SECTION 0B - MAINTENANCE AND LUBRICATION

1. MAINTENANCE SCHEDULE

1.1 MAINTENANCE SCHEDULE UNDER

NORMAL DRIVING CONDITIONS

1.2 MAINTENANCE RECOMMENDED

UNDER SEVERE DRIVING

CONDITIONS

Severe Condition Code

2. MAINTENANCE SERVICE

2.1 ENGINE

Water Pump / Generator Drive Belt

A/C Compressor Drive Belt

Valve Lash (Clearance)

Engine Oil and Oil Filter

Engine Coolant

Exhaust System

2.2 IGNITION SYSTEM

Spark Plugs

2.3 FUE L SY ST E M

Air Cleaner Filter

Fuel Lines and Connections

Fuel Filter

Fuel Tank

2.4 EMISSION CONTROL SYSTEM

PCV Val ve

Fuel Evaporative Emission Control

System

2.5 BRAKES

Front Brake Discs and Pads

Rear Brake Drums and Shoes

Brake Hoses and Pipes

Brake Fluid

Brake Lever and Cable

2.6 CHASSIS AND BODY

Clutch

Tyres / Wheels

Suspension System

Steering System

Drive Shaft (Axle) Boots /

Propeller Shafts

Manual Transmission Oil

Automatic Transmission Fluid

Transfer Oil & Rear Differential Oil

Latches, Hinges and Locks

3. FINAL INSPECTION

Seats

Seat Belt

Battery Electrolyte Level Check

Accelerator Pedal Operation

Engine Start

Exhaust System Check

Clutch (For Manual Transmission)

Gearshift or Select Lever

Brake

Steering

Engine

Body, Wheels and Power

Train System

Meters and Gauges

Lights

Windshield Defroster

4. RECOMMENDED FLUIDS AND

LUBRICANTS

WARNING:

For vehicles equipped with Supplement Restraint (Airbag) System

• Service on and around the airbag system components or wiring must be performed only by an

authorised H OLDEN retailer. Refer to Section 10B AIRBAG SY STEM COMP ONENTS AN D W IRING

LOCATION V IEW in GENERAL DESCRIPTION in order to confirm whether you are performing ser-

vice on or near the airbag system components or wiring. Please observe all W ARNINGS and SER-

VICE PRECAUTIONS, refer to Section 10B ON-VEHICLE SER VICE before perf orming service on or

around the airbag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could re nder the system inoperative. Either or these two

conditions may result in severe injury.

• Technical service work must not be started for at least 90 seconds after the ignition switch is

turned to the “LOCK” position and the negative cable is disconnected from the battery. Other-

wise, the system may be activated by reserve energy in the Sensing and Diagnostic Module

(SDM)

Techline

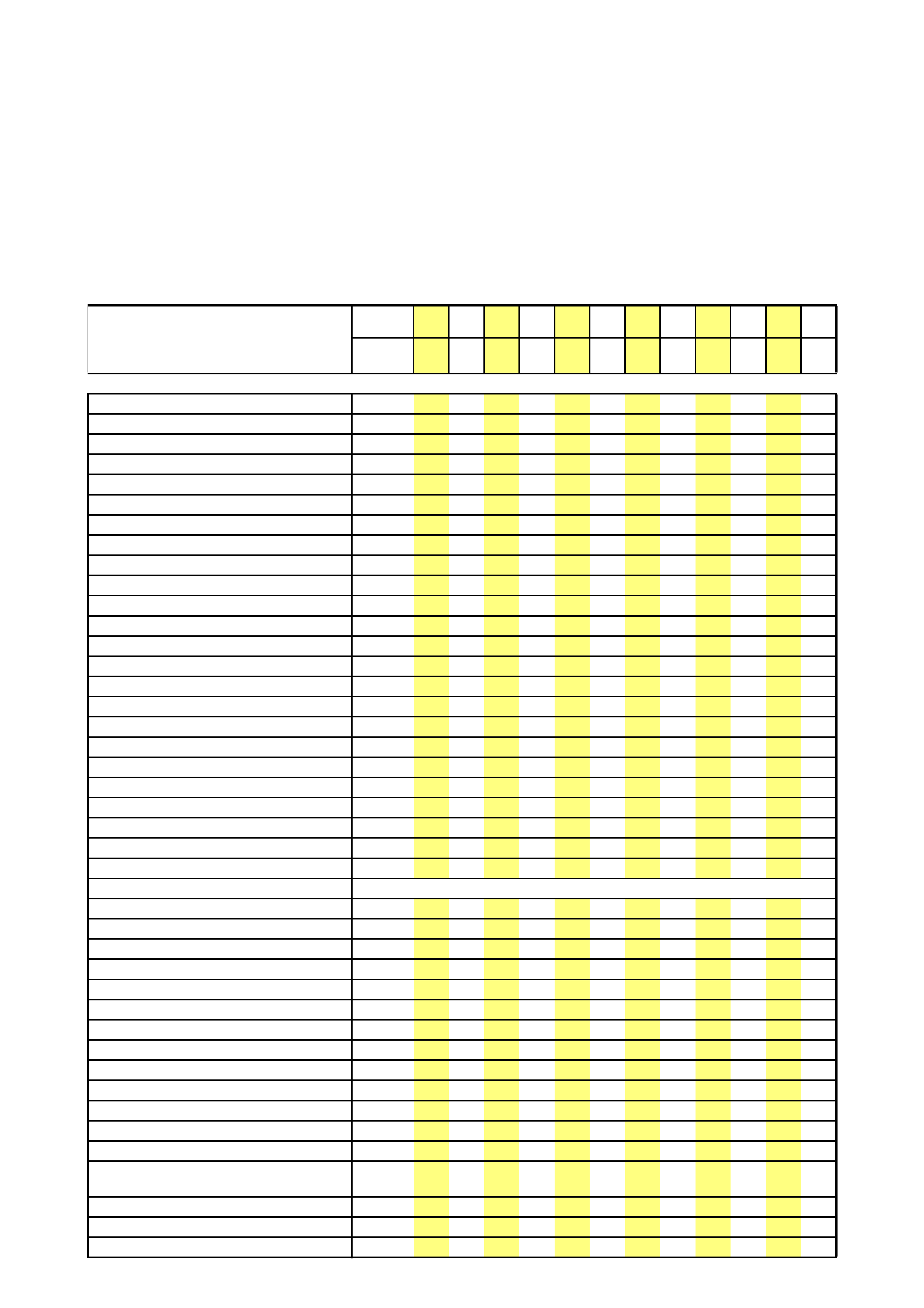

1. MAINTENANCE SCHEDULE

1.1 MAIN TENANCE SCHEDULE UNDER NORMAL DRIVING CONDITIONS

NOTE:

• This interval should be judged by the odometer reading or months, whichever comes first.

Use odometer readings or years, which ever

occurs first.

x1000k

m15 30 45 60 75 90 105 120 135 150 165 180

or

years

12345678910 11 12

Engine oil RRRRRRRRRRRR

Engine oil filter R R R R R R

Fuel filter R R

Fuel Emission System Check I I

PCV Valve Check I I

Air cleaner element I I R I I R I I R I I R

Coolant Level & % Concentration Check II II IIIII

Coola nt - Replac e R R R R

Access ory Drive Belt IIIIIRIIIIIR

Spark plugs R R R R

Valv e clearances A A A A A A

Brake Fluid Level - Inspect IIIIIIIIIIII

Brake Fluid - Change Change every two years (regardless of km)

Automat ic Transmis sio n - Fluid Lev el IIIIII

Automat ic Transm issio n F lui d R

Automatic Transmission Cooler Hoses I I I

Manual Transmission Oil I R R R R

Transfer Case Oil Lev el IIIIII

Rear Differential Oil R I I I I I

Oil/Fl uid Leak s - V isual Ch eck Of Engine

& Transmission IIIIIIIIIIII

Front Brakes - Check Pad Thickness IIIIIIIIIIII

I: Inspect and correct or replace as necessary

R: Replace or change

T: Tighten to specified torque

L: Lubricate

A: Adjust

Under extreme conditions, more frequent maintenance is required. Refer to “1.2 MAINTENANCE RECOMMENDED

UNDER SEVERE DRIVING CONDITIONS” in this Section.

Rear Brakes - Check Drums & Shoes IIIIII

Park Brake - Lever & Cable Adjustment First 15000km Service Only

Brake Pipes & Hoses - Visual Check IIIIII

Exhaust System - Check IIIIII

Fuel Lines & Fuel Tank IIIIII

Suspension System IIIIII

Drive Shaft/Axle Rubber Boots I I I I

St eering Sys tem - Check IIIIII

Wheel Nuts TTTTTTTTTTTT

Tyres - Check Condition & Pressure IIIIIIIIIIII

Headlamps, Rear Lamps, Turn Signals,

St op Lamps - Che c k IIIIIIIIIIII

Warning Lamps & Instruments IIIIIIIIIIII

Windscreen Washers & Wipers IIIIIIIIIIII

Clutch Pedal - Pedal Height & Travel IIIIII

Body & Unde rbody - Check Corrosion

Protection IIIIIIIIIIII

Door, Bonnet, Tailgate Hinges & Locks -

Check IIIIII

Door, Bonnet, Tailgate Hinges & Locks LLLLLL

Keyless Entry System Battery - Replace IIIIII

IIIIIIIIIIII

Road Te st

Use odometer readings or years, which ever

occurs first.

x1000k

m15 30 45 60 75 90 105 120 135 150 165 180

or

years

12345678910 11 12

SERVICE TIMES

11.91.5 1.9 12.51.6 1.9 1.5 1.5 1.6 2.7

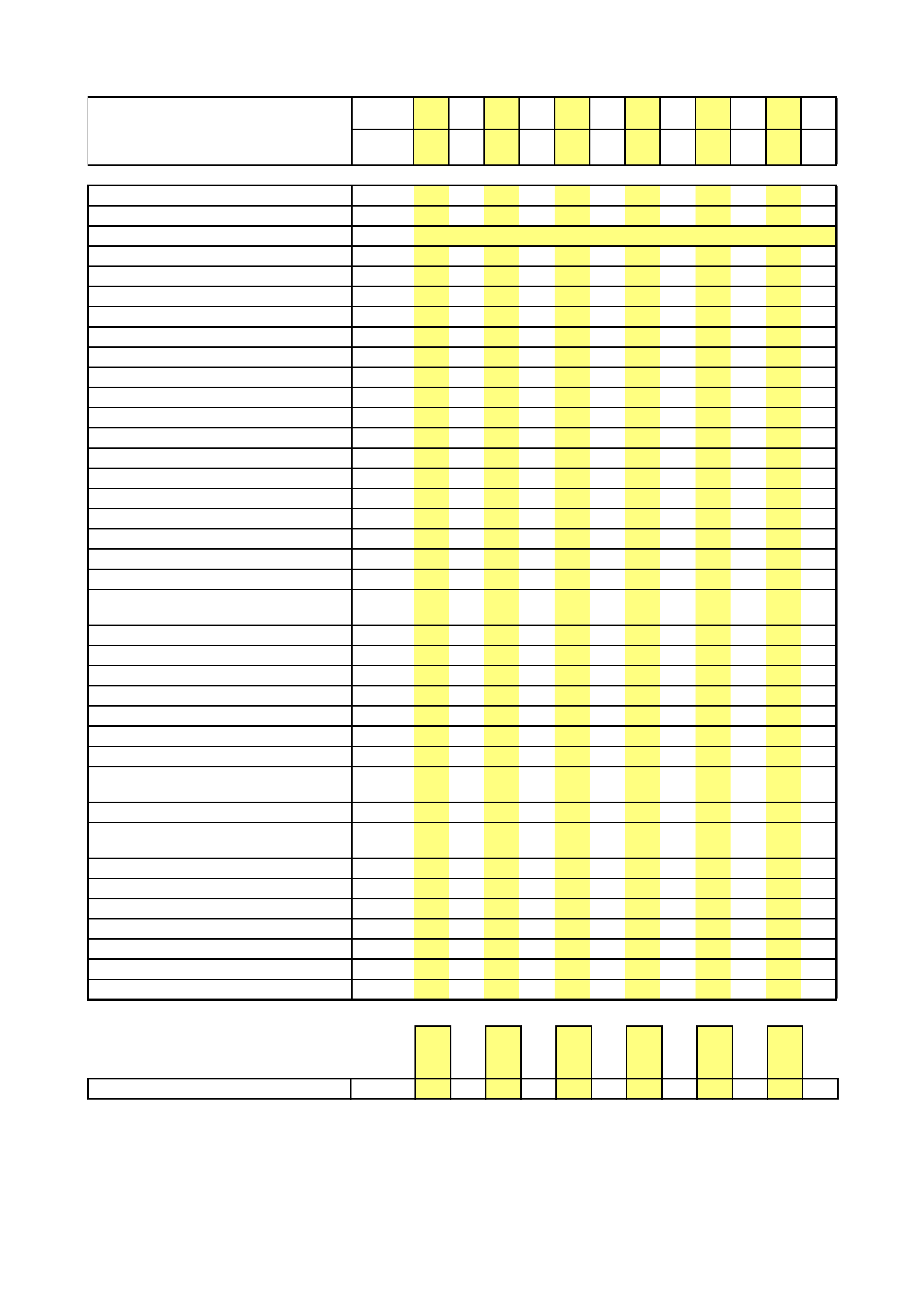

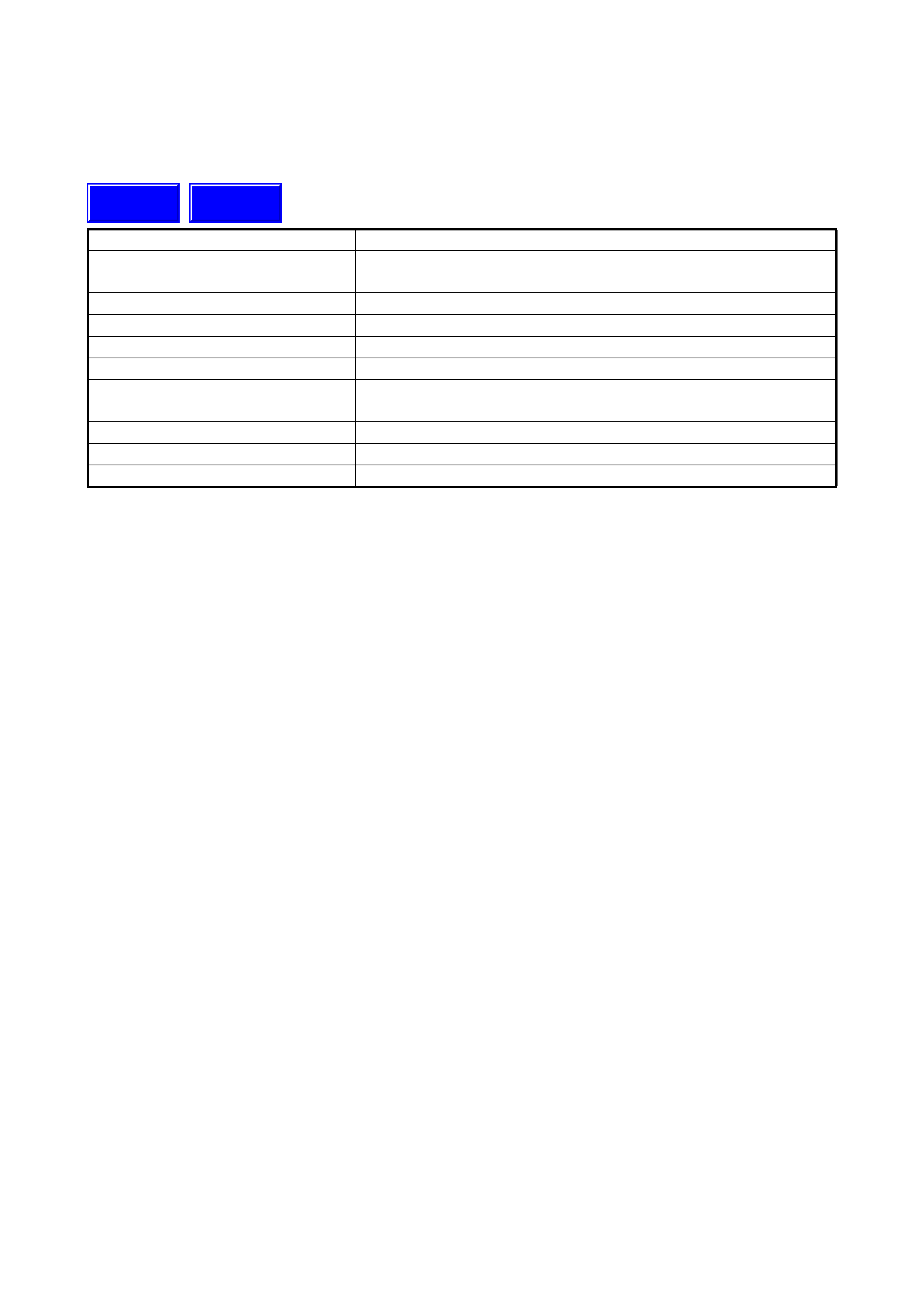

1.2 MAINTENAN CE RECOMMENDED UNDER SEVERE DRIVING CONDITIONS

If the vehicle is usually used under any of the severe condition codes given below, it is recommended that the

applicable maintenance operation be performed at the interval shown in the following table.

SEVERE CONDITION CODE

A: Repeated short trips

B: Driving on rough and/or muddy roads

C: Driving on dusty roads

D: Driving in extremely cold weather and/or salted roads

E: Repeated short trips in extremely cold weather

F: Towing a trailer

NOTE:

• I: Inspect and correct or replace if necessary

• R: Replace or change

•✱1: Inspect more frequently if the vehicle is used under dusty conditions.

Severe

Condition Code Maintenance Maintenance

Operation Maintenance Interval

– B C D – – Drive belt I Every 15,000 km

or 12 months

R Every 45,000 km

or 36 months

A – C D E F Engine oil and oil filter R Every 5,000 km

or 4 months

– – C – – – Air cleaner filter ✱1 I Every 2,500 km

R Every 30,000 km

or 24 months

A B C – E F Spark plugs R Every 10,000 km

or 8 months

– B C D – F Wheel bearings I Every 15,000 km

or 12 months

– B – D E F Drive shafts and propeller shafts I Every 15,000 km

or 12 months

– B – – E F Manual transmission, transfer and

differential oil R At 15,000 km or 12 months

then every 30,000 km or

24 months

– B – – E F Automatic transmission fluid R Every 30,000 km

or 24 months

2. MAINTENANCE SERVICE

2.1 ENGINE

WARNING:

All inspection and replacement is to be

performed with ENGINE NOT RUNNING.

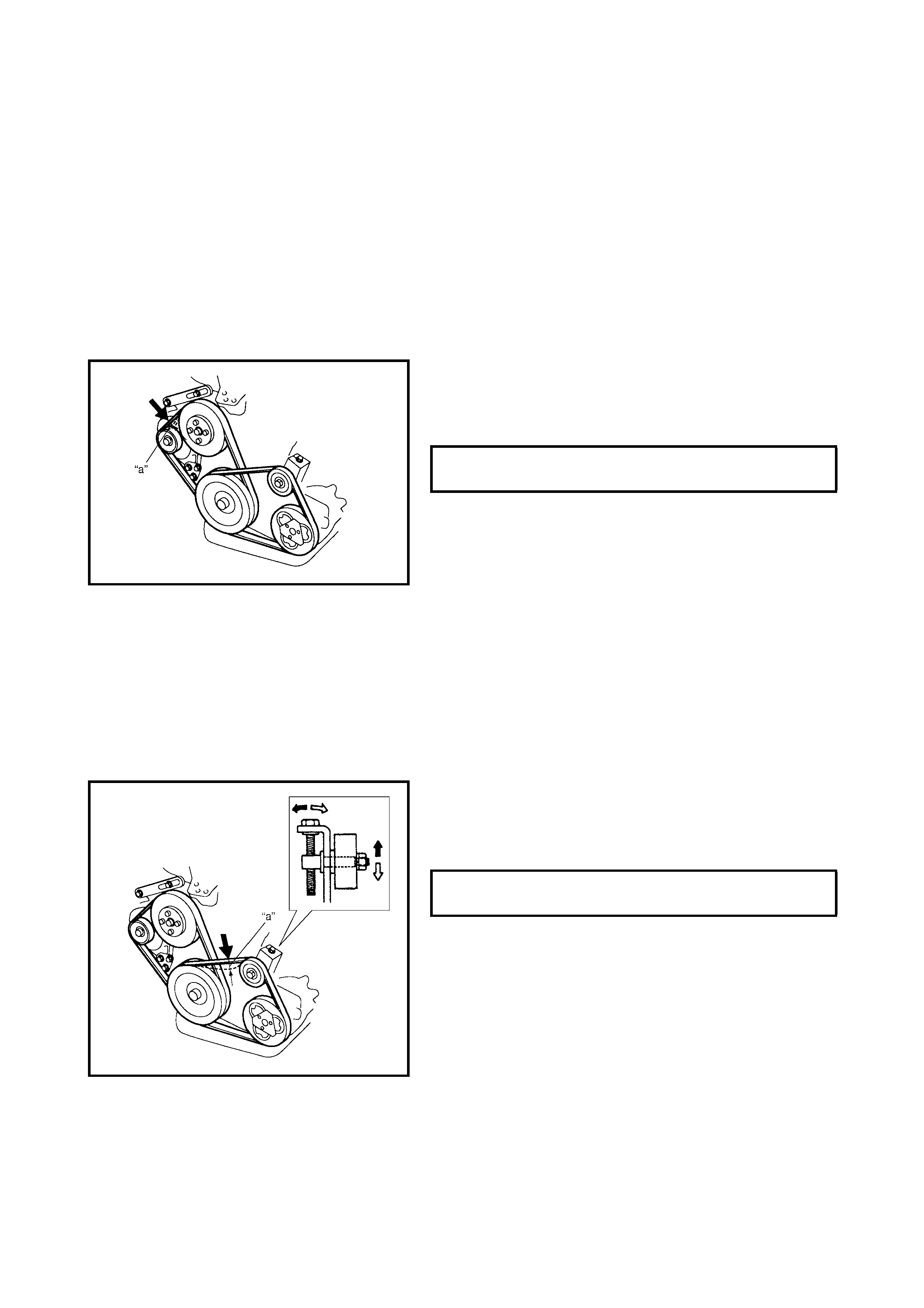

WATER PUMP / GENERATOR DRIVE BELT

Inspection

1. Disconnect negative (–) cable at battery.

2. Inspect the belt for cracks, cuts, deformation, wear and

cleanliness. If any defect exists, replace the belt.

3. Check the belt for tension by measuring the deflection

under thumb pressure.

NOTE:

When installing a new belt, adjust belt tension to

a deflection of 3 - 4 mm.

4. If the belt is too tight or too loose, adjust it to specifica-

tion by adjusting the alternator position.

5. Tighten the alternator adjusting bolts and pivot bolt.

6. Connect negative (–) cable to battery.

Replacement

Refer to Section 6B, 4.9 WATER PUMP / GENERATOR

DRIVE BELT.

A/C COMPRESSOR DRIVE BELT

Inspection

1. Disconnect negative (–) cable at battery.

2. Inspect the belt for cracks, cuts, deformation, wear and

cleanliness. If any defect exists, replace the belt.

3. Check the belt for tension by measuring the deflection

under thumb pressure.

4. If the belt tension is out of specification, adjust it, refer

to Section 1B, 2.5 COMPRESSOR DRIVE BELT.

5. Connect negative (–) cable to battery.

Replacement

Refer to Section 1B, 2.5 COMPRESSOR DRIVE BELT.

WATER PUMP / GENERATOR DRIVE

BELT DEFLECTION (a:) 4.5 –- 5.5 mm @

10 kg pressure

A/C COMMPRESSOR DRIVE BELT

DEFLECTION (a:) 3 –- 5 mm @ 10

kg pressure

VALVE LASH (CLEARANCE)

Inspection

1. Inspect the intake and exhaust valve lash with a

thickness gauge (1). Adjust as necessary, refer to

Section 6A1, 2.5 VALVE LASH.

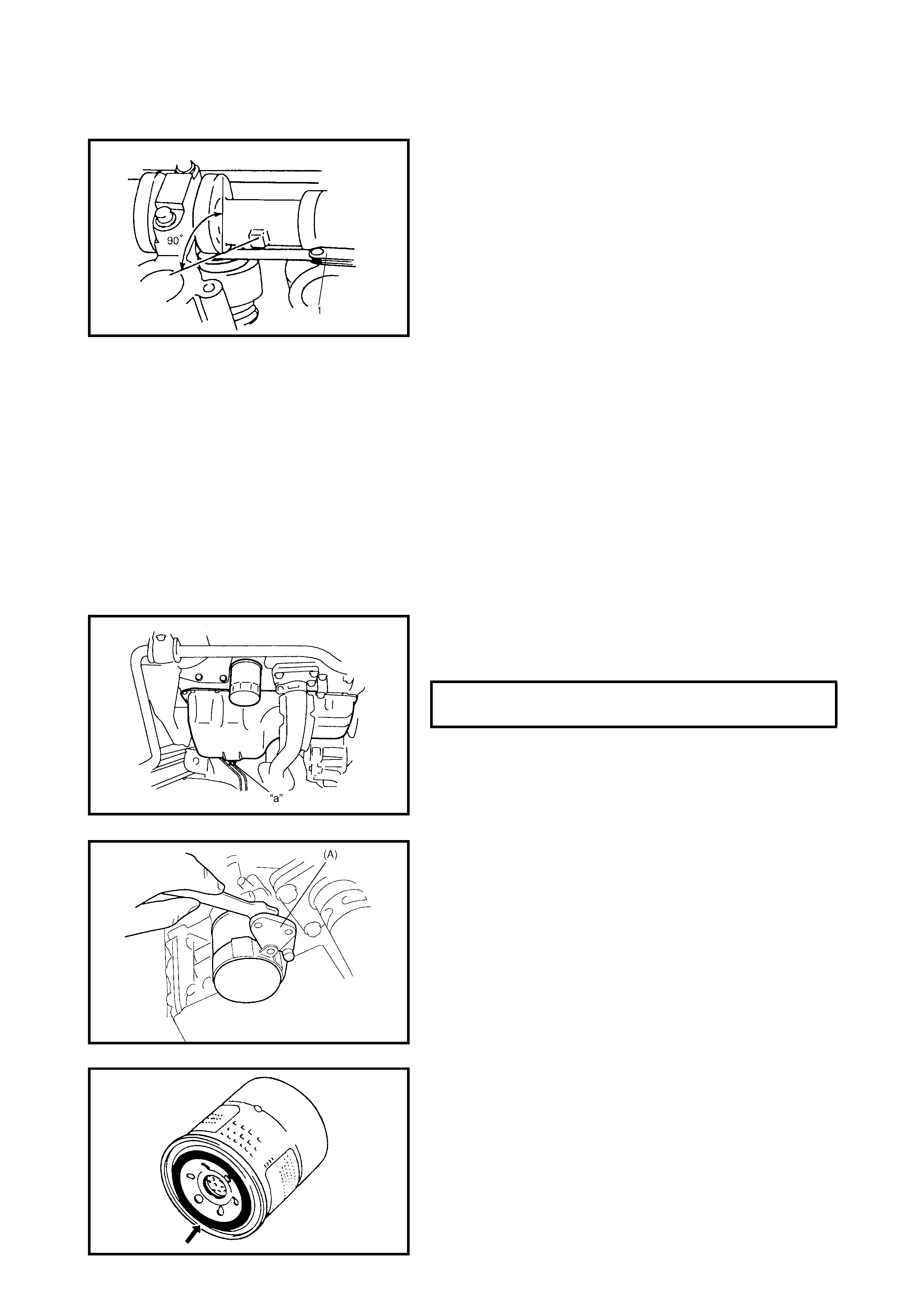

ENGINE OIL AND OIL FILTER

Replacement

WARNING:

• New and used engine oil can be hazardous.

Read WARNING in General Precaution in

Section 0A and observe what in written there.

• Ste p 1 - 7 described below must be performed with

the ENGINE NOT RUNNING. For Step 8, have ade-

quate ventilation while the engine is running.

Before draining the engine oil, check the engine for oil leak-

age. If any evidence of leakage is found, make sure to

repair the defe ctive part before procee ding to the following

work.

1. Drain engine oil by removing drain plug.

2. After drainin g o il, wipe drain plug c lean. R einstall drain

plug, and tighten it securely as specified.

3. Loosen the oil filter with an oil filter wrench, special tool

09915-473 30 (A) .

NOTE:

Before fitting a new oil filter, apply a thin film of

engine oil to its O-ring.

4. Screw a new filter on the oil filter stand by hand until

the filter O-ring con tacts the mountin g surfac e.

NOTE:

To tighten the oil filter properly, it is important to

accurately identify the position at which filter O-ring first

contacts the mounting surface.

ENGINE OIL DRAIN PLUG TORQUE

SPECIFICATION (a) 50 Nm

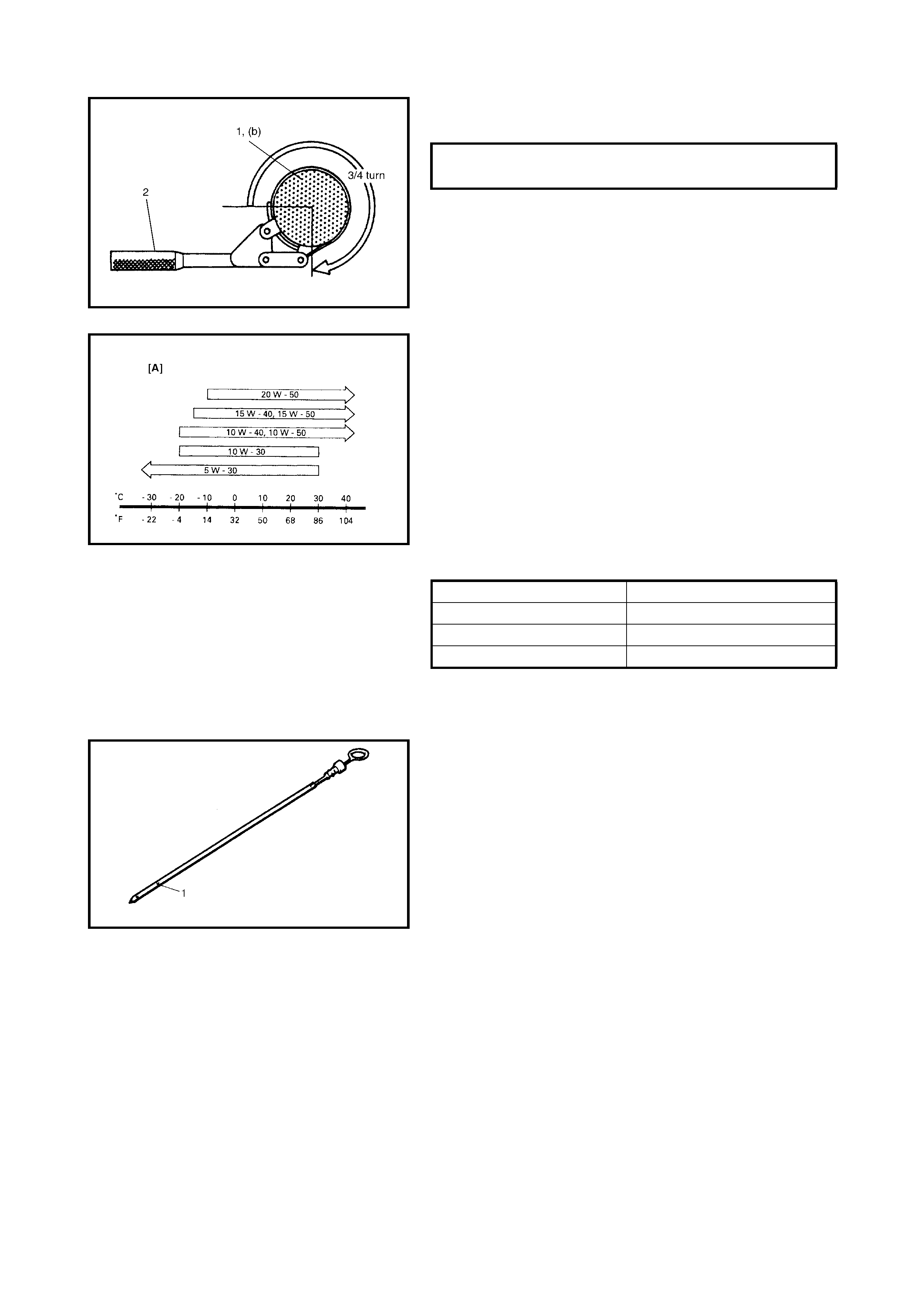

5. Tighten the filter (1) 3/4 turn from the point of contact

with the mounting surface using an oil filter wrench (2).

6. Replenish the engine with oil until the level is brought

to the FULL mark on the dipstick. (oil pan and oil filter

capacity). The filler inlet is at the top of the cylinder

head cover.

It is recommended to use engine oil of ACEA service

classification A2 or A3 viscosity grade 10W-30. Select

the appropriate oil viscosity according to the proper

engine oil viscosity chart [A].

Engine Oil Capacity

NOTE:

The amount of oil required may differ from the

data in the table due to temperat ure, viscosity, etc.

7. Check oil filter and drain plug for oil leakage.

8. Start the engine and run it for 3 minutes. Stop it and

wait 5 minutes before checking the oil level. Add oil, as

necessary, to bring oil level to FULL level mark (1) on

the dipstick.

OIL FILTER TORQUE SPECIFICATION

(b) (ref) 14 Nm

Oil pan capacity Approx. 3.6 litres

Oil filter capacity Approx. 0.2 litre

Others Approx. 0.3 litre

Total Approx. 4.1 litres

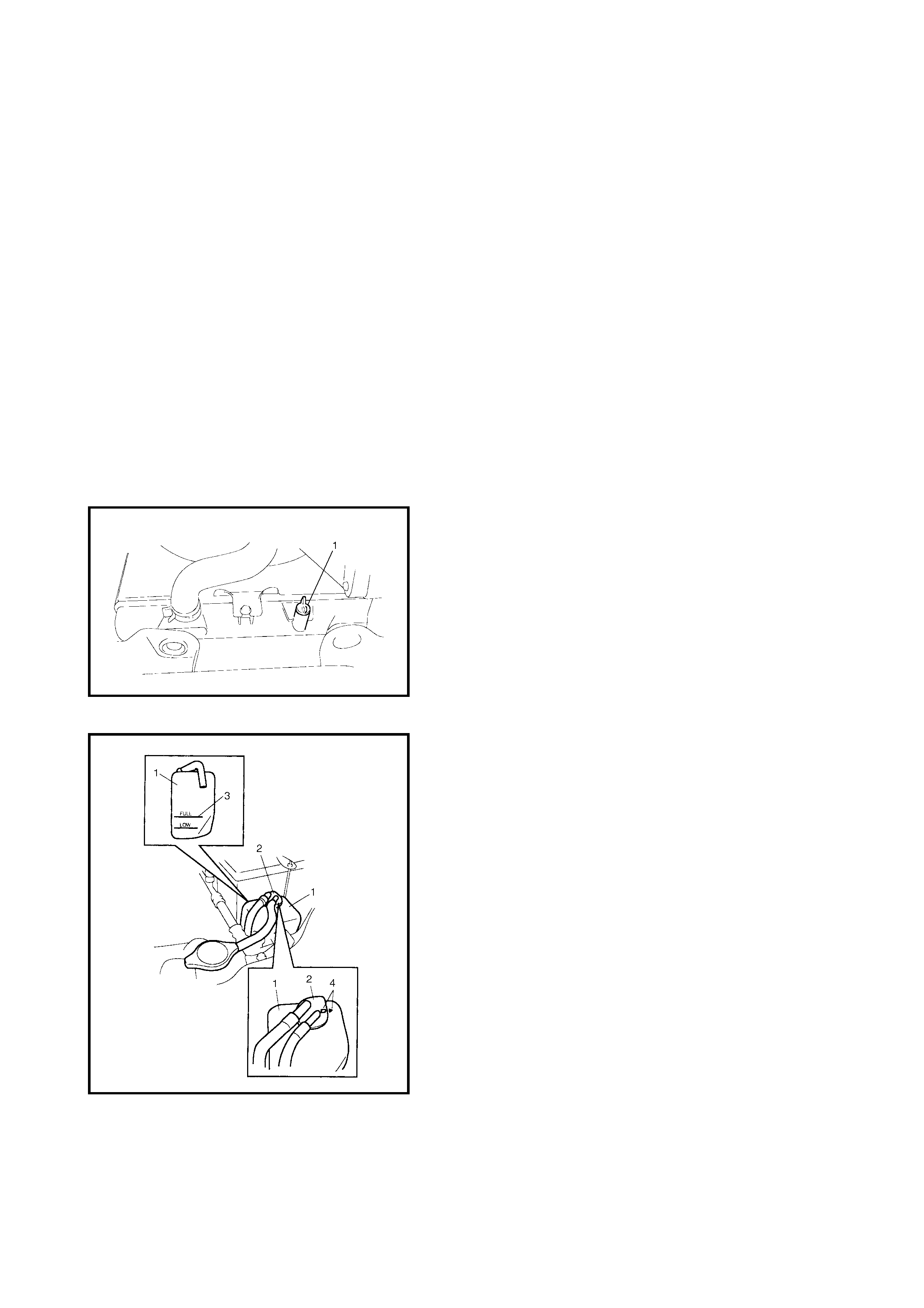

ENGINE COOLANT

Replacement

WARNING:

To avoid danger of being burned, do not

remove the radiator cap while the engine and

radiator are still hot. Scalding fluid and steam can

be blown out under pressure if cap is taken off too

soon

CAUTION: Always use the recommended coolant, refer

to 4. RECOMMENDED FLUIDS AND LUBRICANTS in

this Section. Other coolants may be incompatible and

may adversely affect the cooling system.

As a minimum, when changing engine coolant, use a

mixture of 70% water and 30% Holden Cruze coolant,

part number 92145591 where the ambient temperature

will not fall lower than -16°C. This mixture ratio will

also provide corrosion protection and lubrication.

If it is possible for the ambient temperature to fall

below -16°C, a 50% water and 50% Holden Cruze

coolant should be used.

1. Remove the radiator cap when engine is cool.

2. Loosen the radiator drain plug (1) to drain the coolant.

3. Remove the reservoir and drain.

4. Tighten the plug securely and reinstall the reservoir.

5. Fill the radiator with the specified amount of coolant,

and run the engine for 2 or 3 minutes at idle.

This drives out any air which may still be trapped within

the cooling sy st em.

6. Stop the engine.

7. Add coolan t as required until the cool ant level reac hes

the filler throat of the radiator.

8. Reinstall the radiator cap.

9. Add coolant to the reservoir (1) so that its level aligns

with the FULL mark (3).

10. Reinstall the cap (2), aligning the arrow marks (4) on

reservoir and cap.

EXHAUST SYSTEM

Inspection

WARNING:

To avoid danger of being burned, do not

touch the exhaust system when it is still hot. Any

service on exhaust system should be performed

when it is cool.

When performing periodic maintenance, or the vehicle is

raised for other service, check exhaust system as follows:

• Check the rubber mountings for damage, deterioration,

and incorrect position.

• Check the exhaust system for leakage, loose connec-

tions, dents and damages.

If bolts or nuts are loose, tighten them to specification.

• Check nearby body areas for damaged, missing, or

incorrectly positioned parts, open seams, holes, loose

connections or other defects which could permit

exhaust fumes to seep into the vehicle.

• Ensure that exhaust system components have enough

clearance from the underbody to avoid overheating

and possible damage to the floor carpet.

• Any defects should be fixed at once.

2.2 IGNITION SYSTEM

SPARK PLUGS

Replacement

Replace spark plugs with new ones, refer to Section 6F1,

3.3 SPARK PLUGS.

2.3 FUEL SYSTEM

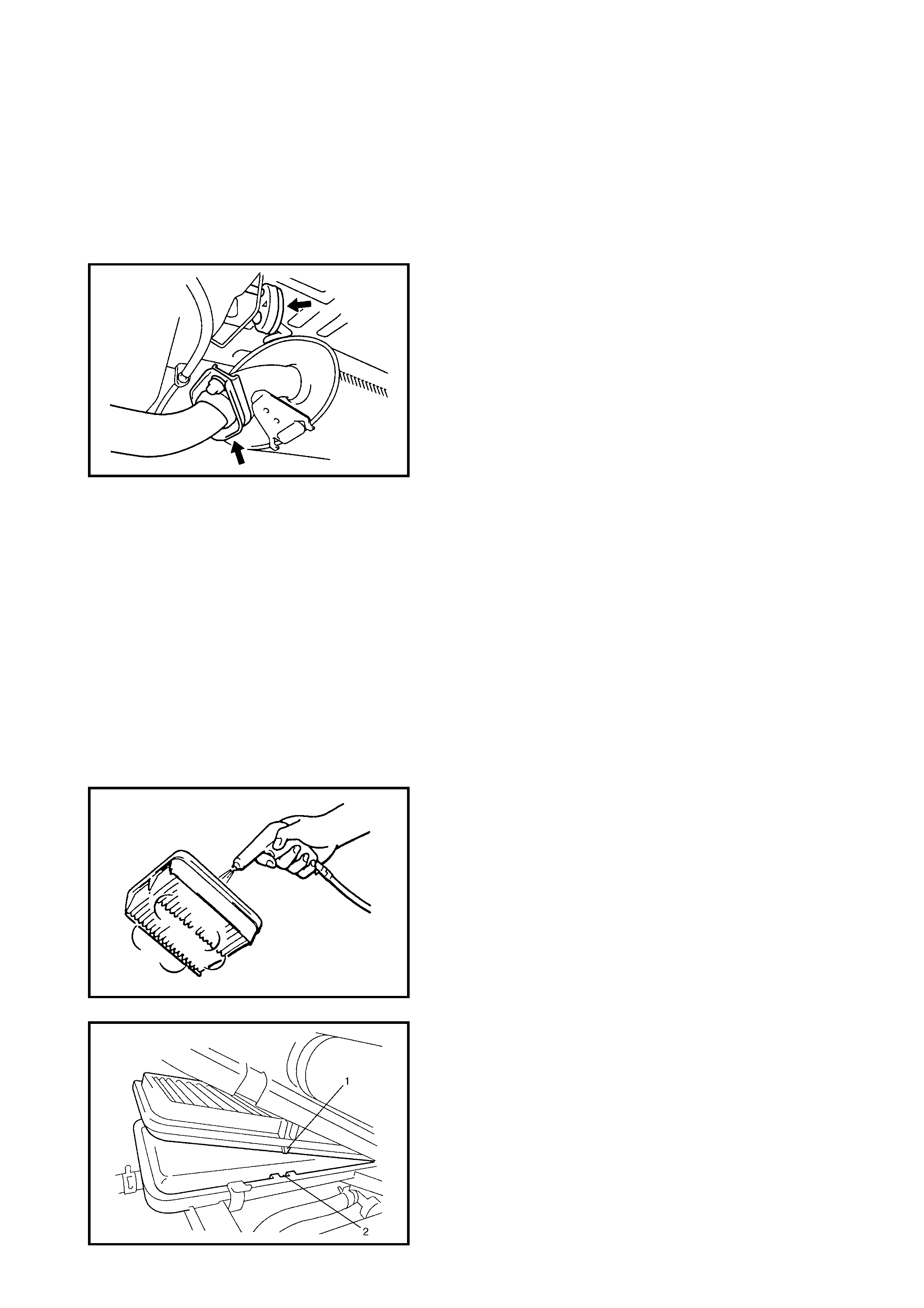

AIR CLEANER FILTER

Inspection

1. Remove the air cleaner case clamps.

2. Ta ke the air cle ane r filter out of the case.

3. Check that the filter is not excessively dirty, damaged

or oily. Clean the filter with compressed air from the air-

outlet side of the filter.

4. Install the air c leane r filter, fi tting th e protrus ion (1) in to

the groove (2) of the case.

5. Clamp the upper case securely.

Replacement

Replace the air cleaner filter with new one as described in

Steps 1., 2. and 4. of INSPECTION.

FUEL LINES AND CONNECTIONS

Inspection

Visually inspect the fuel lines and connections for evidence

of fuel leakage, hose cracking and damage.

Make sure all clamps are secure.

Repair leaky joints, if any.

Replace hoses that are suspected of being cracked.

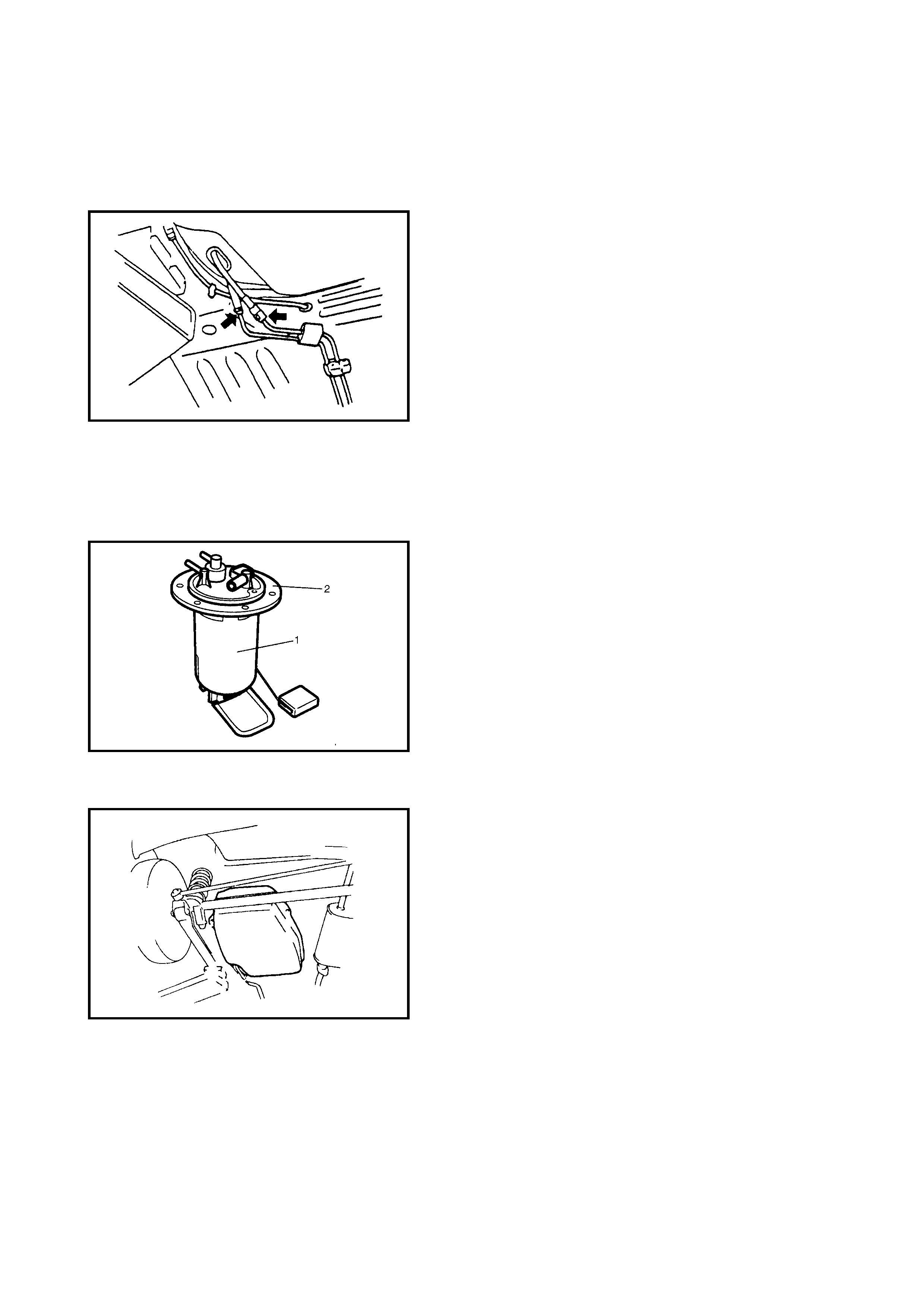

FUEL FILTER

Replacement

WARNING:

This work must be performed in a well

ventilated area and away from any open flames

(such as gas hot water heaters).

The fuel filter (1) is installed in the fuel pump assembly (2)

which is installed in the fuel tank.

Replace the fuel filter with new one, refer to Section 6C,

2.8 FUEL PUMP ASSEMBLY.

FUEL TANK

Inspection

Check the fuel tank for damage, cracks, fuel leakage,

corrosion and the tank bolts for looseness.

If a problem is found, repair or replace.

2.4 EMISSION CONTROL SYSTEM

PCV VALVE

Inspection

Check the crankcase ventilation hose and PCV hose for

leaks, cracks or blockage.

Check the PCV valve for sticking or blockage, refer to

Section 6E1, 2.4 EMISSION CONTROL SYSTEM.

FUEL EVAPORATIVE EMISSION CONTROL

SYSTEM

Inspection

1. Visually inspect the hoses for cracks, damage, or

excessive bends. Inspect all clamps for damage and

correct position.

2. Check the EVAP canister for operation and blockage,

refer to Section 6E1, 2.4 EMISSION CONTROL

SYSTEM.

If a malfunction is found, repair or replace.

2.5 BRAKES

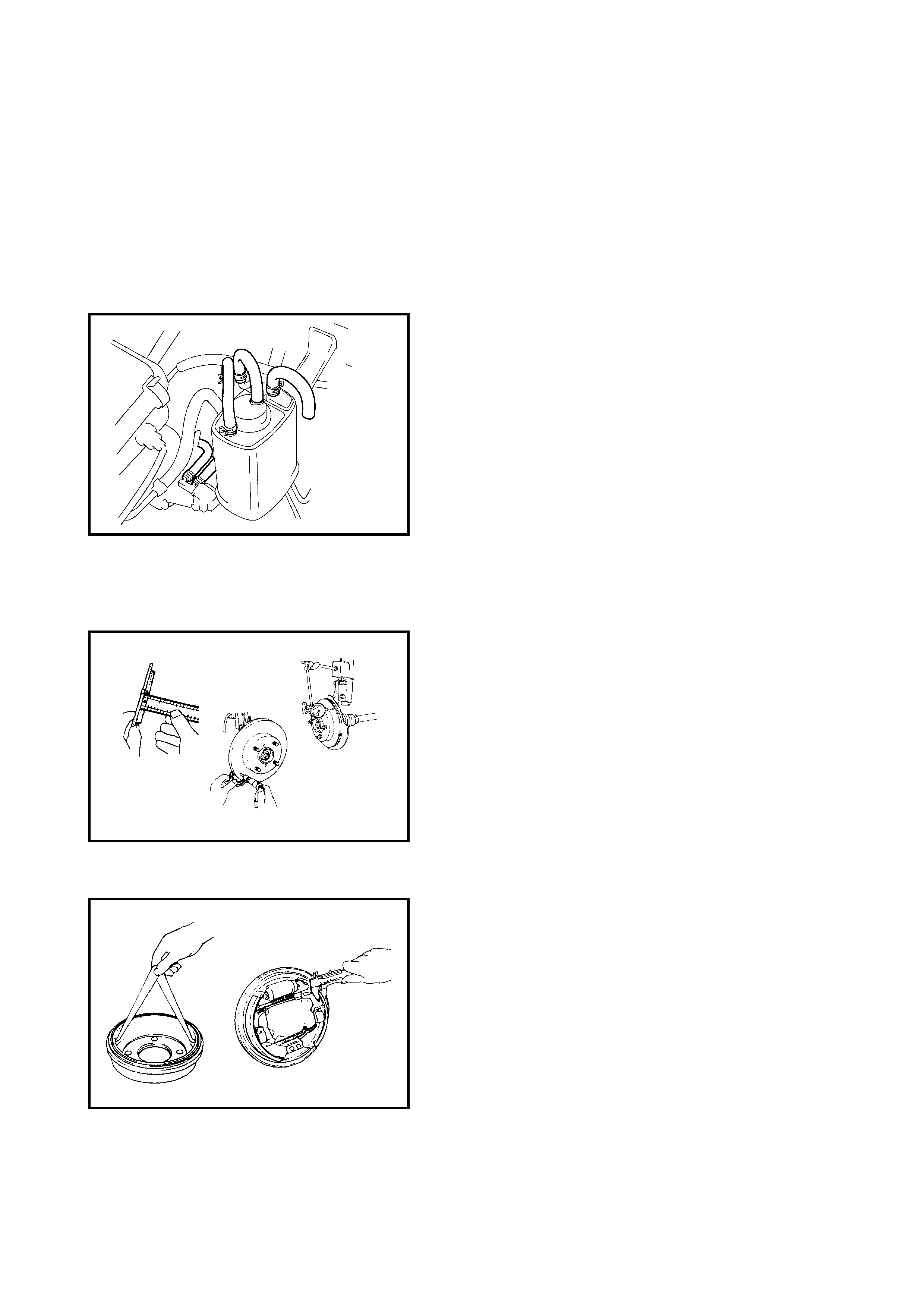

FRONT BRAKE DISCS AND PADS

Inspection

1. Remove the wheel and caliper but don’t disconnect

brake hose from caliper.

2. Check the front disc pads and discs for excessive

wear, damage and deflection. Replace parts as neces-

sary, refer to Section 5, 3.2 FRONT BRAKE.

NOTE: Torque the caliper pin bolts to specification.

REAR BRAKE DRUMS AND SHOES

Inspection

1. Remove the wheel and brake drum.

2. Check the rear brake drums and brake linings for

excessive wear and damage. Also check the wheel

cylinders for leaks. Replace parts as necessary, refer

to Section 5, 3.3 REAR BRAKE.

BRAKE HOSES AND PIPES

Inspection

Perform this inspection where there is enough light and use

a mirror as necessary.

• Check the brake hoses and pipes for correct mounting,

leaks, cracks, chafing and other damage.

• Check that the hoses and pipes are clear of sharp

edges and moving parts.

Repair or replace any of these parts as necessary.

CAUTION:

After replacing any brake pipe or hose,

bleed air from the brake system, refer to Section 5,

3.1 AIR BLEEDING OF BRAKE SYSTEM.

BRAKE FLUID

Replacement

Drain the existing fluid from the brake system completely

and fill with the specified fluid.

Bleed air from the system, refer to Section 5,

3.1 AIR BLEEDING OF BRAKE SYSTEM.

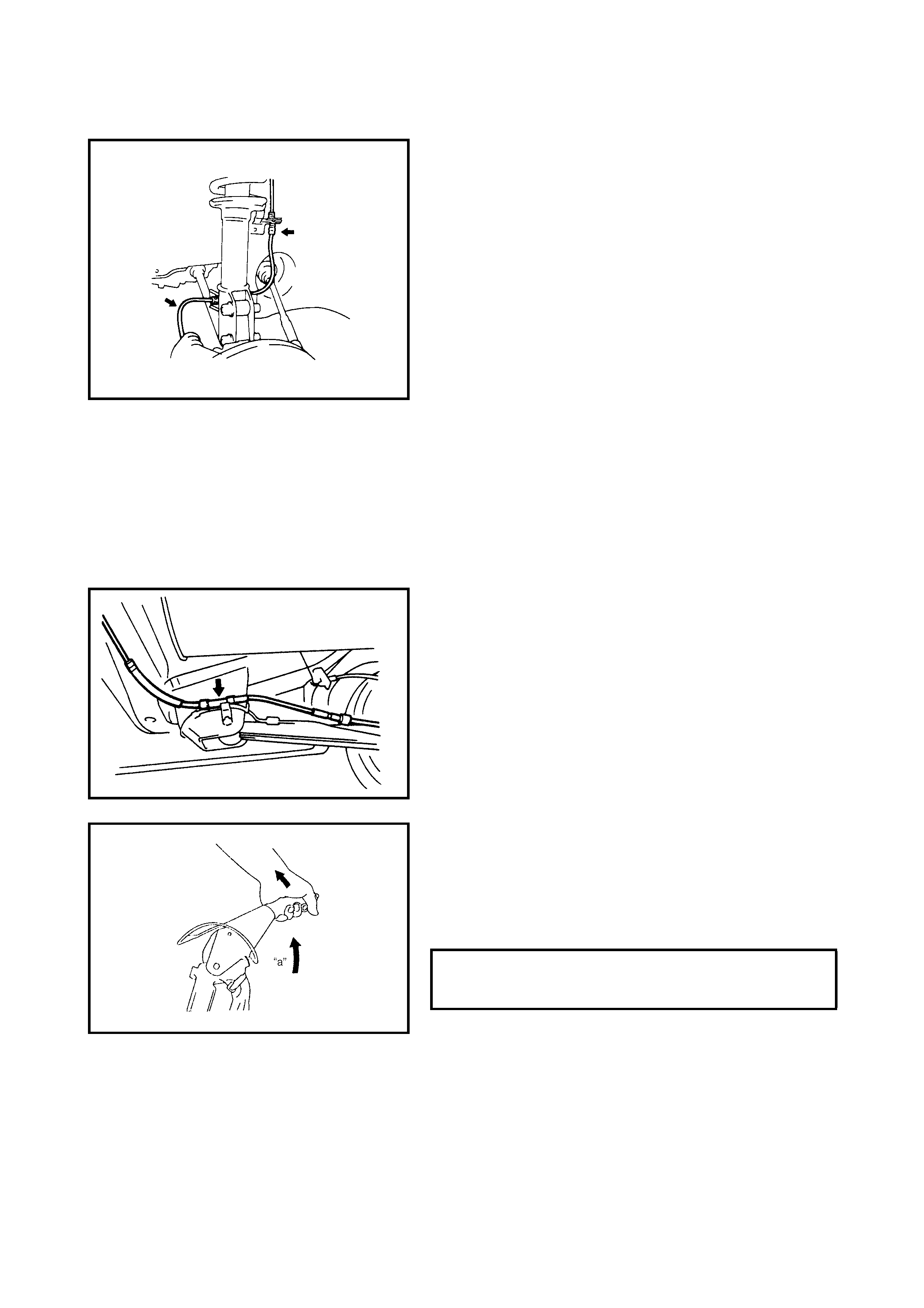

BRAKE LEVER AND CABLE

Inspection

1. Inspect the brake cable for damage and smooth

movement.

Replace the cable if it is in deteriorated condition.

2. Check the tip of each tooth for damage or wear. If any

damage or wear is found, replace the parking lever.

3. Check the parking brake lever for proper operation and

stroke, and adjust it if necessary, refer to

2.10 PARKING BRAKE INSPECTION AND

ADJUSTMENT in Section 5.

PARKING BRAKE STROKE (WHEN

LEVER IS PULLED UP AT 200 N) (20

kg) 4 T O 9 NOTCHES

2.6 CHASSIS AND BODY

CLUTCH

Inspection

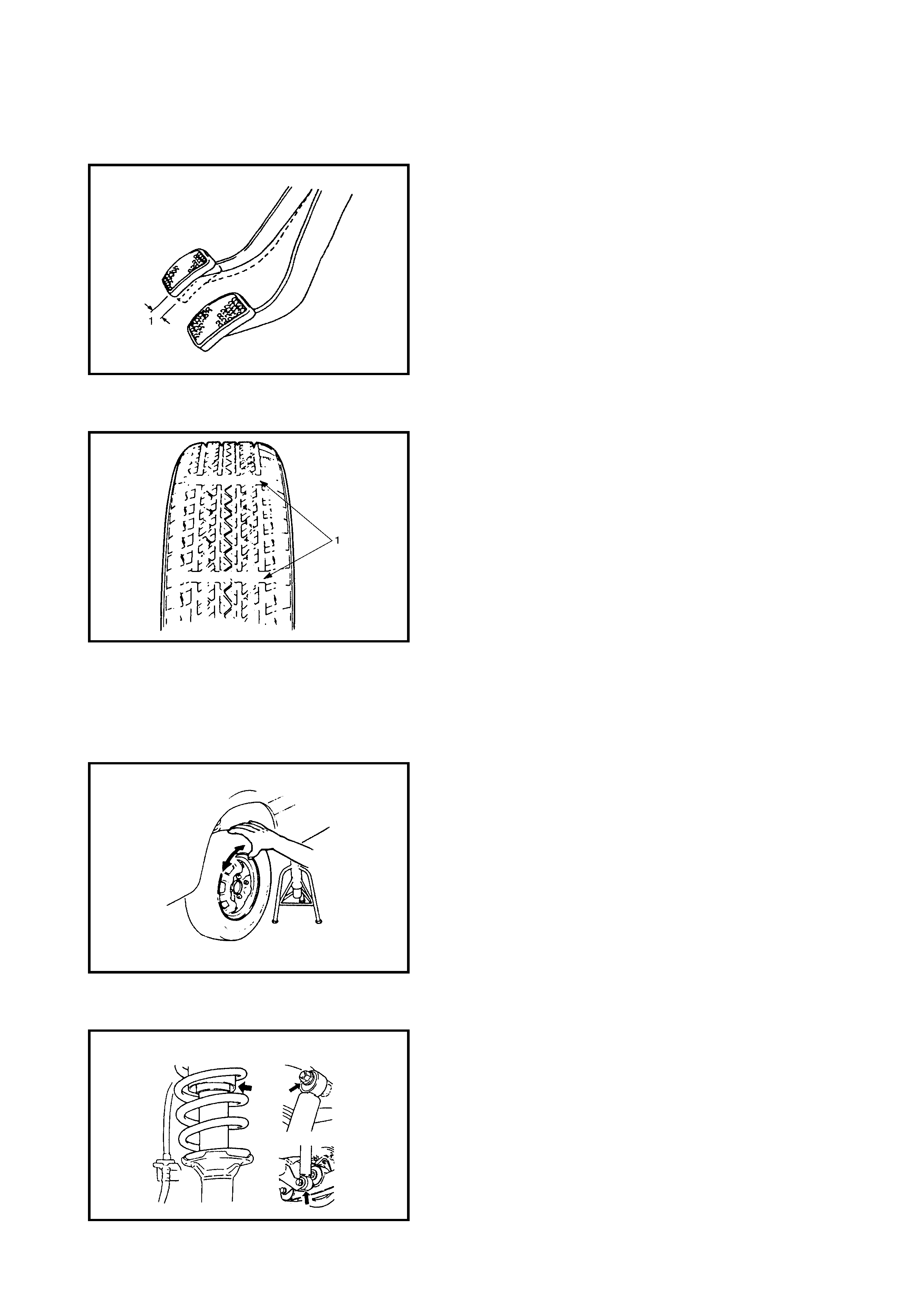

Check the clutch pedal for height and free travel (1), refer

to Section 7C, 3.2 CLUTCH PEDAL AND CLUTCH PEDAL

BRACKET. Adjust or correct if necessary.

TYRES / WHEELS

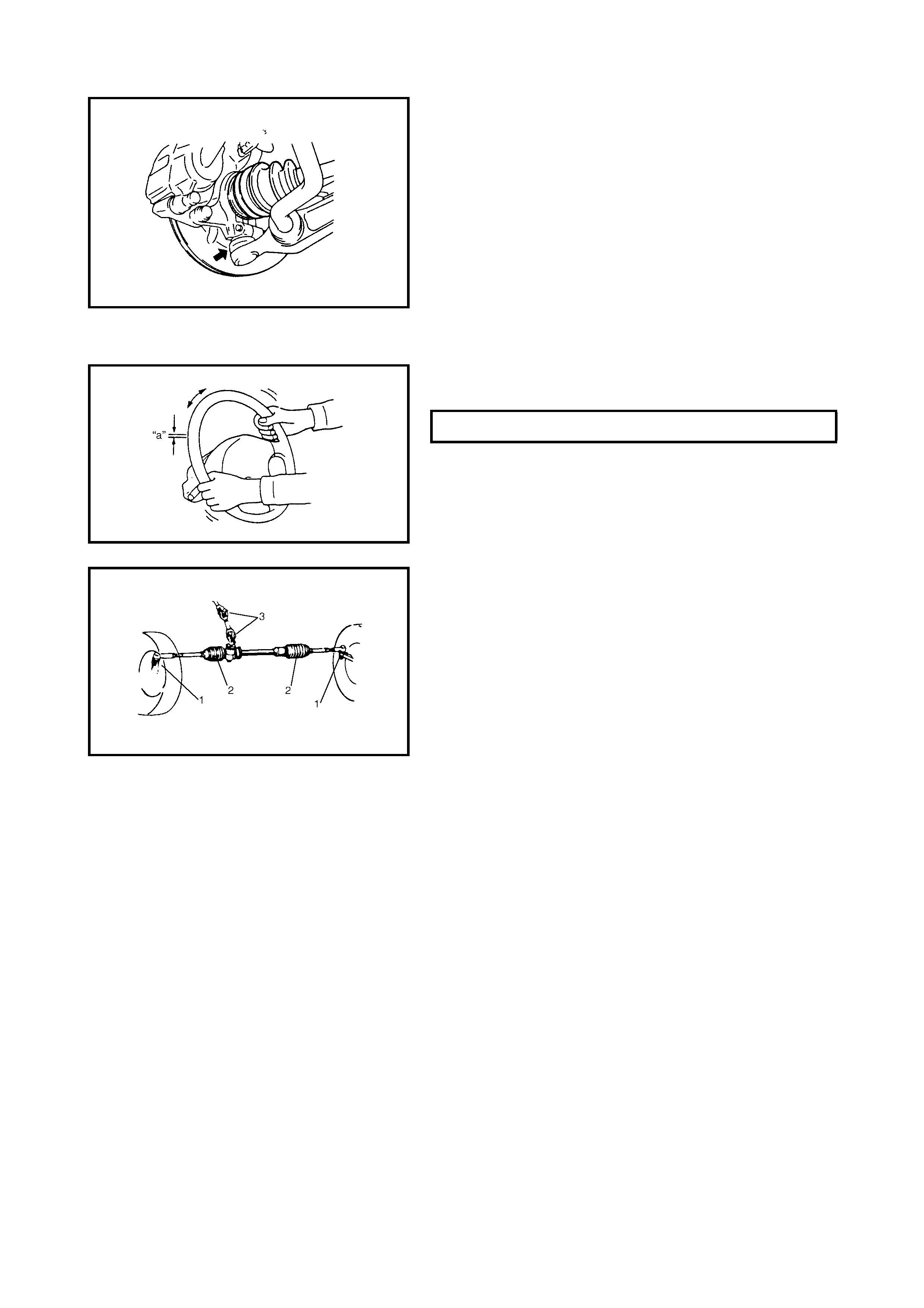

Tyre Inspection

1. Check the tyres for uneven or excessive wear, or

damage.

If defective or worn to the wear indicators (1), replace,

refer to 1.2 TYRE DIAGNOSIS in Section 3 for details.

2. Check the inflation pressure of each tyre and adjust to

specification as necessary.

NOTE: Tyre inflation pressure should be checked when the

tyres are cool. Refer to the vehicle’s tyre placard located on

the right-hand door lock pillar or in the owner’s manual for

specifications.

3. Rotate the tyres, refer to Section 3F,

3.2 TYRE MAINTENANCE.

Wheel Inspection

Inspect each wheel rim for dents, distortion and cracks. A

disc in badly damaged condition must be replaced.

Wheel Bearing Inspection

1. Check the front wheel bearings for wear, damage,

abnormal noise or rattles, refer to Section 3D,

2.7 WHEEL, NUT AND BEARING CHECK.

2. Check the rear wheel bearing for wear, damage,

abnormal noise or rattles, refer to Section 3E,

2.5 WHEEL, NUT AND BEARING CHECK.

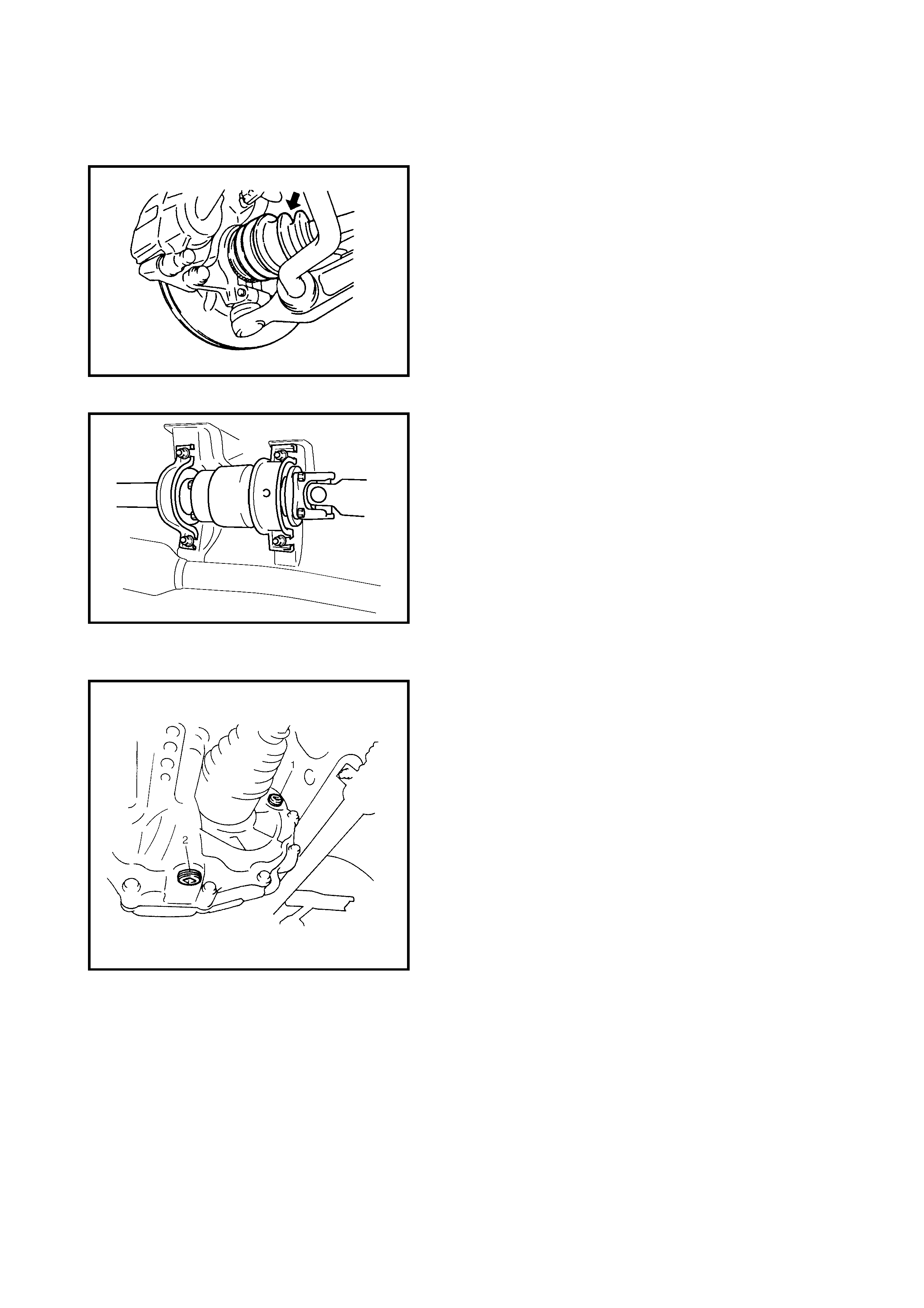

SUSPENSION SYSTEM

Inspection

• Inspect the front struts and rear shock absorbers for

evidenc e of oil lea kage, dents or any other damage on

the sleeves. Inspect the anchor ends for deterioration.

Replace any defective parts.

• Check the front a nd rea r suspe nsion systems for dam-

aged, loose or missing parts, also for parts showing

signs of wear or lack of lubrication.

Repair or replace any defective parts.

• Check the front suspension arm ball joint dust seals for

leakage, detachment, tear or any other damage.

Replace any defective boot.

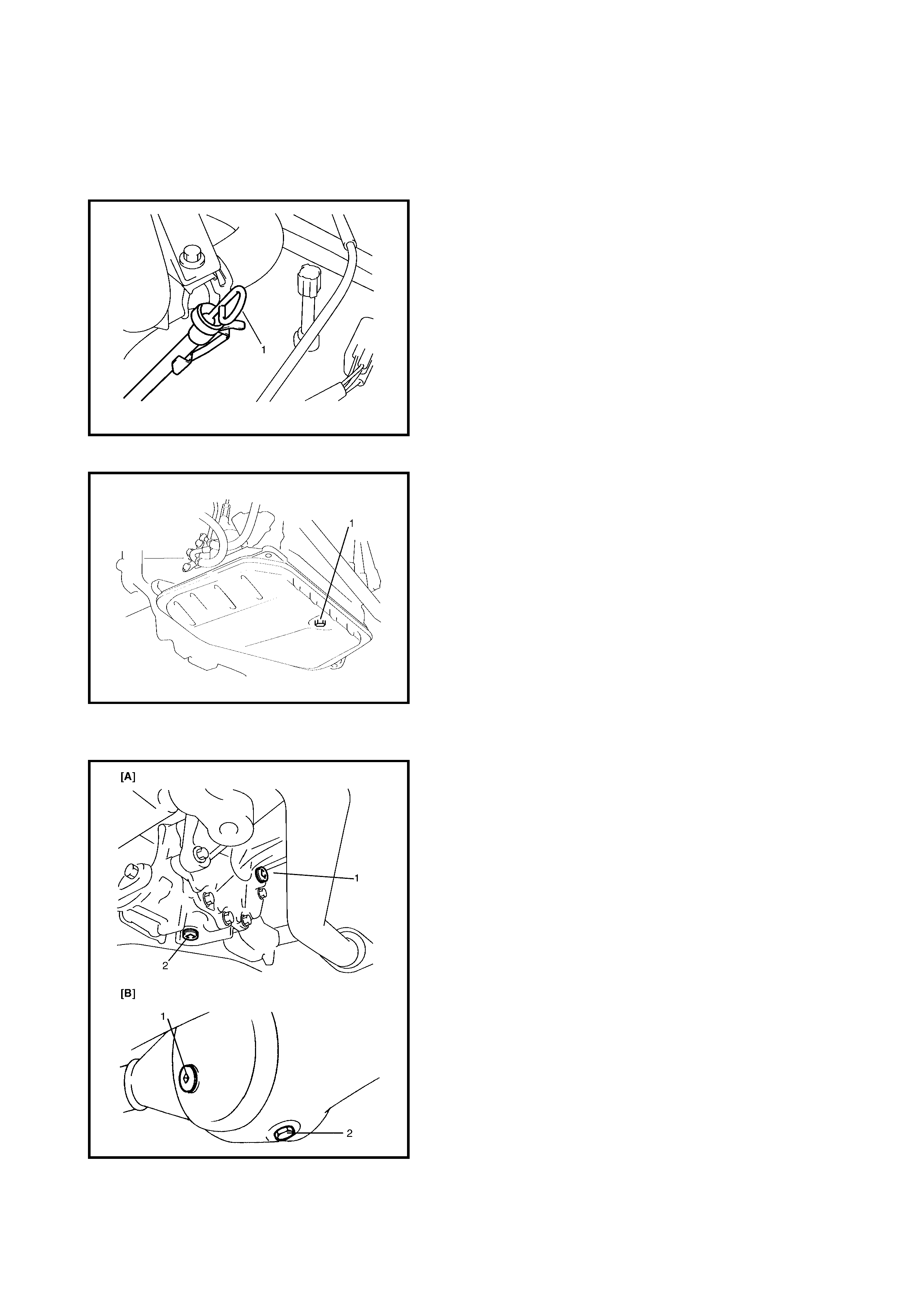

STEERING SYSTEM

Inspection

1. With the steering set straight-ahead, check the

steering wheel for play and rattles.

2. Check the bolts and nuts for tightness and retighten as

necessary. Repair or replace any defective parts.

3. Check the steering linkage for looseness and damage.

Repair or replace any defective parts.

4. Check the steering linkage boots (1) and (2) and

steering gear case for damage (leak, detachment, tear,

etc.). If damage is found, replace the defective boot

with a new one.

If a dent is found on steering gear case boots, correct it

to original the shape by turning steering wheel to the

right or left fully, holding it for a few seconds.

5. Check the steering shaft universal joints (3) for rattles

and damage. If a rattle or damage is found, replace the

defective part with a new one.

6. Check that the steering wheel can be turned fully to the

right and left. Repair or any replace defective parts.

7. Also check that the steering wheel can be turned fully

to the right and left more lightly when engine is running

at idle speed than when it is stopped. Repair if found

faulty.

8. Check wheel alignment, refer to Section 3A, FRONT

END ALIGNMENT.

STEERING WHEEL PLAY (a) 0 – 30 mm

DRIVE SHAFT (AXLE) BOOTS / PROPELLER

SHAFTS

Drive Shaft (Axle) Boots Inspection

Check the drive shaft boots (wheel side and differential

side) for leaks, detachment, tear or other damage.

Replace boot as necessary.

Propeller Shaft Inspection

1. Check the propeller shaft connecting bolts for loose-

ness. If required, tighten to specified torque, refer to

Section 4B, PROPELLER SHAFTS.

2. Check the propeller shaft joints for wear, play and

damage.

If any defect is found, replace.

3. Check the propeller shaft centre support for intrusion of

foreign matter, cracks, abnormal noise and damage. If

any defect is found, replace.

MANUAL TRANSMISSION OIL

Inspection

1. Inspect the transmission case for evidence of oil

leakage. Repair any leaks as required.

2. Make sure that the vehicle is level.

3. Remove the transmission oil filler / level plug (1).

4. Check the oil level.

If oil flows out of the level plug hole or if it is level with

the hole, the oil level is correct.

If the oil level is insufficient, fill with specified oil up to

the level hole.

For the oil specifications, refer to Section 7A,

3.1 OIL CHANGE.

5. Apply sealant to filler/level plug and tighten it to

specified torque.

Replacement

1. Place the vehicle level and drain the oil by removing

the drain plug (2).

2. Apply se alant to drain pl ug after clean ing it a nd tighte n

drain plug to specified torque.

3. Pour specified oil up to level hole.

4. Tighten filler plug to specified torque.

For recommended oil, its amount and tightening torque

data, refer to Section 7A, 3.1 OIL CHANGE.

AUTOMATIC TRANSMISSION FLUID

Inspection

1. Inspect the transmission case for evidence of fluid

leakage. Repair any leaks as required.

2. Place the vehicle level for fluid level check.

3. The oil level is checked by removing the dipstick (1). A

different reading is given if the transmission is hot or

cold, refer to Section 7B, 3.1 MAINTENANCE

SERVICE and perform the check under the specified

conditions. If the fluid level is low, replenish with

specified fluid.

Replacement

1. Inspect the transmission case for evidence of fluid

leakage. Repair any leaks as required.

2. Place the vehicle level for fluid level check.

3. Remove the drain plug (1) and change the fluid, refer

to Section 7B, 3.1 MAINTENANCE SERVICE.

TRANSFER OIL & REAR DIFFERENTIAL OIL

Inspection

1. Check the transfer case or differential for evidence of

oil leakage. Repair any leaks as required.

2. Place the vehicle level for oil level check.

3. Remove the oil filler / level plug (1).

4. Check the oil level for the transfer [A] or rear differential

[B].

If oil flows out of the level plug hole or if it is level with

the hole, the oil level is correct.

If the oil level is insufficient, fill with specified oil up to

the level hole.

For the oil specifications, refer to

Section 7D, 3.1 OIL CHANGE for the transfer or

Section 7F, 3.1 OIL CHANGE for the rear differential.

5. Apply sealant to filler/level plug and tighten it to

specified torque.

Replacement

Remove the drain plug (2) and change the transfer oil

and differential oil with new specified oil , refer to

Section 7D, 3.1 OIL CHANGE or

Section 7F, 3.1 OIL CHANGE for the rear differential.

LATCHES, HINGES AND LOCKS

Inspection

DOORS

Check that each front, rear and back door opens and

closes smoothly and locks securely when closed.

If any ma lfunc tion i s found, l ubricat e the hinge and latc h or

repair door lock system.

ENGINE HOOD

Check that the secondary latch operates properly.

It must ke ep the hoo d from o pening compl etely even when

pulling the hood release handle.)

Also check that the hood opens and closes smoothly, cor-

rectly and locks securely when closed.

If any malfunction is found, lubricate the hinge and latch, or

repair hood lock system.

3. FINAL INSPECTION

SEATS

Check that the seat slid es smoo thly and locks se curely at any p osition. Al so chec k that the reclini ng mecha-

nism of the front seat back can be locked at any angle.

SEAT BELT

Inspect the seat belts including the webbing, buckles, latch plates, retractors and anchors for damage or wear .

Check that the seat belt can be securely locked. If REPLACE BELT label on front seat belt is visible, replace

the seat belt assembly.

BATTERY ELECTROLYTE LEVEL CHECK

Check that the electrolyte level of all battery cells is between the upper and lower level lines on the case. If the

battery is equipped with built-in indicator, check the battery condition by the indicator.

ACCELERAT O R PEDAL OPERATION

Check that the pedal operates smoothly without getting caught or interfered by any other part.

ENGINE START

WARNING:

Before pe rforming th e followi ng check, h ave eno ugh room a round the vehicle, firmly

apply both the parking brake and the regular brakes and do not use the acceler ator pedal. If the

engine starts, be ready to turn OFF the ignition promptly. Take these precautions as the vehicle

could move without warning and possibly cause personal injury or proper ty damage.

For automatic transmission vehicles, try to start the engine in each select lever position. The starter motor

should crank only in P (Park) or N (Neutral).

For manual transmission vehicles, place the shift lever in Neutral, depress clutch pedal fully any try to start.

EXHAUST SYSTEM CHECK

Check for leakage, cracks or loose supports.

CLUTCH (FOR MANUAL TRANSMISSION)

Check for the following:

• Clutch is completely released when depressing the clutch pedal,

• No slipping of the clutch occurs when the releasing pedal and accelerating.

• The clutch itself is free from any abnormal condition.

GEARSHIFT OR SELECT LEVER

Check th e gear shift or sele ct lev er for sm ooth shi fting to all pos ition s and for goo d perfo rmance o f the tran s-

mission in any position.

With an automatic transmission equipped vehicle, also check that the shift indicator indicates correctly

according to which position the select lever is shifted to.

With an automatic transmission equipped vehicle, make sure that the vehicle is at complete stop when shifting

the select lever to P range position and release all brakes.

BRAKE

Foot Brake

Check the fol lowi ng :

• The brake pedal has the correct travel,

• The brakes function properly,

• They are free from noise,

• The vehicle does not pull to one side when brakes are applied.

• The brakes do not drag.

Parking Brake

• Check that the lever has the correct amount of travel.

• Chec k that the parking brak e is fully effectiv e when the ve hicle is stopped on a sl ope with the brak e lever

engaged.

WARNING:

To avoid personal injury or property damage, ensure there is nothing in the way down-

hill. Be prepared to apply the regul a r brakes quickly should the vehicle start to move.

STEERING

• Check to that the steering wheel is free from instability, or abnormally heavy feeling.

• Check that the vehicle does not wander or pull to one side.

ENGINE

• Check that the engine responds readily at all speeds.

• Check that the engine is free from abnormal noises and abnormal vibration.

BODY, WHEELS AND POWER TRAIN SYSTEM

Check t hat the bo dy, wheels and p ower trai n system are free fr om abn ormal noi se and vibrati on or any o ther

abnormal condition.

METERS AND GAUGES

Check that the speedometer, odometer, fuel meter, temperature gauge, etc. are operating accurately.

LIGHTS

Check that all lights operate properly.

WINDSHIELD DEFROSTER

Periodically check that air blows from the defroster outlet when operating the heater or air conditioning.

Set the mode control lever to the defroster position and fan switch lever to HI position for this check.

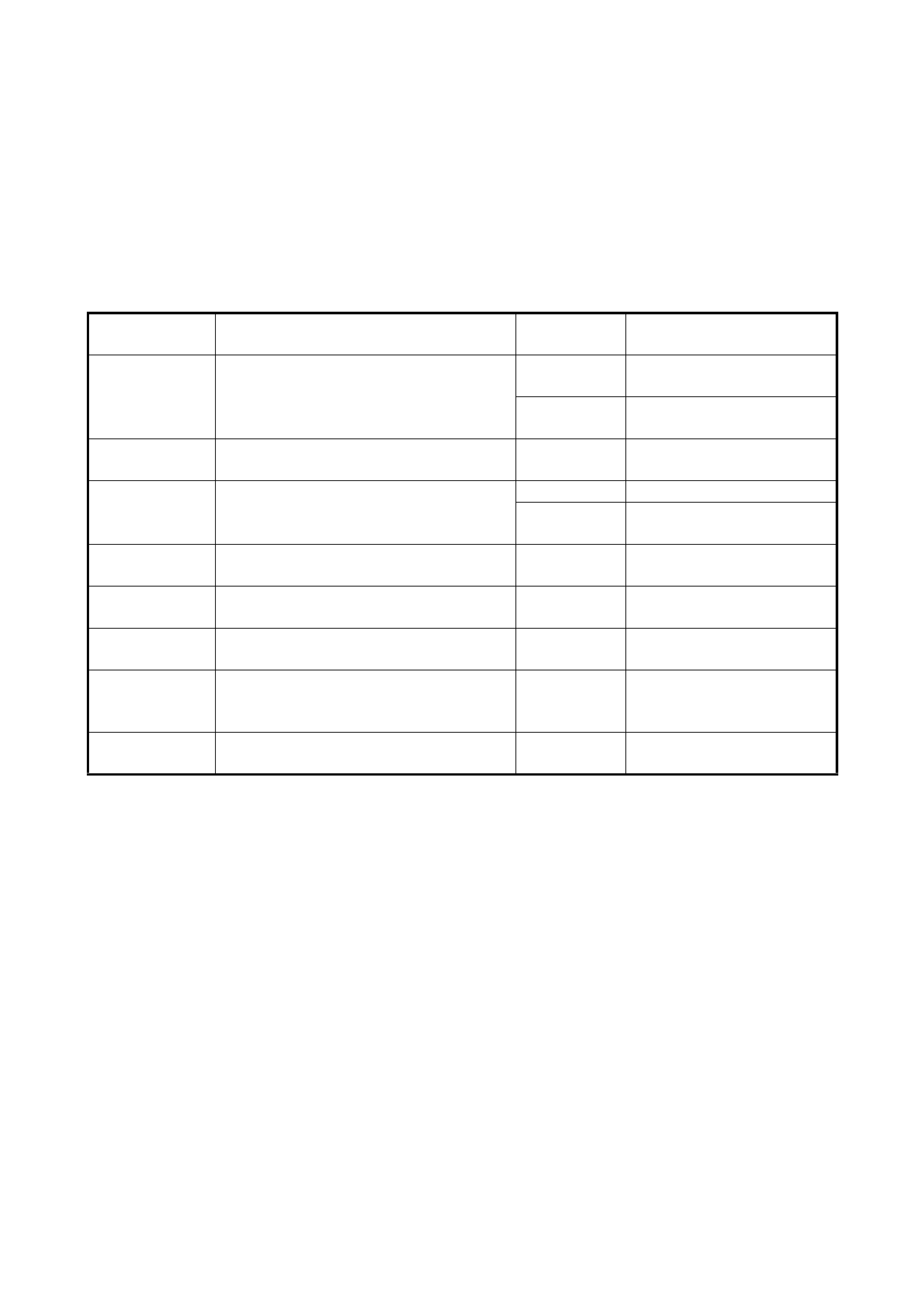

4. RECOMMENDED FLUID S AND LUBR ICAN TS

ENGINE OIL ACEA service classification A2 or A3 viscosity grade 10W-30.

ENGINE COOLANT 30% Holden Cruze coolant part number 92145591 mixed with 70%

water.

BRAKE FLUID DOT 3, SAE spec. J1730

MANUAL TRANSMISSION OIL Gear Oil API GL-4 SAE 75W-90 or equivalent.

TRANSFER OIL Gear Oil API GL-5 SAE 80W-90 Hypoid or equivalent

DIFFERENTIAL OIL Gear Oil API GL-5 SAE 80W-90 Hypoid or equivalent

AUTOMATIC TR ANSMISSION

FLUID ATF DEXRON-III or equivalent

DOOR HINGES Engine oil or water resistant chassis grease

HOOD LATCH ASSEMBLY Engine oil or water resistant chassis grease

KEY LOCK CYLINDER Spray lubricant

Techline

Techline