SECTION 3E - REAR SUSPENSION

1. GENERAL DESCRIPTION

2. DIAGNOSIS

2.1 REAR SHOCK ABSORBER CHECK

2.2 TRAILING ARM, LATERAL ROD,

REAR AXLE, PEAR AXLE HOUSING

AND COIL SPRING CHECK

2.3 BUMP STOPPER/SPRING

UPPER SEAT CHECK

2.4 REAR SUSPENSION FASTENERS

2.5 WHEEL DISC, NUT AND

BEARING CHECK

3. O N- VEH IC L E SER VICE

3.1 LATERAL ROD

Removal

Installation

3.2 REAR SHOCK ABSORBER

Removal

Installation

3.3 COIL SPRING

Removal

Installation

3.4 BUMP STOPPER

Removal

Installation

3.5 SPRING UPPER SEAT

Removal

Installation

3.6 TRAILING ARM

Removal

Installation

3.7 REAR AXLE SHAFT AND

WHEEL BEARING

Removal

Installation

3.8 REAR AXLE SHAFT OIL SEAL

Removal

Installation

3.9 REAR AXLE HOUSING

Removal

Installation

4. REQUIRED SERVICE MATERIAL

5. SPECIAL TOOLS

NOTE:

• All suspension fasteners are important attaching parts that could affect the performance of

vital parts and system s. They must be replaced with items with the same part number or with

an equivalent part if replacement becomes necessary. Do not use a replacement part of

lesser quality or substitute design. Torque values must be used as specified during reassem-

bly to assure proper retention of the part.

• Never at temp t to heat, q uench o r straigh ten any re ar suspen sion pa rt. Rep lace it with a new

part, or damage may result.

Techline

1. GENERAL DESCRIPTION

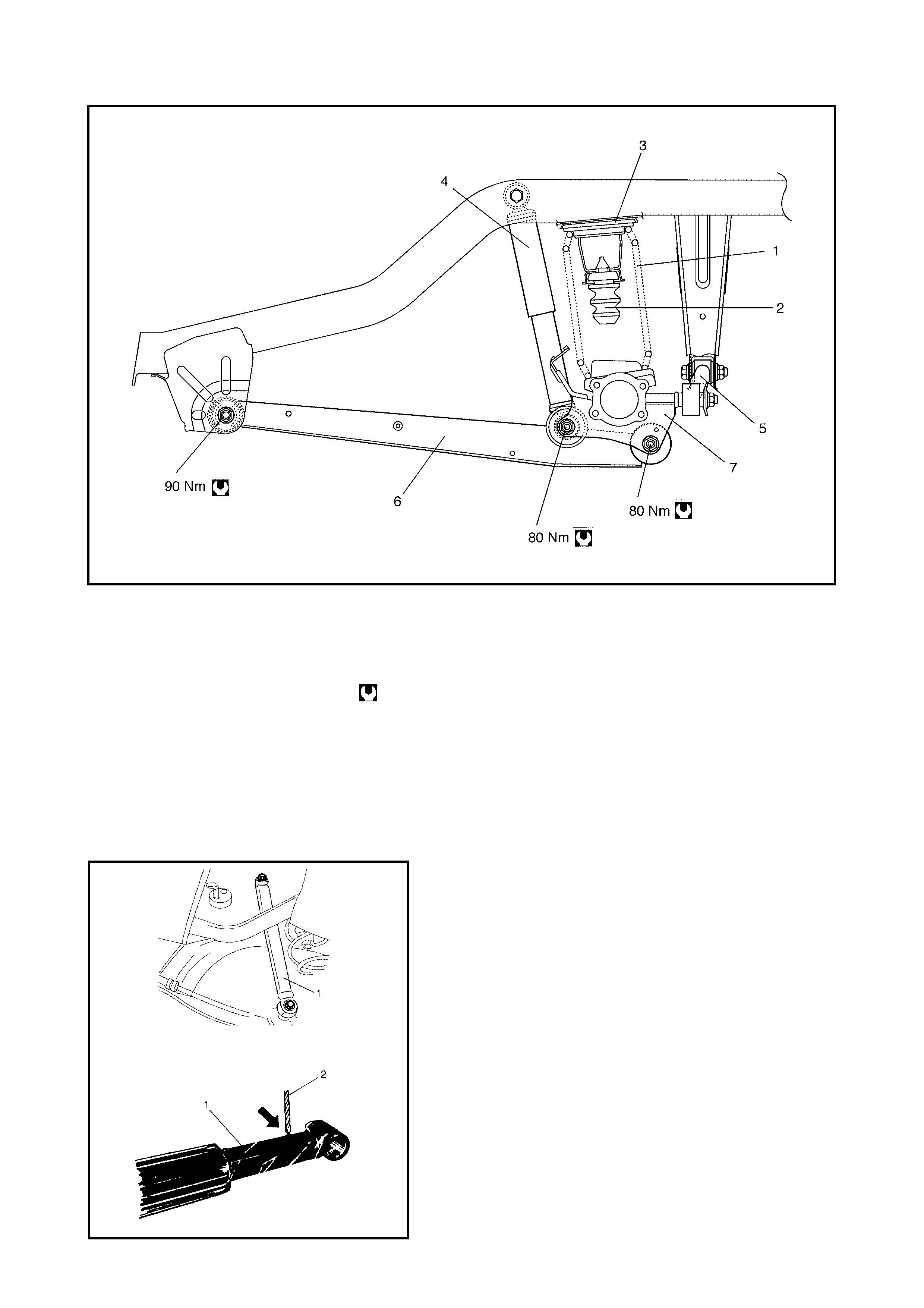

Legend

1. Rear coil spring 8. Wheel Bear ing 14. Wheel bea ring retainer ring

or rear wheel sensor ring

(if equipped with ABS)

2. Rear bump stopp er 9. Brake drum

3. Rear spring upper seat 10. Rear axle shaft

4. Rear shock absorber 11. Breather cap 15. ABS vehicles

5. L a te ral rod 12. Oil seal p ro te c tor 16. Non ABS v e hic les

6. Trailing arm 13. Oil seal Tightening torque

7. Rear axle housing

Legend

2. DIAGNOSIS

2.1 REAR SHOCK ABSORBER CHECK

• Inspect for deformation or damage.

• Inspect bushings for wear or damage.

• Inspect for evidence of oil leakage.

Replace any defective par t.

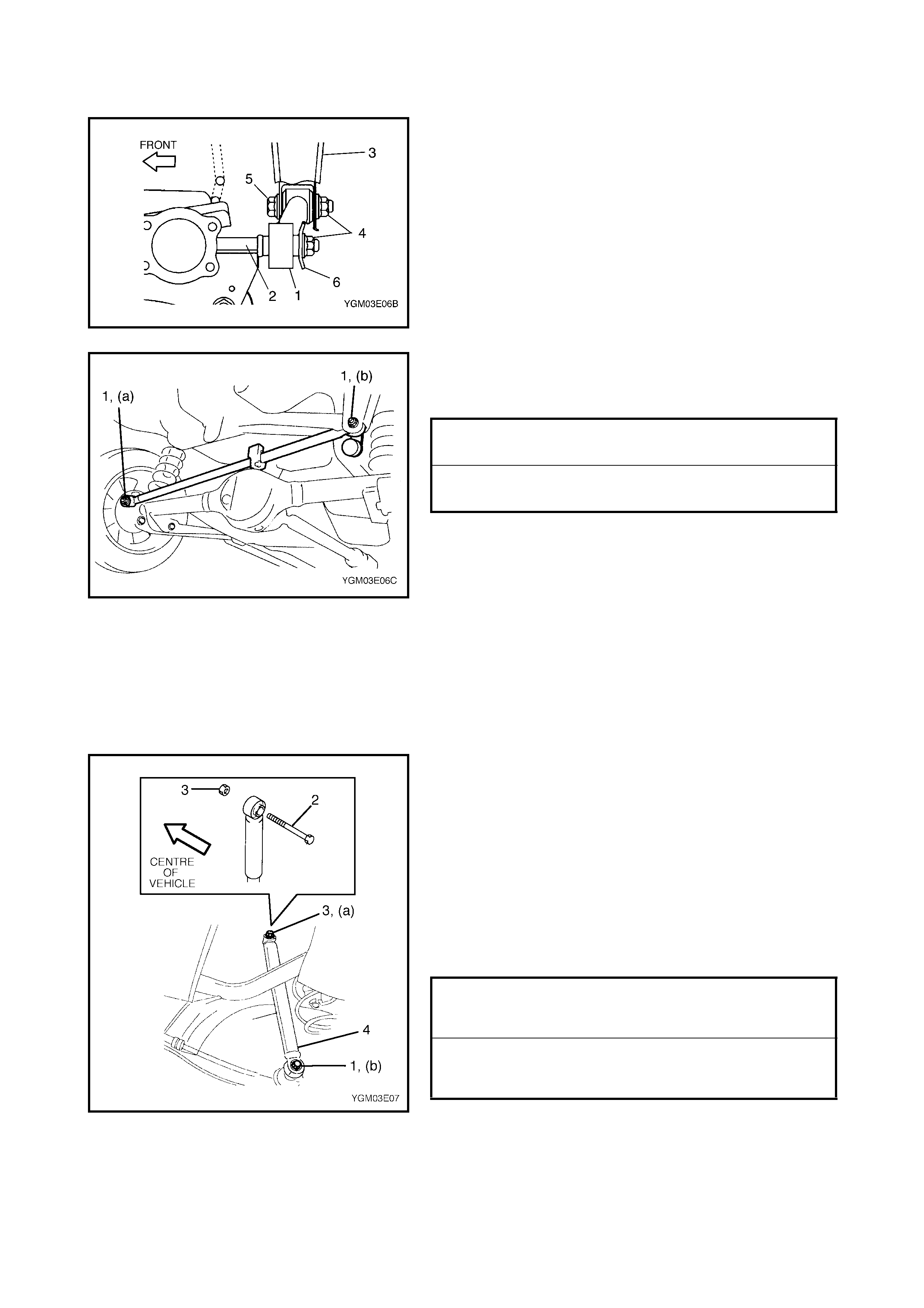

WARNING: When handling rear shock absorber (1) in

which high-pressure gas is sealed, make sure to

observe the following precautions.

• Do not disassemble it.

• Do not place in fire.

• Do not s tore un de r hot c on di t io ns .

• Before disposal, drill a hole (approximately 3 mm

diameter) (2) where shown by the arrow in the fig-

ure to allow gas and oil to escape .

When drilling (2) wear safety goggles. Alt hough the

gas in the shock absorber is harmless it may

escape rapidly along with metal filings creating a

safety risk.

1. Rear coil spring 5. Lat eral rod

2. Rear bump stopper 6. Tr ailing ar m

3. Rear spring upper seat 7. Rear ax le housing

4. Rear shock absorbe r Tightening torque

2.2 TRAILING ARM, LATERAL ROD, REAR AXLE, REAR AXLE HOUSING AND COIL

SPRING CHECK

• Inspect for cracks, deformation or damage.

• Inspect bushing for damage, wear or breakage.

Replace any defective part.

2.3 BUMP STOPPER/SPRING UPPER SEAT CHECK

• Inspect for cracks, deformation or damage.

Replace any defective part.

2.4 REAR SUSPENSION FASTENERS

Check to ensure that all nuts and bolts are tight. Tighten

any loose nuts and bolts to specified torque, refer to

1. GENERAL DESCRIPTION in this Section.

2.5 WHEEL, NUT AND BEARING CHECK

• Inspect each wheel for den ts, distor t ion and cracks.

A badly damaged wheel must be replaced.

• Check wheel nuts are tight and where necessary,

retighten to specification.

• Check wheel bearings for wear. Apply a dial gauge to

the centre of the axle shaft to measure thrust play.

• When measurement exceeds limit, replace bearing.

• Rotate the wheel by hand to check the wheel bearing

fo r noise and smooth rotation. If it is defective, replace

the bear ing.

3 . ON-VEHICLE SERVICE

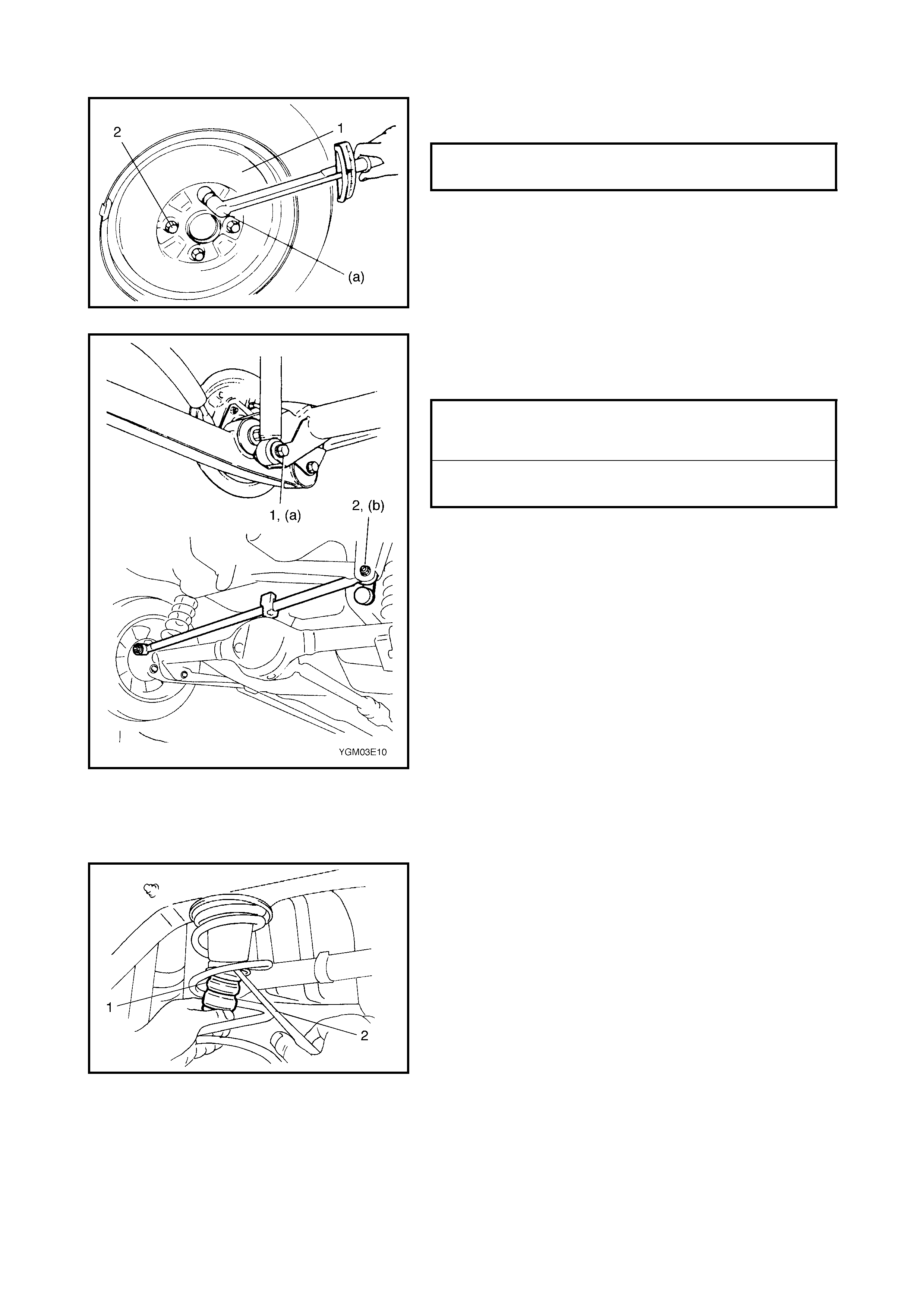

3.1 LATERAL ROD

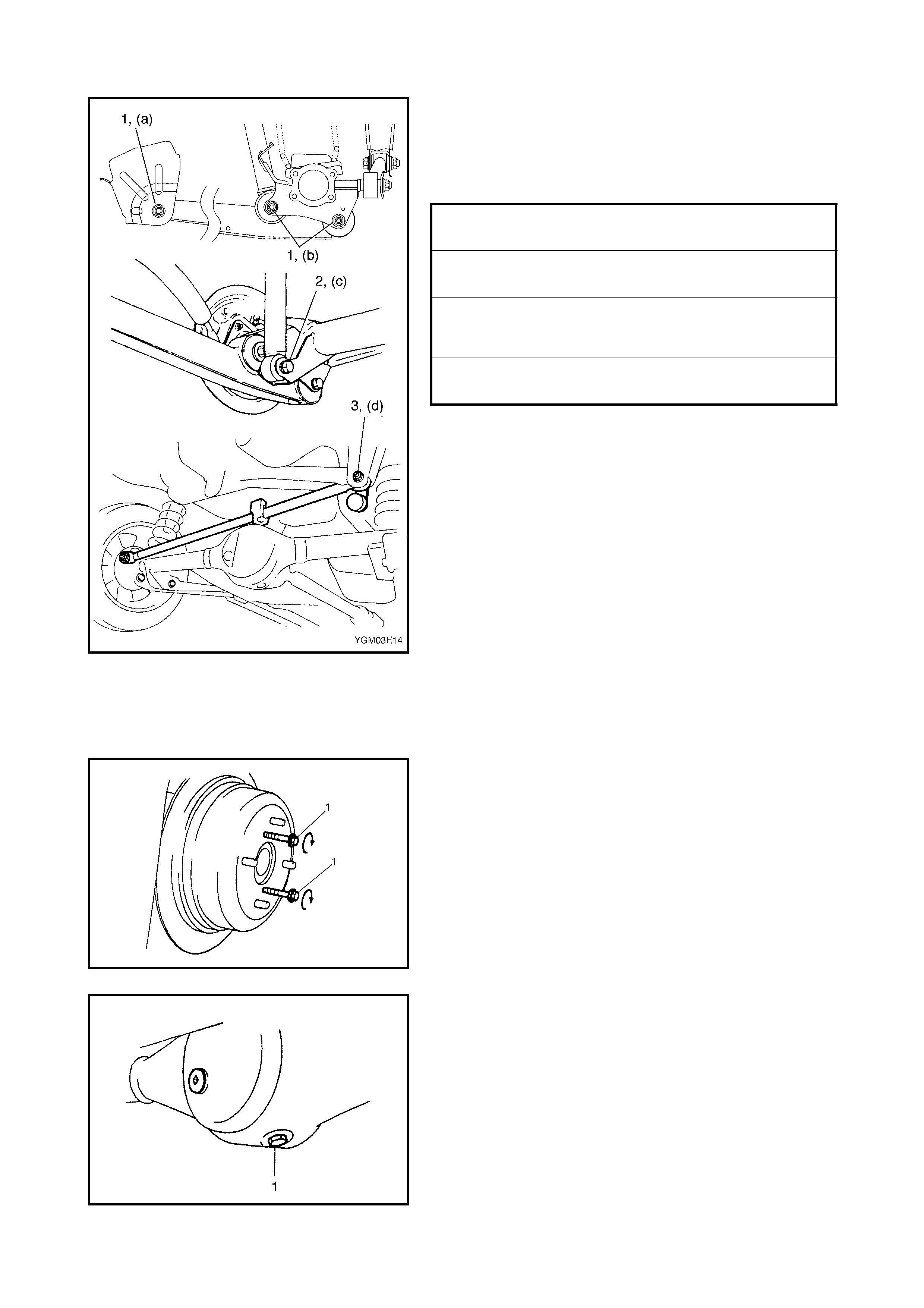

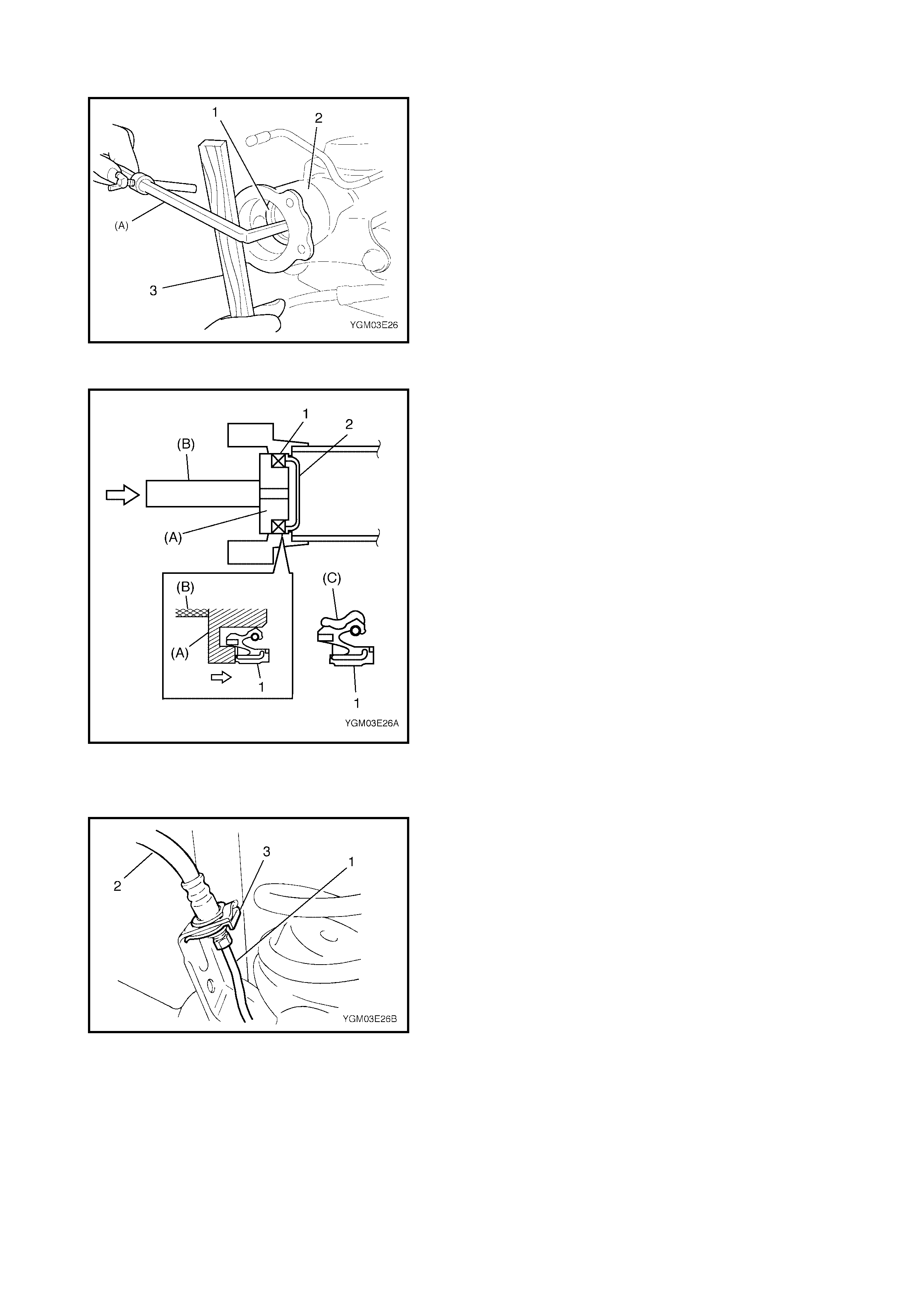

REMOVAL

1. Hoist vehicle.

2. Remove lateral rod nuts (1) and bolt (2).

3. Remov e lateral rod (3).

WHEEL NUTS (a)

TORQUE SPECIFICATION 85 Nm

THRUST PLAY LIMIT (a) 0.1 mm

INSTALLATION

1. Install lateral rod (1) to rear axle housing (2) and

vehicle body (3) referring to the figure for correct instal-

lation direction of nuts (4), bolt (5) and washer (6).

Tighten nuts temporarily by hand at this step.

2. Lower hoist.

3. Tighten lateral rod nuts (1) to specified torque. It is rec-

ommended to have the vehicle off the hoist and in a

no-load condition when tightening the lateral rod nuts.

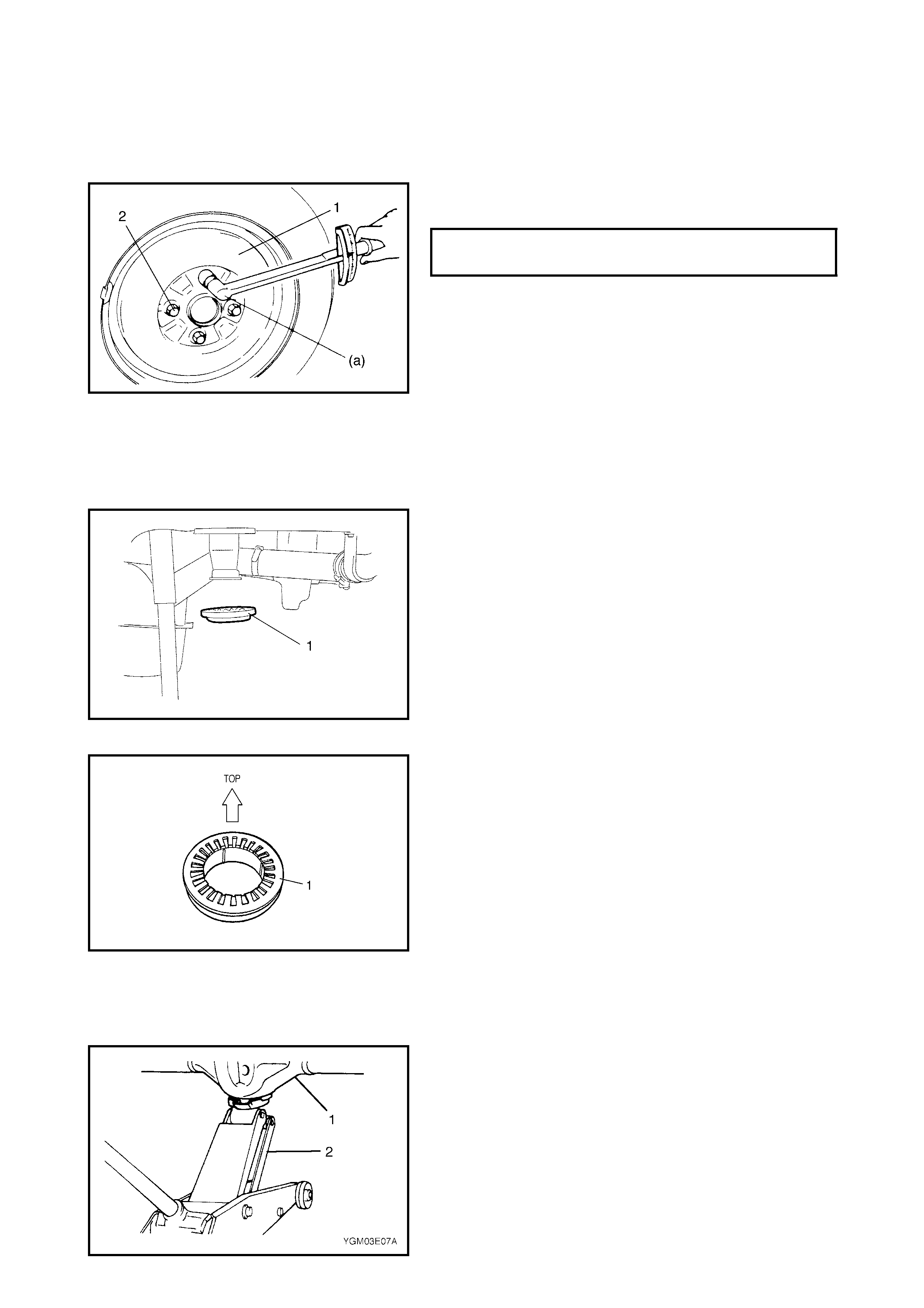

3.2 REAR SHOCK ABSORBER

REMOVAL

1. Hoist vehicle.

2. Support the rear axle housing using a floor jack to

prevent it from dropping when shock absorber is

removed.

3. Remove lower bolt (1).

4. Remove upper bolt (2) and nut (3). Remove shock

absorber (4).

INSTALLATION

1. Install the shock absorber (4) referring to the figure.

Tighten bolt and nut temporarily by hand at this step .

2. Remove the floor jack from the rear axle housing (1)

and lower hoist.

3. With the vehicle in a no-load condition tighten bo lt and

nut to specified torque.

LATERAL ROD LEFT SIDE NUT (a)

TORQUE SPECIFICATION 50 Nm

LATERAL ROD RIGHT NUT (b )

TORQUE SPECIFICATION 65 Nm

REAR SHOCK ABSORBER UPPER

NUT (a)

TORQUE SPECIFICATION 85 Nm

REAR SHOCK ABSORBER LOWER

NUT (b)

TORQUE SPECIFICATION 85 Nm

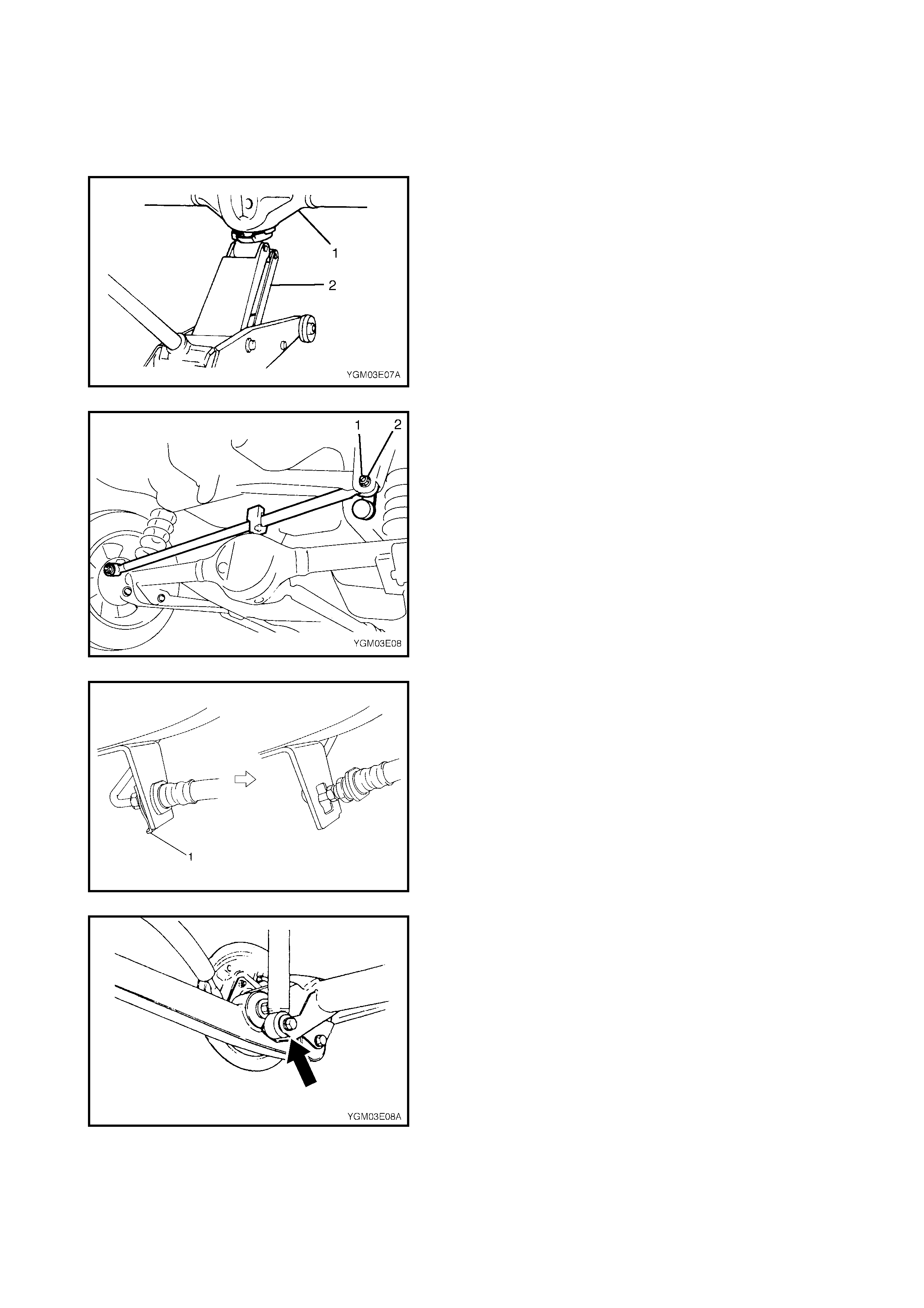

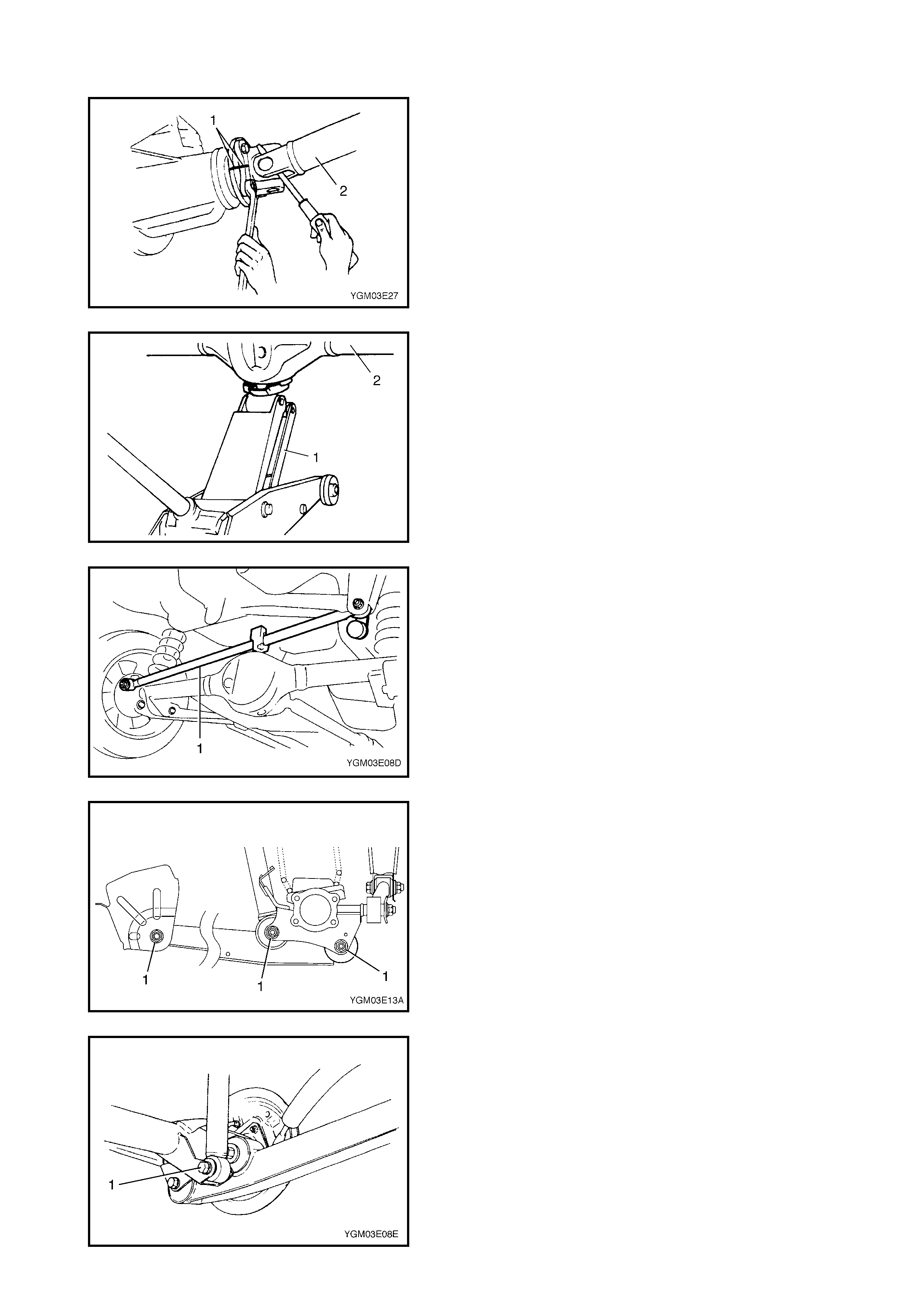

3.3 COIL SPRING

REMOVAL

1. Hoist vehicle and remove the rear wheel (s).

2. Support the rear axle ho using using a floor jack (2) to

prevent it from dropping when spring is removed.

3. Remove the lateral rod r igh t side bolt (1) and nut (2).

4. Detach lateral rod from the vehicle body.

5. Remove the brake flexible hose E-ring (1).

6. Remove the Lo ad S ensing Pr oportioning Valve (LSPV)

adjusting nut and detach the spring end from the axle

housing (if equipped with LSPV - non ABS vehicles).

7. Detach the shock absorber lower end from the rear

axle housing.

8. Lower the rear axle housing gradually, to the point

wher e t he coil spri ng (2 ) ca n be removed.

CAUTION: Be careful not to let the rear axle housing

down too far as it may damage the flexible brake hose.

9. R e mo ve th e coil spr ing .

INSTALLATION

1. Install the coi l spring (1) o n the lower spri ng seat (2) of

the rear axle housing and mate the spring open end

with the stepped part (3) of the spring lower seat and

raise the rear axle housing.

NOTE: The upper and lower diameters of the coil spring

are different. Ensure the larger diameter (b) faces down

and the sma ller diameter (a) faces up.

2. Install the shock absorber (1) lo wer end to t he rear axle

housing.

Tighten the shock absorber lower bolt (2) temporarily

by hand at this step.

3. Install the right side o f the lateral rod (1) to the vehicle

body, refer to the figure for correct installation direction

of bolt (2).

Tighten nut (3) temporarily by hand at this step.

4. Remove the floor jack from the rear axle housing.

5. Install the brake f lexible hose E-ring.

6. Install the load sensing proportioning valve (LSPV)

spr ing to th e axle housing. Tight en LSPV ad justing nut

temporar ily at this step (if equipped with LSPV).

7. Install the wheel (1) and tighten wheel nuts (2) to

specified torque.

8. Lower the hoist and with the vehicle in a no-load condi-

tion, tighten the shock absorber lower bolt (1) and the

lateral rod right side nut (2) to specified torque.

9. If equipped with LSPV, check and adjust LSPV spring,

refer to Section 5, 3.8 LSPV ASSEMBLY (IF

EQUIPPED) INSPECTION AND ADJUSTMENT and

perform a fluid pressure test, refer to Section 5, 2.12

FLUID PRESSURE TEST (IF EQUIPPED WITH

LSPV).

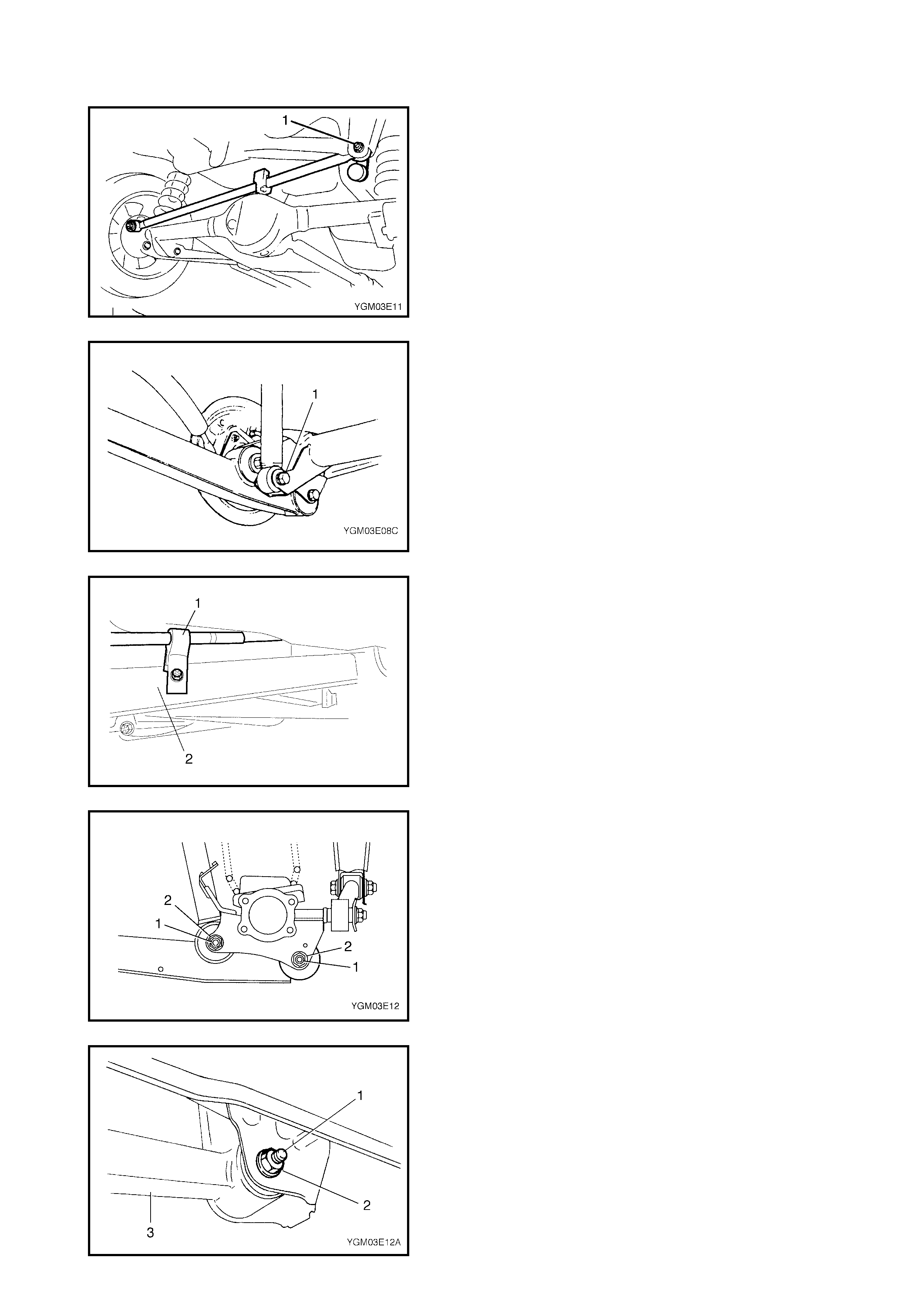

3.4 BUMP STOPPER

REMOVAL

1. Hoist vehicle and remove rear wheel.

2. Remove the bump stopper (1) using flat tip rod (2) or

similar.

WHEEL NUTS (a)

TORQUE SPECIFICATION 85 Nm

REAR SHOCK ABSORBER LOWER

BOLT (a)

TORQUE SPECIFICATION 85 Nm

LATERAL ROD RIGHT SIDE NUT (b)

TORQUE SPECIFICATION 65 Nm

INSTALLATION

1. Install bumper stopper.

NOTE: Before installing bushing apply soapy water to its

outside surface to ease installation.

2. Install wheel (1) and tighten wheel nuts (2) to specified

torque.

3.5 SPRING UPPER SEAT

REMOVAL

1. Remove the coil spring. Refer to 3.3 COIL SPRING in

this Section.

2. Remove the spring upper seat (1).

INSTALLATION

1. Install the spring upper seat (1).

NOTE: For correct installation direction of spring upper

seat (1), refer to the figure.

2. Install the coil spring. Refer to 3.3 COIL SPRING in this

Section.

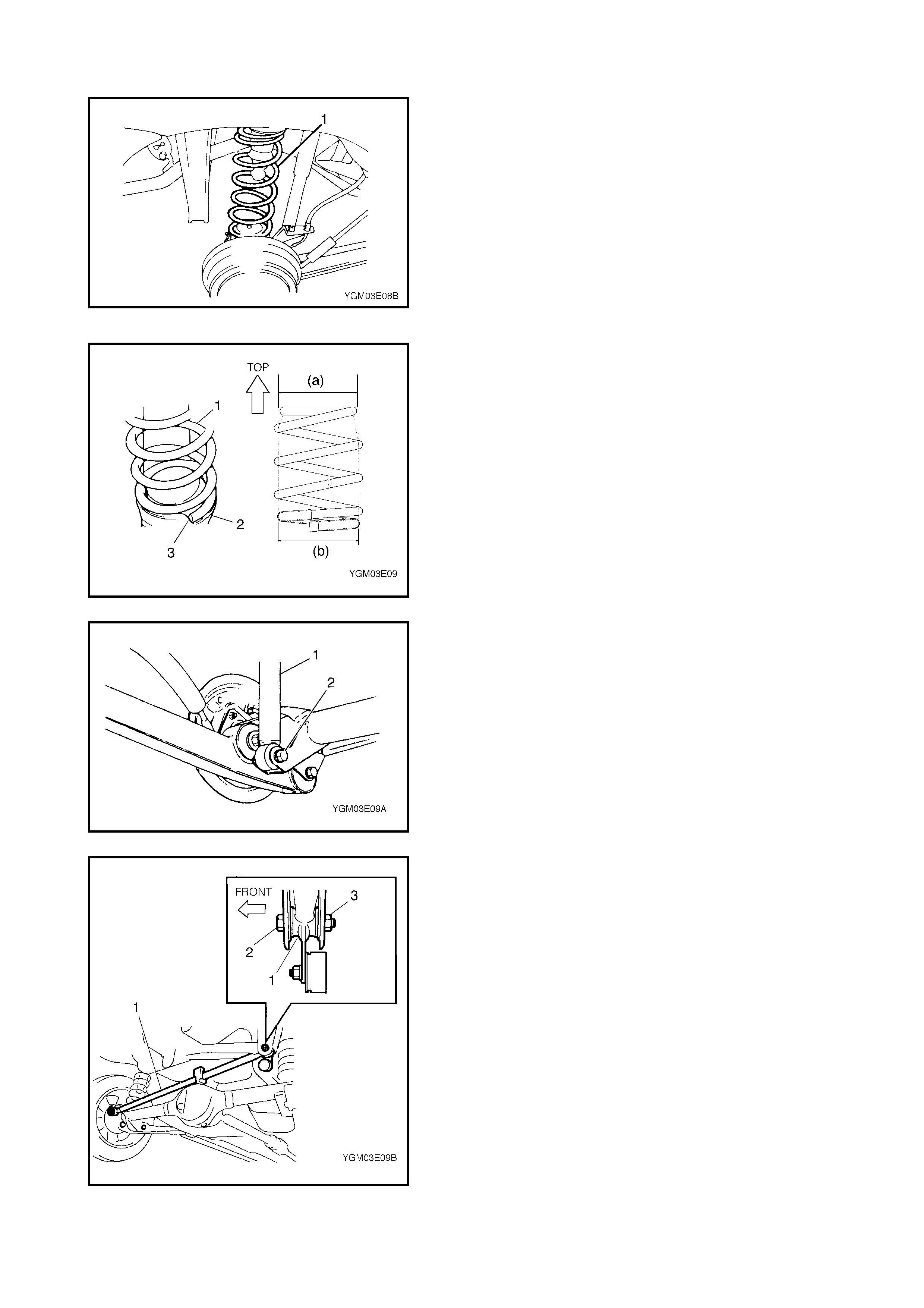

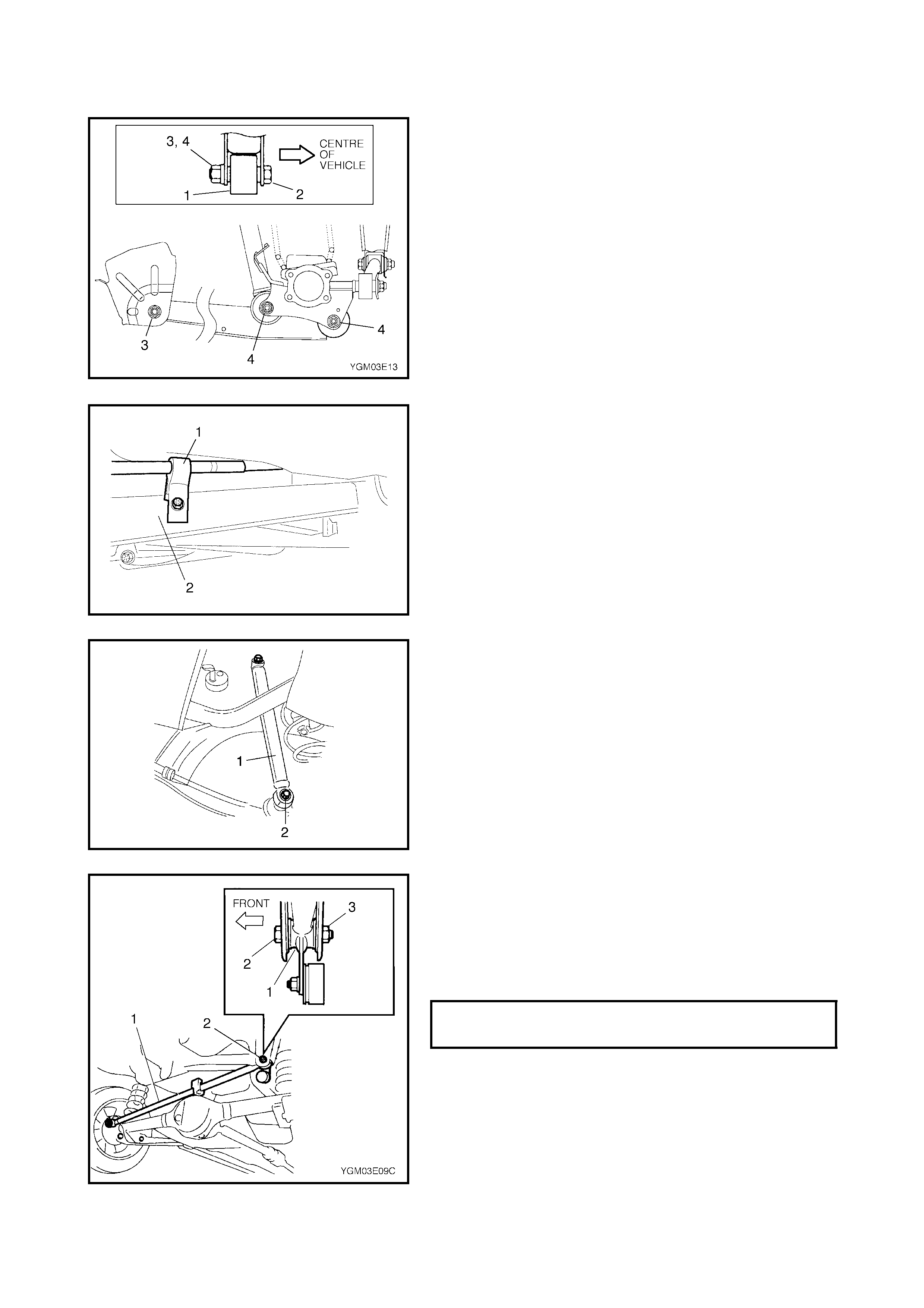

3.6 TRAILING ARM

REMOVAL

1. Hoist vehicle and remove the rear wheel.

2. Support the rear axle housing (1) using a floor jac k (2).

CAUTION: Never apply the floor jack against the lat-

eral rod as it may be deformed.

WHEEL NUTS (a)

TORQUE SPECIFICATION 85 Nm

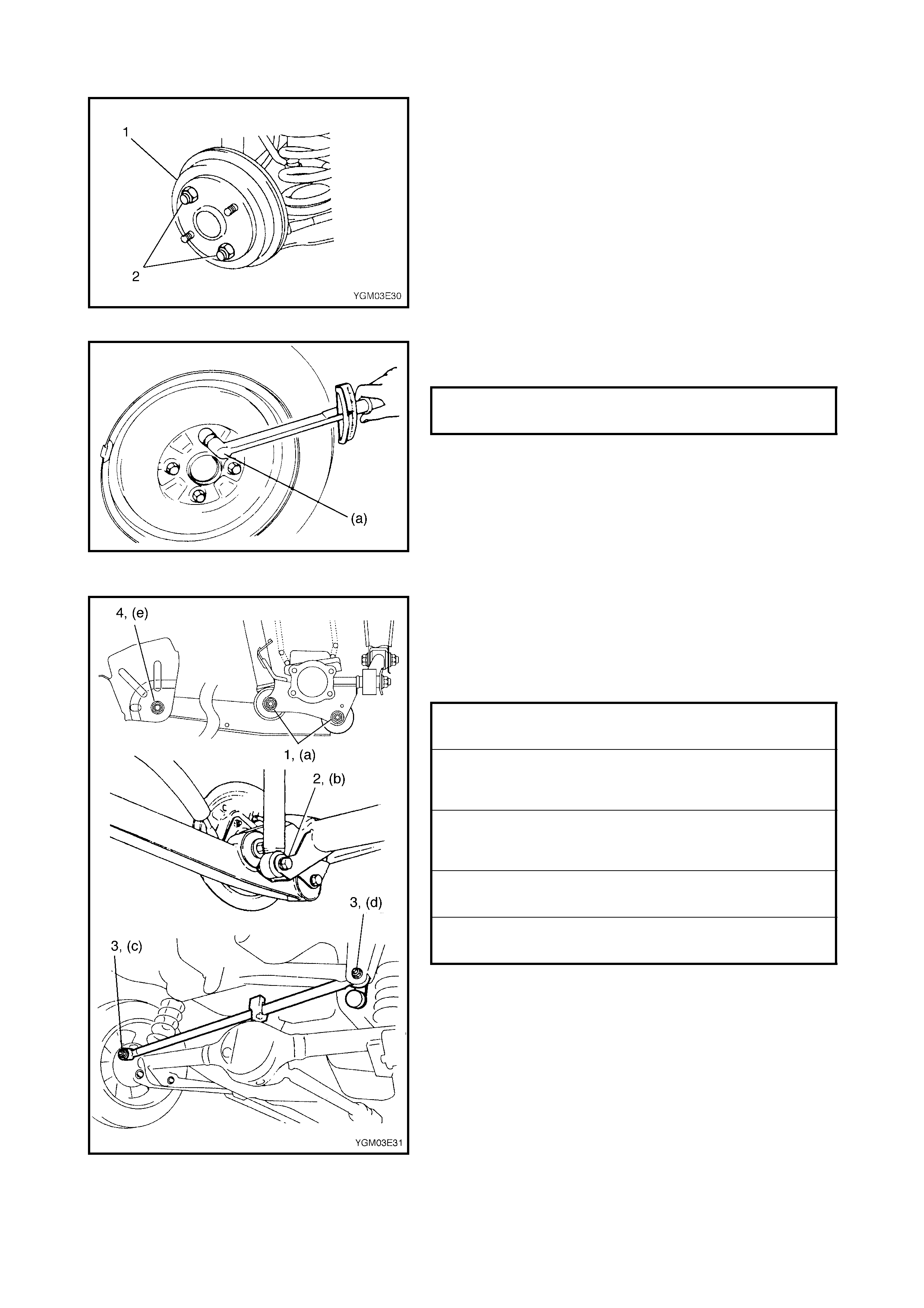

3. Remove the lateral rod right side bolt and nut (1).

4. Remove the right and left side shock absorber lower

bolts (1).

5. Remove the parking brake cable clamp (1) from the

trailing arm (2).

6. Release the wheel speed sensor lead wire clamps

from t he trailin g arm ( if equipped wit h ABS).

7. Remov e the trailing arm rear bolts (1) and nuts (2).

8. Remov e the trailing arm front bolt (1) and nuts (2), then

remove the trailing arm (3).

INSTALLATION

1. Install the trailing arm (1) to the vehicle body and the

rear axle housing, referring to the figure for correct

installation direction of bolts (2).

Tighten the front nut (3) and rear nuts (4) temporarily

by hand at this step.

2. Install the par king brake cable clamp (1) to the trailing

arm (2).

3. Clamp the wheel speed sen sor lead wire to the trailing

arm securely (if equipped with ABS).

4. Install the shock absorber (1) lo wer end to t he rear axle

housing.

Tighten the shock absorber lower bolt (2) temporarily

by hand at this step.

5. Install the lateral rod (1) to the vehicle body, ref e r to the

figure for c orrect installation direction of bolt (2).

Tighten nut (3) temporarily by hand at this step.

6. Remove the floor jack from the rear axle housing.

7. Install the wheel and tighten the wheel nuts to specified

torque.

8. Lower hoist.

WHEEL NUTS

TIGHTENING TORQUE 85 Nm

9. Tighten the front and rear trailing arm nuts (1), the

shock absorber lower bolts (2) and the lateral rod right

side nut (3) to specified torque.

NOTE: When tightening these nuts, be sure that the vehicle

is off the hoist and in a no-load condition.

3.7 REAR AXLE SHAFT AND WHEEL BEARING

REMOVAL

1. Hoist vehicle and remove the rear wheel.

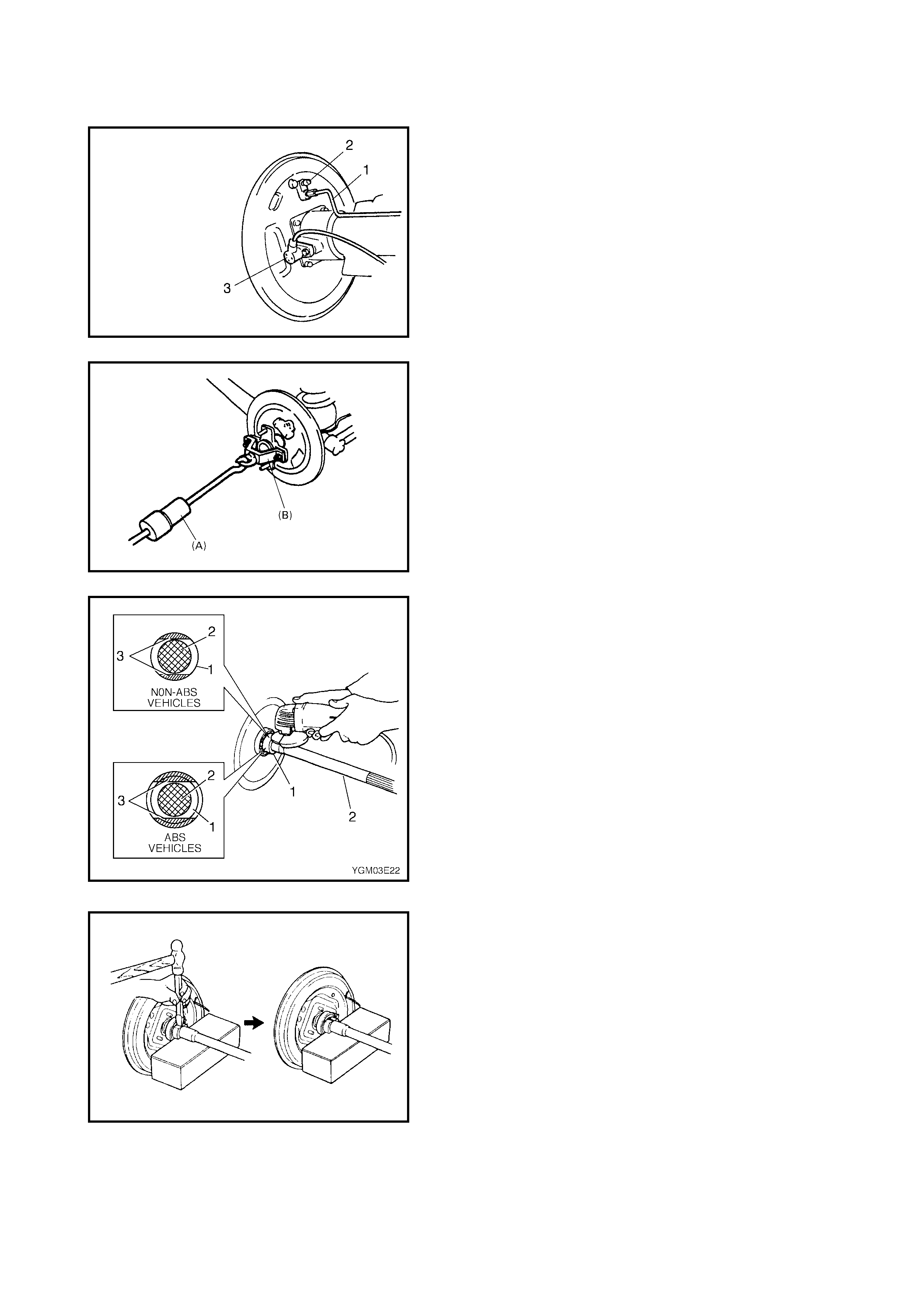

2. Remove the rear brake drum using two 8mm bolts (1)

as shown in figure. For details refer to Section 5, 3.3

REAR BRAKE, BRAKE DRUM REMOVAL.

3. Drain the gear oil from the rear axle housing by

loosening the drain plug (1).

4. Remove the brake shoes, refer to BRAKE SHOE

REMOVAL in Section 5, 3.3 REAR BRAKE.

FRONT TRAILING ARM NUT (a)

TORQUE SPECIFICATION 90 Nm

REAR TRAILING ARM NUTS (b)

TORQUE SPECIFICATION 80 Nm

REAR SHOCK ABSORBER LOWER

BOLTS (c)

TORQUE SPECIFICATION 85 Nm

LATERAL ROD RIGHT SIDE NUT (d)

TORQUE SPECIFICATION 65 Nm

5. Remove parking brake cable from brake back plate.

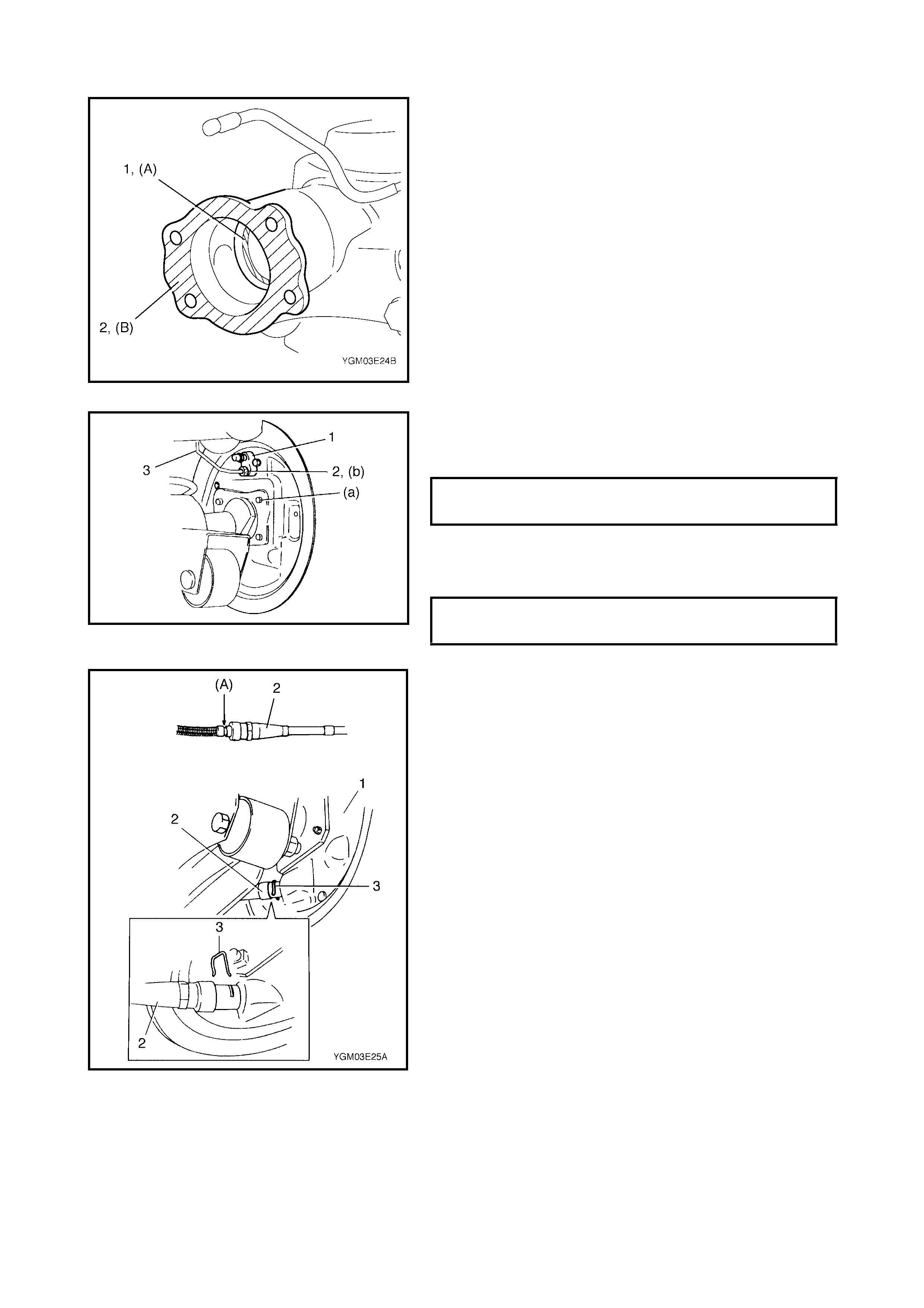

6. Disconnect the brake pipe (1) from the wheel cylinder

and put the wheel cylinder bleeder plug cap (2) onto

the pipe to prevent fluid from spilling.

7. Remove the wheel speed sensor (3) from the axle

housing (if equipped with ABS).

8. Remove the brake back plate bolts from the axle

housing.

9. Using special tools 09942-15511 (A) and 09943-17912

(B), draw out axle shaft with brake back plate.

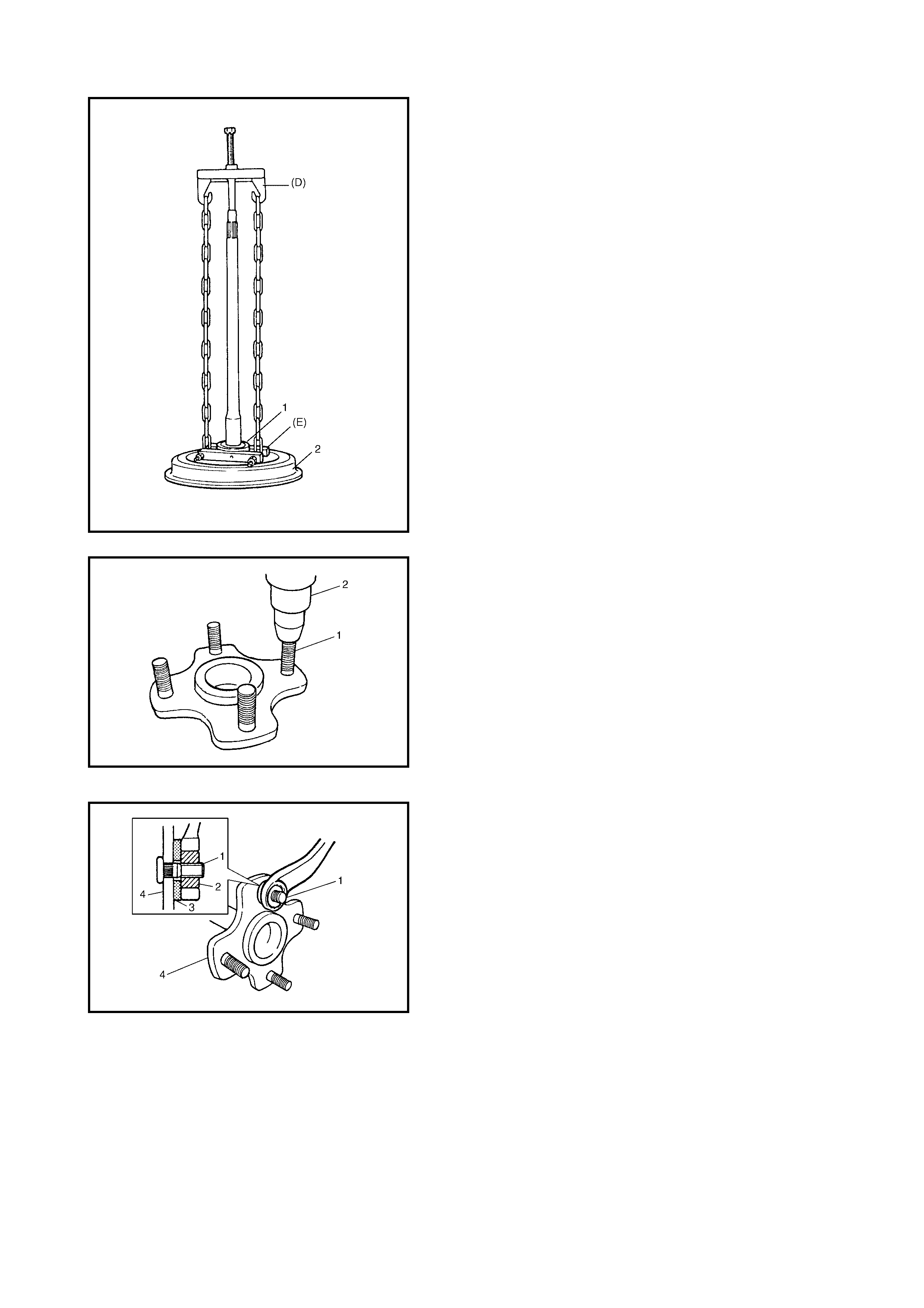

10. To remove the retainer ring (1) from the axle shaft (2),

grind (3) on either side of the bearing retainer ring as

shown in figure until it becomes thin.

CAUTION: Take care not to grind completely through

the retainer ring an d damag e the axle shaft.

11. With a cold chisel, break through the thin section of the

retainer ring and remove as shown in figure.

12. Using special tools 09927-18411 (D) and 09921-57810

(E), remove bearing (1) from shaft then remove brake

back plate (2) and wheel bear ing spac er.

13. Remove the stud bolts (1) using a hyd raulic press (2).

INSTALLATION

Install removed parts in reverse order of removal, noting

the following points.

1. Align the serrations on the new stud bolts (1) and the

flange (4), then pull the new stud bolts and washers (3)

into position using a tightening nut (2) as shown in

figure.

2. Install the new wheel bearing spacer (1) with the

tapered side of its inner diameter facing outwards

(toward the brake drum side).

3. Press fit the new bearing (2) and retainer ring (3) in

order using a hydrauli c press (4).

NOTE:

•Install the wheel bearing with its sealed side facing out-

wards (toward the brake drum side).

•Take care not to cause any damage to the outside of

the retainer ring.

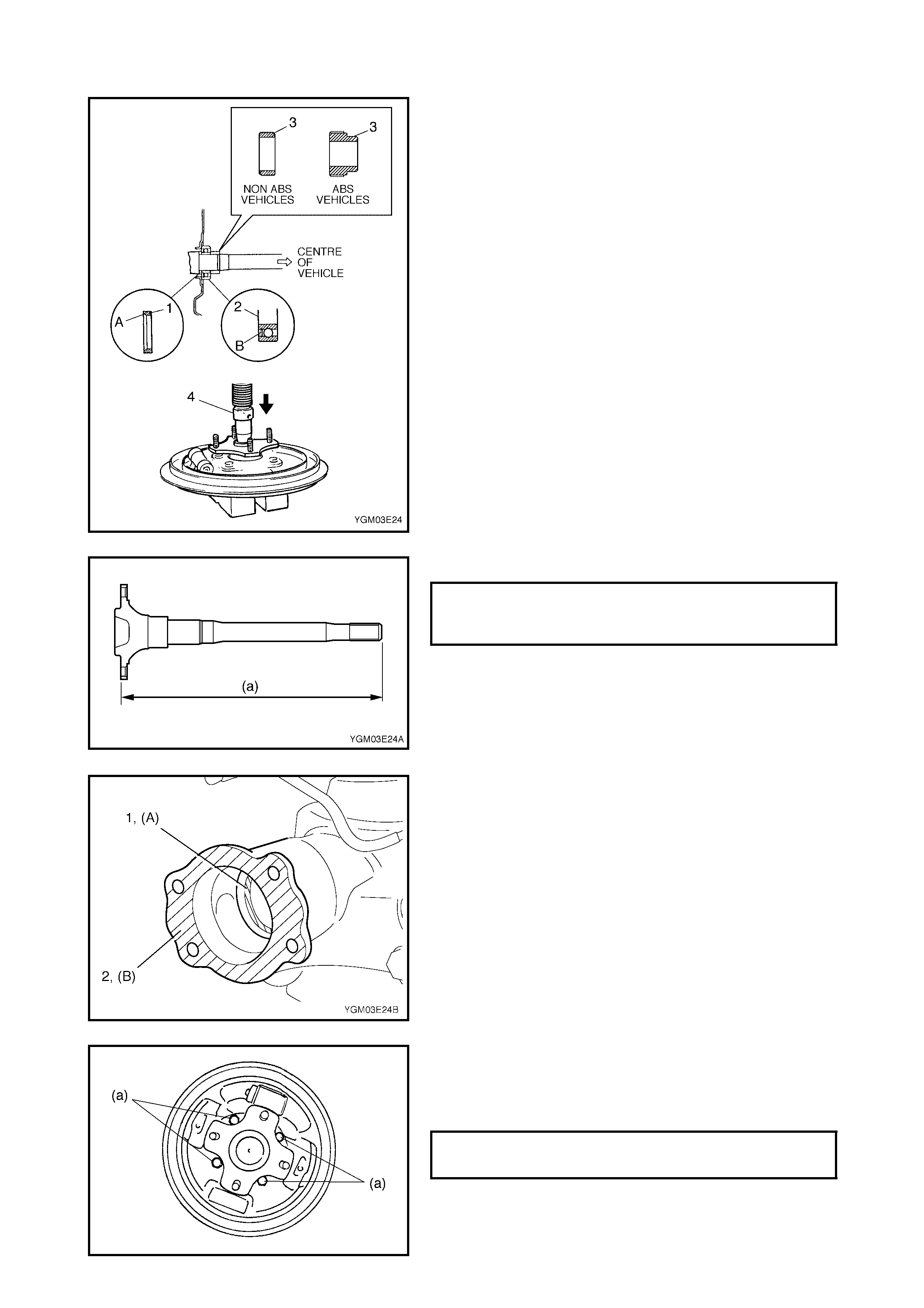

4. Inspect the axle shaft length.

5. Appl y grease to the axle shaft oil s eal lip (1) as s hown

in figure.

(A): Lithium Grease

6. Apply sealant to the mating surfaces of the rear axle

housing (2 ) and the brake back plate.

NOTE: Ens ure any old seal ant is removed before applying

new sealant.

(B): Sealant - Sealing compound 366E

7. Install the rear axle shaft to the rear a xle housing and

tighten the brake back plate bolts to specified torque.

NOTE: When installing the rear axle shaft, be careful not to

damage the oil seal lip in the axle housing.

REAR AXLE SHAFT LENTH (a)

LEFT SIDE

RIGHT SIDE 791.0 mm

672.0 mm

BRAKE BACK PLATE BOLTS (a)

TORQUE SPECIFICATION 23 Nm

8. Connect the brake pipe to the wheel cylinder and

tighten brake pipe flare nut to specified torque.

9. Apply watertight sealant where the brake back plate

and the handbrake cable make contact. Run the

parking brake cable (1) through the brake back plate

(2) and secure it with clip (3).

(A): Sealant - Sealing compound 366E

CAUTION: Check to ensure that the clip is in good

condition before installation. Replace it if it is

deformed or broken.

10. Install the wheel speed sensor (if equipped with ABS).

11. Install the brake shoes, refer to Section 5, 3.3 REAR

BRAKE, BRAKE SHOE INSTALLATION.

12. Install the brake drum. For details refer to Section 5,

3.3 REAR BRAKE, BRAKE DRUM INSTALLATION.

13. Tighten the oil drain plug to specified torque and refill

the rear axle (differential) housing with new specified

gear oil then tighten filler plug to specified torque. Refer

to Section 7F, REAR DIFFERENTIAL.

14. Install the wheel and tighten the wheel nuts to specified

torque.

15. Fill brake reservoir with brake fluid and bleed brake

system. (For bleeding operation refer to Section 5,

3.1 AIR BLEEDING OF BRAKES.

16. Upon completion of all jobs, pull parking brake lever

with a load of approximately 200 Nm (20 kg), three to

five times to obtain correct drum-to-shoe clearance.

Adjust parking brake cable (for adjustment, refer to

Section 5, 2.10 PARKING BRAKE INSPECTION AND

ADJUSTMENT).

17. Check to ensure that the brake drum is free from

dragging and proper braking is obtained.

18. Perform brake test (foot brake and parking brake).

(For brake test, refer to Section 5 BRAKES.)

19. Check each installed part for oil leakage.

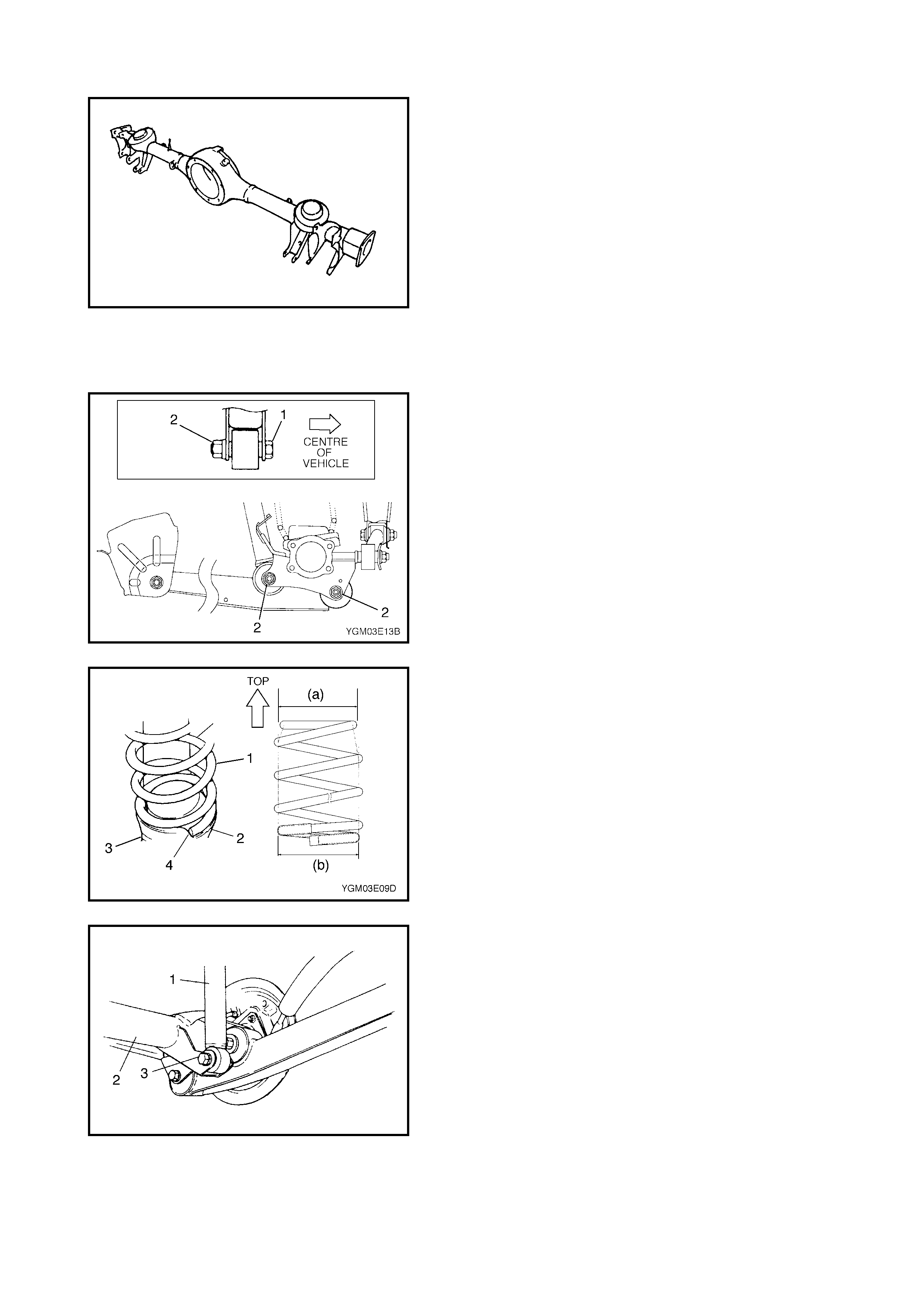

3.8 REAR AXLE SHAFT OIL SEAL

REMOVAL

1. Remove rear axle shaft. For details, refer to Steps 1 to

8, 3.7 REAR AXLE SHAFT AND WHEEL BEARING,

REMOVAL in this Section.

BRAKE PIPE FLARE NUT (a)

TORQUE SPECIFICATION 16 Nm

WHEEL NUTS

TIGHTENING TORQUE 85 Nm

1. Remove the axle shaft oil seal (1) from the axle

housing (2) using a wooden block (3) and special tool

09913-50121 (A).

INSTALLATION

1. Using special tools, 09944-67010 (A) and 09924-

74510 (B), press fit the oil seal (1) until it contacts the

oil seal protector (2) in the axle housing.

NOTE:

• Ensure that the oil seal is not angled as it is installed.

• Ensure that the oil seal is installed in the correct direc-

tion (refer to the figure).

• Apply grease (C) to the inside surface of the seal as

shown in figure.

(C): Lithium Grease

2. To complete the installation, refer to Steps 5 to 17,

3.7 REAR AXLE SHAFT AND WHEEL BEARING in

this Section.

3.9 REAR AXLE HOUSING

REMOVAL

1. Hoist vehicle and remove the rear wheels.

2. If required remove the rear axle shafts (right and left),

refer to Steps 1 to 9, 3.7 REAR AXLE SHAFT AND

WHEEL BEARING in this Section.

3. Disconn ect the brake pipes (1) (right and l eft) from the

fle xible hoses (2) and remov e E-rings (3).

4. Release the wheel speed sensor and wiring clamps

from the axle housing (if equipped with ABS).

5. Remove the LSPV adjusting nut and detach spring end

from the rear axle housing (if equipped with LSPV).

6. Before removing the propeller shaft, make matching

alignment marks (1) on the joint flange and the

propeller shaft (2) as shown.

Remove the propeller shaft.

7. If required, remove the differential carrier assembly,

refer to Section 7F REAR DIFFERENTIAL.

8. The following steps require that the rear axle housing is

suppo rted us ing a floor jack (1) under the axle hou sing

(2).

9. Remov e the lateral rod (1).

10. Loosen the front and rear mounting nuts (1) of the

trailing arm but don’t remove the bolts.

11. Remove the left and right shock absorber lower

mounting bol ts (1).

12. Lower the floor jack until the tension on the rear sus-

pension coil spring is loosened slightly, then remove

the rear mount bolts from the trailing arms (left and

right).

13. Lower the rear axle housing gradually and remove the

coil spring (left and right sides).

14. Remove the axle housing.

INSTALLATION

Install removed parts in reverse order of removal, noting

the following.

1. Place the rear axle housing on the floor jack. Install the

rear trailing arm bolts (1) (right & left) in the correct

direction as shown in figure and tighten nuts (2) tempo-

rarily by hand.

2. Install the coil springs (1) (right & left) on the spring

seat (2) of the rear axle housing (3) and mate the

spr ing o pen end with the steppe d part (4) of the spri ng

lower seat then raise the axle housing.

NOTE: The upper and lower diameters of the coil spring

are different. Ensure the larger diameter (b) faces down

and the sma ller diameter (a) faces up.

3. Install the shock absorber (1) (right and left) to the rear

axle housing (2) and install the bolts in the correct

direction as shown in figure. Tighten the shock

absorber lower bolts (3) (right and left) temporarily by

hand at this step.

4. Install the lateral rod (1) and install the bolt (2) in the

correct direction as shown in the figure. Tighten the

nuts (3) temporarily by hand at this stage.

5. If removed, clean mating surfaces of the axle housing

(1) and the differential carrier and apply sealant to the

housing side.

(A): Sealant Three Bond No. 1215

6. Apply sealant to the carrier bolts and tighten the carrier

bolts to the specified torque

(B): Sealant Three Bond No. 1215.

7. Install the propeller shaft to the joint flange, aligning

matching marks (1) and tighten the flange bolts to

specified torque.

8. Install the load sensing proportioning valve (LSPV)

spr ing to rear axle housing.

Tighten the LSPV adjust nut temporarily at this step. (if

equipped with LSPV).

9. Remov e the floor jack from the axle housing.

10. Connect the brake flexible hoses (1) (right and left) to

the bracket on the axle housing and secure it with E-

r ings (2).

REAR DIFFERENTIAL CARRIER

BOLTS (b)

TORQUE SPECIFICATION 23 Nm

COMPANION FLANGE BOLTS (c)

TORQUE SPECIFICATION 23 Nm

BRAKE PIPE FLARE NUT (a)

TORQUE SPECIFICATION 16 Nm

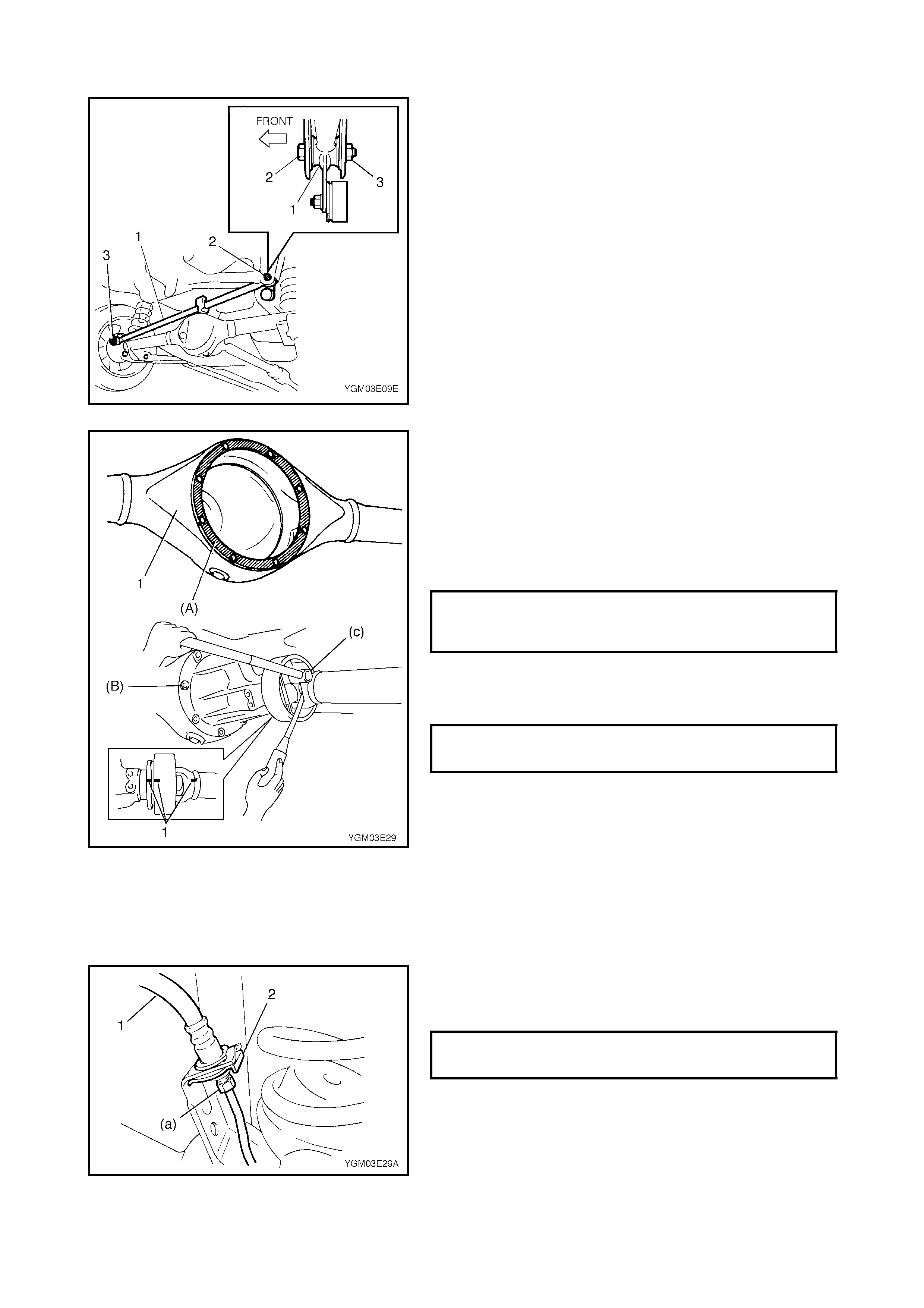

11. If removed, apply grease to the rear axle shaft oil seal

lip (1) (right and left) as shown in the figure.

(A): Lithium Grease

12. Clean the mating surface (2) (left and right) of the rear

axle housing and the brake pack plate and apply

sealant as shown in the figure.

(B): Sealant - Sealing compound 366E

13. Install the rear axle shaft (right & left) to the rear axle

housing and tighten the brake back plate bolts to

specified torque.

14. Connect the brake pipes (3) to the wheel cylinders (1)

(right & left) and tighten the brake pipe flare nuts (2) to

specified torque.

15. Apply watertight sealant where the brake back plate (1)

and the parking brake cable make contact.

(A): Sealant - Sealing compound 366E

NOTE: Check to ensure that the clip is in good condition

before installing it. If it is deformed or broken, replace.

16. Install the parking brake cable clamps to the trailing

arm.

17. Install the wheel speed sensors (right and left) and

clamp wire securely (if equipped with ABS).

18. Install the brake shoes (right and left), refer to Section 5,

3.3 REAR BRAKE, BRAKE SHOE INSTALLATION.

BRAKE BACK PLATE BOLTS (a)

TORQUE SPECIFICATION 23 Nm

BRAKE PIPE FLARE NUTS (b)

TORQUE SPECIFICATIONS 16 Nm

19. Install the brake drums (1) (right and left) after making

sure that the inside of the brake drum and the brake

shoes are free from dirt and oil. Tighten wheel nuts (2)

temporarily by hand.

20. Fill the brake reservoir with specified brake fluid and

bleed the brake system, refer to Section 5, 3.1 AIR

BLEEDING OF BRAKE SYSTEM.

21. Refill the differential gear housing with specified gear

oil, refer to Section 7F, REAR DIFFERENTIAL.

22. Install wheels and tighten wheel nuts to specified

torque.

23. Upon completion of all jobs, pull the parking brake lever

with a load of approximately 200 Nm (20 kg), three to

five times to obtain a correct drum-to-shoe clearance.

Adjust the parking brake cable (for adjustment, refer to

Section 5, 2.10 PARKING BRAKE INSPECTION AND

ADJUSTMENT.

24. Lower hoist.

25. Tighten the right and left trailing arm nuts (1) and shock

absorber lower bolts (2) to specified torque.

Tighten the lateral rod nuts (3) to specified torque.

NOTE: When tightening these bolts and nuts, be sure that

the vehicle is off the hoist and in a no-load condition.

26. Check to ensure that the brake drum is free from

dragging and correct braking is obtained.

27. Perform brake test (foot brake and parking brake).,

refer to Section 5 BRAKES.

28. If equipped with LSPV, check and adjust the LSPV

spring, refer to Section 5, 3.8 LSPV ASSEMBLY (IF

EQUIPPED), INSPECTION AND ADJUSTMENT and

2.12 FLUID PRESSURE TEST (IF EQUIPPED WITH

LSPV).

29. Che ck each installed par t for oil leakage.

WHEEL NUTS (a)

TORQUE SPECIFICATION 85 Nm

REAR TRAILING ARM NUTS (a)

TORQUE SPECIFICATION 80 Nm

REAR SHOCK ABSORBER LOWER

BOLTS (b)

TORQUE SPECIFICATIONS 85 Nm

LATERAL ROD AXLE HOUSING SIDE

NUT (c)

TORQUE SPECIFICATION 65 Nm

LATERAL ROD BODY SIDE NUT (d)

TORQUE SPECIFICATION 65 Nm

FRONT TRAILING ARMNUTS (e)

TORQUE SPECIFICATION 90 Nm

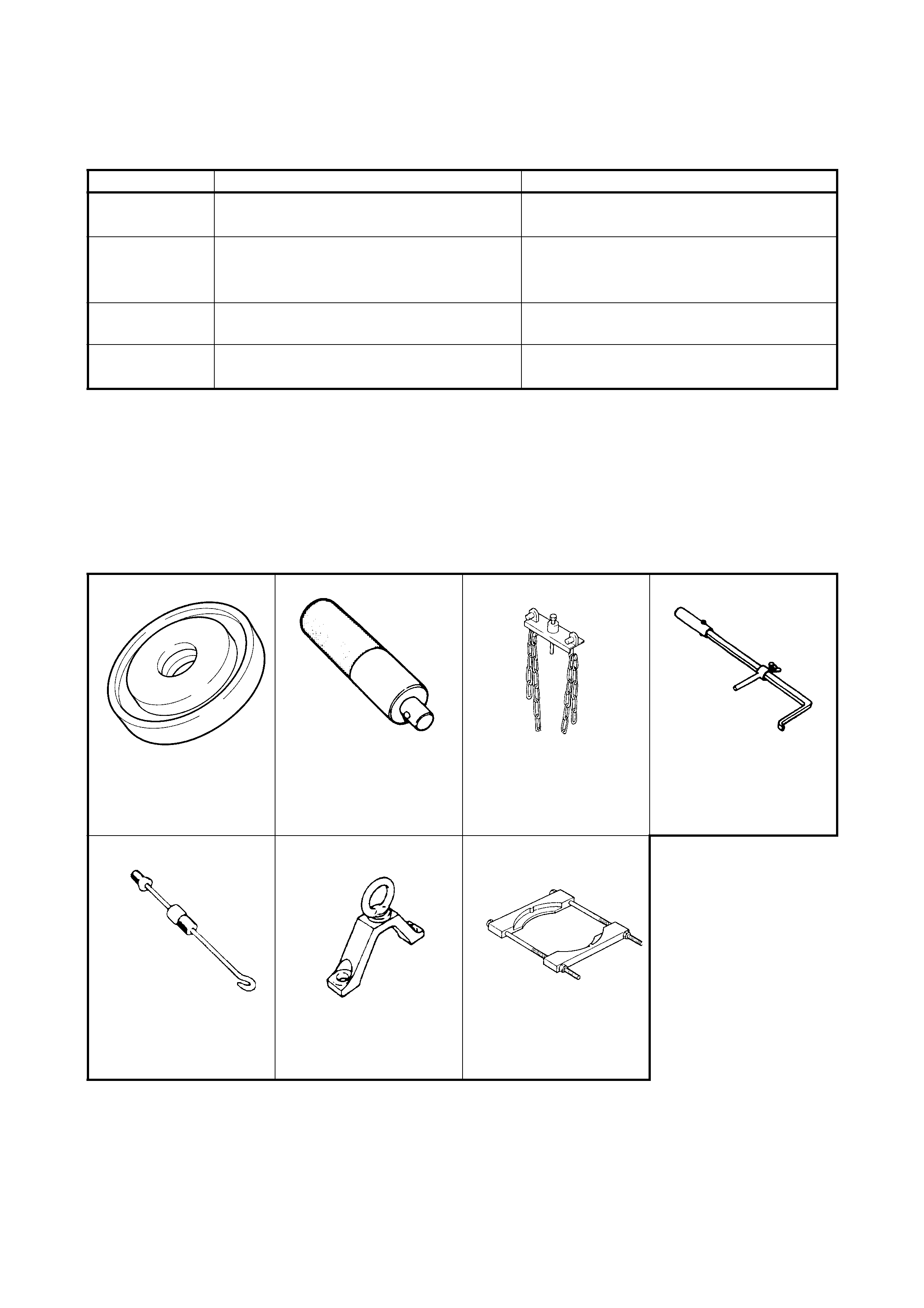

4. REQUIRED SERVICE MATERIAL

5. SPECIAL TOOLS

NOTE: Refer to Section 0A GENERAL INFORMATION – 7. CONSOLIDATED TOOLS for a detailed list of

special tools and the local equivalent if one is available.

Material

Recommended product

Use

Lithium grease Lithium Grease

• Axle shaft oil seal

• Wheel bearing

Sealant Three Bond No. 1215

• Joint seam of differential carrier and

axle housing

• Differential carrier bolt

Gear oil For gear oil information, refer to Section 7F

REAR DIFFERENT IAL. •Differential gear (Rear axle housing)

W a te r tight

sealant Sealing Com pound 366E •Joint sea m of axle housing and brake

back plate

09944-67010 09924-74510 09927-18411 09913-50121

Oil seal installer Installer attachment Universal puller Oil seal remover

09942-15511 09943-17912 09921-57810

Sliding hammer Brak e drum remover Bearing remov er