Occupant Protection System Page 12M–1

Page 12M–1

Section 12M

Occupant Protection System

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information............................................................................................................................... 2

1.1 Driver's Seatbelt Buckle Warning Indicator Switch – LHD Only ........................................................................2

Driver's Seatbelt Buckle Warning Indicator Switch.............................................................................................2

Modes of Operation............................................................................................................................................2

Seatbelt Warning Indicator....................................................................................................................................2

Level 1 and 2 Circuit Diagram...............................................................................................................................3

Level 4 Circuit Diagram .........................................................................................................................................4

Level 5 Circuit Diagram .........................................................................................................................................5

2 Service Operations – Seatbelts............................................................................................................ 6

2.1 Driver's Seatbelt Buckle and Pretensioner Assembly - LHD..............................................................................6

Remove ...................................................................................................................................................................6

Reinstall ..................................................................................................................................................................6

2.2 Rear Seatbelt Assembly – Outboard ....................................................................................................................7

Remove ...................................................................................................................................................................7

Reinstall ..................................................................................................................................................................8

2.3 Rear Seatbelt and Seatbelt Buckle Assembly – Centre, Level 5........................................................................9

Remove ...................................................................................................................................................................9

Reinstall ................................................................................................................................................................10

3 Diagnosis.............................................................................................................................................. 11

3.1 General Description.............................................................................................................................................11

3.2 Driver's Seatbelt Buckle Warning Indicator Switch - LHD Levels 1, 2.............................................................12

Circuit Description...............................................................................................................................................13

Test Description...................................................................................................................................................13

Notes on the Diagnostic Chart............................................................................................................................13

Diagnostic Chart...................................................................................................................................................13

3.3 Driver's Seatbelt Buckle Warning Indicator Switch - LHD Level 4...................................................................15

Circuit Description...............................................................................................................................................16

Test Description...................................................................................................................................................16

Notes on the Diagnostic Chart............................................................................................................................16

Diagnostic Chart...................................................................................................................................................16

3.4 Driver's Seatbelt Buckle Warning Indicator Switch - LHD Level 5...................................................................18

Diagnostic Charts.................................................................................................................................................18

Circuit Description...............................................................................................................................................19

Test Description...................................................................................................................................................19

Notes on the Diagnostic Chart............................................................................................................................20

Diagnostic Chart...................................................................................................................................................20

4 Torque Wrench Specifications........................................................................................................... 22

5 Special Tools........................................................................................................................................ 23

Techline

Techline

Techline

Occupant Protection System Page 12M–2

Page 12M–2

1 General Information

With the following exceptions, MY 2004 WK Series Occupant Protection System information carries over from MY 2003

VY and V2 Series vehicles. For information not contained within this Section, refer to Section 12M Occupant Protection

System in the MY 2003 VY and V2 Series Service Information.

• Driver's seatbelt buckle warning indicator switch – LHD only

• Rear seatbelt assembly – outboard

• Rear seatbelt and seatbelt buckle assembly – centre, Level 5

1.1 Driver's Seatbelt Buckle Warning

Indicator Switch – LHD Only

Driver's Seatbelt Buckle Warning Indicator Switch

The driver’s seatbelt buckle is equipped with a seatbelt buckle warning indicator switch (Production Option WD4).

The purpose of the driver's seatbelt buckle warning indicator switch is to activate the seatbelt warning indicator located in

the instrument cluster assembly when the ignition is turned to the ON position with the driver's seatbelt disengaged from

the buckle.

When the driver's seatbelt is buckled, the seatbelt buckle warning indicator switch is in an open circuit condition and

when unbuckled the switch is in a closed circuit condition.

Modes of Operation

• If the driver's seatbelt is fastened in the buckle after the ignition switch is turned on, the seatbelt warning indicator

will extinguish and the chime (if activated) will turn off.

• If the driver's seatbelt is fastened in the buckle and then the ignition switch is turned on, the seatbelt warning

indicator will illuminate for four seconds and then extinguish.

• If the driver' seatbelt is not fastened in t he buckle and the igni tion switch turned on, the seatbelt w arnin g indic ator

will illuminate, staying on until the seatbelt is fastened or the ignition switch is turned off.

Or

After a 150 second time delay, the warning indicator will flash on and off along with a warning chime until the

driver's seatbelt is fastened or the ignition switch is turned off.

• If the driver's seatbelt is not fastened in the buckle and the vehicle travelling above 25 km/h, the warning indicator

will flash on and off. The rate of the chime sound increases and a warning message ‘FASTEN SEATBELT’ is

displayed on the Multi Function Display until the seatbelt is fastened.

Seatbelt Warning Indicator

The seatbelt warning indicator provides a visual reminder to fasten the driver's seatbelt.

The seatbelt warning indicator is located on the instrument cluster assembly and is illuminated when the ignition control

relay is energised and a ground circuit is completed to the instrument cluster assembly.

Occupant Protection System Page 12M–3

Page 12M–3

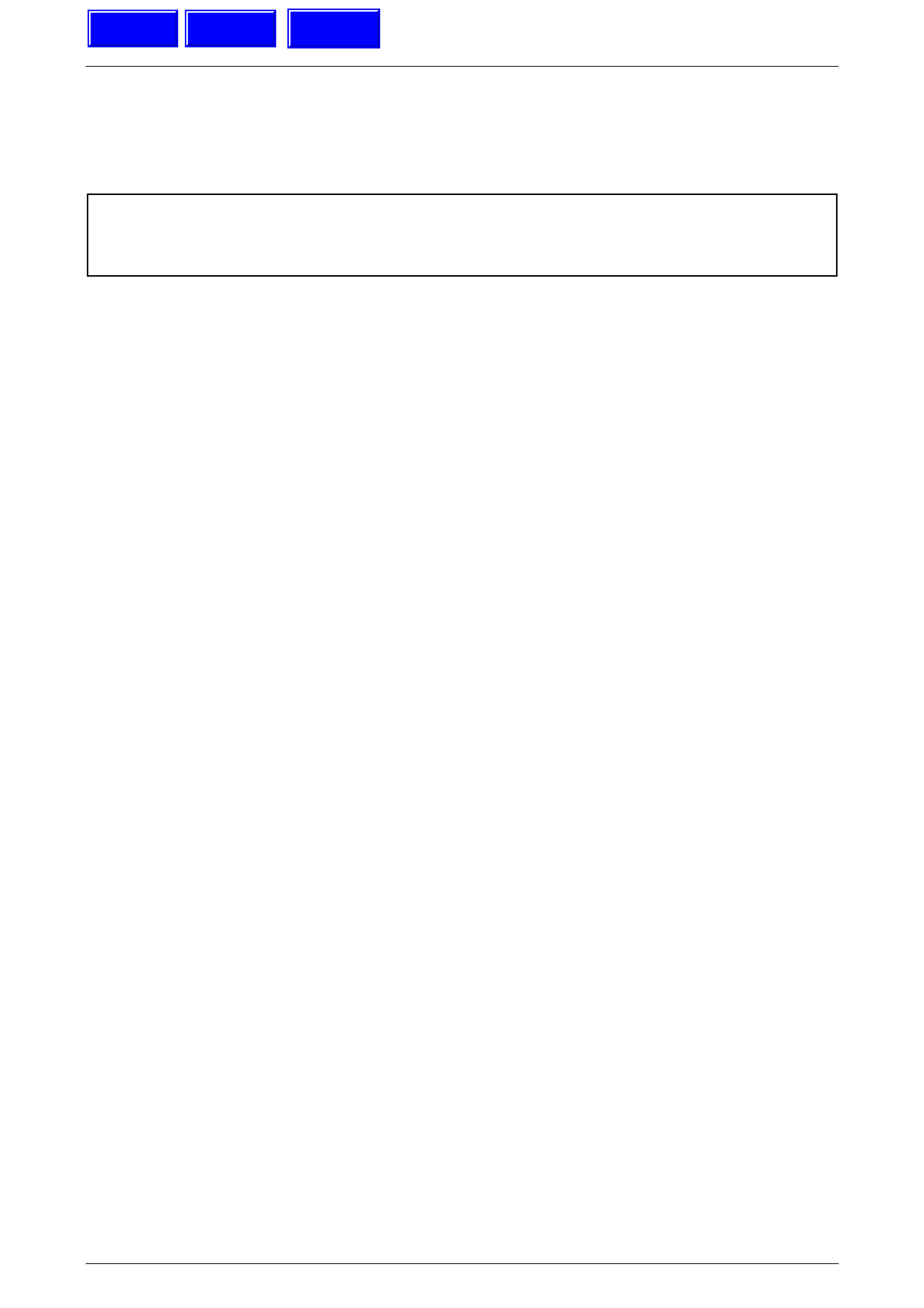

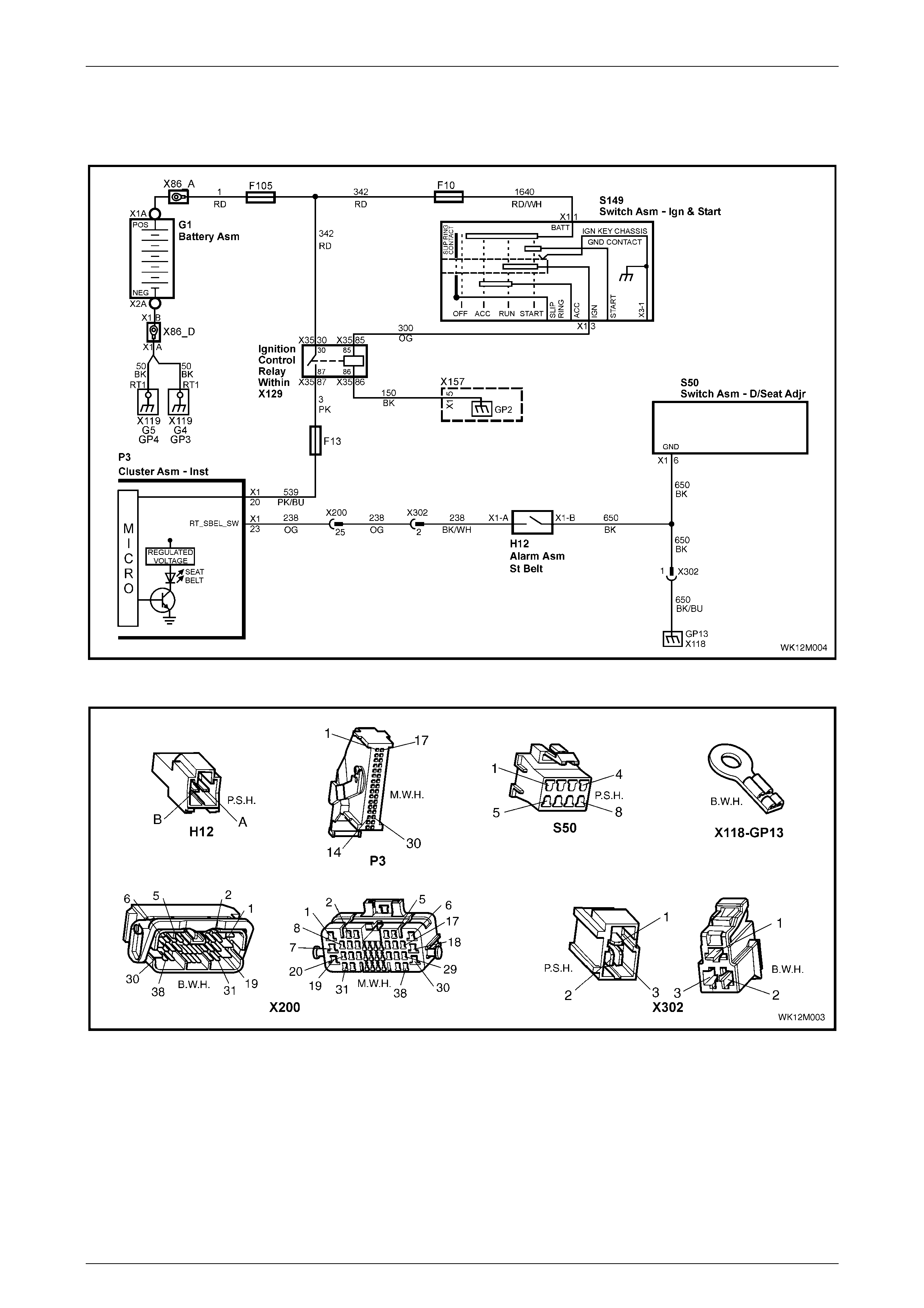

Level 1 and 2 Circuit Diagram

For vehicles with a driver's seatbelt buckle warning indicator switch, a three-pin connector is used instead of a two-pin

connector (X302).

The driver's seat adjuster switch assembly (S50) is used to provide the ground circuit for the instrument cluster assembly

connector P3 – X1 pin 23.

The driver's seatbelt buckle warning indicator switch connector H12 is located under the seat and is attached to the

driver's seatbelt buckle and pretensioner assembly via a pigtail harness.

Figure 12M – 1

Occupant Protection System Page 12M–4

Page 12M–4

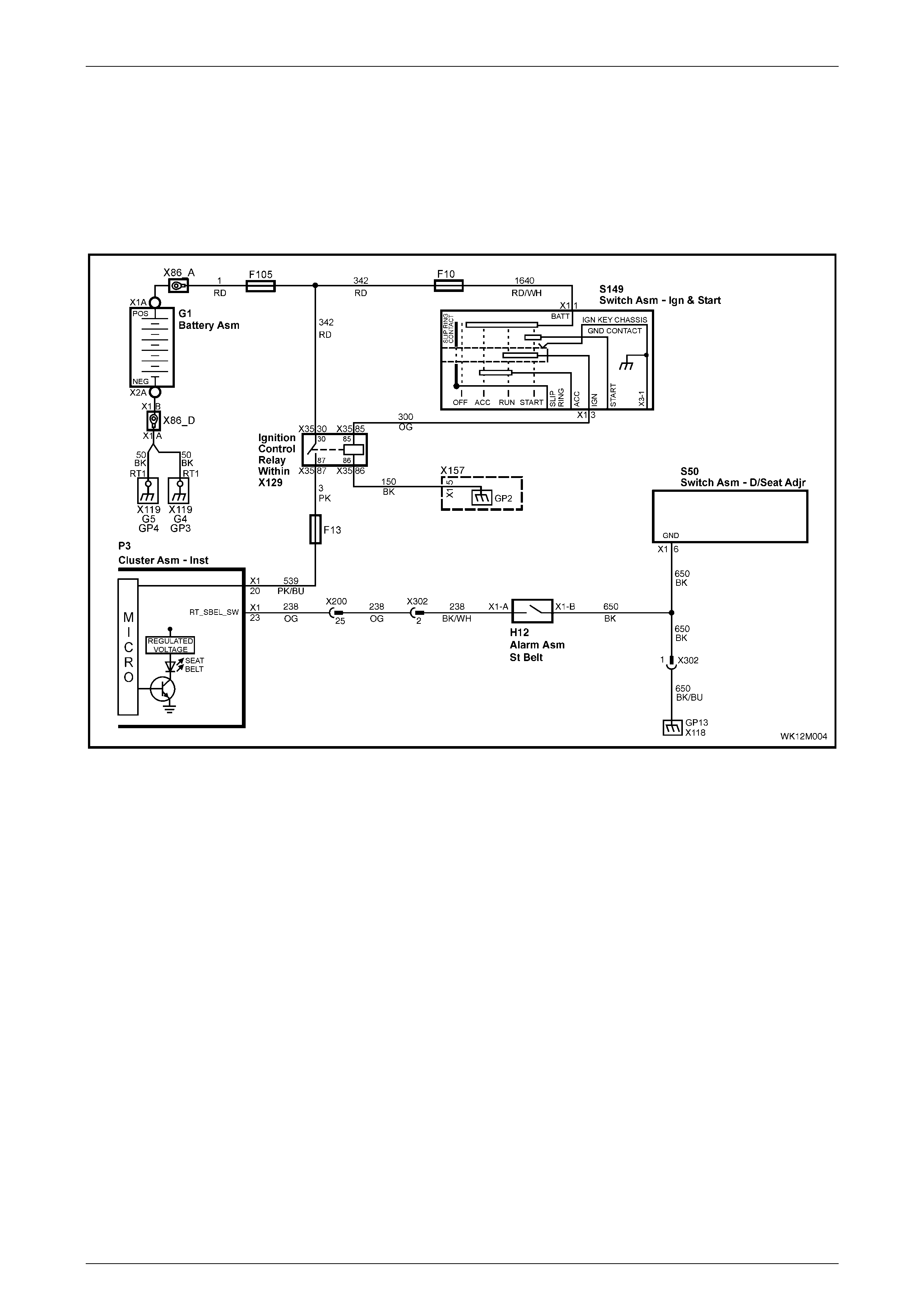

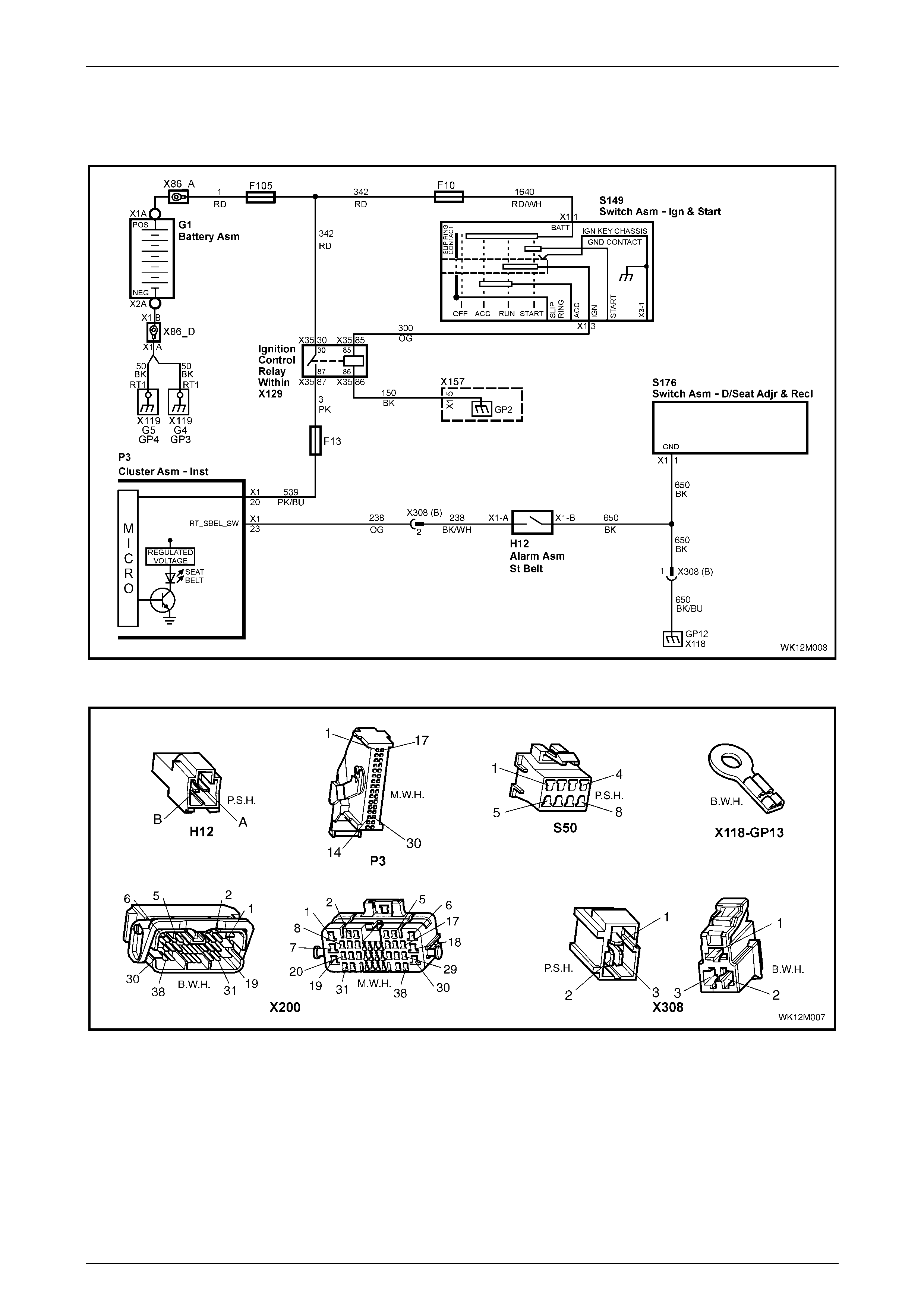

Level 4 Circuit Diagram

For vehicles with a driver's seatbelt buckle warning indicator switch, a three-pin connector is used instead of a two-pin

connector (X308).

The driver's seat adjuster switch assembly (S176) is used to provide the ground circuit for the instrument cluster

assembly connector P3 – X1 pin 23.

The driver's seatbelt buckle warning indicator switch connector H12 is located under the seat and is attached to the

driver's seatbelt buckle and pretensioner assembly via a pigtail harness.

Figure 12M – 2

Occupant Protection System Page 12M–5

Page 12M–5

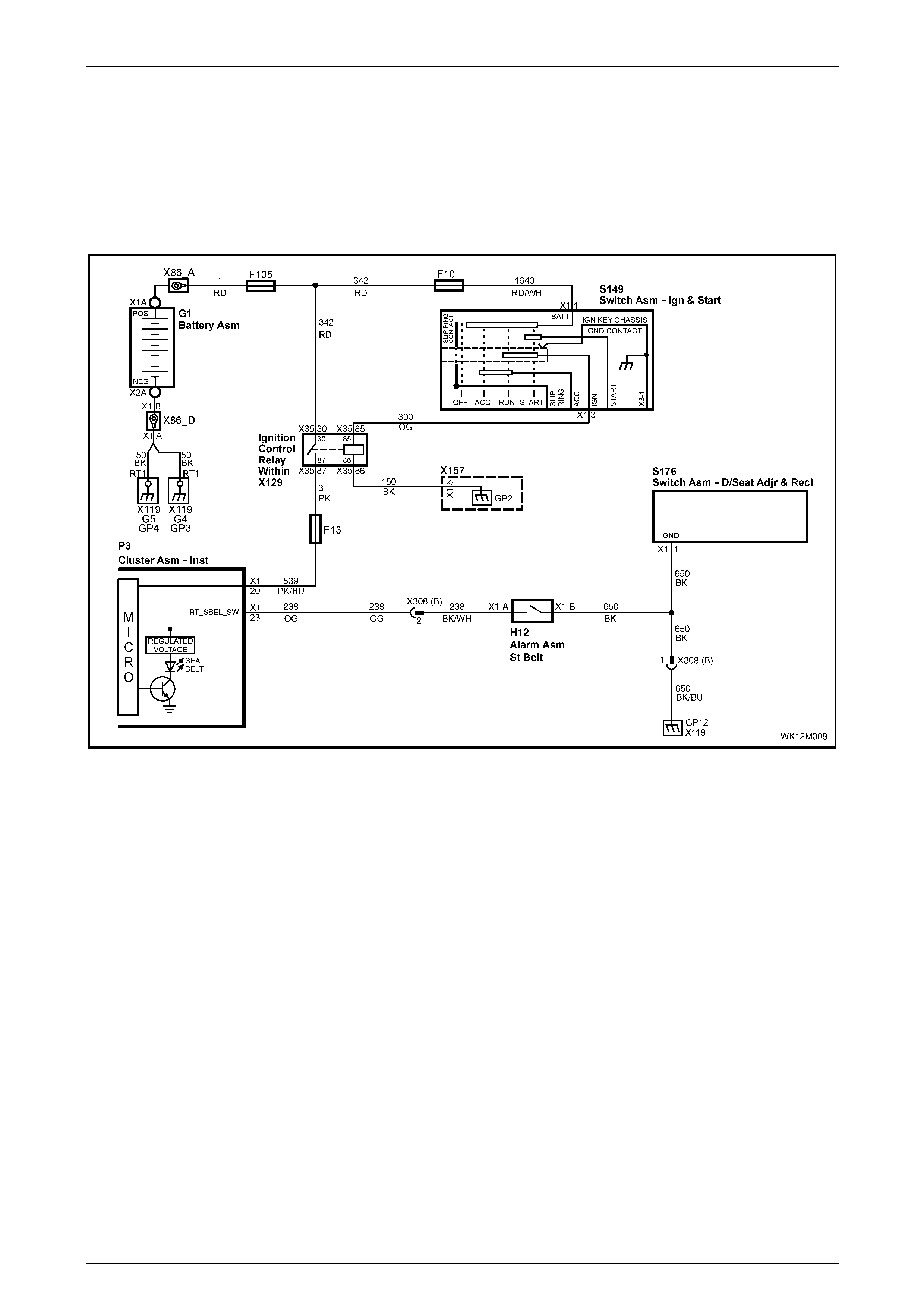

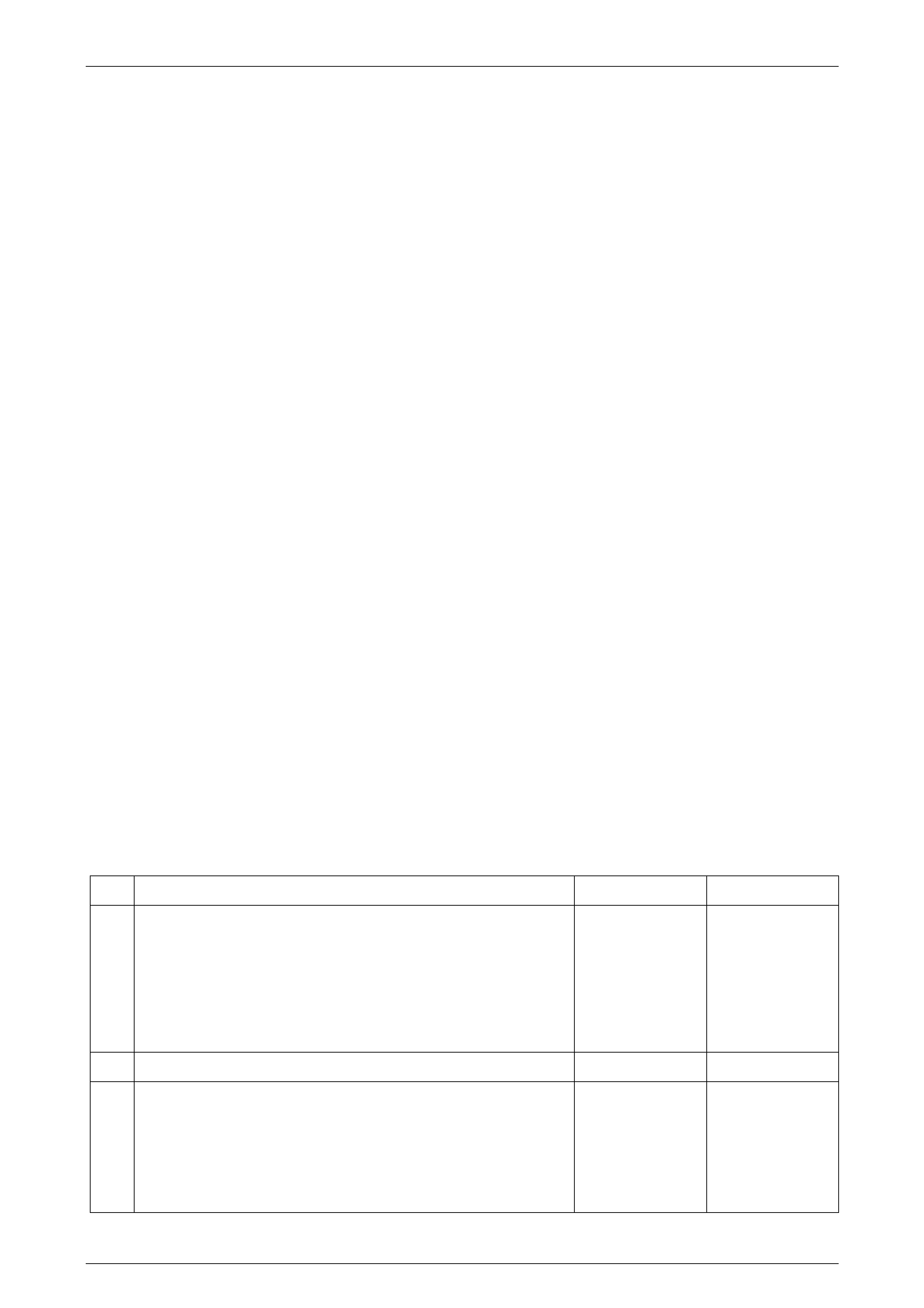

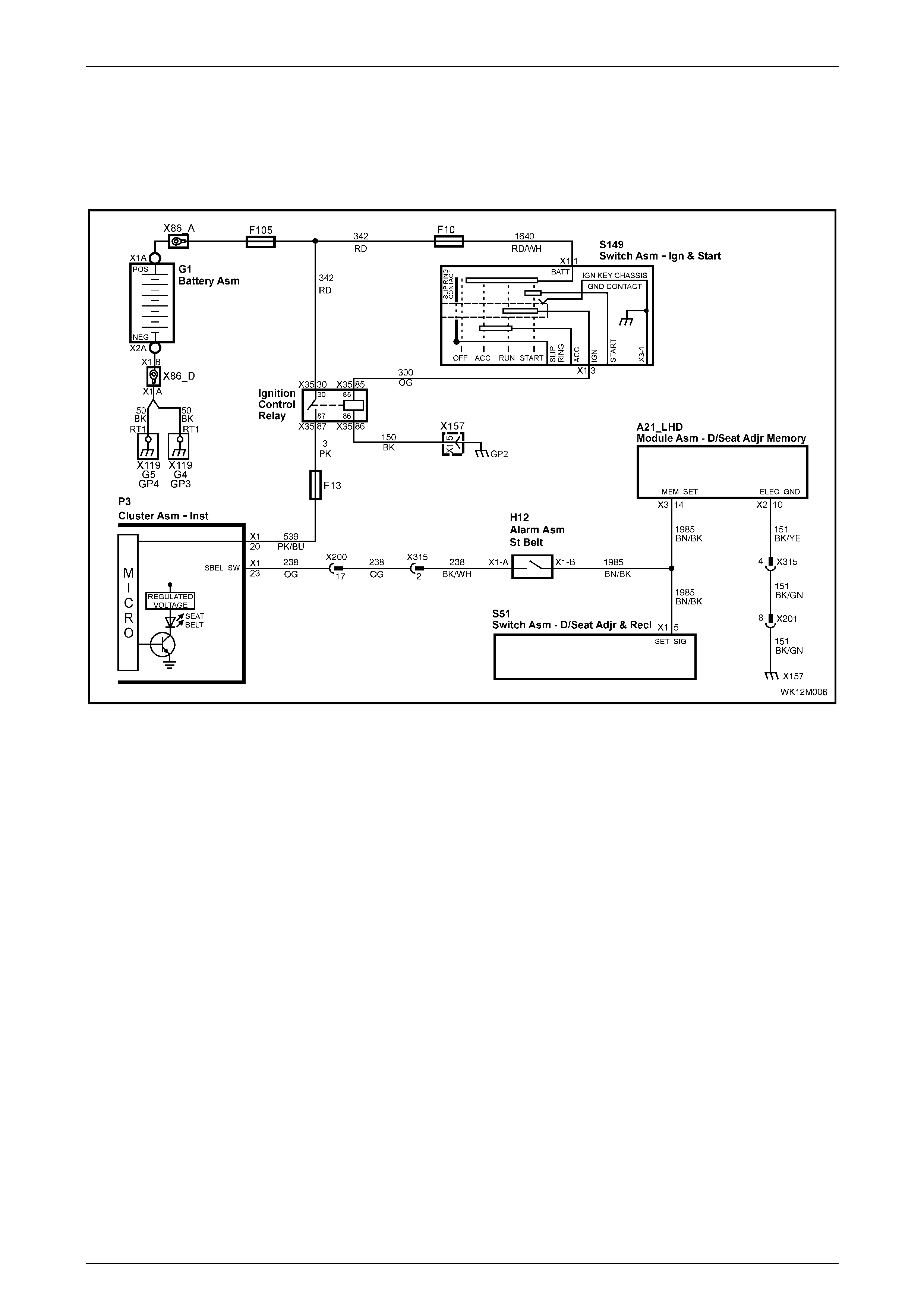

Level 5 Circuit Diagram

For vehicles with a driver's seatbelt buckle warning indicator switch, a three-pin connector is used instead of a two-pin

connector (X315).

The driver's seat memory module assembly (A21_LHD) is used to provide the ground circuit for the instrument cluster

assembly connector P3 – X1 pin 23.

The driver's seatbelt buckle warning indicator switch connector H12 is located under the seat and is attached to the

driver's seatbelt buckle and pretensioner assembly via a pigtail harness.

Figure 12M – 3

Occupant Protection System Page 12M–6

Page 12M–6

2 Service Operations – Seatbelts

2.1 Driver's Seatbelt Buckle and

Pretensioner Assembl y - LHD

LT Section No. 14-400

Remove

1 Disconnect the driver's seatbelt buckle warning indicator switch connector H12 – X1 from underneath the seat.

Remove the harness from any clips.

2 Remove the driver's seatbelt buckle and pretensioner assembly, refer to Section 12M, 3.4 Front Seatbelt Buckle

and Pretensioner Assembly in the MY 2003 VY and V2 Series Service Information.

Reinstall

Reinstallation of the driver's seatbelt buckle warning indicator switch is the reverse of the removal procedure, noting the

following:

1 Ensure that the seatbelt warning indicator operates correctly.

Occupant Protection System Page 12M–7

Page 12M–7

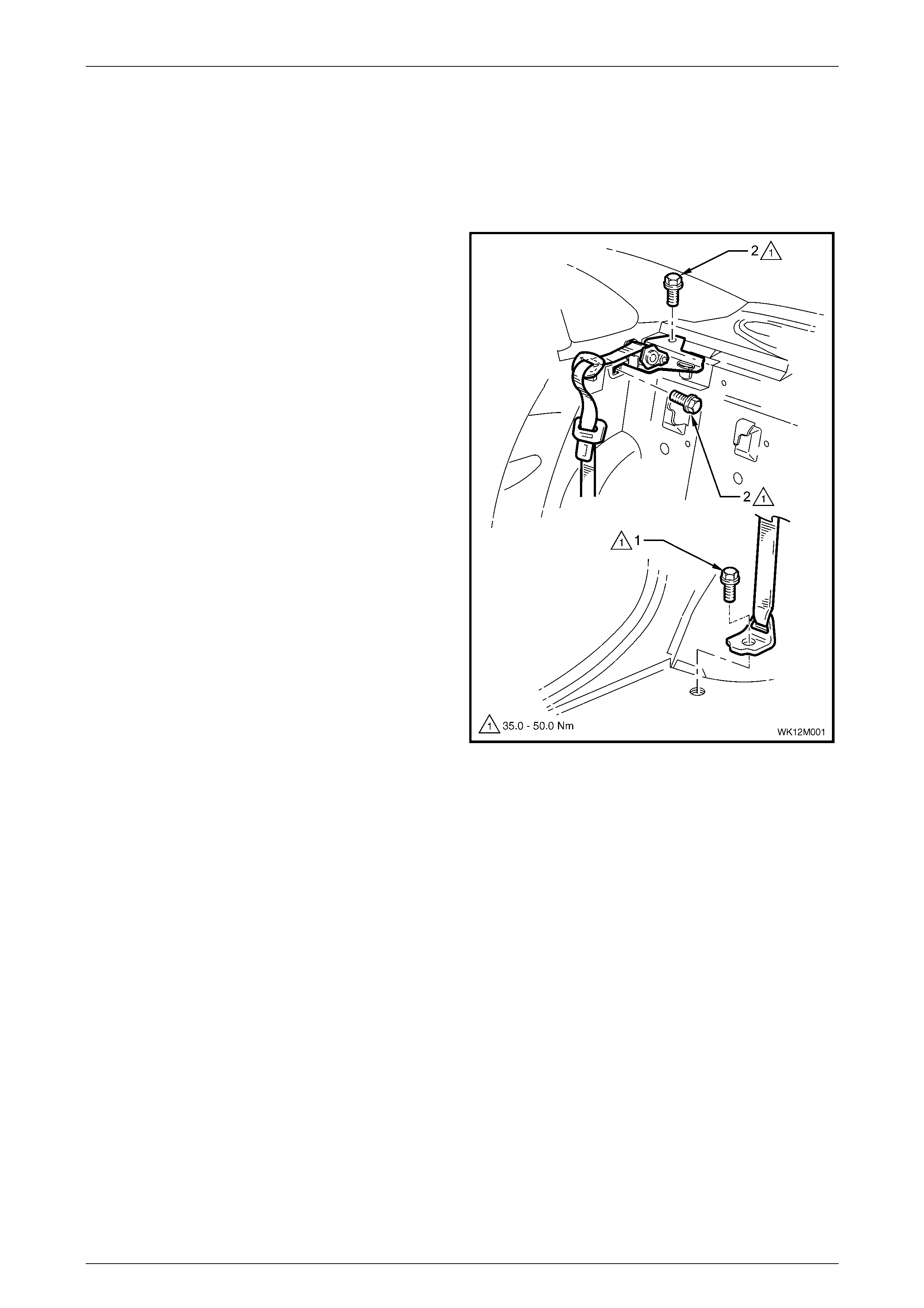

2.2 Rear Seatbelt Assembly – Outboard

LT Section No. – 14-425

Remove

1 Remove the rear seat cushion assembly, refer to

Section 1A7, 7.2 Rear Seat Cushion Assembly.

2 Remove the bolt (1) securing the lower outer seatbelt

anchor to the floor pan.

3 Remove the rear seat-back assembly, refer to

Section 1A7, 7.4 Rear Seat-back Assembly.

4 Remove the rear window trim panel assembly, refer to

Section 1A8, 2.5 Rear Window Trim Panel Assembly.

5 Remove the bolts (2), in two places, securing the rear

seatbelt retractor assembly to the vehicle body and

remove the seatbelt assembly.

6 If required, repeat Steps 1 to 5 for the opposite side of

the vehicle.

Figure 12M – 4

Occupant Protection System Page 12M–8

Page 12M–8

Reinstall

If reinstalling the same retractor assembly,

inspect the anchor plates and retractor

assembly for damage, and the webbing for

abrasions, fraying, cuts, etc. Replace the

seatbelt assembly and seatbelt buckle

assembly with new parts if any damage, etc.

is found.

Installation is the reverse of the removal procedure, noting the following.

1 Ensure that the seatbelt webbing is not twisted and the lower outer seatbelt anchor is installed in the correct

orientation, refer to Figure 12M – 4.

2 Ensure that the body harness and DVD harness (if fitted) is clear of the anchor plate.

3 Ensure that the threads of the lower outer seatbelt anchor bolts are adequately sealed with a commercially

available caul ki ng com pou nd or a non-har den ing sea ler.

4 To avoid cross-threading, hand tighten all seatbelt bolts a minimum of five turns before using tools.

5 Tighten the bolts to the specified torque.

Rear seatbelt retractor assembly

attaching bolt torque specification.......... 35.0 – 50.0 Nm

Rear seatbelt anchor attaching bolt

torque specification ................................35.0 – 50.0 Nm

6 Perform a functional check of the seatbelt to ensure correct operation.

Occupant Protection System Page 12M–9

Page 12M–9

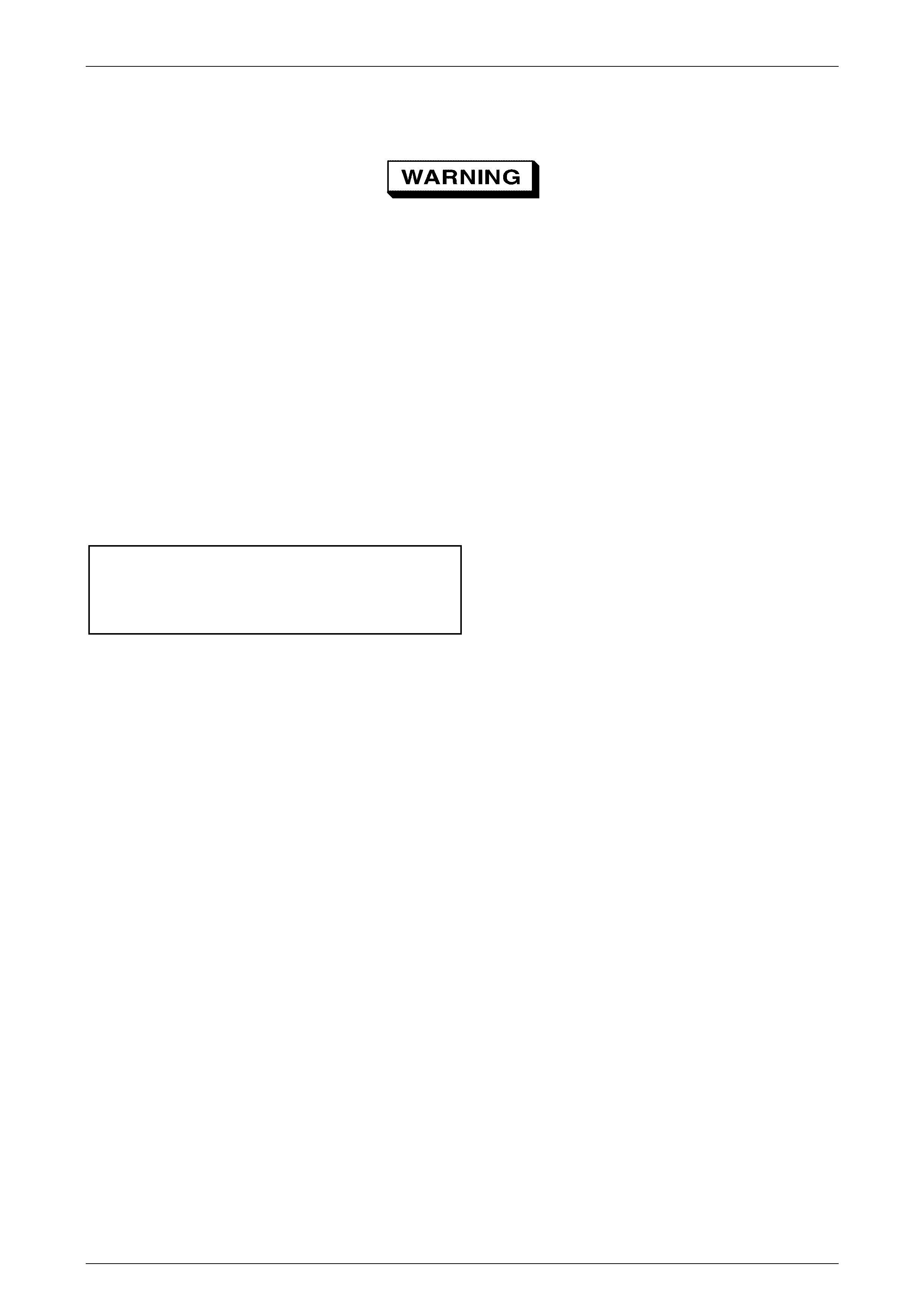

2.3 Rear Seatbelt and Seatbelt Buckle

Assembly – Centre, Level 5

LT Section No. – 14-425

Figure 12M – 5

Legend

1 Middle Rear Seatbelt B uckl e

2 Left Rear Seatbelt Buckle

3 Left Rear Seatbelt Buckle Anchor

4 Left Rear Seatbelt Buckle Anchor Bolt

5 Left Rear Seatbelt Buck l e Cable Stalks

6 Right Rear Seatbelt B uckle

7 Right Rear Seatbelt B uckle Cabl e Stalk

8 Right Rear Seatbelt B uckle Anc hor

9 Right Rear Seatbelt B uckle Anc hor Bolt

10 Dead Pan for DVD bracket

Remove

1 Remove the rear seat cushion assembly, refer to Section 1A7, 7.2 Rear Seat Cushion Assembly.

2 Remove the bolt (4) securing the left rear seatbelt buckle anchor (3) and dead pan (10) to the vehicle, refer to

Figure 12M – 5.

3 Remove the rear window trim panel assembly, refer to Section 1A8, 2.5 Rear Window Trim Panel Assembly.

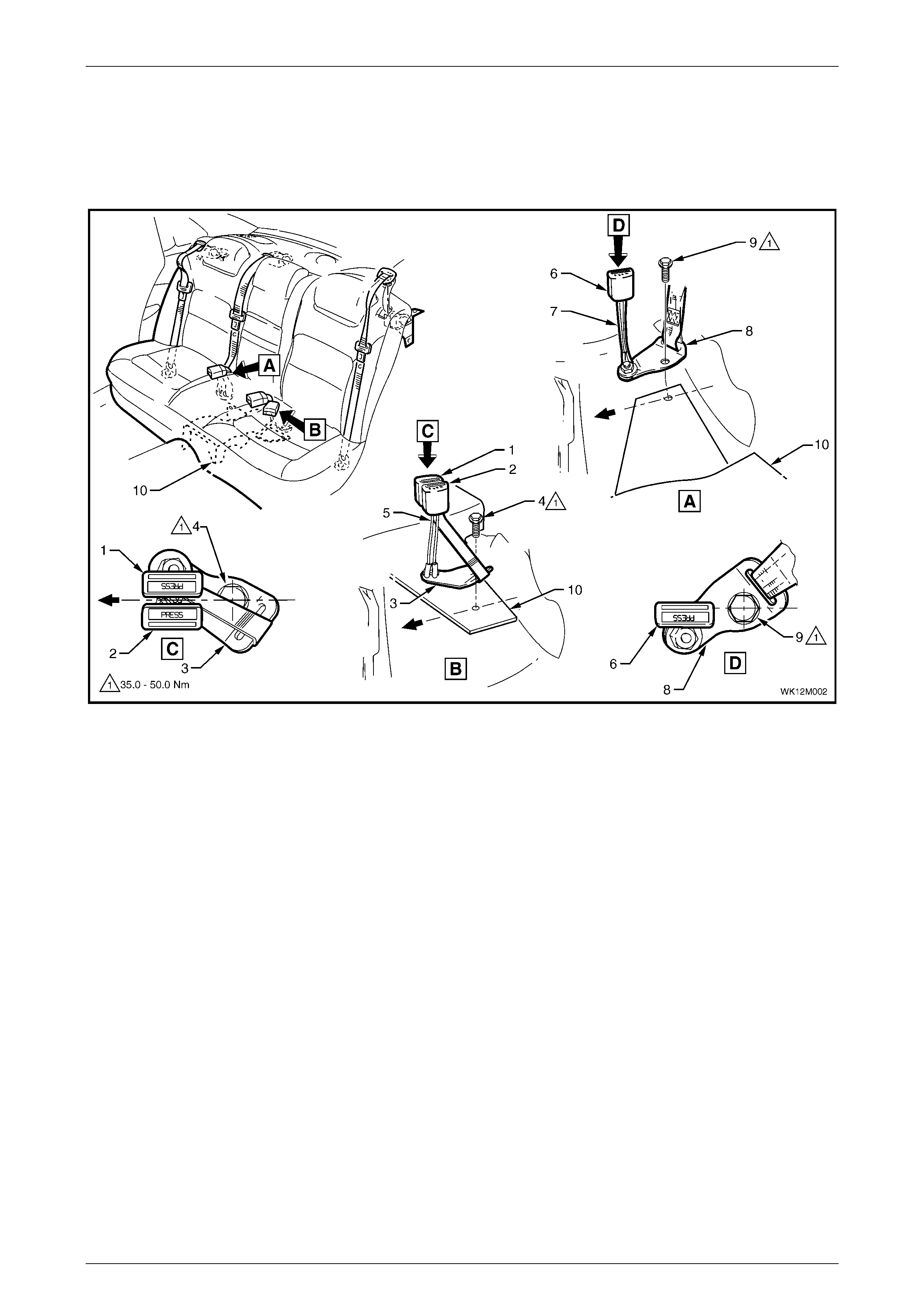

Occupant Protection System Page 12M–10

Page 12M–10

4 Lift off the insulator (1).

5 Remove the bolt (2) attaching the retractor

assembly (3) to the vehicle and remove the seatbelt

assembly.

Figure 12M – 6

Reinstall

If reinstalling the same retractor assembly,

inspect the anchor plates and retractor

assembly for damage, and the webbing for

abrasions, fraying, cuts, etc. Replace the

seatbelt assembly and seatbelt buckle

assembly with new parts if any damage, etc.

is found.

Reinstallation of the rear seatbelt and seatbelt buckle assembly is the reverse of the removal procedure, noting the

following:

1 Ensure that DVD harnesses are clear of the anchor plate and the dead pan.

2 Ensure that the threads of the seatbelt anchor bolts are adequately sealed with a commercially available caulking

compound or a non-hardening sealer.

3 To avoid cross-threading, hand tighten all seatbelt bolts a minimum of five turns before using tools.

4 Tighten the bolts to the specified torque.

Rear seatbelt retractor assembly

attaching bolt torque specification.......... 35.0 – 50.0 Nm

Rear seatbelt buckle anchor attaching

bolt torque specification.......................... 35.0 – 50.0 Nm

5 Perform a functional check of the seatbelt to ensure correct operation.

Occupant Protection System Page 12M–11

Page 12M–11

3 Diagnosis

3.1 General Description

When carrying out wiring checks as directed by the diagnostic charts, use the adaptors contained in connector test

adaptor kit KM-609 and test lead set KM-609-20. This will prevent any possibility of spreading or damaging wire harness

terminals and later on causing a system intermittent failure.

Ensure that at the completion of any diagnostic procedure, all diagnostic tools are removed and all components are

correctly reconnected.

Occupant Protection System Page 12M–12

Page 12M–12

3.2 Driver's Seatbelt Buckle Warning

Indicator Switch - LHD Levels 1, 2

Figure 12M – 7

Figure 12M – 8

Occupant Protection System Page 12M–13

Page 12M–13

Circuit Description

The purpose of the driver's seatbelt buckle warning indicator switch is to activate a seatbelt warning indicator located in

the instrument cluster assembly when the ignition is turned to the on position with the seatbelt disengaged from the

buckle.

When the seatbelt is buckled, the warning indicator switch is in an open circuit condition and when unbuckled the switch

is in a closed circuit condition.

TECH 2 can be used to check the driver's seatbelt buckle warning indicator switch operation, TECH 2 will only display

‘BUCKLED’ or ‘UN-BUCKLED’.

The seatbelt warning indicator will illuminate for four seconds when the ignition switch is turned to the on position,

irrespective of the status of the driver's seatbelt buckle warning indicator switch.

Test Description

The following numbers refer to step numbers in the following diagnostic chart.

1 Checks if the seatbelt indicator illuminates when the ignition is turned on. This can indicate either a faulty

instrument cluster assembly or a faulty power circuit.

2 Checks if the fault is an open circuit or a short circuit.

3 Checks if there is an intermittent fault in the circuit.

4 Checks if there is a faulty instrument cluster assembly or a faulty power circuit.

5 Checks the operation of the driver's seatbelt buckle warning indicator switch.

6 Checks continuity of circuit 650.

7 Checks continuity of circuit 238.

8 Checks the operation of the driver's seatbelt buckle warning indicator switch.

9 Checks for short circuit to ground in circuit 238.

Notes on the Diagnostic Chart

1 For all wiring harness fault diagnosis, refer to Section 12P Wiring Diagrams.

2 For wiring harness repairs, refer to Section 12P Wiring Diagrams.

3 Refer to Section 12O Fuses, Relays and Wiring Harnesses for harness routeing.

4 If at any time the fault is deemed to be intermittent, refer to Section 12P Wiring Diagrams.

Diagnostic Chart

Step Action Yes No

1 1 Install the TECH 2 to the DLC. Select BODY, INSTRUMENTS,

DATA DISPLAY and then INSTRUMENTS from the menu and

scroll down to DRIVERS SEATBELT.

2 Unbuckle the seatbel t.

3 Turn the ignition on with the engine off.

Does the seatbelt warning indicator illuminate?

Go to Step 2. Go to Step 4.

2 Does the TECH 2 display ‘UN-BUCKLED’? Go to Step 3. Go to Step 5.

3 1 Turn the ignition switch off.

2 Buckle the driver's seatbelt.

3 Turn the ignition on with the engine off.

Does the seatbelt warning indicator extinguish after four seconds and

does the TECH 2 display ‘BUCKLED’?

Check for an

intermittent fault,

refer to Note 4.

Go to Step 8.

Occupant Protection System Page 12M–14

Page 12M–14

Step Action Yes No

4 1 Check that the following telltale indicators illuminate when the

ignition is switched on with the engine off:

• ABS

• Brake

• SRS

• Generator

Do the above telltale indicators illuminate when the ignition switch is

turned on with the engine off?

Replace the

instrument cluster

assembly, refer to

Section 12C

Instruments.

Check continuity of

fuse F13,

fuse F105,

circuit 539, circui t 3

and circuit 342.

For additional

information, refer to

Section 12C

Instruments.

5 1 Turn the ignition off and disconnect connector H12.

2 Use a multimeter and Tool KM-609 at connector H12 to probe

the operation of the driver's seatbelt buckle warning indicator

switch. Refer to Note 1.

• Seatbelt unbuckled - continuity

• Seatbelt buckled - no continuity (open circuit)

Does the driver's seatbelt buckle warning indicator switch operate as

required?

Go to Step 6. Replace the driver's

seatbelt bu ckl e and

pretensioner

assembly, refer to

2.1 Driver's

Seatbelt Buckle and

Pretensioner

Assembly - LHD.

6 1 Turn the ignition off and disconnect connector H12.

2 Use a multimeter and Tool KM-609 to probe for continuity of

circuit 650 between connector H12-X1 pin B and ground point

GP13-X118. Refer to Note 1.

Is there continuity?

Go to Step 7. There is an open

circuit in circ uit 650.

Repair or replace

circuit 650 and/or

connector, refer to

Note 2.

7 1 Turn the ignition off and disconnect connector H12.

2 Use a multimeter and Tool KM-609 to probe for continuity of

circuit 238 between connector H12-X1 pin A and P3-X1 pin 23.

Refer to Note 1.

Is there continuity?

Replace the

instrument cluster

assembly, refer to

Section 12C, 2.3

Instrument Cluster

Assembly.

There is an open

circuit in circ uit 238.

Repair or replace

circuit 238 and/or

connector, refer to

Note 2.

8 1 Turn the ignition off and disconnect connector H12.

2 Use a multimeter and Tool KM-609 at connector H12 to probe

the operation of the driver's seatbelt buckle warning indicator

switch. Refer to Note 1.

• Seatbelt unbuckled - continuity

• Seatbelt buckled - no continuity (open circuit)

Does the driver's seatbelt buckle warning indicator switch operate as

required?

Go to Step 9. Replace the driver's

seatbelt bu ckl e and

pretensioner

assembly, refer to

2.1 Driver's

Seatbelt Buckle and

Pretensioner

Assembly - LHD.

9 1 Turn the ignition off and disconnect connector H12.

2 Use a multimeter and Tool KM-609 to probe for a short circuit to

ground in circuit 238 between connector H12-X1 pin A and

P3-X1 pin 23. Refer to Note 1.

Is there a short circuit to ground?

Repair or replace

circuit 238, refer to

Note 4.

Replace the

instrument cluster

assembly, refer to

Section 12C, 2.3

Instrument Cluster

Assembly.

Occupant Protection System Page 12M–15

Page 12M–15

3.3 Driver's Seatbelt Buckle Warning

Indicator Switch - LHD Level 4

Figure 12M – 9

Figure 12M – 10

Occupant Protection System Page 12M–16

Page 12M–16

Circuit Description

The purpose of the driver's seatbelt buckle warning indicator switch is to activate a seatbelt warning indicator located in

the instrument cluster assembly when the ignition is turned to the on position with the seatbelt disengaged from the

buckle.

When the seatbelt is buckled, the warning indicator switch is in an open circuit condition and when unbuckled the switch

is in a closed circuit condition.

TECH 2 can be used to check the driver's seatbelt buckle warning indicator switch operation, TECH 2 will only display

‘BUCKLED’ or ‘UN-BUCKLED’.

The seatbelt warning indicator will illuminate for four seconds when the ignition switch is turned to the on position,

irrespective of the status of the driver's seatbelt buckle warning indicator switch.

Test Description

The following numbers refer to step numbers in the following diagnostic chart.

1 Checks if the seatbelt indicator illuminates when the ignition is turned on. This can indicate either a faulty

instrument cluster assembly or a faulty power circuit.

2 Checks if the fault is an open circuit or a short circuit.

3 Checks if there is an intermittent fault in the circuit.

4 Checks if there is a faulty instrument cluster assembly or a faulty power circuit.

5 Checks the operation of the driver's seatbelt buckle warning indicator switch.

6 Checks continuity of circuit 650.

7 Checks continuity of circuit 238.

8 Checks the operation of the driver's seatbelt buckle warning indicator switch.

9 Checks for short circuit to ground in circuit 238.

Notes on the Diagnostic Chart

1 For all wiring harness fault diagnosis, refer to Section 12P Wiring Diagrams.

2 For wiring harness repairs, refer to Section 12P Wiring Diagrams.

3 Refer to Section 12O Fuses, Relays and Wiring Harnesses for harness routeing.

4 If at any time the fault is deemed to be intermittent, refer to Section 12P Wiring Diagrams.

Diagnostic Chart

Step Action Yes No

1 1 Install the TECH 2 to the DLC. Select BODY, INSTRUMENTS,

DATA DISPLAY and then INSTRUMENTS from the menu and

scroll down to DRIVERS SEATBELT.

2 Unbuckle the seatbel t.

3 Turn the ignition on with the engine off.

Does the seatbelt warning indicator illuminate?

Go to Step 2. Go to Step 4.

2 Does the TECH 2 display ‘UN-BUCKLED’? Go to Step 3. Go to Step 5.

3 1 Turn the ignition switch off.

2 Buckle the driver's seatbelt.

3 Turn the ignition on with the engine off.

Does the seatbelt warning indicator extinguish after four seconds and

does the TECH 2 display ‘BUCKLED’?

Check for an

intermittent fault,

refer to Note 4.

Go to Step 8.

Occupant Protection System Page 12M–17

Page 12M–17

Step Action Yes No

4 1 Check that the following telltale indicators illuminate when the

ignition is switched on with the engine off:

• ABS

• Brake

• SRS

• Generator

Do the above telltale indicators illuminate when the ignition switch is

turned on with the engine off?

Replace the

instrument cluster

assembly, refer to

Section 12C

Instruments.

Check continuity of

fuse F13,

fuse F105,

circuit 539, circui t 3

and circuit 342.

For additional

information, refer to

Section 12C

Instruments.

5 1 Turn the ignition off and disconnect connector H12.

2 Use a multimeter and Tool KM-609 at connector H12 to probe

the operation of the driver's seatbelt buckle warning indicator

switch. Refer to Note 1.

• Seatbelt unbuckled - continuity

• Seatbelt buckled - no continuity (open circuit)

Does the driver's seatbelt buckle warning indicator switch operate as

required?

Go to Step 6. Replace the driver's

seatbelt bu ckl e and

pretensioner

assembly, refer to

2.1 Driver's

Seatbelt Buckle and

Pretensioner

Assembly - LHD.

6 1 Turn the ignition off and disconnect connector H12.

2 Use a multimeter and Tool KM-609 to probe for continuity of

circuit 650 between connector H12-X1 pin B and ground point

GP12-X118. Refer to Note 1.

Is there continuity?

Go to Step 7. There is an open

circuit in circ uit 650.

Repair or replace

circuit 650 and/or

connector, refer to

Note 2.

7 1 Turn the ignition off and disconnect connector H12.

2 Use a multimeter and Tool KM-609 to probe for continuity of

circuit 238 between connector H12-X1 pin A and P3-X1 pin 23.

Refer to Note 1.

Is there continuity?

Replace the

instrument cluster

assembly, refer to

Section 12C, 2.3

Instrument Cluster

Assembly.

There is an open

circuit in circ uit 238.

Repair or replace

circuit 238 and/or

connector, refer to

Note 2.

8 1 Turn the ignition off and disconnect connector H12.

2 Use a multimeter and Tool KM-609 at connector H12 to probe

the operation of the driver's seatbelt buckle warning indicator

switch. Refer to Note 1.

• Seatbelt unbuckled - continuity

• Seatbelt buckled - no continuity (open circuit)

Does the driver's seatbelt buckle warning indicator switch operate as

required?

Go to Step 9. Replace the driver's

seatbelt bu ckl e and

pretensioner

assembly, refer to

2.1 Driver's

Seatbelt Buckle and

Pretensioner

Assembly - LHD.

9 1 Turn the ignition off and disconnect connector H12.

2 Use a multimeter and Tool KM-609 to probe for a short circuit to

ground in circuit 238 between connector H12-X1 pin A and

P3-X1 pin 23. Refer to Note 1.

Is there a short circuit to ground?

Repair or replace

circuit 238, refer to

Note 4.

Replace the

instrument cluster

assembly, refer to

Section 12C, 2.3

Instrument Cluster

Assembly.

Occupant Protection System Page 12M–18

Page 12M–18

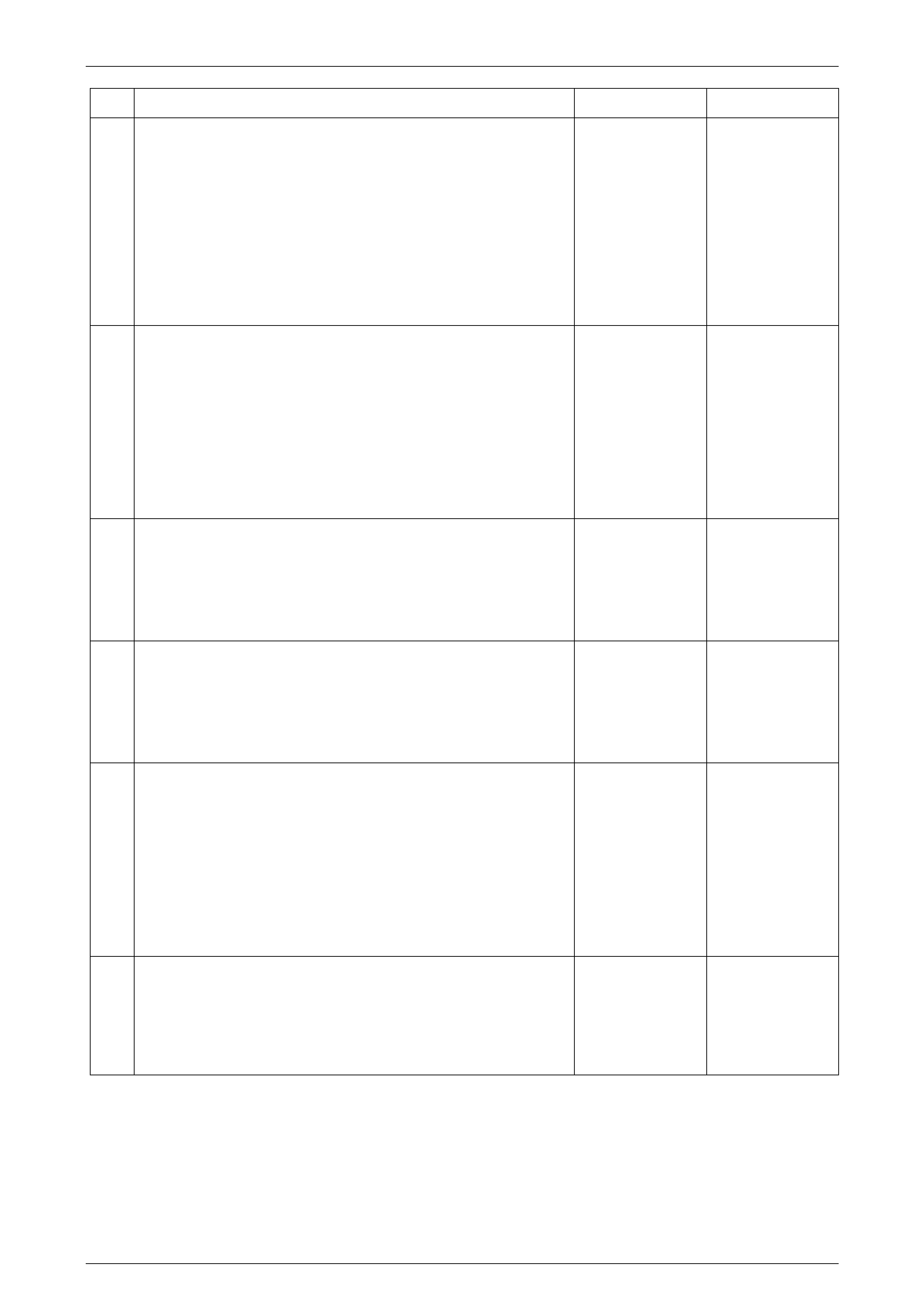

3.4 Driver's Seatbelt Buckle Warning

Indicator Switch - LHD Level 5

Diagnostic Charts

Figure 12M – 11

Occupant Protection System Page 12M–19

Page 12M–19

Figure 12M – 12

Circuit Description

The purpose of the driver's seatbelt buckle warning indicator switch is to activate a seatbelt warning indicator located in

the instrument cluster assembly when the ignition is turned to the on position with the seatbelt disengaged from the

buckle.

When the seatbelt is buckled, the warning indicator switch is in an open circuit condition and when unbuckled the switch

is in a closed circuit condition.

TECH 2 can be used to check the driver's seatbelt buckle warning indicator switch operation, TECH 2 will only display

‘BUCKLED’ or ‘UN-BUCKLED’.

The seatbelt warning indicator will illuminate for four seconds when the ignition switch is turned to the on position,

irrespective of the status of the driver's seatbelt buckle warning indicator switch.

Test Description

The following numbers refer to step numbers in the following diagnostic chart.

1 Checks if the seatbelt indicator illuminates when the ignition is turned on. This can indicate either a faulty

instrument cluster assembly or a faulty power circuit.

2 Checks if the fault is an open circuit or a short circuit.

3 Checks if there is an intermittent fault in the circuit.

4 Checks if there is a faulty instrument cluster assembly or a faulty power circuit.

5 Checks the operation of the driver's seatbelt buckle warning indicator switch.

6 Checks continuity of circuit 151 and circuit 1985.

7 Checks continuity of the driver's seat memory module assembly between A21-X3 pin 14 and A21-X2 pin 10.

8 Checks continuity of circuit 238.

9 Checks the operation of the driver's seatbelt buckle warning indicator switch.

10 Checks for short circuit to ground in circuit 238.

Occupant Protection System Page 12M–20

Page 12M–20

Notes on the Diagnostic Chart

1 For all wiring harness fault diagnosis, refer to Section 12P Wiring Diagrams.

2 For wiring harness repairs, refer to Section 12P Wiring Diagrams.

3 Refer to Section 12O Fuses, Relays and Wiring Harnesses for harness routeing.

4 If at any time the fault is deemed to be intermittent, refer to Section 12P Wiring Diagrams.

Diagnostic Chart

Step Action Yes No

1 1 Install the TECH 2 to the DLC. Select BODY, INSTRUMENTS,

DATA DISPLAY and then INSTRUMENTS from the menu and

scroll down to DRIVERS SEATBELT.

2 Unbuckle the seatbel t.

3 Turn the ignition on with the engine off.

Does the seatbelt warning indicator illuminate?

Go to Step 2. Go to Step 4.

2 Does the TECH 2 display ‘UN-BUCKLED’? Go to Step 3. Go to Step 5.

3 1 Turn the ignition switch off.

2 Buckle the driver's seatbelt.

3 Turn the ignition on with the engine off.

Does the seatbelt warning indicator extinguish after four seconds and

does the TECH 2 display ‘BUCKLED’?

Check for an

intermittent fault,

refer to Note 4.

Go to Step 9.

4 1 Check that the following telltale indicators illuminate when the

ignition is switched on with the engine off:

• ABS

• Brake

• SRS

• Generator

Do the above telltale indicators illuminate when the ignition switch is

turned on with the engine off?

Replace the

instrument cluster

assembly, refer to

Section 12C

Instruments.

Check continuity of

fuse F13,

fuse F105,

circuit 539, circui t 3

and circuit 342.

For additional

information, refer to

Section 12C

Instruments.

5 1 Turn the ignition off and disconnect connector H12.

2 Use a multimeter and Tool KM-609 at connector H12 to probe

the operation of the driver's seatbelt buckle warning indicator

switch. Refer to Note 1.

• Seatbelt unbuckled - continuity

• Seatbelt buckled - no continuity (open circuit)

Does the driver's seatbelt buckle warning indicator switch operate as

required?

Go to Step 6. Replace the driver's

seatbelt bu ckl e and

pretensioner

assembly, refer to

2.1 Driver's

Seatbelt Buckle and

Pretensioner

Assembly - LHD.

6 1 Turn the ignition off and disconnect connector H12, A21-X2 and

A21-X3.

2 Use a multimeter and Tool KM-609 to probe for continuity of

circuit 1985 between connector H12-X1 pin B and connector

A21-X3 pin 14. Refer to Note 1.

3 Use a multimeter and Tool KM-609 to probe for continuity of

circuit 151 between connector A21-X2 pin 10 and ground point

X157. Refer to Note 1.

Is there continuity?

Go to step 7. There is an open

circuit in circuit 189 5

or circuit 151.

Repair or replace

circuit 1895,

circuit 151 and/or

connector, refer to

Note 2.

Occupant Protection System Page 12M–21

Page 12M–21

Step Action Yes No

7 1 Turn the ignition off and disconnect connector H12, A21-X2 and

A21-X3.

2 Use a multimeter and Tool KM-609 to probe for continuity of the

driver's seat memory module assembly between A21-X3 pin 14

and A21-X2 pin 10.

Is there continuity?

Go to step 8. There is an open

circuit in the driver's

seat memory

module assembly.

Replace the driver's

seat memory

module assembly,

refer to Section 1A7,

4.12 Seat Memory

Module.

8 1 Turn the ignition off and disconnect connector H12.

2 Use a multimeter and Tool KM-609 to probe for continuity of

circuit 238 between connector H12-X1 pin A and P3-X1 pin 23.

Refer to Note 1.

Is there continuity?

Replace the

instrument cluster

assembly, refer to

Section 12C, 2.3

Instrument Cluster

Assembly.

There is an open

circuit in circ uit 238.

Repair or replace

circuit 238 and/or

connector. Refer to

Note 2.

9 1 Turn the ignition off and disconnect connector H12.

2 Use a multimeter and Tool KM-609 at connector H12 to probe

the operation of the driver's seatbelt buckle warning indicator

switch. Refer to Note 1.

• Seatbelt unbuckled - continuity

• Seatbelt buckled - no continuity (open circuit)

Does the driver's seatbelt buckle warning indicator switch operate as

required?

Go to Step 10. Replace the driver's

seatbelt bu ckl e and

pretensioner

assembly, refer to

2.1 Driver's

Seatbelt Buckle and

Pretensioner

Assembly - LHD.

10 1 Turn the ignition off and disconnect connector H12.

2 Use a multimeter and Tool KM-609 to probe for a short circuit to

ground in circuit 238 between connector H12-X1 pin A and

P3-X1 pin 23. Refer to Note 1.

Is there a short circuit to ground?

Repair or replace

circuit 238, refer to

Note 4.

Replace the

instrument cluster

assembly, refer to

Section 12C, 2.3

Instrument Cluster

Assembly.

Occupant Protection System Page 12M–22

Page 12M–22

4 Torque Wrench Specifications

Rear seatbelt retractor assembly attaching bolt.........................35.0 – 50.0 Nm

Rear seatbelt anchor attaching bolt...........................................35.0 – 50.0 Nm

Rear seatbelt buckle anchor attaching bolt................................35.0 – 50.0 Nm

Occupant Protection System Page 12M–23

Page 12M–23

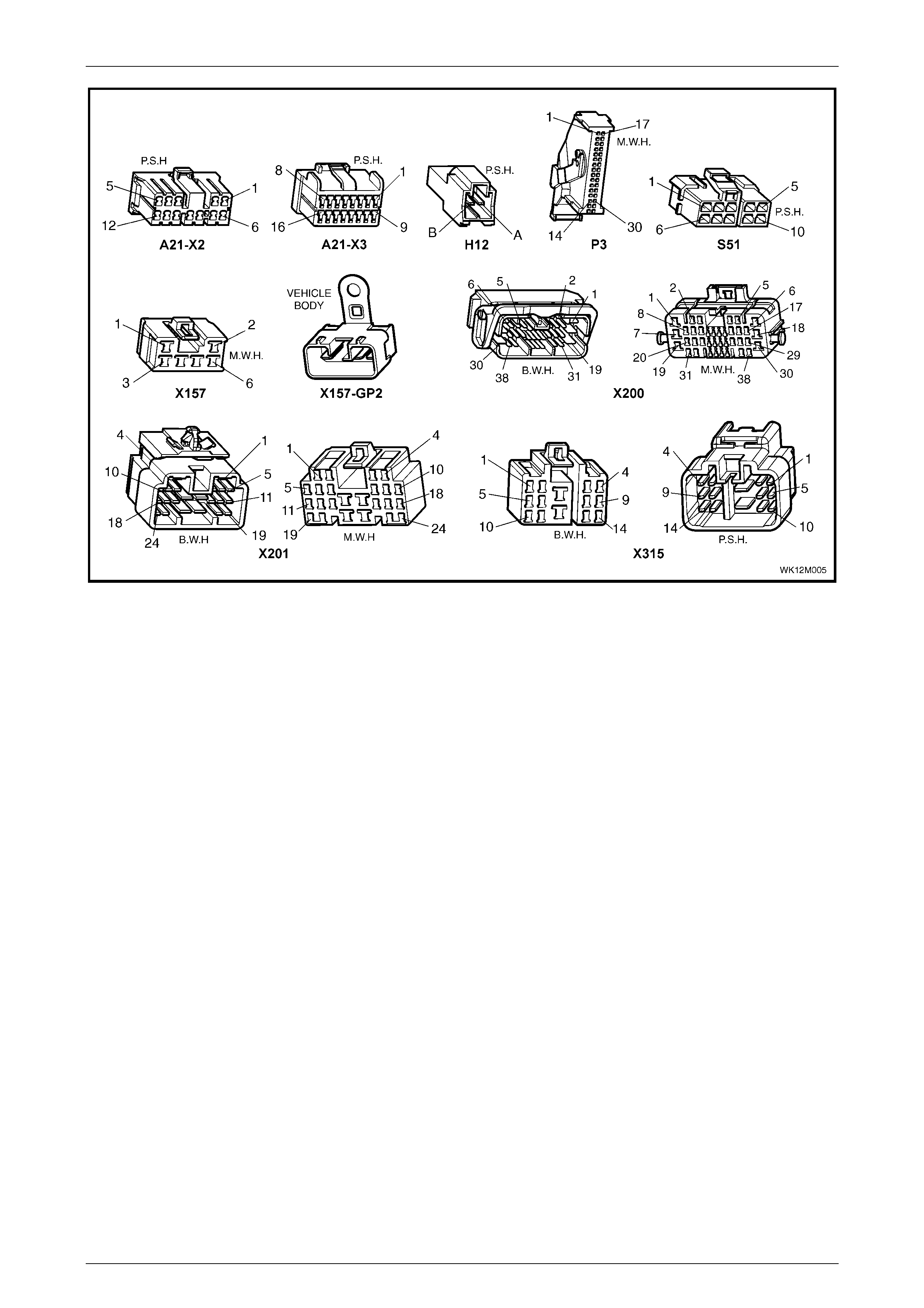

5 Special Tools

Tool Number Illustration Description Tool Classification

KM-609

(J35616-A)

ELECTRONIC KIT

Used in conjunction with a multimeter

for measuring voltages and

resistances without damagi ng wiring

harness con nec tors .

Desirable

J213200

DIGITAL MULTIMETER

Used for various measurement

functions. Must have at least 10 MΩ

input impedance and be capable of

reading capacitance.

Commercially available.

Previously released.

Available