SECTION 1A7 - SEAT AND SEAT BELT ASSEMBLIES

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to

Section 00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or

property damage.

1. GENERAL I NFORMATIO N

The WH Series Statesman and Caprice are fitted with eight-way electrically adjustable driver and front passenger

seats, which also include side impact air bags. In addition, the driver’s seat in the Caprice is fitted with an integrated

memory seat and mirror system which is controlled from a series of buttons located on the side of the driver’s seat.

On key-less entry to the vehicle, the memory seat and mirror system in conjunction with the Body Control Module

(BCM) recognises which ignition key has been used (Priority 1 or Priority 2) and adjusts the seat and external

mirrors accordingly.

The memory seat and mirror system allows the driver to adjust the seat position to any of the positions stored in

memory by pressing one of the control buttons. If reverse gear is selected and the mirror dip button pressed, the

passenger’s side external mirror will automatically dip to a preset position providing a different view of the

passenger’s side of the vehicle during reversing.

Audio and visual feedback for the various functions of the memory seat and mirror system is provided. The system

has a green LED and an audio chime located in the seat assembly which are used to indicate memory saves, the

recall of priority memory numbers and for seat diagnostic procedures.

The external rear vision mirrors on the Caprice are heated, and operate in conjunction with the heated rear window.

The centre rear head restraint is now fitted with a release button to allow downward travel of the head restraint. This

release button is the same type as that fitted to the other head restraints.

This Section should be read in conjunction with Section 1A7 SEAT & SEAT BELT ASSEMBLIES in the VT Series

II Service Information, as well as Section 1A7 SEAT & SEAT BELT ASSEMBLIES in the VT Series I Service

Information.

IMPORTANT: Some of the procedures detailed in 3.6 DIAGNOSTIC PROCEDURES require the use of both the

Priority 1 Key and the Priority 2 Key.

CAUTION: Accessory and after market seat covers MUST NOT be fitted to any vehicle with side air bags

unless approved by Holden. Non-approved seat covers may inhibit the operation of the side air bag,

reducing the protection otherwise provided to the occupants during a side-impact collision.

Techline

Techline

Techline

Techline

Techline

Techline

1.1 GENERAL DESCRIPTION

SEAT A SSEMBLY

Each seat contains four electric, reversible motors. The height of both the front and rear of the seat is controlled by

separate lift motor and gearbox assemblies. Each motor can be operated independently of the other, or operated

together to raise or lower the complete seat assembly. A separate fore/aft movement motor and two gearboxes

control seat forward or rearward positioning. The fourth motor controls the seat backrest recliner position.

Each lift motor and gearbox assembly is bolted to one side of the seat height adjust assembly and when each lift

motor is operating, the lift motor drives the gearbox, which then draws in or extends out the mating worm shaft

which in turn operates on a lever and cross-brace. The cross-brace is connected to another lever on the opposite

side of the seat height adjust assembly and this allows the raising or lowering of that section of the seat. Reversing

the polarity on the lift motor terminals causes the motor to operate in the reverse direction and the seat moves in the

opposite direction.

To control seat fore/aft movement, a worm shaft is attached to each seat rail with the movement motor and

gearboxes attached to the seat height adjust assembly.

When the movement motor is operating, the gearboxes (driven by the movement motor) draw in or extend out each

mating worm shaft. Since each worm shaft is held from moving, the action of the gearboxes meshing with the worm

shafts causes the seat to move (via the seat height adjust assembly) in one direction. Reversing the polarity on the

movement motor terminals causes the motor to operate in the reverse direction and the seat moves in the opposite

direction.

Seat backrest recliner angle is adjusted by a recliner motor attached to the inner seat backrest frame. The motor

output shaft has a drive gear which is meshed with a driven gear attached to the seat backrest frame. Motor

operation causes rotation of the drive gear which turns the driven gear and seat backrest frame, thereby altering the

seat backrest recliner angle. Reversing the polarity on the recliner motor terminals causes the motor to drive in the

reverse direction and the seat backrest moves in the opposite direction.

The driver's seat also contains a seat control module under the lower side cover. The seat control module has a

non-volatile memory , so that removing the battery supply from the module does not erase the seat memory settings.

The lift, movement and recliner motors are common between each seat, except that each motor on the driver's seat

has a potentiometer attached. The potentiometers are used as seat position sensors by the memory seat and mirror

system. The wiring harnesses used for the passenger's side and driver's side seats are different.

Watchdog timers in the memory seat and mirror system limit the time a seat drive motor can operate. The lift and

movement motors are limited to 25 seconds, while the recliner motor is limited to 50 seconds.

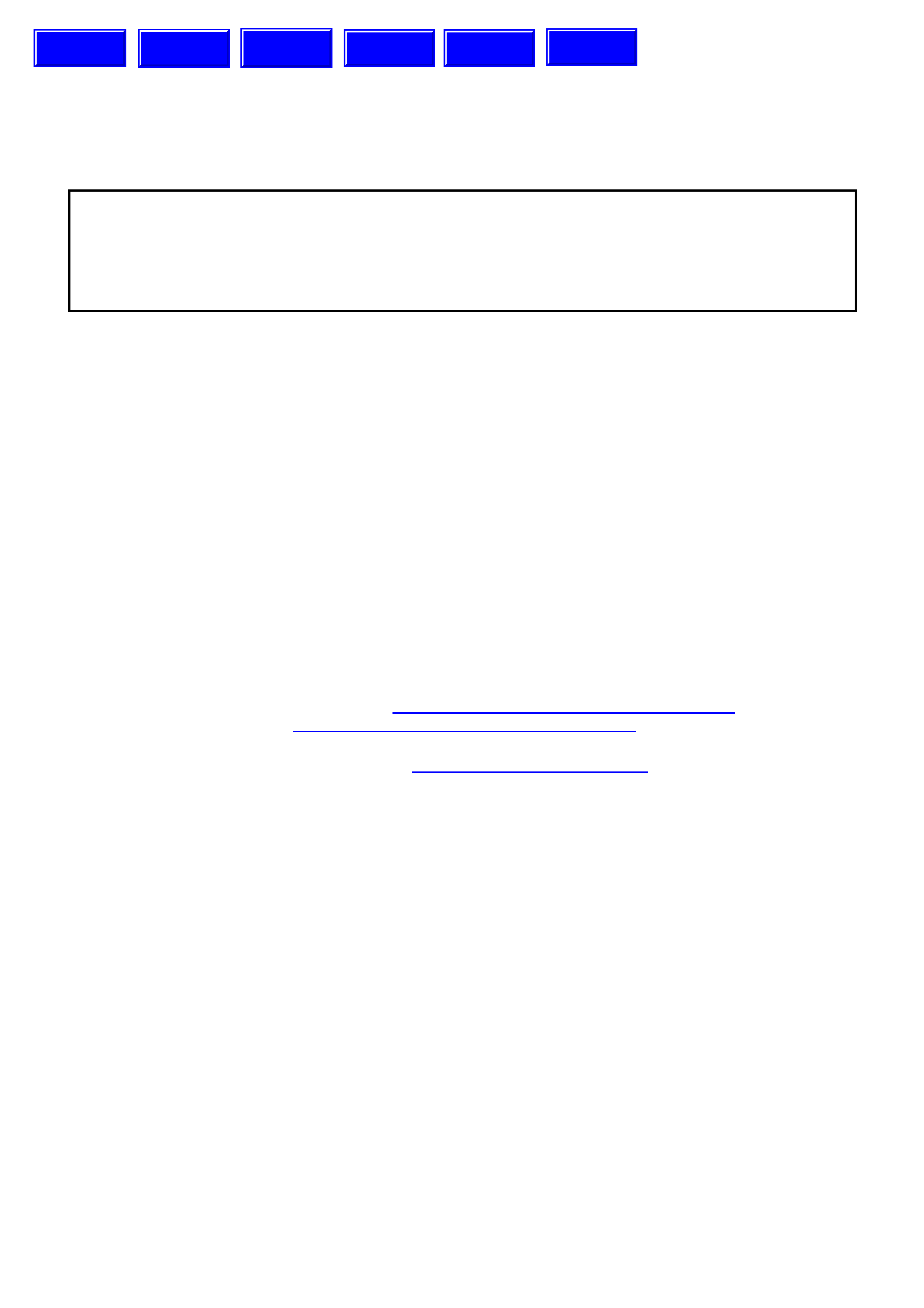

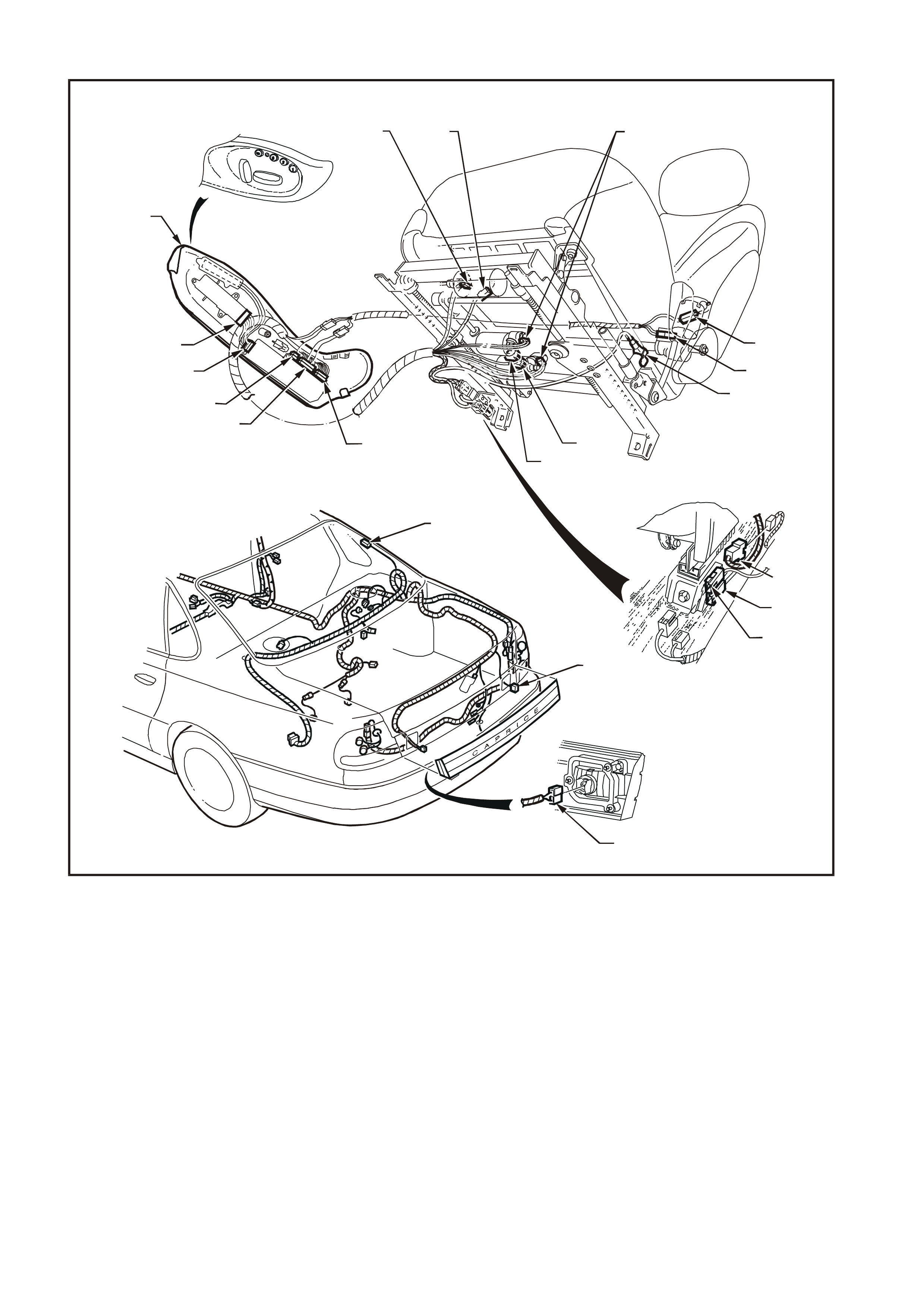

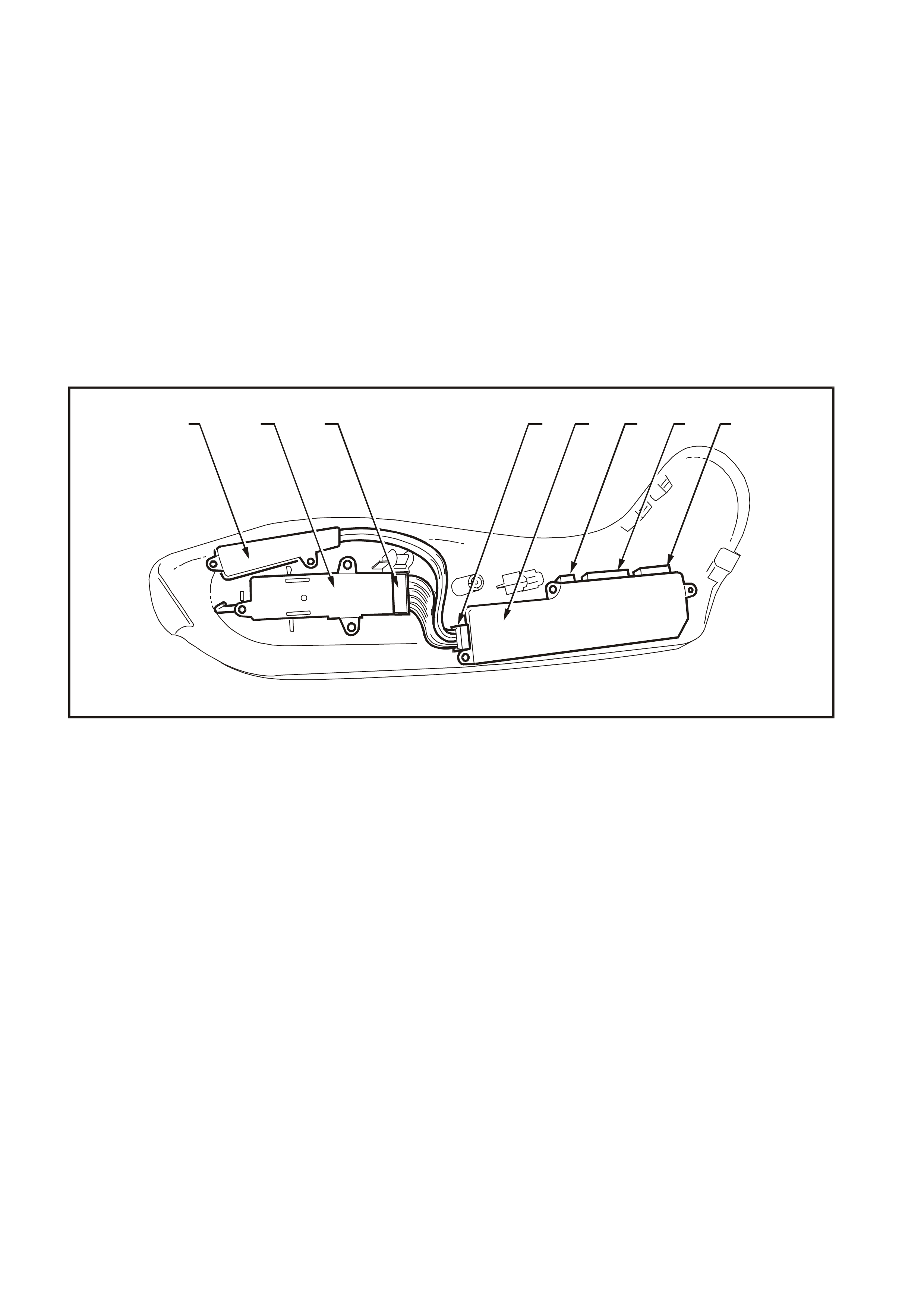

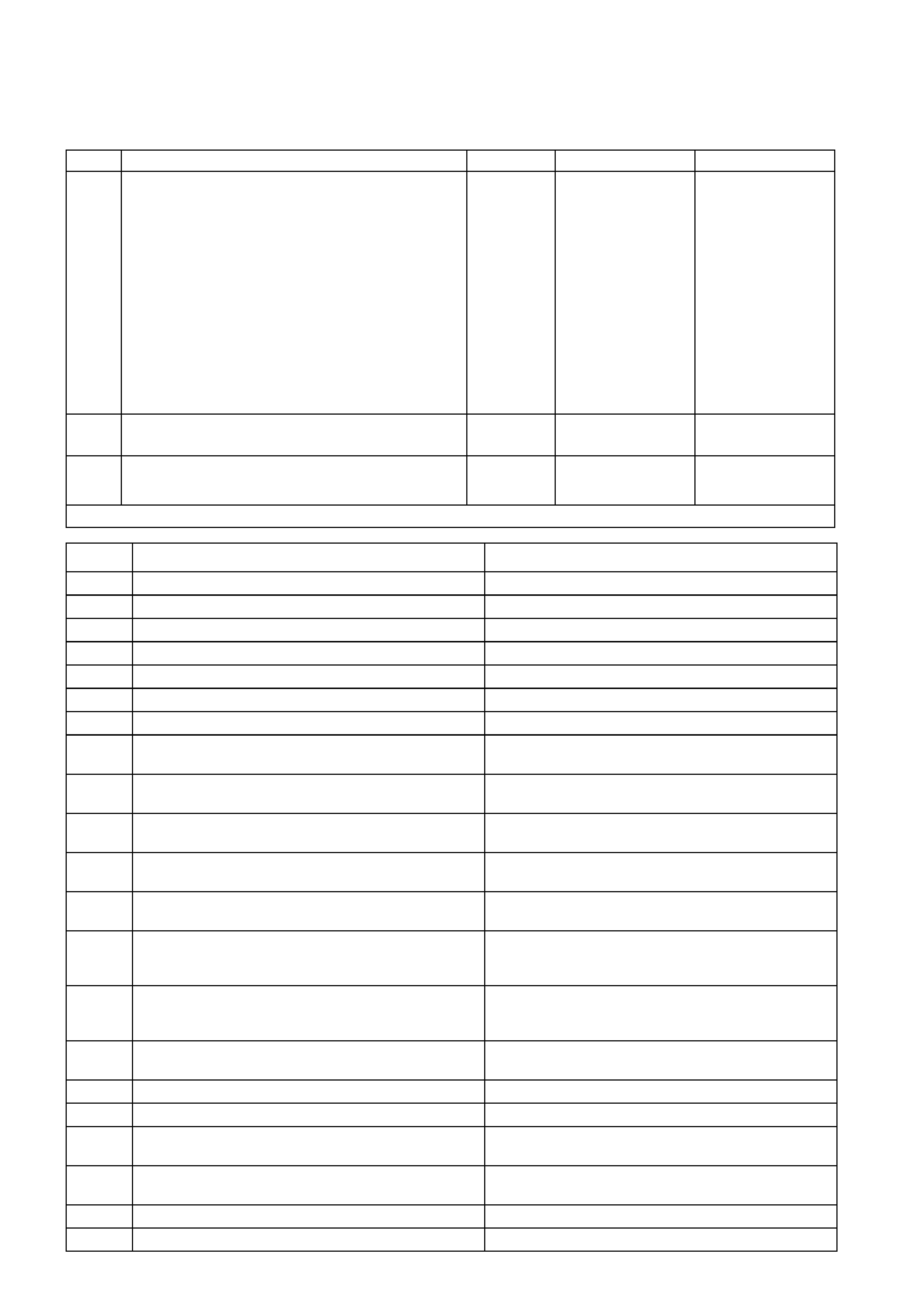

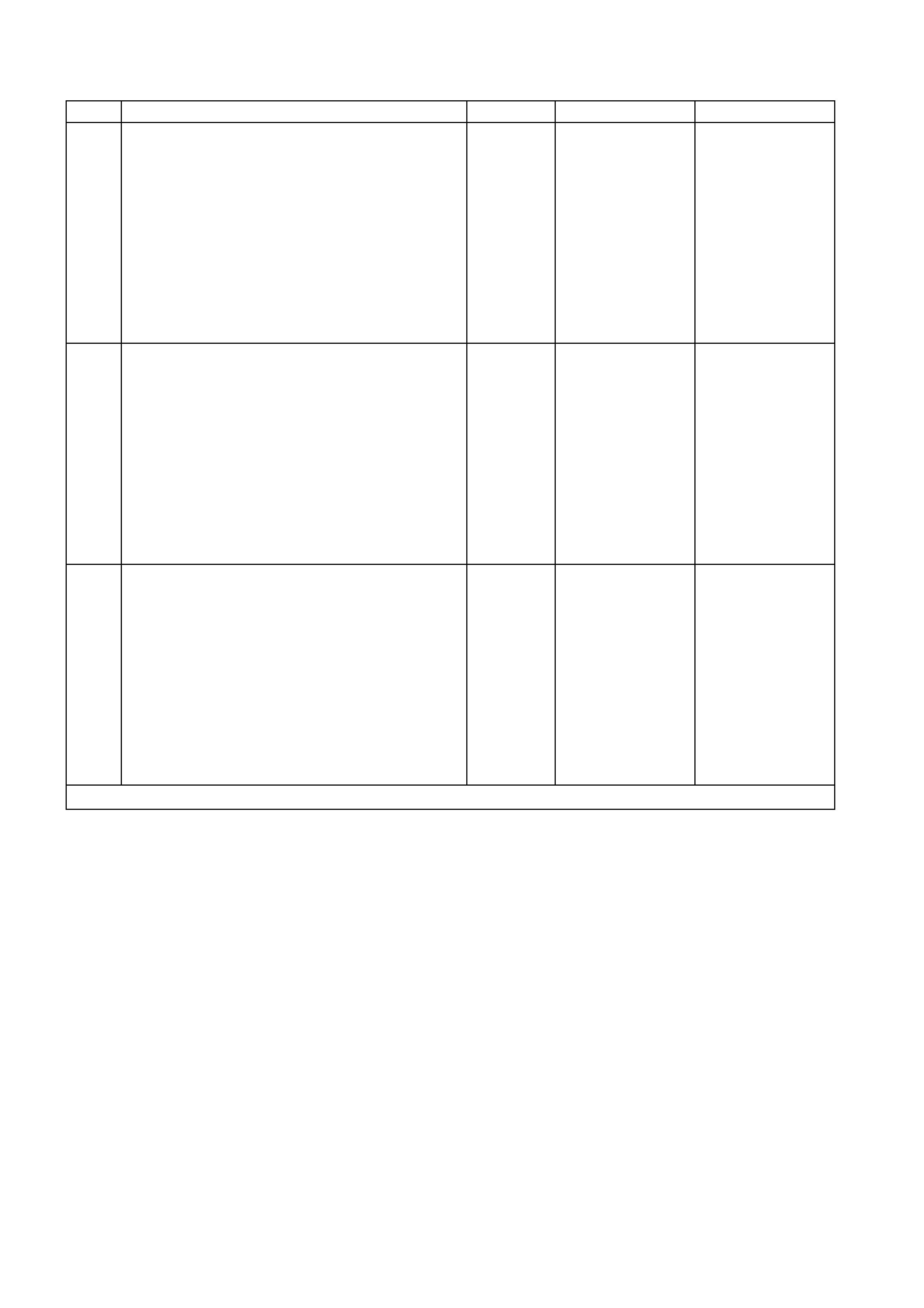

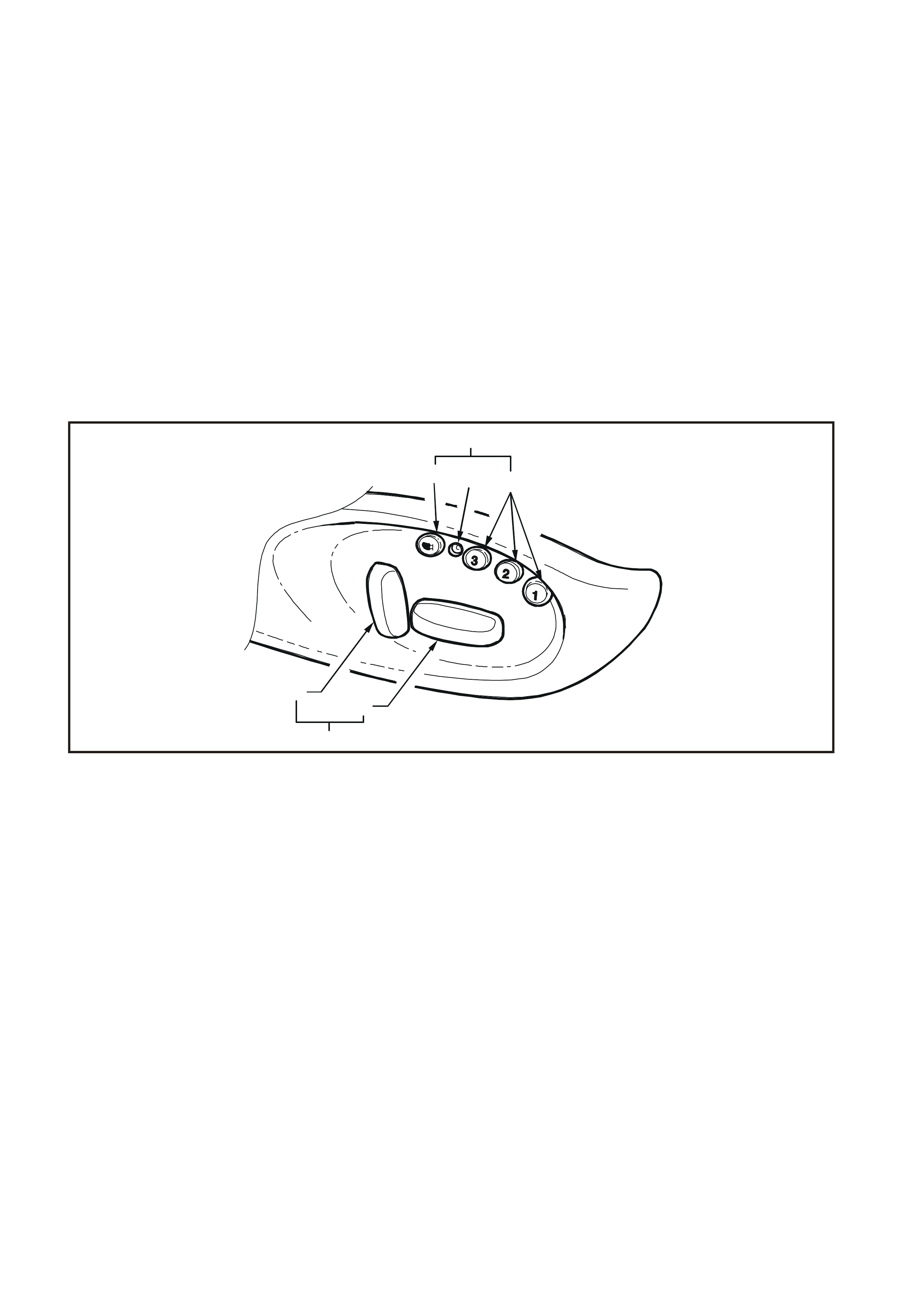

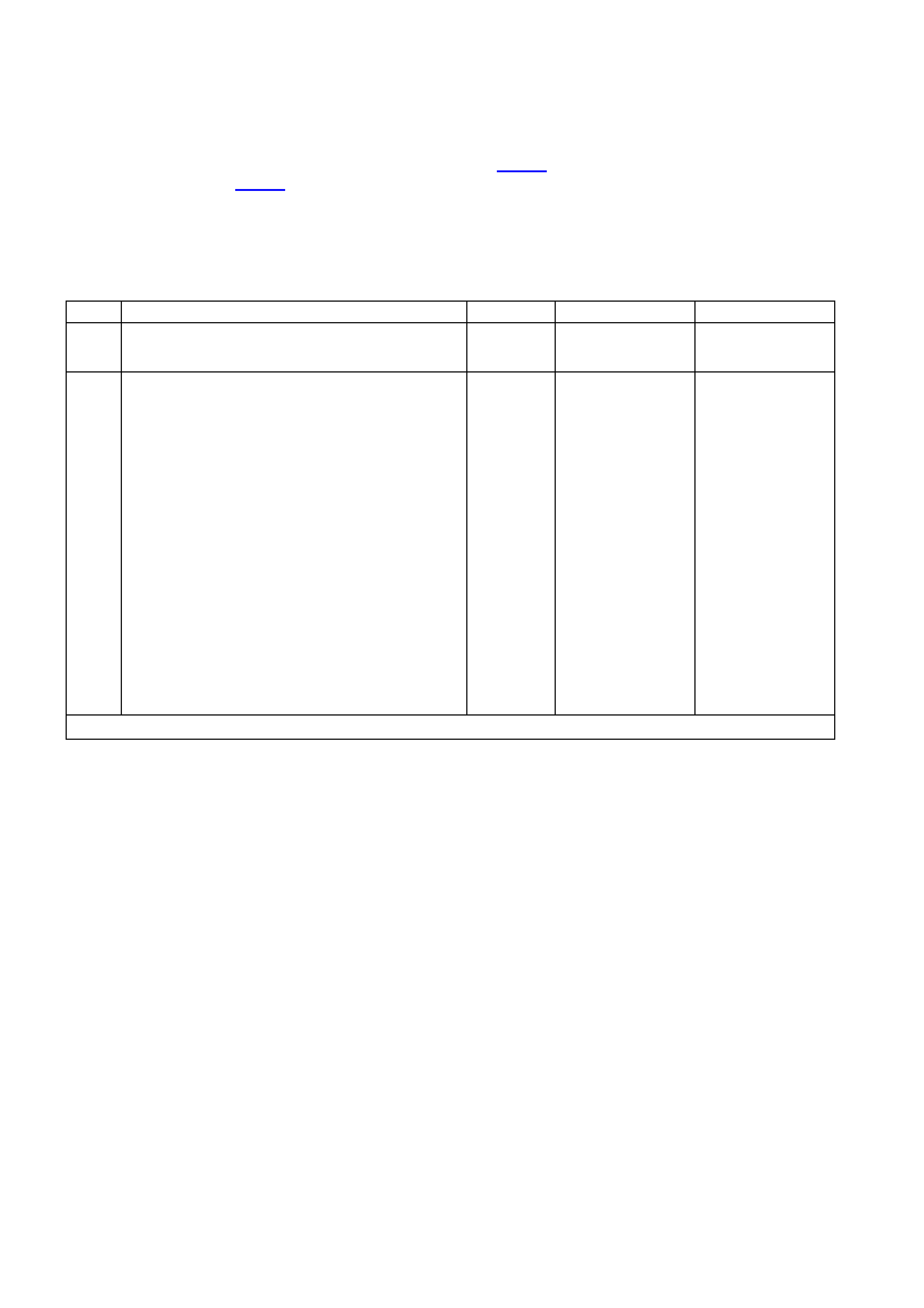

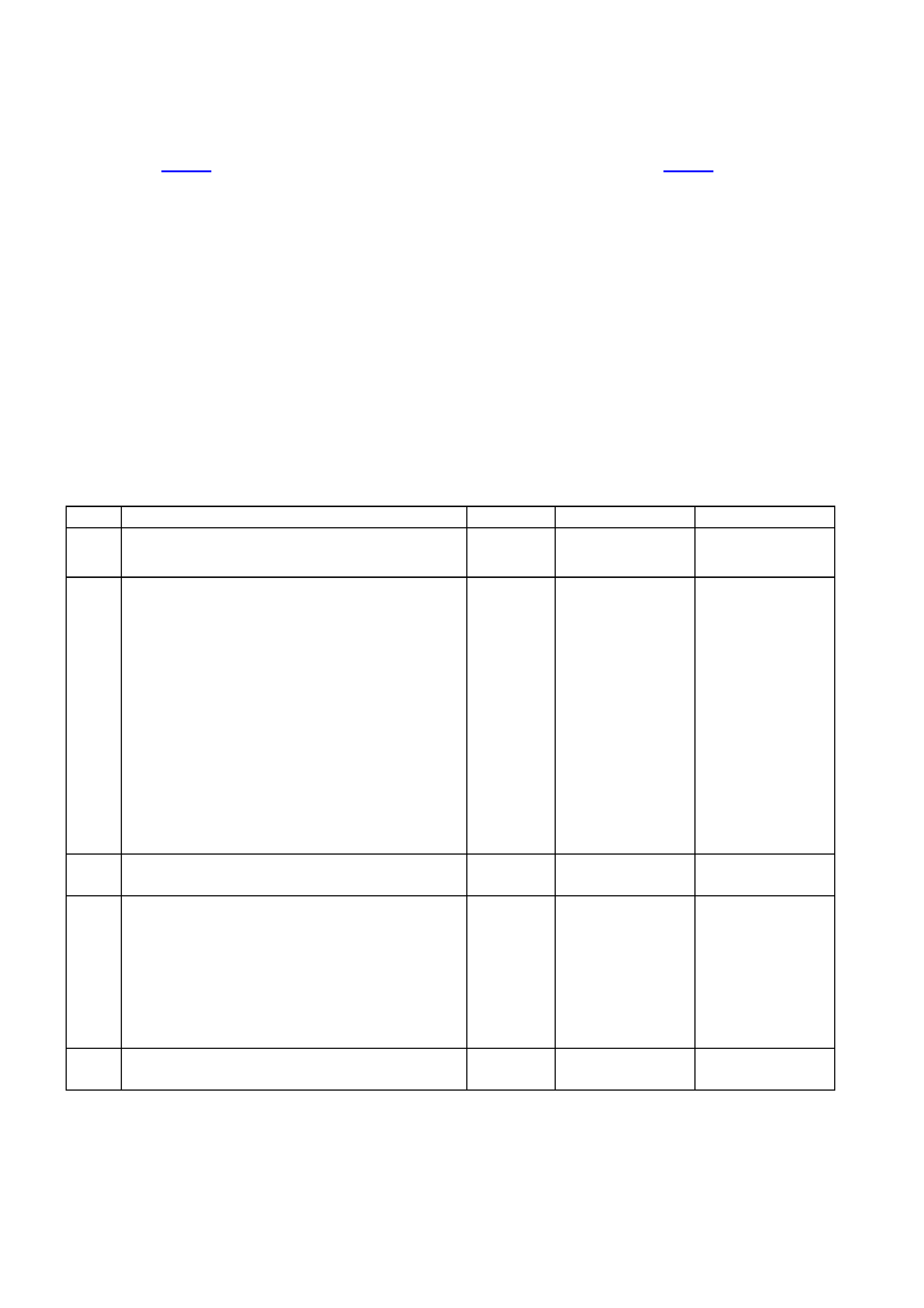

Fig. 1A7-1 illustrates the seat, seat controls and drive motors.

WH1A7001

1

2

3

9

2

3

4

5

8

67

1

Figure 1A7-1

1. Seat Controls 4. Eight-way Seat Position Switch 7. Front Up/Down Drive Motor (Lift Motor)

2. Seat Lower Side Cover 5. Seat Control Module 8. Rear Up/Down Drive Motor (Lift Motor)

3. Memory Position Switch 6. Fore/Aft Drive Motor 9. Backrest Recliner Angle Drive Motor

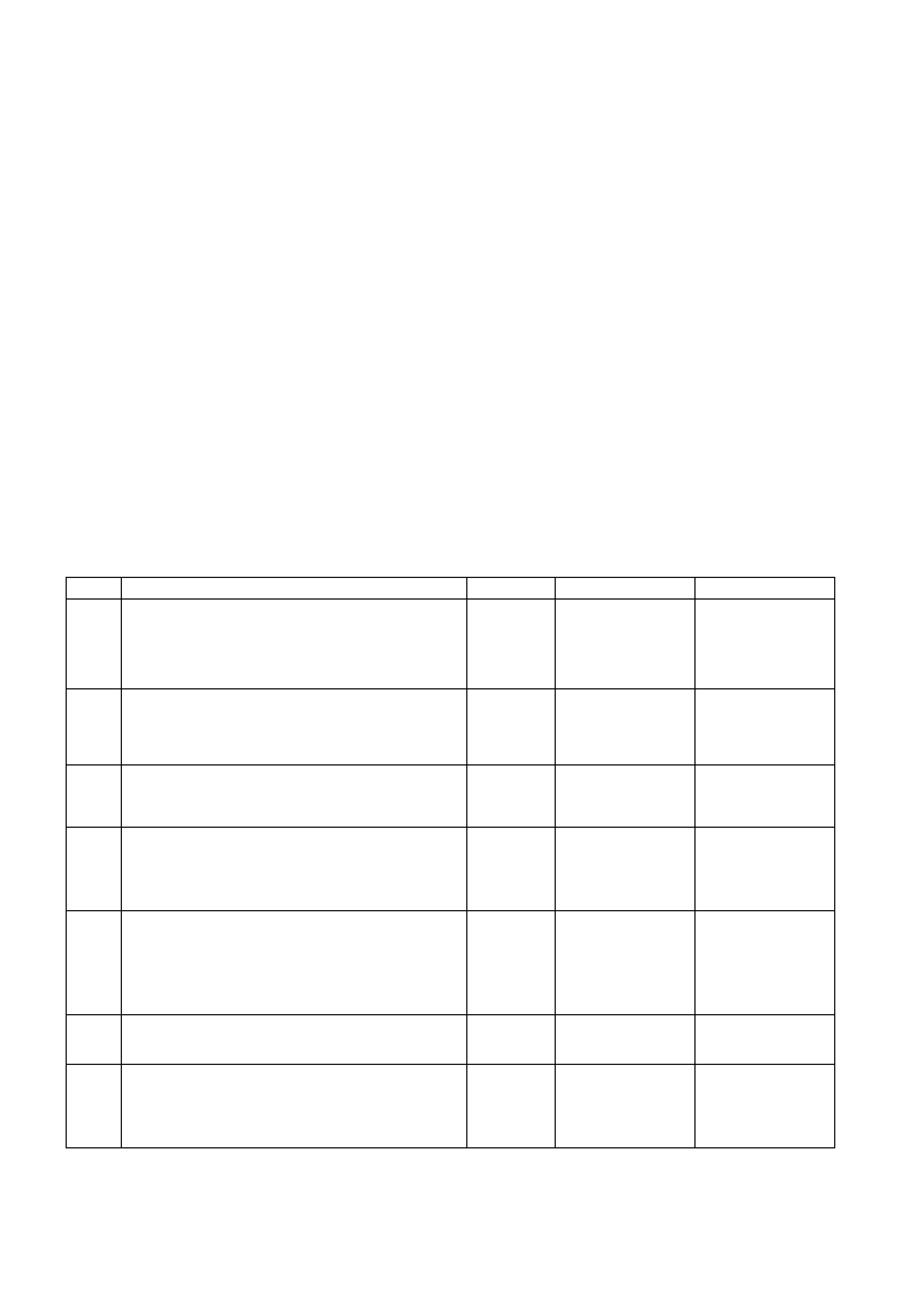

MEMORY SEAT AND MIRROR SYSTEM

The memory seat and mirror system comprises:

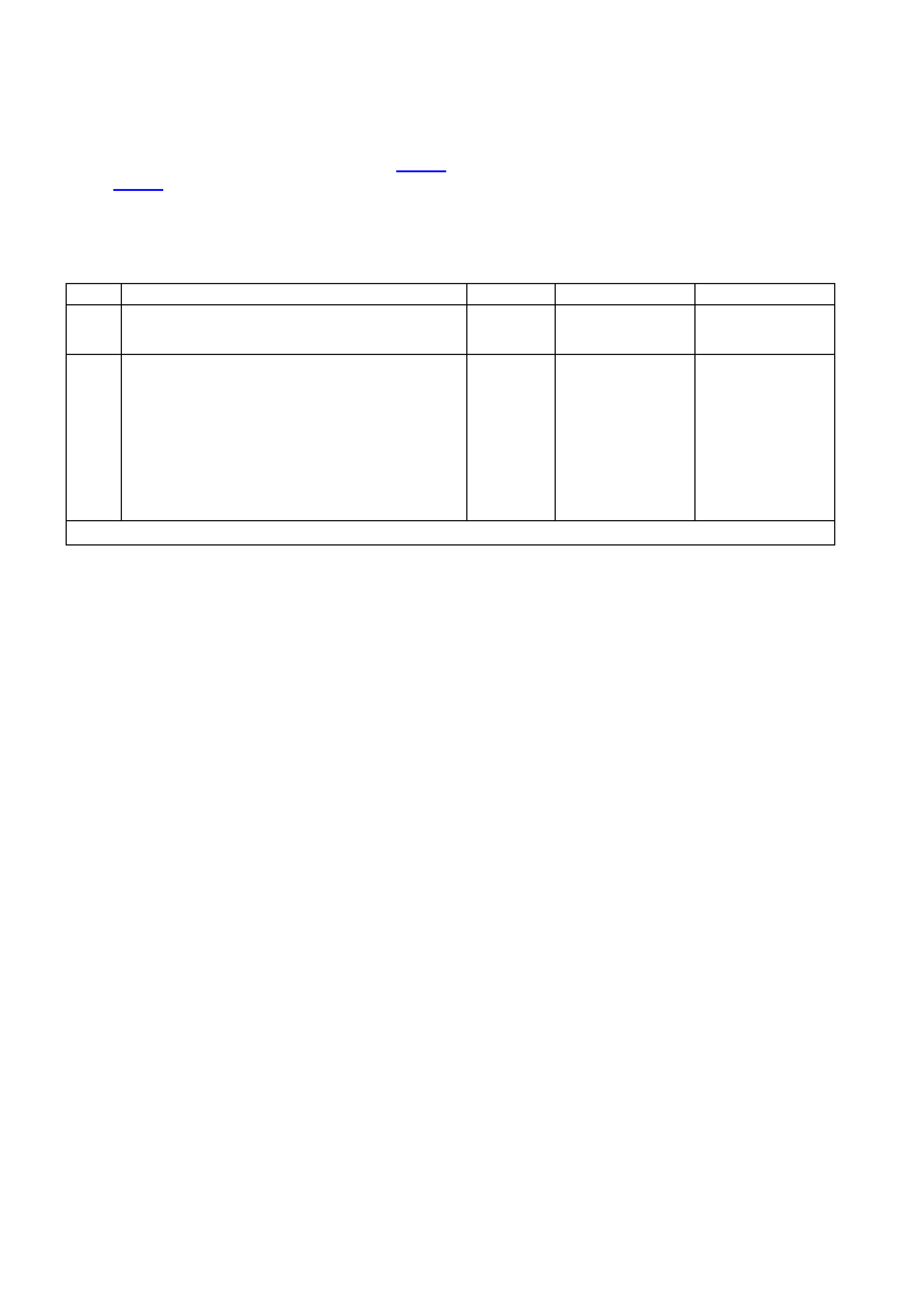

• the seat control module located under the seat lower side cover (refer to Fig. 1A7-1);

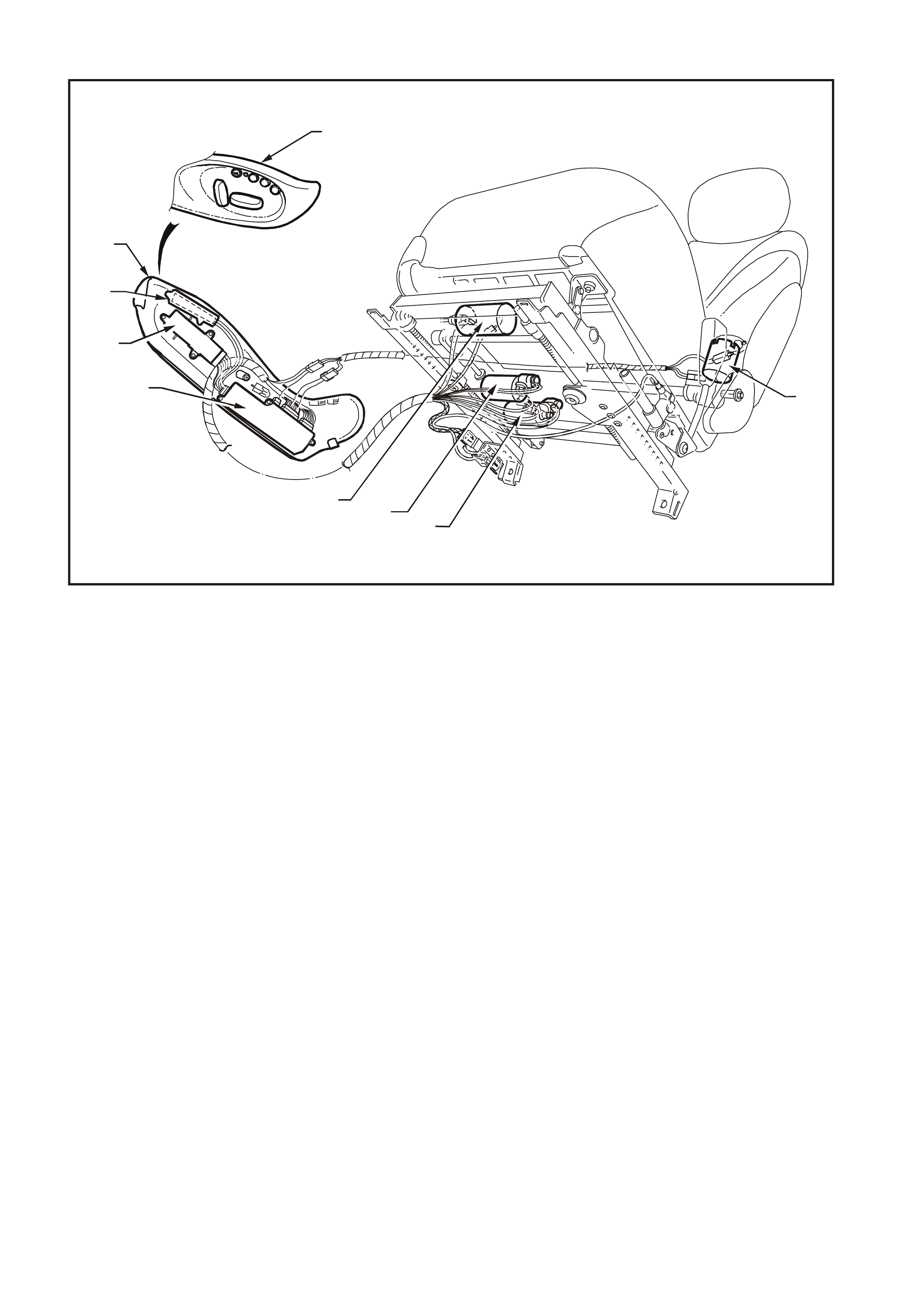

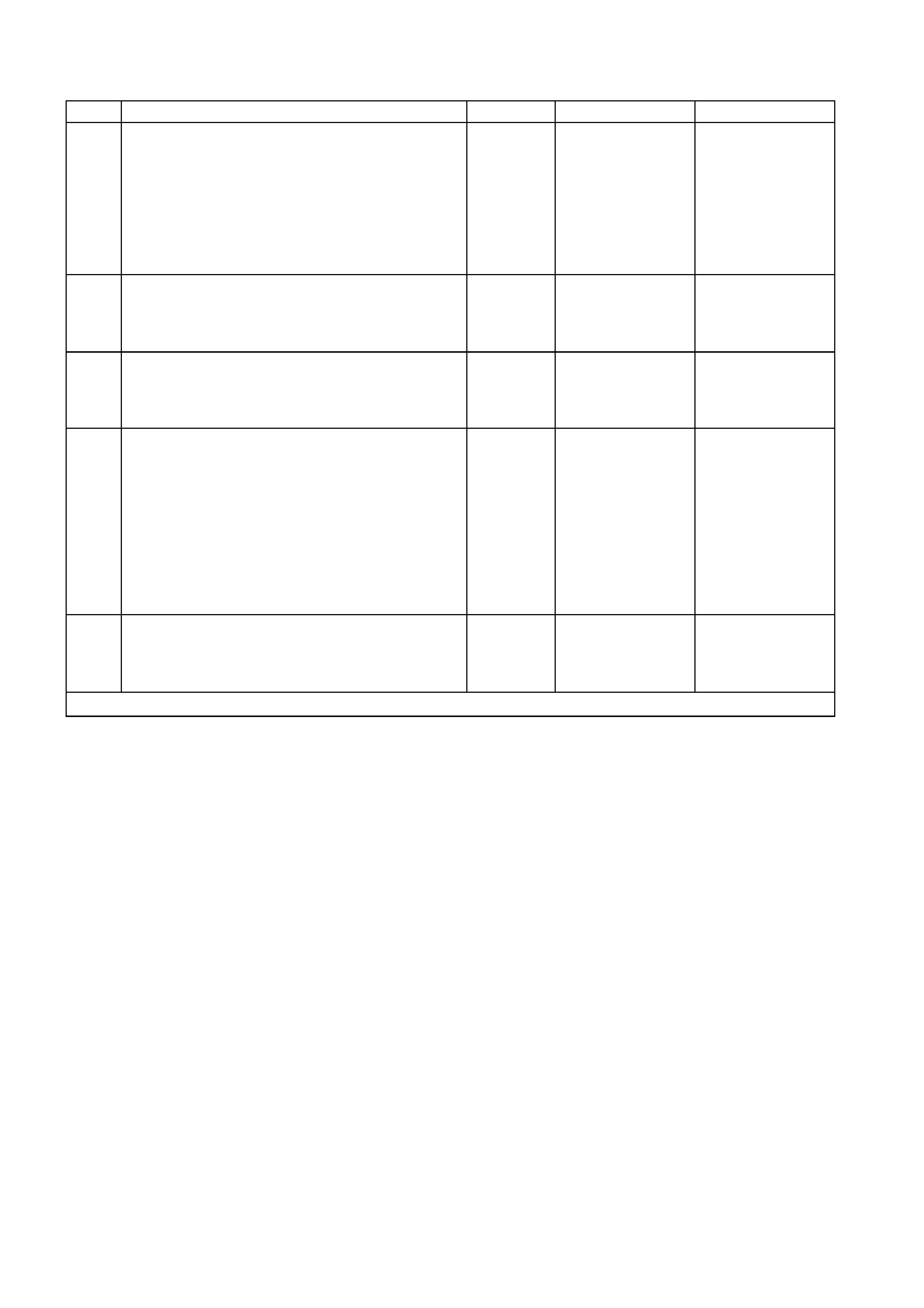

• the memory position switch, which includes memory and mirror dip buttons and associated LED, located on the

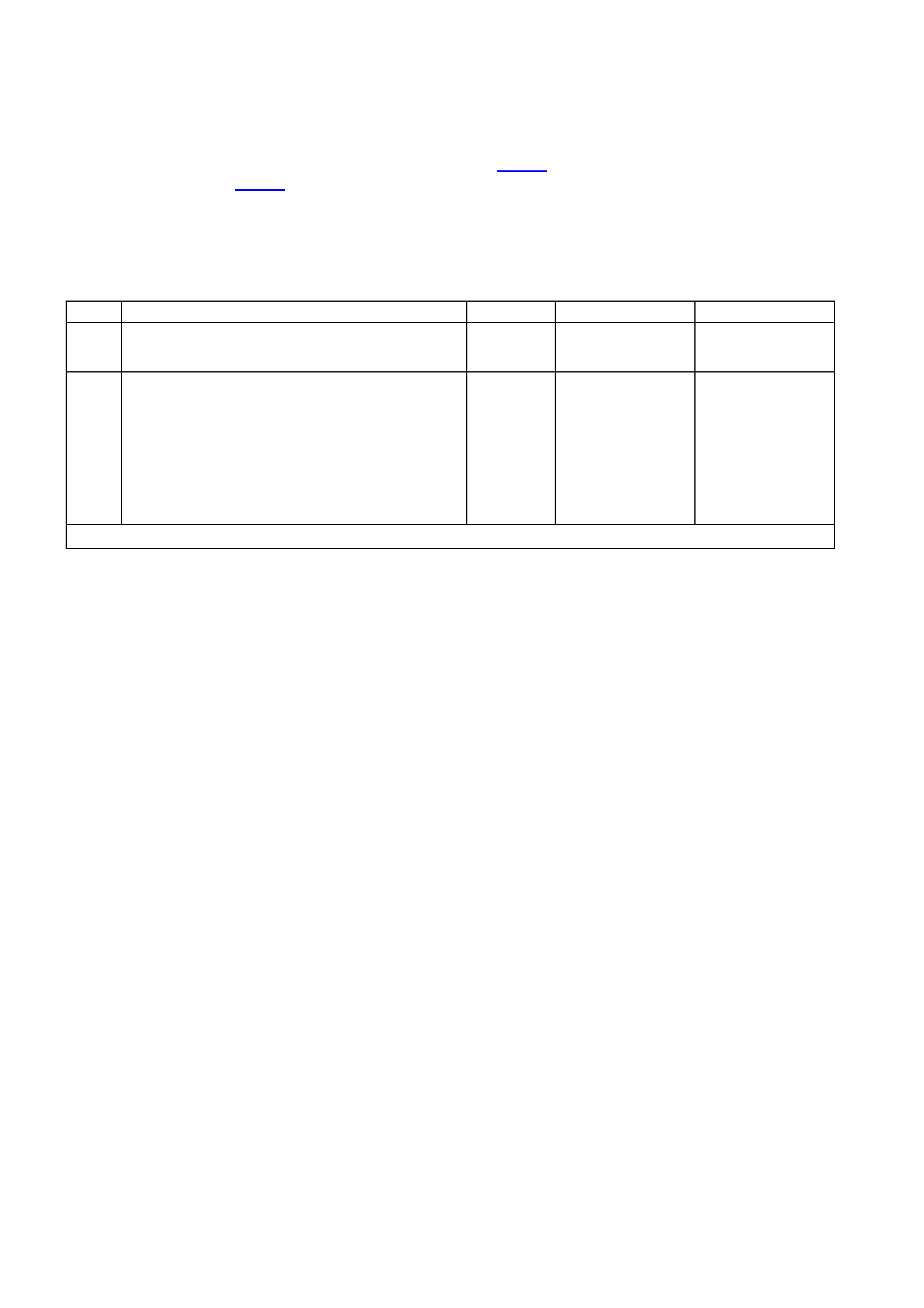

side of the driver’s seat (refer to Fig. 1A7-2);

• the external rear vision mirrors;

• the mirror switch module located in the driver’s door; and

• the mirror switch located on the driver’s door.

The seat control module has five memory sets which allows up to five individual seat and mirror settings to be

stored. Two of these memory settings are associated with the priority keys and the remaining three settings

correspond to the memory buttons 1, 2 and 3 located on the side of the driver’s seat.

The memory seat and mirror system has two modes of operation; a low-current sleep mode and an awake mode. A

5 minute timer circuit switches the system between modes as required, and the current mode is indicated by the

green LED on the side of the seat. When the LED is illuminated the system is in awake mode, and when the LED is

extinguished, the system is in sleep mode.

The sleep mode is entered when:

• the ignition key is in the OFF position, and

• there are no active priority signals, and

• there are no manual seat or mirror adjustments for 5 minutes.

The awake mode is entered when:

• the ignition key is in the IGN position, or

• the priority signals are active, or

• there is a manual seat adjustment, or

• a seat memory button is pressed, or

• the mirror dip button is pressed.

Entering the awake mode resets the 5 minute timer.

Memory Sets

There are five memory sets, as follows:

• Memory set P1 – Priority Key 1,

• Memory set P2 – Priority Key 2,

• Memory set 1 – Button 1 on seat,

• Memory set 2 – Button 2 on seat, and

• Memory set 3 – Button 3 on seat.

Each memory set comprises the following information:

• four co-ordinates for the seat position (in seat control module),

• the mirror dip status (on / off) (in seat control module),

• two co-ordinates for the normal mirror position (in mirror module for each mirror), and

• two co-ordinates for the mirror dip position (in mirror module for each mirror).

Memory Buttons

The three memory buttons and the associated LED are located on the seat lower side cover close to the front edge

of the seat (refer to Fig. 1A7-2). The memory buttons are labelled 1, 2 and 3.

Pressing button 1, 2 or 3 for less than 2 seconds activates the memory recall on release of that button. A low chime

acknowledges the initial button press. The one-touch button recall is only active when the vehicle ignition switch is in

the OFF or ACC position.

Pressing button 1, 2 or 3 for more than 2 seconds updates the system’s memory to the current seat and mirror

positions for that button, including mirror dip positions and status. A high chime acknowledges the system save.

Memory updating is active irrespective of the ignition switch position.

For safety reasons, no memory button recall is allowed when the ignition is on. If a recall is initiated and the ignition

then set to on, the seat and mirror movement recalled from memory will continue until completed.

Pressing any other button, including the mirror switch on the driver’s door, after a memory recall is initiated will

terminate the recall move.

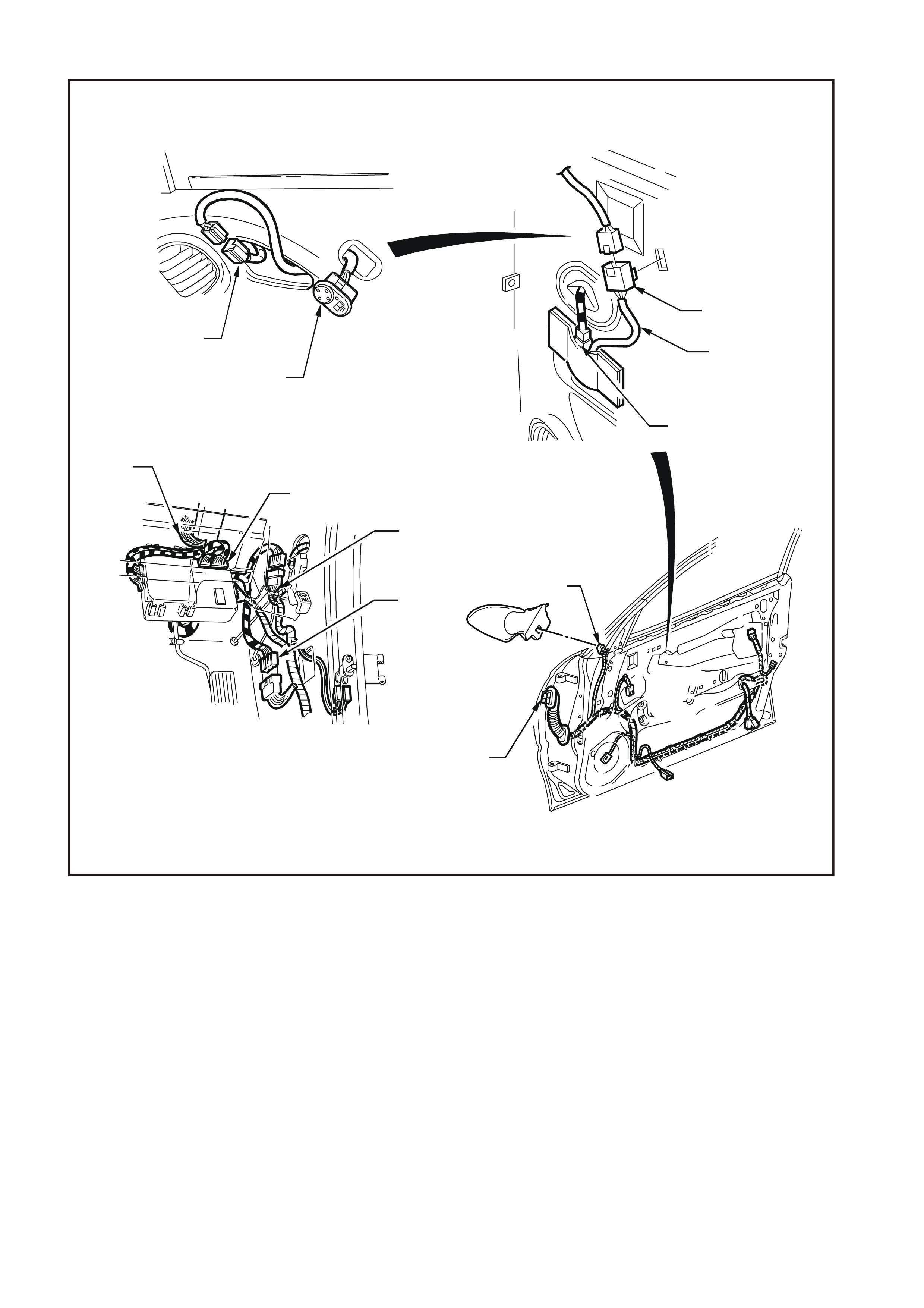

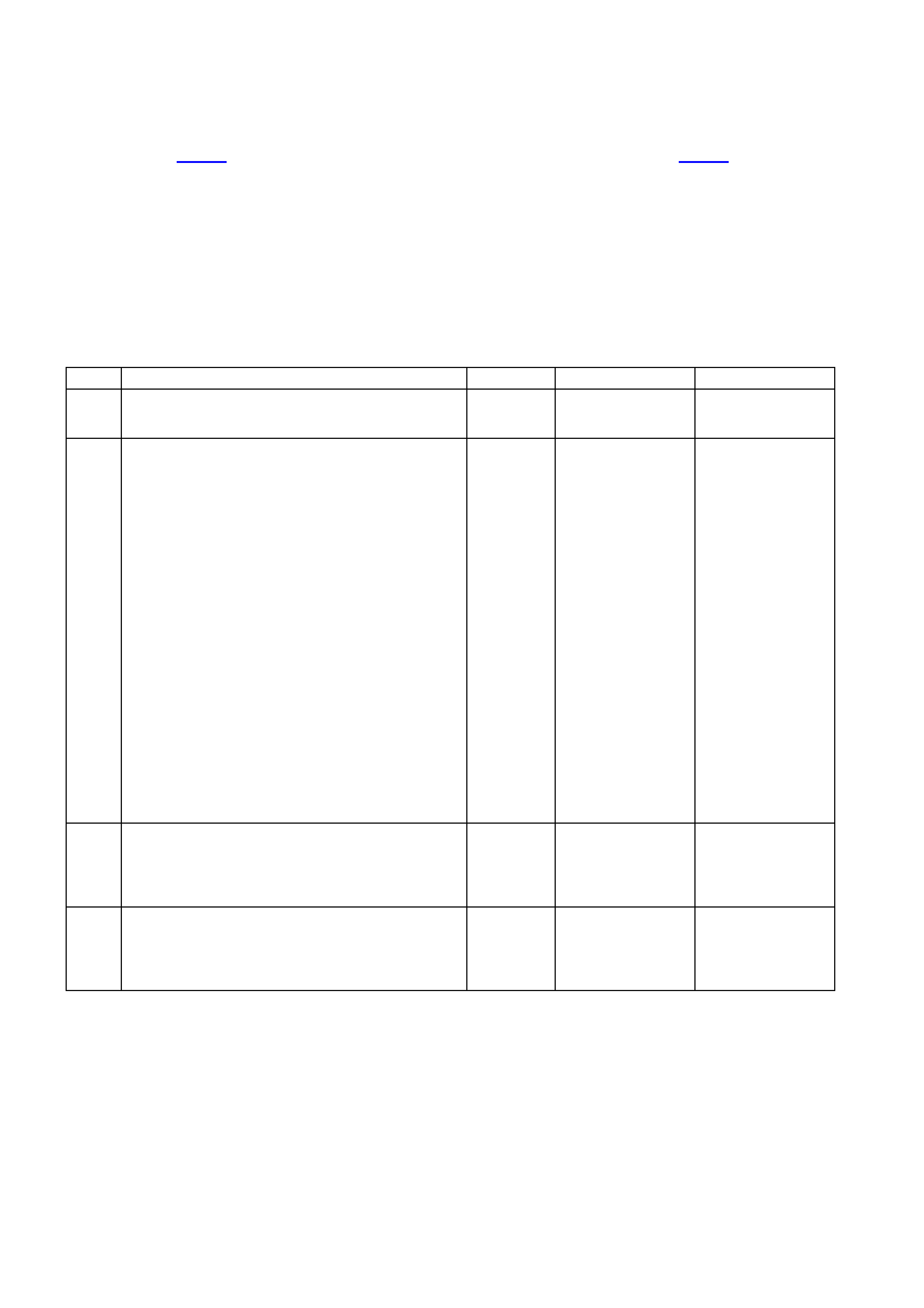

WH1A7002

123

65

7

4

Figure 1A7-2

1. Mirror Dip Button 4. Memory Position Switch 6. Backrest Recliner Angle Adjust

2. Diagnostic LED 5. Fore/Aft/Up/Down/Tilt Adjust 7. Eight-way Seat Position Switch

3. Memory Buttons

Reversing Mirror Dip Function

The mirror dip button is located on the lower seat cover to the rear of the memory buttons and LED (refer to Fig.

1A7-2). The mirror dip button is labelled with a mirror graphic.

The mirror dip button is only active when the ignition is on and reverse gear is selected. Pressing the mirror dip

button toggles the internal mirror dip flag, which initiates a high chime for enabled, or a low chime for disabled.

With the ignition on and the mirror dip flag enabled, selecting reverse gear for longer than 0.5 second sets the

passenger’s external mirror to the dip position. Pressing the button again, or selecting another gear, returns the

mirror to the normal driving position.

Priority Function

The priority recall signals generated by the BCM wake up the memory seat and mirror system to recall the last

saved priority seat and mirror positions associated with the ignition key in use (Priority 1 or Priority 2).

For safety reasons, the priority recall function is activated only when the ignition switch is in the OFF position. No

automatic movement of the system occurs when the ignition switch is set to IGN. If a priority move has been

initiated before the ignition transition from OFF to IGN, the system completes the move before disabling the one-

touch or priority recall function.

After the ignition switch is set to IGN, the system notes the active priority key number used. The system only

updates the current memory when the driver makes a manual adjustment to the seat or mirrors. The update

includes the current seat and mirror position and the last reverse mirror dip position.

When the seat or mirror is adjusted by the driver using the manual buttons, the current priority memory is updated

immediately after the movement stops. Toggling the mirror dip button does not alter the stored normal or dip

settings.

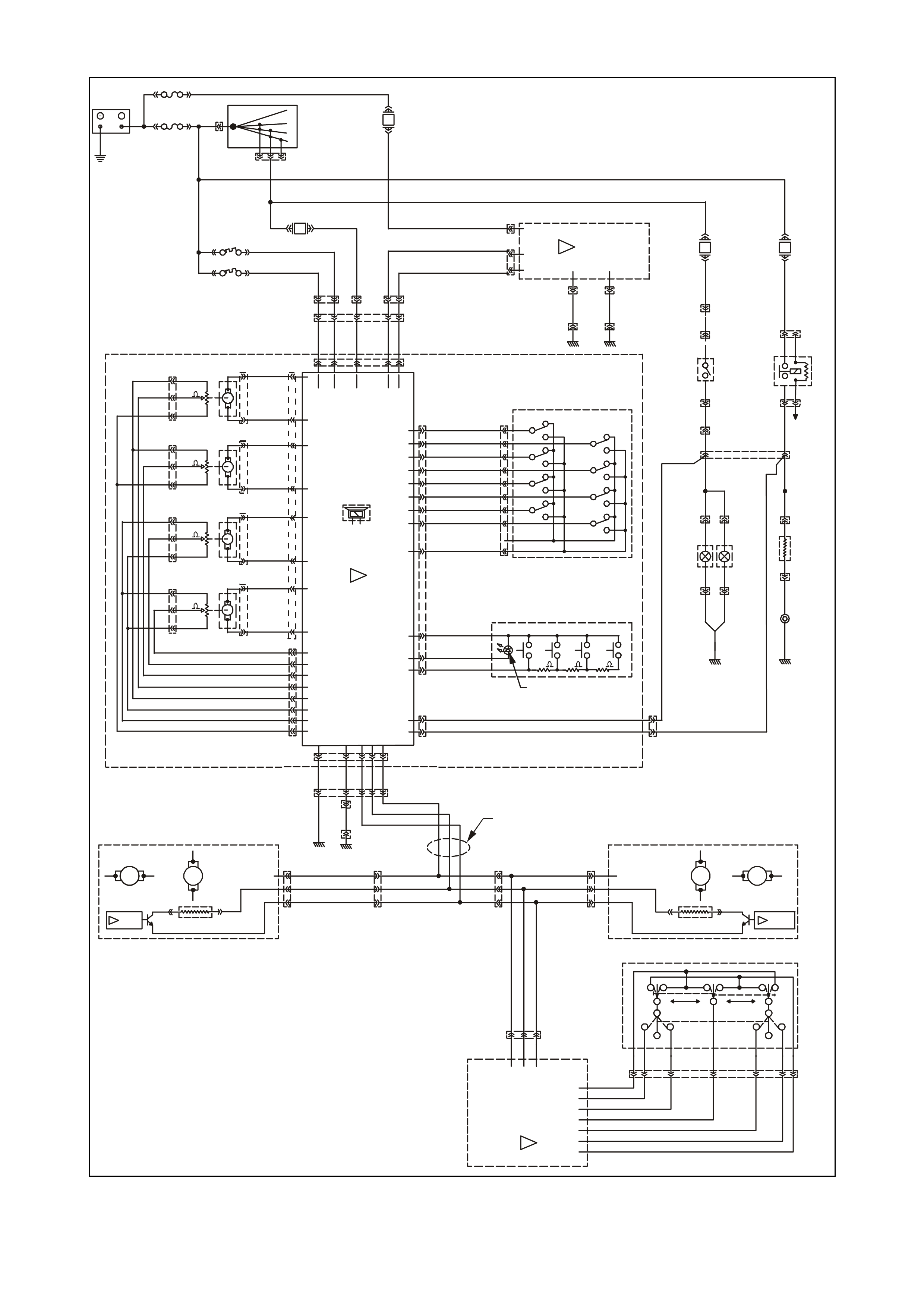

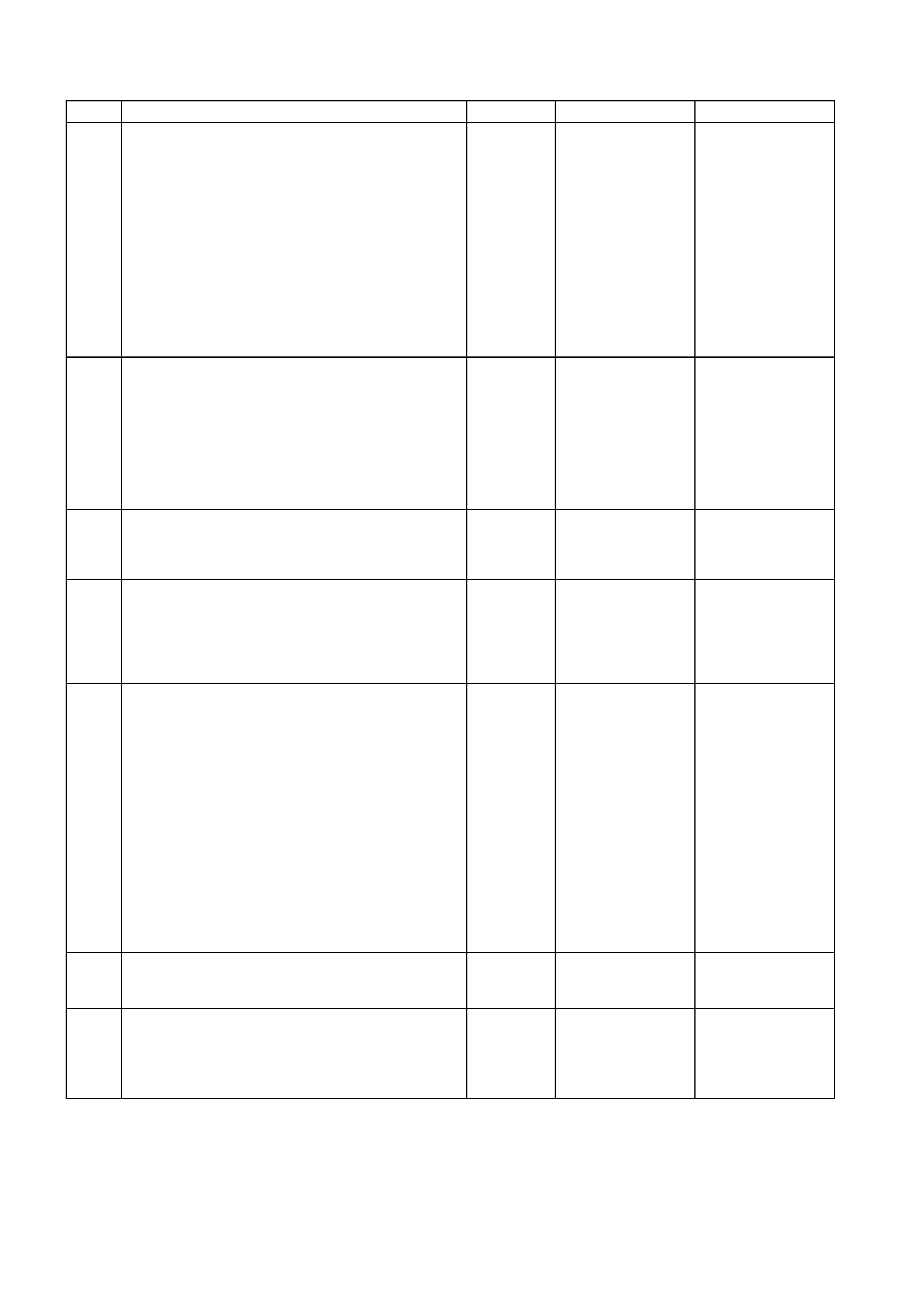

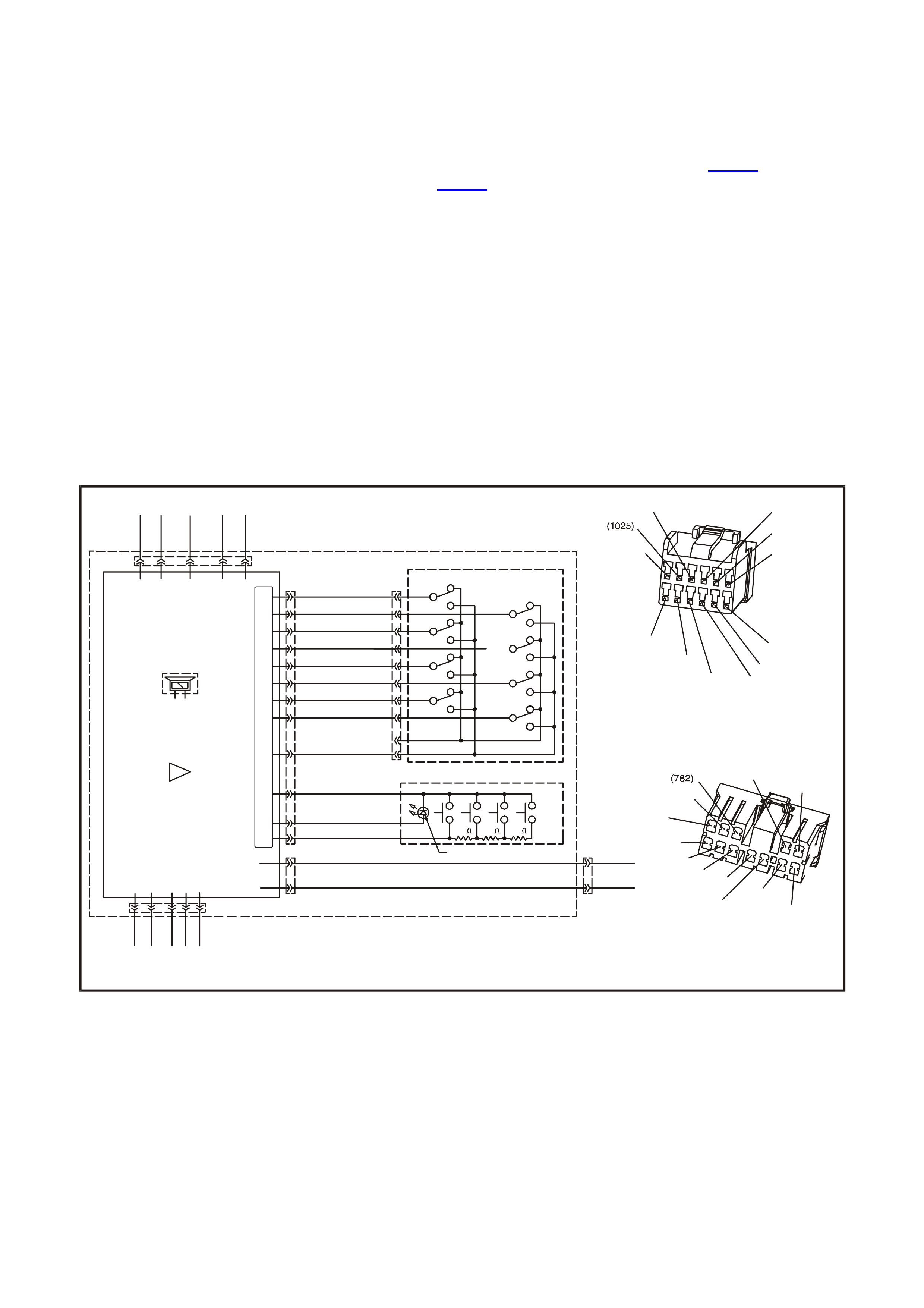

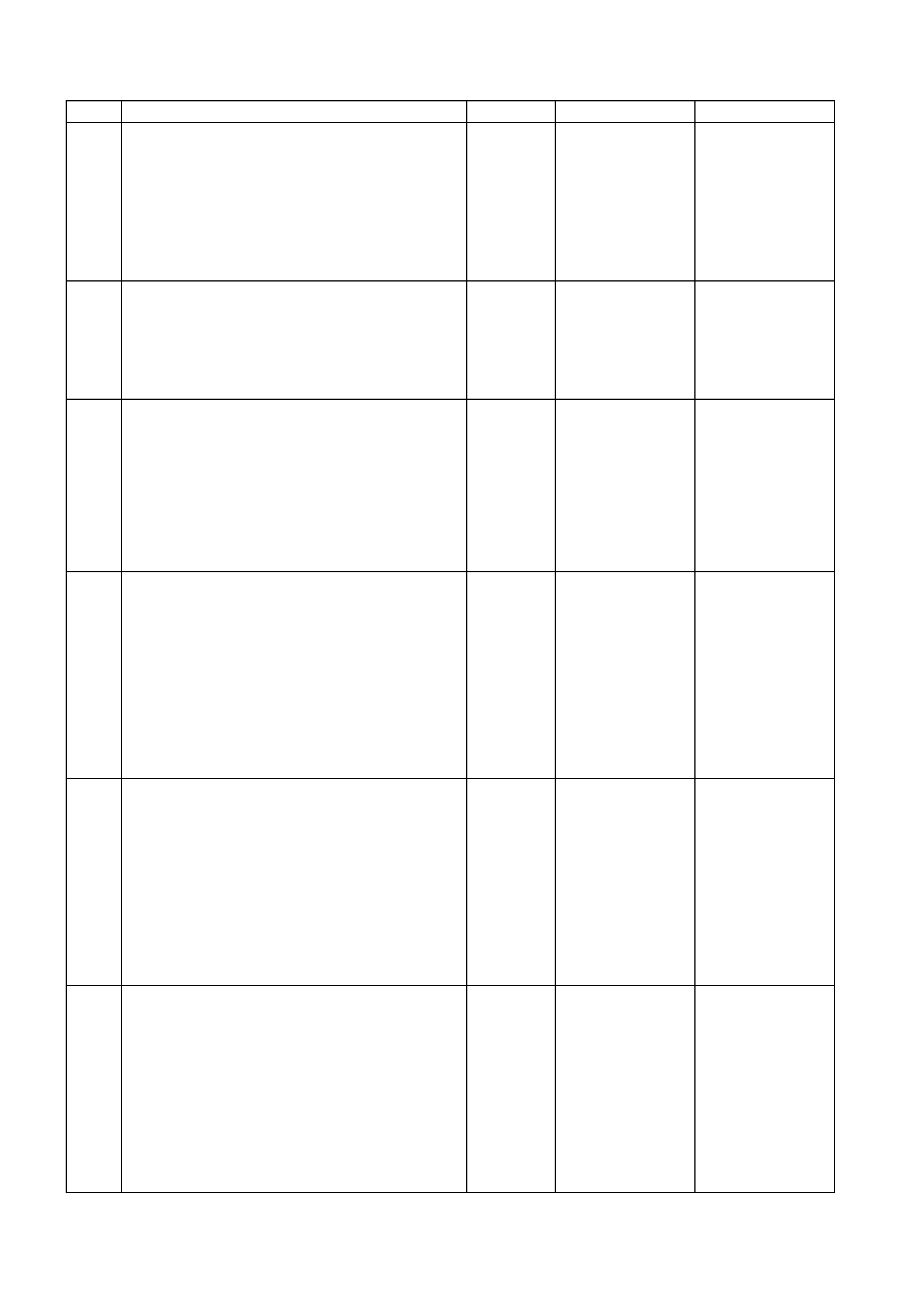

Module Control Signals

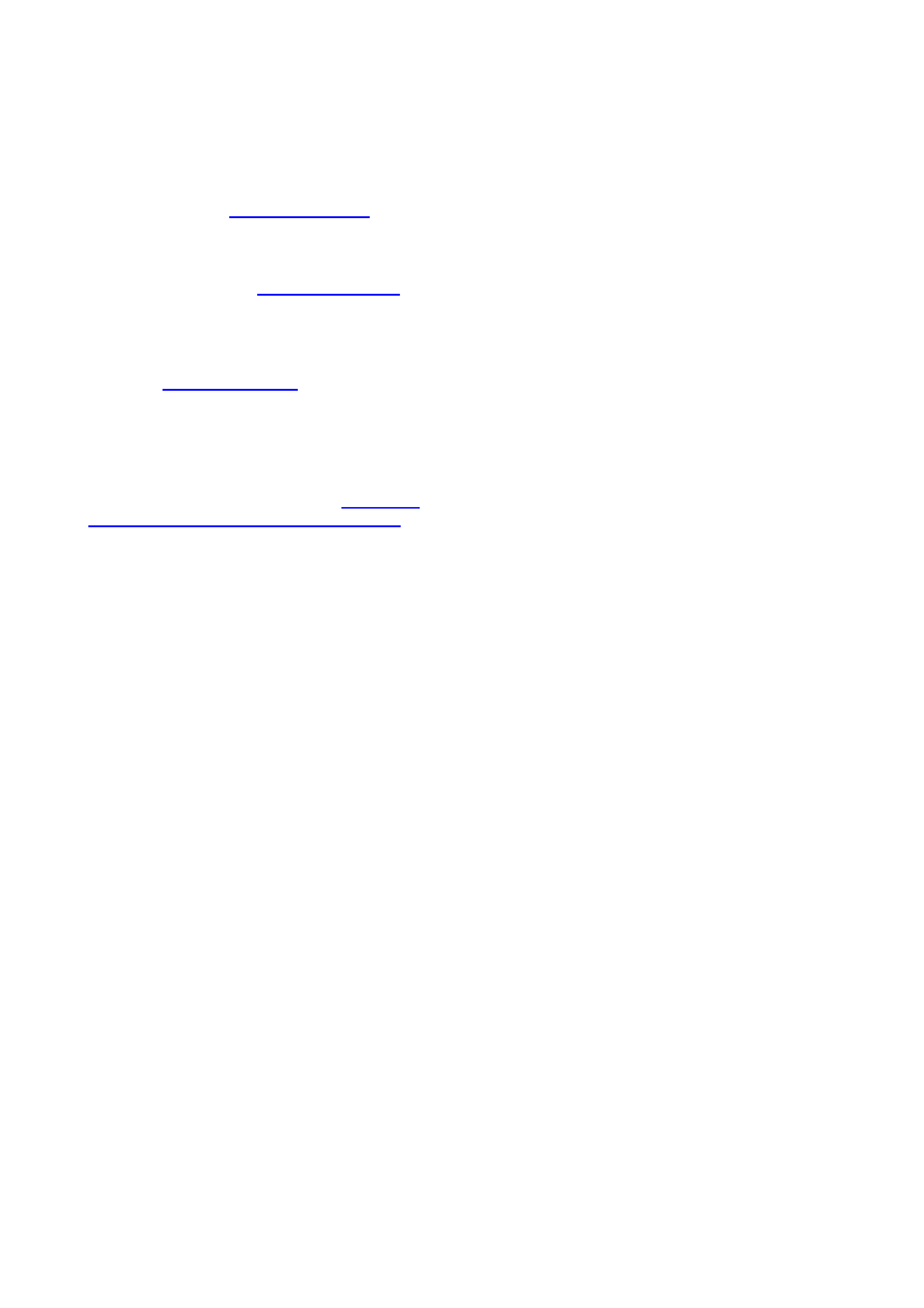

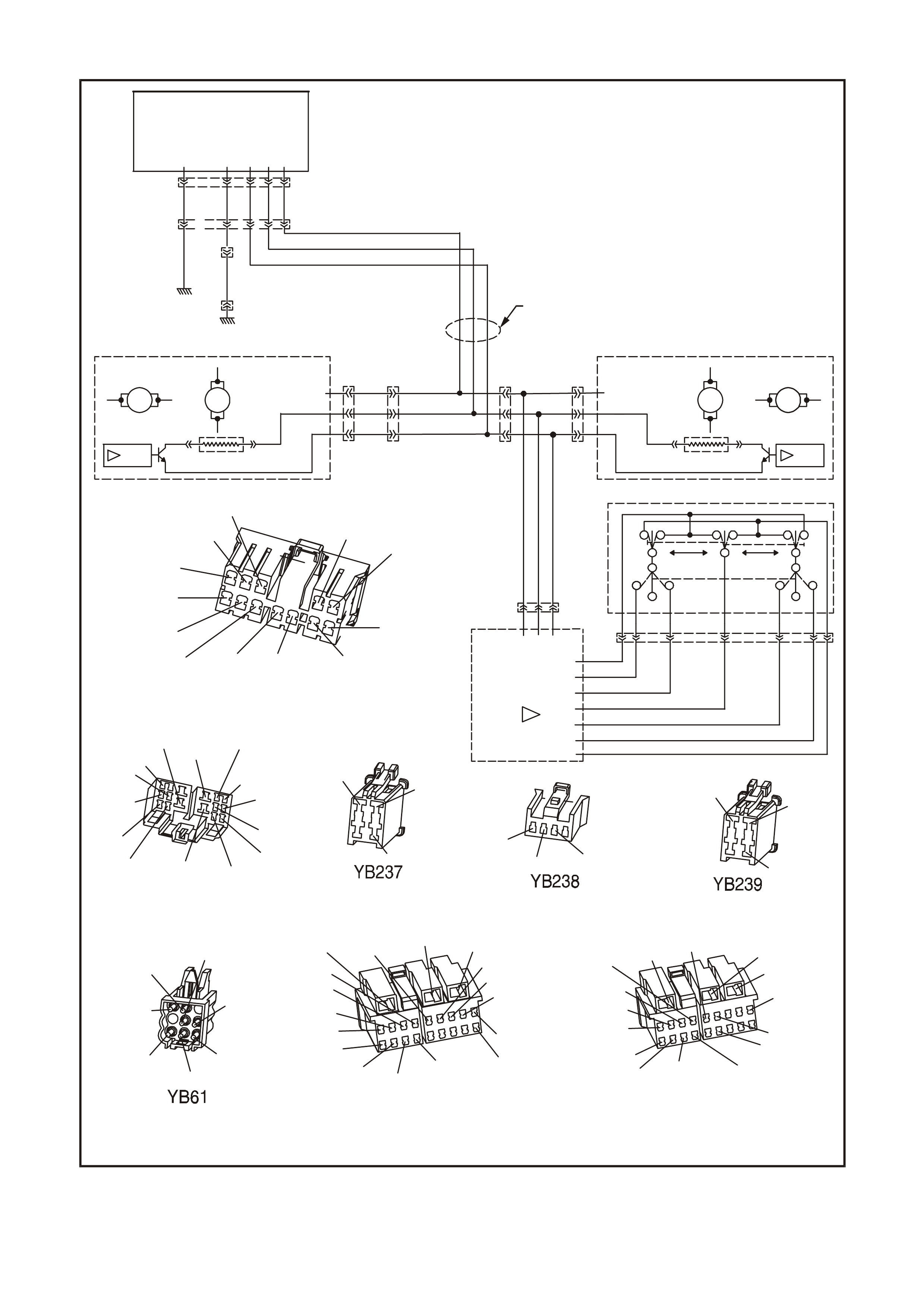

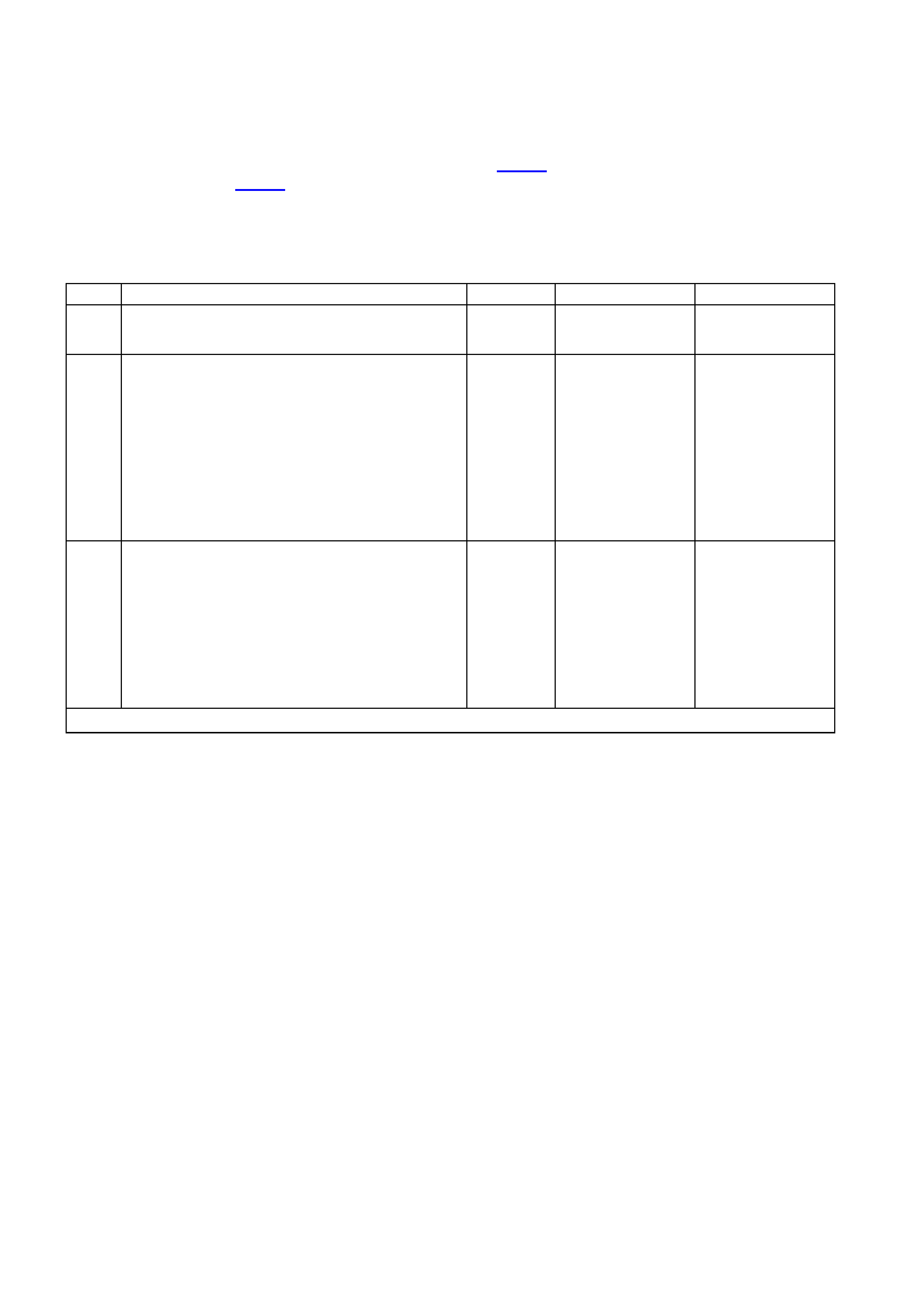

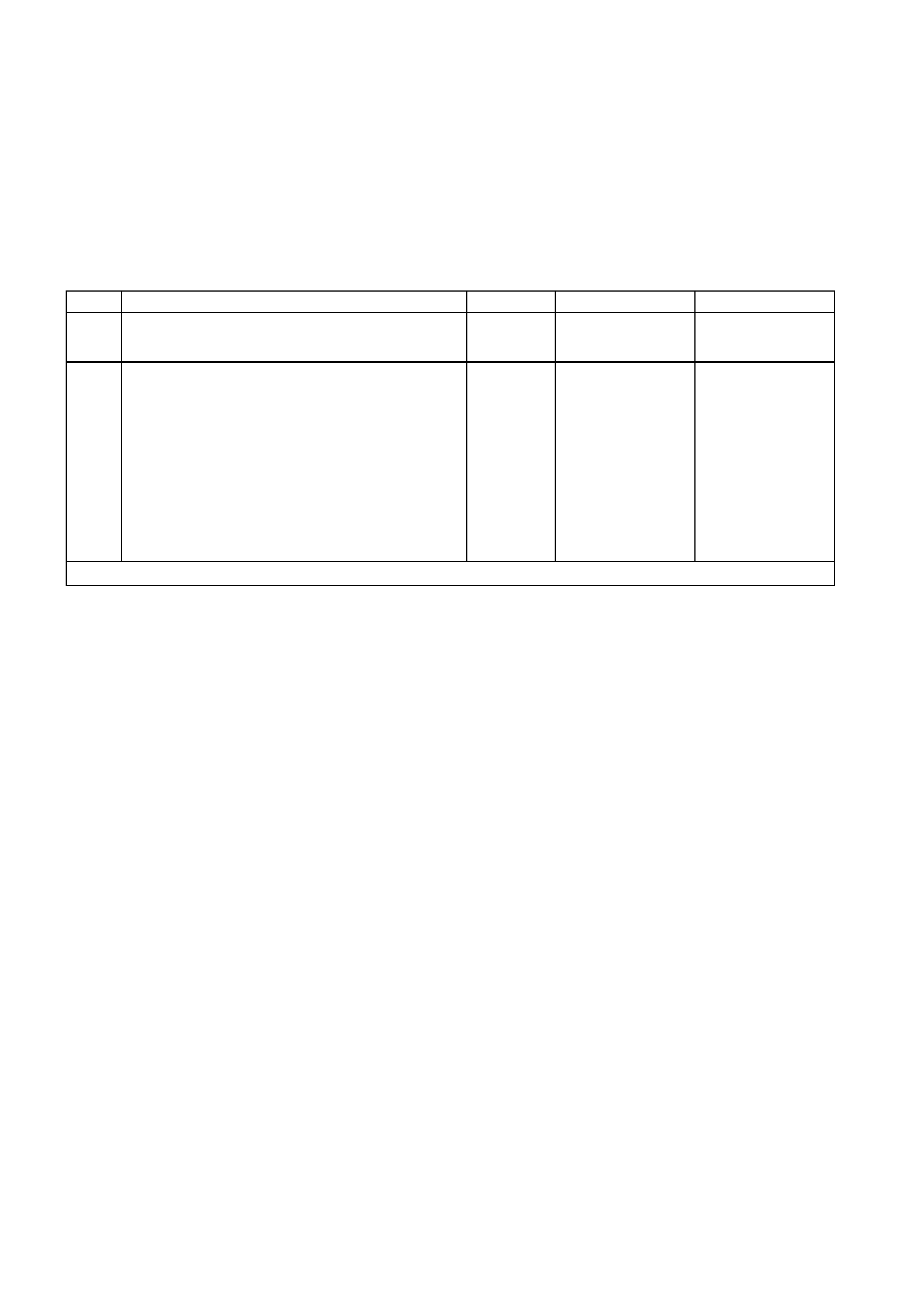

Four electrical connectors are located on the seat control module. The location of each connector is shown in Fig.

1A7-3 and circuit information is shown in Fig. 1A7-6. The seat control module connectors are:

• the memory and position connector YB225,

• the power connector YB227,

• the drive motor connector YB228, and

• the drive motor potentiometer connector YB229.

The memory and position connector YB225 connects the eight-way seat position switch to the seat control module.

Whenever a switch position is selected on the eight-way seat position switch, an earth is applied to the appropriate

input terminal to indicate to the seat control module that a change in seat position is required.

System power and earth as well as the priority key, reverse gear and heated window control signals are all applied

to the seat control module via the power connector YB227. The 12 signals on this connector are:

• The 12 V on circuit 540, which supplies the power for the seat drive motors.

• The 12 V on circuit 641, which supplies the power for the seat control module.

• The 12 V on circuit 139, which indicates the status of the ignition switch to the seat control module.

• The Priority 1 (circuit 782) and Priority 2 (circuit 783) signals, which indicate to the seat control module which

priority key has been used to open the vehicle. This is used to set the seat and mirrors to the position required by

the priority key.

• The Reverse signal on circuit 24, which indicates to the seat control module that the reverse gear has been

selected. This is used to dip the mirror on the passenger’s side of the vehicle.

• The Heated Rear Window signal on circuit 192, which controls the application of the supply voltage to the

external mirrors.

• The mirror serial data bus comprises three circuits; a data line (circuit 925), a 12 V supply line (circuit 929) and

an earth line (circuit 920).

• The earth for the seat drive motors is provided by circuit 156.

• The earth for the seat control module is provided by circuit 151.

The drive motor connector YB228 provides the power and earth circuits for each of the four seat drive motors.

The drive motor potentiometer connector YB229 provides the power and earth circuits for the potentiometers as

well as the seat drive motor position signal from the wiper of each potentiometer.

DIAGNOSTIC READOUT

The green LED located on the side of the driver’s seat is used to indicate the seat mode of operation as well as to

read out the various diagnostic trouble codes stored within the seat control module for fault diagnosis purposes.

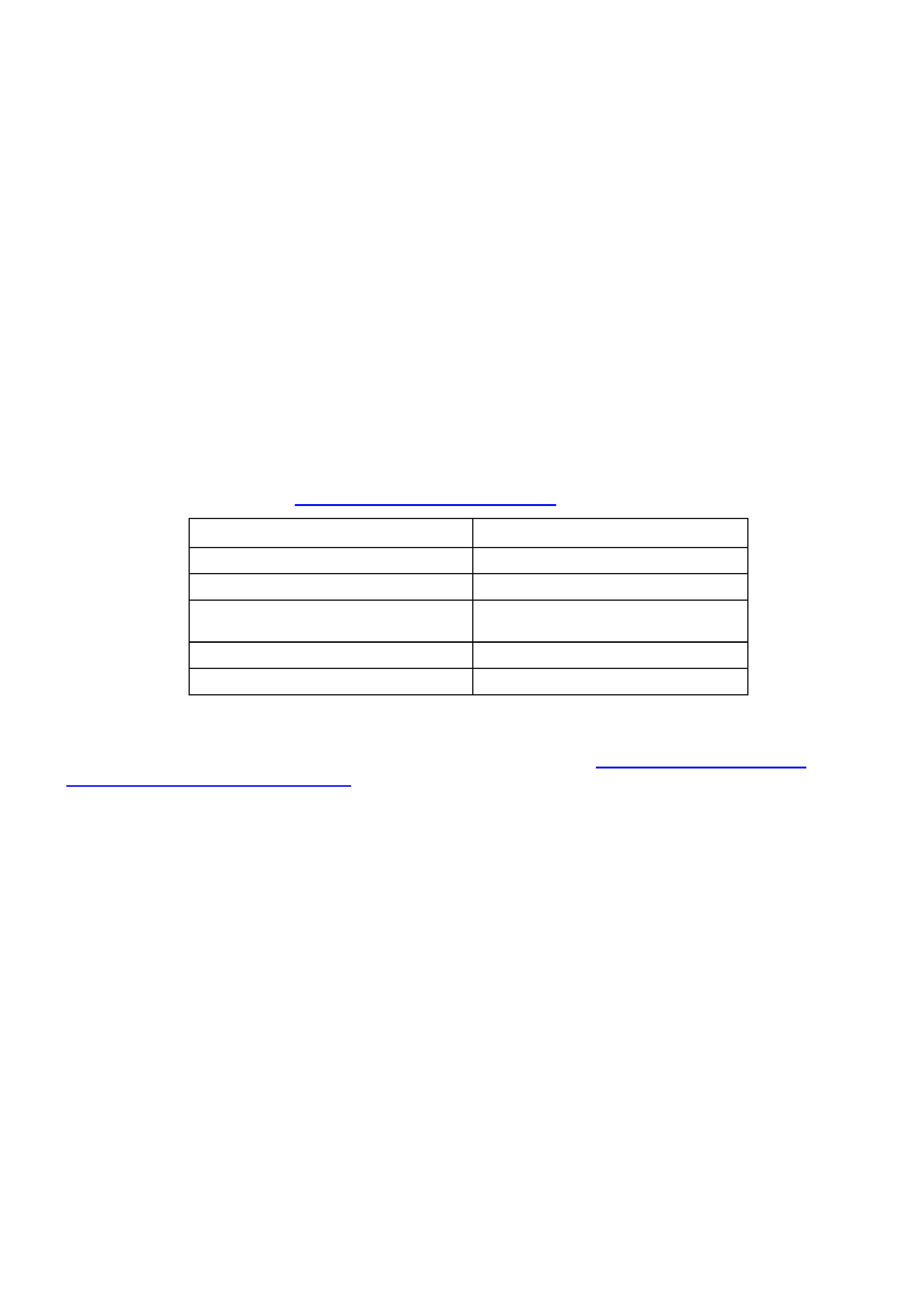

The following table details the indications given by the LED in normal operation. For details on the various

diagnostic trouble codes, refer to 3.3 DIAGNOSTIC TROUBLE CODES in this Section.

MANUAL CONTROLS

The external rear vision mirrors can be controlled manually from the interior of the vehicle by the mirror switch

mounted in the driver's side front door pull handle. For further details, refer to Section 12H ELECTRICA LLY

ADJUSTABLE REAR VISION MIRRORS of the VT Series I Service Information.

An eight-way seat position switch is fitted to the outside of each seat frame. The horizontal switch provides

independent control of front and rear height (up and down movement) and fore/aft movement of seat, while the

vertical switch controls the seat backrest recliner angle.

During manual seat adjustment, the seat control module monitors the position of each motor axis and will shut down

the drive motor just before reaching the end of the track, even if the eight-way seat position switch is held on.

LED STATUS INDICATION

One flash. Priority 1 detected.

Two flashes. Priority 2 detected.

Three flashes when ignition set from

IGN to OFF. Diagnostic trouble code logged.

Steady illumination. System in awake mode.

Extinguished. System in sleep mode.

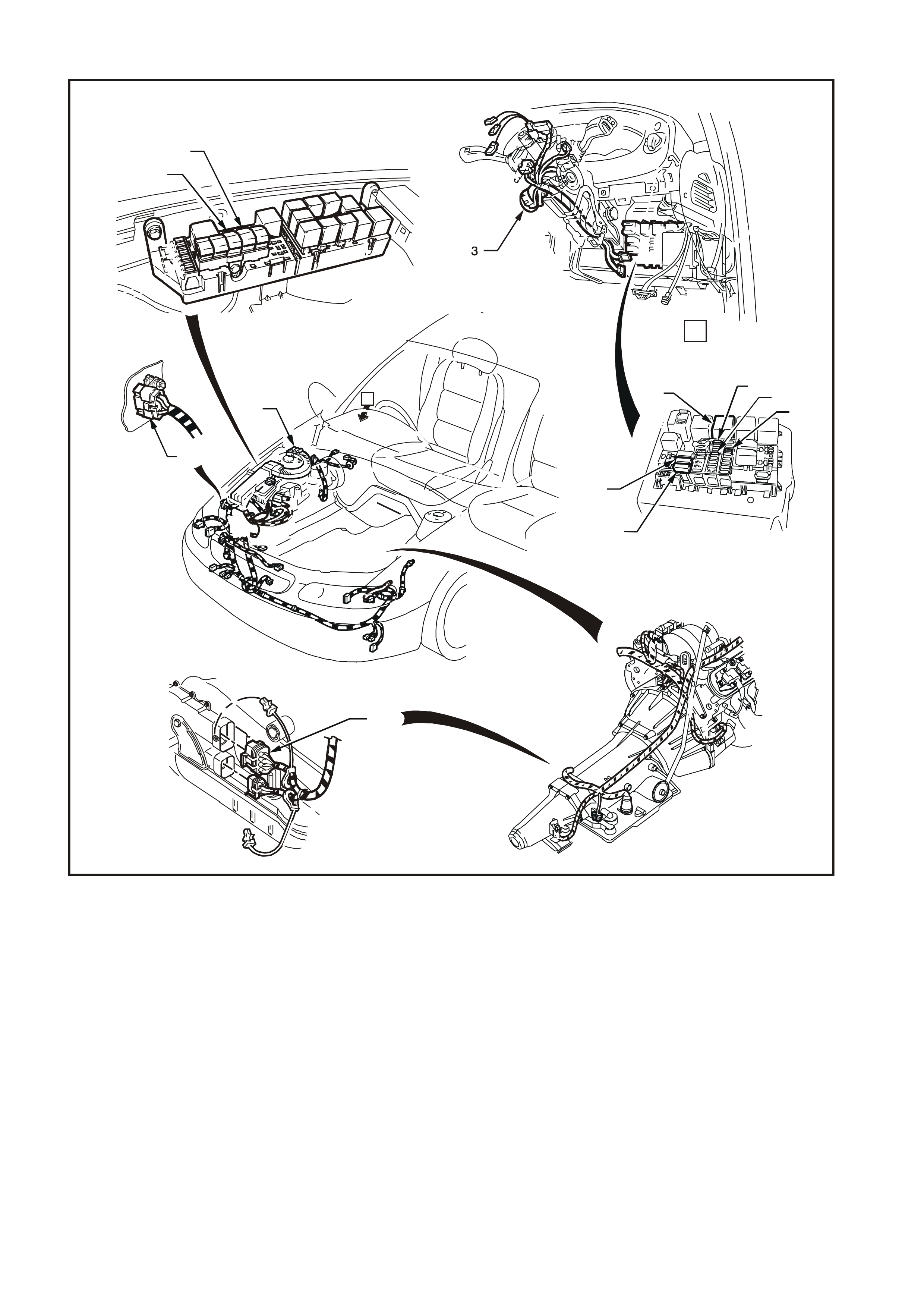

9

234

5

8

6

7

1

10

11

12

13

14

15

17

16

18

19

20

21

,

WH1A7003

Figure 1A7-3

1. YB235 – Fore/Aft Drive Motor

Potentiometer Connector 8. YB221 – Rear Up/Down Drive

Motor Connector 15. Seat Lower Side Cover

2. YB223 – Fore/Aft Drive Motor

Connector 9. YB224 – Front Up/Down Drive

Motor Connector 16. YB226 – Power Seat Harness

Connector

3. YB235 – Front Up/Down Drive

Motor Potentiometer Connector 10. YB227 – Seat Control Module

Power Connector 17. Seat Belt Pre-tensioner Connector

4. YB235 – Rear Up/Down Drive

Motor Potentiometer Connector 11. YB228 – Seat Control Module Drive

Motor Connector 18. Side Air Bag Module Connector

5. YB222 – Recliner Up/Down Drive

Motor Connector 12. YB229 – Seat Control Module Drive

Motor Potentiometer Connector 19. YR53 – Left-hand Back-up Tail

Lamp Connector

6. YB236 – Recliner Drive Motor

Potentiometer Connector 13. YB225 – Seat Control Module

Memory and Position Connector 20. YR53 – Right-hand Back-up Tail

Lamp Connector

7. Seat Belt Pre-tensioner Connector 14. YB220 – Eight-way Seat Position

Switch Connector 21. YR1 – Heated Rear Window

Connector

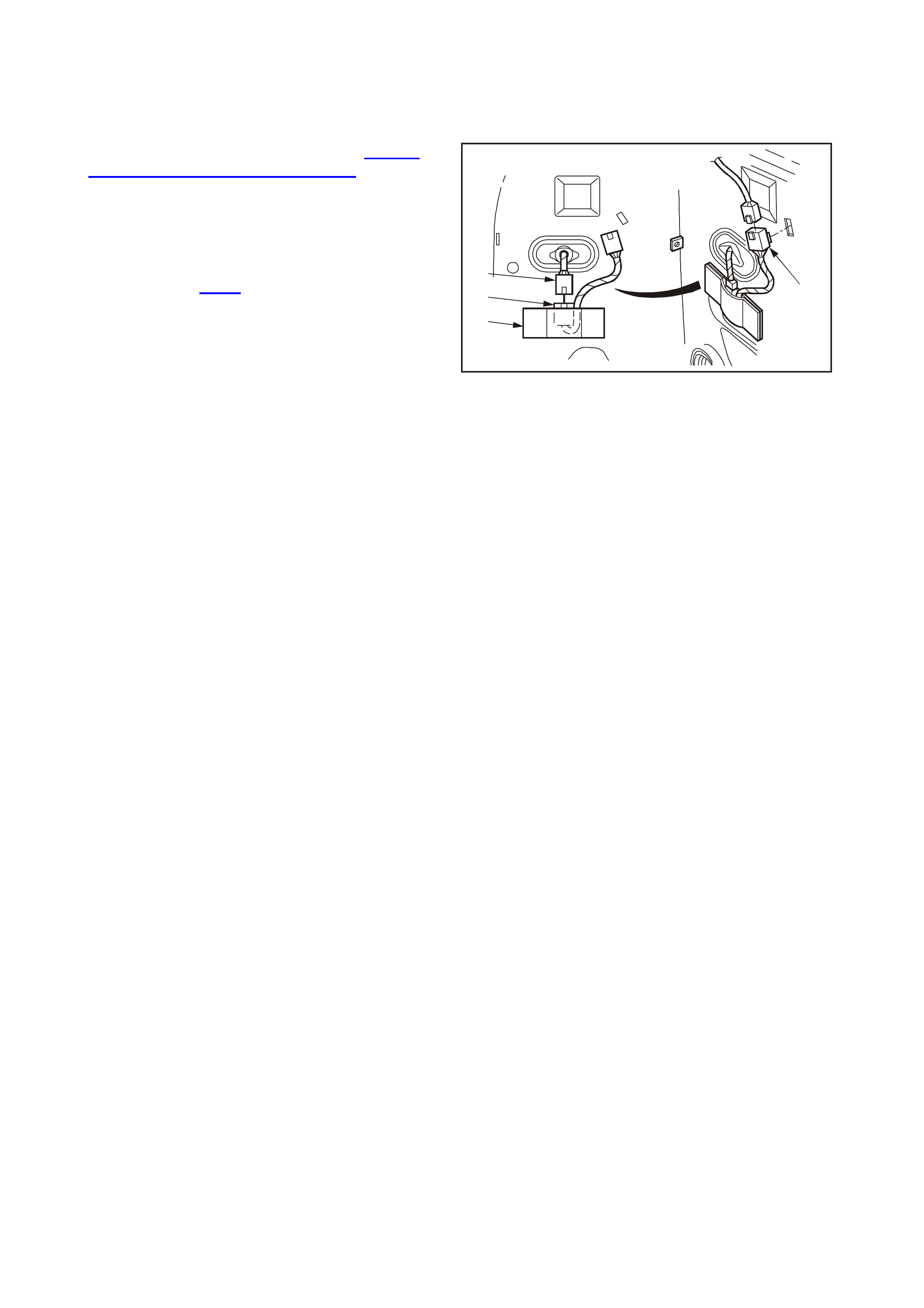

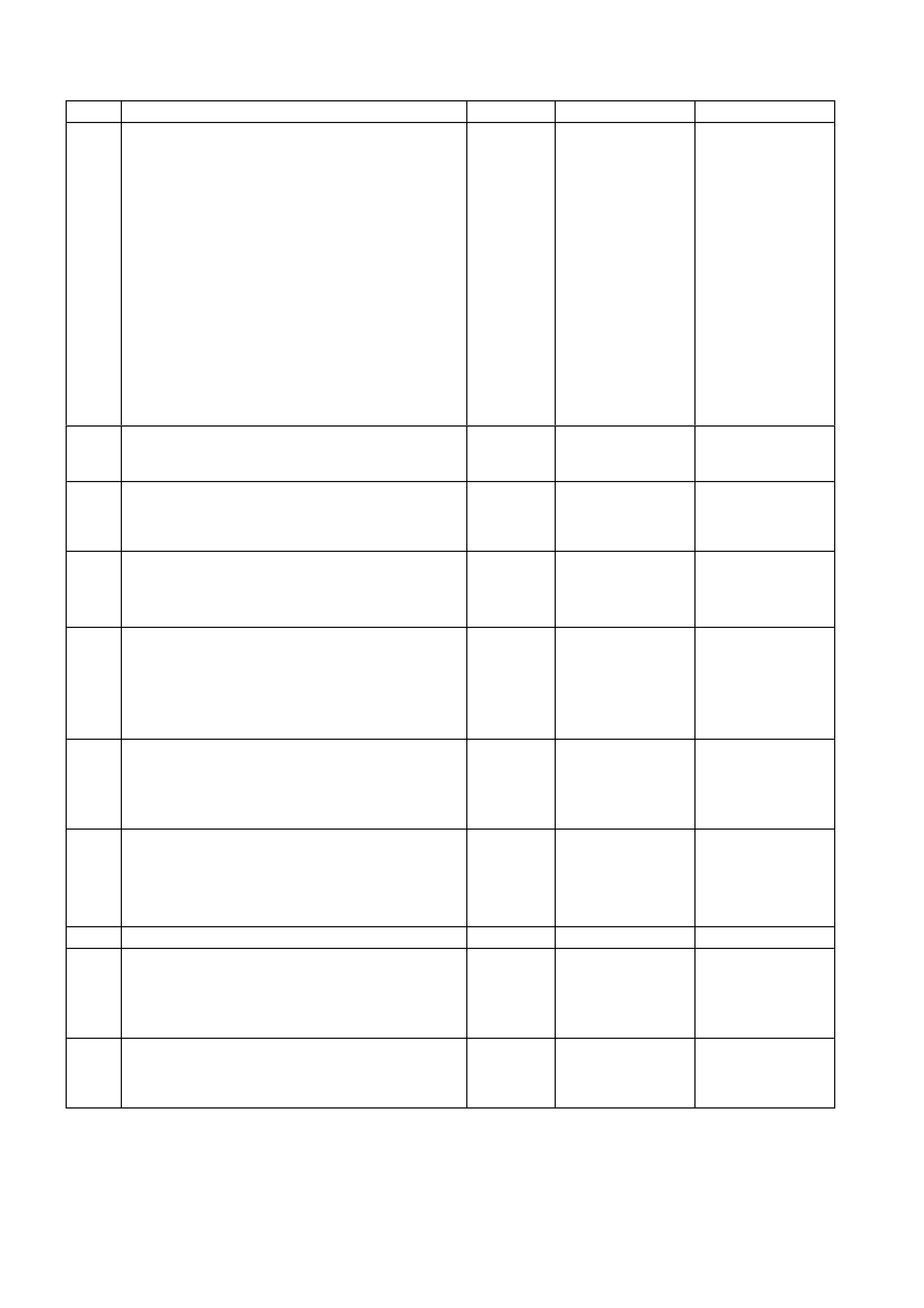

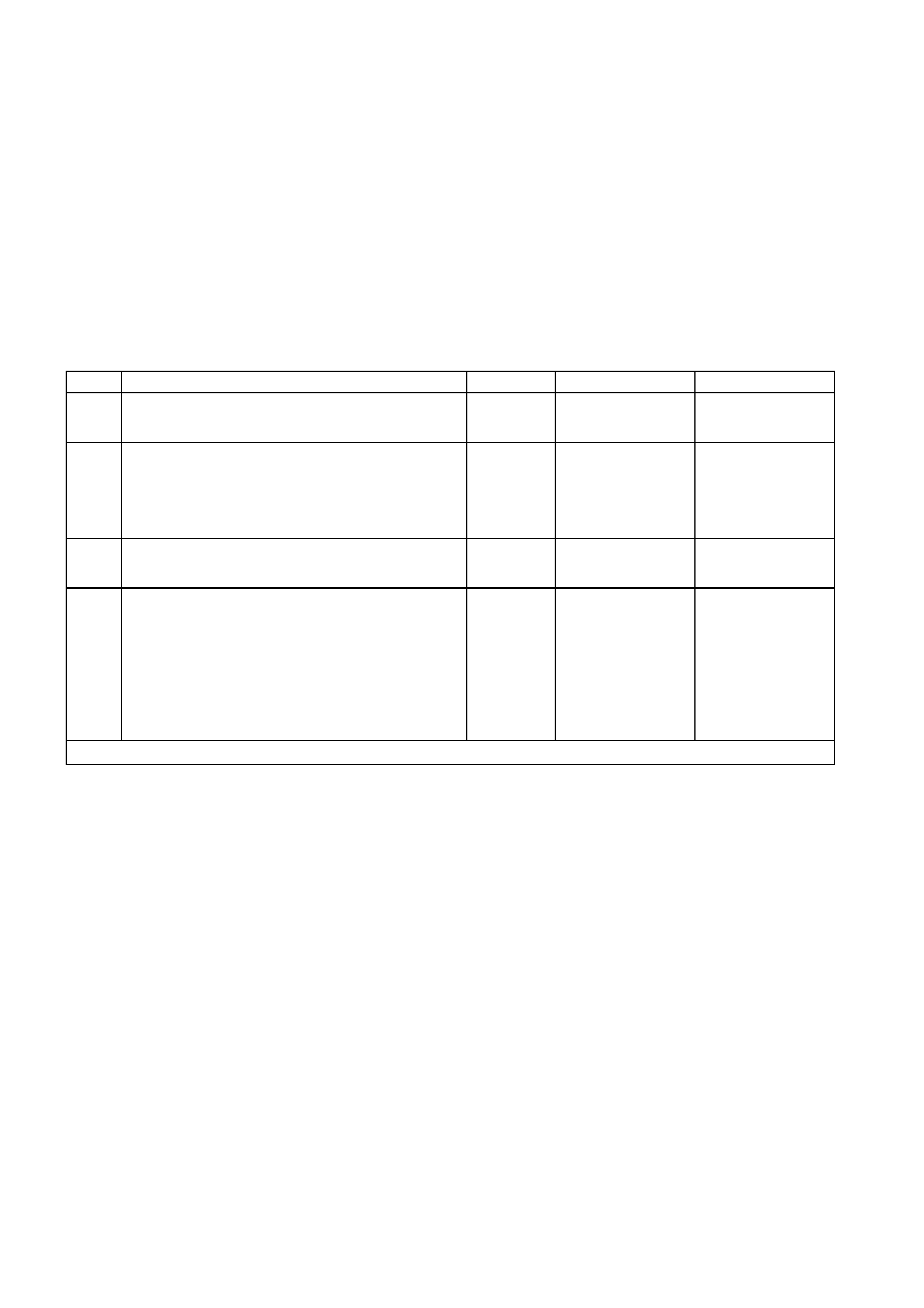

WH1A7004

5

6

7

10

11

1

2

3

49

8

Figure 1A7-4

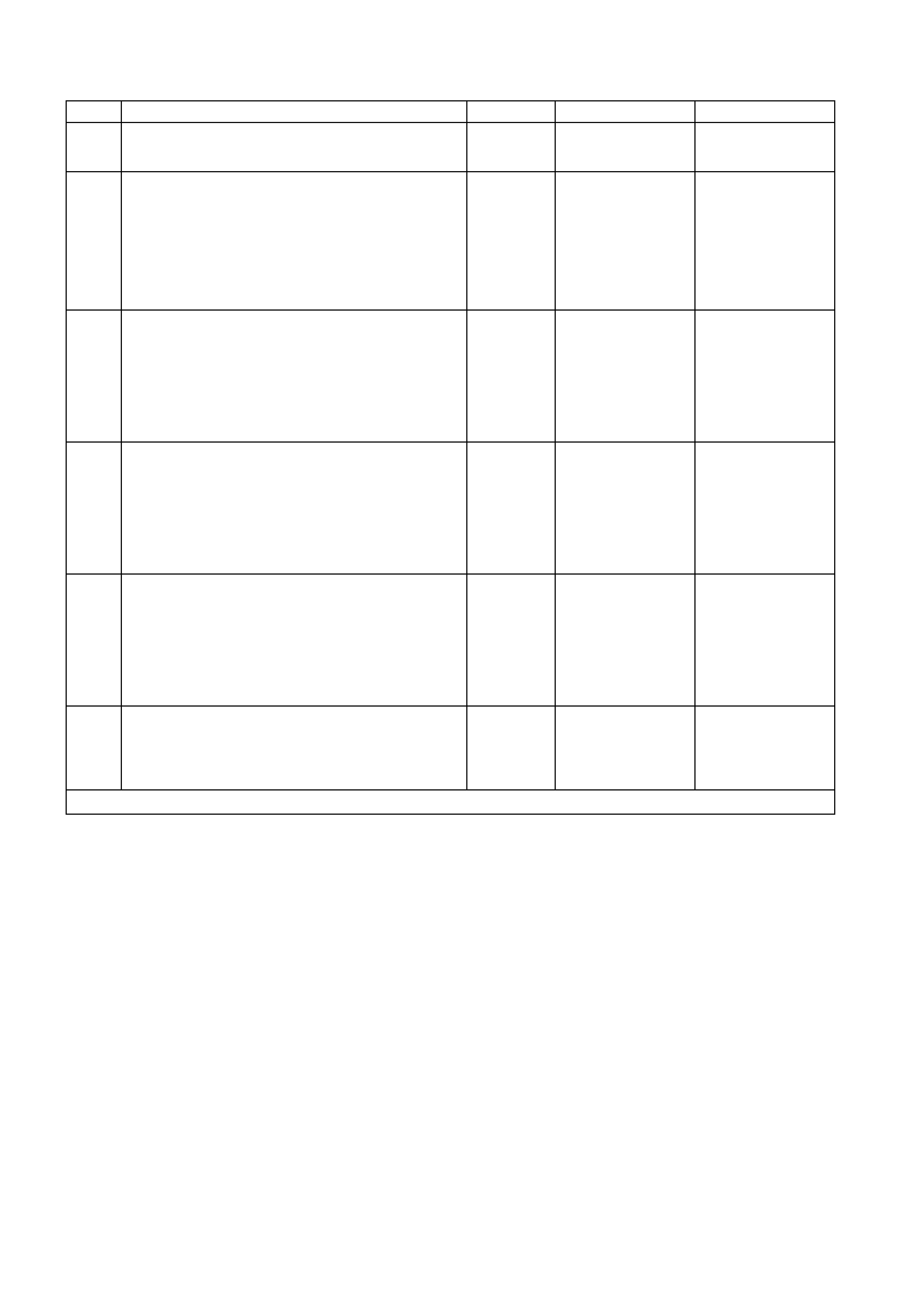

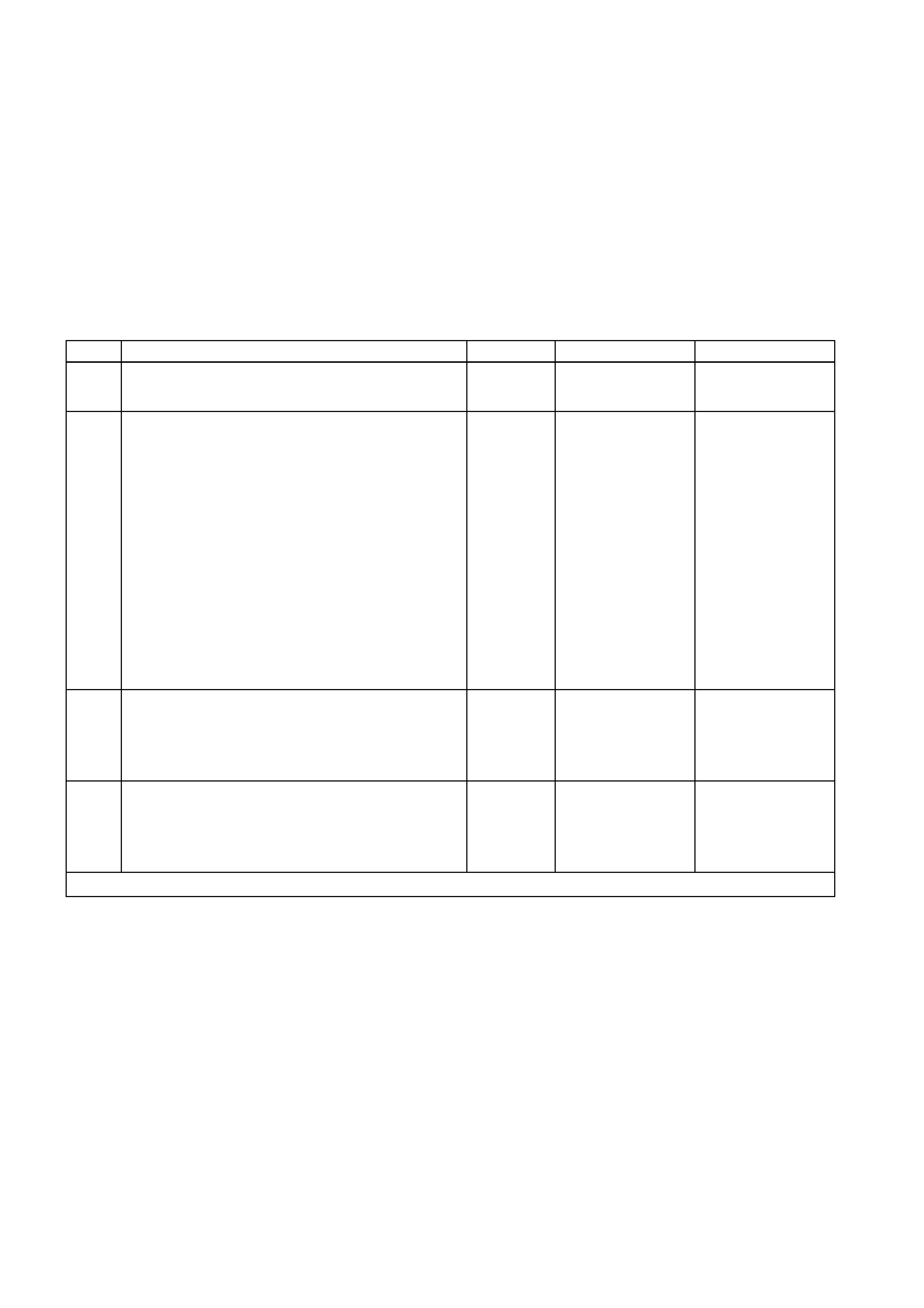

1. YB176 – BCM Connector (4)

2. YB174 – BCM Connector (2)

3. YB39 – Body Harness Connector

4. YB74 – Body Harness Connector

5. YB61 – Mirror Switch Connector

6. Mirror Switch Module (attached to

cable)

7. YB238 – Mirror Switch Module

Connector

8. YB76 – Right-hand Front D oor Harness

Connector (Left-hand is YB77)

9. YB237 – Right-hand Mirror

Connector (Left-hand is YB239)

10. YB61 – Mirror Switch Connector

11. Mirror Switch

WH1A7005

4567

8

9

10

A

11

12

A

1

2

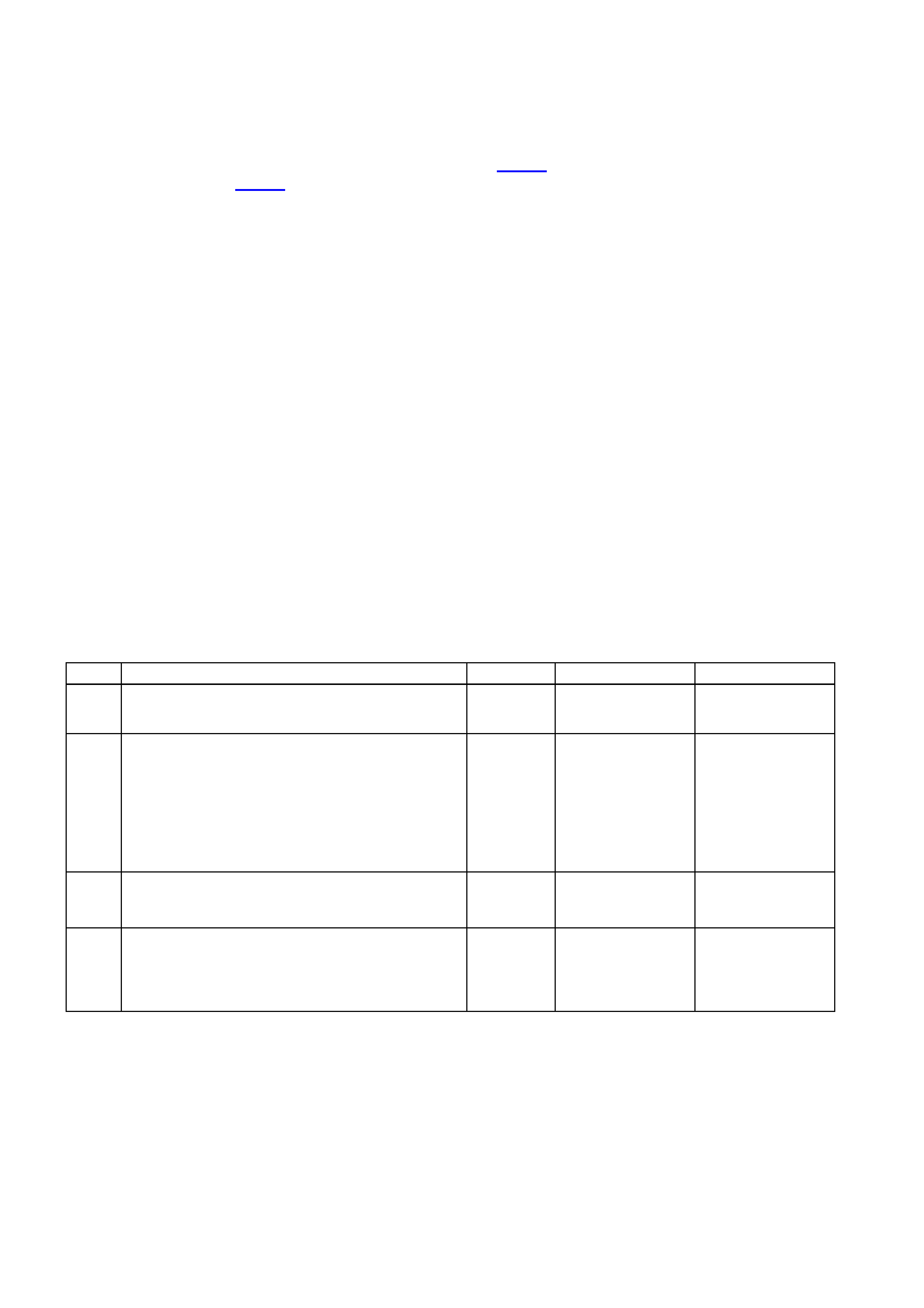

Figure 1A7-5

1. Fusible Link FS

2. Fusible Link FJ

3. YB44 – Ignition Switch Connector

4. Heated Rear Window Relay

(Connector YB41)

5. Fuse F12

6. Fuse F15

7. Fuse F22

8. Circuit Breaker F3

9. Circuit Breaker F2

10. YB35 – Neutral Start and Back-up

Switch Connector

11. YE114 – Earth Location E3 Connector

12. YE112 – Engine Connector (3)

85

(24)

YB41

ACC

YB227

3

YB220

F2

YR53

(641)

F31

YR1

(1027)

5

(177)

YB176

G

G/GY

(614)

(1029)

B/Y

Y

RECLINE UP

FS

AFT

YB44

YR53

YB222

(1023)

Y/P

YB228

(190)

BLU/R

12V

MOTOR 3

E IGHT - WAY SE AT PO SIT IO N S W ITCH

(185)

(155)

SPEAKER

M2

YE114

DIAGNOSTIC

LED

ELECTRONIC

GROUND

(179)

(189)

BACK-UP

SWITCH

O/B

F12

LOC. E6/E7

(40)

(156)

SEAT

CONTROL MODULE

LOC. E1

(2H)

YB41

(564)

B

GY

O/W

B

BODY CONTROL

MODULE

YB35

86

(156)

(783)

5015a

YE112

R/O

FRT UP

F3

(740)(139)

YB221

(1024)

YE114

BR/BLU

(621)

BACK-UP

LAMP

Y/B

(1021)

RECLINE DN

RR UP

B/W

YR53

YB39

(LH)

ENGINE 12V BUS

RECLINE

DRIVER'S SEAT

B/BLU

PRIORITY 1

12V

V/R

MOTOR 1

RR UP/RR DN

YB227

LOC. E3

V

B/G

YB223

(567)

Y

+5V

W

M3

YB174

(566)

1

(1025)

(180)

YR53

YB224

F22

B/BLU

F15

(540)

FJ

(176)

(782)

R/B

BLU/R

B/G

BR

POSITION SIG 3.

(563)

Y/W

87

30

YR1

OFF/ON

LOCK

START

(192)

FWD/AFT

YB174

+5V

(565) 0V

BR

30

P

15

O/B

POWER

GROUND

LG

(RH)

(24)

(192)

FWD

MOTOR 4

B

FRT DN

YB44

LOC. E3

V

(181)

YB35

(1022)

BACK-UP

LAMP

(1040)

YB39

LOC. E9

P

YB225

(42)

PRIORITY 2

(1028)

IGN

12V

B

MOTOR 2

10

0V

DIP

YB176

R/G

POSITION SIG 1.

(560)

(1026)

R

POSITION SIG 4.

(561)

(178)

V/Y

(562) POSITION SIG 2.

G

O

W/P

R

HEATED

REAR

WINDOW

RELAY

YE112

G/Y

BLU

V/G

(3)

DN

UP/FRT FRT

MEMORY POSITION SWITCH

(151)

RR DN

M1

B/Y

YB226

YB229 YB226

YB235

YB235

YB235

YB236

6

PRIORITY 1

PRIORITY 2

12V

YB39

YB74

Y/BLU

B/W

B/O

B/Y

Y

R/G

V

BR/BLU

+12V

REVERSE

SIG

REAR

HEATED

WINDOW

SIG

SERIAL DATA

GND (MIRROR

SERIAL

DATA

BUS)

GND

GND

BATTERY

+

B/BLU

YE114

(151)

YB39

LOC. E6 LOC. E3

(156)

YB227

YB226

GY/R

W/P

R/O

G

GY

(925)

BR

(929)

V

(920)

MIRROR MOTORS

GND

YB61

R

GY

BLU

VERTICAL

GND

MSDB

(920)

YB76

BR

BR

V

V

+12V

GY

(911)

MIRROR HEA TER

(929)

GY

MSDB

LR

B/R

B

SERIAL DATA

HV

SERIAL DATA

YB237

YB77

VERTICAL

(929)

V

LEFT - HAND MIRROR

BR

HORIZONTAL

LBLU

MIRROR HEATER

Y

(905)

MIRROR SW IT CH

W

12V

(929)

L

Y

G

H

(925)

(925)

+12V

V

S

YB238

(904)

(920)

GY

RIGHT - HAND M IRROR

YB239 MIRROR MOTORS

P

HORIZONTAL

BR

B

(909)

(908)

GND

(920)

N

MIRROR SWITCH

MODULE

E

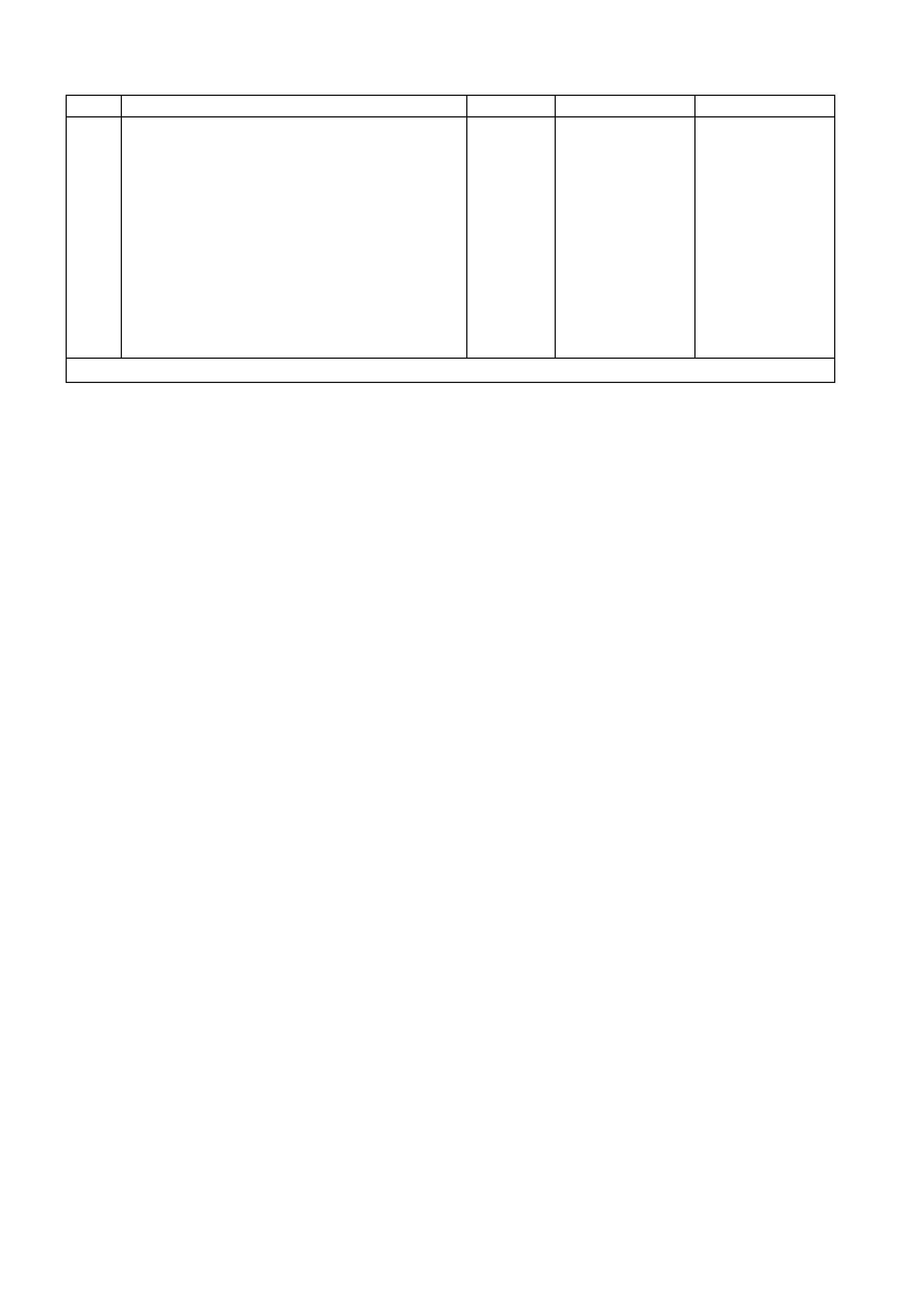

WH1A7006

330

10K

10K

10K

10K

330 330

MIRROR

SERIAL

DATA

BUS

(

192

)

(24)

LG

V/R

Figure 1A7-6

2. SERVICE OPERATIONS

For service operations not covered in this Section refer to Section 1A7 SEAT & SEAT BELT ASSEMBLIES of the

VT Series I Service Information, which should be read in conjunction with Section 1A7 SEAT & SEAT BELT

ASSEMBLIES of the VT Series II Service Information.

2.1 SEAT CONTROL MODULE

REMOVE

1. There are two screws securing the lower side

cover to the seat; one is acces sed f rom the side

of the cover by removing the s cr ew cap f r om the

centre of the cover, and the other is accessed

from beneath the front of the seat. Move the

seat fully forward then remove both screws.

2. Carefully pull the lower side cover from the seat.

3. Remove the three screws securing the seat

control module cover to the seat lower side

cover.

4. Disconnect the four electrical connectors

(YB225, YB227, YB228 and YB229) from the

seat control module, refer to Fig. 1A7-3.

5. Remove the four screws securing the seat

control m odule to the s eat lower s ide c over, and

remove the module.

REINSTALL

Installation is the reverse of the rem oval proc edure,

noting the following.

1. After installation, carry out the drive motor

potentiometer calibration, refer to 2.7 DRIVE

MOTOR POTENTIOMETER CALIBRATION in

this Section.

Techline

Techline

Techline

Techline

2.2 MEMORY POSITION SWITCH

REMOVE

1. There are two screws securing the lower side

cover to the seat; one is acces sed f rom the side

of the cover by removing the s cr ew cap f r om the

centre of the cover, and the other is accessed

from beneath the front of the seat. Move the

seat fully forward then remove both screws.

2. Carefully pull the lower side cover from the seat.

3. Remove the two screws securing the memory

position switch cover to the seat lower side

cover.

4. Disconnect the electrical connector YB225 from

the memory seat control module, refer to Fig.

1A7-3.

5. Disconnect the electrical connector YB220 from

the eight-way seat position switch, refer to Fig.

1A7-3.

6. Remove the memory position switch, complete

with wiring harness.

REINSTALL

Installation is the reverse of the removal procedure.

2.3 EIGHT-WAY SEAT POSITION SWITCH

REMOVE

1. Pull the two knobs from the eight-way seat

position switch.

2. There are two screws securing the lower side

cover to the seat; one is acces sed f rom the side

of the cover by removing the s cr ew cap f r om the

centre of the cover, and the other is accessed

from beneath the front of the seat. Move the

seat fully forward then remove both screws.

3. Carefully pull the lower side cover from the seat.

4. Remove the three screws securing the eight-

way seat position switch cover to the seat lower

side cover.

5. Disconnect the electrical connector YB220 from

the eight-way seat position switch, refer to Fig.

1A7-3.

6. Remove the two screws securing the eight-way

seat position switch to the s eat lower s ide cover ,

and manoeuvre the switch out.

REINSTALL

Installation is the reverse of the removal procedure.

2.4 DRIVE MOTOR

REMOVE

The removal procedure is as follows:

• For the lift motors, refer to Sect io n 1A7 SEAT &

SEAT BELT ASSEMBLIES of the VT Series I

Service Information. Note that the drive motor

and potentiometer are replaced together as an

assembly.

• For the fore/aft drive motor, refer to Section

1A7 SEAT & SEAT BELT ASSEM BLIES of the

VT Series I Service Information. Note that the

drive motor and potentiometer are replaced

together as an assembly.

• For the backrest recliner drive motor, remove

the motor and potentiometer together as

detailed in Section 1A7 SEAT & SEAT BELT

ASSEMBLIES of the VT Series I Service

Information. Press in the two plastic tabs

securing the potentiometer to the drive motor

and separate the potentiometer from the motor.

REINSTALL

The installation procedure is the same as for the

appropriate drive motor of the VT Series II. Ref er to

Section 1A7 SEAT & SEAT BELT ASSEMBLIES

of the VT Series I Service Information, noting the

following.

1. After installation, carry out the drive motor

potentiometer calibration, refer to 2.7 DRIVE

MOTOR POTENTIOMETER CALIBRATION in

this Section.

2.5 DRIVE MOTOR POTENTIOMETER

REMOVE

The removal procedure is as follows:

• For the lift motor potentiometer, replace the

appropriate lift motor and potentiometer as an

assembly. Refer to 2.4 DRIVE MOTOR in this

Section.

• For the fore/aft drive motor potentiometer,

replace the fore/aft motor and potentiometer as

an assembly. Refer to 2.4 DRIVE MOTOR in

this Section.

• For the backrest recliner drive motor

potentiometer, remove the recliner motor and

separate the potentiometer from the motor as

detailed in 2.4 DRIVE MOTOR in this Section.

REINSTALL

Installation is the reverse of the rem oval proc edure,

noting the following.

1. After installation, carry out the drive motor

potentiometer calibration, refer to 2.7 DRIVE

MOTOR POTENTIOMETER CALIBRATION in

this Section.

2.6 MIRROR SWITCH MODULE

REMOVE

1. Remove the driver’s door trim, refer to Section

1A5 FRONT AND REAR DOORS of this

Service Information CD.

2. Unclip the mirror switch connector YB61 (1)

from the door inner panel.

3. Disconnect the electrical connectors YB61 (1)

and YB238 (2) from the mirror switch module

(3), refer to Fig. 1A7-4.

4. Remove the mirror switch module from the

insulating pouch (4).

WH1A7011

2

3

4

1

Figure 1A7-7

REINSTALL

Installation is the reverse of the removal procedure.

2.7 DRIVE MOTOR POTENTIOMETER CALIBRATION

1. The drive motor potentiometer calibration

procedure must be carried out whenever any of

the following have been replaced:

• seat control module,

• a seat drive motor, or

• a drive motor potentiometer.

2. To access the diagnostic function, press and

hold the mirror dip button on the side of the

driver’s seat, while turning the ignition switch

from the OFF position to the IGN position three

time s in 6 seconds, leaving the ignition switch in

the IGN position.

NOTE: Do not turn the ignition switch too rapidly.

The switch must be in the OFF and IGN positions

long enough for the system to register the actual

position.

3. To enter the Drive Motor Potentiometer

Calibration diagnostic mode, press and hold

memory button 2 until a chime is heard, then

press and hold memory button 3. Successful

entry is indicated by a repetitive chime at a 2

second interval.

4. Using the eight-way seat position switch on the

side of the driver’s seat, move the seat fully

forward to the mechanical stop, releasing the

switch as soon as the stop is reached. It is

important that the switch is not held in the on

position after the mechanical stop is reached.

Move the seat slightly rearwards with the eight-

way switch, then move it f ully forward to the stop

again, releasing the switch at the stop. Repeat

this procedure for:

• the rearward direction of seat travel,

• the seat backrest fully forward and fully

reclined positions,

• the seat front fully up and fully down

positions, and

• the seat back fully up and fully down

positions.

5. Using the eight-way seat position switch, move

all four dr ive motors towards the m iddle pos ition

(approximately 3 seconds of travel).

6. Pr ess and hold the m irror dip button on the side

of the driver’s seat for approximately 2 seconds

to enter the calibration details. A multi-tone

chime confirms that the new calibration data has

been successfully stored.

7. Turn the ignition switch to the OFF position to

exit the Drive Motor Potentiometer Calibration

mode.

8. To verify the calibration settings, use the eight-

way seat position switch to move the seat fully

forward to the end of travel and release the

switch when the m otor stops . Operate the eight-

way switch in the same direction and hold for 2

seconds. The seat should move one step

beyond the initial stopping point. Repeat this

procedure for the remaining seat drive motors.

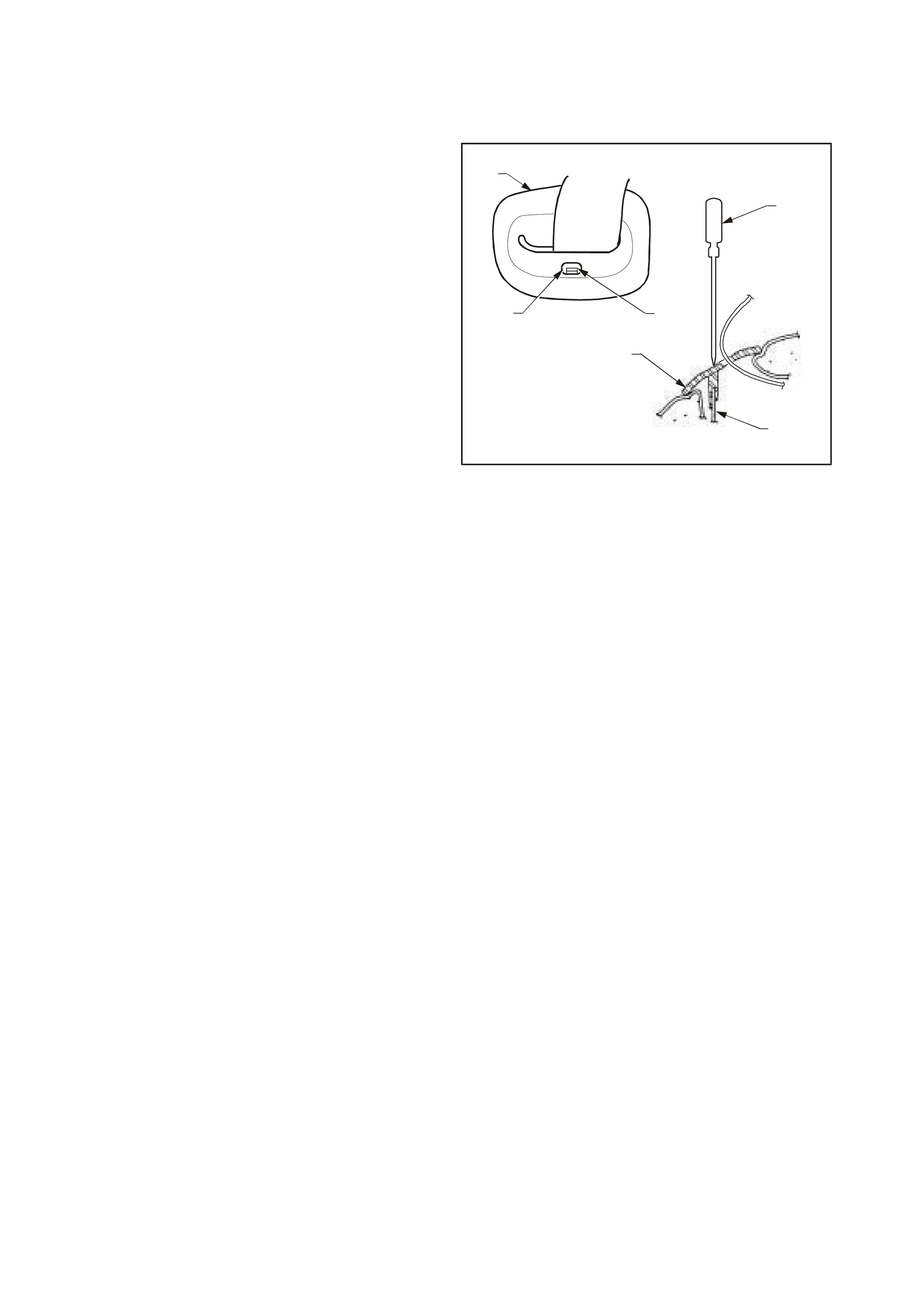

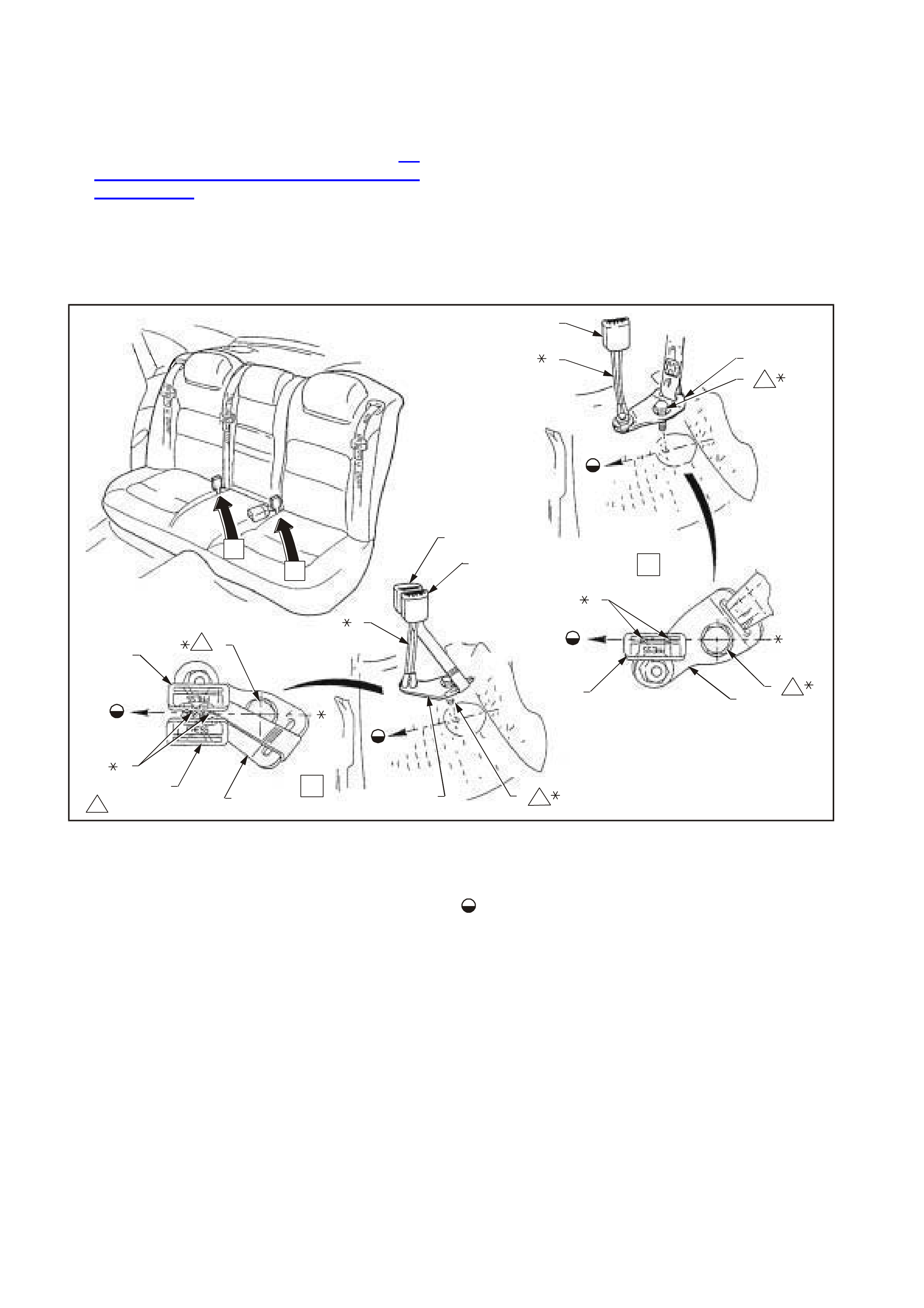

2.8 REAR SEAT CUSHION AND SEAT BACK ASSEMBLIES

REMOVE

1. Lift front edge of rear seat cushion slightly to

gain access to rear seat cushion release

handles. Refer to Fig. 1A7-9.

2. From either the left or right-hand side of the

seat, pull release handles downwards towards

the floor, while at the sam e time lif ting the front

of the rear seat cushion until the lock

mechanism is released.

3. Repeat Step 2 for the oppos ite side of the s eat

and remove the rear seat cushion from the

vehicle.

4. Remove the bolts secur ing the lower outer seat

belt anchors to the floor pan on the left and

right-side.

5. Pull forward and lower the rear seat centre

back.

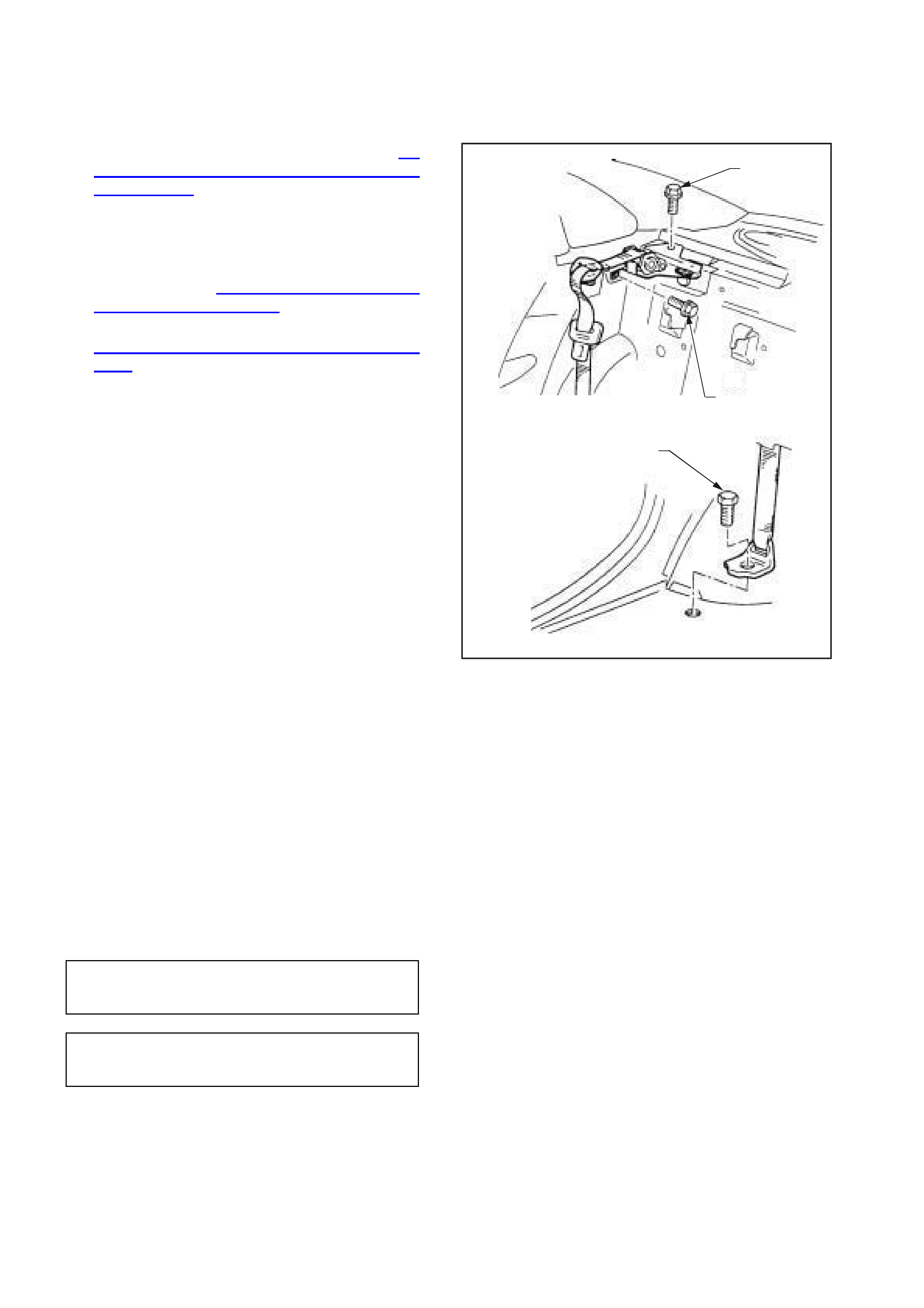

6. Remove the seat belt escutcheon (1) from the

left and right upper seat belt mounting bracket

(2) by inserting a suitable flat-blade sc rewdriver

(3) through the access hole (4) to disengage

the escutcheon retaining tang (5) f rom the seat

belt mounting bracket.

WH1A7015

1

1

2

3

45

Figure 1A7-8

7. Remove the bolts securing the left and right

seat back assemblies to the rear floorpan.

Refer to Fig 1A7-9.

8. Lift left and right seat back assemblies upwards

to disengage seat back hooks from retaining

brackets located on rear compartment front

panel.

9. Push seat belt, seat belt escutcheon and lower

seat belt anchor through the hole in the lef t and

right seat back assembly.

10. Remove the seat back assemblies from the

vehicle.

WH1A7013

3

4

7

6

4

4

59

2

12

8

1

2

3

C

C

A

B

AC

B

Figure 1A7-9

1. Seat cushion release handle

2. Lower outer seat belt anchor

3. Seat belt escutcheon

4. Seat back

5. Lower seat back mount

6. Seat back mounting hook

7. Seat back retaining bracket

8. Seat cushion

9. Floor pan

REINSTALL

Installation is the reverse of removal procedure,

noting the following:

1. Ensure that the threads of the lower outer seat

belt anchor bolts are adequately sealed with a

non-hardening sealer to Holden Specification

HN 1005 or HN 1044.

2. Ensure that all seat belt bolts are hand

tightened a minim um of five turns before using

tools.

3. Tighten all fasteners to the correct torque

specification.

SEAT BACK ASSEMBLY TO

FLOOR PAN RETAINING BOLT

TORQUE SPECIFICATION 25 – 35 Nm

LOWER SEAT BELT ANCHOR

RETAI NI NG B O LT T ORQUE

SPECIFICATION 35 – 50 Nm

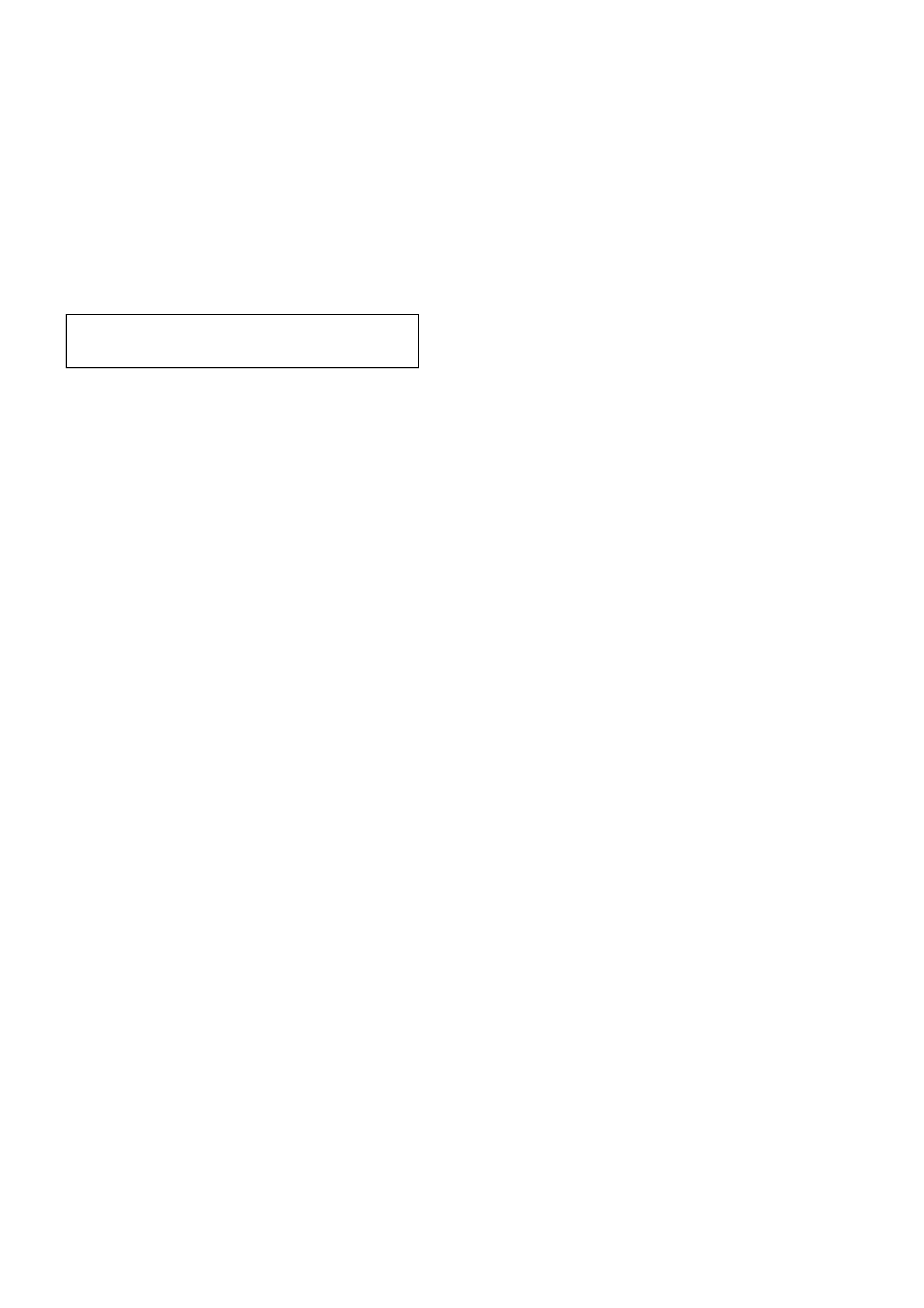

2.9 LEFT AND RIGHT-HAND REAR SEAT BELT RETRACTOR ASSEMBLIES

REMOVE

1. Remove the rear seat cushion. Refer to 2.8

REAR SEAT CUSHION AND BACK

ASSEMBLIES in this Section.

2. Remove the bolt (1) securing the lower outer

seat belt anchor to the f loor pan on the left and

right-hand side.

3. Remove the left and right-hand side seat

backs. Refer to 2.8 REAR SEAT CUSHION

AND BACK ASSEMBLIES in this Section.

4. Remove the rear parcel shelf trim. Refer to

Section 1A8 HEADLINING AND REAR END

TRIM in this Supplement.

5. Remove the two bolts (2) securing the rear seat

belt retractor assem blies to the vehic le body on

the left and right- hand side and remove the

assemblies.

WH1A7014

2

2

1

Figure 1A7-10

REINSTALL

Installation is the reverse of removal procedure,

noting the following:

1. Ensure that the threads of the lower outer seat

belt anchor bolts are adequately sealed with a

non-hardening sealer to Holden Specification

HN 1005 or HN 1044.

2. Ensure that all seat belt bolts are hand

tightened a minim um of five turns before using

tools.

3. Tighten all fasteners to the correct torque

specification.

LOWER OUTER SEAT BELT

ANCHOR RETA INING BOLT

TORQUE SPECIFICATION 35 – 50 Nm

SEAT BELT RETRACTOR

ASSEMBLY RETAINING BOLT

TORQUE SPECIFICATION 35 – 50 Nm

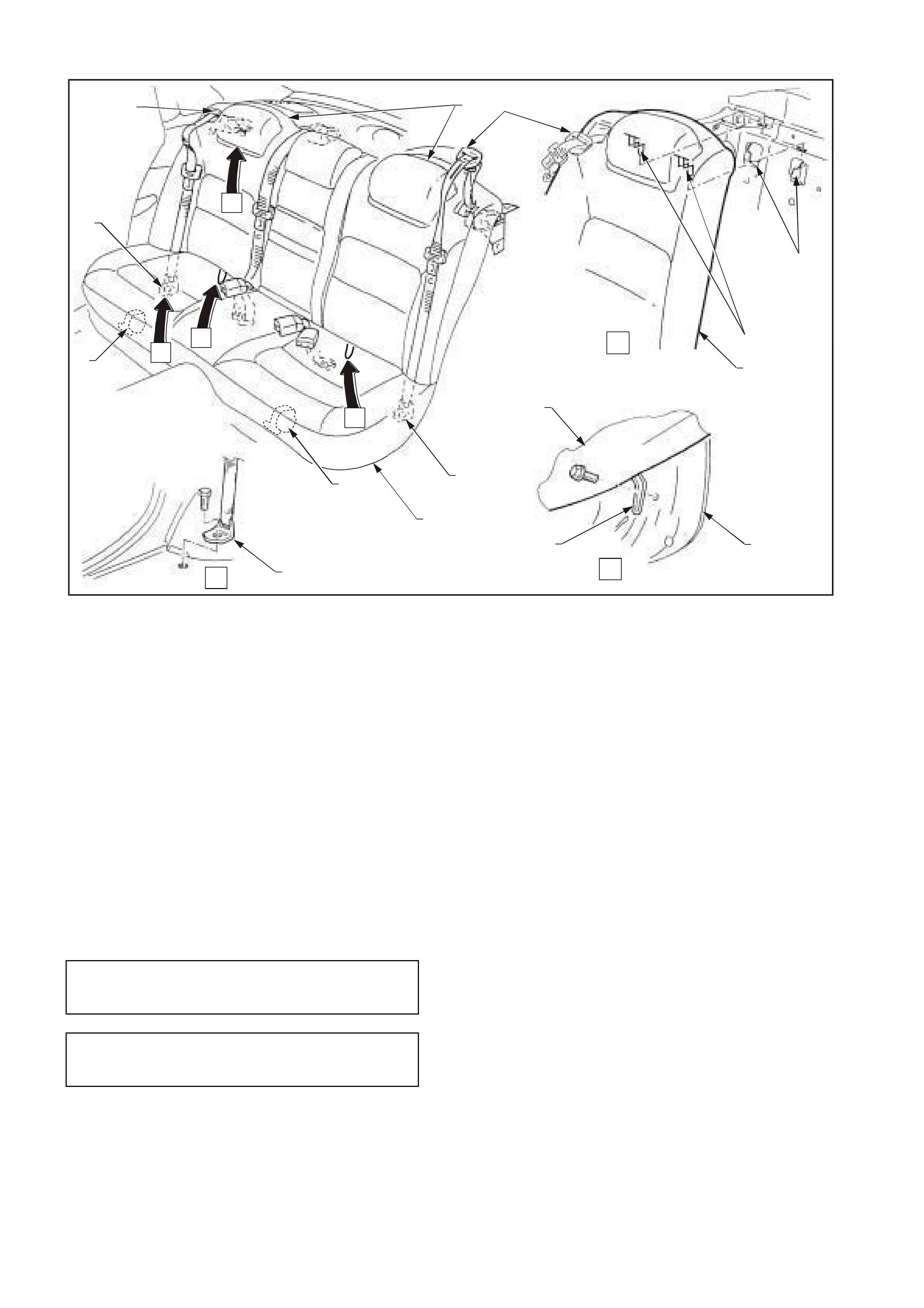

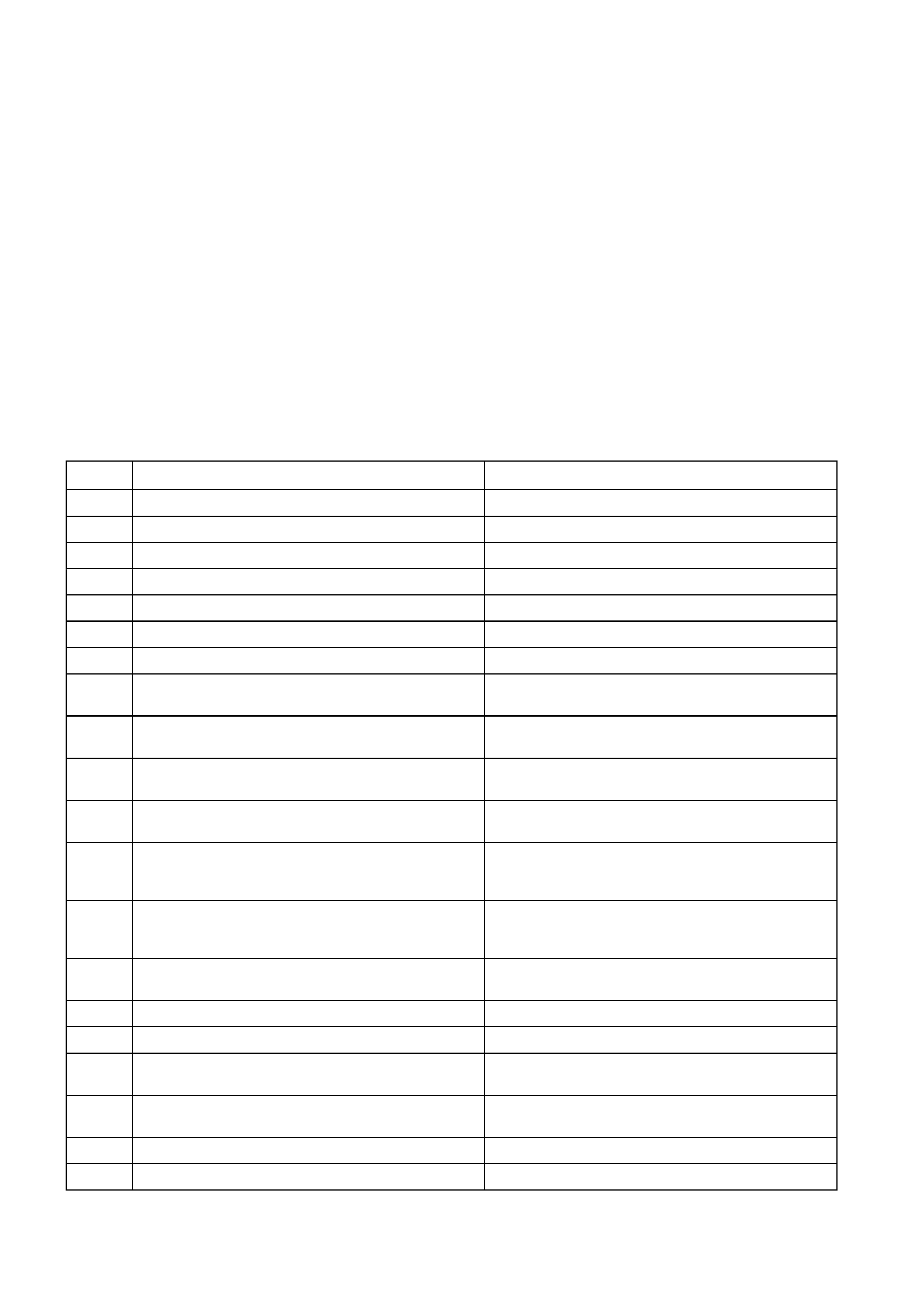

2.10 LEFT AND RIGHT-HAND REAR SEAT BELT BUCKLE

(STALK/WEB TYPE) ASSEMBLIES

REMOVE

1. Remove the rear seat cushion. Refer to 2.8

REAR SEAT CUSHION AND BACK

ASSEMBLIES in this Section.

2. Remove the bolt securing the left and

right-hand seat belt buckle anchor to the floor

pan.

3. Remove the seat belt buckle assembly from

the vehicle.

WH1A7016

6

78

9

9

7

68

3

2

5

14

3

5

1

2

4

B

A

A

B

1

1

1

1

1

35-50 Nm

Figure 1A7-11

1. Middle rear seat belt buckle

2. Left rear seat belt buckle

3. Left rear seat belt buckle anchor

4. Left rear seat belt buckle anchor bolt

5. Left rear seat belt buckle cable stalks

7. Right rear seat belt buckle

8. Right rear seat belt buckle cable stalks

9. Right rear seat belt buckle anchor

10. Right rear seat belt buckle anchor bolt

Indicates front and centre line of vehicle

* Centre line of these components must be parallel to

centre line of vehicle

REINSTALL

Installation is the reverse of removal procedure,

noting the following:

1. Ensure that the threads of the seat belt anchor

bolts are adequately sealed with a

non-hardening sealer to Holden Specification

HN 1005 or HN 1044.

2. Ensure that all seat belt bolts are hand

tightened a minim um of five turns before using

tools.

3. Tighten all fasteners to the correct torque

specification.

SEAT BELT BUCKLE ANCHOR

RETAI NI NG B O LT T ORQUE

SPECIFICATION 35 – 50 Nm

3. DIAGNOSTICS

3.1 GENERAL DIAGNOSTIC INFORMATION

The coded flashing of the LED and the seat chimes are useful tools in the diagnosis of sy stem problems.

The diagnostic function of the seat control module has four individual diagnostic modes to assist in system fault

diagnosis and repair. These are:

• Vehicle Interface Test.

• Display Stored Diagnostic Trouble Codes.

• Diagnostic Switch Test.

• Drive Motor Potentiometer Calibration.

VEHICLE INTERFACE TEST

The Vehicle Interface Test is a comprehensive check of all components of the memory seat and mirror system. If a

fault is detected during this check the corresponding Diagnostic Trouble Code (DTC) is stored in memory . If the

check is completed successfully, DTC 12 (No Fault) is stored in memory.

DISPLAY STORED DIAGNOSTIC TROUBLE CODES

DTC stored in the seat control module can be read out in this mode.

DIAGNOSTIC SWITCH TEST

The Diagnostic Switch Test checks each switch and button used in the seat and mirror circuit. A separate chime is

generated for each component tested successfully.

DRIVE MOTOR POTENTIOMETER CALIBRATION

The drive motor potentiometer calibration mode is used to align a new seat control module, drive motor or motor

potentiometer to the existing seat assembly.

3.2 DIAGNOSTIC FUNCTION

To access the diagnostic function, press and hold the mirror dip button on the side of the driver’s seat, while turning

the ignition switch from the OFF position to the IGN position three times in 6 seconds, leaving the ignition switch in

the IGN position.

NOTE: Do not turn the ignition switch too rapidly. The switch must be in the OFF and IGN positions long enough for

the system to register the actual position.

The seat chime sounds a constant tone and the green LED on the side of the driver’s seat flashes rapidly to indicate

that the diagnostic function has been entered. Using the seat memory buttons, select the actual diagnostic mode

required as follows:

• To enter the Vehicle Interface Test diagnostic mode, press memory button 1 followed by memory button 3.

Successful entry is indicated by a repetitive chime.

• To display the stored Diagnostic Trouble Codes, press memory button 1 followed by memory button 1 again.

Successful entry is indicated by the LED flashing rapidly.

• To enter the Diagnostic Switch Test diagnostic mode, press memory button 3 followed by memory button 3

again. Successful entry is indicated by a different tone sounding when any button or switch is pressed.

• To enter the Drive Motor Potentiometer Calibration diagnostic mode, press memory button 2 followed by

memory button 3. Successful entry is indicated by a repetitive chime at a 2 second interval.

To exit the diagnostic function, set the ignition switch to the OFF position. If in the Vehicle Interface Test diagnostic

mode a timer controls the mode exit process after turning the ignition off.

3.3 DIAGNOSTIC TROUBLE CODES

During the Vehicle Interface Test, the seat control module communicates with the mirrors and the mirror switch

module over the mirror serial data bus. The seat control module polls each component on the bus individually, and

each component responds to the poll with a unique message. Loss of communication with any of these components

will cause a DTC to be set.

DTC are stored in the seat control module as two-digit codes, with each digit being a number from 1 to 5. If a DTC

is present in the seat control module, other than DTC 12, the green LED on the side if the driver’s seat will flash

three times as the ignition is turned from IGN to OFF.

Upon entering the Display Stored Diagnostic Trouble Codes mode, the green LED provides the diagnostic readout

as follows:

• Flashes rapidly to indicate that a DTC is about to be displayed.

• Extinguishes briefly before flashing the ten’s digit.

• Extinguishes briefly before flashing the unit’s digit.

• Flashes rapidly to indicate that the next DTC is about to be displayed.

The DTC are displayed sequentially down the list and repeated until the ignition is switched off, or the diagnostic

mode times out after 1 minute. DTC are cleared by turning the ignition off.

The following table details the complete list of DTC numbers, the corresponding fault description and proposed

corrective action.

DTC DESCRIPTION CORRECTIVE ACTION

11 Not used. —

12 No faults. None required.

13 Not used. —

14 Vehicle Interface Test not completed. Repeat the Vehicle Interface Test.

15 Mirror bus shorted to earth. Go to the Mirror Bus Short Circuit Test.

21 Mirror bus shorted to 12 V. Go to the Mirror Bus Short Circuit Test.

22 No response received from seat control module. Replace the seat control module.

23 No response received from mirror control switch. Faulty wiring to the mirror switch or faulty seat control

module. Go to the Mirror Bus Wiring Test.

24 No response received from right mirror. Faulty wiring to the right-hand mirror or faulty mirror.

Go to the Mirror Bus Wiring Test.

25 No response received from left mirror. Faulty wiring to the left-hand mirror or faulty mirror.

Go to the Mirror Bus Wiring Test.

31 No response received from both mirrors. Faulty wiring to both mirrors or faulty mirrors. Go to

the Mirror Bus Wiring Test.

32 No response received from right mirror and mirror

control switch. Faulty wiring to the right-hand mirror and mirror

control switch, or faulty mirror and mirror control

switch. Go to the Mirror Bus Wiring Test.

33 No response received from left mirror and mirror

control switch. Faulty wiring to the left-hand mirror and mirror control

switch, or faulty mirror and mirror control switch. Go

to the Mirror Bus Wiring Test.

34 No response received from both mirrors and mirror

control switch. Go to the Mirror Bus Wiring Test.

35 Position error right mirror. Faulty right-hand mirror or obstructed mirror glass.

41 Position error left mirror. Faulty left-hand mirror or obstructed mirror glass.

42 Mirror bus power less than 2 V at seat control

module. No power switched from the seat control module to

the mirrors. Replace the seat control module.

43 Mirror bus power less than 8 V at seat control

module. Low voltage on mirror power bus. Go to the Mirror

Bus Wiring Test.

44 – 45 Not used. —

51 – 55 Not used. —

3.4 PRELIMINARY SYSTEM DIAGNOSIS

When investigating any complaint of a memory seat and mirror system problem or malfunction, always begin

diagnosis with a Vehicle Interface Test, refer to 3.6 DIAGNOSTIC PROCEDURES in this Section.

If the Vehicle Interface Test does not find a likely source of the fault, the Diagnostic Circuit Check should then be

carried out.

3.5 DIAGNOSING FAULTS WHICH DO NOT SET A DTC

STALLED MOTOR

If a seat motor has been energised and the corresponding potentiometer (position sensor) does not change state,

then the seat control module determines that the motor has stalled, and removes electrical power from the motor

and sets an internal motor-stalled flag. A DTC is not logged for this fault condition.

To reset the motor-stalled flag and apply power to the motor, push the eight-way seat position switch in the

appropriate direction for 2 seconds.

To check for correct operation of the seat motors, use the Drive Motor and Motor Potentiometer Test. Refer to

3.6 DIAGNOSTIC PROCEDURES in this Section.

SHORTED SWITCH CONTACT

If the seat control module detects that the eight-way seat position switch has been in an active position for too long,

a shorted switch contact condition is declared by the module. A DTC is not logged for this fault condition.

The maximum continuous operating time for the seat fore/aft and lift motors is 25 seconds before a shorted switch

contact condition is declared. For the seat backrest recliner motor, this is extended to a maximum of 50 seconds.

To check for correct operation of the eight-way seat position switch, use the Diagnostic Switch Test. Refer to

3.6 DIAGNOSTIC PROCEDURES in this Section.

3.6 DIAGNOSTIC PROCEDURES

INTRODUCTION

The following charts are designed to provide fast and efficient fault location within the memory seat and mirror

system. Always begin diagnosis with the Vehicle Interface Test which verifies that all the components of the system

are functioning correctly. If the Vehicle Interface Test detects a fault, a DTC will set to assist the fault finding

process.

If the Vehicle Interface Test does not find a likely source of the fault, the Diagnostic Circuit Check should then be

carried out.

Some of the diagnostic procedures require the use of both priority keys.

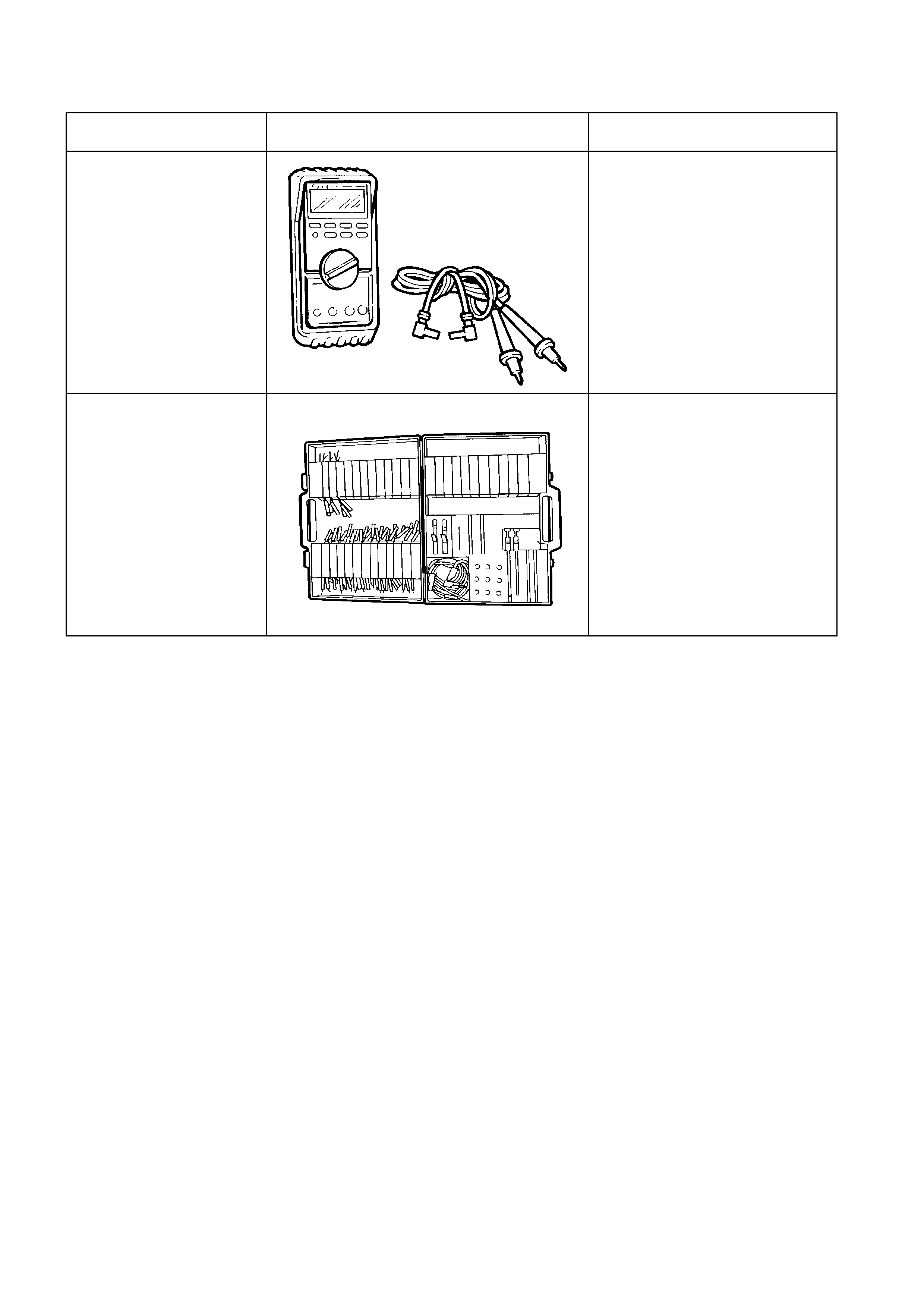

When carry ing out wiring checks as directed by the diagnostic charts, rather than probe terminals and connectors

with incorrect sized multimeter connections, use the adaptors contained in the test adaptor kit KM-609. This will

prevent any possibility of spreading or damaging wiring harness terminals which may later cause a system

intermittent failure.

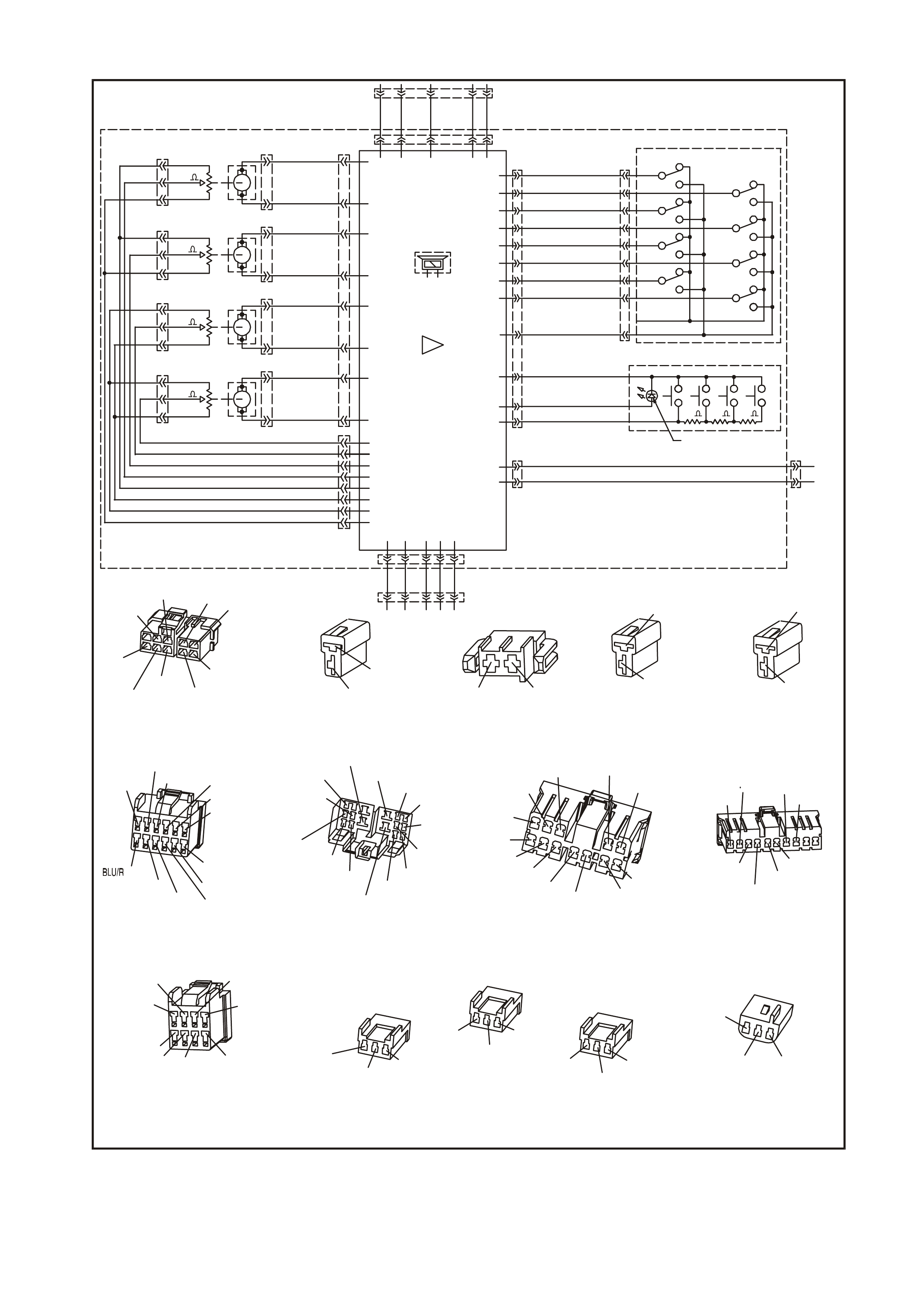

The location of the seat control module and connectors is shown in Fig. 1A7-12.

WH1A7007

123 45678

Figure 1A7-12

1. Memory Position Switch 4. YB225 Seat Control Module

Memory and Position Connector 7. YB228 Seat Control Module Drive

Motor Connector

2. Eight-way Seat Position Switch 5. Seat Control Module 8. YB227 Seat Control Module Power

Connector

3. YB220 Eight-way Seat Position

Switch Connector 6. YB229 Seat Control Module Drive

Motor Potentiometer Connector

VEHICLE INTERFACE TEST

INTRODUCTION

This test provides a comprehensive check of all components of the memory seat and mirror system. The location of

the seat control module connectors is shown in Fig. 1A7-12. For circuit diagram and other connector information,

refer to Figs. 1A7-3 to 1A7-6.

TEST DESCRIPTION

The various steps in the Vehicle Interface Test verify the following functions:

Step 1 — Enters the Vehicle Interface Test mode.

Step 2 — Checks the reverse gear selection.

Step 3 — Isolates a reverse gear selection problem to a circuit wiring fault or a defective seat control module.

Step 4 — Checks the rear window demister and mirror heater selection.

Step 5 — Isolates a rear window demister and mirror heater selection problem to a circuit wiring fault or a defective

seat control module.

Step 6 — Checks for an intermittent fault in the ignition circuit.

Step 7 — Checks the correct identification of priority keys.

Step 8 — Checks the priority signal lines from the BCM.

Step 9 — Identifies that a DTC is stored, or successful completion of the test.

Step 10 — Checks the reverse signal application to the seat control module.

Step 11 — Checks the correct operation of the mirror heater circuits.

Step 12 — Identifies a single faulty mirror heater.

Step 13 — Checks the heated rear window signal at the input to the seat control module.

Step 14 — Checks the decoding of priority key signals.

VEHICLE INTERFACE TEST PROCEDURE

STEP ACTION VALUE YES NO

1 • Remove the lower side cover from the driver’s

seat to gain access to the seat control module,

which is required during this test.

• Press and hold the mirror dip button and turn

ignition switch from OFF to IGN three times within

6 seconds. Leave the ignition switch in the IGN

position.

• After a constant tone sounds, press and hold

memory button 1 until a chime sounds

(approximately 1 second).

• Press and hold memory button 3 for 1 second to

enter the Vehicle Interface Test mode.

• A repetitive chime sounds to indicate that the

Vehicle Interface Test has been successfully

entered.

• Did the repetitive chime change to an alternating

frequency (siren)?

Go to Step 10. Check fuse F15 and

circuit 139. If OK, go

to Step 2.

2 • Select reverse gear.

• Did the repetitive chime change tone? Go to Step 4. Go to Step 3.

3 • Ensure that the ignition switch is still in the IGN

position.

• Using a multimeter, measure the reverse gear

signal voltage on circuit 24 (Violet wire) at the

power connector YB227 while shifting between

reverse and park.

• Are the readings as specified?

Reverse =

12 V

Park = 0 V

Replace faulty seat

control module.

Refer to 2.1 SEAT

CONTROL

MODULE in this

Section.

Check circuit 24 and

repair as necessary.

4 • Set the rear window demister switch to on.

• Did the repetitive chime change tone? Go to Step 6. Go to Step 5.

VEHICLE INTERFACE TEST PROCEDURE (continued)

STEP ACTION VALUE YES NO

5 • Ensure that the ignition switch is still in the IGN

position.

• Using a multimeter, measure the rear window

demister signal voltage on circuit 192 (Brown/Blue

wire) at the power connector YB227 while

switching between off and on.

• Are the readings as specified?

On = 12 V

Off = 0 V Replace faulty seat

control module.

Refer to 2.1 SEAT

CONTROL

MODULE in this

Section.

Check circuit 192

and repair as

necessary.

6 • Turn the ignition switch to the OFF position and

remove t he k ey.

• Did the repetitive chime change tone?

Go to Step 7. Intermittent fault in

the ignition circuit.

Check circuit 139

and repair as

necessary.

7 • Press the door unlock button on Priority Key 1.

• Press the door unlock button on Priority Key 2.

• Did the repetitive chime change tone with Key 1 or

Key 2?

Go to Step 9. Go to Step 8.

8 • Insert Priority Key 1 in the ignition switch.

NOTE: Use adaptors from test adaptor kit KM-609 to

back probe the terminals of power connector YB227.

• Using a multimeter, measure the priority 1 signal

voltage on circuit 782 (Black/Yellow wire) and the

priority 2 signal voltage on circuit 783 (Yellow

wire) at the power connector YB227 while

switching the ignition between OFF and IGN.

• Repeat the measurement of both signals for the

Priority Key 2.

• Are the readings as specified?

4 V in OFF

0.6 V in IGN Replace faulty seat

control module.

Refer to 2.1 SEAT

CONTROL

MODULE in this

Section.

Check circuits 782

or 783 and repair as

necessary.

9 • Did a repeating tone of alternating frequency

sound? Go to Read

Diagnostic Trouble

Code in this Section.

A single burst of

three tones in

increasing frequency

indicates successful

test completion.

10 • Select reverse gear and press the mirror dip

button twice.

• Select park and again press the mirror dip button

twice.

• Did a chime sound for reverse gear but not for

park?

Got to Step 11. Go back to Step 3.

11 • Check that the external rear vision mirrors are

cold.

• Turn the ignition switch to the IGN position.

• Set the rear window demister switch to on.

• Did both mirrors get warm after 2 minutes?

Go to Step 14. Go to Step 12.

12 • Did only one of the two mirrors get warm? Go to Mirror Bus

Wiring Test in this

Section.

Go to Step 13.

13 • Ensure that the ignition switch is still in the IGN

position.

NOTE: Use adaptors from test adaptor kit KM-609 to

back probe the terminals of power connector YB227.

• Using a multimeter, measure the rear window

demister signal voltage on circuit 192 (Brown/Blue

wire) at the power connector YB227 while

switching between off and on.

• Are the readings as specified?

On = 12 V

Off = 0 V Go to Step 14. Check circuit 192

and repair as

necessary.

14 • Turn the ignition switch to the OFF position.

• Press the door unlock button on Priority Key 1 and

observe the seat LED.

• Press the door unlock button on Priority Key 2 and

observe the seat LED.

• Did the LED flash once for Priority Key 1 and twice

for Priority Key 2?

Go to Read

Diagnostic Trouble

Code in this Section.

Go back to Step 8.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COM PLETED, VERIFY CORRECT OPERATION

READ DIAGNOSTIC TROUBLE CODE

INTRODUCTION

The DTC are read from the seat control module using the following procedure.

STEP ACTION VALUE YES NO

1 • Press and hold the mirror dip button and turn

ignition switch from OFF to IGN three times within

6 seconds. Leave the ignition switch in the IGN

position.

• After a constant tone sounds, press and hold

memory button 1 until a chime sounds.

• Press and hold memory button 1 again to enter

the Read Diagnostic Trouble Code diagnostic

mode.

• Observe the green LED on the side of the driver’s

seat. The LED will flash rapidly to indicate that

Read Diagnostic Trouble Code entry has been

successful. The LED will then flash the two digits

of the DTC, commencing with the ten’s digit.

• Did the LED display one or more DTC?

Go to Step 2. Repeat Step 1.

2 • Did the LED display DTC 12? No faults found.

End of diagnosis. Go to Step 3.

3 • Did the LED display DTC other than DTC 12? Refer to the

following diagnostic

chart.

—

W HE N ALL DIAGNOS IS AND RE PAIRS ARE COMPL ETED, VE RIFY CORRECT OPERATION

DTC DESCRIPTION CORRECTIVE ACTION

11 Not used. —

12 No faults. None required.

13 Not used. —

14 Vehicle Interface Test not completed. Repeat the Vehicle Interface Test.

15 Mirror bus shorted to earth. Go to the Mirror Bus Short Circuit Test.

21 Mirror bus shorted to 12 V. Go to the Mirror Bus Short Circuit Test.

22 No response received from seat control module. Replace the seat control module.

23 No response received from mirror control switch. Faulty wiring to the mirror switch or faulty seat control

module. Go to the Mirror Bus Wiring Test.

23 No response received from mirror control switch. Faulty wiring to the mirror switch or faulty seat control

module. Go to the Mirror Bus Wiring Test.

24 No response received from right mirror. Faulty wiring to the right-hand mirror or faulty mirror.

Go to the Mirror Bus Wiring Test.

25 No response received from left mirror. Faulty wiring to the left-hand mirror or faulty mirror.

Go to the Mirror Bus Wiring Test.

31 No response received from both mirrors. Faulty wiring to both mirrors or faulty mirrors. Go to

the Mirror Bus Wiring Test.

32 No response received from right mirror and mirror

control switch. Faulty wiring to the right-hand mirror and mirror

control switch, or faulty mirror and mirror control

switch. Go to the Mirror Bus Wiring Test.

33 No response received from left mirror and mirror

control switch. Faulty wiring to the left-hand mirror and mirror control

switch, or faulty mirror and mirror control switch. Go

to the Mirror Bus Wiring Test.

34 No response received from both mirrors and mirror

control switch. Go to the Mirror Bus Wiring Test.

35 Position error right mirror. Faulty right-hand mirror or obstructed mirror glass.

41 Position error left mirror. Faulty left-hand mirror or obstructed mirror glass.

42 Mirror bus power less than 2 V at seat control

module. No power switched from the seat control module to

the mirrors. Replace the seat control module.

43 Mirror bus power less than 8 V at seat control

module. Low voltage on mirror power bus. Go to the Mirror

Bus Wiring Test.

44 – 45 Not used. —

51 – 55 Not used. —

DIAGNOSTIC CIRCUIT CHECK

INTRODUCTION

The Diagnostic Circuit Check is a detailed system check which verifies that all the components of the system are

functioning correctly and that the seat control module is receiving priority signals from the BCM.

TEST DESCRIPTION

The various steps in the Diagnostic Circuit Check test the following functions:

Step 1 — Input power and circuit protection.

Step 2 — LED test.

Step 3 — Memory button chime function.

Step 4 — Enter diagnostic function successfully.

Steps 5 to 7 — Seat manual move function.

Steps 8 to 10 — Seat memory store and recall function.

Step 11 — Ignition switch disable function.

Steps 12 and 13 — Priority store and recall function.

Step 14 — Mirror manual move function.

Steps 15 to 17 — Mirror memory store and recall function.

Steps 18 and 19 — Priority read from ignition switch function.

Steps 20 to 24 — Mirror dip function.

Steps 25 and 26 — Mirror heater function.

Steps 27 to 29 — Sleep mode function.

DIAGNOSTIC CIRCUIT CHECK PROCEDURE

STEP ACTION VALUE YES NO

1 • Check battery voltage.

• Check circuit breakers F2 and F3, and fuse F15

on the fuse and relay panel located in the lower

dash panel.

• All OK?

Go to Step 2. Replace as

necessary.

Go to Step 2

2 • Turn ignition switch from OFF to IGN.

• Did the seat LED flash?

NOTE: LED flashes once for Priority Key 1 or twice

for Priority Key 2.

Go to Step 3. Go to LED Test in

this Section.

3 • Turn the ignition switch to OFF.

• Press memory buttons 1, 2 and 3 sequentially.

• Did a chime sound for each button pressed?

Go to Step 4. Go to Chime Test in

this Section.

4 • Press and hold the mirror dip button and turn

ignition switch from OFF to IGN three times within

6 seconds. Leave the ignition switch in the IGN

position.

• Did a constant tone sound?

Diagnostic function

operates correctly.

Go to Step 5.

Go to Diagnostic

Mode Test in this

Section.

5 • Turn the ignition switch to OFF and remove the

key.

• Using the eight-way seat position switch, move the

seat fully back, front down, rear down and

backrest fully back.

• Can the seat be moved by all four motors?

Go to Step 7. Go to Step 6.

6 • Is battery voltage above 10 V when driving

motors? Go to Manual Seat

Move Test in this

Section.

Charge or replace

battery, then go to

Step 7.

7 • Using the eight-way switch, move the seat fully

forward, front up, rear up and backrest fully

forward.

• Can the seat be moved to the end-points in both

directions by all four motors?

Seat manual move

function operates

correctly.

Go to Step 8.

Go to Manual Seat

Move Test in this

Section.

DIAGNOSTIC CIRCUIT CHECK PROCEDURE (continued)

STEP ACTION VALUE YES NO

8 • Using the eight-way switch, move the seat to the

middle position for all directions of travel.

• Press and hold memory button 2 for more than

2 seconds to store the seat position in memory set

2.

• Using the eight-way switch, move the seat to the

80% forward and down position.

• Press and hold memory button 1 for more than

2 seconds to store the seat position in memory set

1.

• Press and release memory button 2 within

1 second to recall memory set 2 position.

• Did all four motors move the seat to the middle

position?

Go to Step 9. Go to Drive Motor

and Motor

Potentiometer Test

in this Section.

9 • Using the eight-way switch, move the seat to the

80% back and up position.

• Press and hold memory button 3 for more than

2 seconds to store the seat position in memory set

3.

• Press and release memory button 1 within

1 second to recall memory set 1 position.

• Did all four motors move the seat to the 80%

forward and down position?

Go to Step 10. Go to Drive Motor

and Motor

Potentiometer Test

in this Section.

10 • Press and release memory button 3 within

1 second.

• Did all four motors move the seat to the 80% back

and up position as set in Step 9?

Seat memory store

and recall function

operates correctly.

Go to Step 11.

Go to Drive Motor

and Motor

Potentiometer Test

in this Section.

11 • Insert the key and turn ignition switch from OFF to

IGN.

• Press and release memory button 2 within

1 second to recall memory set 2 position.

• Did all four motors move the seat to the middle

position as set in Step 8?

Go to Vehicle

Interface Test in this

Section.

Ignition switch

disable function

operates correctly.

Go to Step 12.

12 • Turn the ignition switch to OFF and remove the

key.

• Press the door unlock button on Priority Key 1.

The seat may move at this point.

• Press and release memory button 1 within

1 second to recall memory set 1 position. The seat

will move to the 80% forward and down position.

• Press the door unlock button on Priority Key 2.

The seat can move at this point.

• Press and release memory button 2 within

1 second to recall memory set 2 position. The seat

will move to the middle position.

• Press the door unlock button on Priority Key 1.

• Did all four motors move the seat to the 80%

forward and down position, and did the seat LED

flash once?

Go to Step 13. Go to Vehicle

Interface Test in this

Section.

13 • Press the door unlock button on Priority Key 2.

• Did all four motors move the seat to the middle

position, and did the seat LED flash twice?

Go to Step 14. Go to Vehicle

Interface Test in this

Section.

14 • Insert the key and turn ignition switch from OFF to

IGN.

• Move both left and right rear vision mirrors through

all four directions using the mirror control switch.

• Can both mirrors be moved in all directions?

Go to Step 15. Go to Manual Mirror

Move Test in this

Section.

DIAGNOSTIC CIRCUIT CHECK PROCEDURE (continued)

STEP ACTION VALUE YES NO

15 • Using the mirror control switch, centre both

mirrors in the horizontal and vertical planes.

• Press and hold memory button 2 for more than

2 seconds to store the mirror position in memory

set 2.

• Using the mirror control switch, move both mirrors

to the up and out position.

• Press and hold memory button 1 for more than

2 seconds to store the mirror position in memory

set 1.

• Using the mirror control switch, move both mirrors

to the down and in position.

• Press and hold memory button 3 for more than

2 seconds to store the mirror position in memory

set 3.

• Press and release memory button 2 within

1 second to recall memory set 2 position.

• Did both mirrors move to the middle position?

Go to Step 16. Go to Mirror Recall

Test in this Section.

16 • Press and release memory button 1 within

1 second to recall memory set 1 position.

• Did both mirrors move to the up and out position?

Go to Step 17. Go to Mirror Recall

Test in this Section.

17 • Press and release memory button 3 within

1 second to recall memory set 3 position.

• Did both mirrors move to the down and in

position?

Go to Step 18. Go to Mirror Recall

Test in this Section.

18 • Press the door unlock button on Priority Key 1.

• Insert Priority Key 2 in the ignition and turn ignition

switch from OFF to IGN.

• Did the seat LED flash twice?

Go to Step 19. Go to Vehicle

Interface Test in this

Section.

19 • Turn the ignition switch OFF and remove the key.

• Press the door unlock button on Priority Key 2.

• Insert Priority Key 1 in the ignition and turn ignition

switch from OFF to IGN.

• Did the seat LED flash once?

Go to Step 20. Go to Vehicle

Interface Test in this

Section.

If no fault is found in

this test, then fault is

with the key or slip-

ring connection.

20 • Using the mirror control switch, move the

passenger’s rear vision mirror to a forward driving

position.

• Select reverse gear.

• Did the passenger’s mirror move to a dip position?

Go to Step 24. Go to Step 21.

21 • Press the mirror dip button on the side of the seat

twice. A chime w ill sound on pressing the button. If

the last chime had the lowest frequency , press the

mirror dip button again.

• Did a chime sound when the mirror dip button w as

pressed?

Go to Step 22. Go to Diagnostic

Switch Test in this

Section.

22 • Did the passenger’s mirror move to a dip position? Go to Step 24. Go to Step 23.

23 • Using the mirror control switch, move the

passenger’s rear vision mirror to another position.

• Select park.

• Did the passenger’s mirror return from a dip

position to the forward driving position?

Go to Step 25. Go to Vehicle

Interface Test in this

Section.

24 • Press the mirror dip button on the side of the seat.

• Did the passenger’s mirror return from a dip

position to the forward driving position, and did a

chime sound?

Go to Step 25. Go to Diagnostic

Switch Test in this

Section.

STEP ACTION VALUE YES NO

25 • Check that the ignition switch is in the IGN

position and the rear window demister is off.

• Are both rear vision mirrors still cool after

2 minutes?

Go to Step 26. Go to Mirror Heater

Test in this Section.

26 • Set the rear window demister switch to on.

• Did both mirrors get warm after 2 minutes? Go to Step 27. Go to Mirror Heater

Test in this Section.

27 • Turn the ignition switch to OFF and remove the

key. Do not operate any switches for 5 minutes.

• Did the seat LED extinguish after 5 minutes?

Go to Step 28. Go to Sleep Mode

Test in this Section.

28 • Can the mirrors be moved using the mirror switch

while the LED is extinguished? Go to Sleep Mode

Test in this Section. Go to Step 29.

29 • Can the seat be moved using the eight-way seat

position switch? End of diagnosis. Go to Sleep Mode

Test in this Section.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COM PLETED, VERIFY CORRECT OPERATION

CHIME TEST

INTRODUCTION

This test verifies the correct operation of the chime circuit within the seat control module as well as the appropriate

voltage and earth circuits. The location of the seat control module connectors is shown in Fig. 1A7-12. For circuit

diagram and other connector information, refer to Fig. 1A7-13.

TEST DESCRIPTION

The various steps in the Chime Test verify the following functions:

Step 1 — Ensures that the Vehicle Interface Test is carried out eliminate other possible faults.

Step 2 — Checks the chime function for correct operation.

Step 3 — Checks the input voltage.

Step 4 — Checks the terminal retention of chime circuit connector pins.

Step 5 — Checks the chime function at the input to the seat control module.

Step 6 — Checks the voltage circuit protection.

Step 7 — Identifies presence of an intermittent fault.

Step 8 — Checks for a short between the mirror bus power and mirror bus earth circuits.

Step 9 — Isolates the fault to a circuit wiring problem or a defective seat control module.

YB227

YB220

(1027)

+12V

G

REVERSE

SIG

G/GY

(614)

(1029)

B/Y

YRECLINE UP

AFT

(1023)

HEATED REAR

WINDOW

SIG

Y/P

BLU/R

IGN.

12V

EIGHT-WAY SEAT POSITION SWITCH

SPEAKER

M2

DIAGNOSTIC

LED

SEAT CONTROL

MODULE

B

R/O

FRT UP

(1024)

SERIAL DATA

(621)

(1021)

RECLINE DN

RR UP

B/W

YB227

12V

YB227

M3

(1025)

GND

(613)

(24)

(192)

FWD

FRT DN

(1022)

YB225

(1028)

12V

DIP

(1026)

V/Y

W/P

V/G

ME MORY POSITION SWI TCH

RR DN

M1

(MIRROR

SERIAL

DATA

BUS)

Y/BLU

B/W

B/O

B/Y

Y

GY/R

R/G

W/P

R/O

G

V

BR/BLU

YB226

(24)

(192)

LG

V/R

GND

GND

YB225

YB227

MEMORY AND POSITION CONNECTOR

POWER CONNECTOR

(1021)

(1026)

(1022)

(613) (614)

(1029)

(1024)

(1023)

(1028)

(1027)

G

Y

V/Y

BLU/R

Y/P

W/P

B/Y

B/W

G/GY

R/O

V/G

7

1

61

7

12

B(612)

B/Y

Y(783)

(151)

R/G

R/O (929)

Y/BLU (540)

(139)

(925)

(920)

W/PG

B/O

BR/BLU(192) B/W(641)

5

12

6

1

(24)

V

(156)

GY/R

A

B

C

WH1A7008A

2

3

4

5

6

7

12

1

11

8

10

9

JP4

330 330 330

Figure 1A7-13

CHIME TEST PROCEDURE

STEP ACTION VALUE YES NO

1 • Has the Vehicle Interface Test been carried out? Go to Step 2. Go to Vehicle

Interface Test in this

Section.

2 • Press and hold memory button 1 for 2 seconds.

• Did a chime sound after 2 seconds? Chime test

successful.

End of diagnosis.

Go to Step 3.

3 • Remove the lower side cover from the driver’s

seat to gain access to the seat control module.

NOTE: Use adaptors from test adaptor kit KM-609 to

back probe the terminals of power connector YB227.

• Using a multimeter, measure the voltage on circuit

540 (Yellow/Blue wire) at power connector YB227.

• Is voltage as specified?

10 – 13 V Go to Step 3. Go to Step 6.

4 • Disconnect the memory and position connector

YB225 from the seat control module.

• Check the terminal retention of seat control

module connector JP4 pins 8 and 9 with KM-609.

• Is terminal retention OK?

Go to Step 5. Rectify as

necessary.

5 • Connect pins 8 and 9 of the seat control module

connector JP4 together.

• Did a chime sound immediately or after

2 seconds?

Replace faulty

memory position

switch. Refer to 2.2

MEMORY

POSITION SWITCH

in this Section.

Replace faulty seat

control module.

Refer to 2.1 SEAT

CONTROL

MODULE in this

Section.

6 • Check circuit breaker F2 on the fuse and relay

panel located in the lower dash panel.

• Circuit breaker OK?

Check circuit 540

and repair as

necessary.

Go to Step 7.

7 • After circuit breaker resets, does circuit breaker

F2 blow again? Go to Step 8. Go back to Step 2

and repeat the test

procedure and

monitor if the circuit

breaker blows again.

It may be an

intermittent fault.

8 • Disconnect the power connector YB227 from the

seat control module.

• Using an ohmmeter, measure the resistance

between the mirror bus power circuit 929

(Red/Orange wire) and the mirror bus earth circuit

920 (White/Pink wire) at connector YB227.

• Is the reading as specified?

Below 10 ΩGo to Mirror Power

Wiring Short Circuit

Test in this Section.

Go to Step 9.

9 • Leave YB227 disconnected and allow circuit

breaker F2 to reset.

• Does circuit breaker F2 blow again?

Check circuit 540

and repair as

necessary.

Replace faulty seat

control module.

Refer to 2.1 SEAT

CONTROL

MODULE in this

Section.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COM PLETED, VERIFY CORRECT OPERATION

DIAGNOSTIC MODE TEST

INTRODUCTION

The four diagnostic modes are entered by selecting various combinations of the seat memory buttons. This test

verifies the correct operation of the memory position switch circuit as well as the appropriate voltage and earth

circuits. The location of the seat control module connectors is shown in Fig. 1A7-12. For circuit diagram and other

connector information, refer to Figs. 1A7-3 to 1A7-6.

TEST DESCRIPTION

The various steps in the Diagnostic Mode Test verify the following functions:

Step 1 — Ensures that the Vehicle Interface Test is carried out eliminate other possible faults.

Step 2 — Checks the correct operation of the memory position switch.

Step 3 — Checks the voltage from the ignition switch.

Step 4 — Checks the correct operation of each button on the memory position switch.

DIAGNOSTIC MODE TEST PROCEDURE

STEP ACTION VALUE YES NO

1 • Has the Vehicle Interface Test been carried out? Go to Step 2. Go to Vehicle

Interface Test in this

Section.

2 • Turn the ignition switch to the IGN position and

press a memory button for 0.5 second.

• Turn the ignition switch to the OFF position and

press a memory button for 0.5 second.

• Did a chime sound for both switch positions?

Go to Step 3. Go to Step 4.

3 • Remove the lower side cover from the driver’s

seat to gain access to the seat control module.

NOTE: Use adaptors from test adaptor kit KM-609 to

back probe the terminals of power connector YB227.

• Using a multimeter, measure the voltage on circuit

139 (Black/Orange wire) at power connector

YB227 while turning the ignition switch from OFF

to IGN.

• Is voltage as specified?

IGN = 12 V

OFF = 0 V Replace faulty seat

control module.

Refer to 2.1 SEAT

CONTROL

MODULE in this

Section.

Check circuit 139

and repair as

necessary.

4 • Disconnect the memory and position connector

YB225 from the seat control module.

• Connect an ohmmeter across circuit 621 (Black

wire) and circuit 613 (Yellow/Pink wire) at

connector YB225.

• When pressing the memory buttons, are the

ohmmeter readings as specified?

No buttons

=

> 1 MΩ

M1 =

continuity

M2 = 330 Ω

M3 = 660 Ω

DIP = 990 Ω

Replace faulty seat

control module.

Refer to 2.1 SEAT

CONTROL

MODULE in this

Section.

Replace faulty

memory position

switch. Refer to 2.2

MEMORY

POSITION SWITCH

in this Section.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COM PLETED, VERIFY CORRECT OPERATION

MIRROR POWER WIRING SHORT CIRCUIT TEST

INTRODUCTION

This test checks for a short circuit between the mirror power circuit and the mirror earth circuit. The location of the

seat control module connectors is shown in Fig. 1A7-12. For circuit diagram and other connector information, refer

to Fig. 1A7-14.

TEST DESCRIPTION

The various steps in the Mirror Power Wiring Short Circuit Test verify the following functions:

Step 1 — Ensures that the Vehicle Interface Test is carried out eliminate other possible faults.

Step 2 — Checks for a short circuit between the mirror bus power and mirror bus earth circuits.