SECTION 1A9 - EXTERIOR ORNAMENTATION

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to

Section 00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or

property damage.

1. GENERAL DESCRI PTI O N

Exterior ornamentation on WH Series Models includes:

• Body side mouldings for both models.

• Various nameplates, emblems and decals depending.

• A windshield moulding cover.

• Door frame-opening mouldings.

• ‘B’ pillar mouldings.

• Roof finisher and side mouldings.

• Rocker panel skirts.

Exterior ornamentation components are secured to the body using various fasteners, double sided tape and

polyurethane adhesive.

Techline

Techline

2. SERVICE OPERATIONS

2.1 SERVICE NOTES

Numerous clips, fasteners, retainers, bushes, screws, nuts and contact adhesives are used to secure the various

exterior ornamentation components to the vehicle body. To locate the service information applicable a to a

particular component, refer to 2.2 PICTORIAL INDEX in this Section.

When removing, handling or installing exterior ornamentation components, the following care should be exercised:

1. Finishers adjacent to the component being removed should be covered with masking tape to prevent damage to

panels and paint work.

2. Removal of adhesive bonded nameplates and emblems is more easily achieved wi th the aid of a heat lamp

positioned adjacent to the part to be removed.

NOTE: Ensure that the heat lamp is not too close to the body, or the heat to intense to adversely affect the paint

finish.

3. Holes in body panels for screws, bolts, clips, etc. that could permit water entry into the body must be adequately

sealed with either a non-hardening sealer or presealed screws, clips, etc.

4. Using a clean cloth, clean the area of body surface where emblems, mouldings, etc. are to be applied with

‘Prepsol’ solvent or equivalent.

5. It is essential that the body temperature of the vehicle be at least 21°C before adhering adhesive bonded

components to the vehicle.

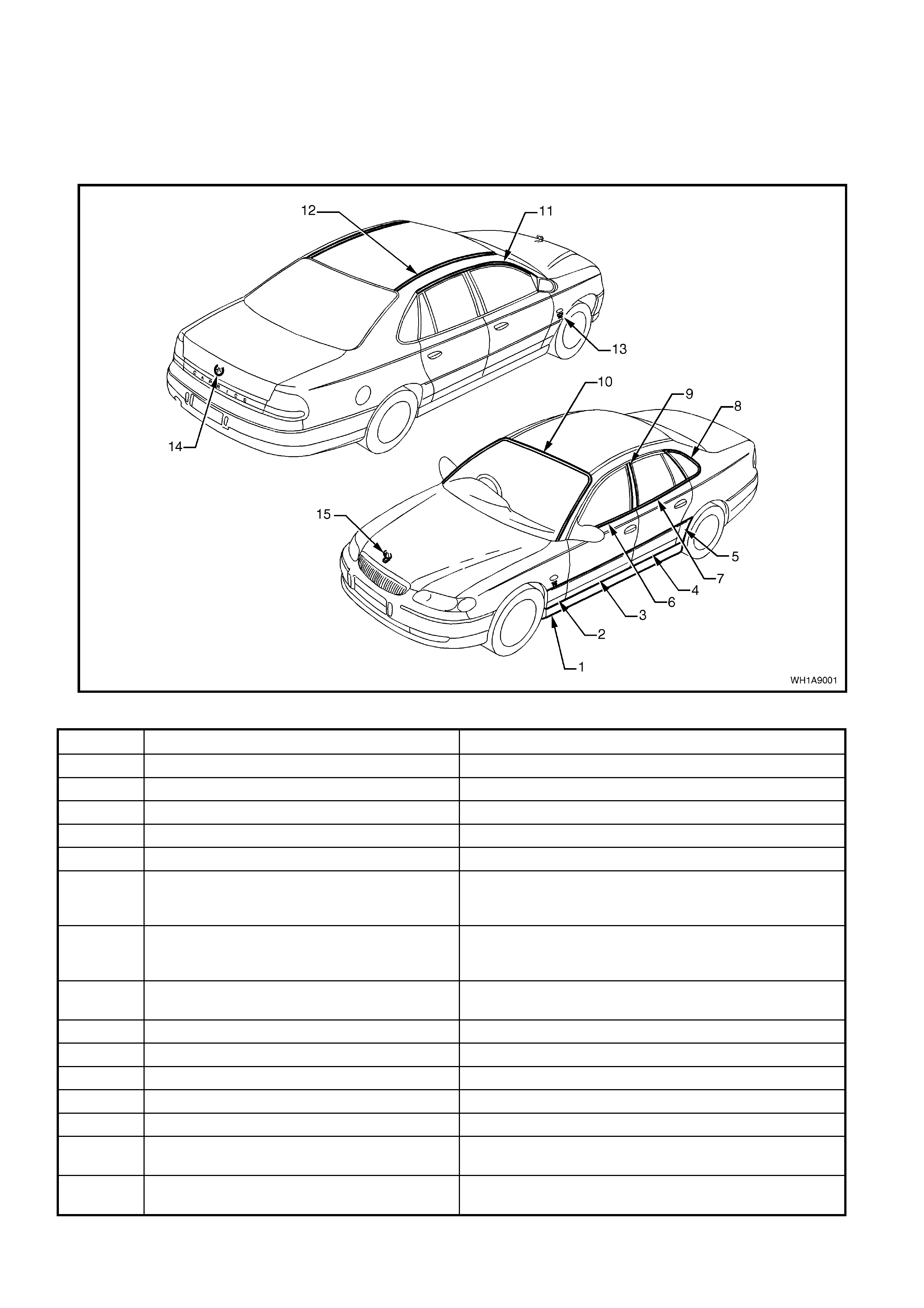

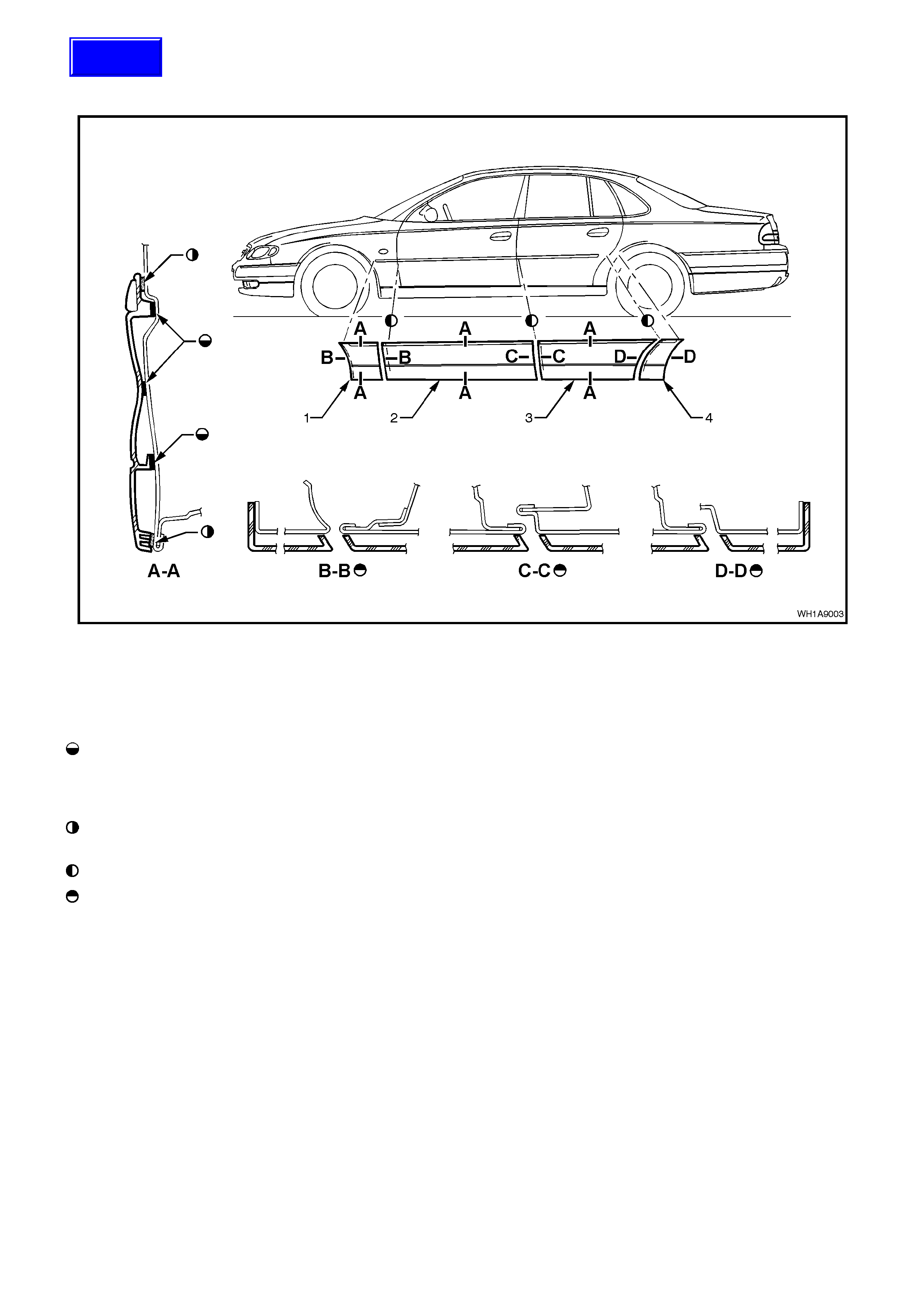

2.2 PICTORIAL INDEX

The following pictograph indexes provide a quick guide to finding the correct service procedure for the applicable

exterior ornamentation component. Within this Section, simply locate the appropriate component in Fig. 1A9-1, and

cross-reference it in the table below the Figure.

STATESMAN AND CAPRICE

Figure 1A9-1

ITEM DESCRIPTION REFERENCE

1 Rocker panel skirt 2.3 ROCKER PANEL SKIRT in this Section

2 Front fender side moulding 2.4 BODY SIDE MOULDINGS in this Section

3 Front door side moulding 2.4 BODY SIDE MOULDINGS in this Section

4 Rear door side moulding 2.4 BODY SIDE MOULDINGS in this Section

5 Rear quarter side moulding 2.4 BODY SIDE MOULDINGS in this Section

6 Front door belt moulding 2.15 FRONT AND REAR DOOR BELT WEATHERSTRIP

AND MOULDING ASSEMBLY in Section 1A5 FRONT AND

REAR DOOR ASSEMBLIES

7 Rear door belt moulding 2.15 FRONT AND REAR DOOR BELT WEATHERSTRIP

AND MOULDING ASSEMBLY in Section 1A5 FRONT AND

REAR DOOR ASSEMBLIES

8 Quarter window frame moulding 3.4 REAR QUARTER WINDOW, Section 1A6

STATIONARY GLASS.

9 ‘B’ pillar moulding 2.5 ‘B’ PILLAR MOULDING in this Section.

10 Windshield moulding cover 2.7 WINDSHIELD MOULDING COVER in this Section

11 Door frame opening moulding 2.8 DOOR FRAME OPENING MOULDING in this Section

12 Roof finisher moulding 2.9 ROOF FINISHER MOULDING - in this Section

13 Engine Badge 2.11 NAME PLATES AND DECALS in this Section

14 Emblem: ‘Lion’ 2.10 ‘LION’ ORNAMENT/EMBLEM – DECK LID in this

Section

15 Ornament: ‘Lion’ 2.10 ‘LION’ ORNAMENT/ EMBLEM – ENGINE HOOD in

this Section

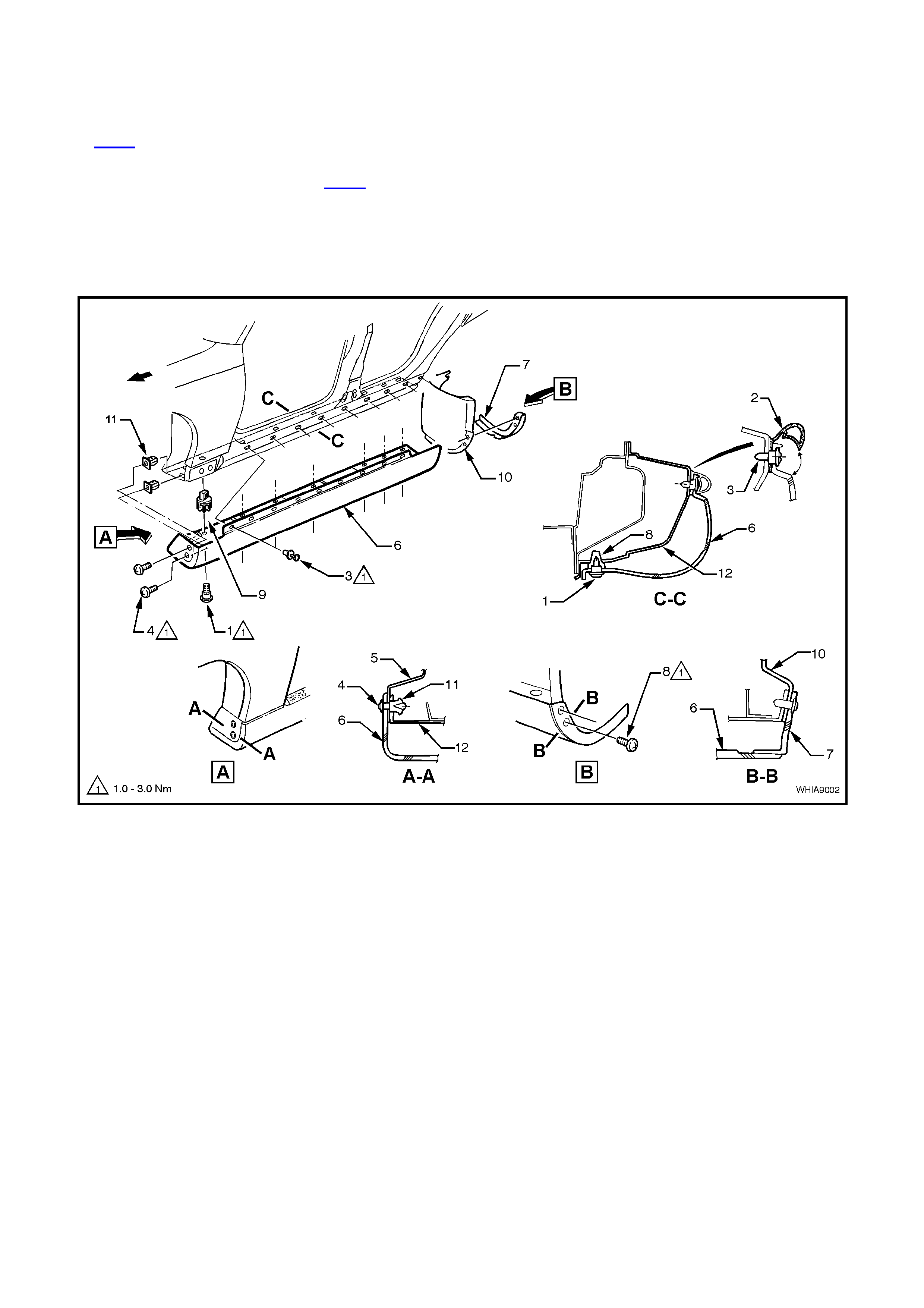

2.3 ROCKER P ANEL SKIRT

REMOVE

1. From under vehicle, remove the seven rocker panel skirt lower retaining screws (1), refer to View C-C in Fig.

1A9-2.

2. Lift up lip of rocker panel skirt weatherstrip (2) to gain access to the nine retaining scrivets (3) and remove

scrivets, refer to View C-C in Fig. 1A9-2.

3. Remove the two screws (4) securing the rocker panel front skirt to the fender liner.

4. Slide rocker panel front skirt forward until it is free from the rocker panel rear skirt, and remove rocker panel

front skirt.

5. Remove the two screws (8) securing the rocker panel rear skirt (7) to the body and remove rocker panel rear

skirt.

Figure 1A9-2

Legend

1. Screw (7 places).

2. Rocker panel skirt weatherstrip assembly.

3. Scrivet (9 places).

4. Screw (2 places).

5. Front fender liner.

6. Rocker panel front skirt.

7. Rocker panel rear skirt.

8. Screw (2 places).

9. Nutsert (7 places).

10. Rear wheelhouse liner.

11. Nut.

12. Door opening frame.

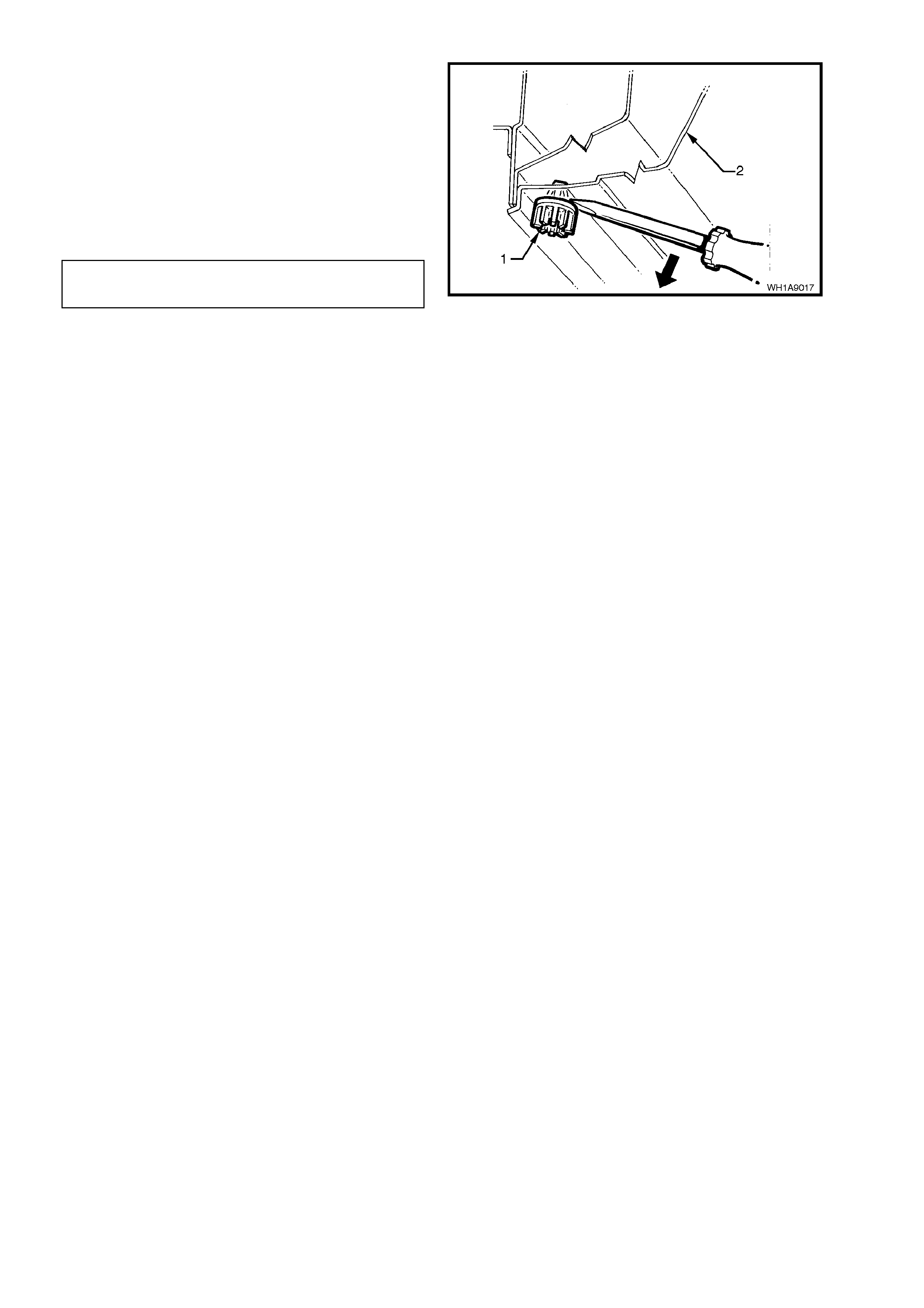

6. If necessary, remove the seven nutserts (1) by

gently levering nutsert out from the body (2),

taking care not to damage paintwork.

REINSTALL

Reinstallation of the rocker panel front and rear

skirts is the reverse of the removal operation,

ensuring that all fasteners are tightened to the

correct torque specification.

ROCKER PANEL SKIRT

RETAI NING SCREWS 1 - 3 Nm

TORQUE SPECIFI CATION Figure 1A9-3

2.4 BODY SIDE MOULDINGS

STATESMAN AND CAPRICE

Figure 1A9-4

Legend

1. Front fender side moulding.

2. Front door side moulding. 3. Rear door side moulding.

4. Rear quarter side moulding.

Service Notes:

Apply a 3.0 mm diameter bead of polyurethane

adhesive suc h as ‘Expandite Betas eal 554.02’ or

equivalent, to Holden Specification HN 1890

over entire length of mouldings.

Double sided adhesive foam tape (part of

moulding assembly).

Top edge of mouldings to be in line.

Front edge of door mouldings to be 1mm back

from door edge.

Techline

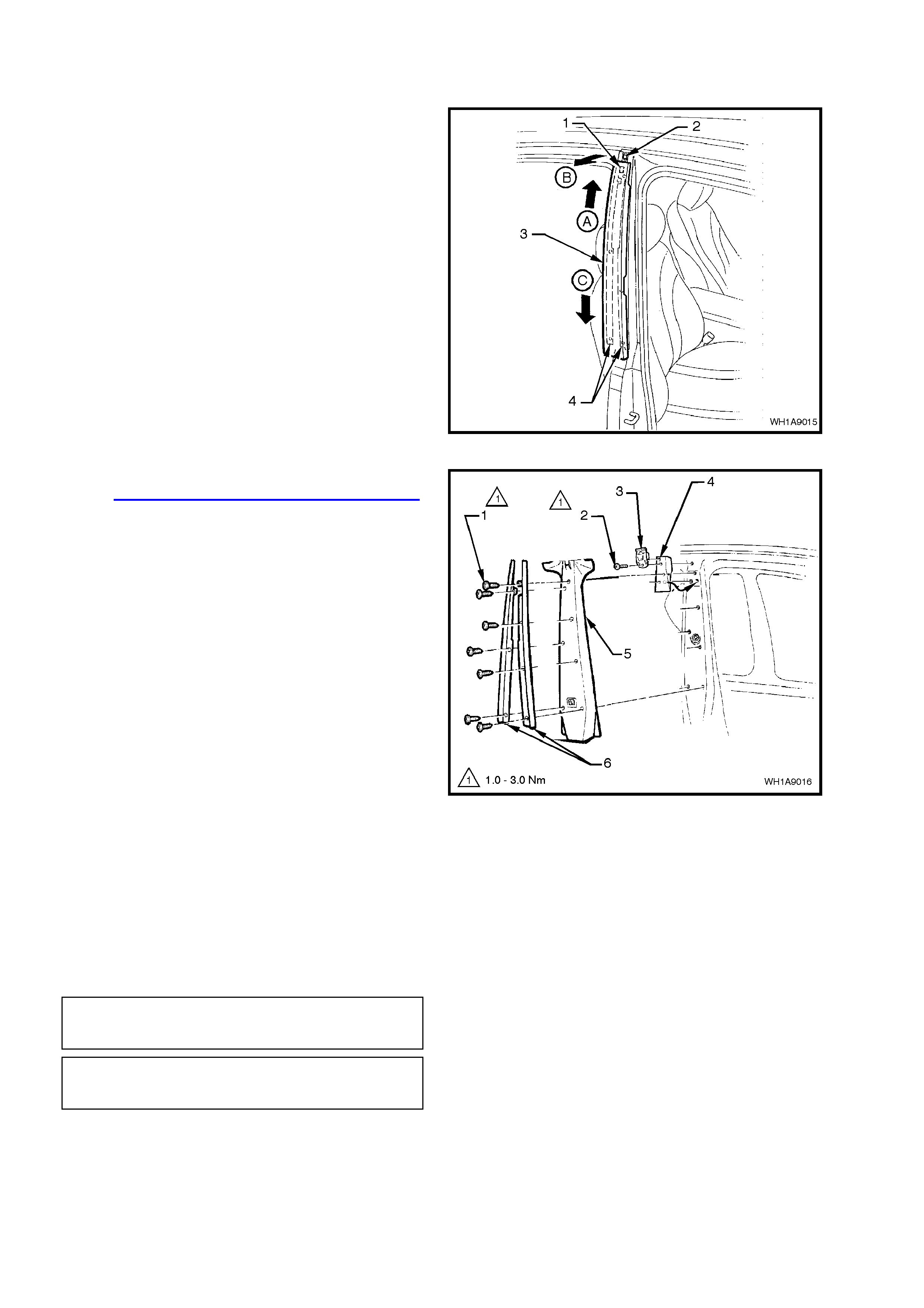

2.5 ‘B’ PILLAR MOULDINGS

REMOVE

1. Open front and rear door on relevant side of

vehicle.

2. To release the outer moulding (3) from the

retaining clip (2), push the outer moulding up by

hand slightly (A) while gently levering top of

moulding out and away from ‘B’ pillar (B).

3. With top of ‘B’ pillar retaining catc h (1) re leased

from retaining clip, hold top of moulding out and

slide moulding down weatherstrip retaining

tracks (C) until moulding rests on rear door

hinge assembly.

4. Jiggle outer moulding until it becomes free from

weatherstrip retaining tracks (4), and remove

outer moulding.

Figure 1A9-5

5. Remove the doorframe opening moulding, refer

to 2.8 DOOR FRAME OPENING MOULDING

in this Section.

6. Remove the seven screws (1curing the ‘B’ pillar

weatherstrips retaining tracks (6) to the ‘B’ pillar

and remove weatherstrip assemblies.

7. Remove inner cover (5) by pulling cover away

from ‘B’ pillar.

8. Remove the screw (2) securing the moulding

retaining clip (3) and mounting (4) to the ‘B’

pillar and remove retaining clip and mounting.

Figure 1A9-6

REINSTALL

Reinstallation of the ‘B’ pillar moulding is the

reverse of the removal procedure, noting the

following:

1. Ensure the inner cover is seated correctly,

under door opening weatherstrips.

2. Ensure all fasteners are tightened to the

correct torque specification.

‘B’ PILLAR MOULDING RETAINING

CLIP SECURING SCREW 1 - 3 Nm

TORQUE SPECIFICATION

‘B’ PILLAR WEATHERSTRIP

ASSEMBLY SECURING SCREW 1 - 3 Nm

TORQUE SPECIFICATION

3. Slide the outer moulding up and press it in at

the top so that it engages into the retaining clip.

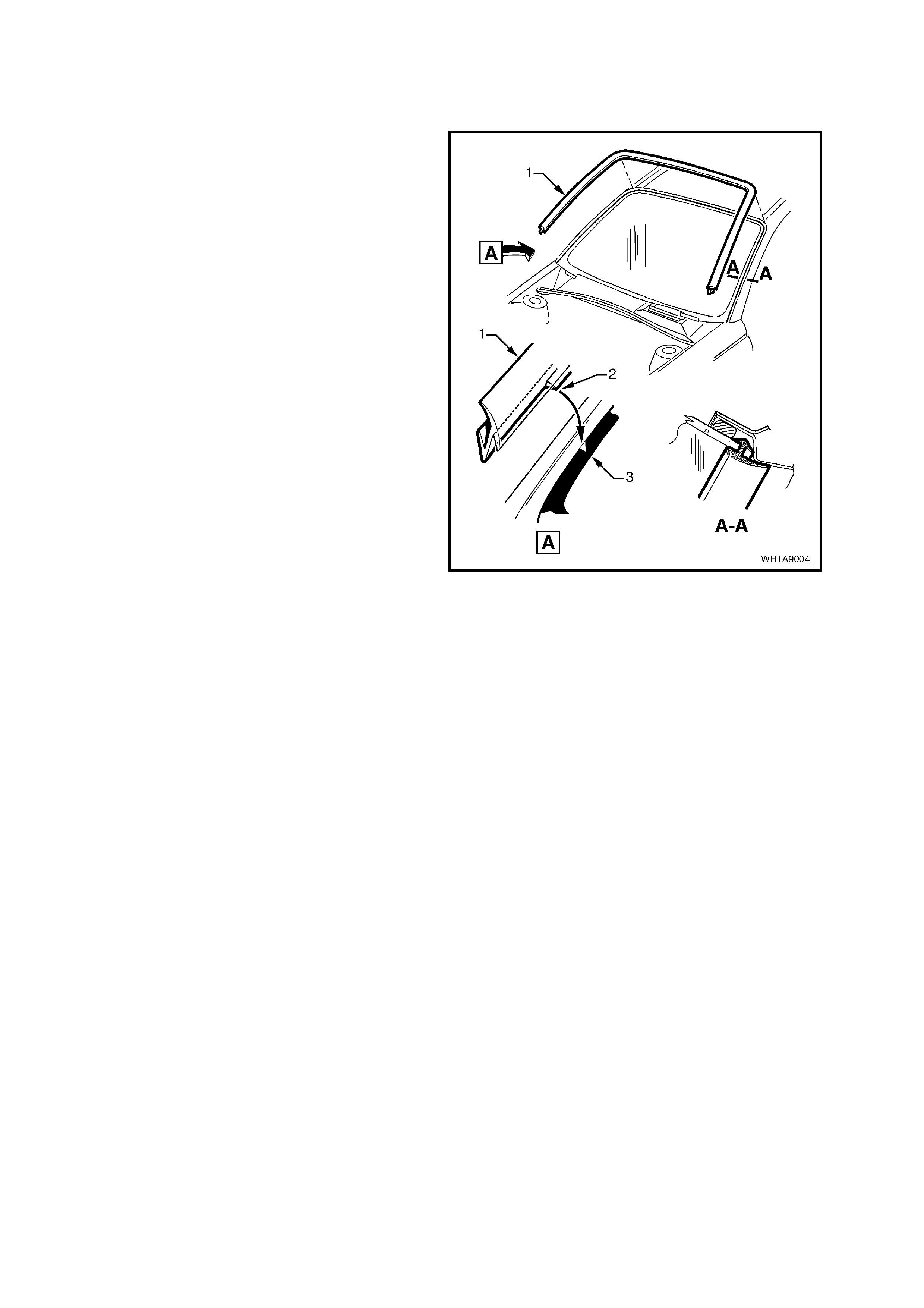

2.7 WINDSHIELD MOULDING COVER

REMOVE

Starting at lower corner of the windshield moulding

cover (1), gently pry windshield moulding cover

from windshield opening.

REINSTALL

1. Insert drivers side lower end of windshield

moulding c over (1) loos ely behind top of guard.

Begin installing windshield moulding cover at

drivers side lower corner of windshield. Align

datum mark on windshield (3) with datum

section on moulding cover (2).

2. Insert passenger side lower end of windshield

moulding cover loosely behind top of guard.

Align datum mark on windshield with datum

section on moulding cover. Attach moulding to

passenger side windshield, working from lower

corner to upper corner of windshield.

3. Install upper portion of windshield moulding

cover, work ing from driver side upper c orner to

passenger side upper corner.

Figure 1A9-7

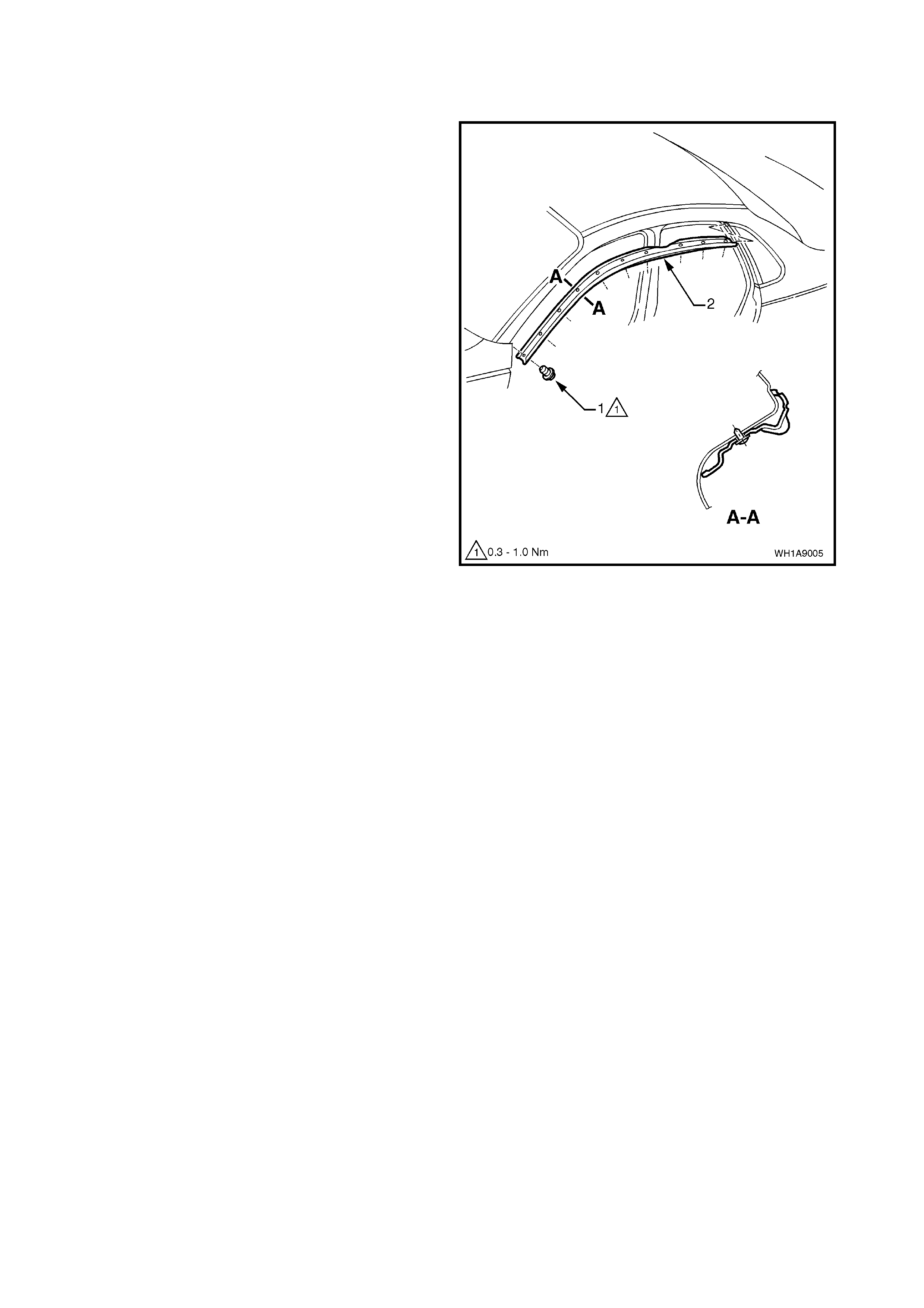

2.8 DOOR FRAME OPENING MOULDING

REMOVE

1. Open front and rear door on relevant side of

vehicle.

2. Remove the screws (1) securing door frame

opening moulding (2) to body (11 places) and

remove moulding.

Figure 1A9-8

REINSTALL

Reinstallation is the reverse of the removal procedure.

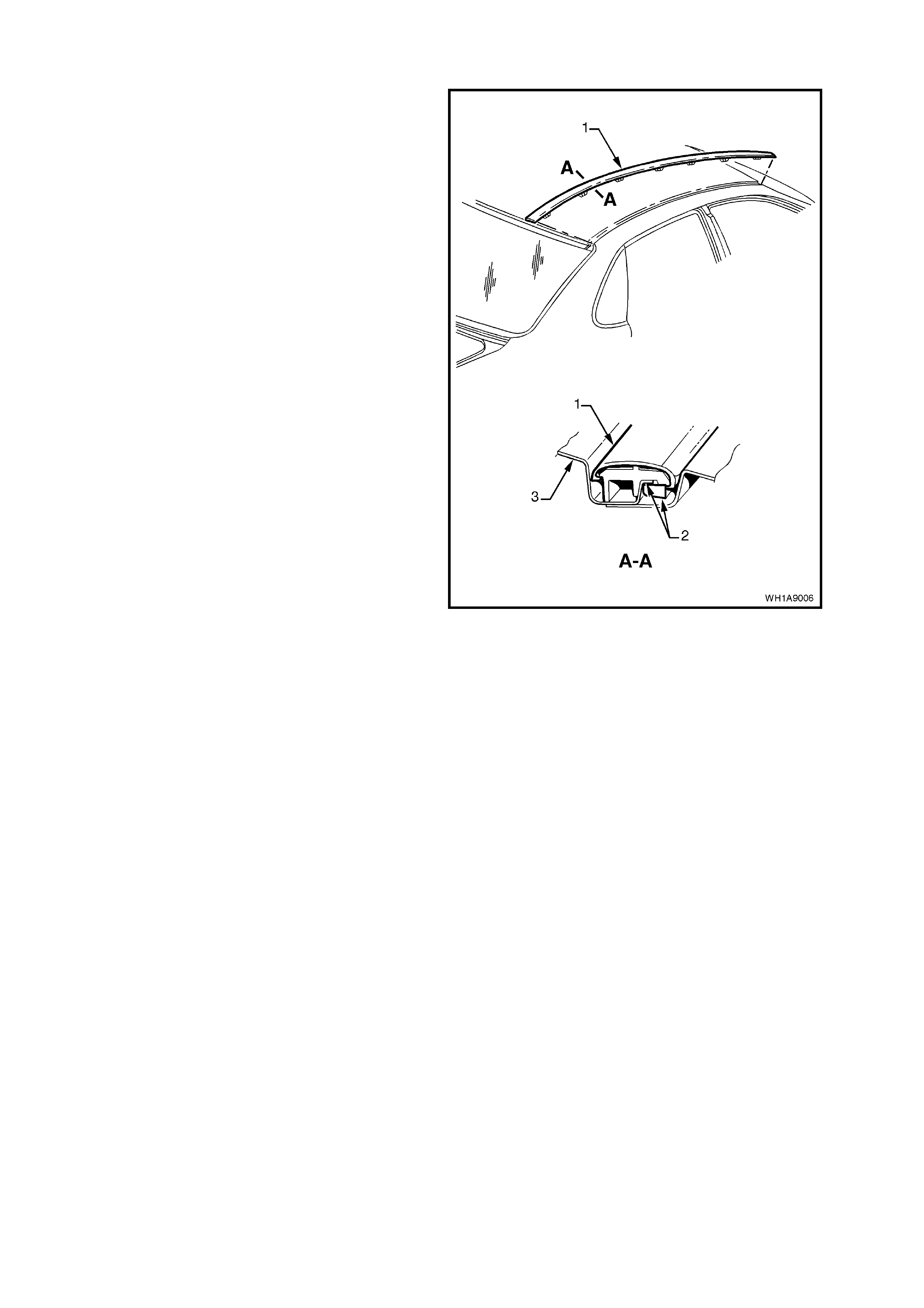

2.9 ROOF FINISHER MOULDING

REMOVE

1. Using a screw driver with a clean shop rag to

prevent paint work damage, pry the front of the

roof f inis her moulding (1) out of the r oof c hannel

between the top of the windscreen to the top of

the rear window.

2. Slide the roof finisher moulding out of the side

moulding retaining channel.

REINSTALL

1. Engage roof finisher moulding over side

moulding and slide along until roof finisher

moulding is in line with back window moulding

2. Engage roof finisher moulding clips along roof

until roof finisher m oulding s its f lush agains t the

roof (3), ensure clips engage under roof panel

flange.

NOTE: The roof finisher moulding must be installed

under the windshield moulding cover. Figure 1A9-9

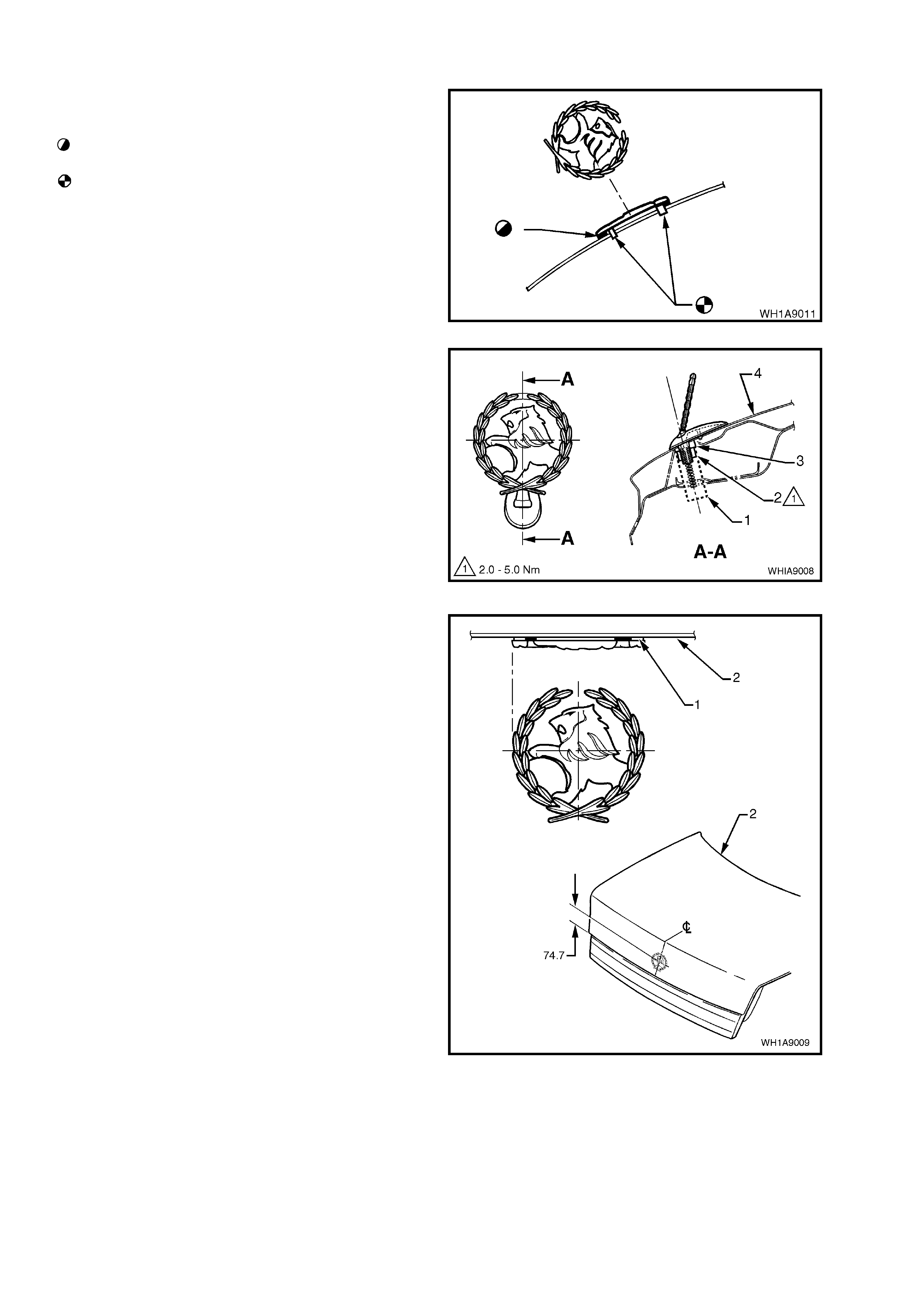

2.10 ‘LION’ EMBLEM/ORNAMENT

ENGINE HOOD-STATESMAN

Service notes

Before installation, remove release paper from

adhesive foam tape.

After removing release paper from adhesive

foam tape, ensure there is a band of adhesive

foam tape around base of locating pins.

Figure 1A9-10

ENGINE HOOD - CAPRICE

Service notes

Install ornament in existing holes at centre line of

engine hood outer panel.

Legend

1. Nut runner

2. Retaining nut

3. Hood ornament spacer.

4. Engine hood outer panel.

Figure 1A9-11

DECK LID

Service notes

NOTE 1: Before installation, remove release paper

from adhesive foam tape.

Dimensions shown in mm.

Legend

1. Adhesive foam tape.

2. Deck lid.

Figure 1A9-12

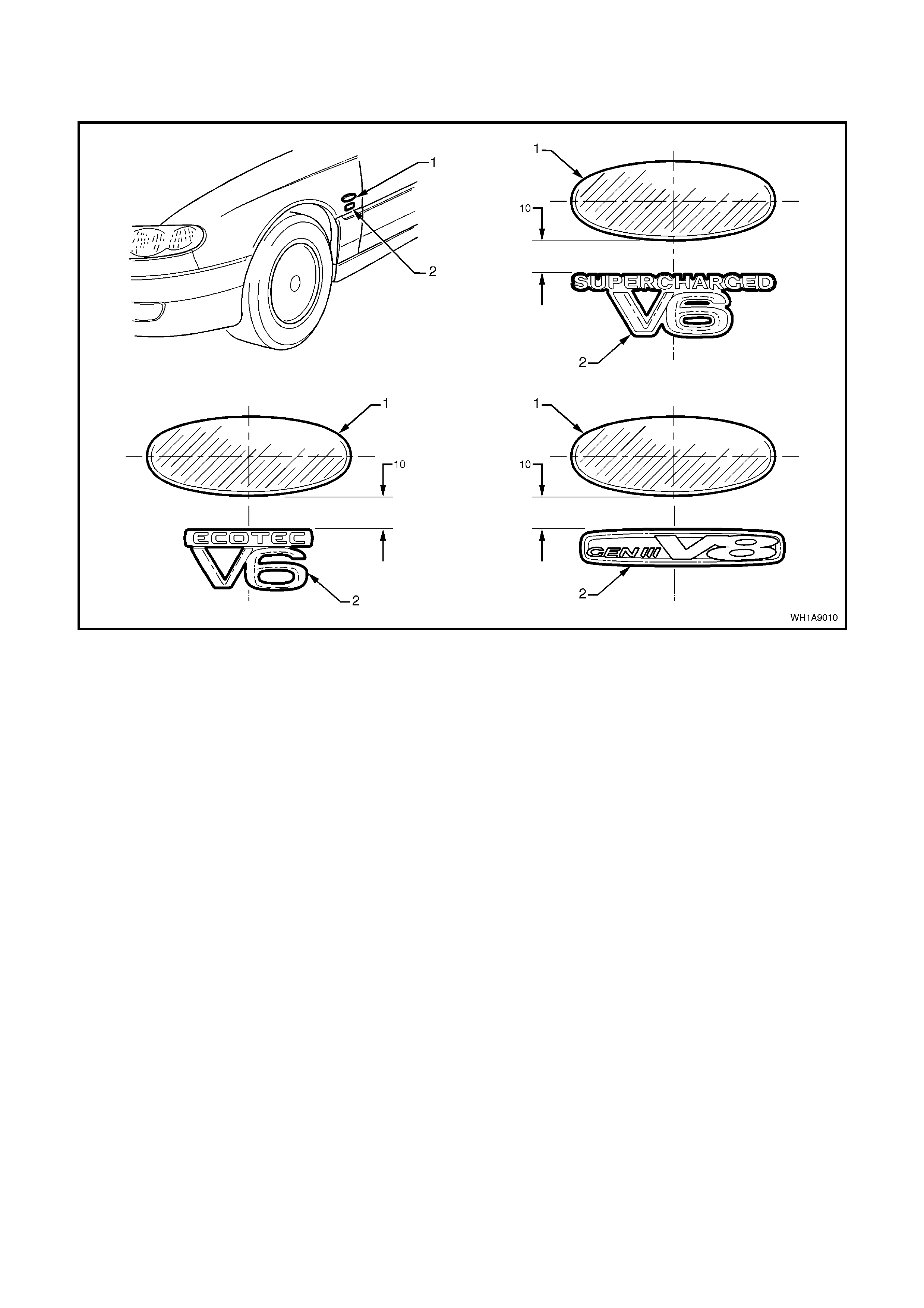

2. 11 NAME PLATES AND DECALS

STATESMAN AND CAPRICE

Figure 1A9-13

Legend

1. Side repeater lamp. 2. Engine badge.

Dimensions shown in mm.

3. TORQUE WRENCH SPECIFI CATIONS

Nm

Rocker Panel Skirt Retaining Screw..................................... 1 - 3

‘B’ Pillar Moulding Retaining Clip Retaining Screw............... 1 - 3

‘B’ Pillar Weatherstrip Assembly Securing Screw................. 1 - 3

Door Frame Opening Moulding Securing Screw.................. 0.3 - 1.0