Fuel Tank Page 8A1–1

Page 8A1–1

Section 8A1

Fuel Tank

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices w ith regard to safety and/or property damage.

1 General Information............................................................................................................................... 3

1.1 Modular Fuel Pump and Sender Assembly..........................................................................................................6

Single Turbine Fuel Pump.....................................................................................................................................6

Functional Description of Modular Fuel Pump and Sender Assembly .............................................................7

V6 Engine...........................................................................................................................................................7

GEN III V8 Engine..............................................................................................................................................7

Single Line Fuel Delivery System .........................................................................................................................8

V6 Engine...........................................................................................................................................................8

GEN III V8 Engine..............................................................................................................................................8

Pressure Regulator................................................................................................................................................9

Fuel Level Sender Assembly.................................................................................................................................9

Rollover Valve.........................................................................................................................................................9

1.2 System Components............................................................................................................................................10

V6 Engine..............................................................................................................................................................10

GEN III V8 Engine.................................................................................................................................................12

2 Service Operations.............................................................................................................................. 14

2.1 Fuel Tank ..............................................................................................................................................................14

Remove .................................................................................................................................................................14

Reinstall................................................................................................................................................................16

2.2 Fuel Tank Support Straps....................................................................................................................................17

Remove .................................................................................................................................................................17

Reinstall................................................................................................................................................................17

2.3 Support Bracket ...................................................................................................................................................18

Remove .................................................................................................................................................................18

Reinstall................................................................................................................................................................19

2.4 Modular Fuel Pump and Sender Assembly — V6..............................................................................................20

Remove .................................................................................................................................................................20

Test........................................................................................................................................................................22

Fuel Level Sender ............................................................................................................................................22

Disassemble.........................................................................................................................................................23

Reassemble..........................................................................................................................................................29

Reinstall................................................................................................................................................................29

2.5 Modular Fuel Pump and Sender Assembly — GEN III V8.................................................................................31

Remove .................................................................................................................................................................31

Test........................................................................................................................................................................34

Fuel Level Sender ............................................................................................................................................34

Disassemble.........................................................................................................................................................34

Reassemble..........................................................................................................................................................40

Reinstall................................................................................................................................................................40

2.6 Fuel Filter Assembly............................................................................................................................................42

Remove .................................................................................................................................................................42

Reinstall................................................................................................................................................................42

2.7 Fuel Level Sender Assembly...............................................................................................................................43

Disassemble.........................................................................................................................................................43

Reassemble..........................................................................................................................................................48

Techline

Techline

Fuel Tank Page 8A1–2

Page 8A1–2

2.8 Pressure Regulator..............................................................................................................................................49

V6 Engine..............................................................................................................................................................49

Remove............................................................................................................................................................49

Reinstall............................................................................................................................................................49

GEN III V8 Engine.................................................................................................................................................50

Remove............................................................................................................................................................50

Reinstall............................................................................................................................................................50

2.9 Suction Filter........................................................................................................................................................51

Remove .................................................................................................................................................................51

Reinstall................................................................................................................................................................51

2.10 Modular Fuel Pump..............................................................................................................................................52

Remove .................................................................................................................................................................52

Reinstall................................................................................................................................................................53

2.11 Rollover Valve.......................................................................................................................................................54

2.12 Fuel Pipe Arrangement........................................................................................................................................55

V6 Engine..............................................................................................................................................................55

GEN III V8 Engine.................................................................................................................................................57

3 Specifications....................................................................................................................................... 60

4 Torque Wrench Specifications........................................................................................................... 61

5 Special Tools........................................................................................................................................ 62

Fuel Tank Page 8A1–3

Page 8A1–3

1 General Information

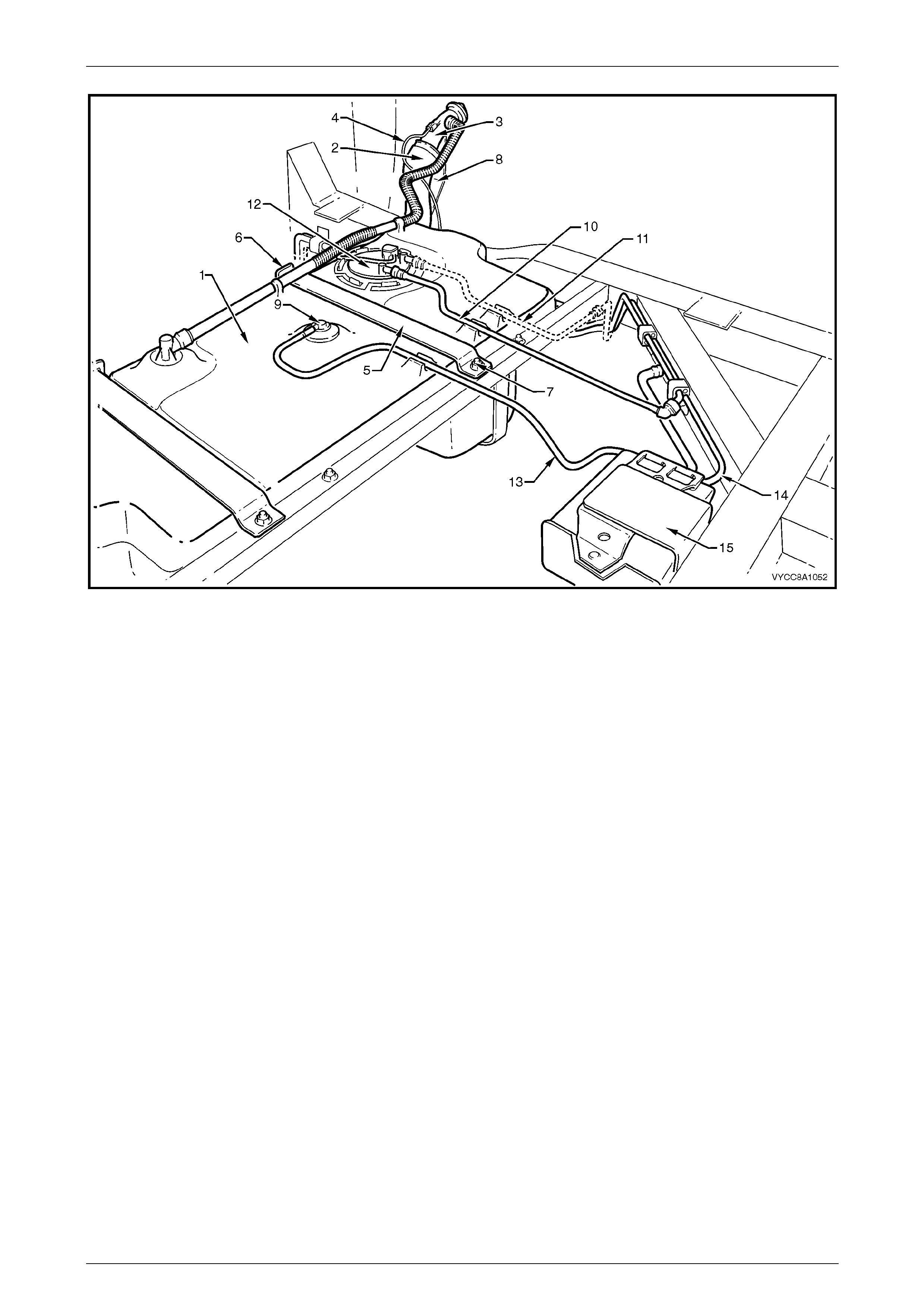

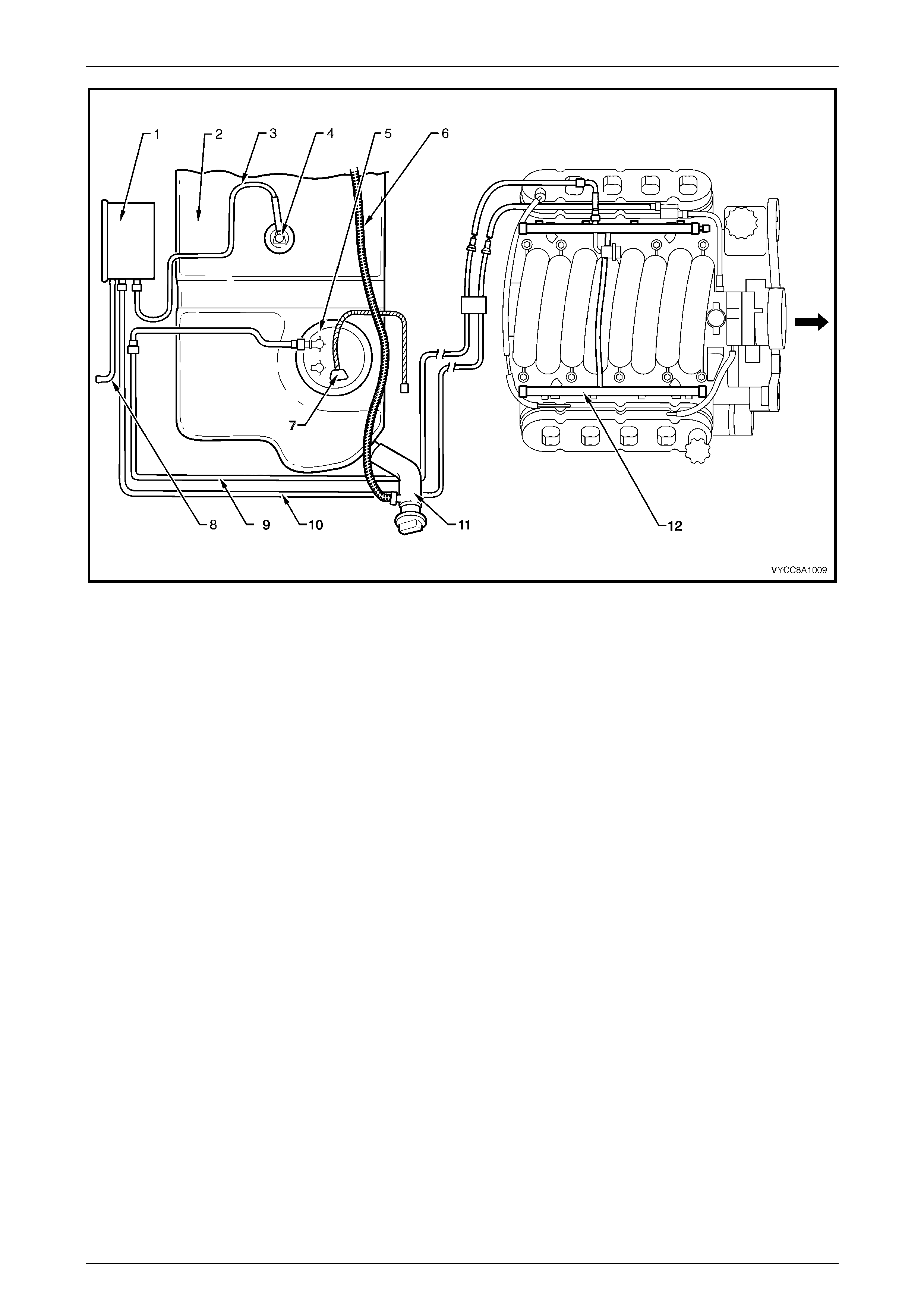

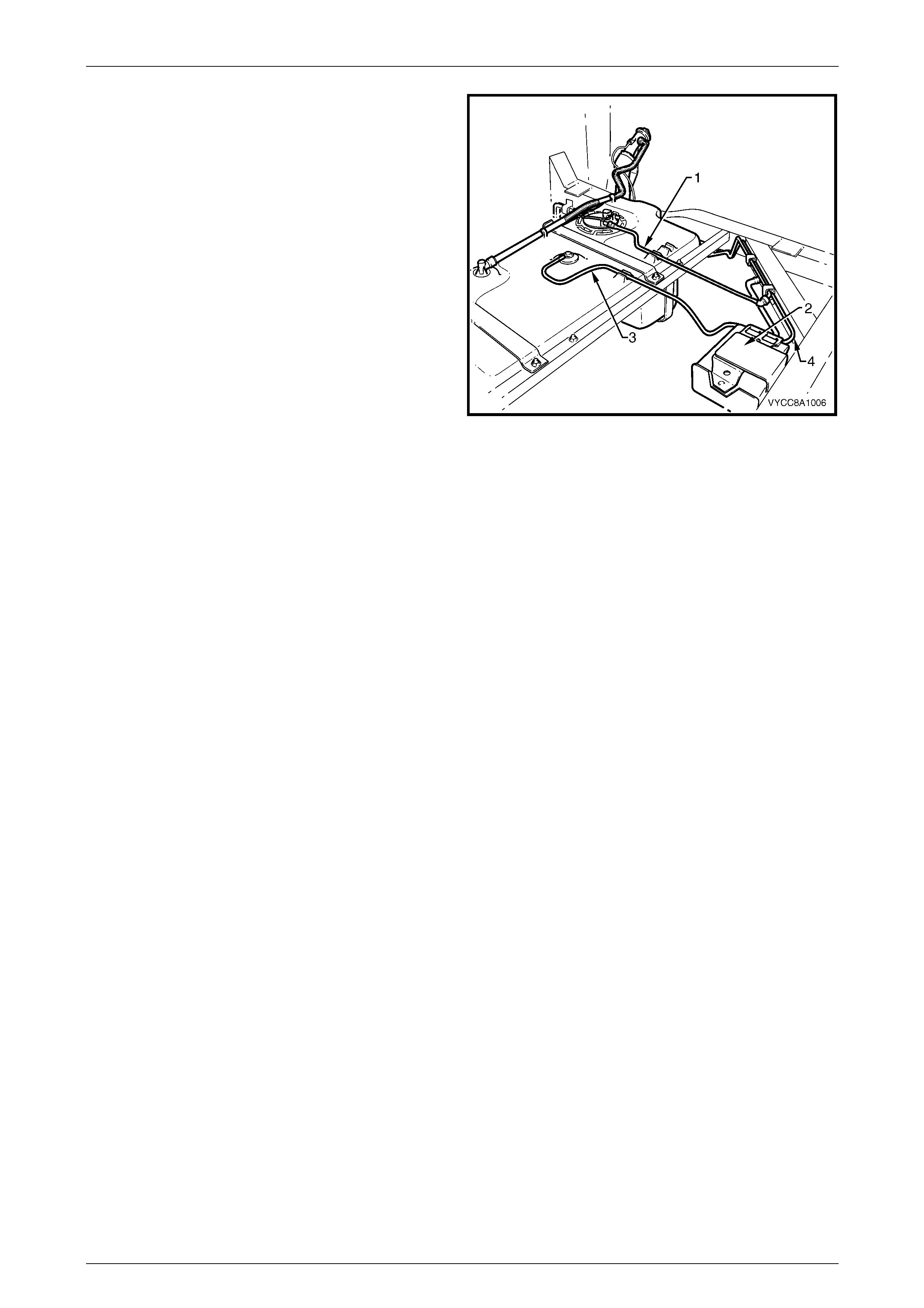

The 68.5-litre fuel tank (1) fitted to MY 2003 VY Series Regular Cab vehicles is a 'W'-type high-density multi-layer

polyethylene construction with a separate fuel filler neck, refer to Figure 8A1 – 1. The fuel filler neck consists of a

flexible rubber centre section (2) with hose clamps either end and a steel upper pipe (3) that incorporates the filler neck

vent fitting and counter-syphon mechanism, and an earthing wire (4). The fuel tank is fitted on a removable frame

underneath the load floor front panel assembly. The fuel tank is retained by two steel mounting straps (5) that fit into

keyed steel risers (6) welded to the forward chassis crossmember. Both steel mounting straps are anchored with a nut

and spring washer to studs (7) welded to the rear chassis crossmember.

The fuel filler neck is fixed to a support bracket (8) bolted to the chassis. The fuel tank is not repairable and, if

damaged, must be replaced. A rollover valve (9) is fitted directly into the top of the fuel tank, but is not serviceable.

Refer to 2.2 Fuel Tank Support Straps for information on the removable frame underneath the fuel tank.

Quick-connect fittings are used on the fuel feed (10) and fuel return lines (11) at both the modular fuel pump and sender

assembly (12) and engine ends. Quick-connect fittings are also used on the fuel tank vent line (13) and the fuel vapour

canister purge line (14) at the fuel vapour canister (15).

For vehicles fitted with the GEN III V8 engine, the modular fuel pump and sender assembly also incorporates a pressure

regulator; the pressure regulator on vehicles fitted with the V6 engine is located on the fuel rail in the engine bay.

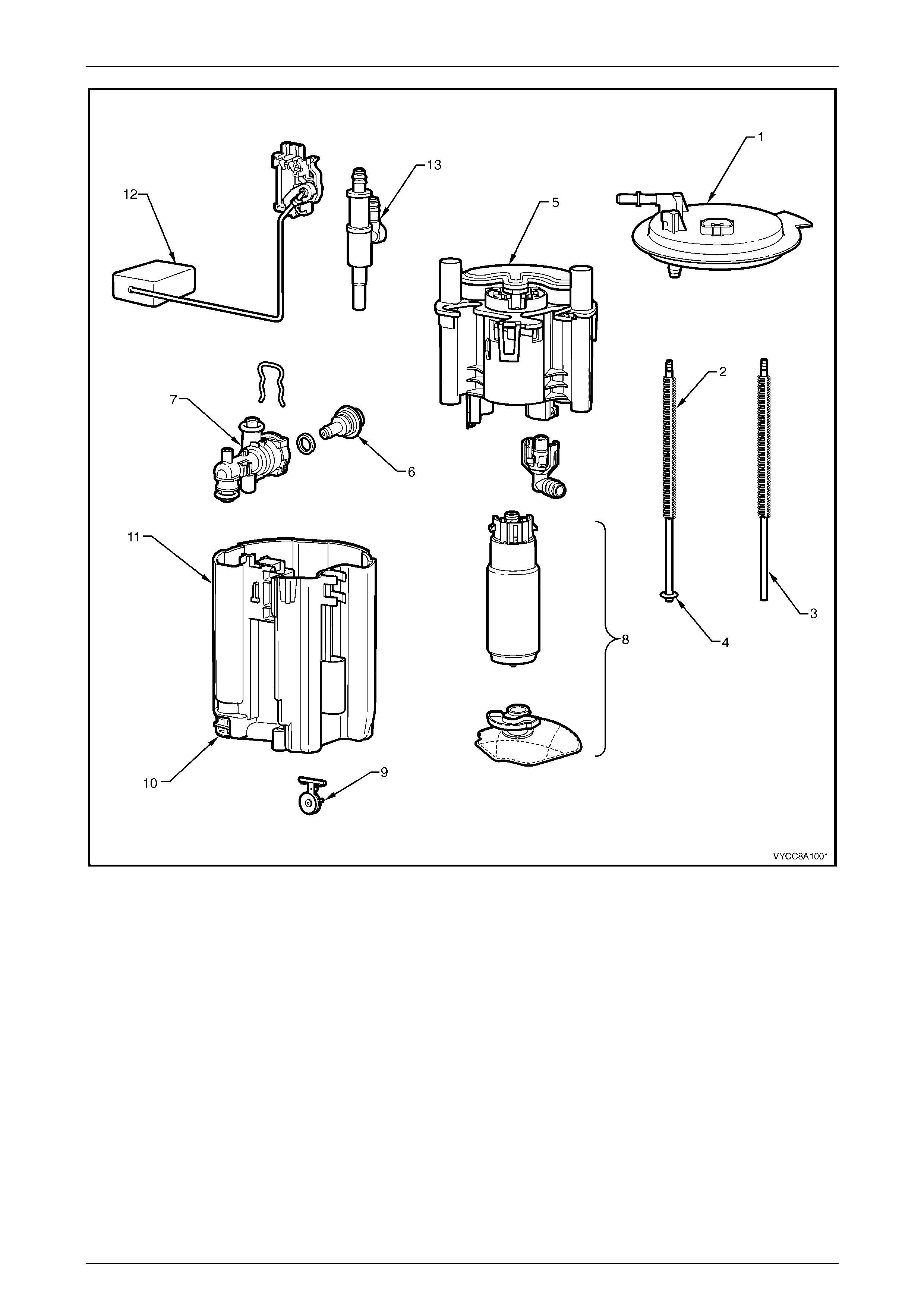

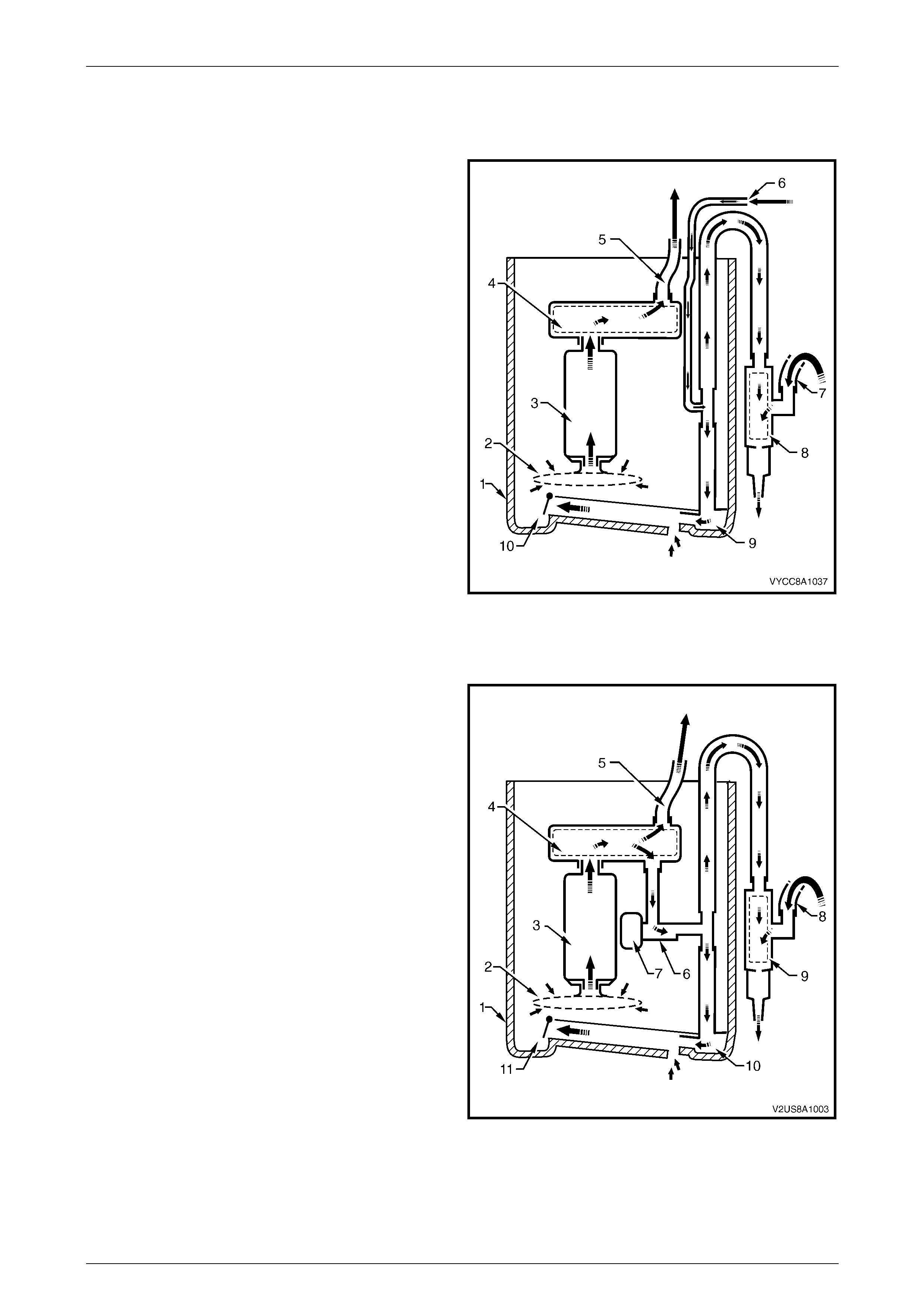

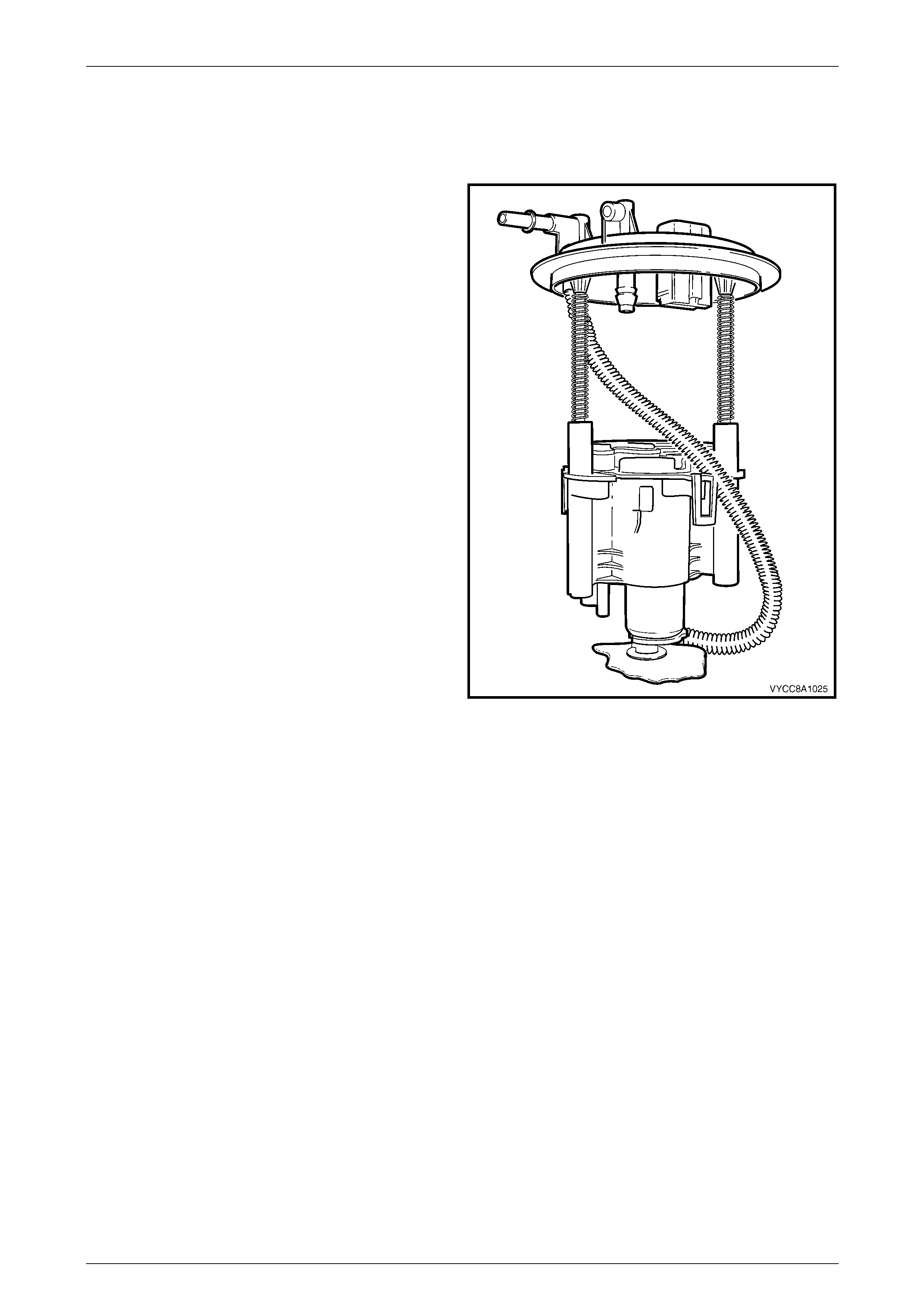

The in-tank, modular fuel pump and sender assembly includes a fuel pump and suction filter assembly, pressure

regulator holder (7), pressure regulator (6 — GEN III V8 only), reservoir (11), fuel level sender assembly (12), reservoir

jet pump (10) and cover (1), refer to Figure 8A1 – 2.

Servicing details for these and other fuel tank and fuel line related items are covered in this Section.

Both the fuel pump and suction filter assembly, and the fuel level sender assembly are serviceable items. For service

intervals of these items, refer to Section 0B Lubrication and Service.

NOTE

Figure 8A1 – 1 is a generic illustration for V6 and

GEN III V8 vehicles.

Fuel Tank Page 8A1–4

Page 8A1–4

Figure 8A1 – 1

Legend

1 Fuel Tank

2 Fuel Filler Neck Flexible

Rubber Centre Sec t i on

3 Fuel Filler Neck S t eel Upper

Pipe

4 Earthing Wire

5 Fuel Tank Mounting S trap

(2 places)

6 Fuel Tank Mounting S trap Front

Anchoring P oi nt

7 Stud (2 places)

8 Fuel Inlet S upport Brack et

9 Rollover Valve

10 Fuel Feed Line

11 Fuel Return Line

(V6 Vehic l es Only)

12 Modular Fuel Pum p and

Sender Assembl y

13 Fuel Tank Vent Li ne

14 Fuel Vapour Canis t er Purge Line

15 Fuel Vapour Canister

Fuel Tank Page 8A1–5

Page 8A1–5

Figure 8A1 – 2

Legend

1 Modular Fuel Pump and Sender

Assembly Cover

2 Spring (2 places)

3 Shaft (2 pl aces)

4 Circlip

5 Fuel Filter Assembly

6 Pressure Regulator

(GEN III V8 Only)

7 Pressure Regulator Holder

8 Fuel Pump and Suct i on Fi lter Ass embly

9 Flapper Valve

10 Reservoir Jet Pump

11 Reservoir

12 Fuel Level Sender Assembly

13 Transfer J et Pump

For additional information regarding the pressure regulator and fuel system electrical diagnostic procedures not

contained in this Section refer to:

• Section 6C1 Powertrain — V6 Engine, and

• Section 6C3 Powertrain — GEN III V8 Engine.

Fuel Tank Page 8A1–6

Page 8A1–6

1.1 Modular Fuel Pump and Sender

Assembly

The modular fuel pump and sender assembly maintains an optimum fuel level in the reservoir. This ensures a

continuous fuel flow under all fuel level conditions and vehicle attitudes. The modular fuel pump and sender assembly

also provides an accurate means of measuring the fuel level within the fuel tank.

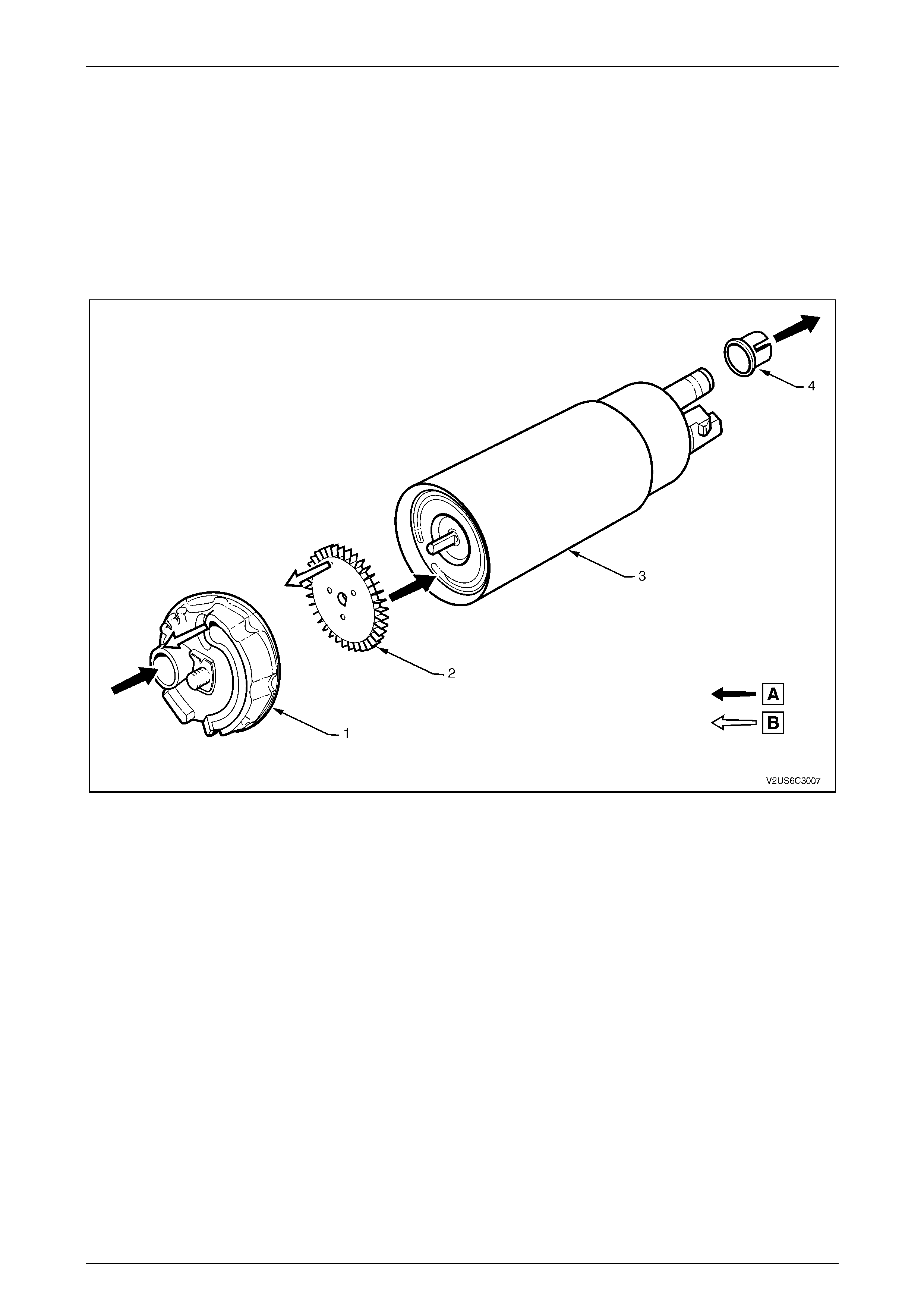

Single Turbine Fuel Pump

Figure 8A1 – 3 details fuel flow through the single turbine fuel pump used with the V6 and GEN III V8 engines.

Figure 8A1 – 3

Legend

A Fuel

B Vapour Out 1 Fuel Pump End Cap

2 Impeller

3 Fuel Pump Body

4 Fuel Pump Outlet O-ri ng Coll ar

Fuel Tank Page 8A1–7

Page 8A1–7

Functional Descri pt i on of Modular Fuel Pump and Sender Assembly

V6 Engine

Fuel is pumped from the fuel tank to the engine via an

internal pump in the modular fuel pump and sender

assembly.

Fuel in the reservoir (1) is drawn through the suction

filter (2) and fuel pump (3), driven by a constant-speed

motor. Fuel flows under pressure through the fuel filter

assembly (4) and flex pipe (5), exits the modular fuel pump

and sender assembly through the fuel feed port on the

modular fuel pump and sender assembly cover, then

through fuel lines into the engine.

When the engine is operating, fuel returning via the fuel

return line (6) mixes with fuel drawn from the other side of

the fuel tank baffle via the low fuel level fuel feed pipe (7),

then through the transfer jet pump (8). Returned fuel also

flows through the reservoir jet pump (9) and valve (10) into

the reservoir. This flow ensures the reservoir is always full

of fuel; the valve prevents fuel from exiting the reservoir

when the engine is turned off.

At high fuel levels, the modular fuel pump and sender

assembly is immersed in fuel. At low fuel levels, the fuel

level is to the top of the reservoir.

Electrical power is supplied to the fuel pump by an integral

connector on the modular fuel pump and sender assembly

cover. An internal harness assembly completes the

connection to the pump.

Figure 8A1 – 4

GEN III V8 Engine

Fuel is pumped from the fuel tank to the engine via an

internal pump in the modular fuel pump and sender

assembly.

Fuel in the reservoir (1) is drawn through the suction

filter (2) and fuel pump (3), driven by a constant-speed

motor. Fuel flows under pressure through the fuel filter

assembly (4) and flex pipe (5), exits the modular fuel pump

and sender assembly through the fuel feed port on the

modular fuel pump and sender assembly cover, then

through fuel lines into the engine.

When the engine is operating, fuel flows through the

pressure regulator holder (6); if fuel pressure increases, the

pressure regulator (7) limits the fuel flow. Fuel is drawn

from the other side of the fuel tank baffle via the low fuel

level fuel feed pipe (8), then through the transfer jet

pump (9). Fuel from the pressure regulator holder also

flows through the reservoir jet pump (10) and valve (11) into

the reservoir. This flow ensures the reservoir is always full

of fuel; the valve prevents fuel from exiting the reservoir

when the engine is turned off.

At high fuel levels, the modular fuel pump and sender

assembly is immersed in fuel. At low fuel levels, the fuel

level is to the top of the reservoir.

Electrical power is supplied to the fuel pump by an integral

connector on the modular fuel pump and sender assembly

cover. An internal harness assembly completes the

connection to the pump.

Figure 8A1 – 5

Fuel Tank Page 8A1–8

Page 8A1–8

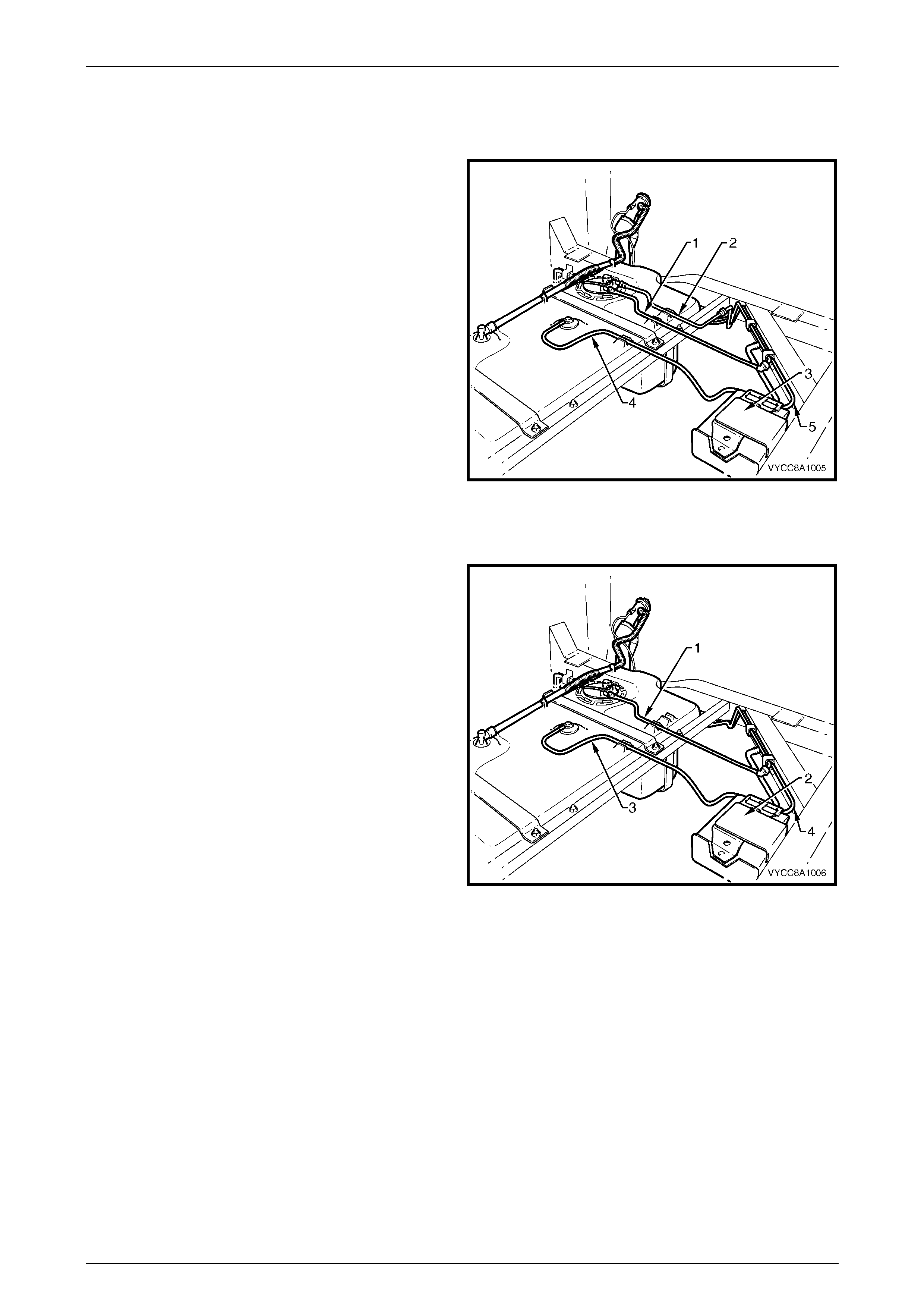

Single Line Fuel Delivery System

V6 Engine

Fuel is directed from the modular fuel pump and sender

assembly, then through the flexible fuel feed line (1) and on

to the engine bay and fuel rail.

When fuel line pressure exceeds the pre-determined value

of 400 kPa (+/–3 kPa), the pressure regulator attached to

the fuel rail opens, allowing excess fuel at system pressure

to return to the fuel tank via the fuel return line (2). This

process occurs continuously while the pump is operating.

A three-port fuel vapour canister (3) is mounted in a bracket

on a chassis crossmember behind the fuel tank. The fuel

vapour canister stores fuel tank vapour via the fuel tank

vent line (4) and releases it to the fuel vapour canister

purge line (5).

Figure 8A1 – 6

GEN III V8 Engine

Fuel is directed from the modular fuel pump and sender

assembly, then through the flexible fuel feed line (1) and on

to the engine bay and fuel rail.

When fuel line pressure exceeds the pre-determined value

of 400 kPa (+/–3 kPa), the pressure regulator in the

modular fuel pump and sender assembly opens, allowing

excess fuel at system pressure to return to the modular fuel

pump and sender assembly via the reservoir jet pump. This

process occurs continuously while the pump is operating.

A three-port fuel vapour canister (2) is mounted in a bracket

on a chassis crossmember behind the fuel tank. The fuel

vapour canister stores fuel tank vapour via the fuel tank

vent line (3) and releases it to the fuel vapour canister

purge line (4).

Figure 8A1 – 7

Fuel Tank Page 8A1–9

Page 8A1–9

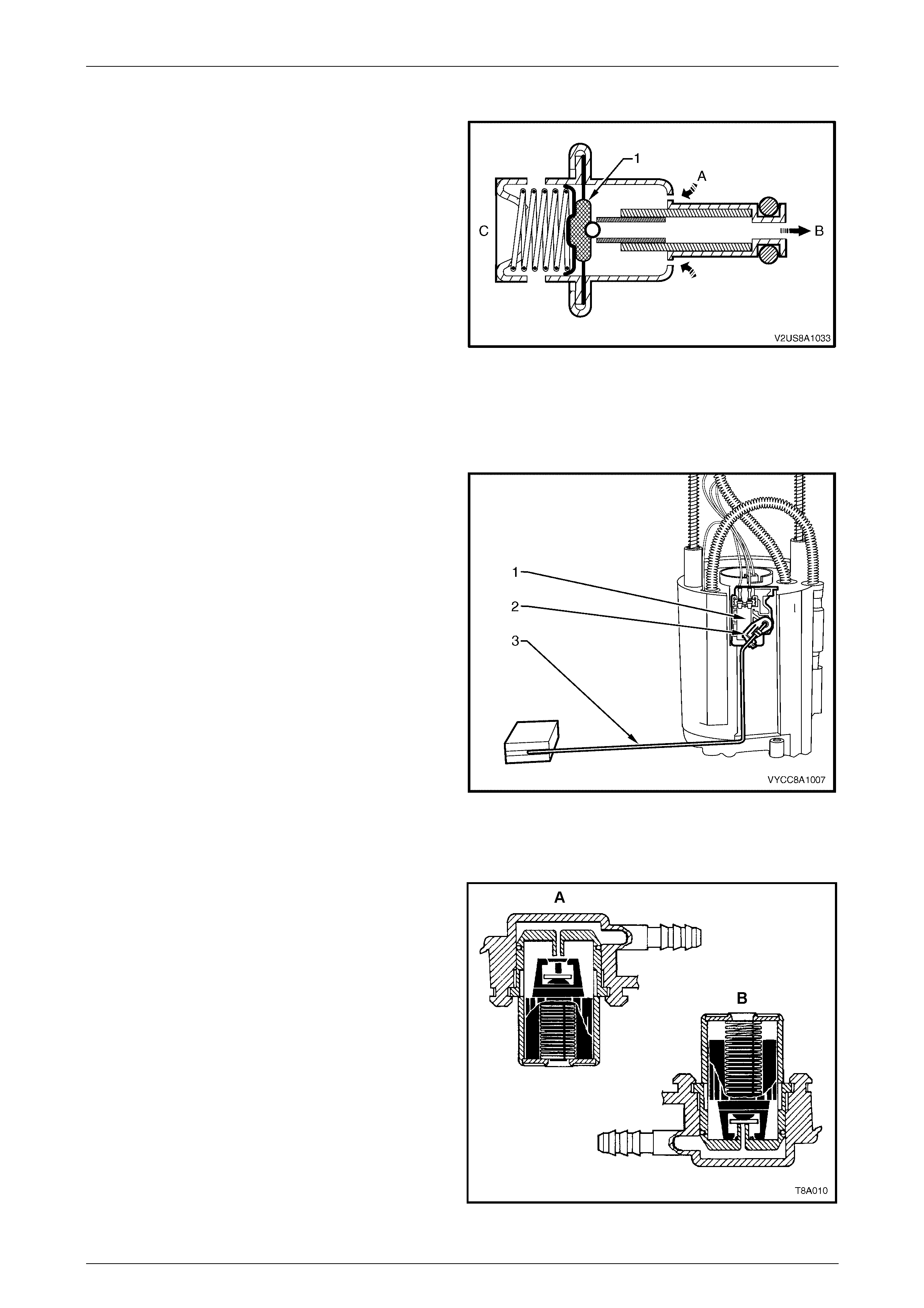

Pressure Regulator

The pressure regulator is a diaphragm-operated relief valve.

On vehicles fitted with the V6 engine, the pressure regulator

is fitted to the engine fuel rail; on vehicles fitted with the

GEN III V8 engine it is in the modular fuel pump and sender

assembly reservoir. The pressure regulator maintains a

controlled pressure at the injectors at all times by regulating

fuel flow into the fuel feed line.

Fuel flows from the fuel pump, through the fuel filter

assembly and exits into the fuel feed line or pressure

regulator entry port (A). When pressure builds in the fuel

feed line, the diaphragm and valve (1) is progressively

pushed out, allowing fuel to exit through the port (B). The

valve is normally closed by mechanical spring pressure (C).

Fuel exiting the pressure regulator is directed into the

transfer and reservoir jet pumps to provide continuous fuel

circulation.

Figure 8A1 – 8

Fuel Level Sender Assembly

The fuel level sender assembly consists of a variable

resistor card holder (1), detachable nylon wiper piece (2)

and a fuel level sender float and arm (3). These

components convert the fuel level in the fuel tank into a

variable electrical signal that provides the fuel level

information on the fuel gauge in the instrument panel.

The fuel level sender assembly mounting is part of the

reservoir moulding. Two wires connect the variable resistor

card to the modular fuel pump and sender assembly wiring

harness.

The variable resistor card varies the resistance, dependent

upon the position of the fuel level sender float and arm and

sends that signal via hard wire to the instrument cluster.

This resistance signal changes relative to the wiper contact

position on the conductive bars of the resistor card.

Figure 8A1 – 9

Rollover Valve

The fuel tank incorporates a rollover valve. The rollover

valve limits vapour venting to the fuel vapour canister using

a fixed-sized orifice that is normally open (View A). If the

vehicle rolls over (View B), the fuel tank vent line to the fuel

vapour canister is safely shut off by the rollover valve,

preventing liquid fuel from flooding the fuel vapour canister.

NOTE

The rollover valve is fitted directly onto the tank

and is not serviceable separately. If it is faulty,

the tank (with a new rollover valve fitted) must

be replaced.

Figure 8A1 – 10

Fuel Tank Page 8A1–10

Page 8A1–10

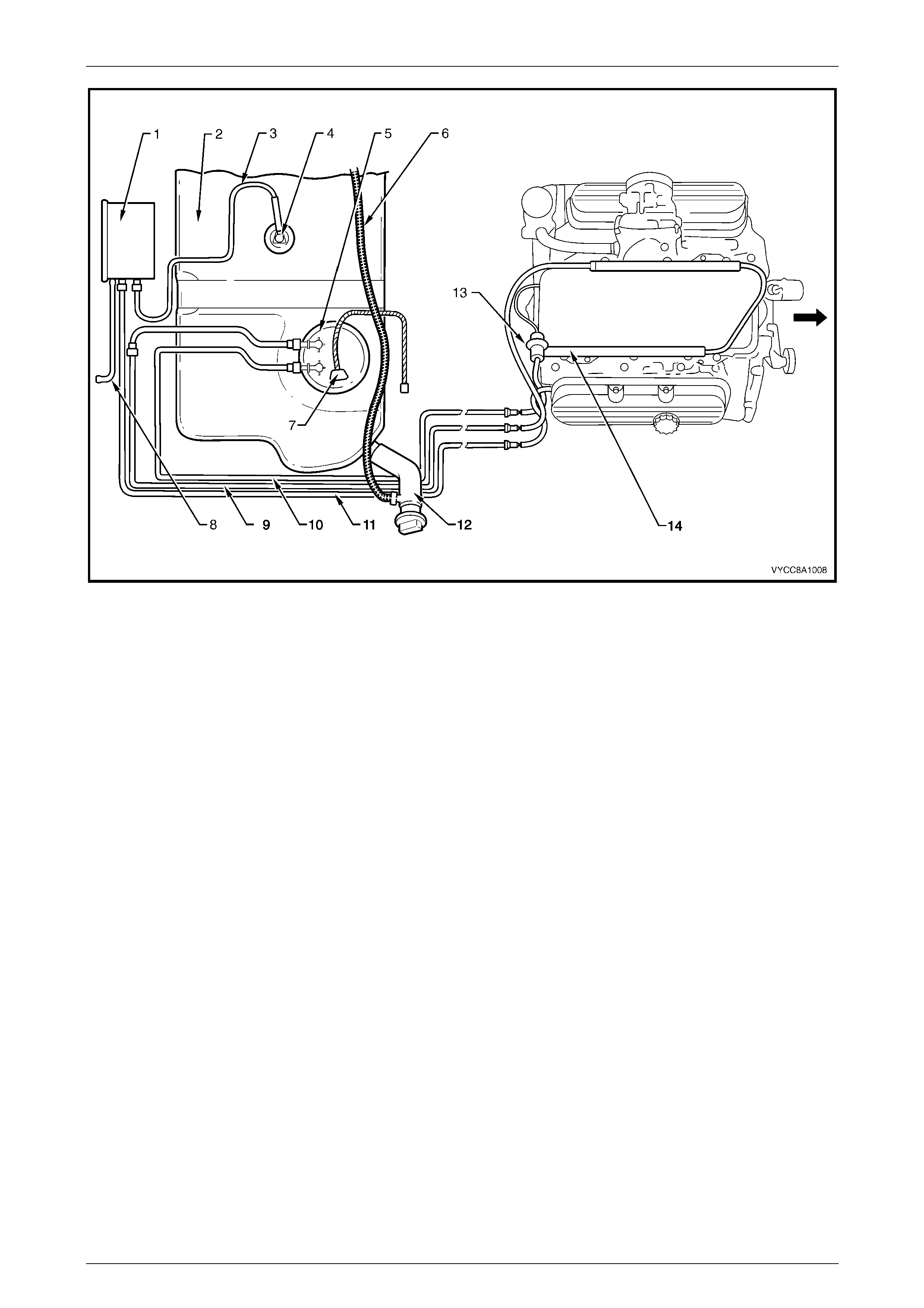

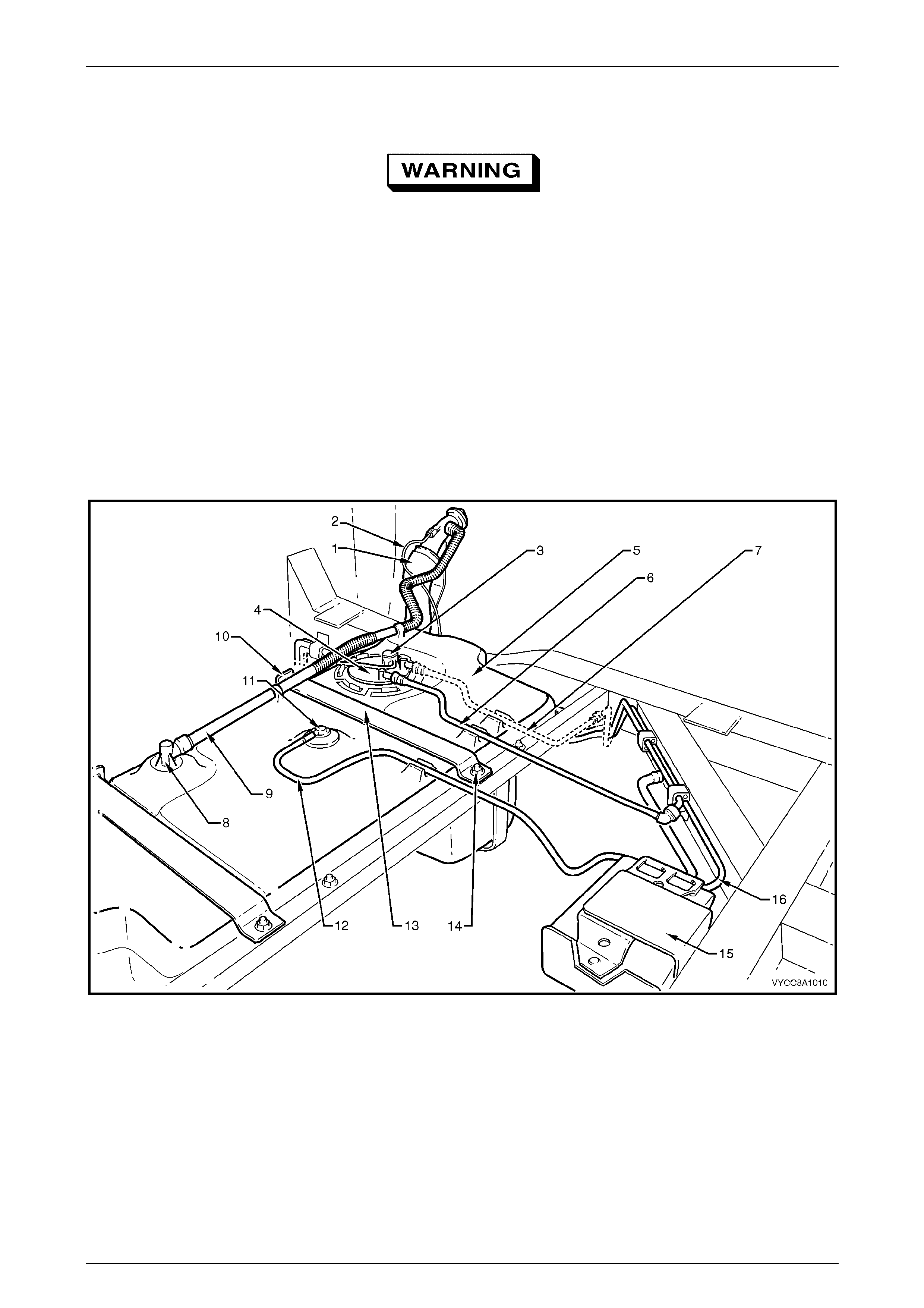

1.2 System Components

V6 Engine

The pressure regulator on vehicles fitted with the V6 engine is located on the fuel rail in the engine bay. Vehicles fitted

with the V6 engine have a fuel return line from the pressure regulator that passes through the modular fuel pump and

sender assembly cover. The fuel control system consists of the following components, refer to Figure 8A1 – 11 for the

V6 engine:

• fuel vapour canister (1);

• fuel tank (2);

• fuel tank vent line (3);

• rollover valve (4);

• modular fuel pump and sender assembly (5), consisting of:

• modular fuel pump and sender assembly cover,

• sleeve rods and retaining springs,

• reservoir,

• fuel pump and suction filter assembly,

• fuel level sender assembly,

• reservoir jet pump (integral with reservoir),

• valve and cap,

• transfer jet pump,

• fuel pipes, and

• wiring harness and connectors;

• inlet breather pipe (6);

• modular fuel pump and sender assembly harness connector (7);

• fuel vapour overload breather pipe (8);

• fuel feed line (9);

• fuel return line (10);

• fuel vapour canister purge line (11);

• fuel filler neck (12);

• pressure regulator (13);

• fuel rail (14);

• power train control module (PCM);

• fuel pump relay; and

• injectors.

Fuel Tank Page 8A1–11

Page 8A1–11

Figure 8A1 – 11

Legend

1 Fuel Vapour Canis ter

2 Fuel Tank

3 Fuel Tank Vent Line

4 Rollover Valve

5 Modular Fuel Pump and Sender

Assembly

6 Inlet B reather Pipe

7 Modular Fuel Pump and Sender

Ass embly Harnes s Connector

8 Fuel Vapour Overload B reather Pipe

9 Fuel Feed Line

10 Fuel Return Line

11 Fuel Vapour Canis t er Purge Line

12 Fuel Filler Neck

13 Pressure Regulator

14 Fuel Rail

Fuel Tank Page 8A1–12

Page 8A1–12

GEN III V8 Engine

The pressure regulator on vehicles fitted with the GEN III V8 engine is located in the modular fuel pump and sender

assembly. The fuel return line port on the modular fuel pump and sender assembly cover on vehicles fitted with the

GEN III V8 engine is plugged. The fuel control system consists of the followi ng components, refer to Figure 8A1 – 12 for

the GEN III V8 engine:

• fuel vapour canister (1);

• fuel tank (2);

• fuel tank vent line (3);

• rollover valve (4);

• modular fuel pump and sender assembly (5), consisting of:

• modular fuel pump and sender assembly cover,

• sleeve rods and retaining springs,

• reservoir,

• fuel pump and suction filter assembly,

• fuel level sender assembly,

• reservoir jet pump (integral with reservoir),

• valve and cap,

• transfer jet pump,

• pressure regulator,

• fuel pipes, and

• wiring harness and connectors;

• inlet breather pipe (6)

• modular fuel pump and sender assembly harness connector (7);

• fuel vapour overload breather pipe (8);

• fuel feed line (9);

• fuel vapour canister purge line (10);

• fuel filler neck (11);

• fuel rail (12);

• power train control module (PCM);

• fuel pump relay; and

• injectors.

Fuel Tank Page 8A1–13

Page 8A1–13

Figure 8A1 – 12

Legend

1 Fuel Vapour Canis ter

2 Fuel Tank

3 Fuel Tank Vent Line

4 Rollover Valve

5 Modular Fuel Pump and Sender

Assembly

6 Inlet B reather Pipe

7 Modular Fuel Pump and Sender

Ass embly Harnes s Connector

8 Fuel Vapour Overload B reather Pipe

9 Fuel Feed Line

10 Fuel Vapour Canis t er Purge Line

11 Fuel Filler Neck

12 Fuel Rail

Fuel Tank Page 8A1–14

Page 8A1–14

2 Service Operations

2.1 Fuel Tank

Remove

A depressurised fuel system contains fuel in

the fuel filter and fuel lines that can be spilled

during service operations.

Fuel vapour remains in the fuel tank even

when completely empty. Seal all openings in

the fuel tank using suitable material or a

plastic plug. Ensure no naked flames or other

ignition sources are nearby. Ensure all

mobile phones (and transmission devices

that may cause any metal objects to become

unintentional receiving antennas) are

switched off.

Wear safety glasses when using compressed

air. Do not blow compressed air onto any

body part.

1 Depressurise the fuel system, refer to:

• For V6 engine vehicles only, Section 6C1–3, 3.1 Fuel Pump Relay, or

• For GEN III V8 engine vehicles only, Section 6C3–3, 3.7 Fuel Pressure Relief Procedure.

2 Remove the fuel pump relay R16, refer to Section 12O, 1.4 Relays.

3 Remove the tray, refer to Section 1B1, Tray.

4 Use compressed air to ensure that all dirt and foreign materials are removed from all fuel connections before the

parts are disconnected, refer to Figure 8A1 – 13.

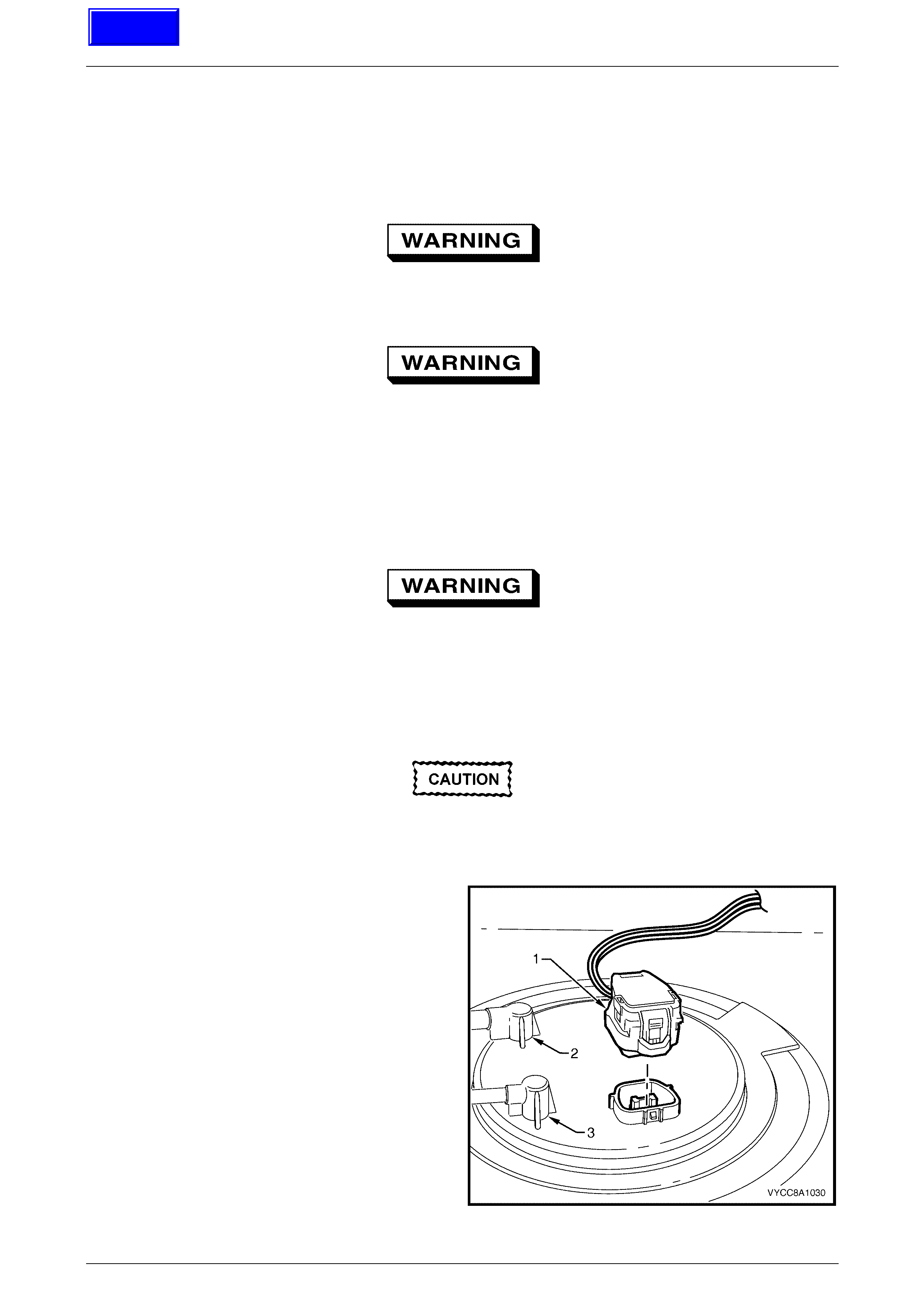

5 Disconnect the modular fuel pump and sender assembly harness connector (3), refer to Figure 8A1 – 13.

6 Tag, remove and cover the following items with a suitable material to prevent foreign objects from entering:

a the fuel feed line (6),

b for V6 engine vehicles only, the fuel return line (7),

NOTE

For information on quick-connect fittings for

Regular Cab and Crew Cab vehicles, refer to

MY 2003 VY and V2 Series Service Information,

Section 8A1 Fuel Tank, 2.10 Quick-connect

Fittings.

c inlet breather pipe (9) from the vapour collector, and

d fuel tank vent line (12).

Fuel Tank Page 8A1–15

Page 8A1–15

7 Remove the modular fuel pump and sender assembly (4), refer to 2.4 Modular Fuel Pump and Sender

Assembly — V6 or 2.5 Modular Fuel Pump and Sender Assembly — GEN III V8.

Ensure fuel is pumped or syphoned from both

sides of the baffle in the fuel tank.

8 Drain the fuel tank by pumping or syphoning fuel through the hole in the fuel tank (from which the modular fuel

pump and sender assembly was removed) using commercially available equipment.

NOTE

A permanent floodgate restriction in the lower

fuel filler neck prevents the fuel tank from being

drained through the filler aperture.

NOTE

Figure 8A1 – 13 is a generic illustration for V6

and GEN III V8 vehicles.

Figure 8A1 – 13

Legend

1 Fuel Filler Neck

2 Earthing Wire

3 Modular Fuel Pump and Sender

Ass embly Harnes s Connector

4 Modular Fuel Pump and Sender

Assembly

5 Fuel Tank

6 Fuel Feed Line

7 Fuel Return Line

(V6 Vehic l es Only)

8 Vapour Collector

9 Inlet B reather Pipe

10 Fuel Tank Mounting Strap Front

Anchoring P oi nt

11 Rollover Valve

12 Fuel Tank Vent Li ne

13 Fuel Tank Mounting S t rap (2 pl aces)

14 Stud (2 plac es)

15 Fuel Vapour Canister

16 Fuel Vapour Canis t er Purge Line

Fuel Tank Page 8A1–16

Page 8A1–16

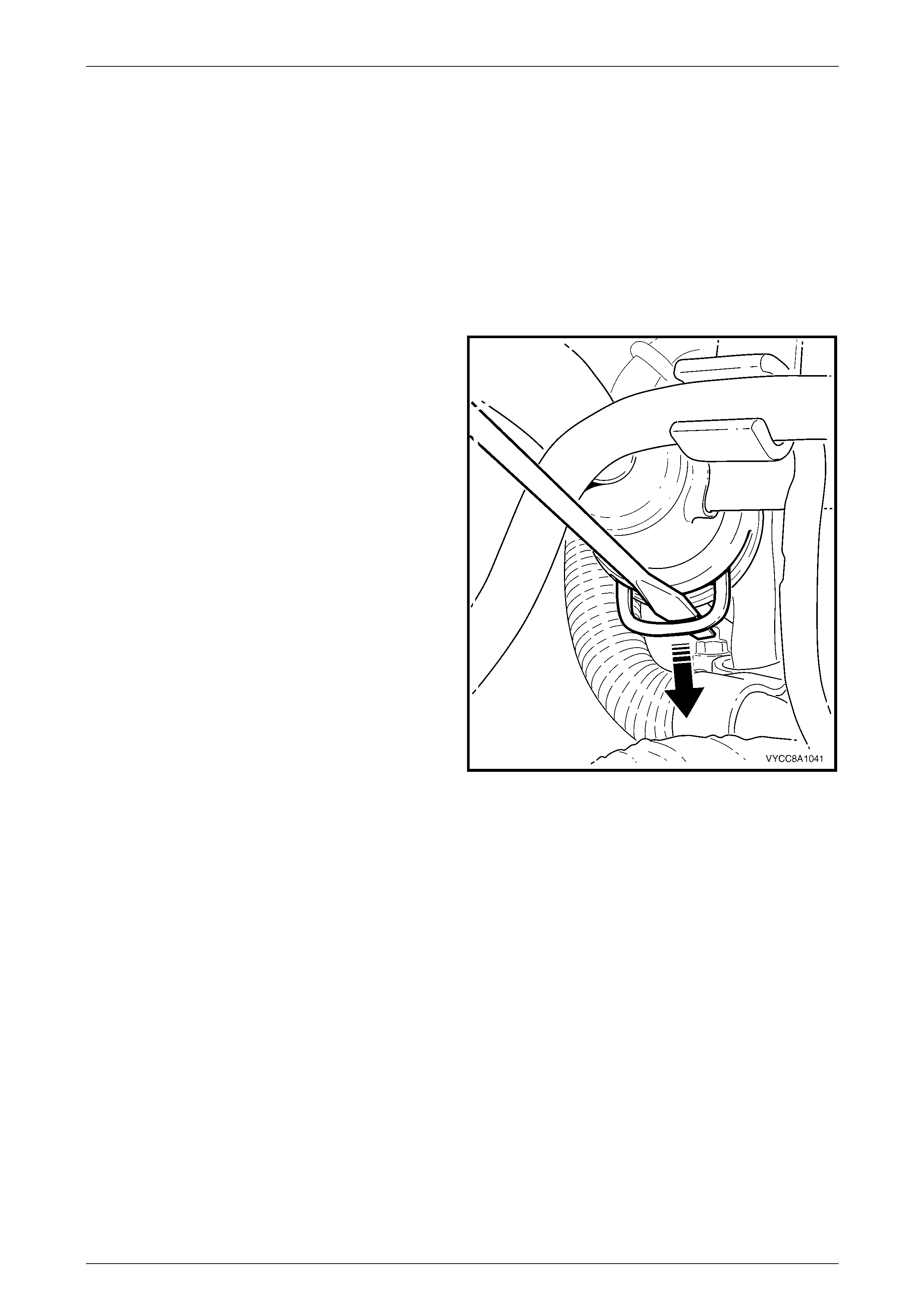

9 Remove the earthing wire (1) from the spade

connector on the fuel filler neck.

10 Remove the earthing wire from the spade connector

screw mounting on the chassis member.

11 Place the earthing wire in a safe location away from

the immediate worksite.

12 Loosen the screw clamp holding the flexible fuel inlet

pipe (2) onto the fuel filler neck.

13 Use compressed air to ensure that all dirt and foreign

materials are removed from the inlet breather pipe (3)

and fuel filler neck.

14 Remove the quick-connect fitting holding the inlet

breather pipe onto the fuel filler neck.

15 Cover the flexible fuel inlet pipe and inlet breather

pipe with a suitable material to prevent foreign objects

from entering.

Figure 8A1 – 14

16 Loosen the screw clamps (1) from both ends of the

flexible fuel filler neck.

17 Remove the flexible fuel filler neck from the fuel tank

and support bracket.

18 Cover the flexible fuel filler neck with a suitable

material to prevent foreign objects from entering.

Figure 8A1 – 15

19 Remove the nuts from both fuel tank mounting strap studs (14).

20 Lift the fuel tank mounting straps away from the front anchoring points (10) and place in a safe location away from

the immediate worksite.

21 Remove the fuel tank from its support frame.

Reinstall

The installation procedure for the fuel tank is the reverse of the removal procedure, noting the following:

1 Ensure all parts are dust-free and clean before reinstalling.

2 Tighten both fuel tank mounting strap nuts to the correct torque specification.

Fuel tank mounting strap

nuts torque specification ........................20.0 – 25.0 Nm

Fuel Tank Page 8A1–17

Page 8A1–17

2.2 Fuel Tank Support Straps

Remove

1 Remove the fuel tank, refer to 2.1 Fuel Tank.

2 Remove the rear park brake cable(s) from the fuel

tank support straps, refer to Section 5A Service and

Park Braking System.

3 Remove the intermediate muffler, refer to Section 8B

Exhaust System.

4 Remove the heat shield from the left fuel tank support

strap, refer to Section 8B Exhaust System.

5 Remove the fuel tank support straps and place the

nuts in a safe location away from the immediate

worksite.

Figure 8A1 – 16

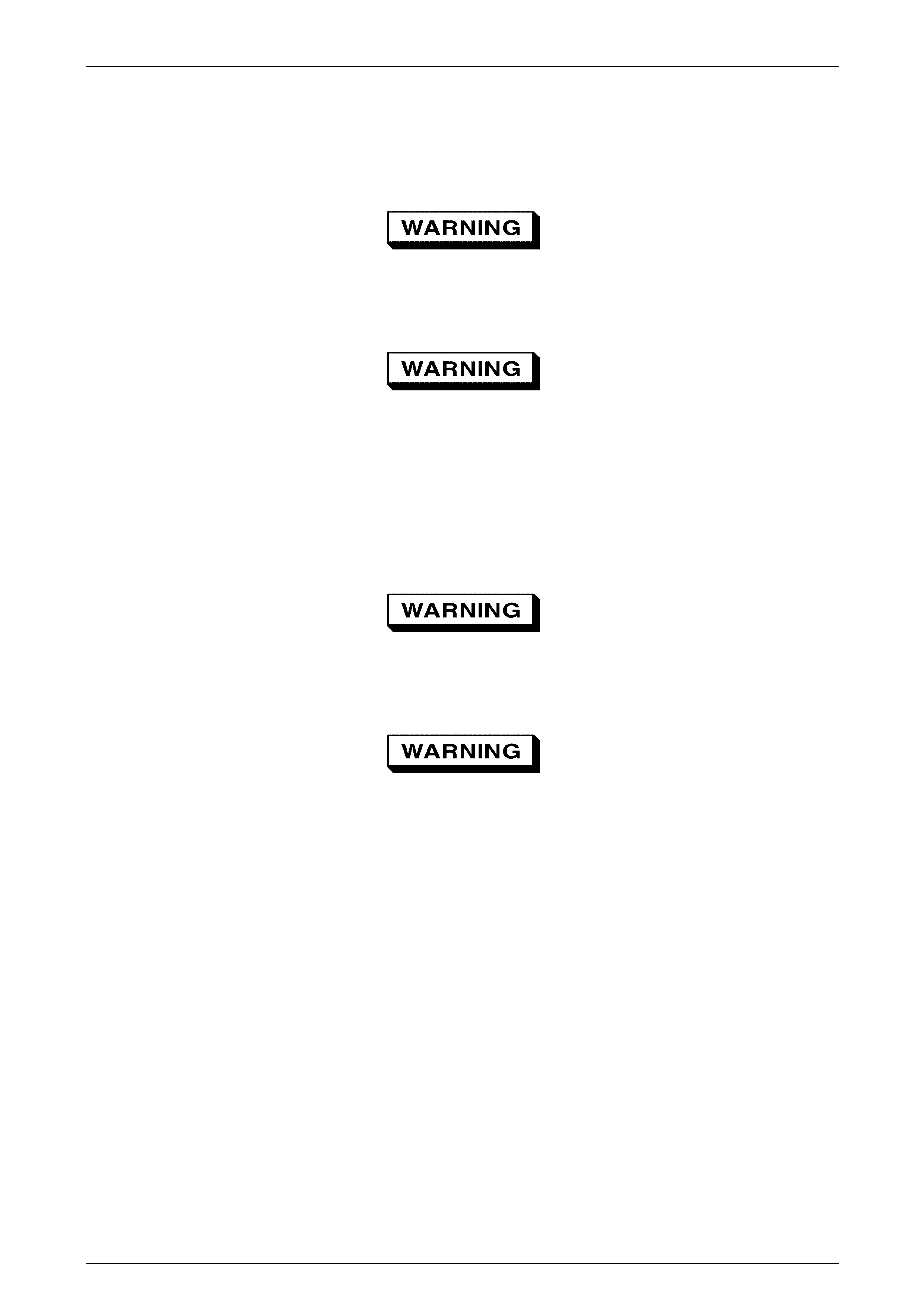

Reinstall

The installation procedure is the reverse of the removal procedure, noting the following:

1 Ensure all parts are dust-free and clean before reinstalling.

2 Tighten the nuts that secure the fuel tank support straps to the correct torque specification.

Fuel Tank Support Straps......................30.0 – 40.0 Nm

Fuel Tank Page 8A1–18

Page 8A1–18

2.3 Support Bracket

Remove

A depressurised fuel system contains fuel in

the fuel filter and fuel lines that can be spilled

during service operations.

Fuel vapour remains in the fuel tank even

when completely empty. Seal all openings in

the fuel tank using suitable material or a

plastic plug. Ensure no naked flames or other

ignition sources are nearby. Ensure all

mobile phones (and transmission devices

that may cause any metal objects to become

unintentional receiving antennas) are

switched off.

Wear safety glasses when using compressed

air. Do not blow compressed air directly onto

any body part.

Ensure fuel is pumped or syphoned from both

sides of the baffle in the fuel tank.

1 Remove the modular fuel pump and sender assembly, refer to MY 2003 VY Series Service Information,

Section 8A1 Fuel Tank.

2 Drain the fuel tank by pumping or syphoning fuel through the hole in the fuel tank (from which the modular fuel

pump and sender assembly was removed) using commercially available equipment.

NOTE

A permanent floodgate restriction in the lower

fuel filler neck prevents the fuel tank from being

drained through the filler aperture.

Fuel Tank Page 8A1–19

Page 8A1–19

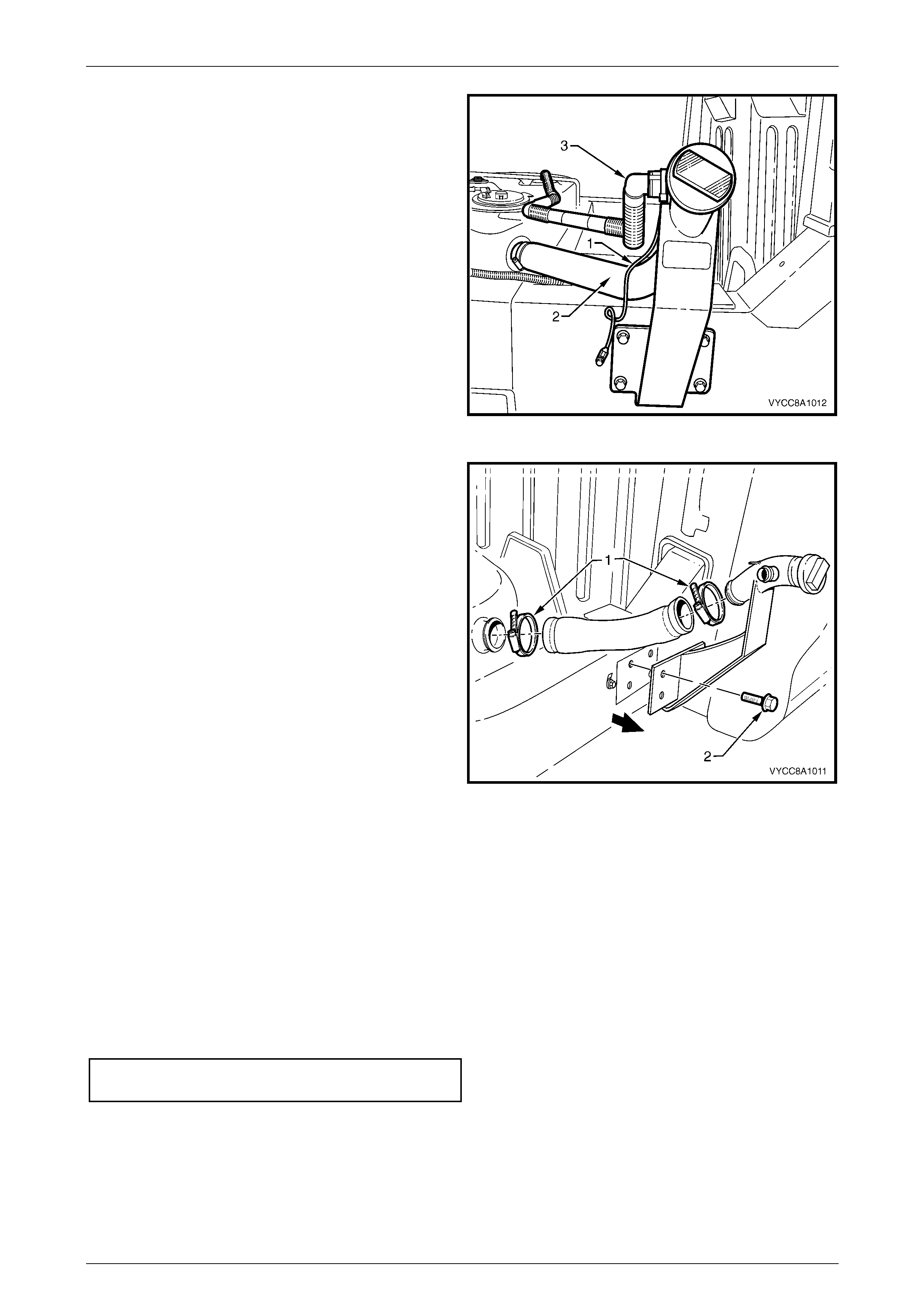

3 Remove the earthing wire (1) from the spade

connector on the fuel filler neck.

4 Remove the earthing wire from the spade connector

screw mounting on the chassis member.

5 Place the earthing wire in a safe location away from

the immediate worksite.

6 Loosen the screw clamp holding the flexible fuel inlet

pipe (2) onto the fuel filler neck.

7 Use compressed air to ensure that all dirt and foreign

materials are removed from the inlet breather pipe (3)

and fuel filler neck.

8 Remove the quick-connect fitting holding the inlet

breather pipe onto the fuel filler neck.

9 Cover the flexible fuel inlet pipe and inlet breather

pipe with a suitable material to prevent foreign objects

from entering.

Figure 8A1 – 17

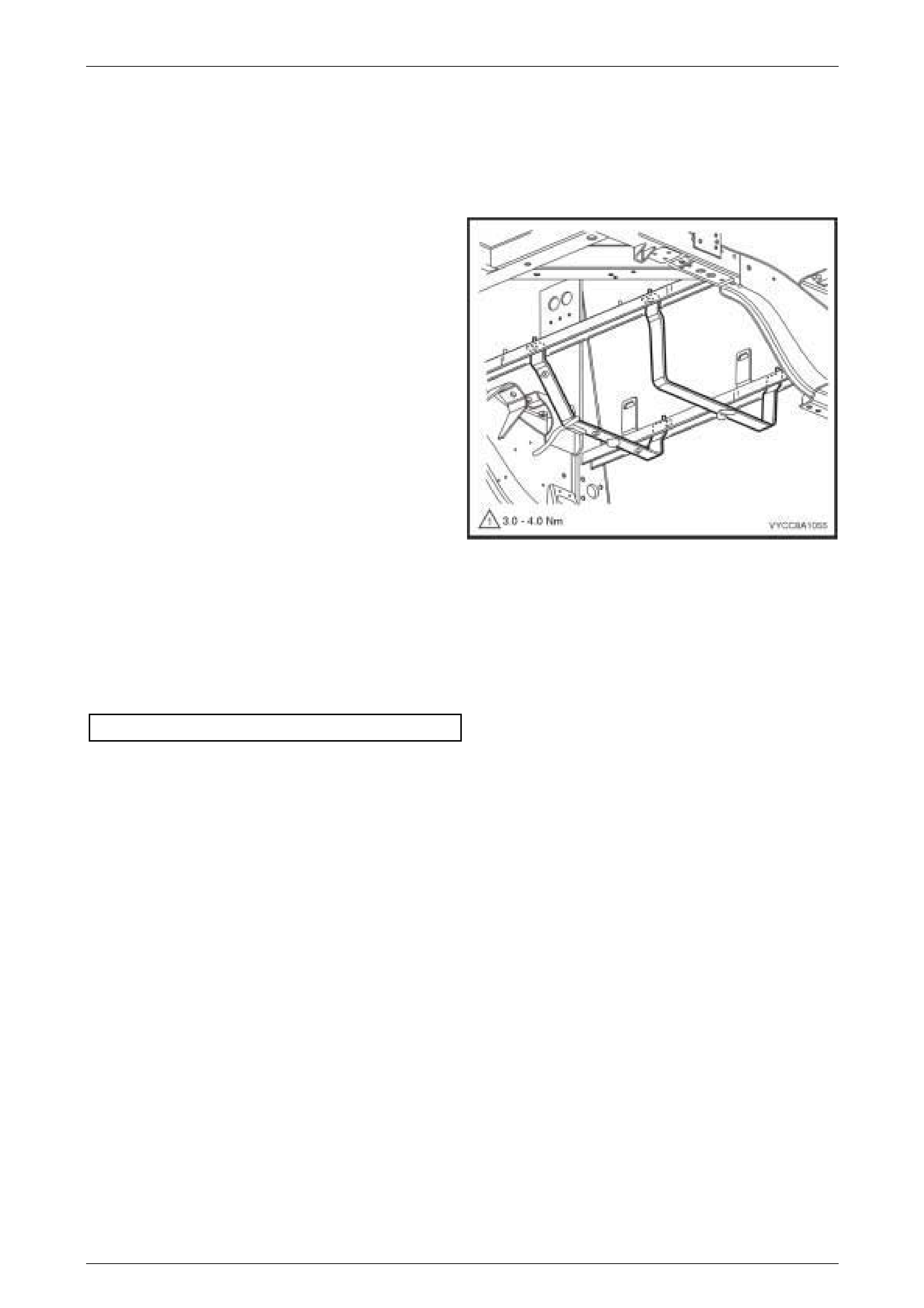

10 Remove both screw clamps (1) holding the flexible

fuel inlet pipe onto the fuel filler neck.

11 Remove the four screws (2) holding the support

bracket backing plate onto the chassis.

12 Cover the flexible fuel filler neck with a suitable

material to prevent foreign objects from entering.

Figure 8A1 – 18

Reinstall

The installation procedure is the reverse of the removal procedure, noting the following:

1 Ensure all parts are dust-free and clean before reinstalling.

2 Tighten the screws that secure the support bracket backing plate on the chassis to the correct torque specification.

Support bracket backing

plate attaching screws

torque specification................................20.0 – 25.0 Nm

Fuel Tank Page 8A1–20

Page 8A1–20

2.4 Modular Fuel Pump and Sender

Assembly — V6

Remove

A depressurised fuel system contains fuel in

the fuel filter and fuel lines that can be spilled

during service operations.

Fuel vapour remains in the fuel tank even

when completely empty. Seal all openings in

the fuel tank using suitable material or a

plastic plug. Ensure no naked flames or other

ignition sources are nearby. Ensure all

mobile phones (and transmission devices

that may cause any metal objects to become

unintentional receiving antennas) are

switched off.

Wear safety glasses when using compressed

air. Do not blow compressed air directly onto

any body part.

1 Remove the tray, refer to Section 1B1, Tray.

2 Use compressed air to ensure that all dirt and foreign materials are removed from all fuel connections before the

parts are disconnected.

Before proceeding, clean all traces of dirt and

other foreign material from the top of the fuel

tank, near the modular fuel pump and sender

assembly.

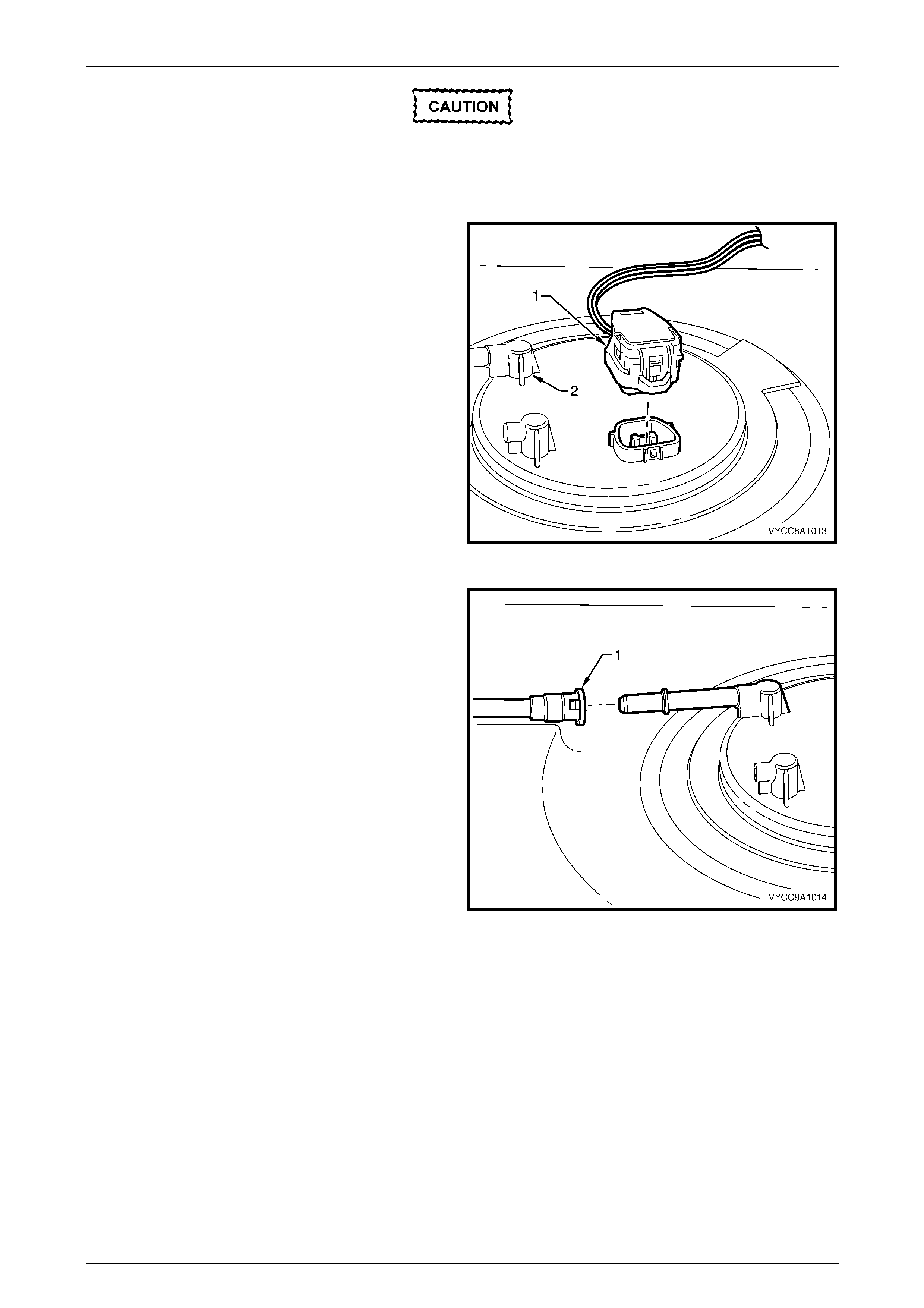

3 Disconnect the modular fuel pump and sender

assembly harness connector (1).

4 Tag the fuel feed line connecting the fuel feed port (2)

on top of the modular fuel pump and sender

assembly.

5 Tag the fuel return line connecting the fuel return

port (3) on top of the modular fuel pump and sender

assembly.

Figure 8A1 – 19

Techline

Fuel Tank Page 8A1–21

Page 8A1–21

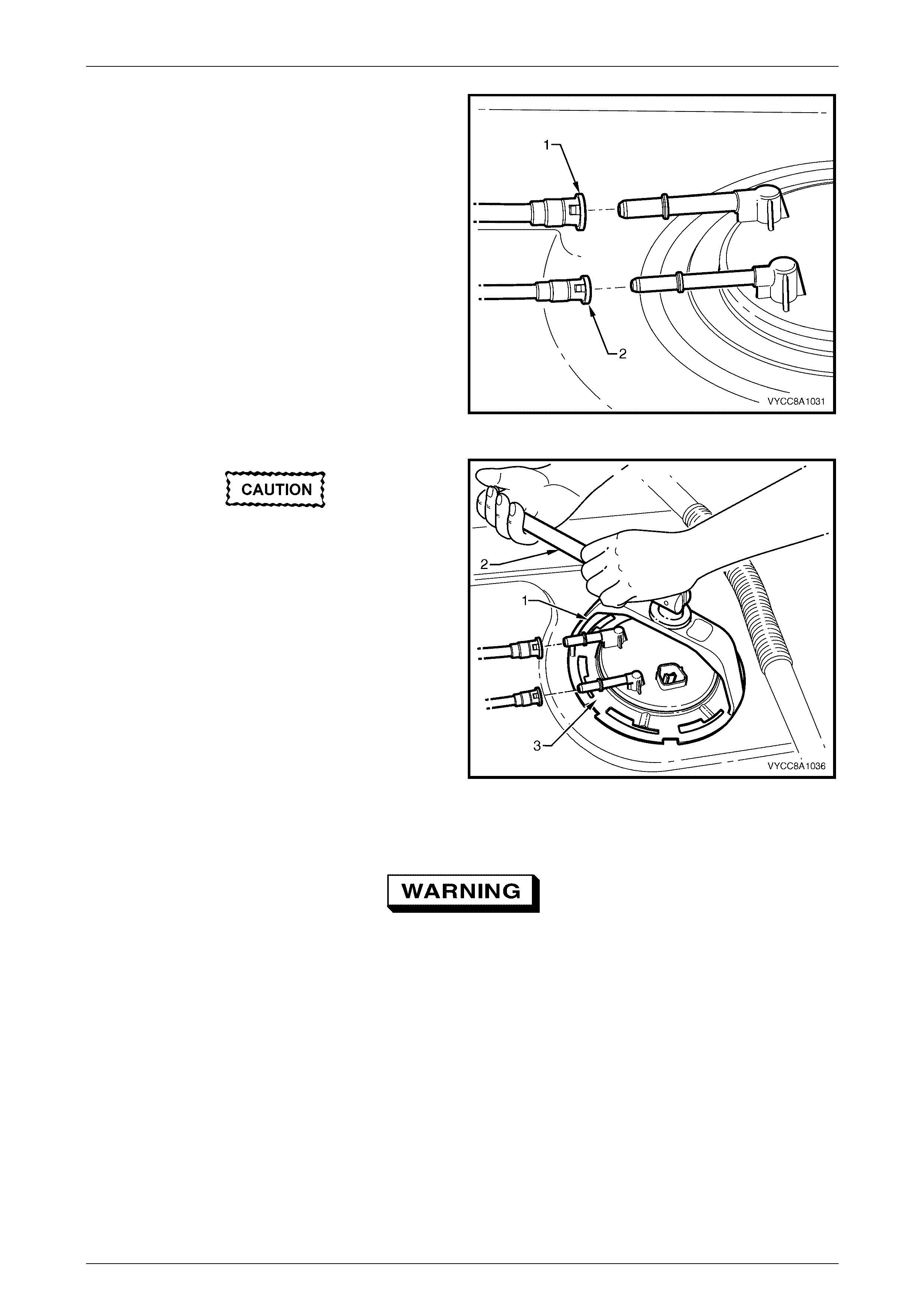

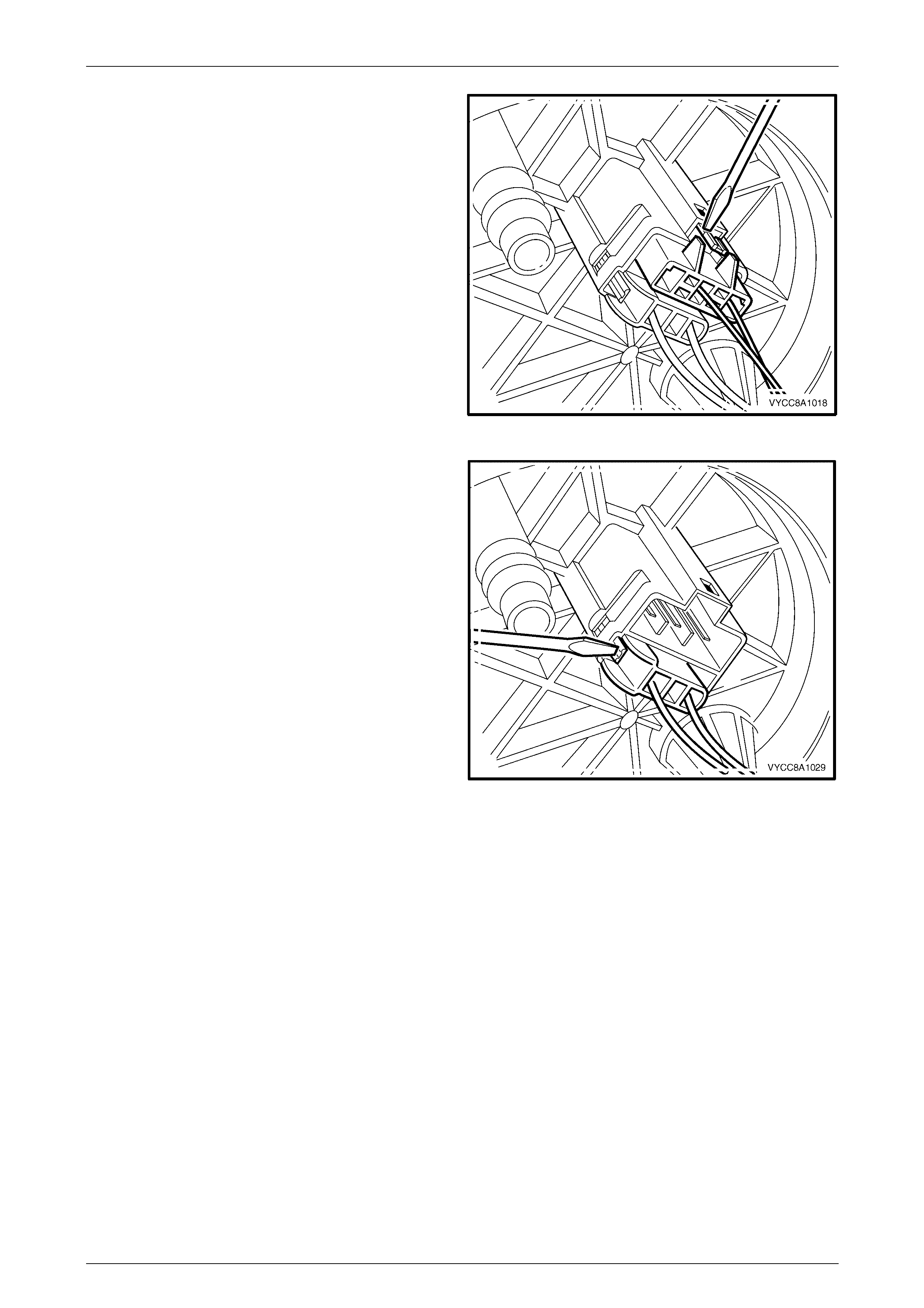

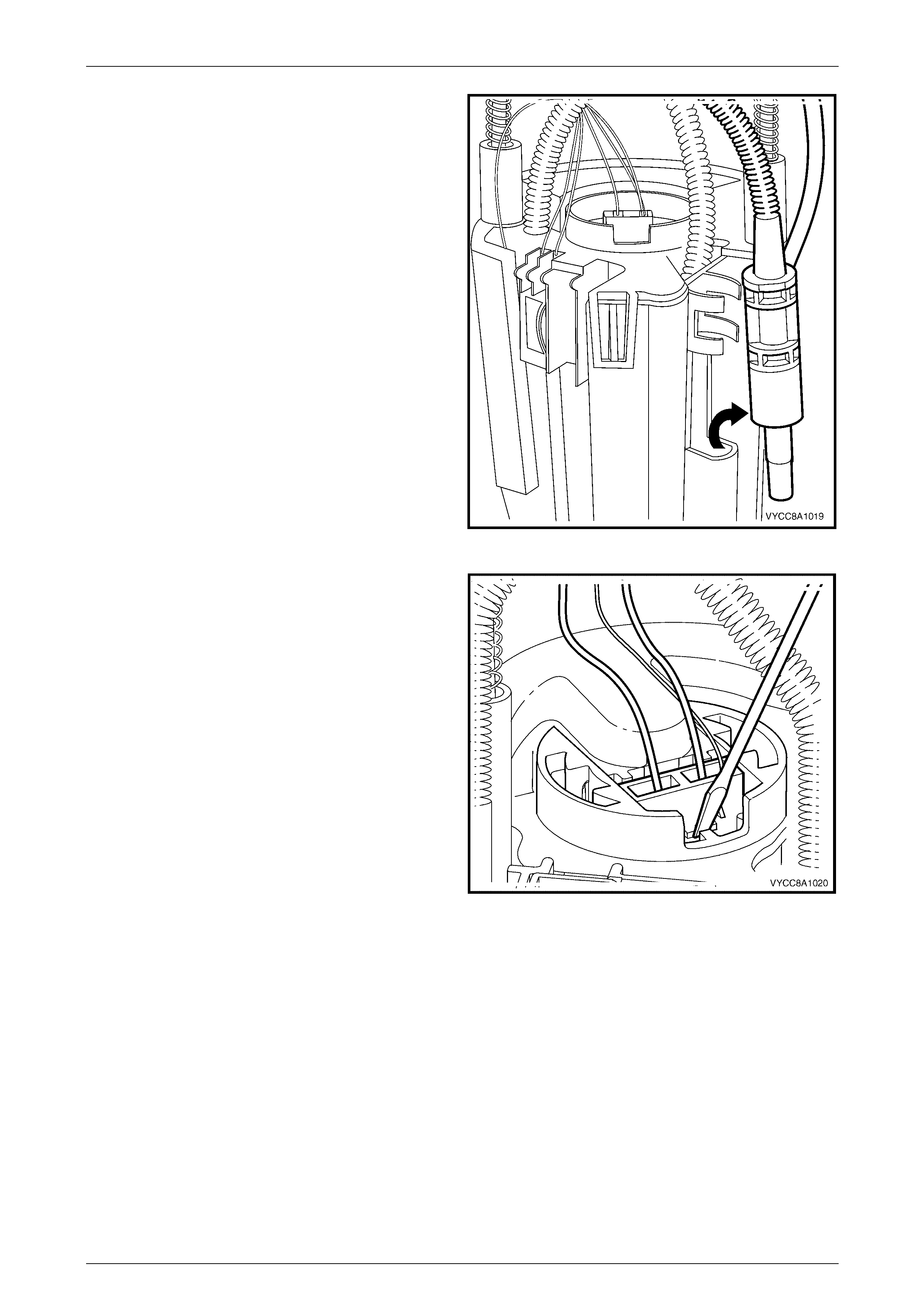

6 Disengage the fuel feed line quick-connect fitting (1)

using special tool AU533 (3/8-inch).

7 Disengage the fuel return line quick-connect fitting (2)

using special tool AU533 (5/16-inch).

NOTE

For information on quick-connect fittings for cab

chassis vehicles, refer to MY 2003 VY and V2

Series Service Information, Section 8A1 Fuel

Tank, 2.10 Quick-connect Fittings.

Figure 8A1 – 20

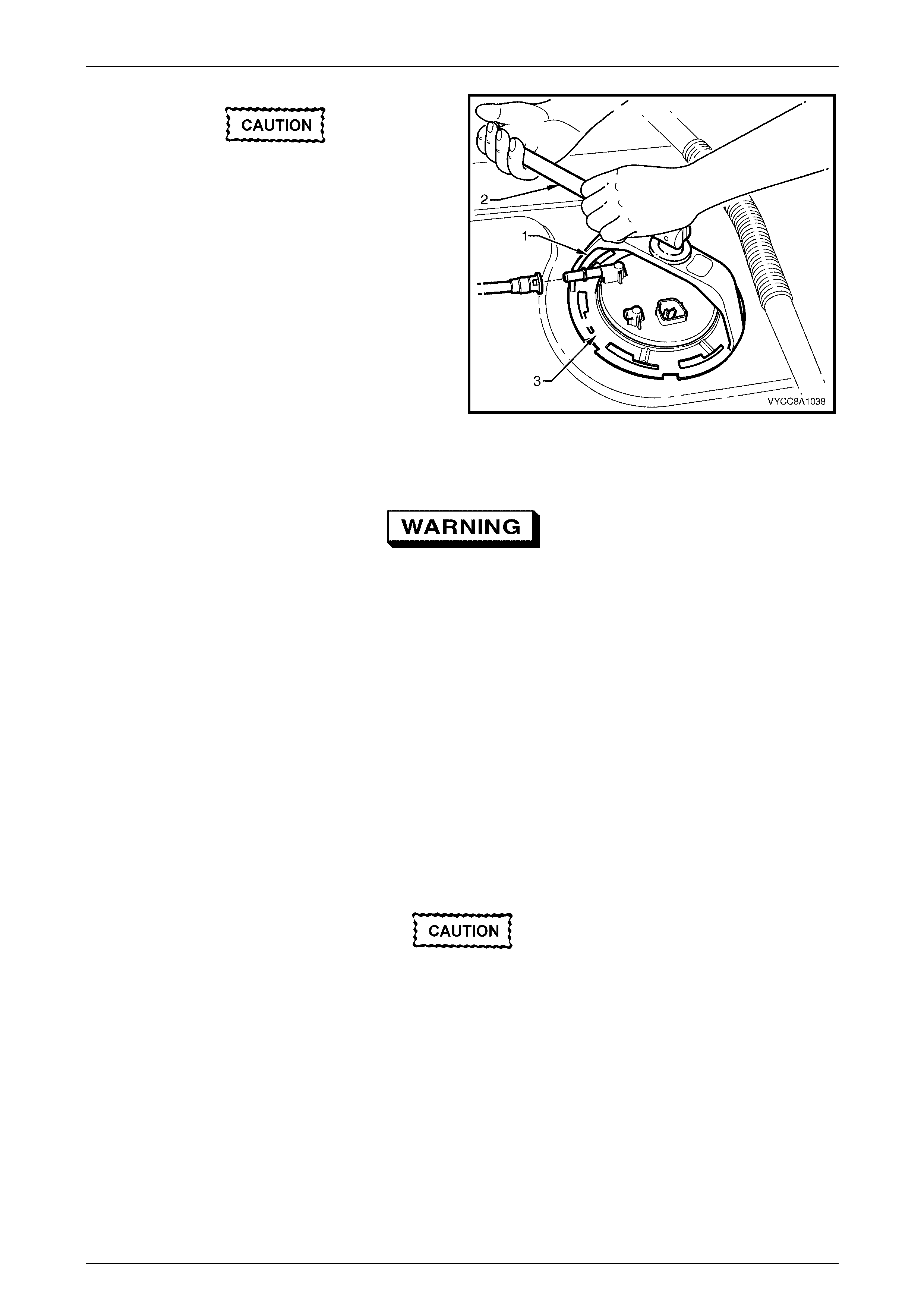

Ensure special tool J45722 is seated firmly

and positively in the modular fuel pump and

sender assembly cover retainer lock ring

while removing the modular fuel pump and

sender assembly.

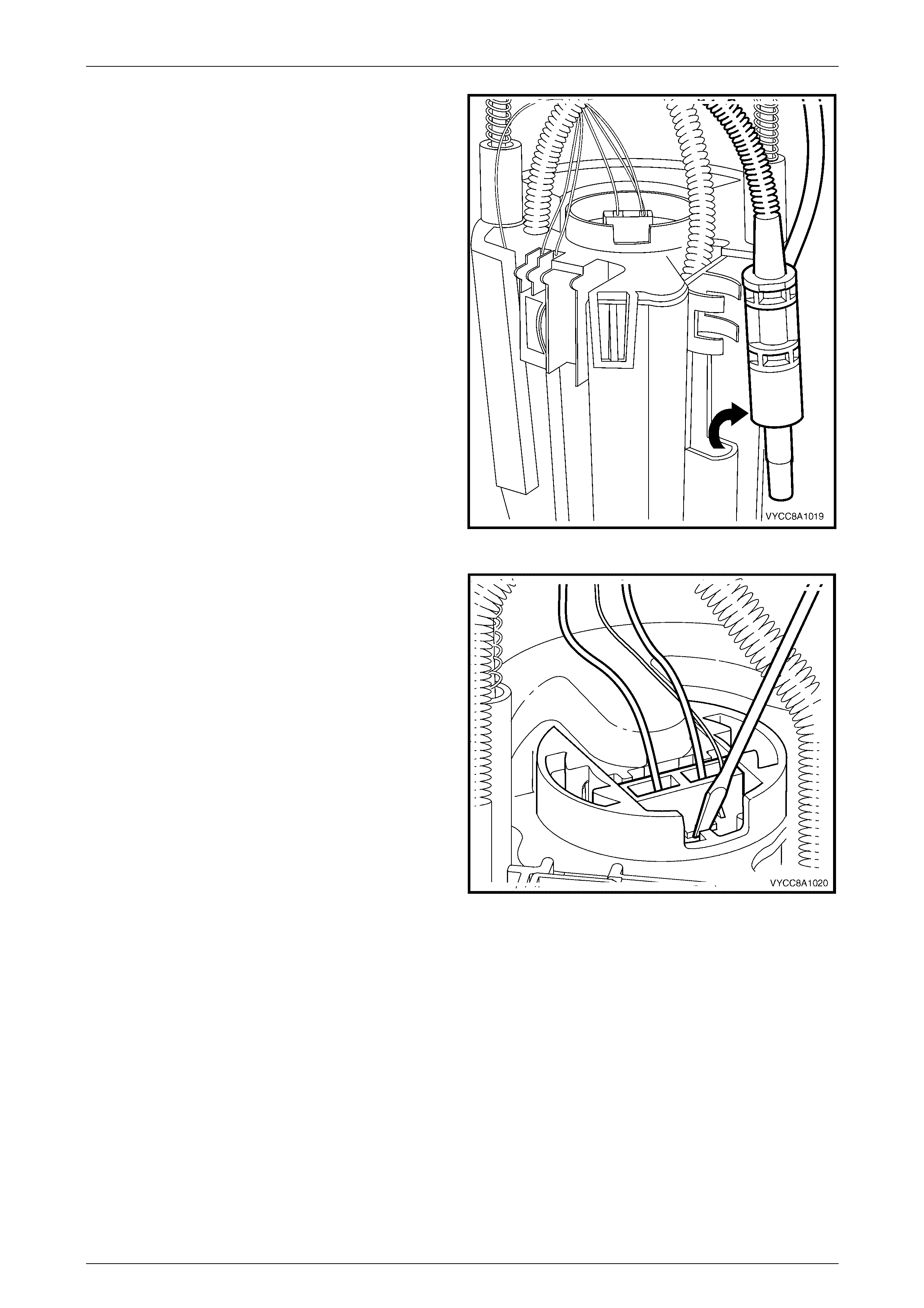

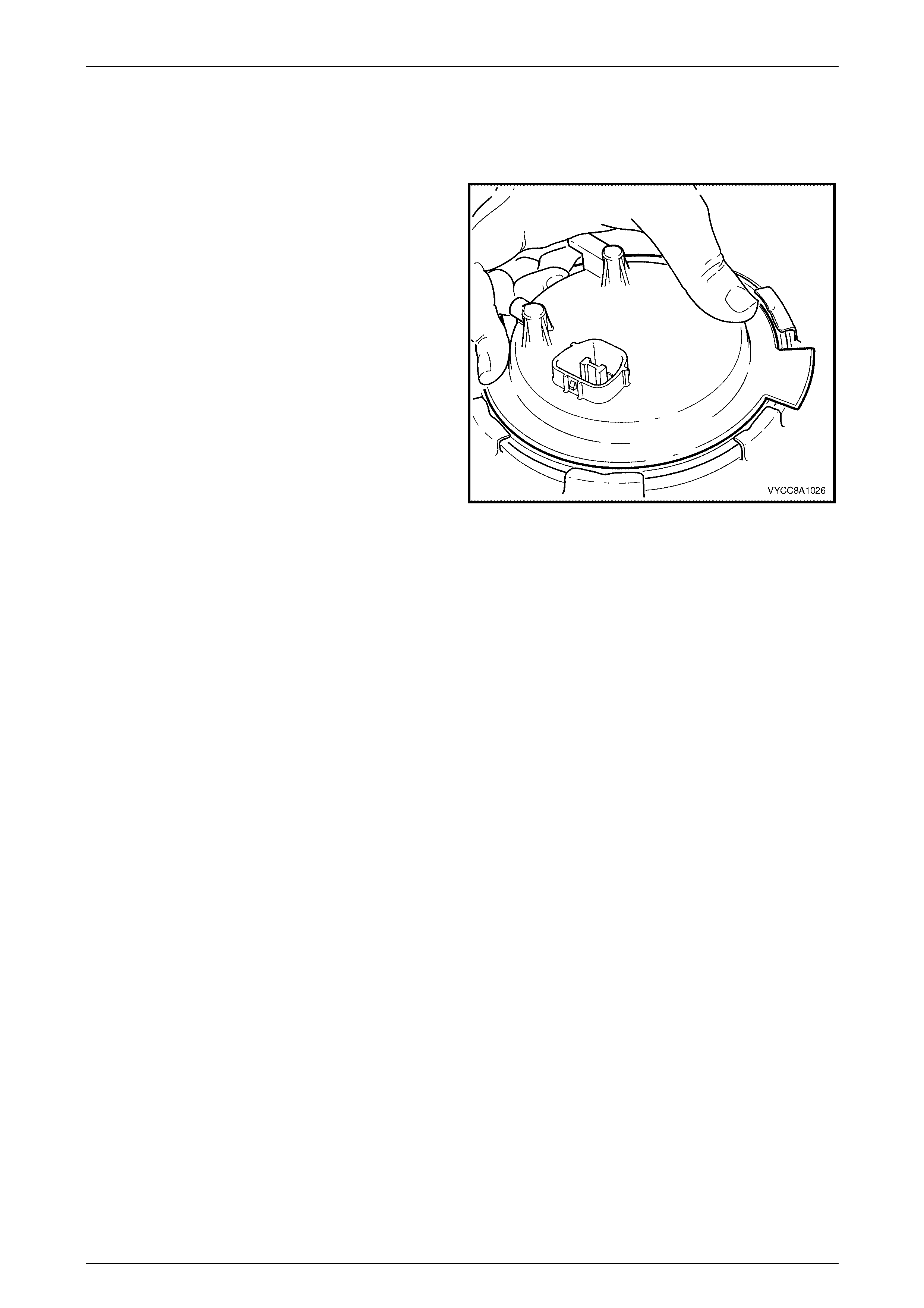

8 Using special tool J45722 (1) and a half-inch breaker

bar (2), remove the modular fuel pump and sender

assembly cover retainer lock ring (3) by turning in an

anti-clockwise direction.

9 Remove the modular fuel pump and sender assembly

cover retainer lock ring.

NOTE

The modular fuel pump and sender assembly

cover springs up when the retainer is removed.

Figure 8A1 – 21

The reservoir will be full of fuel. When the

modular fuel pump and sender assembly is

removed from the fuel tank, pour any

remaining fuel in the reservoir into a suitable

container. Do not drain or store fuel into an

open container, due to the possibility of fire

or explosion.

10 Carefully lift the modular fuel pump and sender assembly from the fuel tank, taking care not to:

• damage the fuel level sender float and arm, and

• spill any fuel remaining in the reservoir.

Fuel Tank Page 8A1–22

Page 8A1–22

NOTE

The fuel sender float arm is not serviced

separately. If damaged, it is replaced as part of

the fuel level sender assembly.

Fuel vapour remains in the tank even when

completely empty. Seal all the openings in

the fuel tank using suitable material or a

suitable plastic plug.

11 Place a suitable material over the opening in the fuel tank to prevent any foreign matter from entering the fuel

system.

12 Remove and discard the sealing O-ring and spacer.

Test

Fuel Level Sender

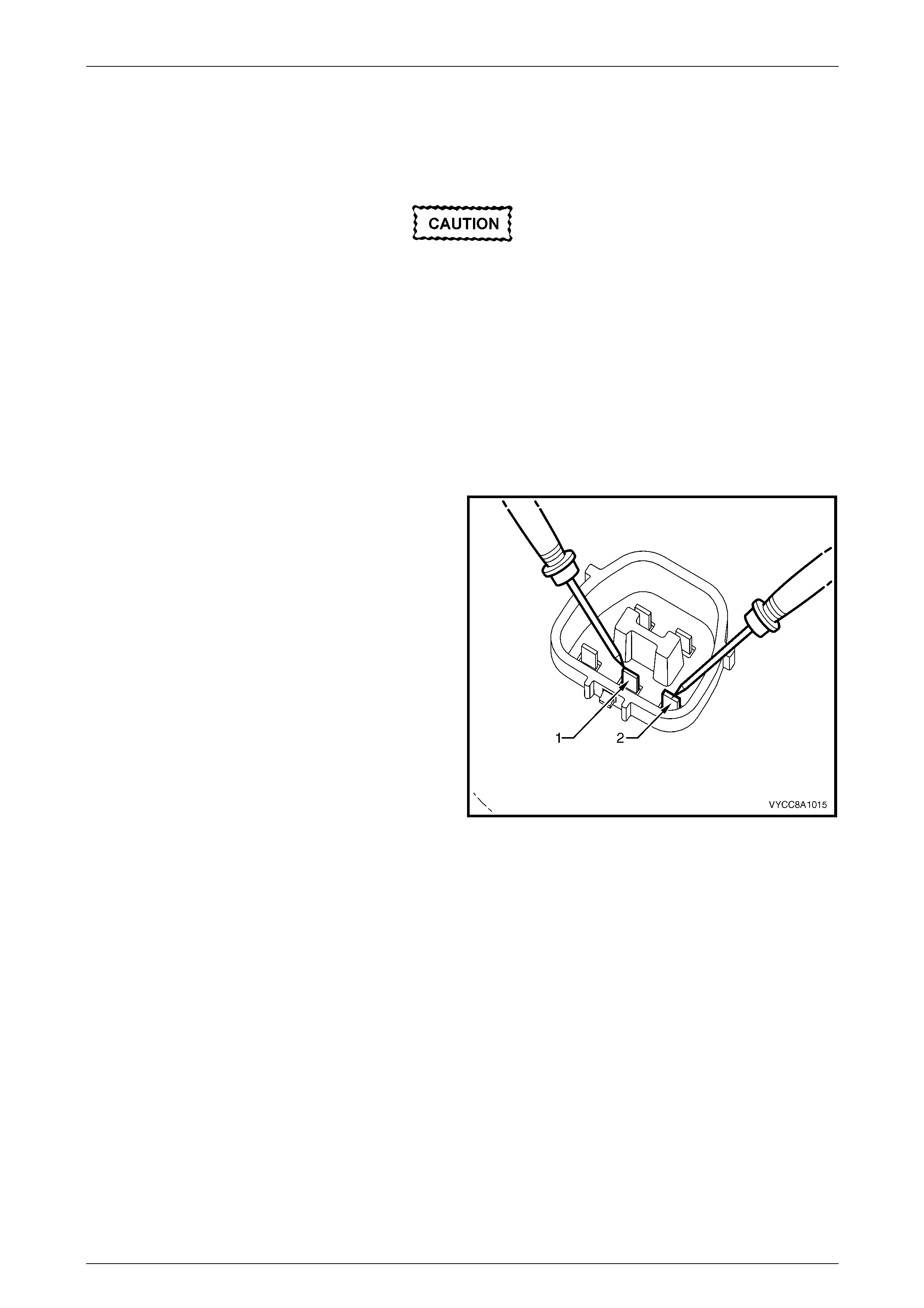

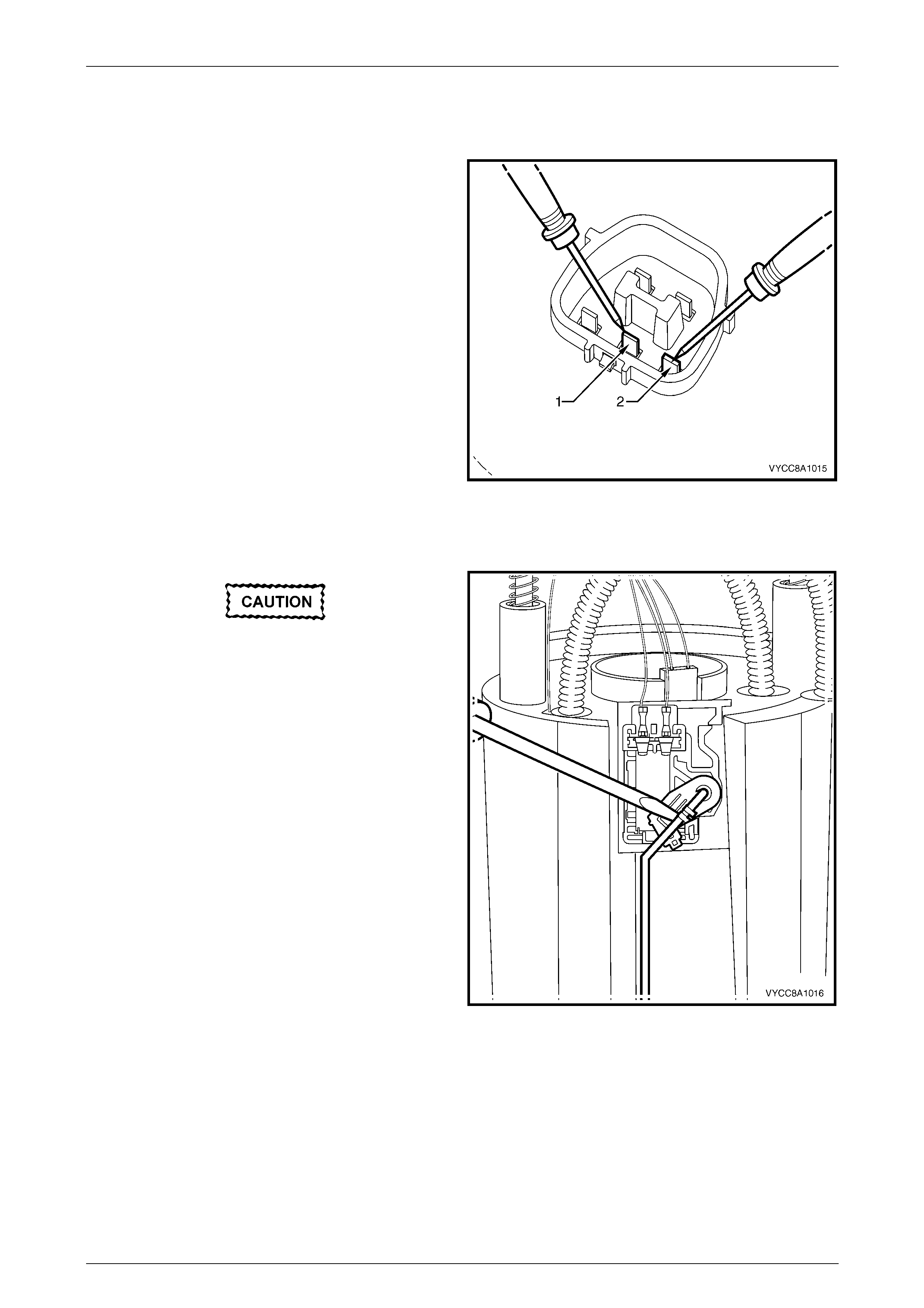

1 Measure the resistance across the positive (1) and

negative (2) fuel level sender terminals of the fuel

pump motor connector. Take the following

measurements:

a With the fuel level sender assembly in the empty

position, the resistance should be 40 ohms

(+/–2.5 ohms).

b With the fuel level sender assembly rotated to

the full position, the resistance should be

248.5 ohms (+/–3.3 ohms).

2 If the resistance at either of these positions is not

within tolerance, replace the fuel level sender

assembly, refer to 2.7 Fuel Level Sender Assembly.

Figure 8A1 – 22

Fuel Tank Page 8A1–23

Page 8A1–23

Disassemble

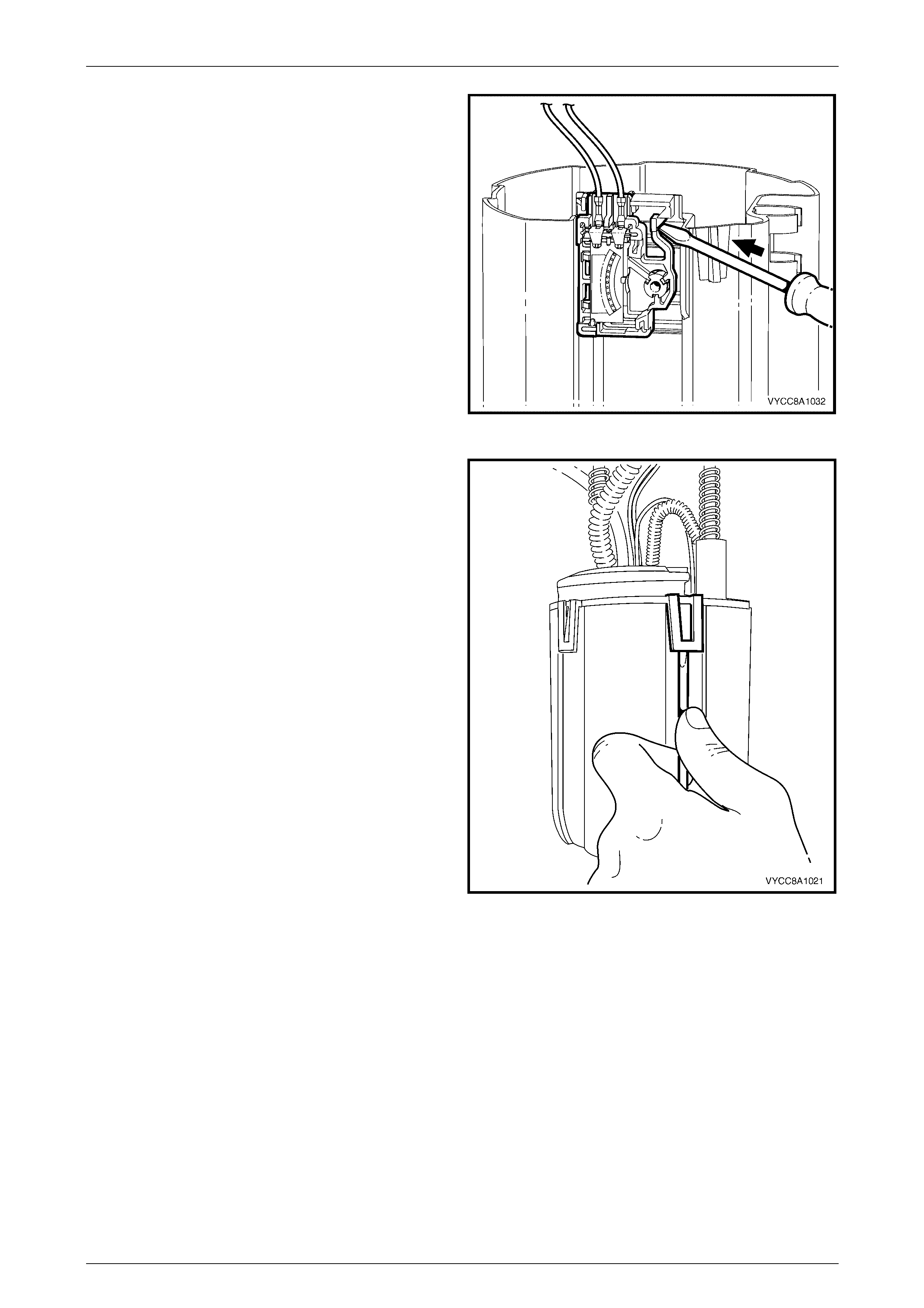

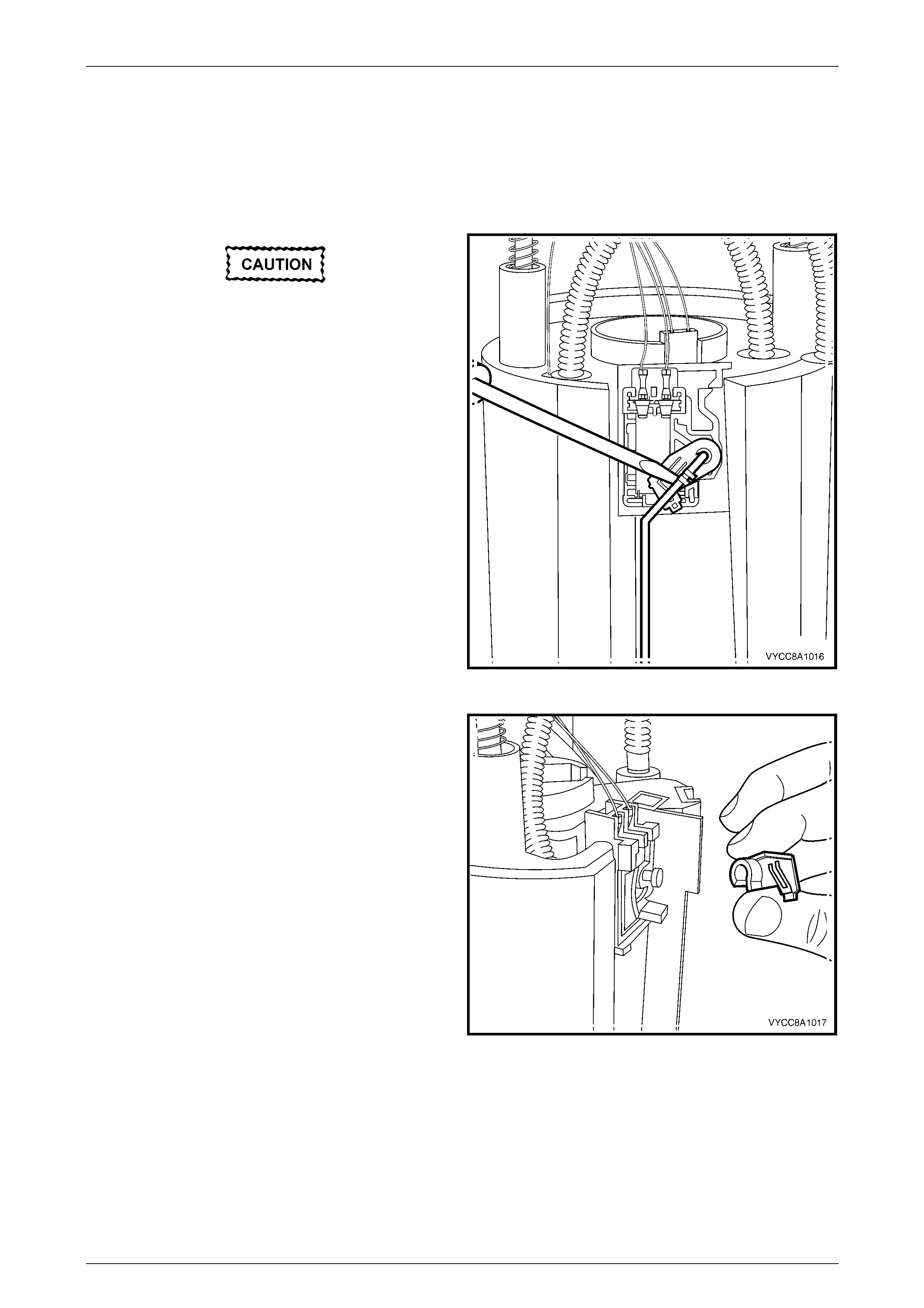

Do not touch the variable resistor card; if it is

touched inadvertently, clean it immediately

with isopropyl alcohol.

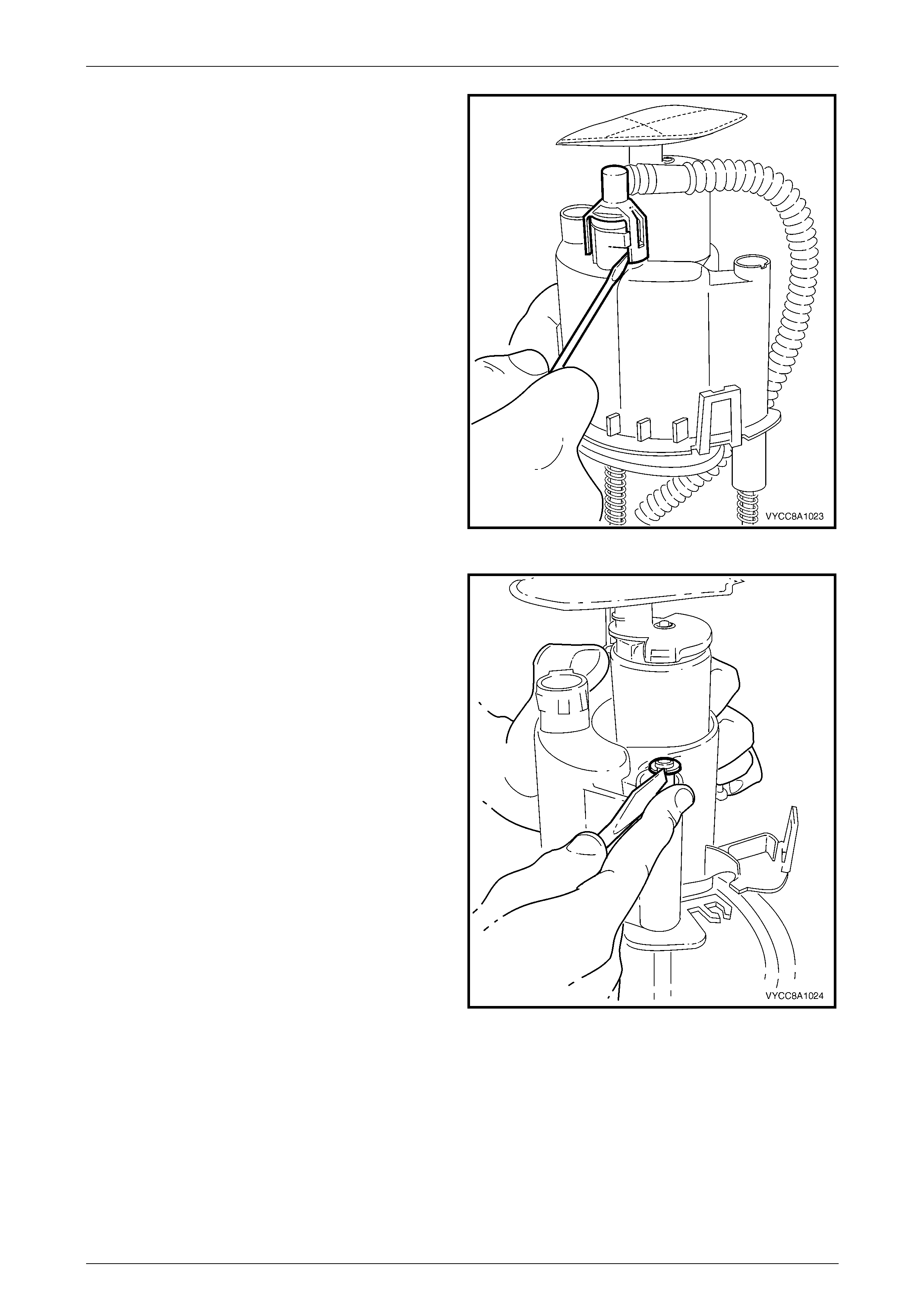

1 Prise the tang open that holds the fuel level sender

float and arm onto the nylon wiper piece.

2 Lift the fuel level sender float and arm away from the

nylon wiper piece and place in a safe location away

from the immediate worksite.

Figure 8A1 – 23

3 Lift the nylon wiper piece off the variable resistor card

holder, then place in a safe location away from the

immediate worksite.

Figure 8A1 – 24

Fuel Tank Page 8A1–24

Page 8A1–24

4 Remove the 3-pin connector (the fuel level sender

assembly wires) from underneath the modular fuel

pump and sender assembly cover.

Figure 8A1 – 25

5 Remove the 2-pin connector (the fuel pump motor

wires) from underneath the modular fuel pump and

sender assembly cover.

Figure 8A1 – 26

Fuel Tank Page 8A1–25

Page 8A1–25

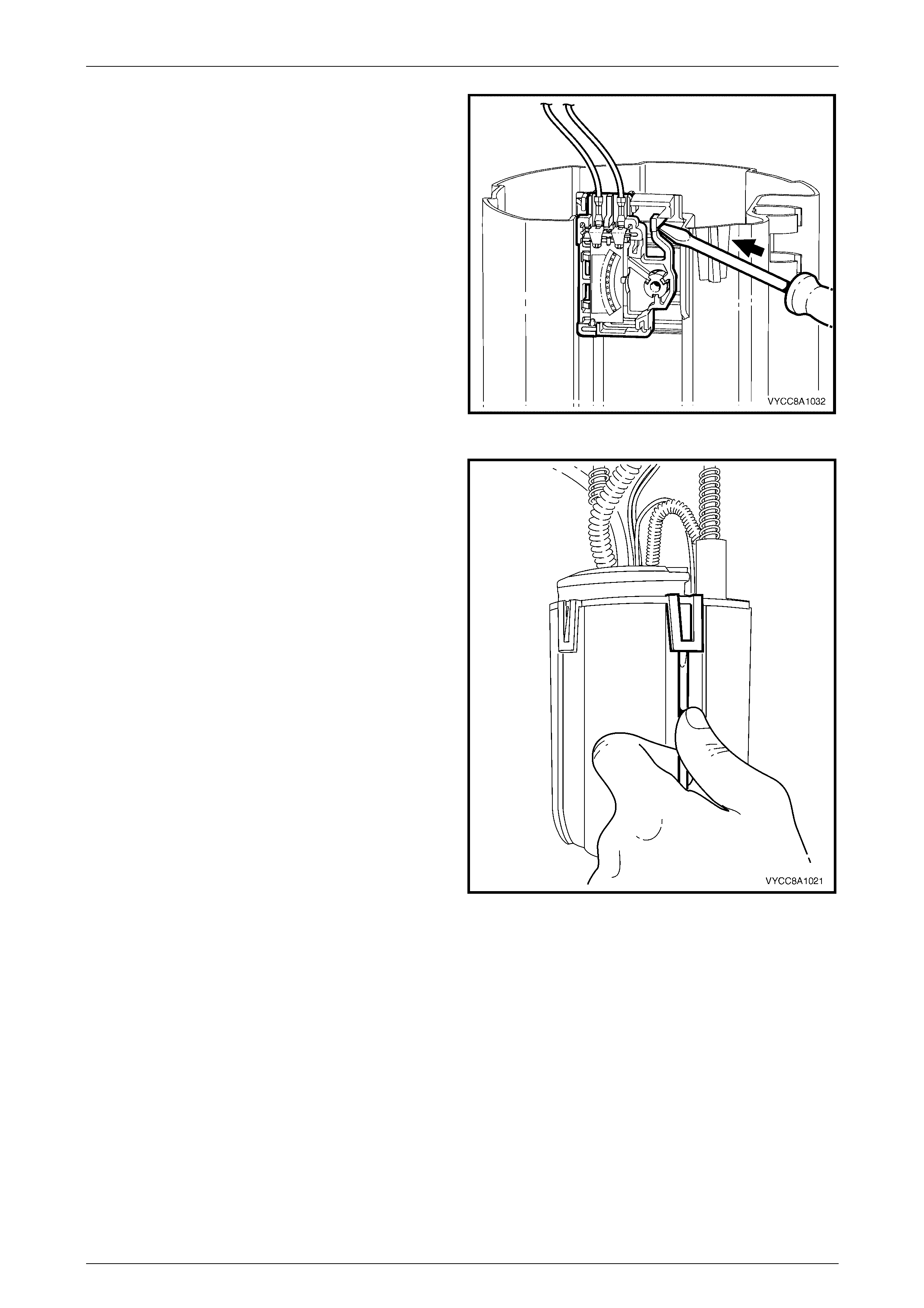

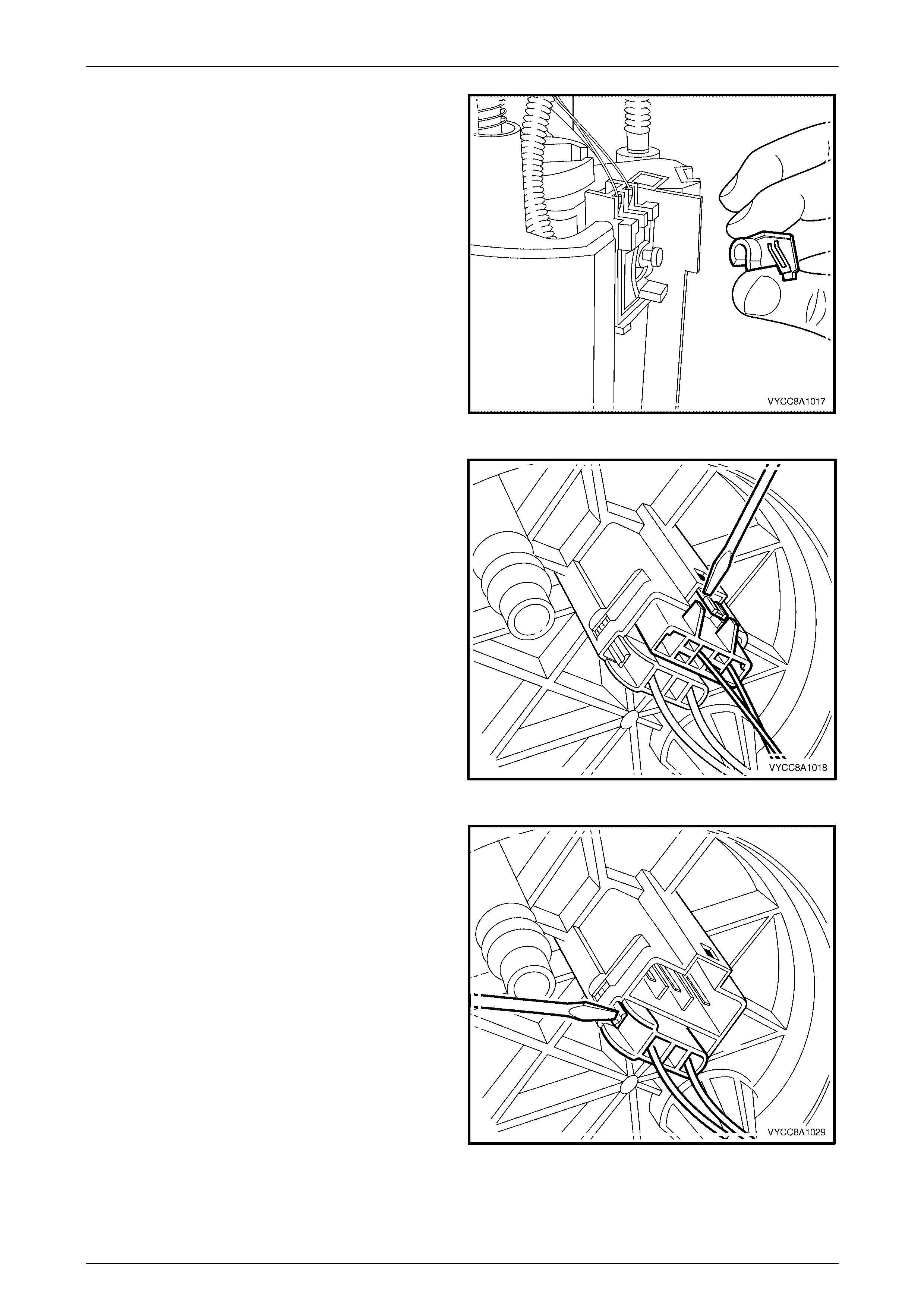

6 Prise the transfer jet pump from the clips, then remove

from the reservoir.

Figure 8A1 – 27

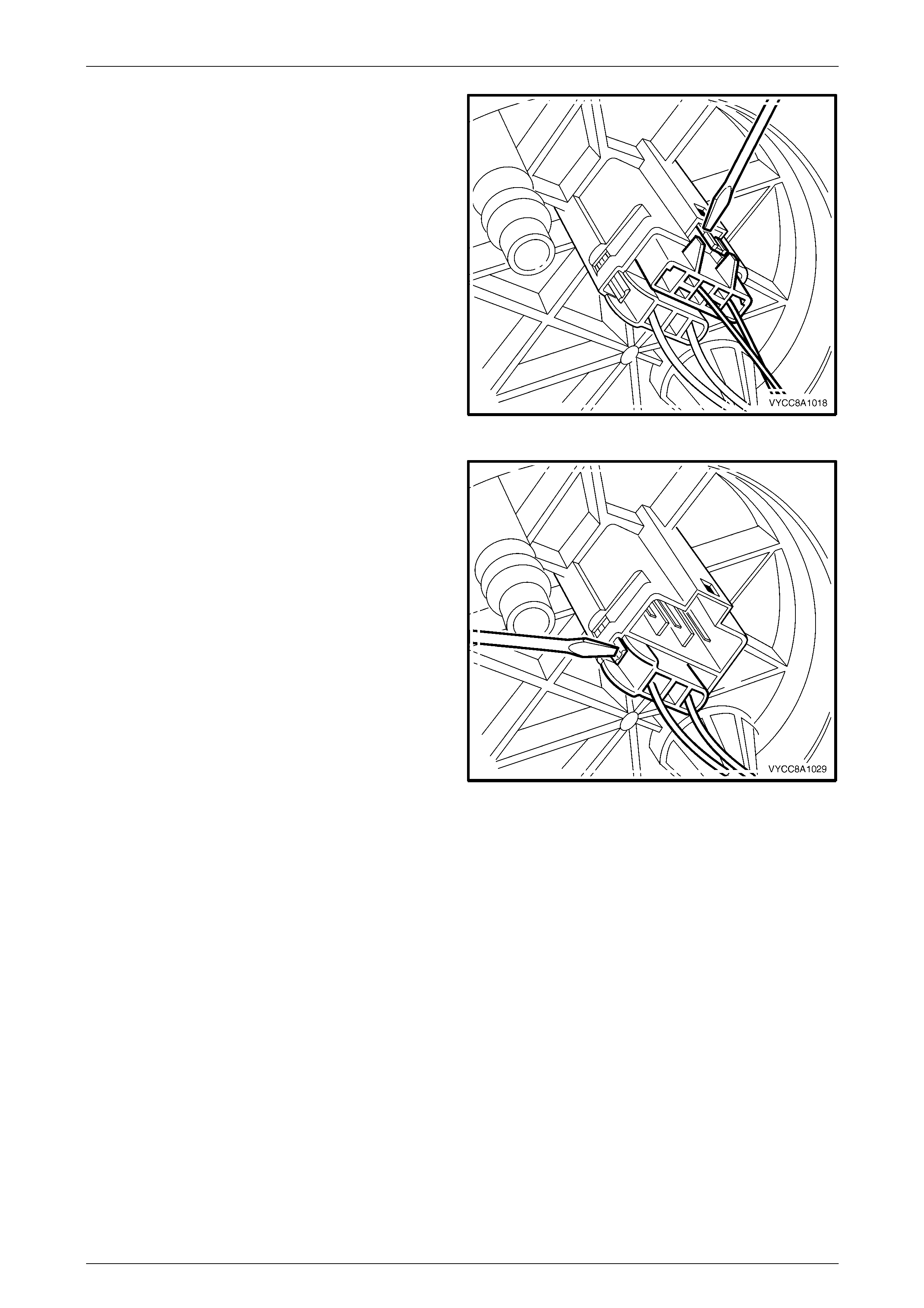

7 Press in the tang retaining the 2-pin connector on the

fuel pump and suction filter assembly, then remove

the connector.

Figure 8A1 – 28

Fuel Tank Page 8A1–26

Page 8A1–26

8 Prise the tang open that holds the variable resistor

card holder to the side of the reservoir, then lift it off

the reservoir.

Figure 8A1 – 29

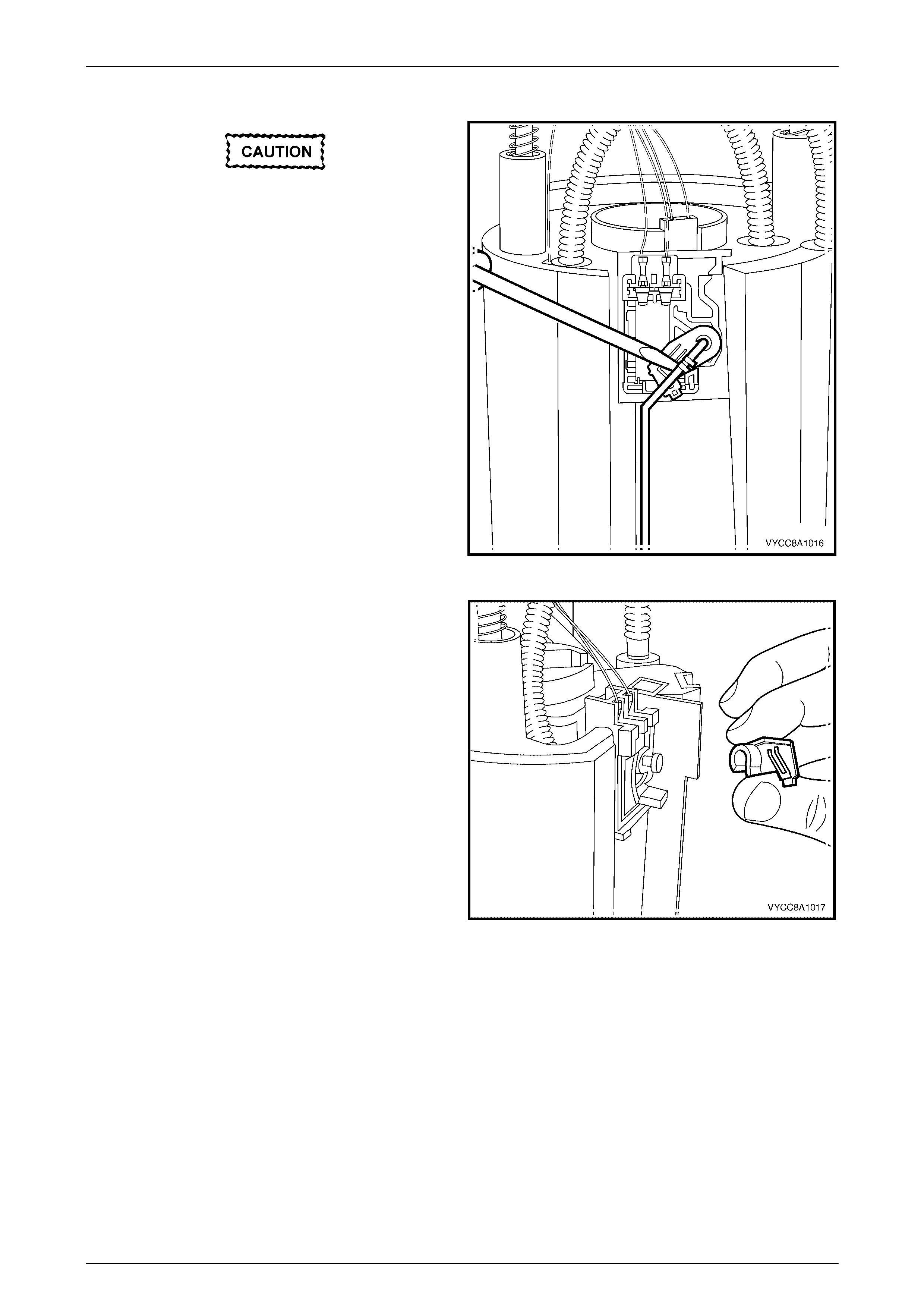

9 Prise the four tangs with a flat-bladed screwdriver,

then remove the fuel pump and suction filter

assembly, and modular fuel pump and sender

assembly cover from the reservoir.

NOTE

Another person may have to assist in removing

the fuel pump and suction filter assembly from

the reservoir.

Figure 8A1 – 30

Fuel Tank Page 8A1–27

Page 8A1–27

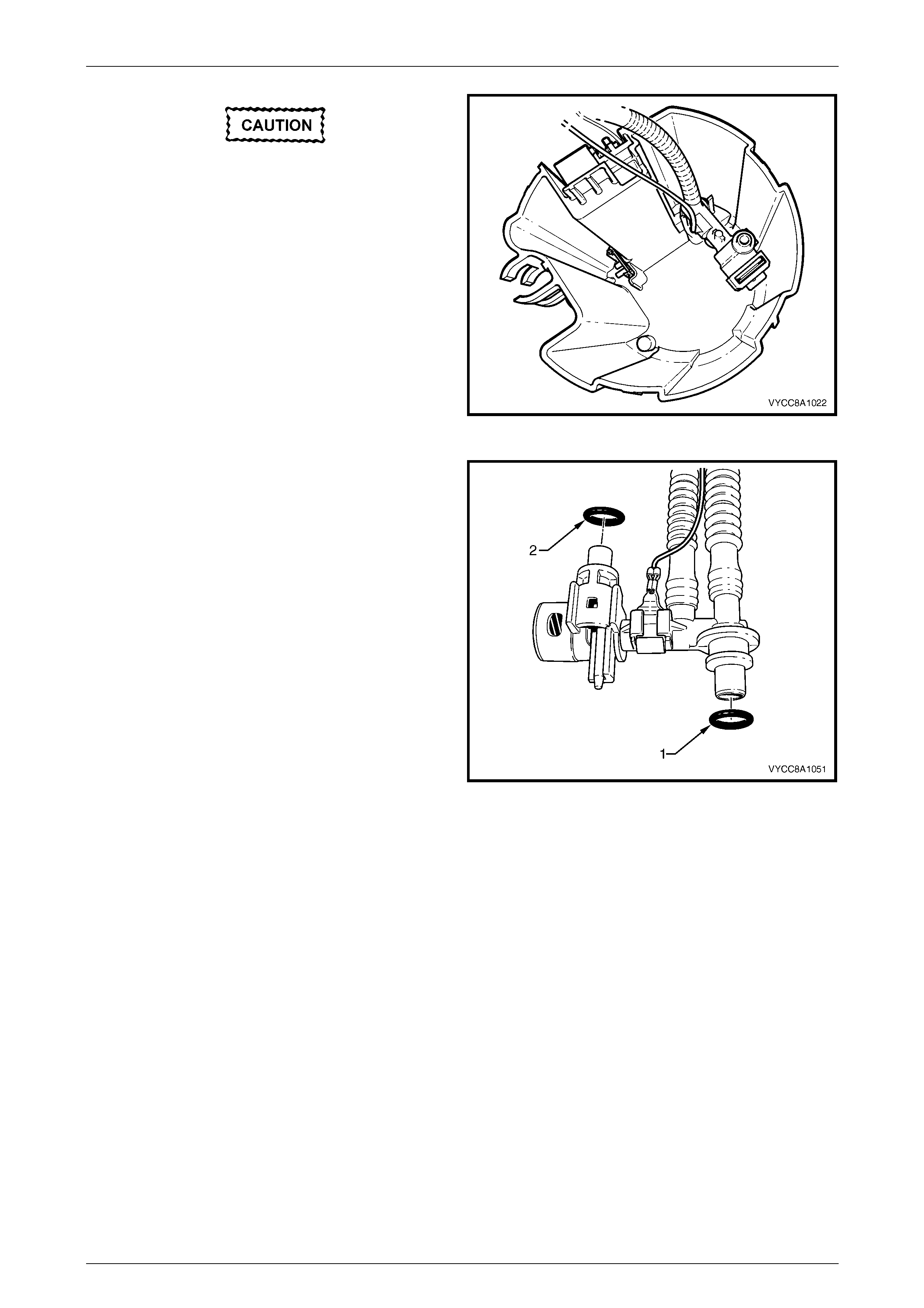

Do not bend the spade connector on the

pressure regulator holder; this can be easily

damaged or broken.

10 Pull the modular fuel pump and sender assembly

cover, fuel pump and suction filter assembly, pressure

regulator holder, and fuel feed pipe and fuel return

pipe from the reservoir body.

NOTE

Some difficulty may be experienced when lifting

these items from the reservoir body due to the

limited space available.

Figure 8A1 – 31

11 Remove and discard the O-ring (1) from the bottom of

the pressure regulator holder.

NOTE

The O-ring may be lodged in the reservoir body.

12 Remove and discard the O-ring (2) from the top of the

pressure regulator holder.

NOTE

The O-ring may be lodged either in the base of

the fuel pump and suction filter assembly.

Figure 8A1 – 32

Fuel Tank Page 8A1–28

Page 8A1–28

13 Prise open both tangs on the fuel outlet connector on

the bottom of the fuel pump and suction filter

assembly, then remove the fuel outlet pipe from the

fuel pump and suction filter assembly.

14 Remove and discard the O-ring from the fuel feed line

outlet underneath the fuel pump and suction filter

assembly.

NOTE

The O-ring may remain in the base of the fuel

pump and suction filter assembly.

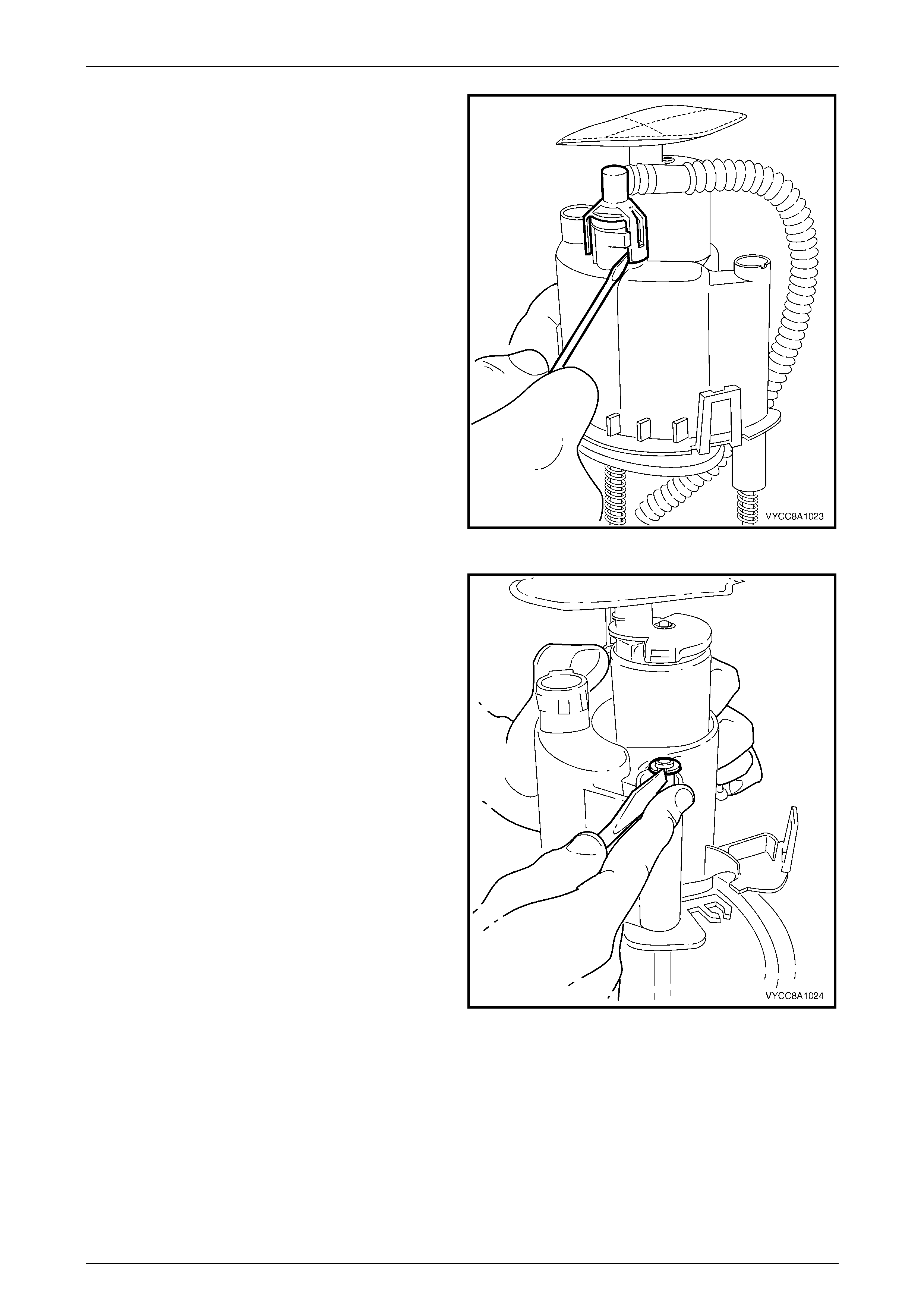

Figure 8A1 – 33

15 Push the fuel pump and suction filter assembly down

the sprung shafts and remove the circlip (only one

shaft is fitted with a circlip) from the end of the shaft.

Place the circlip in a safe location away from the

immediate worksite.

Figure 8A1 – 34

Fuel Tank Page 8A1–29

Page 8A1–29

Reassemble

The procedure for reassembling the modular fuel pump and sender assembly is the reverse of the disassembly

procedure, noting the following:

1 Locate and press the fuel outlet connector to its

position on the bottom of the fuel pump and suction

filter assembly (looping the fuel outlet pipe through the

recess near the right-side top when the fuel filter

assembly is on the side facing away from you).

Figure 8A1 – 35

2 Ensure the wires to both electrical connectors and the variable resistor card are inboard of the fuel feeder pipe.

3 Ensure the wires to the variable resistor card and both connectors do not interfere when reassembling the fuel

pump and suction filter assembly into the reservoir.

Reinstall

The procedure for reinstalling the modular fuel pump and sender assembly is the reverse of the removal procedure,

noting the following:

1 Position a new O-ring seal in the fuel tank recess.

2 Rest the modular fuel pump and sender assembly on a flat surface.

3 Measure the distance between the centre of the fuel sender float and the flat surface.

4 Ensure the centre of the fuel level sender float is a nominal 18.5 mm above the surface. If not, carefully bend the

fuel level sender float arm to achieve the required distance.

Fuel Tank Page 8A1–30

Page 8A1–30

NOTE

Do not damage the fuel level sender float and

arm when placing the modular fuel pump and

sender assembly into the fuel tank.

5 Ensure the low fuel level feed pipe is located in the

fuel tank correctly (that is, on the side of the baffle

furthest away from the modular fuel pump and sender

assembly).

6 Ensure the locator in the modular fuel pump and

sender assembly cover engages in the slot in the tank

opening.

Figure 8A1 – 36

Fuel Tank Page 8A1–31

Page 8A1–31

2.5 Modular Fuel Pump and Sender

Assembly — GEN III V8

Remove

A depressurised fuel system contains fuel in

the fuel filter and fuel lines that can be spilled

during service operations.

Fuel vapour remains in the fuel tank even

when completely empty. Seal all openings in

the fuel tank using suitable material or a

plastic plug. Ensure no naked flames or other

ignition sources are nearby. Ensure all

mobile phones (and transmission devices

that may cause any metal objects to become

unintentional receiving antennas) are

switched off.

Wear safety glasses when using compressed

air. Do not blow compressed air directly onto

any body part.

1 Remove the tray, refer to Section 1B1, Tray.

2 Use compressed air to ensure that all dirt and foreign materials are removed from all fuel connections before the

parts are disconnected.

Techline

Fuel Tank Page 8A1–32

Page 8A1–32

Before proceeding, clean all traces of dirt and

other foreign material from the top of the fuel

tank, near the modular fuel pump and sender

assembly.

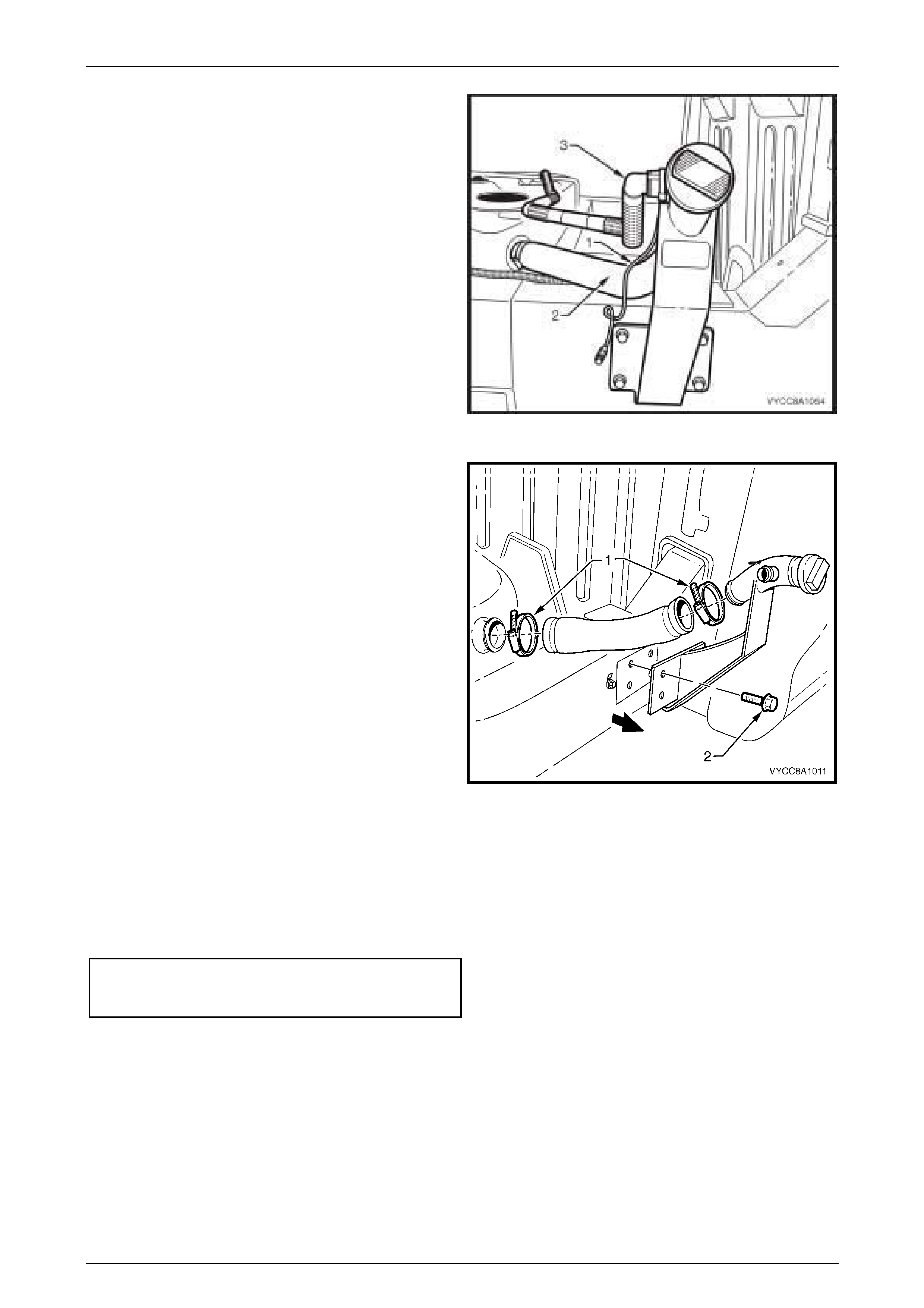

3 Disconnect the modular fuel pump and sender

assembly harness connector (1).

4 Tag the fuel feed line connecting the fuel feed port (2)

on top of the modular fuel pump and sender

assembly.

Figure 8A1 – 37

5 Disengage the fuel feed line quick-connect fitting (1)

using special tool AU533 (3/8-inch).

NOTE

For information on quick-connect fittings for cab

chassis vehicles, refer to MY 2003 VY and V2

Series Service Information, Section 8A1 Fuel

Tank, 2.10 Quick-connect Fittings.

Figure 8A1 – 38

Fuel Tank Page 8A1–33

Page 8A1–33

Ensure special tool J45722 is seated firmly

and positively in the modular fuel pump and

sender assembly cover retainer lock ring

while removing the modular fuel pump and

sender assembly.

6 Using special tool J45722 (1) and a half-inch breaker

bar (2), remove the modular fuel pump and sender

assembly cover retainer lock ring (3) by turning in an

anti-clockwise direction.

7 Remove the modular fuel pump and sender assembly

cover retainer lock ring.

NOTE

The modular fuel pump and sender assembly

cover springs up when the retainer is removed.

Figure 8A1 – 39

The reservoir will be full of fuel. When the

modular fuel pump and sender assembly is

removed from the fuel tank, pour any

remaining fuel in the reservoir into a suitable

container. Do not drain or store fuel into an

open container, due to the possibility of fire

or explosion.

8 Carefully lift the modular fuel pump and sender assembly from the fuel tank, taking care not to:

• damage the fuel level sender float and arm, and

• spill any fuel remaining in the reservoir.

NOTE

The fuel sender float arm is not serviced

separately. If damaged, it is replaced as part of

the fuel level sender assembly.

Fuel vapour remains in the tank even when

completely empty. Seal all the openings in

the fuel tank using suitable material or a

suitable plastic plug.

9 Place a suitable material over the plugged opening in the fuel tank to prevent any foreign matter from entering the

fuel system.

10 Remove and discard the sealing O-ring and spacer.

Fuel Tank Page 8A1–34

Page 8A1–34

Test

Fuel Level Sender

1 Measure the resistance across the positive (1) and

negative (2) fuel level sender terminals of the fuel

pump motor connector. Take the following

measurements:

a With the fuel level sender assembly in the empty

position, the resistance should be 40 ohms

(+/–2.5 ohms).

b With the fuel level sender assembly rotated to

the full position, the resistance should be

248.5 ohms (+/–3.3 ohms).

2 If the resistance at either of these positions is not

within tolerance, replace the fuel level sender

assembly, refer to 2.7 Fuel Level Sender Assembly.

Figure 8A1 – 40

Disassemble

Do not touch the variable resistor card; if it is

touched inadvertently, clean it immediately

with isopropyl alcohol.

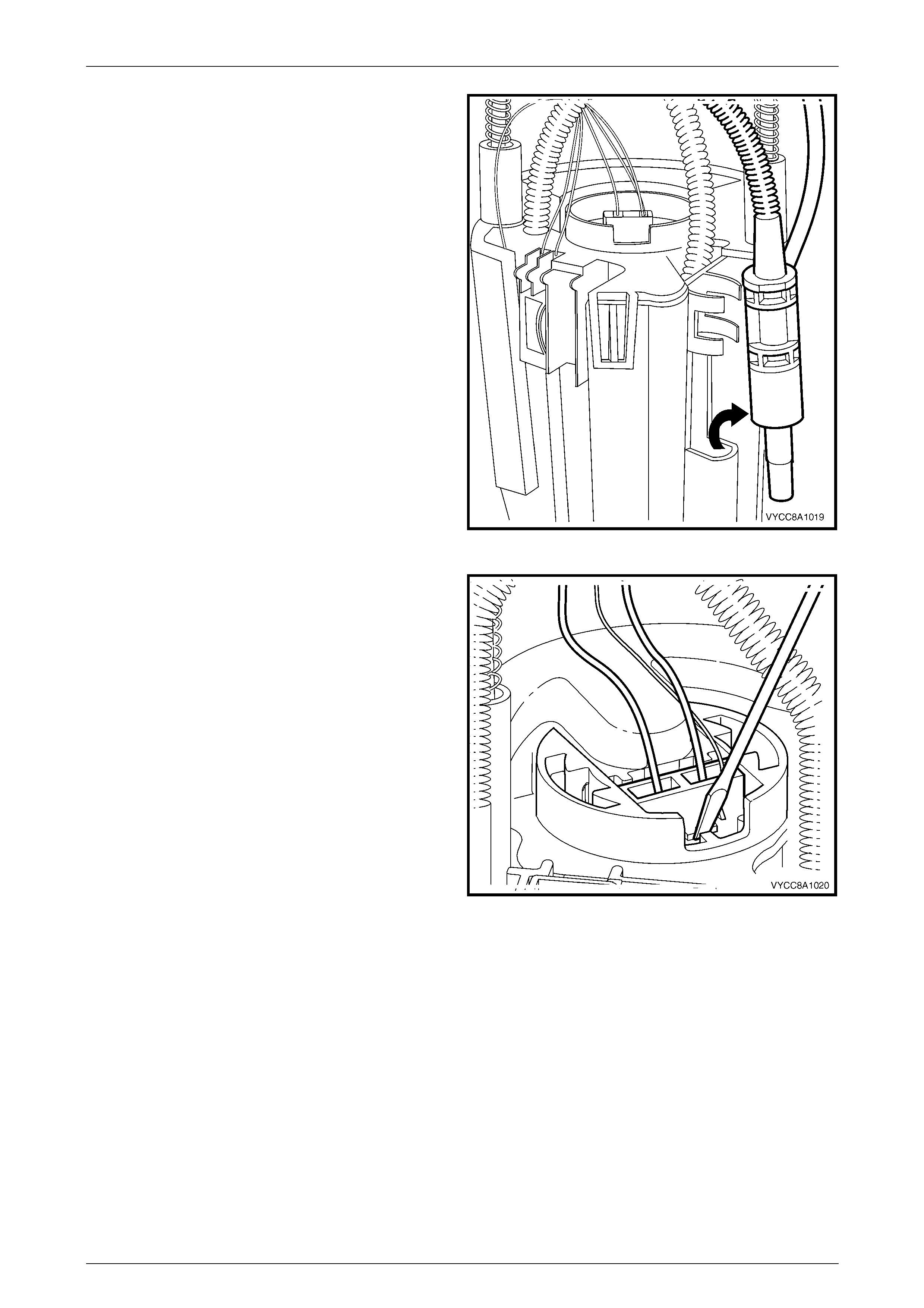

1 Prise the tang open that holds the fuel level sender

float and arm onto the nylon wiper piece.

2 Lift the fuel level sender float and arm away from the

nylon wiper piece and place in a safe location away

from the immediate worksite.

Figure 8A1 – 41

Fuel Tank Page 8A1–35

Page 8A1–35

3 Lift the nylon wiper piece off the variable resistor card

holder, then place in a safe location away from the

immediate worksite.

Figure 8A1 – 42

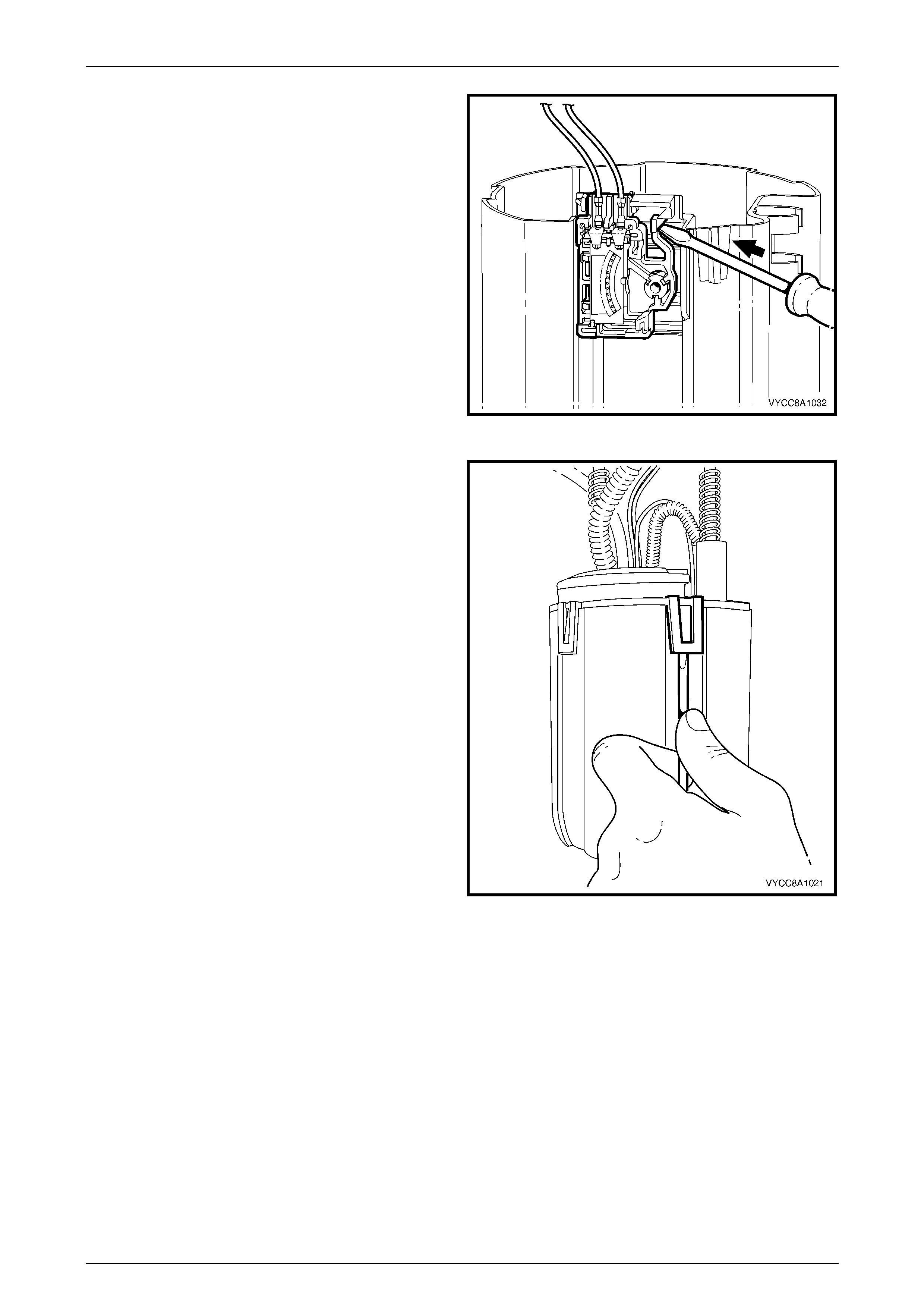

4 Remove the 3-pin connector (the fuel level sender

assembly wires) from underneath the modular fuel

pump and sender assembly cover.

Figure 8A1 – 43

5 Remove the 2-pin connector (the fuel pump motor

wires) from underneath the modular fuel pump and

sender assembly cover.

Figure 8A1 – 44

Fuel Tank Page 8A1–36

Page 8A1–36

6 Prise the transfer jet pump from the clips, then remove

from the reservoir.

Figure 8A1 – 45

7 Press in the tang retaining the 2-pin connector on the

fuel pump and suction filter assembly, then remove

the connector.

Figure 8A1 – 46

Fuel Tank Page 8A1–37

Page 8A1–37

8 Prise the tang open that holds the variable resistor

card holder to the side of the reservoir, then lift it off

the reservoir.

Figure 8A1 – 47

9 Prise the four tangs with a flat-bladed screwdriver,

then remove the fuel pump and suction filter

assembly, and modular fuel pump and sender

assembly cover from the reservoir.

NOTE

Another person may have to assist in removing

the fuel pump and suction filter assembly from

the reservoir.

Figure 8A1 – 48

Fuel Tank Page 8A1–38

Page 8A1–38

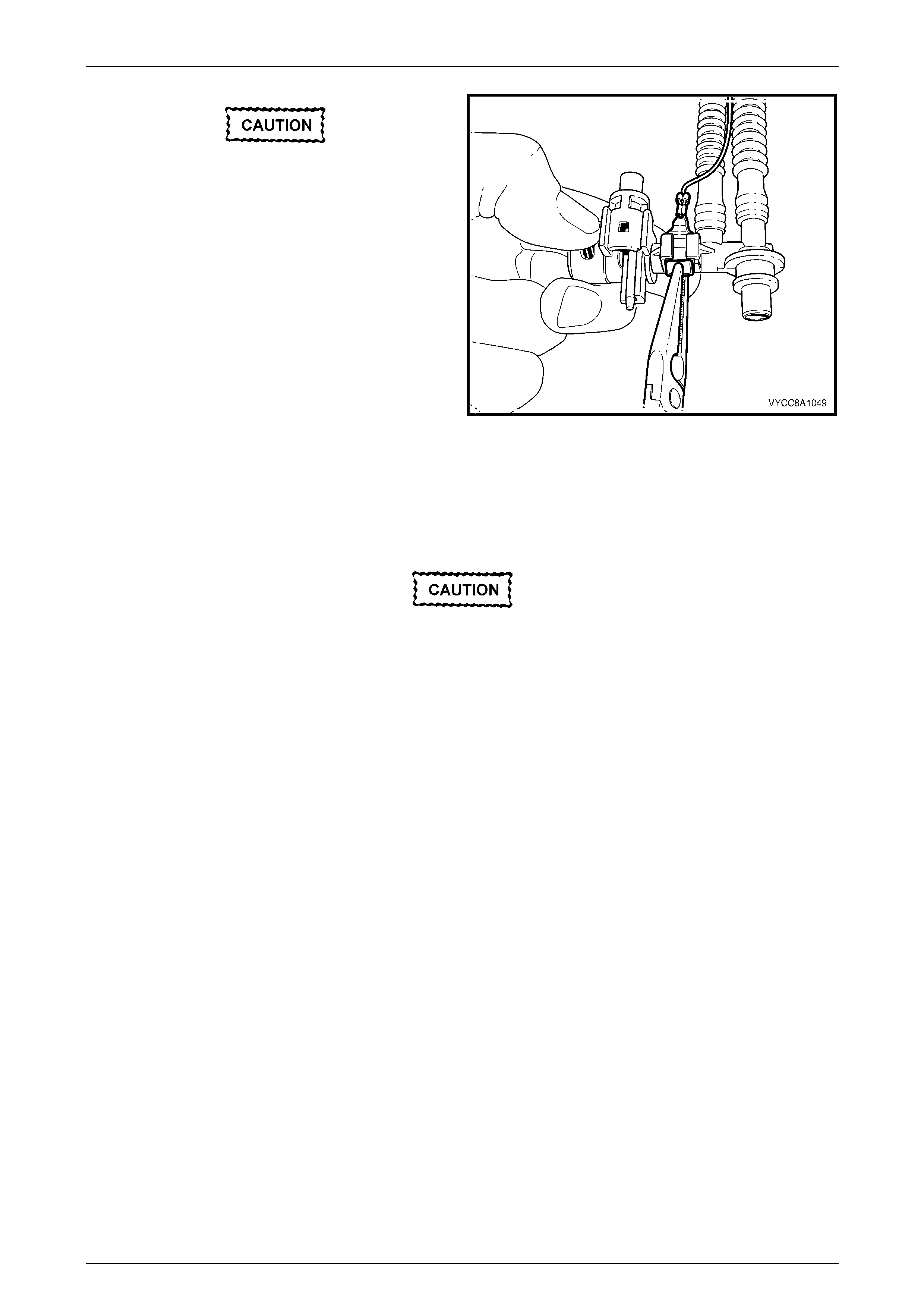

Do not bend the spade connector on the

pressure regulator holder; this can be easily

damaged or broken.

10 Pull the modular fuel pump and sender assembly

cover, fuel pump and suction filter assembly, pressure

regulator holder and fuel feed pipe from the reservoir

body.

NOTE

Some difficulty may be experienced when lifting

these items from the reservoir body due to the

limited space available.

Figure 8A1 – 49

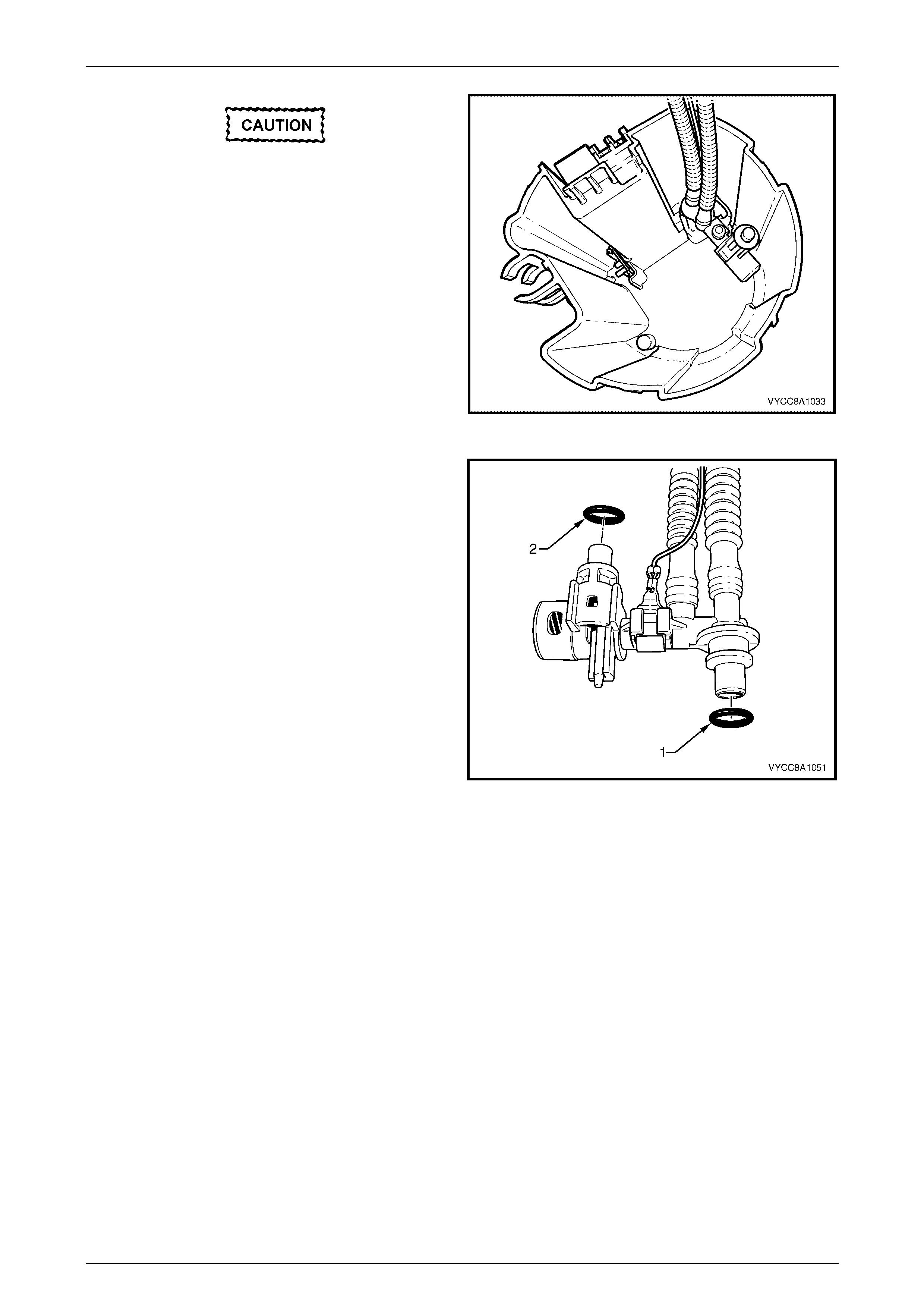

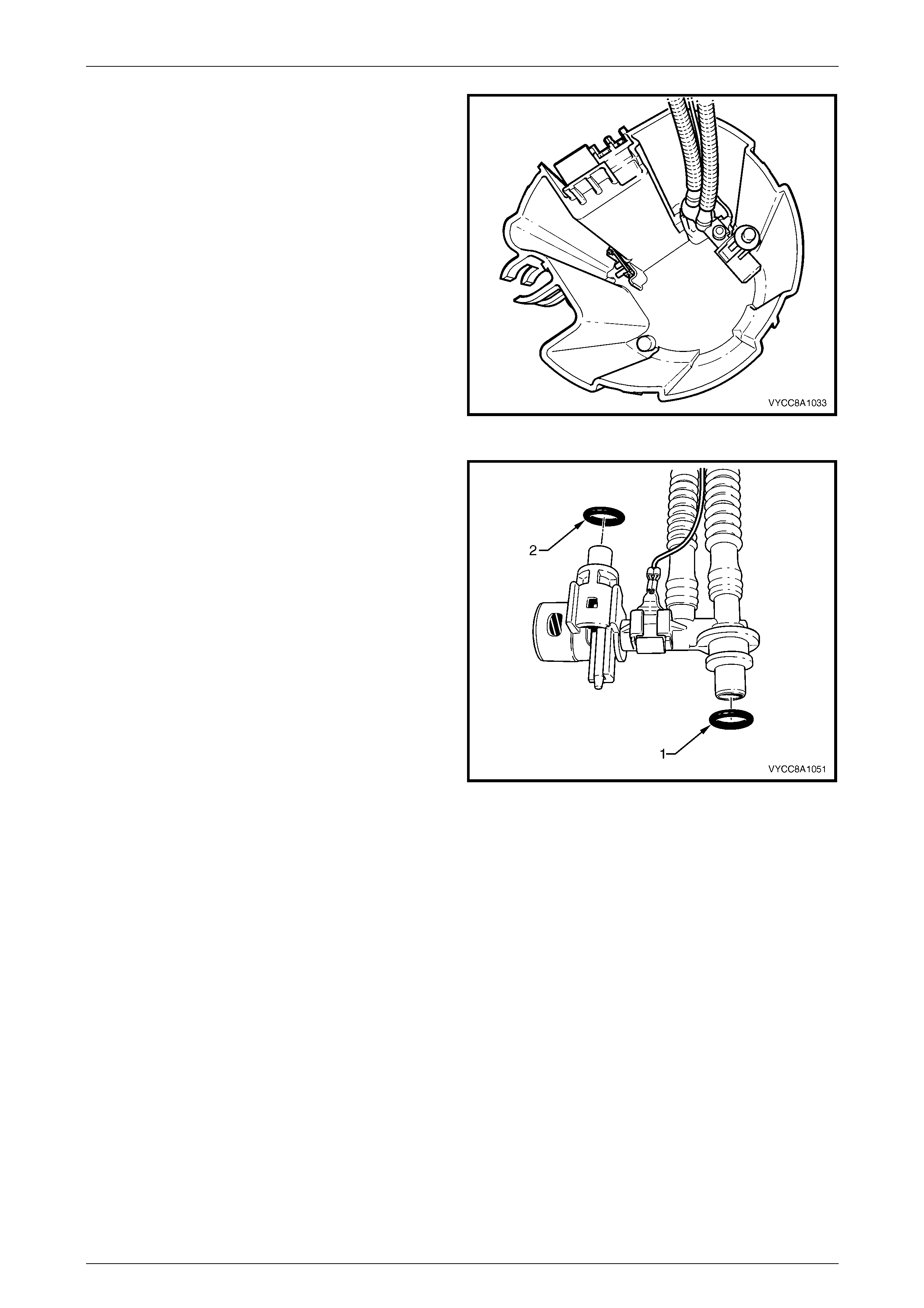

11 Remove and discard the O-ring (1) from the bottom of

the pressure regulator holder.

NOTE

The O-ring may be lodged in the reservoir body.

12 Remove and discard the O-ring (2) from the top of the

pressure regulator holder.

NOTE

The O-ring may be lodged either in the base of

the fuel pump and suction filter assembly.

Figure 8A1 – 50

Fuel Tank Page 8A1–39

Page 8A1–39

13 Prise open both tangs on the fuel outlet connector on

the bottom of the fuel pump and suction filter

assembly, then remove the fuel outlet pipe from the

fuel pump and suction filter assembly.

14 Remove and discard the O-ring from the fuel feed line

outlet underneath the fuel pump and suction filter

assembly.

NOTE

The O-ring may remain in the base of the fuel

pump and suction filter assembly.

Figure 8A1 – 51

15 Push the fuel pump and suction filter assembly down

the sprung shafts and remove the circlip (only one

shaft is fitted with a circlip) from the end of the shaft.

Place the circlip in a safe location away from the

immediate worksite.

Figure 8A1 – 52

Fuel Tank Page 8A1–40

Page 8A1–40

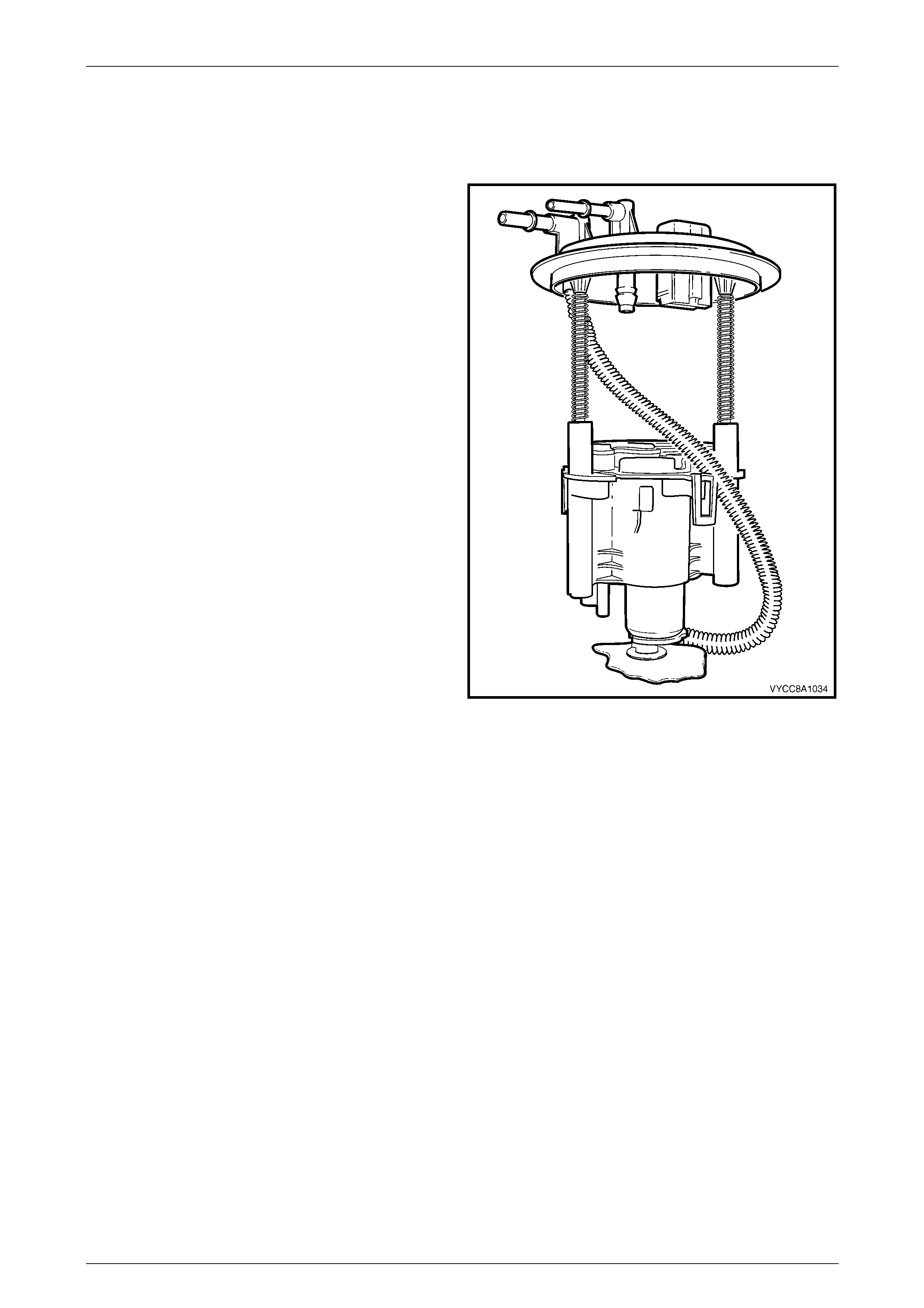

Reassemble

The procedure for reassembling the modular fuel pump and sender assembly is the reverse of the disassembly

procedure, noting the following:

1 Locate and press the fuel outlet connector to its

position on the bottom of the fuel pump and suction

filter assembly (looping the fuel outlet pipe through the

recess near the right-side top when the fuel filter

assembly is on the side facing away from you).

Figure 8A1 – 53

2 Ensure the wires to the variable resistor card, pressure regulator and both connectors are inboard of the fuel

feeder pipe.

3 Ensure the wires to the variable resistor card, pressure regulator and both connectors do not interfere when

reassembling the fuel pump and suction filter assembly into the reservoir.

Reinstall

The procedure for reinstalling the modular fuel pump and sender assembly is the reverse of the removal procedure,

noting the following:

1 Position a new O-ring seal in the fuel tank recess.

2 Rest the modular fuel pump and sender assembly on a flat surface.

3 Measure the distance between the centre of the fuel sender float and the flat surface.

4 Ensure the centre of the fuel level sender float is a nominal 18.5 mm above the surface. If not, carefully bend the

fuel level sender float arm to achieve the required distance.

Fuel Tank Page 8A1–41

Page 8A1–41

NOTE

Do not damage the fuel level sender float and

arm when placing the modular fuel pump and

sender assembly into the fuel tank.

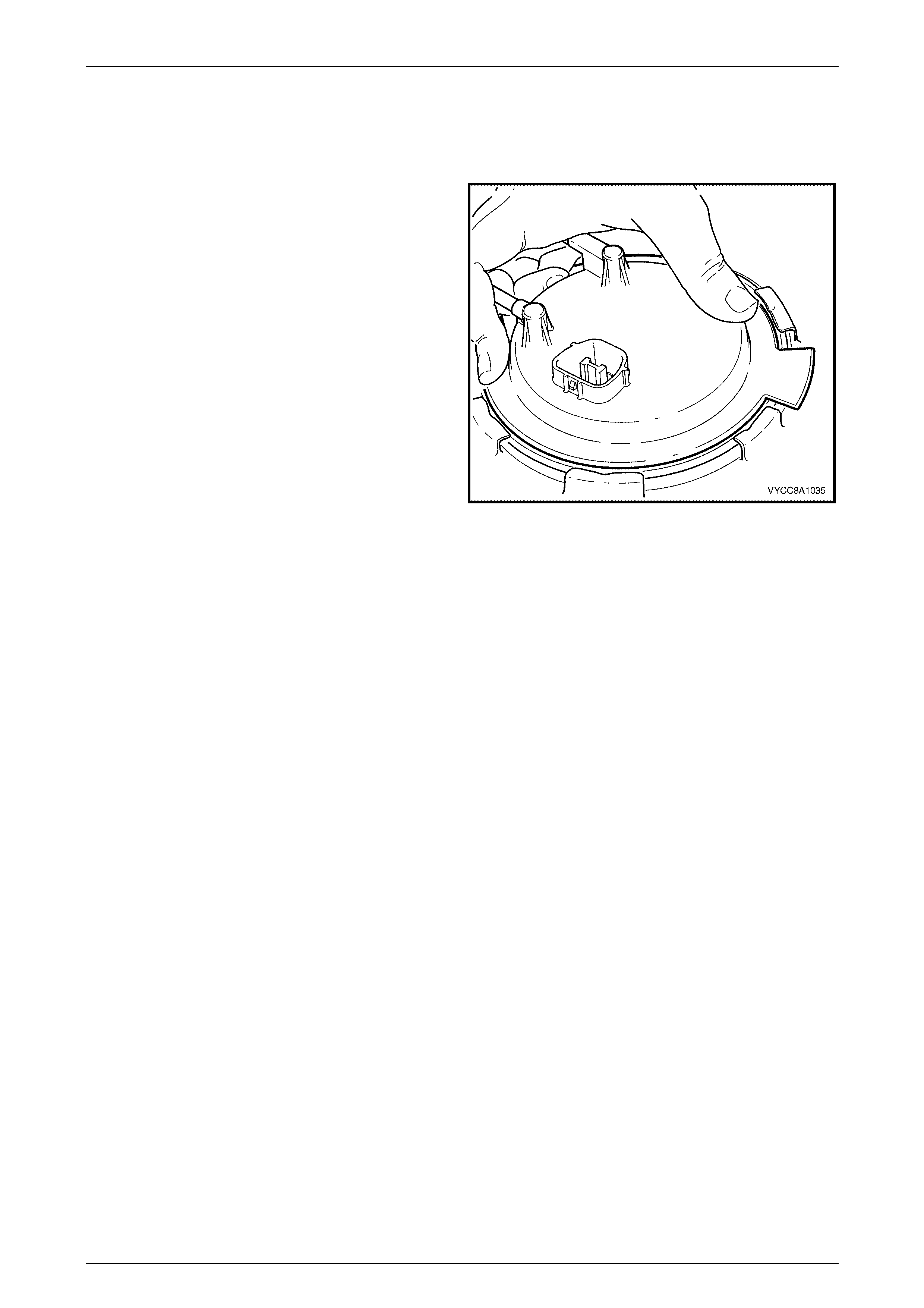

5 Ensure the low fuel level feed pipe is located in the

fuel tank correctly (that is, on the side of the baffle

furthest away from the modular fuel pump and sender

assembly).

6 Ensure the locator in the modular fuel pump and

sender assembly cover engages in the slot in the tank

opening.

Figure 8A1 – 54

Fuel Tank Page 8A1–42

Page 8A1–42

2.6 Fuel Filter Assembly

Remove

Remove the fuel filter assembly from the modular fuel pump and sender assembly, refer to the removal procedure in

2.9 Suction Filter.

Reinstall

Reinstallation of the fuel filter assembly is the reverse of the removal procedure, refer to 2.9 Suction Filter.

Fuel Tank Page 8A1–43

Page 8A1–43

2.7 Fuel Level Sender Assembly

Disassemble

1 Remove the modular fuel pump and sender assembly from the fuel tank, refer to 2.4 Modular Fuel Pump and

Sender Assembly — V6 or 2.5 Modular Fuel Pump and Sender Assembly — GEN III V8.

Do not touch the variable resistor card; if it is

touched inadvertently, clean it immediately

with isopropyl alcohol.

2 Prise the tang open that holds the fuel level sender

float and arm onto the nylon wiper piece.

3 Lift the fuel level sender float and arm away from the

nylon wiper piece and place in a safe location away

from the immediate worksite.

Figure 8A1 – 55

4 Lift the nylon wiper piece off the variable resistor card

holder, then place in a safe location away from the

immediate worksite.

Figure 8A1 – 56

Fuel Tank Page 8A1–44

Page 8A1–44

5 Remove the 3-pin connector (the fuel level sender

assembly wires) from underneath the modular fuel

pump and sender assembly cover.

Figure 8A1 – 57

6 Remove the 2-pin connector (the fuel pump motor

wires) from underneath the modular fuel pump and

sender assembly cover.

Figure 8A1 – 58

Fuel Tank Page 8A1–45

Page 8A1–45

7 Prise the transfer jet pump from the clips, then remove

from the reservoir.

Figure 8A1 – 59

8 Press in the tang retaining the 2-pin connector on the

fuel pump and suction filter assembly, then remove

the connector.

Figure 8A1 – 60

Fuel Tank Page 8A1–46

Page 8A1–46

9 Prise the tang open that holds the variable resistor

card holder to the side of the reservoir, then lift it off

the reservoir.

Figure 8A1 – 61

10 Prise the four tangs with a flat-bladed screwdriver,

then remove the fuel pump and suction filter

assembly, and modular fuel pump and sender

assembly cover from the reservoir.

NOTE

Another person may have to assist in removing

the fuel pump and suction filter assembly from

the reservoir.

Figure 8A1 – 62

Fuel Tank Page 8A1–47

Page 8A1–47

11 Pull the modular fuel pump and sender assembly

cover, fuel pump and suction filter assembly, pressure

regulator holder and fuel feed pipe (and fuel return

pipe in vehicles with the V6 engine) from the reservoir

body.

NOTE

Some difficulty may be experienced when lifting

these items from the reservoir body due to the

limited space available.

Figure 8A1 – 63

11 Remove and discard the O-ring (1) from the bottom of

the pressure regulator holder.

NOTE

The O-ring may be lodged in the reservoir body.

12 Remove and discard the O-ring (2) from the top of the

pressure regulator holder.

NOTE

The O-ring may be lodged either in the base of

the fuel pump and suction filter assembly.

Figure 8A1 – 64

Fuel Tank Page 8A1–48

Page 8A1–48

Do not bend the spade connector on the

pressure regulator holder; this can be easily

damaged or broken.

14 Remove the spade connector from the pressure

regulator holder.

NOTE

The pressure regulator holder for the V6

modular fuel pump and sender assembly is

shown. The spade connector on the GEN III V8

modular fuel pump and sender assembly is on

the opposite side of the pressure regulator

holder.

Figure 8A1 – 65

Reassemble

The procedure for reassembling the fuel level sender assembly is the reverse of the disassembly procedure, noting the

following:

Do not touch the variable resistor card; if it is

touched inadvertently, clean it immediately

with isopropyl alcohol.

NOTE

Do not separate the fuel level sender float arm

from the nylon wiper piece on the replacement

fuel level sender assembly.

Fuel Tank Page 8A1–49

Page 8A1–49

2.8 Pressure Regulator

V6 Engine

NOTE

The pressure regulator in vehicles with the V6

engine is located in the engine bay at the end of

the fuel rail.

Remove

1 Remove the retaining clip from the pressure regulator

holder and place in a safe location away from the

immediate worksite.

2 Prise both halves of the pressure regulator holder

apart and pull the pressure regulator from the

pressure regulator holder.

Figure 8A1 – 66

Reinstall

The procedure for reinstalling the pressure regulator is the reverse of the removal procedure.

Fuel Tank Page 8A1–50

Page 8A1–50

GEN III V8 Engine

Remove

1 Remove the modular fuel pump and sender assembly from the fuel tank, refer to the removal procedure in

2.5 Modular Fuel Pump and Sender Assembly — GEN III V8.

2 Disassemble the modular fuel pump and sender assembly, refer to the disassembly procedure in

2.5 Modular Fuel Pump and Sender Assembly — GEN III V8.

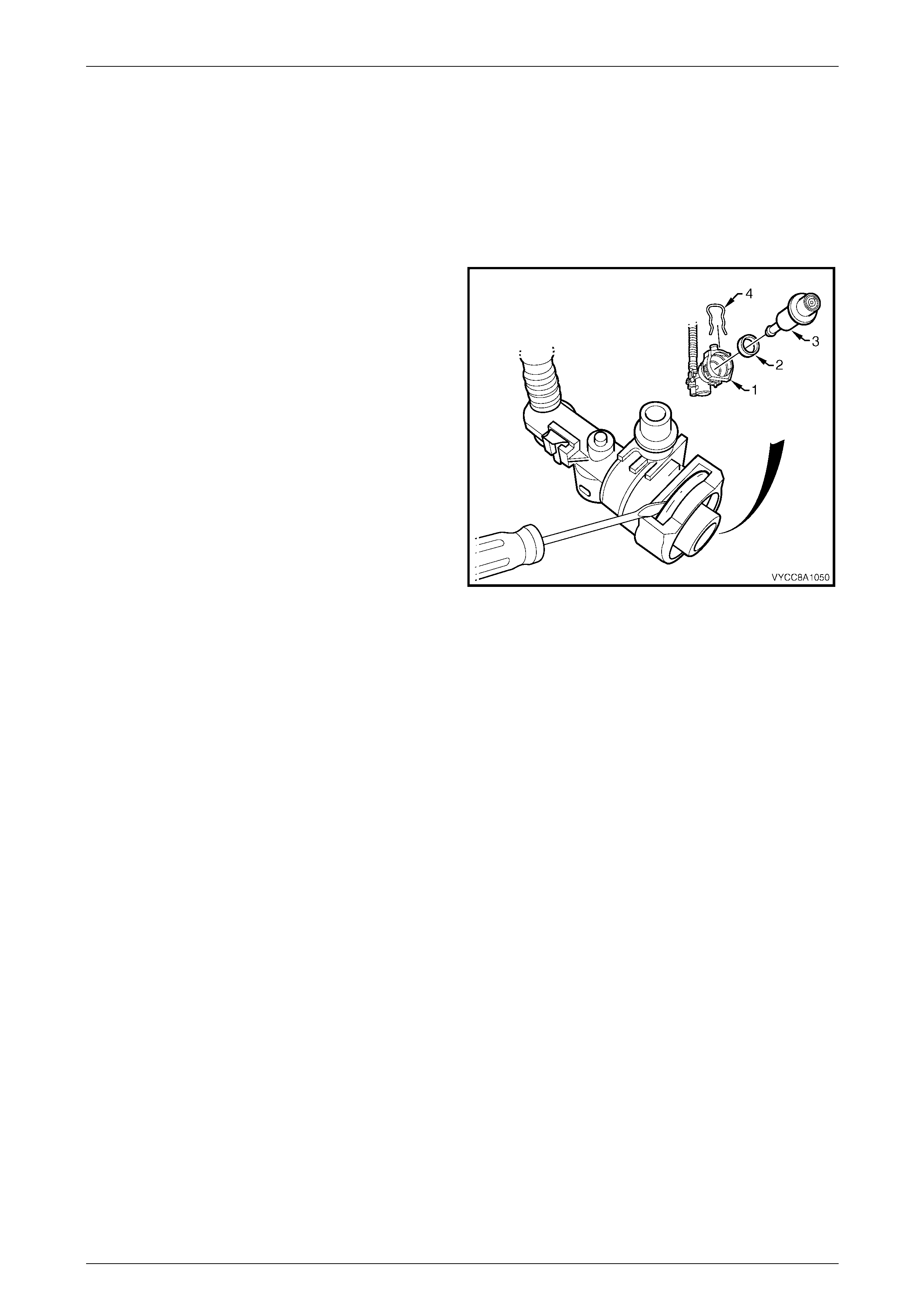

3 Remove the retaining clip (4) from the top of the

pressure regulator holder and place in a safe location

away from the immediate worksite.

4 Using a flat-bladed screwdriver, prise the pressure

regulator (3) from the pressure regulator holder (1).

5 Remove the nylon spacer (2) from the pressure

regulator holder and place in a safe location away

from the immediate worksite.

Figure 8A1 – 67

Reinstall

The procedure for reinstalling the pressure regulator is the reverse of the removal procedure.

Fuel Tank Page 8A1–51

Page 8A1–51

2.9 Suction Filter

The suction filter is attached by an 'easy washer' to the fuel pump end cap. The suction filter is accessible after removal

of the fuel pump and fuel filter from the modular fuel pump and sender assembly reservoir.

Remove

1 Remove the modular fuel pump and sender assembly from the fuel tank, refer to the removal procedure in

2.4 Modular Fuel Pump and Sender Assembly — V6 or 2.5 Modular Fuel Pump and Sender Assembly —

GEN III V8.

2 Disassemble the fuel pump and suction filter assembly, and modular fuel pump and sender assembly cover from

the reservoir, refer to the disassembly procedure in 2.4 Modular Fuel Pump and Sender Assembly — V6 or

2.5 Modular Fuel Pump and Sender Assembly — GEN III V8.

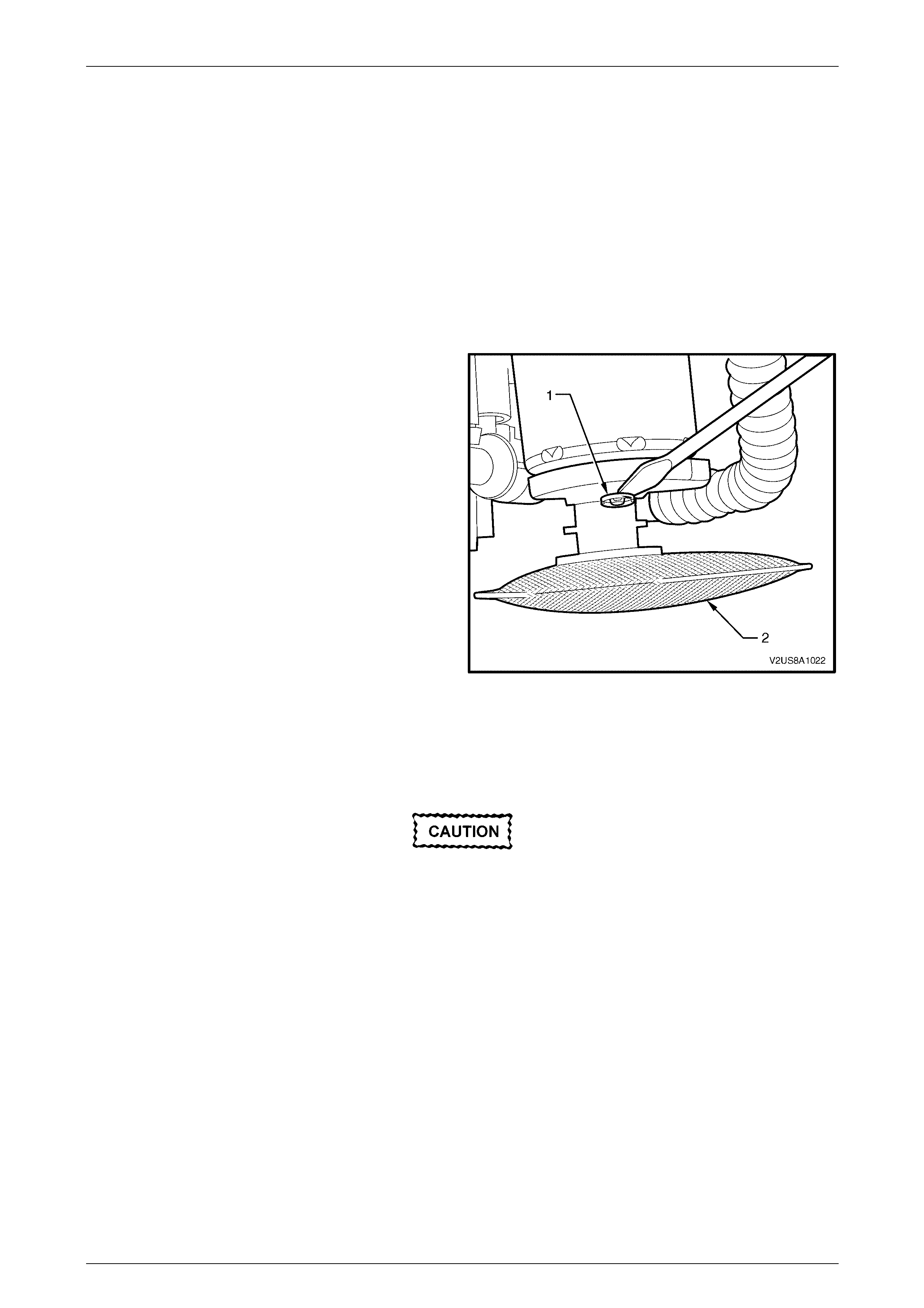

3 Using a suitable blade or a flat-bladed screwdriver,

remove the 'easy washer' (1) from the fuel pump end

cap post.

4 Remove the suction filter (2).

Figure 8A1 – 68

Reinstall

Reinstallation of the suction filter is the reverse of the removal procedure, noting the following:

Check the 'easy washer' for serviceability and

replace if necessary.

Ensure the 'easy washer' is firmly installed along the fuel pump end cap post and firmly pressed up against the suction

filter moulding.

Fuel Tank Page 8A1–52

Page 8A1–52

2.10 Modular Fuel Pump

The modular fuel pump is contained within the fuel filter assembly.

Remove

NOTE

This procedure can not be performed until the

suction filter removal procedure described in 2.9

Suction Filter has been completed.

1 Remove the fuel pump and suction filter assembly from the modular fuel pump and sender assembly, refer to

2.4 Modular Fuel Pump and Sender Assembly — V6 or 2.5 Modular Fuel Pump and Sender Assembly —

GEN III V8.

2 Disassemble the modular fuel pump and sender assembly, refer to 2.4 Modular Fuel Pump and Sender Assembly

— V6 or 2.5 Modular Fuel Pump and Sender Assembly — GEN III V8.

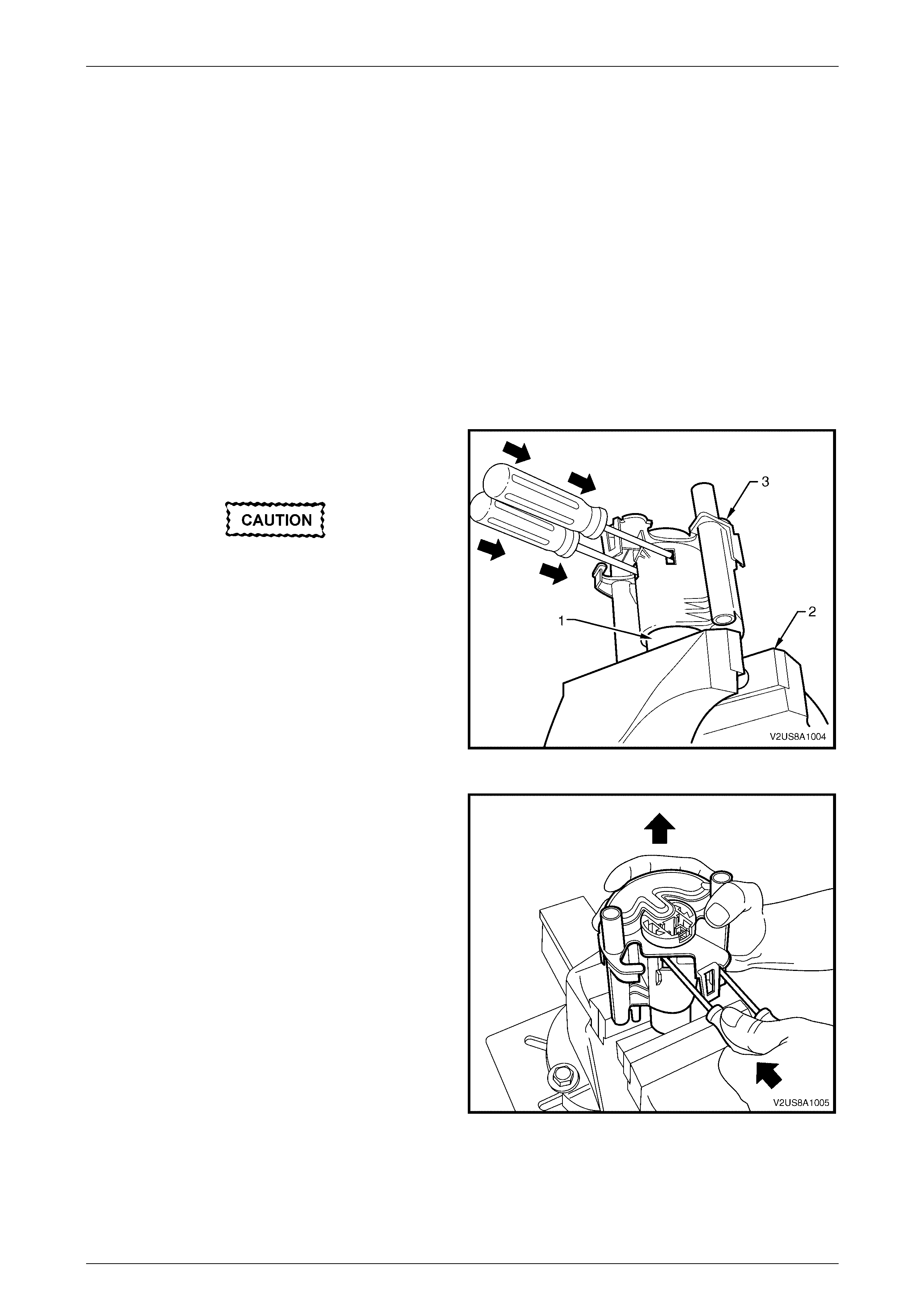

3 Clamp the protruding end of the fuel pump body (1) in

a soft-jawed vice (2) to support the modular fuel pump

and fuel filter assembly (3) in place.

Do not overtighten the vice grips as this may

damage the fuel pump.

4 Insert a medium-sized flat-bladed screwdriver through

each of the service holes in the fuel filter assembly.

5 Slide the screwdriver blade between the fuel pump

end cap and the internal fuel filter clips that hold the

fuel pump body in place.

Figure 8A1 – 69

6 Push the screwdrivers in far enough so the internal

fuel filter clips are deflected just free of each of the

fuel pump end cap retainer shoulders.

7 While holding the screwdrivers in place with one

hand, manipulate the fuel filter assembly upwards to

separate it from the fuel pump.

Figure 8A1 – 70

Fuel Tank Page 8A1–53

Page 8A1–53

Reinstall

Do not use any tool that may damage either

the fuel pump body or the fuel filter assembly.

1 Reinstall the fuel pump body using the following procedure:

a Using hands only, locate the fuel pump body in its correct orientation into the fuel filter assembly.

b Push the fuel pump body firmly into place and lock the fuel pump into the fuel filter assembly.

2 Reassemble the modular fuel pump and sender assembly, refer to 2.4 Modular Fuel Pump and Sender Assembly

— V6 or 2.5 Modular Fuel Pump and Sender Assembly — GEN III V8.

3 Reinstall the modular fuel pump and sender assembly, refer to 2.4 Modular Fuel Pump and Sender Assembly — V6

or 2.5 Modular Fuel Pump and Sender Assembly — GEN III V8.

Fuel Tank Page 8A1–55

Page 8A1–55

2.12 Fuel Pipe Arrangement

V6 Engine

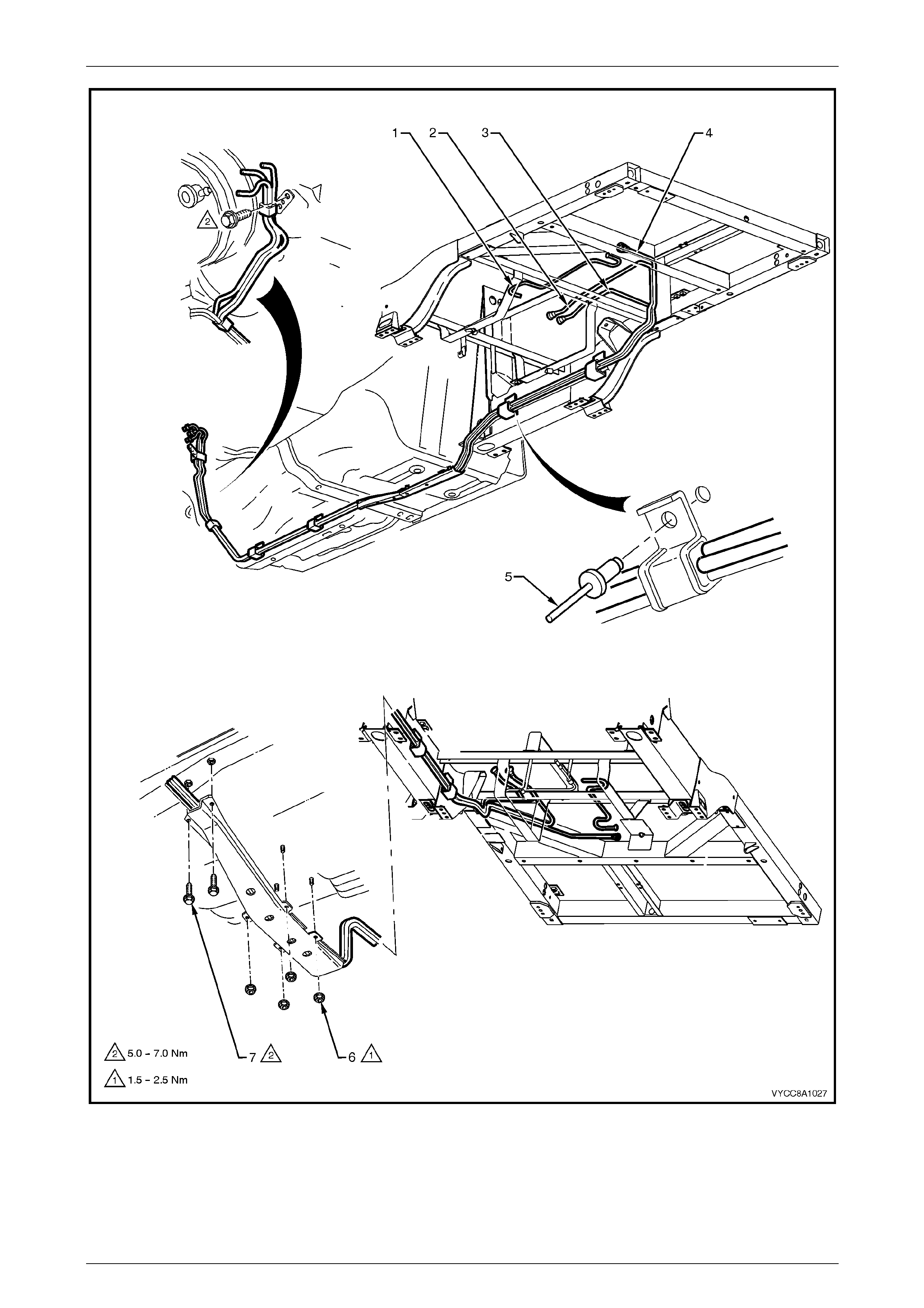

Figure 8A1 – 71 illustrates the fuel pipe layout and location of other items relating to the fuel tank in vehicles with the V6

engine. For the fuel pipe arrangement for vehicles fitted with the LPG system, refer to Section 8A2 – LPG System in

this service information.

Fuel Tank Page 8A1–56

Page 8A1–56

Figure 8A1 – 71

Legend

1 Fuel Tank Vent Line

2 Fuel Feed Line

3 Fuel Return Line

4 Fuel Vapour Canister Purge Line

5 Fuel Line Bracket B l i nd Ri vet

6 Stone Guard S ecuring Nut (4 places)

7 Stone Guard S ecuring Bolt (2 pl aces)

Fuel Tank Page 8A1–57

Page 8A1–57

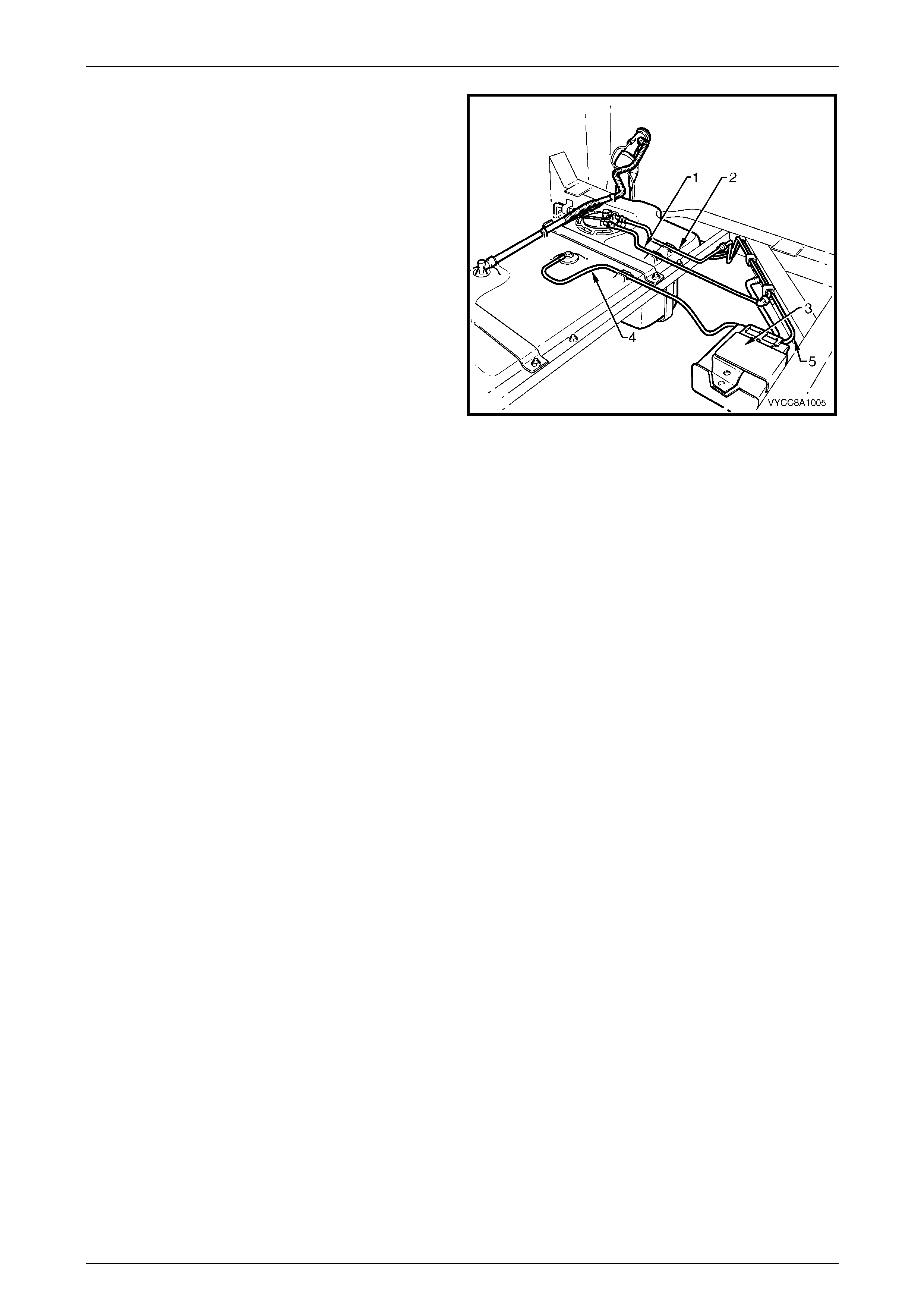

NOTE

For V6 engines, use special tool AU533 to

remove the fuel feed line (1) and fuel return

line (2) quick-connect fittings, refer to MY 2003

VY and V2 Series Service Information,

Section 8A1 Fuel Tank, 2.10 Quick-connect

Fittings.

Figure 8A1 – 72

Legend

1 Fuel Feed Line

2 Fuel Return Line 3 Fuel Vapour Canis ter

4 Fuel Tank Vent Line 5 Fuel Vapour Canister Purge Line

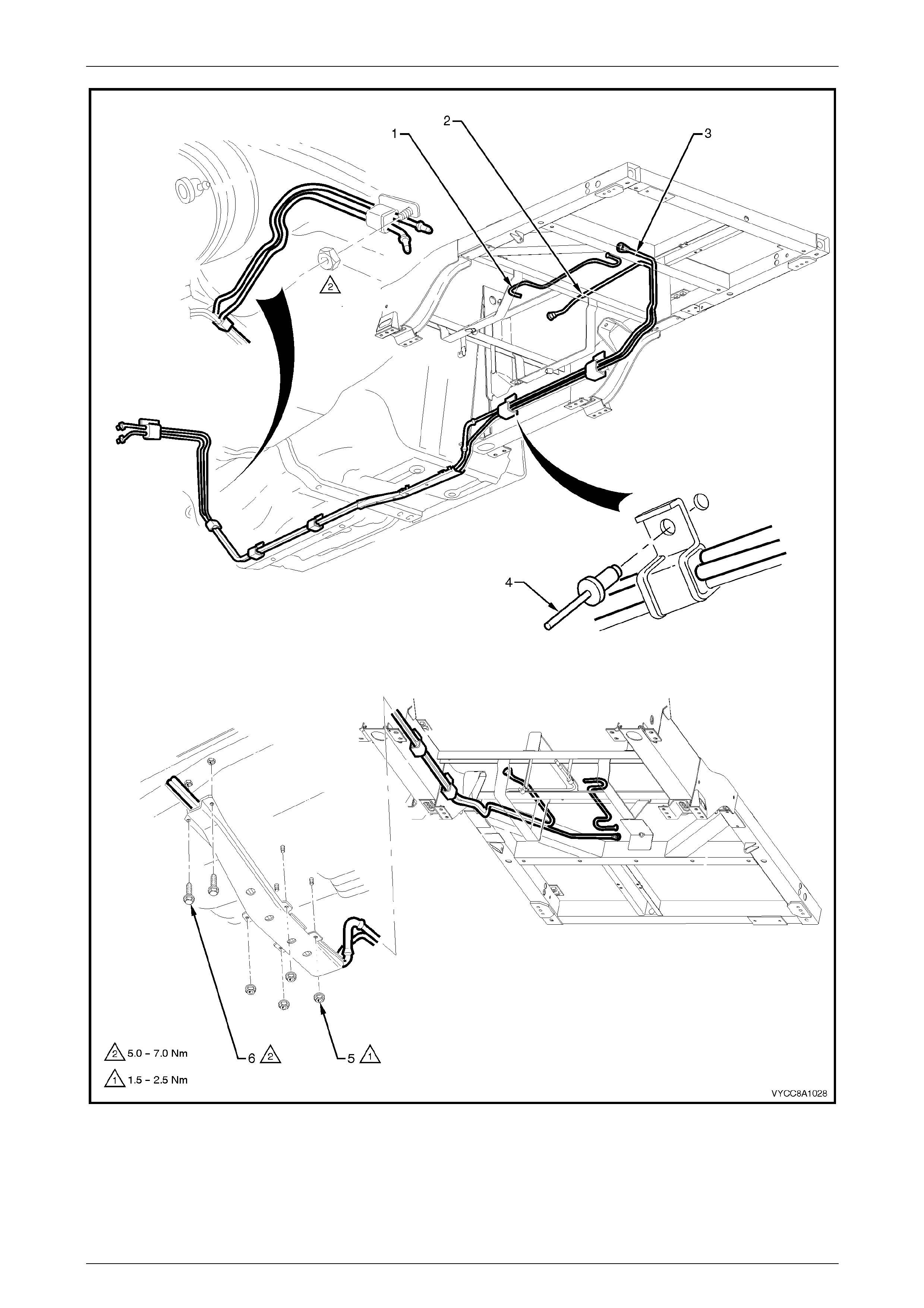

GEN III V8 Engine

Figure 8A1 – 73 illustrates the fuel pipe layout and location of other items relating to the fuel tank in vehicles with

GEN III V8 engine. For the fuel pipe arrangement for vehicles fitted with the LPG system, refer to Section 8A2 – LPG

System in this service information.

Fuel Tank Page 8A1–58

Page 8A1–58

Figure 8A1 – 73

Legend

1 Fuel Tank Vent Line

2 Fuel Feed Line 3 Fuel Vapour Canister Purge Line

4 Fuel Line Bracket B l i nd Ri vet 5 Stone Guard S ecuring Nut (4 places)

6 Stone Guard S ecuring Bolt (2 pl aces)

Fuel Tank Page 8A1–59

Page 8A1–59

NOTE

For GEN III V8 engines use special tool AU533

to remove the fuel feed line (1) quick-connect

fitting, refer to MY 2003 VY and V2 Series

Service Information, Section 8A1 Fuel Tank,

2.10 Quick-connect Fittings.

Figure 8A1 – 74

Legend

1 Fuel Feed Line

2 Fuel Vapour Canis ter 3 Fuel Tank Vent Line

4 Fuel Vapour Canister Purge Line

Fuel Tank Page 8A1–60

Page 8A1–60

3 Specifications

Fuel Tank Capacity:

..................................................................................................................................68.5 litres

Fuel Tank Material:

..........................................................................'W'-type high density multi-layer polyethylene

Fuel Filler Location:

........................................................Attached to support bracket underneath right side of tray

Fuel Pump Type:

........................................................................................................................... Single turbine

Pressure Regulator Location:

V6 Engine .............................................................................................................. Engine bay

GEN III V8 Engine....................................................Modular fuel pump and sender assembly

Fuel Pump Location:

................................................................................................................................In fuel tank

Fuel Pump Regulated Pressure:

..................................................................................................................400 kPa (+/– 3 kPa)

Minimum Fuel Pump Flow Capacity (at Regulated Pressure):

............................................................................................................2.95 L/min @ 13.5 volts

Fuel Pump Current Draw (Steady State at Regulated Pressure):

................................................................................................................11.0 Amps maximum

O-rings:

Pressure regulator (P/N 195306–0010)................................................................4.25 mm i.d.

Pressure regulator holder — top (P/N 195506–0150) ..........................................7.52 mm i.d.

Pressure regulator holder — bottom (P/N 167529–0010) ......................................8.2 mm i.d.

Fuel pump outlet (P/N 167529–0010).....................................................................8.2 mm i.d.

Pressure regulator (P/N 195306–0110)................................................................15.4 mm i.d.

Fuel Tank Page 8A1–61

Page 8A1–61

4 Torque Wrench Specifications

Fuel Tank Support Straps..........................................................30.0 – 40.0 Nm

Fuel Tank Mounting Strap Nuts.................................................20.0 – 25.0 Nm

Support Bracket Backing Plate Attaching Screws.....................20.0 – 25.0 Nm

Fuel Filter Bracket Screw...............................................................5.0 – 8.0 Nm

Fuel Vapour Canister Mounting Nu t ..............................................2.0 – 5.0 Nm

Stone Guard Securing Nut.............................................................1.5 – 2.5 Nm

Stone Guard Securing Bolt............................................................5.0 – 7.0 Nm

Fuel Tank Page 8A1–62

Page 8A1–62

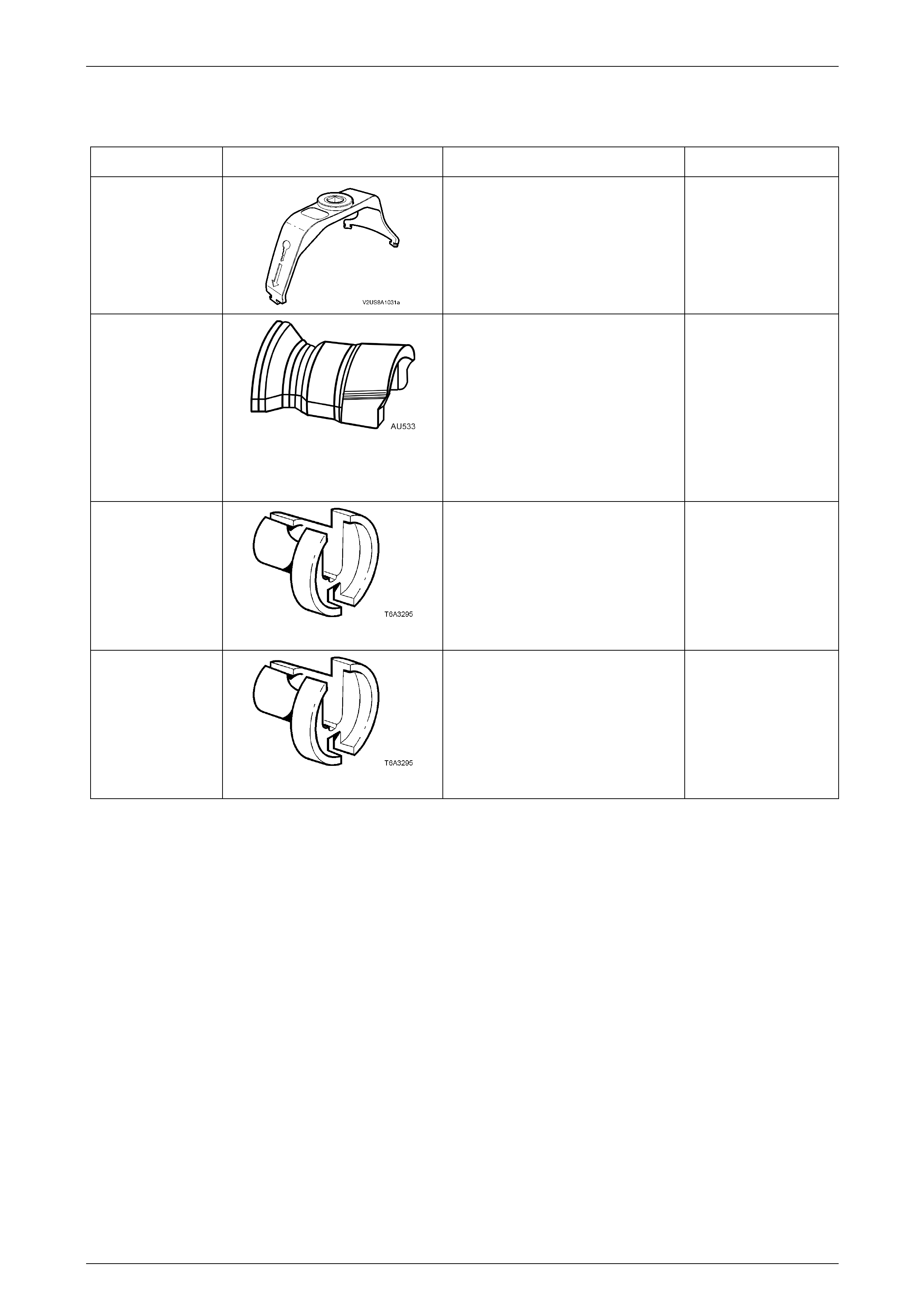

5 Special Tools

Tool Number Illustration Description Tool Classification

J45722

Modular fuel pump and sender

assembly lock ring remove and install

tool.

New release.

Mandatory

AU533

Quick-connect fitting release tool

Released in two sizes:

• Red for 5/16-inch fittings, and

• Blue for 3/8-inch fittings.

Commercially available under

P/N AUSP45.

Previously released.

Desirable

7370

Quick-connect release tool —

5/16-inch

Used for releasing fuel hose quick

connects at the dash panel and fuel

rail connections, after the fuel system

has been depressurised.

Previously released.

Mandatory

7371

Quick-connect release tool —

3/8-inch

Used for releasing fuel hose quick

connects at the dash panel and fuel

rail connections, after the fuel system

has been depressurised.

Previously released.

Mandatory