SECTION 7A2 - CLUTCH – GEN III V8 ENGINE

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL INFORMATION

1.1 SELF-ADJUSTING CLUTCH PRESSURE PLATE

1.2 CLUTCH CONTROL

ARRANGEMENT

OPERATION

2. SERVICE OPERATIONS

2.1 SERVICE NOTES

2.2 FLUID LEVEL CHECK

2.3 CLUTCH HYDRAULIC SYSTEM, BLEED

2.4 CLUTCH FLUID – CHANGE

2.5 CLUTCH MASTER CYLINDER

2.6 CLUTCH SLAVE CYLINDER

REMOVE

DISASSEMBLE

CLEAN AND INSPECT

REINSTALL

2.7 CLUTCH THROWOUT BEARING

REMOVE

CLEAN AND INSPECT

REINSTALL

2.8 CLUTCH PEDAL ASSEMBLY

2.9 CLUTCH PEDAL SWITCH

REMOVE

REINSTALL

2.10 CLUTCH AND PRESSURE PLATES

REMOVE

INSPECT

CLUTCH PRESSURE PLATE ADJUSTMENT

REINSTALL

2.11 ENGINE FLYWHEEL

REPLACE

2.12 RING GEAR

REPLACE

2.13 CRANKSHAFT SPIGOT BEARING

REPLACE

3. DIAGNOSIS

4. SPECIFICATIONS

5. TORQUE WRENCH SPECIFICATIONS

6. SPECIAL TOOLS

Techline

Techline

Techline

Techline

Techline

Techline

Techline

1. GENERAL INFORMA TION

1.1 SELF-ADJUSTING CLUTCH PRESSURE PLATE

The self-adjusting feature for the clutch pressure plate fitted to the GEN III V8 engine and the six speed manual

transmission, has been retained, that achieves several advantages:

a. The clutch pedal loading is maintained at a consistent level throughout the life of the assembly, as the

diaphragm spring leverage over the pivot rings remains the same.

b. This also results in the fact that the clutch ‘take-up’ re mains at a c onstant poi nt, with the clutc h pedal f eel also

remaining constant.

c. No maintenance adjustments are required.

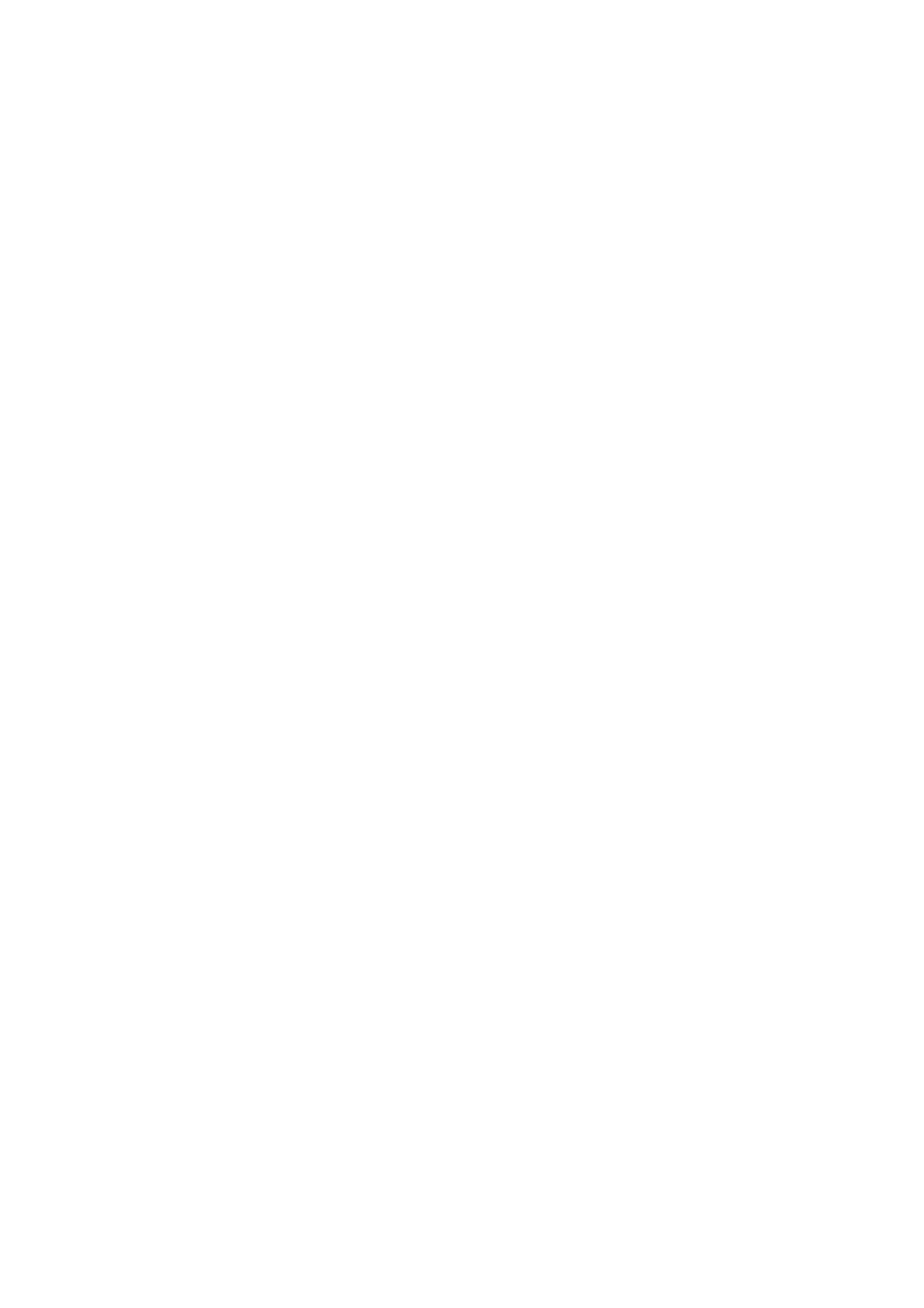

Figure 7A2 – 1 Clutch Components

Legend

1. Bearing - Clutc h Pil ot

2. Flywheel - Engine

3. Bolt - Flywheel (6 places)

4. Plate - Clutch Dri ven

5. Plat e - Clutch Press ure

6. Bolt - P ressu re P lat e (6 places)

7. Assem bl y - Clutch Slave

8. Bolt - Slave Cylinder (2 places)

1.2 CLUTCH CONTROL

Hydraulic actuation for the clutch has been retained for the GEN III V8 engine application in MY 2003 VY and V2

Series vehicles and uses some common components with the V6 engined vehicle. For example, apart from the

changed orientation of the outlet fitting, the clutch master cylinder remains unchanged.

The clutch pedal is also common, except for those vehicles fitted with cruise control, when a small bracket is

welded to the pedal for clutch switch control.

Clutch control component changes that are unique for the GEN III V8 engine are:

• Hydraul ic piping from the flexible hose t o the centra l clutch slave c ylinder , routed acr oss the top of the m anual

transmission.

• An integrated clutch throwout bearing and concentric slave cylinder, mounted to the front of the transmission

adaptor plate.

ARRANGEMENT

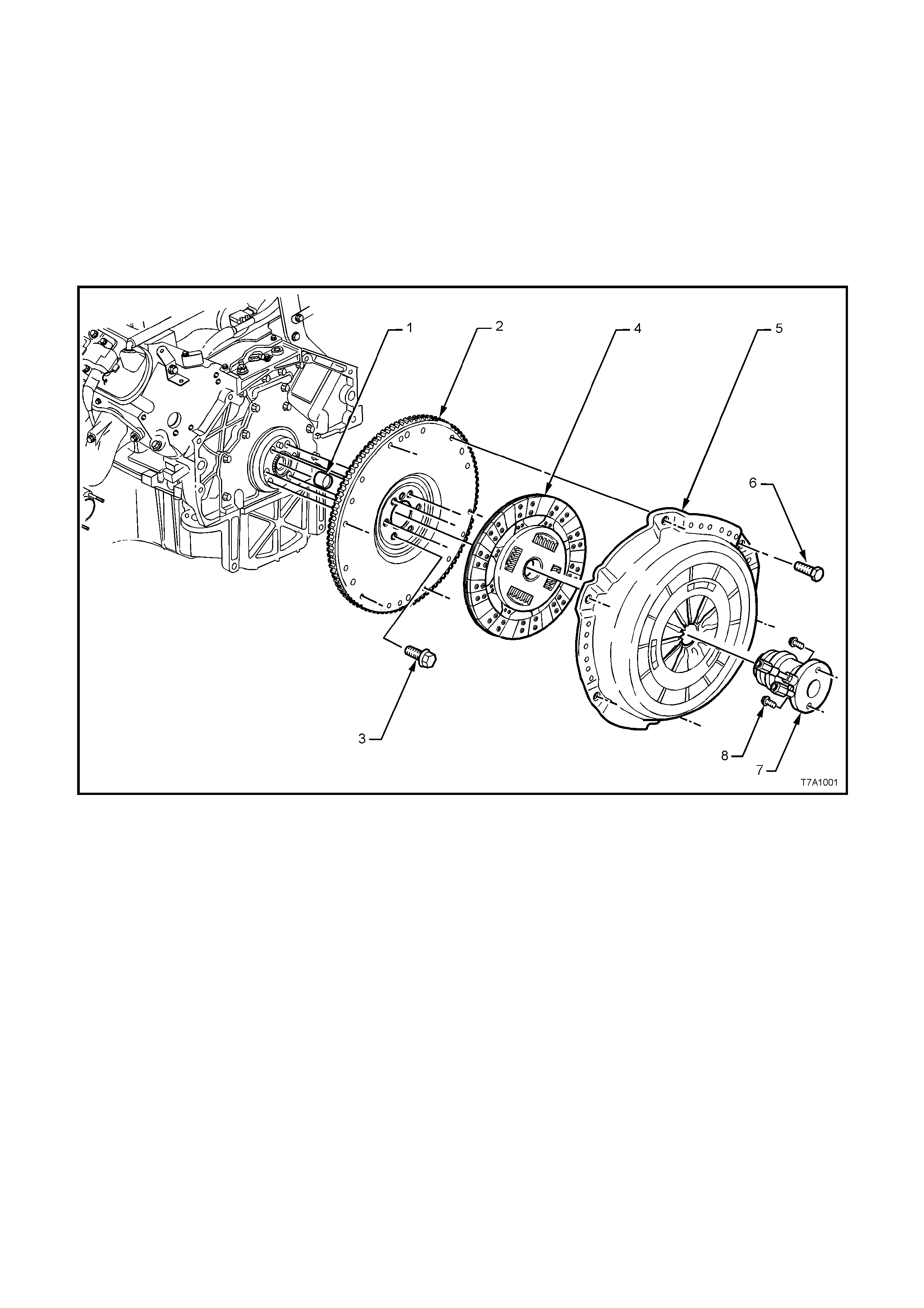

Figure 7A2 – 2 Clutch Control Layout

Legend:

1. Reservoir – Clutch Fluid

2. Bracket – Clutch Fluid Reservoir

3. Hose – Reservoir to Master Cylinder

4. Master Cylinder

5. Pipe – Master Cylinder to Flexible Hose

6. Hose – Master Cyli nder Pipe to Slave Cylinder Pipe

7. Assem bl y – Slave Cylinder and Bearing

8. Pipe – Hose to Slave Cylinder

9. Pedal – Clutch

10. Bush – Master Cylinder Push Rod

11. Retainer – Push Rod Bush

12. Switch – Clutch (Cruise Control only)

OPERATION

Brak e fluid is fed to the cl utch mas ter cylinder fr om

a remote reservoir mounted to a bracket, bolted to

the end of the brake mas ter cylinder. A flexi ble line

connects the two components.

The m aster cylinder and vacuum booster assem bly

is attached to the firewall in the engine

compartment.

The clutch pedal is mounted in the clutch/brake

pedal support bracket, bolted to the dash panel.

The clutch master cylinder piston is connected to

the clutch pedal by a quick connect fitting on the

end of the push rod, that clips onto a grooved pin

attached to the clutch pedal.

No clutch adjustments are required.

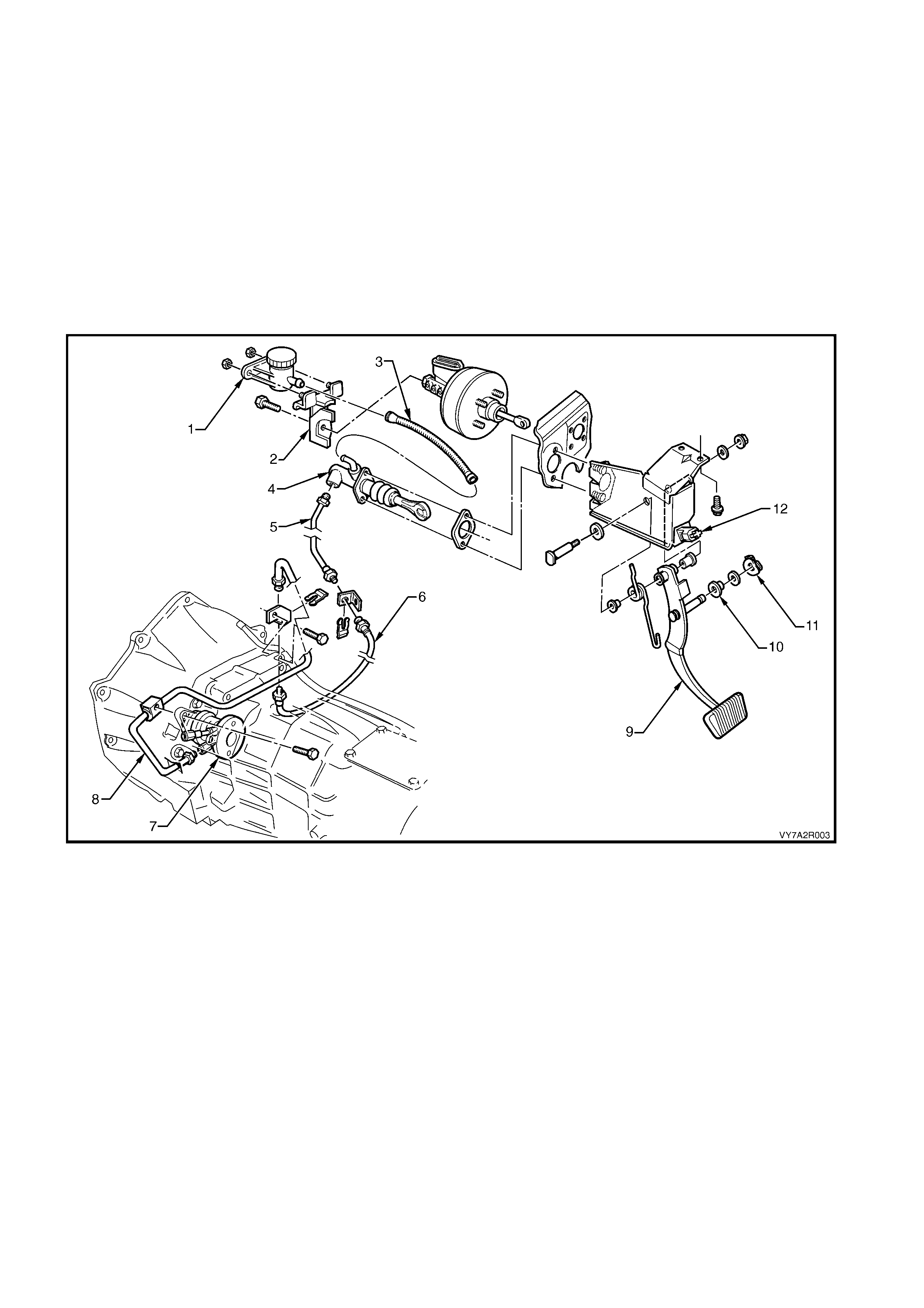

Stroking of the clutch throwout bearing is achieved

by using a concentric hydraulic clutch slave

cylinder (2) mounted to the front of the

transmission adaptor plate housing.

Hydraulic connection to the master cylinder is by

steel piping from the master cylinder, flexible hose

to the transmission and steel pipe again from the

flexible hose to the slave cylinder (1) (Also see

Figure 7A2-2) .

The slave cylinder is fitted with a bleed valve to

assist in removal of air from the hydraulic system.

Apart fr om the thro wout be ar ing ass embly and l oad

spring, there are no other serviceable parts in the

slave cylinder and, if found to be faulty, the

assembly must be replaced.

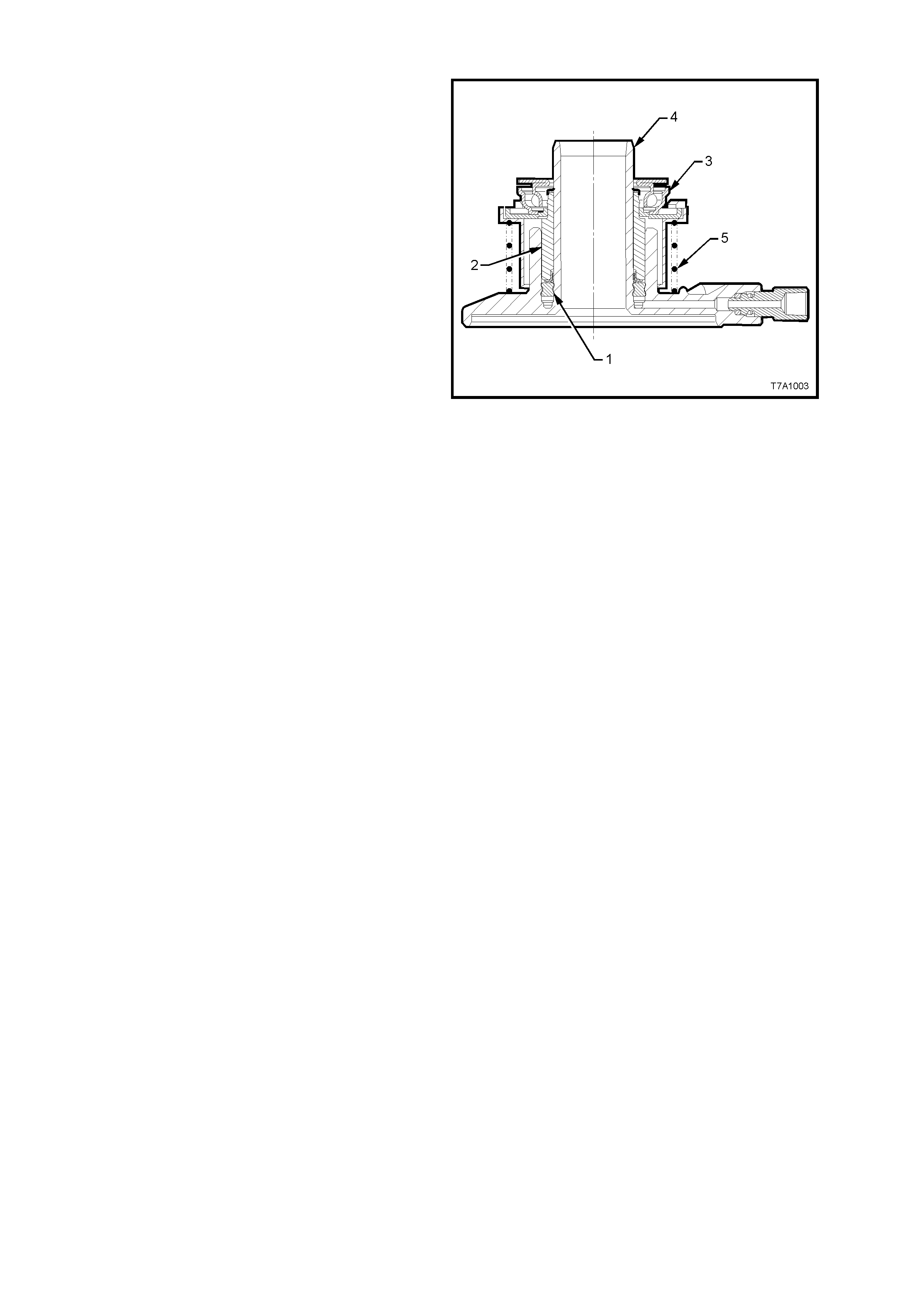

Figure 7A2 – 3

CLUTCH MASTER CYLINDER OPERATION

As the oper ation of the clutc h mas ter cylinder fitted

to GEN III V8 engined vehicles is the same as for

all manual tr ansm iss ion equip ped MY 200 3 VY and

V2 Series vehicles, refer to the description in

Section 7A1 CLUTCH.

CLUTCH SLAVE CYLINDER OPERATION

When pressurised fluid from the clutch master

cylinder acts upon the seal (1), the seal moves,

stroking the sleeve (2) before it. As the throwout

bearing assembly (3) is attached to the sleeve (2),

the throwout bearing als o moves with the sleev e, to

forc e the dia phra gm fingers of the pr ess ur e p lat e to

move against its in-built spring force.

As the slave cylinder sleeve (2) continues to be

moved along th e guide of the cylinder bod y (4), the

force applied to the pressure plate diaphragm

spring causes the spring to pivot, thus releasing

the applied force on the clutch driven plate,

allowing it to spin. When this situation occurs, the

frictional link between the engine flywheel and the

transmission input shaft is broken and gear

changing c a n th en s af ely take place, witho ut u ndu e

stress being placed upon the transmission

synchromesh assemblies.

When the clutch pedal is released, the pressure

plate diaphragm spring force, moves the throwout

bearing (3) and slave cylinder sleeve (2), back

along the slave cylinder body guide (4), returning

displaced fluid back to the master cylinder

reservoir.

Coil spring (5) acts to maintain constant contact of

the throwout bearing with the pressure plate

diaphragm spring fingers, thereby reducing pedal

travel to begin initial movement by compensating

for any slight finger height variation in the

diaphragm spring.

Figure 7A2 – 4

As the clutch pressure plate is self-adjusting, the ‘at

rest’ position of the throwout bearing and clutch

slave cylinder sleeve (2), remains relatively

constant throughout the life of the assembly,

compared to other clutch control systems.

2. SERVICE OPERATIONS

2.1 SERVICE NOTES

Important Items

1. W hile GM’s clutch parts are not asbes tos based in th eir m ater ial com position, a danger exists that replac em ent

non-genuine parts may contain asbestos.

Not only is it in the interests of personal safety but also the safe and reliable operation of the clutch sy stem, that

only genuine parts are used for replacement purposes.

Even so, when ser vicing c lutch par ts, do not c rea te dust by grind ing or s anding the c lutch pla te, or cl ean cl utch

parts with a dry brush or with compressed air. Breathing in dust that may contain asbestos fibres can cause

serious bodily harm over a protracted period of time.

A water dampened cloth or water based solution should be used to remove any dust on clutch parts.

Equipment is commercially available to perform this washing function. These wet methods prevent clutch

component fibres from becoming airborne.

2. The polyglycol brake fluid used in the MY 2003 VY and V2 Series vehicles is hygroscopic and absorbs

moisture from the air through the flexible clutch hose etc. Therefore, for maximum clutch effectiveness, a two

yearly change of brake fluid is mandatory, refer to 2.4 CLUTCH FLUID - CHANGE.

To prevent the absorption of moisture from the air or other contamination, it is recommended that the brake

fluid be stored in small (500 ml) containers and that any surplus fluid remaining in a container after use be

discarded.

NOTE: The only approved brake fluid is DOT 4 Plus or Super DOT 4 Plus and is available in 250 and 500 ml

containers . If pr es sur e bl ee din g eq uipment is us ed, it must be of an a pproved t yp e with a dia phragm s eparating the

brake fluid from the air.

CAUTION: Brake fluid is extremely damaging to paint. If fluid should accidentally come into contact with a

painted surface, immediately wash the fluid from the paint and clean the painted surface.

2.2 FLUID LEVEL CHECK

Check that the fluid level is between the two

guidelines on the translucent reservoir housing.

Should the add it ion of fluid be required , remove the

reservoir cap and use heavy duty brake f luid, such

as DOT 4 Plus or Super DOT 4 Plus.

Figure 7A2 – 5

2.3 CLUTCH HYDRAULIC SYSTEM, BLEED

The c lutch hydraulic s ystem must be bled when ever the h ydraulic line has been disconnected, or when a le ak has

allowed air to enter the system. Air trapped in the system can prevent full disengagement of the clutch.

During bleeding operations, the master cylinder reservoir must be kept at least half full with hydraulic brake fluid.

1. Carefully clean any dirt from around the fluid reservoir cap.

2. Remove the filler cap and top up reservoir as required, with heavy duty hydraulic brake fluid, such as DOT 4

Plus or Super DOT 4 Plus.

3. Using an 11 mm, 3/8 drive socket, short

extension and socket bar, loosen the slave

cylinder bleeder, located in the upper aperture

of the transmission adaptor plate/clutch

housing, on the left hand side.

4. Then, using just the socket and extension,

tighten the bleeder, using light finger force

only.

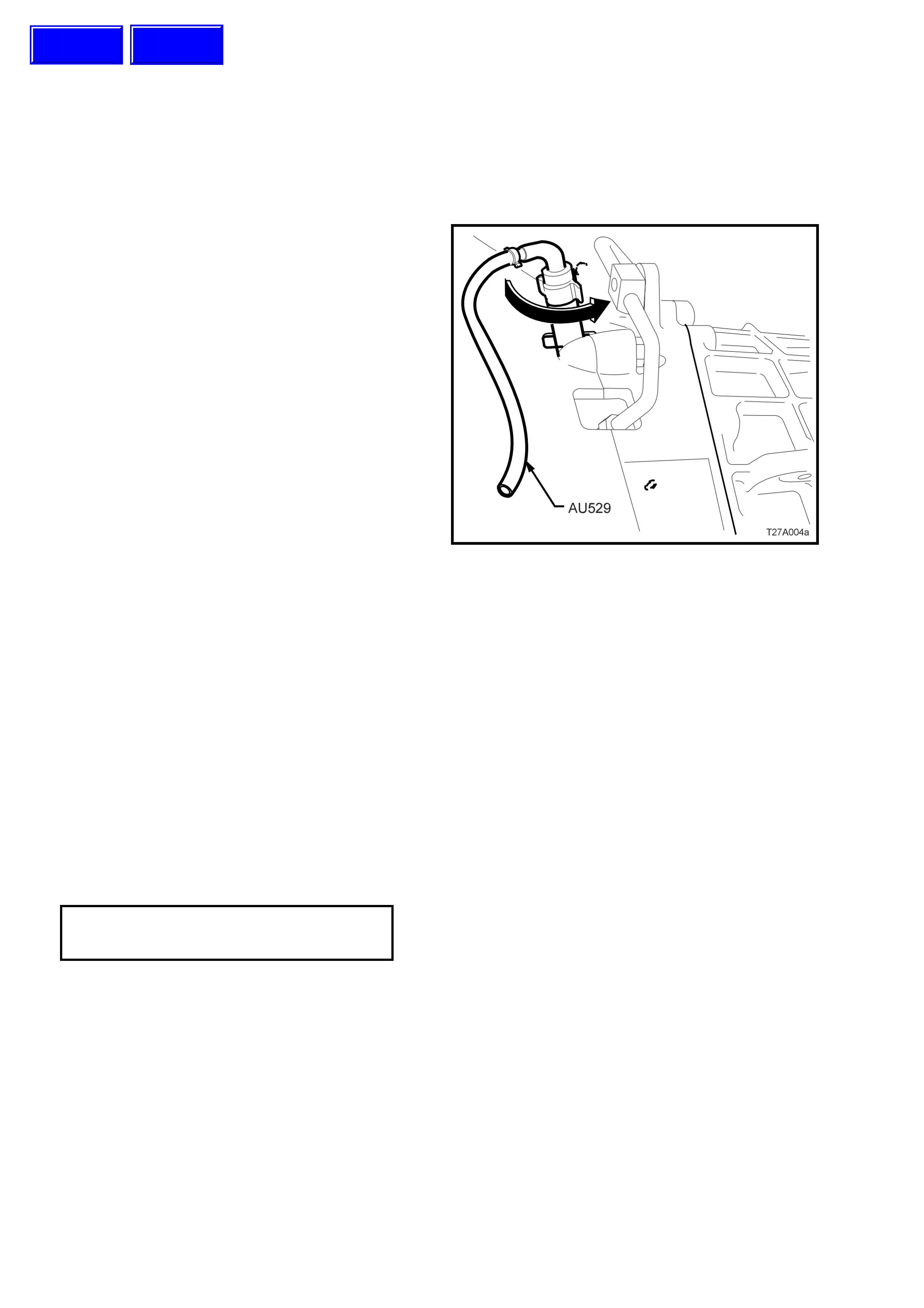

5. Insert the end of the rubber tube of Tool AU529

over the e nd of the ble eder, posit ioned at the 9

o’clock position.

6. With the other end of the bleeder tool inserted

into a clean glass container such as a jar, that

has been partially filled with new brake fluid,

open the bleeder 1/4 turn, using the rubber on

the bleeder tool to provide the required grip.

Ensure that the end of the hose always

remains submerged in the brake fluid during

bleeding oper at io ns .

7. Using an assistant, slowly depress the clutch

pedal by hand, one single time and, while

holding the pe dal depresse d, close the bleeder

using T ool AU529. Once the b leeder is closed,

the clutch pedal can be allowed to slowly

release. Ensure that the pedal fully returns to

the 'UP' position – lift by hand, if required.

Repeat this process until all bubbles cease to

appear at the end of the bleeder hose.

NOTE: Do not pump the clutch pedal repeatedly

during bleeding operations, as entrapped air will

cause the fluid to foam, making air removal

extremely difficult.

Figure 7A2 – 6

Also, as the hydraulic steel piping is routed over the top of the transmission housing, air can be trapped in that

section.

8. When all air has been removed, close off the bleeder and remove Tool AU529. With the clutch pedal still

depressed, tighten the bleeder screw to the correct torque specification.

CLUTCH SLAVE CYLINDER

BLEEDER SCREW

TORQUE SPECIFICATION 18 Nm

9. Once all bleeding operations have been completed, ensure that the fluid level in the reservoir is correct.

NOTE: Alternative methods of bleeding would be to use either a pressure bleeder, with a commercially available

reservoir cap or use the vacuum method, with the assistance of a ha nd operated vacuum pump such as Tool No.

J23738-A (also commercially available as a ‘MityVac’™) and an air tight, glass container.

Techline

Techline

2.4 CLUTCH FLUID - CHANGE

At the int erval spec ified in the O wners Han dbo ok, the c lutch f luid mus t be change d. Discol ourat ion of the f lui d is no

reason for fluid replacement. The recommended method is to use a commercially available pressure bleeder,

together with an appropriate fluid reservoir cap. Follow the manufacturer’s instructions regarding the use of the

pressure bleeding equipment.

1. Fit bleeder adaptor AU529 to the slave cylinder bleeder as described in 2.3 CLUTCH HYDRAULIC SYSTEM,

BLEED, in this Section, then use the pressure bleeder to force fluid through the hydraulic system.

2. Continue allowing fluid to flow through the system until the fluid runs clear in the bleeder hose , immersed in

clean glass container .

3. Following the fluid change operation, ensure that the fluid level in the reservoir is correct and that the slave

cylinder bleeder screw is tightened to the correct torque specification.

CLUTCH SLAVE CYLINDER

BLEEDER SCREW

TORQUE SPECIFICATION 18 Nm

NOTE: An alternati ve method wou ld be to us e t he vacuum method, with th e as s is tanc e of a han d op er ated vac uum

pump such as Tool No. J23738-A (also commercially available as a ‘MityVac’™) and an air tight, glass container.

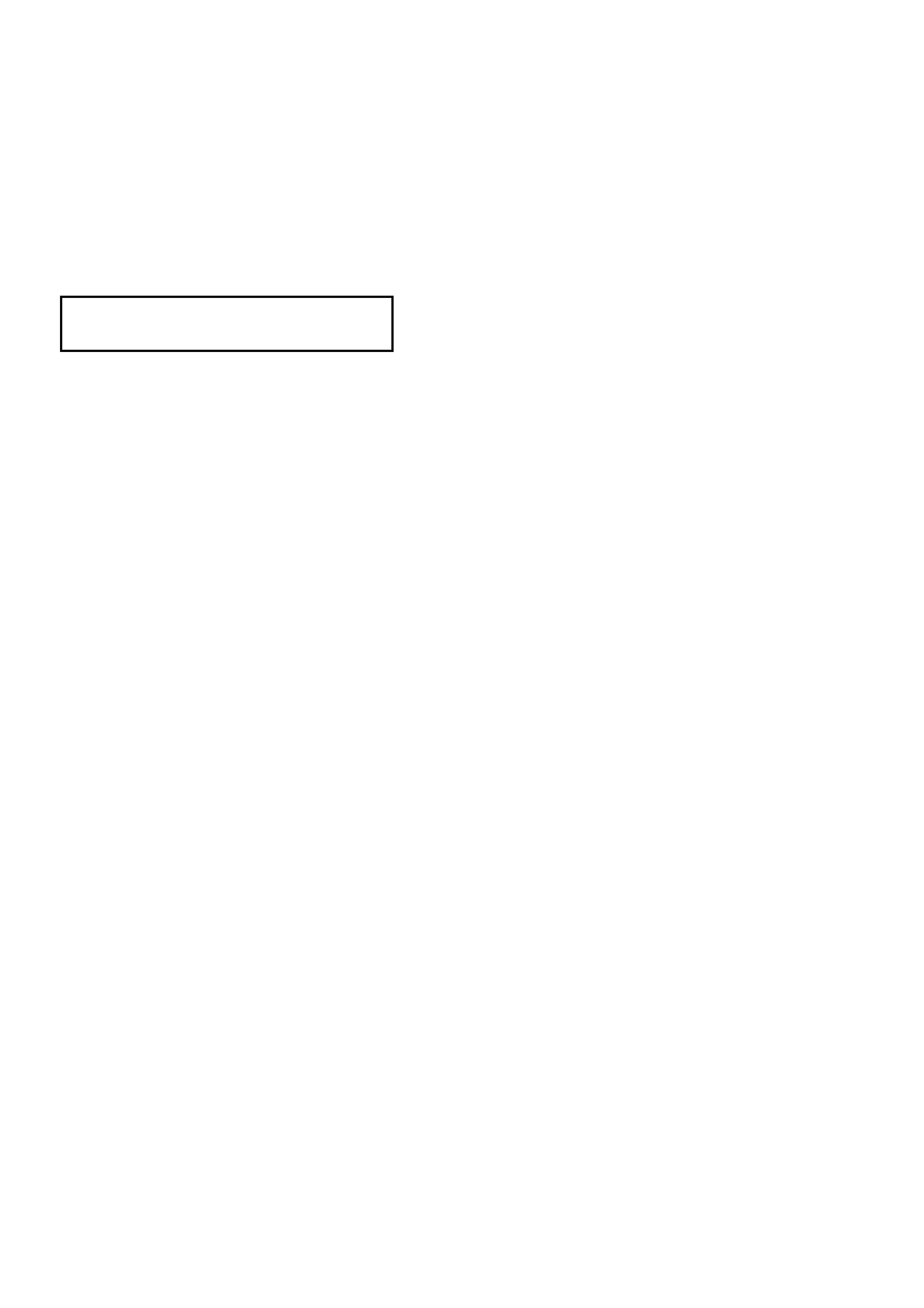

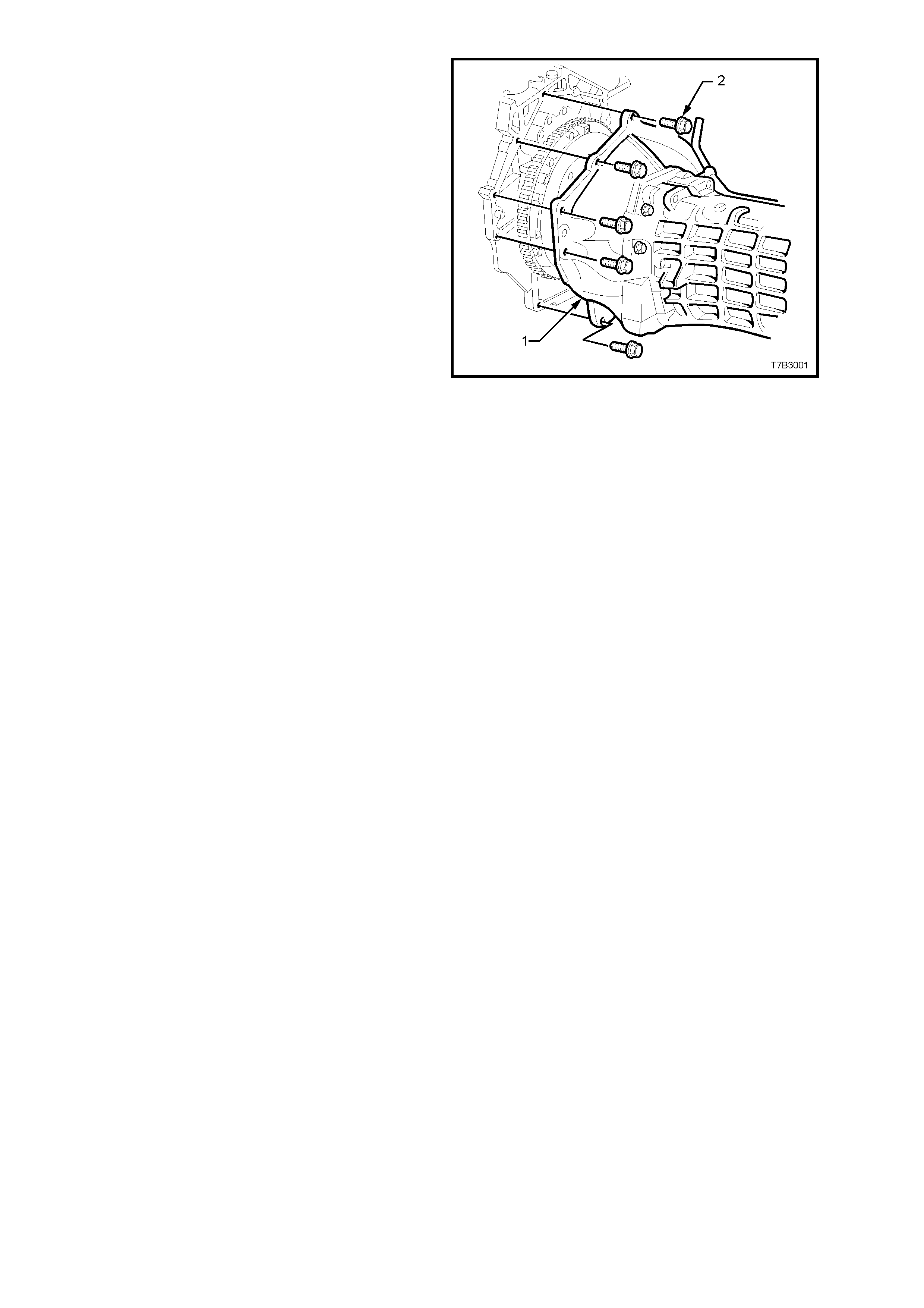

2.6 CLUTCH SLAVE CYLINDER

REMOVE

1. Remove the transmission from the vehicle.

Refer to Section 7B2, 4.2 TRANSMISSION

ASSEMBLY, Remove.

2. Unscrew the pipe fitting (1) from the clutch

slave cylinder (2).

3. Remove the two bolts (3) securing the clutch

slave cylinder assembly to the transmission

adaptor plate, then remove the slave cylinder.

DISASSEMBLE

If required, remove the throwout bearing. Refer to

2.7 CLUTCH THROWOUT BEARING.

NOTE: Apart from this bearing and the spring

behind it, there are no other serviceable parts in

the clutch slave cylinder assembly.

CLEAN AND INSPECT

IMPORTANT: Do not wash hands in petrol or oil

before cleaning or handling clutch slave cylinder

parts. Always use a soap and water based hand

cleaning product.

1. Inspect the slave cylinder for any evidence of

fluid leakage. If found, replace the assembly.

2. Remove the bleeder screw and inspect the

slave cylinder threaded apertures for damage.

Replace the slave cylinder assembly as

necessary.

3. Check that the bleeder screw thread is

undamaged and that the drilled passage is

clear of debris.

4. Inspect the throwout bearing. Refer to

2.7 CLUTCH THROWOUT BEARING.

Figure 7A2 – 7

REINST ALL

Installation is the reverse of removal operations except for the following points:

1. Install slave cylinder and the 2 retaining bolts, then tighten the bolts to the correct torque specification.

CLUTCH SLAVE CYLINDER BOLT

TORQUE SPECIFICATION 10 Nm

2. Install and tighten hydraulic pipe flare nut to the slave cylinder, tightening to the correct torque specification.

HYDRAULIC PIPE FLARE NUT TO

SLAVE CYLINDER

TORQUE SPECIFICATION 13 Nm

3. Reinstall the transmission. Refer to Section 7B2, 4.2 TRANSMISSION ASSEMBLY, Reinstall.

4. Bleed the clutch hydraulic system, as detailed in 2.3 CLUTCH HYDRAULIC SYSTEM, BLEED.

5. Following bleeding operations, check that the hydraulic fluid level is correct, as detailed in

2.2 FLUID LEVEL CHECK.

6. Road test the vehicle and check for correct clutch and transmission operation.

Techline

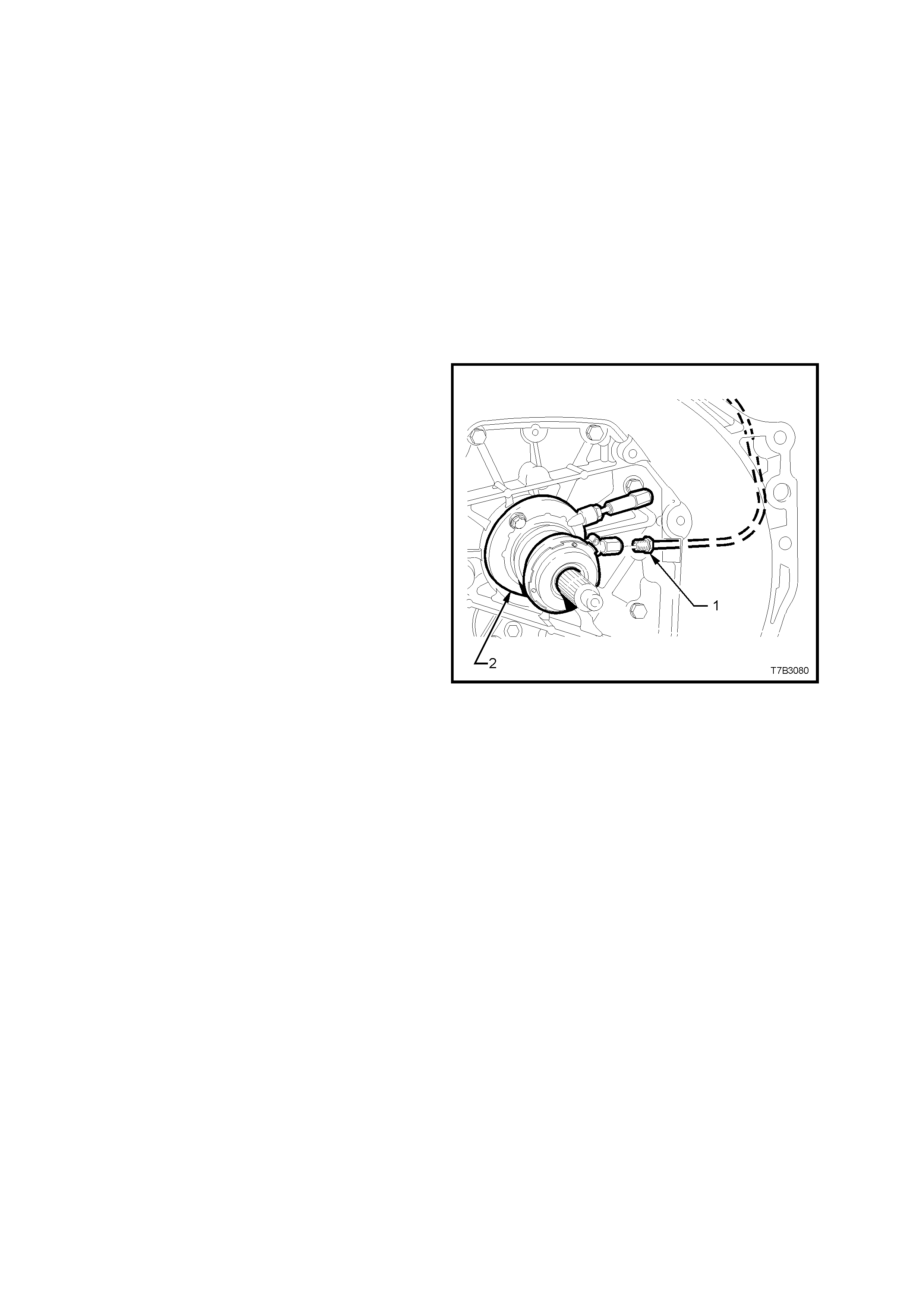

2.7 CLUTCH THROWOUT BEARING

REMOVE

1. Remove the transmission. Refer to

Section 7B2, 4.2 TRANSMISSION

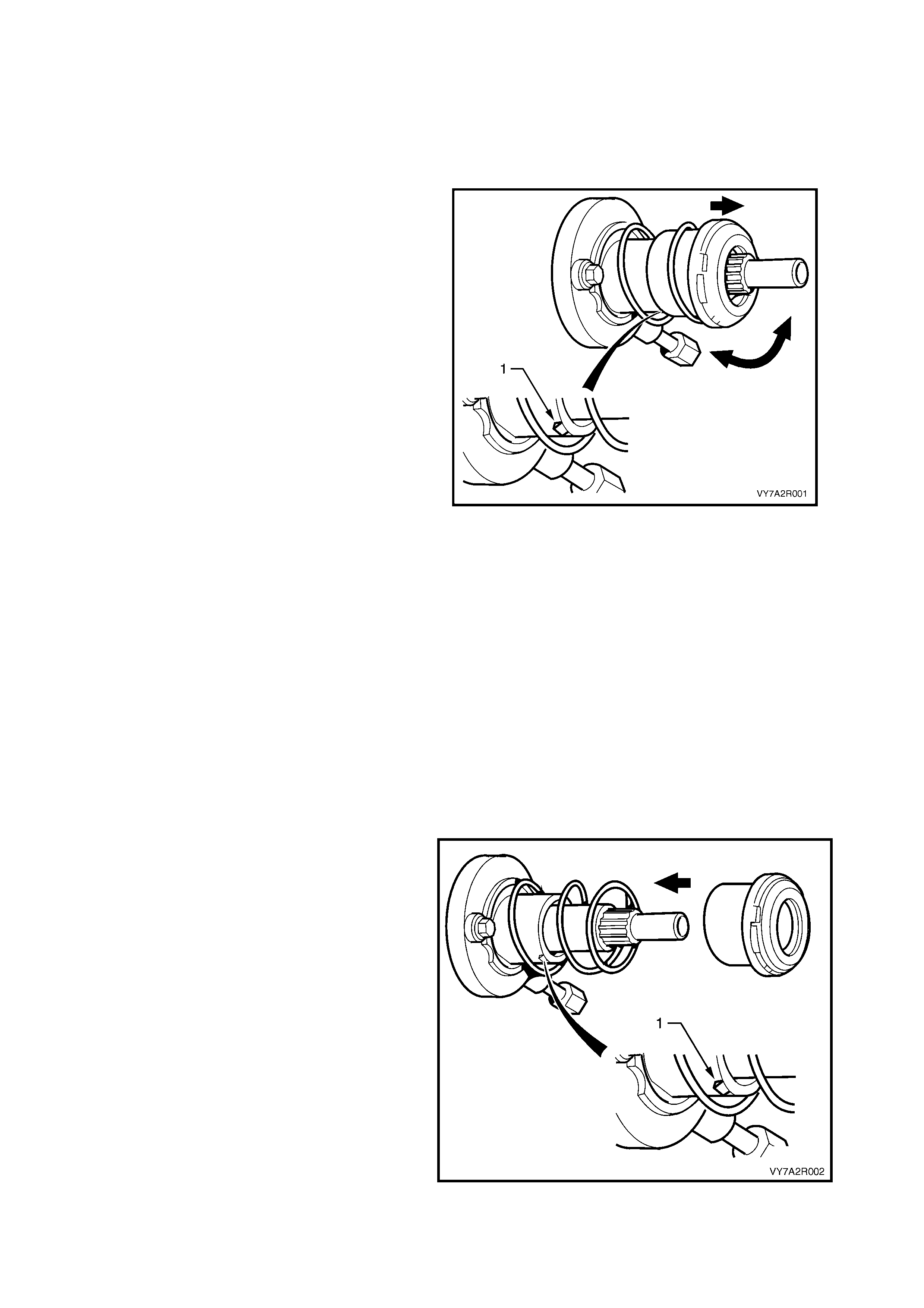

ASSEMBLY, Remove.

2. W hilst grasping the thro wout beari ng, twist and

pull the bearing to release the slave cylinder

guide sleeve retaining tab (1) from the throwout

bearing guide sleeve.

Figure 7A2 – 8

CLEAN AND INSPECT

IMPORTANT: Do not use cleaners or chemicals on the bearing guide sleeve.

1. Ins pect the thro wout bear ing for any signs of r oughnes s or drynes s by rotating the beari ng when a light loa d is

applied. If either of these conditions are evident, replace the throwout bearing.

2. Examine the bearing guide sleeve for signs of damage, abrasion or scuffing. Renew the throwout bearing if

either of these conditions exist.

NOTE: The throwout bearing guide is not serviceable and is supplied complete with the throwout bearing.

3. Inspect the slave cylinder. Refer to 2.6 CLUTCH SLAVE CYLINDER.

4. Use a water dampened cloth or water based solution to wipe the slave cylinder clean.

REINST ALL

1. Using a clean dry rag, wipe the exposed portion of the throwout bearing guide sleeve.

2. Apply molybdenum disulphide grease to the slave cylinder guide sleeve.

NOTE: If replacing the throwout bearing, grease may have been applied to the new clutch throwout bearing.

3. Install the clutch throwout bearing to the guide

sleeve, b y firm ly pushing the new bearing on to

the sleeve, until it snaps into place over the

retaining tab (1).

4. Install the transmission. Refer to Section 7B2,

4.2 TRANSMISSION ASSEMBLY, Reinstall.

5. Road test the vehicle and check for correct

clutch and transmission operation.

Figure 7A2 – 9

2.9 CLUTCH PE DAL SWITCH

REMOVE

CAUTION: Disable the SRS (Air Bag). Refer 'DISABLING THE SRS’, in Section 12M, OCCUPANT

PROTECTION SYSTEM.

1. Disconnect batt ery ground lead.

IMPORTANT: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00 CAUTIONS, 5. Battery Disconnection Procedures before disconnecting the battery.

2. Remove ignition keys from ignition switch.

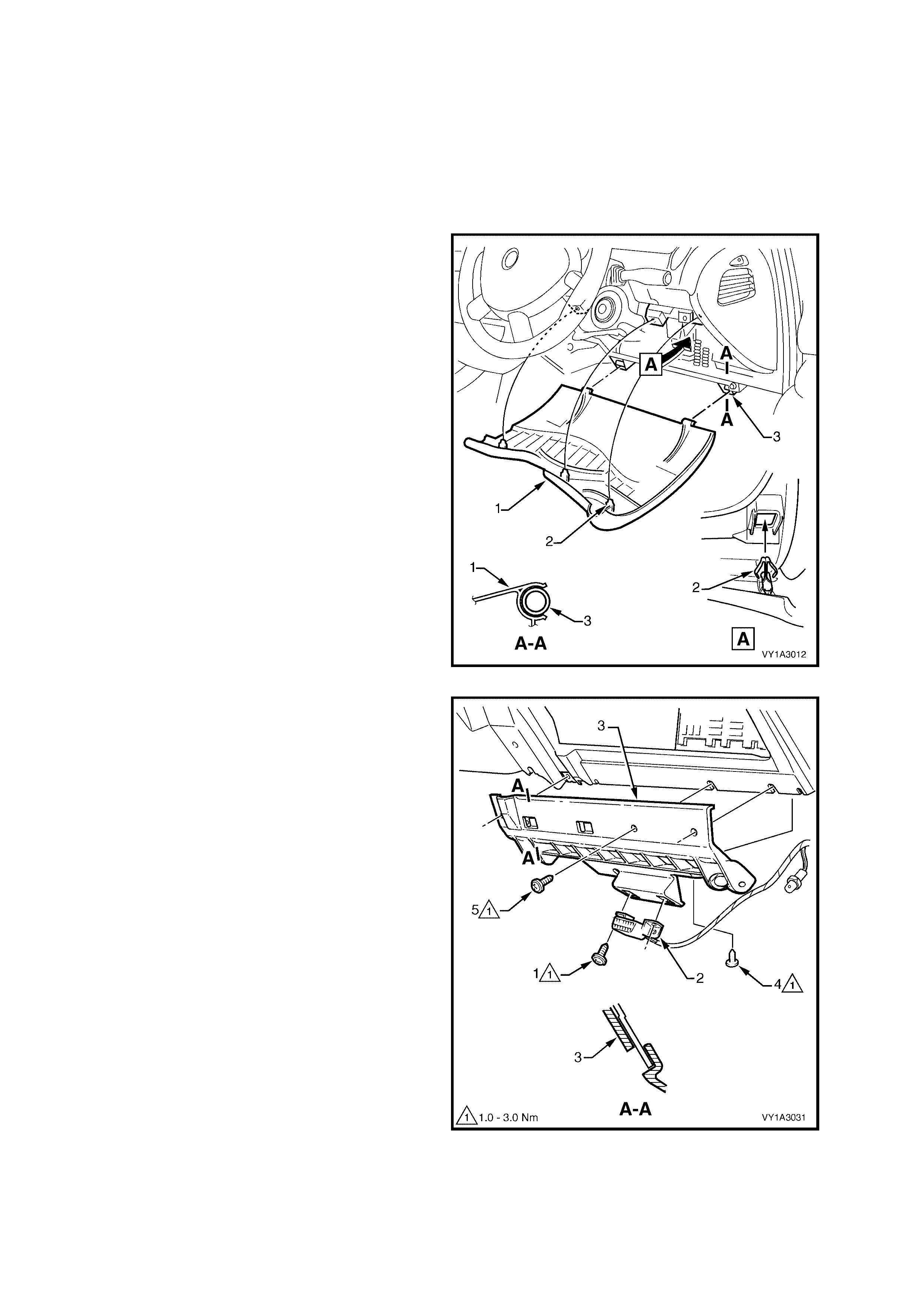

3. Lower the instrument panel lower fuse panel

cover assembly (1) by grasping the top edge

on each side of the steering column with the

finger tips and pulling the top edge out, to free

the retaining lugs (2) from the clips (3).

4. Release the steering column tilt/reach clamp

lever, lower the column and lock the clamp

lever in this position.

Figure 7A2 – 10

5. Remove the screw (1), two places, attaching

the Data Link Connector (2) to the instrument

panel lower trim panel retainer (3).

6. Rem ove the screw (4) a ttaching the retainer to

the air duct.

7. Remove the screw (5), three places, attaching

the retainer to the instrument panel assembly

and instrument panel.

8. Slide the retainer downwards to disengage the

two lugs from the instrument panel assembly

and remove the retainer.

Figure 7A2 – 11

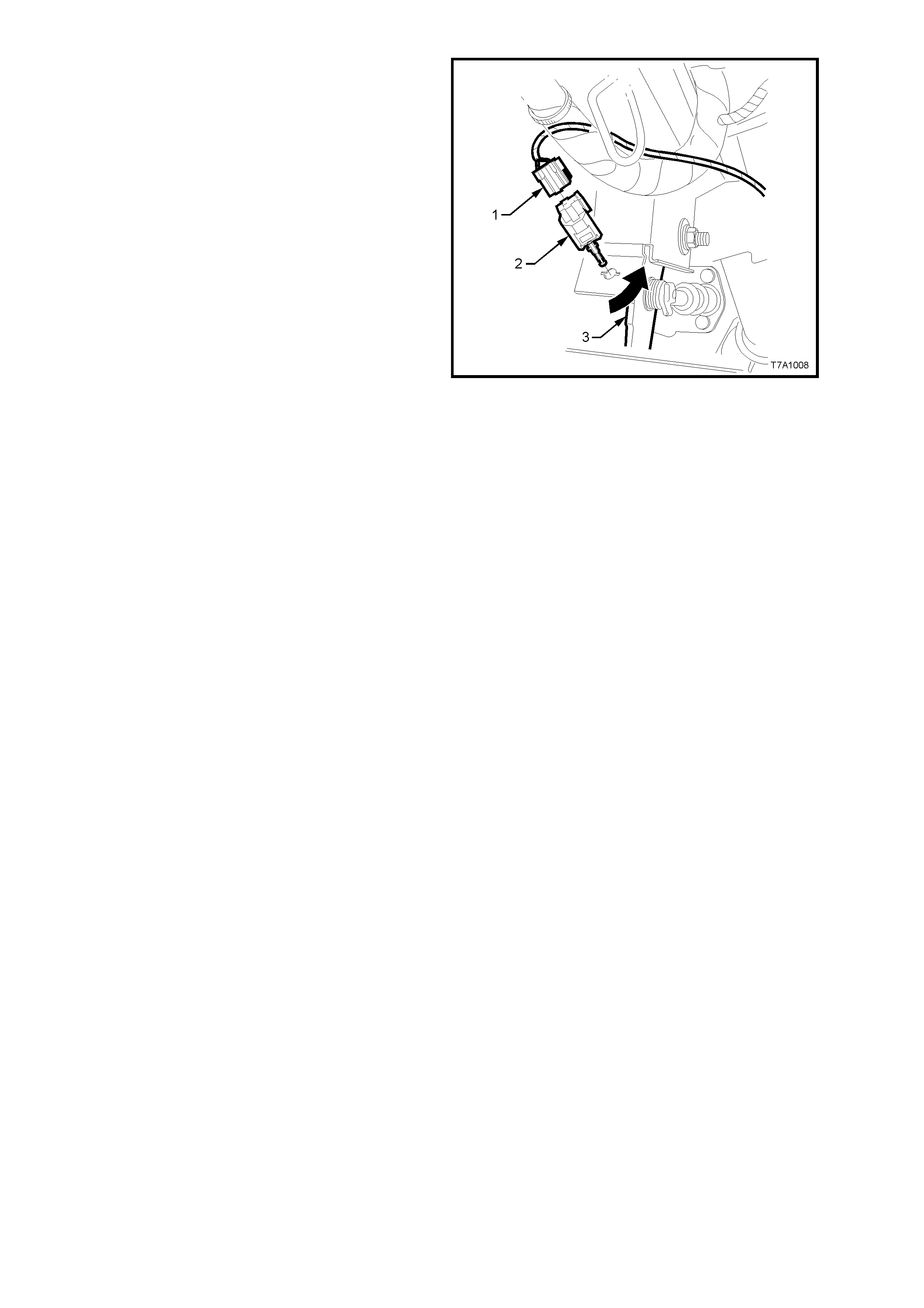

9. Remove the clutch switch wiring harness

connector (1), then remove the clutch switch

(2) by rotating counter-clockwise (to the left)

1/4 turn, then pull to free the switch bayonet

lugs.

Figure 7A2 – 12

REINST ALL

1. Reinstall the switch and rotate 1/4 turn clockwise to lock the switch bayonet lugs, then reinstall the wiring

harness connector.

2. Reinstall all removed instrument panel components in the reverse to removal operations.

3. Road test vehicle to check clutch switch operation. Refer Section 12E CRUISE CONTROL.

IMPORTANT: Enable the SRS (Air Bag). Refer 'ENABLING THE SRS’, in 12M OCCUPANT PROTECTION

SYSTEM.

2.10 CLUTCH AND PRESSURE PLATES

REMOVE

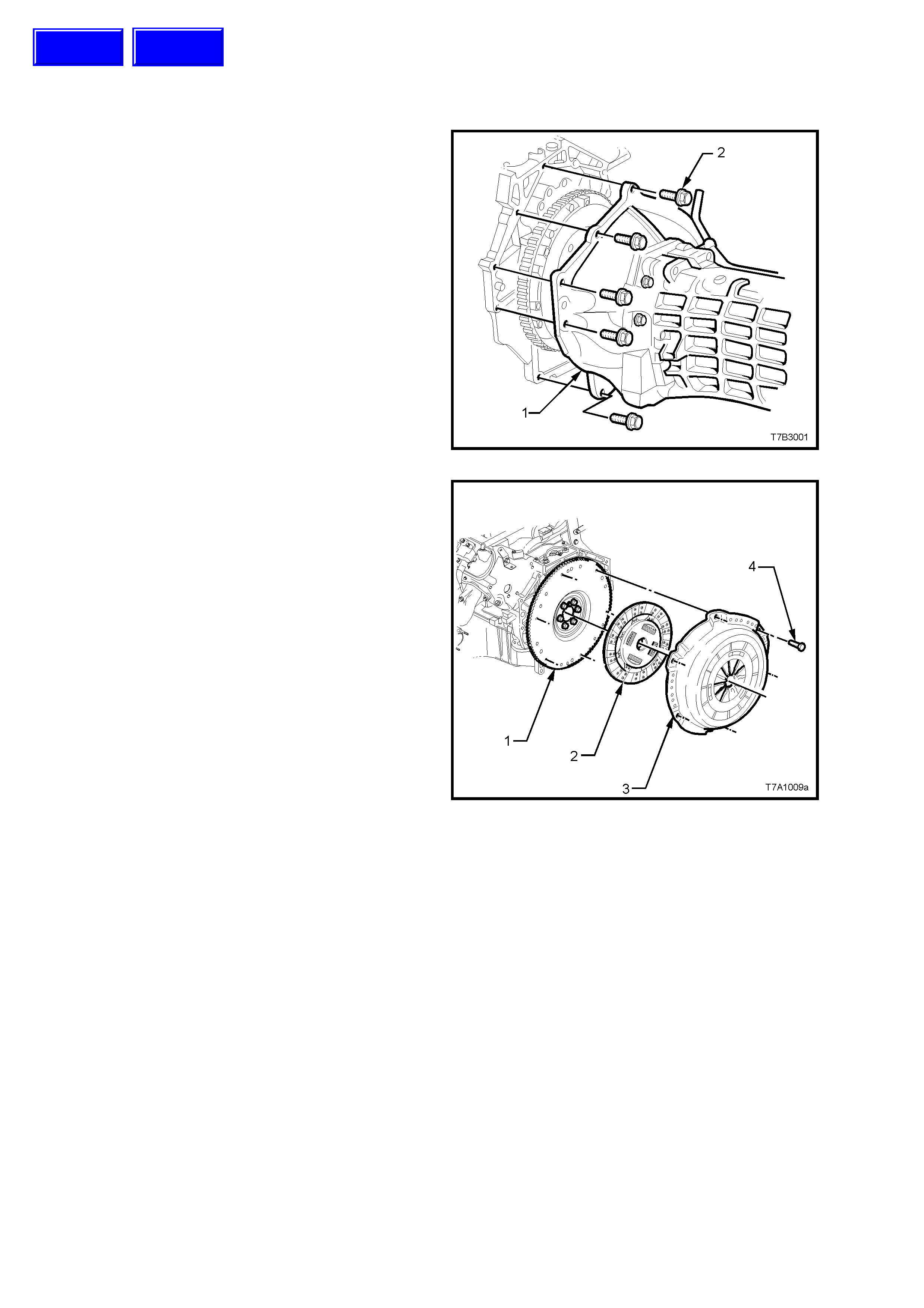

1. Remove transmission assembly (1). Refer

Section 7B2 MANUAL TRANSMISSION -

GEN III ENGINE.

Figure 7A2 – 13

2. Initia lly loosen a ll pressur e plate ret aining bo lts

(4), working from opposite sides, to avoid

distortion of the cover (3).

3. Continue loosening bolts from opposite sides,

until all are removed, then lift the clutch driven

plate (2) and pressure plate (3) assemblies

from the flywheel (1).

NOTE: The two locating dowel pins in the flywheel

are set 170° apart, which means that marking the

pressure plate relationship to the flywheel is not

required.

Figure 7A2 – 14

INSPECT

1. Use a water dampened cloth or water based solution to wipe the pressure plate and flywheel surfaces.

NOTE: Do not wash the pressure plate with liquid petroleum based products or use compressed air.

2. Inspect and clean the slave cylinder. Refer to 2.6 CLUTCH SLAVE CYLINDER.

NOTE: Do not attempt to clean the slave cylinder and throwout bearing with any fluid solvents or compressed air.

3. Inspec t the cranks haft spigot bearing f or wear. If neces sary, replace the bear ing. Refer to 2.13 CRANKSH AFT

SPIGOT BEARING.

4. Inspect flywheel and clutch pressure plate friction surfaces for burn marks scoring or roughness. Slight

roughness may be smoothed with fine emery cloth. Scoring of flywheel or pressure plate surfaces will require

replacement of the damaged component/s.

5. Inspect clutch driven plate for lining wear or other damage, such as oil or fluid contamination.

NOTE: If oil or fluid is found on the clutch linings, locate and correct the cause of the leak before proce eding with

any clutch repairs.

6. Before installing the clutch driven plate, check clutch hub for a free sliding fit on maindrive gear clutch shaft

splines.

Techline

Techline

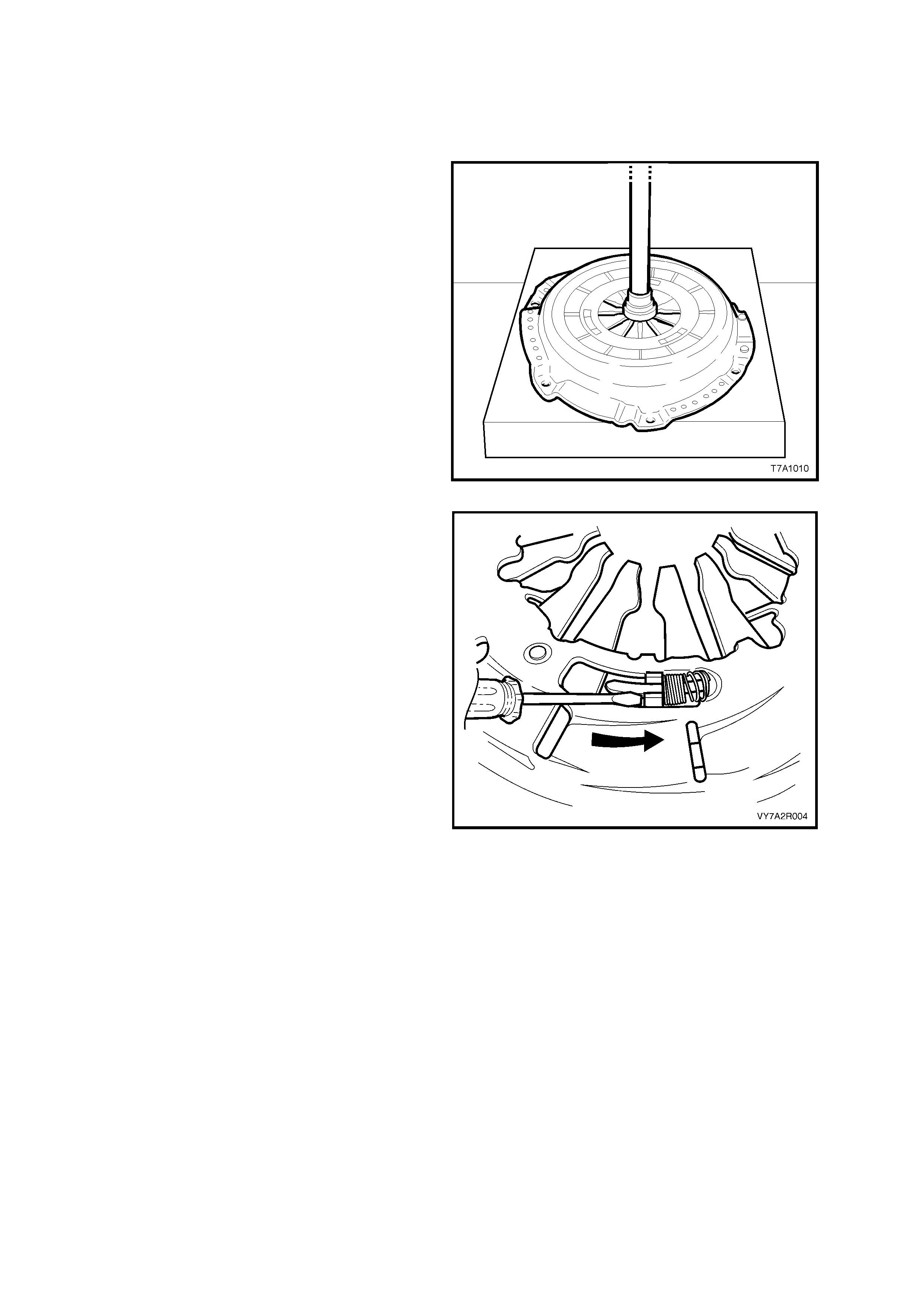

CLUTCH PRESSU RE PLAT E ADJUSTMENT

IMPORTANT: Prior to the installation of the

pressure plate, the self-adjusting feature must be

pre-set. If not carried out before installation, then

probable failure of the pressure plate will result.

1. Place the flat side of the clutch plate

downwards on flat press plates, then place the

pressur e plate ass embly over it.

2. Using a hydraulic press, compress the

pressur e plate d iap hr agm spring un til tens i on is

released from the clutch driven plate.

NOTE: Care mus t be exercised when com pressing

the pressure plate diaphragm spring. If the

diaphragm spring is compressed to far, damage to

the pressure plate may result.

Figure 7A2 – 15

3. Hold a screwdriver (1) or other suitable tool,

against the stepped adjusting ring tension

spring stop (2) in front of the adjusting ring

tension spring (3)

4. Using the screwdriver, rotate the stepped

adjusting ring, counter-clockwise (arrow), fully

compressing the tension springs.

NOTE 1: Minimal effort is required to rotate the

adjustment ring. If difficulty is experienced in

rotating the adjustment ring check that the

diaphragm spring has been adequately

compressed.

NOTE 2: Do not force the adjustment ring as

damage to the pressure plate may result.

5. While holding the tension springs in the fully

loaded position, release the force on the

diaphragm spring. This will then retain the

springs in the fully loaded position.

6. Remove the pressure plate and clutch driven

plate from the press.

Figure 7A2 – 16

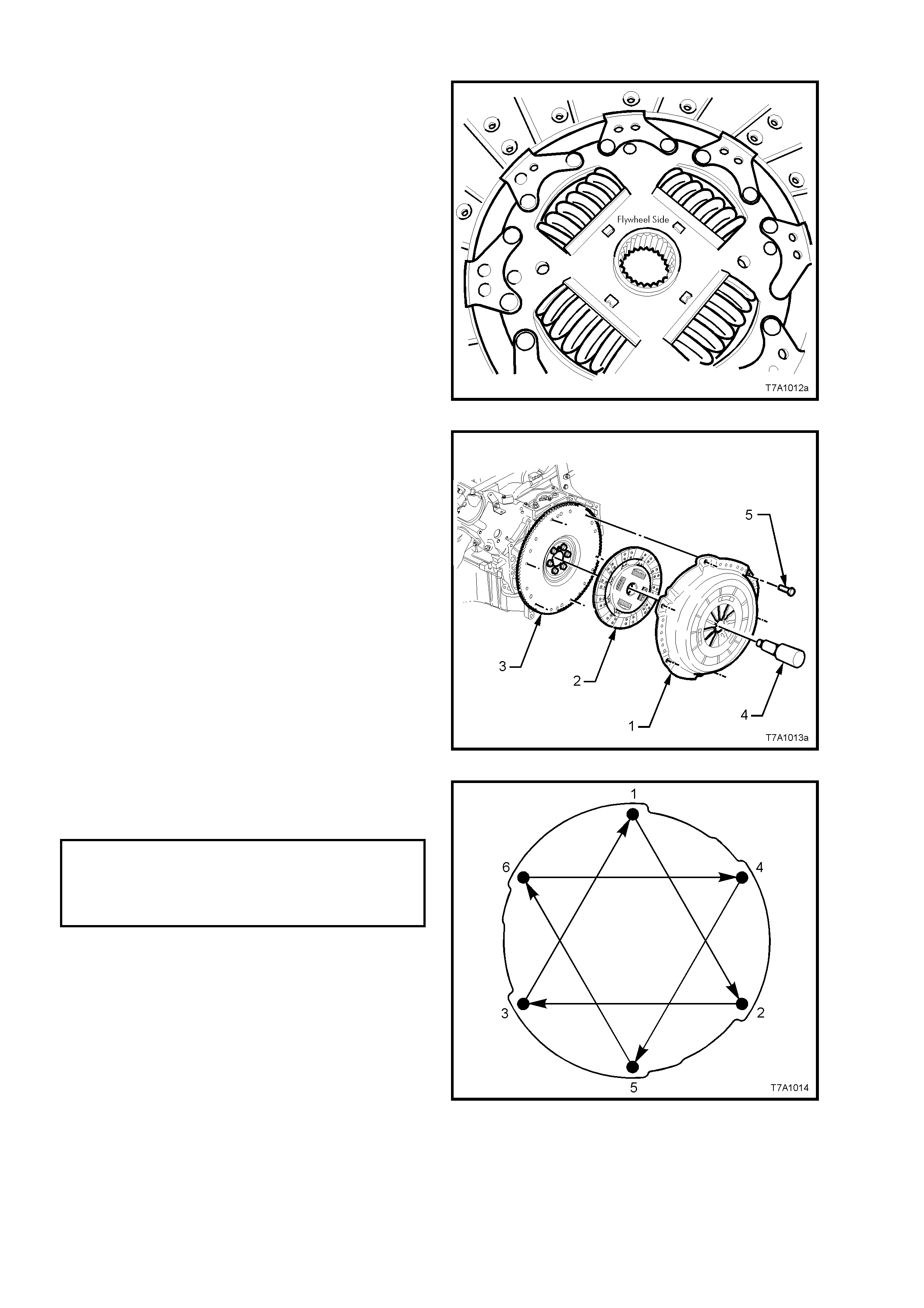

REINST ALL

1. While holding the clutch driven plate up to the

engine flywheel, insert a suitable clutch

centring tool (commercially available) into the

spigot bearing, through the driven plate.

NOTE: The clutch driven plate is installed with the

flat side of the hub, facing forward to the flywheel.

The word ‘Flywheel Side’ is also stamped on the

inner surface, as shown.

Figure 7A2 – 17

2. Reinstall the pressure plate assembly (1) over

the alignment tool (4) and clutch driven plate

(2), aligning the offset dowel pins in the

flywheel (3) with the mating holes in the

pressure plate cover (1).

3. Loosely install the six pressure plate to

flywheel bol ts (5).

Figure 7A2 – 18

4. Tighten the 6 pressure plate retaining bolts in

sequence and evenly over 4 stages until the

correct torque specification is reached.

CLUTCH PRESSURE PLATE

BOLT TORQUE SPECIFICATION Stage 1: 15 Nm

Stage 2: 35 Nm

Stage 3: 55 Nm

Stage 4: 70 Nm

IMPORTANT: Tightening to the torque settings,

stages and in the sequence listed are all

necessary, to avoid permanent distortion of the

pressure plate cover.

Figure 7A2 – 19

IMPORTANT: Under no circumstances should a

lubricant be applied to the bearing face off the

clutch throwout bearing, the gearbox input shaft

splines or the input shaft spigot. Should a lubr icant

be applied, premature clutch failure may result.

5. Reinstall the transmission assembly. Refer to

Section 7B2 MANUAL TRANSMISSION,

GEN III V8 ENGINE.

NOTE: When installing the transmission, do not

allow it to ‘hang’ on the maindrive gear splines, as

the clutch driven plate will be damaged.

6. Bleed the hydraulic clutch actuating system.

Refer to 2.3 CLUTCH HYDRAULIC SYSTEM,

BLEED.

7. Depr ess the c lutch pedal s evera l tim es to all ow

the self- adjusting functi on of the pressure plate

to take effect.

8. Start engine, and check for exhaust leaks

before road testing the vehicle for satisfactory

clutch operation.

Figure 7A2 – 20

3. DIAGNOSIS

CONDITION PROBABLE CAUSE CORRECTIVE ACTION

SLIPPING Worn or oil-soaked lining.

Grease on linings from excessive

use of grease on splines.

Driven plate sticking on

transmission input shaft splines.

Weak or broken diaphragm spring.

Master or slave cylinder defective.

Replace driven plate, correct oil

leak.

Replace driven plate, remove

excess lubrication.

Clean spli nes and check clutch hub

for a free sliding fit.

Replace pressure plate assembly.

Refer to 2.10 Clutch and Pressure

Plates.

Overhaul defective cylinder as

outlined under 2.5 Mas ter Cylinder

or 2.6 Clutch Slave Cylinder.

DRAG OR FAILURE TO

RELEASE Air trapped in hydraulic system.

Leak In hydraulic system.

Clutch master or slave cylinder

defective.

Cracked or oil-soaked linings.

Excess ive dri ven pl ate run- out or

distorted.

Driven plate sticking on splines.

Transmission input shaft spigot

partially seized in crankshaft spigot

bearing.

Bleed system as outlined under

2.3 Clutch Hydraulic System,

Bleed.

Correct leak and bleed hydraulic

system .

Replace defective cylinder as

outlined under 2.5 Master Cylinder

or 2.6 Clutch Slave Cylinder.

Replace driven plate. Refer to

2.10 Clutch and Pressure Plates.

Replace driven plate. Refer to

2.10 Clutch and Pressure Plates.

Clean splines and check clutch hub

for a free sliding fit.

Remove clutch, replace bush.

Refer to 2.13 Crankshaft Spigot

Bearing.

GRAB OR CHATTER Oil on linings.

Worn transmission input shaft

splines.

Rough, or grooved, flywheel or

pressure plate.

Loose engine m ountings .

Loose or worn prope ll er sh af t

couplings or rear universal joint

flange.

Defective clutch dr i ven plat e.

Replace driven plate, correct oil

leak.

Replace transmission input shaft.

Refer to Section 7B2, Manual

Transmission – GEN III V8 Engine.

Replace flywheel or replace both

flywheel and pressure plate. Refer

to 2.10 Clutch and Pressure Plates

or 2.11 Engine Flywheel.

Tighten or replace mountings.

Refer Section 6A3 Engine

Mechanic al GEN III V8 Engine.

Tighten or replace universal

coupling/s and/or pinion flange.

Refer Section 4C Propeller Shaft

And Universa l Joi nts .

Replace clutch driven plate. Refer

to 2.10 Clutch and Pressure Plates.

HARD OR STIFF CLUTCH

ACTION Clutch pedal bush seized or tight

on pedal shaft.

Blockage in fluid hydraulic pipe.

Replace bushes as detailed in

2.8 Clutch Pedal Assembly.

Clean lines and bleed hydraulic

system. Refer to 2.3 Clutch

Hydraulic System, Bleed.

CONDITION PROBABLE CAUSE CORRECTIVE ACTION

CLUTCH ENGAGEMENT TOO

SLOW Blockage in fluid hydraulic pipe.

Clutch master or slave cylinder

defective.

Incorrect brake fluid used.

Clean lines and bleed hydraulic

system. Refer 2.3 Clutch Hydraulic

System, Bleed.

Replace defective cylinder as

outlined under 2.5 Mas ter Cylinder

or 2.6 Clutch Slave Cylinder.

Flush and bleed hydraulic system.

Refer to 2.3 Clutch Hydraulic

System, Bleed.

4. SPECIFICATIONS

Note: Only th ose specif ications relat ing specif icall y to this sec tion ar e quoted her e. for al l rem aining spec ific ations,

refer to Section 7A1 CLUTCH.

MASTER CYLINDER:

.................................................................................... All Engines

Type .................................................................................... Compensating port.

Bore Size............................................................................... 19.05 mm

Nominal Stroke...................................................................... 30 mm

CLUTCH SLAVE CYLINDER:

Type .................................................................................... Concentric hydraulic slave cylinder with side feed

.................................................................................... and ble ed ports

Bore Size............................................................................... I.D. 36 mm/O.D 47.6 mm (nominal)

Available Stroke .................................................................... 22.8 mm (nominal)

BRAKE FLUID:

Type .................................................................................... DOT 4 Plus or Super DOT 4 Plus.

CLUTCH DRIVEN PLATE:

Type .................................................................................... Single plate dry disc.

Disc Facing:

Outside Diameter ............................................................... 297 mm

Inside Diameter.................................................................. 198 mm

Thickness of disc assembly with 10,000 N load applied.... 8.7 ± 0.35 mm

CLUTCH PRESSURE PLATE:

T ype .................................................................................... Self-adjusting with a press ed steel cover plat e and

a multi- f ingered Be ll ev il le dia phr ag m spring.

CLUTCH THROWOUT BEARING:

Type .................................................................................... Ball race.

Lubrication............................................................................. Sealed with grease for life.

LUBRICANT:

Slave cylinder guide sleeve................................................... Molybdenum disulphide grease.

5. TORQUE WRENCH SPECIFIC ATIONS

Note: only those torque specifications referred to in this section are quoted here. for all remaining torque

specifications, refer to Section 7A1 CLUTCH. Nm

Clutch pressure plate bolt to flywheel Stage 1........................................ 15

Stage 2........................................ 35

Stage 3........................................ 55

Stage 4........................................ 70

Clutch slave cylinder bleed screw .................................................... 18

Clutch slave cylinder mounting bolt .................................................... 10

Flywheel to crankshaft mounting bolts Stage 1........................................ 20

Stage 2........................................ 50

Stage 3........................................100

Hydraulic pipe flare nut to slave cylinder and flexible hose......................... 13

Master cylinder hydraulic pipe to flexible hose flare nut.............................. 13

6. SPECIAL TOOLS

TOOL

NUMBER ILLUSTRATION DESCRIPTION CLASSIFICATION

AU529

CLUTCH SLAVE CYLINDER

BLEED TOOL

Used to bleed air from the Central

Slave Cylinder (CSC) fitted to the

T56, 6 speed manual transmission

available for the GEN III V8

engine.

Previo us ly Releas e d

Desirable

J23738-A

HAND VACUUM PUMP

Used for many applications,

including diagnostic checks or

anywhere that an appli ed v acuum

would be useful.

Previously released and

comm er c ially available

Available

N/A CLUTCH CENTRING TOOL

Commercially available.