SECTION 6D1-1B - CHARGING SYSTEM –

V6 ENGINE (120 AMP)

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section 00,

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL INFORMATION

1.1 OPERATION

CIRCUIT OVERVIEW

STANDBY MODE

BACKUP MODE

WARNING LAMP CONDITIONS

2. MINOR SERVICE OPERATIONS

2.1 SAFETY PRECAUTIONS

2.2 MAINTENANCE AND ON-VEHICLE TESTING

REGULAR CHECKS

GENERATOR ON-VEHICLE CHECKS

3. MAJOR SERVICE OPERATIONS

3.1 GENERATOR

REMOVE

DISASSEMBLE

CLEANING AND INSPECTION

REASSEMBLE

REINSTALL

4. DIAGNOSIS

CIRCUIT DIAGRAM

5. SPECIFICATIONS

6. TORQUE WRENCH SPECIFICATIONS

7. SPECIAL TOOLS

1. GENERAL INFORM ATION

This service information applies to all models fitted with production option T82 (daytime running lights – Telstra

option) or 9C1 (national police pack) and all LHD models fitted with a V6 engine. For charging system information

relating to the VY Series RHD models, refer to Section 6D1-1A, CHARGING SYSTEM – V6 ENGINE (100 AMP).

The V6 engine is fitted with a Mitsubishi 120 amp generator. This generator is also available as a production

option to the VY Series RHD models. For mounting bracket removal and installation information, refer to

Section 6A1 V6 ENGINE MECHANICAL or Section 6A2 V6 S/C ENGINE MECHANICAL.

The Mitsubishi 120 am p generator can be identif ied visually as it has two lower m ounting lugs. It does not have an

external cooling fan.

The generator is three phase, incorpor ating a rotor with six pole pairs fitted and two cooling fans ; one on the drive-

end and one on the slip-ring end. The rotor is supported by ball bearings in both the drive and slip-ring end

housings. Surrounding the rotor is a stator, which has a three phase star c onnected output winding construction on

a ring shaped lamination pack.

The output of the stator winding is rectified by eight diodes that are contained within the slip-ring end housing.

Excitation current is supplied to the rotor field coil via the voltage regulator, the brushes and slip-rings. The

electronic voltage regulator requires no adjustment in service.

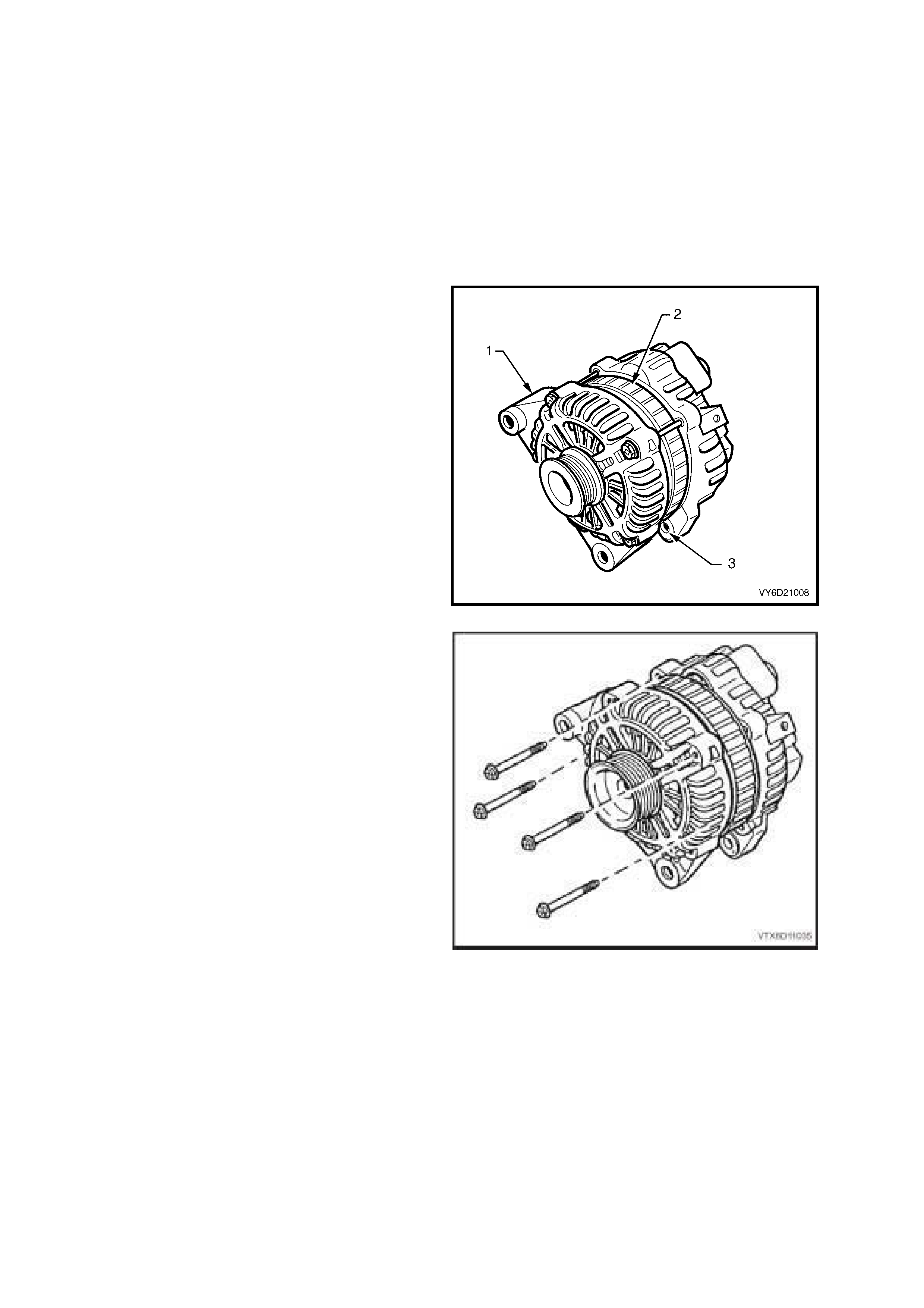

The generator has four external connections (refer to Figures 6D1-1B-1 and 6D1-1B-2):

•

••

•

B+ lead to the battery positive terminal

•

••

•

L lead to the generator warning lamp (max. 2 watts)

•

••

•

S lead for battery voltage sensing

•

••

•

ground connection (via the installation bolts).

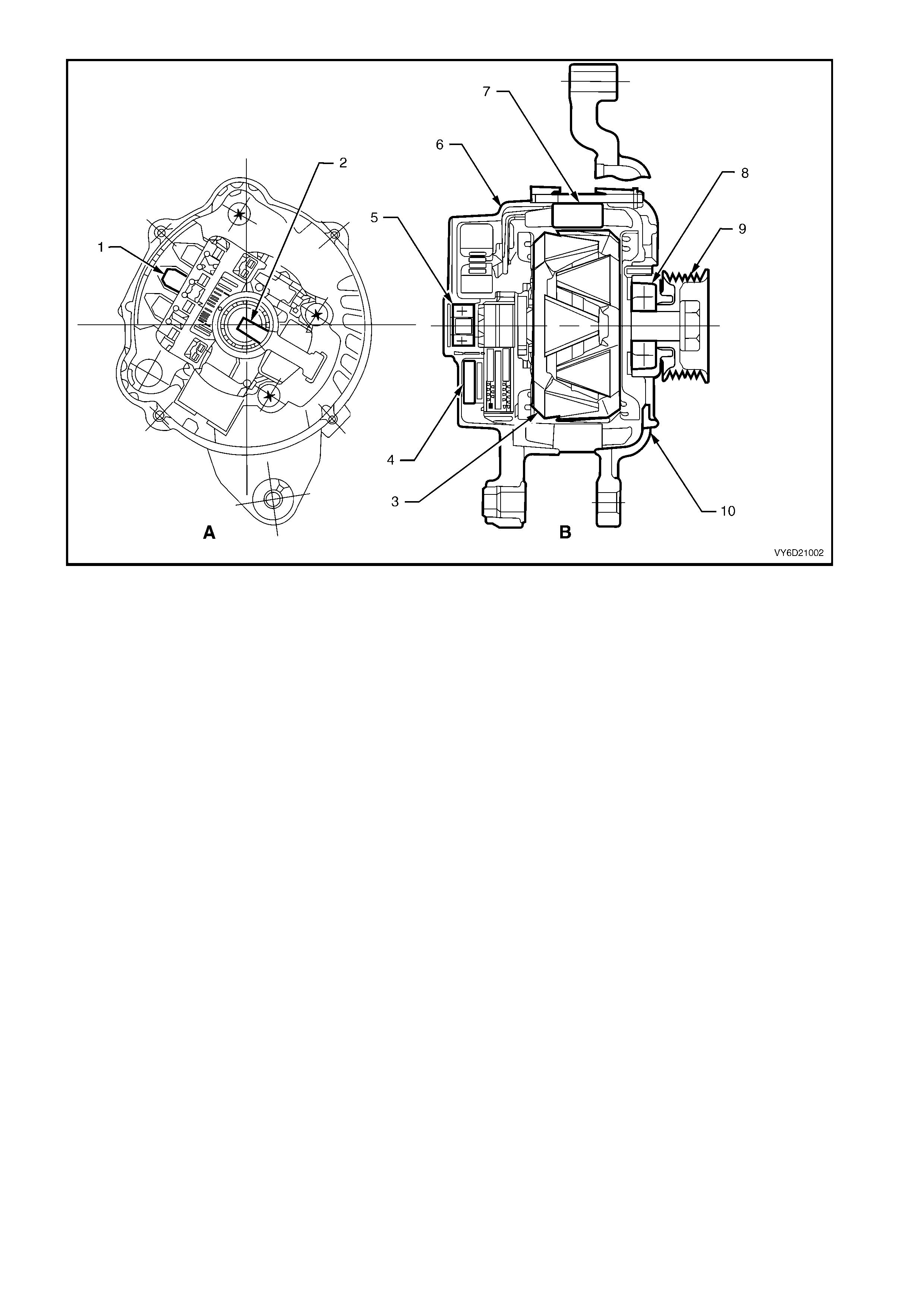

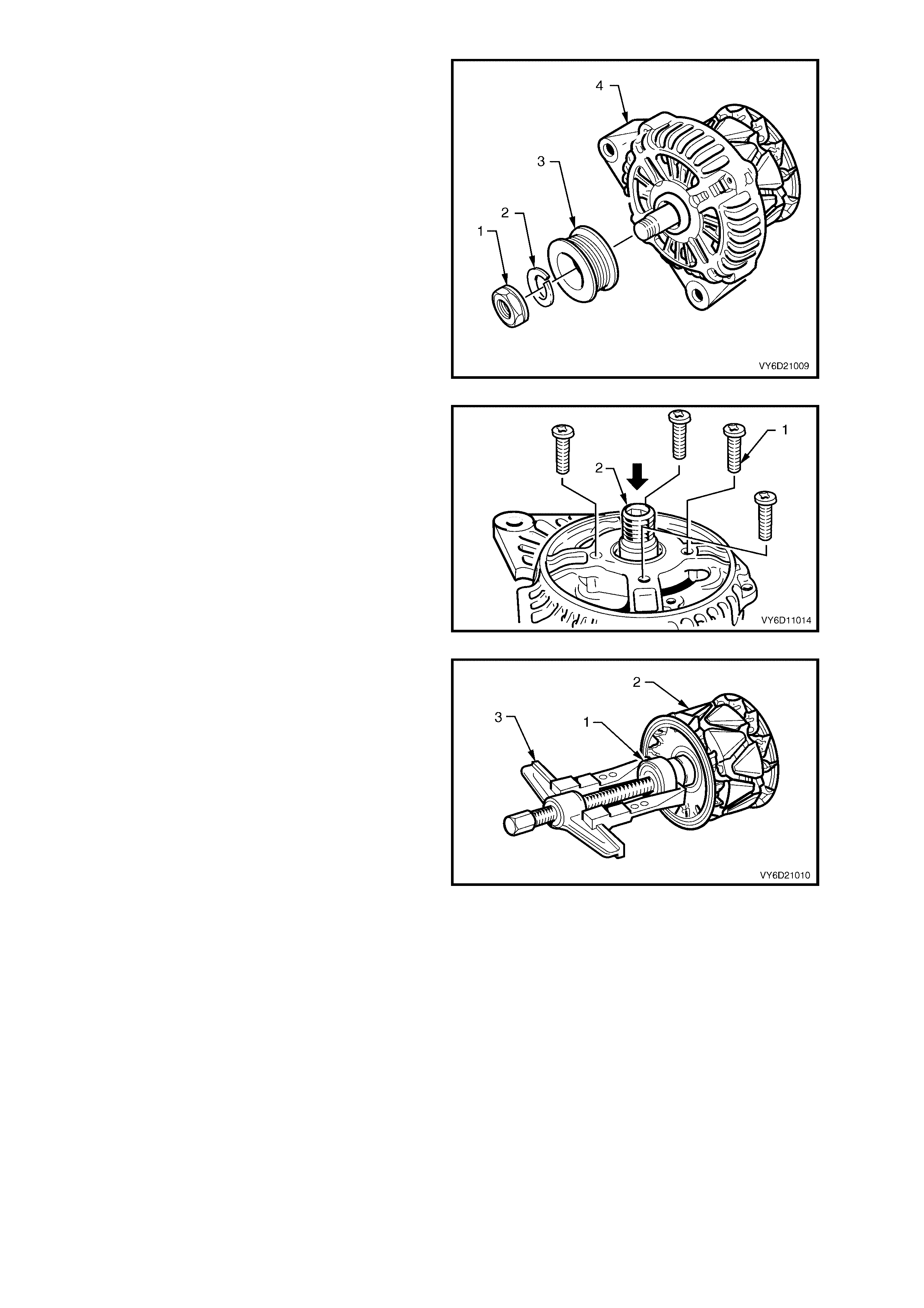

Figure 6D1-1B-3 shows an exploded view of the 120 amp generator.

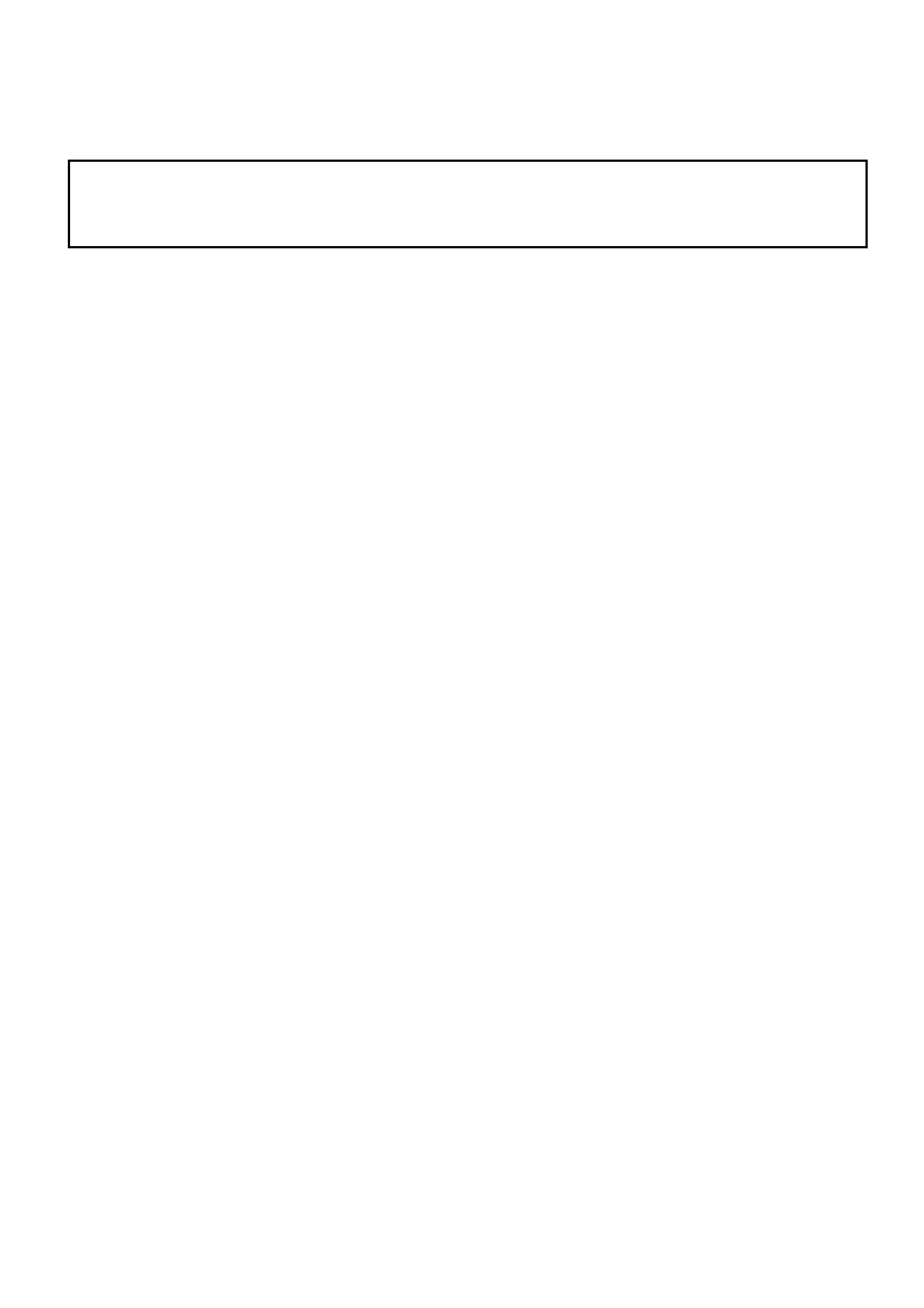

Figure 6D1-1B-1

Legend

A. Side view of generator

B. Rear view of generator

1. B+ Terminal (Battery) 2. L Terminal (Warning Lamp) 3. S Terminal (Sensing)

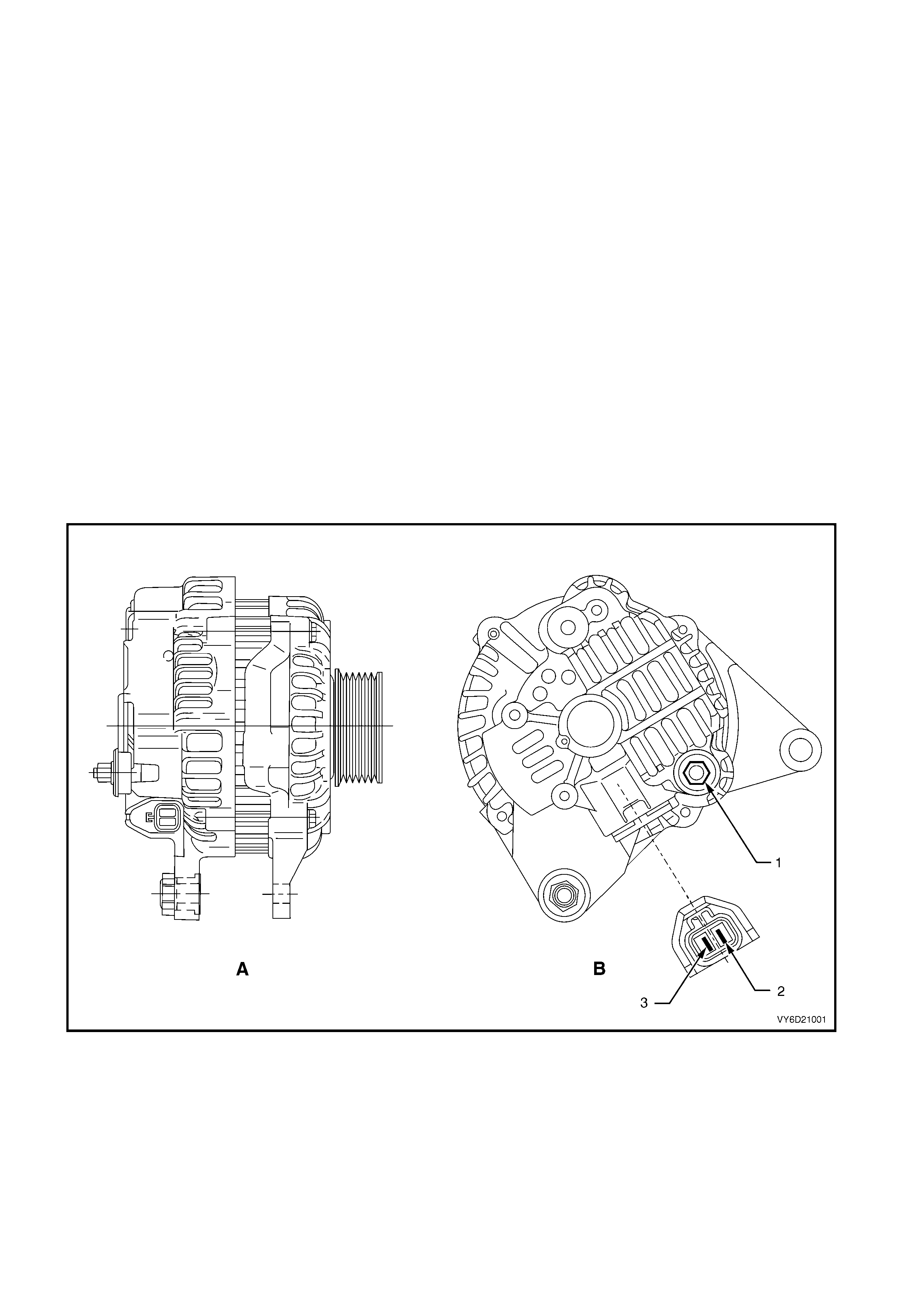

Figure 6D1-1B-2

Legend

A. Rear cross-sectional view of generator

B. Side cross-sectional view of generator

1. Rectifier 5. Bearing 9. Pulley

2. Brushes 6. Rear bracket 10. Front bracket

3. Rotor 7. Stator

4. IC Regulator 8. Bearing

Figure 6D1-1B-3

Legend

1. Through-Bolt (4) 7. Bearing Retaining Plate 14. Brush

2. Bearing Retaining Plate Screw (4) 8. Rotor 15. Thrust Washer

3. Nut 9. Slip-Ring End Bearing 16. Rectifier Assembly

4. Drive Pulley 10. Stator 17. Rear Bracket Assembly (Includes

5. Front Bracket Assembly (Includes 11. Regulator and Brush Screws Items 11 – 16 and 18 – 19.)

Items 2, 5, 6 and 7) 12. Brush Retaining Plate 18. Terminal Cover Bush

6. Front Bearing 13. Regulator 19. Nut

1.1 OPERATION

CIRCUIT OVERVIEW

W ith the ignition switch in the ON position and the engine at rest, current is supplied via the warning lamp to the L

terminal of the regulator. This initiates current flow (within the regulator) from the generator B+ terminal, to the

brushes and rotor winding, to ‘excite’ the circuit.

The current in the rotor winding creates m agnetic fields between adjac ent rotor poles. As the r otor spins, the st ator

windings cut through this field and induce voltage. As the speed is increased, this induced voltage increases.

Current then flows through the three phase diode bridge in the rectifier to convert the AC voltage to DC. This is

supplied to the B+ output and then to the battery.

The regulator S terminal monitors the system voltage. When this voltage reaches approximately 14.2 volts, the

regulator breaks the circuit through the rotor winding, causing the generator output voltage to drop. When the

regulator S term inal sens es a voltage below a pres et voltage, the regulator com pletes the cir cuit and voltage to the

battery again increases. This cycle repeats very rapidly.

If the warning lam p f ails, the generator self-ex cites using cur rent from the phase c onnection until the voltage builds

up to the regulating level.

Current does not flow through the rotor winding when the engine is cranking.

STANDBY MODE

W ith the ignition switch in the ON position and the engine at rest, the regulator defaults active standby mode. This

limits the current through the rotor by switching on and off at a 50% duty cycle with a frequency of approximately

4 kHz. It is normal for this to be audible at times.

BACKUP MODE

The regulator com pares voltage at the B+ terminal with voltage sensed at the S terminal. The regulator defaults to

backup mode if the difference exceeds a preset value. Backup mode limits the output voltage to a safe level This

level is approximately 1 – 3 volts above the normal setting.

WARNING LAMP CONDITIONS

The regulator illuminates the warning lamp when it detects f ault conditions in the generator or external circuits . The

warning lamp remains illuminated until the fault is repaired.

Fault conditions include:

1. Open circuit in the regulator battery sensing wire (S terminal).

2. Open circuit or excessive voltage drop in the B+ cable.

3. Open circuit in the generator phase connection.

4. Overcharging of the battery.

5. Short circuit in the regulator output stage.

6. Open circuit in the rotor winding.

7. Poor contact in a wiring harness connector.

8. Poor contact between the rectifier and the regulator.

9. High resistance in the fusible link assembly.

10. Poor contact between the battery terminals and cables.

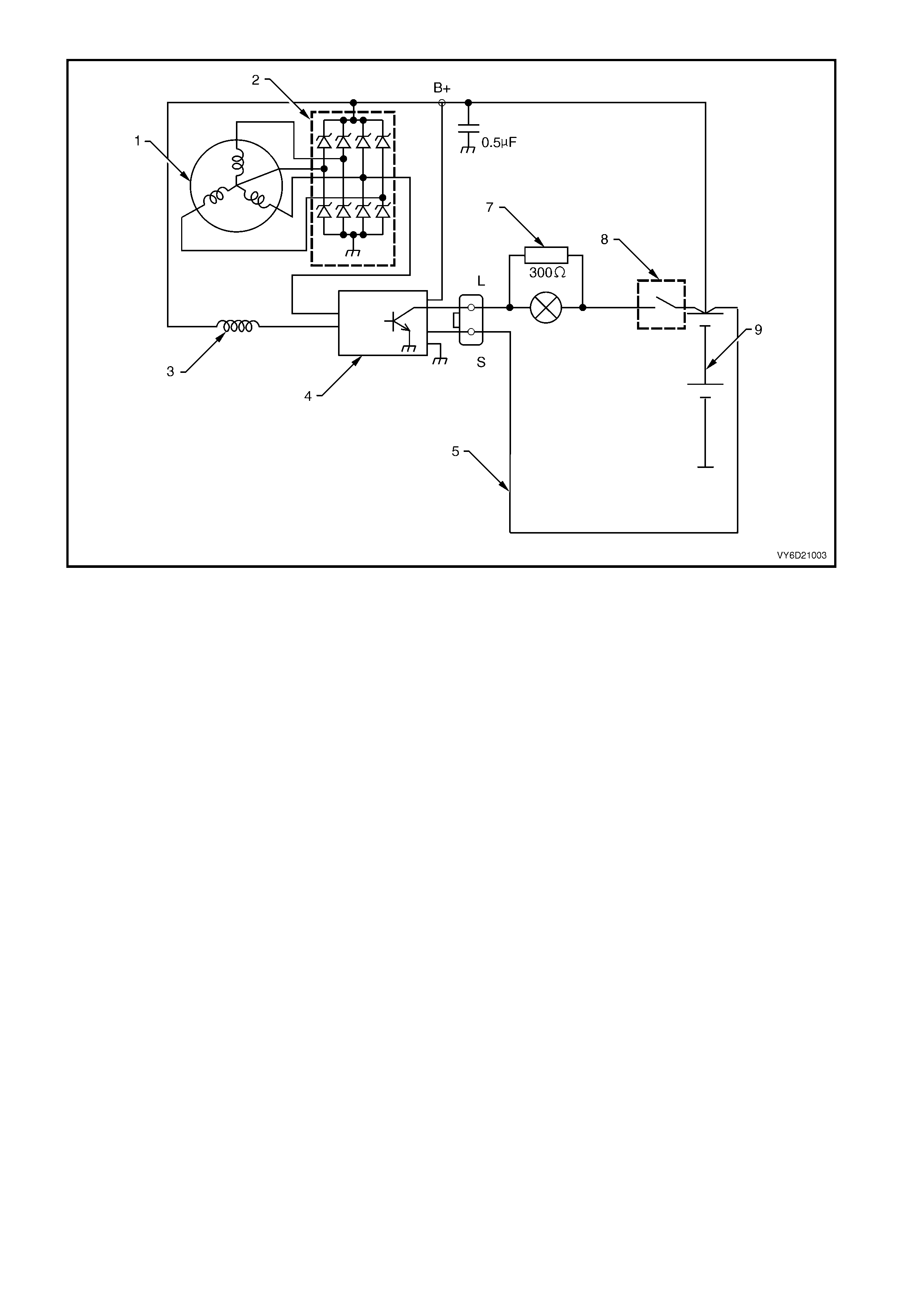

Figure 6D1-1B-4

Legend

1. Stator 4. IC Regulator 7. Current Limiting Resister

2. Rectifier 5. Battery Sensing Wire 8. Ignition Switch

3. Rotor 6. Warning Lamp 9. Battery

2. MI NOR SERVICE OPERATIONS

2.1 SAFETY PRECAUTIONS

Observe the following precautions. Failure to observe these precautions can result in serious damage to the

generator.

•

••

•

The generator and voltage regulator are designed for use only on a negative ground system.

•

••

•

When installing a battery, fit the positive (+) cable to the battery first. Then fit the negative cable.

•

••

•

When a slave battery is used for starting purposes, ensure that both batteries are connected in parallel, ie.

positive terminals connected and negative terminals connected.

•

••

•

Ensure that any jumper leads used have surge protection.

•

••

•

Disconnec t both battery cables when charging the battery. This is olates the generator f rom the batter y and from

the external charging equipment.

•

••

•

Do not operate the generator within an open circuit (i.e. without a battery in the circuit).

•

••

•

Do not disconnect the battery while the generator is running.

•

••

•

Do not attempt to polarise the generator.

•

••

•

Always ensure that the generator warning lamp glows when the ignition switch is in the ON position.

•

••

•

Do not connect the L terminal of the generator to 12 volts (the battery or ignition circuits). This damages the

generator warning lamp circuit.

•

••

•

Som e batter y powered tim ing lights can pr oduce high trans ient voltages when connected or disconnec ted. Only

disconnect or connect timing lights when the engine is switched off.

NOTE: The gener ator warning lam p circ uit ass ists in the ex citation of the rotor field windings. Repair all faults in the

generator warning lamp circuit before proceeding.

IMPORTANT: Ensure the rating of the warning lamp does not exceed 2 watts.

2.2 MAINTENANCE AND ON-VEHICLE TESTING

REGULAR CHECKS

Check the following at regular intervals:

•

••

•

generator terminals – for corrosion and loose connectors

•

••

•

wiring – for damaged insulation

•

••

•

mounting bolts – for tightness

•

••

•

drive belt – for alignment and wear

•

••

•

drive pulley – for damage.

IMPORTANT: T he drive-belt adjustm ent for the engine ancillaries (i.e. generator and water pump) is provided by a

spring-loaded tensioner. The drive belt does not require adjustment.

Lubrication

High tolerance bearings are used in this generator. If the bearings are removed during disassembly, fit new

bearings to restore the generator to original specification. The ball bearings supporting the rotor shaft are pre-

lubricated and sealed. Do not lubricate these during servicing.

IMPORTANT: Two special tools (Bosch tool numbers 9881 066 600 and 9881 066 601) are available to ensure

correct dismantling and assembly procedure of the rotor bearings. It is extremely difficult to remove the bearings

without damaging the rotor fans. The assembly tool ensures that the bearings are installed correctly and are

properly aligned to ensure long service life.

GENERATOR ON-VEHICLE CHECKS

Prerequisites

Before testing the generator output, ensure that:

•

••

•

all generator circuit connections are clean and tight

•

••

•

the generator is always connected to the battery during testing (to prevent damage to the diodes)

•

••

•

the battery is fully charged

•

••

•

the specific gravity does not vary more than 0.025 between cells. It is recommended that the average specific

gravity is 1.260 or higher. Refer to Section 12A, BATTERY AND CABLES.

Carry out a load test on the battery to determine its ability to supply and accept current. T his is a good indicator of

the general condition of the battery. For details on battery testing, refer to Section 12A, BATTERY AND CABLES.

Inspect the drive belt and tens ioner markings to determine if the dr ive belt is within operating limits . Replace the belt

if it is excessively worn or outside the operating range of the tensioner.

For further details, refer to Section 6A1, ENGINE MECHANICAL – V6.

IMPORTANT: The generator warning lamp is necessary for initial field excitation in addition to indicating that the

generator is charging.

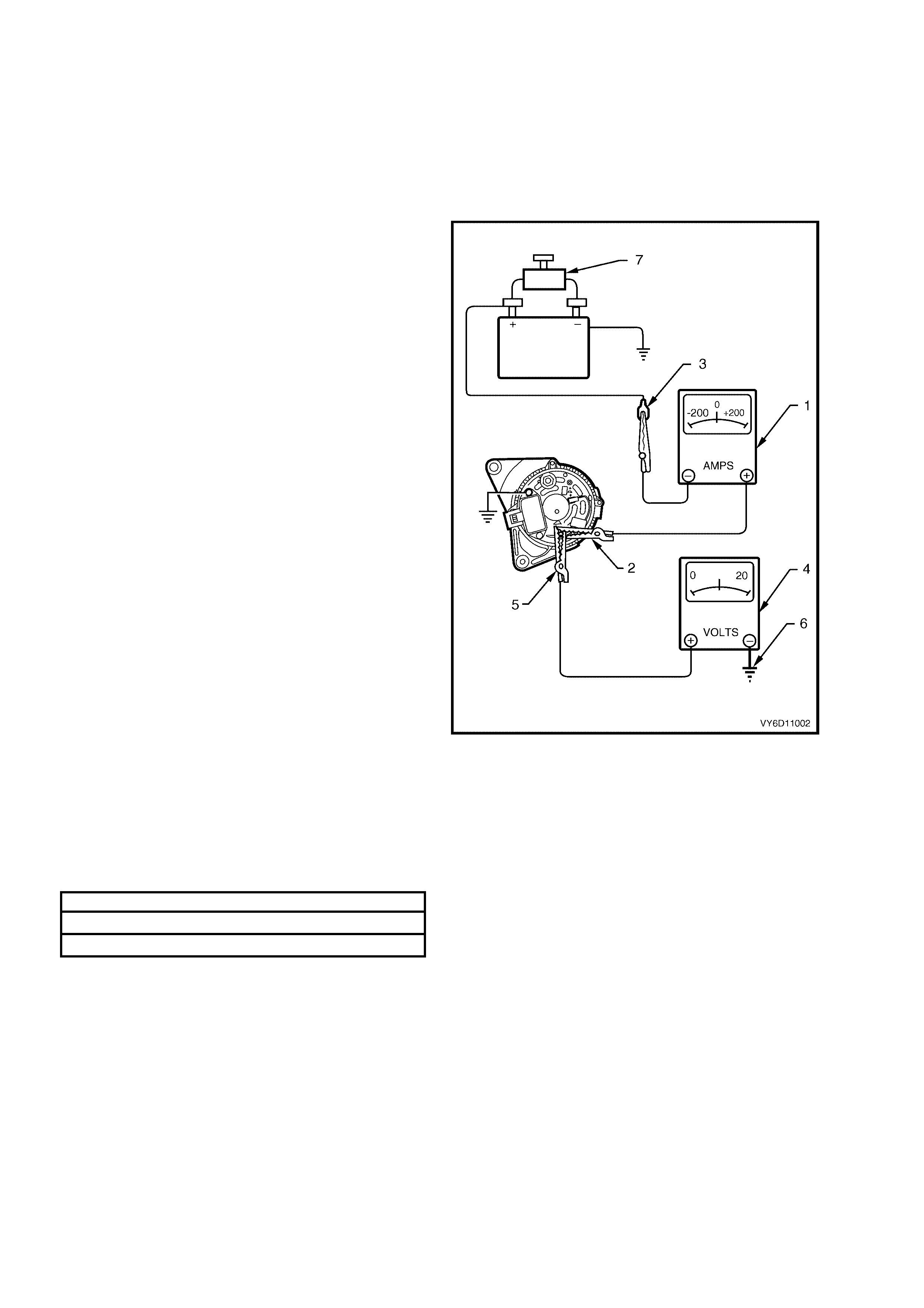

Regulating Voltage On-Vehicle Test

1. Ensure that the ignition switch is in the OFF

position and all electrical equipment is turned

off.

2. Refer to Section 00, CAUT IONS AND NOT ES

before disconnecting the battery.

3. Disconnect the battery ground cable at the

battery.

4. Disconnect the generator positive lead (red

wire) from the generator B+ terminal.

5. Connect the positive lead of an am meter (amp

scale of zero – 200) (1) to the generator B+

terminal (2).

6. Connect the negative ammeter lead to the

disconnected generator positive lead (red wire)

(3).

7. Connect the pos itive lead of a voltmeter ( 0 – 20

volt scale minimum) (4) to the generator B+

terminal (5).

8. Connect the negative voltmeter lead to a good

ground connection on the generator housing

(6).

CAUTION: Insulate the terminal of the generator

positive lead (red wire) to prevent contact with

any metal part of the vehicle. If the terminal is

grounded, damage to the charging circuit will

result when the battery is reconnected.

9. Reconnect the battery ground cable.

10. Fit a loading device (7) across the battery

terminals, e.g. an adjustable carbon pile.

IMPORTANT: The loading device must have a

minimum power consumption of 1000 watts.

11. Record the voltmeter reading before starting

the engine. This reading should increase when

the engine is running, indicating generator

output.

12. Start the engine.

13. Increase the engine speed and adjust the load

(using the ammeter reading) as outlined in the

chart below.

14. Check the generator output voltage (voltmeter

reading) against the specification.

ENGINE RPM 1300

LOAD 5 – 10 amps

VOLTMETER READING 13.8 – 14.5 volts

Figure 6D1-1B-5

Load Regulation Test

1. Connect the voltmeter, ammeter and carbon pile as in the previous test.

2. Increase the engine speed to 2350 rpm (approximately 5000 generator rpm).

3. Increase the load to 90% of full output (approximately 90 amps).

IMPORTANT: A decrease in the regulating voltage should not exceed 0.5 volt of the readings obtained in the

previous test.

If the decrease in the regulating voltage is greater than 0.5 volt, the regulator is defective. Replace the regulator.

Generator Output Test at Full Load

1. Connect the voltmeter, ammeter and carbon pile as in previous tests:

2. Increase the engine speed to 2350 rpm (approximately 5000 generator rpm).

3. Increase the load until the generator output voltage drops to 13.5 volts. Full generator output (120 amps) is

required; adjust the throttle as required to maintain this.

4. Record the ammeter reading.

5. Reduce the engine speed to idle.

IMPORTANT: Keep the time for this test to a minimum to avoid undue heating and high engine speeds.

6. If the generator does not provide approx imately 120 am ps at 5000 generator rpm , disassem ble and ins pect the

generator for faults. Refer to 3.1 GENERATOR in this Section.

CAUTION: On completion of the generator output test, return the engine to idle and disconnect the loading

device from the battery terminals. This prevents excessive battery discharge.

7. Disconnect the battery ground cable at the battery.

8. Remove the volt and ammeters.

9. Reconnect the generator positive lead (red wire) to the generator B+ terminal.

10. Reconnect the battery ground cable to the battery.

Charging Circuit Voltage Drop Test

IMPORTANT: Ensure that the generator connections are clean and tight.

1. Connect the positive lead of a low range voltmeter to the generator positive terminal and the negative lead to

the battery positive post.

2. Switch the headlamps on.

3. Start the engine.

4. Increase the engine speed to approximately 2500 rpm.

5. Record the voltmeter reading.

6. Reduce the engine speed to idle.

7. Connect the voltmeter positive lead to the battery negative post and the negative lead to the generator housing.

8. Increase the engine speed to approximately 2500 rpm.

9. Record the voltmeter reading.

10. Reduce the engine speed to idle.

11. Check the two readings. If the readings exceed 0.3 volt, there is a high resistance in the charging circuit.

12. Trace the cause and correct the problem.

3. MAJOR SERVICE OPERATIONS

3.1 GENERATOR

LT Section – 02-140

REMOVE

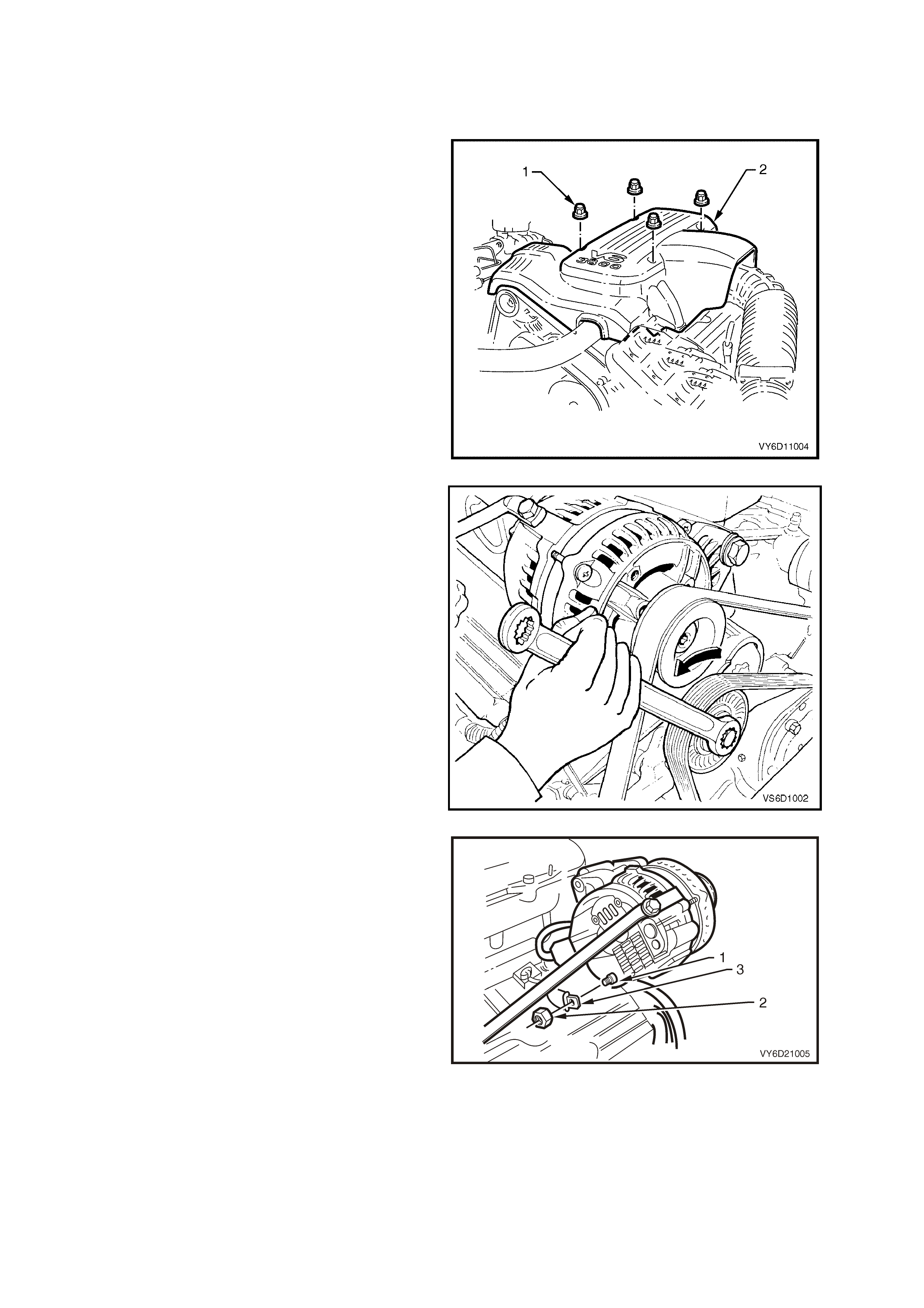

1. Refer to Section 00, CAUT IONS AND NOTES

before disconnecting the battery.

2. Disconnect the battery ground lead.

3. Remove the four dome nuts (1) securing the

engine dress cover assembly (2).

4. Lift and remove the cover assembly.

Figure 6D1-1B-6

5. Use a 15 mm ring spanner on the drive belt

tensioner pulley pivot bolt to rotate the

tensioner pulley assembly anti-clockwise.

6. Rotate the assem bly and remove the drive belt

from the generator drive pulley.

7. Release the drive belt tensioner.

Figure 6D1-1B-7

8. Pull the battery harness cap back from the B+

terminal (1), remove the nut (2) and remove the

positive lead (3).

Figure 6D1-1B-8

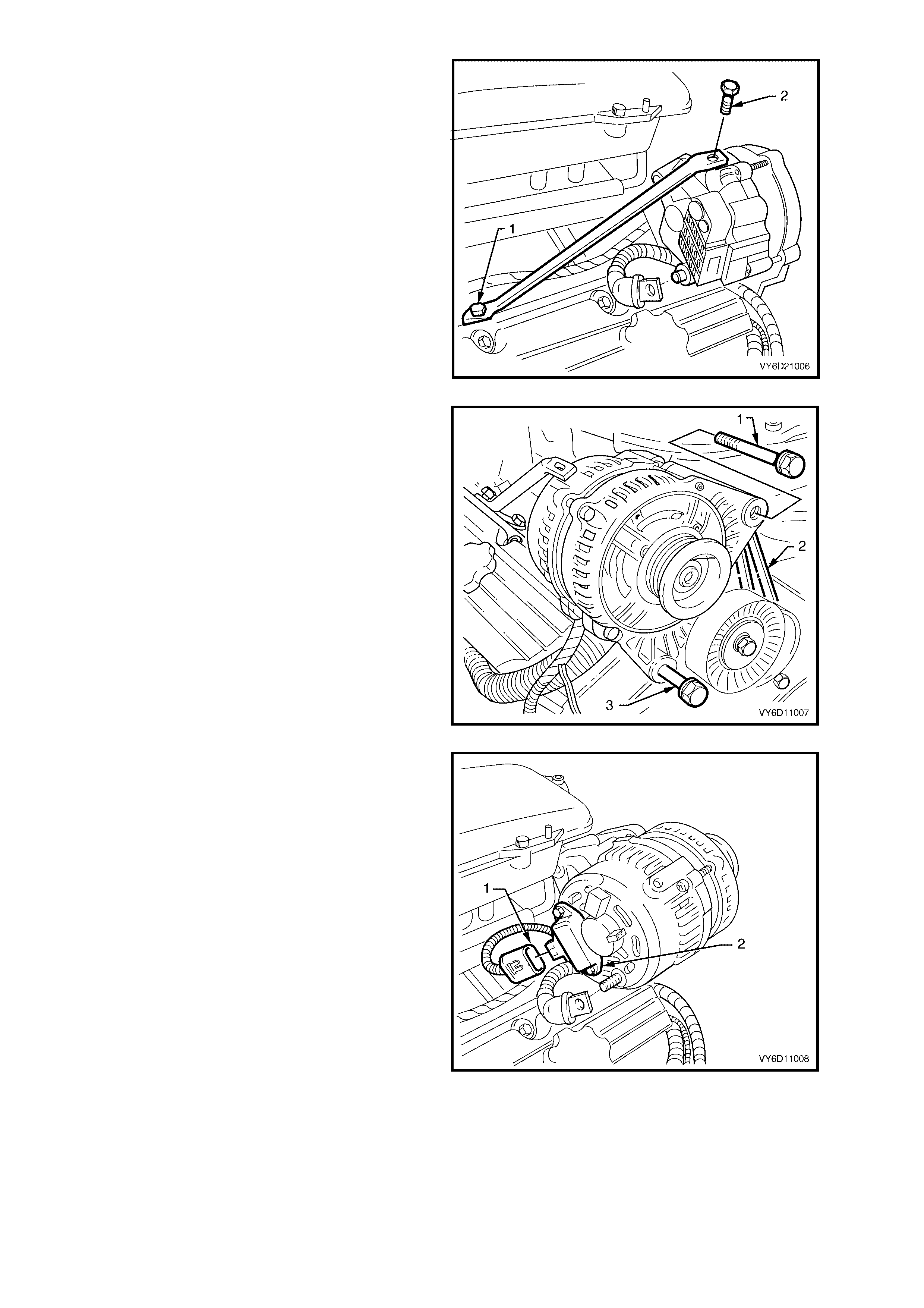

9. Loosen the brace-to-engine attaching bolt (1).

10. Remove the brace-to-generator attaching

bolt (2).

Figure 6D1-1B-9

11. Remove the upper bolt (1) from the drive-belt

tensioner bracket (2).

12. Loosen the lower bolt (3).

Figure 6D1-1B-10

13. Swing the generator away from the intake

manifold.

14. Depress the batter y harnes s connector retainer

and remove the connector (1) from the

regulator and brush assembly (2).

15. Remove the drive-belt tensioner bracket lower

bolt.

16. Remove the generator assembly.

Figure 6D1-1B-11

DISASSEMBLE

Precautions

When testing the generator for faulty components, ensure that:

•

••

•

the RMS output of the AC type tester for checking the rectifier diodes does not exceed 12.0 volts

•

••

•

the stator is disconnected before testing the diodes

•

••

•

all diodes have the same Zener voltage (when testing the diode breakdown voltages)

•

••

•

voltage does not exceeding 110 V for a series test lamp when testing the insulation on the rotor and stator

•

••

•

the rectifier is disconnected from the stator prior to testing the stator.

IMPORTANT: Due to the very low resistanc e value of the s tator winding, accurate readings m ight not be achieved

when using a conventional ohmmeter.

1. Use a permanent-marking pen to mark the

relative positions of the drive-end housing (1),

the stator frame (2) and the slip-ring end

housing (3).

Figure 6D1-1B-12

2. Remove the four through-bolts.

3. Carefully separate the slip-ring end housing

and stator (as an assem bly) from the rotor and

drive-end housing.

NOTE: Do not lever against, or put strain on, the

stator windings.

Figure 6D1-1B-13

4. Clamp the rotor in a vice that has soft-jaws.

NOTE: Do not distort or damage the rotor poles.

5. Remove the drive pulley attaching nut (1) and

lock washer (2).

6. Remove the drive pulley (3) and the front

bracket (4).

Figure 6D1-1B-14

7. Remove the four screws (1) securing the

bearing retaining plate to the front bracket.

8. Press the bearing and rotor (2) from the front

bracket.

9. Replace this bearing with a new bearing.

Figure 6D1-1B-15

10. Remove the slip-ring end bearing (1) from the

rotor (2) using a bearing puller (3).

11. T ak e car e not to dam age the plastic s ide of the

slip-ring or distort the rear fan.

NOTE: Replace this bearing with a new bearing.

12. Remove the nut, wave washer, flat washer and

insulating washer from the B+ terminal bolt.

13. Remove the rectifier retaining screw.

14. Remove the two brush-holder retaining screws.

15. Remove the stator and rectifier (as an

assembly) from the rear bracket.

16. Unsolder and remove each brush and spring

assembly.

Figure 6D1-1B-16

17. Unsolder the three stator windings (1) from the

rectifier (2), as follows:

a. Grasp the stator wires close to the wire

loop with a pair of pointed nose pliers.

b. Heat the joint with a soldering iron until the

solder starts to melt.

c. Apply a slight twisting motion to the wire

and pull it upwards and away.

NOTE: Use only as much heat as required to melt

the solder. Excessive heat damages the diodes.

IMPORTANT: Service the rectifier only as a

complet e assembly.

18. Unsolder the two joints connecting the

regulator assembly to the rectifier.

19. Remove the brush holder assembly from the

rectifier.

Figure 6D1-1B-17

CLEANING AND INSPECTION

1. Clean and inspect the disassembled

components.

NOTE: Do not clean the stator or rotor windings

with cleaning solvent. This can damage the

insulation.

2. W ash all components (except the stator, rotor,

rectifier and regulator) in a suitable cleaning

solvent.

CAUTION: Use a non-volatile agent in a well-

ventilated area. Observe the safety regulations

and precautions of the cleaning agent in use.

3. Carefully clean the rotor and stator with

compressed air.

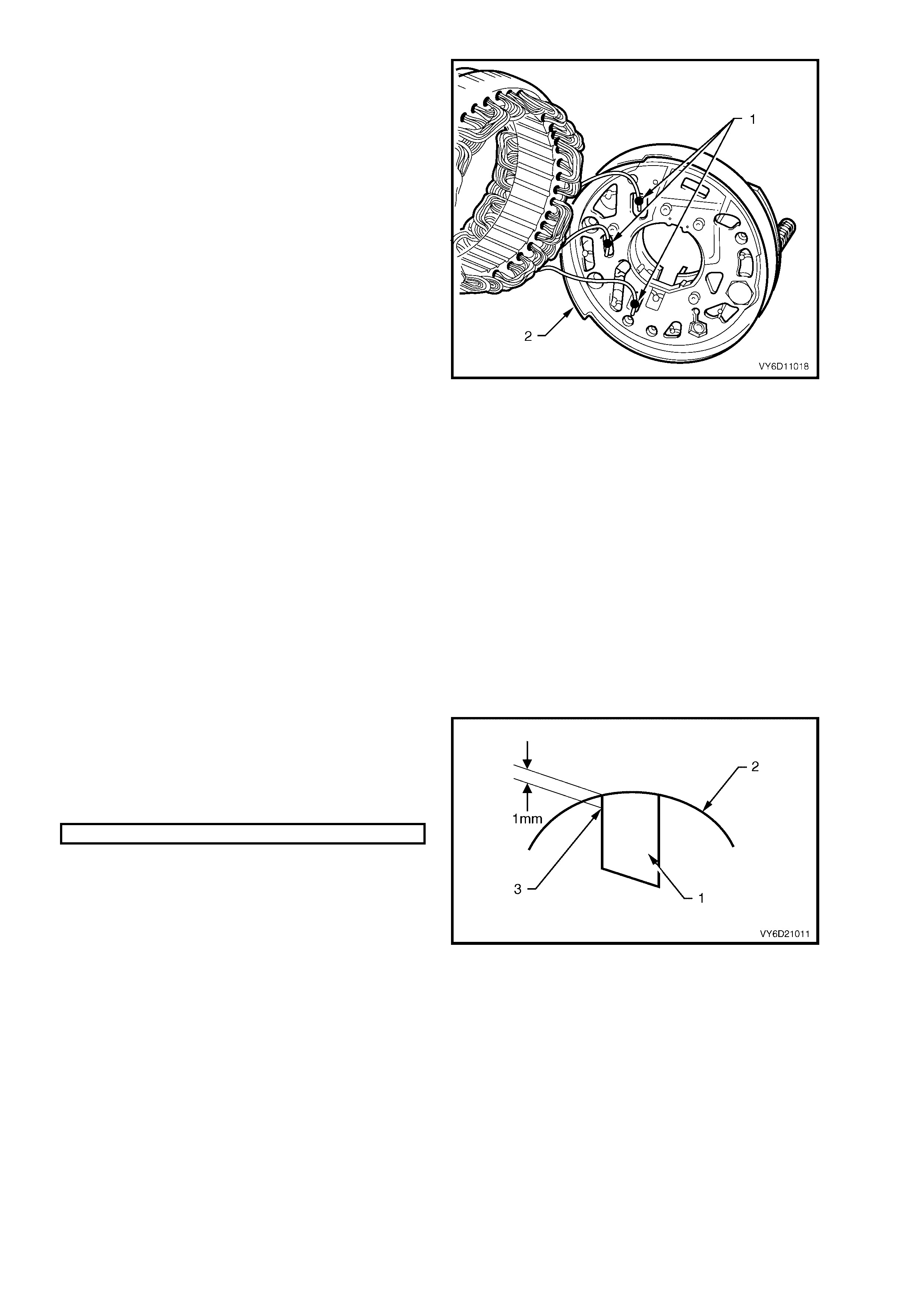

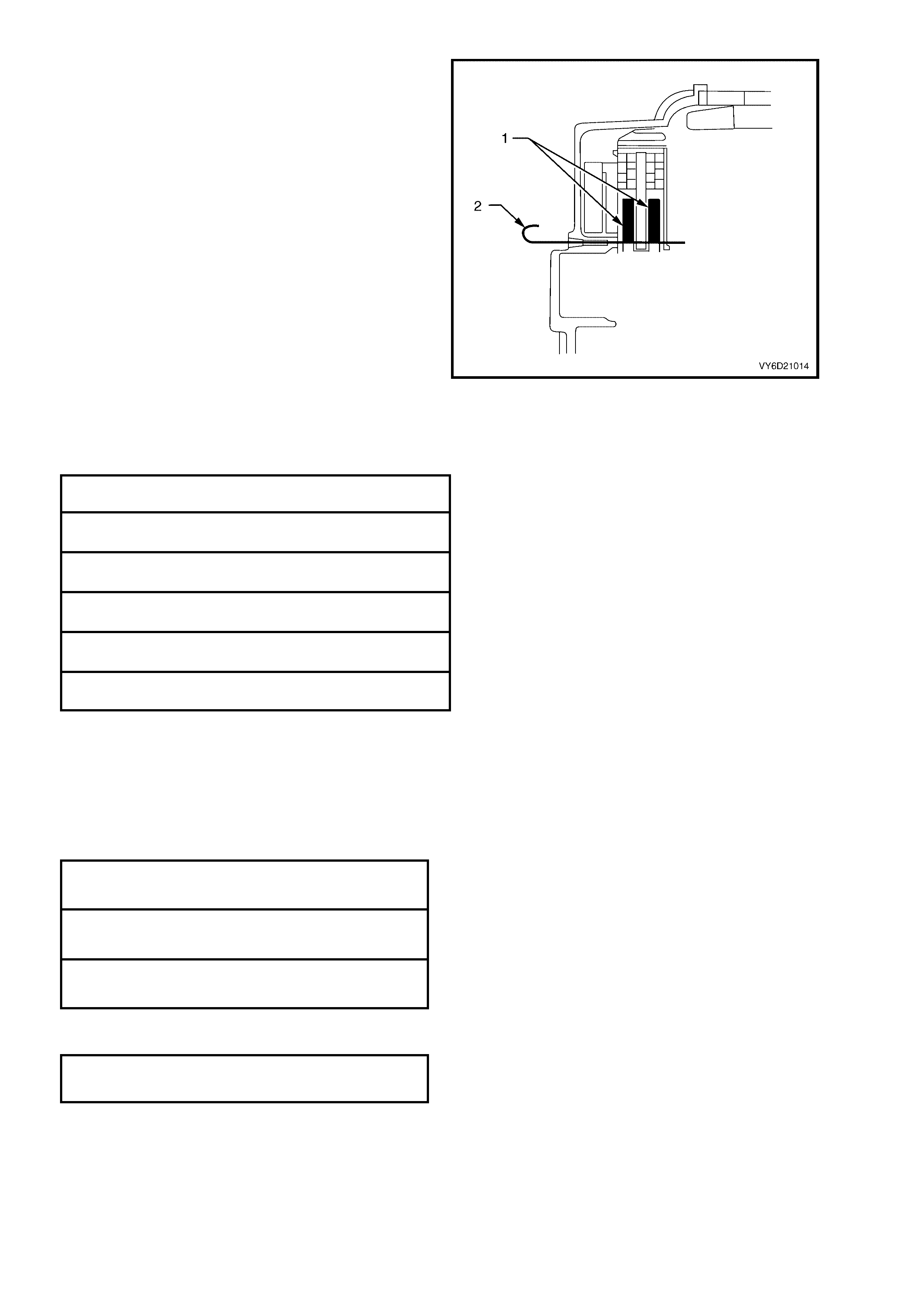

Check the Brushes

1. Check the length of the brushes (1) protruding

from the regulator brush assembly (2).

2. Measure along the centre line of each brush.

3. Check the brushes for abnormal wear or

cracks.

MINIMUM BRUSH LENGTH 5.0 mm

NOTE: If a br us h is s hor ter than s pec if ied or s hows

abnormal wear or cracks, replace both brushes.

4. Clean the brushes and brush holder with a

clean cloth.

5. Check the brush holder for cracks and

damage.

6. Replace the brush holder if it has cracks or

damage.

7. Check that the brush s prings function corr ectly,

as follows:

a. Push the brush into the brush holder until

the wear limit line of the brush protrudes 1

mm from the brush holder moulding (3).

Figure 6D1-1B-18

b. Release the brush.

c. Repeat this action to ens ure that the spring

returns fully and smoothly.

NOTE: If either spring does not function correctly,

replace both brush springs.

Check the Diodes

The following test equipment is essential for correctly testing the diodes:

•

••

•

DC output diode tester that does not exceed 14 volts output at the test probes.

•

••

•

Multimeter with a diode test feature that does not exceed 14 volts output at the test probes.

•

••

•

AC tester rated at 12 volts RMS. This ensures that the forward and reverse voltage checks are not incorrect

due to Zener breakdown.

•

••

•

Zener diode tester with a DC output in excess of 30 volts. This should incorporate internal current lim iting of 5

mA to prevent high currents during testing.

NOTE 1: The rectifier assembly is not repairable and should be replaced if any diodes are faulty.

NOTE 2: Complete steps 1 to 5 before the Zener voltage of each diode is tested.

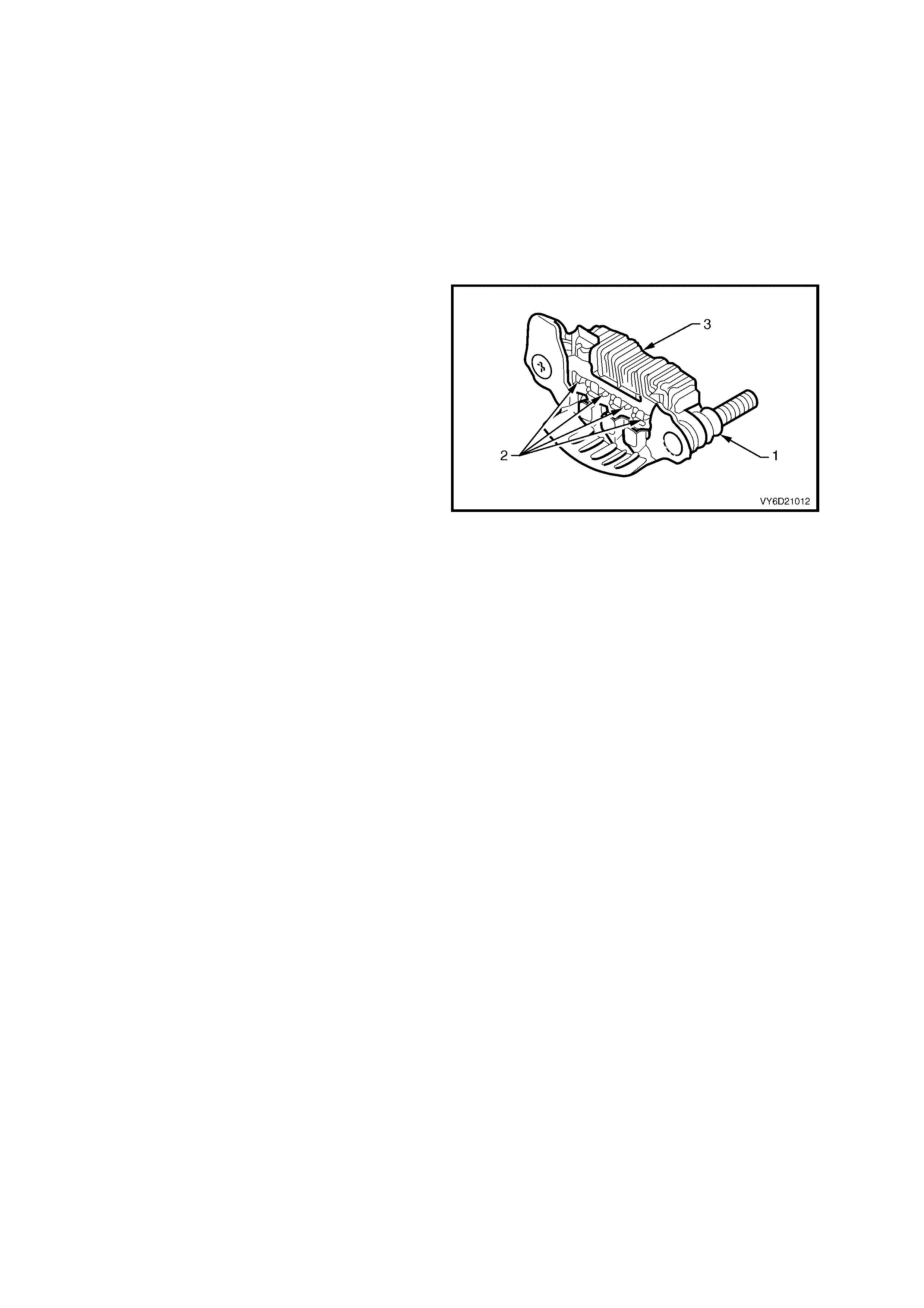

1. Attach the negative probe to the positive

heatsink (1) of the rectifier assembly.

2. Attach the positive probe to each pos itive diode

(2) in turn.

3. Check for a low resistance reading or the

forward voltage drop across the diode.

4. Reverse the probe connections and again test

each diode in turn.

5. Check for a high resistance reading or higher

reverse voltage.

6. Repeat the test to ensure that c urrent is able to

flow in one direction only.

7. Repeat the above procedure on the negative

heatsink (3).

8. Attach the positive test probe to the negative

heatsink of the rectifier assembly.

Figure 6D1-1B-19

9. Attach the negative probe to the negative diode connections.

10. Check for a low resistance reading or the forward voltage drop across the diode.

11. Reverse the probe connections and again test each diode in turn.

12. Check for a high resistance reading or higher reverse voltage.

13. Repeat the test to ensure that current is able to flow in one direction only.

NOTE: When using an AC tester in steps 1 to 5, ens ure that the rever se voltage applied is les s than 14 volts DC or

12 volts RMS.

14. Identify the Zener voltage of each diode. (Refer to the numbers on the base of each diode.)

NOTE: All diodes within a rectifier must have the same Zener voltage.

IMPORTANT: The recommended Zener tester is: Durst model 600 with five mA test current (Bosch approved).

15. Test the Zener voltage (reverse bias) of the positive diodes, as follows:

a. Connect the positive lead to the positive heat sink.

Connect the negative lead of the tester to each positive diode in turn.

Gradually increase the test voltage from the Zener diode tester and read Zener breakdown voltage.

NOTE: Ensure that the tester is current limited to five mA.

16. Check that the voltage reading is steady; it should not increase with increased voltage.

17. Test the Zener voltage (reverse bias) of the negative diodes, as follows:

a. Connect the positive lead to the negative heat sink.

b. Connect the negative lead of the tester to each negative diode in turn.

18. Replace the rectifier assembly as necessary.

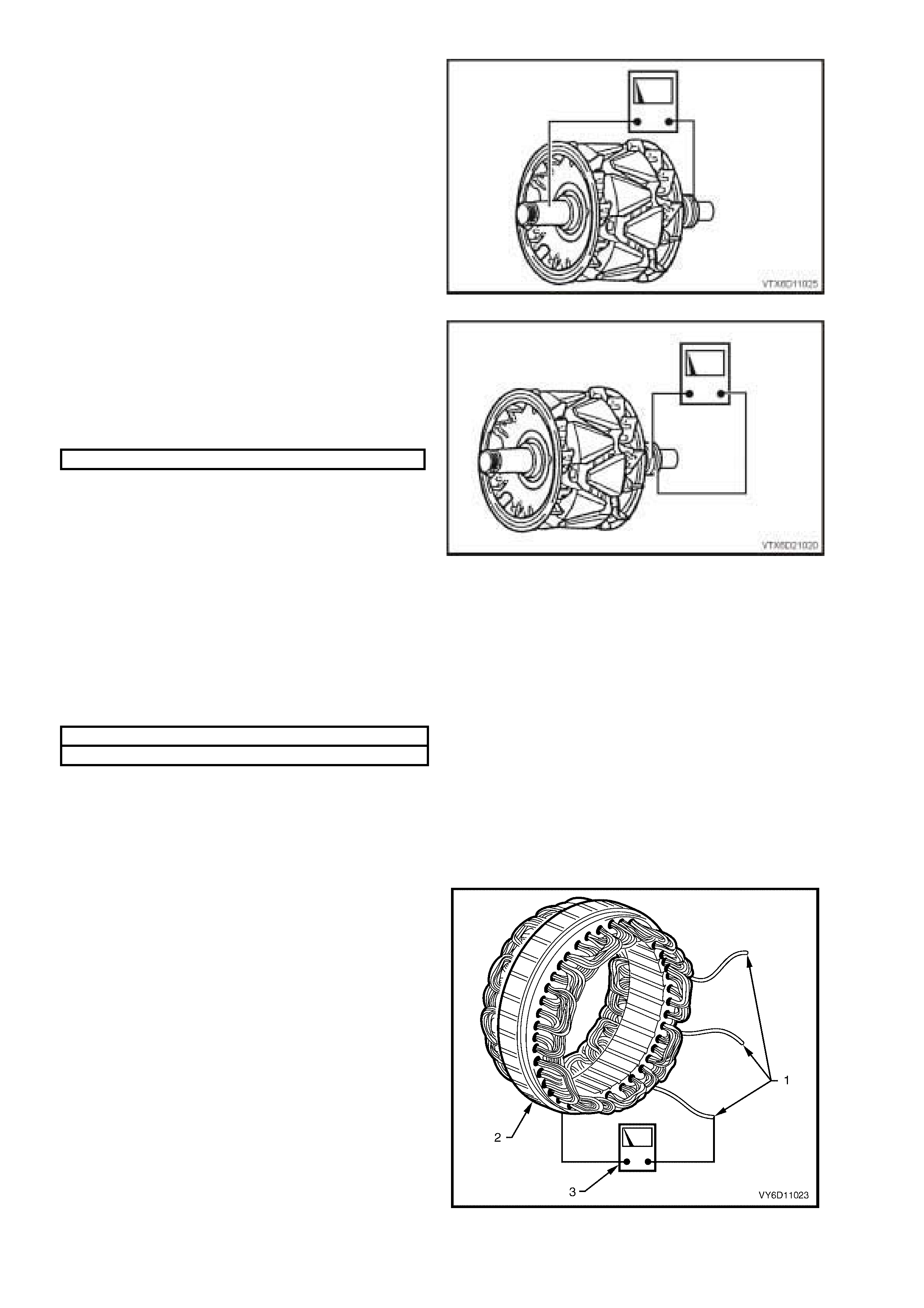

Check the Rotor

1. Clean any dirt or particles from the rotor with compressed air and/or a clean cloth.

2. Test the rotor insulation between the slip-rings

and rotor core or shaft.

IMPORTANT: Use an insulation tester or a series

test lamp up to 110 V. An insulation tester should

indicate an open circuit (greater than 1 Megohm)

and a test light should not glow.

3. Replace the rotor if an open circuit does not

exist.

Figure 6D1-1B-20

4. Test the rotor circuit, by connecting the

ohmmeter probes across the slip-rings.

5. Record the resistance reading.

6. Check the reading against the chart below.

7. Replace the rotor if the resistance of the rotor

winding is not to specification.

ROTOR WINDING RESISTANCE @ 20°C 1.9 ohms

8. Check the slip-rings for wear or damage.

9. Machine the slip-rings if they are worn, scored,

damaged or out-of-round beyond

specifications.

Figure 6D1-1B-21

CAUTION: Exercise extreme care when

machining the slip-rings to avoid the turning

tool fouling the rear rotor cooling fan.

10. Check that the slip-rings are within

specifications (especially after machining).

11. Replace the rotor if the slip-ring is outside the

specifications.

SLIP-RING OUTER DIAMETER 22.7 mm

SLIP-RING SERVICE LIMIT 22.1 mm

Bearings

The bearings used in this generator are a high

tolerance type. Use only genuine replacement

bearings during the reconditioning process to

restore the generator to original specifications.

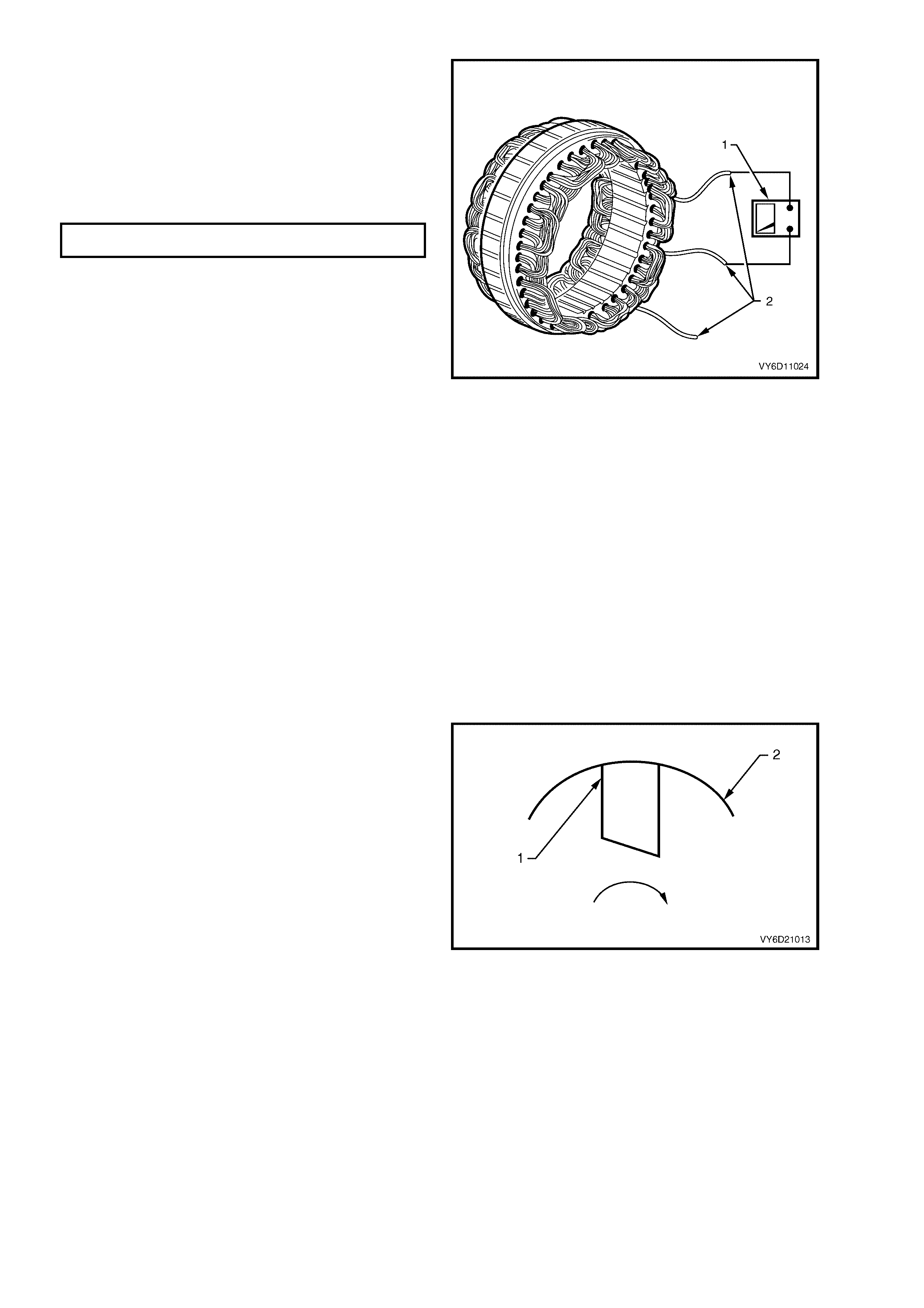

Check the Stator

1. Inspect the stator for damage, loose

connections or discoloured windings. Replace if

necessary.

2. Test the stator insulation between any stator

lead (1) and the stator frame (2).

IMPORTANT: Use a powered test lam p r ated up to

40 volts, an ohmm eter or an insulation tes ter (3). A

test light should not glow and an ohmmeter or an

insulation tester should indicate an open circuit

(greater than 1 Megohm).

3. Replace the stator if an open circuit does not

exist.

Figure 6D1-1B-22

4. Test the stator winding circuits by connecting

an ohmm eter (1) between any two stator leads

(2).

5. Check that the ohmmeter does not register a

significant resistance.

6. Repeat this test between the remaining stator

leads.

7. Replace the stator if it is outside specifications.

STATOR WINDINGS

RESISTANCE @ 20°C 0.048 ohm

Figure 6D1-1B-23

REASSEMBLE

Refer to Figure 6D1-1B-3 for identification of

components.

1. Reassemble the generator in the revers e order

of the disassembly procedure.

CAUTION: It is important that all parts are

thoroughly dried before assembly, taking care

not to breath any vapours in.

2. Check the bearing box for oil.

3. Completely remove any oil on the bearing box

to prevent bearing creep.

NOTE 1: Do not lubricate the bearings; they are

pre-lubricated.

NOTE 2: Do not apply grease to rotor bearings that

have resin bands.

4. Position the brushes (1) in the brush holder (2)

as shown in Figure 6D1-1B-24.

5. Ensure that the new brushes extend at least

13 mm from the brush holder.

6. Solder the brushes using a high temperature

solder (melting point 230°C) and a 180 – 270

watt soldering iron.

NOTE: Do not use excessive heat as this can

damage the rectifier.

Figure 6D1-1B-24

7. Push the brushes (1) fully back into the brush

holder in the rear bracket assembly.

8. Insert a suitable wire (2) f rom the outs ide of the

rear bracket assembly to hold the brushes in

the retracted position.

9. Carefully heat the area around the rear bracket

bearing box to 50 – 60°C. This aids in

assembly and avoids damaging the tight fitting

components.

10. Install the rotor into the rear assembly.

11. Align the front bracket, stator frame and rear

bracket accurately. Use the markings made

prior to disassembly.

IMPORTANT: When removing the wire, listen for

both brushes to click into position on the slip-ring.

12. Remove the wire.

Figure 6D1-1B-25

NOTE: Do not over tighten the terminal B+ nut. This damages the insulating washer.

13. After assembly, rotate the pulley slowly by hand to verify that the rotor turns smoothly.

14. Ensure all fasteners are tightened to the correct torque specifications.

DRIVE PULLEY AT T A CHING NUT

TIGHTENING TORQUE 99 – 137 Nm

THROUGH-BOLT

TIGHTENING TORQUE 3.5 – 5.3 Nm

BEARING RETAINER SCREWS

TIGHTENING TORQUE 2.0 – 5.3 Nm

BRUSH HOLDER RETAINING SCREWS

TIGHTENING TORQUE 2.0 – 5.3 Nm

RECTIFIER RETAINING SCREWS

TIGHTENING TORQUE 2.0 – 5.3 Nm

B+ TERMINAL NUT

TORQUE SPECIFICATION 12.8 – 18.6 Nm

REINSTALL

1. Assemble the drive belt tensioner bracket and install the lower mounting bolt, leaving it loose.

2. Install the battery harness connector into the regulator assembly.

NOTE: Ensure that the retainer clip on the connector locks into place.

3. Swing the generator up toward the intake manifold and install the tensioner bracket attaching bolt.

4. Position the generator brace onto the generator housing and install the attaching bolt.

GENERAT O R T O BRACE

ATTACHING BOLT (x2)

TORQUE SPECIFICATION 20 – 30 Nm

GENERATOR TO DRIVE BELT

TENSIONER BRACKET BOLT

TORQUE SPECIFICATION 20 – 34 Nm

TENSIONER BRACKET

LOWER BOLT

TORQUE SPECIFICATION 40 – 50 Nm

5. Install the battery harness positive lead (r ed wire) and nut onto the B+ ter minal and tighten the nut to the correc t

torque specification.

B+ TERMINAL BATTERY

HARNESS ATTACHING NUT

TORQUE SPECIFICATION 5 – 12 Nm

6. Fit the cap over the B+ terminal.

7. Use a 15 mm ring spanner to rotate the drive belt tensioner anti-clockwise.

8. Rotate the assembly and fit the drive belt to the generator drive pulley .

9. Release the tensioner.

10. Ensure that the drive belt ribs are correctly positioned in all pulleys and the crankshaft balancer.

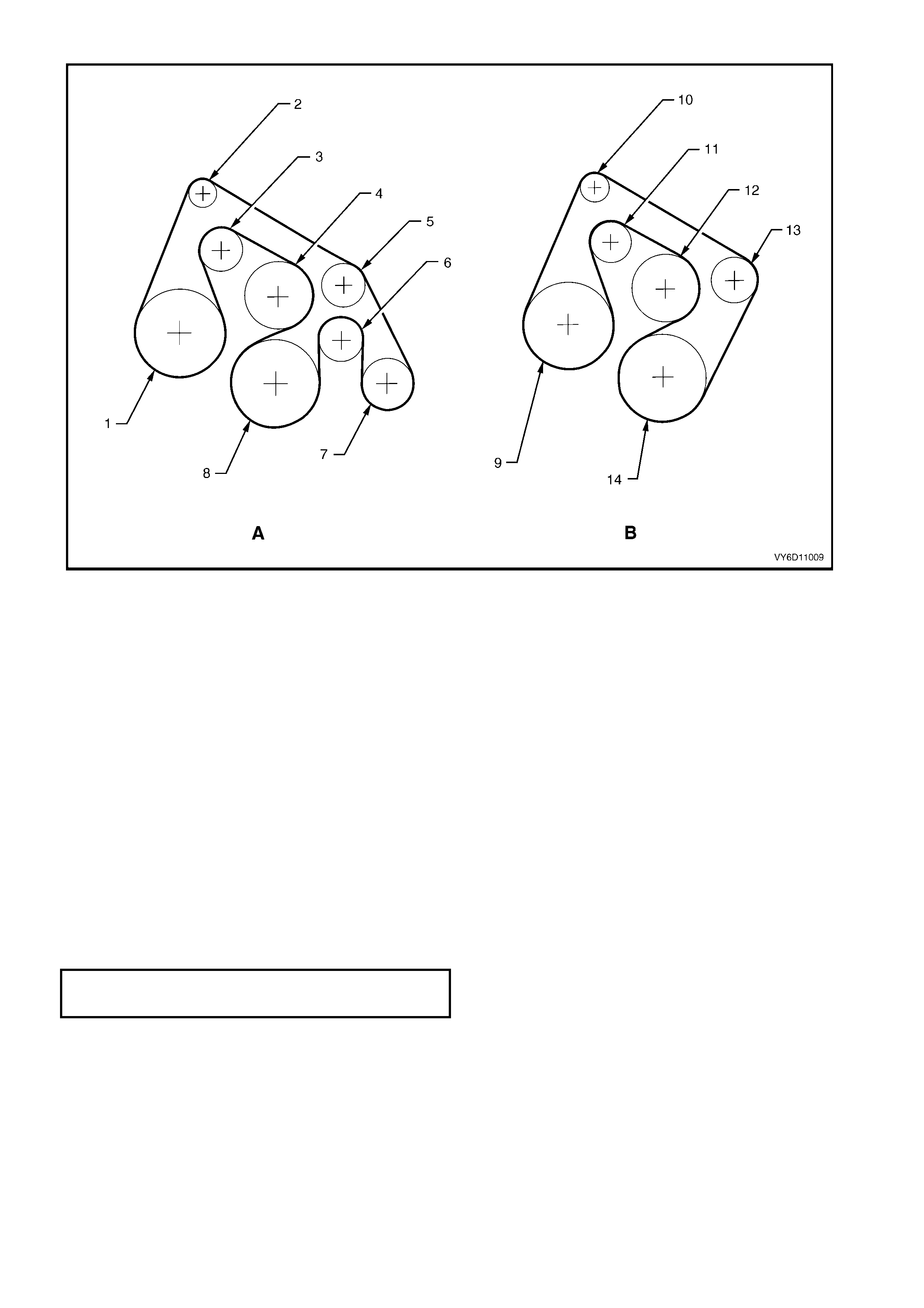

Figure 6D1-1B-26

Legend

A. Vehicles With Air Conditioning (Long Drive Belt).

B. Vehicles Without Air Conditioning (Short Drive Belt).

1. Power Steering Pump 6. Idler 11. Tensioner

2. Generator 7. Air Conditioner Compressor 12. Water Pump

3. Tensioner 8. Crankshaft Pulley 13. Idler

4. Water Pump 9. Power Steering Pump 14. Crankshaft Pulley

5. Idler 10. Generator

11. Connect the battery ground lead.

12. Start the engine.

13. Check the generator warning lamp operation.

14. Check the drive belt alignment.

15. Check the generator output (refer to 2.2 MAINTENANCE AND ON-VEHICLE TESTING in this Section).

16. Check the voltage regulator operation (refer to 2.2 MAINTENANCE AND ON-VEHICLE TESTING in this

Section).

17. Reinstall the engine dress cover to the intake manifold ensuring that the stud grommets in the dress cover

remain in place.

18. Install the dome nuts and tighten them to the correct torque specifications.

ENGINE DRESS COVER TO

INTAKE MANIFOLD DOME NUT

TORQUE SPECIFICATION 4 – 6 Nm

4. DIAGNOSIS

Refer to Section 12A, BATTERY AND CABLES for battery testing.

UNDERCHARGED BATTERY

a. Defective battery

b. Loose connection in charging system

c. Corroded connections in charging circuit

d. Defective wiring

e. Faulty generator

f. Faulty voltage regulator

OVERCHARGED BATTERY

a. Shorted battery cell

b. Faulty voltage regulator

c. Short circuit in rotor winding

d. Voltage drop in sense wire

FAULTY INDICATOR LAMP OPERATION

(LAMP DOES NOT GLOW)

a. Burnt out bulb

b. Defective bulb socket

c. Defective wiring

d. Defective rectifier

e. Defective regulator

FAULTY INDICATOR LAMP OPERATION

(LAMP REMAINS ON)

a. Negative diode failure

b. Defective voltage regulator

c. Faulty generator

d. B+ cable off or broken

e. S cable off or broken

f. Battery overcharged

g. Open circuit in rotor winding

NOISY GENERATOR OPERATION

a. Normal magnetic hum

b. Badly discharged battery

c. Generator mounting brackets loose or bolts loose

d. Worn or frayed drive belt

e. Worn bearings

f. Loose drive pulley attaching nut

g. Open or shorted diodes

h. Open or shorted stator winding

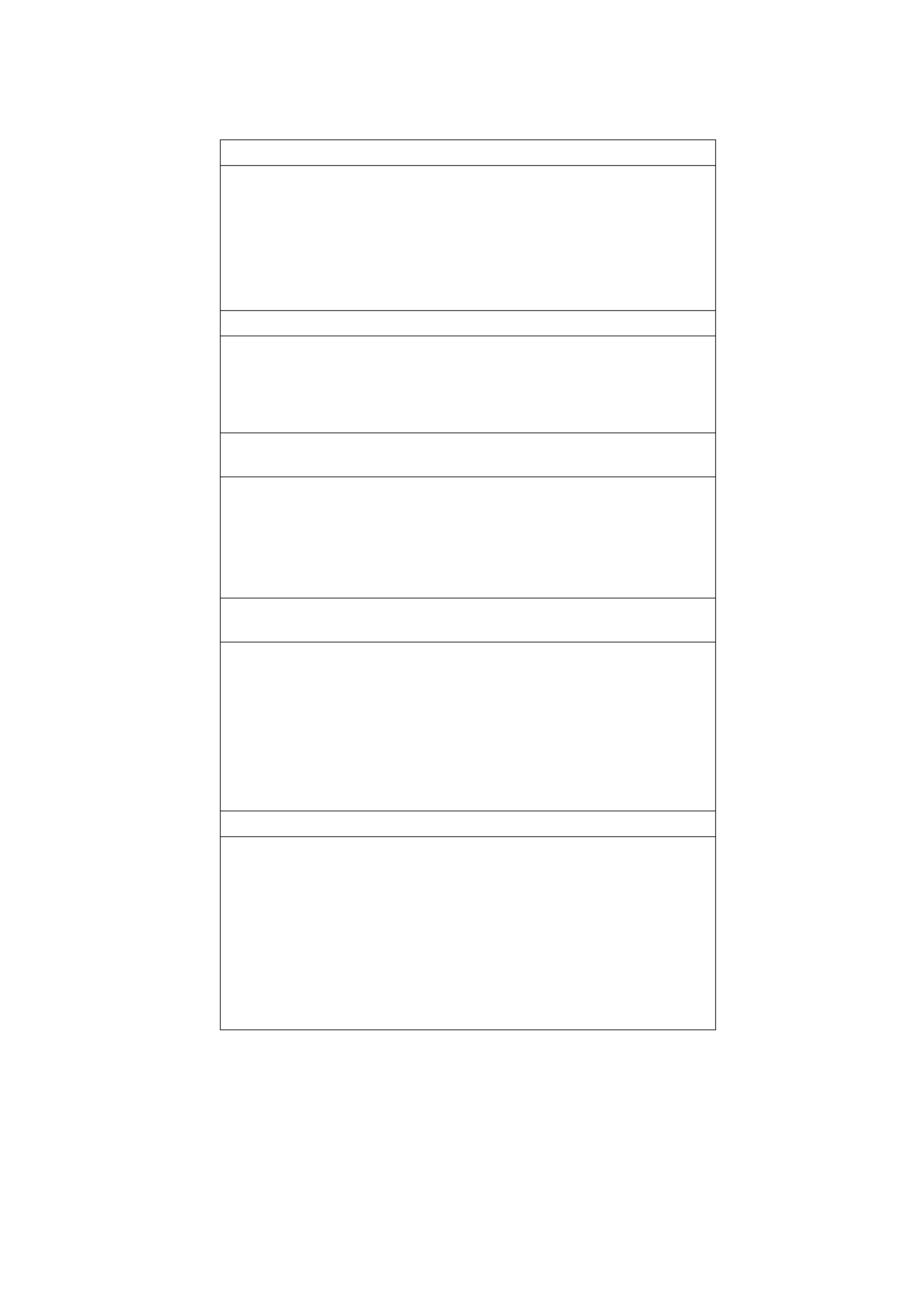

CIRCUIT DIAGRAM

Refer to the V6 engine charging circuit diagram (Figure 6D1-1B-27) to assist with diagnosing charging system

faults.

Figure 6D1-1B-27

5. SPECIFICATIONS

Ground Polarity................................................................ Negative

Nominal Voltage.............................................................. 12 volts

Nominal Output ............................................................... 120 amps

Voltage Regulator Setting................................................ 13.8 – 14.5 volts

Rotor Winding Resistance @ 20°C................................. 1.9 ohms

Slip-ring Outer Diameter.................................................. 22.7 mm

Slip-ring Service Limit...................................................... 22.1 mm

Stator Winding Resistance @ 20°C................................ 0.048 ohm

Brush Length New........................................................... 18.5 mm

Minimum Brush Length ................................................... 5.0 mm

Direction of Rotation (viewed from pulley)....................... Clockwise

6. TORQUE WRENCH SPECIFICATIONS

Nm

Drive Pulley Attaching Nut .................................................... 99 – 137

Through-bolts........................................................................ 3.5 – 5.3

Bearing Retainer Screws...................................................... 2.0 – 5.3

Brush Holder Retaining Screws............................................ 2.0 – 5.3

Rectifier Retaining Screws.................................................... 2.0 – 5.3

B+ Terminal Nut.................................................................... 12.8 – 18.6

Generator to Brace Bolts ...................................................... 20 – 30

Generator to Drive Belt Tensioner Bracket Bolt.................... 20 – 34

Tensioner Bracket Lower Bolt............................................... 40 – 50

B+ Terminal Battery Harness Nut......................................... 5 – 12

Engine Dress Cover to Intake Manifold Dome Nut............... 4 – 6

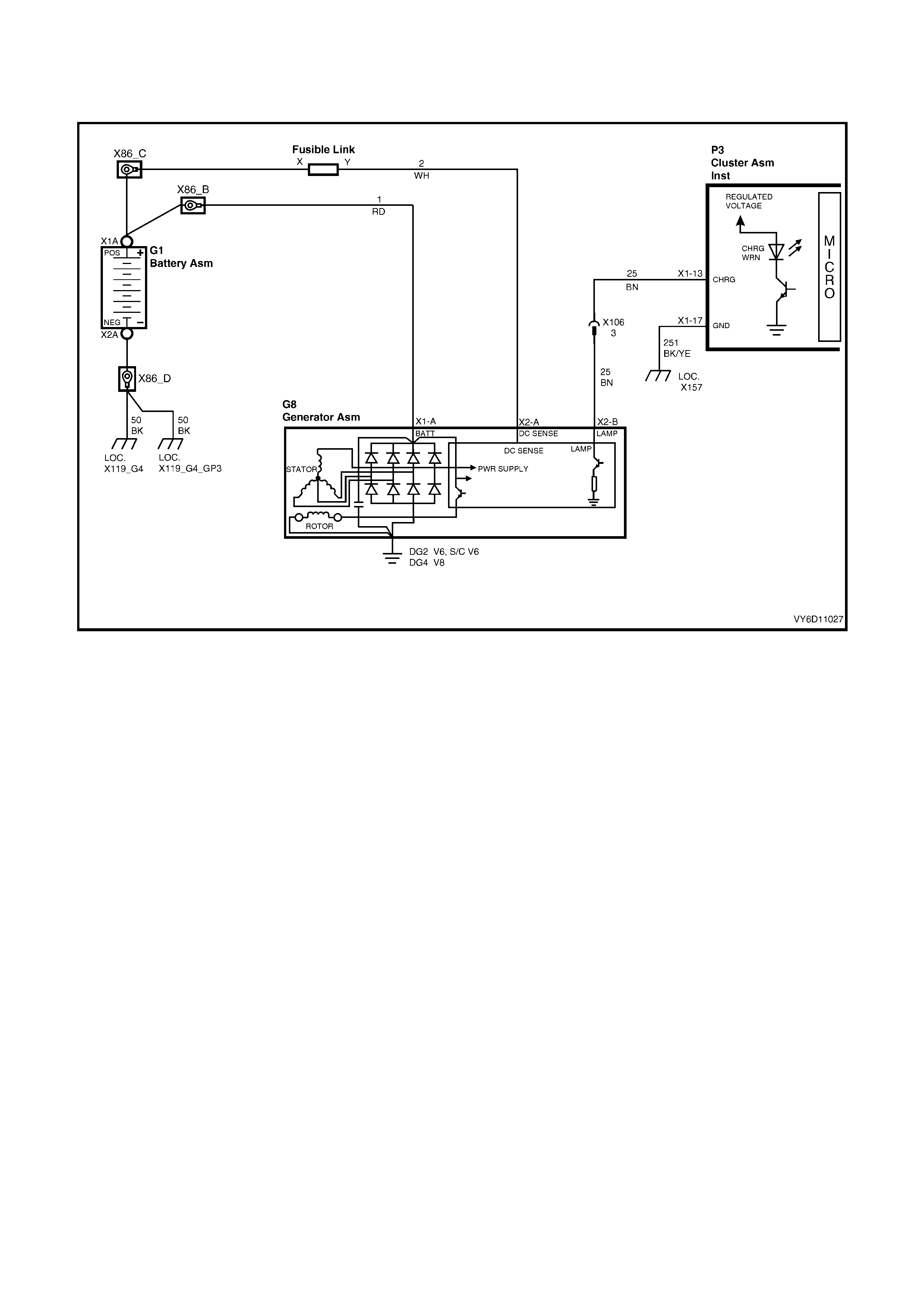

7. SPECIAL TOOLS

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

9981 066 600

BEARING ASSEMBLY FIXTURE

Used for many applications for

pressing on and off components.

Previously released.

Desirable

9981 066 601 ROTOR BEARING REMOVAL

TOOL Used with forcing screw

E6661S and adaptor AU412 to

remove side bearing cups from final

drive screw adjusters.

Previously released.

Desirable

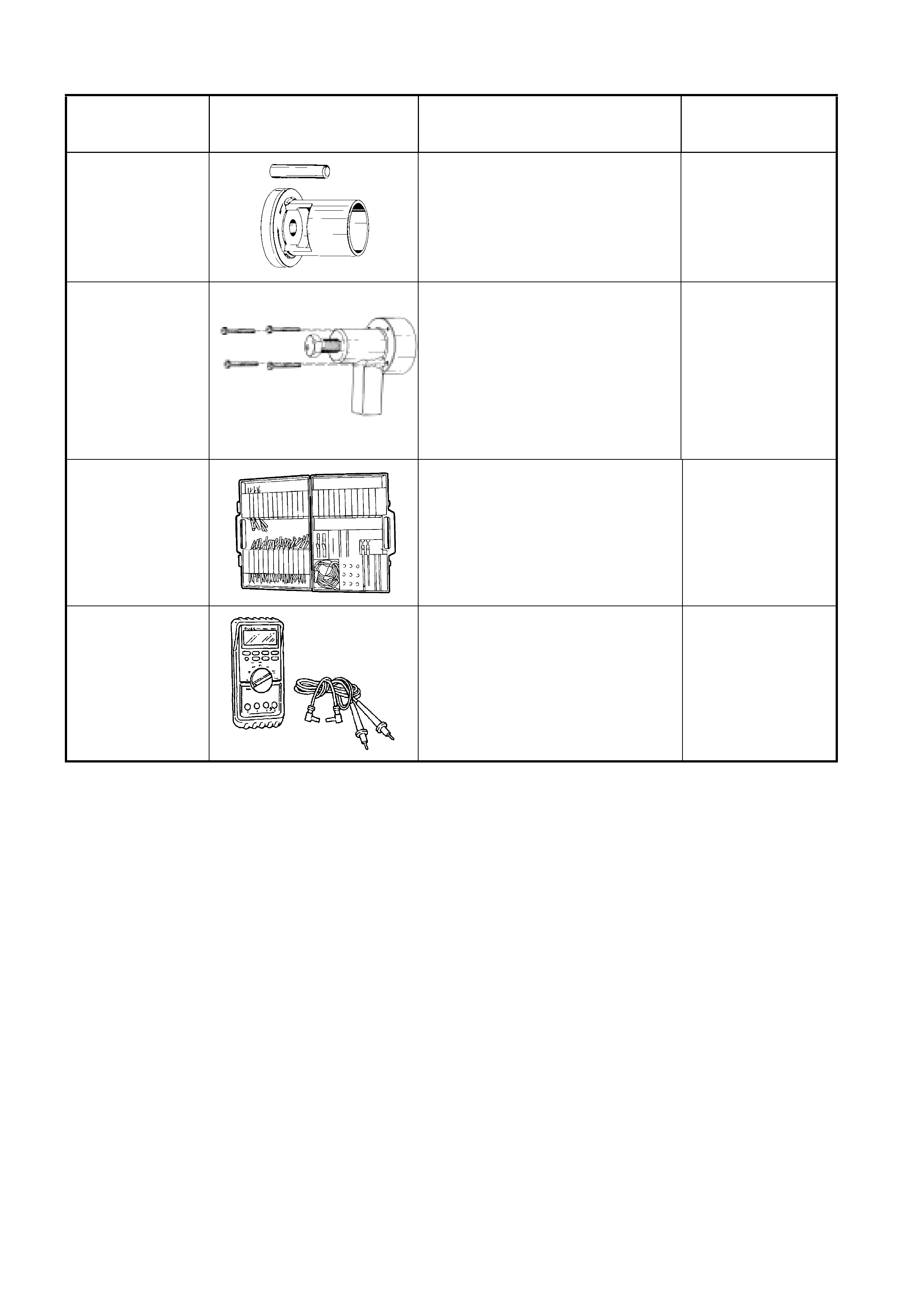

J35616-A

(KM609)

CONNECTOR TEST ADAPTOR

KIT

Used when carrying out electrical

diagnostic circuit checks.

Previously released.

Desirable

3588

(J39200)

DIGITAL MULTIMETER

Must have at least 10 MΩ input

impedance and be capable of

reading frequencies.

Previously released.

Available