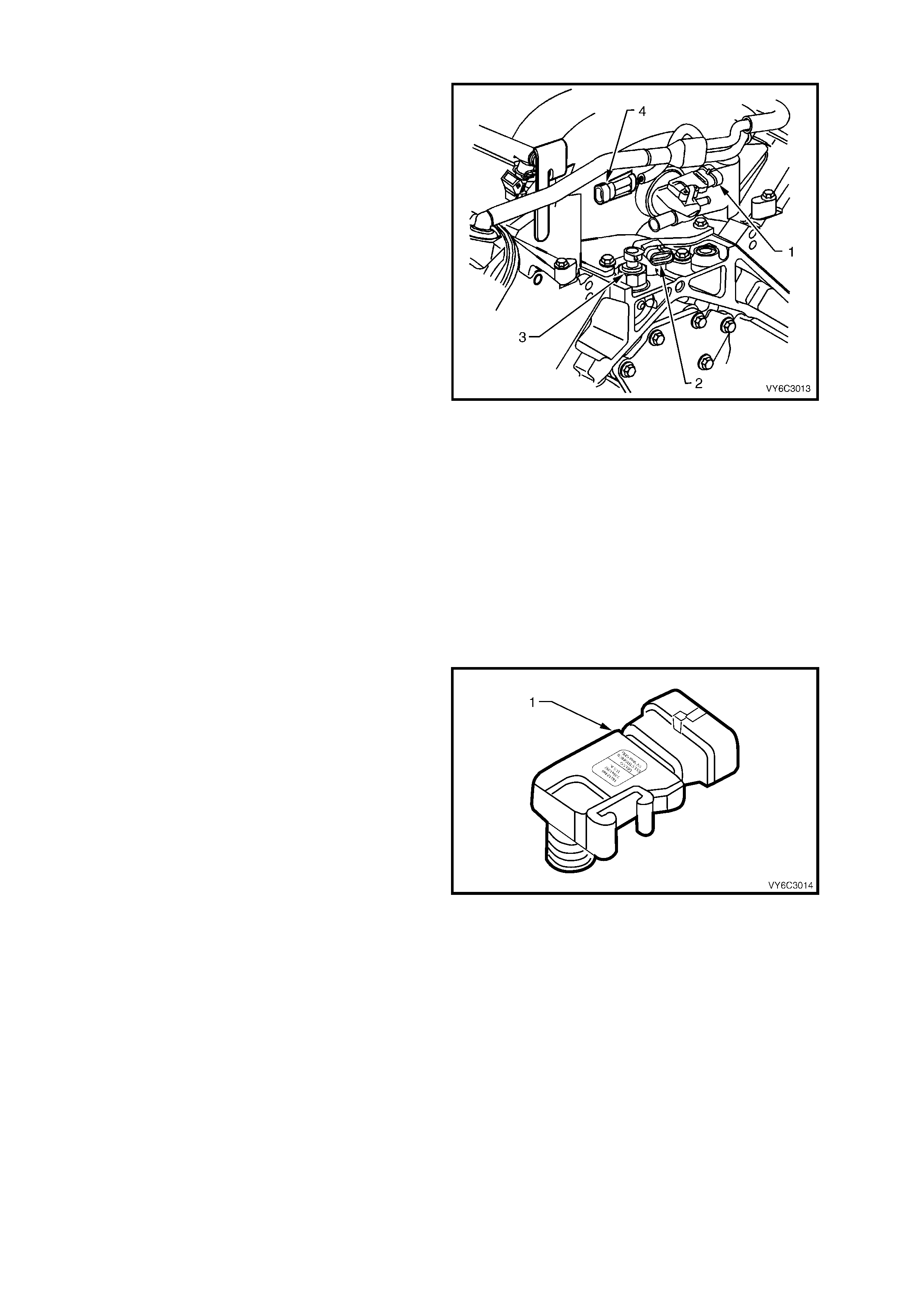

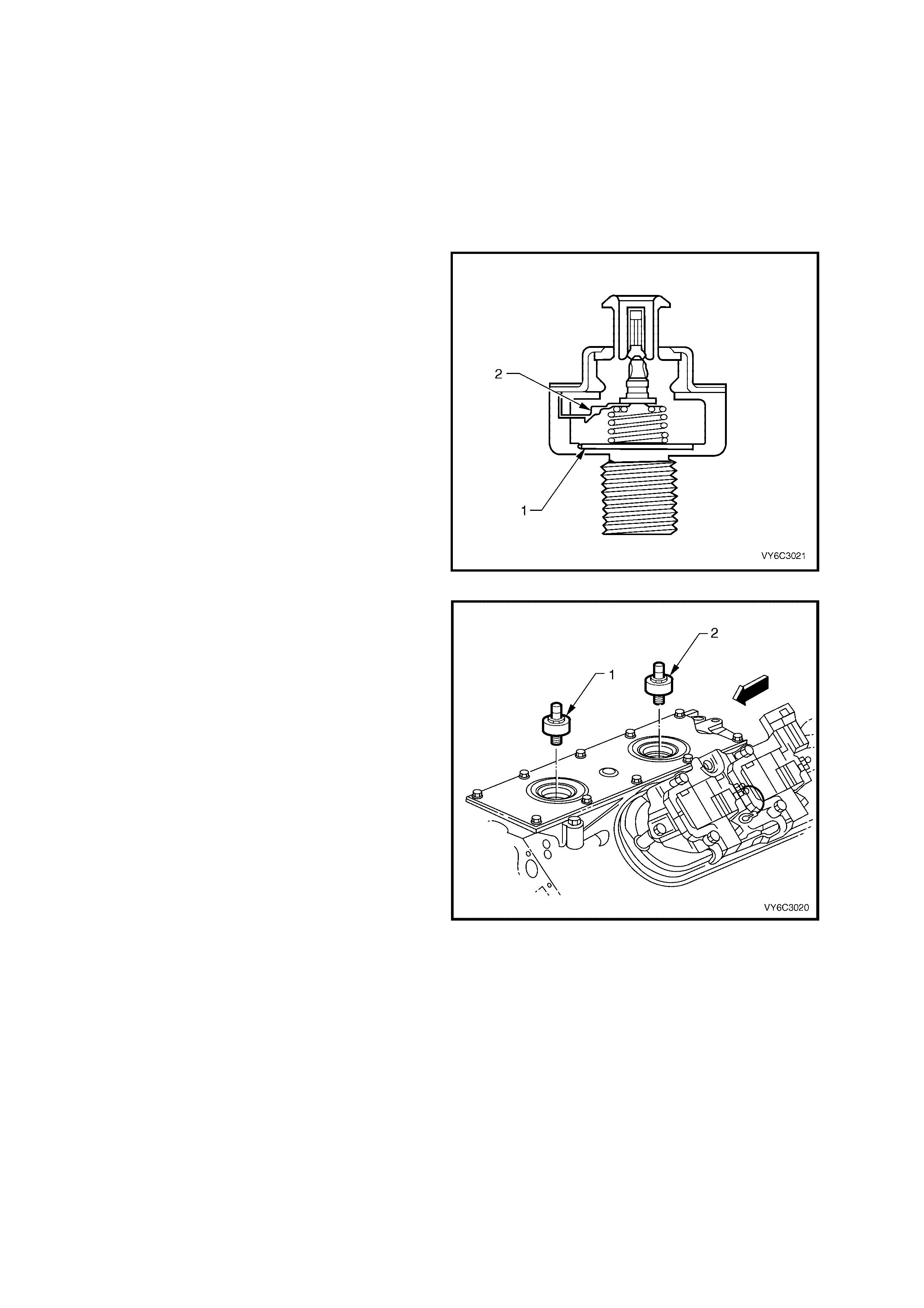

Figure 6C3-1-37

Manifold Absolute Pressure (MAP) Sensor Location

Legend:

1. Manifold Absolute Pressure (MAP) Sensor

2. Camshaft Position (CMP) Sensor

3. Oil Pressure Sensor

4. Connector to Knock Sensor Jumper Harness

The MAP sensor (1) is used for the following:

• Altitude determination.

• Ignition timing control.

• Speed density fuel management default.

Figure 6C3-1-38

Manifold Absolute Pressure (MAP) Sensor

SPEED DENSITY SYSTEM

Three specific data sensors provide the PCM with

the basic information for the fuel management

portion of its operation. That is three specific

signals to the PCM establish the engine speed and

air dens ity factor s. The engine speed s ignal comes

from the Crankshaft Position (CKP) Sensor.

The PCM us es this inf or mation to determine engine

speed (RPM). Air density is derived from IAT and

MAP sensor inputs. The IAT sensor measures the

air tem perature that is entering the engine. T he IAT

signal works in conjunction with the MAP sensor to

determ ine air dens ity. This inf or mation f r om the IAT

and MAP sensors is used by the PCM to control

injector pulse width.

The speed density system is only needed when

there is a Mass Air Flow (MAF) sensor m alfunc tion.

If the PCM detects a malfunction with the MAF

sensor circuit, the PCM will default to Speed

Density fuel management.

The following DTCs are set if the PCM detects a

malfunction in the MAP sensor circuit:

• DTC P0107: MAP Sensor Circuit Low Voltage.

• DTC P0108: MAP Sensor Circuit High Voltage.

Legend:

1. Manifold Absolute Pressure (MAP) Sensor

2. MAP Sensor Harness Connector

Figure 6C3-1-39

Manifold Absolute Pressure (MAP) Sensor Location

DTC P0107 MANIFOLD ABSOLUTE PRESSURE SENSOR CIRCUIT LOW VOLTAGE

Conditions for running DTC P0107

• No TP or ECT sensor DTCs are set.

• The engine is running.

• The TP angle is above 20% when the engine speed is greater than 1200 RPM.

OR

• The TP angle is below 18% when the engine speed is below 1000 RPM.

Conditions for setting DTC P0107

• The MAP sensor voltage is less than 0.10 volts.

• The conditions present for at least two seconds.

Action taken when DTC P0107 Sets

• The PCM activates the Malfunction Indicator Lamp (MIL) when the diagnostic runs and fails.

• The PCM records the operating conditions at the time the diagnostic fails. The PCM stores this information in

the Freeze Frame/Failure Records.

Conditions for clearing the Malfunction Indicator Lamp (MIL) and DTC P0107

• T he PCM deactivates the Malf unction Indic ator Lam p (MIL) after one ignition cycle that the diagnostic runs and

does not fail.

• A last test failed (current DTC) clears when the diagnostic runs and does not fail.

DTC P0108 MANIFOLD ABSOLUTE PRESSURE SENSOR CIRCUIT HIGH VOLTAGE

Conditions for running DTC P0108

• No TP or ECT sensor DTCs are set.

• The engine is running.

• The TP angle is above 20% when the engine speed is greater than 1000 RPM.

OR

• The TP angle is below 18% when the engine speed is below 1200 RPM.

Conditions for setting DTC P0108

• The MAP sensor voltage is greater than 4.3 volts.

• The conditions present for at least four seconds.

Action taken when DTC P0108 Sets

• The PCM activates the Malfunction Indicator Lamp (MIL) when the diagnostic runs and fails.

• The PCM records the operating conditions at the time the diagnostic fails. The PCM stores this information in

the Freeze Frame/Failure Records.

Conditions for clearing the Malfunction Indicator Lamp (MIL) and DTC P0108

• T he PCM deactivates the Malf unction Indicator Lam p (MIL) after one ignition cycle that the diagnostic runs and

does not fail.

• A last test failed (current DTC) clears when the diagnostic runs and does not fail.

Figure 6C3-1-40 – MAP Sensor Circuit

HEATED OXYGEN SENSORS (HO2S)

The GEN III V8 engine incorporates the use of

Heated Exhaust Gas Oxygen Sensors (HO2S). The

oxygen sensors are the key to closed-loop fuel

control. The PCM uses information from the

oxygen sensors to precisely fine tune its fuel

injector pulse width calculations, based on the

unused, left-over oxygen content in the exhaust.

The system uses, two four wire heated oxygen

sensors. The oxygen sensors have a Zirconia

element that, when heated to temperatures above

360° C, produces voltages based on the amount of

oxygen content surrounding the tip, as compar ed to

oxygen in the atmosphere.

The sensors are mounted in the exhaust pipe with

the sensing portion exposed to the exhaust gas

stream. When the sensor has reached an operating

temperature of more than 360° C, it acts as a

voltage generator, producing a rapidly changing

voltage of between 10 - 1000 millivolts. This voltage

output is dependent upon the ox ygen content in the

exhaust gas, as compared to the sensor's

atmospheric oxygen reference cavity. The

refer ence cavity of an oxygen sensor is exposed to

the atmosphere through the connector, by air

entering the atmospheric chamber by moving

through the wires between the conductor material

and the insulation.

The oxygen sensors have an internal heating

element that is used to heat the Zirconia element

faster inside the sensors, thereby decreasing the

amount of time before the fuel control system can

begin running in closed loop.

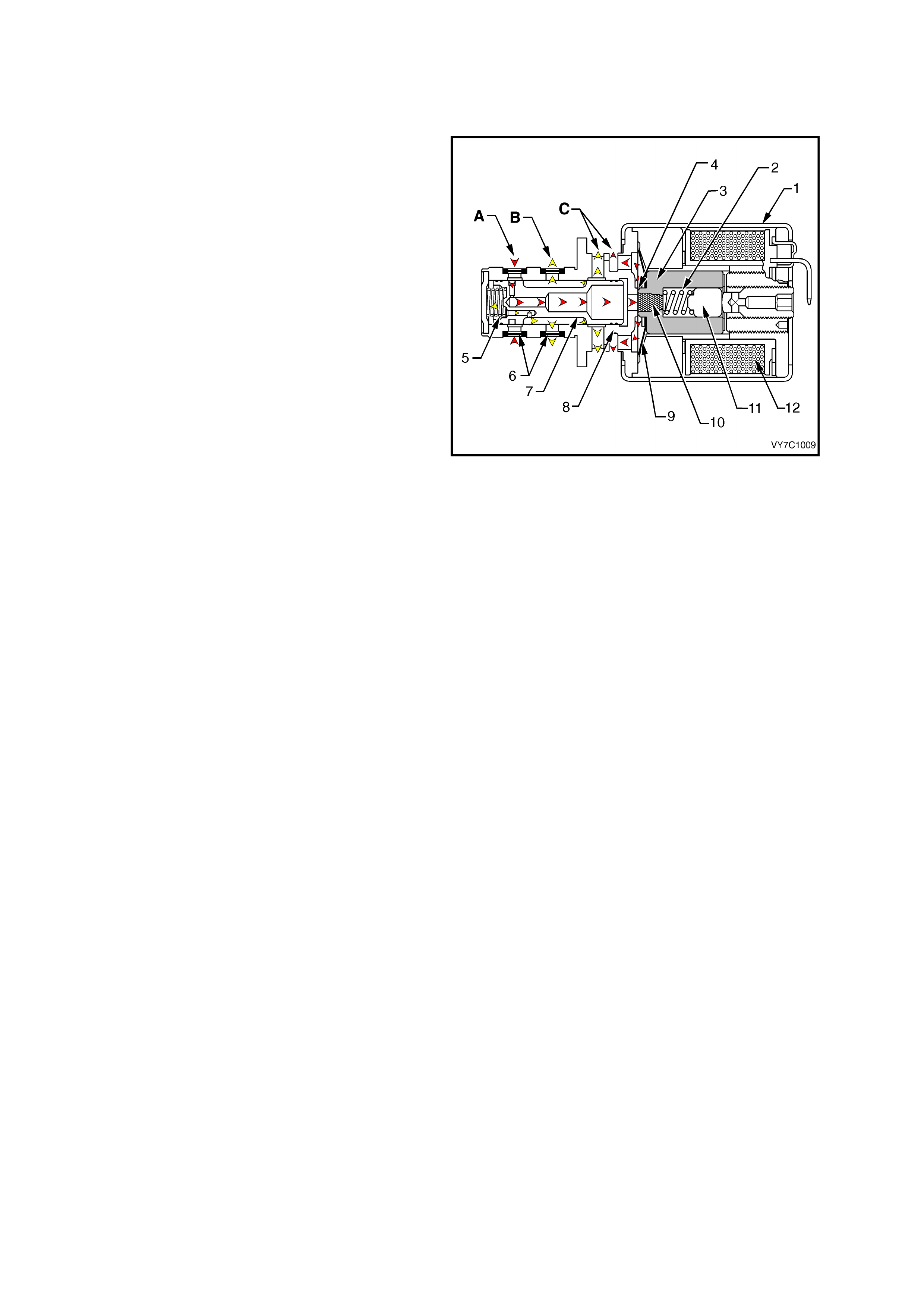

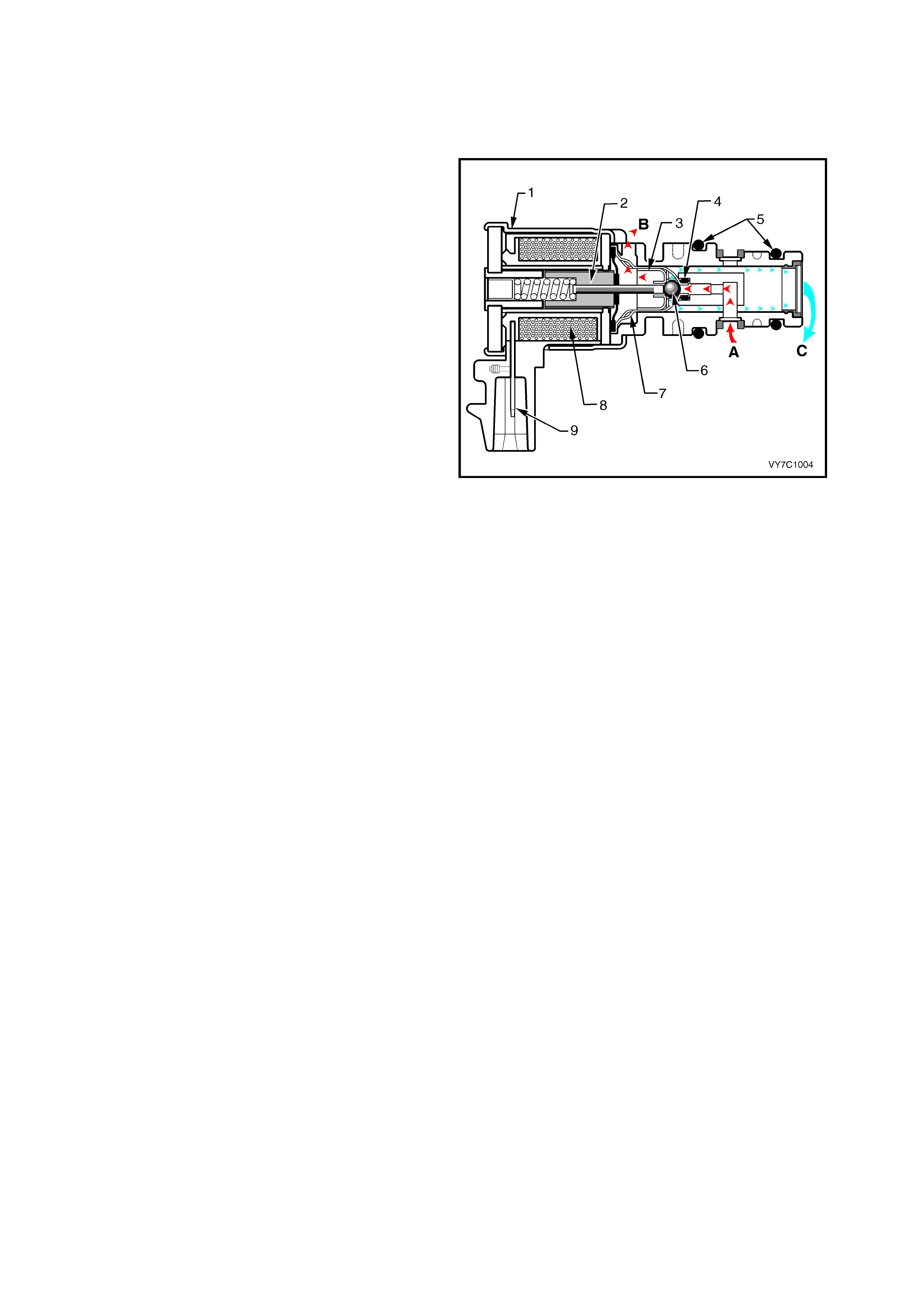

Figure 6C3-1-41

Sectioned – Heated Oxygen Sensor (HO2S) Cutaway

The heated oxygen sensors have four wires, with two for the internal Positive Temperature Co-efficient (PTC)

thermistor type heater circuit. One of these wires has 12 volts continually applied to the heater element

whenever the ignition is on. The other wire is f or the heater element ground. When the sensor is cold, m ax im u m

current (approximately 4 amps) flows through the heater circuit and gradually reduces to approximately 0.5

amps as the sensor reaches full operating tem perature. The other two sensor wires are for the sensor's signal

to the PCM, and the sensor ground.

Legend (Figure 6C3-1-14)

1. Four Wire In-Line Connector

2. Heater Termination

3. Water Shield Assembly

4. Sensor Lead

5. Sensor Body

6. Seat Gasket

7. Outer Electrode and Protective Coating

8. Rod Heater

9. Inner Electrode

10. Zirconia Element

11. Insulator

12. Clip Ring

13. Gripper

The reference cavity of a heated oxygen sensor is

exposed to the atmosphere by the air that passes

between the wire strands and insulation of the

oxygen sensor leads. The signal and heater leads

used on the oxygen sensor are of the stranded

type. Stranded leads have small spaces between

the wire strands and the insulation. These spaces

allow a satisfactory amount of air to pass through

the lead to maintain an adequate air reference.

When the sensor is cold, it produces either no

voltage, or an unusable, slowly changing one. Also

when cold, its internal electrical resistance is

extremely high – many million ohms. The PCM

always supplies a steady 450 millivolt, very low

current bias voltage to the oxygen sensor circuit.

When the sensor is cold and not producing any

voltage, the PCM detects only this steady bias

voltage. As the sensor begins heating, its internal

resistance decreases and it begins producing a

rapidly changing voltage that will overshadow the

PCM's supplied steady bias voltage.

When the PCM detects the changing voltage, it

knows the oxygen sensor is hot and its output

voltage can be used for fine-tuning the fuel injector

pulse width.

Figure 6C3-1-42

Heated Oxygen Sensor (HO2S) Locations

Legend:

1. Right Hand Oxygen Sensor, Bank 2 Sensor 1

2. Left Hand Oxygen Sensor, Bank 1 Sensor 1

The PCM monitors the oxygen sensor's changing voltage for going above and below a mid-range voltage band

(approximately 300 - 600 millivolts), to help decide when to operate in the closed-loop mode.

When the fuel system is correctly operating in the closed-loop mode, the oxygen sensor voltage output is rapidly

changing several tim es per second, f luctuating from approximately 100m V (high oxygen content – lean mixture) to

900mV ( low ox ygen content – rich m ixture). T he PCM monitors the c hanging voltage, and decides the needed fuel

mixture correction.

The oxygen sensors are mounted in the exhaust pipes and are referred to as Bank 1 Sensor 1 (left exhaust pipe)

and Bank 2 Sensor 1 (right exhaust pipe).

NOTE: As an OBD requirement, Bank 1 is always identified by the location of cylinder No. 1. Therefore, it is a

generic term used for all ‘V’ car engines.

The following DTCs set when the PCM detects a HO2S signal circuit that is low:

DTC P0131: Bank 1 Sensor 1 HO2S.

DTC P0151: Bank 2 Sensor 1 HO2S.

The following DTCs set when the PCM detects a HO2S signal circuit that is high:

DTC P0132: Bank 1 Sensor 1 HO2S.

DTC P0152: Bank 2 Sensor 1 HO2S.

The following DTCs set when the PCM detects no HO2S activity:

DTC P0134: Bank 1 Sensor 1 HO2S.

DTC P0154: Bank 2 Sensor 1 HO2S.

A fault in the oxygen sensor heater element or its ignition feed or ground results in an increase in time to Closed

Loop fuel control. This may cause increased emissions, especially at start-up. The following DTCs set when the

PCM detects a malfunction in the HO2S heater circuits:

• DTC P0135: Bank 1 Sensor 1 HO2S heater.

• DTC P0155: Bank 2 Sensor 1 HO2S heater.

RESPONSE TIME

Not only is it necessary for the oxygen sensors to produce voltage signals for rich or lean exhaust, it is also

impor tant to respond quick ly to changes . If the oxygen sensors res pond slowly, the customer m ay complain of poor

fuel economy, rough idle, surging or lack of performance. The PCM will set a DTC that indicates degraded HO2S

performance if a HO2S response switching, transition time, or ratio problem is detected.

DTC P1133: Insufficient Switching Bank 1 Sensor 1.

DTC P1134: Transition Time Ratio Bank 1 Sensor 1.

DTC P1153: Insufficient Switching Bank 2 Sensor 1.

DTC P1154: Transition Time Ratio Bank 2 Sensor 1.

OXYGEN SENSOR CONTAMINANTS

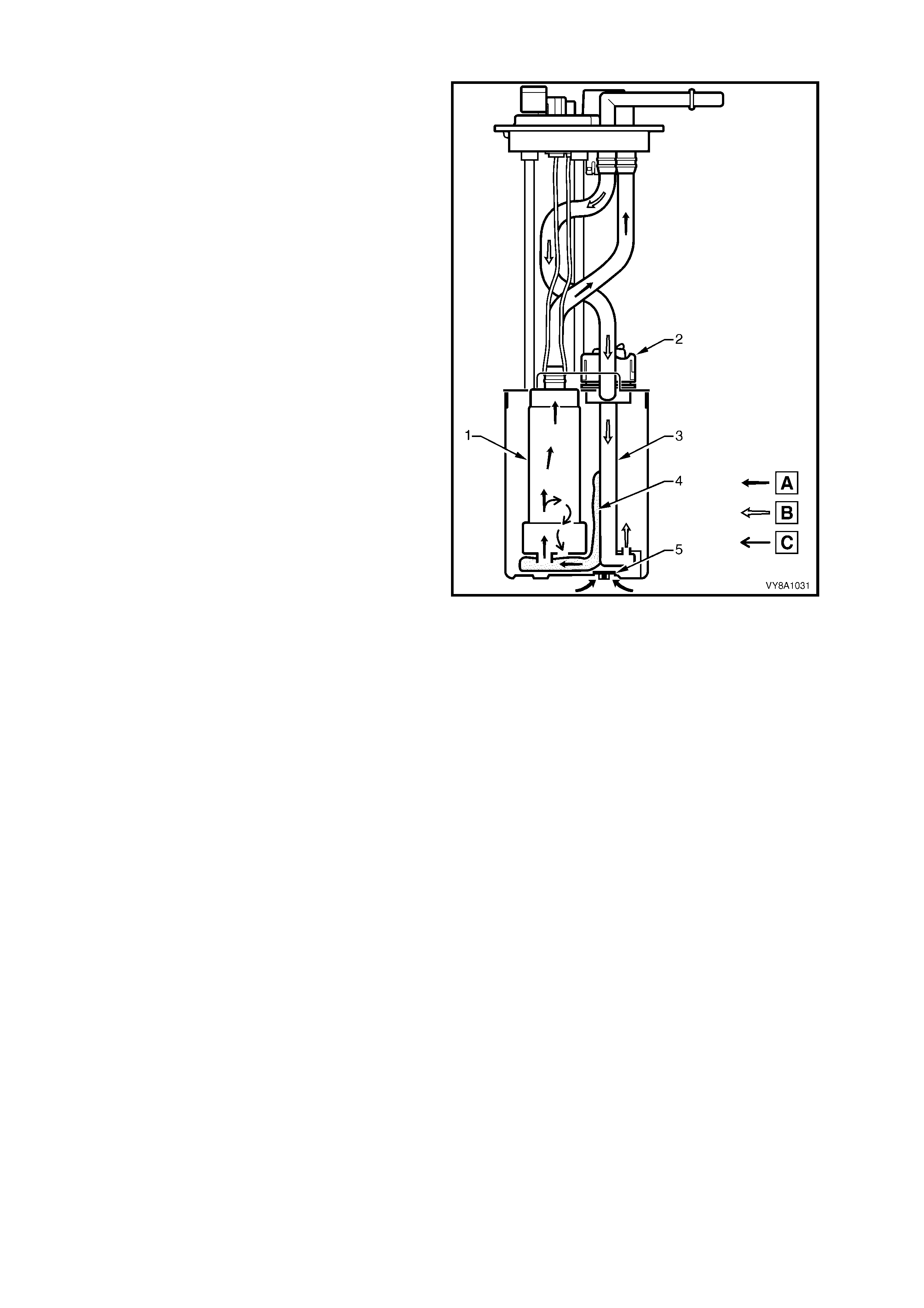

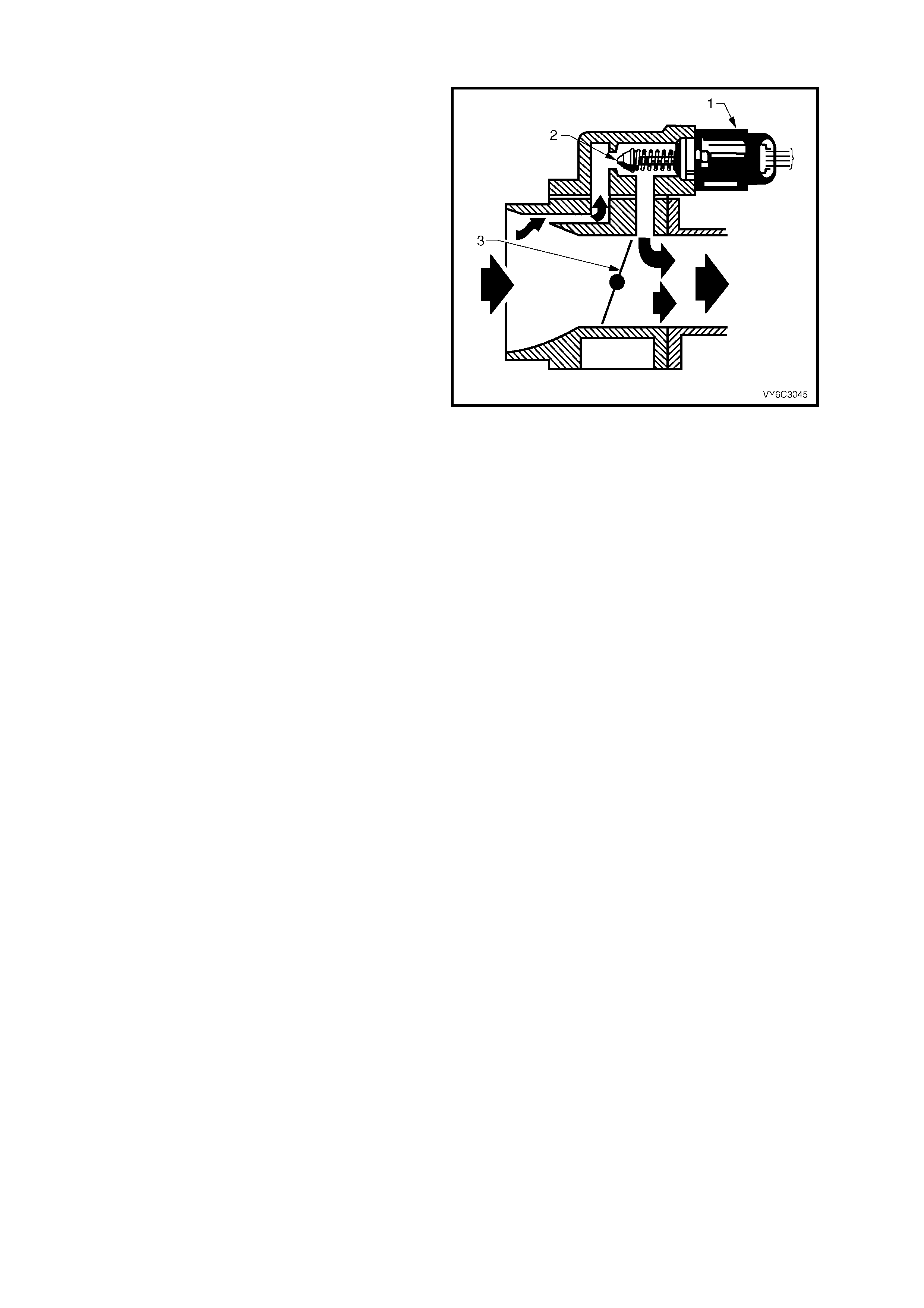

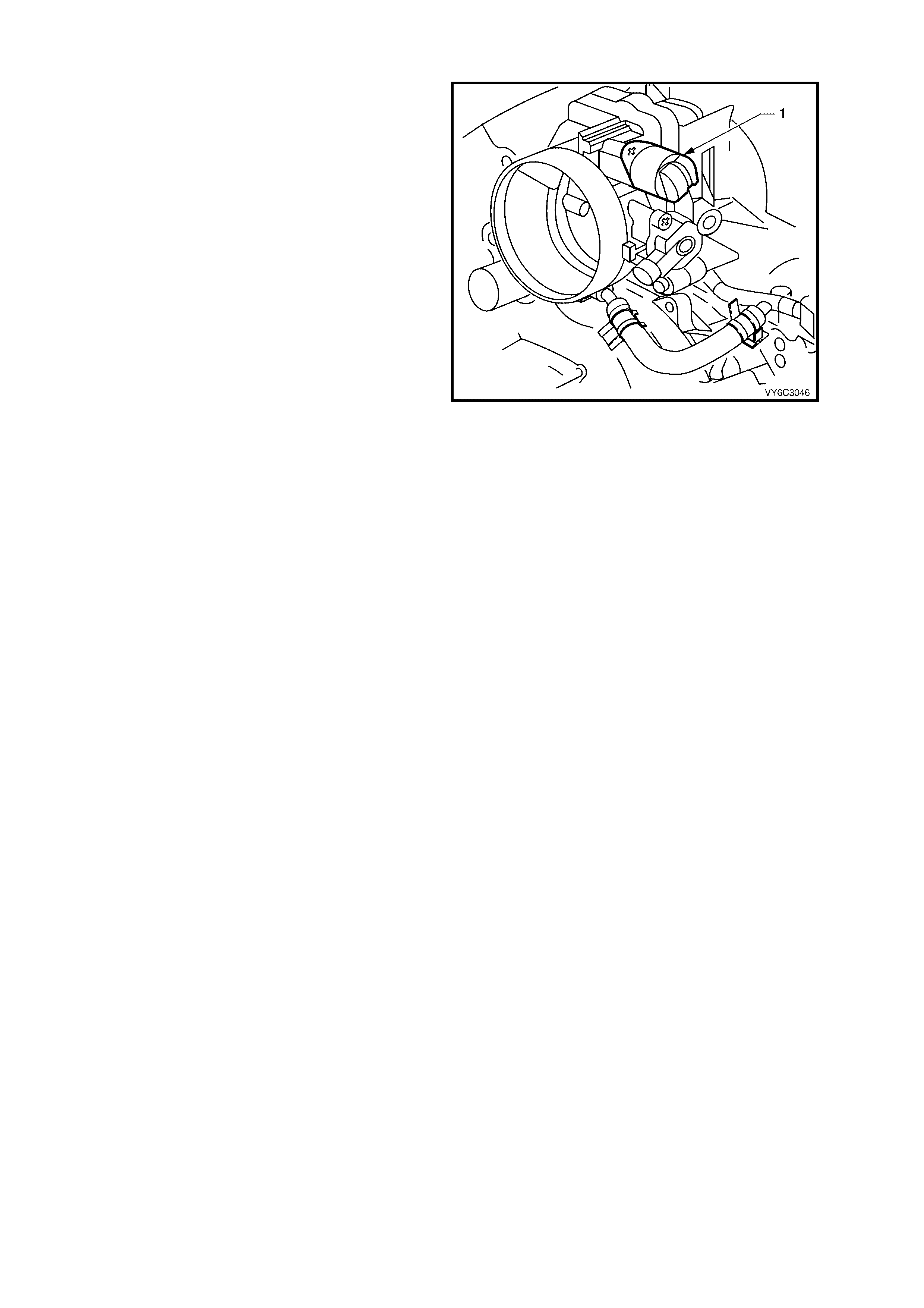

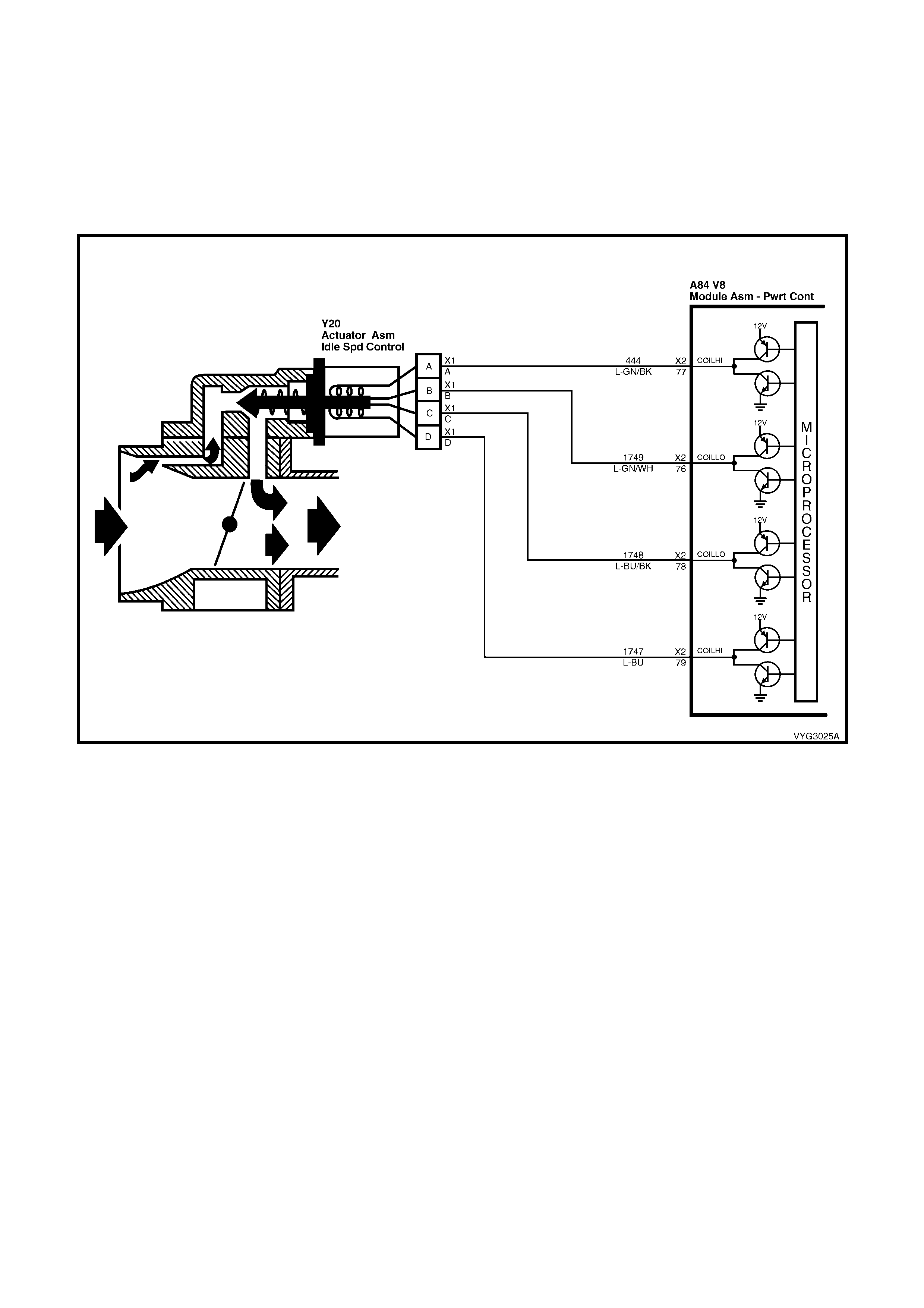

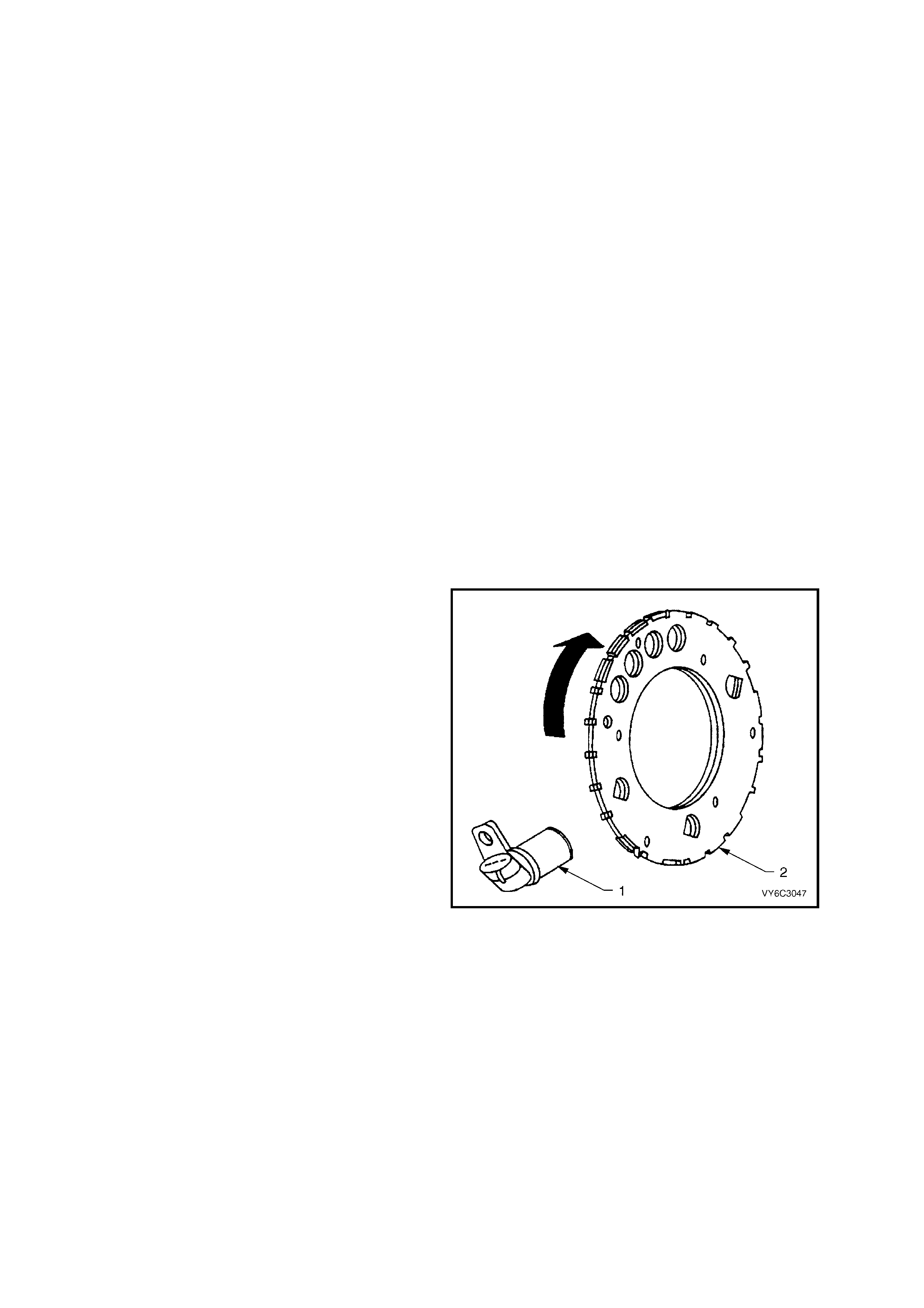

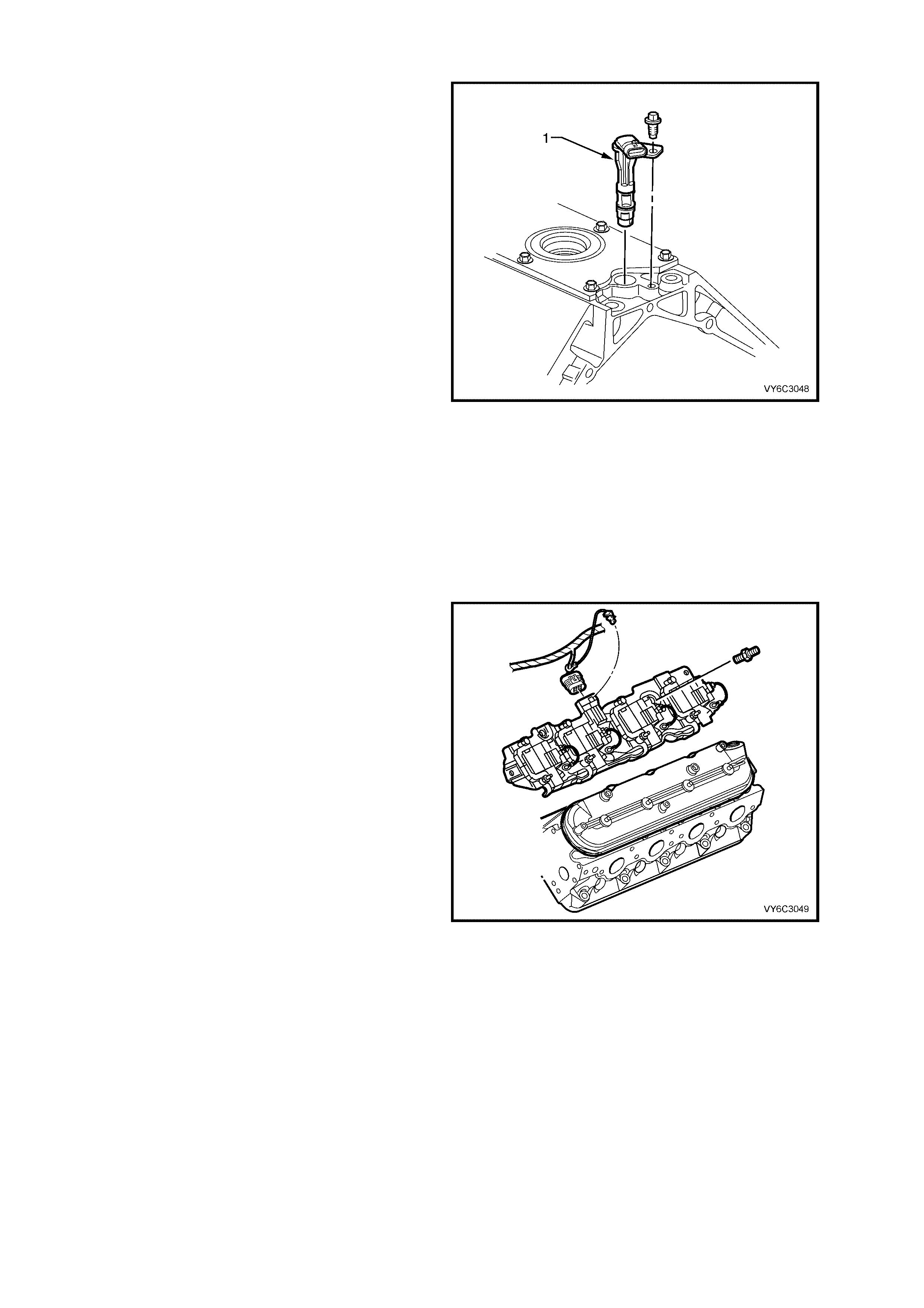

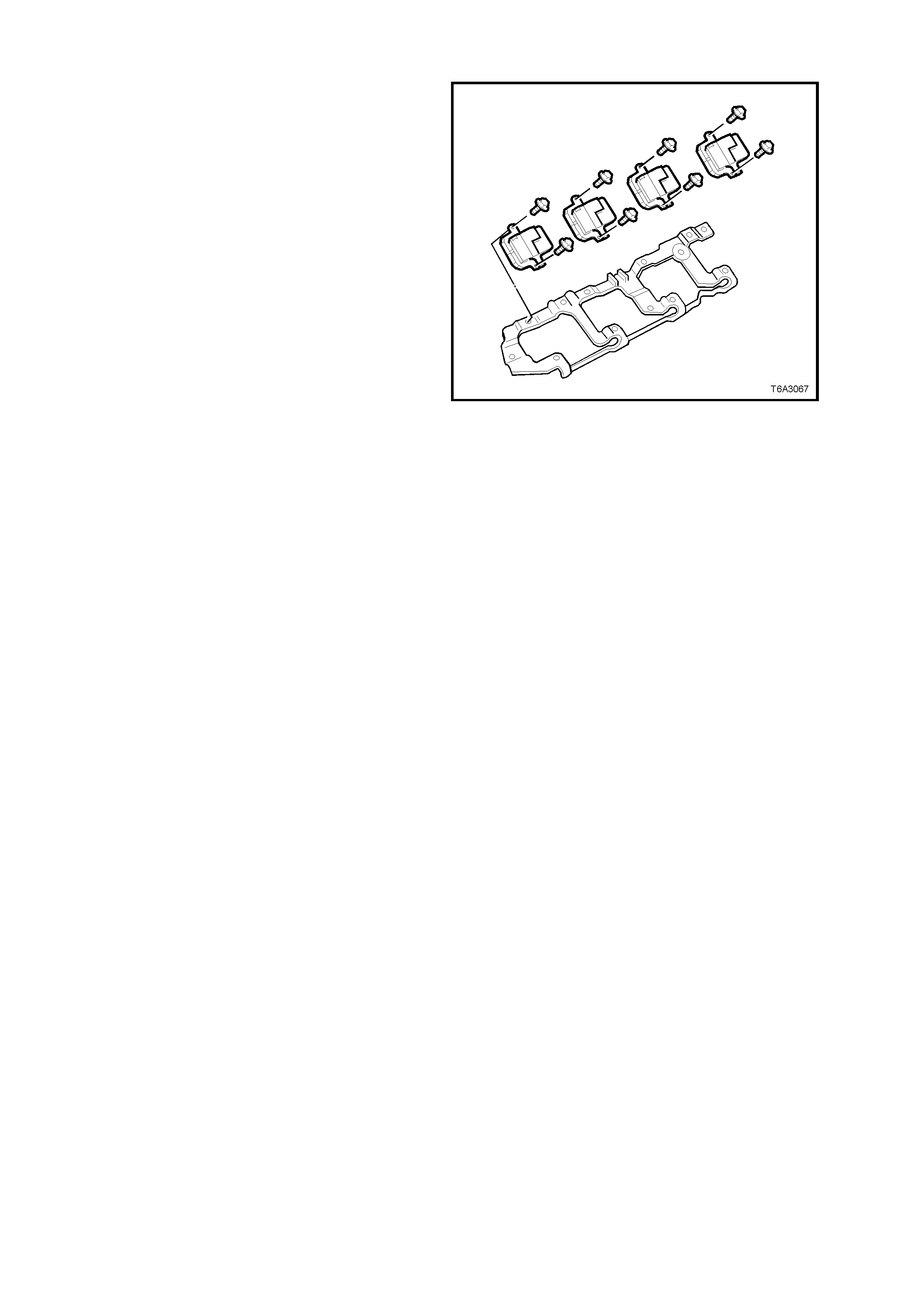

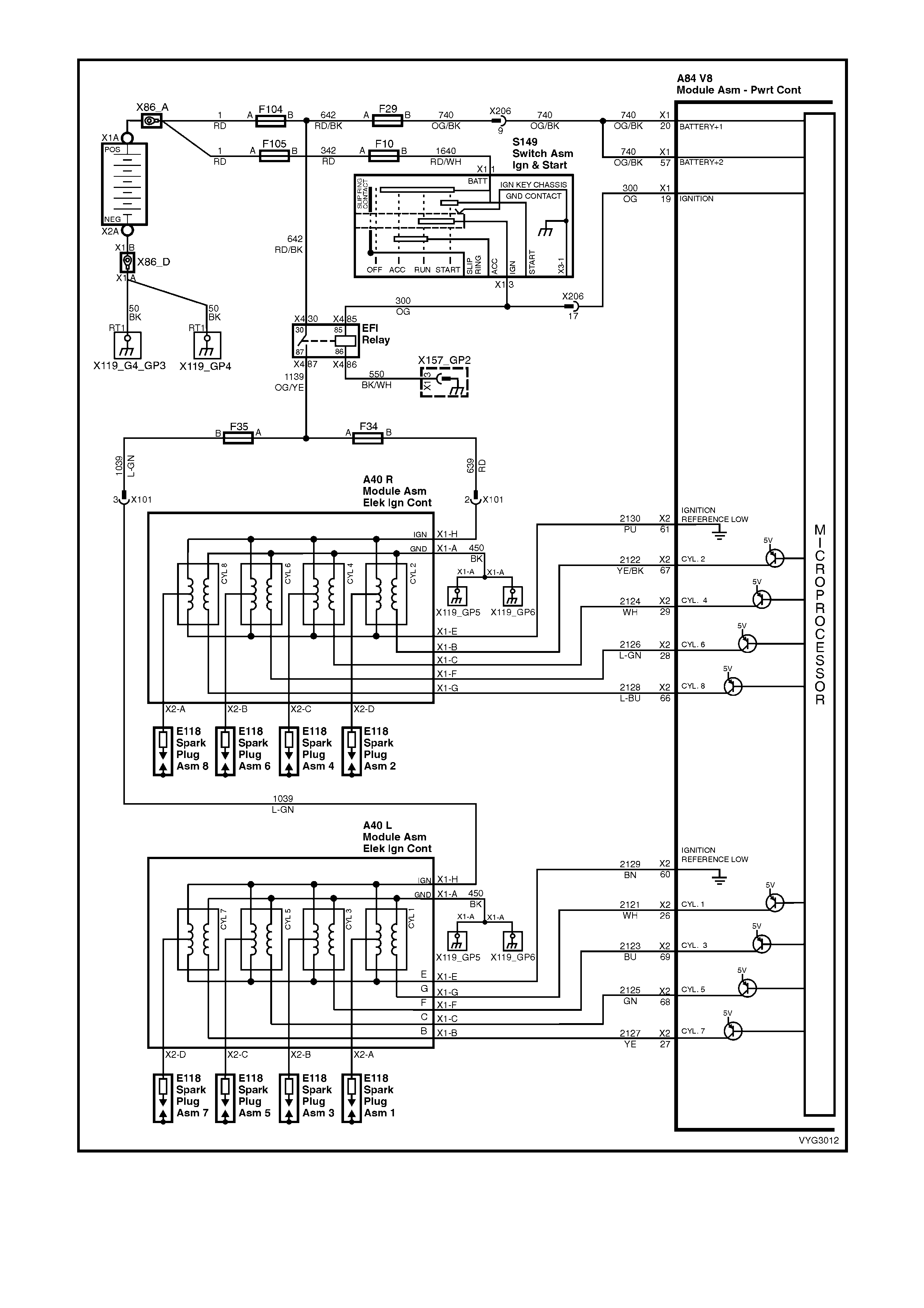

Carbon