Stationary Windows Page 1A6–1

Page 1A6–1

Section 1A6

Stationary Windows

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

WARNINGS, CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property

damage.

1 General Information............................................................................................................................... 2

2 Service Operations................................................................................................................................3

2.1 Quarter Window Assembly....................................................................................................................................3

Remove ...................................................................................................................................................................3

Reinstall ..................................................................................................................................................................4

2.2 Rear Window Assembly.........................................................................................................................................6

Remove ...................................................................................................................................................................6

Reinstall – Short Method .......................................................................................................................................8

Description..........................................................................................................................................................8

Preparation.........................................................................................................................................................8

Reinstall..............................................................................................................................................................9

Reinstall – Long Method......................................................................................................................................11

Description........................................................................................................................................................11

Preparation.......................................................................................................................................................12

Rear Window Opening Check ..........................................................................................................................12

Reinstall............................................................................................................................................................13

2.3 Rear Window Lower Finisher..............................................................................................................................16

Remove .................................................................................................................................................................16

Reinstall ................................................................................................................................................................16

3 Torque Wrench Specifications........................................................................................................... 17

Techline

Stationary Windows Page 1A6–2

Page 1A6–2

1 General Information

With the following exceptions, MY 2004 WK Series Stationary Windows information carries over from MY 2003 VY

Series vehicles. For information not contained within this Section, refer to Section 1A6 STATIONARY WINDOWS in the

MY 2003 VY and V2 Series Service Information.

• Quarter window assembly

• Rear window assembly

• Rear window lower finisher

The quarter window assembly is secured to the vehicle using plastic nuts and a self adhesive foam weatherstrip is

attached to the glass to seal the window opening.

The rear window is surrounded by a one piece rubber weatherstrip. The join is on the vertical centre line at the base of

the window assembly.

A moulded plastic finisher is fitted between the rear window weatherstrip and the rear compartment lid weatherstrip.

Toughened safety glass is used for all the windows except the windshield assembly.

Stationary Windows Page 1A6–3

Page 1A6–3

2 Service Operations

2.1 Quarter Window Assembly

LT Section No. – 11-030

Safety glasses and work gloves must be worn

at all times when operating with glass.

Care must be taken during any operation

involving the quarter window assembly

removal or installation, not to exert any load

on the window. Failure to observe this may

result in damage to the window.

NOTE

The following component WILL REQUIRE

REPLACEMENT when performing this operation:

• Quarter window nut.

If required, first remove the body lock pillar garnish, refer to Section 1A8, 2.2 BODY LOCK PILLAR GARNISH.

Remove

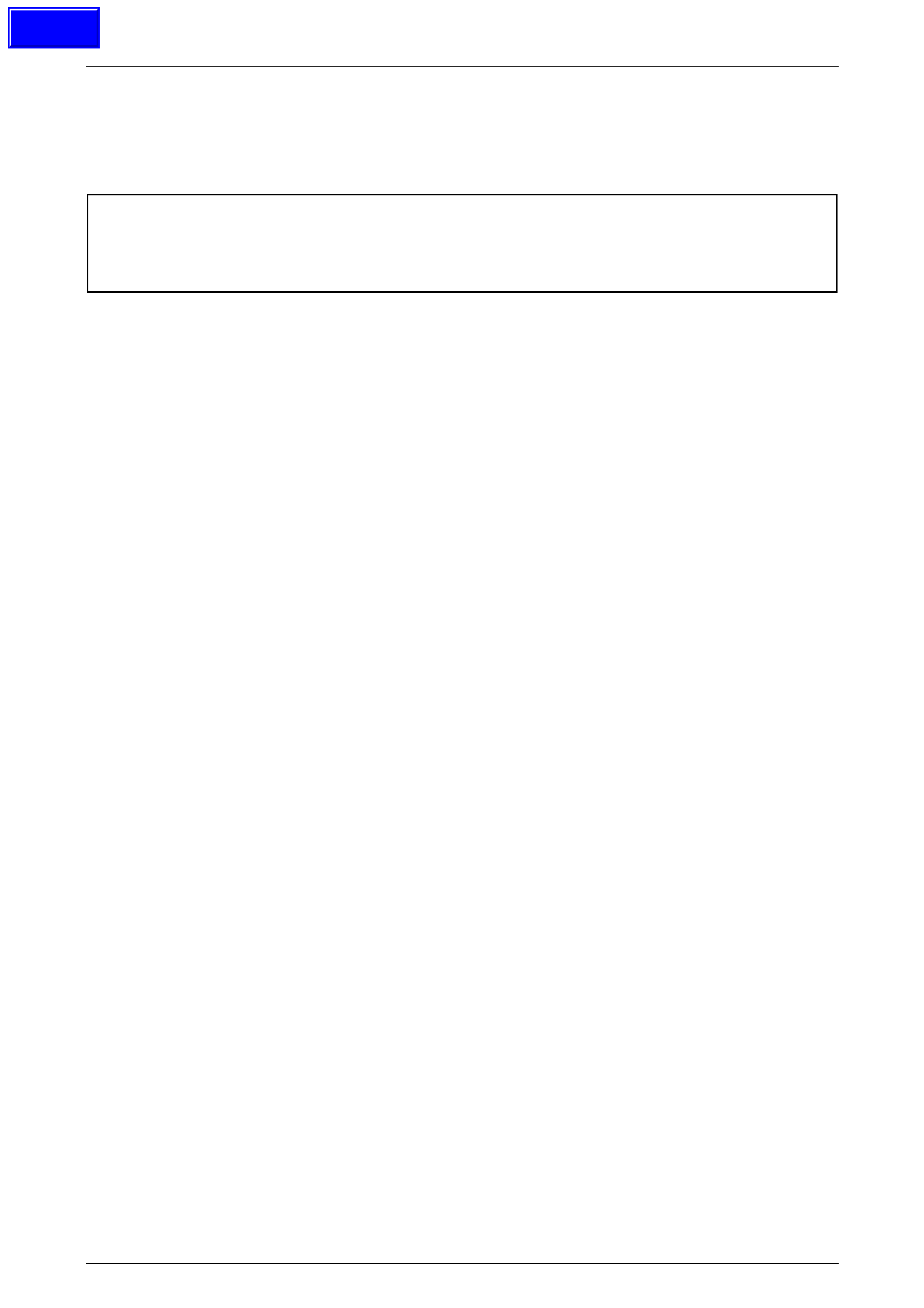

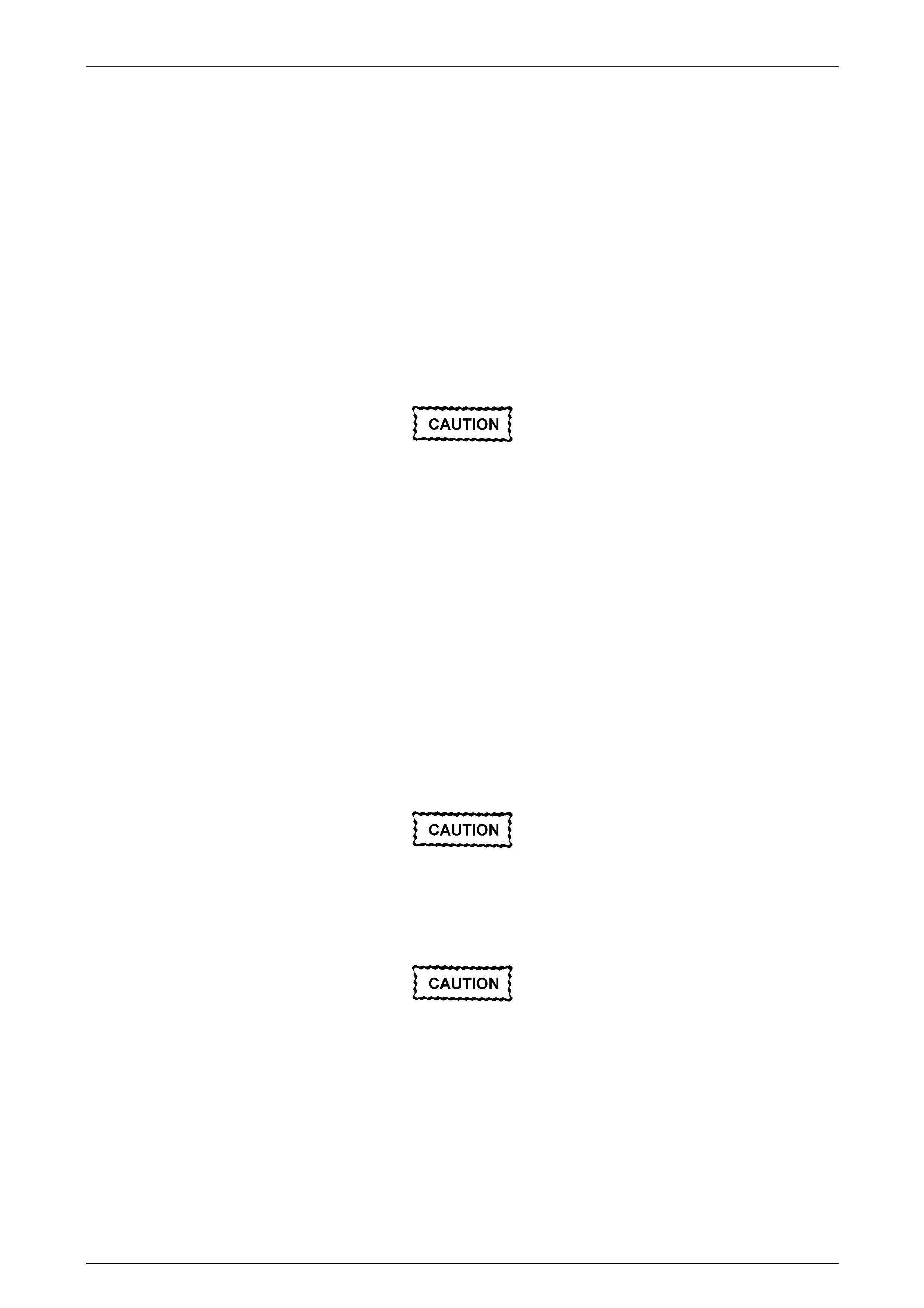

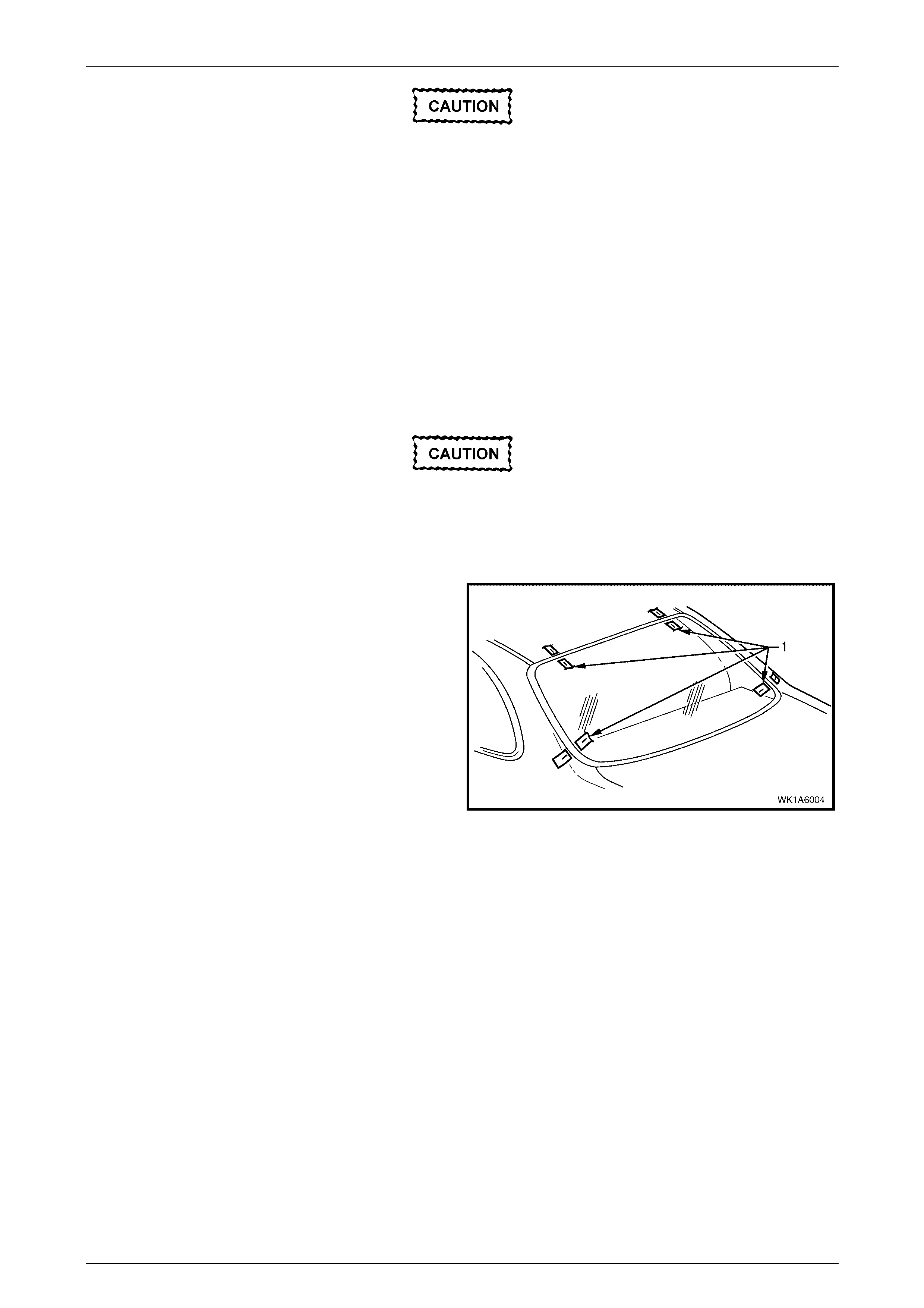

1 Remove the three screws (1) from the rear door

opening and partially remove the rear section of the

door opening moulding (2), disengaging it from the

quarter window assembly tab (3).

Figure 1A6 – 1

Stationary Windows Page 1A6–4

Page 1A6–4

2 Remove the quarter window nut (1) five places, securing the quarter window assembly (2) to the body opening,

refer to Figure 1A6 – 2.

Take care when removing the quarter window

from the body opening that the attaching pins

are clear of the outer body.

3 Carefully lift the window from the vehicle.

Figure 1A6 – 2

Legend

1 Quarter Window Nut (5 places) 2 Quarter Window Assembly

Reinstall

Reinstallation of the quarter window assembly is the reverse of removal procedure noting the following:

1 Use new quarter window nuts (five places).

2 Leave the nuts loose, until the door opening moulding is fastened into position.

3 Install the door opening moulding screws and tighten to the specified torque.

NOTE

The screws are encapsulated with a wax sealer.

It is recommended that the screws be replaced

once removed, however if this is impractical apply

a small amount of sealer to the end of the thread.

4 Position the quarter window assembly and tighten the nuts to the correct torque specification.

5 Reinstall the body lock pillar garnish as required.

Stationary Windows Page 1A6–5

Page 1A6–5

Door opening moulding retaining

screws torque specification .......................1.0 – 2.0 N.m

Quarter window assembly retaining nut

torque specific atio n ...................................1.0 – 3.0 N.m

Stationary Windows Page 1A6–6

Page 1A6–6

2.2 Rear Window Assembly

LT Section No. – 11-020

Safety glasses and work gloves must be worn

at all times when operating with glass.

Care must be taken during any operation

involving the rear window assembly removal

or installation not to exert any load on the

window. Failure to observe this may result in

damage to the window.

Only use urethane adhesives such as

Betaseal 15685 or equivalent for rear window

installation. It is imperative that the

procedures in this Section for replacing

bonded windows are followed, as incorrect

installation may lead to injury or death.

NOTE

The following component WILL REQUIRE

REPLACEMENT when performing this operation:

• Rear Win dow M ouldin g.

The rear window assembly removal procedure is the same for both the short and long installation methods, with one

exception. If the short method installation is to be used, care must be taken during removal to ensure that an even

surface of the original urethane remains in the body opening. This will serve as a base for the new urethane bead and

the replacement rear window.

To prevent damage and to minimise clean up of the paint finish and the trim, mask-up and place protective covers over

parts adjacent to the rear window.

If required, remove the following components:

1 Roof joint moulding, refer to Section 1A9, 2.8 ROOF JOINT MOULDING.

2 Body lock pillar garnish, refer to Section 1A8, 2.4 BODY LOCK PILLAR GARNISH.

Remove

A high mount stop lamp assembly is installed

below the rear window trim panel assembly.

Care must be taken to avoid damage to the

lamp assembly during window removal

procedure. It is not necessary to remove the

lamp assembly, but to ensure that it is clear of

any debris before window installation.

1 Carefully disconnect the rear window electrical demister connectors and cellular telephone antenna if fitted.

2 If the rear window is broken, carefully remove all fragments of glass from the window opening.

Stationary Windows Page 1A6–7

Page 1A6–7

3 Using special tool J36020, thread one end of the piano wire through the urethane, starting at the windshield upper

corner, pulling the end of the wire through with pliers.

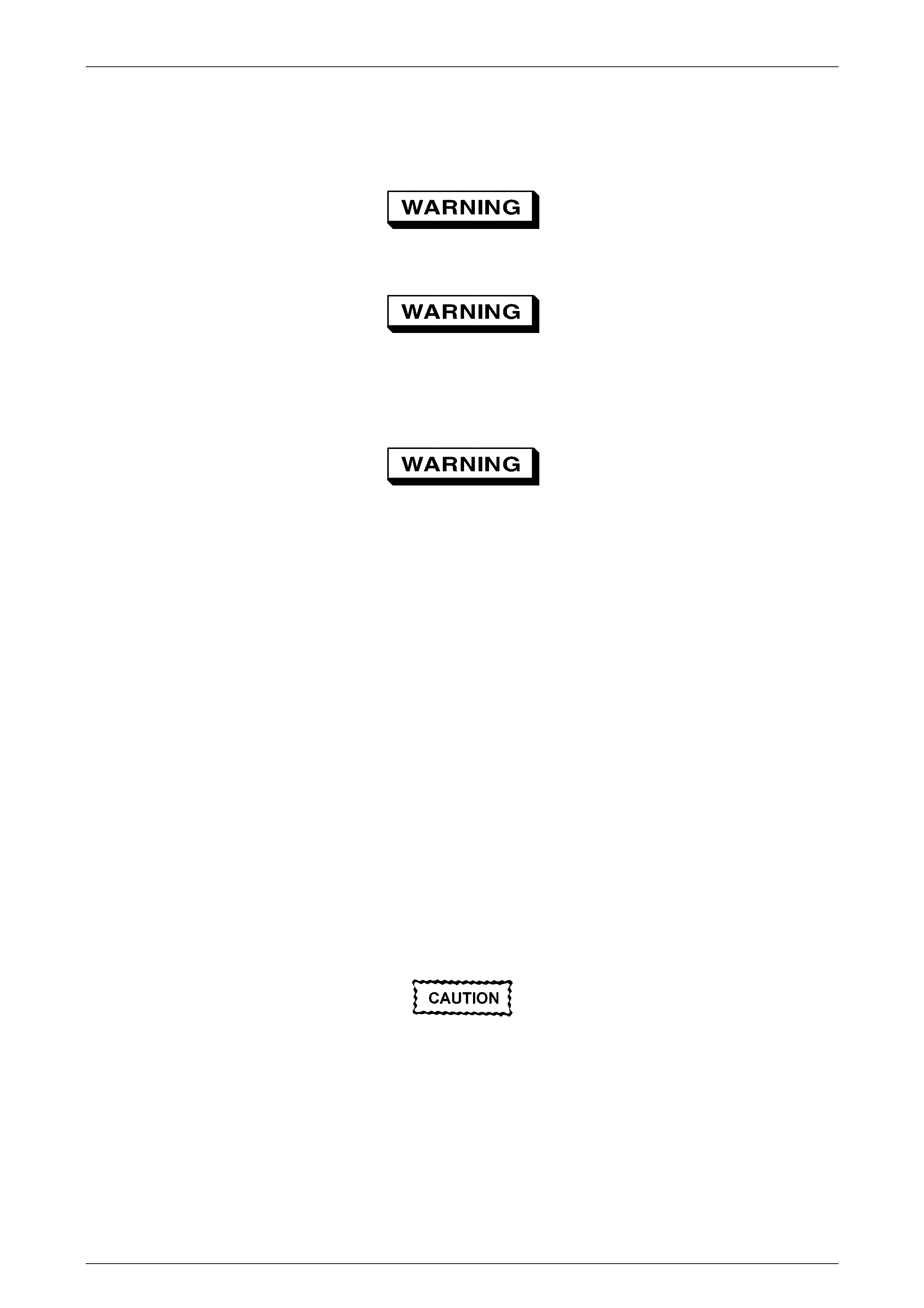

4 Alternately, manufacture two T-handles to the

dimensions shown. Secure at least 700mm of piano

wire to one handle, thread the other end of the wire

through the urethane as previously described.

Ensure that the headlining and other trim

items are not damaged.

Figure 1A6 – 3

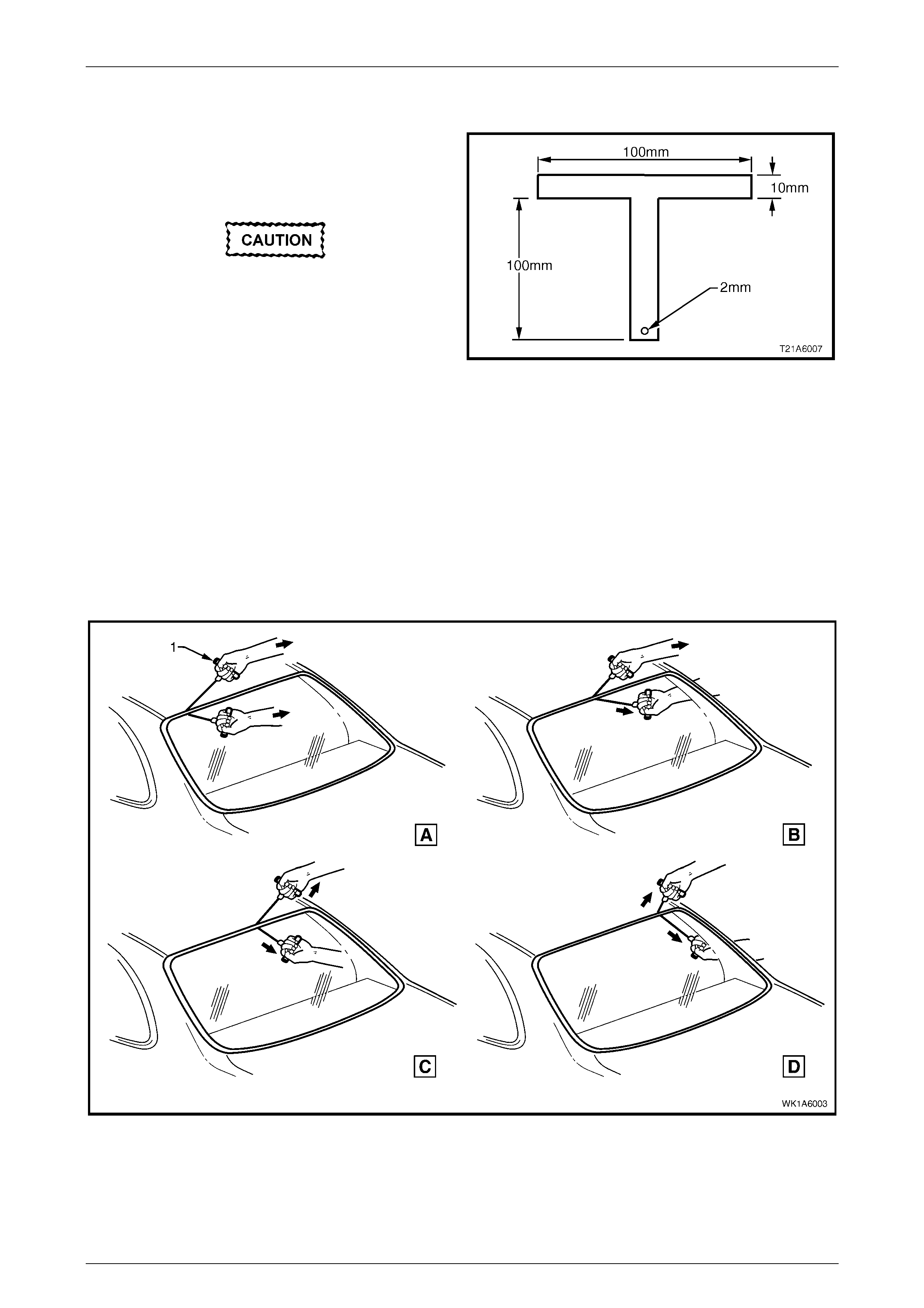

5 Connect the wire to the remaining T-handle and with the aid of an assistant, commence cutting the urethane bead,

keeping the outside T-handle (1) parallel to the edge of the window using the full length of the wire to prevent heat

build-up in the wire, refer to Figure 1A6 – 4.

NOTE

To minimise damage to the interior of the vehicle,

the operator inside the vehicle should act as an

anchor point, holding the T-handle as close as

possible to the window at all times. The outside

operator pulls the wire up to the interior T-handle

in a 'walking' motion, refer to Figure 1A6 – 4.

Figure 1A6 – 4

6 Carefully lift the rear window out of the rear opening. If there is evidence of the window adhering to the urethane,

cut the area again with the piano wire.

7 If the original rear window is to be installed again, place the window on a clean protected surface or a holding

fixture.

Stationary Windows Page 1A6–8

Page 1A6–8

NOTE

The use of suction cups will greatly assist in the

handling of the rear window.

NOTE

All traces of urethane must be removed from the

rear window for the 'long method' of reinstallation.

It is not necessary to remove all traces of the

original urethane from the body opening for the

‘short method’ of reinstallation, however, any

original urethane remaining must be smooth and

firm.

Reinstall – Short Method

Ensure that door windows are partially

lowered to eliminate pressure build up which

can be caused by slamming doors. A curing

time of 24 hours is recommended, although

the vehicle may be driven after 5 hours,

providing it is driven only on a smooth road at

speeds not exceeding 80 km/h with the door

windows partially lowered.

Description

The short method installation involves the maximum amount of the original urethane being left intact on the rear window

opening to form a sound base for the replacement urethane and rear window assembly.

This method is recommended when replacing a cracked or broken window, or a leak condition that cannot be overcome

by using minor water leak repair procedures, refer to Section 1A6, 2.1 MINOR WATER LEAK CORRECTION in the

MY 2003 VY and V2 Series Service Information.

If material other than urethane has been used for previous servicing of the rear window, the long method installation

procedure (complete removal of adhesive) is mandatory to achieve an effective window to metal bond.

Care should be taken to ensure that the rear

window does not strike the rear window

opening. Chipped edges can lead to

subsequent breakage of the window.

Do not use petroleum based solvents to clean

the rear window assembly or the rear opening

flange, as the presence of the oil in the

solvent will prevent the adhesion of the new

urethane.

Preparation

1 Using a sharp scraper, carefully remove any original urethane from around the rear window. Clean the rear window

to be installed with a suitable oil free cleaning agent.

Stationary Windows Page 1A6–9

Page 1A6–9

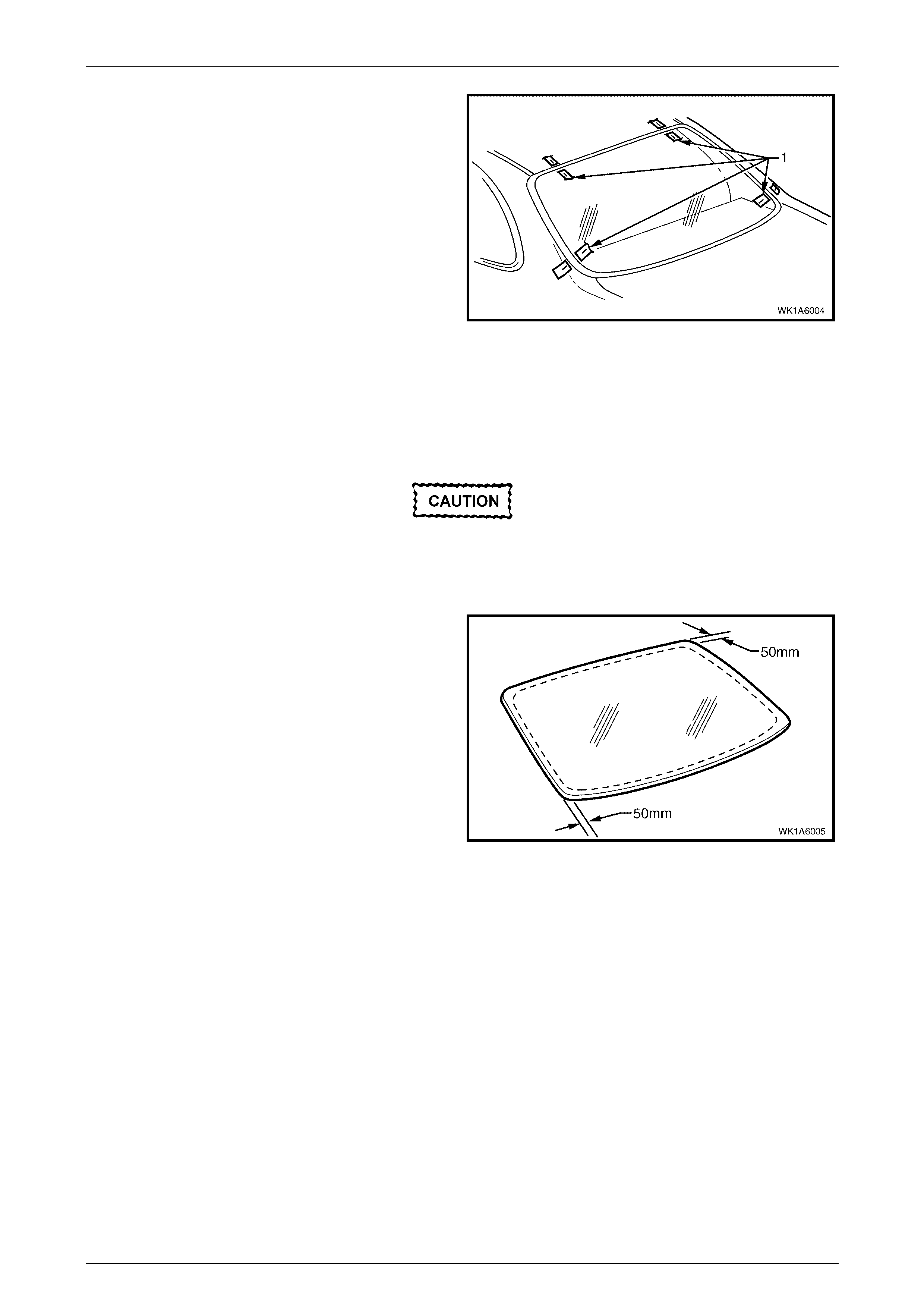

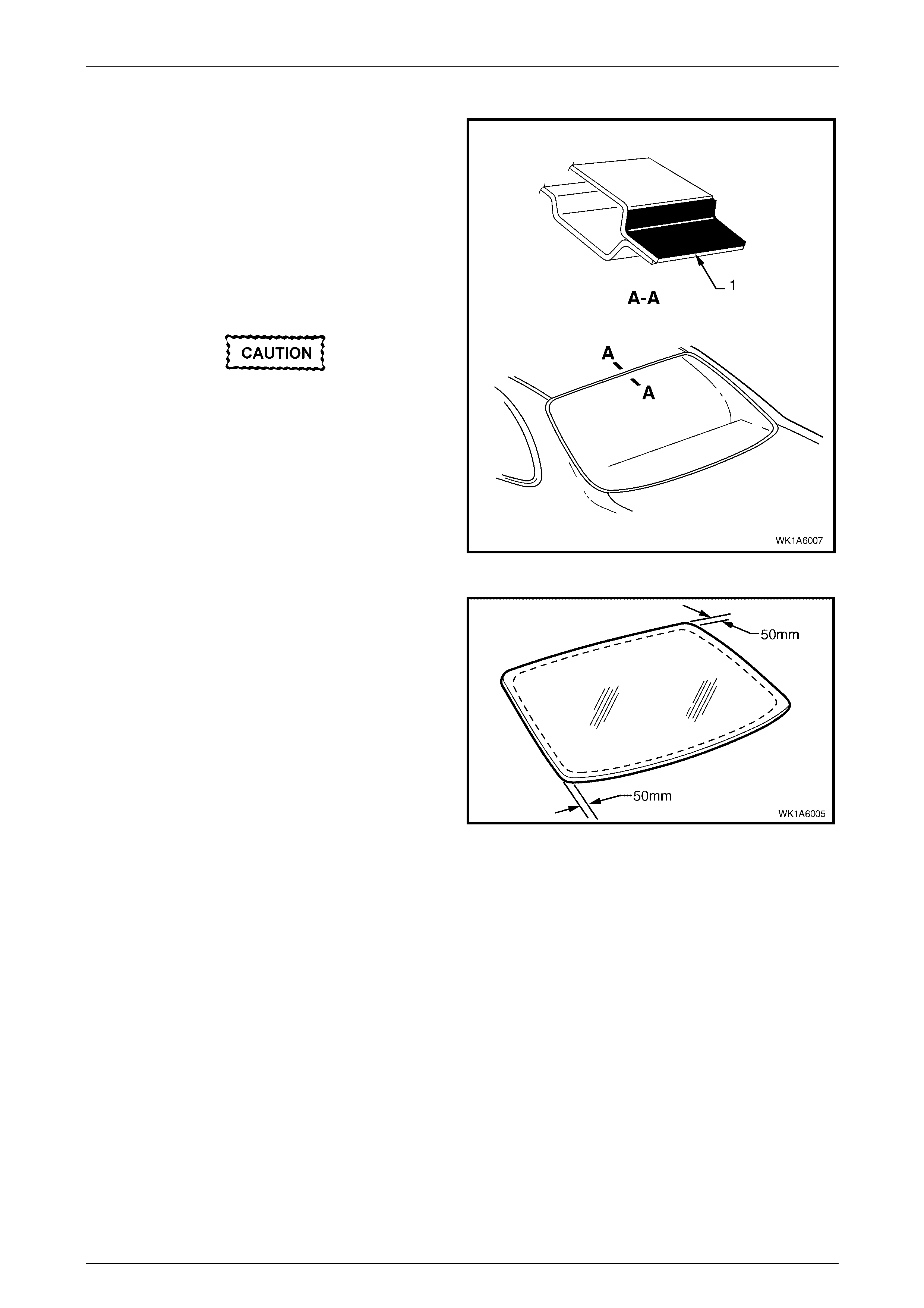

2 To check for correct alignment, temporarily place the

rear window in the body opening.

3 Ensure the rear window is centralised in the body

opening left to right, by checking that the gaps

between the rear window and body opening are even

on both sides of the vehicle.

4 With masking tape (1), mark the outer top of the roof

and the rear quarter panel.

NOTE

This procedure will assist in the alignment of the

window in the correct horizontal and vertical

plane during final window installation.

5 Remove and place the rear window assembly face

down on a clean protected surface or fixture.

Figure 1A6 – 5

Reinstall

1 Thoroughly clean the inner surface and edges of the rear window assembly to which the urethane is to be applied,

using clean lint-free cloths and a suitable oil free cleaning solvent.

Do not use petroleum based solvents to clean

the rear window assembly or the rear opening

flange as the presence of the oil in the solvent

will prevent the adhesion of the new urethane.

2 Apply clear window adhesive primer, over the width of

the solid black ceramic pattern (or a width of 50 mm),

to the inner surface around the perimeter of the rear

window. Immediately wipe off with a lint-free cloth.

3 Remove the old rear window moulding and replace.

Figure 1A6 – 6

4 Install the rear window moulding (1) over the edge of the window. Ensure the moulding is fitted correctly to the

glass with the moulding joint at the bottom middle (2) of the rear window, refer to Figure 1A6 – 7.

5 Check the condition of the original urethane around the window opening flange for voids or looseness and cut away

any loose pieces.

6 Using a suitable spatula, spread fresh urethane smoothly into any voids or uneven sections.

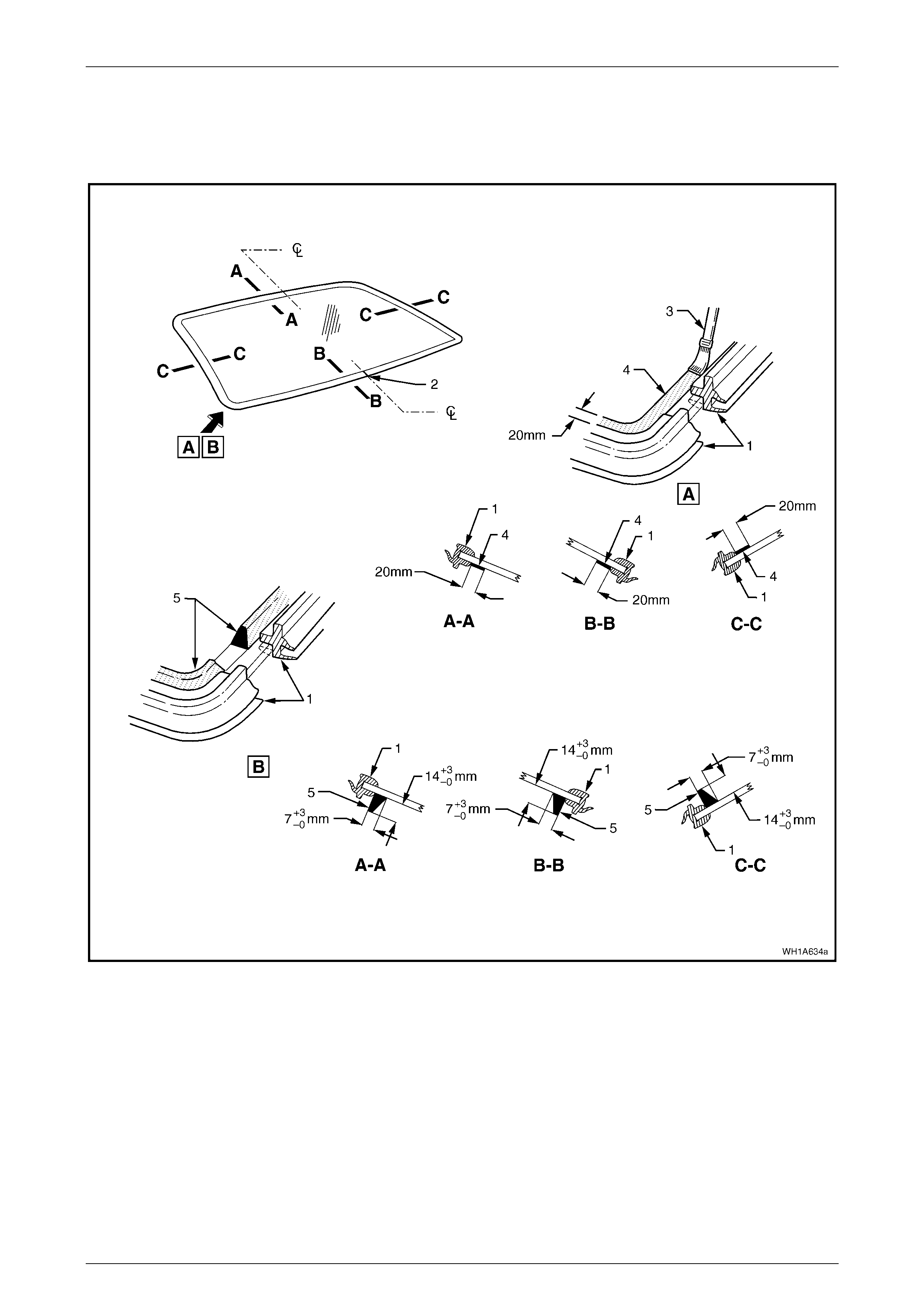

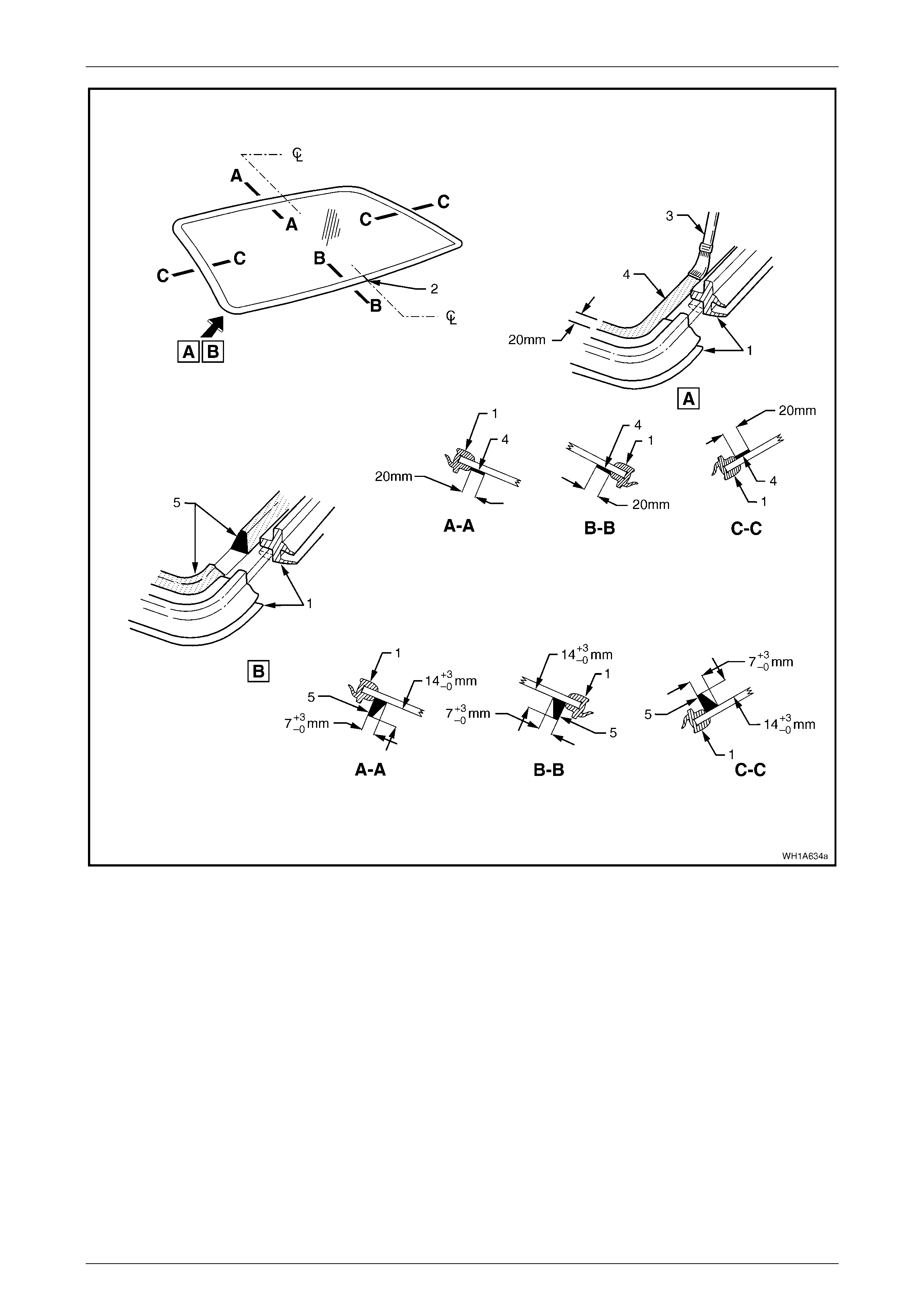

7 Using the applicator (3) included in the service kit, apply black window adhesive primer (4) to the inner surface of

the rear window over a width of 20 mm, along the inside edge of the window moulding (1).

8 Using a hand or automatic applicator, apply a smooth continuous bead of window adhesive (urethane) (5), such as

Betaseal 15685 or equivalent, around the perimeter of the window, along the inside edge of the moulding (1). The

bead dimensions are shown in Figure 1A6 – 7.

NOTE

Depending on the amount of original urethane

remaining on the body opening flange, the

amount of the new urethane should be reduced

accordingly, while maintaining adequate strength

and sealing properties. The dimensions shown

are the maximum allowable and are only for

reference.

Stationary Windows Page 1A6–10

Page 1A6–10

NOTE

In cold weather, the placement of cartridges

adjacent to a source of warmth will assist in the

flow of urethane when using a hand applicator.

Figure 1A6 – 7

Legend

1 Moulding

2 Moulding Joint Position (on Centre Line)

3 Applicator

4 Black Glass Primer

5 Urethane Adhesive

Stationary Windows Page 1A6–11

Page 1A6–11

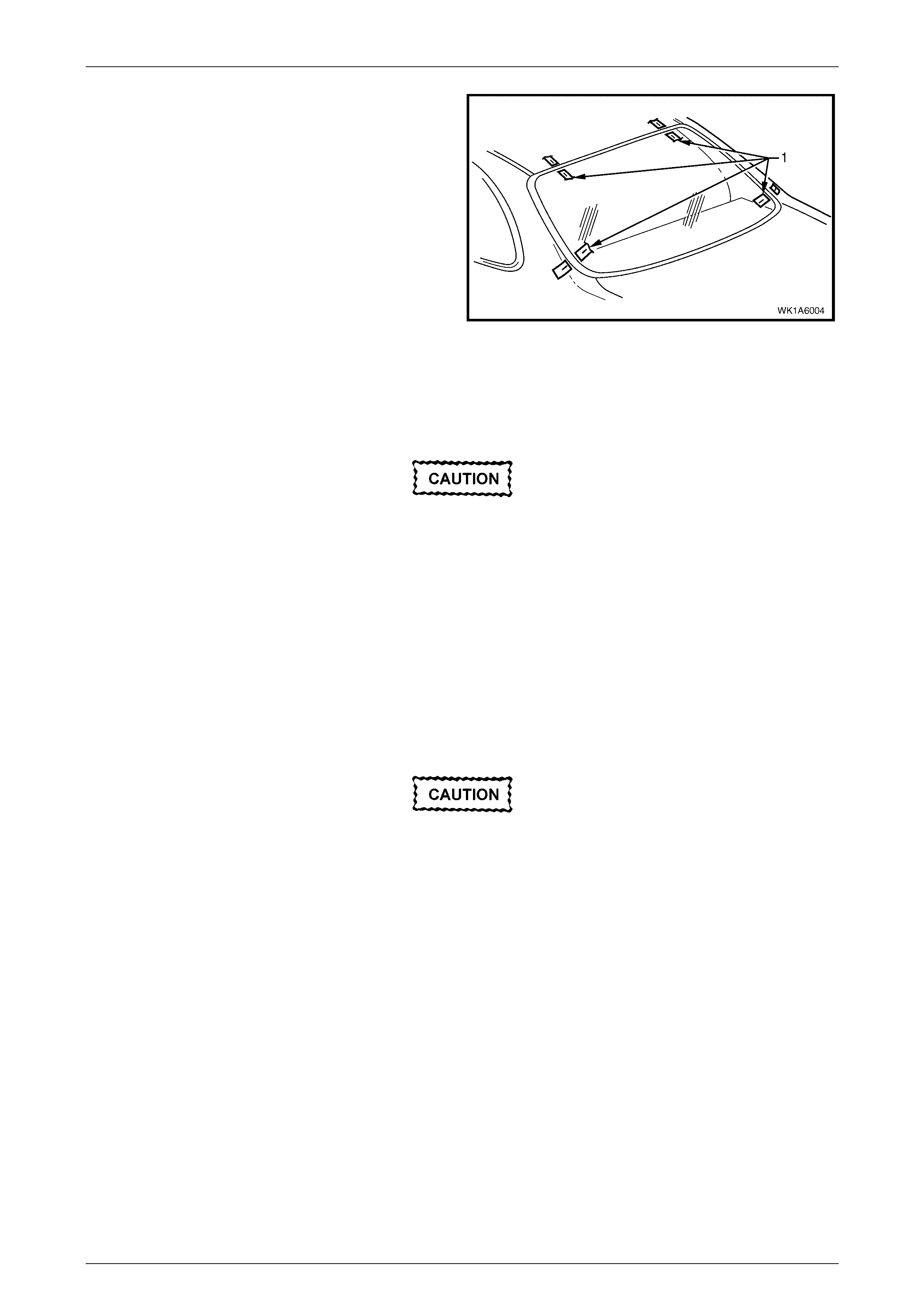

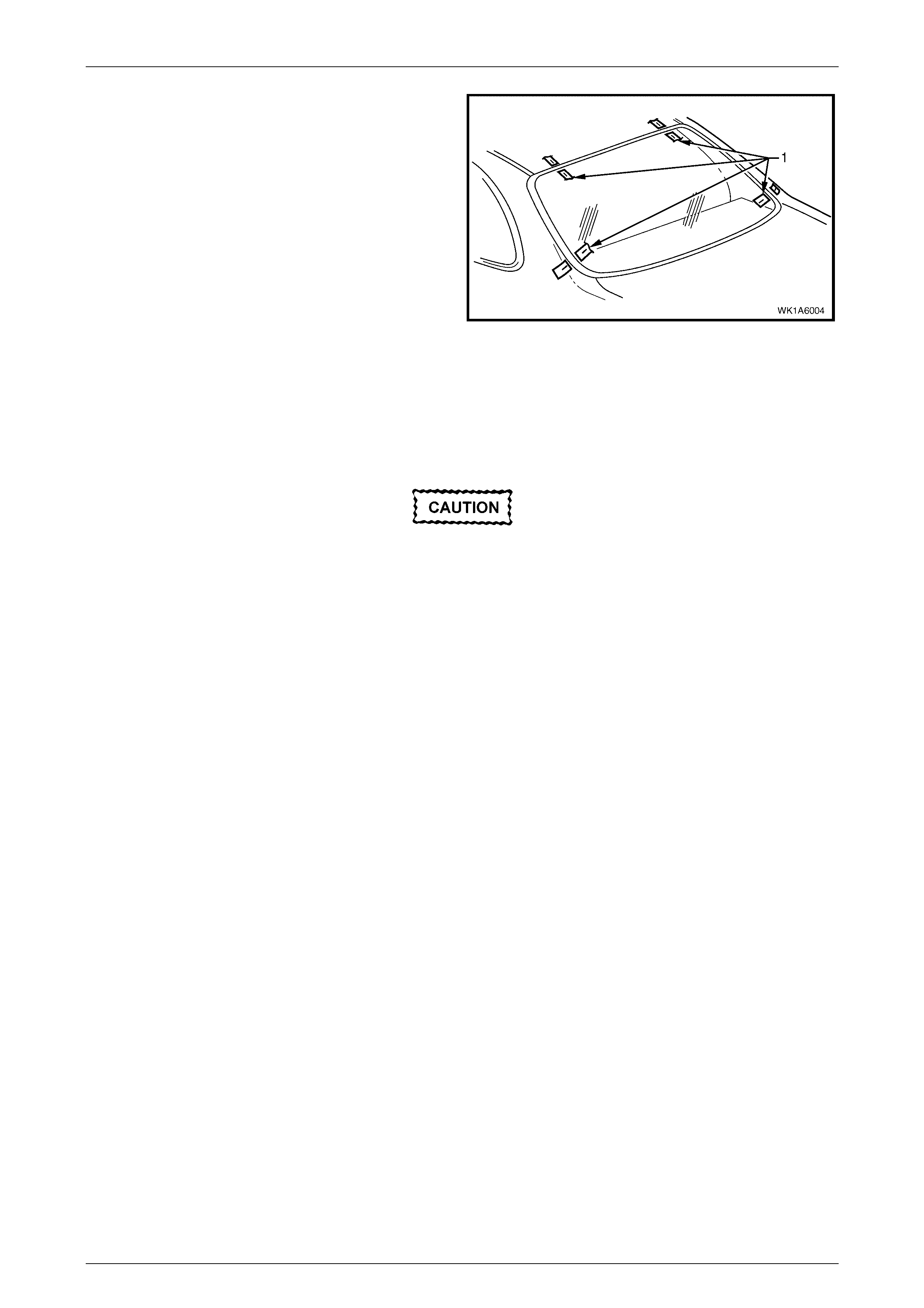

9 With the aid of an assistant, install the rear window

assembly, using the previously attached masking tape

(1) on the roof and the rear quarter panel to ensure

accurate align ment.

NOTE

Ensure the rear window is centralised in the

body opening left to right by checking that the

gaps between the window moulding and body

opening are even on both sides of the vehicle.

10 Press the rear window firmly into position.

Figure 1A6 – 8

11 Check effectiveness of sealing from inside the vehicle. Should any gaps in the sealing exist, apply additional

urethane to fill these gaps.

12 Wait two hours then water test the rear window, using a moderate spray of water.

Do not direct a heavy stream of water onto

freshly applied urethane. If a water leak is

evident, apply additional urethane to the leak

area, using a spatula to work the urethane

into the source of the leak.

13 Clean off any excess urethane using Prepsol or white spirit. Clean the rear window, then remove the masking tape

previously installed.

14 Connect the electrical demist connectors and cellular telephone antenna if fitted.

15 Reinstall the trim and hardware as required.

Reinstall – Long Method

Ensure that door windows are partially

lowered to eliminate pressure build up which

can be caused by slamming doors. A curing

time of 24 hours is recommended, although

the vehicle may be driven after 5 hours,

providing it is driven only o n a smooth road at

speeds not exceeding 80 km/h with the door

windows partially lowered.

Description

The long method for the rear window assembly replacement is used when the original urethane adhesive material cannot

serve as a base for the replacement rear window.

This method should be used on vehicles requiring metal or paint repair to the rear window opening when the original

adhesive is completely removed and replaced with new urethane for the window installation.

This method is also used when the rear window has been previously replaced using the short method. In such instances,

the build-up of urethane could position the window assembly too high in the opening.

Stationary Windows Page 1A6–12

Page 1A6–12

Do not use petroleum based solvents to clean

the rear window or the rear opening flange, as

the presence of the oil in the solvent will

prevent the adhesion of the new urethane.

Preparation

1 Using a sharp scraper, carefully remove any original urethane from around the rear window. Clean the wi ndow to

be installed with a suitable oil free cleaning agent.

2 Using a knife or sharp scraper, remove the original urethane from around the entire perimeter of the window

opening flange. Avoid the removal of paint when removing urethane from opening flange.

Rear Window Opening Check

1 Thoroughly check the rear window opening flange for any irregularities before installing the rear window assembly.

Care should be taken to ensure that the rear

window does not strike the rear window

opening. Chipped edges can lead to

subsequent breakage of the window

assembly.

2 To check for correct alignment, temporarily place the

rear window in the body opening.

3 If necessary, re-form the rear window opening flange

to produce a uniform flange to the window contour.

4 Ensure the rear window is centralised in the body

opening left to right, by checking that the gaps

between the rear window and body opening are even

on both sides of the vehicle.

5 With masking tape (1), mark the outer top of the roof

and the rear quarter panel.

NOTE

This procedure will assist in the alignment of the

window in the correct horizontal and vertical

plane during final window installation.

6 Remove and place the rear window assembly face

down on a clean protected surface or fixture.

Figure 1A6 – 9

Stationary Windows Page 1A6–13

Page 1A6–13

Reinstall

NOTE

Flange primer is NOT required if using the

recommended urethane adhesive Betaseal

15685.

If not using Betaseal 15685, a nd are using an equiv al ent

system, refer to technical data supplied by the

manufacturer.

If required by the manufacturer, apply flange primer (1) as

directed.

Do not use petroleum based solvents to

clean the rear window assembly, or the rear

opening flange as the presence of the oil in

the solvent will prevent the adhesion of the

new urethane.

1 Thoroughly clean the inner surface and edges of the

rear window assembly to which the urethane is to be

applied, using cle an lint-free cloths and a suitable oil

free cleaning solvent.

Figure 1A6 – 10

2 Apply clear window adhesive primer, over the width of

the solid black ceramic pattern (or a width of 50 mm),

to the inner surface around the perimeter of the rear

window. Immediately wipe off with a lint-free cloth.

3 Remove the old rear window moulding and replace.

Figure 1A6 – 11

4 Install the rear window moulding (1) over the edge of the window. Ensure the moulding is fitted correctly to the

window with the moulding joint at the bottom middle (2) of the rear window, refer to Figure 1A6 – 12.

5 Check the condition of the original urethane around the window opening flange for voids or looseness.

6 Use the applicator (3) included in the service kit, to apply black window adhesive primer (4) to the rear window as

described in the following step.

7 Apply black window adhesive primer (4) to the inner surface, around the perimeter of the window over a width of

20 mm, along the inside edge of the window moulding (1).

8 Using a hand or automatic applicator, apply a smooth continuous bead of window adhesive (urethane) (5), such as

Betaseal 15685 or equivalent, around the perimeter of the window, along the inside edge of the mouldings (1). The

bead dimensions are shown in Figure 1A6 – 12.

NOTE

In cold weather, the placement of cartridges

adjacent to a source of warmth will assist the flow

of urethane when using a hand applicator.

Stationary Windows Page 1A6–14

Page 1A6–14

Figure 1A6 – 12

Legend

1 Moulding

2 Moulding Joint Position (on Centre Line)

3 Applicator

4 Black Glass Primer

5 Urethane Adhesive

Stationary Windows Page 1A6–15

Page 1A6–15

9 With the aid of an assistant, install the rear window

assembly, using the previously attached masking tape

(1) on the roof and the rear quarter panel to ensure

accurate instal lati on.

NOTE

Ensure the rear window is centralised in the

body opening left to right by checking that the

gaps between the window moulding and the

body opening are even on both sides of the

vehicle.

Figure 1A6 – 13

10 Press the rear window firmly into position.

11 Check effectiveness of sealing from insi de the vehicle. Should any gaps in the sealing exist, apply additional

urethane to fill these gaps.

12 Wait two hours then water test the rear window, using a moderate spray of water.

Do not direct a heavy stream of water onto

freshly applied urethane. If a water leak is

evident, apply additional urethane to the leak

area, using a spatula to work the urethane

into the source of the leak.

13 Clean off any excess urethane using Prepsol or white spirit. Clean the rear window, then remove the masking tape

previously installed.

14 Connect the electrical demist connectors and cellular telephone antenna if fitted.

15 Reinstall the trim and hardware as required.

Stationary Windows Page 1A6–16

Page 1A6–16

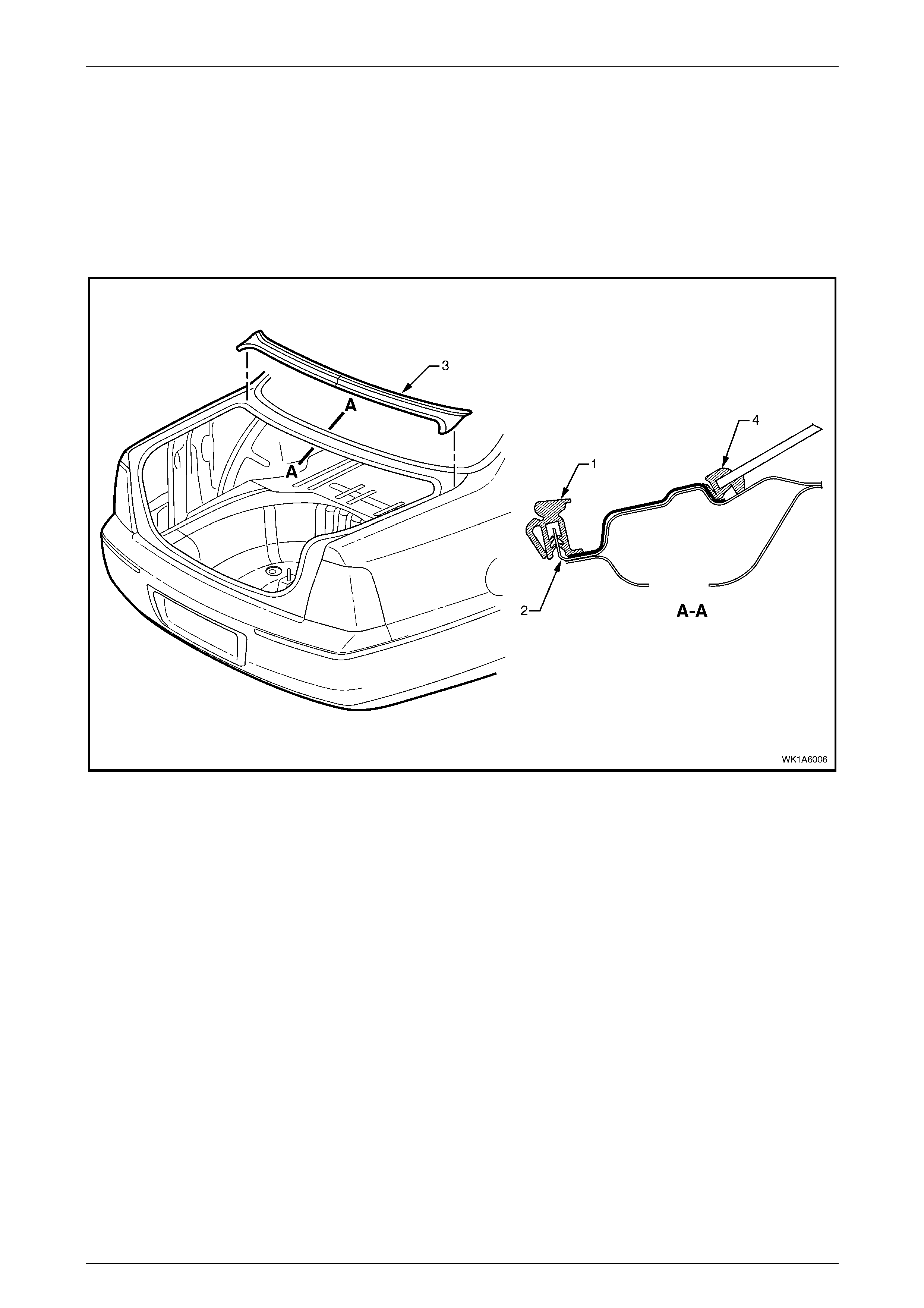

2.3 Rear Window Lower Finisher

Remove

1 Remove the rear compartment lid weatherstrip (1) from around the lip flange of the rear compartment (2), refer to

Figure 1A6 – 14.

2 Starting from one end, carefully remove the rear wi ndow lower finisher (3) by pulling it out from under the rear

window weatherstrip (4).

Figure 1A6 – 14

Reinstall

1 Gently lift the rear window weatherstrip using a fine bladed screw driver and insert the lower finisher underneath it.

2 Reinstall the rear compartment lid weatherstrip on the lip flange around the rear compartment.

Stationary Windows Page 1A6–17

Page 1A6–17

3 Torque Wrench Specifications

Door opening moulding retaining screw........................................1.0 – 2.0 N.m

Quarter window assembly retaining nut........................................1.0 – 3.0 N.m