SECTION 7C4 - HYD RA-MATIC 4L60-E AUTOM ATIC

TRANSMISSION – ON-VEHICLE SERVICING

IMPORTANT

Before performing any Service Operation or other procedure descri bed in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL INFORMATION

1.1 GENERAL SERVICE PRECAUTIONS

RECOMMENDATIONS

OIL COOLER PIPES

2. MAINTENANCE AND GENERAL INFORMATION

2.1 FLUID LEVEL CHECK

GENERAL INFORMATION

TRANSMISSION FLUID COLOUR

TRANSMISSION FLUID CHECKING

PROCEDURE

2.2 TRANSMISSION COOLER REVERSE FLUSH

AND FLOW RATE CHECK – ALL

REVERSE FLUSH

FLOW RATE CHECK

3. ON-VEHICLE SERVICE OPERATIONS

3.1 FLUID CHANGE & FILTER REPLACE

3.2 SELECTOR LINKAGE

REMOVE

INSPECT

REINSTALL

ADJUST

3.3 SELECTOR CONTROL LEVER ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

3.4 NEUTRAL START AND BACK-UP LAMP SWITCH

REMOVE

REINSTALL

ADJUST

3.5 VEHICLE SPEED SENSOR

REMOVE

REINSTALL

3.6 MANUAL SHAFT OIL SEAL

REPLACE

3.7 CASE EXTENSION OIL SEAL

REPLACE

3.8 EXTENSION HOUSING AND/OR BUSH

REPLACE

3.9 1–2 ACCUMULATOR ASSEMBLY

REMOVE

CLEAN AND INSPECT

REINSTALL

3.10 CONTROL VALVE BODY WIRING HARNESS

REMOVE

REINSTALL

3.11 CONTROL VALVE BODY

REMOVE

DISASSEMBLE, CLEAN, INSPECT AND

REASSEMBLE

REINSTALL

3.12 SPACER PLATE, CHECK BALLS, FILTER

SCREENS AND 3-4 ACCUMULATOR

REMOVE

CLEAN AND INSPECT

REINSTALL

3.13 FILLER TUBE

REPLACE

3.14 TRANSMISSION ASSEMBLY

REMOVE

REINSTALL

3.15 TRANSMISSION COOLER PIPES

V6 ENGINES – REMOVE

V6 ENGINES – REINSTALL

GEN III V8 ENGINE – REMOVE

GEN III V8 ENGINE – REINSTALL

4. SPECIFICATIONS

5. TORQUE WRENCH SPECIFICATIONS

6. SPECIAL TOOLS

Techline

Techline

Techline

1. GENERAL INFORMATION

As detailed in 7C1, material contained within this Section, details service operations that can be carried out on a

transmission while it is still installed in the vehicle. In addition, the procedures required to remove and reinstall the

transmission assembly from/to the vehicle are also detailed.

General servicing information is also included in this Section and it is recommended that this material be read and

followed, whenever servicing operations are to be carried out on this transmission.

Dependent on vehicle specifications for different markets, the gearshift selector mechanism may be fitted with a

Brake Transmission Selector Interlock (BTSI) device that is colloquially referred to as “Bitsi”. Refer to

Section 7C1 GENERAL INFORMATION for a description of this device and its operation. Within this Section, the

service procedures for both selector types are described.

1.1 GENERAL SERVICE PRECAUTIONS

RECOMMENDATIONS

When servicing the transmission, all parts should be cleaned and inspected as outlined under 'Clean and Inspect',

in these recommendations. Individual units should be reassembled before disassembly of other units to avoid

confusion and interchanging of parts.

1. Thoroughly clean the transmission exterior before removal of any component.

2. Disassembly and reassembly must be made on a clean work bench. Cleanliness is of the utmost importance.

The bench tools, and parts must be kept clean at all times.

3. Before installing screws and other fasteners into aluminium parts, DIP SCREWS INTO TRANSMISSION FLUID

(Only use Dexron III) to prevent galling aluminium threads and to prevent screws from seizing.

4. To prevent thread stripping, always use a torque wrench when installing screws.

5. If threads in aluminium parts are stripped or damaged, the part can be made serviceable by the use of

commercially available, thread inserts.

6. Protective tools must be used when assembling seals to prevent damage. The slightest flaw in the sealing

surface of the seal can cause an oil leak.

7. Aluminium castings and valve parts are very susceptible to nicks, burrs, etc., and should be handled with care.

8. Internal snap rings should be expanded and external snap rings compressed if they are to be re-used. This will

ensure proper seating when reinstalled.

9. O-rings, gaskets and oil seals that are removed should not be re-used.

10. Teflon oil seal rings should not be removed unless damaged.

11. During assembly of each unit, all internal moving parts must be lubricated with transmission fluid.

OIL COOLER PIPES

Should any transmission fluid cooling pipe suffer accidental damage, then a genuine replacement pipe must be

fitted. Refer to the current release of PartFinder® to determine the correct part number for the particular engine

and pipe involved. Reworking of damaged pipes or hand made replacements are not permitted.

Clean And Inspect

After complete disassembly of a component, wash all metal parts in a clean solvent and dry with compressed air.

Blow oil passages out and check to make sure they are not obstructed. Small passages should be checked with tag

wire. All parts should be inspected to determine which parts are to be replaced.

Pay particular attention to the following:

1. Inspect linkage and pivot points for excessive wear.

2. Bearing and thrust surfaces of all parts should be checked for excessive wear and scoring.

3. Check for broken seal rings, damaged ring lands and damaged threads.

4. Inspect seal and O-rings.

5. Mating surf aces of cas tings should be chec ked for burrs . Irregularities m ay be rem oved by lapp ing the surf ace

with emery paper. The emery paper is laid on a flat surface, such as a piece of plate glass.

6. Castings should be checked for cracks and porosity.

NOTE: Do not use solvents on neoprene seals, composition faced clutch plates or thrust washers as damage to

parts may occur.

2. MAINTENANCE AND GENERAL INFORMATION

2.1 FLUID LEVEL CHECK

GENERAL INFORMATION

W hen adding or c ha ng ing t he tr ansmiss ion f luid, use o nly Dexron® III a utomatic trans miss ion fluid. Ref er to t he M Y

2003 VY and V2 Series Owner's Handbook for servicing intervals.

Because th is transm ission flui d changes c olour and de velops an o dour ver y earl y in its life, thes e indicat ors shou ld

not necessarily be relied upon to diagnose either transmission internal condition nor fluid deterioration.

If, when following the Fluid Checking Procedure, a dark brown fluid colour is observed, coupled with a reported

delayed shift pattern, this may only indicate that the fluid requires replacement and alone, is not a definite indication

of a potential transmission failure.

NOTE: Do not o verfill th e trans miss ion. Overfillin g will cause f oaming of the fluid, loss of fluid, s hift com plaints and

possible damage to the transmission.

TRANSMISSION FLUID COLOUR

Transmission fluid colour when new and unused, is red. A red dye is added so that it can be distinguished from

other oils and lubricants. The red dye is not an indicator of fluid quality and is not permanent. As the vehicle is

driven, the transmission fluid will quickly begin to look darker in colour. The colour will then appear light brown. A

DARK brown colour with a distinctively burnt odour MAY indicate fluid deterioration and a need for the fluid to be

changed.

TRANSMISSION FLUID CHECKING PROCEDURE

1. Start engine and drive vehicle for a distance of 24 km, or until transmission normal operating temperature is

reached.

NOTE: As temperature greatly affects transmission fluid levels, this operation must only be carried out with the

transmission at normal operating temperature (82° – 94° C). If the vehicle is not at normal operating temperature,

and the proper checking procedures are not followed, the result could be a false reading of the fluid level on the

dipstick.

2. Park vehicle on a level surface.

3. With the engine idlin g and t he foot brak e f irml y applied , m ove th e gear s elec tor l ever thr ough each gear r ang e,

pausing for about 3 seconds in each selected range. Finally, select the 'PARK' position.

4. Apply park brake.

5. Let engine idle for 3 minutes with accessories turned off.

6. Lift the locking lever on the red coloured dipstick indicator, remove dipstick, wipe clean, then reinsert into the

indicator tu be. W ait 3 seconds, then remove the le ver once again. Check the level of fluid on each side of the

indicator. The fluid level should be between the cross hatched, 'HOT' indicator section.

7. If the fluid level is low, add only enough Dexron® III to bring the level into the “HOT” area.

IMPORTANT: Inac curate f luid le vel readin gs will r esult if check ed imm ediately aft er the vehic le has been o perated

under any or all of the following conditions:

a. In high ambient temperatures above 32° C.

b. At sustained high speeds.

c. In heavy city traffic during hot weather.

d. Towing.

e. In commercial use (e.g. taxi).

If the vehicle has been operated under the above conditions, switch the engine off and allow the vehicle to

'cool' for approxim atel y thirty m inutes. Af ter the cool- down per iod, re- start the v ehic le and contin ue f rom s tep 2,

above.

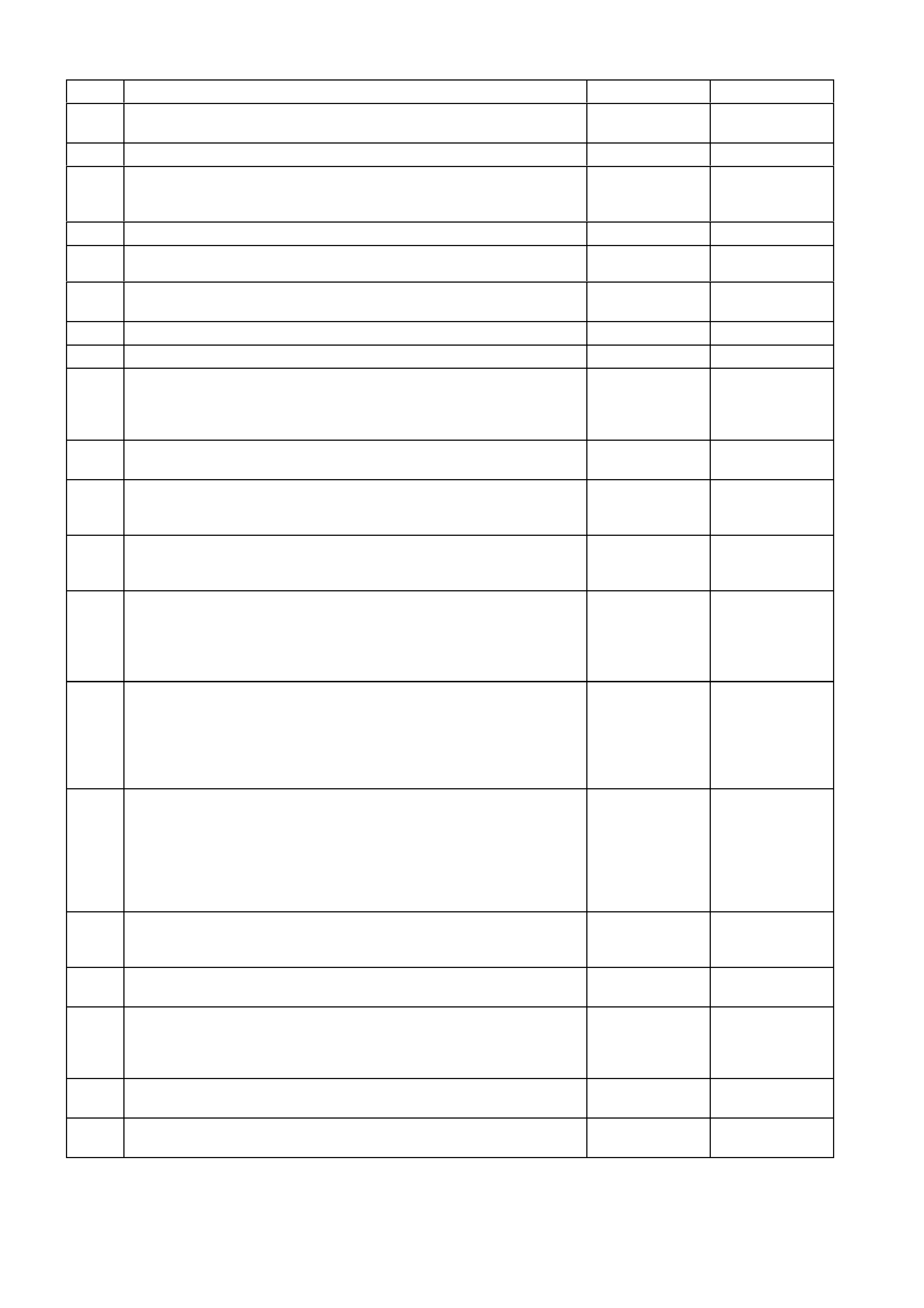

4L60-E TRANSMISSION FLUID CHECKING PROCEDURE

STEP ACTION YES NO

1. 1. Check the fluid colo ur.

Is the fluid colour red? Go to Step 5 Go to Step 2

2. Is the fluid a non-transparent pink in colour? Go to Step 13 Go to Step 3

3. NOTE: Fluid may turn a dark brown from normal use. This colour does

not always indicate an oxidation or a contamination concern.

Is the fluid a light brown in colour?

Go to Step 6 Go to Step 4

4. Is the fluid black in colour and/or have a "burnt" smell? Go to Step 15 Go to Step 5

5. Does the fluid appear to be 'foamy' or full of bubbles on the dipstick

indicator? Go to Step 13 Go to Step 6

6. 1. Check the fluid level as detailed in Steps 1 to 6 above.

Is the fluid level satisfactory? Fluid Check is

Complete Go to Step 7

7. Is the fluid level high on the dipstick indicator? Go to Step 12 Go to Step 8

8. Is the fluid level low on the dipstick indicator? Go to Step 9 –

9. 1. Check for any external leak or leaks. Refer to 2.11 Fluid Leak

Diagnosis and Repair, in 7C3 A/T HYDRAULIC/MECHANICAL

DIAGNOSIS.

Were any external leak or leaks found?

Go to Step 10 Go to Step 11

10. 1. Correct any leak or leaks, as required?

Is the action complete? Go to Step 11 Go to Step 9

11. 1. Add Dexron® III transmission fluid until the level is in the middle of

the cross-hatched area on the dipstick indicator.

Is the level OK?

Fluid Check is

Complete –

12. 1. Remove excess fluid via the dipstick tube, using commercially

available pumping equipment.

Is the level now correct?

Go to Step 20 –

13. 1. With both transmission cooler pipes disconnected at the radiator,

pressure test the engine cooling system (refer to ENGINE

COOLING (6B1 – V6, 6B2–- V6 S/C, 6B3 – GEN III V8).

2. Check if engine coolant lea ks f rom the fluid co oler pip e fitt ing s.

Does engine coolant leak from the cooler pipe fittings?

Go to Step 14 Go to Step 17

14. 1. Replace the radiator (transmission cooler is not serviced

separately).

2. Refer to information contained in 2.10 Engine Coolant in

Transmission, in 7C3 A/T HYDRAULIC/MECHANICAL

DIAGNOSIS.

Are the actions complete?

Go to Step 16 –

15. IMPORTANT: A small amount of friction material in the oil pan is a

'normal' condition but large pieces and/or metal particles indicate that a

co mplete transmission overhaul is requi red.

1. Remove transmission oil pan, drain fluid and inspect oil pan residue

and magnet.

Is there a sign or signs of internal transmission damage found in the

bottom of the oil pan?

Go to Step 18 Go to Step 16

16. 1. Reverse flush the oil cooler and lines. Refer to 2.2 Transmission

Reverse Flush and Flow Rate Check, in this Section.

Is action complete?

Go to Step 17 –

17. 1. Replace the transmission fluid filter and fluid.

Is the replacement complete? Go to Step 20 –

18. 1. Overhaul the transmission or fit a SRTA unit. Refer to 7C5 UNIT

REPAIR and/or 3.14 Transmission Assembly, Remove/Reinstall in

this Section.

Is action complete?

Go to Step 19 –

19. 1. Add new Dexron® transmission fluid.

Is action complete? Go to Step 20 –

20. 1. Is the fluid level satisfactory? If not, correct as necessary.

Is action complete? Fluid Check is

Complete –

2.2 TRANSMISSION COOLER REVERSE FLUSH AND FLOW RATE CHECK – ALL

LT SECTION NO. – 04A-200

IMPORTANT: It is essential that a reverse flush and oil cooler flow rate check is performed, after ANY of the

following situations:

• Transmission is replaced.

• Fluid contamination is suspected.

• Whenever the oil pump and/or torque converter is replaced.

NOTE: The reverse flush must be completed prior to conducting a flow rate check.

REVERSE FLUSH

The recommended procedure for reverse flushing the transmission cooler and lines, particularly after an

overhauled or replaced transmission has been installed into the vehicle, is as follows:

1. Dis connect both c ool er lin es at t he transm iss ion and at th e radiat or coo ler en d. R efer to 3 .15 TR ANSM ISSI ON

COOLER PIPES/HOSES, in this Section. Do not lose the pipe to fitting sealing washer, when the pipe is

removed.

2. Car efull y check the coo ler inlet f ittin g (lo wer) to s ee whether an y material is evi dent at this point. If s o, dislo dge

and remove with a suitable tool and/or compressed air blown in the reverse direction through the cooler.

3. Using a commercially available pressure spray gun and clean solvent, such as white spirit:

a. Back flush through both cooler lines.

b. Back flush through the cooler, including an external cooler (if fitted).

c. Blow compressed air through return and inlet pipes to remove solvent.

d. Flush pipes with transmission fluid.

4. Check the cooler pipe to cooler fitting, sealing washers for damage, replacing as required.

5. Reconnect cooler lines to the transmission and cooler but leave the cooler return line to transmission

connection ope n.

6. Conduct a flow rate test as described below, to ensure that any restriction has been cleared.

7. If flow rate is satisfactory, reconnect the return line to the transmission quick connect fitting.

8. Tighten the cooler pipe flange buts at the cooler end (V6 engines only) to the specified torque. Refer to

3.15 TRANSMISSION COOLER PIPES/HOSES, Reinstall for the correct procedure.

OIL COOLER PIPE TO

RADIATOR FITTING

TORQUE SPECIFICATION V6 Engines 25 Nm

9. Lower vehicle and check fluid level as detailed in 2.1 FLUID LEVEL CHECK, in this Section.

FLOW RATE CHECK

IMPORTANT: Do not run e ngine an y longer th an abso lutely nec essar y, as too low a fluid le vel can cause aeration

and foaming.

1. When installing the transmission assembly, leave the cooler return line disconnected from the transmission

(upper fitting).

2. Ensure that the fluid level is to the recommended level, as detailed in 2.1 FLUID LEVEL CHECK, in this

Section.

3. Place a container underneath the disconnected cooler line.

4. With the selector lever in the Neutral position, start the engine and observe the fluid flow into the container,

after all air bubbles have ceased and a steady flow is evident. Measure the flow rate.

Result: The fluid flow rate should be approximately 0.7 litre in a 20 second period, with cold automatic transmission

fluid (ATF). With ATF at normal operating temperature (86 – 93° C), the flow rate will increase and should be

approximately 1.2 litres in a 20 second period.

If the f low rate is l ess than this specif icati on, the s ourc e of the r estric tion m us t be locate d and r ectif ied. Pos sibil ities

are either radiator tank cooler, faulty flexible hoses and/or external cooler (if fitted).

5. Reinstall the cooler return line to the transmission quick connect. Refer to 3.15 TRANSMISSION COOLER

PIPES/HOSES, Reinstall for the correct procedure.

Techline

3. ON-VEHICLE SERVICE OPERATIONS

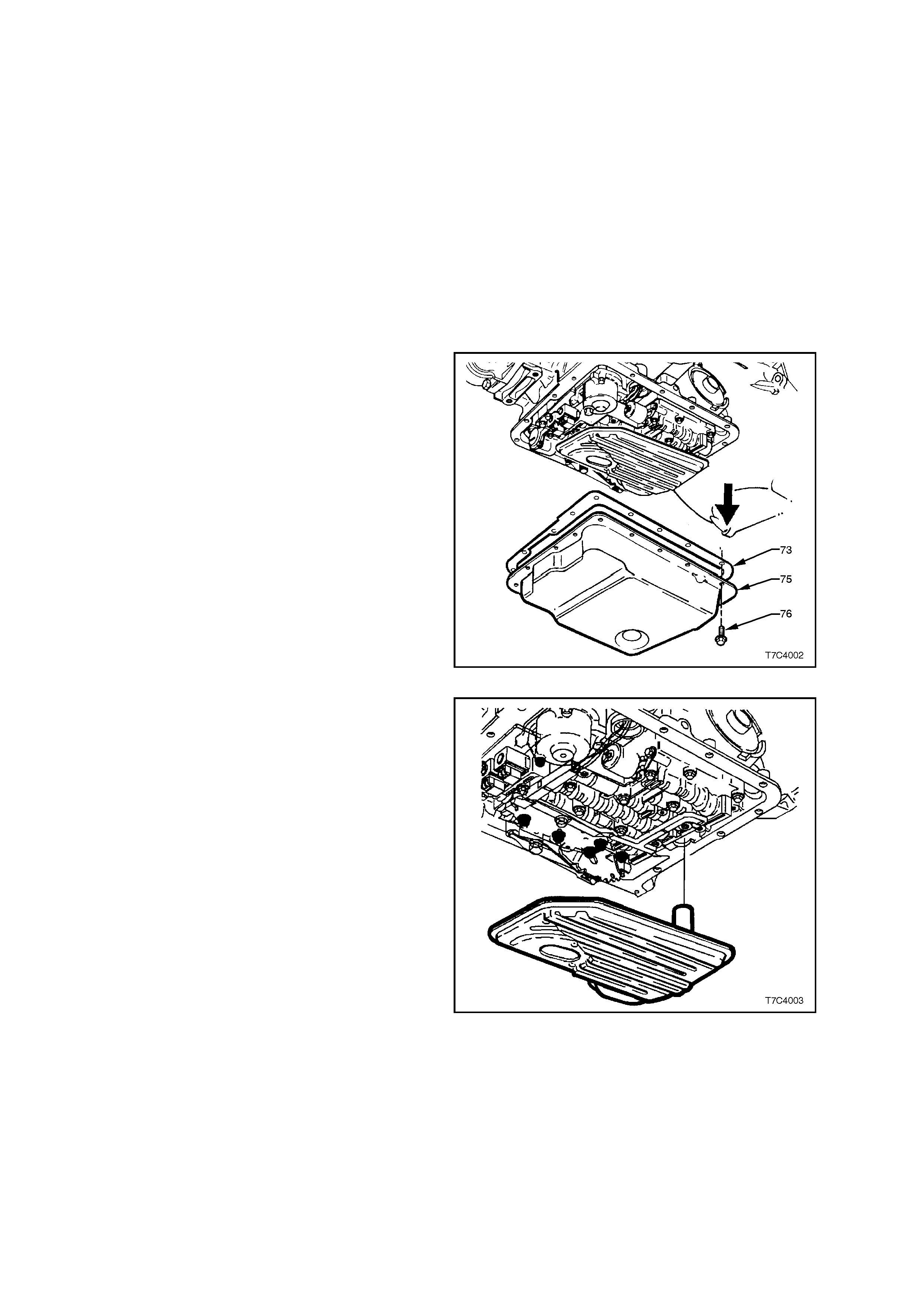

3.1 FLUID CHANGE & FILTER REPLACE

LT Section No. – 04A-220

CAUTION: To avoid personal injury from

accidental hot oil spillage, perform fluid change

only when transmission fluid is cold.

1. Raise front of vehicle and support on safety

stands. Refer to Section 0A GENERAL

INFORMATION in the MY 2003 VY and V2

Series Service Information, for the location of

jacking and support points.

2. Clean all dirt from around oil pan and

transmission case.

3. Place drain tray under transmission.

4. Hold oil pan in place and, remove the oil pan

bolts from the front and both sides.

5. Loosen the rear oil pan bolts by about 4 turns

each and, while still supporting the oil pan,

lightly tap the sides with a rubber hammer to

break the gasket seal.

6. Lower the fr ont of the oil p a n and dr a in t he f lui d

into a suitable container, then remove the oil

pan from the transmission.

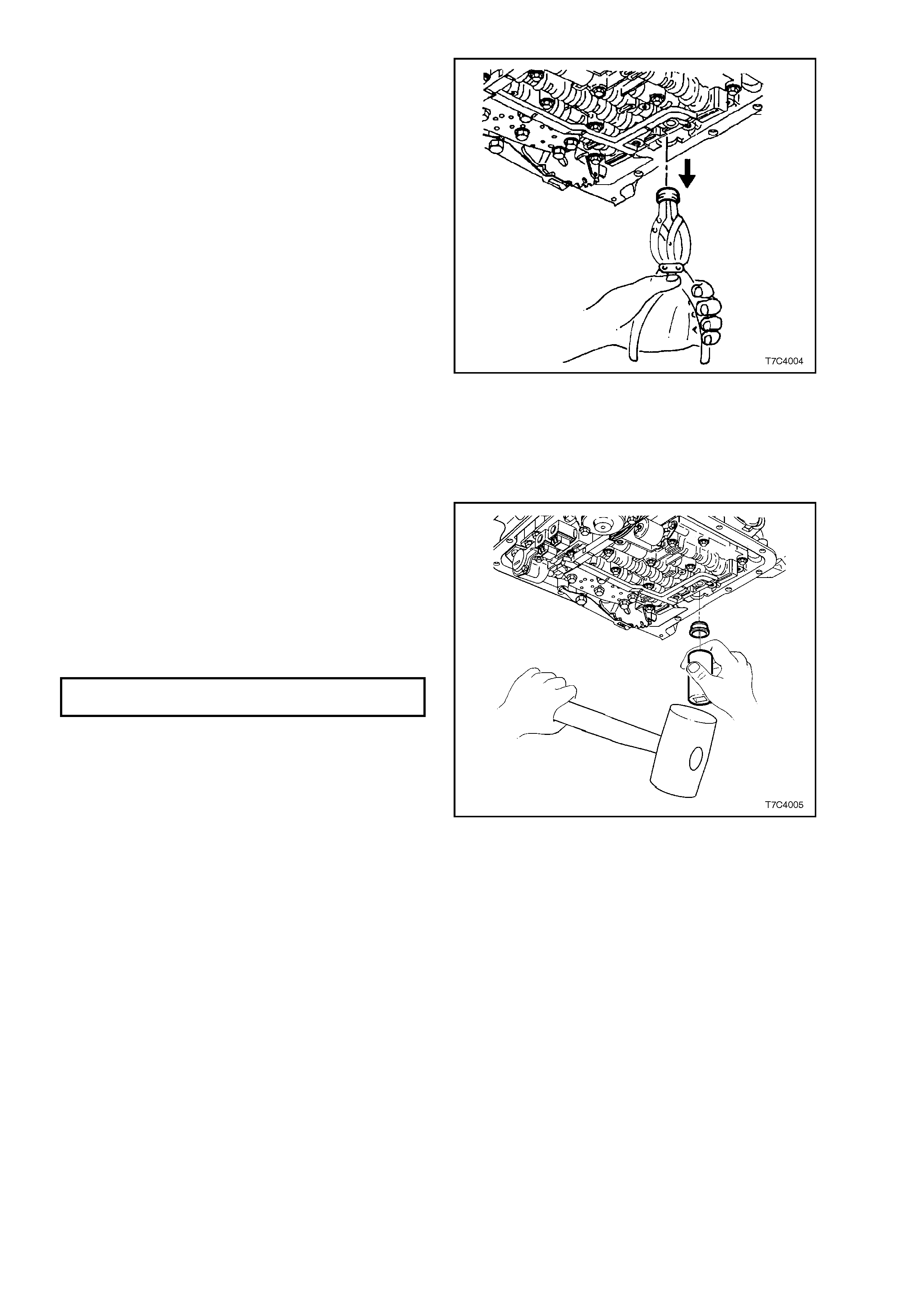

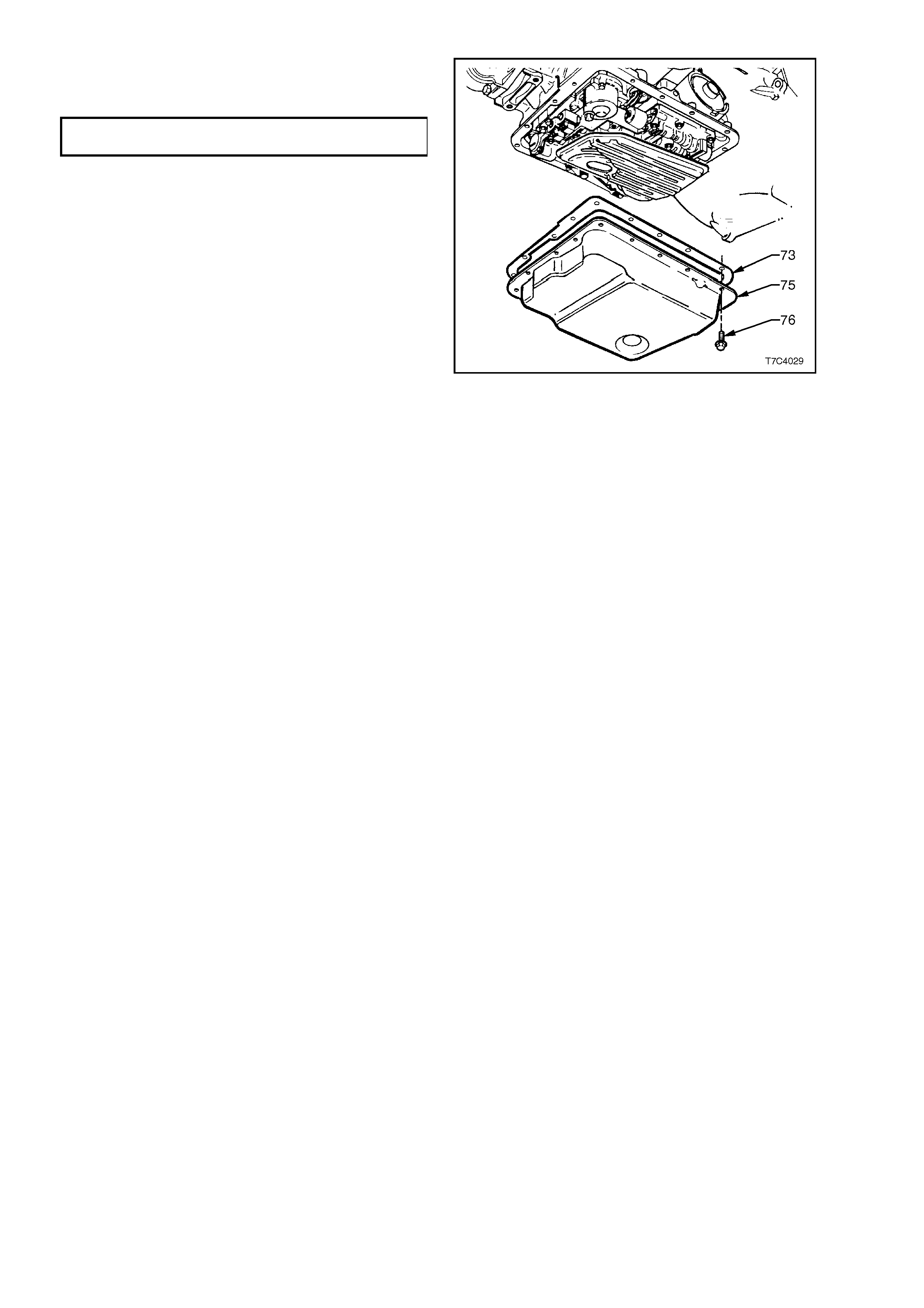

Figure 7C4-1

7. At the same time, pull down and twist the filter

to remove it from the transmission case.

8. Open the filter by prying the metal crimping

away from the top of the filter and pull apart.

Inspect the filter material for particles that m ay

indicate evidence of a potential transmission

problem. Examples of the type of material to

look for, are;

– Clutch friction material.

– Bronze slivers , ind icating bush wear .

– Steel particles.

Figure 7C4-2

9. Using suitable circlip pliers or a two legged

puller and s lide ham m er, r em ove the f ilter s eal.

Take care not to scratch the oil pump bore

during the process.

NOTE: If the seal bore is scratched, fluid leakage

could occur from this point, once the vehicle has

been put back into service.

Figure 7C4-3

9. Remove old oil pan gasket and discard.

10. Clean the transmission case, oil pan and oil

pan gasket surface, drying with compressed

air. Ensur e that all traces of the old gasket are

removed.

11. Lubricate a new filter seal with petroleum jelly

(Vaseline™ or equivalent) and install into the

oil pum p bore, using a suit able sized sock et or

piece of tubing.

12. Install a new filter into the transmission case.

13. Check that the magnet is functional and

located in the designated position in the oil

pan. Install new gasket and reinstall oil pan.

Tighten bolts to specified torque.

OIL PAN BOLT

TORQUE SPECIFICATION 12 Nm

14. Lower vehicle and add approximately 4.8 litres

(V6 engine) or 5.0 litres (GEN III V8 engine) of

Dexron III automatic transmission fluid.

15. Operate the vehicle for about 24 km or until

normal operating temperatures are reached.

Check that there are no fluid leaks from the oil

pan area.

16. Check tr ansmission f luid leve l, refer 2.1 F LUID

LEVEL CHECK in this Section.

Figure 7C4-4

3.2 SELECTOR LINKAGE

LT Section No. – 04A-170

REMOVE

1. Set transmission selector lever to the 'PARK'

position.

2. Raise front of vehicle and place on safety

stands Refer to Section 0A GENERAL

INFORMATION in the MY 2003 VY and V2

Series Service Information for the location of

the recommended jacking and support points.

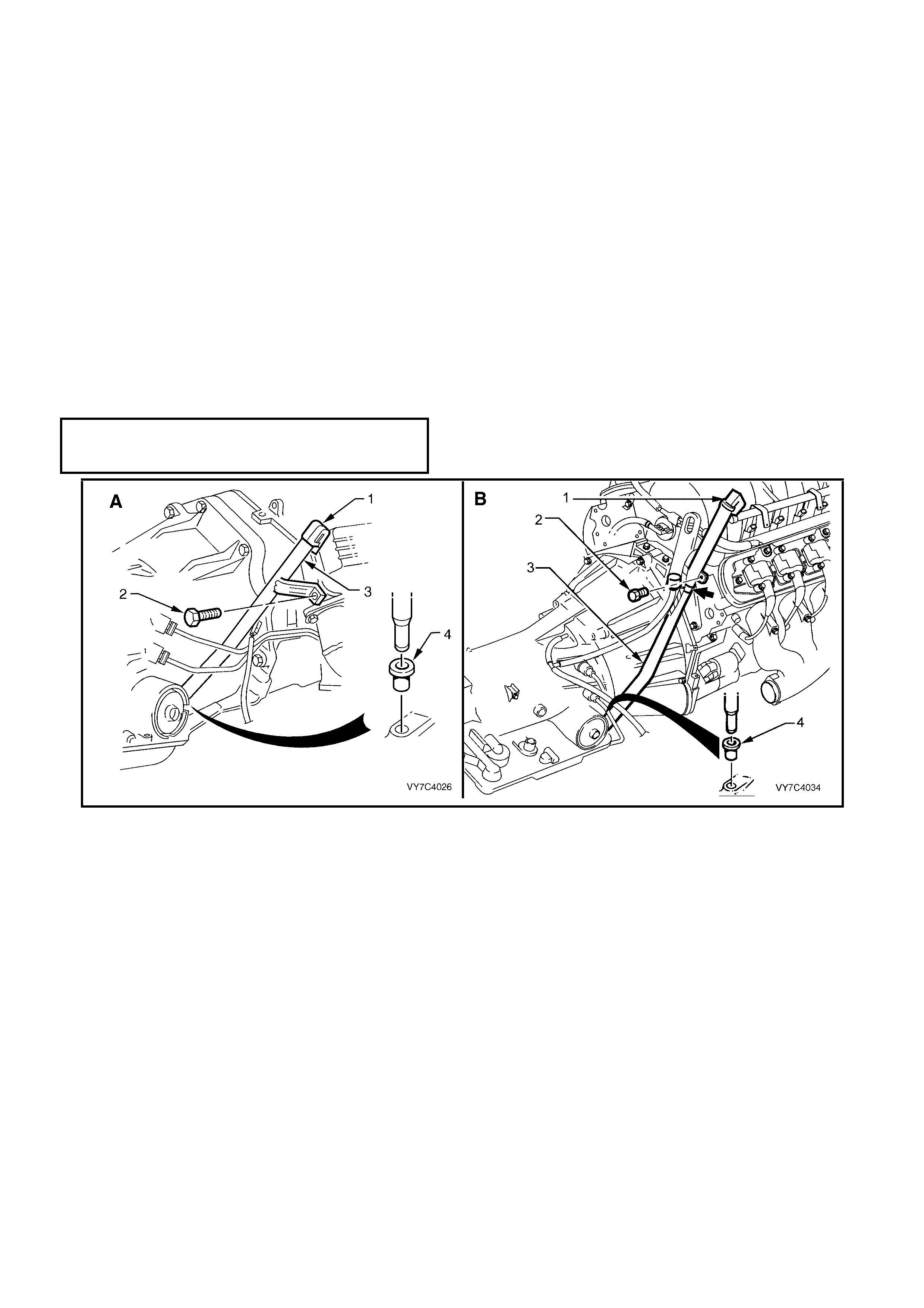

3. Remove locking b olt ( 1), dis hed wash er ( 2) , f lat

washer (3), insulator (4) and sleeve (5) from

lower end of selector lever (9).

4. Slide trunnion (6) from selector rod (7).

5. While holding the transmission selector lever

with an adjustable wrench, remove retaining

nut (8), rod and lever assembly (7) from

transmission manual shaft.

INSPECT

Check all items for wear and/or damage, replace

all worn or dam aged items.

REINST ALL

Reinstallation is the reverse of the removal

procedure, except for:

1. Tighten the selector lever retaining nut (8) and

the selector lever locking bolt (1), to the

specified torque settings.

MANUAL SHAFT LEVER NUT

TORQUE SPECIFICATION 25 Nm

SELECTOR LEVER

LOCKING BOLT

TORQUE SPECIFICATION 25 Nm

2. Adjust linkage as described below.

Figure 7C4-5

ADJUST

Refer to Figure 7C4-5.

1. Loosen locking bolt (1) at selector lever (9).

2. Position transmission selector lever in the

'PARK' position.

3. Position gearshift lever in the 'PARK' position,

then tighten the locking bolt at the selector

lever, to the specified torque.

SELECTOR LEVER

LOCKING BOLT

TORQUE SPECIFICATION 25 Nm

4. Lower vehicle and test that the vehicle

operates correctly.

5. Ensure that engine can be started only in

'PARK' and 'NEUTRAL'. If required, adjust the

Neutral Start and Back-Up Lamp switch. Refer

3.4 NEUTRAL START AND BACK-UP LAMP

SWITCH, in this Section.

3.3 SELECTOR CONTROL LEVER ASSEMBLY

LT Section No. – 04A-190

REMOVE

1. Raise vehicle and place on safety stands.

Refer Section 0A GENERAL INFORMATION

in the MY 2003 VY and V2 Series Service

Information for the location of recommended

jacking and support points.

2. Remove floor console cover, lower extension

side trim panels and the floor console

assembly. Refer Section 1A3 INSTRUMENT

PANEL & CONSOLE, in the MY 2003 VY and

V2 Series Service Information.

3. Disconnect the wiring harness connector from

the selector patch harness.

4. From beneath the vehicle, disconnect the

selector rod and trunnion from the selector

lever. Refer 3.2 SELECTOR LINKAGE, in this

Section.

5. Remove the four nuts securing the selector

lever assembly to the floor pan.

6. From inside the vehicle, lift the selector lever

assembly from the floor pan.

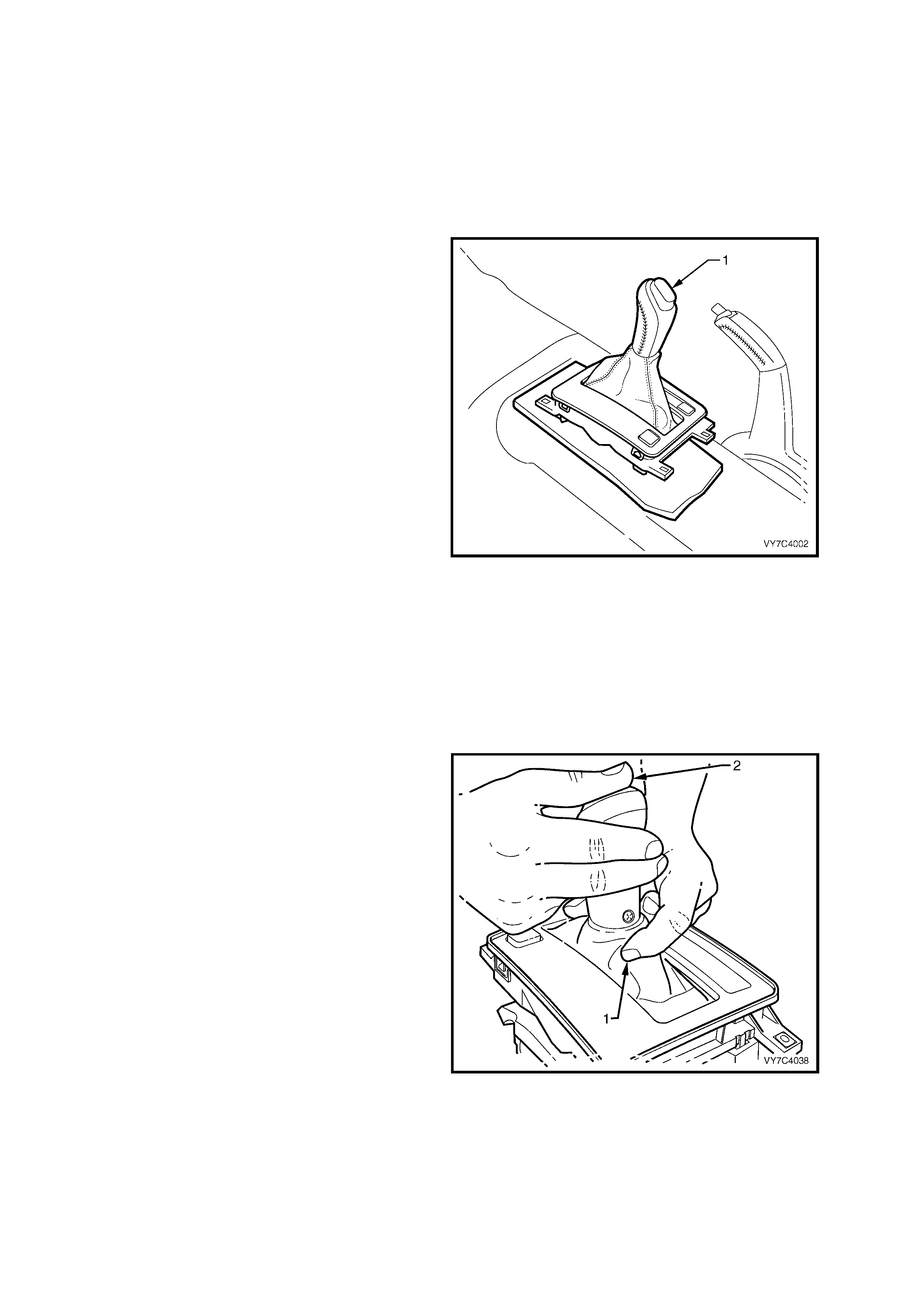

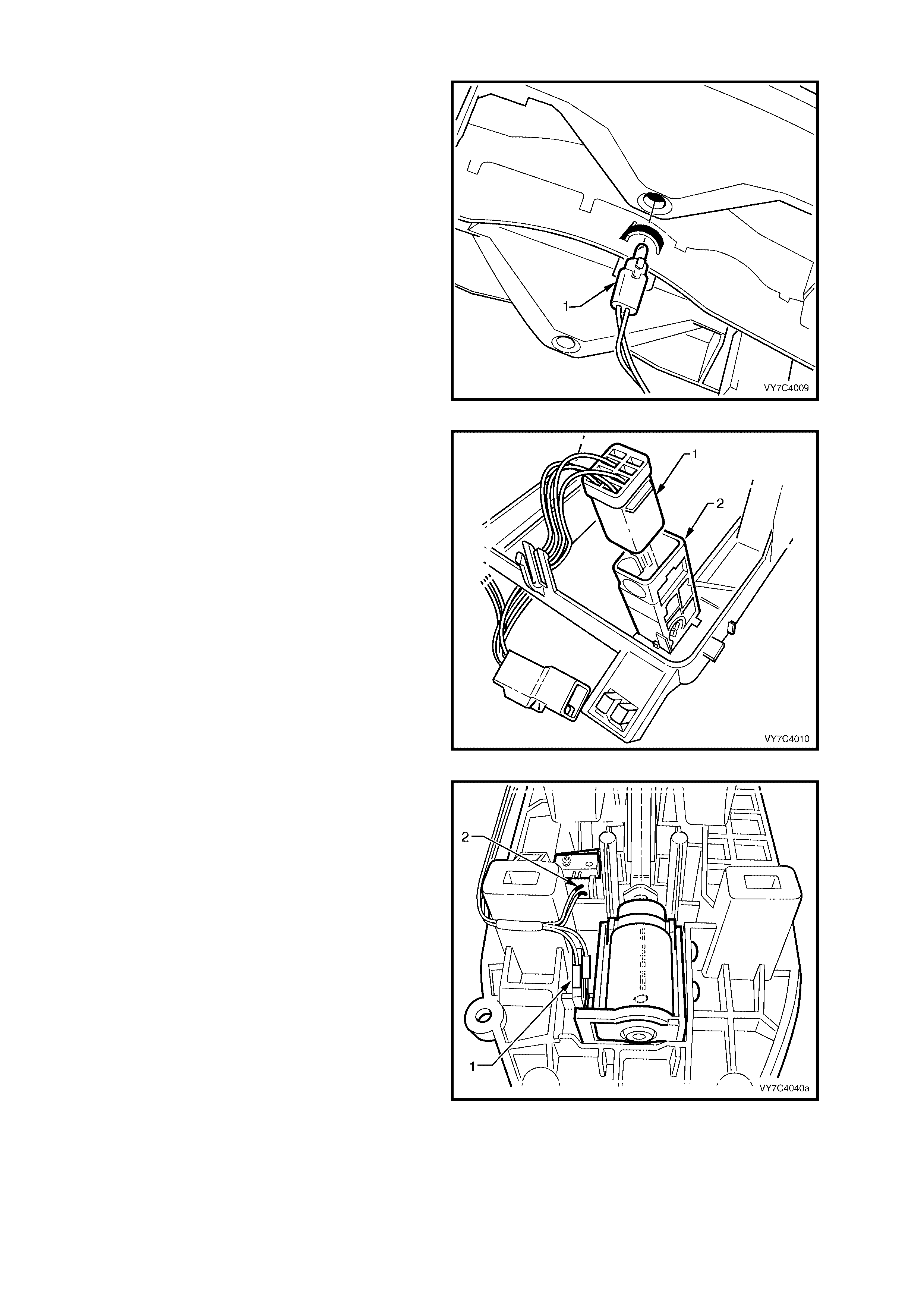

Figure 7C4-6

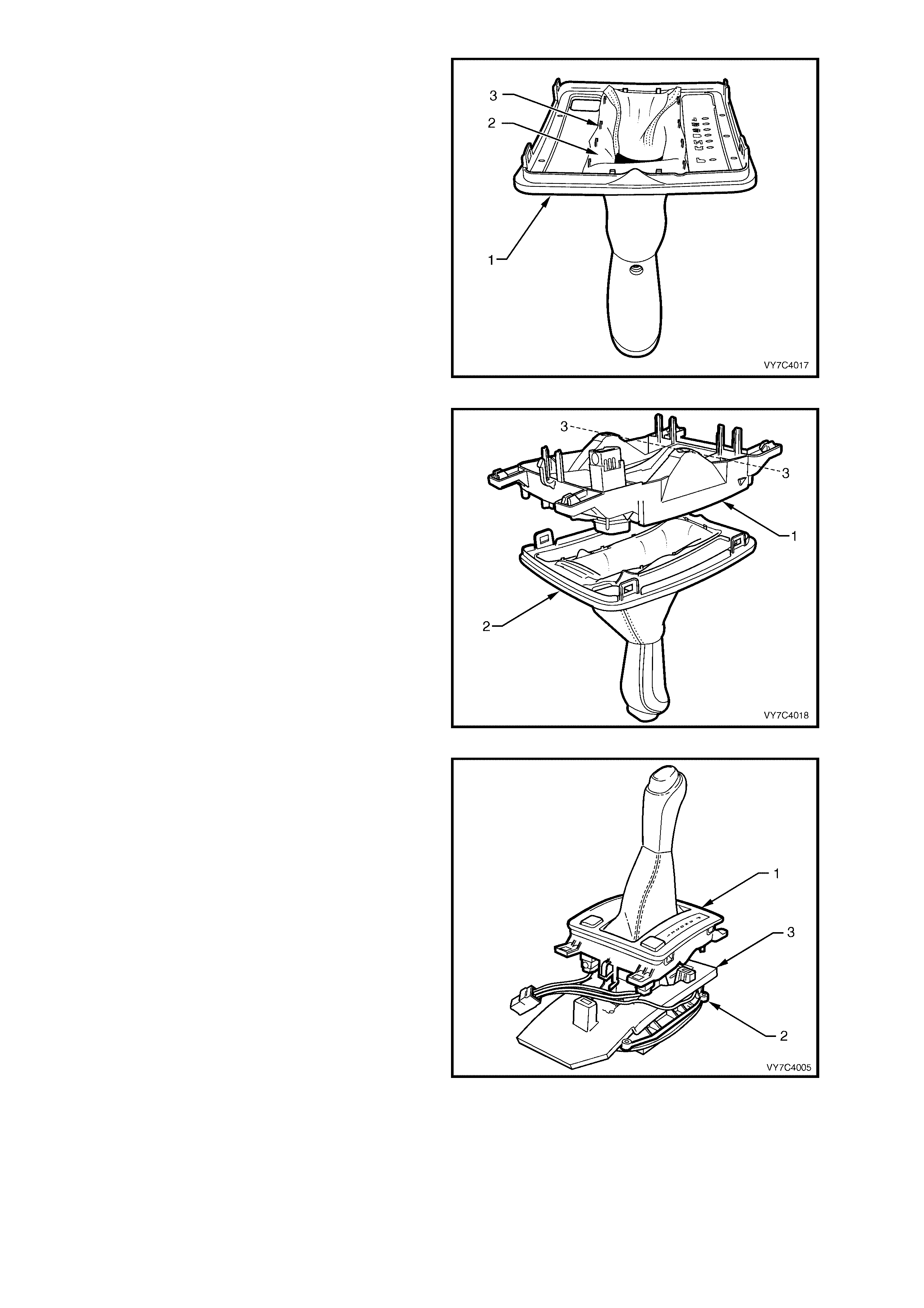

DISASSEMBLE

NOTE 1: Unless specifically noted, the following

procedures can be used for either design of

selector lever assembly.

NOTE 2: W hile most views show the RHD version

of the selector control lever assembly, LHD

procedures can be assumed to be the same

unless otherwise noted.

1. If the selector control lever assembly is of the

BTSI design, manually release the interlock

mechanism, as follows:

a. First, press inwards at the front of the

selector le ver, jus t be low th e gear shif t k nob, as

shown (1).

b. Then, while still pressing inward (1), depress

the selector knob with the other hand (2) and

move the lever from the Park position and into

‘D’ Driv e.

NOTE: This is the recommended reassembly

position.

Figure 7C4-7

2. Using a commercially available Torx Plus

(TX20) and suitable equipment, remove the

self tapping screw (1). Select ‘D’ Drive.

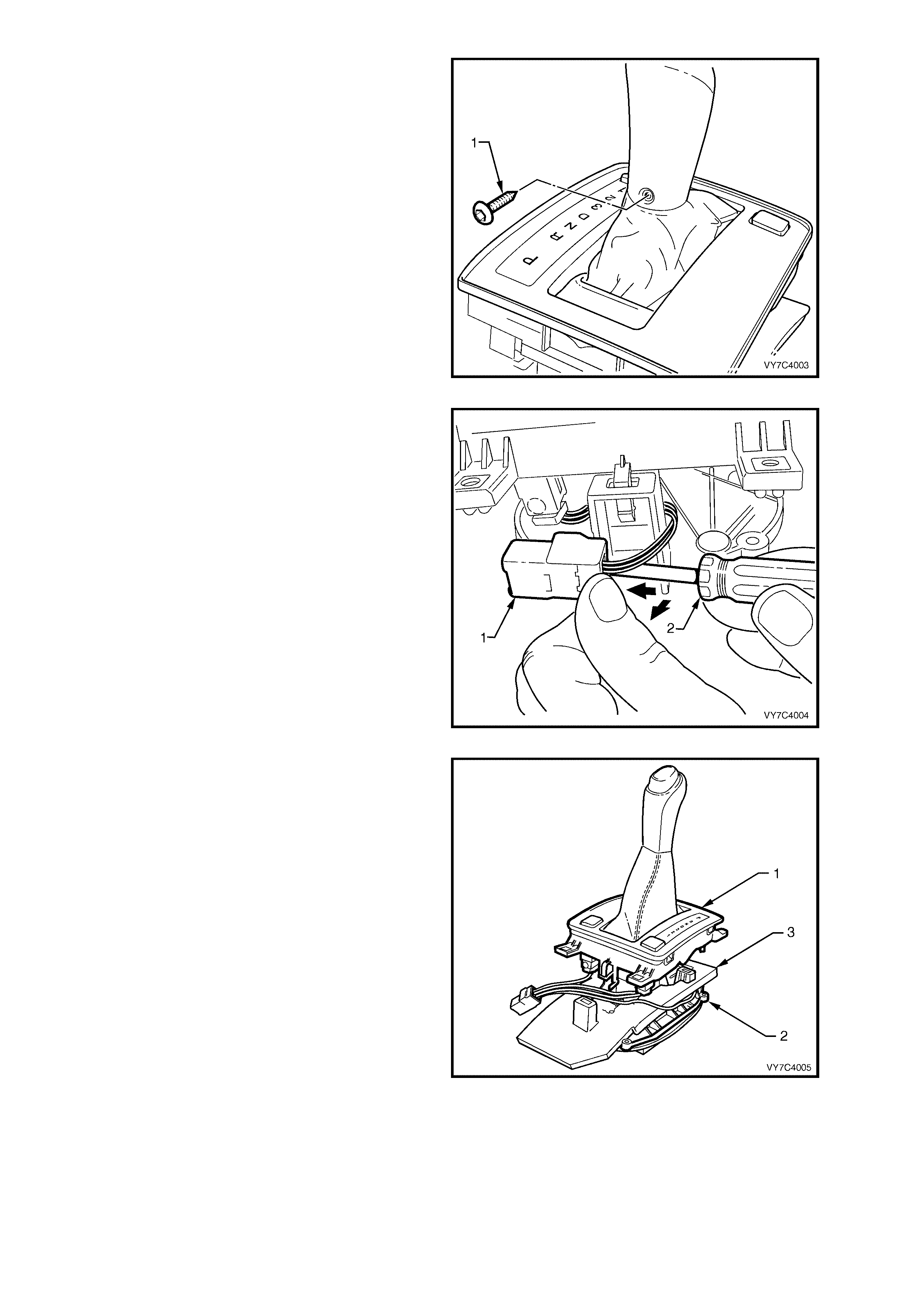

Figure 7C4-8

3. Using a sm all screwdr iver (2), pris e the locking

tab on the wiring harness connector (1) at the

rear of the shift selector assembly, while

pushing away from the lower housing, as

shown.

NOTE: This operation is optional with the BTSI

shifter, as:

a. The patch harness can be disconnected at the

micro switch and the solenoid (in which case,

step 3 is required).

OR

b. Following separation of the lower housing and

the base (see step 4), the wiring harness

connectors could be removed from the ‘PWR’

and ‘T/C’ (if fitted) switches, leaving the

harness with the base (step 3 not being

required).

Figure 7C4-9

4. With the wiring harness connector free,

disconn ect the lower hous ing f rom the base (1)

by pressing the tangs on each of the retaining

legs (two front, one rear).

5. Lift the lower housing (1) from the base (2),

together with the switch/es, patch wiring

harness, boot and shift lever knob. Set the

assembly to one side.

NOTE: With the BTSI shifter, when the patch

harness is left behind (choice ‘b’ in step 3), the

removed components will be; the lower housing

(1), together with the s witc h/es, boot and s hift l ever

knob.

6. As required, lift the insulator (3) from the base

(2) and set to one side.

Figure 7C4-10

NOTE: With the shift lever assembly now

separate d, selec t fr om the follo wing choic es f or the

service operation/s required.

Boot, Shift Lever Knob Remove

7. W hile holding the lower housing in an inverted

position, gently prise each of the four securing

lugs (1) to free the cover (2) from the lower

housing (3). Lift the lower housing (3) from the

gearshift selector knob, boot and upper cover

assembly (2) and set to one side.

NOTE: If the lower housing assembly is not

inverted before separation, then the boot will

probabl y becom e dis lodged from the locati ng tangs

in the upper cover.

8. If boot replacement is required, free the boot

from the upper cov er loc at i ng ta ngs an d set th e

cover t o one si de, being caref ul not to dis lodge

nor damage the PRNDL indicator lens in the

process.

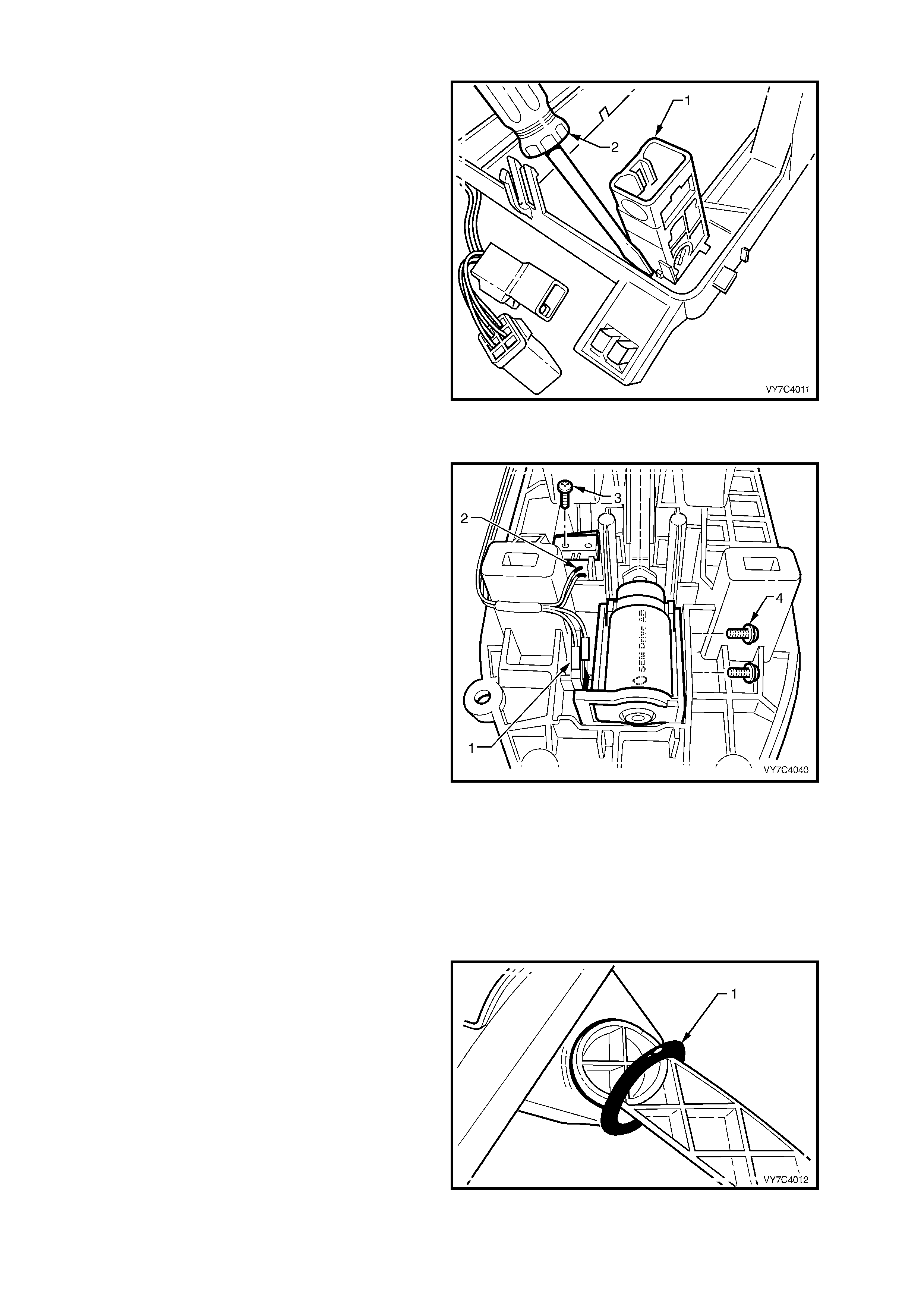

Figure 7C4-11

9. Turn the boot (2) inside out, over the gearshift

selector knob, then cut the plastic tie (1)

securing the boot to the knob. Remove the

boot from the gearshift lever knob and discard.

NOTE: The plastic tie is a unique design and is

markedly different from the usual cable tie.

Figure 7C4-12

10. If the gearshift knob needs to be dismantled,

use a small knife (2) or similar to free the lugs

securing the control rod button from the

gearshift knob (1).

IMPORTANT: The knob is spring loaded and may

fly free once dislodged.

11. Remove the two Phillips head self tapping

screws, (located under the control rod button),

then separate the knob components.

Figure 7C4-13

Patch Harness Removal

12. Remove th e selector indicator lam p and holder

from the switch housing by turning the lamp

holder 90° to the left (counter-clockwise), then

pull.

Figure 7C4-14

13. If not removed previously (step 3), release the

switch connector retaining lug/s, then remove

the connector/s.

NOTE: W hile each s witch patch h arness conn ector

is the same colour (white), the Traction Control

(“T/C”) switch (when fitted) connector wiring is

taped to the PRNDL indicator lamp wiring, as this

switch will always be on the same side as this

lamp. This situation remains the same for both

RHD and LHD vehicles.

Figure 7C4-15

14. If the shift lever assembly is of the BTSI

design, remove the patch harness wiring

connectors from the soleno id (1) and the m icro

switch (2), taking note of the patch harness

routing, for correct reinstallation.

15. Remove the patch harness and set to one side.

Figure 7C4-16

Switch Removal

NOTE: For this operation, the cover must be split

from the lower housing. Refer to Step 4 in this

procedure.

16. To remove the PWR and/or T/C switch (if

fitted), use a small bladed screwdriver and

lever one of the switch retaining tangs from

under the lower housing to free the particular

switch, cock to one side, release the second

tang and then remove the switch from above.

IMPORTANT: Take note of the locating lug on the

switch body that ensures the correct orientation of

the switch when reinstalled.

Figure 7C4-17

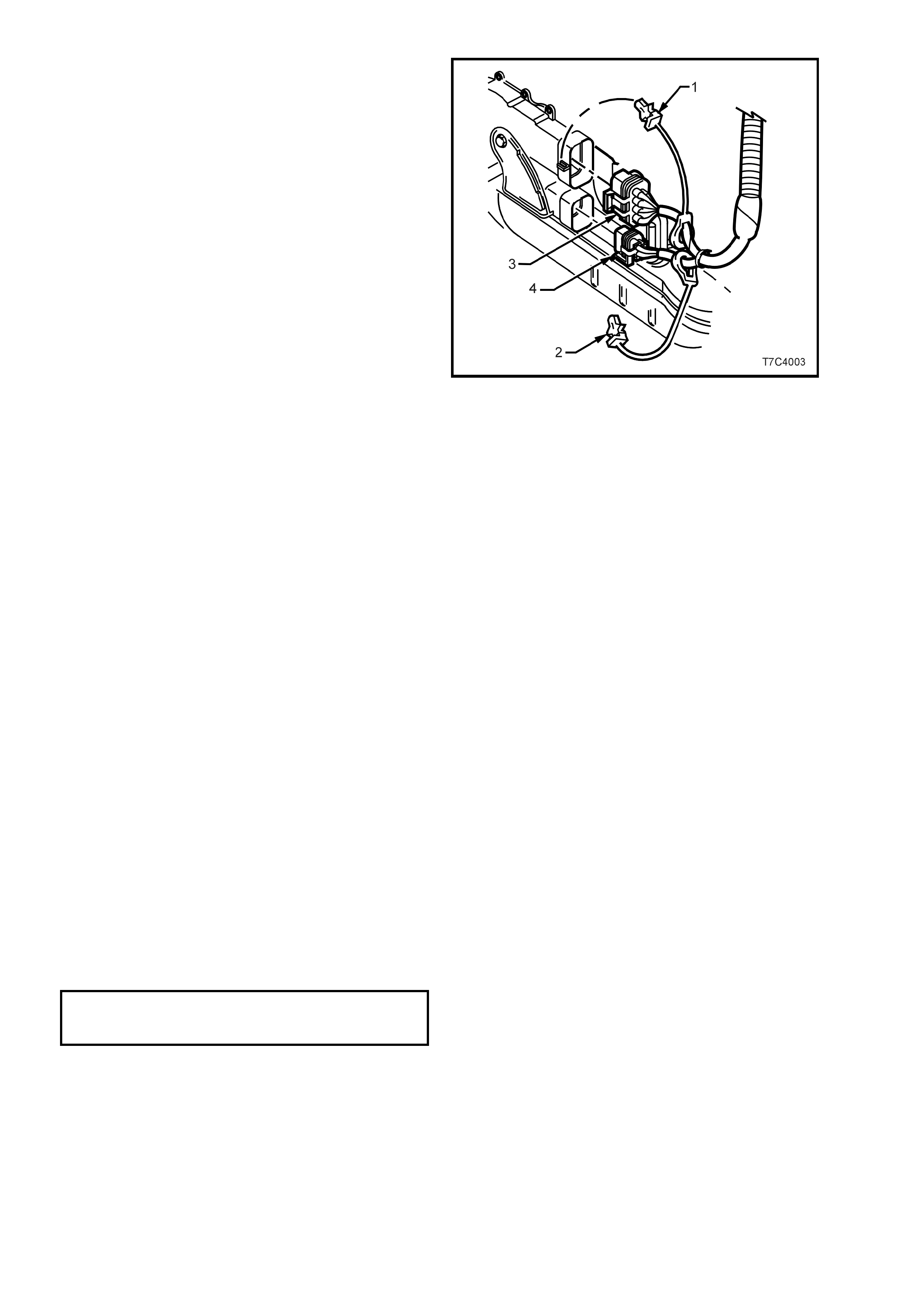

BTSI Solenoid and/or Micro Switch

17. With the lower cover separated from the base,

lift the insulator back and over the shift lever.

18. With the patch harness connectors (2 and 1)

removed from the solenoid, remove the two

Phillips headed screws (4) securing the

solenoid or the single self tapping screw (3)

from the micro switch.

19. Remove the solenoid and/or micro switch from

the BTSI base.

Figure 7C4-18

Base Disassemb l y

20. If not rem oved previousl y, rem ove the shif t rod

trunnion bolt from the lower end of the shift

lever arm. Slide the trunnion from the arm,

then remove the ins u lat in g grom met.

NOTE: This is necessary to provide clearance for

the lever to be removed from the lower housing.

21. Remove the external seal (1) from the lever

arm and set to one side.

Figure 7C4-19

22. To rem ove the le ver lock ing piece, use a sm all

screwdriver (1) to lever the locking tang free

while pulling on the locking piece (2) with long

nosed pliers (3).

23. Push the lever assembly inwards to release the

inner support pin and bush

NOTE: The bush will probably remain in the lower

housing.

24. Lift the shift lever from the lower housing.

NOTE: W hile it will be nec es sar y to manoeuvr e the

lever somewhat, sufficient space is provided to

overcome any need to apply force to the lever

assembly.

Figure 7C4-20

Lever Disassembly

Regardless of the shift lever type, further

disassembly is not recommended, as there is a very

real possibility that, during reinstallation of the roll

pin, the shift lever will be cracked, unless

sophisticated jigs are used. For this reason, the shift

lever is only serviced as an assembly.

REASSEMBLE

Base Reassembly

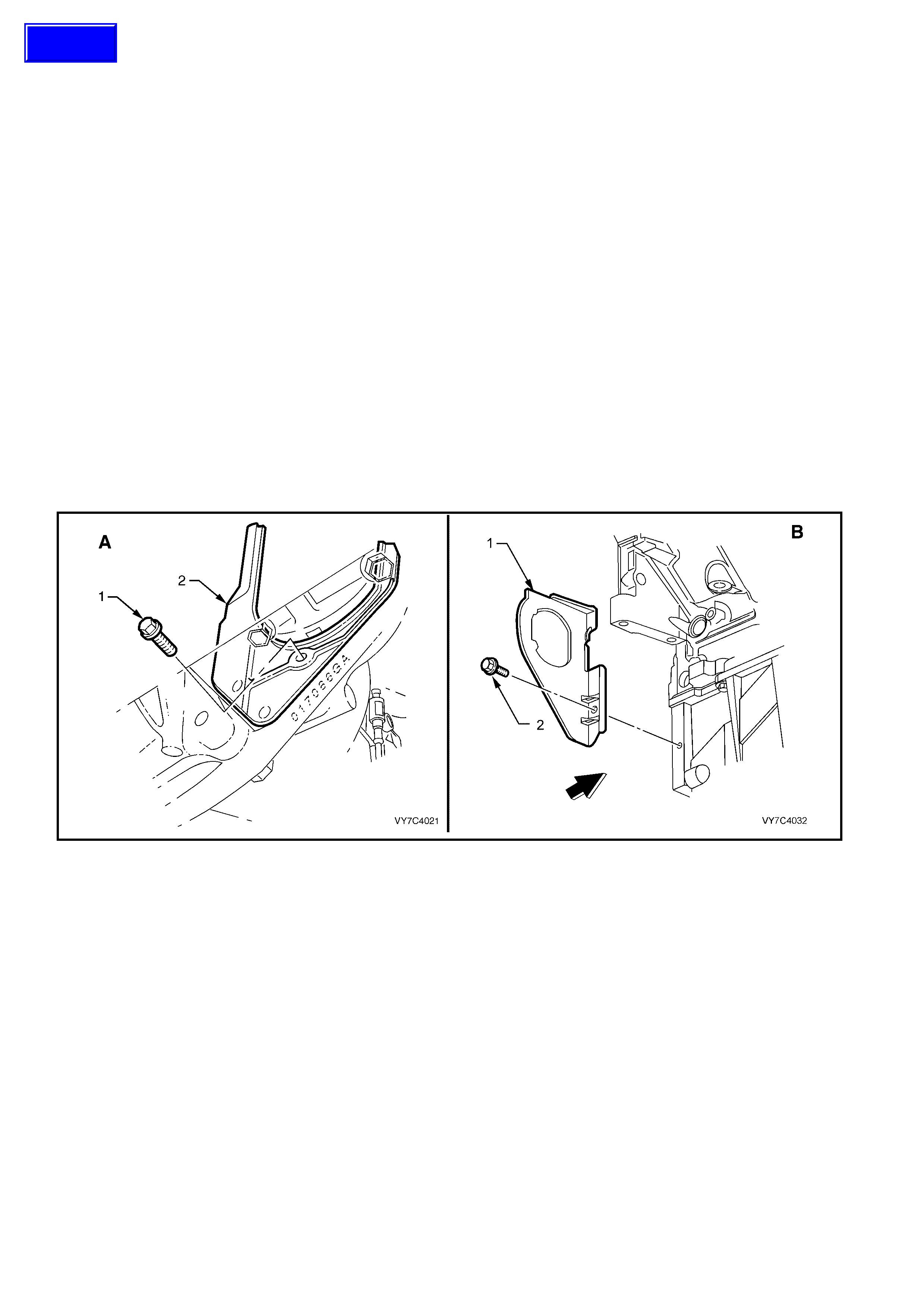

1. Inspect the ext ernal lever, inner bushing (1) f or

damage, replacing as required. Lubricate with

a multi-purpose chassis grease such as NLGI

No. 1 Lithium grease.

2. Reinstall the split inner support bush (2) to the

selector lever pin, aligning the split in the bush

with the k ey on the selector lever pin. Lubr icat e

the external bush surface with a multi-purpose

chassis grease such as NLGI No. 1 Lithium

grease.

3. Reinstall the selector lever assembly (3), into

the base. Align the small bush with the

aperture in the base then push across to fully

install the lever.

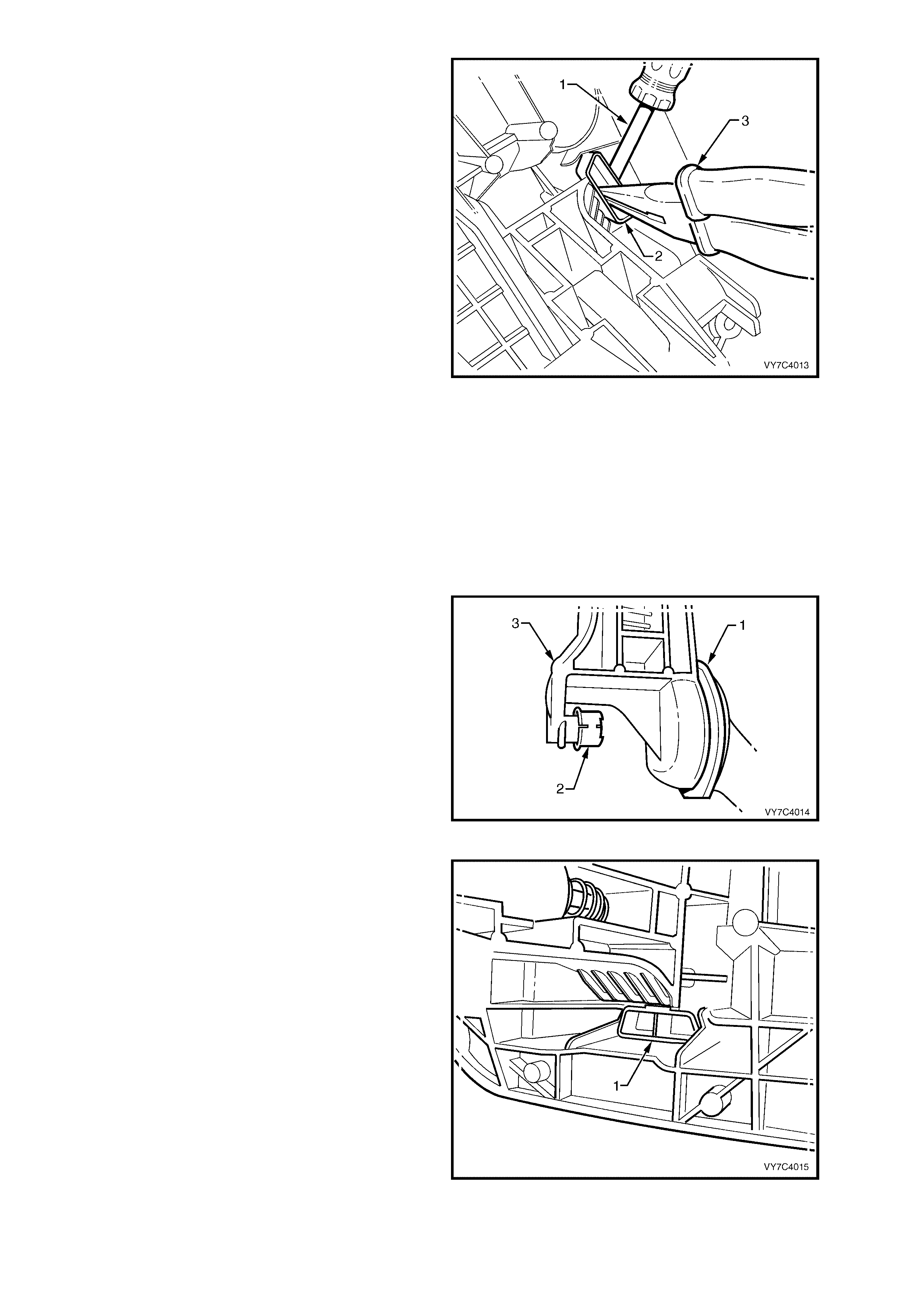

Figure 7C4-21

4. Reinstal l the lever lock ing piece (1) , using long

nosed pliers. Correct reinstallation will have

occurred when an audible click is heard,

indicating that the tang on the locking piece

has been installed correctly.

NOTE: While a standard shift lever is shown, the

reinstallation is the same for the BTSI design.

Figure 7C4-22

5. Appl y a sm ear of multi-pur pose chassis grease

such as NLGI No. 1 Lithium grease to the

outer, lipped seal (1), then reinstall over the

external lever.

Figure 7C4-23

BTSI Sole noi d and/or Micr o Switc h

6. Reinstall the solenoid and/or micro switch to

the base, securing with two screws (4) for the

solenoid and/or single self tapping screw (3) for

the micro switch. Do not over-tighten the

screws.

7. Reinstall the patch wiring harness connectors

to the micro switch (2) and/or solenoid (1).

8. Reposition the insulating foam into position.

NOTE: No adjustment is required for the BTSI

solenoid.

Figure 7C4-24

Lower Housing

9. If removed, reinstall the switch/es to the lower

housing, ensuring that the locating lug on the

switch body engages with the slot in the lower

housing. If the vehicl e is equipped with tract ion

control, the c orrec t loc ation fo r this s witc h, is in

the right hand aperture for RHD vehicles (the

opposite side for LHD vehicles). This will

always be behind the PRNDL indicator lens.

10. Reinstall the patch wiring harness, ensuring

that the switch connector/s connection is

correct. Also reinstall the PRNDL lamp and

holder, by inserting and turning the holder a

quarter turn to the left (counter-clockwise).

If of the BTSI design, it is recommended that

the patch harness be reinstalled to the

solenoid and micro switch first, then to the

PWR and/or T/C switch (if fitted), prior to

reassembling the lower housing assembly to

the base (refer to Figure 7C4-28). In this

instance, the wiring harness connector should

also be installed to the bracket on the base, at

this time.

11. If a new selector lever boot is to be installed,

use the tie strap included with the new boot to

firmly secure the boot to the gearshift selector

knob. Trim excess length and discard.

12. With the upper cover (1) inverted, locate the

boot (2) over each of the cover locating tangs

(3), working gradually around until every tang

is covered.

NOTE: The weight of the selector knob will be

sufficient to keep the boot engaged with the tangs.

Figure 7C4-25

13. To reduce the possibility of the boot from

becoming dislodged from the upper cover

retaining tangs, reinstall the lower housing (1)

to the cover (2), working in an inverted

position, as shown.

NOTE: Before reassem bling the lower cover to the

base, chec k that the colour ed indictor is in line with

the two PRN DL displa y la mp holes (3). T his will be

the approximate position for correct reassembly.

14. Engage each of the tabs on the upper cover

with the retaining lugs on the lower housing.

When all four tabs have been engaged, the

boot will be clamped and can no longer

become disengaged.

Figure 7C4-26

15. Ensure that the PRNDL indicator slide in the

lower housing, is at the “D” position (the red

colour will sho w oppos ite t he “D ” in the PRN DL

lens).

16. After checking that the insulator (3) is

undamaged, reinstall to the base (2).

17. After checking that the selector lever is also in

the Drive position, reinstall the lower housing

(1) over the shift lever and engage each of the

three legs with the base apertures. Check that

the PRNDL indicator slide pin is engaged with

the slot in the selector lever.

Figure 7C4-27

NOTE: If the shifter is of the BTSI design, before

reassembling to the base, reinstall the patch

harness connector/s (1) to the PWR and/or T/C

switch (if fitted).

18. Reinst all the selec tor indica tor lam p and holder

(2) by inserting, then turn to the right

(clockwise), to secure.

19. Re-engage the selector lever knob with the

selector lever, aligning the control rod with the

hole in the selector knob.

NOTE: Correct engagement of the PRNDL

indicator can be easily checked by moving the

selector lever. Should the coloured portion not

move with the le ver, then engagem ent is incorrect.

Separate the lower housing and base and repeat

steps 13 to 15 above.

IMPORTANT: If the shifter is of the BTSI design,

do not engage the Park position during this testing

process. If this does occur, the interlock will need

to be manually released again (refer to Step 1 of

the Disassemble process).

Figure 7C4-28

20. Reinstall the selector knob retaining screw,

using a TX20 Torx bit and suitable equipment,

being caref ul not to over-tighten.

21. Reinstall the selector lever knob and spring,

pushing down until the two locking tangs

engage.

NOTE: If the selector lever knob and spring have

not been removed, then re-engagement with the

selector lever can still be achieved but some

manoevering may be necessary.

22. If removed, reinstall the wiring harness

connector t o the br ack et at the e nd of the bas e

and push until the looking tang engages.

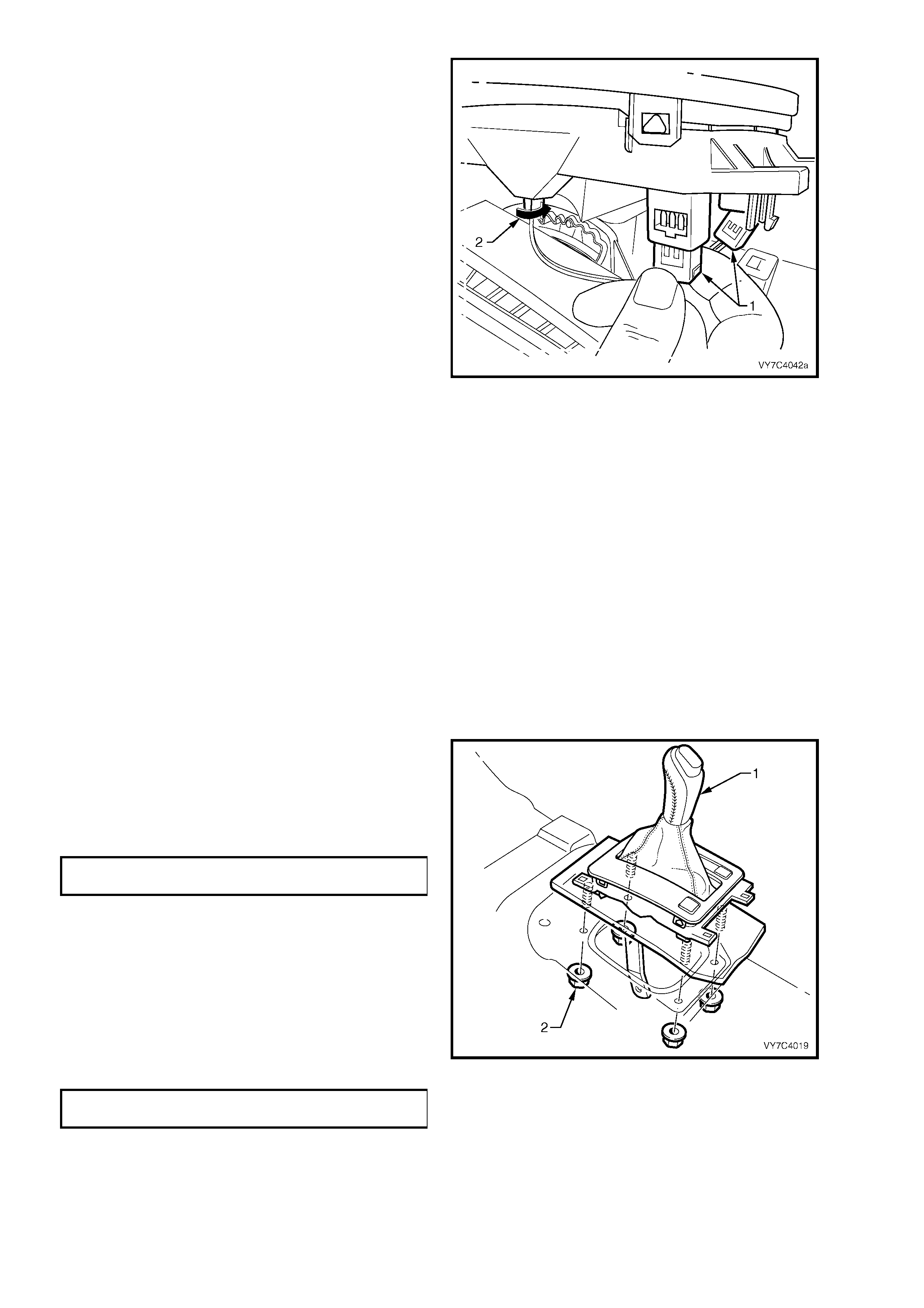

REINST ALL

1. Clean m ating surf aces of floor pan and ins pect

the base seal for damage, replacing if

necessary.

2. Reinstall selector lever assembly to the floor

pan, install the four retaining nuts (1) and

tighten to the correct torque specification.

SELECTOR BASE RETAINING

NUT TORQUE SPECIFICATION 15 Nm

3. The remainder of the reinstallation is the

reverse of the rem oval pro cedure. As r equired,

refer to Section 1 A3 INSTRUM ENT PANEL &

CONSOLE for the reinstallation procedures of

the floor console assembly, lower extension

side trim panels and floor console cover.

4. Adjust shift linkage as detailed in

3.2 SELECTOR LINKAGE in this Section,

tightening the selector rod locking bolt to the

correct torque specification.

SELECTOR LEVER LOCKING

BOLT TORQUE SPECIFICATION 25 Nm

Figure 7C4-29

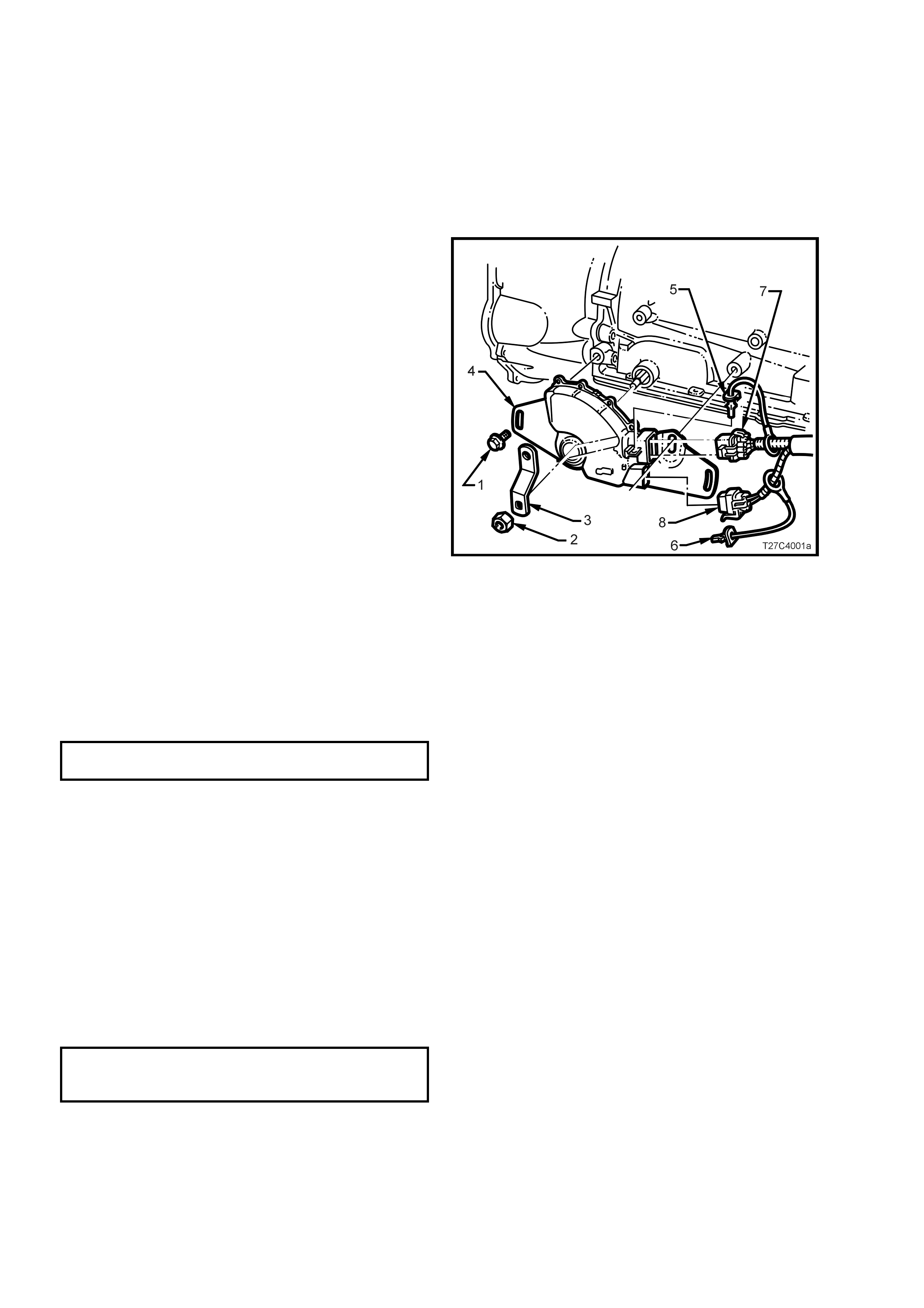

3.4 NEUTRAL START AND BACK-UP LAMP SWITCH

LT Section No. – 04A-170

REMOVE

1. Raise front of vehicle and support on safety

stands. Refer to Section 0A GENERAL

INFORMATION in the MY 2003 VY and V2

Series Service Information, for the location of

jacking and support points.

2. While holding the lower selector lever (3) with

an adjustable wrench, remove the retaining

nut (2).

3. Carefully remove the lever (3) from the

transmission manual shaft.

4. Prise the wiring harness connector CPA

(Connector Position Assurance) securing pins

(5 and 6) from the neutral start and back-up

lamp switch (4), taking care not to break the

pins in the process. Disconnect the two wiring

harness connectors (7 and 8) from the switch

assembly (4).

5. Remove the two switch retaining screws (1),

then slide the switch assembly (4) over the

manual shaft and remove from the vehicle.

NOTE: If the GEN III V8 engine is fitted, the front

bolt will also retain the oil cooler pipe support

bracket. If so, carefully bend the bracket clear of

the switch.

Figure 7C4-30

REINST ALL

Reinstallation of the neutral start and back-up lamp switch is the reverse of the removal procedure except for the

following:

1. When reinstalling the two switch securing screws, leave them finger tight, until the adjustment process has

been completed.

2. After reinstalling the selector lever and retaining nut, hold the lever with an adjustable wrench and tighten the

nut to the correct torque specification.

MANUAL SHAFT LEVER NUT

TORQUE SPECIFICATION 25 Nm

3. Reinstall the wiring harness connector/s but do not reinstall the CPA securing pin/s at this stage.

4. Check the selector linkage adjustment. Refer 3.2 SELECT O R LINKAGE, in this Sect ion.

5. On completion of the neutral start and back-up lamp switch adjustment procedure that follows, check that the

engine can only be started when the gearshift lever is either in the ‘P’ (Park) or ‘N’ (Neutral) positions.

ADJUST

1. With the vehicle still raised, rotate the neutral start and back-up lamp switch back and forth until a central

position is attained, then lightly tighten the front bolt to retain.

2. With the ignition switched to the ON position, check that the engine can only be started in both the Park and

Neutral selector positions. A further minor adjustment may be required to achieve this state.

Also check that the Reverse lamps illuminate when Reverse range is selected.

3. After the switch adjustment, tighten the switch retaining screws to the correct torque specification.

NOTE: To gain access to the rear screw, it will be necessary to remove the wiring harness connector, once again.

NEUTRAL START & BACK-UP

LAMP SWITCH RETAINING SCREW

TORQUE SPECIFICATION 25 Nm

4. Following the bolt tightening procedure, reinstall the connector/s and the CPA securing pin/s.

5. Lower the vehicle to the ground and check the operation of the neutral start and back-up lamp switch. The

vehicle should on l y st art i n eith er ‘ P’ ( Park) or ‘N’ (Neutr al) r an ges an d t he r e verse lamps s houl d o nly illum inate

when the ‘R’ (Reverse) range is selected.

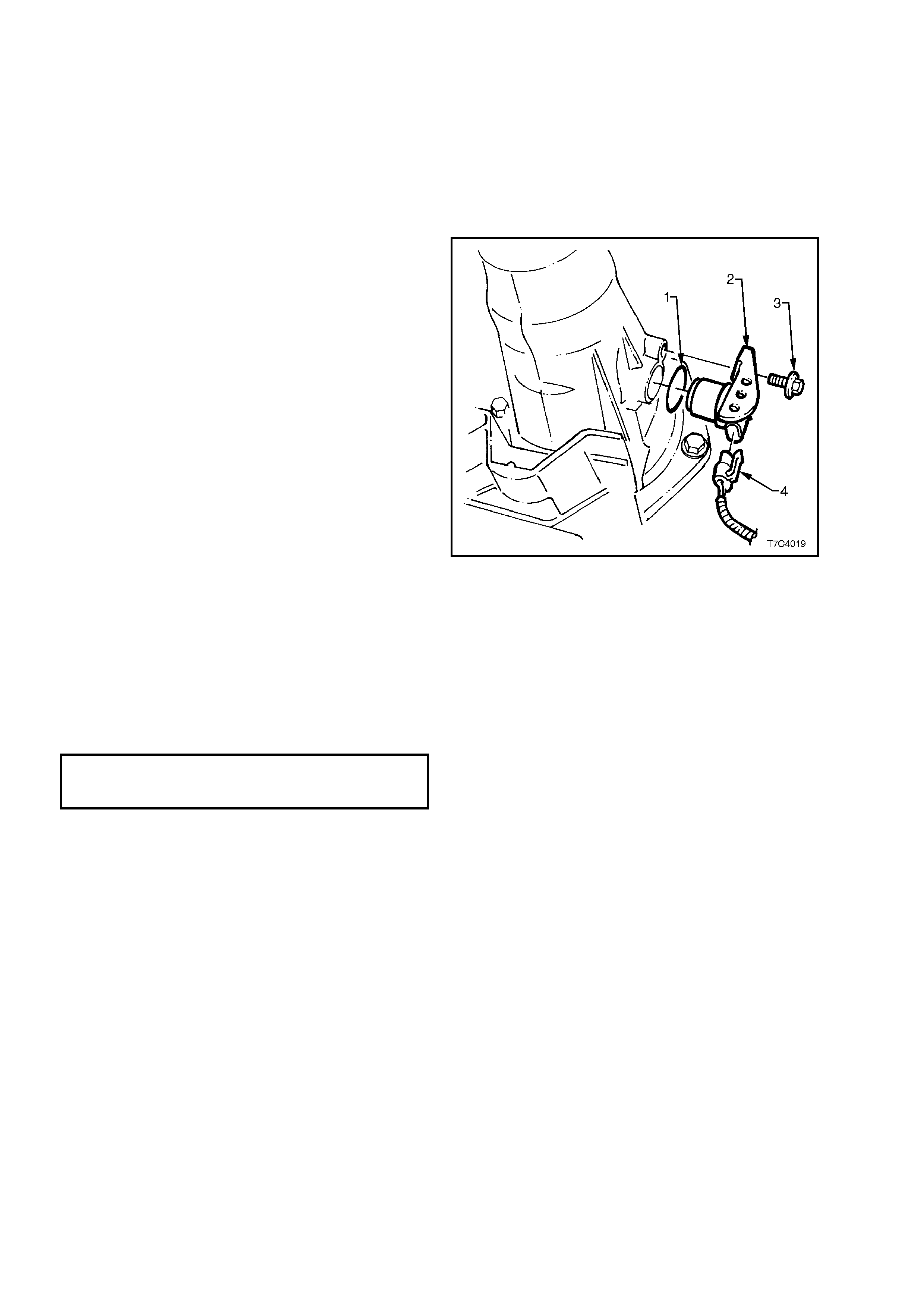

3.5 VEHICLE SPEED SENSOR

LT Section No. – 04A-200

REMOVE

1. Raise rear of vehicle and support on safety

stands. Refer to Section 0A GENERAL

INFORMATION in the MY 2003 VY and V2

Series Service Information, for the location of

jacking and support points.

2. Place drip tray beneath speed sensor.

3. Disconnect electrical connector (4) from the

vehicle speed sensor (2).

4. Unscrew vehicle speed sensor retaining screw

(3).

5. With a pulling/turning motion, remove vehicle

speed s ensor assem bly (2) and O- ring seal (1)

from the transmission extension housing.

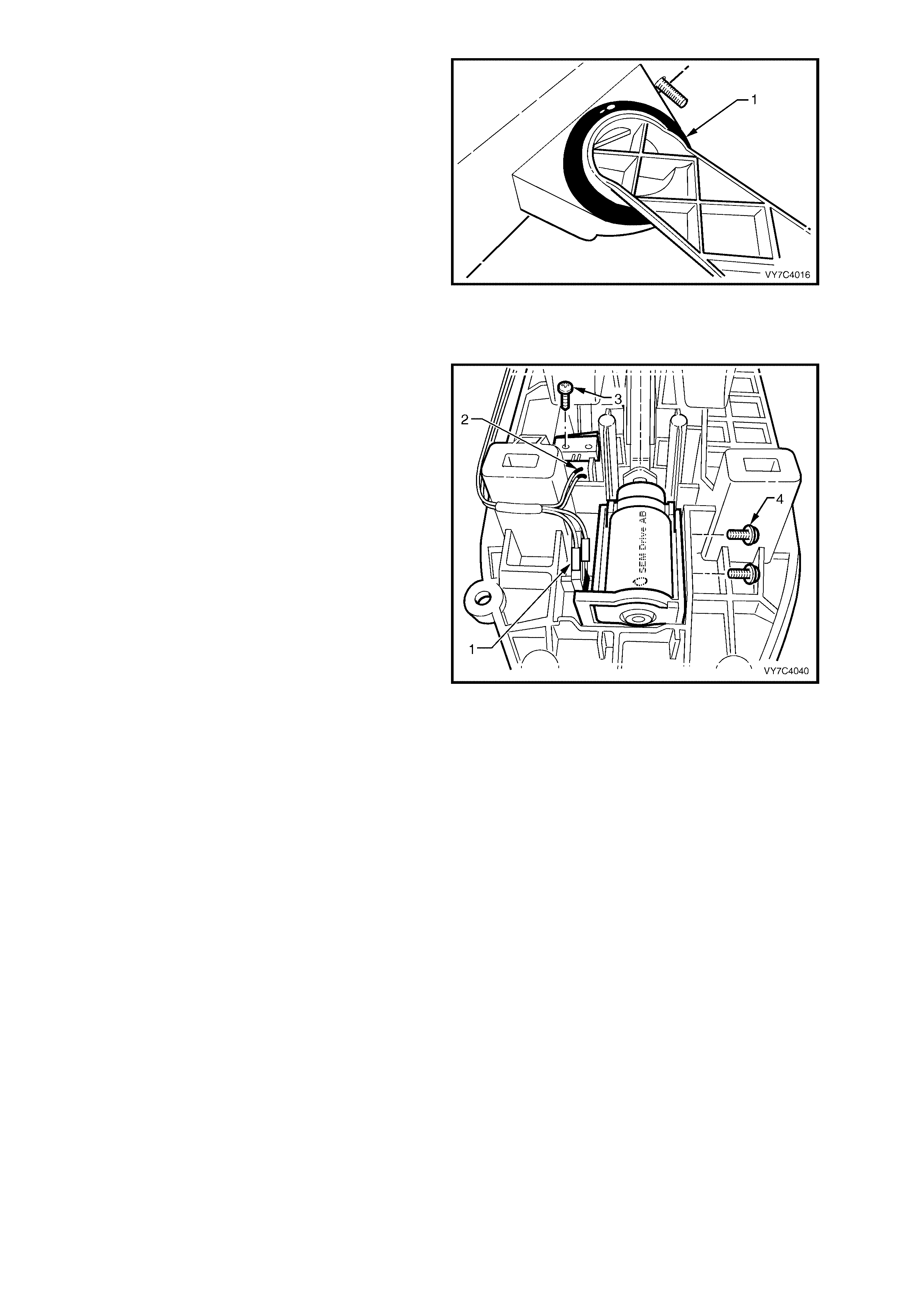

Figure 7C4-31

REINSTALL

1. Lubricate a new O-ring seal (1) with p etroleum

jelly (Vaseline™ or equivalent) and install on

the vehicle speed sensor (2).

2. Install the speed sensor (2) into the

transmission extension housing.

3. Reinstall retaining screw (3) and tighten to the

specified torque.

SPEED SENSOR

RETAINING SCREW

TORQUE SPECIFICATION 12 Nm

4. Reinstall the wiring harness connector (4) to

the speed sensor (2).

5. Lower vehicle and check fluid level. Refer

2.1 FLUID LEVEL CHECK in this Section.

3.6 MANUAL SHAFT OIL SEAL

REPLACE

NOTE: This procedure requires the use of special

tool No. AU583. Should this tool not be available,

the seal can still be replaced but involves the

rem oval of the selector s haft from the transm ission

case. This procedure is detailed in Section 7C5

UNIT REPAIR, in the MY 2003 VY and V2 Series

Service Information.

1. Raise front of vehicle and support on safety

stands. Refer to Section 0A GENERAL

INFORMATION in the MY 2003 VY and V2

Series Service Information, for the location of

jacking and support points.

2. Remove the Neutral Start and Back-Up Lamp

Switch. Refer 3.4 NEUTRAL START AND

BACK-UP LAMP SWITCH in this Section.

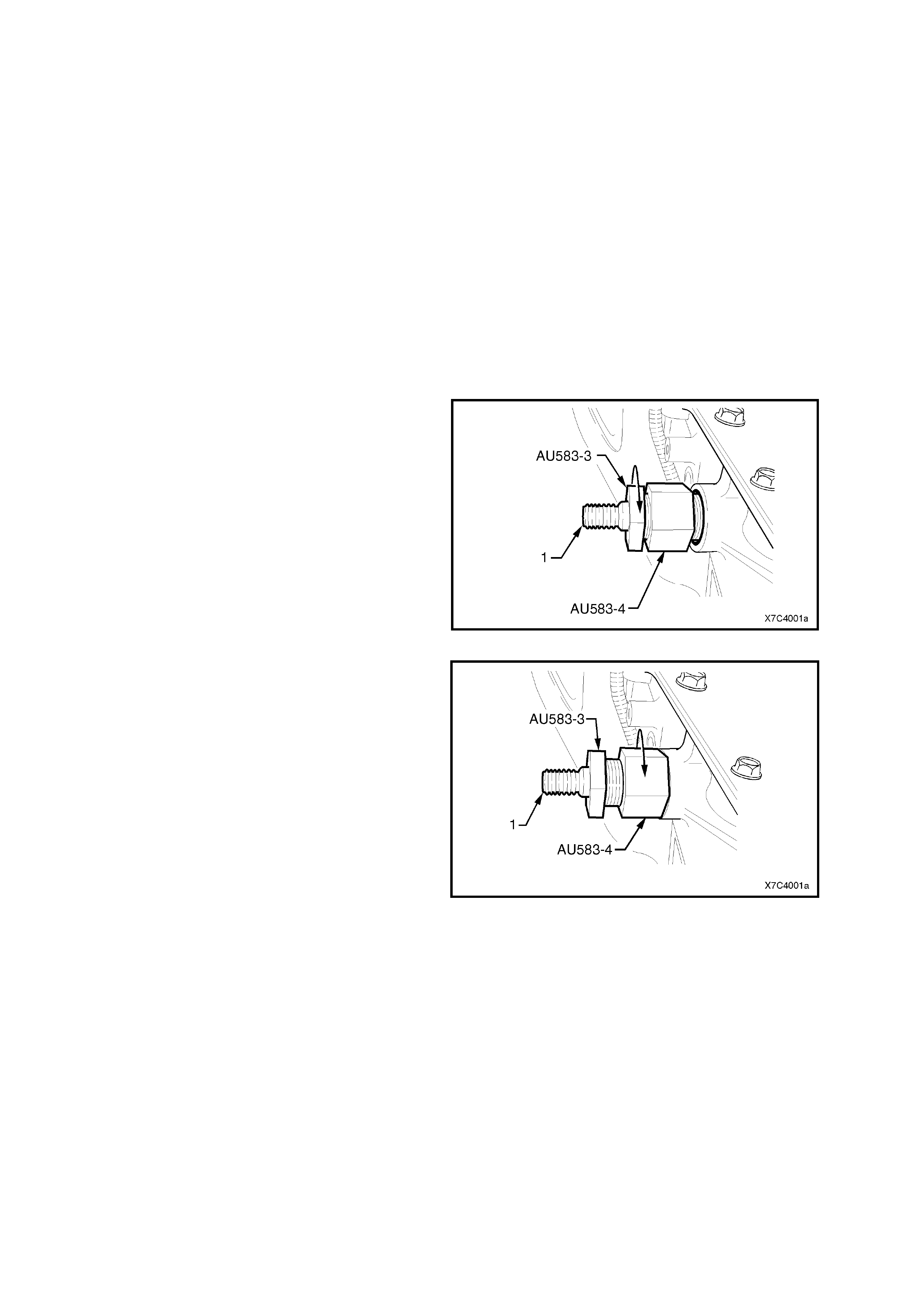

3. Assemble the rem over nut (Tool No. AU583-4)

with the threaded section closest to the

hexagonal head of the seal remover AU583-3.

Install the nut up to the hexagonal end.

4. Install the pre-assembled remover (Tool Nos.

AU583-3 and AU583-4) over the manual shaft

(1) and engage the tapered thread end of the

seal remover into the seal. Tighten the seal

remover until the tool thread grips the steel

shell of the seal.

NOTE: Do not overtighten the seal remover in the

seal.

Figure 7C4-32

5. While holding the seal remover (AU583-3),

screw the remover nut (AU583-4) up to the

transmission case.

6. Continue tightening the remover nut until the

seal is removed into the remover nut cavity.

7. Discard the removed seal.

Figure 7C4-33

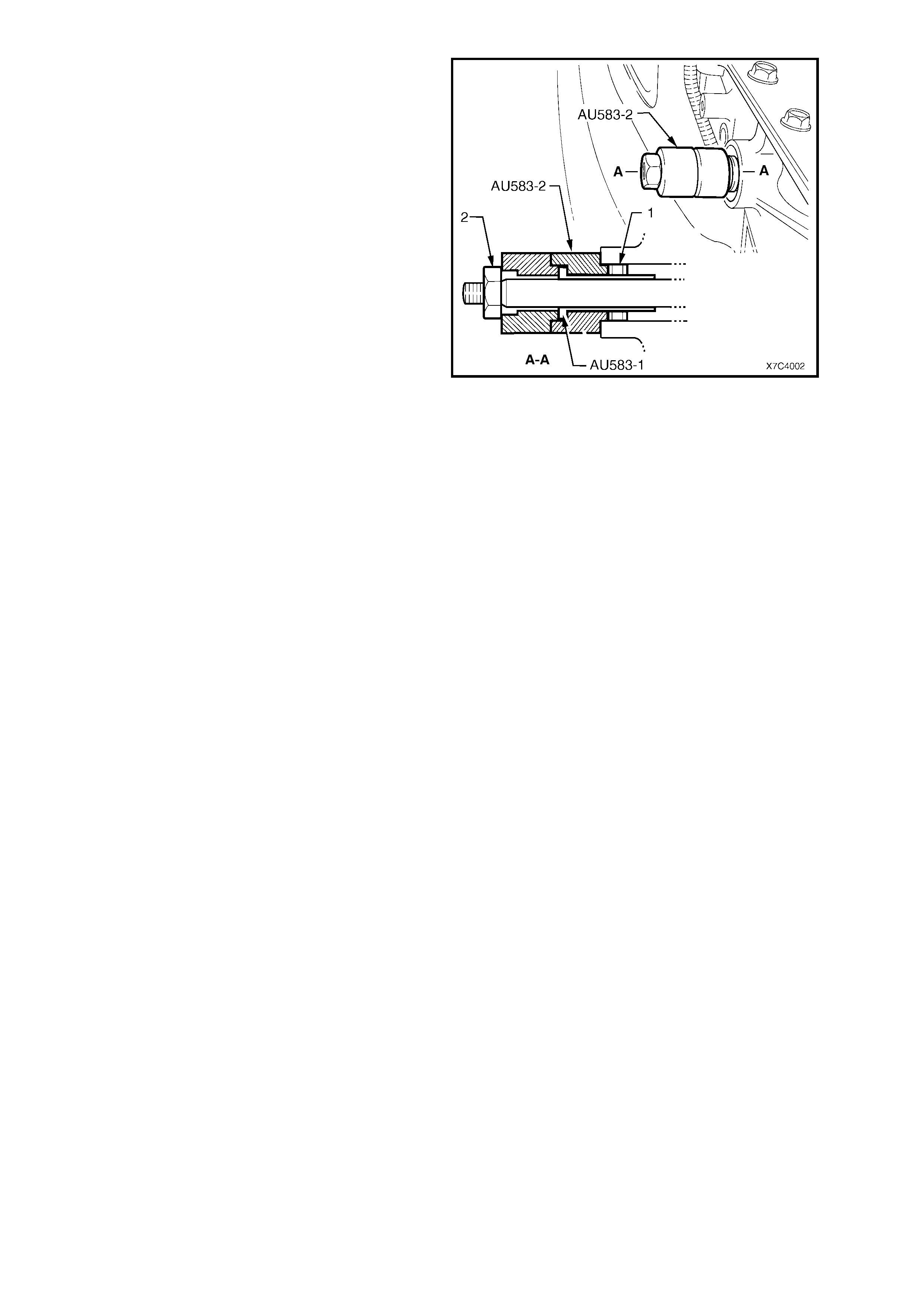

8. Pre-assemble the seal pr ot ec tor ( AU583- 1) into

one of the plastic seal installers (AU583-2), as

shown in the sectioned view.

9. Lubricate the seal lip of a new seal (1) with

Dexron® III automatic transmission fluid, then

install it (with the steel seal casing facing the

installer) over the seal protector sleeve

(AU583-1).

10. Install the seal protector (AU583-1), seal

installer (AU583-2) and seal (1), over the

manual shaft and up to the transmission case.

NOTE: If the sleeve jams on the manual shaft, then

the shaf t wil l be burr ed o ver the f lats that loc ate the

selector l ever. Use a fin e file to rem ove burrs, then

proceed.

11. Install the s econd pl astic seal ins taller over the

manual shaft until it seats against the first

installer.

12. Install the manual shaft lever retaining nut (2)

and tighten it to install the seal fully into place

in the transmission case.

NOTE: Two plastic seal installers (AU583-2) are

required, because of the restricted space between

the end of the manual shaft and the floor pan.

13. Remove installer tools, AU583-2 (two pieces)

and seal protector AU583-1 from the manual

shaft.

Figure 7C4-34

14. Reinstall the Neutral Safety and Back-Up

Lamp Switch and adjust. Refer 3.4 NEUTRAL

START AND BACK-UP LAMP SWITCH, in

this Section.

15. Lo wer the vehic le to t he gr ound, chec k and top

up the automatic transmission fluid level, as

required. Refer 2.1 FLUID LEVEL CHECK, in

this Section.

3.7 CASE EXTENSION OIL SEAL

LT Section No. – 04A-200

REPLACE

1. Rais e r ear of t he vehicl e and s uppor t on saf ety

stands. Refer to Section 0A GENERAL

INFORMATION in the MY 2003 VY and V2

Series Service Information, for the location of

jacking and support points.

2. Place a drip tray beneath rear of transmission.

3. Remove propeller shaft assembly, refer to

Section 4C PROPELLER SHAFT AND

UNIVERSAL JOINTS in the MY 2003 VY and

V2 Series Service Information.

4. Using a suitable seal removal tool, such as

E308 or equivalent, pr ise the oil seal f rom rear

of case extension.

IMPORTANT: Take care not to scratch the

machined seal recess in the extension housing as

transmission fluid may weep past the outside of the

installed seal once the vehicle is put back into

service.

5. Thoroughl y clean ar ou nd seal bor e in c ase and

ensure there are no burrs.

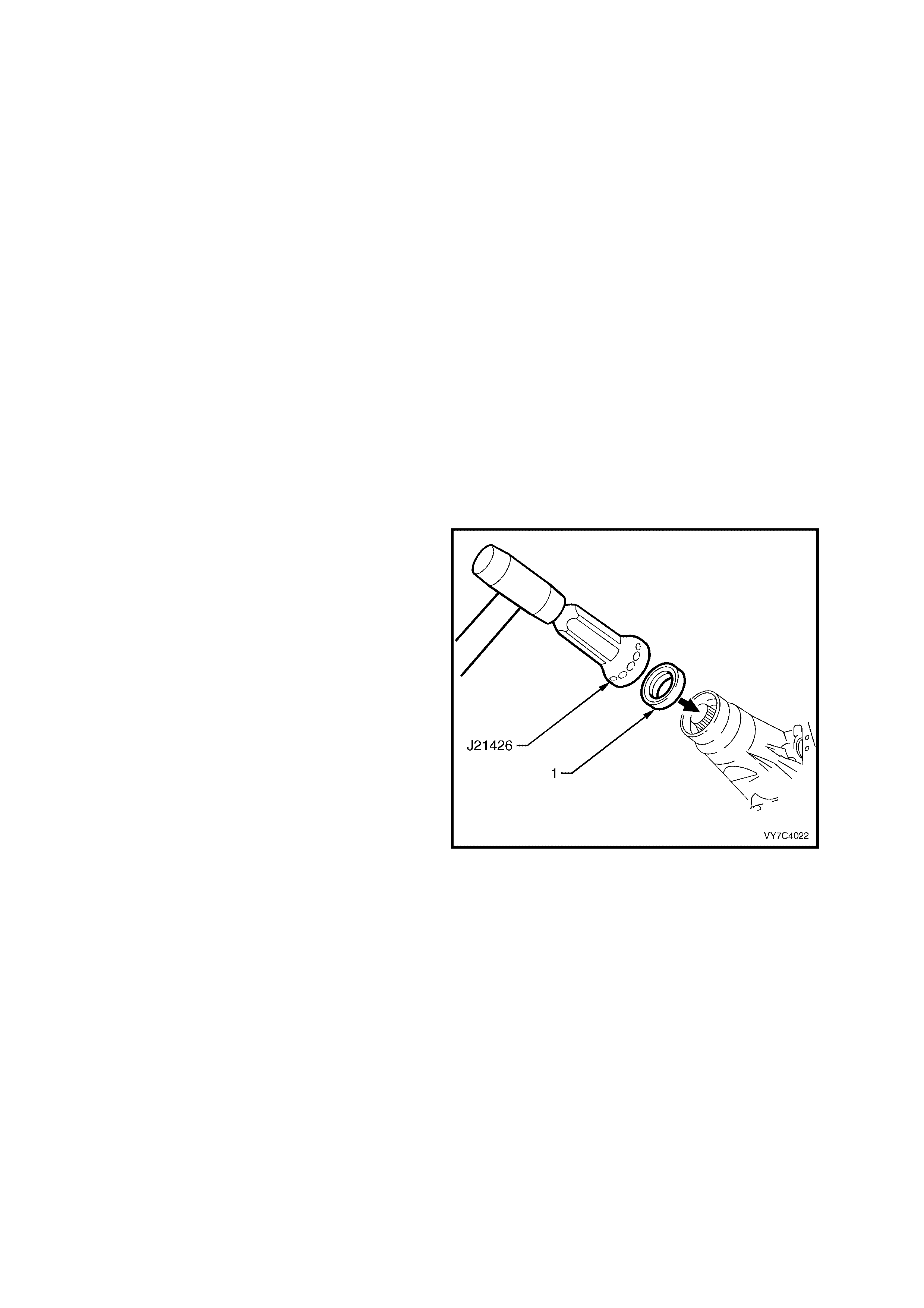

6. Tap new seal (1) into place, using Tool No.

J21426 and a soft faced hammer.

7. Reinstall propeller shaft. Refer Section 4C

PROPELLER SHAFT AND UNIVERSAL

JOINTS, in the MY 2003 VY and V2 Series

Service Information.

8. Lower vehic le to the grou n d and c h eck the f luid

level, refer to 2.1 FLUID LEVEL CHECK in this

Section.

Figure 7C4-35

3.8 EXTENSION HOUSING AND/OR BUSH

LT Section No. – 04A-200

REPLACE

1. Raise vehicle and support on safety stands.

Refer to Section 0A GENERAL

INFORMATION in the MY 2003 VY and V2

Series Service Information, for the location of

jacking and support points.

2. With vehicles fitted with the V6 e ngine , rem ove

the twin exhaust pipe and catalytic converter

assembly. For those vehicles fitted with either

the V6 Supercharged or GEN III V8 engines,

remove the exhaust system from the rear of

both catalytic converters rearwards. Refer to

Section 8B EXHAUST SYSTEM in the MY

2003 VY and V2 Series Service Information.

3. Place drip tray beneath case extension.

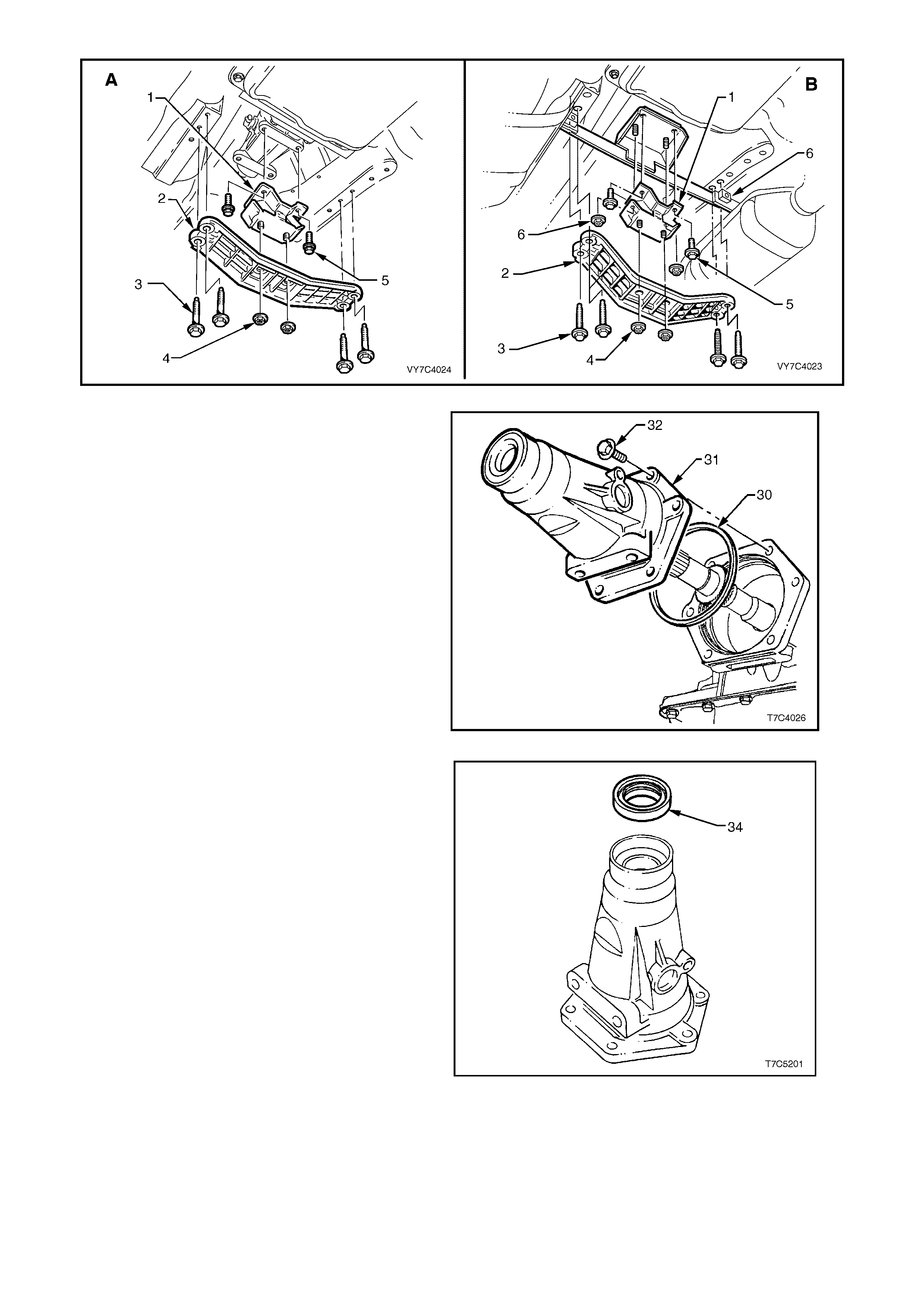

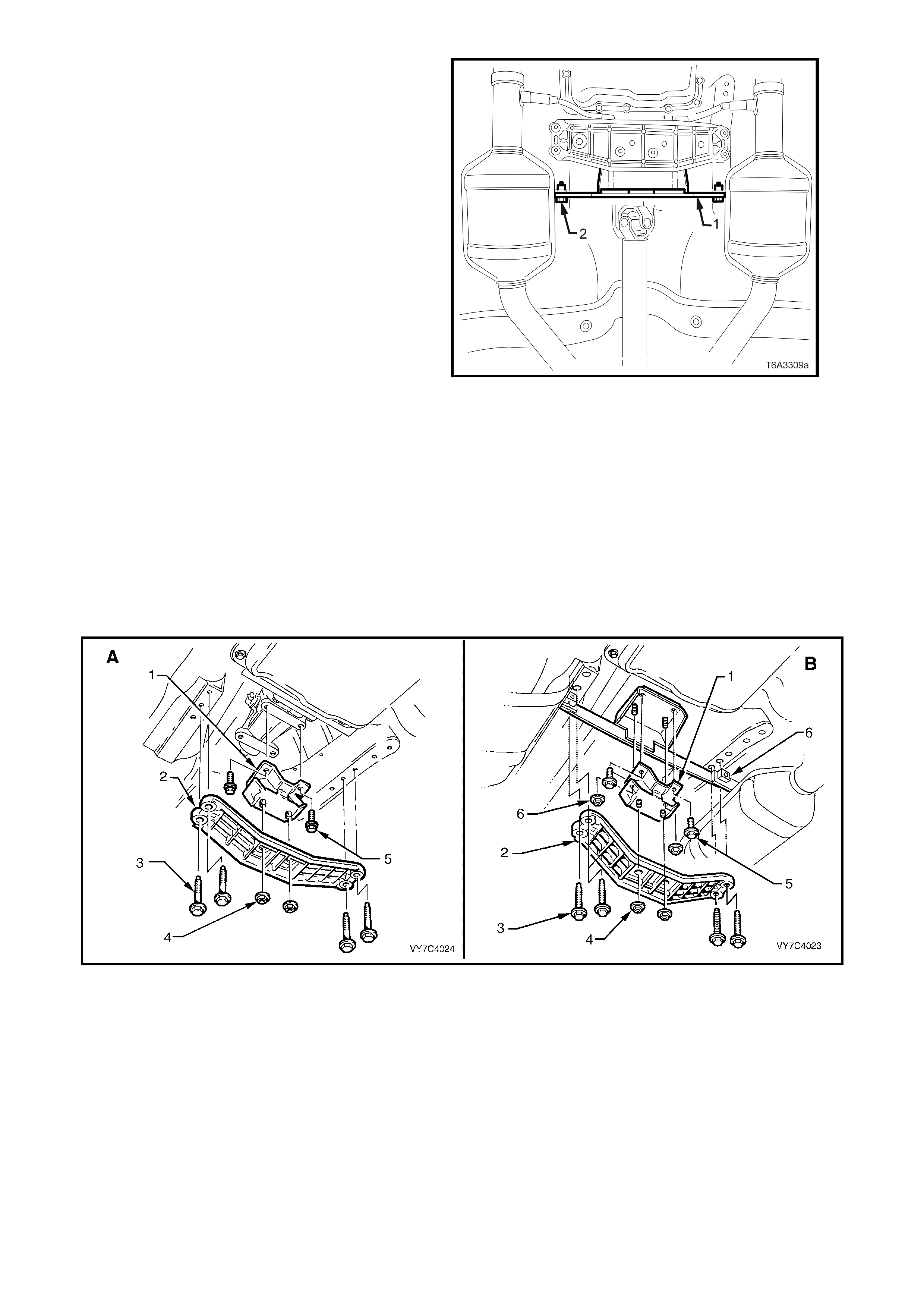

4. For those vehicles fitted with the GEN III V8

engine, remove the two bolts (2) securing the

catalytic converter bracket (1) to each catalytic

converter.

Figure 7C4-36

5. Remove propeller shaft, refer to Section 4C

PROPELLER SHAFT AND UNIVERSAL

JOINTS in the MY 2003 VY and V2 Series

Service Information.

6. Use a sharp scriber to mark the exact location

of the crossmember (2) to the side frame,

before loosening any of the four crossmember

to side frame attaching bolts (3) (refer to

Figure 7C4-37) .

IMPORTANT: This st ep is c r itic al to t he c or rec t

powertrain alignment on reassembly. If not

carried out, then vehicle vibration and/or

handling problems could result!

7. Remove two bolts (5) securing rear engine

mount to transmission.

8. Support transm ission with a jack . Do not place

the support beneath case extension or oil pan.

9. Remove the four crossmember to side frame

bolts (3) and remove crossmember (2) and

rear engine mount (1) from the vehicle.

Figure 7C4-37

10. Rem ove vehicle s peed sen sor ass embly wiring

harness connector, then remove the sensor

from the extension housing. Refer to

3.5 VEHICLE SPEED SENSOR in this Section

for details.

11. Remove six bolts securing case extension to

transmission case.

12. Remove case extension (31) and seal

assembly (30) from the rear of the transmission

case.

Figure 7C4-38

13. If bush is to be replaced, remove the case

extension oil seal (34), using a removing tool

such as Tool E308 or commercial equivalent.

Figure 7C4-39

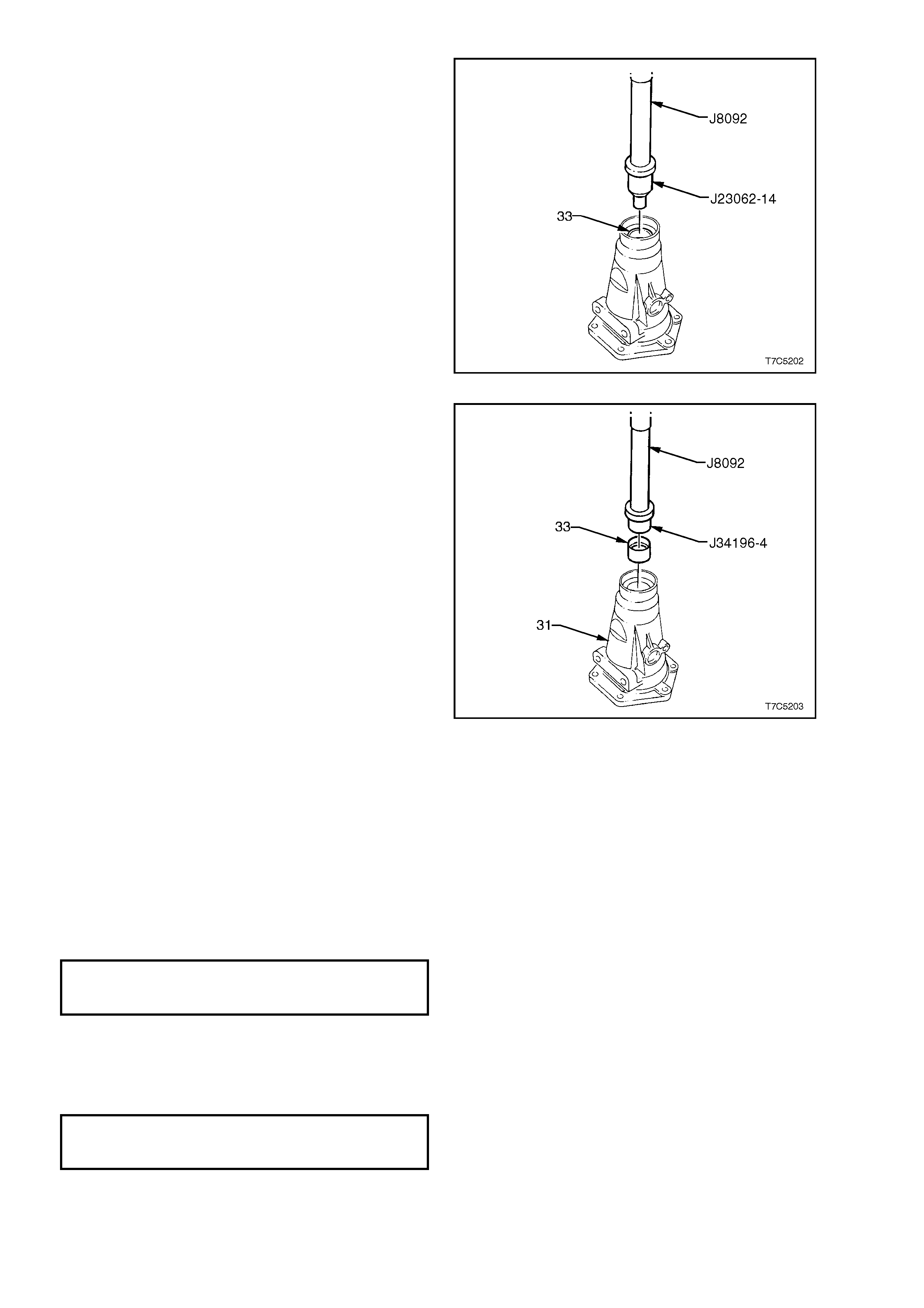

14. Using bush remover, Tool J23062-14 and

driver handle J8092, press the bush (33) from

the extension housing.

NOTE: Take note of the orientation of the split in

the bush for installation purposes.

Figure 7C4-40

15. Lubricate the outside of a new bush with

automatic transmission fluid to reduce the

chance of material pick-up.

16. Install a new bush (33) into the extension

housing (31), using installer J34196-4 and

driver handle J8092, ensuring that the split in

the bush is in the same orientation as the

original.

Figure 7C4-41

Reinstallation of components is in the reverse

order to r emoval (S teps 1 t o 10 abo ve) , taking note

of the following points:

17. Lubric ate t he s eal lips of a ne w case extens ion

oil seal and install, using Tool No. J21426.

18. Lubricate a new extension housing to case

seal ring with automatic transmission fluid,

then install to the extension housing. Reinstall

the housing to the transmission case and

tighten the six bolts to the correct torque

specification.

EXTENSION HOUSING

TO CASE BOLT

TORQUE SPECIFICATION 45 Nm

19. Lubricate a new vehicle speed sensor O-ring

with automatic transmission fluid, then install

to the sensor. Reinstall the sensor to the

extension housing and tighten the retaining

screw to the correct torque specification.

SPEED SENSOR

RETAINING SCREW

TORQUE SPECIFICATION 12 Nm

20. If removed, reinstall the rear engine mounting

to the crossmember, after noting the

orientation of the rear crossmember relative to

the installe d e ngine.

21. Tighten the engine mounting nuts to the correct

torque specification.

REAR ENGINE MOUNTING TO

CROSSMEMBER NUT

TORQUE SPECIFICATION 25 Nm

22. Reinstall the rear crossmember, ensuring that

it is aligned with the scribe lines made prior to

removal, before tightening the attaching bolts

to the correct torque specification.

REAR ENGINE MOUNTING TO

EXTENSION HOUSING BOLT

TORQUE SPECIFICATION 58 Nm

REAR CROSSMEMBER TO SIDE

RAIL ATTACHING BOLT

TORQUE SPECIFICATION 58 Nm

Figure 7C4-42

23. For reinstallation of the exhaust system, refer

to Section 8B EXHAUST SYSTEM in the MY

2003 VY and V2 Series Service Information.

24. Reinstall the propeller shaft. Refer to Section

4C PROPELLER SHAFT AND UNIVERSAL

JOINTS, in the MY 2003 VY and V2 Series

Service Information.

25. Lower vehicle and check transmission fluid

level. Ref er 2.1 FLUID LEVEL CHECK, in this

Section).

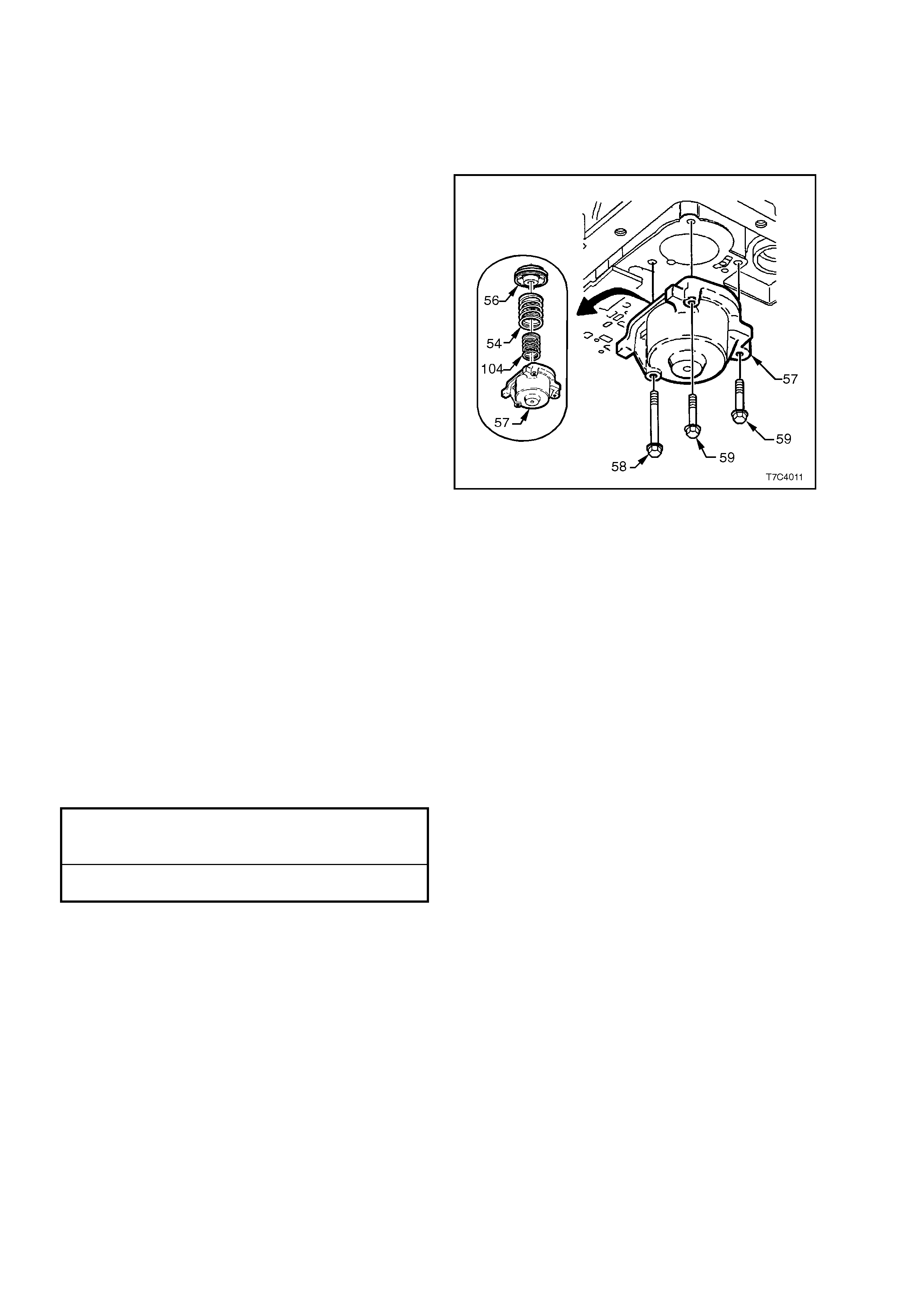

3.9 1-2 ACCUMULATOR ASSEMBLY

REMOVE

1. Remove oil pan and filter, refer

3.1 FLUID LEVEL CHANGE AND FILTER

REPLACEMENT in this Section.

2. Progressively loosen, then remove the three

accum ulator cover bolts (58 an d 59), the cover

(57) and pin assembly, piston and seal

assembly (56) and the two springs (54 and

104), from the control valve body spacer plate.

3. Using LOW press ure air, apply to the dr illing in

the cover to r emove the 1-2 acc umulator pis t on

(56). Remove and discard the piston seal.

4. Remove the two 1-2 accumulator springs (54

and 104).

Figure 7C4-43

CLEAN AND INSPECT

1. Clean components with a suitable solvent and

air dry.

2. Check that springs are not distorted, or broken.

3. Lubricate new seal with petroleum jelly and

install on piston. Check that piston seal does

not bind in the piston groove.

4. Check all machined surfaces for damage or

wear.

REINST ALL

Reinstallation is the reverse of the removal

procedure.

However, use a new oil pan gasket and tighten all

fasteners to the correct torque specification.

1 – 2 ACCUMULATOR

COVER BOLT

TORQUE SPECIFICATION 12 Nm

OIL PAN BOLT

TORQUE SPECIFICATION 12 Nm

3.10 CONTROL VALVE BODY WIRING HARNESS

LT Section No. – 04A-275

REMOVE

1. Raise vehicle and support on safety stands.

Refer to Section 0A GENERAL

INFORMATION in the MY 2003 VY and V2

Series Service Information, for the location of

jacking and support points.

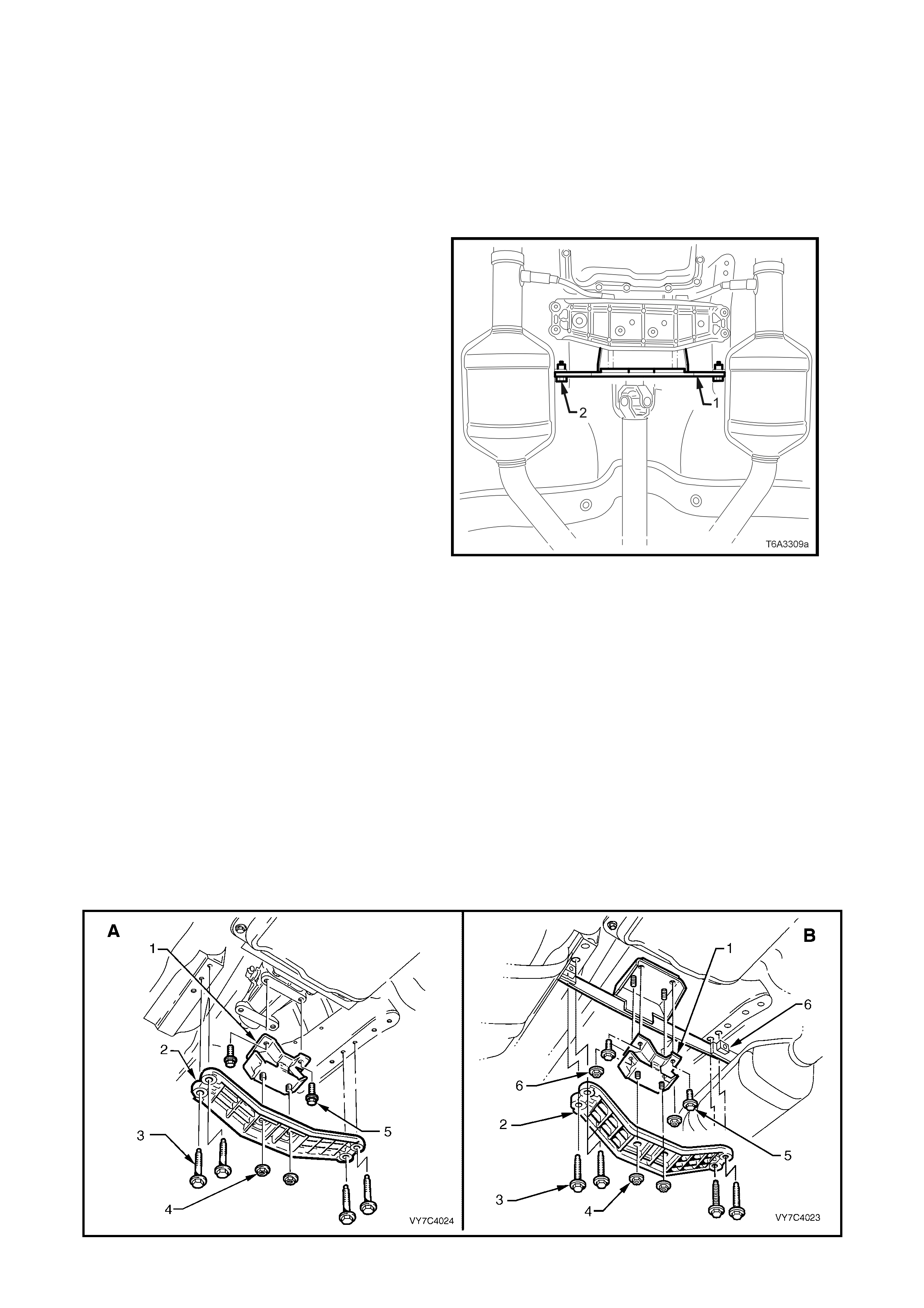

2. For those vehicles fitted with the GEN III V8

engine, remove the two bolts (2) securing the

catalytic converter bracket (1) to each catalytic

converter.

Figure 7C4-44

3. For those vehicles fitted with the V6 engine, remove the twin exhaust pipe and catalytic converter assembly.

For those vehicles fitted with either the V6 Supercharged or GEN III V8 engines, remove the exhaust system

from the rear of both c atalytic converters rearwards . Refer to Section 8B EXH AUST SY STEM in the MY 2003

VY and V2 Series Service Information.

4. Place drip tray beneath case extension.

5. Rem ove pr opel ler shaf t, ref er to Sectio n 4C PRO PEL LER SHAFT AND UNIVER S AL JOINTS in th e MY 20 03

VY and V2 Series Service Information.

6. Use a s harp sc riber to m ark the exact loc ation of the cros smem ber (2) to the s ide fram e, before l oosenin g any

of the four crossmember to side frame attaching bolts (3).

IMPORTANT: This step is critical to the correct powertrain alignment on reassembly. If not carried out, then

vehicle vibration and/or handling problems could result!

7. Remove two bolts (5) (and two nuts for GEN III V8 equipped vehicles) securing rear engine mount to

transmission and to the catalytic converter bracket.

8. Support transmission with a jack. Do not place the support beneath case extension or oil pan.

9. Remove the f our c rossm em ber to side f ram e bolts (3) and rem ove cr ossm em ber (2) and rear engine m ount (1)

from the vehicle.

Figure 7C4-45

10. Remove oil pan and filter, refer

3.1 FLUID LEVEL CHANGE AND FILTER

REPLACEMENT in this Section.

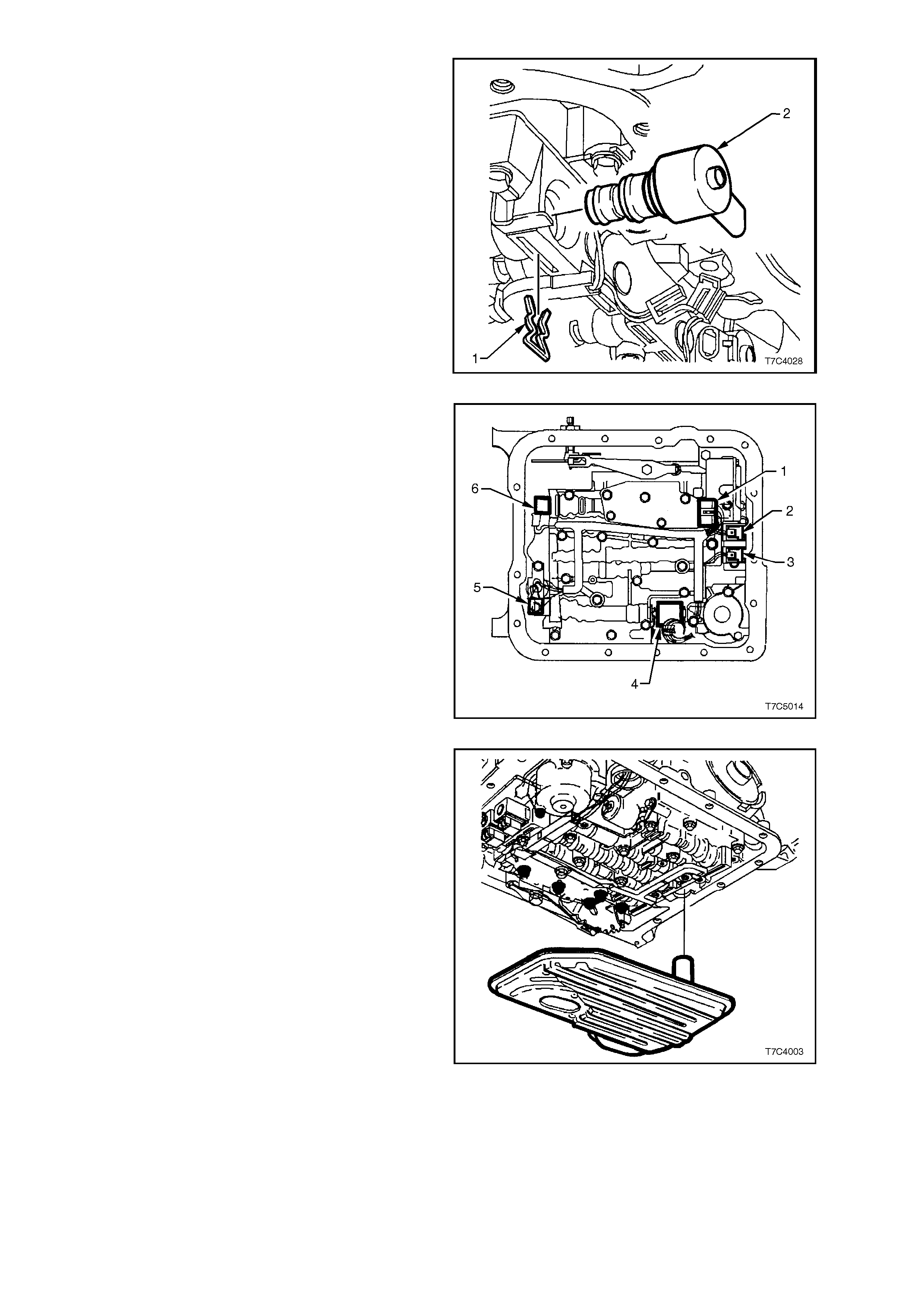

11. Disconnect wiring harness connectors from all

electrical components, except the Torque

Converter Clutch (TCC) Solenoid, that is hard

wired.

NOTE: The connector to the pressure control

solenoid (4) is different for the HAD transmission.

Security and removal however, is the same as for

the TCC PWM solenoid (5).

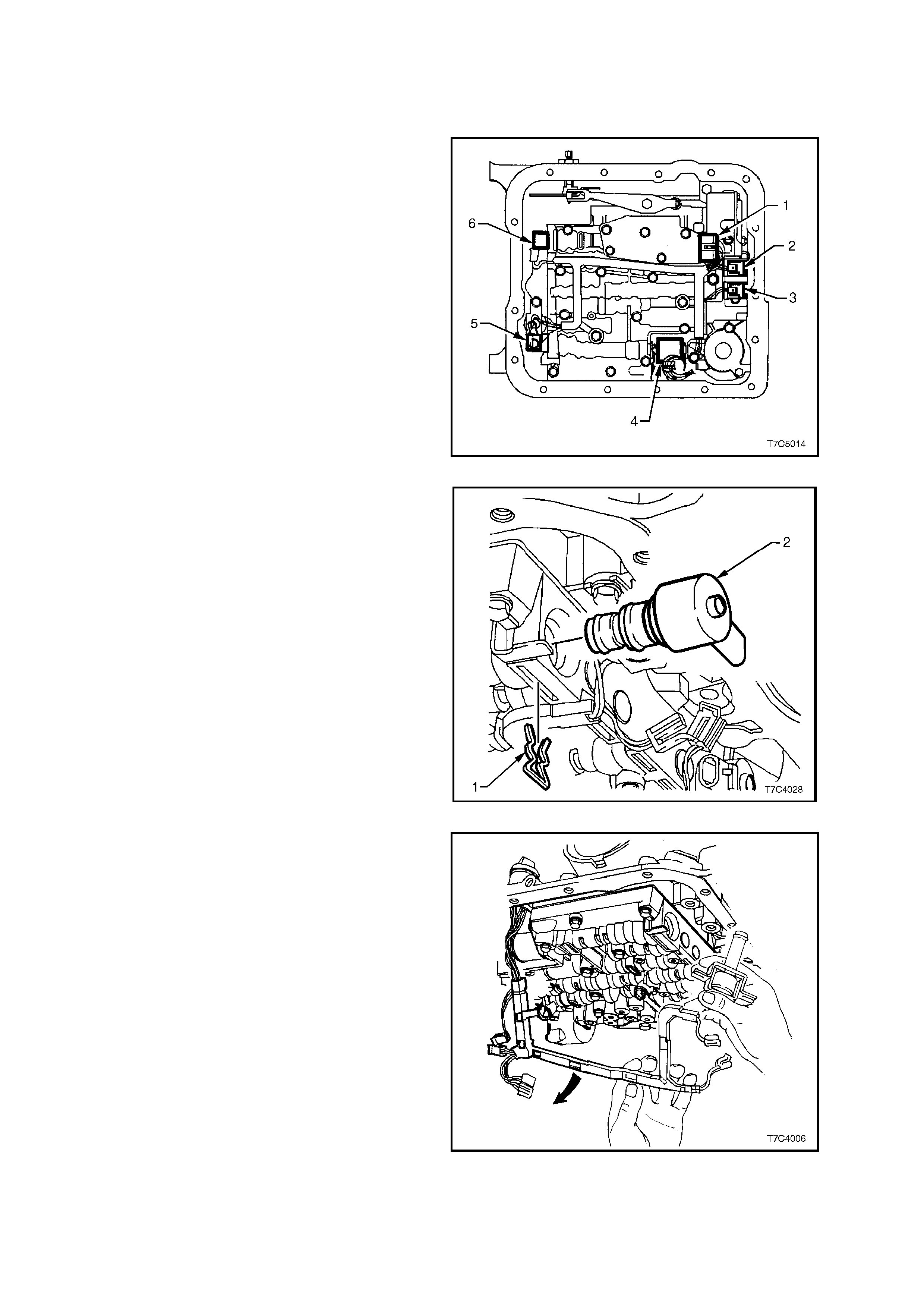

Electrical Connector Identification:

1. TFP Manual Valve Positi on Switch

2. 1-2 Shift Valve Solenoid ‘A’

3. 2-3 Shift Valve Solenoid ‘B’

4. Pressure Control Solenoid (PCS)

5. TCC Pulse Width Modulated (TCC PWM)

Solenoid

6. 3-2 Control Solenoid

Figure 7C4-46

12. Use a hooked piece of wire or a small bladed

screwdriver and prise the TCC PWM solenoid

retaining clip (1) free.

CAUTION: Wear eye protection to prevent

personal injury should the clip fly out

uncontrolled on removal.

13. Remove the TCC PWM solenoid (2) from the

control valve body, with a twisting and pulling

motion.

Figure 7C4-47

14. Remove two bolts securing TCC solenoid

assembly.

15. Withdraw TCC solenoid assembly from pump.

16. Lower the wiring harness and TCC solenoid to

hang from the pass-thru connector.

17. Remove the control valve body. Refer to

3.11 CONTROL VALVE BODY, in this

Section.

NOTE: This is necessary to provide clearance for

the pass-thru connector to be removed.

Figure 7C4-48

18. Lower t he rear of the transm ission ass embl y to

provide space between the floor pan and the

pass-thru connector, located at the right hand

rear of the tr ans m ission cas e. Refer to Step s 5

to 9 inclusive, of 3.8 EXTENSION HOUSING

AND/OR BU SH, in this Sec t ion .

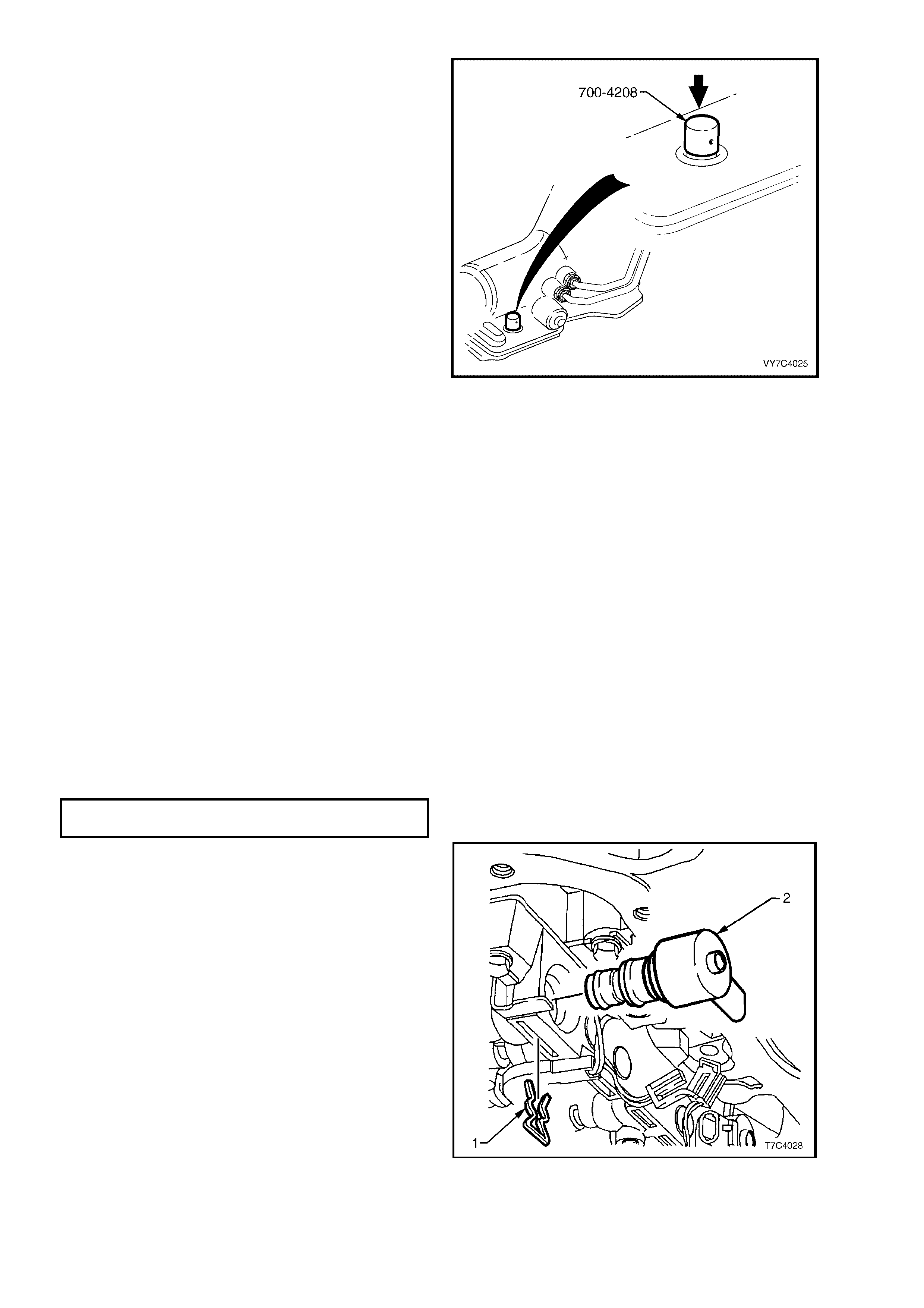

19. Install Tool No. 700-4208 over the pass-thru

connector, t hen use ha nd f orc e to pus h t he t ool

down, compressing the four retaining tangs on

the connector. Pull the pass-thru connector

free from the transmission case, removing the

harness and TCC solenoid assembly from the

transmission.

Figure 7C4-49

REINST ALL

Reinstallation is the reverse of removal operations

except for the items detailed here.

1. Lubricate a new pass-thru connector O-ring

with petroleum jelly such as Vaseline™ or

equivalent, then reinstall the connector up

through the hole in the transmission case and

push until all four of the retaining lugs have

emerged through to the outside of the

transm iss ion case. T ug on the co nnector (NOT

the wiring) to check that full engagement has

take place.

2. Reinstall the control valve body. Refer to

3.11 CONTROL VALVE BODY, in this

Section.

3. Coat a new TCC solenoid O-ring with

petroleum jelly and install on solenoid, then

reinstall TCC solenoid assembly into the oil

pump body. Secure with the two bolts and

tighten to the correct torque specification.

TCC SOLENOID BOLT

TORQUE SPECIFICATION 12 Nm

4. Coat a new TCC PWM solenoid O-ring with

petroleum jelly, install on the solenoid (2). Then

reinstall the solenoid into the control valve

body, securing with retaining clip (1).

Figure 7C4-50

5. Reinstall the wiring harness connectors as

shown, then reinstall the two harness frame

retaining clips over the control valve body

bolts.

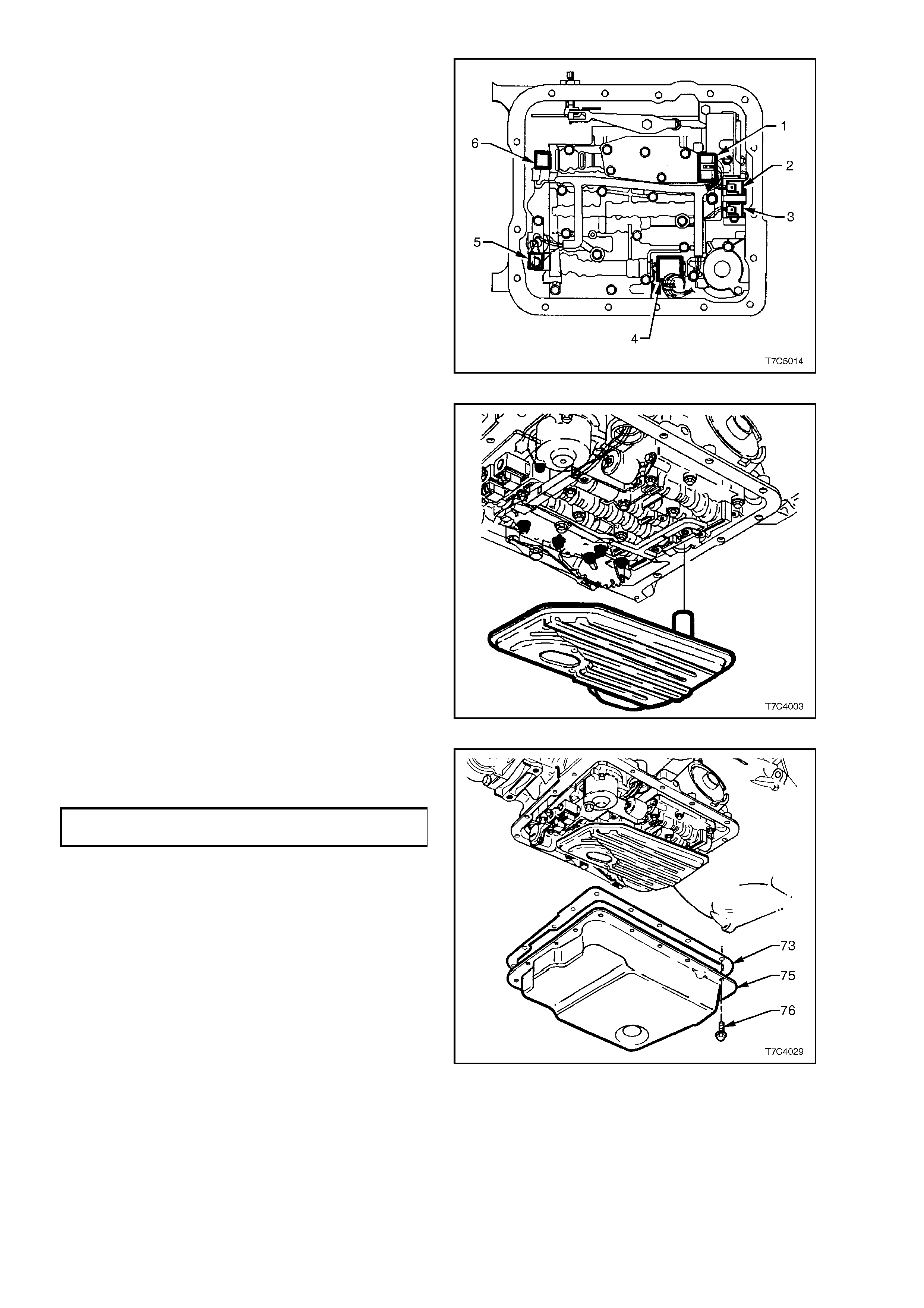

Electrical Connector Identification:

1. TFP Manual Valve Positi on Switch

2. 1-2 Shift Valve Solenoid ‘A’

3. 2-3 Shift Valve Solenoid ‘B’

4. Pressure Control Solenoid (PCS)

5. TCC Pulse Width Modulated (TCC PWM)

Solenoid

6. 3-2 Control Solenoid

Figure 7C4-51

6. Reinstall oil filter into the oil filter seal.

Figure 7C4-52

7. Reinstall a new oil pan gasket (73), then

reinstall the oil pan (75), tightening the bolts

(76) to the correct torque specification.

OIL PAN BOLT

TORQUE SPECIFICATION 12 Nm

8. Fill transmission with Dexron III automatic

transmission fluid, as detailed in 3.1 FLUID

CHANGE AND FILTER REPLACEMENT, in

this Section.

9. Lower vehicle and road test until the

transmission has reached operating

temperature.

10. Re-check fluid level (see 2.1 FLUID LEVEL

CHECK, in this Section) and check for fluid

leaks from the oil pan area.

Figure 7C4-53

3.11 CONTROL V ALVE BODY

LT Section No. – 04A-275

REMOVE

1. Refer to 3.10 CONTROL VALVE BODY

WIRING HARNESS, in this Section and

remove the harness to the stage where it is

hanging from the pass-thru connector.

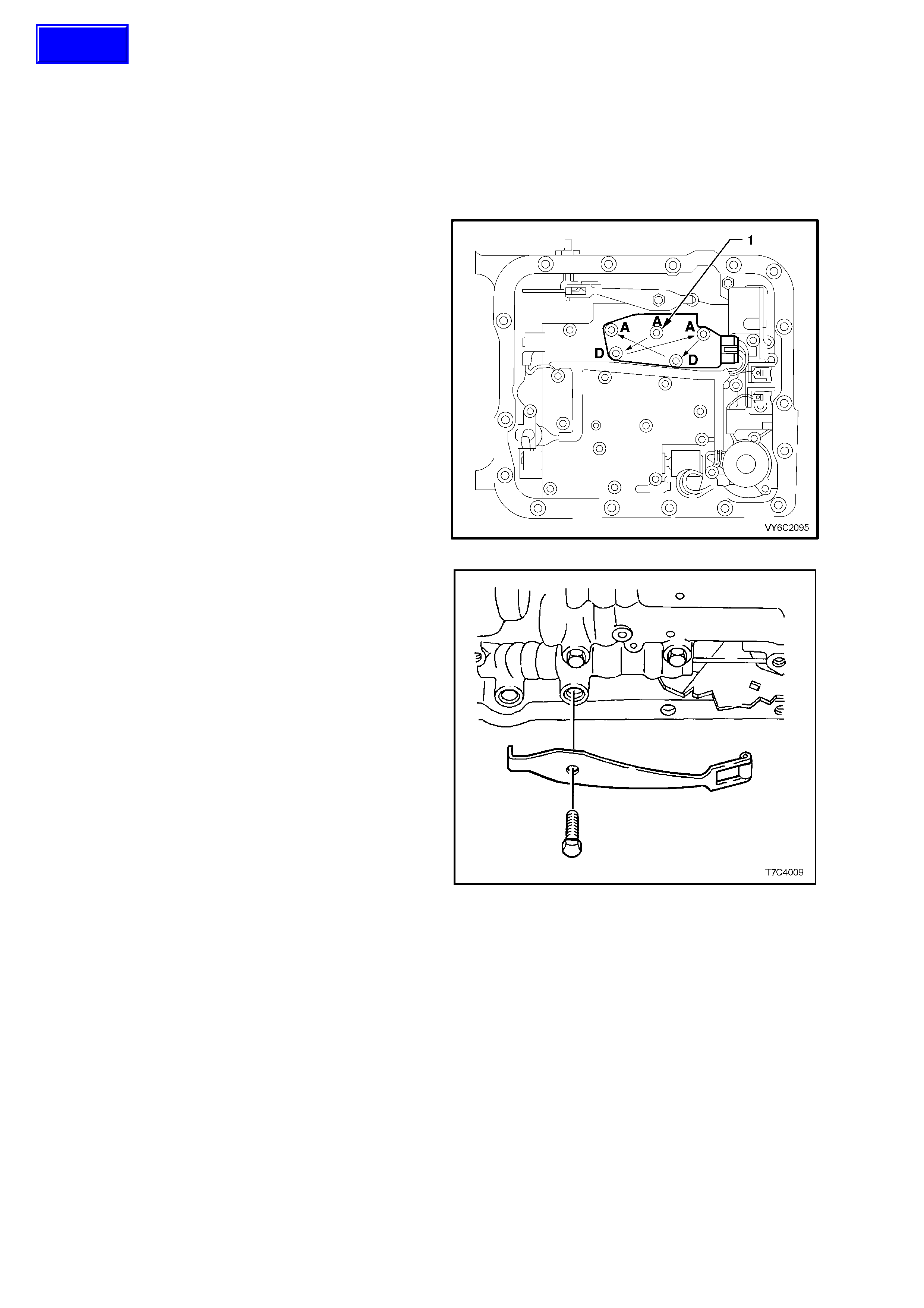

2. Remove the Transmission Fluid Pressure

(T FP) Manua l Va lve Switc h As sem bl y retaini ng

bolts (‘A’ and ‘D’), then remove the shield.

Discard the removed shield.

Figure 7C4-54

3. Remove the bolt (64) securing the manual

detent spring (63).

Figure 7C4-55

Techline

4. Remove the control valve body retaining bolt

(62) securing the dipstick stop bracket (93).

5. Remove remaining control valve body bolts.

6. Remove control valve body assembly by

supporting at the rear with one hand, while

holding the m anual va lve with th e other. As the

valve bod y is being lo wered, rotate it s lightly to

release the manual valve link from the manual

valve.

7. Remove manual valve link from inner detent

lever.

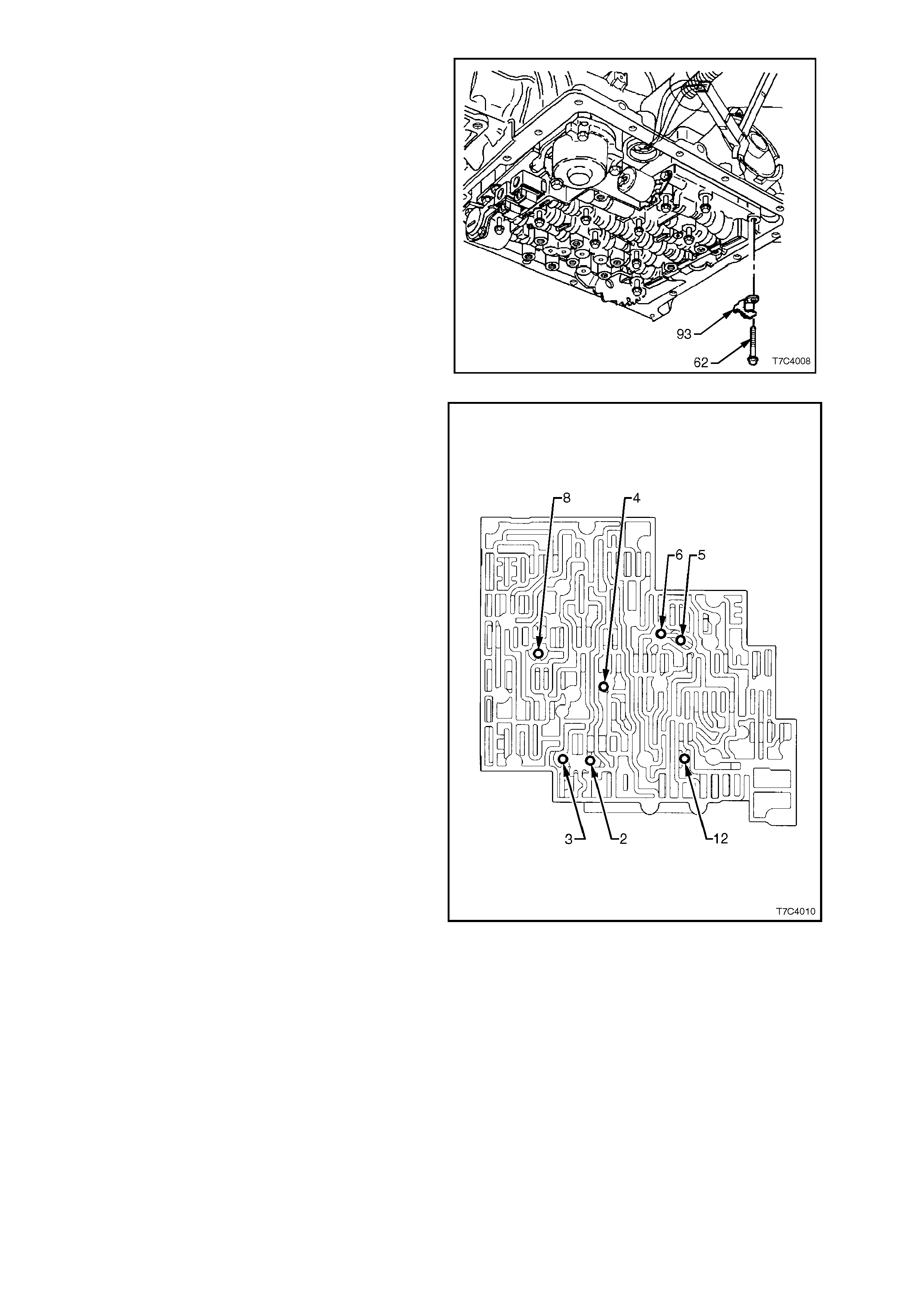

Figure 7C4-56

NOTE: T ake ca re not to lo se the s even c hec k balls

that are located under the control valve body.

Locations for the seven check balls are as shown.

Figure 7C4-57

DISASSEMBLE, CLEAN, INSPECT AND REASSEMBLE

For these operations, refer to 2.16 CONTROL

VALVE BODY in Section 7C5, AUTOMATIC

TRANSMISSION - UNIT REPAIR in the MY 2003

VY and V2 Series Service Information.

REINST ALL

1. Ensure spacer plate gasket is in satisfactory

condition. If gasket needs to be replaced,

refer to 3.12 SPACER PLATE, CHECK

BALLS, FILTER SCREENS AND 3-4

ACCUMULATOR in this Section.

2. Reinstall check balls in control valve body as

shown in Figure 7C4-56 and secure with

petroleum jelly.

3. Reinstall the manual valve link into the inner

detent lever.

4. While supporting the manual valve link in one

hand and the va lve body in the other, rotat e the

valve body slightly and connect the link with

the manual valve. Move the manual valve

forward to retain the link connection and

carefully offer the valve body up, into position.

NOTE: Be careful not to damage the two filter

screens attached to the spacer plate, during this

operation.

Figure 7C4-58

5. Fit a new shield (1) to the Transmission Fluid

Pressure (TFP) Manual Valve Switch

Assembly (2), then reinstall to the control valve

body and r etain with the f ive bolts ( 4 and 5) but

do not tighten at this stage.

Figure 7C4-59

6. Reinstall the dipstick stop bracket (93) and

retaining bolt (62). Do not tighten at this stage.

7. Loosely reinstall the remainder of the control

valve body bolts.

Figure 7C4-60

8. Reinstall the manual detent spring assembly

retaining bolt.

Figure 7C4-61

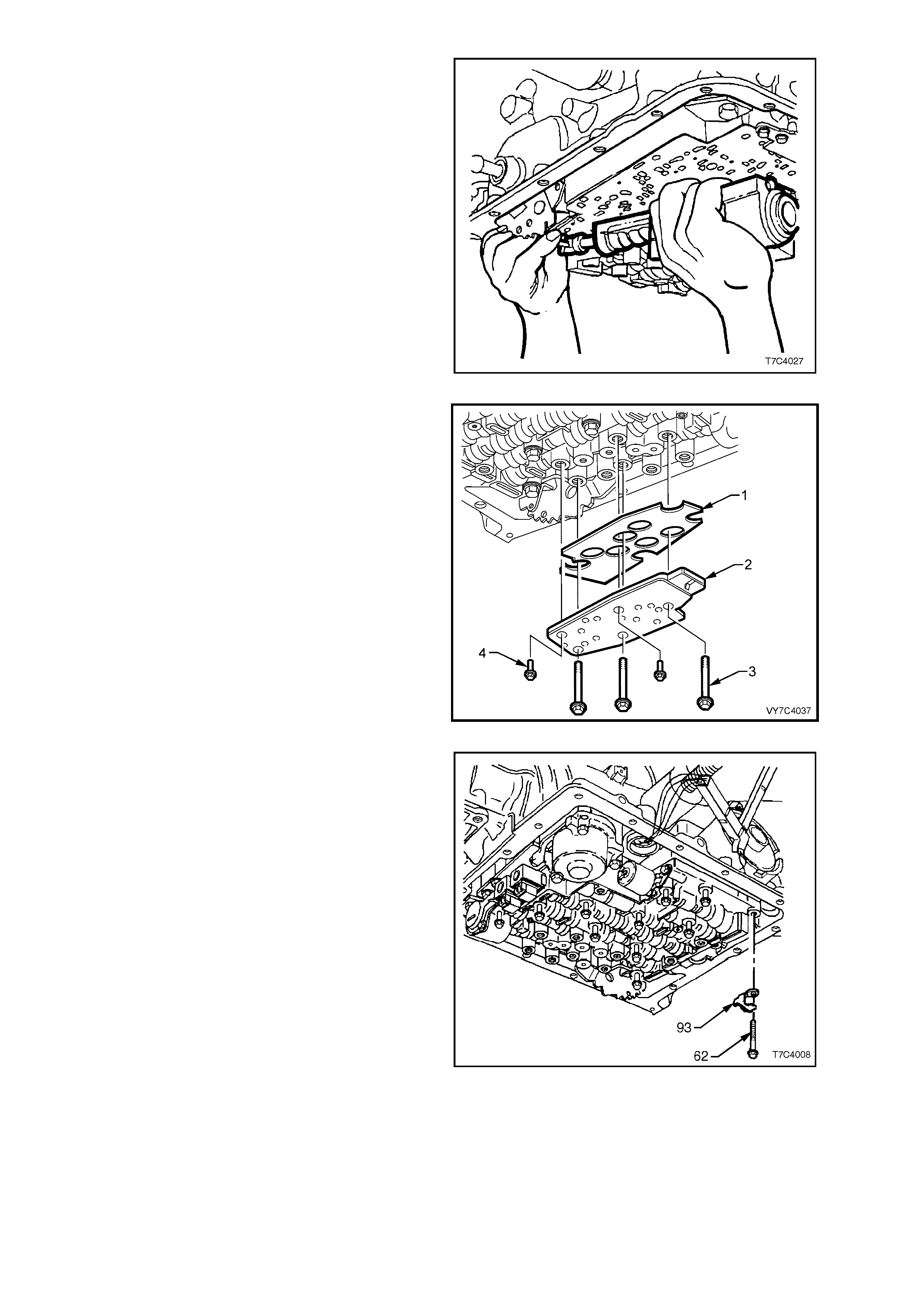

9. T ighten all control valve body retaining bolts to

the specified torque specification, starting from

the centre (bold arrow), in the order shown.

CONTROL VALVE BODY AND TFP

MANUAL VALVE POSITION SWITCH

ASM TORQUE SPECIFICATION 12 Nm

MANUAL DETENT SPRING

BOLT TORQUE SPECIFICATION 23 Nm

IMPORTANT: The control valve body bolts must

be tightened in an outward spiral from the centre

(bold arrow), as shown. Failure to follow this

pattern may distort the valve body, causing valves

to jam in their bores.

10. Coat a new TCC solenoid O-ring with

petroleum jelly and install on solenoid, then

reinstall TCC solenoid assembly into the oil

pump body. Secure with the two bolts and

tighten to the correct torque specification.

TCC SOLENOID BOLT

TORQUE SPECIFICATION 12 Nm

NOTE: There are 7 different bolt sizes used, the

dimensions of which are indicated by the letters

shown.

Figure 7C4-62

CONTROL VALVE BODY FASTENER

SPECIFICATIONS

A M6 x 1.00 x 65.0

B M6 x 1.00 x 54.4

C M6 x 1.00 x 47.5

D M6 x 1.00 x 18.0

E M6 x 1.00 x 35.0

F M8 x 1.25 x 20.0

G M6 x 1.00 x 12.0

11. Coat a new O-ring with petroleum jelly, install

on the solenoid (2). Then reinstall the solenoid

into the control valve body, securing with

retaining clip (1).

Figure 7C4-63

12. Reinstall the wiring harness connectors as

shown, then reinstall the two harness frame

retaining clips over the control valve body

bolts.

Electrical Connector Identification:

1. TFP Manual Valve Positi on Switch

2. 1-2 Shift Valve Solenoid ‘A’

3. 2-3 Shift Valve Solenoid ‘B’

4. Pressure Control Solenoid (PCS)

5. TCC Pulse Width Modulated (TCC PWM)

Solenoid

6. 3-2 Control Solenoid

Figure 7C4-64

13. Reinstall oil filter into the oil filter seal.

Figure 7C4-65

14. Reinstall a new oil pan gasket (73), then

reinstall the oil pan (75), tightening the bolts

(76) to the correct torque specification.

OIL PAN BOLT

TORQUE SPECIFICATION 12 Nm

15. Fill transmission with Dexron III automatic

transmission fluid, as detailed in 3.1 FLUID

CHANGE AND FILTER REPLACEMENT, in

this Section.

16. Lower vehicle and road test until the

transmission has reached operating

temperature.

17. Re-check fluid level (see 2.1 FLUID LEVEL

CHECK, in this Section) and check for fluid

leaks from the oil pan area.

Figure 7C4-66

3.12 SPACE R PLATE, CHECK BALLS, FILTER SCREENS AND 3-4 ACCUMULATOR

LT Section No. – 04A-275

REMOVE

1. Remove control valve body as described in

3.11 CONTROL VALVE BODY AND WIRING

HARNESS in this Section.

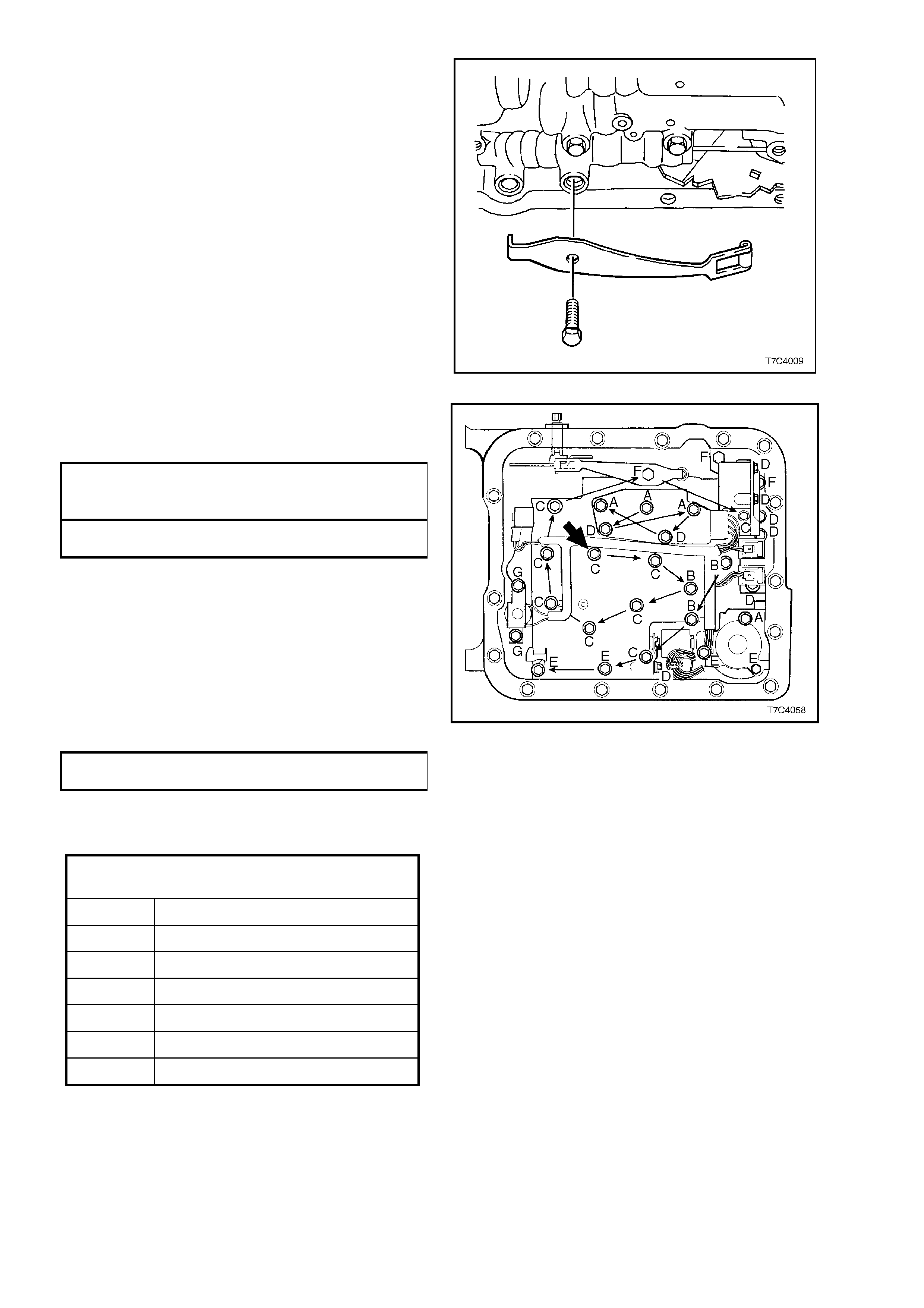

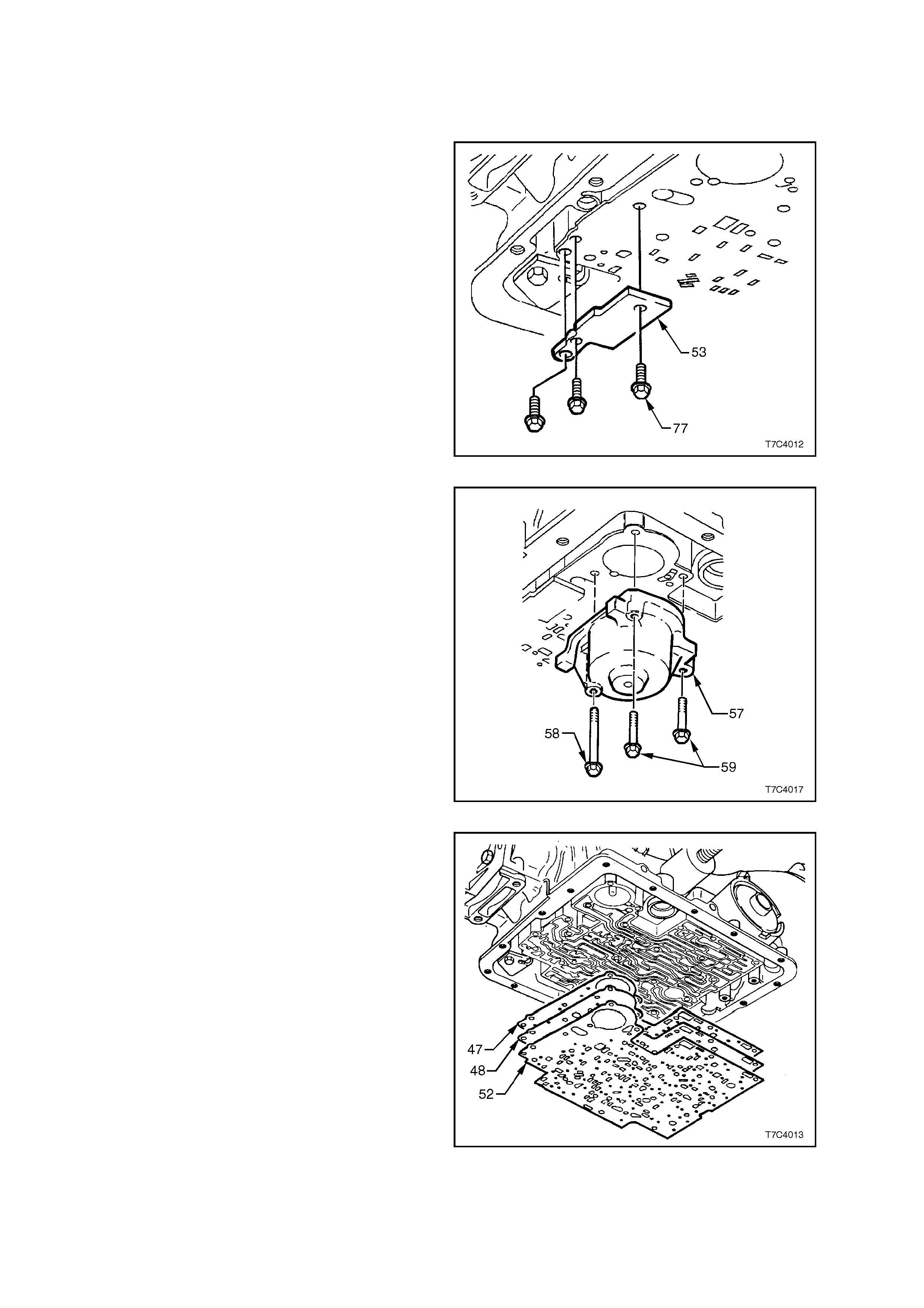

2. Remove the three spacer plate retaining plate

bolts (77) and plate (53).

Figure 7C4-67

3. While supporting the spacer plate, remove the

1-2 accumulator assembly retaining bolts (58

and 59), then carefully lower the accumulator

assem bly (57) f rom the spacer plat e and set to

one side, assuming that removal of the piston

and springs is not required.

NOTE: The 3-4 accumulator spring may push the

spacer plate away from transmission case when

the accumulator cover is removed.

Figure 7C4-68

4. Remove the spacer plate (48) and two spacer

plate gaskets (47 and 52) from the

transmission case.

IMPORTANT: As the spac er plate and gask ets are

lowered from the transmission, a check ball and

the 3-4 accumulator spring will also come away.

Do not lose the check ball.

Figure 7C4-69

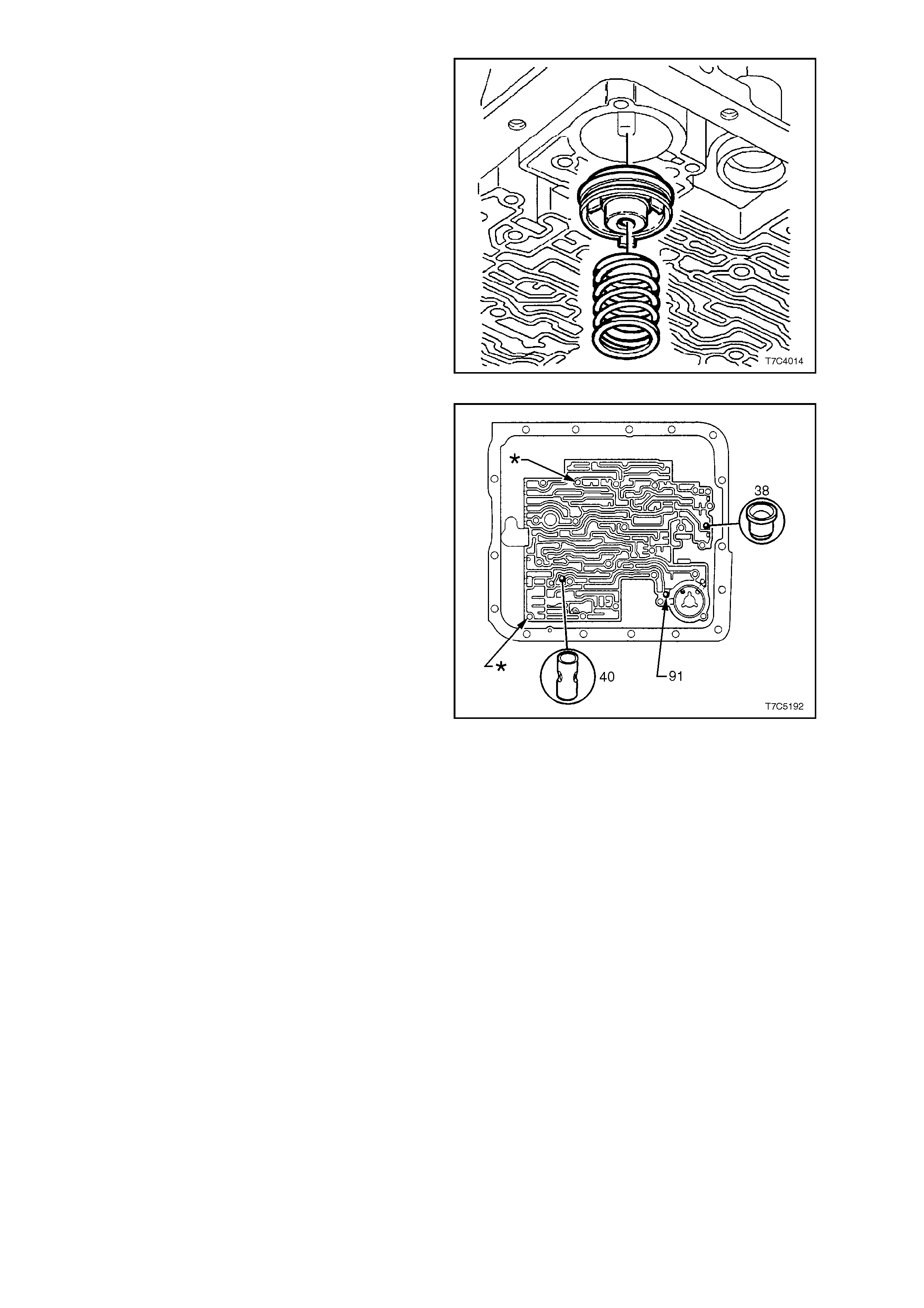

5. If removal of the 3-4 accumulator piston is

required, use snap ring pliers and rotate the

piston while pulling it from the case. Remove

and discard the piston seal.

NOTE: For the HAD trans m ission fitted to t he GEN

III V8 engine, there is no 3-4 accumulator spring

fitted.

Figure 7C4-70

6. The c heckball (91), 3rd accum ulator check ball

assembly (40) and orifice cup plug (38) in the

transmission case, are located, as shown.

NOTE: The locations marked as (,

,,

,) are for two

guide studs to be inserted during reassembly.

Figure 7C4-71

CLEAN AND INSPECT

1. Wash components in clean solvent.

2. Dry with compressed air.

3. Inspect pist on f or por os ity, ring gro ov e damage

or pin hole damage.

4. Check spring for distortion or damage.

5. Inspect accumulator bore for wear or damage.

6. Check spacer plate, filter screens and check

balls for damage.

REINST ALL

1. Lubricate new seal (55) with petroleum jelly

and install on 3-4 accumulator piston (54).

2. Reinstall pin in case.

3. Reinstal l piston onto p in so that the pisto n side

with three lugs, faces out of bore, as indicated.

4. Install guide pins (J25025-1) into transmission

case in the locations shown (,

,,

,) in Figure 7C4-

70.

NOTE: Ensure that the guide pins are fully installed

so that no thread is visible. Otherwise the spacer

plate gasket could become caught in a thread

during installation, resulting in incorrect alignment.

5. Reinstall the check ball in the transmission

case as shown (Figure 7C4-70) and use

petroleum jelly to hold the ball in place.

6. Reinstall 3-4 accumulator spring (if fitted).

Figure 7C4-72

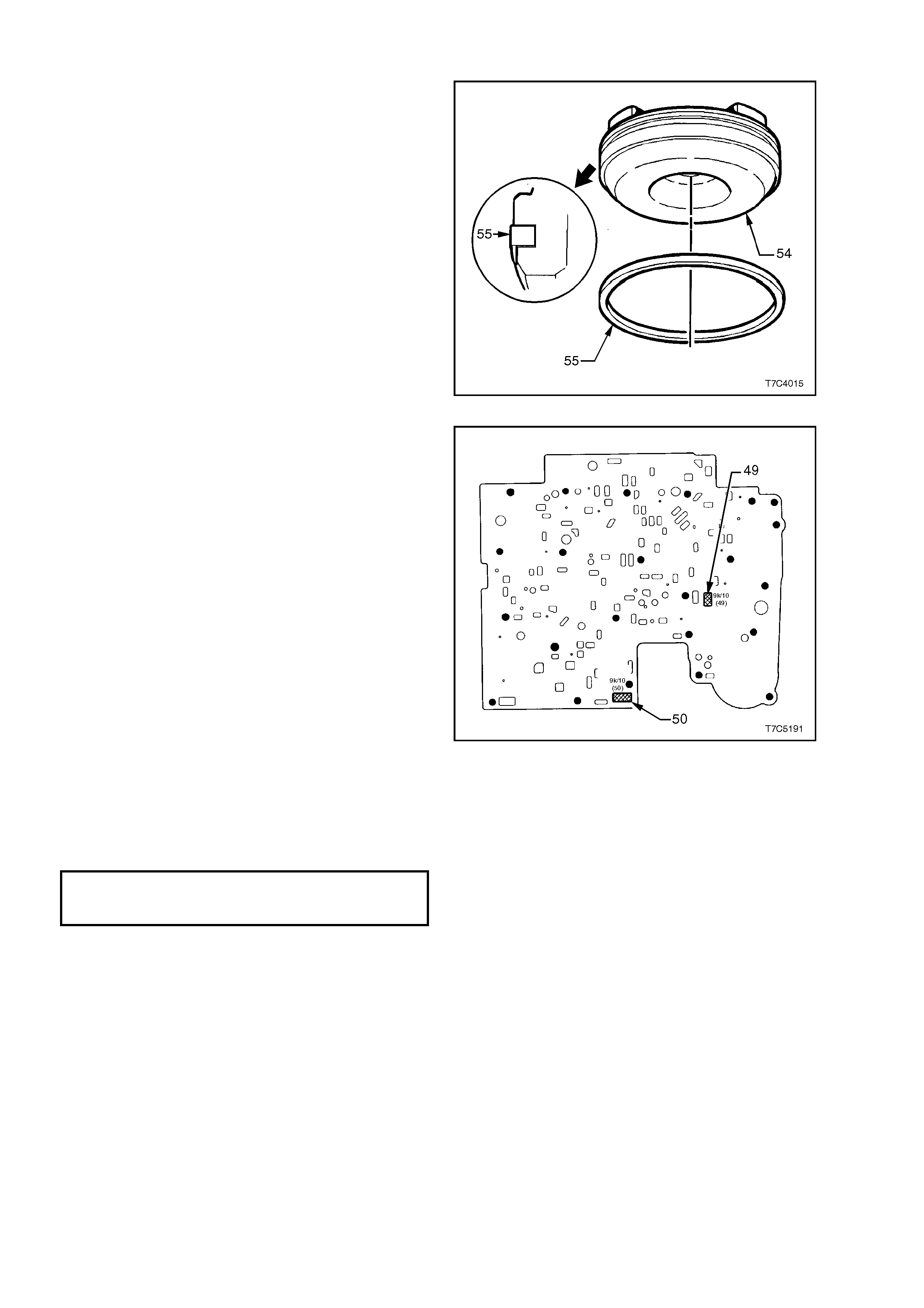

7. If a new spacer plate is to be install ed, it wil l be

necessary to fit two filter screens (49 and 50)

to the spacer plate before fitment. Locations of

these screens are as shown.

8. Reinstall spacer plate with new gaskets that

have been smeared with petroleum jelly and

hold in place until accumulator is reinstalled.

NOTE: The gasket marked 'CA' is fitted between

spacer plate and transmission case and gasket

marked 'VB' is located between spacer plate and

control valve body. Refer to Spacer Plate and

Gaskets, in 2. TRANSMISSION CHANGES FOR

MY2003, in Section 7C1 - GENERAL

INFORMATION.

Figure 7C4-73

9. Reinstall accumulator. Refer to

3.9 1-2 ACCUMULATOR in this Section.

10. Reinstall spacer plate support plate (53) and

retaining bolt (77), tightening to the correct

torque specification.

SPACER PLATE SUPPORT

PLATE RETAINING BOLT

TORQUE SPECIFICATION 12 Nm

11. Remove guide pins (J25025-1) from the

transmission case.

12. Reinstall control valve body. Refer to

3.11 CONTROL VALVE BODY in this Section.

13. Reinstall filter and oil pan. Refer to 3.1 FLUID

CHANGE AND FILTER REPLACEMENT in

this Section.

3.13 FILLER TUBE

LT Section No. – 04A-010

REPLACE

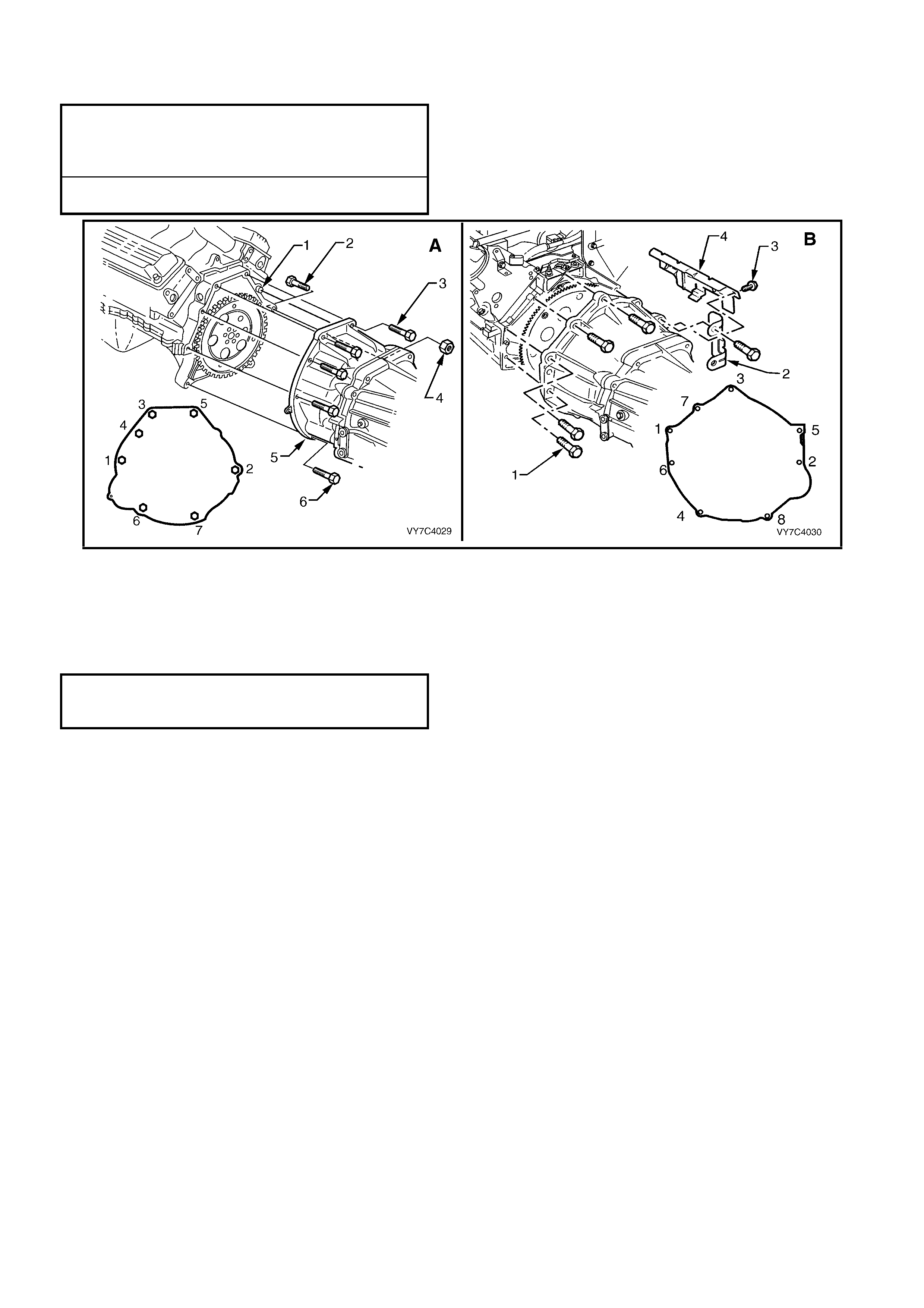

NOTE: In the views shown in Figure 7C4-71, ‘A’ represents the V6 engine, while view ‘B’ shows the GEN III V8

arrangement.

1. Disconnect the battery ground lead.

2. Release the dipstick lock down lever (1) and remove the transmission dipstick.

3. Remove the bolt securing transmission filler tube to the right hand cylinder head.

4. Using a twisting/pu ll in g motion, r emove f iller t ube ( 2) from transmiss ion cas e s ea l ( 4) and with dr a w f rom engine

compartment.

5. Release th e transmis sion breather tube fr om the dipstick bracket ( arrow), after lower ing the d ipstick enough to

gain access.

6. Replace the filler tube seal (4), lubricate with transmission fluid and install into transmission case.

7. Reinstall th e f il ler t ube ( 2 or 6) i n th e r e vers e or der t o removal bu t sec ur e the tran smis s ion breat her hose to the

hole in the filler tube bracket (arrow), before the tube is installed into the transmission case seal (4).

8. Tighten the filler tube bracket retaining bolt (3 or 7) to the correct torque specification.

FILLER TUBE RETAINING

BRACKET BOLT

TORQUE SPECIFICATION All Engines 30 Nm

Figure 7C4-74

3.14 TRANSMISSION ASSEMBLY

LT Section No. – 04A-200

REMOVE

1. Disconnect the battery ground lead.

2. Raise vehicle and support on safety stands. Refer to Section 0A GENERAL INFORMATION in the MY 2003

VY and V2 Series Service Information, for the location of jacking and support points. Place drip tray beneath

transmission.

3. Remove filler tube as detailed above.

4. Plug filler tube hole to prevent dirt entry.

5. Remove propeller shaft assembly: Refer to Section 4C PROPELLER SHAFT AND UNIVERSAL JOINTS, in

the MY 2003 VY and V2 Series Service Information.

6. Disconnect electrical connectors from vehicle speed sensor and oxygen sensors.

7. If not alr eady rem oved in Step 5, remove ex haust pipe s from the ex haust manifol ds to the re ar of the cata lytic

converter (only required for the V6 engine).

8. Hold the transmission selector lever with an adjustable wrench while loosening the retaining nut. Remove the

selector lever from the manual shaft.

9. Remove the starter motor. Refer 6D1-2 (V6), 6D2-2 (V6 S/C) or 6D3-2 (GEN III V8) STARTING SYSTEM, in

the MY 2003 VY and V2 Series Service Information, for the necessary procedure.

10. Remove the close-out cover retaining screw on each side, then remove both covers.

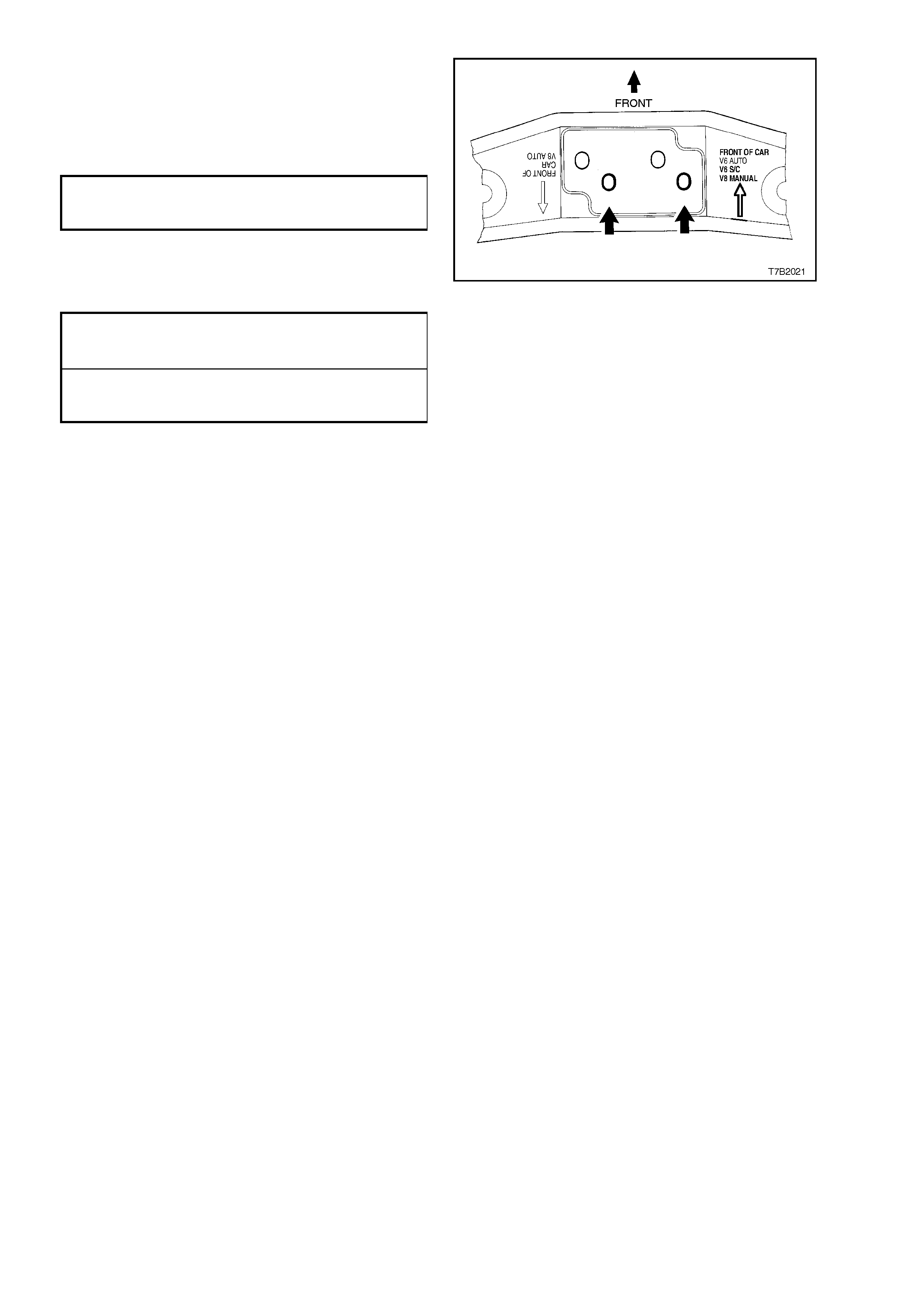

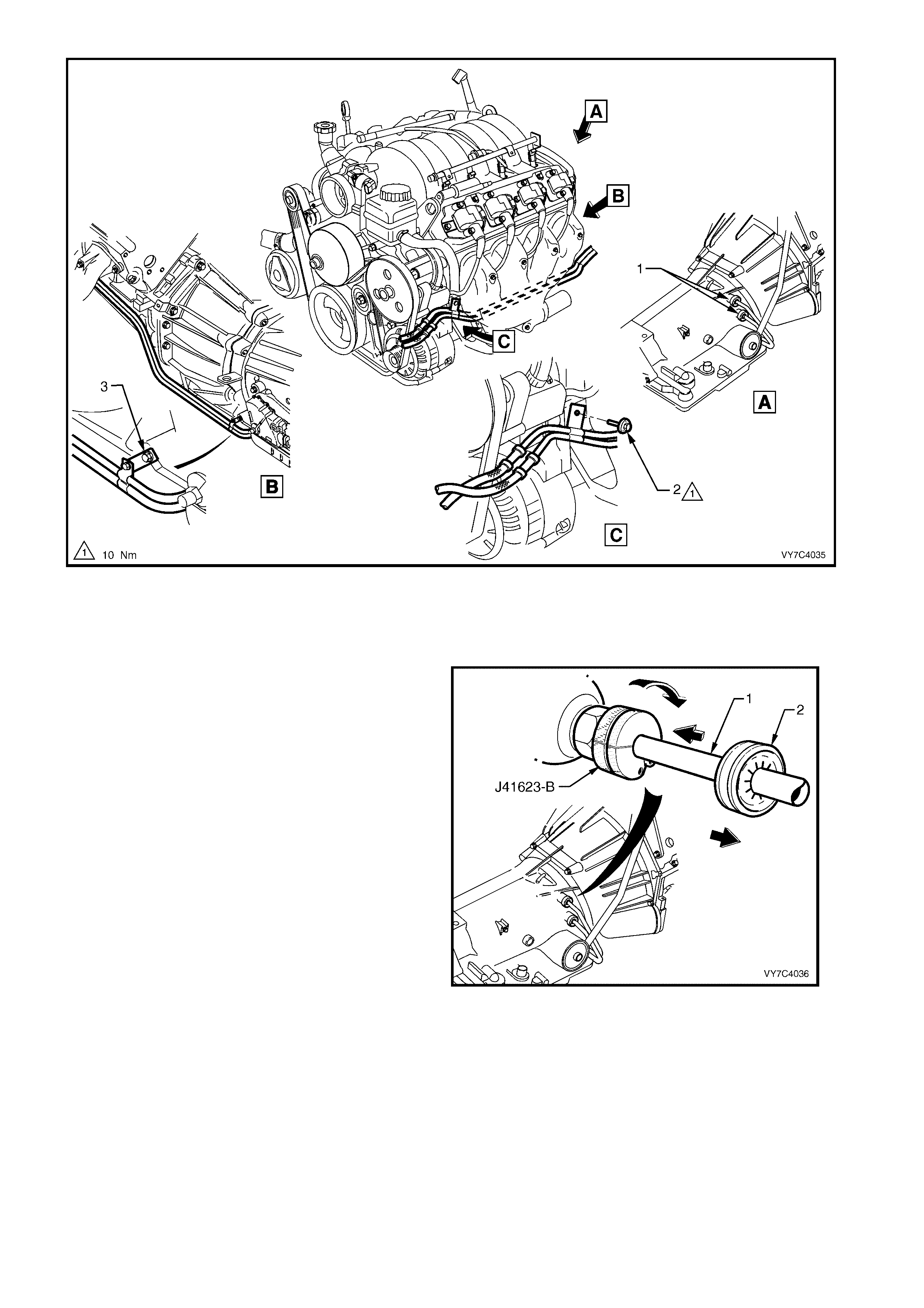

NOTE: Figure 7C4-72 shows the V6 arrangement (‘A’) and GEN III V8 (‘B’) for the starter motor side only. The

procedure for the remaining side is similar.

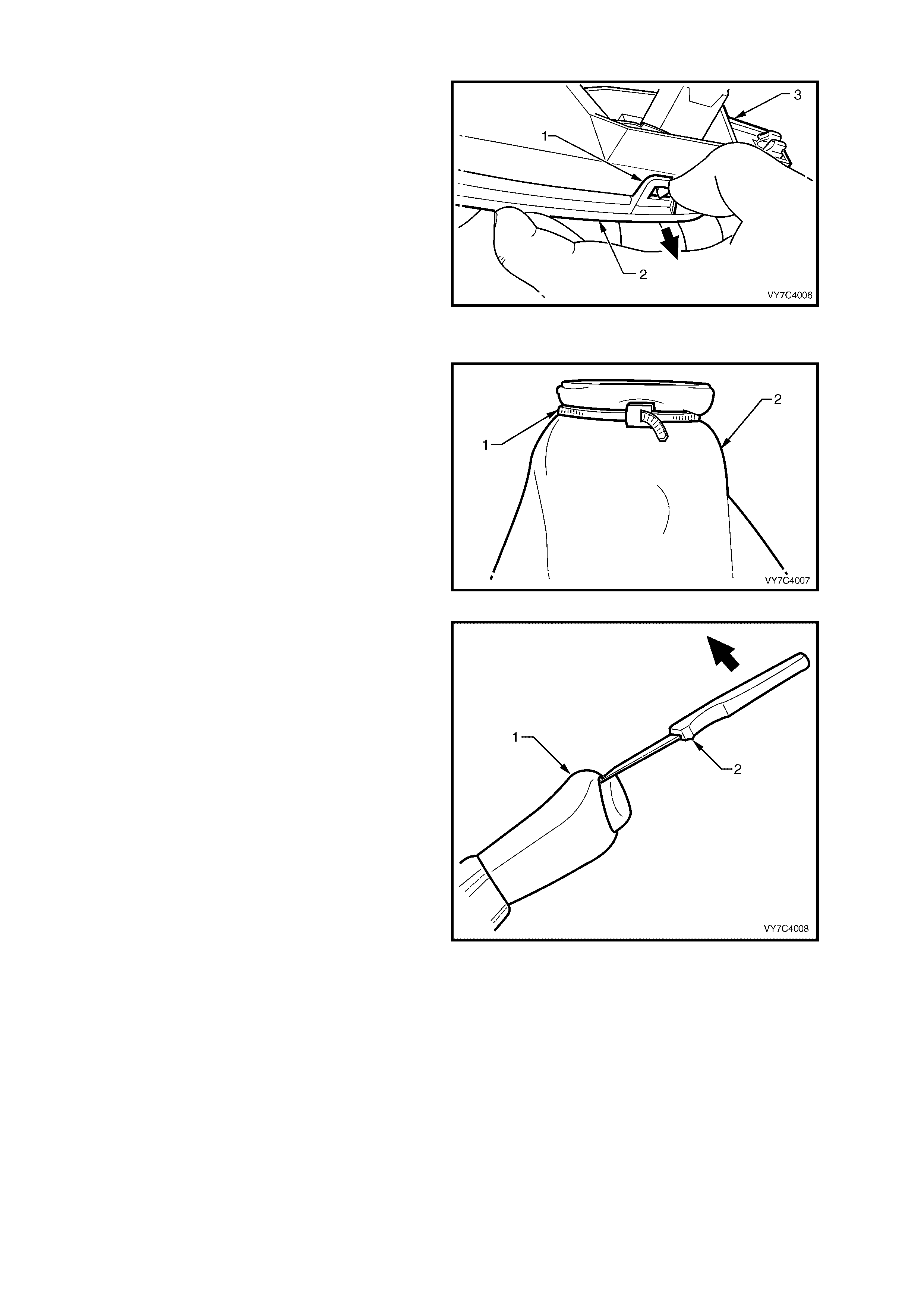

Figure 7C4-75

11. Mark relative position of torque converter and flexplate, then remove three torque converter to flexplate

attaching bolts. Discard the removed bolts.

Techline

12. For those vehicles fitted with the GEN III V8

engine, remove the two bolts (2) securing the

catalytic converter bracket (1) to each catalytic

converter.

Figure 7C4-76

13. Use a sh arp scriber to m ark the ex act locati on of the crossm ember (2) to the sid e fram e, before loos ening any

of the four crossmember to side frame attaching bolts (3).

IMPORTANT: This s tep is c ritic al t o th e c or rec t po wer t rain alignment on re as sembl y. If not ca rr ied ou t, th en veh icle

vibration and/or handling problems could result!

14. Remove two bolts (5) securing rear engine mount to transmission.

NOTE: For those vehicles fitted with the GEN III V8 engine, also remove the two nuts (6) securing the engine

mount to the catalytic converter brace.

15. Support transmission with a jack. Do not place the support beneath case extension or oil pan.

16. Rem ove the f our cr ossm em ber to side f ram e bolts (3) and r em ove cros sm ember ( 2) and rear eng ine m ount (1)

from the vehicle.

NOTE: View ‘A” shows the V6 arrangement, while view ‘B’ shows the GEN III V8.

Figure 7C4-77

17. Lower rear of transm ission to prov ide suffic ient

clearance, without placing any strain on any

electrical wiring and remove electrical

connector from the transmission as follows:

NOTE: Take care when lowering rear of

transm ission that the inl et m anifold does not hit th e

firewall.

• Roll back the dust boot from the connector, to

gain access to the connector.

• Squeeze the widest side of the connector

inwards (A) and PULL DIRECTLY UPWARD.

IMPORTANT: Do not wriggle the connector

from side to side while removing it! If this

situation occurs, there is a very real possibility

of the connector pins being permanently

damaged.

18. Remove the wiring harness clip retaining

screws from both the right and left sides of the

transmission case.

Figure 7C4-78

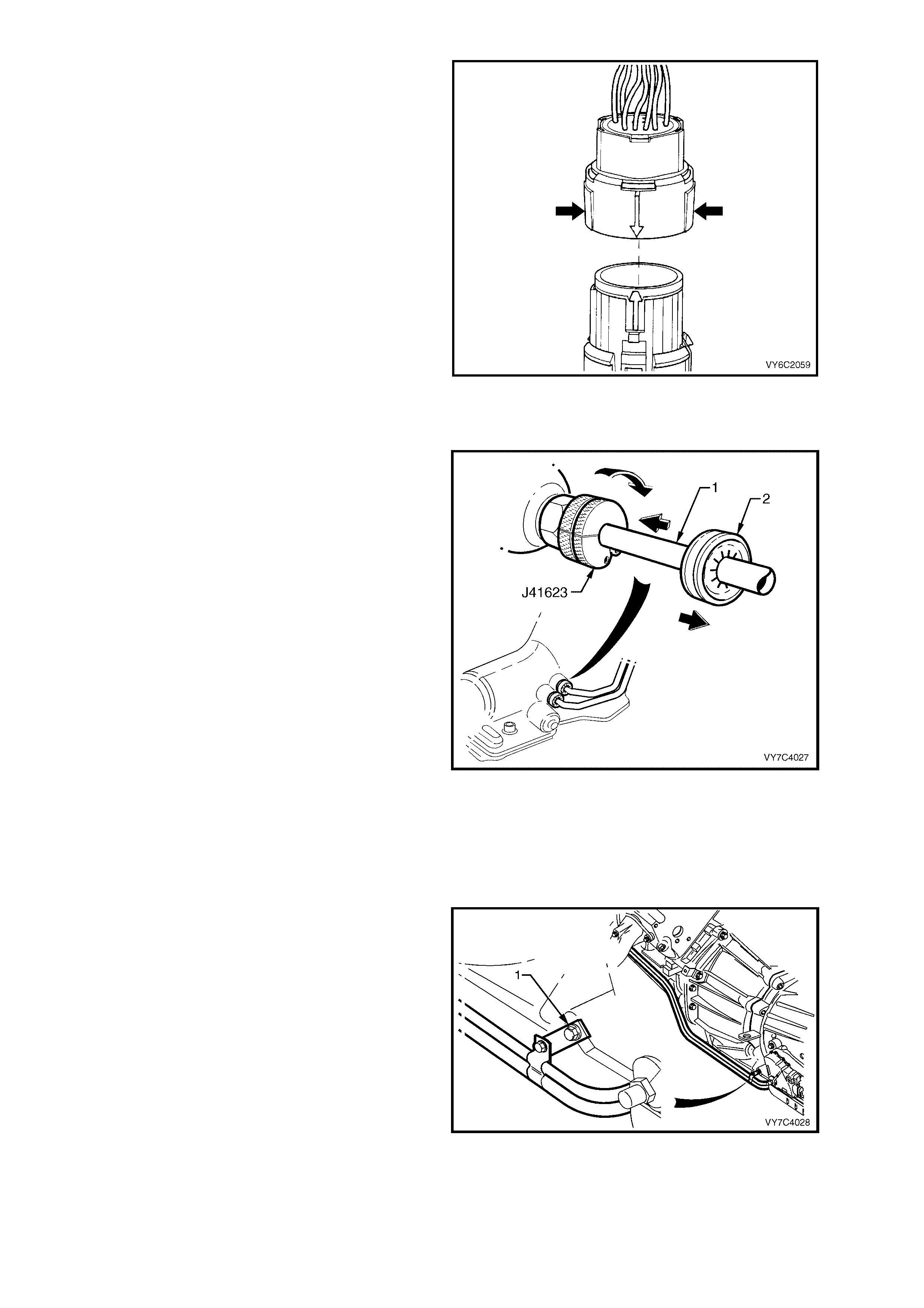

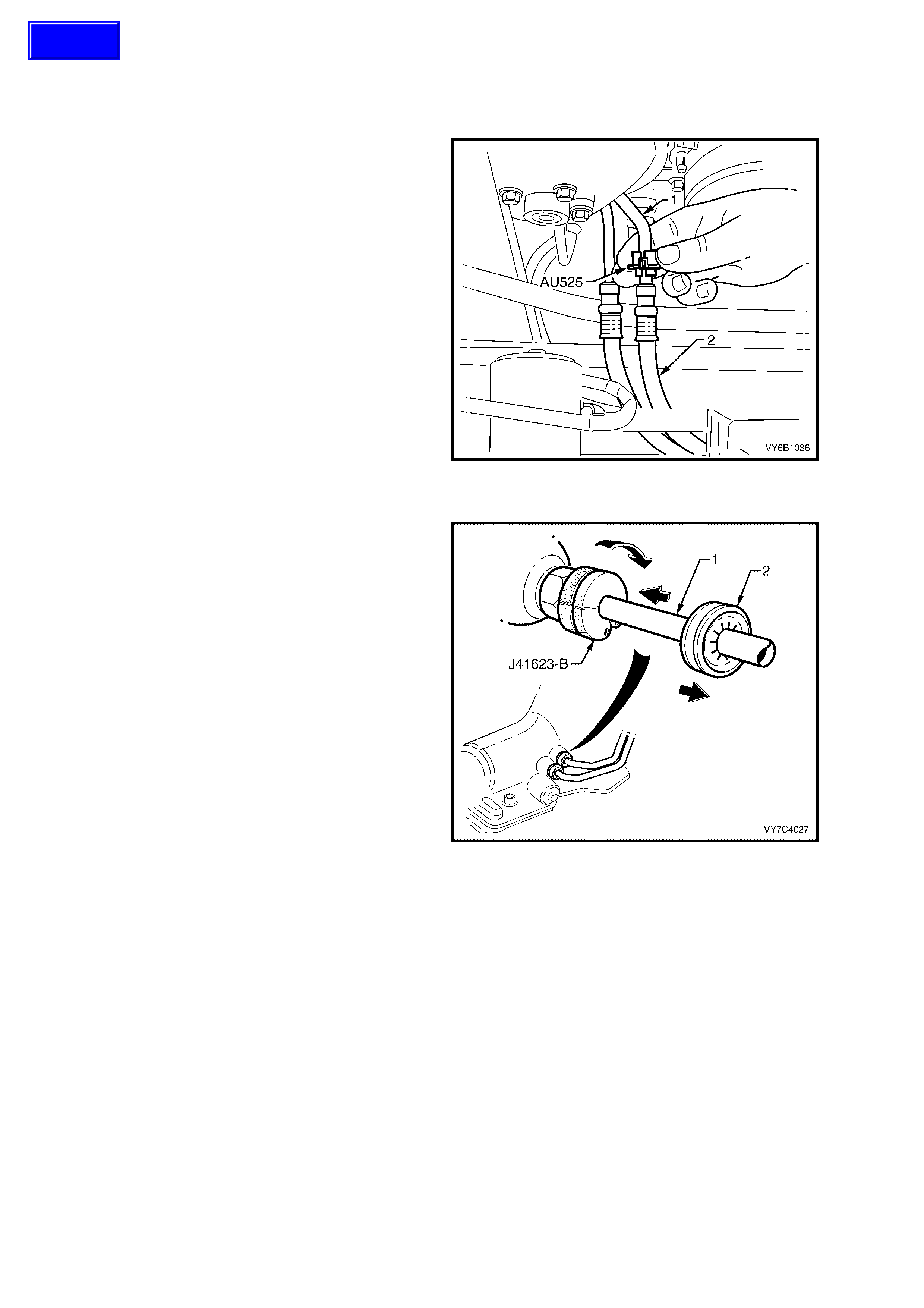

19. While the rear of the transmission is lowered,

disconnect cooler pipes from transmission.

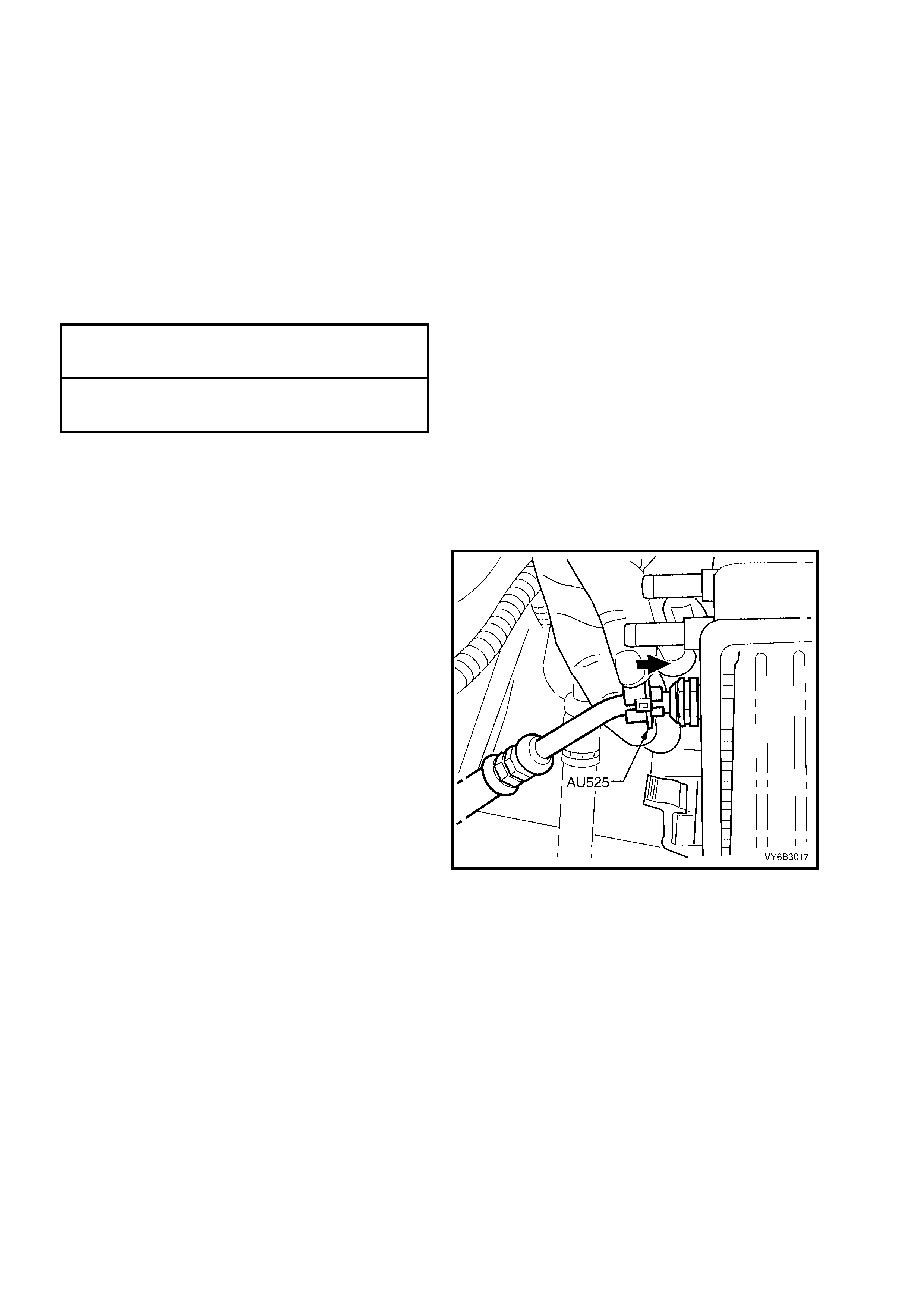

a. Release the verif ier disc (2) by pulling back

with the fingertips, then slide back down

the cooler pipe (1).

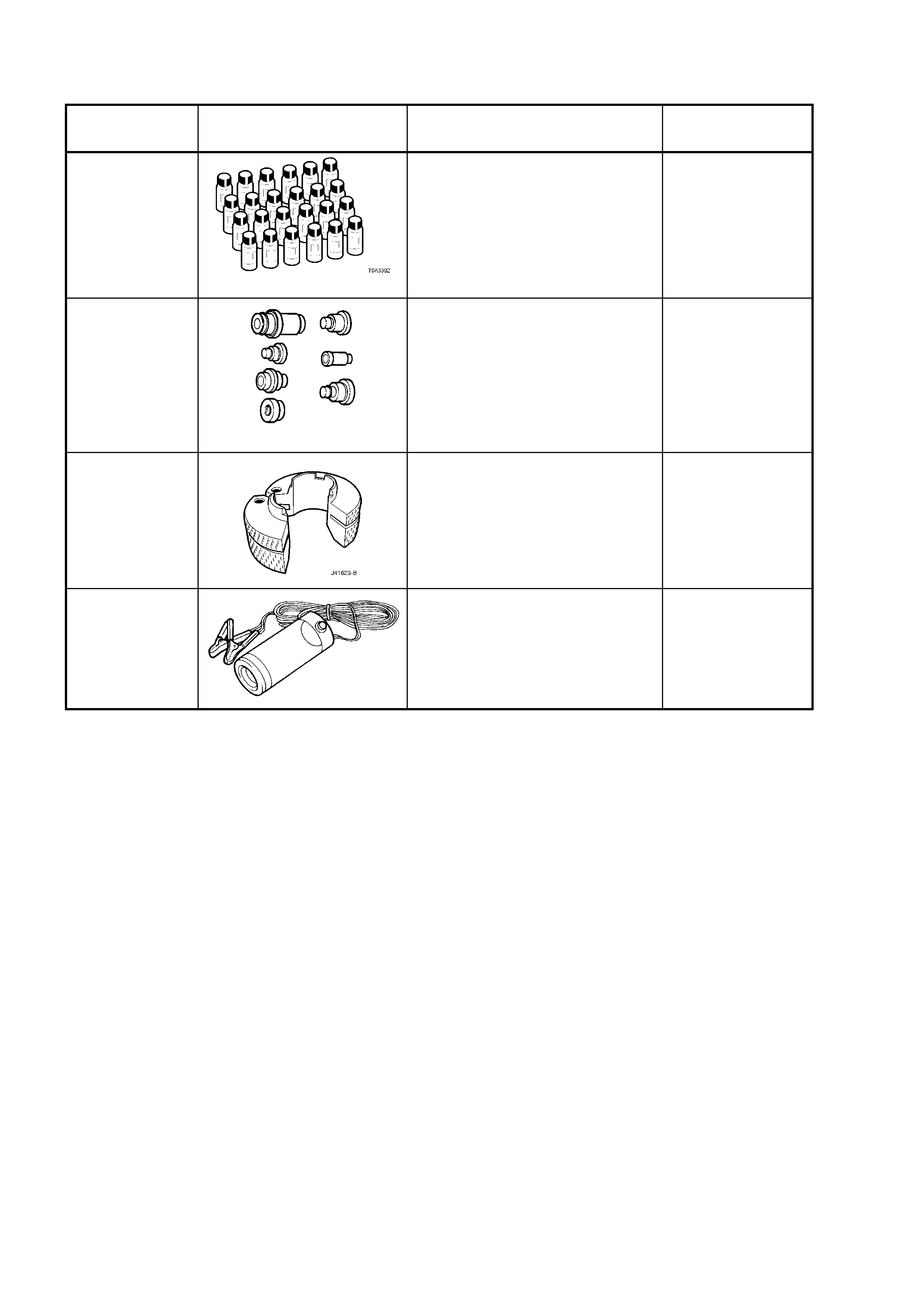

b. Open cooler line release Tool J-41623-B

and slip over cooler pipe to be

disconn ected from the transm ission, abo ve

the verifier disc (2), as shown.

c. Slide the release tool along the pipe to

engage with the quick-connect fitting.

d. While pushing inwards, rotate the tool

about one sixth of a turn to release the

spring clip holding the pipe.

e. With the release tool held in this position,

pull back on the cooler pipe to release.

f. Repeat this process with the remaining

pipe and quick-connect fitting.

g. Plug all openings to prevent foreign m atter

entry.

NOTE: Should the spring clip and/or O-ring seal in

the “Jiffy Tite” quick connect fitting be damaged

during the pi pe removal pr o c ess , then the c omplete

fitting must be replaced.

Figure 7C4-79

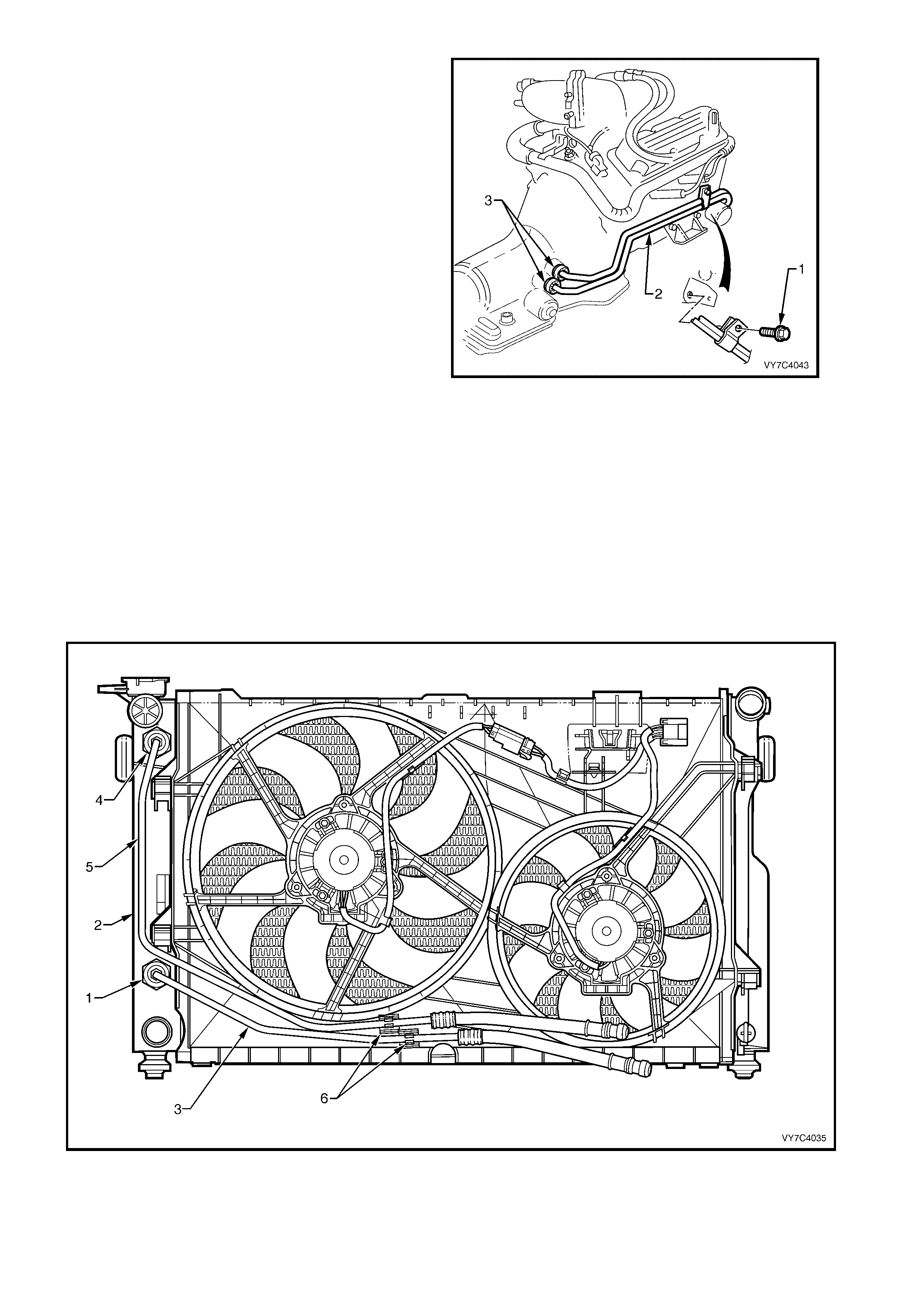

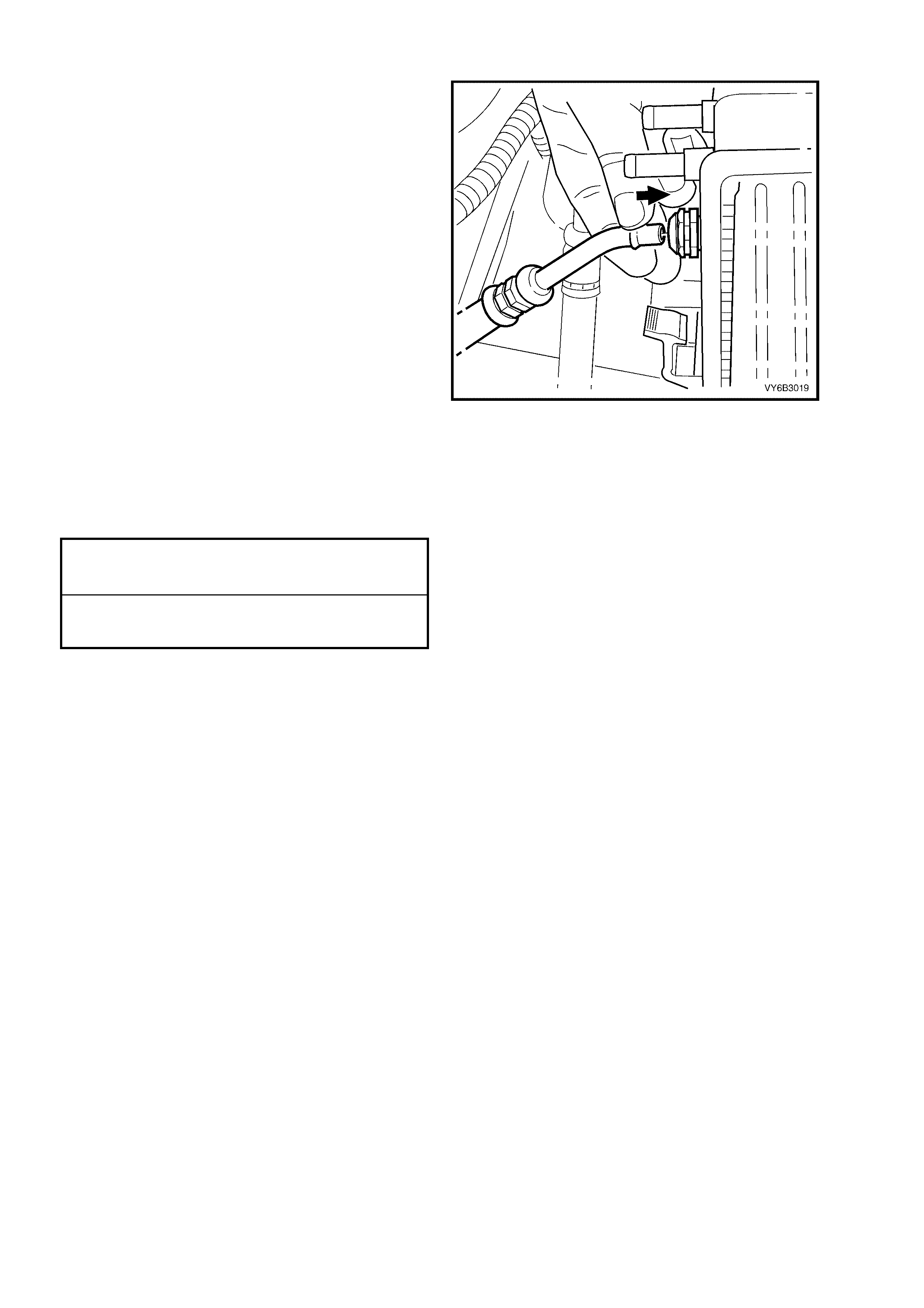

h. On GEN III V8 engines, remove the front

bolt of the Neutral Safety and Back-Up

Lamp switch (1) that also secures the

cooler pipe bracket.

i. Plug all open pipes and quick-connects to

prevent dirt entry.

Figure 7C4-80

20. Remove the wiring harness CPA (Connector

Position Ass urance) secur ity p in (1 and 2) from

the neutra l start and back -up lamp s witch, then

remove the connectors (3 and 4) from the

switch.

Figure 7C4-81

21. Lower rear of trans miss ion f urther if nec es sary,

to gain access to the converter housing to

engine bolts. Then, using a long socket

extension, a universal joint and a suitable size

socket, remove the remaining converter

housing bolts (and nut, for V6 engine).

22. Support transmission assembly on a suitable

cradle and secure. Also place a suitable

support under engine oil pan rail to support

engine after transmission has been removed.

23. Remove transmission assembly from the

vehicle.

24. Install suitable converter holding tool to

prevent converter becoming dislodged.

REINST ALL

IMPORTANT: If transmission has been replaced, the fluid is contaminated, a converter and/or oil pump has been

replaced, a reverse flush of the cooler lines and a flow rate check MUST be completed. Refer 2.2 TRANSMISSION

COOLER REVERSE FLUSH AND FLOW RATE CHECK in this Section for details.

Reinstallation is the reverse of the removal procedure, noting the following points:

1. Ensure transmission and engine mating surfaces are clean and free of burrs.

2. Lubricate the torque converter spigot with high temperature, wheel bearing grease, prior to installation.

3. Ensure locating dowels completely enter converter housing holes.

4. Prior to reinstalling NEW converter to flexplate bolts, ensure locating marks on converter and flexplate are

aligned.

5. Remove the access ho le cover plate in the lo wer surfac e of the torqu e converter housing an d lever the tor que

converter forward, prior to installing and tightening the torque converter to flexplate attaching bolts. Reinstall