ABS Page 5B –1

Page 5B–1

Section 5B

ABS

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1 General Information............................................................................................................................... 2

1.1 General Description...............................................................................................................................................2

2 Service Operations................................................................................................................................5

2.1 Service Notes..........................................................................................................................................................5

General Information...............................................................................................................................................5

2.2 Rear Wheel Speed Sensor.....................................................................................................................................7

Remove ...................................................................................................................................................................7

Inspect.....................................................................................................................................................................8

Reinstall ..................................................................................................................................................................8

2.3 Rear ABS Pulse Ring.............................................................................................................................................9

Remove ...................................................................................................................................................................9

Install.....................................................................................................................................................................10

3 Specifications....................................................................................................................................... 11

4 Torque Wrench Specifications........................................................................................................... 12

5 Special Tools........................................................................................................................................ 13

Techline

Techline

Techline

Techline

Techline

ABS Page 5B –2

Page 5B–2

1 General Information

1.1 General Description

The Antilock Braking System (ABS) as fitted to MY2003 VY Series Cab Chassis Models, mainly carries over from

previous MY 2003 VY Series Utility Models, noting the following exceptions:

• The rear wheel ABS sensors along with associated wiring are new to accommodate the rigid live axle design and

are unique to MY2003 VY Series Cab Chassis Models.

• The rear wheel ABS sensors are located in a dedicated aperture of each rear brake backing plate. The rear disc

brake backing plates and shields are unique to MY2003 VY Series Cab Chassis Models. For further serving details

refer to Section 5A, Service And Park Braking System in MY2003 VY Series Cab Chassis Models Service

Information.

• MY2003 VY Series Cab Chassis Models equipped with ABS are not equipped with Traction Control Systems (TCS).

For further servicing details of the service and park braking system, as fitted to MY2003 VY Series Cab Chassis Models,

refer to Section 5A, Service And Park Braking System in the MY2003 VY Series Cab Chassis Models Service

Information.

For further servicing details of the ABS Braking System, as fitted to MY2003 VY Series Cab Chassis Models,

refer to Section 5B, ABS & ABS-TCS in the MY 2003 VY and V2 Series Service Information.

There is only one type of Antilock Braking System (ABS) fitted to MY2003 VY Series Cab Chassis Models (production

option JL9). On all MY2003 VY Series Cab Chassis Models fitted with ABS, the master cylinder has a screw-in blanking

plug installed into the lower of the two front brake outlets. Each front wheel hub also includes the wheel speed sensor as

part of the assembly. Internally toothed pulse rings are attached to each of the inner axle shaft flanges, which provide a

signal that is detected by indi vidual ABS wheel speed sensors located in the rear axle backing plate of each side.

At road speeds above approximately 6 km/h, the ABS is designed to control brake fluid pressure so that the wheels are

prevented from locking-up during braking, irrespective of the road conditions and tyre grip. The system starts to regulate

when one wheel is detected to be decelerating faster than the other wheels, tending to lock. The vehicle remains

steerable, even in the event of panic braking, for instance on bends or when swerving to avoid an obstacle.

The ABS, modulates braking pressure separately at each front wheel, with the rear wheels sharing a single ABS

modulated hydraulic circuit. This Antilock Braking System (ABS) is referred to as a three-channel system, as three

separate hydraulic brake circuits are used to achieve anti-lock braking function.

The Tech 2 diagnosti c scan tool is programmed to assist with MY2003 VY Series Cab Chassis Models, electrical

diagnosis and probl em so lv ing , includ ing ABS.

Tech 2, connects to the ABS or ABS/TCS serial data communication information via the Data Link Connector (DLC),

which is attached to the instrument panel lower trim, to the right of the steering column. For additional information on

DLC location and system diagnosis, refer to 3. ABS Diagnosis in this Section or Section 5B, ABS & ABS-TCS in MY

2003 VY and V2 Series Service Information.

For additional and more comprehensive information regarding Tech 2, refer to Section OC, 6 TECH 2 Diagnostics in

MY 2003 VY and V2 Series Service Information.

ABS Page 5B –3

Page 5B–3

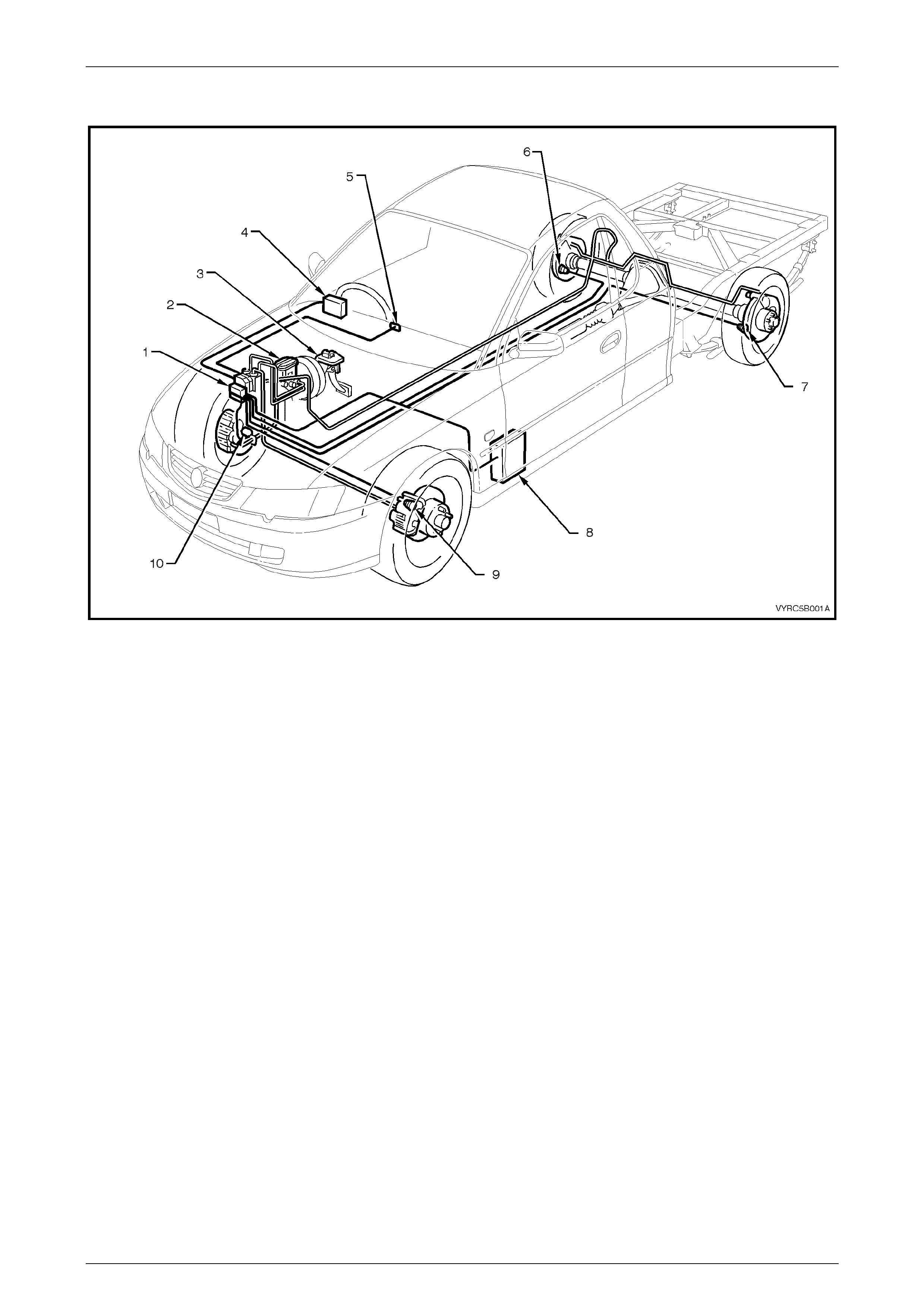

Typical Location for ABS Components Fitted to a Vehicle with V6 Engine.

Figure 5B-1

Legend

1 Hydraulic Modulator and Control Module

Assembly

2 Brake Master Cylinder

3 Stop Lamp Switch

4 Body Control Module (BCM)

5 ABS OFF Warning Lamp

6 Right-Hand Rear Wheel Speed Sensor

7 Left-Hand Rear Wheel Speed Sensor

8 Powertrain Control Module (PCM) – For ABS Only

9 Left-Hand Front Wheel Speed Sensor

10 Right-Hand Front Wheel Speed Sensor

ABS Page 5B –4

Page 5B–4

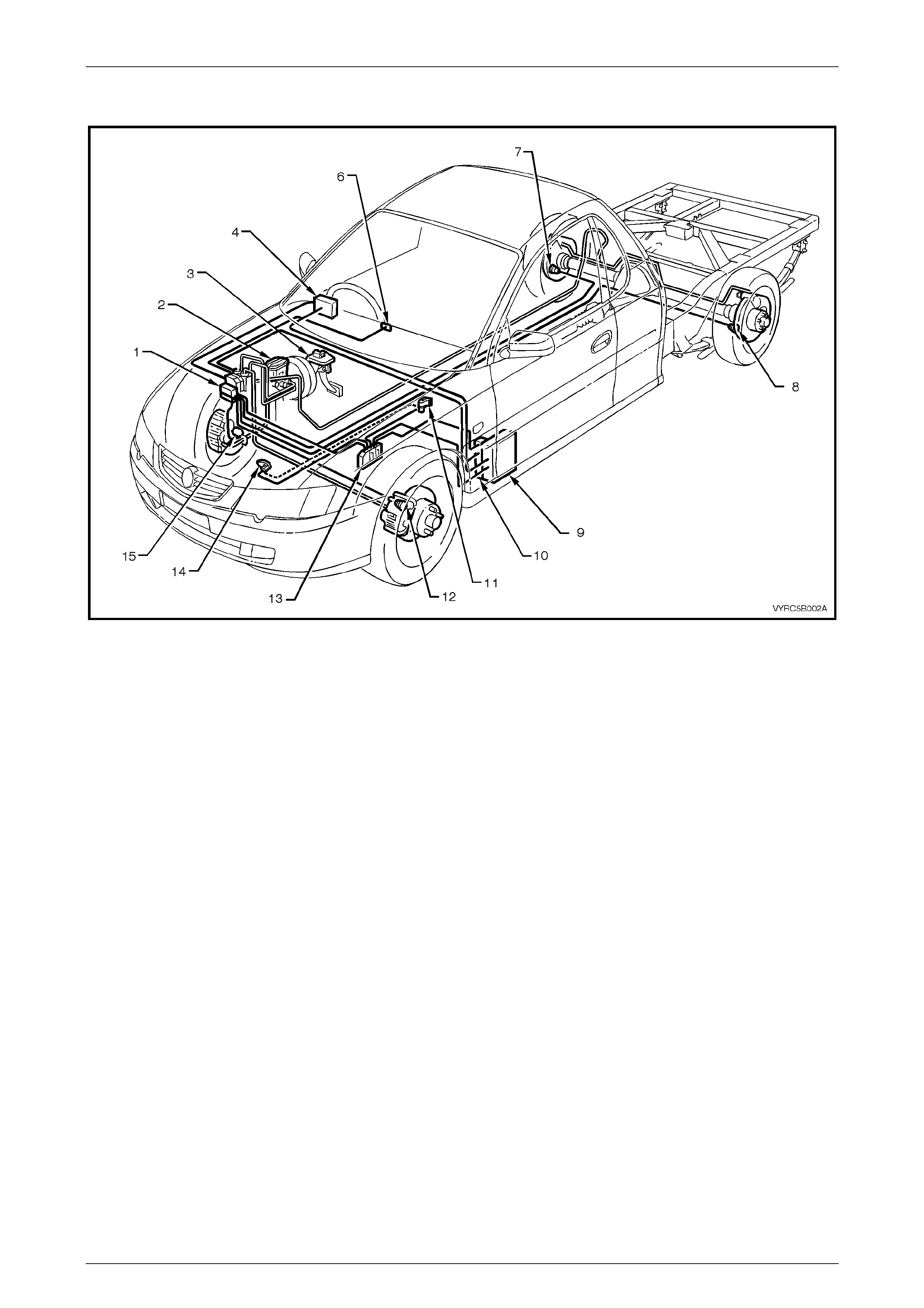

Typical Location for ABS Components fitted to a Vehicle with GEN III V8 Engine.

Figure 5B-2

Legend

1 Hydraulic Modulator and Control Module

Assembly

2 Brake Master Cylinder

3 Stop Lamp Switch

4 Body Control Module (BCM)

5 ABS OFF Warning Display

6 Traction Control On/Off Switch (in Console)

7 Right-Hand Rear Wheel Speed Sensor

8 Left-Hand Rear Wheel Speed Sensor

9 Powertrain Interface Module (PIM)

10 Throttle Relaxer (Actuator) Control Module

11 Throttle Relaxer (Ac tuator) Assembly

12 Left-Hand Front Wheel Speed Sensor

13 Powertrain Control Module (PCM) – For ABS/TCS

Only

14 Throttle Position Sensor (TP Sensor)

15 Right-Hand Front Wheel Speed Sensor

ABS Page 5B –5

Page 5B–5

2 Service Operations

ATTENTION

All rear axle fasteners are important attaching parts as they affect the performance of vital components

and/or could result in major repair expense. Where specified in this section, fasteners MUST be replaced with

parts of the same part number or a GM approved equivalent. Do not use fasteners of an inferior quality or

substitute design.

Torque values must be used as specified during reassembly to ensure proper retention of all steering

components.

Through out this section, fastener torque wrench specifications may be accompanied with the following

Identification marks:

+

++

+ Fasteners must be replaced after loosening.

!

!!

! Vehicle must be at curb height before final tightening.

6

66

6 Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

2.1 Service Notes

General Informat io n

The service operations, for the Antilock Braking System (ABS) as fitted to MY2003 VY Series Cab Chassis Models

mainly carry over from previous MY2003 VY Series Models, noting the following:

• The rear wheel ABS sensors along with associated wiring are new to accommodate the rigid live axle design.

• The rear wheel ABS sensors are located in a dedicated aperture of each rear brake backing plate.

• The rear disc brake backing plates and shields are unique.

• A load sensing proportioning valve is fitted to MY2003 VY Series Cab Chas sis Models, refer to Section 5A, Service

And Park Braking System, 2.5 Load Sensing Proportioning Valve in this Service Information.

For further servicing details of the service and park braking system, as fitted to MY2003 VY Series Cab Chassis Models,

refer to Section 5A, Service And Park Braking System in the MY2003 VY Series Cab Chassis Models Service

Information.

For further servicing details of the ABS Braking System, as fitted to MY2003 VY Series Cab Chassis Models,

refer to Section 5B, ABS & ABS-TCS in the MY 2003 VY Series and V2 Series Service Information.

For additional servicing details on the ABS, reference can also be made to:

1 Section 3, Front Suspension in MY 2003 VY Series and V2 Series Service Information, for information relating to

front wheel bearing hub removal and/or reinstallation operations.

2 Section 4B, Rear Axle in this Service Information, for details of rear axle sensor related components.

3 General brake bleeding operations is described in Section 5A, Service And Park Braking Systems in this Service

Information.

ABS Page 5B –6

Page 5B–6

IMPORTANT

When bleeding operations are carried out,

that involve the ABS Hydraulic Control

Module, then specific procedures must be

followed that require the use of Tech 2. Refer

to Section 5B, ABS & ABS-TCS, 4.8 Tech 2

Test Modes And Screen Displays for ABS &

TCS Diagnosis in the MY2003 VY Series and

V2 Series Service Information.

The Tech 2 diagnostic scan tool is programmed to assist with MY 2003 VY Series Cab Chassis vehicle electrical

diagnosis and probl em so lv ing , includ ing ABS.

Tech 2 connects to the ABS serial data communication information via the Data Link Connector (DLC), attached to the

instrument panel lower trim, to the right of the steering column. For additional information on DLC location and system

diagnosis, refer to 4. ABS DIAGNOSIS in this Section. For additional and more comprehensive information regarding

Tech 2, refer to Section 5B, 4.8 Tech 2 Test Modes and Screen Displays For ABS & TCS Diagnosis in MY 2003 VY and

V2 Series Service Information.

ABS Page 5B –7

Page 5B–7

2.2 Rear Wheel Speed Sensor

LT Section No: H901400

ATTENTION

The following fasteners have either micro encapsulation or incorporate a mechanical thread lock and should

only be used once. If in doubt, replacement is recommended when performing this operation:

$ ABS wheel speed sensor-attaching bolt.

Remove

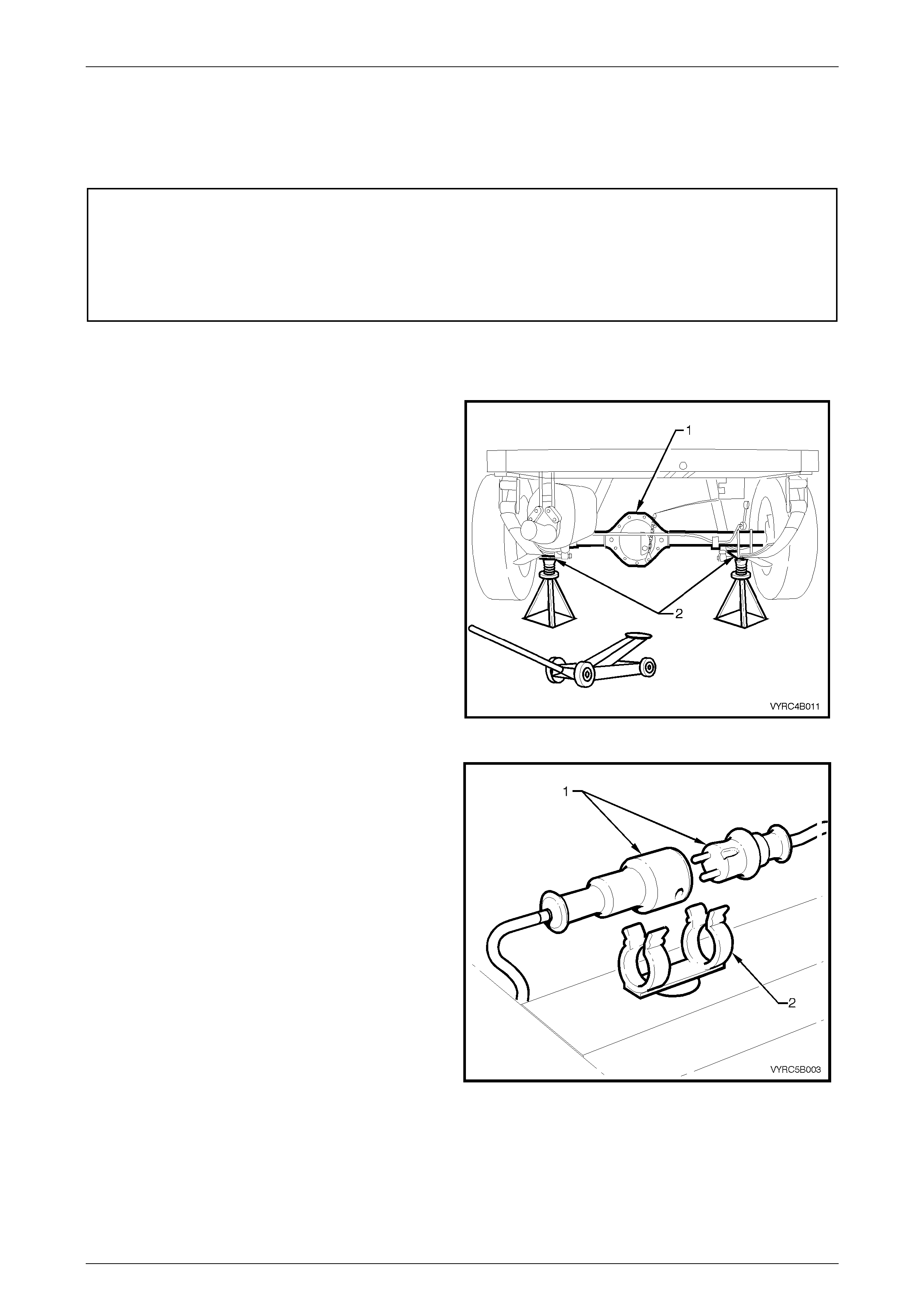

1 Using a floor jack under the centre of the rear axle

assembly (1), jack up the rear of the vehicle, then

place safety stands under the rear leaf spring retainer

plates (2) to support the weight of the vehicle as

shown in Figure 5B-3.

Figure 5B-3

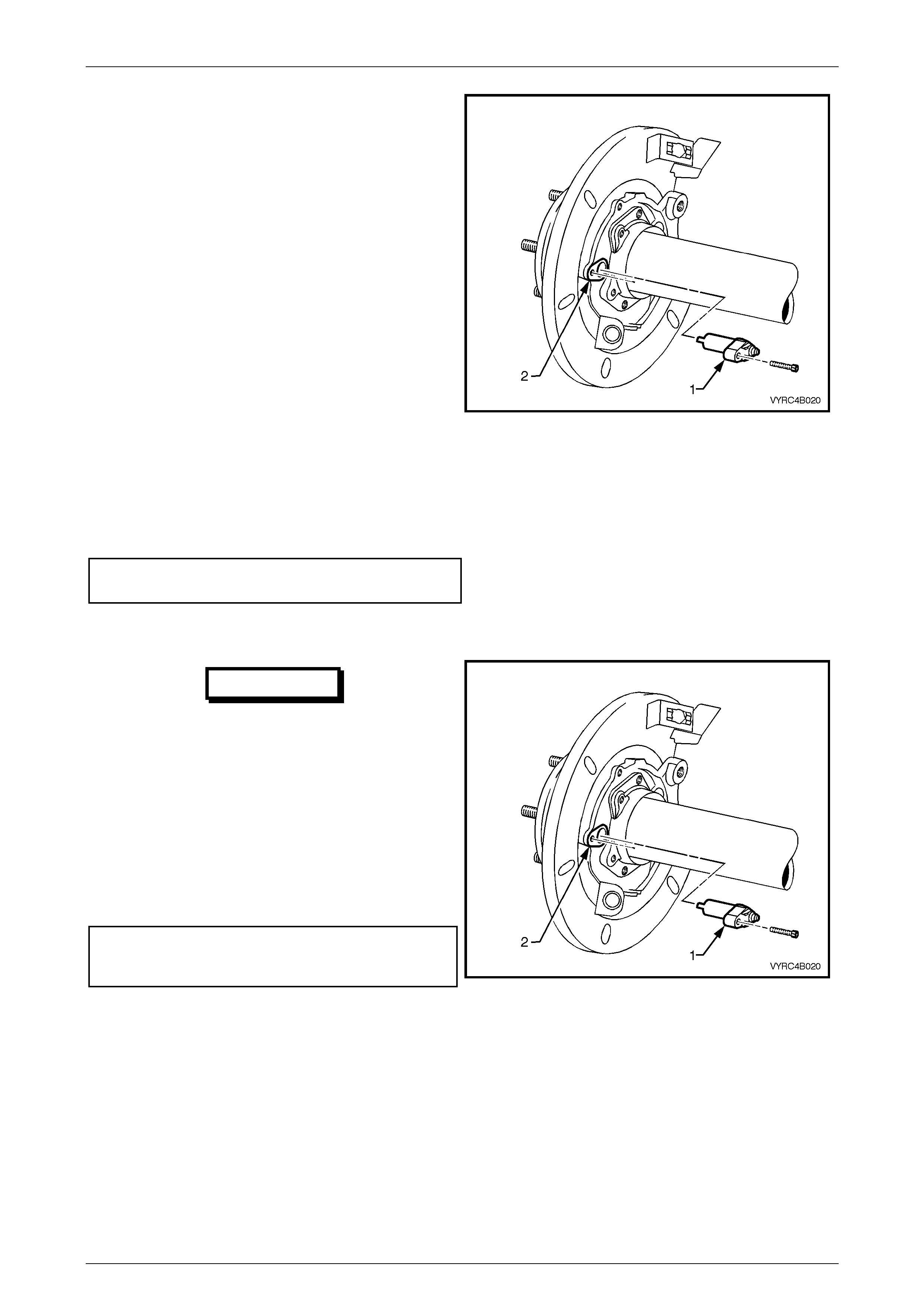

2 Disconnect the rear ABS sensor wiring harness

connector (1) mounted on the chassis by a retaining

clip (2) as shown in Figure 5B-4.

Figure 5B-4

ABS Page 5B –8

Page 5B–8

3 Remove the ABS wheel speed sensor (1) from the

rear axle housing ABS sensor aperture (2) as shown

in Figure 5B-5.

Figure 5B-5

Inspect

1 Clean and inspect the sensor for signs of damage and replace if required.

2 Check that the resistance of the sensor is to specification

Rear wheel ABS sensor

resistance..................................................1.6 KΩ ± 10%

Reinstall

IMPORTANT

A replacement wheel sensor must only be taken out its

packaging immediately before installing on the vehicle.

1 Reinstall the ABS wheel speed sensor (1) to the ABS

sensor aperture (2) and re-connect the sensor to the

wiring harness.

2 Install the ABS wheel speed sensor attaching bolt to

the rear axle housing.

3 Tighten the ABS wheel speed sensor attaching bolt to

the correct torque specification as shown in Figure

5B-6.

($) ABS wheel speed sensor

attaching bolt

torque specification ........................................ 6 – 14 Nm

Figure 5B-6

ABS Page 5B –9

Page 5B–9

2.3 Rear ABS Pulse Ring

LT Section No. – 05-400

Remove

1 Remove the rear axle shaft assembly from the

vehicle. For the removal procedure refer to

Section 4B, 2.8 Rear Axle Shaft Assembly in this

Service Information.

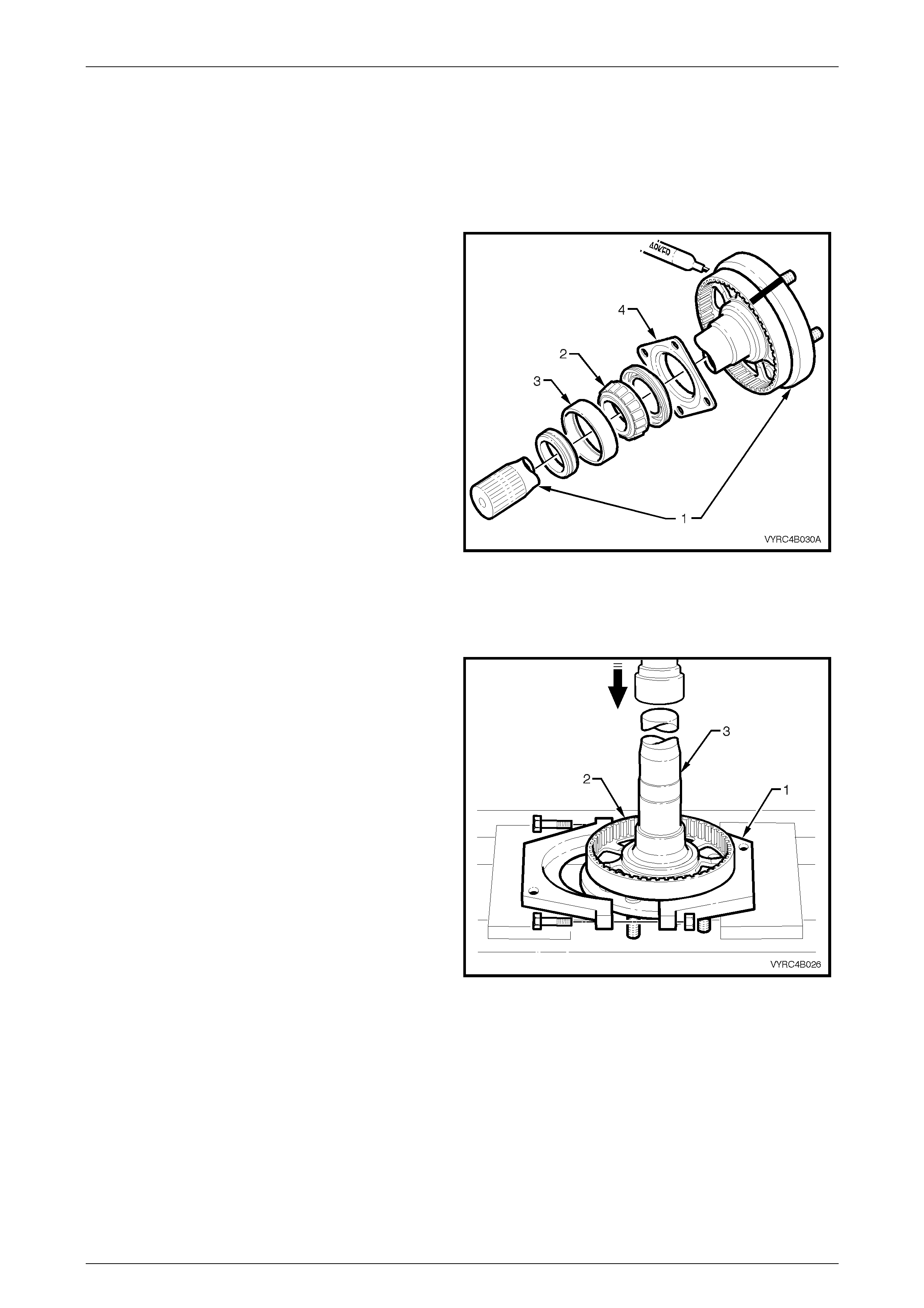

2 To remove the ABS pulse ring it is necessary to

remove the rear axle bearing retainer collar, bearing

cone (3), inner bearing race (2), oil seal and retainer

plate (4) from the rear axle shaft (1). Refer to Figure

5B-7. For the removal procedure refer to Section 4B,

2.8 Rear Axle Shaft Assembly in this Service

Information.

3 Use a felt tipped pen to scribe relationship marks on

the side of both the rear axle shaft flange and the

ABS pulse ring. Refer to Figure 5B-7.

NOTE:

The relationship marking of the axle shaft flange

and ABS pulse ring is necessary to align the

large hole in the axle shaft flange with an

opening between the webbing of the ABS pulse

ring to facilitate removal of the axle shaft

retainer plate attaching bolts. Refer to Figure

5B-7.

Figure 5B-7

4 Using Tool No. AU607-1 (1 ) a suitable hydraulic press

and support pl ates, remove the ABS pulse ring (2)

from rear axle shaft (3). For the removal procedure

refer to Section 4B, 2.8 Rear Axle Shaft Assembly in

this Service Information.

Figure 5B-8

ABS Page 5B –10

Page 5B–10

Install

Reinstallation of the ABS pulse ring, thrust retainer plate, oil seal, inner bearing race, and new retaining collar to the axle

shaft is the reversal of the removal procedure noting the following points.

NOTE:

If installing a new ABS pulse ring, ensure the

relationship mark scribed on the old pulse ring is

transferred to the new pulse ring. The relationship

marking of the axle shaft flange and ABS pulse

ring is necessary to align the large hole in the

axle shaft flange with an opening between the

webbing of the ABS pulse ring to facilitate

removal of the axle shaft retainer plate attaching

bolts.

IMPORTANT

The bearing retainer collar can only be used

once and must be replaced.

NOTE:

Before installation, pre-lubricate the inner seal

lips of the oil seal with Lithium No.2 Grease.

NOTE:

Care must be taken to ensure the bearing race

and retaining collar is fitted squarely during

installation.

NOTE:

Apply sufficient load to ensure the proper seating

of all components.

ABS Page 5B –11

Page 5B–11

3 Specifications

Rear Wheel Speed Sensors

Resistance.........................................................................................................1.6 KΩ ± 10%

ABS Page 5B –12

Page 5B–12

4 Torque Wrench Specifications

ATTENTION

All ABS fasteners are important attaching parts as they affect the performance of vital components and/or

could result in major repair expense. Where specified in this section, fasteners MUST be replaced with parts

of the same part number or a GM approved equivalent. Do not use fasteners of an inferior quality or

substitute design.

Torque values must be used as specified during reassembly to ensure proper retention of all ABS

components.

Through out this section, fastener torque wrench specifications may be accompanied with the following

Identification marks:

+

++

+ Fasteners must be replaced after loosening.

!

!!

! Vehicle must be at curb height before final tightening.

6

66

6 Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

Nm

$ Rear Wheel Speed Sensor Attaching Bolt.............................................6 – 14

ABS Page 5B –13

Page 5B–13

5 Special Tools

TOOL NUMBER ILLUSTRATION DESCRIPTION CLASSIFICATION

AU607 ABS PULSE RING REMOVER AND

INSTALLER

Used to remove and install the ABS

pulse ring from the rear axle shaft.

Includes:

1. AU607-1 ABS Pulse Ring

Remover

2. AU607-2 ABS Pulse Ring

Installer.

Unique

3588

DIGITAL MULTIMETER

Also Previously released as J39200

(or use commercial equivalent).

NOTE: The instrument must have

10 Megohms impedance and be

capable of reading frequencies.

Available