SECTION 1A - HEATING AND VENTILATION

1. GENERAL DESCRIPTION

2. DIAGNOSIS

2.1 DIA GNOS IS TAB L E

2.2 WIRING CIRCUIT

3. O N- VEH IC L E SER VICE

3.1 HEATER UNIT

Removal

Installation

3.2 BLOWER FAN MOTOR

Removal

Inspection

Installation

3.3 BLOW ER FAN MOTOR RESISTOR

Removal

Inspection

Installation

3.4 HEATER CONTROL ASSEMBLY

Removal

Installation

Inspection

3.5 A IR INLET BOX

Removal

Installation

3.6 VENTILATION LOUVRE

Removal

Installation

4. REQUIRED SERVICE MATERIAL

WARNING:

For vehicles equipped with Supplement Restraint (Airbag) System

• Service on and around the airbag sys tem components or wiring must be performed only by

an authorised HOLDEN retailer. Refer to Section 10B AIRBAG SYSTEM-COMPONENTS AND

WIRING LOCATION VIEW in GENERAL DESCRIPTION in order to confirm whether you are

performing service on or near the airbag system components or wiring. Please observe all

WARNINGS and SERVICE PRECAUTIONS, refer to Section 10B ON-VEHICLE SERVICE before

performing service on or around the airbag system components or wiring. Failure to follow

WARNINGS could result in u nintentional activation of the system or could render the system

inoper ative. Either or these two co nditions may result in severe injury.

• Technical service work must not be started for at least 90 seconds after the ignition switch is

turned to the “LOCK” position and the negative cable is di sconnected from the battery. Oth-

erwise, the system may be activated b y reserve energy in the Sensing and Diagnostic Module

(SDM).

NOTE:

The link mech anism of the heater varies depending on the specifications.

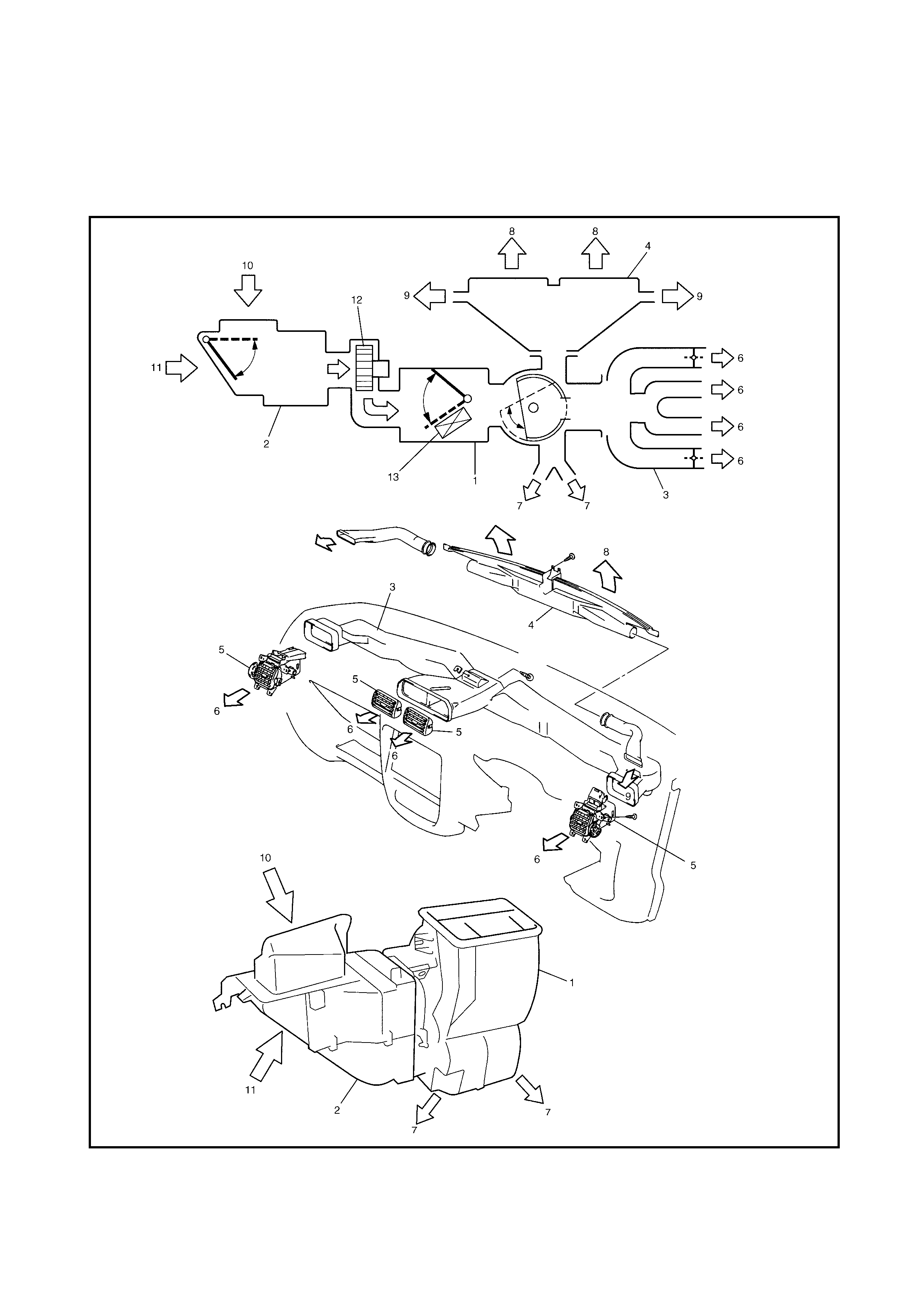

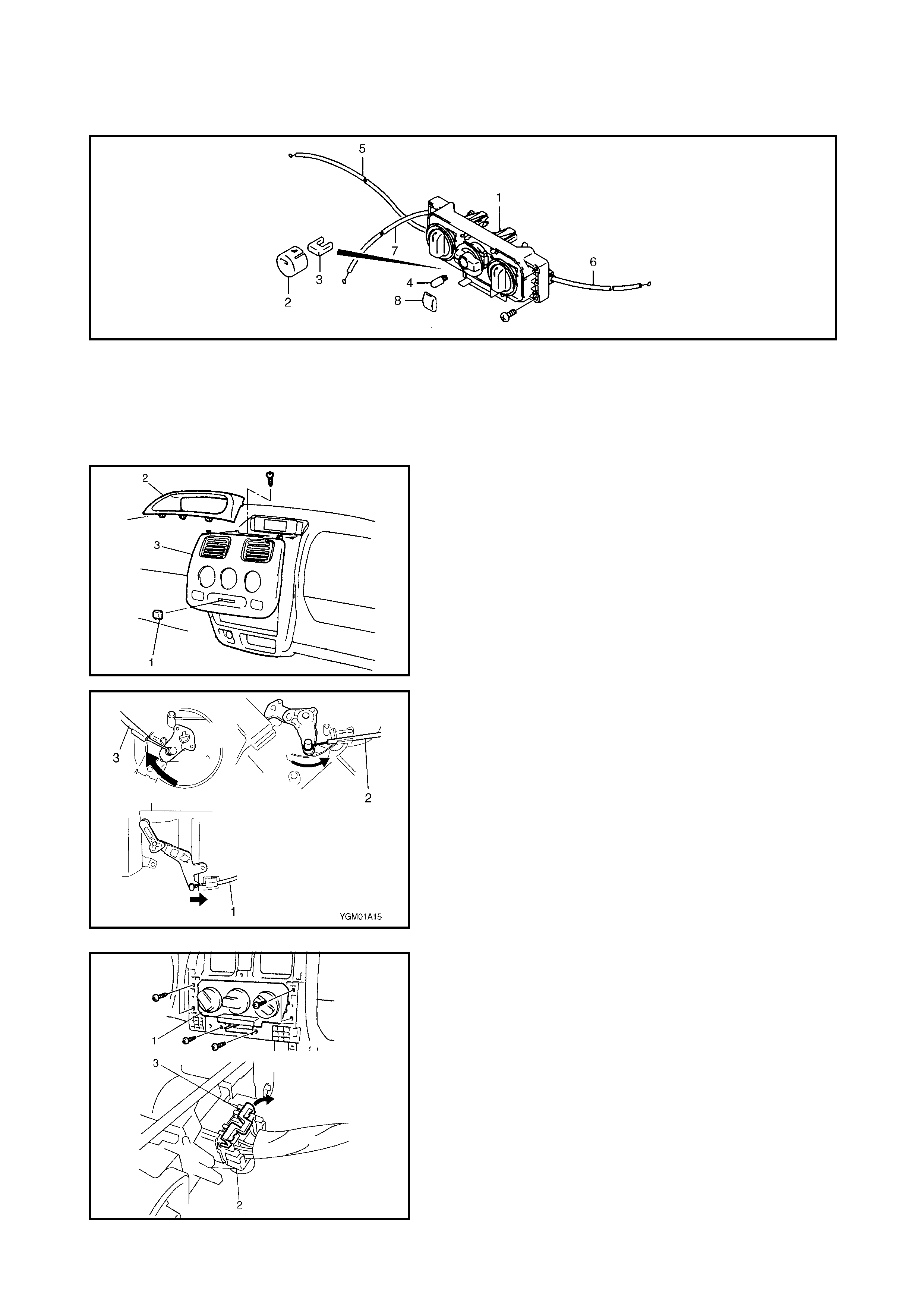

1. GENERAL DESCRIPTION

Legend

1. Heater unit 5. Ventilation louvre 9. Demister air 12. Blower fan

mot or asse mb ly

2. Air inlet box 6. Ventilation air 10. F resh air

3. Vent il ator duct 7. Foot air 11. Recirculation air 13. Heater core

4. Defroster nozzle 8. Defroster air

2. DIAGNOSIS

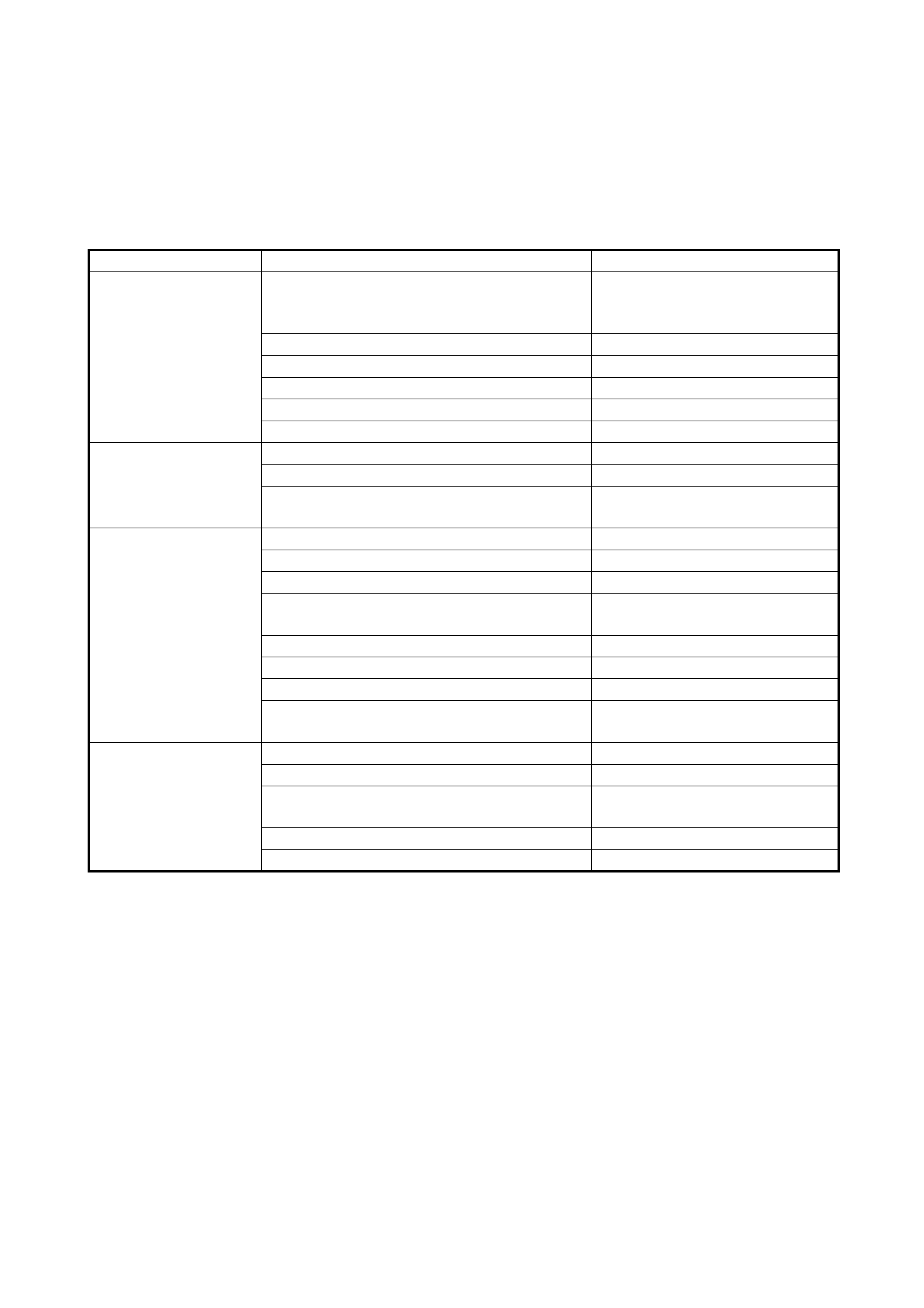

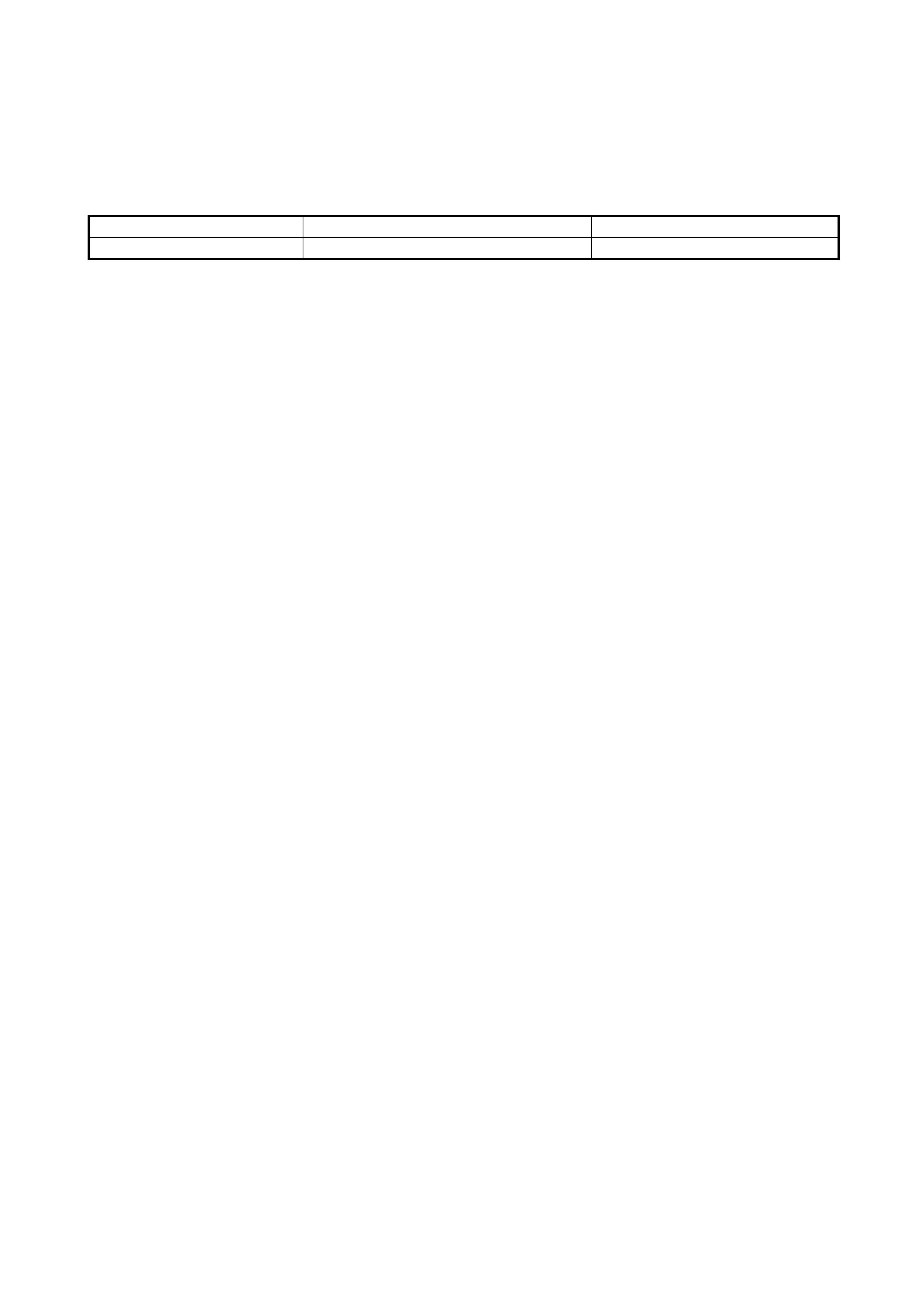

2.1 DIAGNOSIS TABLE

Condition P ossible Cause Correction

H eater blower fan

m ot or do e s not

operate with fan

switch ON

Fuse blown Check “HEATER” fuse, main

heater fuse and check for short cir-

cuit to ground.

Blower main relay fa ulty Check blower main relay.

Blower fan motor resisto r faulty Check resistor.

Blow er fan m otor sw itch fau lty Check blower fan swi tch.

Blower fan m otor fau lty Replace motor.

Wiring or grounding fau lty Repair as necessary.

H eater blower fan

does not opera t e

when fa n switch is in

m aximum position.

Blow er maximum relay faulty Check blower maximum relay.

Blow er fan m otor sw itch fau lty Check blower fan swi tch.

Wiring or grounding fau lty Check wiring, grounding and

repair as necessary.

Incorrect tempera-

tu re outp ut. Control cables broken or binding Check cabl es.

Temperature control lever faulty Check control lever.

Position of control cable clam p is fau lty Ch eck and adjustment.

Temperature door assembl y broken Repair temperature door

assembly.

Air ducts clogged Repair air ducts .

Heater core leaking or clogged Replace core.

Heater hoses leaking or clogged Re place hoses.

Therm ost at fa ulty Check therm os tat, referr ing to

Sect ion 6B.

When mode control

lever is chang ed, air

outlet port do es not

change or lever posi-

tion does not match

a ir ou tlet po rt .

Control cable broken or binding Check cabl e.

Mode control lever faulty Check control lever.

Position of control cable clam p is fau lty Ch eck and adjust clamp

position.Check and adjustment.

Air damper broken Repair dam per.

Air ducts l eak ing or clogged Repair air ducts.

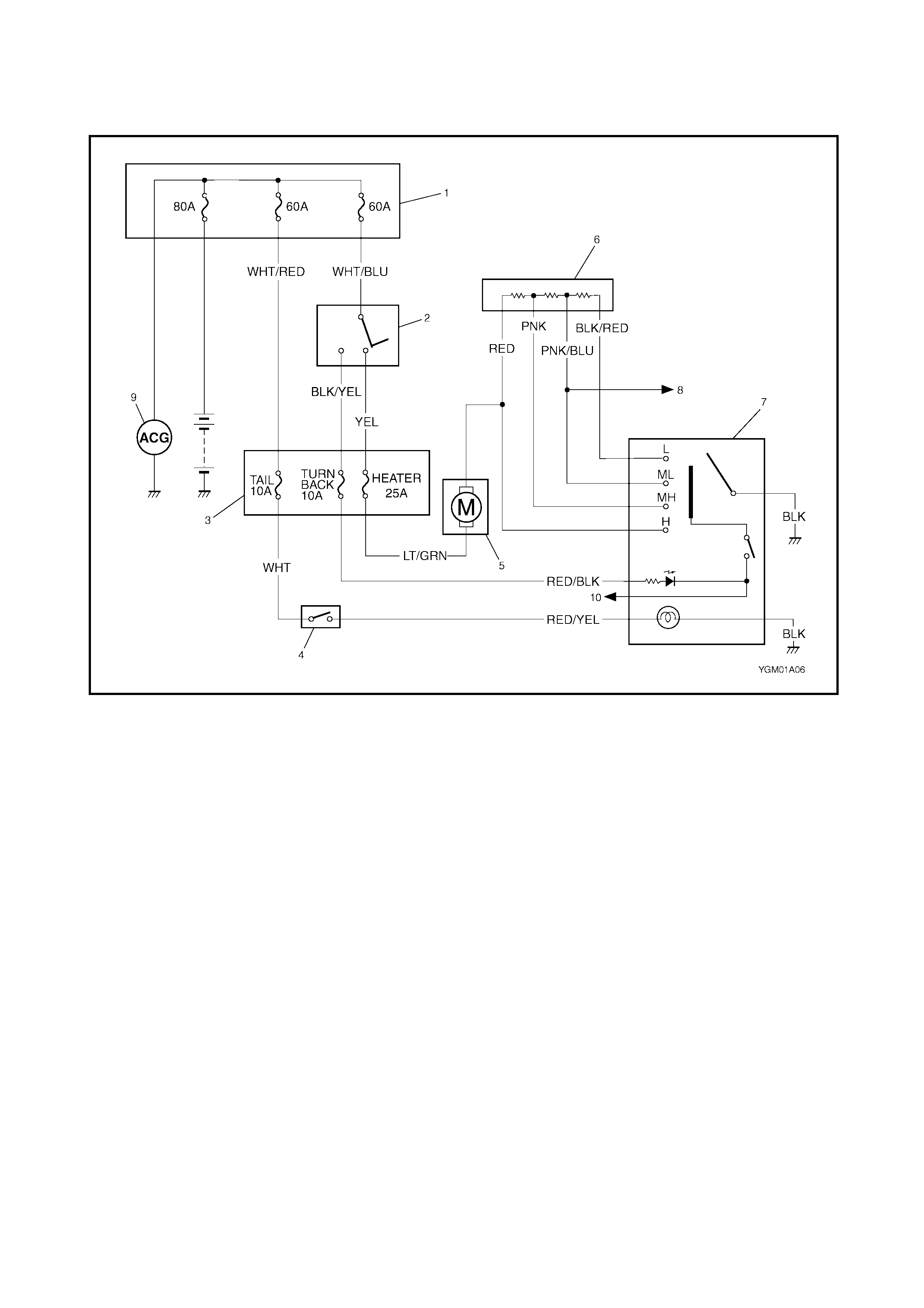

2.2 WIRING CIRCUIT

Legend

1. Main fuse box 4. Lighting switch 7. Blower fan switch 10. To ECM

2. Ignition swi tch 5. Bl ower fan motor 8. To ECM (idle up signal)

3. Circuit fuse box 6. Blower fan motor

resistor 9. Generator

3 . ON-VEHICLE SERVICE

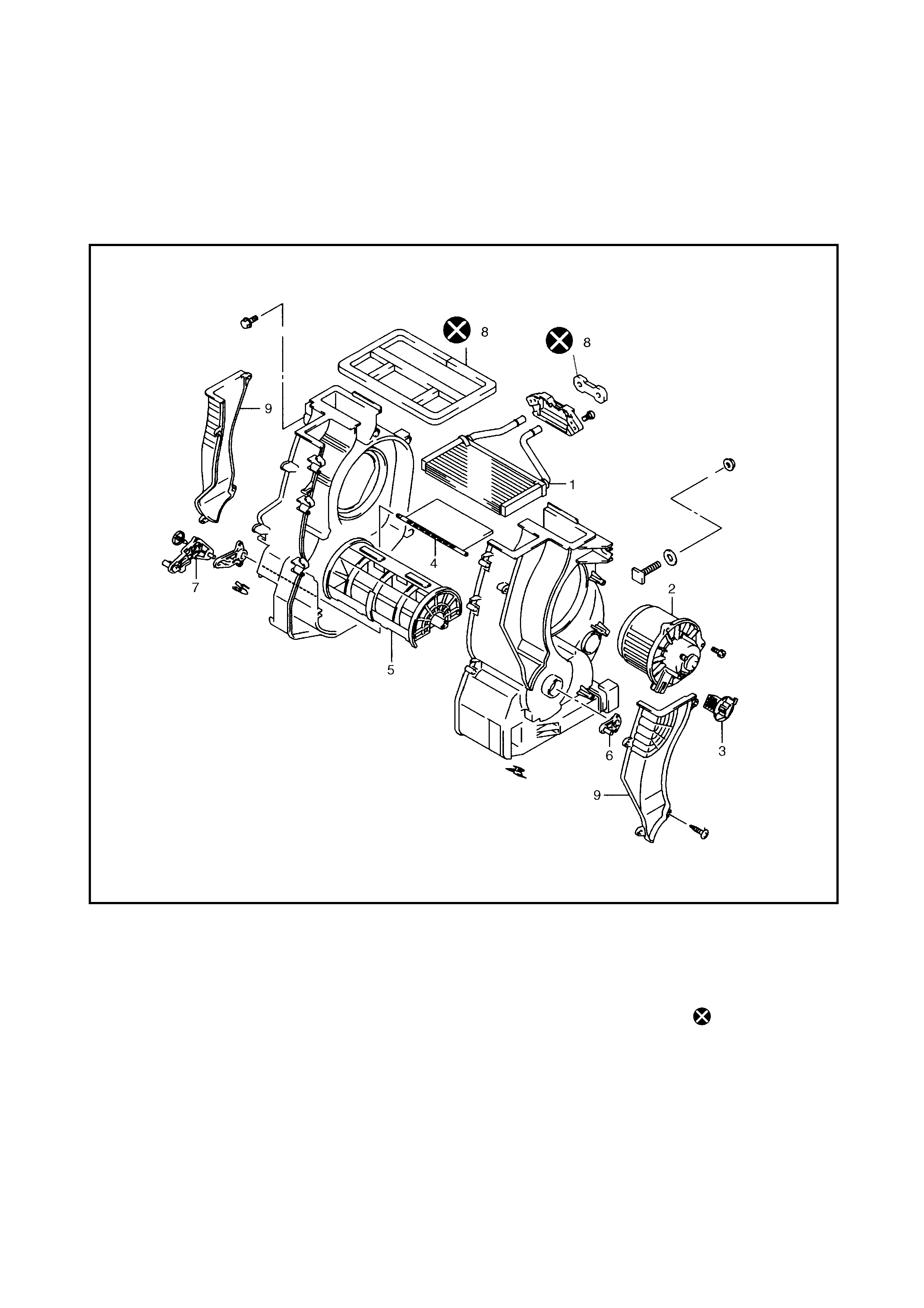

3.1 HEATER UNIT

Legend

1. Heater core 4. Temperature door

assembly 6. Air outlet control

lever assembly 8. Seal

2. Blower fan motor

assembly 9. Dem ister air

outl e t ca se

5. Air outlet control door

assembly 7. Temperature lever

assembly

3. Blower fan motor

resistor Do not reuse

CAUTION: Sealing problems may occur when

disassembling and reassembling the heater case. If

the case leaks when reassembled, tighten with (1)

M4 x 16 self tapping screws (1) as shown in figure.

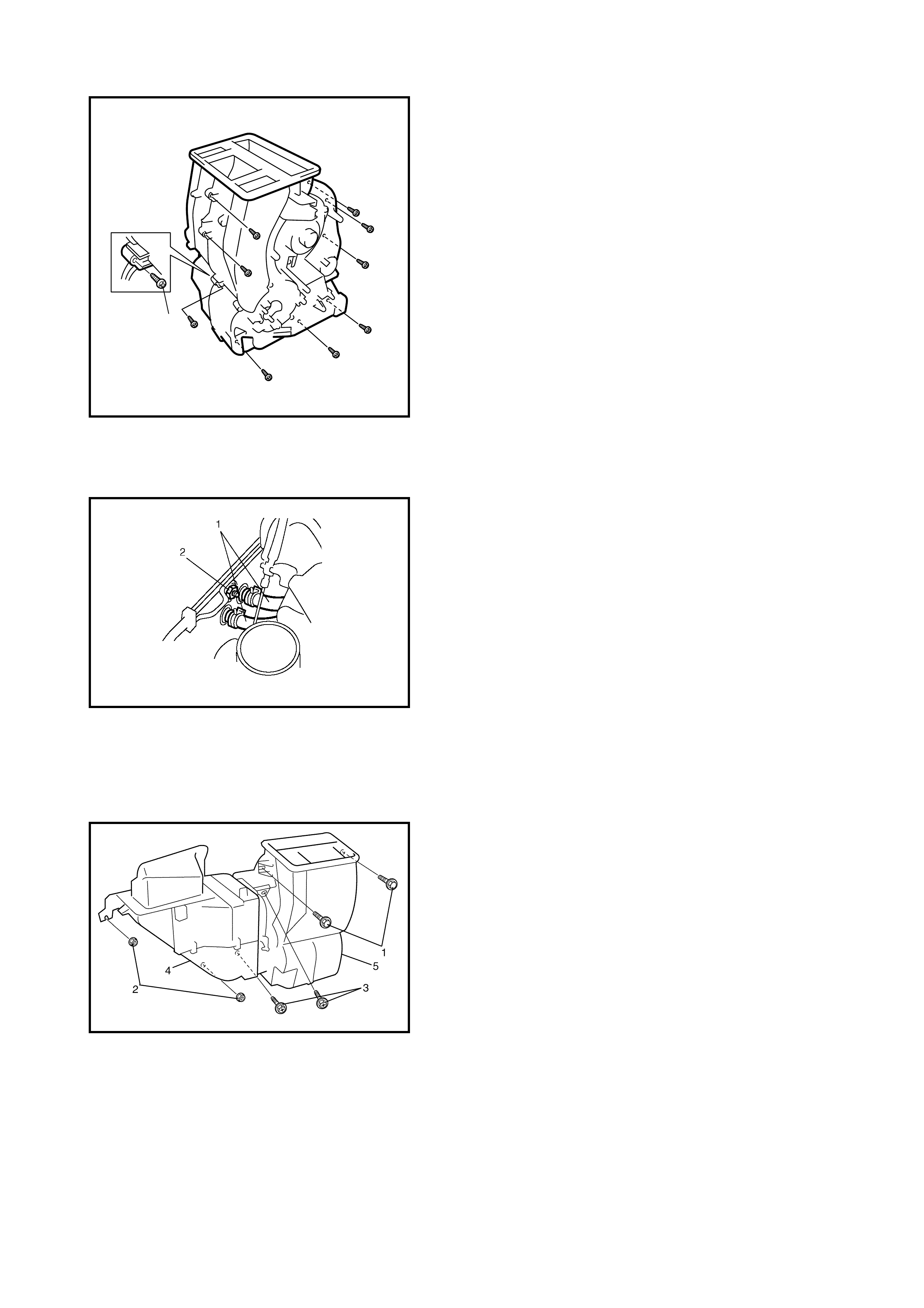

REMOVAL

1. Disconnect negative (–) cable at battery.

2. Drain engine coolant and disconnect heater hoses (1)

from heater unit.

3. Remove heater unit mounting nut (2).

4. Remove instrument panel, refer to Section 9,

3.1 INSTRUMENT PANEL REMOVAL.

5. Disconnect blower motor and resistor couplers from

heater unit.

6. Remove bolts (1), nuts (2) and screws (3) as shown.

7. Remove cooling unit (4) and heater unit (5) from

vehicle.

INSTALLATION

Reverse removal procedure to install heater unit noting the

following instructions.

• When installing each part, be careful not to catch any

cables or wiring harnesses.

• Adjust heater control cable, refer to 3.4 HEATER

CONTROL LEVER ASSEMBLY in this Section.

• Che ck coolant level and fill to correct level if required.

1

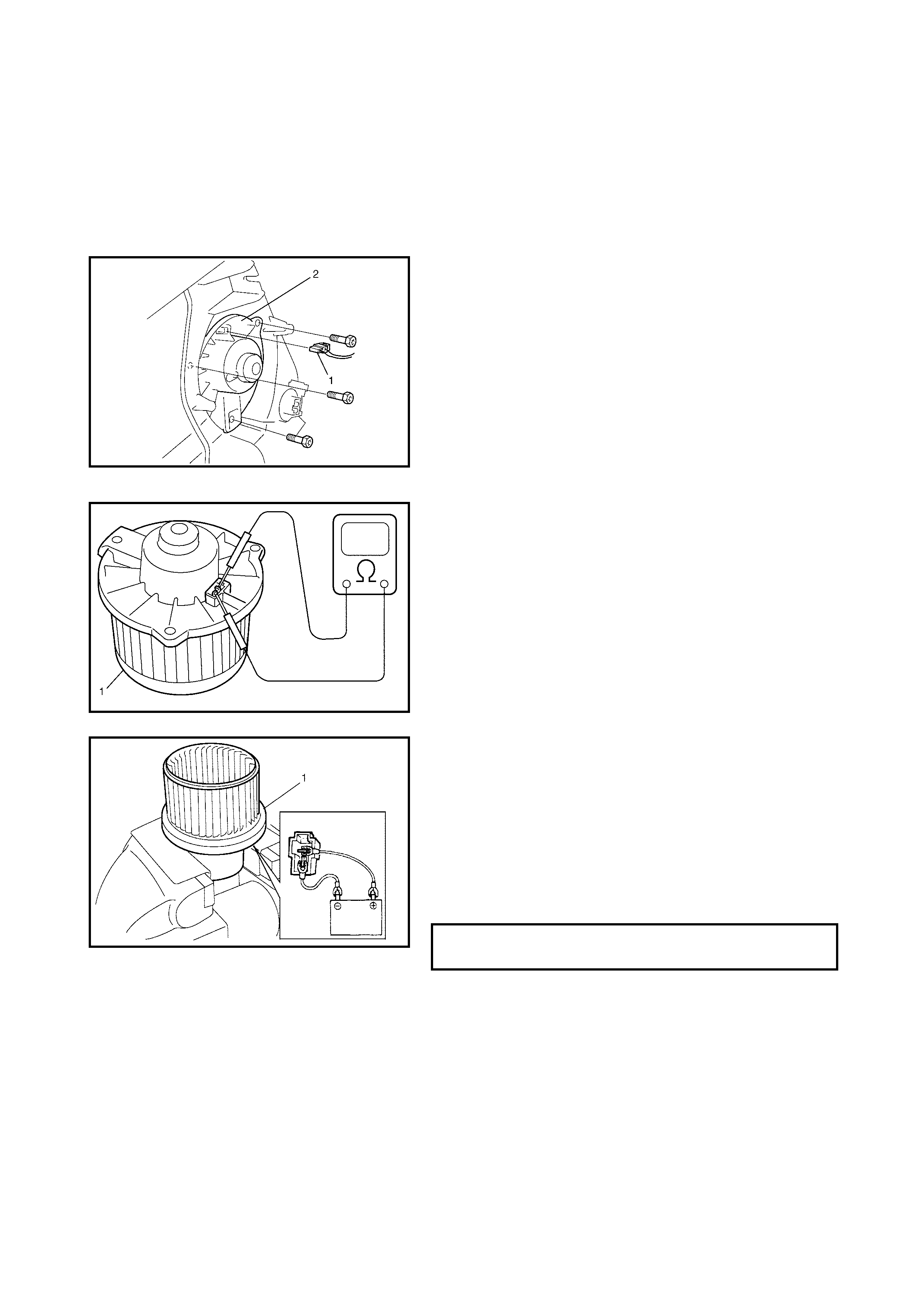

3.2 BLOWER FAN MOTOR

REMOVAL

1. Disconnect negative (–) cable at battery.

2. Remove steering column hole cover.

3. Remove brake and clutch pedal bracket from vehicle

body, refer to Section 7C, 3.2 CLUTCH PEDAL AND

CLUTCH PEDAL AND BRACKE T.

4. Disconn ect blower motor connector (1).

5. Remov e b lo wer f an motor (2).

INSPECTION

1. Check continuity between the two termi nals as shown.

If there is no continuity, replace blower fan motor

assembly (1).

2. Check operation and current flow.

a. Secure blower fan motor assemb ly (1) using a vice.

b. Connect battery to blower fan motor assembly (1)

as shown.

c. Check that blower fan motor operates smoothly

and there is no abnormal noise.

d. Check that amme ter indicates specified current.

If current measure is incorrect, replace blower fan

motor.

INSTALLATION

Reverse removal procedure for ins tallation.

BLO WER FAN SPECIFIED CURRENT

@ 12 VOLT 18 A MAX.

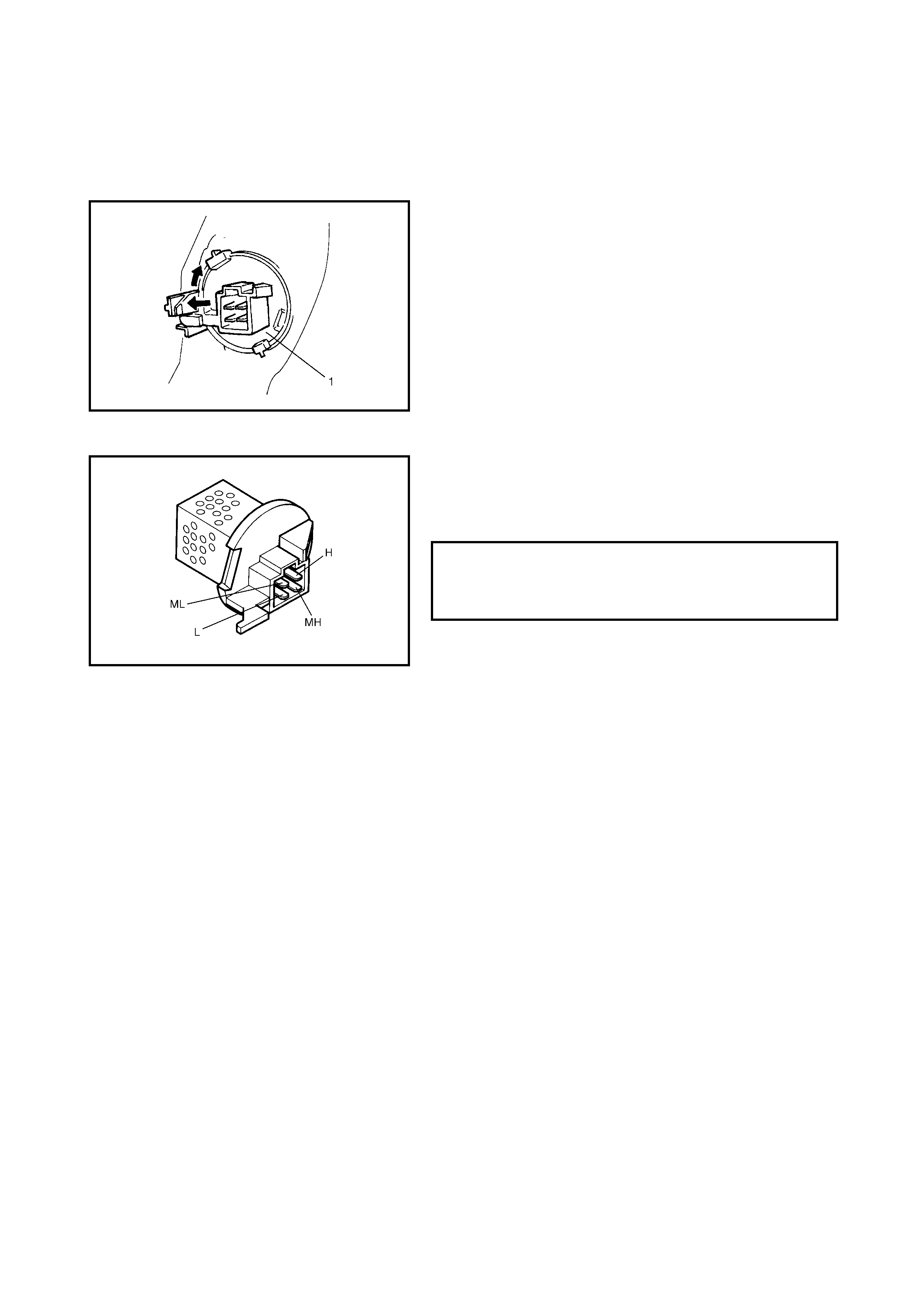

3.3 BLOWER FAN MOTOR RESISTOR

REMOVAL

1. Disconn ect negative (–) cab le at battery.

2. Disconnect blower f an motor resistor connector.

3. Remove bl ower fan motor resistor (1) as shown.

INSPECTION

Measure each terminal-to-terminal resistance on blower

motor resistor

If measured resistance is incorrect, replace blower motor

resistor.

INSTALLATION

Reverse removal procedure for ins tallation.

BLO WER FAN MOTOR RESISTANCE

H–MH (APPROX.)

H–ML (APPROX.)

H–L (APPROX.)

0.5 9 AT 25°C

1.5 9 AT 25°C

3.0 9 AT 25°C

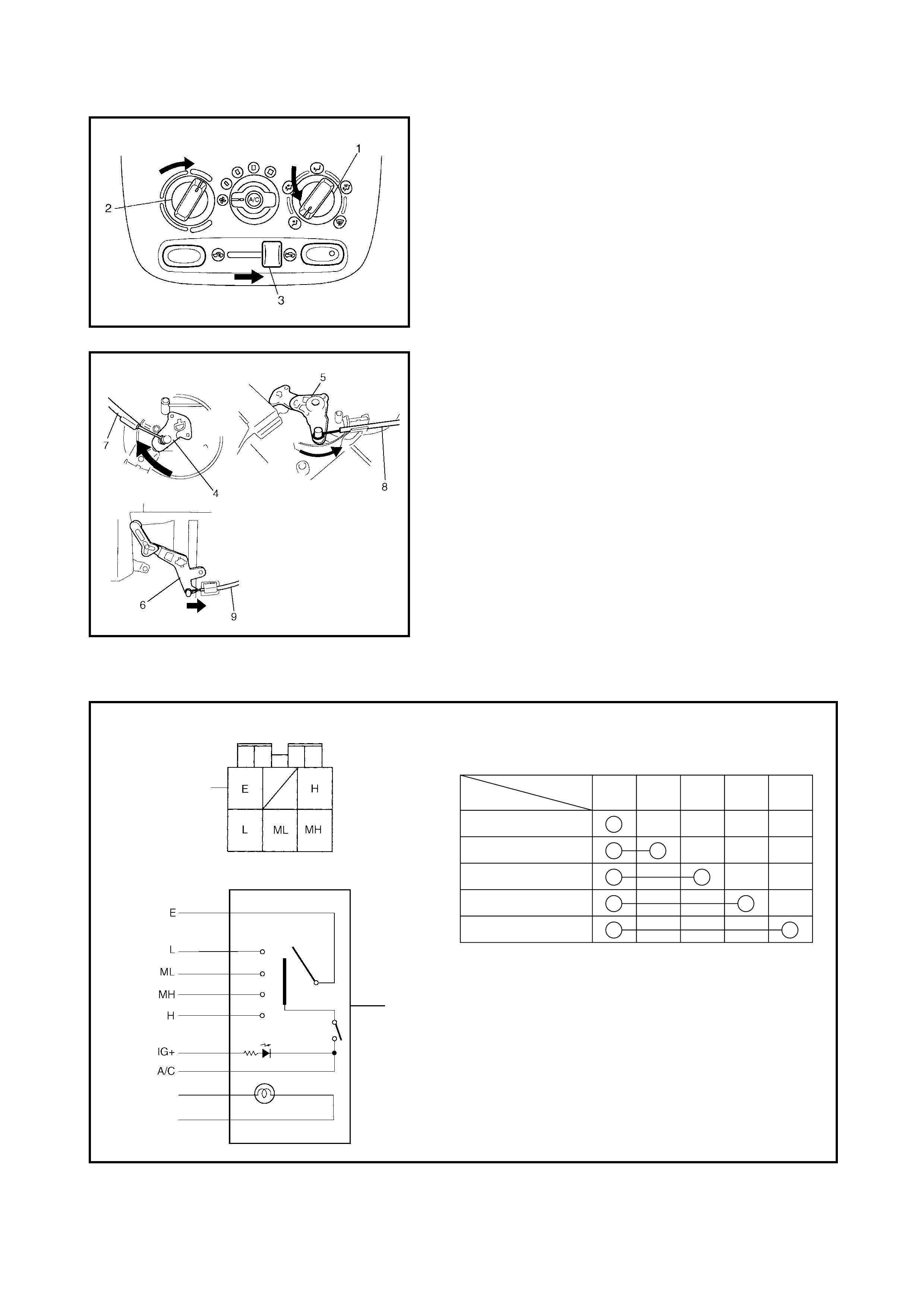

3.4 HEATER CONTROL ASSEMBLY

Legend

REMOVAL

1. Disconnect negative (–) cable at battery.

2. Remove steering column hole cover.

3. Remove heater control knob (1), centre upper console

surround (2) and centre lower console cover (3).

4. Remove glovebox, refer to Section 9,

3.1 INSTRUMENT PANEL.

5. Disconnect air outlet control cable (3), temperature

control cable (2) and fresh air control cabl e (1).

6. Remove heater control assembly (1), then unlock (3)

blower fan switch connector (2) and disconnect as

shown.

1. Heater control

assembly 3. A /C switch LED

(if equipped) 5. F resh air control

cable 7. Temperatu re

control cable

2. A/C switch knob

(if equipped) 4. B ulb 6. A ir outlet control

cable 8. Heater control knob

INSTALLATION

1. Reverse removal procedure for ins tallation.

2. Adju st the following items.

a. Move the air outlet control dial (1), temperature

control dial (2) a nd f resh air con trol lever (3) fully in

direction shown in figure.

b. Push air outlet lever (4), temperature lever (5) and

door link (6) fully in direction shown in figu re then fit

and clamp air outlet control cable (7), temperature

control cable (8) and fresh air control cable (9) as

shown in figure.

NOTE: After installing control cables, ensure that control

levers move smoot hly and stop in their correct positions.

INSPECTION

Check blower fan switch for each terminal-to-terminal continuity.

Legend

POSITIONTERMINAL E

OFF

L

ML

MH

H

LMLMHH

Circuit table of blower fan switch

1

2

ILM S/W

GND

1

1. Term ina l arrangement of blower fan sw itch 2. Blower fan switch

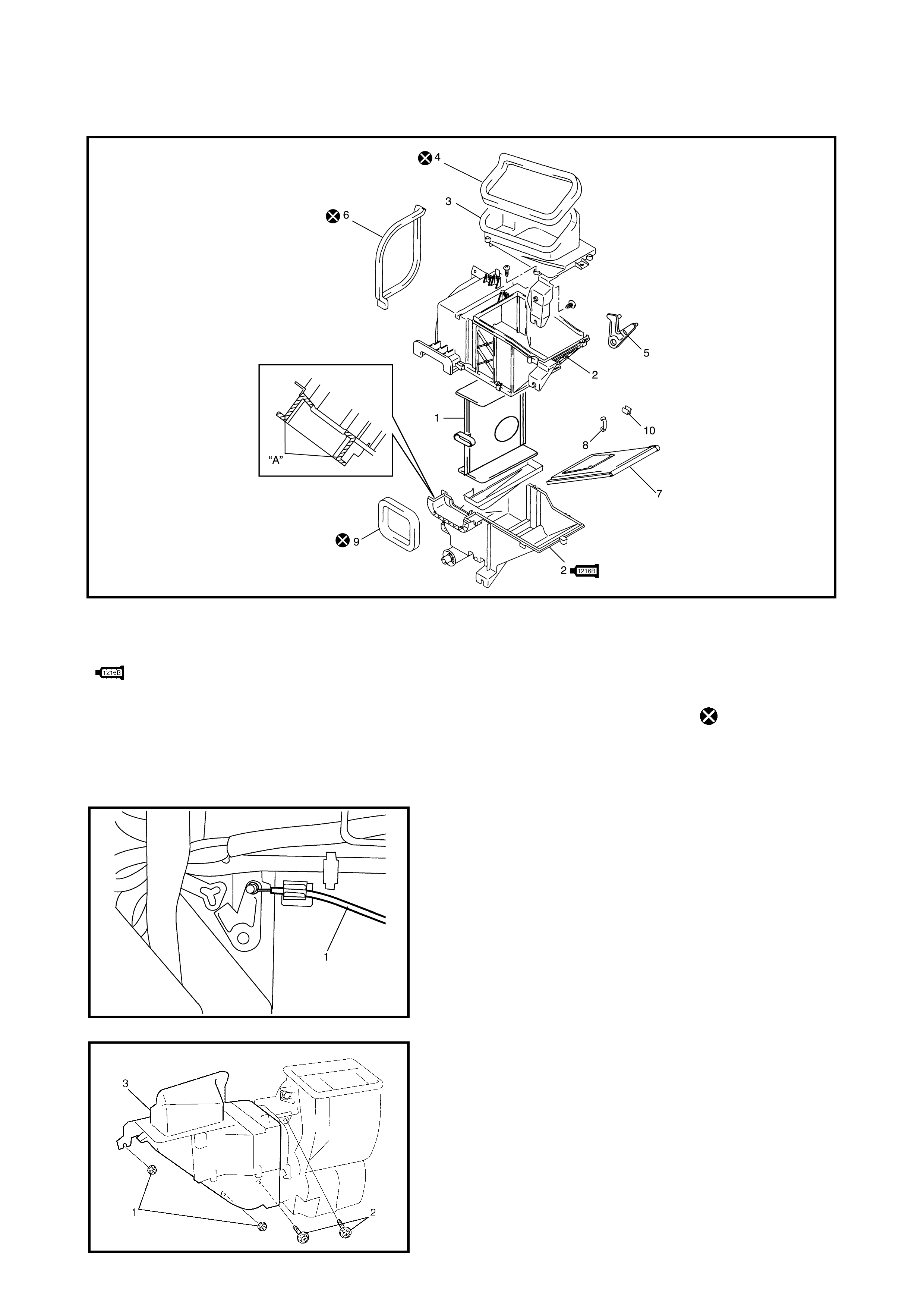

3.5 AIR INLET BOX

Legend

REMOVAL

NOTE: If vehic le is equipp ed with Air C onditi oning, refer to

Section 1B, 5.5 COOLING UNIT.

1. Disconnect negative (–) cable at battery.

2. Remove glovebox, refer to Section 9,

3.1 INSTRUMEN T PANEL .

3. Disable air bag system, refer to Section 10B,

3.1 SERVICE PREC A UT IO NS - DI SA BL ING

AIRBAG SYSTEM.

4. Disconnect fresh air control cable (1) from air inlet box.

5. Remove air inlet box mounting nuts (1) and screws (2).

6. Remove air inlet box (3).

1. Resistance board 3. Fresh air duct

case 5. Door link 8. Clip

2. Air inl e t case

: Apply Sealant Three Bond

1216 B to hatched part “A”

6. H eate r unit

packing 9. Dash packing

4. F res h air duct

pac k ing 10. Cable clamp

7. Air inlet door Do not reuse

INSTALLATION

Reverse removal procedure to install air inlet box noting the

following instructions.

• Adjust fresh air control cable, refer to 3.4 HEATER

CONTROL ASSEMBLY in this Section.

• Enable airbag system, refer to Section 10B,

3.1 SERVICE PREC A UT IO NS - EN ABLING

AIRBAG SYSTEM.

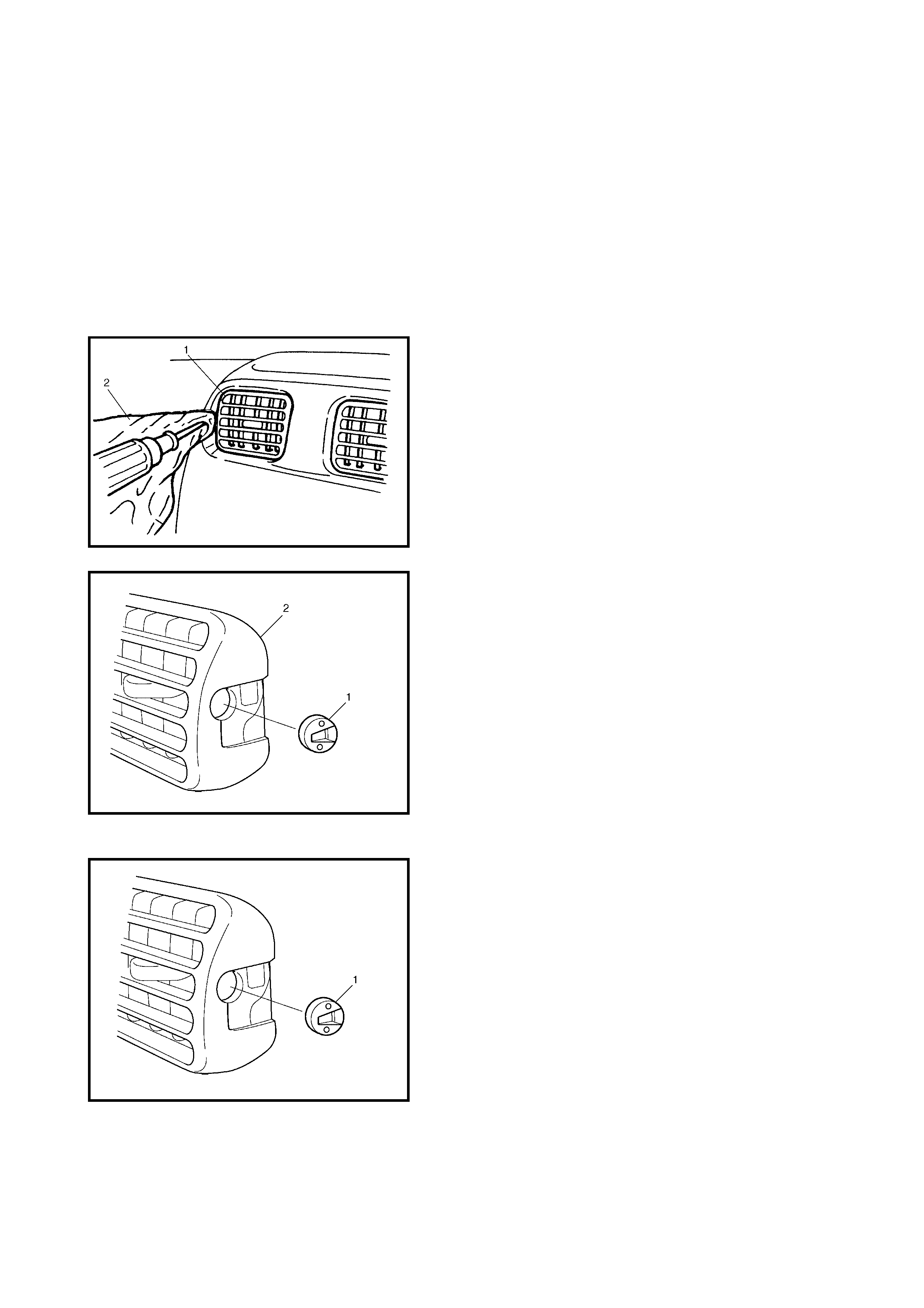

3.6 VENTILATION LOUVRE

REMOVAL

1. Remove ventilation louvre (1) using flat blade screw-

driver c ov ered with a r ag (2) for p ro tec tio n a s shown in

figure.

NOTE: Take care not to damage fascia.

2. Remove ventilation louvre holder (1) from ventilation

louvr e (2).

INSTALLATION

Reverse removal procedure to install ventilation louvre

noting the following instruction.

• Be sure to install ventilation louvre holder (1) in the

correct direction as shown.

4. REQUIRED SERVICE MATERIAL

Ma te ria l Recom m ende d Prod uct Use

Sealant Three Bond No. 1216B •Ai r in le t b ox