SECTION 8B - EXHAUST SYSTEM

IMPORTANT

Before perfo rming any Service Operation or other procedu re described in this Section , refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL DESCRIPTION

1.1 EXHAUST SYSTEM CONFIGURATION

V6 ENGINE EXHAUST SYSTEM

V6 ENGINE EXHAUST SYSTEM –

EXPORT FOR INDONESIA

V6 SUPERCHARGED ENGINE

EXHAUST SYSTEM

GEN III V8 ENGINE EXHAUST SYSTEM

1.2 CATALYTIC CONVERTER

2. SERVICE OPERATIONS – V6

2.1 SERVICE NOTES

CATALYTIC CONVERTER

OXYGEN SENSORS

2.2 EXHAUST SYSTEM

COMPLETE EXHAUST SYSTEM

TIGHTENING SEQUENCE

REAR EXHAUST ASSEMBLY

INTERMEDIATE EXHAUST ASSEMBLY

FRONT EXHAUST ASSEMBLY

3. SERVICE OPERATIONS – V6

SUPERCHARGED

3.1 SERVICE NOTES

CATALYTIC CONVERTER

OXYGEN SENSORS

3.2 EXHAUST SYSTEM

COMPLETE EXHAUST SYSTEM

TIGHTENING SEQUENCE

REAR EXHAUST ASSEMBLY

INTERMEDIATE EXHAUST ASSEMBLY

FRONT EXHAUST ASSEMBLY

4. SERVICE OPERATIONS – V8 GEN III

4.1 SERVICE NOTES

CATALYTIC CONVERTER

OXYGEN SENSORS

4.2 EXHAUST SYSTEM

COMPLETE EXHAUST SYSTEM

TIGHTENING SEQUENCE

REAR EXHAUST ASSEMBLY

INTERMEDIATE EXHAUST ASSEMBLY

FRONT EXHAUST ASSEMBLY

5. SERVICE OPERATIONS – EXHAUST

SYSTEM HEAT SHIELDS

5.1 HEAT SHIELDS

HEAT SHIELD – REAR MUFFLER

HEAT SHIELD – INTERMEDIATE MUFFLER

REFLECTIVE FOIL INSULATORS

6. EXHAUST SYSTEM CLEARANCES

6.1 V6 EXHAUST SYSTEM CLEARANCES

6.2 V6 SUPERCHARGED AND V8 GEN III

EXHAUST SYSTEM CLEARANCES

7. EXHAUST SYSTEM DIAGNOSIS

8. SPECIFICATIONS

9. TORQUE WRENCH SPECIFICATIONS

Techline

1. GENERAL DESCRIPTION

Information contained within this section describes the general exhaust system configurations for MY2003 VY and

V2 Series vehicles. The exhaust system f itted to a particular vehicle will depend on series, engine type and model

specifications.

IMPORTANT: All illustrations in this Section represent a right-hand drive vehicle. For left-hand drive vehicles, any

procedure or item that is not a direct mirror of a right-hand drive vehicle in left-hand drive configuration, will be

highlighted and a procedure or illustration produced to accommodate the difference.

1.1 EXHAUST SYSTEM CONFIGURATIONS

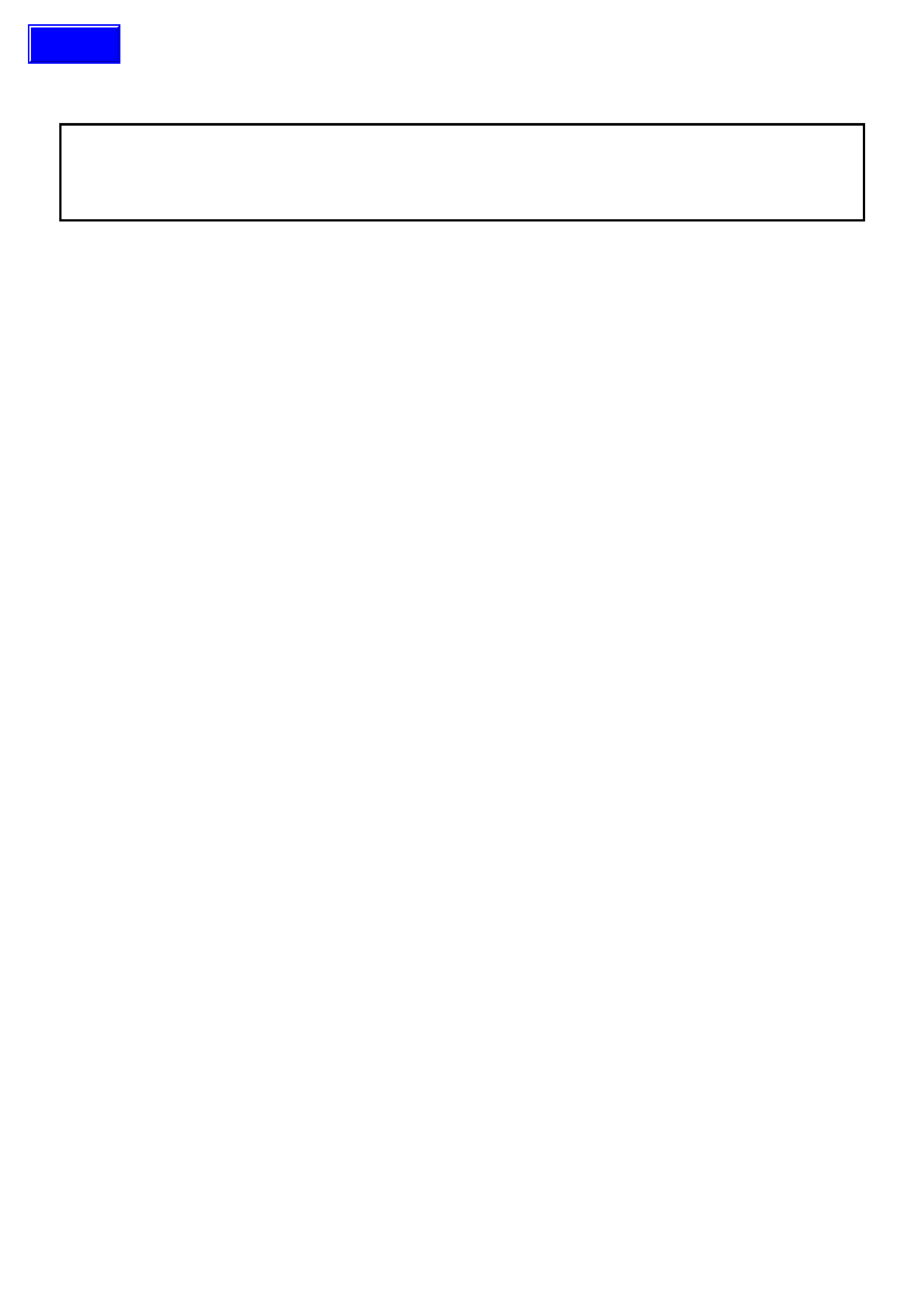

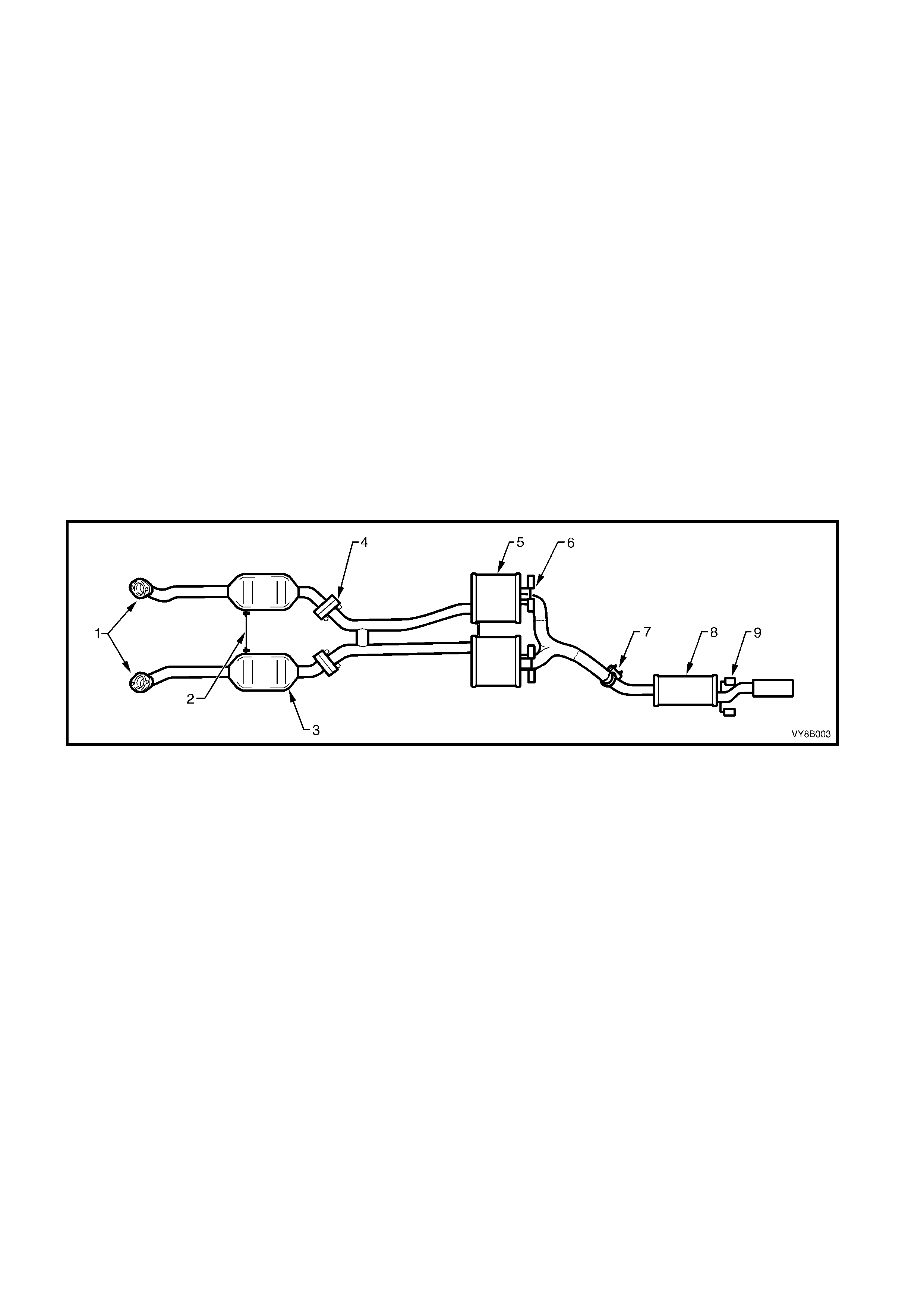

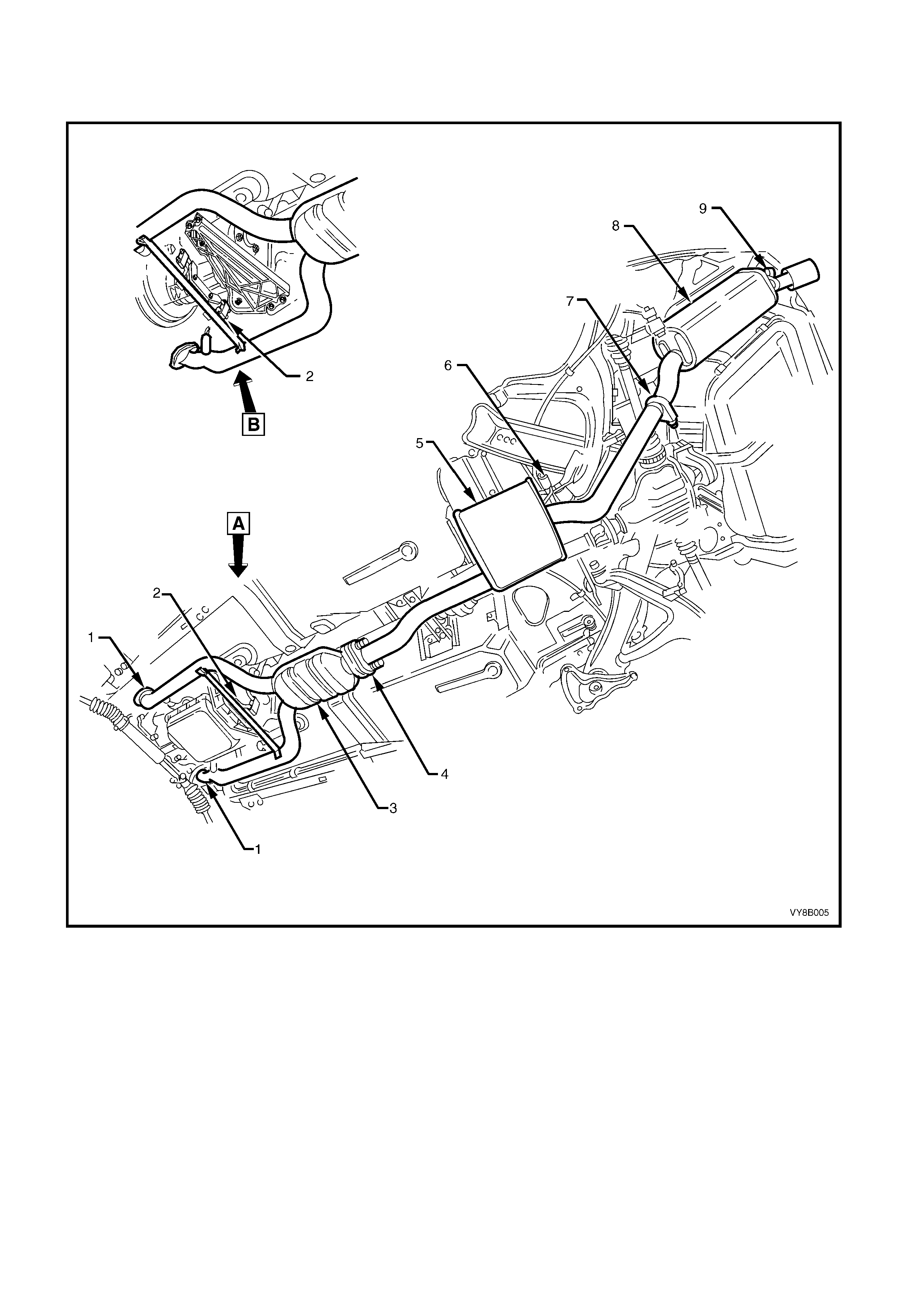

V6 ENGINE EXHAUST SYSTEM

Refer to Figure 8B-1 for the following.

The V6 engine exhaust manifolds are connected to a pair of stainless steel front pipes, by flanged joints (1). The

exhaust system featur es a single, three way catalytic c onverter (4), which f orm s a welded junction point f or each of

the front and intermediate exhaust pipes. A brace (2) and hanger peg assembly is welded across both of the front

engine pipes.

A flanged joint (5) with an internal sealing ring is used to join the catalytic converter to the intermediate exhaust

pipe. The flange mating faces are held together by two spring loaded bolts. The intermediate to rear muffler slip joint

(8) is fastened together with a U-bolt clamp, located behind the rear axle, before the rear muffler (9).

The interm ediate exhaust assem bly is supported by two support rubbers (7) that are attac hed to hangers welded to

the vehicle underbody and to pegs welded to the rear of the inter mediate m uff ler (6). T he rear exhaus t assem bly is

supported by two support rubbers (10) that are attached to hangers welded to the vehicle underbody and to pegs

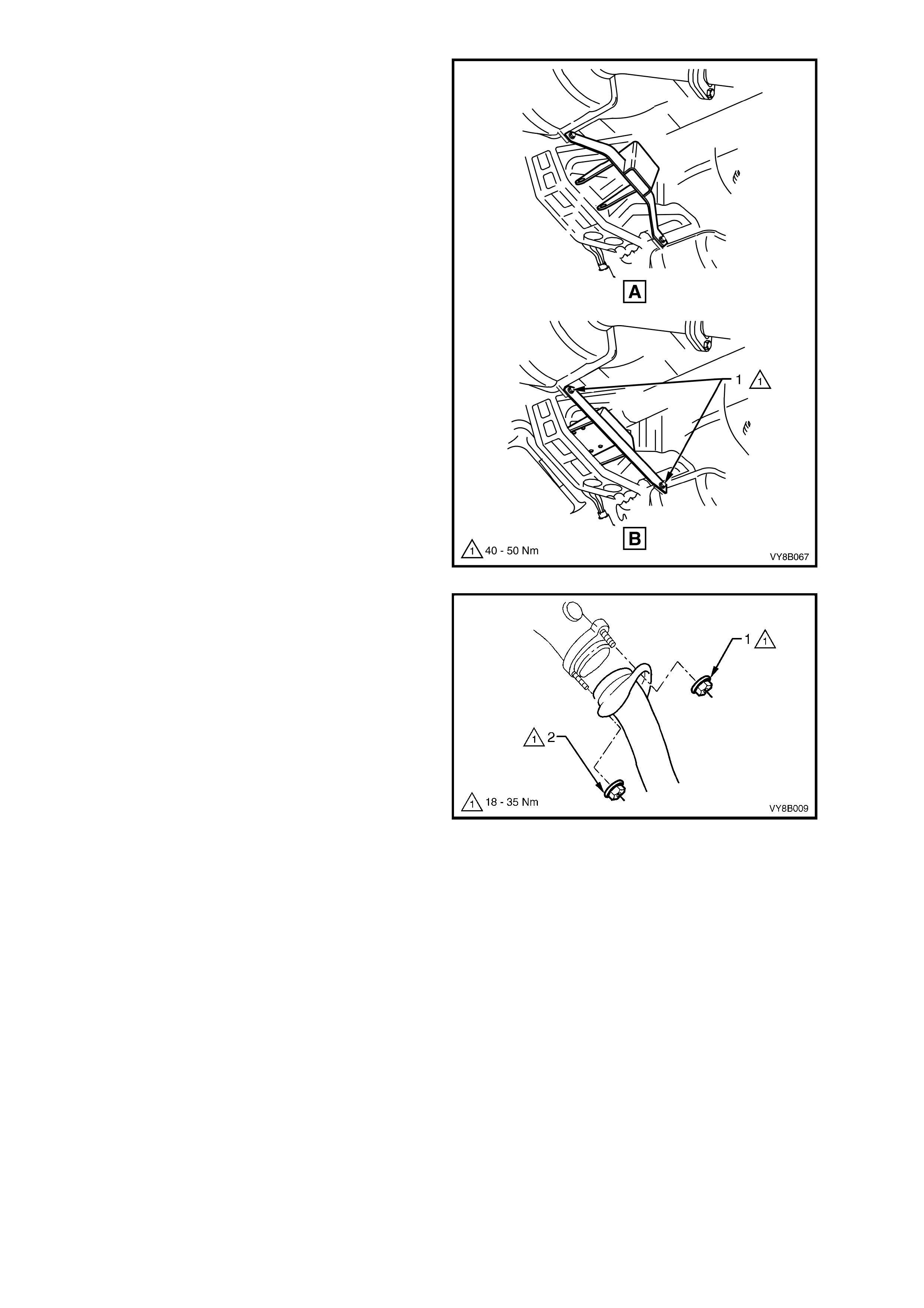

welded to the rear tail pipe. For autom atic transm ission vehicles ( View A) , the front exhaust ass embly is supported

by a r ubber s upport (3) attached to a hanger c onnected to the transmiss ion extension hous ing and to a peg welded

to the front exhaust pipe brace (2). For manual transmission vehicles (View B), the front exhaust assembly is

supported by two support rubbers (3) attached to hangers bolted to the extension housing and to pegs welded to the

brace (2). The support rubbers are a common part for all locations and are secured by retainer clips at the

intermediate and rear body hangers. Flanged pegs are used at other locations.

Figure 8B-1

Legend

A Configuration – A/T

B Configuration – M/T 1. Manifold to Front Pipe Flange

2. Front Exhaust Brace

3. Front Support Rubber/s

4. Catalyst

5. Catalyst to Intermediate Pipe

Flange Joint

6. Intermediate Muffler

7. Intermediate Muffler Support Rubbers

8. Intermediate to Rear Pipe Slip Joint and

U-bolt clamp

9. Rear Muffler

10. Rear Muffler Support Rubbers

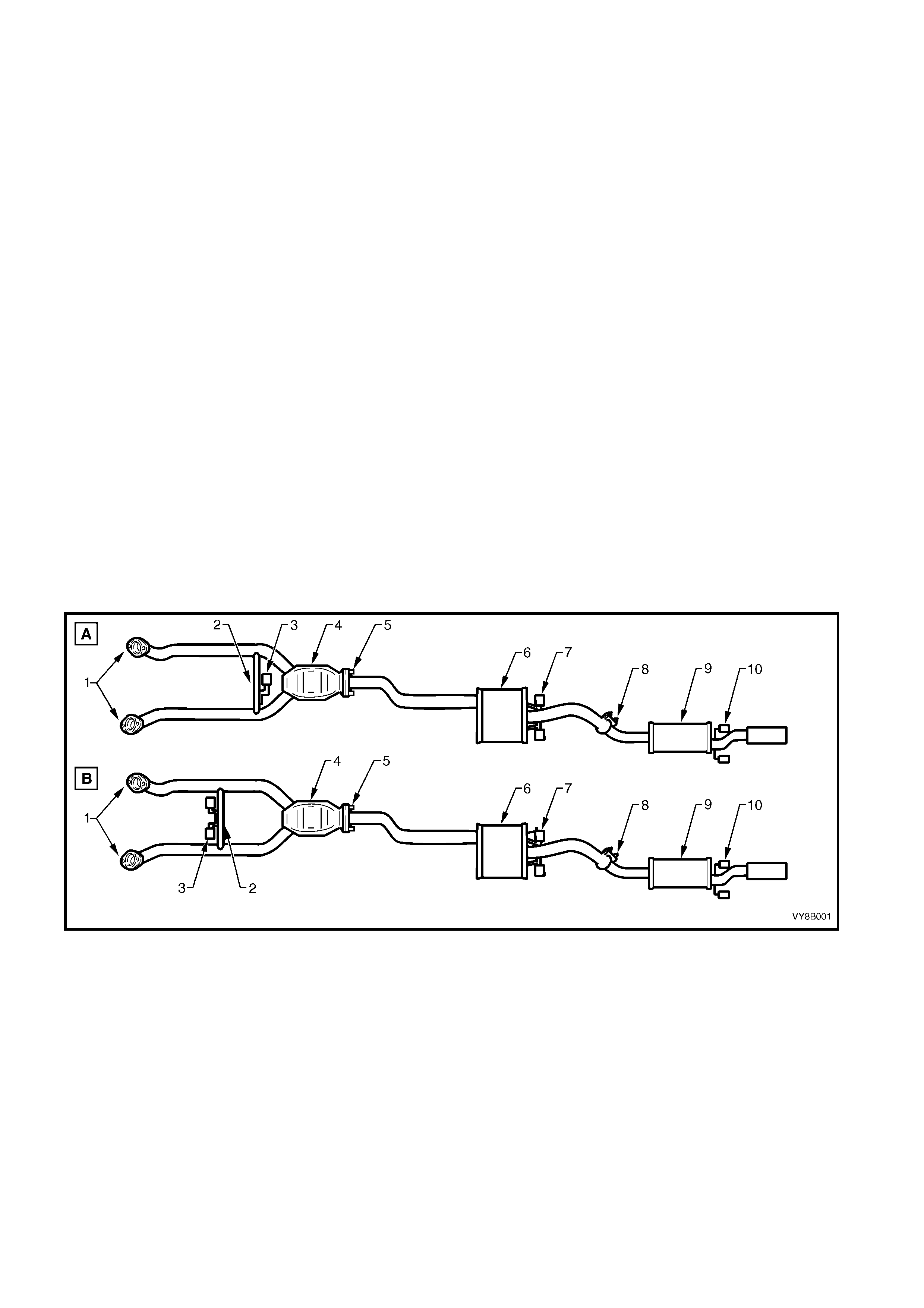

V6 ENGINE EXHAUST SYSTEM – EXPORT FOR INDONESIA

Refer to Figure 8B-2 for the following.

The exhaust system fitted to Indonesian export vehicles is identical to the standard V6 engine exhaust (refer to

V6 ENGINE EXHAUST SYST EM ) ex c ept that the c atalytic conver ter is replac ed with a m uffler ( 1) . View A and view

B show automatic and manual transmission configurations respectively.

Figure 8B-2

Legend

A Configuration – A/T

B Configuration – M/T 1. Muffler

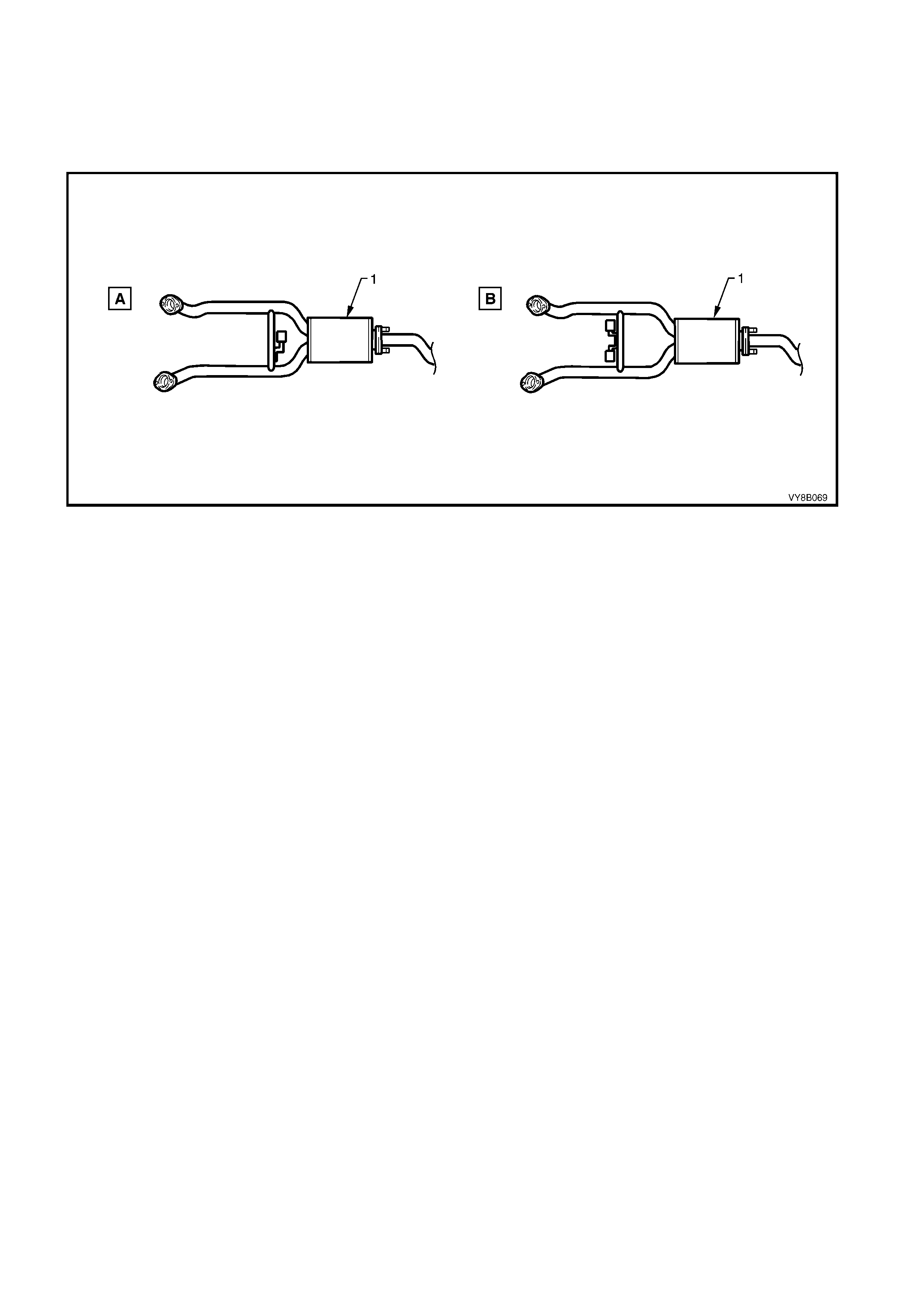

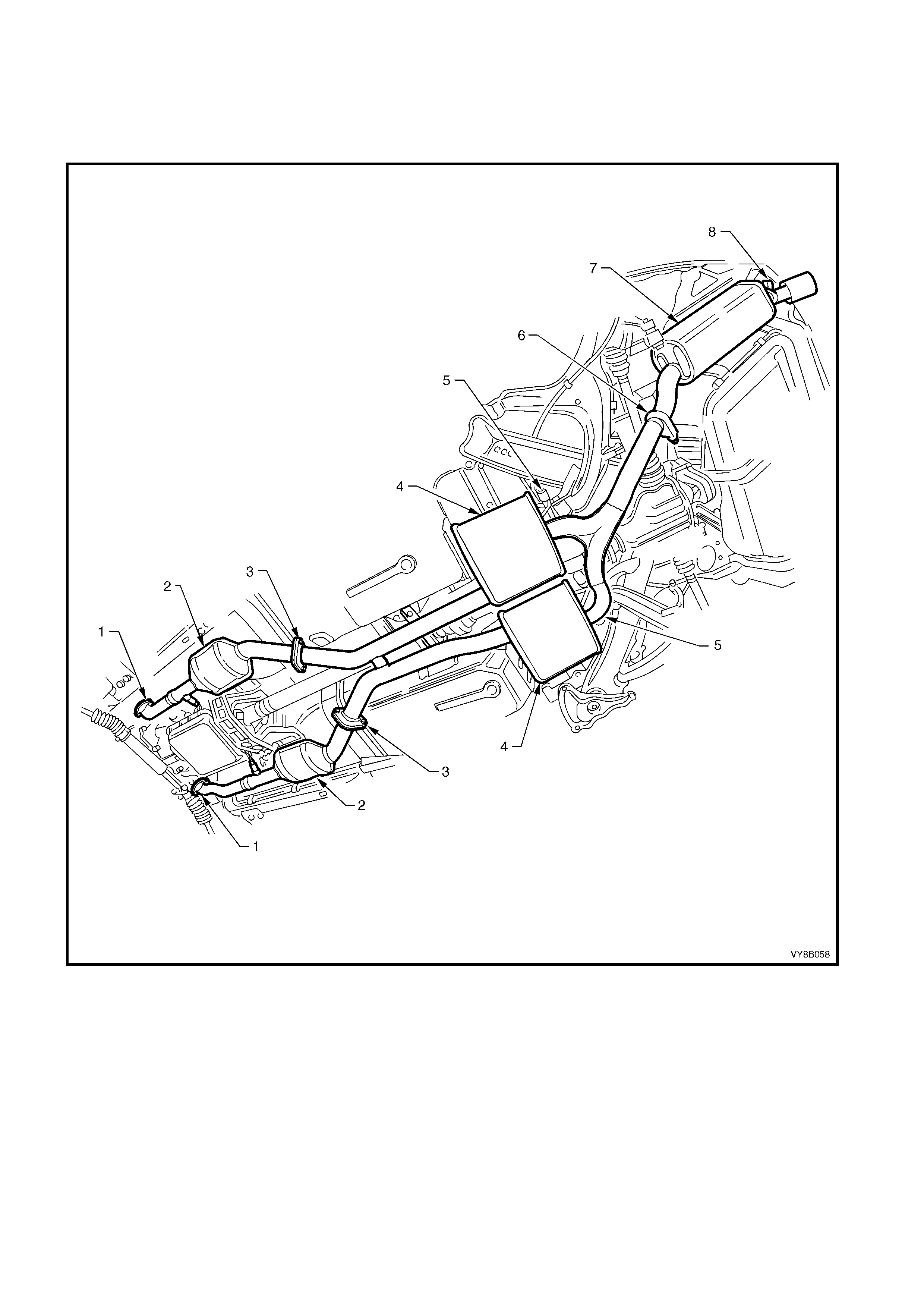

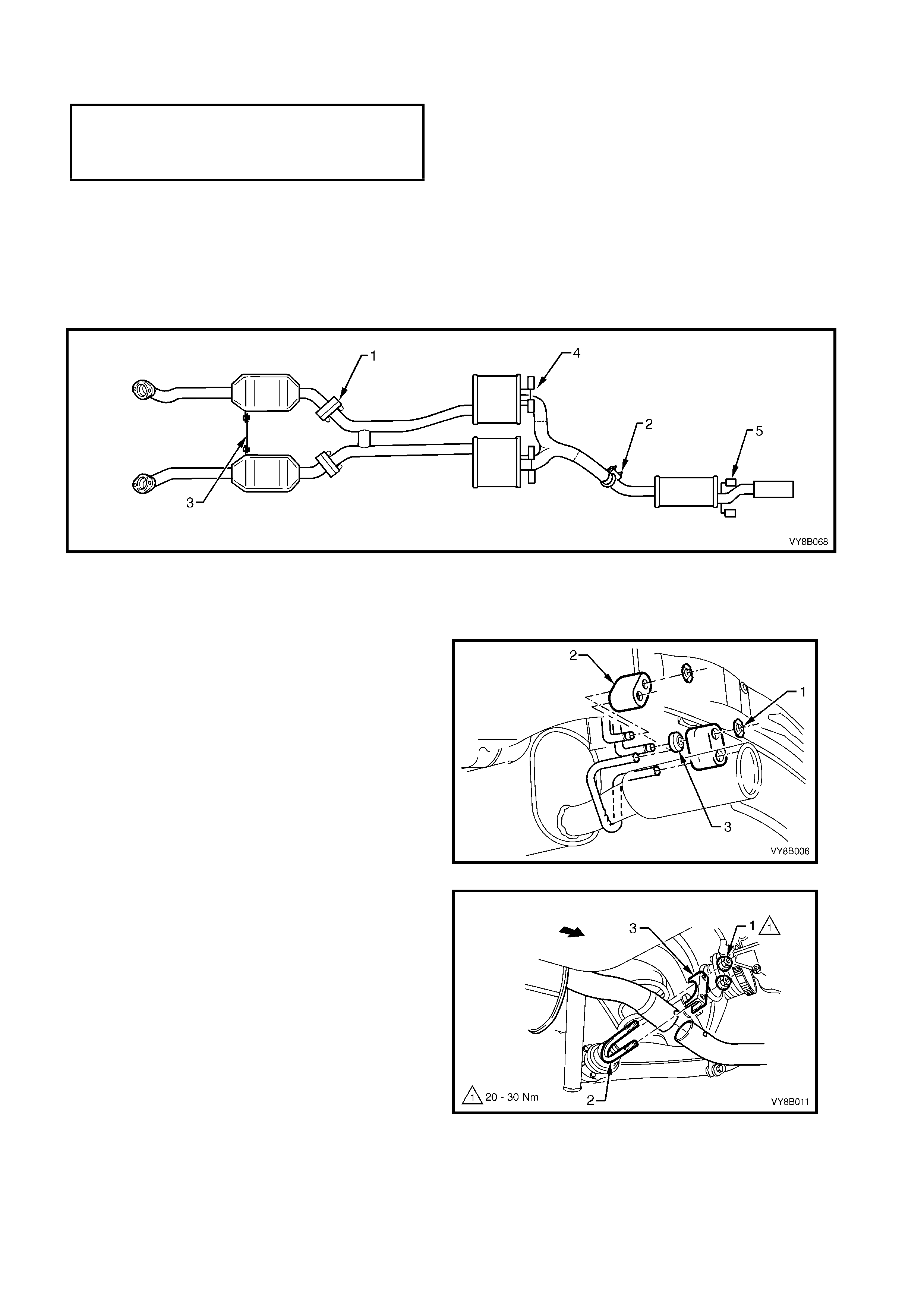

V6 SUPERCHARGED ENGINE EXHAUST SYSTEM

Refer to Figure 8B-3 for the following.

The V6 Supercharged engine exhaust manifolds are connected to a pair of stainless steel front pipes, by flanged

joints (1). The exhaust system features a low backpressure exhaust configuration and maintains a dual exhaust

system back to the rear of the twin intermediate mufflers (4).

The pipes then c onverge into a s ingle pipe that is jo ined to the rear exhaus t as s embly with a s lip j oint (6) and U-bolt

clam p. Coupe vehicles use a gas keted f lange joint at this location. A catalytic converter (2) is welded to each of the

front engine pipes and a flanged, gasketed joint (3) connects each converter to the twin, intermediate exhaust

pipes. The two intermediate exhaust pipes are stiffened by a welded bridging piece at points before the twin

intermediate mufflers. This bridging piece also acts as an exhaust balance pipe.

The intermediate exhaust assembly is supported at each of the intermediate mufflers by a pair of support rubbers

(5) attached to hangers welded to the vehicle underbody. The rear exhaust assembly is supported by two support

rubbers ( 8), which ar e attac hed to hangers welded to the vehicle underbody and to pegs welded to the rear tail pipe,

behind the rear muffler (8). The support rubbers are a common part for all locations and are secured by retainer

clips at both the intermediate and rear body hangers. Flanged pegs are used at other locations.

Figure 8B-3

Legend

1. Manifold to Front Pipe Flange

2. Catalyst

3. Catalyst to Intermediate Pipe Flange Joint

4. Intermediate Muffler

5. Intermediate Muffler Support Rubbers

6. Intermediate to Rear Pipe Slip Joint and U-clamp

7. Rear Muffler

8. Rear Muffler Support Rubbers

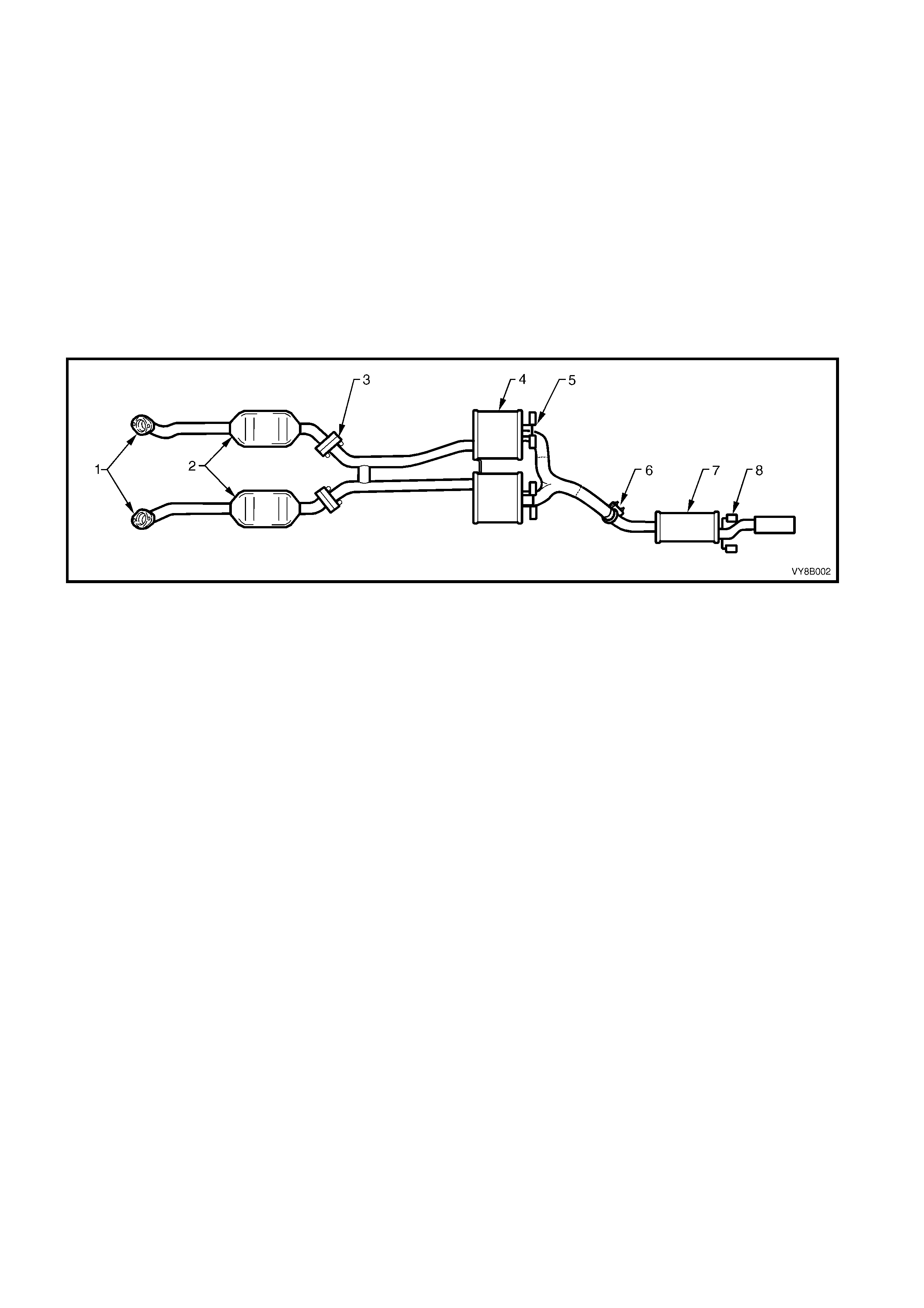

GEN III V8 ENGINE EXHAUST SYSTEM

Two exhaust s ystem conf igurations , Standard and Perf orm ance, ar e available for vehic les fitted with the GEN III V8

engine. The type installed will depend on the particular vehicle’s specifications.

Standard:

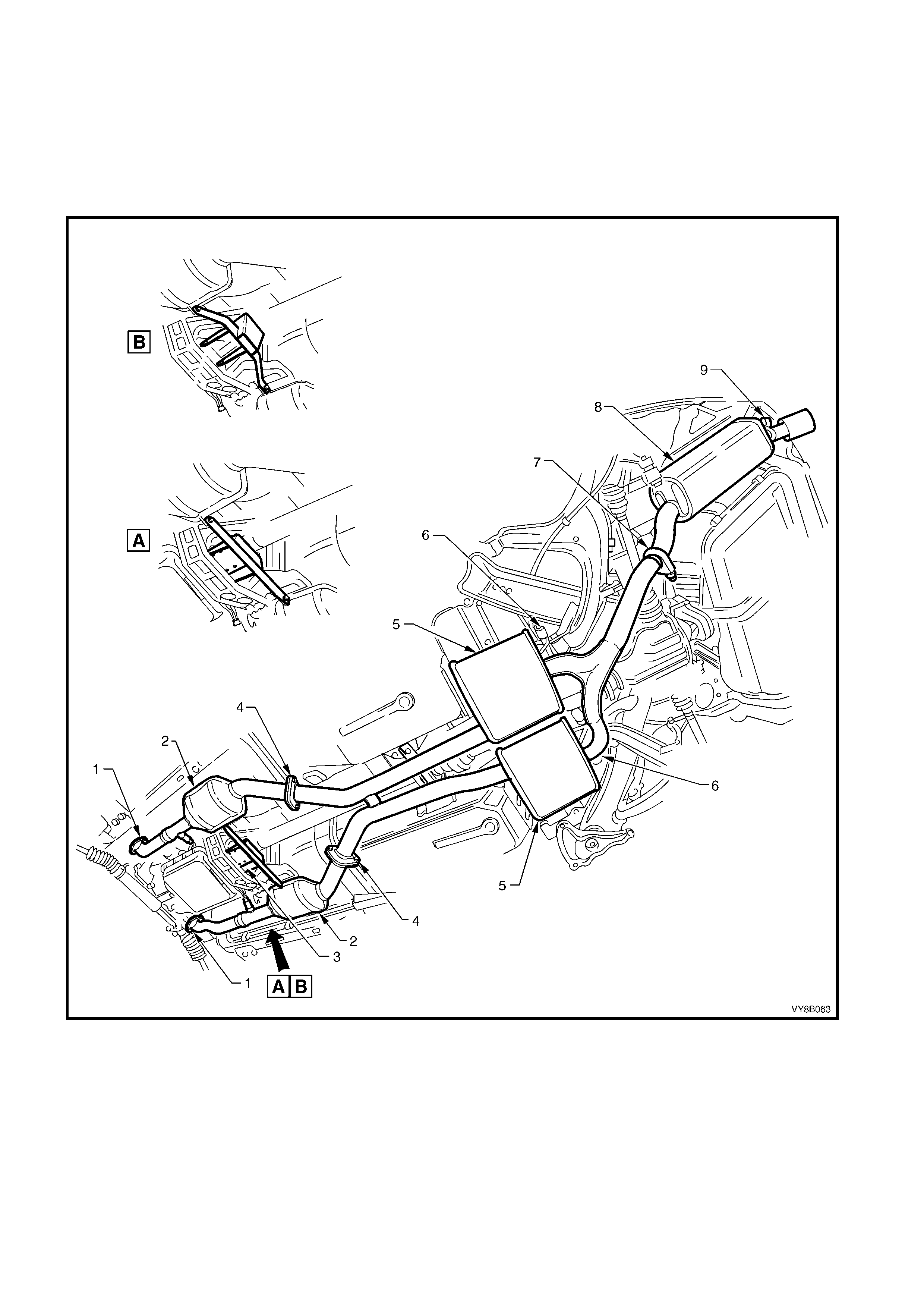

Refer to Figure 8B-4 for the following.

The G EN III V8 engine exhaust m anif olds are c onnected to a pair of stainles s steel f ront pipes by flanged joints (1).

The front exhaust pipes feature a dual wall air gap construction. A dual exhaust system is retained past the twin

intermediate mufflers (5). The pipes then converge into a single pipe that is joined to the rear exhaust assembly with

a slip joint (7) and U-bolt clamp. Coupe vehic les use a gasketed f lange joint at this location. T he rear exhaust pipe

joins to the rear muffler (8), which features a single tail exhaust pipe.

A catalytic converter (3) is welded to each front exhaust pipe, with a flanged, gasketed joint (4) connecting each

converter to the twin, intermediate exhaust pipes. The two intermediate exhaust pipes are stiffened by a welded

bridging piece at points before the twin interm ediate mufflers. This bridging piece also acts as an exhaust balance

pipe.

The intermediate exhaust assembly is supported at each of the intermediate mufflers (5) by a pair of support

rubbers (6) attached to hangers welded to the vehicle underbody. The rear exhaust assembly is supported by two

support rubbers (9) attached to hangers welded to the vehicle underbody and to pegs welded to the rear tail pipe.

For further support, a bracket (2) is bolted between each converter and is fastened to the transmission extension

housing. T his s upport conf iguration is diff erent f or autom atic and m anual transm issions. T he support rubber s are a

common part for all locations and are secured by retainer clips at both the intermediate and rear body hangers.

Flanged pegs are used at other locations.

NOTE: Left-hand drive Sedan, Wagon and Coupe export vehicles use a similar exhaust configuration.

Figure 8B-4

Legend

1. Manifold to Front Pipe Flange

2. Front Exhaust Brace

3. Catalyst

4. Catalyst to Intermediate Pipe Flange Joint

5. Intermediate Muffler

6. Intermediate Muffler Support Rubbers

7. Intermediate to Rear Pipe Slip Joint and U-clamp

8. Rear Muffler

9. Rear Muffler Support Rubbers

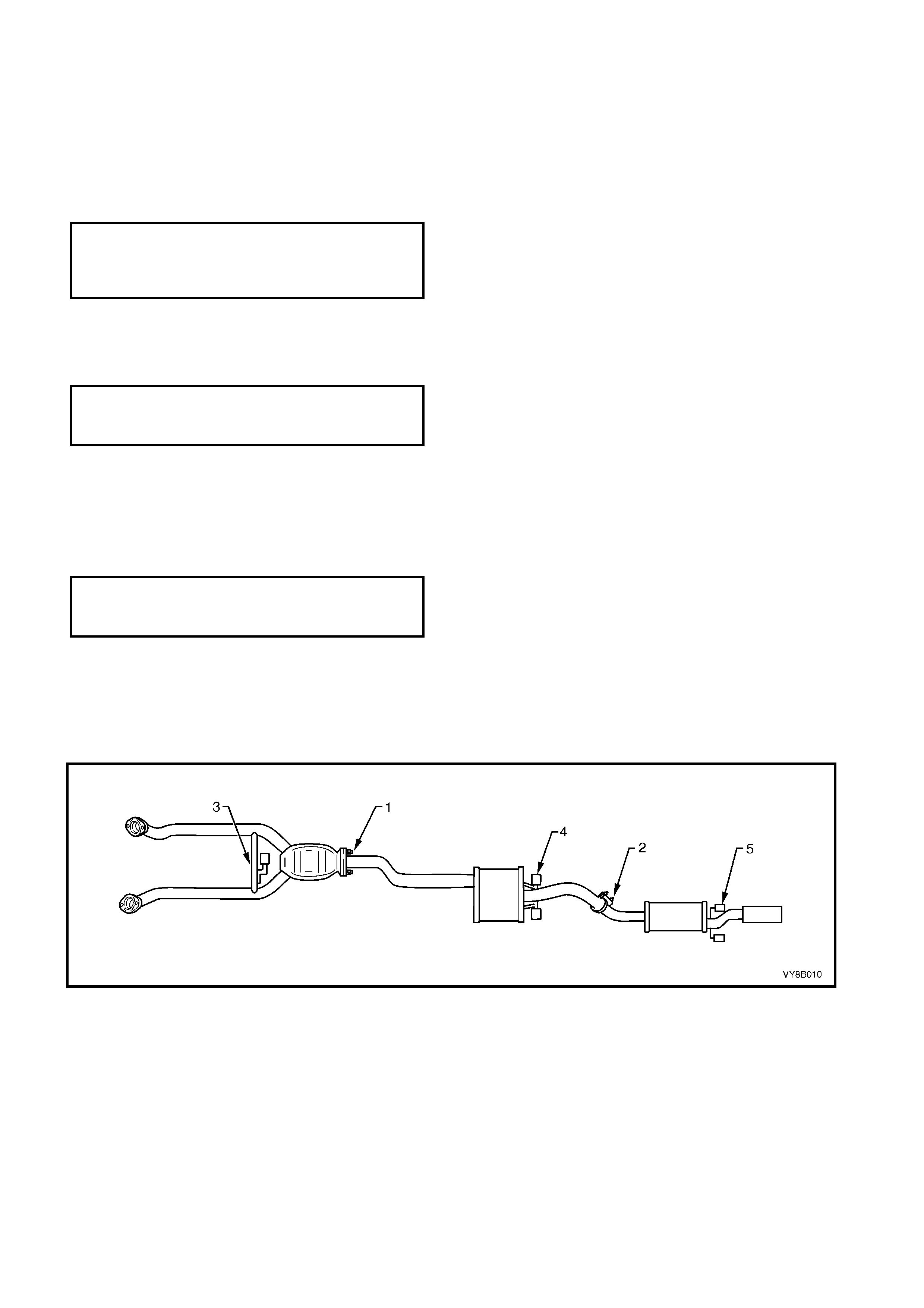

Performance:

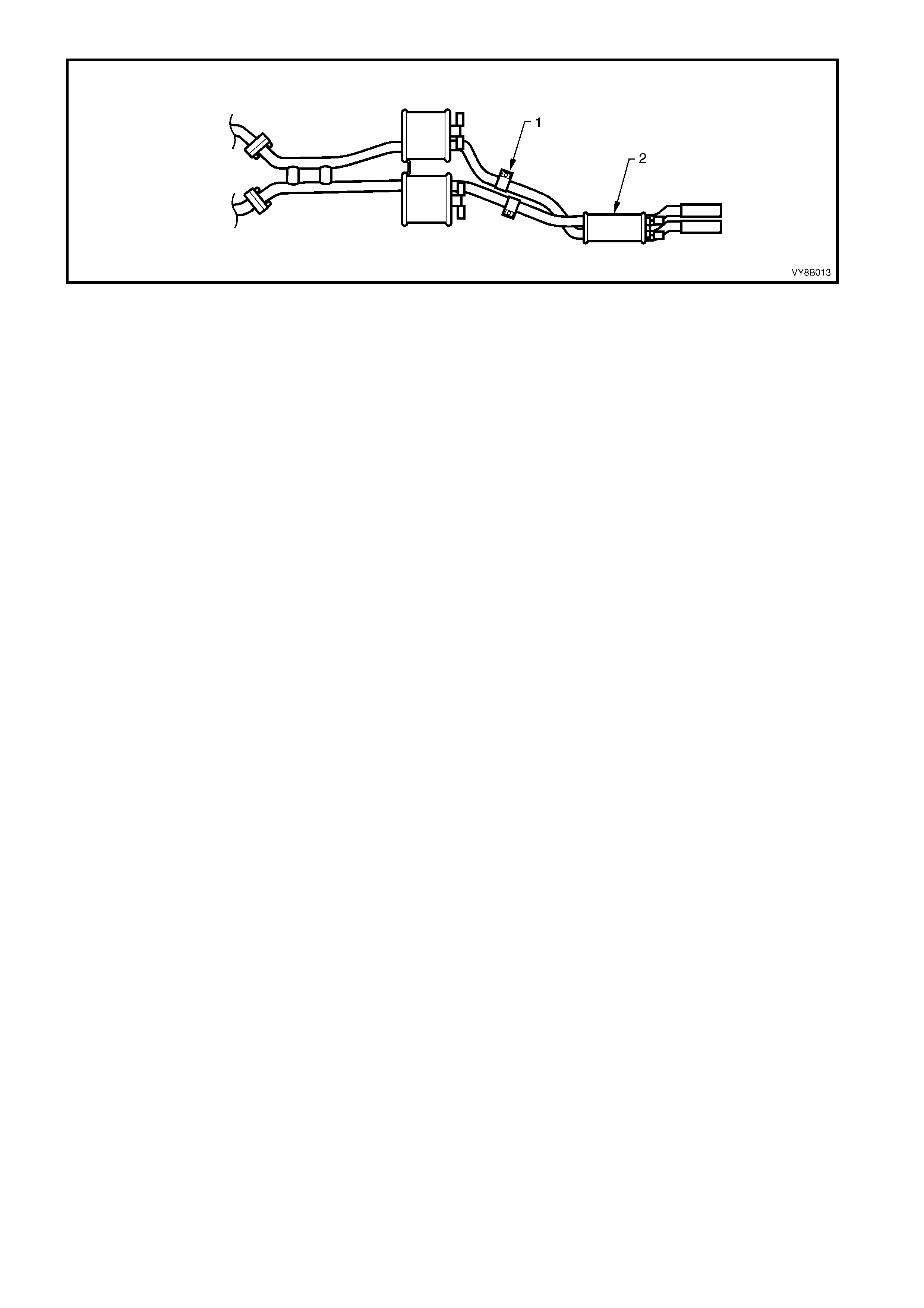

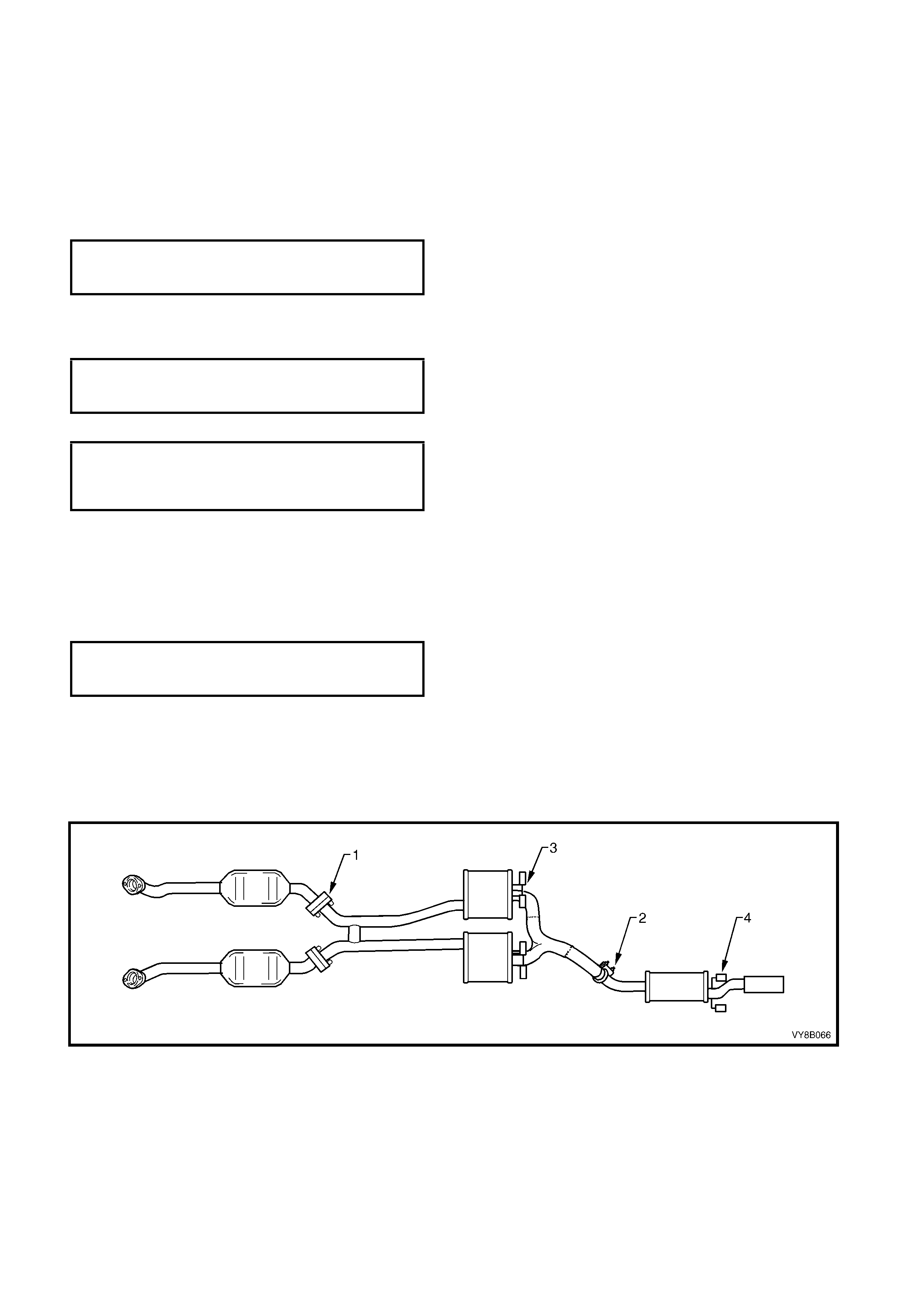

Refer to Figure 8B-5 for the following.

The front exhaust assembly of the Performance exhaust system is identical to the Standard front exhaust assembly,

as shown in Figure 8B-4. The intermediate exhaust assembly incorporates two exhaust balance pipes welded at

points befor e the twin interm ediate m uff lers. T he pipes r unning from the interm ediate m u ff lers are j oined to the rear

exhaust pipes with individual slip j oints and ring clam ps (1). The rear ex haust pipes join to a s ingle rear m uffler ( 2),

which features dual tail exhaust pipes.

Figure 8B-5

Legend

1. Intermediate to Rear Pipe Slip Joints and Ring Clamps

2. Rear Muffler

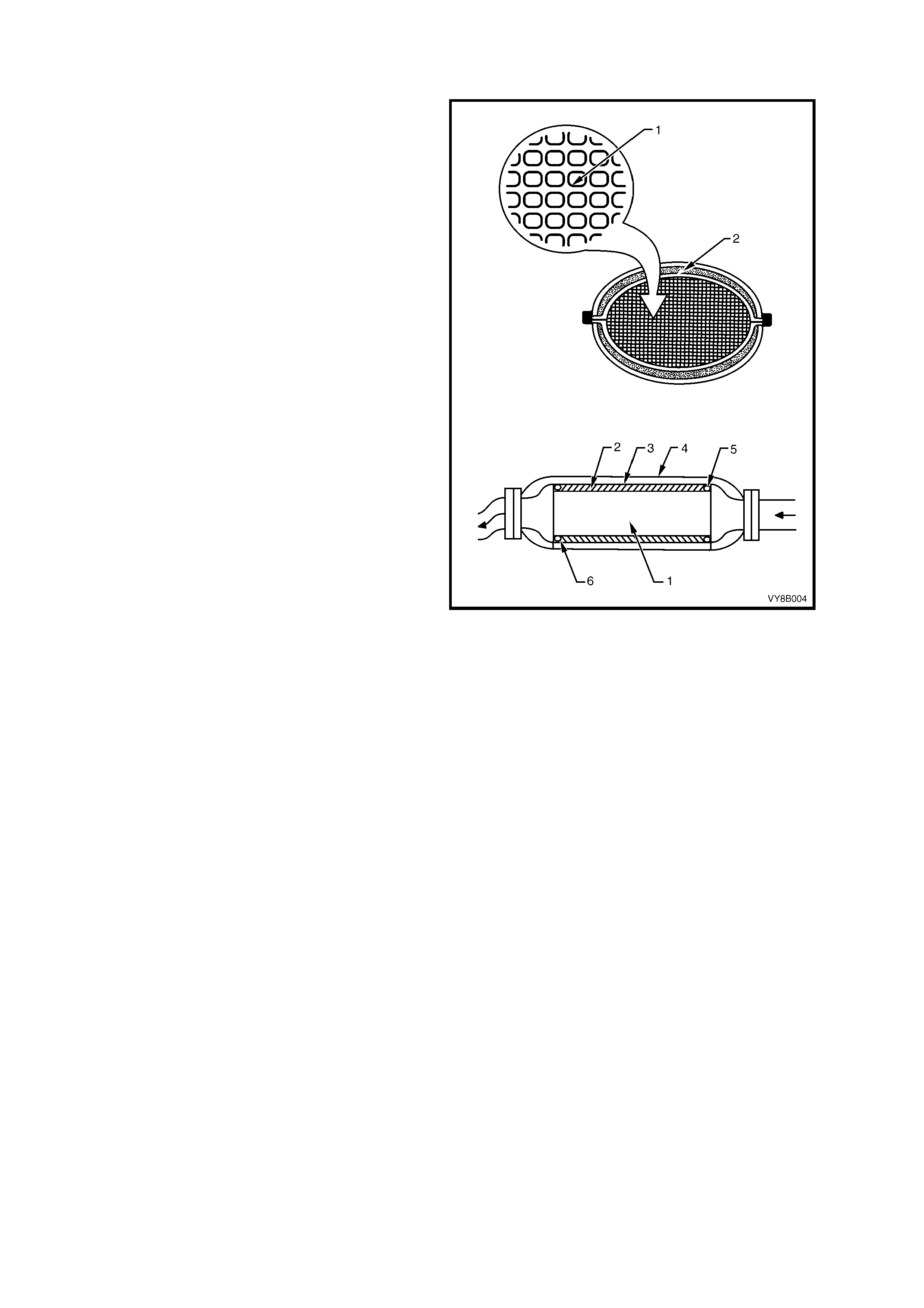

1.2 CATALYTIC CONVERTER

NOTE: Catalytic converters are fitted to all vehicles,

except those exported to Indonesia.

The catalytic converter is similar to a muffler in

appearance however, within the outer stainless

steel shell (4), the there is a ceramic monolith (1)

which is honeycombed in the direction of exhaust

flow, as shown. The ceramic monolith is

surrounded by a mat (2), which has the primary

function of holding the monolith firmly in place to

prevent any contact with the inner shell (3). A mesh

seal (5 and 6) at each end of the converter

prevents exhaust gases from fouling and eroding

the mat.

Surfaces of the ceramic monolith that are exposed

to exhaust gases are coated with a catalytic

material. This material contains rhodium and

platinum, which act to facilitate the chemical

reactions necessary to oxidise carbon monoxide

and hydrocarbons into harmless carbon dioxide.

The c atalytic ma terial is very sensitive to the ef f ec ts

of a rich or lean f uel mixture, which m ay cause the

temperature of the converter to rise rapidly. The

catalytic converter normally operates at

approximately 600° C.

CAUTION: Excessively rich or lean fuel mixture

can cause sudden failure of the catalytic

converter.

The catalytic converter is also sensitive to the use

of leaded petrol. Using leaded fuel can cause

deposits to form in the converter, which restrict

exhaust f low and prevent the catalyst from work ing.

This will result in an increase in exhaust

backpressure and converter temperature.

NOTE: The use of unleaded petrol results in black

tailpipe deposits rather than the grey colour that

some people may normally associate with an

acceptable combustion condition. This blac k colour

resulting from the use of unleaded fuel does not

necessarily indicate a state of poor engine tune.

Refer to Section 6E1, EMISSION CONTROL, for

more information regarding this topic.

Figure 8B-6

2. SERVICE OPERATIONS - V6

2.1 SERVICE NOTES

When installing any exhaust system component, care must be taken to install each component in the correct

relationship to the other. Ensure that correct assembly, installation, tightening sequence, tightening torque and

clearances for the system involved are observed. When exhaust system service work is required, refer to the

various illustrations and instructions provided in this section.

NOTE 1: T he inc or rec t as s embly of exhaust system c omponents c an f r equently be the cause of rattles and ‘booms'

due to incorrec t alignment or clearance of body or suspens ion parts. Ensure that the correc t tightening s equence is

observed upon installation of exhaust system components.

NOTE 2: Catalytic converters and oxygen sensors are fitted to all vehicles, except those exported to Indonesia.

Illustrations within this section represent vehicles with these components fitted. Any significant differences in

service oper ations for vehicles ex ported to Indonesia will be highlighted and a procedure or illus tration produced to

accommodate the difference.

CATALYTIC CONVERTER

The catalytic converter is serviced as a complete assembly only. If removing or replacing the converter, always

check the sealing ring for damage and replace if necessary.

OXYGEN SENSORS

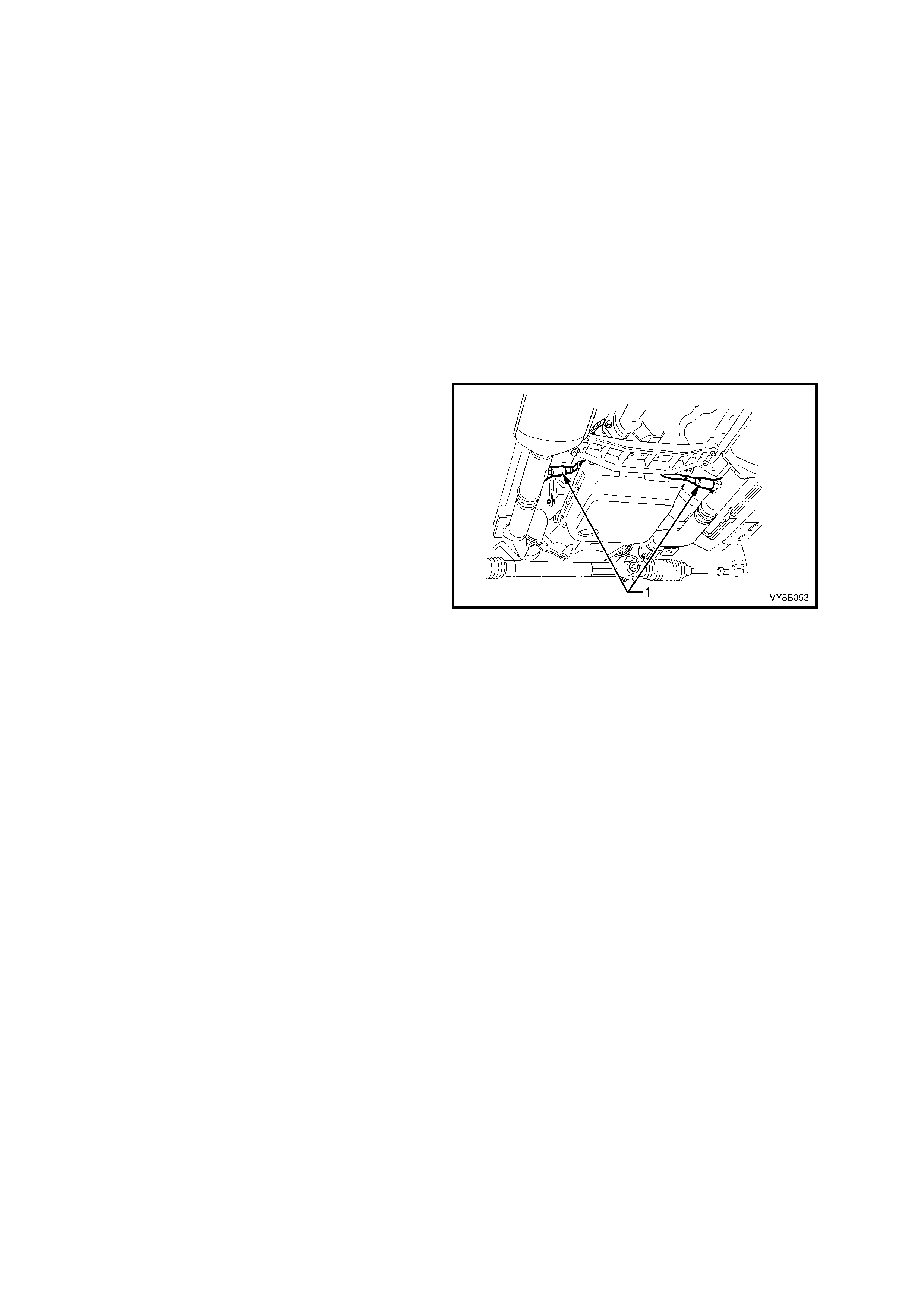

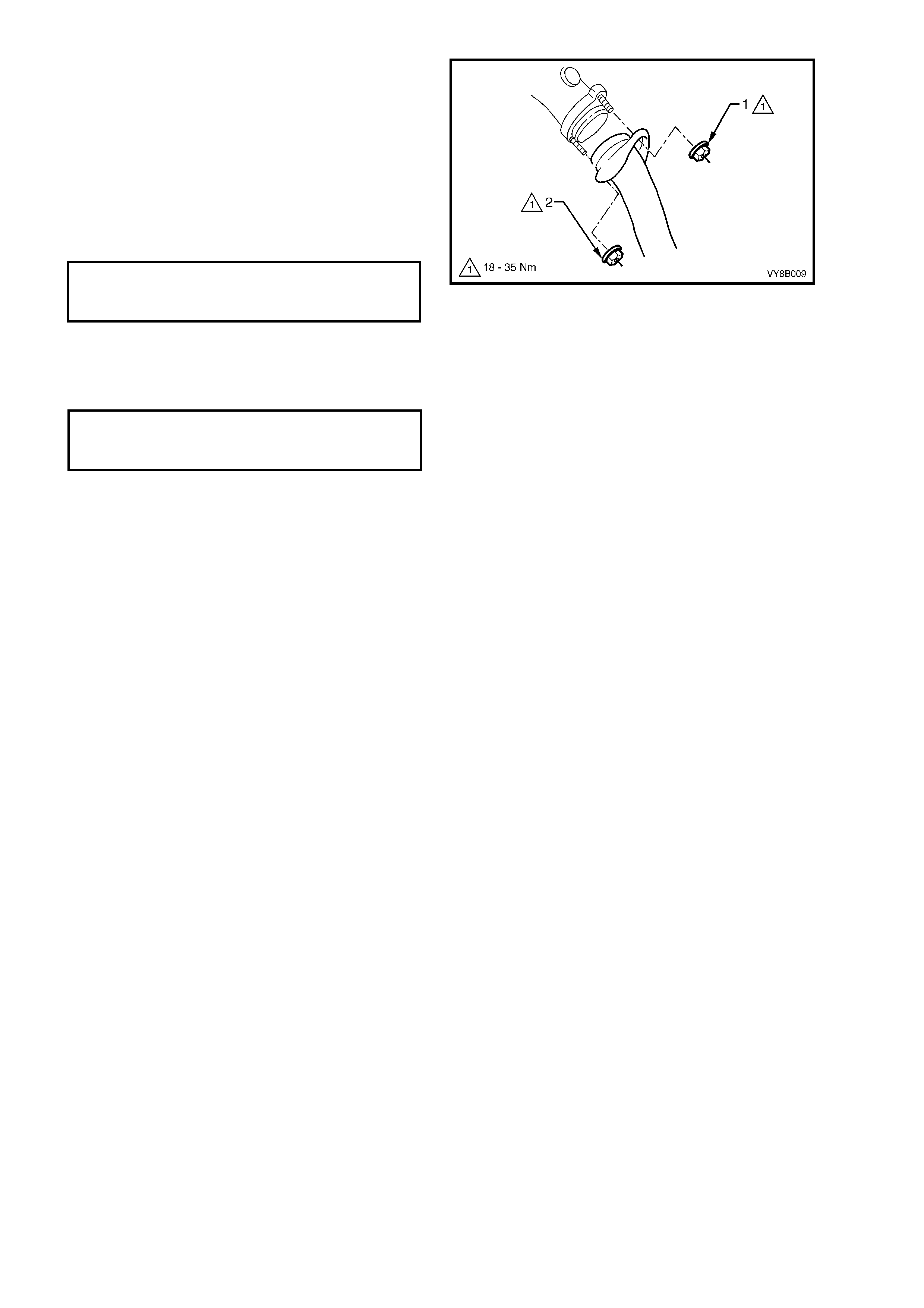

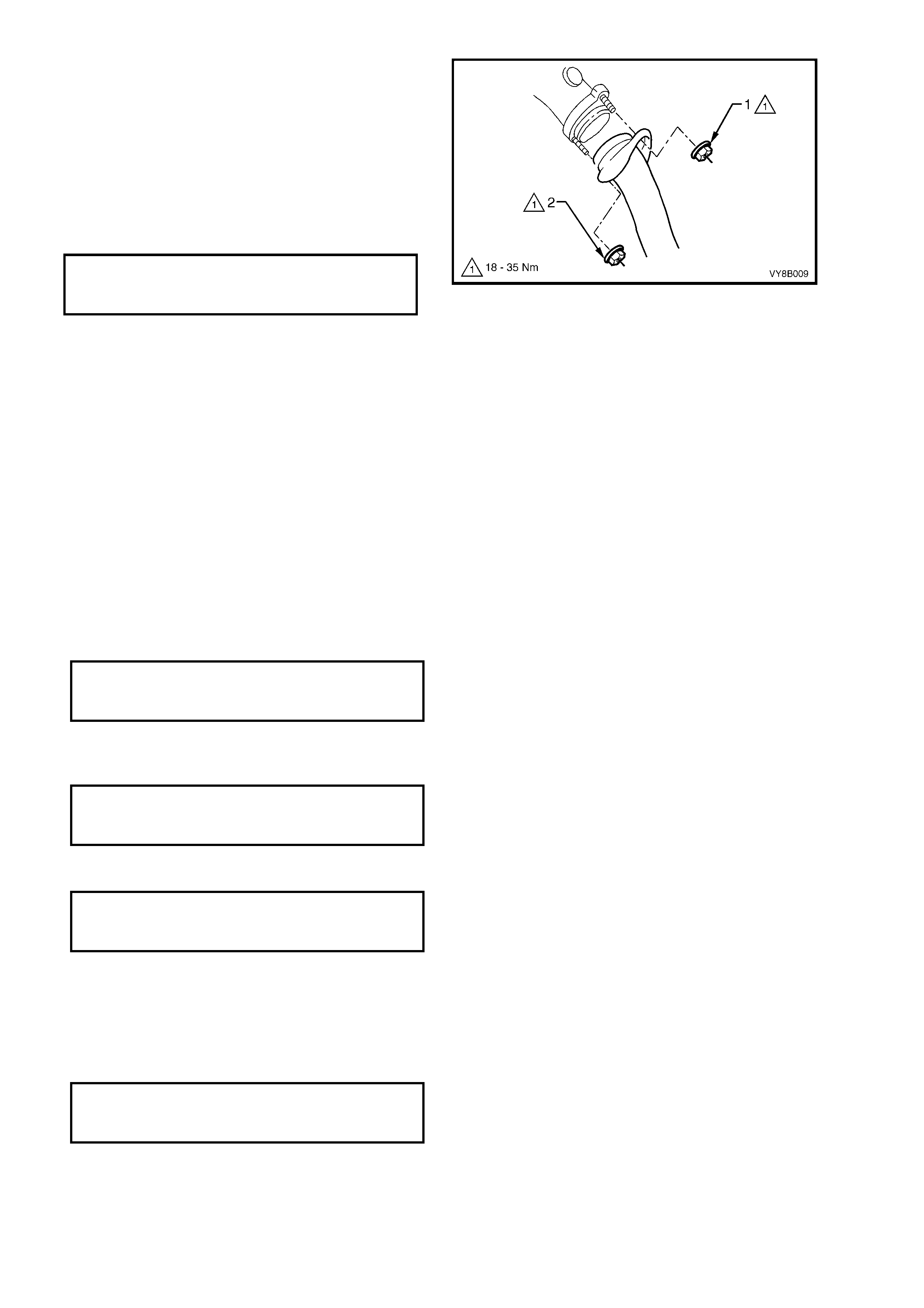

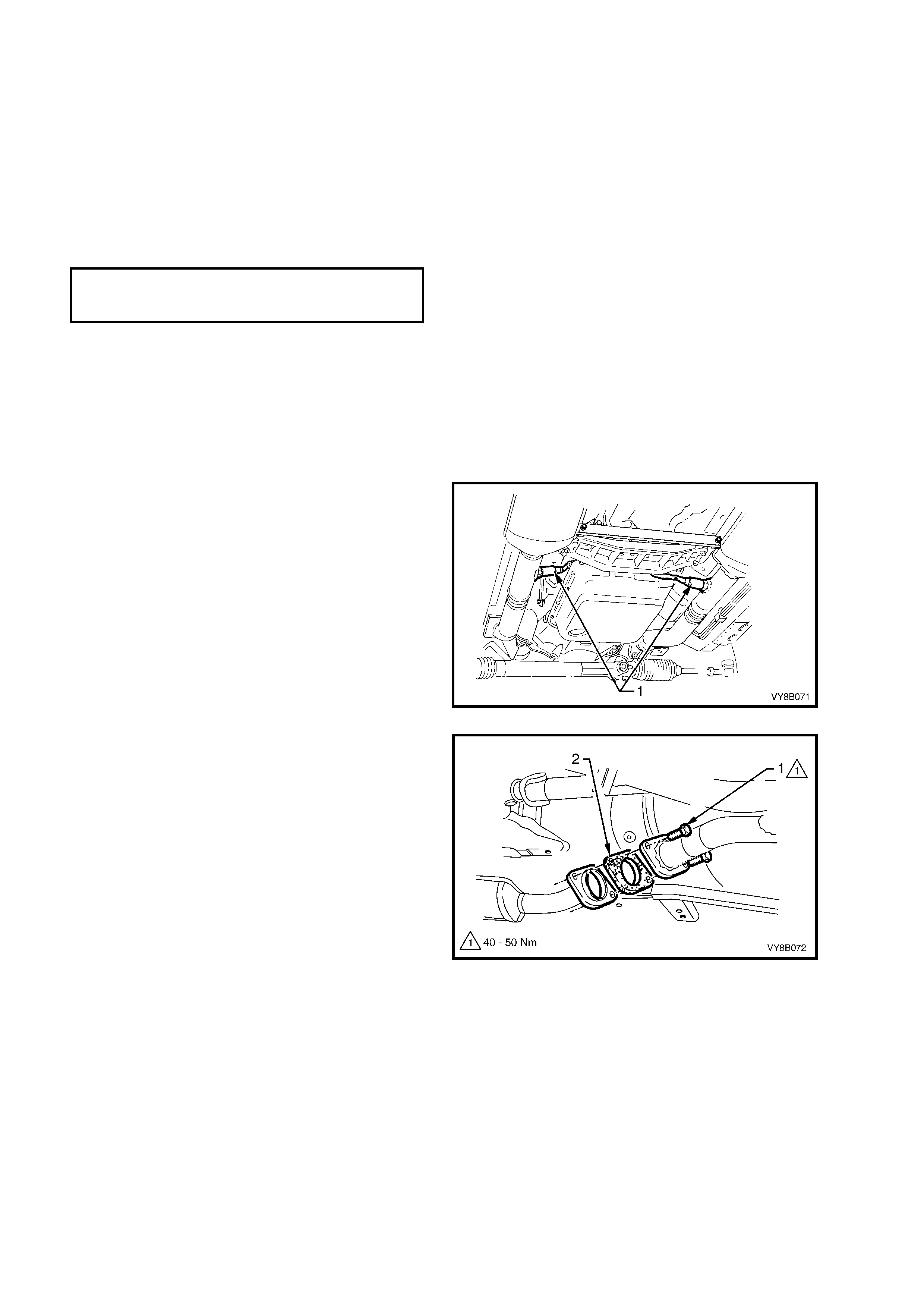

When removing the front exhaust pipes, it

is necessary to disconnect the wiring harness

connectors from each of the two oxygen

sensors (1).

For oxygen sensor replacement, refer to

Section 6C1-3, 2.6 OXYGEN SENSOR.

NOTE: Oxygen sensors are not fitted to Indonesia

vehicles.

Figure 8B-7

2.2 EXHAUST SYSTEM

Figure 8B-8 illustrates the exhaust system configuration used with the V6 engine.

Figure 8B-8

Legend

A Configuration – A/T

B Configuration – M/T 1. Manifold to Front Pipe Flange

2. Front Exhaust Brace and Rubber

Support

3. Catalyst (muffler used on Export for

Indonesia vehicles)

4. Flange Joint

5. Intermediate Muffler

6. Intermediate Muffler Support

Rubbers

7. Intermediate to Rear Pipe Slip

Joint and U-clamp

8. Rear Muffler

9. Rear Muffler Support Rubbers

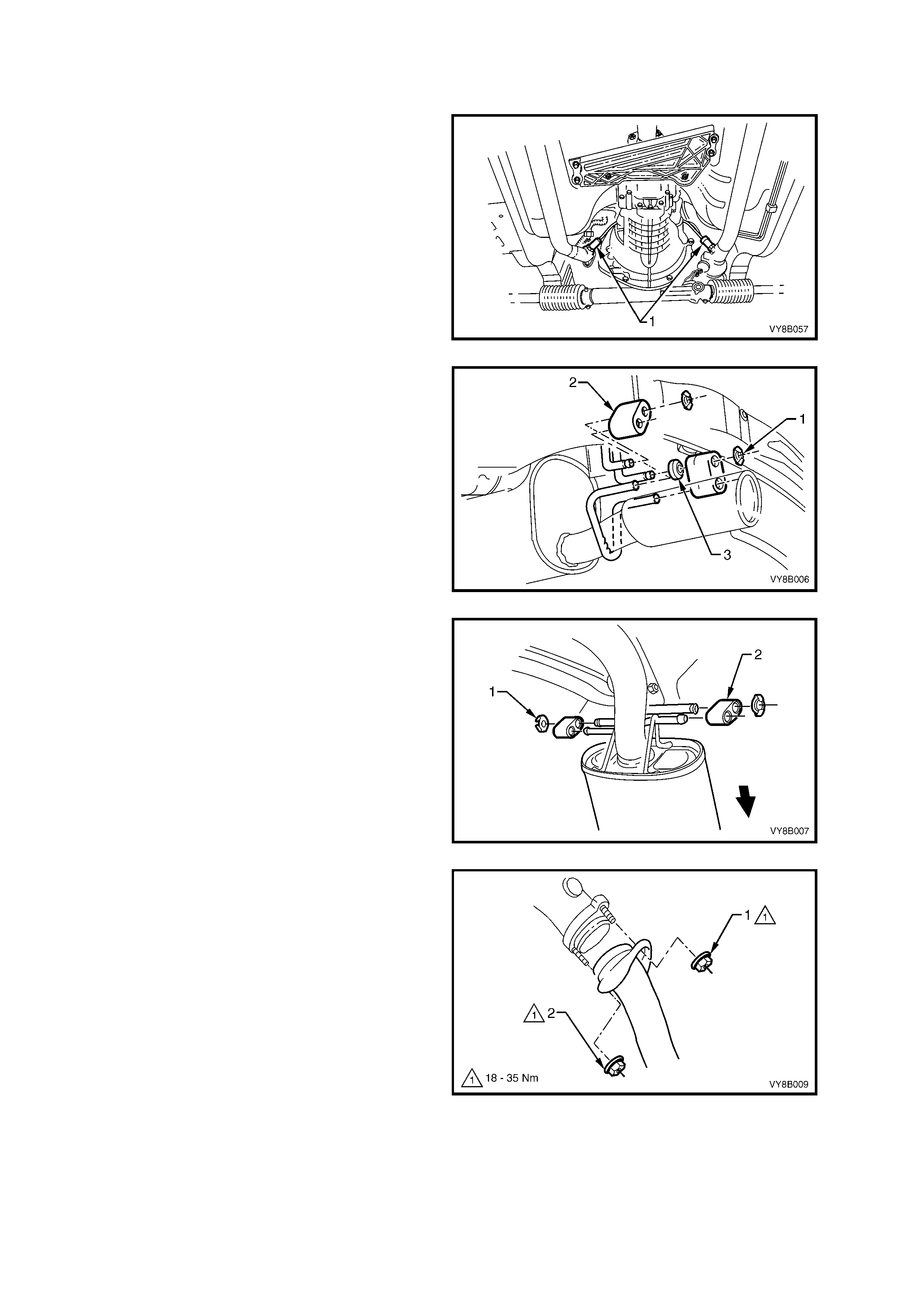

COMPLETE EXHAUST SYSTEM ASSEMBLY

Remove

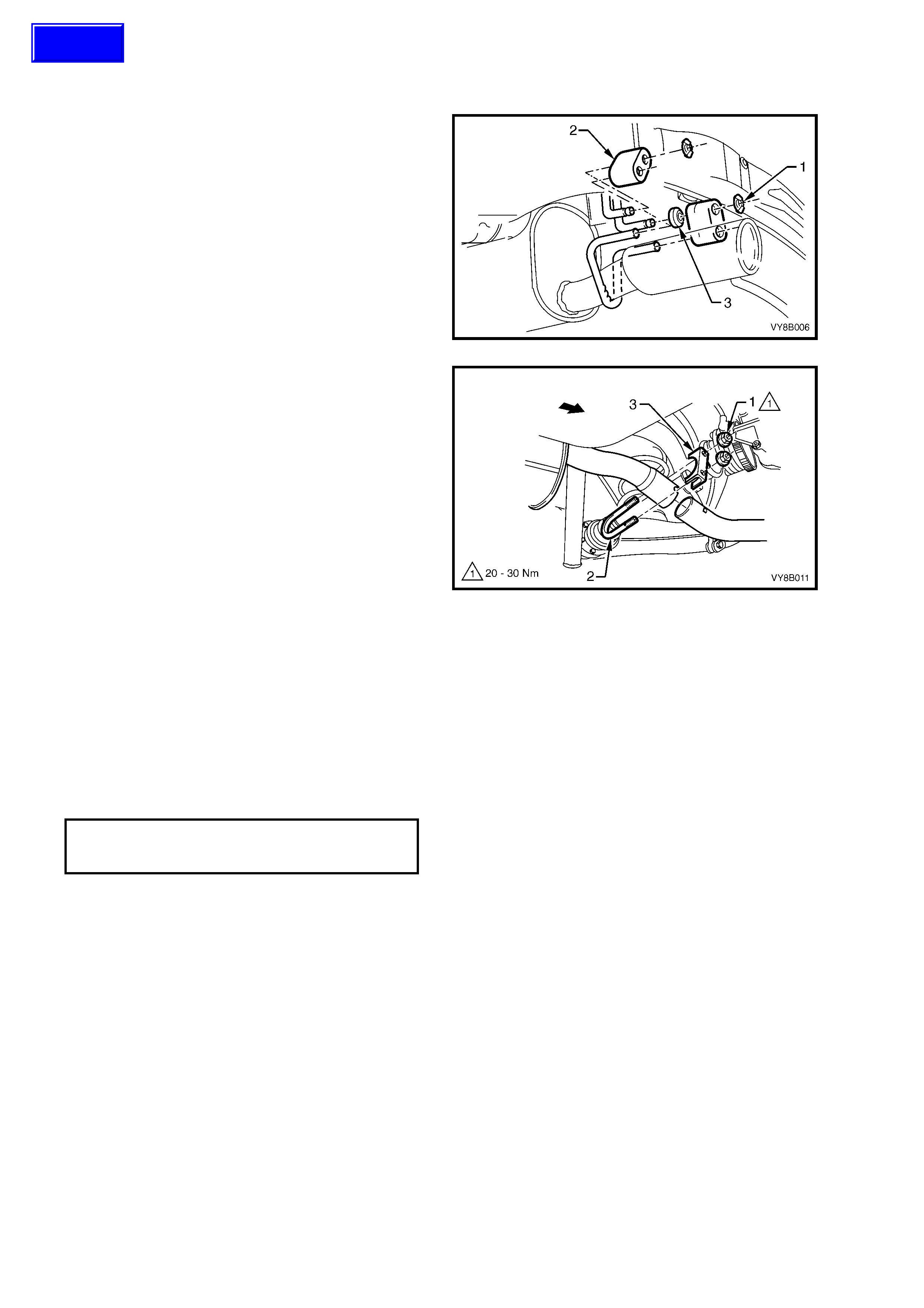

1. Disconnect the wiring harnes s connectors f rom

each of the two oxygen sensors (1).

NOTE: Oxygen sensors are not fitted to Indonesia

vehicles.

Figure 8B-9

2. Disconnect the rear muffler from the support

hangers by removing the two retainer clips (1)

and two support rubbers (2).

NOTE: The additional bumper washer (3) is fitted

to Utility vehicles only.

Figure 8B-10

3. Support the exhaust system and disconnect the

intermediate muffler from the support hangers

by removing the two retainer clips (1) and the

two support rubbers (2).

Figure 8B-11

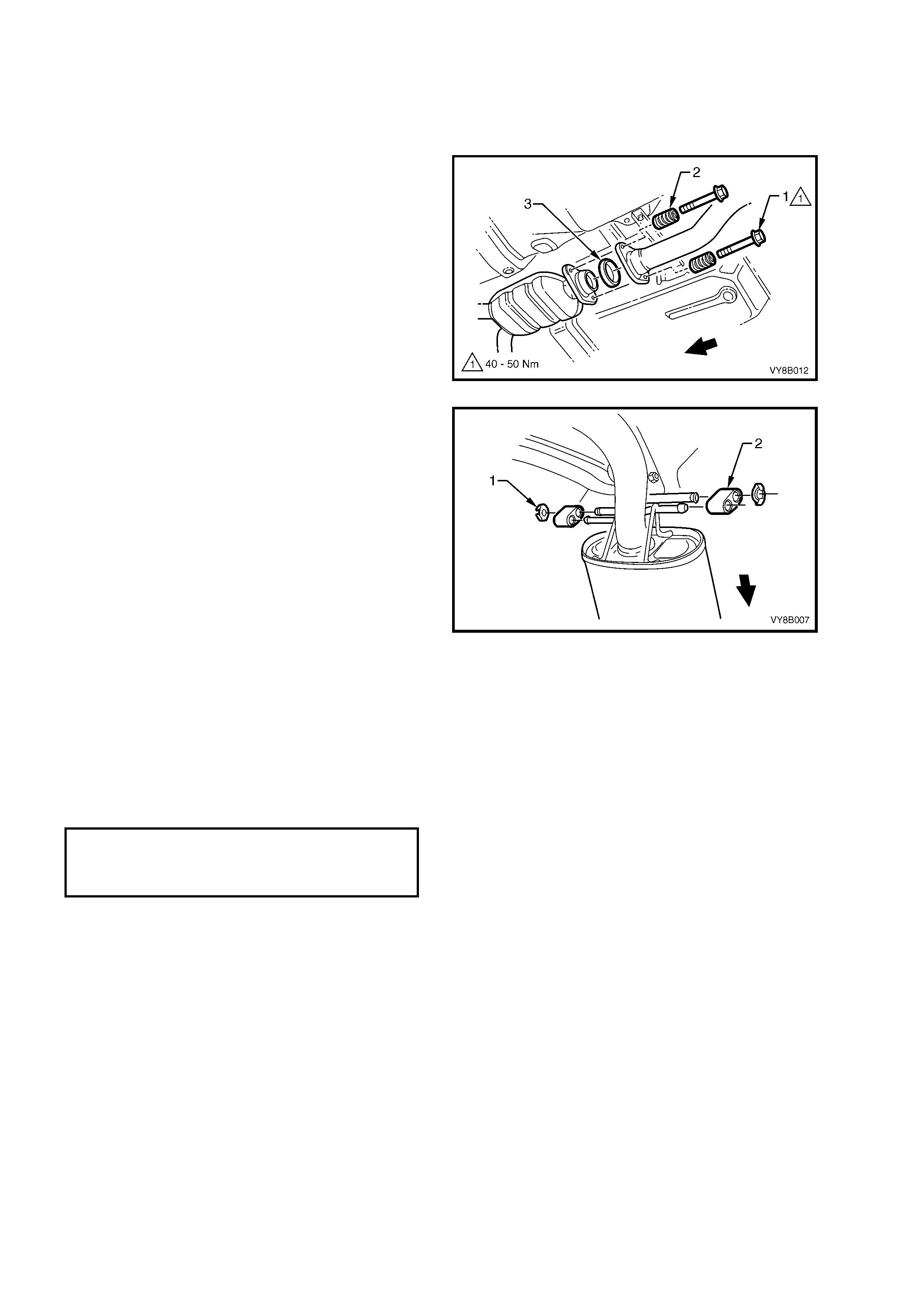

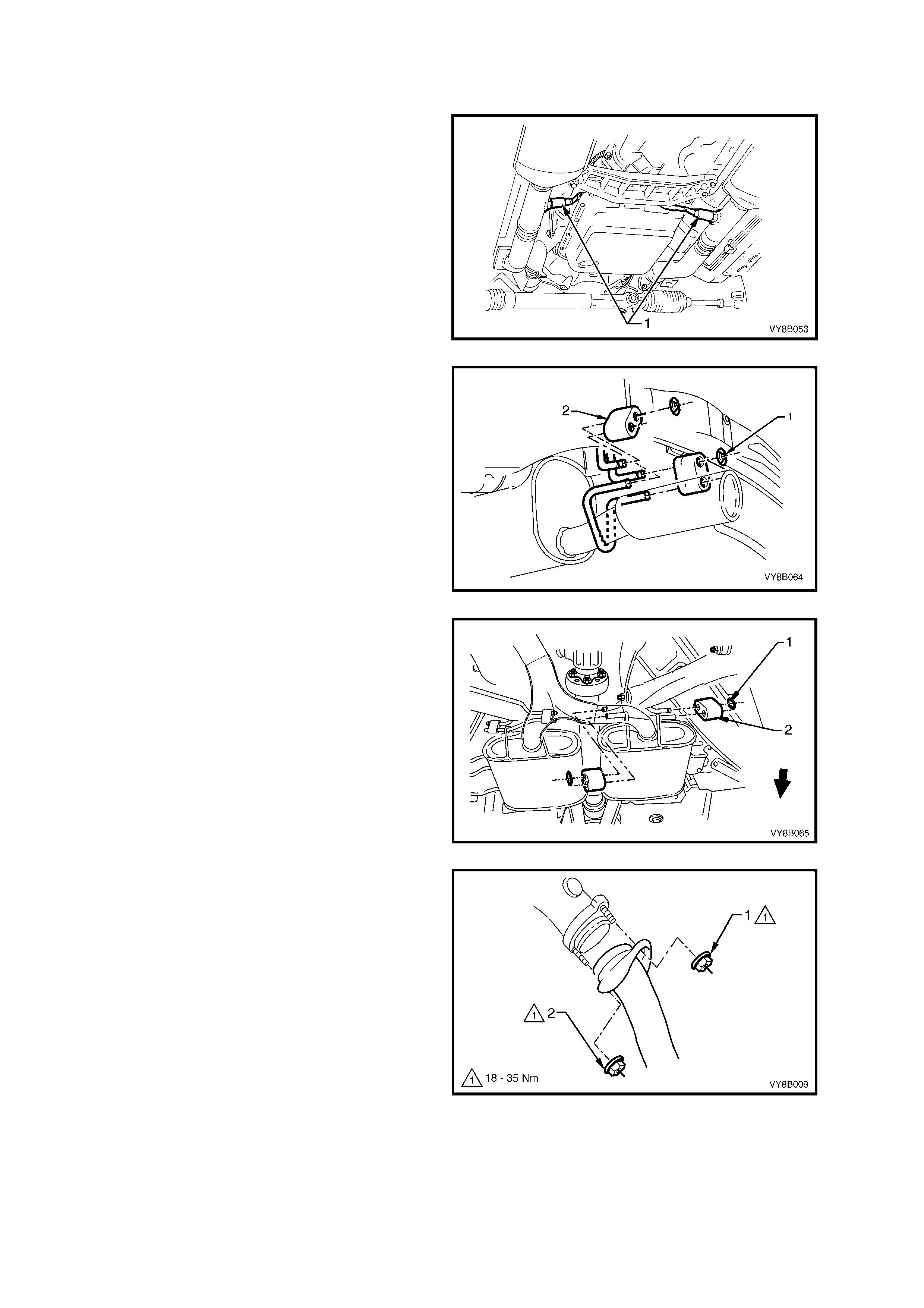

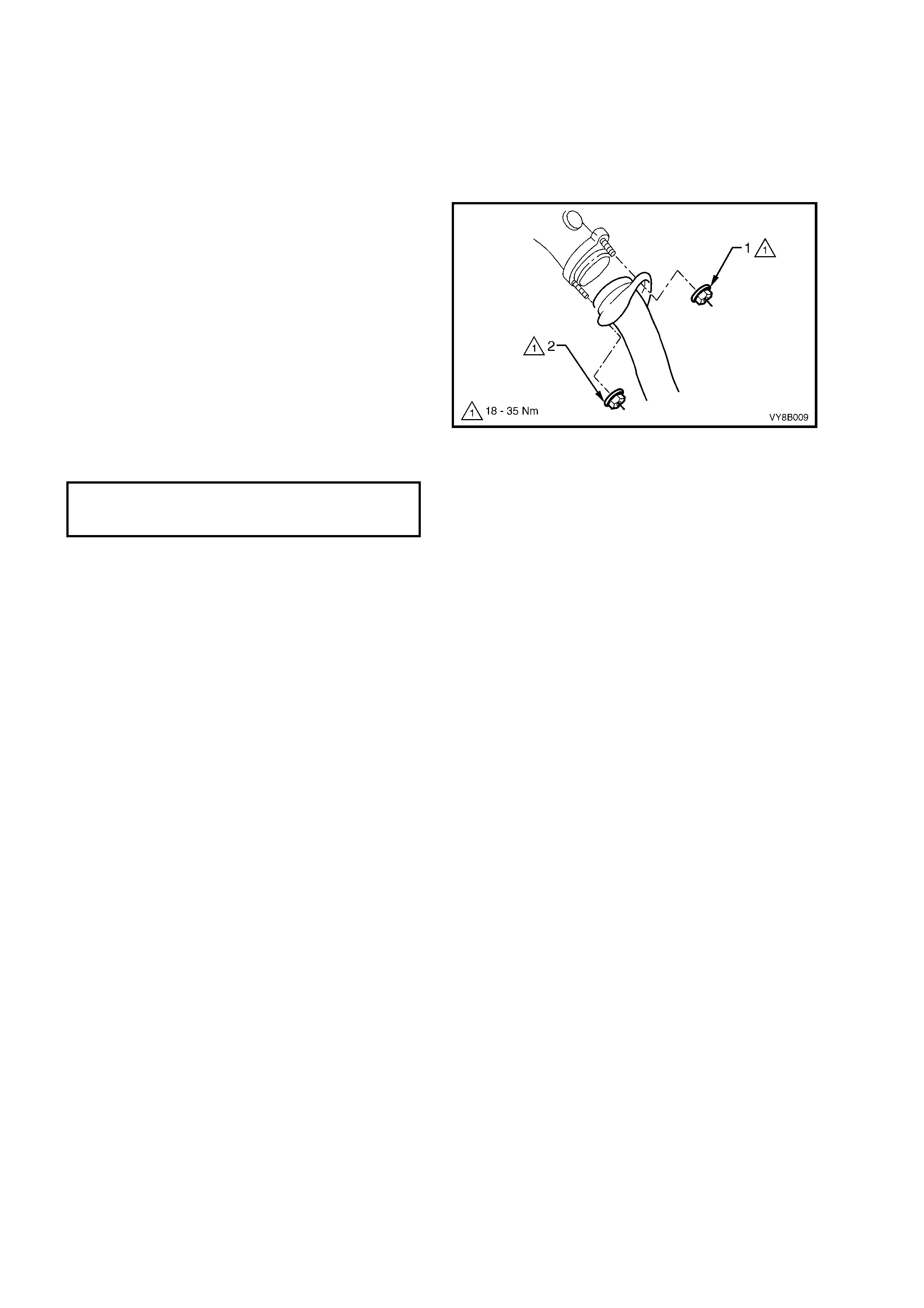

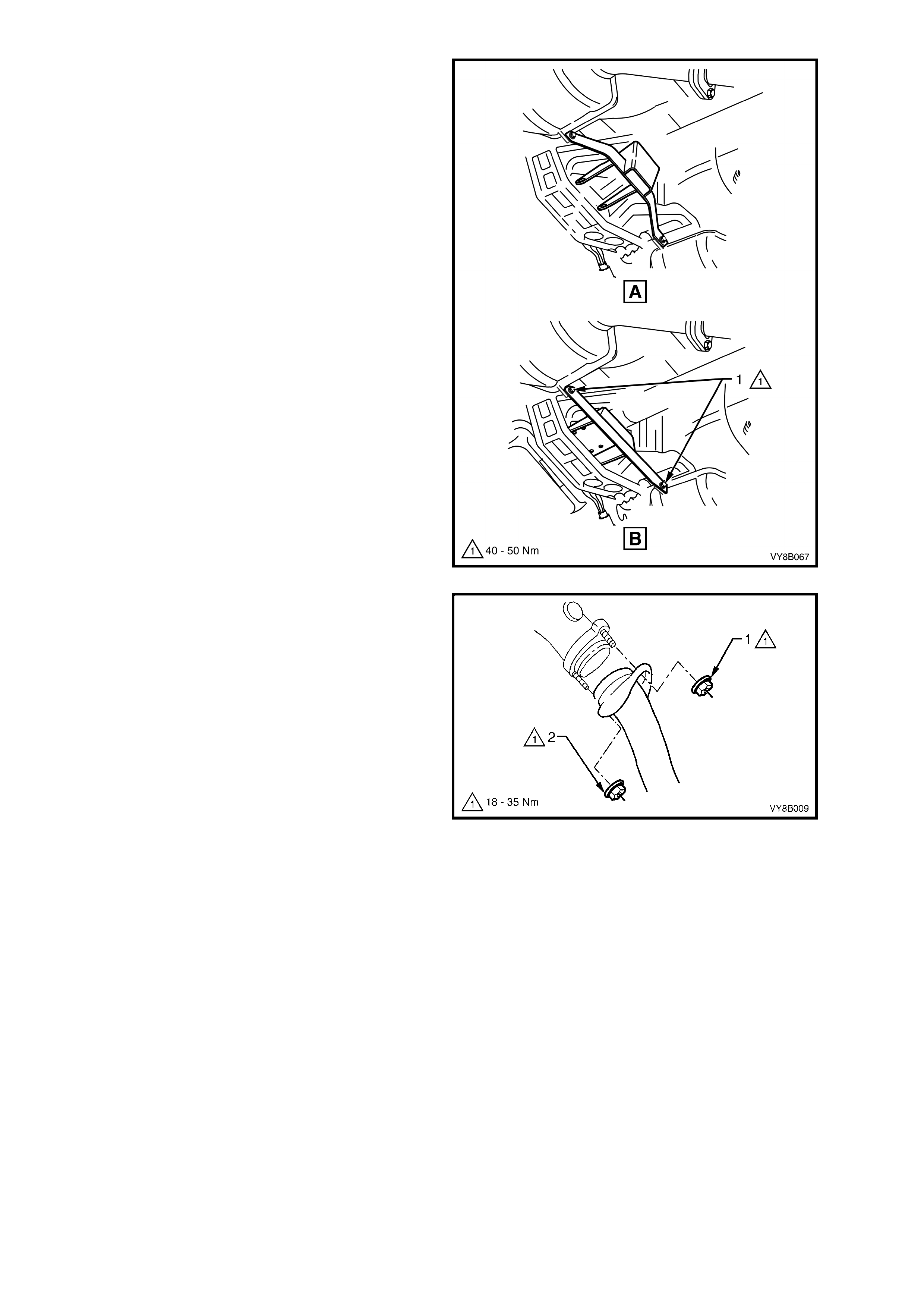

4. Support the exhaust system and remove the

upper (1) and lower (2) fastening nuts from the

exhaust manifold to exhaust pipe flange studs

on both sides.

Figure 8B-12

5. Remove the support rubbers:

a. For automatic transmission vehicles, refer to

View A. Disc onnect the front ex haust assem bly

by disconnecting the support rubber (1) from

the peg welded to the exhaust pipe brace.

b. For manual transmission vehicles, refer to

View B. Disconnect the f ront exhaust asse mbly

by disconnecting the two support rubbers (2)

from either side of the transmission extension

housing.

6. Carefully lower and remove the exhaust

assembly from the vehicle, taking care not to

damage the exhaust gas oxygen sensors.

Figure 8B-13

Reinstall

The installation of complete exhaust system is the

reverse of the removal procedure, noting the

following points:

1. Support the exhaust system at all times.

2. Clean the threads of the manifold to exhaust

pipe flange studs with a suitable cleaning

solvent.

3. Apply a high temperature anti-seize compound

to the exhaust manifold to exhaust pipe flange

studs and align the front pipe flange over the

studs.

4. Install the upper f as tening nut (1) to the s tud on

both sides.

5. Install the lower fas tening nut (2) to the stud on

both sides.

6. Tighten the upper and lower fastening nuts so

that approxim ately equal amounts of thread are

showing.

7. Tighten the exhaust manifold to front pipe

flange attaching nuts (1 and 2) to the specified

torque.

Figure 8B-14

8. Ensure all support rubbers are under load

9. Ensure that correct body clearances are maintained throughout the full exhaust system. Refer to 6.1 V6

EXHAUST SYSTEM CLEARANCES.

NOTE: If steps 8 or 9 are not achieved, refer to TIGHTENING SEQUENCE in this Section.

10. Connect the wiring harness connectors for each of the two oxygen sensors.

EXHAUST MANIFOLD TO FRONT PIPE

FLANGE ATTACHING NUT

TORQUE SPECIFICATION 18 – 35 Nm

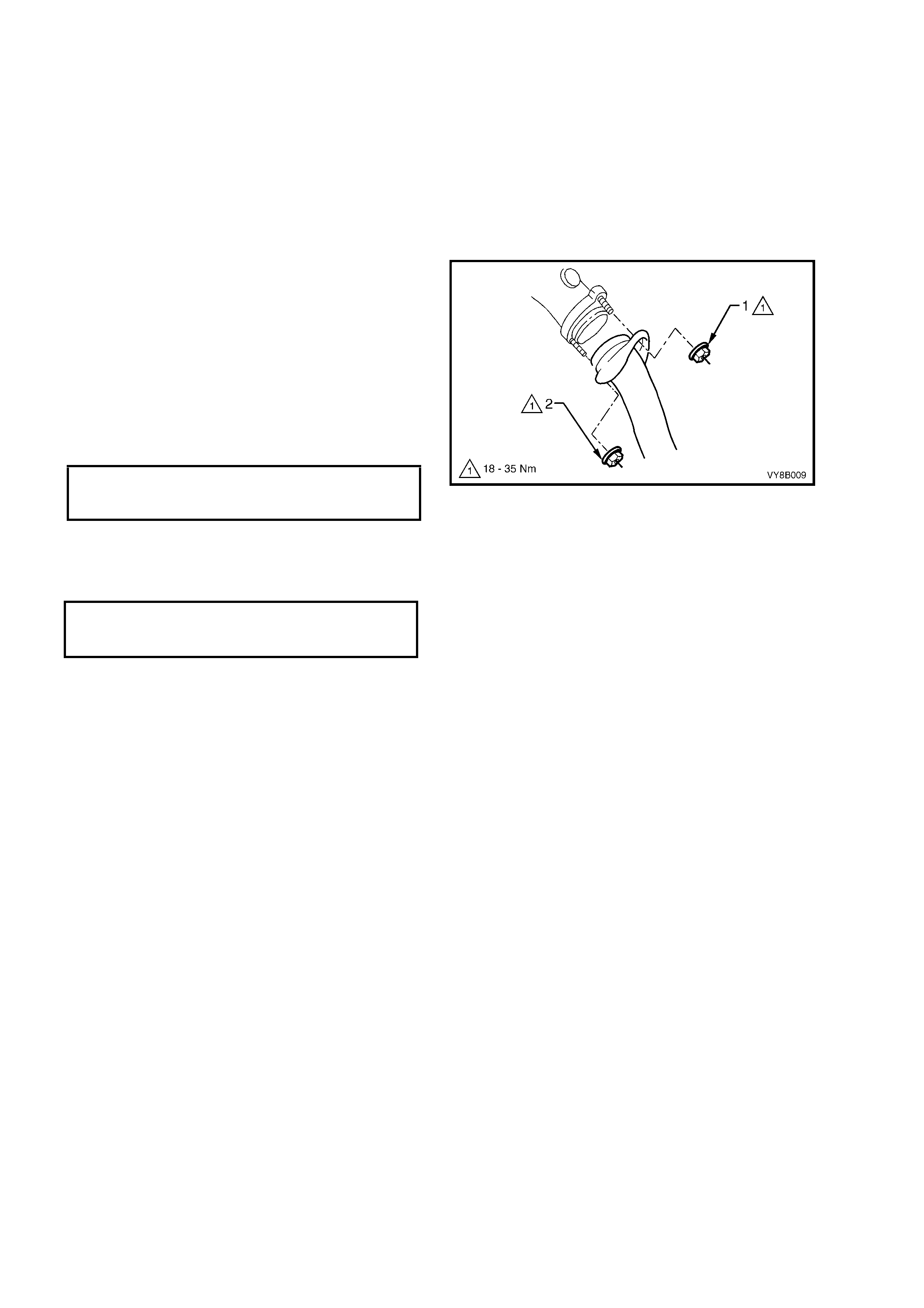

TIGHTENING SEQUENCE

This procedure is only to be performed if the exhaust system positioning is not to specification.

Refer to Figure 8B-15 for the following.

IMPORTANT: For all gasketed joints requiring adjustment, ensure that new gaskets are installed.

Ensure that all fasteners mentioned in steps 1 to 6 below are loose before conducting this procedure.

1. Tighten the intermediate exhaust to catalytic converter flange attaching bolts (1) at the rear of the catalytic

converter to the specified torque.

INTERMEDIATE EXH AUST TO

CATALYTIC CONVERTER

FLANGE ATTACHING BOLT

TORQUE SPECIFICATION 40 – 50 Nm

NOTE: A muffler replaces the catalyst for Indonesia vehicles.

2. Check that the rear exhaust pipe aligning tab is seated within the intermediate exhaust pipe’s end slip joint

groove. Position the U-bolt clamp along the intermediate to rear slip joint and tighten the pair of fastening

nuts (2) to the specified torque.

U-BOLT CLAMP ASSEMBLY

SECURING NUTS

TORQUE SPECIFICATION 20 – 30 Nm

3. Install the upper fastening nut (1) to the stud on both sides, refer to Figure 8B-14.

4. Install the lower fastening nut (2) to the stud on both sides, refer to Figure 8B-14.

5. Tighten the nuts joining the exhaust manifold to the front exhaust pipe flange, so that approximately equal

amounts of thread are showing.

6. Tighten the exhaust m anifold to front exhaus t pipe flange attaching nuts (1 and 2) to the spec ified torque, refer

to Figure 8B-14.

EXHAUST MANIFOLD TO FRONT PIPE

FLANGE ATTACHING NUT

TORQUE SPECIFICATION 18 – 35 Nm

7. Ens ure that all support rubbers (3, 4 and 5) are under load, ref er to Figure 8B-15. If this is not achieved, loos en

the respective joints in the reverse order to steps 1 to 6. Load the hangers and re-tighten in the sequence

described, from steps 1 to 6.

NOTE: The exhaus t s ystem should be s elf- aligning and not require f urther adj ustm ent, provided s tep 7 is ac hieved.

To ensure that correct clearances are maintained throughout the complete exhaust system, refer to

6.1 V6 EXHAUST SYSTEM CLEARANCES for the correct values.

Figure 8B-15

REAR EXHAUST ASSEMBLY

Remove

1. Remove the two support hanger retainer

clips (1) and the two support rubbers (2) from

the support hangers.

NOTE: The additional bumper washer (3) is used

on utility vehicles only.

Figure 8B-16

2. Rem ove the two retaining nuts (1) and the rear

muf fler U-bolt (2) and clam p (3) from along the

intermediate exhaust pipe to rear muffler

exhaust pipe slip joint.

3. Carefully slide the rear exhaust pipe out of the

intermediate exhaust pipe end slip joint and

remove the rear exhaust assembly.

Figure 8B-17

Reinstall

Installation of the rear exhaust assembly is the

reverse of the removal procedure, noting the

following:

1. Ensure that the rear exhaust pipe slides

unobstructed into the intermediate exhaust pipe

slip joint, and that the alignment tab is

positioned in the slip joint groove. Tighten the

U-bolt clamp securing nuts to the specified

torque.

2. Ensure all support rubbers are under load and

all clearances are within the specifications. If

this is not achieved, refer to TIGHTENING

SEQUENCE in this Section.

U-BOLT CLAMP ASSEMBLY

SECURING NUTS

TORQUE SPECIFICATION 20 – 30 Nm

Techline

INTERMEDIATE EXHAUST ASSEMBLY

Remove

1. Remove the rear muffler. Refer to

REAR EXHAUST ASSEMBLY in this Section.

2. Support the intermediate exhaust assembly

and rem ove the two stepped fas tening bolts ( 1)

and springs (2) from the intermediate exhaust

to catalytic converter flange joint.

3. Separate the intermediate exhaust assembly

from the front exhaust assembly and remove

the sealing ring (3) from within the flange joint.

NOTE: A muffler replaces the catalyst for

Indonesia vehicles.

Figure 8B-18

4. Remove the two retainer clips (1) and support

rubbers (2) from the support hangers and

remove the intermediate exhaust assembly.

Figure 8B-19

Reinstall

Installation of the inter mediate exhaust assem bly is

the reverse of the removal procedure, noting the

following:

1. Ensure all support rubbers are under load and

all clearances are within specification. If this is

not achieved, refer to TIGHTENING

SEQUENCE in this Section.

INTERMEDIATE EXH AUST TO

CATALYTIC CONVERTE R FLANGE

ATTACHING BOLT

TORQUE SPECIFICATION 40 – 50 Nm

FRONT EXHA UST ASSEMBLY

Remove

1. Disconnect the wiring harnes s connectors f rom

each of the two oxygen sensors (1).

NOTE: Oxygen sensors are not fitted to Indonesia

vehicles.

Figure 8B-20

2. Support the intermediate exhaust assembly

and rem ove the two stepped fas tening bolts ( 1)

and springs (2) from the intermediate exhaust

to catalytic converter flange joint.

3. Separate the intermediate exhaust assembly.

Figure 8B-21

4. Support the front exhaust assembly and

remove the upper (1) and lower (2) fastening

nuts f rom the exhaus t manif old to exhaust pipe

flange studs on both sides.

Figure 8B-22

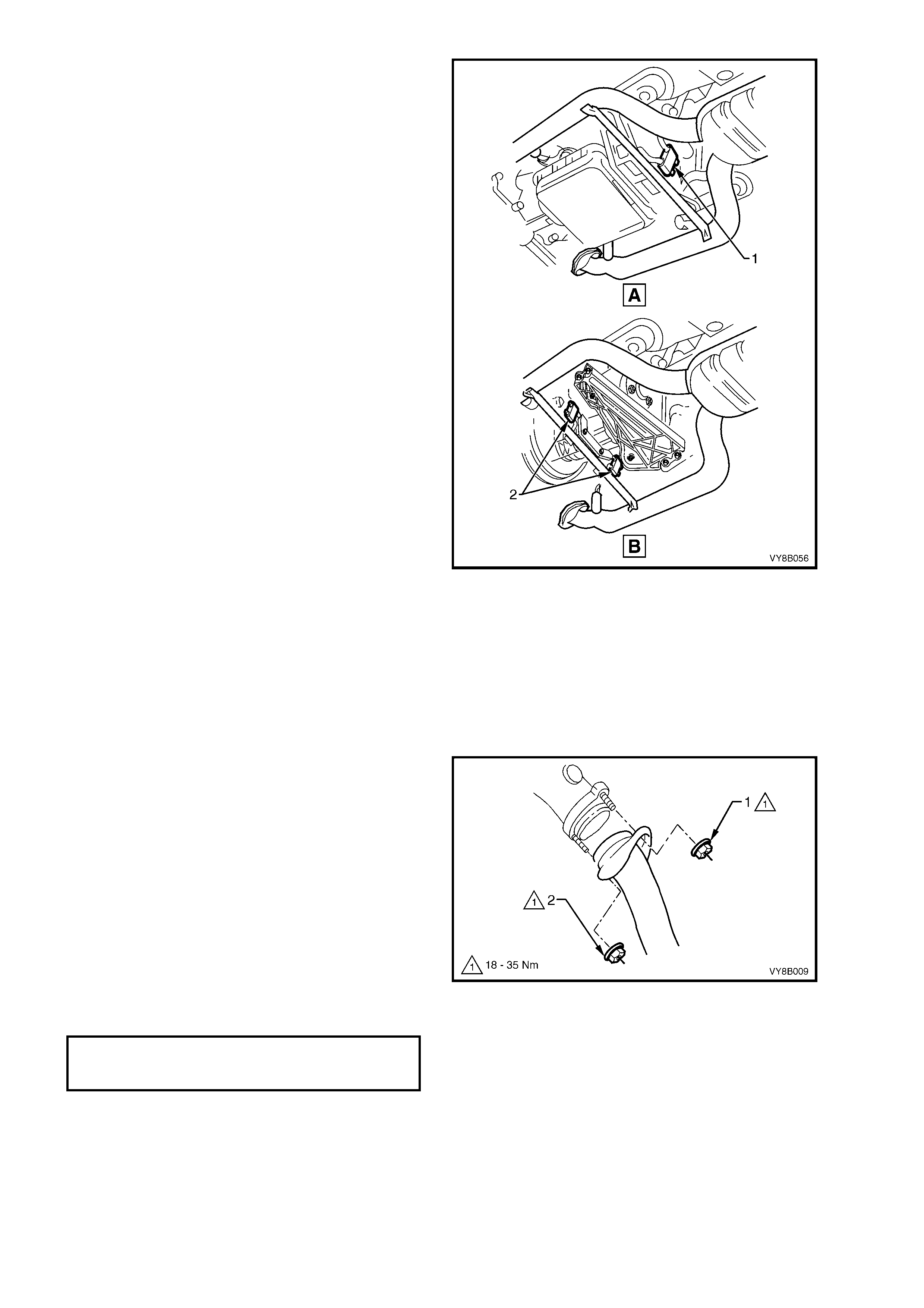

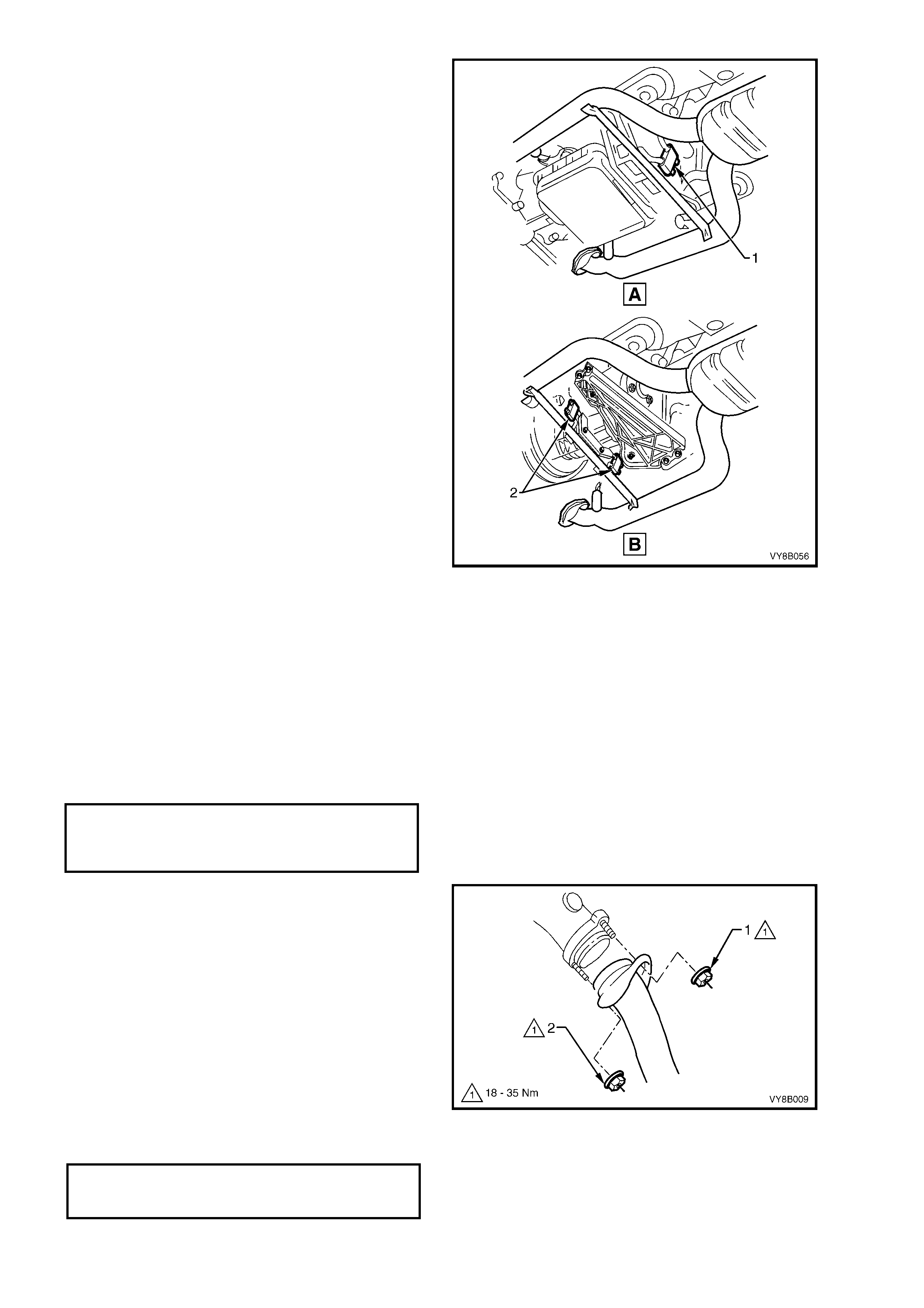

5. Remove the support rubbers:

a. For automatic transmission vehicles, refer to

view A. Disconnect the front exhaust assembly

by disconnecting the support rubber (1) from

the peg welded to the exhaust pipe brace.

b. For manual transmission vehicles, refer to

view B. Disconnect the front exhaust assembly

by disconnecting the two support rubbers (2)

from either side of the transmission extension

housing.

6. Carefully lower and remove the front exhaust

assembly from the vehicle, taking care not to

damage the exhaust gas oxygen sensor.

Figure 8B-23

Reinstall

Installation of the front exhaust assembly is the

reverse of the removal procedure, noting the

following points:

1. Support the exhaust system at all times.

2. Clean threads of all f lange bolts and studs with

a suitable cleaning solvent.

3. Tighten the intermediate exhaust to catalytic

converter f lange attaching bolts to the specified

torque.

4. Apply a high temperature anti-seize compound

to the exhaust manifold to exhaust pipe flange

studs and align the front pipe flange over the

studs.

5. Install the upper f as tening nut (1) to the s tud on

both sides.

6. Install the lower fas tening nut (2) to the stud on

both sides.

7. Tighten the upper and lower fastening nuts so

that approxim ately equal amounts of thread are

showing.

8. Tighten the exhaust manifold to front pipe

flange attaching nuts (1 and 2) to the specified

torque.

Figure 8B-24

INTERMEDIATE EXH AUST TO

CATALYTIC CONVERTE R FLANGE

ATTACHING BOLT

TORQUE SPECIFICATION 40 – 50 Nm

EXHAUST MANIFOLD TO FRONT

PIPE FLANGE ATTACHING NUT

TORQUE SPECIFICATION 18 – 35 Nm

9. Ensure all support rubbers are under load

10. Ensure that correct body clearances are maintained throughout the full exhaust system. Refer to

6.1 V6 EXHAUST SYSTEM CLEARANCES.

NOTE: If steps 9 or 10 are not achieved, refer to TIGHTENING SEQUENCE in this Section.

11. Connect the wiring harness connectors for each of the two oxygen sensors.

3. SERVICE OPERATIONS - V6 SUPERCHARGED

3.1 SERVICE NOTES

When installing any exhaust system component, care must be taken to install each component in the correct

relationship to the other. Ensure that correct assembly, installation, tightening sequence, tightening torque and

clearance for the syst em involved is observed. W hen exhaust s ystem service work is required, ref er to the various

illustrations and instructions provided in this Section.

NOTE: The incorrect assembly of exhaust system components can frequently be the cause of rattles and ‘booms'

due to incorrec t alignment or clearance of body or suspens ion parts. Ensure that the correc t tightening s equence is

observed upon installation of exhaust system components.

CATALYTIC CONVERTER

Catalytic converters are serviced as part of the com plete left or right front exhaust assemblies only. If rem oving or

replacing a front exhaust assembly, always check the flange gaskets for damage and replace if necessary.

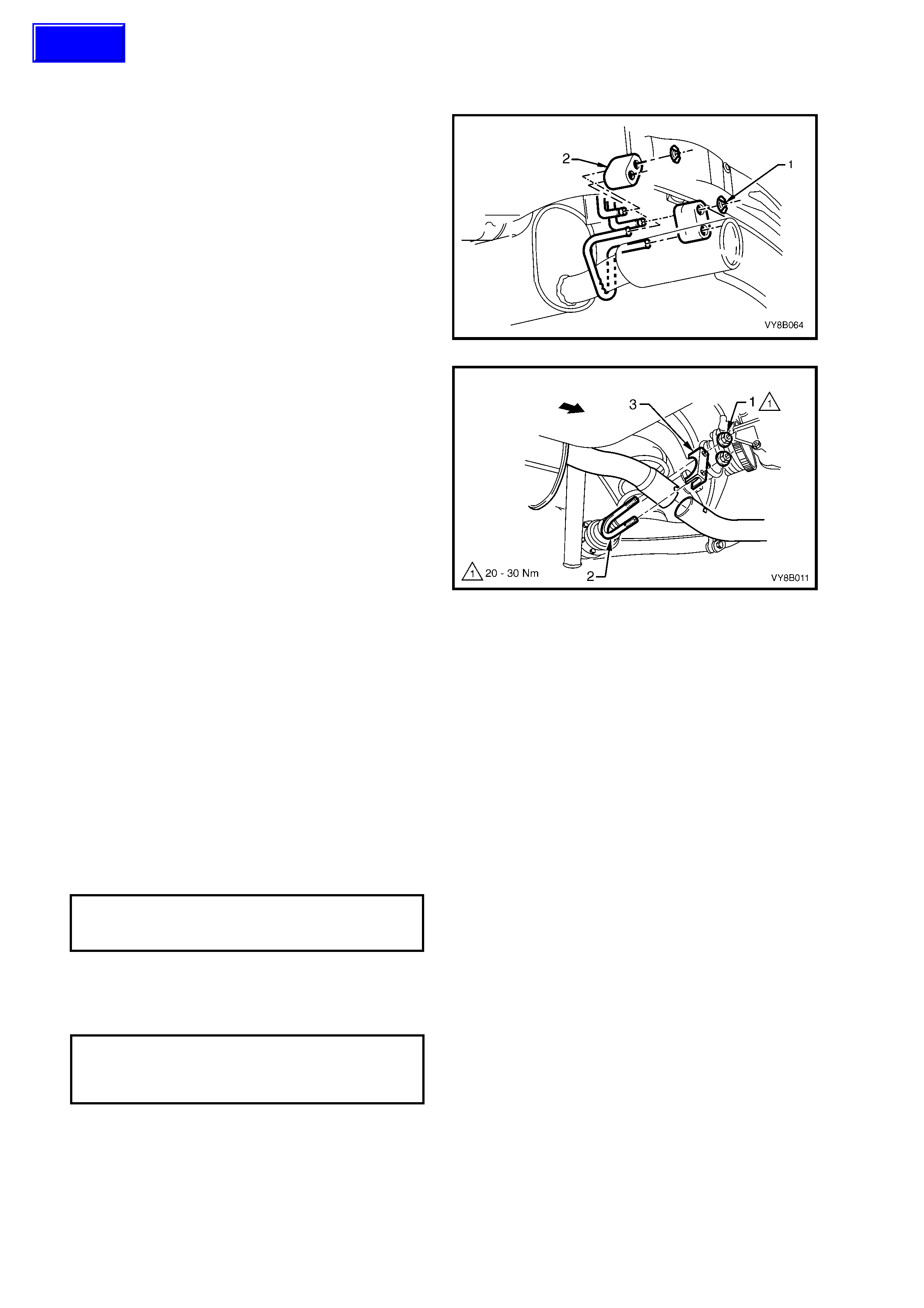

OXYGEN SENSORS

When removing the front exhaust pipes, it is

necessary to disconnect the wiring harness

connectors from each of the two oxygen sensors

(1).

For oxygen sensor replacement, refer to

Section 6C2-3, 2.7 OXYGEN SENSORS.

Figure 8B-25

3.2 EXHAUST SYSTEM

The following layout drawing illustrates the exhaust system configuration used on V6 Supercharged Sedan vehicles.

NOTE: For Coupe, a gas keted flange joint and two f astening s tuds are us ed to j oin the inter mediate to rear ex haust

assemblies.

Figure 8B-26

Legend

1. Manifold to Front Pipe Flange

2. Catalyst

3. Catalyst to Intermediate Pipe Flange Joint

4. Intermediate Muffler

5. Intermediate Muffler Support Rubbers

6. Intermediate to Rear Pipe Slip Joint and U-bolt

clamp (Flange Joint for Coupe)

7. Rear Muffler

8. Rear Muffler Support Rubbers

COMPLETE EXHAUST SYSTEM ASSEMBLY

Remove

1. Disconnect the wiring harnes s connectors f rom

each of the two oxygen sensors (1).

Figure 8B-27

2. Disconnect the rear muffler from the support

hangers by removing the two retainer clips (1)

and support rubbers (2).

Figure 8B-28

3. Support the exhaust system and disconnect the

intermediate muffler from the support hangers

by removing each of the retainer clips (1) and

support rubbers (2).

Figure 8B-29

4. Support the exhaust system and remove the

upper (1) and lower (2) fastening nuts from the

exhaust manifold to exhaust pipe flange studs

on both sides.

5. Carefully lower and remove the complete

exhaust system from the vehicle, taking care

not to damage the oxygen sensors in the

process.

Figure 8B-30

Reinstall

The installation of complete exhaust system is the

reverse of the removal procedure, noting the

following points:

1. Support the exhaust system at all times.

2. Clean the threads of the flange and stepped

bolts with a suitable cleaning solvent.

3. Apply a high temperature anti-seize compound

to the exhaust manifold to exhaust pipe flange

studs and align the front pipe flange over the

studs.

4. Install the upper f as tening nut (1) to the s tud on

both sides.

5. Install the lower fas tening nut (2) to the stud on

both sides.

6. Tighten the upper and lower fastening nuts so

that approxim ately equal amounts of thread are

showing.

7. Tighten the exhaust manifold to front pipe

flange attaching nuts (1 and 2) to the specified

torque.

8. Ensure all support rubbers are under load

9. Ensure that correct body clearances are

maintained throughout the full exhaust system.

Refer to 6.2 V6 SUPERCHARGED AND GEN

III V8 EXHAUST SYSTEM CLEARANCES.

NOTE: If steps 8 or 9 are not achieved, refer to

TIGHTENING SEQUENCE in this Section.

10. Connect the wiring harness connectors for

each of the two oxygen sensors.

Figure 8B-31

EXHAUST MANIFOLD TO FRONT PIPE

FLANGE ATTACHING NUT

TORQUE SPECIFICATION 18 – 35 Nm

TIGHTENING SEQUENCE

This procedure is only to be performed if the exhaust system positioning is not to specification.

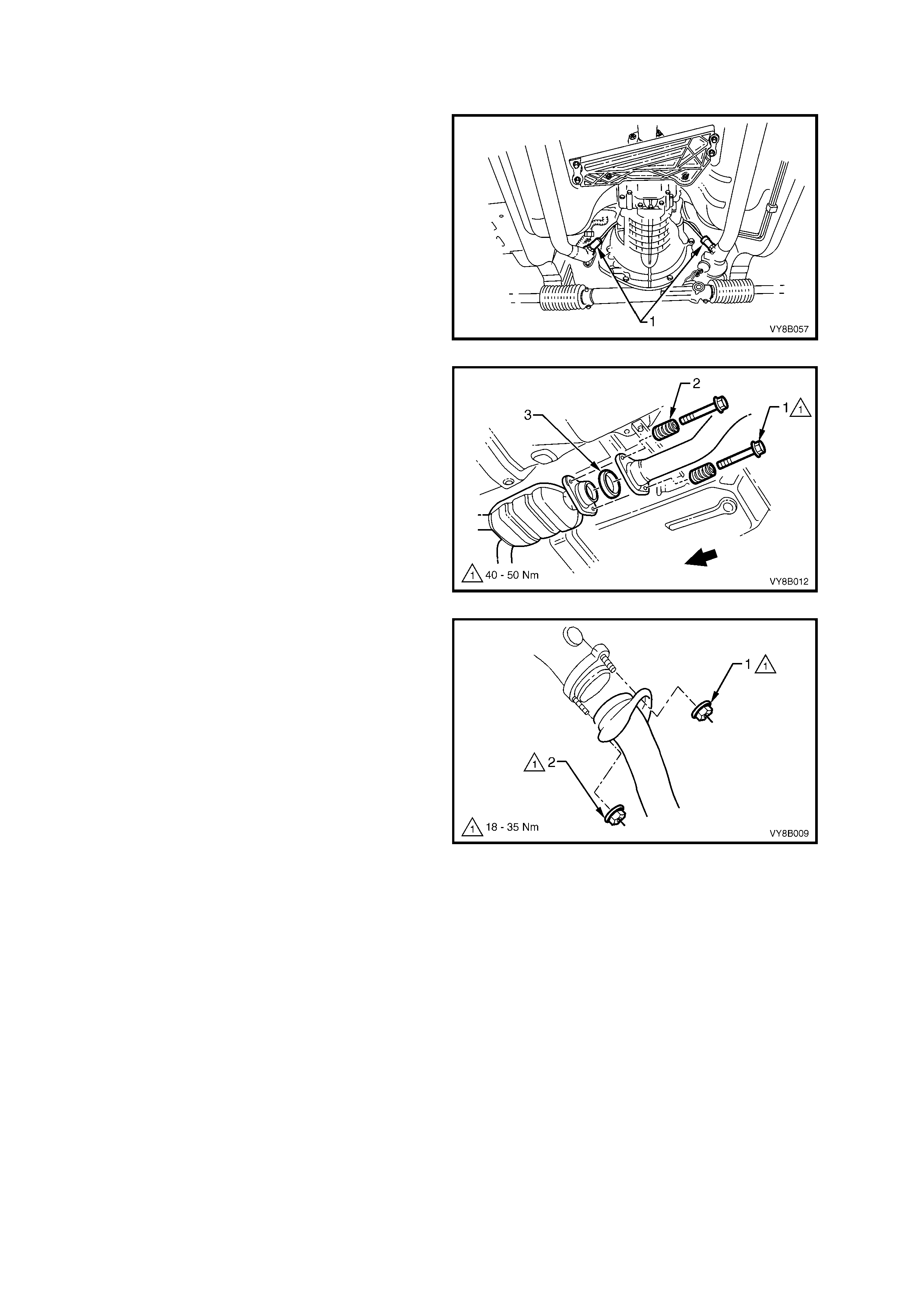

Refer to Figure 8B-32 for the following.

IMPORTANT: For all gasketed joints requiring adjustment, always check gasket for serviceability and replace

where required.

Ensure that all fasteners mentioned in steps 1 to 6 below are loose before conducting this procedure.

1. T ighten the front pipe to interm ediate pipe flange attaching bolts (1) at the rear of the catalytic converters to the

specified torque.

FRONT PIPE TO INTERMEDIATE PIPE

FLANGE ATTACHING BOLT

TORQUE SPECIFICATION 40 – 50 NM

2. For Sedan, Wagon and Ute, check that the rear exhaust pipe aligning tab is seated within the intermediate

exhaust pipe’s end slip joint groove. Position the U-bolt clamp along the intermediate to rear slip joint and

tighten the pair of fastening nuts (2) to the specified torque.

U-BOLT CLAMP ASSEMBLY

SECURING NUTS

TORQUE SPECIFICATION 20 – 30 NM

3. For Coupe, tighten the pair of intermediate to rear exhaust pipe flange bolts to the correct torque specification.

INTERMEDIATE PIPE TO

REAR PIPE FLANGE JOINT

ASSEMBLY FLANGE BOLTS

TORQUE SPECIFICATION 40 – 50 NM

4. Install the upper fastening nut (1) to the stud on both sides, refer to Figure 8B-31.

5. Install the lower fastening nut (2) to the stud on both sides, refer to Figure 8B-31.

6. Tighten all the nuts joining the exhaust manifold to the front exhaust pipe flange, so that approximately equal

amounts of thread are showing.

7. Tighten the exhaust manifold to front pipe flange attaching nuts (1 and 2) to the specified torque, refer to

Figure 8B-31.

EXHAUST MANIFOLD TO FRONT PIPE

FLANGE ATTACHING NUT

TORQUE SPECIFICATION 18 – 35 NM

8. Ensure that all six suppor t r ubbers (3 and 4) ar e under load, ref er to Figure 8B-32. If this is not achieved, loosen

the respective joints in the reverse order to steps 1 to 7. Load the hangers and re-tighten in the sequence

described, from steps 1 to 7.

NOTE: The exhaust system should be self-aligning and not require further adjustment, provided step 8 is

achieved. To ensure that correct clearances are maintained throughout the full exhaust system, refer to

6.2 V6 SUPERCHARGED AND GEN III V8 EXHAUST SYSTEM CLEARANCES for the correct values.

Figure 8B-32

REAR EXHAUST ASSEMBLY

Remove

1. Remove the two support hanger retainer

clips (1) and the two support rubbers (2) from

the support hangers.

Figure 8B-33

2. For Sedan, Wagon and Ute:

a. Rem ove the two retaining nuts (1) and the rear

muffler U-bolt (2) and clamp plate (3) from

along the intermediate exhaust pipe to rear

muffler exhaust pipe slip joint.

b. Carefully slide the rear exhaust pipe out of the

intermediate exhaust pipe end slip joint.

3. For Coupe:

a. Remove the two bolts from the intermediate to

rear exhaust pipe flange joint. Separate the

intermediate exhaust assemblies and remove

the flange gasket.

NOTE: Sedan, Wagon and Ute slip joint shown,

Coupe uses a gasketed flange joint.

4. Remove the rear exhaust assembly.

Figure 8B-34

Reinstall

Installation of the rear exhaust assembly is the

reverse of the removal procedure, noting the

following:

1. Ensure that the rear exhaust pipe slides

unobstructed into the intermediate exhaust pipe

slip joint, and that the alignment tab is

positioned in the slip joint groove.

2. For Sedan, evenly tighten the U-bolt clamp nuts

to the correct torque specification.

3. For Coupe, tighten the pair of intermediate to

rear exhaust pipe flange bolts to the correct

torque specification.

4. Ensure all support rubbers are under load and

all clearances are within the specifications. If

this is not achieved, refer to TIGHTENING

SEQUENCE in this Section.

INTERMEDIATE PIPE TO

REAR PIPE FLANGE JOINT

ASSEMBLY FLANGE BOLTS

TORQUE SPECIFICATION 40 – 50 Nm

U-BOLT CLAMP ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 20 – 30 Nm

Techline

INTERMEDIATE EXHAUST ASSEMBLY

Remove

CAUTION: The f ront exhaust assembly must be

supported during and after this procedure.

1. Remove the rear muffler. Refer to

REAR EXHAUST ASSEMBLY in this Section.

2. Support the intermediate and front exhaust

assemblies and remove the two bolts (1) from

each of the two flange joints.

3. Separate the intermediate exhaust assembly

from the front exhaust assembly and remove

each flange gasket from between each of the

flange joints.

Figure 8B-35

4. Remove the pair of retainer clips (1) and

support rubbers (2) from both of the right-hand

side and left-hand side intermediate muffler

support hangers. Remove the intermediate

exhaust assembly.

Figure 8B-36

Reinstall

Installation of the inter mediate exhaust assem bly is

the reverse of the removal procedure, noting the

following:

1. Support the exhaust system at all times.

2. Clean the threads of all flange bolts with a

suitable cleaning solvent.

3. Tighten the front pipe to intermediate pipe

flange attaching bolts at the rear of the catalytic

converters to the specified torque.

4. Ensure all support rubbers are under load

and all clearances are within specification. If

this is not achieved, refer to TIGHTENING

SEQUENCE in this Section.

FRONT PIPE TO INTERMEDIATE PIPE

FLANGE ATTACHING BOLT

TORQUE SPECIFICATION 40 – 50 Nm

FRONT EXHA UST ASSEMBLY

Remove

1. Disconnect the wiring harness connectors from

each of the two oxygen sensors (1).

Figure 8B-37

2. Support the intermediate and front exhaust

assemblies and remove the two bolts (1) from

each of the two flange joints.

3. Separate the intermediate exhaust assembly

from the front exhaust assembly and remove

the flange gasket from between the flange joint.

Figure 8B-38

4. Support the front exhaust assembly and

remove the upper (1) and lower (2) fastening

nuts f rom the exhaust m anifold to exhaust pipe

flange studs on both sides.

5. Carefully lower and remove the front exhaust

assembly from the vehicle, taking care not to

damage the oxygen sensors.

Figure 8B-39

Reinstall

Installation of the front exhaust assembly is the

reverse of the removal procedure, noting the

following points:

1. Support the exhaust system at all times.

2. Clean threads of all f lange bolts and studs with

a suitable cleaning solvent.

3. Apply a high temperature anti-seize compound

to the manifold to front pipe flange studs and

align the front pipe flange over the studs.

4. Install the upper f as tening nut (1) to the s tud on

both sides.

5. Install the lower fas tening nut (2) to the stud on

both sides.

6. Tighten the upper and lower fastening nuts so

that approxim ately equal amounts of thread are

showing.

7. Tighten the exhaust manifold to front pipe

flange attaching nuts (1 and 2) to the specified

torque.

8. Tighten the front pipe to intermediate pipe

flange attaching bolts at the rear of the catalytic

converters to the specified torque.

9. Ensure all exhaust system support rubbers are

under load.

10. Ensure that correct body clearances are

maintained throughout the full exhaust system.

Refer to 6.2 V6 SUPERCHARGED AND GEN

III V8 EXHAUST SYSTEM CLEARANCES.

11. Reconnect the wiring harness connectors for

each of the two oxygen sensors.

NOTE: If steps 9 or 10 are not achieved, refer to

TIGHTENING SEQUENCE in this Section.

Figure 8B-40

EXHAUST MANIFOLD TO FRONT PIPE

FLANGE ATTACHING NUT

TORQUE SPECIFICATION 18 – 35 Nm

FRONT PIPE TO INTERMEDIATE PIPE

FLANGE ATTACHING BOLT

TORQUE SPECIFICATION 40 – 50 Nm

4. SERVICE OPERATIONS – GEN III V8

4.1 SERVICE NOTES

When installing any exhaust system component, care must be taken to install each component in the correct

relationship to the other. Ensure that correct assembly, installation, tightening sequence, tightening torque and

clearance for the syst em involved is observed. W hen exhaust s ystem service work is required, ref er to the various

illustrations and instructions provided in this section.

NOTE: The incorrect assembly of exhaust system components can frequently be the cause of rattles and ‘booms'

due to inc or rec t alignment or c learanc e of body or suspension par ts. Ens ur e that the c orr ect tightening sequenc e is

observed upon installation of exhaust system components.

CATALYTIC CONVERTER

Catalytic converters are serviced as part of the com plete left or right front exhaust assemblies only. If rem oving or

replacing a front exhaust assembly, always check the flange gaskets for damage and replace if necessary.

OXYGEN SENSORS

When removing the front exhaust pipes, it is

necessary to disconnect the wiring harness

connectors from each of the two oxygen sensors

(1).

For oxygen sensor replacement, refer to

Section 6C3-3, 2.8 HEATED OXYGEN

SENSORS.

Figure 8B-41

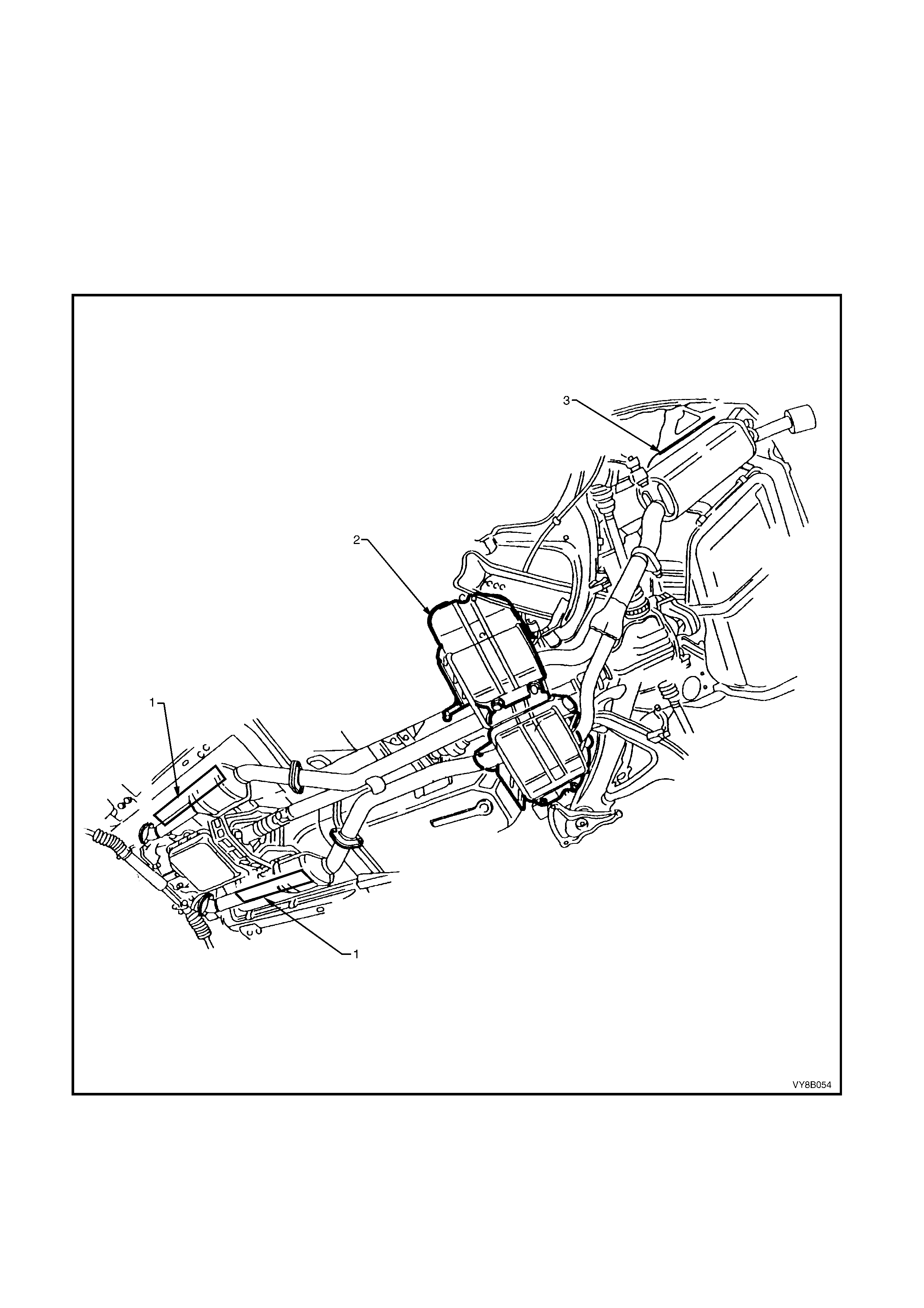

4.2 EXHAUST SYSTEM

The following removal and installation service operations should be referred to when conducting work on Standard

and Performance exhaust systems, Refer to 1.1 EXHAUST SYSTEM CONFIGURATIONS, Figure 8B-4 and

Figure 8B-5 respectively within this Section. The illustrations provided represent the right-hand drive Standard

exhaust system, however any significant differences in procedure or configuration for left-hand drive or

Performance exhaust systems will be highlighted to accommodate servicing differences.

Figure 8B-42 provides a reference to the location of relevant exhaust system removal and installation components.

Figure 8B-42

Legend

A Transmission to Catalyst

Mounting Bracket - A/T

B Transmission to Catalyst

Mounting Bracket - M/T

1. Manifold to Front Pipe Flange Joint

2. Catalyst

3. Transmission to Catalyst Mounting

Bracket

4. Catalyst to Intermediate Pipe Flange

Joint

5. Intermediate Muffler

6. Intermediate Muffler Support

Rubbers

7. Intermediate to Rear Pipe Slip

Joint and Clamp

8. Rear Muffler

9. Rear Muffler Support Rubbers

COMPLETE EXHAUST SYSTEM

Remove

1. Disconnect the wiring harnes s connectors f rom

each of the two oxygen sensors (1).

Figure 8B-43

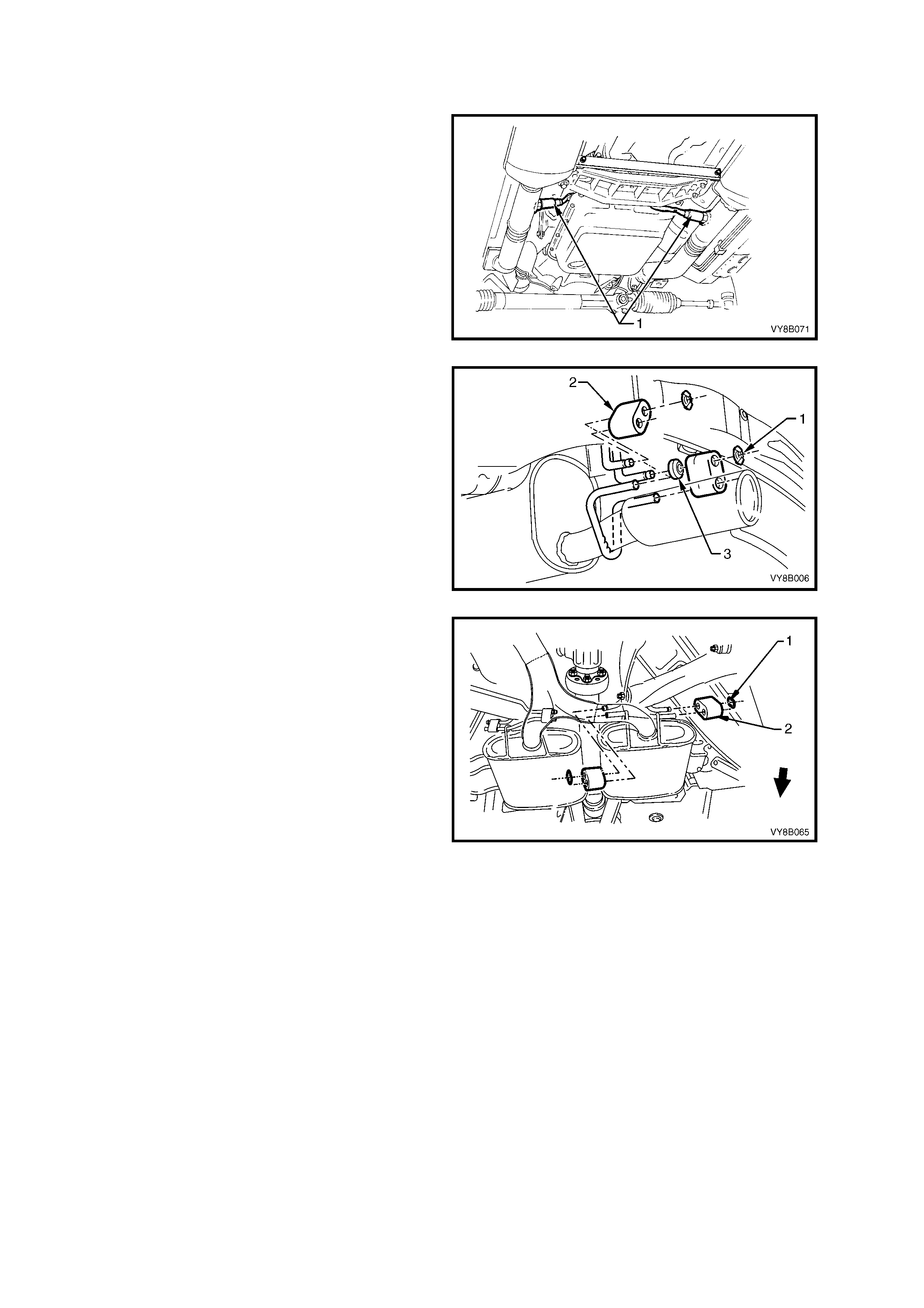

2. Disconnect the rear muffler from the support

hangers by removing the two retainer clips (1)

and support rubbers (2).

NOTE: The additional bumper washer (3) is used

on utility vehicles only.

Figure 8B-44

3. Support the exhaust system and disconnect

each intermediate muffler from the support

hangers by removing the retainer clips (1) and

the support rubbers (2).

Figure 8B-45

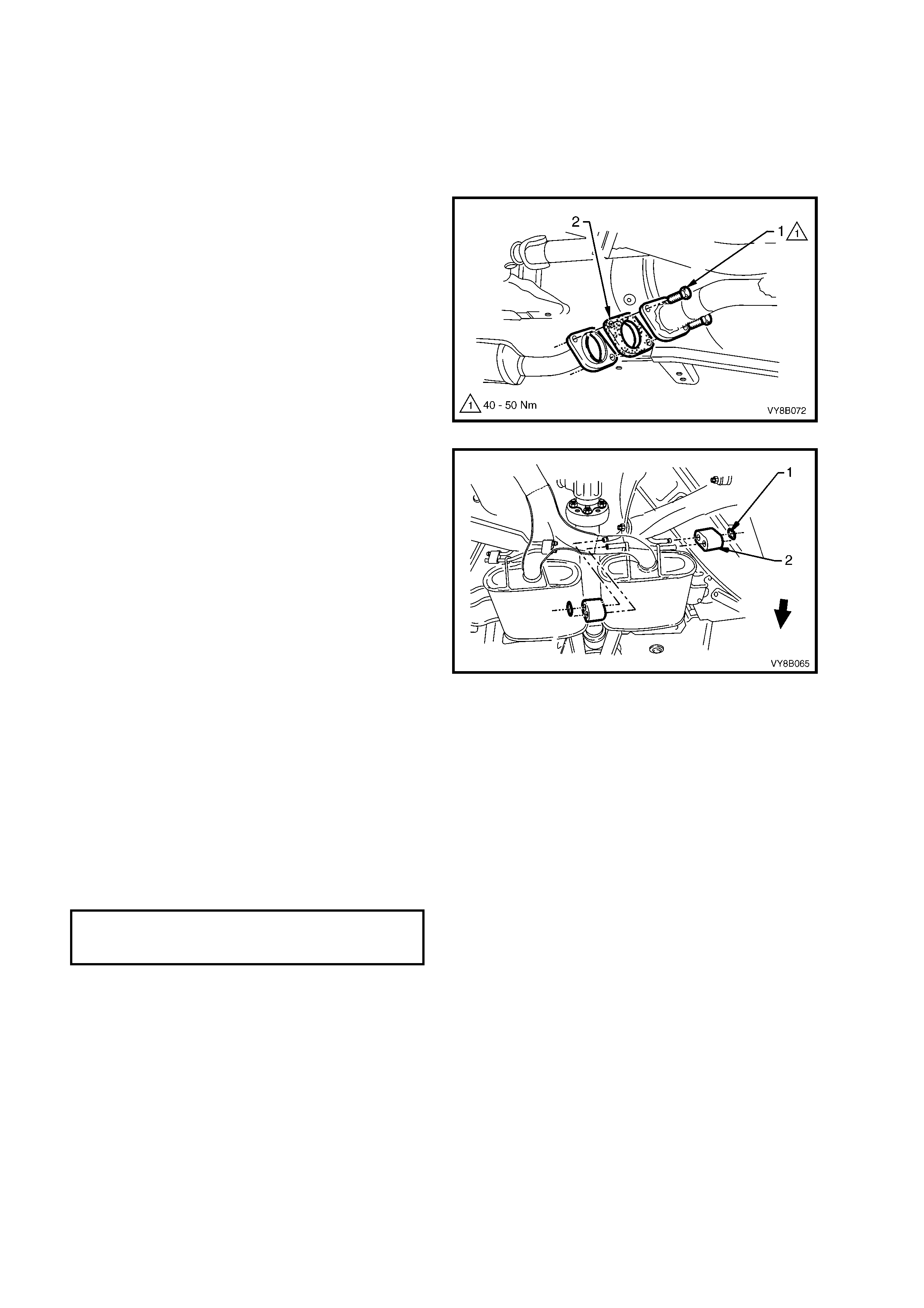

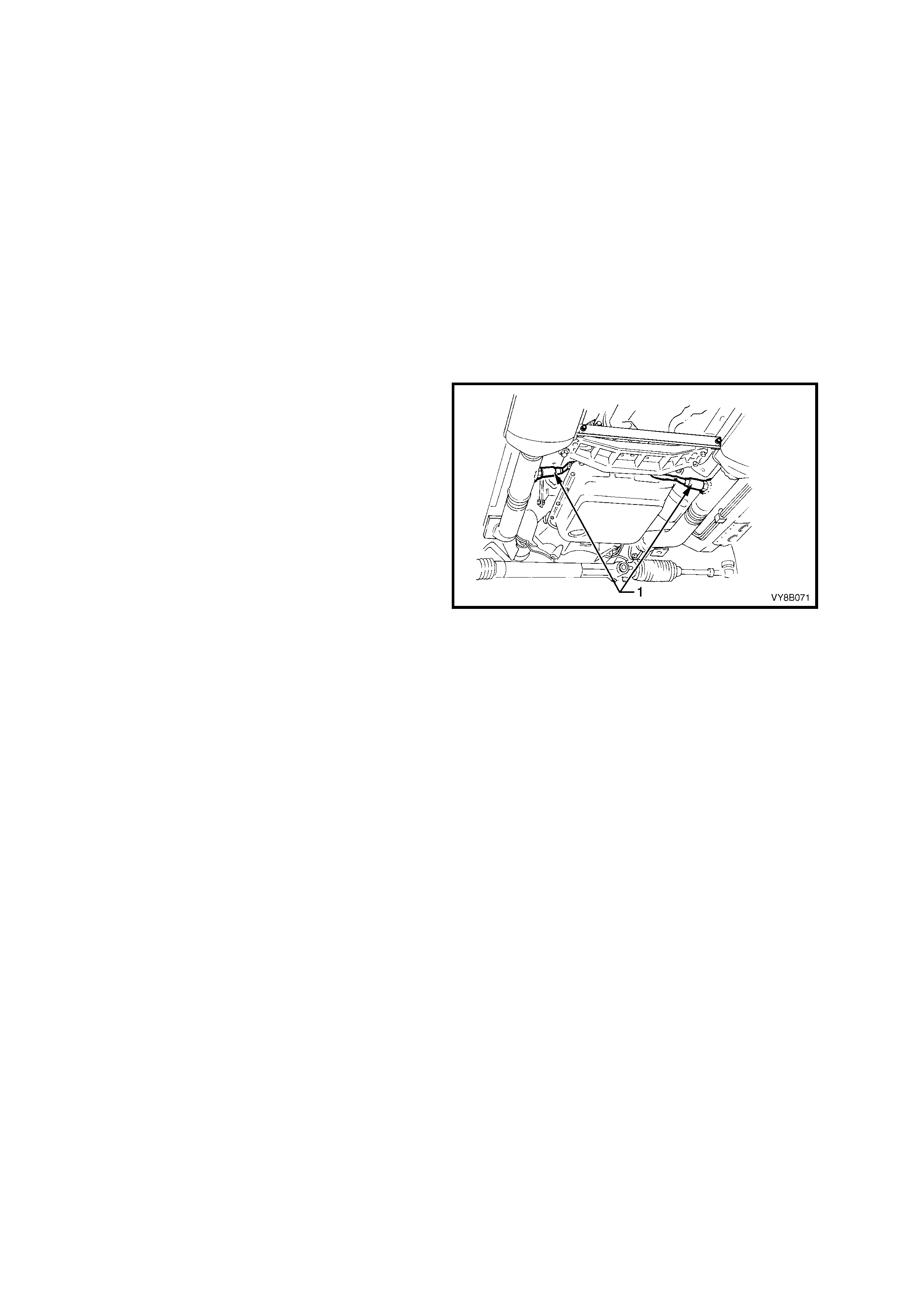

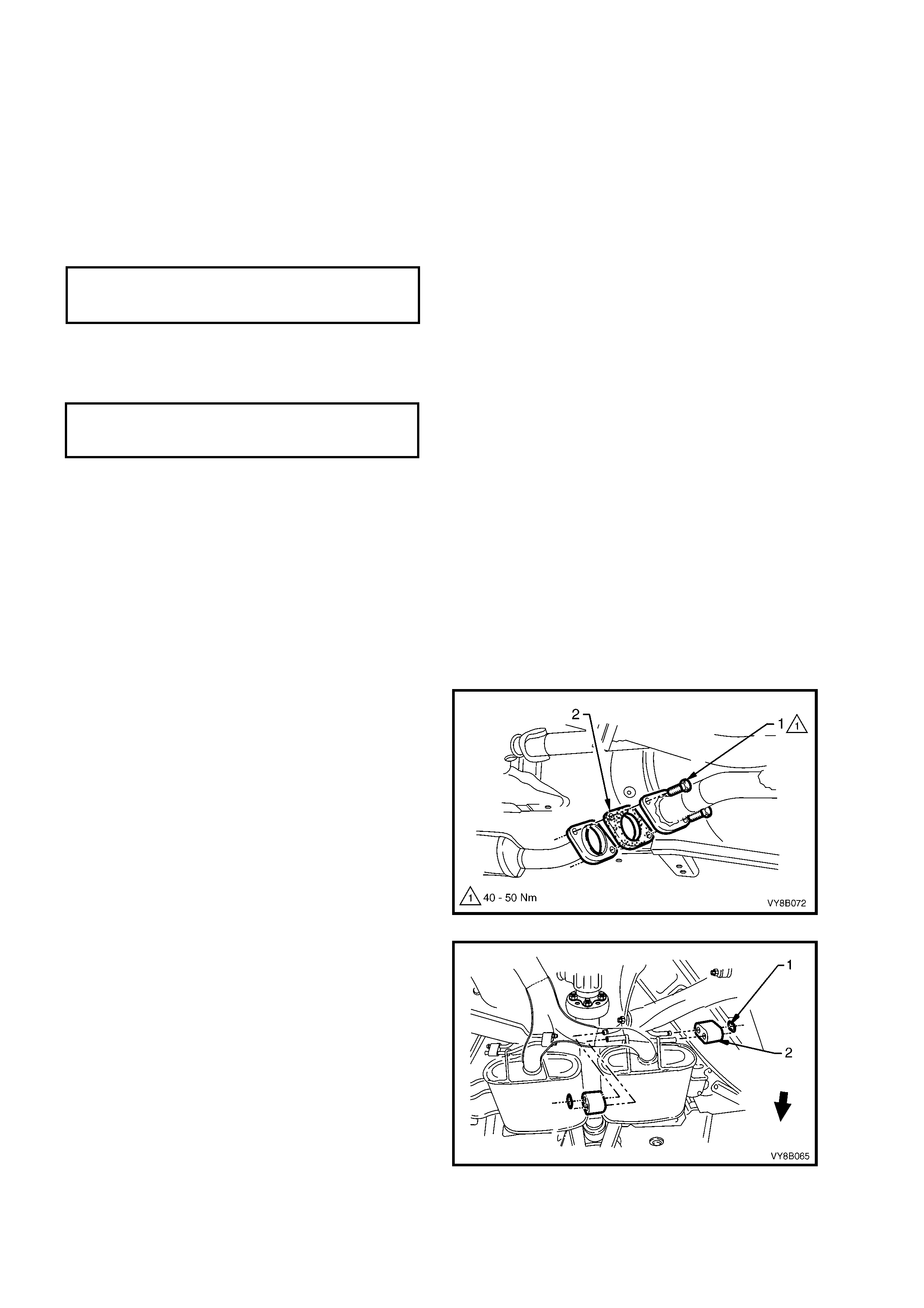

4. Remove the transmission to catalyst mounting

bracket bolts (1).

NOTE: For manual transmission vehicles, refer to

View A. For automatic transmission vehicles, refer

to View B.

Figure 8B-46

5. Support the exhaust system and remove the

upper (1) and lower (2) fastening nuts from the

exhaust manifold to exhaust pipe flange studs

on both sides.

6. Carefully lower and remove the exhaust

assembly from the vehicle, taking care not to

damage the exhaust gas oxygen sensors.

Figure 8B-47

Reinstall

Installation of the f ull exhaust s ys tem is the reverse

of the removal procedure, noting the following

points:

1. Support the exhaust system at all times.

2. Clean threads of flange and fastening bolts with

a suitable cleaning solvent.

3. Apply high temperature anti- seize com pound to

the manifold to fr ont pipe f lange studs and align

the front pipe flange over the studs.

4. Install the upper f as tening nut (1) to the s tud on

both sides.

5. Install the lower fas tening nut (2) to the stud on

both sides.

6. Tighten the upper and lower fastening nuts so

that approxim ately equal amounts of thread are

showing.

7. Tighten the exhaust manifold to front pipe

flange attaching nuts (1 and 2) to the specified

torque.

8. Ensure all support rubbers are under load

9. Ensure that correct body clearances are

maintained throughout the full exhaust system.

Refer to 6.2 V6 SUPERCHARGED AND GEN

III V8 EXHAUST SYSTEM CLEARANCES.

10. Connect the wiring harness connectors for

each of the two oxygen sensors.

NOTE: If steps 8 or 9 are not achieved, refer to

TIGHTENING SEQUENCE in this Section.

Figure 8B-48

TIGHTENING SEQUENCE

This procedure is only to be performed if the exhaust system positioning is not to specification.

Refer to Figure 8B-49 for the following.

IMPORTANT: For all gasketed joints requiring adjustment, always check flange gaskets for serviceability and

replace where required.

1. T ighten the f ront pipe to inter m ediate pipe flange attac hing bolts (1) at the r ear of the catalytic converters to the

specified torque.

FRONT PIPE TO INTERMEDIATE PIPE

FLANGE ATTACHING BOLT

TORQUE SPECIFICATION 40 – 50 Nm

2. For the Standard exhaust system, check that the rear exhaust pipe aligning tab is seated within the intermediate

exhaust pipe’s end slip joint groove. Position the U-bolt clamp along the intermediate to rear slip joint and

tighten the pair of fastening nuts (2) to the specified torque.

U-BOLT CLAMP ASSEMBLY

SECURING NUTS

TORQUE SPECIFICATION 20 – 30 Nm

3. For the Performance exhaust system, check that the rear exhaust pipe aligning tab is seated within the

intermediate exhaust pipe’s end slip joint groove and tighten each fastening bolt to the specified torque.

RING CLAMP ASSEMBLY

FASTENING BOLT

TORQUE SPECIFICATION 37 – 50 Nm

4. Install the upper fastening nut (1) to the stud on both sides, refer to Figure 8B-48.

5. Install the lower fastening nut (2) to the stud on both sides, refer to Figure 8B-48.

6. Tighten all the nuts joining the exhaust manifold to the front exhaust pipe flange, so that approximately equal

amounts of thread are showing.

7. Tighten the exhaust manifold to front pipe flange attaching nuts (1 and 2) to the specified torque, refer to

Figure 8B-48.

EXHAUST MANIFOLD TO FRONT PIPE

FLANGE ATTACHING NUT

TORQUE SPECIFICATION 18 – 35 Nm

EXHAUST MANIFOLD TO FRONT PIPE

FLANGE ATTACHING NUT

TORQUE SPECIFICATION 18 – 35 Nm

8. Tighten the front pipes to transmission extension housing bracket assembly bolts (3) to the specified torque,

refer to Figure 8B-49.

CATALYST TO TRANSMISSION

EXTENSION HOUSING BRACKET

ASSEMBLY BOLTS

TORQUE SPECIFICATION 40 – 50 Nm

9. Ensure that all six support rubbers (4 and 5) are under load. If this is not achieved, loosen the respective

joints in the reverse order to steps 1 to 8. Load the hangers and re-tighten in the sequence described, from

steps 1 to 8.

NOTE: The exhaus t s ystem should be s elf- aligning and not require f urther adj ustm ent, provided s tep 9 is ac hieved.

To ensure that correct clearances are maintained throughout the full exhaust system, refer to

6.2 V6 SUPERCHARGED AND GEN III V8 EXHAUST SYSTEM CLEARANCES for the correct values.

Figure 8B-49

REAR EXHAUST ASSEMBLY

Remove

1. Remove the two support hanger retainer

clips (1) and the two support rubbers (2) from

the support hangers.

NOTE: The additional bumper washer (3) is used

on utility vehicles only.

Figure 8B-50

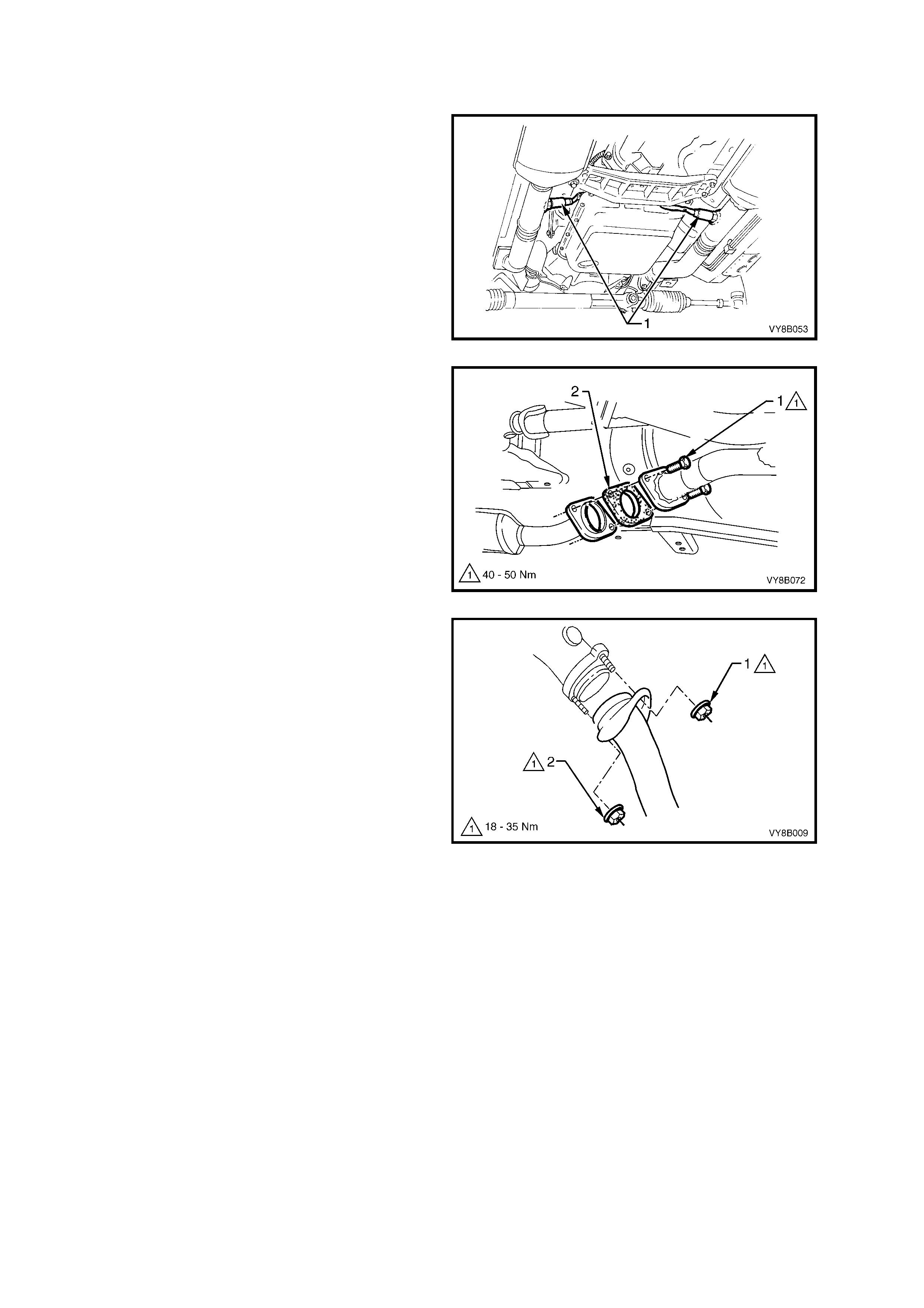

2. For Standard exhaust:

a. Rem ove the two retaining nuts (1) and the rear

muffler U-bolt (2) and clamp plate (3) from the

intermediate exhaust pipe to rear muffler

exhaust pipe slip joint.

b. Carefully slide the rear exhaust pipe out of the

intermediate exhaust pipe end slip joint.

3. For Performance exhaust:

a. Loosen the two ring clamp fastening bolts.

b. Car efully slide the rear exhaust pipes out of the

intermediate exhaust pipe end slip joints.

4. Remove the rear exhaust assembly.

Figure 8B-51

Reinstall

Installation of the rear exhaust assembly is the

reverse of the removal procedure, noting the

following:

1. Ensure that the rear exhaust pipe slides

unobstructed into the intermediate exhaust pipe

slip joint, and that the alignment tab is

positioned in the slip joint groove.

2. For Standar d exhaust, evenly tighten the U-bolt

clamp nuts to the correct torque specification.

3. For Performance exhaust, tighten each

fastening bolt to the specified torque.

4. Ensure all support rubbers are under load and

all clearances are within the specifications. If

this is not achieved, refer to TIGHTENING

SEQUENCE in this Section.

INTERMEDIATE EXHAUST ASSEMBLY

Remove

1. Remove the rear exhaust assembly. Refer to

REAR EXHAUST ASSEMBLY in this Section.

CAUTION: The f ront exhaust assembly must be

supported during and after this procedure.

2. Support the intermediate and front exhaust

assemblies and remove the two bolts (1) from

each of the two flange joints.

3. Separate the intermediate exhaust assembly

from the front exhaust assembly and remove

each flange gasket (2) from between each of

the flange joints.

Figure 8B-52

4. Remove the pair of retainer clips (1) and

support rubbers (2) from both of the right-hand

side and left-hand side intermediate muffler

support hangers. Remove the intermediate

exhaust assembly.

Figure 8B-53

RING CLAMP ASSEMBLY

FASTENING BOLTS

TORQUE SPECIFICATION 40 – 50 Nm

U-BOLT CLAMP ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 20 – 30 Nm

Reinstall

Installation of the inter mediate exhaust assem bly is

the reverse of the removal procedure, noting the

following:

1. Support the exhaust system at all times.

2. Clean the threads of all flange bolts with a

suitable cleaning solvent.

3. Tighten the front pipe to intermediate pipe

flange attaching bolts at the rear of the catalytic

converters to the specified torque.

4. Ensure all support rubbers are under load and

all clearances are within specification. If this is

not achieved, refer to TIGHTENING

SEQUENCE in this Section.

FRONT EXHA UST ASSEMBLY

Remove

1. Disconnect the wiring harnes s connectors f rom

each of the two oxygen sensors (1).

Figure 8B-54

2. Support the intermediate and front exhaust

assemblies and remove the two bolts (1) from

each of the two flange joints.

3. Separate the intermediate exhaust assembly

from the front exhaust assembly and remove

the flange gasket (2) from between the flange

joint.

Figure 8B-55

FRONT PIPE TO INTERMEDIATE PIPE

FLANGE ATTACHING BOLT

TORQUE SPECIFICATION 40 – 50 Nm

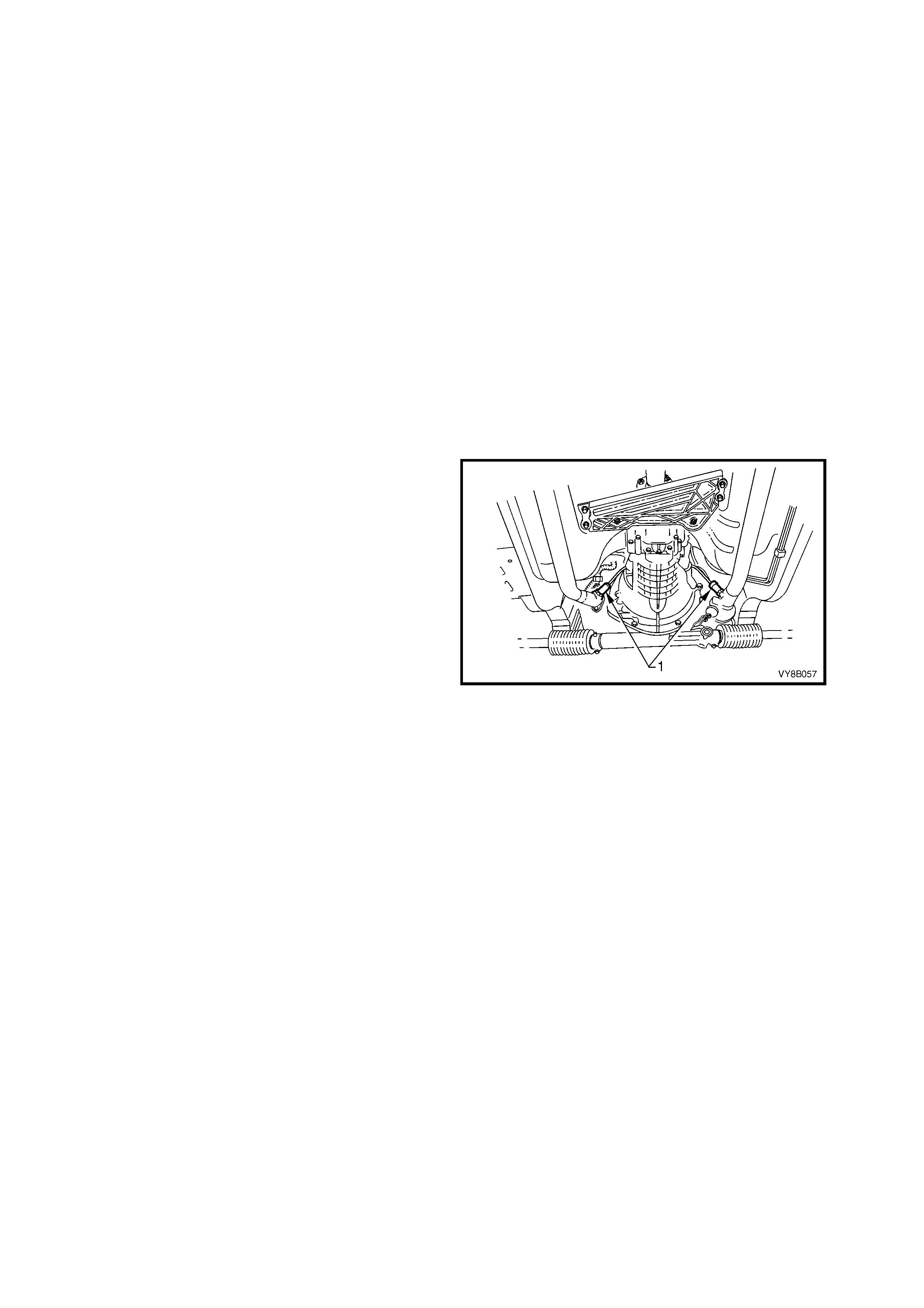

4. Remove the transm ission to catalys t mounting

bracket bolts (1).

NOTE: For manual transmission vehicles, refer to

view A. For automatic transmission vehicles, refer

to view B.

Figure 8B-56

5. Support the front exhaust assembly and

remove the upper (1) and lower (2) fastening

nuts f rom the exhaus t manif old to exhaust pipe

flange studs on both sides.

6. Carefully lower and remove the front exhaust

assembly from the vehicle, taking care not to

damage the oxygen sensors in the process.

Figure 8B-57

Reinstall

Installation of the front exhaust assembly is the

reverse of the removal procedure, noting the

following points:

1. Support the exhaust system at all times.

2. Clean threads of flange and stepped bolts with

a suitable cleaning solvent.

3. Apply a high temperature anti-seize compound

to the manifold to front pipe flange studs and

align the front pipe flange over the studs.

4. Install the upper f as tening nut (1) to the s tud on

both sides.

5. Install the lower fas tening nut (2) to the stud on

both sides.

6. Tighten the upper and lower fastening nuts so

that approxim ately equal amounts of thread are

showing.

7. Tighten the exhaust manifold to front pipe

flange attaching nuts (1 and 2) to the specified

torque.

8. Tighten the front pipe to intermediate pipe

flange attaching bolts to the specified torque.

9. Ensure all exhaust system support rubbers are

under load.

10. Ensure that correct body clearances are

maintained throughout the full exhaust system.

Refer to 6.2 V6 SUPERCHARGED AND GEN

III V8 EXHAUST SYSTEM CLEARANCES.

11. Connect the wiring harness connectors for

each of the two oxygen sensors.

NOTE: If steps 9 or 10 are not achieved, refer to

TIGHTENING SEQUENCE in this Section.

Figure 8B-58

FRONT PIPE TO INTERMEDIATE PIPE

FLANGE ATTACHING BOLT

TORQUE SPECIFICATION 40 – 50 Nm

EXHAUST MANIFOLD TO FRONT PIPE

FLANGE ATTACHING NUT

TORQUE SPECIFICATION 18 – 35 Nm

5. SERVICE OPERATIONS – EXHAUST SYSTEM HEAT SHIELDS

5.1 HEAT SHIELDS

Should any of the heat shields or reflective foil insulators require replacement, the following procedure is

recommended.

CAUTION: To av oid the possibility of personal injury by burns, allow the exhaust pipe system to cool down

before attempting this operation and wear heat resistant protective gloves when handling heated foil.

NOTE 1: No rear muffler heat shield is fitted to Utility vehicles.

NOTE 2: Do not attempt to re-use a remould reflective foil insulator. Always use a new part.

Figure 8B-59 provides a reference to the location of the muffler heat shields and the reflective foil insulators.

Figure 8B-59

Legend

1. Reflective Foil Heat Shield 2. Intermediate Muffler Heat Shield 3. Rear Muffler Heat Shield

HEAT SHIELD – REAR MUFFLER

Remove

1. If required, remove the rear exhaust assem bly,

refer to:

• 2.2 EXHAUST SYSTEM – REAR

EXHAUST ASSEMBLY for V6.

• 3.2 EXHAUST SYSTEM – REAR

EXHAUST ASSEMBLY for V6

Supercharged.

• 4.2 EXHAUST SYSTEM – REAR

EXHAUST ASSEMBLY for GEN III V8.

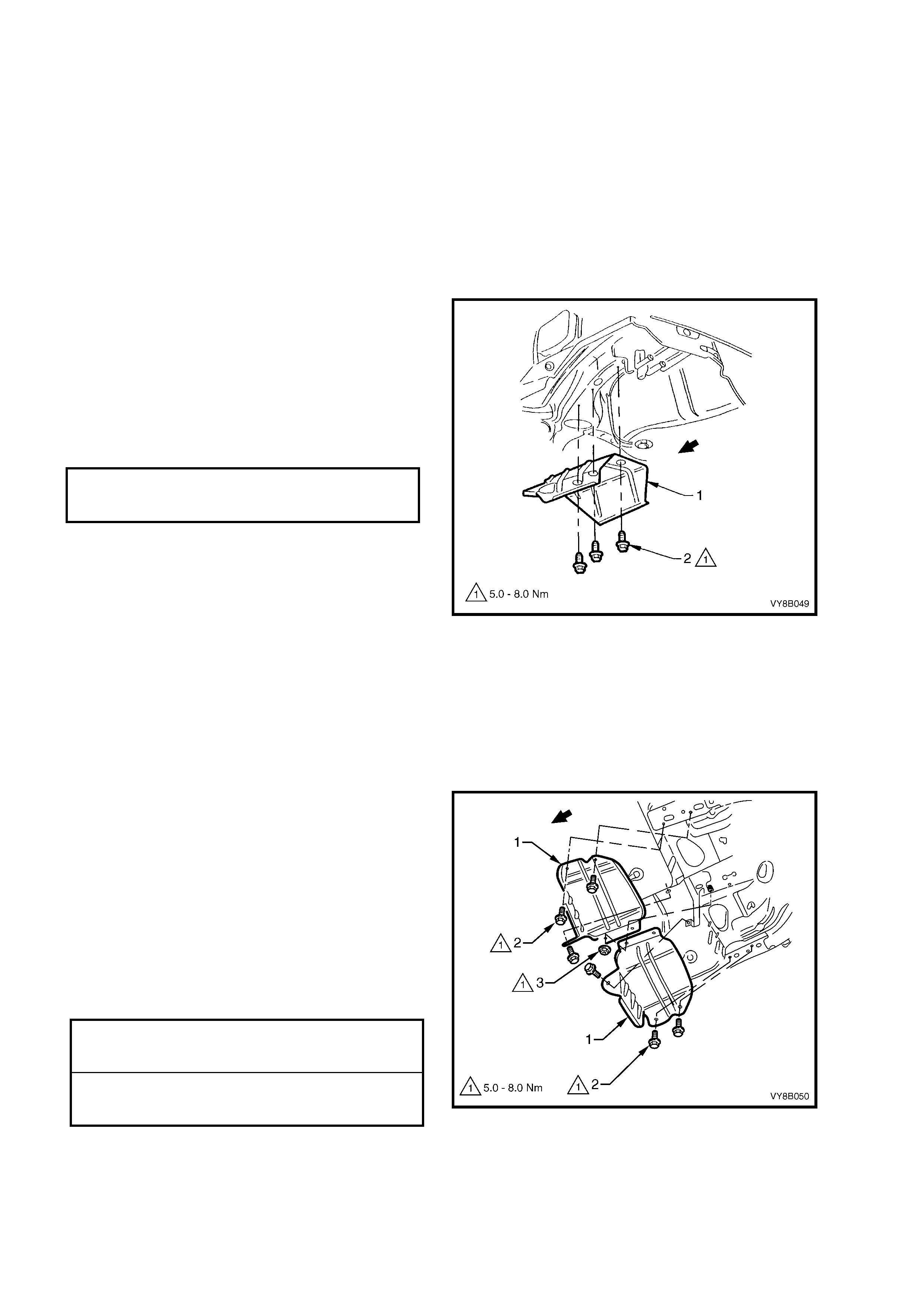

2. Remove the rear muffler heat shield (1) by

removing the three attaching screws (2).

Reinstall

Installation of the rear muffler heat shield is the

reverse of the removal procedure, noting the

following:

1. Tighten the body attaching screws to the

correct torque specification:

Figure 8B-60

HEAT SHIELD – INTERMEDIATE MUFFLER

Remove

1. If required, remove the intermediate exhaust assembly, refer to:

• 2.2 EXHAUST SYSTEM – INTERMEDIATE EXHAUST ASSEMBLY for V6.

• 3.2 EXHAUST SYSTEM – INTERMEDIATE EXHAUST ASSEMBLY for V6 Supercharged.

• 4.2 EXHAUST SYSTEM – INTERMEDIATE EXHAUST ASSEMBLY for GEN III V8.

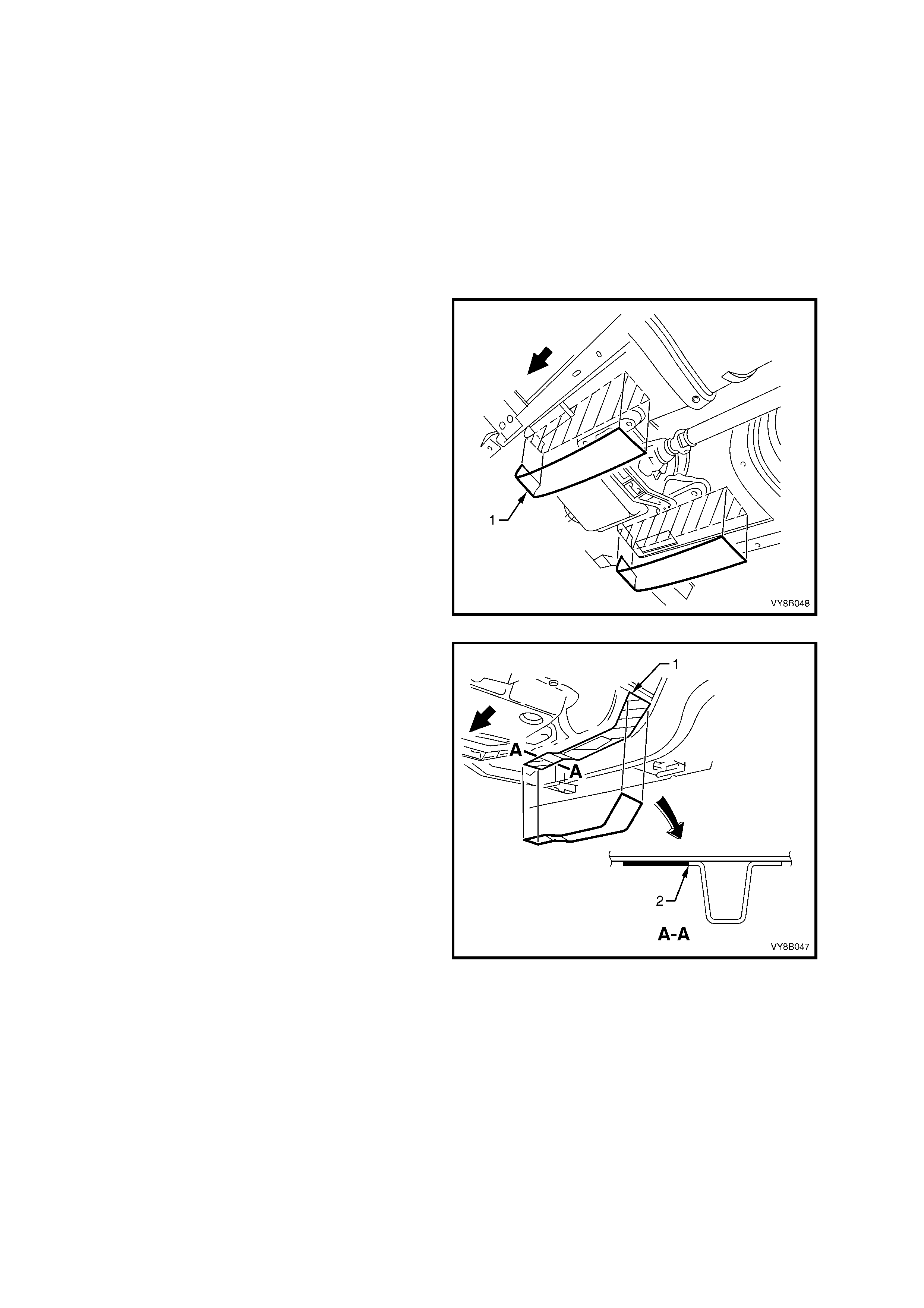

NOTE: For V6 (non-supercharged) vehicles, there

is one intermediate muffler heat shield.

2. Remove the intermediate heat shield/s (1) by

removing the attaching screws (2) and the

single stud nut (3).

Reinstall

Installation of the intermediate heat shield is the

reverse of the removal procedure, noting the

following:

1. T ighten the body attaching screws and stud nut

to the correct torque specification.

Figure 8B-61

REAR MUFFLER HEAT SHIELD

ATTACHING SCREW

TORQUE SPECIFICATION 5.0 – 8.0 Nm

INTERMEDIATE MUFFLER HEAT

SHIELD ATTACHING SCREW

TORQUE SPECIFICATION 5.0 – 8.0 Nm

INTERMEDIATE MUFFLER HEAT

SHIELD STUD ATTACHING NUT

TORQUE SPECIFICATION 5.0 – 8.0 Nm

REFLECTIVE FOIL INSULATORS

Remove

1. If requir ed, rem ove the fr ont exhaust as sem bly,

refer to

• 2.2 EXHAUST SYSTEM – FRONT

EXHAUST ASSEMBLY for V6.

• 3.2 EXHAUST SYSTEM – FRONT

EXHAUST ASSEMBLY for V6

Supercharged.

• 4.2 EXHAUST SYSTEM – FRONT

EXHAUST ASSEMBLY for GEN III V8.

2. Peel the reflective foil insulator/s (1) to be

replaced from the under floor and discard.

3. Use a solvent soaked rag to remove all traces

of the old insulator adhesive, sealer overspray

or paint overspray, should the vehicle have

been repaired.

Reinstall

NOTE: Do not attempt to re-use a removed

reflective foil insulator. Always use a new part.

1. Use a solvent soaked rag to remove all traces

of the old insulator adhesive, sealer overspray

or paint overspray, should the vehicle have

been repaired.

2. Heat a new reflective foil insulator to 40 ± 5° C.

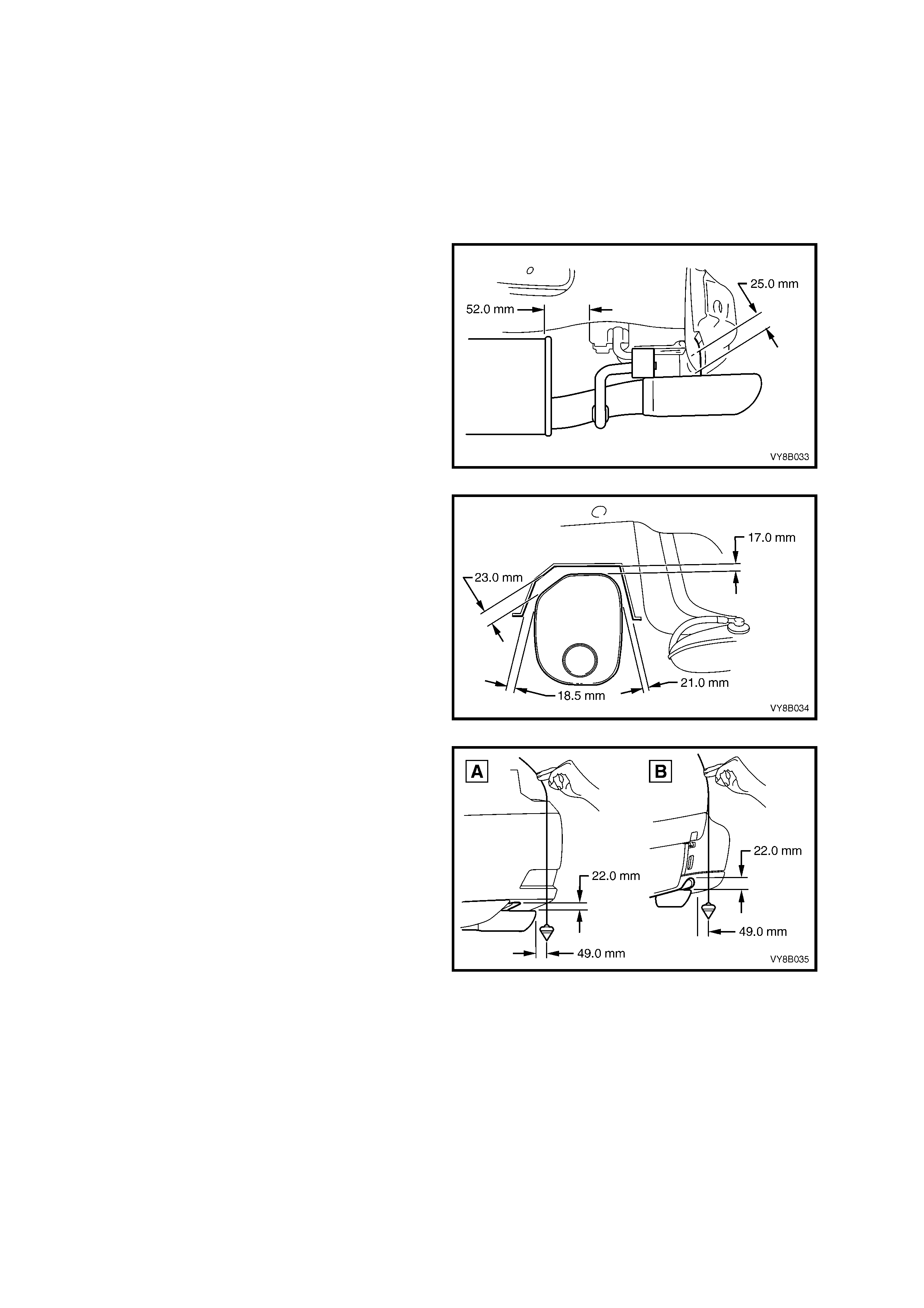

Figure 8B-62

3. Wearing heat resistant protective gloves, peel

the adhesive protective paper from the new

reflective foil heat insulator and apply the

insulator to the cleaned under floor area in the

same position as the removed part. The front

facing end of the foil should start at the join in

the floor (1) and align with the edge of the front

side rail f lange (2). Smooth out any air bubbles

in the process.

Figure 8B-63

6. EXHAUST SYSTEM CLEARANCES

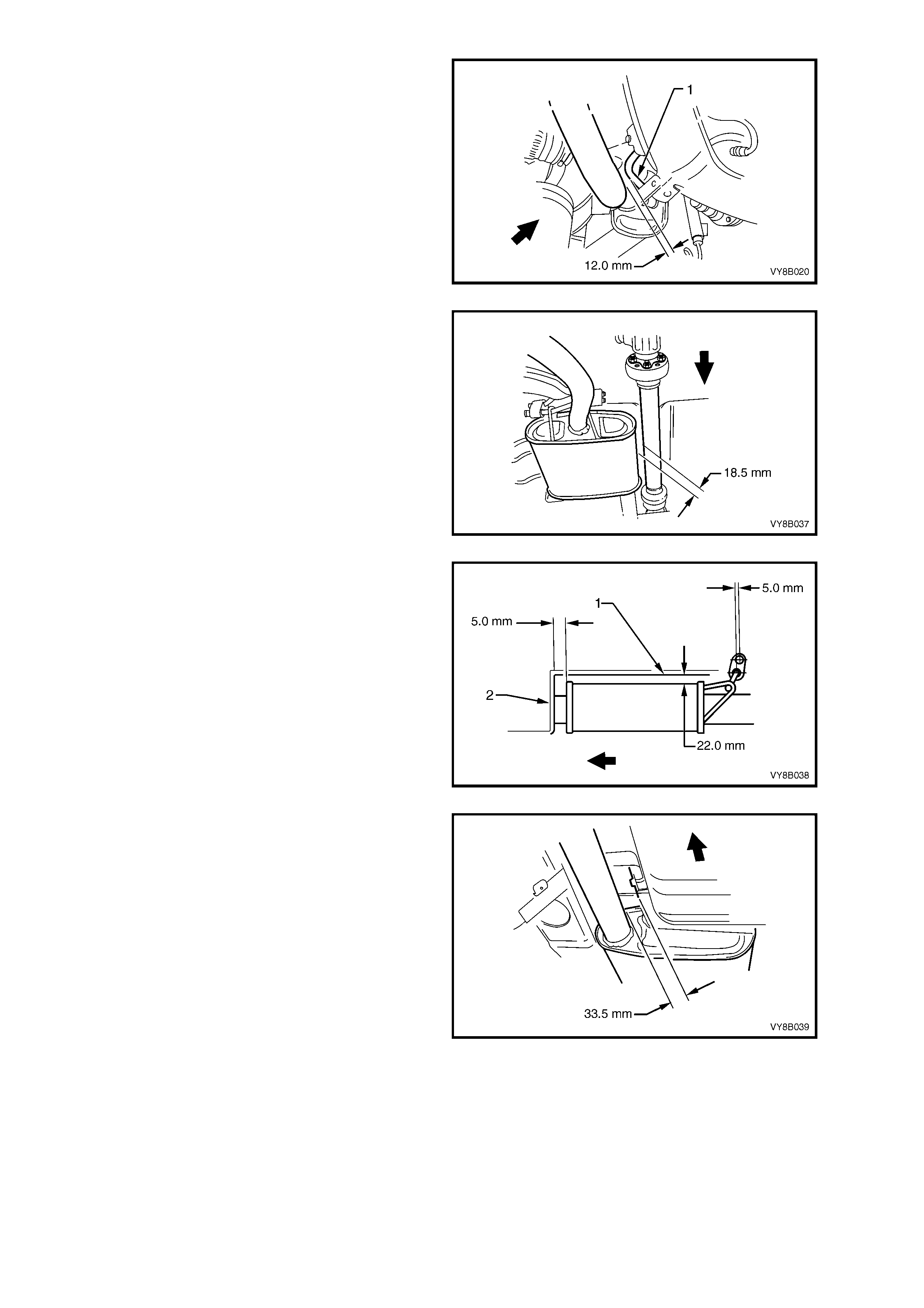

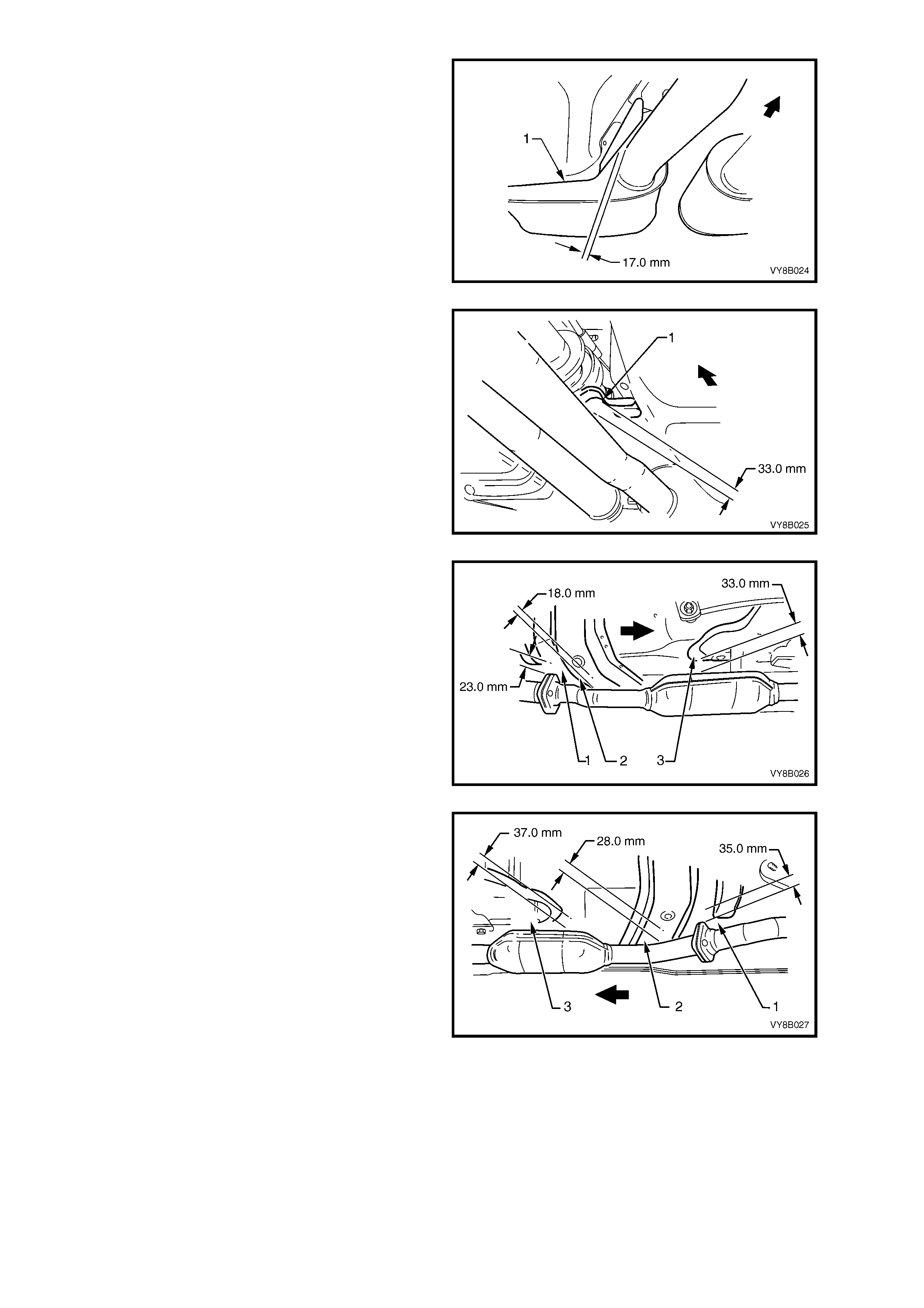

6.1 V6 EXHAUST SYSTEMS CLEARANCES

The following diagrams indicate the exhaust system clearances specified for vehicles fitted with the V6 engine.

Clearances should be checked upon installation of exhaust components to prevent parts interference and ensure

correct alignment. Refer to Figure 8B-8 for the location of exhaust system parts.

CAUTION: To avoid the possibility of personal injury, allow the exhaust system to cool down before

attempting this operation.

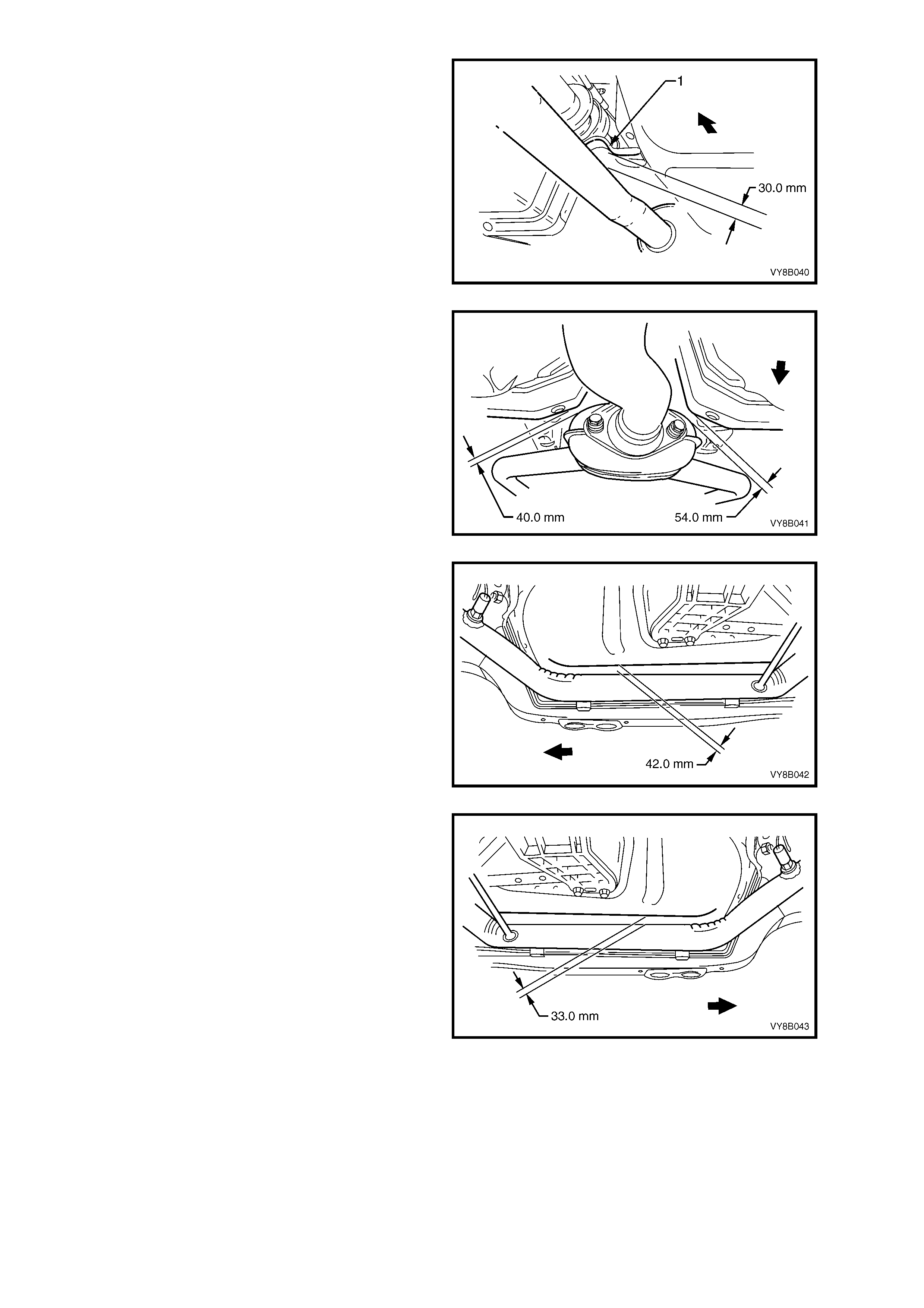

1. Check the rear tail pipe to rear end panel

clearances and rear muffler to tail pipe hanger

mounting clearances.

Figure 8B-64

2. Check the rear exhaust muffler to rear heat

shield clearances.

Figure 8B-65

3. Check the clearance between the rear tail pipe

exhaust tip and the underside of the bumper

fascia.

4. Holding a weighted string over the r ear bumper

fascia, in line with the exhaust tip, determine

the horizontal clearance between the exhaust

tip and rear bumper.

NOTE: Refer to View A for Sedan, Wagon and

Coupe. Refer to View B for Utility.

Figure 8B-66

5. Check the intermediate to rear exhaust pipe to

stabiliser bar linkage (1) clearances.

Figure 8B-67

6. Check the intermediate exhaust hanger to

propeller shaft clearances.

Figure 8B-68

7. Check intermediate exhaust muffler to

intermediate heat shield (1) and rear footwell

(2) clearances; nominal clearance provided.

The horizontal clearance provided between the

body hanger and support peg is for reference

only .

Figure 8B-69

8. Check the intermediate exhaust pipe to

intermediate heat shield clearances.

Figure 8B-70

9. Check the intermediate exhaust pipe to centre

bearing carrier (1) clearance.

Figure 8B-71

10. Check the catalytic converter to transmission

tunnel roof support clearances. Muffler

clearances for Indonesia vehicles similar.

Figure 8B-72

11. Check the right-hand side f ront exhaust pipe to

underbody foot well clearances. Nominal

clearance provided.

Figure 8B-73

12. Check the left-hand side front exhaust pipe to

underbody foot well clearances. Nominal

clearance provided.

Figure 8B-74

13. Check the front exhaust pipe to the right-hand

side front longitudinal assembly clearances.

Figure 8B-75

14. Check the front left-hand side exhaust pipe to

engine block clearances.

Figure 8B-76

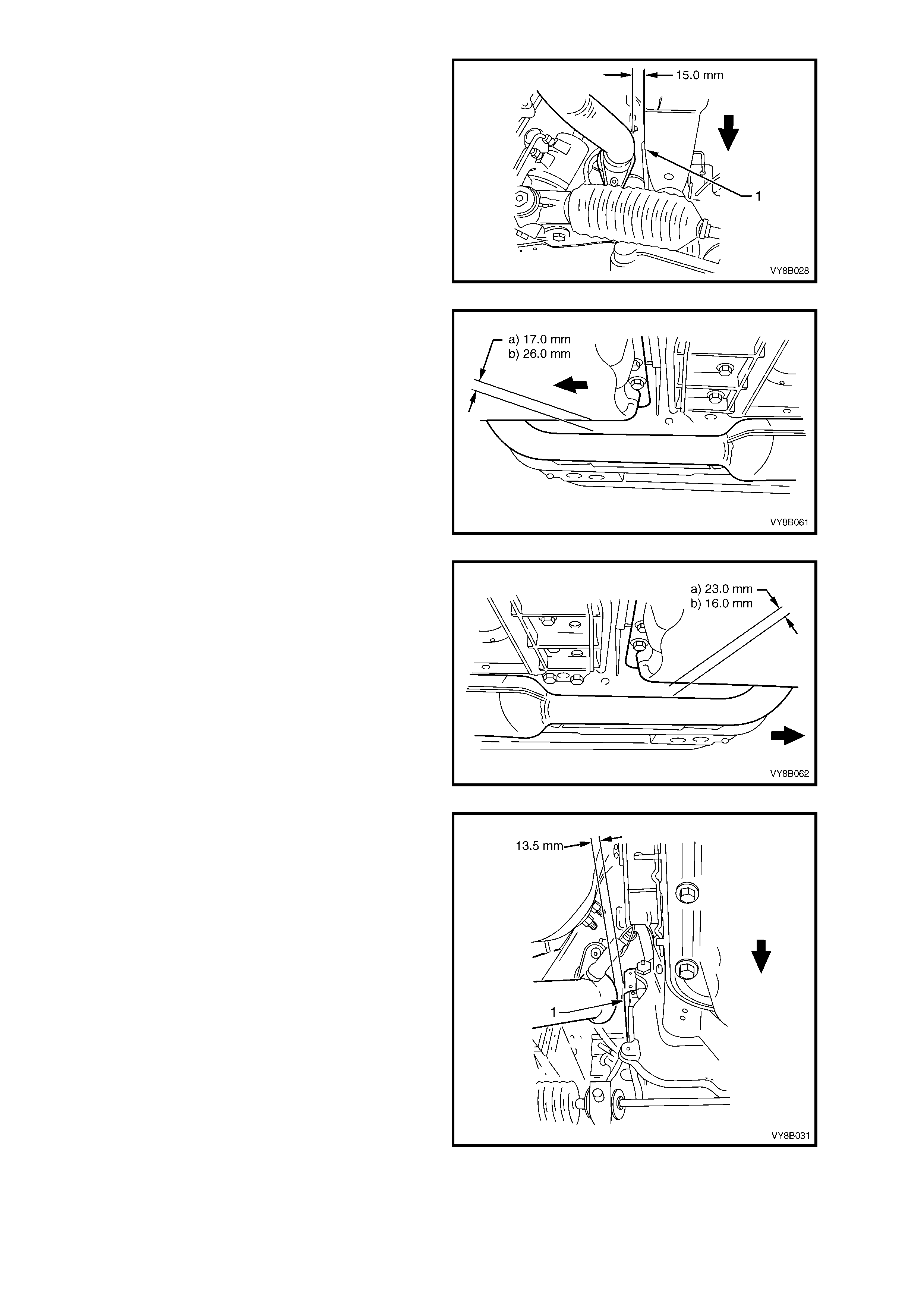

6.2 V6 SUPERCHARGED AND V8 GEN III EXHAUST SYSTEM CLEARANCES

The following diagrams indicate the exhaust system clearances specified for vehicles fitted with either the V6

Supercharged or Gen III V8 Engine. Both standard and performance type exhaust systems are included.

Clearances should be checked upon installation of exhaust components to prevent parts interference and ensure

correct parts alignment. Refer to Figure 8B-26 for V6 Supercharged and Figure 8B-42 GEN III V8 part locations.

CAUTION: To avoid the possibility of personal injury, allow the exhaust system to cool down before

attempting this oper ation.

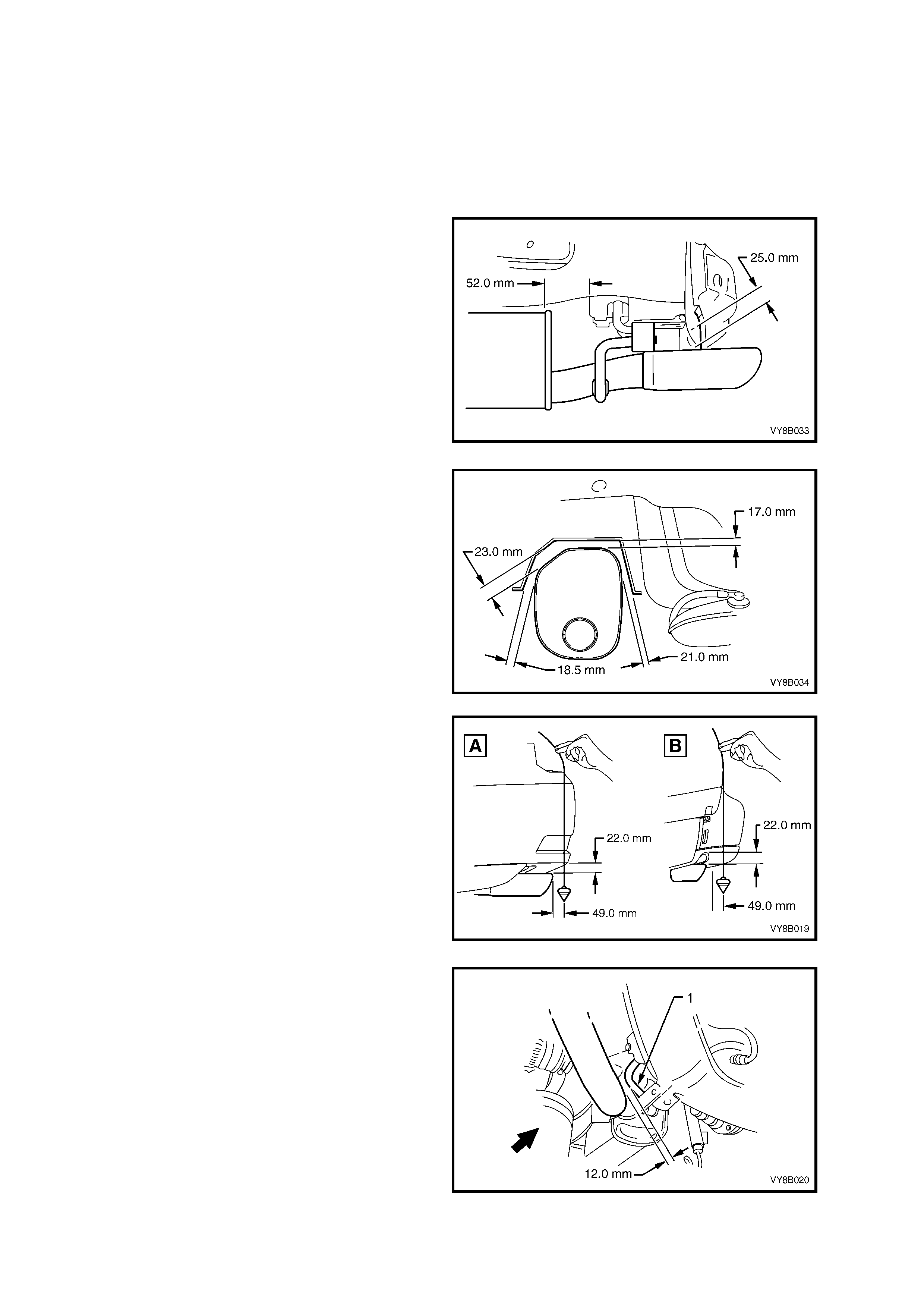

1. Check the rear tail pipe to body panel

clearances and rear muffler to tail pipe hanger

mount clearances.

Figure 8B-77

2. Check the rear exhaust muffler to heat shield

clearances.

Figure 8B-78

3. Check the clearance between the rear tail pipe

exhaust tip and the underside of the bumper

fascia.

4. Holding a weighted string over the r ear bum per

fascia, in line with the exhaust tip, determine

the horizontal clearance between the exhaust

tip and rear bumper.

NOTE: Refer to View A for Sedan, Wagon and

Coupe. Refer to View B for Utility.

Figure 8B-79

1. For V6 Superchar ged and GEN III V8 Standard

exhausts:

a. Check the rear intermediate exhaust pipe to

stabiliser bar linkage (1) clearances.

Figure 8B-80

2. For GEN III V8 Performance exhaust:

a. Check the rear exhaust pipe to differential

carrier (1) clearances.

Figure 8B-81

b. Check the rear exhaust pipe to inner axle

shaft (1) clearances.

Figure 8B-82

c. Check the intermediate exhaust pipe to

suspension member (1) clearances.

Figure 8B-83

d. Check the intermediate exhaust pipe to

rubber coupling (1) clearances.

Figure 8B-84

e. Check the intermediate exhaust pipe to

suspension cross member elbow (1)

clearances.

Figure 8B-85

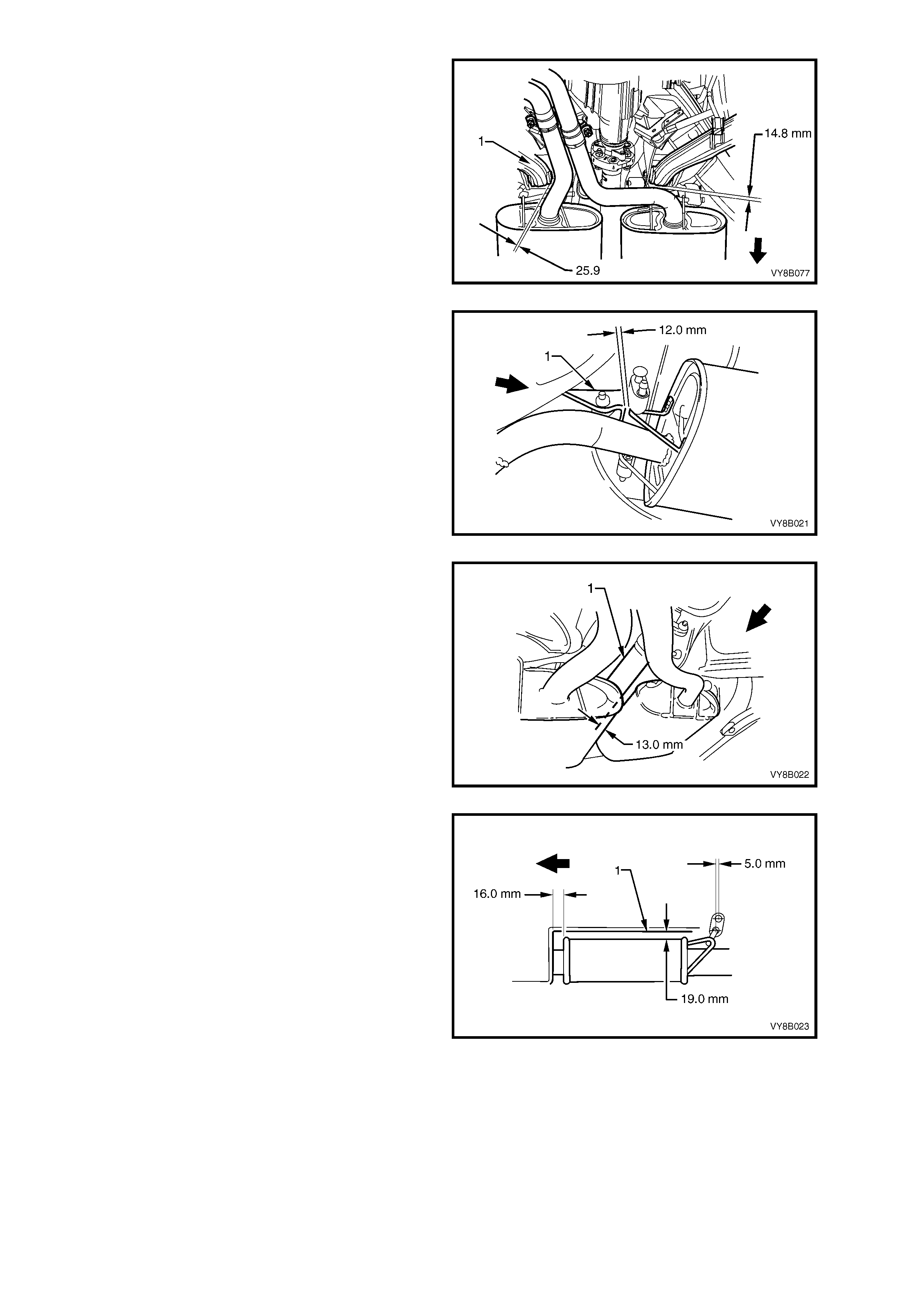

3. Check the intermediate exhaust hanger to

underbody mounting (1) clearances.

Figure 8B-86

4. Check the intermediate exhaust muffler to

propeller shaft (1) clearances.

Figure 8B-87

5. Check the intermediate exhaust muffler to

intermediate heat shield (1) clearances.

NOTE: The clearance between the intermediate

exhaust muffler and the horizontal section of the

heat shield is nominal.

Figure 8B-88

6. Check the intermediate exhaust pipe to

intermediate heat shield clearances.

Figure 8B-89

7. Check the intermediate exhaust pipe to centre

bearing carrier (1) clearances.

Figure 8B-90

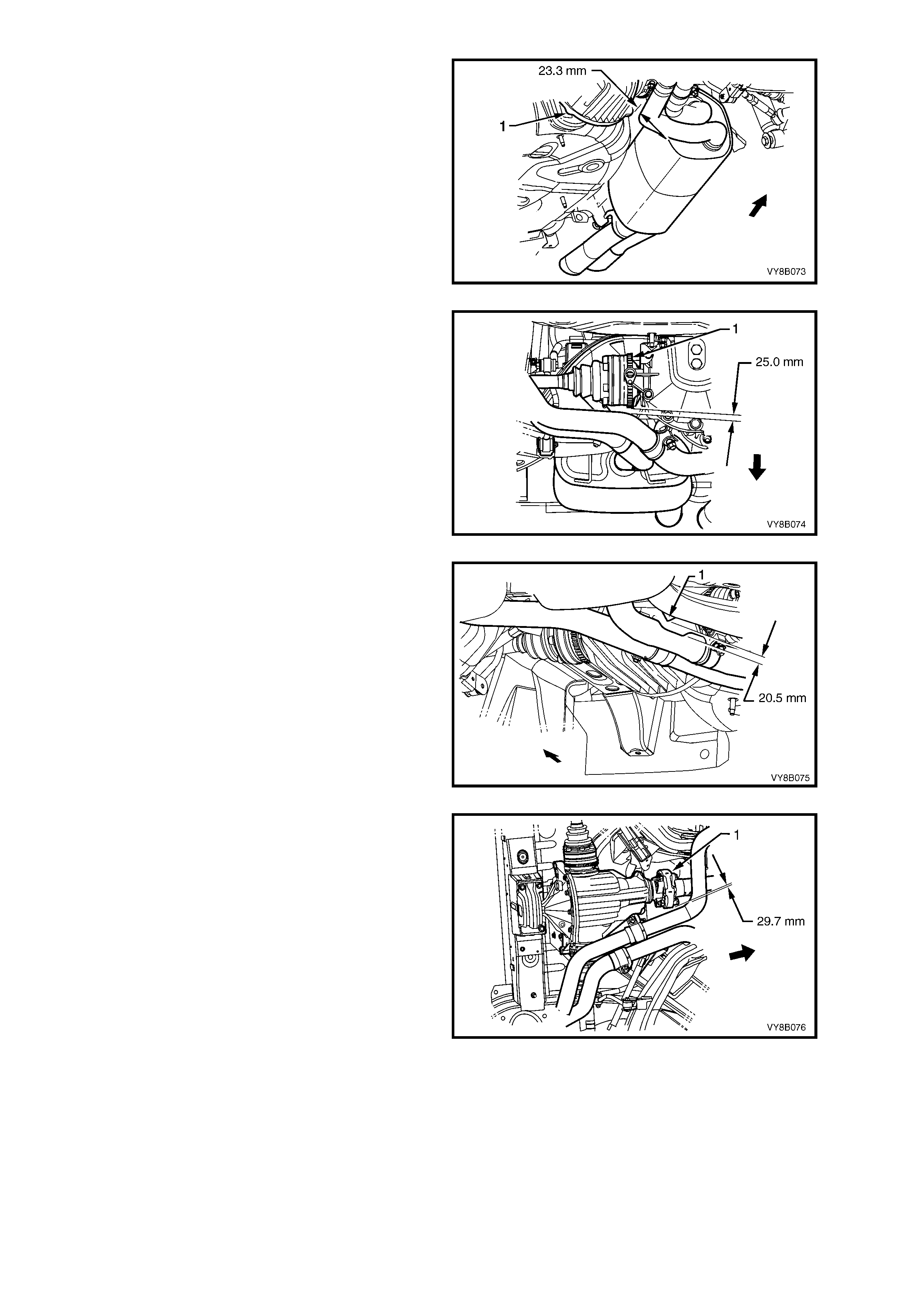

8. Check the left-hand side intermediate exhaust

pipe flange to underbody panel (1) clearances.

9. Check the left-hand side front exhaust pipe to

transmission tunnel roof support (2) clearance.

10. Check the left-hand side catalyst to

transmission cr oss mem ber suppor t br acket (3)

clearance.

Figure 8B-91

11. Check the right-hand side interm ediate exhaust

pipe flange to underbody panel (1) clearances.

12. Check the right-hand side f ront exhaust pipe to

transmission tunnel roof support (2) clearance.

13. Check the right-hand side catalyst to

transmission cr oss mem ber suppor t br acket (3)

clearance.

Figure 8B-92

14. Check the front exhaust pipe to sub frame

clearances.

Figure 8B-93

15. Check the right-hand side f ront exhaust pipe to

automatic transmission oil pan clearances.

For V6 Supercharged vehicles, refer to

dimension a); for V8 Gen III vehicles, refer to

dimension b).

Figure 8B-94

16. Check the LHS front exhaust pipe to autom atic

transmission oil pan clearances. For V6

Supercharged vehicles, refer to dimension a),

for V8 Gen III vehicles, refer to dimension b).

Figure 8B-95

17. Check the front exhaust pipe to engine block

(1) clearances.

Figure 8B-96

7. EXHAUST SYSTEM DIAGNOSIS

CONDITION PROBABLE CAUSE CORRECTION

Leaks at pipe joints. Tighten U-bolt nuts and joint bolts

to the specified torques.

Damaged or improperly installed

converter sealing ring/gaskets. Replace sealing ring/gasket as

necessary.

Leaking exhaust gases

Burned or rusted out exhaust pipe

or muffler/s. Replace component as necessary.

Leaks at manifold or pipe

connections.

Tighten clamps at leaking

connections to specified torques.

Replace gasket as required.

Burned or blown out pipe or

muffler/s. Replace pipe/muffler assembly as

necessary.

Exhaust manifold/s cracked or

broken. Replace manifold.

Exhaust noises

Leak between manifold/s and

cylinder head/s. Tighten manifold to cylinder head

studs to specified torque.

Clogged catalytic converter (may

result from serious engine

malfunction). Replace catalytic converter.

Loss of engine power, hesitation,

surging, poor fuel economy,

stalling or hard starting Crushed pipe work. Replace pipe work.

Dislodged tubes and/or baffles in

muffler. Replace muffler.

Internal rattling in muffler Catalytic converter monolith has

crumbled and pieces blown into

muffler.

Replace catalytic converter

assembly and affected muffler.

Damaged, worn, missing or

improperly installed support

rubbers. Check and replace as necessary.

Damaged mounting hangers or

pegs. Service / replace hangers or pegs

as necessary.

Check clearances and adjust joint

alignment as necessary.

Improper alignment. Tighten all fasteners according to

tightening sequence and the

specified torques.

Rattling or knocking exhaust

system

Damaged or incorrect exhaust

system components. Replace damaged or incorrect

components as necessary.

8. SPECIFICATIONS

TYPE:

V6............................................................................... Single system

V6 Supercharged ....................................................... Dual system to rear of twin intermediate mufflers with a

single pipe rear muffler/tailpipe arrangement.

GEN III V8: Standard................................................ Dual system to rear of twin intermediate mufflers with a

single pipe rear muffler/tailpipe arrangement.

Performance.......................................... Dual system back to a single rear muffler with dual tail

pipes.

MATERIAL:

Engine Pipes .............................................................. 409 stainless steel

Intermediate Muffler ................................................... 409 stainless steel

Rear Muffler................................................................ 409 stainless steel

CATALYTIC CONVERTER:

Make........................................................................... AC Australia

Type............................................................................ Three way monolith

Outer Steel Shell

Material.................................................................. 409 stainless steel

Inlet Diameter

V6...................................................................... 50.8 mm x 2

V6 Supercharged .............................................. 50.8 mm

Gen III V8 A/T ................................................... 50.8 mm

Gen III V8 M/T................................................... 60.5 mm

Outlet Diameter

V6...................................................................... 60.5 mm

V6 Supercharged .............................................. 50.8 mm

Gen III V8 M/T................................................... 50.8 mm

Gen III V8 A/T ................................................... 60.5 mm

Monolith

Material.................................................................. Extruded Cordierite

Volume

V6 Engine......................................................... 1.8 litres

V6 Supercharged A/T and V8 GEN III A/T....... 1.4 litres each

V8 GEN III M/T................................................. 1.8 litres each

Cells/cm2............................................................... 62

9. TORQUE WRENCH SPECIFICATIONS

Intermediate exhaust to catalytic converter flange

attaching bolt...........................................................................................40 – 50 Nm

U-bolt clamp assembly securing nuts .....................................................20 – 30 Nm

Exhaust manifold to front pipe flange attaching nut................................18 – 35Nm

Intermediate pipe to rear pipe flange joint assembly

flange bolts..............................................................................................40 – 50 Nm

Front pipe to intermediate pipe flange attaching bolt ..............................40 – 50 Nm

Ring clamp assembly fastening bolt........................................................37 – 50 Nm

Catalyst to transmission extension housing

bracket assembly bolts............................................................................40 – 50 Nm

Rear muffler heat shield attaching screw................................................5.0 – 8.0 Nm

Intermediate muffler heat shield attaching screw....................................5.0 – 8.0 Nm

Intermediate muffler heat shield stud attaching nut................................5.0 – 8.0 Nm