SECTION 1A2 - BODY DIMENSIONS

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to

Section 00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or

property damage.

1. GENERAL DESCRI PTI O N

The WH Series is a new vehicle des ign with sheetm etal, interior trim , and air c onditioning system c hanges.

Front bumper fascias accommodate engine cooling entry. Head, turn signal and rear lamps complement

the design changes.

2. SERVICE OPERATIONS

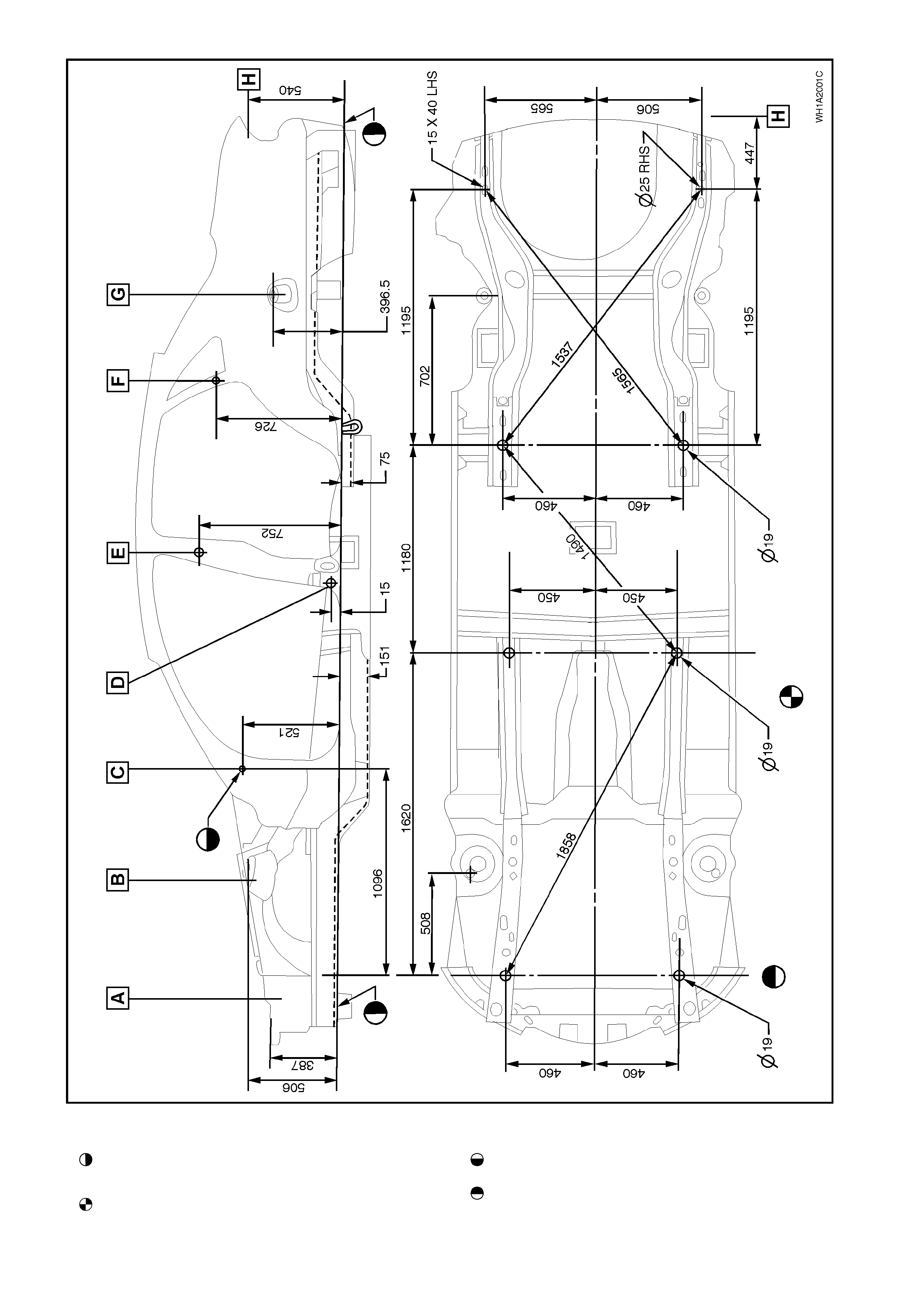

2.1 BODY DIMENS IONS

Correct underbody alignment is essential, as any misalignment of the underbody can adversely affect

suspension, fitment of doors, engine hood or rear compartment lid. The underbody should therefore be

aligned to within ±1.5 mm of dimensions specified in Figures 1A2-1, 1A2-2, 1A2-3, 1A2-4, and 1A2-5.

These dimensions should be accurately checked with a tram gauge consisting of a parallel bar or rod, fitted

with two adjustable trammels, capable of gauging all underbody dimensions specified.

In preparing for an underbody alignment check, place the vehicle on a level surface with the weight of the

body supported at wheel locations.

Dimensions to holes are to be taken from the centreline.

Body dimensions are to be taken to the outside surface of the sheetmetal.

All dimensions are to be measured as shown.

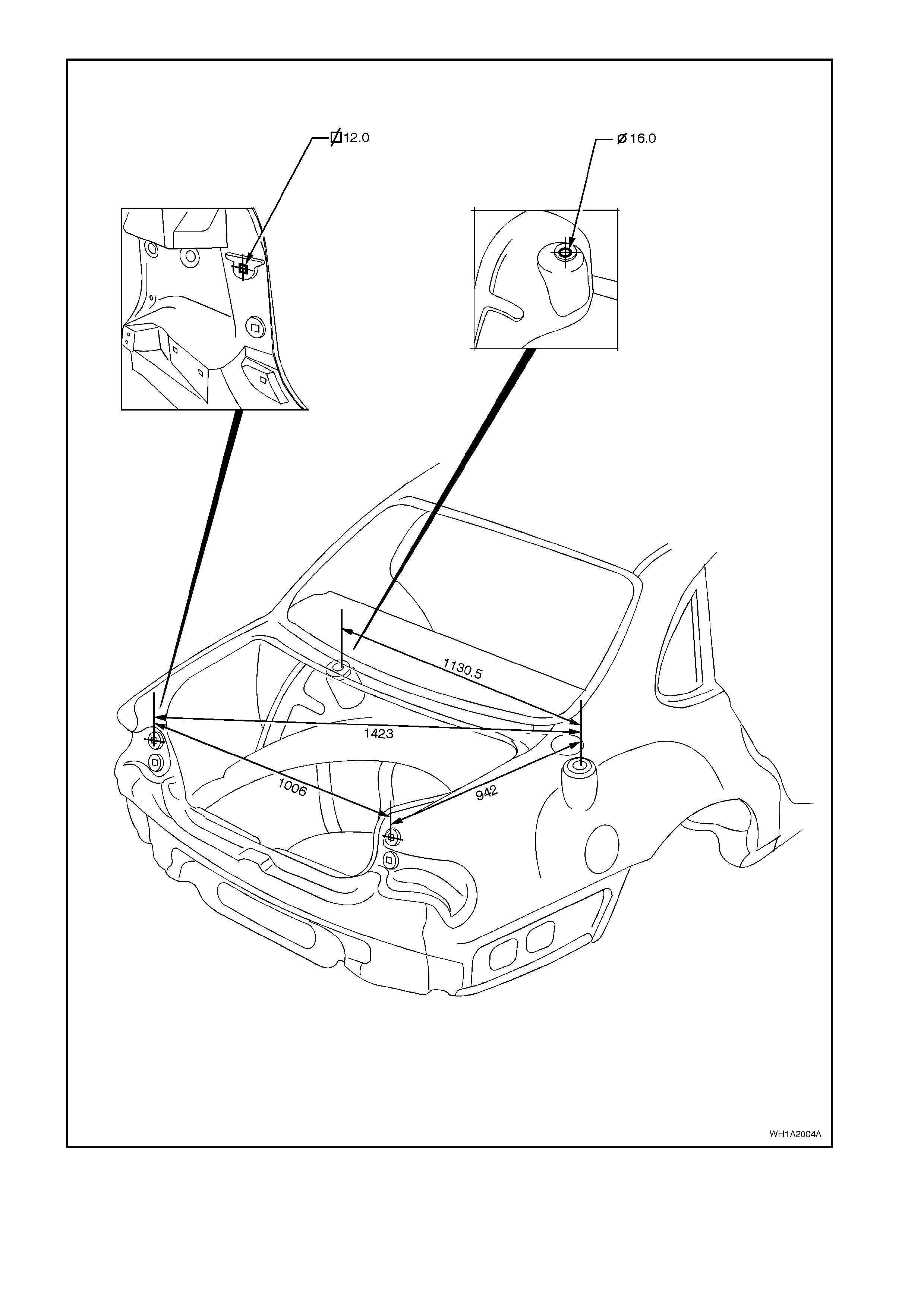

Figure 1A2-1

Legend

Datum surface under side of longitudinal R &

LH.

All dimensions in mm. measured from centre

of holes on outside of metal.

Cockpit module attachment.

Datum surface under side of longitudinal R &

LH.

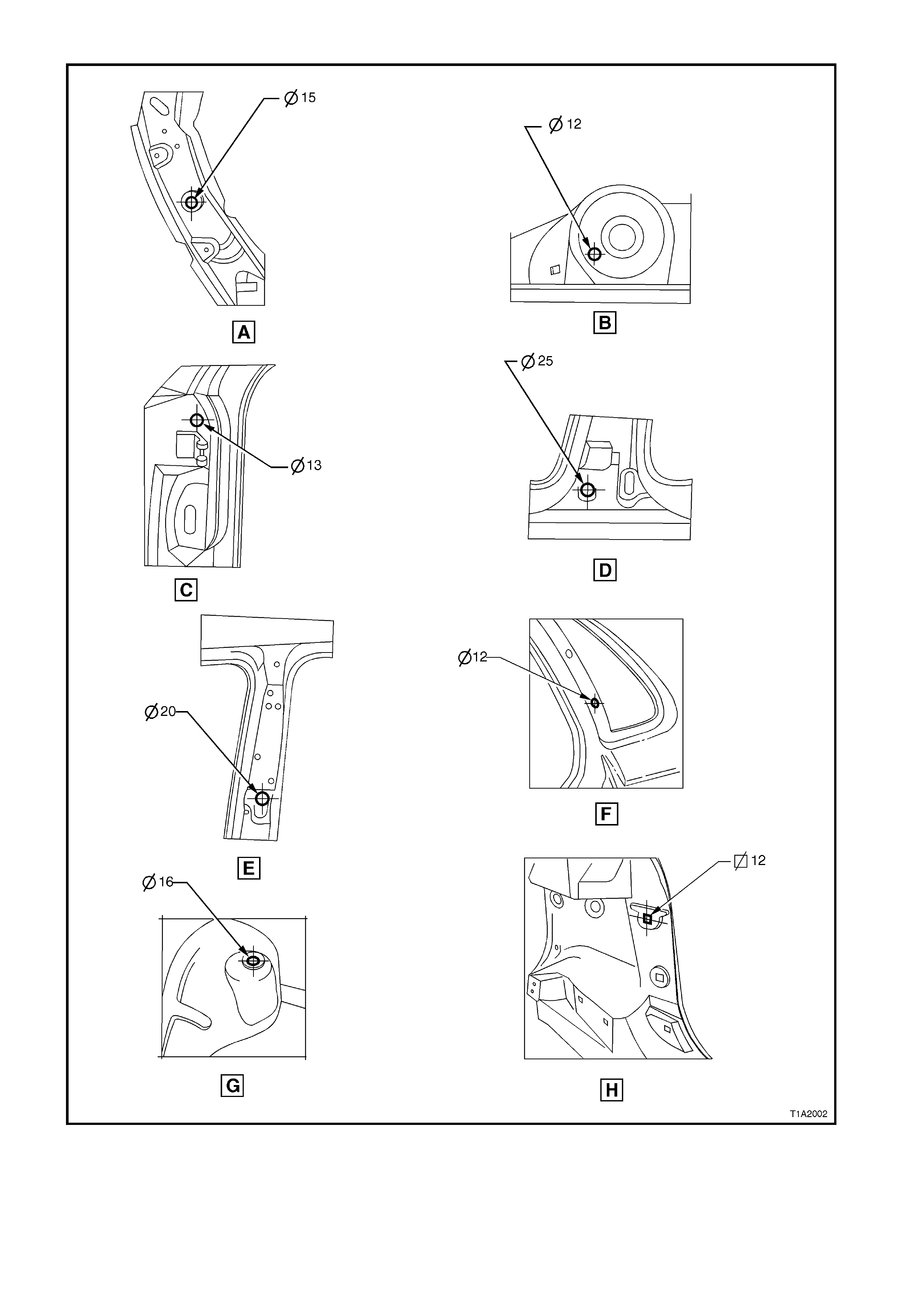

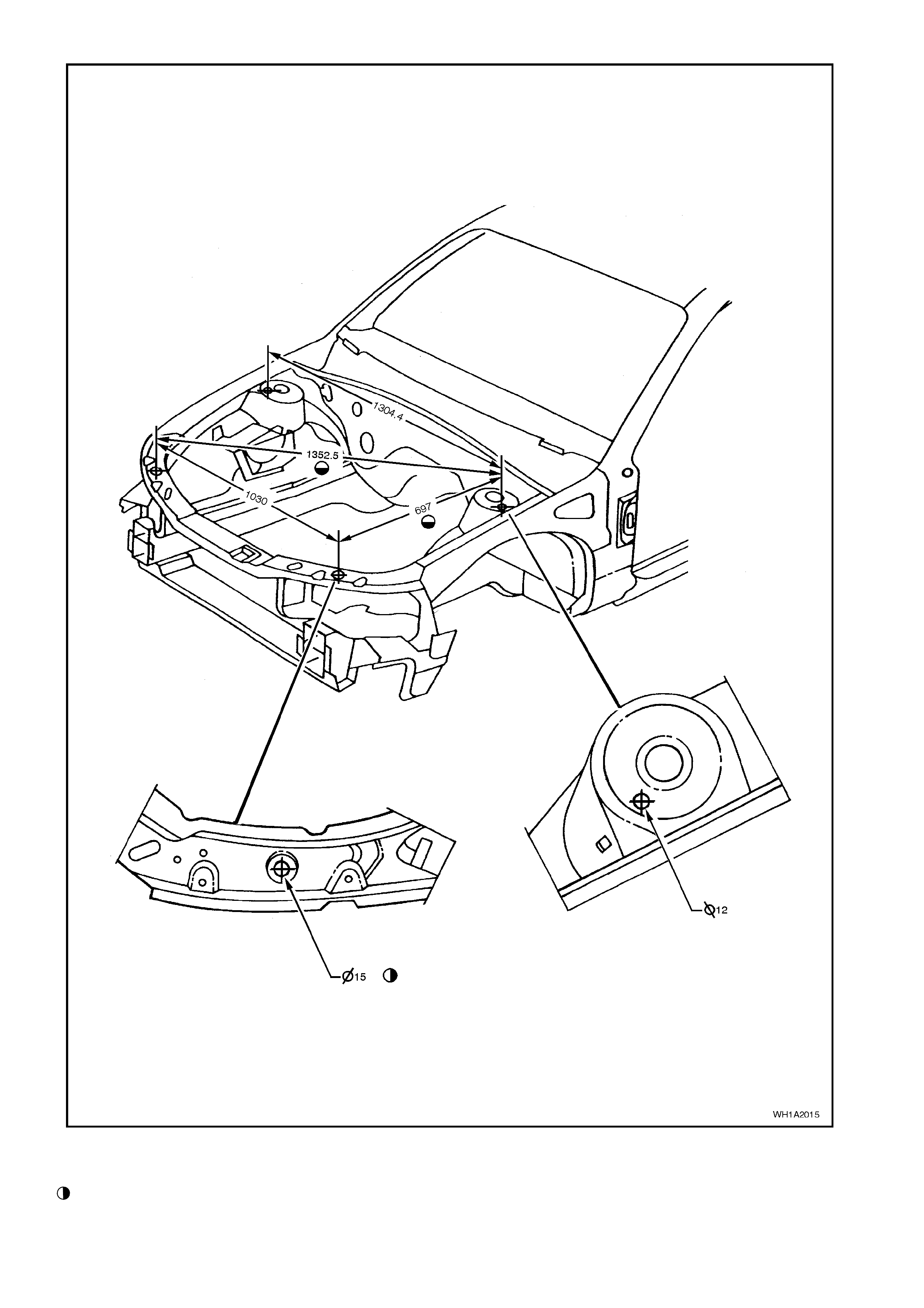

Figure 1A2-2

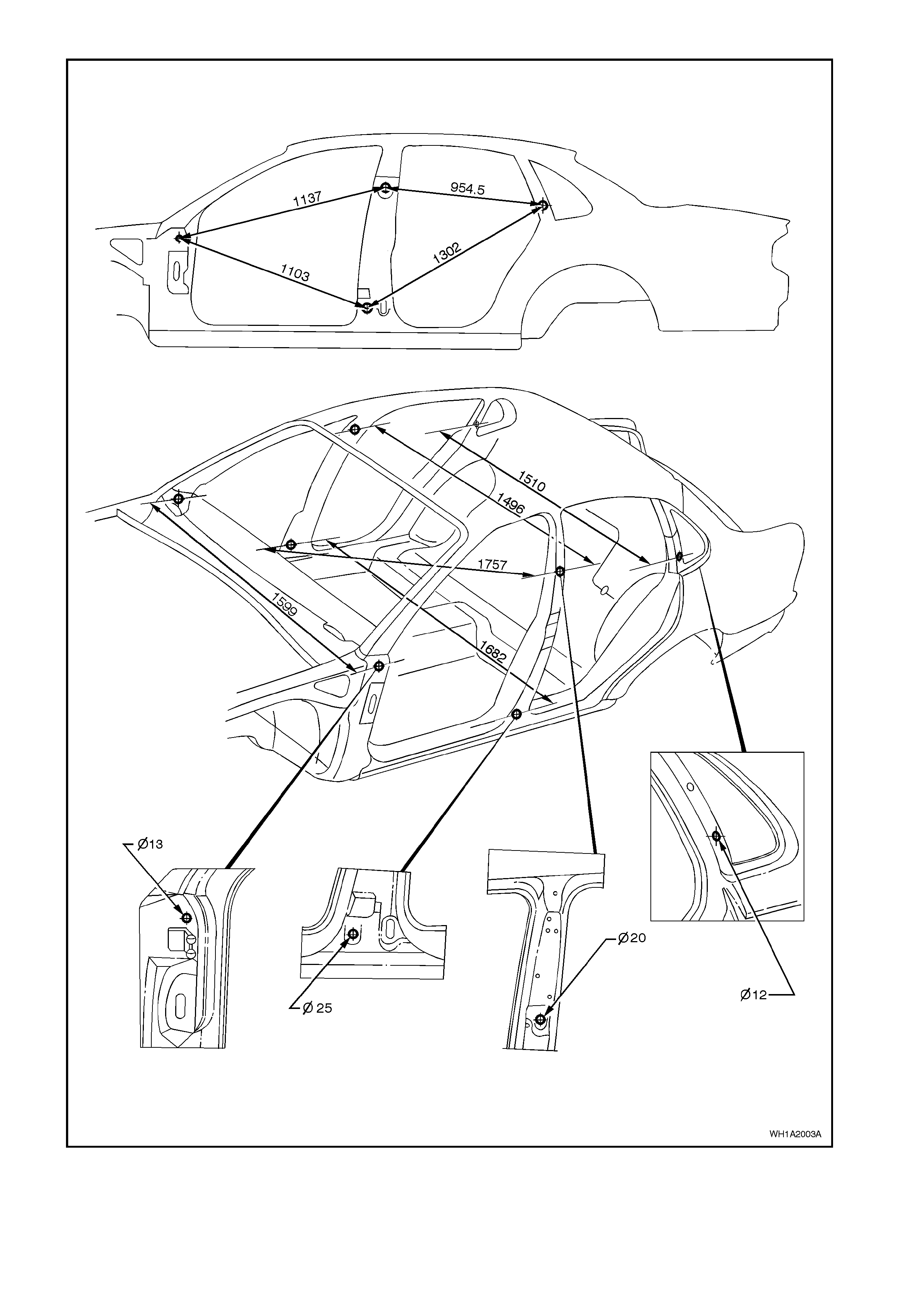

Figure 1A2-3

Figure 1A2-4

Figure 1A2-5

Legend

All dimensions in mm. measured from centre of

holes on outside of metal.

2.2 FRONT SUSPENSION CROSSMEMBER ALIGNMENT

NOTE: Ensure that body dimensions are within specified limits prior to commencing any crossmember

alignment. Refer to 2.1 BODY DIMENSIONS in this Section.

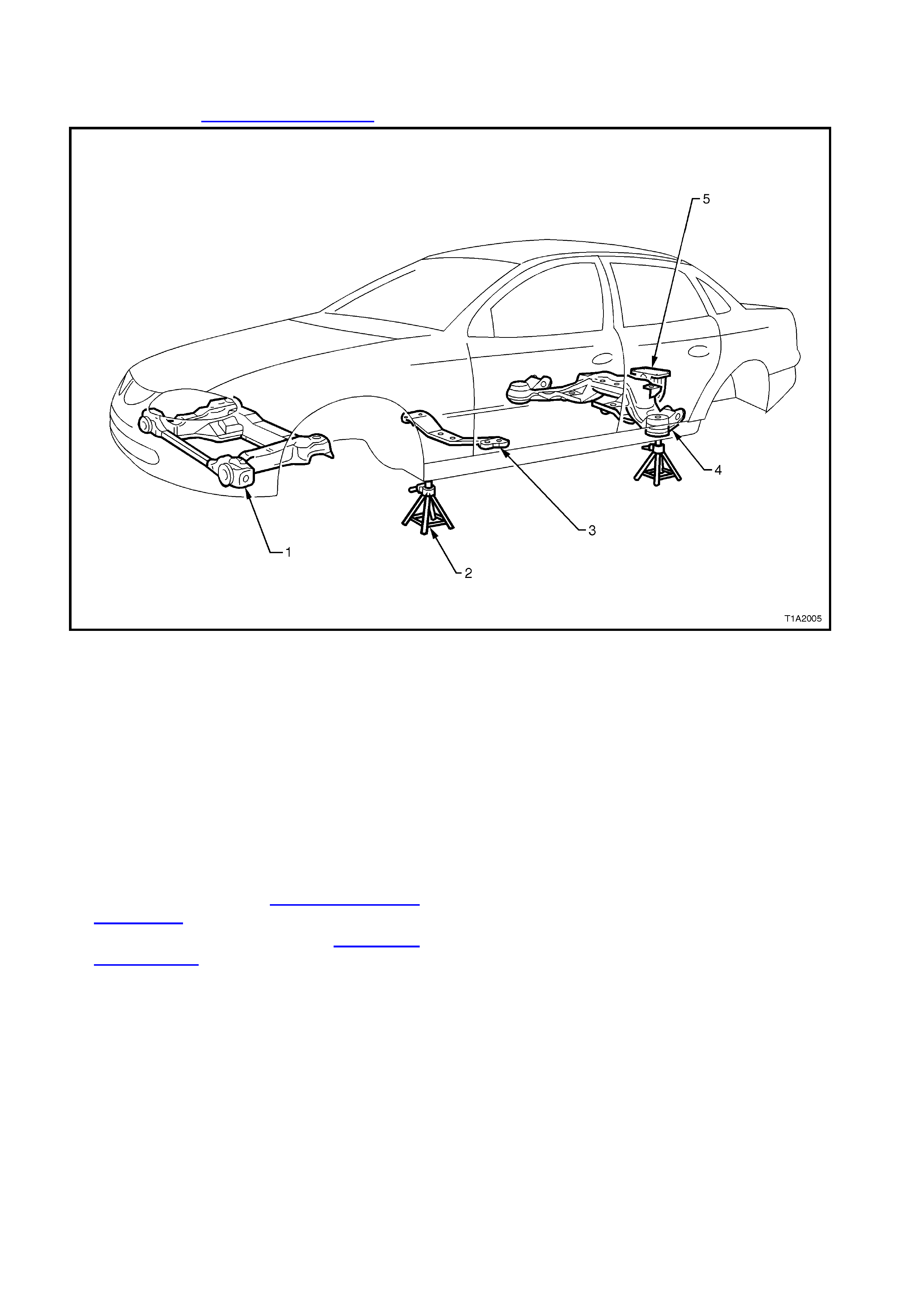

Figure 1A2-6

Legend

1. Front suspension crossmember.

2. Chassis stands.

3. Transmission crossmember.

4. Rear suspension crossmember.

5. Final drive rear mount.

NOTE: Front suspension crossmember centring

tool needs to be held in position during the

alignment procedure. Therefore, assistance will be

required to complete this operation.

1. Using chassis stands support vehicle at hoist

pad locations.

2. Remove wheels, refer to Section 10 WHEELS

AND TYRES.

3. Remove engine hood, refer to Section 1B

SHEETMETAL.

4. Support engine with overhead lifting device and

raise slightly to take weight off engine mounts.

5. From underneath vehicle loosen front

crossmember attaching bolts.

6. Remove left hand rear attaching bolt and

replace with the locating pin with front

suspension crossmember centering tool No.

AU 457.

7. Fit front suspension c rossm ember centring tool

No. AU 457.

NOTE: Front suspension crossmember centring

tool locates into ∅ 19 mm body datum holes

positioned towards front of vehicle.

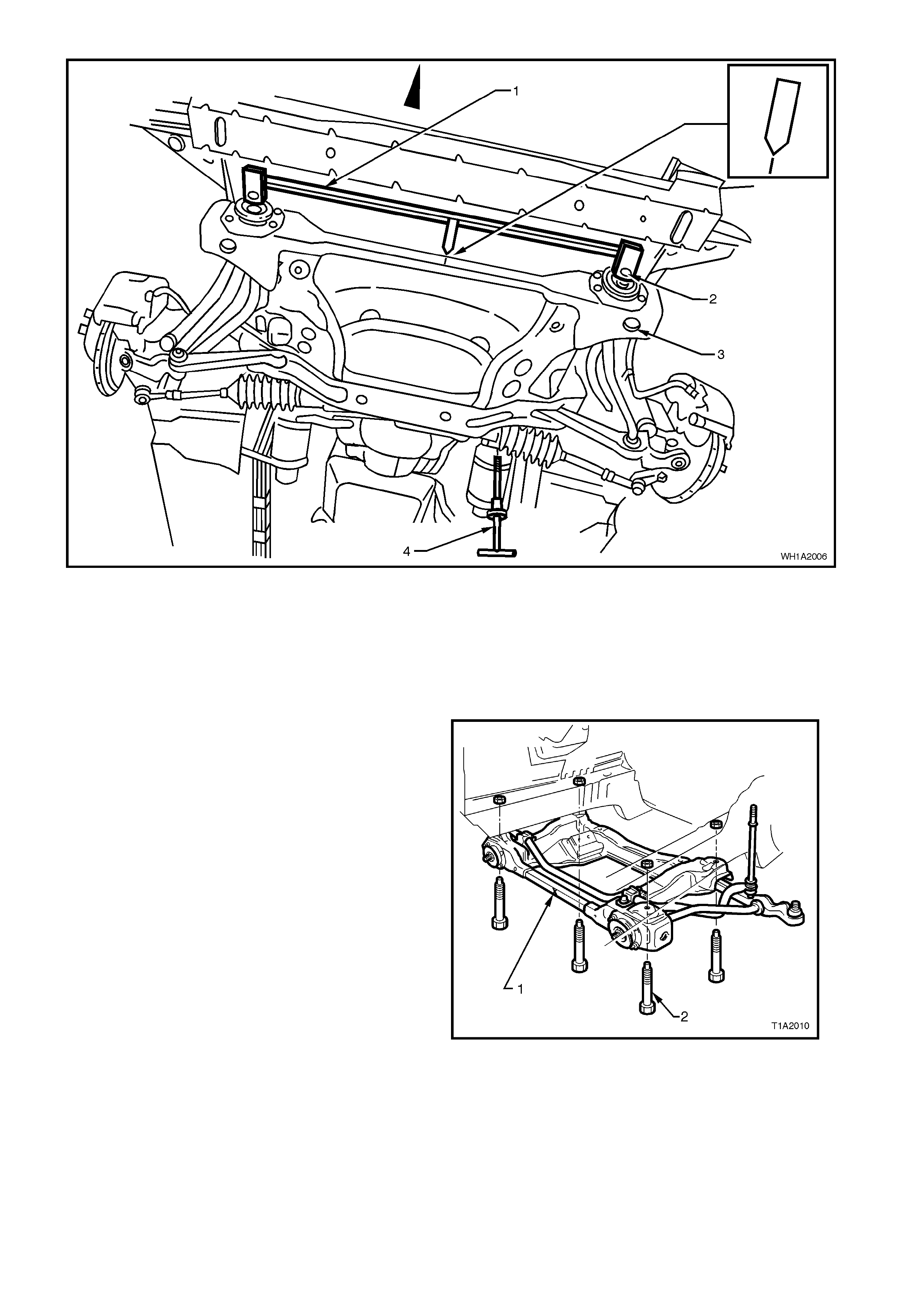

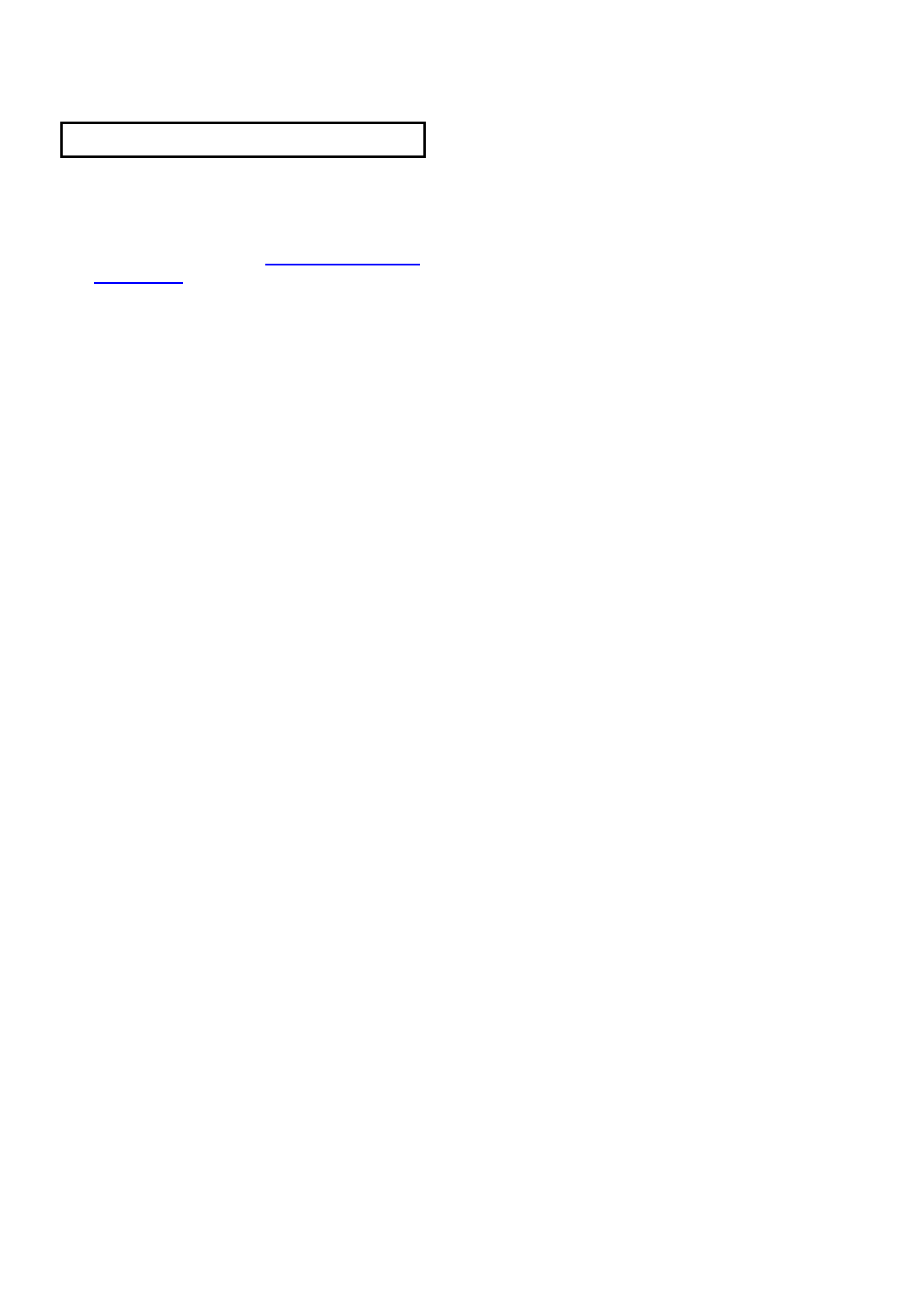

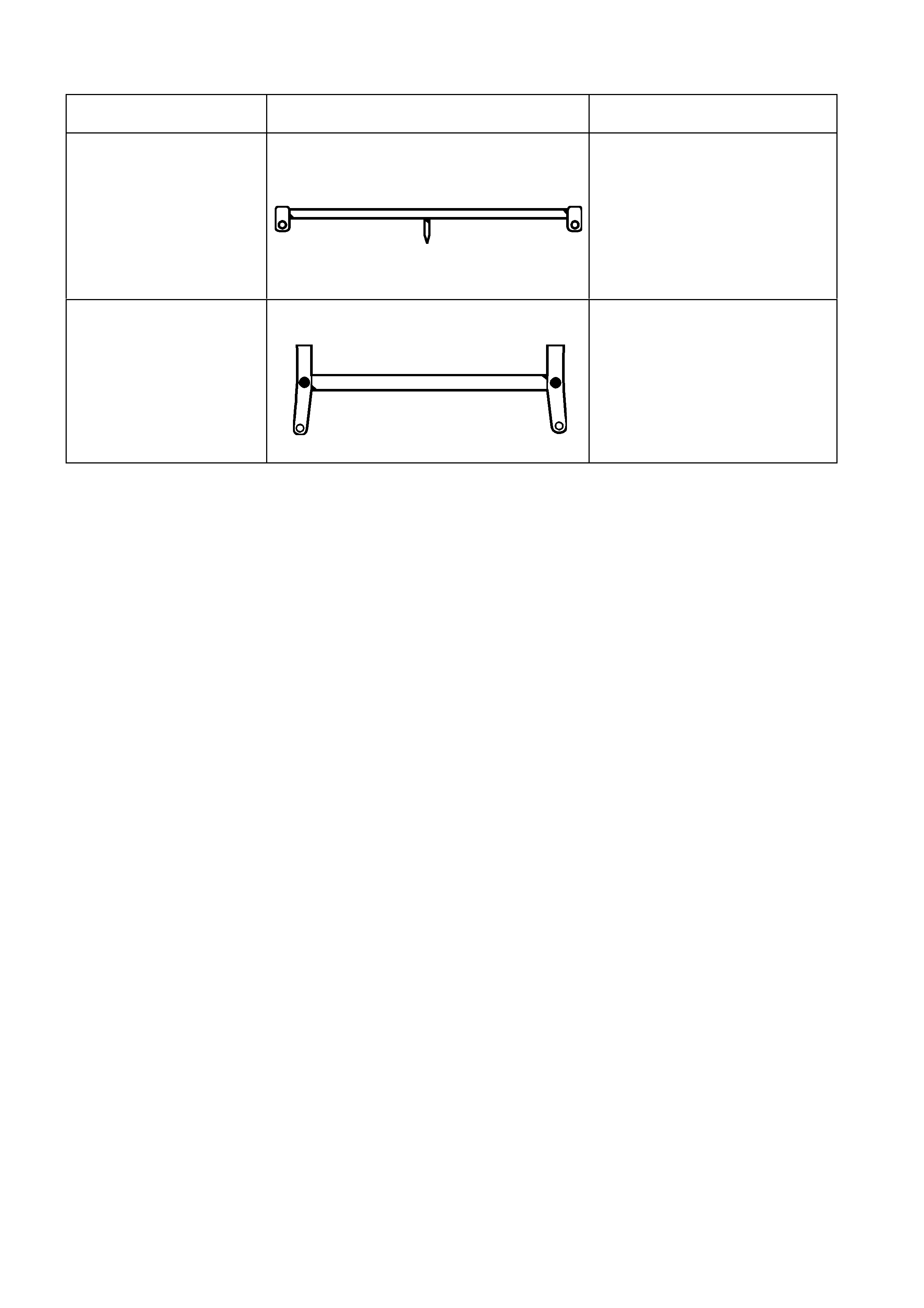

Figure 1A2-7

Legend

1. Front crossmember centering Tool No.

AU457.

2. Datum pin (2 places).

3. Attaching bolt (8 places).

4. Locating pin position.

5. Front crossmember centering tool no. AU 457

8. With the help of an assistant, manoeuvre the

front suspension crossmember so that the

reference mark on the crossmem ber is aligned

with the pointer on the centring tool.

NOTE: Front suspension crossmember has an ‘I’

stamped on the front to aid in aligning to fixture

pointer.

IMPORTANT: Front suspension crossmember

attaching bolts must be renewed after each

loosening and may be replaced one at a time

during this alignment procedure.

Alignment of crossmember must be completed

within 20 minutes from installation of new bolts.

Attaching bolts are supplied with a

microencapsulated locking compound applied to

threads that will start to set immediately after

installation and will reach 20% adhesion after 30

minutes. Figure 1A2-8

9. When crossmember is aligned, tighten the

three crossmember attaching bolts.

10. Remove locating pin.

FRONT CROSSMEMBER ATTA CHING 120 - 125

BOLTS T ORQUE SPE CIFICAT ION Nm

11. Reinstall left rear crossmember attaching bolt

and washer and tighten.

12. Remove crossmember aligning fixture.

13. Gently lower engine and remove lifting device.

14. Attach wheels, refer to Section 10 WHEELS

AND TYRES.

15. Remove vehicle from chassis stands.

2.3 TRANSMISSION CROSSMEMBER ALIGNMENT

NOTE: Ensure that body dimensions are within

specified limits prior to commencing any

crossmember alignment. Refer to 2.1 BODY

DIMENSIONS in this Section.

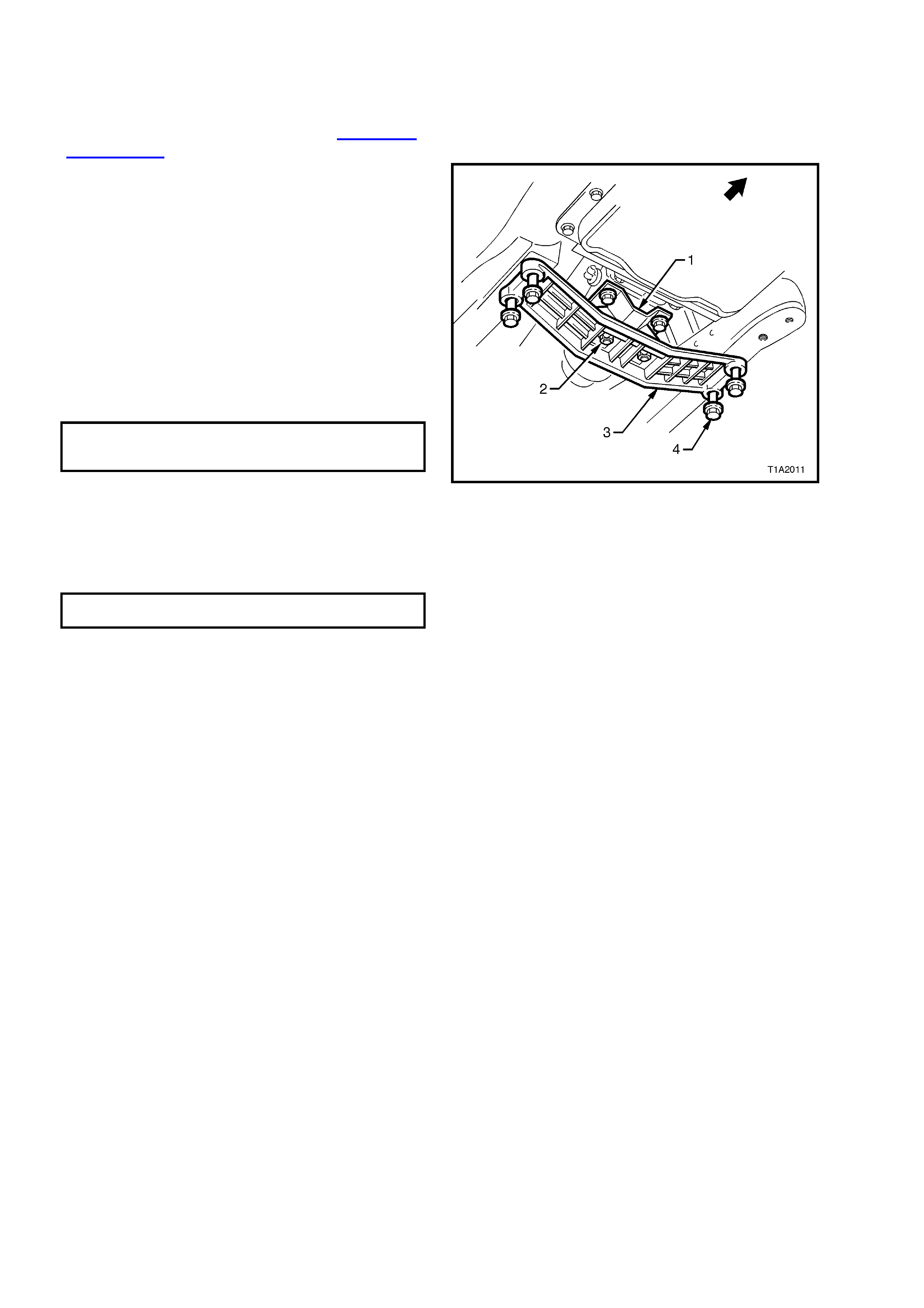

1. Using chassis stands support vehicle at hoist

pad locations.

2. From underneath the vehicle, support

transmission with a trolley jack and raise

slightly to take weight off transmission mount

(1).

3. Remove two M8 nuts (2) secur ing transm ission

mount (1) to transmission crossmember (3).

4. Loosen four attaching bolts (4) securing

transmission crossmember to underbody.

5. Centralise transmission crossmember (3)

within bolt holes (4).

6. Tighten the four attaching bolts.

TRANSMISSION CROSSMEMBER

ATTACHING BOLTS TORQUE 50 - 65 Nm

SPECIFICATION

7. With the help of an assistant manoeuvre the

transmission to ensure that the studs

protruding through the crossmember are

centralised within the stud holes.

8. Reinstall M8 nuts (2) securing transmission

mount to transmission crossmember.

TRANSMISSION MOUNT M8 NUTS 20 - 30

TORQUE SPECIFICATION Nm

9. Gently lower trolley jack and remove from

under vehicle.

10. Remove vehicle from chassis stands.

Figure 1A2-9

2.4 REAR SUSPENSION CROSSMEMBER ALIGNMENT

NOTE: 1 Ensure that body dimensions are within

specified limits prior to commencing any

crossmember alignment. Refer to 2.1 BODY

DIMENSIONS in this Section.

NOTE: 2 Rear suspension crossmember centring

tool needs to be held in position during the

alignment pr ocedure. T herefore, as sistance will be

required to complete this operation.

1. Using chassis stands (3) support vehicle at

hoist pad locations.

2. Remove wheels, refer to Section 10 WHEELS

AND TYRES.

3. Remove intermediate muffler and pipe

assembly together with rear muffler and pipe

assembly refer to Section 8B1 EXHAUST

SYSTEM.

4. From underneath the vehicle, support final

drive with a trolley jack and raise s lightly to take

weight off final drive mount.

5. Loosen three M10 screws (2) securing

crossmember to body brace left hand side and

right hand side.

6. Loosen rear suspension crossmember (1)

attaching bolts (M14) (4) left hand side and

right hand side.

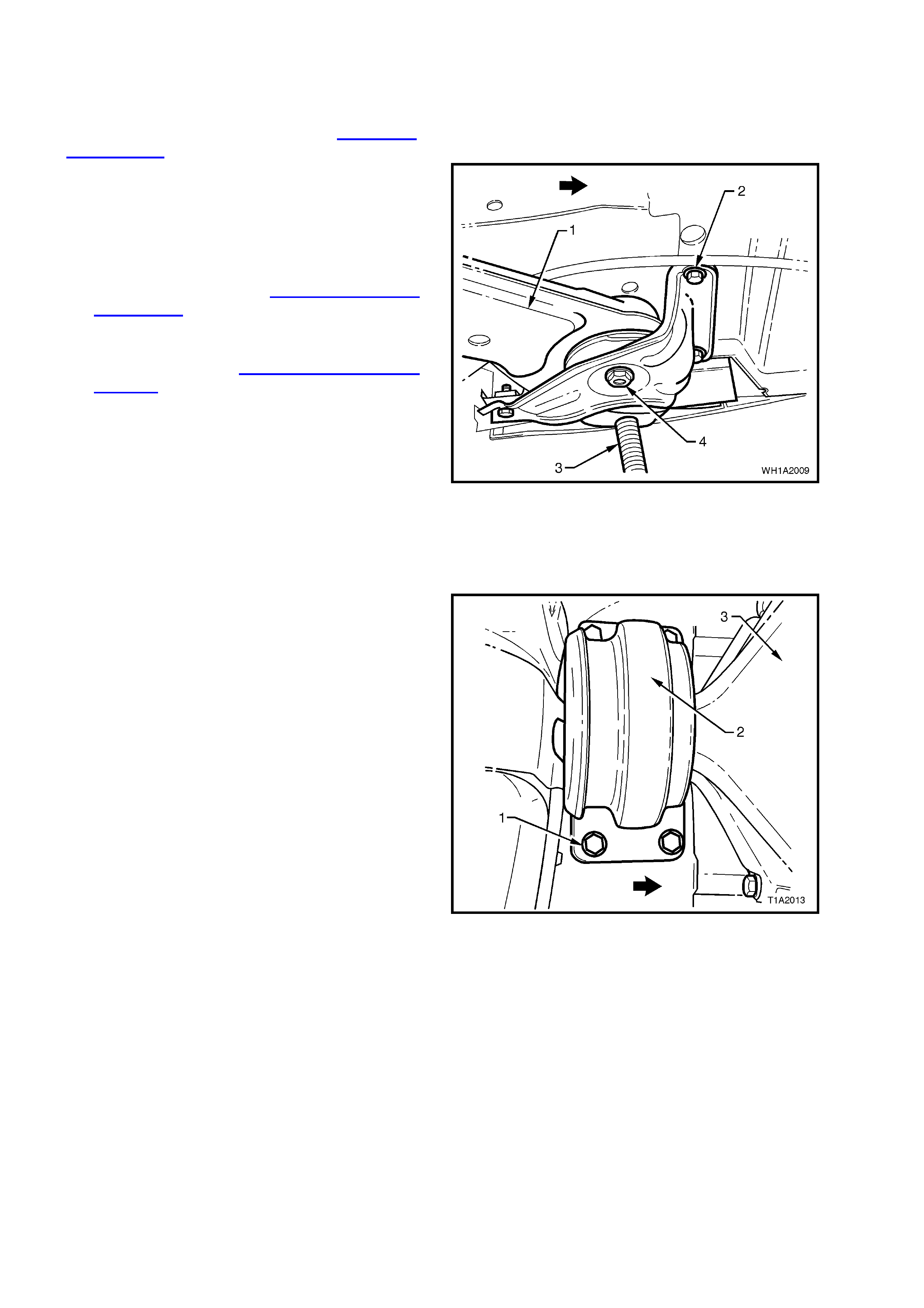

Figure 1A2-10

7. Loosen four bolts (1) securing final drive rear

mount (2) to vehicle underbody.

IMPORTANT: Rear suspension crossmember

attaching bolts and final drive rear m ount attaching

screws must be renewed after each loosening and

may be replaced one at a time during this

alignment procedure.

Alignment of crossmember must be completed

within 20 minutes from installation of new bolts.

Attaching bolts are supplied with a micro

encapsulated locking compound applied to threads

that will start to set immediately after installation

and will reach 20% adhesion after 30 minutes.

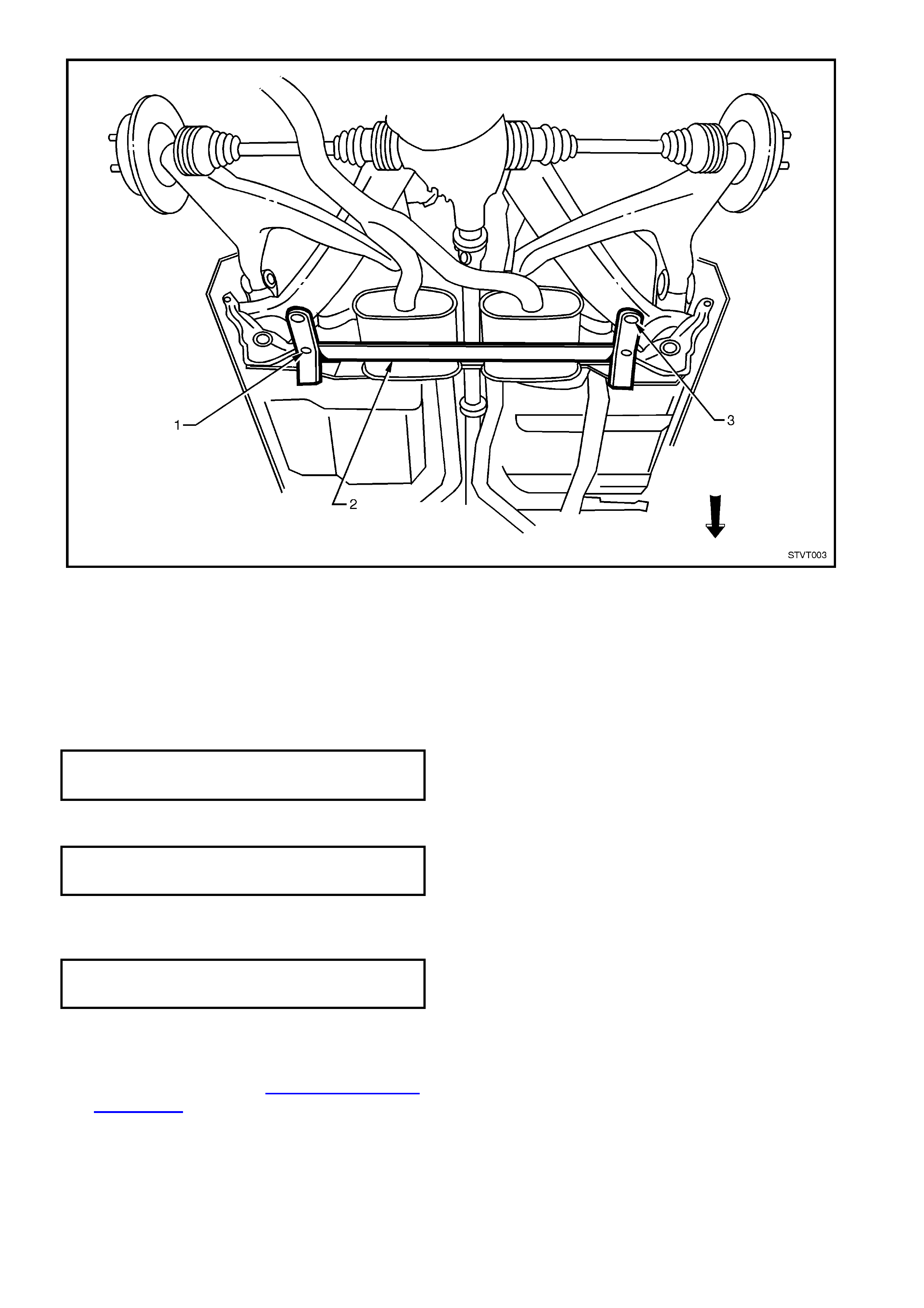

Figure 1A2-11

8. Fit rear suspension centring tool No. AU 458.

NOTE: Rear suspension crossmember centring

tool locates into ∅ 19 mm body datum holes

positioned forward of rear suspension

crossmember.

9. With the help of an assistant, manoeuvre the

rear sus pens ion cr os s mem ber until the loc ation

pins of the rear crossmember centring tool

engages the alignment holes on the rear

suspension crossmember.

Figure 1A2-12

Legend

1. Datum pin (2 places).

2. Rear crossmember centering Tool No.

AU 458.

3. Locating pins (2 places).

10. Tighten rear suspension crossmember

attaching bolts (M14) left hand side and right

hand side.

REAR SUS P ENSION 125 Nm, rota t e

CROSSMEMBER ATTACHING 30° - 45° with a

BOLTS TORQUE S PECIFI CA T ION mi n. of 135 Nm

11. Tighten four screws securing final drive rear

mount.

FINAL DRIVE RE AR MOUNT

ATTACHING SCREWS 30 - 45 Nm

TORQUE SPECIFICATIONS

12. Tighten three M10 screws securing

crossmember to body brace lefthand side and

righthand side.

CROSSMEMBE R M10 SECURING

SCREWS TORQUE 60 - 85 Nm

SPECIFICATION

13. Remove rear crossmember centring tool.

14. Gently lower trolley jack and remove from

under vehicle.

15. Attach wheels, refer to Section 10 WHEELS

AND TYRES.

16. Remove vehicle from chassis stands.

3. TORQUE WRENCH SPECIFI CATIONS Nm

Front crossmember attaching bolts ...................................... 120 - 125

Transmission crossmember attaching bolts......................... 50 - 65

Transmission mount securing nuts....................................... 20 - 30

Rear suspension crossmember attaching bolts (M14) ......... 125 Nm and rotate

30° - 45° with a

min. of 135 Nm

Final drive rear mount attaching screws............................... 30 - 45

Crossmember securing screws (M10).................................. 60 - 85

4. SPECIAL TOOLS

TOOL NO. REF IN TEXT TOOL DESCRIPTION COMMENTS

AU 457 FRONT CROSSMEMBER CENTRING

TOOL PREVIOUSLY RELEASED

AU 458 REAR CROSSMEMBER CENTRING TOOL

PREVIOUSLY RELEASED