SECTION 8 - BODY ELECTRICAL SYSTEM

1. DIAGNOSIS

1.1 HEADLIGHT

1.2 TURN SIGNAL AND HAZARD WARNING

LIGHTS

1.3 CLEARANCE, TAIL AND LICENCE

PLATE LIGHT

1.4 BACK-UP LIGHT

1.5 BRAKE LIGHT

1.6 FRONT FOG LIGHT

1.7 SPEEDOMETER AND VSS

1.8 FUEL GAUGE AND FUEL LEVEL

SENSOR (GAUGE UNIT)

1.9 ENGINE COOLANT TEMPERAT URE

(ECT) GAUGE AND ECT SENSOR

1.10 ENGINE OIL PRESSURE WARNING

LIGHT

1.11 BRAKE AND PARKING BRAKE

WARNING LIGHT

1.12 REAR WINDOW DEFOGGER

1.13 FRONT & REAR WIPERS AND

WASHERS

1.14 POWER WINDOW CONTROL SYSTEM

1.15 CIGARETTE LIGHTER

1.16 POWER DOOR LOCK SYSTEM WITH

KEYLESS ENTRY SYSTEM

1.17 POWER DOOR MIRROR CONTROL

SYSTEM

1.18 INTERIOR LIGHT

1.19 HORN

1.20 IGNITION KEY REMINDER AND LIGHT

REMINDER WARNING BUZZER

1.21 SEAT BELT WARNING LIGHT

2. ON-VEHICLE SERVICE

2.1 CAUTIONS IN SERVICING

2.2 HEADLIGHT AND POSITION LIGHT

Headlight and Position Light Switch

Headlight Assembly

Headlight Bulb

Position Light Bulb

Headlight Aiming Adjustment with

Screen

2.3 TURN SIGNAL AND HAZARD WARNING

LIGHTS

Turn Signal and Hazard Warning

Lights System Circuit

Turn Signal and Hazard Warning

Lights System Circuit Check

Turn Signal Switch

Front Turn Signal Assembly

Front Turn Signal Bulb

Front Fender Turn Signal Assembly

Front Fender Turn Signal Bulb

Rear Turn Signal Assembly

Rear Turn Signal Bulb

Turn Signal and Hazard Relay

Hazard Switch

2.4 FRONT FOG LIGHTS

Front Fog Light Switch

Front Fog Light

Front Fog Light Bulb

Front Fog Light Aiming Adjustment

with Screen

WARNING:

For vehicles equipped with Supplement Restraint (Airbag) System

• Service on and around the airbag system components or wiring must be performed only by

an authorised HOLDEN retailer. Refer to Section 10B AIRBAG SYSTEM COMPONENTS AND

WIRING LOCATION VIEW in GENERAL DESCRIPTION in order to confirm whether you are

performing service on or near the airbag system components or wiring. Please observe all

W ARNINGS and SERVICE PRECAUTIONS, refer to Section 10B ON-VEHICLE SERVICE before

performing service on or around the airbag system components or wiring. Failure to follow

WARNINGS could result in unintentional activation of the system or c ould render the system

inoperative. Either or these two condit ions may result in severe inju ry.

• Technical service work must not be started for at least 90 sec onds after the ignition s witch is

turned to the “LOCK” position and the negative cable is disconnected from the battery.

Otherwise, the system may be activated by reserve energy in the Sensing and Diagnostic

Module (SDM).

2.5 BRAKE AND TAIL LIGHT

Brake Light Switch

Tail Light Switch

Brake and Tail Light Assembly

Brake and Tail Light Bulb

High Mount Brake Light Assembly

High Mount Brake Light Bulb

2.6 BACKUP LIGHT

Backup Light Switch (M/T)

Transmission Range Sensor (Shift

Switch) (A/T)

Backup Light Assembly

Backup Light Bulb

2.7 LICENCE PLATE LIGHT

Licence Plate Light Switch

Licence Plate Light Assembly

Licence Plate Light Bulb

2.8 ILLUMINATION CONTROLLER

Inspection

2.9 IGNITION SWITCH

On-vehicle Inspection

Removal

Installation

2.10 COMBINATION METER

Removal

Installation

Inspection

2.11 FUEL GAUGE AND FUEL LEVEL

SENSOR (GAUGE UNIT)

Fuel Gauge

Fuel Level Sensor (Gauge Unit)

Inspection

2.12 SPEEDOMETER AND VEHICLE SPEED

SENSOR (VSS)

Vehicle Speed Sensor (VSS)

2.13 ENGINE COOLANT TEMPERATURE

(ECT) GAUGE AND SENSOR

Engine Coolant Temperature (ECT)

Gauge

ECT Sensor

2.14 ENGINE OIL PRESSURE WARNING

LIGHT

Engine Oil Pressure Switch

2.15 BRAKE SYSTEM WARNING LIGHT

(PARKING BRAKE INDICATOR, BRAKE

FLUID WARNING AND EBD SYSTEM

WARNING LIGHT)

Brake Fluid Level Switch

Parking Brake Switch

2.16 REAR WINDOW DEFOGGER

Defogger Switch

Defogger Wire

2.17 WIPERS AND WASHERS

Components

Front Wiper and Washer Switch

Front Wiper Motor

Washer Tank and Washer Pump

Rear Wiper and Washer Switch

Rear Wiper Motor

2.18 IGNITION KEY REMINDER AND LIGHT

REMINDER WARNING BUZZER

Removal

Installation

2.19 POWER WINDOW CONTROL SYSTEM

Power Window Main Switch

Power Window Sub Switch

2.20 DOOR SWITCH

Inspection

2.21 POWER DOOR LOCK SYSTEM WITH

KEYLESS ENTRY SYSTEM

Component Location

System Description

Change of Signal Mode

Power Door Lock System Operation

Power Door Lock System Circuit

Power Door Lock Vehicle Operation

Power Door Lock System Circuit

Check

Driver’s Door Knob Switch

Door Lock Actuator

Keyless Entry System Operation

Keyless Entry System Circuit

Keyless Entry System Circuit Check

Transmitter

Code Registration Procedure

2.22 POWER DOOR MIRROR CONTROL

SYSTEM

Mirror Switch

2.23 DOOR MIRROR ACTUATOR

Removal

Inspection

Installation

2.24 MULTI INFORMATION DISPLAY

Removal

Inspection

Installation

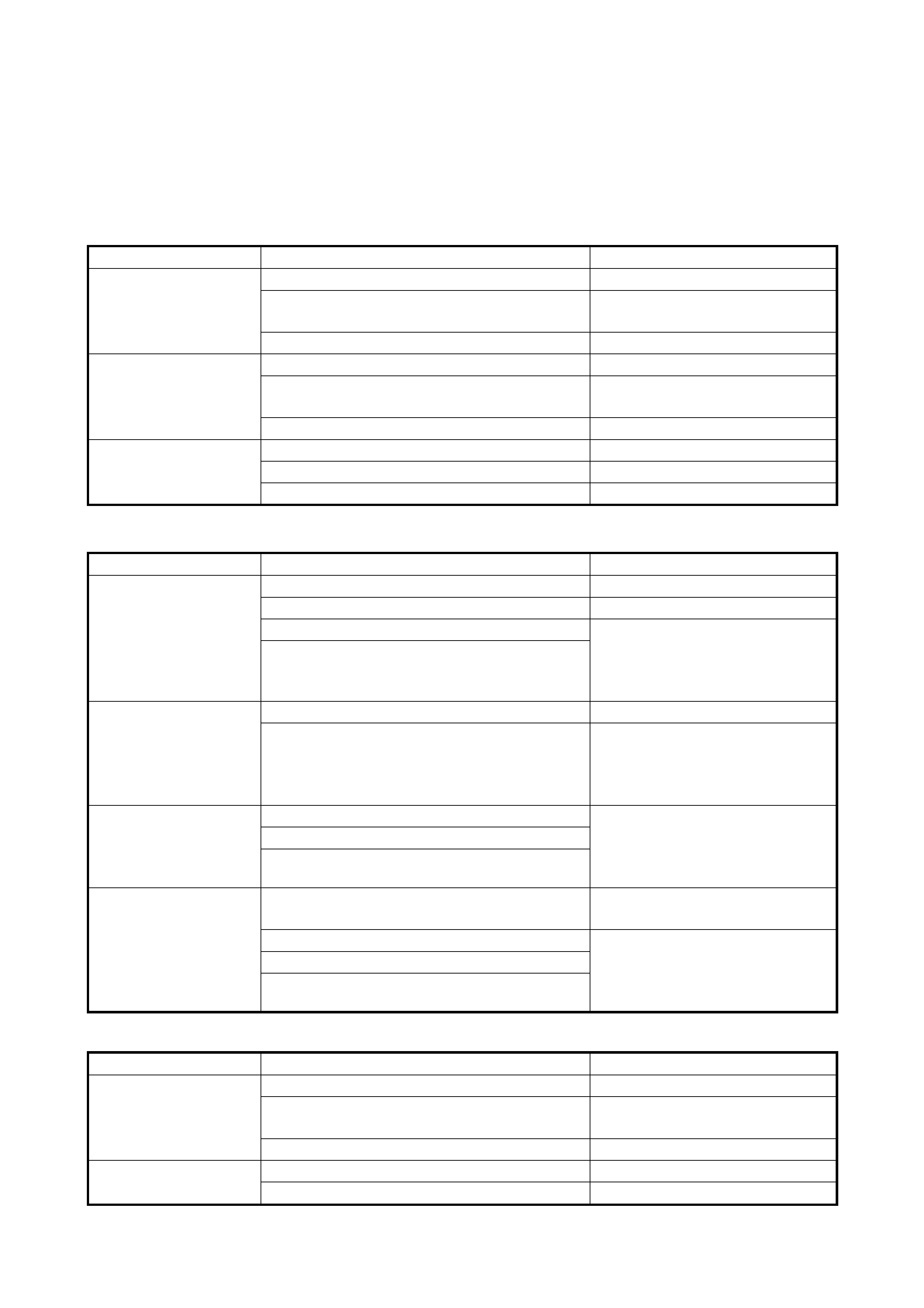

1. DIAGNOSIS

1.1 HEADLIGHT

1.2 TURN SIGNAL AND HAZARD WARNING LIGHTS

1.3 CLEARANCE, TAIL AND LICENCE PLATE LIGHT

Condition Possible Cause Correction

Headlights do not

illuminate

Lighting or dimmer switch faulty. Check headlight switch.

HEADLIGHT R and L fuses (15A) in main fuse

box blown. Replace fuse to check for short.

Wiring or grounding faulty. Repair circuit .

One he ad light does

not illum inate

Bulb blown. Replace bulb.

HEADLIGHT R or L fuse (15A) in main fuse

box blown. Replace fuse to check for short.

Wiring or grounding faulty. Repair circuit .

One be am (Hi or Lo)

does no t illu mi na te

Bulb blown. Replace bulb.

Lighting or dimmer switch faulty. Check switch.

Wiring or grounding faulty. Repair circuit .

Condition Possible Cause Correction

Flash rate high or

only one si de flashe s

Bulb blown on ‘flash rate high’ - side Replace bulb.

Incorrect bulb. Replace bulb.

Turn signal and hazard warning relay faulty. Check system, refer to 2.3 TURN

SIGNAL AND HAZARD

WARNING LIGHTS SYSTEM in

this Section.

Wiring or grounding faulty

Flas h rate low

Supply voltage low Check charging system

Turn signal and hazard warning relay faulty Check system, refer to 2.3 TURN

SIGNAL AND HAZARD

WARNING LIGHTS SYSTEM in

this Section.

One si de o nly

flashes

Turn signal switch faulty Check system, refer to 2.3 TURN

SIGNAL AND HAZARD

WARNING LIGHTS SYSTEM in

this Section.

Turn signal and hazard warning relay faulty

Wiring or grounding faulty

No flashing

HORN fuse (15A) and/or METER fuse(s)

blown. After checking for short circuit,

replace MSTER fuse.

Turn signal and hazard relay faulty. Check system, refer to 2.3 TURN

SIGNAL AND HAZARD

WARNING LIGHTS SYSTEM in

this Section.

Combination switch or hazard switch faulty.

Wiring or grounding faulty.

Condition Possible Cause Correction

All lights do not illu-

minate

TAlL fuse blown. Replace fuse to check for short.

Combination switch (lighting and dimmer

switch) faulty. Check switch.

Wiring or grounding faulty. Repair circuit .

Some lights do not

illuminate

Bulb(s) blown. Replace bulb(s).

Wiring or grounding faulty. Repair circuit .

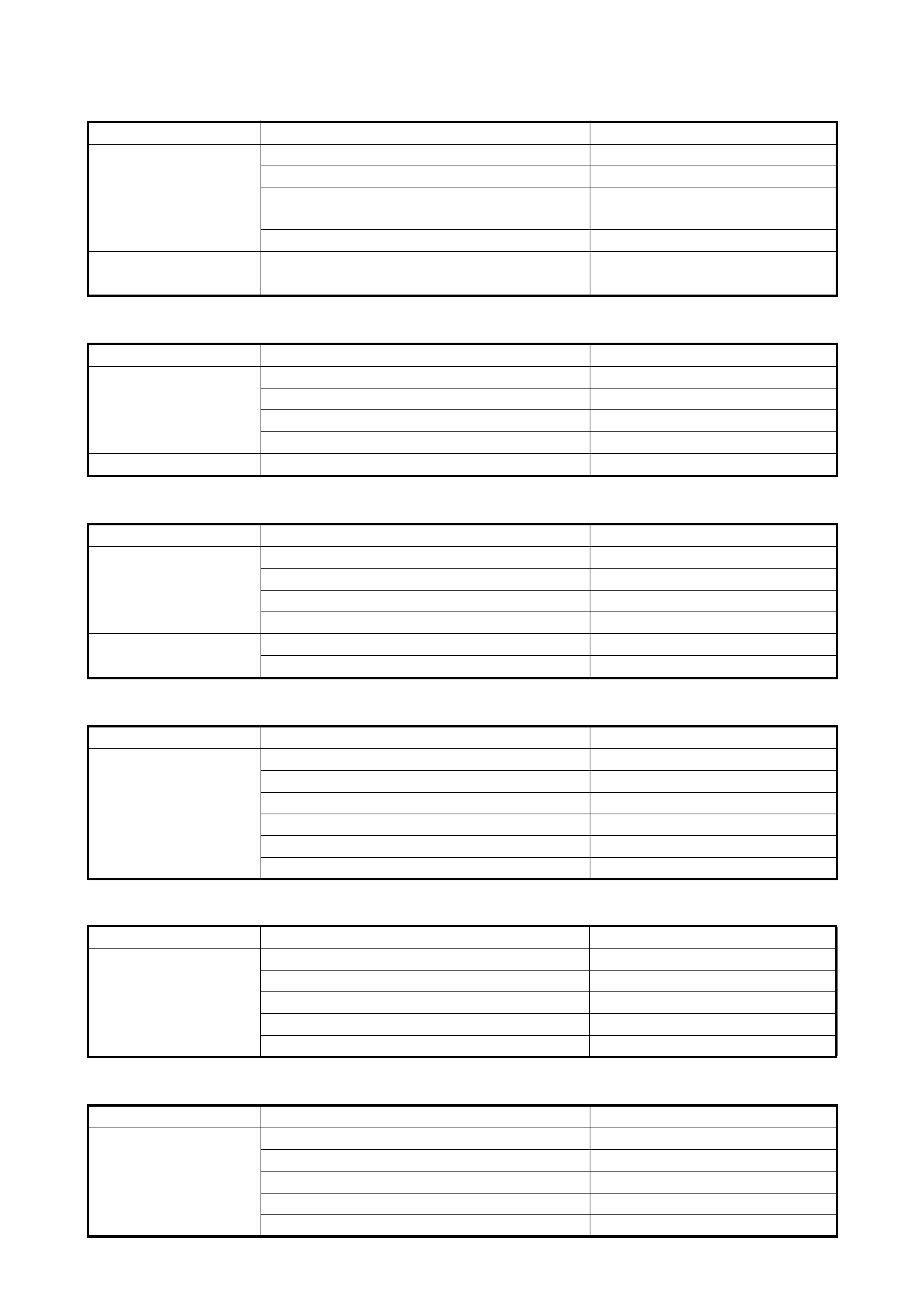

1.4 BACK-UP LIGHT

1.5 BRAKE LIGHT

1.6 FRONT FOG LIGHT

1.7 SPEEDOMETER AND VSS

1.8 FUEL GAUGE AND FUEL LEVE L SENSOR (GAUGE UNIT)

1.9 ENGINE COOLANT TEMPERATURE (ECT) GAUGE AND ECT SENSOR

Condition Possible Cause Correction

Back-u p lig hts do

not illum inate

Bulb(s) blown. Replace bulb(s).

BACK fuse blown. Replace fuse to check for short.

Back-up light switch or transmission range

sensor (shift) switch faulty. Check or rep lace.

Wiring or grounding faulty. Repair circuit .

Back-up lights stay

on

Back- up light swi tc h fault y or trans mi ssio n

range sensor (shift) switch faulty. Check or rep lace.

Conditio n Pos sibl e Ca us e Correcti on

Brake lights do not

illuminate

Bulb(s) blown. Replace bulb(s).

STOP fuse blown. Replace fuse to check for short.

Brake light switch faulty. Check switch.

Wiring or grounding faulty. Repair circuit.

Brake lights stay on

Brake light switch faulty. Check, adjust or replace switch.

Conditio n Pos sibl e Ca us e Correcti on

Front fog lights do

not illum inate

Front fog light switch faulty. Check front fog light switch.

TAIL fuse (15A) in circuit fuse box blown. Replace fuse to check for short.

Front fog light relay faulty. Check relay.

Wiring or grounding faulty. Repair circuit.

One lig ht do es not

illuminate

Bulb blown. Replace bulb.

Wiring or grounding faulty. Repair circuit.

Conditio n Pos sibl e Ca us e Correcti on

Speedomet er shows

no operation or

incorrect operation

METER and/or RADIO.DOME fuse(s) blown. Replace fuse(s) to check for short.

VSS faulty. Check VSS.

Printed plate in combination meter faulty. Check printed plate.

Wiring or grounding faulty. Repair circuit.

Signal rotor on differential case faulty. Check signal rotor.

Speedometer faulty. Check speedometer.

Condition Possible Cause Correction

Fuel ga uge show s

no opera tion or

incorrect operation

METER fuse blown. Replace fuse to check for short.

Fuel gauge unit faulty. Check fuel gauge unit.

Printed plate in combination meter faulty. Check printed plate.

Fuel gauge faulty. Check fuel gauge.

Wiring or grounding faulty. Repair circuit.

Conditio n Pos sibl e Ca us e Correcti on

Engine coolant

temp. gauge shows

no operation or

incorrect operation

METER fuse blown. Replace fuse to check for short.

ECT gauge faulty. Check ECT gauge.

Printed plate in combination meter faulty. Check printed plate.

ECT sensor faulty. Check ECT sensor.

Wiring or grounding faulty. Repair circuit.

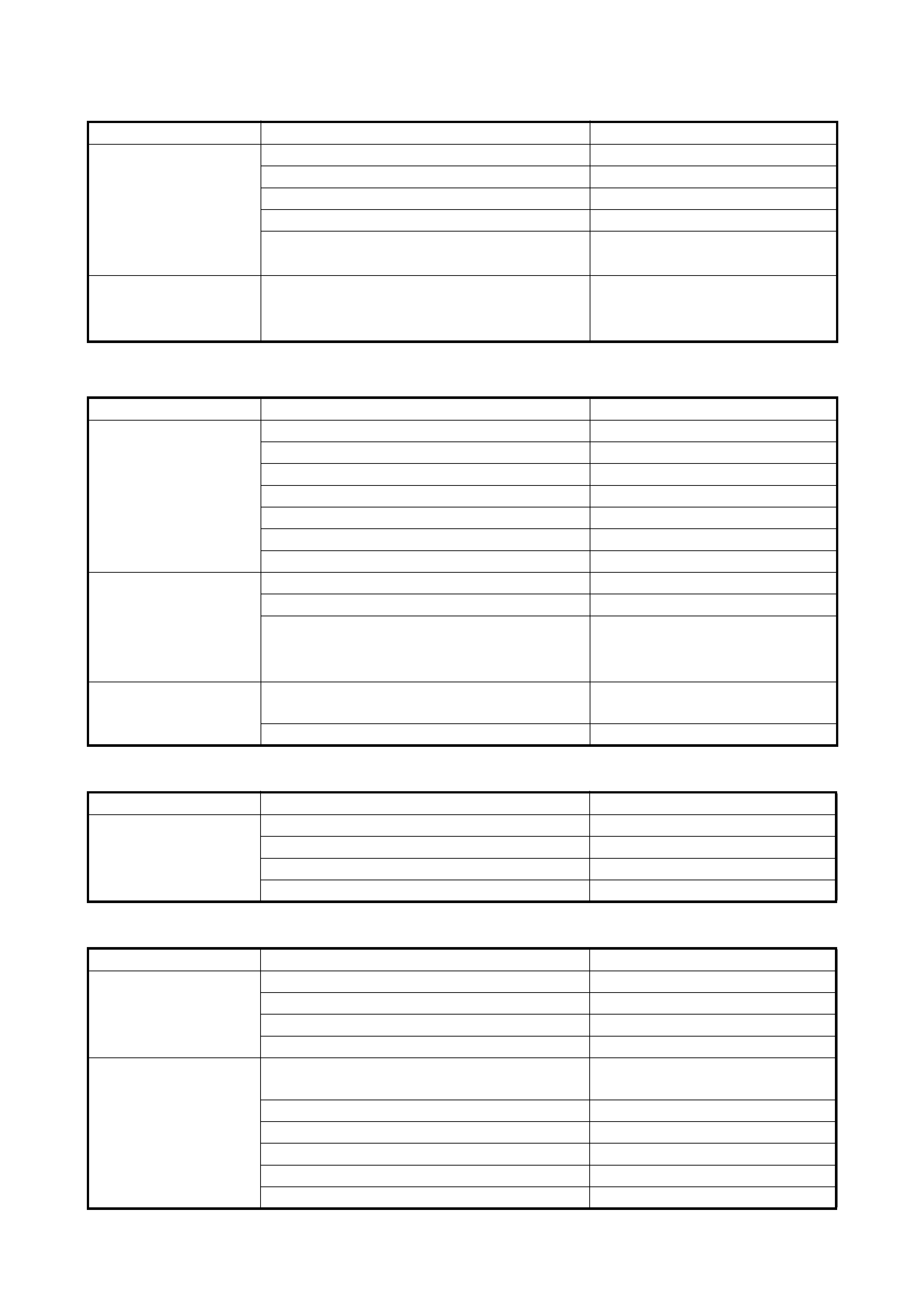

1.10 ENGINE OIL PRES SURE WARNING LIGHT

1.11 BRAKE AND PARKIN G BRA KE WARN ING LIGHT

1.12 REAR WINDOW DEFOGGER

1.13 FRONT & REAR WIPERS AND WASHERS

Conditio n Pos sibl e Ca us e Correcti on

Engine oil pressure

warning light does

not illum inate when

the ignition switch is

turned to ON posi-

tion w ith engine off

Bulb in combination meter blown. Replace bulb.

METER fuse blown. Replace fuse to check for short.

Printed plate in combination meter faulty. Check printed plate.

Oil pressure switch faulty. Check oil pressure switch.

Wiring or grounding faulty. Repair circuit.

Engine oil pressure

warnin g light stays

on

Oil pressure switch faulty. Check oil pressure switch.

Conditio n Pos sibl e Ca us e Correcti on

Brake warning light

does no t illu mi na te

(when fluid level low,

parking brake pulled

up and/or EBD sys-

tem faulty)

Bulb in combination meter blown. Replace bulb.

Printed plate in combination meter faulty. Check printed plate.

METER fuse blown. Replace fuse to check for short.

Brake fluid level switch faulty. Check brake fluid level switch.

Parking brake switch faulty. Check parking brake switch.

ABS control module faulty. Check ABS control module.

Wiring or grounding faulty. Repair circuit.

Brake warning light

does no t illu mi na te

when cranking (igni-

tion swi tch t urned to

ST position)

Ignition switch faulty. Check ignition switch.

Printed plate in combination meter faulty. Check printed plate.

Wiring or grounding faulty. Repair circuit.

Brake system warn-

ing light stays on

Brake fluid level switch, parking brake switch

and/or ABS control module faulty. Check switch.

Electrical circuit shorted to ground. Repair circuit.

Condition Possible Cause Correction

Defogger does not

operate

REAR DEFG fuse blown. Replace fuse to check for short.

Defogger wire faulty. Repair defogger wire.

Rear window defogger switch faulty. Check switch.

Wiring or grounding faulty. Repair circuit.

Condition Possible Cause Correction

Wiper malfunctions

WIPER.WASHER fuse blown. Replace fuse to check for short.

Wiper motor faulty. Check wiper motor.

Combination switch (wiper switch) faulty. Check wiper switch.

Wiring or grounding faulty. Repair circuit.

Washer malfunc-

tions

W asher hose or nozzle clogged. Clean or repair clogged hose or

nozzle.

WIPER.WASHER fuse blown. Replace fuse to check for short.

Washer pump faulty. Check washer pump.

Rear wiper relay faulty. Check wiper relay.

Combination switch (wiper switch) faulty Check wiper switch.

Wiring or grounding faulty. Repair circuit.

1.14 POWER WINDOW CONTROL SYSTEM

1.15 CIGARETTE LIGHTER

1.16 POWER DOOR LOCK SYS TEM WITH KEYLES S EN TRY SYSTEM

Conditio n Pos sibl e Ca us e Correcti on

All power windows

do not operate

POWER WINDOW fuse blown. Replace fuse to check for short.

Ignition switch faulty. Check ignition switch.

Power window main switch faulty. Check power window main switch.

Wiring or grounding faulty. Repair circuit.

One power window

does not operate

Wiring and/or connector faulty. Check wiring and/or connector.

Power window switch (main or sub) faulty. Check power window switch.

Window actuator faulty. Check window actuator.

Grounding faulty. Repair.

Condition Possible Cause Correction

Cigarette lighter

shows no operation

CIGAR fuse blown. Replace fuse to check for short.

Ignition switch faulty. Check ignition switch.

Cigarette lighter faulty. Check cigarette lighter.

Wiring or grounding faulty. Repair circuit.

Conditio n Possible Ca us e Correcti on

All the doors are not

locked/unlocked by

the drivers side door

key switch

DOOR LOCK fuse blown. After checking for short circuit,

replace fuse.

Drivers side door knob switch faulty Check system, refer to 2.21

POWER D OOR LOCK SYSTEM

WITH KEYLESS ENTRY SYSTEM

in this Section.

Power door lock controller faulty

Wiring or grounding faulty.

Only one door is not

locked/unlocked

Power door lock actuator faulty Check system, refer to 2.21

POWER D OOR LOCK SYSTEM

WITH KEYLESS ENTRY SYSTEM

in this Section.

Wiring or grounding faulty

All doo rs are not

locked/unlocked by

keyless entry trans-

mitter

Transmitter battery dead Replace battery.

Transmitter faulty Replace transmitter

Code registration error Perform code registration

Door switch faulty Check system, refer to 2.21

POWER D OOR LOCK SYSTEM

WITH KEYLESS ENTRY SYSTEM

in this Section

Key remainder switch (in ignition switch) faulty

Power door lock controller faulty

Wiring or grounding faulty

Turn signal lights are

not flashed when

doors are locked/

unlocked by trans-

mitter

Keyless entry system is in interior light signal

mode Change signal mode, refer to 2.21

POWER D OOR LOCK SYSTEM

WITH KEYLESS ENTRY SYSTEM

— CHANGE OF S IGNAL MODE in

this Section.

Turn signal and hazard warning system faulty Check system, refer to 2.3 TURN

SIGNAL AND HAZARD WARNING

LIGHTS in this Section

Power door lock controller faulty

Wiring or grounding faulty

Interior light does not

turn ON when interior

light switch is at

DOOR position and

doors are unlocked

by transmitter

Power door lock controller faulty Check system, refer to 2.21

POWER D OOR LOCK SYSTEM

WITH KEYLESS ENTRY SYSTEM

in this Section

Wiring or grounding faulty

1.17 POWER DOOR MIRROR CONTROL SYSTEM

1.18 INTERIOR LIGHT

1.19 HOR N

1.20 IGNITION KEY REMINDER AND LIGHT REMINDER WARNING BUZZER

1.21 SEAT BELT WARNING LIGHT

Conditio n Pos sibl e Ca us e Correcti on

All power mirrors do

not operate

CIGAR fuse blown. Replace fuse to check for short.

Power door mirror switch faulty. Check switch.

Wiring or grounding faulty. Repair circuit.

One power mirror

does not operate

Power door mirror switch faulty. Check switch.

Actuator (power door mirror motor) faulty. Check actuator.

Wiring or grounding faulty. Repair circuit.

Conditio n Pos sibl e Ca us e Correcti on

Interior lights do not

illuminate

Bulbs blown. Replace bulb s.

RADIO.DOME fuse blown. Replace fuse to check for short.

Interior light switch faulty. Check switch.

Door switch faulty. Check switch.

Wiring or grounding. Repair circuit.

One int eri or lig ht

does no t illu mi na te

Bulb blown. Replace bulb.

Interior light switch faulty. Check switch.

Door switch faulty. Check switch.

Wiring or grounding. Repair circuit.

Conditio n Pos sibl e Ca us e Correcti on

Horn does not ope r-

ate

HORN.HAZARD fuse blown. Replace fuse to check for short.

Horn switch faulty. Check horn switch.

Horn relay faulty. Check horn relay.

Horn faulty. Replace horn.

Conditio n Pos sibl e Ca us e Correcti on

Ignition key

reminder and light

reminder warning

buzzer does not

sound

Buzzer faul ty. Replace buz zer.

Wiring or grounding faulty. Repair circuit.

Driver side door switch faulty. Check door switch.

Ignition switch faulty. Check ignition switch.

Conditio n Pos sibl e Ca us e Correcti on

Seat belt warning

light does not illumi-

nate

Bulb in combination me ter blown. Replace bulb.

METER fuse blown. Replace fuse to check for short.

Seat bel t switch faulty. Check se at belt switch.

Wiring or grounding faulty. Repair circuit.

2. ON-VEHICLE SERVICE

2.1 CAUTIONS IN SERVICING

When performing work related to electrical systems, observe the cautions described in Section 0A, GENERAL

INFORMATION for the purpose of protection of electrical parts and prevention of a fire.

2.2 HEADLIGHT AND POSITION LIGHT

HEADLIGHT AND POSITION LIGHT SWITCH

Removal and Installation

Refer to 3.5 CONTACT COIL AND COMBINATION SWITCH ASSEMBLY in Section 3C.

Inspection

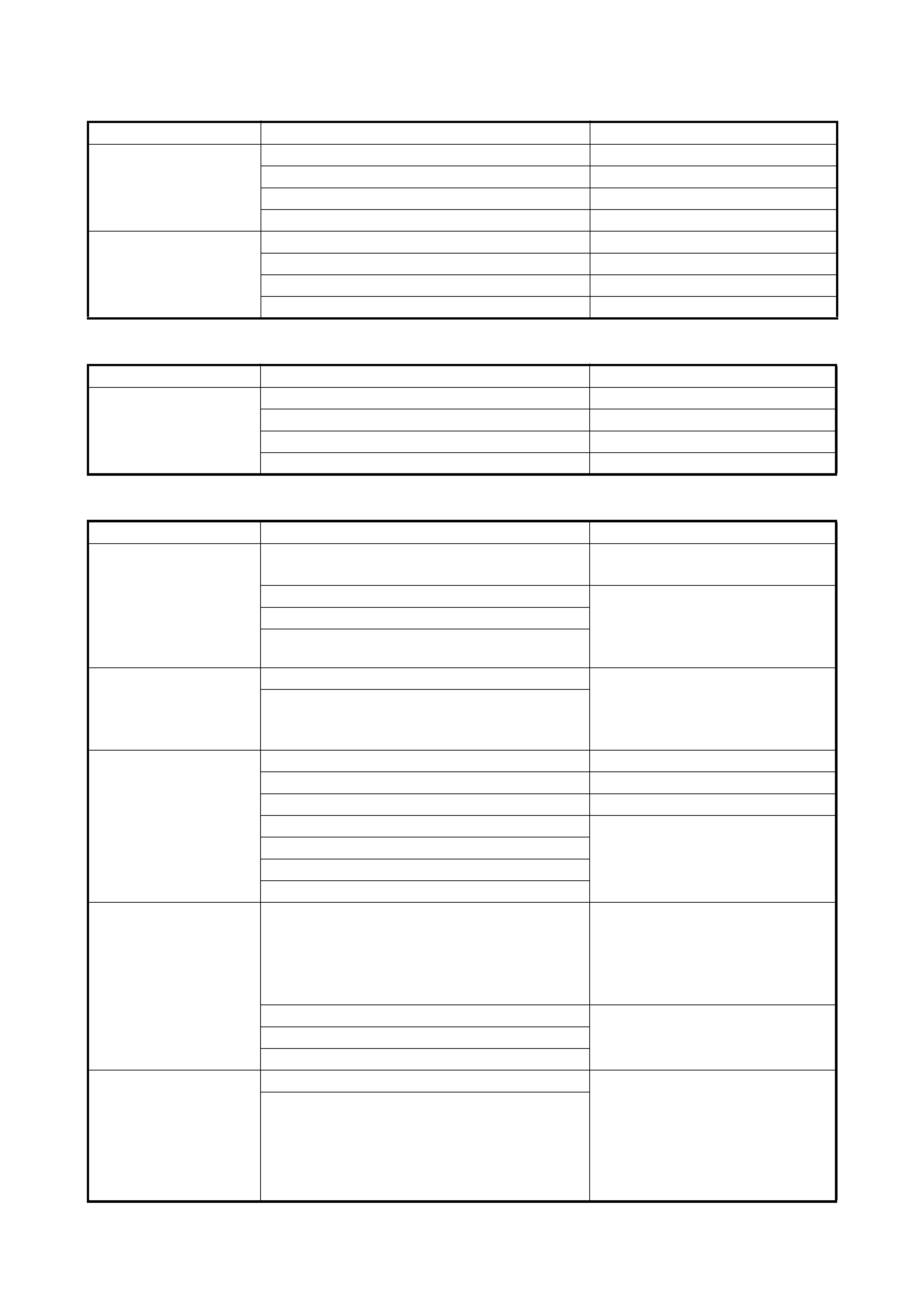

Check for conti nuity between the termi nals at ea ch switc h position a s shown b elow. If the check r esult i s not

as sp ecified, replace the switch.

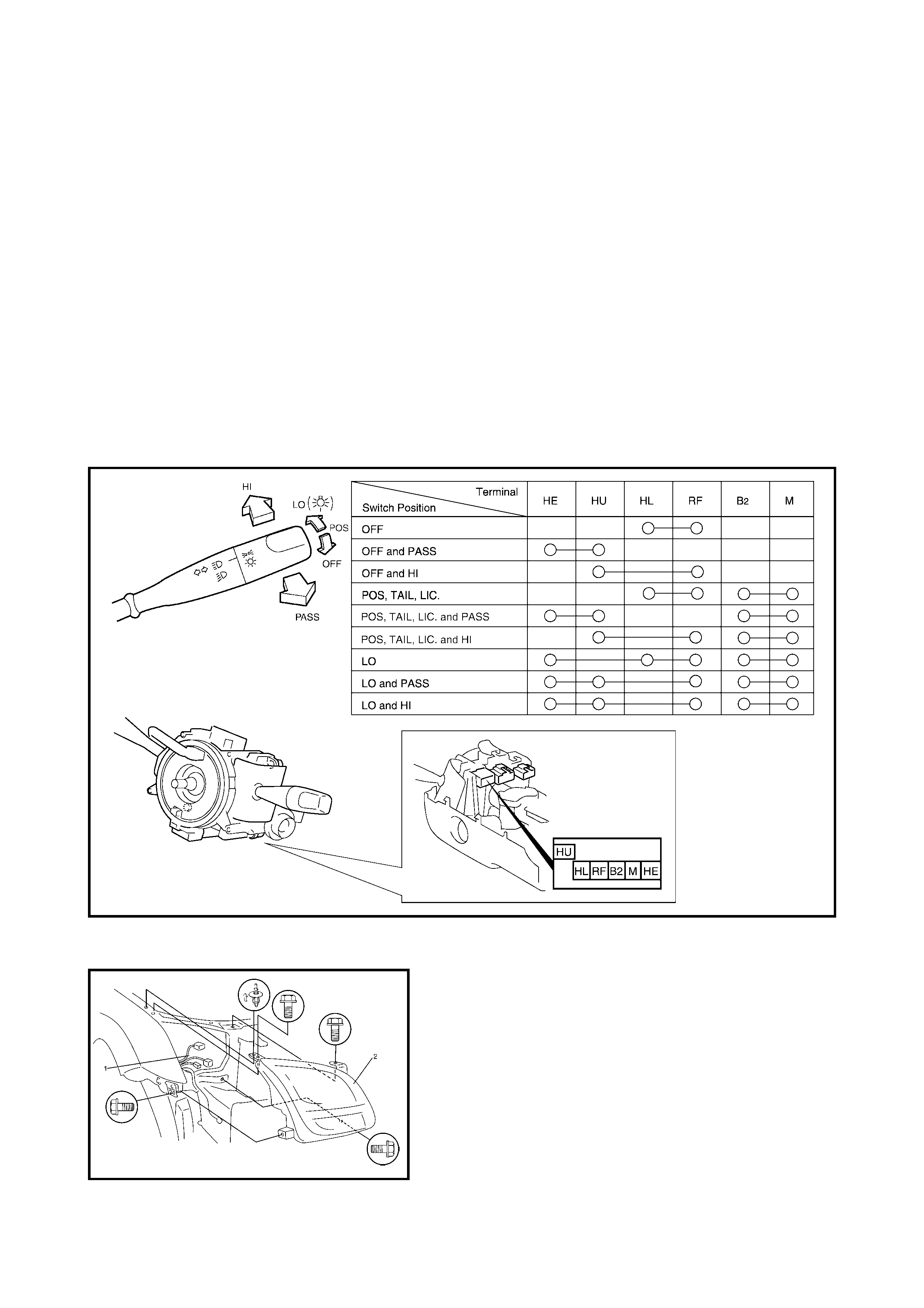

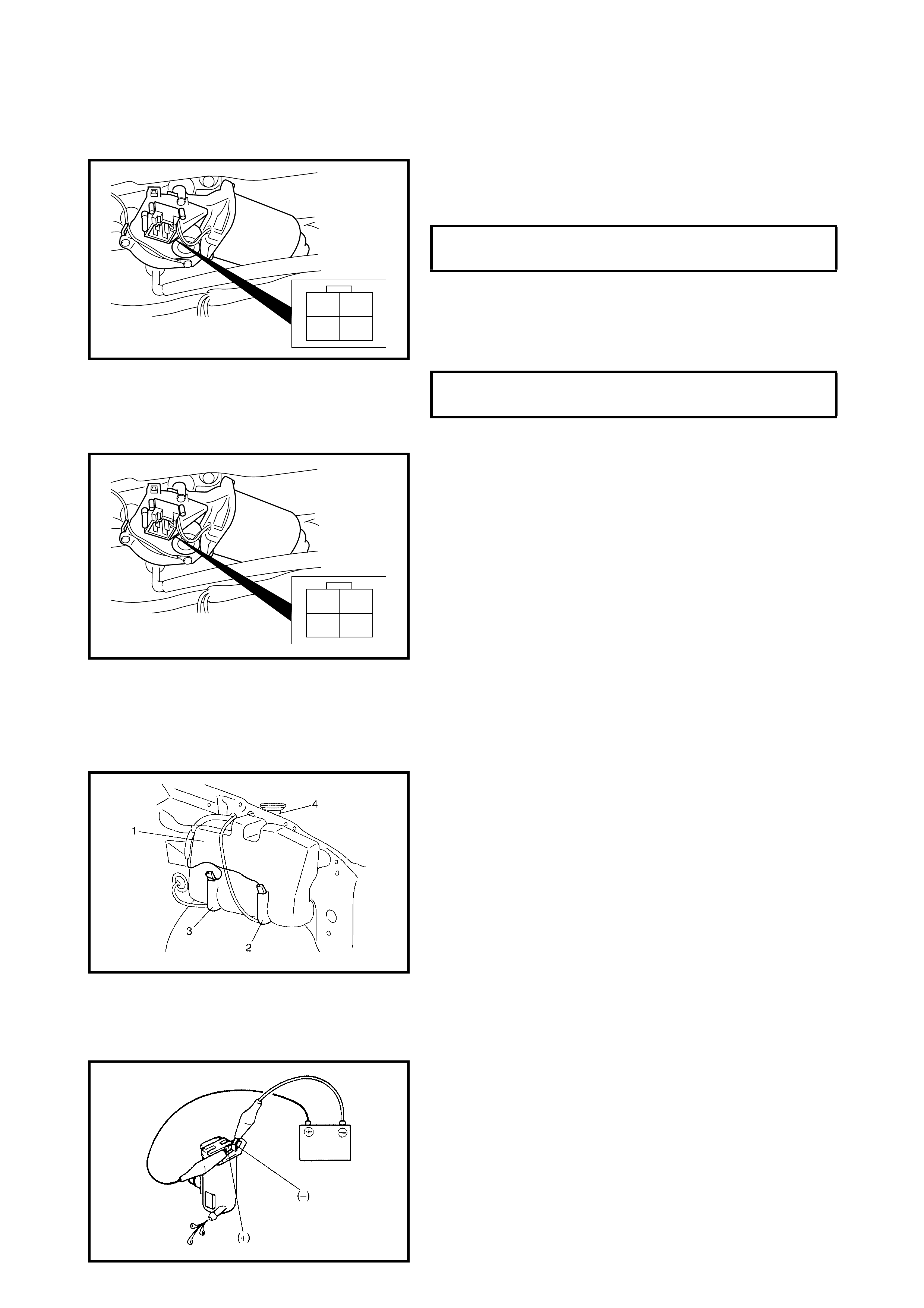

HEADLIGHT ASSEMBLY

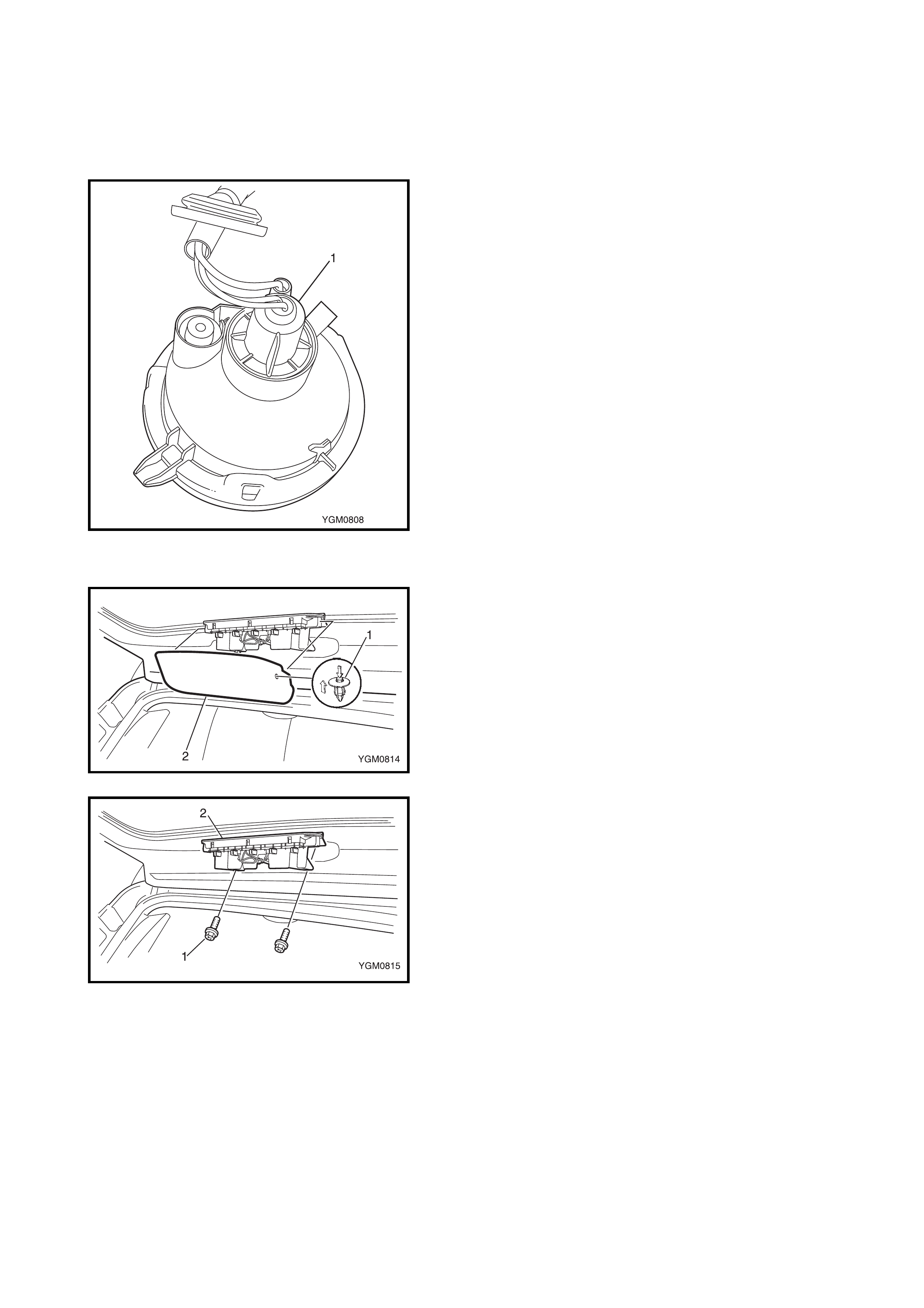

Removal

1. Disconnect the negative cable at battery.

2. Remove the front bumper. Refer to 2.12 FRONT

BUMPER in Section 9.

3. Remove the headlight mounting bolts and clip.

4. Detach the headlight assembly (1) from the vehicle.

5. Disconnect the connectors (2) from the headlight

assembly.

Installation

Reverse removal procedure for installation.

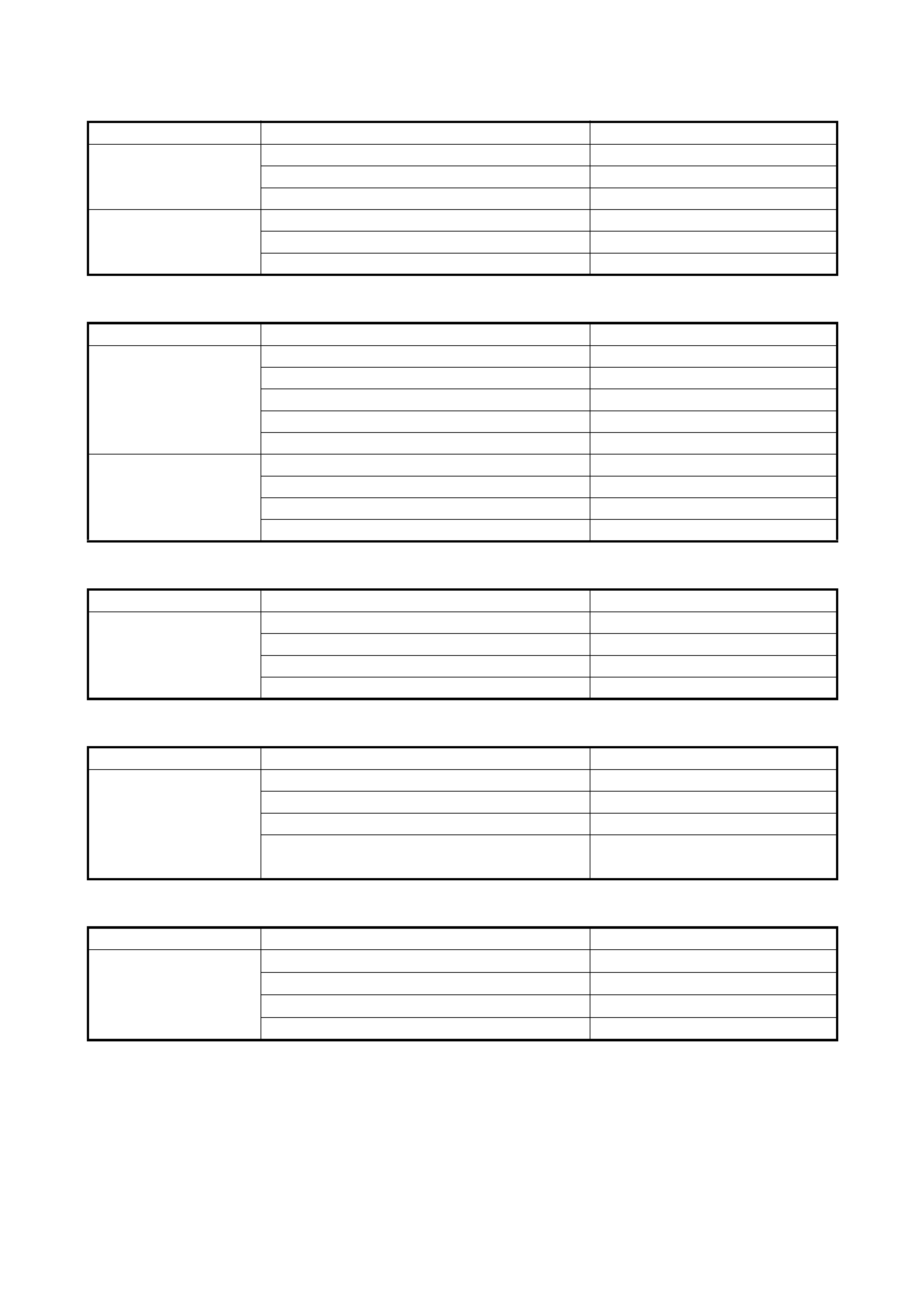

HEADLIGHT BULB

Replacement

WARNING:

• To avoid being burned, don't touch the bulb when

hot.

• Do not touch headlight bulb glass surface.

1. Disconnect negative cable at battery.

2. If required, remove the headlight assembly, refer to

HEADLIGHT ASSEMBLY in this Section.

3. Disconnect the connector from the bulb.

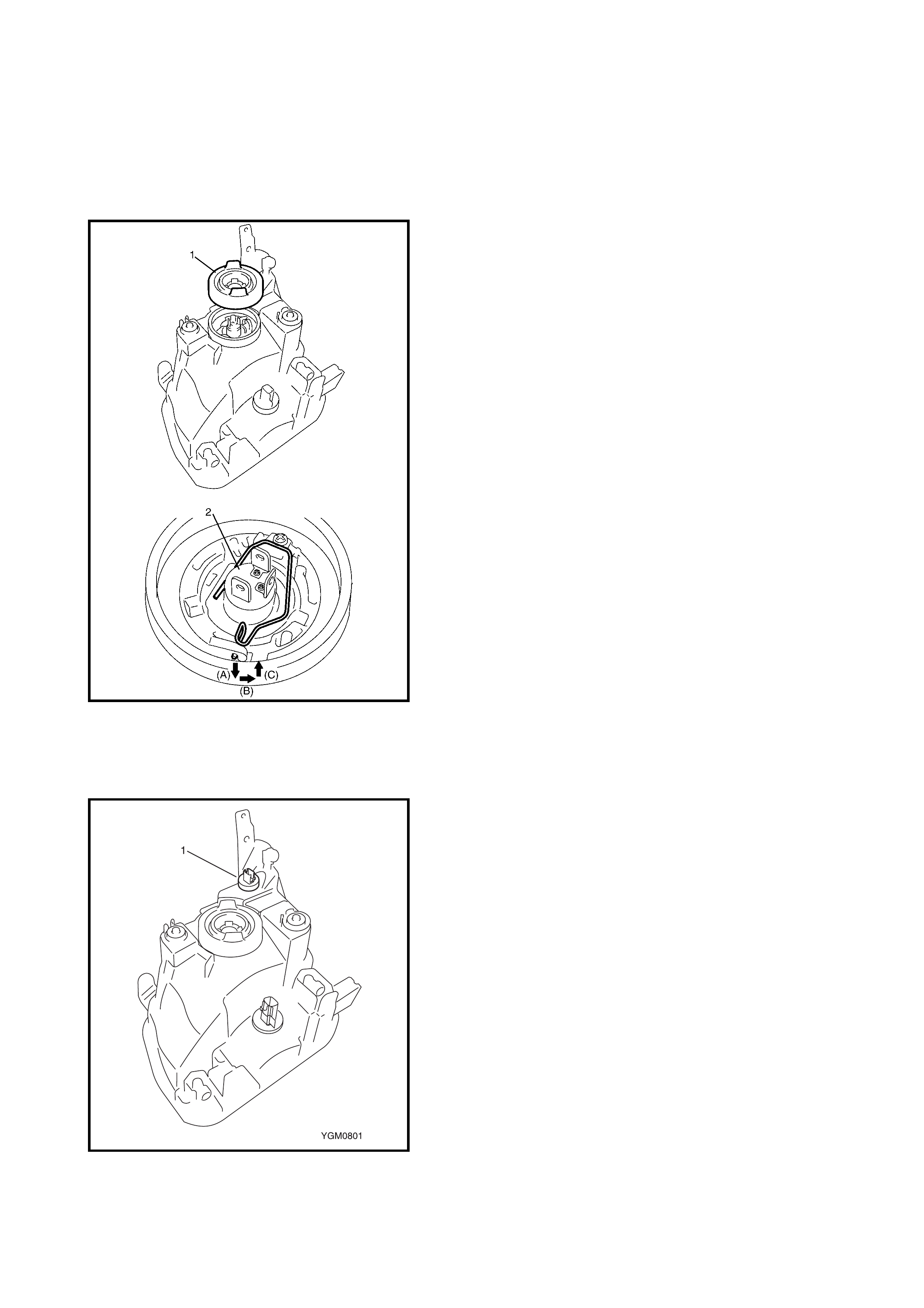

4. Remove the headlight socket cover (1) and replace the

bulb (2) by unhooking the retainer (A, B, C).

5. Remove the position light socket (3) by twisting 90°

anti clockwise and replace the bulb.

6. Reassemble all removed parts.

POSITION LIGHT BULB

Replacement

WARNING: To avoid being burned, don't touch t he bulb

when hot.

1. Disconnect negative cable at battery.

2. Disconnect the connector from the bulb.

3. Remove the position light socket (1) by twisting 90°

anti clockwise.

4. Replace the bulb.

5. Reassemble removed parts.

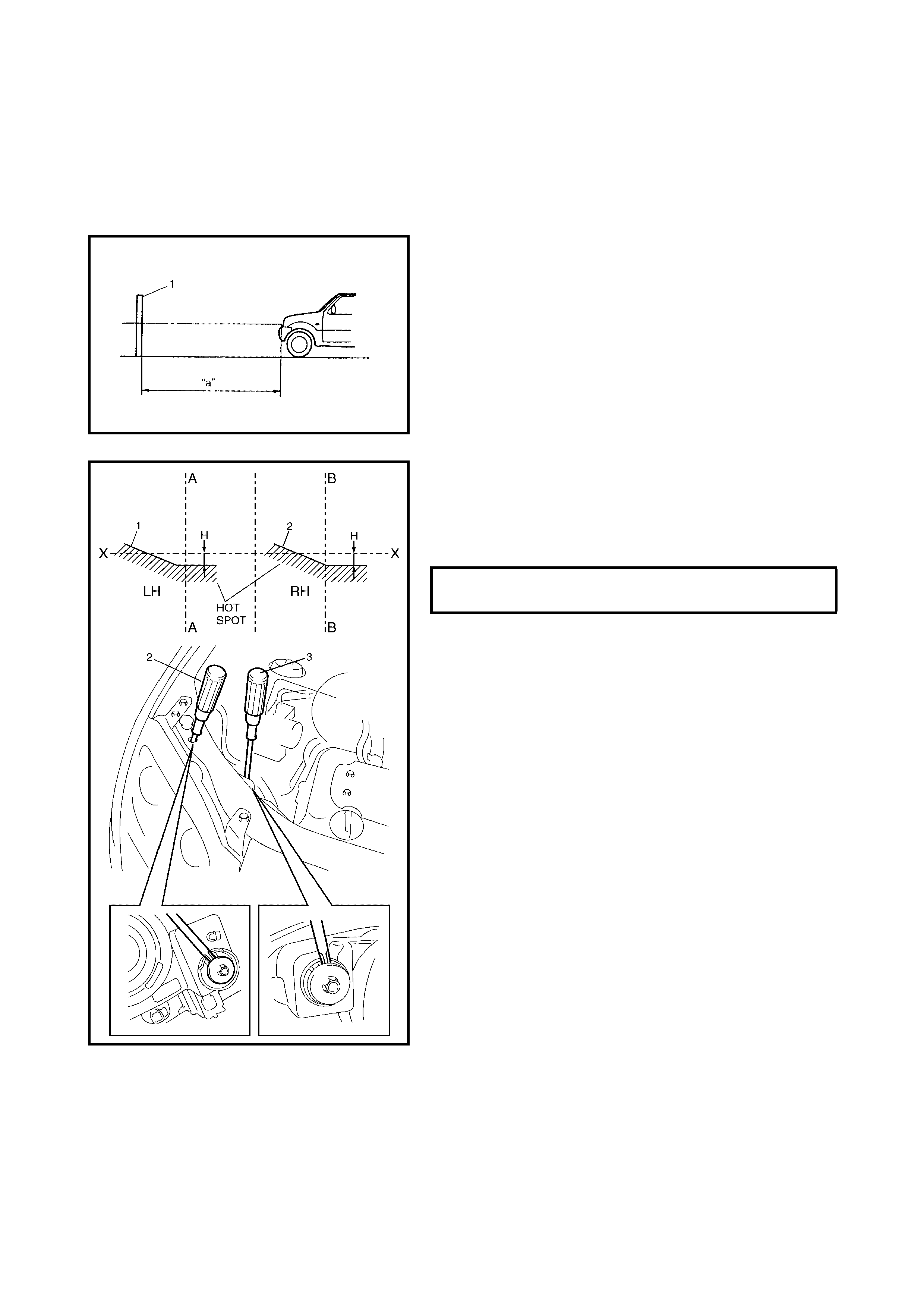

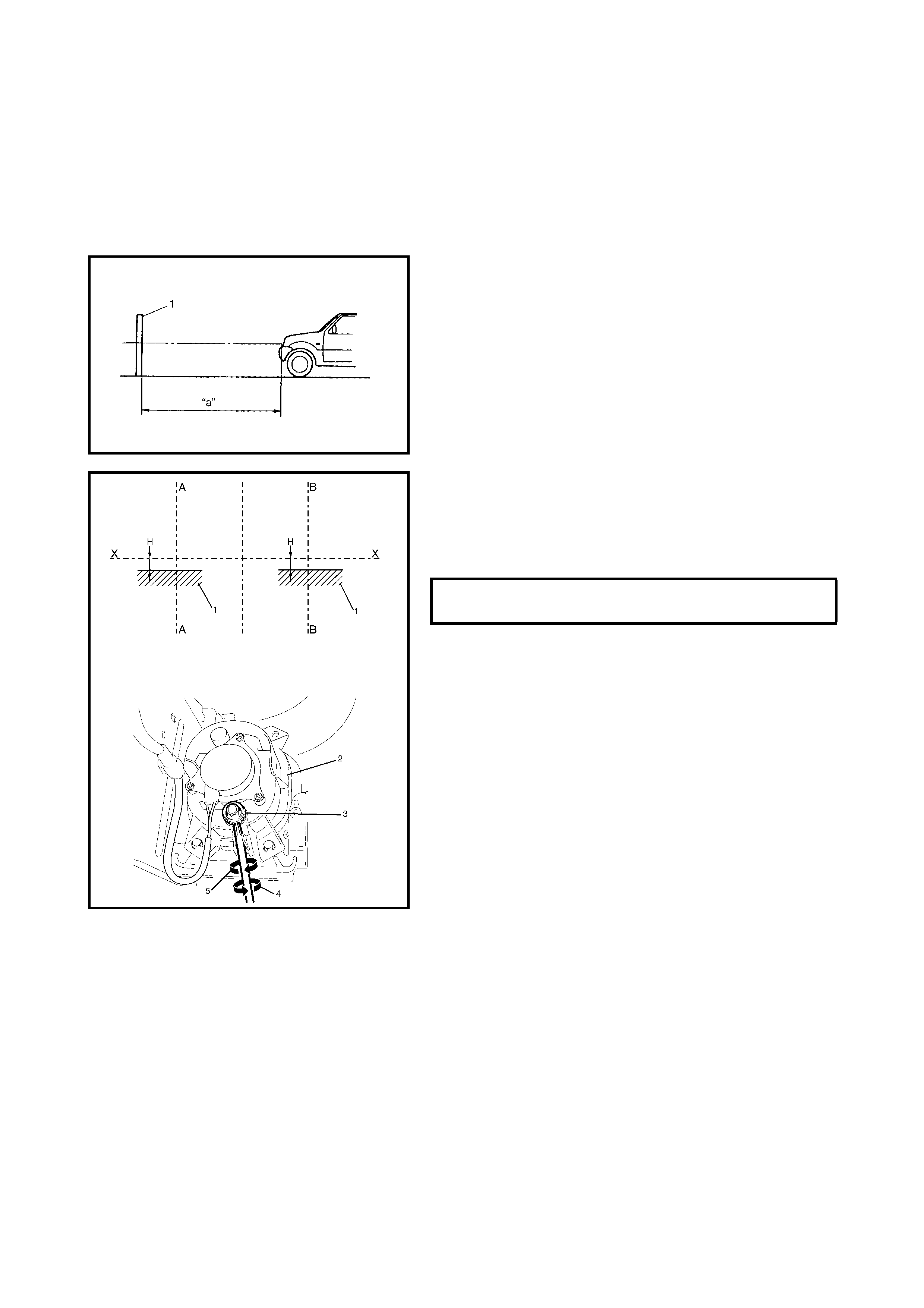

HEADLIGHT AIMING ADJUSTMENT WITH

SCREEN

NOTE:

• Unless otherwise obligated by local regulations, adjust

the headlight aiming according to following procedure.

• After replacing a headlight, always check and adjust

aiming as required.

1. Make sure the following items:

• Place the vehicle on a flat surface in front of blank wall

(screen) (1) 10 m (a) ahead of the headlights.

• Adjust the tyre air pressure the specified value, refer to

the vehicle tyre placard or owner’s manual.

• Bounce vehicle up and down by hand to stabilise sus-

pension.

• Have one person weighing approx. 75 kg seated in the

driver’s seat.

2. Turn the headlights ON to low beam.

3. Check to see if the cut line (1) and axis of each beam

hot spot (high intensity zone) aligns on the screen with

each vertical headlight centreline (A-A, B-B) and the

specified distance (H) below the headlight horizontal

centreline (X).

4. If required, align headlight to specification by adjusting

aiming gear with a screwdriver (3) for vertical adjust-

ment and/or (2) for horizontal adjustment.

LOW BEAM HOT SPOT

SPECIFICATION: H Approx. 130 mm

2.3 TURN SIGNAL AND HAZARD WARNING LIGHTS

TURN SIGNAL AND HAZARD WARNING LIGHTS

SYSTEM CIRCUIT

Inspection

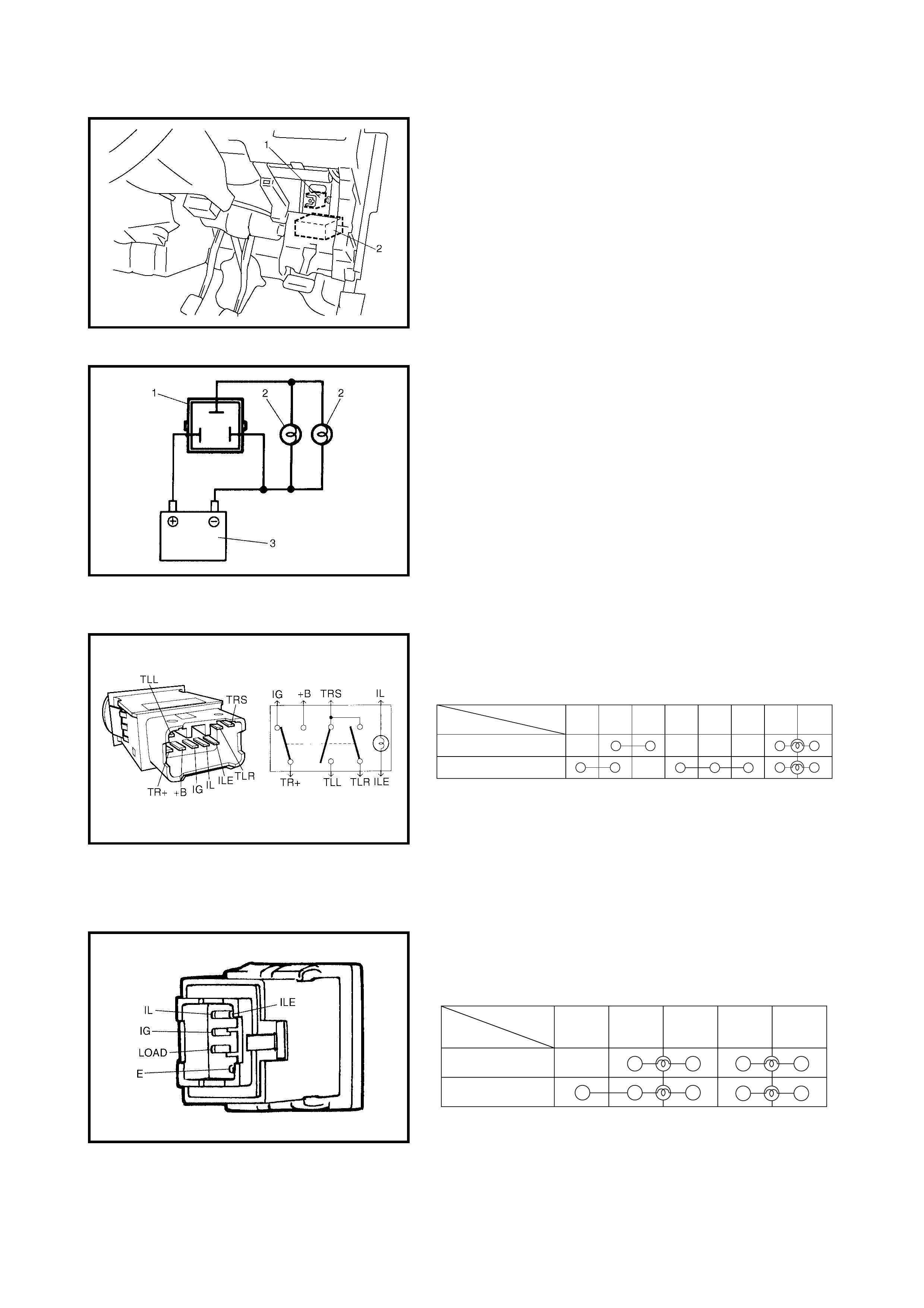

1. Disconnect negative (–) cable from the battery

2. Disconnect the turn signal and hazard warning relay

connector G42 (1) from above the fusebox (2).

3. Connect negative (–) cable to battery.

4. Confirm that the right or left side turn signal lights turn

on when terminal G42-4 (1) is connected to terminal

G42-2 or G42-3 with a service wire.

If the turn s ignal light doe s not turn on, che ck the bulb

or repair the applicable circuit.

5. Check that the voltage and continuity between the

following terminals on connector G42 (1) and body

ground are within specification under each condition.

If the ch eck resul t is not as sp ecified, r epair applic able

circuit.

If the check result is OK, replace turn signal and

hazard warning relay and recheck.

TURN SIGNAL AND HAZARD WARNING LIGHTS SYSTEM CIRCUIT CHECK

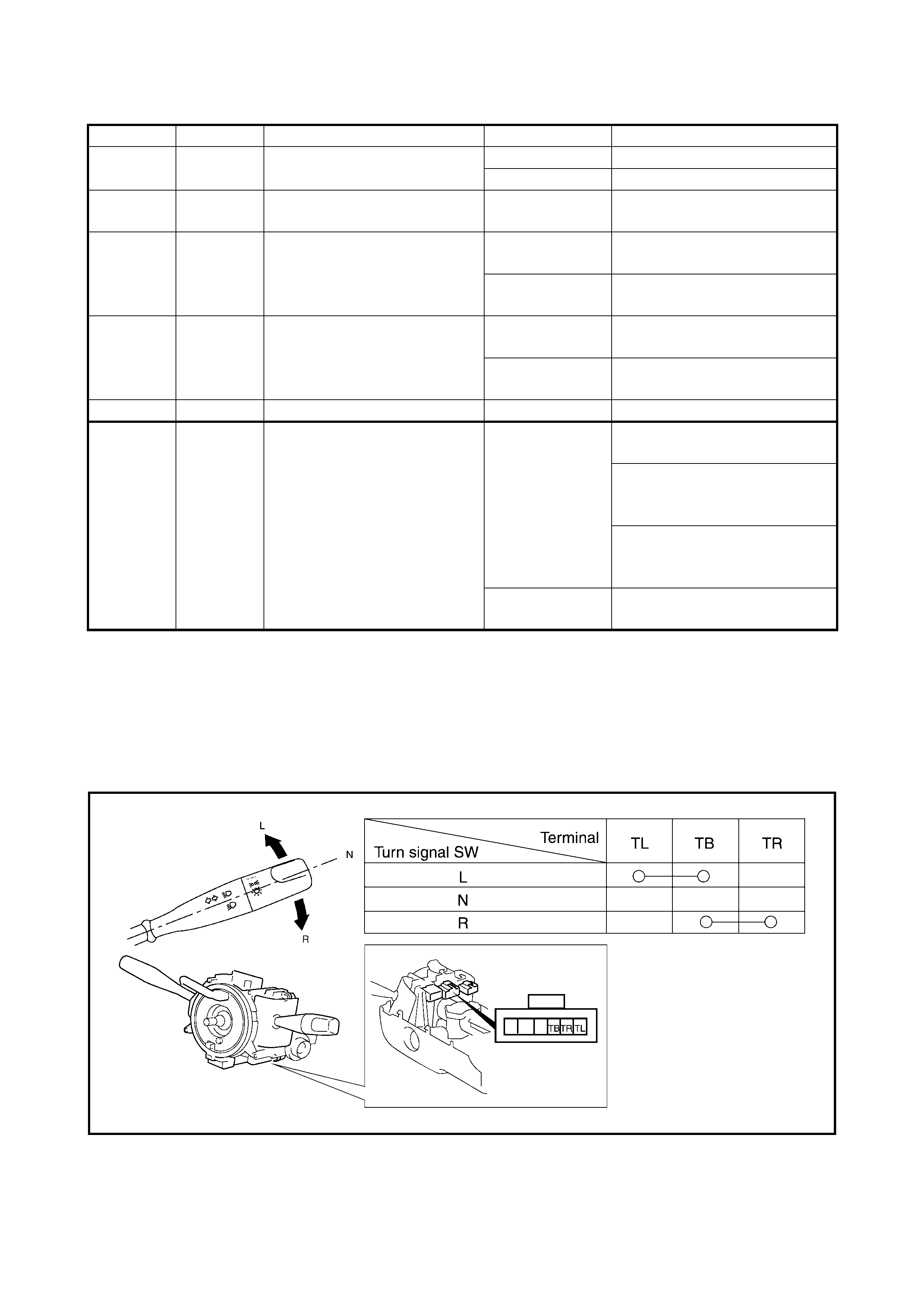

TURN SIGNAL SWITCH

Removal and Installation

Refer to 3.5 CONTACT COIL AND COMBINATION SWITCH ASSEMBLY in Section 3C.

Inspection

Check fo r continuity between the terminals at each swit ch position as shown below. If check result is not as

specified, replace the switch.

.

Terminal Wire Circuit Specification Condition

G42-1 BLU‘ Ignition switch circuit 10 — 14 V Ignition switch is in ON position

0 — 1 V Ignition switch is in ON position

G42-4 GRN/WHT Power supply for turn signal

and hazard warning lights 10 — 14 V —

G42-5 BLU/RED Right side turn signal light

switch circuit

Continuity Turn signal light switch is in R

position

No continuity Turn signal light switch is in N

or L position

G42-6 GRN/YEL Left side turn signal light

switch circuit

Continuity Turn signal light switch is in L

position

No continuity Turn signal light switch is in N

or R position

G42-7 BLK Ground 0 — 1 V —

G42-8 YEL/RED Hazard warning switch and

keyless entry system circuits

Continuity

Hazard warning swi tch is in ON

position

Approx. 1.2 seconds after

pushing UNLOCK button on

transmitter.

Approx. 0.6 seconds after

pushing LOCK button on trans-

mitter.

No continuity Driver side door knob switch is

in LOCK position.

FRONT TURN SIGNAL ASSEMBLY

Removal and Installation

Refer to Headlight Assembly in 2.2 HEADLIGHT AND

POSITION LIGHT in this Section.

FRONT TURN SIGNAL BULB

Replacement

WARNING: To avoid being burned, don't touch t he bulb

when hot.

1. Disconnect negative cable at battery.

2. Disconnect the connector from the bulb.

3. Remove the position light socket (1) by twisting 90°

anti-clockwise.

4. Replace the bulb.

5. Reassemble removed parts.

FRONT FENDER TURN SIGNAL ASSEMBLY

Removal

1. Disconnect the negative cable at the battery.

2. Partially remove the rear section of the front fender

liner, refer to 2.14 FRONT FENDER in Section 9.

3. From behin d the fe nder, s queez e the retaini ng lugs (1)

and push the turn signal light from the fender.

4. Disconne ct the wi re c on nector (2) and r em ove t he tur n

signal assembly.

Installation

Reverse removal procedure for installation.

FRONT FENDER TURN SIGNA L BULB

Replace

WARNING: To avoid being burned, don't touch t he bulb

when hot.

1. Disconnect the negative cable at the battery.

2. Locate a fine flat bla de screwdriv er in the notch on the

underside of the turn signal lamp lens, and carefully

prise the lens from the turn signal lamp housing.

3. Replace the bulb.

4. Clip the lens into position on the housing.

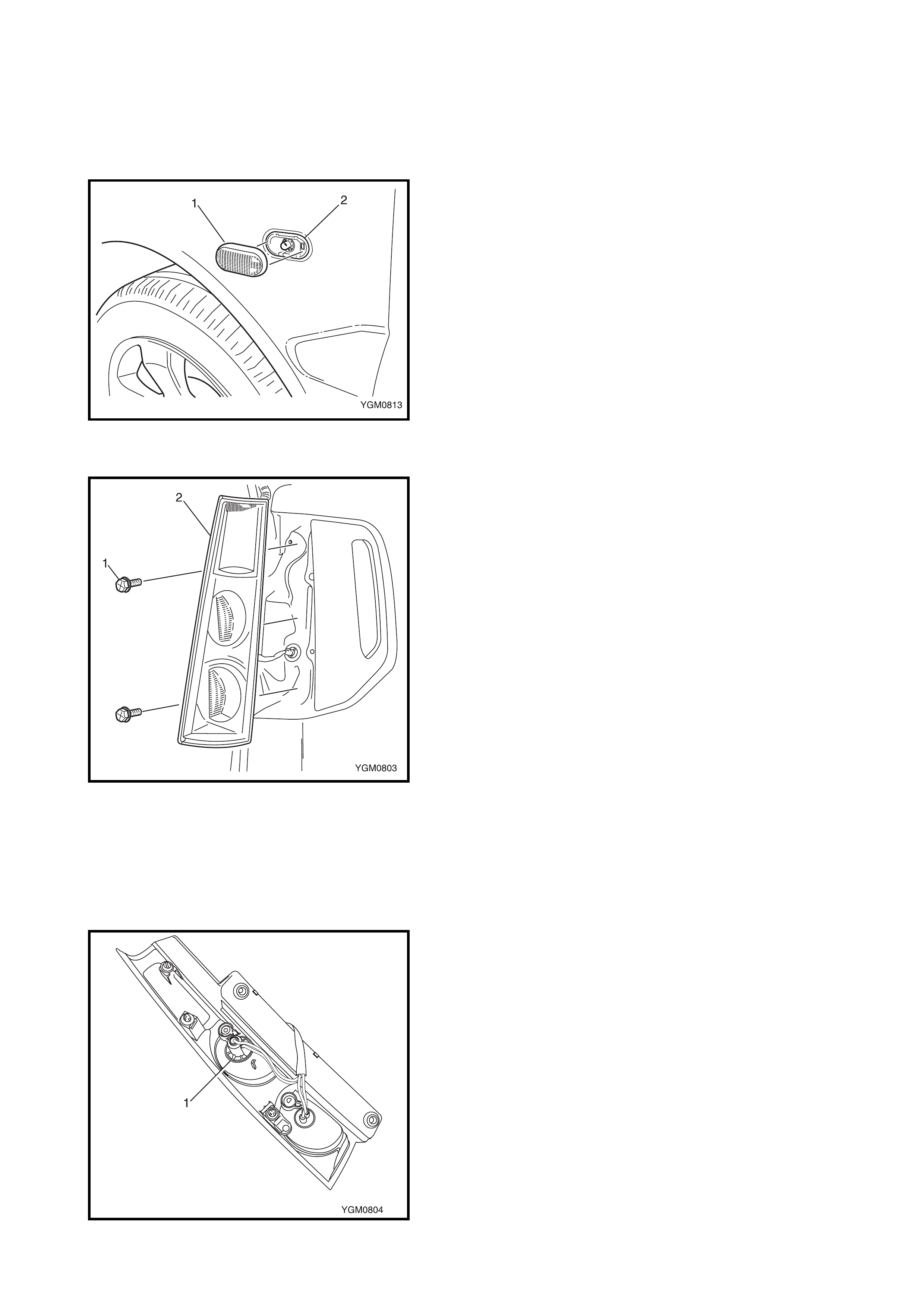

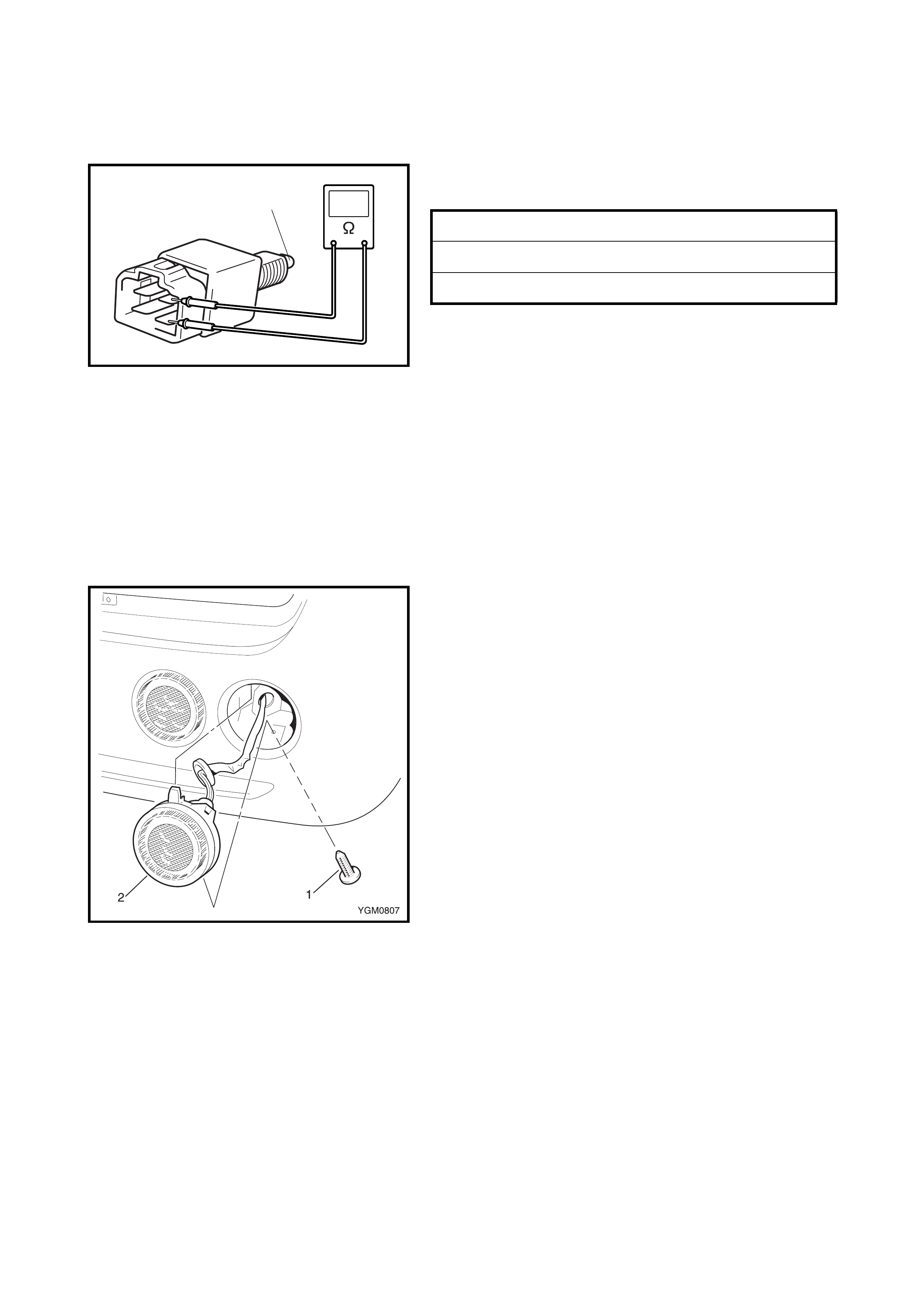

REAR TURN SIGNAL ASSEMBLY

Removal

1. Disconnect negative cable at battery.

2. Remove the two screws (1).

3. Carefully prise the lamp assembly (2) from the vehicle

to disengage the three retaining clips (3).

4. Remove the light sockets by twisting 90° anti-clockwise

and remove the light assembly.

Installation

Reverse removal procedure for installation.

REAR TURN SIG NAL BULB

Replace

WARNING: To avoid being burned, don't touch t he bulb

when hot.

1. Disconnect negative cable at battery.

2. Remove the rear turn signal light assembly as previ-

ously described.

3. Remove the position light socket (1) by twisting 90°

anti-clockwise.

4. Replace the bulb.

5. Reassemble removed parts.

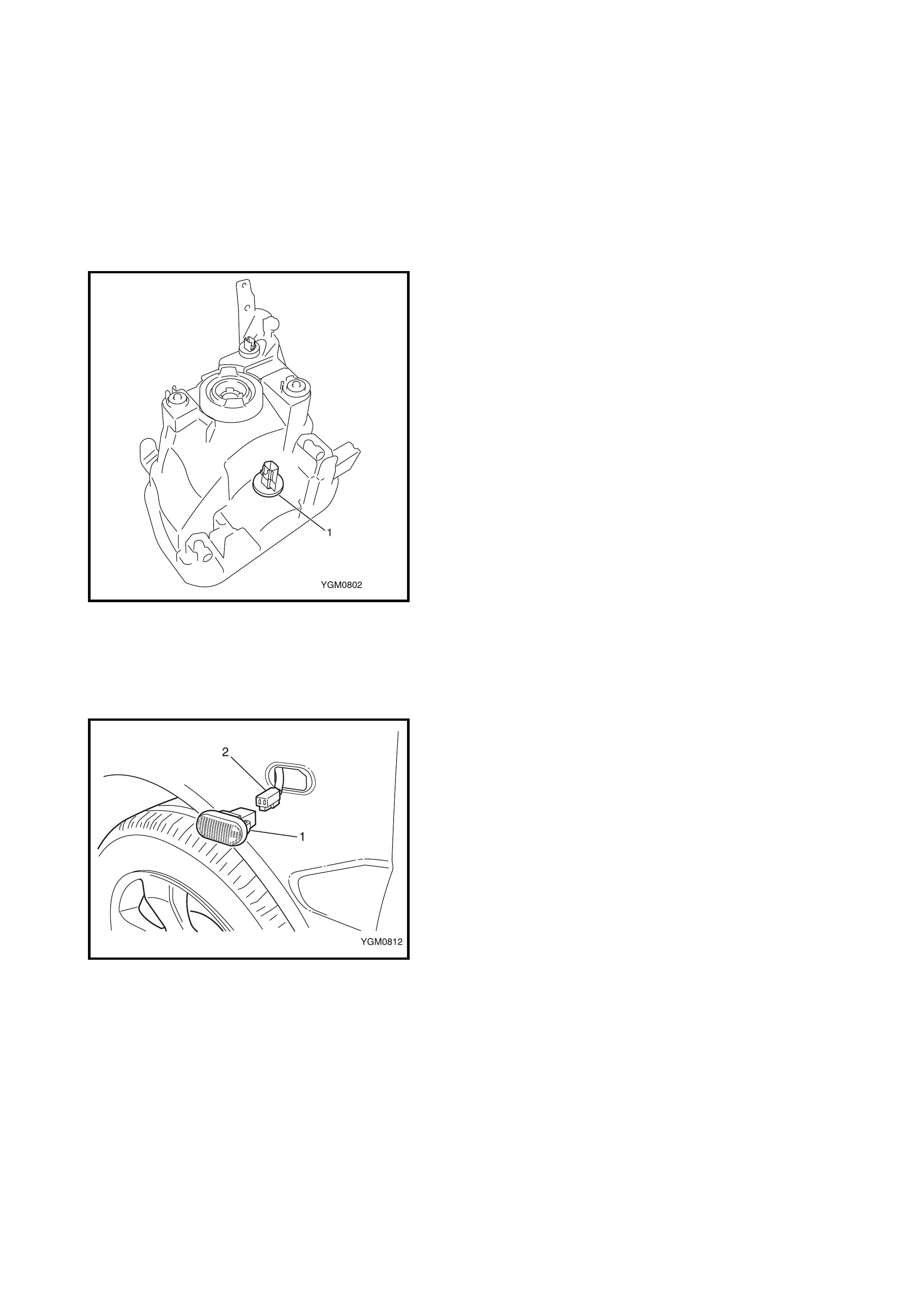

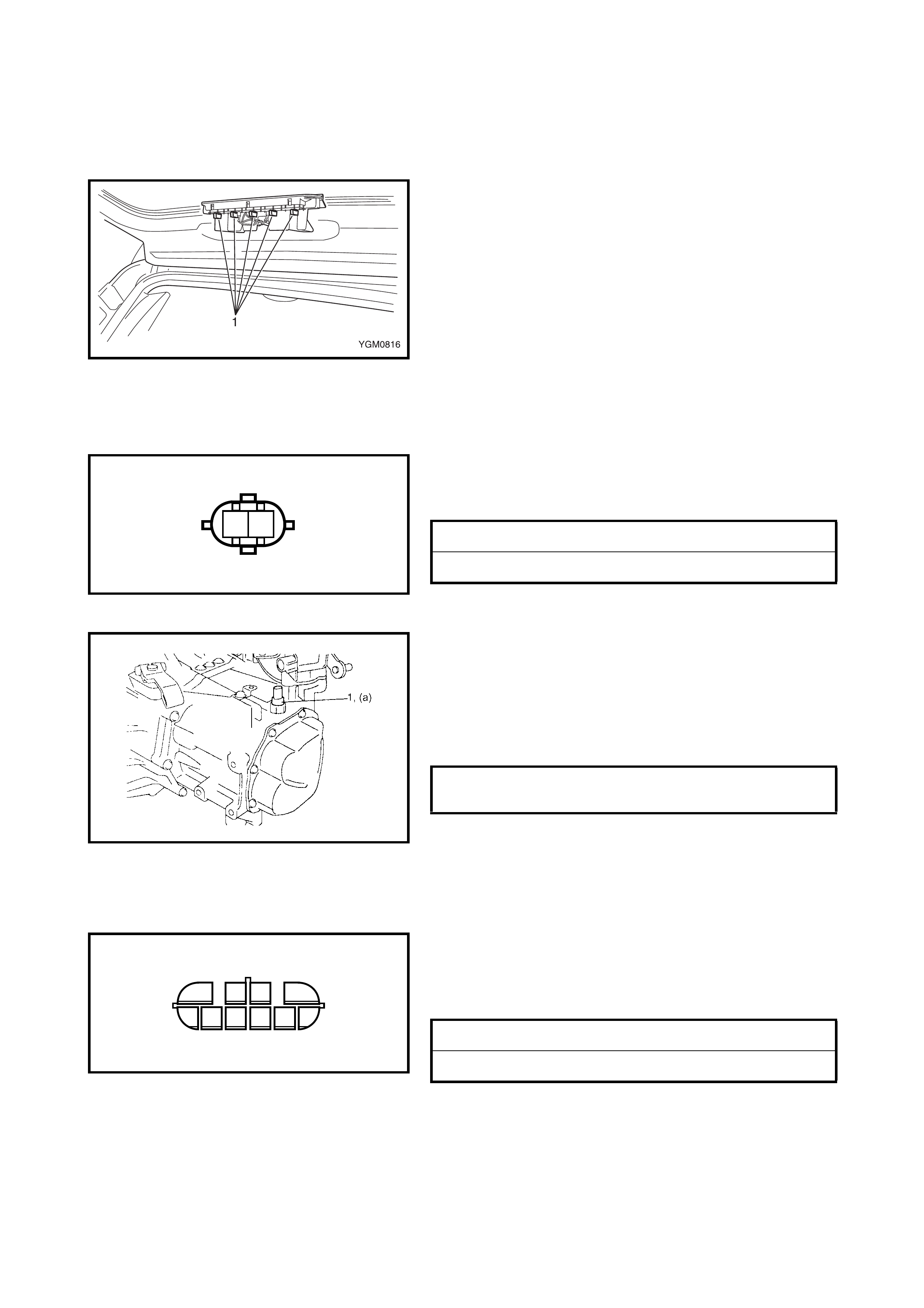

TURN SIGNAL AND HAZARD RELAY

The turn signal and hazard relay (1) is located near the

circuit fuse box (2 ).

Inspection

Connect the turn signal and hazard relay (1), battery (3)

and two test bulbs (12 V, 27 W) (2) as shown.

Unless a continued flashing off approx. 60 – 120 cycles

per minute on and off is visible, replace the relay.

HAZARD SWITCH

Inspection

Check for continuity between the terminals at each switch

position as shown below. If the check result is not as speci-

fied, replace the switch.

2.4 FRONT FOG LIGHTS

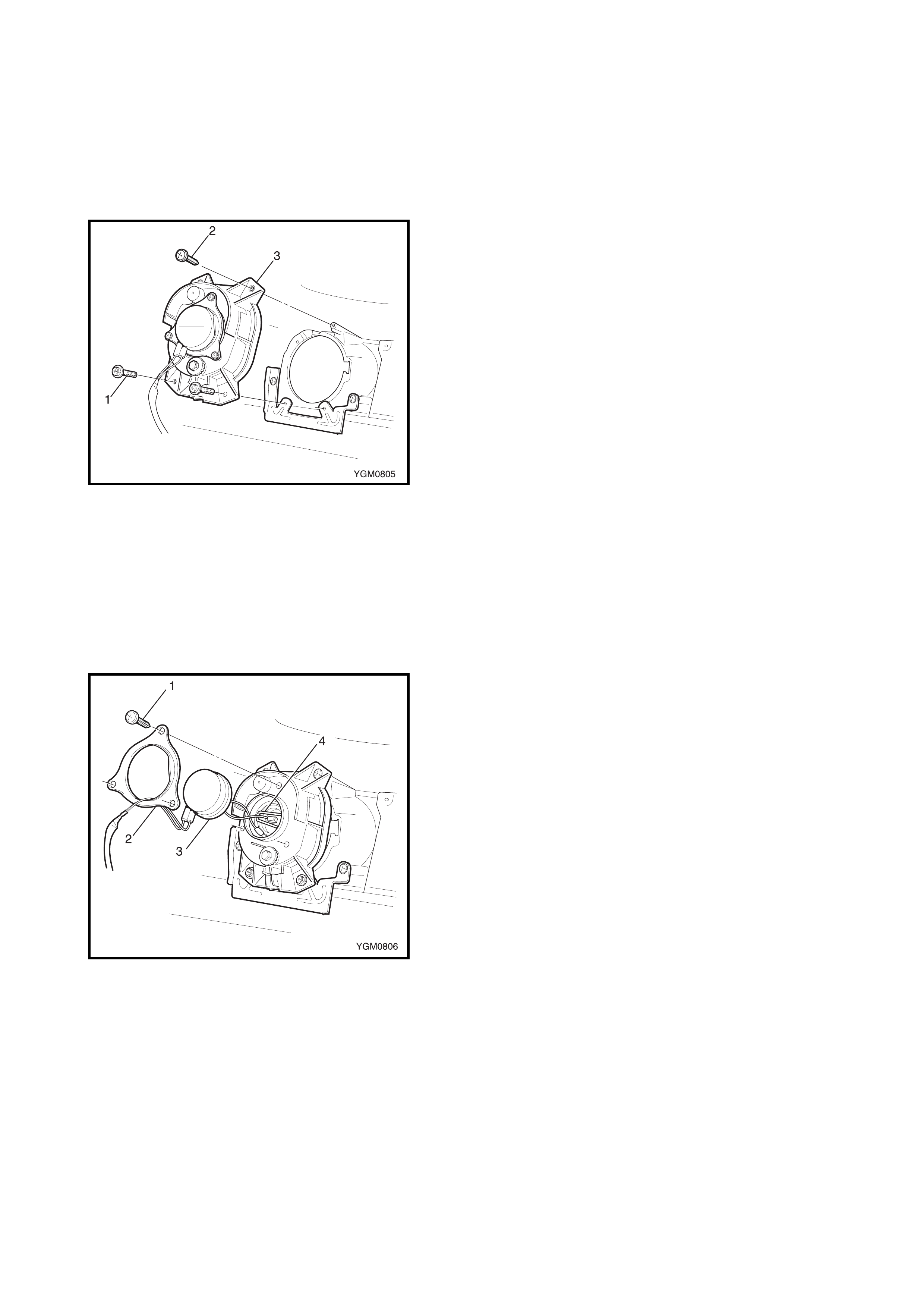

FRONT FOG LIGHT SWITCH

Inspection

Check for continuity between the terminals at each switch

position as shown below. If the check result is not as speci-

fied, replace the switch.

Hazard SW Terminal

OFF

ON

+B TR+ IG TRS TLL TLR IL ILE

Switch

Position

Terminal

ON

IG LOAD E IL ILE

OFF

FRONT FOG LIGHT

NOTE: This procedure describes the removal of the fog

light as sembl y from i ts mountin g brack et on the ve hicle. To

remove the fog light and mounting bracket refer to

2.12 FRONT BUMPER in Section 9.

Removal

1. Disconnect the negative cable at battery.

2. Partially remove the front fender liner, refer

2.14 FRONT FENDER in Section 9.

3. Disconnect the front fog light wiring connector.

4. Remove the three screws (1) attaching the front fog

light and remove the light.

Installation

Reverse removal procedure for installation.

FRONT FOG LIGHT BULB

Replacement

WARNING:

• To avoid being burned, don't touch the bulb when

hot.

• Do not touch fog light bulb glass surface.

1. Disconnect the negative cable at battery.

2. Partially remove the front fender liner, refer

2.14 FRONT FENDER in Section 9.

3. Remove the three screws (1) attaching the socket

cover retainer (2).

4. Remove the retainer and socket cover (3).

5. Disconnect the front fog light bulb wiring connectors

(4).

6. Release the bulb retainer and replace the bulb.

7. Reassemb le the remov ed parts.

FRONT FOG LIGHT AIMING ADJUSTMENT WITH

SCREEN

NOTE:

• Unless otherwise obliga ted by local regulat ions, adjust

the front fog light aiming according to following

procedure.

• After replacing a front fog light, always check and

adjust aiming as required.

1. Make sure the following items:

• Place the ve hicl e on a flat surfac e in front of blank wall

(screen) (1) 10 m (a) ahead of the front fog lights.

• Adjust the tyr e air pre ssur e the sp ec ified value, refe r to

the vehicle tyre placard or owner’s manual.

• Bounce vehicle up and down by hand to stabilise sus-

pension.

• Have one perso n wei ghing appr ox. 75 k g s eate d in the

driver’s seat.

2. Turn the front fog lights ON.

3. Check to see if the cut line of each beam hot spot (1)

(high intensity zone) aligns on the screen with each

vertical front fog light centreline (A-A, B-B) and the

specifi ed distanc e (H) below the front fog ligh t horizon-

tal centreli ne (X).

4. If required, align the front fog light to specification as

follows:

• Remove the front po rtion of the front fe nder li ner, refer

to 2.14 FRONT FENDER in Section 9.

• From the rear of the front fog light (2), turn the aiming

gear (3) with a screwdriver (4) for upward adjustment

and/or (5) for downward adjustment.

FRONT FOG LIGHT HOT SPOT

SPECIFICATION: H Approx. 350 mm

2.5 BRAKE AND TAIL LIGHT

BRAKE LIGHT SWITCH

Inspection

Check brake light switch for continuity as shown.

If found detective, replace the switch.

Adjust

Refer to 2.7 BRAKE LIGHT SWITCH ADJUSTMENT in

Section 5.

TAIL LIGHT SWITCH

Refer to Headlight Switch in 2.2 HEADLIGHT AND

POSITION LIGHT in this

Section.

BRAKE AND TAIL LIGHT ASSEMBLY

Remove

1. Disconnect negative cable at battery.

2. Partially remove the rear fender liner, refer

2.13 REAR BUMPER in Section 9.

3. Disconnect the brake and tail light connector from

behind the rear bumper.

4. Remove the screw ( 1) atta ch ing the brak e an d tail l ight

(2) to the rear bumper.

5. Remove the lower part of the brake and tail light and

disengage the retaining lug.

6. Remove the brake and tail light, pulling the harness

through the bumper.

Installation

Reverse removal procedure for installation.

BRAKE LIGHT SWITCH

SWITCH DEPRESSED (1) (ON) Continuity

SWITCH RELEASED (1) (OFF) No continuity

1

BRAKE AND TAIL LIGHT BULB

Replacement

WARNING: To avoid being burned, don't touch t he bulb

when hot.

1. Disconnect negative cable at battery.

2. Remove the brake and tail light assembly as previously

described.

3. Remove the brake and tail light socket (1) by twisting

90° anti-clockwise.

4. Replace the bulb.

5. Reassemb le the remov ed parts.

HIGH MOUNT BRAKE LIGHT ASSEMBLY

Remove

1. Disconnect negative cable at battery.

2. Remove the retainer (1) from each side of the high

mount brake light cover (2) and remove the cover.

3. Remove the two screws (1) attaching the high mount

brakelight (2) to the tailgate.

4. Disconnect the wire connector and remove the light.

Installation

Reverse removal procedure for installation.

HIGH MOUNT BRAKE LIGHT BULB

Replacement

WARNING: To avoid being burned, don't touch t he bulb

when hot.

1. Disconnect negative cable at battery.

2. Remove the high mount brake light cover as previously

described.

3. As required, remove one or more high mount brake

light sockets (1) by twisting 90°.

4. Replace the bulb.

5. Reassemb le the remov ed parts.

2.6 BACKUP LIGHT

BACKUP LIGHT SWITCH (M/T)

Inspection

Check brak e light s witch for co ntinui ty betwee n termin als 1

and 2 as shown.

If found detective, replace the switch.

Removal

1. Disconnect the wire connector.

2. Remove the backup light switch (1) from the tran-

saxle.

Installation

1.

Install the backup light switch (1) and tighten to the

specified torque

.

2. Connect the wire connector and confirm the function of

the back up light switch in reverse position.

TRANSMISION RANGE SENSOR (SHIFT SWITCH)

(A/T)

Inspection

Check tr ansm ission r ange s enso r (shift swi tch) for conti nu-

ity between terminals 7 and 8 as shown.

If not as specified, check for correct adjustment and if

required replace the sensor.

Removal / Adjustment

Refer to 3.4

TRANSMISION RANGE SENSOR

(SHIFT SWITCH) in Section 7B.

BACKUP LIGHT ASSEMBLY

Remove / Installation

Refer to 2.3 TURN SIGNAL AND HAZARD WRANING

LIGHTS in this Section.

REVERSE GEAR ENGAGED (ON) Continuity

EXCEPT REVERSE GEAR (OFF) No continuity

12

BACKUP LAMP SWITCH

TORQUE SPECIFICAT ION (a): 19.0 Nm

REVERSE GEAR ENGAGED (ON) Continuity

EXCEPT REVERSE GEAR (OFF) No continuity

12

56

3

97 8

4

10

BACKUP LIGHT BULB

Replacement

WARNING: To avoid being burned, don't touch t he bulb

when hot.

1. Disconnect negative cable at battery.

2. Remove the rear turn signal light assembly, refer

2.3 TURN SIGNAL AND HAZARD WARNING LIGHTS

in this Sectio n.

3. Remove the backup light socket (1) by twisting 90°

anti-clockwise.

4. Replace the bulb.

5. Reassemble removed parts.

2.7 LICENCE PLATE LIGHT

LICENCE PLATE LIGHT SWITCH

Removal / Inspection

Refer to Headlight Switch in 2.2 HEADLIGHT AND

POSITION LIGHT in this

Section.

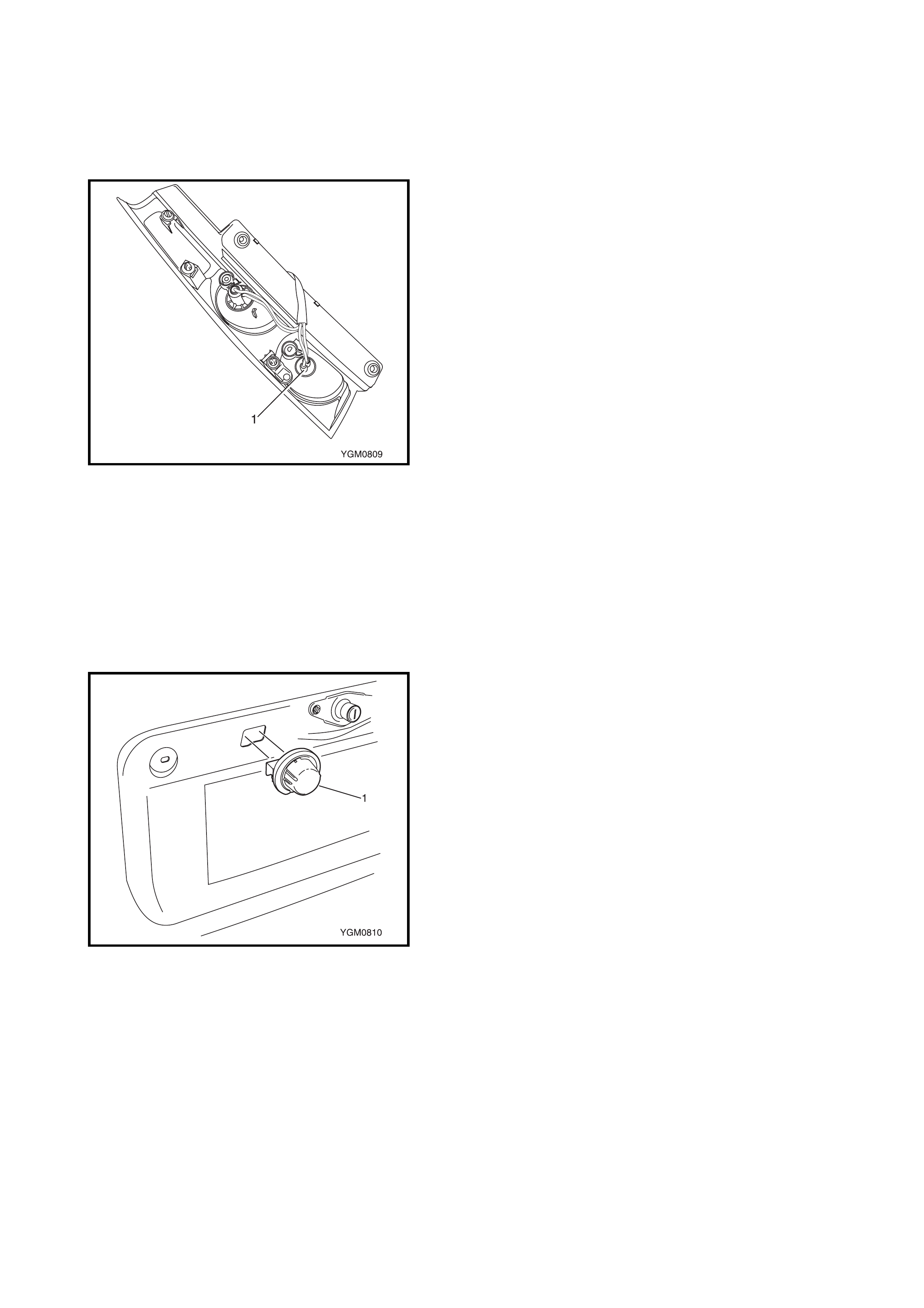

LICENCE PLATE LIGHT ASSEMBLY

Remove

1. Disconnect negative cable at battery.

2. Remove the back door trim and back door licence

garnish, refer to 2.3 BACK DOOR ASSEMBLY in

Section 9.

3. Disconnect the licence plate light connector from within

the back door.

4. Depress the retaining lug on the back of the light and

remove.

Installation

Reverse removal procedure for installation.

LICENCE PLATE LIGHT BULB

Replacement

WARNING: To avoid being burned, don't touch t he bulb

when hot.

1. Disconnect negative cable at battery.

2. If requir ed, remove th e licence pl ate light ass embly as

previou sly desc ribed .

3. Remove the licence plate light cover (1) by twisting

anti-clockwise.

4. Replace the bulb.

5. Reassemb le the remov ed parts.

2.8 ILLUMINATION CONTROLLER

INSPECTION

1. Connect a battery (1) and test light (3) to the illumina-

tion controlle r (2) as shown.

2. Turn the illumination controller (1) up to brighten the

test lamp and down to darken it.

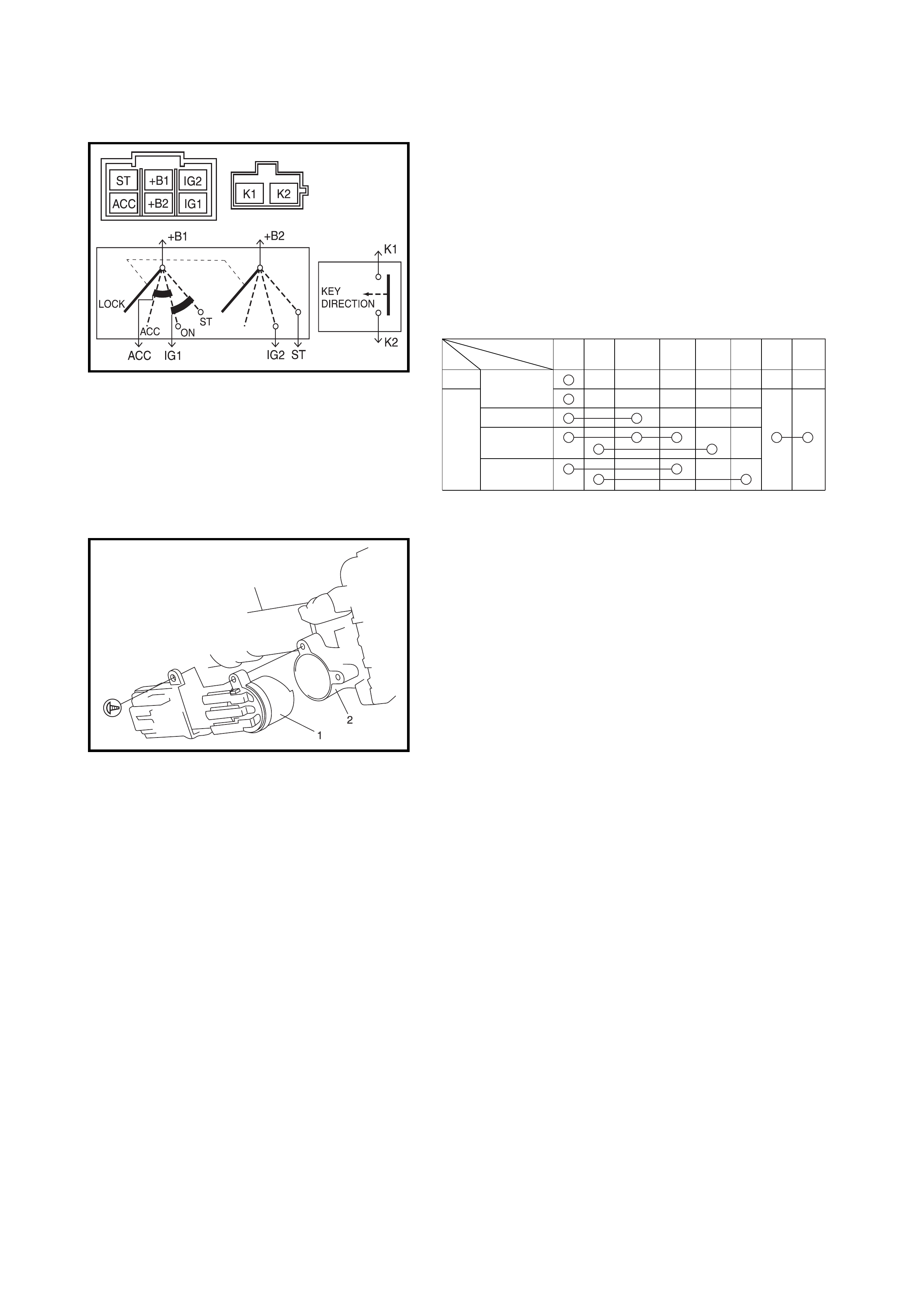

2.9 IGNITION SWITCH

ON-VEHICLE INSPECTION

1. Disconnect negative cable at battery.

2. Remove the steering column hole cover and the

steering column upper and lower covers, refer

3.6 STEERING COL UMN AS SE MBLY in Section 3C.

3. Disconnect the main harness connectors from the

ignition swi tch.

4. Check for continuity between the terminals at each

switch position as shown below. If the check result is

not as specifi ed, re pla ce the switc h.

REMOVAL

1. Disconnect negative cable at battery.

2. Remove the steering column hole cover and the

steering column upper and lower covers, refer

3.6 STEERING COL UMN AS SE MBLY in Section 3C.

3. Disconnect the main harness connectors from the

igniti on switch (1).

4. Remove ignition switch (1) from key cylinder (2).

INSTALLATION

Reverse r emoval procedure for installation.

PositionKey

OUT LOCK

ACC

ON

START

IN

+B1 +B2 +ACC IG1 IG2 ST K1 K2

Terminal

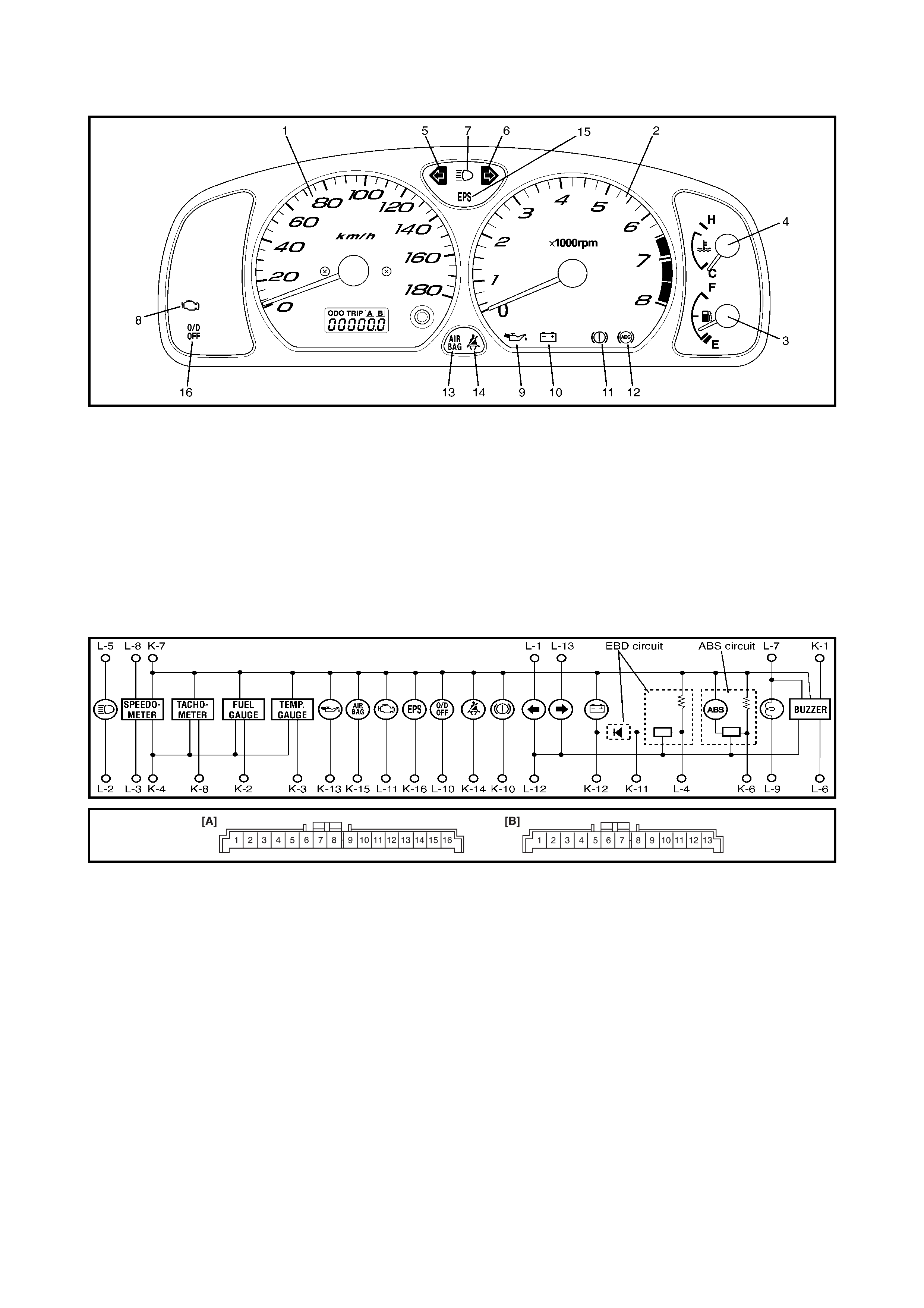

2.10 COMBINAT ION ME TER

Legend

Legend

1. Speedometer 10. Battery charging light

2. Tachometer 11. Brake system warning light (park brake

indicator, brake fluid warning, EBD system warning)

3. Fuel level gauge

4. Water temperature gauge 12. Anti-lock brake system (ABS) warning light

5. Turn signal indicator (LH) 13. AIR BAG warning light

6. Turn signal indicator (RH) 14. Seat belt light

7. High beam indicator 15. Electronic power steering (EPS) warning light

8. Malfunction indicator light (MIL) 16. O/D OFF indicator (A/T only)

9. Engine oil pressure warning light

[A]: Connector K [B]: Connector L

1. To EPS YEL 1. To combination switch (tur n R) BLU/YEL

2. To SDM YEL/BLK 2. To ground BLK

3. To seat belt switch BRN/YEL 3. To ECM PPL/WHT

4. To oil pressure switch YEL/BLK 4. To TCM RED/BLK

5. To generator WHT/BLU 5. To ground RED/BLU

6. To parking brake switch RED/BLK 6. To main fuse WHT/RED

7. To brake fluid level switch RED/BLK 7. To combination switch (dimmer) RED/YEL

8. Blank – 8. To door switch BLK/YEL

9. To ECM BRN 9. To main fuse WHT/BLU

10. To ignition switch BLU 10. To ABS control module PNK/BLU

11. To ABS control module RED/BLU 11. To VSS PPL

12. Blank – 12. To combination switch (dimmer) RED

13. To ground BLK/ORN 13. To combination switch (turn L) GRN/RED

14. To ECT sensor YEL/BLU

15. To fuel level gauge YEL/RED

16. To ignition switch BLU/YEL

REMOVAL

1. Disconnect negative cable at battery.

2. Loosen the steering column mounting nuts, refer to

3.6 STEERING COL UMN AS SE MBLY in Section 3C.

3. Remove the combination meter cluster panel (1).

4. Disconnect all connectors from the combination meter

and remove the combination meter (2).

INSTALLATION

Reverse removal procedure for installation.

INSPECTION

Check the printed plate (1) visually for scratches, cracks

and discolouration.

If any fault is found, replace the printed plate (1).

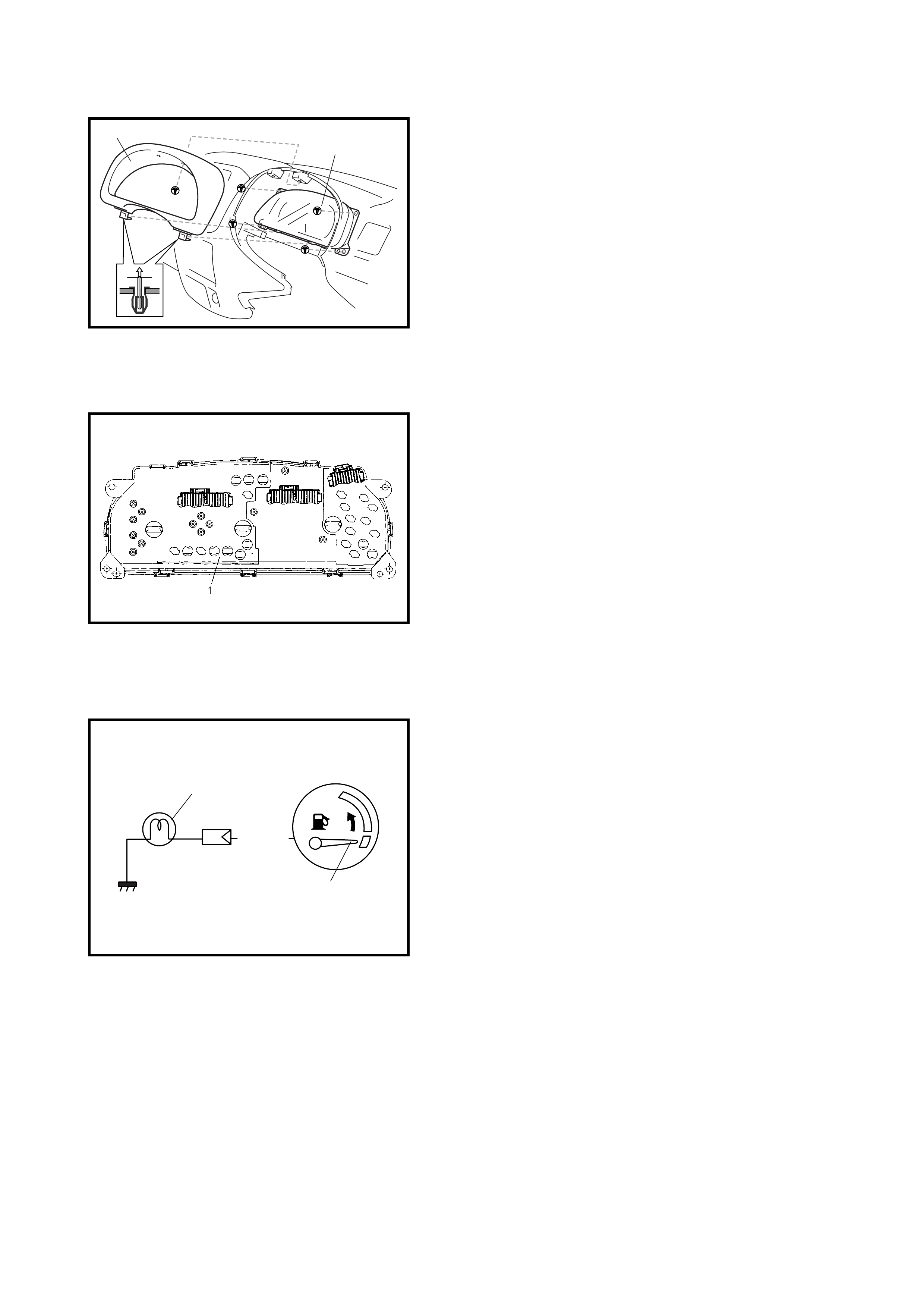

2.11 FUE L GAUGE AND FUE L LEVEL SENSOR (GAUGE UNIT)

FUEL GAUGE

Operation Check

1. Remove the combination meter as previously

described.

2. Remove the YEL/RED wire terminal from the combina-

tion meter connector and reconnect the combination

connectors to the combination meter.

3. Tu rn the ig nit ion switc h ON, and check t hat the poi nter

(2) of fuel gauge indicates E.

4. Turn ignition switch OFF.

5. Short the YEL/RED wire terminal to body ground

through a 3.4 W bulb (1) as shown.

6. Turn the ignition switch ON, and check that the bulb

illuminates and the gauge pointer (2) moves from E

to F.

If the check result is not satisfied, replace the fuel

gauge.

FUEL LEVEL SENSOR (GAUGE UNIT)

Removal

Remove th e fuel p ump as sembly, refer to 2.8 FUEL P UMP

ASSEMBLY in Section 6C.

Installation

Install the fuel pump assembly, refer to

2.8 FUEL PUMP

ASSEMBLY in

Section 6C.

12

YEL/RED

F

E

2

1

INSPECTION

• Check that the resistance between terminals a and b of

fuel level s en so r c onn ect or o n the top o f t he fue l pum p

assembly (1) changes with movement of float position.

• Check the resistance between terminals a and b in

each float position below.

If the measured value is out of specification, replace.

2.12 SPEEDOMETER AND VEHICLE SPEED SENSOR (VSS)

VEHICLE SPEED SENSOR

(VSS)

Removal and Installation

Refer to 3.4 VEHICLE SPEED SENSOR (VSS) in

Section 7A.

Inspection

Refer to 2.22 DTC P0500 (DTC No.16) VEHICLE SPEED

SENSOR (VSS) MALFUNCTION in Section 6.

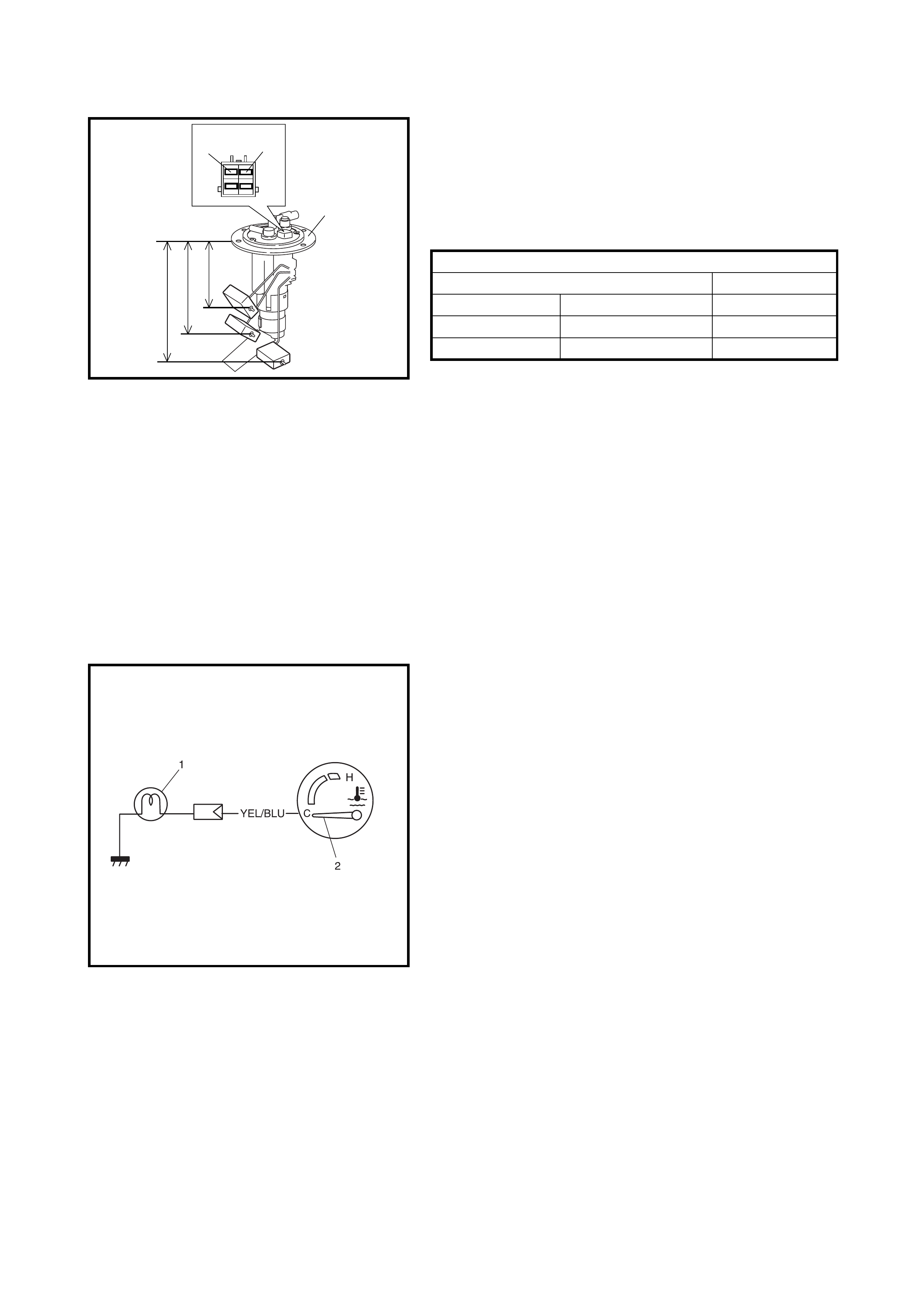

2.13 ENGINE COOLANT TEMPERATURE (E CT) GAUGE AND SENSOR

ENGINE COOLANT TEMPERATURE (ECT) GAUGE

Inspection

1. Remove the combination meter, refer to

2.10 COMBINATION METER in this Section.

2. Remove the YEL/BLU wire terminal from the combina-

tion meter connector and reconnect the combination

connectors to the combination meter.

3. Tu rn the ig nit ion switc h ON, and check t hat the poi nter

(2) of the ECT gauge indicates C as shown.

4. Turn the ignition switch OFF.

5. Short the YEL/BLU wire terminal to body ground

through a 3.4 W bulb (1) as shown.

6. Turn the ignition switch ON, and check that the bulb

illuminates and the gauge pointer (2) moves from C

to H.

If the check result is not satisfied, replace the gauge.

ECT SENSOR

Removal, Installation and Inspection

Refer to 2.3 ELECTRONIC CONT ROL SYSTE M in

Section 6E1.

Fuel Level Sensor Specification

Float Position Resistance (Ω)

Full Upper (c) 59.6 mm 2 - 4

Middle (1/2) (d) 121.6 mm 29.5 - 35.5

Full Lower (e) 202.3 mm 119 - 121

“a” “b”

1

“c”

“d”

“e”

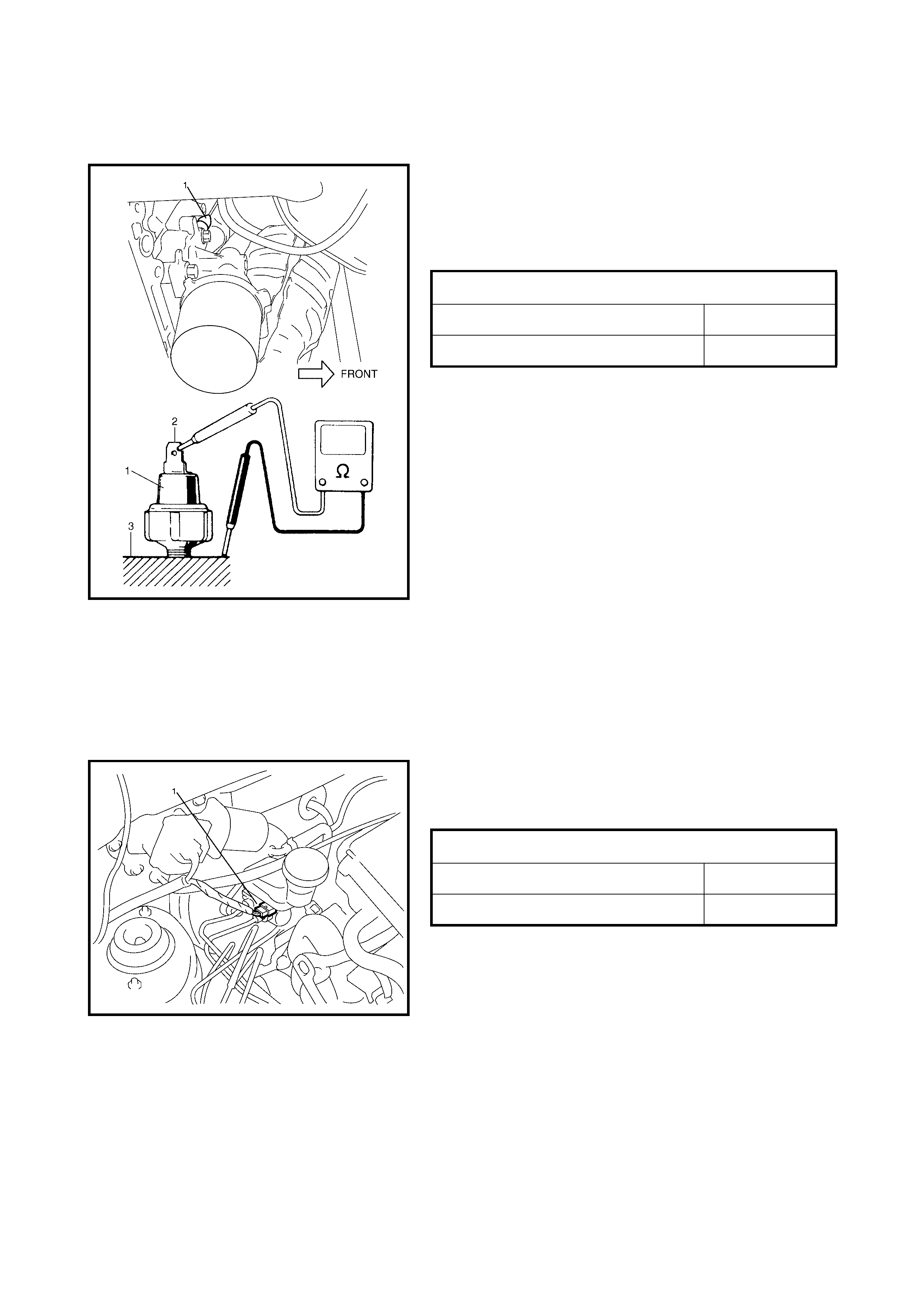

2.14 ENGINE OIL PRES SURE WARNING LIGHT

ENGINE OIL PRESSURE SWITCH

On-vehicle Inspection

1. Disconnect the engine oil pressure switch (1) lead wire.

2. Check for continuity between the engine oil pressure

switch terminal (2) and the cylinder block (3) as shown.

If not to specification, replace the engine oil pressure

switch.

Removal and Installation

Refer to 2.4 OIL PRESSURE CHECK in Section 6A1.

2.15 BRAKE SYSTEM WARNING LIGHT (PARKING BRAKE INDICATOR, BRAKE

FLUID WARNING AND EBD S YSTEM WARNING LIGHT)

BRAKE FLUID LEVEL SWITCH

Inspection

Check for continuity between the terminals of the brake

fluid level switch connector (1).

If found defective, replace the switch.

ENGINE OIL PRESSURE SWI TCH SPECIF ICATION

DURING ENGINE RUNNING: No Continuity

AT ENGINE STOP: Continuity

BRAKE FLUID LEVE L SWI TCH SPECIFICATION

OFF (FLOAT UP): No Continuity

ON (FLOAT DOWN): Continuity

PAR KING BRAKE SWITCH

Inspection

Check for conti nui ty betwe en the parking br ake switc h

terminal and body ground as shown.

If found defective, replace the switch.

2.16 REAR WINDOW DEFOGGER

DEFOGGER SWITCH

Inspection

Check for continuity between the terminals at each switch

position as shown below. If the check result is not satisfied,

replace the switch.

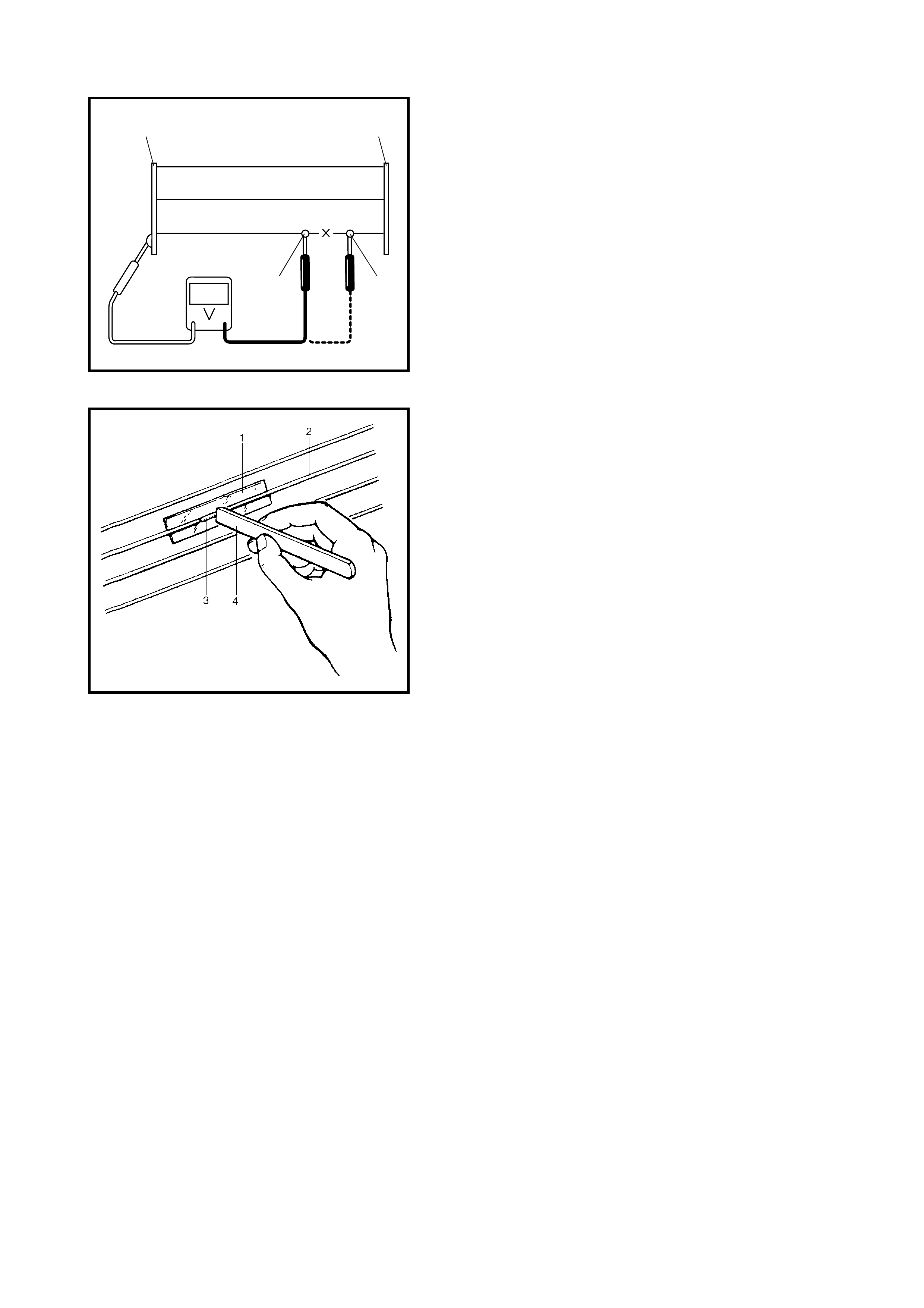

DEFOGGER WIRE

Inspection

NOTE:

• When cleaning the rear window glass, use a dry cloth

to wipe along the heat wire (1) direction.

• When cleaning the glass, do not use detergent or

abrasive-containing glass cleaner.

• When measuring wire voltage, use a tester with

negative probe (2) wrapped in tin foil (3) which should

be held down on the wire by finger pressure.

• Wire damage inspection:

a. Turn the ignition switch ON.

b. Turn the defogger switch ON.

c. Check the voltage at the centre (1) of each heat

wire as shown below.

If the measured voltage is 10V, the wire must be

damaged (x) between its centre and positive (+)

end (5).

If the voltag e is 0 V, the wi re must be damage d (x)

between its centre and ground (-) end (6).

PARKING BRAKE SWITCH SPECIFICATION

OFF (PARKING BRAKE RELEASED)

(1): No Continui ty

ON (PARKING BRAKE ENGAGED) (2): Continuity

SwitchPosition

Terminal

ON (PUSH IN)

IG LOAD E IL ILE

OFF

Voltage Criteria

Approx. 4 - 6 V (2) Good (No break in wire)

Approx. 9 - 11 V (3) or 0 - 2 V (4) Broken wire

• Damage point (x) locating:

a. Turn the ignition switch ON.

b. Turn the defogger switch ON.

c. Touch the voltmeter positive (+) lead to the heat

wire positive terminal end (1).

d. Touch the voltmeter negative (-) lead with a foil strip

to the heat wire positive terminal (+) end (1), then

move it along the wire to the negative terminal (-)

end (2).

e. The place where the vo ltm ete r flu ctuates fr o m 0 - 2

V (3) to several volts (4) is where there is damage.

Repair

1. Use white gasoline for cleaning.

2. Apply masking tape (1) at both the upper and lower

sides of the heat wire (2) to be repaired.

3. Apply a commercially-available repair agent (3) with a

fine-tip brush (4).

4. 2 to 3 minutes later, remove the masking tape (1).

5. Leave the repaired heat wire as it is for at least 24

hours before operating rear defogger.

+-

3

12

4

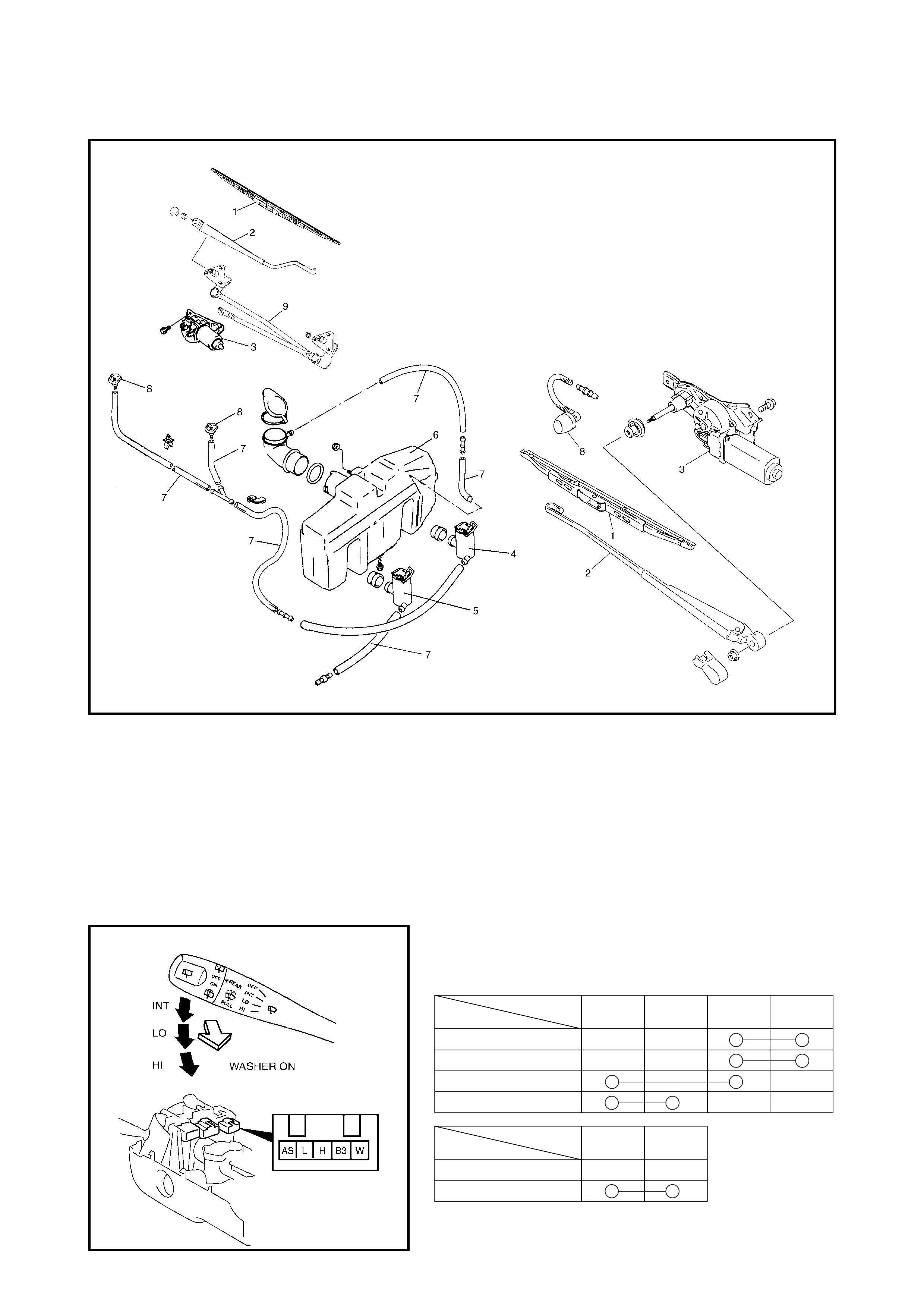

2.17 WIPERS AND WASHERS

COMPONENTS

Legend

FRONT WIPER AND W ASHER SWITCH

Removal and Installation

Refer to 3.5 CONTACT COIL AND COMBINATION

SWITCH ASSEMBLY in Section 3C.

Inspection

Check for continuity between the terminals at each switch

pos ition as shown below.

If the check result is not as specified, replace the switch.

1. Wiper blade 4. Washer pump (for front washer) 7. Washer hose

2. Wiper arm 5. Washer pump (for rear washer) 8. Washer nozzle

3. Wiper motor 6. Washer tank 9. Wiper link

Terminal

Wiper SW

OFF

INT

LO

B3 H L AS

HI

Terminal

Washer SW

OFF

ON

B3 W

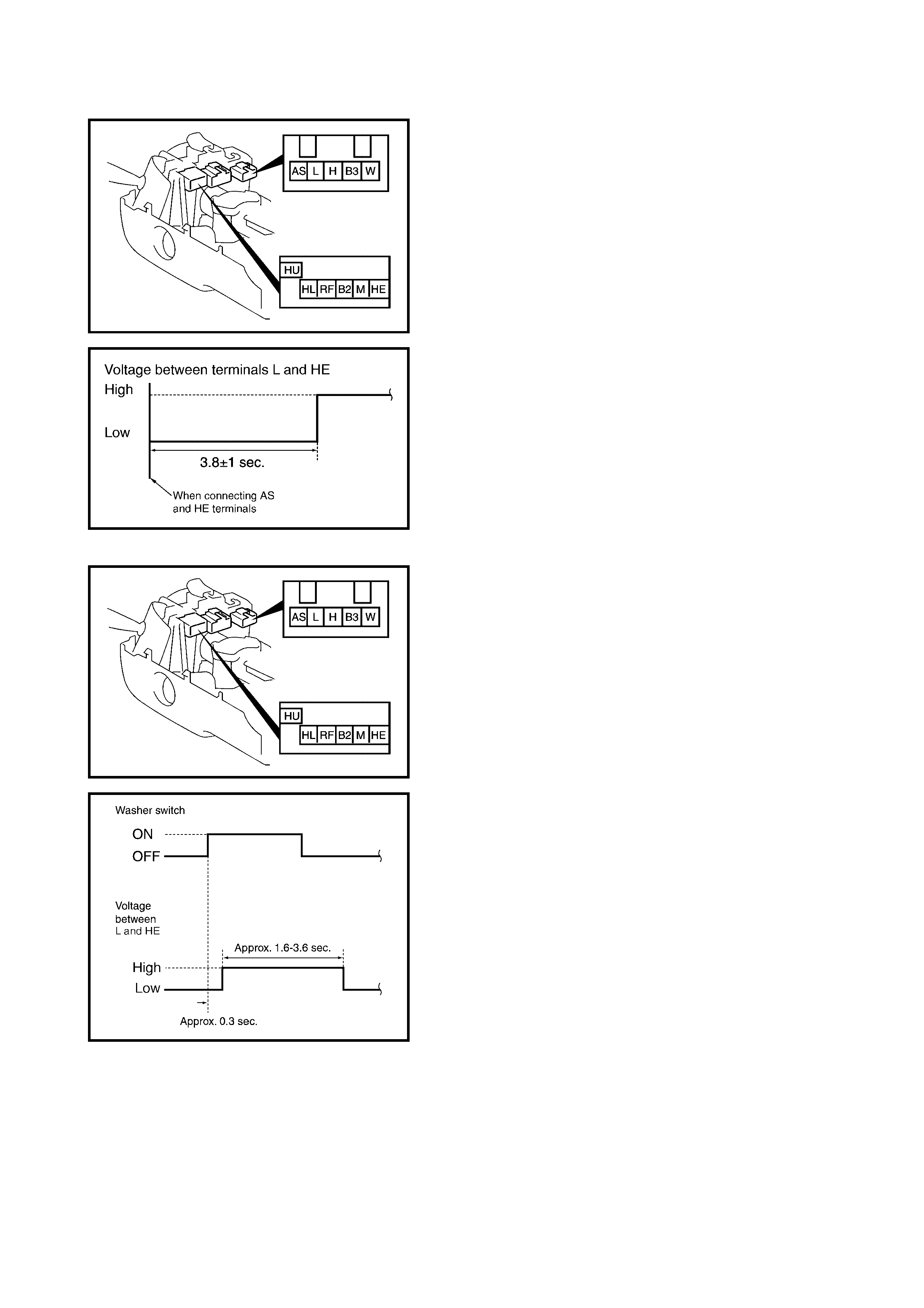

Intermittent Wiper Relay Circuit Inspection

1. Turn the front wiper switch to INT position.

2. Connect battery positive to terminal B3 and negative to

terminal HE.

3. Connect a voltmeter positive lead to terminal L and

negative lead to terminal HE.

4. Check that the voltmeter indicates battery voltage

(10 – 14 V).

5. Connect a jumper wire between terminal AS and

terminal B3 for 5 seconds or more.

6. Disconnect the jumper wire from terminal B3.

7. Connect the disconnected end of the jumper wire to

terminal HE and check that the voltage between

terminal L and terminal HE changes as shown.

If check result is not satisfied, replace.

Washer Linked Circuit Inspection

1. Make sure that the front wiper switch is OFF position.

2. Connect battery positive to terminal B3 and negative to

terminal HE.

3. Connect a voltmeter positive lead to terminal L and

negative lead to terminal HE.

4. When the front washer switch is ON (pushed to

forward), check that the voltage changes as shown in.

FRONT WIPER MOTOR

Inspection

Motor Operation (Low Speed)

1. Connect battery positive to terminal L and negative to

the motor bracke t (wip er ground) .

2. Check motor revolution speed.

Motor Operation (High Speed)

1. Connect battery positive to terminal H and negative to

the motor bracke t (wip er ground) .

2. Check motor revolution speed.

Automatic Stop Operation

1. Connect battery positive to terminal L and negative

terminal to the motor bracket (wiper ground) and let the

motor turn.

2. Disconne ct term inal L from the batt ery pos itive, and let

the motor stop.

3. Connect terminal L and S with a jumper wire, and

connect terminal B to battery positive. Observe that the

motor turns once again and then stops at a specified

position.

4. Repeat Steps 1 to 3 several times and check that the

motor stops at the specified position every time.

If check result is not satisfied, replace the front wiper

motor.

WASHER TANK AND WASHER PUMP

Removal

1. Disconnect the battery negative cable.

2. Remove the RH front fender liner, refer

2.14 FRONT FENDER in Section 9.

3. Remove the washer tank attaching nuts and inlet pipe

(4).

4. Disconnect the pump wire connector(s) and hoses.

5. Remove the washer tank (1).

6. Remove the front washer pump (2) and rear washer

pump (3) from the washer tank.

Installation

Reverse removal procedure for installation.

Inspection

1. Connect battery (+) and (-) to the pump (+) and (-)

terminal s re sp ec tivel y.

2. Check motor operation for both front and rear washer

pumps.

FRONT WIPER MOTOR SPECIFICA-

TION (LOW SPEED) 44 – 52 rpm

FRONT WIPER MOTOR SPECIFICA-

TION (HIGH SPEED) 64 – 78 rpm

LH

S

B

LH

S

B

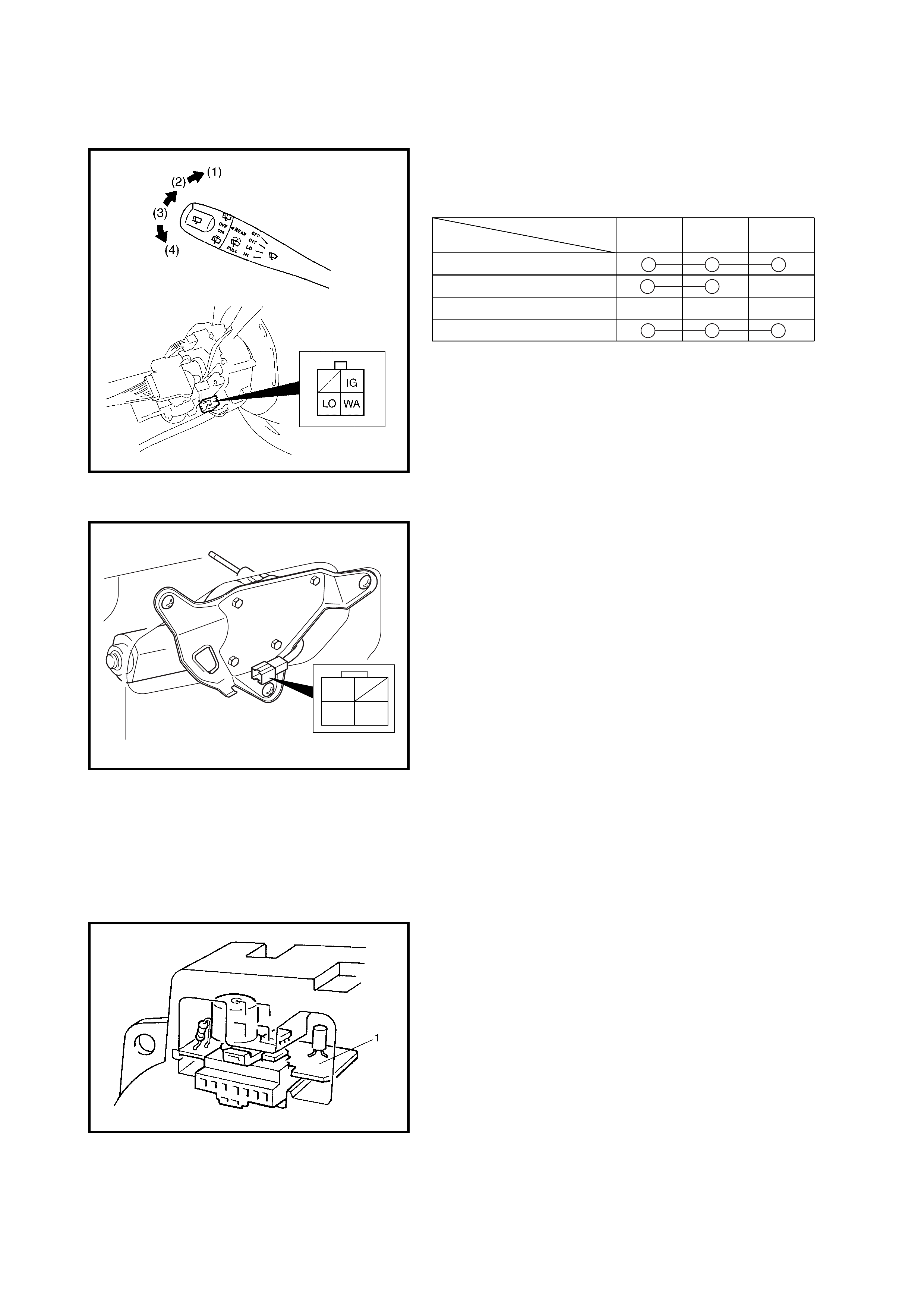

REAR WIPER AND W ASHER SWITCH

Inspection

Check for continuity between the terminals at each switch

pos ition as shown below.

If the check result is not as specified, replace the switch.

REAR WIPER MOTOR

Inspection

Wiper Motor

Use a 1 2 V battery and connect its (+) and (-) termin als to

terminal L and terminal E respectively. The motor should

rotate at 35 to 45 rpm.

Automatic Stop Operation

1. Connect battery positive to terminal L and negative to

terminal E and let the motor turn.

2. Disconnect the battery from terminal L and let the

motor stop.

3. Connect battery positive to terminal B. Observe that

the motor turns once again and then stops at a

specified position.

4. Repeat Steps 1 to 3 several times and check that the

motor stops at the specified position every time.

If check result is not satisfied, replace the rear wiper

motor.

2.18 IGNITION KEY REMINDER AND LIGHT REMINDER WARNING BUZZER

REMOVAL

1. Remove the combination meter. Refer to

2.10 COMBINATION METER in this Section.

2. Remove the buzzer unit (1) from combination meter.

INSTALLATION

Reverse removal procedure for installation.

Terminal

Position

(1) WIPER and WASHER ON

(2) WIPER ON

(3) OFF

IG LO WA

(4) WASHER and WASHER ON

B

E

L

2.19 POWER WINDOW CONTROL SYSTEM

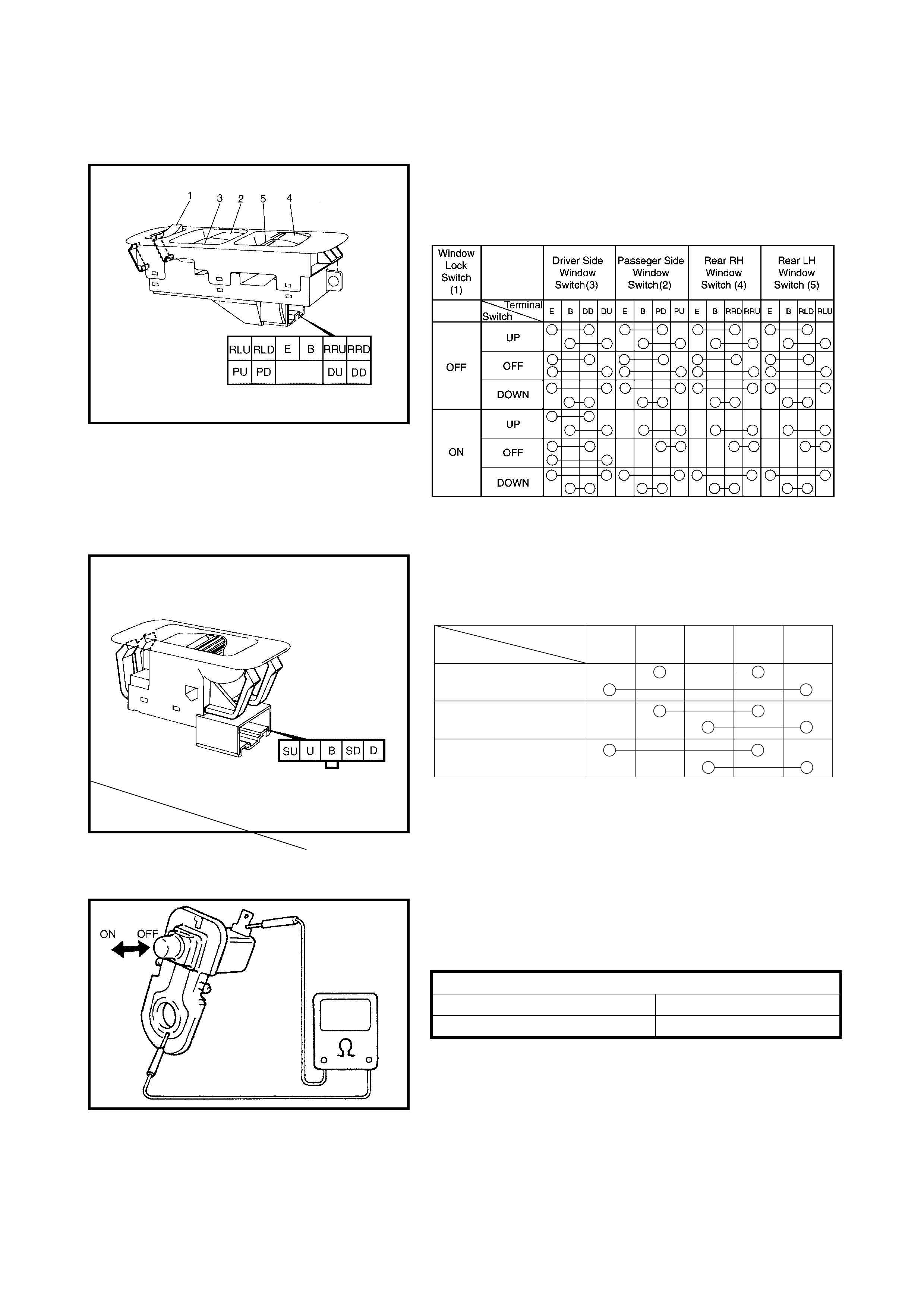

POWER WINDOW MAIN SWITCH

Inspection

Check for continuity between the terminals at each switch

position as shown below. If the check result is not as

specified, replace the switch.

POWER WINDOW SUB SWITCH

Inspection

Check for continuity between the terminals at each switch

conditi on as sh own bel ow.

If the check result is not as specified, replace the switch.

2.20 DOOR SWITCH

INSPECTION

Remove the door switch and check for continuity as

specified.

If found detective, replace the switch.

Terminal

Switch

Position

UP

BSDSUD U

OFF

DOWN

Door Switch Specification

OFF position (Door closed) No continuity

ON position (Door open) Continuity

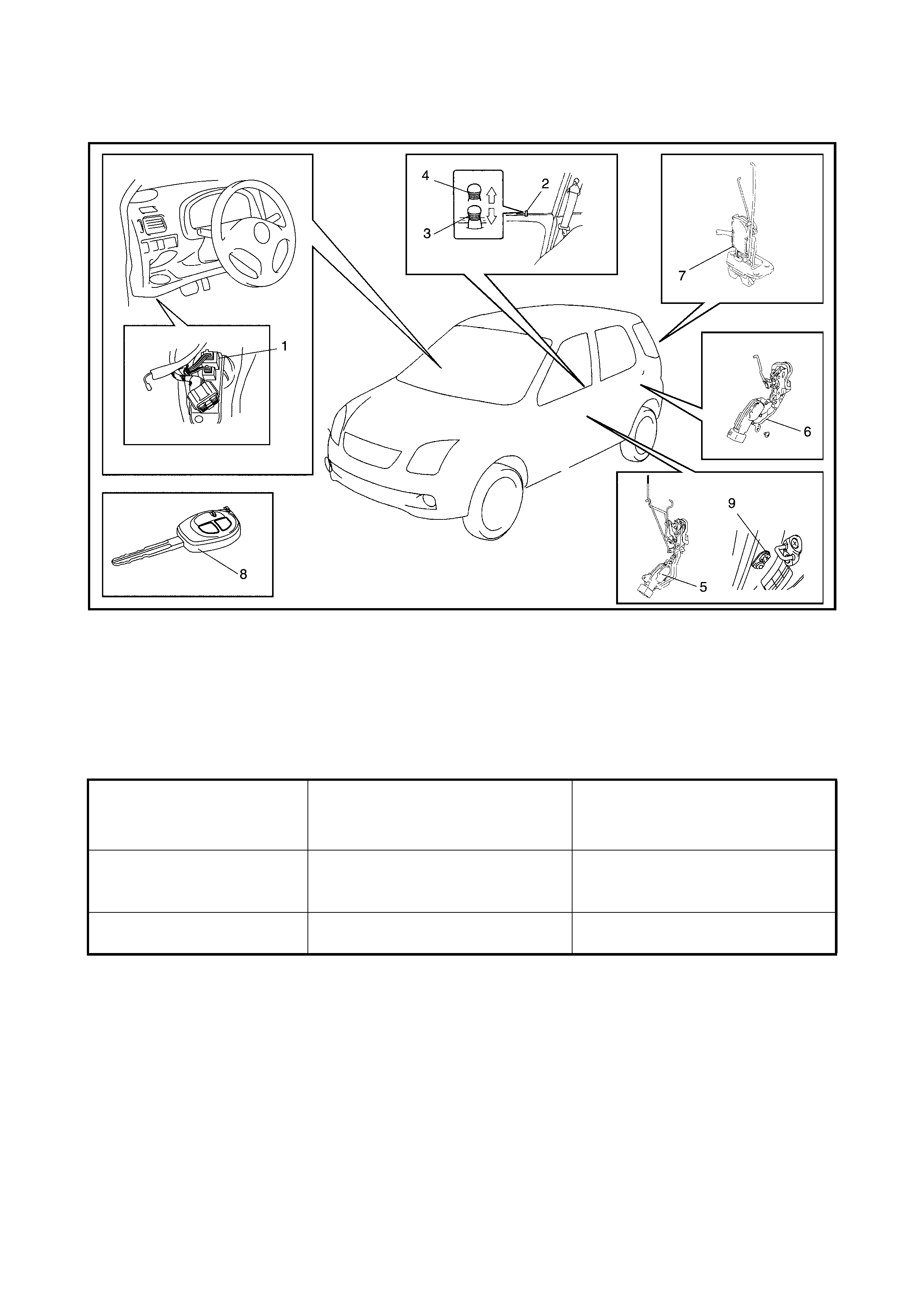

2.21 POWER DOOR LOCK SYSTEM WITH KEYLESS ENTRY SYSTEM

COMPONENT LOCATION

Legend

SYSTEM DESCRIPTION

The ke yless e ntry s ystem has the foll owing signal mod es in orde r to feed back the si gnal wh en the co ntrol ler

received LOCK and UNLOCK signals from the transmitter.

NOTE:

• These signal modes can be changed, refer to CHANGE OF SIGNAL MODE in this Section.

• The default condition is the hazard warning light signal mode.

CHANGE OF SIGNAL MODE

1. Confirm that all doors are closed and that the ignition key is out of the ignition switch.

2. Perform the following procedures within 15 seconds:

a. Insert, then withdraw the ignition key from the ignition switch.

b. Repeat Step a. two times.

c. Insert the ignition key in the ignition switch again then push the LOCK button on the transmitter more

than five times.

3. Confirm that the hazard warning light or interior light flashes once. The ‘change of signal mode’ is now

complete.

1. Power door lock controller 4. UNLOCK position 7. Back door actuator

2. Driver side door knob switch 5. Front door actuator 8. Transmitter

3. LOCK position 6. Rear door actuator 9. Door switch

Received Signal LOCK Signal UNLOCK Signal

Signal Mode

Hazard warning light signal

mode The hazard warning lights flash once. The hazard warning lights flash twice

and the interior light turns on for

about 15 seconds

Interior light signal mode The interior light flashes twice The interior light turns on for about

15 seconds

POWER DOOR LOCK SYSTEM OPERATION

Inspection

1. Check the following operation:

a. when the drivers side key cylinder is turned to

LOCK, check all doors lock.

b. When the drivers side door key cylinder is turned to

UNLOCK, check all doors unlock.

POWER DOOR LOCK SYSTEM CIRCUIT

Inspection

1. Disconne ct the negati ve (–) ca ble from the battery.

2. Disconnect the door lock controller coupler, G40 (1).

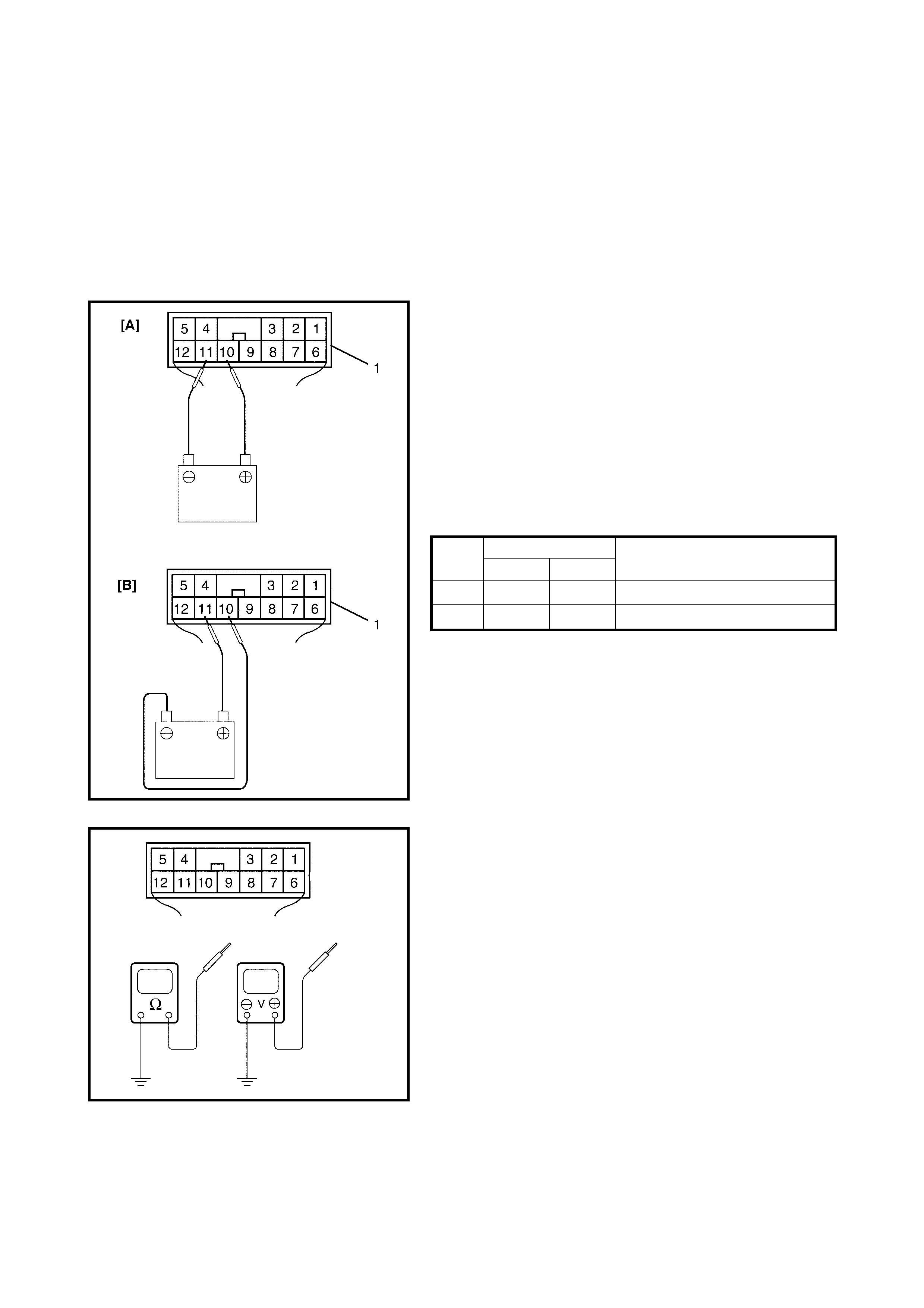

(Coupler is viewed from the harness side in the figure).

3. Confirm that all doors are unlocked. Connect battery

positive (+ ) and neg ative (–) terminals to the door lock

controller coupler terminals and check the power door

lock operation as follows:

If it does not op erate as speci fied c heck ac tuator, refer

to DOOR LOCK ACTUATOR in this Section. If actuator

is OK, repair applicable circuit.

POWER DOOR LOCK VEHICLE OPERATION

4. Connect negative (–) cable to battery.

5. Check that the voltage and continuity between the

following terminals and body ground are to

specification under each condition.

If check result is not as specified, check driver’s door

knob switch, refer to DRIVER’S DOOR KNOB

SWITCH. If driver’s side door knob switch is OK, repair

applicable circuit.

Step TERMINAL OPERATION

G40-10 G40-11

1 [A]

+–

UNLOCK — LOCK

2 [B]

–+

LOCK — UNLOCK

POWER DOOR LOCK SYSTEM CIRCUIT CHECK

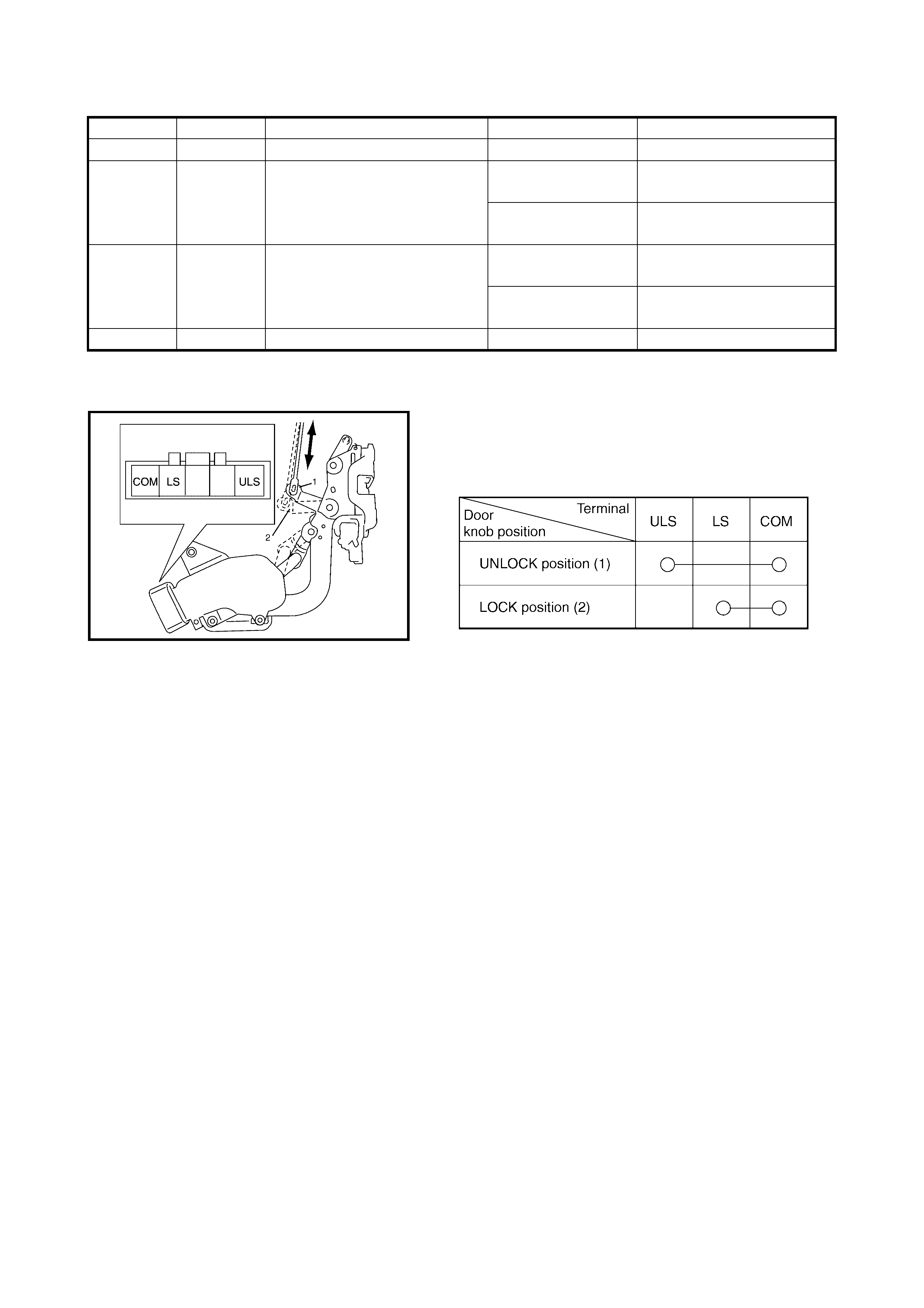

DRIVER’S DOOR KNOB SWITCH

On-vehicle Inspection

1. Remove the dr iver’s do or trim an d discon nect the door

lock switch connector.

2. Check for continuity as shown below between

terminals at each switch condition.

Terminal Wire Circuit Specification Condition

G40-7 WHT/GRN Main power supply 10 – 14 V –

G40-8 BRN Driv er s side door kno b switch

LOCK signal circuit

Continuity Driver s side d oor knob i s in

LOCK position

No Continuity Driver s sid e door knob is i n

UNLOCK pos iti on

G40-9 BRN/WHT Dr iver s si de door kno b swit ch

UNLOCK signal circuit

Continuity Driver s side d oor knob i s in

UNLOCK pos iti on

No Continuity Driver s sid e door knob is i n

LOCK position

G40-12 BLK Ground 0 – 1 V –

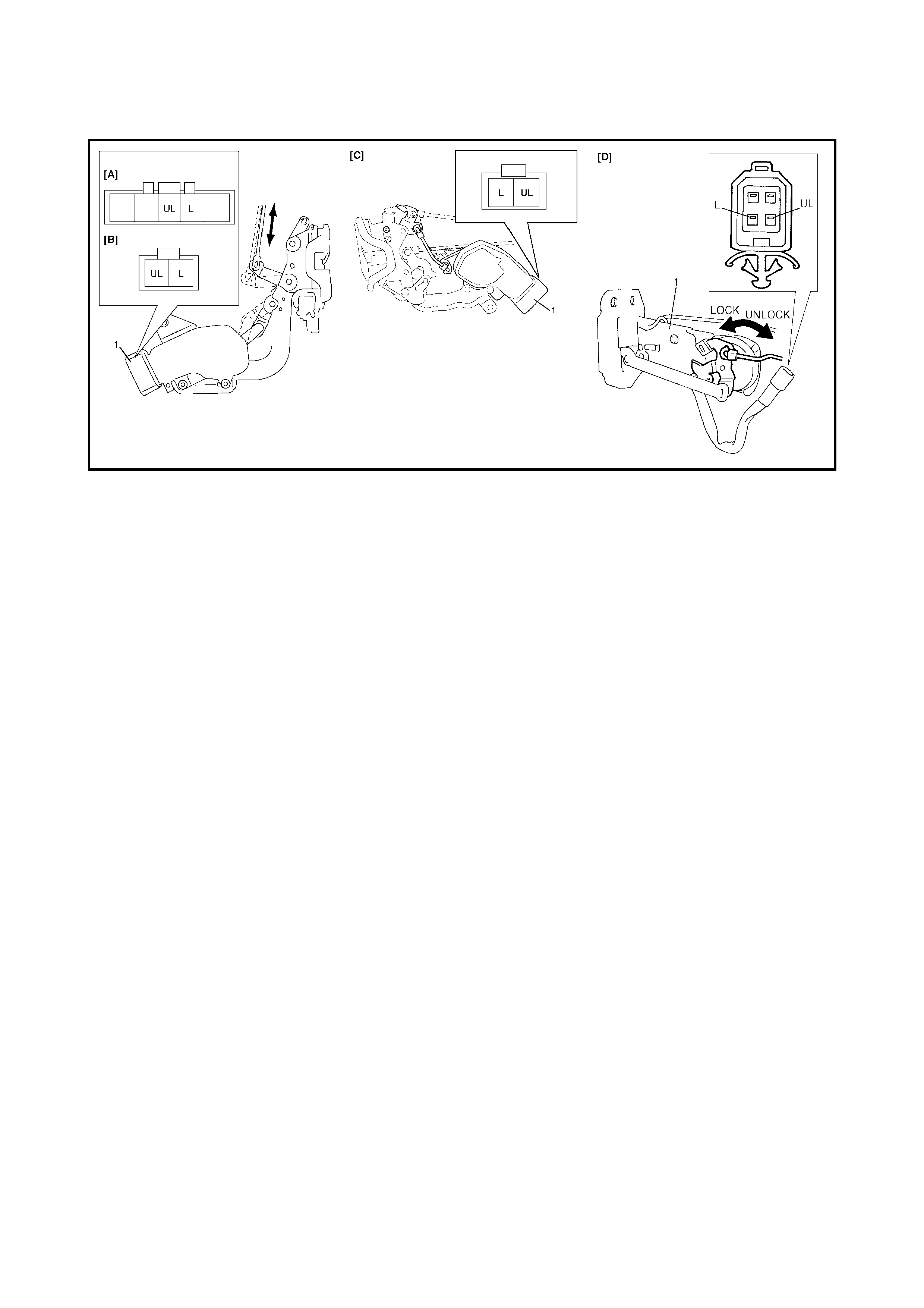

DOOR LOCK ACTUATOR

On-vehicle Inspection

Legend

1. Remove th e door tri m (front, r ear or b ack) and discon-

nect the door lock actuator (1) connector.

2. Connect battery (+) to terminal L and (-) to terminal UL.

Check that the door lock actuator (1) is in the LOCK

position.

If check result is not satisfied, replace the actuator.

3. Connect batte ry ( +) to term inal UL and (-) t o termi nal L.

Check that the door lock actuator (1) is in the UNLOCK

position.

If check result is not satisfied, replace the actuator.

[A]: Front Door Driver Side [C]: Rear Door

[B]: Front Door Passenge r Side [D]: Back Door

KEYLESS ENTRY SYSTEM OPERATION

Inspection

NOTE: If the keyles s entr y sy ste m is in ‘inter i or lig ht sig nal ’

mode, change it to ‘hazard warning light signal’ mode, refer

to CHANGE OF SIGNAL MODE.

1. Confirm that the power door lock system is in good

condition, refer to POWER DOOR LOCK SYSTEM

OPERATION in this Section.

2. Confirm that the turn signal and hazard warning light

system is in good condition, refer to 2.3 TURN SIGNAL

AND HAZARD WARNING LIGHTS in this Section.

3. Check the transmitter for a dead battery. Replace the

battery if it is dead, refer to TRANSMITTER in this

Section.

4. Confirm that all doors are closed and unlocked.

5. Check the following operation:

a. When pushing the LOCK button (1) on the transmit-

ter (2), check all doors lock and hazard warning

lights flash once.

b. When push ing UNLO CK butt on ( 3) on the tran smit-

ter (2), check that all doors unlock and the hazard

warning l ights flas h tw ic e an d the int erior ligh t tur ns

on for about 15 seconds with the interior light

switch in the middle position.

If the check result is not satisfactory, go to KEYLESS

ENTRY SYSTEM CIRCUIT – INSPECTION as follows.

KEYLESS ENTRY SYSTEM CIRCUIT

Inspection

NOTE: If the keyless entry syst em is in ‘interio r light signa l

mode’, change to ‘h azard warning light signal mode’, refer

to CHANGE OF SIGNAL MODE in this Section.

Check that the voltage and continuity between the following

terminals and body ground are to the specifications under

each condition.

If the che ck resul t is not as speci fied, check ap plicable ci r-

cuit.

If the circuit is normal, recheck the keyless entry system

circuit as follows:

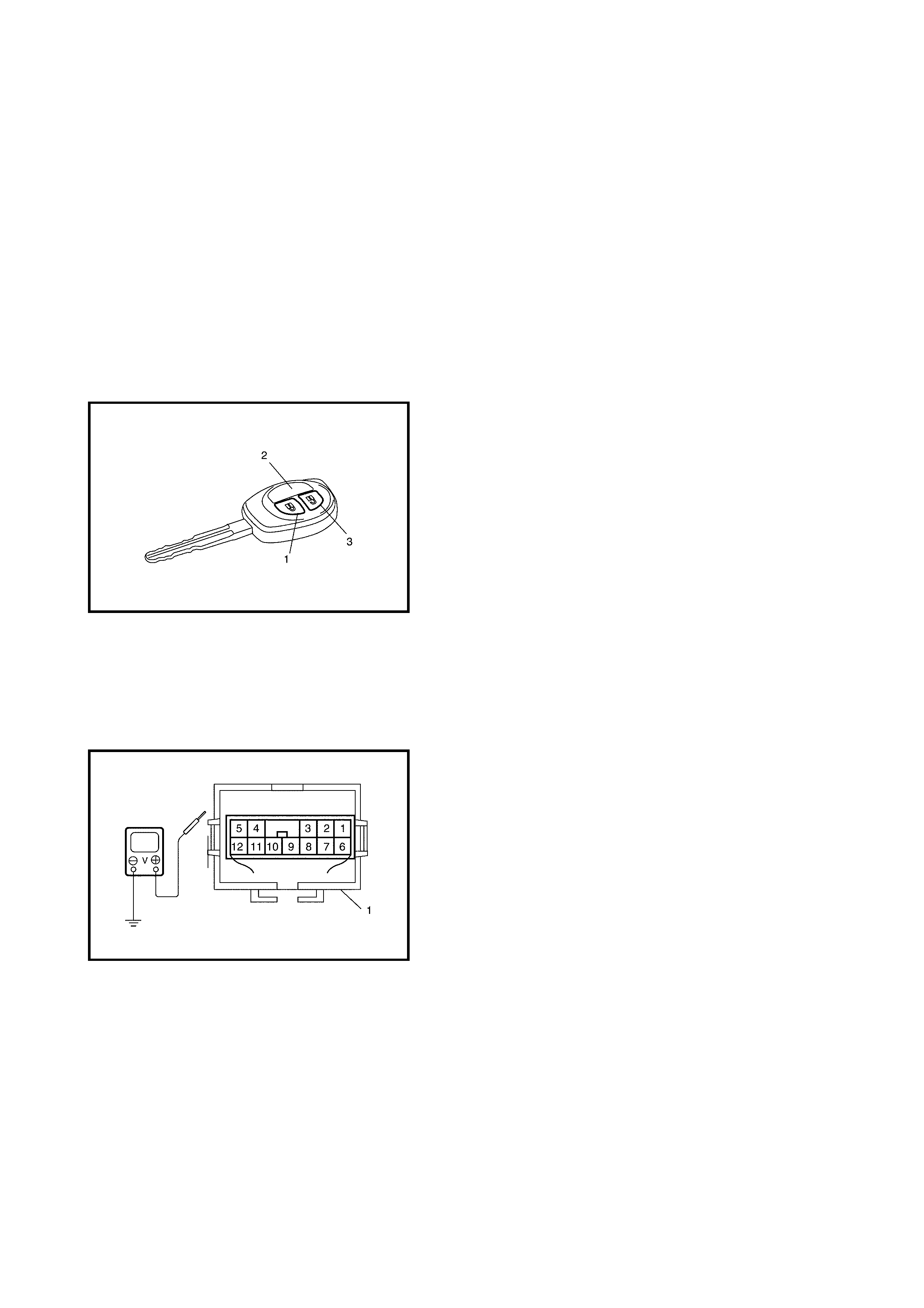

1. Substitute a known-good door lock controller (1).

2. Register the key code, refer to CODE REGISTRATION

PROCEDURE in this Section.

3. Recheck the keyless entry system circuit.

KEYLESS ENTRY SYSTEM CIRCUIT CHECK

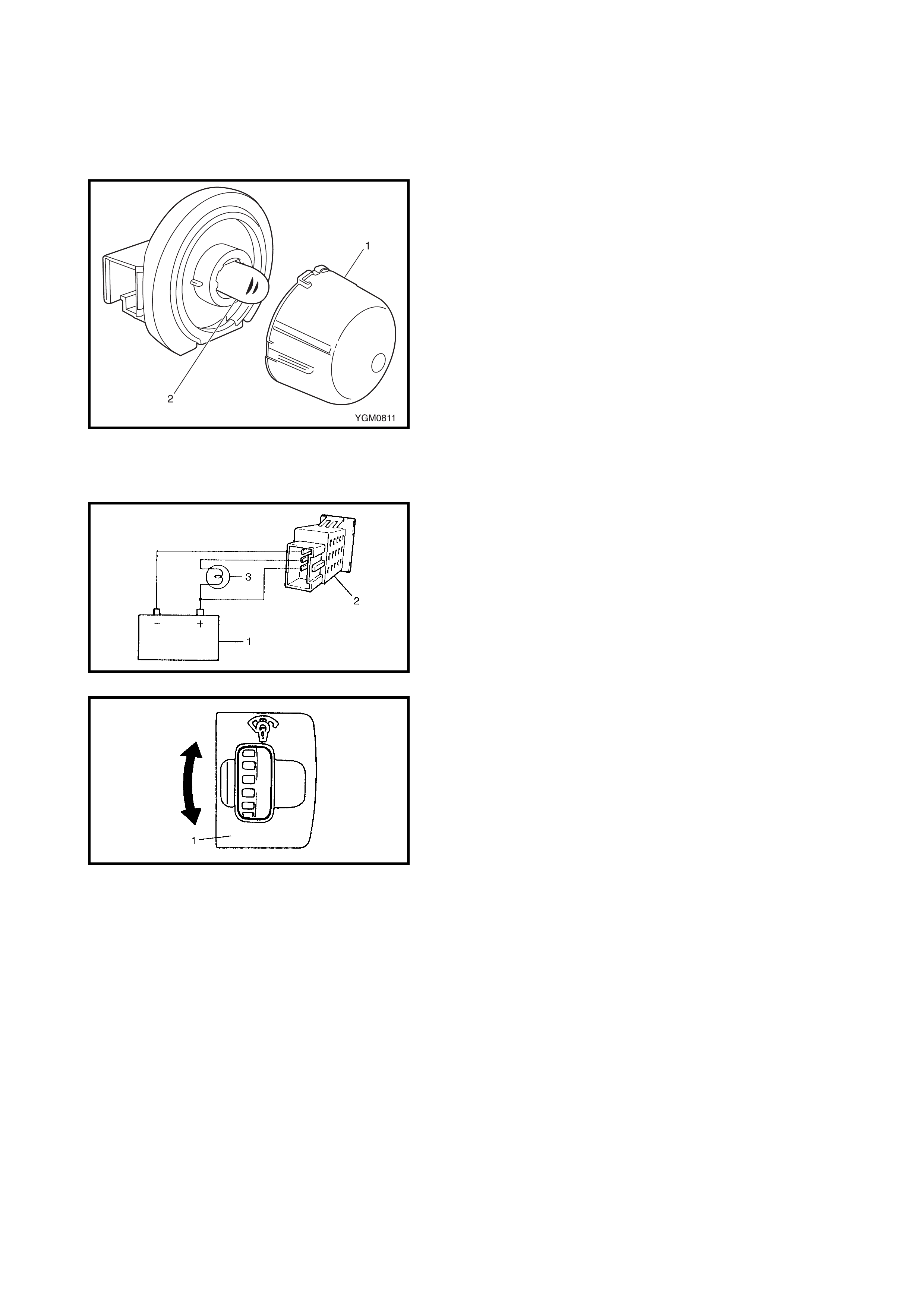

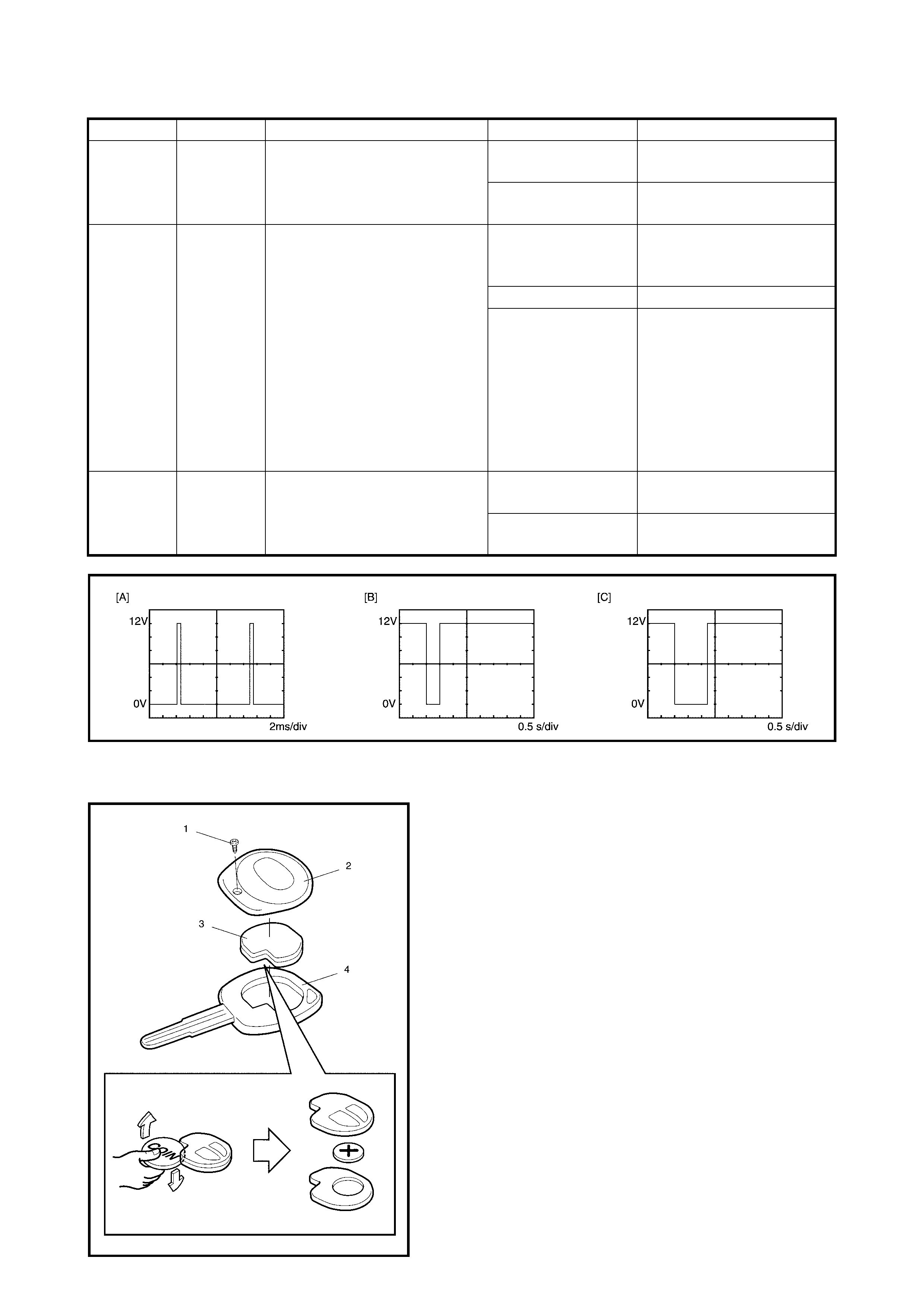

TRANSMITTER

Battery Replacement

If the tra nsmitter becomes unr eliable, r eplace the tr ansmit-

ter battery as follows:

1. Remove the screw (1) and transmitter cover (2).

2. Remove the transmitter ( 3) from the trans mitter holder

(4).

3. Put the edge of a coin or flat blade screwdriver in the

slot of the transmitter (3) and pry it open.

4. Replace the battery (lithium disc-type CR1616 or

equivale nt battery) so its

+

termin als faces ‘+’ mark on

transmitter.

5. Fit the transmitter together (3) and install it into the

transmitter holder (4).

6. Install the transmitter cover (2) and screw (1).

7. Make sure that the door locks can be operated with the

transmitter.

CAUTION: Do not allow the printed circuit board or the

battery to be contaminated with grease or dirt.

NOTE:

• To prevent theft, break the transmitter before discarding.

• Dispose of the used battery according to applicable

rules a nd regulations . Do not di spose of lithium batte r-

ies with ordinary household rubbish.

Terminal Wire Circuit Specification Condition

G40-2 BLU/YEL Key remainder circuit 10 – 14 V Ignition key is in ignition

switch

0 – 1 V Ignition key is not in ignition

switch

G40-4 BLK/RED Door switch & interior light

circuit

0 – 1 V Drivers side, passenger

side, rear passenger side

or back door is open.

10 – 14 V All doors are closed.

Figure [A]

• Fulfill the fol lowi ng

conditions:

• All doors are closed.

• Interior light switch is in

middle pos ition

• 15 seconds after pu shing

UNLOCK button on

transmitter.

G40-5 YEL/RED Hazard warning signal circuit Figure [B] Push the LOCK button on

the transmitter

Figure [C] Push the UNLOCK button

on the transmitter

CODE REGISTRATION PROCEDURE

If the transmitter or door lock controller is replaced with a

new one, register the key code as follows:

1. Confirm that the vehicle is the following condition:

• All doors are closed.

• Ignition key is out of ignition switch.

• Driver side door is unlocked, and the window is open

2. Disconnect negative (–) cable from battery.

3. After 30 seconds, perform the following procedure

within 60 secon ds....

a. Connect negative (–) cable to battery.

b. Operate the driver door snib to LOCK and then

from LOCK to UNLOCK twice.

c. Push the “LOCK” button on the transmitter and

confirm that all door snibs cycle.

d. Move the driver door snib to the “LOCK” position.

e. Push the “LOCK” button on the transmitter twice

and confirm that all door snibs cycle.

This completes the registration procedure.

NOTE:

• Two transmitter codes can be registered.

• If an attempt is made to register a third transmitter

code, the first one will be cleared.

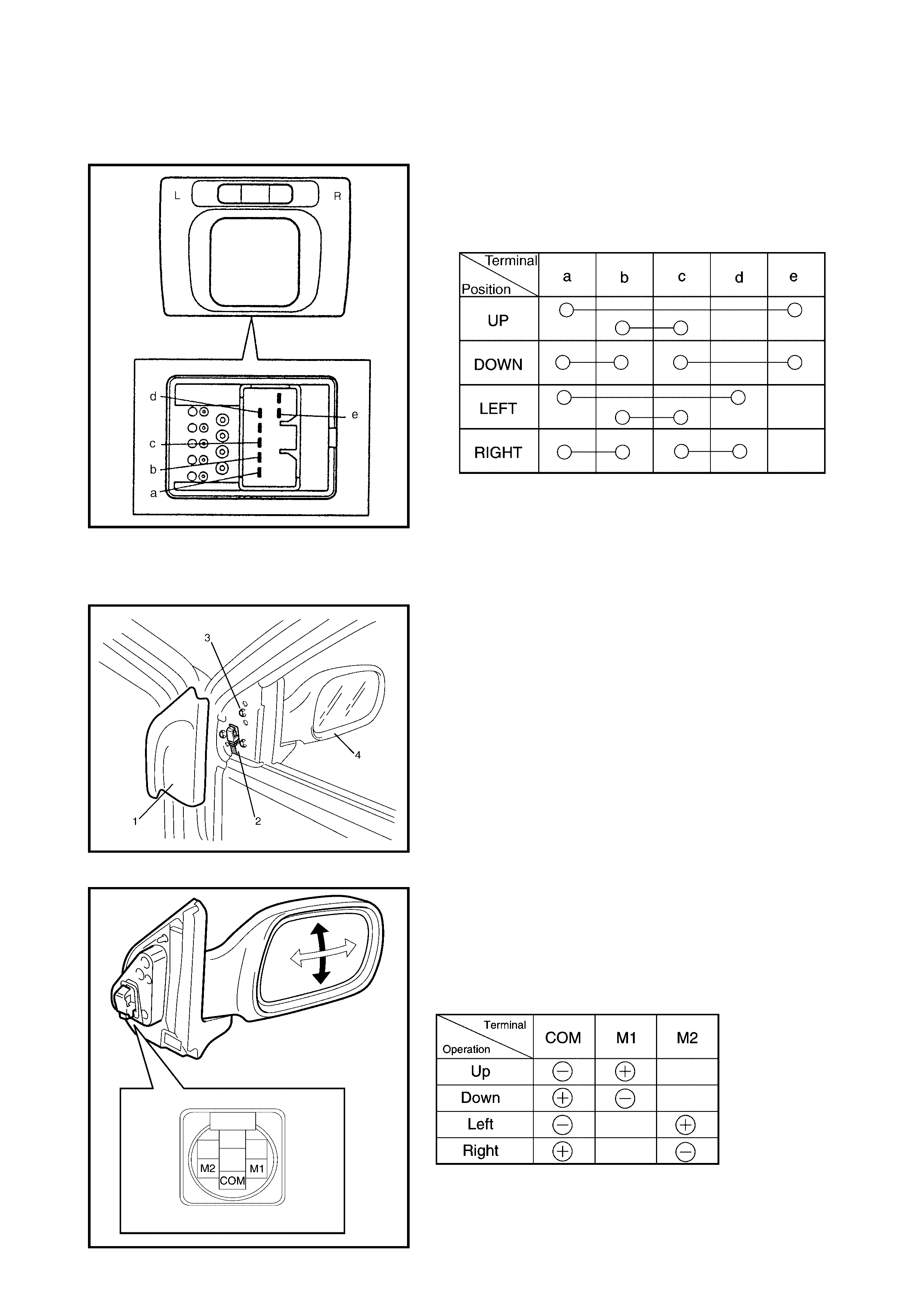

2.22 POWER DOOR MIRROR CONTROL SYSTEM

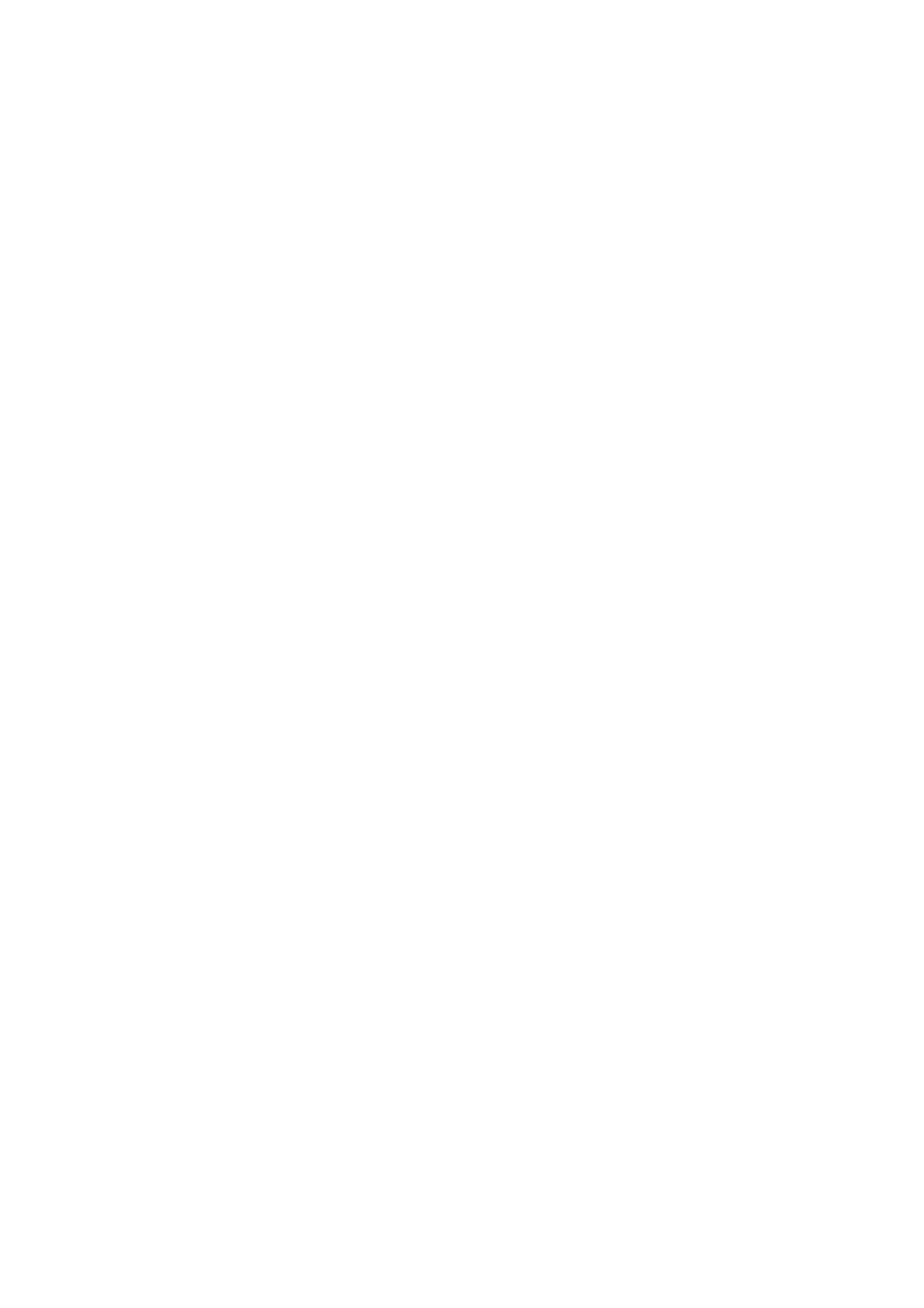

MIRROR SWITCH

Inspection

1. Remove the mirror switch from the instrument panel.

2. Check for continuity between terminals at each switch

position as show below.

If ch eck re sul t is not as sp ecif ied, repl ace m irr or sw itch.

2.23 DOOR MIRROR ACTUATOR

REMOVAL

1. Remove the garnish (1).

2. Disconnect the door mirror connector (2).

3. Remove the three door mirror mounting bolts (3) and

remove the door mirror assembly (4).

INSPECTION

Check that the door m irror operates properly when b attery

voltage is applied to the connector terminals as follows.

• Connect battery positive and negative to the door

mirror terminals shown below.

If it does not follow the table’s operation, replace door

mirror assembly.

CAUTION:

Never short positive and negative probes

to prevent wire harness from damage.

INSTALLATION

Revers e remo val p rocedur e to ins tall door mi rror a ssem bly

ensuring not to pinch the harness between the door and

door mirror.

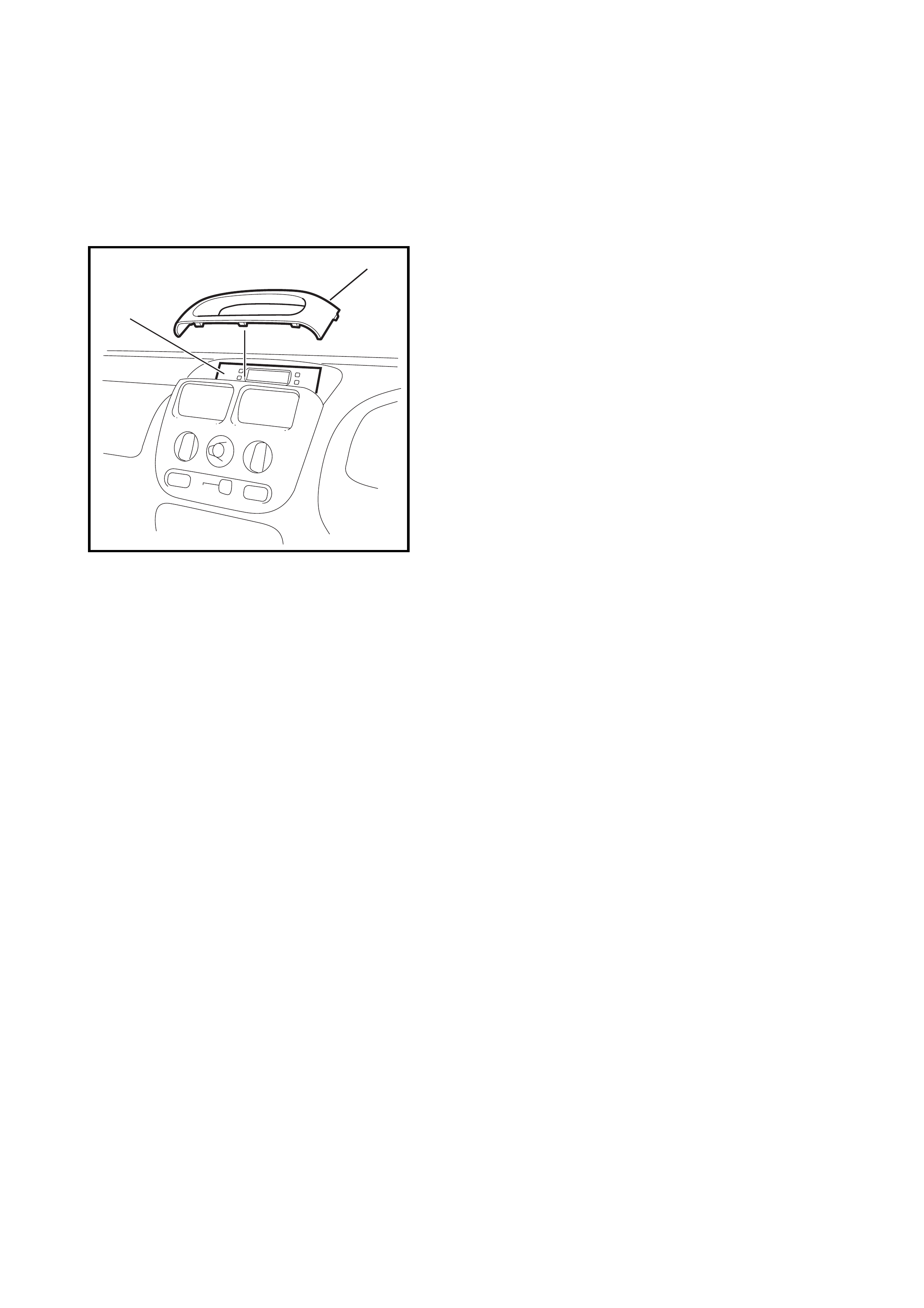

2.24 MULTI INFORMATION DISPL AY

REMOVAL

1. Unclip the centre-upper console (1) from the instru-

ment panel.

2. Remove the 3 multi information display mounting

screws.

3. Disconnect the multi information display coupler.

4. Remove the multi information display (2).

INSPECTION

Check the multi information display wire harness and

grounding, refer to 7.27 F-2 MULTI INFORMATION

DISPLAY in Section 8A CIRCUITS AND

CONNECTORS.

If the wire harness and connections are OK and the clock

still malfunctions, replace the multi function display.

INSTALLATION

The multi information display installation procedure is the

revers e of the removal.

1

2

YGM0817