SECTION 3C - STEERING WHEEL

AND COLUMN

1. GENERAL DESCRIPTION

1.1 STEERING COLUMN

1.2 ST EERING WHEEL AND DRIVER

AIRBAG (INFLATOR) MODULE

2. DIAGNOSIS

2.1 INSPECTI ON AND REPAIR

REQUIRED AFTER ACCIDENT

3. O N- VEH IC L E SER VICE

3.1 SERVICE PRECAUTIONS

Service and Diagno sis

Disabling Air Bag System

Enabling Air Bag System

Handling and Storage

Disposal

3.2 DRIVER AIRBAG (INFLATOR)

MODULE

Removal

Inspection

Installation

3.3 STEERING WHEEL

Removal

Installation

3.4 CENTRING CONTACT COIL

3.5 CONTACT COIL AND COMBINATION

SWITCH ASSEMBLY

Removal

Inspection

Installation

3.6 STEERING COLUMN ASSEMBLY

Removal

Inspection

Installation

3.7 STEERING LOCK ASSEMBLY

(IGNITI ON SWITCH)

Removal

Installation

3.8 STEERING LOWER SHAFT

Removal

Installation

3.9 CHECKING STEERING COLUMN

ASSEMBLY AND LOW ER SHAFT

FOR ACCIDENT DAMAGE

Checking Procedure

4. SPECIAL TOOLS

WARNING:

For vehicles equipped with Supplemental Restraint (Airbag) System:

• Service on and around the a irbag system components or wiring must be performed only by

an au tho ris ed HO LDE N ret ail er. P leas e obs erv e all WA RNIN G S and SE RVI CE PR EC AUTI ONS

refer to Se ction 1 0B AIRBAG SYST EM, ON-VE HICLE SE RVICE befo re performing s ervice on

or around t he airbag system components or wiring. Failure to follow WARNINGS could result

in unintentional activation of the system or could render the system inoperative. Either of

these two conditions may result in severe injury.

• The procedures in this section must be followed in the order listed to temporarily disable the

airbag system an d preve nt fal se diagnost ic codes f rom setting. Failure to follow p roced ures

could result in possible airbag system activation, personal injury or otherwise unneeded air-

bag system repairs.

CAUTION:

When fastene rs are rem ov ed, always reins tall them at the same lo cation from which th ey were

removed. If a fastener needs to be replaced, use the correct part number fastener for that appli-

cation. If the correct part number fastener is not available, a fas tener of equal size and strength

(or stronger) may be used. Fasteners that are not reused, and those requiring thread-locking

compound, will be c alled o ut. T he c orre ct torque value must be u s ed w he n ins tallin g faste ne rs

that require it. If the above p rocedures are not followed, parts or system damage could result.

1. GENERAL DESCRIPTION

1.1 STEERING COLUMN

This double tube type steering column has following three important features in addition to the steering

function:

• The column is energy absorbing, designed to compress in a front-end collision.

• The ignition switch and lock are mounted conveniently on this column.

• With the column mounted lock, the ignition and steering operations can be locked to inhibit theft of the

vehicle.

To insure the energy absorbing action, it is important that only the specified screws, bolts, and nuts be used as

designated and that they are tightened to the specified torque.

When the column assembly is removed from the vehicle, special care must be taken in handling it. Use of a

steering wheel puller other than the one recommended in this manual or a sharp blow on the end of the steer-

ing shaft, leaning on the assembly, or dropping the assembly could shear the plastic shear pins which main-

tain column length and position.

1.2 STEERING WHEEL AND DRIVER AIRBAG (INFLATOR) MODULE

• The driver airbag (inflator) module is one of the supplemental restraint (airbag) system components and is

mounted to the centre of the steering wheel. During certain front end crashes, the airbag system supple-

ments the restraint of the driver’s and passenger’s seat belts by deploying the airbags.

• The airbag (inflator) module should be handled with care to prevent accidental deployment. When servic-

ing, be sure to observe all WARNINGS and CAUTIONS and SERVICE PRECAUTIONS, refer to

Section 10B, 3 ON-VEHICLE SERVICE.

2. DIAGNOSIS

For maintenance service of the steering wheel and column, refer to Section 0B GENERAL INFORMATION.

For diagnosis of the steering wheel and column, refer to Section 3 STEERING, SUSPENSION, WHEELS

AND TYRES.

For diagnosis of the airbag system, refer to Section 10B AIRBAG SYSTEM.

2.1 INSPECTION AND REPAIR REQUIRED AFTER ACCIDENT

After an accident, w hether the a irbag has been d eployed or no t, be sure to perfor m che cks, inspect ions and

repairs, refer to 3.9 CHECKING STEERING COLUMN ASSEMBLY AND LOWER SHAFT FOR ACCIDENT

DAMAGE in this Section, also refer to Section 10B, 3.2 REPAIRS AND INSPECTIONS REQUIRED AFTER A

COLLISION

3. ON-VEHICLE SERVICE

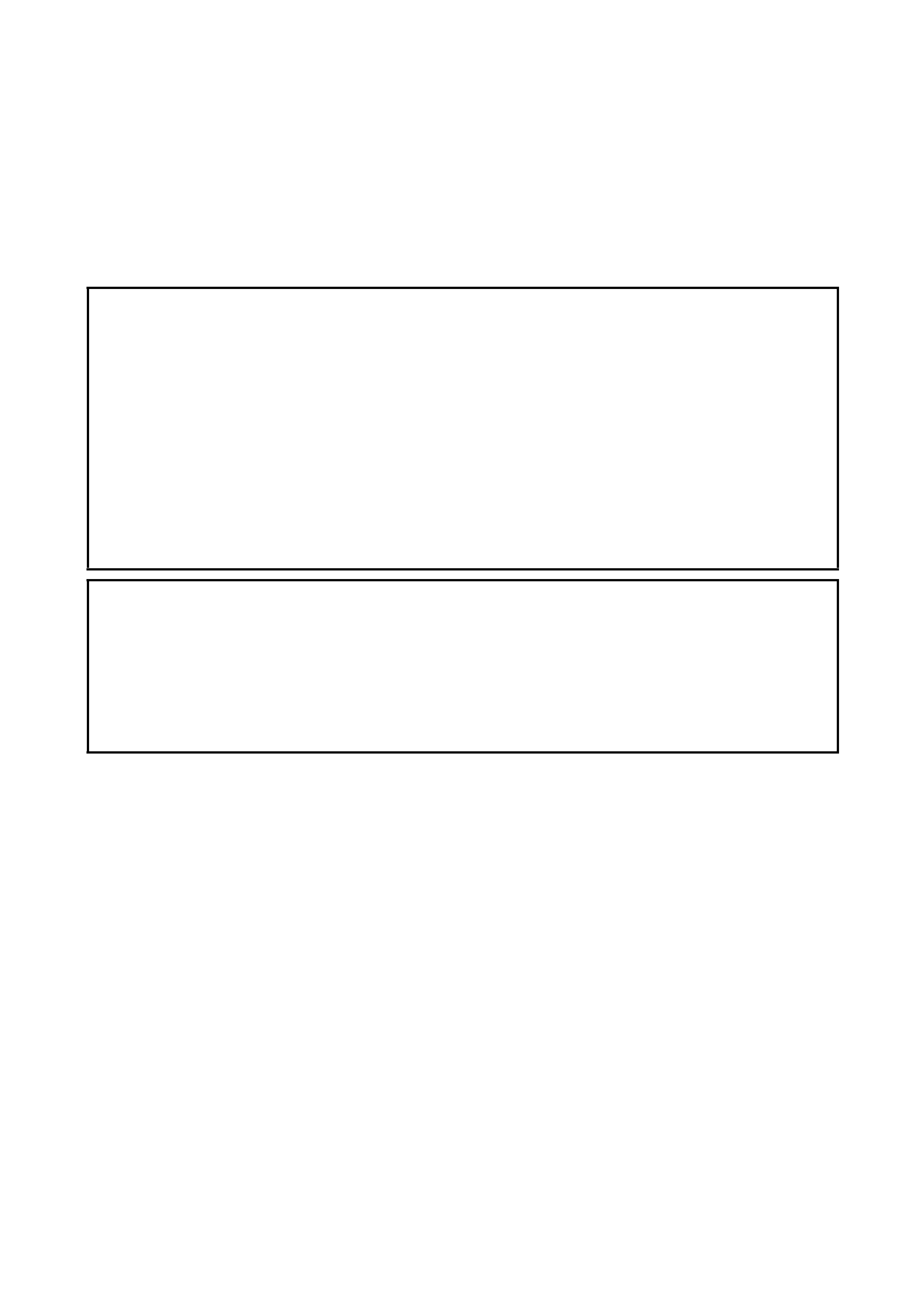

Legend

3.1 SERVICE PRECAUTIONS

For service precautions, refer to Section 10B, 3.1 SERVICE PRECAUTIONS under 3. ON-VEHICLE

SERVICE. SERVICE AND DIAGNOSIS

For diagnosis and servicing, refer to Section 10B, 3.1 SERVICE PRECAUTIONS under 3. ON-VEHICLE

SERVICE. DIS ABLING AIRB AG SYSTEM

For disabling airbag system, refer to DISABLING AIRBAG SYSTEM in Section 10B, 3.1 SERVICE

PRECAUTIONS.ENABLING AIRBAG SYSTEM

For enabling airbag system, refer to ENABLING AIRBAG SYSTEM in Section 10B, 3.1 SERVICE

PRECAUTIONS.HANDLING AND STORAG E

For handling and storage, refer to HANDLING AND STORAGE in Section 10B, 3.1 SERVICE

PRECAUTIONS.DISPOSAL

For disposal, refer to HANDLING AND STORAGE in Section 10B, 3.1 SERVICE PRECAUTIONS.

1. Dr iver ai rb ag (inflator) module 9. P/S control mod ule

(if equipped) 14. Upper and lower joint bolt

: A ft e r ti gh te ning l owe r jo int

bolt, tighten upper joint bolt.

2. Steering wheel

3. Steering wheel n ut 10. Motor for P/S system

4. Contact coil & combination

switch assembly (if equipped) 15. Steering column

mounting nut

: A ft e r ti gh te ning l owe r nu t,

tighten upper nut.

11. Steeri ng lower shaft

5. Steering column upper cover 12. Tilt le ver

6. Steering column lower cover 13. Immobiliser control module

(if equipped)

7. Steering column assembl y Tightening torque

8. Steer ing loc k a s sembl y

(ignition switch)

3.2 DRIVER AIRBAG (INFLATOR) MODULE

WARNING: When handling an airbag (inflator) module, be sure to read Section 10B, 3.1 SERVICE

PRECAUTIONS and observe each instruction. Failure to follow them could cause a damage to the

airbag (inflator) module or result in personal injury.

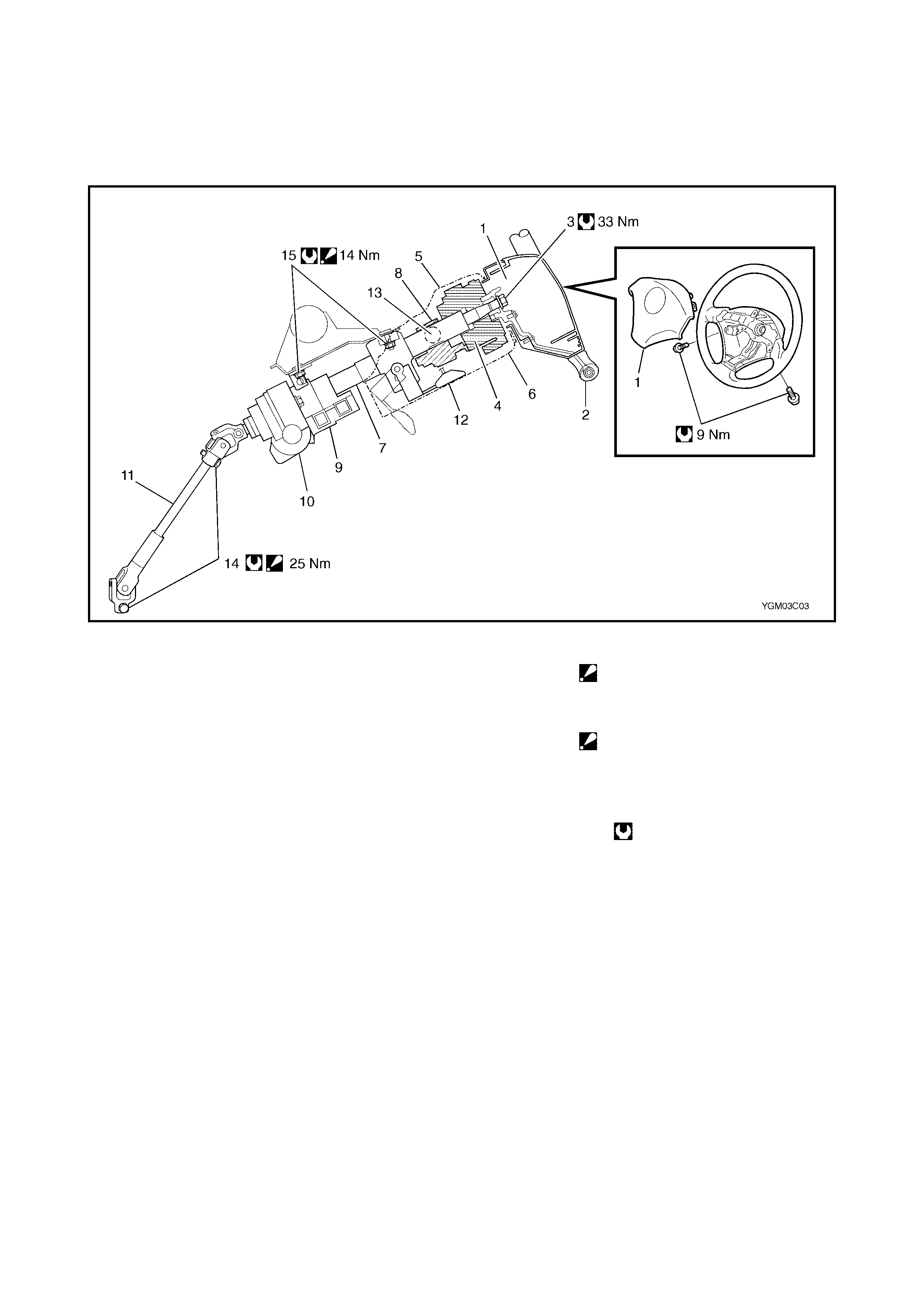

REMOVAL

1. Disconnect negative cable at battery.

2. Disable airbag system. Refer to DISABLING AIRBAG

SYSTEM in Section 10B, 3.1 SERVICE

PRECAUTIONS.

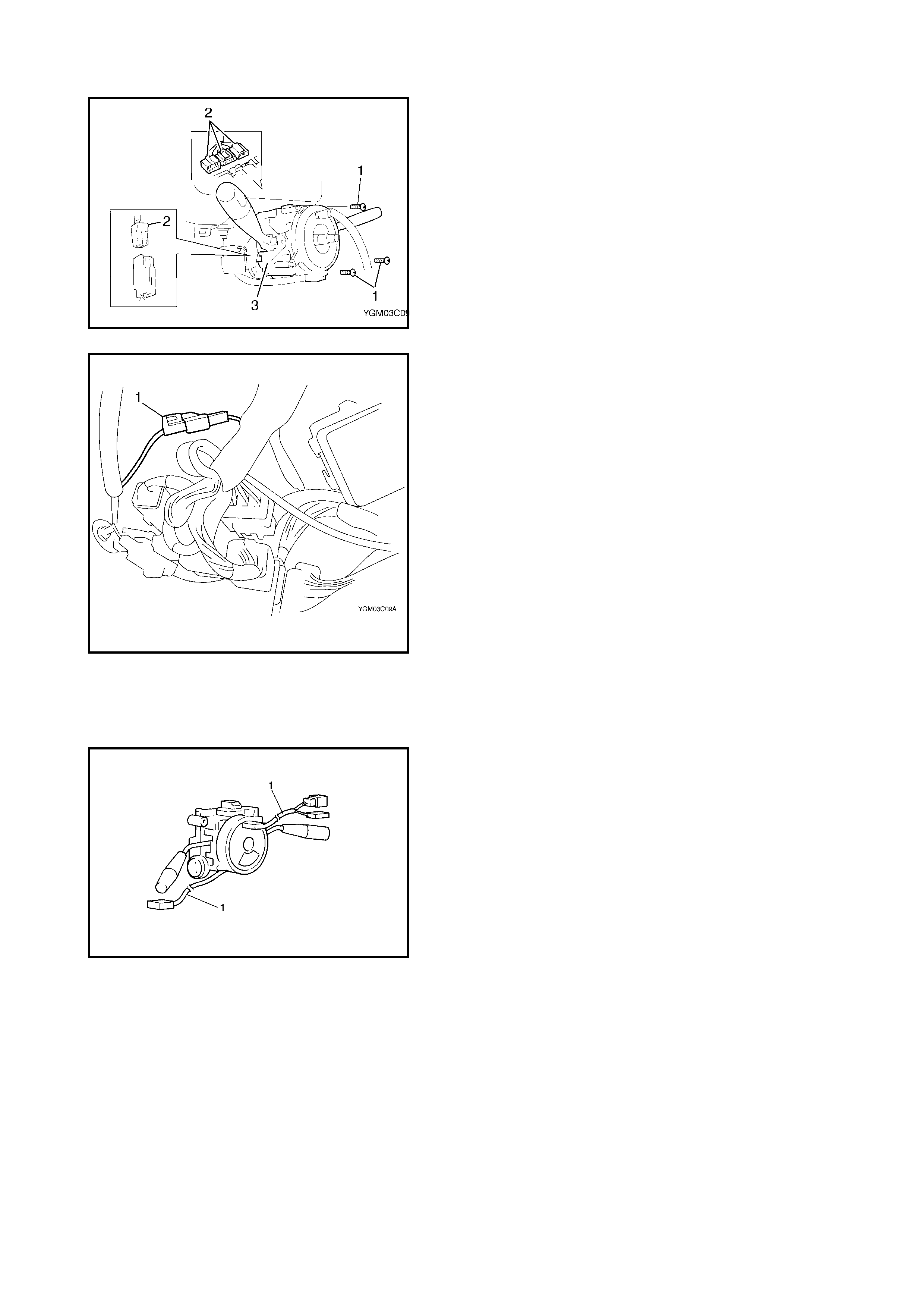

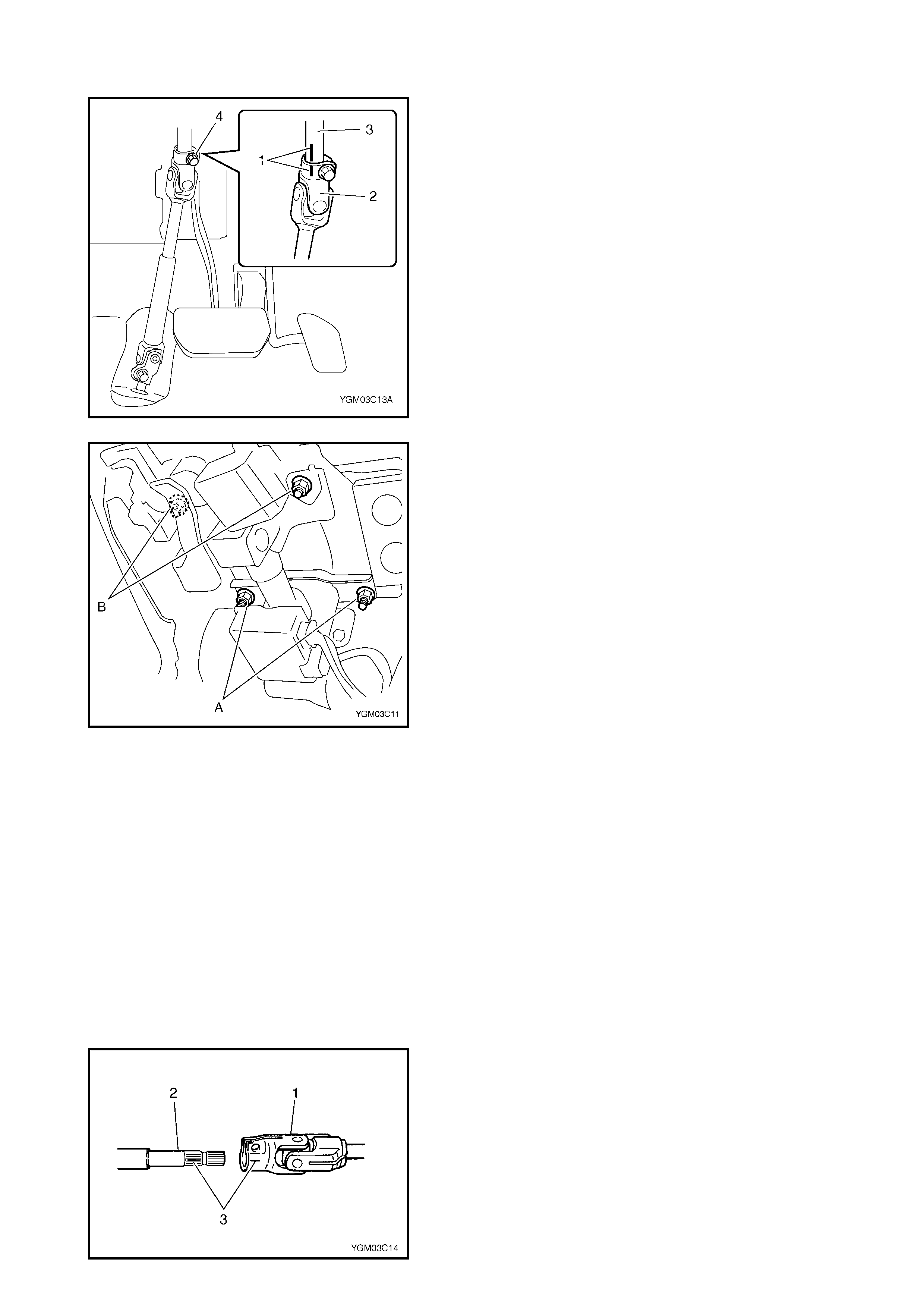

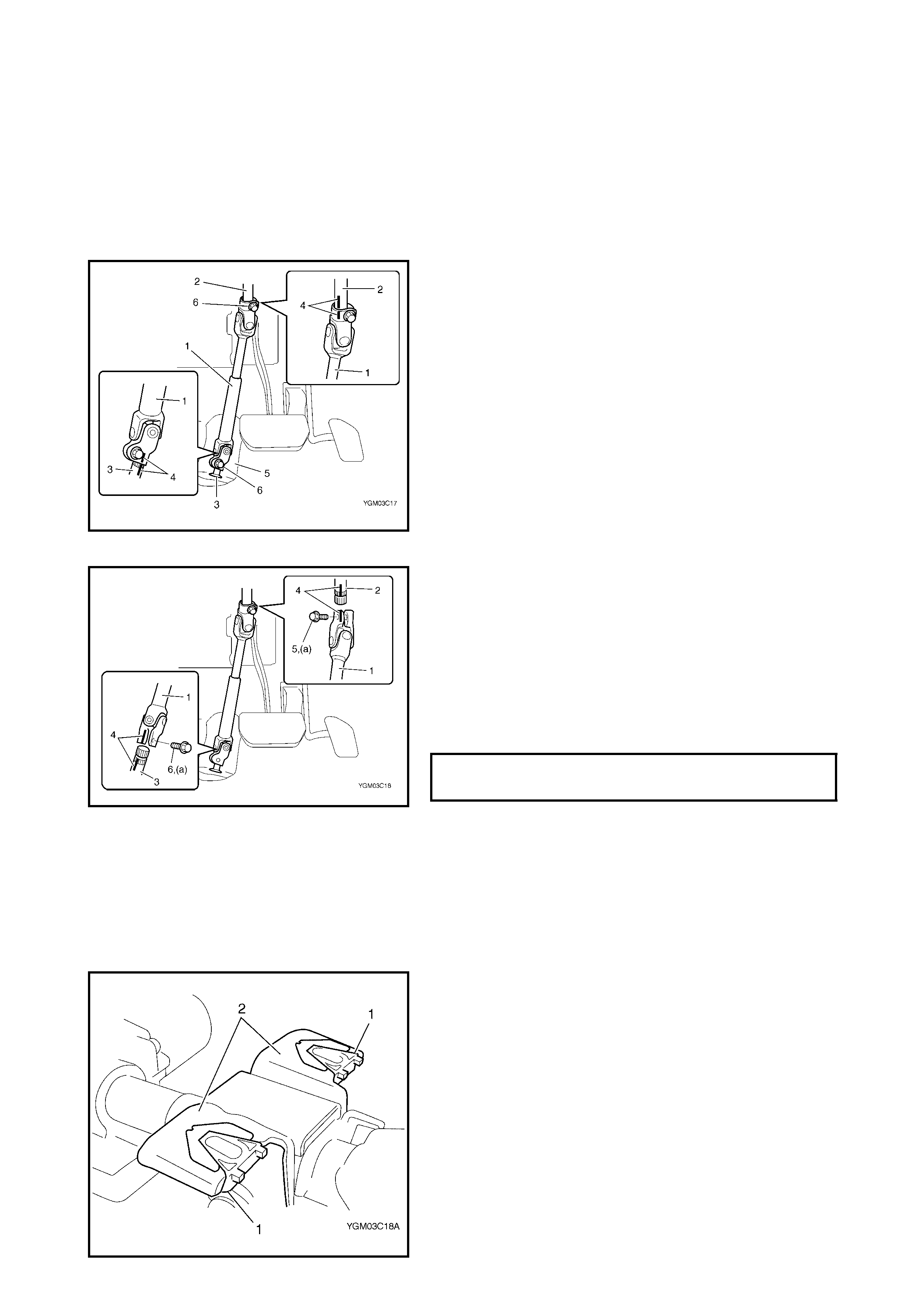

3. Loosen 2 mounting bolts (1) on both sides of driver

airbag (inflator) module.

4. Remove driver airbag (inflator) module (3) from

steeri ng wheel.

5. Disconnect yellow connector (1) of driver airbag (infla-

tor) module and horn connector (2) in order a) – d)

shown in figure.

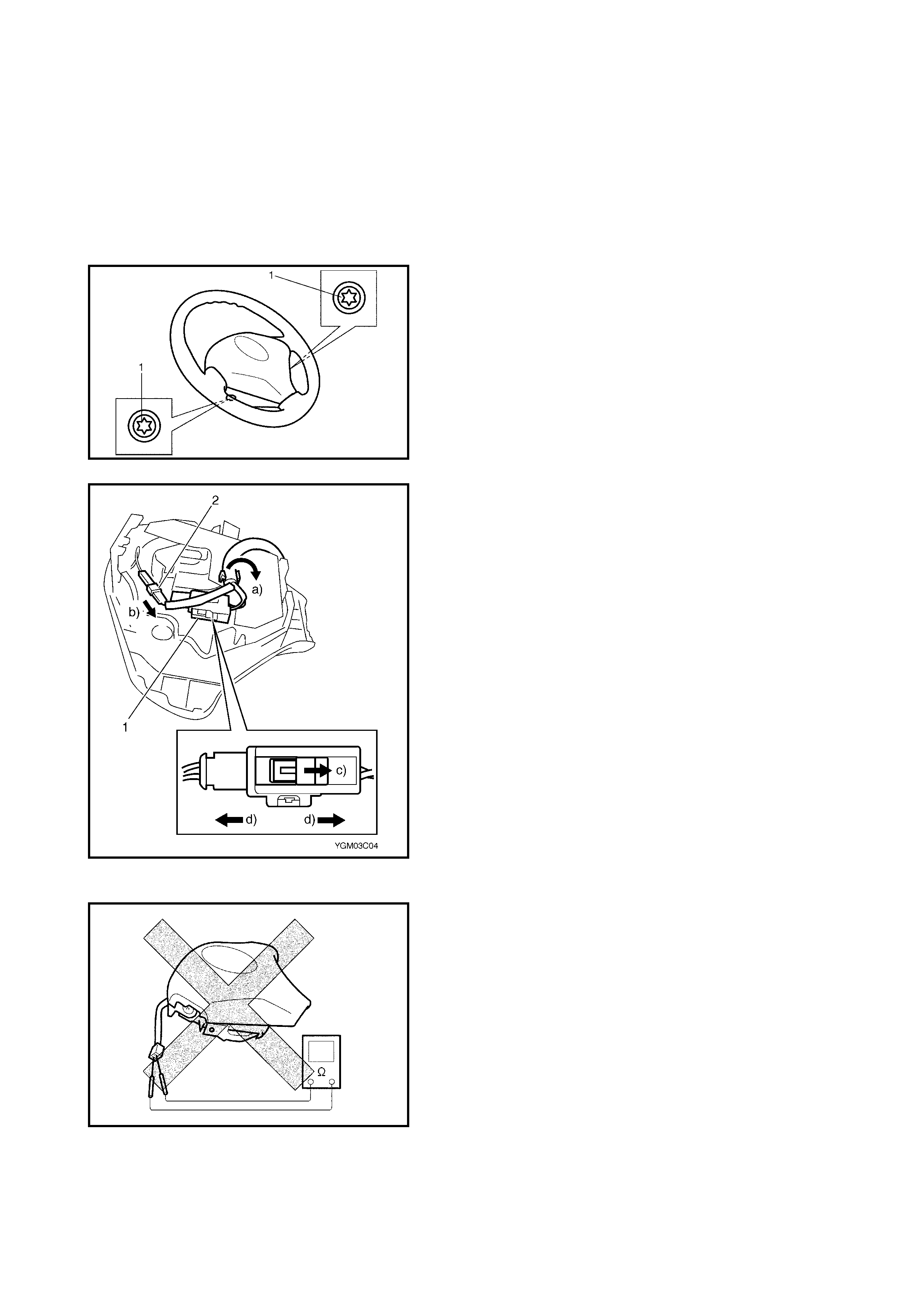

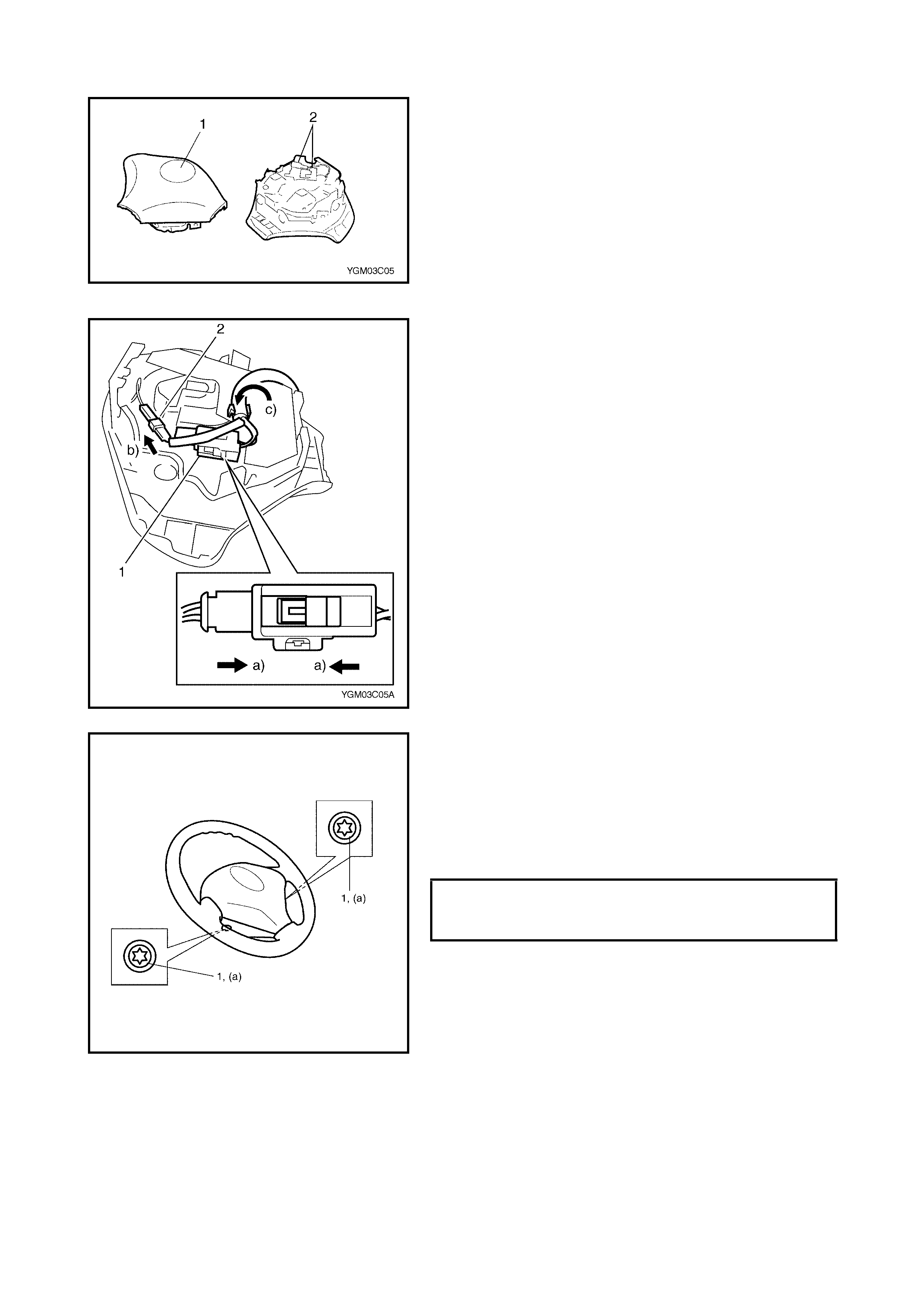

INSPECTION

WARNING: Never disassemble driver airbag (infla-

tor) module or measure its resistance. Otherwise,

personal injury may result.

CAUTION: If airbag (inflator) module was dropped

from a height of 90 cm or more, it should be

replaced.

Check airbag (inflator) module visually and if any of the fol-

lowing is found, replace it with a new one.

• Airbag being deployed

• Trim cover (pad surface) (1) is cracked

• Wire harness or connector (2) is damaged

• Airbag (inflator) module is damaged or has been

exposed to strong impact (dropped).

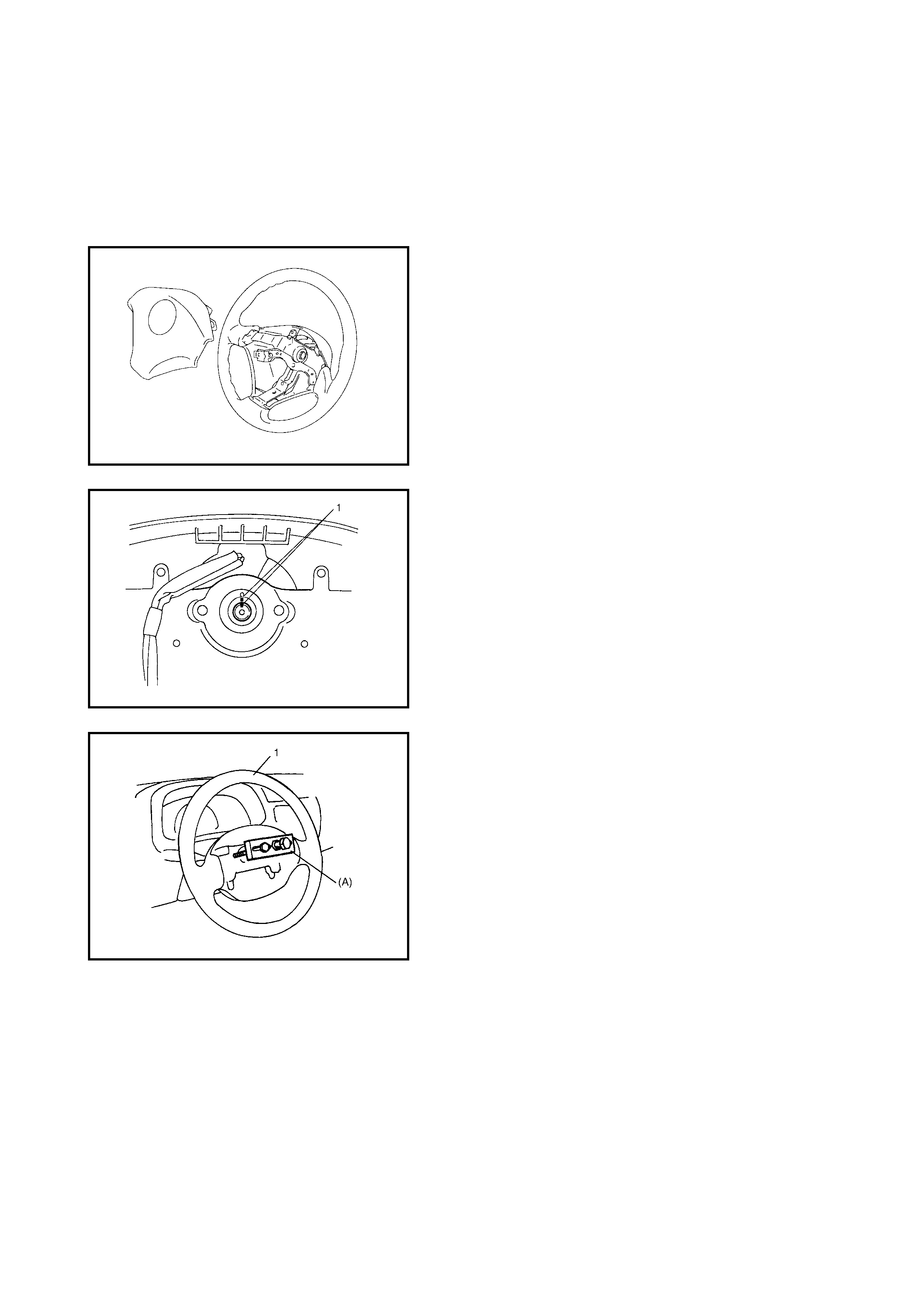

INSTALLATION

1. Check that horn wire is connected to horn connector

(2) securely.

2. Connect yellow connector (1) of driver airbag (inflator)

module (3) and horn connector securely in order a) – c)

as shown in figure.

3. Install the driver airbag (inflator) module to the steering

wheel, taking care that no part of the wiring harness is

caught between them.

4. Make sure that the clearance between the module and

the steering wheel is uniform in all places.

5. Tighten driver airbag (inflator) module mounting bolts

(1) to specified torque.

6. Connect negative cable at battery.

7. Enable airbag system. Refer to ENABLING AIRBAG

SYSTEM in Section 10B, 3.1 SERVICE

PRECAUTIONS.

DRIVER AIRBAG (INFLATOR) MOD-

ULE MOUNTING BOLT (a)

TORQUE SPECIFICATION 9 Nm

3.3 STEERING WHEEL

CAUTION: Removal of the steering wheel allows the contact coil to turn freely but do not turn the

contact coil (on the combination switch) more than allowable number of turns (about two and a

half turns from the centre position clockwise or counterclockwise respectively), or coil will break.

REMOVAL

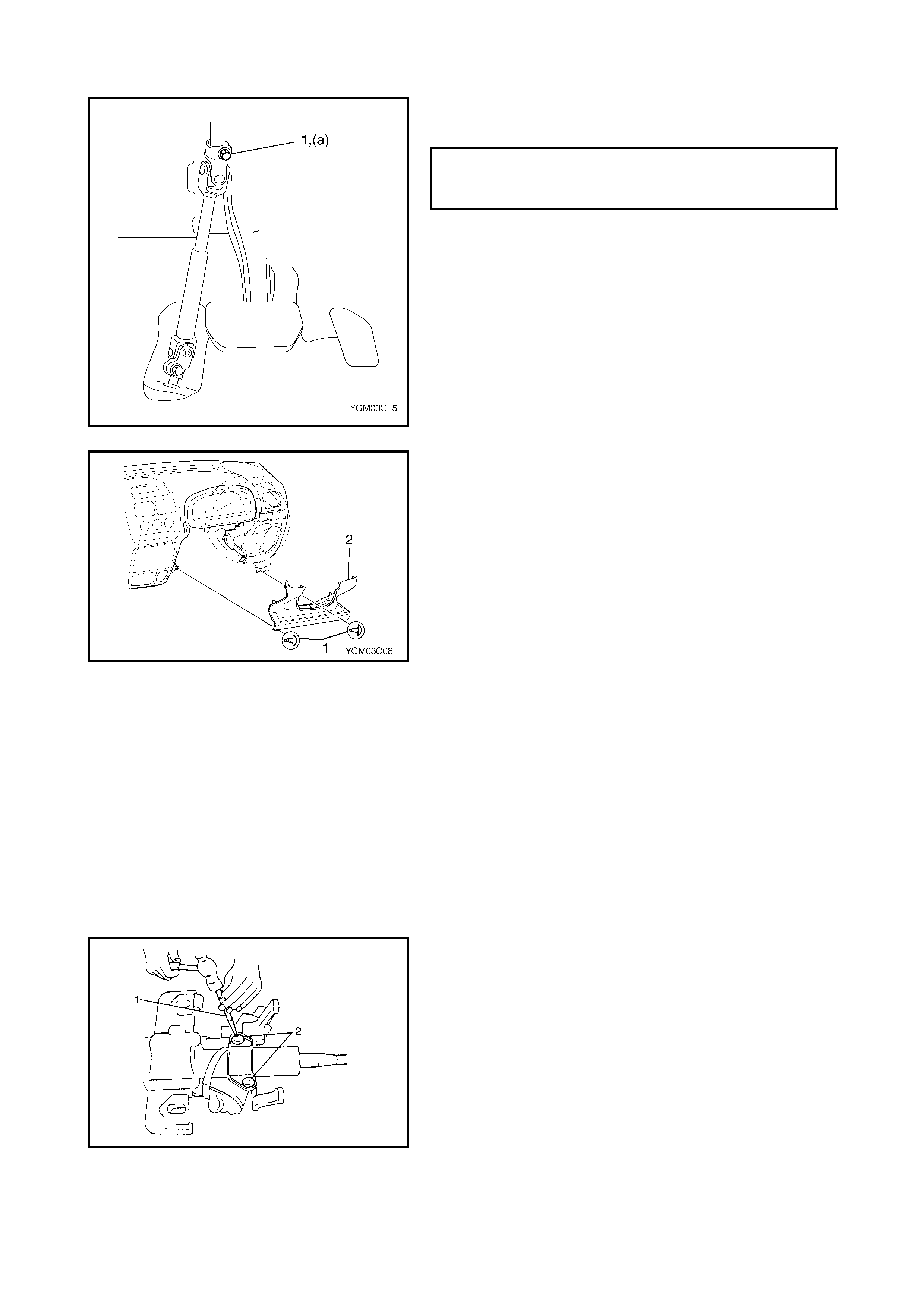

1. Remove driver airbag (inflator) module from steering

wheel. Refer to 3.2 DRIVER AIRBAG (INFLATOR)

MODULE in this Section.

2. Remov e steering shaft nut.

3. Make align men t mar k s (1) on st eeri ng wheel and sh aft

for a guide during reinstallation.

CAUTION: Do n ot hammer the e nd of the shaft. Ham-

mering it will loosen the plastic shear pins which main-

tain the column length and impair the collapsible

design of the column.

4. Remove steering wheel (1) with special tool (A) 09944-

36011.

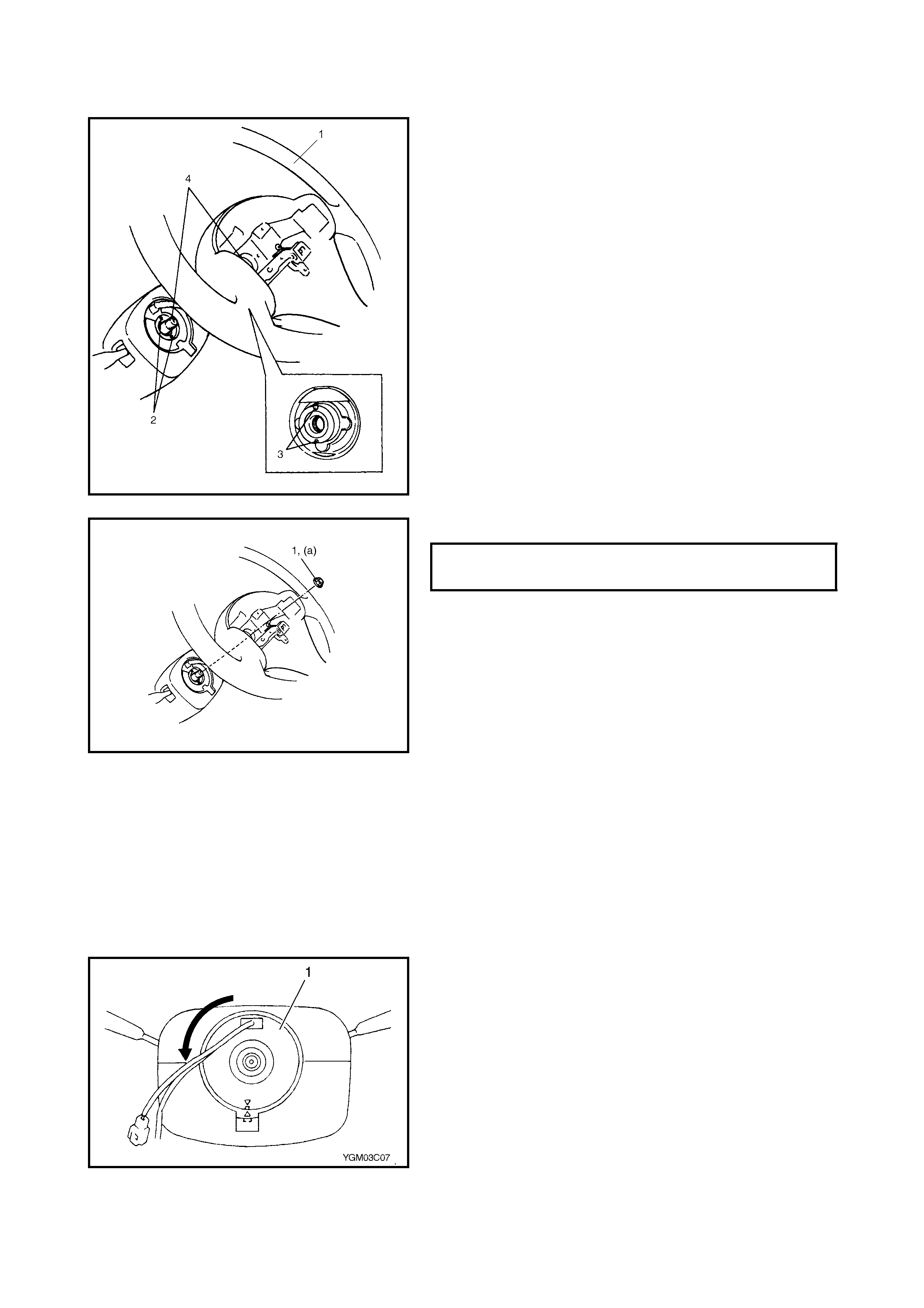

INSTALLATION

1. Check that the vehicle’s front tyres are in the straight-

ahead position and the contact coil is centred. Refer to

3.4 CENTRING CONTACT COIL in this Section.

CAUTION: These two conditions are a prerequisite

for installation of the steering wheel. If the steering

wheel has been installed without these conditions

being met, the contact coil will break when the steer-

ing wheel is turned.

2. Install steering wheel (1) to steering shaft with 2 lugs

(2) on contact the coil fitted in two grooves (3) in the

back of the steering wheel and also aligning marks (4)

on the steering wheel and steering shaft.

3. Tighten steering shaft nut (1) to specified torque.

4. Install driver airbag (inflator) module to steering wheel.

Refer to 3.2 DRIVER AIRBAG (INFLATOR) MODULE

in this Section.

3.4 CENT RING CONTACT COIL

1. Check that vehicle’s wheels (front tyres) are set in the

straight-ahead pos ition.

2. Check that ignition switch is in “LOCK” position.

3. Turn contact coil counterclockwise slowly with a light

force until contact coil will not turn any further.

NOTE: Contact coil can turn a maximum o f about 5 turns,

that is, if it is in the centre position, it can turn about two

and a half tur ns both clockwise and count erclockwise.

STEERING SHAFT NUT (a)

TORQUE SPECIFICATION 33 Nm

4. From the position where the contact coil was unable to

turn any further (it stopped), turn it back clockwise

about two and a half rotations and align centre (1) with

alignment mark.

3.5 CONTACT COIL AND COMBINATION SWITCH ASSEMBLY

CAUTION: Do not turn contact coil (on combination switch) more than the allowable number of

turns (about two and a half turns from the centre position clockwise or counterclockwise respec-

tively), or coil will break.

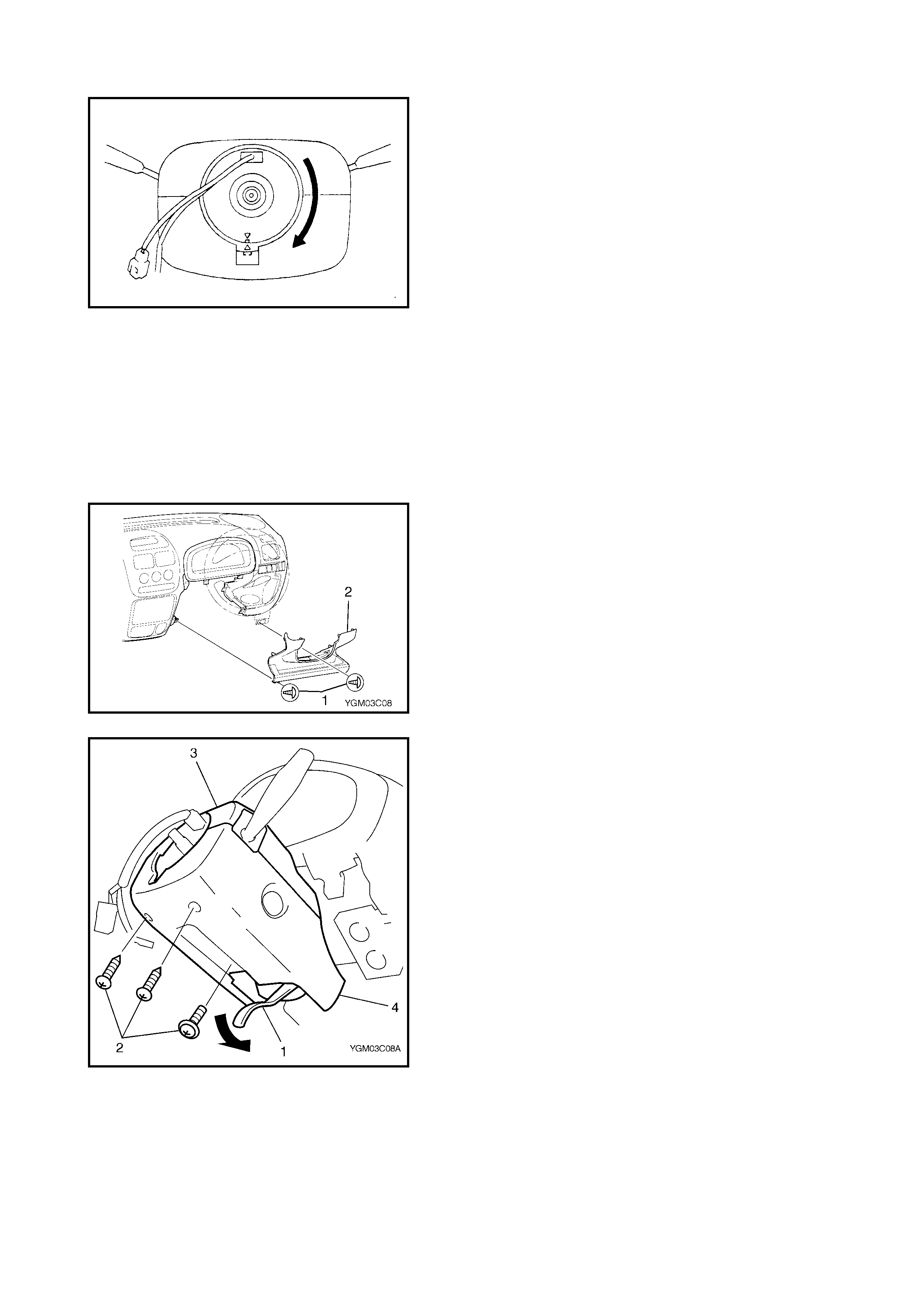

REMOVAL

1. Remove the steering wheel from the steering column,

refer to 3.3 STEERING WHEEL in this Section.

2. Remov e steering column hole cover (1).

3. Pull down tilt lever (1), then remove the steering

column cover screws (2).

4. Separate upper cover (3) and lower cover (4), and

remove them.

5. Remove the contact coil and combination switch

assembly screws (1) and disconnect connectors (2)

from combination switch (3).

6. Disconnect horn connector (1) from instrument panel

harness.

7. Remove c ont act coil a nd combi nation switch ass em bly

from steering column.

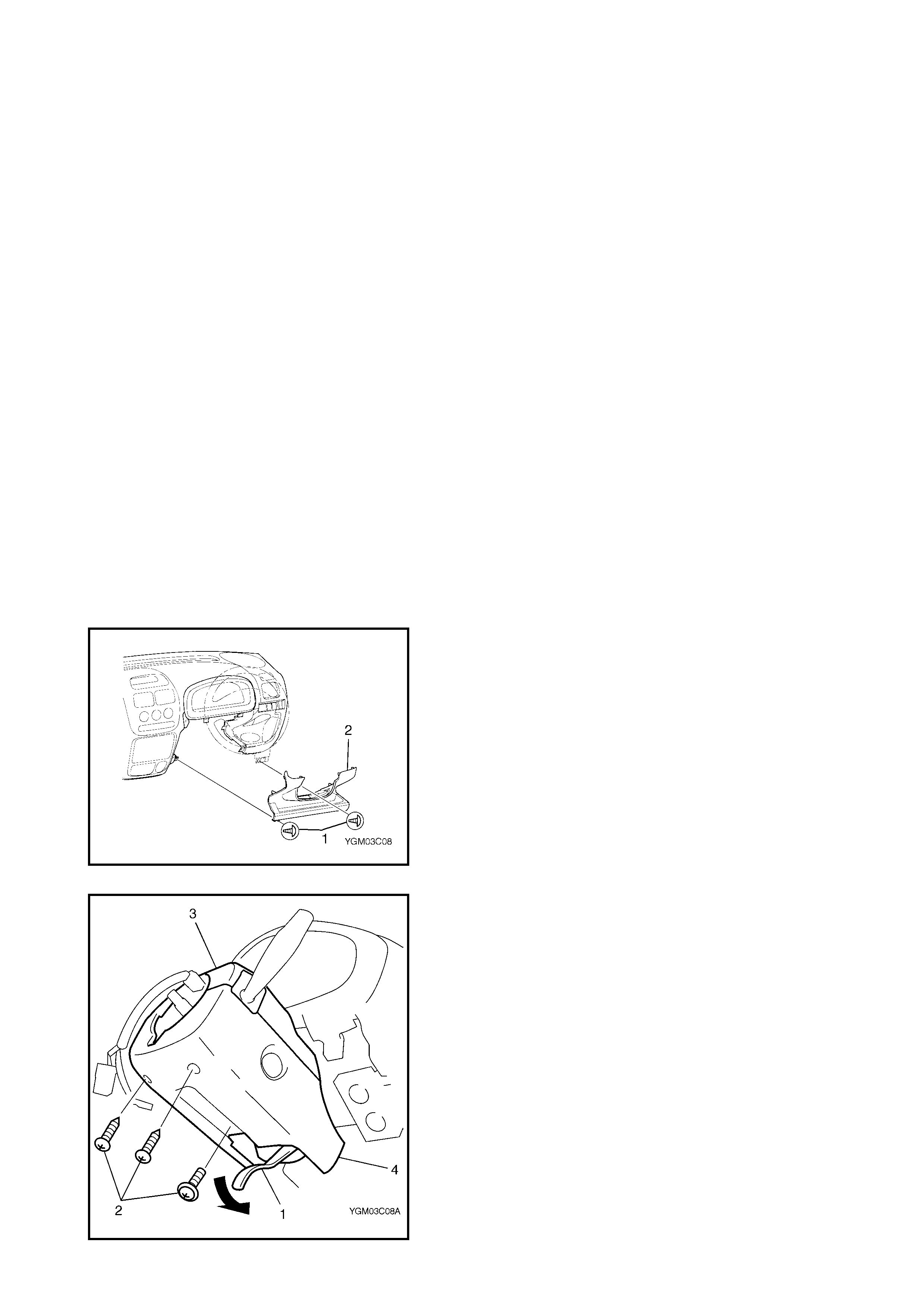

INSPECTION

Check contact coil harness (1) for any signs of scorching,

melting or other damage.

If it is damaged, replace it.

INSTALLATION

1. Check to make sure that the vehicle’s front tyres are

set in the straight-ahead position and the ignition

switch is in th e “LOC K ” pos it io n.

2. Connect all connectors disconnected in REMOVAL.

3. Install contact coil and combination switch assembly

(3) to steering column.

NOTE: New contact coil and combination switch assembly

is supplied with contact coil set and held at its centre posi-

tion with a lock pin (1) and seal (2). Remove this lock pin

after installing contact coil and combination switch assem-

bly to steering column.

4. Install steering column upper cover (2) and lower cover

(3), and then tighten steering column cover screws (1).

CAUTION: When installing lower cover (3) and

upper cover (2), take care that the contact coil and

combination switch lead wire is not caught between

covers.

5. Install steering column hole cover (1).

6. Install steering wheel to steering column. Refer to

3.3 STEERING WHEEL in this Section.

3.6 STEERING COLUMN ASSEMBLY

CAUTION: Once the steering column is removed from the vehicle, the column is extremely suscepti-

ble to damage.

• Dropping the column assembly on its end could collapse the steering shaft or loosen the plastic

shear pins which maintain column length.

• Leaning on the column assembly could cause it to bend or deform.

Any of the above damage could impair the column’s collapsible design.

NOTE: When servicing the steering column or any column-mounted component, remove the steering wheel.

But when removing the steering column simply to gain access to instrument panel components, leave the

steering wheel installed on the steering column. REMOVAL

WARNING: Never rest a steering column assembly on the steering wheel with the airbag (infla-

tor) module face down and column vertical. Otherwise, personal injury may result.

1. Disconnect negative cable at battery.

2. Disable airbag system. Refer to DISABLING AIRBAG SYSTEM in Section 10B, 3.1 SERVICE

PRECAUTIONS.

3. If it is nec essary to remove the steeri ng wheel and c ontac t coil and comb ination switch assembly, refer to

3.3 STEERING WHEEL and 3.5 CONTACT COIL AND COMBINATION SWITCH ASSEMBLY in this

Section.

If it is not necessary to remove the steering wheel and contact coil and combination switch assembly,

perform the following procedure.

a. Turn steer ing wheel so that vehicle’s fron t tyres are at straight-ahead position .

b. Turn ignition switch to “LOCK” position and remove key.

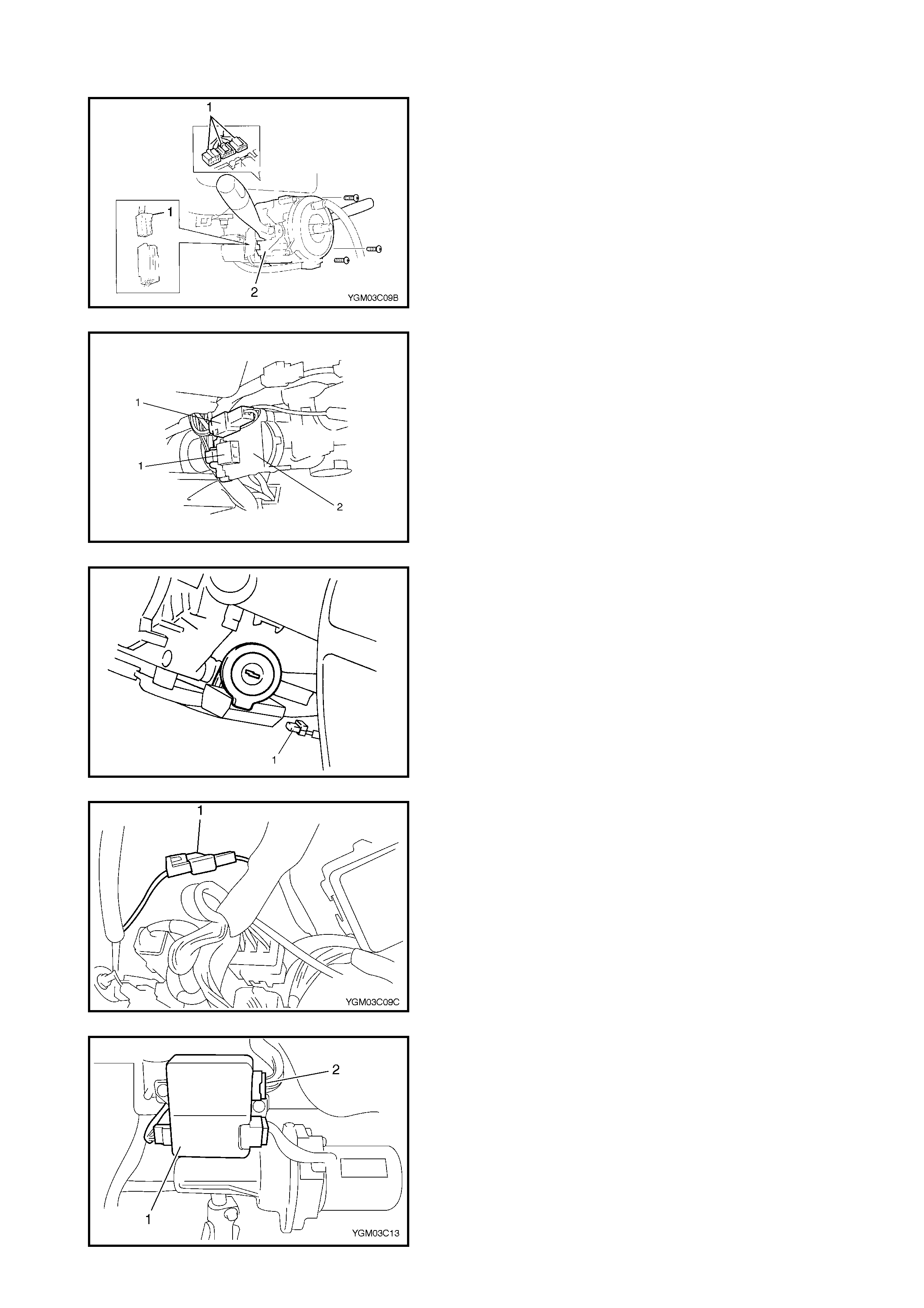

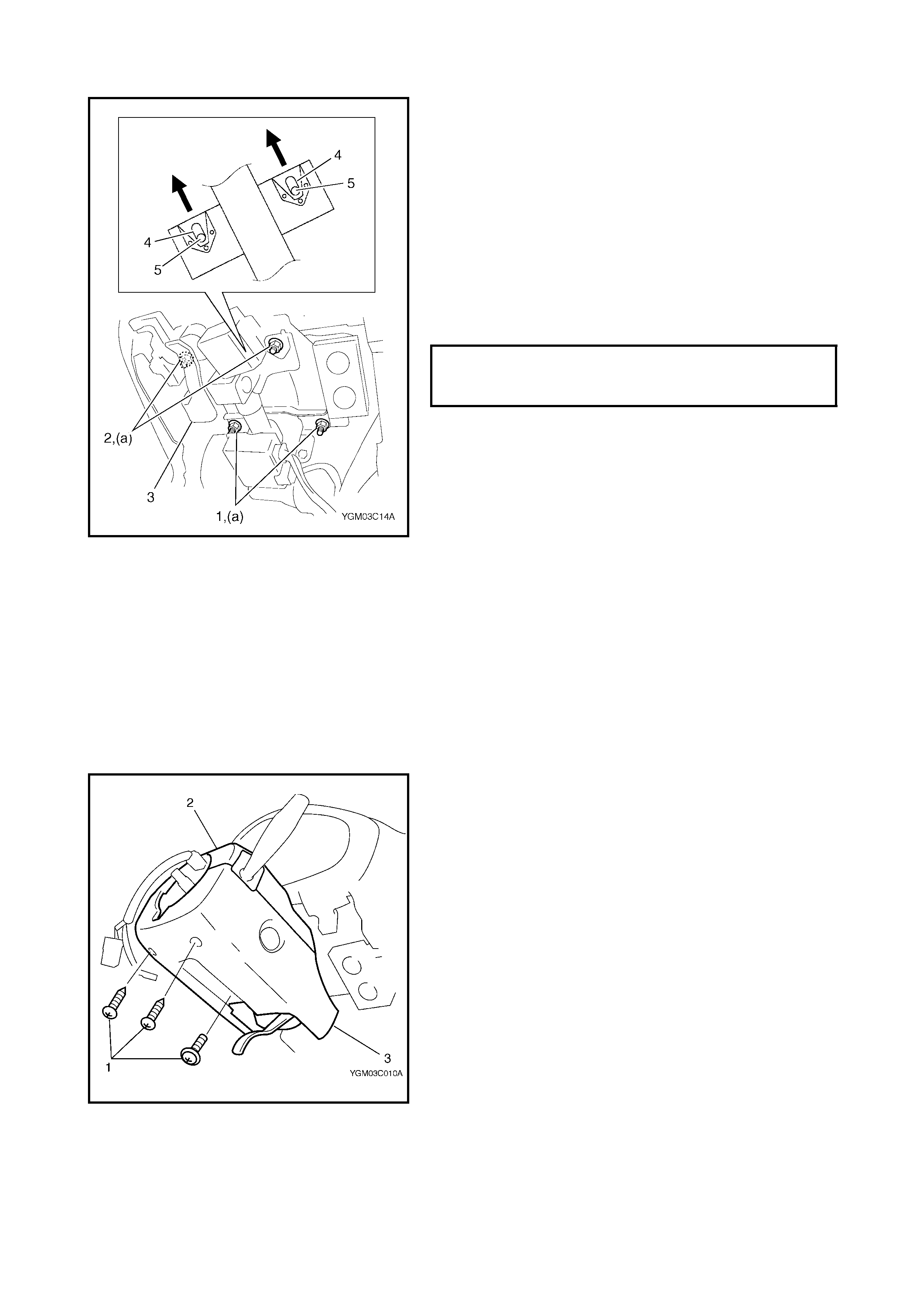

4. Remove steering column hole cover screws (1) and

remove steering col umn hole cover by unclipping in six

places.

5. Pull down lilt lever (1) and then remove steering

column cover screws (2).

6. Separate upper column cover (3) and lower column

cover (4), then remove them .

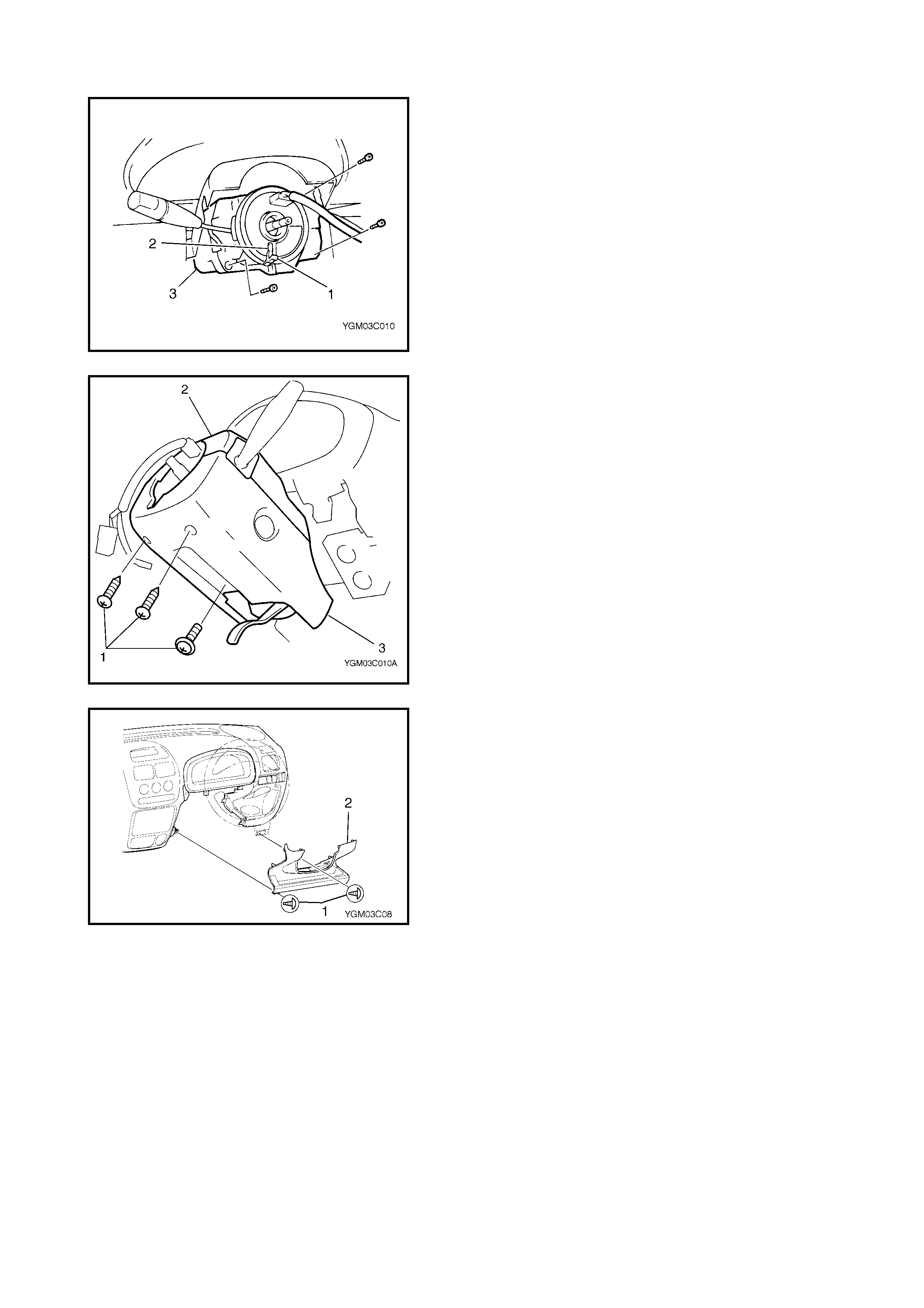

7. Disconnect connectors (1) from combination switch

assembly (2).

8. Disconnect ignition switch connectors (1) from ignition

switch (2).

9 . Dis c on nec t im mob ilis e r c o ntro l mod ule conn ec tor (1)

(if equipped).

10. Disconnect horn connector (1) from instrument panel

harness.

11. If equipped with power steering (P/S) system, discon-

nect connector (2) from P/S control module (1).

12. Remove steering joint cover.

13. Make alignment marks (1) on joint (2) of steering lower

shaft (3) and steering column for a guide during rein-

stallation.

14. Remove joint bolt (steering column side) (4).

15. Pull up tilt lever to lock steering column.

NOTE: Do not release tilt lever lock with steering column

removed from vehicle, otherwise steering column base

position must be adjusted at installion.

16. Remove steering column mounting nuts (A, B).

17. Remove steering column assembly from vehicle.

CAUTION: Do not separate steering column assem-

bly into steering column and shaft. If column or

shaft is defective, replace it as an assembly.

18. If it is necessary to remove the steering lock assembly

(ignition switch), refer to 3.7 STEERING LOCK

ASSEMBLY (IGNITION SWITCH) in this Section.

INSPECTION

NOTE: Vehicles involved in accidents resulting in body damage, where the steering column has been

impacted (or airbag deployed), may have a damaged or misaligned steering column. For the checking proce-

dure of the steering column assembly, refer to 3.9 CHECKING STEERING COLUMN ASSEMBLY AND

LOWER SHAFT FOR ACCIDENT DAMAGE in this Section.

INSTALLATION

CAUTION: Steering column mounting nuts should be tightened first, followed by shaft joint bolts.

The wrong tightening order could cause damage to shaft joint.

1. Be sure that front wheels and steer ing wheel are in the

straight ahead position.

If steering lock assembly (ignition switch) is removed,

install it, refer to 3.7 STEERING LOCK ASSEMBLY

(IGNITION SWITCH) in this Section.

2. Install steering lower shaft joint (1) to steering column

shaft (2) aligning matching marks (3) made before

removal.

3. Install steering column and tighten steering column

lower and upper mounting nuts (1,2) temporarily at this

step.

4. If tilt lever lock is released, adjust steering column base

position as follows:-

a. Be sure to release tilt lever (3).

b. Fit steering column upper bracket slot ends (4) to

steering column hanger upper stud bolts (5).

c. Fix steering column by pulling up tilt lever (3).

5. Tighten steering column lower and upper mounting

nuts (1,2) to specified torque in the order (1)-(2)

indicated in the figure.

6. Connect all connectors disconnected in REMOVAL.

• Ignition switch

• Combination switch

• P/S control module (if equipped)

• Horn

• Immobiliser control module (if equipped)

7. If contact coil and combination switch assembly is

removed, install it.

Refer to 3.5 CONTACT COIL AND COMBINATION

SWITCH ASSEMBLY in this Section.

8. Install upper and lower column covers (2,3) to steering

column assembly with screws (1).

STEERING COLUMN UPPER AND

LO WER MOUNTING NUTS (a)

TORQUE SPECIFICATIONS 25 Nm

9. Tighten joint bolt (1) (steering column side) to specified

torque.

10. Install steering joint cover.

11. Install steering column hole cover (1).

12. If steering wheel is removed, install steering wheel.

Refer to 3.3 STEERING WHEEL in this Section.

13. Enable airbag system. Refer to ENABLING AIRBAG

SYSTEM in Section 10B, 3.1 SERVICE

PRECAUTIONS.

14. Connect negative battery cable.

3.7 STEERING LOCK ASSEMBLY (IGNITION SWITCH)

REMOVAL

1. Remove steering column. Refer to 3.6 STEERING

COLUMN ASSEMBLY in this Section.

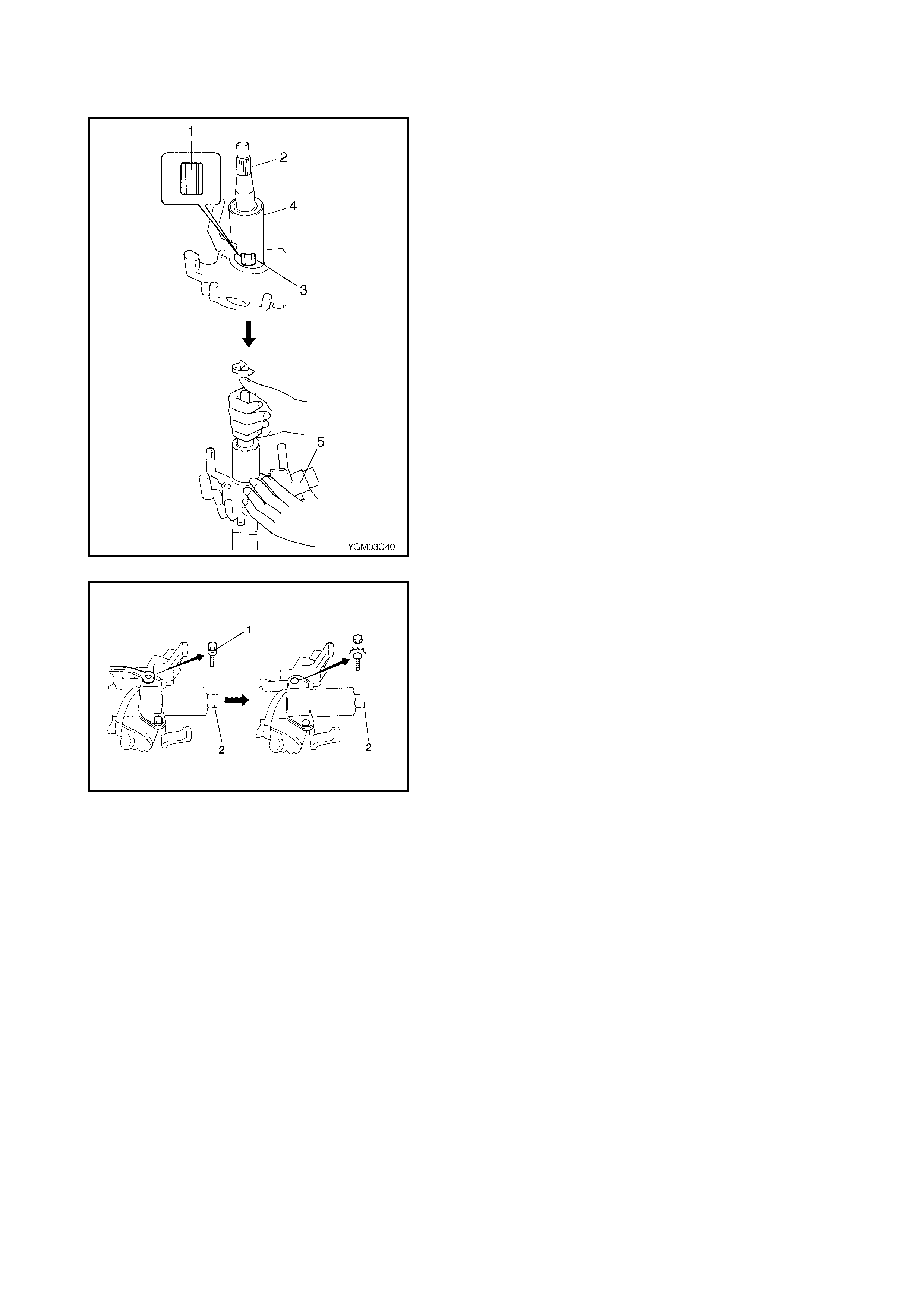

2. Using centre punch (1), loosen and remove steering

lock mounting bolts (2).

NOTE: Use ca re not to da mage a luminum p ar t of stee r-

ing lock body with centre punch.

3. Turn ignition key to “ACC” or “ON” position and remove

steeri ng lock assem bly fro m steering column.

STEERING SHAFT JOINT BOLT

(STEERING COLUMN SIDE) (a)

TORQUE SPECIFICATION 25 Nm

INSTALLATION

1. Position oblong hole (1) of steering shaft (2) in the

centre of hole (3) in column (4).

2. Turn ignition key to “ACC” or “ON” position and install

steering lock assembly (5) onto column (4).

3. Now turn ignition key to “LOCK” position and pull it out.

4. Align hub on lock with oblong hole (1) of steering shaft

(2) and rotate shaft to assure that steering shaft (2) is

locked.

5. Tighten new bolts (1) until the head of each bolt has

broken off.

6. Turn ignition key to “ACC” or “ON” position and ensure

that steering shaft (2) rotates smoothly. Also check the

lock operation.

7. Install steering column. Refer to 3.6 STEERING

COLUMN ASSEMBLY in this Section.

3.8 STEERING LOWER SHAFT

CAUTION: Never turn steering wheel while steering lower shaft is removed.

If it has been turned and contac t coil (on com bination switch) has moved from its centred position, it

will need to be recentred. Also, turning steering wheel more than about two and a half turns will break

contact coil .

REMOVAL

1. Turn steering wheel so that vehicle’s front tyres are at

the straight-ahead position .

2. Turn ignition switc h to “LOCK” position and remove key.

3. Remov e steering joint cover (5).

4. Make alignment marks (4) on lower shaft (1) and

steering column shaft (2) and l ower shaft (1) and pinion

shaft (3) for a guide duri ng reinstallation.

5 . R e mo ve low e r sh a ft jo in t b o lts (6).

6. Remov e steering lower shaft (1).

INSTALLATION

1. Be sure that front wheels and steer ing wheel are in the

straight ahead position.

2. Insert lower shaft (1) into steering column shaft and

align mark s made dur ing rem oval (4).

3. Insert lower shaft (1) into pinion shaft (3) and align

marks made during removal (4).

4. Tighten joint bolt (pinion shaft side) (6) to specified

torque first and then joint bolt (steering column side)

(5) to specified torque.

5. Install steer ing joint cover.

3.9 CHECKING STEERING COLUMN ASSEMBLY AND

LOWER SHAFT FOR ACCIDENT DAMAGE

NOTE: Vehicles involved in accidents resulting in body damage, where steering column has been

impacted (or airbag deployed) may have a damaged or misaligned steering column.

CHECKING PROCEDURE

1. Check that each caps ule (1) is attached to the st eeri ng

column bracket (2) securely.

If capsules are loose, replace steering column

assembly.

2. Check the two capsules for damage for signs of

cracking or breakage.

If any faults are found, replace the whole steering

column assembly.

STEERING SHAFT JOUNT BOLT (a)

TORQUE SPECIFICATION 25 Nm

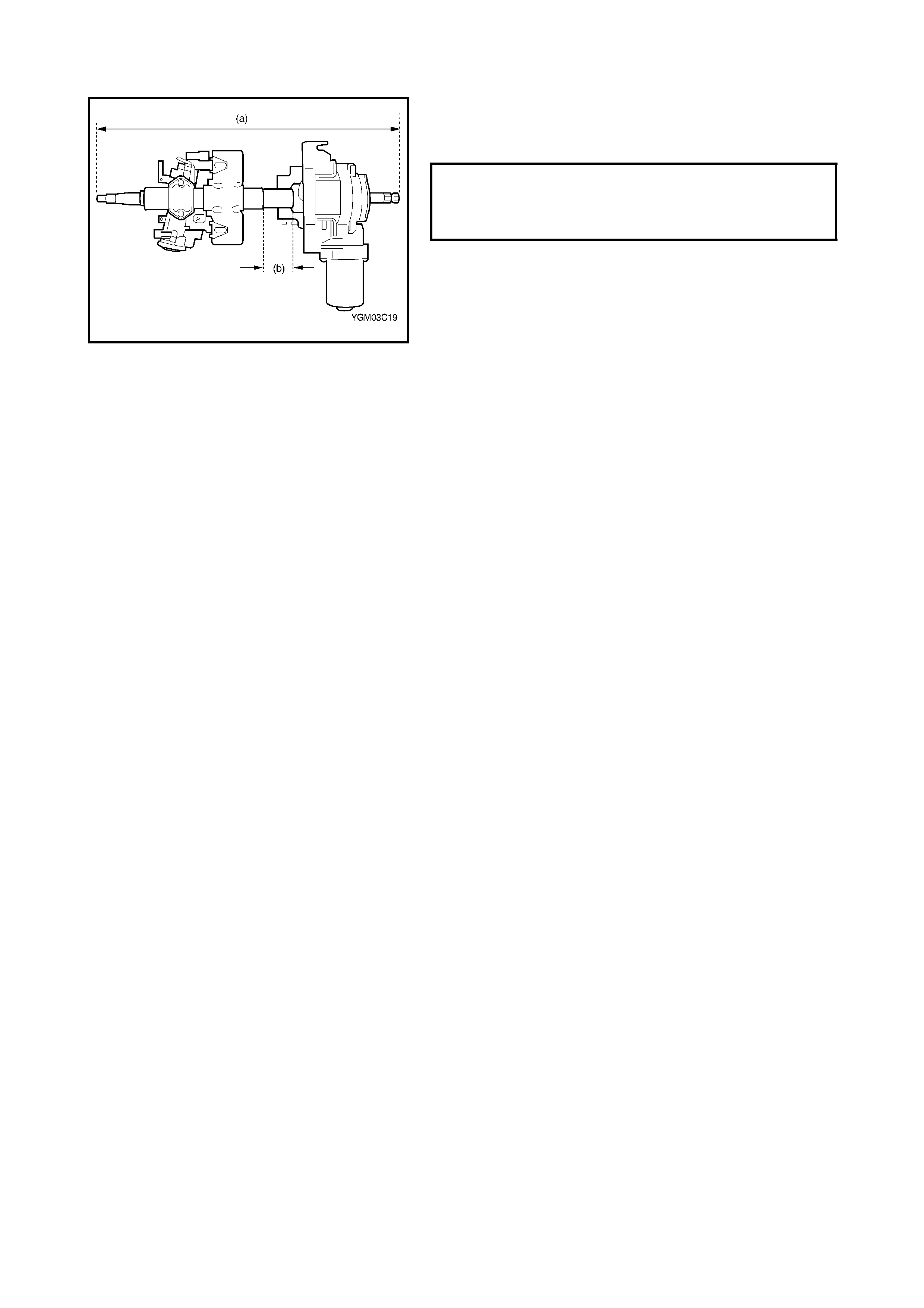

3. Take m eas urem ents (a) and (b) as shown.

If either is shorter than the specified length, replace the

column assem bly with a new one.

4. Check steering lower shaft joints and steerin g shaft for

any damage such as cracks, breakage, malfunction or

e xce ssiv e p lay.

If anything is found to be faulty, replace the whole

steeri ng colum n assembly.

5. Check the steering shaft for smooth rotation .

If found to be defective, replace the whole steering

column assembly.

6. Check the steering shaft and col umn to ensure it is not

bent, cracked or def ormed.

If found to be defec tive, replace.

STEERING SHAFT AND COLUMN

LENGTH (a)

(b) 49 1 - 494 mm

49 - 50 mm