SECTION 6E1 - EMISSION CONTROL –

V6 ENGINE

IMPORTANT

Before perfo rming any Service Operation or other procedu re described in this Section , refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL INFORMATION

1.1 VEHICLE EMISSION CONTROL

INFORMATION LABEL

1.2 EMISSIONS MANAGEMENT

1.3 ENGINE VENTILATION

RESULTS OF INCORRECT OPERATION

1.4 EVAPORATIVE EMISSION CONTROL

RESULTS OF INCORRECT OPERATION

1.5 EXHAUST GAS RECIRCULATION

PRINCIPLES OF OPERATION

1.6 THREE-WAY CATALYTIC CONVERTER

PRINCIPLES OF OPERATION

SERVICE NOTES

2. SERVICE OPERATIONS

2.1 POSITIVE CRANKCASE VENTILATION

VALVE

REPLACEMENT AND FUNCTIONAL

CHECK

2.2 EVAPORATIVE EMISSION CONTROL CANISTER

REMOVE

REINSTALL

SERVICE CHECKS

2.3 CANISTER PURGE SOLENOID VALVE

REMOVE

REINSTALL

2.4 LINEAR EGR VALVE

REMOVE

REINSTALL

3. DIAGNOSIS

3.1 POSITIVE CRANKCASE VENTILATION

3.2 EVAPORATIVE EMISSION CONTROL

4. SPECIAL TOOLS

5. TORQUE WRENCH SPECIFICATIONS

1. GENERAL INFORMATION

An emission control system is installed on MY 2003 VY Series and V2 Series II vehicles fitted with V6 engines.

These vehicles feature electronically controlled fuel injection and ignition systems and are designed to comply the

requirements of Australian Design Rule, ADR 37/01 and ECE R83.00 level B emission compliance.

In order to meet these specifications, the vehicles operate on unleaded petrol and are fitted with the following

emission control systems:

• Engine ventilation

• Evaporative emission control

• Three-way catalytic converter

• Exhaust gas recirculation

NOTE: Vehic les that ar e produc ed f or Indones ia are not fitted with oxygen s ens ors and a muffler is f itted in place of

the catalytic converter.

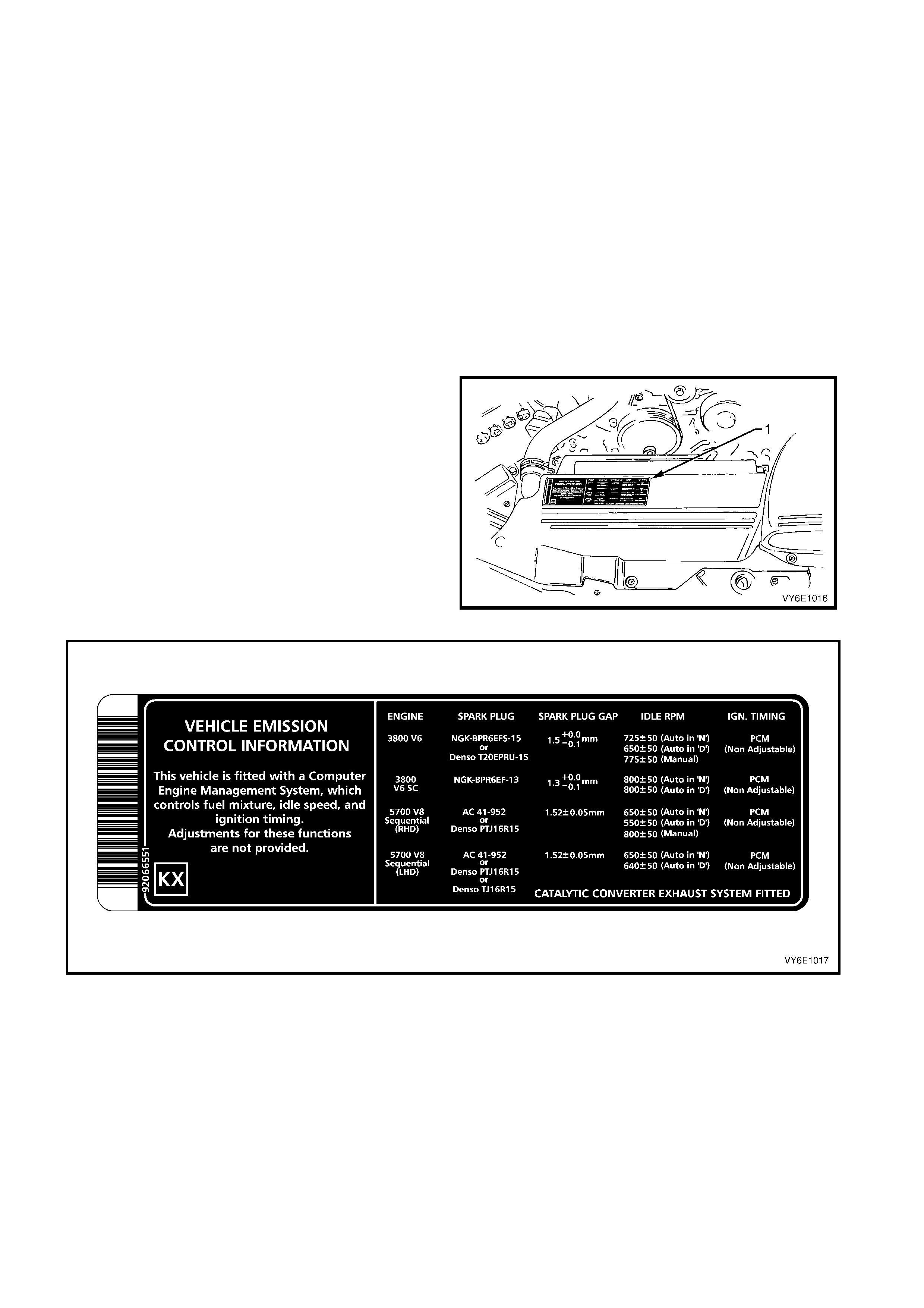

1.1 VEHICLE EMISSION CONTROL INFORMATION LABEL

The vehicle emission control information label is

located in the engine compartment.

The label contains im portant engine tune conditions to

achieve the correct emission levels, and should be

referred to before making any adjustments. For all

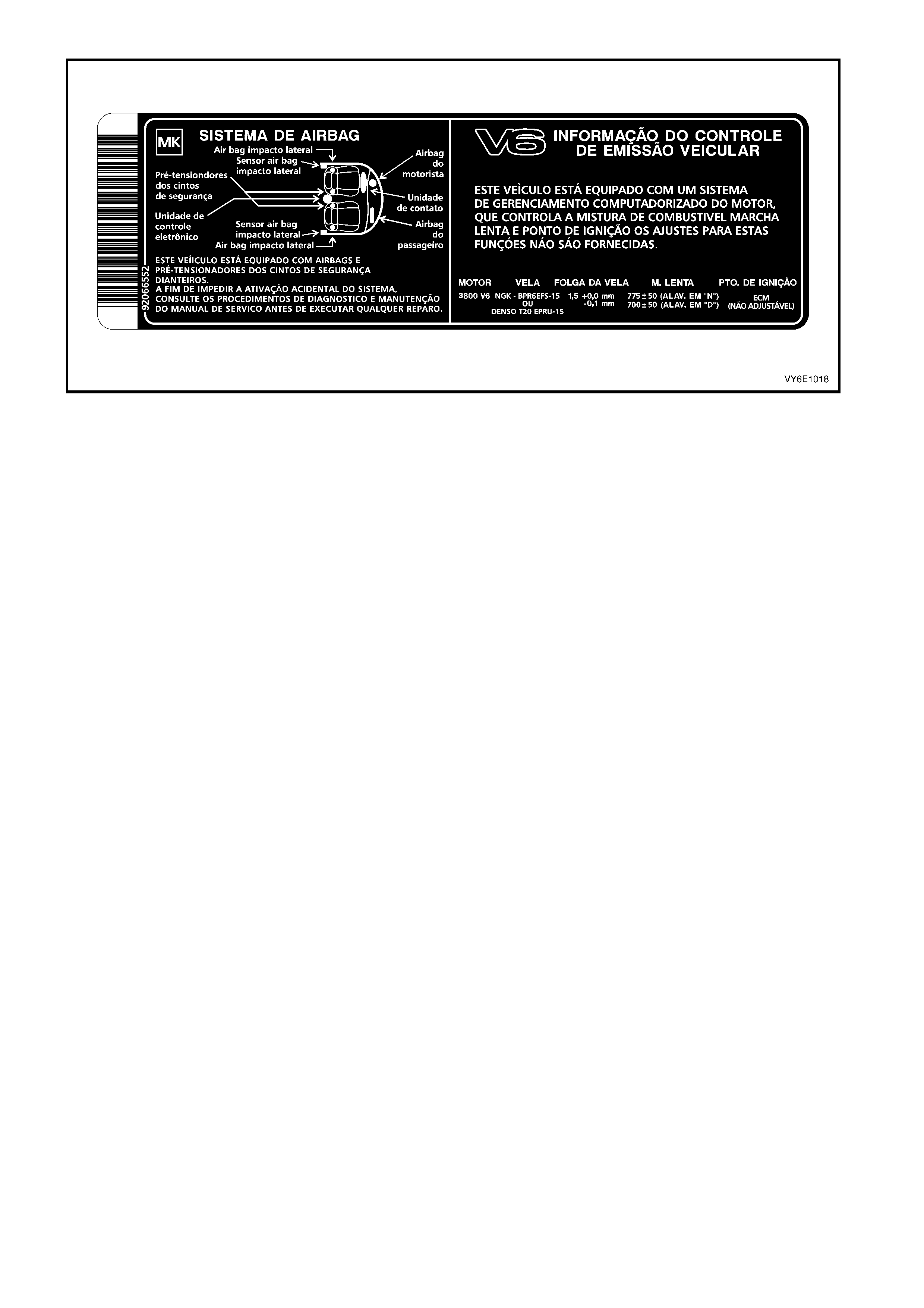

vehicles except for Brazil, refer to Figure 6E1-2. For

Brazil vehicles, refer to Figure 6E1-3.

Figure 6E1-1

Figure 6E1-2

Figure 6E1-3

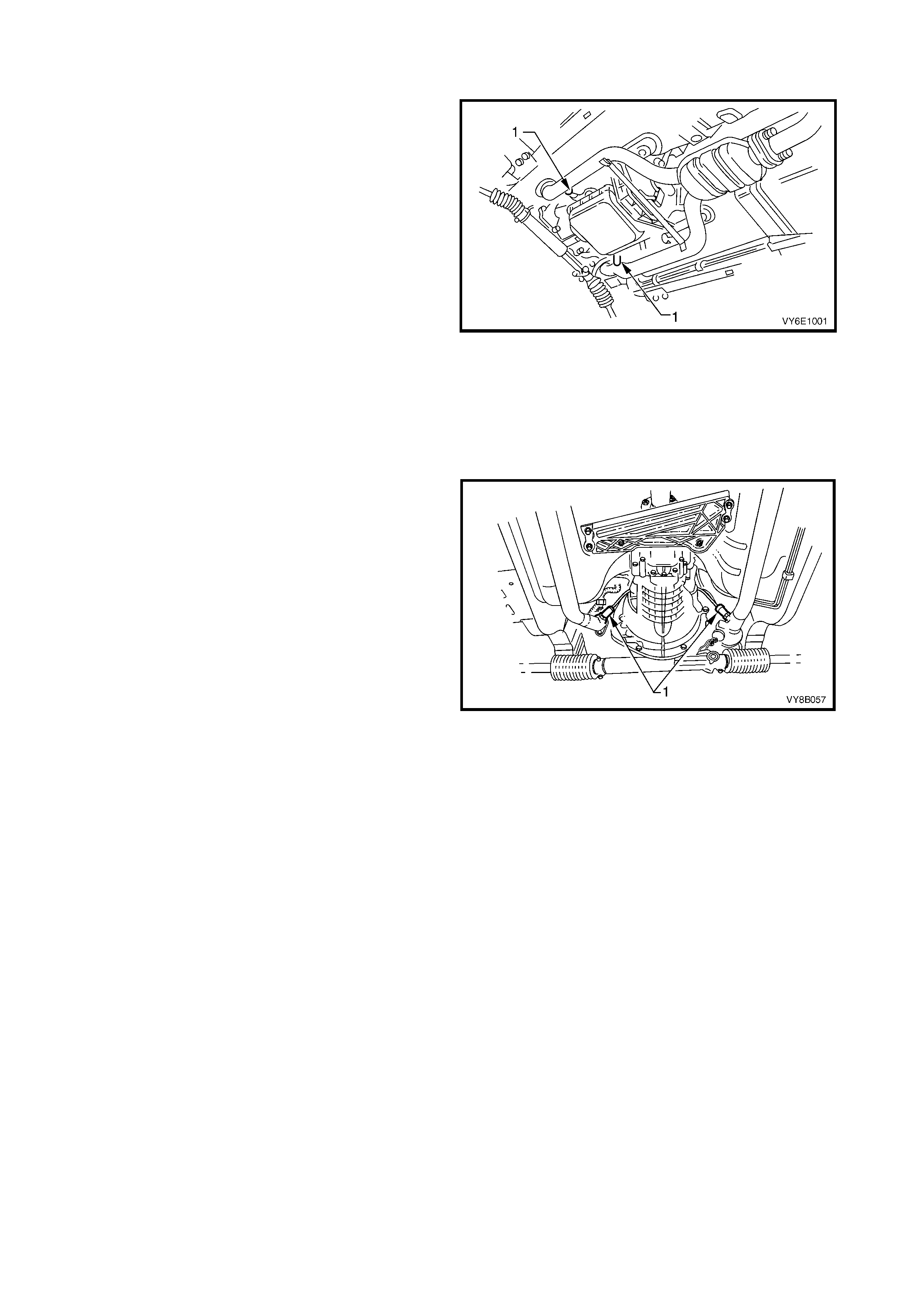

1.2 EMISSIONS MANAGEMENT

All aspects of engine air/f uel ratio and spark tim ing are

controlled by the Powertrain Control Module (PCM).

The mixture control is a closed loop system that

incorporates dual oxygen sensors (1), located in the

exhaust system engine pipes, f orward of eac h catalytic

converter.

While the engine ventilation system requires no

outside control, the operation of the evaporative

emission control system is controlled by the PCM via

an EVAP canister purge valve, mounted on the engine

intake manifold.

NOTE: Vehicles that are produced for Indonesia are

not fitted with oxygen sensors and a muffler is fitted in

place of the catalytic converter.

The PCM and associated systems are described in

Section 6C1 POWERTRAIN MANAGEMENT - V6

ENGINE.

Refer to Figure 6E1-4 for the position of oxygen

sensors on vehicles fitted with an automatic

transmission.

Figure 6E1-4

Refer to Figure 6E1-5 for the position of oxygen

sensors (1) on vehicles fitted with a manual

transmission.

Figure 6E1-5

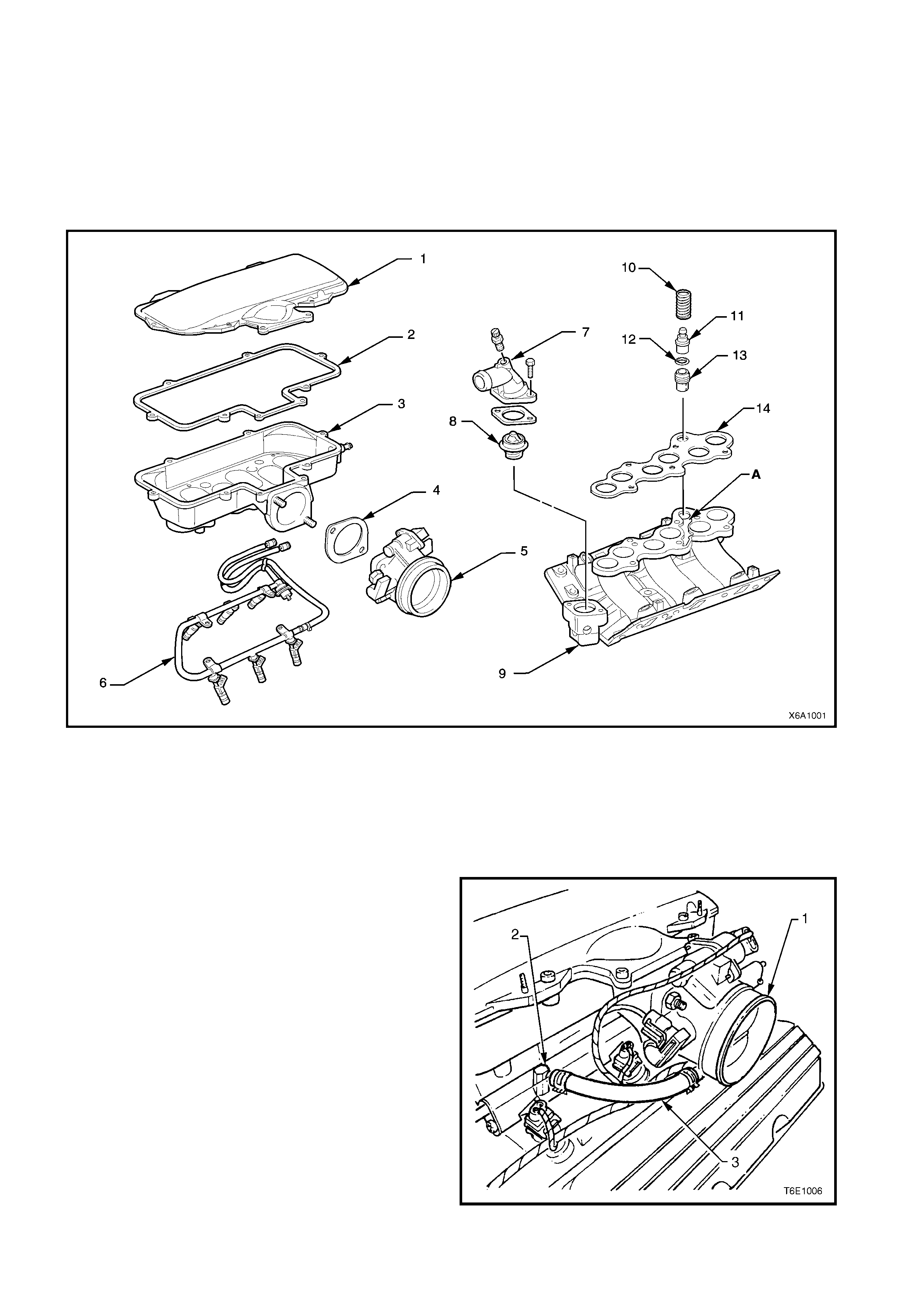

1.3 ENGINE VENTILATION

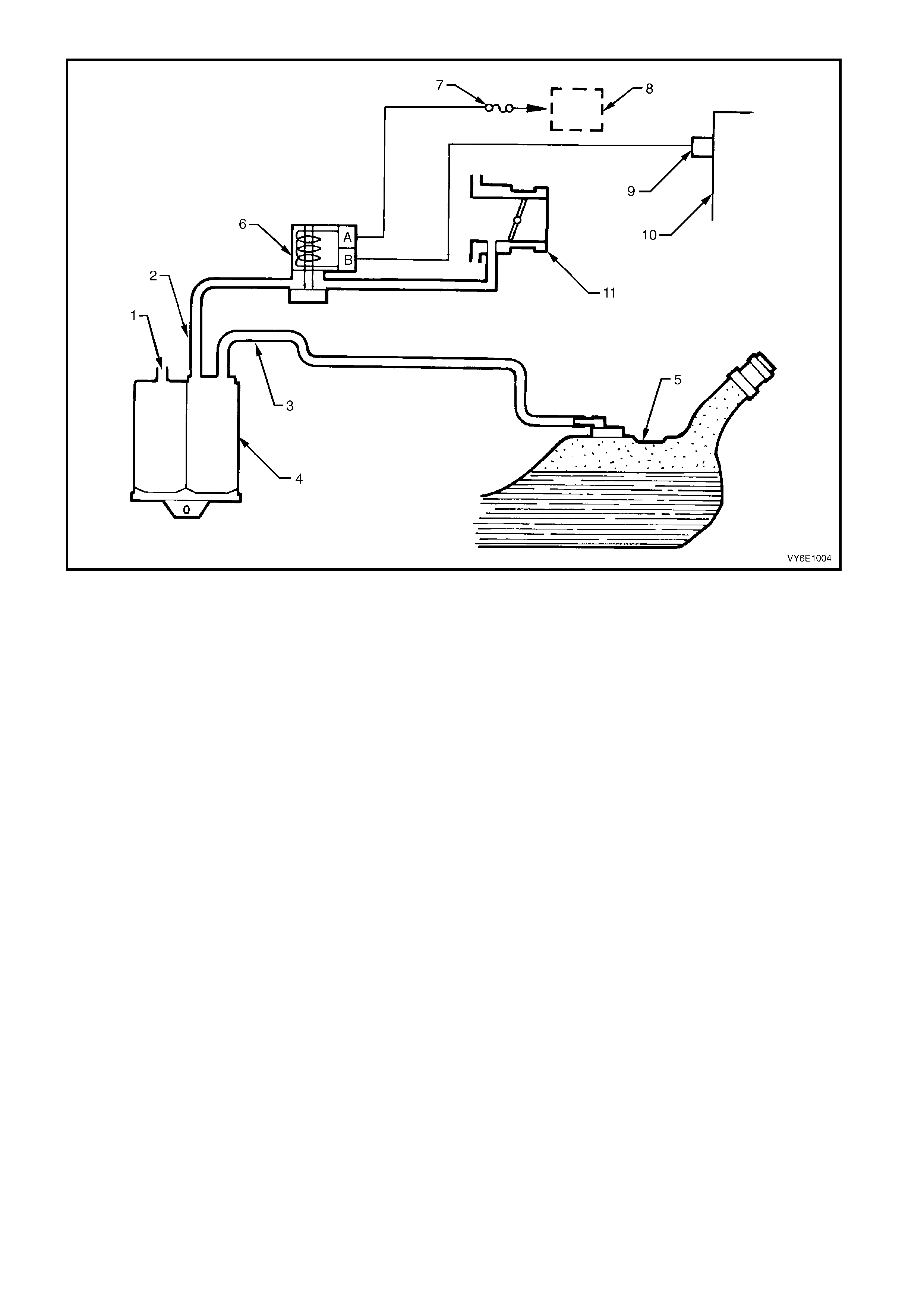

The engine ventilation s ystem uses a Positive Crank case Ventilation (PCV) valve (11) which is located in the lower

inlet manif old ( 9), refer to Figure 6E1-6. T he channel (A) provides an even distribution of crank case fum es, thereby

impr oving spark plug reliability and a reduction in emis sions. T he PCV valve is a non-servic eable item and must be

replaced if defective.

W hen the upper inlet m anifold is s eparated from the lower half, per form a functional check of the PCV valve. Also,

clean the PCV valve passage in the lower manifold to avoid any possibility of the passage becoming clogged with

condensed engine oil fumes.

Figure 6E1-6

Legend

1. Upper Inlet Manifold Cover 6. Fuel Injector and Rail Assembly 11. PCV Valve

2. Upper Inlet Manifold gasket 7. Thermostat Housing & Bleeder 12. PCV Valve O-Ring Seal

3. Upper Inlet Manifold 8. Thermostat 13. Oil Separation Baffle

4. Throttle Body Gasket 9. Lower Inlet Manifold 14. Upper to Lower Inlet Manifold Gasket

5. Throttle Body 10. Spring – PCV Valve

During normal driving conditions, crankcase vapours

are drawn into the inlet manifold via the PCV valve.

Vapours are then delivered through the inlet manifold

plenum chamber into the combustion chamber, to be

burnt with the air/fuel mixture.

Fresh air is drawn into the crankcase via a breather

hose (3), which is connected between the throttle

body (1) and a port on the inlet manifold (2).

The PCV valve meters the mixture of fresh air and

crankcase vapours into the induction system at a rate

dependant upon manifold vacuum.

To maintain idle quality, the PCV valve restricts the

flow when inlet manifold vacuum is high. If abnormal

manifold conditions arise, the system is designed to

allow excess ive am ounts of crank case vapours to flow

back through the breather hose, into the throttle body

to be consumed by normal combustion.

Figure 6E1-7

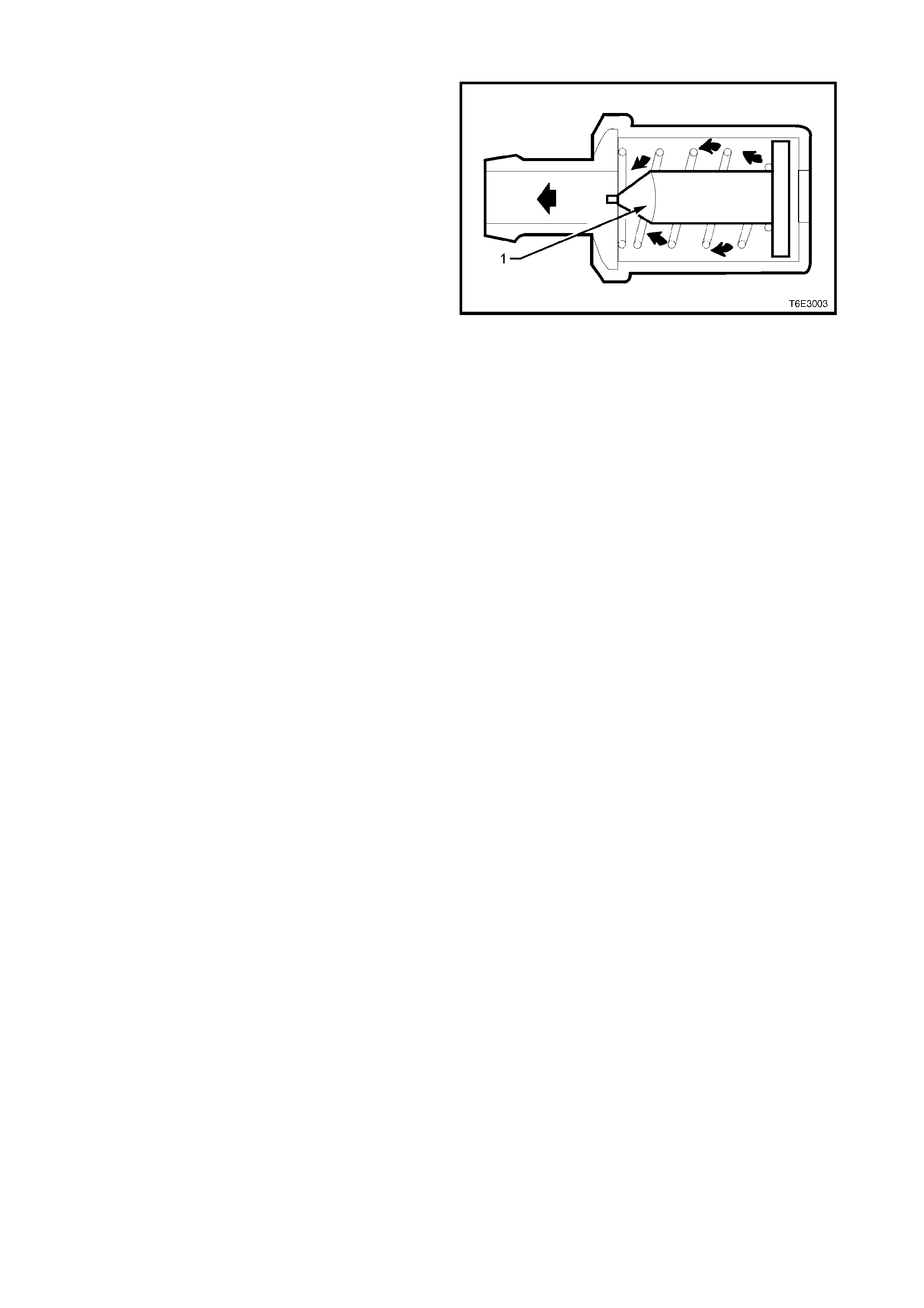

RESULTS OF INCORRECT OPERATION

A blocked or partially blocked PCV check valve (1) may

cause:

• Rough idle.

• Stalling or slow idle speed.

• Oil leaks.

• Sludge in engine.

A leaking valve would cause:

• Rough idle.

• Stalling.

• High idle speed.

Figure 6E1-8

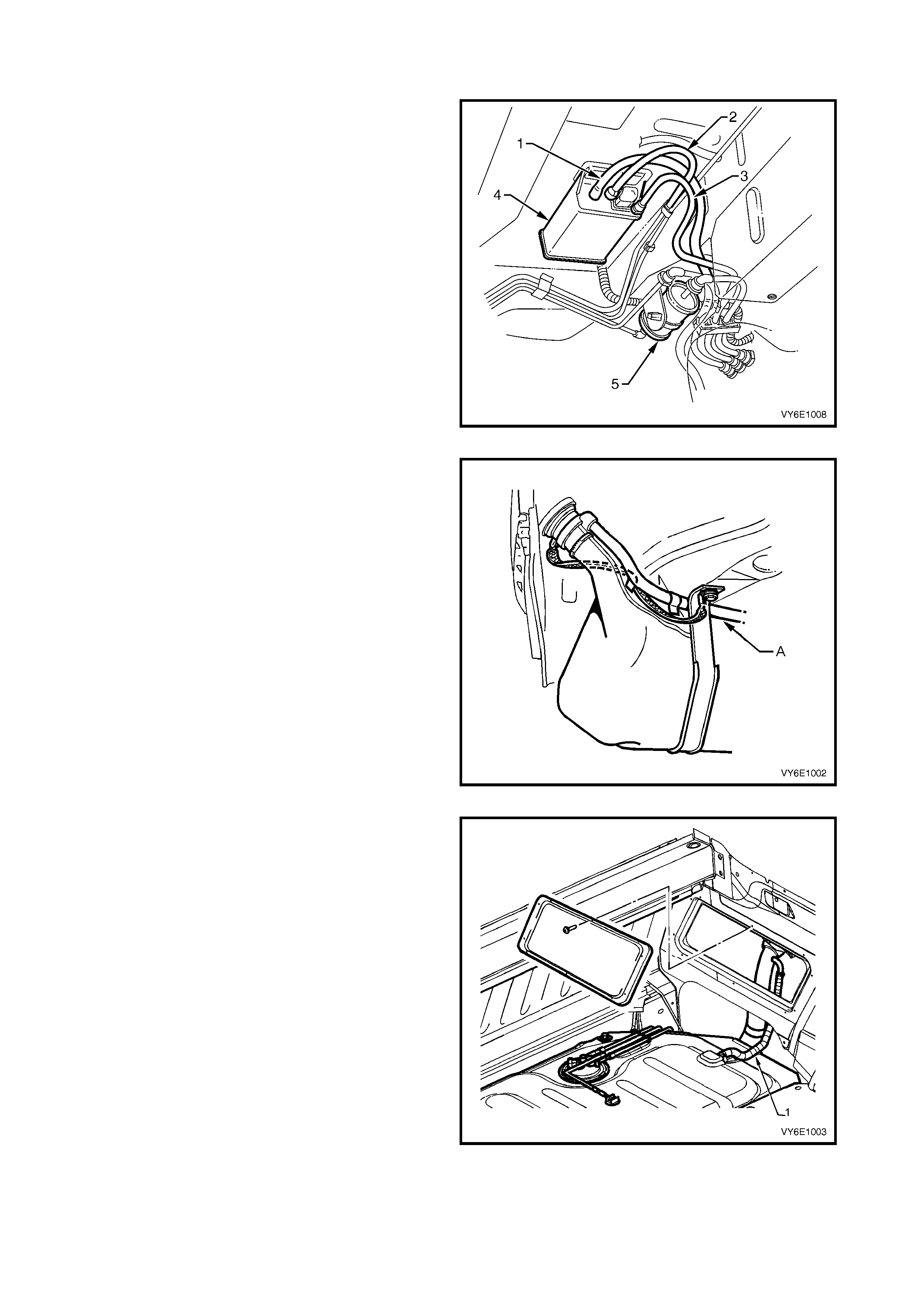

1.4 EVAPORATIVE EMISSION CONTROL

The evaporative emission control system used on this

vehicle is the activated carbon (charcoal) canister

storage method. This fuel vapour canister (4) is a three

port design and is mounted in a bracket underneath

the vehicle, near the fuel filter (5).

The canister cannot be repaired and is serviced only

as an assembly. Periodically check the canister at the

time or distance intervals specified in Section 0B

LUBRICATION AND SERVICE.

The canister is designed to store fuel tank vapour via

the tank vent line (3) and release it to the engine via

the canister purge line (2).

The canister vent line (1) is routed to the fuel filler

neck.

Figure 6E1-9

Figure 6E1-10 shows the canister vent line (A)

attachm ent to the fuel f iller neck on all vehicles except

Utility.

Figure 6E1-10

Figure 6E1-11 shows the canister vent line (1)

attachment to the fuel filler neck on the Utility.

For removal of the f r ont inner s ide panel c over, r ef er to

Section 1B, 2.8 FRONT INNER SIDE PANEL

COVER.

Figure 6E1-11

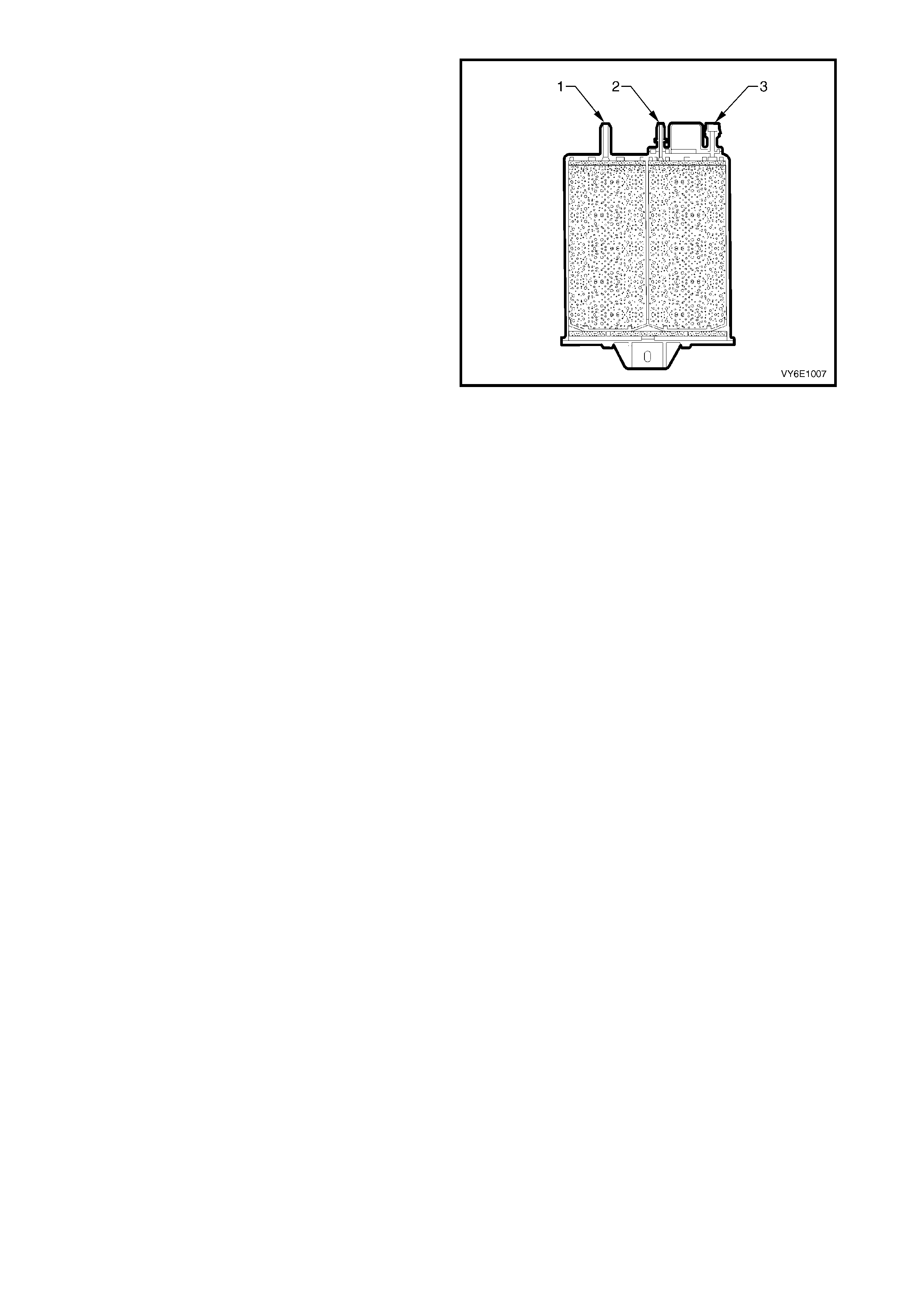

Fuel vapour from the fuel tank enters the canister via

the tank vent port (3). The fuel vapour is absorbed by

the charcoal within the canister.

W hen the engine is running at or above idle, manifold

vacuum on the canis ter purge port (2) caus es air to be

drawn in from the canister vent port (1). This air flow

purges fuel vapour from the canister which is then

transferred to the throttle body. The fuel vapour is

consumed in the normal combustion process.

The EVAP canister purge valve controls the manifold

vacuum that is applied to the canister. The PCM

energises the EVAP canister purge valve by supplying

an earth signal (purge on). The EVAP canister purge

valve control is Pulse Width Modulated (PWM). (This

means that the canister purge valve is turned on and

off several times a second.)

The PCM c ontrolled PW M output is com manded when

the appropriate conditions have been met, such as:

• Engine coolant temperature is below 20 °C at cold

start up and the engine has been running longer

than 3 minutes and 10 seconds, or

• Engine coolant temperature is above 80 °C and

the engine has been running longer than

5 seconds, or

• Engine is not in decel fuel cutoff mode and the

throttle opening is less than 96%, or

• The engine is in closed loop fuel mode.

Figure 6E1-12

A higher purge rate is used under conditions that are

likely to produce large amounts of vapour, when the

following conditions have been met:

• Intake Air Temperature (IAT) is above 50 °C, or

• Engine Coolant Temperature (ECT) is above

100 °C, or

• The engine has been running for more than

15 minutes.

The EVAP purge PW M duty cycle varies according to

operating conditions determined by mass air flow, fuel

trim and intake air temperature. The EVAP canister

purge valve is re-enabled when throttle position angle

decreases below 96%.

Figure 6E1-13

Legend

1. Canister Vent Port 5. Fuel Tank 9. PCM Terminal X1_A10

2. Canister Purge Line 6. EVAP Canister Purge Valve 10. PCM

3. Tank Vent Line 7. Fuse F33 11. Throttle Body

4. Canister 8. EFI Relay

RESULTS OF INCORRECT OPERATION

Poor idle, stalling and poor driveability can be caused by:

• Inoperative EVAP canister purge valve.

• Damaged canister.

• Hoses split, cracked and/or not connected to the correct locations.

• Throttle body and canister hoses interchanged on the EVAP canister purge valve connections.

NOTE: The canister purge port is marked with CAN.

Evidence of fuel loss or fuel vapour odour can be caused by:

• Liquid fuel leaking from fuel lines.

• Cracked or damaged canister.

• Disconnected, incorrectly routed, kinked, deteriorated or damaged hoses.

If the EVAP canis ter purge valve is s tuc k open, or the contr ol cir cuit is s horted to ear th, the c anis ter will purge to the

intake manif old all the tim e. This can allow extra f uel at idle or during warm -up, which can c ause rough or unstable

idle or a rich fuel operation.

If the canister purge solenoid is always closed, the canister can become overloaded resulting in noticeable fuel

odour.

1.5 EXHAUST GAS RECIRCULATION

PRINCIPLES OF OPERATION

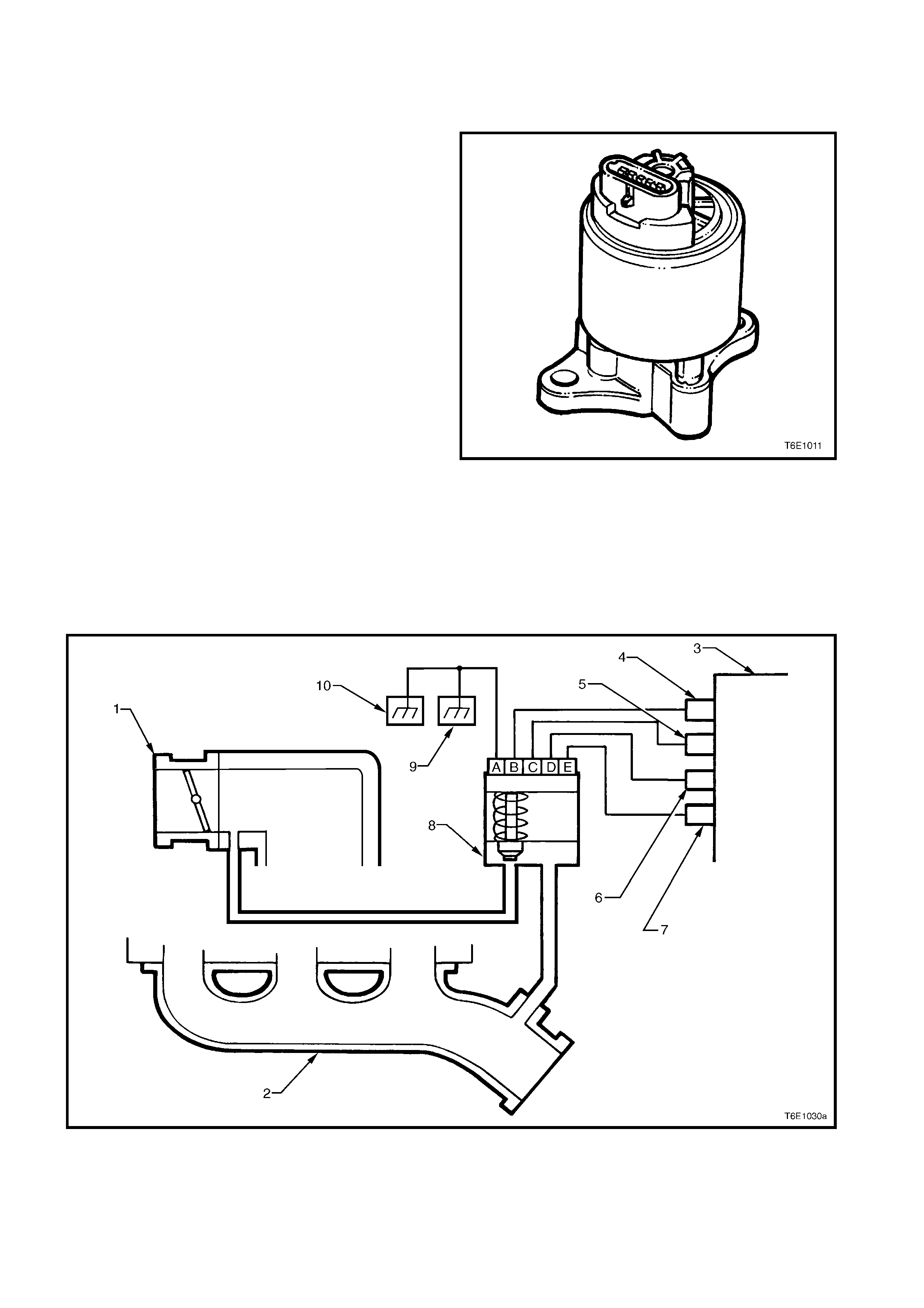

The V6 engine is equipped with an Exhaust Gas

Recirculation (EGR) system. T he EGR system is used

to lower Oxides of Nitrogen (NOx) emission levels,

caused by high combustion temperature.

A linear EGR valve feeds small amounts of exhaust

gas back into the combustion chamber. This dilutes

the air/fuel mixture and combustion temperatures are

reduced.

The linear EGR valve is designed to accurately supply

exhaust gas to the engine independent of the intake

manif old vacuum. T he valve contr ols gas f low from the

exhaust to the intak e m anif old through an orif ice with a

PCM controlled pintle. During operation, the PCM

controls pintle pos ition by m onitoring the pintle position

feedback signal.

The linear EGR valve is usually activated under the

following conditions:

• Warm engine operation.

• Above idle speed.

The PCM monitors actual EGR position and adjusts

the pintle ac cordingly. The PCM us es inform ation fr om

the following sensors to control pintle position:

• Engine Coolant Temperature (ECT) sensor.

• Throttle Position (TP) sensor.

• Mass Air Flow (MAF) sensor.

• Engine RPM.

Figure 6E1-14

Figure 6E1-15

Legend

1. Throttle Body 5. PCM Terminal X2_C8 9. Ground Point, Front Right Hand of Engine Block

2. Exhaust Manifold 6. PCM Terminal X2_B5 10. Ground Point, Rear Left Hand of Engine Block

3. PCM 7. PCM Terminal X3_E12

4. PCM Terminal X2_C16 8. Linear EGR Valve

1.6 THREE-WAY CATALYTIC CONVERTER

PRINCIPLES OF OPERATION

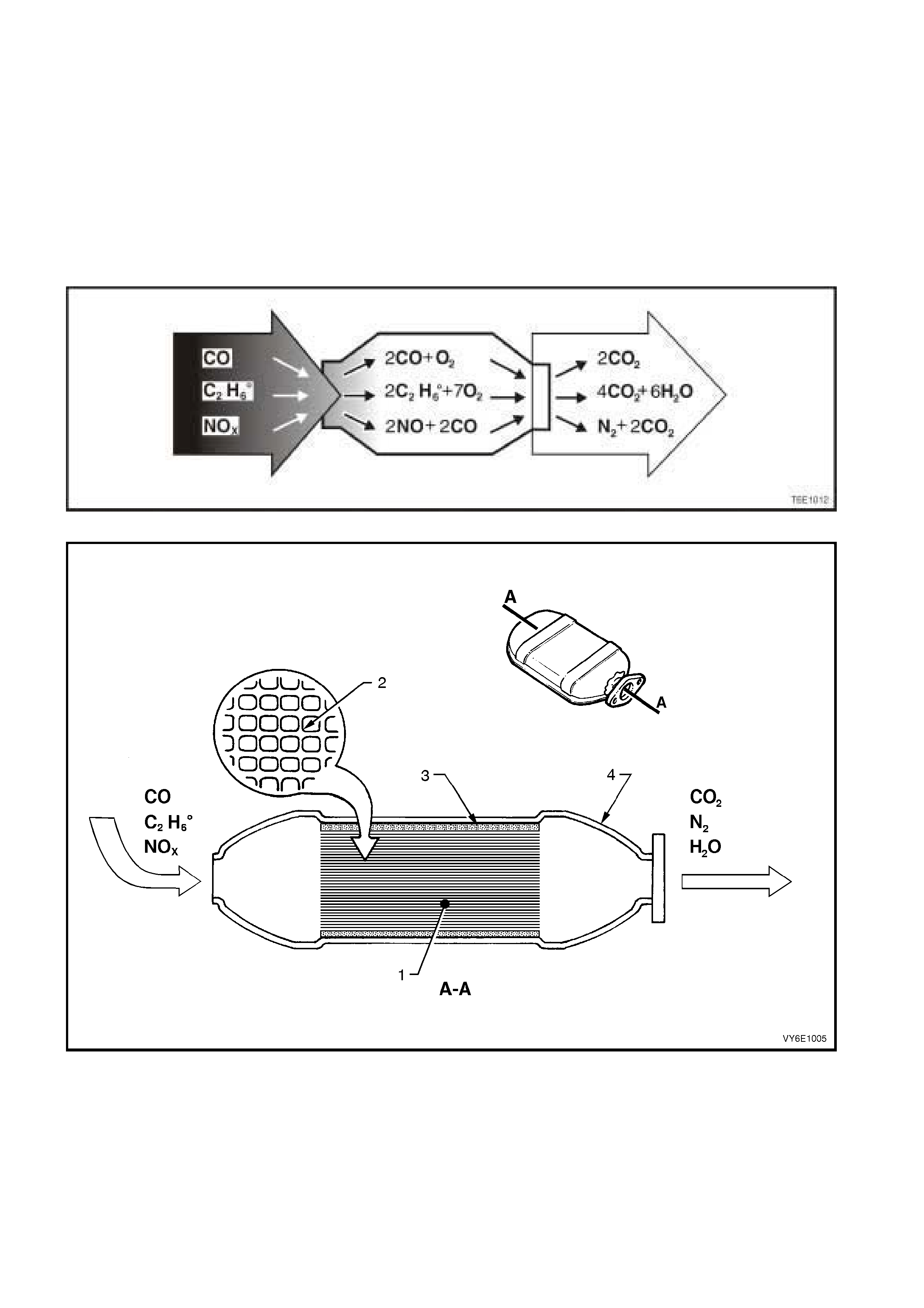

The catalytic converter consists of a stainless steel housing that encloses a ceramic monolith. The monolith is an

extruded high temperature ceramic with approximately 62 cells/sq.cm in cross section. This gives the monolith a

large surface area for its mass. Distributed over the monolith surface is a catalyst that consists of platinum and

rhodium. A catalyst is a substance that accelerates a chemical reaction without itself being changed.

Engine exhaust gases contain carbon m onoxide (CO), hydrocarbons (HC) and oxides of nitrogen (NOX). When the

exhaust gases flow through the monolith, reactions with the catalyst occur. CO and HC are converted by oxidation

with oxygen (O2) in the exhaust gas es to produce carbon diox ide (CO2) and water vapour (H2O). NOX is conver ted

by reduction with CO to produce nitrogen (N2) and CO2. The converter is called a three-way type because it

simultaneously converts three components of exhaust gas (CO, HC and NOX) to harmless natural gases.

Figure 6E1-16

Figure 6E1-17

Legend

1. Ceramic Monolith 3. Ceramic Mat Securing Monolith

2. Cross Section of Ceramic Monolith 4. Stainless Steel Shell

The catalytic converter can only reduce exhaust emissions if:

a. The engine is designed for use with a catalytic converter and unleaded petrol, since lead contaminates the

catalytic coating and prevents it from functioning.

b. It is integrated in the exhaust system in such a way that the exhaust emission conversion occurs in the most

effective temperature range – in the vicinity of 600 degrees Celsius.

c. The catalysts function ef fectively within certain air/fuel ratios only. As a c onsequence, the air/fuel r atio supplied

to the engine mu st be controlled within strict lim its for emission c onversion and long converter lif e. This contr ol

is off ered by oper ating under a closed loop mix ture control system with dual oxygen sensors. F or details of the

oxygen sensors refer to Section 6C1-3, 2.6 OXYGEN SENSORS.

The catalytic converter can be damaged, or rendered ineffective:

a. If operated outside the limits of the closed loop mixture control system, or

b. If the engine burns excessive amounts of oil, or

c. If the exhaust temperature at the converter is too high (above 850 degrees Celsius).

SERVICE NOTES

1. Do not operate the vehicle with leaded petrol. Lead will contaminate the ceramic monolith.

2. Do not drop the catalytic converter as it will damage the ceramic monolith.

3. Replace the catalytic converter if it is damaged.

4. Do not allow water, oil or fuel to enter the converter as the ceramic monolith will be contaminated.

5. Do not use engine additives. Many additives contain phosphorous that will contaminate the ceramic monolith.

6. In order to prevent the catalytic converter from overheating, the following sequence must be followed when

carrying out a cylinder balance test:

a. Maximum time each cylinder may be switched off is 8 seconds.

b. Pause for at least 8 seconds between each switch off.

c. If repeating a cylinder balance test, allow the engine to idle for a least 60 seconds before retesting.

7. T he vehicle m ust not be s tarted by pushing or towing, as unburned f uel could reach the c atalytic c onverter and

destroy the ceramic monolith. Always use jumper leads to start a vehicle that has a flat or defective battery.

8. When carrying out a compression test, remove fuse F34 from the engine compartment relay housing, refer to

Section 6A1-1, 2.6 COMPRESSION TEST. This prevents fuel injection and ignition during engine cranking.

9. Do not drive the vehicle with the engine misfiring or with the spark plug leads disconnected as the catalytic

converter will overheat.

10. Do not coast downhill with the engine misfiring or with the spark plug leads disconnected.

11. T he catalytic converter is integrated with the exhaust system. For removal and installation instructions, refer to

Section 8B EXHAUST SYSTEM.

2. SERVICE OPERATIONS

2.1 POS I TIVE CRANKCASE VENTILATION VALVE

LT Section No. – 00-249

REPLACEMENT AND FUNCTIONAL CHECK

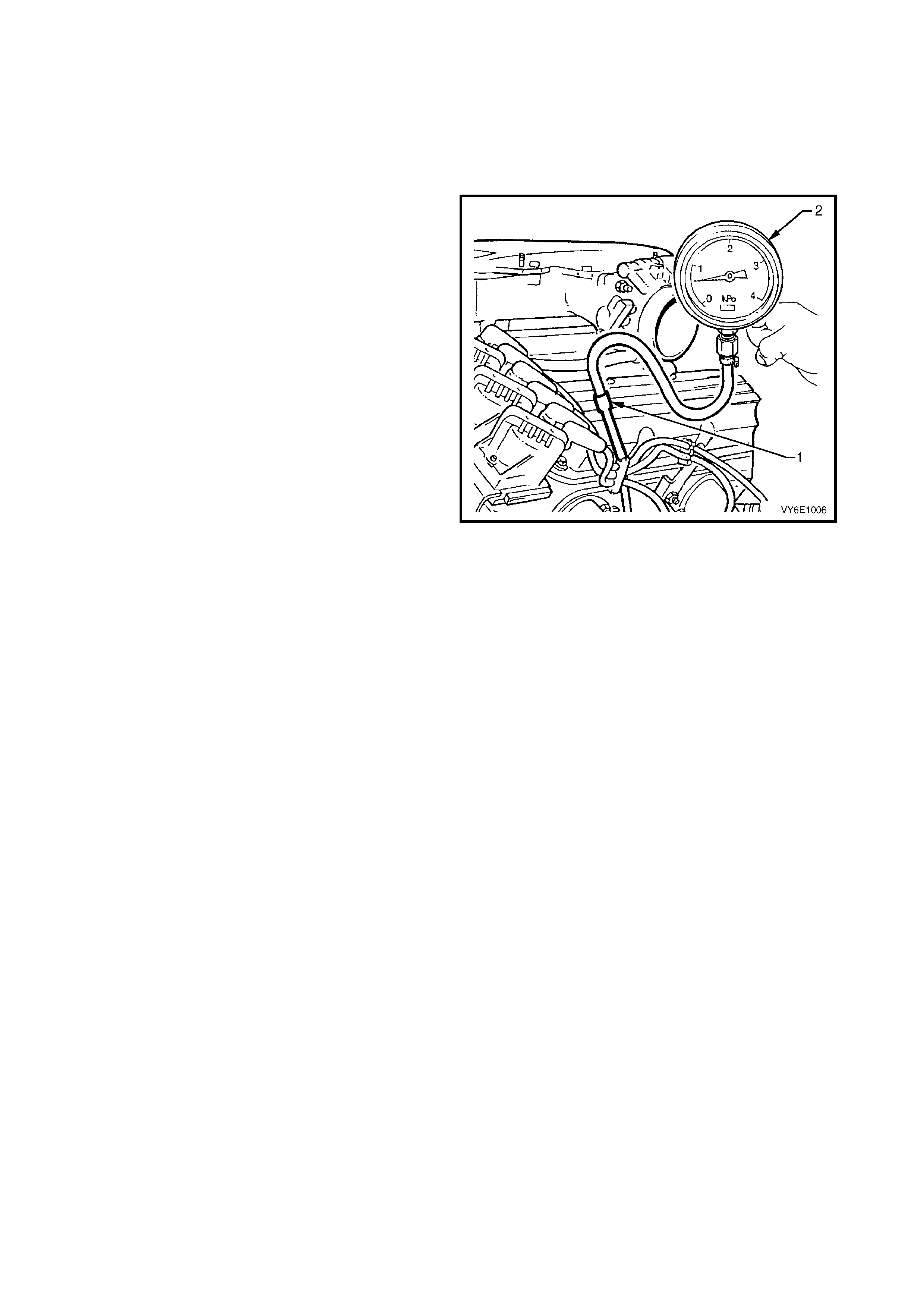

1. Remove the engine oil dipstick.

2. Connect a commercially available vacuum

gauge (2) with a scale of approx imately 0 to -4 kPa

to the engine oil dipstick tube (1), ensuring a tight

seal.

3. Allow the engine to idle and read the vacuum

gauge. If a vacuum of approximately -0.2 to -1.00

kPa is present, the PCV valve and PCV system

are functioning correctly.

If no vacuum or a possible positive pressure is

registered, this can indicate one or more faults:

• The engine may not be sealed and/or is drawing

outside air. Check engine crankcase, valve cover,

oil pan gasket, etc. for leaks.

• The engine may be badly worn causing excessive

engine blow-by.

• The PCV valve may be blocked and requires

further investigation using the following procedure.

1. Remove the PCV valve from inlet manifold, refer to

Section 6A1-1, 2.11 LOWER INLET MANIFOLD.

2. Shake the PCV valve and listen for a rattle of the

check valve inside the valve housing. If valve does

not rattle, discard and install new PCV valve and

O-ring.

3. Reinstall the PCV valve with O-ring, refer to

Section 6A1-1, 2.11 LOWER INLET MANIFOLD.

NOTE: It is possible (and normal) to have a positive

pressure reading at the engine oil dipstick tube while

the vehicle is under driving conditions at wide open

throttle.

CAUTION: Do not clamp the PCV valve outlet to

throttle body hose when the engine is running, as this

can cause damage to the engine.

Figure 6E1-18

2.2 EVAPORATIVE EMISSION CONTROL CANISTE R

LT Section No. – 03-165

REMOVE

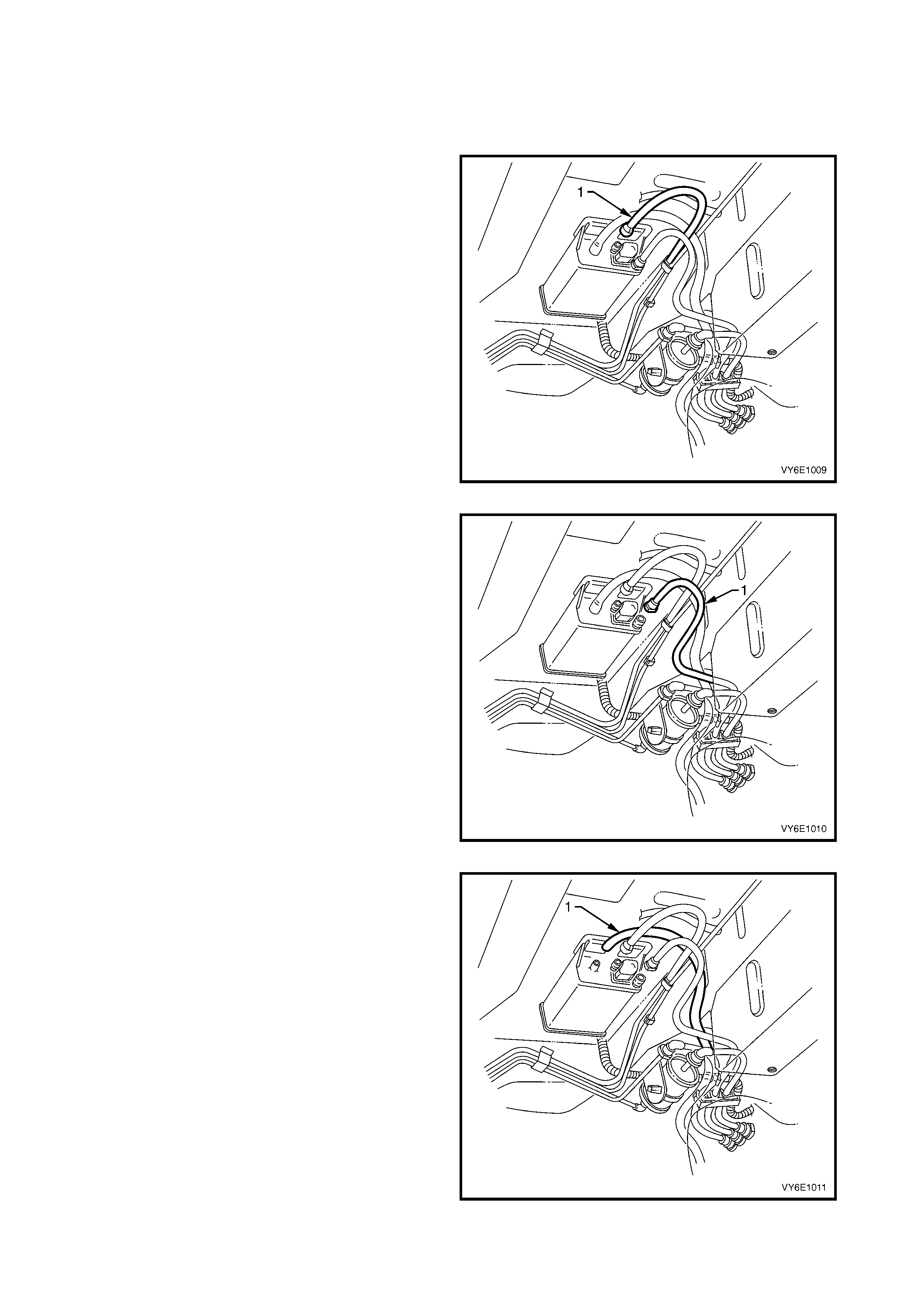

1. Disconnect the canister purge line (1) by using the

following procedure:

a. Gr asp both sides of the quick -c onnect f itting. Twist

the connector 1/4 turn in each direction in order to

loosen any dirt within the quick-connect fitting.

Caution: Wear safety glasses when using

compressed air.

b. Using compressed air, blow any dirt out of the

quick connect fitting.

c. Gr as p the quick-c onnect f itting and pus h it towards

the canister.

d Squeeze the quick-connect fitting to release the

retaining tabs, then pull back on the connector to

remove the canister purge line from the canister.

Figure 6E1-19

2. Disconnect the tank vent line (1) by using the

following procedure:

a. Gr asp both sides of the quick -c onnect f itting. Twist

the connector 1/4 turn in each direction in order to

loosen any dirt within the quick-connect fitting.

Caution: Wear safety glasses when using

compressed air.

b. Using compressed air, blow any dirt out of the

quick connect fitting.

c. Gr as p the quick-c onnect f itting and pus h it towards

the canister.

d Squeeze the quick-connect fitting to release the

retaining tabs, then pull back on the connector to

remove the tank vent line from the canister.

Figure 6E1-20

3. Rem ove the canis ter vent line (1) from the canister

by twisting and pulling it off.

Figure 6E1-21

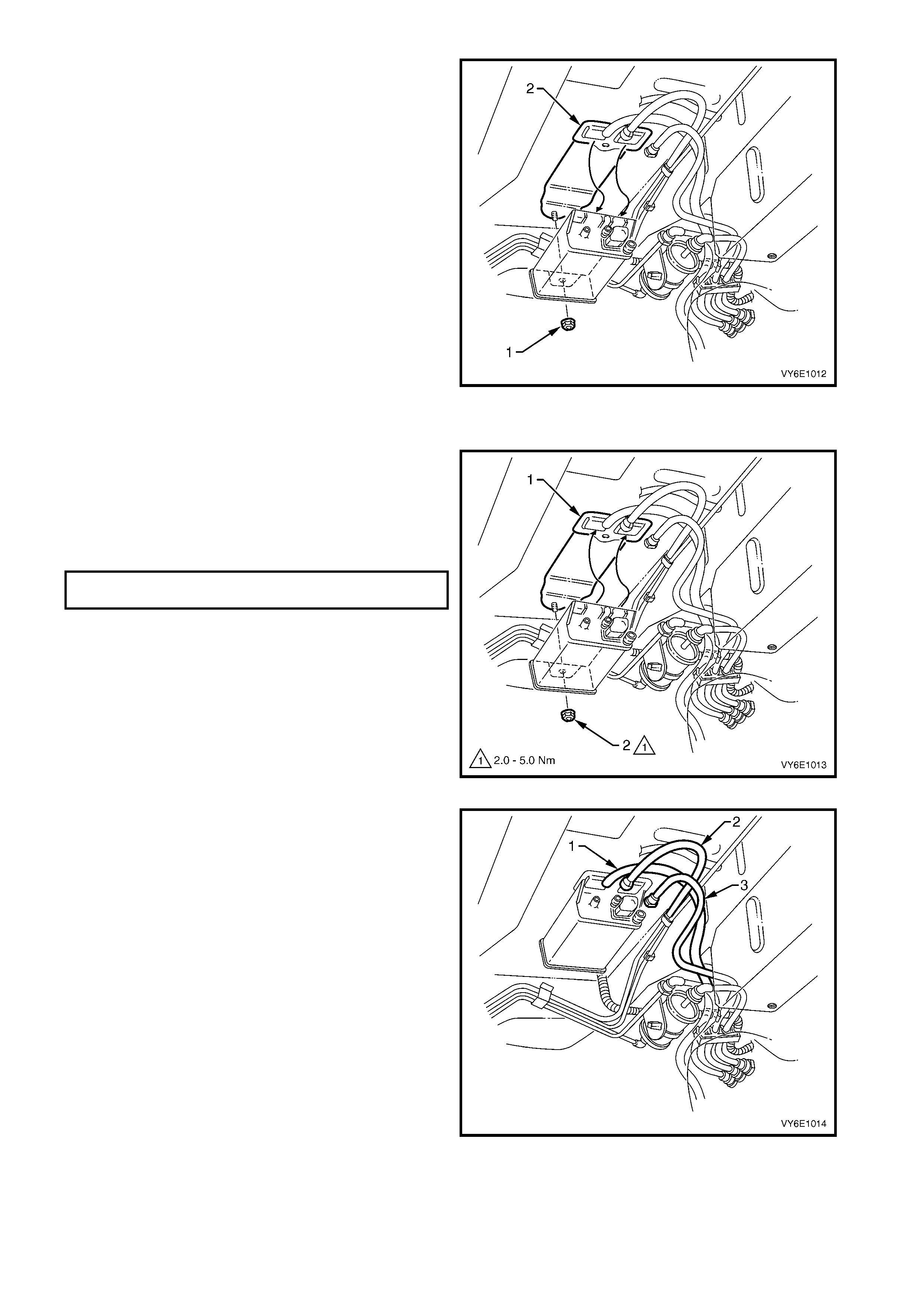

4. Remove the canister retaining nut (1).

5. Remove the canister from the retaining stud and

then slide the canister out of the retainer (2).

Figure 6E1-22

REINSTALL

1. Reinstall the canister into the retainer (1) and over

the retaining stud.

2. Reinstall the canister retaining nut (2) and hand

tighten.

3. Push canister toward centre of vehicle and tighten

the canister retaining nut to the specified torque.

CANISTER RETAINING NUT

TORQUE SPECIFICATION 2.0 - 5.0 Nm

Figure 6E1-23

4. Reinstall the canister vent line (1).

5. Align the canister purge line quick connector (2)

with the canister purge line port. Push the

connector firmly onto the port.

6. Align the tank vent line quick connector (3) with the

tank vent port. Push the connector firmly onto the

port.

7. Once installed, pull on each quick connect to

ensure the connections are secure and locked in

position.

Figure 6E1-24

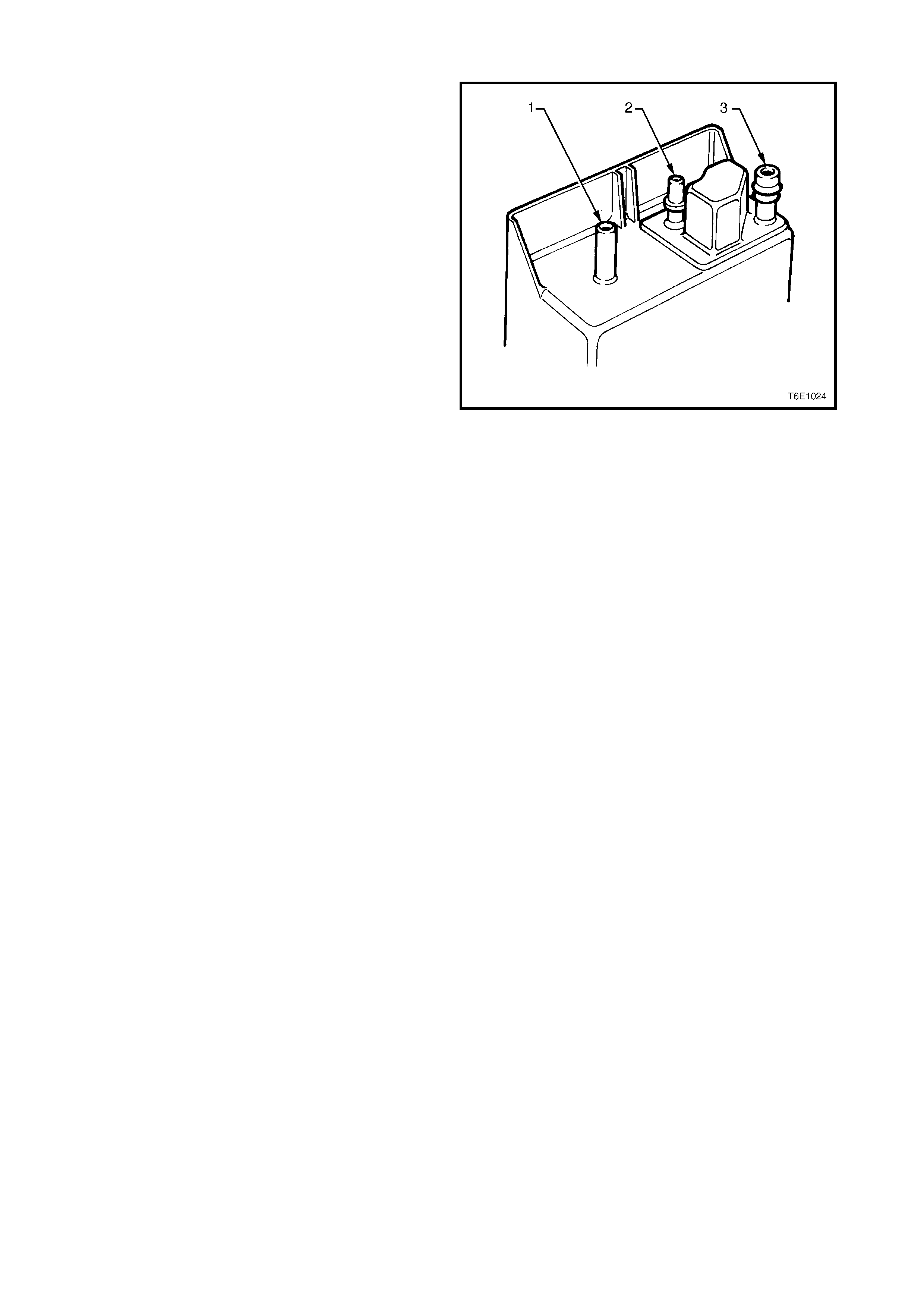

SERVICE CHECKS

1. Remove canister as described in this Section.

2. Shake the canister. There should be no audible

sound of carbon movement.

3. Using low pressure compressed air (20-35 kPa),

blow into the tank vent port (3). Check that air

flows freely from the canister vent port (1). Block

the canister vent port (1) and air should flow from

the canister purge port (2).

4. If airflow through the canister vent port (2) is poor,

clean the atm os pheric f ilter by blocking of f the tank

vent port (3) and blowing compressed air at

approximately 300 kPa through the canister purge

port (2).

5. Check airflow through the filter as in Step 3. If

airflow through the canister vent port (1) is still

poor, replace the canister.

6. Block the canister vent port (1) and the canister

purge port (2). Apply low pressure compressed

air (20-35 kPa) to the tank vent port (3). If any air

leaks from the canister, i.e. around ports or

seams, the canister must be replaced.

Figure 6E1-25

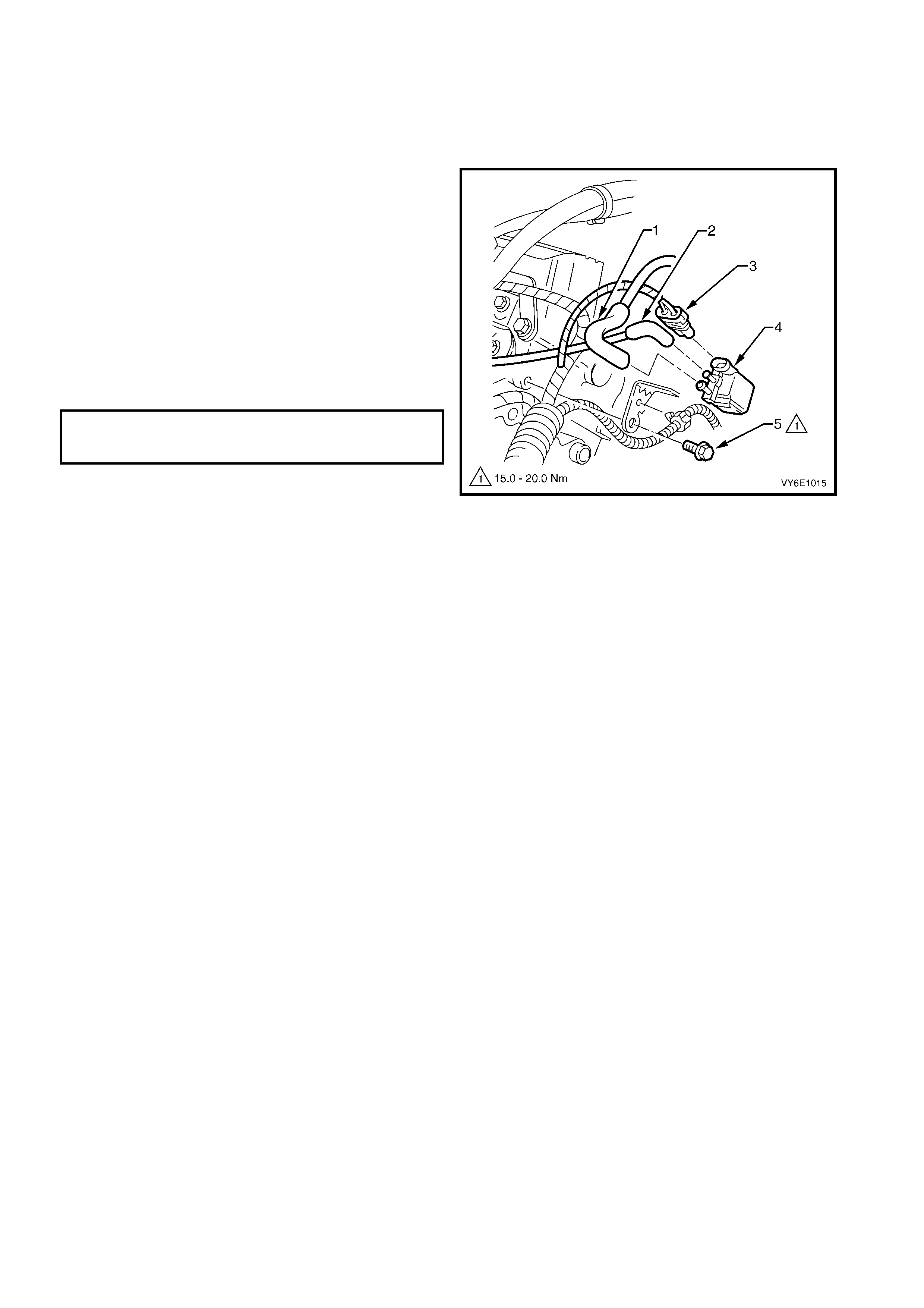

2.3 CANISTER PURGE SOLENOID VALVE

LT Section No. – 03-165

REMOVE

1. Ensure that the ignition switch is off.

2. Mark the hoses on canister purge solenoid

valve (1, to fuel vapour canister and 2, from throttle

body), and remove the hoses from the valve.

3. Remove the wiring harnes s connector (3) from the

solenoid valve (4).

4. Remove the screw from the solenoid valve

bracket.

5. Remove the solenoid valve.

REINSTALL

1. Reinstall the canister purge solenoid valve to the

rear of the cylinder head and install the bracket

screw. Tighten the screw to the specified torque.

CANISTER PURGE SOLENOID VALVE

BRACKET SCREW

TORQUE SPECIFICATION 15.0 – 20.0 Nm

2. Apply Loctite 4210 adhesive to both vacuum

hoses. Connect the vacuum hoses to the purge

solenoid valve ensuring that the connections are

correct.

3. Reconnect the wiring harness connector to the

canister purge solenoid valve.

Figure 6E1-26

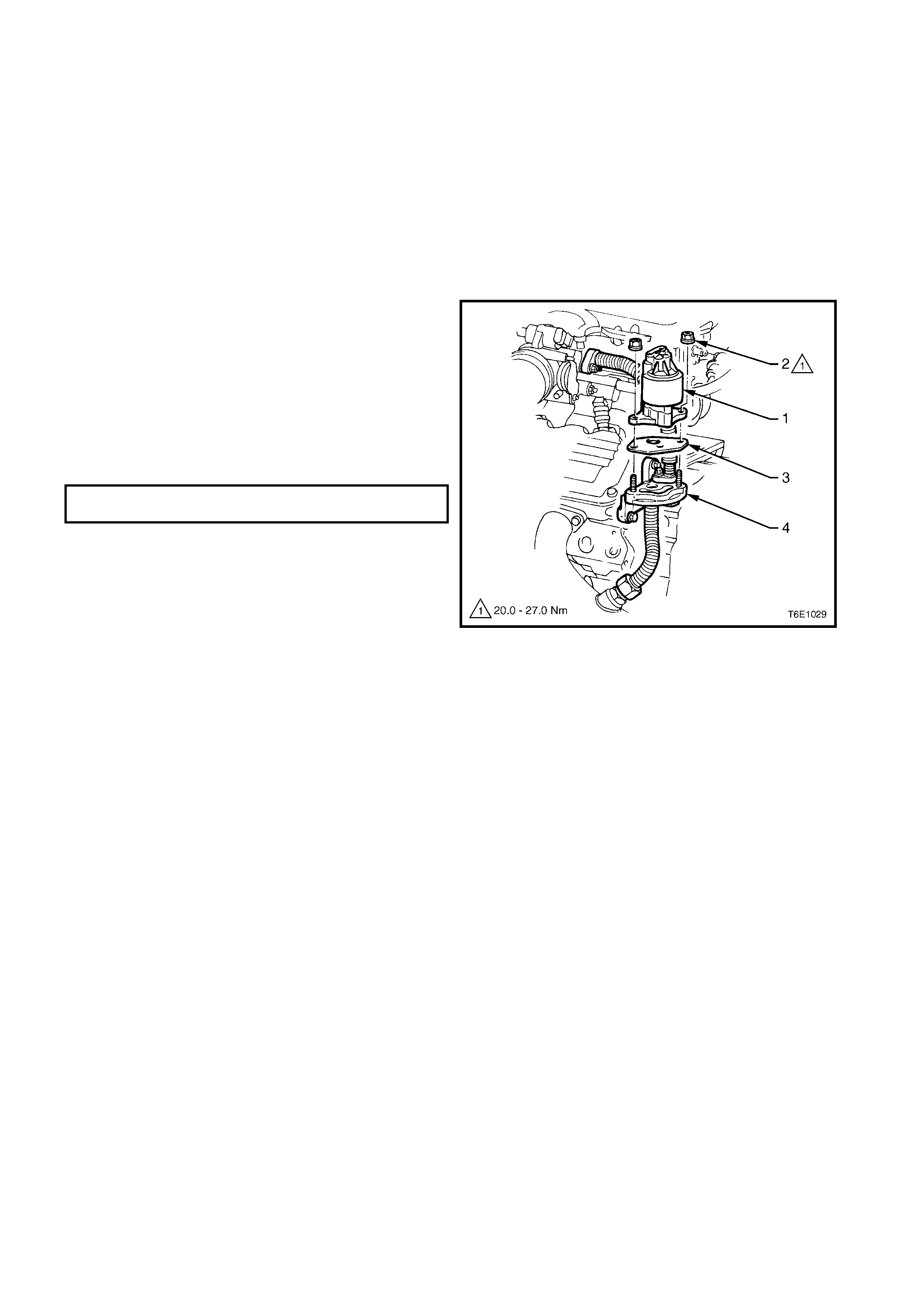

2.4 LINEAR EGR VALVE

LT Section No. – 03-300A

REMOVE

IMPORTANT: Disconnection of the battery affects

certain vehicle electronic systems. Refer to

Section 00, 5. BATTERY DISCONNECTION

PROCEDURES before disconnecting the battery.

1. Disconnect the battery earth lead.

2. Remove the engine dress cover.

3. Disconnect the EGR valve electrical connector.

4. Remove the EGR valve retaining nuts (2).

5. Remove the EGR valve (1) and gasket (3) from

EGR adaptor assembly (4).

REINSTALL

1. Reinstall a new EGR valve gasket.

2. Reinstall the EGR valve and retaining nuts.

3. Tighten the EGR valve retaining nuts to the

specified torque.

EGR VALVE RETAINING NUTS

TORQUE SPECIFICATION 20.0 – 27.0 Nm

4. Reinstall the engine dress cover.

5 Reconnect the battery earth lead.

Figure 6E1-27

3. DIAGNOSIS

3.1 POS ITIVE CRANKCASE VENTILATION

CONDITION PROBABLE CAUSE CORRECTIVE ACTION

Rough, slow idle or stalling 1. PCV valve blocked.

2. Blocked or damaged

ventilation hose.

Clean valve or replace.

Clean or replace hose.

Rough, fast idle or stalling 1. PCV valve stuck in

intermediate position.

2. PCV valve leaking.

Clean valve or replace.

Check valve O-ring, replace if

necessary.

Check valve installation.

Excessive sludging or diluting of

oil Engine is not vented. Check for clogged PCV valve

circuit and clogged ventilation

circuit.

3.2 EVAPORATIVE EMISSION CONTROL

CONDITION PROBABLE CAUSE CORRECTIVE ACTION

Loss of fuel from filler cap 1. Unsatisfactory sealing

between cap and filler neck.

2. Malfunction of filler cap relief

valve.

Replace filler cap.

Replace filler neck if damaged.

Replace filler cap.

Loss of fuel from fuel lines 1. Loose line connection.

2. Faulty connector.

3. Split or cracked fuel line.

Secure connection.

Replace fuel line.

Replace fuel line.

Loss of fuel from canister 1. Fuel tank overfilled. When the

fuel temperature increases,

excess fuel is discharged into

the canister, flooding it.

2. Kinked hoses at filler neck or

canister.

3. Blocked, damaged or

disconnected purge valve.

Avoid overfilling of tank.

Replace damaged hoses. Ensure

that the hoses are installed

correctly.

Check purge valve operation.

Collapsed fuel tank or pressure in

tank 1. Faulty fuel filler cap. In high

temperature operating

conditions some pressure in

the fuel tank is a normal

condition.

2. Blocked or kinked hoses at

filler neck or canister.

3. Defective canister (usually

internal blocked).

4. Purge solenoid valve is closed

causing canister to become

overloaded.

Replace filler cap.

Replace damaged hoses. Ensure

that the hoses are installed

correctly

Replace canister.

Refer to 6C1 POWERTRAIN

MANAGEMENT – V6 ENGINE.

Rough idle 1. Improperly routed or

disconnected purge line.

2. Purge solenoid valve is open

or not receiving power.

Check purge line.

Refer to 6C1 POWERTRAIN

MANAGEMENT – V6 ENGINE.

For diagnosis of faults pertaining to vehicle performance, refer to Section 6C1 POWERTRAIN MANAGEMENT –

V6 ENGINE.

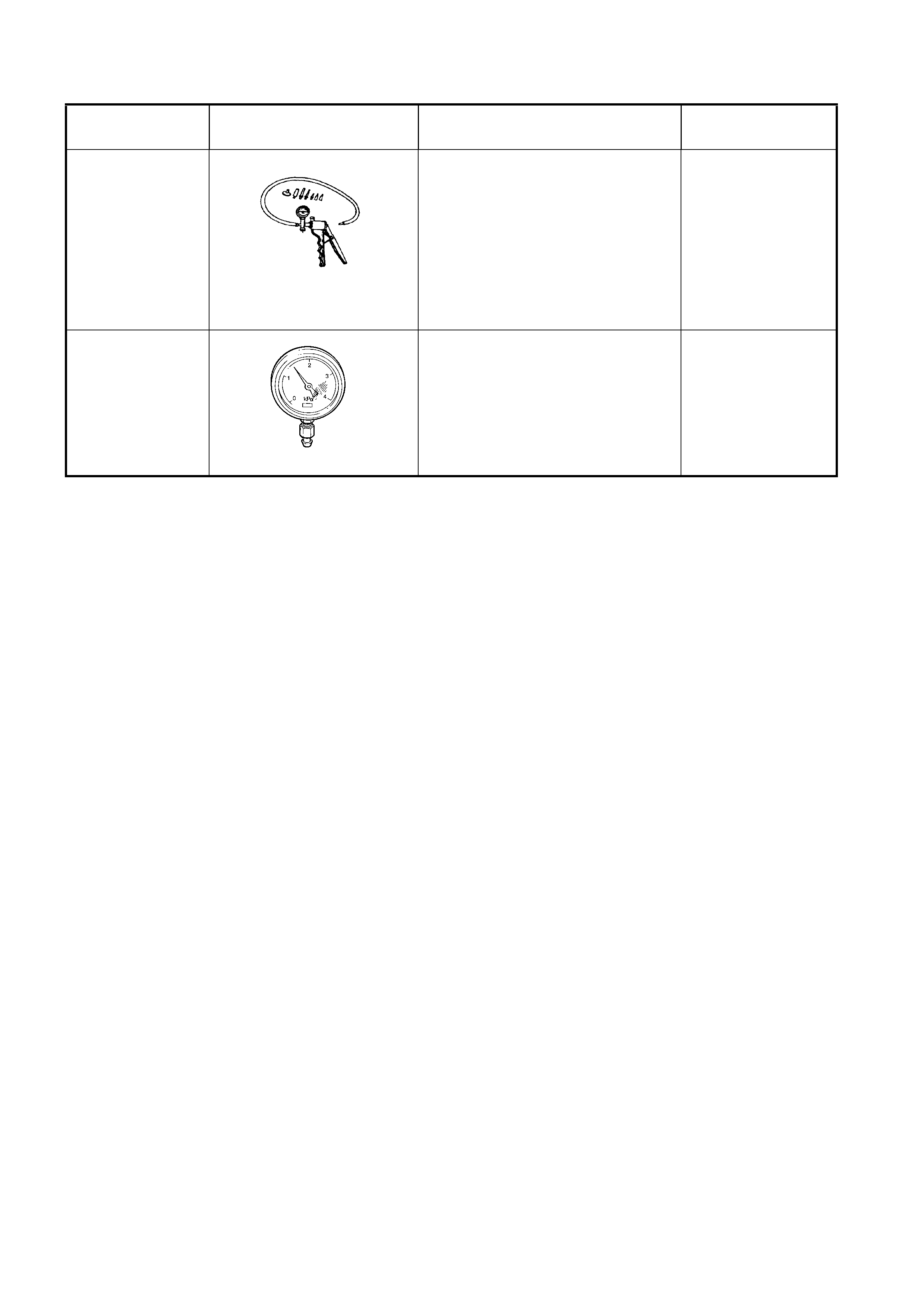

4. SPECIAL TOOLS

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J23738-A

VACUUM PUMP (20 IN. HG

MINIMUM)

Used for many applications,

including engine, automatic

transmission, steering gear,

diagnostic checks.

Previously released.

Mandatory

N/A

VACUUM GAUGE

Vacuum gauge with scale of 0 to

-4kPa. Used for checking P.C.V.

valve operation and function.

Previously released.

Mandatory

5. TORQUE WRENCH SPECIFICATIONS

Canister retaining nut............................................................2.0 – 5.0 Nm

Canister purge solenoid valve bracket screw .......................15.0 – 20.0 Nm

EGR valve retaining nuts ......................................................20.0 – 27.0 Nm