SECTION 6F1 - ENGINE TUNE – V6 ENGINE

IMPORTANT

Before perfo rming any Service Operation or other procedu re described in this Section , refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL INFORMATION

1.1 VEHICLE EMISSION CONTROL INFORMATION

2. ENGINE TUNE RECOMMENDATIONS

3. ENGINE TUNING DATA

3.1 TUNING SERVICE NOTES

3.2 CYLINDER BALANCE CHECK

IGNITION

FUEL

MECHANICAL

4. SPECIAL TOOLS

1. GENERAL INFORMATION

Engine tuning, although simplified by electronic control of the air/fuel mixture and ignition timing, is of great

importance due to the susceptibility of the catalytic converter to damage caused by rich air/fuel mixture. The

Powertrain Control Module (PCM) controls the air/fuel ratio to near optimum condition. A rich mixture can be

induced by faulty spark plugs or leads or a fault in the engine management system, refer to

Section 6C1, POWERTRAIN MANAGEMENT – V6 ENGINE.

The PCM will set a Diagnostic Trouble Code (DTC) and the words “Check Engine” together with an icon will be

displayed in the instrument cluster multi-function display, in the event of the mixture continuing to operate outside

the specified limits. Prolonged operation with a rich mixture may damage the catalytic converter, refer to

Section 6E1, 1.6 THREE-WAY CATALYTIC CONVERTER.

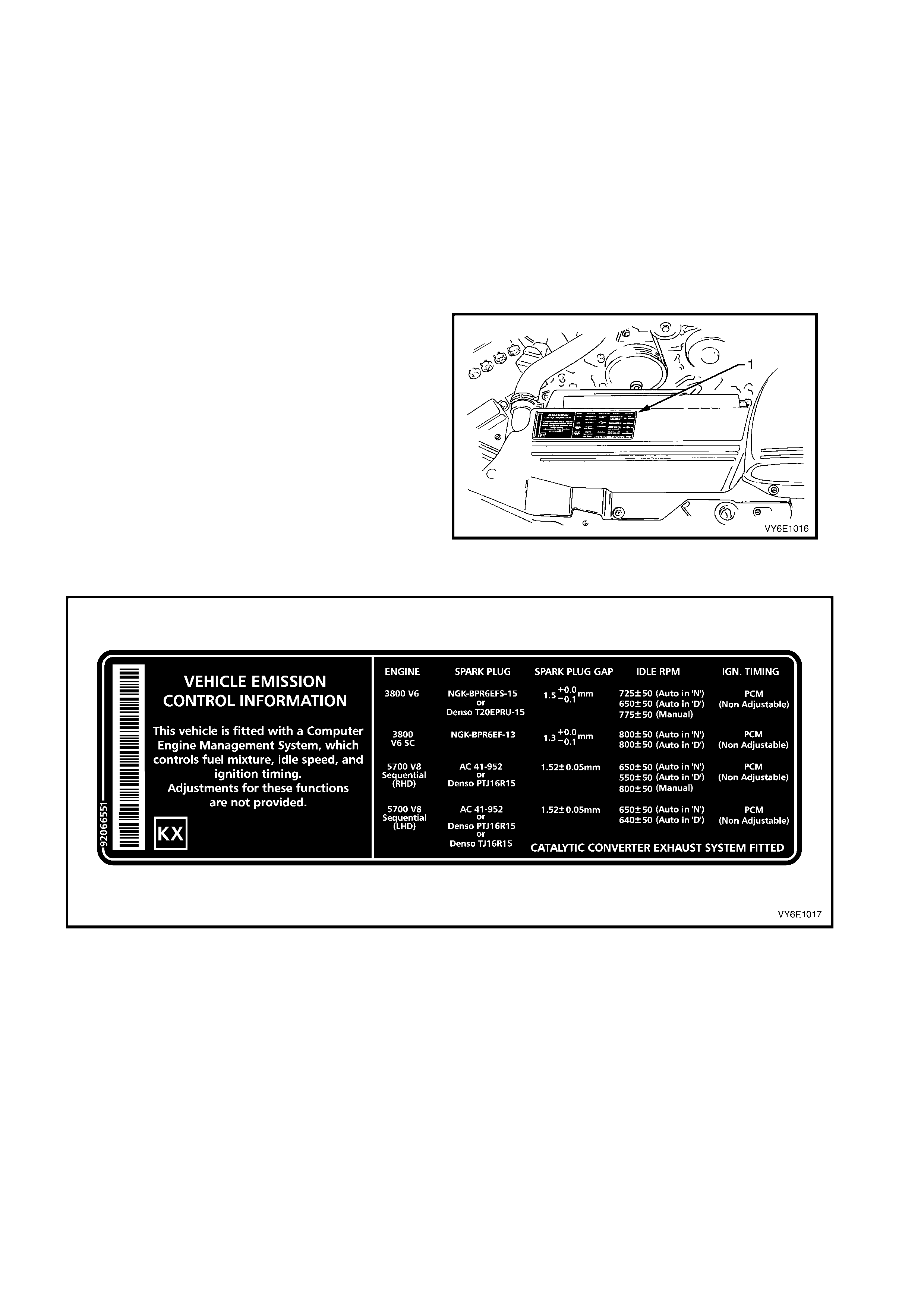

1.1 VEHICLE EMISSION CONTROL INFORMATION

Engine tune specifications necessary to achieve

the correct emission levels are located on the

Vehicle Emission Control Information Label,

located in the engine compartment. Refer to the

label before adjusting the engine.

To maintain the performance and emission control

levels specified for the vehicle, it is necessary for

regular maintenance to be performed in

accordance with the schedule set out in the VY

Series Owner's Handbook.

Figure 6F1-1

Figure 6F1-2

The following engine tune recommendation chart lists the items that require attention when tuning the engine.

Cross-references to the appropriate section in the VY service manual are also provided.

There is no provis ion for ignition tim ing, idle s peed and idle m ixture adj ustm ents on the VY Series Models with a V6

engine, refer to Section 6C1, POWERTRAIN MANAGEMENT – V6 ENGINE.

The Engine Tune Data Chart provides condensed engine tuning data.

NOTE: The use of unleaded petrol will result in black tail pipe deposits rather than the familiar grey colour.

Therefore, the black colour does not indicate a poor state of engine tune.

2. ENGINE TUNE RECOMM E NDATIONS

ENGINE TUNE RECOMMENDATI ONS VY SERVICE MANUAL

REFERENCE SECTI ON

ENGINE COMPRESSION TEST SECTION 6A 1, 2.6 COMPRESSI ON

CHECK, ALSO REFER TO 3.1 TUNI NG

SERVICE NOTES.

ENGINE DRIVE BELT CHECK SECTION 6A1, 2.7 DRIVE BELT.

COOLING SYST E M CHECK FOR LEAKS SECTION 6B 1, 3.3 CHECKI NG A ND

FILLING COOLING SYSTEM.

VALVE LASH ADJUSTMENT NON-ADJUSTABLE HYDRAULIC

LIFTERS

IDLE SPEED NON-ADJUSTABLE

IDLE MIXTURE NON-ADJUSTABLE

AIR CLEANER CHECK OR REPLACE, TEST FOR LEAKS SECTION 6C1-3, 3.5 AIR CLEA NE R

ASSEMBLY.

FUEL FILTER CHECK AND REP LACE SECTION 6C1-3 9 FUEL FILTER.

SPARK PLUGS CLEAN, ADJUST OR REPLACE SECTION 6C1-3, 4.7 SPARK PLUGS.

SPARK PLUG LEADS T EST FOR CONT INUITY SECTION 6C1-3, 4.6 SPARK PLUG

LEADS.

IGNITION TIMING NON-ADJUSTABLE

EXHAUST SYSTEM CHECK FO R EXCESSIVE BACK

PRESS URE, GENERAL CONDITION A ND

OXYGEN SENSOR OPERATION

SECTION 8B, EXHAUST SYSTEM,

SECTION 6C1-3, 2.6 OXYGEN SENSOR

ENGINE VENTILA T ION CHECK SECTION 6E1, 1.3 ENGINE

VENTILATION.

EVAPORATIVE EMISSION CONTROL CHECK LI NE S, HOSES AND CANISTER SECTION 6E1, 1.4 EVAPORATIVE

EMISSION CONTROL.

BATT ERY AND CAB L E S CHECK SECTION 12A , BATT E RY AND CABLES.

3. ENGINE TUNI NG DATA

SPARK PLUGS

ENGINE TRANSMISSION IDLE SPEED (RPM) IGNITI ON TIMING TYPE GAP (mm)

MANUAL 775 ± 50

725 ± 50

(IN NEUTRAL)

3.8 LITRE P.F.I. V6

NORMALLY

ASPIRATED

AUTOMATIC 650 ± 50

(IN DRIV E)

PCM

CONTROLLED

(NON-

ADJUSTABLE)

NGK

BPR6EFS-15

OR

DENSO

T20EPRU-15

1.5 + 0.0

- 0.1

775 ± 50

(IN NEUTRAL)

3.8 LITRE P.F.I. V6

NORMALLY

ASPIRATED

(BRAZIL)

AUTOMATIC 700 ± 50

(IN DRIV E)

PCM

CONTROLLED

(NON-

ADJUSTABLE)

NGK

BPR6EFS-15

OR

DENSO

T20EPRU-15

1.5 + 0.0

- 0.1

NOTE: Idle speed is controlled by the P CM and varies with: – Battery vol tage

– Engine temperature

– Air conditioning usage

3.1 TUNING SERVI CE NOTES

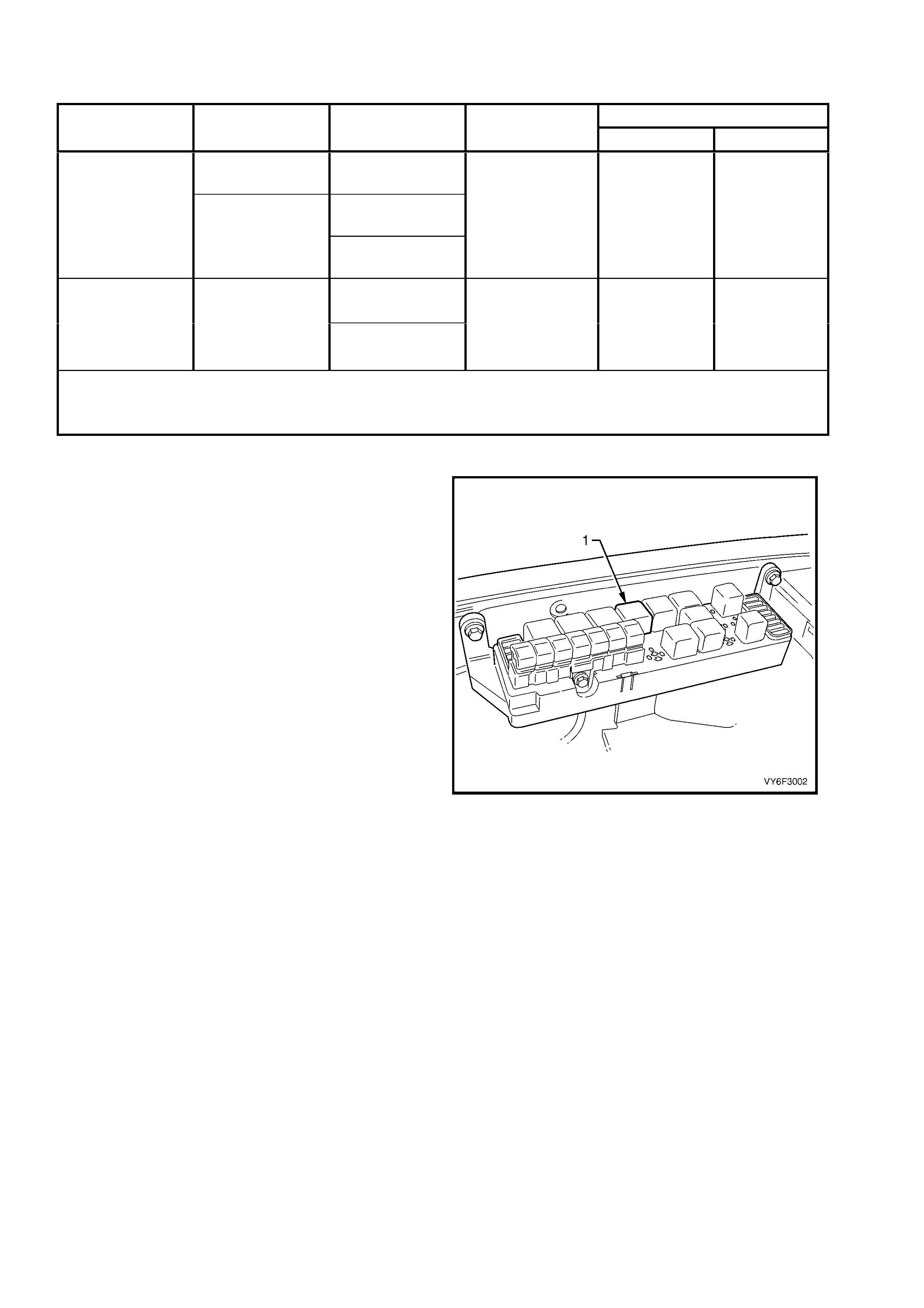

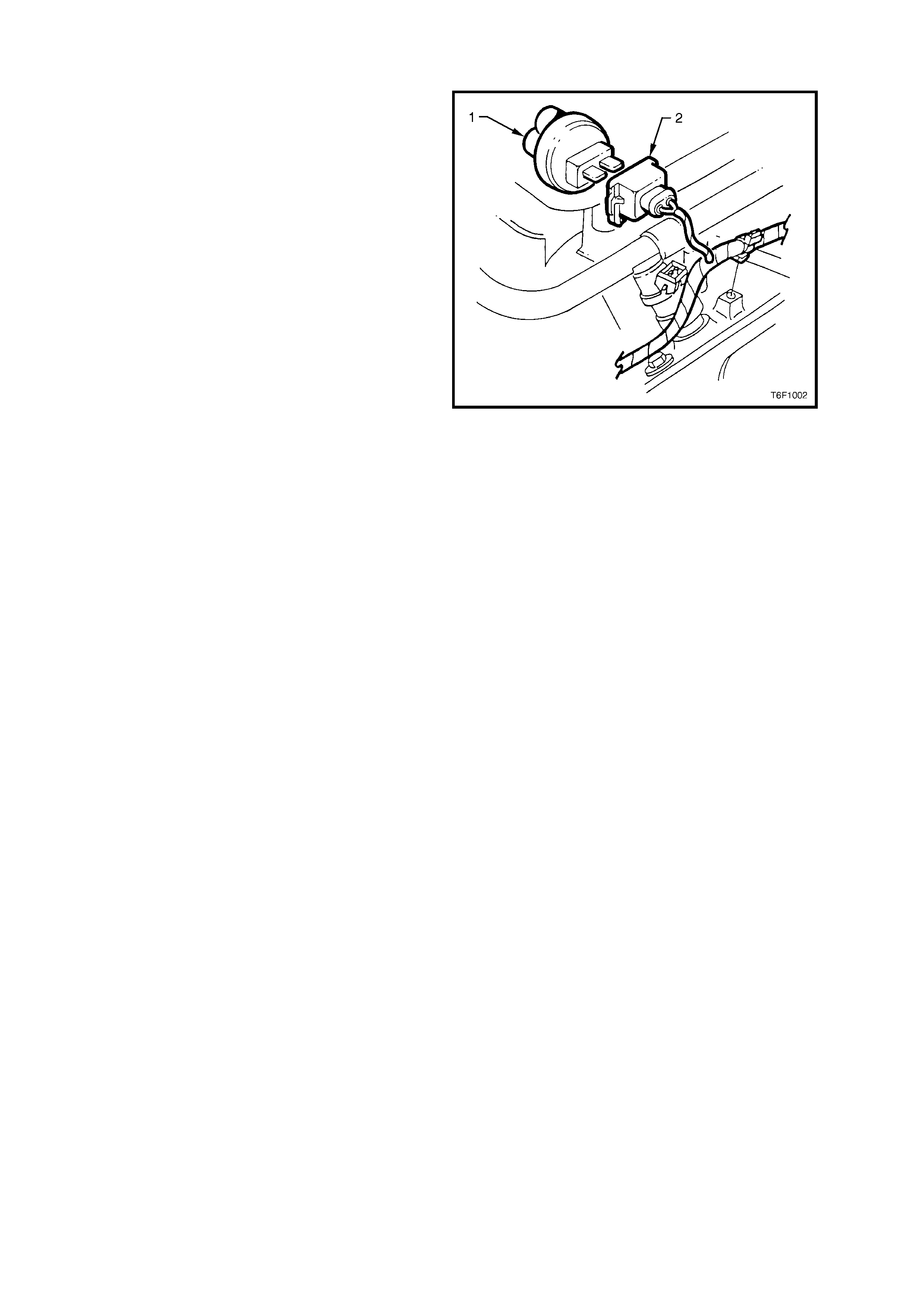

CAUTION: To prevent fuel being injected into

the cylinders and the ignition during cranking,

remove the EFI relay (1) when performing a

compression test. This will avoid damaging the

catalytic converter with unburned fuel.

For compression testing procedure and

specifications, refer to Section 6A1, 2.6

COMPRESSION CHECK.

1. Do not oper ate the engine with any spark plugs

or spark plug leads disconnected as:

a. The ignition system or PCM may be damaged.

b. The resultant mixture could damage the

catalytic converter.

2. Make all engine checks with engine coolant

and oil at normal operating temperatures,

preferably those temperatures reached while

driving.

3. Ensure the air conditioning, where fitted, is

switched OFF.

4. Verify that the words “Check Engine” and

accompanying icon are not displayed in the

instrument cluster multi-function display when

the engine is running.

Figure 6F1-3

3.2 CYLINDER BALANCE CHECK

1. Connect the Tech 2 (4) to the Data Link

Connector (DLC) (1) via the DLC Adaptor (2)

and DLC Cable (3).

2. Select VY Commodore / Engine / Functional

Tests / Power Balance.

3. Perform Power Balance as directed by the

Diagnostic Scan Tool.

NOTE 1: RPM readings displayed on the

Diagnostic Scan Tool should be within 50 RPM of

the idle engine speed for all cylinders

NOTE 2: Any cylinder that does not caus e a drop in

engine idle speed is misfiring.

NOTE 3: For further information on the usage of

Tech 2, refer to Section 0C, TECH 2.

Once the problematic cylinder has been identified,

the cause of the problem will still need to be

determined. Reasons for the fault include fuel,

spark or engine mechanical problems.

The following checks are to assist in isolating

the cause of the engine misfire. For

additional diagnostic information, refer to

Section 6C1, POWERTRAIN MANAGEMENT –

V6 ENGINE.

Figure 6F1-4

IGNITION

1. Remove the spark plug lead from the plug and

the engine harness connector from the injector

of the misfiring cylinder.

2. Install the Test Plug, Tool No. 7230 (1) and

connect it to an engine earth point.

NOTE 1: Failure to properly earth the Test Plug

may result in damage to the ignition system

components due to excessive secondary voltages

required to fire it.

NOTE 2: Avoid placing the test plug near sensors,

modules or other electronic equipment that m ay be

affected by electromagnetic interference.

3. Disconnect the spark plug wire and the engine

wiring harness from the injector of the

corres ponding cylinder. Connect the spark plug

lead directly to the engine earth.

4. Start and run the engine. If the tester shows a

good spark, check for faulty spark plug.

5. If there is a weak spark or no spark at all,

check the spark plug lead for a short circuit to

the earth, or open or very high resistance

NOTE: If any lead is open circuited, recheck coil

secondary resistance, it may have been damaged

by high voltage produced by open circuit.

Figure 6F1-5

FUEL

1. Disconnect the engine harness connector from

the injector of cylinder that is misfiring.

2. Install injector node light tester (1), Tool No.

J34730-2C into connector (2) and start engine.

3. Check the tester for a light flashing.

a. If the injector node light does not flash or

flashes erratically, check engine harness

between connector and PCM.

b. If the injec tor node light test er flashes regularly,

check for blocked or faulty injector, refer to

Section 6C1, POWERTRAIN MANAGEMENT

– V6 ENGINE.

Figure 6F1-6

MECHANICAL

Perform a compression test, refer to Section 6A1,

2.6 COMPRESSION CHECK.

4. SPECIAL TOOLS

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

7000086I

TECH 2

DIAGNOSTIC SCAN TOOL

Used for diagnosis of vehicle

electrical system.

Previously released.

Mandatory

7230

(ST-125)

HEI TESTER

(TEST PLUG)

Used in diagnostic checks with

engine management system.

Previously released.

Mandatory

J34730-2C

(BT-8329)

INJECTOR NODE LIGHT

TESTER

Used when carrying out engine

management electrical

diagnostic checks.

Previously released.

Mandatory