Body Page 1A1–1

Page 1A1–1

Section 1A1

Body

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

WARNINGS, CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property

damage.

1 General Description............................................................................................................................... 2

2 Service Operations................................................................................................................................3

2.1 Fuel Filler Door Cable Assembly, RHD.................................................................................................................3

Remove ...................................................................................................................................................................3

Reinstall ..................................................................................................................................................................4

2.2 Fuel Filler Door Cable Assembly, LHD.................................................................................................................5

Remove ...................................................................................................................................................................5

Disassemble ...........................................................................................................................................................6

Reinstall ..................................................................................................................................................................6

Diagnosis................................................................................................................................................................7

Wiring Schematic................................................................................................................................................7

Connector Views.................................................................................................................................................8

2.3 Front Suspension Strut Brace...............................................................................................................................9

Remove ...................................................................................................................................................................9

Reinstall ..................................................................................................................................................................9

3 Torque Wrench Specifications........................................................................................................... 10

Body Page 1A1–2

Page 1A1–2

1 General Description

With the following exceptions, MY 2004 WK Series Body information carries over from MY 2003 VY Series vehicles. For

information not contained within this Section, refer to Sect ion 1A1, Body, in the MY 2003 VY and V2 Series Service

Information.

• Fuel filler door cable assembly.

• Front suspension strut brace assembly on Level 5 Models.

A new design fuel filler door cable is fitted to MY 2004 WK Series vehicles. Attachment is with two screws and a bracket

from within the fuel filler housing. Buffers are attached to the fuel filler door cable bracket to prevent damage to the fuel

filler door.

LHD vehicles also use this style cable which is attached to an actuator assembly in the rear compartment. A release

switch is on the instrument panel similar to VY Series vehicles.

Body Page 1A1–3

Page 1A1–3

2 Service Operations

2.1 Fuel Filler Door Cable Assembly, RHD

LT Section No. – 03-028

If required, first remove the following components:

1 Right-hand side sill trim and seat adjuster outer front cover, refer to Section 1A8, 2.2 Side Sill Trim & Plate in the

MY 2003 VY and V2 Series Service Information.

2 Rear seat cushion assemblies, refer to Section 1A7, Seat Assemblies.

3 Right-hand quarter inner rear side carpet, refer to Section 1A8, 2.7 Quarter Inner Rear Side Carpet.

Remove

1 Open the fuel filler door by operating the release lever.

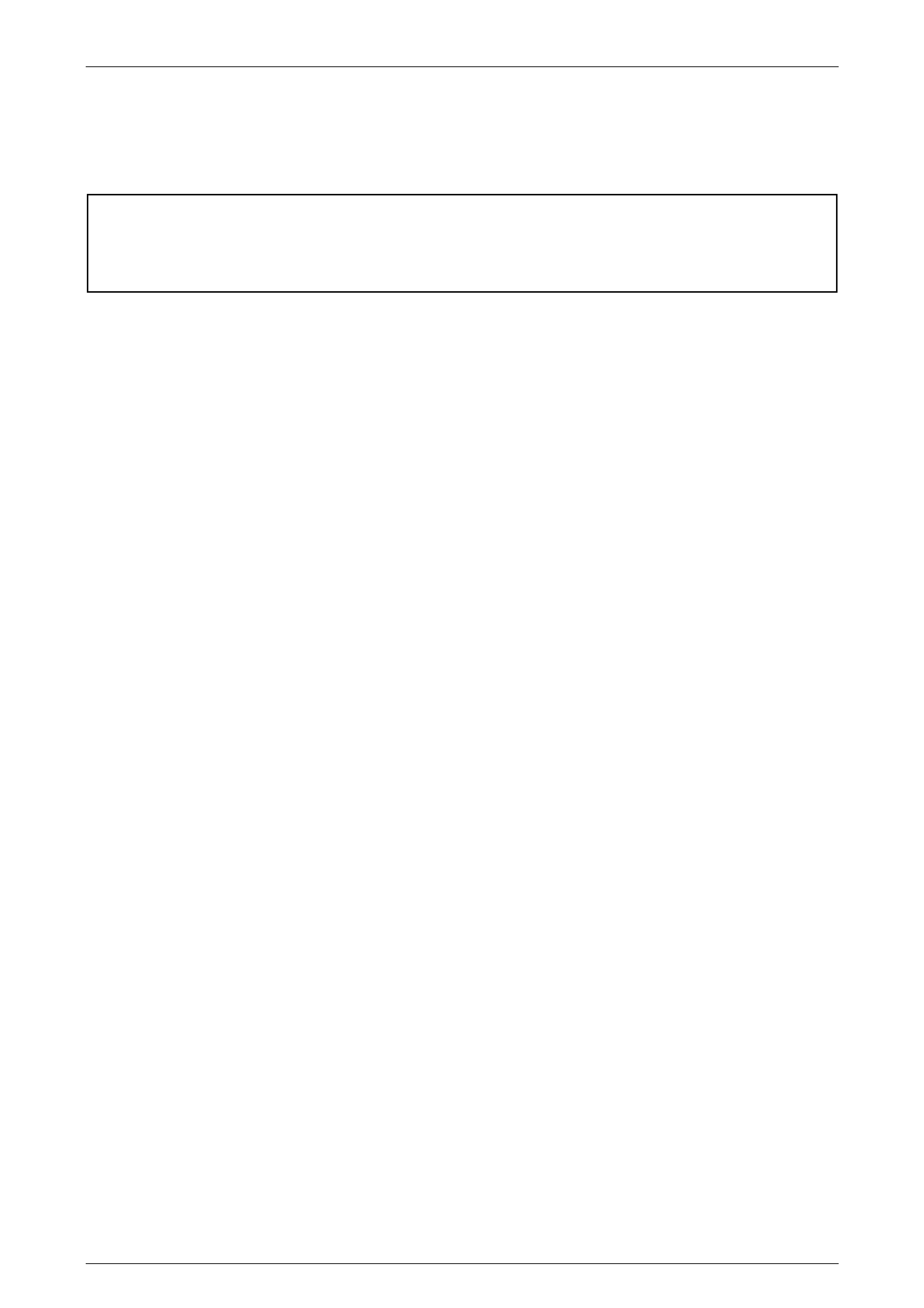

2 From inside the vehicle, remove the screw (1) attaching the cable assembly lever (2) to the rocker panel, refer to

Figure 1A1 – 1.

NOTE

The previously removed screw (3) attaches the

seat adjuster outer front cover (4) and the cable

assembly lever.

3 Unclip the cable from the harness formers (5), six places, and bend the retaining tab (6) to release the cable

assembly.

4 Unclip the cable from the release lever.

Figure 1A1 – 1

Body Page 1A1–4

Page 1A1–4

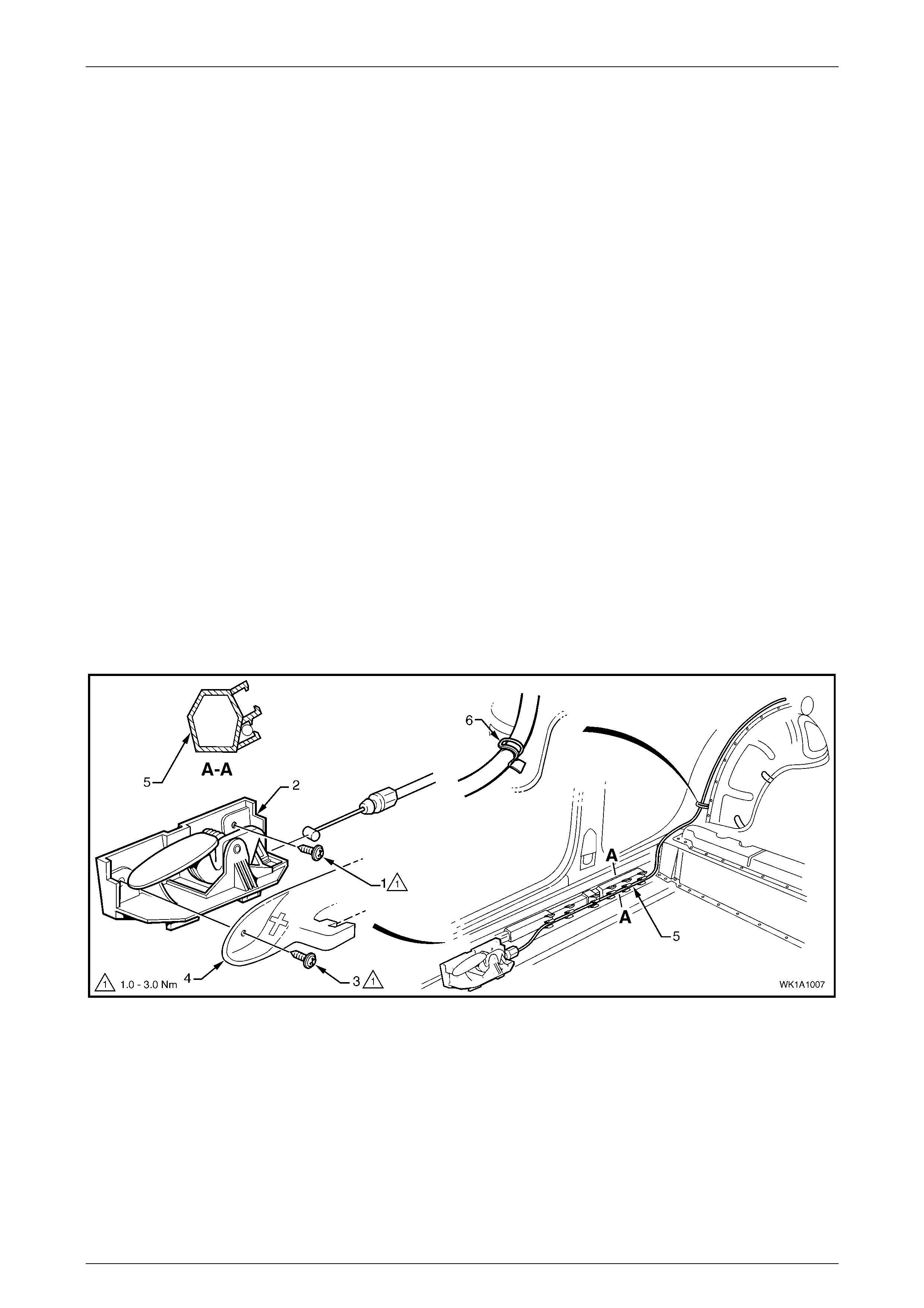

5 Pull the cable (1) through the back panel upper into

the rear compartment.

Figure 1A1 – 2

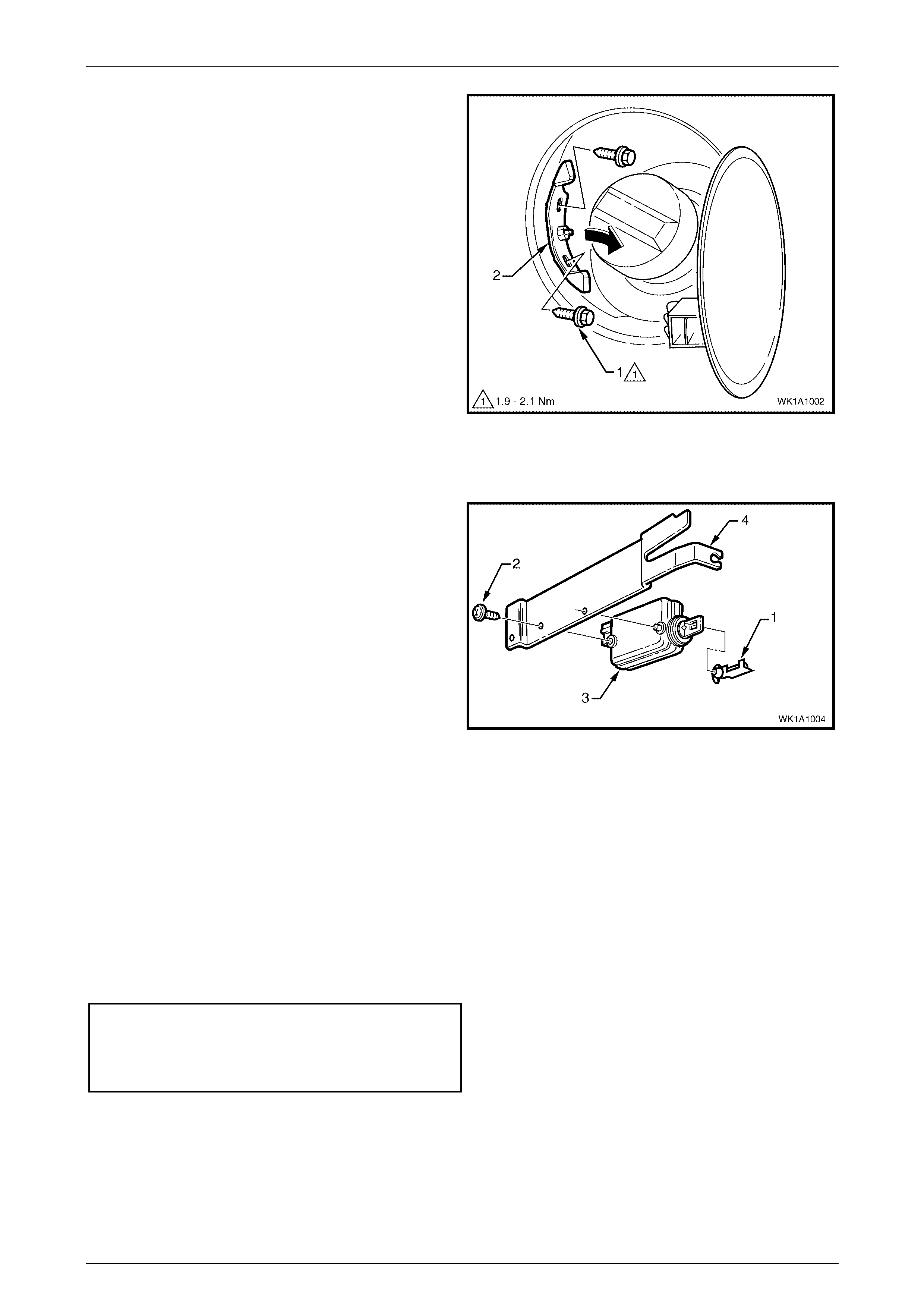

6 From within the fuel filler housing, remove the two

screws (1) attaching the cable assembly retainer (2).

7 Withdraw the cable assembly from the fuel filler

housing.

Figure 1A1 – 3

Reinstall

1 Installation is the reverse of removal. Ensure the components are tightened to the specified torque.

NOTE

Ensure the cable assembly is routed correctly as

shown in Figure 1A1 – 2.

NOTE

Ensure the cable assembly operates correctly

and the plunger completely retracts prior to

closing the fuel filler door. If satisfactory, close

the door ensuring it does not require excess

force. The door should spring ajar when the

release is operated.

Fuel filler door cable assembly release lever

attaching screw torque specification.......... 1.0 – 3.0 N.m

Fuel filler door cable assembly attaching

screw torque specification.........................1.9 – 2.1 N.m

Body Page 1A1–5

Page 1A1–5

2.2 Fuel Filler Door Cable Assembly, LHD

LT Section No.-03-028

NOTE

For removal of the fuel filler door switch

assembly, refer to the disassembly procedure in

Section 1A3, 3.12 Instrument Cluster Trim

Assembly.

If required, first remove the right-hand quarter inner rear side carpet, refer to Section 1A8, 2.7 Quarter Inner Rear Side

Carpet.

Remove

1 Open the fuel filler door by operating the fuel filler door switch on the instrument panel.

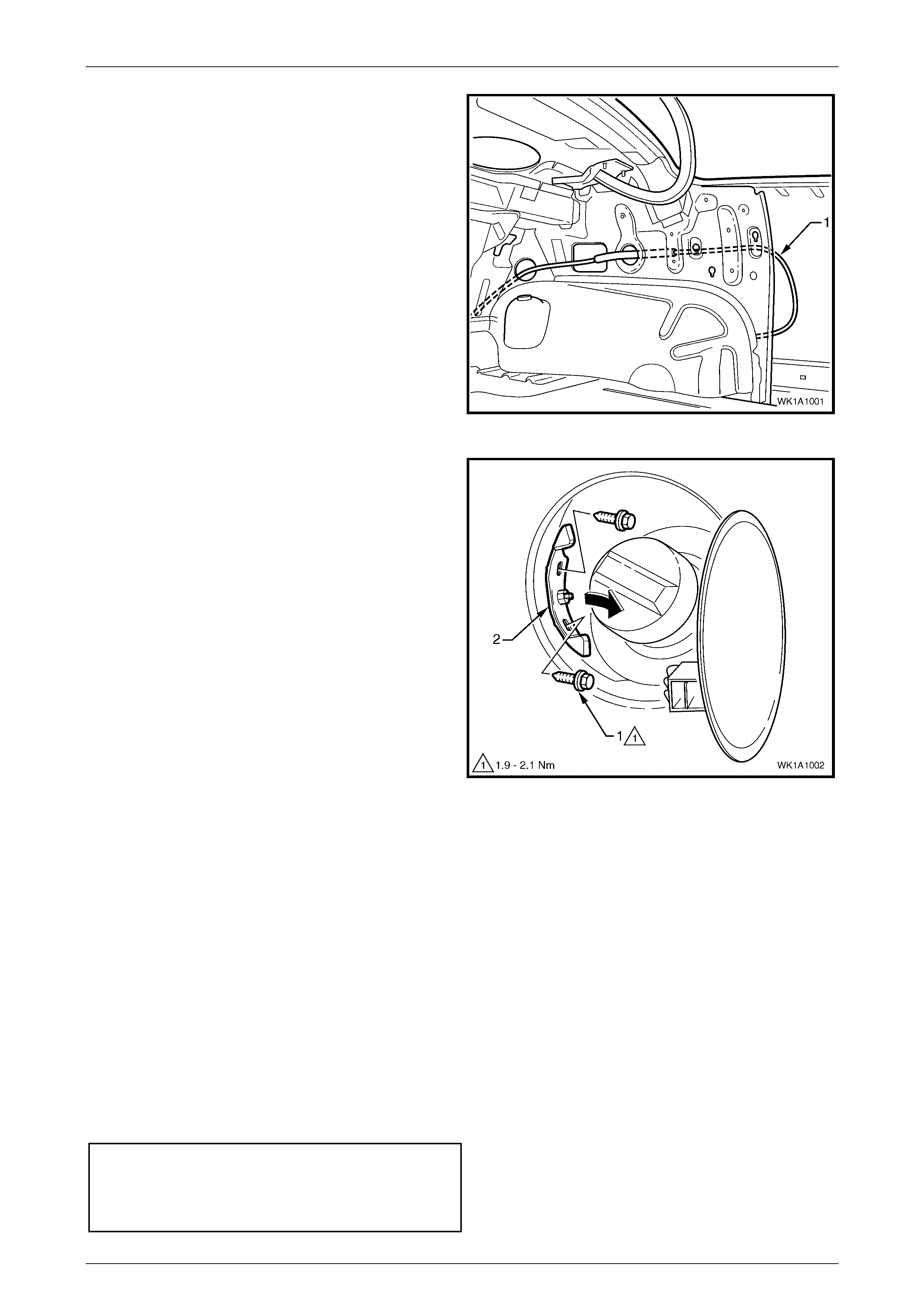

2 Loosen or remove the screw (1) attaching the actuator assembly (2) to the side panel inner, refer to Figure 1A1 – 4.

3 Slide the front of the assembly up and remove from the keyhole.

4 Withdraw the rear tab from its locating hole.

5 Disconnect the wiring connector (3).

6 Unclip the retainer (4) and remove the cable (5) from the actuator.

Figure 1A1 – 4

Body Page 1A1–6

Page 1A1–6

7 From within the fuel filler housing, remove the two

screws (1) attaching the cable assembly retainer (2).

8 Withdraw the cable assembly from the fuel filler

housing.

Figure 1A1 – 5

Disassemble

1 Unclip the retainer (1) from the cable end by raising

the locking tab.

2 Remove the screw (2) attaching the actuator (3) to the

mounting plate (4).

Figure 1A1 – 6

Reinstall

1 Installation is the reverse of removal. Ensure the components are tightened to the specified torque.

NOTE

Ensure the actuator assembly operates correctly

and the plunger completely retracts prior to

closing the fuel filler door. If satisfactory, close

the door ensuring it does not require excess

force. The door should spring ajar when the

release is operated.

Fuel filler door cable assembly actuator

attaching screw torque specification.......... 2.0 – 5.0 N.m

Fuel filler door cable assembly attaching

screw torque specification.........................1.9 – 2.1 N.m

Body Page 1A1–7

Page 1A1–7

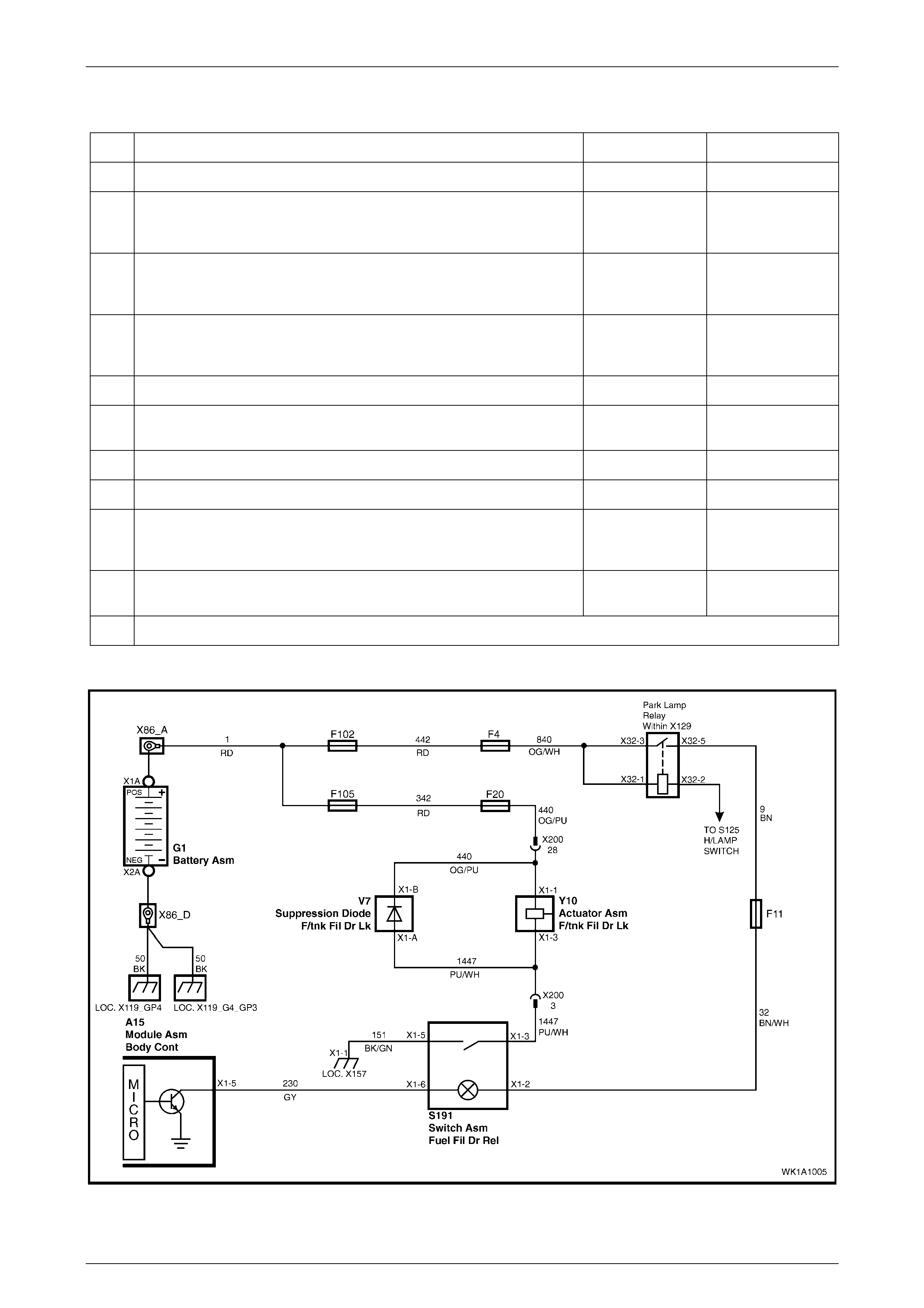

Diagnosis

Step Action Yes No

1 Press the filler door release switch. Does the fuel filler door open? OK. End Go to 2

2 Press the fuel filler door release switch. Does the actuator emit a

clicking sound? Door jammed or

cable is broken.

Repair or replace

Go to 3

3 Check Fuse 105 in the engine compartment fuse and relay panel

assembly. Is it OK? Go to 4 Replace fuse. If it

blows again test for

a short to ground

4 Check Fuse 20 in the passenger compartment fuse and relay panel

assembly. Is it OK? Go to 5 Replace fuse. If it

blows again test for

a short to ground

5 Ground the switch connector S191 pin 3. Does the actuator operate? Go to 6 Go to 7

6 Ground the switch connector S191 pin 5 and press the switch. Does

the actuator operate? Repair circuit 151 Replace switch *

7 Ground connector Y10 pin 3. Does the actuator operate? Repair circuit 1447 Go to 8

8 Check for B+ at the actuator connector Y10 pin 1 Replace actuator Go to 9

9 Check for B+ at connector X42 pin 22 in the passenger compartment

fuse and relay panel assembly Repair circuit 440

between fuse 20

and the actuator

Go to 10

10 Check for B+ at connector X18 pin 104 in the engine compartment fuse

and relay panel assembly Repair circuit 342 Repair circuit 1

* Also check the suppression diode for continuity between pins A to B but not B to A

Wiring Schematic

Figure 1A1 – 7

Body Page 1A1–8

Page 1A1–8

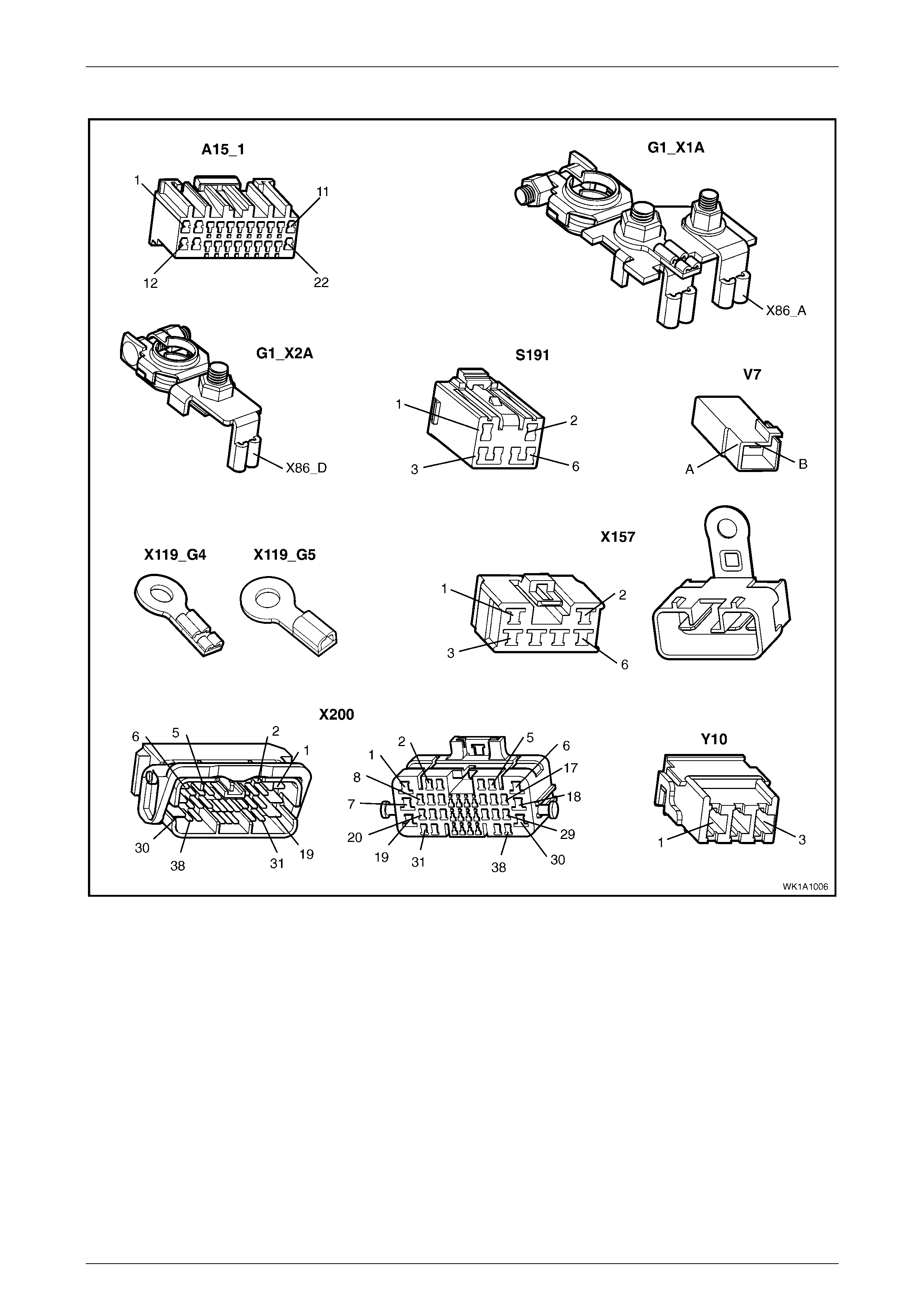

Connector Views

Figure 1A1 – 8

Body Page 1A1–9

Page 1A1–9

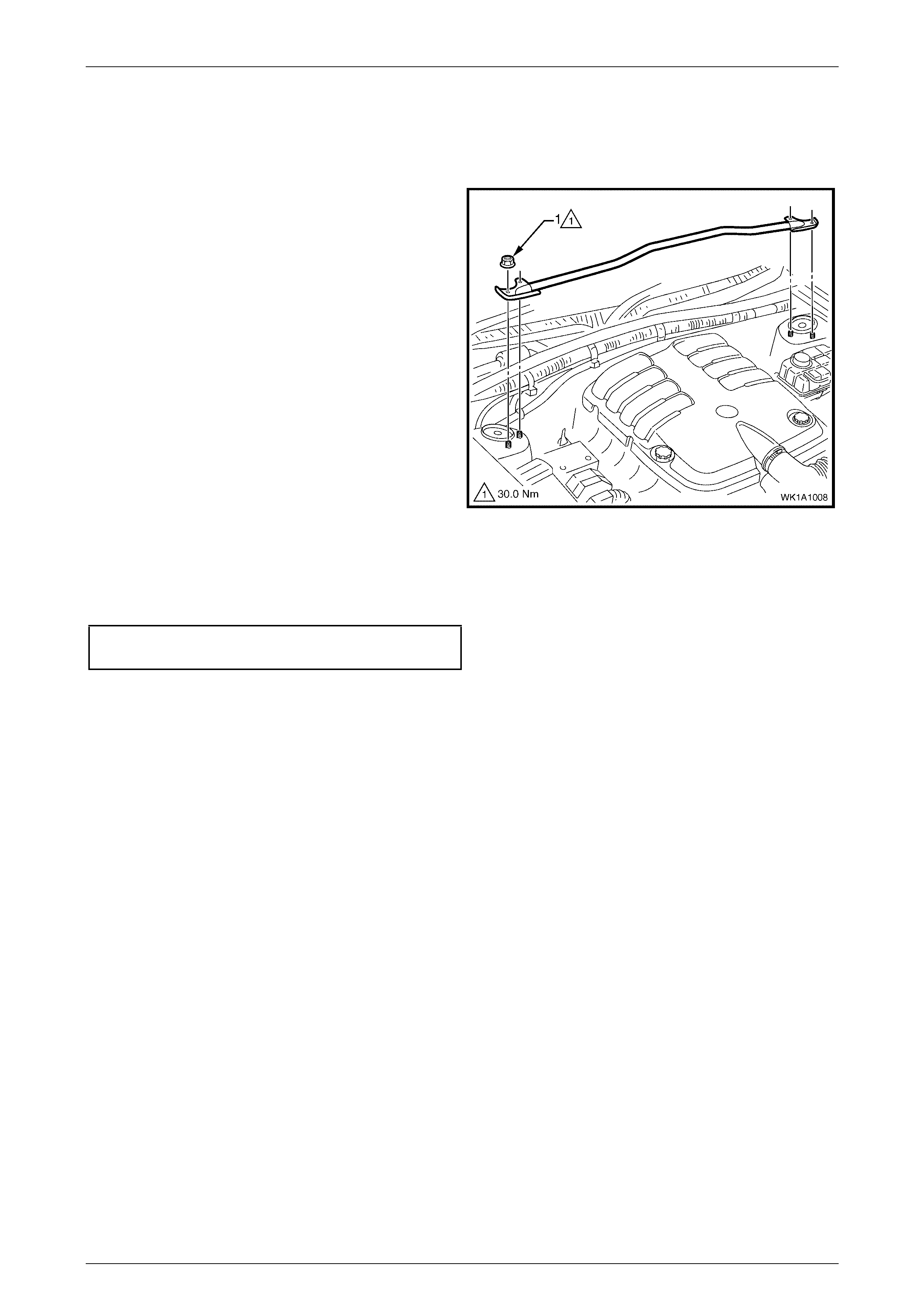

2.3 Front Suspension Strut Brace

Remove

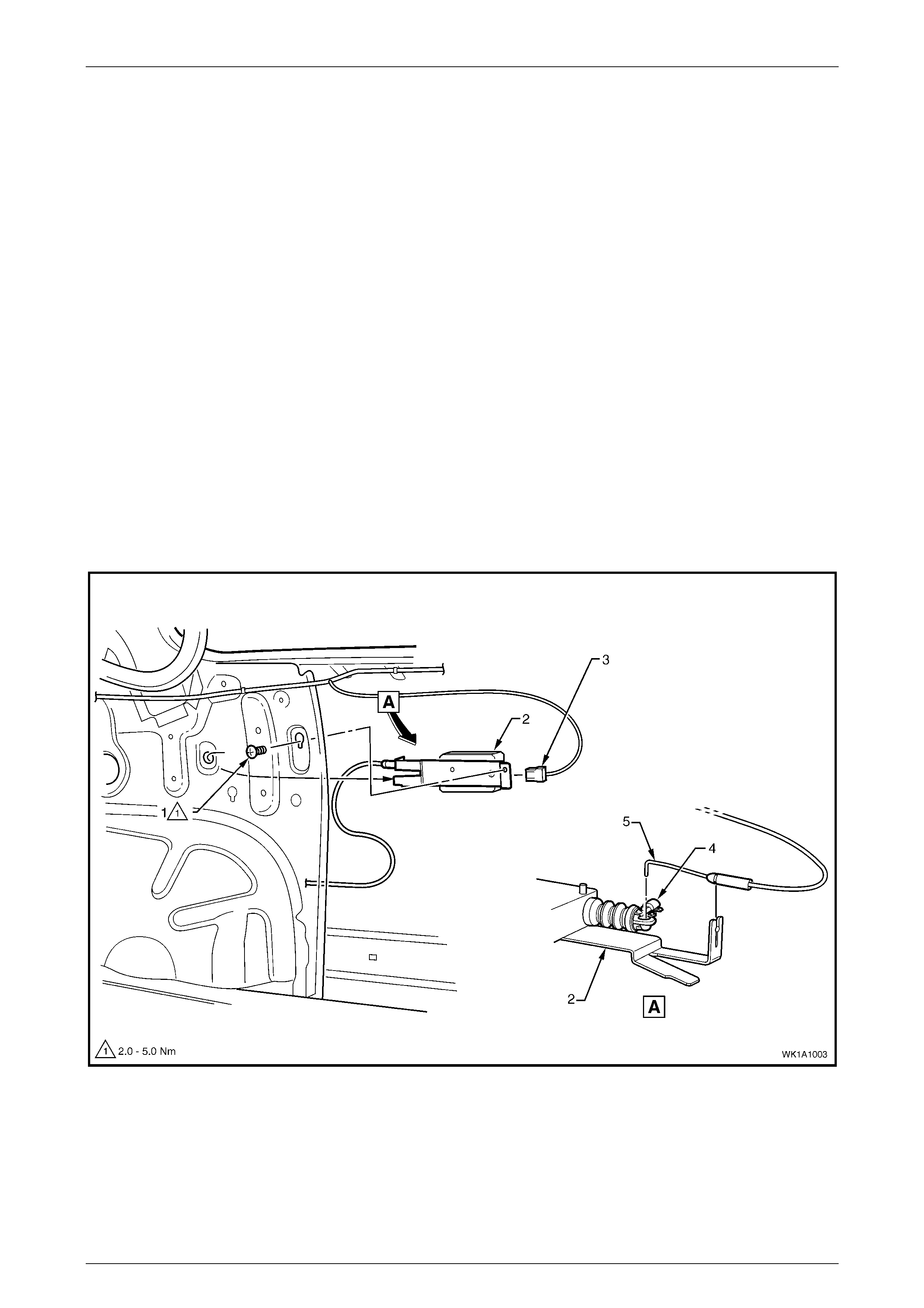

1 Remove the nuts (1), four places, attaching the front

suspension strut brace to the suspension strut towers.

2 Remove the brace from the towers.

Figure 1A1– 9

Reinstall

Reinstallation is the reverse of removal. Ensure the components are tightened to the specified torque.

Front Suspension Strut Brace

Attaching Nut Torque Specification.....................30 N.m

Body Page 1A1–10

Page 1A1–10

3 Torque Wrench Specifications

Fuel filler door cable assembly attaching screw............................1.9 – 2.1 N.m

Fuel filler door cable assembly release lever attaching screw......1.0 – 3.0 N.m

Fuel filler door cable assembly actuator attaching screw .............2.0 – 5.0 N.m

Front Suspension Strut Brace Attaching Nut Torque Specification.........30 N.m