Exhaust System Page 8B–1

Page 8B–1

Section 8B

EXHAUST SYSTEM

IMPORTANT

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices w ith regard to safety and/or property damage.

1 General Description............................................................................................................................... 3

1.1 Emission Reductions.............................................................................................................................................3

Catalytic Converter Close Coupling.....................................................................................................................3

Euro 2 Emissions Standards.................................................................................................................................3

1.2 Exhaust System Configurations...........................................................................................................................4

V6 Engine Exhaust System ...................................................................................................................................4

GEN III V8 Engine Exhaust System.......................................................................................................................5

Standard.............................................................................................................................................................5

Performance.......................................................................................................................................................6

2 Service Operations - V6......................................................................................................................... 7

2.1 Service Notes .........................................................................................................................................................7

Catalytic Converter.................................................................................................................................................7

Oxygen Sensors.....................................................................................................................................................7

2.2 Exhaust System......................................................................................................................................................8

Complete Exhaust System Assembly...................................................................................................................9

Remove..............................................................................................................................................................9

Reinstall............................................................................................................................................................10

2.3 Rear Exhaust Assembly.......................................................................................................................................11

Remove .................................................................................................................................................................11

Reinstall................................................................................................................................................................11

2.4 Intermediate Exhaust Single Pipe and Muffler Assembly ................................................................................12

Remove .................................................................................................................................................................12

Reinstall................................................................................................................................................................12

2.5 Intermediate Exhaust Y-Pipe Assembly.............................................................................................................13

Remove .................................................................................................................................................................13

Reinstall................................................................................................................................................................14

2.6 Front Exhaust Assembly.....................................................................................................................................15

Remove .................................................................................................................................................................15

Reinstall................................................................................................................................................................16

2.7 Tightening Sequence...........................................................................................................................................17

3 Service Operations – GEN III V8......................................................................................................... 19

3.1 Service Notes .......................................................................................................................................................19

Catalytic Converter...............................................................................................................................................19

Oxygen Sensors...................................................................................................................................................19

3.2 Exhaust System....................................................................................................................................................20

3.3 Complete Exhaust System Assembly.................................................................................................................21

Remove .................................................................................................................................................................21

Reinstall................................................................................................................................................................22

3.4 Rear Exhaust Assembly.......................................................................................................................................23

Remove .................................................................................................................................................................23

Reinstall................................................................................................................................................................24

Techline

Exhaust System Page 8B–2

Page 8B–2

3.5 Intermediate Exhaust Assembly.........................................................................................................................25

Remove .................................................................................................................................................................25

Reinstall................................................................................................................................................................25

3.6 Front Exhaust Assembly.....................................................................................................................................26

Remove .................................................................................................................................................................26

Reinstall................................................................................................................................................................27

3.7 Tightening Sequence...........................................................................................................................................28

4 Service Operations – Exhaust System Heat Shields........................................................................ 30

4.1 Heat Shields ..........................................................................................................................................................30

Rear Muffler Underbody Mounted Heat Shield..................................................................................................32

Remove............................................................................................................................................................32

Reinstall............................................................................................................................................................32

Intermediate Muffler Underbody Mounted Heat Shield.....................................................................................33

Remove............................................................................................................................................................33

Reinstall............................................................................................................................................................33

Front Exhaust Assembly Underbody Mounted Heat Shields...........................................................................34

Remove............................................................................................................................................................34

Reinstall............................................................................................................................................................34

Front Exhaust Assembly On-pipe Heat Shields – Pre Catalytic Converter.....................................................35

Remove............................................................................................................................................................35

Reinstall............................................................................................................................................................35

Front Exhaust Assembly On-pipe Heat Shields - Post Catalytic Converter....................................................35

Remove............................................................................................................................................................35

Reinstall............................................................................................................................................................36

Butyl Patch Reflective Foil Heat Shields – V6 Supercharged Only..................................................................37

Remove............................................................................................................................................................37

Reinstall............................................................................................................................................................37

5 Exhaust System Clearances............................................................................................................... 38

5.1 V6 Exhaust Systems Clearances........................................................................................................................38

5.2 GEN III V8 Exhaust System Clearances .............................................................................................................42

6 Exhaust System Diagnosis................................................................................................................. 47

7 Specifications....................................................................................................................................... 48

Type.......................................................................................................................................................................48

Material..................................................................................................................................................................48

Catalytic Converter...............................................................................................................................................48

8 Torque Wrench Specifications........................................................................................................... 49

9 Special Tools........................................................................................................................................ 50

Exhaust System Page 8B–3

Page 8B–3

1 General Description

Information contained within this section describes the general exhaust system configurations for MY 2004 WK Series

vehicles. The exhaust system fitted to a particular vehicle will depend on engine type and model specifications. With the

following exceptions, MY 2004 WK Exhaust System information carries over from MY 2003 VY and V2 Series vehicles.

V6 exhaust system:

• Complete system update except for rear exhaust assembly, which carries over from MY 2003 VY and V2 Series.

The new system incorporates two close-coupled catalytic converters, on-pipe heat shielding and reconfigured front

to intermediate exhaust assemblies.

V6 Supercharged exhaust system:

• Similar to VY V6 Supercharged, except for the use of shortened butyl patch reflective foil heat shields and revised

catalytic converter volume specifications. Refer to V6 Supercharged exhaust system information contained within

the MY 2003 VY and V2 Series Service Information.

GEN III V8 exhaust system:

• Revised front exhaust assemblies incorporating close-coupled catalytic converters, revised under body heat shield

configuration and new on-pipe heat shields.

• GEN III V8 vehicles produced before 11 September 2003 are fitted with long on-pipe heat sheilds to the front

exhaust assembly. Vehicles produced from this date onwards are fitted with short on-pipe heat shields to the front

exhaust assembly.

NOTE

All illustrations in this Section represent a

right-hand drive vehicle. For left-hand drive

vehicles, any procedure or item that is not a

direct mirror of a right-hand drive vehicle in

left-hand drive configuration, will be highlighted

and a procedure or illustration produced to

accommodate the difference.

For information not contained within this Section, refer to Section 8B Exhaust System, in the MY 2003 VY and V2 Series

Service Information.

1.1 Emission Reductions

Through developments in various vehicle emissions reduction systems, significant reductions in emissions have been

achieved on WK vehicles with V6 and GEN III V8 engines. The developments have been primarily concerned with

refinements in engine calibration and the optimisation of exhaust system catalytic converter configurations. For WK

Series exhaust systems, the major modifications made to reduce emissions from previous Series vehicles includes the

incorporation of two catalytic converters on V6 vehicles and a close-coupled catalytic converter configuration

incorporated across both V6 (non-supercharged) and GEN III V8 vehicles.

Catalytic Converter Close Coupling

As optimum catalytic converter performance is reached above 500oC, a close coupling of the catalytic converter with the

exhaust manifold ensures that upon engine startup, the engine exhaust gasses are able to heat the catalytic converter

to optimum temperatures in as short a time as possible. This period of catalytic converter warm up is often referred to as

catalytic converter ‘light up’.

Euro 2 Emissi ons St andar ds

WK vehicles with V6 (non-supercharged) and GEN III V8 engines now meet Euro 2 emissions standards. The Euro 2

emissions standard is a European standard which aims at setting vehicle emissions targets to encourage vehicle

manufacturers to reduce harmful vehicle emissions such as Carbon Monoxide (CO), Hydrocarbons (HC) and the various

oxides of Nitrogen (NOx).

For further information on catalytic converter construction and operation, refer to Section 8B, 1.2 Exhaust Catalytic

Converter, in the MY 2003 VY and V2 Series Service Information.

Exhaust System Page 8B–4

Page 8B–4

1.2 Exhaust System Configurations

V6 Engine Exhaust System

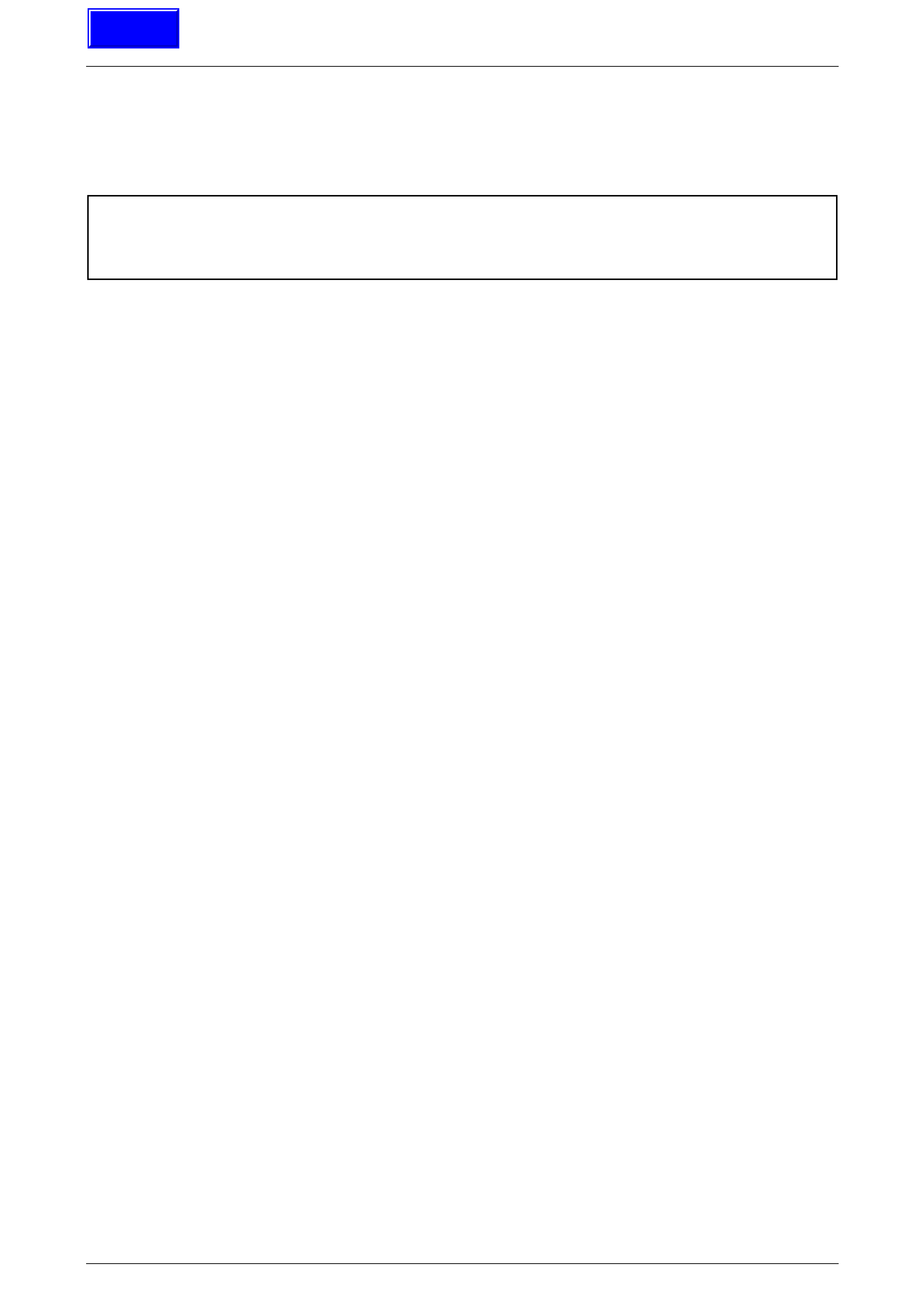

Refer to Figure 8B – 1 for the following.

The V6 engine exhaust manifolds are connected to a pair of stainless steel front pipes by flanged joints (1). Each front

pipe runs into a close-coupled three-way catalytic converter (3) and then continues from the rear of the converter to join

up with the intermediate Y-pipe exhaust assembly. These pipes are joined by gasketed flange joints (5). The

intermediate Y-pipe assembly merges into a single pipe and joins onto the intermediate single pipe and muffler

assembly with a flanged swivel joint (7). An internal sealing ring is fitted within the joint. The flanged swivel joint is held

together with a pair of stepped fastening bolts and coil springs. Combined, the Y-pipe and single pipe and muffler

assemblies (items B and C)are identified as the intermediate exhaust assembly.

The intermediate single pipe runs on into the intermediate muffler (8) and extends from the rear of the muffler to join up

with the rear exhaust pipe and muffler assembly. The intermediate to rear pipes are joined with a slip joint and U-bolt

clamp (10).

The front of the exhaust assembly is supported through a rubber support (6) attached to a hanger connected to the

transmission extension housing and to a cross brace and peg assembly welded across the intermediate Y-pipe exhaust

assembly. The intermediate single pipe and muffler exhaust assembly is supported by two support rubbers (9) that are

attached to hangers welded to the vehicle underbody and to pegs welded to the rear of the intermediate muffler. The

rear exhaust assembly is supported by two support rubbers (12) that are attached to hangers welded to the vehicle

underbody and to pegs welded to the tailpipe just downstream of the rear muffler (11).

The support rubbers are a common part for all locations and are secured by retainer clips at the intermediate and rear

body hangars. Flanged pegs are used at other locations.

Pre catalytic converter on-pipe heat shields (2) and post catalytic converter on-pipe heat shields (4) are used along the

front exhaust pipe assemblies. Metal plate heat shields attached to the underbody are used above the intermediate and

rear mufflers. Foil plate heat shields are attached to the underbody just to the rear of each catalytic converter.

Figure 8B – 1

Legend

A Front Exhaust Assem bli es

B Intermediate Y-Pipe Exhaust

Assembly

C Intermediate Si ngl e Pipe and

Muffler Assembly

D Rear Exhaust Assembly

1 Manifold to Front P i pe Fl ange

2 Pre Catalyt i c Converter Heat S hi el ds

and Oxygen Sensor Mounting Boss

3 Catalytic Converter

4 Post Catalytic Converter Heat Shiel ds

5 Front Pipe to Y-Pipe Flange Joi nt

6 Front Exhaust Brace and Support

Rubber

7 Swivel Joint Flange

8 Intermediate Muffler

9 Intermediate Muff l er Support Rubbers

10 Intermediate to Rear Pipe Slip Joint and

U-clamp

11 Rear Muffler

12 Rear Muffler Support Rubbers

Exhaust System Page 8B–5

Page 8B–5

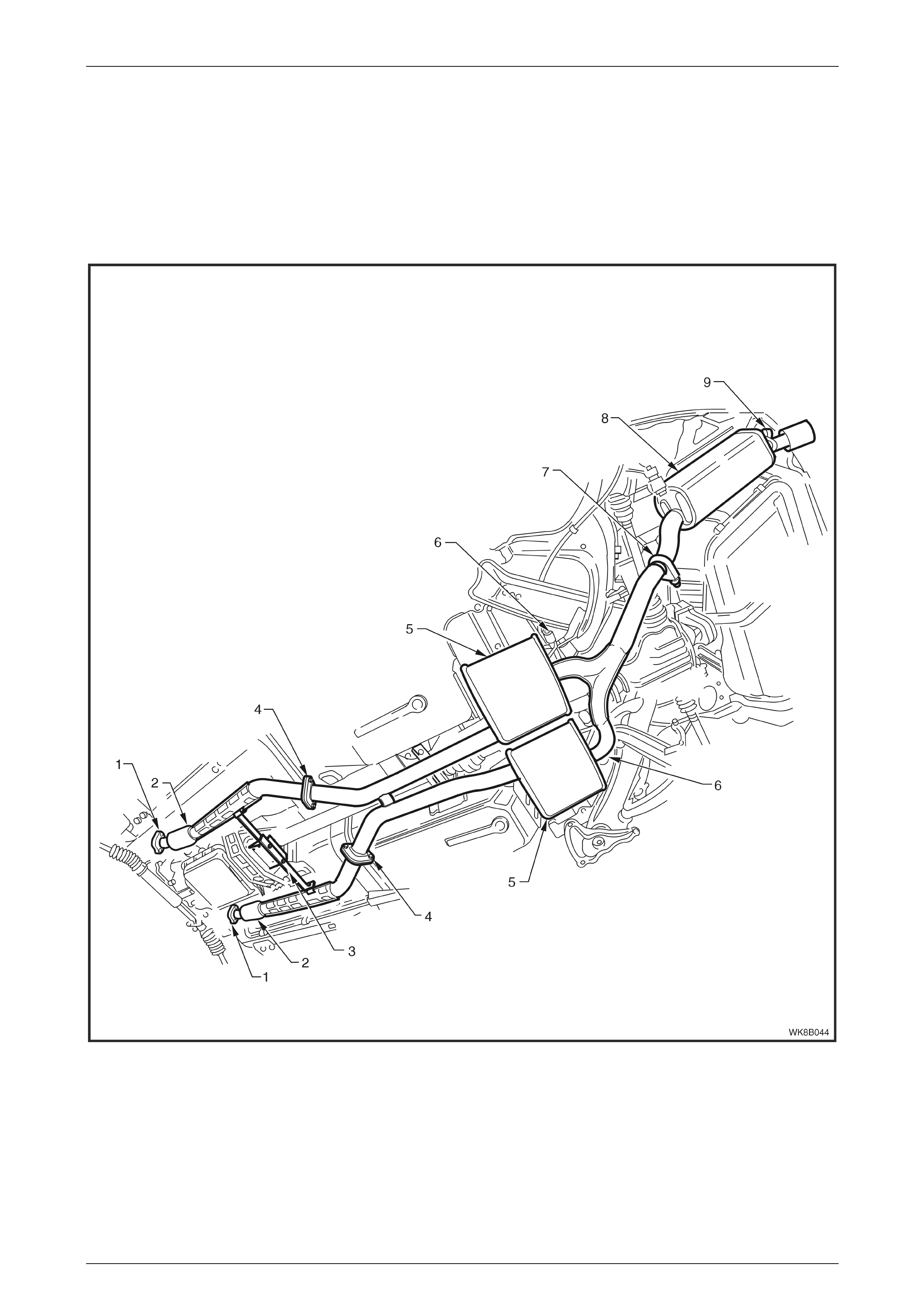

GEN III V8 Engine Exhaust System

Two exhaust system configurations, Standard and Performance, are available for vehicles fitted with the GEN III V8

engine. The type installed will depend on the particular vehicle’s specifications. Details of both of these systems are

included.

Standard

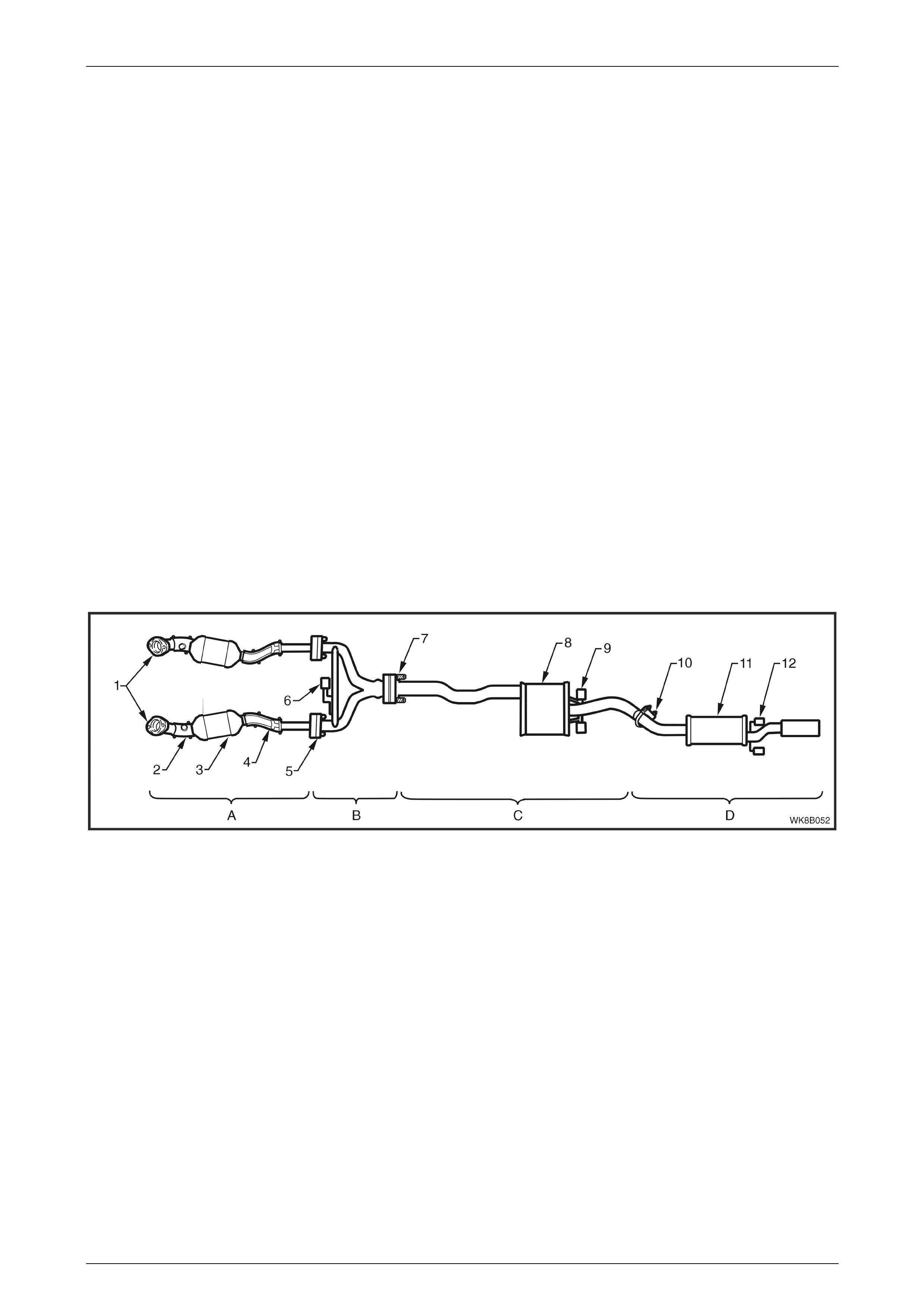

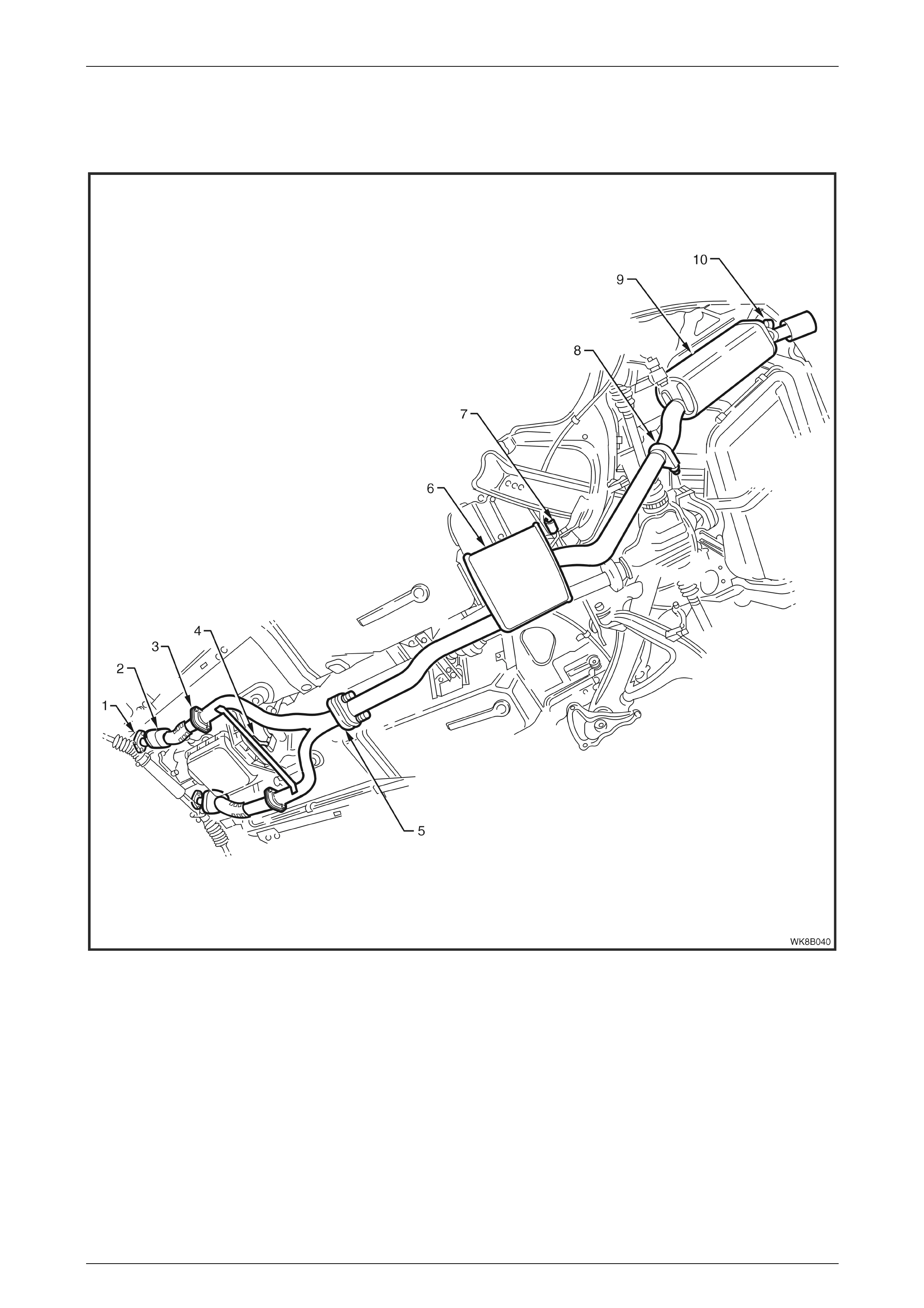

Refer to Figure 8B – 2 for the following.

The GEN III V8 engine exhaust manifolds are connected to a pair of stainless steel front pipes by flanged joints (1). A

dual exhaust system is retained past the twin intermediate mufflers (8). The pipes then converge into a single pipe that

is joined to the rear exhaust assembly with a slip joint and U-bolt clamp (10).

A catalytic converter (3) is welded to each front exhaust pipe, with a flanged, gasketed joint (6) connecting each

converter to the twin, intermediate exhaust pipes.

The front of the exhaust assembly is supported through a cross brace and transmission mount (5), which bridges

between each of the front exhaust pipes and is bolted onto the transmission extension housing. The two intermediate

exhaust pipes are stiffened by a welded bridging piece, located before the twin intermediate mufflers. The bridging piece

also functions as an exhaust balance pipe (7). The intermediate exhaust assembly is supported by two pairs of support

rubbers (9) attached to hangers welded to the vehicle underbody and to pegs welded to the rear of the intermediate

mufflers (8). The rear exhaust assembly is supported by two support rubbers (12) attached to hangers welded to the

vehicle underbody and to pegs welded to the rear tail pipe.

The support rubbers are a common part for all locations and are secured by retainer clips at both the intermediate and

rear body hangers. Flanged pegs are used at other locations.

Pre catalytic converter on-pipe heat shields (2) and post catalytic converter on-pipe heat shields (4) are used along each

of the front exhaust pipes. Metal plate heat shields attached to the underbody are used above the intermediate and rear

mufflers. Foil plate heat shields are attached to the underbody, just to the rear of each catalytic converter.

Figure 8B – 2

Legend

A Front Exhaust Assem bli es

B Intermediate Exhaust A ssem bl y

C Rear Exhaust Assembly

1 Manifold to Front P i pe Fl ange

2 Pre Catalyt i c Converter Heat S hi el ds

and Oxygen Sensor Mounting Boss

3 Catalytic Converter

4 Post Catalytic Converter Heat Shiel ds

5 Cross B rac e and Transmi ssion Mount

6 Front Pipe t o I ntermediat e Fl ange Joint

7 Exhaust Balance Pipe

8 Intermediate Muffler

9 Intermediate Muff l er Support Rubbers

10 Intermediate to Rear Pipe Slip Joint and

U-clamp

11 Rear Muffler

12 Rear Muffler Support Rubbers

Exhaust System Page 8B–6

Page 8B–6

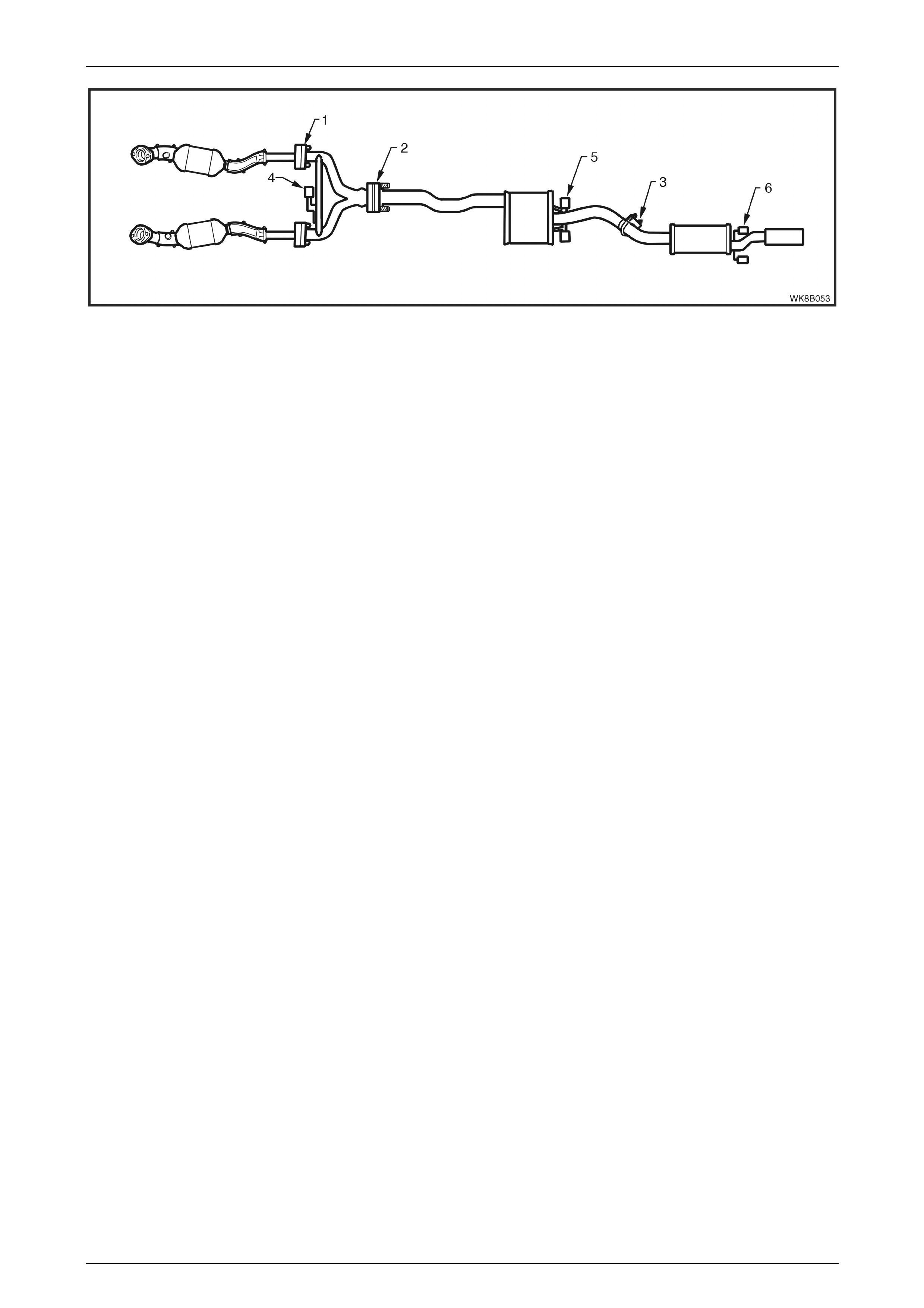

Performance

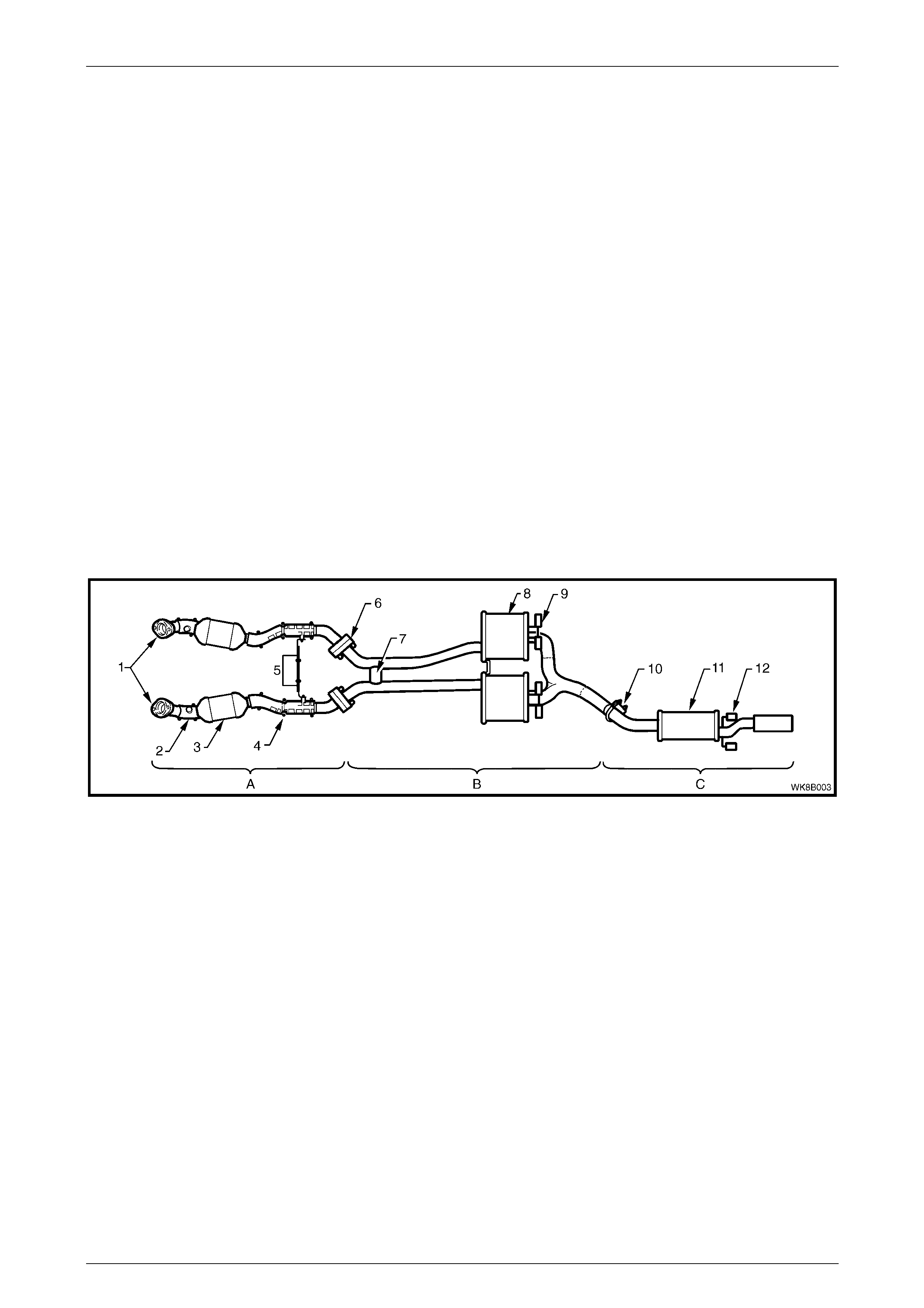

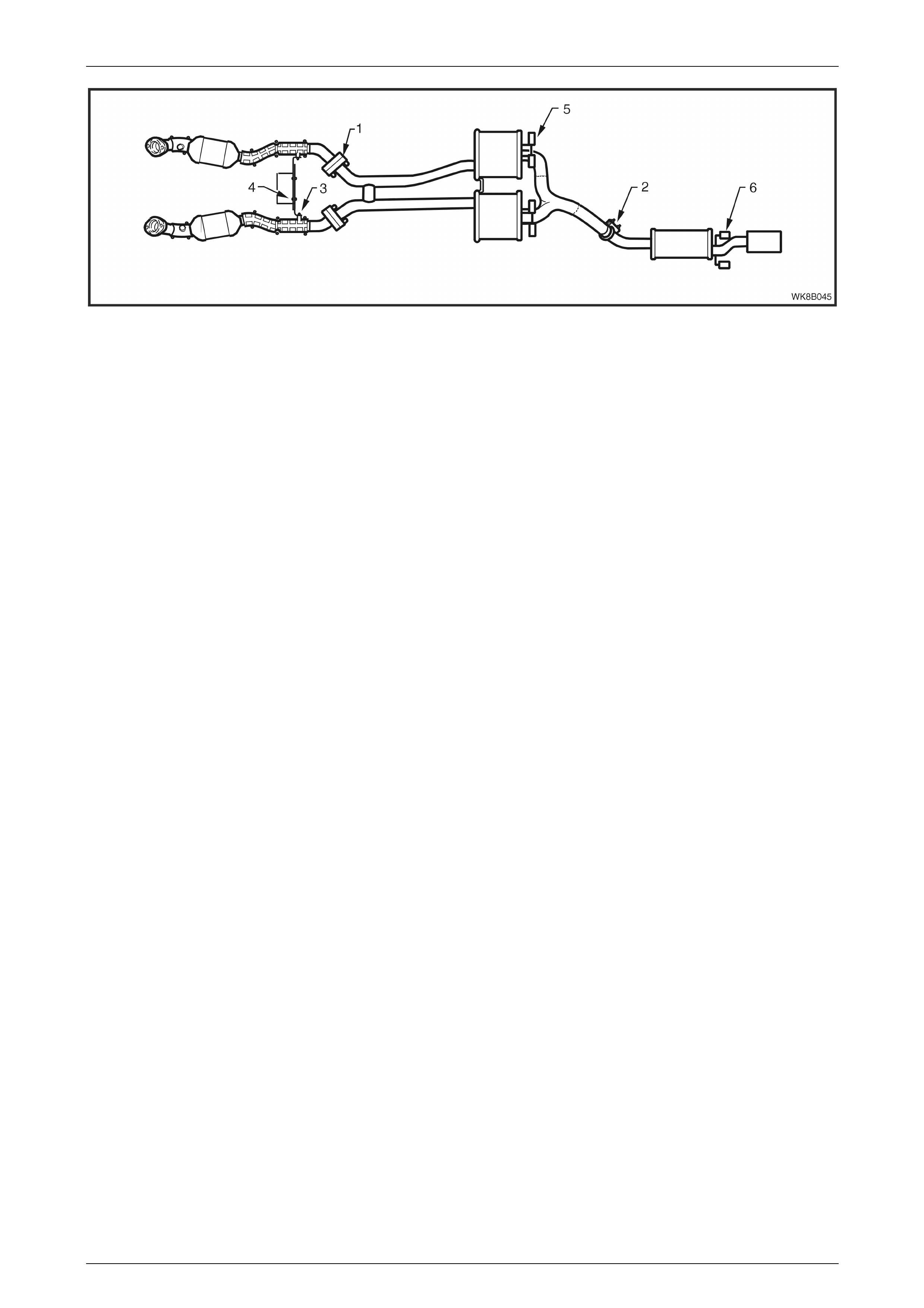

Refer to Figure 8B – 3 for the following.

The front exhaust assemblies of the Performance exhaust system are identical to the Standard front exhaust

assemblies. The intermediate exhaust assembly incorporates two exhaust balance pipes (1) welded at points before the

twin intermediate mufflers (2). The pipes running from the intermediate mufflers are joined to the rear exhaust pipes with

individual slip joints and ring clamps (3). The rear exhaust pipes join to a single rear muffler (4), which features dual tail

exhaust pipes.

Figure 8B – 3

Legend

A Intermediate Exhaust S ystem

B Rear Exhaust Assembly 1 E xhaust bal ance pipes

2 Intermediate mufflers 3 Intermediate to Rear Pipe Slip Joints

and Ring Clam ps

4 Rear Muffler

Exhaust System Page 8B–7

Page 8B–7

2 Service Operations - V6

2.1 Service Notes

When installing any exhaust system component, care must be taken to install each component in the correct

relationship to the other. Ensure that correct assembly, installation, tightening sequence, tightening torque and

clearances for the system involved are observed. When exhaust system service work is required, refer to the various

illustrations and instructions provided in this section.

The incorrect assembly of exhaust system

components can frequently be the cause of

rattles and ‘booms' due to incorrect

alignment or clearance of body or suspension

parts. Ensure that the correct tightening

sequence is observed upon installation of

exhaust system components.

NOTE

Service operations on exhaust system

components must be carried out with all parts at

ambient temperatures to ensure correct

clearances are maintained.

Catalytic Converter

Catalytic converters are serviced as part of the left or right front exhaust pipe assemblies only.

NOTE

If removing or replacing the catalytic converter as

part of a complete front pipe assembly, always

check the flange gaskets for damage and replace

if necessary.

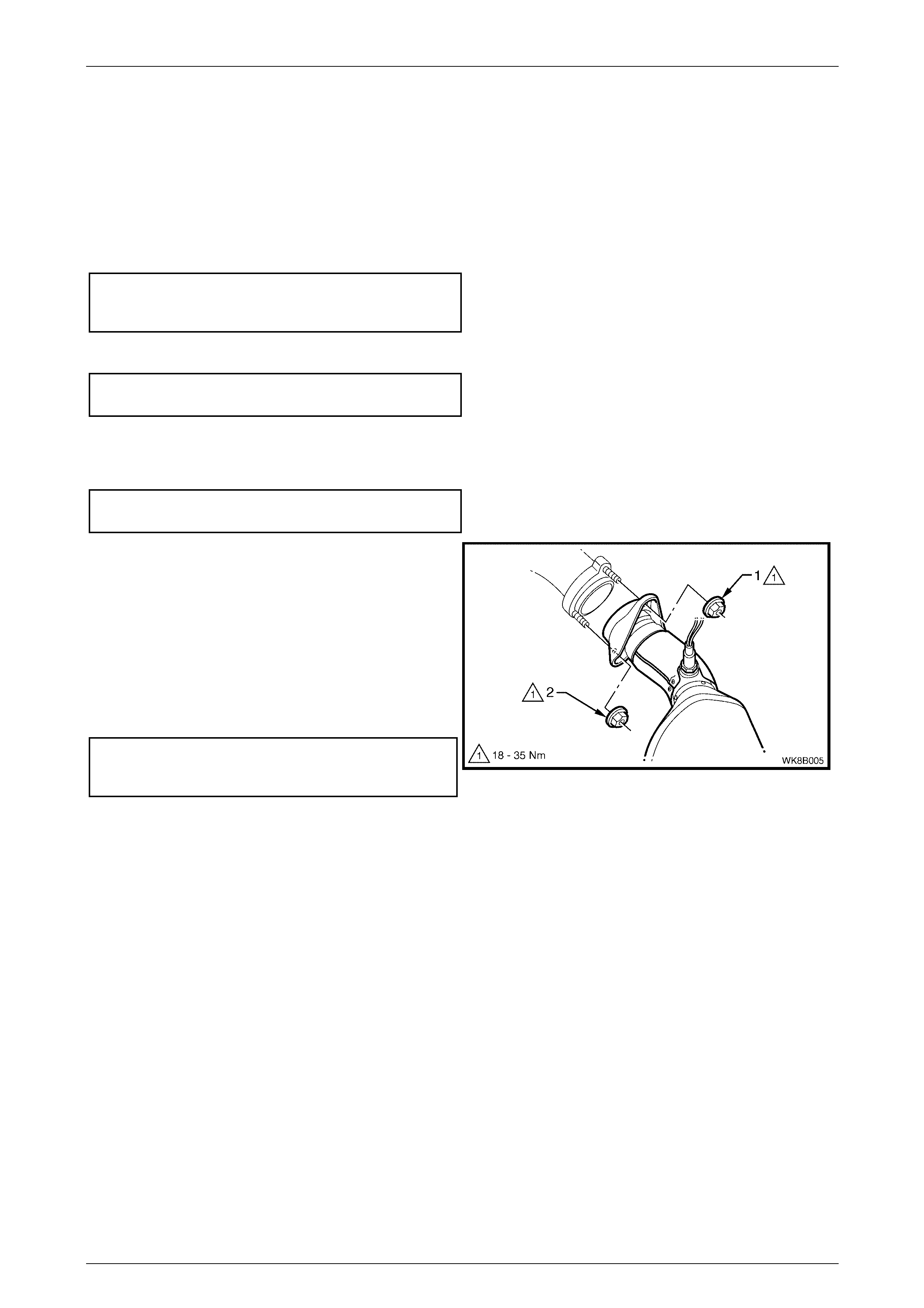

Oxygen Sensors

When removing the front exhaust pipes, it is necessary to

disconnect the wiring harness connectors from each of the

two oxygen sensors (1).

For oxygen sensor replacement, refer to Section 6C1, 6.1

Oxygen Sensor.

Figure 8B – 4

Exhaust System Page 8B–8

Page 8B–8

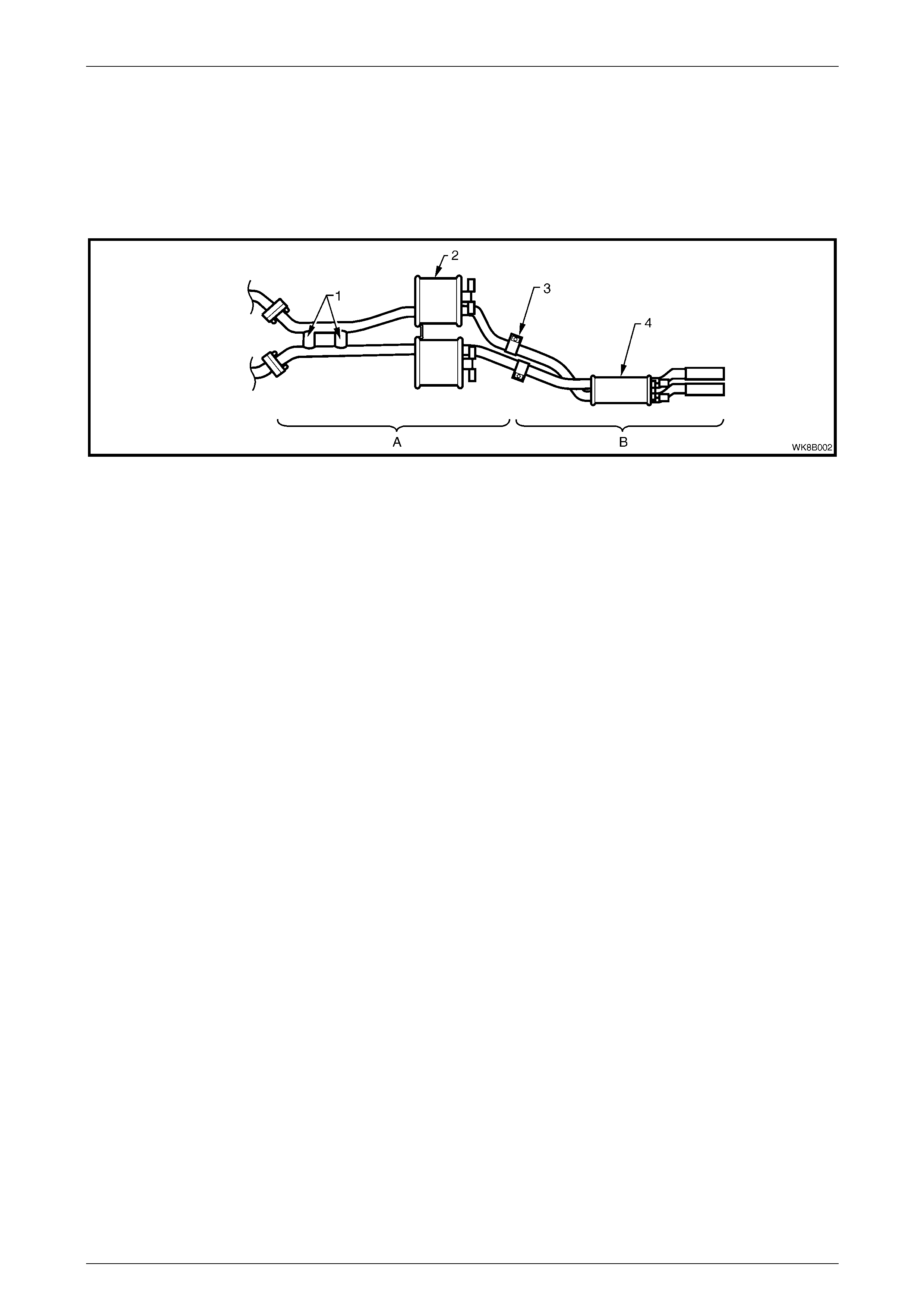

2.2 Exhaust System

Figure 8B – 5 illustrates the exhaust system configuration used with the V6 engine.

Figure 8B – 5

Legend

1 Manifold to Front P i pe Fl ange

2 Catalytic Converter

3 Front pipe to I nt ermediate Y -Pipe Flange

4 Y-Pipe Brace and Rubber Support

5 Flange Swivel Joint

6 Intermediate Muffler

7 Intermediate Muff l er S upport Rubbers

8 Intermediate to Rear Pipe Slip Joint and U-cl amp

9 Rear Muffler

10 Rear Muffler Support Rubbers

Exhaust System Page 8B–9

Page 8B–9

Complete Exhaust System Assembly

Remove

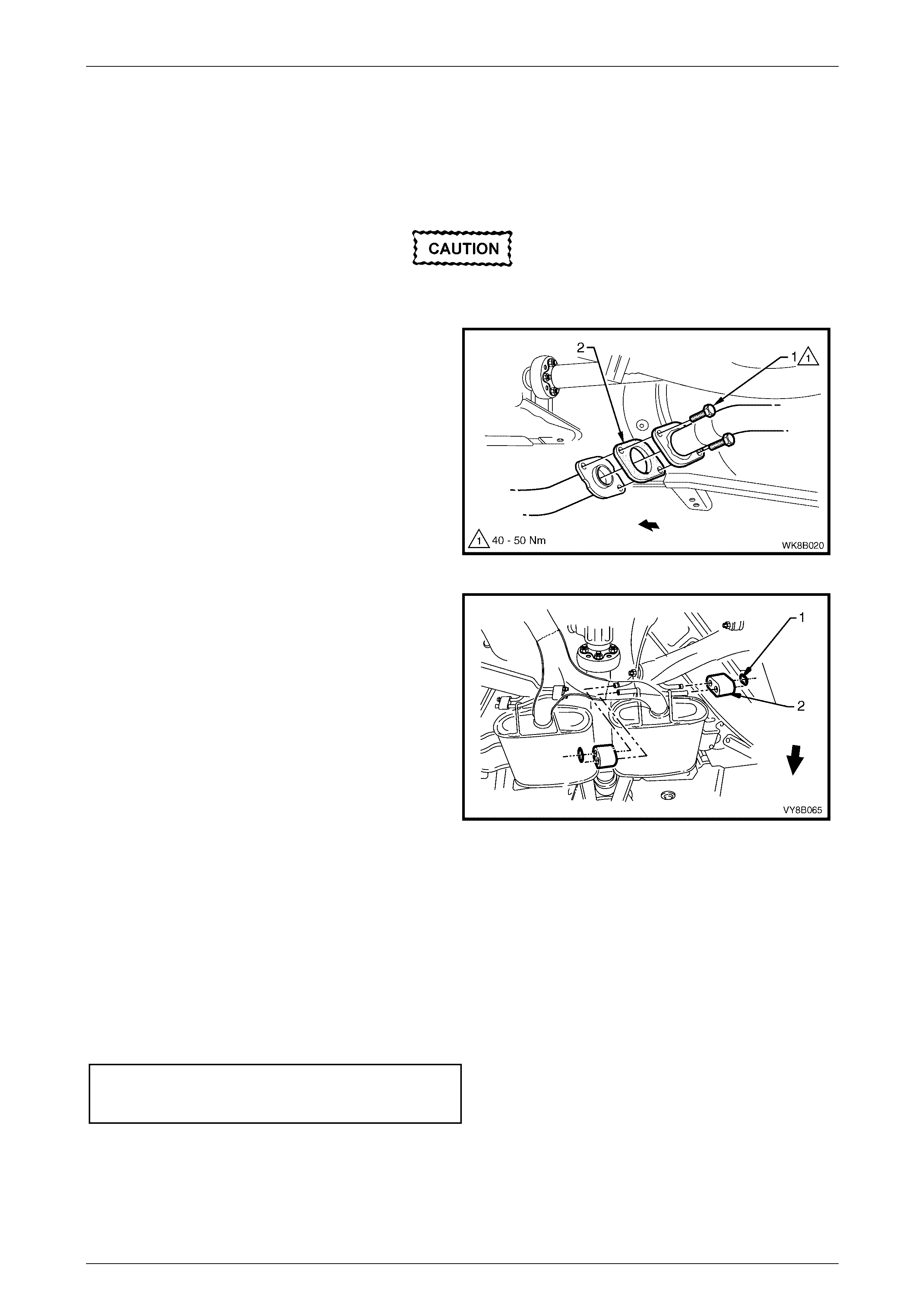

1 Disconnect the wiring harness connectors from each

of the two oxygen sensors (1).

Figure 8B – 6

2 Support the exhaust system and remove the

upper (1) then lower (2) fastening nuts from the front

exhaust assembly to exhaust manifold flange studs

on both sides.

Figure 8B – 7

3 Disconnect the rear muffler from the support hangers

by removing the two retainer clips (1) and support

rubbers (2).

Figure 8B – 8

Exhaust System Page 8B–10

Page 8B–10

4 Support the exhaust system and disconnect the

intermediate muffler from the support hangers by

removing the two retainer clips (1) and the two

support rubbers (2).

Figure 8B – 9

5 Disconnect the front exhaust assembly by removing

the support rubber (1) from the peg welded to the

exhaust pipe brace.

6 Carefully lower and remove the exhaust assembly

from the vehicle, taking care not to damage the

exhaust gas oxygen sensors.

Figure 8B – 10

Reinstall

Installation of the complete exhaust system is the reverse of the removal procedure, noting the following points:

1 Support the exhaust system at all times.

2 Clean the threads of the manifold flange studs with a suitable cleaning solvent.

3 Hand tighten the upper fastening nut (1) to the stud

on both sides.

4 Hand tighten the lower fastening nut (2) to the stud

on both sides.

5 Tighten the upper then lower fastening nuts so that

approximately equal amounts of stud thread are

showing.

6 Tighten the upper then lower fastening nuts to the

specified torque.

Front exhaust assembly to exhaust

manifold flange stud fastening nut

torque specification..................................... 18 – 35 Nm

Figure 8B – 11

7 Ensure all support rubbers are under load.

8 Check the exhaust system for clearances, refer to 5.1 V6 Exhaust Systems Clearances. If the clearances are not

within tolerance, loosen off all fasteners and perform the tightening sequence procedure, refer to 2.7 Ti ghtening

Sequence.

9 Connect the wiring harness connectors for each of the two oxygen sensors.

Exhaust System Page 8B–11

Page 8B–11

2.3 Rear Exhaust Assembly

Remove

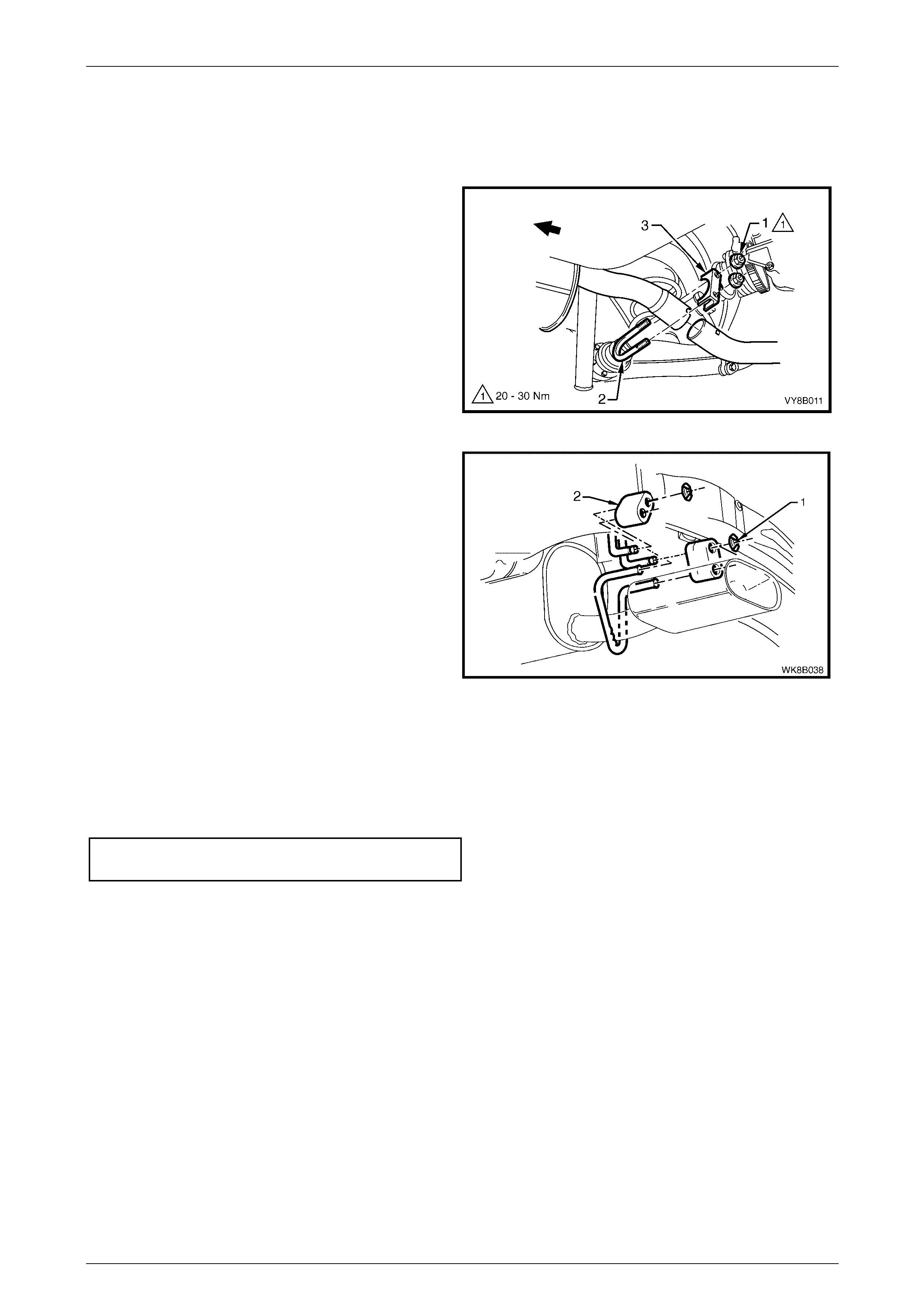

1 Remove the two retaining nuts (1) and the rear

muffler U-bolt (2) and clamp (3) from along the

intermediate exhaust pipe to rear muffler exhaust

pipe slip joint.

Figure 8B – 12

2 Remove the two support hanger retainer clips (1) and

the two support rubbers (2) from the support hangers.

3 Carefully slide the rear exhaust pipe out of the

intermediate exhaust pipe end slip joint and remove

the rear exhaust assembly.

Figure 8B – 13

Reinstall

Installation of the rear exhaust assembly is the reverse of the removal procedure, noting the following:

1 Ensure that the rear exhaust pipe slides unobstructed into the intermediate exhaust pipe slip joint, and that the

alignment key is positioned in the slip joint channel. Tighten the U-bolt fastening nuts to the specified torque.

U-bolt clamp assembly fastening

nuts torque specification .............................. 20 – 30 Nm

2 Ensure all support rubbers are under load.

3 Check the exhaust system for clearances, refer to 5.1 V6 Exhaust Systems Clearances. If the clearances are not

within tolerance, loosen off all fasteners and perform the tightening sequence procedure, refer to 2.7 Tightening

Sequence.

Exhaust System Page 8B–12

Page 8B–12

2.4 Intermediate Exhaust Single Pipe and

Muffler Assembly

Remove

1 Remove the rear exhaust assembly, refer to 2.3 Rear Exhaust Assembly in this Section.

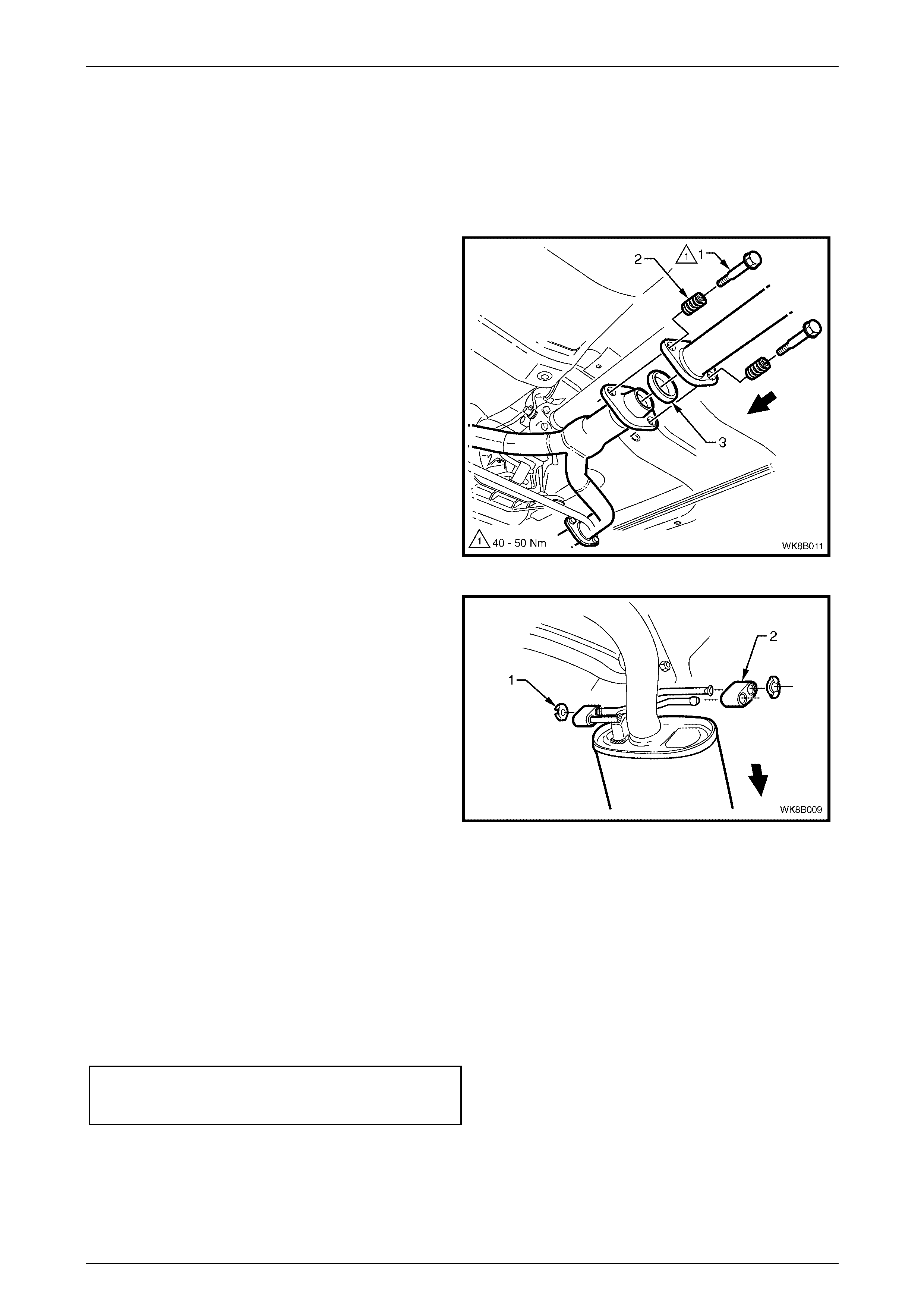

2 Support the exhaust assembly and remove the two

stepped fastening bolts (1) and springs (2) from the

intermediate single pipe and muffler assembly to

intermediate Y-pipe flange joints.

3 Separate the intermediate single pipe and muffler

exhaust assembly from the intermediate Y-pipe

exhaust assembly and remove the sealing ring (3)

from within the flange joint.

Figure 8B – 14

4 Remove the two retainer clips (1) and support

rubbers (2) from the support hangers and remove the

intermediate exhaust single pipe and muffler

assembly.

Figure 8B – 15

Reinstall

Installation of the intermediate exhaust single pipe and muffler assembly is the reverse of the removal procedure, noting

the following:

1 Support the exhaust system at all times.

2 Clean threads of the stepped fastening bolts and Y-pipe flange with a suitable cleaning solvent.

3 Check condition of sealing ring upon reinstallation and replace if necessary.

4 Tighten the intermediate single pipe to Y-pipe exhaust assembly flange fastening bolts to the specified torque.

Intermediate single pipe to

Y-Pipe exhaust assembly flange

fastening bolt torque specification................40 – 50 Nm

5 Ensure all support rubbers are under load.

6 Check the exhaust system for clearances, refer to 5.1 V6 Exhaust Systems Clearances. If the clearances are not

within tolerance, loosen off all fasteners and perform the tightening sequence procedure, refer to 2.7 Ti ghtening

Sequence.

Exhaust System Page 8B–13

Page 8B–13

2.5 Intermediate Exhaust Y-Pipe Assembly

Remove

1 Disconnect the wiring harness connectors from each

of the two oxygen sensors (1).

Figure 8B – 16

2 Support the intermediate exhaust assembly and

remove the two stepped fastening bolts (1) and

springs (2) from the intermediate exhaust single pipe

to intermediate exhaust Y-pipe flange joint.

3 Separate the intermediate single pipe and muffler

exhaust assembly and remove the sealing ring (3)

from within the flange joint.

Figure 8B – 17

Exhaust System Page 8B–14

Page 8B–14

4 Remove the two pairs of fastening nuts (1) from each

of the front two Y-pipe flange studs and remove both

flange gaskets.

5 Remove the support rubber (2) from the cross brace

peg and remove the Y-pipe exhaust assembly.

Figure 8B – 18

Reinstall

Installation of the exhaust Y-pipe assembly is the reverse of the removal procedure, noting the following points:

1 Support the exhaust system at all times.

2 Clean threads of all flange bolts and studs with a suitable cleaning solvent.

3 Always check condition of flange gaskets upon reinstallation and replace if necessary.

4 Tighten the intermediate single pipe to Y-pipe exhaust assembly flange fastening bolts to the specified torque.

Intermediate single pipe to

Y-Pipe exhaust assembly flange

fastening bolt torque specification................40 – 50 Nm

5 Tighten the front pipe to Y-pipe flange fastening bolts to the specified torque.

Front pipe to exhaust

Y-Pipe flange fastening bolt

torque specification......................................40 – 50 Nm

6 Ensure all support rubbers are under load.

7 Check the exhaust system for clearances, refer to 5.1 V6 Exhaust Systems Clearances. If the clearances are not

within tolerance, loosen off all fasteners and perform the tightening sequence procedure, refer to 2.7 Ti ghtening

Sequence.

8 Connect the wiring harness connectors for each of the two oxygen sensors.

Exhaust System Page 8B–15

Page 8B–15

2.6 Front Exhaust Assembly

Remove

1 Disconnect the relevant wiring harness connector/s

from the oxygen sensor/s (1).

Figure 8B – 19

2 Support the intermediate Y-pipe exhaust assembly

and remove the necessary fastening bolts (1) from

the Y-pipe to front pipe flange joint/s.

Figure 8B – 20

4 Support the exhaust system and remove the

upper (1) then lower (2) fastening nuts from the front

exhaust assembly to exhaust manifold flange studs

on both sides.

5 Carefully lower and remove the front exhaust

assembly from the vehicle, taking care not to damage

the exhaust gas oxygen sensor.

Figure 8B – 21

Exhaust System Page 8B–16

Page 8B–16

Reinstall

Installation of the front exhaust assembly is the reverse of the removal procedure, noting the following points:

1 Support the exhaust system at all times.

2 Clean threads of flange bolts and studs with a suitable cleaning solvent.

3 Always check condition of flange gaskets upon reinstallation and replace if necessary.

4 Tighten the intermediate Y-pipe to front exhaust assembly flange fastening bolts to the specified torque, refer to

Figure 8B – 20.

Intermediate Y-Pipe to front exhaust

assembly flange fastening bolt

torque specification......................................40 – 50 Nm

5 Apply a high temperature anti-seize compound to the exhaust manifold to exhaust pipe flange studs and align the

front pipe flange over the studs.

6 Hand tighten the upper fastening nut (1) to the stud

on both sides.

7 Hand tighten the lower fastening nut (2) to the stud

on both sides.

8 Tighten the upper then lower fastening nuts so that

approximately equal amounts of stud thread are

showing.

9 Tighten the upper then lower fastening nuts to the

specified torque.

Front exhaust assembly to exhaust

manifold flange stud fastening nut

torque specification..................................... 18 – 35 Nm

Figure 8B – 22

10 Ensure all support rubbers are under load.

11 Check the exhaust system for clearances, refer to 5.1 V6 Exhaust Systems Clearances . If the clearances are not

within tolerance, loosen off all fasteners and perform the tightening sequence procedure, refer to 2.7 Ti ghtening

Sequence.

12 Connect the wiring harness connectors for each of the two oxygen sensors.

Exhaust System Page 8B–17

Page 8B–17

2.7 Tightening Sequence

This procedure is only to be performed if the exhaust system positioning is not to specification.

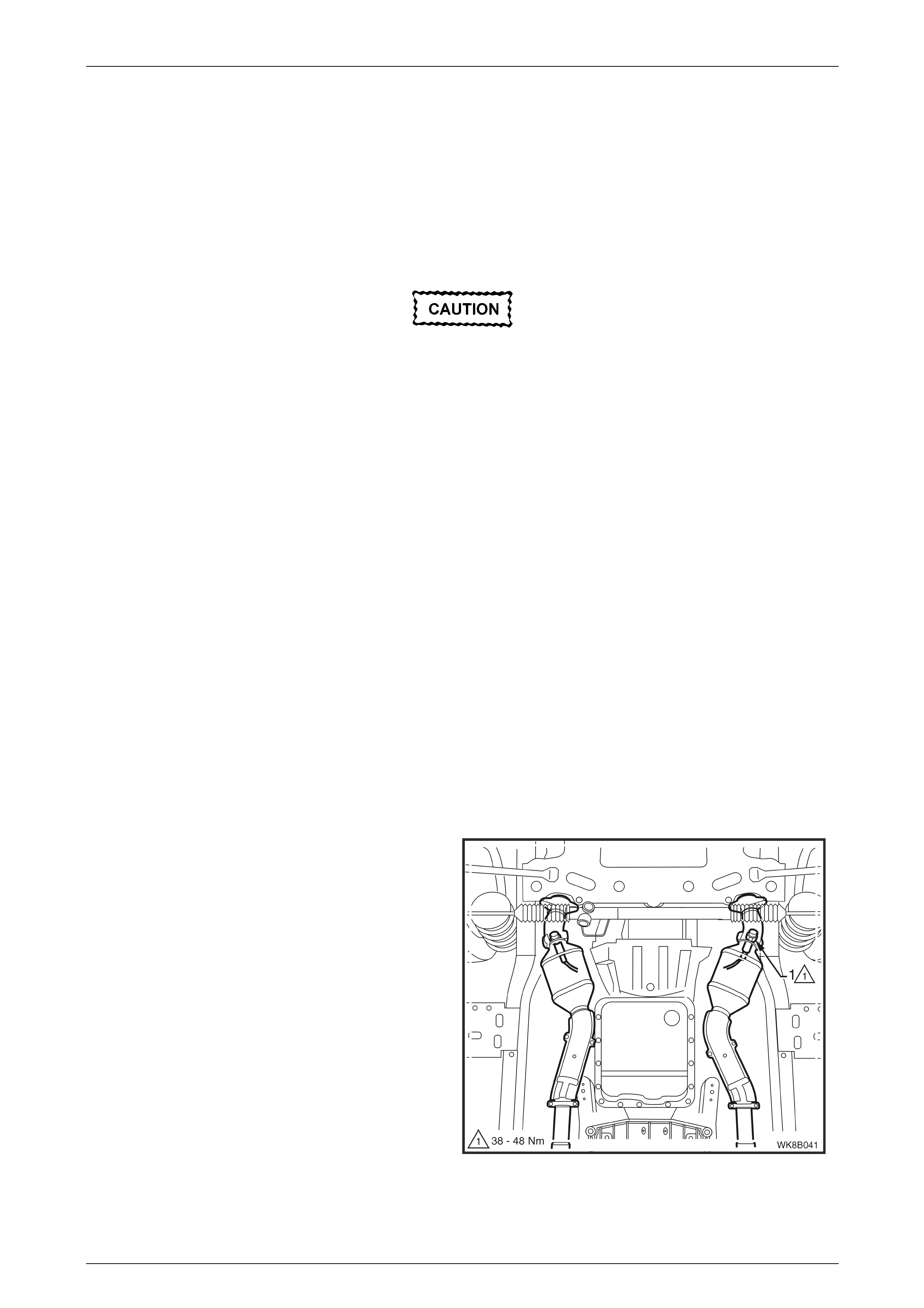

Refer to Figure 8B – 24 for the following.

Ensure that all fasteners mentioned in steps 1 to 7 below are loose before conducting this procedure.

1 Tighten each of the intermediate Y-pipe to front exhaust assembly flange fastening bolts (1) to the specified

torque.

Intermediate Y-pipe to front exhaust

assembly flange fastening bolt

torque specification......................................40 – 50 Nm

2 Tighten the swivel joint flange stepped fastening bolts (2) to the specified torque.

Swivel joint flange stepped fastening

bolt torque specification ............................... 40 – 50 Nm

3 Check that the rear exhaust pipe aligning key is fully seated within the intermediate single pipe and muffler

exhaust assembly end slip joint channel. Position the U-bolt clamp (3) along the slip joint and tighten the pair of

fastening nuts to the specified torque.

U-bolt clamp assembly fastening

nuts torque specification .............................. 40 – 50 Nm

4 Hand tighten the upper fastening nut (1) to the stud

on both sides.

5 Hand tighten the lower fastening nut (2) to the stud

on both sides.

6 Tighten the upper then lower fastening nuts so that

approximately equal amounts of stud thread are

showing.

7 Tighten the upper then lower fastening nuts to the

specified torque.

Front exhaust assembly to exhaust

manifold flange stud fastening nut

torque specification..................................... 18 – 35 Nm

Figure 8B – 23

8 Ensure that all support rubbers (4, 5 and 6) are under load, refer to Figure 8B – 24. If this is not achieved, loosen

the respective joints in the reverse order to steps 1 to 7. Load the hangers and re-tighten in the sequence

described, from steps 1 to 7.

NOTE

The exhaust system should be self-aligning and

not require further adjustment, provided step 8 is

achieved. To ensure that correct clearances are

maintained throughout the complete exhaust

system, refer to 5.1 V6 Exhaust Systems

Clearances for the correct values.

Exhaust System Page 8B–18

Page 8B–18

Figure 8B – 24

Exhaust System Page 8B–19

Page 8B–19

3 Service Operations – GEN III V8

3.1 Service Notes

Two exhaust system configurations, Standard and Performance, are available for vehicles fitted with the GEN III V8

engine. The type installed will depend on the particular vehicle’s specifications. Details of both of these systems are

included.

When installing any exhaust system component, care must be taken to install each component in the correct

relationship to the other. Ensure that correct assembly, installation, tightening sequence, tightening torque and

clearance for the system involved is observed. When exhaust system service work is required, refer to the various

illustrations and instructions provided in this Section.

The incorrect assembly of exhaust system

components can frequently be the cause of

rattles and ‘booms' due to incorrect

alignment or clearance of body or suspension

parts. Ensure that the correct tightening

sequence is observed upon installation of

exhaust system components.

NOTE

Service operations on exhaust system

components must be carried out with all parts at

ambient temperatures to ensure correct

clearances are maintained.

Catalytic Converter

Catalytic converters are serviced as part of the complete front pipe assemblies only. If removing or replacing either of

the front exhaust pipe assemblies, always ensure that new flange gaskets are installed on reassembly. Check flange

gaskets for damage and replace if necessary.

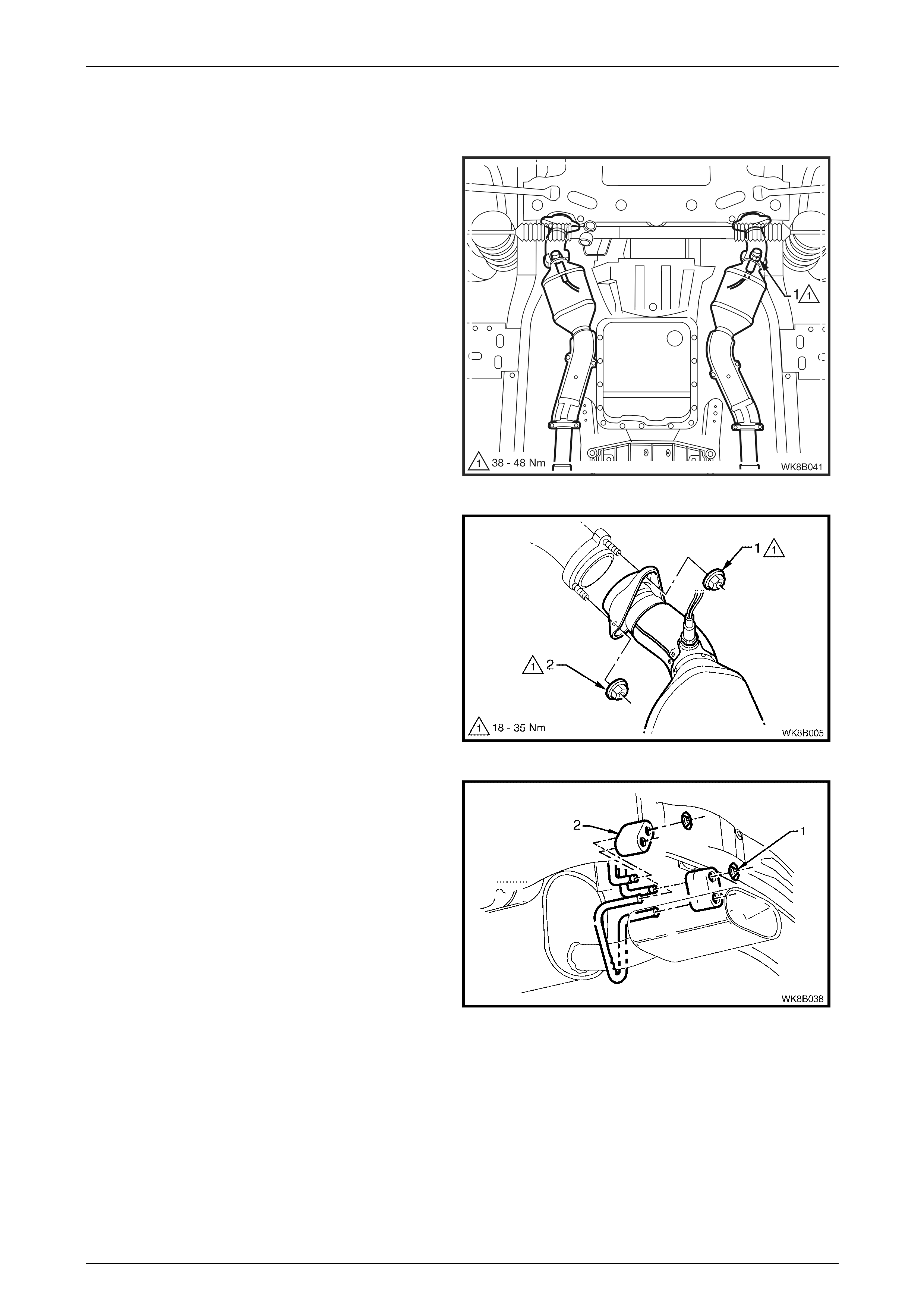

Oxygen Sensors

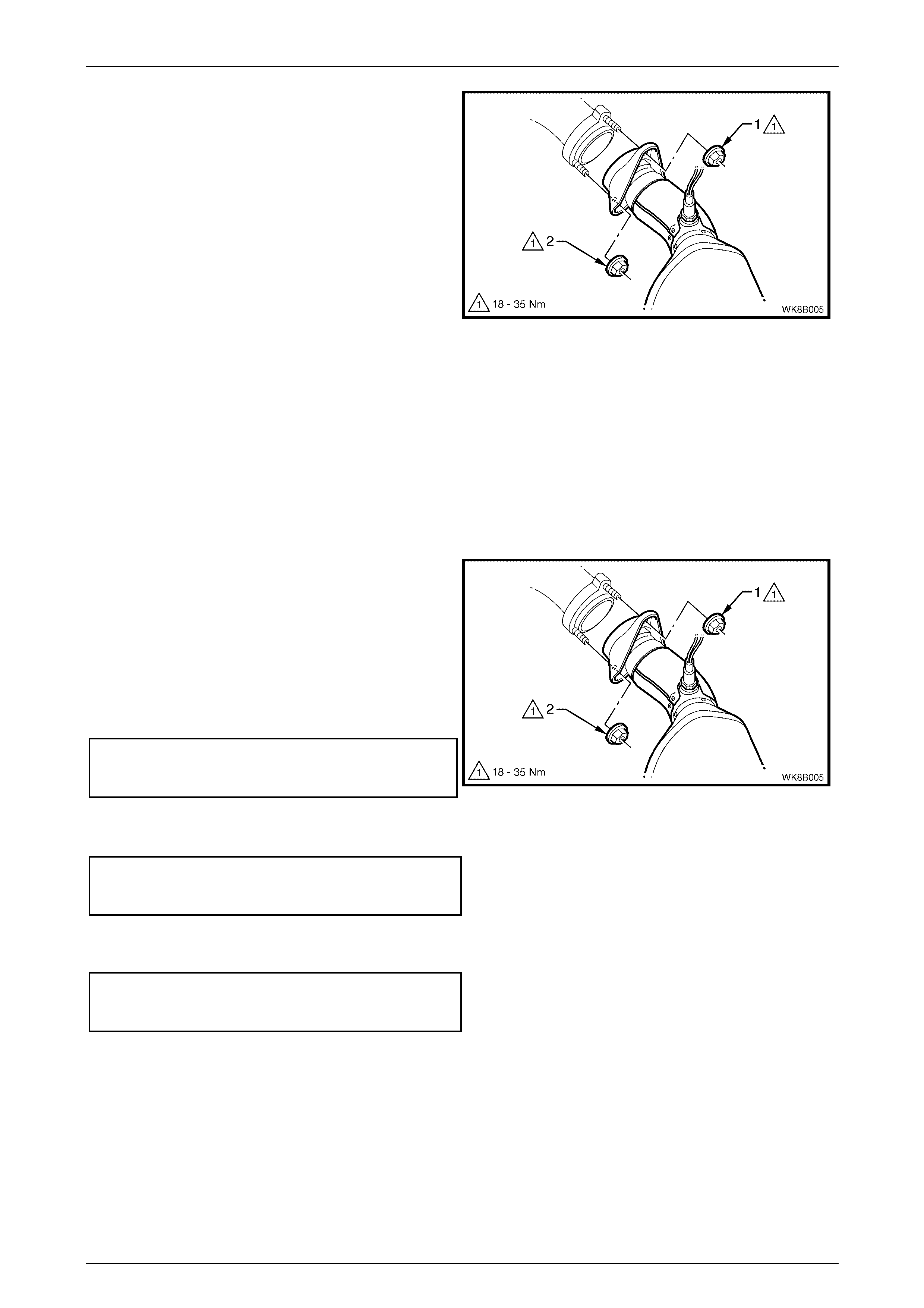

When removing the front exhaust pipes, it is necessary to

disconnect the wiring harness connectors from each of the

two oxygen sensors (1).

For oxygen sensor replacement, refer to Section 6C3-3,

2.8 Heated Oxygen Sensors in the MY 2003 VY and V2

Series Service Information.

Figure 8B – 25

Techline

Exhaust System Page 8B–20

Page 8B–20

3.2 Exhaust System

The following removal and installation service operations should be referred to when conducting work on Standard and

Performance exhaust systems, Refer to 1.2 Exhaust System Configurations, Figure 8B – 2 and Figure 8B – 3

respectively within this Section. The illustrations provided represent the right-hand drive Standard exhaust system,

however any significant differences in procedure or configuration for left-hand drive or Performance exhaust systems will

be highlighted to accommodate servicing differences.

Figure 8B – 26 provides a reference to the location of relevant exhaust system removal and installation components.

Figure 8B – 26

Legend

1 Manifold to Front P i pe Fl ange J oi nt

2 Catalytic Converter

3 Transm i ssion to Front Pipe Ass embly Mounting Bracket

4 Front to Int ermediate P i pe Fl ange Joint

5 Intermediate Muffler

6 Intermediate Muff l er S upport Rubbers

7 Intermediate to Rear Pipe Slip J oi nt and Fastening

8 Rear Muffler

9 Rear Muffler Support Rubbers

Exhaust System Page 8B–21

Page 8B–21

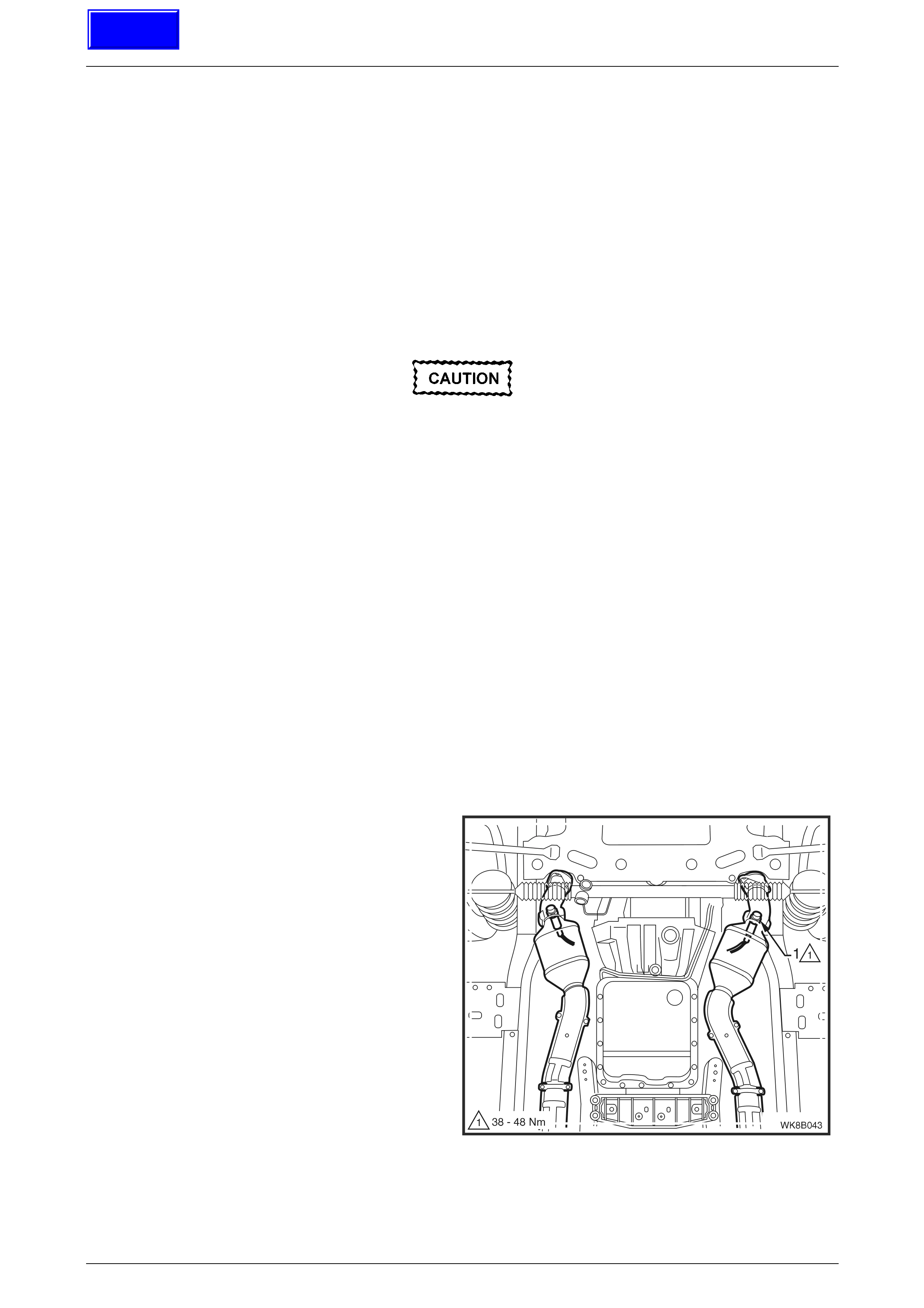

3.3 Complete Exhaust System Assembly

Remove

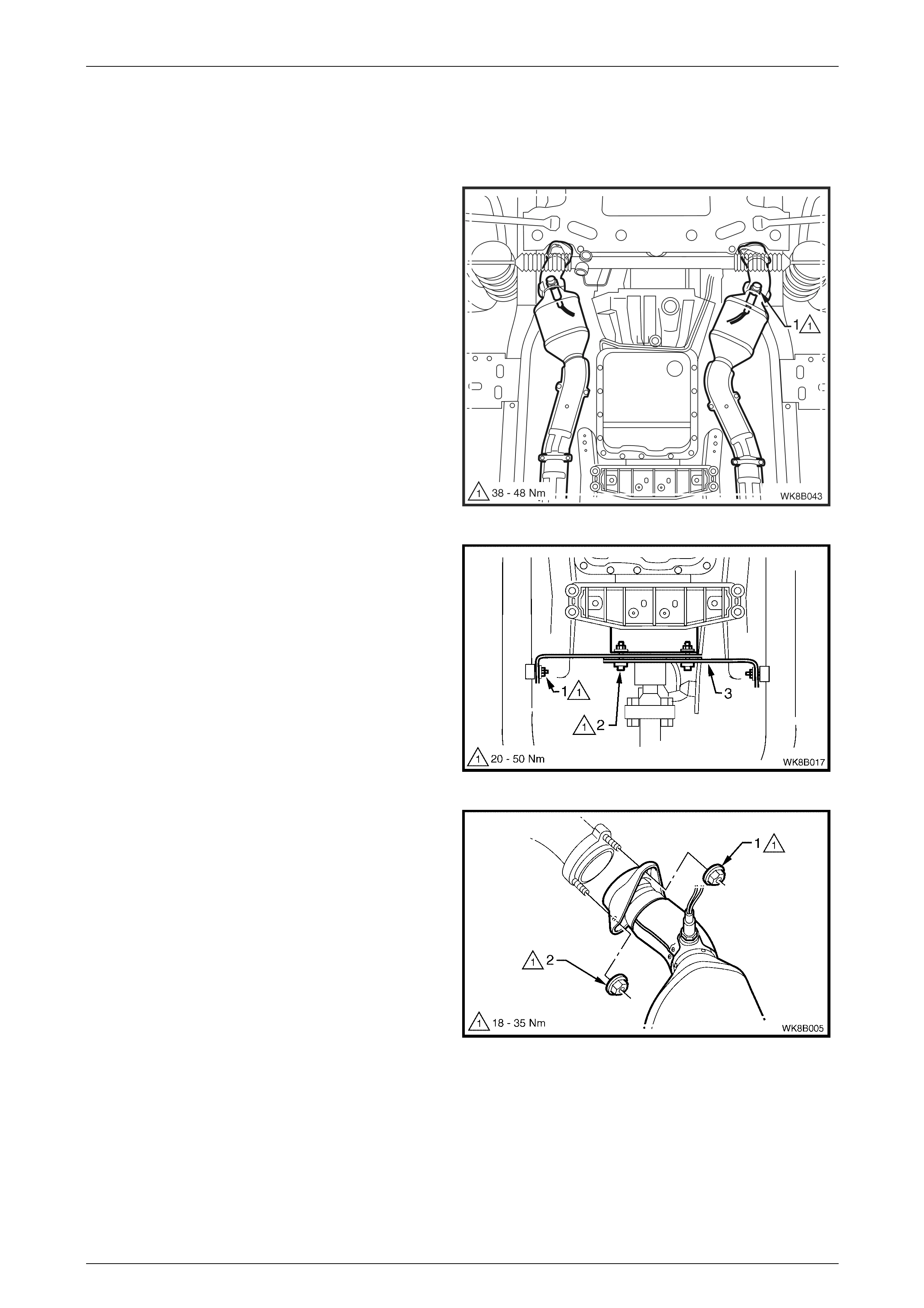

1 Disconnect the wiring harness connectors from each

of the two oxygen sensors (1).

Figure 8B – 27

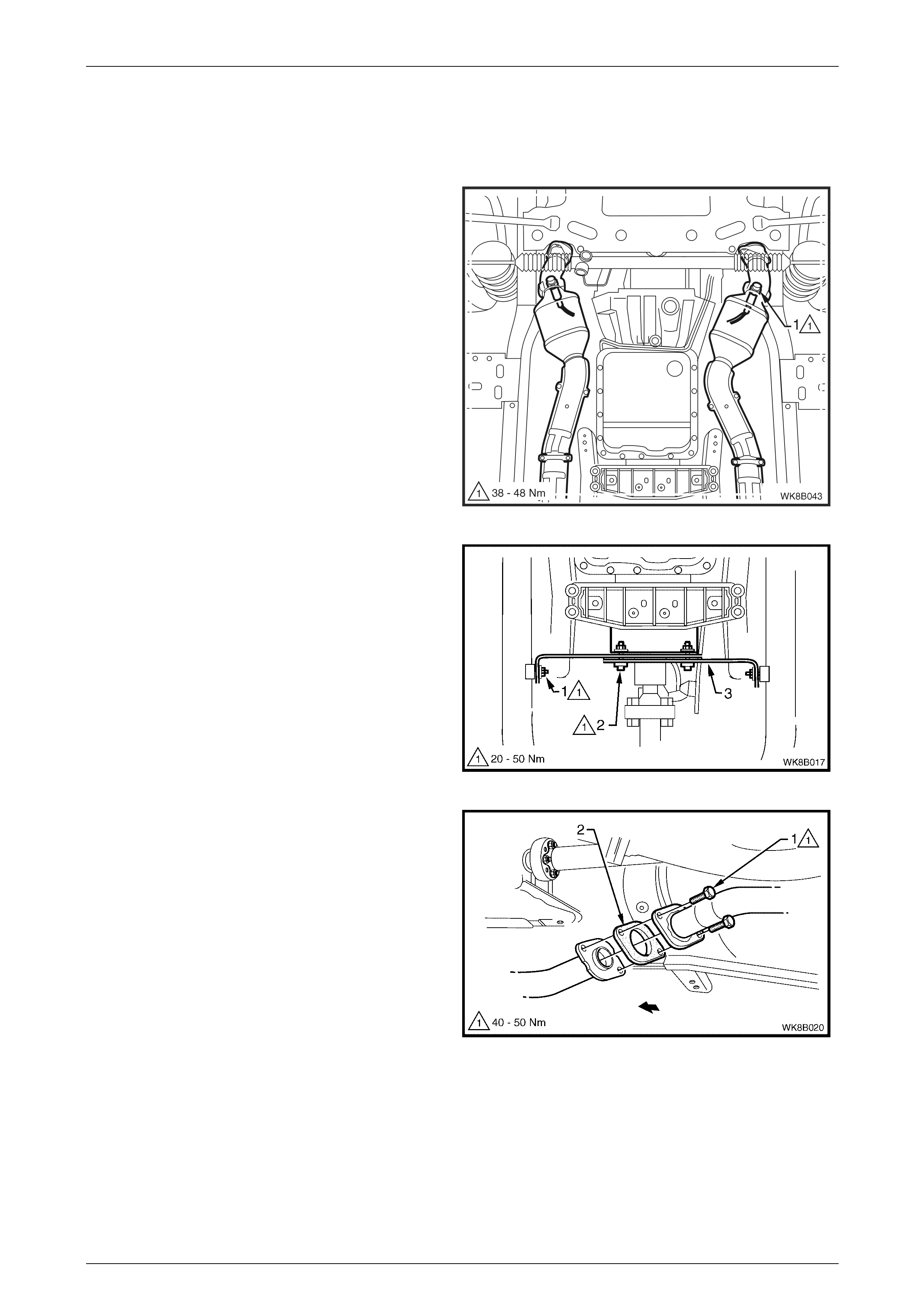

2 Remove the transmission to front pipe assembly

mounting bracket nuts (1 and 2).

Figure 8B – 28

3 Support the exhaust system and remove the

upper (1) then lower (2) fastening nuts from the front

exhaust assembly to exhaust manifold flange studs

on both sides.

Figure 8B – 29

Exhaust System Page 8B–22

Page 8B–22

4 Disconnect the rear muffler from the support hangers

by removing the two retainer clips (1) and support

rubbers (2).

Figure 8B – 30

5 Support the exhaust system and disconnect each

intermediate muffler from the support hangers by

removing the retainer clips (1) and the support

rubbers (2).

6 Carefully lower and remove the exhaust assembly

from the vehicle, taking care not to damage the

exhaust gas oxygen sensors.

Figure 8B – 31

Reinstall

Installation of the full exhaust system is the reverse of the removal procedure, noting the following points:

1 Support the exhaust system at all times.

2 Clean threads of flange and fastening bolts with a suitable cleaning solvent.

3 Always check condition of flange gaskets upon reinstallation and replace if necessary.

4 Apply high temperature anti-seize compound to the manifold to front pipe flange studs and align the front pipe

flange over the studs.

5 Hand tighten the upper fastening nut (1) to the stud

on both sides.

6 Hand tighten the lower fastening nut (2) to the stud

on both sides.

7 Tighten the upper then lower fastening nuts so that

approximately equal amounts of stud thread are

showing.

8 Tighten the upper then lower fastening nuts to the

specified torque.

Front exhaust assembly to exhaust

manifold flange stud fastening nut

torque specification..................................... 18 – 35 Nm

Figure 8B – 32

9 Ensure all support rubbers are under load.

10 Check the exhaust system for clearances, refer to 5.2 GEN III V8 Exhaust System Clearances . If the clearances

are not within tolerance, loosen off all fasteners and perform the tightening sequence procedure, refer to

3.7 Tightening Sequence.

11 Connect the wiring harness connectors for each of the two oxygen sensors.

Exhaust System Page 8B–23

Page 8B–23

3.4 Rear Exhaust Assembly

Remove

1 For Standard exhaust:

a Remove the two retaining nuts (1) and the rear

muffler U-bolt (2) and clamp plate (3) from the

intermediate exhaust pipe to rear muffler

exhaust pipe slip joint.

Figure 8B – 33

2 For Performance exhaust:

a Loosen each of the two ring clamp fastening

nuts.

Figure 8B – 34

3 Remove the two support hanger retainer clips (1) and

the two support rubbers (2) from the support hangers.

4 Support the intermediate exhaust assembly and slide

the rear exhaust assembly out from the intermediate

exhaust pipe end slip joint/s.

5 Remove the rear exhaust assembly.

Figure 8B – 35

Exhaust System Page 8B–24

Page 8B–24

Reinstall

Installation of the rear exhaust assembly is the reverse of the removal procedure, noting the following:

1 Ensure that the rear exhaust pipe slides unobstructed into the intermediate exhaust pipe slip joint, and that the

alignment key is positioned in the slip joint channel.

2 For Standard exhaust, evenly tighten the U-bolt clamp nuts to the correct torque specification, refer to

Figure 8B – 33.

U–bolt clamp assembly fastening

screw torque specification............................ 20 – 30 Nm

3 For Performance exhaust, position each ring clamp along the two intermediate to rear slip joints and tighten each

fastening bolt to the specified torque, refer to Figure 8B – 34.

Ring clamp assembly fastening

bolts torque specification ............................. 37 – 50 Nm

4 Ensure all support rubbers are under load.

5 Check the exhaust system for clearances, refer to 5.2 GEN III V8 Exhaust System Clearances. If the clearances

are not within tolerance, loosen off all fasteners and perform the tightening sequence procedure, refer to

3.7 Tightening Sequence.

Exhaust System Page 8B–25

Page 8B–25

3.5 Intermediate Exhaust Assembly

Remove

1 Remove the rear exhaust assembly, refer to 3.4 Rear Exhaust Assembly in this Section.

The front exhaust assembly must be

supported during and after this procedure.

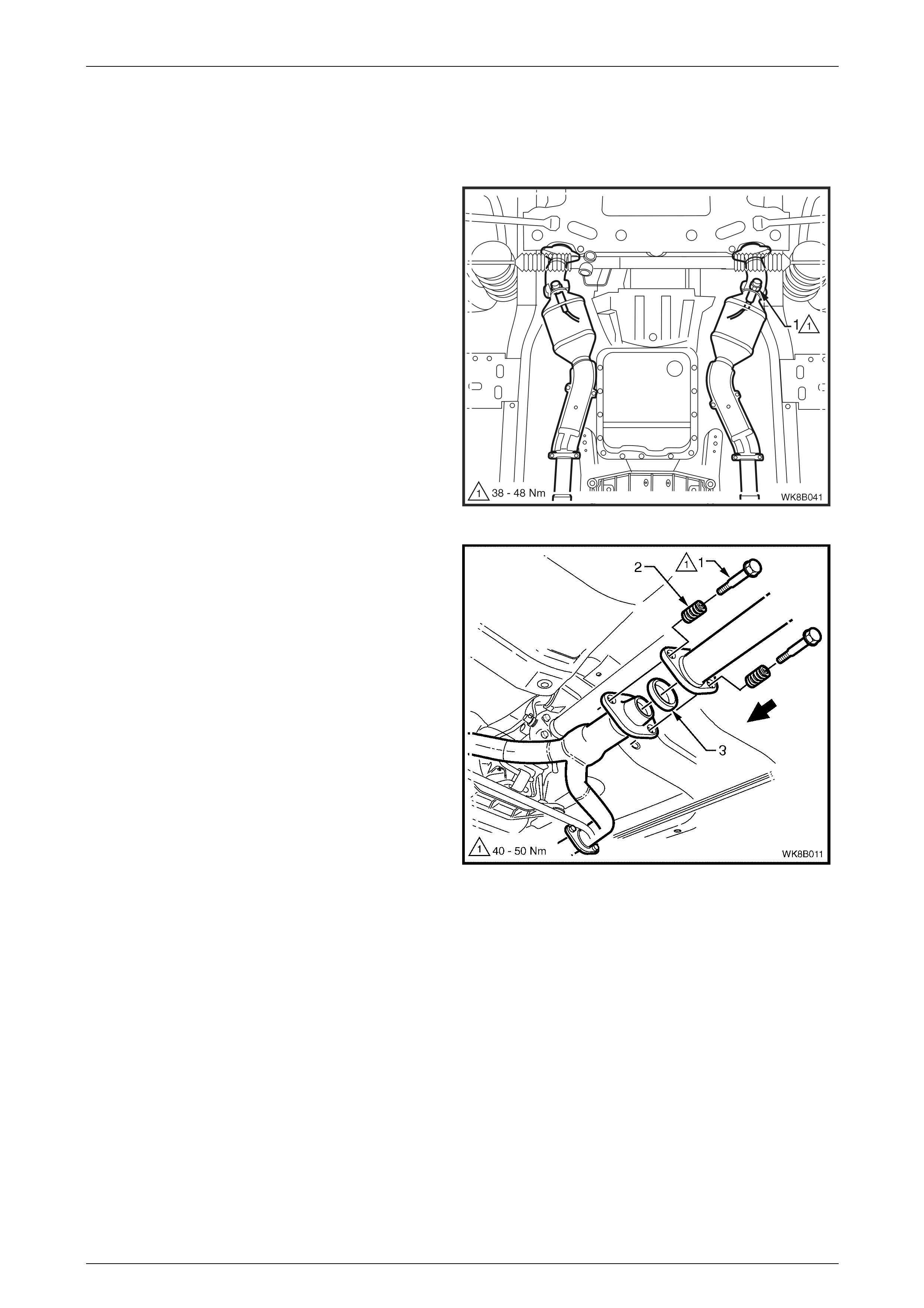

2 Support the intermediate and front exhaust

assemblies and remove the two bolts (1) from each of

the two flange joints.

3 Separate the intermediate exhaust assembly from the

front exhaust assembly and remove each flange

gasket from between each of the flange joints.

Figure 8B – 36

4 Remove the pair of retainer clips (1) and support

rubbers (2) from both of the right-hand side and

left-hand side intermediate muffler support hangers

and remove the intermediate exhaust assembly.

Figure 8B – 37

Reinstall

Installation of the intermediate exhaust assembly is the reverse of the removal procedure, noting the following:

1 Support the exhaust system at all times.

2 Clean the threads of flange bolts with a suitable cleaning solvent.

3 Always check condition of flange gaskets upon reinstallation and replace if necessary.

4 Tighten the front pipe to intermediate pipe flange fastening bolts at the rear of the catalytic converters to the

specified torque.

Intermediate to front exhaust

assembly flange fastening bolt

torque specification......................................40 – 50 Nm

5 Ensure all support rubbers are under load.

5 Check the exhaust system for clearances, refer to 5.2 GEN III V8 Exhaust System Clearances. If the clearances

are not within tolerance, loosen off all fasteners and perform the tightening sequence procedure, refer to

3.7 Tightening Sequence.

Exhaust System Page 8B–26

Page 8B–26

3.6 Front Exhaust Assembly

Remove

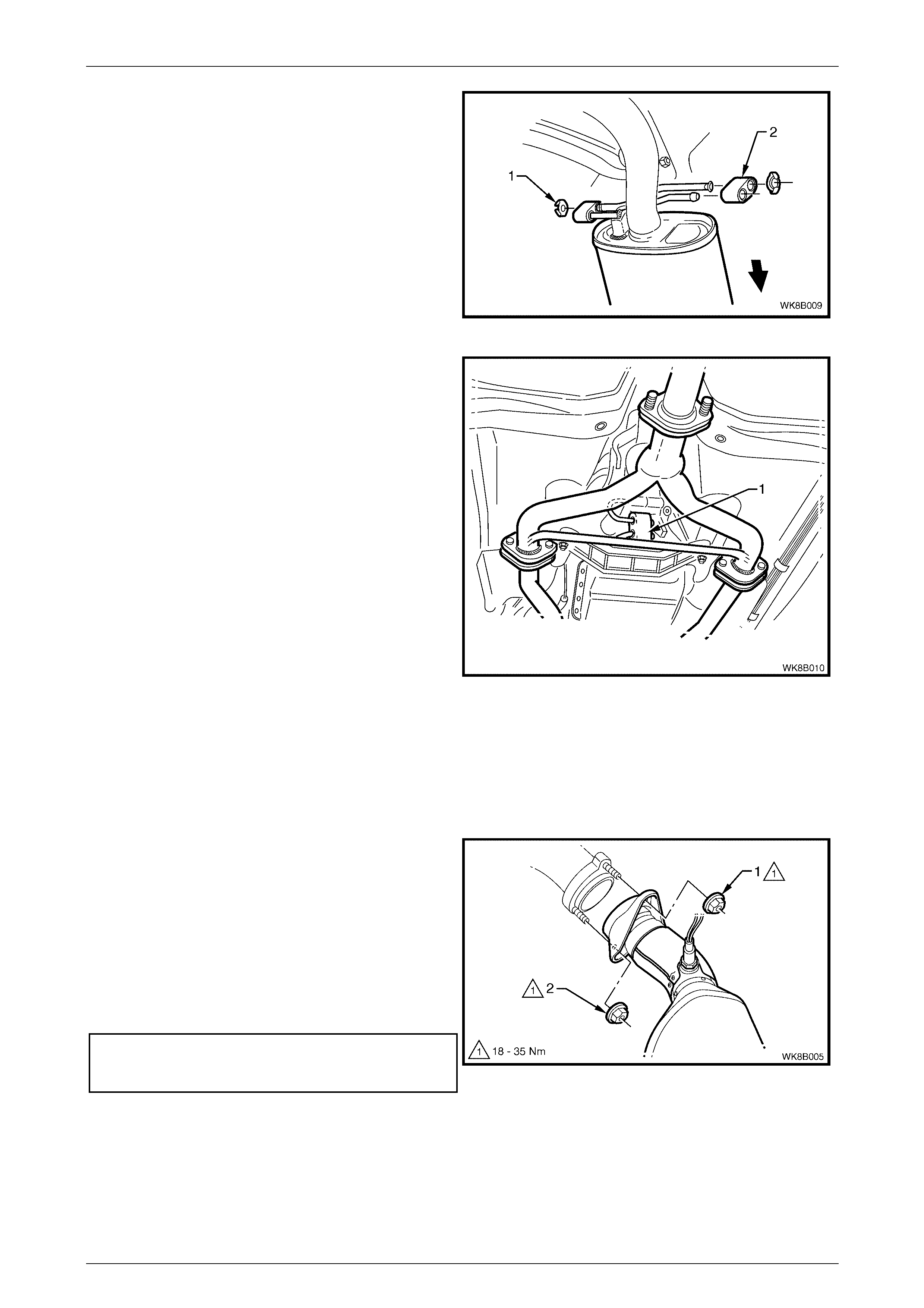

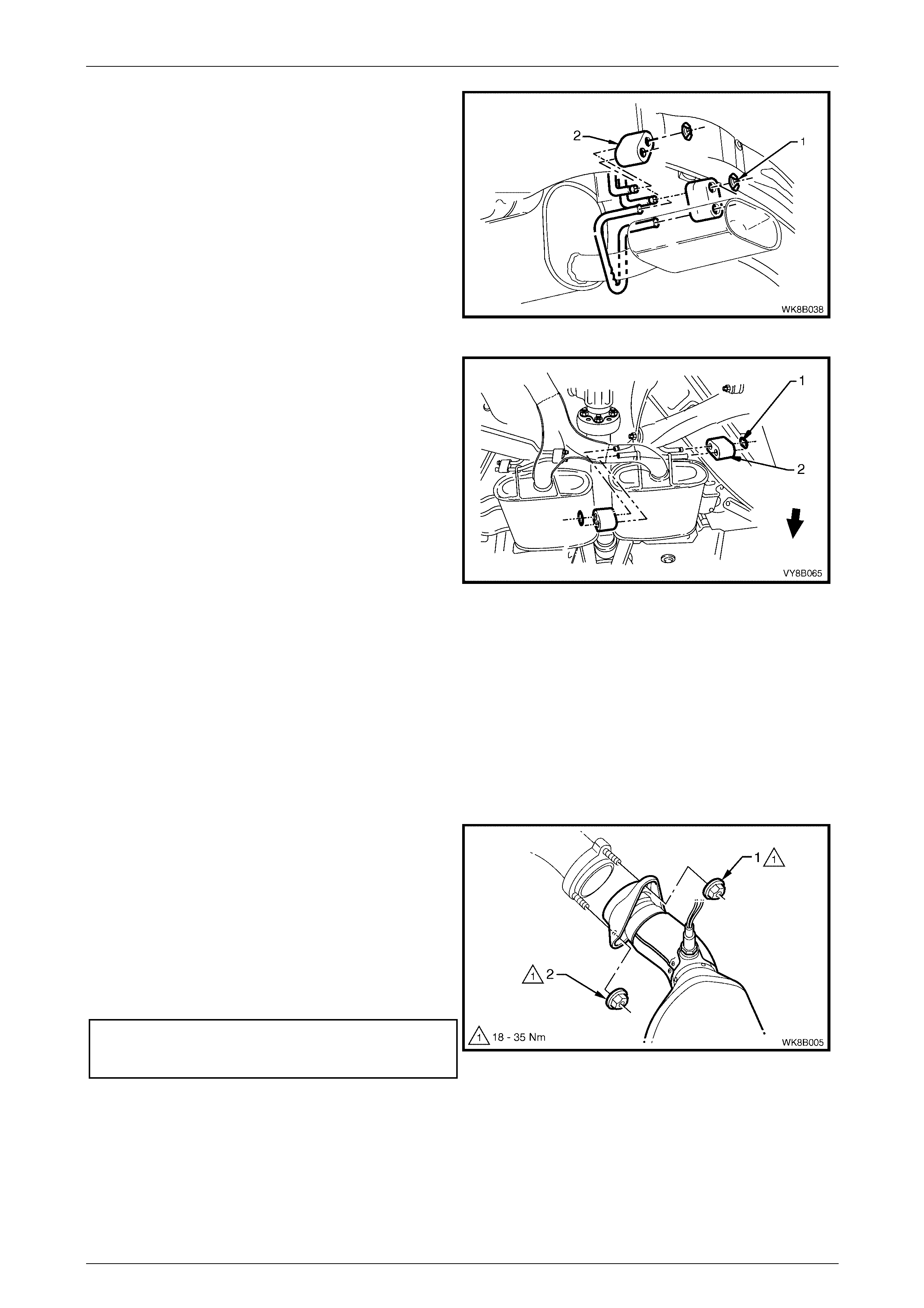

1 Disconnect the wiring harness connector from the

relevant oxygen sensor (1).

Figure 8B – 38

2 Remove the transmission to front pipe assembly

mounting bracket nuts (1 and 2).

Figure 8B – 39

3 Support the intermediate and front exhaust

assemblies and remove the two bolts (1) from the

relevant flange joint.

4 Separate the intermediate exhaust assembly from the

front exhaust assembly and remove the flange gasket

from between the flange joint.

Figure 8B – 40

Exhaust System Page 8B–27

Page 8B–27

5 Support the front exhaust assembly and remove the

upper (1) and lower (2) fastening nuts from the

exhaust manifold to exhaust pipe flange studs on

both sides.

6 Carefully lower and remove the front exhaust

assembly from the vehicle, taking care not to damage

the oxygen sensors in the process.

Figure 8B – 41

Reinstall

Installation of the front exhaust assembly is the reverse of the removal procedure, noting the following points:

1 Support the exhaust system at all times.

2 Clean threads of flange bolts with a suitable cleaning solvent.

3 Always check condition of flange gaskets upon reinstallation and replace if necessary.

4 Apply a high temperature anti-seize compound to the manifold to front pipe flange studs and align the front pipe

flange over the studs.

5 Install the upper fastening nut (1) to the stud on both

sides.

6 Install the lower fastening nut (2) to the stud on both

sides.

7 Tighten the upper and lower fastening nuts so that

approximately equal amounts of thread are showing.

8 Tighten the exhaust manifold to front pipe flange

fastening nuts (1 and 2) to the specified torque.

Front exhaust assembly to exhaust

manifold flange stud fastening nut

torque specification..................................... 18 – 35 Nm

Figure 8B – 42

9 Tighten the front pipe to intermediate pipe flange fastening bolts to the specified torque, refer to Figure 8B – 40.

Intermediate to front exhaust

assembly flange fastening bolt

torque specification......................................40 – 50 Nm

10 Tighten the transmission to front pipe assembly mounting bracket nuts to the specified torque, refer to

Figure 8B – 39.

Transmission to front pipe

assembly mounting bracket nut

torque specification......................................20 – 50 Nm

11 Ensure all support rubbers are under load.

12 Check the exhaust system for clearances, refer to 5.2 GEN III V8 Exhaust System Clearances . If the clearances

are not within tolerance, loosen off all fasteners and perform the tightening sequence procedure, refer to

3.7 Tightening Sequence.

13 Connect the wiring harness connector to the relevant oxygen sensor.

Exhaust System Page 8B–28

Page 8B–28

3.7 Tightening Sequence

This procedure is only to be performed if the exhaust system positioning is not to specification.

Refer to Figure 8B – 44 for the following:

NOTE

Ensure that all fasteners mentioned in steps 1

to 8 are loose before conducting this procedure.

1 Tighten the intermediate to front exhaust assembly flange fastening bolts (1) to the specified torque.

Intermediate to front exhaust

assembly flange fastening bolt

torque specification......................................40 – 50 Nm

2 For a Standard exhaust system, check that the rear exhaust pipe aligning key is seated within the channel

provided in the intermediate exhaust pipe’s end slip joint. Position the U-bolt clamp along the intermediate to rear

slip joint and tighten the pair of fastening nuts (2) to the specified torque.

U–bolt clamp assembly fastening

nut torque specification................................20 – 30 Nm

3 For a Performance exhaust system, position each ring clamp along the two intermediate to rear slip joints and

tighten each fastening nut to the specified torque.

Ring clamp assembly fastening nut

torque specification......................................37 – 50 Nm

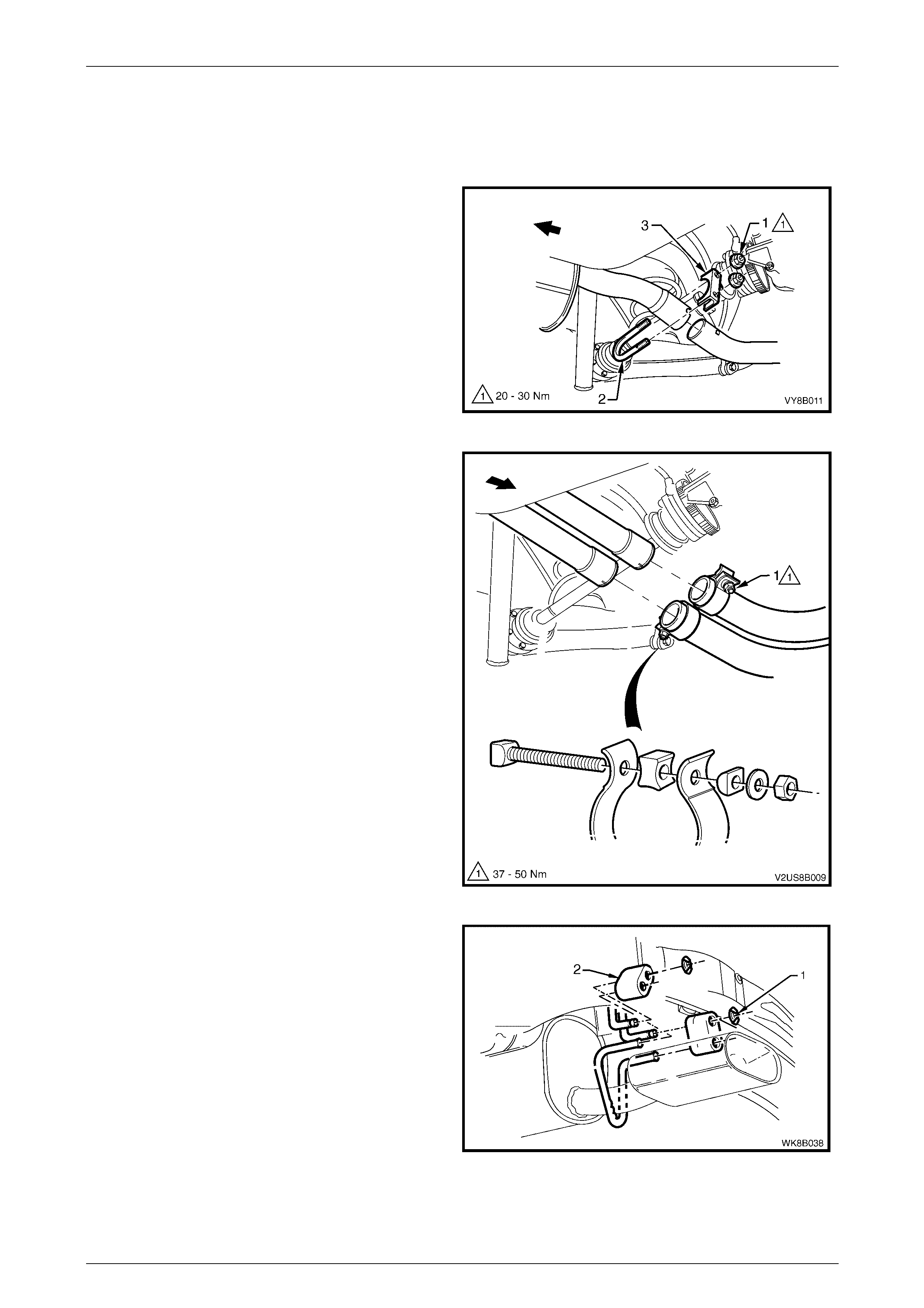

4 Hand tighten the upper fastening nut (1) to the stud

on both sides.

5 Hand tighten the lower fastening nut (2) to the stud

on both sides.

6 Tighten the upper then lower fastening nuts so that

approximately equal amounts of stud thread are

showing.

7 Tighten the upper then lower fastening nuts to the

specified torque.

Front exhaust assembly to exhaust

manifold flange stud fastening nut

torque specification..................................... 18 – 35 Nm

Figure 8B – 43

8 Tighten the cross brace to exhaust front pipe nuts (3) to the specified torque.

Cross brace to front pipe assembly

mounting bracket nut torque specification ... 20 – 50 Nm

9 Tighten the cross brace bracket nuts (4) to the specified torque.

Cross brace bracket fastening

nut torque specification................................20 – 50 Nm

10 Ensure that all six support rubbers (5 and 6) are under load, refer to Figure 8B – 44. If this is not achieved, loosen

the respective joints in the reverse order to steps 1 to 9. Load the hangers and re-tighten in the sequence

described, from steps 1 to 9.

NOTE

The exhaust system should be self-aligning and

not require further adjustment, provided step 10

is achieved. To ensure that correct clearances

are maintained throughout the full exhaust

system, refer to 5.2 GEN III V8 Exhaust System

Clearances for the correct values.

Exhaust System Page 8B–29

Page 8B–29

Figure 8B – 44

Exhaust System Page 8B–30

Page 8B–30

4 Service Operations – Exhaust

System Heat Shields

4.1 Heat Shields

Should any of the heat shields require replacement, the following procedure is recommended.

To avoid the possibility of personal injury by

burns, allow the exhaust system to cool down

before attempting this operation.

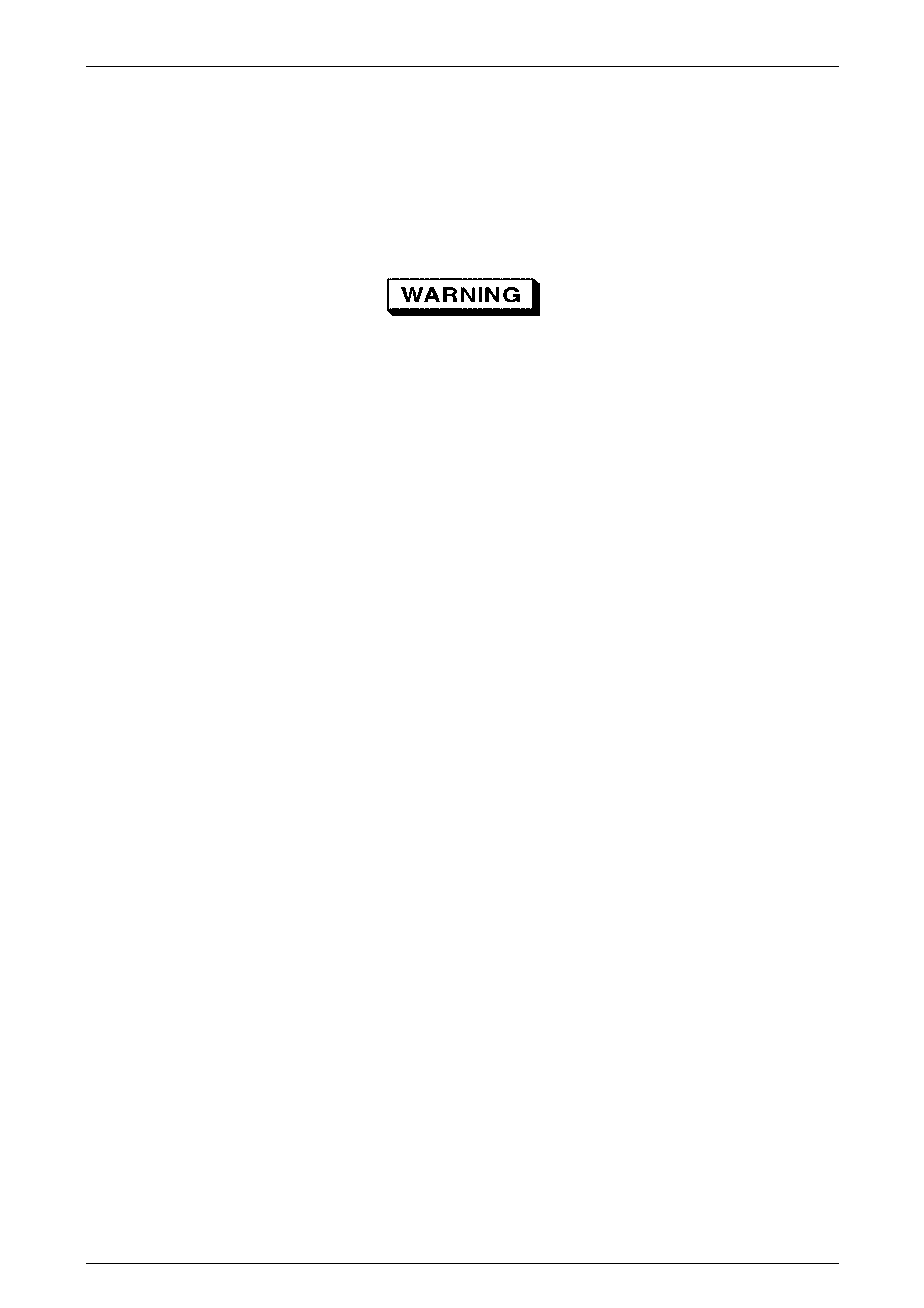

Figure 8B – 45 provides a reference to the location of heat shields fitted to all WK Series vehicles.

Exhaust System Page 8B–31

Page 8B–31

Figure 8B – 45

Legend

A Configuration – V6 and GEN III

V8

B Configurati on – V 6 S /C

1 Pre Catalyt i c Converter On-pipe Heat

Shield

2 Front Foil Heat S hi el d

3 Post Cat al ytic Converter On-pi pe Heat

Shield

4 Long Butyl Patch Underfloor Heat Shield

5 Intermediate Heat Shields

6 Rear Heat Shiel d

7 Short Butyl Patc h Underfloor Heat

Shield

Exhaust System Page 8B–32

Page 8B–32

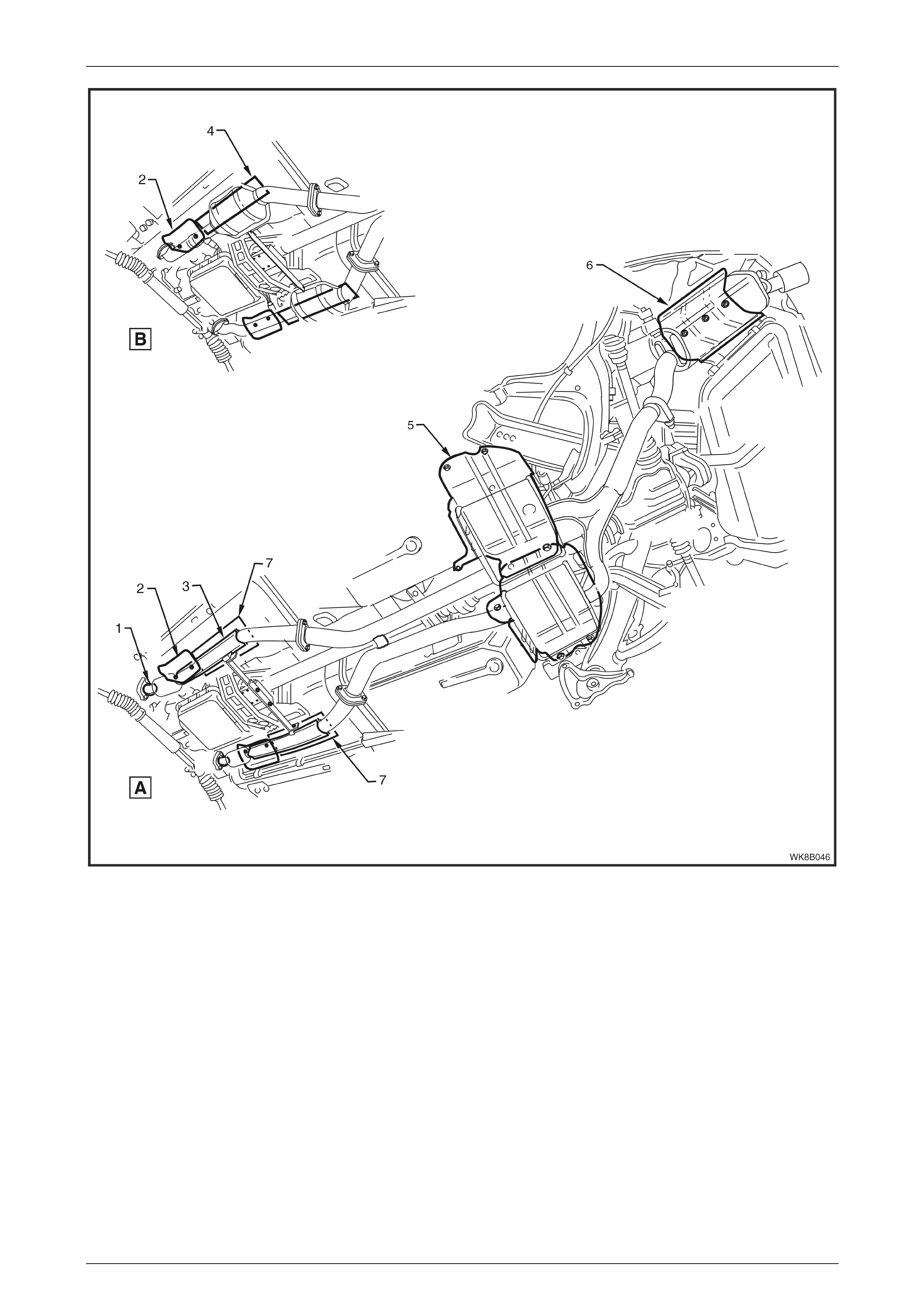

Rear Muffl er Underbody Mounted Heat Shield

Remove

1 If required, remove the rear exhaust assembly, refer to the following:

• 2.3 Rear Exhaust Assembly for V6.

• 3.4 Rear Exhaust Assembly for GEN III V8.

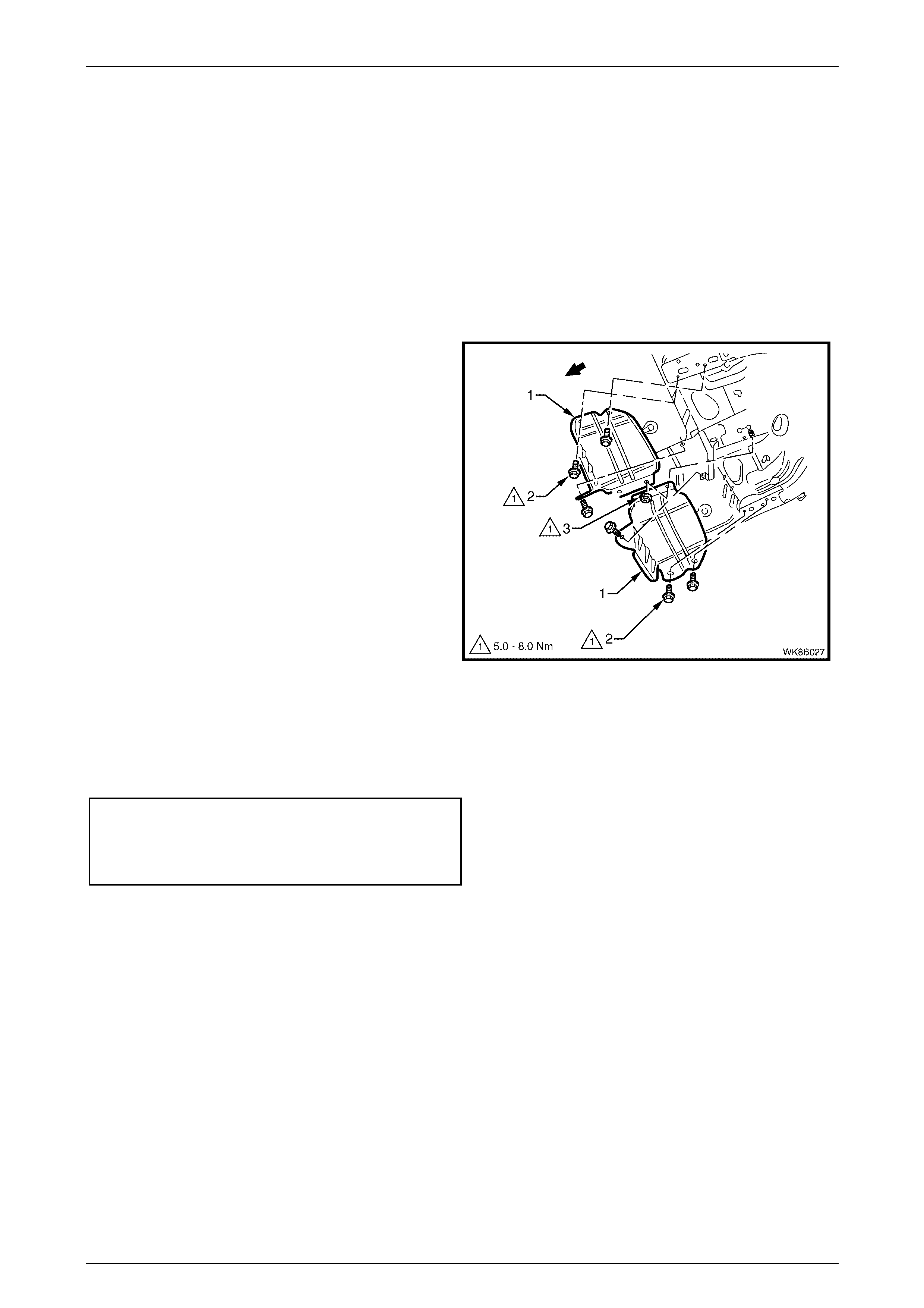

2 Remove the rear muffler heat shield (1) by removing

the three fastening screws (2).

Figure 8B – 46

Reinstall

Installation of the rear muffler heat shield is the reverse of the removal procedure, noting the following:

1 Tighten the body fastening screws to the correct torque specification:

Rear muffler heat shield fastening

screw torque specification.......................... 5.0 – 8.0 Nm

Exhaust System Page 8B–33

Page 8B–33

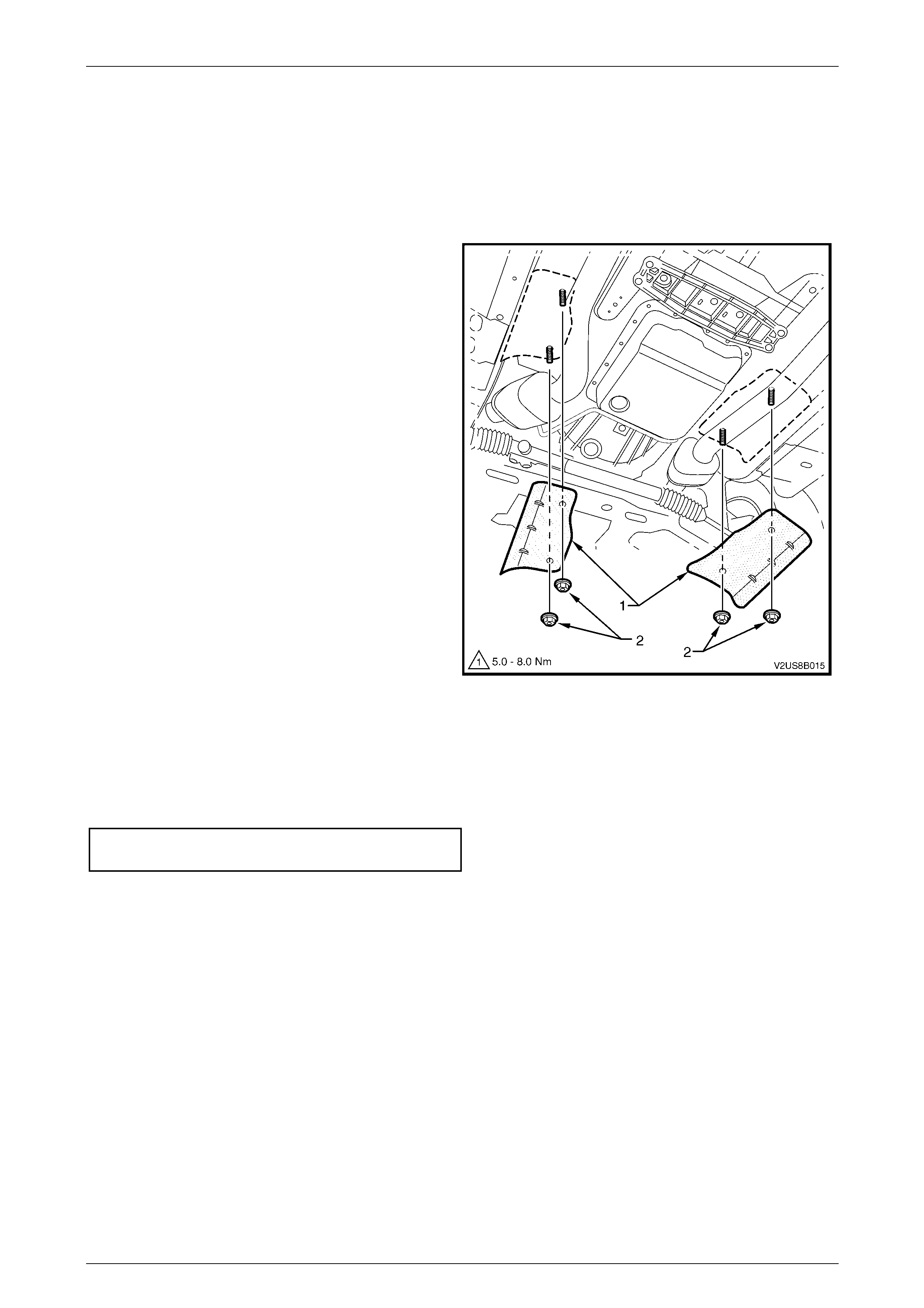

Intermediat e M uf f ler Underbody Mounted Heat Shield

Remove

1 If required, remove the intermediate exhaust assembly, refer to:

• 2.4 Intermediate Exhaust Single Pipe and Muffler Assembly for V6.

• 3.5 Intermediate Exhaust Assembly for GEN III V8.

NOTE

For V6 vehicles, there is only one intermediate

muffler heat shield; installed above the single

intermediate muffler.

2 Remove the intermediate heat shields (1) by

removing the fastening screws (2) and the single stud

nut (3).

Figure 8B – 47

Reinstall

Installation of the intermediate heat shield is the reverse of the removal procedure, noting the following:

1 Tighten the body fastening screws (2) and stud nut (3) to the correct torque specification, refer to Figure 8B – 47.

Intermediate muffler heat shield

fastening screw torque specification..........5.0 – 8.0 Nm

Intermediate muffler heat shield

stud fastening nut torque specification.......5.0 – 8.0 Nm

Exhaust System Page 8B–34

Page 8B–34

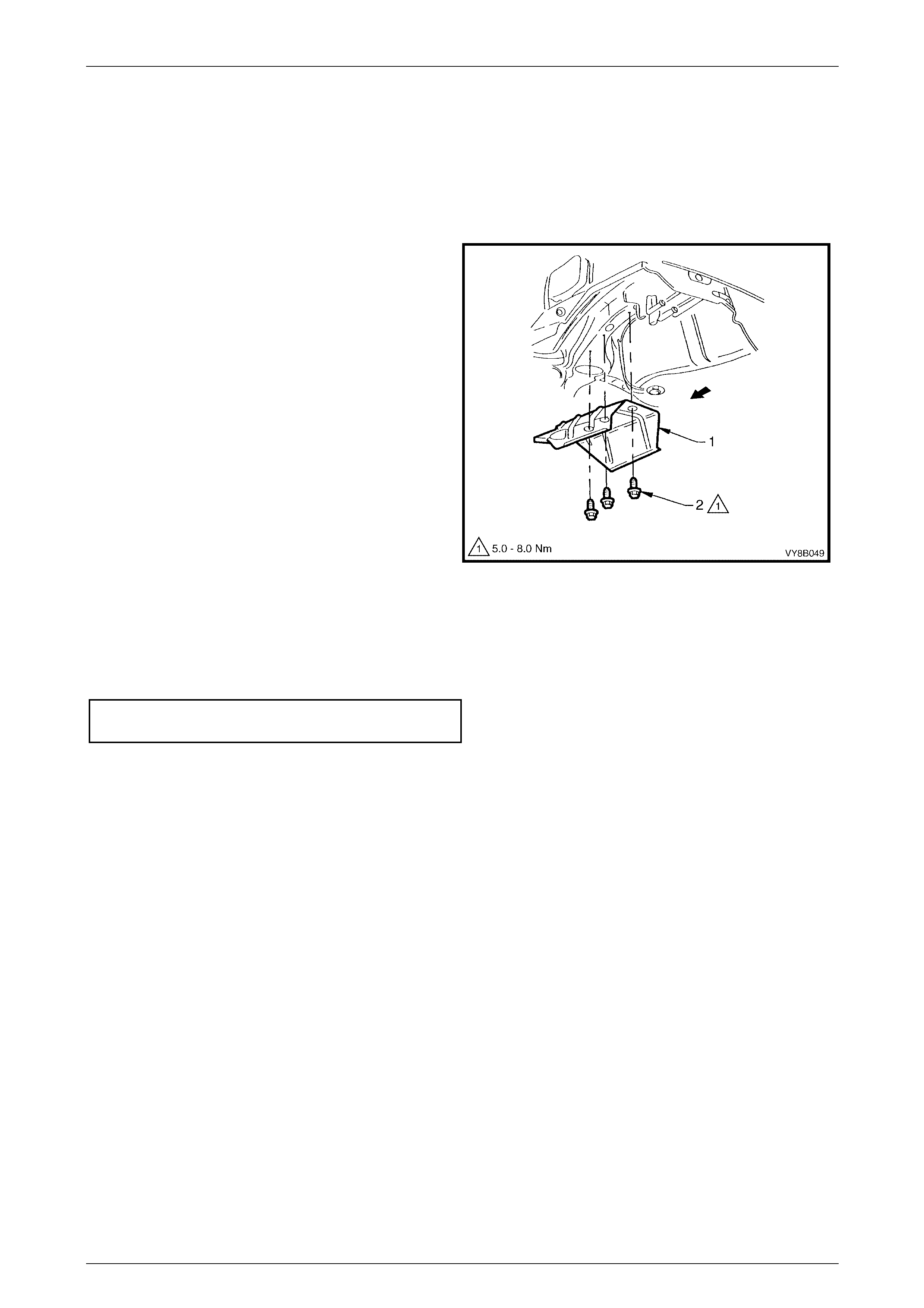

Front Exhaust Assembly Underbody Mount ed Heat Shi elds

Remove

1 If required, remove the front exhaust assembly, refer to:

• 2.6 Front Exhaust Assembly for V6.

• 3.6 Front Exhaust Assembly for GEN III V8.

2 Remove the front underbody mounted heat

shields (1) by removing each of the fastening

nuts (2).

Figure 8B – 48

Reinstall

Installation of the intermediate heat shield is the reverse of the removal procedure, noting the following:

1 Tighten the front underbody mounted heat shield fastening nuts (2) to the correct torque specification, refer to

Figure 8B – 48.

Front underbody mounted heat shield

fastening nut torque specification .............. 5.0 – 8.0 Nm

Exhaust System Page 8B–35

Page 8B–35

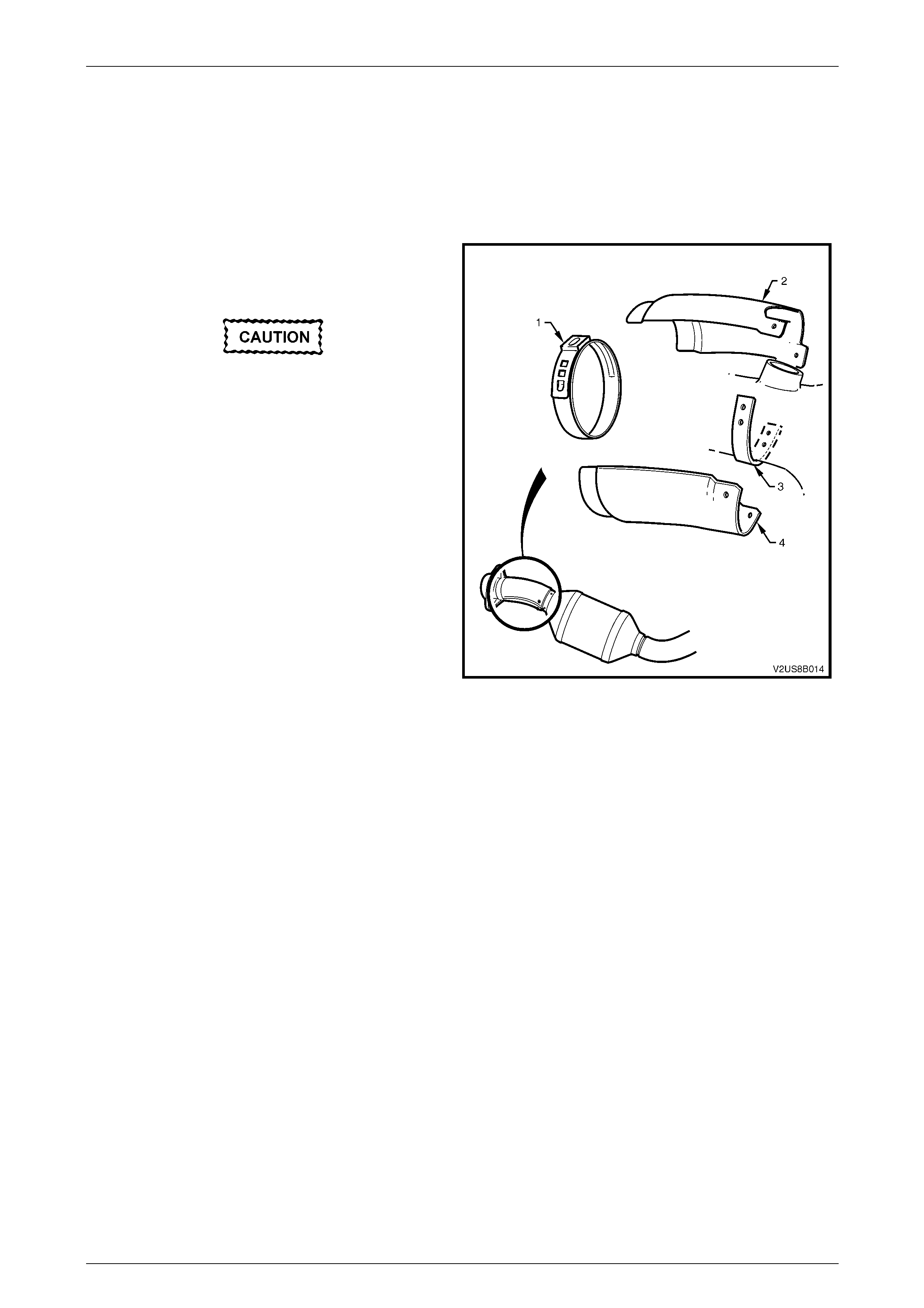

Front Exhaust Assembly On-pipe Heat Shields – Pre Cat al ytic Converter

Remove

1 If required, remove the front exhaust assembly, refer to:

• 2.6 Front Exhaust Assembly for V6.

• 3.6 Front Exhaust Assembly for GEN III V8.

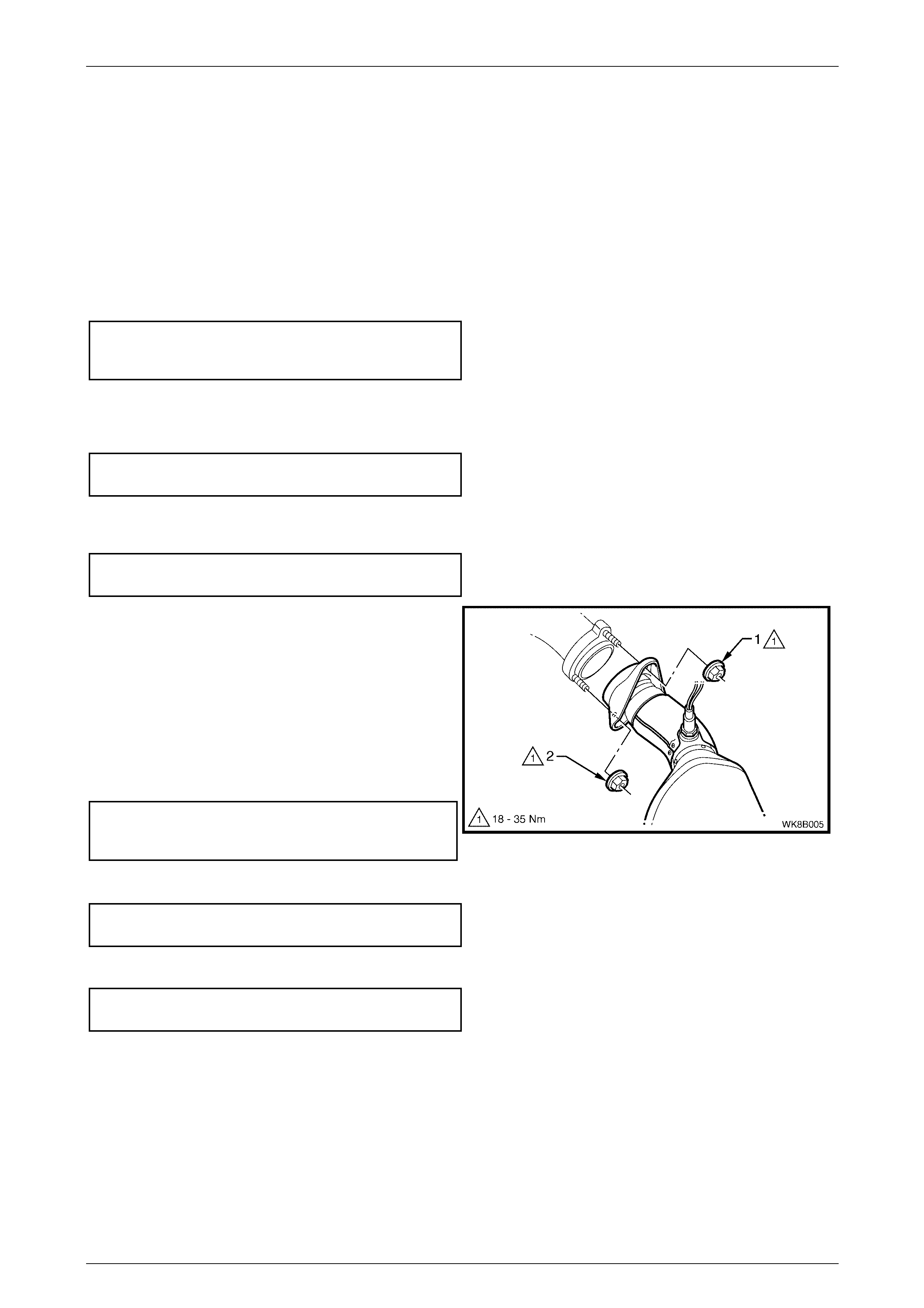

2 Use special tool J22610 to cut through the ear (1) of

the ear-type clamp and remove and dispose of

clamp.

Do not use excessive force when drilling

out heat shield rivets. Excessive force

may result in the drill being pushed into

and piercing the exhaust pipe

underneath.

3 Drill out each of the four rivets securing the upper

and lower facing on-pipe heat shields (2 and 4) to

the welded-on exhaust pipe bracket (3).

Figure 8B – 49

Reinstall

Installation of the on-pipe heat shields is the reverse of the removal procedure, noting the following:

1 Rivet on the upper and lower on-pipe heat shields (2 and 4) onto the front exhaust pipe bracket (3), refer to

Figure 8B – 49.

2 Install a new ear-type clamp (1) by hand and crimp to fasten using special tool J22610, refer to Figure 8B – 49.

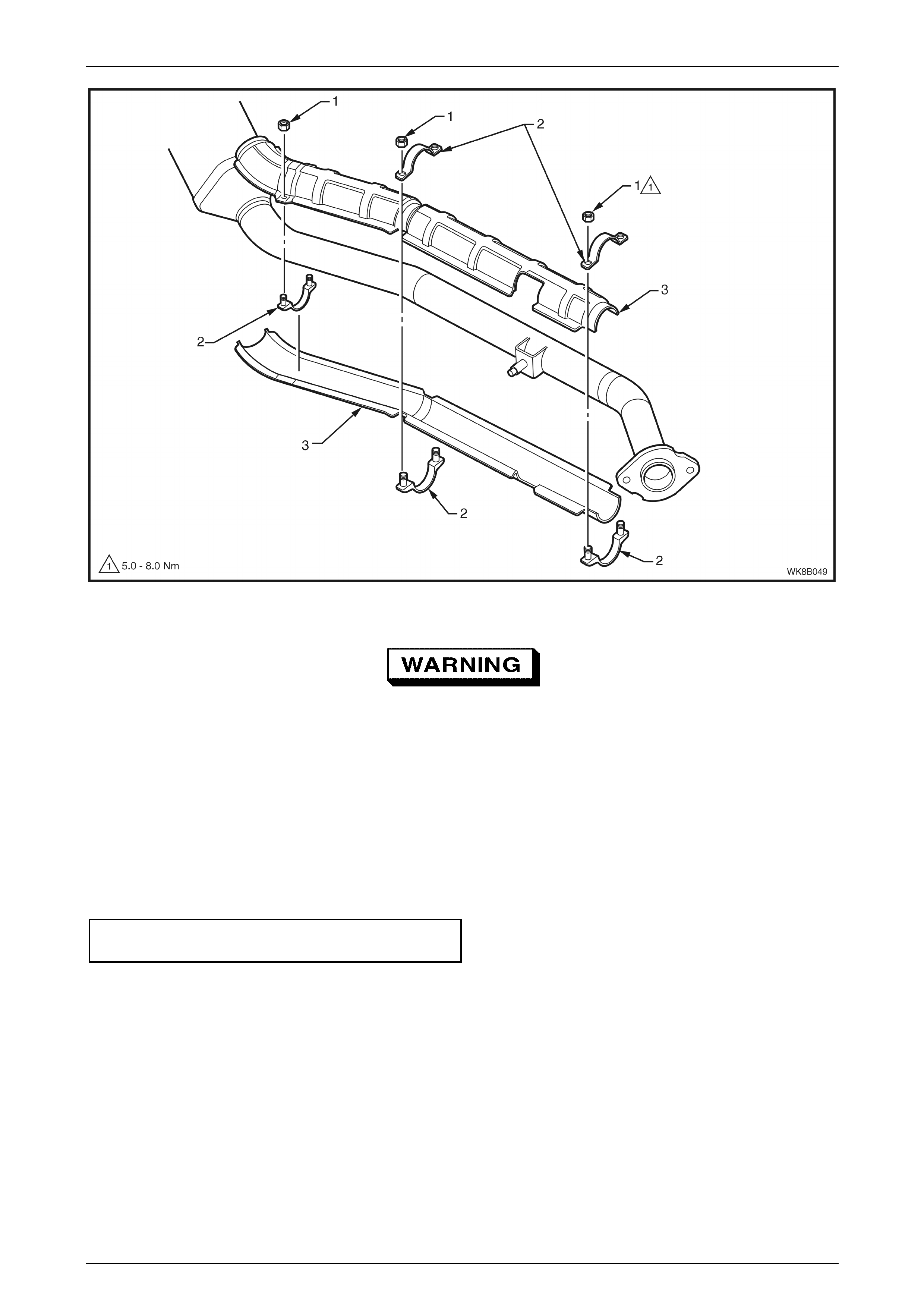

Front Exhaust Assembly On-pipe Heat Shields - Post Catalytic Converter

NOTE

Figure 8B-50 shows GEN III V8 long on-pipe

heat-shield. For V6 and GEN III V8 produced

after 11 September 2003 short op-pipe

heatshields are used. Similar removal and

installation procedures are used for both.

Remove

1 If required, remove the front exhaust assembly, refer to:

• 2.6 Front Exhaust Assembly for V6.

• 3.6 Front Exhaust Assembly for GEN III V8

Exhaust System Page 8B–36

Page 8B–36

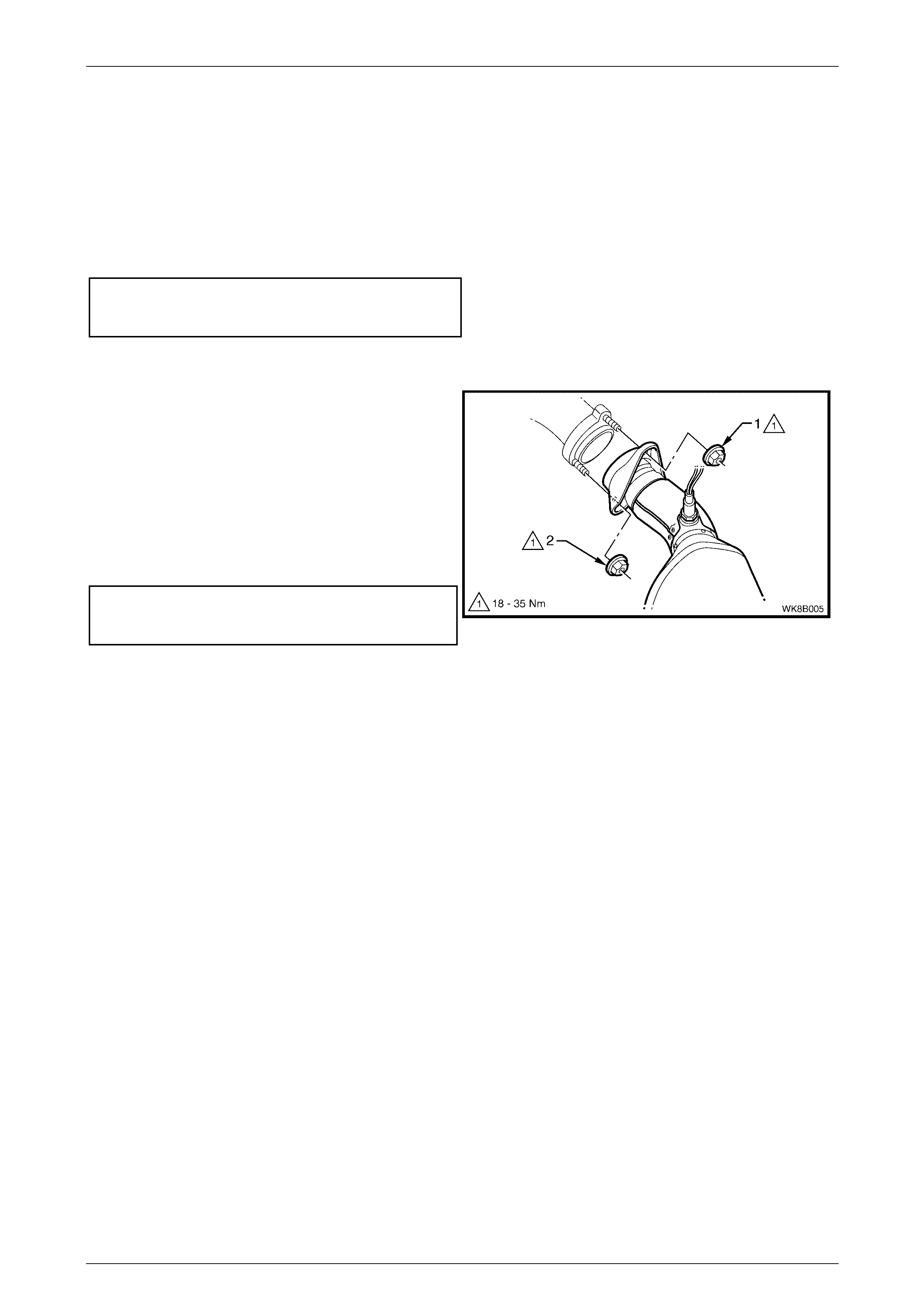

Figure 8B – 50

The lower heat shield and clamps will drop

away from exhaust w hen all attaching nuts (1)

are removed.

2 Supporting the lower heat shield, remove the attaching nuts (1) and clamps (2), refer to Figure 8B – 50.

3 Remove the lower and upper heat shield (3).

Reinstall

Installation of the on-pipe heat shields is the reverse of the removal procedure, noting the following:

1 Tighten each of the on-pipe heat shield attaching nuts (1) to the correct torque specification.

Post catalytic converter on-pipe heat shield

attaching nut torque specification .................... 5 – 8 Nm

Exhaust System Page 8B–37

Page 8B–37

Butyl Patch Reflective Foil Heat Shields – V6 Supercharged Only

Remove

1 If required, remove the front exhaust assembly, refer to Section 8B Exhaust System, 3 Service Operations -

V6 Supercharged in the MY2003 VY and V2 Service Information for removal and reinstallation procedures.

2 Peel the butyl patch reflective foil insulators (1) to be

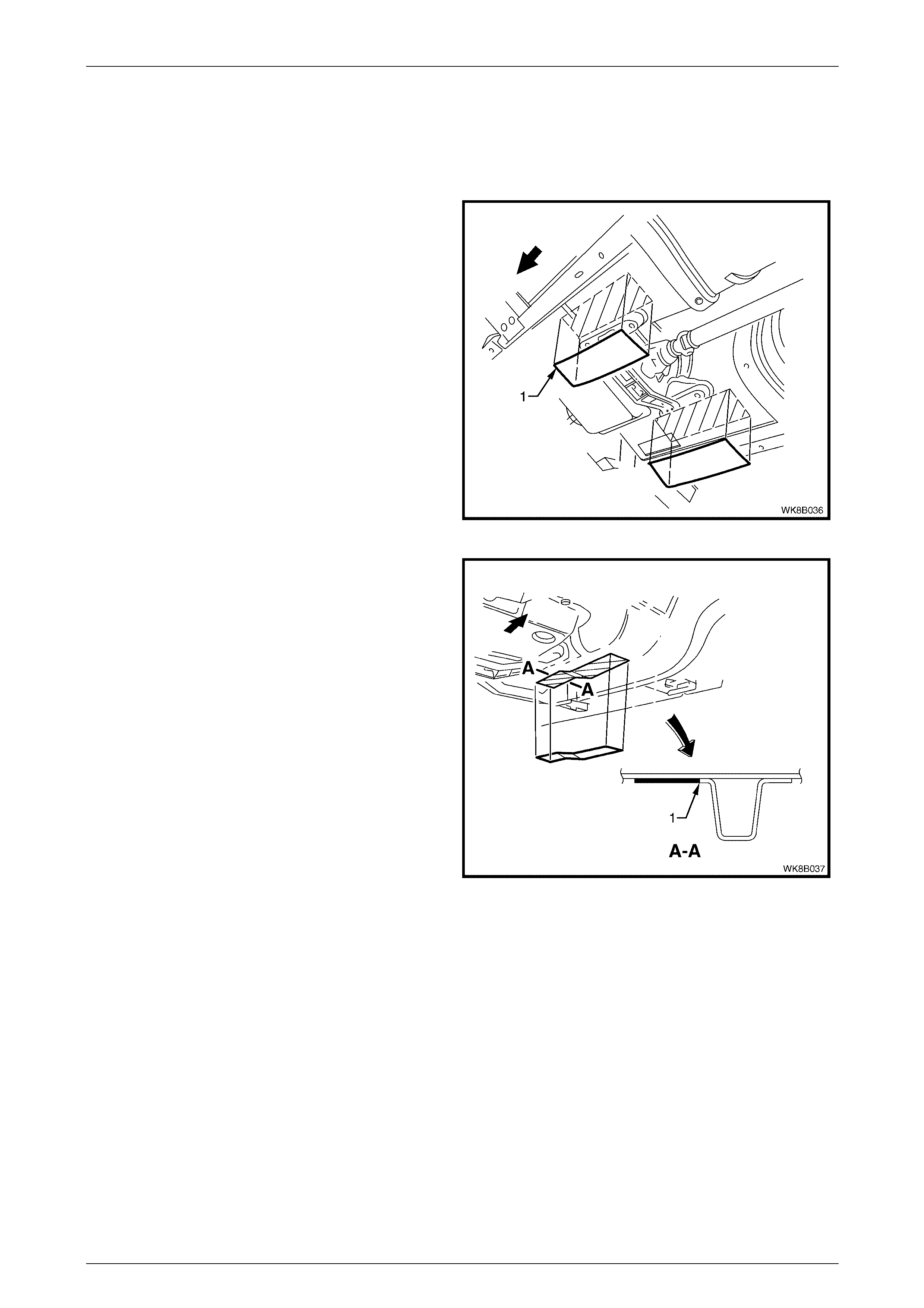

replaced from the under floor and discard.

3 Use a solvent soaked rag to remove all traces of the

old insulator adhesive, sealer overspray or paint

overspray, should the vehicle have been repaired.

Reinstall

NOTE

Do not attempt to re-use a removed butyl patch

reflective foil insulator. Always use a new part.

1 Use a solvent soaked rag to remove all traces of the

old insulator adhesive, sealer overspray or paint

overspray, should the vehicle have been repaired.

2 Heat a new butyl reflective foil insulator to 40 ± 5° C.

Figure 8B – 51

3 Wearing heat resistant protective gloves, peel the

adhesive protective paper from the new butyl

reflective foil insulator and apply the insulator to the

cleaned under floor area in the same position as the

removed part. The edge of the patch should align

with the edge of the longitudinal flange (1). Smooth

out any air bubbles in the process.

Figure 8B – 52

Exhaust System Page 8B–38

Page 8B–38

5 Exhaust System Clearances

5.1 V6 Exhaust Systems Clearances

The following diagrams indicate the exhaust system clearances specified for vehicles fitted with the V6 engine.

Clearances should be checked upon installation of exhaust components to prevent parts interference and ensure

correct alignment. Refer to Figure 8B – 5 for the location of exhaust system parts.

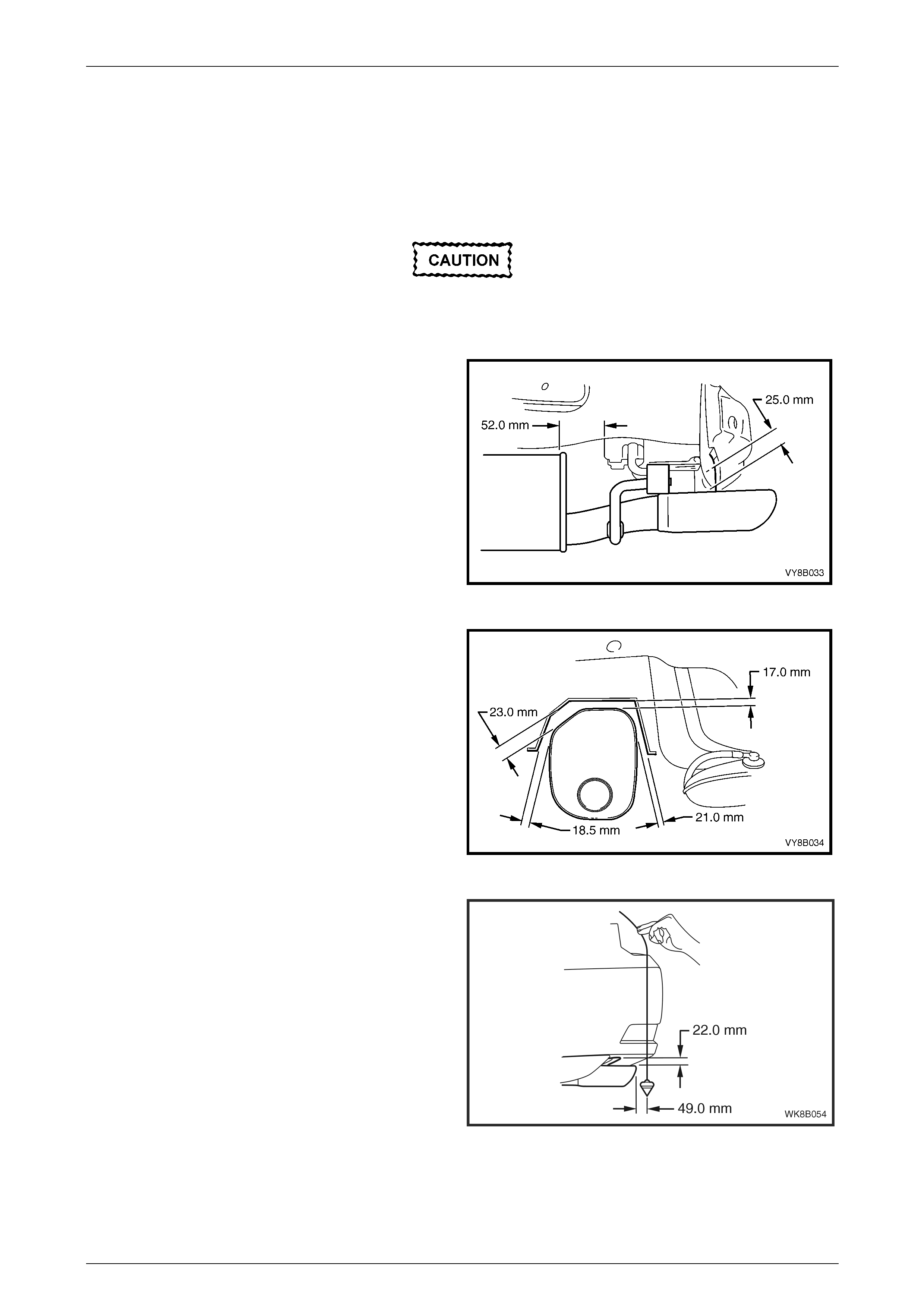

To avoid the possibility of personal injury,

allow the exhaust system to cool dow n before

attempting this operation.

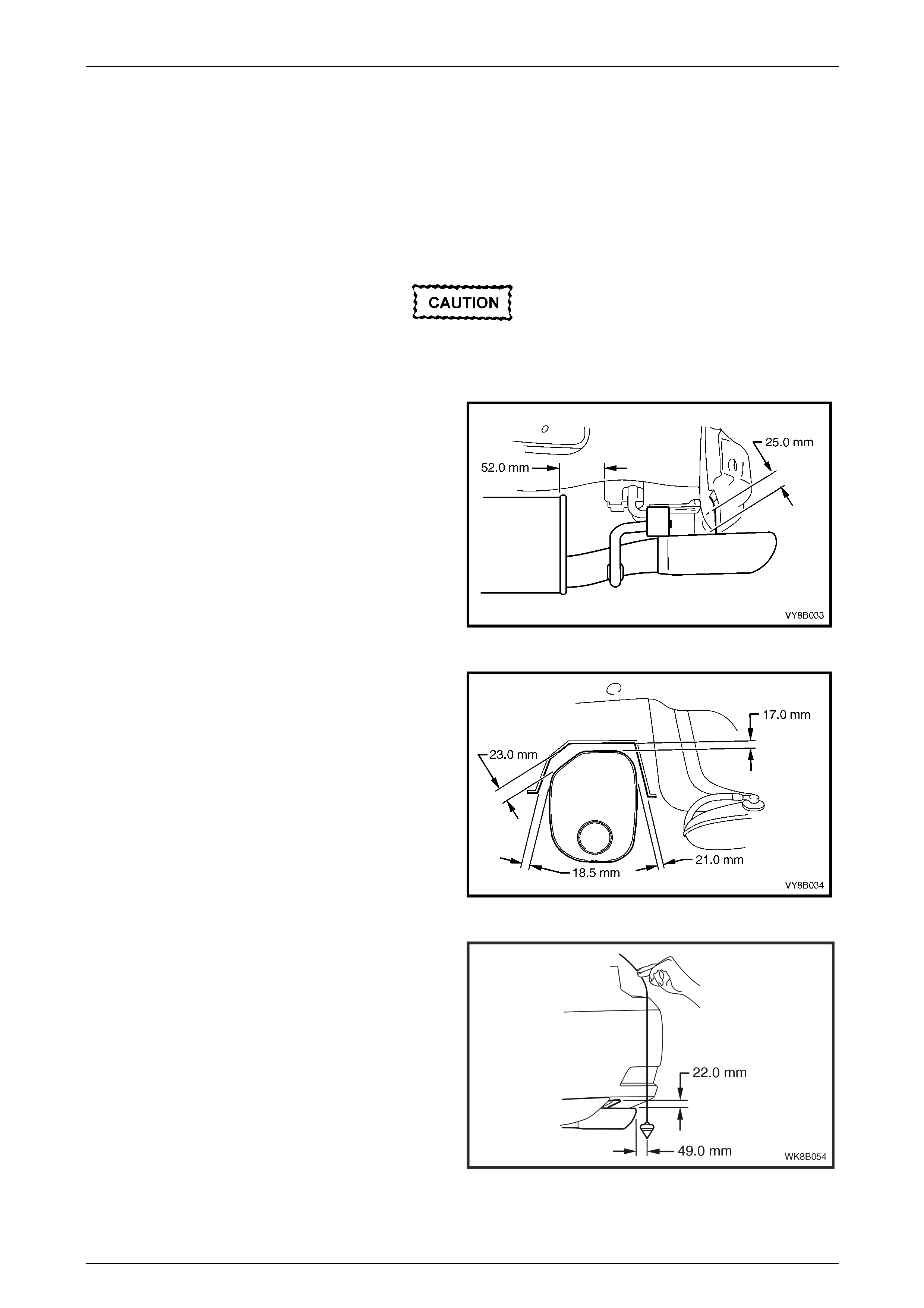

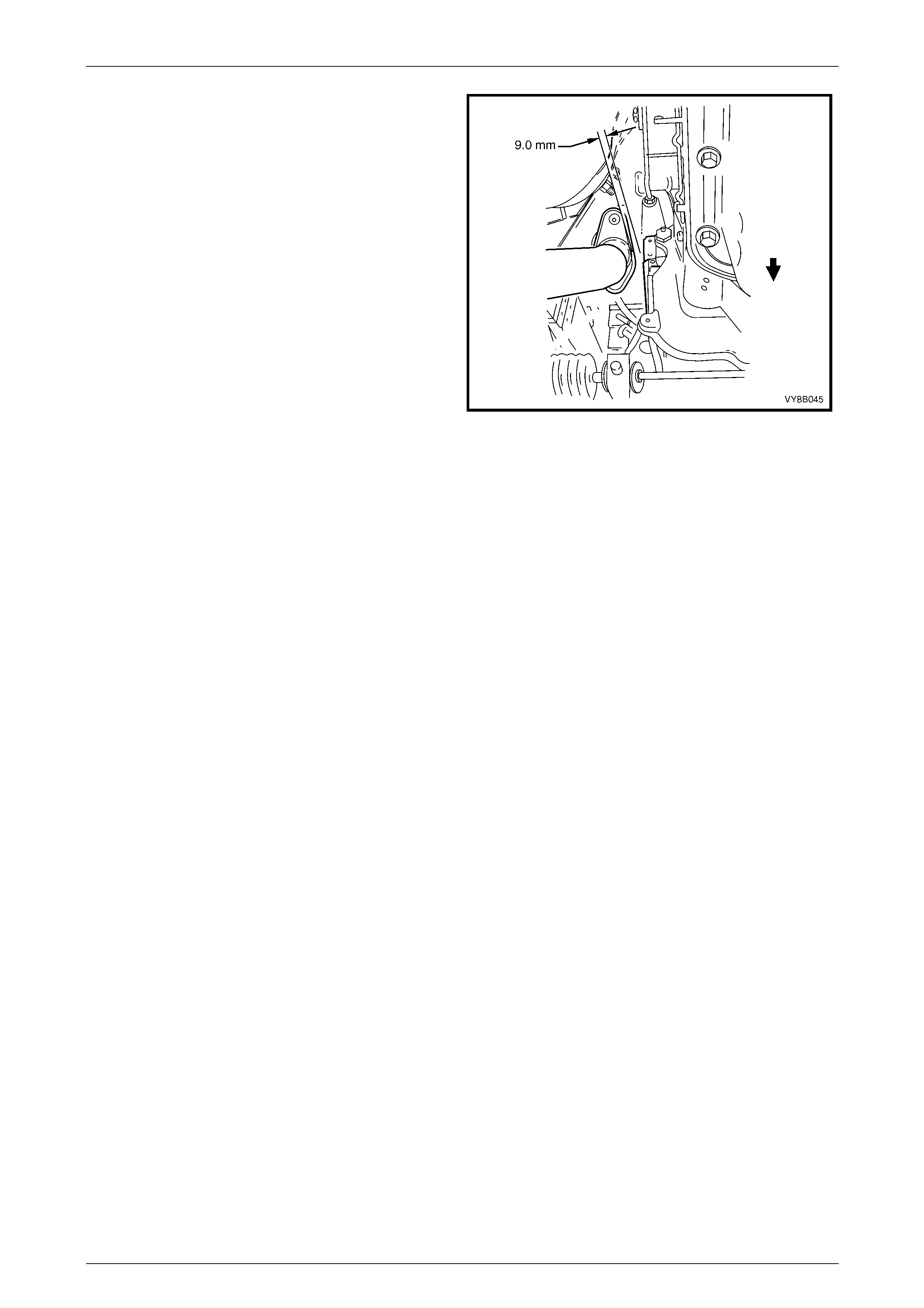

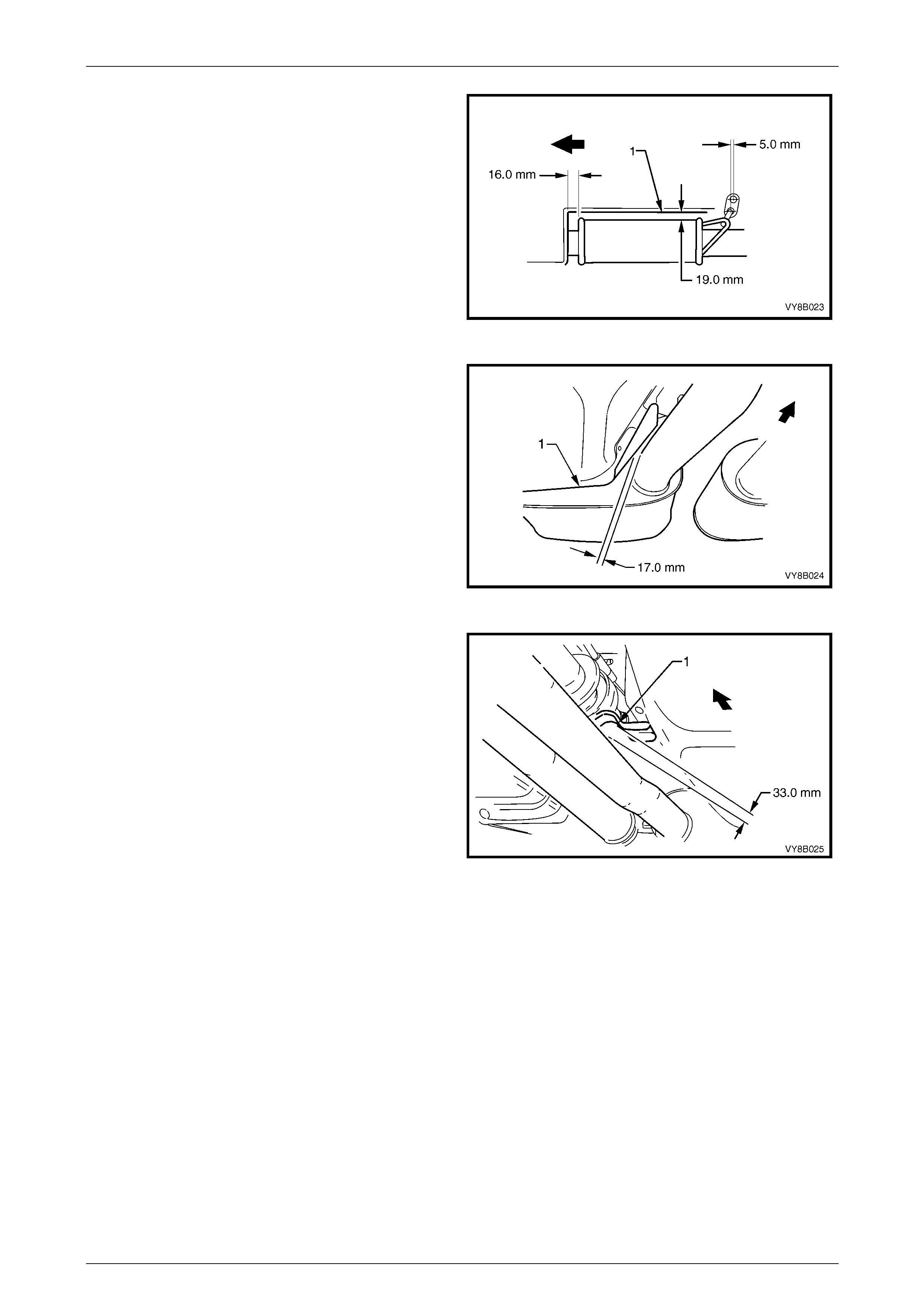

1 Check the rear tail pipe to rear end panel clearances

and rear muffler to tail pipe hanger mounting

clearances.

Figure 8B – 53

2 Check the rear exhaust muffler to rear heat shield

clearances.

Figure 8B – 54

3 Check the clearance between the rear tail pipe

exhaust tip and the underside of the bumper fascia.

4 Holding a weighted string over the rear bumper fascia,

in line with the exhaust tip, determine the horizontal

clearance between the exhaust tip and rear bumper.

Figure 8B – 55

Exhaust System Page 8B–39

Page 8B–39

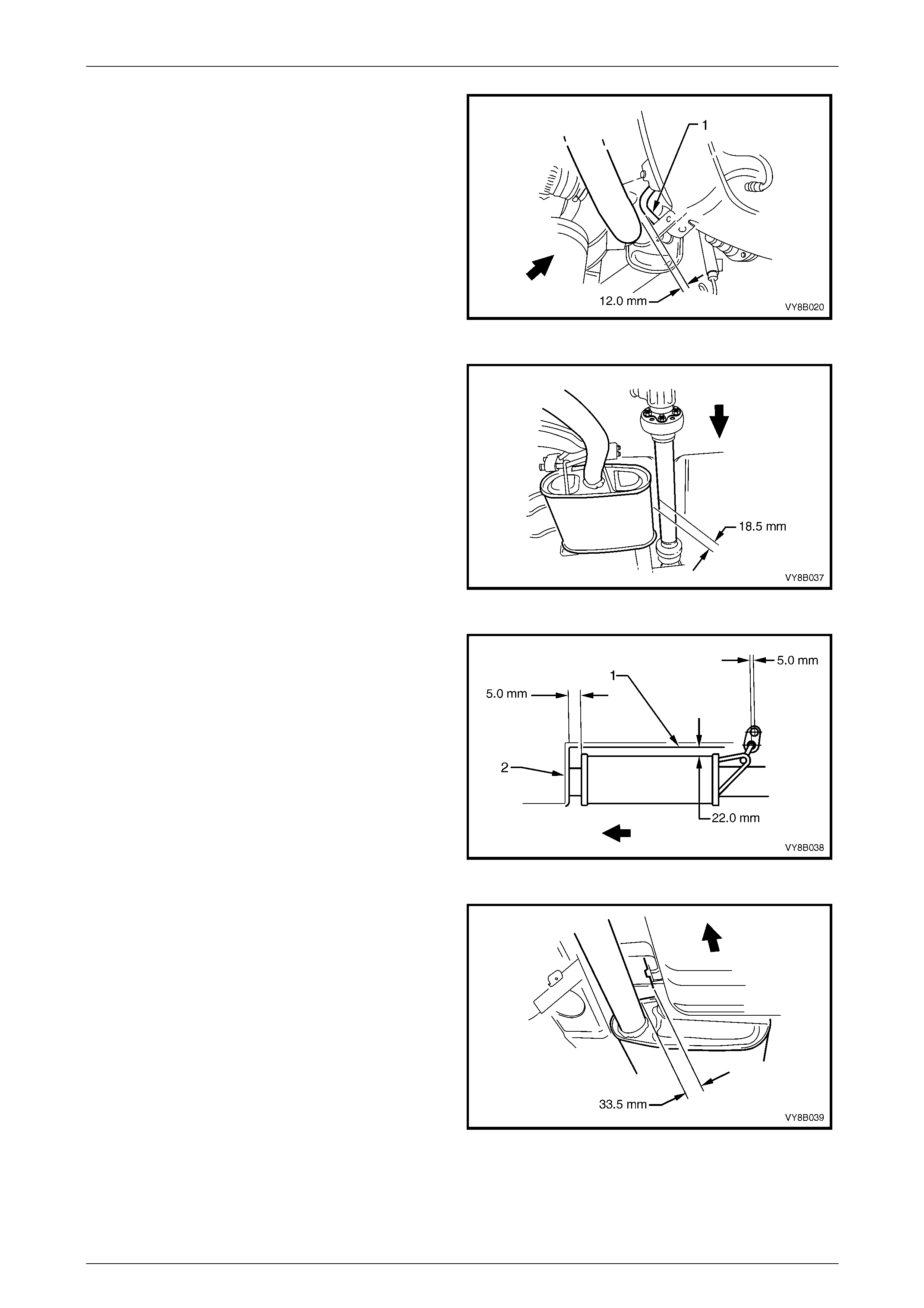

5 Check the intermediate to rear exhaust pipe to

stabiliser bar linkage (1) clearances.

Figure 8B – 56

6 Check the intermediate exhaust hanger to propeller

shaft clearances.

Figure 8B – 57

7 Check intermediate exhaust muffler to intermediate

heat shield (1) and rear footwell (2) clearances;

nominal clearance provided. The horizontal clearance

provided between the body hanger and support peg is

for reference only.

Figure 8B – 58

8 Check the intermediate exhaust pipe to intermediate

heat shield clearances.

Figure 8B – 59

Exhaust System Page 8B–40

Page 8B–40

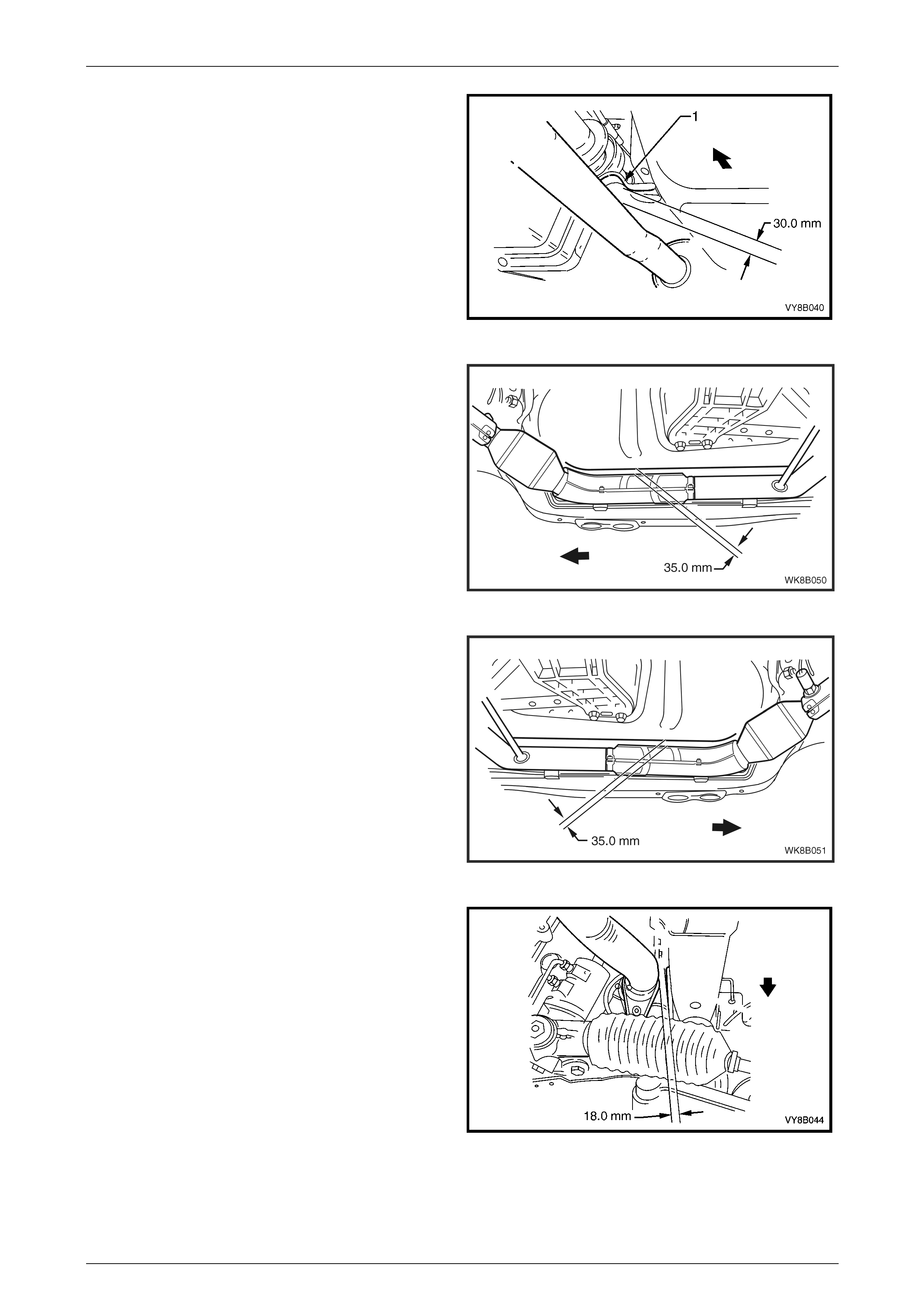

9 Check the intermediate exhaust pipe to centre bearing

carrier (1) clearance.

Figure 8B – 60

10 Check the right-hand side front exhaust pipe to

underbody foot well clearances. Nominal clearance

provided.

Figure 8B – 61

11 Check the left-hand side front exhaust pipe to

underbody foot well clearances. Nominal clearance

provided.

Figure 8B – 62

12 Check the clearance between the front exhaust pipe

and the front longitudinal assembly clearance.

Figure 8B – 63

Exhaust System Page 8B–41

Page 8B–41

13 Check the front left-hand side exhaust pipe to engine

block clearances.

Figure 8B – 64

Exhaust System Page 8B–42

Page 8B–42

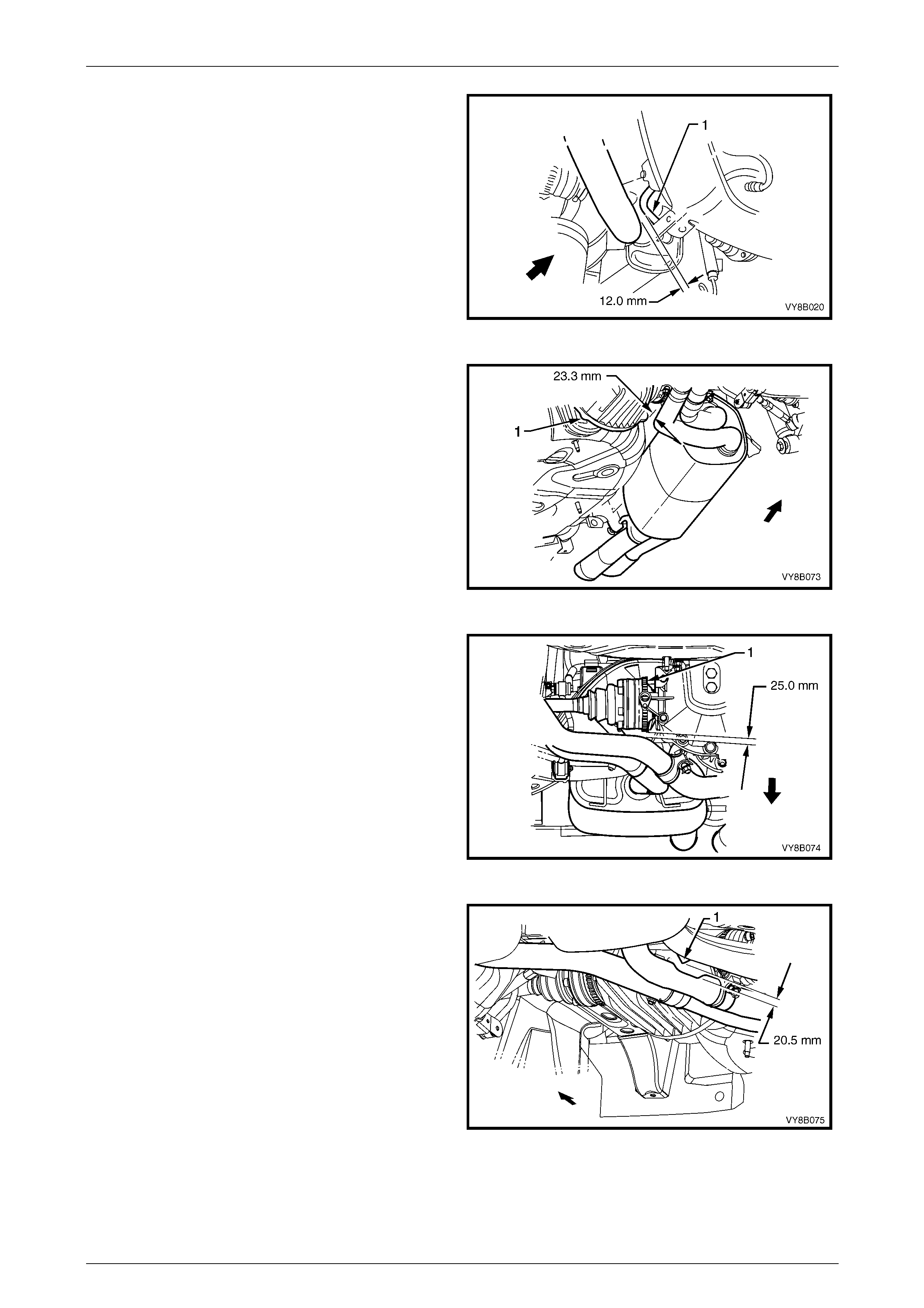

5.2 GEN III V8 Exhaust System Clearances

The following diagrams indicate the exhaust system clearances specified for vehicles fitted with the Gen III V8 Engine.

Both standard and performance type exhaust systems are included. Clearances should be checked upon installation of

exhaust components to prevent parts interference and ensure correct parts alignment. Refer to Figure 8B – 26 for

GEN III V8 part locations.

To avoid the possibility of personal injury,

allow the exhaust system to cool dow n before

attempting this operation.

1 Check the rear tail pipe to body panel clearances and

rear muffler to tail pipe hanger mount clearances.

Figure 8B – 65

2 Check the rear exhaust muffler to heat shield

clearances.

Figure 8B – 66

3 Check the clearance between the rear tail pipe

exhaust tip and the underside of the bumper fascia.

4 Holding a weighted string over the rear bumper fascia,

in line with the exhaust tip, determine the horizontal

clearance between the exhaust tip and rear bumper.

Figure 8B – 67

Exhaust System Page 8B–43

Page 8B–43

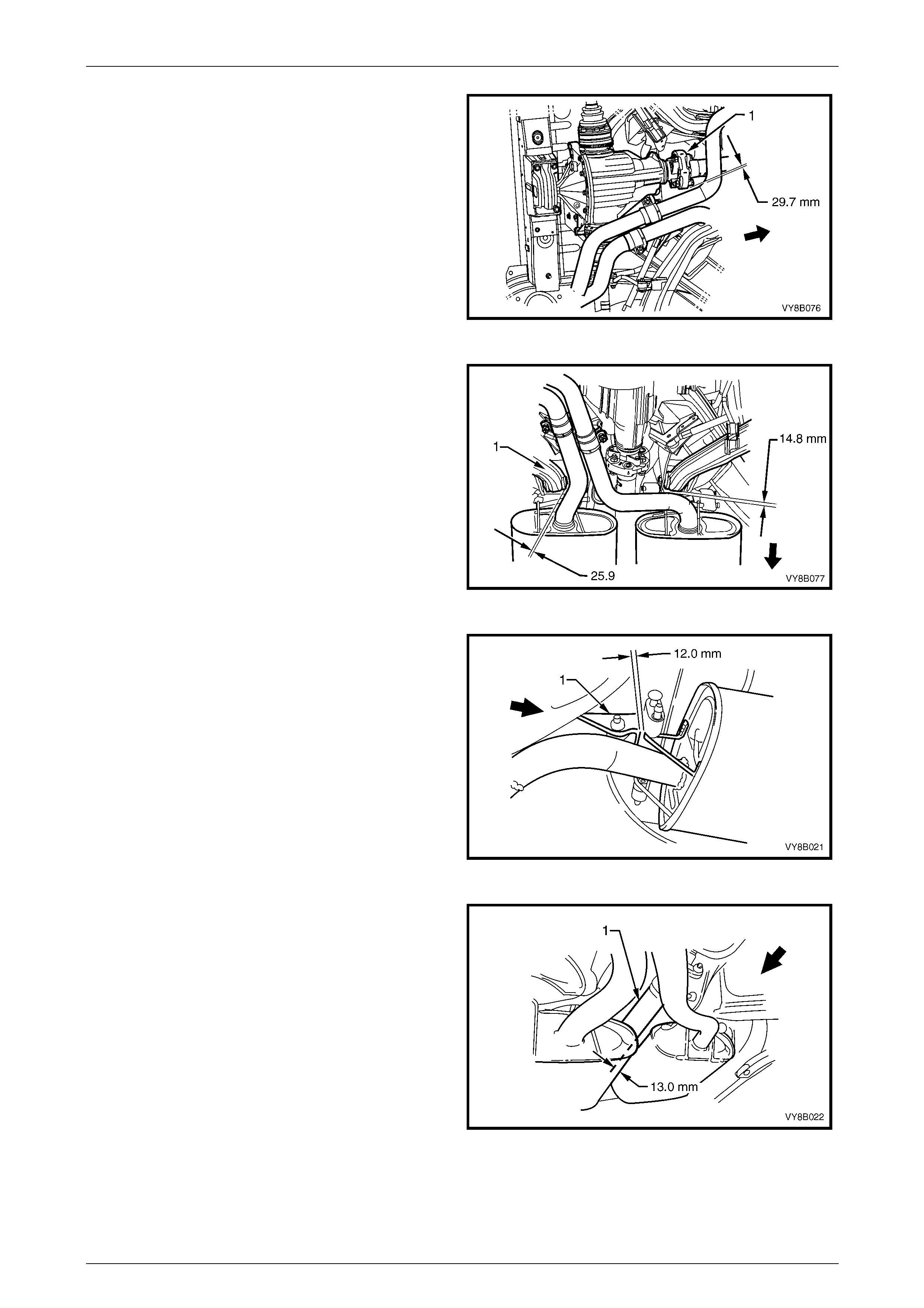

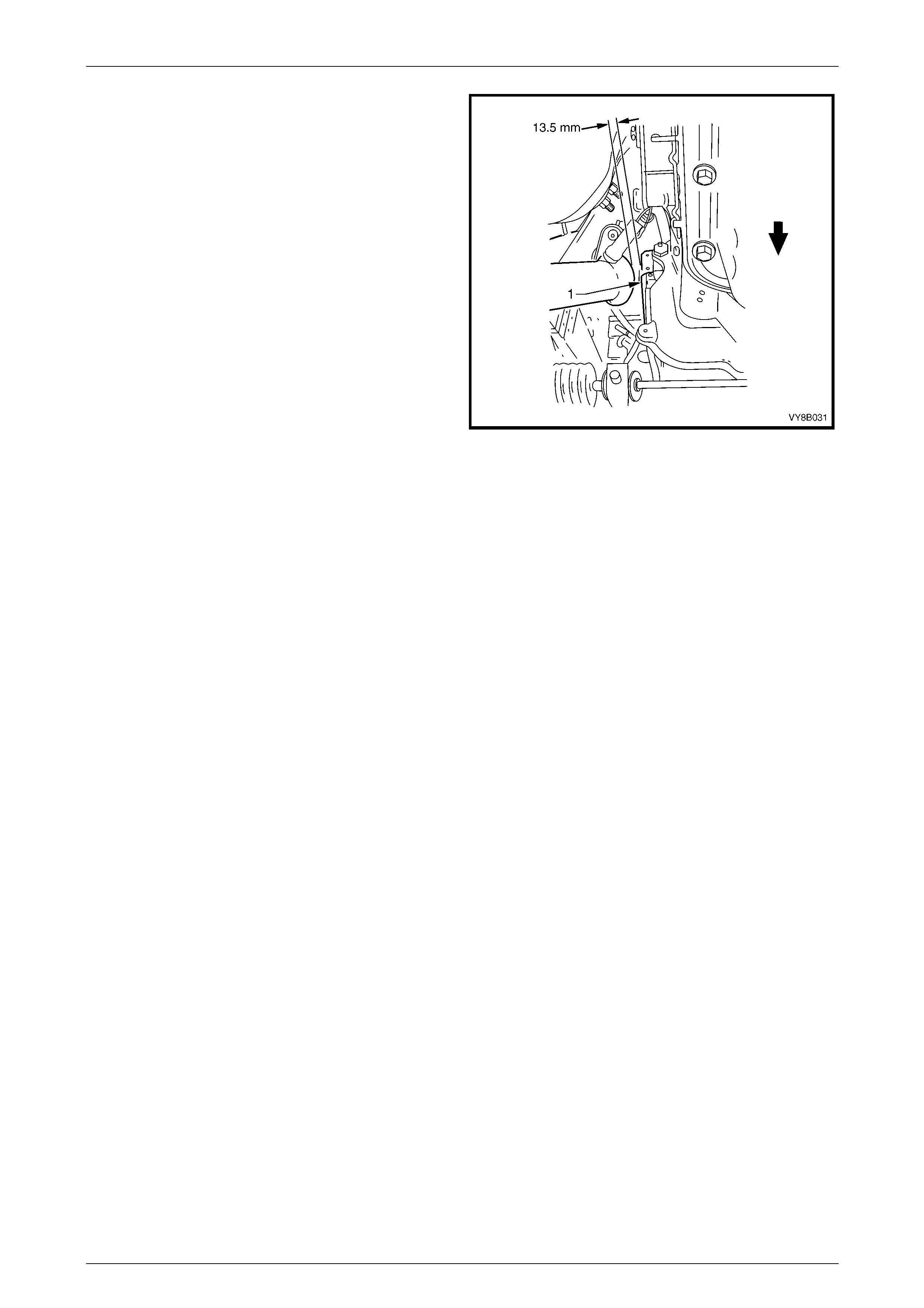

5 Check the rear intermediate exhaust pipe to stabiliser

bar linkage (1) clearances.

Figure 8B – 68

6 Check the rear exhaust pipe to differential carrier (1)

clearances.

Figure 8B – 69

7 Check the rear exhaust pipe to inner axle shaft (1)

clearances.

Figure 8B – 70

8 Check the intermediate exhaust pipe to suspension

member (1) clearances.

Figure 8B – 71

Exhaust System Page 8B–44

Page 8B–44

9 Check the intermediate exhaust pipe to rubber

coupling (1) clearances.

Figure 8B – 72

10 Check the intermediate exhaust pipe to suspension

cross member elbow (1) clearances.

Figure 8B – 73

11 Check the intermediate exhaust hanger to underbody

mounting (1) clearances.

Figure 8B – 74

12 Check the intermediate exhaust muffler to propeller

shaft (1) clearances.

Figure 8B – 75

Exhaust System Page 8B–45

Page 8B–45

13 Check the intermediate exhaust muffler to

intermediate heat shield (1) clearances.

NOTE

The clearance between the intermediate exhaust

muffler and the horizontal section of the heat

shield is nominal.

Figure 8B – 76

14 Check the intermediate exhaust pipe to intermediate

heat shield clearances.

Figure 8B – 77

15 Check the intermediate exhaust pipe to centre bearing

carrier (1) clearances.

Figure 8B – 78

Exhaust System Page 8B–46

Page 8B–46

16 Check the front exhaust pipe to engine block (1)

clearances.

Figure 8B – 79

Exhaust System Page 8B–47

Page 8B–47

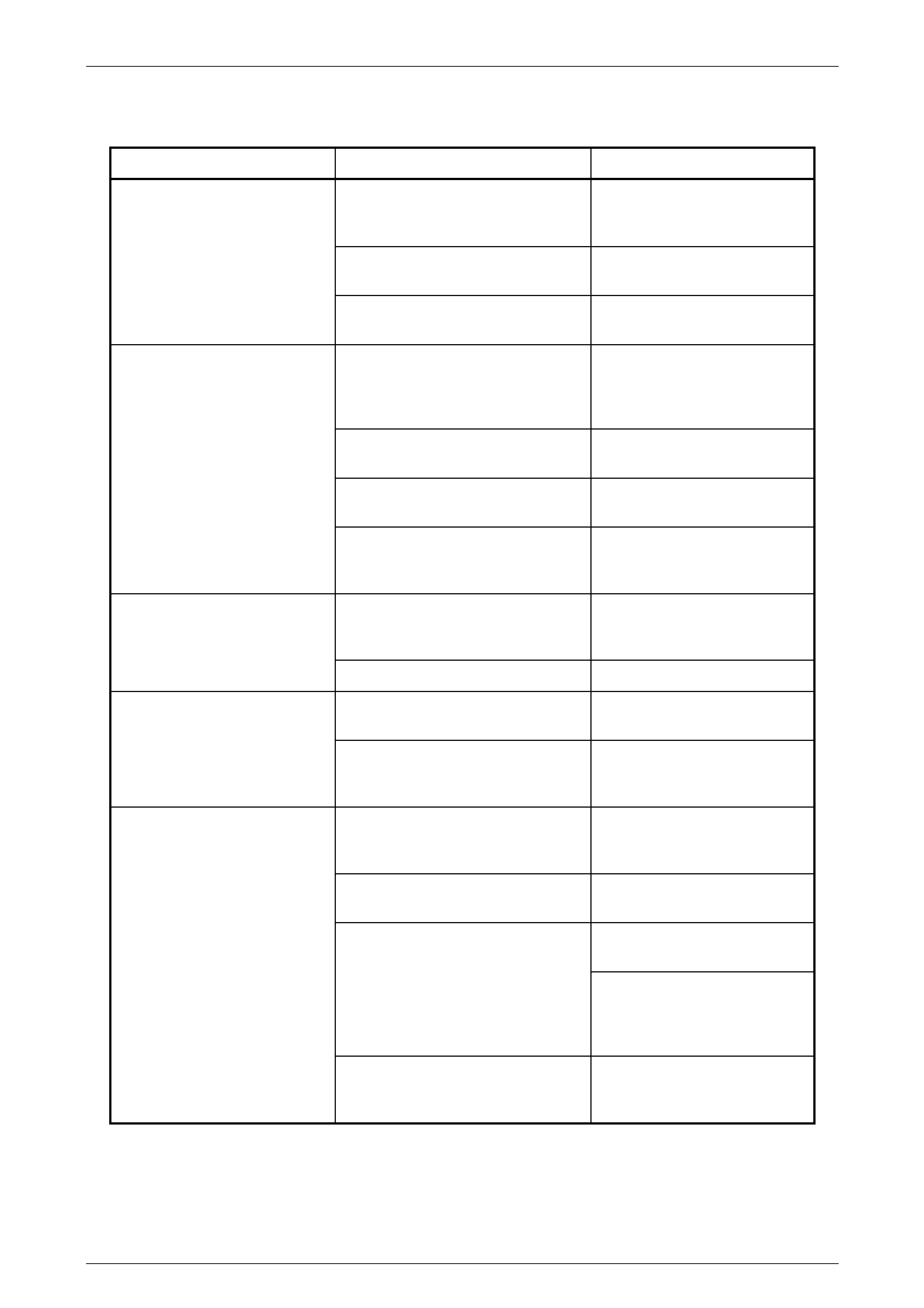

6 Exhaust System Diagnosis

CONDITION PROBABLE CAUSE CORRECTION

Leaks at pipe joints. Tighten U-bolt nuts, ring

clamps and joint bolts to the

specified torques.

Damaged or improperly installed

converter sealing ring/gaskets. Replace sealing ring/gasket

as necessary.

Leaking exhaust gases

Burned or rusted out exhaust pipe

or muffler/s. Replace component as

necessary.

Leaks at manifold or pipe

connections.

Tighten clamps at leaking

connections to specified

torques. Replace gasket as

required.

Burned or blown out pipe or

muffler/s. Replace pipe/muffler

assembly as necessary.

Exhaust manifold/s cracked or

broken. Replace manifold.

Exhaust noises

Leak between manifold/s and

cylinder head/s.

Tighten manifold to cylinder

head studs to specified

torque.

Clogged catalytic converter (may

result from serious engine

malfunction). Replace catalytic converter.

Loss of engine power,

hesitation, surging, poor fuel

economy, stalling or hard

starting Crushed pipe work. Replace pipe work.

Dislodged tubes and/or baffles in

muffler. Replace muffler.

Internal rattling in muffler Catalytic converter monolith has

crumbled and pieces blown into

muffler.

Replace catalytic converter

assembly and affected

muffler.

Damaged, worn, missing or

improperly installed support

rubbers.

Check and replace as

necessary.

Damaged mounting hangers or

pegs. Service / replace hangers or

pegs as necessary.

Check clearances and adjust

joint alignment as necessary.

Improper alignment. Tighten all fasteners

according to tightening

sequence and the specified

torques.

Rattling or knocking exhaust

system

Damaged or incorrect exhaust

system components.

Replace damaged or

incorrect components as

necessary.

Exhaust System Page 8B–48

Page 8B–48

7 Specifications

Type

V6

Dual front pipes with individual close coupled catalytic

converters incorporated along each front pipe. One

intermediate muffler and one rear muffler.

V6 Supercharged

Dual system to rear of twin intermediate mufflers with

a single pipe rear muffler/tailpipe arrangement.

Individual catalytic converters incorporated along

each front pipe.

GEN III V8 Standard

Dual system to rear of twin intermediate mufflers with

a single pipe rear muffler/tailpipe arrangement.

Individual close coupled catalytic converters

incorporated along each front pipe.

GEN III V8 Performance

Dual system back to a single rear muffler with dual tail

pipes. Front pipes similar to those used on standard

type GEN III V8 exhaust system.

Material

Engine Pipes

....................................................................................................................409 stainless steel

Intermediate Muffler

....................................................................................................................409 stainless steel

Rear Muffler

....................................................................................................................409 stainless steel

Catalytic Converter

Make

............................................................................................................................. AC Australia

Type

..................................................................................................................Three way monolith

Outer Steel Shell

....................................................................................................................409 stainless steel

Monolith Material

...................................................................................................................Extruded Cordierite

Cells/cm2

............................................................................................................................................. 62

Exhaust System Page 8B–49

Page 8B–49

8 Torque Wrench Specifications

Intermediate to front exhaust assembly swivel-joint

flange stepped fastening bolt...........................................................40 – 50 Nm

Cross brace to front pipe assembly mounting bracket

fastening nut....................................................................................20 – 50 Nm

Cross brace bracket fastening nut...................................................20 – 50 Nm

U-bolt clamp assembly fastening nuts.............................................20 – 30 Nm

Front exhaust assembly to exhaust manifold flange

stud fastening nut............................................................................18 – 35 Nm

Intermediate to rear exhaust assembly flange joint

fastening bolts .................................................................................40 – 50 Nm

Intermediate to front exhaust assembly flange fastening bolt .........40 – 50 Nm

Intermediate Y–pipe to front exhaust assembly

flange fastening bolt ........................................................................40 – 50 Nm

Ring clamp assembly fastening nut.................................................37 – 50 Nm

Rear muffler heat shield fastening screw ......................................5.0 – 8.0 Nm

Intermediate muffler heat shield fastening screw..........................5.0 – 8.0 Nm

Intermediate muffler heat shield stud fastening nut.......................5.0 – 8.0 Nm

Front exhaust assembly heat shield fastening screw....................5.0 – 8.0 Nm

Post catalytic converter on-pipe heat shield attaching nut ............5.0 – 8.0 Nm

Exhaust System Page 8B–50

Page 8B–50

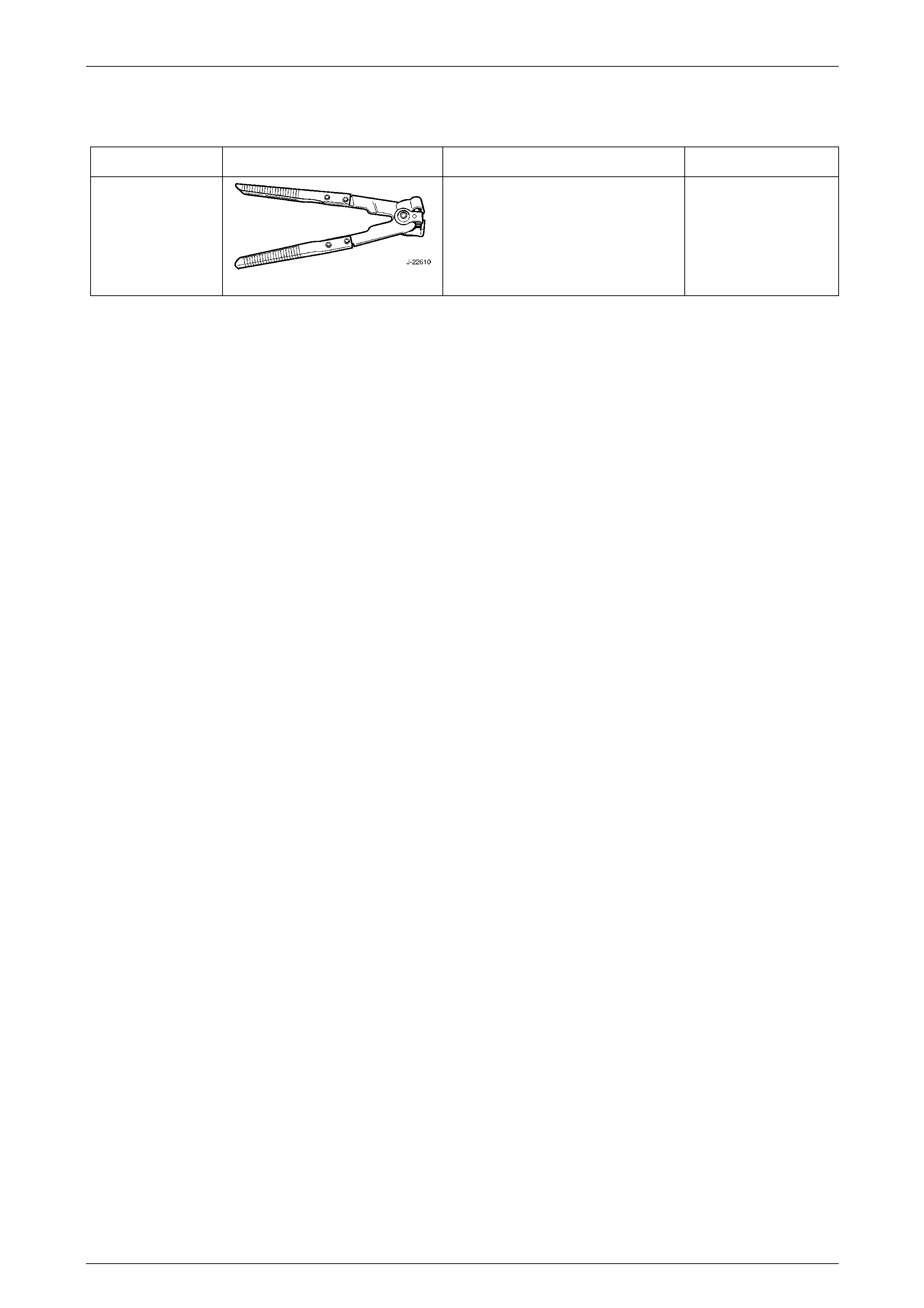

9 Special Tools

Tool Number Illustration Description Tool Classification

J22610

KEYSTONE CLAMP PLIERS

Used to tighten ear-type clamps. Essential