Wheels and Tyres Page 10–1

Page 10–1

Section 10

Wheels and Tyres

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1 General Information............................................................................................................................... 2

1.1 Wheel and Tyre Combinations..............................................................................................................................2

1.2 Tyre Placards..........................................................................................................................................................4

1.3 Tyre Markings.........................................................................................................................................................5

1.4 Spare Wheel and Tool Stowage............................................................................................................................6

Tool Stowage..........................................................................................................................................................6

Spare Wheel Stowage............................................................................................................................................7

2 Service Operations................................................................................................................................ 8

2.1 Spare Wheel Hoist..................................................................................................................................................8

Remove ...................................................................................................................................................................8

Reinstall ..................................................................................................................................................................8

3 Specifications......................................................................................................................................... 9

Steel Wheels...........................................................................................................................................................9

Alloy Wheels...........................................................................................................................................................9

Inflation Pressures.................................................................................................................................................9

4 Torque Wrench Specifications........................................................................................................... 10

Techline

Wheels and Tyres Page 10–2

Page 10–2

1 General Information

With the following exceptions, MY 2003 VY Series Cab Chassis Wheel and Tyre information carries over from MY 2003

VY Series vehicles. For information not covered within this Section, refer to Section 10, Wheels And Tyres in the MY

2003 VY and V2 Series Service Information.

• The spare wheel hoist mounting and access is unique.

• The stowage of the jack, jack/wheel nut wrench and hoist crank handle is unique.

• The steel wheel as fitted to cab chassis base models is unique to accommodate the increased load carrying

requirements.

• The alloy wheel as fitted to cab chassis ‘S’ Pack is unique to accommodate the increased load carrying

requirements.

• The tyres as fitted to all cab chassis models are unique to accommodate the increased load carrying requirements.

1.1 Wheel and Tyre Combinations

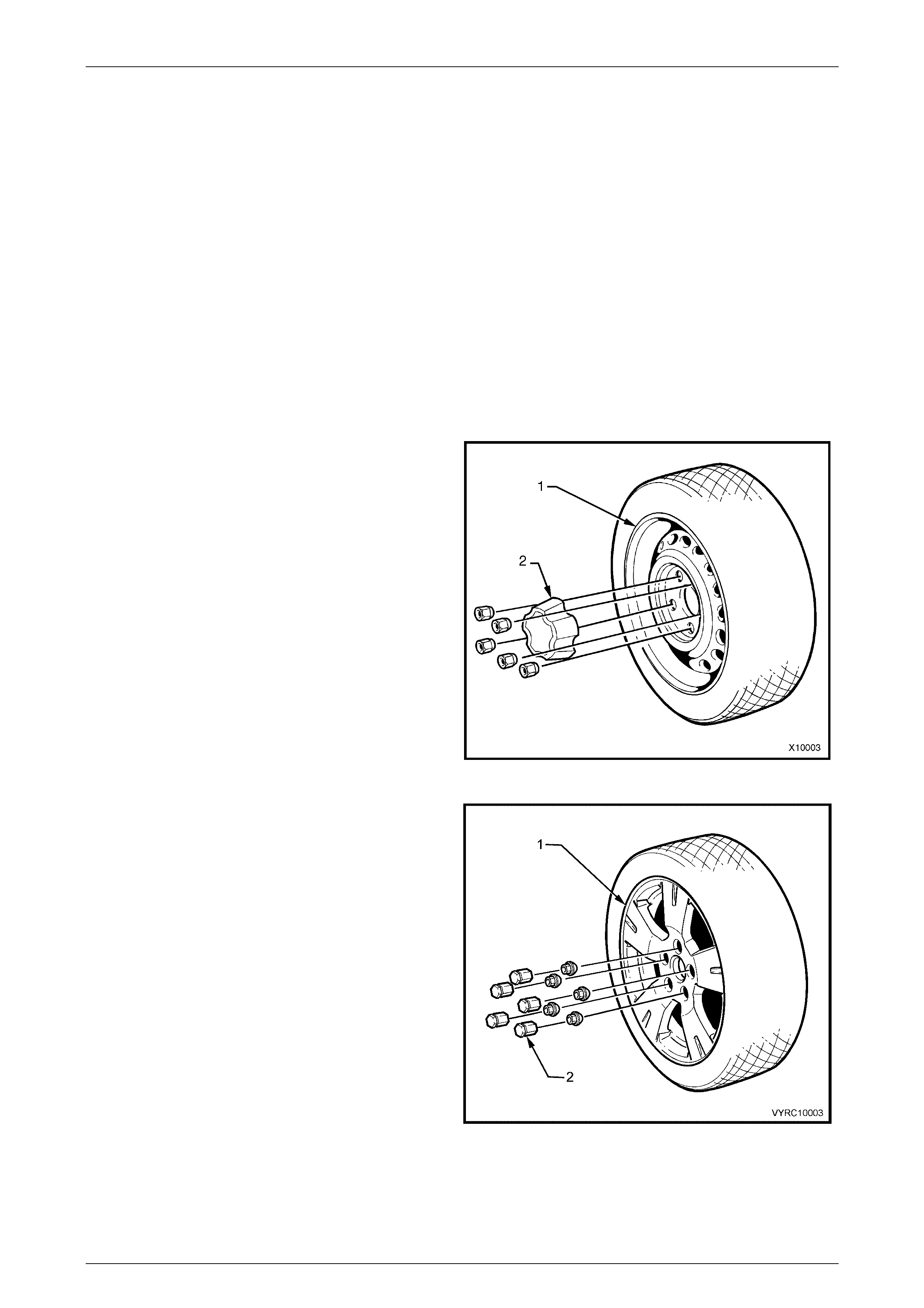

Figure 10-1 illustrates the silver steel wheel (1) and centre

cap (2) fitted as standard equipment to the MY 2003 VY

Series Cab Chassis Base Models.

Road wheels 7J x 15

Tyres 215/65R15C 104R

Figure 10-1

Figure 10-2 illustrates the alloy wheel (1) and centre cap (2)

fitted as standard equipment to MY 2003 VY Series Cab

Chassis ‘S’ Pack.

Road Wheels 7J x 16 alloy

Tyres 215/65R16C 106R

Figure 10-2

Wheels and Tyres Page 10–3

Page 10–3

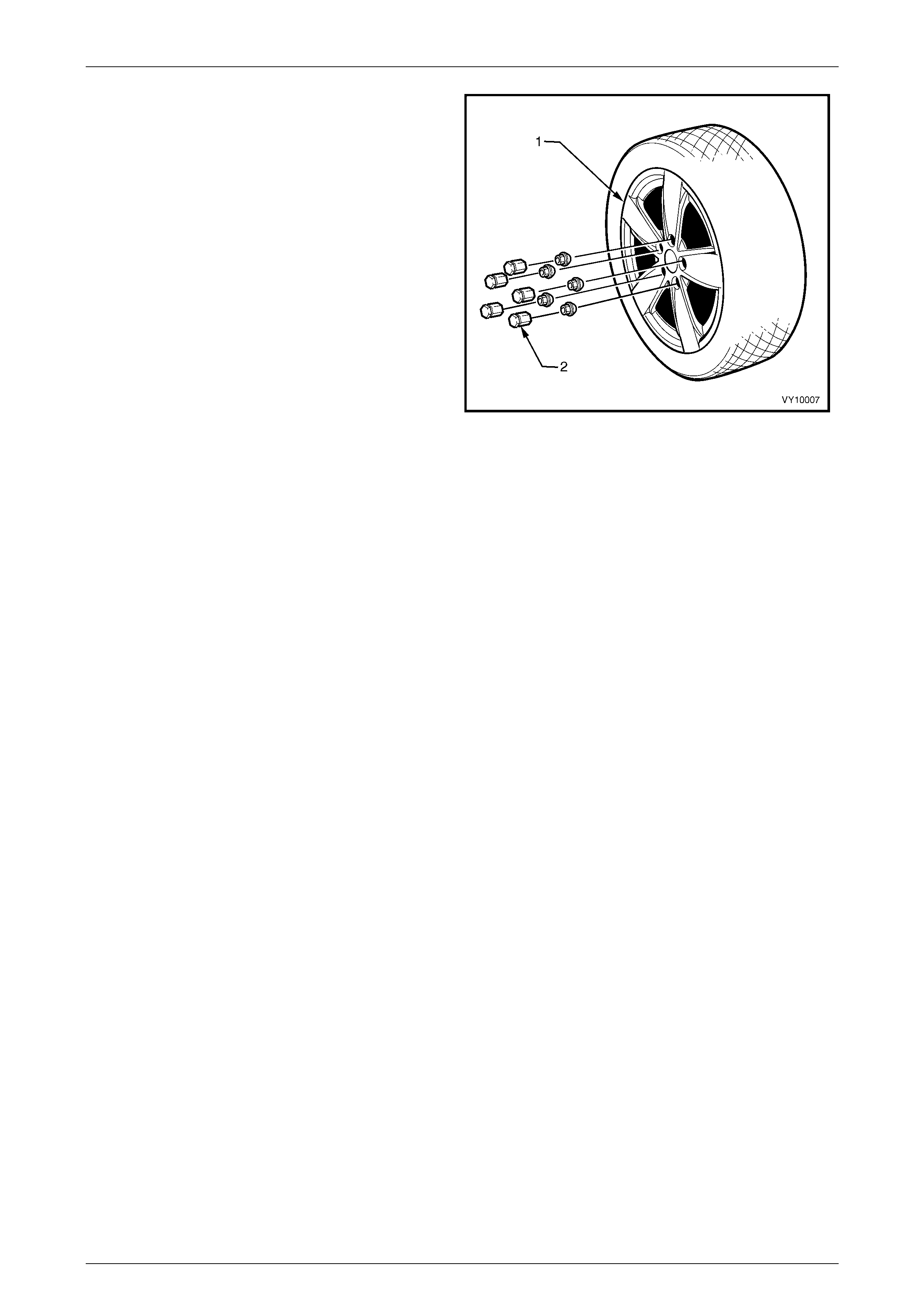

Figure 10-3 illustrates the alloy wheel (1) and centre cap (2)

fitted as standard equipment to the MY 2003 VY Series

Cab Chassis ‘SS’ Pack.

Road Wheels 8J x 17 alloy

Tyres 225/55R17 97H

Figure 10-3

Wheels and Tyres Page 10–4

Page 10–4

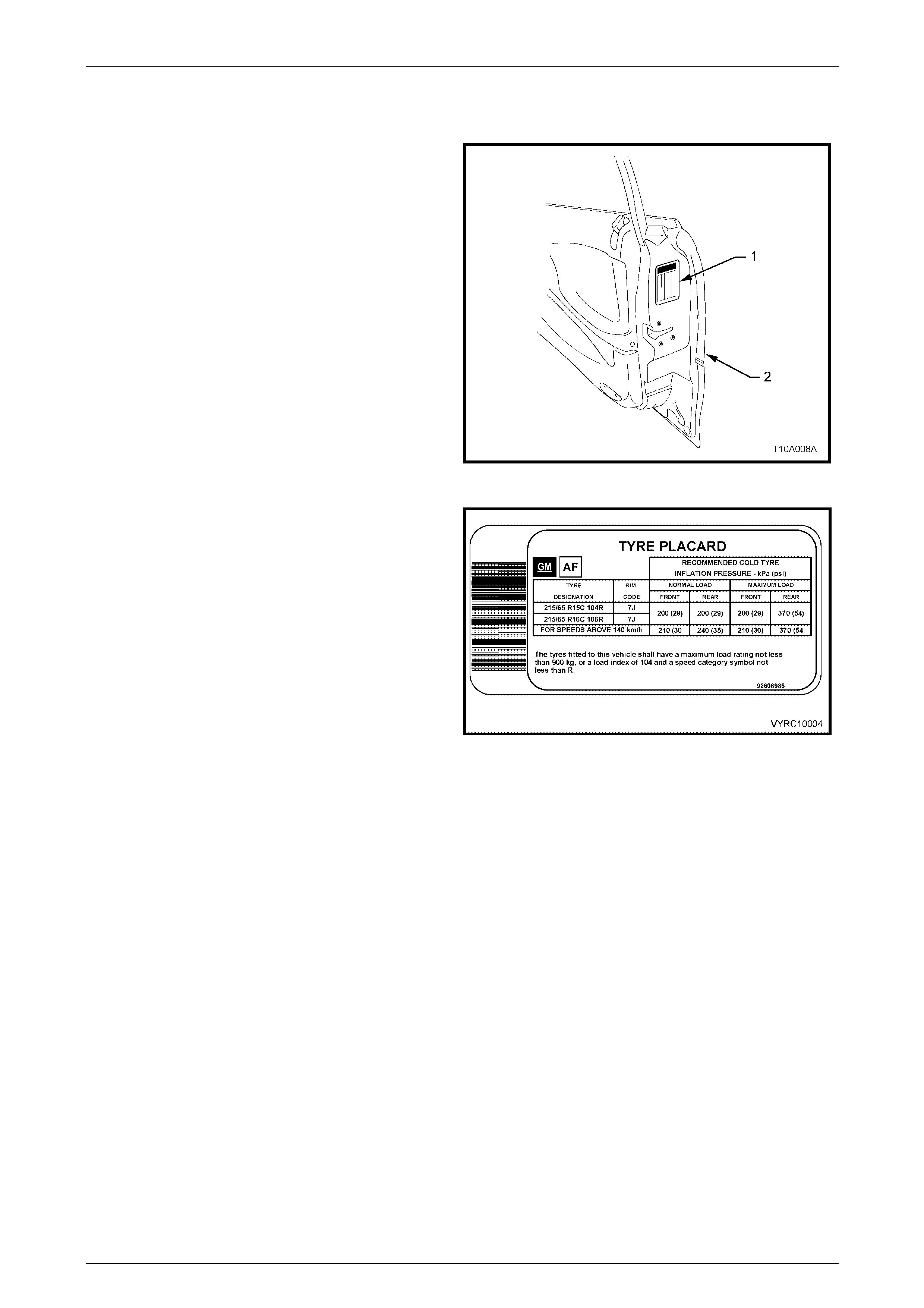

1.2 Tyre Placards

Wheel and tyre sizes, inflation pressures and load capacity

are specified on a tyre placard (1) located on the end

surface of the driver door (2).

Always check tyre pressures, with COLD tyres (after

vehicle has stood for three hours or more, or driven less

than 2 km) and should be checked weekly or before any

extended trip.

When checking ty re pressur e, v isual ly inspect tyres for

excessive wear, sharp objects embedded in the tyre or

damage to the sidewalls.

NOTE

Clean valve exterior, prior to applying air pressure nozzle

when inflating tyre.

NOTE

Always install valve caps to keep out dust and water.

Figure 10-4

The tyre placard shown in Figure 10-5 is typical of those

fitted to MY 2003 VY Series Cab Chassis Models.

Refer to 3. Specifications in this Section or the vehicle

tyre placard for the correct wheel/tyre size and

corresponding tyre inflation pressures.

Figure 10-5

Wheels and Tyres Page 10–5

Page 10–5

1.3 Tyre Markings

The tyre sidewall has a coded mark ing system, w hich

provides information about the tyre.

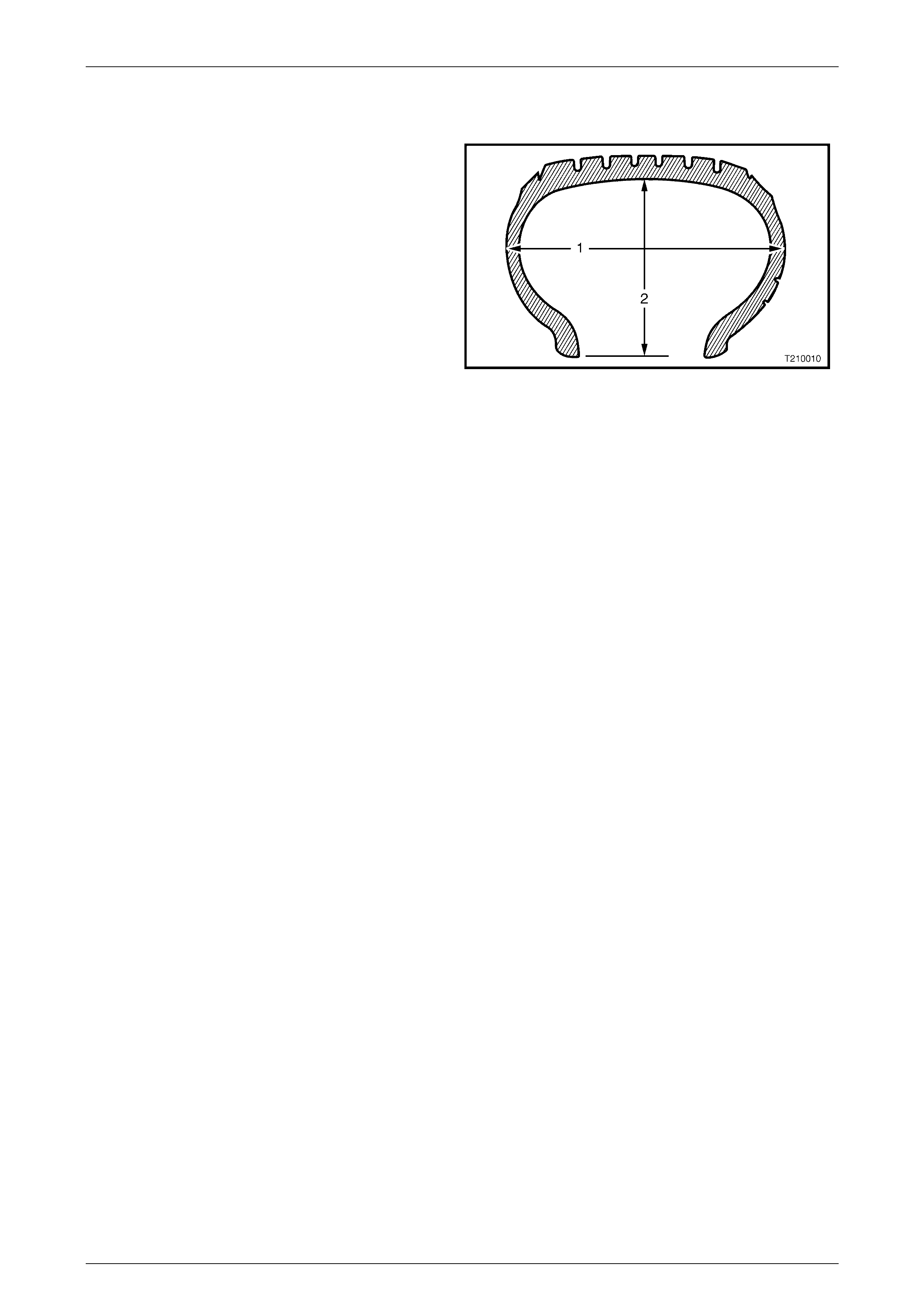

Tyre Marking Example:

215 65 R 15 C 104 R

215 = Section Width (1) – mm (215 mm)

65 = Aspect Ratio % i.e.Section Height (2) to

Section Width (1)

(55 = 55%)

(60 = 60%)

(65 = 65%)

R = Tyre Construction

(R = Radial)

15 = Rim Diameter – inches

(15 = 15”)

(16 = 16”)

(17 = 17”)

C = Service Application Code

(C or LT = Light Truck or Multi-purpose

Passenger Vehicle)

NOTE

Some European and Japanese light truck tyres

use C instead of LT for the same purpose.

104 = Load Index – kg @ 250 kPa (36 psi) cold

inflation pressure

(97 = 730 kg max. load)

(104 = 900 kg max. load)

(106 = 950 kg max. load)

R = Speed Rating

(R = 170 km/h)

(H = 210 km/h)

Figure 10-6

Wheels and Tyres Page 10–6

Page 10–6

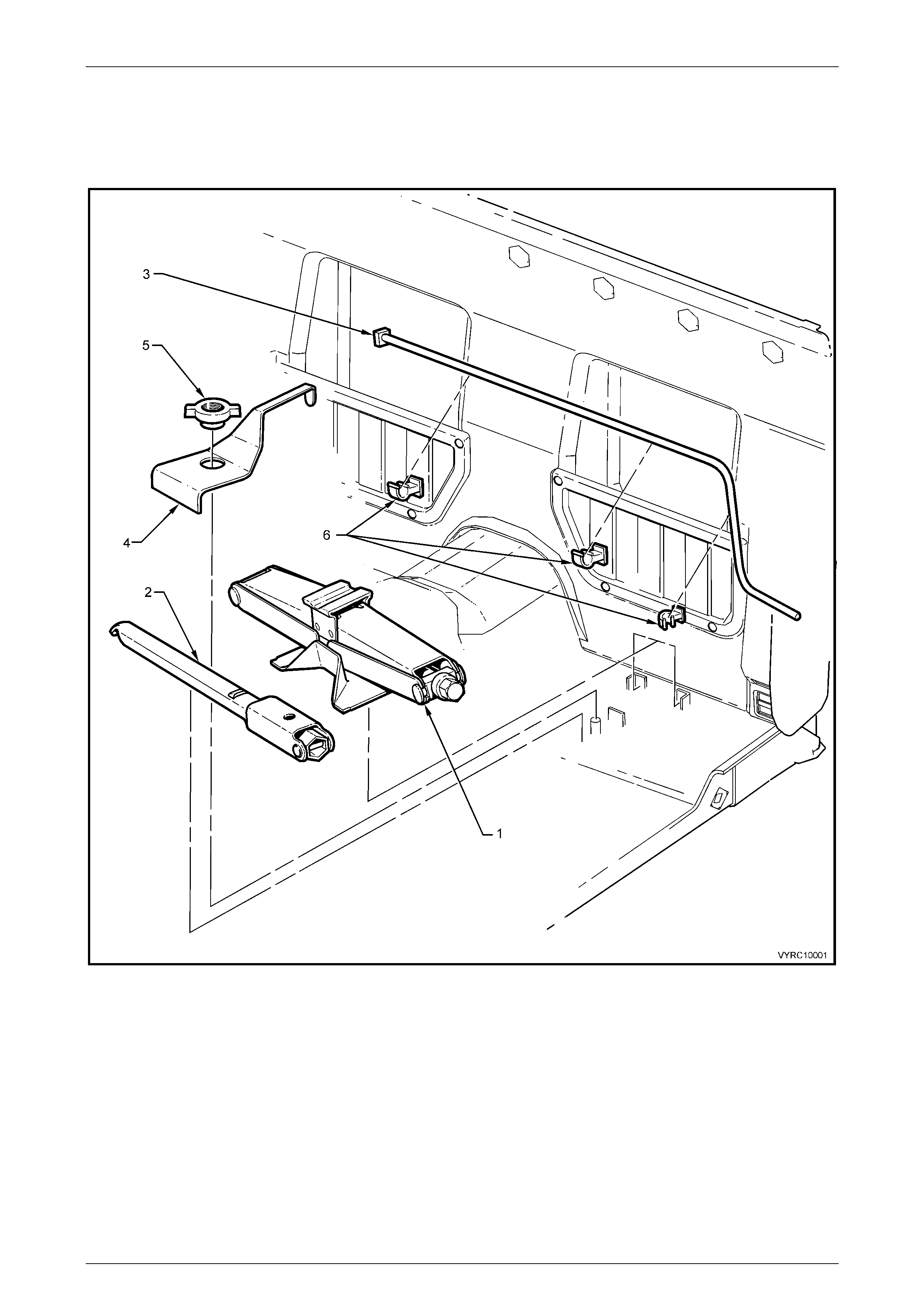

1.4 Spare Wheel and Tool Stowage

Tool Stowage

Figure 10-7

Legend

1 Jack Assembly

2 Jack and Wheel Nut Wrench

3 Spare Wheel Hoist Crank Handle

4 Jack and Handle Trim Cover

5 Trim Cover Retaining Nut

6 Crank Handle Retainers

Wheels and Tyres Page 10–7

Page 10–7

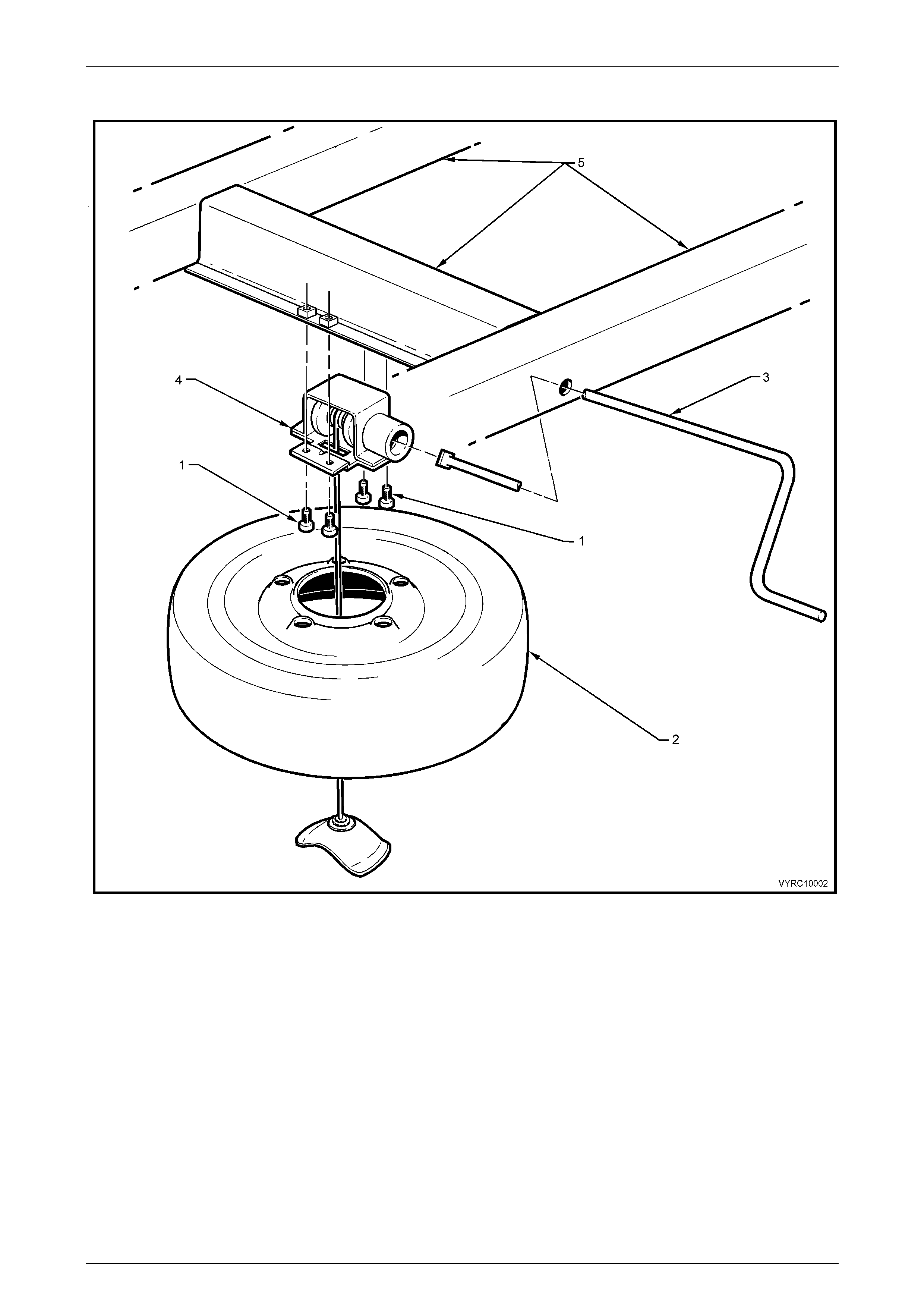

Spare Wheel Stowage

Figure 10-8

1 Spare Wheel Hoist Attaching Bolts (4 places)

2 Spare Wheel

3 Spare Wheel Hoist Crank Handle

4 Spare Wheel Hoist

5 Rear Frame Assembly

Wheels and Tyres Page 10–8

Page 10–8

2 Service Operations

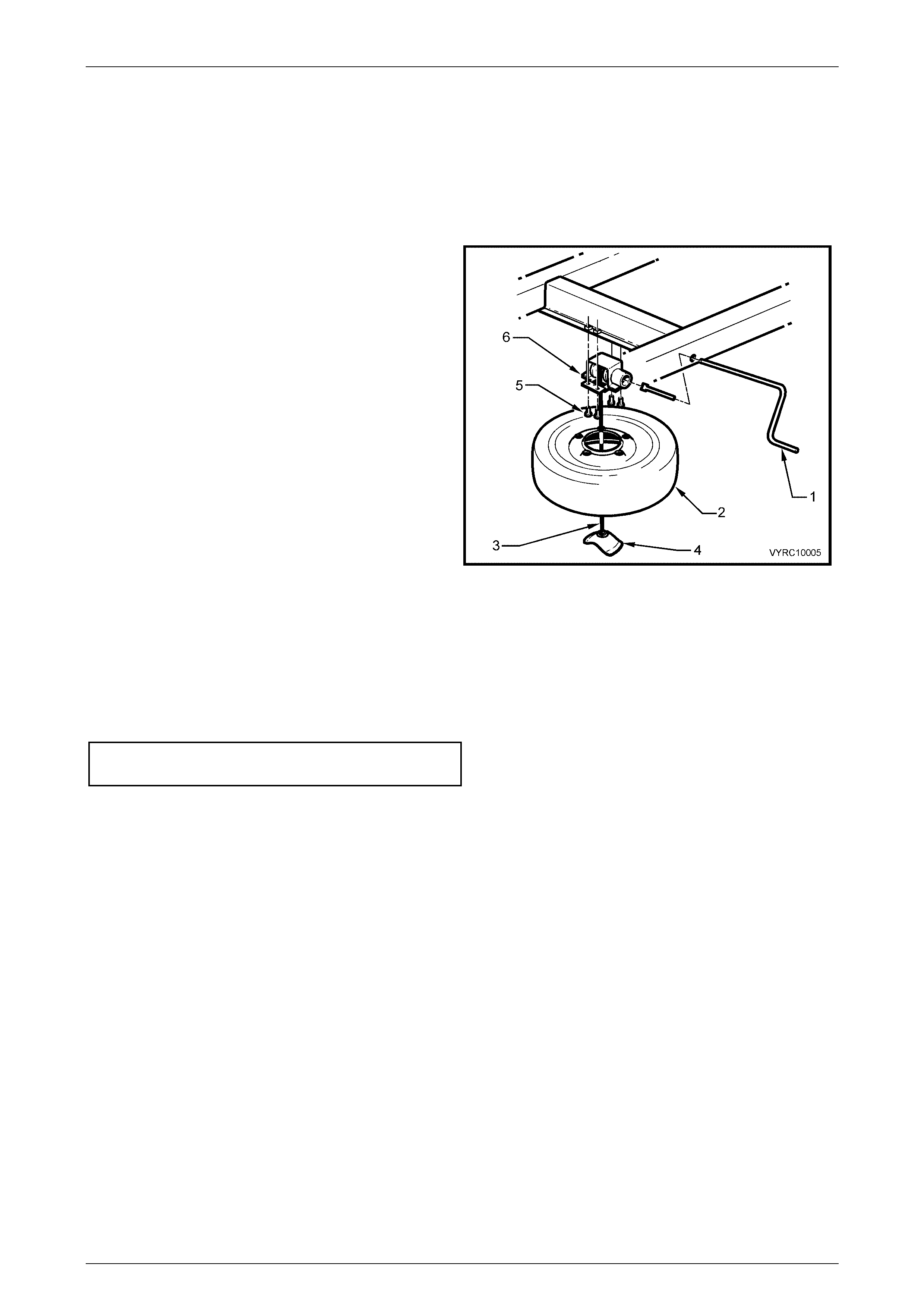

2.1 Spare Wheel Hoist

Remove

1 Insert the spare wheel hoist crank handle (1) into the

aperture located at the rear of the vehicle.

2 Rotate the handle in a counter-clockwise direction

until the spare wheel (2) is completely lowered and

some slack exists in the spare wheel hoist

cable (3).

3 Support the spare wheel with one hand, and tilt the

wheel retainer (4) upward, then feed the retainer

through the wheel centre.

4 Remove the spare wheel from below the vehicle.

5 Remove the four screws (5) and lower the hoist

assembly (6) from the vehicle.

Figure 10-9

Reinstall

Installation of the spare wheel hoist is the reverse of the removal procedure, noting the following:.

• Ensure that the hoist is installed with the square coupling towards the rear of the vehicle.

• Tighten the hoist-attaching screws to the correct torque specification.

SPARE WHEEL HOIST ATTACHING

SCREW TORQUE SPECIFIC ATION ...........15 – 35 Nm

Wheels and Tyres Page 10–9

Page 10–9

3 Specifications

Steel Wheels

Rim Width Code

All Steel Wheels....................................................................................................................7J

Diameter Code

All Steel Wheels................................................................................................................... 15

Maximum Permissible Radial Run-out

All Steel Wheels........................................................................................................... 1.5 mm

Maximum Permissible Lateral Run-out

All Steel Wheels........................................................................................................... 1.5 mm

Offset

All Steel Wheels.............................................................................................43 mm (positive)

Al l oy Wheels

Rim Width Code

‘S’ Pack.................................................................................................................................7J

‘SS’ Pack...............................................................................................................................8J

Diameter Code

‘S’ Pack................................................................................................................................ 16

‘SS’ Pack.............................................................................................................................. 17

Maximum Permissible Radial Run-out

All Alloy Wheels........................................................................................................... 1.5 mm

Maximum Permissible Lateral Run-out

All Alloy Wheels........................................................................................................... 1.5 mm

Offset

All Alloy Wheels.............................................................................................48 mm (positive)

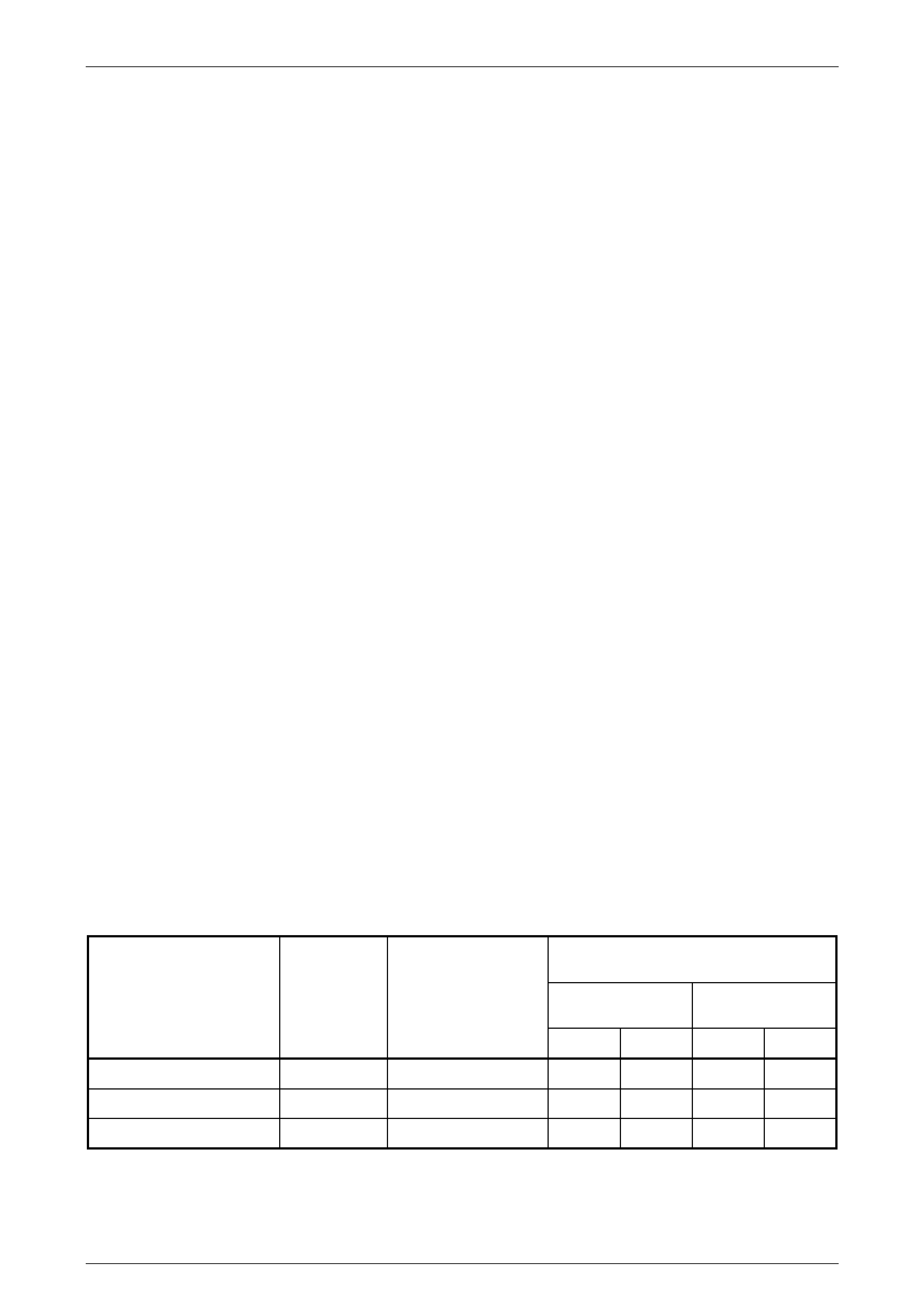

Inflation Pressures

RECOMMENDED COLD INFLATION –

kPa

MODEL WHEEL TYRE DESIGNATION

Up to 3

Passengers Up to Max. Load

Front Rear Front Rear

Base 7J x 15 Steel 215/65 R15C 104R 200 200 200 370

‘S’ Pack 7J x 16 Alloy 215/65 R16C 106R 200 200 200 370

‘SS’ Pack 8J x 17 Alloy 235/45 R17 97H 200 200 220 280

Wheels and Tyres Page 10–10

Page 10–10

4 Torque Wrench Specifications

Nm

Spare Wheel Hoist to Frame Attaching Screw.......................................15 – 35

Road Wheel Attaching Nut (All Wheels)............................................110 – 140