1. GENERAL DESCRIPTION

1.1 COMPONENTS

The wheel-side of the front drive shafts use fixed, ball type constant velocity joints. The transaxle or transfer

ends use doub le offset type constant velocity joints. The drive shafts can slide through the double offset joints

(DOJ) in the extension/contraction direction.

2. DIAGNOSIS

2.1 DIAGNOSIS TABLE

2.2 DRIVE SHAFT BOOT CHECK

Inspect the drive shaft boot for tears.

If even a small tear is noted, replace the boot.

Co ndition Pos s ible C a use Co rrection

Abnormal Noise Worn or broken drive shaft joint Replace.

Worn or broken ce ntre spline shaft or hole Replace.

3 . ON-VEHICLE SERVICE

Legend

3.1 DRIVE SHAF T ASSEMBLY

REMOVAL

1. Unstake (A) and remov e drive s haft nut (1) and washer.

2. Raise vehicle on hoist.

3. Remov e the wheel.

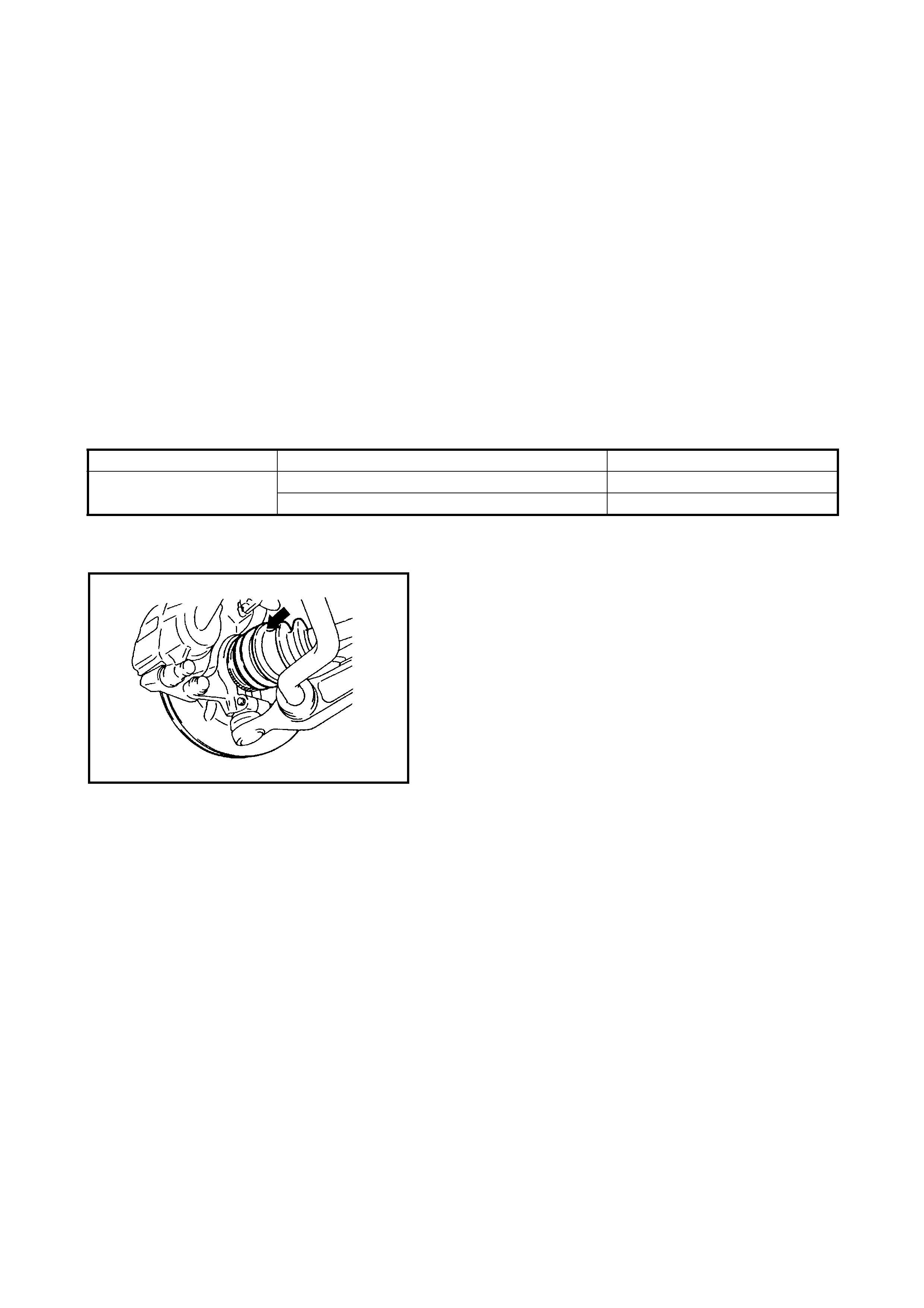

1. Boot 7. Side joint (LH)

: Apply black grease incl uded in spare

par t to joint

2. Circlip

3. Boot band (Small)

4. Snap ring 8. Transfer side joint (RH)

: Apply black grease incl uded in spare

pa rt to jo in t.

5. Wheel side joint (Constant velocity joint)

: Apply black gre as e included in spare

pa rt to join t. Do not reuse.

6. Boot band (Large)

4. Drain the transaxle or transfer oil, refer to Section 7A

MANUAL TRANSMISSION or 7B AUTOMATIC

TRANSMISSION and 7D TRANSFER.

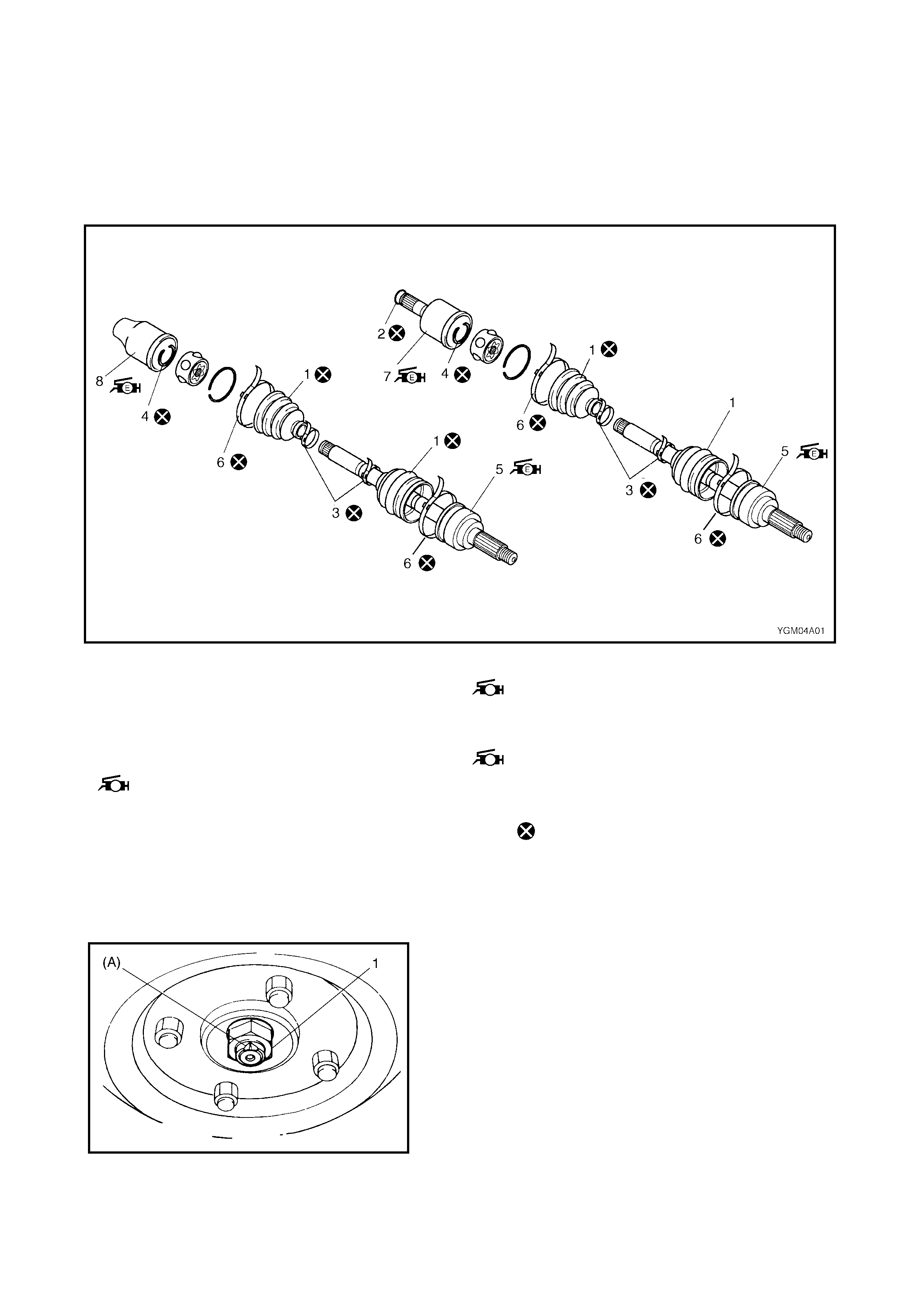

5. Remove the tie rod end split pin (1) and castle nut (2).

6. Disconnect the tie rod end (3) from the steering

knuckle (4) using special tool 09913-65210 (A).

7. Left side:

Using a tyre le ver (1) or similar, leve r out t he drive shaft

joint (2) to allow the snap ring fitting to be released

from the joint spline on the differential-side.

Right side:

Using plastic hammer, knock out the drive shaft joint

(2) to allow the snap ring fitting to be released fro m the

joint spline on the intermediate shaft of the tr ansfer.

8. Remove the two stabiliser mount brackets from the

vehicle body.

9. Disconnect the front suspension control arm ball stud

(1) from the steering knuckle (2) by pushing down on

the stabiliser bar (4) after removing the ball stud bolt

(3).

10. Remove driv e shaft assembly.

CAUTION: Take care not to damage the rubber boots

when removing the drive shaft assemb ly.

DISASSEMBLY

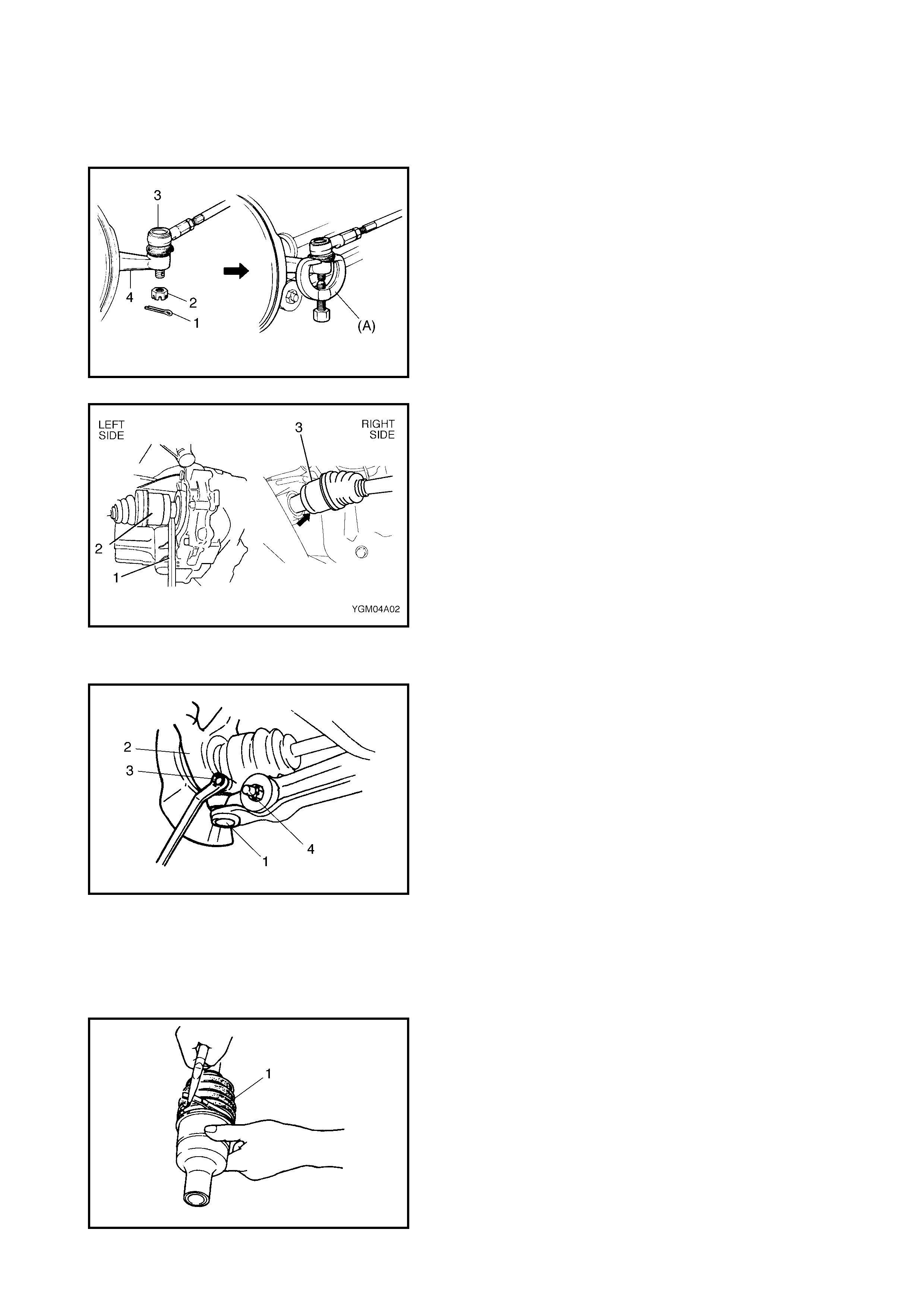

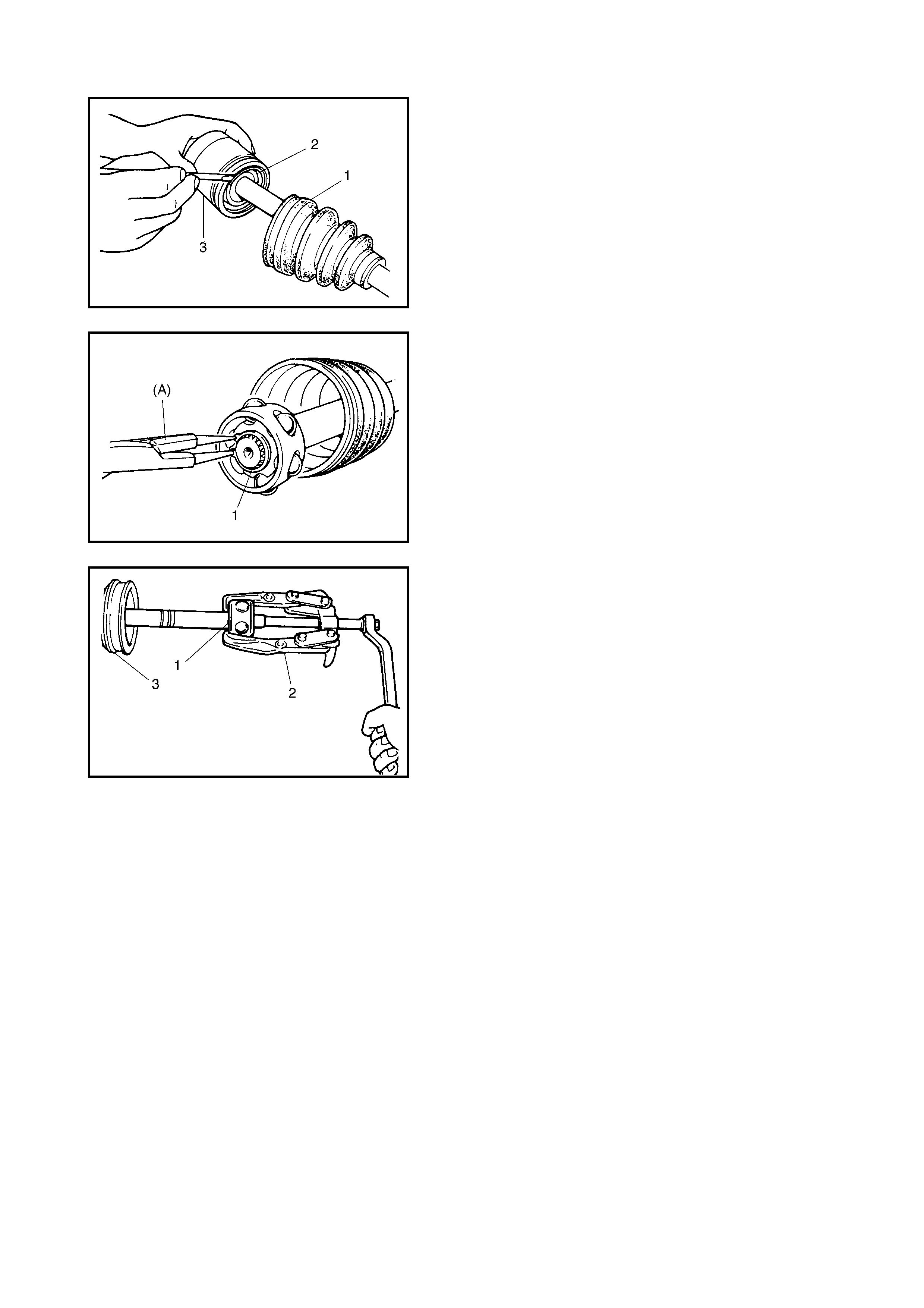

1. Remove the large boot band (1) from the differential-

side joint.

2. Slide the boot (1) towards the centre of the shaft and

remove the snap ring (2) from the joint housing.

Remov e the shaft from the joint housing (3).

3. Wipe off the grease and remove the circlip (1) used to

secure the cage using special tool 09900-06107(A).

4. Pull away the c age (1) using a bearing puller (2).

5. Remove t he sm all boot band then rem ove the d ifferen-

tial-side boot from the shaft.

6. Undo the large and small boot bands from the wheel-

side joint boot and remove t he boot from the shaft.

CAUTION: Do not disassemble wheel-side joint. If

there are any signs of breakage or wear, replace as a

compl ete assembly.

ASSEMBLY

After assessing wear and damage noted before disassem-

bly, verify through visual i nspec tion and determ ine replace-

ment part s required.

Make sure that the w heel-side joint assembly (1) and DOJ

housing (2) are washed thoroughly and air dried. Rubber

boots (3) should be clean ed with a clean cloth if they are to

be reused.

CAUTION: To ens ure new joints p erform as designed,

be sure the correct type and quantity of grease is used.

1. Wash disassembled parts (except boots). After

washing, dry parts completely with compressed air.

2. Clean boots with cloth. Do not wash boots in

degreaser, such as gasoline or kerosene, etc.

Washing in degreaser can cause deterior ation of boot.

3. Apply grease to wheel side joint. Use specified grease

in tube included in wheel side boot set.

4. Install wheel side boot on shaft, fill up inside of boot

with grease then fast en boot with bands (1).

CAUTION:

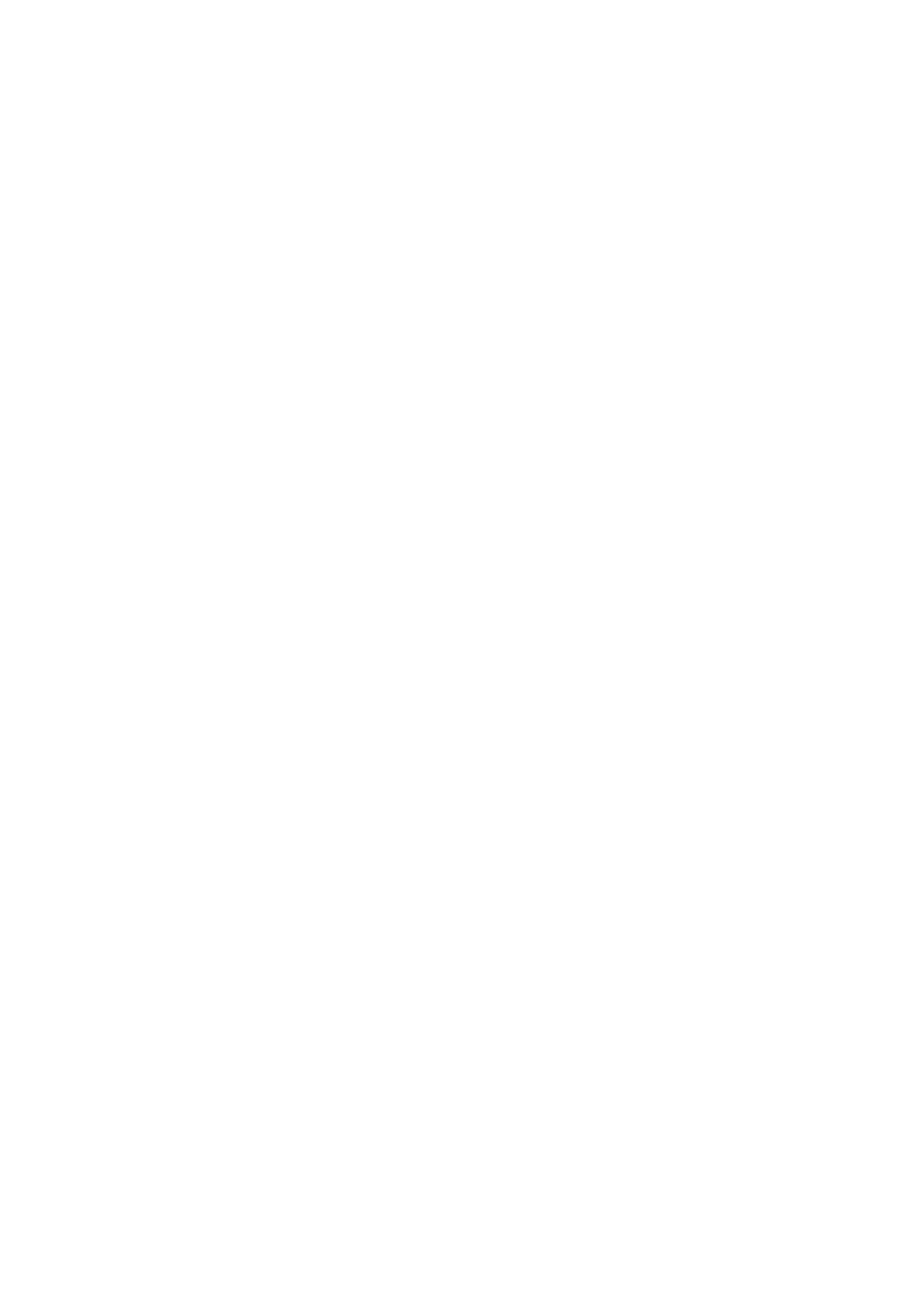

• Bend each boot band against forward rotation (A).

• Do not squeeze or distort boots when fastening

them with bands.

5. Fit the new differential-sid e band (small) and the

differ ential-side boot on the driv e shaft temporarily.

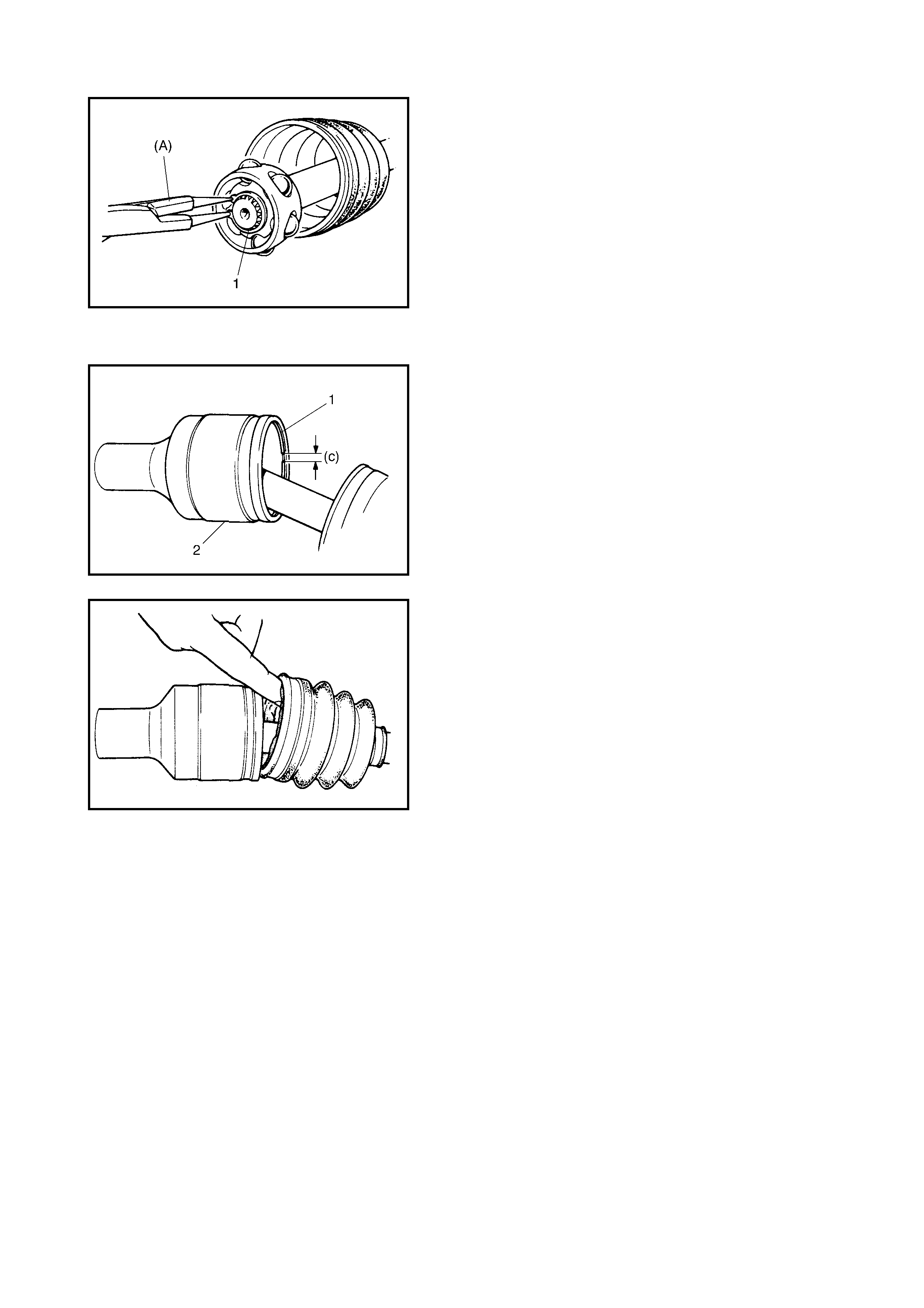

6. Drive in the cage (1) using a pipe (2) as shown in

figure.

CAUTION: Install cage with smaller outside diameter

facin g the wheel side .

BLACK GREASE (A) 45 - 65 gm

BLACK GREASE (B) [LIGHTER T HAN (A)]

LEFT SIDE SHAFT

(EXCEPT A/T VEHICLES)

LEFT SIDE SHAFT ( A/T VEHI CLES ONLY) 70 - 90 gm

55 - 75 gm

DRIVE SHAFT JOINT CA GE

INSTALLATION PIPE DIAMETER (a) 22.5 mm or MORE

DRIVE SHAFT JOINT CA GE

INSTALLATION PIPE DIAMETER (b) 30.0 mm or LESS

7) Install circlip (1) using special tool 09900-06107

(A).

8. Appl y grease to the entire surface of the cage.

Use specified g rease in tube included in spare parts.

9. Insert the cage into the joint housing and fit the snap

r ing (1) into the groove of the joint housing (2).

CAUTION: P osition the opening of the snap ring (c) so

that it is not in line with a ball.

10. Apply grease to the inside of the joint housing and fit

the boot. Once fitted, insert a screwdriver under the

edge of the boot on the joint housing side, to allow air

to enter the boot cavity. This equalises the air press ure

in the boot with the atmospheric pressure.

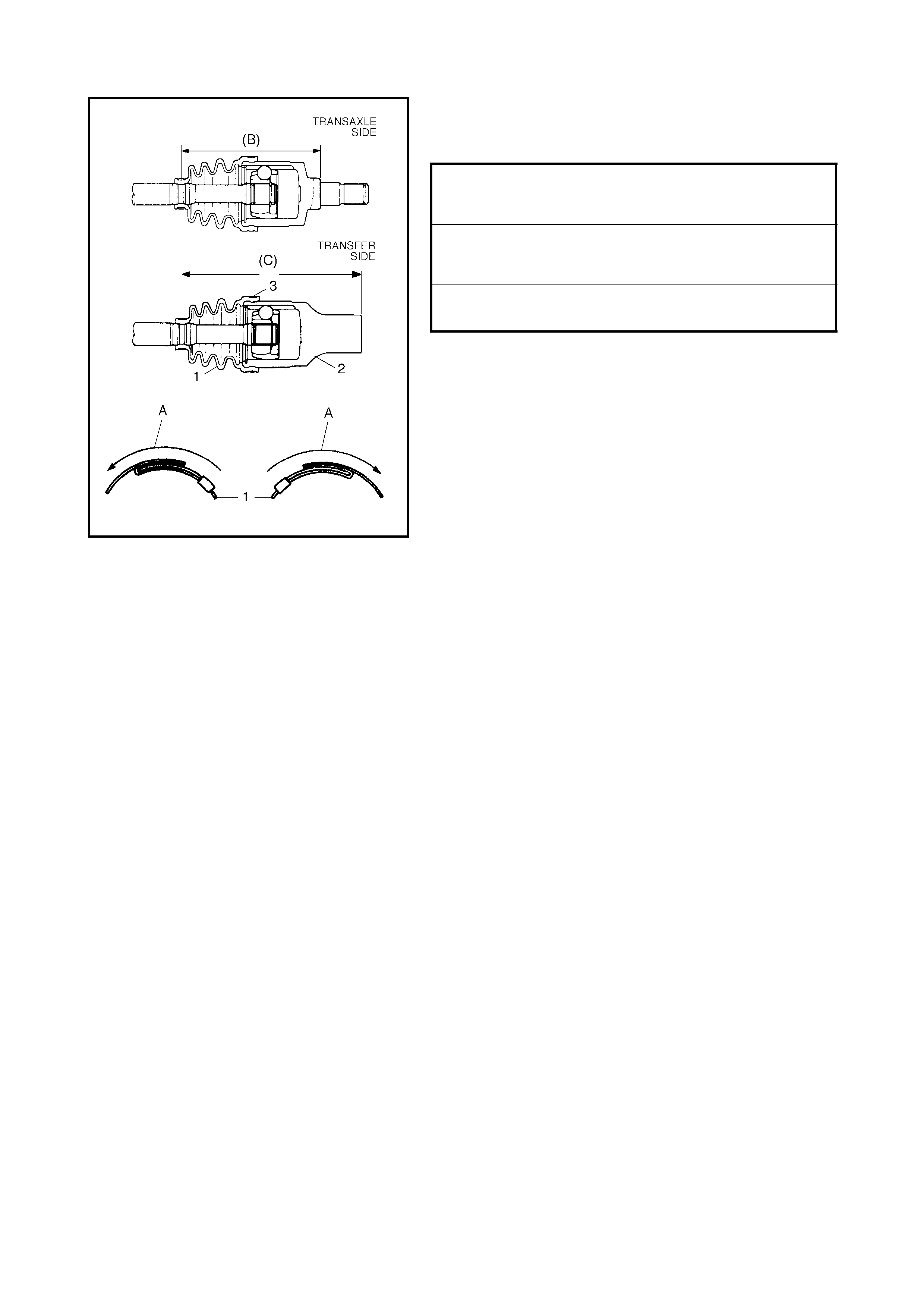

11. When fixing the boot (1) t o the joi nt housing (2) with the

differential-side band (l arge) (3), adj ust to t he measure-

ments indicated below.

CAUTION: Do no t wash joint bo ots. Cl ean wi th a cloth

only.

• Bend each boot band against forward rotation (A).

• Do not squeeze or distort boot when fastening it

w ith band s .

INSTALLATION

CAUTION:

• Avoid excessive expansion of boot and conse-

quential disconnection of joint in boot when

installing drive shaft.

• Protect oil seals and boots from damage when

installing drive shaft.

• Do not hit joint boot with hammer. Insert joint by

hand on ly.

• Make su re th at the differential-side joint is inser ted

fully and its snap ring is seated c orre ctly.

Install the drive shaft assembly by reversing remov al proce-

dure and noting the f ollowing points.

DRIVE SHAFT BOOT FIXING POSITION

LEFT SIDE DRIVESHAFT

ON A/T VEHCILES (B) 147.0 mm

DRIVE SHAFT BOOT FIXING POSITION

LEFT SIDE DRIVESHAFT

ON M/T VEHCILES (B) 162.5 mm

DRIVE SHAFT BOOT FIXING POSITION

RIGHT SIDE DRIVESHAFT (C) 196.5 mm

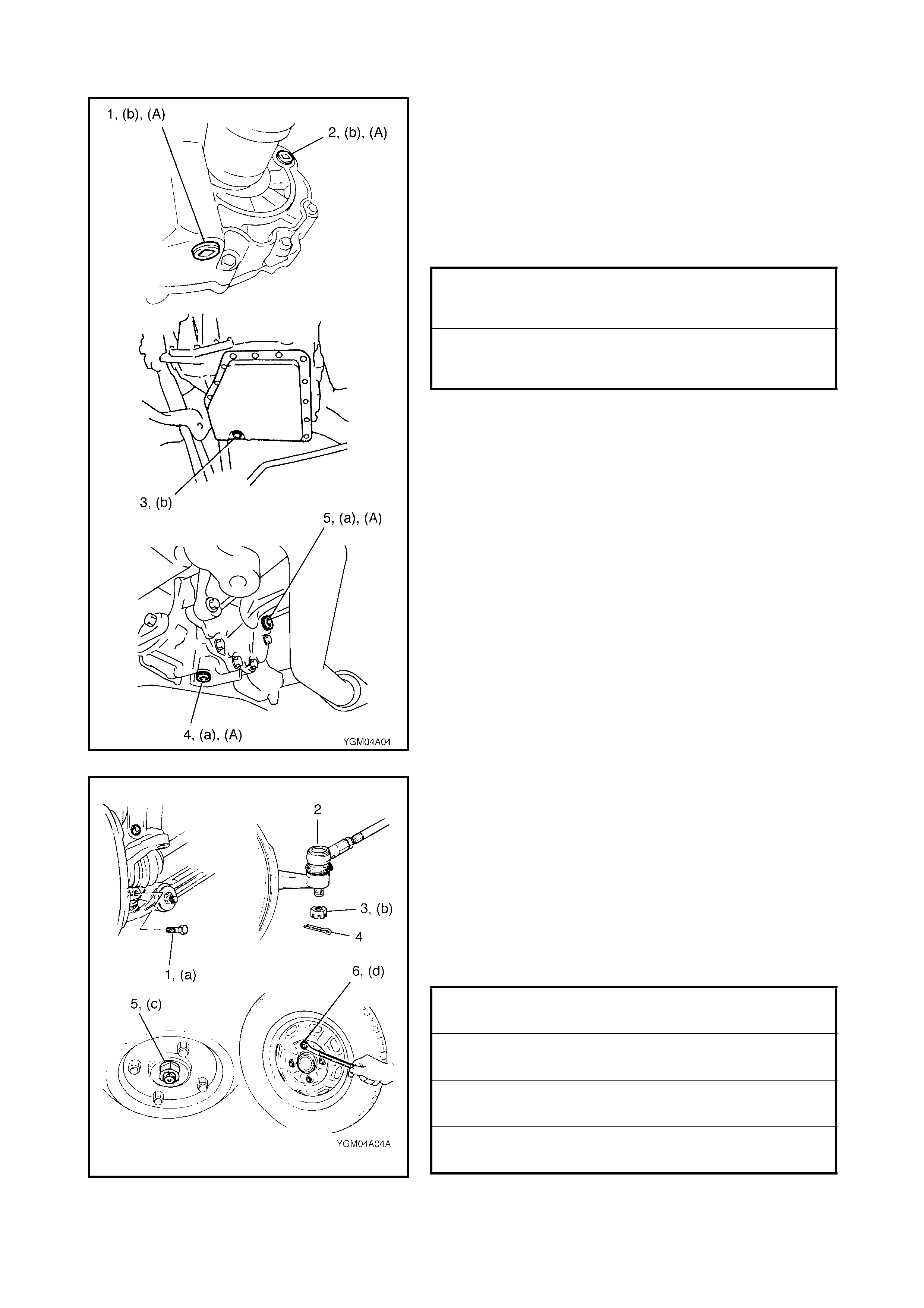

• Tighten each bolt and nut to the specified torque.

• Apply sealant to drain plug (1) and filler/level plug (2)

on manual transmission vehicles.

(A): Sealant - Three Bond No. 1216B

• Refit drain plug (3) on automatic transmission vehicles.

• Apply sealant to drain plug (4) and filler/level plug (5)

on transfer.

(A): Sealant - Three Bond No. 1216B

• Refit ball stud bolt (1).

• Connect tie rod end (2) to steering knuckle and tighten

tie rod end castle nut (3).

• Install new split pin (4) and bend pin ends securely

against castle nut.

• Depress foot brake pedal and hold. Install new drive

shaft nut (5) and washer.

• Stake drive shaft nut, refer to Section 3D, 3.3 WHEEL

HUB AND STEERING KNUCKLE.

• Fit wheel and tighten wheel nuts (6).

• Fill transmission or transfer with oil as specified, refer

to Section 7A MANUAL TRANSMISSION,

7B AUTOMATIC TRANSMISSION or 7D TRANSFER.

TRANSFER OIL FILLER/LEVEL AND

DRAIN PLUGS (a)

TORQUE SPECIFICATION 21 Nm

TRANSMISSION OIL FILLER/LEVEL

AND DRAIN PLUGS (b)

TORQUE SPECIFICATION 21 Nm

BALL STUD BOLT (a)

TORQUE SPECIFICATION 60 Nm

TIE ROD AND CASTLE NUT (b)

TORQUE SPECI FICATI ON 30 - 55 Nm

DRIVE SHAFT NUT (c)

TORQUE SPECIFICATION 175 Nm

WHEEL NUT (d)

TORQUE SPECIFICATION 85 Nm

4. REQUIRED SERVICE MATERIAL

5. SPECIAL TOOLS

NOTE: Refer to Section 0A GENERAL INFORMATION – 7. CONSOLIDATED TOOLS for a detailed list of

special tools and the local equivalent if on e is available.

Material Recom mend ed Product Use

Sealant Three Bond No. 1216B • Oil drain and filler plug for manual

transa xle or tran sfe r

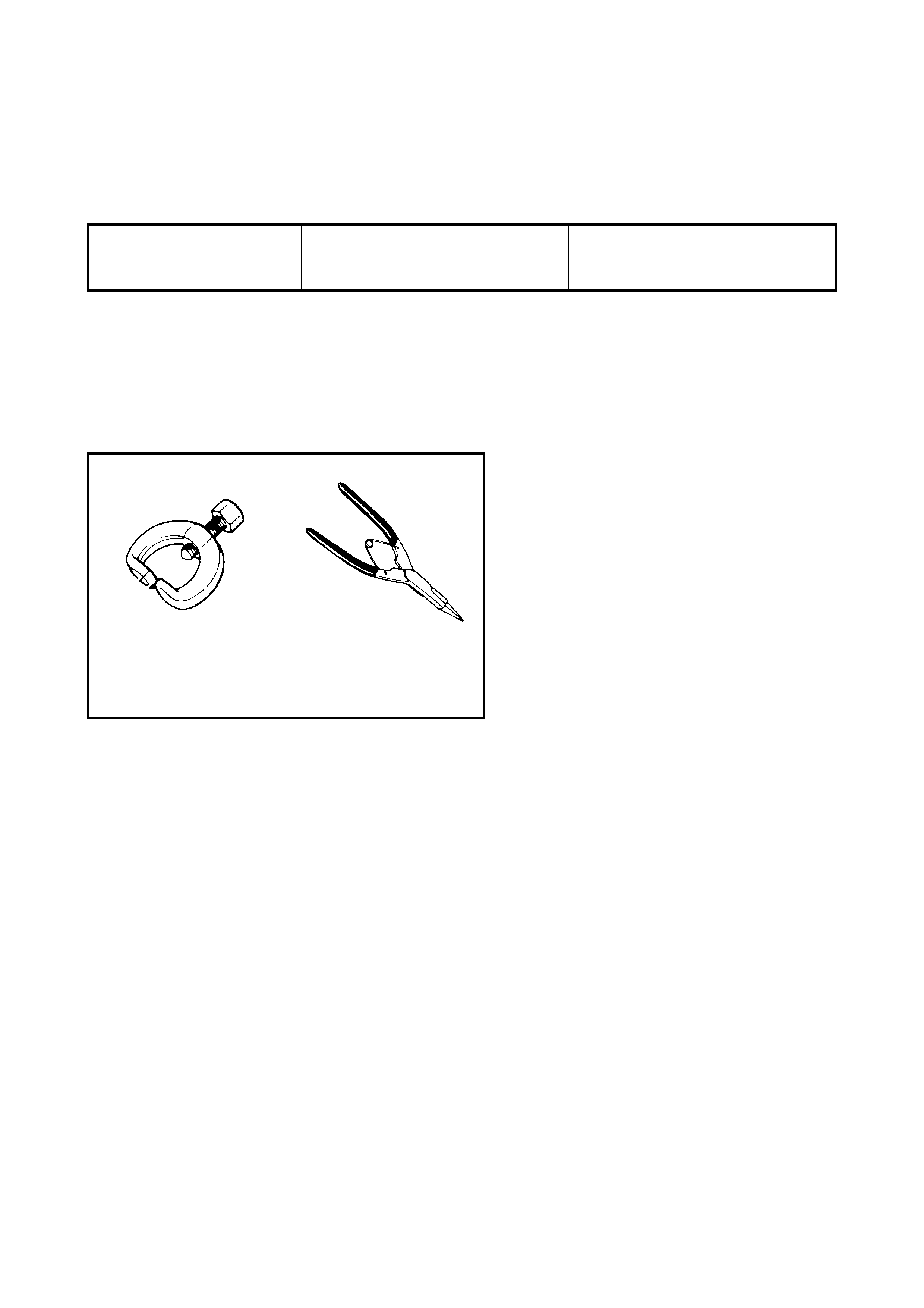

09913-65210 09900-06107

Tie-rod end remover Snap ri ng pliers (Open

type)