SECTION 1F - SUNROOF

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1. GENERAL I NFORMATI O N

The sunroof is a tinted glass panel, electrically operated, two-way sliding and tilting type, equipped with an internal

sliding sunshade and front edge wind deflector. The sunroof is operated by a rocker type switch (which is backlit)

centrally located in the vehicle's headlining in front of the sunroof vent aperture. A Sunroof Control Unit (SCU)

provides several pre-programmed functions and the facility to program an additional option.

PRE-PROGRAMMED FUNCTIONS

Soft touch

By a single touch of the switch the roof can be fully opened to the maximum tilt position or the maximum slide

position.

Variable tilt position

The panel can be closed from tilt in four steps by continuously pressing the switch and releasing in the desired

position.

Jamming protection (Safety Feature)

When closing the sunroof by soft touch or by autoclose, the sunroof automatically opens when it encounters an

obstacle. The roof will continue to try to close until the obstacle is removed.

Auto-close function

Three seconds after switching off the ignition the sunroof will close automatically. This can be prevented by pressing

the switch once within three seconds after the ignition is switched off.

One-way closing

This feature always closes the glass panel from above, assuring a flush fit of the panel.

OPTIONAL PROGRAMMABLE FUNCTION

Comfort position in the sliding range

With this featur e you will be able to progr am a preset s topping position of the glass panel in the sliding range of the

sunroof. The glass panel will stop at the preset position when opened via the soft touch operation.

1.1 GENERAL DESCRIPTION

Glass panel movement into the venting and sliding positions is controlled by:

Continuous Control (pressing the switch longer than 0.3 second):

• Full control over the glass panel movement in slide position.

• Releasing the switch will stop the glass panel movement.

• A full stop in maximum slide and closed position.

Four Steps Down Tilt Adjustment (pressing the switch longer than 0.3 second):

• W hen closing the sunroof from minimum tilt position by pressing the switch c ontinuously, the glas s panel

will stop briefly in four intermediate positions.

• Releasing the switch will stop the glass panel movement.

• To continue the stepped operation, press the switch again.

One Touch Control (pressing and releasing the switch within 0.3 second):

• Automatic glass panel movement towards full open or full closed position (slide and tilt).

• Anti-jamming protection while closing.

• The glass panel movement can be interrupted by pressing the switch.

Auto-close

When the ignition is switched off, the glass panel will close after a three-second delay:

• Anti-jamming protection while closing.

• Pressing the switch within three seconds after the ignition switch off will cancel Auto-close.

• Auto-close will not be activated if any other function is active.

One Way Closing

To ensure perfect positioning of the glass panel after closing, the glass panel will always close from above

(even when closed from a slide position).

Interior Trim

Sunshade

Sunshade operation depends on glass panel movement as follows:

• Moving the glass panel to tilt position, the sunshade automatically opens to a vent position and can be

moved to full open position by hand.

• Moving the glass panel into slide position, the sunshade will move together and can also be further

opened by hand.

• Closing the sunshade always has to be done manually. The sunshade can only be closed completely

when the glass panel is in closed position.

Wind Deflector

The wind defector automatically comes up when the glass panel moves into sliding positions and goes down

when the glass panel closes again.

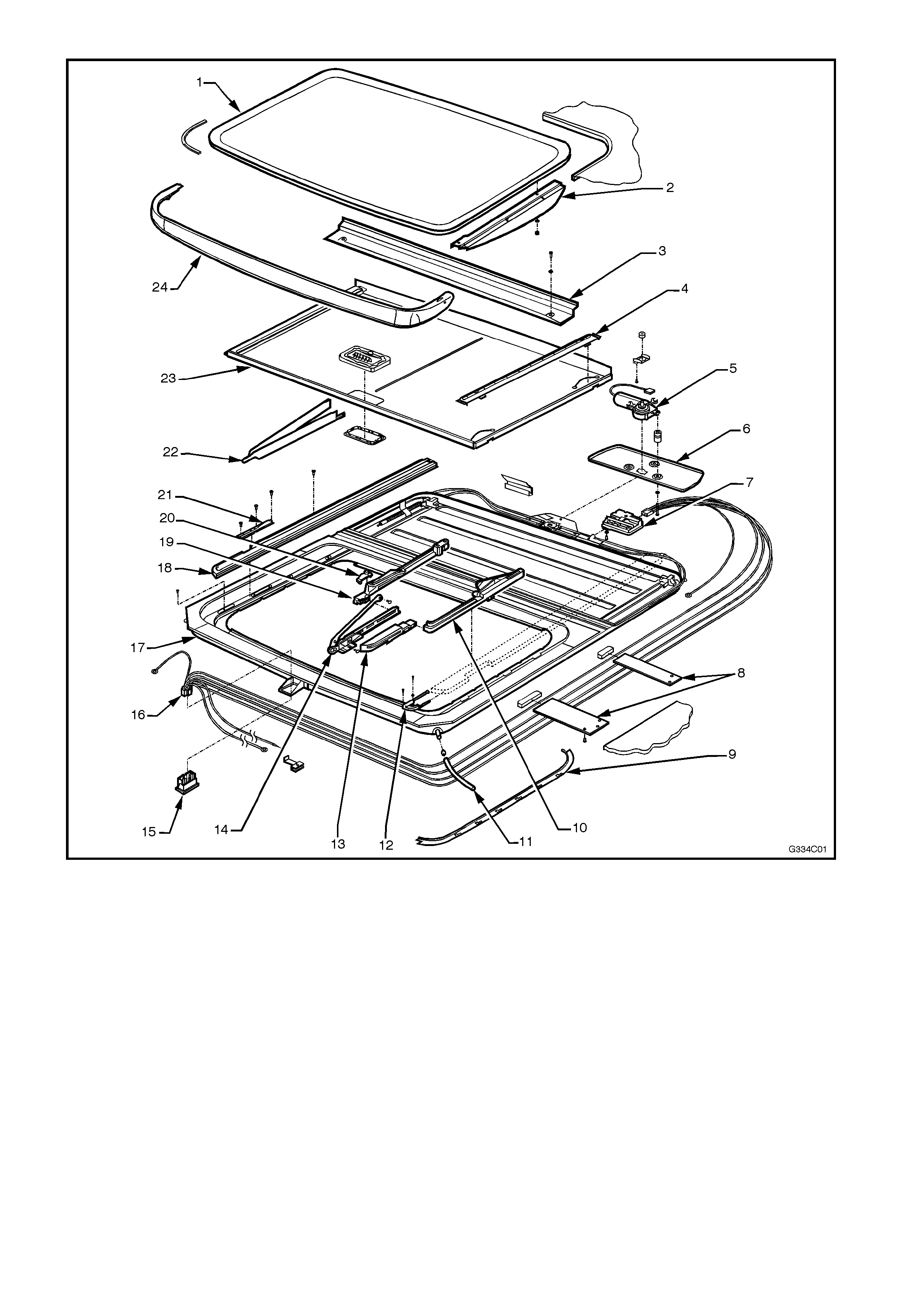

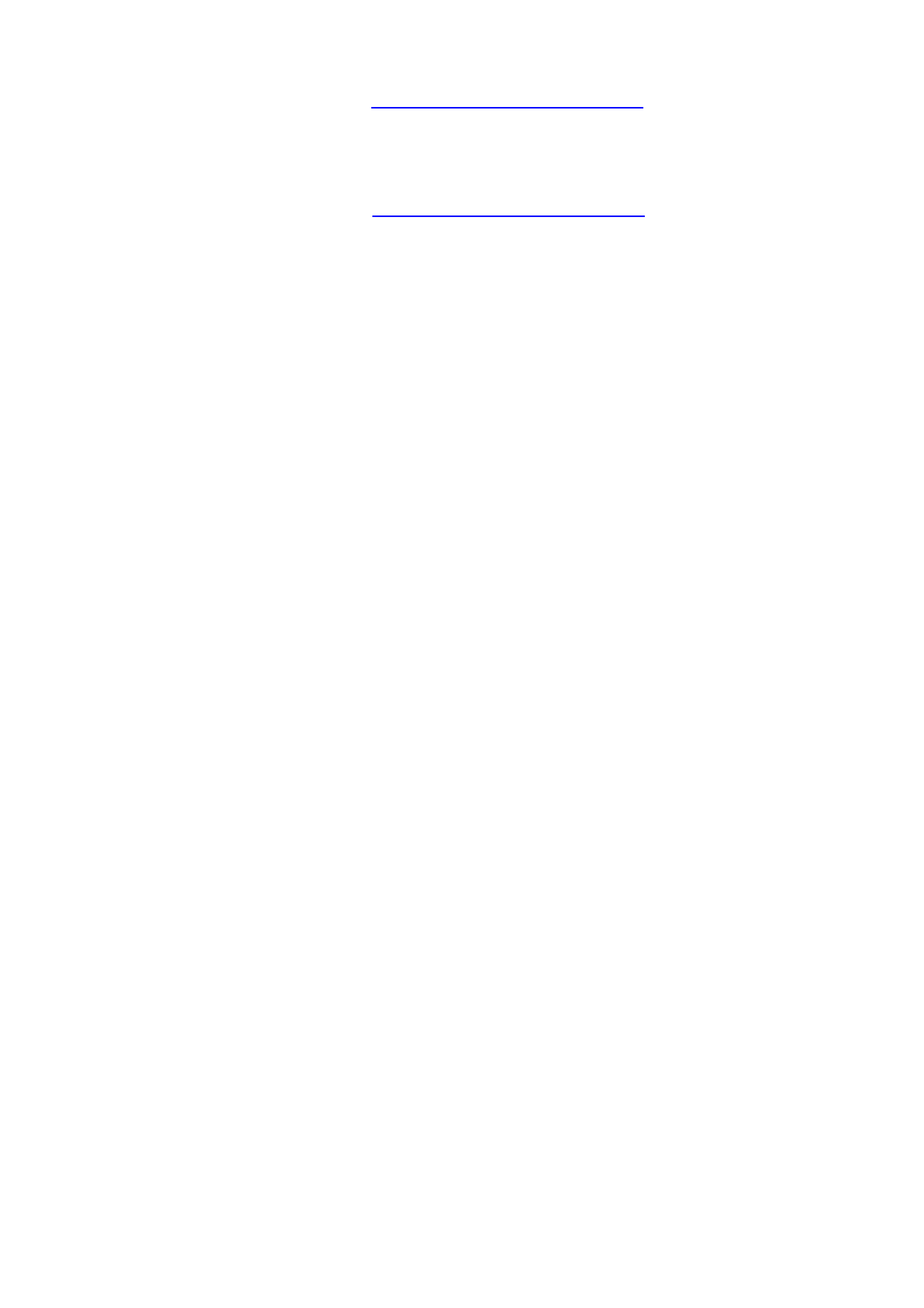

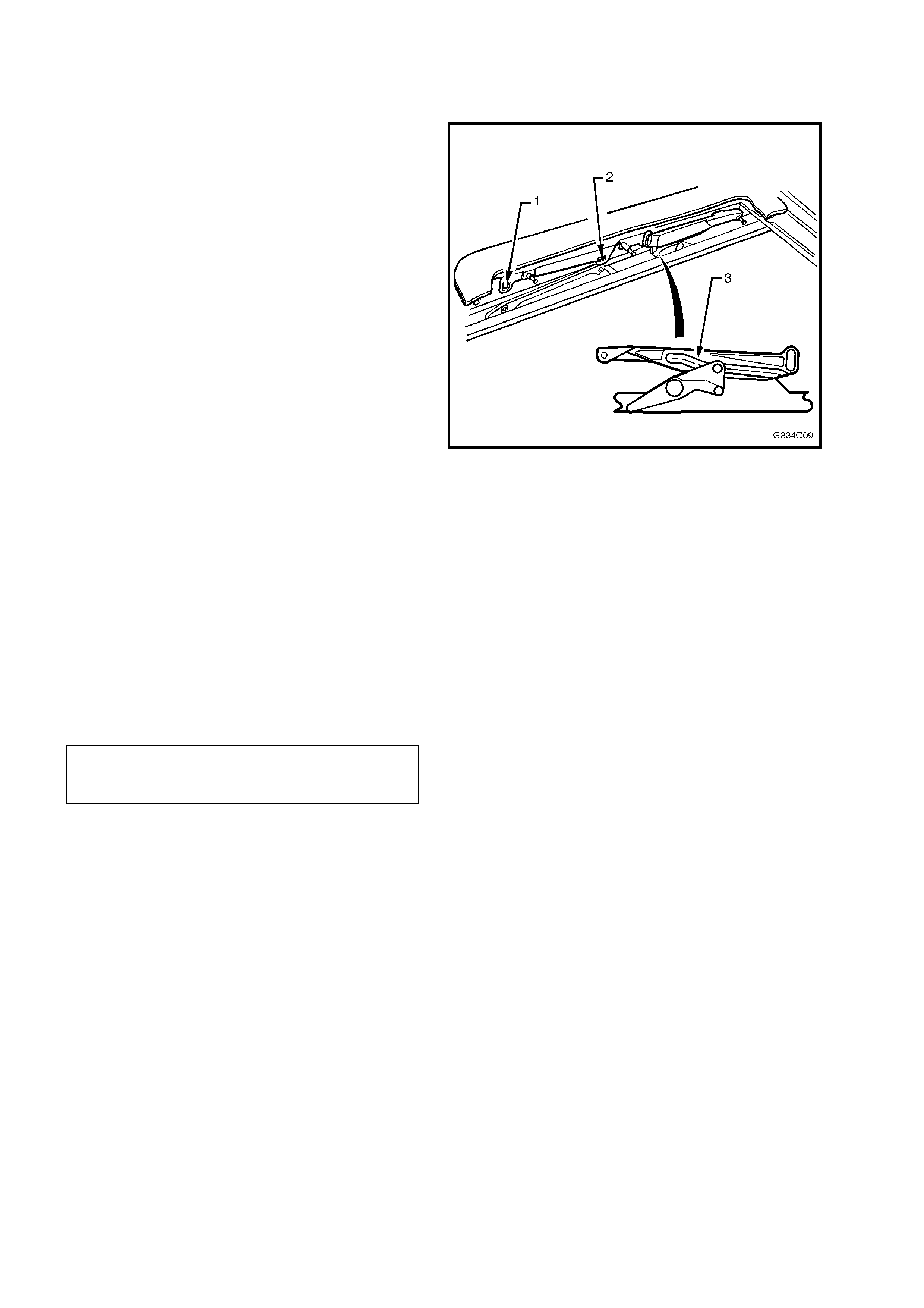

Figure 1F-1

1 Glass Panel (includes Curve-

on Panel – not shown) 10 Rear Driving Slide 19 Guide Rail Mechanism (Track)

2 Exterior Cover 11 Drain Tube 20 Rear Basic Slide

3 Drain Channel 12 Retraction Mechanism 21 Blocking Catch

4 Sunshade Guide 13 Front Driving Slide 22 Locator

5 Drive Motor 14 Fuse and Fuse Holder 23 Mechanism Cover

6 Drive Motor Cover 15 Front Basic Slide 24 Sunshade

7 Sunroof Control Unit (SCU) 16 Switch 25 Wind Deflector

8 Side Support Bracket 17 Harness

9 Side Trimming 18 Frame

2. SERVICE OPERATIONS

The following service operations for the sunroof are those that can be performed by the general service technician.

The procedure for the removal and installation of the sunroof assembly has deliberately been omitted due to the

skills and special tools required, which would be beyond the scope of the general repair technician.

Also, as the sunroof assembly is chemically bonded to the vehicle’s roof panel, damage to the sunroof and roof

panel will result if removal is performed, necessitating sunroof replacement and roof panel repair.

If assistance is required in the servicing or installation of the sunroof assembly, contact the authorised Hollandia

sunroof specialist in your area or contact Hollandia Sunroofs Australasia on (02) 9540 4811.

2.1 DRIVE MOTOR

REPLACE

1. Remove or drop rear of headlining to access

drive motor cover.

2. Rem ove the bolts securing the dr ive motor and

cover, drive motor now drops down.

3. Disconnect the drive motor connector from the

sunroof control unit.

4. Connect new drive motor wiring harness

connector to sunroof control unit.

5. Check drive motor for proper operation in both

directions, refer to 3.3 T EST ING EL ECTRICAL

COMPONENTS in this Section.

6. Install drive motor, spacers, cover and

attaching bolts.

7. Check the sunroof for correct operation.

8. Install the headlining.

2.2 SUNROOF CONTROL UNIT (SCU)

REPLACE

1. Remove or drop rear of headlining to access

drive motor cover.

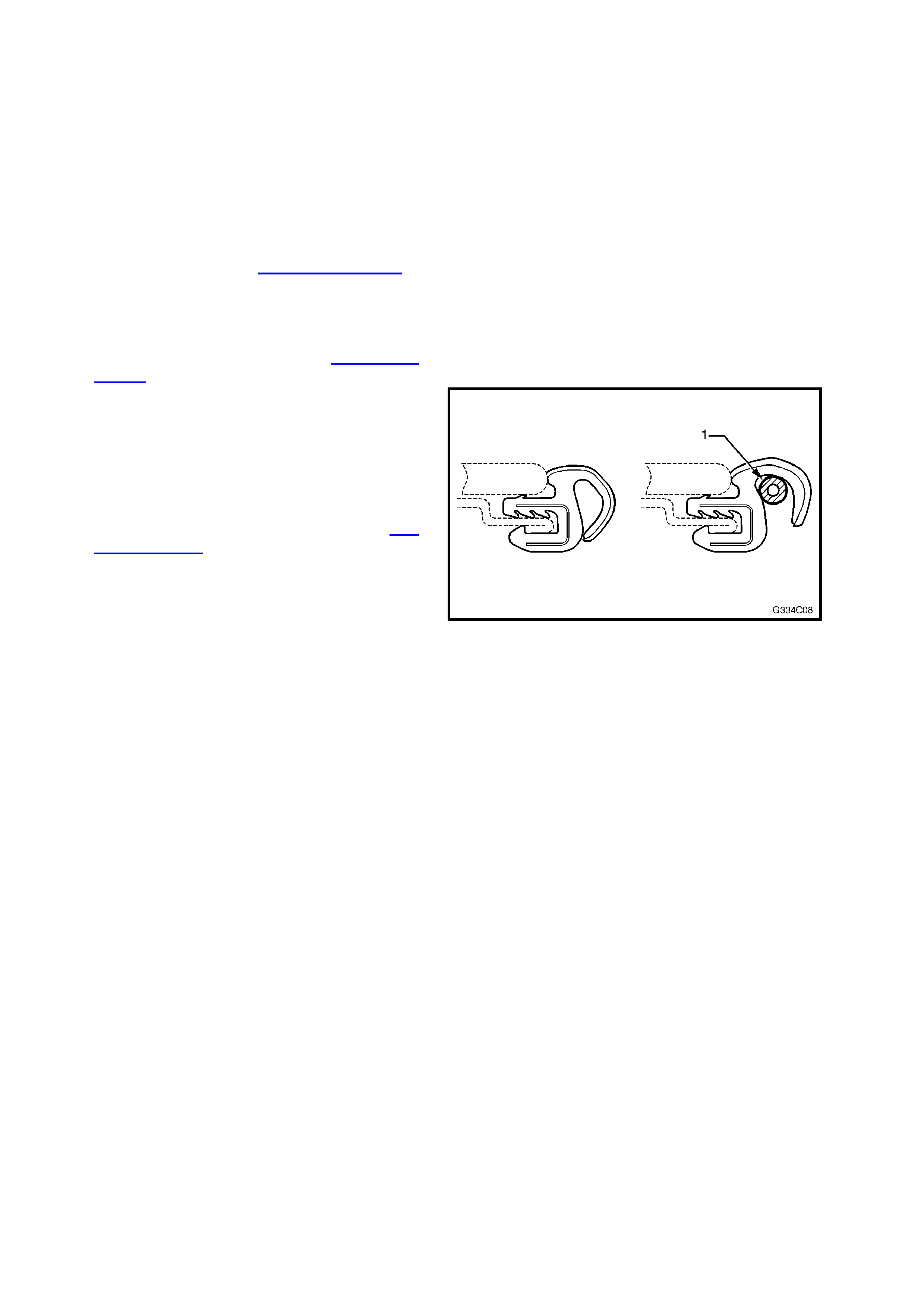

2. Utilising a manual crank, vent the glass panel

completely.

3. Remove the LH mechanism cover.

4. Utilising the manual crank, close the glass

panel 1.5 revolutions.

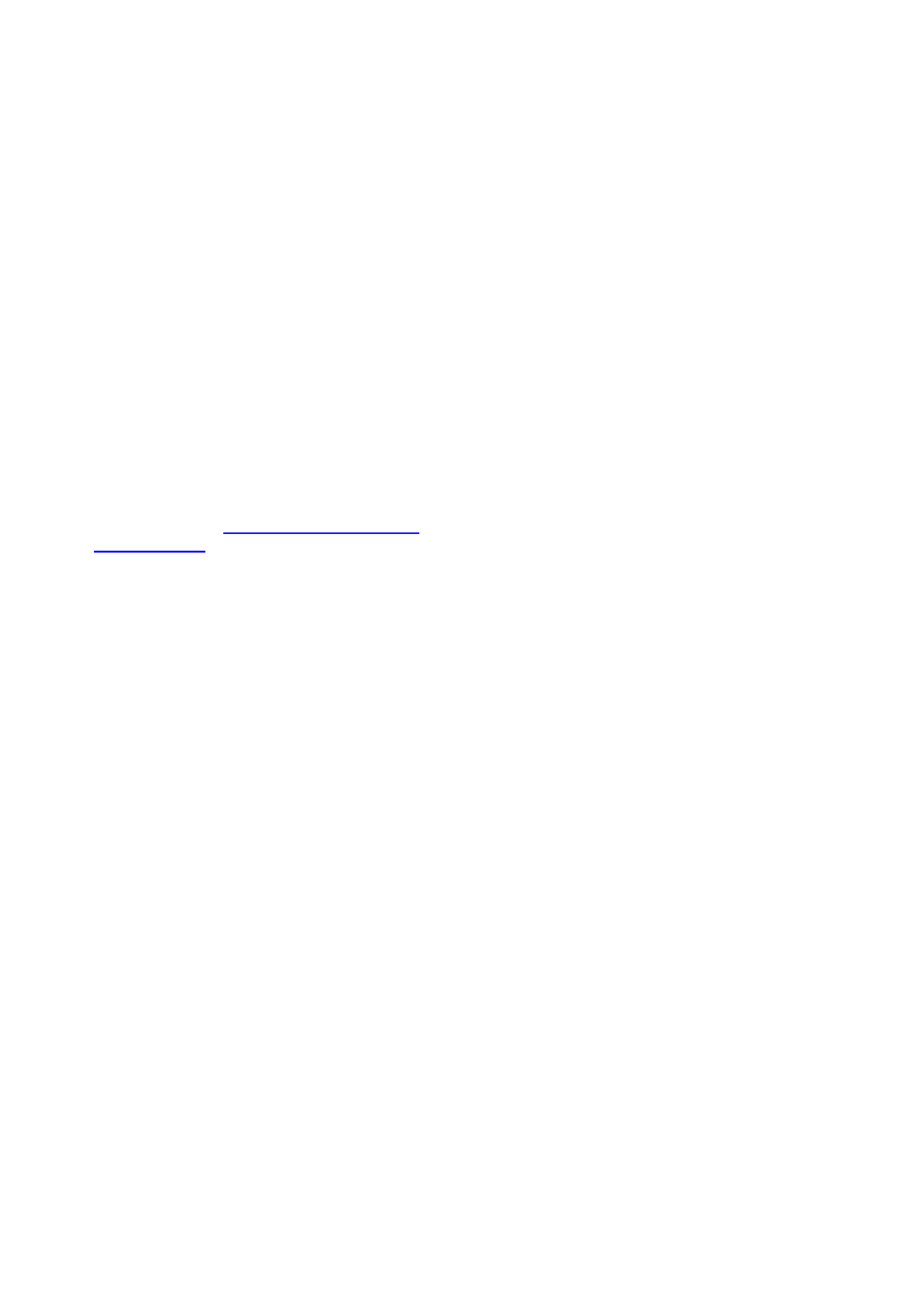

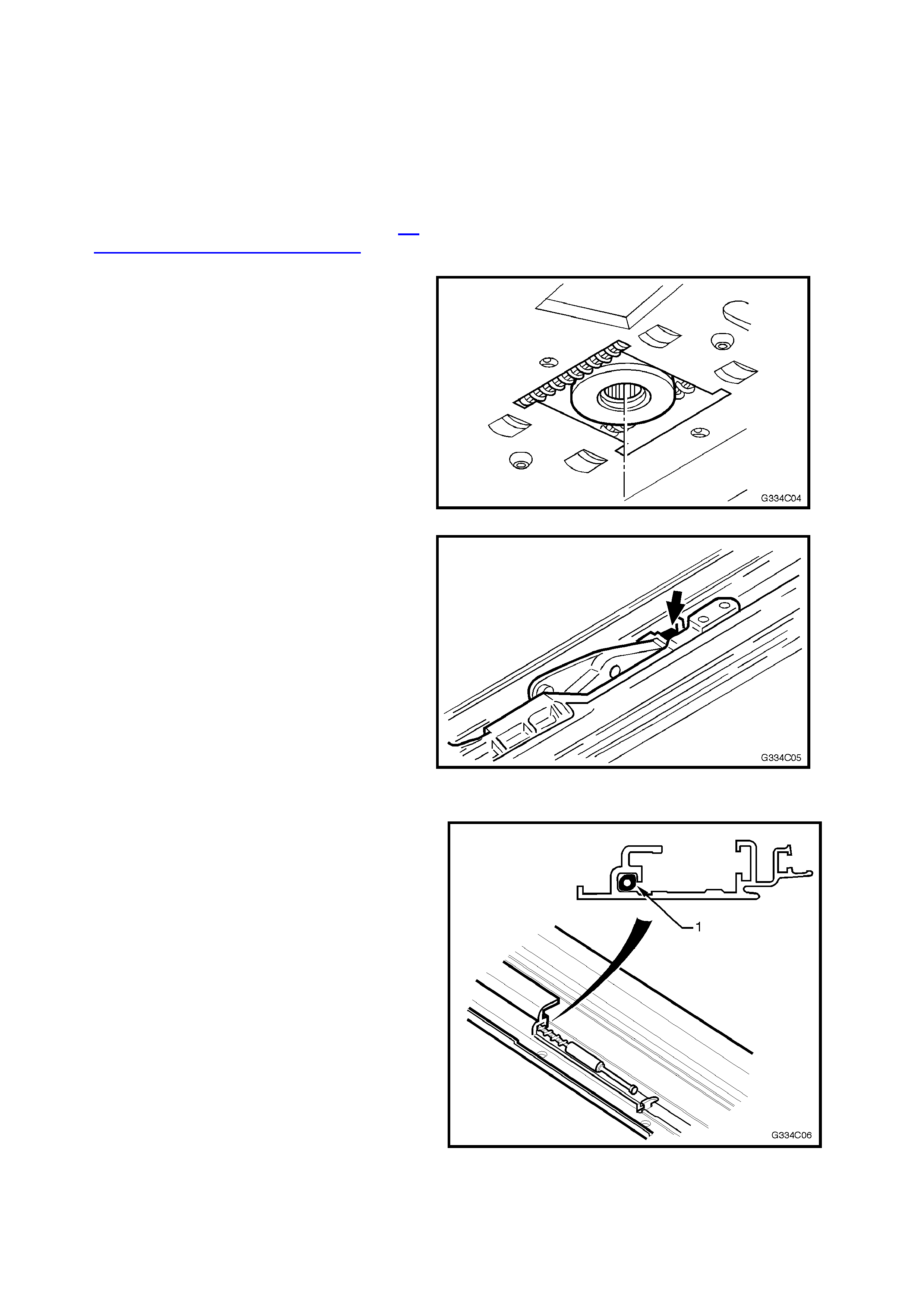

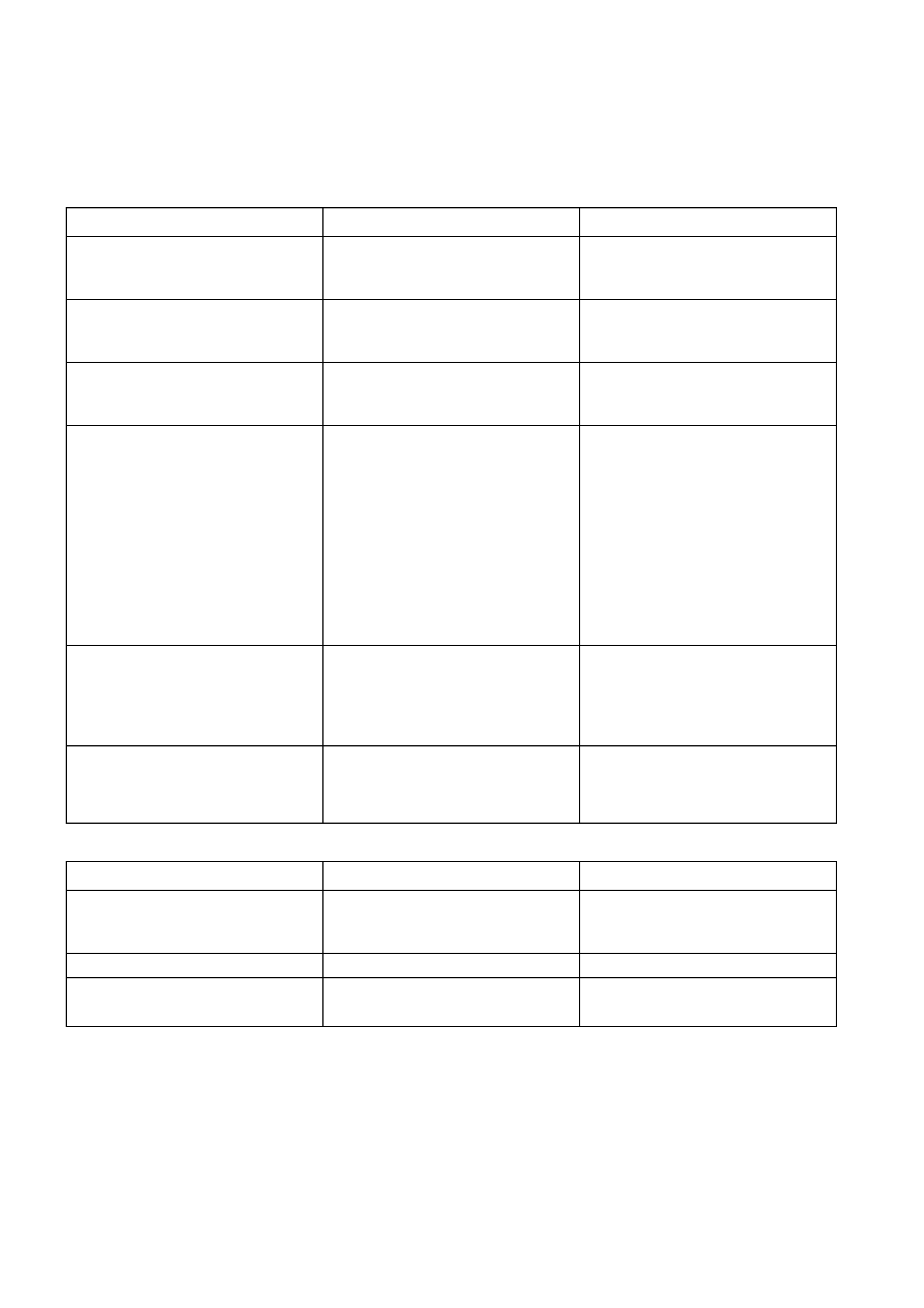

5. Place pin in each 2.5 mm bras s hole as shown.

Venting the glass panel, turn crank handle a

quarter of a turn forward. T he pin (1) stops the

mechanism at the desired location.

Figure 1F-2

6. Rem ove the bolts securing the dr ive motor and

cover, drive motor now drops down.

7. Disconnect the drive motor wiring harness

connector from the SCU and remove the drive

motor.

8. Disconnect the remaining wiring harness

connector from the SCU.

9. Rem ove the screw securing the SCU, lower the

front of the SCU to clear the cable. Slide the

SCU back and remove.

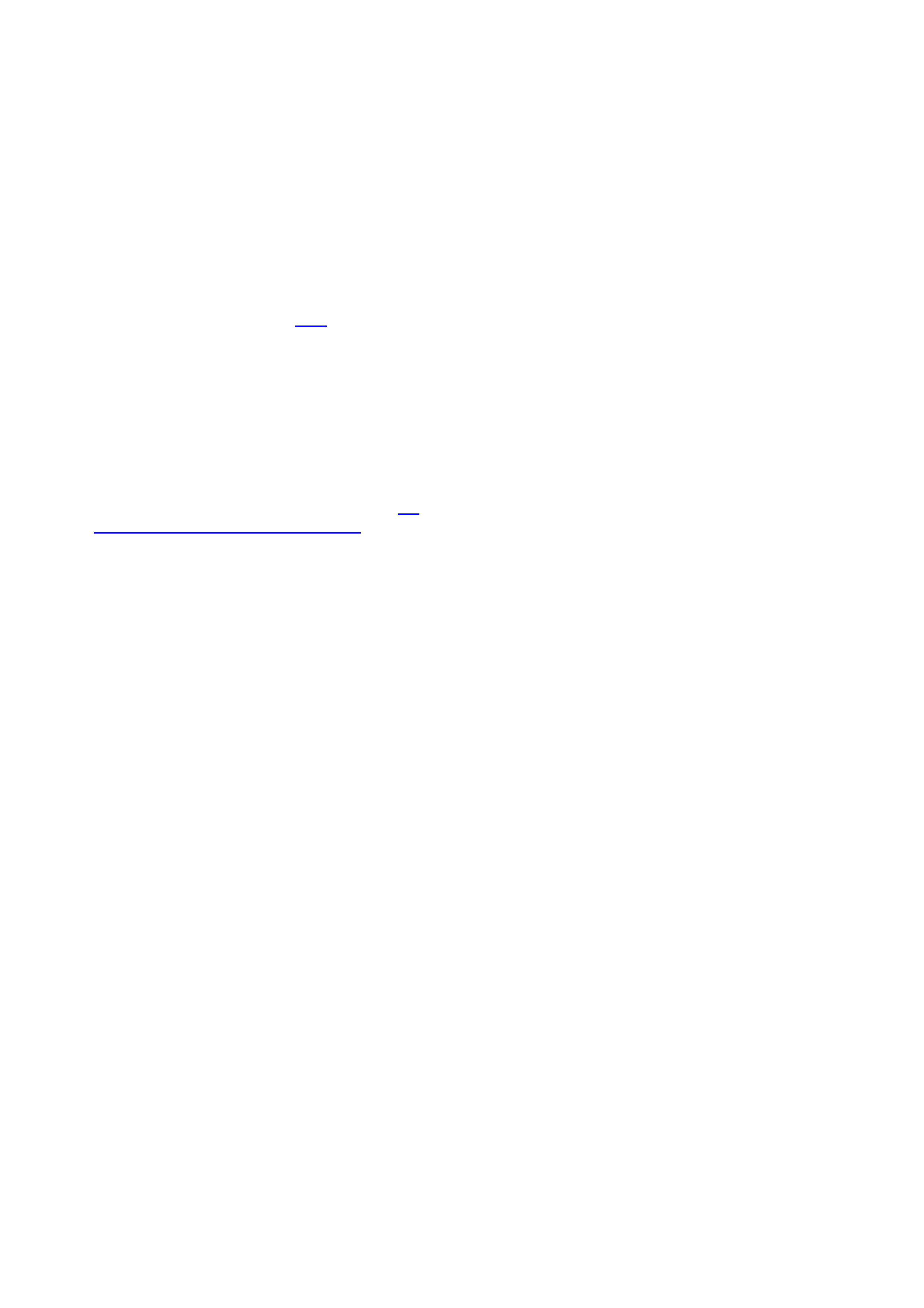

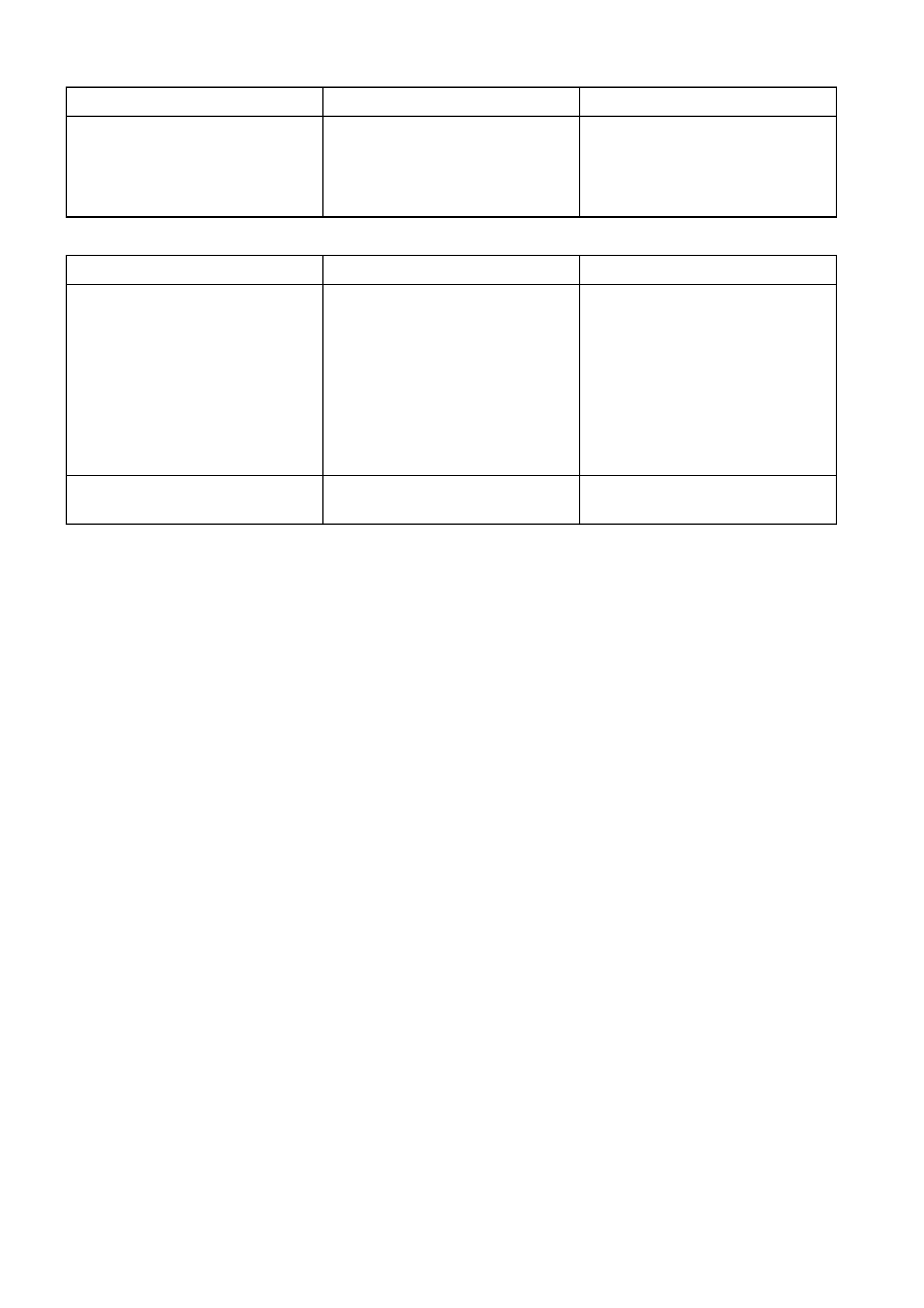

10. Inspect the new SCU for proper alignment of

spots on gearwheel in the viewfinder, refer to

Fig. 1F-3 and as described in 2.3

SYNCHRONISATION OF SCU in this Section.

Lowering the front of the SCU low enough for

cable clearance, slide forward, engage the lip

of cable plate in the SCU slot. Straighten SCU

horizontally and tighten screw.

NOTE: If the spots are not aligned, turn the top

mount cable gear until each spot appears aligned

over one another in the view finders (refer to

Fig. 1F-3).

11. Connect both wiring harness connectors to the

SCU and install drive motor and cover.

12. Check the sunroof for correct operation.

13. Install the headlining.

14. Install the LH mechanism cover.

Figure 1F-3

2. 3 SYNCHRONISATION OF SCU

1. Remove the SCU and drive motor, refer 2.2 SUNROOF CONTROL UNIT (SCU) in this Section.

2. Align the two spots in the viewfinders Turn the exposed black cable gear mounted in top centre of the

SCU. When each spot appears directly in line with the other, top to bottom, stop.

NOTE: If the spots are not aligned, turn the top m ount cable gear until each spot appears aligned over one

another in the view finders (refer to Fig. 1F-3).

3. Reinstall the SCU and drive motor, refer 2.2 SUNROOF CONTROL UNIT (SCU) in this Section.

2.4 DRIVE CABLES

REPLACE

1. Rem ove mechanism covers, glas s panel, drain

channel, wind deflector, sunshade and

adjustment bracket.

2. Place mechanism in closed position.

3. Remove drive motor and SCU, refer 2.2

SUNROOF CONTROL UNIT (SCU) in this

Section.

4. Remove the gearwheel housing by removing

the two screws.

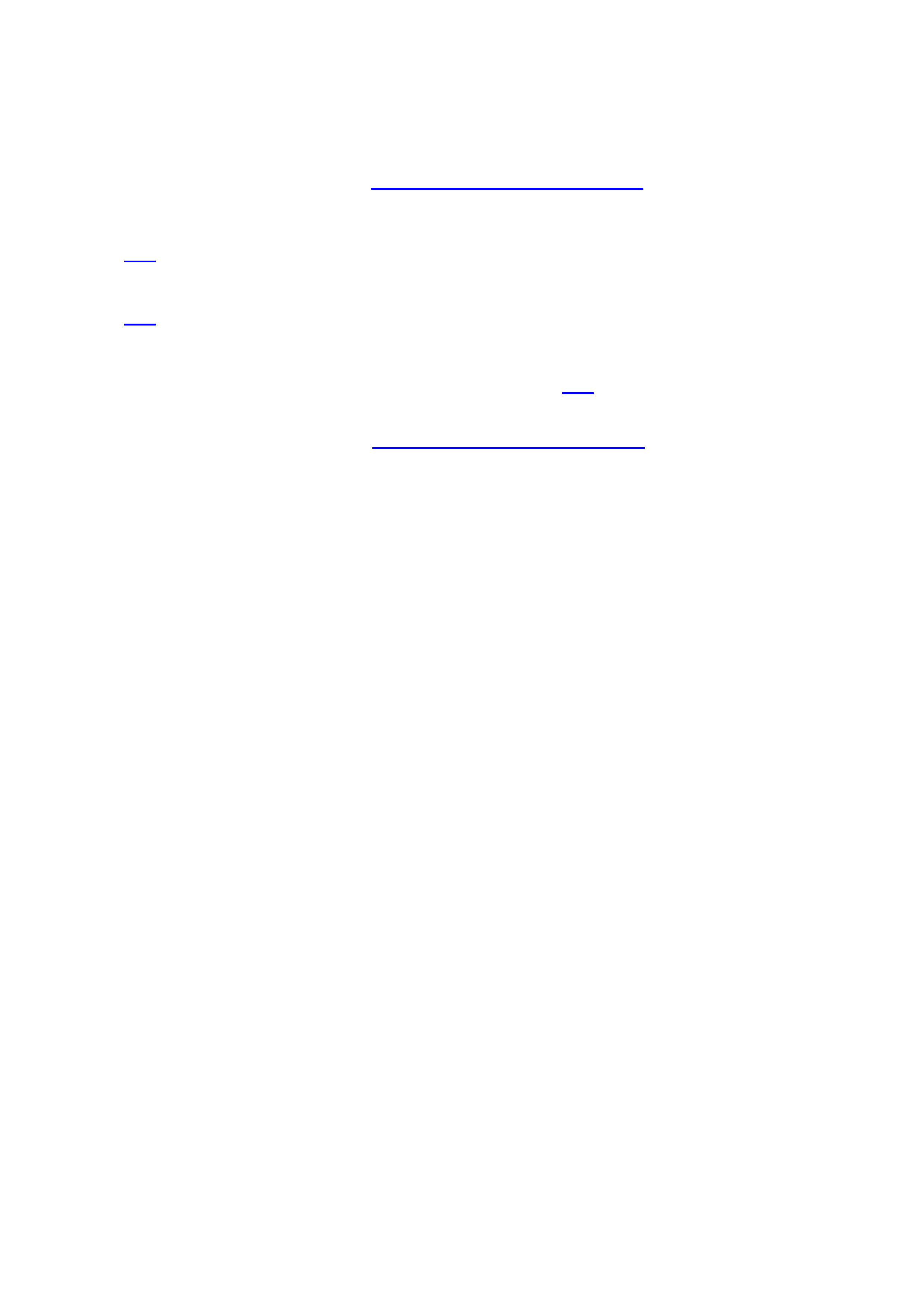

5. Remove gearwheel by inserting a screwdriver

and pushing forward and the gearwheel drops

down (refer to Fig. 1F-4).

Figure 1F-4

6. Remove the locator being careful to rem ember

the positioning of screws and the blocking

catch.

7. Pull mechanism all the way forward.

8. Push the mechanis m into tilt position as in Step

6, taking care not to inadvertently dislodge the

mechanism. Keep the front of the mechanism

down.

9. Rem ove the f ront s c rew and slide the r etrac tion

mechanism forward. Do not take out.

10. Slide mechanism in tilt position further forward.

11. Lift out cable and pull forward out from the

guide rail track.

Figure 1F-5

12. Inspect for proper length of new cable.

Lubricate the cable using Applied Chemicals

Tefoil + PTFE, Part No. 8-830, and slide into

the rail. Ensure oval shaped copper head of

cable seats firmly and diagonally across guide

channel (refer to Fig. 1F-6).

13. To check that cable is positioned correctly,

grasp long lever in tilt position with one hand,

the pivoting adjustment bracket in the other

hand and slide backwards. It should slide into

place (if blocked, turn cable slightly to reseat

copper oval head properly).

14. Pivot arm of adjustment bracket back down

into place. Slide the curve-on panel back into

place over the cap on long lever and ins tall the

Torx screw.

15. While holding the adjustment bracket stable,

push the catch mechanism into the slide

position as in Step 6. If mechanism stops after

approximately 100 mm preventing a full

rearward positioning, you failed to hold the

adjustment bracket stable, repeat this step.

Figure 1F-6

16. Slide whole mechanism rearwards to allow

installation of locator.

17. Slide the retraction mechanism rearwards,

install the screw and locator.

18. Repeat Steps 7 to 17 to replace the other

cable.

19. Slide both LH and RH mec hanisms to the f ront

position.

20. Push LH and RH mechanisms to the closed

position. Insert a pin in each 2.5 mm br ass hole

(pointed object) . Slide mechanism forward until

the pin stops the mechanisms movement at the

desired location (refer to Fig. 1F-2).

21. Install the new gearwheel, ensuring that it is

centred in the hole in the drive motor bracket.

Note that the core or centre of the gear has

splines (teeth). The splines do not extend

completely to one side of the gears inner core.

This is the down (bottom) side for mounting

(refer to Fig. 1F-4, refer above).

22. Install the new gearwheel housing.

23. Reinstall the drive motor and SCU, refer 2.2

SUNROOF CONTROL UNIT (SCU) in this

Section.

24. Inspect the sunroof for proper electrical and

mechanical functioning.

25. Install the headlining.

26. Install adjustment bracket, sunshade, drain

channel, glass panel, wind deflector and

mechanism covers.

27. Check the sunroof for correct operation.

2.5 TIMING OF DRIVE CABLES

1. Fully tilt panel.

2. Remove LH and RH mechanism covers & panel.

3. Put mechanism in fully closed position.

4. Remove the drive motor and SCU, refer 2.2 SUNROOF CONTROL UNIT (SCU) in this Section.

5. Remove the gearwheel housing by removing the two screws.

6. Remove gearwheel by inserting a screwdriver, push forward and the gearwheel drops down refer to

Fig. 1F-4.

7. Push the LH and RH mechanisms to the closed position. Place a pin in each 2.5 mm brass hole. Slide

the mechanism forward until the pin stops the mechanism’s movement at the desired location, refer to

Fig. 1F-2.

8. Install the new gearwheel, ensuring that it is centred in the hole in the drive motor bracket.

NOTE: The core or centre of the gear has splines. The splines do not extend completely to one side of the

gear’s inner core. This is the down (bottom) side for mounting, refer Fig. 1F-4.

9. Install the gearwheel housing.

10. Reinstall the drive motor and SCU, refer 2.2 SUNROOF CONTROL UNIT (SCU) in this Section.

11. Inspect the sunroof for proper electrical and mechanical functioning.

12. Install the headlining.

13. Install the LH and RH mechanism covers.

14. Check the sunroof for correct operation.

2.6 SEAL

REPLACE

1. Remove the LH and RH mechanism covers, glass panel and exterior covers.

2. Remove seal from the glass panel.

3. Remove all foreign debris from around the glass frame.

4. Install new seal, beginning at the centre front of the glass frame retaining channel.

5. Utilising your thumbs, insert the seal with enough pressure to ensure that the seal is flush (tight to frame).

6. Trim the glass panel seal length. When cutting excess, leave approximately six mm extra then work it

into the retaining channel.

7. Install the glass panel, refer to 2.11 GLASS PANEL in this Section.

8. Install the LH and RH mechanism cover.

9. Check the sunroof for correct operation.

2.7 SEAL

ADJUST

The proper positioning of the panel should result in

the seal firm ly contacting either the EPDM trim ring

or flanged metal circumference of the sunroof

opening. If the panel fits properly but gaps remain

between seal and trim ring it can be corrected as

follows:

1. Adjust glass panel properly against the rear of

the trim pr ofile, refer to 2.11 GL ASS PANEL in

this Section.

2. With a grease pencil mark the boundaries of

insufficient contact on the panel (at the front).

3. Remove the glass panel, refer to 2.11 GLASS

PANEL in this Section.

4. In the areas marked, insert a spacer (1) inside

the rubber seal. ( refer to Fig. 1F-7). Use a vinyl

tube with outer diameter of 3 mm for spacer

material.

5. Glue the spacer material to the seal with super

glue.

6. Install glass panel and adjust, refer to 2.11

GLASS PANEL in this Section.

Figure 1F-7

2.8 RETRACTION MECHANISM

REPLACE

1. Retract the glass panel completely.

2. Remove the wind deflector mounting nuts, and remove the wind deflector.

3. Remove the two screws and take the retraction mechanism forwards out of rail.

4. Install new retraction mechanism in rail.

5. Install the wind deflector.

6. Check the sunroof for correct operation.

2.9 GUIDE RAIL MECHANISM

REPLACE

1. Tilt mechanism completely.

2. Remove LH and RH mechanism covers, glass

panel, drain channel, wind deflector and

sunshade.

3. Fully retract mechanism.

4. Rem ove the locator, retraction mechanism and

rail screw.

5. Remove the wind deflector mounting nuts.

6. Slide rail sideways to unlock, then lift front up.

7. With rail front up, grasp retractor mechanism

and remove, then lower rail.

8. Fully close mechanism.

9. Lift and pull rail slowly forward over

mec hanism , as soon as the f ront of drive cable

appears at end of guide, lift out cable, now pull

mechanism carefully forward and lift out rail.

Inspect the new replacem ent rail & mec hanism

for cleanliness and completeness.

10. Slide the mechanism rearward out of rail for

cable installation access.

11. Install cable, then push m echanism forward on

rail (maintain access to rear rail area).

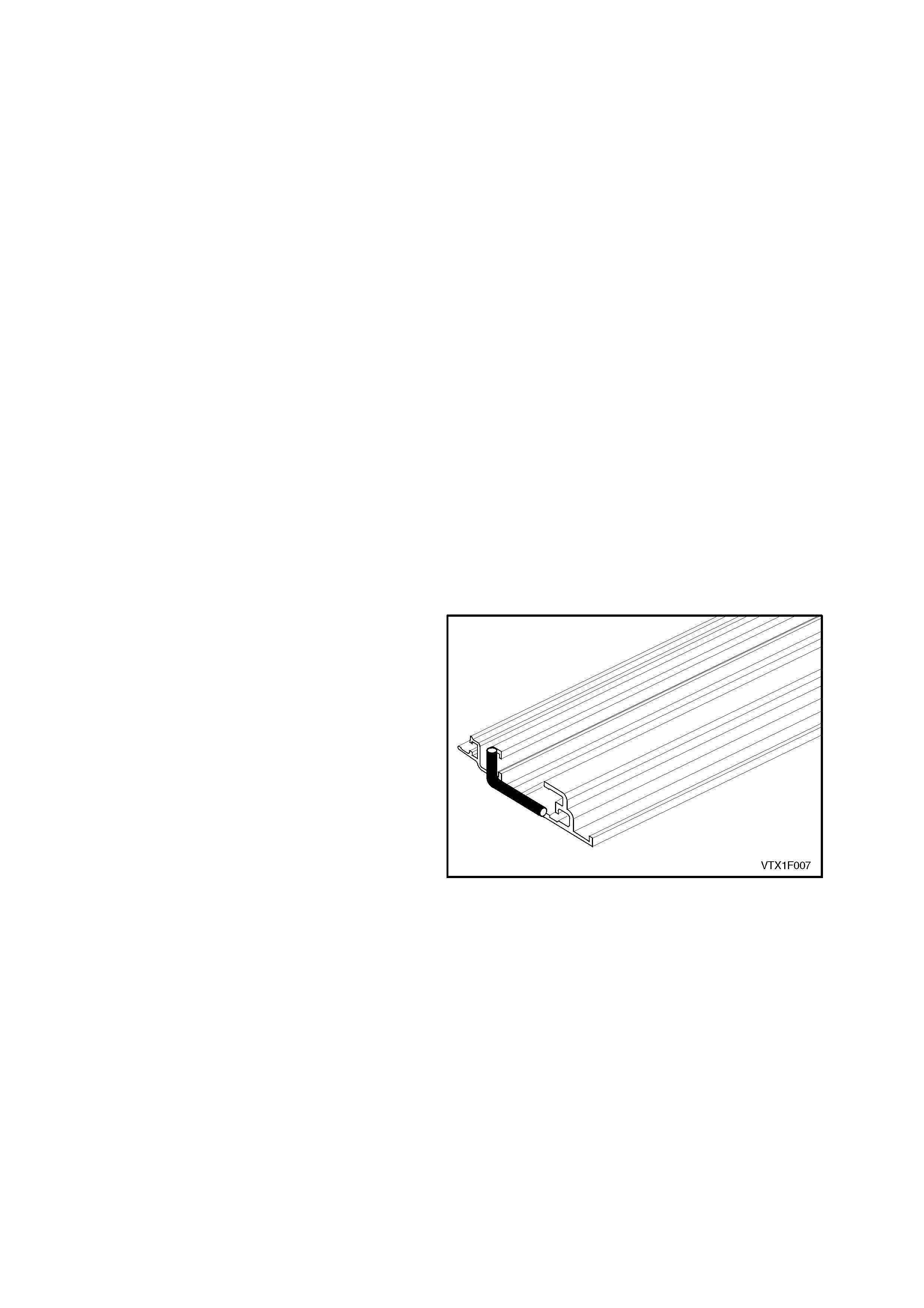

12. Apply a bend of liquid butyl as indicated on

Figure 1F-8.

13. Slide rail rearward over mechanism and drive

cable while holding the front of the mechanism

in place. As soon as the rail is fully extended

rearward, drop the front to frame and push rail

rearward into rail s top. Line up the screw holes

for proper positioning.

14. Retract mechanism totally.

15. Lift front of rail to reinstall retractor mechanism.

16. Drop rail down, push inboard until it locks in

place under the frame tabs.

17. Install all new rail screws starting at front for

proper positioning. Use original positioning of

screws by size.18. Replace wind deflector

mounting nuts loosely.

19. Tilt mechanism completely.

20. Inspect for proper mechanical functioning of

mechanism.

21. Install sunshade, drain channel, panel and wind

deflector.

22. Inspect functioning of sunroof, reinstall LH and

RH mechanism covers.

Figure 1F-8

2.10 BLOCKING CATCH

REPLACE

1. Remove the LH and RH mechanism covers and glass panel.

2. Fully retract mechanism.

3. Remove the locator.

4. Fully tilt the mechanism.

5. Remove the blocking catch by lifting out.

6. Clean out broken blocking catch debris if required.

7. Install new block ing c atch in mec hanis m, inser t the c irc ular eye stud into the m ec hanis m making s ur e the

second smaller stud falls cleanly into the mechanism slot.

8. Fully retract mechanism.

9. Install the locator.

10. Check for correct mechanical operation.

11. Install the glass panel and LH and RH mechanism covers.

2.11 GLASS PANEL

REMOVE

1. Place the glass panel in the tilt position.

2. Remove the two front screws (1) and the two

centre screws (2) and remove the glass panel.

REINSTALL AND ADJUST

1. Slide mechanism to the tilt position.

2. Inspect rubber seal and glass panel for

damage. Insert the glass panel.

3. Place the height adjustment curve (3), (which is

at the rear of the glass panel), over the

mechanism. Place vertical front lips on panel

between the right-hand and left-hand

mechanisms.

4. Lift the mechanism mounting bracket from the

inside and install two front and two centre

screws, leaving the four s cr ews loos e, ens uring

big washer is to front.

5. Put glass panel in closed position.

6. Adjust the glass panel to the front. Using a

business card, for example, check the tension

of the seal against the trim ring at the rear.

7. Tighten both centre screws (2).

8. Adjust height at the front and tighten front

screws (1).

9. Adjust height at the rear by loosening Torx

screws of the adjustment curve, adjust the

glass level with roof skin and tighten screws

(refer to Fig. 1F-9).

Figure 1F-9

GLASS PANEL HEIGHT

ADJUSTING SCREWS

TIGHTENING TORQUE 3.5 Nm

10. Check functioning of mechanism and

adjustments. Repeat Steps 6 to 9 to readjust

the glass panel if necessary.

3. DIAGNOSIS

3.1 FAULT DIAGNOSTIC CHARTS

The fault diagnostic charts included in this Section list possible causes and solutions and provide a reference to

a particular service operation to resolve the fault.

REPAIR ADVICE FOR MECHANICAL FAILURES

PROBLEM POSSIBLE CAUSE SOLUTION

While c yc l i ng the panel from tilt to cl ose it

begins sl i di ng rearward. Blocking catch is broken. Replace bloc king cat ch, refer t o 2.10

BLOCKING CATCH in this Section.

While c ycling full y open panel forward, it

begins ti l t i ng under roof ski n. Blocking catch is broken. Replace bloc king cat ch, refer t o 2.10

BLOCKING CATCH in this Section.

Panel is mis al i gned side to si de. Timi ng of dri ve c abl es incorrec t. Retim e dri ve c abl es, refer t o 2.5 TIMING OF

DRIVE CABLES in this Section.

Panel sl i di ng t oo slowly (with 13.5 V power

supply panel s houl d not take more than

7 seconds to cycle from f ul l retracti on t o

closure).

Weak bat tery.

Misaligned panel creating drag or fri ction.

Faulty drive m otor.

Dirty mechanism.

Charge or replace.

Retim e dri ve c abl es, refer t o 2.5 TIMING OF

DRIVE CABLES in this Section.

Test the dri ve motor as detailed in 3. 3

TESTING ELECTRICAL COMPONENTS in

this S e ction. If necessary, repl ace drive

motor, refer to 2.1 DRIVE MOTOR in this

Section.

Clean and grease mechanis m or replac e i f

necessary, refer to 2.9 GUIDE RAIL

MECHANISM in this Section.

Glass panel stopping prematurely. Sunroof control unit adj usted improperly.

Obstac l e i n mechanism or gui de track.

Synchronis e sunroof control unit, refer to

2.3 SYNCHRONI SATION OF SCU in this

Section.

Find object and remove.

Sunshade fai l s to open when glass panel i s

opened to tilt posit i on. Retraction mechani sm broken. Replace retraction mechanism, refer to

2.8 RETRACTI ON MECHA NI SM in this

Section.

REPAIR ADVICE FOR RATTLING NOISES

PROBLEM POSSIBLE CAUSE SOLUTION

Drain channel rat tles. Inspec t for ins ul at or tape between drain

channel and mechanis m.

Felt Pad

Add insul ator tape.

Add Felt Pad.

Rattles from side(s). Mounting bracket screws loose. Tighten cover pl at e screws.

Rattli ng i n dri ve motor area. Cover plate on drive motor has l oose

screws. Tighten c over pl at e screws.

REPAIR ADVICE FOR WIND NOISES

PROBLEM POSSIBLE CAUSE SOLUTION

Panel cl osed, excessi ve wind nois e. Glass panel seal not ti ght to trim ring.

Blocking catch broken.

Correct glass panel adjustment, ref er to

2.11 GLASS PANEL in this Section.

Replace bloc king cat ch, refer to

2.10 BLOCKING CATCH in thi s Section.

REPAIR ADVICE FOR WATER LEAKS

PROBLEM POSSIBLE CAUSE SOLUTION

Water c oming t hrough panel openi ng area. Blocked drain tubes.

Misaligned or k i nked drain tubes .

Housing frame dis t orted, seal to rail

disconnected.

Rear rail brack et has broken seal.

Inspec t drai n tubes cl ean openi ng, blow out

tubes.

Ensure t hat drai n tubes are co rrectly routed

through front and rear pillars .

Correct f rame curvature if nec essary reseal

rail to frame.

Reseal at rear rai l seal point, refer to

2.9 GUIDE RAIL MECHANISM in thi s

Section.

Headliner wet in front. Either f rame seam has i ncorrect seal. Reseal at seam.

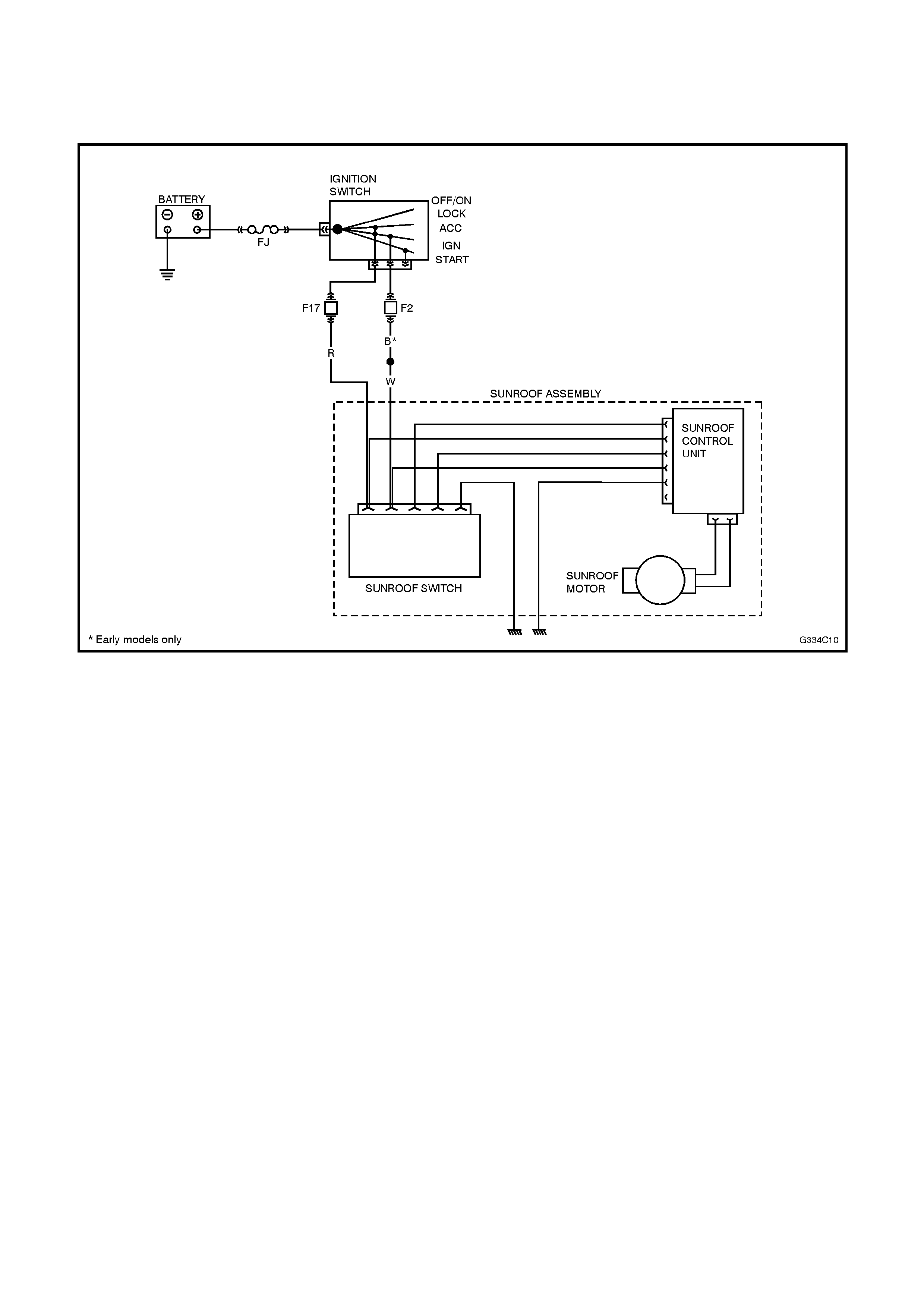

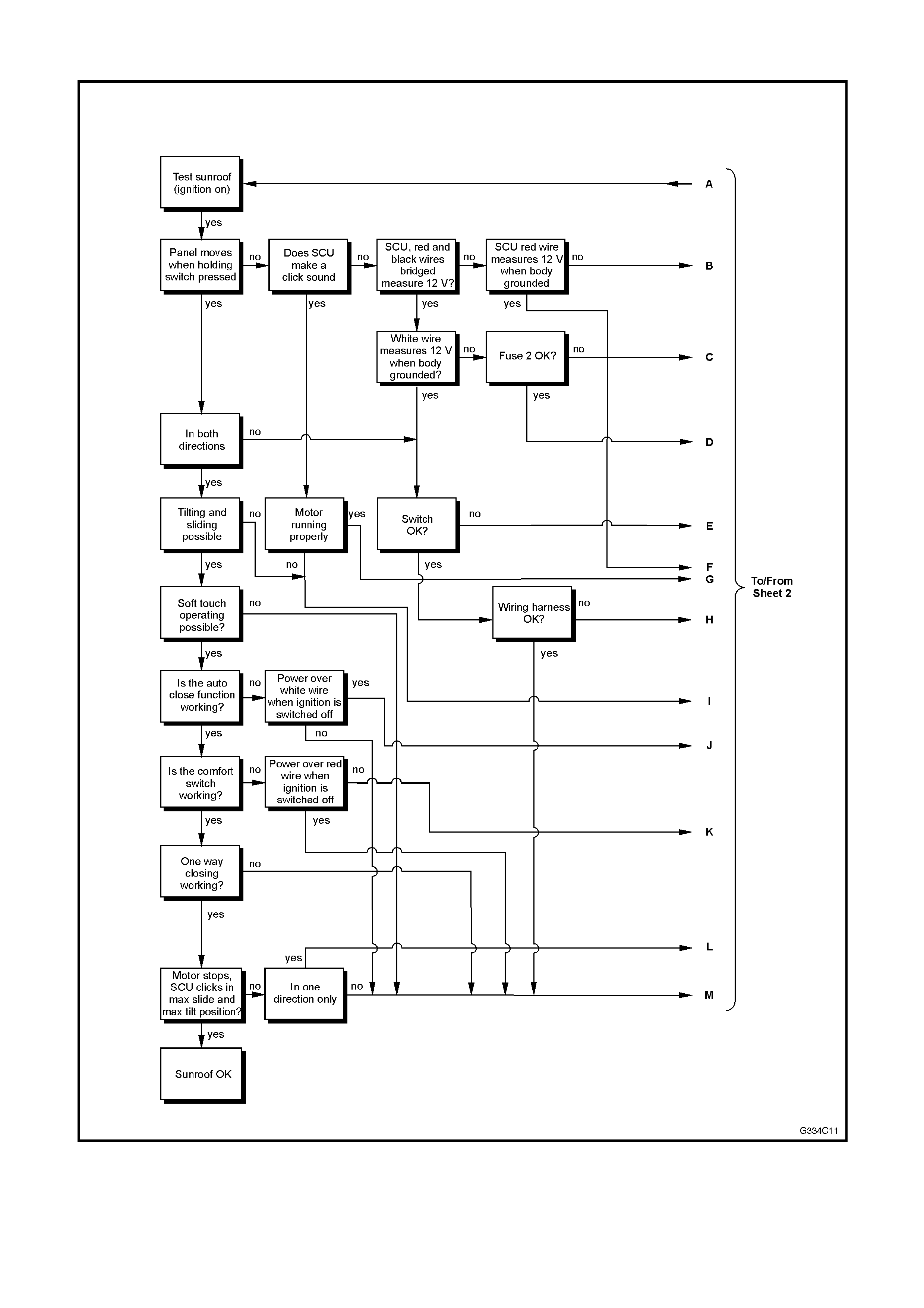

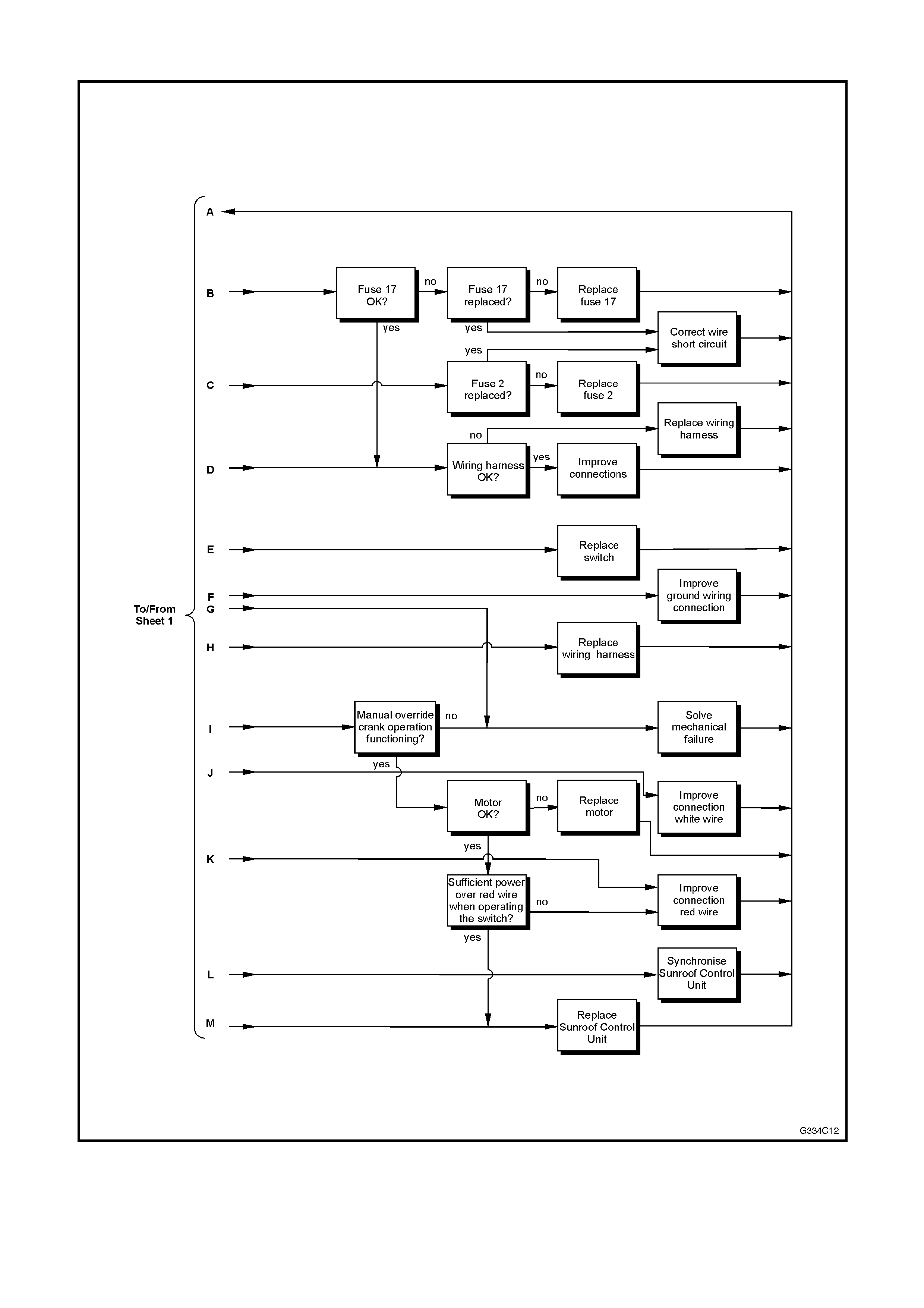

3.2 ELECTRICAL FAILURES

Use the following trouble shooting guide to locate

electrical failures or related problems. The circuit is

shown in Figure 1F-10.

Figure 1F-10

TROUBLE SHOOTING GUIDE (SHEET 1 OF 2)

TROUBLE SHOOTING GUIDE (SHEET 2 OF 2)

3.3 TESTING ELECTRICAL COMPONENTS

Ensure that during testing electrical components, the sunroof is connected to a power source supplying 12 to 14 V.

If the Sunroof is installed, the battery needs to be attached and operable. During testing the ignition/accessory

switch should be on. This test can be accomplished with a test light or multimeter. Cable harness and drive motor

inspection requires the headlining to be removed.

FUSE

Visually inspect the fuse for damage.

WIRE HARNESS

Check if the power supply on the Red and Red/Black wires is OK. Inspect for broken/damaged wires. Inspect for

secure connection to the sunroof control unit. The wire harness connector is numbered to aid in proper installation:

SWITCH

Inspect for correct power supply to the sunroof operating switch, accomplished by using a test light on the connector

at the switch bracket. Operate the switch connector to assure movement in front and rear sliding positions.

DRIVE MOTOR

Disconnect the drive motor wire (Green/Black) from the sunroof control unit. Remove the drive motor. Using a

double wire of sufficient length, connect direct to battery. Check the drive motor for correct operation in both

directions. This is accomplished by reversing the connection of the double wire. The drive motor has an in-built

thermal cutout device that automatically switches the drive motor off during periods of overload. After a cooling

down period the drive motor will function properly.