SECTION 8A2 - LPG SYSTEM

IMPORTANT

Before p erforming any Serv ice Operation or other procedu re described in this Section , refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1 GENERAL INFORMATION

1.1 SAFETY PRECAUTIONS7

1.2 IDENTIFICATION PLATES & WARNING

LABELS

2. PRINCIPLES OF OPERATION

2.1 LPG SYSTEM (TYPICAL)

2.2 LPG TANK

SEDAN & UTILITY

WAGON

2.3 FILLER VALVE

2.4 AUTOMATIC FILL LIMITER (AFL)

2.5 PRESSURE RELIEF VALVE

2.6 MANUAL SERVICE VALVE ASSEMBLY

MANUAL SHUT-OFF VALVE

SOLENOID VALVE

EXCESS FLOW VALVE

2.7 SMART UNIT

2.8 TANK FUEL GAUGE ASSEMBLY

2.9 LPG LOCK-OFF

2.10 SERVICE LINE

2.11 CONVERTER

PRIMARY REGULATION

SECONDARY REGULATION

2.12 FUEL CONTROL VALVE

2.13 REGULATOR CHECK VALVE

2.14 MIXER

2.15 FUEL MODE SWITCH

2.16 INSTRUMENT CLUSTER DISPLAY

2.17 TRACTION CONTROL OPERATION

2.18 POWERTRAIN CONTROL MODULE

PETROL MODE

LPG MODE

3. SERVICE OPERATIONS

3.1 SERVICE LINE DRAINING

3.2 LPG TANK UNLOADING

3.3 LEAK TESTING

COMBUSTIBLE GAS DETECTORS

FOAM

LEAK TEST PROCEDURE

3.4 FILLER VALVE & CONNECTOR PIPE

SEDAN

WAGON

UTILITY

3.5 FILLER LINE

SEDAN

WAGON

UTILITY

3.6 LPG TANK

SEDAN

WAGON

UTILITY

3.7 VENT TUBE FLANGE

SEDAN

WAGON

UTILITY

3.8 SMART UNIT & SOLENOID VALVE

REMOVE

REINSTALL

3.9 MANUAL SERVICE VALVE ASSEMBLY

EXCESS FLOW VALVE

REMOVE

REINSTALL

3.10 PICK-UP PIPE & STRAINER

REMOVE

REINSTALL

3.11 AUTOMATIC FILL LIMITER (AFL)

TEST

REMOVE

REINSTALL

3.12 PRESSURE RELIEF VALVE

REMOVE

REINSTALL

3.13 TANK FUEL GAUGE ASSEMBLY

REMOVE

REINSTALL

CONTENTS GAUGE

3.14 FRONT SERVICE LINE

REMOVE

REINSTALL

3.15 REAR SERVICE LINE

SEDAN

WAGON

UTILITY

3.16 INTERMEDIATE SERVICE LINE

REMOVE

REINSTALL

3.17 LPG LOCK-OFF

REMOVE

FILTER ELEMENT REPLACEMENT

TEST

REINSTALL

3.18 CONVERTER

CONVERTER ON-VEHICLE TEST

REMOVE

OVERHAUL

CONVERTER OFF-VEHICLE TEST

REINSTALL

3.19 REGULATOR CHECK VALVE

TEST

REMOVE

REINSTALL

3.20 FUEL CONTROL VALVE

REMOVE

TEST

REINSTALL

3.21 MIXER

TEST

REMOVE

OVERHAUL

REINSTALL

3.22 FUEL MODE SWITCH

REMOVE

TEST

REINSTALL

3.23 COOLANT HOSES

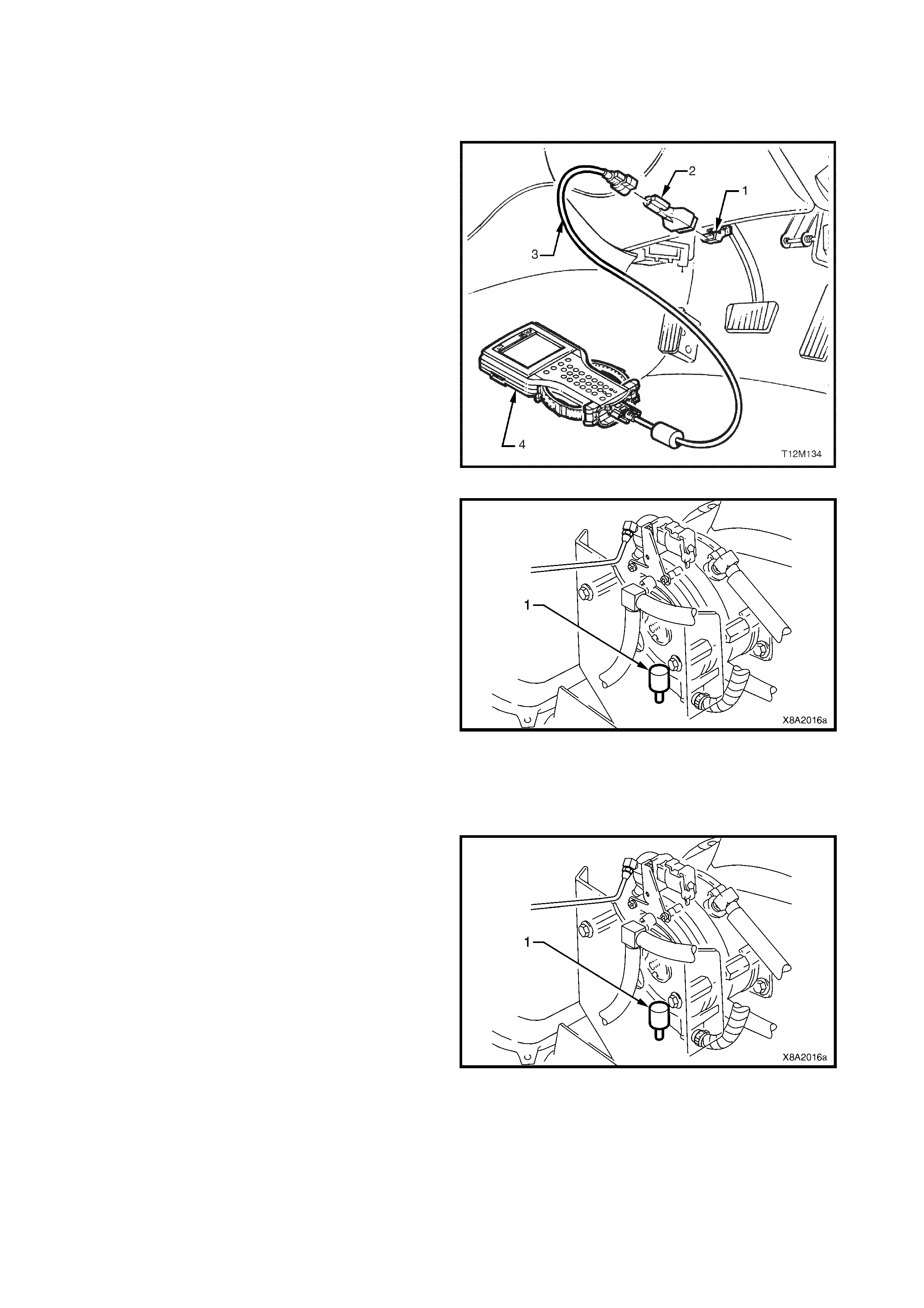

Techline

Techline

3.24 AIR CLEANER ASSEMBLY

REMOVE

REINSTALL

3.25 SPARE WHEEL CARRIER, WAGON

REMOVE

REINSTALL

4. TECH 2 PROCEDURES

4.1 LPG SETUP PROCEDURE

4.2 LPG FCV TEST

4.3 LPG ENABLE TEST

5. AFTER INSTALLATION CHECK

5.1 GENERAL INFORMATION

5.2 UNDERBODY

5.3 REAR COMPARTMENT

5.4 UNDER HOOD

5.5 LEAK CHECK

6. DIAGNOSIS

6.1 PREREQUISITES TO DIAGNOSIS AND

TROUBLESHOOTING

PRELIMINARY SYSTEM REQUIREMENTS

SAFETY REQUIREMENTS

CHECKING EQUIPMENT

6.2 GENERAL INFORMATION

6.3 LPG VEHICLE PRELIMINARY DIAGNOSIS

6.4 DOES NOT OPERATE ON LPG

6.5 FUEL MODE SWITCH DOES NOT OPERATE

6.6 ENGINE DOES NOT CRANK

6.7 ENGINE CRANKS BUT WILL NOT

START ON LPG

TEST 1

TEST 2

TEST 3

6.8 ENGINE BACKFIRES ON LPG

6.9 POOR PERFORMANCE, FLAT

SPOTTING, SLUGGISH OR POOR

FUEL CONSUMPTION WHEN

OPERATING ON LPG

6.10 FUEL CONTROL VALVE DOES NOT

OPERATE

6.11 TECH 2 SCAN TOOL: ENGINE DATA

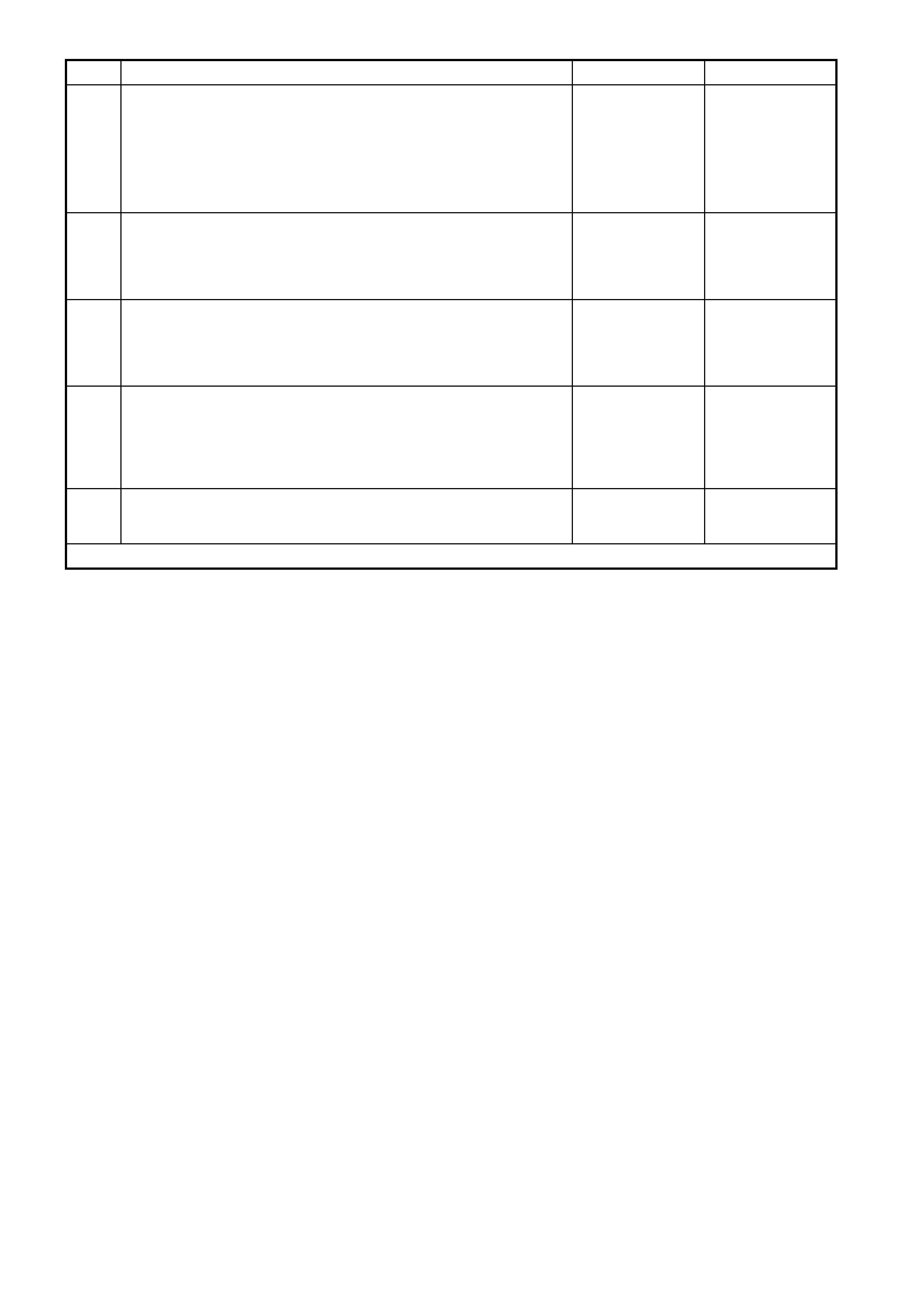

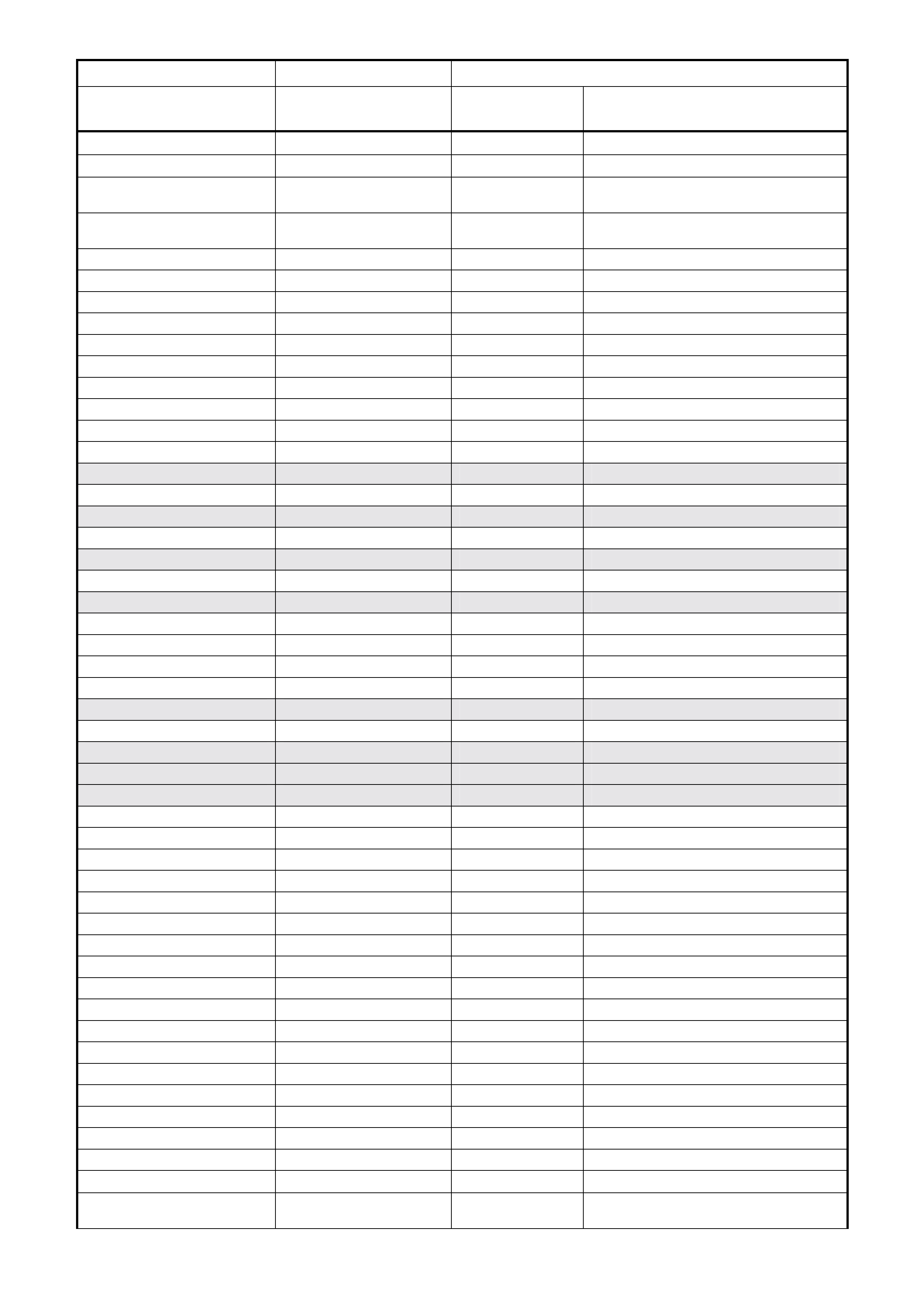

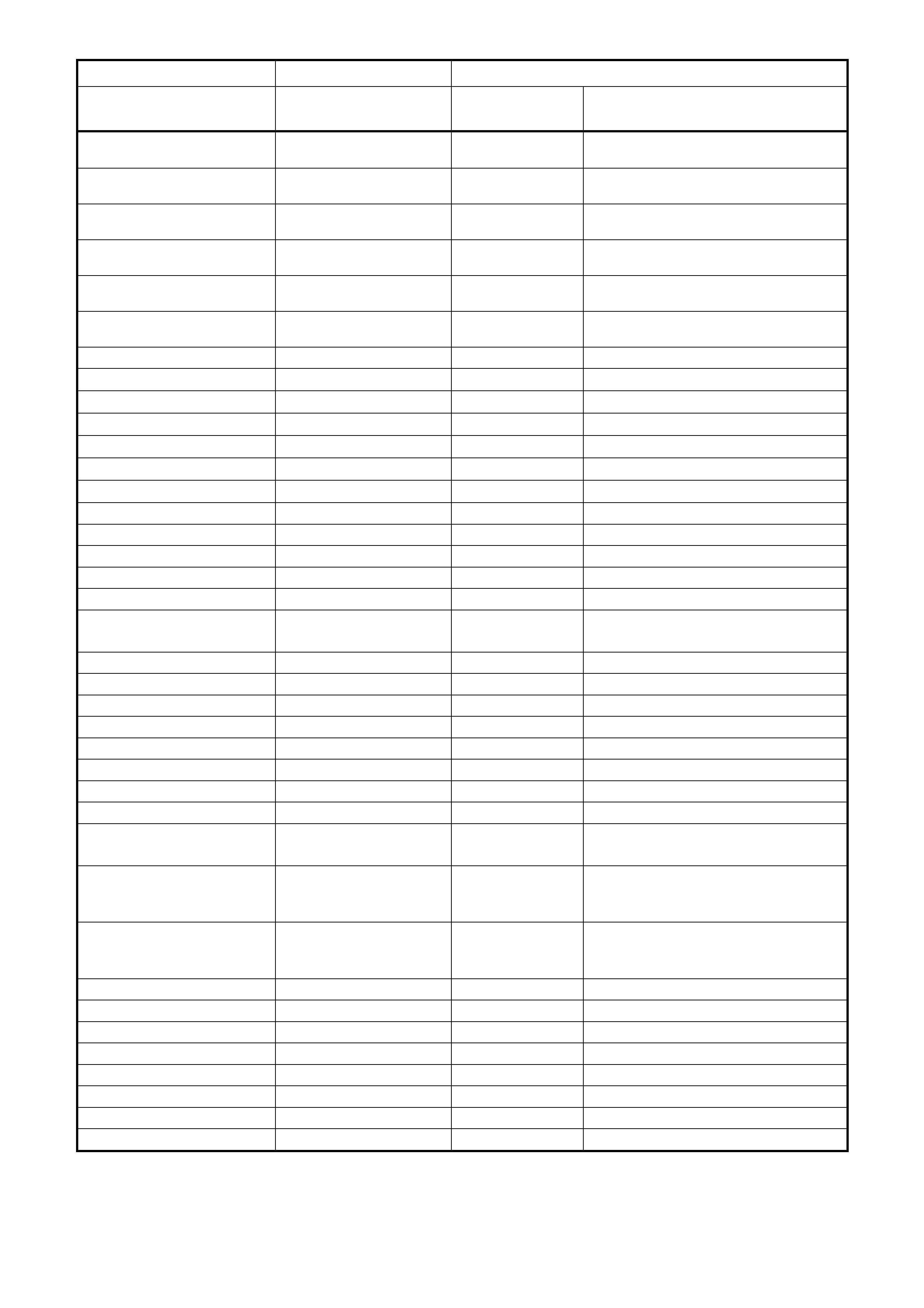

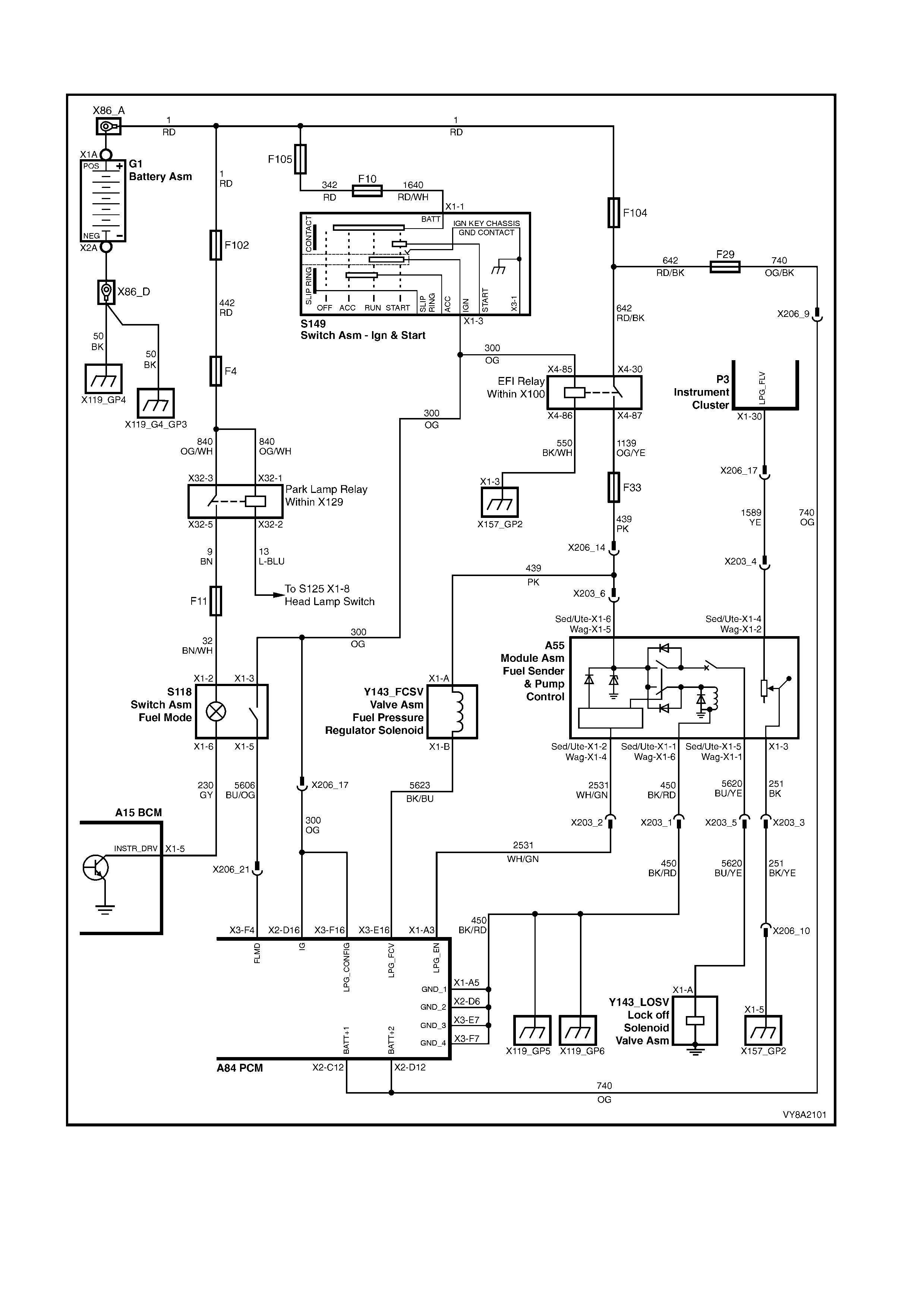

7. WIRING & CONNECTORS

8. SPECIFICATIONS

9. TORQUE WRENCH SPECIFICATIONS

10. SPECIAL TOOLS

1. GENERAL INFORMATION

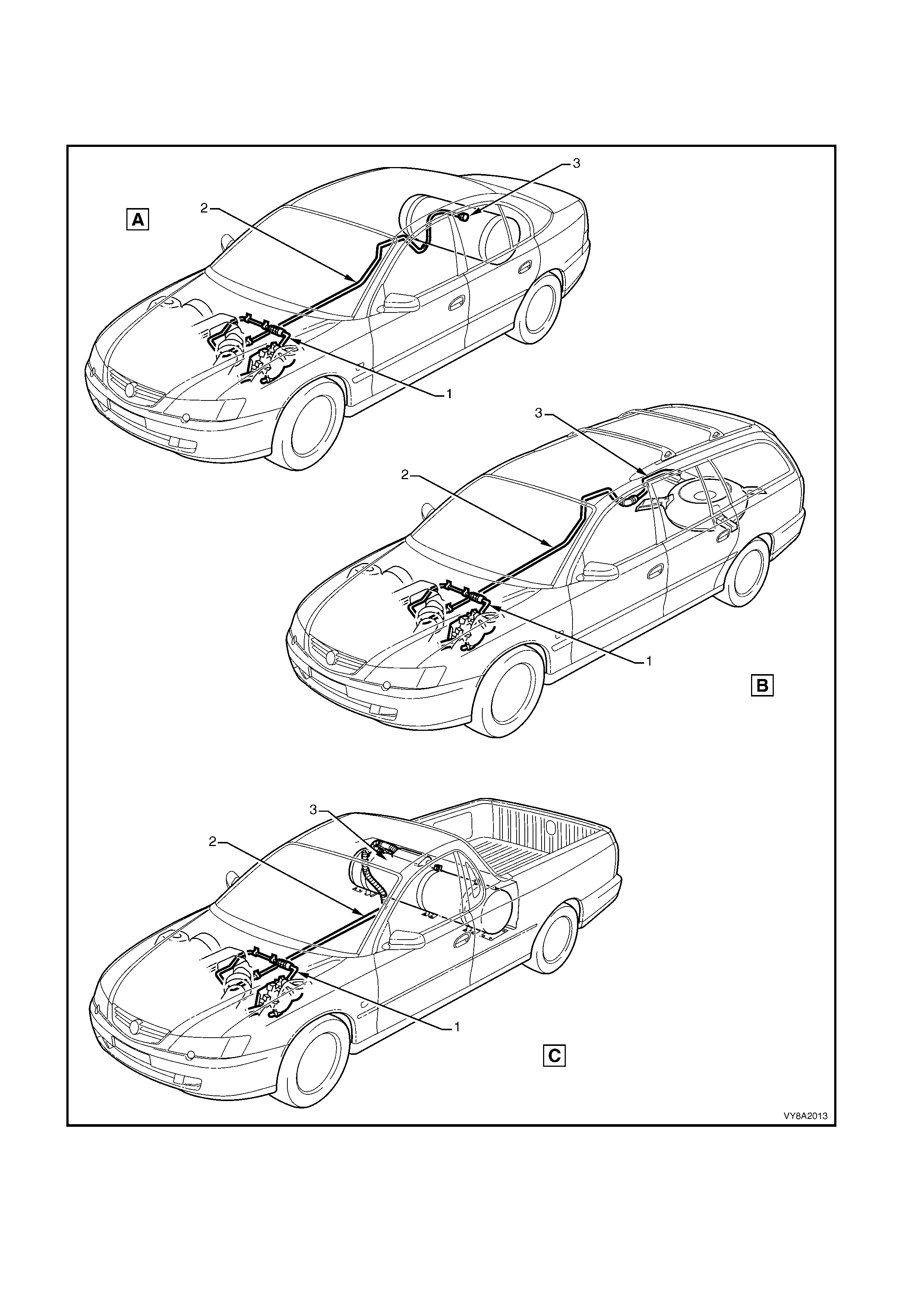

Liquefied Petroleum Gas ( LPG) , pr oduction option KL7, is available f or domestic MY2003 VY Series Sedan, Wagon

and Utility vehicles fitted with a V6 engine and automatic transmission.

The LPG system is identical across all vehicles with the exception of the LPG tank and filler assembly, which are

unique for each body style.

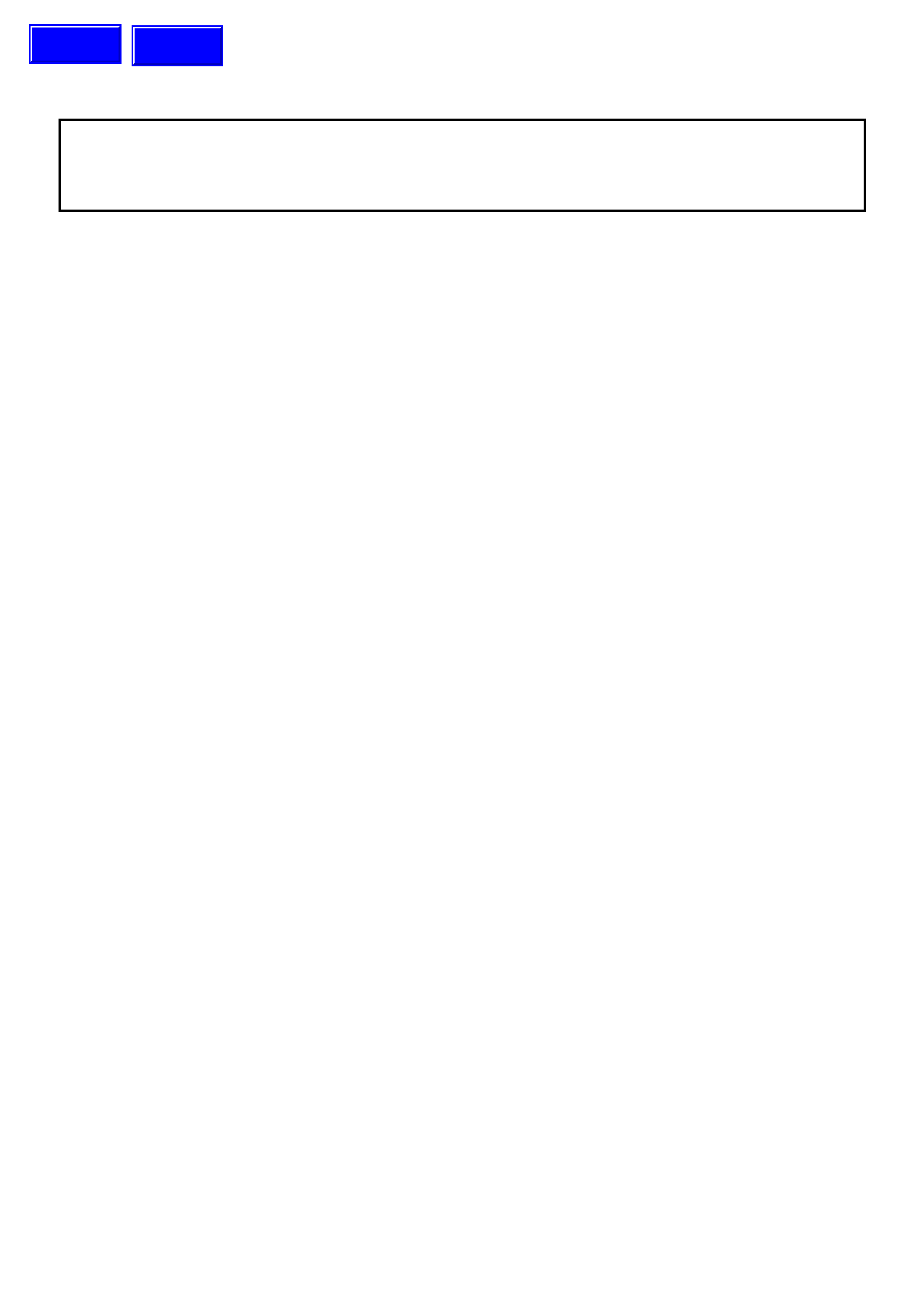

Sedan vehicles are fitted with a conventional cylindrical tank mounted in the rear compartment between the rear

wheelhouses, refer to Figure 8A2-1.

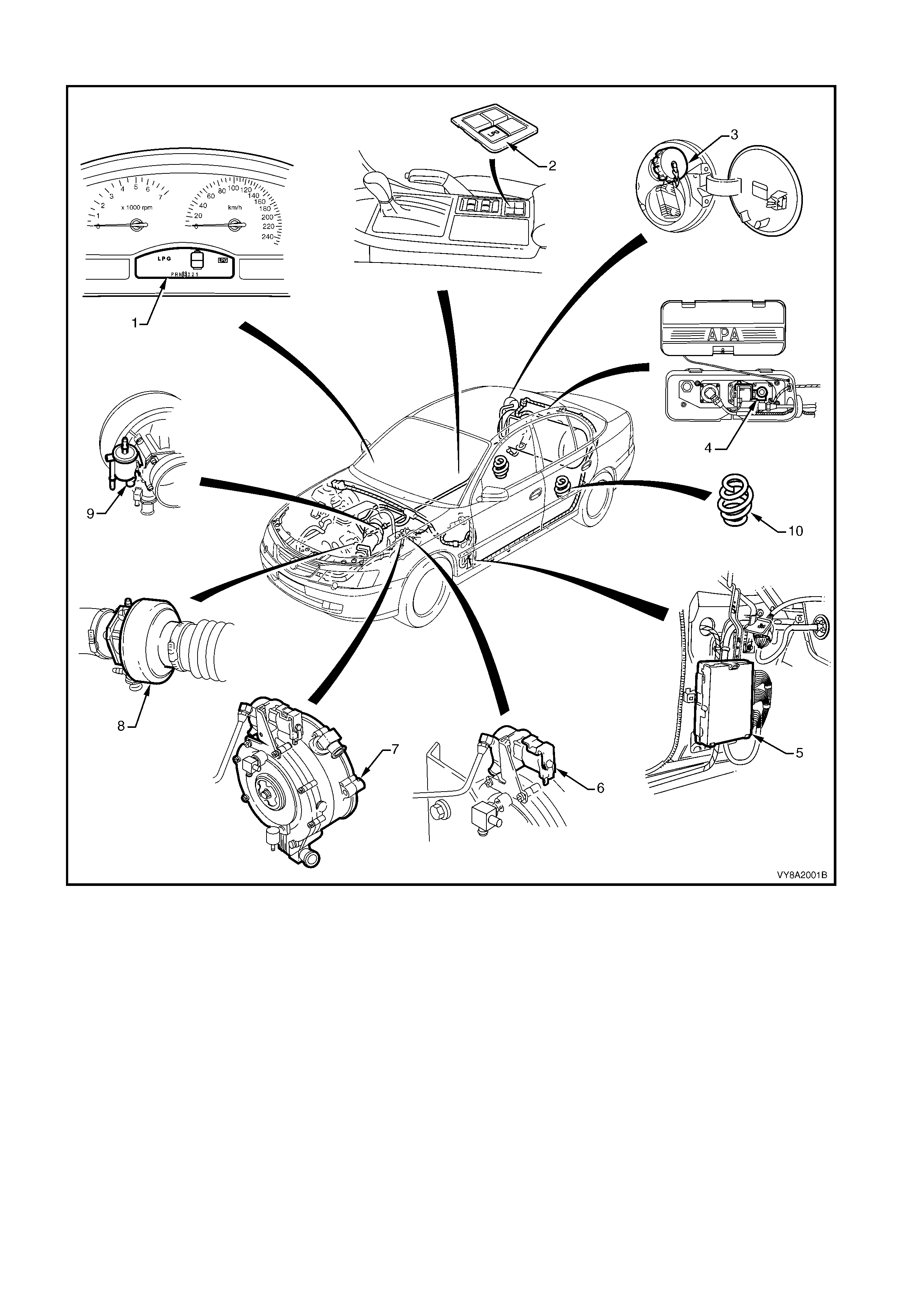

W agon vehic les employ a toroidal tank, als o com monly known as a doughnut tank . The tank is fitted into the spar e

wheel-well necessitating relocation of the spare wheel to an upright position in a carrier mounted on the right-hand

side of the rear compartment. Due to the increase in height of the tank compared to the spare wheel, a modified

rear compartment floor carpet is fitted, refer to Figure 8A2-2.

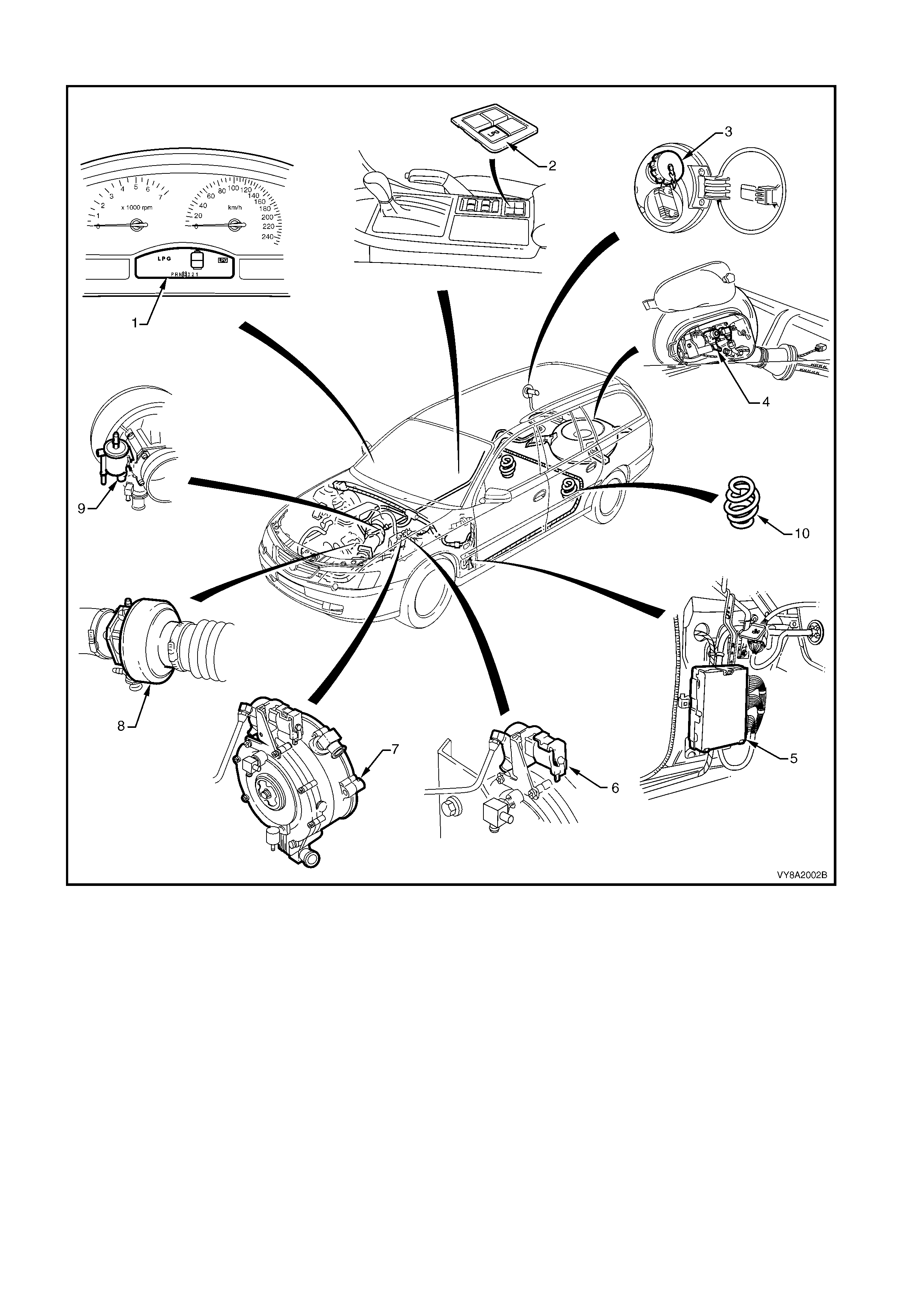

The tank fitted to Utility vehicles is also cylindrical in shape, but is wider and lower in profile to allow installation at

the front of the load compartment, under the rear window. A metal cover is fitted to protect the tank from damage

from objects placed in the load compartment, refer to Figure 8A2-3.

All filler valves are located within the fuel filler pocket above the petrol filler, however due to the tank differences,

routing and installation is unique to each body style.

The rear service lines ar e also unique for each body s tyle as is the rear connection of the interm ediate service line,

which is routed within the fuel and brak e line harness assembly. From this point, each system is com mon with the

intermediate line connecting to the converter via a front service line within the engine compartment. The converter is

incorporated into the cooling system circuit to aid vaporisation of the gas.

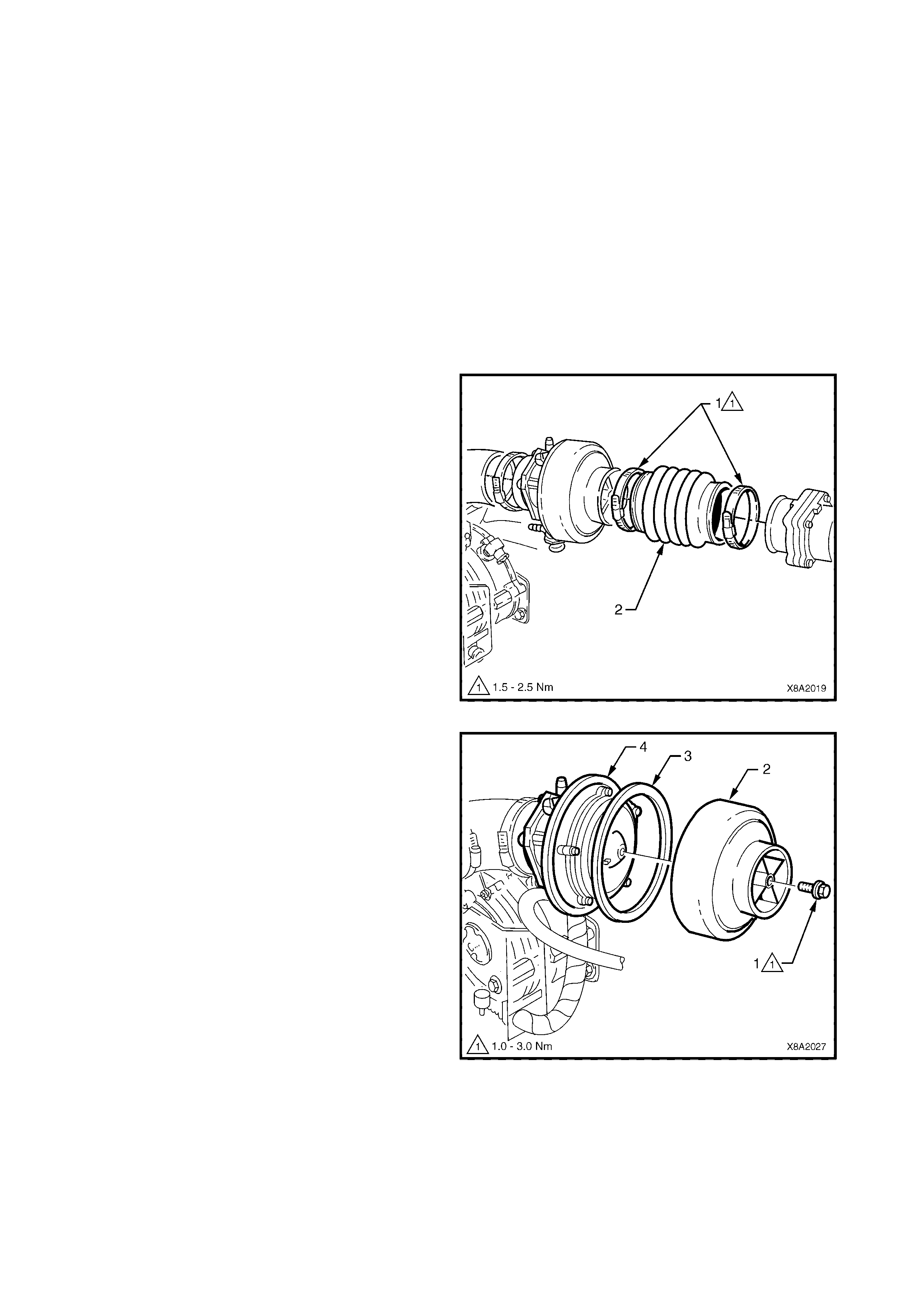

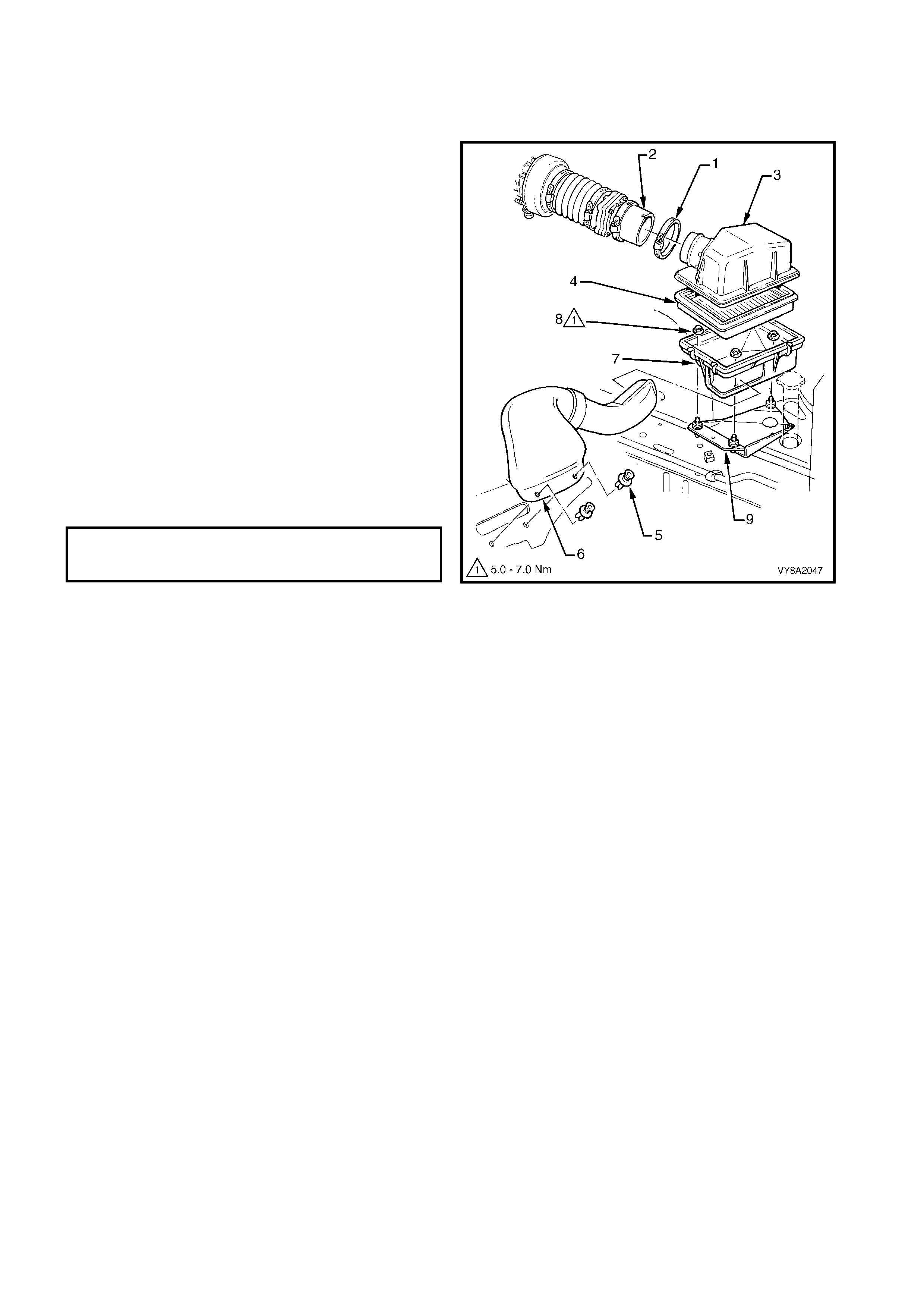

The last major component in the system is the mixer. The mixer is fitted in-line of the air inlet ducting and is

responsible for combining the LPG vapour with the inlet air prior to entering the engine.

The LPG system is controlled by the Powertrain Control Module (PCM), which is set to a unique program for LPG

operation. This allows for ease of set-up and provides optimum control of the system. Diagnostic functions and

trouble codes within the PCM support the LPG system.

The driver is able to switch the vehicle to LPG or petrol operation via a fuel mode switch, located in the front floor

console, even while the vehic le is being dr iven. An icon is dis played on the instrum ent c lus ter when LPG is s elec ted

and the standard fuel gauge changes from displaying the contents of the petrol tank to the LPG tank contents.

Further description of the LPG system operation and components is provided in 2. PRINCIPLES OF OPERATION.

All vehicles fitted with the KL7 LPG option are fitted with upgraded springs. For service information, refer to

Section 4A, REAR SUSPENSION.

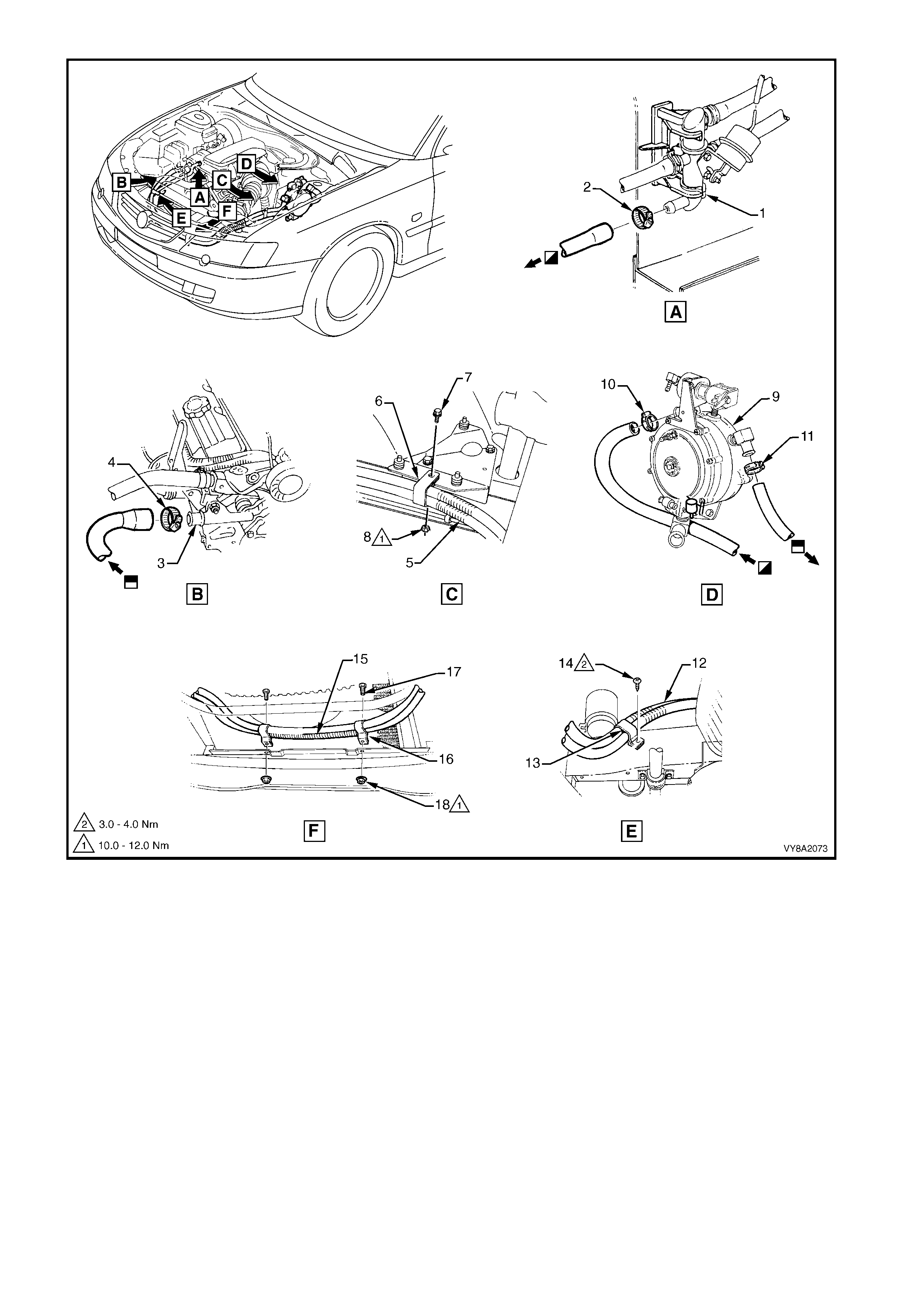

SEDAN

Figure 8A2-1

Legend

1. Instrument Cluster Display LPG Icons 6. LPG Lock-off

2. Fuel Mode Switch 7. Converter

3. LPG Filler Valve 8. Mixer

4. Manual Service Valve Assembly 9. Fuel Control Valve

5. Powertrain Control Module (PCM) 10 Rear Springs

WAGON

Figure 8A2-2

Legend

1. Instrument Cluster Display LPG Icons 2. LPG Lock-off

3. Fuel Mode Switch 4. Converter

5. LPG Filler Valve 6. Mixer

7. Manual Service Valve Assembly 8. Fuel Control Valve

9. Powertrain Control Module (PCM) 10. Rear Springs

UTILITY

Figure 8A2-3

Legend

1. Instrument Cluster Display LPG Icons 6. LPG Lock-off

2. Fuel Mode Switch 7. Converter

3. LPG Filler Valve 8. Mixer

4. Manual Service Valve Assembly 9. Fuel Control Valve

5. Powertrain Control Module (PCM)

1.1 SAFETY PRECAUTIONS

• Any servicing or testing of the LPG system high pressure area must be performed by trained and/or licensed

LPG installers or fitters, in a Specialist Gas Workshop and in accordance with Australian Standards

AS 2746-1985 and AS 1425-1989.

• Norm al vehicle m aintenance ser vice and any s ervicing of the LPG system not affecting the high- pressure area

(filler line, LPG tank , servic e line, LPG lock - off and converter ) m ay be perform ed by dealership technicians who

are not accredited installers or fitters.

• DO NOT smoke or allow naked flames, or any ignition source near the vehicle.

• LPG m ust never com e in contact with any part of the body as it can caus e severe frostbite. Due to its very low

boiling point, LPG readily absorbs heat from its surroundings or any surface it comes in contact with when

released into the atmosphere.

• When working on the LPG system, suitable protective clothing including gloves and safety goggles must be

worn to prevent personal injury.

• LPG in the vapour form is highly flammable. In the interests of safety, the LPG system should be leak tested

and isolated by turning off the m anual service valve and draining the s ervice lines of LPG prior to c omm encing

any work on the vehicle, refer to 3.1 SERVICE LINE DRAINING.

• During servic ing, the m anual servic e valve m ust r em ain off at all tim es, except when gas is specif ically required

for servicing or testing of the LPG system.

• Whenever any service operation is performed on the high-pressure area of the system (filler line, LPG tank,

service line, LPG lock -off and converter ), a leak test m ust be perf ormed on the com plete LPG system, r efer to

3.3 LEAK TESTING.

• Prior to the removal of any component from the LPG tank, the LPG tank must be emptied of LPG, refer to

3.2 LPG TANK UNLOADING. The LPG tank must then be safety tested in accordance with Australian Standard

AS 2030-1 and according to the laws of the state in which the vehicle is registered. A leak test must be

performed on the complete LPG system before the LPG tank is returned to service in the vehicle.

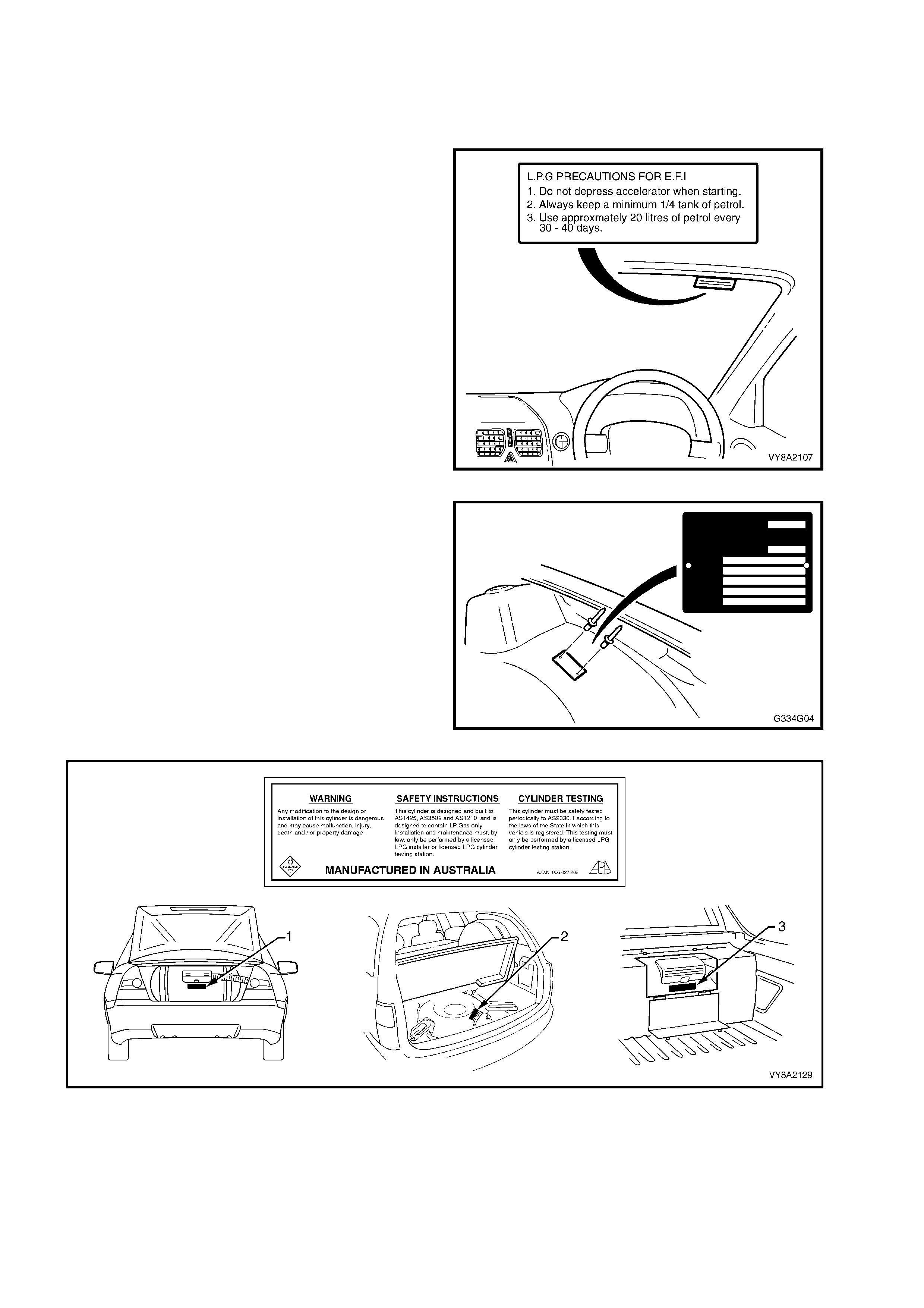

1.2 IDENTIFICATION PLATES & WARNING LABELS

Several identification plates and warning labels are fitted to vehicles with LPG, as shown below .

NOTE: If the vehicle is repaired or the components that the labels / plates are attached to are replaced, the

label or plate must also be replaced.

1. The LPG precaution label, fitted to the

windscreen right-hand upper, provides the driver

with information for operating the vehicle on LPG.

Figure 8A2-4

2. An LPG compliance plate, if required by State

regulations, is riveted to the left-hand front

wheelhouse.

3. A warning label is affixed to the LPG tank (1 –

Sedan, 2 – Wagon, 3 – Utility) and provides

important information regarding the tank

assembly, refer to Figure 8A2-6.

Figure 8A2-5

Figure 8A2-6

4. A Holden By Design identification plate is riveted

to the front upper panel.

Figure 8A2-7

2. PRINCIPLES OF OPERATION

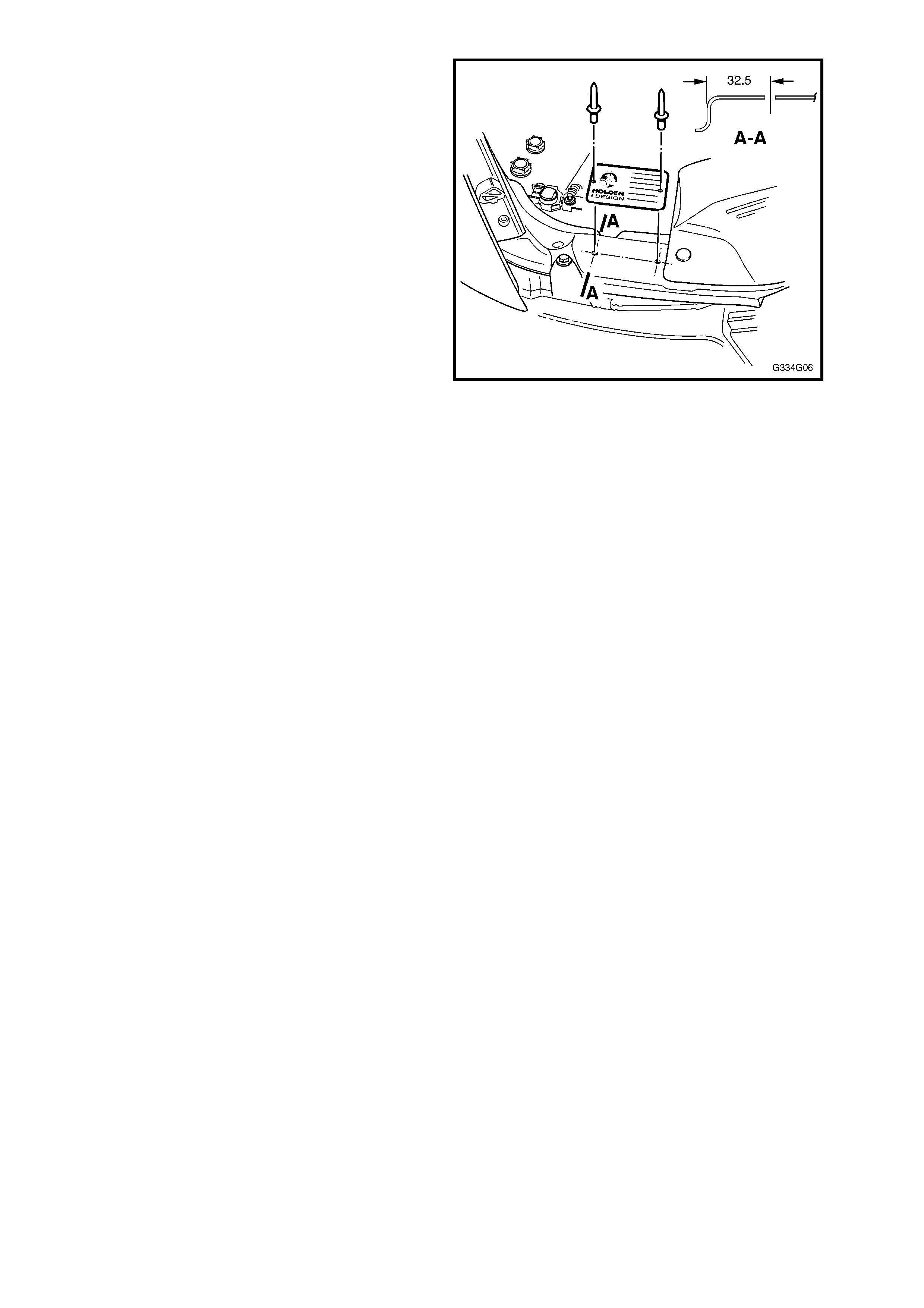

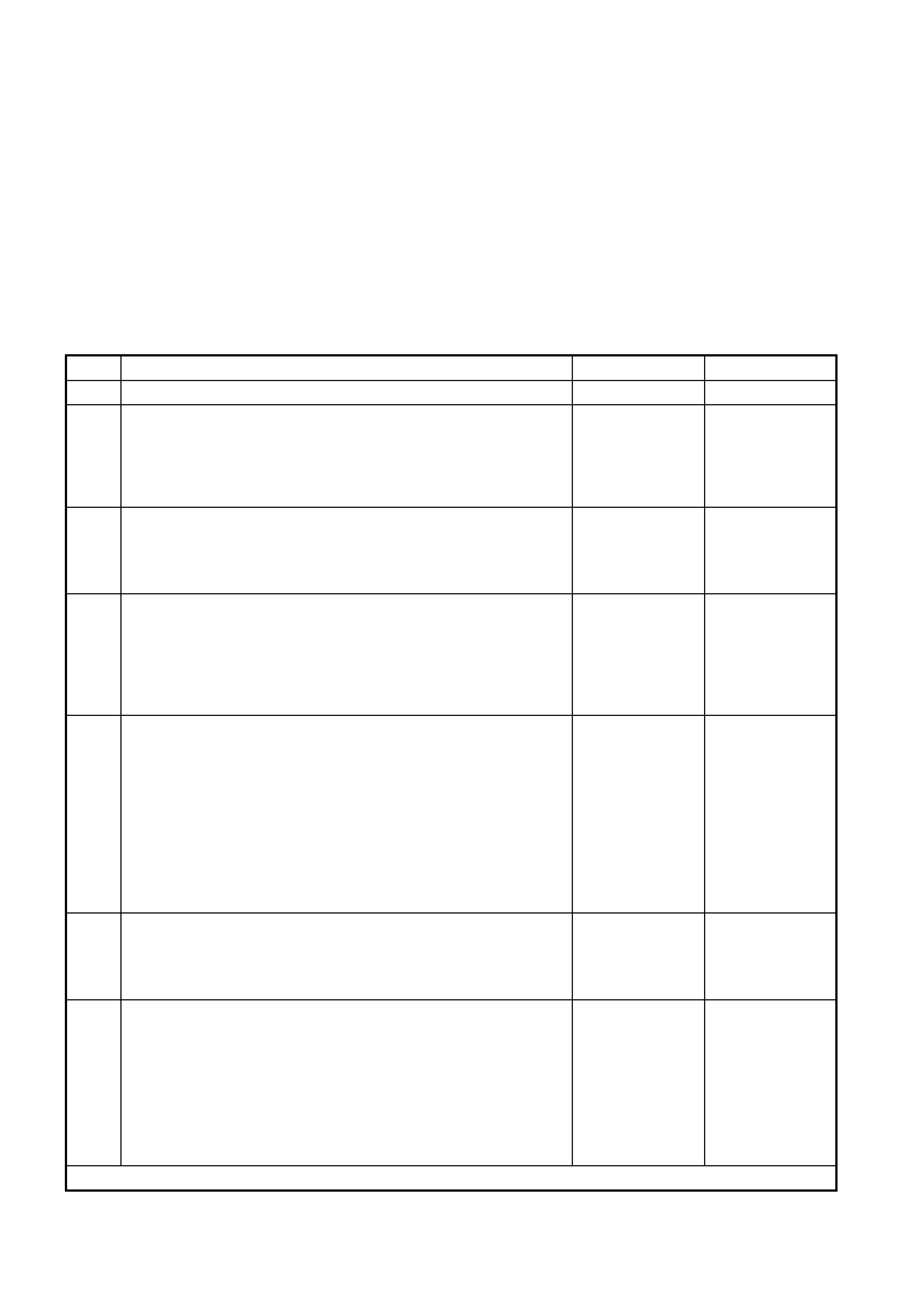

2.1 LPG SYSTEM (TYPICAL)

Figure 8A2-8

Legend

1. LPG Filler Valve 11. LPG Lock-off

2. Filler Line 12. Converter A. Liquid

3. AFL 13. Fuel Control Valve B. Vapour

4. LPG Tank Assembly 14. Mixer C. Vacuum

5. Relief Valve 15. Wiring Harness D. Coolant

6. Fuel Contents Gauge / Sender 16. Powertrain Control Module (PCM) E. Breather

7. Manual Service Valve Assembly 17. Fuel Mode Switch F. Balance / Vacuum

8. Rear Service Line 18. Instrument Cluster Display LPG Icons G. Air Intake

9. Intermediate Service Line 19. Instrument Cluster Fuel Gauge H. To Engine Inlet Manifold

10. Front Service Line 20. Coolant Hoses

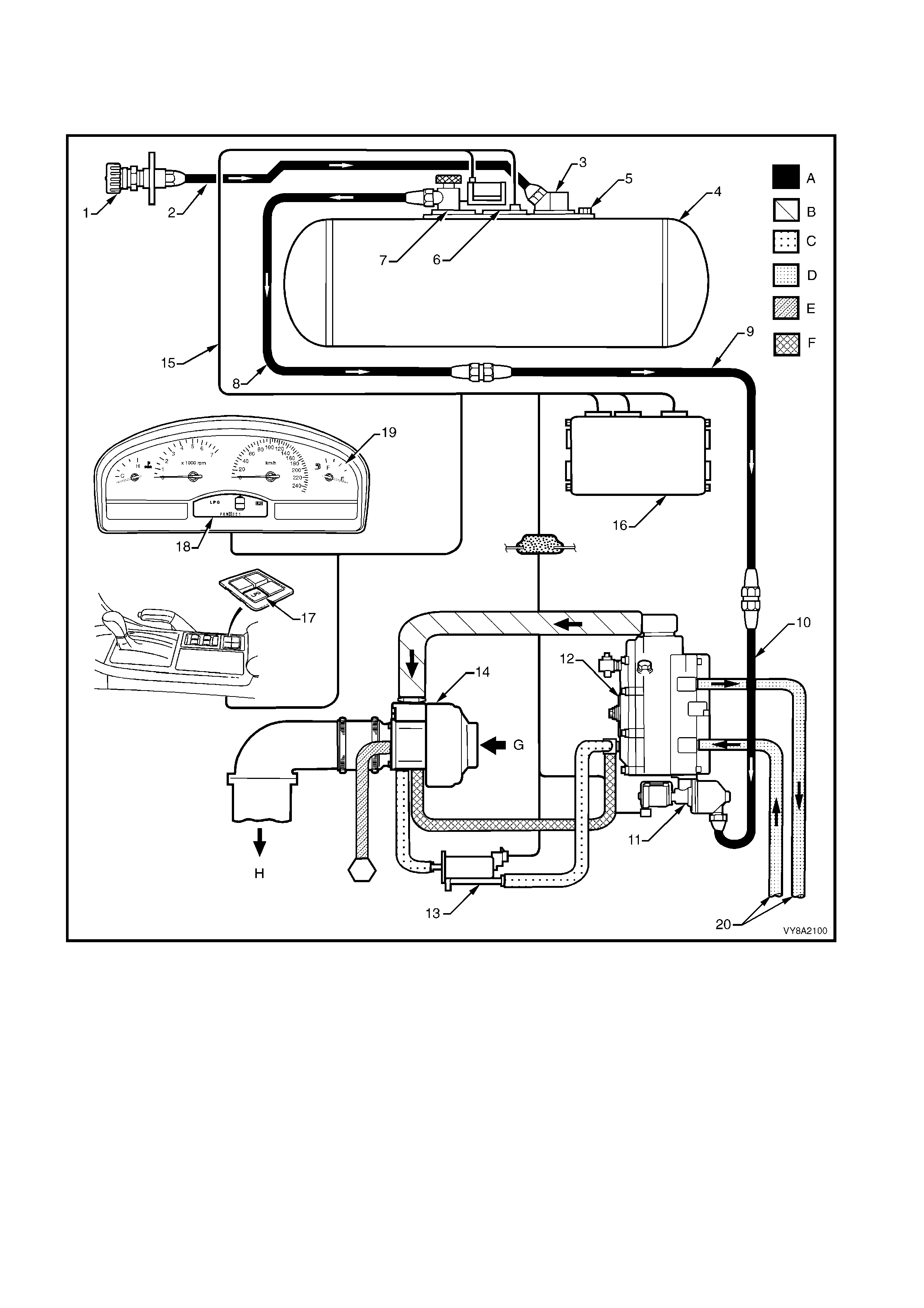

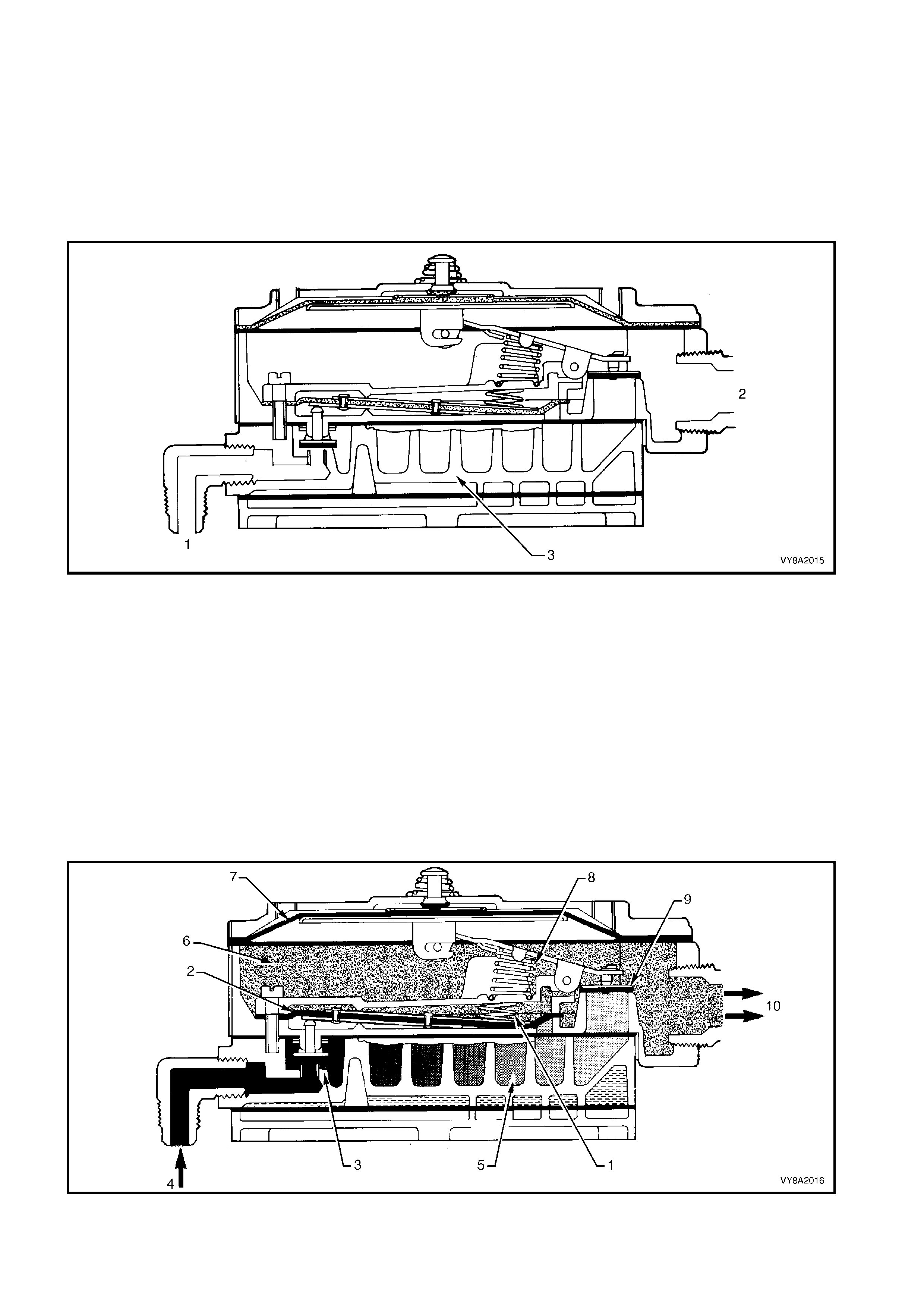

2.2 LPG TANK

The LPG Tank is made of carbon steel and is

manufactured to stringent safety standards.

LPG m ust be stored at appr oxim ately 750 k Pa at 20°C

to remain a liquid. The vapour pres s ur e inside the LPG

tank will vary with ambient temperature, as the ambient

temperature rises so does the vapour pressure.

The LPG tank is heat treated during manufacture and

MUST NOT be heated or welded in any way.

SEDAN & UTILITY

For sedan vehicles, the LPG tank is fitted in the rear

compartment, under the rear parcel shelf.

Utility vehicles have the tank mounted at the front of

the load compartment, below the rear window.

The LPG tank incorporates a gas-tight compartment

(valve box) which is vented to atmosphere via a vent

hose and contains the following components, refer to

Figure 8A2-10 (Sedan, Utility is similar):

1. Pressure relief valve,

2. Smart unit, solenoid, manual service valve and

excess flow valve,

3. Tank fuel gauge assembly, and

4. Automatic fill limiter (AFL).

Thes e components are either attached into or onto the

LPG tank. As the LPG tank is loc ated in the luggage or

load compartments, if any of these components were

to leak, or there was an excess pressure discharge,

the LPG would be vented to atmosphere via the vent

hose and will not vent into the vehicle.

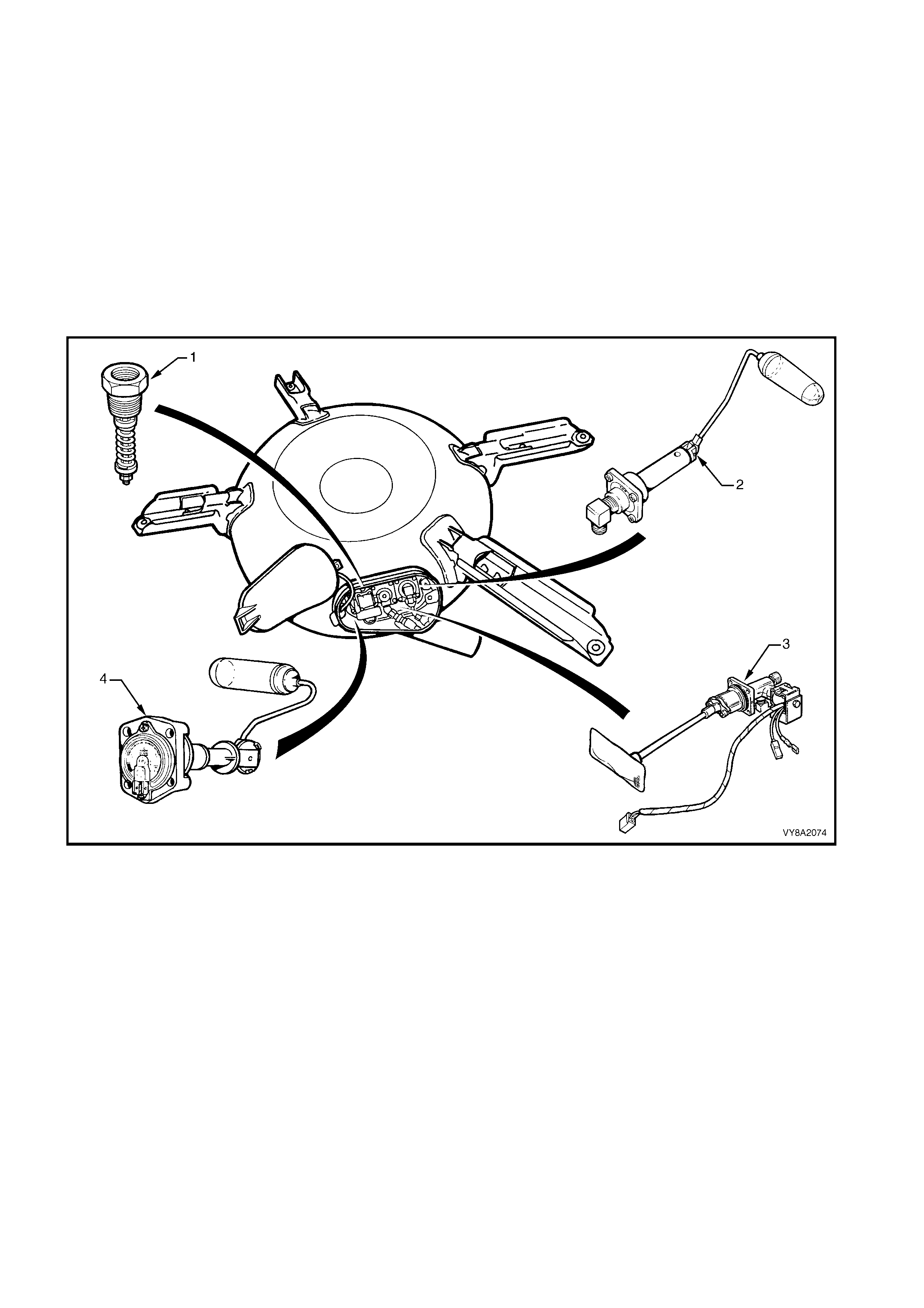

Figure 8A2-9

Figure 8A2-10

Legend

1. Pressure Relief Valve 3. Tank Fuel Gauge Assembly

2. Smart Unit, Solenoid, Manual Service Valve and Excess Flow Valve 4. Automatic Fill Limiter (AFL)

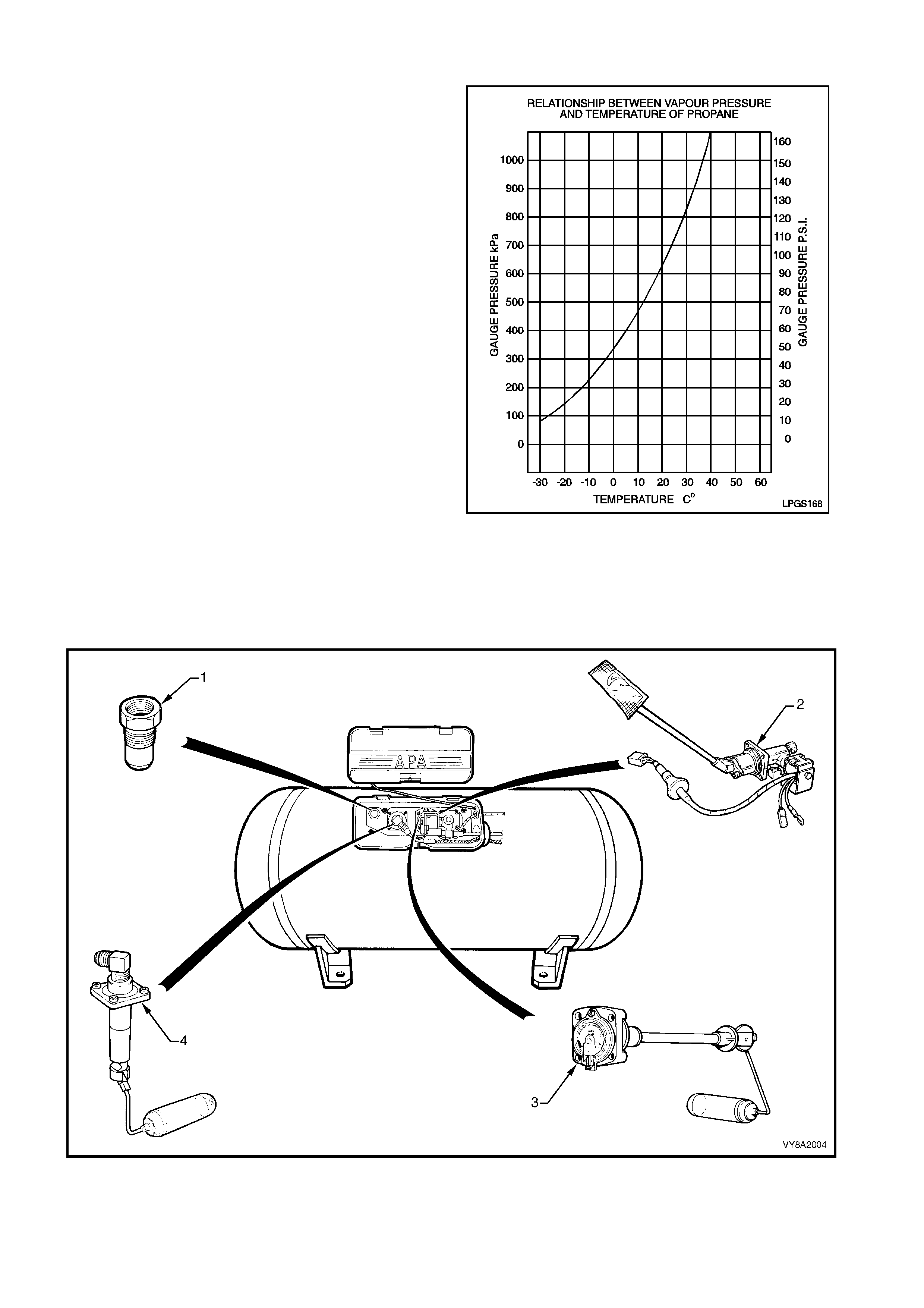

WAGON

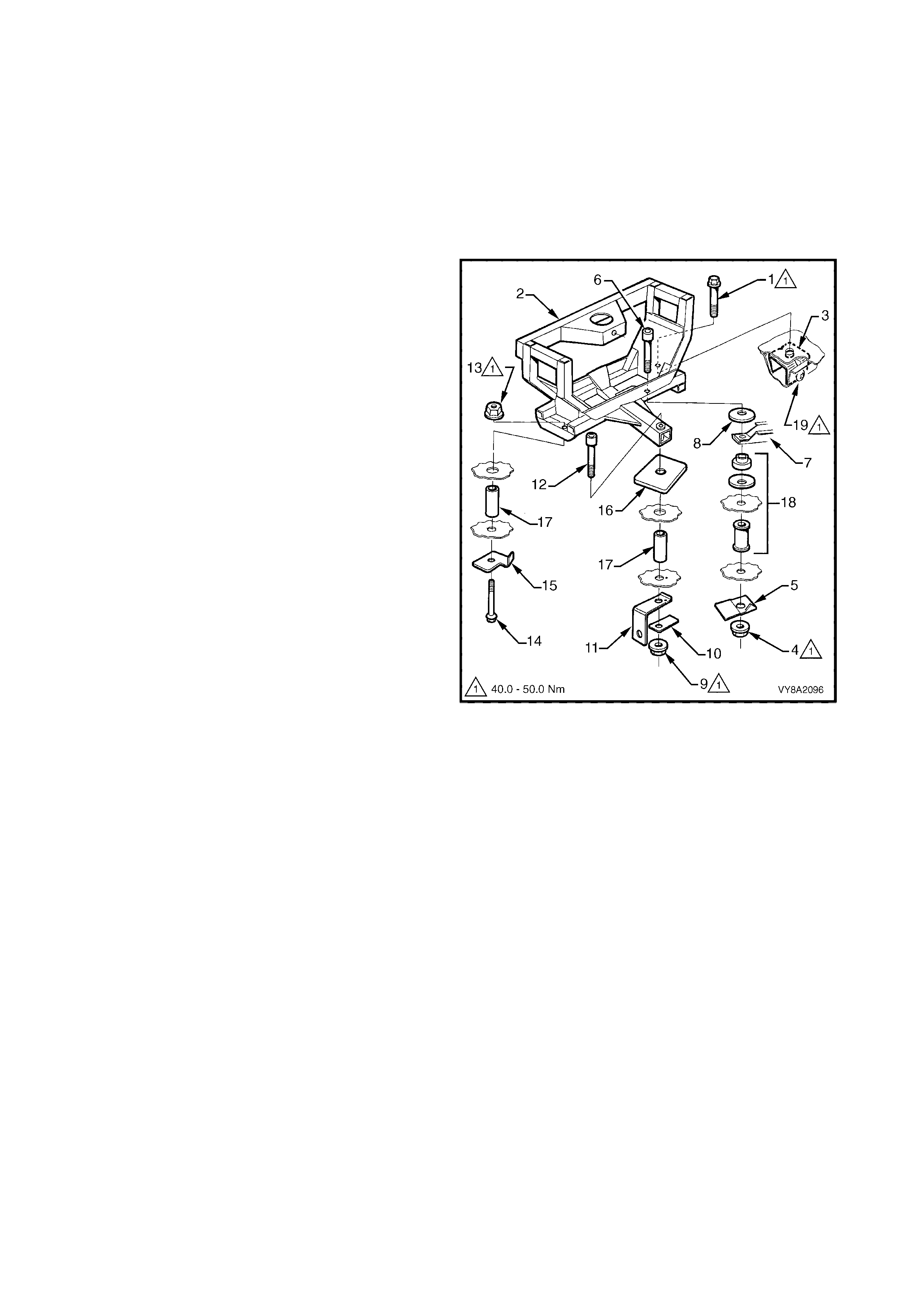

Due to s pace lim itations, a toroidal s haped tank is fitted to Wagon vehic les. It is designed to fit within the spare

wheel compartment, necessitating the relocation of the spare wheel to a bracket assembly on the right-hand side

of the luggage compartment.

The LPG tank fitted to Wagon vehicles also has a gas-tight compartment (valve box), which contains the

following components, refer to Figure 8A2-11:

1. Pressure relief valve,

2. Automatic fill limiter (AFL),

3. Smart unit, solenoid and manual service valve assembly, and

4. Tank fuel gauge assembly.

These components are either attached into or onto the LPG tank. As the LPG tank is located in the luggage

compartment, if any of these components were to leak, or there was an excess pressure discharge, the LPG

would be vented to atmosphere via a vent hose and will not vent into the vehicle.

Figure 8A2-11

Legend

1. Pressure Relief Valve 3. Smart Unit, Solenoid, Manual Service Valve and Excess Flow Valve

2. Automatic Fill Limiter (AFL) 4. Tank Fuel Gauge Assembly

2.3 FILLER VALVE

The filler valve is located in the fuel filler pocket,

adjacent to the petrol filler.

The valve incorporates two spring-loaded non-return

valves (1 & 2) and a sealed cap (3) fitted to the filling

connection (4).

The c onnection is designed to shear off in the event of

the vehicle being driven away with the filler hose

inadvertently attached. In this situation, the lower valve

remains intact, avoiding the LPG discharging.

The filler valve is connected to the LPG tank AFL inlet

elbow by a filler line, which is routed through the LPG

tank vent hose.

Figure 8A2-12

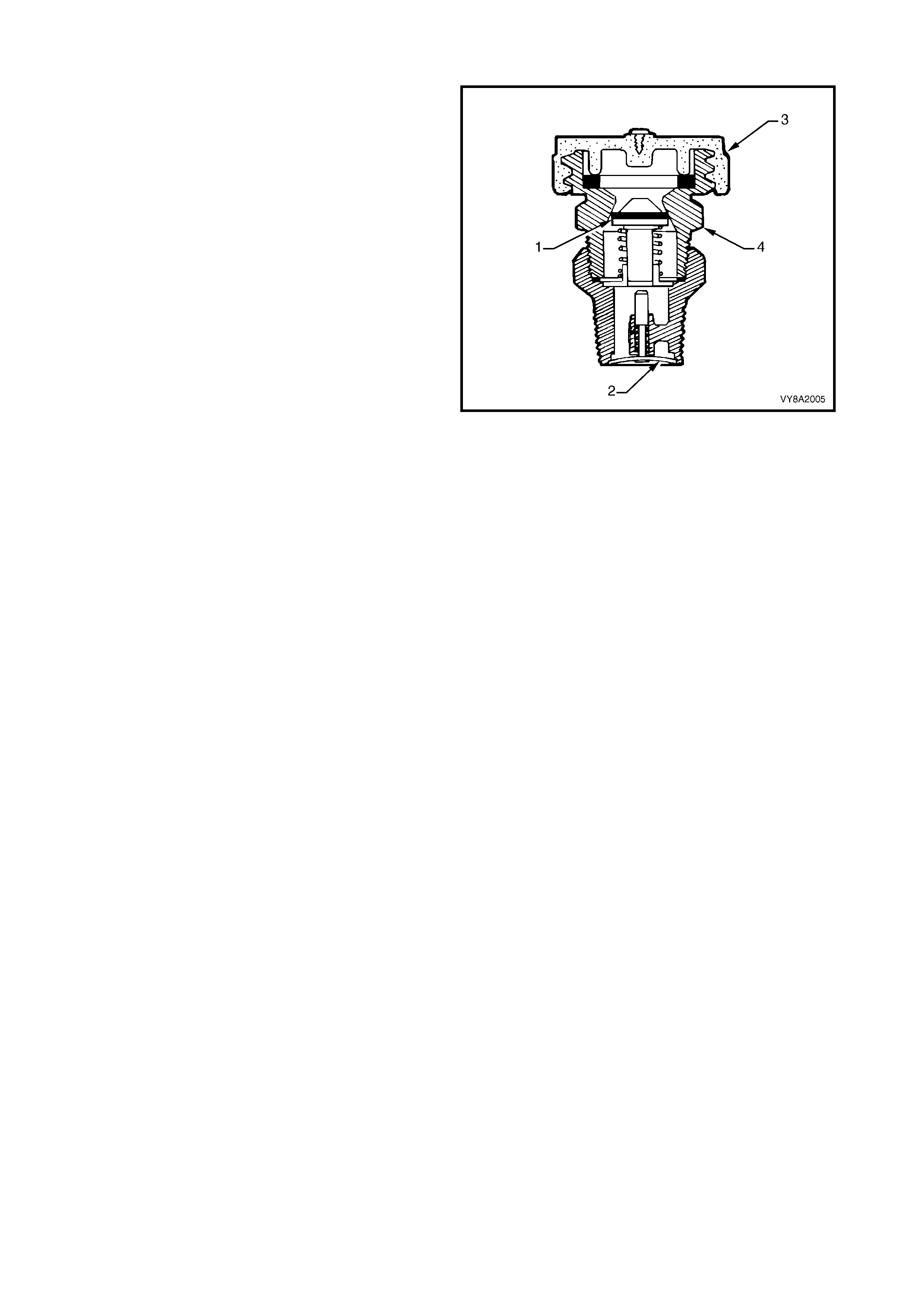

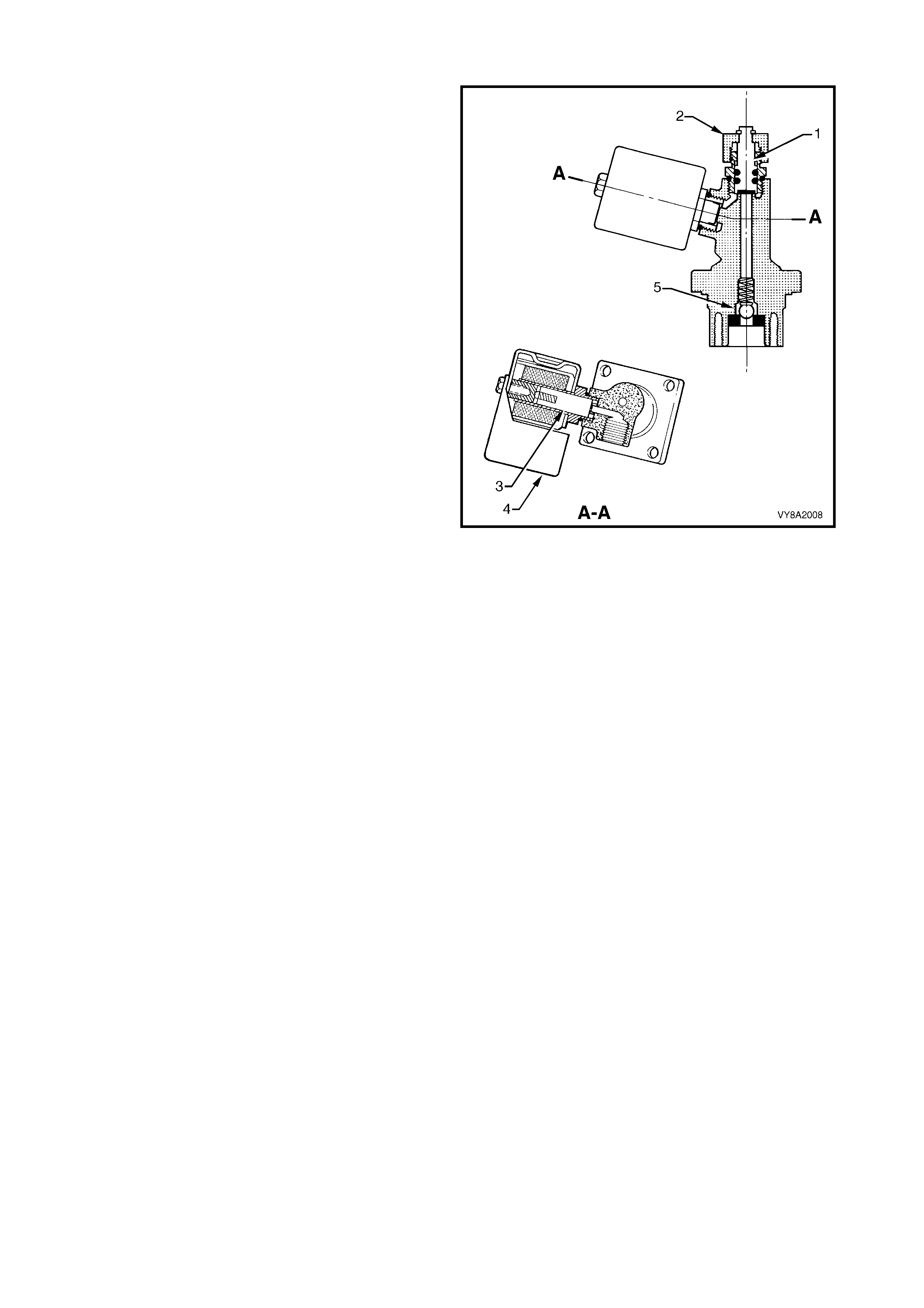

2.4 AUTOMATIC FILL LIMITER (AFL)

The Automatic fill limiter (AFL) is fitted into the LPG

tank. T he inlet elbow (1) connects the to the LPG filler

line.

W hen the tank is being filled with liquid LPG, the AFL

float (2) rises with the liquid within the LPG tank. The

float arm is connected to an actuator (3) that operates

a shut-off piston (4). When the level reaches

approximately 80% full, the piston is in the closed

position, shutting off the flow of LPG into the tank.

The remaining 20% of the tank volume is necessary

vapour space to allow for the expansion of the liquid

that occurs as the temperature of the liquid increases.

The AFL is also fitted with a non-return valve (5) to

prevent the gas escaping.

Figure 8A2-13

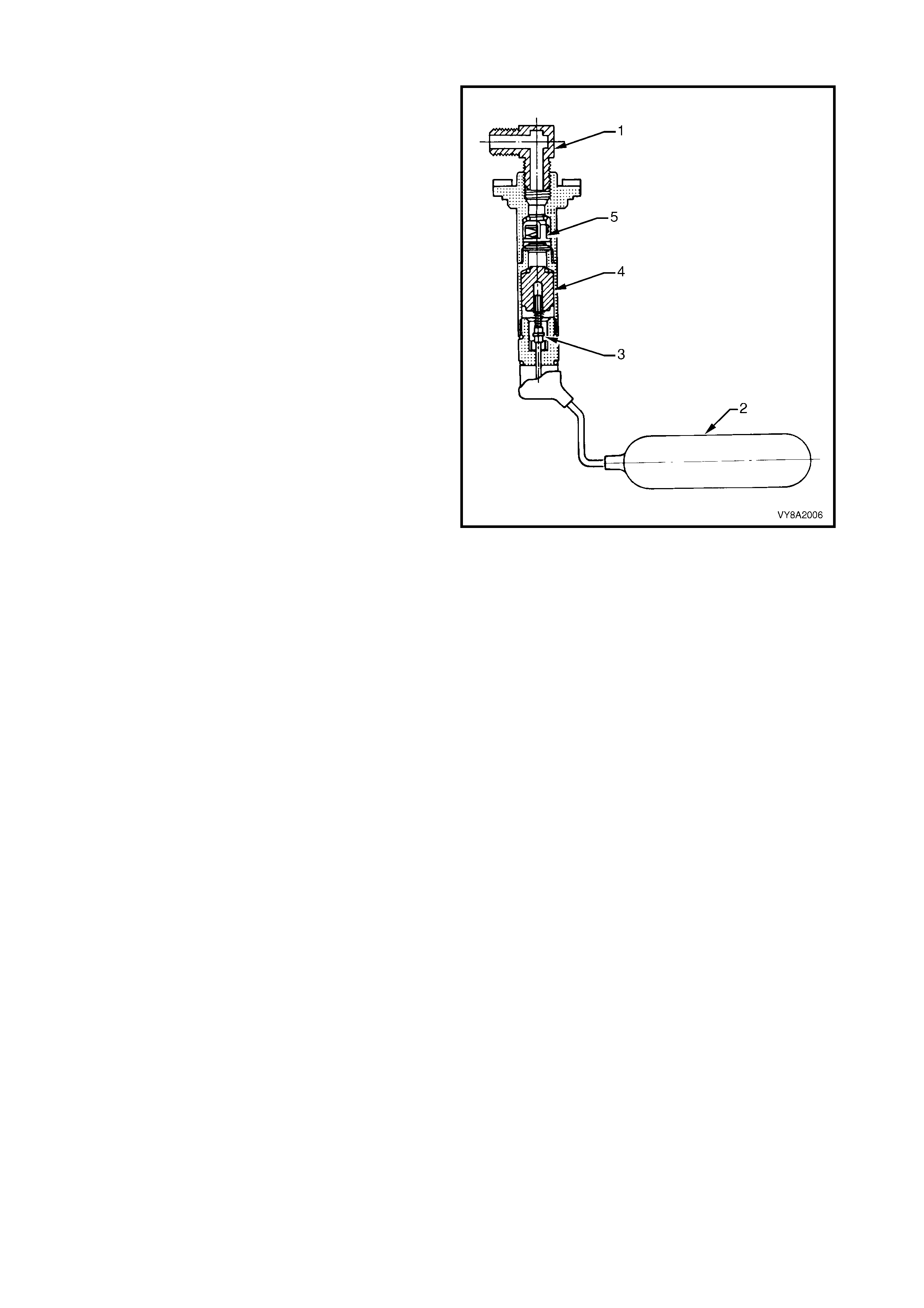

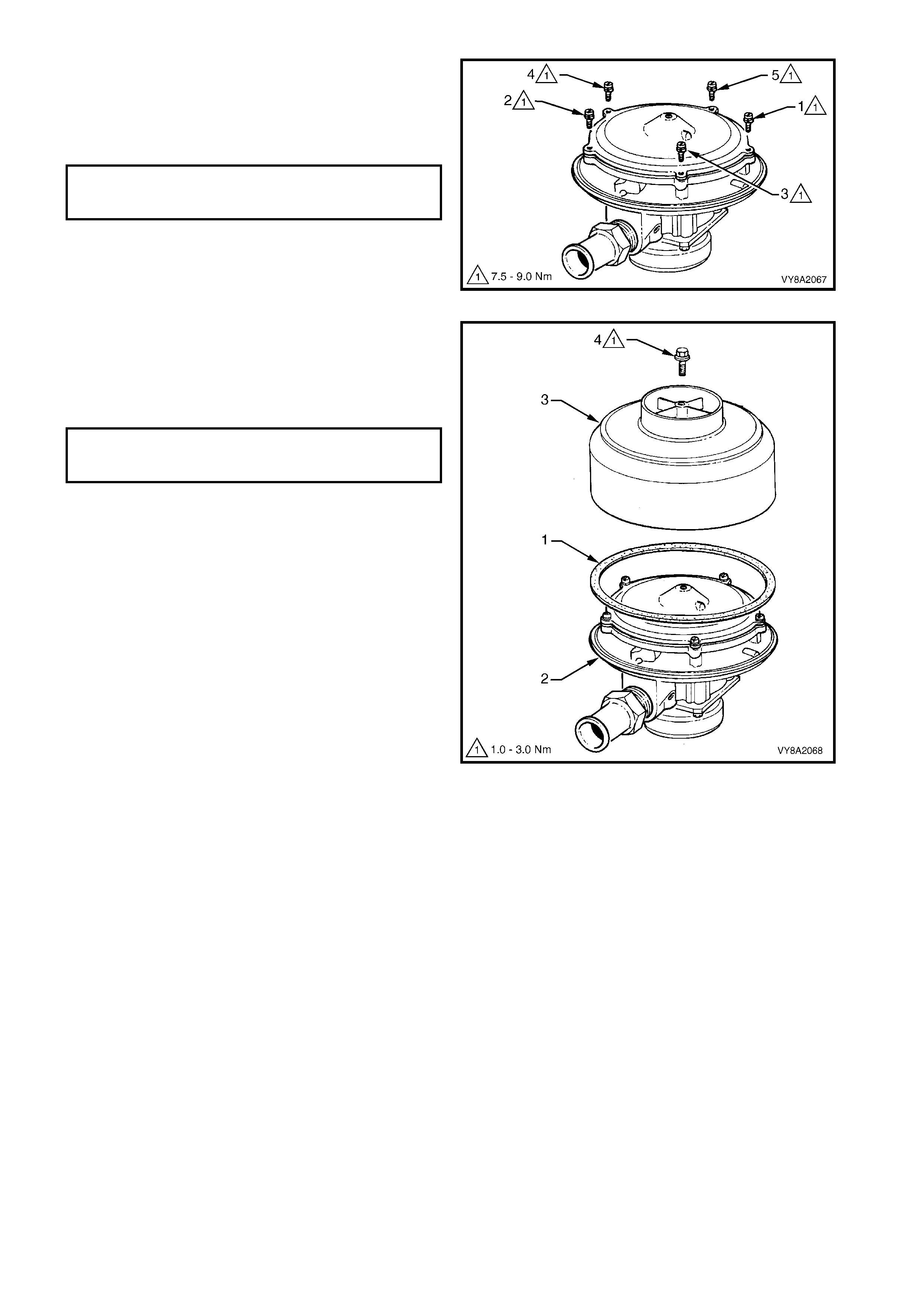

2.5 PRESSURE RELIEF VALVE

The pressure relief valve is housed within the valve

box and attached into the LPG tank.

Pressur e within the LPG tank exceeding approxim ately

2,550 kPa c auses the valve (1) to open by overcom ing

spring tension (2). The excess pressure will then be

vented into the valve box through the orifice (3) and

then to atmosphere via the vent hose.

The valve will continue to vent the LPG tank until the

pressur e drops below 2,550 k Pa and the spring closes

the valve.

During normal operating conditions the pressure relief

valve should not operate.

Figure 8A2-14

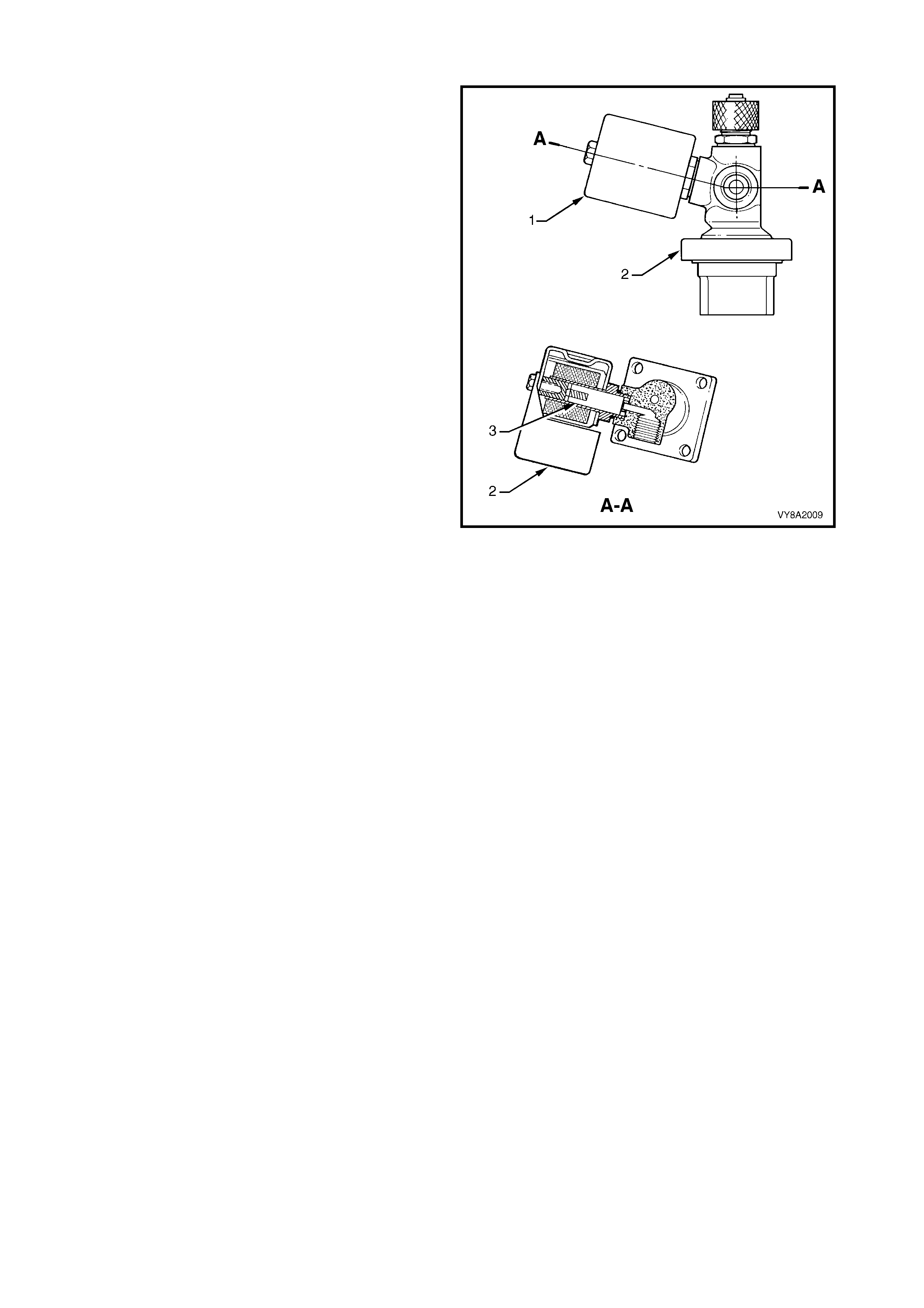

2.6 MANUAL SERVICE VALVE ASSEMBLY

The manual service valve assembly is attached onto

the LPG tank and is three valves in one:

• manual shut off valve,

• electrically operated solenoid valve, and

• excess flow valve.

The manual service valve assembly also incorporates

the smart unit, refer to 2.7 SMART UNIT.

MANUAL SHUT OFF VALVE

The manual s hut of f valve (1) allows the s upply of LPG

to be manually shut off for servicing, if a leak in the

system develops, or in the event of a vehicle accident

by turning the knob (2).

SOLENOID VALVE

The s olenoid valve (3) is an electric ally oper ated valve,

which allows the flow of LPG from the tank into the

service line when energised by the smart unit (4). The

solenoid valve is energis ed f or thr ee seconds when the

ignition key is first turned on, or constantly while the

engine is being cranked or is running.

The solenoid valve will s hut off the LPG f low when the

ignition is switched off and/or the engine stops running.

EXCESS FLOW VALVE

The ex cess f low valve (5) will close autom atically if the

flow of liquid LPG is excessive, shutting off the supply

of liquid LPG. The valve will automatically reopen when

the excess flow condition has ceased.

The ex ces s f low valve is des igned to shut off if the flow

exceeds a specified amount, as would occur if the

service line was severed or opened.

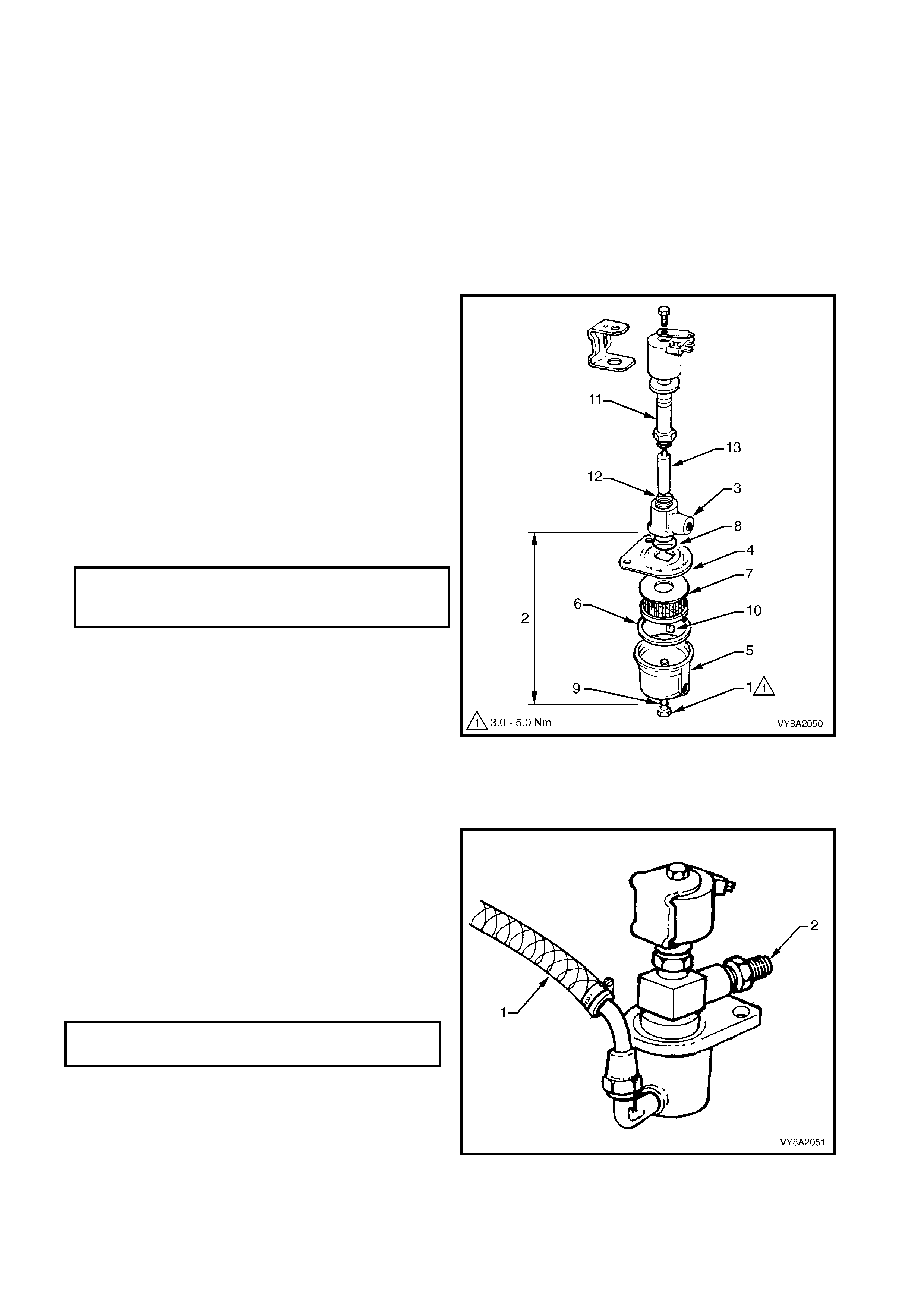

Figure 8A2-15

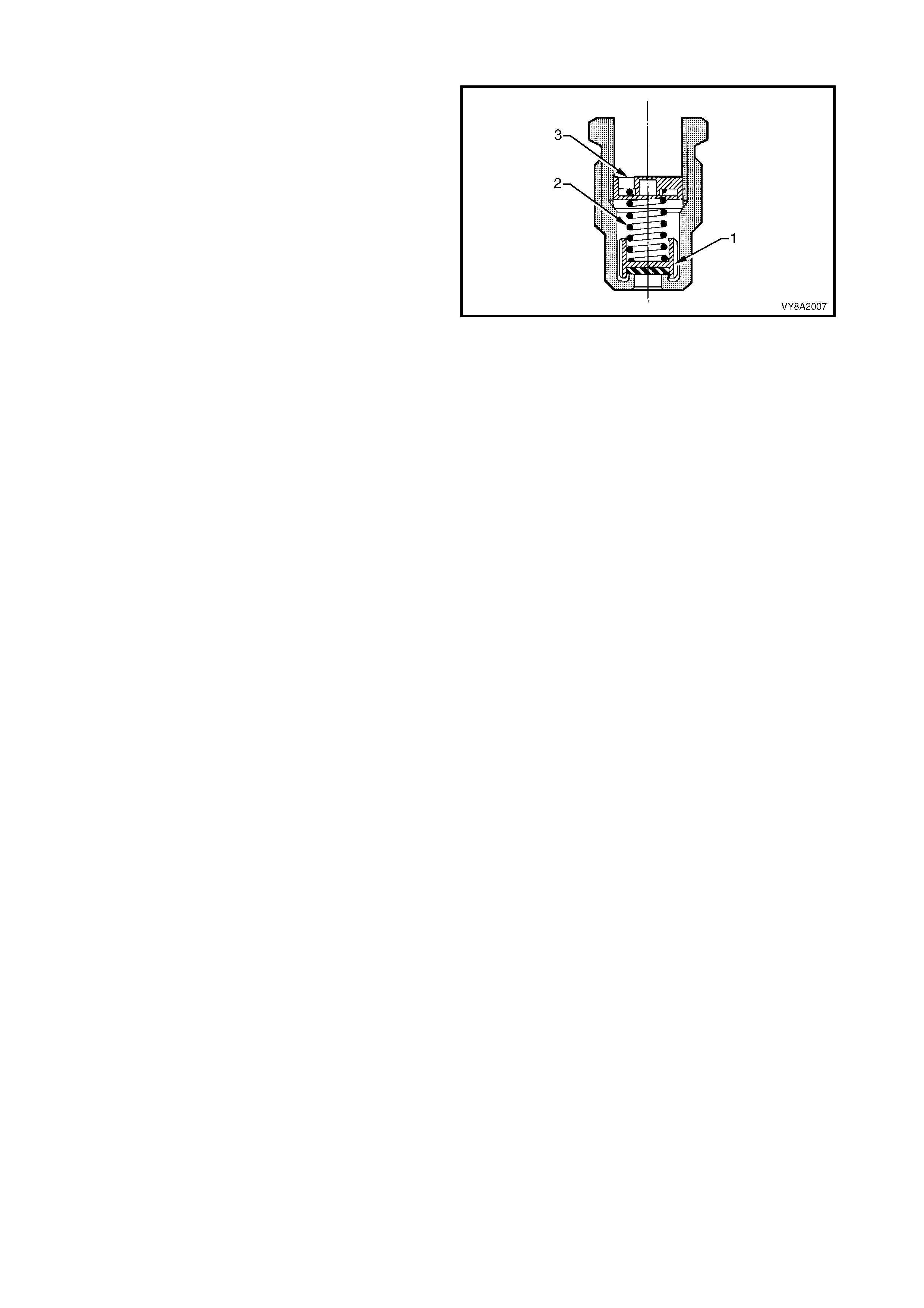

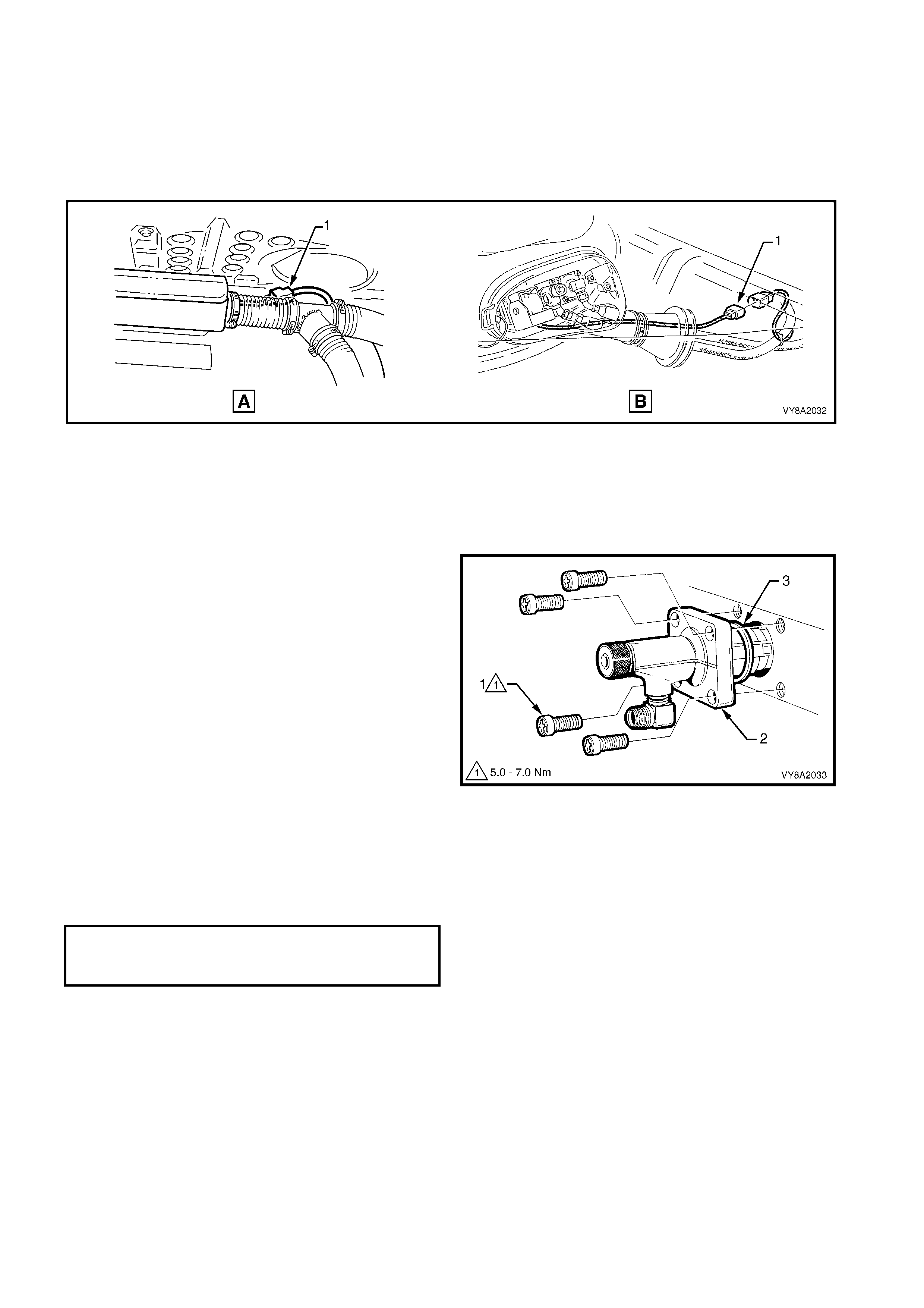

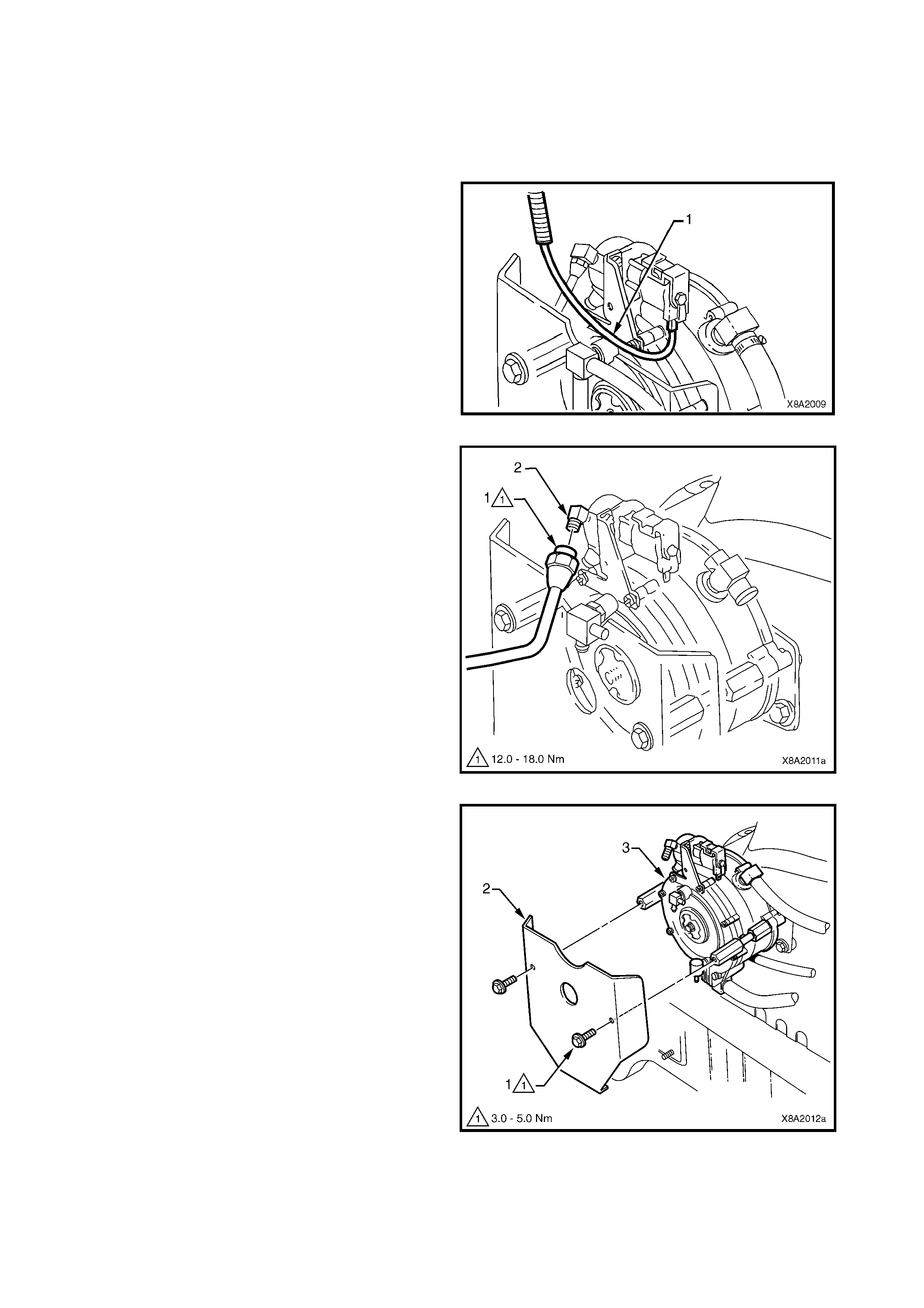

2.7 SMART UNIT

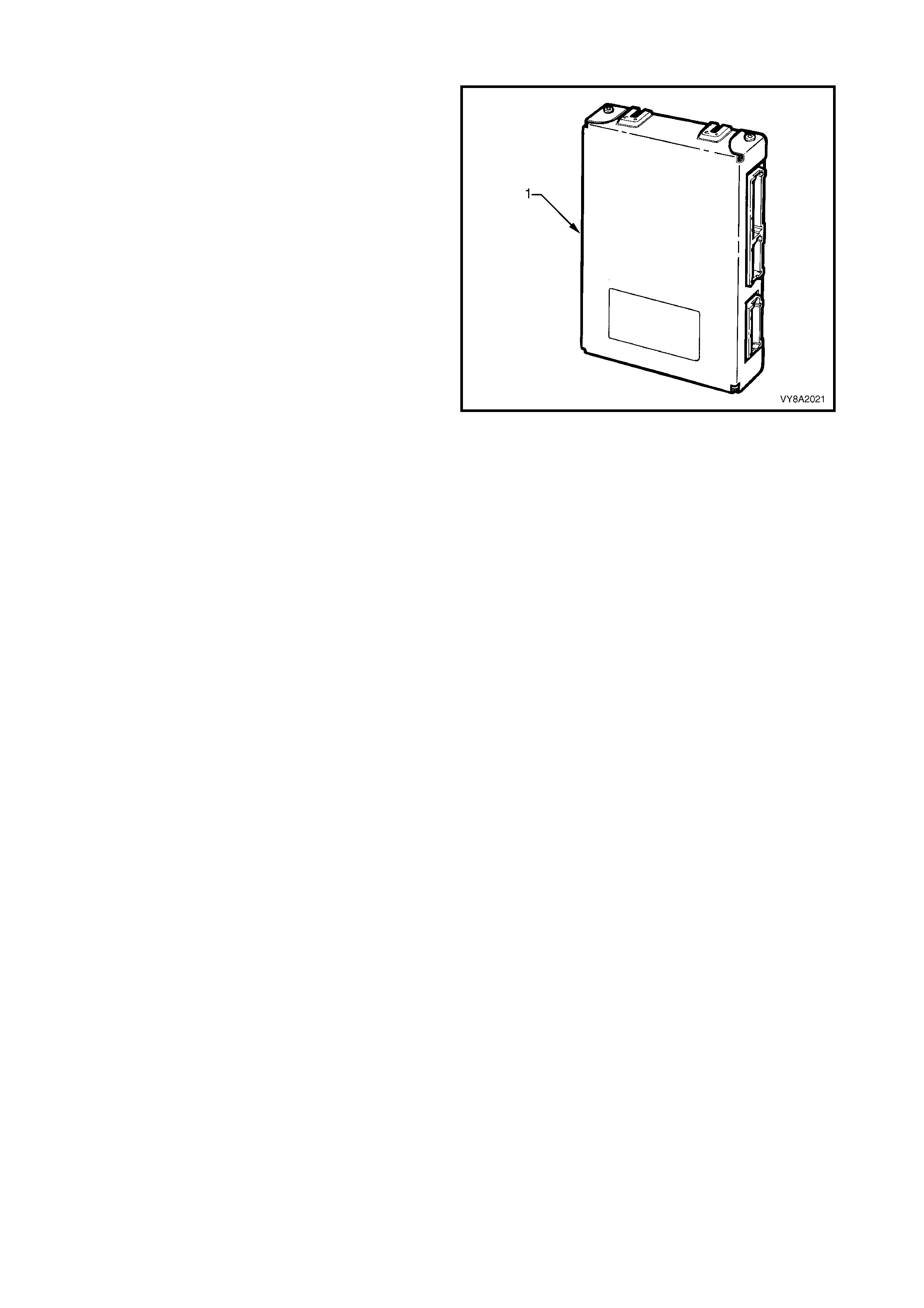

The smart unit (1) is attached to the manual

service valve (2) and controls the operation of the

solenoid valve (3) and the LPG lock-off, refer to

2.9 LPG LOCK-OFF.

W hen operating in LPG m ode, the PCM will signal the

smart unit to energise the solenoid valve and LPG

lock-off for three seconds when the ignition switch is

first turned on or when the engine is being cranked

and while the engine is running.

If the engine stops running, the PCM signal to the

smart unit will cease and the smart unit will de-

energise the so lenoid valve and LPG lock -of f . The f low

of LPG will then stop.

Figure 8A2-16

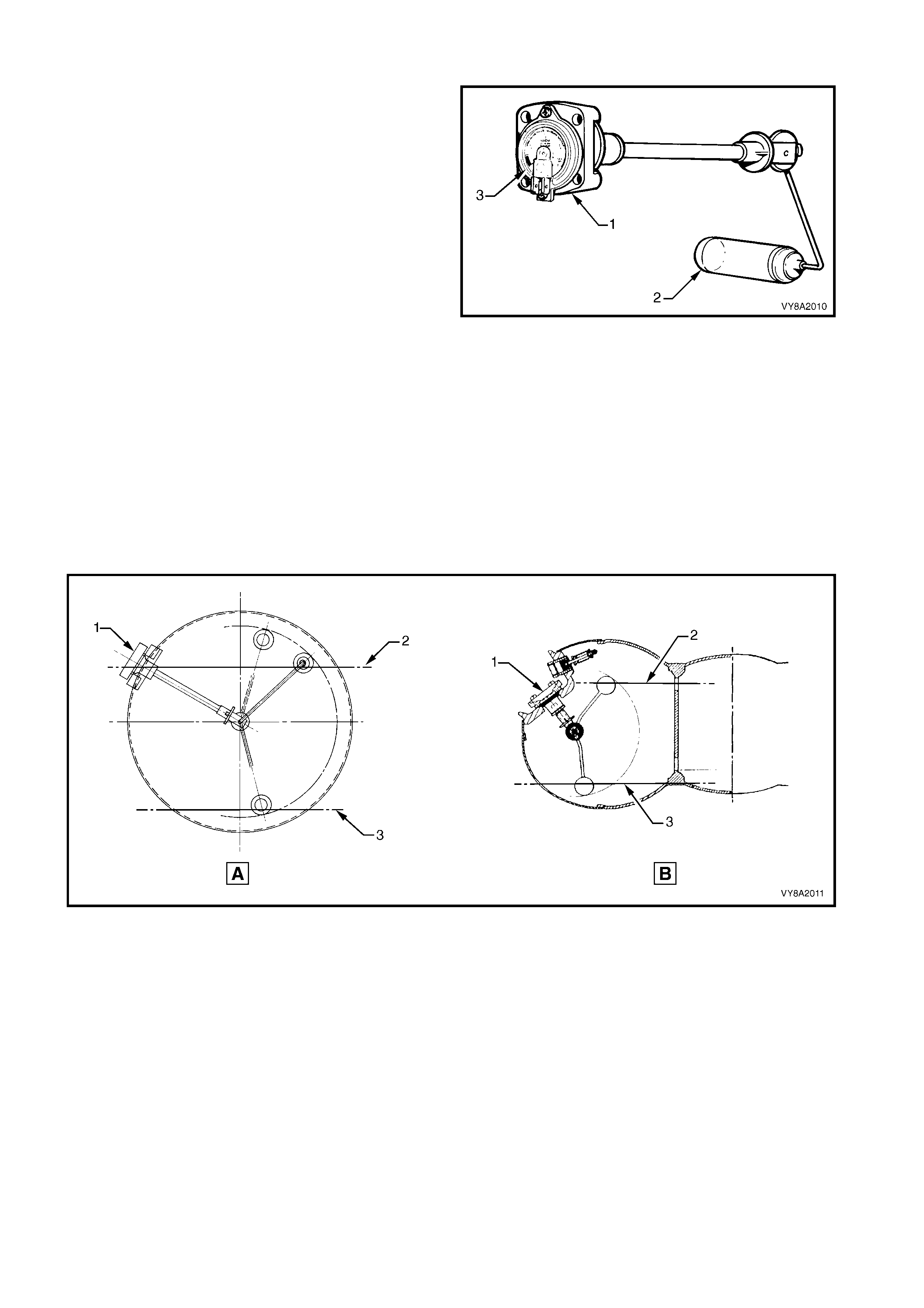

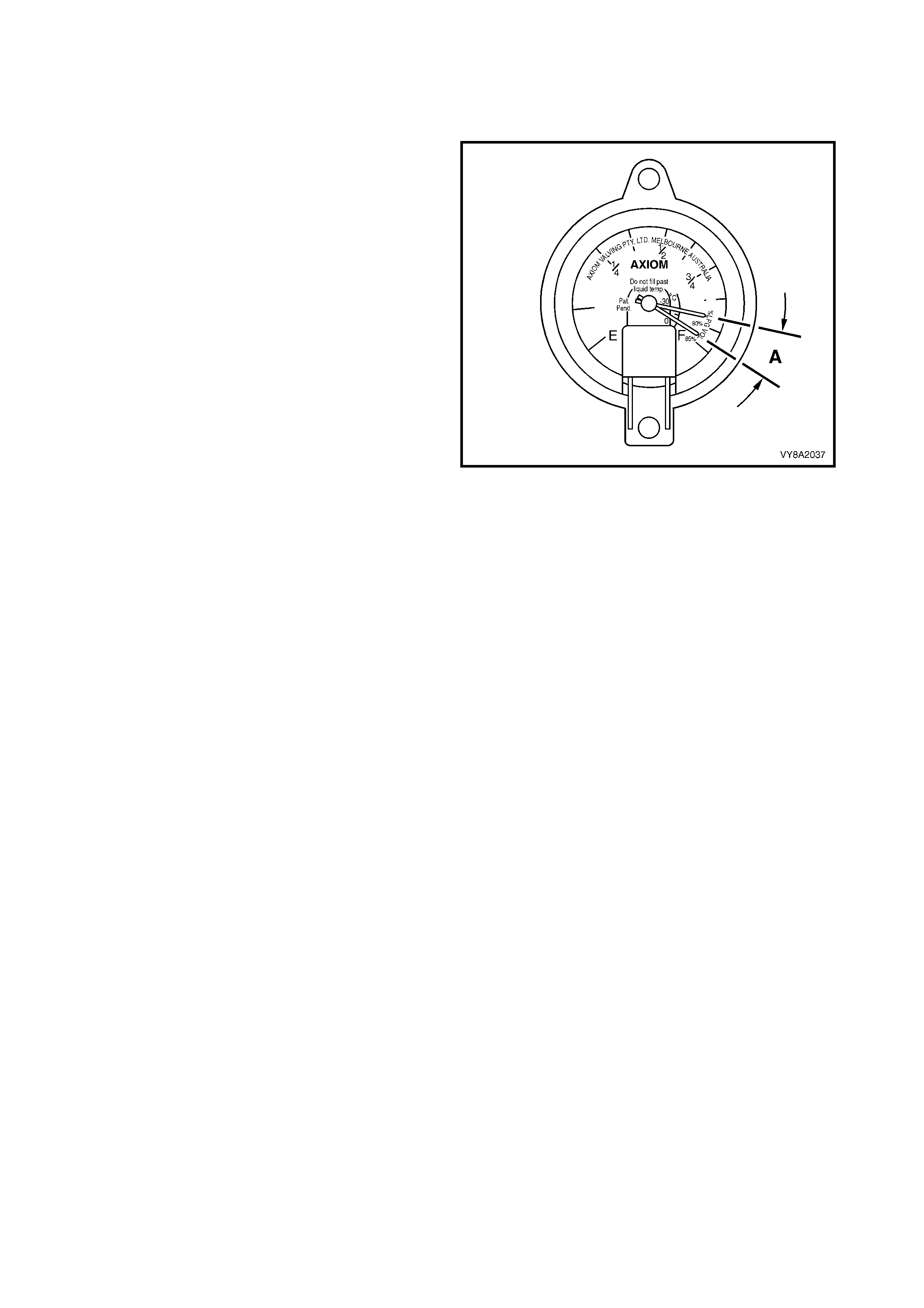

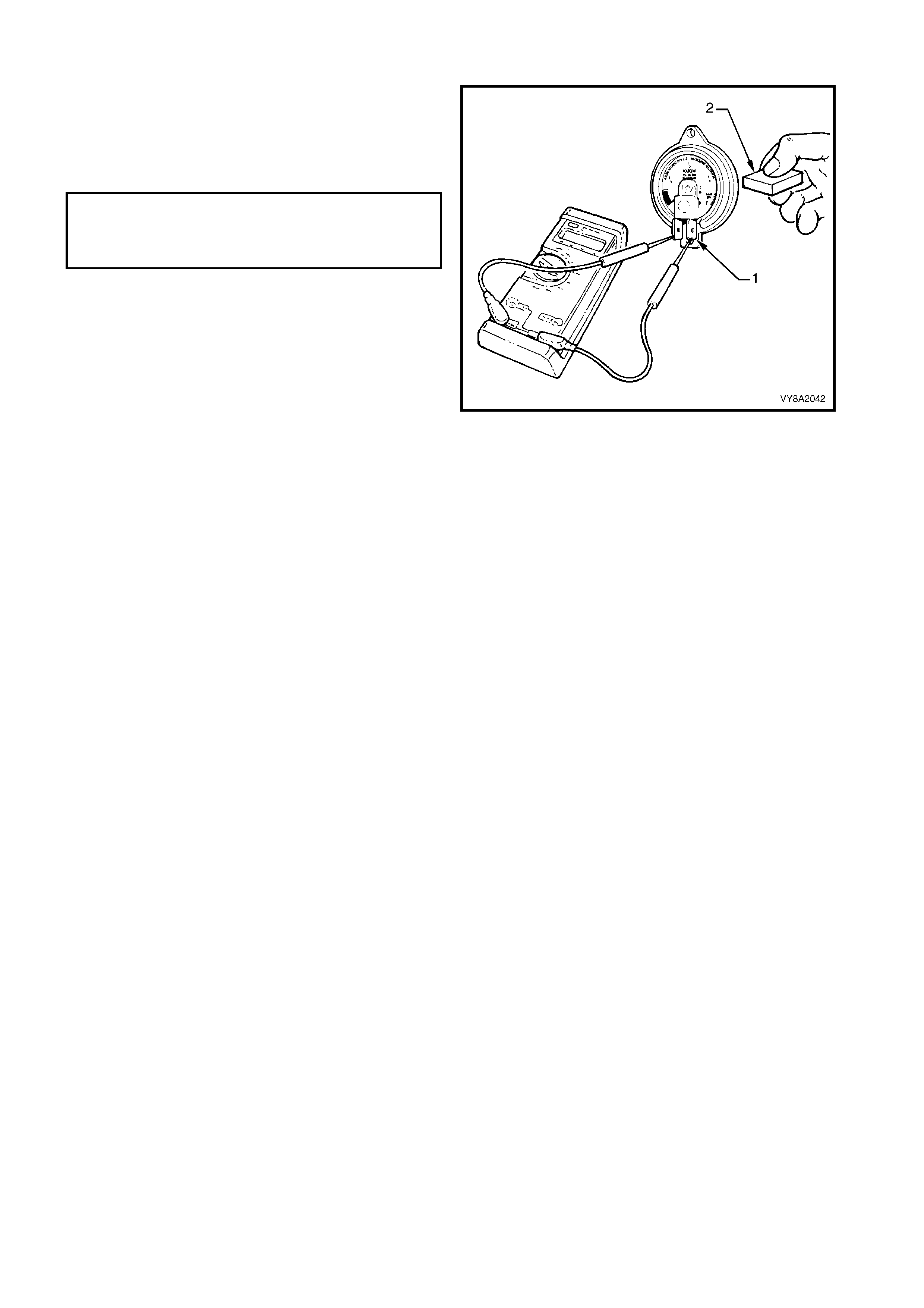

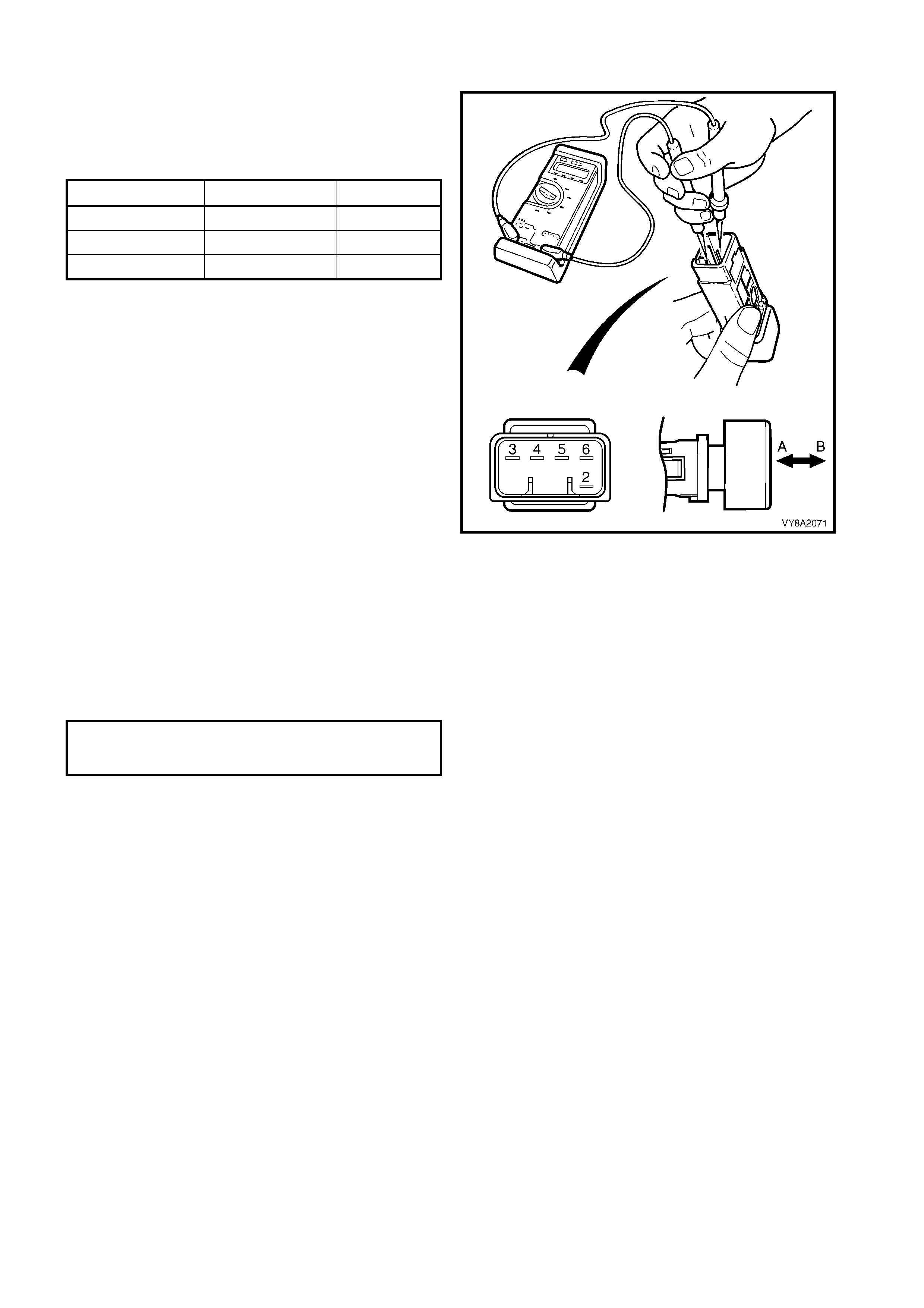

2.8 TANK FUEL GAUGE ASSEMBLY

The tank fuel gauge assembly (1, typical) has a float

(2) similar to a petrol gauge sender unit, and a fuel

contents gauge (3).

As the liquid level in the LPG tank rises, so to does the

float. The float is connected to a magnet within the

assem bly. Any change in the position of the liquid level

is transmitted to the fuel contents gauge via the float

and magnet.

The magnetic field produced by the magnet causes the

fuel contents gauge mounted on the exterior of the

tank to move in relation to the magnet's position.

Referr ing to Figure 8A2- 18, (A) Sedan and Utility or (B)

Wagon, the f uel c ontents gauge (1) will show full when

the liquid level in the tank is at 80% (2). It will show

empty when the tank contents falls to approximately

8.5 litres (3).

The fuel gauge sender unit within the fuel contents

gauge incorporates a variable resistor, which will vary

its resistance from approximately 40 ohms when the

tank is empty to approximately 255 ohms when the

tank is full.

This change in resistance is sensed by the instrument

cluster fuel gauge, which will display the contents of

the LPG tank when the vehicle is operating on LPG. If

the vehicle is switched back to petrol operation, the

contents of the petrol tank will be displayed.

Figure 8A2-17

Figure 8A2-18

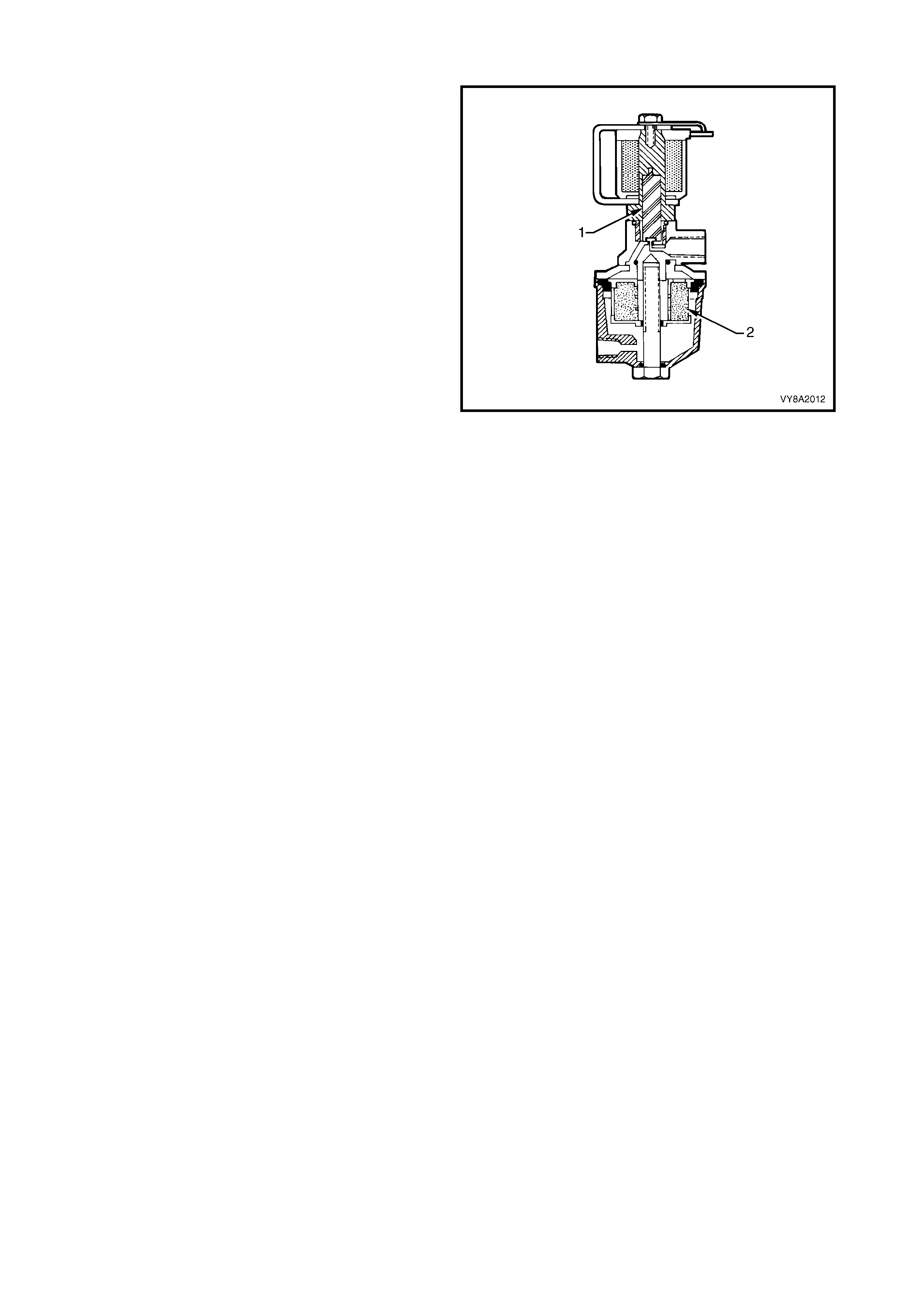

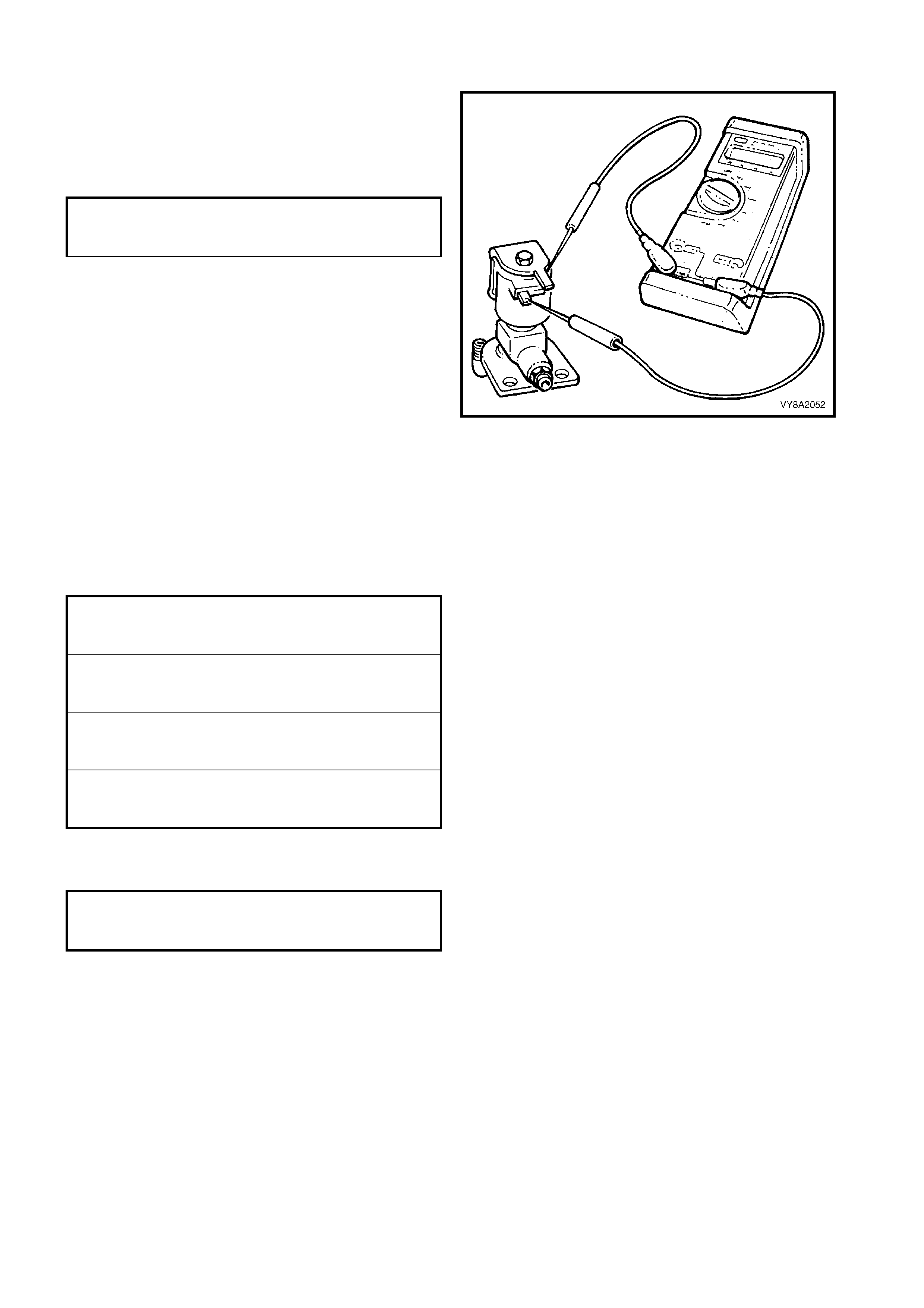

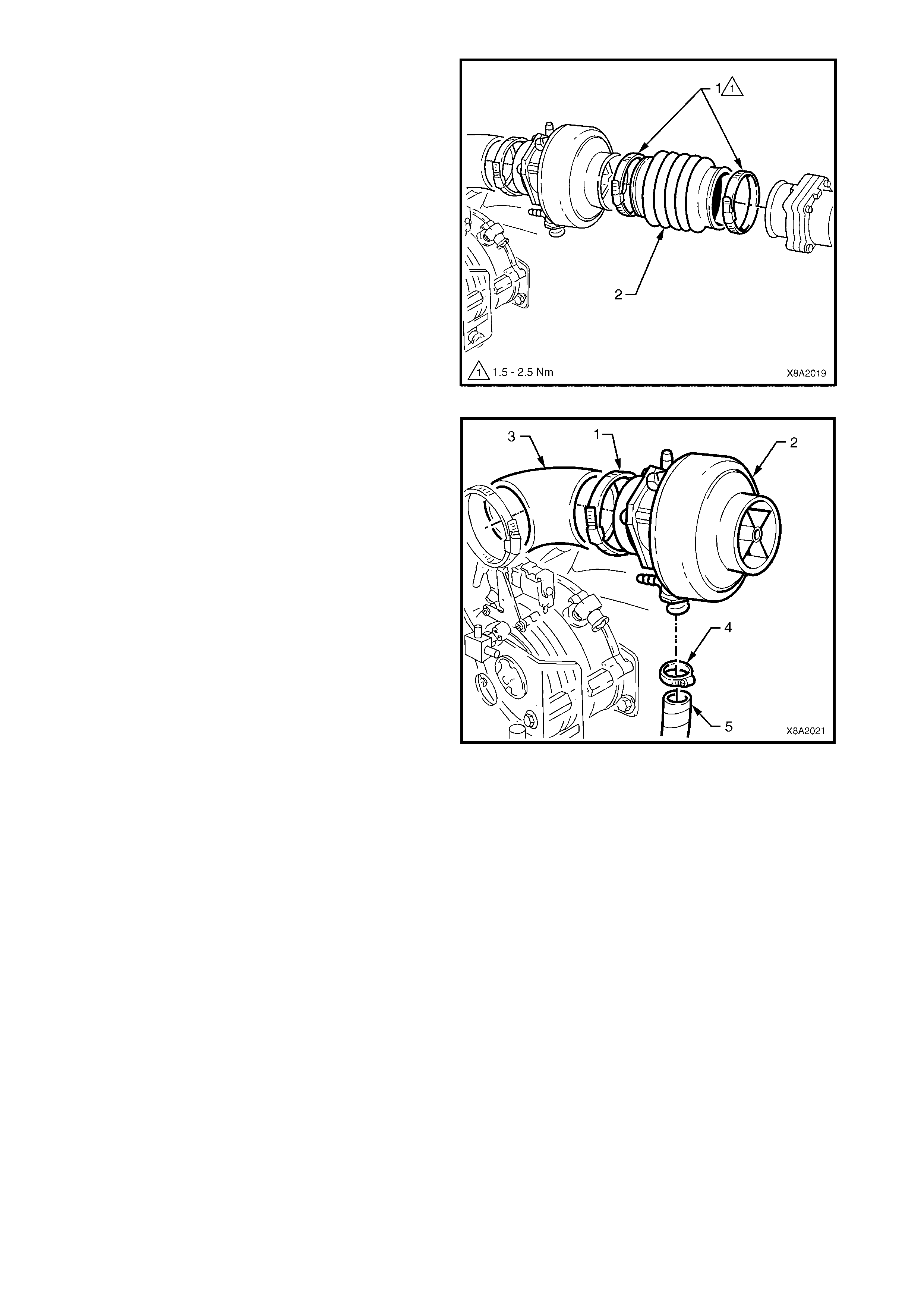

2.9 LPG LOCK-OFF

The LPG lock-off is an electrically operated solenoid

valve, which allows or prevents the flow of LPG to the

converter when energised or de-energised by the

smart unit.

The LPG lock-off is energised for three seconds when

the ignition is turned on, or c onstantly while the engine

is being cranked or is running.

The valve (1) opens and allows LPG from the tank to

flow through a fuel filter (2) and then to the converter.

When the engine stops running, or the ignition is

turned off, the smart unit de-energises the LPG lock-

off and the supply of LPG is shut off.

Figure 8A2-19

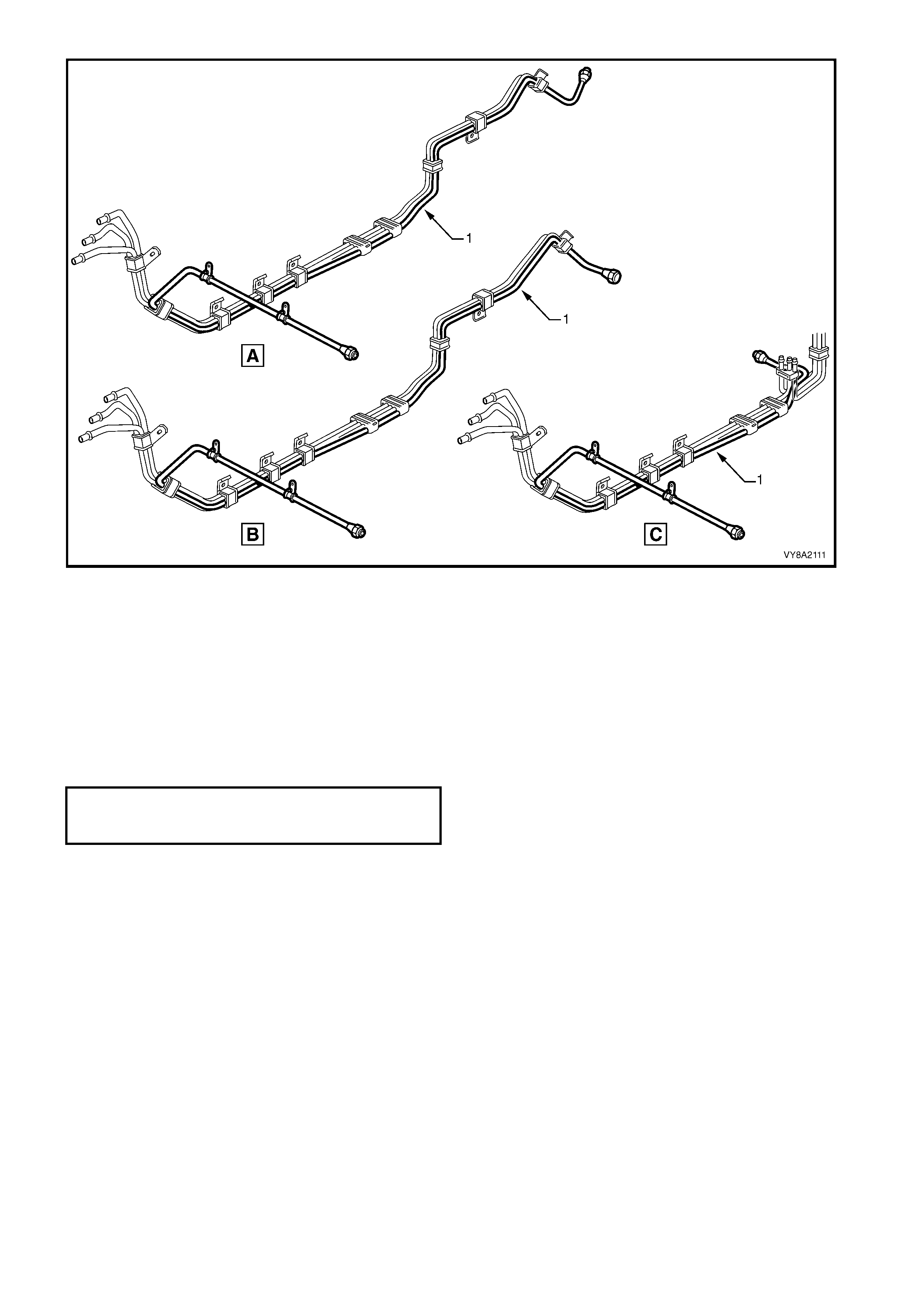

2.10 SERVICE LINE

The service line carries the liquid LPG from the manual service valve to the LPG lock-off. The service line

consists of thr ee major components: the front (1), intermediate (2) and r ear (3) service lines, ref er to Figure 8A2-

20, (A) Sedan, (B) Wagon, (C) Utility.

Figure 8A2-20

Legend

1. Front Service Line A. Sedan

2. Intermediate Service Line B. Wagon

3. Rear Service Line C. Utility

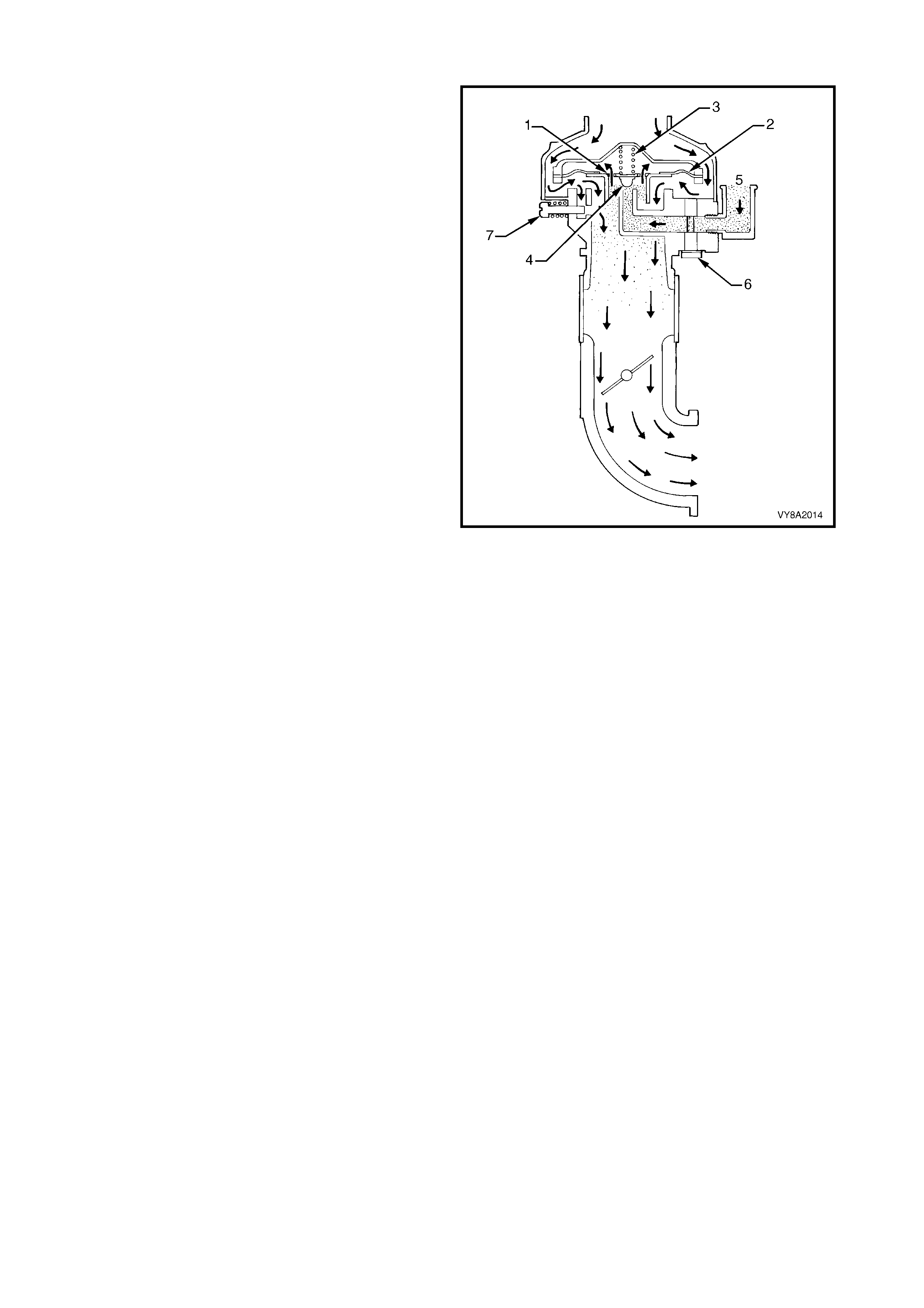

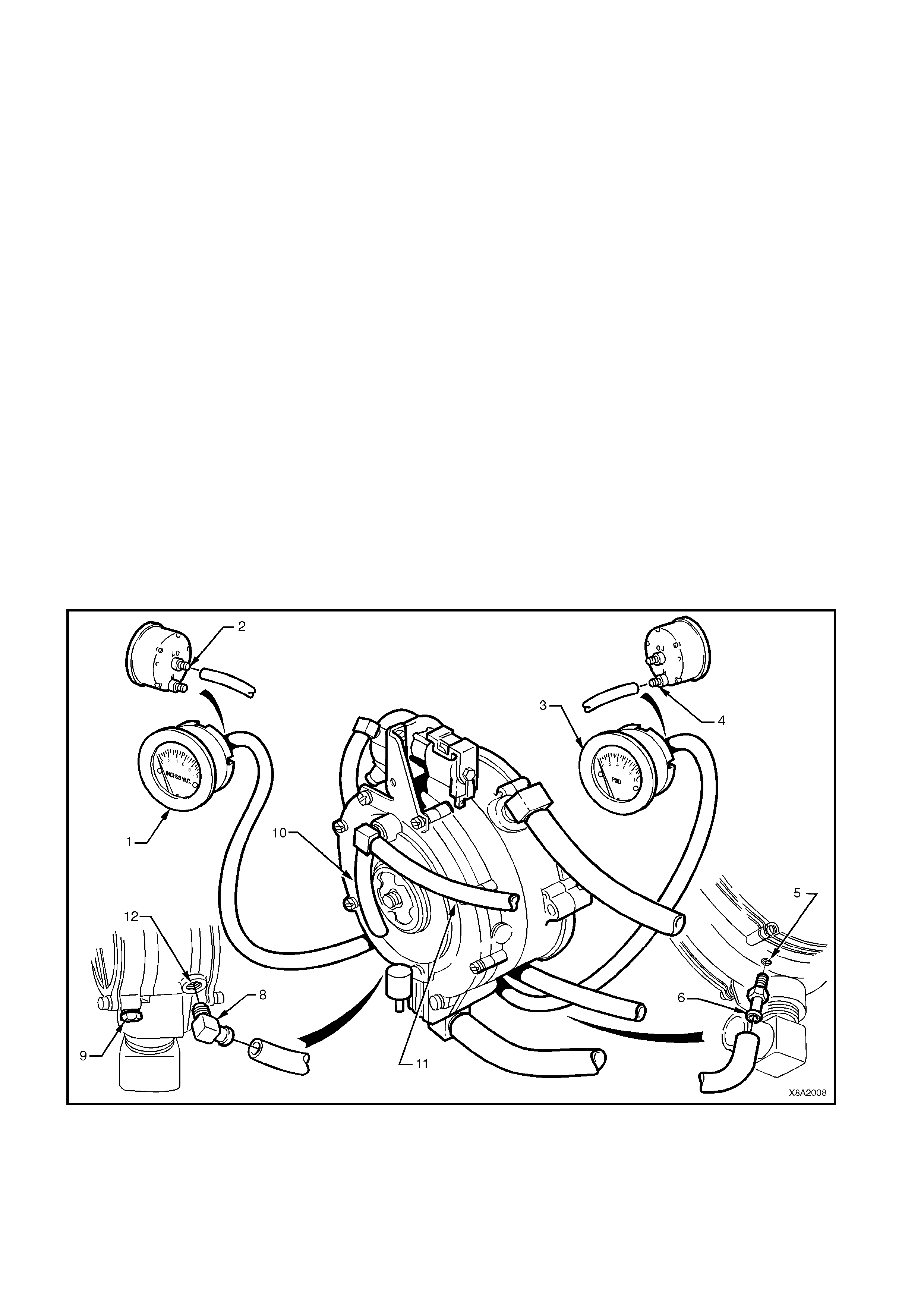

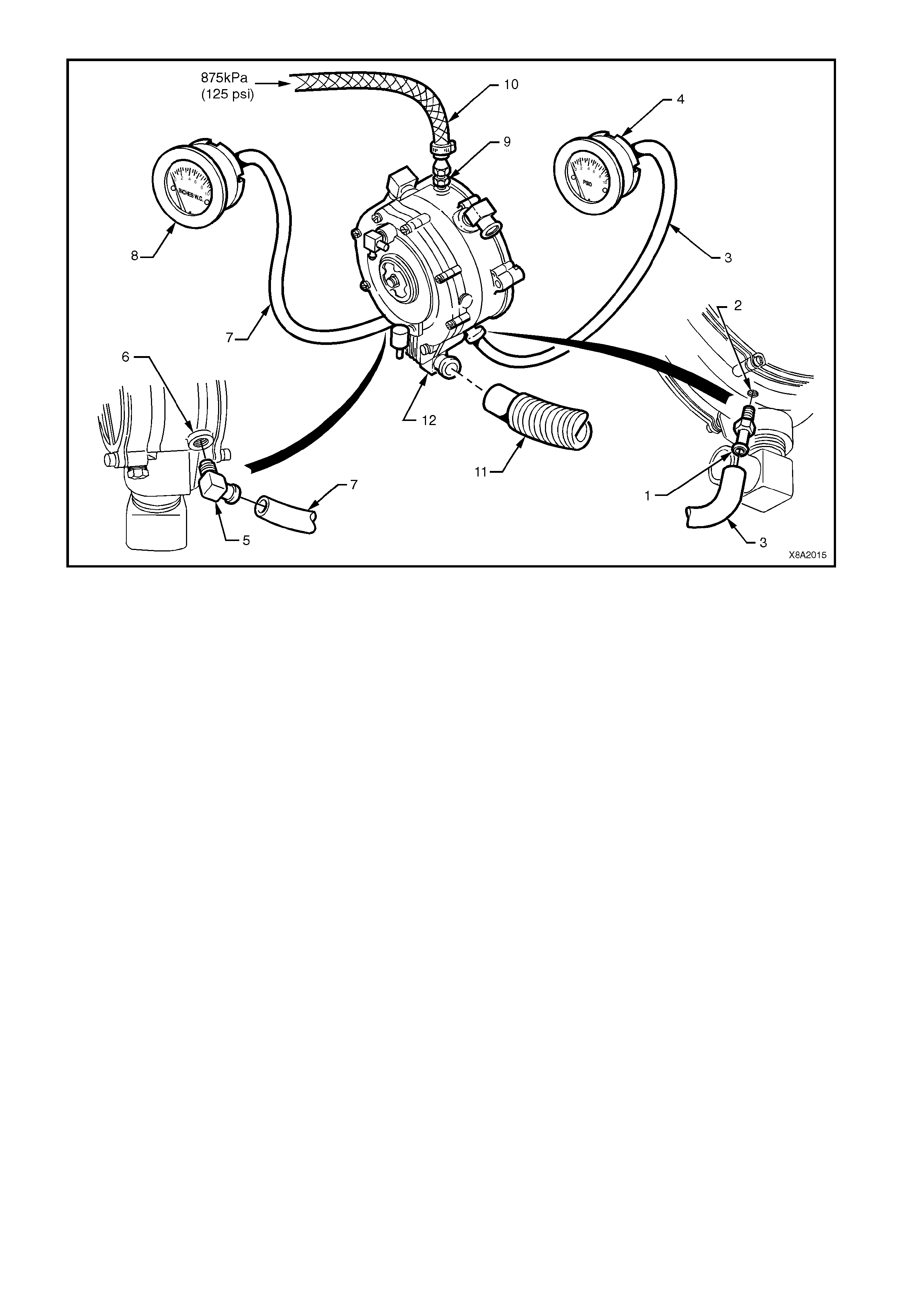

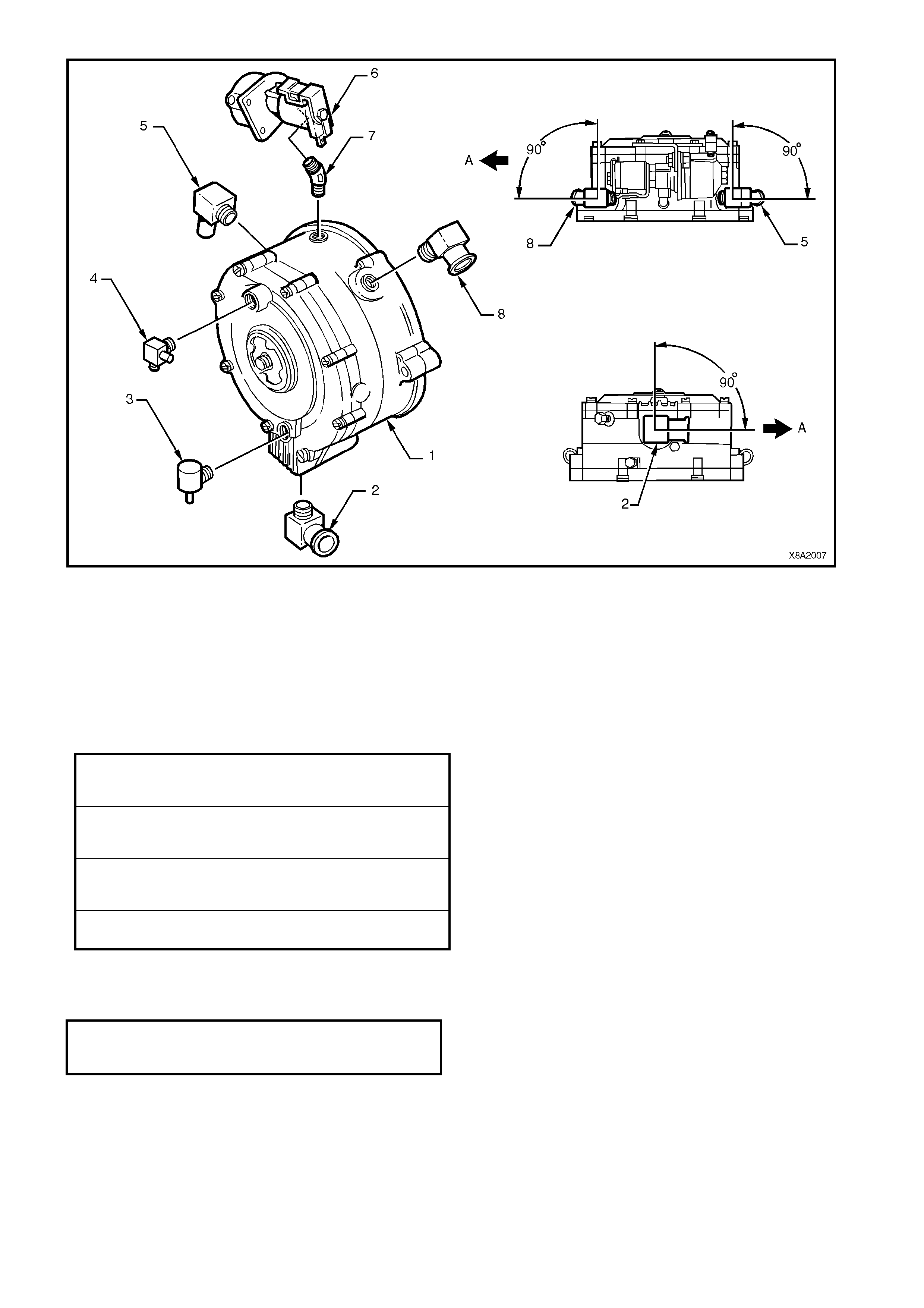

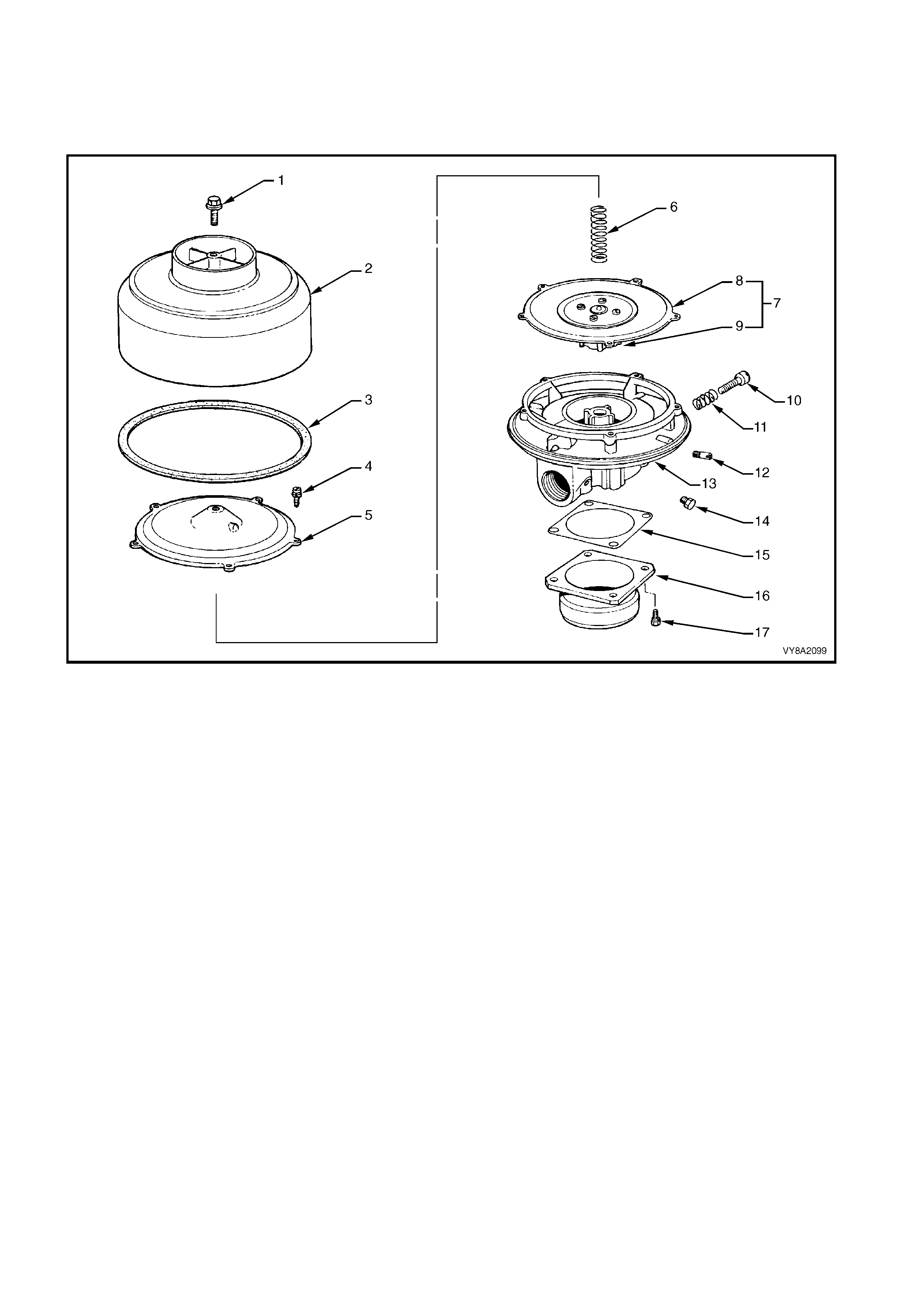

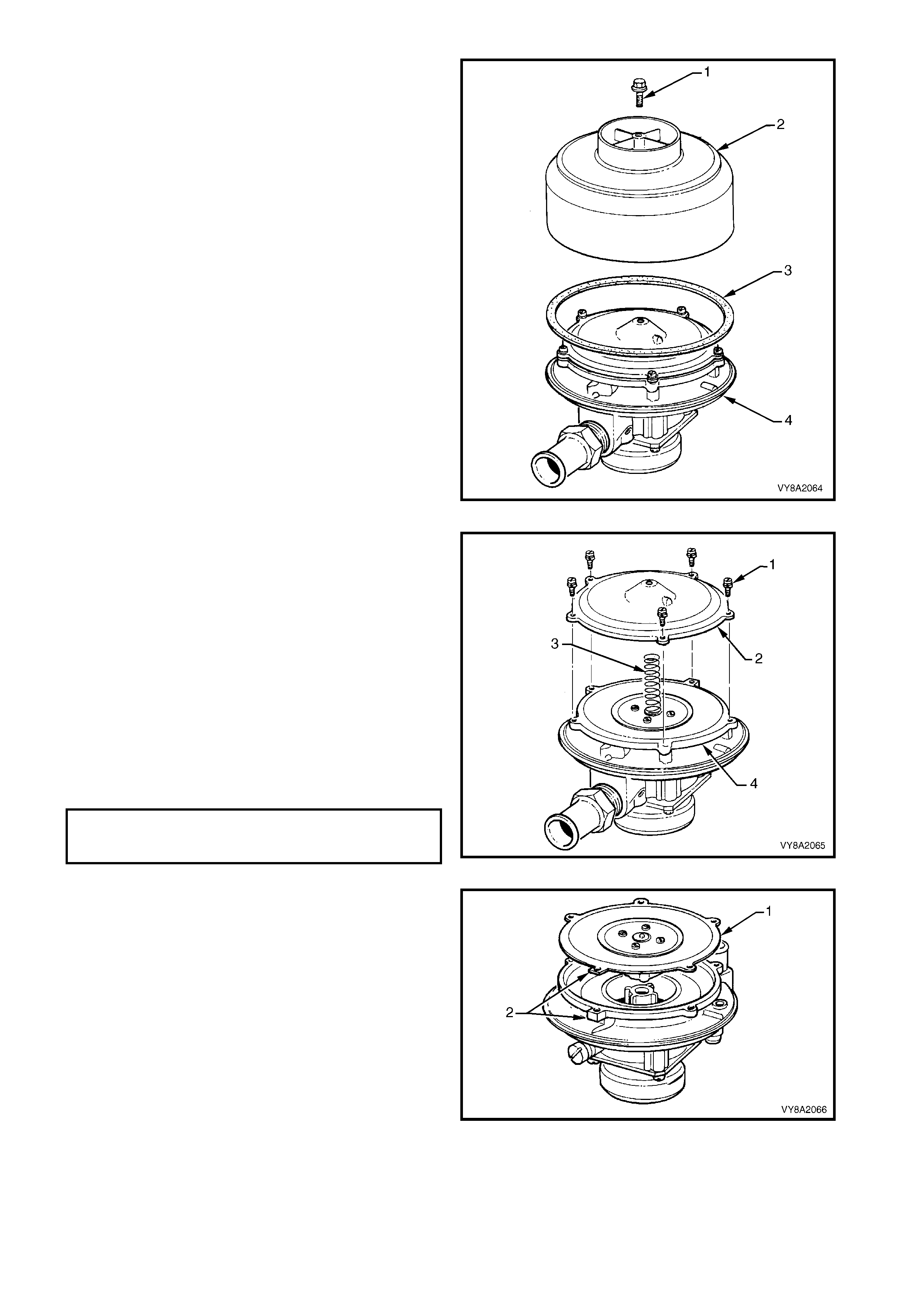

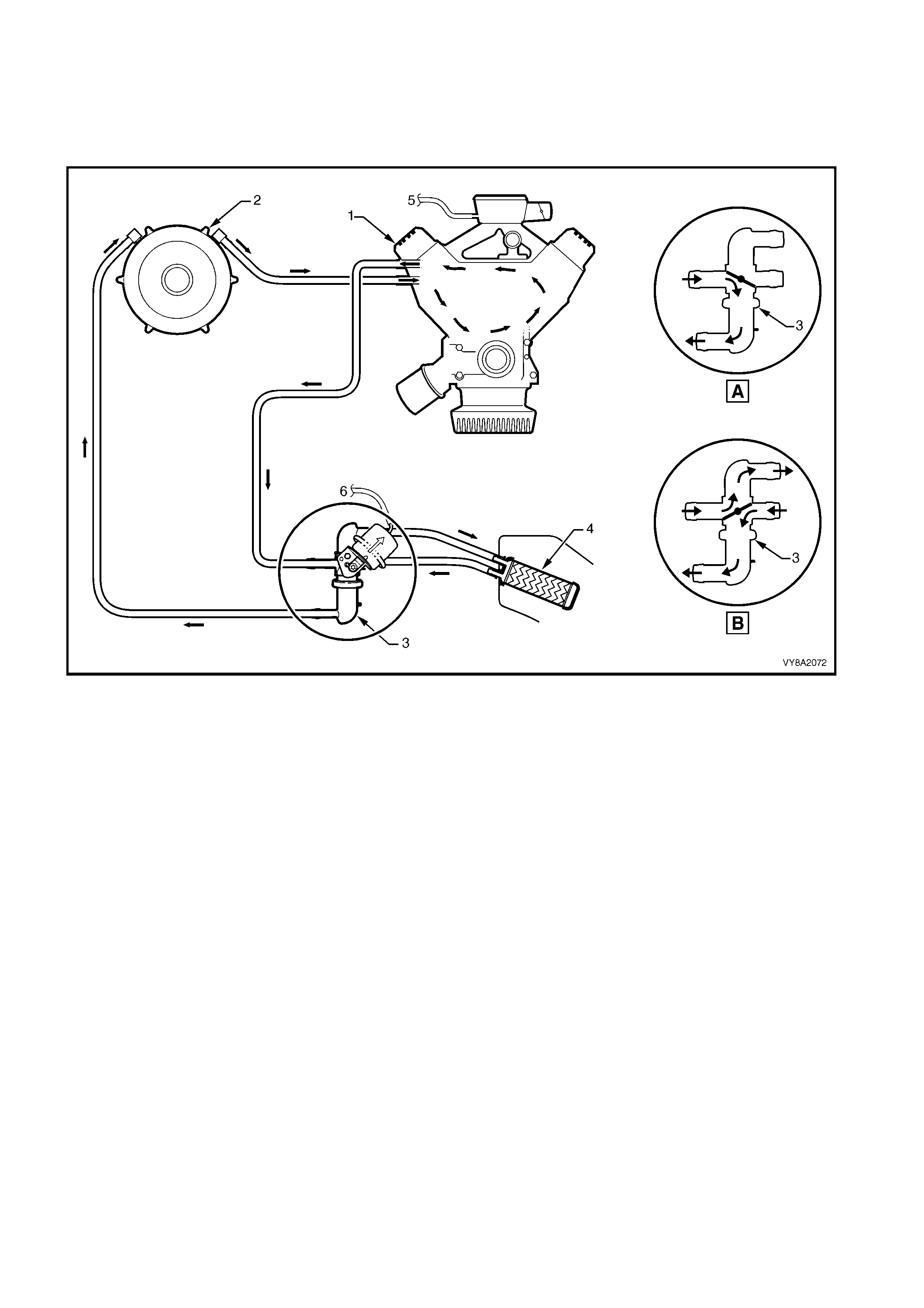

2.11 CONVERTER

The converter is a combined two-stage regulator and vaporiser.

It receives LPG (1) at tank pressure from the LPG lock-off and reduces that pressure in two stages to slightly

less than atmospheric. When the engine is cranked or running, a partial vacuum is created in the vapour line

from the mixer, which opens the converter permitting LPG to flow to the mixer (2), refer to Figure 8A2-21.

In the process of reducing the pressure from approximately 1260 kPa in the tank to atm ospheric pressure, the

LPG expands to become a vapour, causing refrigeration. To compensate for this and to assist in vaporisation,

coolant from the engine cooling system circulates through a heat exchanger (3). The converter seals off LPG

flow when the engine is stopped.

Figure 8A2-21

PRIMARY REGULATION

The primary regulator spring (1), acting on the upper side of the primary diaphragm (2), pushes the primary

diaphragm down. This opens the primary valve (3) and allows LPG to enter the converter (4), which then flows

through the heat exchanger (5) where the LPG changes state from a liquid to a gas.

The pressure of the LPG acting on the underneath side of the primary diaphragm causes the diaphragm to move

upward, closing off the primary valve.

SECONDARY REGULATION

W hen the engine is cranked or running, a vacuum is created by the mixer in the secondary chamber (6). This

vacuum (slightly below atmospheric) acting on the underneath of the secondary diaphragm (7), overcomes the

secondary spring force (8), allowing LPG as a vapour to enter the secondary chamber. This increases the

pressure acting on the underneath side of the diaphragm, overcoming the secondary spring force, causing the

diaphragm to move upward closing off the secondary valve (9). The gas can then flow to the mixer (10).

Figure 8A2-22

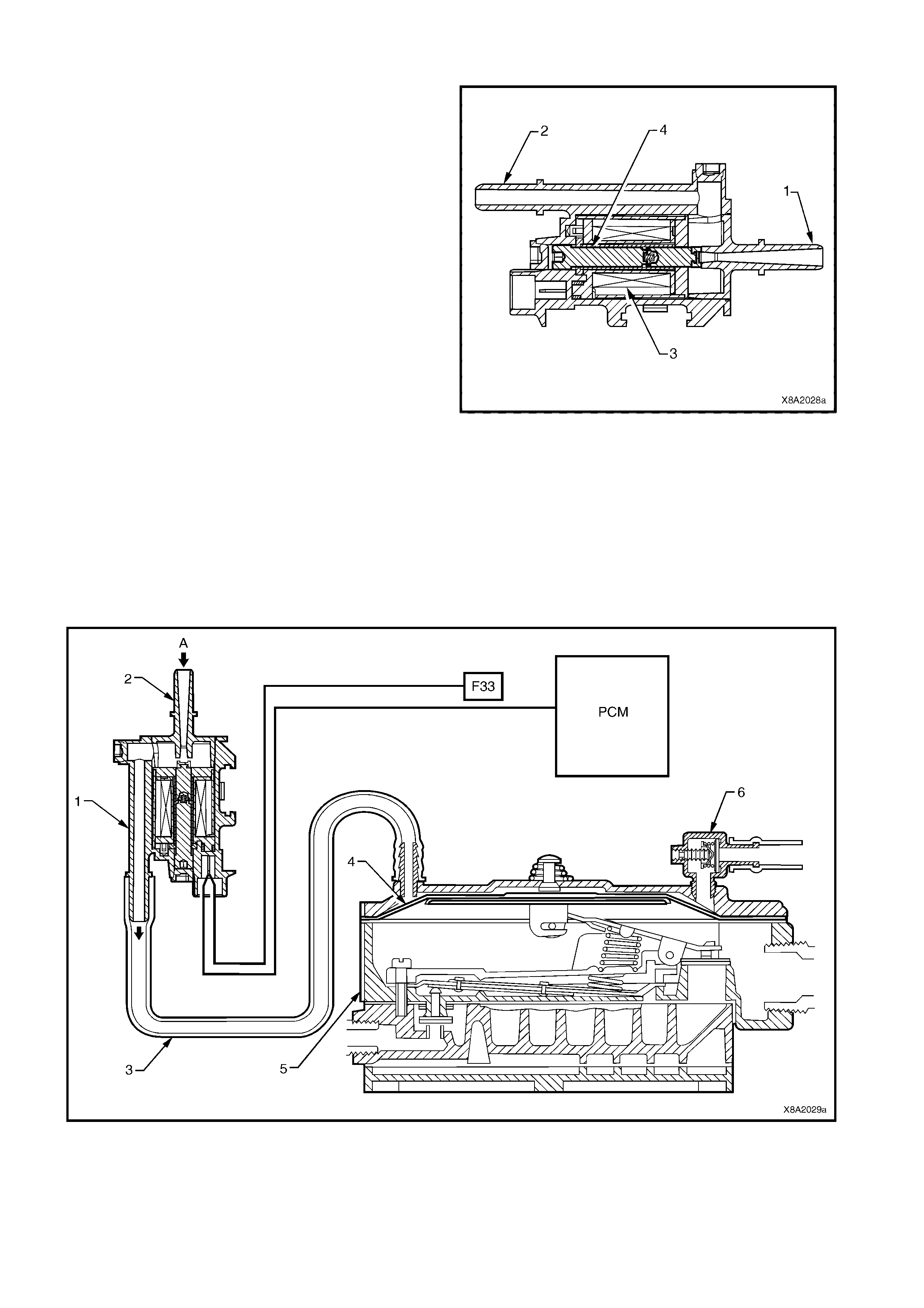

2.12 FUEL CONTROL VALVE

The fuel control valve (FCV) is used to control fuel

delivery.

Because the diaphragm of the converter is very large,

little movement is required to control the amount of

LPG deliver ed. T he f uel contr ol valve is connec ted into

the balance line between the atmospheric vent of the

converter secondary diaphragm (2) and the air valve

venturi of the mixer (1).

This applies a very low vacuum to the atmospheric

side of the converter secondary diaphragm. Any

pressure less than atmospheric results in a reduction

in LPG delivery. This assures extremely accurate LPG

delivery and rapid response time.

With the exhaust gas oxygen sensor at operating

temperature and the powertrain control module (PCM)

operating in closed loop mode, there is a wide range of

control. This permits the PCM to optimise the air/fuel

mixture to varying engine requirements.

The FCV is controlled by the PCM. To open the FCV

and decrease the pressure acting on the secondary

diaphragm of the converter, the PCM pulses the FCV

coil (3) on and off at a frequency of 10 Hz. The ratio

between the on and off time is called the duty cycle.

To open the FCV plunger (4) the PCM increases the

duty cycle, which decreases the pressure applied to

the secondary diaphragm. The amount of time the

FCV is on will determine the pressure acting on the

converter secondary diaphragm. In this way, the PCM

can control the air/fuel ratio.

Figure 8A2-23

Figure 8A2-24

Legend

1. FCV 4. Secondary diaphragm A. Vacuum from mixer

2. Vacuum inlet 5. Converter

3. Balance hose 6. Regulator check valve

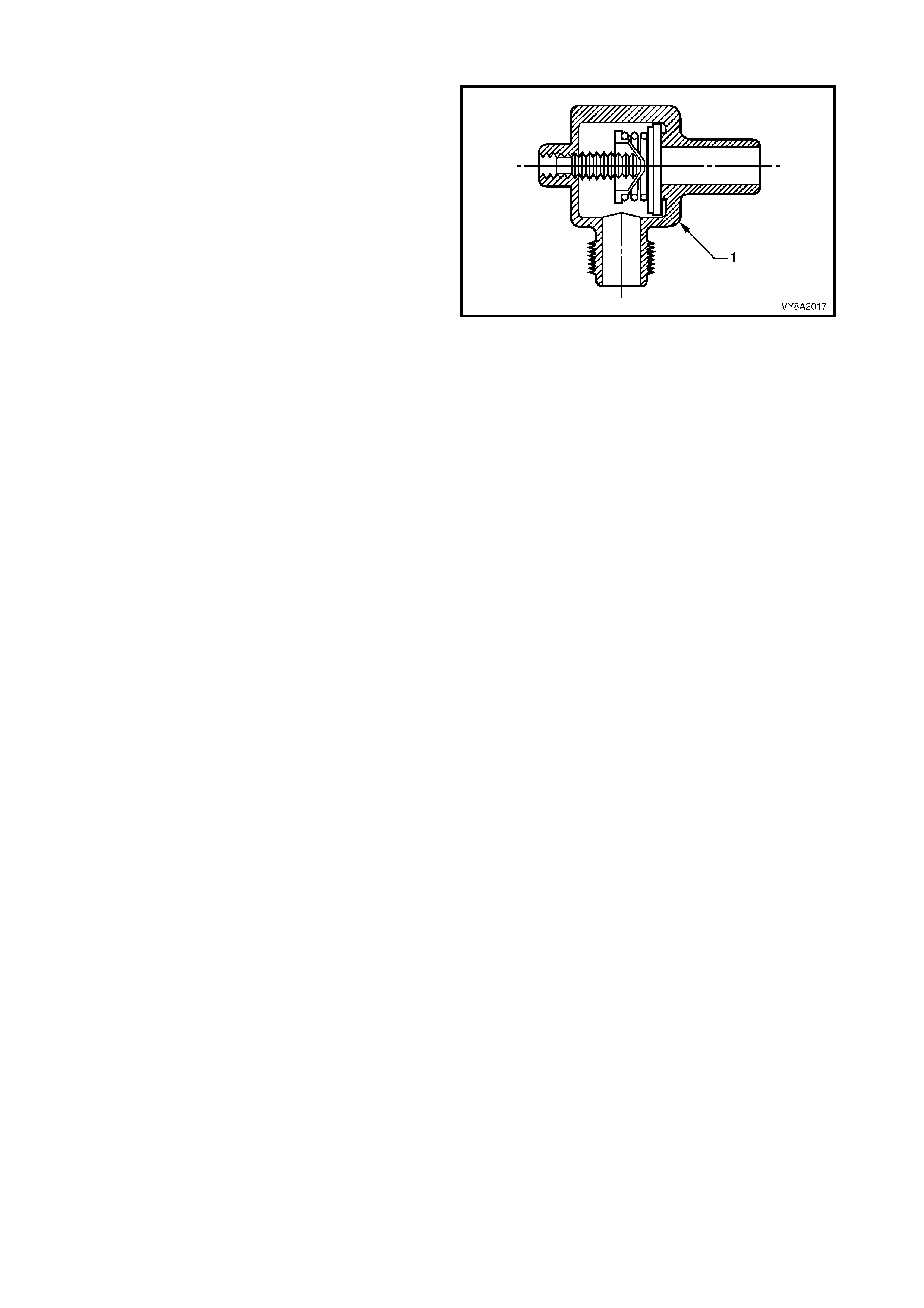

2.13 REGULATOR CHECK VALVE

To maintain correct control during normal driving the

pressur e above the s ec ondary diaphragm is inf luenc ed

by the air valve vacuum but is finally controlled by the

FCV.

However, when the accelerator is depressed quickly,

the pressure in the air valve chamber will rise very

quickly, far above its normal working value. This is

because the movement of the mixer diaphragm and

air-gas valve will lag behind the movement of the

throttle valve. This will momentarily subject the air

valve chamber to a high vacuum.

Because the FCV duty cycle has been controlling the

air fuel ratio with a steady vacuum value, this sudden

increase in vacuum will delay the movement of the

converter diaphragm at precisely the time it needs to

move freely. This would cause a lean air/fuel ratio.

Whenever the vacuum above the diaphragm exceeds

16” W C i.e. when the diaphragm needs to m ove down

quickly as the accelerator is suddenly depressed, the

regulator check valve (1) will open and allow

atmospheric pressure to act on the secondary

diaphragm.

Figure 8A2-25

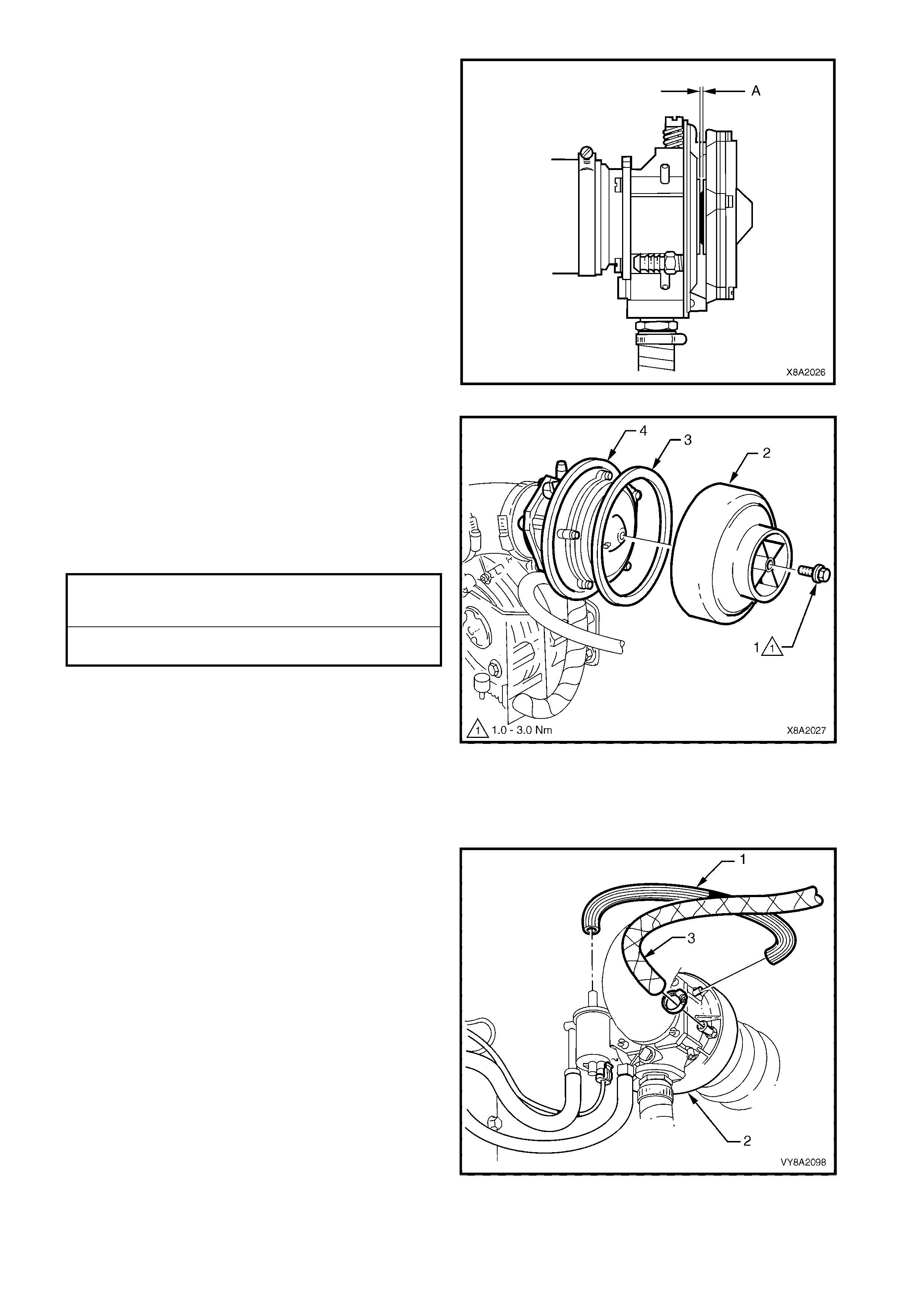

2.14 MIXER

The mixer is installed between the engine intake

manifold and the intake air filter.

When the engine is cranked or running, manifold

vacuum is transm itted through vacuum ports in the air

valve (1) to the upper side of mixer diaphragm (2). As

a result, atmospheric pressure pushing upwards on the

underneath side of the diaphragm, lifts it against the

downward force of the metering valve spring (3).

The pressure applied to the upper side of the

diaphragm varies with engine speed and throttle

position. The pressure difference between

atmos pheric pr essur e acting on the underneath s ide of

the diaphragm and the pressure acting on the upper

side of the diaphragm determines the metering valve

(4) position.

The position and the shape of the metering valve

determines the amount of LPG (5) delivered to the

engine.

Maximum fuel delivery is determined by the power

valve (6), which limits the maximum fuel flow. The

power valve is pre-calibrated in the factory and is not

adjustable in service.

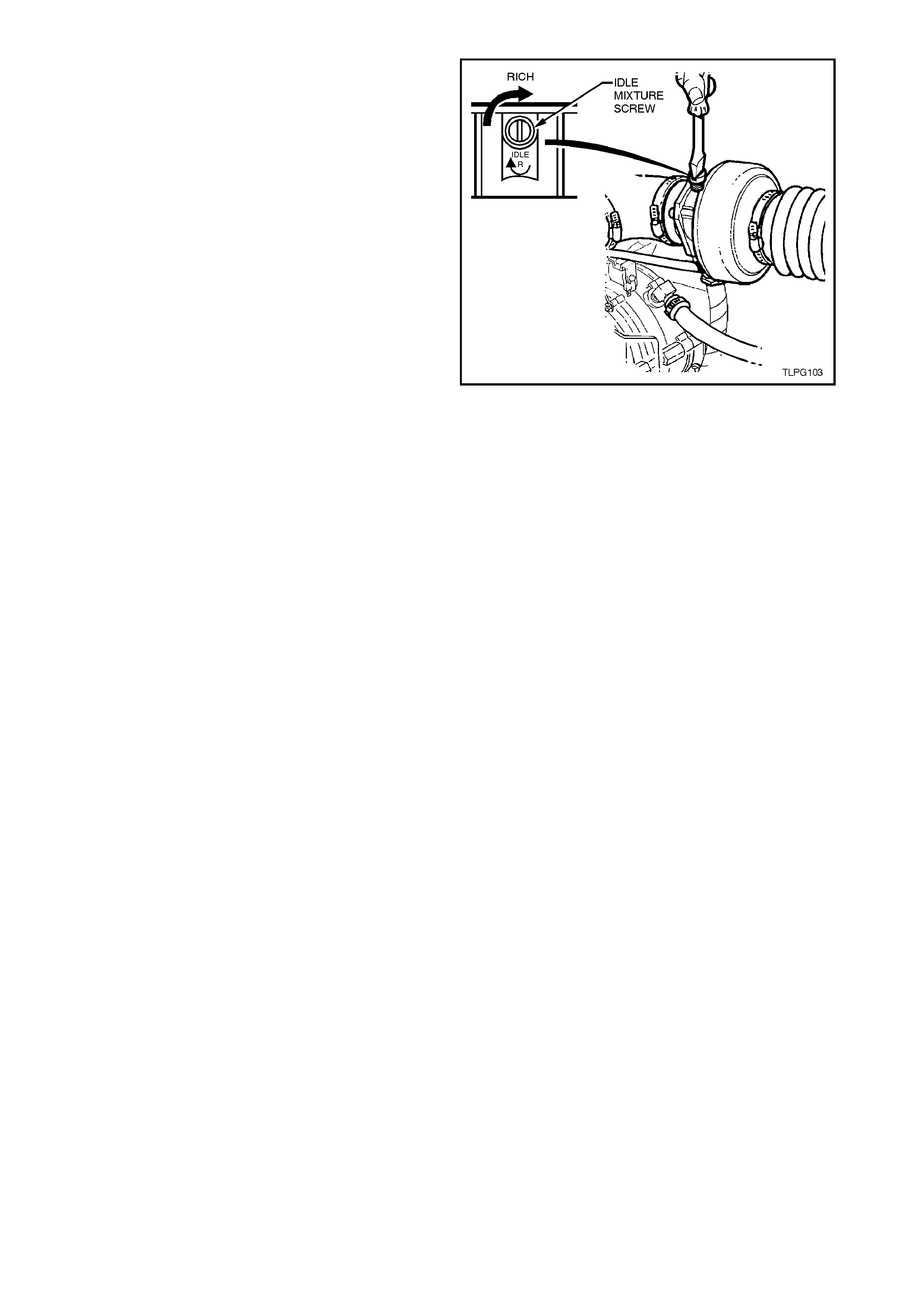

Idle air by-pass adjustment is provided by the

adjustment screw (7).

Figure 8A2-26

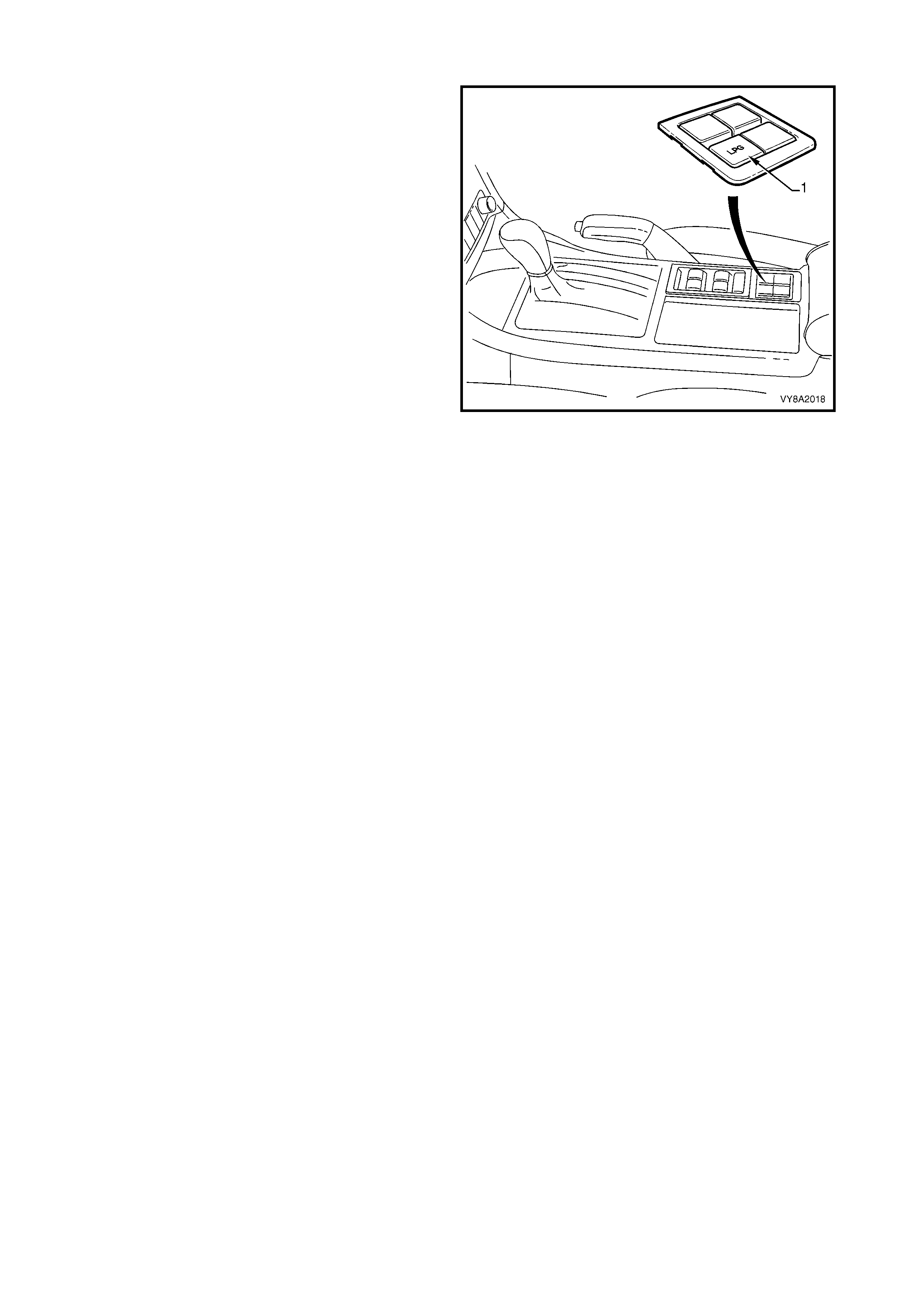

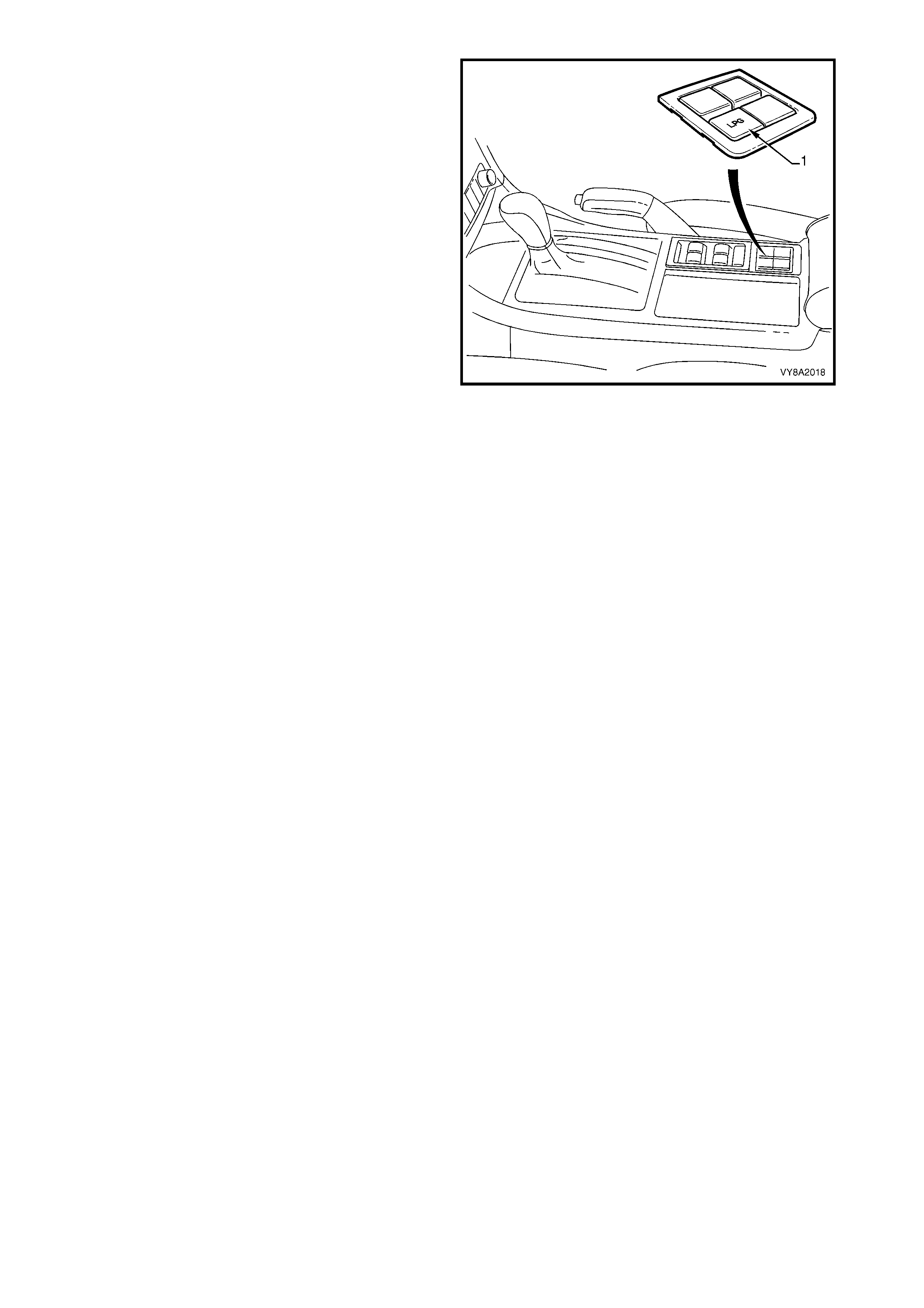

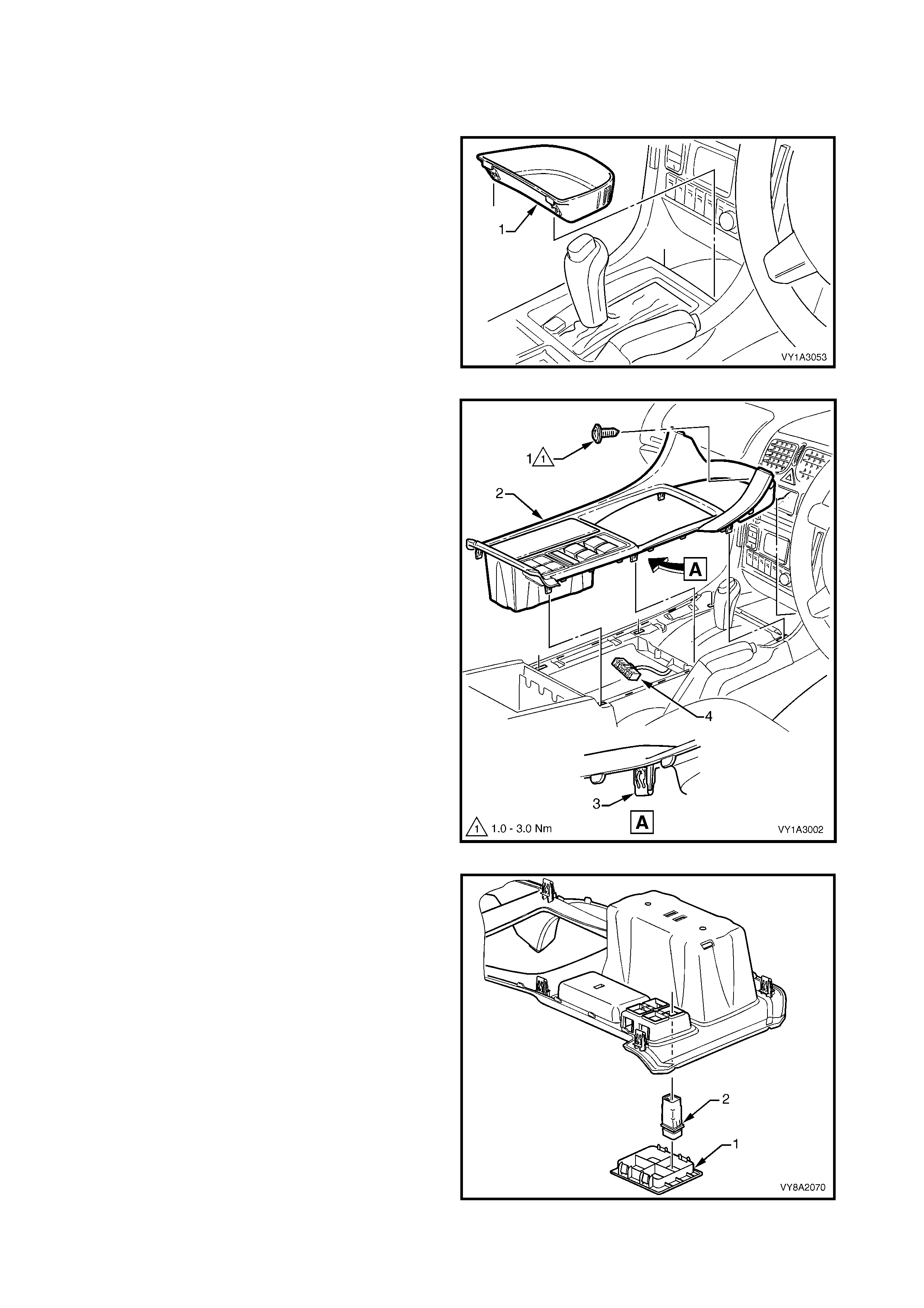

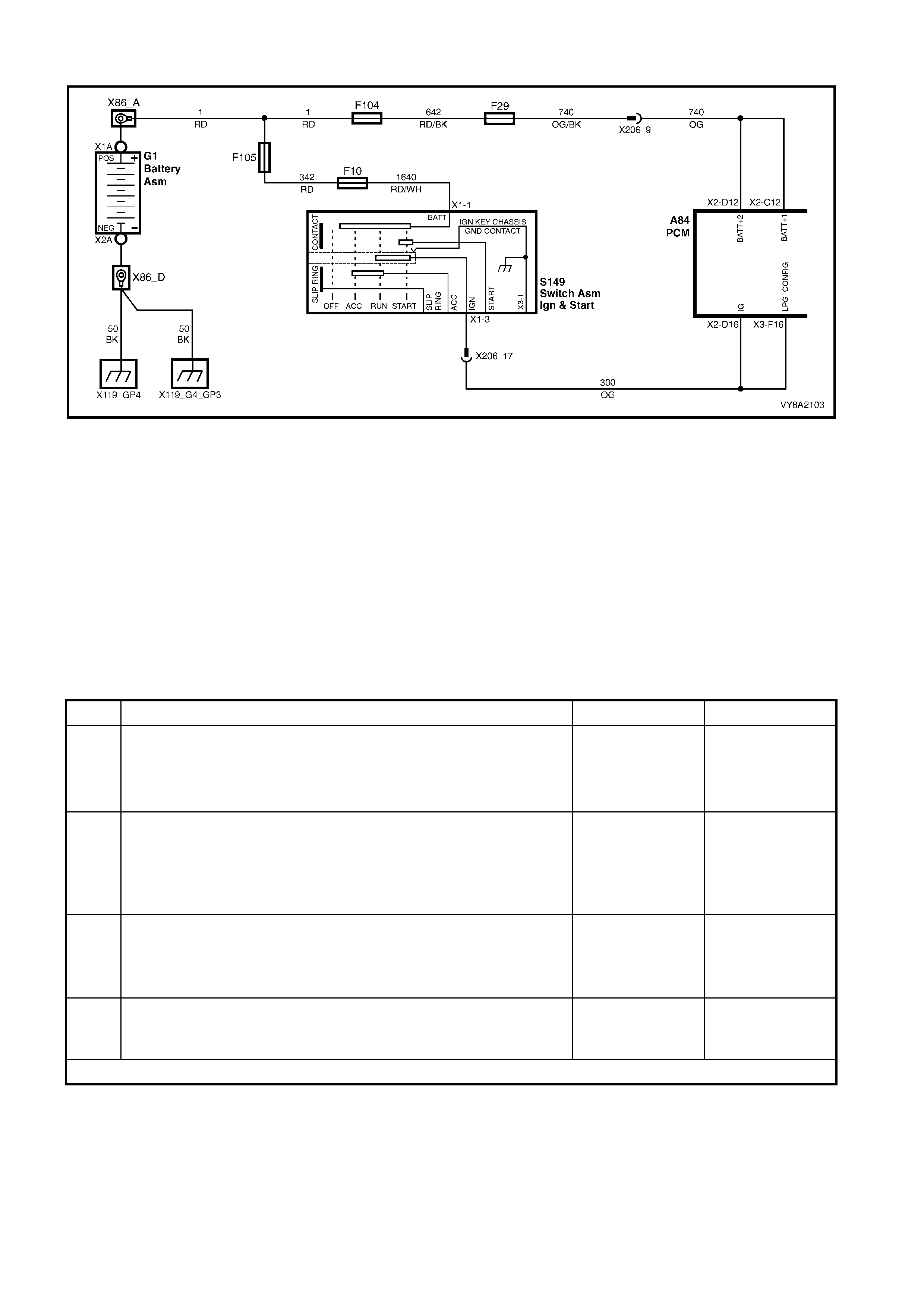

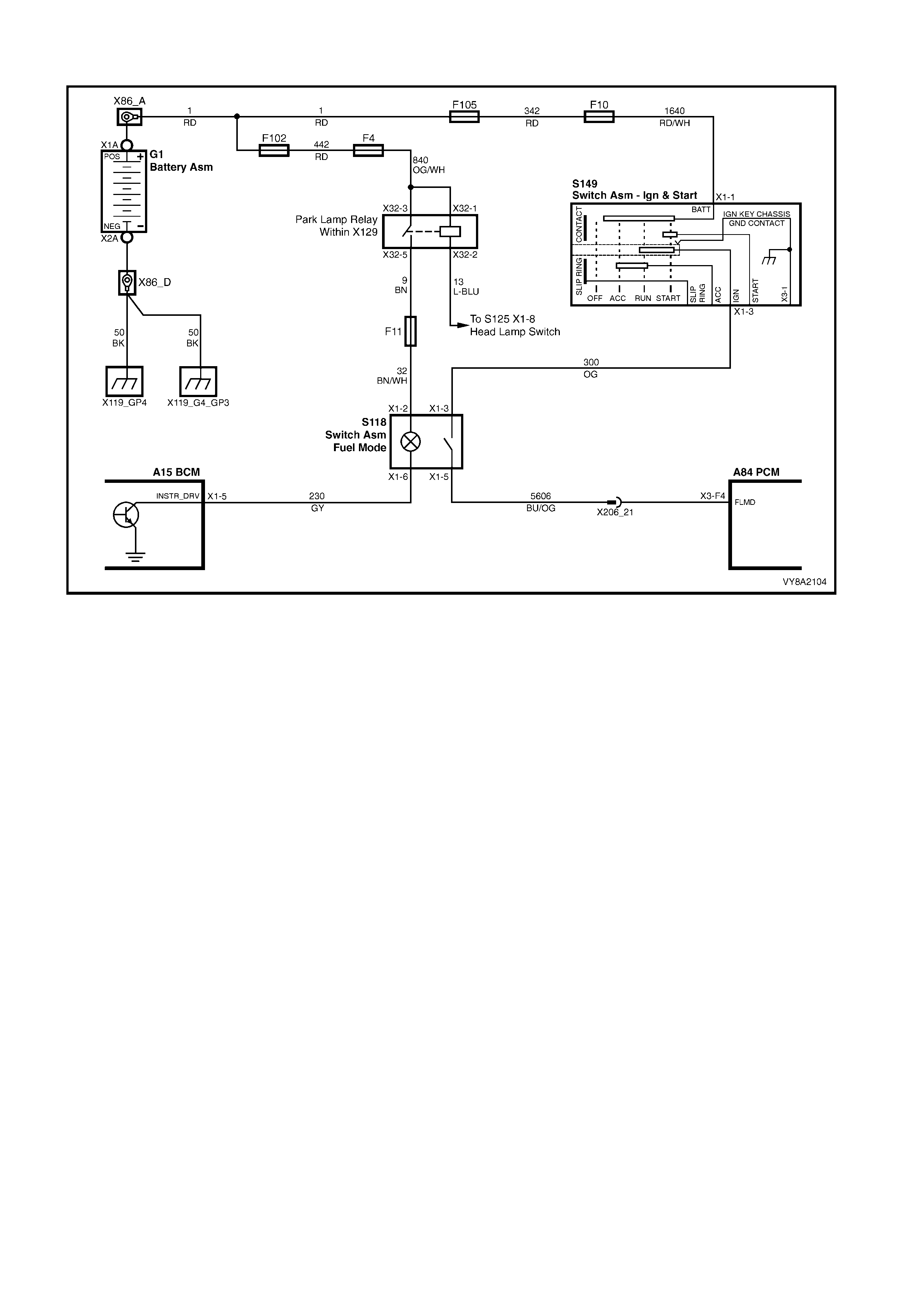

2.15 FUEL MODE SWITCH

On all vehicles f itted with a LPG system, the fuel m ode

switch (1) is mounted in the floor console.

When the fuel mode switch is pressed, the switch

supplies B+ volts to PCM terminal X3-F4. The PCM

sees this voltage as a request to change over from

petrol to LPG or from LPG to petrol.

NOTE: The PCM will only toggle between the petrol

and LPG mode if the ignition is on and the engine is

not running, or if the engine speed is greater that 1500

RPM.

The operational mode that the PCM is in is stored in

the PCM mem or y so that the engine starts in the same

mode on the next ignition cycle.

Figure 8A2-27

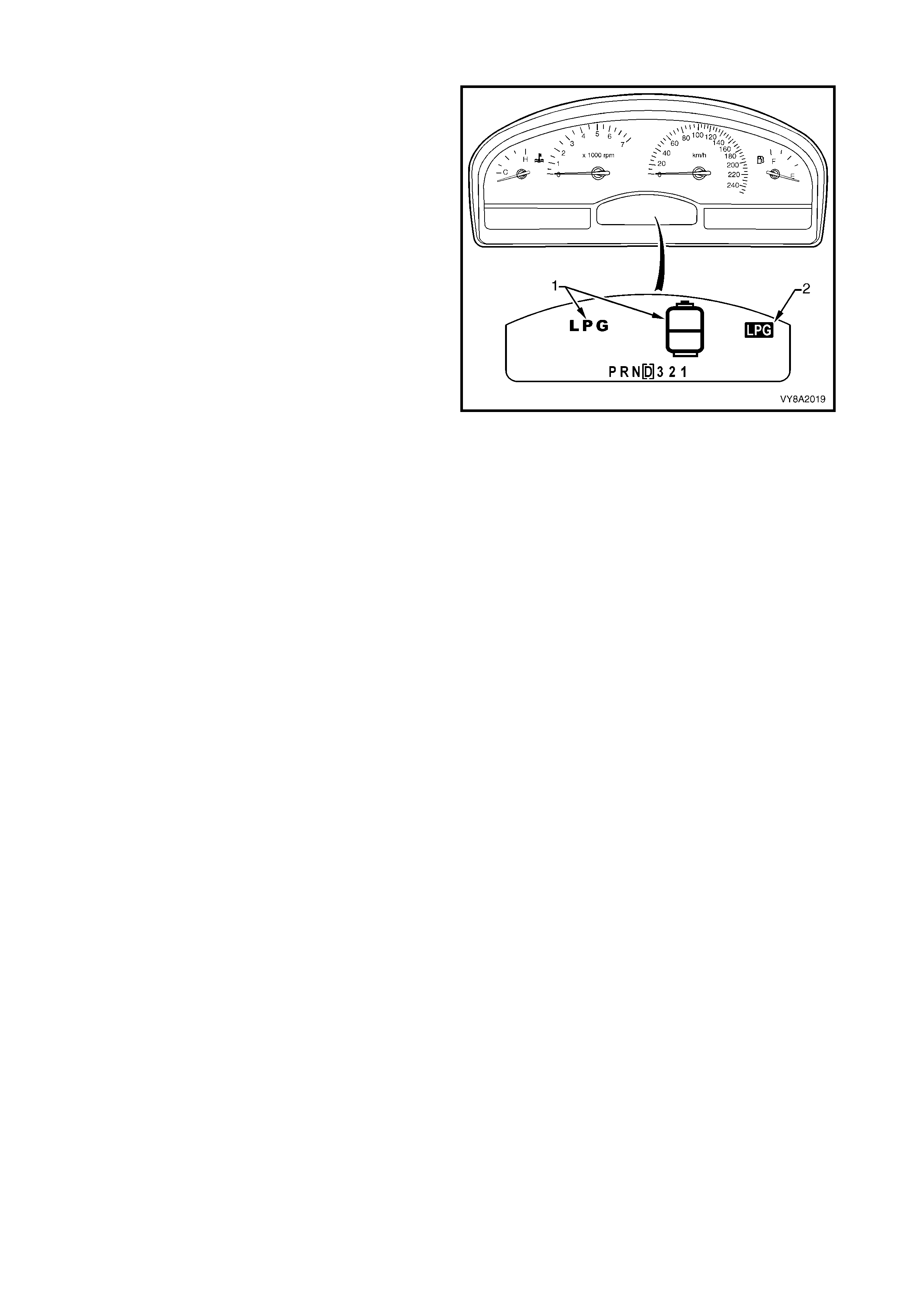

2.16 INSTRUMENT CLUSTER DISPLAY

Whenever the vehicle is switched from petrol to LPG

mode, the LPG tank icon and letters LPG (1) will be

displayed in the instrument cluster multifunction display

(MFD) for two seconds.

In addition, the icon LPG (2) will also be displayed in

the upper right corner of the MFD while the vehicle

remains in LPG mode.

When the vehicle is in LPG mode the fuel gauge

displays the amount of LPG within the tank.

W hen the level falls to a pr edeterm ined point, the LPG

tank icon is displayed with the words Low LPG in tank .

If the level decreases further to second predetermined

point, the icon is displayed again with the words Very

Low LPG in tank. T hese warnings are accom panied by

a warning chime.

NOTE: As the vehicle may continue to use a small

amount of petrol during LPG operation, the level of

the petrol tank is also monitored, refer to

2.18 POWERTRAIN CONTROL MODULE. If the level

falls below predetermined points, similar warnings will

be issued regarding the petrol status, even though the

fuel gauge is displaying LPG tank status.

For further information refer to Section 12C

INSTRUMENT CLUSTER.

Figure 8A2-28

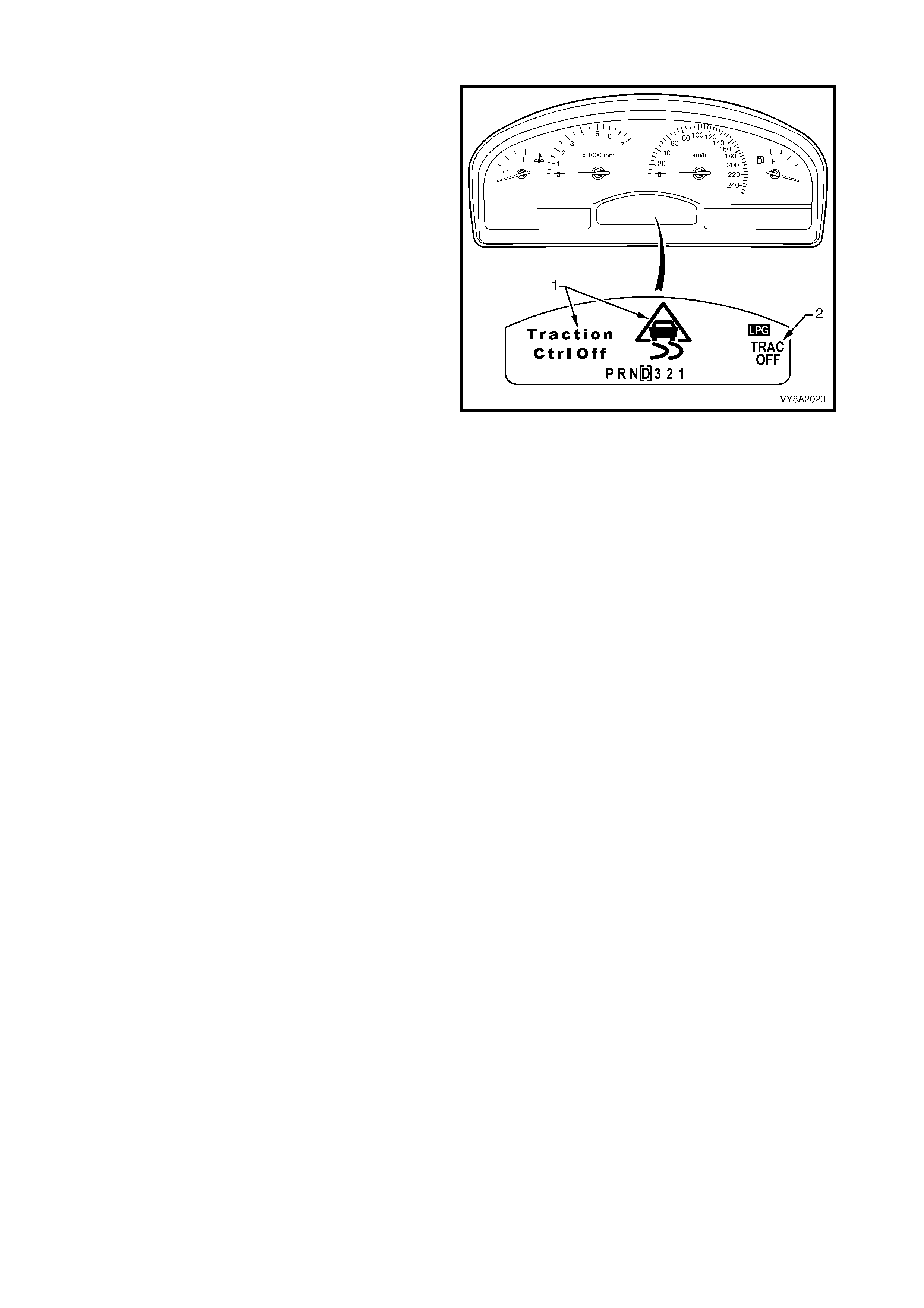

2.17 TRACTION CONTROL OPERATION

Whenever the vehicle is operating in the LPG mode,

the traction control system (if fitted) is disabled. The

traction control off icon (1) and the words Traction Ctrl

Off will be displayed in the instrument cluster

multifunction display (MFD) for two seconds.

In addition, the icon TRAC OFF will also be displayed

on the right-hand side of the MFD while the traction

control system remains disabled.

The traction control system is disabled by the PCM,

which sends a message to the ABS/ETC control

module via the serial data circuit, requesting the

traction control system be switched off.

Figure 8A2-29

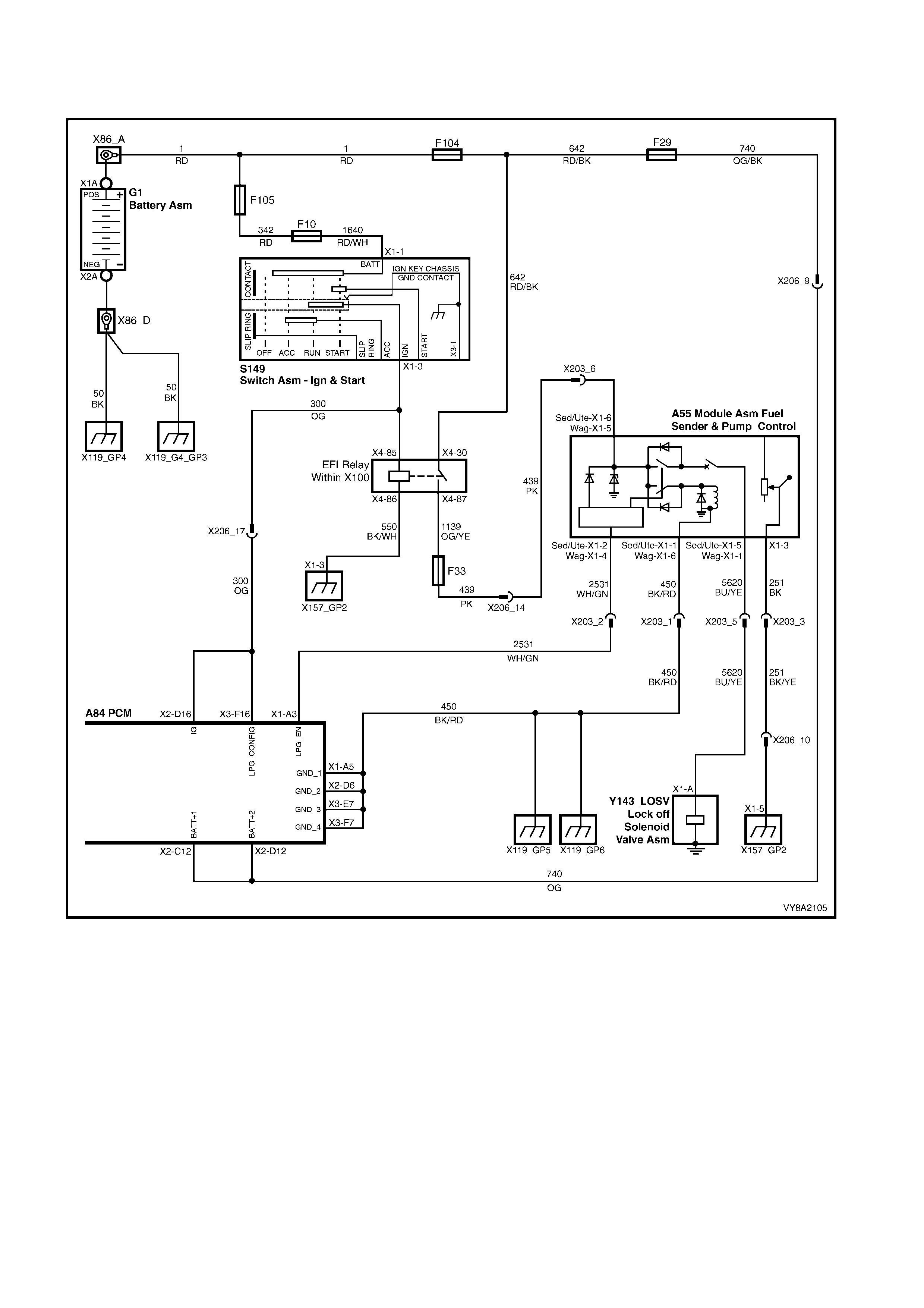

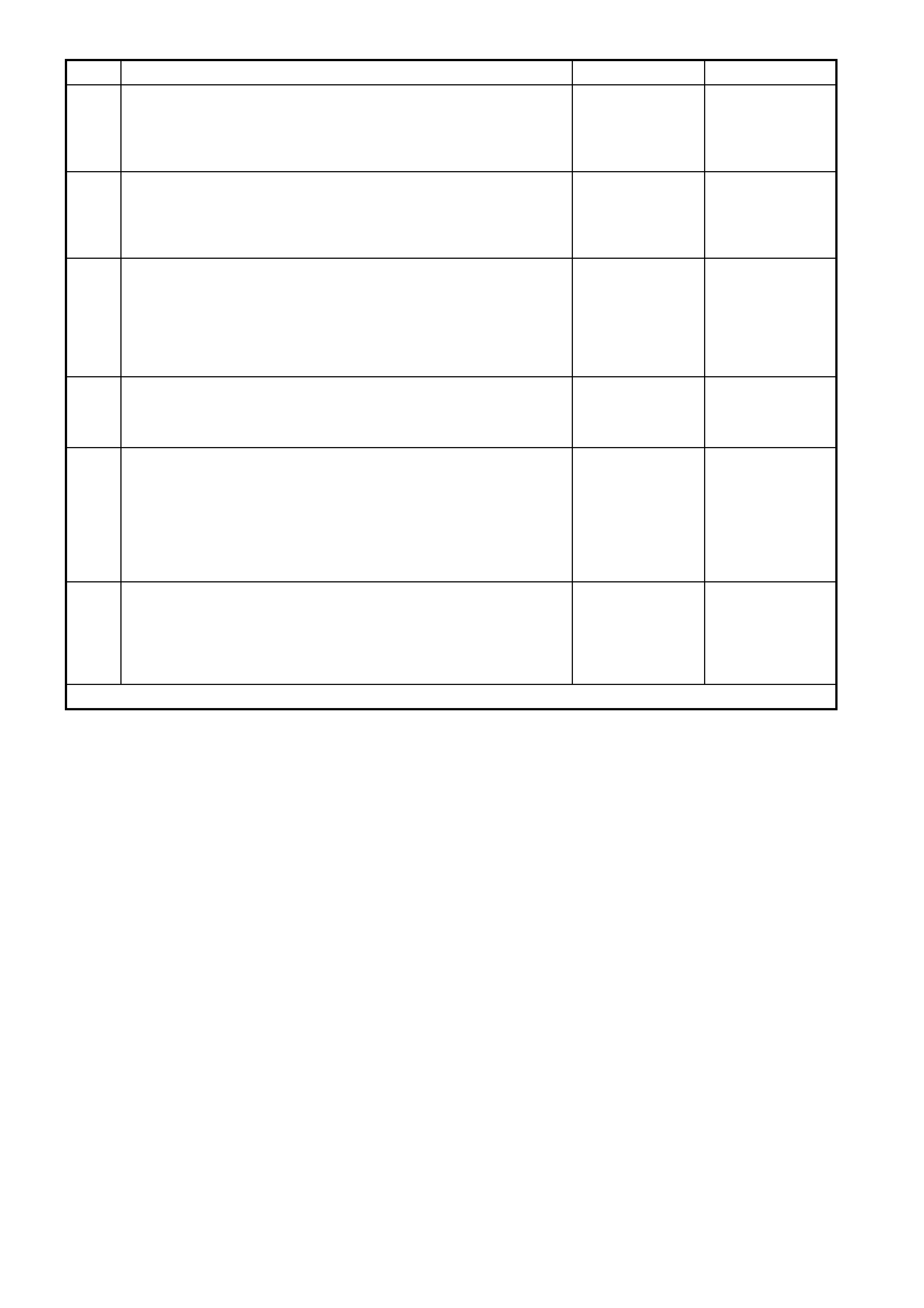

2.18 P O WERTRAIN CONTROL MODULE

When programmed with the correct LPG calibration,

the Powertrain Control Module (PCM) is capable of

operating in either of two operating modes: Petrol or

LPG.

PETROL MODE

When operating in petrol mode, the LPG system is

turned off and the vehicle operates on petrol with full

engine management control in the same manner as a

vehicle not fitted with LPG. In this mode, the

instrument cluster fuel gauge will show the amount of

petrol in the petrol fuel tank.

LPG MODE

When operating in the LPG mode, the engine

management s ystem is switched to LPG mode and the

LPG system is turned on, enabling the vehicle to

operate on LPG. In this mode the LPG lamp will be

illuminated and the instrument cluster fuel gauge will

show the amount of LPG in the LPG tank.

The PCM c ontrols the f low of LPG, by sending a signal

to the smart unit via circuit 2531. On receiving this

signal the sm art unit energise s the solenoid valve. The

smart unit also energises the LPG lock-off valve via

circuit 5620.

To aid engine starting, a small amount of petrol is

injected during engine cranking.

NOTE: In the LPG mode, the following changes have

been made so the engine can operate on LPG. These

changes only effect the operation of the PCM when

operating in LPG mode.

Figure 8A2-30

INJECTOR PULSE WIDTH

The injector pulse width is set to zero in all LPG operating modes, except during engine cranking or, when the

vehicle runs in engine valve recession protection mode.

During engine crank ing the amount of petrol delivered is determ ined by the engine coolant tem perature and the

engine crank time. If the engine stalls, no petrol will be injected during cranking unless the ignition is cycled off

and on.

W hen operating in LPG mode under conditions of prolonged high speed / high load, a sm all amount of petrol is

injected into the engine to cool the valves and catalytic converter.

FUEL PUMP

To provide petrol when starting in the LPG mode, the fuel pump will run for two seconds when the ignition is

turned to the ON position and continue to run when the engine is being cranked, but will be turned off five

seconds after the engine starts.

The fuel pump will also operate under high load conditions. This allows for petrol to be injected into the engine

when the vehicle goes into the engine valve recession protection mode.

To protect the fuel pump, the PCM will switch off the fuel pump and disable the engine valve seat recession

protection mode, if ther e is less than s ix litres of f uel in the petr ol tank. T he PCM monitors the s er ial data normal

mode message to determine the amount of fuel in the petrol tank.

ELECTRONIC SPARK TIMING

The PCM has been programmed with a specific Electronic Spark Timing (EST ) map that provides optimal LPG

operation. If the engine speed drops below 300 RPM, the PCM prevents the spark plugs from firing by setting

the ignition dwell to zero.

FUEL USAGE SIGNAL OUTPUT

The PCM f uel us age output signal is us ed by the trip com puter to deter m ine the fuel c onsum ption display and is

re-calibrated to suit LPG.

ENGINE CRANKING

If the throttle opening is greater than 7% when operating in LPG mode, the PCM will prevent the engine from

cranking by not energising the starter relay.

3. SERVICE OPERATIONS

3.1 SERVICE LINE DRAINING

LT Section –

CAUTION: T he vehicle cannot be operated on LPG in the workshop, unless the workshop is a Specialist

Gas Workshop (in accordance with the current Australian Standards AS 2746-1985) and LPG is

specifically required for testing. Therefore, only at the completion of the following procedure, with the

manual service valve closed, all the LPG in the service lines exhausted and the vehicle running on

petrol, can the vehicle be driven into the workshop.

1. Park the vehicle in a well ventilated area, away from any ignition source when performing this operation.

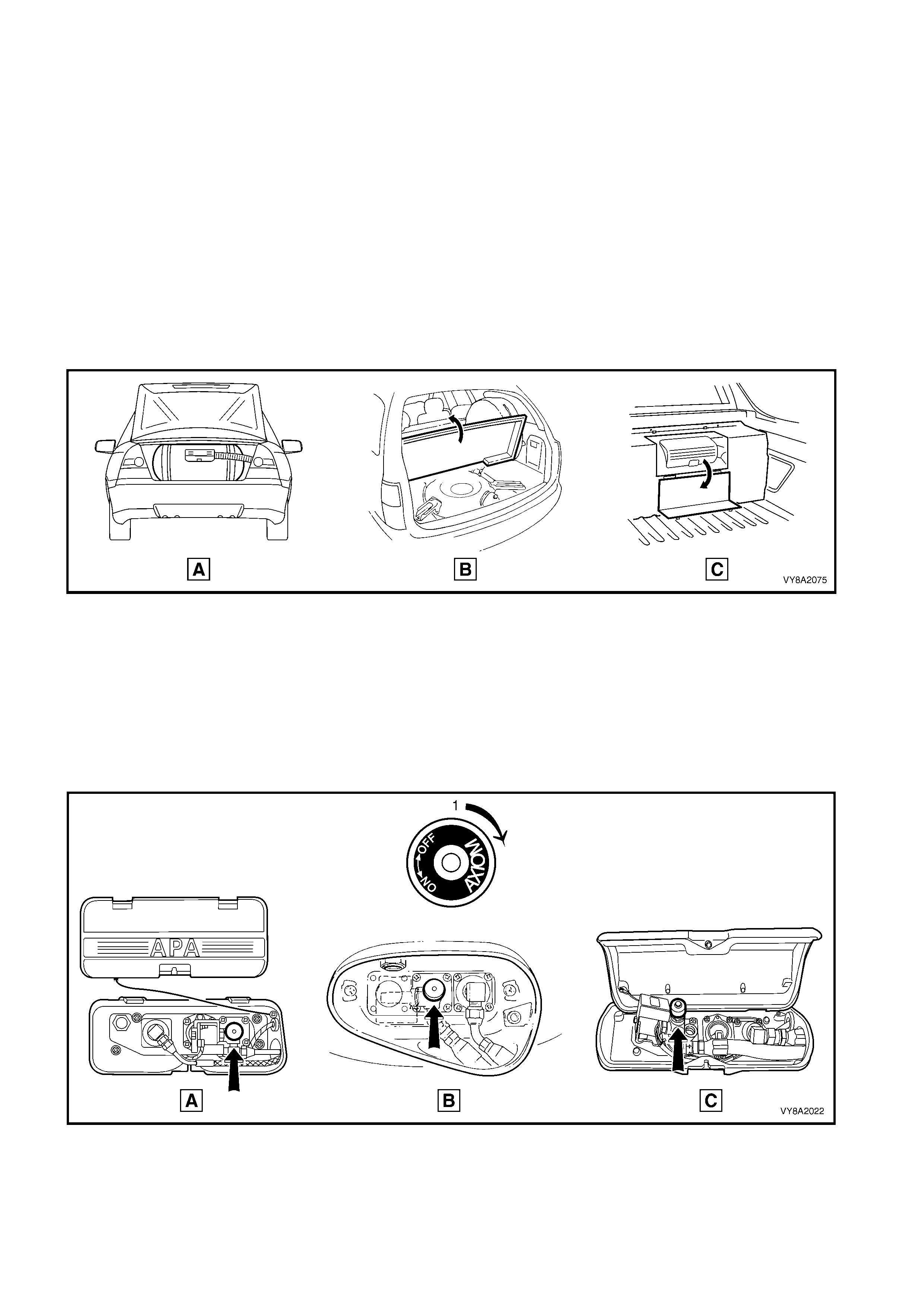

2. For Sedan, open the rear compartment lid (A).

For Wagon, open the liftgate and raise the rear compartment floor carpet (B).

For Utility, open the access cover on the LPG tank cover (C).

Refer to Figure 8A2-31.

Figure 8A2-31

3. Remove or open the LPG tank valve box cover.

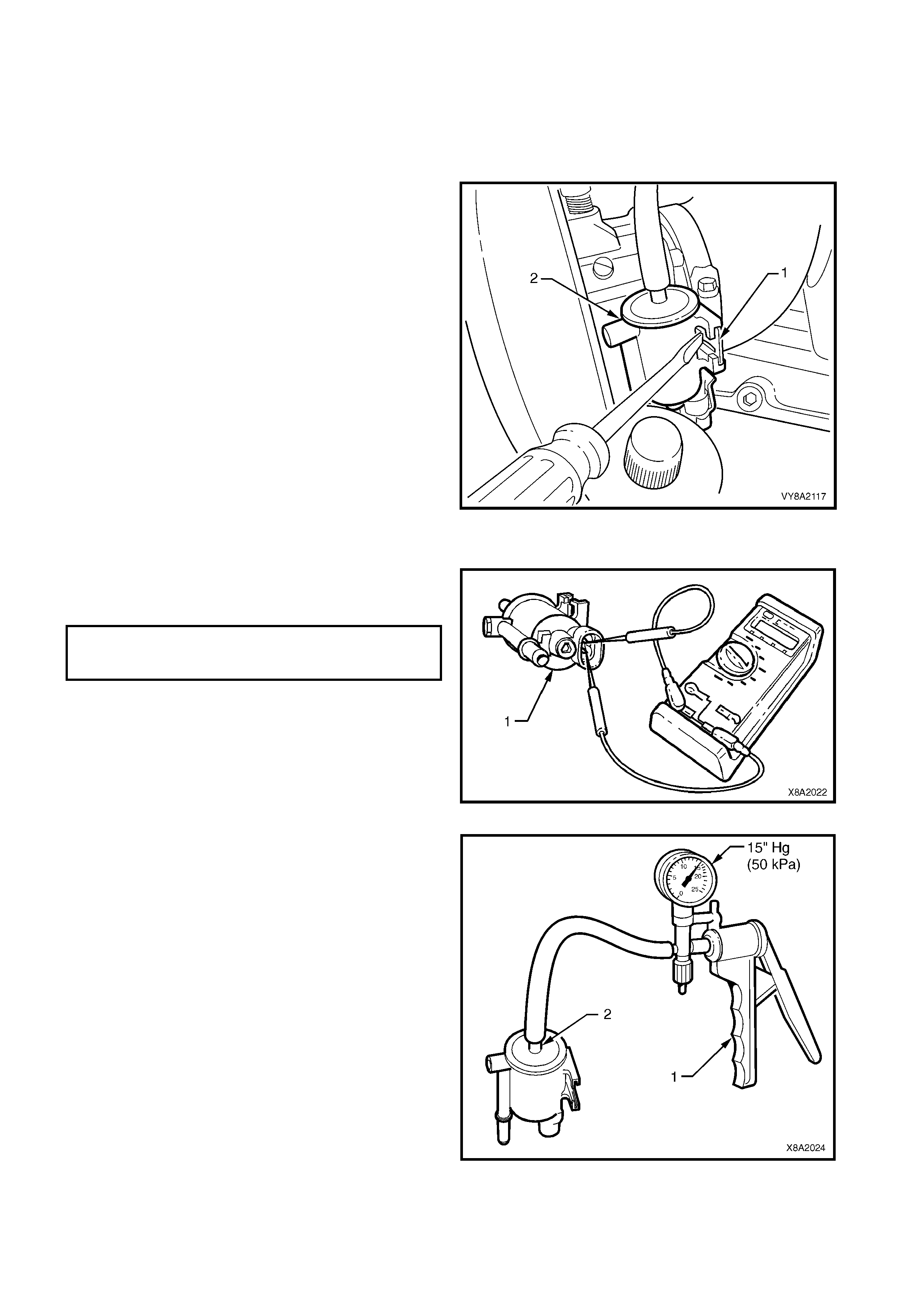

4. T urn the manual s ervice valve off in the dir ection shown (1), ref er to Figure 8A2-32, (A) Sedan, ( B) W agon,

(C) Utility.

CAUTION: If at any time the manual service valve becomes stuck, no service operations on the system

will be possible. Should for any reason the valve stick, the tank will have to be returned to the tank

manufacturer (APA) to arrange a replacement tank.

Contact: APA Industries, 190 Colchester Road, Kilsyth, Victoria 3137.

Figure 8A2-32

5. If required, press the f uel m ode switch (1) to place

the vehicle in LPG m ode. With the ignition on, the

LPG icon should be displayed on the instrument

cluster multi-function display.

6. Start the engine and allow to run on LPG until the

engine stalls, then crank the engine several times

to ensure the service lines are empty of LPG.

7. Press the fuel mode switch again to place the

vehicle in petrol mode. With the ignition on, the

LPG icon should not be displayed on the

instrument cluster multi-function display.

8. Disconnect the battery earth lead before

performing any service operations.

NOTE: If it is not possible to start and run the engine

out of LPG, the service lines should be cracked open

to allow them to be em ptied of LPG in accordance with

the current Australian Standards AS 2746 - 1985.

Figure 8A2-33

3.2 LPG TANK UNLOADING

LT Section –

1. Park the vehicle in a well ventilated area, away

from any ignition source.

2. Drain the LPG service lines, refer to

3.1 SERVICE LINE DRAINING.

3. Disconnect the battery earth lead and ensure the

manual service valve is turned off.

4. Disconnect the rear service line from the LPG

tank, refer to 3.15 REAR SERVICE LINE.

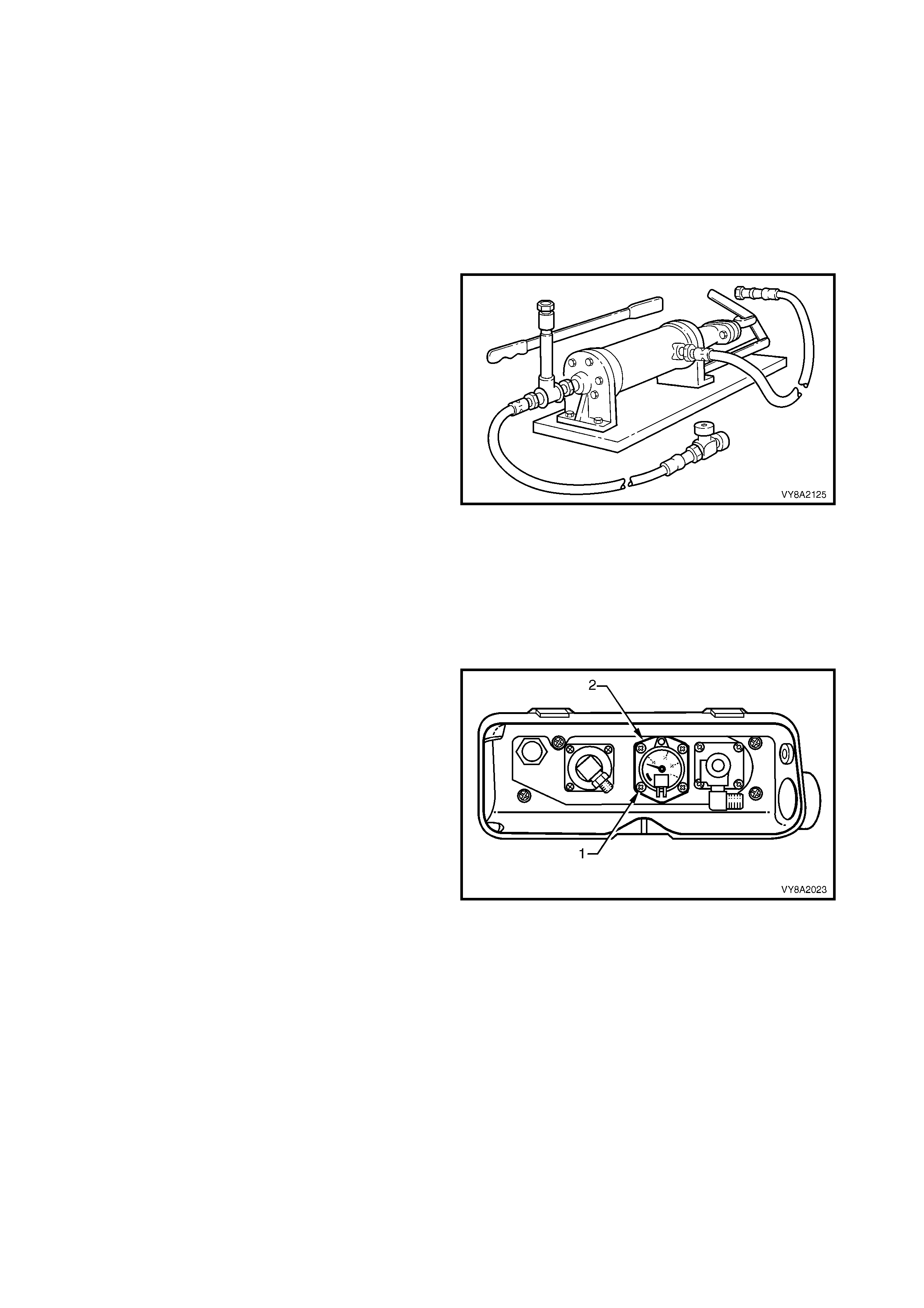

5. Connect an Apollo LPG pum p or equivalent to the

manual service valve assembly connection. Refer

to 10. SPECIAL TOOLS for further pump details.

6. Open the manual service valve and pump-out the

LPG tank, following the instructions provided by

the LPG pump manufacturer for the particular

pump you are using and in accordance with the

current Australian Standards AS 2746-1985.

CAUTION: The LPG tank must be pumped-out until

completely empty.

7. W hen the LPG tank is com pletely empty, close the

manual service valve and disconnect the pump.

8. Carefully open the manual service valve.

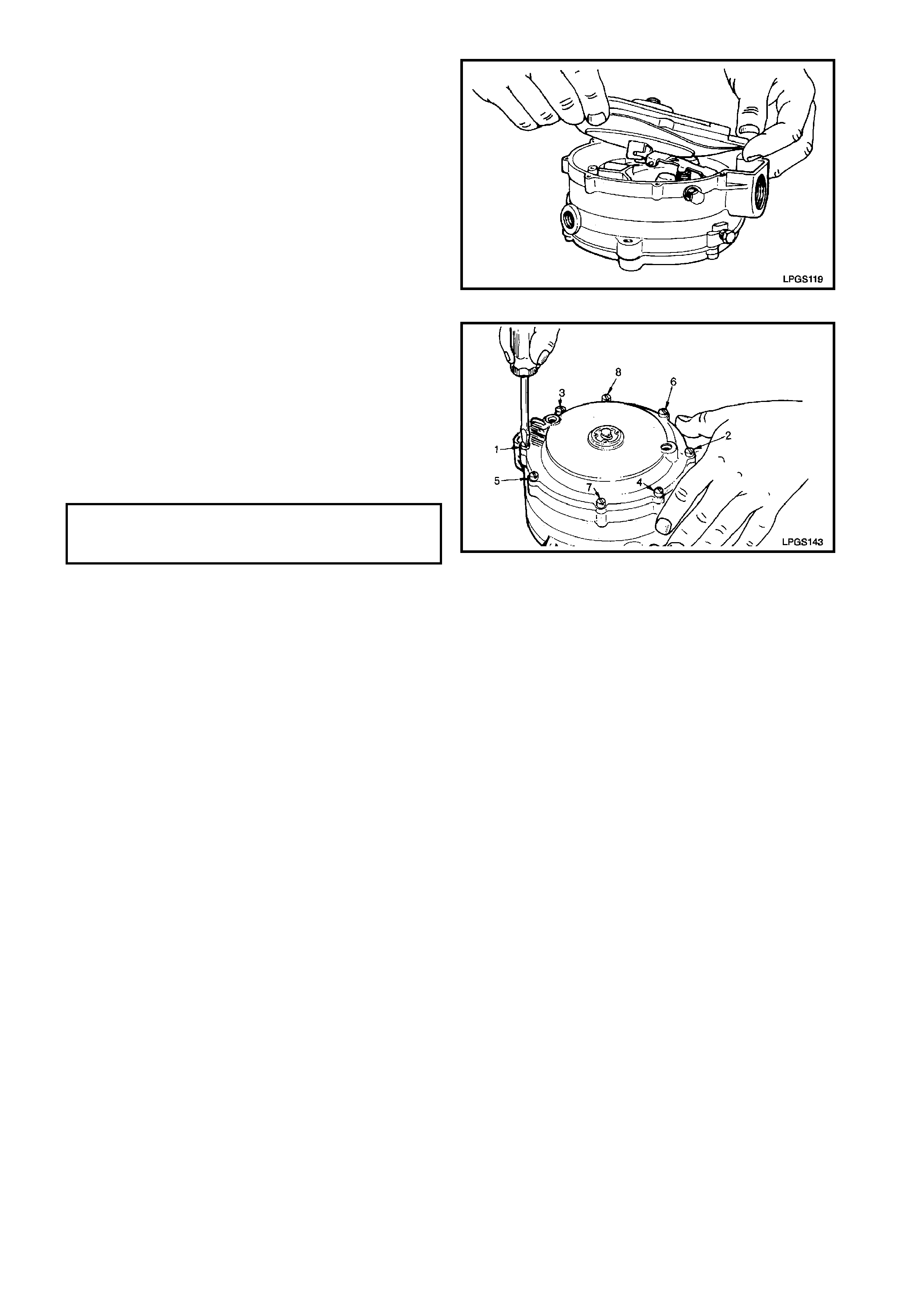

9. Remove the wiring connections from the tank fuel

gauge assembly.

10. Remove the smart unit and solenoid valve

from the manual service valve, refer to

3.8 SMART UNIT & SOLENOID VALVE.

11. Remove the filler line from the AFL valve, refer to

the 3.5 FILLER LINE.

Figure 8A2-34

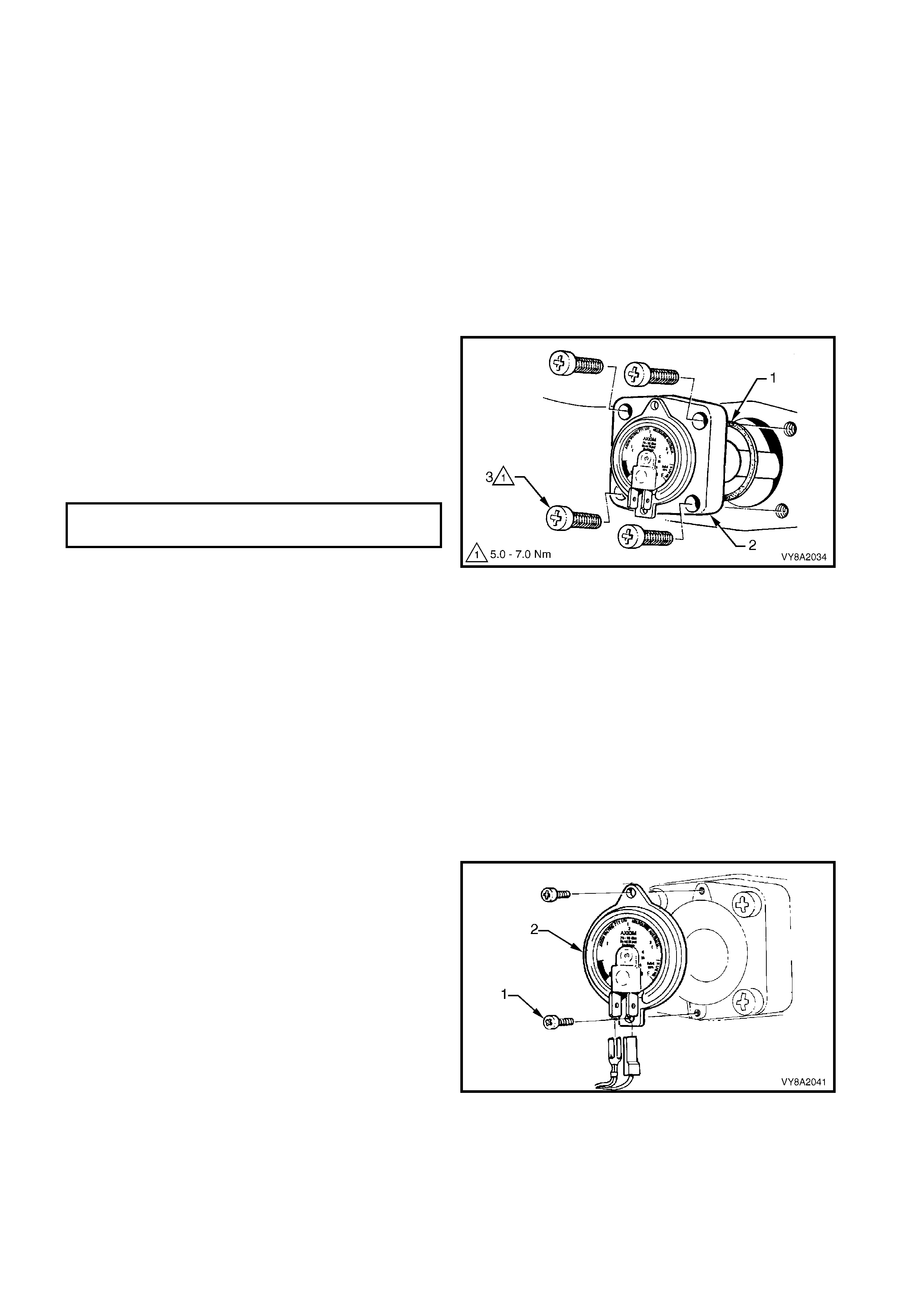

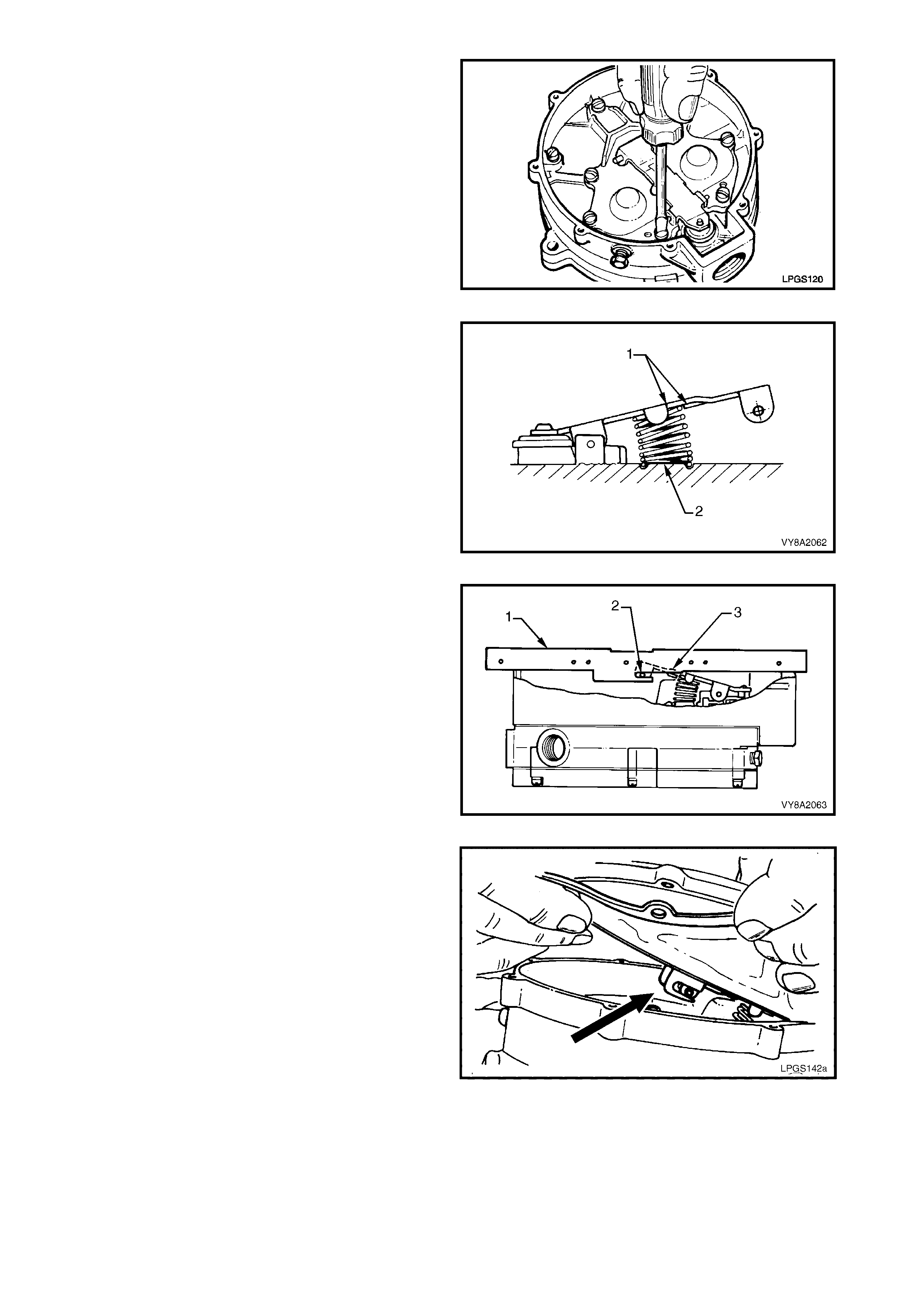

12. Loosen the tank fuel gauge assembly retaining

screw (1), four places, one turn, Sedan shown,

Wagon and Utility similar.

13. Rock the tank fuel gauge assembly to relieve any

residual pressure in the LPG tank.

14. Continue to loosen the tank fuel gauge assembly

screws one turn at a time. Continue rocking the

tank fuel gauge assembly to ensure the LPG tank

has no residual pressure.

15. Completely remove the tank fuel gauge assembly

screws.

16. Remove the tank fuel gauge assembly (2), being

careful not to damage the float.

17. Purge the LPG tank with nitrogen to ensure there

is no residue of LPG in the tank.

CAUTION: After any valve or component has been

removed and reinstalled to the LPG tank, the LPG

tank must be pressure and leak tested in

accordance with the current Australian Standard

AS 2030-1 before the LPG tank is returned to

service.

18. If required, reinstall the tank fuel gauge assembly,

refer to 3.13 TANK FUEL GAUGE ASSEMBLY.

Figure 8A2-35

3.3 LEAK TESTING

LT Section – AA-650Q

The f ollowing leak test procedure is to be perf orm ed on the LPG s ystem high-pr essur e com ponents and is to be

performed at each normal maintenance service.

IMPORTANT: The leak test is to be perform ed in the open air in a well-ventilated area, away from any ignition

source and prior to bringing the vehicle into the workshop.

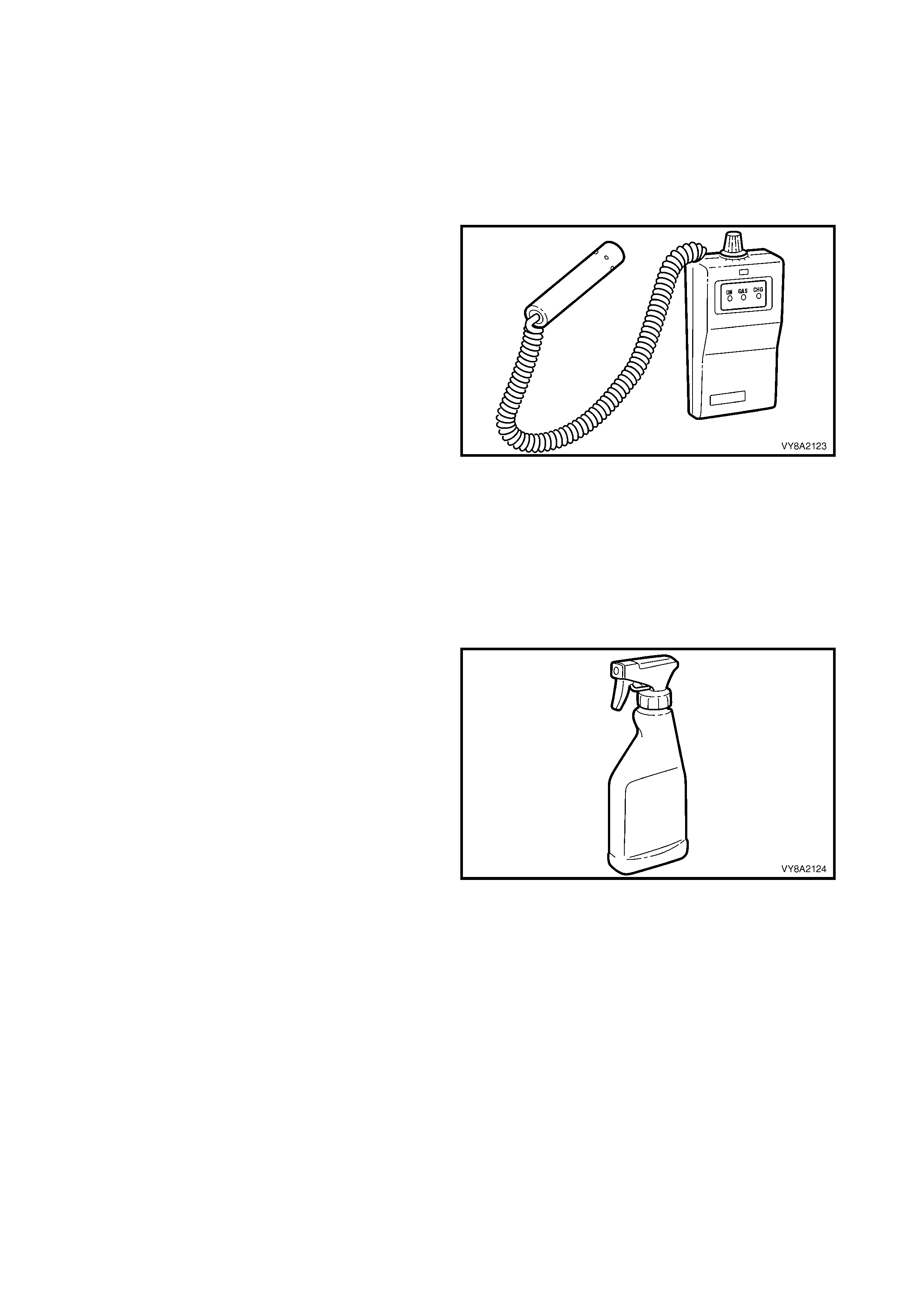

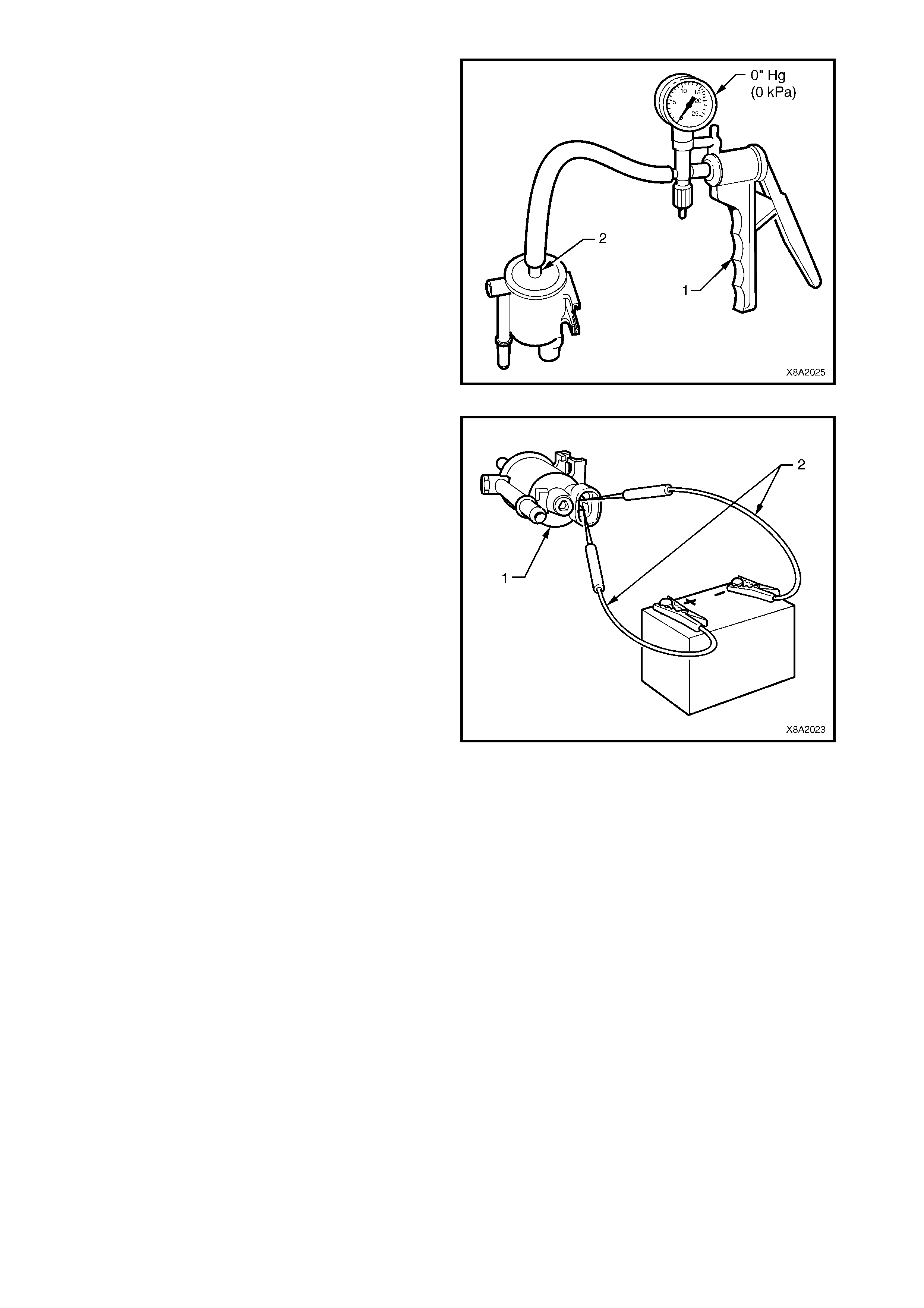

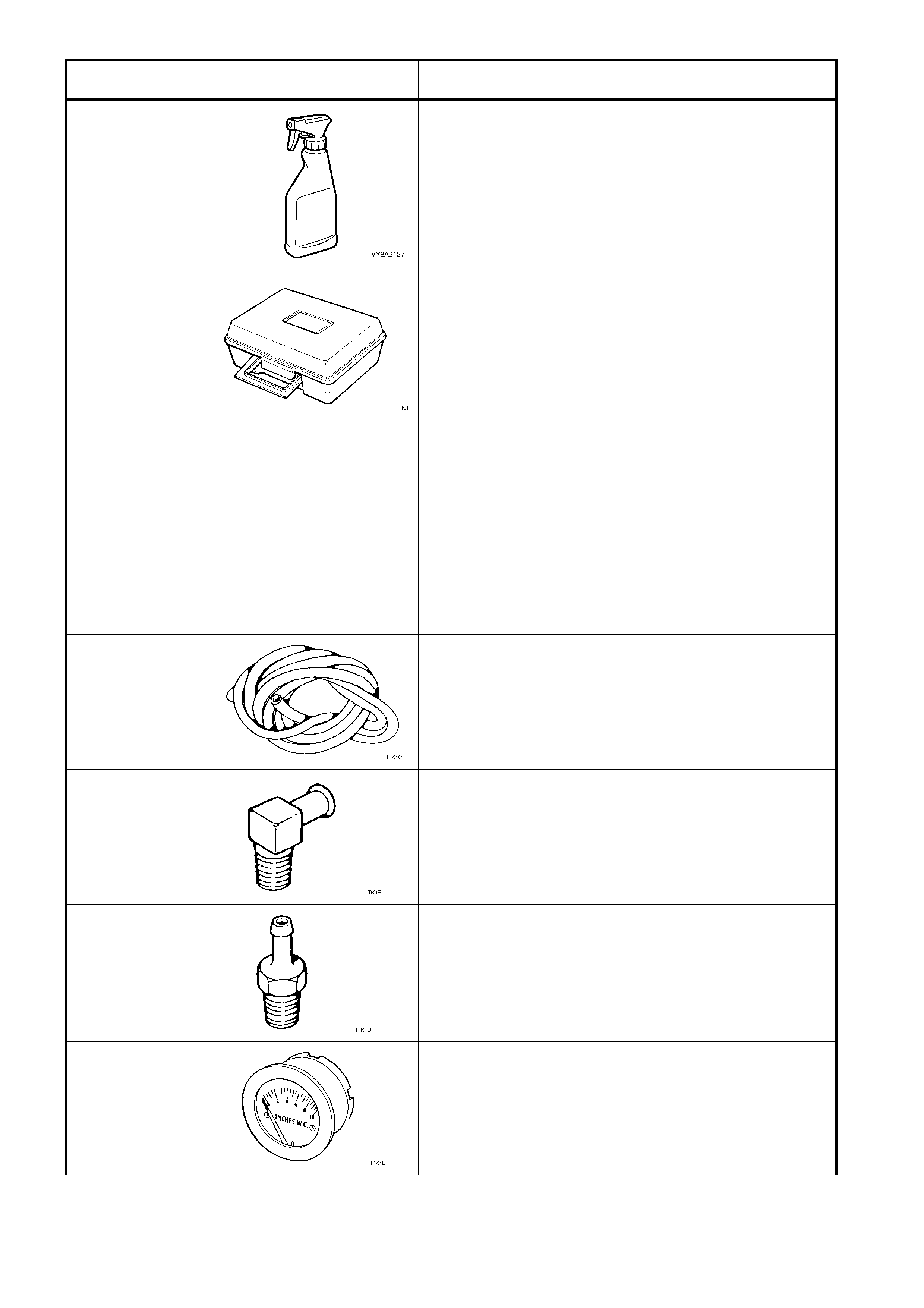

COMBUSTIBLE GAS DETECTORS

If a combustible gas detector is to be used for leak

testing of the LPG system, the combustible gas

detector should be capable of detecting 25 parts per

million (PPM) of LPG in air. A detector such as a LD-

9001 LP Gas Leak Detector or equivalent is

recommended.

Whichever leak detector is used, it is important to

follow the manufacturer's instructions in regard to

adjustment and setting the instrument prior to

conducting the leak test.

Care in interpretation is necess ary, as the detector can

respond to the pres ence of any of several vapours that

are com bus tible, som e of which m ay not be LPG, such

as oil smears, joining compounds, etc. It may also

detect residual LPG vapours that are present for

reasons other than leakage, and which must be

cleared before a valid test for leakage can be made.

If a leak is present, a detector will signal its existence

but not its size, and will indicate its general location,

but may not be able to locate it exactly. A proving or

follow up check with foam is often desirable.

Figure 8A2-36

FOAM

If foam is to be used, the foaming agent should be a

propriety leak test solution, formulated specifically for

the purpose, such as Gameco Leak Check TM or a

similar solution.

The solution should be fr esh and the whole of the ar ea

to be tested should be coated, and time allowed for

bubbles to form. All areas under test must be able to

be observed during the leak test.

Whichever foaming agent is used, it is important to

follow the manufacturer's instructions.

Foam testing is more effective for small leaks. Large

leaks tend to blow the solution away from the leak

without forming a bubble, so care in application is

necessary.

The leak test is performed by directing a spray of

solution at each of the pos sible leak points in the high-

pressure side of the system.

After applying the solution, look carefully for no less

than 15 seconds.

A leak is indicated by the presence of gas bubbles

(foaming) in the solution at the leak source

Figure 8A2-37

NOTE: LPG is heavier than air so test thoroughly below all components and fittings.

If a leak is detected at a joint, the relevant component/s must be removed as described in the appropriate service

operation in this Section. All mating threads must be thoroughly cleaned, then resealed using the specified

sealant and tightened to the specified torque. Once installed, thoroughly leak test the component/s again.

At the completion of each test, dry the leak test area of the foam ing agent with low-pressure com pressed air or

shop cloths and spray the immediate area with a water-dispersing agent such as WD40 or RP7, etc.

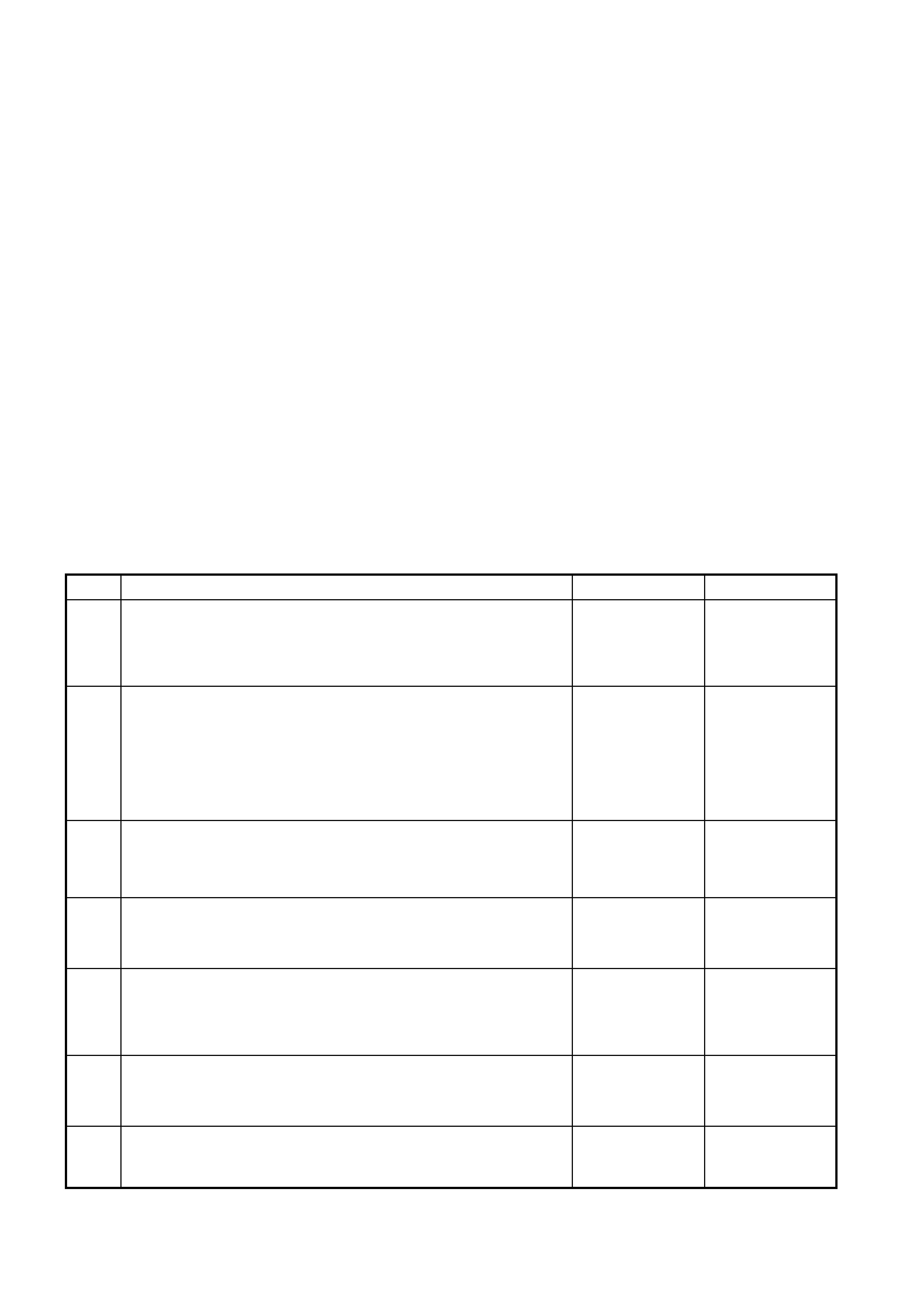

LEAK TEST PROCEDURE

With 3 litres of LPG in the LPG tank, leak test the complete LPG system following the instructions.

1. Park the vehicle in a dry, well ventilated area.

CAUTION: Do not smoke or allow naked flames or any ignition source near the vehicle during the testing

operations.

2. Ensure the vehicle is operating on LPG and run the engine for at least 30 seconds to fully pressurise the

system, then stop the engine.

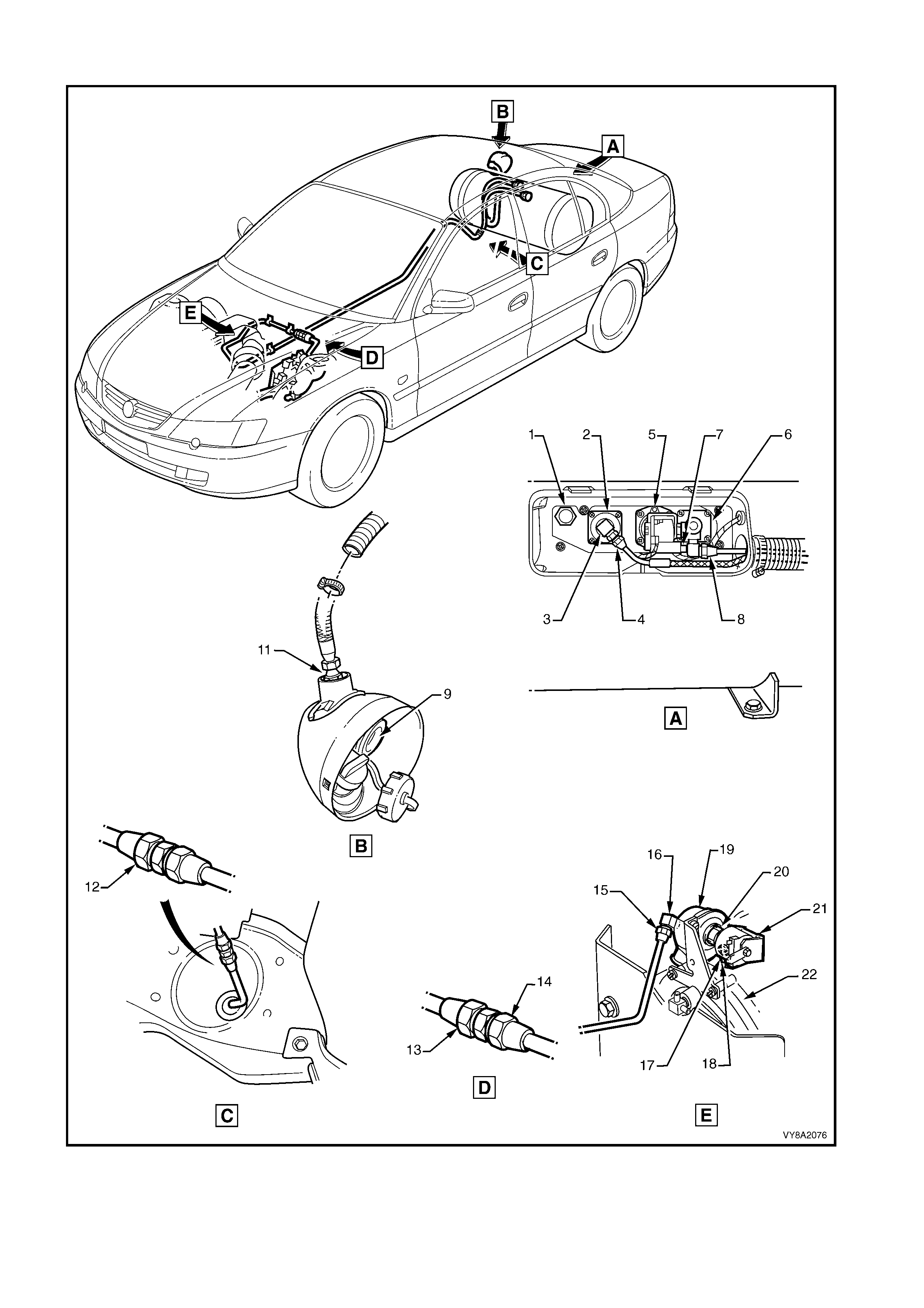

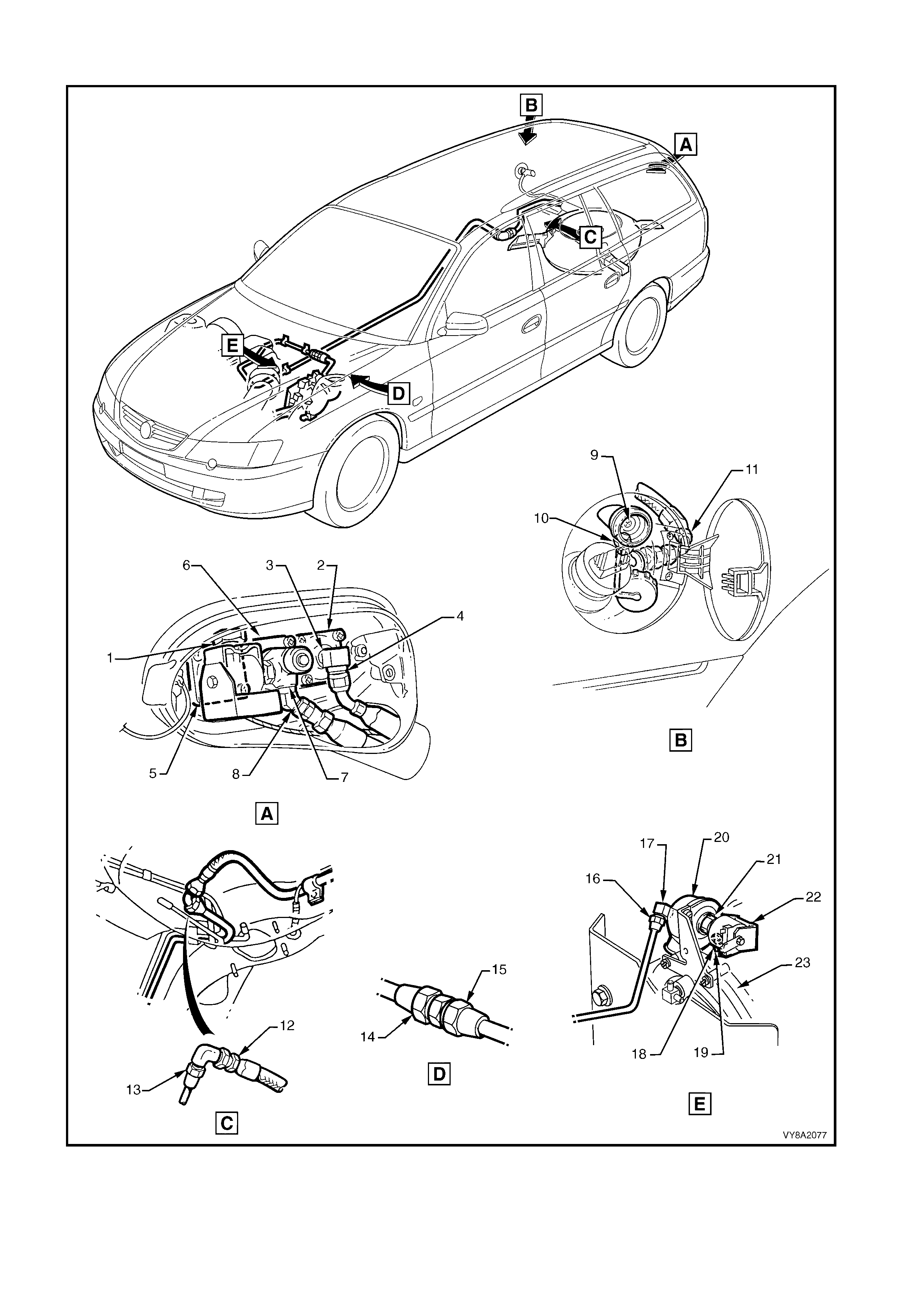

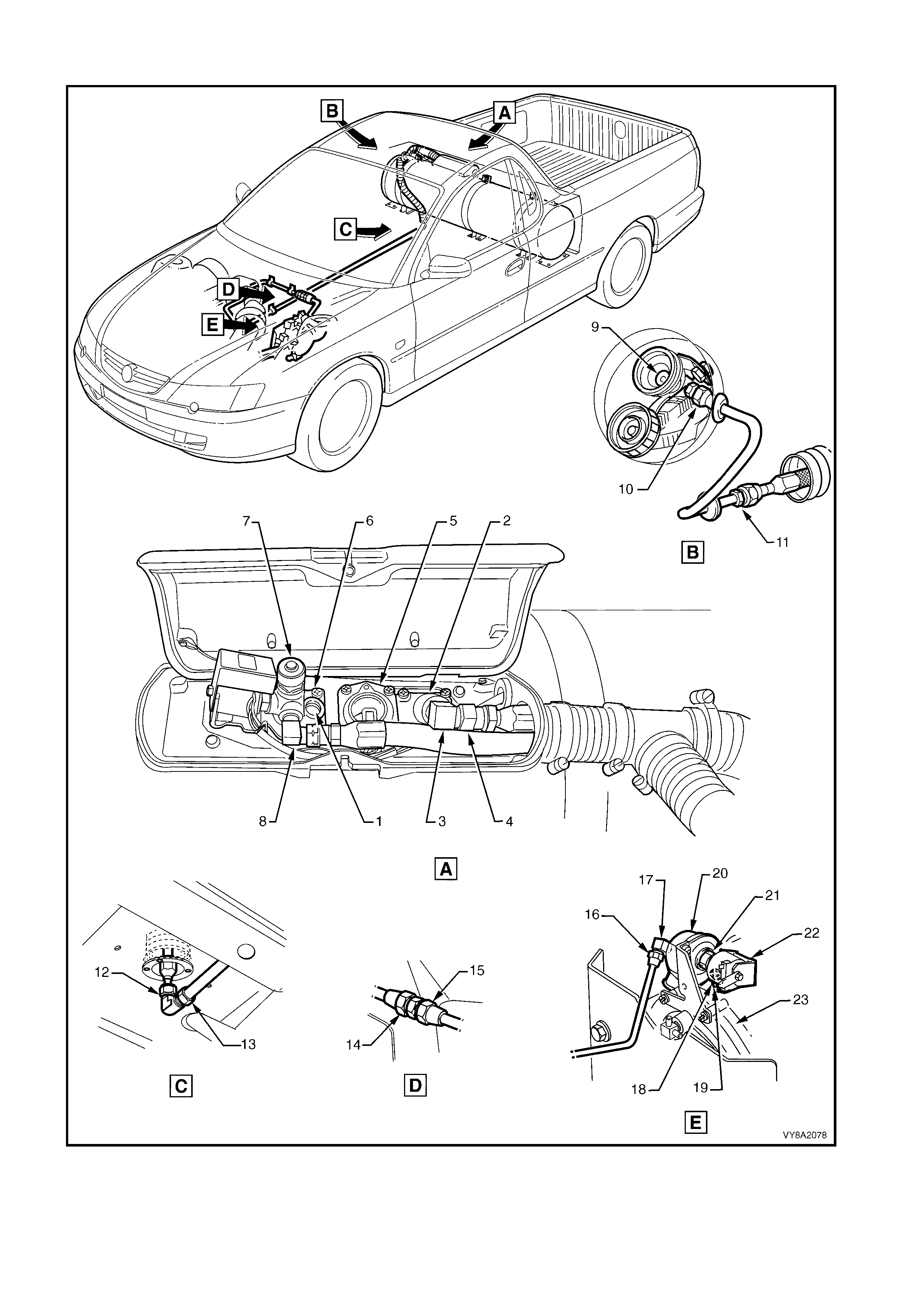

3. Perform the following test sequence, referring to Figure 8A2-38 – Sedan, 8A2-39 – Wagon or 8A2-40 –

Utility:

View A

Remove the valve box cover and leak test at and around the:

• Pressure relief valve (1)

• AFL to LPG tank (2)

• AFL inlet elbow to the AFL (3)

• Filler line to the AFL inlet elbow connection (4)

• Tank fuel gauge assembly (5)

• Manual service valve assembly to the LPG tank (6)

• Manual service valve assembly (7)

• Rear service line to the manual service valve assembly elbow connection (8)

View B

Open the fuel filler door and leak test at and around the:

• Filler valve check ball (9)

Wagon & Utility only:

• Leak test at and around the filler valve to filler line connecting pipe (10)

Sedan: Remove the right-hand quarter inner rear side carpet, refer to 2.17 QUART ER INNER REAR SIDE

CARPET in Section 1A8.

W agon: Rem ove the right-hand r ear wheelhouse liner, refer to 3.2 REAR WHEELHOUSE LINER in Section

1A1.

Utility: Remove the lower vent hose clamp at the flange and pull back the hose to expose the filler line

connection.

• Leak test at and around the filler line connecting pipe to the filler line (11)

View C

Raise the rear of the vehicle and support on safety stands, refer to Section 0A GENERAL INFORM ATION

for the location of jacking points. Leak test at around the:

Utility: Remove the connection protector plate, refer to 3.15 REAR SERVICE LINE.

• Rear service line to rear service line joiner or elbow (12)

• Rear service line joiner or elbow to intermediate service line (13)

View D

Leak test in the engine compartment at and around the:

• Intermediate service line to front service line joiner (14)

• Front service line joiner to front service line (15)

View E

Leak test in the engine compartment at and around the:

• Front service line to lock-off inlet connection (16)

• Lock-off inlet connection to lock-off valve (17)

• Lock-off valve to lock-off outlet connection (18)

• Lock-off outlet connection to converter (19)

• Lock-off valve assembly (20, 21, 22)

• Converter mounting faces (23

Sub-compartment

The sub compartment including the vent hoses are incorporated into the system so that in the event any

LPG es c apes from the tank f ittings, press ure r elief valve or the s ervic e line c onnection the LPG is allowed to

vent to the atm osphere and not into the passenger compartm ent of the vehicle. It is im perative that the sub

compartment and hoses are checked at regular intervals in accordance with AS 1425-1999.

A compartment or sub compartment shall be tested to ensure that it is gastight to the vehicle interior by

blowing tracer gas into the compartment or sub compartment and testing the surrounding atmosphere for

gas leak age with a c ombustible gas detec tor. Passages between the compar tment and the outs ide air s uch

as ventilation provisions or an access hatch or door of a permanently inbuilt compartment, shall be sealed

during testing.

If any leakage is detected, the leak shall be rectified and the leak test is to be repeated.

If any leaks are detec ted, at the com pletion of the leak tes t close the m anual service valve, s tart the engine and

run the engine until all the LPG in the service line is exhausted. W ith the engine stopped, switch to petrol and

start the engine. The vehicle can now be driven into the workshop and any leaks rectified by referring to the

appropriate service procedures in 3. SERVICE OPERATIONS.

NOTE: The vehicle cannot be operated on LPG in the workshop unless the workshop is a Specialist Gas

Workshop, refer to Australian Standard AS 2746-1985.

SEDAN

Figure 8A2-38

Legend

1. Pressure Relief Valve 12. Rear Service Line Joiner to Intermediate Service Line

2. Automatic Fill Limiter (AFL) to LPG Tank 13. Intermediate Service Line to Front Service Line Joiner

3. AFL Inlet Elbow to AFL 14. Front Service Line Joiner to Front Service Line

4. Filler Line to AFL Inlet Elbow 15. Front Service Line to Lock-off Inlet Connection

5. LPG Tank Fuel Gauge Assembly 16. Lock-off Inlet Connection to Lock-off Valve

6. Manual Service Valve to LPG Tank 17. Lock-off Valve to Lock-off Outlet Connection

7. Manual Service Valve Assembly 18. Lock-off Outlet Connection to Converter

8. Rear Service Line to Manual Service Valve 19. Lock-off Valve Assembly

9. Filler Valve Check Ball 20. Lock-off Valve Assembly

10. Not Applicable for Sedan 21. Lock-off Valve Assembly

11. Filler Line to Filler Valve 22. Converter Mounting Faces

WAGON

Figure 8A2-39

Legend

1. Pressure Relief Valve 13. Rear Service Line Elbow to Intermediate Service Line

2. Automatic Fill Limiter (AFL) to LPG Tank 14. Intermediate Service Line to Front Service Line Joiner

3. AFL Inlet Elbow to AFL 15. Front Service Line Joiner to Front Service Line

4. Filler Line to AFL Inlet Elbow 16. Front Service Line to Lock-off Inlet Connection

5. LPG Tank Fuel Gauge Assembly 17. Lock-off Inlet Connection to Lock-off Valve

6. Manual Service Valve to LPG Tank 18. Lock-off Valve to Lock-off Outlet Connection

7. Manual Service Valve Assembly 19. Lock-off Outlet Connection to Converter

8. Rear Service Line to Manual Service Valve 20. Lock-off Valve Assembly

9. Filler Valve Check Ball 21. Lock-off Valve Assembly

10. Filler Valve to Filler Line Connecting Pipe 22. Lock-off Valve Assembly

11. Filler Line Connecting Pipe to Filler Line 23. Converter Mounting Faces

12. Rear Service Line to Rear Service Line Elbow

UTILITY

Figure 8A2-40

Legend

1. Pressure Relief Valve 13. Rear Service Line Elbow to Intermediate Service Line

2. Automatic Fill Limiter (AFL) to LPG Tank 14. Intermediate Service Line to Front Service Line Joiner

3. AFL Inlet Elbow to AFL 15. Front Service Line Joiner to Front Service Line

4. Filler Line to AFL Inlet Elbow 16. Front Service Line to Lock-off Inlet Connection

5. LPG Tank Fuel Gauge Assembly 17. Lock-off Inlet Connection to Lock-Off Valve

6. Manual Service Valve to LPG Tank 18. Lock-off Valve to Lock-off Outlet Connection

7. Manual Service Valve Assembly 19. Lock-off Outlet Connection to Converter

8. Rear Service Line to Manual Service Valve 20. Lock-off Valve Assembly

9. Filler Valve Check Ball 21. Lock-off Valve Assembly

10. Filler Valve to Filler Line Connecting Pipe 22. Lock-off Valve Assembly

11. Filler Line Connecting Pipe to Filler Line 23. Converter Mounting Faces

12. Rear Service Line to Rear Service Line Elbow

3.4 FILLER VALVE & CONNECTOR PIPE

LT Section – AA-650R

SEDAN

REMOVE

CAUTION: Ensure that there are no naked flames or other sources of ignition in the vicinity.

1. Drain the service lines of LPG and note all cautions, refer to 3.1 SERVICE LINE DRAINING.

2. Remove the r ight-hand quar ter inner rear s ide carpet, ref er to 2.17 QUARTER INNER REAR SIDE CARPET

in Section 1A8.

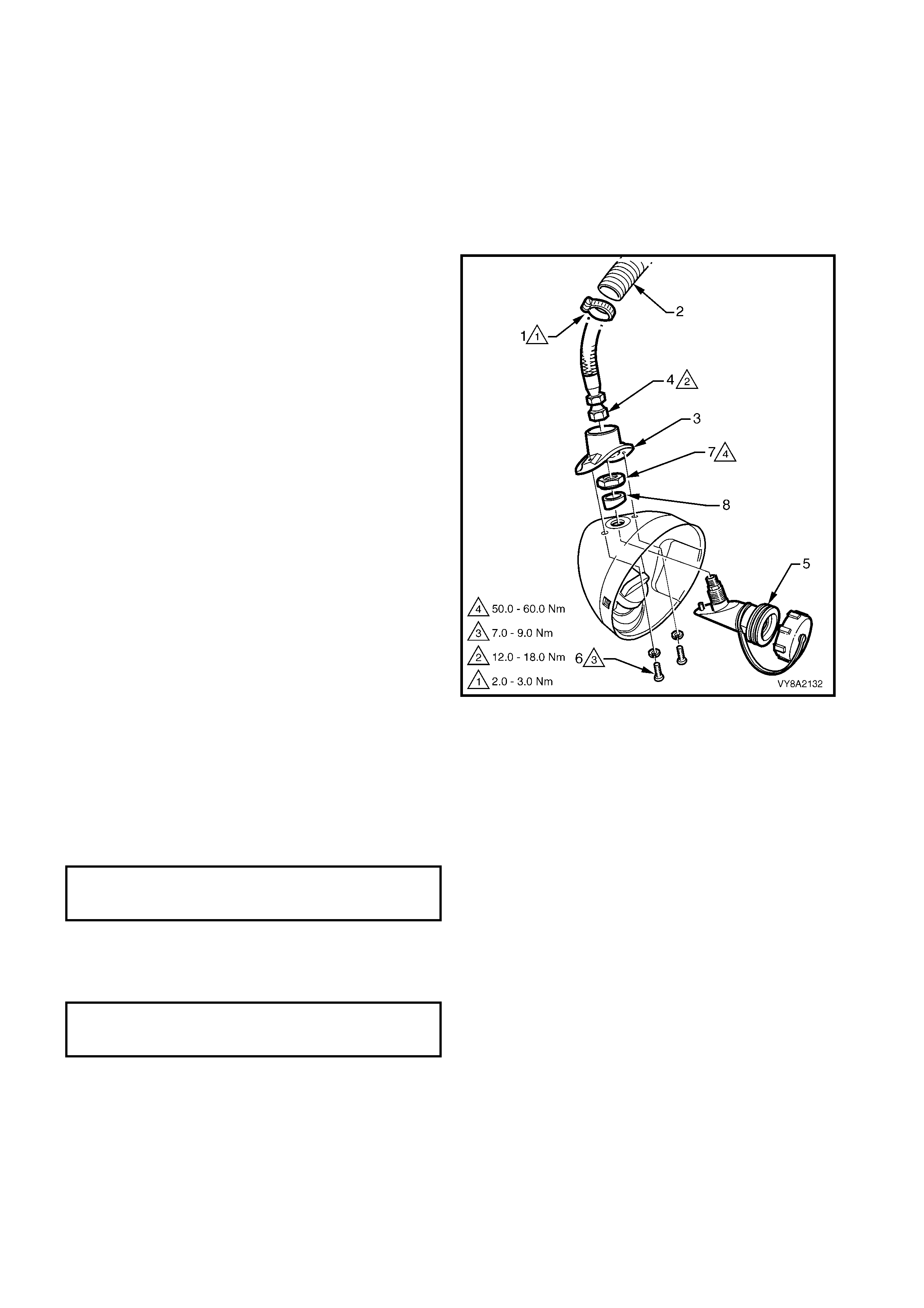

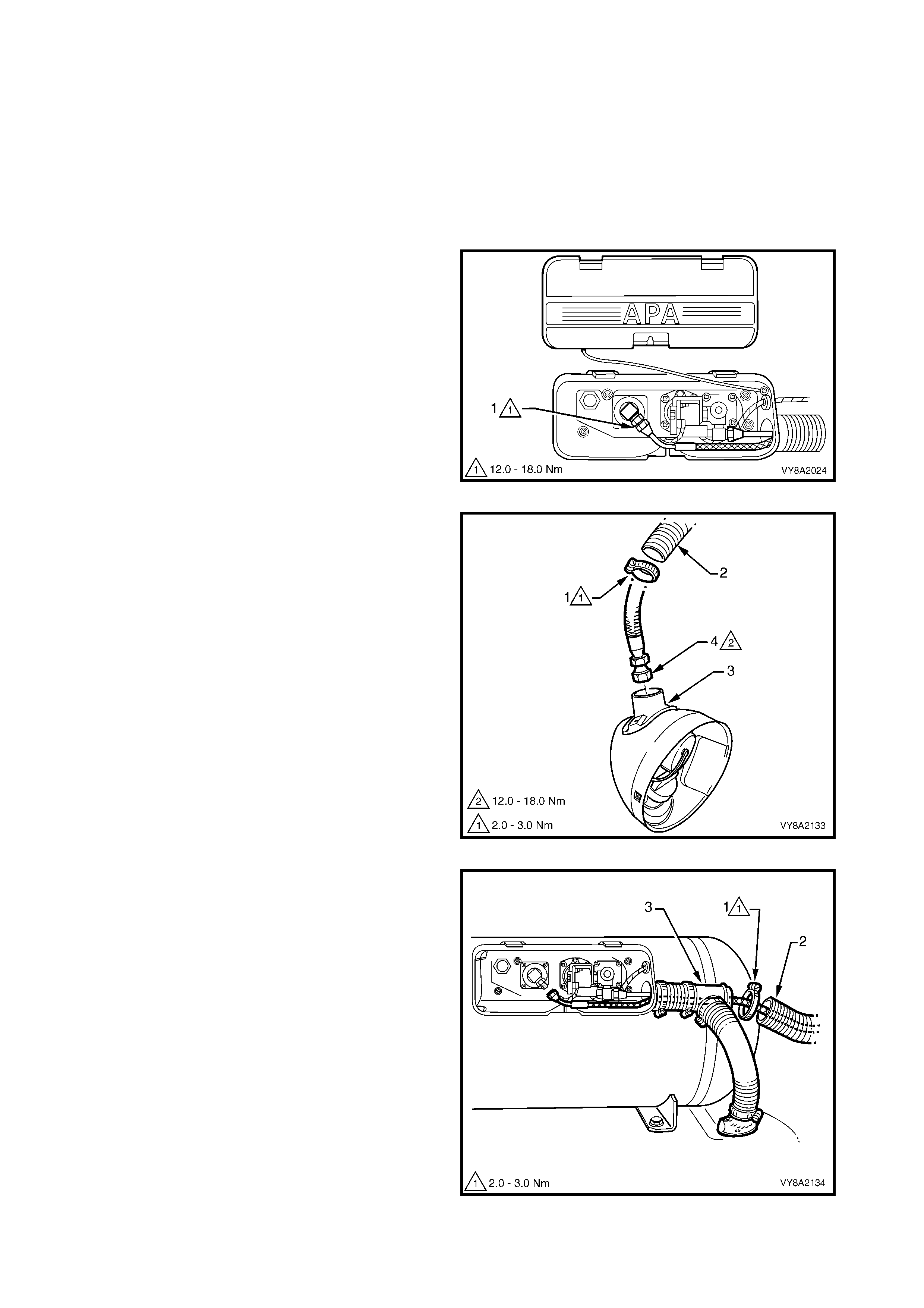

3. From within the rear c om partm ent, loosen the vent

tube clamp (1) and pull the vent tube (2) from the

filler valve flange (3).

4. Crack open the filler line connector (4) from the

filler valve (5) and allow any residual gas to

escape.

CAUTION: The filler line may contain LPG under

pressure.

5. Once the LPG in the line has dispersed, unscrew

the filler line connector completely and move the

filler line and vent tube away from the filler valve

flange.

6. Remove the two screws ( 6) and washers attac hing

the filler valve flange to the fuel filler housing.

7. Us ing a flat-blade screwdriver , prise the filler valve

flange from the fuel filler housing to break the

silicone sealer.

8. Remove the filler valve nut (7) and spacer (8) and

remove the filler valve.

Figure 8A2-41

REINSTALL

Installation if the filler valve is the reverse of the removal procedure, noting the following:

1. If new m ounting holes are r equired, use the tem plate supplied with the new part. Carefully drill the holes and

apply paint to any bare metal.

2. Clean the mating threads on the filler line and filler valve connector pipe.

3. Install the filler valve and tighten the retaining nut to the specified torque.

4. Apply silicone sealer to the mating surface of the filler valve flange.

5. Tighten the filler valve flange screws to the specified torque.

FILLER VALVE

RETAINING NUT

TORQUE SPECIFICATION 50.0 – 60.0 Nm

FILLER VALVE FLANGE

ATTACHING SCREW

TORQUE SPECIFICATION 7.0 – 9.0 Nm

6. Apply Loctite 577 sealant to the filler line and filler valve threads.

7. Tighten the filler line connector to the specified torque.

R

R

R

8. Leak test the LPG system, refer to 3.3 LEAK TESTING.

9. Reinstall the filler line vent tube and tighten the clamp to the specified torque.

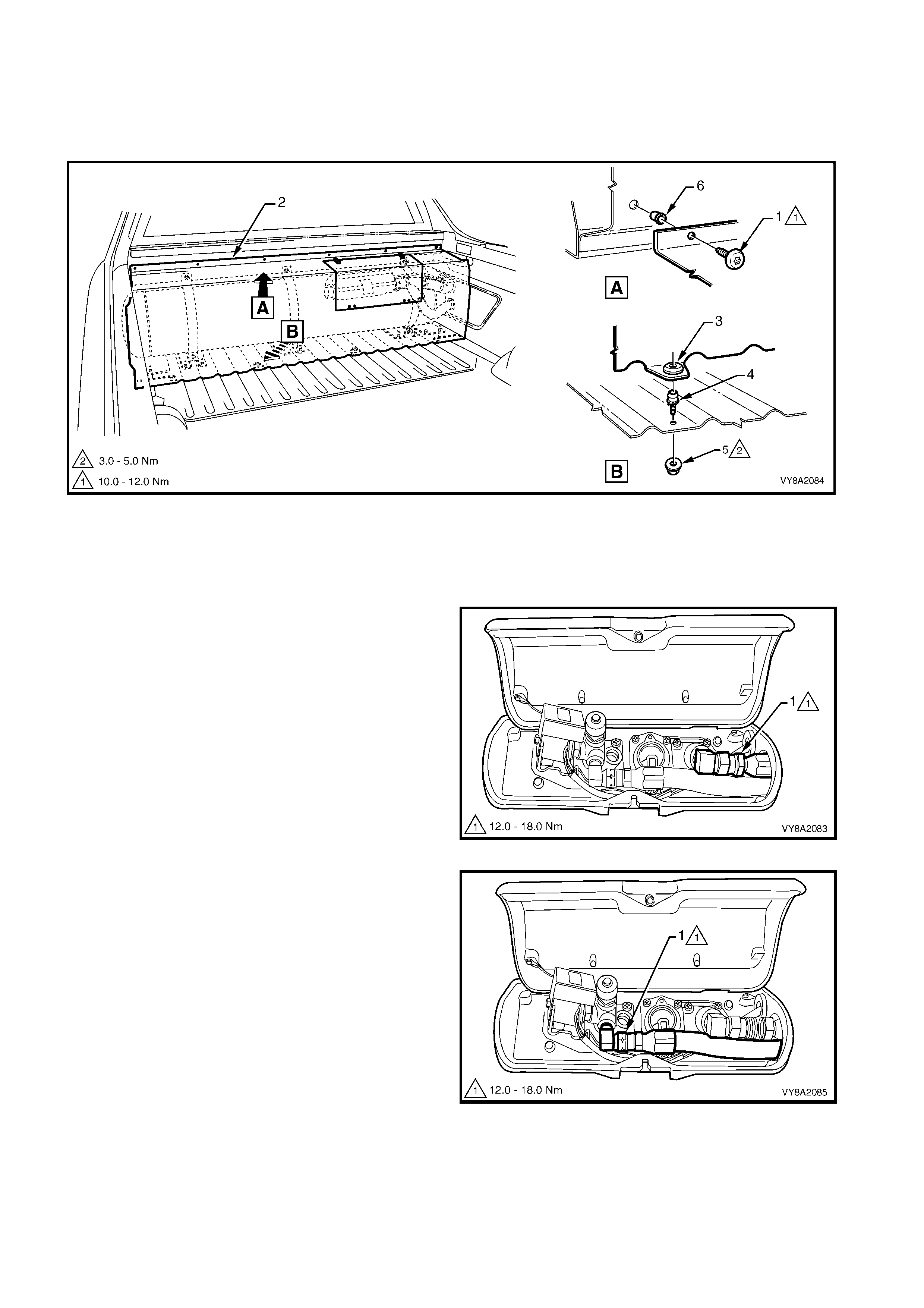

WAGON

REMOVE

CAUTION: Ensure that there are no naked flames or other sources of ignition in the vicinity.

1. Drain the service lines of LPG and note all cautions, refer to 3.1 SERVICE LINE DRAINING.

2. Remove the right-hand quarter inner trim panel, refer to Section 1A8, 3.11 QUARTER INNER TRIM

PANEL.

3. Remove the right-hand rear wheelhouse liner, refer to Section 1A1, 3.2 REAR WHEELHOUSE LINER,

EXCEPT UTILITY.

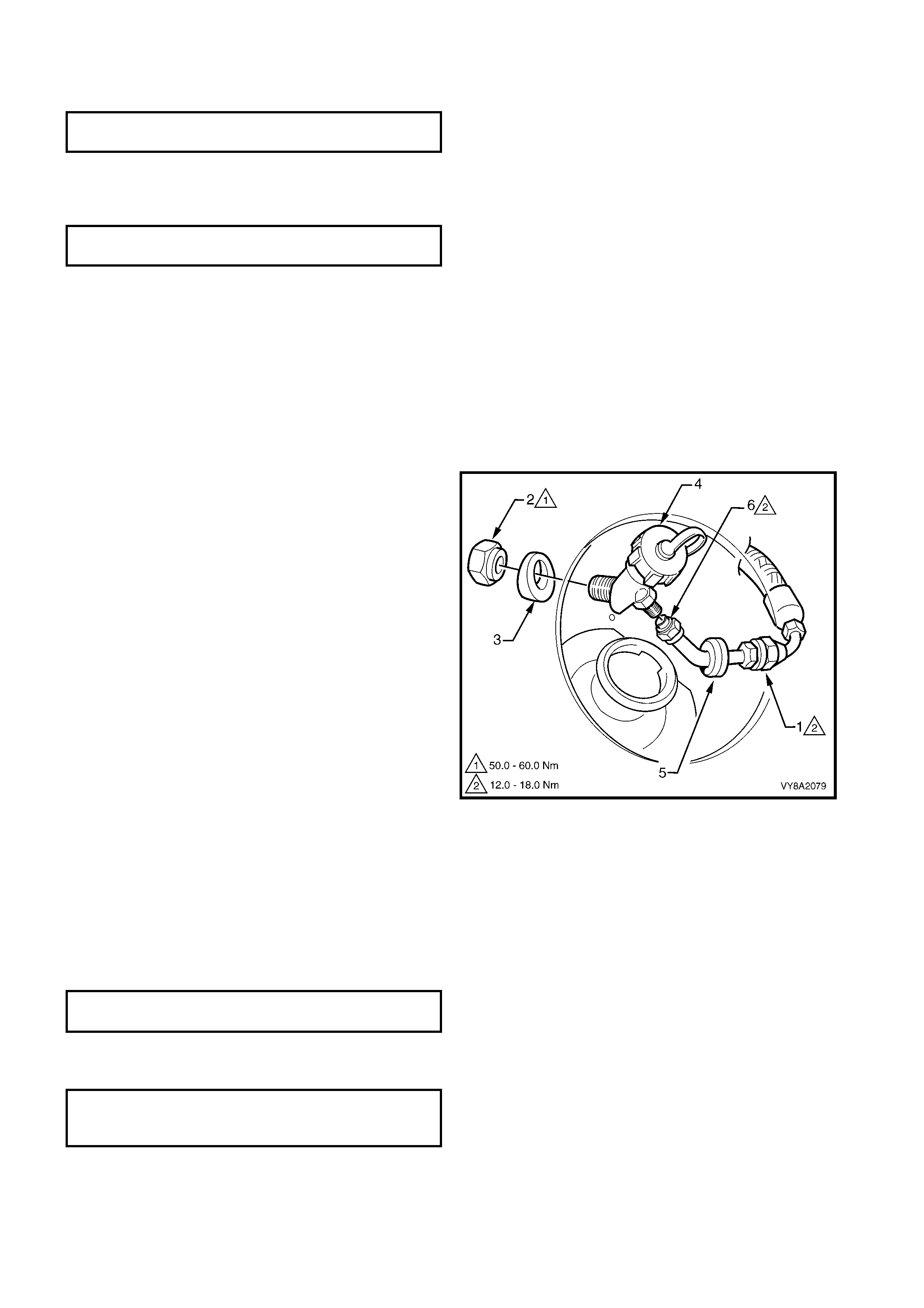

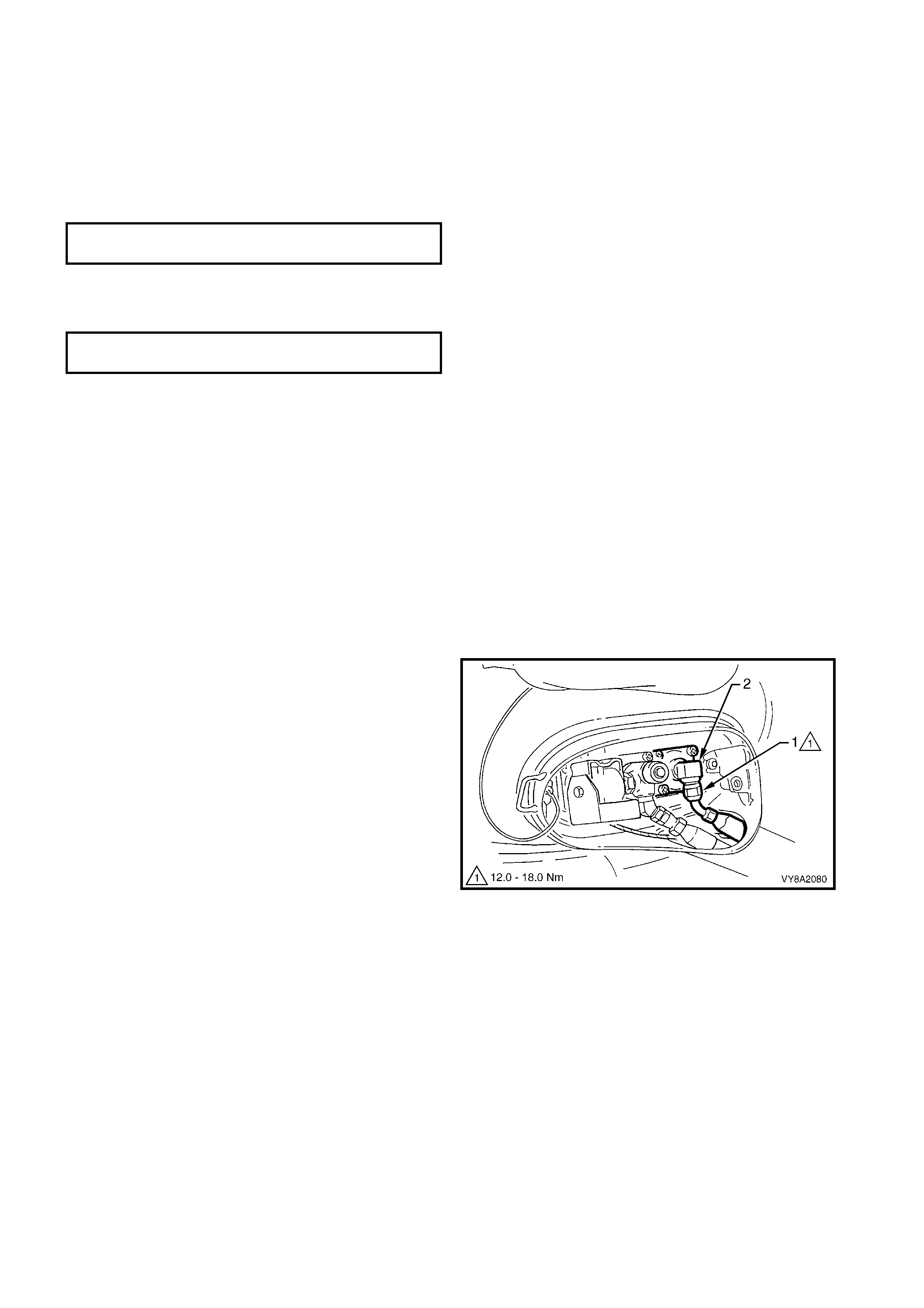

4. From within the wheelhouse, crack open the filler

line connector ( 1) while holding the connector pipe

and allow residual LPG to escape.

CAUTION: The filler line may contain LPG under

pressure.

5. Once all the LPG in the line has dispersed,

unscrew the filler line connector completely.

6. From within the vehicle, remove the nut (2) and

spacer (3) retaining the filler valve (4).

7. Prise the grommet (5) from the filler pocket and

carefully manoeuvre the filler valve and connector

pipe into the fuel filler pocket and remove.

8. If required, disconnect the connector pipe (6) from

the filler valve.

Figure 8A2-42

REINSTALL

Installation if the filler valve and connector pipe is the reverse of the removal procedure, noting the following:

1. If new mounting holes are required, us e the tem plate supplied with the new part. Carefully drill the holes and

apply paint to any bare metal.

2. Clean the mating threads on the filler line, connector pipe and filler valve.

3. Apply Loctite 577 sealant to the filler line, connector pipe and filler valve threads.

4. Tighten the filler valve retaining nut to the specified torque.

5. Tighten the filler line connectors to the specified torque.

6. Leak test the LPG system, refer to 3.3 LEAK TESTING.

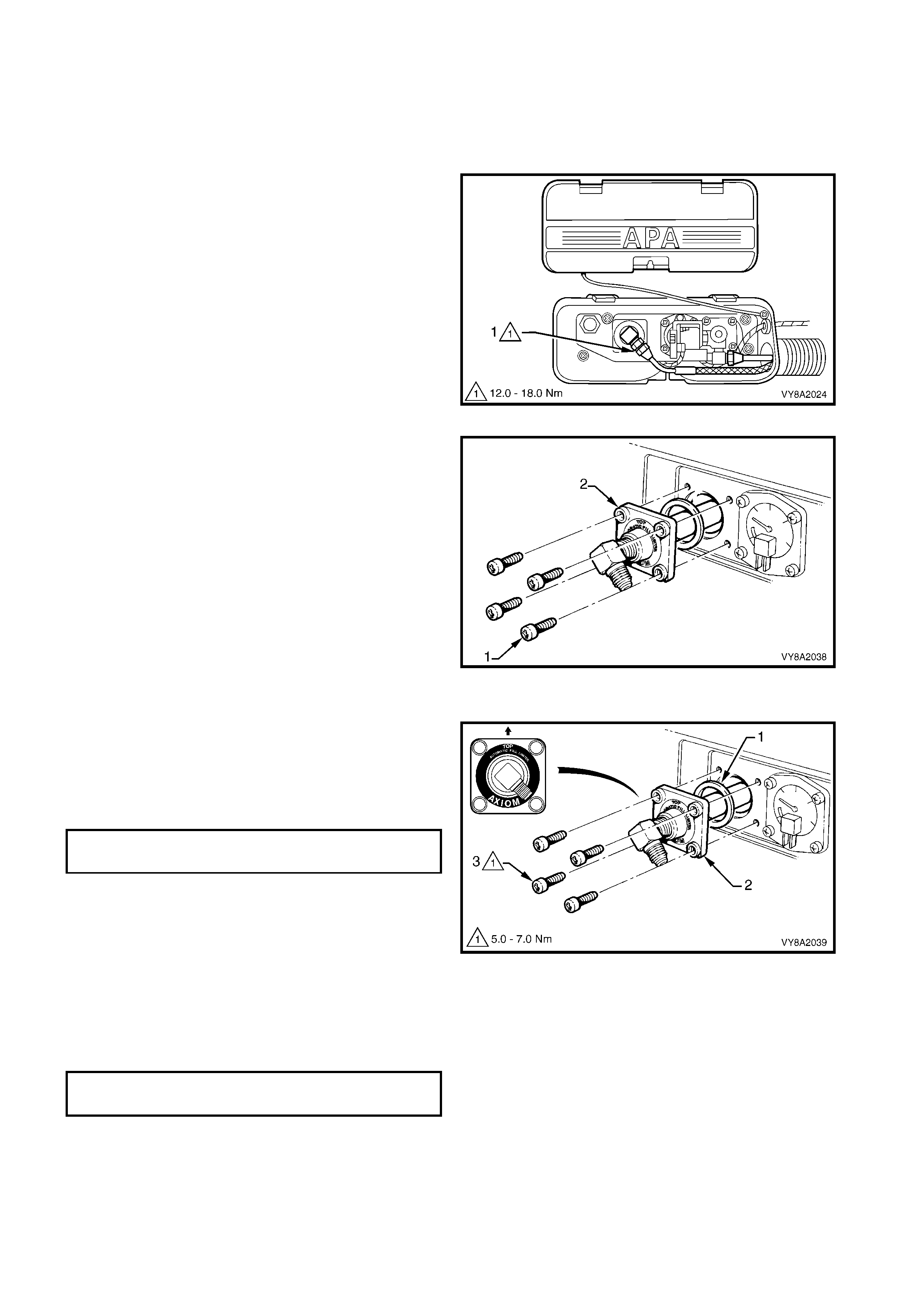

FILLER VALVE RETAINING NUT

TORQUE SPECIFICATION 50.0 – 60.0 Nm

CONNECTOR PIPE TO FILLER

LINE & FILLER VALVE

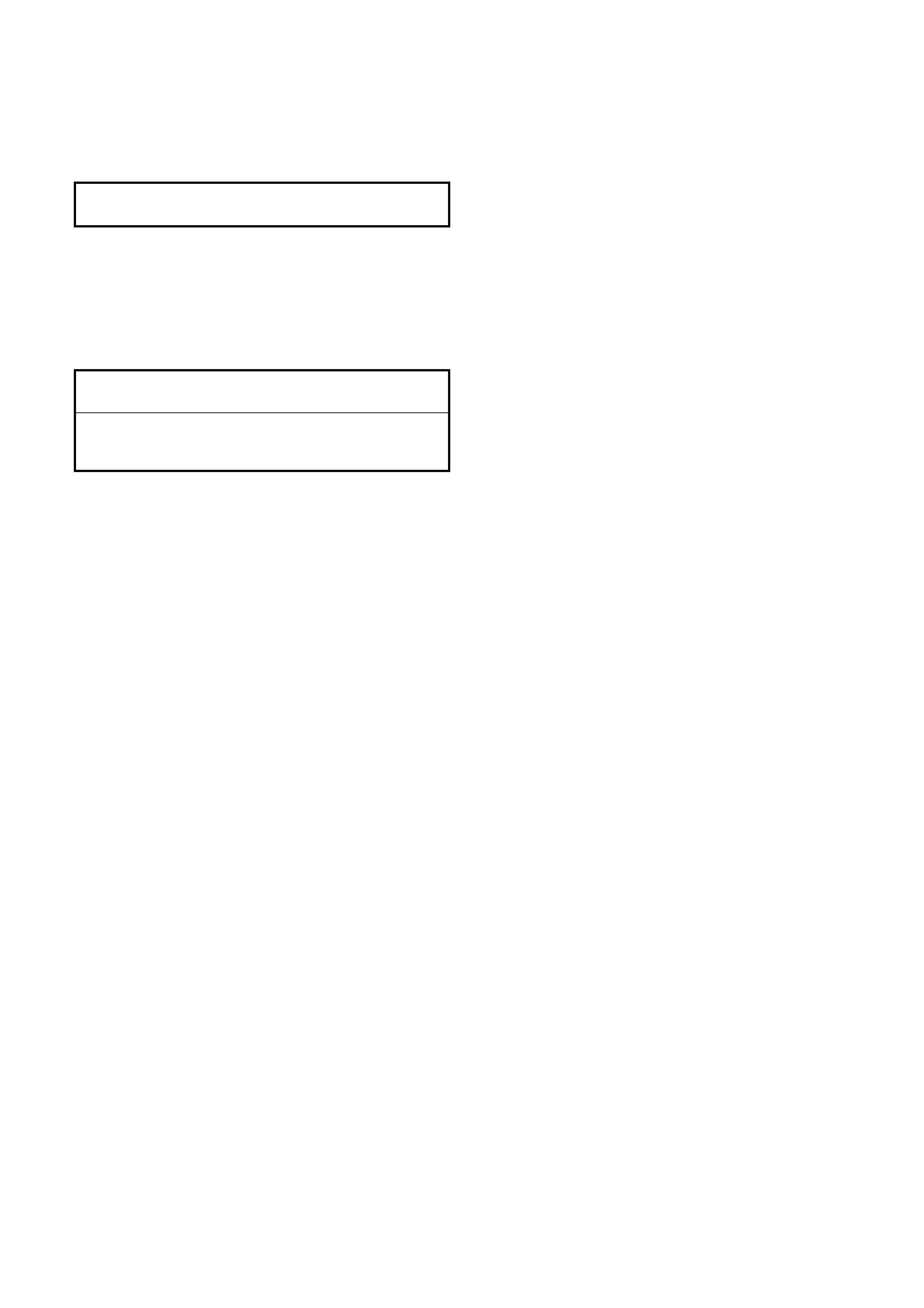

TORQUE SPECIFICATION 12.0 – 18.0 Nm

FILLER LINE TO FILLER VALVE

TORQUE SPECIFICATION 12.0 – 18.0 Nm

VENT TUBE HOSE CLAMP

TORQUE SPECIFICATION 2.0 – 3.0 Nm

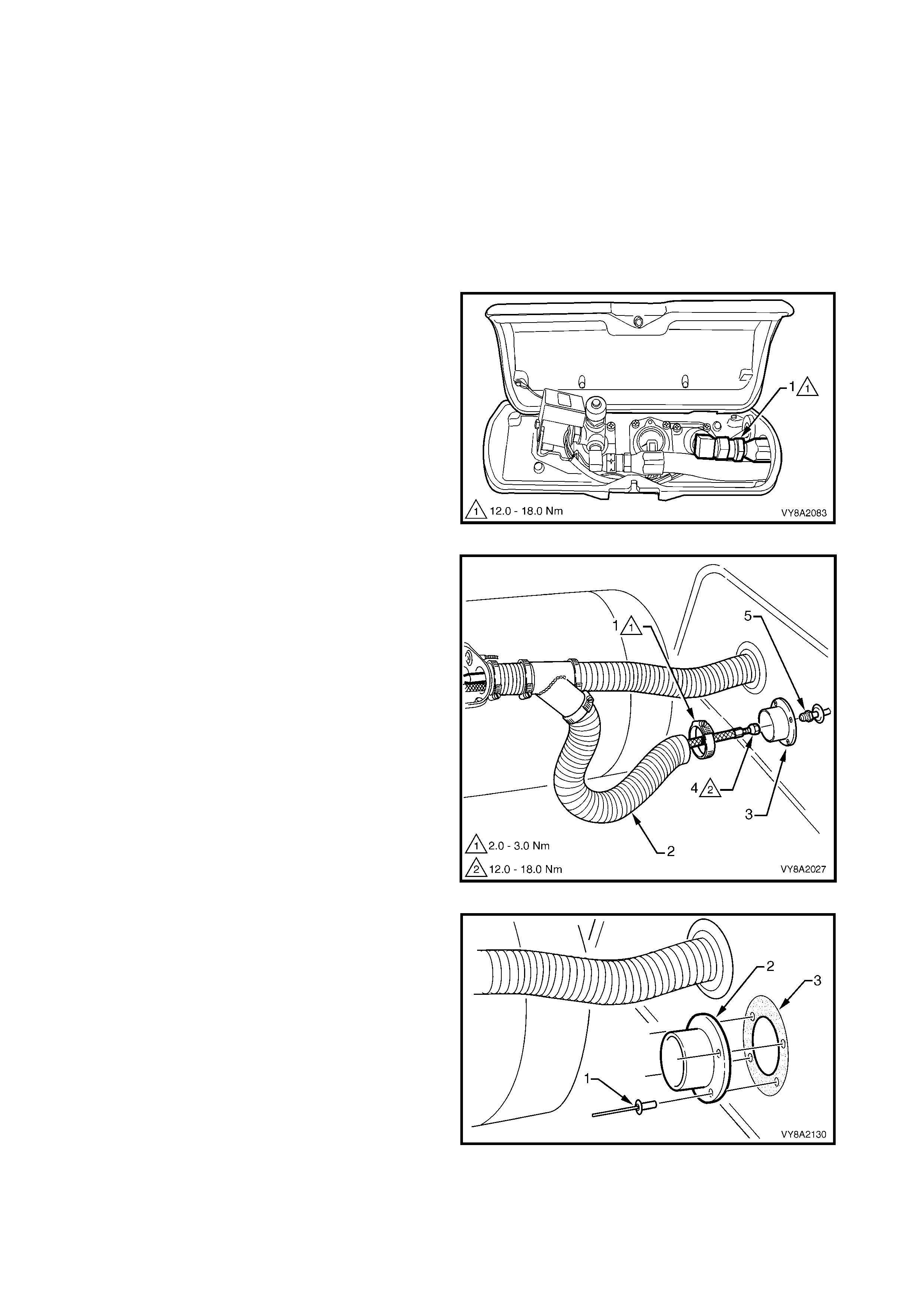

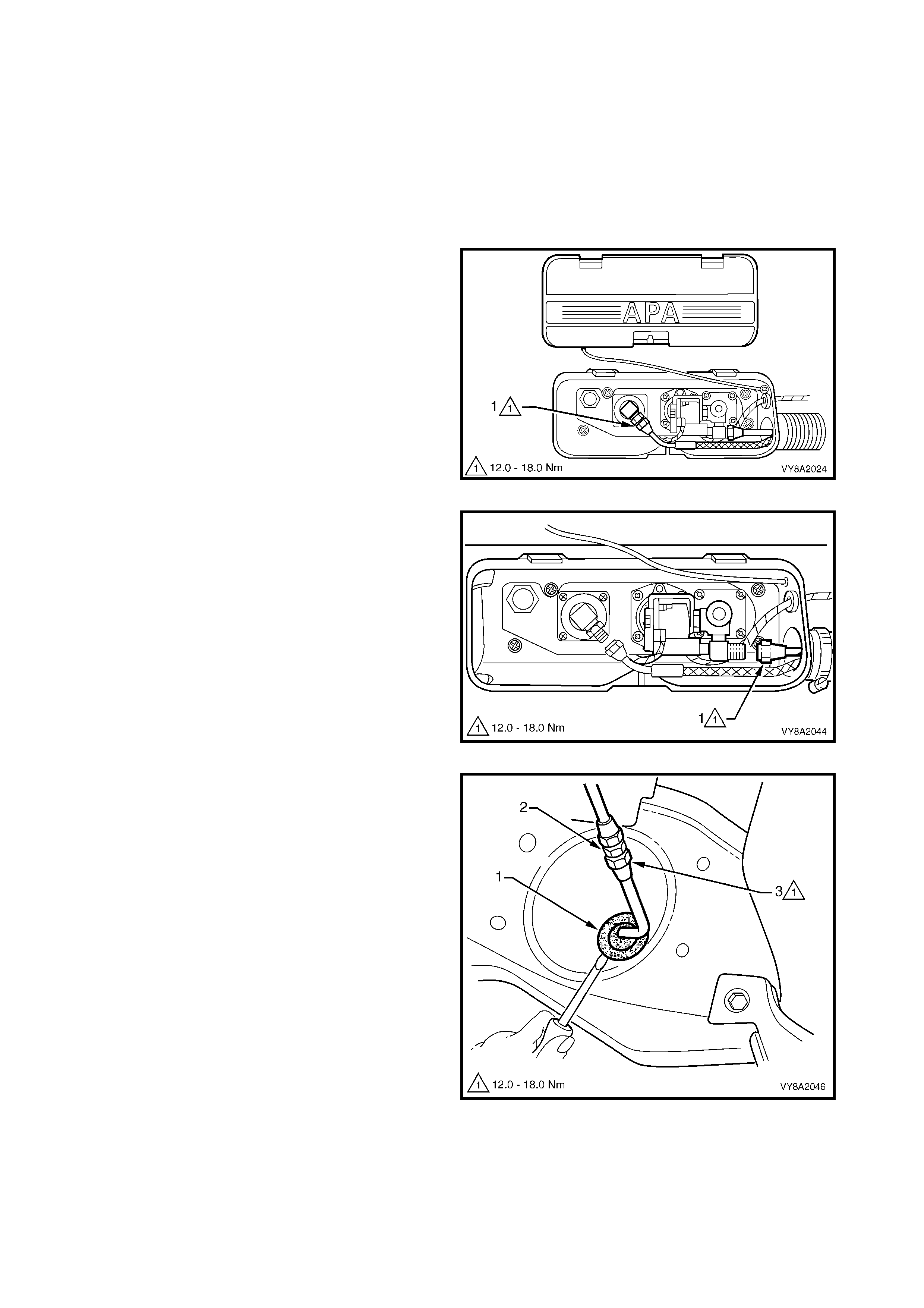

UTILITY

REMOVE

CAUTION: Ensure that there are no naked flames

or other sources of ignition in the vicinity.

1. Drain the service lines of LPG and note all

cautions, refer to 3.1 SERVICE LINE DRAINING.

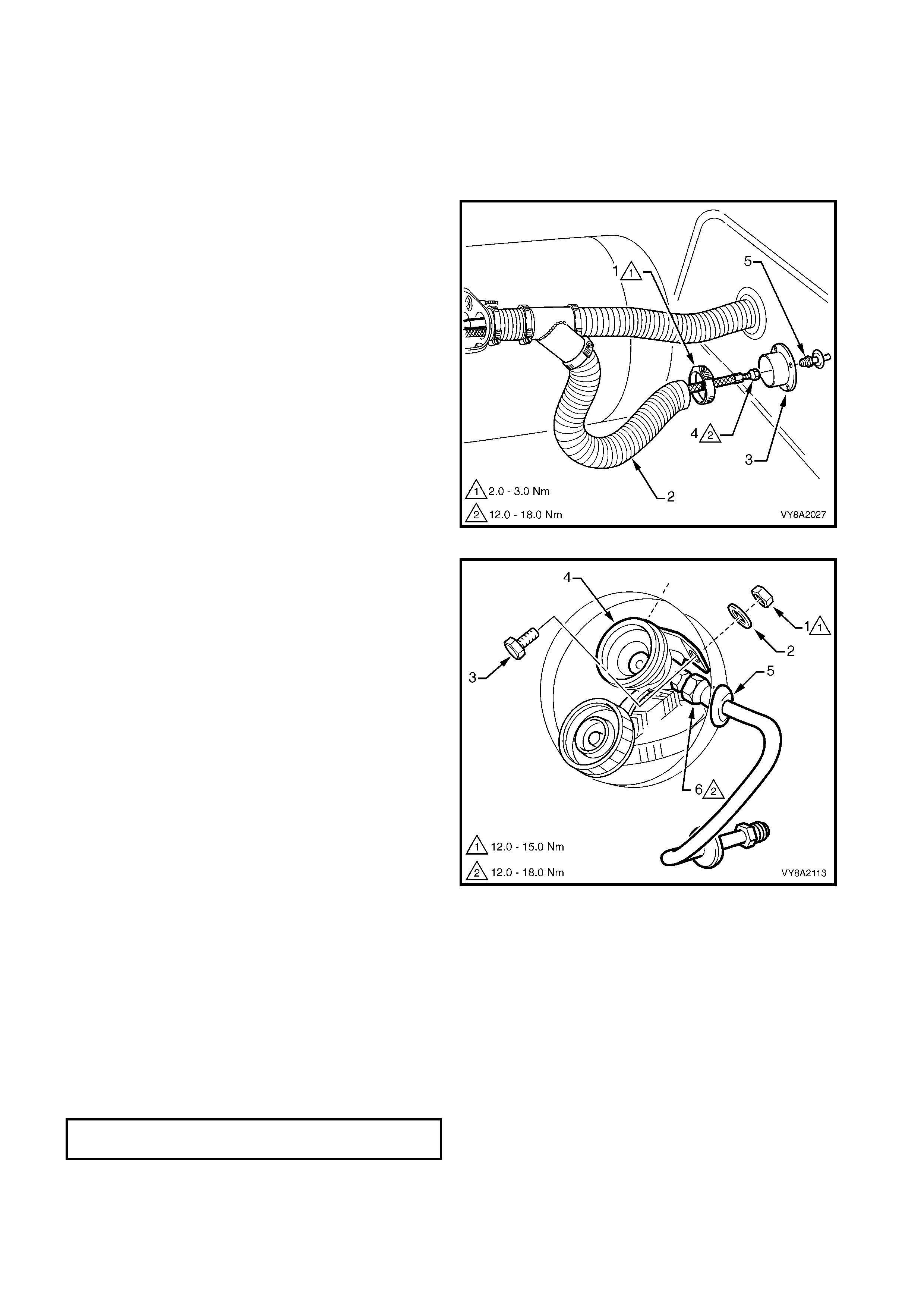

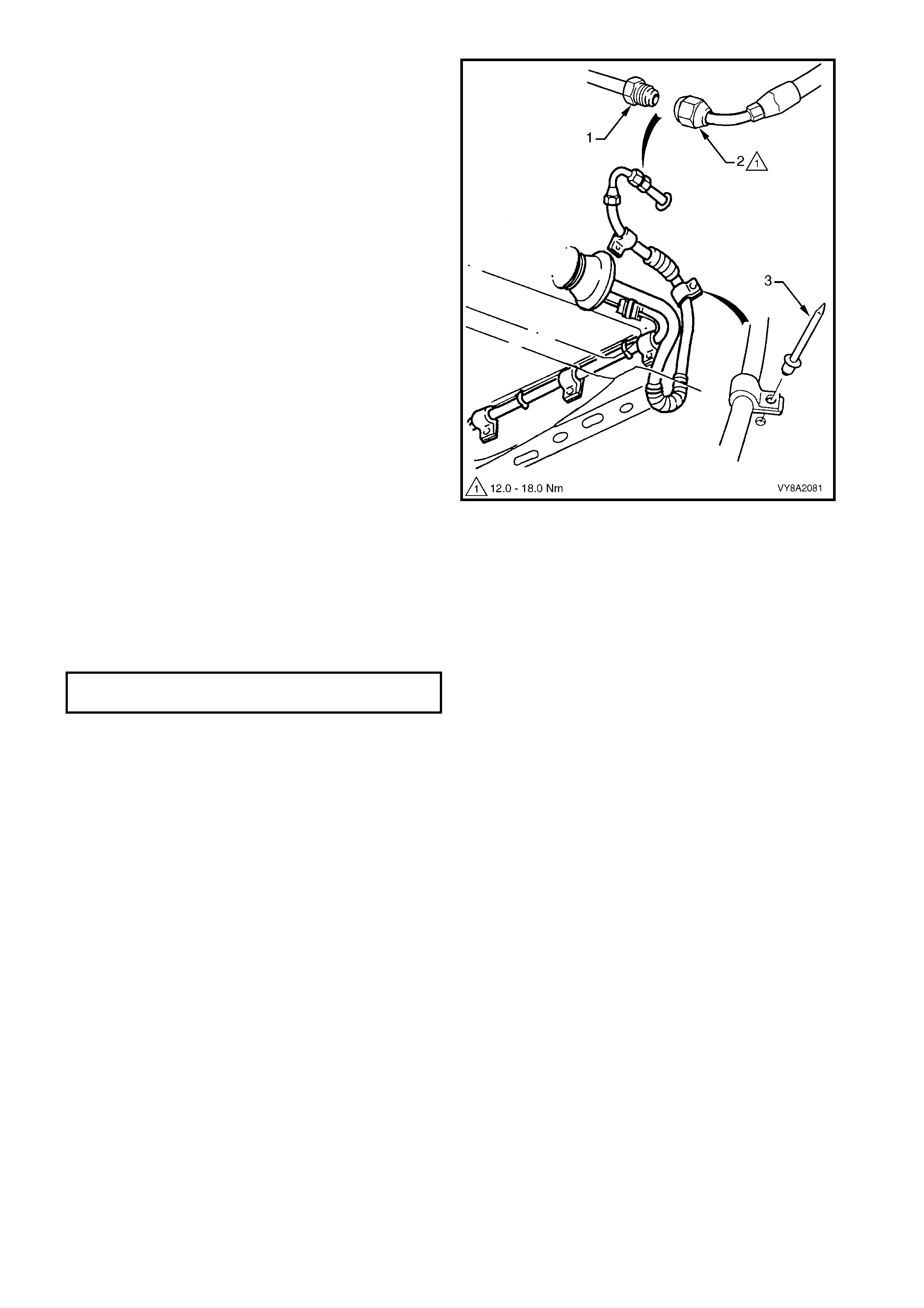

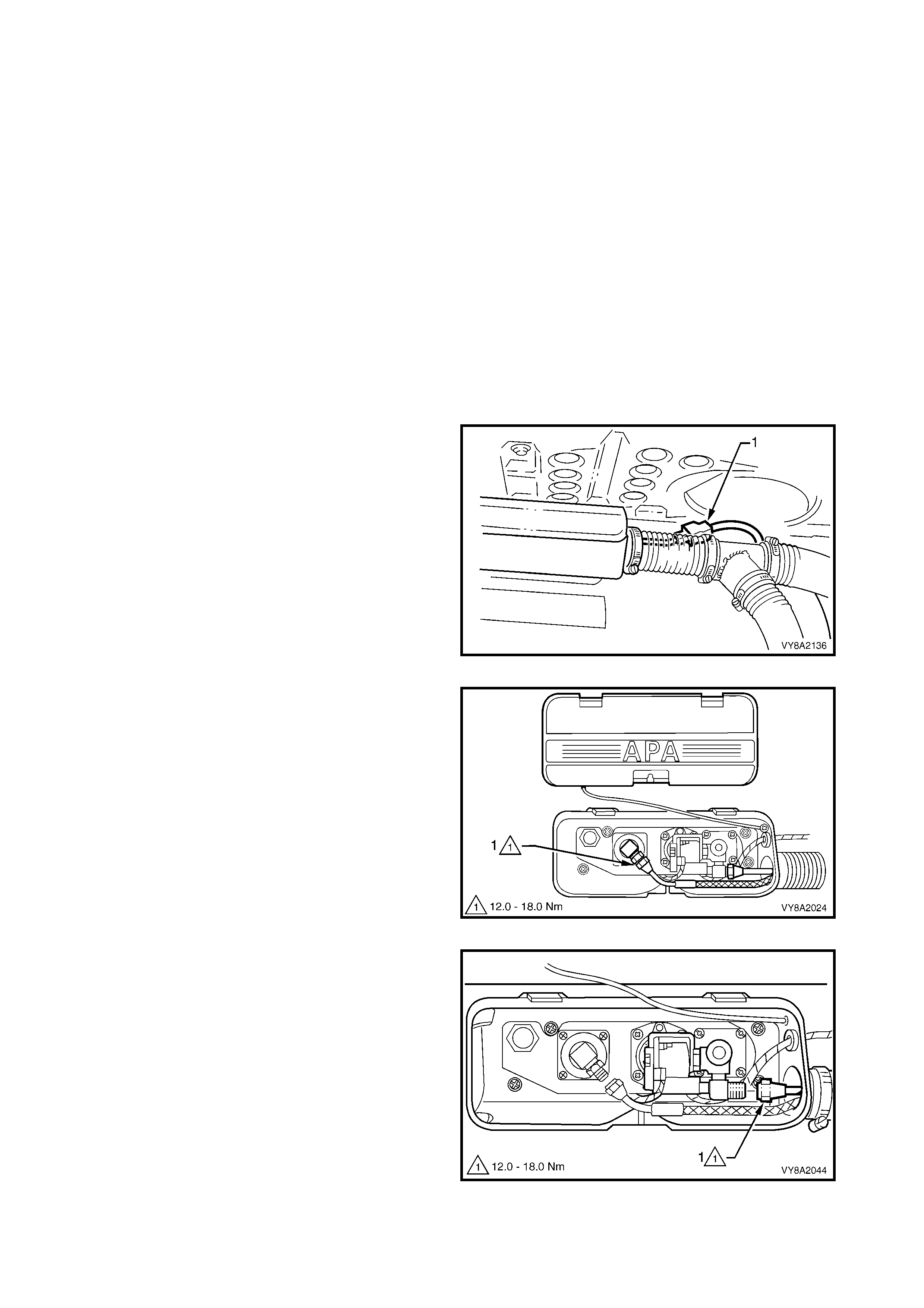

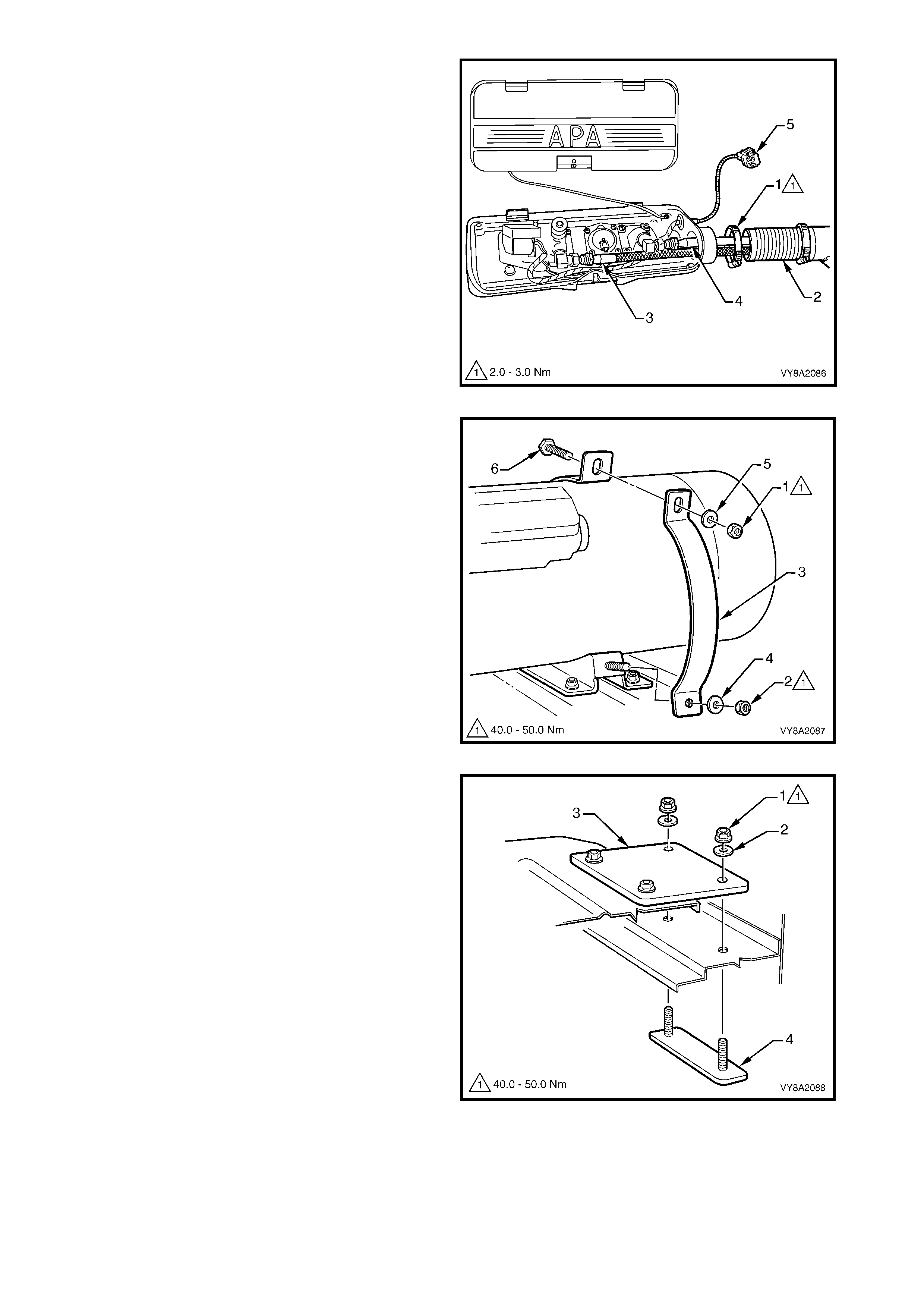

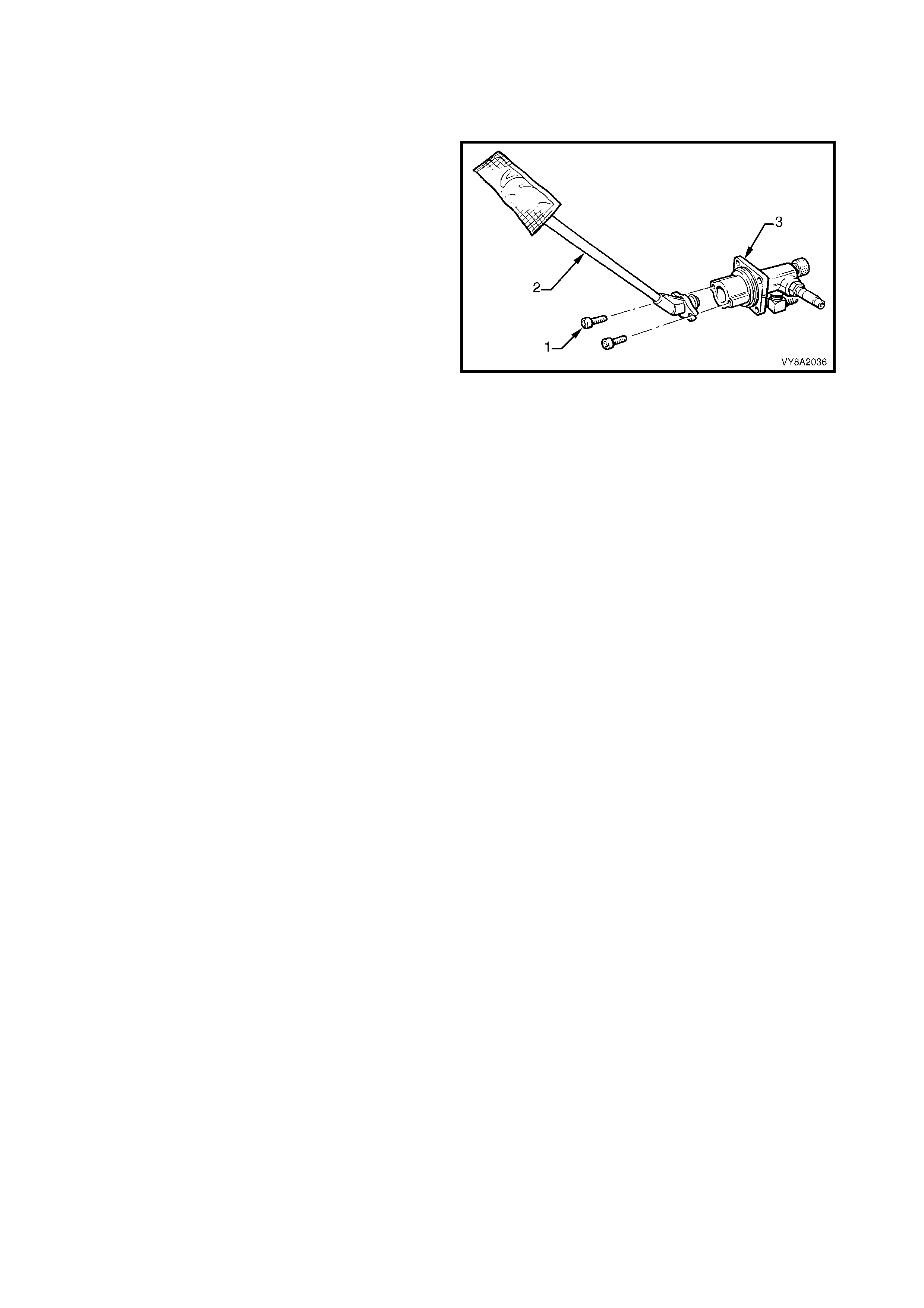

2. Loosen the hose clamp (1) securing the filler line

vent tube (2) to the vent tube flange (3).

3. Crack open the filler line connector (4) while

holding the connector pipe (5) and allow residual

LPG to escape.

CAUTION: The filler line may contain LPG under

pressure.

4. Once all the LPG in the line has dispersed,

unscrew the filler line connector completely.

5. Remove the inner side panel front cover, refer to

Section 1B, 2.8 INNER SIDE PANEL FRONT

COVER.

NOTE: A right-angle screwdriver may be required to

access the front screws.

6. Remove the fuel filler door and the fuel filler pipe

seal retainer, refer to Section 1A1, 4.3 FUEL

FILLER DOOR ASSEMBLY, UTILITY.

Figure 8A2-43

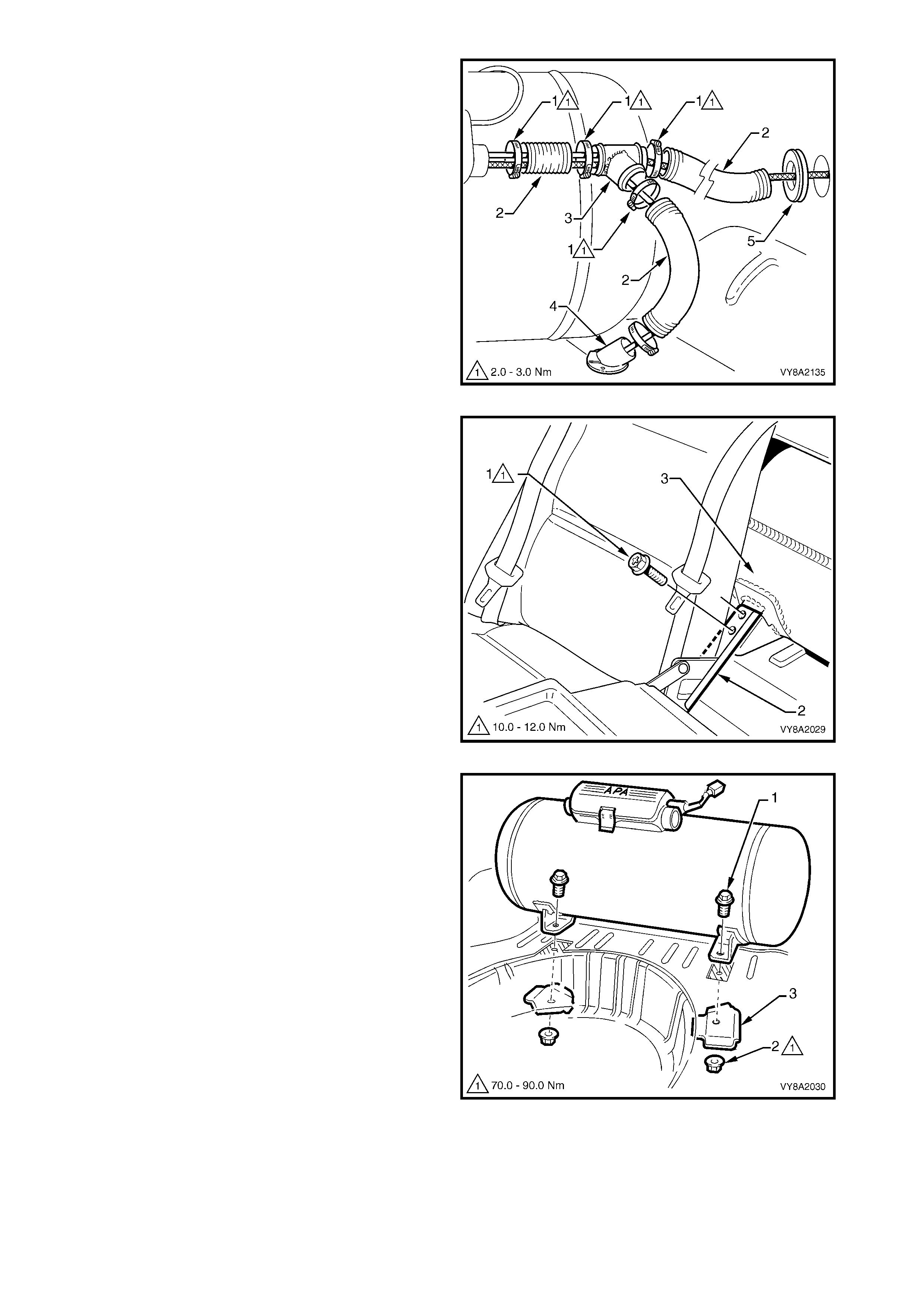

7. From within the vehicle, remove the nut (1) and

washer (2) while an assistant holds the screw (3),

two places, retaining the filler valve (4).

9. As required, fold the fuel filler pipe seal out of the

way and prise the grommet (5) from the filler

pocket.

10. Carefully manoeuvre the filler valve and connector

pipe into the fuel filler pocket and remove.

8. If required, disconnect the connector pipe (6) from

the filler valve.

Figure 8A2-44

REINSTALL

Installation of the filler valve and connector pipe is the reverse of the removal procedure, noting the following:

1. If new m ounting holes are r equired, use the tem plate supplied with the new part. Carefully drill the holes and

apply paint to any bare metal

2. If the filler pocket has been replaced and new mounting holes are required, use the template provided with

the new filler valve assembly. Drill holes as required and coat any bare metal with primer.

3. Clean the mating threads on the filler line, connector pipe and filler valve.

4. Apply Loctite 577 sealant to the filler line, connector pipe and filler valve threads.

5. Tighten the filler valve retaining nut to the specified torque.

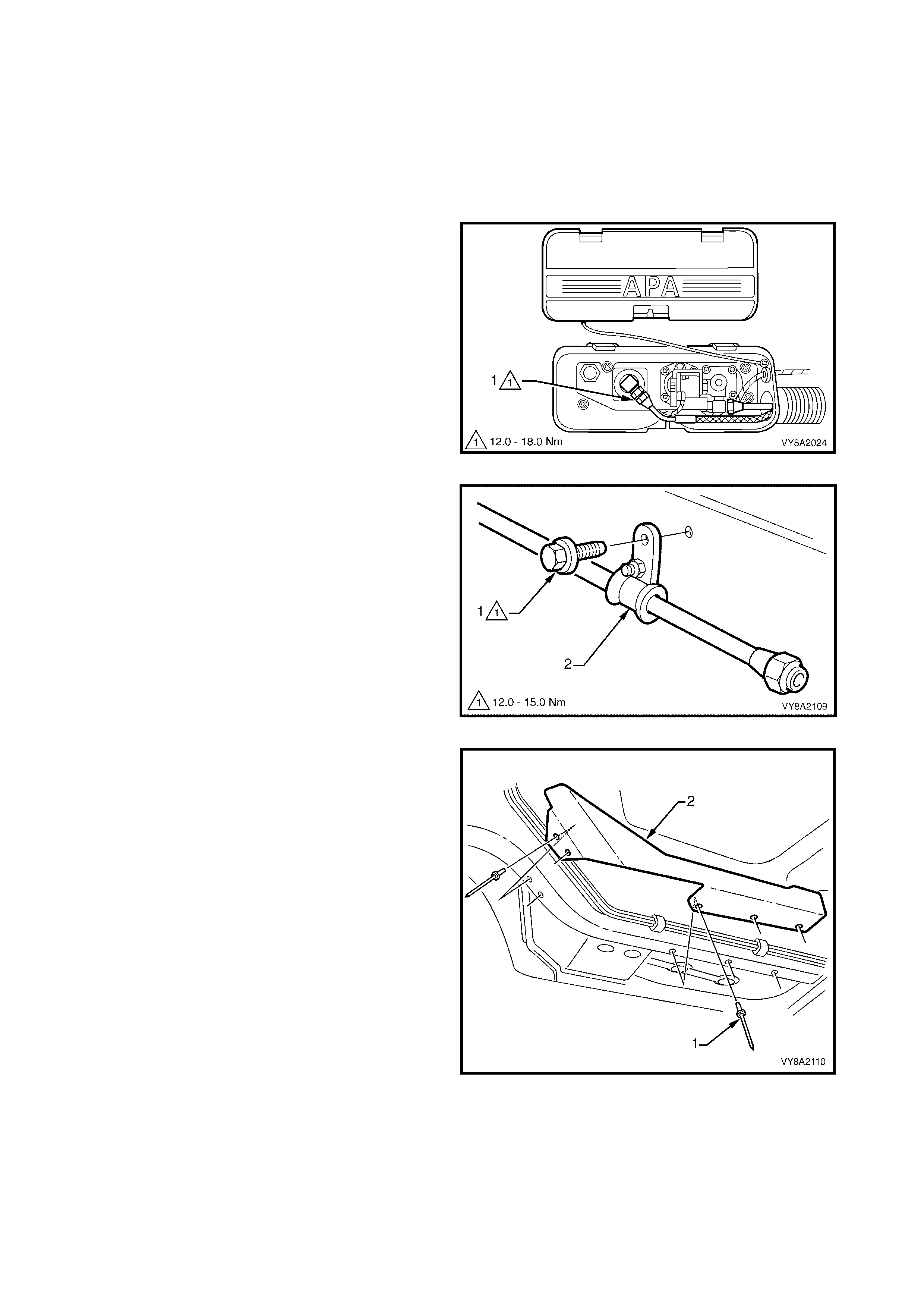

FILLER VALVE RETAINING NUT

TORQUE SPECIFICATION 12.0 – 15.0 Nm

6. Tighten the filler line connectors to the specified torque.

7. Leak test the LPG system, refer to 3.3 LEAK TESTING.

8. Reinstall the filler line vent tube and tighten the clamp to the specified torque.

CONNECTOR PIPE TO FILLER

VALVE & FILLER LINE

TORQUE SPECIFICATION 12.0 – 18.0 Nm

VENT TUBE HOSE CLAMP

TORQUE SPECIFICATION 2.0 – 3.0 Nm

3.5 FILLER LINE

LT Section – AA-650R

SEDAN

REMOVE

CAUTION: Ensure that there are no naked flames

or other sources of ignition in the vicinity.

1. Drain the service lines of LPG and note all

cautions, refer to 3.1 SERVICE LINE DRAINING.

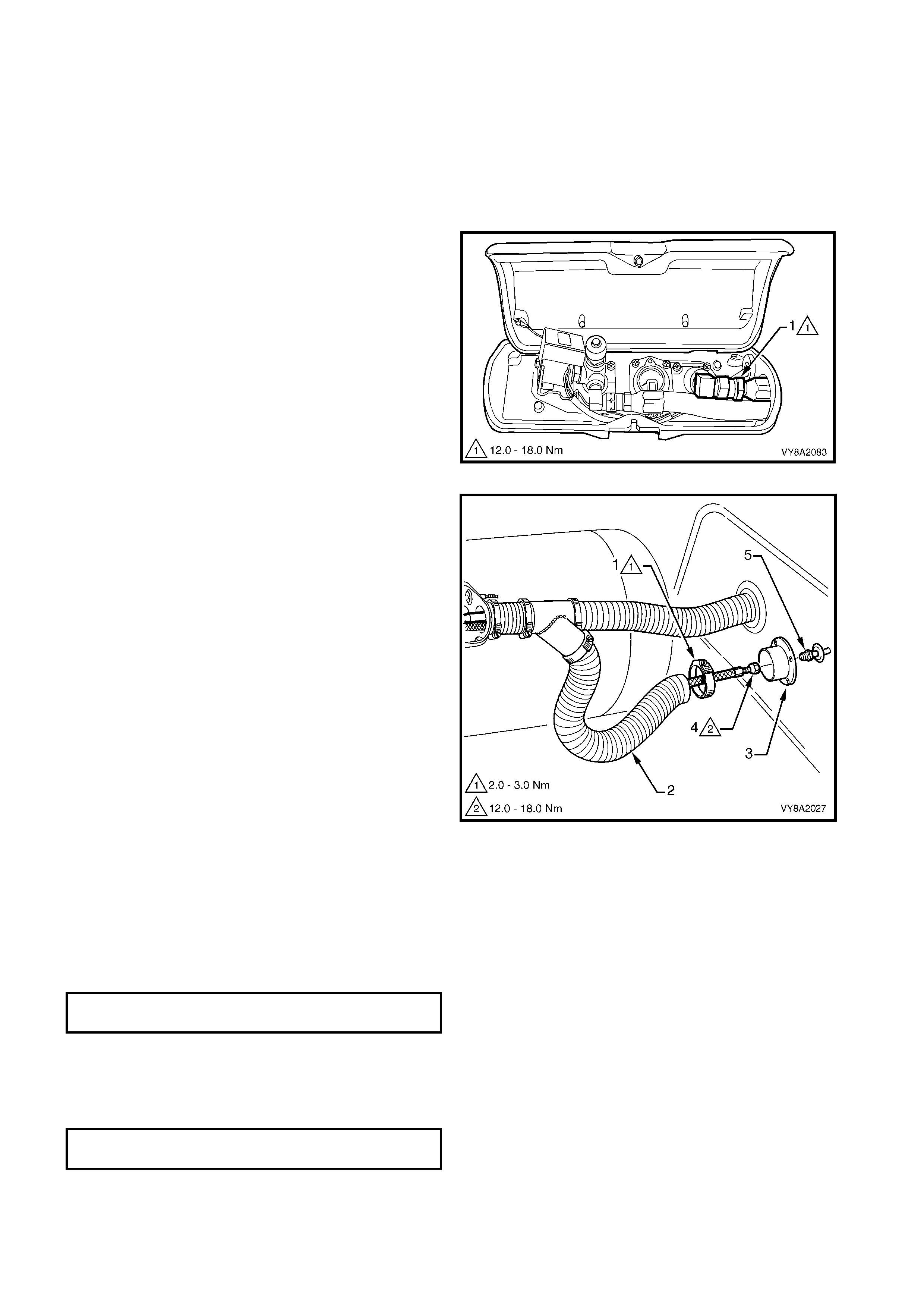

2. From within the LPG valve box, crack open the

filler line to AFL elbow connector (1) while holding

the AFL elbow and allow residual LPG to escape.

CAUTION: The filler line will contain LPG under

pressure.

3. Once all the LPG in the line has dispersed,

unscrew the filler line connector completely from

the AFL elbow.

4. Disconnect the filler line from the AFL elbow

connector.

5. Remove the right-hand quarter inner rear side

carpet, refer to 2.17 QUARTER INNER REAR

SIDE CARPET in Section 1A8.

Figure 8A2-45

6. From within the rear c om partm ent, loosen the vent

tube clamp (1) and pull the vent tube (2) from the

filler valve flange (3).

7. Unscrew the filler line connector (4) from the filler

valve flange.

Figure 8A2-46

8. Loosen the vent tube clamp (1) and pull the vent

tube (2) from the vent tube joiner (3).

9. Withdraw the filler line through the vent tube and

remove.

Figure 8A2-47

REINSTALL

Reinstallation of the filler line is the reverse of the removal procedure, noting the following:

1. Clean the mating threads on the LPG tank AFL elbow, filler line and filler valve connector pipe.

2. Apply Loctite 577 sealant to the LPG tank AFL elbow and filler pipe connector threads, ensuring that the

flared surfaces are free of sealant and contaminants.

3. Tighten the filler line connections to the specified torque.

4. Leak test the LPG system, refer to 3.3 LEAK TESTING.

5. Reinstall the filler line vent tube and tighten the clamp to the specified torque.

6. Reinstall the LPG tank box cover.

WAGON

REMOVE

CAUTION: Ensure that there are no naked flames

or other sources of ignition in the vicinity.

1. Drain the service lines of LPG and note all

cautions, refer to 3.1 SERVICE LINE DRAINING.

2. De-pressurise the fuel (petrol) system, refer to

Section 6C1 POWERTRAIN MANAGEMENT.

3. Remove the fuel (petrol) tank assembly, refer to

Section 8A FUEL TANK.

4. From within the LPG tank valve box, crack open

the filler line hose to AFL elbow connector (1) while

holding the AFL elbow (2) and allow residual LPG

to escape.

CAUTION: The filler line will contain LPG under

pressure.

5. Once all the LPG in the line has dispersed, remove

the filler line hose connector completely from the

AFL elbow.

Figure 8A2-48

FILLER LINE CONNECTORS

TORQUE SPECIFICATION 12.0 – 18.0 Nm

VENT TUBE HOSE CLAMP

TORQUE SPECIFICATION 2.0 – 3.0 Nm

6. From underneath the vehicle, while holding the

filler valve connecting pipe (1) from turning,

disconnect the filler line hose (2).

7. Us ing a suitable sized drill bit, drill into the head of

the two filler line hose retaining rivets (3) and

remove the filler line hose.

8. Using a suitable size pin-punch and hammer,

knock out remains of the rivets.

Figure 8A2-49

REINSTALL

Reinstallation of the filler line is the reverse of removal, noting the following:

1. Clean the mating threads of the LPG tank AFL elbow, filler line, and filler valve connecting pipe.

2. Apply Loctite 577 sealant to the LPG tank AFL elbow and filler pipe connector threads, ensuring that the

flared surfaces are free of sealant and contaminants.

3. Tighten the filler line connections to the specified torque.

4. Secure the filler line hose using a new rivets, before the fuel (petrol) tank is reinstalled.

5. Before starting the vehicle or opening the manual service valve, perform a fuel (petrol) system leak test,

refer to Section 6C1 POWERTRAIN MANAGEMENT - V6 ENGINE.

6. Leak test LPG system, refer to 3.3 LEAK TESTING.

7. Reinstall the LPG tank valve box cover.

FILLER LINE CONNECTORS

TORQUE SPECIFICATION 12.0 – 18.0 Nm

UTILITY

REMOVE

CAUTION: Ensure that there are no naked flames

or other sources of ignition in the vicinity.

1. Drain the service lines of LPG and note all

cautions, refer to 3.1 SERVICE LINE DRAINING.

2. Remove the LPG tank cover, refer to

3.6 LPG TANK, UTILITY.

3. From within the LPG valve box, crack open the

filler line to AFL elbow connector (1) while holding

AFL elbow and allow residual LPG to escape.

CAUTION: The filler line will contain LPG under

pressure.

4. Once all the LPG in the line has dispersed, remove

the filler line connector completely from the AFL

elbow.

Figure 8A2-50

4. Loosen the hose clamp (1) securing the filler line

vent tube (2) to the vent tube flange (3).

5. Disconnect the filler line (4) from the filler pipe (5)

and remove the LPG filler line from within vent

tube.

Figure 8A2-51

REINSTALL

Reinstallation if the filler line is the reverse of the removal procedure, noting the following:

1. Clean the mating threads of the LPG tank AFL elbow, filler line and filler valve connecting pipe.

2. Apply Loctite 577 sealant to the LPG tank AFL elbow and filler pipe connector threads, ensuring that the

flared surfaces are free of sealant and contaminants.

3. Tighten the filler line connections to the specified torque.

4. Leak test the LPG system, refer to 3.3 LEAK TESTING.

5. Apply a commercially available silicone sealer to the vent tube mating surfaces.

6. Tighten the vent tube clamps to the specified torque.

7. Reinstall the LPG tank box cover.

FILLER LINE CONNECTOR

TORQUE SPECIFICATION 12.0 – 18.0 Nm

VENT TUBE HOSE CLAMP

TORQUE SPECIFICATION 2.0 – 3.0 Nm

3.6 LPG TANK

LT Section – AA-650Q

SEDAN

REMOVE

CAUTION 1: After any valve or component has

been removed and reinstalled to the LPG tank, the

LPG tank must be pressure and leak tested in

accordance with current Australian Standard

AS 2030-1 and / or the laws of the State in which

the vehicle is registered, before the LPG tank is

refitted to the vehicle.

CAUT ION 2: Ensure th at there are no naked flames

or other sources of ignition in the vicinity.

1. Drain the service lines of LPG and note all

cautions, refer to 3.1 SERVICE LINE DRAINING.

2. Unload the LPG tank of LPG, refer to

3.2 LPG TANK UNLOADING.

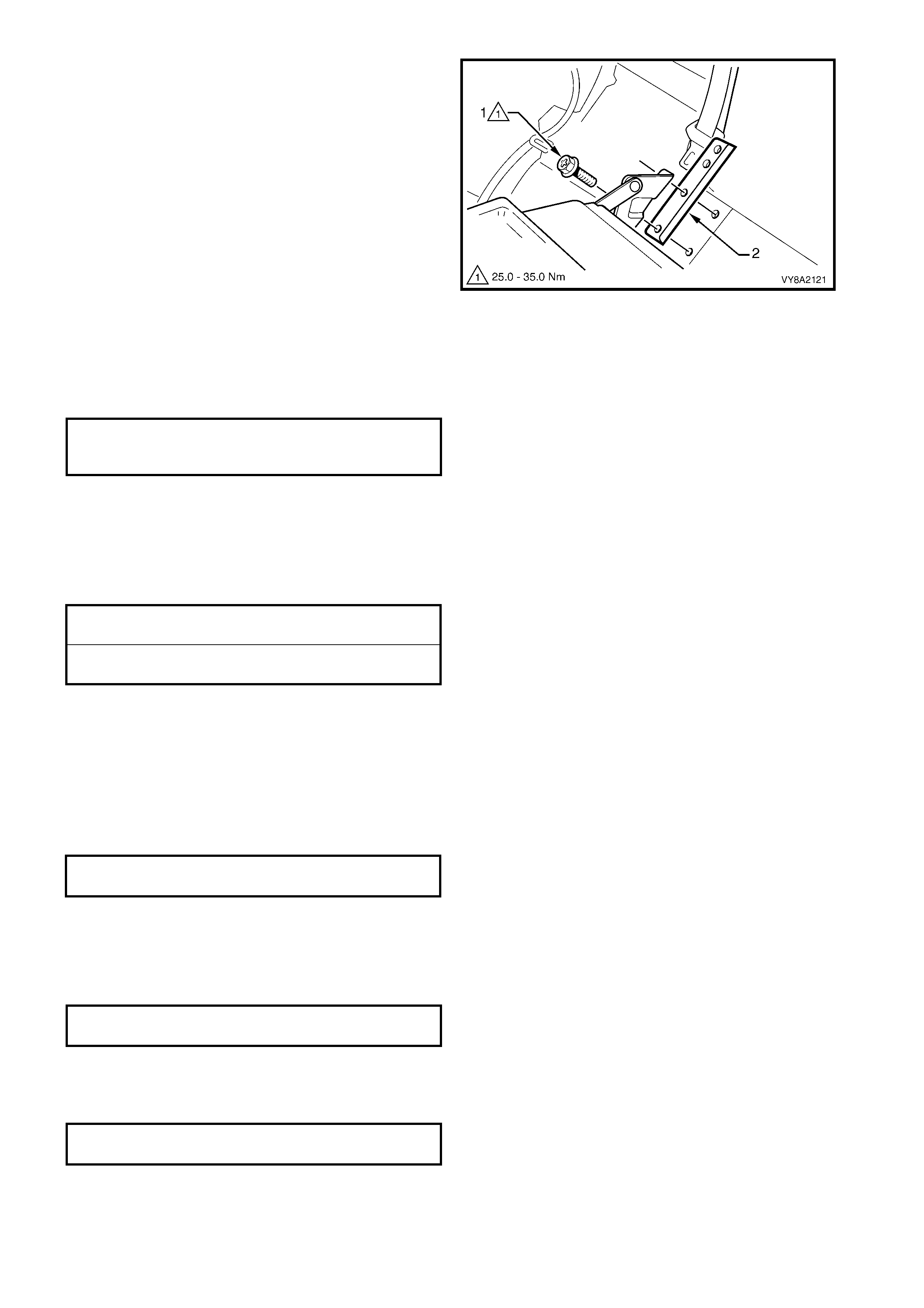

3. Disconnect the LPG body harness connector (1)

from the LPG tank harness connector.

Figure 8A2-52

4. From within the LPG valve box, crack open the

filler line to AFL elbow connector (1) while holding

the AFL elbow and allow residual LPG to escape.

CAUTION: The filler line will contain LPG under

pressure.

5. Once all the LPG in the line has dispersed, remove

the filler line connector completely from the AFL

elbow.

Figure 8A2-53

11. From within the LPG tank valve box, unscrew the

rear service line connector (1) from the manual

service valve assembly.

Figure 8A2-54

12. As required, rem ove the hose clamps (1) securing

the vent tubes ( 2) to the valve box , vent tube j oiner

(3) or floor flange (4).

13. W ithdr aw the filler and se rvice lines fr om the valve

box.

14. If required withdraw the vent tube from the

grommet (5) and remove.

Figure 8A2-55

15. Open the rear seat centre back and remove the

top two retaining screws (1) from the LPG tank

retaining bracket (2) on each side of the vehicle.

Figure 8A2-56

16. Fold the rear compartment carpet away from the

LPG tank rear mounting points.

17. With the aid of an assistant to hold the LPG tank

retaining scr ew (1), rem ove the LPG tank retaining

nut (2) and reinforcement plate (3) from beneath

the each side of the vehicle.

18. With help f r om the assis tant, remove the LPG tank

from the rear compartment.

Figure 8A2-57

19. If required, remove the LPG tank retaining bracket:

a. Remove the rear seat back assembly, refer to

Section 1A7, 6.3 REAR SEAT-BACK

ASSEMBLY.

b. Remove the two retaining screws (1) attaching

the rear seat back centre hinge and the LPG

tank retaining bracket (2) to the vehicle and

remove the bracket from behind the hinge.

c. Repeat for the opposite side if required.

Figure 8A2-58

REINSTALL

Installation of the LPG tank is the reverse of the removal procedure, noting the following:

1. If removed, install the front tank mounting brackets and rear seat-back hinges. Tighten the screws to the

specified torque.

2. If the floor panel, etc. has been replaced and new mounting holes are required, seat the tank to the front

mounting brackets and use the tank as a template. Drill holes as required and coat any bare metal with

primer.

3. Ensure the two LPG tank reinforcement plates are installed and all fasteners are tightened to the correct

specified torque.

4. Clean the mating threads on the manual service valve assembly, intermediate to rear service line joiner,

both rear service line connectors, AFL valve and filler line connector.

5. Apply Loctite 577 sealant to the intermediate to rear service line joiner threads, ensuring that the flared

surfaces are free of sealant and contaminants.

6. Assemble the rear service connector to intermediate to rear service line joiner and to the manual service

valve assembly.

7. Tighten both rear service line connectors to the specified torque.

8. Apply Loctite 577 sealant to the LPG tank AFL elbow threads, ensuring that flared surfaces are free of

sealant and contaminants.

9. Install the filler line c onnector to the LPG tank AF L elbow and tighten the filler line c onnector to the s pecif ied

torque.

10. Leak test the LPG system, refer to 3.3 LEAK TESTING.

11. Reinstall the vent tube(s) as required and tighten the clamp(s) to the specified torque.

12. Reinstall the LPG tank box cover

FRO NT LPG TANK R ETAINING

SCREW TORQUE SPECIFICATION 10.0 – 12.0 Nm

REAR LPG TANK RETAINING NUT

TORQUE SPECIFICATION 70.0 – 90.0 Nm

REAR SERVICE LINE CONNECTOR

TORQUE SPECIFICATION 12.0 – 18.0 Nm

FILLER LINE CONNECTOR TO AFL

ELBOW TORQUE SPECIFICATION 12.0 – 18.0 Nm

FRONT LPG TANK MOUNTING

BRACKET RETAINING SCREW

TORQUE SPECIFICATION 25.0 – 35.0 Nm

VENT TUBE HOSE CLAMP

TORQUE SPECIFICATION 2.0 – 3.0 Nm

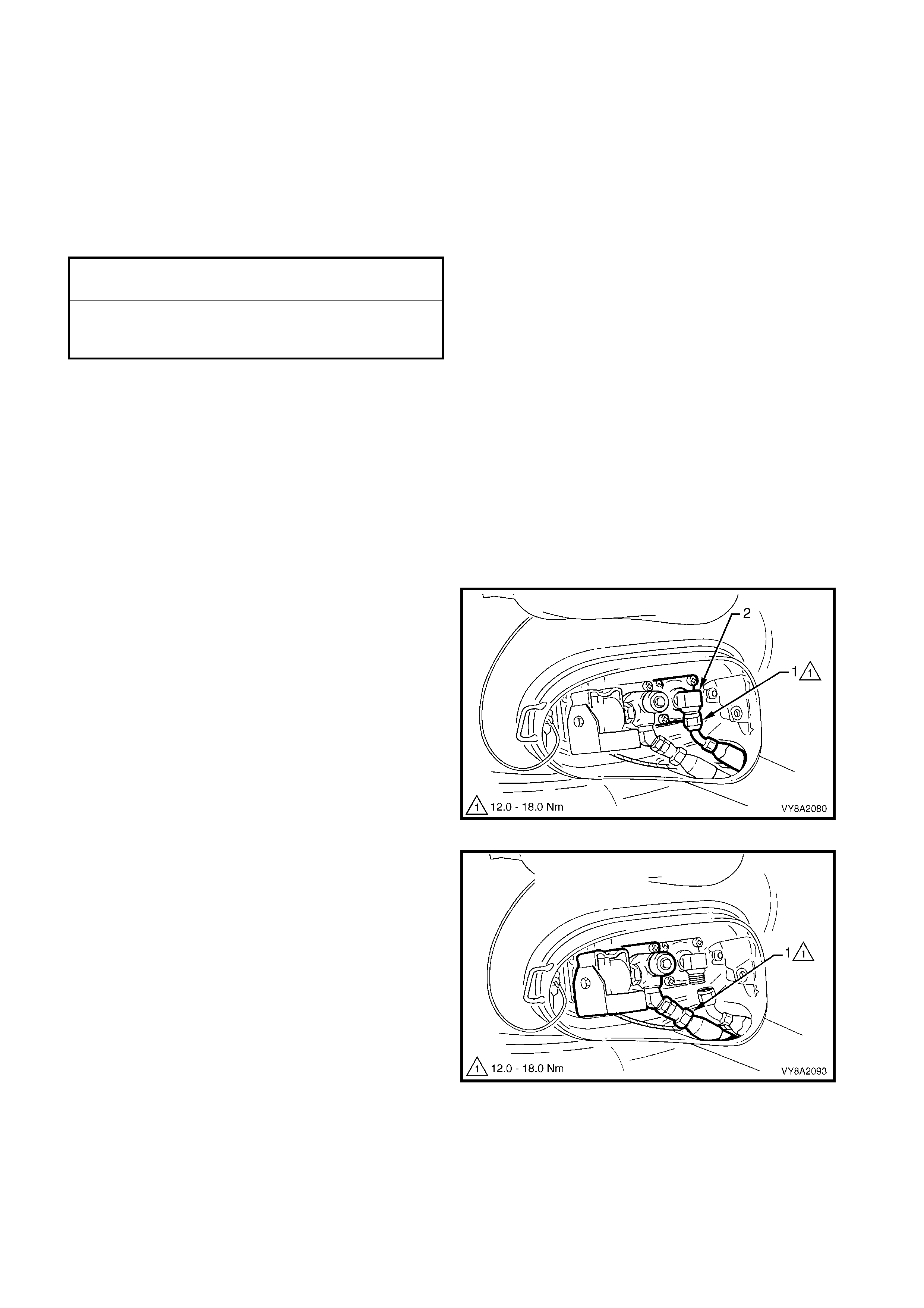

WAGON

REMOVE

CAUTION 1: After any valve or component has

been removed and reinstalled to the LPG tank, the

LPG tank must be pressure and leak tested in

accordance with current Australian Standard

AS 2030-1 and / or the laws of the State in which

the vehicle is registered, before the LPG tank is

refitted to the vehicle.

CAUT ION 2: Ensure th at there are no naked flames

or other sources of ignition in the vicinity.

1. Remove the rear compartment floor carpet, refer

to Section 1A8, 3.21 REAR COMPARTMENT

FLOOR CARPET ASSEMBLY AND SPARE

WHEEL COVER, WITH LPG.

2. Drain the service lines of LPG and note all

cautions, refer to 3.1 SERVICE LINE DRAINING.

3. Unload the LPG tank of LPG, refer to

3.2 LPG TANK UNLOADING.

NOTE: The service line will be disconnected at this

step.

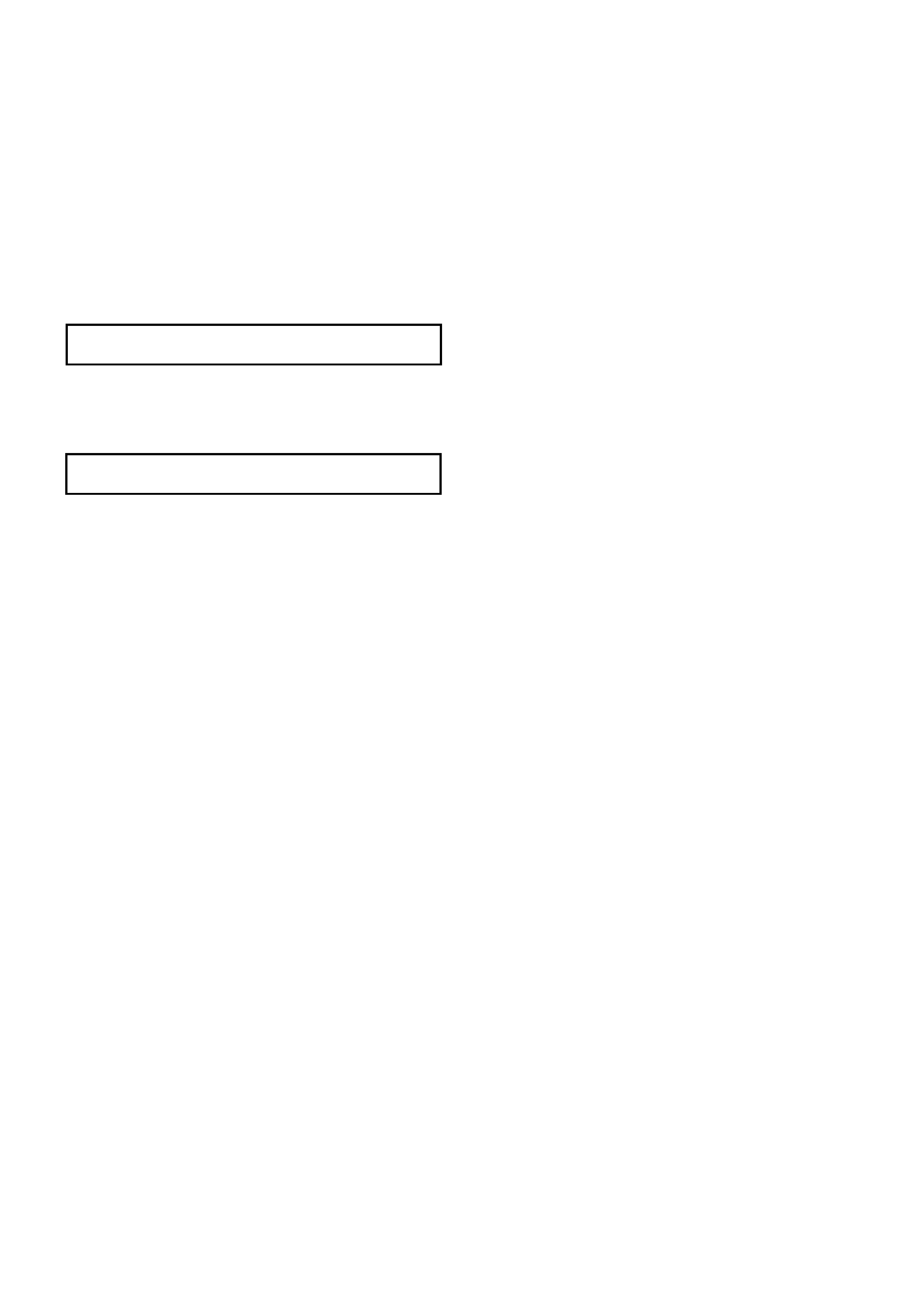

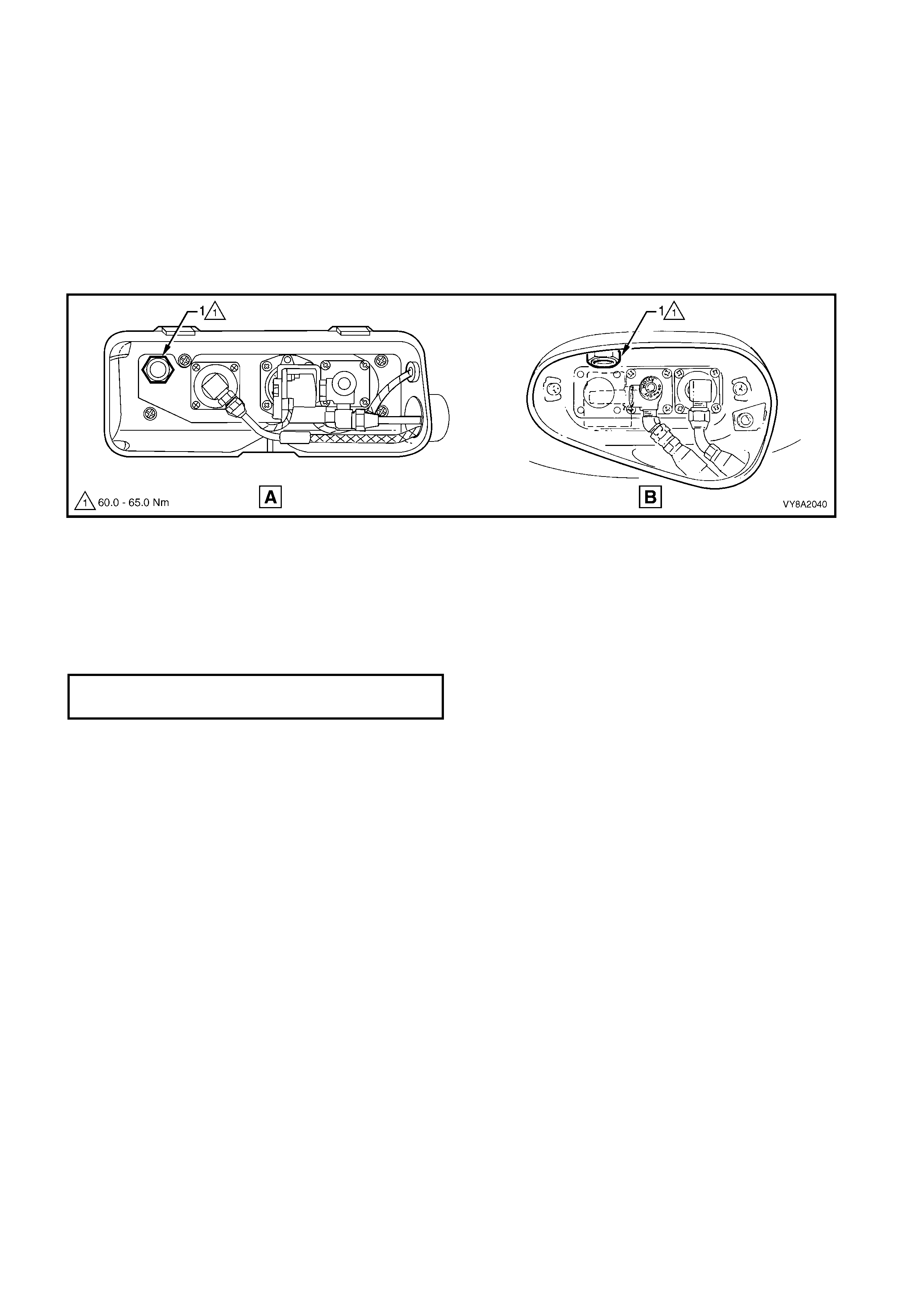

4. Disconnect the LPG tank harness wiring connector

(1) from underneath the vehicle.

Figure 8A2-59

5. From within the LPG valve box, crack open the

filler line to AFL elbow connector (1) while holding

the AFL elbow and allow residual LPG to escape.

CAUTION: The filler line will contain LPG under

pressure.

6. Once all the LPG in the line has dispersed, remove

the filler line connector completely from the AFL

elbow.

Figure 8A2-60

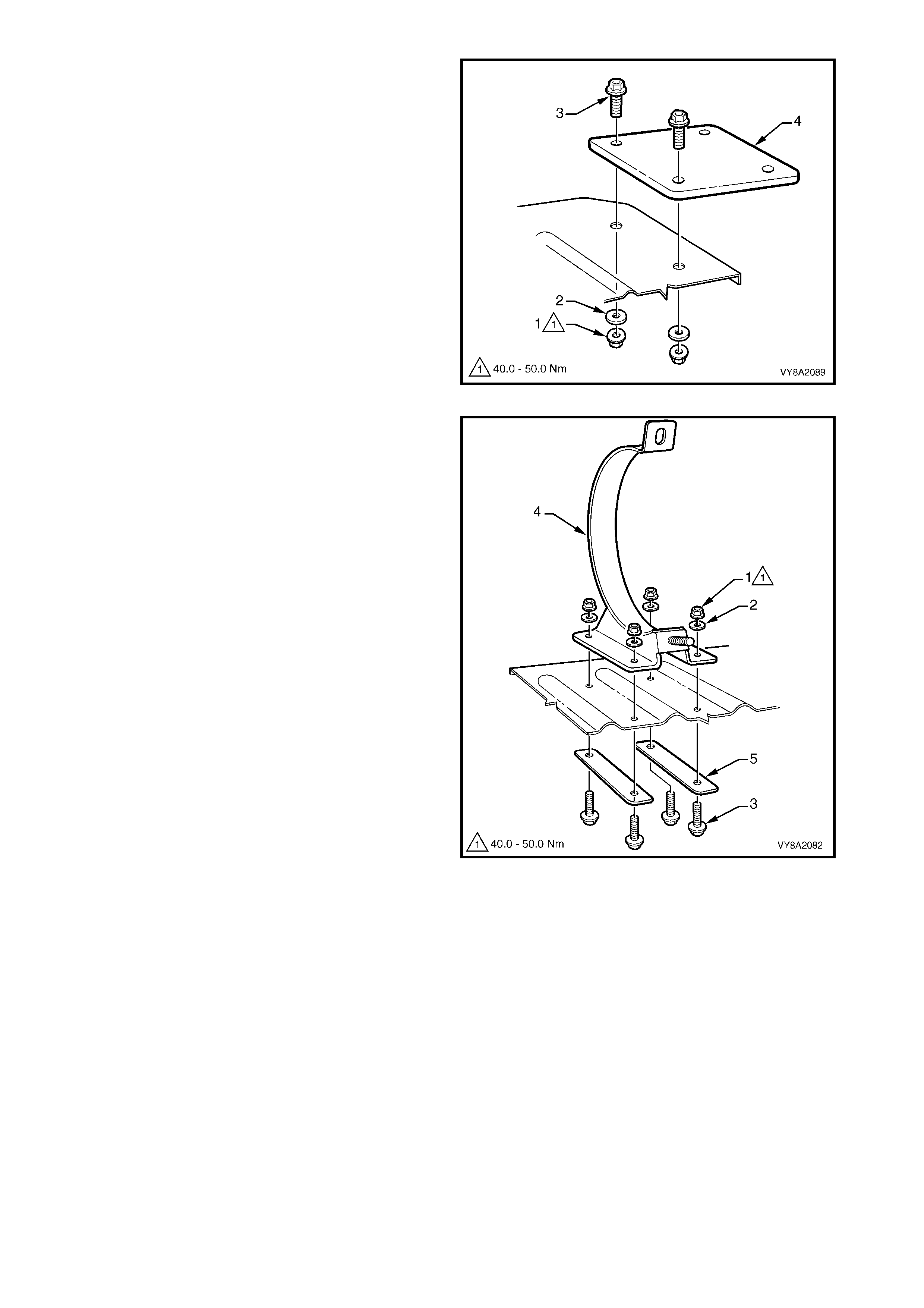

7. Remove the Torx screw (1), two places, attaching

the valve box flange (2) to the LPG tank.

8. Pull the valve box flange and seal (3) away from

the LPG tank so that there is sufficient clearance

to remove the LPG tank.

9. With the aid of an assistant, remove the left-hand

front LPG tank retaining bolt (1), washer (2) and

from underneath the vehicle the nut (3) and plate

(4), refer to Figure 8A2-62.

10. Loosen and remove the two lock-nuts, (5, 6 & 7),

three places, attaching the LPG tank to the LPG

tank brackets.

11. With the aid of an assistant, lift the LPG tank up

and remove from the vehicle.

12. Remove the isolator (8) and washer (9) and if

required the spacer (10).

Figure 8A2-61

Figure 8A2-62

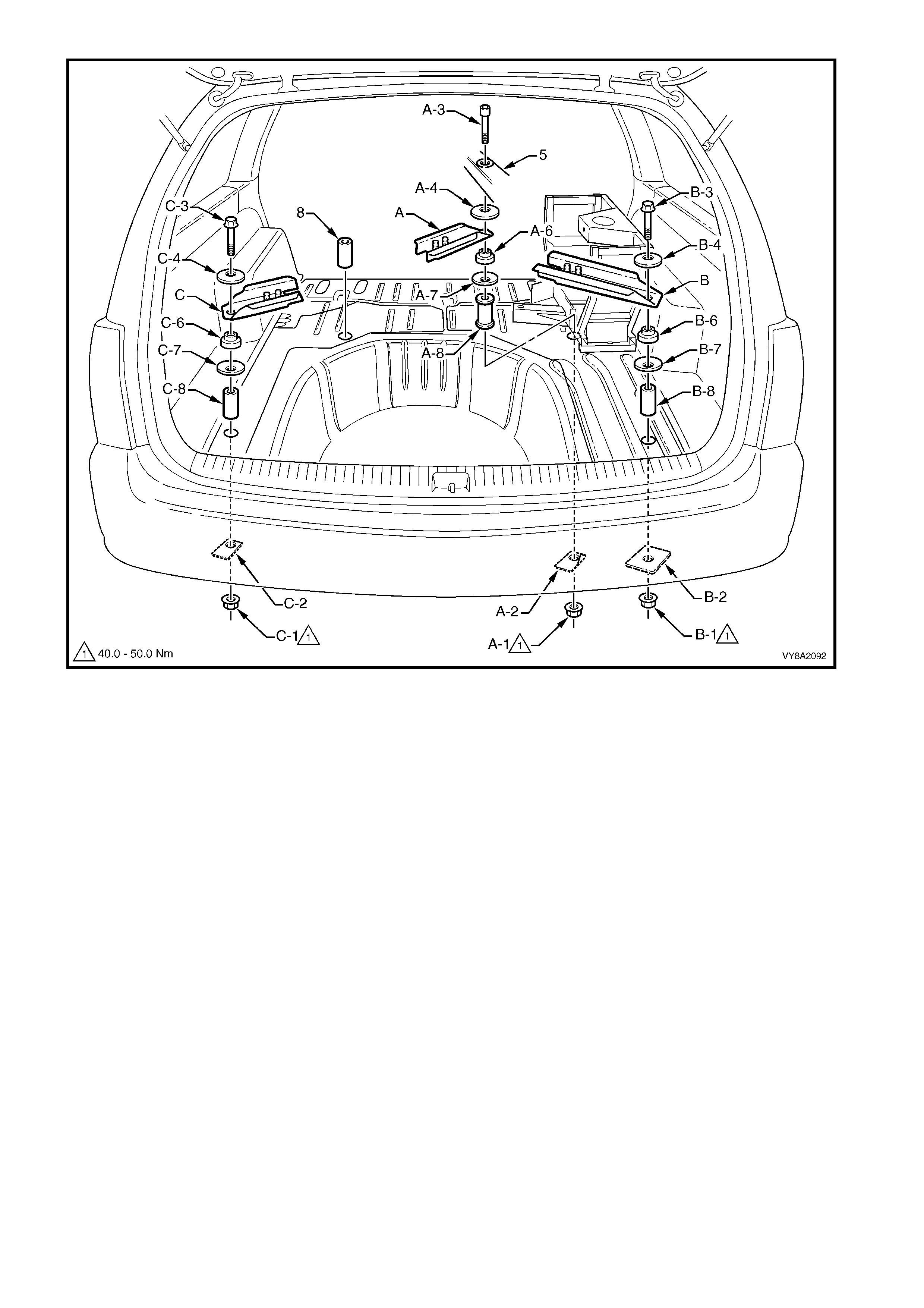

13. As required, with the aid of an ass istant remove the nut, ( 1), plate (2), bolt (3) and washer (4) attaching the

LPG tank mounting brackets (A, B &/or C), refer to Figure 8A2-63.

NOTE: The mounting bracket (A) and its washer (A-4) are seated under the spare wheel carrier (5).

14. Once the bracket(s) are removed, remove the isolator (6), washer (7) and spacer (8) from the floor box-

section.

Figure 8A2-63

Legend

A. Right-hand Front LPG Tank Mounting Bracket 4. Washer

B. Right-hand Rear LPG Tank Mounting Bracket 5. Spare Wheel Carrier

C. Left-hand Rear LPG Tank Mounting Bracket 6. Isolator

1. Nut 7. Washer

2. Reinforcement Plate 8. Spacer

3. Bolt

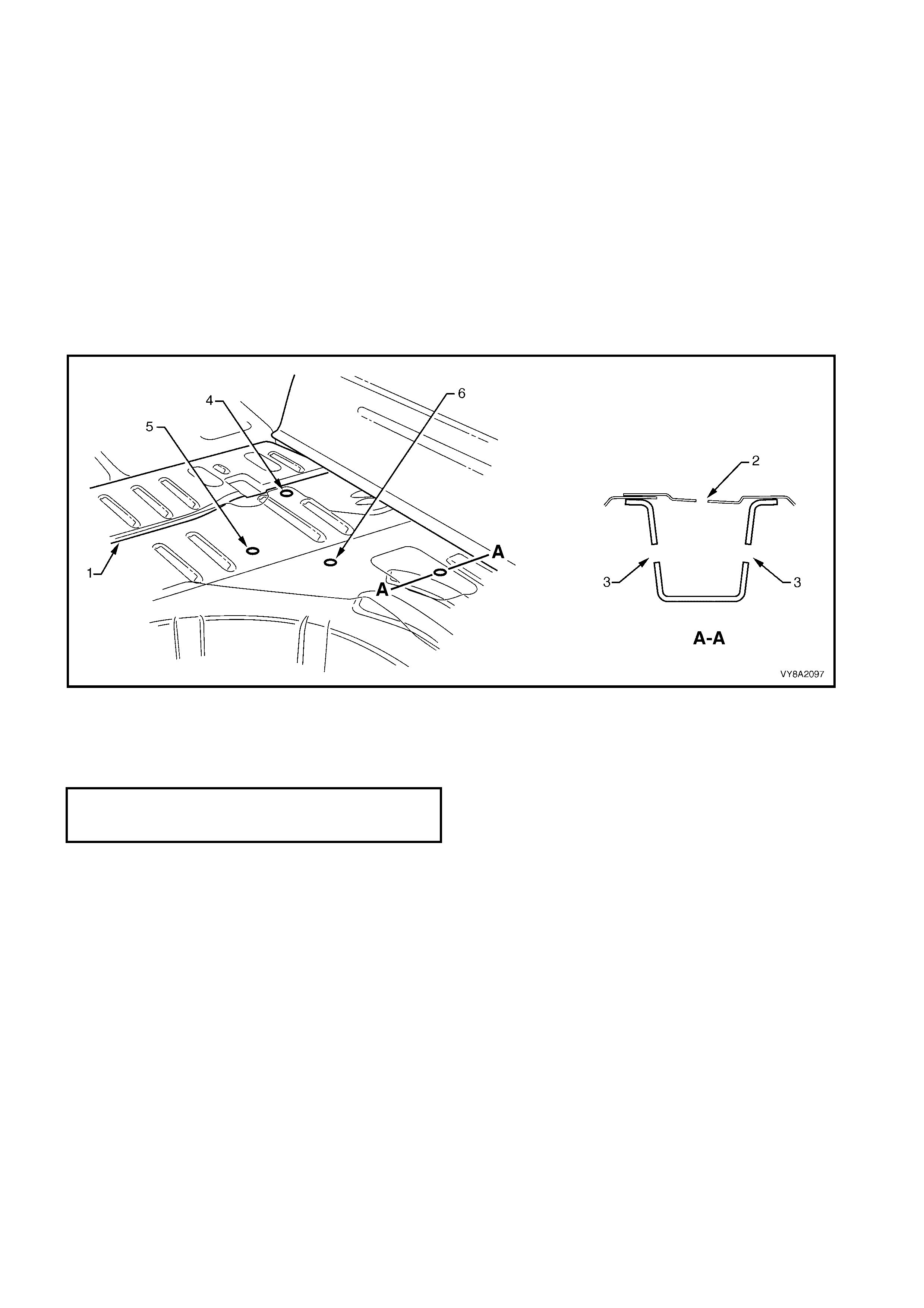

REINSTALL

1. If the floor panel, etc . has been replac ed and new mounting holes are required, align the tank assem bly with

the spare wheel carrier at position A, refer to Figure 8A2-63, seat the tank centrally within the spare wheel-

well, use the tank as a template and ens ure the holes are central within the floor ribs. Drill holes as required

and coat any bare metal with primer.

• Position B, C and D – 12 mm hole through the floor panel and rear chassis rail followed by a 17 mm hole

in the floor panel only.

NOTE: For drilling details of position A and the spare wheel carrier refer to 3.25 SPARE WHEEL CARRIER.

2. If the mounting brackets have been removed, install them as required, referring to Figure 8A2-63. Hand

tighten the nuts at this stage.

3. If required, install the spacer for the left-hand front mount.

4. With the aid of an assistant, place the tank onto the LPG tank bracket studs, six places. Hand tighten the

nuts.

5. W ith the aid of an as sistant, install the lef t-hand f ront retaining bolt, and nut, ens uring the spac ers, is olators,

washers and reinforcement plates are installed correctly, refer to Figure 8A2-62.

6. While holding the retaining bolt, tighten all of the retaining nuts to the specified torque.

7. Install the valve box f lange, ensuring the valve box seal is s eated corr ectly. Tighten the two valve box flange

retaining screws to the specified torque.

8. Clean the mating threads on the manual service valve assembly, intermediate to rear service line joiner,

both rear service line connectors, AFL valve and filler line connector.

9. Apply Loctite 577 sealant to the intermediate to rear service line joiner threads, ensuring that the flared

surfaces are free of sealant and contaminants.

10. Assemble the rear service connectors to the intermediate service line joiner and the manual service valve

assembly.

11. Tighten both rear service line connectors to the specified torque.

12. Apply Loctite 577 sealant to the LPG tank AFL elbow threads, ensuring that flared surfaces are free of

sealant and contaminants.

13. Install the f iller line c onnector to the LPG tank AF L elbow and tighten the filler line c onnector to the s pecif ied

torque.

14. Leak test the LPG system, refer to 3.3 LEAK TESTING.

15. Reinstall the valve box cover.

16. Reinstall the luggage com par tm ent floor c over, ref er to Sect ion 1A8, 3.21 REAR COM PAR TM ENT FL OOR

COMPARTMENT ASSEMBLY & SPARE WHEEL COVER, WITH LPG.

UTILITY

REMOVE

CAUTION 1: After any valve or component has been removed and reinstalled to the LPG tank, the LPG

tank must b e pressure and leak test ed in accordance w ith curren t Au stralian Standard AS 2030-1 befo re

the LPG tank is refitted to the vehicl e.

CAUTION 2: Ensure that there are no naked flames or other sources of ignition in the vicinity.

LPG TANK RETAINING NUT

TORQUE SPECIFICATION 40.0 – 50.0 Nm

VALVE BOX ATTACHING SCREW

TORQUE SPECIFICATION 7.0 Nm

REAR SERVICE LINE CONNECTOR

TORQUE SPECIFICATION 12.0 – 18.0 Nm

FILLER LINE CONNECTOR

TO AFL ELBOW

TORQUE SPECIFICATION 12.0 – 18.0 Nm

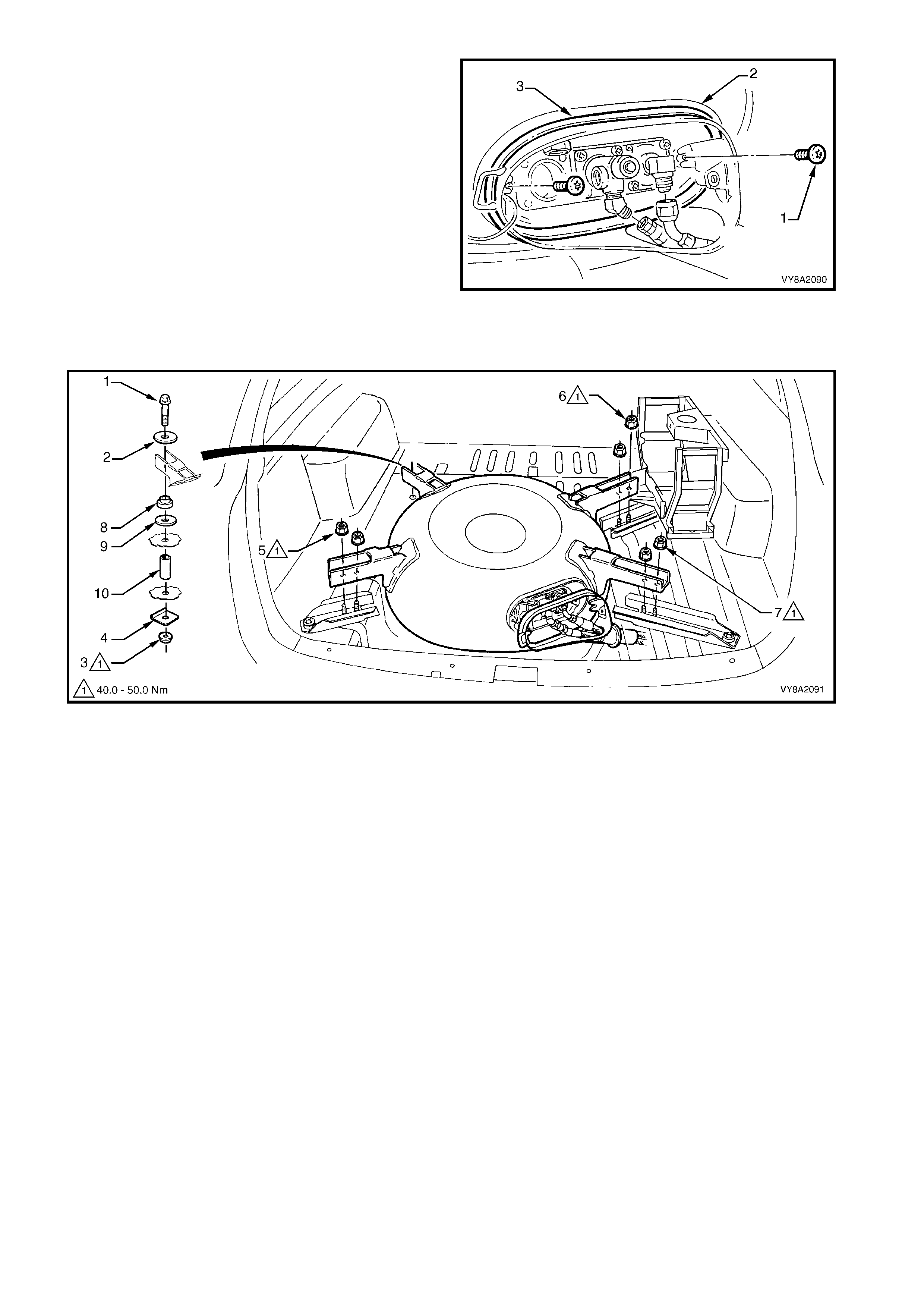

1. Rem ove the Tor x sc rew (1), six places, attac hing the LPG tank c over (2) to the vehic le. Pull back the upper

edge of the tank cover slightly, refer to Figure 8A2-64.

2. Lift the tank cover upwards until the lower inner retainer grommet (3) disengages from ball stud (4) at four

places.

3. Remove the cover.

Figure 8A2-64

4. Drain the service lines of LPG and note all

cautions, refer to 3.1 SERVICE LINE DRAINING.

5. Unload the LPG tank of LPG, refer to

3.2 LPG TANK UNLOADING.

6. From within the LPG valve box, while holding the

AFL elbow, crack open the filler line to AFL elbow

connector (1) and allow residual LPG to escape.

CAUTION: The filler line will contain LPG under

pressure.

7. Once all the LPG in the line has dispersed, remove

the filler line connector completely from the AFL

elbow.

Figure 8A2-65

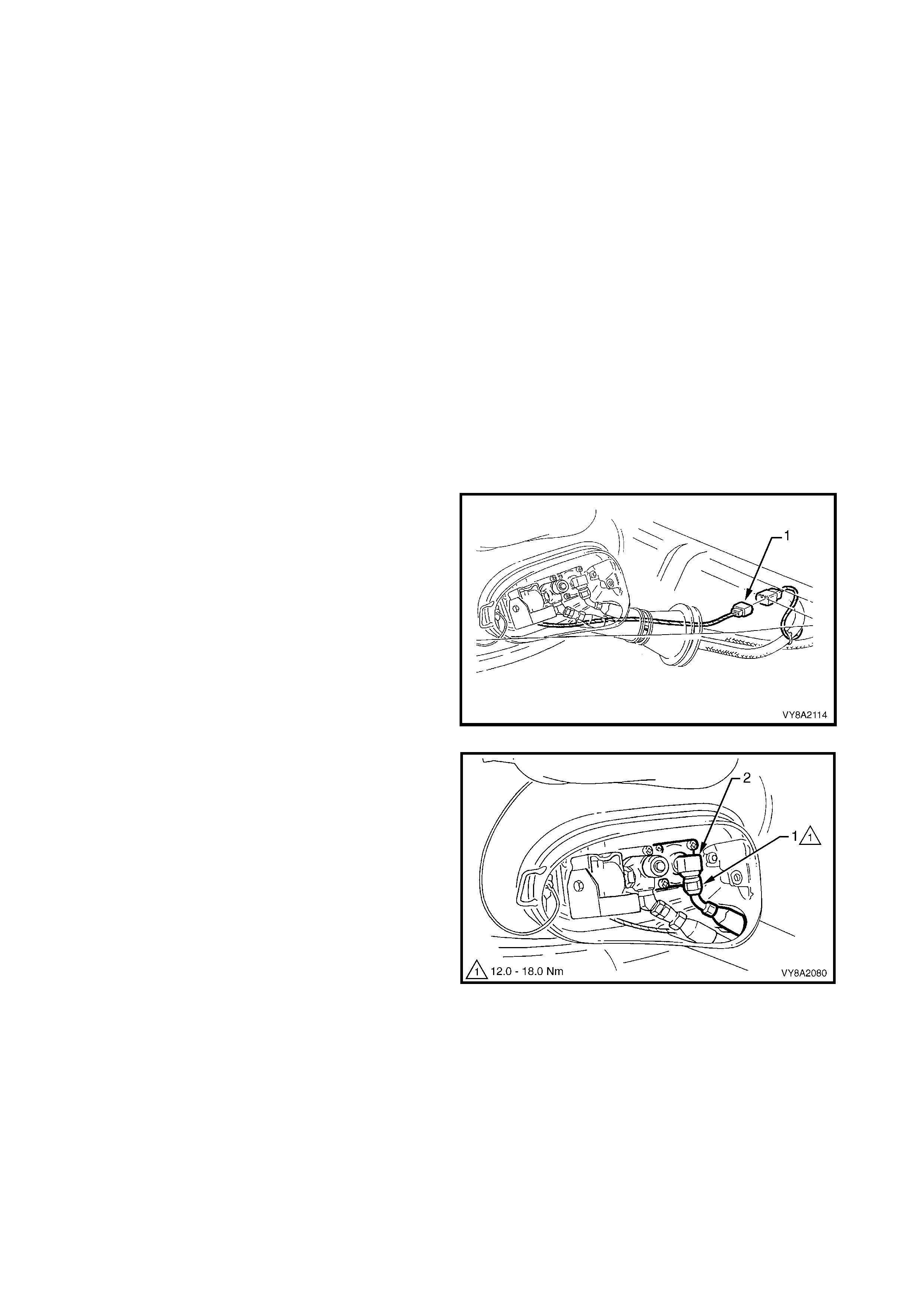

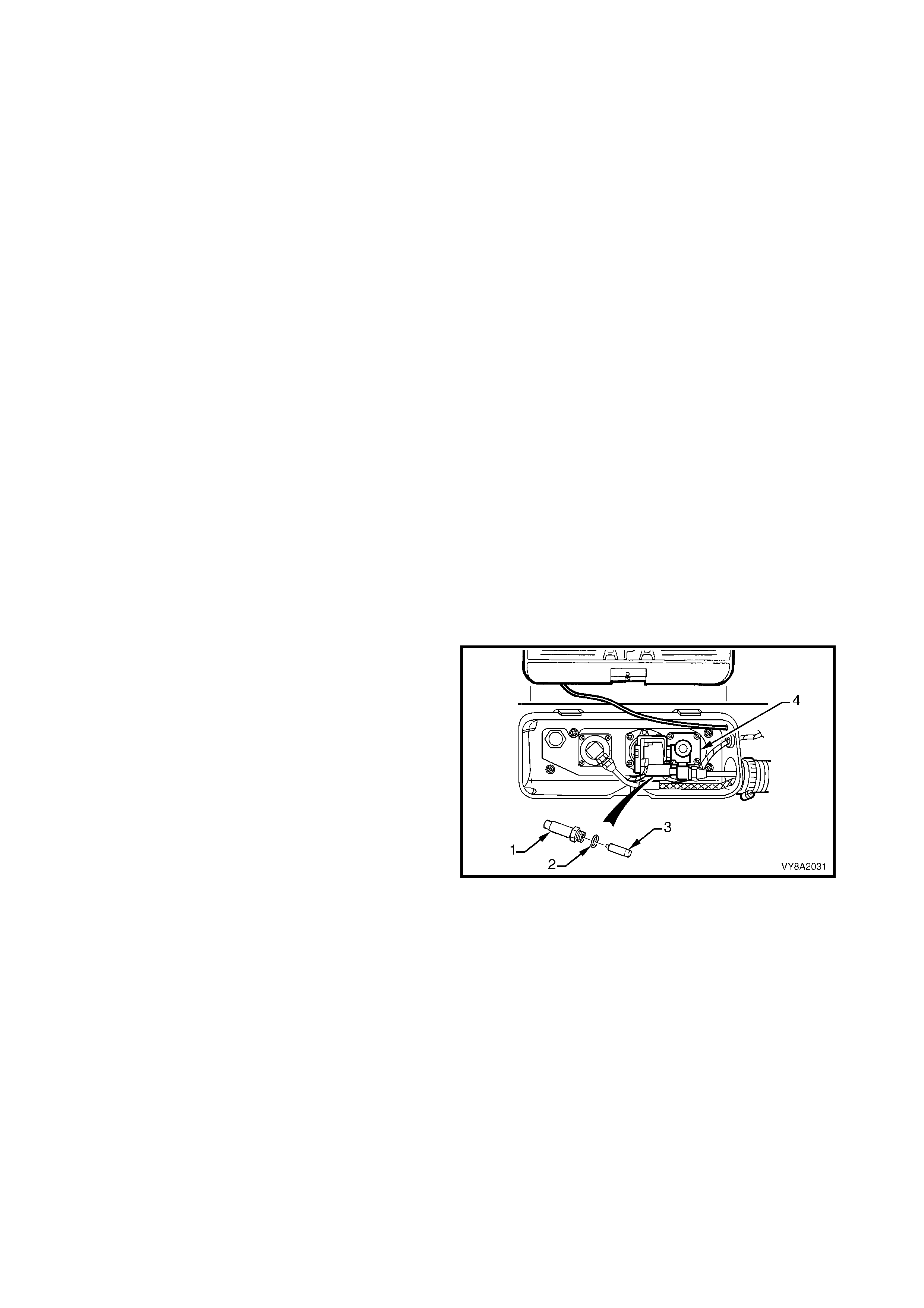

8. From within the LPG valve box, disconnect the

service line connector (1) from the manual service

valve elbow.

Figure 8A2-66

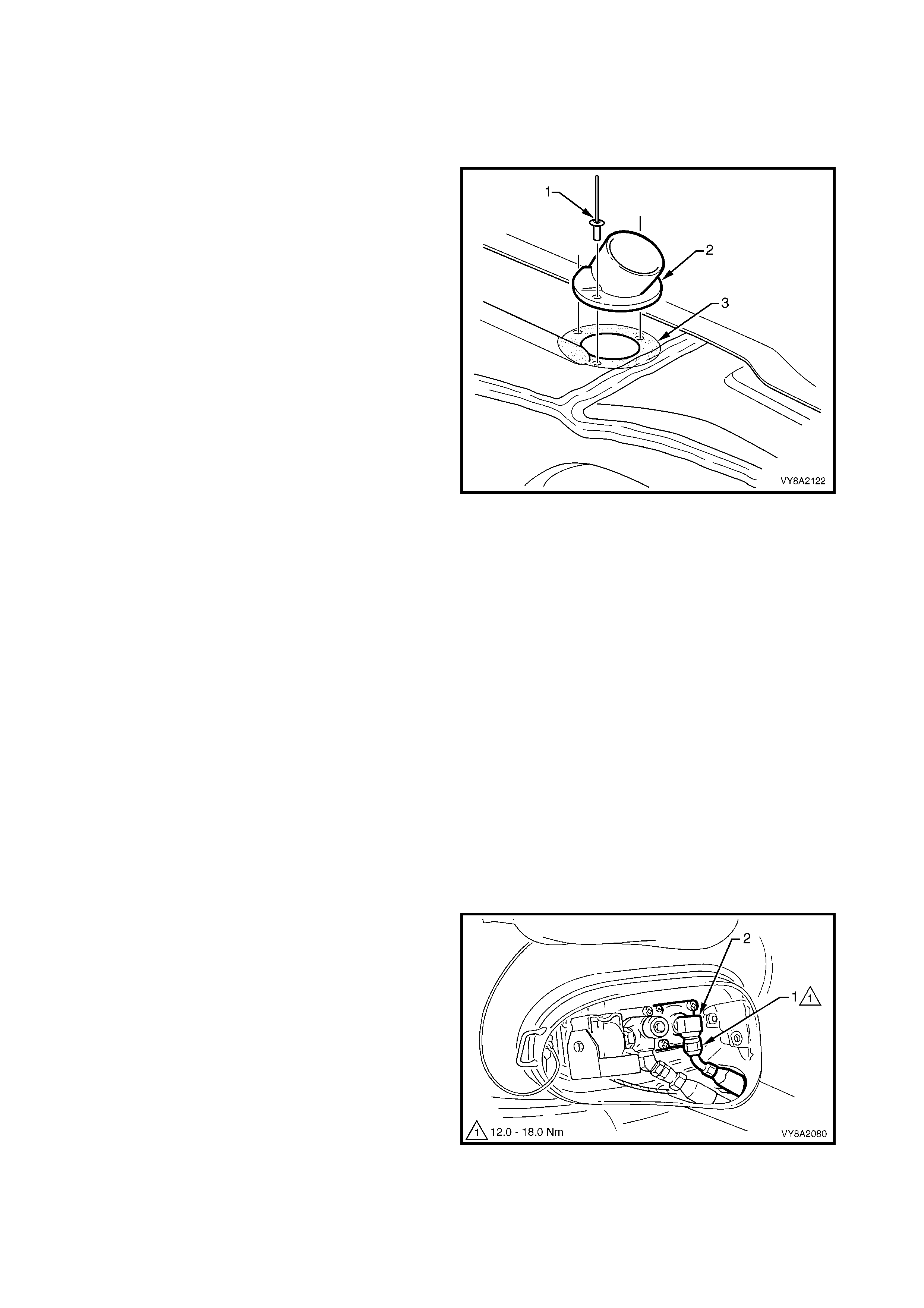

9. Rem ove the hos e clam p (1) securing the vent tube

(2) to the tank valve box.

10. Withdraw the LPG service (3) and filler lines (4)

from the valve box.

11. Disconnect the LPG tank harness connector (5)

from the LPG body wiring harness connector.

Figure 8A2-67

12. Loosen the upper nut (1) and lower nut (2)

securing the LPG tank strap (3).

13. Completely remove the lower nut and washer (4).

14. Remove the upper nut, washer (5) and screw (6)

and remove the strap.

15. Repeat for each LPG tank strap.

16. With the aid of an ass istant, rem ove the LPG tank ,

manoeuvring the left-hand side rearward to

provide clearance for the vent tube.

Figure 8A2-68

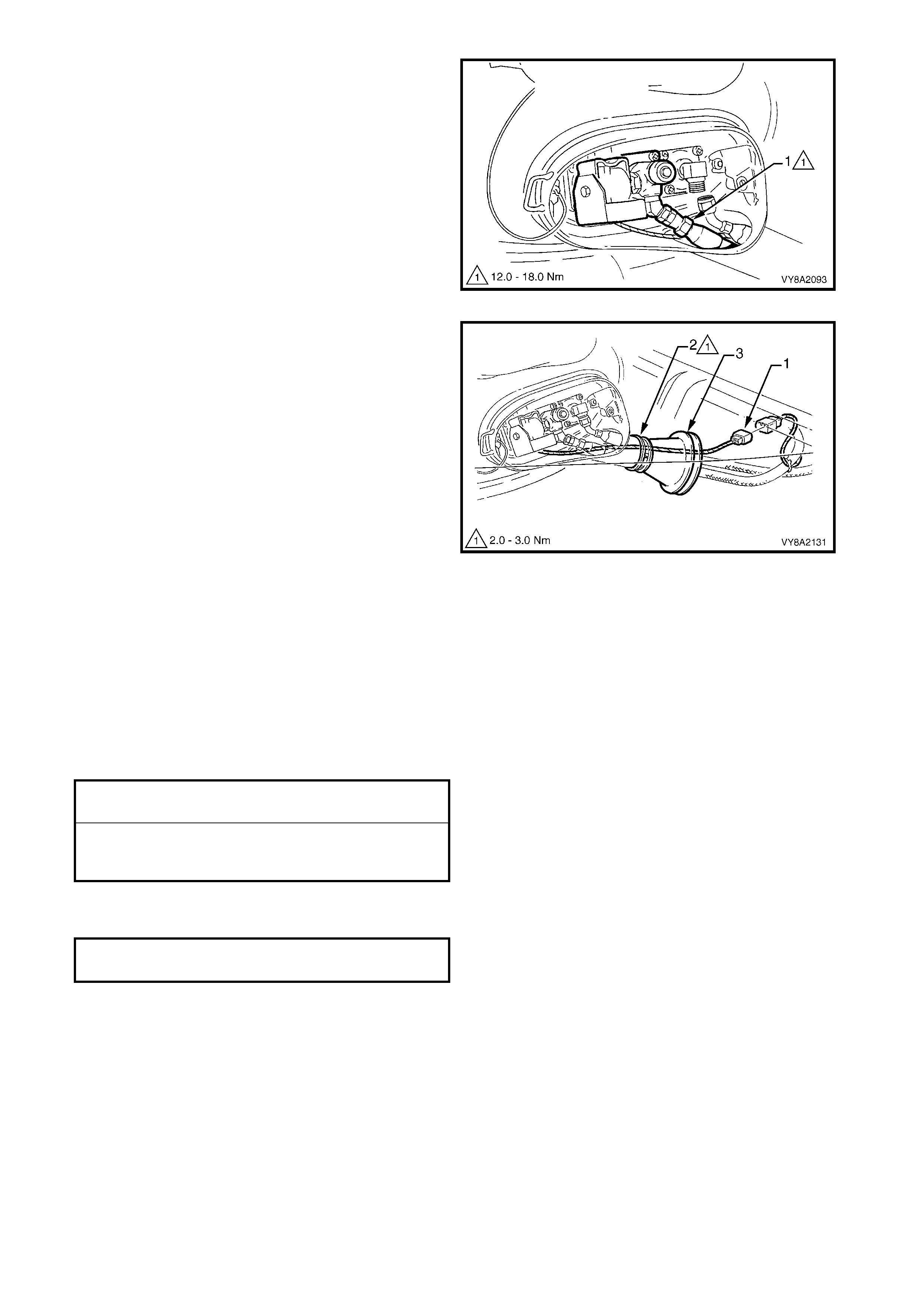

17. If required, remove the nut (1) and washer (2)

attaching the upper connecting plate (3) to the

lower connecting bar (4).

18. Remove the load floor front panel assembly,

refer to 2.7 LOAD FLOOR FRONT PANEL

ASSEMBLY, UTILITY in Section 1B.

Figure 8A2-69

19. Rem ove the nut (1), washer (2) and screw (3), two

places, attaching the upper connecting plate (4) to

the load floor front panel assembly.

20. Remove the plate.

Figure 8A2-70

21. Rem ove the nut (1) , washer ( 2) and s c rew (3), four

places, attaching the tank support bracket (4) and

the backing bar (5), two places, to the load floor

front panel assembly.

22. Remove the support bracket and backing bar.

Repeat as required.

Figure 8A2-71

REINSTALL

Installation of the LPG tank and support assembly is the reverse of the removal procedure, noting the following:

1. If the floor panel, etc. has been replaced and new mounting holes are required, use the old floor as a

reference and the tank as a template. Drill holes as required and coat any bare metal with primer.

2. If removed, reins tall the tank cover ball s tuds (4) , r ef er to Figure 8A2-64. Tighten the nuts (5) to the specif ied

torque.

3. Install the support brackets and connecting plates in the reverse of removal.

4. Tighten the nuts to the specified torque.

5. Install the LPG tank into support brackets. Install the three LPG tank retaining straps, and all retaining

screws, washers and nuts.

6. Tighten to the nuts to the specified torque.

7. Clean the mating threads on the m anual servic e valve assem bly, rear service line connector, AFL valve and

filler line connector.

8. Apply Loctite 577 sealant to the rear service line connector threads, ensuring that the flared surfaces are

free of sealant and contaminants.

9. Assemble the rear service connector to the manual service valve assembly.

10. Tighten the rear service line connector to the specified torque.

11. Apply Loctite 577 sealant to the LPG tank AFL elbow threads, ensuring that flared surfaces are free of

sealant and contaminants.

12. Install the f iller line c onnector to the LPG tank AF L elbow and tighten the filler line c onnector to the s pecif ied

torque.

13. Reconnect the LPG body wiring harness connector to LPG tank connector.

14. Leak test LPG system, refer to 3.3 LEAK TESTING.

15. Apply a commercially available silicone sealant to the vent tube mating surface.

16. Tighten vent tube clamps to specified torque.

17. If required, install new Nutserts (6) with a commercially available Nutsert gun, refer to Figure 8A2-64.

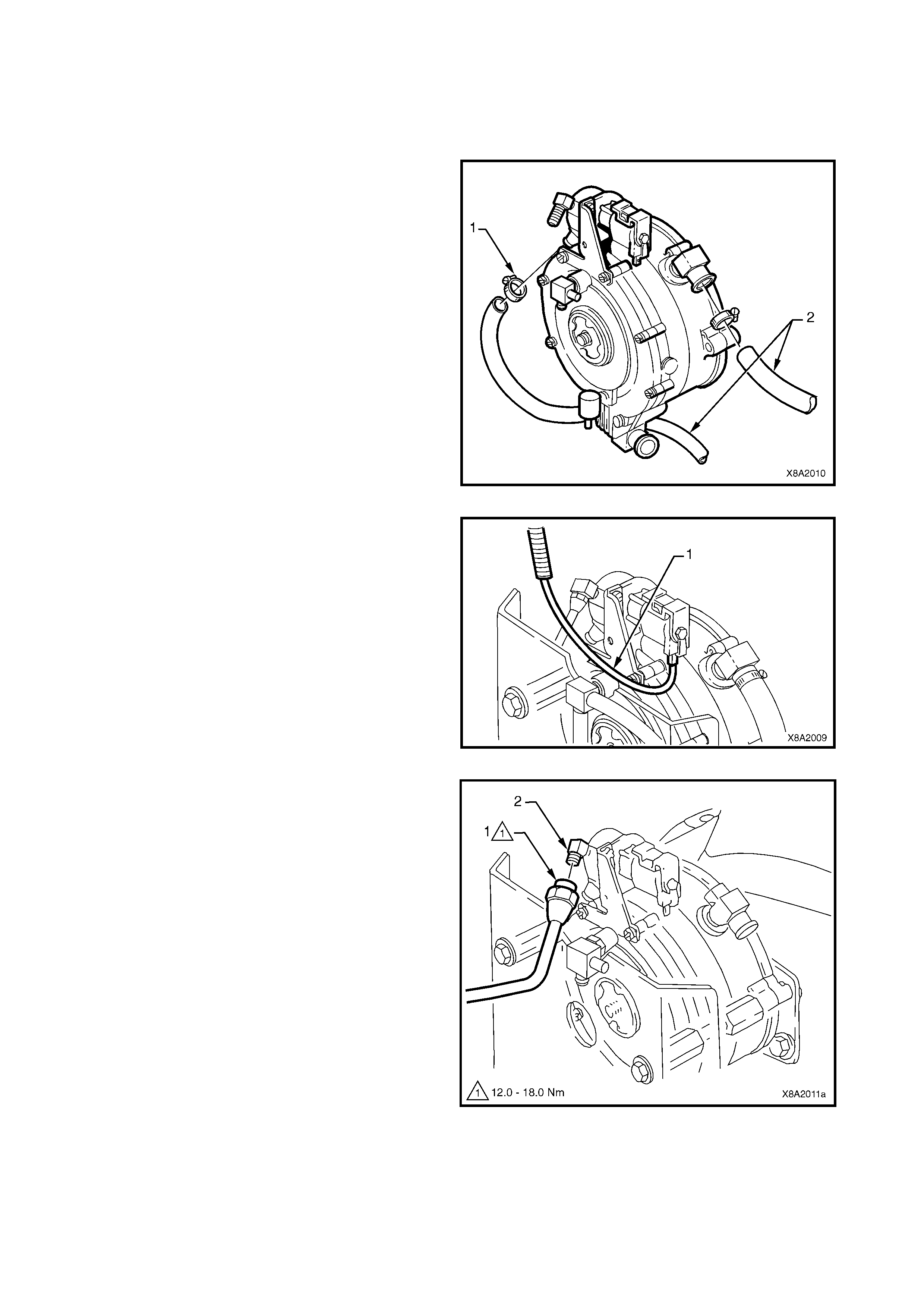

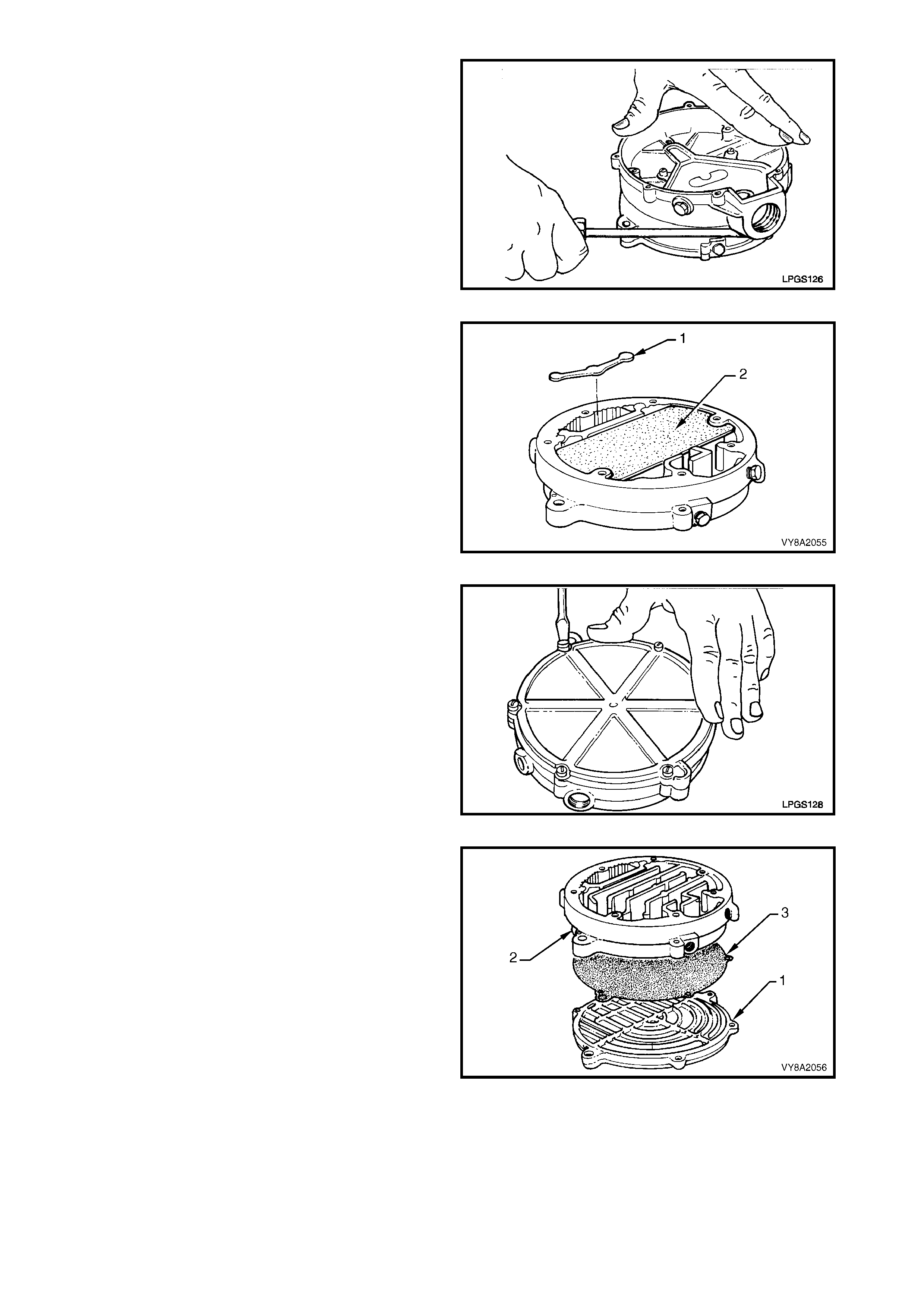

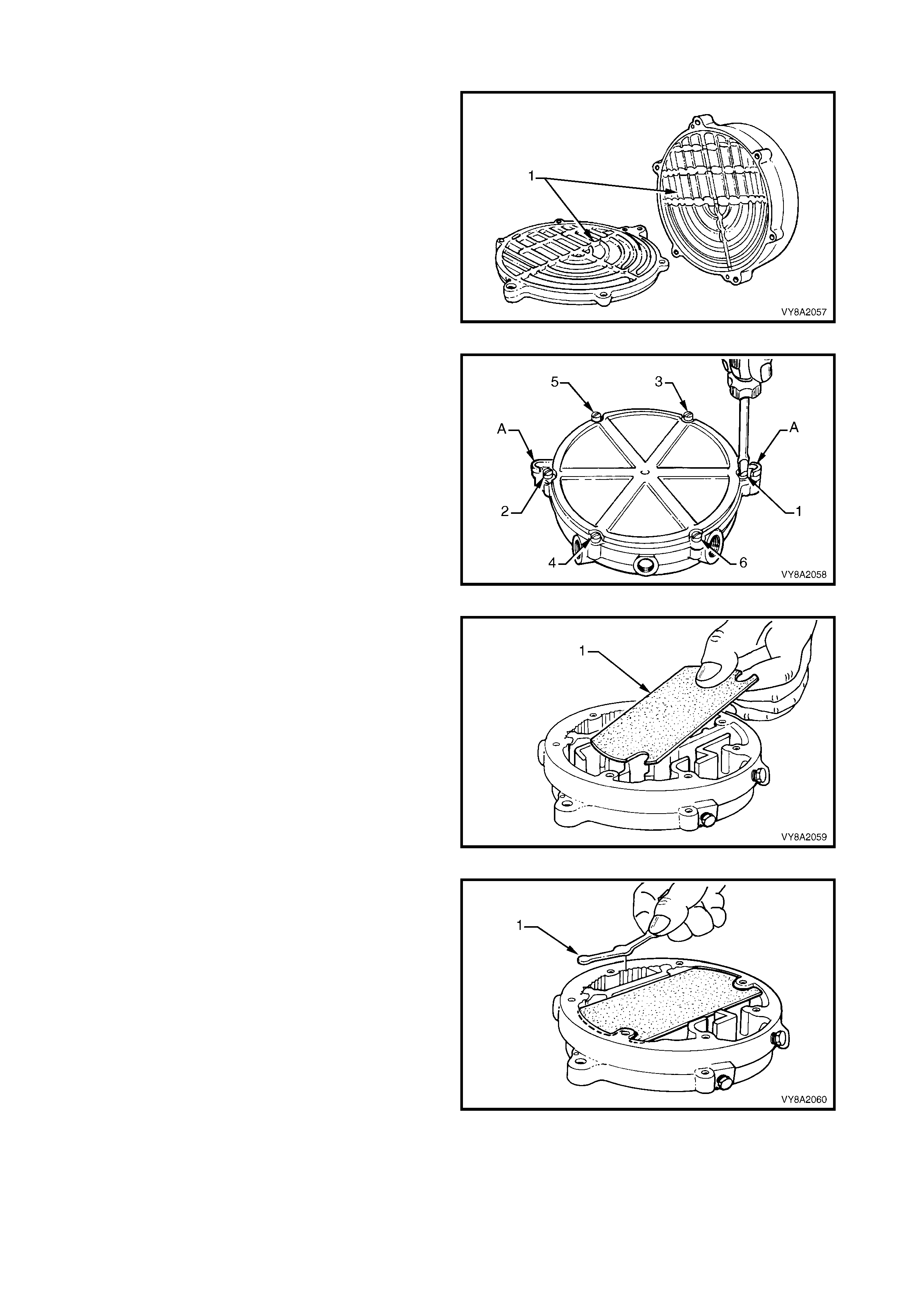

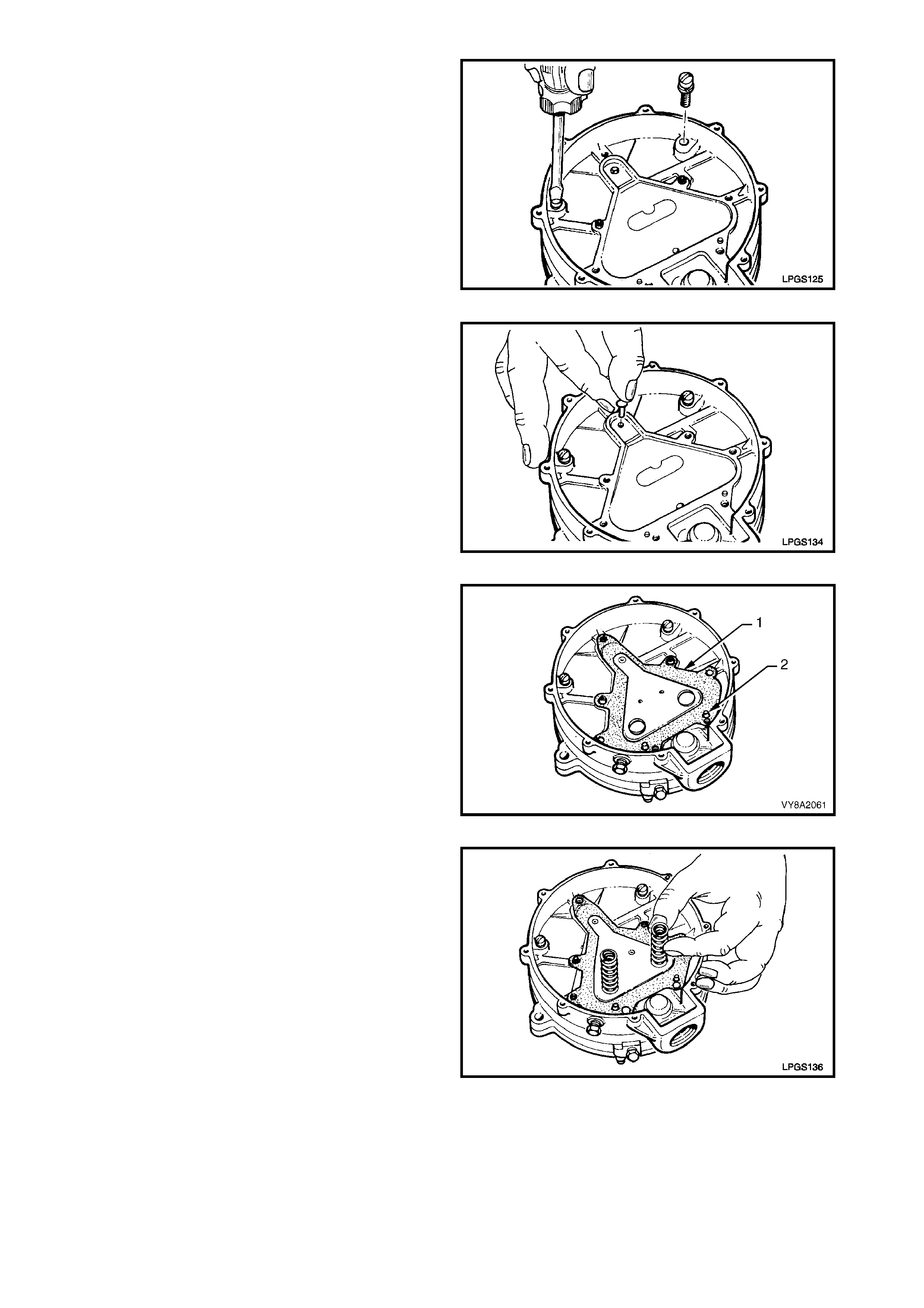

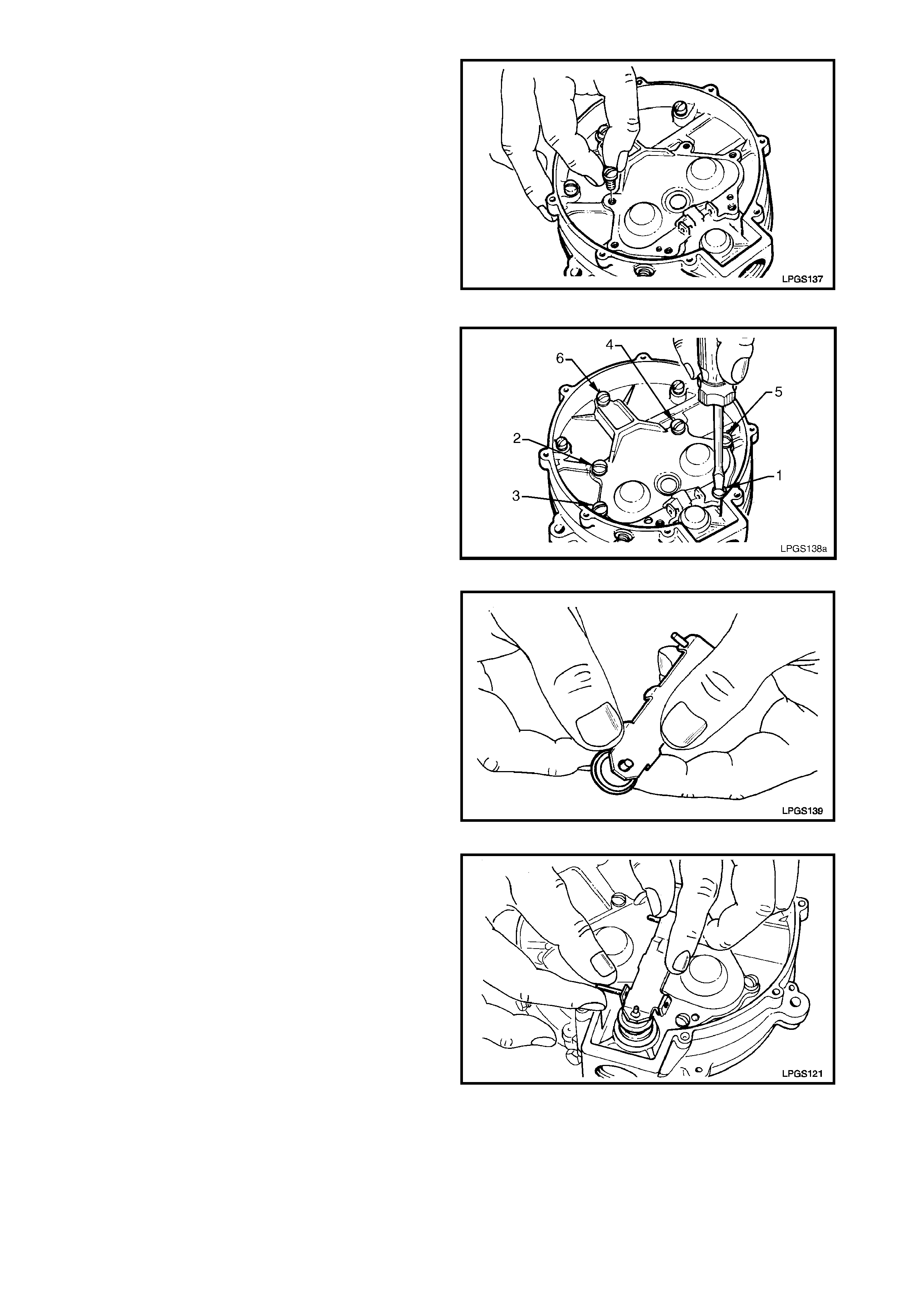

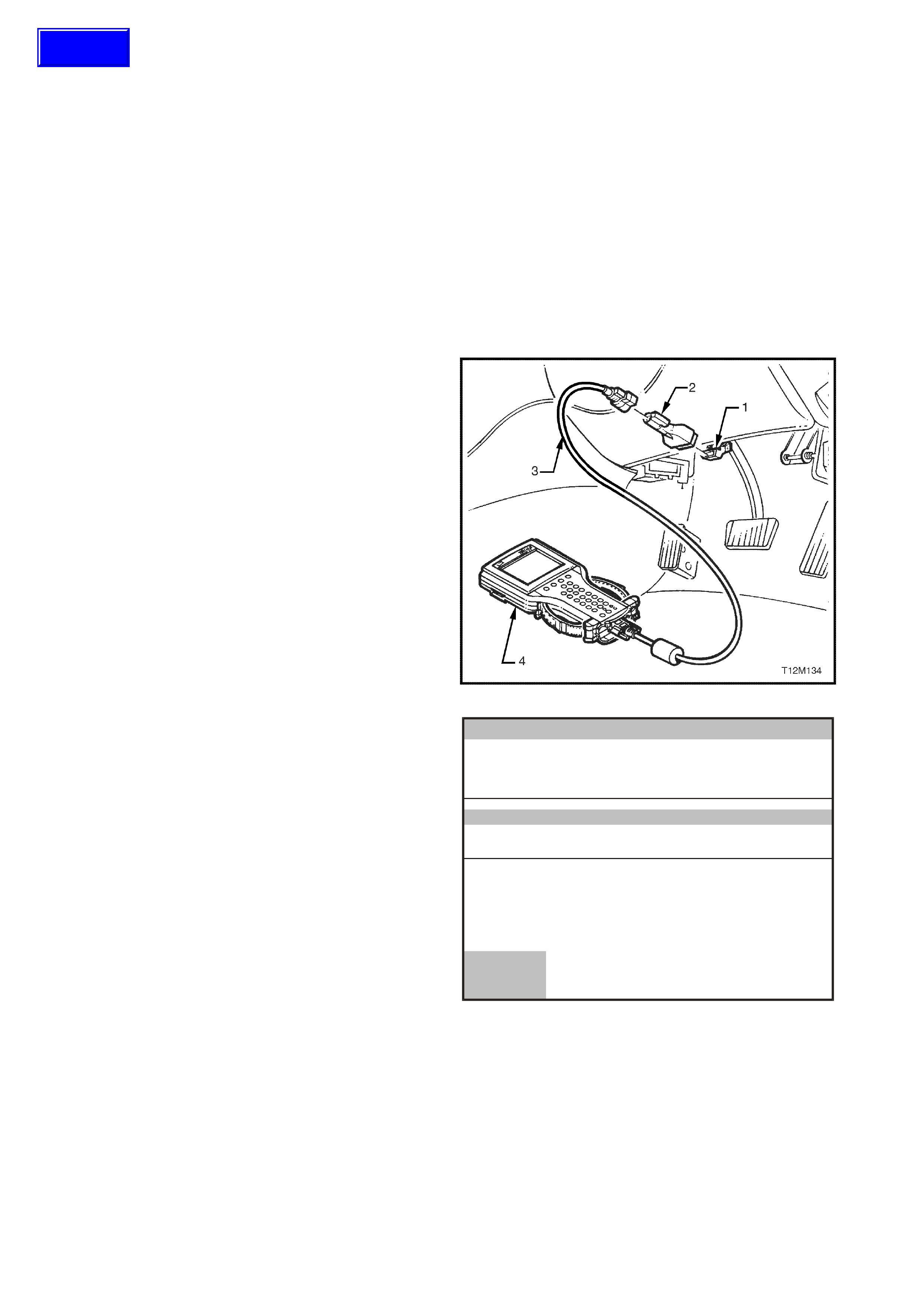

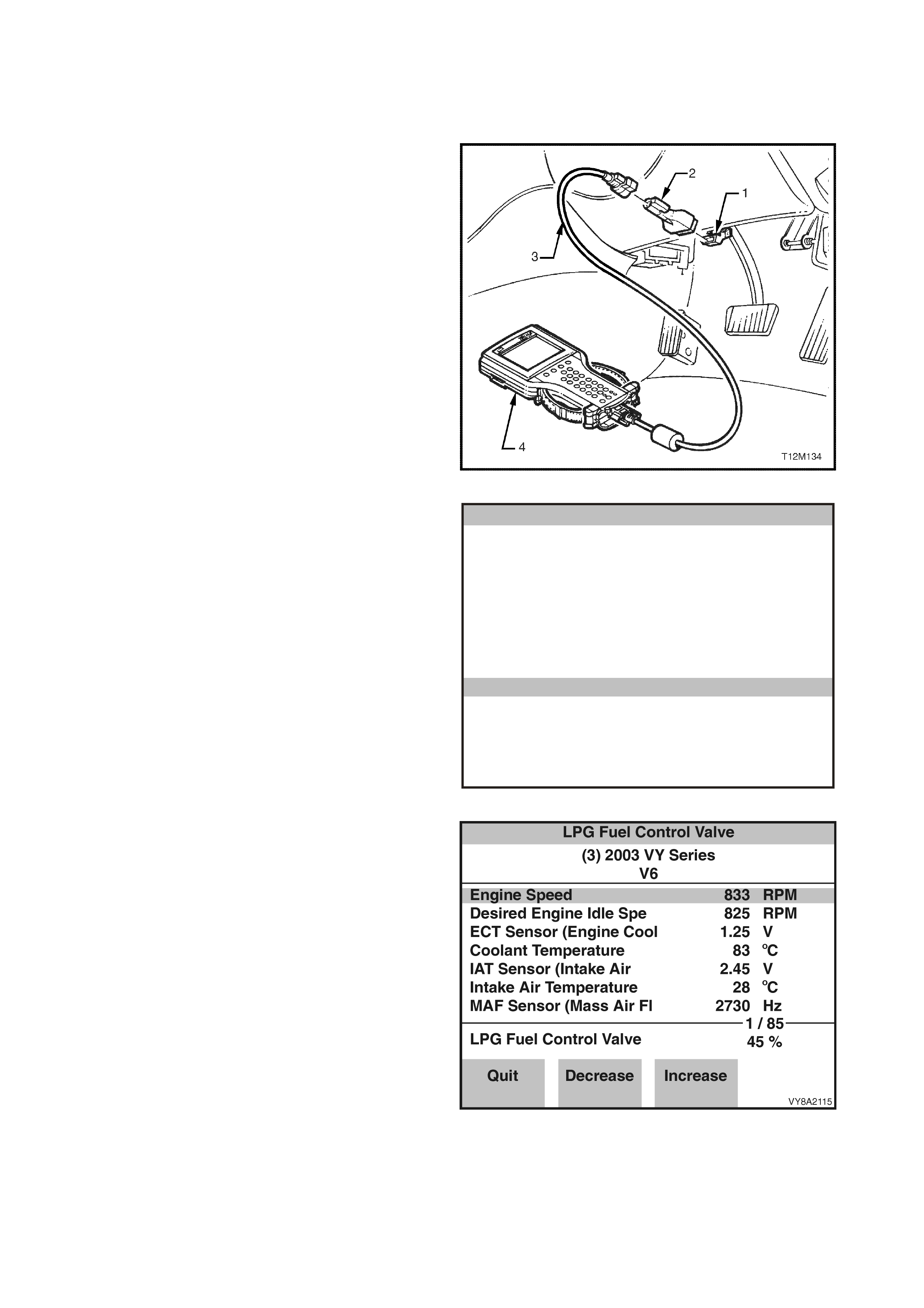

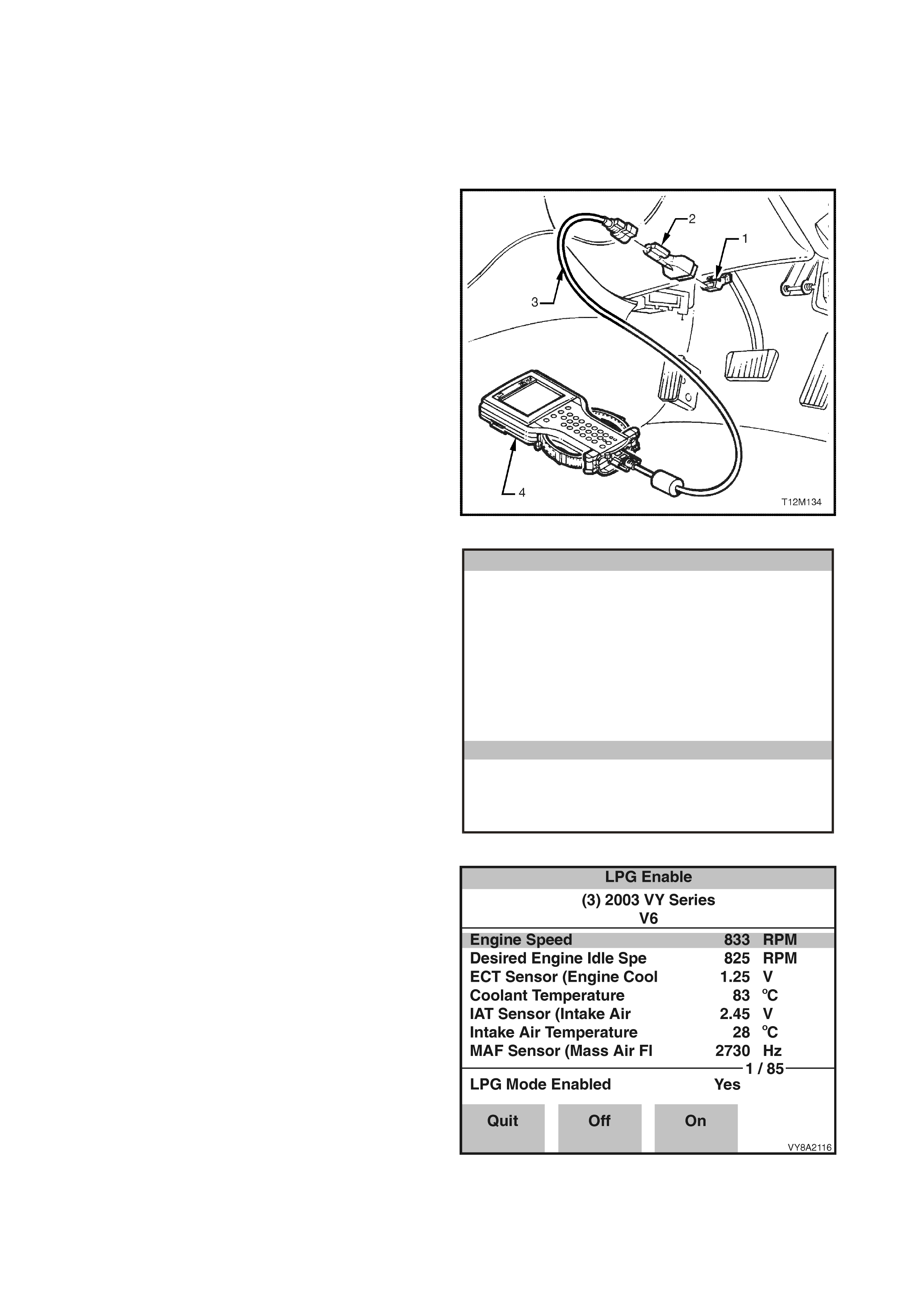

18. Reinstall the LPG tank cover onto the locating studs.