Hydra-Matic 4L60-E A utomatic Transmission Page 7C–1

28–FEB–2003 Page 7C–1

Section 7C

Hydra-Matic 4L60-E Automatic Transm ission

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1 General Information............................................................................................................................... 2

2 Electrical Diagnosis............................................................................................................................... 3

3 Hydraulic/Mechanical Diagnosis..........................................................................................................4

4 On-Vehicle Servicing............................................................................................................................. 5

4.1 Selector Control Lever Assembly.........................................................................................................................5

Remove ...................................................................................................................................................................5

Disassemble...........................................................................................................................................................5

Boot, Shift Lever Knob Remove .........................................................................................................................7

Chrome Escutcheon Remove.............................................................................................................................8

Patch Harness Remove......................................................................................................................................8

Switch Remove...................................................................................................................................................9

BTSI Solenoid and/or Micro Switch ....................................................................................................................9

Base Disassembly............................................................................................................................................10

Lever Disassembly ...........................................................................................................................................10

Reassemble..........................................................................................................................................................11

Base Reassembly.............................................................................................................................................11

BTSI Solenoid and/or Micro Switch ..................................................................................................................12

Lower Housing..................................................................................................................................................12

Reinstall ................................................................................................................................................................14

5 Unit Repair............................................................................................................................................15

Techline

Techline

Techline

Techline

Techline

Hydra-Matic 4L60-E A utomatic Transmission Page 7C–2

28–FEB–2003 Page 7C–2

1 General Information

With the following exceptions, MY 2004 WK Series Hydra-Matic 4L60-E four speed automatic transmission general

information carries over from MY 2003 VY Series vehicles. For all Hydra-Matic 4L60-E automatic transmission general

information not contained in this Section, refer to Section 7C1, Hydra-Matic 4L60-E Automatic Transmission: General

Information in the MY 2003 VY and V2 Series Service Information.

• The selector control lever contains an additional chrome escutcheon on the upper face of the lower housing cover.

Hydra-Matic 4L60-E A utomatic Transmission Page 7C–3

28–FEB–2003 Page 7C–3

2 Electrical Diagnosis

MY 2004 WK Series Hydra-Matic 4L60-E four speed automatic transmission electrical diagnosis information carries over

from MY 2003 VY Series vehicles. With the increased complexity of the electrical/electronic diagnosis and servicing of

both the engine and transmission management systems, all information relating to the electrical/electronic diagnosis of

these items has now been combined. For all Hydra-Matic 4L60-E four speed automatic transmission electrical diagnosis

information, refer to the following:

• For vehicles with the V6 engine, refer to Section 6C1, Powertrain Management - V6 Engine in the MY 2003 VY and

V2 Series Service Information.

• For vehicles with the V6 Supercharged engine, refer to Section 6C2, Powertrain Management - V6 Supercharged

Engine in the MY 2003 VY and V2 Series Service Information.

• For vehicles with the GEN III V8 engine, refer to Section 6C3, Powertrain Management - Gen III V8 Engine in the

MY 2003 VY and V2 Series Service Information.

Hydra-Matic 4L60-E A utomatic Transmission Page 7C–4

28–FEB–2003 Page 7C–4

3 Hydraulic/Mechanical Diagnosis

MY 2004 WK Series Hydra-Matic 4L60-E four speed automatic transmission hydraulic and mechanical diagnosis

information carries over from MY 2003 VY Series vehicles.

For all Hydra-Matic 4L60-E four speed automatic transmission hydraulic and mechanical diagnosis information, refer to

Section 7C3, Hydra-Matic 4L60-E Automatic Transmission: Hydraulic/Mechanical Diagnosis in the MY 2003 VY Series

and V2 Series Service Information.

Hydra-Matic 4L60-E A utomatic Transmission Page 7C–5

28–FEB–2003 Page 7C–5

4 On-Vehicle Servicing

With the following exceptions, MY 2004 WK Series Hydra-Matic 4L60-E four speed automatic transmission on-vehicle

servicing information carries over from MY 2003 VY Series vehicles. For all Hydra-Matic 4L60-E automatic transmission

on-vehicle servicing information not contained in this Section, refer to Section 7C4, Hydra-Matic 4L60-E Automatic

Transmission: On-Vehicle Servicing in the MY 2003 VY and V2 Series Service Information.

• The selector control lever contains an additional chrome escutcheon on the upper face of the lower housing cover.

4.1 Selector Control Lever Assembly

LT Section No. – 04-190

Remove

The removal procedure for the selector control lever assembly carries over from MY 2003 VY Series vehicles. For all

information relating to the removal procedure for the selector control lever, refer to Section 7C4, 3.3 Selector Control

Lever Assembly in the MY 2003 VY Series and V2 Series Service Information.

Disassemble

NOTE

Unless specifically noted, the following

procedures can be used for either design of

selector lever assembly.

NOTE

While most views show the RHD version of the

selector control lever assembly, LHD procedures

can be assumed to be the same unless otherwise

noted.

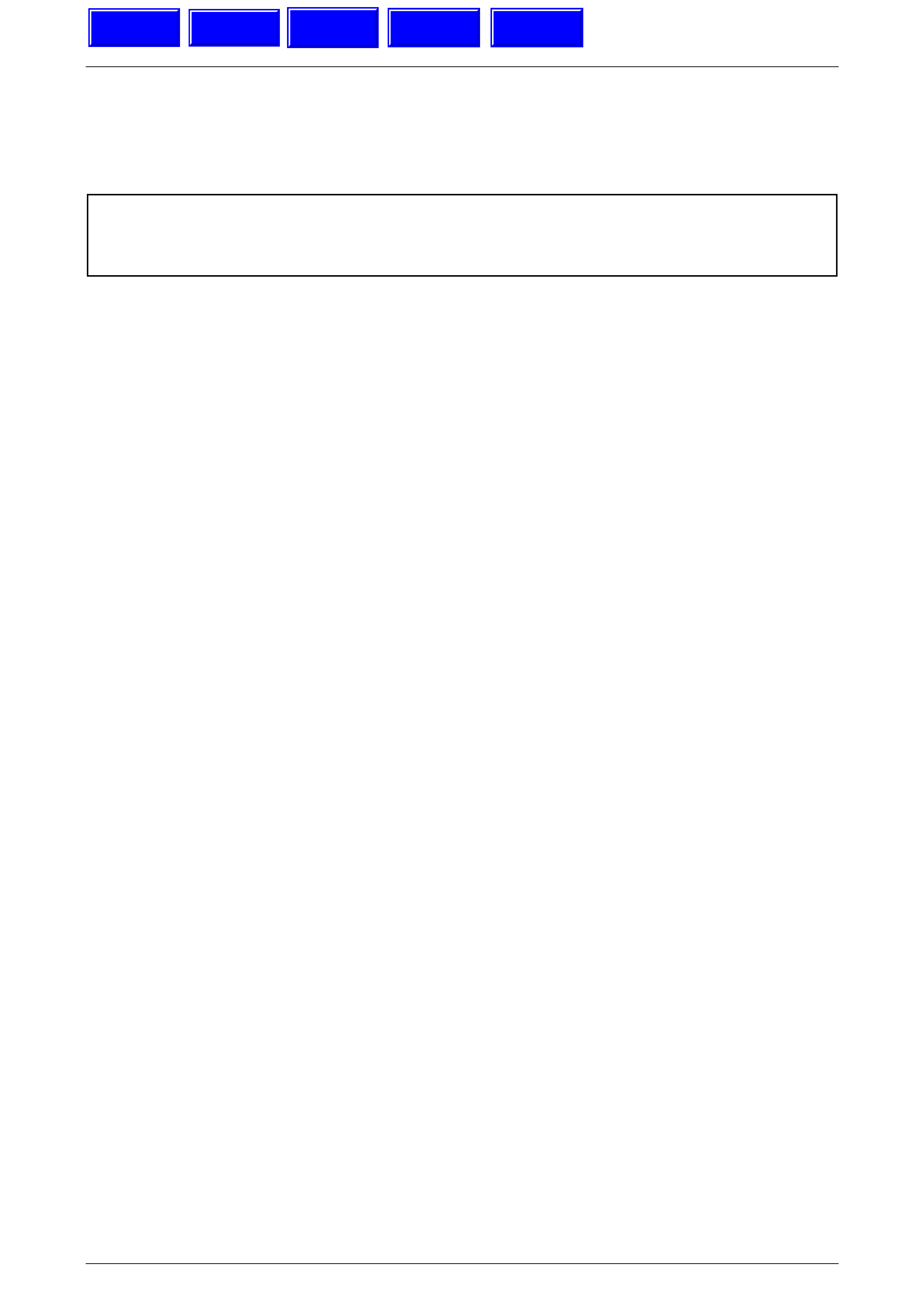

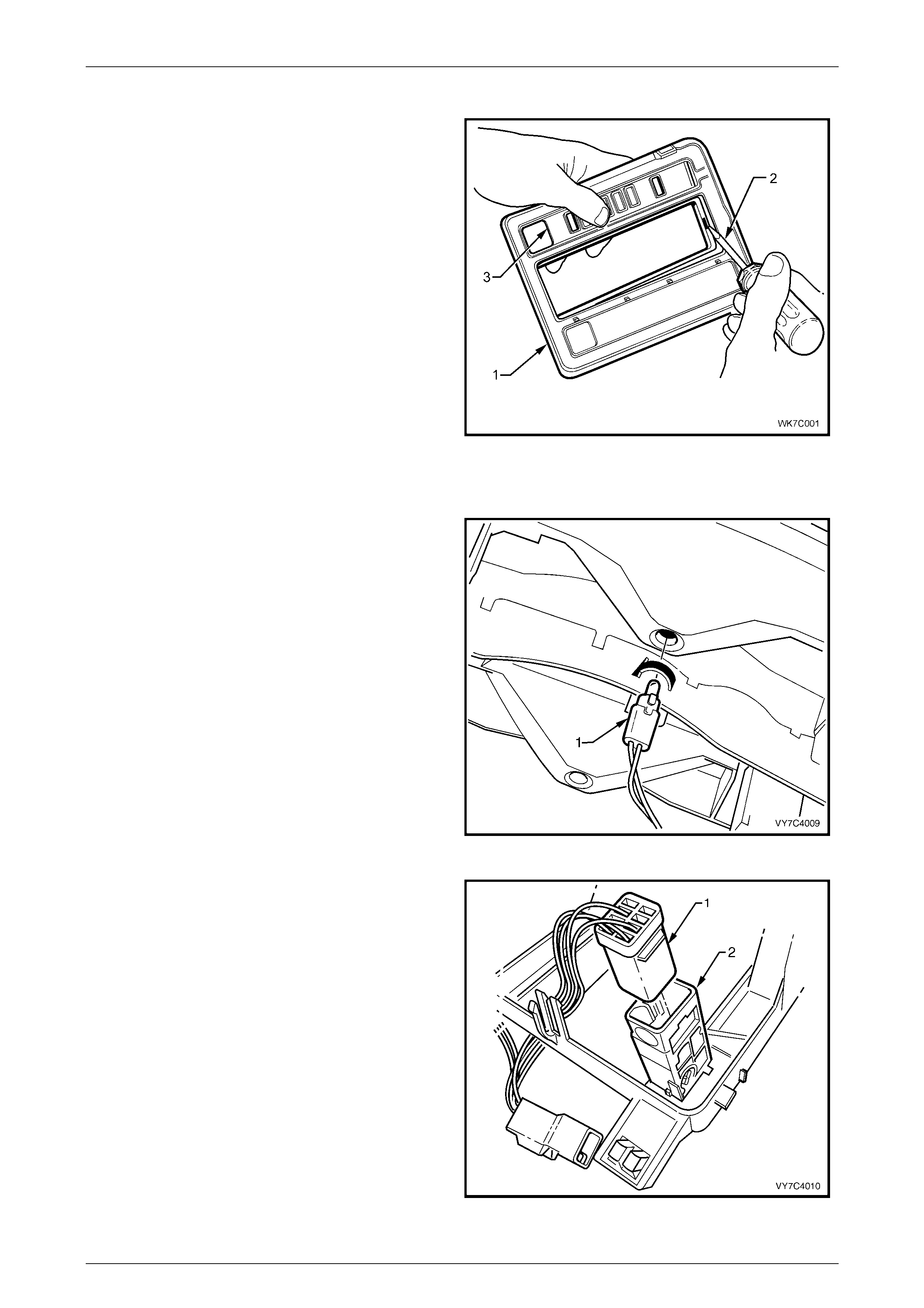

1 If the selector control lever assembly is of the BTSI

design, manually release the interlo ck mecha nism, as

follows:

a. First, press inwards at the front of the selector

lever (1), just below the gearshift knob, as

shown.

b. Then, while still pressing inward (1), depress the

selector knob with the other hand (2) and move

the lever from the Park position and into the ‘D’

position.

NOTE

This is the recommended reassembly position.

Figure 7C-1

Hydra-Matic 4L60-E A utomatic Transmission Page 7C–6

28–FEB–2003 Page 7C–6

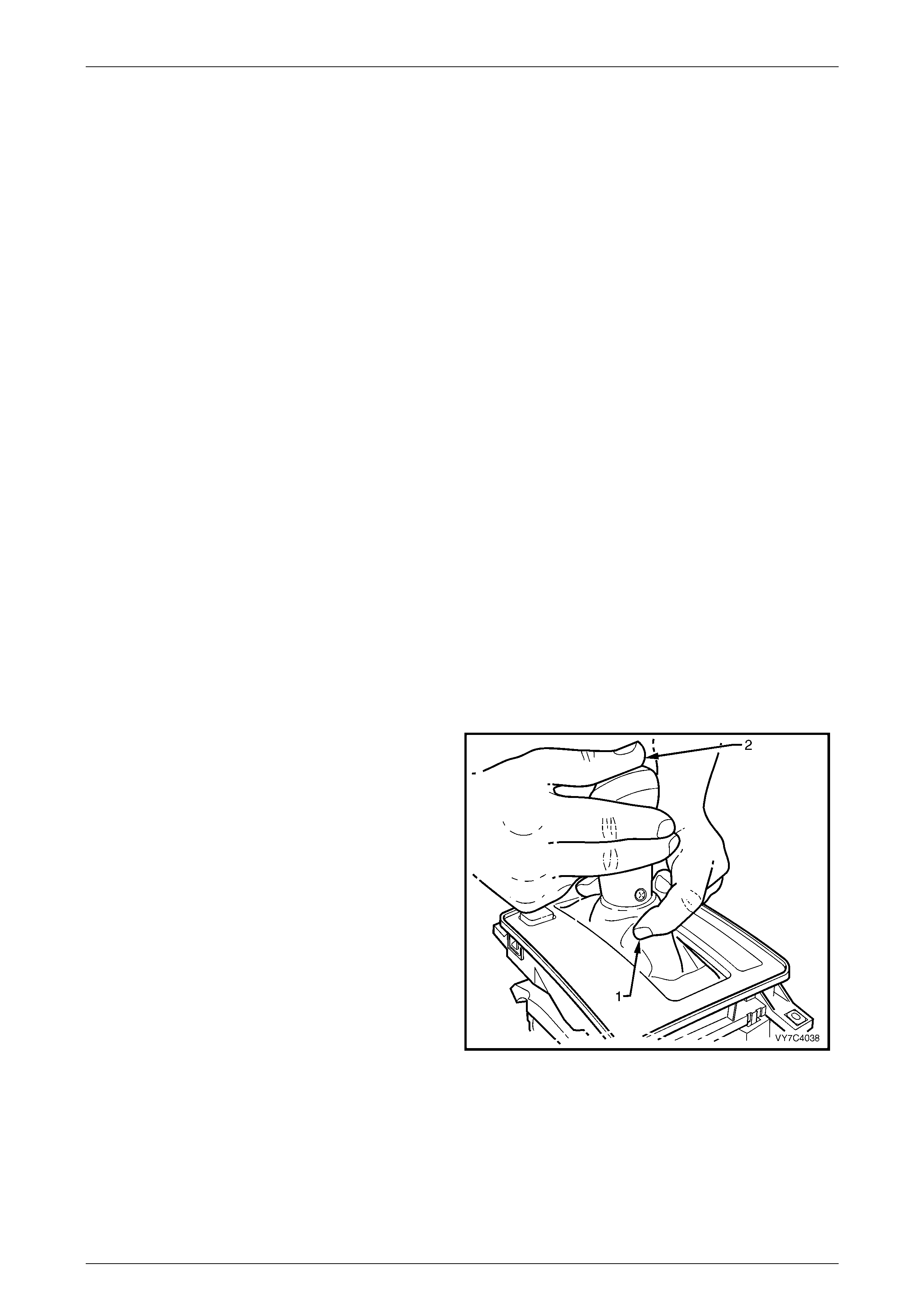

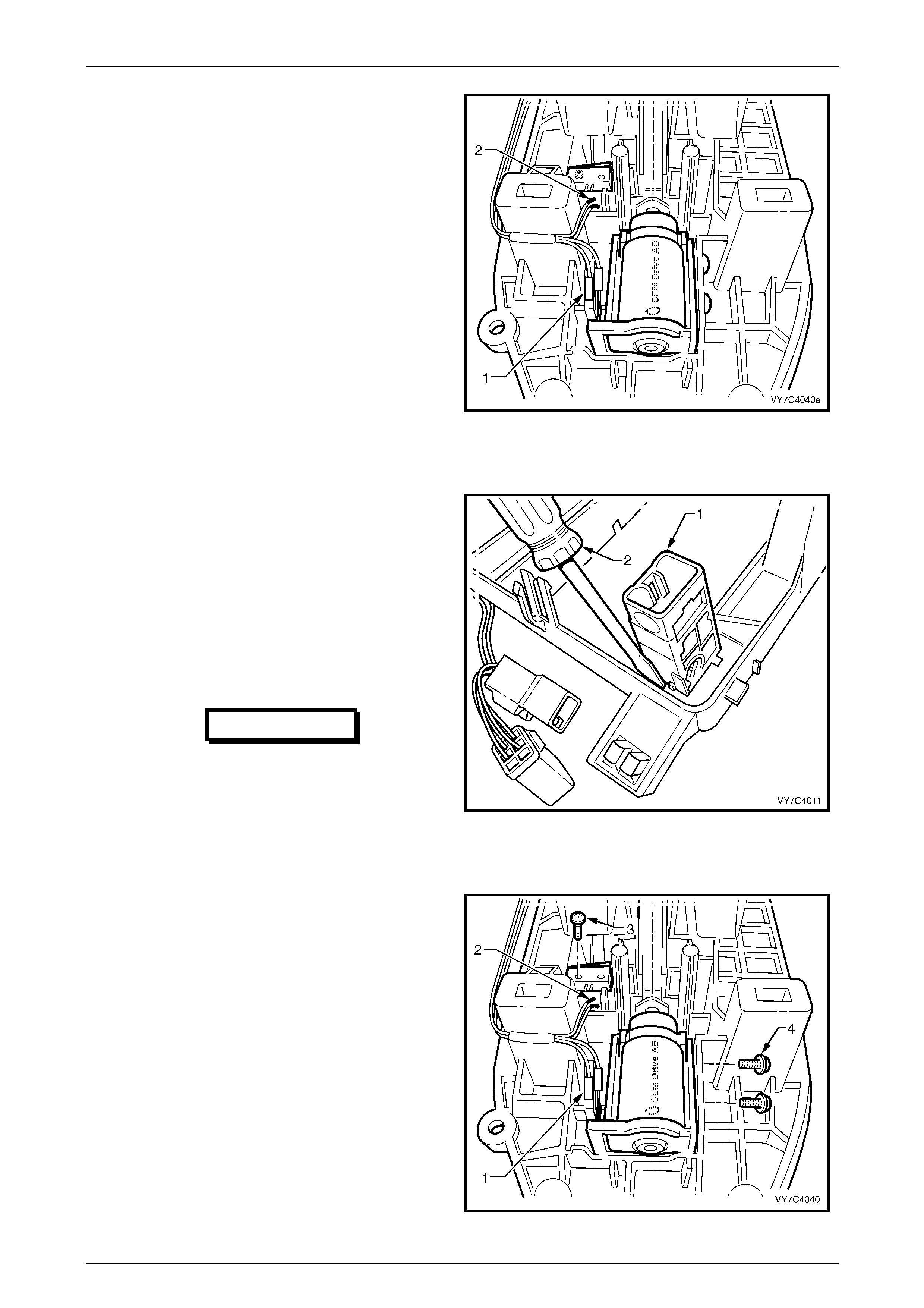

2 Using a commercially available Torx Plus (TX20) and

suitable equipment, remove the self-tapping

screw (1). Select the ‘D’ position.

Figure 7C-2

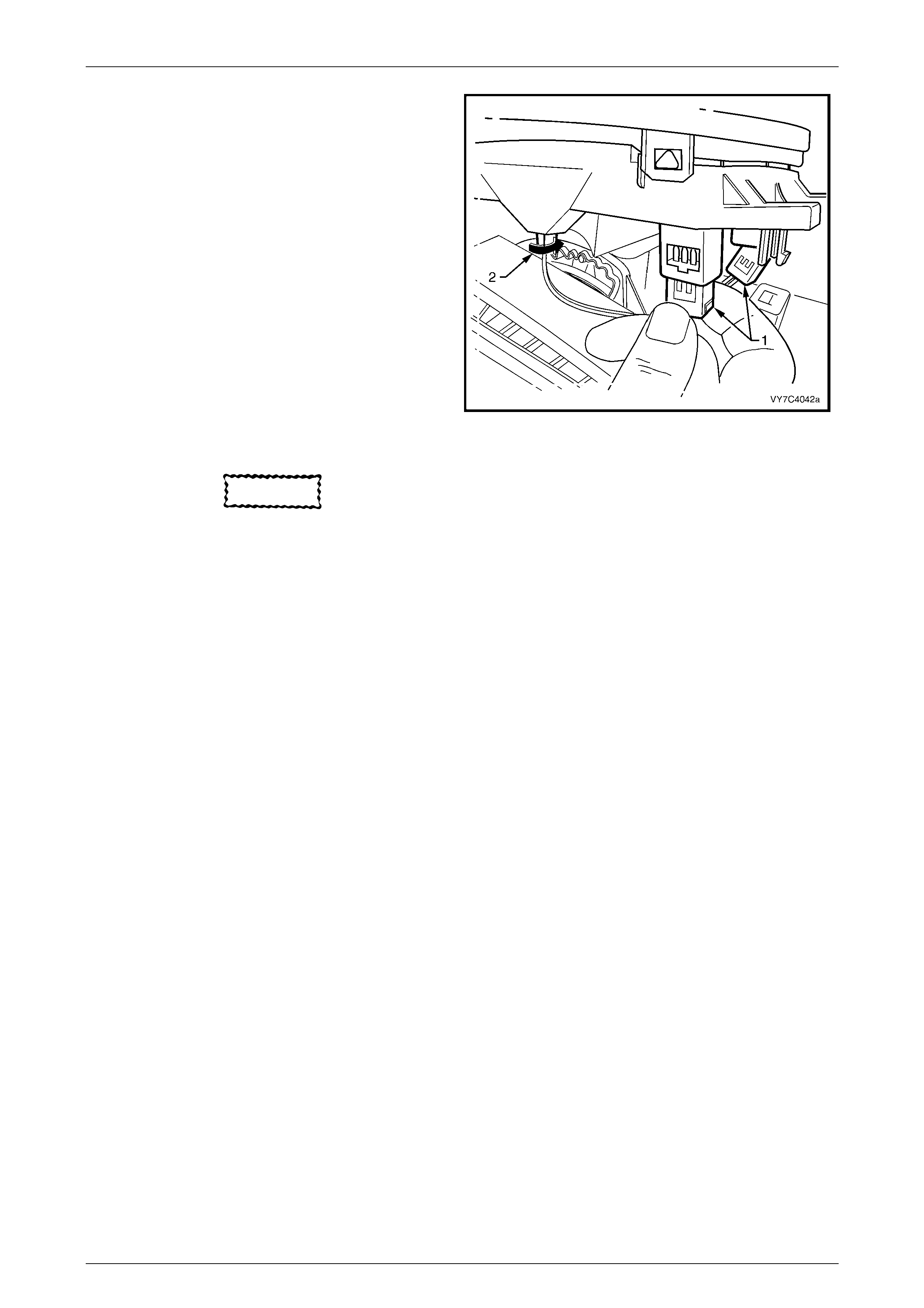

3 Using a small screwdriver (2), prise the locking tab on

the wiring harness connector (1) at the rear of the

shift selector assembly, while pushing away from the

lower housing, as shown.

NOTE

This operation is optional with the BTSI shifter,

as:

a. The patch harness can be disconnected at the

micro switch and the solenoid (in which case,

step 3 is required).

OR

b. Following separation of the lower housing and

the base (see step 4), the wiring harness

connectors could be removed from the ‘PW R’

and ‘T/C’ (if fitted) switches, leaving the harness

with the base (step 3 not being required). Figure 7C-3

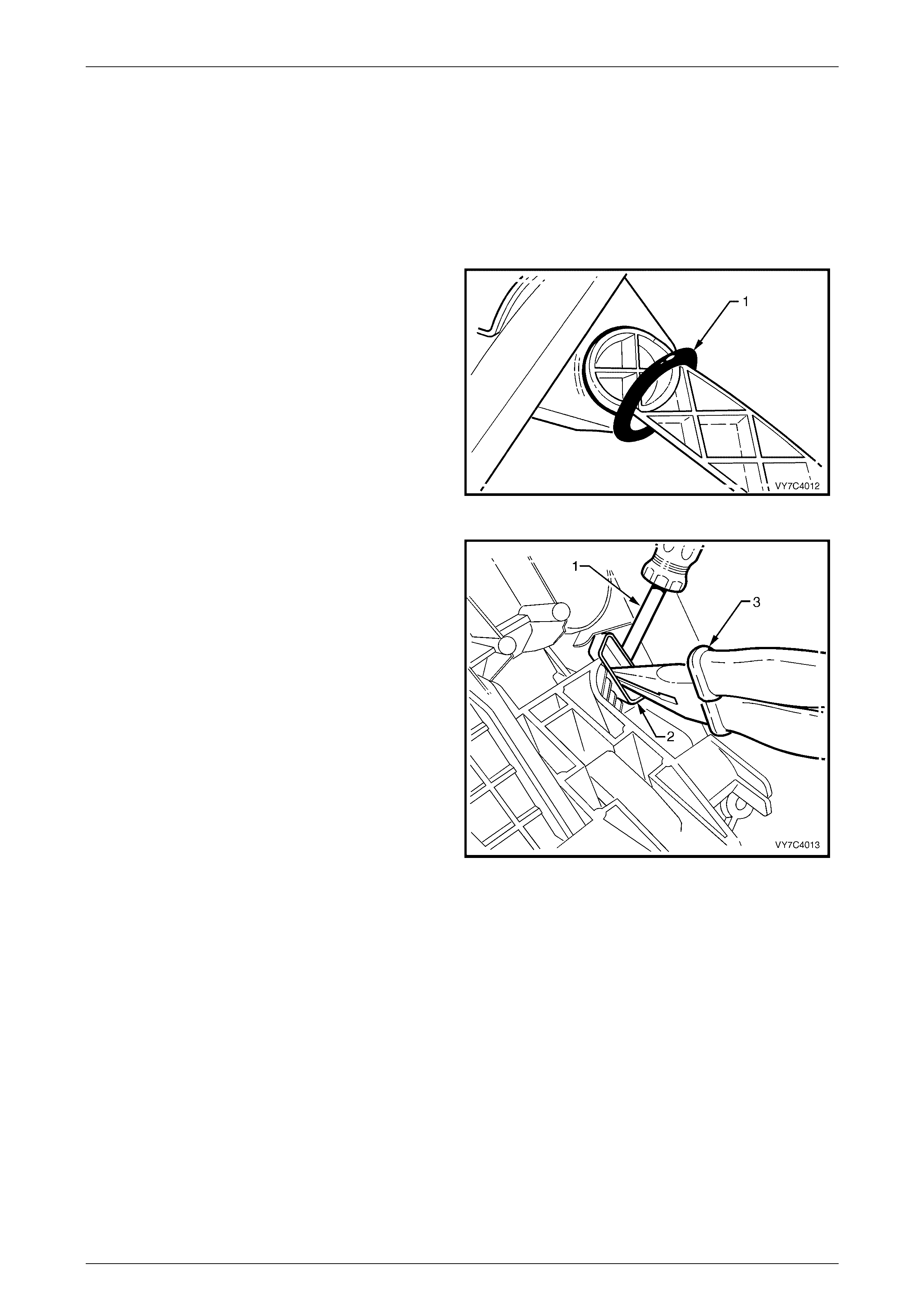

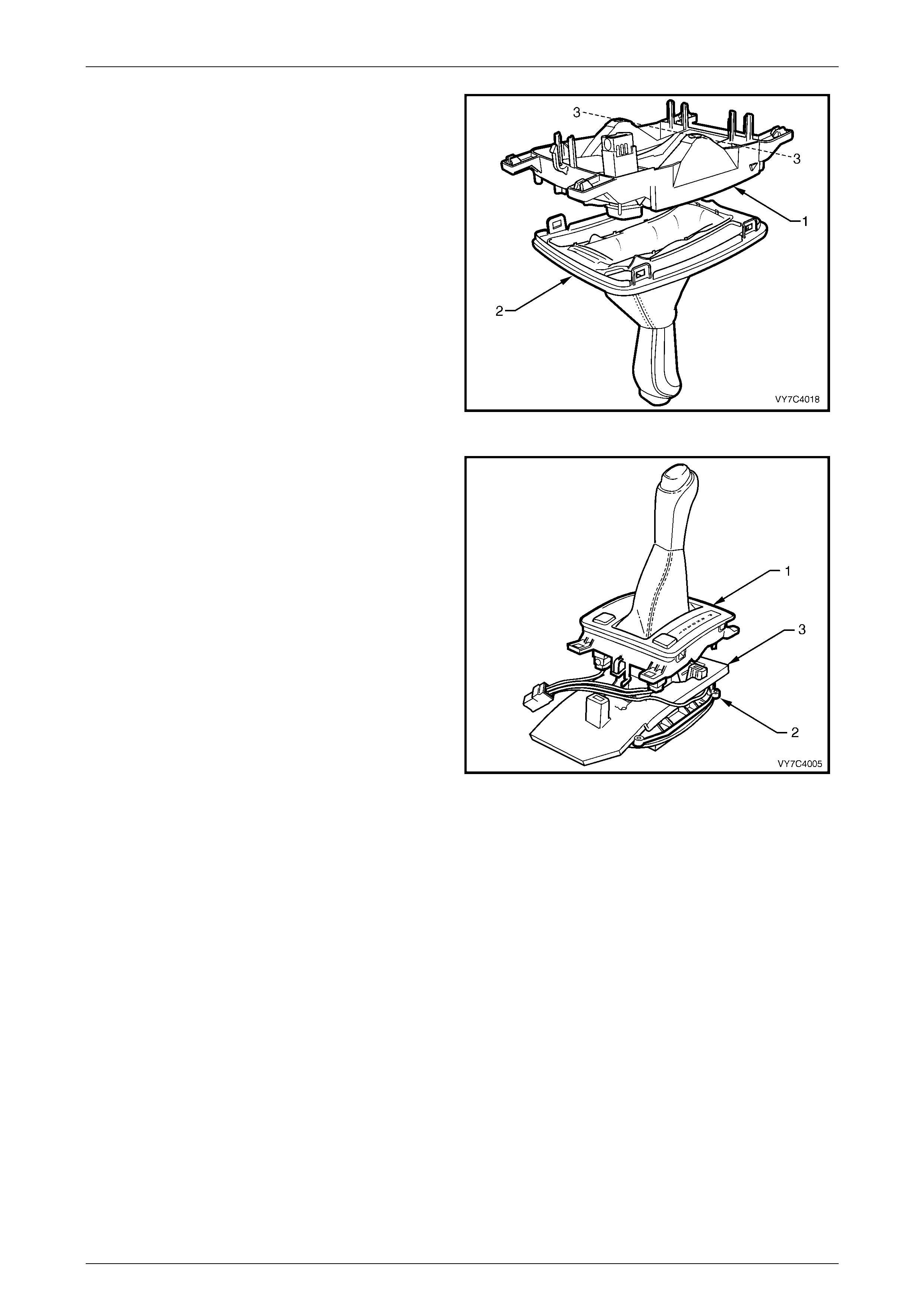

4 With the wiring harness connector removed,

disconnect the lower housing from the base (1) by

pressing the tangs on each of the retaining legs (two

front, one rear).

5 Lift the lower housing (1) from the base (2), together

with the switch/es, patch wiring harness, boot and

shift lever knob. Set the asse mbly to one side.

NOTE

With the BTSI shifter, when the patch harness is

left behind (choice ‘b’ in step 3), the removed

components will be; the lower housing (1),

together with the switch/es, boot and shift lever

knob.

6 As required, lift the insulator (3) from the base (2) and

set to one side.

Figure 7C-4

Hydra-Matic 4L60-E A utomatic Transmission Page 7C–7

28–FEB–2003 Page 7C–7

NOTE

With the shift lever assembly now separated,

select from the following choices for the service

operation/s required.

Boot, Shift Lever Knob Remove

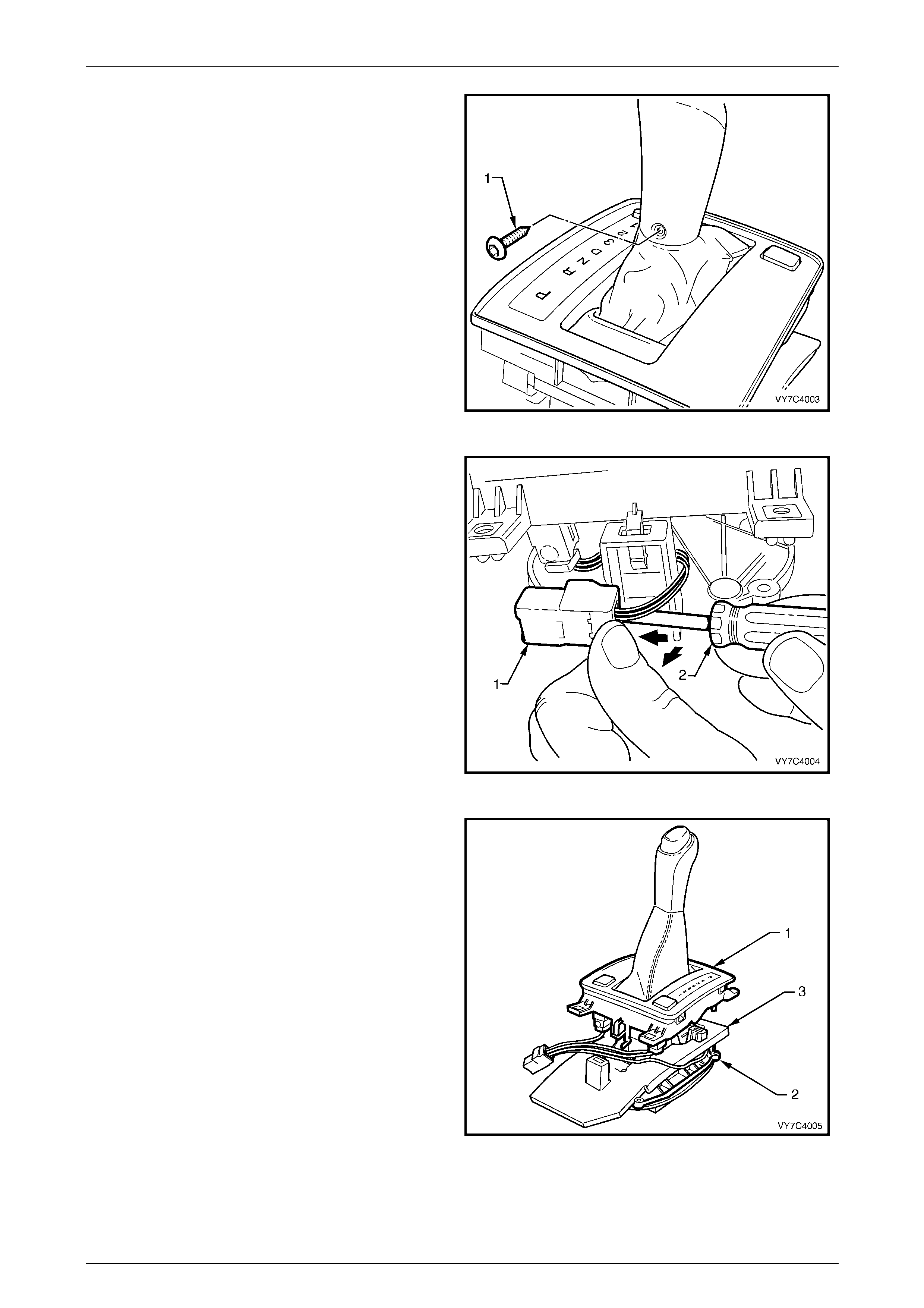

1 While holding the lower housing in an inverted

position, gently prise each of the four securing lugs

(1) to free the cover (2) from the lower housing (3).

Lift the lower housing (3) from the gearshift selector

knob, boot and upper cover assembly (2) and set to

one side.

NOTE

If the lower housing assembly is not inverted

before separation, then the boot will probably

become dislodged from the locating tangs in the

upper cover.

2 If boot replacement is required, free the boot from the

upper cover locating tangs and set the cover to one

side, being careful not to dislodge nor damage the

PRNDL indicator lens in the process.

Figure 7C-5

3 Turn the boot (2) inside out, over the gearshift

selector knob, then cut the plastic tie (1) securing the

boot to the knob. Remove the boot from the gearshift

lever knob and discard.

NOTE

The plastic tie is a unique design and is

markedly different from the usual cable tie.

Ensure to use the correct part when

replacement of the cable tie is required.

Figure 7C-6

4 If the gearshift knob needs to be dismantled, use a

small knife (2) or similar to free the lugs securing the

control rod button from the gearshift knob (1).

CAUTION

The knob is spring loaded and may fly

free once dislodged.

5 Remove the two Phillips head self-tapping screws,

(located under the control rod button), then separate

the knob components.

Figure 7C-7

Hydra-Matic 4L60-E A utomatic Transmission Page 7C–8

28–FEB–2003 Page 7C–8

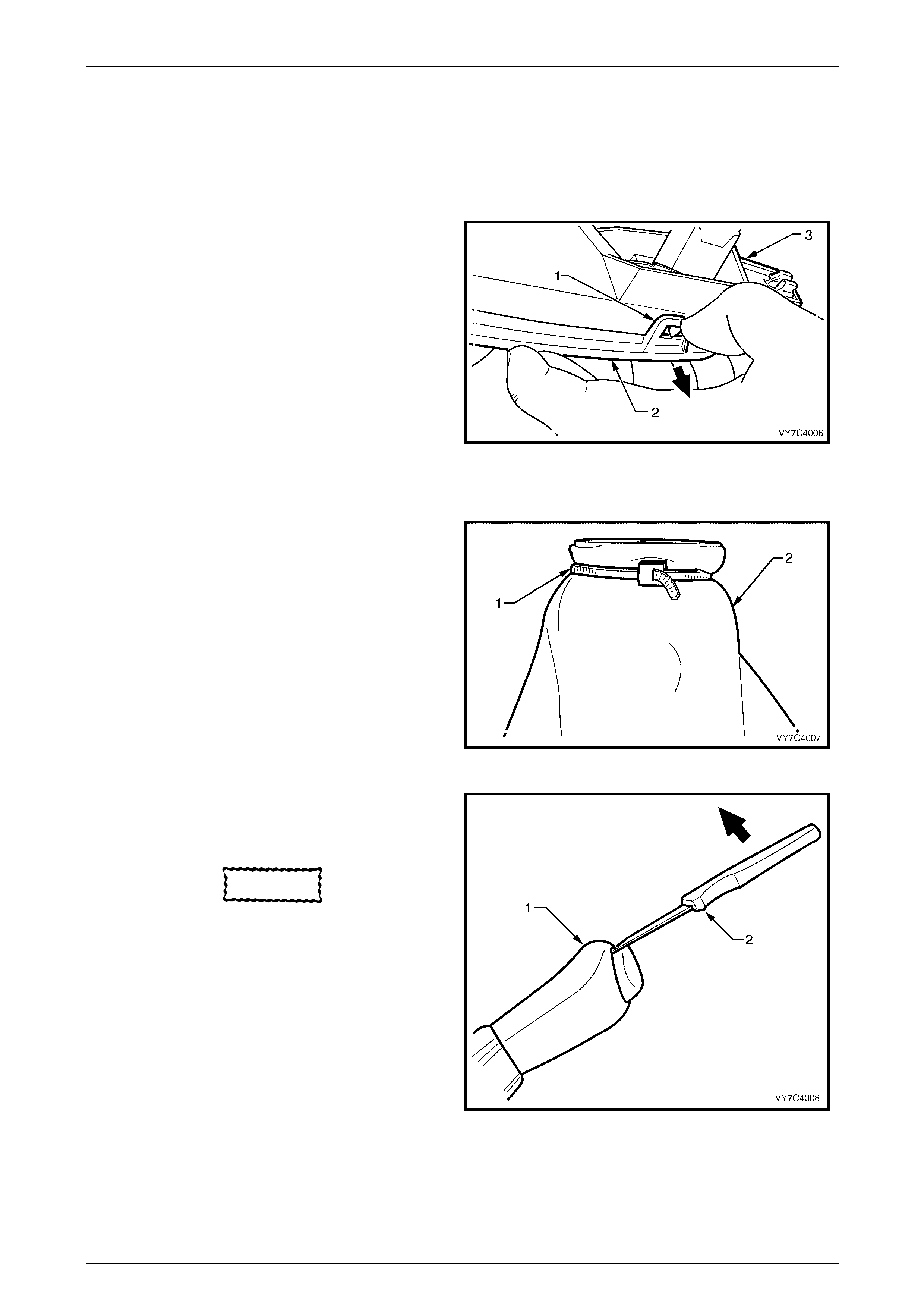

Chrome Escutcheon Remov e

1 Hold the lower housing cover (1) upside down and

using a fine flat tip screw driver (2), carefully prise the

eight retaining tangs on the chrome escutcheon (3)

free from the edge of the shift lever boot opening.

2 Remove the chrome escutcheon from the lower

housing.

Figure 7C-8

Patch Harness Remove

1 Remove the selector indicator lamp and holder from

the switch housing by turning the lamp holder 90° to

the left (counter-clockwise), and withdraw the holder.

Figure 7C-9

2 If not removed previously (step 3), release the switch

connector retaining lug/s, then remove the

connector/s.

NOTE

While each switch patch harness connector is

the same colour (white), the Traction Control

('T/C') switch (where fitted) connector wiring is

taped to the PRNDL indicator lamp wiring, as

this switch will always be on the same side as

this lamp. This situation remains the same for

both RHD and L HD vehicles.

Figure 7C-10

Hydra-Matic 4L60-E A utomatic Transmission Page 7C–9

28–FEB–2003 Page 7C–9

3 If the shift lever assembly is of the BTSI design,

remove the patch harness wiring connectors from the

solenoid (1) and the micro switch (2), taking note of

the patch harness routing, for correct reinstallation.

4 Remove the patch harness and set to one side.

Figure 7C-11

Switch Remove

NOTE

For this operation, the cover must be separated

from the lower housing. Refer to Step 4 in this

procedure.

1 To remove the PWR and/or T/C switch (if fitted), use

a small bladed screwdriver and lever one of the

switch retaining tangs from under the lower housing

to free the particular switch, cock to one side, release

the second tang and then remove the switch from

above.

IMPORTANT

Take note of the locating lug on the

switch body that ensures the correct

orientation of the switch when reinstalled.

Figure 7C-12

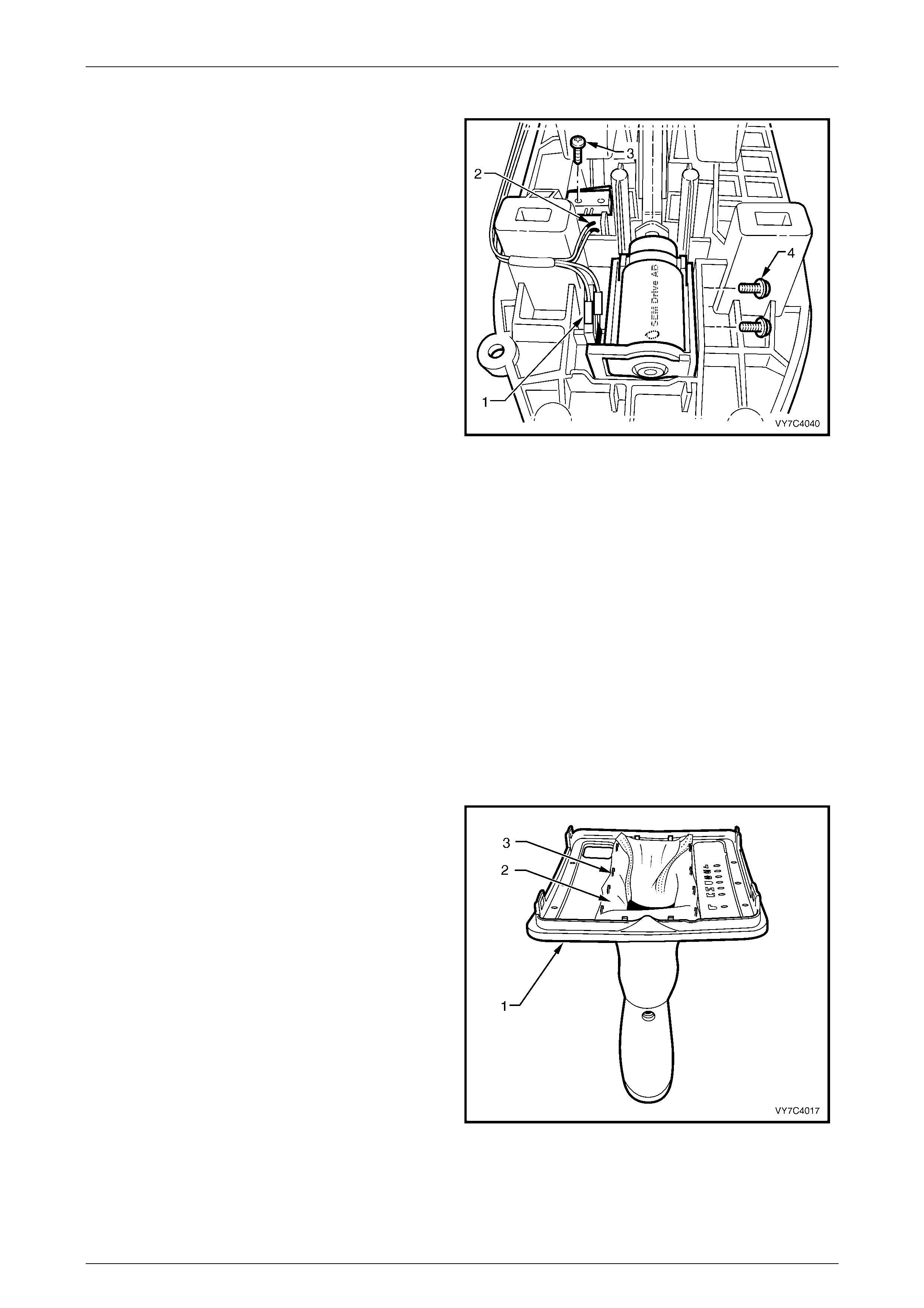

BTSI Solenoid and/or Micro Switch

1 With the lower cover separated from the base, lift the

insulator back and over the shift lever.

2 With the patch harness connectors (1 and 2) removed

from the micro switch and the solenoid, remove the

two Phillips headed screws (4) securing the solenoid

or the single self tapping screw (3) from the micro

switch.

3 Remove the solenoid and/or micro switch from the

BTSI base.

Figure 7C-13

Hydra-Matic 4L60-E A utomatic Transmission Page 7C–10

28–FEB–2003 Page 7C–10

Base Disassemb l y

1 If not removed previously, remove the shift rod trunnion bolt from the lower end of the shift lever arm. Slide the

trunnion from the arm, then remove the insulating grommet.

NOTE

This is necessary to provide clearance for the

lever to be removed from the lower housing.

2 Remove the external seal (1) from the lever arm and

set to one side.

Figure 7C-14

3 To remove the lever locking piece, use a small

screwdriver (1) to lever the locking tang free while

pulling on the locking piece (2) with long nosed

pliers (3).

4 Push the lever assembly inward to release the inner

support pin and bush.

NOTE

The bush will probably remain in the lower

housing.

5 Lift the shift lever from the lower housing.

NOTE

While it will be necessary to manoeuvre the

lever somewhat, sufficient space is provided to

prevent any need to apply force to the lever

assembly.

Figure 7C-15

Lever Disassembly

NOTE

Regardless of the shift lever type, further

disassembly is not recommended, as it is highly

possible that, during reinstallation of the roll pin,

the shift lever will be cracked, unless

sophisticated jigs are used. For this reason, the

shift lever is only serviced as an assembly.

Hydra-Matic 4L60-E A utomatic Transmission Page 7C–11

28–FEB–2003 Page 7C–11

Reassemble

Base Reassembl y

1 Inspect the external lever, inner bushing (1) for

damage, replacing as required. Lubricate with multi-

purpose chassis grease such as NLGI No. 1 Lithium

grease.

2 Install the split inner support bush (2) to the selector

lever pin, aligning the split in the bush with the key on

the selector lever pin. Lubricate the external bush

surface with multi-purpose chassis grease such as

NLGI No. 1 Lithium grease.

3 Install the selector lever assembly (3), into the base.

Align the small bush with the aperture in the base

then push across to fully install the lever.

Figure 7C-16

4 Install the lever locking piece (1), using long nosed

pliers. Correct reinstallation will have occurred when

an audible click is heard, indicating that the tang on

the locking piece has been installed correctly.

NOTE

While a standard shift lever is shown, the

reinstallation is the same for the BTSI design.

Figure 7C-17

5 Apply a smear of multi-purpose chassis grease such

as NLGI No. 1 Lithium grease to the outer, lipped seal

(1), then reinstall over the external lever.

Figure 7C-18

Hydra-Matic 4L60-E A utomatic Transmission Page 7C–12

28–FEB–2003 Page 7C–12

BTSI Solenoid and/or Micro Switch

1 Install the solenoid and/or micro switch to the base,

securing with two screws (4) for the solenoid and/or

single self tapping screw (3) for the micro switch. Do

not over-tighten the screws.

2 Install the patch wiring harness connectors to the

micro switch (2) and/or solenoid (1).

3 Place the insulating foam into position.

NOTE

No adjustment is required for the BTSI solenoid.

Figure 7C-19

Lower Housing

1 If removed, install the switch/es to the lower housing, ensuring that the locating lug on the switch body engages

with the slot in the lower housing. If the vehicle is equipped with traction control, the correct location for this switch,

is in the right hand aperture for RHD vehicles (the opposite side for LHD vehicles). This will always be behind the

PRNDL indicator lens.

2 Install the patch wiring harness, ensuring that the switch connector/s connection is correct. Also reinstall the

PRNDL lamp and holder, by inserting and turning the holder a quarter turn to the left (counter-clockwise).

3 If of the BTSI design, it is recommended that the patch harness be reinstalled to the solenoid and micro switch first,

then to the PWR and/or T/C switch (if fitted), prior to reassembling the lower housing assembly to the base (refer to

Figure 7C-23). In this instance, the wiring harness connector should also be installed to the bracket on the base, at

this time.

4 If a new selector lever boot is to be installed, use the tie strap included with the new boot to firmly secure the boot

to the gearshift selector knob. Trim excess length and discard.

5 If necessary, install the chrome escutcheon on to the lower housing cover by gently pressing into place until the

eight retaining tangs snap firmly into place.

6 With the upper cover (1) inverted, locate the boot (2)

over each of the cover locating tangs (3), working

gradually around until every tang is covered.

NOTE

The weight of the selector knob will be sufficient

to keep the boot engaged with the tangs.

Figure 7C-20

Hydra-Matic 4L60-E A utomatic Transmission Page 7C–13

28–FEB–2003 Page 7C–13

7 To reduce the possibility of the boot from becoming

dislodged from the upper cover retaining tangs,

reinstall the lower housing (1) to the cover (2),

working in an inverted position, as shown.

NOTE

Before reassembling the lower cover to the

base, check that the coloured indicator is in line

with the two PRNDL display lamp h oles (3). This

will be the approximate position for correct

reassembly.

8 Engage each of the tabs on the upper cover with the

retaining lugs on the lower housing. When all four

tabs have been engaged, the boot will be clamped

and can no longer become disengaged.

Figure 7C-21

9 Ensure that the PRNDL indicator slide in the lower

housing, is at the 'D' position (the red colour will show

opposite the 'D' in the PRNDL lens).

10 After checking that the insulator (3) is undamaged,

reinstall to the base (2).

11 After checking that the selector lever is also in the

Drive position, reinstall the lower housing (1) over the

shift lever and engage each of the three legs with the

base apertures. Check that the PRNDL indicator slide

pin is engaged with the slot in the selector lever.

Figure 7C-22

Hydra-Matic 4L60-E A utomatic Transmission Page 7C–14

28–FEB–2003 Page 7C–14

NOTE

If the shifter is of the BTSI design, before

reassembling to the base, reinstall the patch

harness connector/s (1) to the PWR and/or T/C

switch (if fitted).

12 Install the selector indicator lamp and holder (2) by

inserting, then turn to the right (clockwise), to secure.

13 Engage the selector lever knob with the selector

lever, aligning the control rod with the hole in the

selector knob.

NOTE

Moving the selector lever can easily check

correct engagement of the PRNDL indicator.

Should the coloured portion not move with the

lever, then engagement is incorrect. Separate

the lower housing and base and repeat Steps

13 to 15.

CAUTION

If the shifter is of the BTSI design, do not

engage the Park position during this

testing process. If this does occur, the

interlock will need to be manually

released again (refer to Step 1 of the

Disassemble process).

Figure 7C-23

14 Install the selector knob retaining screw, using a TX20 Torx bit and suitable equipment, being careful not to over-

tighten.

15 Install the selector lever knob and spring, pushing down until the two locking tangs engage.

NOTE

If the selector lever knob and spring have not

been removed, then re-engagement with the

selector lever can still be achieved but some

manoeuvring may be necessary.

16 If removed, install the wiring harness connector onto the bracket at the end of the base and push until the locking

tang engages.

Reinstall

The reinstall procedure for the selector control lever assembly carries over from MY 2003 VY Series vehicles. For all

information relating to the reinstallation procedure for the selector control lever assembly, refer to Section 7C4, 3.3

Selector Control Lever Assembly in the MY 2003 VY Series and V2 Series Service Information.

Hydra-Matic 4L60-E A utomatic Transmission Page 7C–15

28–FEB–2003 Page 7C–15

5 Unit Repair

MY 2004 WK Series Hydra-Matic 4L60-E four speed automatic transmission unit repair information carries over from MY

2003 VY Series vehicles.

For all Hydra-Matic 4L60-E four speed automatic transmission unit repair information, refer to Section 7C3, Hydra-Matic

4L60-E Automatic Transmission: Hydraulic/Mechanical Diagnosis in the MY 2003 VY Series and V2 Series Service

Information.