Rear Suspension Page 4A –1

Page 4A–1

Section 4A

Rear Suspension

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1 General Information............................................................................................................................... 2

2 Service Operations................................................................................................................................4

2.1 Suspension and Trim Height, Check....................................................................................................................4

2.2 Rear Leaf Springs...................................................................................................................................................5

Remove ...................................................................................................................................................................5

Disassemble ...........................................................................................................................................................6

Inspect.....................................................................................................................................................................6

Reassemble ............................................................................................................................................................7

Reinstall ..................................................................................................................................................................7

2.3 Rear Leaf Spring Eye and S hackle Bushes..........................................................................................................9

Remove ...................................................................................................................................................................9

Inspect...................................................................................................................................................................10

Reassemble ..........................................................................................................................................................11

2.4 Rear Shock Absorbers.........................................................................................................................................12

Remove .................................................................................................................................................................12

Inspect...................................................................................................................................................................12

Reinstall ................................................................................................................................................................13

2.5 Rear Stabilizer Bar ...............................................................................................................................................14

Remove .................................................................................................................................................................14

Inspect...................................................................................................................................................................14

Reinstall ................................................................................................................................................................15

2.6 Rear Suspension Bump Stop..............................................................................................................................16

Remove .................................................................................................................................................................16

Inspect...................................................................................................................................................................16

Reinstall ................................................................................................................................................................16

3 Diagnosis.............................................................................................................................................. 17

3.1 Checking and Testing Shock Absorbers ...........................................................................................................17

Preliminary Checks..............................................................................................................................................17

Testing Shock Absorber Action..........................................................................................................................17

5 Specifications....................................................................................................................................... 18

6 Torque Wrench Specifications........................................................................................................... 19

7 Special Tools........................................................................................................................................ 20

Rear Suspension Page 4A –2

Page 4A–2

1 General Information

The rear suspension system for MY2003 VY Series, Cab Chassis Models incorporate two multiple leaf spring assemblies

in conjunction with shock absorbers and a stabilizer bar as standard equipment. The rear suspension system provides

support and control of the movement of the rear axle assembly during vehicle motion, as well as when stationary.

The rear suspension system is mounted to the chassis at four locations via the leaf spring shackle mount brackets, the

spring eye bushing mount brackets and bolts. Two ‘U’ Bolts on each side attach the rear axle assembly to each rear leaf

spring retainer bracket. Torque reaction or the natural resistance or tension of the leaf springs controls wind-up of the

rear axle assembly. Rear axle assembly vertical over-travel is restricted by bump stops mounted to the chassis just

above the rear axle housing tube on each side.

A decoupled stabilizer bar is attached to the rear axle assembly by two mounting brackets and insulati ng bushes, while

at each end of the stabilizer bar a ball joint and connecting rod is attached. Each stabilizer bar connecting rod is then

attached to the chassis via a ball joint.

The rear suspension system dampening is controlled by two double acting shock absorbers mounted between the

chassis frame and the rear leaf spring retainer brackets.

Rear Suspension Page 4A –3

Page 4A–3

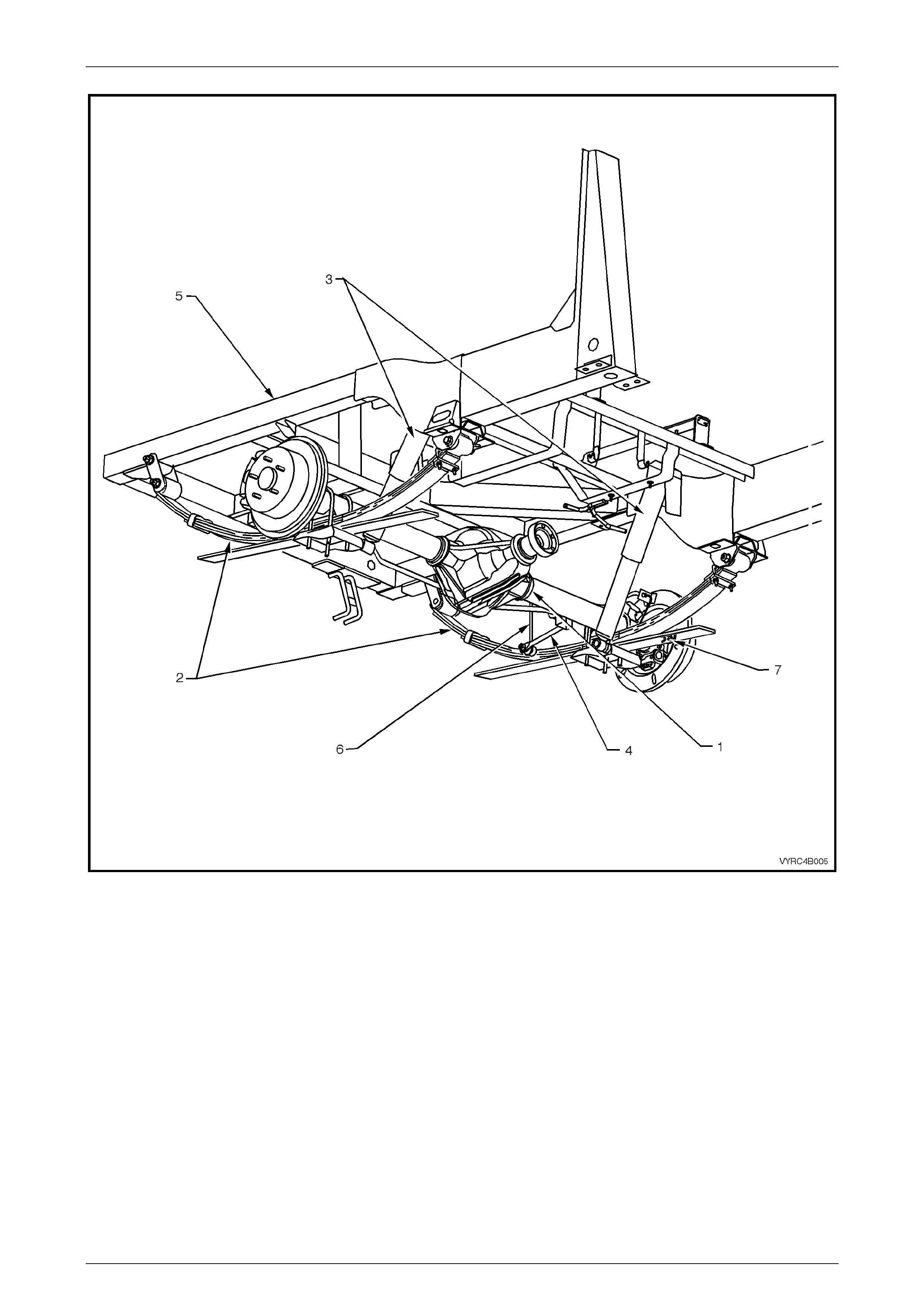

Figure 4A-1

Legend

1 Rear Axle Assembly

2 Rear Leaf Spring Assembly

3 Rear Shock Absorber

4 Rear Suspension Stabilizer

5 Rear Chassis

6 Rear Stabilizer Bar to Chassis Link

7 Rear ABS Sensor

Rear Suspension Page 4A –4

Page 4A–4

2 Service Operations

ATTENTION

All rear axle fasteners are important attaching parts as they affect the performance of vital components

and/or could result in major repair expense. Where specified in this section, fasteners MUST be replaced with

parts of the same part number or a GM approved equivalent. Do not use fasteners of an inferior quality or

substitute design.

Torque values must be used as specified during reassembly to ensure proper retention of all steering

components.

Through out this section, fastener torque wrench specifications may be accompanied with the following

Identification marks:

+

++

+ Fasteners must be replaced after loosening.

!

!!

! Vehicle must be at curb height before final tightening.

6

66

6 Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

2.1 Suspension and Trim Height, Check

For suspension and trim height checks and specifications, refer to Section 3, Front Suspension in MY2003 VY Series,

Cab Chassis Service Information.

Rear Suspension Page 4A –5

Page 4A–5

2.2 Rear Leaf Springs

LT Section No: F1000000

ATTENTION

The following fasteners MUST have the ve hicle at curb height before final tightening.

!

!!

! Rear leaf spring shackle attaching nuts.

!

!!

! Rear leaf spring eye attaching bolt and nut.

!

!!

! Rear shock absorber lower mounting attaching bolt.

The following fasteners MUST be replaced when performing this operation:

+ Rear leaf spring shackle attaching nut s.

+ Rear leaf spring eye attaching bolt and nut.

+ Leaf spring centre pin attaching nut.

+ Rear shock absorber lower mounting attaching bolt.

+ Rear leaf spring and retainer plate ‘U’ bolt attaching nuts.

Remove

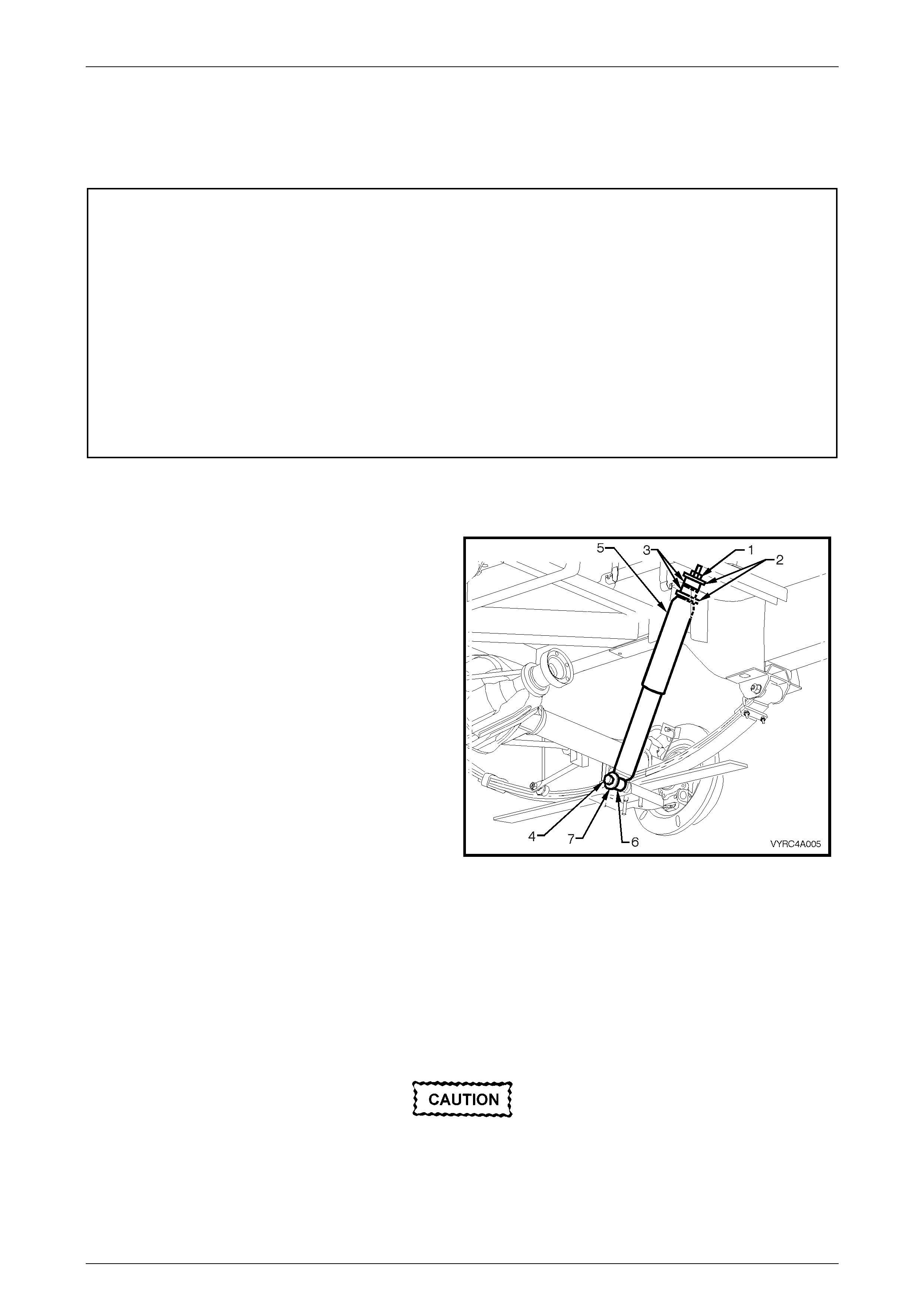

1 Using a floor jack under the centre of the rear axle

assembly (1), jack up rear of vehicle, then place

safety stands under the rear chassis (2) on both the

left-hand and right-hand sides to support the weight of

the vehicle as shown in Figure 4A-3.

2 With the floor jack still under the centre of the rear

axle assembly, take-up the weight of the rear axle

housing, while observing the leaf springs and

shackles to gain the desired height to relieve any

spring tension. Place further safety stands to support

the rear axle assembly weight at each side and

remove the floor jack.

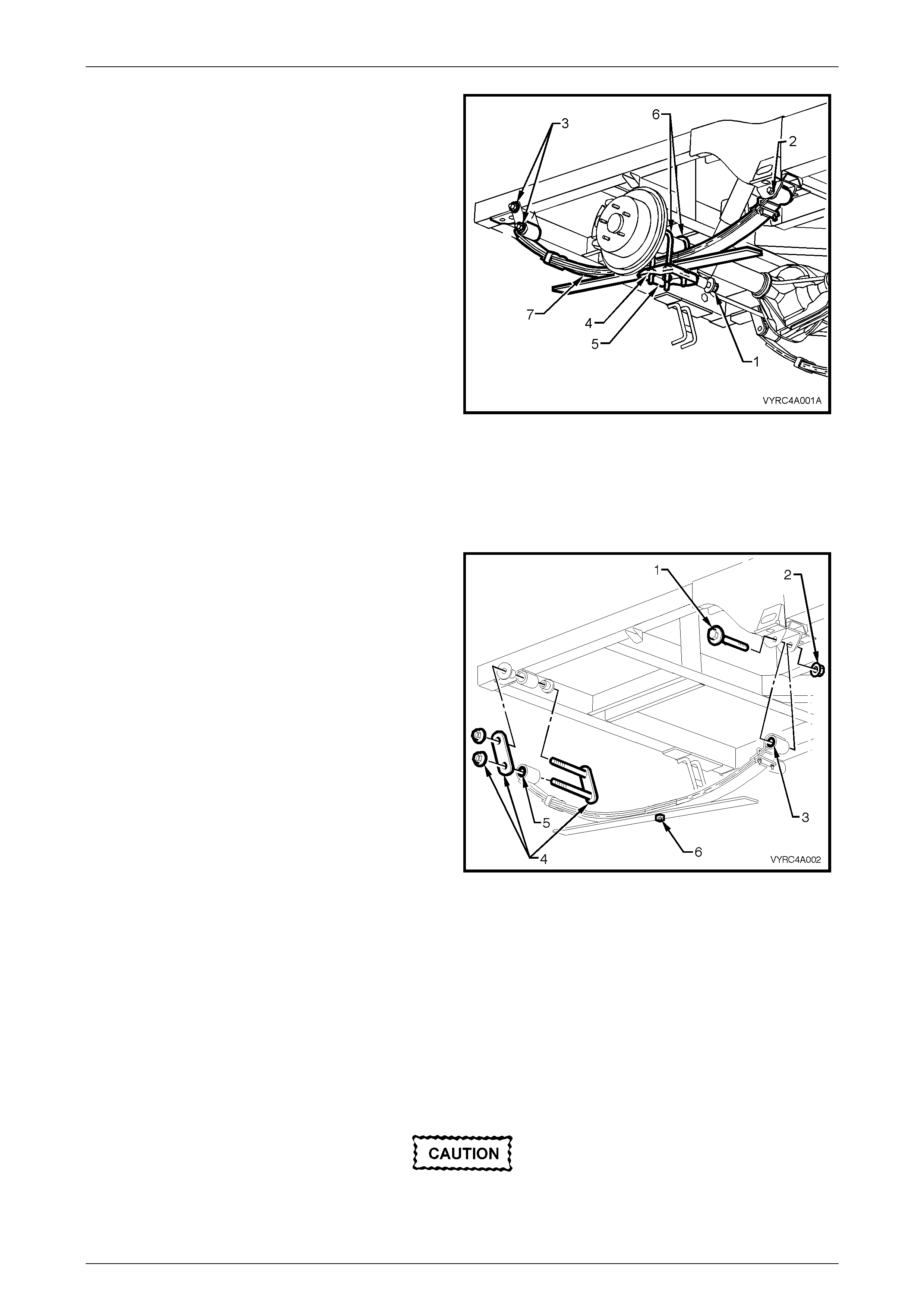

Figure 4A-2

Rear Suspension Page 4A –6

Page 4A–6

3 Using suitable sockets and bar loosen the following

as shown in Figure 4A-3.

a. Lower shock absorber to leaf spring retainer plate

attaching bolt (1).

b. Front leaf spring eye to mounting bracket bolt (2).

c. Rear leaf spring shackle attaching nuts (3).

d. Rear axle housing to leaf spring retainer plate ‘U’

bolt attaching nuts (4).

4 Remove the lower shock absorber to leaf spring

retainer plate attaching bolt (1).

5 Remove rear axle housing to leaf spring retainer plate

‘U’ bolt attaching nuts (4), leaf spring retainer plate (5)

and ‘U’ bolt’s (6).

6 Remove the front leaf spring eye to mounting bracket

bolt (2).

7 Remove the rear leaf spring shackle and attaching

nuts (3).

8 Remove the leaf spring assembly (7) from the vehicle.

Figure 4A-3

Disassemble

1 Remove the leaf spring eye to mounting bracket

attaching bolt (1) and nut (2). If replacing the leaf

spring eye bush (3) refer to 2.3, Rear Leaf Spring Eye

and Shackle Bushes in this section.

2 Remove the leaf spring shackle to mounting bracket

and shackle to leaf spring attaching nuts (4). If

replacing the leaf spring shackle bushes (5) refer to

2.3, Rear Leaf Spring Eye and Shackle Bushes in this

section.

3 Remove the leaf spring assembly centre pin retaining

nut (6) by using a suitable brass drift to drive the

centre pin from the leaf spring assembly to separate

the spring leaves. Refer to Figure 4A-4.

Figure 4A-4

Inspect

Clean all components using a suitable solvent and inspect the following:

1 The leaf spring eye bush for excessive wear.

2 The leaf spring shackles and bushes for excessive w ear.

3 The general condition of each spring leaf for signs of fatigue or cracking.

4 The interleaf spacers for excessive wear.

5 The centre pin for straightness and excessive wear.

Worn or damaged components must be

replaced.

Rear Suspension Page 4A –7

Page 4A–7

Reassemble

The procedure for reassembly of the leaf spring is the reverse of the disassemble procedure noting the following points:

1 If replacing the leaf spring eye or shackle bushes refer to 2.3, Rear Leaf Spring Eye and Shackle Bushes in this

section.

2 The leaf spring centre pin spindle should be lightly lubricated with Molybdenum Disulphide grease prior to

installation.

3 Ensure all leaves of the spring are aligned prior to tightening the centre pin, attaching nut.

4 Tighten the centre pin, attaching nut to the correct torque.

(+) Leaf spring centre pin

attaching nut

torque specific atio n ..............................................25 Nm

Reinstall

The procedure for reinstallation of the leaf spring assembly is the reverse of the removal procedure noting the following

points:

(+) Leaf spring and retainer

plate ‘u’ bolt attaching nut

torque specific atio n ..............................................90 Nm

NOTE

Preliminary torque of the leaf spring to shackle

attaching nuts is for initial set-up only. A final

torque must be carried out with all four wheels on

the ground and normal vehicle weight applied.

(+) Leaf spring to shackle

attaching nut (preliminary)

torque specific atio n .............................................5.0 Nm

NOTE

Final torque of the leaf spring to shackle

attaching nuts must be carried out with all four

wheels on the ground and normal vehicle weight

applied.

(+ !) Leaf spring to shackle

attaching nut (final)

torque specific atio n ............................................110 Nm

NOTE

Preliminary torque of the leaf spring eye,

attaching bolt and nut is for initial set-up only. A

final torque must be carried out with all four

wheels on the ground and normal vehicle weight

applied.

(+) Leaf spring eye

attaching bolt and nut (preliminary)

torque specific atio n .............................................5.0 Nm

Rear Suspension Page 4A –8

Page 4A–8

NOTE

Final torque of the leaf spring eye, attaching bolt

and nut must be carried out with all four wheels

on the ground and normal vehicle weight applied.

(+ !) Leaf spring eye

attaching bolt and nut (final)

torque specific atio n ............................................130 Nm

NOTE

Preliminary torque of the rear shock absorber

lower mounting, attaching nut is for initial set-up

only. A final torque must be carried out with all

four wheels on the ground and normal vehicle

weight applied.

(+) Rear shock absorber

lower mounting attaching bolt

(preliminary) torque specification.........................5.0 Nm

NOTE

Final torque of the rear shock absorber lower

mounting, attaching nut must be carried out with

all four wheels on the ground and normal vehicle

weight applied.

(+ !) Rear shock absorber

lower mounting attaching bolt

(final) torque specification ..................................110 Nm

Rear Suspension Page 4A –9

Page 4A–9

2.3 Rear Leaf Spring Eye and Shackle

Bushes

LT Section No: F111000

Remove

1 Remove the rear leaf spring assembly; refer to

2.2, Rear Leaf Springs in this sect ion .

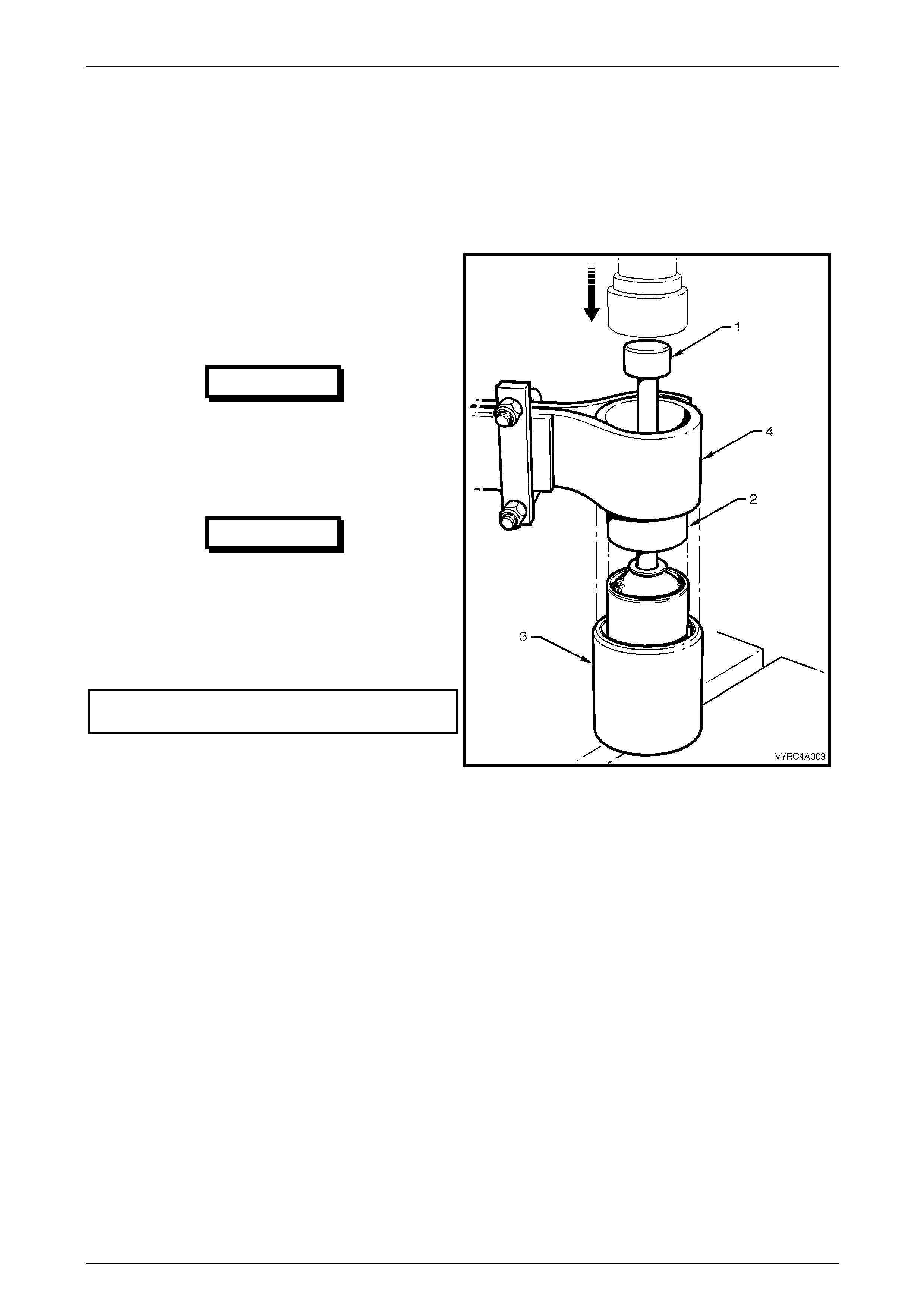

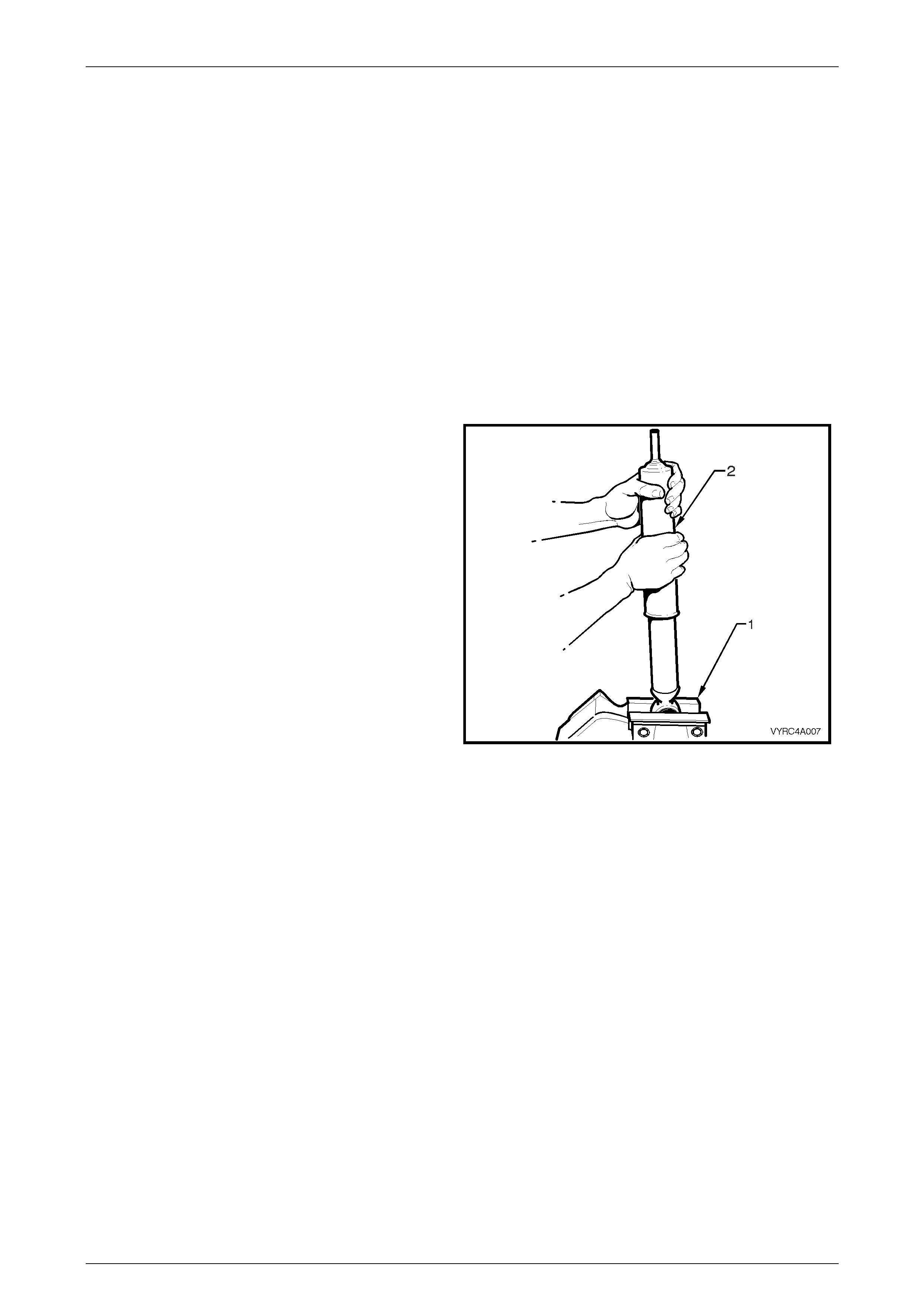

2 Using Tool No’s. AU606-1 (1), AU606-2 (2), AU606-3

(3) and suitable press, place the leaf spring (4) along

with the tools on suitable press plates.

IMPORTANT

When removing the bush from the leaf

spring eye, record the force exerted

during the pressing operation. If the force

exerted is less than 7.5 kN, the leaf spring

must be replaced.

IMPORTANT

The eye bush once removed must be

replaced with new eye bush.

3 Remove the leaf spring eye bush by pressing the

bush with Tool No.AU606-1 (1) along with Tool No.

AU606-2 (2), through the eye of the leaf spring (4)

and into Tool No. AU606-3 (3). Refer to Figure 4A-5.

Leaf spring eye bush

press exertion force.......................................... 7.5 kN

4 Remove the leaf spring shackle; shackle plate and

attaching nuts.

5 Remove the shackle bushes by carefully prying the

bushes from the leaf spring with a suitable probe.

Figure 4A-5

Rear Suspension Page 4A –10

Page 4A–10

Inspect

IMPORTANT

If the eye bush has been removed it must be

replaced with new eye bush.

IMPORTANT

If the eye bush extraction force is less than

7.5 kN the leaf spring must be replaced.

Worn or damaged components must be

replaced.

Clean all components using a suitable solvent and inspect the following:

1 The leaf spring eye for damage or wear.

2 The leaf spring shackles and bushes for excessive w ear.

3 The general condition of the spring leaf for signs of fatigue or cracking.

Rear Suspension Page 4A –11

Page 4A–11

Reassemble

IMPORTANT

When installing the bush into the leaf

spring eye, the force exerted during the

pressing operation should be at least 7.5

kN. If the force exerted is less than 7.5 kN,

the leaf spring must be replaced.

IMPORTANT

A new eye bush must be installed.

1 Using Tool No’s. AU606-1 (1), AU606-4 (2), AU606-3

(3) and suitable press, place the leaf spring (4) along

with the leaf spring eye bush (5) on a suitable press

plate.

2 Install the front leaf spring eye bush by pressing the

bush into the leaf spring eye using Tool No.AU606-1

(1) along with Tool No. AU606-4 (2) and Tool No.

AU606-3 (3) to guide the new bush (4) into the leaf

spring eye (5). Refer to Figure 4A-6.

Leaf spring eye bush

press exertion force.......................................... 7.5 kN

3 Install the rear shackle bushes by hand into the leaf

spring using soapy water to assist installation.

4 Install the shackle, shackle plates and attaching nuts.

5 Tighten the spring to shackle attaching nut to the

correct preliminary torque.

NOTE

Preliminary torque of the leaf spring to shackle

attaching nuts is for initial a set-up only. A final

torque must be carried out with all four wheels

on the ground and normal vehicle weight

applied.

(6) Leaf spring to shackle

attaching nut

(preliminary)

torque specific atio n .........................................5.0 Nm

6 Reinstall the rear leaf spring assembly; refer to

2.2, Rear Leaf Springs in this sect ion .

Figure 4A-6

Rear Suspension Page 4A –12

Page 4A–12

2.4 Rear Shock Absorbers

LT Section No: F120000

ATTENTION

The following fasteners MUST have the ve hicle at curb height before final tightening.

!

!!

! Rear shock absorber lower mounting attaching bolt.

The following fasteners MUST be replaced when performing this operation:

+ Rear shock absorber upper mounting attaching nut.

+ Rear shock absorber lower mounting attaching bolt.

Remove

1 Using a floor jack under the centre of the rear axle

assembly, jack up the rear of the vehicle, then place

safety stands under the chassi s to support the veh icl e

weight

2 Leave the floor jack under the centre of the rear axle

to assist in removing the shock absorber.

3 Using suitable spanners remove the upper shock

absorber attaching nut (1), support washer (2) and

mounting bush (3).

4 Lower the floor jack enough to remove any load on

the shock absorber.

5 Remove the lower shock absorber attaching bolt (4)

and remove the shock absorber (5).

6 Remove the remaining upper mounting bush (6) and

support washer (7) from the shock absorber. Refer to

Figure 4A-7.

Figure 4A-7

Inspect

Clean all components using a suitable solvent and inspect the following:

1 The upper and lower shock absorber bushes for excessive wear.

2 The shock absorber action.

3 The general condition of the shock absorber mounting points of the chassis and rear axle.

Worn or damaged components must be

replaced.

Rear Suspension Page 4A –13

Page 4A–13

Reinstall

The procedure for reinstallation of the shock absorber is the reverse of the removal procedure noting the following points:

(+) Rear shock absorber

upper mounting attaching nut

torque specific atio n ..............................................45 Nm

NOTE

Preliminary torque of rear shock absorber lower

mounting attaching nut is for initial set-up only. A

final torque must be carried out with all four

wheels on the ground and normal vehicle weight

applied.

(+) Rear shock absorber

lower mounting attaching bolt

(preliminary)

torque specific atio n .............................................5.0 Nm

NOTE

Final torque of the rear shock absorber lower

mounting, attaching nut must be carried out with

all four wheels on the ground and normal vehicle

weight applied.

(+ !) Rear shock absorber

lower mounting attaching bolt

(final)

torque specific atio n ............................................110 Nm

Rear Suspension Page 4A –14

Page 4A–14

2.5 Rear Stabilizer Bar

LT Section No: F122100

ATTENTION

The following fasteners have either micro encapsulation or incorporate a mechanical thread lock and should

only be used once. If in doubt, replacement is recommended when performing this operation:

6 Rear stabilizer bar drop link upper and lower ball joint to stabilizer bar attaching nut.

The following fasteners MUST be replaced when performing this operation:

+ Rear stabilizer bar mounting to rear axle housing attaching bolt.

Remove

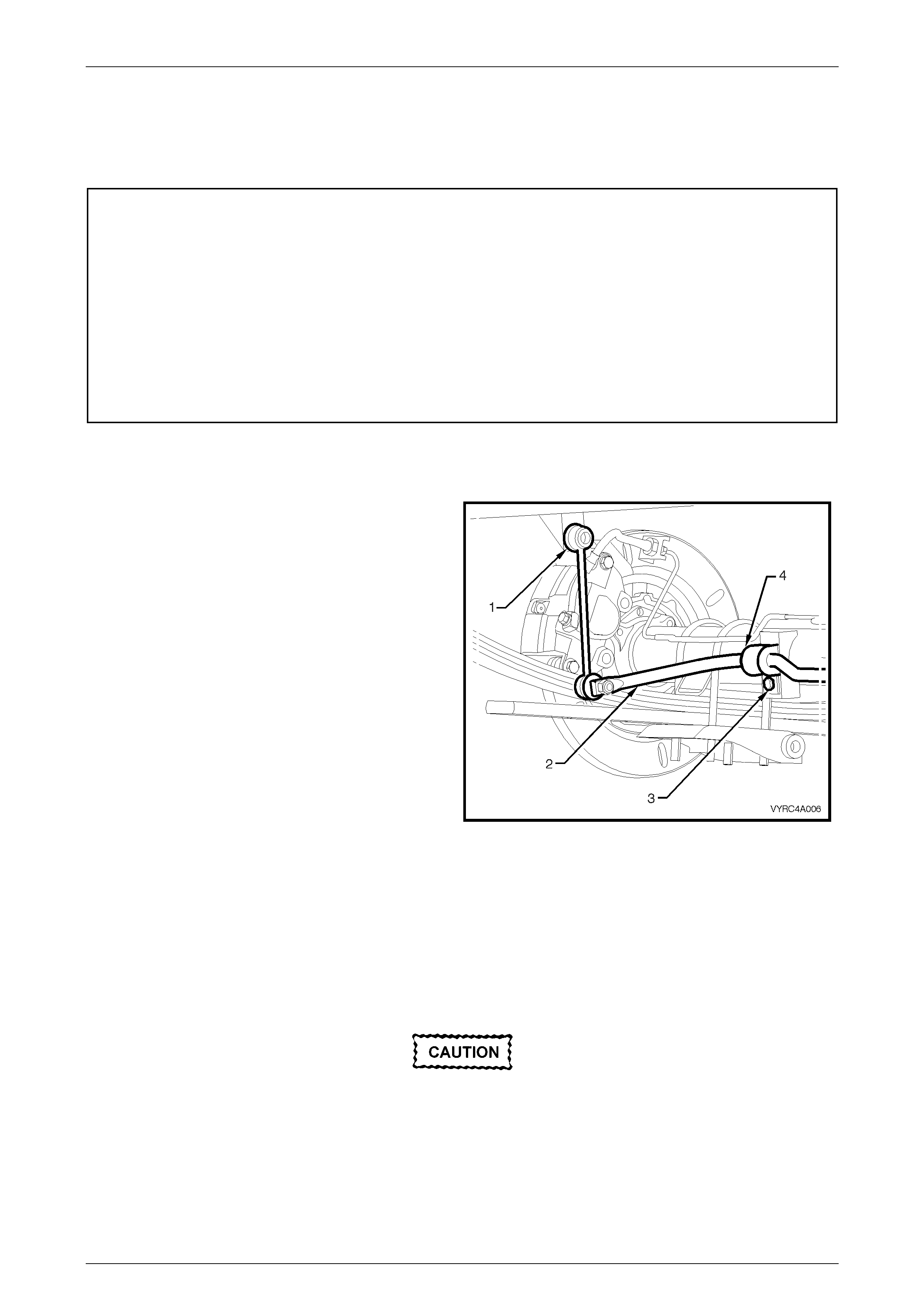

1 Using suitable spanners remove the upper drop link

ball joint (1) for the stabilizer bar (2) from each side of

the chassis.

2 Remove each attaching bolt (3) from the stabilizer bar

mounting’s (4) on the rear axle. Refer to Figure 4A-8.

Figure 4A-8

Inspect

Clean all components using a suitable solvent and inspect the following:

1 The upper and lower upper drop link ball joints for excessive wear.

2 The stabilizer bar mountings and the general condition of the stabilizer mounting points of the chassis and rear

axle.

Worn or damaged components must be

replaced.

Rear Suspension Page 4A –15

Page 4A–15

Reinstall

The procedure for reinstallation of the stabilizer bar is the reverse of the removal procedure noting the following points:

(+) Rear stabilizer bar mounting

to rear axle housing attachi ng

bolt torque specification ........................................ 25 Nm

(6) Rear stabilizer bar drop link

upper and lower ball joint

to stabilizer bar attaching nut

torque specification ...................................... 45 – 55 Nm

Rear Suspension Page 4A –16

Page 4A–16

2.6 Rear Suspension Bump Stop

LT Section No: F109100

ATTENTION

The following fasteners MUST be replaced when performing this operation:

+ Rear suspension bump stop, attaching bolt.

Remove

Using suitable spanners remove the attaching bolts from each side of the bump stop

Inspect

Clean all components using a suitable solvent and inspect the following:

• The general condition of the bump stop and mounting points to the chassis.

Worn or damaged components must be

replaced.

Reinstall

The procedure for reinstallation of the bump stop is the reverse of the removal procedure noting the following point:

(+) Rear suspension bump stop

to chassis frame attaching bolt

torque specific atio n ..............................................25 Nm

Rear Suspension Page 4A –17

Page 4A–17

3 Diagnosis

3.1 Checking and Testing Shock Absorbers

Preliminary Checks

Before proceeding with the removal of shock absorber assemblies, it is good practise to check and make sure the noise

is not emanating from some other source.

Conduct a visual inspection of all shock absorber components along other rear suspensi on relate d comp one nts che ck ing

for anything that may appear unusual.

Check the torque of all attaching fasteners for tightness and check all mounting bushes for alignment. If the bushes are

worn, loose fitting or misaligned, they must be replaced.

Testing Shock Absorber Action

NOTE:

The following test is for non-gas pressurised

shock absorbers.

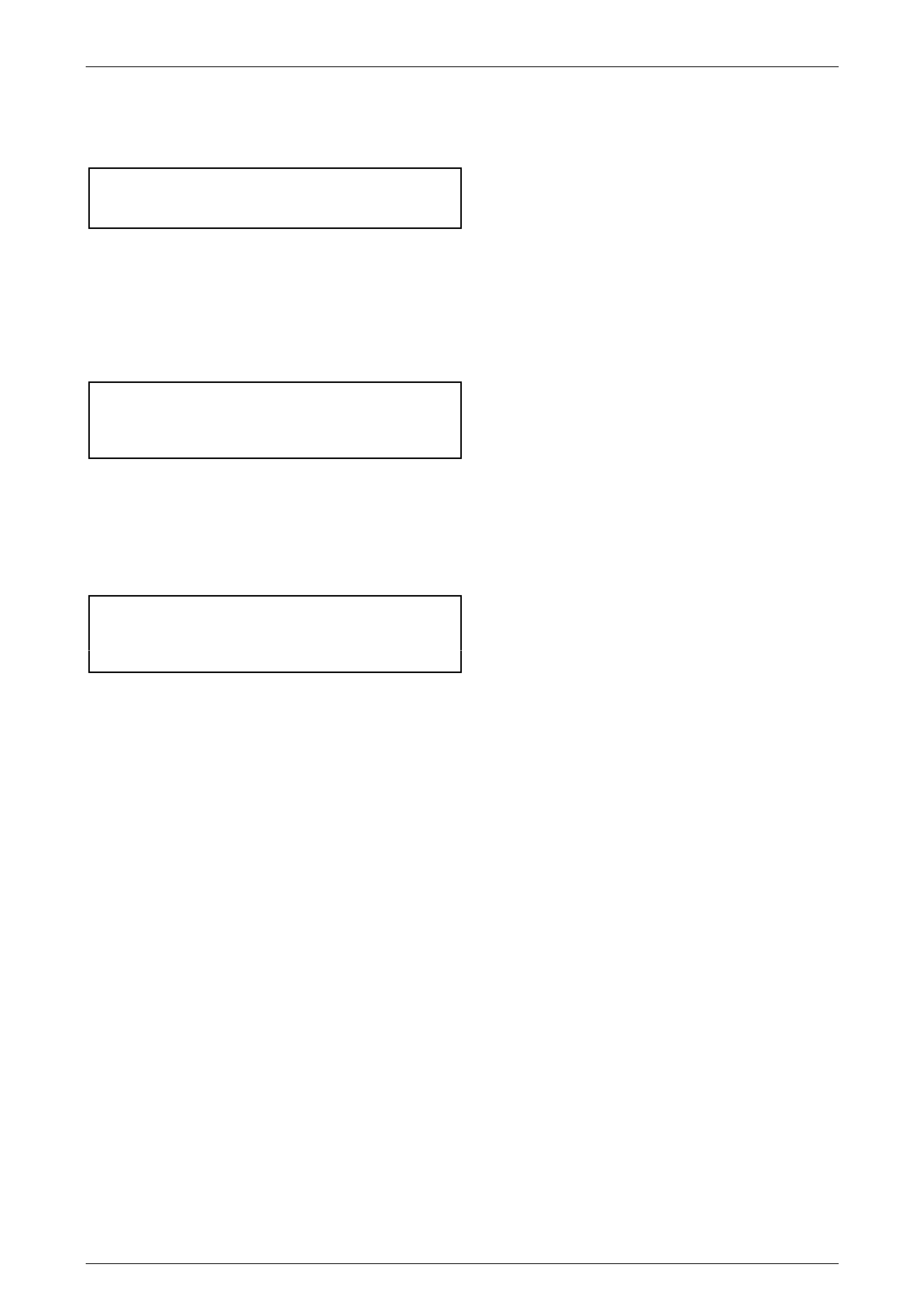

1 Using a suitable vice equipped with soft jaw’s (1),

support the shock absorber (2) by its lower mount.

Refer to Figure 4A-9.

2 Slowly pump the shock absorber up and down its full

stroke at least six times to prime the internal valves of

the shock absorber.

3 Move the shock absorber up and down at various

rates of speed while monitoring the resistance. The

resistance sho uld be consistent through out both

stokes and there shoul d be no slack sp ots. If sla ck

spots are detected this indicates either a lack of oil or

the internal valves are defective.

NOTE:

It is normal for a hissing (orifice swish) noise to

be detected during shock absorber testing.

4 The following conditions are considered outside the

normal function parameters and replacement is

recommended:

a. A skip or lag at reversal of the stroke mid way

through.

b. A seize (except at the extreme end of travel).

c. A noise such as a grunt or squeal after the

completing one ful l str oke in both direct ion s.

d. A clicking noise at fast reversal of the stroke.

e. Fluid leakage.

Figure 4A-9

Rear Suspension Page 4A –18

Page 4A–18

5 Specifications

General

Rear Suspension Assembly.............................................................................................Dana

Type..........................................................................................................................Hotchkiss

...............................................................(Live axle, Stabilizer Bar, Semi elliptical leaf springs)

Number of Primary Leaves .................................................................................................... 3

Number of Secondary Leaves................................................................................................ 1

Shock Absorber

Hydraulic (non-adjustable)................................................................................. Double acting

Stabilizer Bar

Torsional Steel Bar with Drop Link Ball Joint Mounting................................................. 14 mm

Thread Locking Compound

Rear Suspension Fasteners.......................................Loctite 242 or commercial equivalent to

GM Specification 9985283.

Rear Suspension Page 4A –19

Page 4A–19

6 Torque Wrench Specifications

ATTENTION

All Rear Suspension fasteners are important attaching parts as they affect the performance of vital

components and/or could result in major repair expense. Where specified in this section, fasteners MUST be

replaced with parts of the same part number or a GM approved equivalent. Do not use fasteners of an inferior

quality or substitute design.

Torque values must be used as specified during reassembly to ensure proper retention of all steering

components.

Through out this section, fastener torque wrench specifications may be accompanied with the following

Identification marks:

+

++

+ Fasteners must be replaced after loosening.

!

!!

! Vehicle must be at curb height before final tightening.

6

66

6 Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

Nm

+ Rear Leaf Spring And Retainer Plate ‘U’ Bolt Attaching Nuts .....................90

+ Leaf Spring Centre Pin Attaching Nut.........................................................25

+ Rear Leaf Spring Shackle Mounting Plate to Chassis Attaching Bolts........90

+ Rear Leaf Spring Shackle Attaching Nuts (Preliminary).............................5.0

+ ! Rear Leaf Spring Shackle Attaching Nuts (Final) ...................................110

+ Rear Leaf Spring Eye Mounting Plate to Chassis Attaching Bolts ..............90

+ Rear Leaf Spring Eye Attaching Bolt And Nut (Preliminary).......................5.0

+ ! Rear Leaf Spring Eye Attaching Bolt And Nut (Final) .............................130

+ Rear Shock Absorber Upper Mounting Attaching Nut ................................45

+ ! Rear Shock Absorber Lower Mounting Attaching Bolt (Preliminary)........5.0

+ ! Rear Shock Absorber Lower Mounting Attaching Bolt (Final).................110

+ Rear Stabilizer Bar Mounting Attaching Bolt...............................................25

6 Rear Stabilizer Bar Drop Link Upper And Lower Ball Joint To

Stabilizer Bar Attaching Nut ..................................................................45 – 55

+ Rear Suspension Stop Bump To Chassis Frame Attaching Bolt.................25

Rear Suspension Page 4A –20

Page 4A–20

7 Special Tools

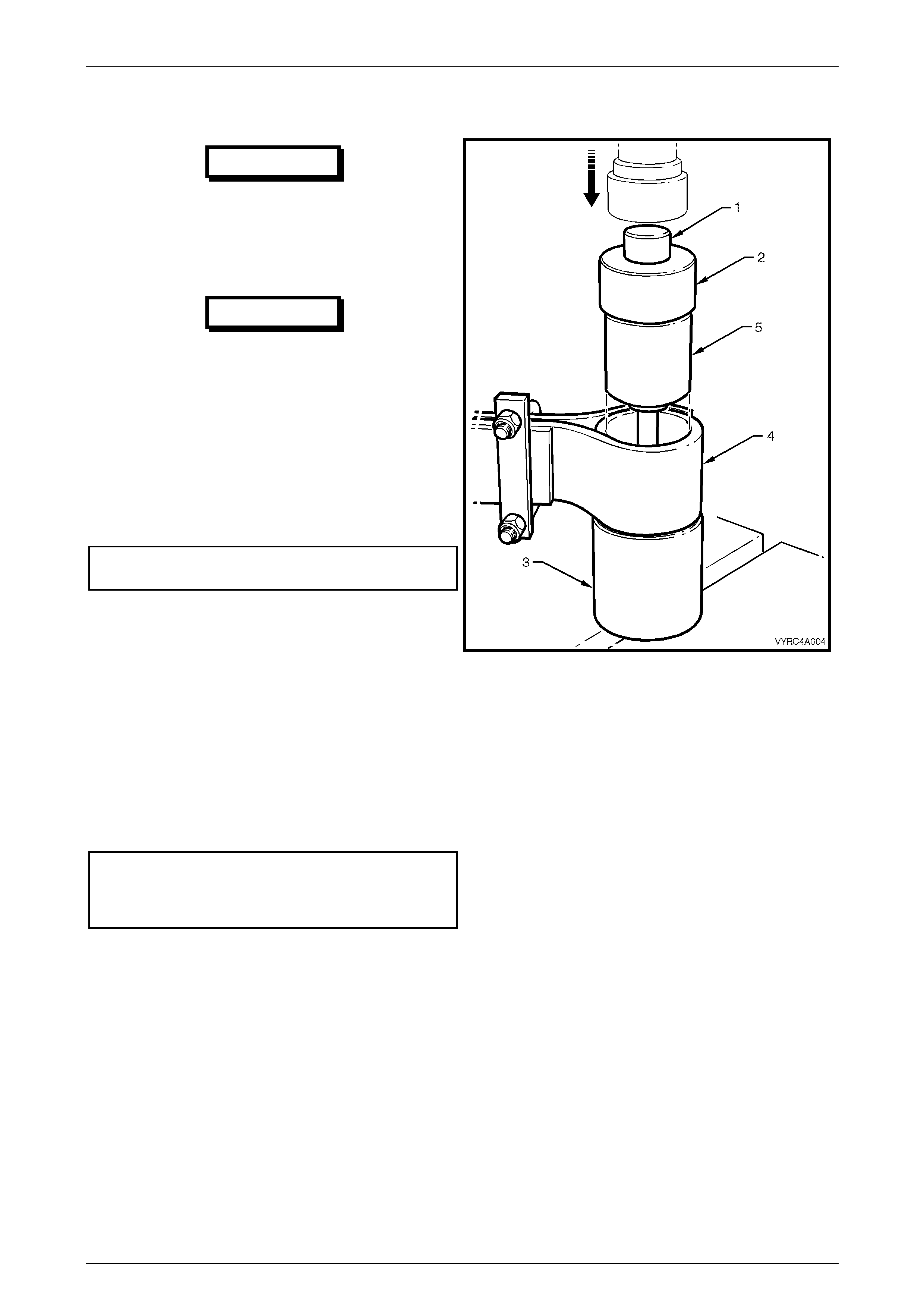

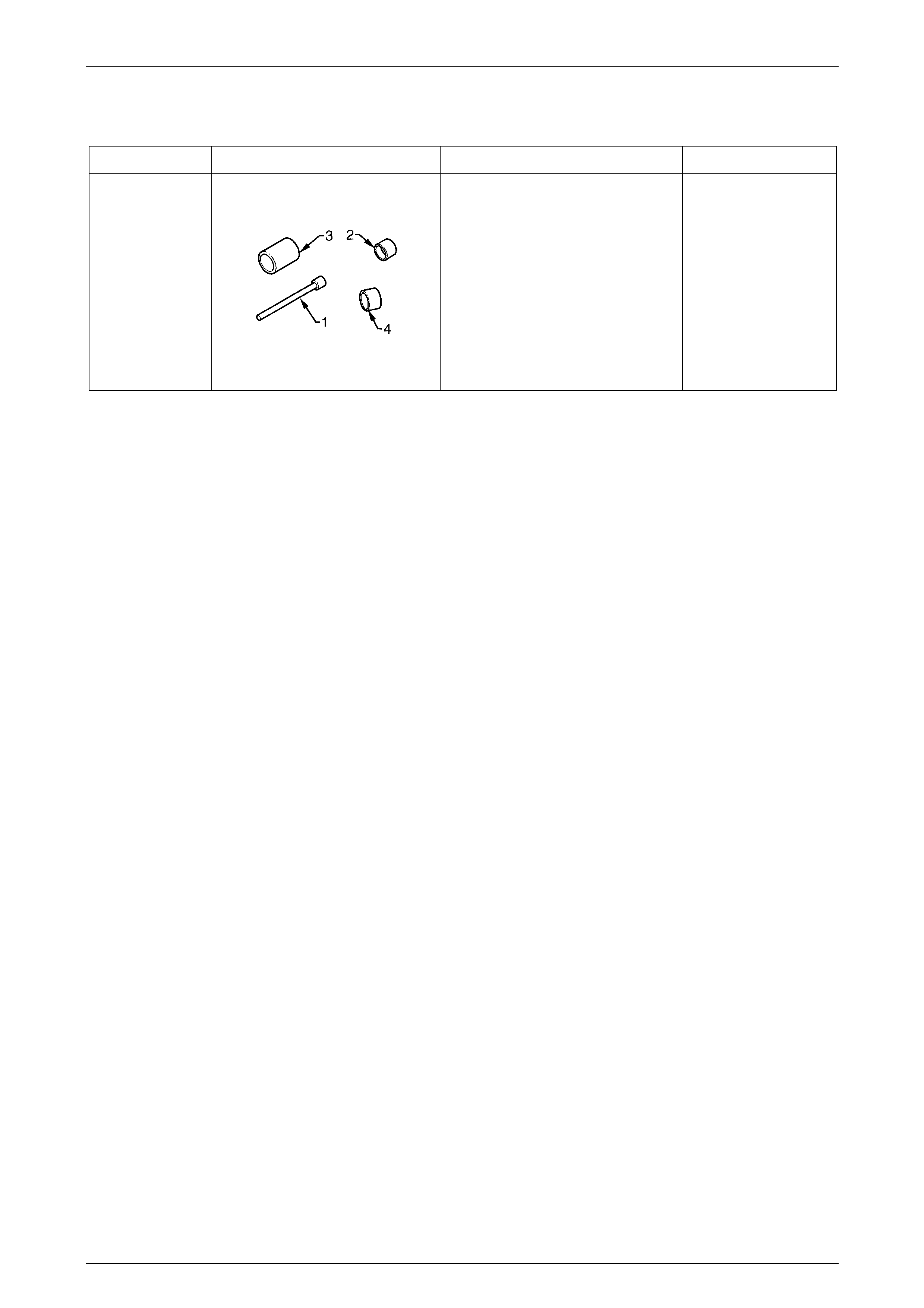

TOOL NUMBER ILLUSTRATION DESCRIPTION CLASSIFICATION

AU606

PRESS TOOL

Used to remove/install leaf spring

eye bush.

Consists of:

1. AU606-1 – Centre Spigot

2. AU606-2 – Bush Remover

3. AU606-3 – Bush Catcher

4. AU606-4 – Bush Installer

Unique