SECTION 7C1 - HYDRA-MATIC 4L60-E AUTOMATIC

TRANSMISSION: GENERAL INFORMATION

IMPORTANT

Before perfo rming any Service Operat ion or oth er procedure described in this Section , refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. SECTION DESCRIPTIONS

2. TRANSMISSION CHANGES FOR MY2003

2.1 ‘HAD’ MODEL TRANSMISSION

3-4 CLUTCH

2.2 ALL MY2003 TRANSMISSIONS

PRESSURE CONTROL SOLENOID (PCS)

BOOST VALVE BUSHING

2.3 BRAKE TRANSMISSION SHIFT

INTERLOCK (BTSI)

MANUAL OVERRIDE

OPERATION

3. TRANSMISSION OPERATION -OVERVIEW

3.1 GENERAL DESCRIPTION

TRANSMISSION COMPONENT SUMMARY

MATCHING ENGINE TORQUE AND

LINE PRESSURE

ECONOMY, POWER & CRUISE MODES

ADAPTIVE CONTROLS

ENGINE TORQUE MANAGEMENT

SYSTEM PROTECTIVE DEVICES

SELF DIAGNOSIS

PCM SENSORS AND ACTUATORS

TRANSMISSION IDENTIFICATION

TRANSMISSION SPEED RANGES

RANGE REFERENCE CHART

3.2 PULSE WIDTH MODULATED TCC SOLENOID

DUTY CYCLE

TCC PWM SOLENOID OPERATION

3.3 TORQUE CONVERTER CLUTCH

GENERAL DESCRIPTION

TORQUE CONVERTER CLUTCH –

RELEASED

TORQUE CONVERTER CLUTCH – APPLIED

3.4 3-2 DOWNSHIFT CONTROL SOLENOID

GENERAL DESCRIPTION

3-2 CONTROL SOLENOID OPERATION

4. TRANSMISSION DEFINITIONS AND

ABBREVIATIONS

4.1 DEFINITIONS

4.2 ABBREVIATIONS

5. SERVICE NOTES

5.1 FASTENERS

5.2 GENERAL WORKSHOP PRACTICE

Techline

Techline

1. SECTION DESCRIPTIONS

A multi-section approach to the Hydra-matic 4L60-E Automatic Transmission has been adopted for MY2003

vehicles.

7C1: HYDRA-MATIC AUTOMATIC TRANSMISSION: GENERAL INFORMATION

The purpos e of this s ection is to provide an over view of the autom atic transm ission, by brief ly describing what each

of the various sub-sections contains.

In addition, an overview of the transmission features is provided, that includes;

• A general description of the transmission, its operation and control, as well as transmission identification

information.

• A brief description of some salient sy stems such as torque converter clutch and 3-2 downshift controls.

• A glossary of generic terms that are used.

• Some notes that address safe workshop practices.

• Service notes relating to fasteners and consumable items used at various stages throughout this section.

7C2 HYDRA-MATIC AUTOMATIC TRANSMISSION:- ELECTRICAL DIAGNOSIS

As the electrical systems and diagnosis for this transmission are controlled by the Powertrain Control

Module (PCM), for the V6 and V6 Supercharged engines or the PCM/Powertrain Interface Module (PIM) for the

GEN III V8 engine, this material has now been included in the appropriate sections relating to the PCM; namely

Section 6C1 POWERTRAIN MANAGEMENT – V6 ENGINE, Section 6C2 POWERTRAIN MANAGEMENT – V6

SUPERCHARGED ENGINE and Section 6C3 POWERTRAIN MANAGEMENT – GEN III V8 ENGINE.

7C3 HYDRA-MATIC AUTOMATIC TRANSMISSION:- HYDRAULIC/MECHANICA L DIAGNOSIS

As distinct from the previous section, 7C3 contains information that will assist in the diagnosis of the mechanical

and hydraulic components in the 4L60-E automatic transmission, with the unit installed in the vehicle.

Examples of the type of diagnostic information contained within this section are; transmission functional test, fluid

checking procedure, shift speed and line pressure information. Other material contained in this section refers to

some fluid flow and hydraulic circuit descriptions, plus fluid passage identification diagrams relating to the

transmission.

7C4 HYDRA -MATIC AUTOMATIC TRANSMISSION:- ON-VEHICLE SERVICING

Inform ation in this s ection c overs tr ansm iss ion fluid level c heck ing and diagnosis, as well as spec ific infor m ation for

servicing some components while the transmission remains installed in the vehicle.

This section also contains the necessary procedures for the removal and installation of the transmission.

7C5 HYDRA-MATIC AUTOMATIC TRANSMISSION:- UNIT REPAIR

This section contains the procedures necessary for the disassembly, inspection, overhaul and reassembly

operations of the mechanical components, once the transmission is removed from the vehicle. Also included is

information relating to the measurement of certain clearances, the correct use of special tools and torque

specifications required for assembly.

2. TRANSMISSION CHANGES FOR MY2003

Apart from some minor changes detailed here, the transm ission carries over f rom MY2002. One change however,

has not been detailed previously and is now included here for general information.

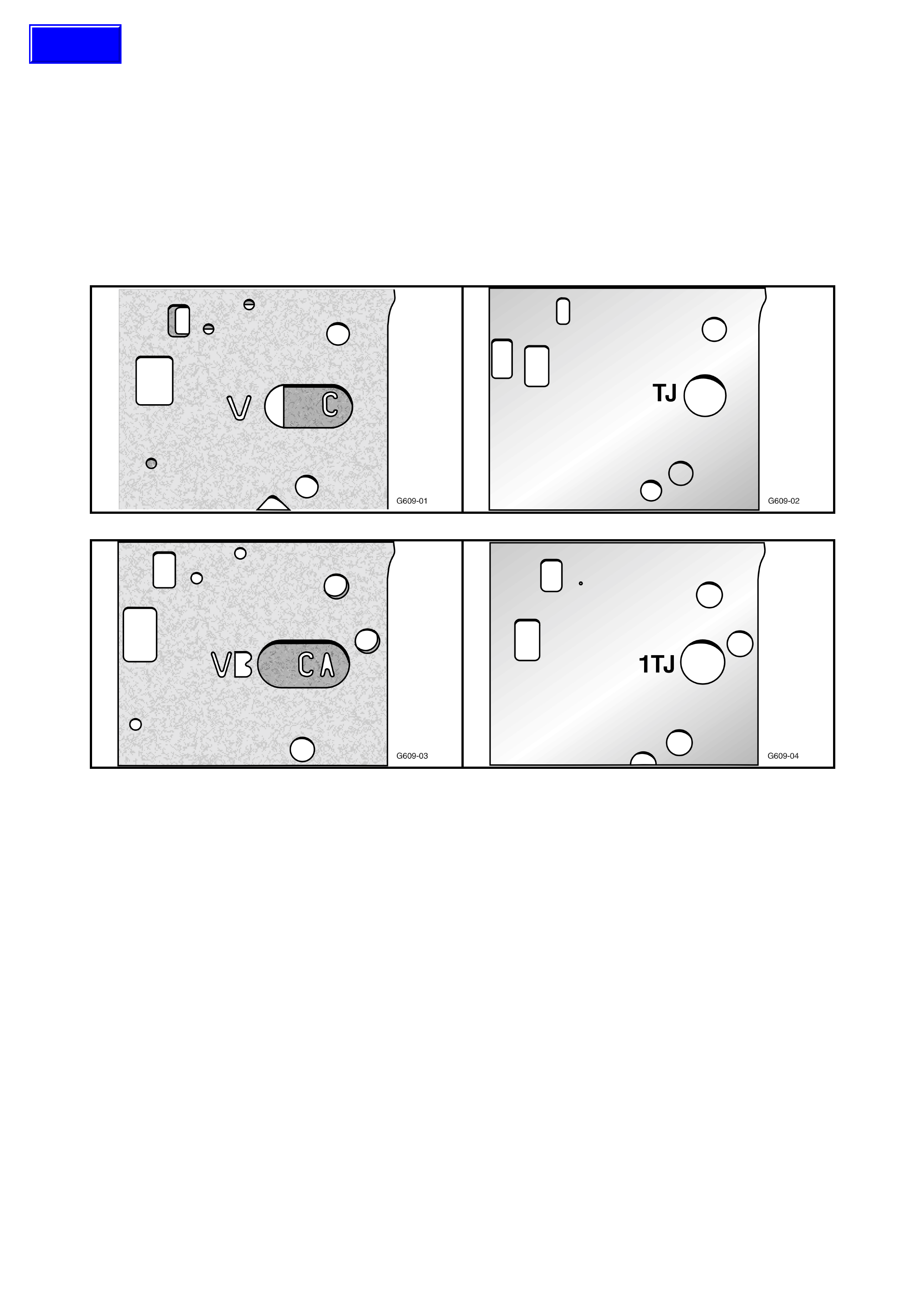

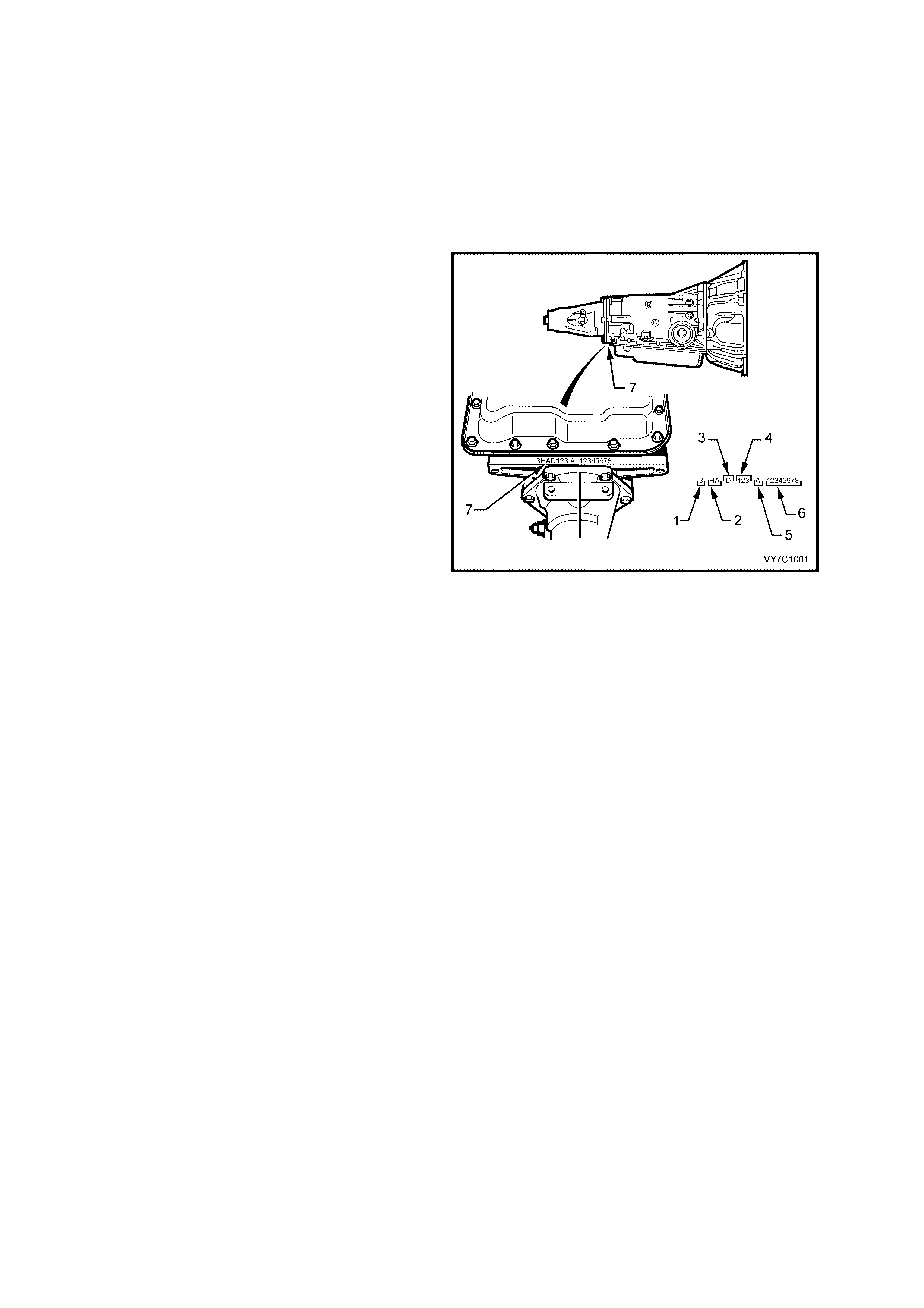

SPACER PLATE AND GASKETS

Effective from a Julian build date (refer Figure 7C1-4), of “1HXD002 X XXXXXXX”, the Torque Converter Clutch

(TCC) Regulator Valve exhaust port was reduced in size. This change has meant that, not only has the control valve

body changed but the spacer plate and both gaskets have also been modified. The early and later gaskets and

spacer plates can be physically identified as shown next.

Control Valve Body Gaskets Control Valve Body Spacer Plate

A B

C D

Figure 7C1-1

Legend

A. Pre-Change Gaskets – ‘V’ = Valve body side, ‘C’ =

Case Gasket

B. Pre-Change Spacer Plate – Identification is embossed

‘TJ’

C. Post-Change Gaskets – ‘VB’ is the Valve body side, ‘CA’

is the Case Gasket

D. Post-Change Spacer Plate – Identification in an

embossed ‘1TJ’

Techline

2.1 ‘HAD’ MODEL TRANSMISSION

To increase durability of the 4L60-E automatic transmission fitted to the GEN III V8 engine, a change to the

3-4 clutch pack has been effected for the 2003MY transmission release. Resulting from these changes the

transmission prefix has been changed from ‘HPD’ to ‘HAD’.

3-4 CLUTCH

The number of plates in the 3-4 clutch pack has been increased from six to seven plates. To achieve this result

without undergoing major internal com ponent changes, the plates are thinner. This means that the same selective

plates can be used to achieve the same end float specification.

Apart from the change in part number, the HAD clutch plates can be physically identified by;

Composition plates – Thickness of new plates (1.62 ± 0.10 mm) and by one or more lightly coloured stripes

across the friction surfaces.

Steel plates – Thickness of new plates (2.42 +0.08 –0.07 mm).

2.2 ALL MY2003 TRANSMISSIONS

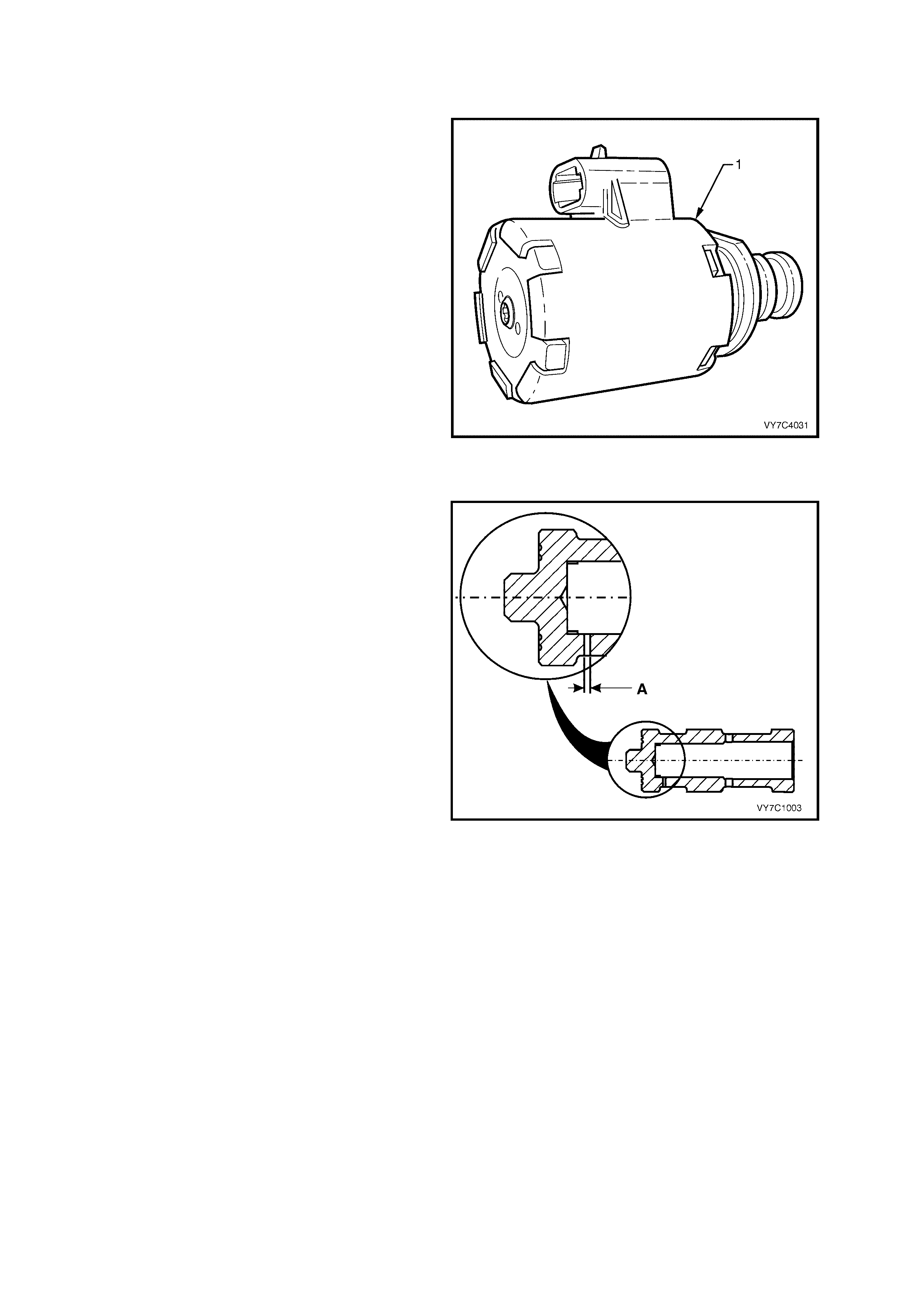

PRESSURE CONTROL SOLENOID (PCS)

The Pressure Control Solenoid (PCS) (1) is a new

design and, as the design of the terminal

connection is also new, the internal transmission

wiring harness also changes.

With the change in the PCS, the line pressure has

been affected and that results in a change in the

pressure checking procedure and results. Refer to

2.4 LINE PRESSURE CHECK in Section 7C3,

HYDRAULIC/ MECHANICAL DIAGNOSIS, for

specific details.

Figure 7C1-2

BOOST VALVE BUSHING

The orifice size (‘A’) in the boost valve sleeve,

(mounted in the oil pump housing) has been

reduced from a nominal 1.08 mm to 0.89 mm

(+0.07 mm/–0.06 mm), which affects the ATF

pressure boost characteristics of the valve.

Apart from this changed dimension, the bushing

has a new part number and has yellow dye applied

to it, for identification purposes.

Figure 7C1-3

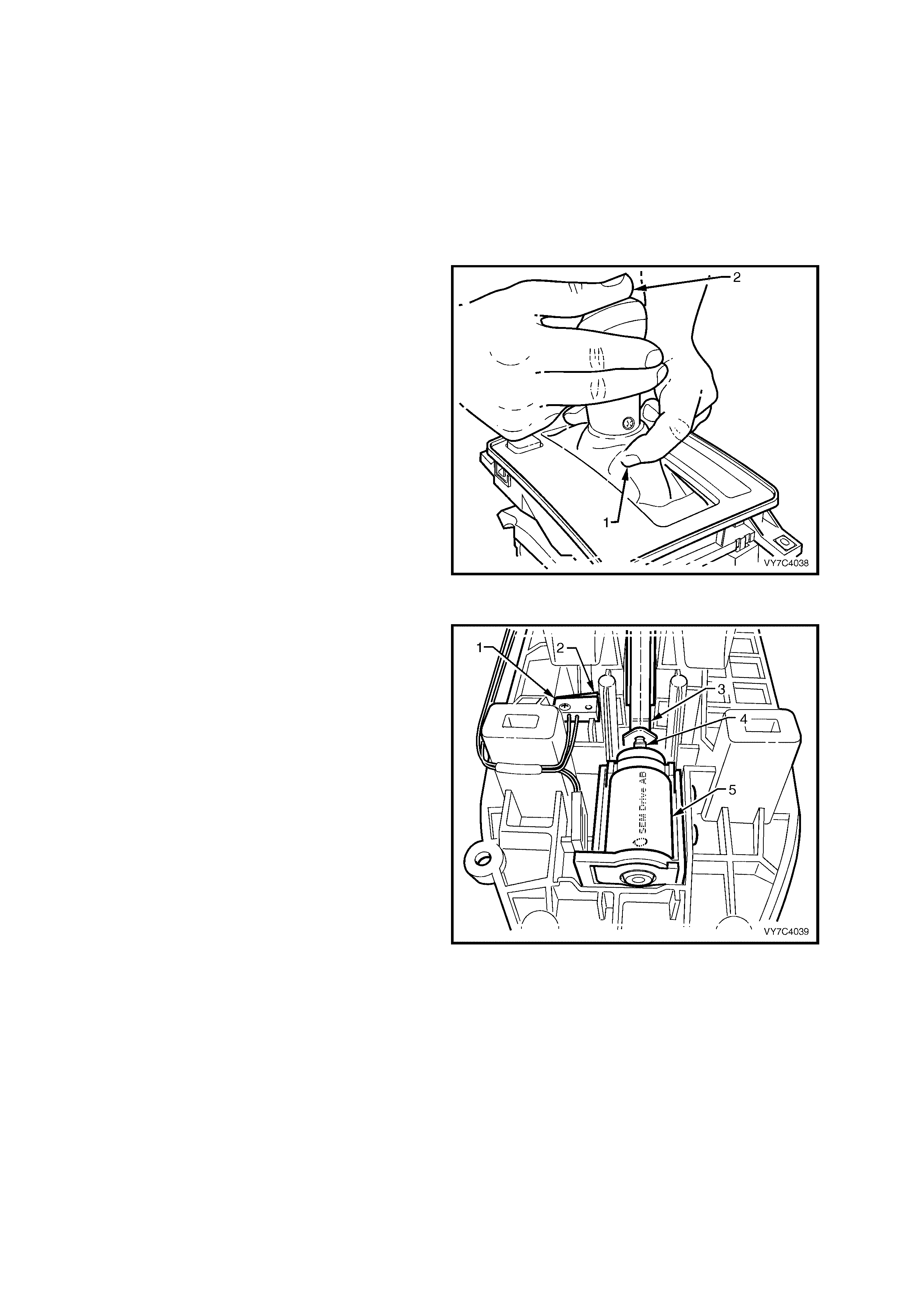

2.3 BRAKE TRANSMISSION SHIFT INTERLOCK (BTSI)

Dependent on vehicle specifications for different markets, the gearshift selector mechanism for MY 2003 VY and V2

Series vehicles, may be fitted with a Brake Transmission Selector Interlock (BTSI) device.

The selector lever cannot be moved from the Park position, unless the ignition switch is turned to the ON position

and the f oot brak e is applied. Because the foot br ake mu st be applied to release the m echanism, this device then,

assists in preventing the selection of Reverse when the vehicle is at rest say, when stationary at traffic lights.

Should the vehicle battery power be lost for some reason, then a manual override is provided, to allow shift lever

movement. This override will also be necessary, should the selector mechanism require disassembly, when

removed from the vehicle. Refer to Section 7C4 ON-VEHICLE SERVICING for these disassembly procedures.

MANUAL OVERRIDE

To release the selector lever manually (no battery

power available);

a. First, press inwards on the boot, at the front of

the selector lever and just below the gearshift

knob, as shown (1).

b. Then, while still pressing inward (1), depress

the selector knob with the other hand (2) and

move the lever from the Park position.

NOTE: While the illustration shows the shift lever

assem bly rem oved from the vehicle, the procedure

is exactly the same for an in-car situation.

Figure 7C1-4 – Releasing Interlock

OPERATION

When the shift lever is in the Park position (as

shown), the interlock lever (3) is pushed rearward

by the spring loaded solenoid plunger (4), against

the lever’s spring force. This causes a step on the

interlock lever to be positioned in such a away that

downward movement of the handle button is

blocked.

NOTE: It is this interlock lever that is manually

pressed at the top end (through the shift lever

boot), that frees the button pushrod movement.

With the selector lever in this position (Park) and

the ignition switch in the ON position (with the foot

brake applied), current flows from the stop lamp

switch ‘C’, thr ough the now closed m icro s witch (1),

the solenoid (5) and ground, through the same

circuit used for the transmission Power/Economy

switch circuit. This activates the solenoid (5). Also

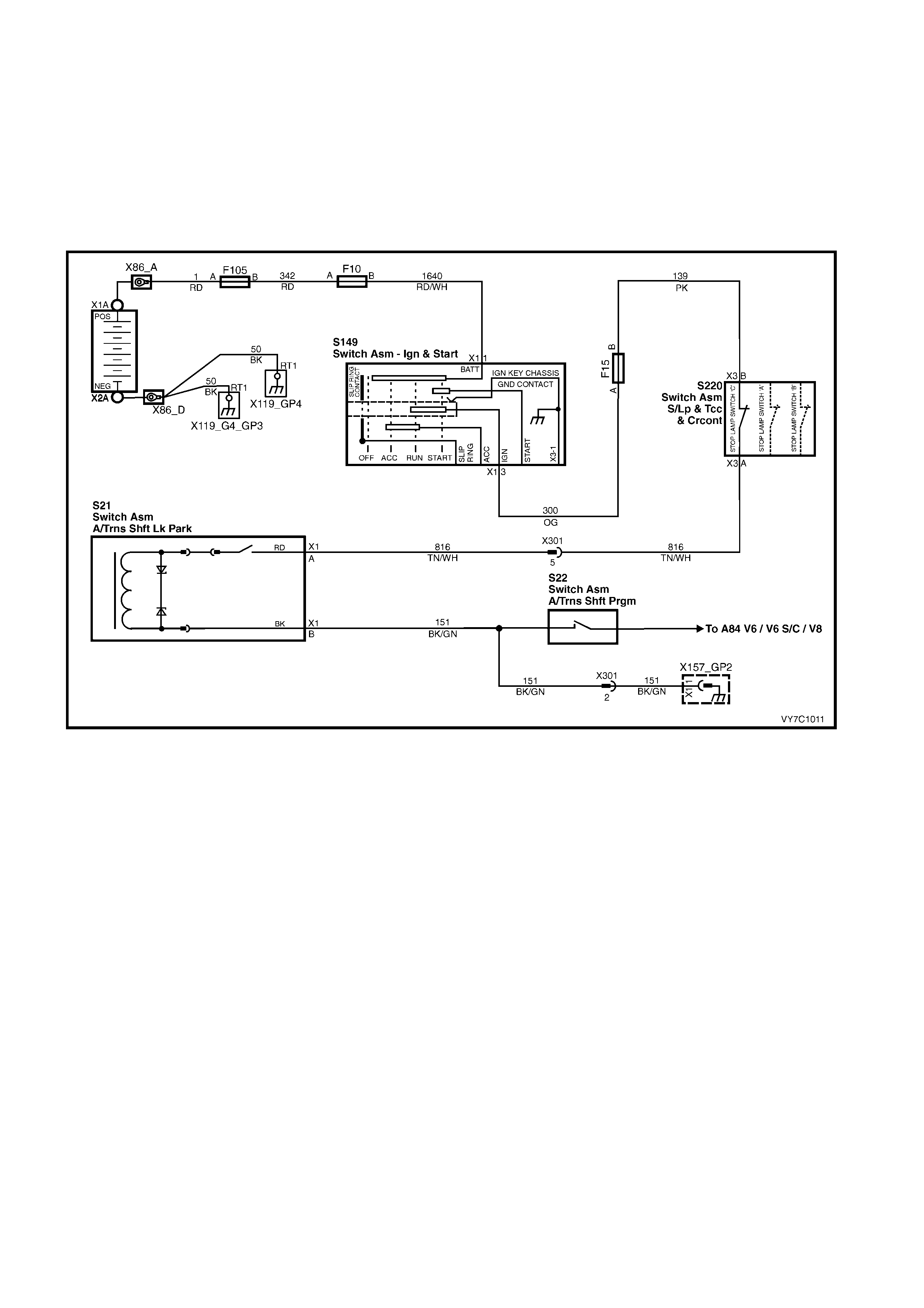

refer to the electrical circuit shown in Figure 7C1-6.

With the solenoid activated, the plunger (4) is

retracted, allowing the spring loaded isolating lever

(3) to move f orward at the s olenoid end. This action

positions the lever stop to clear the selector lever

button rod. The selector button can now be

depressed, and the selector lever to be moved

from the Park position.

Figure 7C1-5 – BTSI Components

Once the selector lever is moved from the Park

position, the released tension on the micro switch

spring lever (2), opens the electrical circuit,

isolating the solenoid (5).

This condition remains until the Park position is

selected once again.

NOTE: The insulating foam has been removed

from this view to mo re clearly show the mec hanism

arrangement.

Figure 7C1-6 – BTSI Electrical Circuit

3. TRANSMISSION OPERATION - OVERVIEW

3.1 GENERAL DESCRIPTION

The Hydra-matic 4L60-E is a fully automatic, four speed, rear wheel drive transmission. It consists primarily of a four

element torque converter, two planetary gear sets, various clutches, an oil pump and a control valve body.

The four element torque converter contains a pump, a turbine, a pressure plate splined to the turbine and a stator

assembly. The torque converter acts as a fluid coupling to transmit power smoothly from the engine to the

transm ission. It also hydraulically pr ovides additional torque multiplic ation when required. The press ure plate, when

applied, provides a mechanical 'direct drive' coupling of the engine to the transmission.

The two planetary gear sets provide the four forward gear ratios and reverse. Changing of the gear ratios is fully

automatic and is accomplished through the use of various electronic sensors that provide input signals to the

Powertrain Control Module (PCM). The PCM inter prets thes e signals to send c urrent to the var ious solenoids inside

the transmission.

By using electronics, the PCM controls shift points, shift feel and torque converter clutch apply and release, to

provide proper gear ranges for maximum fuel economy and vehicle performance.

Five m ultiple-dis c clutc hes, one roller clutch, a s prag clutch and a brak e band provide the f riction elem ents required

to obtain the various ratios with the planetary gear sets.

An hydraulic system (including the control valve body), pressurised by a vane type pump, provides the working

pressure needed to operate the friction elements and automatic controls.

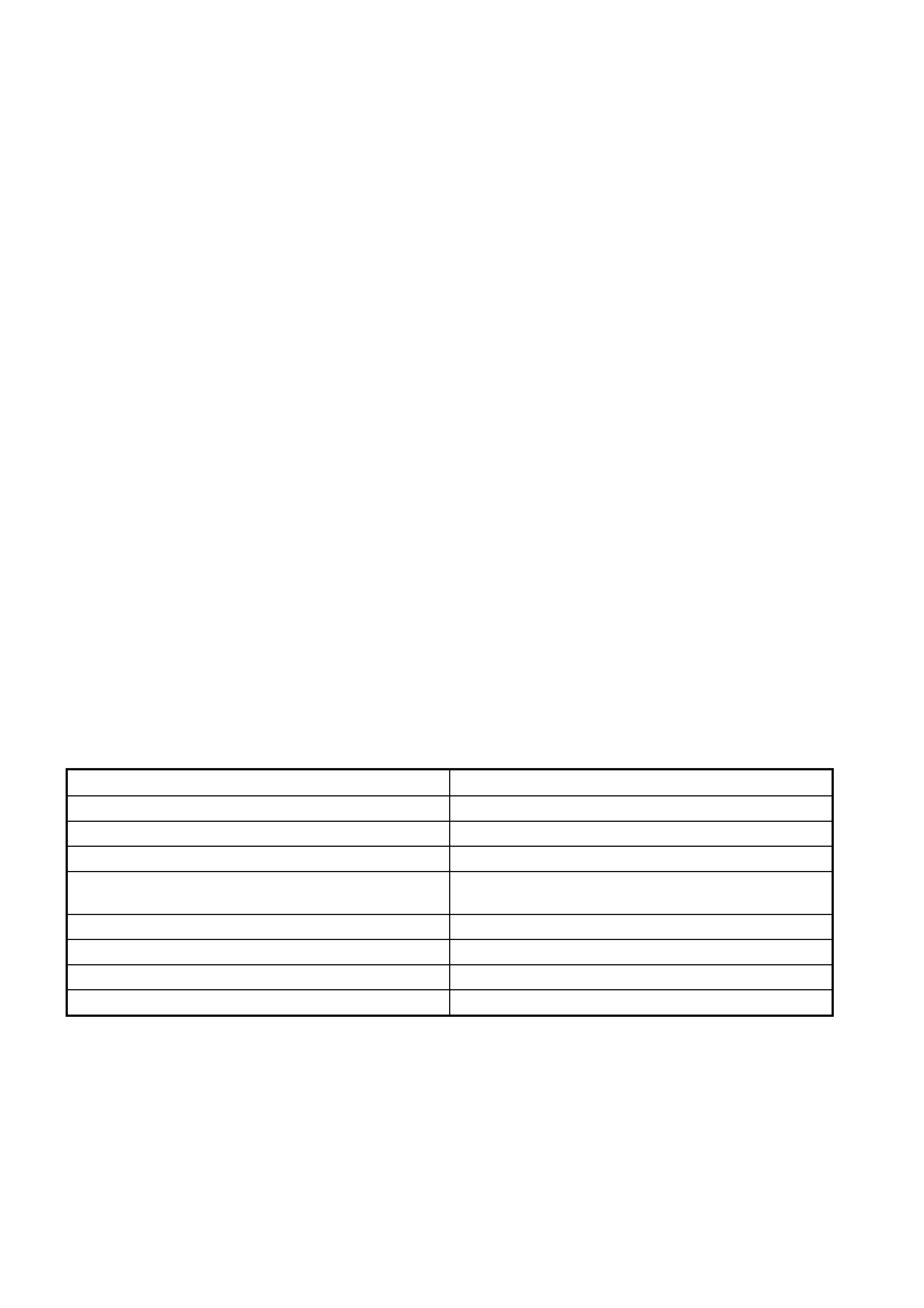

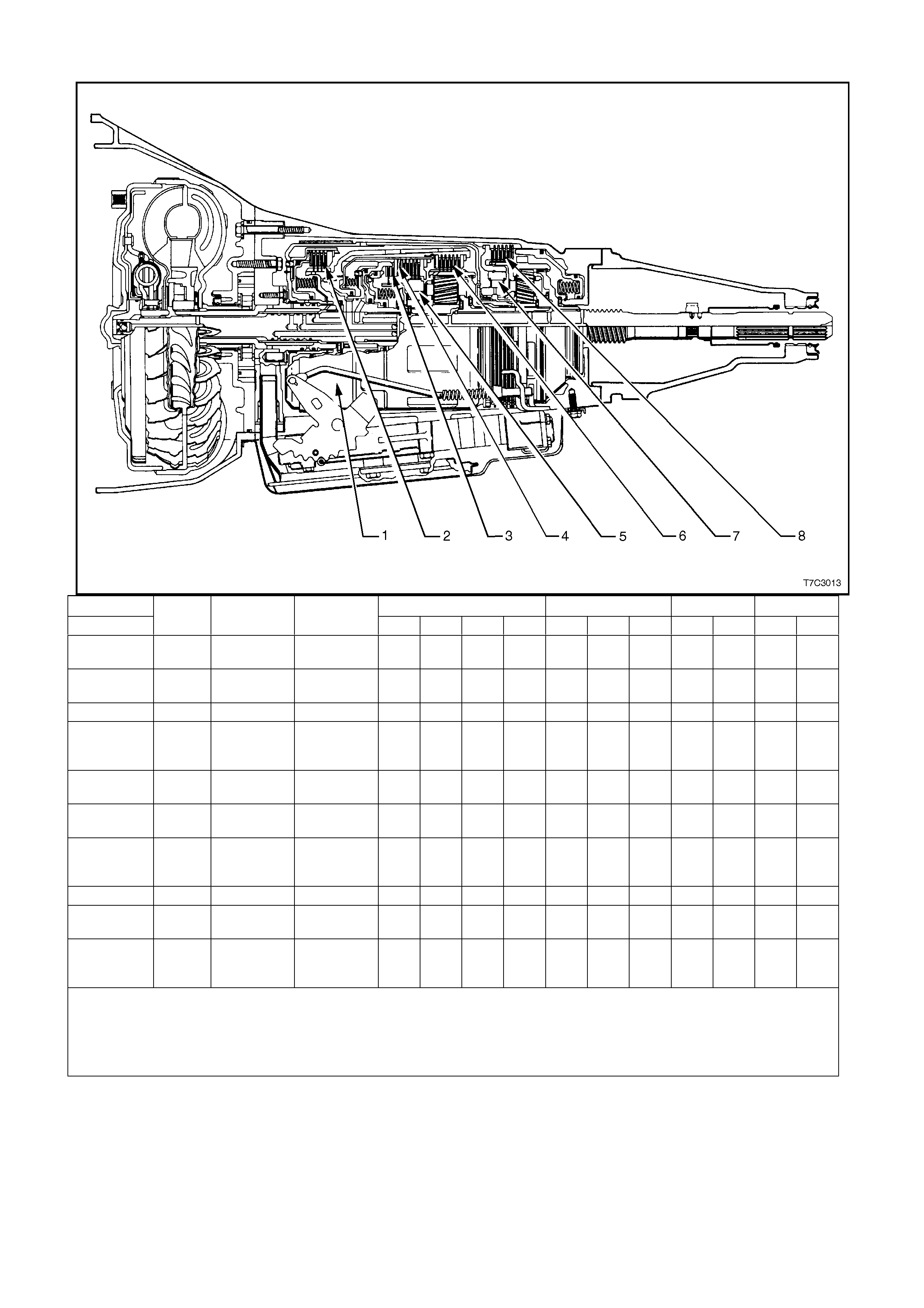

The general arrangement of both the majority of mechanical and hydraulic components is as shown next.

With traditional, hydraulically controlled transmissions, the gear shifts are controlled by the opposing pressures of

hydraulic fluid in a complex system of spring-loaded valves. In this electronically controlled Hydra-matic 4L60-E

transmission, gear shift points and shift feel are determined by electrical signals sent from the Powertrain Control

Module (PCM).

The PCM proc ess es data every 25 millisec onds f rom various sensor s, such as throttle position, vehicle speed, gear

range, temperature, engine load and other inputs. Using this data, a signal is transmitted to the valve body shift

solenoids, which ac tivate the shift valves f or precise shif t control. Shift points ar e therefore prec isely controlled and

are identical from vehicle to vehicle.

Shift feel is also elec tronica lly controlled by the PCM, by signals sent to the Var iable Force Solenoid, which c ontrols

fluid line pres sur e and it is this pres s ure that prec is ely determines how the shif ts will feel. In this way, the Powertrain

Control Module (PCM) electronically synchronises the engine and transmission into a single, integrated powertrain

system, for optimum performance, shift timing, fuel efficiency and emission control.

NOTE: While the Variable Force Solenoid (also referred to as the Pressure Control Solenoid – ‘PCS’), is now a

different design for the HAD transmission fitted to the GEN III V8 engine, the purpose and operation are the same.

TRANSMISSION COMPONENT SUMMARY

Mechanical/Hydraulic Electrical

Torque Converter with Converter Clutch Two Shift Solenoids

13 Vane, Variable Displacement Oil Pump. Effectively, an ON/OFF, 3-2 Downshift Solenoid

Five Multiple Disc Clutch Packs A Pressure Control Solenoid (PCS) or ‘Force Motor’

A 2-4 Band Assembly An ON/OFF, Torque Converter Clutch (TCC)

Solenoid

Two Planetary Gear Sets One Pulse Width Modulated (PWM) TCC Solenoid

One Sprag Clutch Transmission Fluid Temperature Sensor

One Roller Clutch Fluid Pressure Switch Assembly

A Control Valve Body Assembly Vehicle Speed Sensor

Figure 7C1-7

Legend

1. Case Assembly

2. Reverse Input Clutch

3. Input Clutch Housing

4. Overrun Clutch

5. Forward Clutch

6. Forward Clutch Sprag Assembly

7. 3–4 Clutch

8. Input Planetary Gear Set

9. Low and Reverse Clutch

10. Low Roller Clutch Assembly

11. Reaction Planetary Gear Set

12. Output Shaft

13. Speed Sensor

14. Parking Pawl

15. Parking Lock Actuator Assembly

16. Control Valve Assembly

17. Manual Shaft

18. Inside Detent Lever

19. 2–4 Band Assembly

20. Pump Assembly

21. Stator Roller Clutch

22. Torque Converter Assembly

23. Turbine Shaft

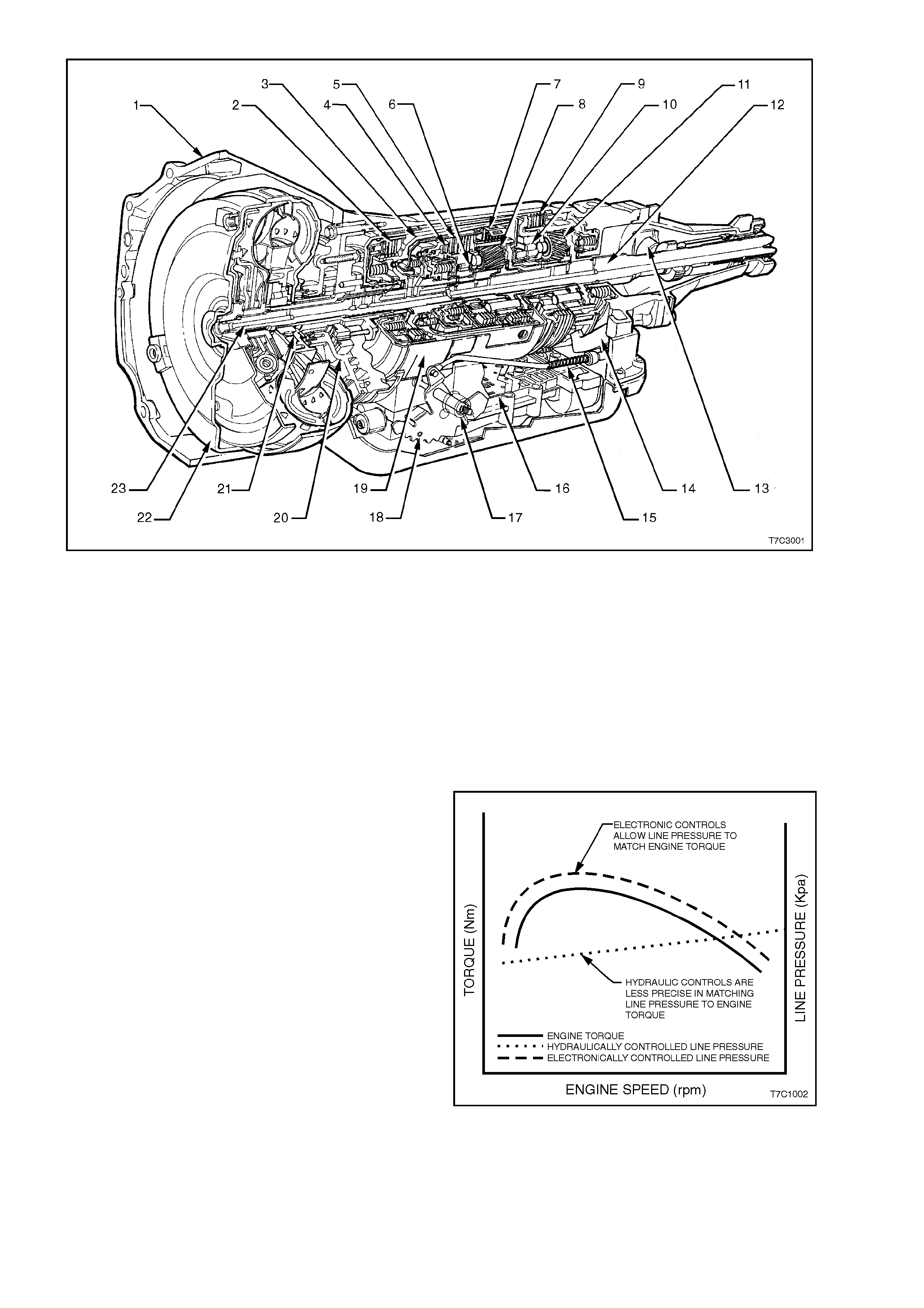

MATCHING ENGINE TORQUE AND LINE PRESSURE

The torque output f rom an engine varies in relation

to engine speed, in an inconsistent manner that

results in the typical curve, as shown. By using

springs and hydraulic pressure to control fluid line

pressure in an automatic transmission, control is

purely linear (indicated by the dotted line) and this

does not provide an ideal match to engine output.

With the Hydra-matic 4L60-E automatic

transm ission, the use of electronic control over line

pressure means that a much more precise, match

with engine performance is possible and the ‘shift

feel' more closely approximates engine output.

Figure 7C1-8

ECONOMY, POWER & CRUISE MODES

The programming in the Powertrain Control Module (PWM) provides for these different shift patterns which are

driver c ontr ollable, through the us e of the Ec onomy/Power button, located in the centre cons ole or the c r uis e contr ol

lever (where fitted).

Economy Mode

The calibration for this mode is for maximum comfort, with minimal intrusion of engine noise and smooth shifts

under all driving conditions. When additional power is required for acceleration, full throttle upshifts are similar to

those calibrated for the Power Mode.

Power Mode

When activated, the PCM modifies the transmission calibration in the following way s:

1. When the throttle is less than 80% open, later upshift points are provided.

2. Shift time is reduced.

3. The Torque Converter Clutch (TCC) will be applied in both third and fourth speed ranges.

Cruise Mode

When the driver activates the cruis e control ( where fitted), the ‘Power’ icon in the Instr um ent, Multi-Function Display

(MFD) will be deactivated (provided the vehicle was operating in ‘Power’ m ode) and the transmission shift pattern

will switch to the cruise control pattern. When in this mode, the PCM modifies the shift pattern so that earlier

downshift and later upshift points are provided.

Through the electronic programming of the logic processes contained in the Powertrain Control Module, the

frequenc y of gear shifting and tor que converter clutc h application and release is minim ised. The end result of these

logic processes, is that transmission 'busyness' (a quick series of upshifts and downshifts; e.g. a '4-3-4' shift

pattern) is minimised.

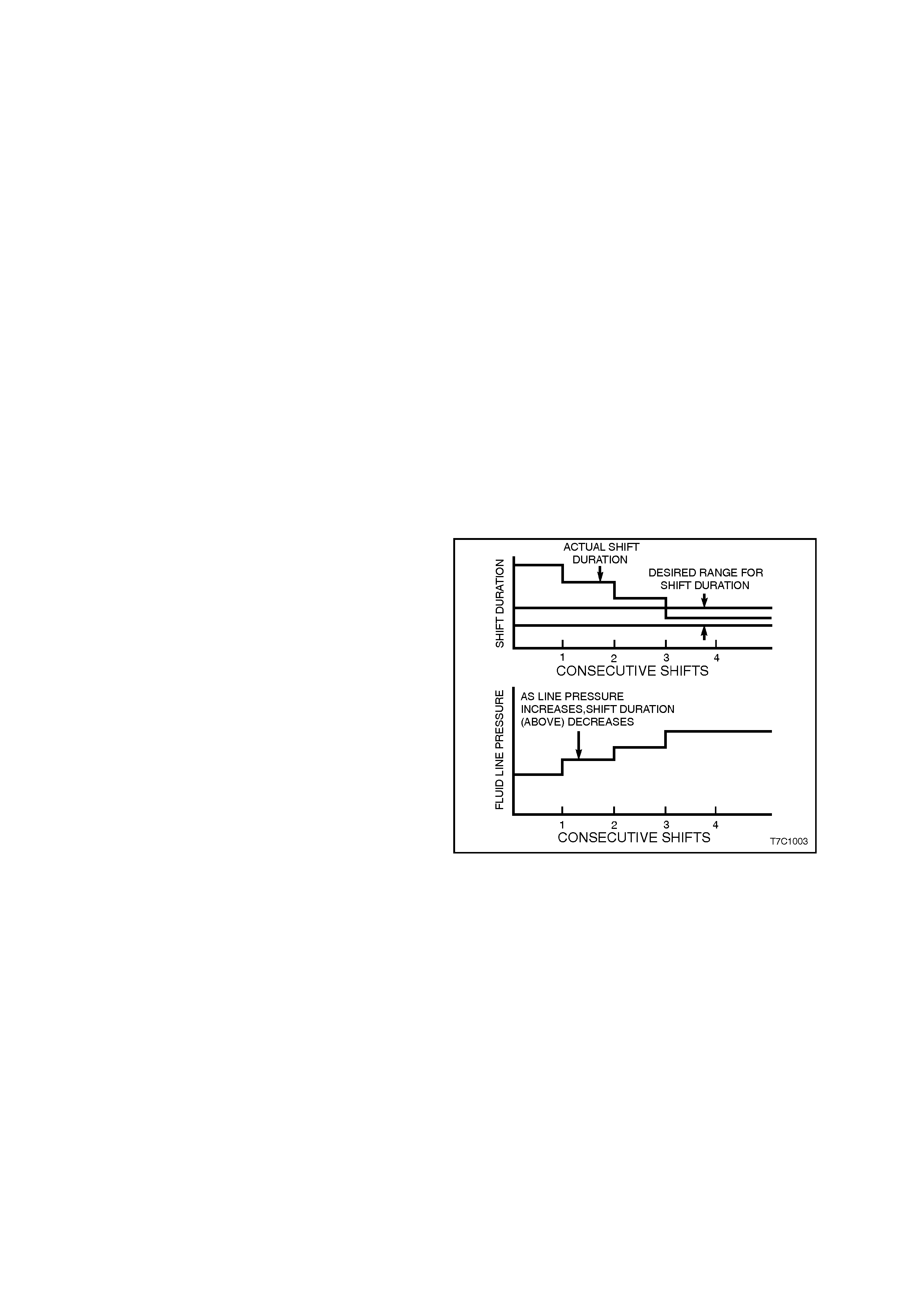

ADAPTIVE CONTROLS

As a normal part of its operation, the PCM

continually monitors the transmission's shift time

(duration) for the 1-2 upshift and compares this with

it's pre-programmed information. As normal

transmission wear occurs, such as with friction

material and spring tensions, the time that is taken

for this shift to occur, will change.

When the PCM finds that the time is outside it's

programmed limits, the transmission fluid line

pressure is modified via the pressure control

solenoid and this 'adapts' the change time to

maintain the c orrec t shif t feel. Line pres sure can be

adapted to values ranging from 35 kPa below, to 70

kPa above normal line pressure. This 'learning'

feature is similar to what is used for fuel control.

Figure 7C1-9

ENGINE TORQUE MANAGEMENT

W hen the GEN III V8 engine is fitted with the 4L60-E transmission, Torque Management is a function of the PCM

that reduces engine power under certain conditions, included in which, is the transmission upshifts and downshifts.

Torque Management is performed for the following reasons:

1. To prevent overstress of the powertrain components.

2. To prevent damage to the vehicle during certain abusive manoeuvres.

3. To reduce engine speed when the IAC is out of the normal operating range.

The PCM monitors the following sensors and engine parameters to calculate engine output torque;

• Air/Fuel ratio

• Mass Air Flow

• Manifold Absolute P ressure

• Intake Air Temperature

• Spark Advance

• Engine Speed

• Engine Coolant Temperature

• A/C Clutch Status

The PCM monitors the torque converter status, the transmission gear ratio, and the engine speed in order to

determ ine if torque r educ tion is r equir ed. T he PCM r etards the s park as appr opriate to r educ e engine torque output

if torque reduction is required. T he PCM. also shuts off the fuel to certain injectors to reduce the engine power In

the case of an abusive manoeuvres.

Instances when engine power reduction is likely to be experienced, are:

a. During transmission upshifts and downshifts.

b. Heavy acceleration from a standing start.

c. The IAC is out of the normal operating range.

d. W hen the driver is performing stress-inducing (abusive) manoeuvres such as shifting into gear at high throttle

angles or shifting the transmission from reverse to drive to create, a rocking motion.

The driver is unlikely to notice the torque management actions in the first two instances. The engine power output

will be moderate at full throttle in the other two cases.

The PCM c alculates the am ount of spark retard nec essary to reduce the engine power by the desir ed amount. For

example the PCM disables the fuel injectors for cylinders 1, 4, 6, and 7 in the case of an abusive manoeuvres.

SYSTEM PROTECTION DEVICES

a. Should 1st gear be selected and left in that range, the PCM will protect the engine from an over-speeding

condition by upshifting to 2nd speed at a pre-determined point. Similarly, the PCM provides high speed,

downshift protection by preventing a manual shift into 1st gear above pre-determined engine speeds.

b. Under severe operating conditions such as towing in high ambient temperatures, fluid temperatures rise to the

point where lubr ication break down c an occur. W ith the VR range of vehicles, in addition to having an oil cooler

fitted, the 4L60-E transmission is also fitted with a transmission fluid temperature sensor located in the

Transmission Range (TR) Pressure Switch Assembly (PSA).

When fluid temperatures in excess of 135° C are sensed, the Torque Converter Clutch is applied as

programmed, in 3rd or 4th gear.

This action reduces further fluid temperatures that could arise in normal operation of the torque converter.

W hile these high f luid temper atures are sens ed, Torque Conver ter Clutch apply is not available however, when

the throttle opening is above 50%.

Similarly , when the fluid temperature is below 29° C, the PCM prevents Torque Converter Clutch apply.

c. Should a condition occ ur that prevents electr onic control of the transm ission's functions, a "Fail Safe" mode will

default the transmission to 3rd gear (when either Drive 'D' or '3' is selected) and also apply maximum line

pressure. While in this mode, the vehicle operator can still manually select '2', '1', Reverse, Park or Neutral,

should the need arise.

SELF DIAGNOSIS

Should any transmission operation controlled by the PCM begin to operate outside pre-set parameters, the PCM

has the ability to store a range of diagnostic codes that can be accessed by the servicing Technician, thereby

localising the problem circuit.

PCM SENSORS AND ACTUATORS

As indicated earlier, there are a number of sensors and switches that provide input information for the PCM

programming that will allow the PCM to make decisions about such things as; shift pattern, shift feel and torque

converter clutch operation.

The PCM does this by comparing this input information with its ‘Look up' tables on Shift Pattern, Fluid Pressure

maps, Shift Duration parameters, Extreme Heat Protection programming and Adaptive Controls.

In addition, each input signal and output actuator operation is also m onitored and, if outside pre-set parameters, a

diagnostic code is logged for future reference by the servicing Technician.

TRANSMISSION IDENTIFICATION

The 4L60-E automatic transm is sion application and

identification can be determined from the stamping

in the rear of the transmission case at the rear, in

the location shown (7).

The coded number can be interpreted from the

following breakdown;

1. Model Year (‘3’ = 2003)

2. Model:

3.8 litre V6 (LN3).................. HF

3.8 litre V6 S/C (L67)............ HN

5.7 litre GEN III V8 (LS1) ..... HA

3. Transmission Model Identifier (‘D’ = 4L60-E)

4. Julian Date (Day of the Year)

5. Shift Build ‘A’, ‘B’, ‘J’ = First Shift;

‘C’, ‘H’, ‘W’ = Second Shift

6. Individual Transmission Serial Number

Figure 7C1-10

TRANSMISSION SPEED RANGES

The Hydra-matic 4L60-E transmission can be operated in any one of the following seven modes:

P Park position enables the engine to be started while preventing the vehicle from rolling either forward or

backward. For safety reasons, the parking brake should be used in addition to the park position. Since the

output shaft is mechanically locked to the case through the parking pawl and reaction internal gear, 'Park'

position should not be selected until the vehicle has come to a complete stop.

R Reverse allows the vehicle to be operated in a rearward direction.

N Neutral allows the engine to be started and operated without driving the vehicle. If necessary, this position

should be selected to re-start the engine while the vehicle is moving.

D Drive range should be used for all normal driving conditions for maximum efficiency and fuel economy. This

range provides four gear ratios plus converter clutch operation. Downshifts are available for safe passing by

depressing the accelerator or by manually selecting a lower gear with the shift selector.

NOTE: W hen towing, if 4 - 3 - 4 shifts occur, then it is recommended that the ‘3 Drive’ mode of operation be

selected.

3 Drive position is used for city traffic and hilly terrain. It provides three gear ranges. Again, downshifts are

available for safe passing by depressing the accelerator.

2 Manual second is used to provide acceleration, engine braking, or greater traction from a stopped situation.

When manual second is selected, the vehicle will start off and remain in second gear. This range maybe

selected at any vehicle speed.

1 Manual first is used to provide maximum engine braking. This range may also be selected at any speed,

however the transmission will not shift into first gear until the vehicle speed is below approximately 48 to 56

km/h. Above this speed the transmission will remain in second gear. Manual first is particularly useful for

maintaining maximum engine braking while descending steep grades.

Referenc e to Figu re 7C1-7, shows the application of the various com ponents that are applied in each of the speed

ranges.

RANGE REFERENCE CHART

RANGE D 3 2 1

GEAR PARK REVERSE NEUTRAL 1st 2nd 3rd 4th 1st 2nd 3rd 1st 2nd 1st 2nd

1-2 Shift

Solenoid ON* ON* ON* ON* OFF OFF ON* ON* OFF OFF ON* OFF ON* OFF

2-3 Shift

Solenoid ON* ON* ON* ON* ON* ON* OFF ON* ON* OFF ON* ON* ON* ON*

2-4 Band – – – – A – A – A – – A – A

Reverse

Input

Clutch – A – – – – – – – – – – – –

Overrun

Clutch – – – – – – – – – A A A A A

Forward

Clutch – – – A A A A A A A A A A A

Forward

Sprag

Clutch – – – H H H – H – H – – – –

3-4 Clutch – – – – – A A – – A – – – –

Low Roller

Clutch – – – H – – – – H – H – H –

Low/

Reverse

Clutch A A – – – – – – – – – – A –

A = Applied H = Holding

ON = The Solenoid is E nergi sed OFF = The Solenoid is De-energi sed

* Shift Solenoid state is a func t i on of vehicl e speed and may change if t he vehi cle speed increases suffi cientl y in Park, Reverse or

Neutral. However this odes not affect the operation of he t ransm i ssion.

** In Manual First , Second gear i s only available above approximately 70 k m/h to prevent engine over-s peedi ng.

Figure 7C1-11

3.2 PULSE WIDTH MODULATED TCC SOLENOID

A Torque Converter Clutch Pulse Width Modulated (TCC PWM) solenoid is used in conjunction with the Torque

Converter Clutch ( TCC) solenoid to contr ol torque converter clutc h apply and release. This control is accom plished

by the Powertrain Control Module (PCM) varying the solenoid's duty cycle percent time energised, according to

various PCM input signals. This feature is in addition to the ON/OFF control of the TCC solenoid.

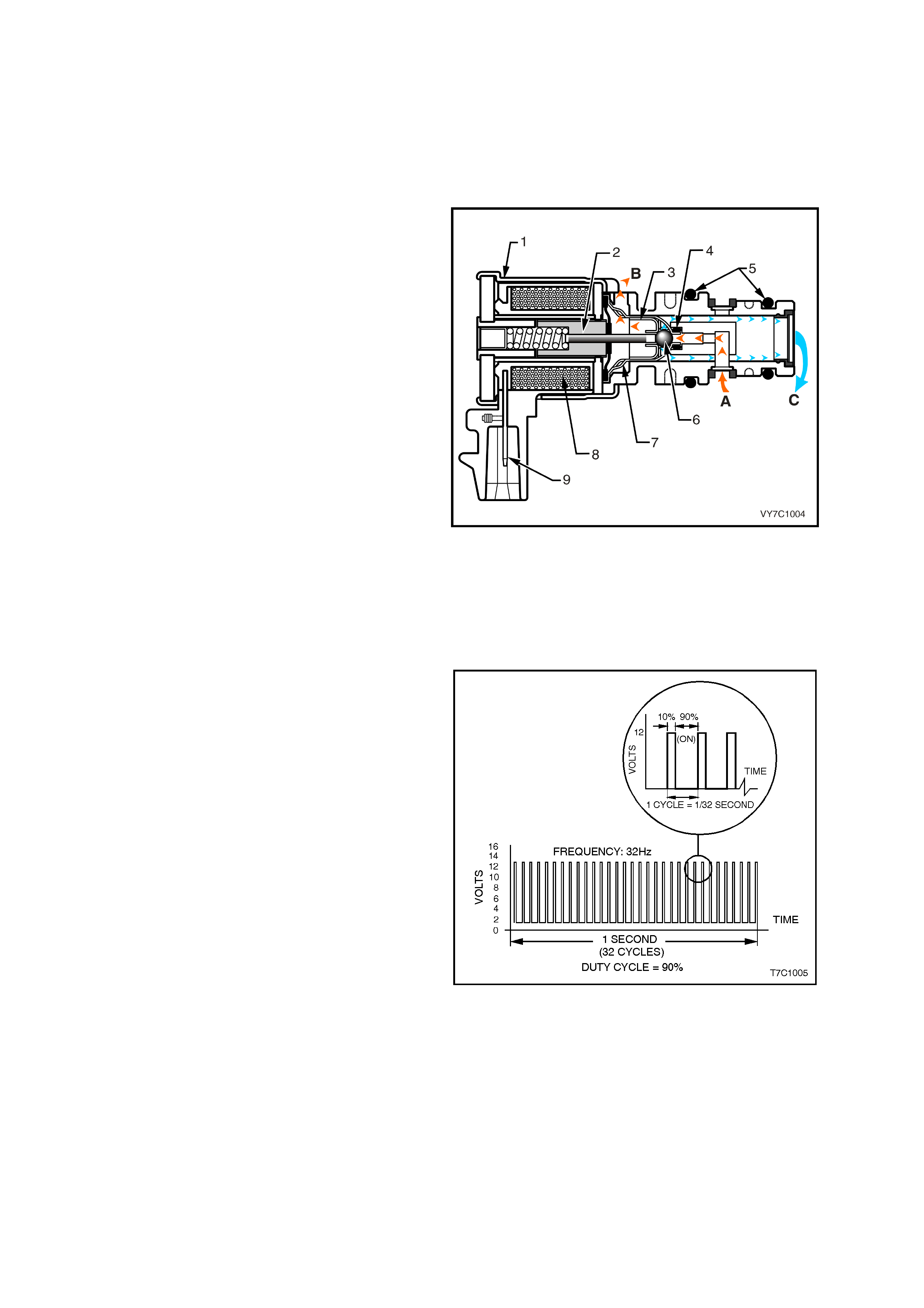

DUTY CYCLE

The TCC PWM solenoid operates on a negative

duty c ycle, which m eans that the earth (negative or

low) side of the solenoid circuit is controlled by the

PCM.

Therefore, the TCC PWM solenoid is constantly fed

approximately 12 volts to the high (positive) side

and the PCM controls the length of time the

electrical circuit path to earth is closed (i.e. duty

cycle).

When the PCM closes the solenoid earth circuit,

current flows through the TCC PW M solenoid, and

the earth circuit (or negative side) is at a low

voltage state (0 volts and solenoid energised).

Legend:

1 Housing

2 Armature

3 Exhaust Seat

4 Internal O-Ring

5 O-Rings

6 Metering Ball

7 Inlet Seat

8 Coil Assembly

9 Connector Terminal

A Actuat or Feed Li mit (A FL) Fl ui d

B Exhaust

C Converter Clutch Signal (CC S IGNAL) Fluid

Figure 7C1-12

Shown is an example of the TCC PWM solenoid

operating with a 90% negative duty cycle at a

constant operating frequency of 32 Hz (cycles per

second). The frequency means that the solenoid is

pulsed (energised) with current from the PCM 32

times per second. The 90% negative duty cycle

means that during each of these 32 cycles the

solenoid is energis ed (ON) and 0 volts is m easur ed

on the low (negative) side of the circuit, 90% of the

time.

At road speeds below approximately 13 km/h, the

negative duty cycle will be 0%, which means that

no current will flow through the TCC PWM

solenoid, deactivating it. When in this condition,

spring force will move the plunger (refer

Figure 7C1-9), seating the metering ball and

blocking the filtered Actuator Feed Lim it (AFL) fluid

from entering the Converter Clutch Signal (CC

SIGNAL) circuit. This action opens the Converter

Clutch Signal fluid circuit to exhaust through the

solenoid.

Above road speeds of approximately 13 km/h, the

TCC PWM solenoid will be operating at about a

90% duty cycle. T his action will cause the metering

ball to close off the path to exhaust, most of the

time and allow AFL fluid to flow past the metering

ball and into the CC SIGNAL circuit, in readiness

for the apply of the torque converter clutch.

Figure 7C1-13

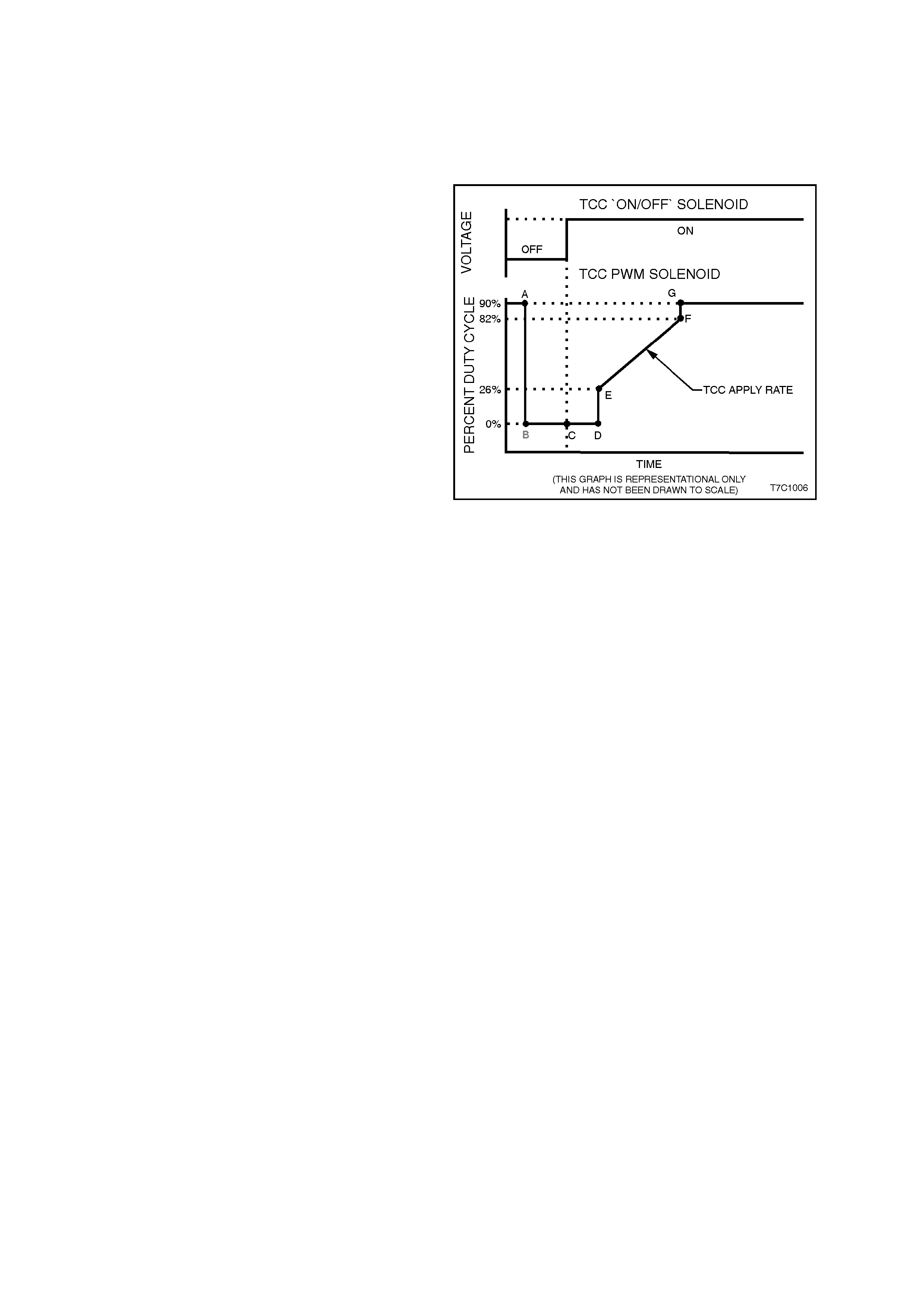

When the PCM signals TCC apply, the TCC PWM solenoid operates with a variable, negative duty cycle, ranging

from 90% to 0%, with an operating f requency of 32 Hz. This allows the PCM to control the cur rent flow through the

solenoid coil according to the duty cycle it sets. This has the effect of creating a variable magnetic field, that

magnetis es the s olenoid core, attrac ting the m etering ball to seat agains t spring force. A high percentage duty cyc le

keeps the metering ball will be seated more often, thereby creating higher TCC signal fluid pressures.

TCC PWM SOLENOID OPERATION

When vehicle road speed rises above about 13

km/h, the PCM causes the TCC PWM solenoid

duty cycle to change from 0% to 90% (point 'A'), in

readiness for an apply of the torque converter

clutch.

To apply the torque converter clutch, the process

the PCM adopts, is as follows;

• The duty cycle is dropped to 0% (point 'B') and

a m easurable am ount of tim e is allowed for the

'ON/OFF' TCC solenoid to turn on. This is

shown as the time between points 'B' and 'C', in

Figure 7C1-8. Note that, at point 'C', the TCC

'ON/OFF' solenoid is activated.

• The time from point 'C' to 'D' is used to allow

converter feed (CONV FD) fluid to build in

pressur e and move the Converter Clutc h Valve

into the apply position.

• At this point, with the TCC 'ON/OFF' solenoid

applied, the PCM then increases the duty cycle

to about 26% (point 'E'). From this point, the

duty cycle is 'ramped' to around the 82% point

('E' to 'F'). The rate at which the duty cycle is

increased over this period of time, determines

how quickly the value of the regulated apply

fluid increases and therefore, how quickly the

torque converter clutch is applied.

Figure 7C1-14

This rate of change also affects the converter

clutch apply 'feel'.

• As soon as the duty cycle reaches the 82%

value, it is then immediately increased to the

ma ximum of 90%, to ac hieve f ull apply pressure

in the regulated apply fluid circuit (point 'G').

NOTE: Both the duty cycle and apply pressure will

continually vary, depending on vehicle specific ation

and operating conditions.

3.3 TORQUE CONVERTER CLUTCH

GENERAL DESCRIPTION

W hile the Powertrain Control Module (PCM) continues to control the apply/releas e of the Torque Conver ter Clutch,

via the use of the T orque Conver ter Clutch s olenoid (as it does in earlier tr ansm issions ), the use of the Pulse Width

Modulated Torque Conver ter Clutch, ( T CC PWM) s olenoid (r ef er Figure 7C1-9), provides the ability of being able to

control more precisely, the rate of Torque Converter Clutch (TCC) apply and release.

Essentially the TCC PW M solenoid changes actuator feed limit (AFL) f luid to converter clutch signal (CC SIGNAL)

fluid, that is dir ected to the base of the Is olator Valve. Depending on the PCM controlled duty cycle, the T CC PW M

solenoid determines the value of the CC SIGNAL fluid pressure.

By having an electronically controllable, variable fluid pressure acting on the end of the Isolator Valve, the force

controlling the position of the REGULATED APPLY (REG APPLY) Valve is also variable.

This means that the Regulated Apply Valve can now vary the REGULATED APPLY (REG APPLY) fluid pressure

that is directed to the Converter Clutch Valve.

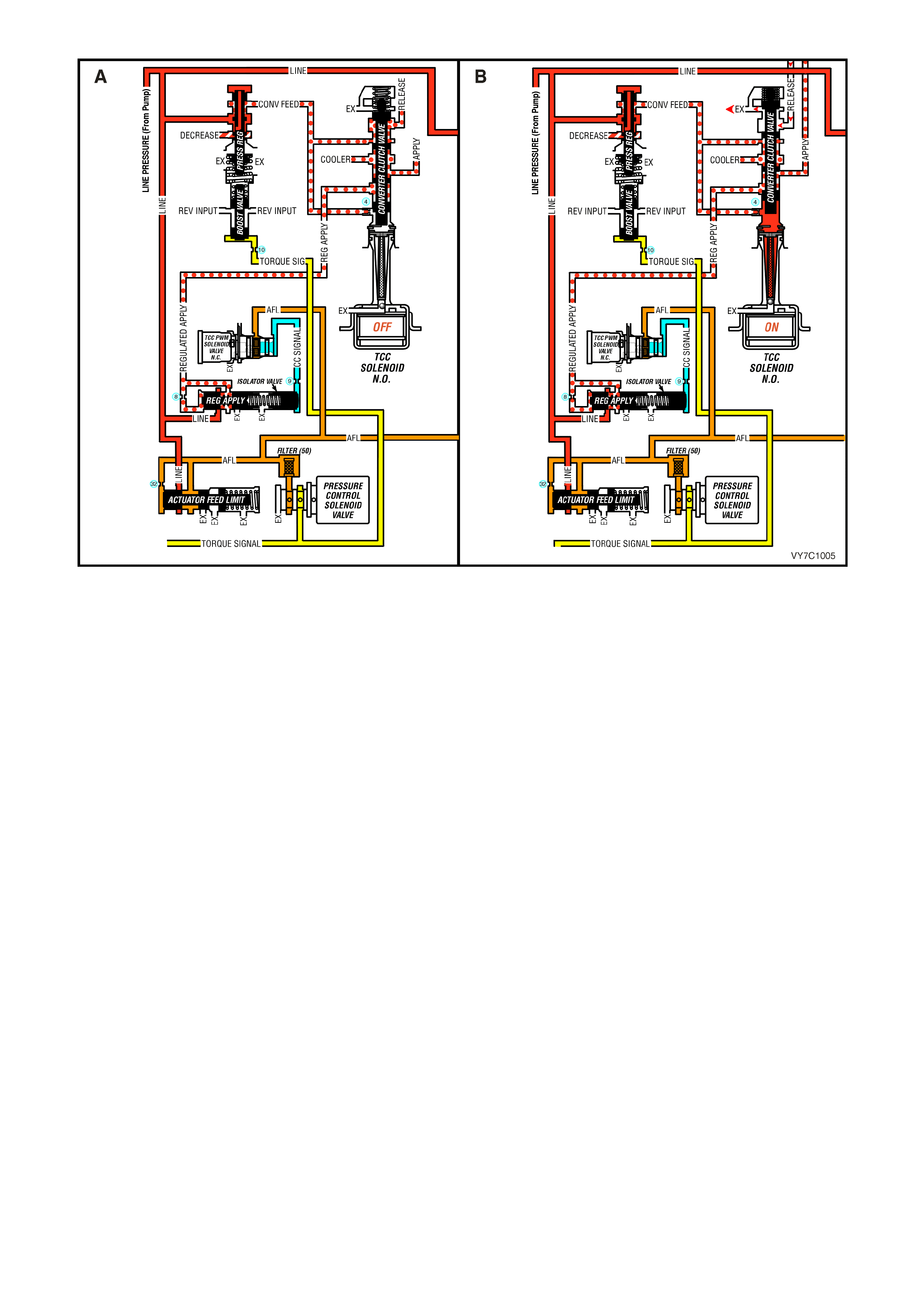

TORQUE CONVERTER CLUTCH – RELEASED

With the TCC 'ON/O FF ' s olenoid de-ac tivated (as deter mined by the PCM), the spring for ce acting on the end of the

Converter Clutch Valve positions the valve so that the torque converter hydraulic circuits function as follows:

• REGULATED APPLY fluid rests at the Converter Clutch Valve.

• Converter f eed (CONV FEED) fluid fr om the Pres sure Regulator Valve, (c onverted from LINE fluid) both passes

through an orifice at the base of the Converter Clutch Valve, to exhaust at the Normally Open (N.O.) TCC

'ON/OFF' solenoid and is directed through the Converter Clutch Valve to become RELEASE fluid.

• This circuit feeds RELEASE fluid to the front of the torque converter, past the torque converter pressure plate,

circulating through the torque converter to exit as APPLY fluid.

• After passing through the Converter Clutch Valve, APPLY fluid becomes COOLER fluid. Then, after it flows

through the cooler, it is used in the transmission LUBE circuits.

TORQUE CONVERTER CLUTCH – APPLIED

When the PCM determines that the torque converter clutch should be applied, the TCC 'ON/OFF' solenoid is

activated, closing off the exhaust port at the base of the Converter Clutch Valve. As previously explained, during this

period the TCC PWM solenoid duty cycle is dropped to zero.

This action causes the following hydraulic/electronic circuit changes to take place:

• Converter feed (CONV FEED) fluid pressure rapidly builds at the base of the Converter Clutch Valve, m oving it

upwards against spring force.

• Depending on the duty cyc le selected by the PCM, the rate of torque conver ter clutc h apply, is directly c ontrolled

by the TCC PWM solenoid. As previously stated, this occurs because the CC SIGNAL f luid acting on the end of

the Isolator Valve, changes the value of the spring force, that dictates the position of the Regulator Apply Valve.

Through this electronic control then, variable regulator apply (REGULATED APPLY) fluid now becomes

converter APPLY fluid, af ter it pass es through the Conver ter Clutch Valve. Theref or e, the r ate of apply, is direc tly

related to the value of this fluid pressure.

• Converter RELEASE fluid passes through to exhaust at the spring end of the Converter Clutch Valve. This action

allows the torque converter pressure plate to be for ced against the front face of the torque converter, creating a

frictional grip between the Impeller and the Turbine, effectively locking the assembly.

• Converter feed (CONV FEED) fluid now flows through the Converter Clutch Valve to become COOLER and

provide fluid flow through the cooler and supply LUBE fluid for various transmission components.

Figure 7C1-15 – Torque Converter Clutch – Released (‘A’) and Applied (‘B’)

3.4 3-2 DOW NS HIFT CONTROL SO LENOID

GENERAL DESCRIPTION

The 3-2 downshift control solenoid is a normally

closed solenoid and is used to control the 3-2

downshift.

During a 3-2 downshift, the 2-4 band is applied as

the 3-4 c lutch r eleases . The tim ing between the 3-4

clutch release and the 2-4 band apply not only must

be timed but it also must be varied, depending on

vehicle speed and throttle.

The PCM will turn the 3-2 control solenoid either

ON or OFF to control 3rd accumulator (3RD

ACCUM) pressure so that the release of the 3-4

clutch and the apply of the 2-4 band is such that a

bind-up or flair does not occur.

The normally closed 3-2 control solenoid is ON in

all drive gear s, ex c ept dur ing a 3-2 downshif t, when

the solenoid is turned O FF. T he am ount of tim e the

solenoid is ON, is determined by throttle position,

vehicle speed and the commanded gear.

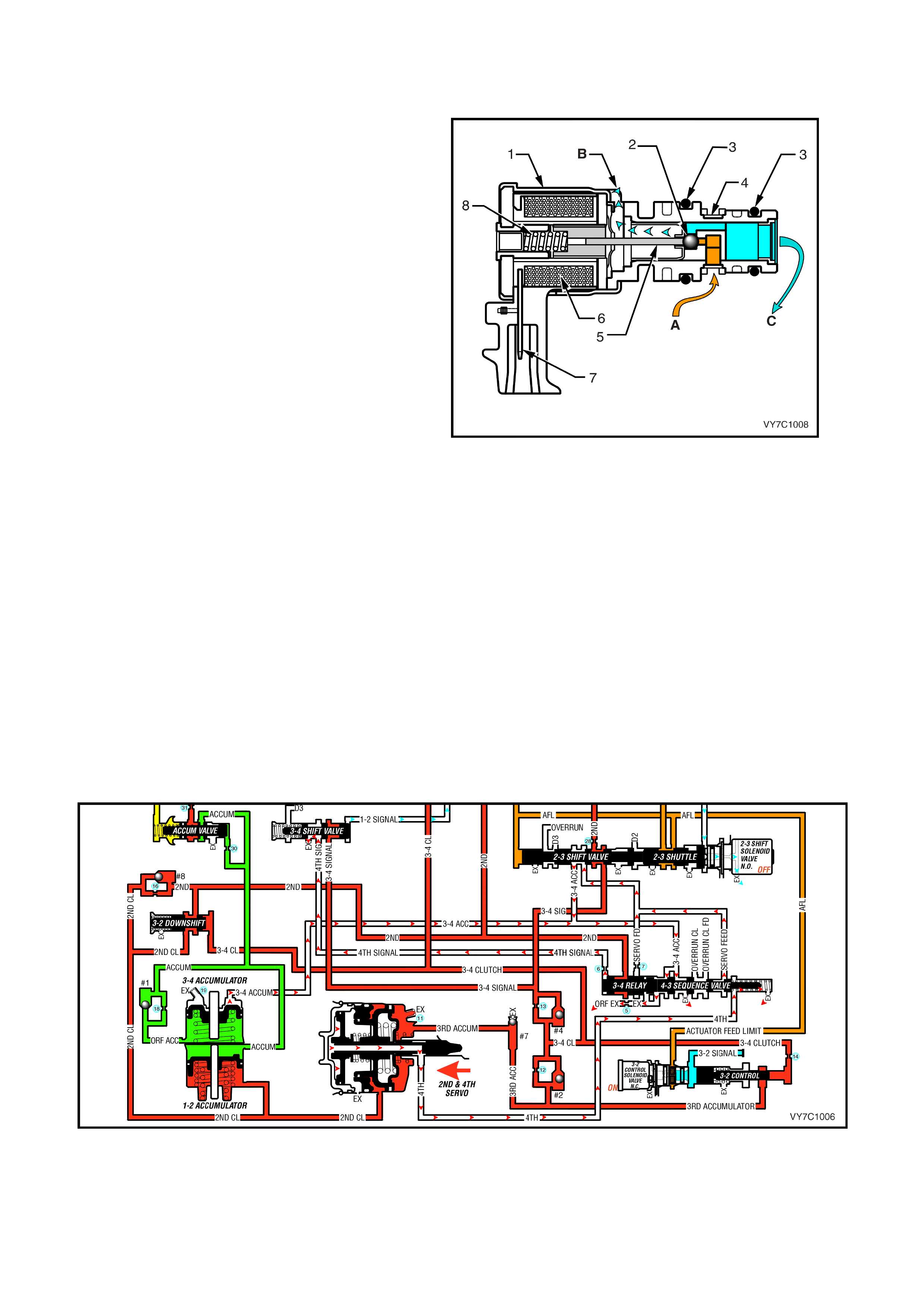

Legend

1 Housing

2 Metering Ball

3 O-Ring

4 Fluid Screen

5 Plunger

6 Coil Assembly

7 Connector Terminals

8 Spring

A Pressure Apply (A FL)

B Exhaust

C Pressure Control (3-2 S i gnal )

Figure 7C1-16

3-2 CONTROL SOLENOID OPERATION

Solenoid ON

W hen the solenoid is activated by the PCM, current flows through the solenoid coil, creating a magnetic field that

magnetises the solenoid core. This attracts the metering ball, moving the ball and plunger against spring force to

block the internal exhaust port, opening the valve and allowing ACTUATOR FEED LIMIT (AFL) fluid to act on the

end of the 3-2 c ontrol valve. When the f luid pressu re increas es enough, the valve will m ove away from the s olenoid

against spring force, closing the 3-2 control valve.

Figure 7C1-17 – 3-2 Downshift Control Solenoid ON

Solenoid OFF

W hen the solenoid is OFF, no current flows to the solenoid coil. A spring inside the solenoid, holds a plunger and

ball against the fluid inlet port that blocks ACTUATOR FEED LIMIT (AFL) fluid from acting on the large end of the 3-

2 control valve. This allows the 3-2 control valve spring force to push the valve to the solenoid, holding the 3-2

Control Valve open, exhausting any residual fluid through the solenoid.

Figure 7C1-18 – 3-2 Downshift Control Solenoid OFF

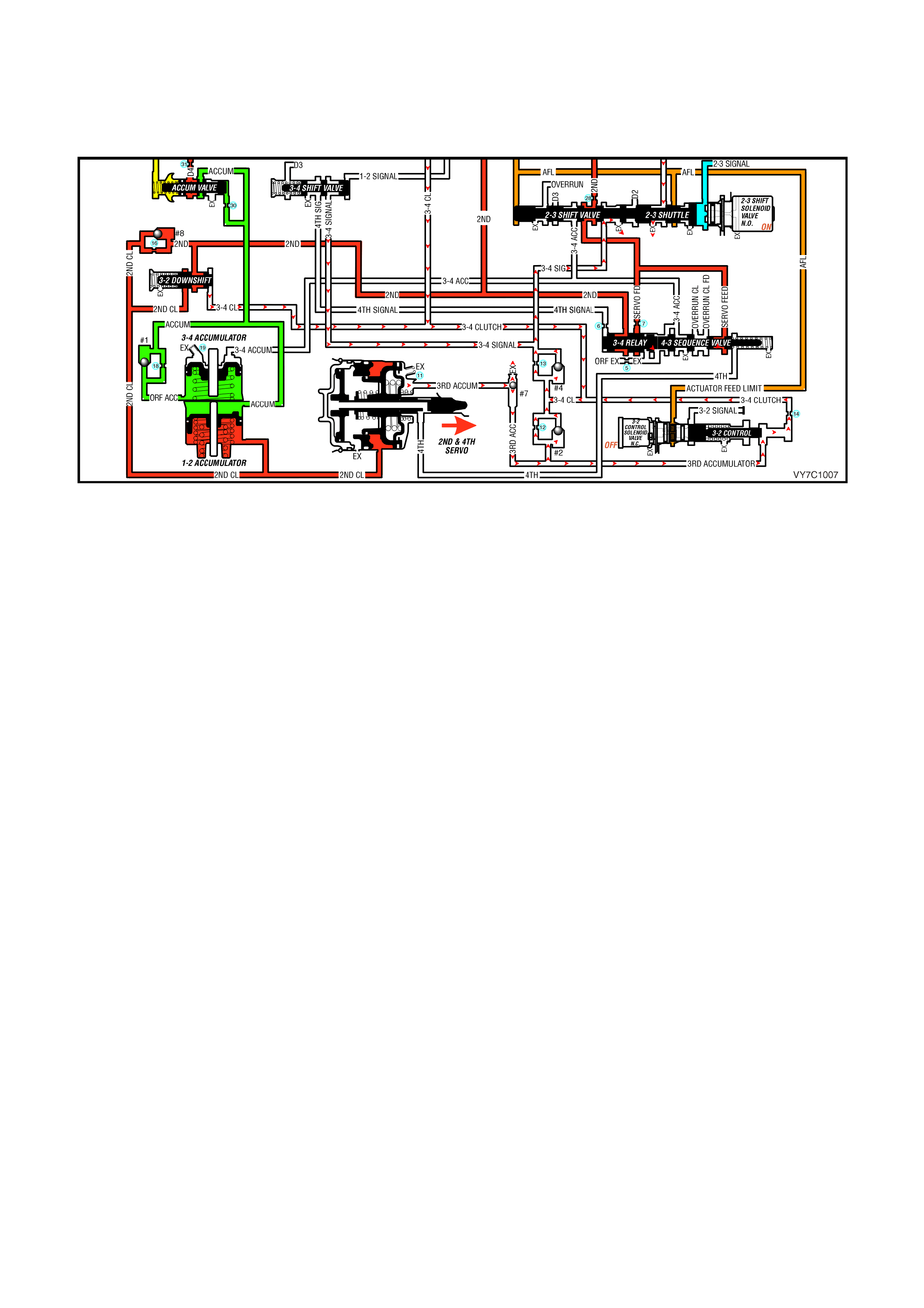

3-2 Downshift Timing

At higher vehicle speeds, the apply of the 2-4 band must be delayed to allow engine speed to increase suff iciently

for a smooth transfer of engine load to the 2-4 band. This is achieved by delaying the exhaust of 3rd

ACCUMULATOR (3RD ACCUM) fluid. Under these conditions (see Figure 7C1-14), the 3-2 control solenoid is

commanded ON, moving the 3-2 control valve away from the solenoid (closing the 3-2 Control Valve) during the

shift. This causes the exhausting 3-4 clutch fluid (3-4 CL) to seat check ball #4 and flow through orifice #13 to

exhaust at the 2-3 shift valve, via the 3-4 Signal (3-4 SIG) circuit.

While this 3-4 clutch exhaust is in process, the apply rate of the 2-4 band is governed by the exhausting 3rd

accumulator (3RD ACC) fluid. The initial fluid flow seats check ball #7 and, with the 3-2 control valve closed, 3rd

accumulator (3RD ACC) fluid also seats check ball #2. Fluid then must pass through both orifice #12 and #13 to

exhaust through the 3-4 signal (3-4 SIG) passage. This action delays the apply of the 2-4 band to effect a sm ooth

downshift.

At lower vehicle speeds (see Figure 7C1-15), when the band must be applied more quickly, the PCM commands

the 3-2 control solenoid OFF, allowing spring force to move the control valve to the solenoid (opening the valve).

This now opens another circuit, allowing 3rd accum ulator (3RD ACC) fluid to f low thr ough both orifice #12 and #14

to exhaust with the 3-4 clutch fluid. This allows the 2-4 band to be applied more quickly for the correct shift timing

under these operating conditions.

4. TRANSMISSI ON DEFINITIONS AND ABBREVIATIONS

The following definitions and abbreviations are provided to establish a common language and assist the user in

describing transmission related conditions. The use of these terms and/or conditions can be found in the various

parts of the automatic transmission sections of the MY2003 Service Information, but more particularly, in

Section 7C3 HYDRAULIC/MECHANICAL DIAGNOSIS.

4.1 DEFINITIONS

The following definitions have been arranged in alphabetical order and are intended to assist the user with an

explanation of their meaning, in order to gain the maximum benefit from those Sections of the MY2003 Service

Inform ation that deal with the Hydra-matic 4L60-E, Autom atic T rans m ission. T here are additional, unique def initions

in Section 7C3 HYDRAULIC/MECHANICAL DIAGNOSIS that should also be refer red to when using that partic ular

information.

Accumulator - A component of the transmission that absorbs hydraulic pressure during the apply of a clutch or

band. Accumulators are designed to control the quality of a shift from one gear range to anther. within

Adaptive Learning - Programming within the PCM that automatically adjusts hydraulic pressures in order to

compensate for changes in the transmission (i.e. component wear).

Applied - An 'Applied Com ponent' is one that is holding another com ponent to which it is splined or as sembled to.

Also referred to as "engaged".

Apply Components - Hydraulically operated clutches, servo’s, bands and mechanical one-way roller or sprag

clutches that drive or hold members of a planetary gear set.

Apply Plate - A steel clutch plate in a clutch pack, located next to the (apply) piston.

Backing Plate - A steel plate in a c lutch pack that is usually the last plate in that clutch ass em bly (furthest f rom the

clutch piston).

Band - An apply component that cons ists of a flex ible strip of steel and f riction mater ial that wraps around a drum.

When applied, it tightens around the drum and prevents the drum from rotating.

Brake Switch - An electrical device that provides signals to the Powertrain Control Module (PCM), based on the

position of the brake pedal. The PCM uses this information to apply or release the torque converter clutch (TCC).

Centrifugal Force - A force that is imparted on an object (due to rotation) that increases as that object moves

further away from a centre-point of rotation.

Checkball - A spherical, hydraulically controlled component (usually of steel) that either seals or opens fluid circuits.

It is also referred to as a check valve.

Clutch Pack - An assembly of components generally consisting of clutch plates, an apply plate and a backing plate.

Clutch Plate - An hydraulically activated component that has two basic designs : ( 1) all s teel, or (2 ) a s teel c ore with

friction material bonded to one or two sides of the plate.

Control Valve Body - A machined metal casting that contains valve trains and other hydraulically controlled

components that shift the transmission.

Coupling Speed - The speed at which a vehicle is travelling and no longer requires torque multiplication through

the torque converter. At this point, the stator 'free wheels' to allow fluid leaving the turbine to flow directly to the

pump. (Also see Torque Converter).

De-energise(d) - To interrupt the electrical current that flows to an electronically controlled device, making it

electrically inoperable.

Direct Drive - A condition in a gears set where the input speed and input torque equals the output speed and output

torque. The gear ratio through the gear set is 1:1.

Downshift - A change in a gear ratio where both input speed and torque increases.

Duty Cycle - In reference to an electronically controlled solenoid, it is the amount of time (expressed as a

percentage) that current flows through the solenoid coil.

Energise(d) - To supply a current to an electronically controlled device, enabling it to perform its designed function.

Engine Compression Braking - A condition where com pression from the engine is used with the transm ission to

decrease vehicle speed.

Exhaust - The release of fluid pressure from a hydraulic circuit. (The words 'exhausts' and 'exhausting' are also

used and have the same intended meaning.)

Fail-Safe Mode - A condition whereby a component (i.e. engine or transmission) will partially function even if its

electrical circuit is disabled.

Fluid - In this Section of the Service Manual, 'fluid' refers primarily to Automatic Transmission Fluid (or ATF) and,

for the Hydra-matic 4L60-E transmission, the only recommended fluid is Dexron III®.

Fluid Pressure - A pressure that is consistent throughout a given fluid circuit.

Force - A measurable effort that is exerted on an object (component).

Freewheeling - A condition where power is lost through a driving or holding device (i.e. roller or sprag clutches).

Friction Material - A heat and wear resistant fibrous material, bonded to clutch plates and bands.

Gear - A round, toothed device that is used for transmitting torque through other components.

Gear Range - A specific speed to torque ratio at which the transmission is operating (i.e. 1st gear, 2nd gear etc.).

Gear Ratio - Revolutions of an input gear as compared to the revolutions of an output gear. It can also be

expressed as the number of teeth on a gear as compared to the number of teeth on a gear that it is in mesh with.

Hydraulic Circuit - A fluid passage which often includes the mechanical components in that circuit designed to

perform a specific function.

Input - A starting point for torque, revolutions or energy into another component of the transmission.

Internal Gear - The outer m ost m em ber of a gear s et that has gear teeth in c onstant m esh with the planetary pinion

gears of the gear set.

Land (Valve Land) - The larger diameters of a spool valve that contact the valve bore or bushing.

Line Pressure - The main fluid pressure in a hydraulic system created by the pump and pressure regulator valve.

Manual Valv e - A spool valve that distributes fluid to various hydraulic circuits and is mechanically linked to the gear

sele ctor lever.

Orifice - A restricting device (usually a hole in the spacer plate) for controlling pressure build up into another circuit.

Overdrive - An operating condition in the gear set allowing output speed to be higher than input speed and output

torque to be lower than input torque.

Overrunning - The function of a one-way mechanical clutch that allows the clutch to freewheel during certain

operating conditions of the transmission.

Pinion Gears - Pinion gears ( housed in a car rier) that ar e in constant m es h with a circum f erential internal gear and

centralised sun gear.

Planetary Gear Set - An ass em bly of gears that consis ts of an internal gear, planet pinion gears with a carrier, and

a sun gear.

Powertrain Control Module (PCM) - An electronic device that manages the vehicle's engine and automatic

transmission functions.

Pressure - A measurable force that is exerted on an area and expressed as kilopascals (kPa).

Pulse Width Modulated (PWM) - An electronic signal that continuously cycles the ON and OFF time of a device

(such as a solenoid) while varying the amount of ON time.

Race (Inner or Outer) - A highly polished steel surface that contacts bearings or sprag or roller elements.

Reduction (Gear Reduction) - An oper ating condition in the gear set allowing output speed to be lower than input

speed and output torque to be higher than input torque.

Residual Fluid Pressure - Excess pressure contained within an area after the supply pressure has been

terminated.

Roller Clutch - A mechanical clutch (holding device) consisting of roller bearings assembled between inner and

outer races.

Servo - A spring loaded device consisting of a piston in a bore that is operated (stroked) by hydraulic pressure to

apply or release a band.

Spool Valve - A round hydraulic control valve often containing a variety of land and valley diameters.

Sprag Clutch - A mechanical clutch (holding device consisting of "figure eight" like elements assembled between

inner and outer races.

Throttle Position - The travel of the throttle plate that is expressed in percentages and measured by the Throttle

Position Sensor (TP Sensor).

Torque - A measurable twisting force expressed in terms of Newton metres (Nm).

Torque Converter - A component of an automatic transmission, (attached to the engine flexplate) that transfers

torque from the engine to the transmission through a fluid coupling.

Variable Capacity Pump - The device that provides fluid for operating the hydraulic circuits in the transmission.

The amount of fluid supplied varies depending on vehicle operating conditions.

4.2 ABBREVIATIONS

2WD – Two Wheel Drive.

AC – Alternating Current

A/C – Air Conditioning

AFL – Actuator Feed Limit

DC – Direct Current

D.C. – Duty Cycle

DLC – Diagnostic Link Connector

DTC – Diagnostic Trouble Code

ECT Sensor – Engine Coolant Temperature Sensor.

N.C. – Normally Closed

N.O. – Normally Open

PCM – Powertrain Control Module.

PCS – Pressure Control Solenoid (or Force Motor)

PIM – Powertrain Interface Module (GEN III V8 Engine Only )

PWM – Pulse Width Modulated

RWD – Rear Wheel Drive.

TCC – Torque Converter Clutch.

TFP Switch – Transmission Fluid Pressure Manual Valve Position Switch

TFT – Transmission Fluid Temperature Sensor.

TP Sensor – Throttle Position Sensor.

VS Sensor – Vehicle Speed Sensor.

5. SERVICE NOTES

In the interests of safety to personnel, equipm ent and to the vehicle and its com ponents, the following notes should

be read and adhered to whenever servicing operations are to be carried out on the Hydra-matic 4L60-E autom atic

transmiss ion. In addition, s ome of this inf or mation also r ef er s to the adher enc e to sound workshop pr ac tices and, to

achieve the design life of affected components, it is also recommended that these points are taken into account.

5.1 FASTENERS

• Always reinstall fasteners in the same locations as they were removed.

• If a f astener requires replacem ent, always use a par t of the correc t part num ber or of equal s ize and st rength or

stronger.

• Tighten fasteners to correct torque value when required. Torque values are specified for dry, unlubricated

fastener threads.

5.2 GENERAL WORKSHOP PRACTICE

• Keep work area and tools clean.

• To avoid unnecessary contamination, always clean the exterior of the transmission before removing any parts.

• Do not use wiping cloths or rags because of the risk of lint being trapped in the transmission.

• Do not use solvents on:

− neoprene seals.

− composition faced clutch plates.

− thrust washers.

• Always wear eye protection when using compressed air on components.

• Blow out all passages with compressed air. Only probe small passages with soft, thin wire.

• Handle parts with care to avoid nicks and scratches.

• Do not remove Teflon oil seal rings unless damaged or performing a complete overhaul.

• Expand internal snap rings and compress external snap rings to maximise retention and security.

• Lubricate all internal parts with transmission fluid (Only use Dexron® III), as they are being installed.

• When installing cap screws into aluminium castings:

− always use a torque wrench.

− always dip screw threads in transmission fluid (Only use Dexron® III).

− Stripped or damaged threads in aluminium castings may be reconditioned by using commercially available

thread inserts.

• Once removed, replace all gaskets, seals and O-rings with new parts and:

− always use seal protectors where indicated and do not use gasket cement or sealant on any joined face

unless specified to do so.