1. DIAGNOSIS

1.1 GENERAL DIAGNOS IS

Since prob lems in steering, suspensi on, wheels and tyres could involve several syst ems , t hey must all be con-

sidered when diagnosing a complaint. To avoi d incorrect diagnosis, alwa ys road test the vehicle first. Proceed

with the foll owi ng preliminary inspection and correct any def ects which are found.

1. Inspect tyres for proper pressure and uneven wear.

2. Raise vehicle on a hoist and inspect front and rear suspension and steering system for loose or damaged

parts.

3. Spin front wheels. Inspect for out-of-round tyres, out-of-balance tyres, bent rims, loose and/or rough

wheel bearings.

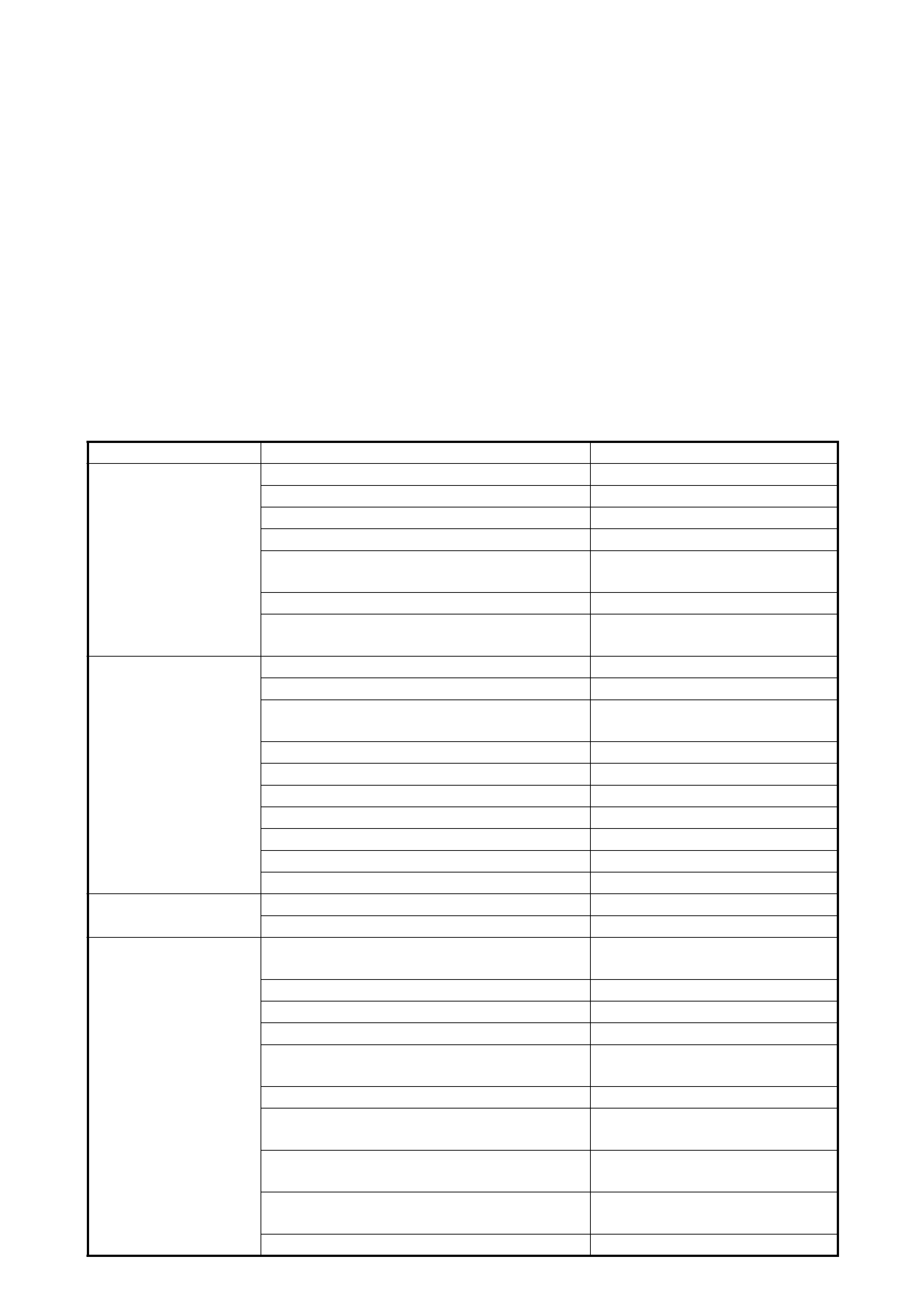

DIAGNOSIS TABLE

Condition P ossible Cause Correction

Veh icle Pulls (Leads) Mismatched or uneven tyres Replace tyre.

Tyres not adequately inflated Adju st tyre pressure.

Broken or s aggi ng spring s Re place sprin g.

Radial tyre lateral force Replace tyre.

Disturbed wheel alignment Check and adjust front wheel

alignment.

Brak e dragging in one road wheel Repair brake.

Loose, bent or broken f ront or rear suspension

parts Tighten or replace suspension

parts.

Abnormal or

Excessive Tyre W ear Sagging or broken spring Replace sp rin g.

Tyre out of balance Adju st balance or replace tyre.

Disturbed wheel alignment Check and adjust front wheel

alignment.

Faulty strut (shock abso rber) Re place strut.

Hard driving Replace tyre.

Overloaded vehicle Replace tyre .

Not rota ting tyr e Replace or rota te tyr e.

Worn or loose wheel bearing Re place wheel bear ing .

Wobbly wheel or tyre Replace wheel or tyre.

Tyres not adequately inflated Adju st tyre pressure.

W hee l Tramp Blister or bump on tyre Replace tyre.

Improper strut (shock absorber) action Replace str ut.

S himmy, S h a ke o r

Vibration Tyre or wheel out of balance Balance wheels or replace tyre

and/o r wheel.

Loose wheel bearin gs Replace wheel bearing .

Worn tie rod ends Replace tie rod end.

Worn lower ball joints Replace front susp ension ar m .

Excessive wheel runout Repair or replace wheel and/or

tyre.

Blister or bump on tyre Replace tyre.

Excessively loaded radial runout of tyre/wheel

assembly Replace tyre or wheel.

Disturbed wheel alignment Check and adjust front wheel

alignment.

Loose or worn steerin g linkage Tighten or replace steer ing link-

age.

Loose steering gear case bolts Tighten c ase bolts.

Hard Steering Tyre not adequately inflated Inflate tyres to proper pressure.

Malfunction of power steering sy stem Ch eck and correct.

Bind in tie rod end ball studs or lower ball joints Replace tie rod end or front sus-

pens ion ar m.

Disturbed front wheel alignment Check and adjust front wheel

alignment.

Rack and pinion adjustment Check and adjust rack and pinion

torque.

Bind in steering column Repair or replace.

Too Much Play i n

Steering Wheel bearings worn Replace.

Loose steering gear case bolts Tighten.

Rack and pinion adjustments Check and adjust rac k and pinion

torque.

Worn steering shaf t joints Replace joint.

Worn tie rod ends or tie rod inside ball joints Replace tie rod end or tie rod.

Worn lower ball joints Replace front suspens ion control

arm.

Poor Returnabil it y Bind in tie rod end ball studs Replace tie rod end.

Bind in ball joi nts Replace.

Bind in steering column Repair or replace.

P oorly lubricated rac k and pinion Check, repair or lubricate rack and

pinion.

Disturbed front end alignmen t Ch eck and adjust fr on t end align-

ment.

Rack and pinion adjustment Check and adjust rack and pinion

torque.

Tyres not adequate ly inflated Adju st tyre pressure.

R a ck and Pinion

Noise

(Rattle or Chuckle)

Loose steering gear case bolts Tighten.

Worn rack bush Replace.

Rack and pinion adjustment Check and adjust rack and pinion

torque.

Abnormal Noise,

Front End Worn, sticky or loose tie rod ends, low er ball

join ts, tie rod in s ide ball jo int s o r drive shaft

joints

Replace tie rod end, suspens ion

ar m , tie rod or drive sh aft joint.

Damaged str uts or mountings Repair or replace.

Worn suspension arm bushings Replace.

Loose stab iliser bar Tighten bolt s or nuts, replace

bushes.

Loose wheel nuts Tighten wheel nuts.

Loose suspens ion bolts or nuts Tighten s uspens ion bolts or nuts.

Broken or otherwise damaged wheel bearings Replace.

Broken suspension springs Replace.

Poorl y lubricat ed or worn str ut bear ings Replace strut bear ing.

Condition P ossible Cause Correction

Wand er or Poo r

Steer ing Stab ility Mismatched or uneve n tyres Re place or in flate tyres to proper

pressure.

Loose ball joints and tie rod ends Replace suspension arm or tie rod

end.

Fa ulty s tru ts o r mo u ntin gs Repl a c e stru t o r repa ir m o u nting .

Loose stabiliser bar Tighten or replace stabiliser bar or

bush.

Broken or s aggi ng spring s Re place sprin g.

Rack and pinion adjustment Check and adjust rack and pinion

torque.

Disturbed front wheel alignment Check and adjust front wheel

alignment.

Erratic Steering When

Braking Worn wheel bearing s Re place.

Broken or s aggi ng spring s Re place coil spring.

Tyres are inflated unequally Inflate tyres to proper pressure.

Disturbed front end alignmen t Ch eck and adjust fr on t end align-

ment.

Brak es not working in unison Check and adjustment brake sys-

tem.

Leaking wheel cylinder or caliper Repair or replace wheel cylinder or

caliper.

Wa rped discs Replace brake disc.

Badly worn brake linings Re place brake shoe lining.

Drum is out of round in some brakes Replace brake drum.

Defe ctive wheel cylinders Replace or repair wheel cylinder.

Low or Uneven Tr im

Height

Re fer NOTE * 1.

Broken or s aggi ng spring s Re place.

Over loaded Check loading.

Incorrect springs Replace.

Ride Too Soft Faulty struts (shock absorbe r) Replace str ut.

Suspension Bottoms Overloade d Ch eck loading.

Faulty struts (shock absorbe r) Replace str ut.

Incorrect, broken or sa gging springs Replace.

Body Leans or Sways

in Corners Loose stabiliser bar Tighten stabiliser bar bolts or nuts,

or replace bu shes.

Faulty struts (shock absorbers) or moun tings Re place str ut or tighten mount ing.

Broken or s aggi ng spring s Re place.

Overloade d Ch eck loading.

C upped Ty res Front str uts defe ctive Replace.

Worn wheel bearing s Re place.

Excessive tyre or wheel run-out Replace tyre or wheel disc.

Worn ball joints Replace front su spension arm .

Tyre out of balance Adjust tyre balance.

Condition P ossible Cause Correction

NOTE: 1: Right-to-left trim height (“H”) difference should be

within 15 mm with vehi cle at curb weight (same with rear).

1.2 TYRE DIAGNOSIS

IRREGULAR AND/OR PREMATURE WEAR

Irregular and premature wear has many causes. Some of

them are: incorrect inflation pressu res, lack of tyre rotation,

dr ivin g habits, improper alignme nt.

If the following conditions are noted, rotation is necessary:

• Front tyre wear is diffe rent from rear.

• Uneven wear exists across the tread of any tyre.

• F ront tyre wear is unequal between the right and left.

• Rea r tyre wear i s unequal between the ri ght and left.

• There is cupping, flat spotting, etc.

A wheel alignment check is necessary if following condi-

tion s are noted:

• F ront tyre wear is unequal between the right and left.

• Wear is uneven acro ss the tread of any f ront tyre.

• Front tyre treads have scuffed appearance with

“fe athe r” edges on one side of tread ribs or blocks.

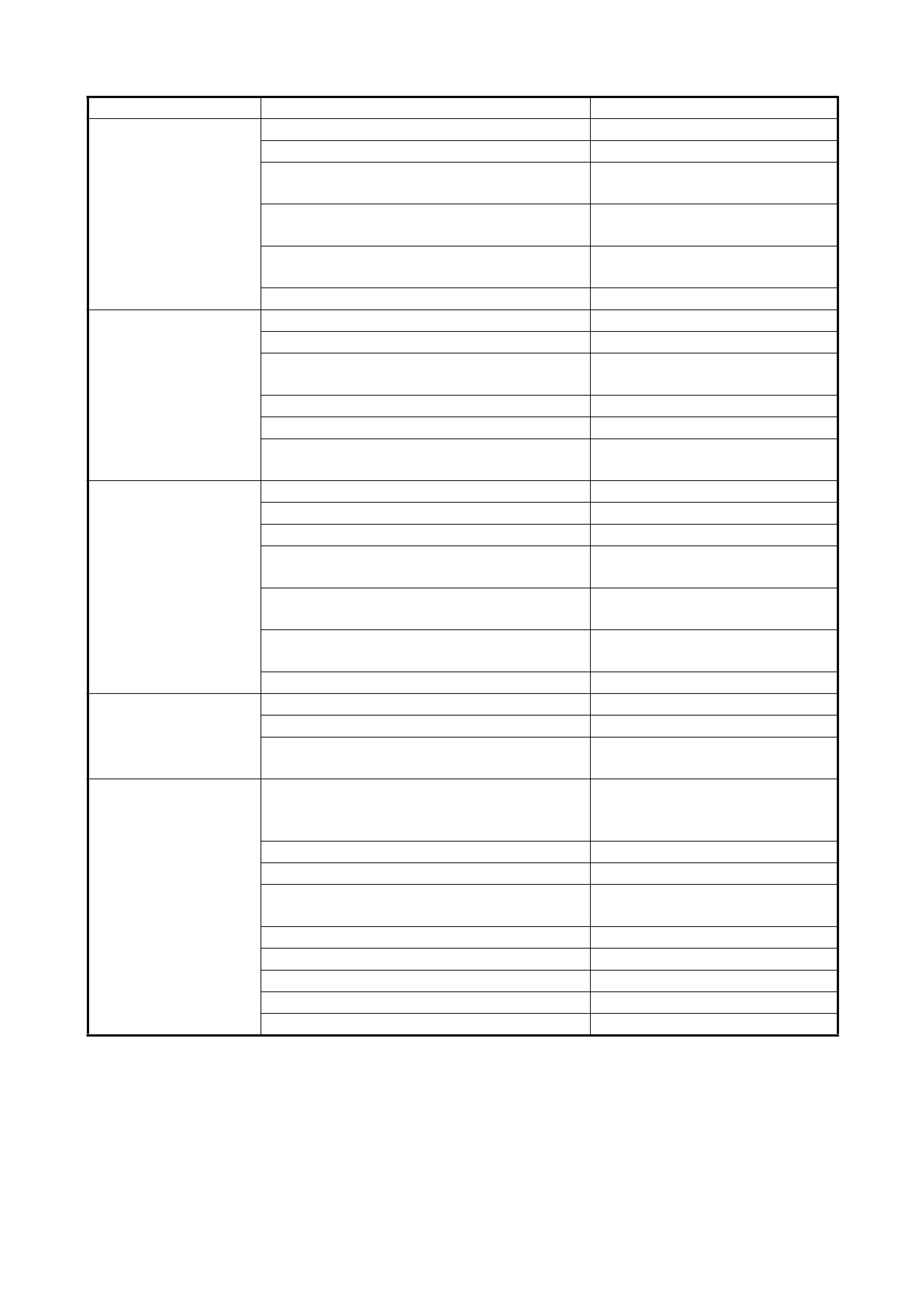

Tyre wear as i ndicated in (A) could be a re su lt of hard cor-

nerin g, unde r inflation or lack of tyre rotation.

Tyre wear as indicated in (B) could be a result of incorrect

wheel alignment, tyre construction not uniform or heavy

acceleration.

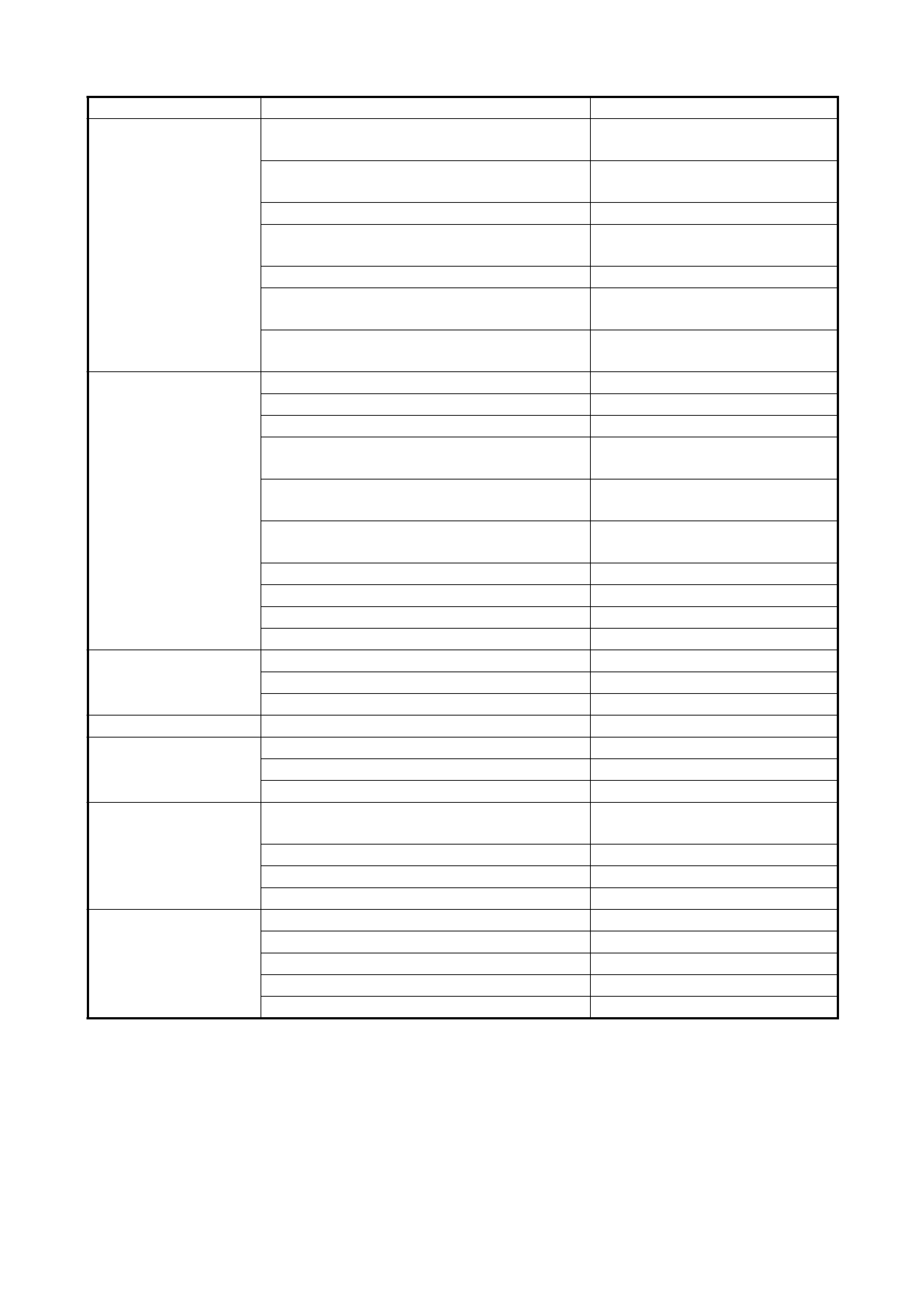

WEAR INDICATORS

Original equipm ent t yres h ave built-in tread wear indi cators

(1) to show when they need replacement.

These indicators (1) will appear as 12 mm wide bands

when the tyre tread depth becomes 1.6 mm.

When the indicators (1) appear in 3 or more grooves at 6

locations, tyre replacement is recommended.

“H”

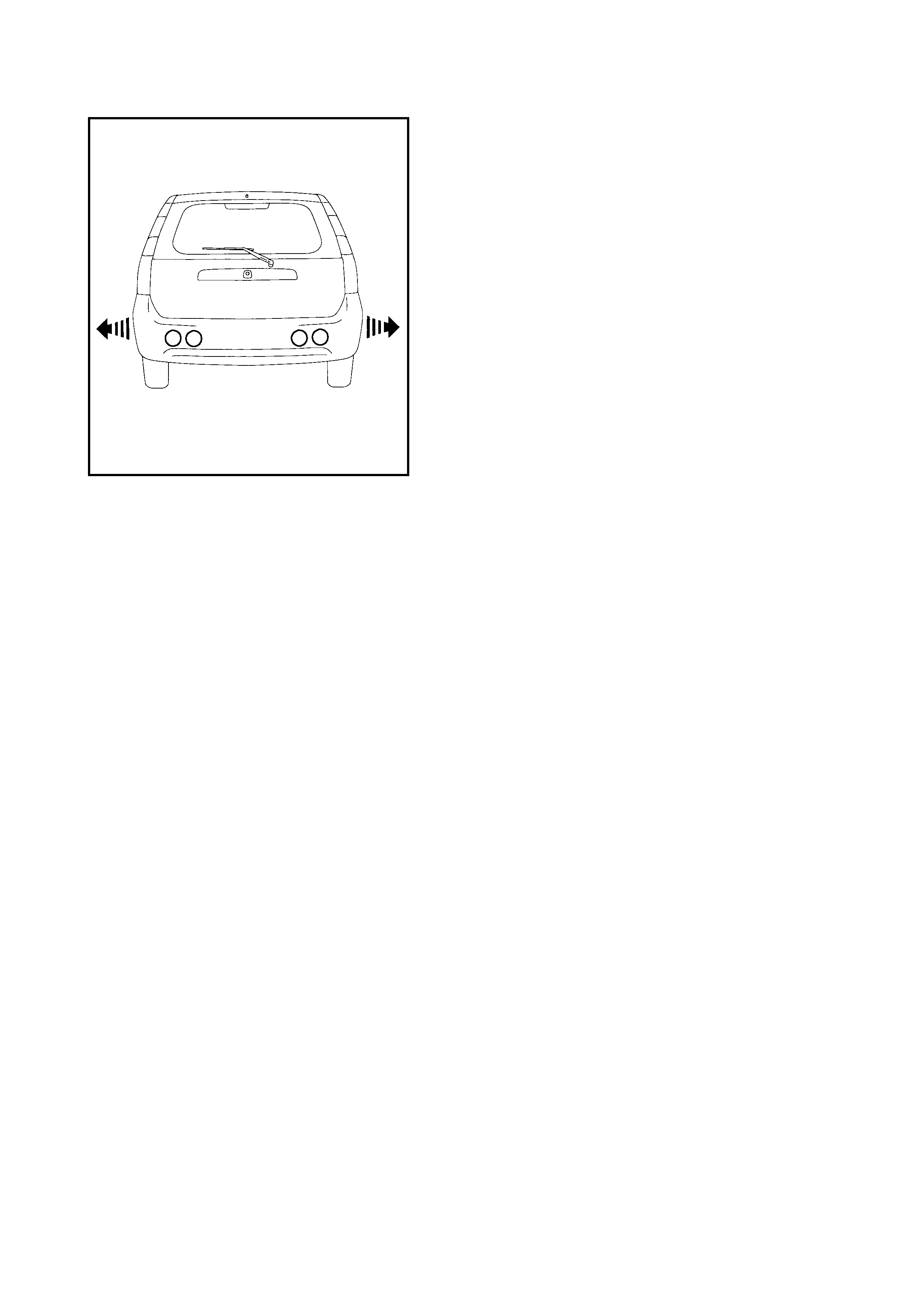

RADIAL TYRE WADDLE

Waddle is side to s ide movement at the f ront and/or rear of

the vehicle. It is caused by the steel belt not being straight

within the t yre. It is m os t not iceable at a low speed, 8 to 48

km/h.

It is possible to locate the faulty tyre by road testing the

vehicle. If it is on the rear, the rear end of the vehicle

shakes from side to side or “waddles”. To the driver in the

seat, it feels as though someone is pushing on the side of

vehicle.

If the faulty tyre is on the front, waddling is more visual. The

front sheet metal appea rs to be moving back an d for th and

the dr iver feels as though he is at the pivo t point in veh icle.

Waddle can be qu ickly diagno sed by using a Tyre Problem

Detector (TPD) and fol lowi ng the equipment manufacturer’s

recommendations.

If a TPD is no t available, an alter native method of substitut-

ing known -g ood tyre/whee l assemblies can be used a s fol-

lows, although it takes a l onger time.

1. Drive vehicle to determine whether the front or rear

waddles.

2. I nstall tyres and wheels that are known to be good (on

similar vehicle) in place of those on waddling end of

vehicle. If waddling end cannot be id entified, subs titute

rear ones.

3. Road test again. If improvement is noted, reinstall

originals one at a ti me until w addle causal tyre is f ound.

If no improvem ent is noted, install known-good tyres in

place of all four. Then reinstall originals in the same

manner as above.

RADIAL TYRE LEAD

“Lead” is t he deviation of the vehicle from a s traight path on a l eve l, eve n road wit h no pres sure on the s t eer-

i ng wheel.

Lead is usually caused by:

•Incorrect alignment.

•Uneven brake ad justment.

•Tyre c onstr uction.

The way i n which a tyre i s built can produc e l ead in a vehicle. An example of this is pl ac eme nt of the belt. Off

centre belts on radial tyres can cause the tyre to develop a side force while rolling straigh t down the road. If

one side of the tyre has a little larger diameter than the other, the tyre will tend to roll to one side. This will

develop a side force which can produce vehicle lead.

The procedure in the fo llowing Lead Dia gnosis table should be used to make sure that fron t alignment is not

mistaken for tyre lead.

•Part of the lead diagnosis procedure is diff erent f rom the proper tyre rotation pattern currently in the owner

and service manuals. I f a medium to high mileage tyre is moved to the other side of the vehicle , be sure to

check that ride roughness has not developed

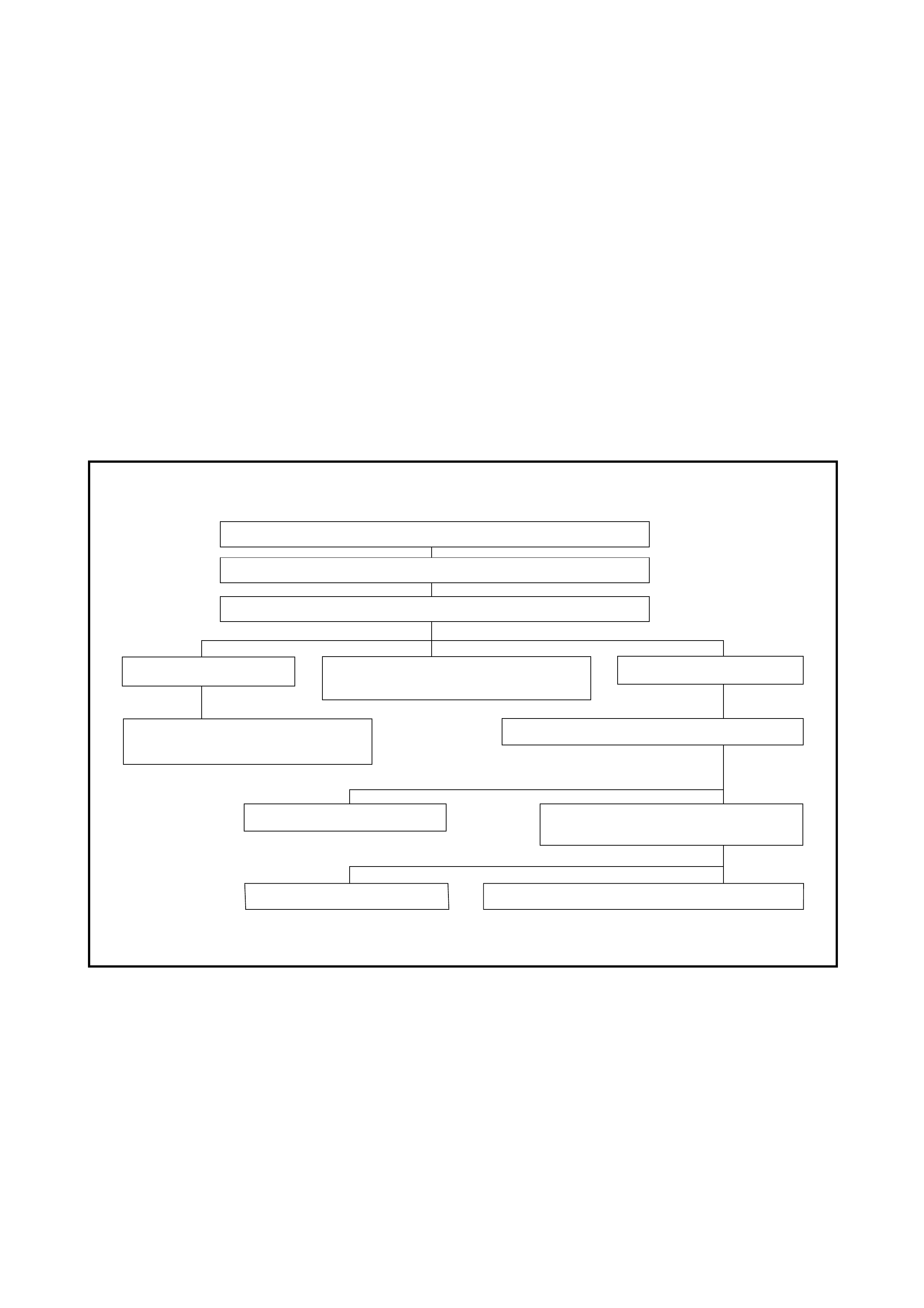

Rear tyres will not cause lead. LEAD DIAG NO SIS TABLE

Inflate tyres to recommended pressure

Road test vehicle on level uncrowned road in both directions

Switch front tyres side to side and road test again

Lead corrected,

if roughness results, replace tyres

Leads in same direction Leads reverses direction

Put tyres back in original position

and check alignment Install a known-good tyre on one front side

Lead remains install a known-good

tire in place of other front tyre

Lead remains known-good tyres are not goodLead corrected replace tyre

Lead corrected replace tyre

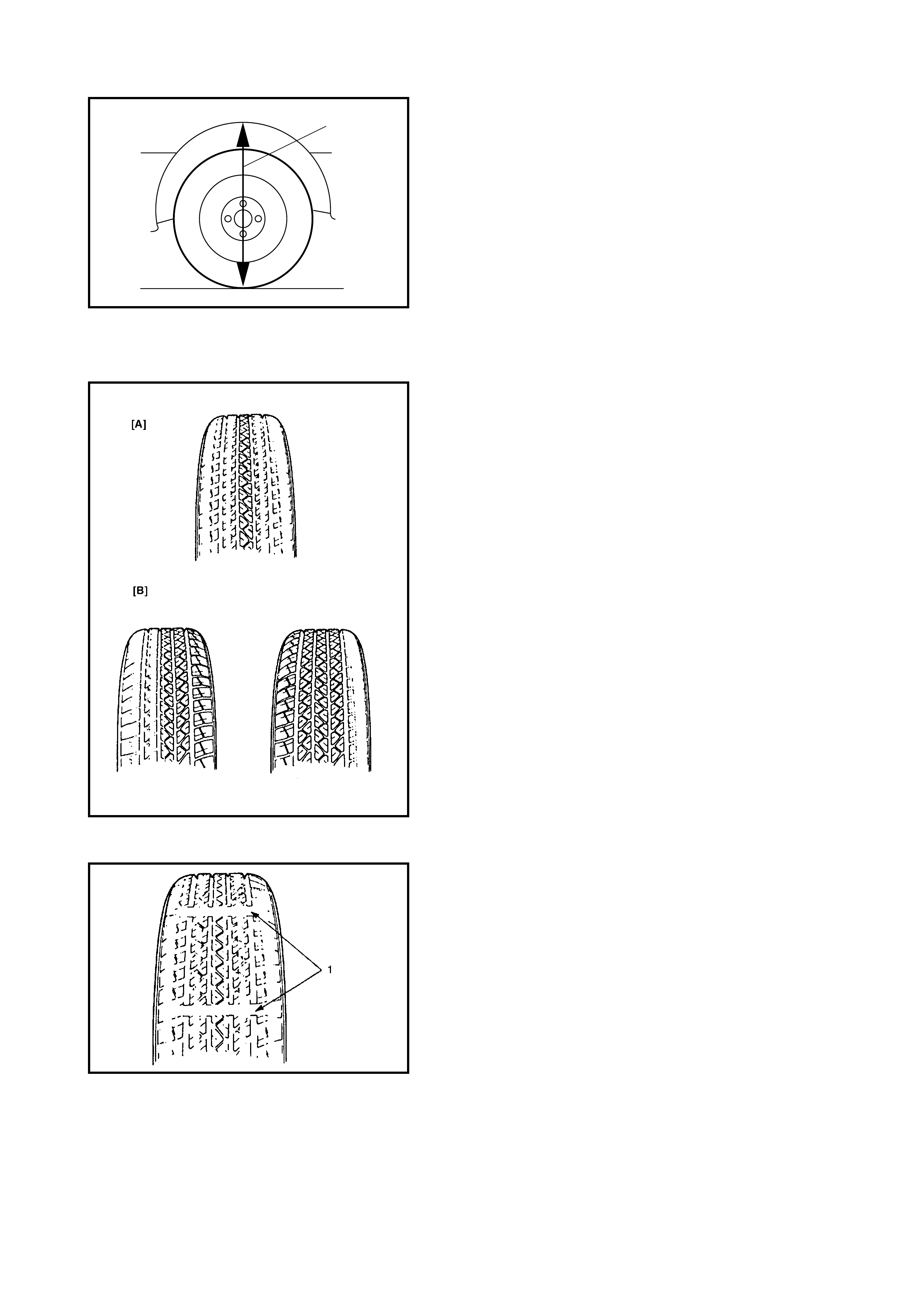

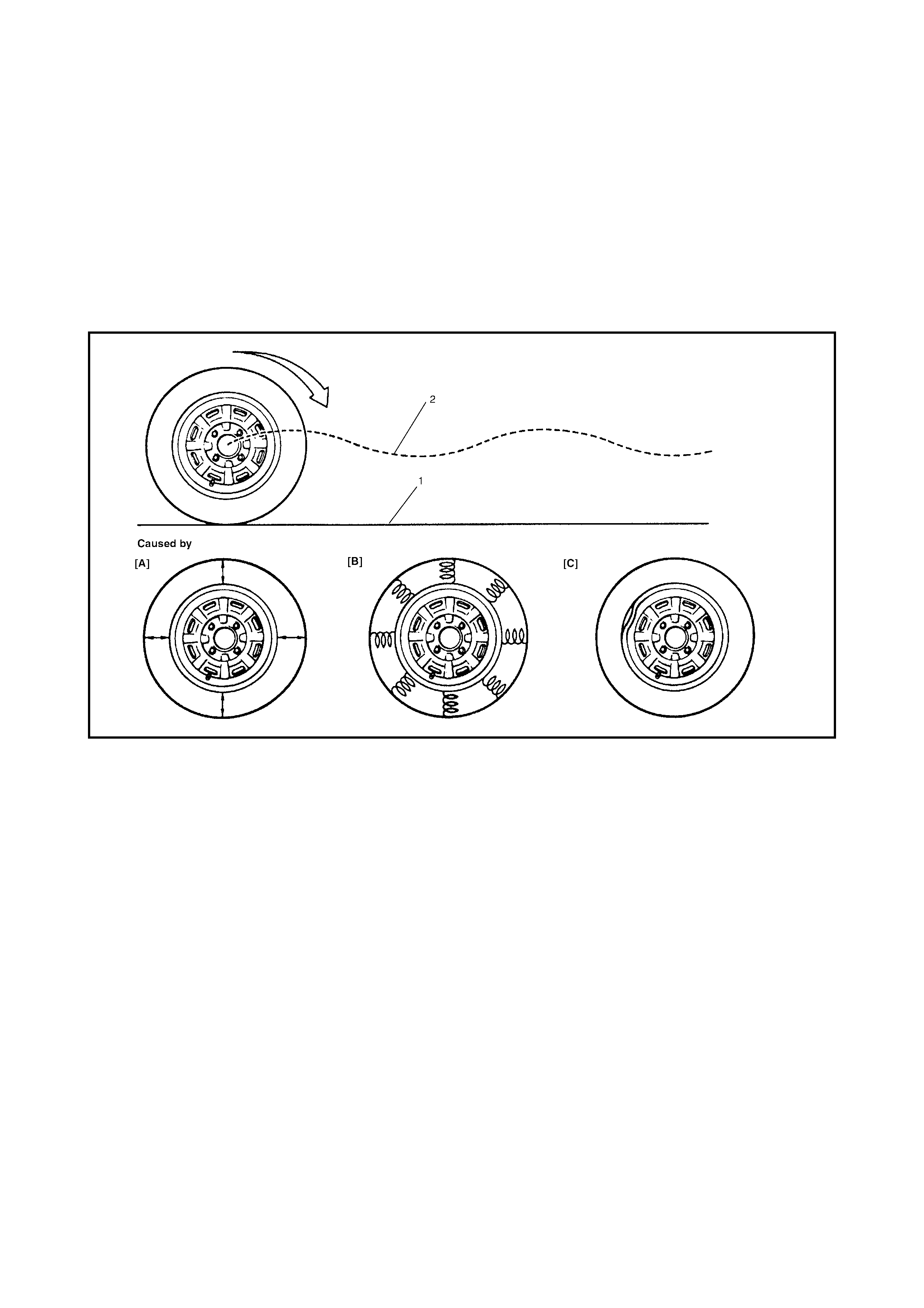

1.3 VIBRATION DIAGNOSIS

Wheel unbal ance causes most of the hi ghway speed vibration proble ms. If a vibration remains after dynamic

balancing, its possible causes are as follows .

•Tyre runout.

•Wheel runo ut.

•Tyre s tiffness variation.

Measuring tyre and/or wheel free runout will uncover only part of the problem. All three causes, known as

loaded radia l r unout , must be checked by us ing a Tyre Problem Det ecto r (TPD). If TPD is not availabl e, alter-

native method of substituting known-good tyre and wheel assemblies on the problem vehicle can be used,

although it takes a longer time.

Legend

[A] : Tyre out of round 1. Smooth road

[B] : Tyre stiffness variation 2. Suspension m ovement

(loaded runout)

[C] : Rim bent or out of round