SECTION 3F - WHEELS AND TYRES

1. GENERAL DESCRIPTION

1.1 TYRES

1.2 WHEELS

1.3 REPLACEMENT TYRES

1.4 REPLACEMENT WHEELS

How to Meas ure Wheel Runo ut

Metric Lug Nuts and Wheel Studs

2. DIAGNOSIS

2.1 DIA GNOSIS TA BLE

2.2 BAL ANCING WHEELS

2.3 GENERAL BALANCE

PROCEDURES

Off-vehicle Balancing

On-vehicle Balancing

3. MAINTENANCE AND MINOR

ADJUSTMENTS

3.1 WHEEL MAINTENANCE

Wheel Attaching Studs

3.2 TYRE MAINTENANCE

Tyre P lac ard

Inf l at io n of Ty res

Tyre Rotation

4. ON-VEHICLE SERVICE

4.1 WHEEL

Removal

Installation

4.2 TYRE

Installatio n and Removal

Repair

NOTE:

Wheel fasteners are important attaching parts because they could affect the performance of

vital parts and systems, and/or could result in major repair expenses. They must be replaced

with one of the same part number or with an equivalent part if replacement becomes neces-

sar y. Do no t u se a rep la cemen t p ar t of l esse r qu ali ty o r s ubst itu te desi gn. Torque values mu st

be used as specified during reassembly to assure proper rete ntion of all parts.

There is to be no welding as it may result in extensive damage and weakening of the metal.

1. GENERAL DESCRIPTION

1.1 TYRES

This vehicle is equipped with the following tyre.

Tyre size

175/65R15

The tyre is of tubeless type. The tyre is designed to operate satisfactorily with loads up to the full ra ted load

capacity when inflated to the recommended inflation press ures.

Correct tyre pressures and driving habits have an important influence on tyre life. Heavy cornering, exces-

sivel y rapid acceleration and unnecessary sharp braking increase tyre wear.

1.2 WHEELS

Standard equip men t wheels are aluminium alloy.

Wheel size

15 x 5 1/2 J

1.3 REPLACEMENT TYRES

When repla cement is necessar y, the origi nal equipment t ype tyre should be us ed. Refe r to the Tyre Placard.

Replacement tyres should be of the same size, load range and construction as those originally on the vehicle .

Use of any other size or type tyre may affect ride, handling, speedometer/odometer calibration, vehicle ground

clearance and tyre or snow chain clearance to the body and chassis.

It is recomm end ed t hat new tyres be i nstalled i n pairs on th e sam e ax le. If it is necess ar y t o repl ace only one

tyre, it should be paired with the tyre with the most tread, to equalise braking tractio n.

WARNING: Do not mix different types of tyres on the same vehicle such as radial, bias and bias-

belted tyres except in emergencies, because handling may be seriously affected and may result in

loss of control.

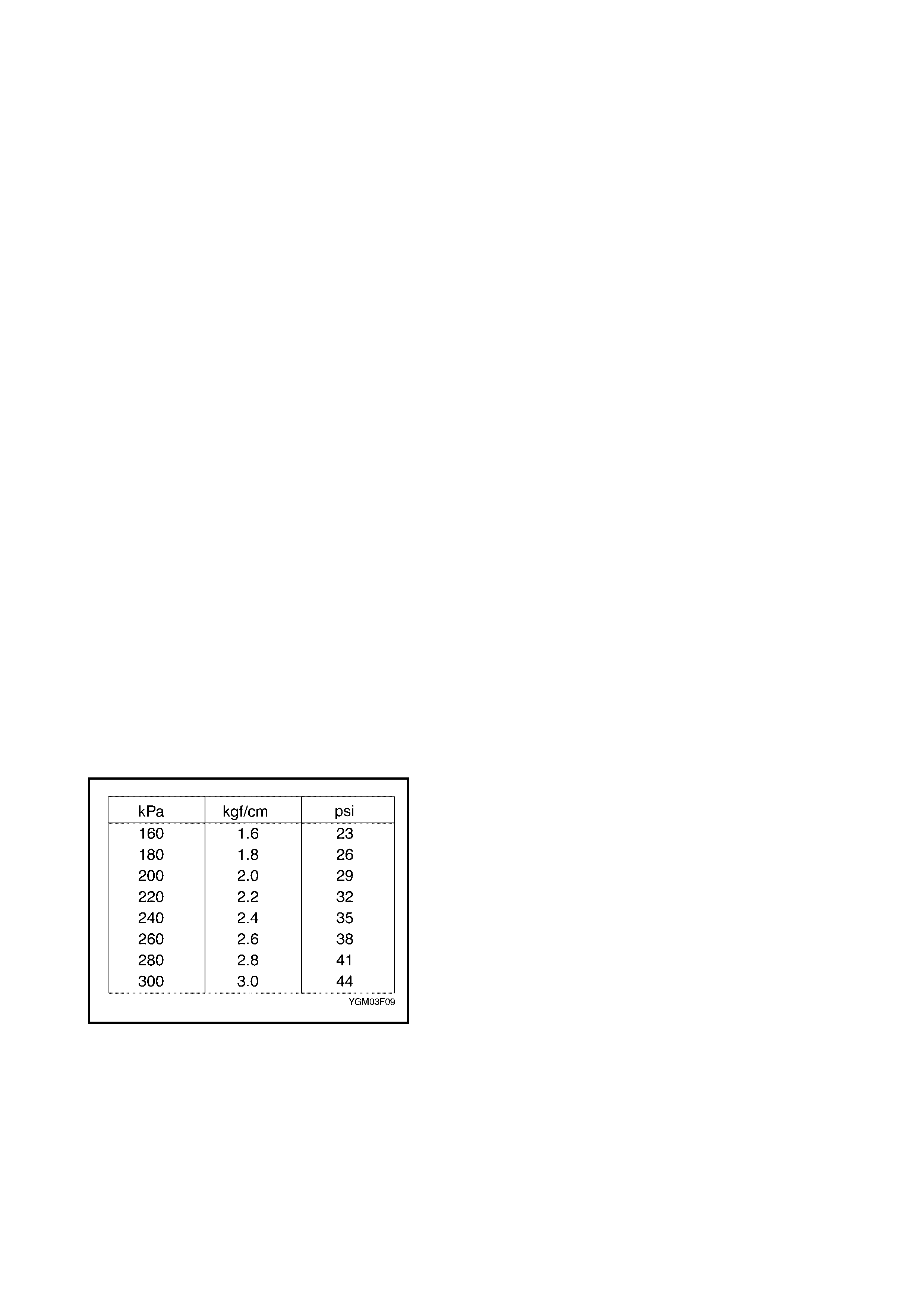

The m etr i c te rm for tyre inflation press ure is the kilo pas cal

(kPa). Tyre pressures are usually printed in both kPa and

psi on t he Ty re Plac ard.

Metr i c tyre gauges are available from tool suppliers.

The accompanying table, converts commonly used inflation

pre ssures from kPa to ps i.

1.4 REPLACEMENT WHEELS

Wheels must be replaced if they are bent, dented, have excessive lateral or radial runout, air leaks through

welds, have e longa ted bolt holes, if lug nuts won’t stay tight, or if they are heavily rusted. Wheel s with greater

runout than shown in the following figure may cause objectionable vibrations.

Replacement wheels must be equival ent t o t he original equipment wheels in load capacity, diameter, rim width

offset a nd moun ting c onfiguration. A wheel of im proper size or t ype may affect wh eel and bearing life, brake

cooling, speedometer/odometer calibration, vehicle ground clearance and tyre clear ance to body and chassis.

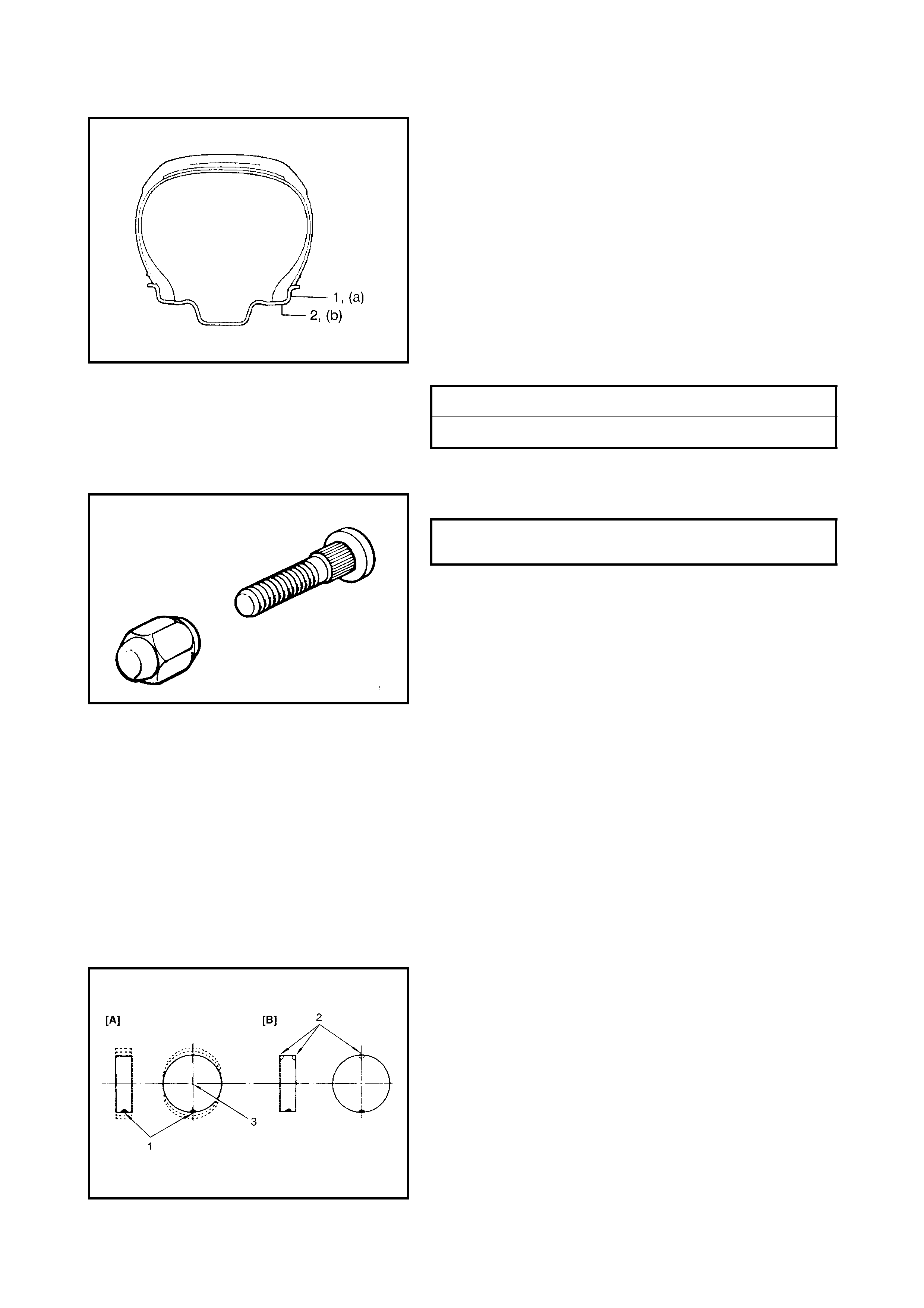

HOW TO MEASURE WHEEL RUNOUT

To measure the wheel runout, it is necessary to use an

accurate dial indicator. The tyre may be on or off the wheel.

The wheel should be installed on a wheel balancer for

proper measurement.

Take measurements of both lateral runout (1) and radial

runout (2) on both the inside and outside of the rim flange.

With the dial indicator set in place securely, turn the wheel

slowly one full revolution and record the reading from the

indicator.

When the measured runout exceeds the specification and

correction by the balancer adjustment is impossible,

replace the wheel. If the reading is affected by welding,

paint or scratches, it should be ignored.

METRIC LUG NUTS AND WHEEL STUDS

All models use metric lug nuts and wheel studs.

2. DIAGNOSIS

2.1 DIAGNOSIS TABLE

Refer to Section 3 STEERING, SUSPENSION, WHEELS

AND TYRES.

2.2 BALANCING WHEELS

There are two types of wheel and tyre balance: static and

dynamic. Static balance, as shown in left figure, is the

equal distribution of weight around the wheel. Wheel s that

are statically unbalanced cause a bouncing action called

tramp. This condition will eventually cause uneven tyre

wear.

Legend

LATERAL RUNO UT LIMIT (a) 1.40 mm

RADIAL RUNOUT LI MIT (b) 1.14 mm

METRIC LUG NUTS AND WHEEL

STUDS SIZE M12 x 1.25

1. Heavy spot wheel tramp [A] : Before correction

2. Balance weights

addit ion point [B] : Correctiv e weights

3. C/L of spindle

Dynamic balance, as shown in the figure, i s the equal distri-

bution of weight on each side of the wheel centreline so

that when the tyre spins there is no tendency for the

assembly to move from side to side. Wheels that are

dynamically unbalanced may cause shimmy

Legend.

2.3 GENERAL BALANCE PROCEDURES

Deposits of mud, etc. must be cleaned from inside of rim.

WARNING: Stones should be removed from the tread in order to avoid operator injury during spin

ba lan c i ng and to obt ain good bal anc e.

Each tyre should be inspected for any damage, then balanced according to equipment manufacturer’s recom-

mendation.

OFF-VEHICLE BALANCING

Most electr onic off -veh icle b alancers are more ac curate than t he on-vehicle spin ba lancers. T hey are eas y t o

use and giv e a dynamic (two plane) balance. Although they do not correct for drum or disc unbalance as does

on-vehicle spin balancing , this is overcome by their accuracy, usually to with in 1/8 ounce.

ON-VEHICLE BALANCING

On-vehicle balancing metho ds var y with equi pment and tool manufacturers. Be sure to foll ow each manufac-

turer’s instructi ons during balancing operation.

WARNING: Wheel spin should be limited to 55 km/h as in dicated on the speedometer.

This limit is neces sary because the speedometer only indicates one -half of actual wh eel speed when

one drive wh eel is spinn ing and the other drive wheel is stationery.

Unless care is taken in limiting drive wheel spin, the spinning wheel can reach excessive speeds. This

can result in possible tyre disintegration or differential failure, which could cause serious personal

in j ury or exte nsive ve hicle da m a ge.

CAUTION: F or ve hicles eq uippe d w ith A BS, us ing t he on -ve hicle bal ancin g met hod with t he ig nition

switch ON, may set a malfunc tion diagnostic trouble code (DTC) for the ABS even when the system is

in good co nditi on.

Never turn the ignition switch ON while the wheels are spinning.

1. Heavy spot wheel sh immy [C] : Before correction

2. Balance weights addition

point [D] : Corrective weights

3. C/L of spindle

3. MAINTENANCE AND MINOR ADJUSTMENTS

3.1 WHEEL MAINTENANCE

Wheel repairs that use welding, heating, or peening are not approved. All damaged wheels should be

replaced. WHEEL ATTACHING STUDS

If a broken stud is found, refer to Section 3E REAR SUSPENSION or Section 3D FRONT SUSPENSION for

notes and replacem ent procedures.

3.2 TYRE MAINTENANCE

TYRE PLACARD

The Tyre Placard is located on the right door lock pillar and should be re ferred to for tyre infor mation .

INFLATION OF TYRES

The pressu re recomm ended for any model is carefully calculated to give a satisfactor y ri de, stability, steer ing,

tread wear, tyre life and resistance to bruises.

Tyre pressure, w ith t yres cold, (after vehicle has sat for 3 hours or more, or dri ve n less th an one mile) should

be checked mont hly or be fore any extended trip. Inflate to the specifications on the “Tyre Placard” located on

the righ t door lock pillar.

It is normal for tyre pressure to increase when the tyres become hot during driving.

Do not bleed or re duc e tyre pressure after driving. Bleeding reduces the “Cold Inflation Pressure”.

Higher than rec omm en ded tyre pressure can cau se:

• Hard ride

• Tyre bru ising or carcass damage

• Rapid tread wear at centre of tyre

Unequ al tyre pressur e on same axle can cau se:

• Uneven bra king

• Steering lead

• Reduced handling

• Swerv e on acceleration

Lower than recommended tyre pressure can cause:

• Tyre squeal on tur ns

• Dif ficu lty Steerin g

• Rapid and uneve n wear on the edges of the trea d

• Tyre rim bru ises and rupt ure

• Tyre cord breakage

• High tyre temper ature

• Reduced handling

• High fuel consumption TYRE ROTATION

To equalise wear, rotate tyres according to the accompan y-

ing figure. Radial tyres should be rotated periodically.

Ensure correct tyre pressures are set.

NOTE: D ue to t heir design, radial tyres te nd to wear fa ster

in the shou lder area, particul arly on t he front of the vehicle.

This makes regular rotation especially necessar y.

4 . ON-VEHICLE SERVIC E

4.1 WHEEL

REMOVAL

1. Loose n wheel nuts by approximately 180° (half a

rotation).

2. Hoist vehicle.

3. Remove wheel.

CAUTION: Never use heat to loosen tight wheel nuts

because application of heat to the wheel can shorten

the life of the wheel and damage whe el be arings.

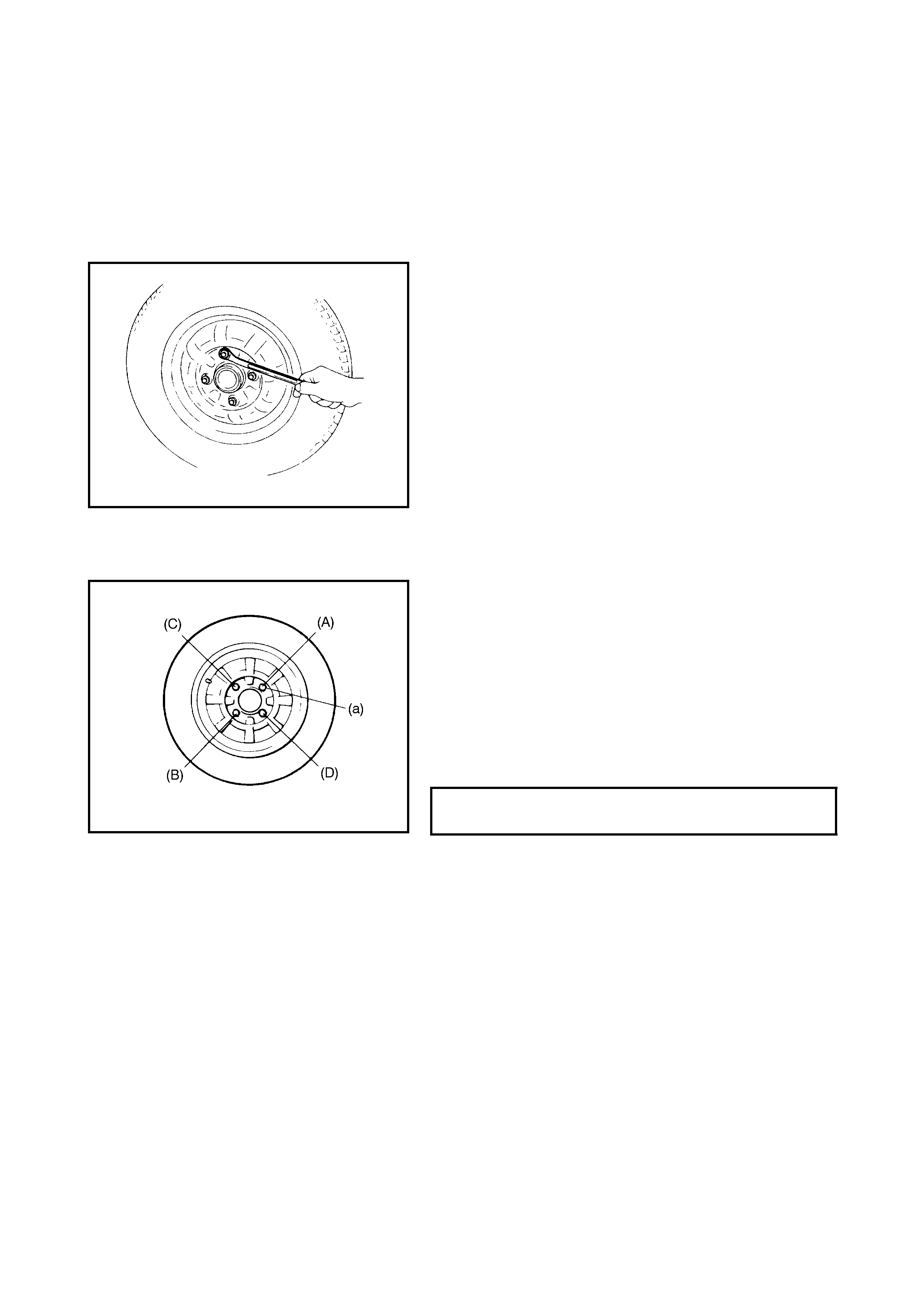

INSTALLATION

For installation, rev erse removal procedure, noti ng the

following.

• Wheel nuts must be tightened in sequence and to

proper torque to avoid bending whee l or brake d isc .

NOTE: Before installing wheels, remove any build-up of

corrosion on wheel mounting surface and brake disc

moun ting surface by scraping and wire bru shing. Installing

wheels without good metal-to-metal contact on mounting

surfaces can cause wheel nuts to loosen, which could

result in a wheel coming off while the vehicle is moving.

Tightening order

:(A)-(B)-(C)-(D)

WHEEL NUT (a)

TORQUE SPECIFICATION 85 Nm

4.2 TYRE

INSTALLATION AND REMOVAL

Use a tyre changing machine to mount or dismount tyres. Follow equipment manufacturer’s instructions. Do

not use hand tools or tyre irons alone to change tyres as they may damage tyre beads or wheel rim.

Rim bead seats should be cleaned with a wire brush or coarse steel wool to remove lubricants, old rubber and

light rus t. Before m ounting or dismounting a tyre, bead area should be well lubricate d with approved tyre

lubricant.

After mounting, inflate to specified pressure shown on tyre placard so that beads are completely seat ed.

WARNING: Do not stand over tyre when inflating. Bead may break when bead snaps over rim’s safety

hump an d caus e serio us pe rsonal injury.

Do no t exceed s pecified pr essu re wh en inflating. If sp ecified pres sure will not seat b eads, deflate, re-

lubricate and reinflate.

Over in flation may cause bead to break and cause seri ous persona l injury.

Install val ve core and inflate t o proper press ure.

REPAIR

There are many different materials and techniques on the market to repair tyres. As not all of these work on all

types of tyres, tyre manufacturers have published detailed instructions on how and when to repair tyres.

These instr uc tions can be obtained from each tyre manufacturer.