7B

WARNING:

For vehicles equipped with a Supplemental Restraint (Air Bag) System:

• Service on and around the air bag system components or wiring must be performed only by an

authorized Holden dealer. Refer to “System Components and Wiring Location View and

Connectors” under “General Description” in Section 10B in order to confirm whether you are

performing service on or near the air bag system components or wiring. Please observe all

WARNINGs and “Service Precautions” under “On-Vehicle Service” in Section 10B before

performing service on or around the air bag system components or wiring. Failure to follow

WARNINGs could result in unintentional activation of the system or could render the system

inoperative. Either of these two conditions may result in severe injury.

• Technical service work must be started at least 90 seconds after the ignition switch is turned to

the “LOCK” position and the negative cable is disconnected from the battery. Otherwise, the

system may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

For the items not listed below, refer to the Section 7B.

General Description

Specifications

Transmission Control Module (TCM)

Automatic Gear Shift Diagram

Diagnosis

Diagnostic Trouble Code (DTC) Table

Manual Road Test

SECTION 7B1 - AUTOMATIC TRANSAXLE (2004 UPDATE)

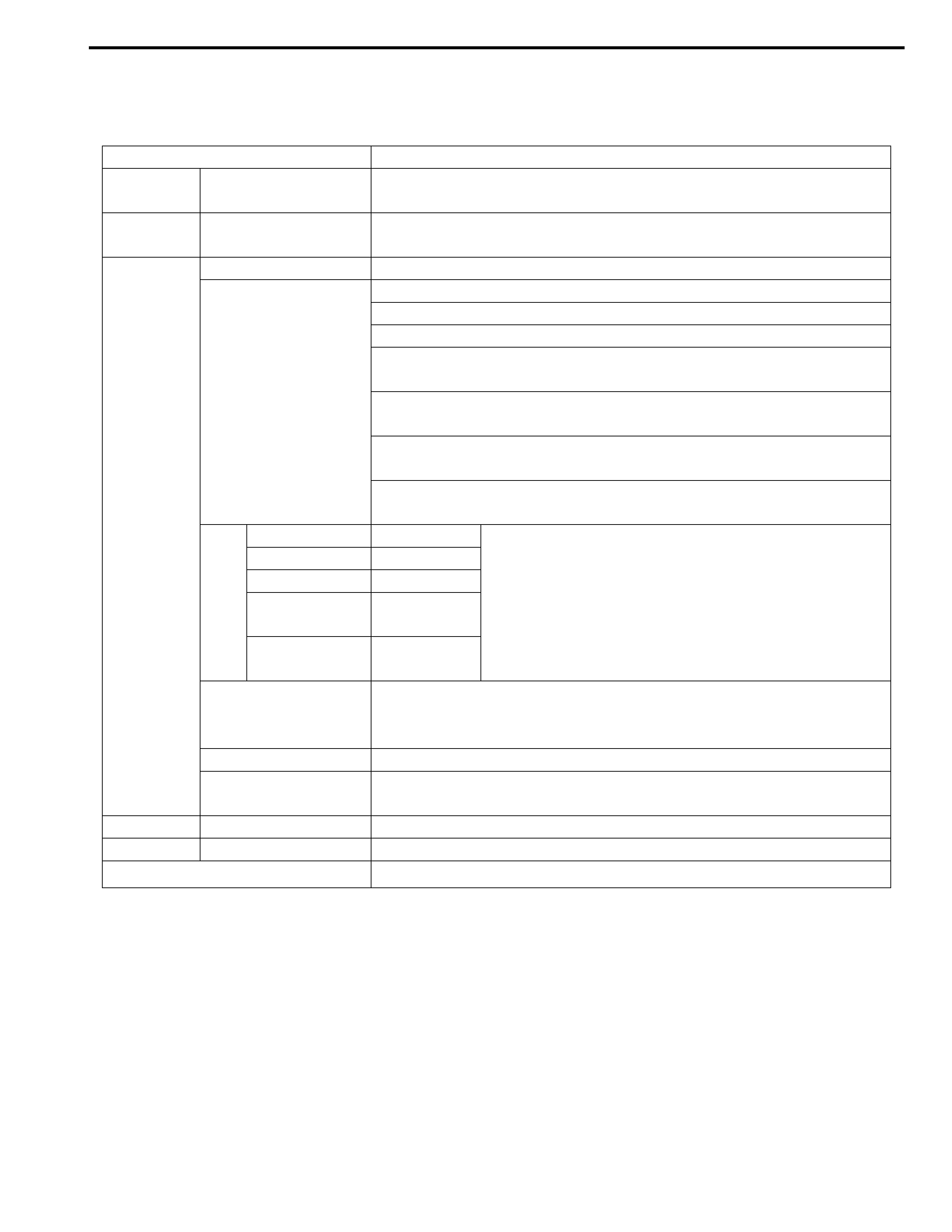

General Description

Specifications

Item Specifications

Torque

converter

Typ e

Stall torque ratio

3-element, 1-step, 2-phase type (with TCC (lock-up) mechanism)

1.9 – 2.1

Oil pump Ty p e

Drive system

Internal involute gear type oil pump (non crescent type)

Engine driven

Gear

change

device

Type Forward 4-step, reverse 1-step planetary gear type

Shift position

“P” range Gear in neutral, output shaft fixed, engine start

“R” range Reverse

“N” range Gear in neutral, engine start

“D” range

(O/D ON)

Forward 1st ↔ 2nd ↔ 3rd ↔ 4th (O/D)

automatic gear change

“D” range

(O/D OFF)

Forward 1st ↔ 2nd ↔ 3rd ← 4th

automatic gear change

“2” range Forward 1st ↔ 2nd ← 3rd

automatic gear change

“L” range Forward 1st ← 2nd ← 3rd reduction, and fixed at 1st

gear

Gear

ratio

1st 2.875 Number of teeth Front sun gear: 24

2nd 1.568 Rear sun gear: 30

3rd 1.000 Long planet pinion: 20

4th

(overdrive gear) 0.697 Short planet pinion: 19

Ring gear: 69

Reverse

(reverse gear) 2.300

Control elements

Wet type multiple-disc clutch... 3 sets

Wet type multiple-disc brake... 3 sets

One-way clutch... 2 sets

Reduction gear ratio 1.022

Final gear reduction

ratio 4.277

Lubrication Lubrication system Force feed system by oil pump

Cooling Cooling system Radiator assisted cooling (water-cooled)

Fluid used DEXRON-III

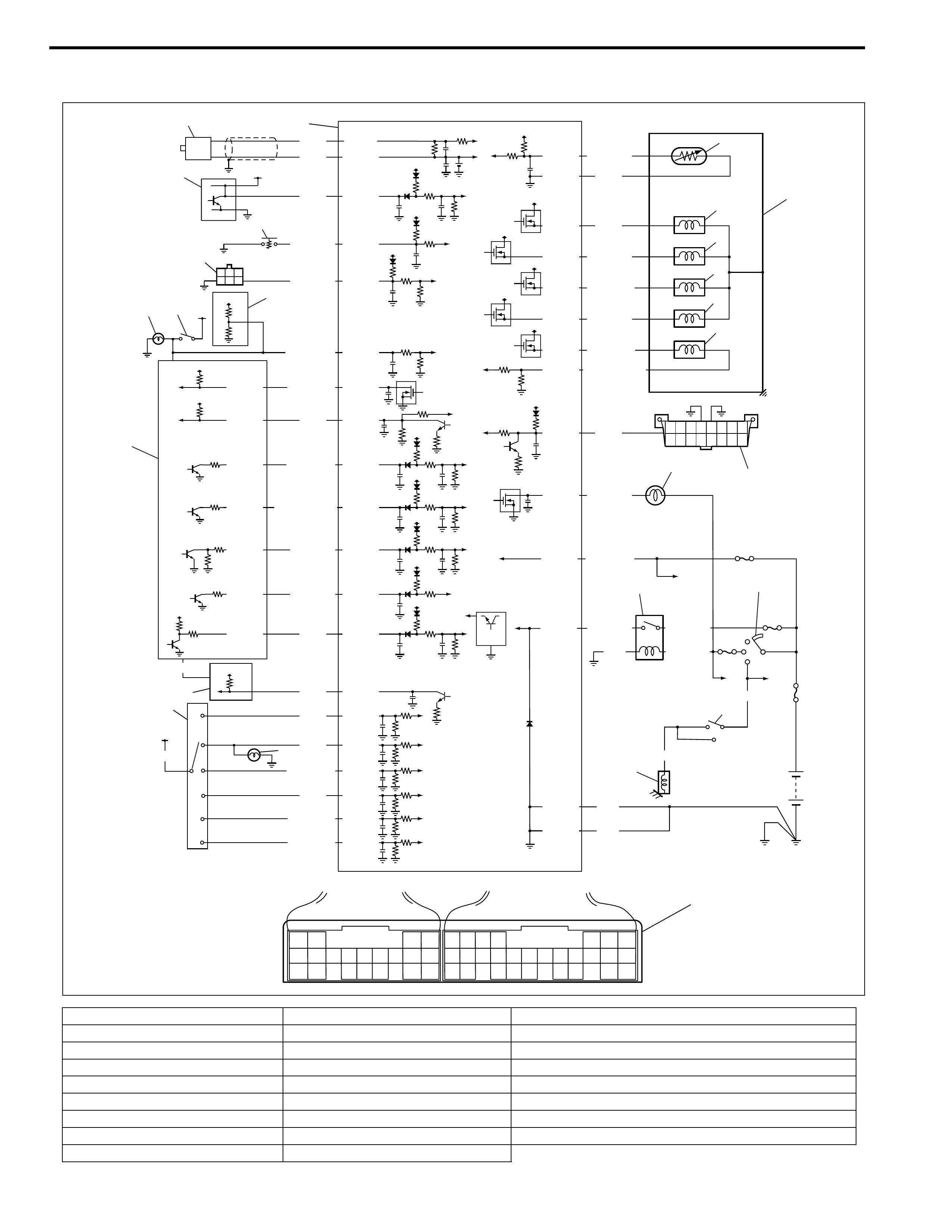

Transmission Control Module (TCM)

1. TCM 10. Speedometer (in combination meter) 19. A/T

2. Input shaft speed sensor 11. Transmission range sensor 20. Data link connector (DLC)

3. Output shaft speed sensor (VSS) 12. Backup lamp 21. “O/D OFF” lamp

4. O/D off switch 13. Transmission fluid temperature sensor 22. A/T relay

5. Monitor connector (color in Black) 14. Shift solenoid valve-A (No.1) 23. Ignition switch

6. Brake light (Stop lamp) 15. Shift solenoid valve-B (No.2) 24. Inhibitor switch

7. Brake light switch (Stop lamp switch) 16. Timing solenoid valve 25. Starter motor relay

8. ABS control module 17. TCC (lock-up) solenoid valve 26. Terminal arrangement of TCM connector (viewed from harness)

9. ECM 18. Pressure control solenoid valve

43

13 12 11 10 9 8

20 19 18 17 16

76 5

21

15 14

19 18

28 27

17 16

7654

15 14

26 25 24

13 12 11

23 22

10 9 8

21 20

321

C43 G99

5

IG1

+BB

4

12V

12V

12V

12V

12V

11

10

P

R

N

D

2

L

12

PPL/YEL

GRN/WHT

GRN/RED

GRY/RED

LT GRN/RED

RED/BLU

G99-5

12V 2.5V

12V

5V

12V

12V

12V

12V

12V

5V

12V

12V

12V

12V

12V

12V

IG11

IG1

24

25

12V

WHT

BLK

GRN

BRN

BLK

BLK

BLK

BLU

YEL

PNK

BRN

PPL

PPL

ORN

RED

GRN

GRY/YEL

YEL/GRN

GRN/ORN

GRN/YEL

IG11

RED/BLK

BLU/WHT

G99-17 C43-5

C43-14

C43-4

C43-3

C43-10

C43-12

C43-11

C43-8

G99-27

G99-10

C43-15

C43-19

C43-20

G99-24

G99-3

C43-6

C43-16

G99-12

G99-18

G02-6

G02-17

G02-15

G02-5

G02-4

G02-16

G02-12

G99-7

G99-6

G99-23

G99-14

G99-15

G99-28

G99-2

G99-1

G99-9

G99-8

G99-21

G99-20

BLU/RED

BLK/YEL

WHT/RED

WHT/BLU

RED/BLU

YEL/BLK

YEL/GRN

BLK/WHT

+BB

C43-13 WHT/RED

BLK/YEL

BLK/RED

BRN/YEL

LT GRN/RED

P

N

13

19

14

15

16

17

18

1

2

3

8

7

6

9

20

21

22 23

26

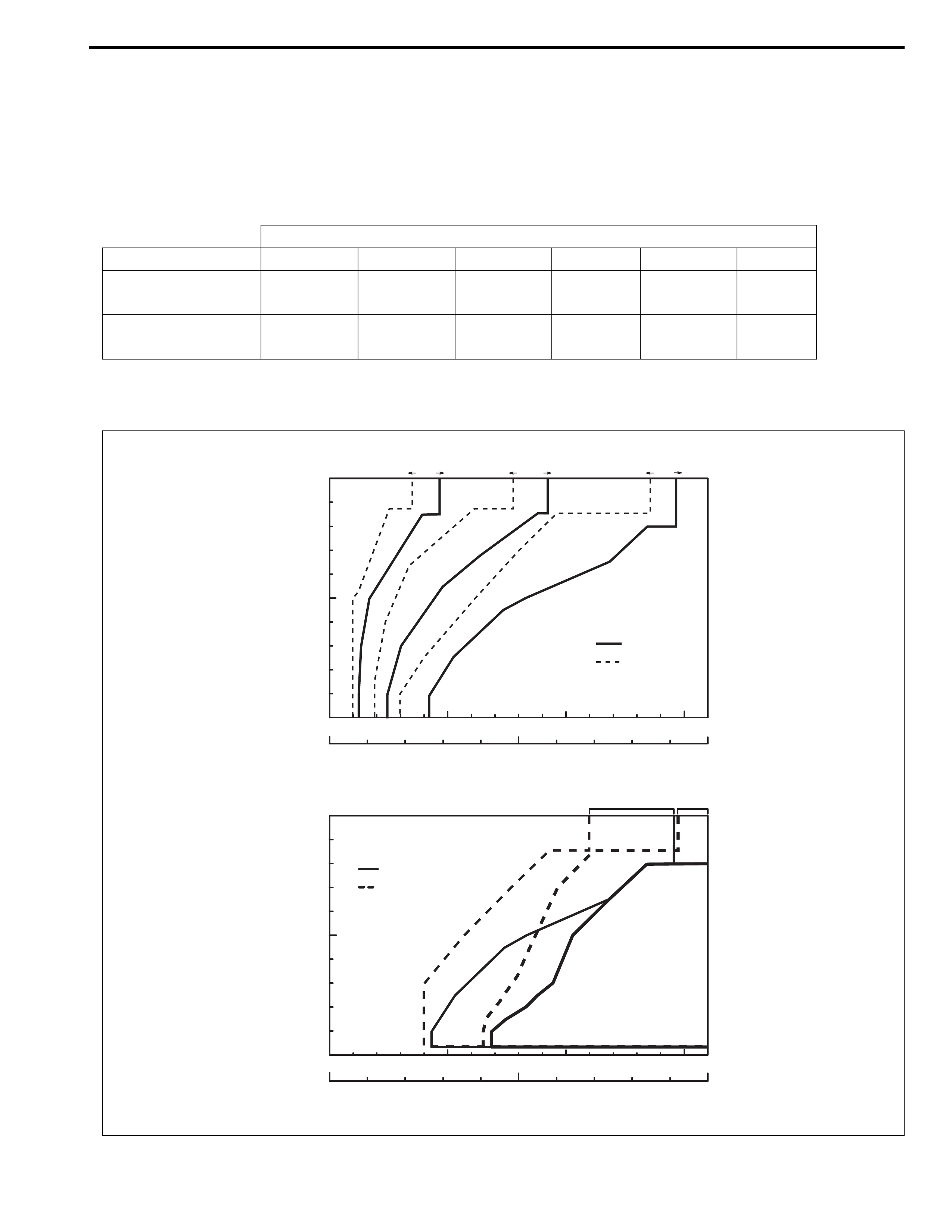

Automatic Gear Shift Diagram

Automatic shift schedule as a result of shift control is shown below. In case that selector lever is shifted to “L”

range at a higher than 46 km/h (29 mile/h) speed, 2nd gear is operated and then down shifts to 1st at a speed

lower than that.

The same as, the select lever is shifted to “2” range at a higher than 92 km/h (57 mile/h) speed, 3rd gear is oper-

ated and then down shifts to 2nd at a speed lower than that.

Gear Shift Diagram [A] and TCC Lock-up Diagram [B]

Shift

Throttle opening 1→22→33→44→33→22→1

Full throttle km/h

(mile/h)

46 (29) 92 (57) 146 (91) 136 (85) 78 (48) 35 (22)

Closed throttle km/h

(mile/h)

12 (8) 24 (15) 42 (26) 30 (17) 19 (12) 10 (6)

100

(%)

50

00 50 100 150

100

(km/h)

(mile/h)500

Throttle valve opening

Vehicle speed

100

(%)

50

00 50 100 150

100

(km/h)

(mile/h)500

Throttle valve opening

Vehicle speed

12

12 23 23 34

34

Upshift

Downshift

Look-up ON

Look-up OFF

4th gear3rd gear(O/D OFF)

[A]

[B]

Diagnosis

Diagnostic Trouble Code (DTC) Table

NOTE:

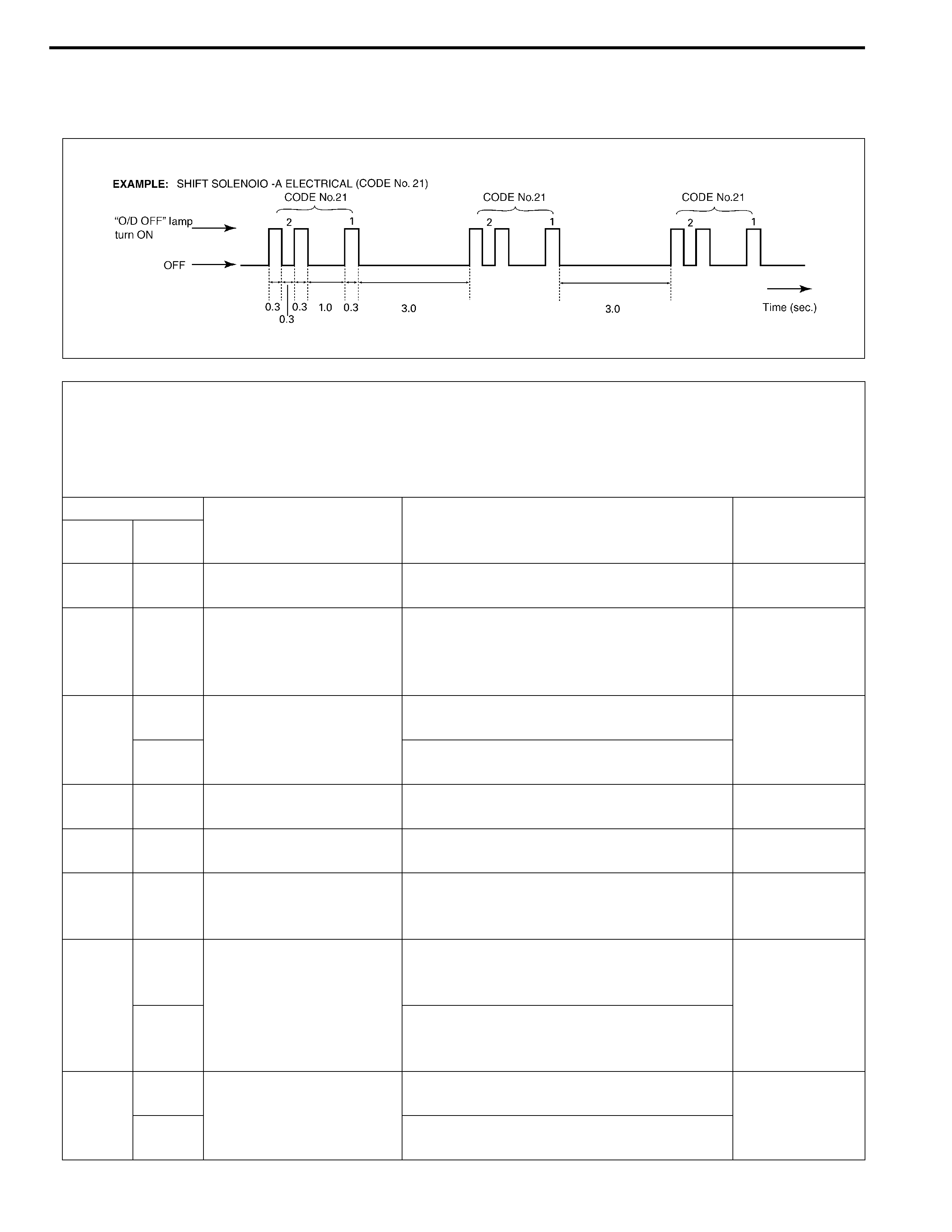

• Type I of DTC: DTC code which can be checked by using scan tool

• Type II of DTC: DTC code which can be checked by flashing “O/D OFF” lamp in combination meter

with monitor connector diagnosis terminal connected to ground.

• *1: Application of “O/D OFF” lamp flashing by TCM when the malfunction is detected.

DTC NO.

DETECTING ITEM DETECTING CONDITION

(DTC will set when detecting:)

*1

“O/D OFF”

lamp flashing

Type I Type II

–12

Normal (No malfunction is

detected.) ––

P0705 34 Transmission range sen-

sor circuit malfunction

• No sensor signal is inputted.

or

• Multiple signals are inputted simulta-

neously

Not applicable

P0710

36 Transmission fluid tem-

perature sensor circuit

malfunction

Sensor output voltage is too high (Circuit

open or shored to power circuit) Applicable

38 Sensor output voltage is too low (Circuit

shored to ground)

P0715 14 Input/Turbine speed sen-

sor circuit malfunction

No sensor signal is detected although output

shaft speed sensor signal is detected. Applicable

P0720 31 Output speed sensor

(VSS) circuit malfunction

No sensor signal is inputted although input

shaft speed sensor signal is inputted. Applicable

P0725 35 Engine speed input cir-

cuit malfunction

No engine speed signal is inputted although

engine is running and engine temperature

sensor signal is in normal condition.

Applicable

P0743

25

Torque converter clutch

system electrical

Voltage of TCC solenoid terminal is high

although TCM is commanding TCC solenoid

to turn OFF. Applicable

26

Voltage of TCC solenoid terminal is low

although TCM is commanding TCC solenoid

to turn ON.

P0748

41 Pressure control solenoid

electrical

No electric flow is detected on solenoid cir-

cuit. Applicable

42 Too much electric flow is detected on pres-

sure control solenoid circuit.

DTC NO.

DETECTING ITEM DETECTING CONDITION

(DTC will set when detecting:)

*1

“O/D OFF”

lamp flashing

Type I Type II

P0753

21

Shift solenoid-A (No.1)

electrical

Voltage of shift solenoid terminal is high

although TCM is commanding shift solenoid

to turn OFF. Applicable

22

Voltage of shift solenoid terminal is low

although TCM is commanding shift solenoid

to turn ON.

P0758

23

Shift solenoid-B (No.2)

electrical

Voltage of shift solenoid terminal is high

although TCM is commanding shift solenoid

to turn OFF. Applicable

24

Voltage of shift solenoid terminal is low

although TCM is commanding shift solenoid

to turn ON.

P0785 13 Timing solenoid

• Voltage of timing solenoid terminal is high

although TCM is commanding timing sole-

noid to turn OFF.

or

• Voltage of timing solenoid terminal is low

although TCM is commanding timing sole-

noid to turn ON.

Applicable

P1700

32 Throttle position signal

circuit malfunction

Too short low signal of pulse signal from

ECM to TCM continues out of specification. Applicable

33 Too long low signal of pulse signal from ECM

to TCM continues out of specification.

P1702 52 Internal malfunction of

TCM

Calculation of current data stored in TCM is

not correct comparing with pre-stored check-

ing data in TCM.

Applicable

P1705 51

Engine coolant tempera-

ture signal circuit malfunc-

tion

• Too long high signal of pulse signal from

ECM to TCM continues out of specifica-

tion.

or

• Too long low signal of pulse signal from

ECM to TCM continues out of specifica-

tion.

or

• Too long or short low signal of pulse signal

from ECM to TCM is detected in continu-

ous 8 pulses.

Applicable

P1730 64 Engine torque signal cir-

cuit malfunction

• Too short low signal of pulse signal from

ECM to TCM continues out of specifica-

tion.

or

• Too long low signal of pulse signal from

ECM to TCM continues out of specifica-

tion.

Applicable

P1895 27 Torque reduction signal

circuit malfunction

Voltage of torque reduction signal circuit ter-

minal is low although TCM does not require

ECM to reduce engine torque

Applicable

Manual Road Test

This test checks the gears being used in “L”, “2” or “D” range

when driven with unoperated gear shift control system. Test drive

vehicle on a level road.

1) With select lever in “P”, start engine and warm it up.

2) After warming up engine, turn ignition switch OFF and dis-

connect valve body harness connector (1).

3) With select lever in “L” range, start vehicle and check that 3rd

gear is being used referring to table shown below.

Vehicle speed per 1000 rpm in engine speed (V1000 table,

reference)

4) While vehicle is running, shift select lever to “2” range and

check that 3rd gear is being used.

5) While vehicle is running, shift select lever to “D” range and

check that 3rd gear is being used.

6) After above checks, stop vehicle then turn ignition switch

OFF, and connect valve body harness connector.

7) Clear DTC.

Troubleshooting

NOTE:

Before this test, check diagnostic trouble code (DTC).

Gear position Vehicle speed

1st 8.8 km/h (5.5 mile/h)

2nd 16.2 km/h (10.1 mile/h)

3rd 25.4 km/h (15.8 mile/h)

4th (O/D) 36.5 km/h (22.7 mile/h)

Reverse 11.0 km/h (6.8 mile/h)

Condition Possible Cause Correction

Operated gear is not

correct

Faulty valve body component Replace valve body assembly.

Faulty clutch or brake Inspect clutch and brake. If any

parts are faulty, replace them.