SECTION 8G - IMMOBILISER CONTROL SYSTEM

1. GENERAL DESCRIPTION

1.1 WIRING DIAGRAM

1.2 ON-BOARD DIAGNOSTIC SYSTEM

(SELF-DIAGNOSIS FUNCTION)

2. DIAGNOSIS

2.1 PRECAUTIONS IN DIAGNOSING

TROUBLES

Precautions in Identifying

Diagnostic Trouble Code

Intermittent Troubles

2.2 DIAGNOSTIC FLOW TABLE

2.3 DIAGNOSTIC TROUBLE CODE (DTC)

CHECK (IMMOBILISER CONTROL

MODULE)

Using Tech 2

2.4 DIAGNOSTIC TROUBLE CODE (DTC)

CHECK (ECM)

Using Tech 2

Not Using Tech 2

2.5 DIAGNOSTIC TROUBLE CODE TABLE

Immobiliser Control Module

ECM

2.6 TABLE A - DTC IS NOT OUTPUT FROM

IMMOBILISER CONTROL MODULE

Wiri ng Diagra m

Inspection

2.7 DTC11/32 TRANSPONDER CODE NOT

MATCHED

Description

Inspection

2.8 DTC31 TRANSPONDER CODE NOT

REGISTERED

Description

Inspection

2.9 DTC12 FAULT IN IMMOBILISER

CONTROL MODULE

Description

Inspection

2.10 DTC13 NO TRANSPONDER CODE

TRANSMITTED OR COIL ANTENNA

OPENED / SHORTED

Wiring Diagram

Description

Inspection

2.11 DTC21 ECM / IMMOBILISER CONTR OL

MODULE CODE NOT MATCHED

(IMMOBILISER CONTROL MODULE

SIDE)

2.12 DTC81 P1623 ECM / IMMOBILIS ER

CONTROL MODULE CODE NOT

MATCHED (ECM SIDE)

2.13 DTC84 P1620 ECM / IMMOBILIS ER

CONTROL MODULE CODE NOT

REGISTERED

Description

Inspection

2.14 DTC P1622 FAULT IN ECM

Description

Inspection

WARNING:

For vehicles equipped with Supplement Restraint (Airbag) System

• Service on and around the airbag system components or wiring must be performed only by an

authorised H OLDEN retailer. Refer to Section 10B AIRBAG SY STEM COMP ONENTS AN D W IRING

LOCATION VIEW in GENERAL DESCRIPTION in order to confir m whether you are performing ser-

vice on or near the airbag system component s or wiring. Please observe all WARNINGS and SER-

VICE PRECAUTIONS, refer to Section 10B ON-VEHICLE SER VICE before perf orming service on or

around the airbag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either or these two

conditions may result in severe injury.

• Technical service work must not be started for at least 90 seconds after the ignition switch is

turned to the “LOCK” position and the negative cable is disconnected from the battery.

Otherwise, the system may be activated by reserve energy in the Sensing and Diagnostic Module

(SDM).

IMPORTANT:

Prior to connecting Tech 2 to the vehicle, refer to Section 0C TECH 2.

Techline

2.15 DTC22 IGNITION SWITCH CIRCUIT

OPEN/SHORT

Wiri ng Diagra m

Description

Inspection

2.16 DTC23 NO ECM / IMMOBILISER

CONTROL MODULE CODE

TRANSMITTED FROM ECM OR DLC

CIRCUIT OPENED / SHORTED

2.17 DTC83 (P1621) NO ECM / IMMOBILISER

CONTROL MODULE CODE

TRANSMITTED FROM IMMOBILISER

CONTROL MODULE OR DLC CIRC UIT

OPEN ED / SH ORT E D

Wiri ng Diagra m

Description

Inspection

2.18 INSPECTION OF ECM, IMMOBILISER

CONTROL MODULE AND ITS CIRCUIT

Voltage Check

3. ON-VEHICLE SERVICE

3.1 PRECAUTIONS IN HANDLING

IMMOBILISER CONTROL SYSTEM

3.2 IMMOBILISER CONTROL MODULE

Removal

Installation

4. IMMOBILISER FUNCTIONS

5. HOW TO REGISTER IGNITION KEY

6. PROCEDURE AFTER ICM &/OR ECM

REPLACEMENT

7. SPECIAL TOOLS

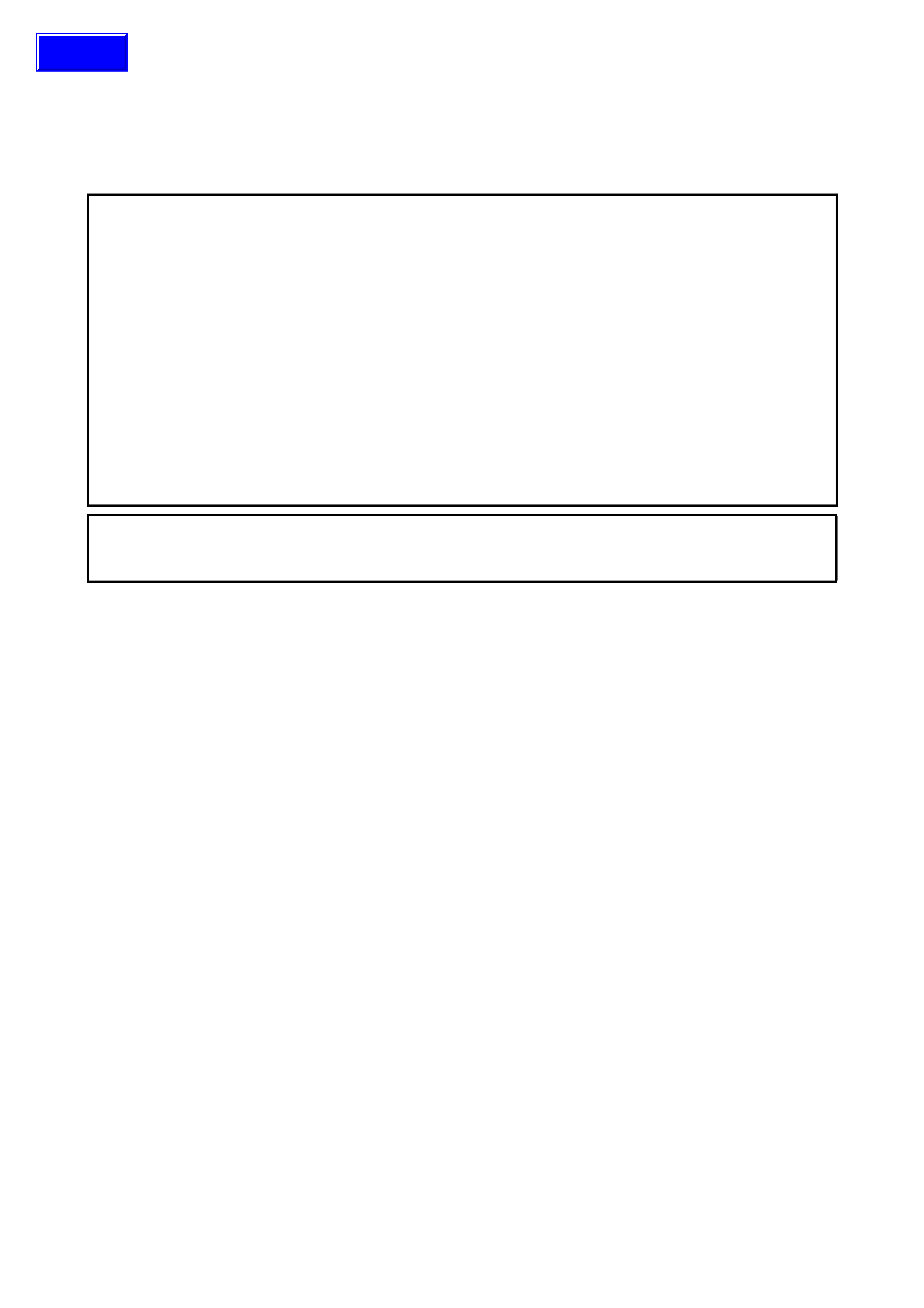

1. GENERAL DESCRIPTION

The immobiliser control system is designed to prevent vehicle theft and consists of the following components:

• Engine control module (ECM),

• Immobiliser control module (1) with coil antenna,

• Ignition key (2) with built-in transponder.

Operation of this system is as follows.

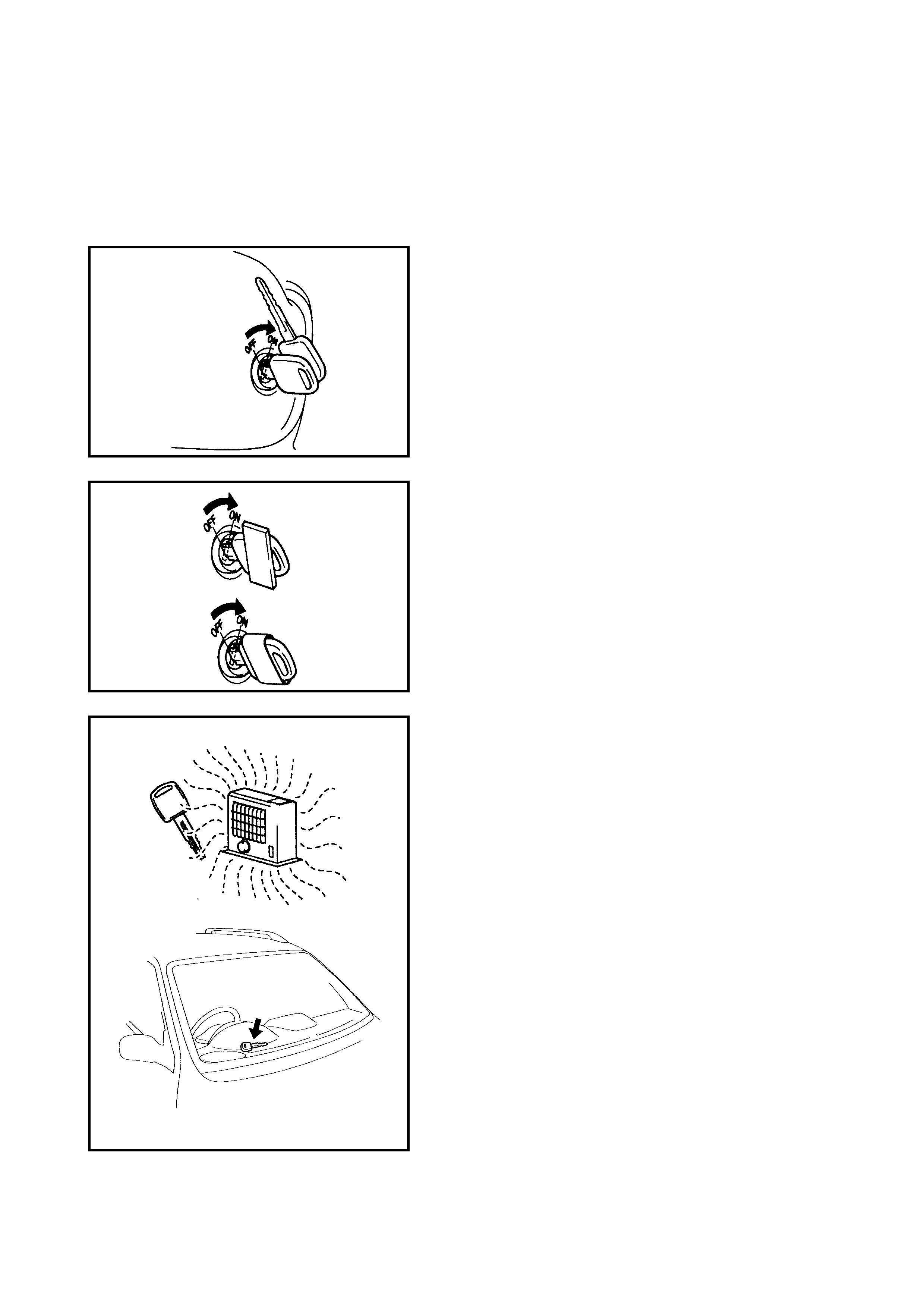

i. Each ignition key has its own code (transponder code) stored in memory. When the ignition switch is

turned O N, the immob iliser control modul e rea ds the tr anspon der code throu gh the coi l ante nna in stalled

with the steering lock assembly.

ii. The immob iliser c ontro l modu le com pares the tr ansp onder co de rea d in Step i. with tha t regi stered i n the

immobiliser control module memory and checks if they match.

iii. When it is confirmed that the two transponder codes match each other, the immobiliser control module

and ECM check if the ECM / immobiliser control module codes registered match.

iv. Only when it is confirmed that the ECM / immobiliser control module codes match is the engine able to

start. If th e t ra ns pon der c od es in Step ii. or the E CM / immobili se r c ontr ol m odu le co des in Ste p i ii. d o n ot

match, the ECM will stop operation of the injectors and spark plugs.

Legend

1. Immobiliser control module with coil antenna 4. Monitor connector

2. Ignition key with built-in transponder 5. ECM

3. Data link connector (DLC) 6. Malfunction indicator lamp (MIL)

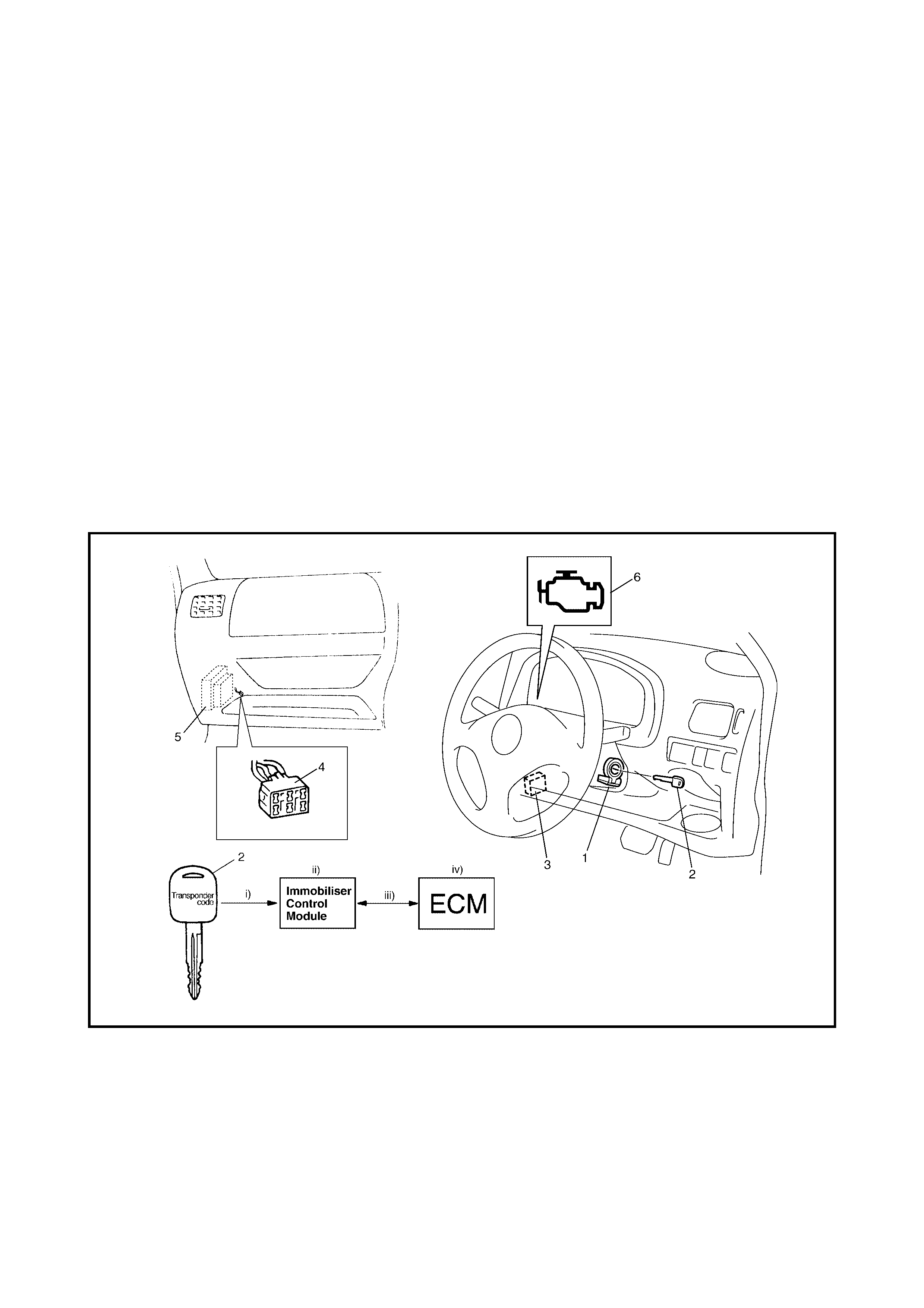

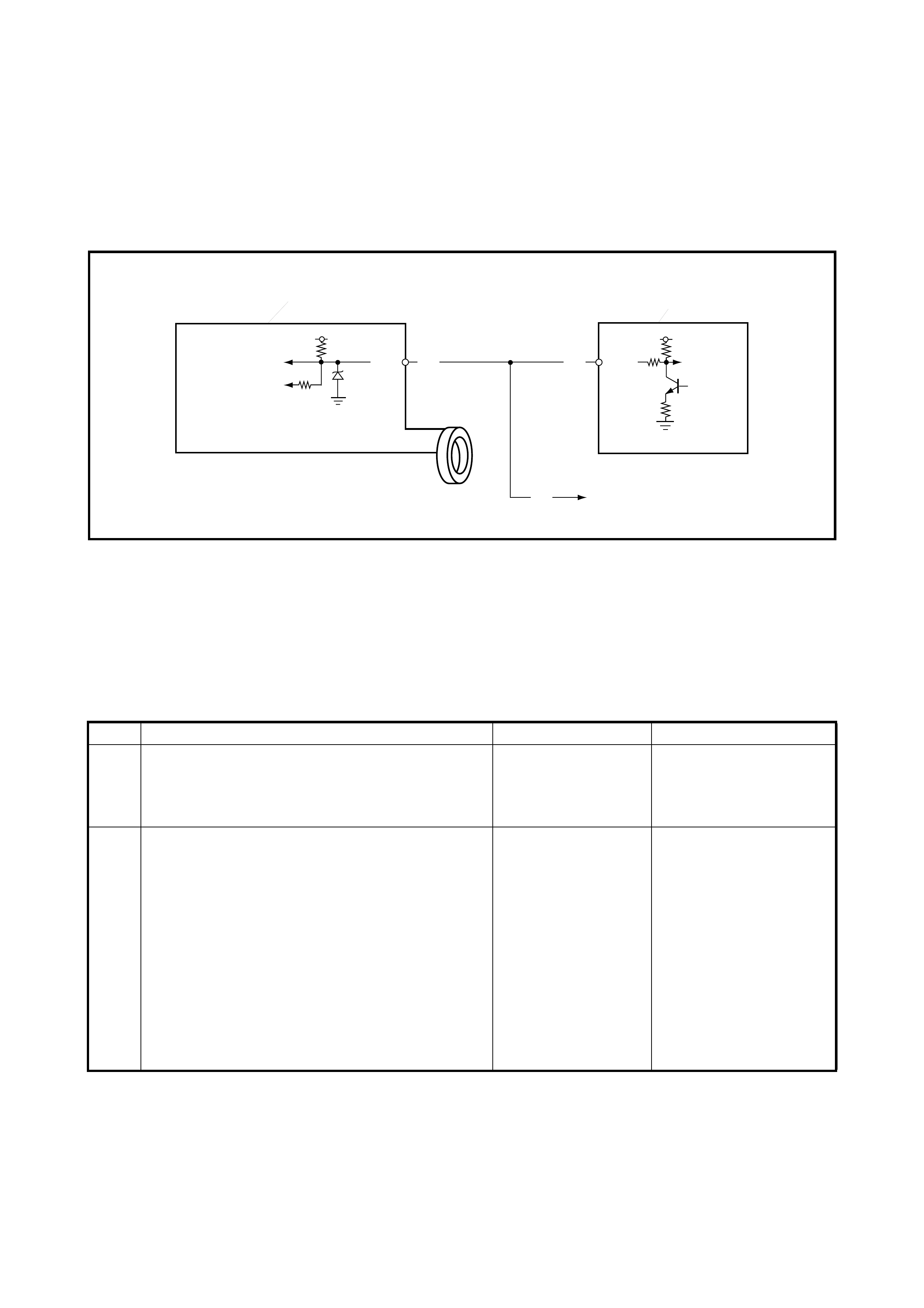

1.1 WIRING DIAGRAM

Legend

1. Immobiliser Control Module 6. Main fuse

2. ECM 7. Data Link Connector (DLC)

3. Main relay 8. To ABS control module, SDM and TCM

4. Ignition switch 9. Malfunction Indicator Lamp (MIL)

5. Fuse 10. Monitor connector

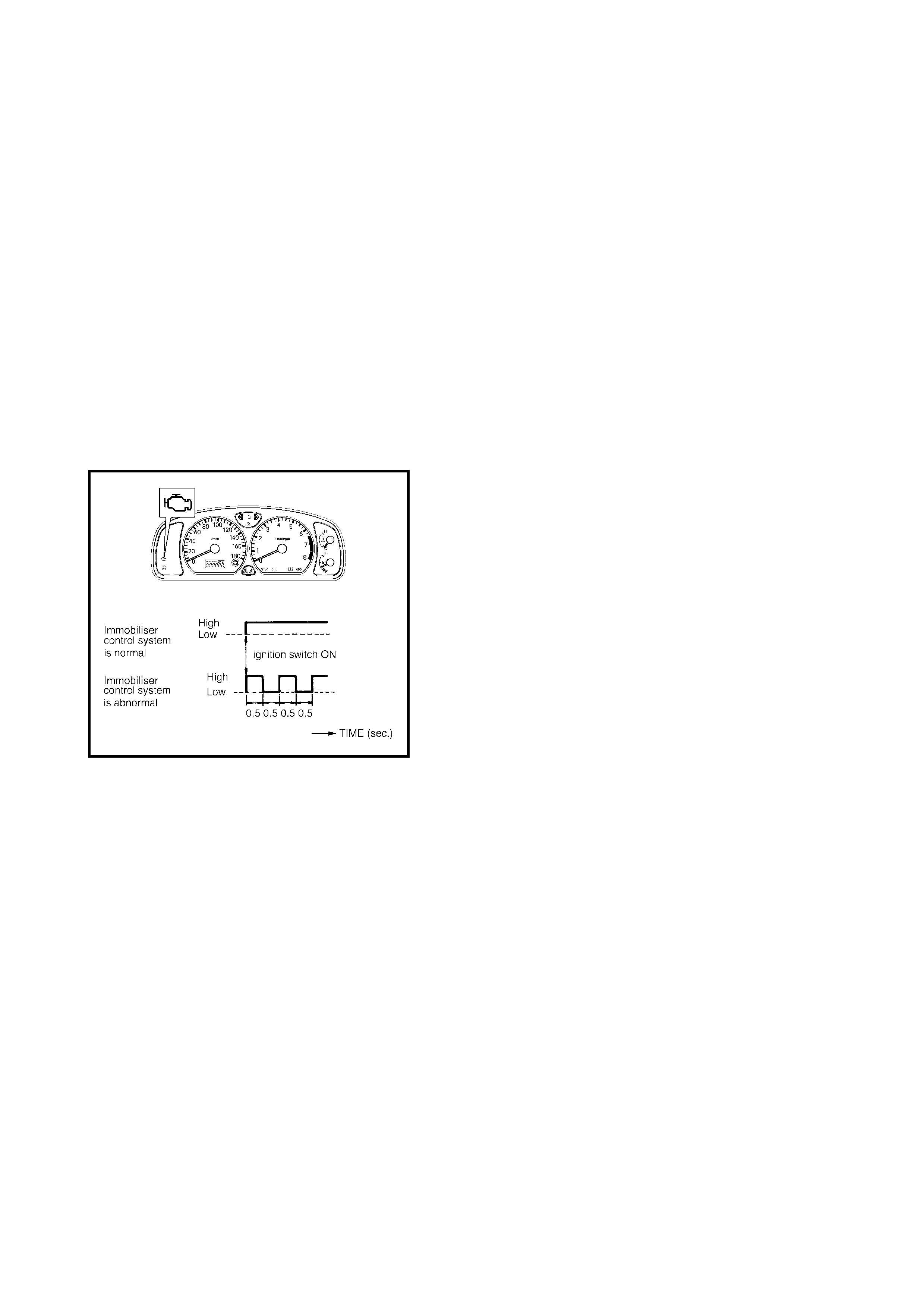

1.2 ON-BOARD DIAGNOSTIC SYSTEM

(SELF-DIAGNOSIS FUNCTION)

The immobiliser control module and ECM diagnose faults

which may occur in the following areas when the ignition

switch is ON.

ECM:

• ECM / immobiliser control module code

• Serial data link circuit

•ECM

Immobiliser Control Module:

• Transponder code

• Coil antenna

• ECM / immobiliser control module code

• Serial data link circuit

• Immobiliser control module

• Ignition signal

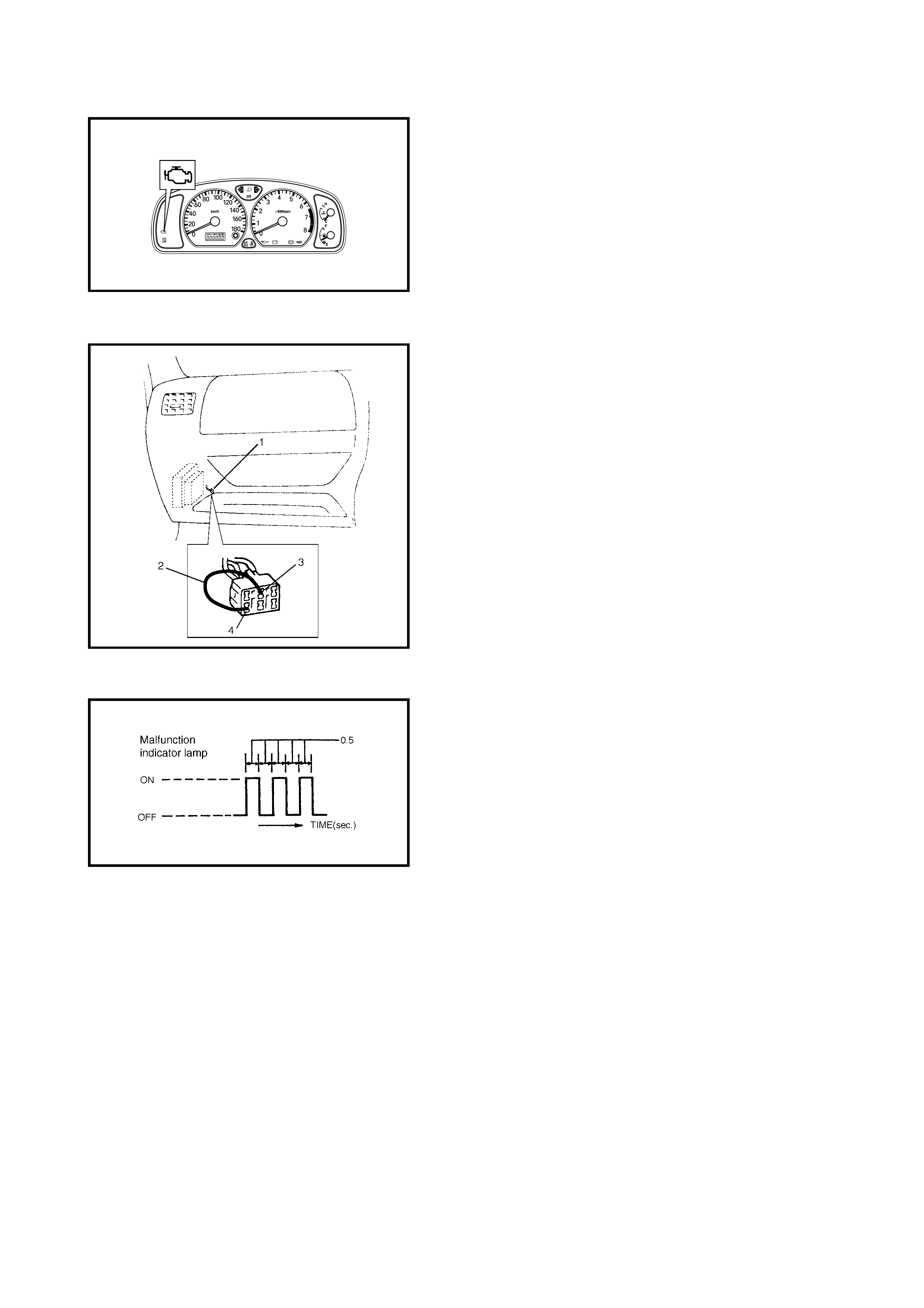

With the ignition switch ON and engine stationary, the

Malfunction Indicator Lamp (MIL) will indicate if a failure

has occurred in either the engine management or

immobiliser systems.

Malfunction Indicator Lamp ON

• No fault exists in the immobiliser control system.

Malfunction Indicator Lamp Flashing:

• ECM or immobiliser control module has detected some

fault in the immobiliser control system.

NOTE:

• Immobiliser system DTC’s can only be viewed with

TECH 2.

• Engine Management System DTC’s can be displayed

either on TECH 2 or as MIL flash codes.

NOTE:

As soon as the ignition switch is turned ON, the ECM

and immobiliser control module perform a diagnostic

self-check of the immobiliser control system. While the

diagnostic self-check is performed, the

Malfunction Indi-

cator Lamp

rema ins ON . If no fa ult is d etected , the MIL

will remain illuminated until the engine is started or the

ignition is turned OFF.

Should a fault be detected, the MIL will begin flashing

aft er ap proxima tely 3 seconds . If no faul t is detec te d, the

MIL will remain illuminated until the engine is started or

the igni tio n is tu rned OFF.

When the ECM and immobiliser

control module detects a trouble, it stores the DTC corre-

sponding to the exact trouble area in the ECM and immobi-

liser control module memory.

DTCs stored in memory of each control module can be

read by using the procedure described in

2.3 DIAGNOSTIC TROUBLE CODE CHECK

(IMMOBILISER CONTROL MODULE) and

2.4 DIAGNOSTIC TROUBLE CODE CHE CK (ECM) in this

Section.

2. DIAGNOSIS

2.1 PRECAUTIONS IN DIAGNOSING TROUBLES

PRECAUTIONS IN IDENTIFYING DIAGNOSTIC TROUBLE CODE

ECM

• Do no t d isco nne ct the E CM co nne cto rs, ba tter y o r the E CM gr oun d wi re h ar ness from the e ngi ne be for e

identifying Diagnostic Trouble Codes (DTCs) indicated by the Malfunction Indicator Lamp (MIL) or

TECH 2, .

Removing the ECM power supply or ground connections will clear any DTCs stored in the ECM memory.

• If an abnormality or malfunction exists in two or more areas, the Malfunction Indicator Lamp (MIL) indi-

cates the applicable Diagnostic Trouble Code s (DTCs) three times. Flashing of these codes is repeated

as long as the diagnosis terminal is grounded and the ignition switch remains ON.

• Diagnostic Trouble Codes (DTCs) are displayed in the order of priority.

Immobiliser Control Module

• Diagnostic Trouble Codes (DTCs) are displayed in the order of priority.

INTERMITTENT FAULTS

• There maybe a case where TECH 2 or the Malfunction Indicator Lamp (MIL) indicate a Diagnostic Trouble

Code (DTCs) representing a fault which occurred temporarily and is no longer present. In such case,

parts may be unne ce ssar i ly r eplac ed . To prev en t thi s oc cu rri ng, fol low the instr uc ti ons gi ve n b elo w whe n

checking by using 2.2 DIAGNOSTIC FLOW TABLE in this Section.

When the fault can be identified, it is not an intermittent one. In this case, perform the following:

• Check the coil antenna, ignition key, wires and each connection. If they are all in good condition, sub-

stitute a known-good ECM and recheck.

When the fault cannot be identified but TECH 2 indicates a trouble code:

• Attempt to diagnose the fault by using that DTC.

• If the igniti on key, coil a nten na, wi res and c on nec tio ns ar e al l in good con di tio n, turn O F F the i gnition

switch and then ON.

• If a DTC has set again, substitute a known-good ECM or immobiliser control module and check again.

If TECH 2 th en ind icate s “N o fa ult fo und ”, it me ans that the fau lt is inter m itte nt. In this c ase, re check

wires and connections.

2.2 DIAGNOSTIC FLOW TABLE

NOTE:

After replacing a known-good ECM, register the ECM /

immobiliser control module

code in the

ECM by perf orming the procedure described in 6. PROCEDURE AFTER ECM REPLACEMENT in this

Section.

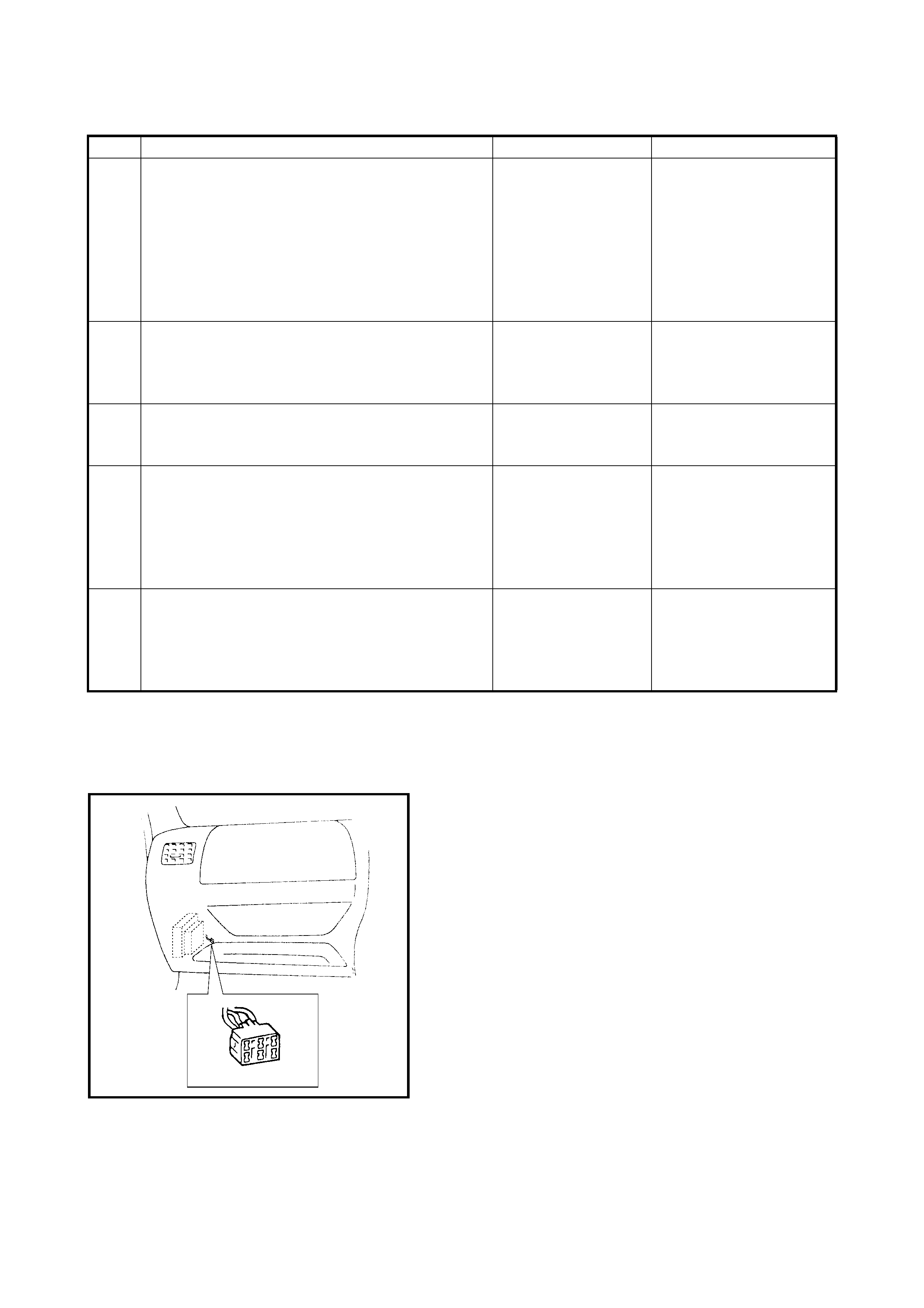

Fig. 1 for Step 1

Step Action Yes No

1 1. Ensure the diagnosis switch terminal in the

monitor connector is not grounded with a

service wire. See Fig.1.

2. Check the Malfunction Indicator Lamp while

the ignition switch is ON (but without starting

the engine). See Fig.2.

Does the malfunction indicator lamp flash?

Go to Step 3. If the malfunction indica-

tor lamp remains ON, go

to Step 2.

If the malfunction indica-

tor lamp remains OFF, go

to MALFUCTION

INDICATOR LAMP

CHECK in Section 6.

2 Using a service wire, ground the diagnostic switch

terminal in the monitor connector. See Fig.3.

Does the malfunction indicator lamp flash?

The immobiliser con-

trol system is in good

condition.

Go to MALFUCTION

INDICATOR LAMP

CHECK in Section 6.

3 Does the malfunction indicator lamp flash as

Fig.4? Go to Step 4. Go to MALFUCTION

INDICATOR LAMP

CHECK in Section 6.

4 1. Check DTC stored in the immobiliser control

module, refer to 2.3 DIAGNOSTIC

TROUBLE CODE CHECK (IMMOBLISER

CONTROL MODULE) in this Section.

Are there any DTC(s) stored?

Go to flow table for

that DTC. Go to Step 5.

5 1. Check DTC stored in ECM, refer to

2.4 DIAGNOSTIC TROUBLE CODE

CHECK (ECM) in this Section.

Are there any DTC(s) stored?

Go to flow table for

that DTC. Substitute a known good

ECM and recheck.

See NOTE below.

Fig. 2 for Step 1

Legend

Fig. 3 for Step 2

Fig. 4 for Step 3

1. Monitor connector

2. Service wire

3. Diagnostic switch terminal

4. Ground terminal

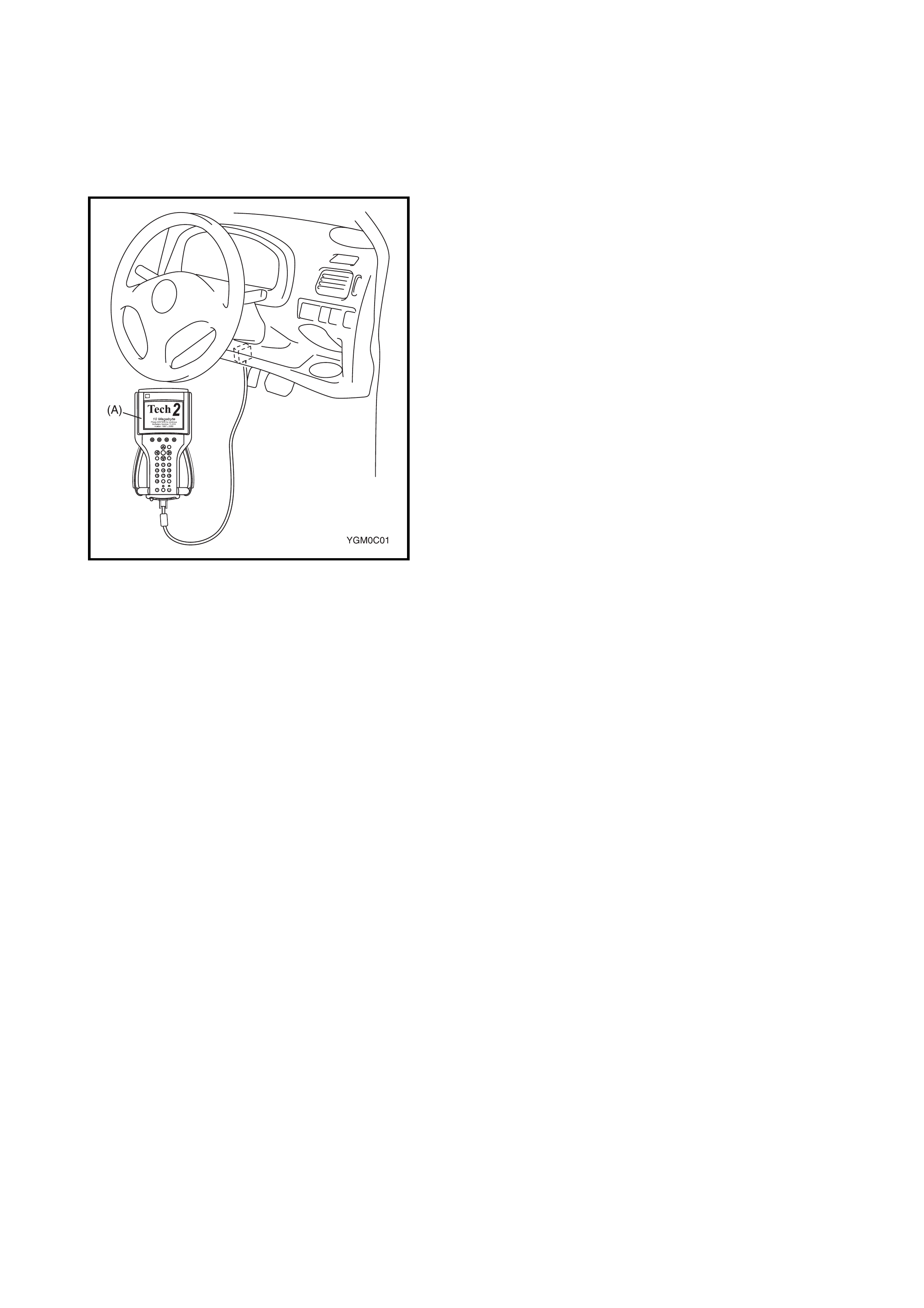

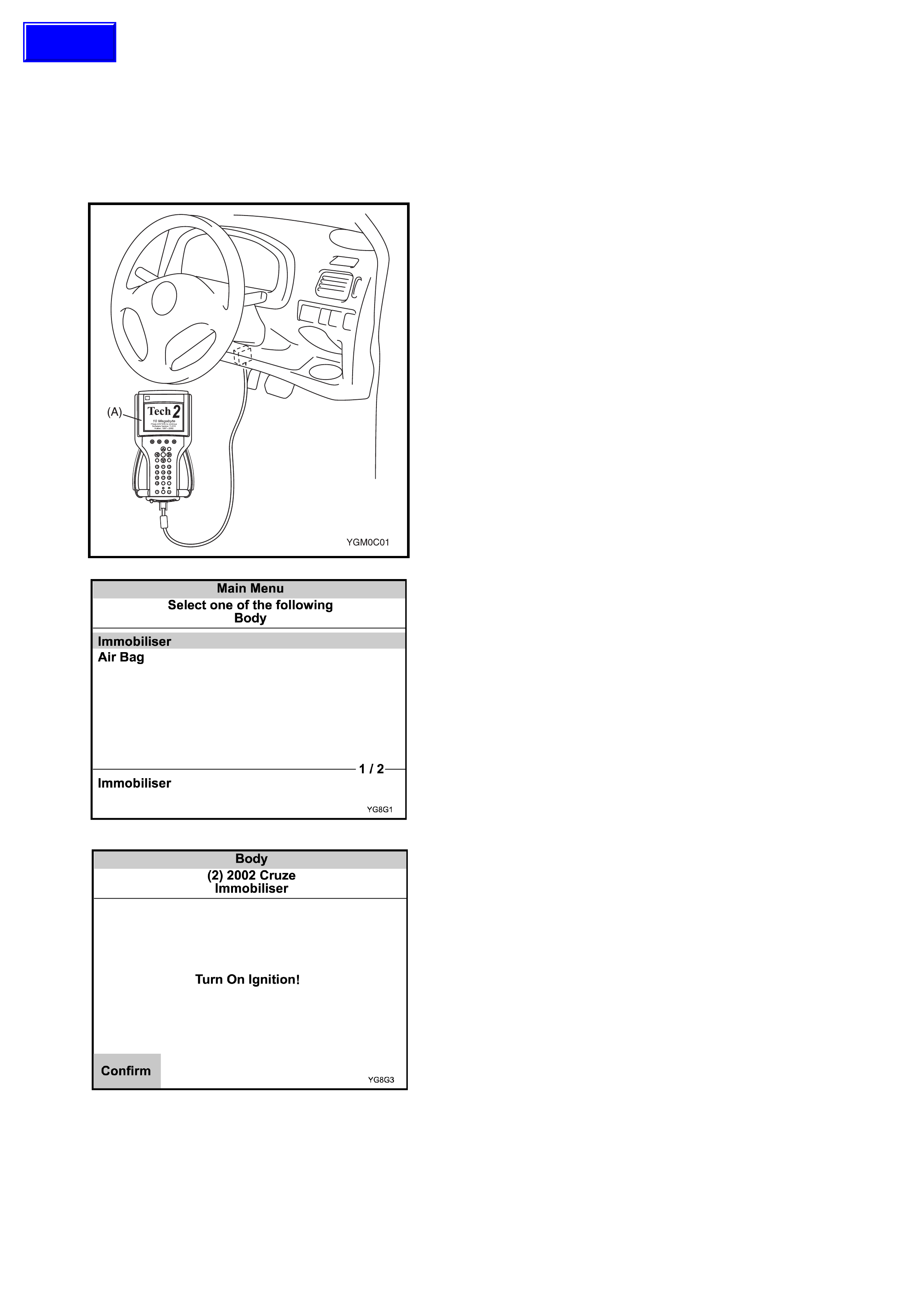

2.3 DIAGNOSTIC TROUBLE CODE (DTC) CHECK

(IMMOBILISER CONTROL MODULE)

USING TECH 2

1. Turn ignition switch OFF.

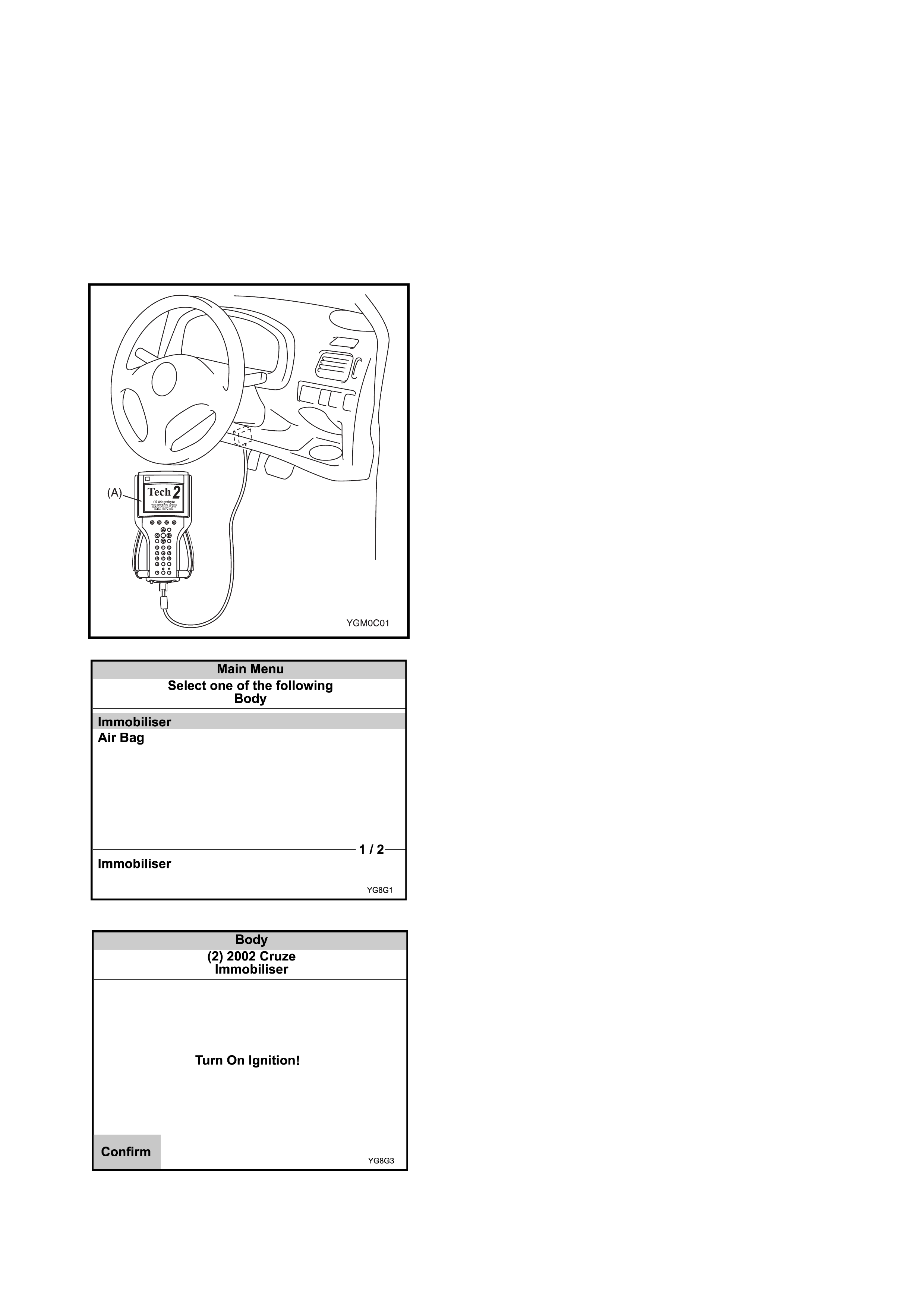

2. After fitting the card into Tech 2 (A), connect it to the

data link connector (DLC) (1) located on underside of

instrument panel at driver’s seat side.

3. Turn the ignition switch ON.

4. Read the DTC stored in the immobiliser control module

accord ing to i nstruct ion s displ ayed o n Tech 2 and pri nt

it or write it down. Refer to the Tech 2 operator's

manual for further details.

If communication between Tech 2 and the immobiliser

control module is not possible, go to 2.6 TABLE A D TC

IS NOT OUTPUT FROM IMMOBILISER CONTROL

MODULE.

NOTE:

When reading DTCs stored in the

immobiliser

contro l module

using Tech 2, select BCM from the appli-

cation s menu and IMMOBILI SER fro m the sel ect syste m

menu displayed on Tech 2.

5. After completing the check, turn ignition switch OFF

and disconnect Tech 2 from the data link connector

(DLC).

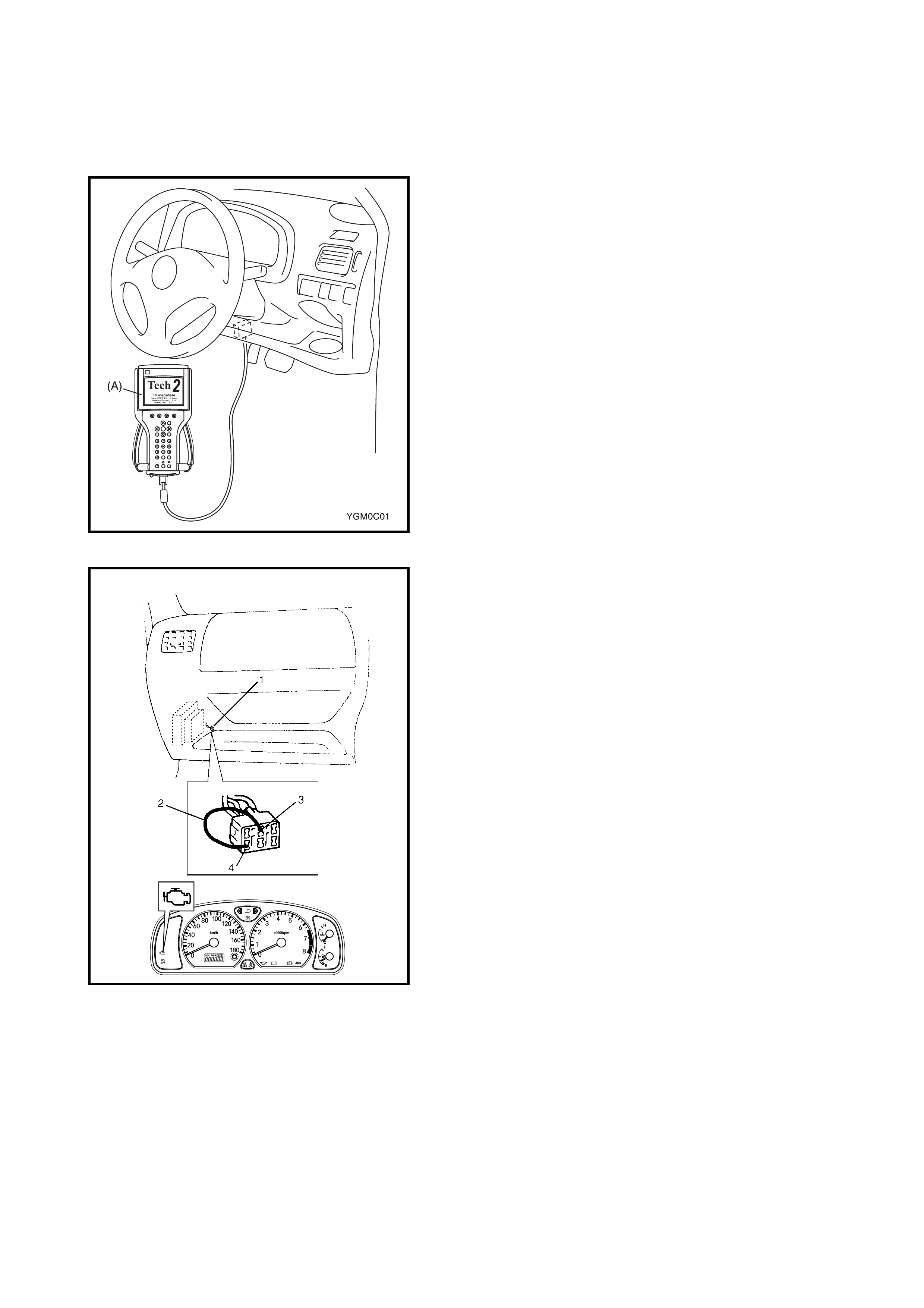

2.4 DIAGNOSTIC TROUBLE CODE (D TC) CHECK (ECM)

USING TECH 2

1. Turn ignition switch OFF.

2. After fitting the card into Tech 2 (A), connect it to the

data link connector (DLC) (1) located on underside of

instrument panel at driver’s seat side.

3. Turn ignition switch ON.

4. Read the DTC stored in the ECM according to the

instructions displayed on Tech 2, refer

Section 0C TECH 2 for further details.

If communication between Tech 2 and the ECM is not

possibl e, c he ck if Tech is c om mu nic ab le b y c on nec tin g

it to the ECM in another vehicle. If communication is

possible in this case, the Tech 2 is in good condition.

Check the data link connector and serial data line

(circuit) in the vehicle with which communication was

not possibl e.

NOT USING TECH 2

1. Ground the monit or connector (1) using a s ervice wir e

(2) connector between the ground terminal (3) and

diagnostic switch terminal (4).

2. Turn ignition switch ON.

3. Read the DTC from the flashing pattern of the malfunc-

tion indicator lamp (MIL) as shown in the example

below and write it down.

For details of the DTCs, refer to ECM in

2.5 DIAGNOSTIC TROUBLE CODE TABLE in this

Section.

If the lamp remains ON, refer to Malfunction Indicator

Lamp (MIL) Check in 2.4 ENGINE DIAGNOSTIC

FLOW TABLE in Section 6.

NOTE: If an abnormality or malfunction exists in two or

more a reas, the m alfunction ind icator lamp (MIL) indic ates

the applicable codes three times each. Flashing of these

codes is repeated for as long as the diagnosis terminal is

grounded and the ignition switch is ON.

4. After completing the check, turn the ignition switch

OFF and disconnect the service wire from the m onitor

connector.

2.5 DIAGNOSTIC TROUBLE CODE TABLE

IMMOBILISER CONTROL MODULE

ECM

Refer to Section 6 for how to read diagnostic codes (DTCs) from a flashing malfunction indicator lamp.

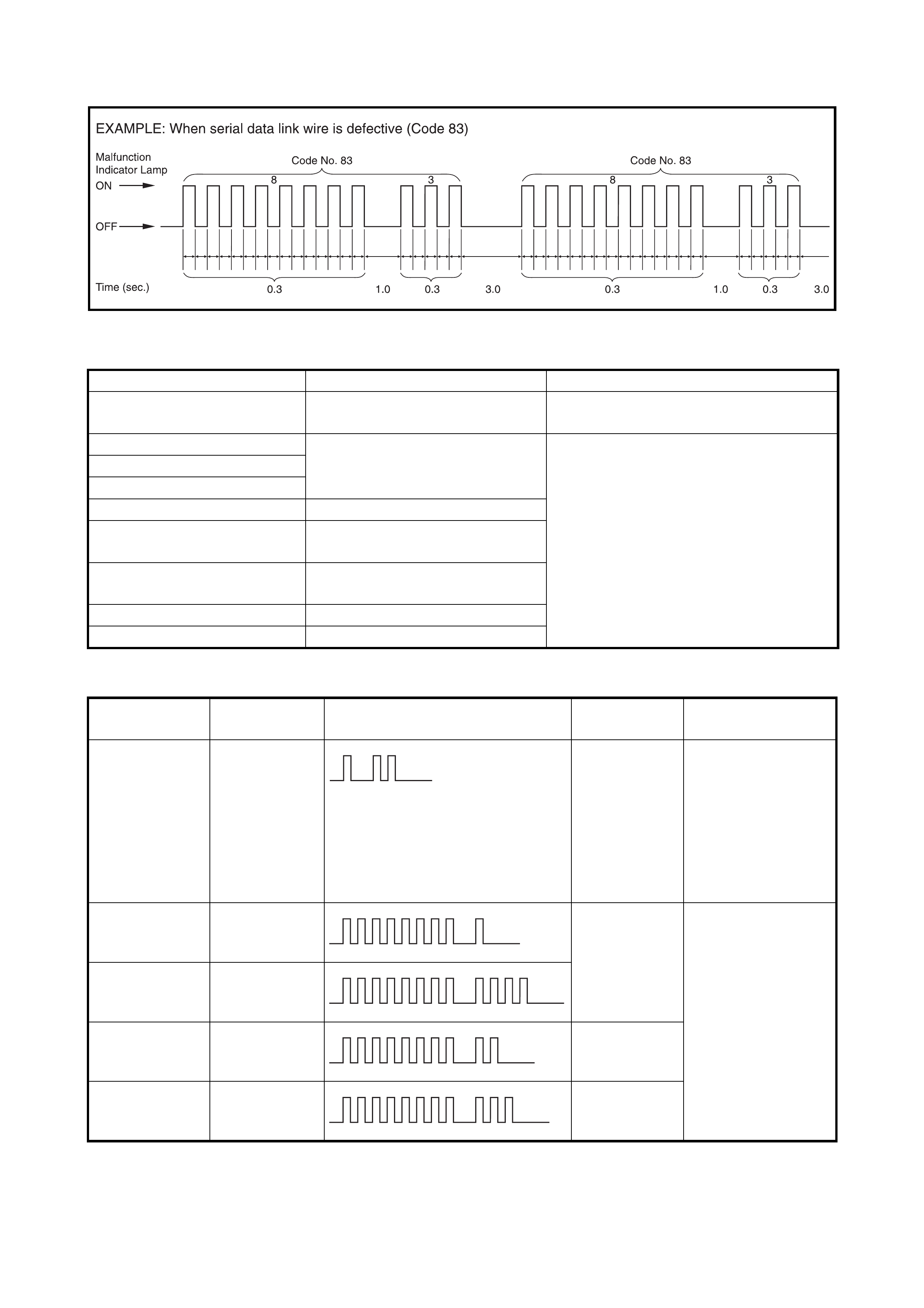

DTC (indicated on Tech 2) DIAGNOSTIC AREA DIAGNOSIS

NO DTC Normal (No code) This code appears when no other codes

are identified.

1 1 Transponder code Diagnose trouble according to Diagnostic

Flow Table corresponding to each code

No.

31

32

12 Immobiliser control module

13 Coil antenna or ignition key with

built- in trans pon der

21 ECM / immobiliser control module

code

22 Ignition switch circuit

23 Serial data link circuit

DTC (indicated

on Tech 2) DTC (indicated

on MIL) MIL PATTERN DIAGNOSTIC

AREA DIAGNOSIS

NO DTC 12 Normal This code appears

when it is confirmed

that no other trouble

codes are set for

immobiliser control

system or engine and

emission control sys-

tem.

P1623 81 ECM / immobil-

iser control

module code

Diagnose trouble

according to

DIAGNOSTIC FLOW

TABLE

corresponding to

each code No.

P1620 84

P1622 82 ECM

P1621 83 Serial data link

wire

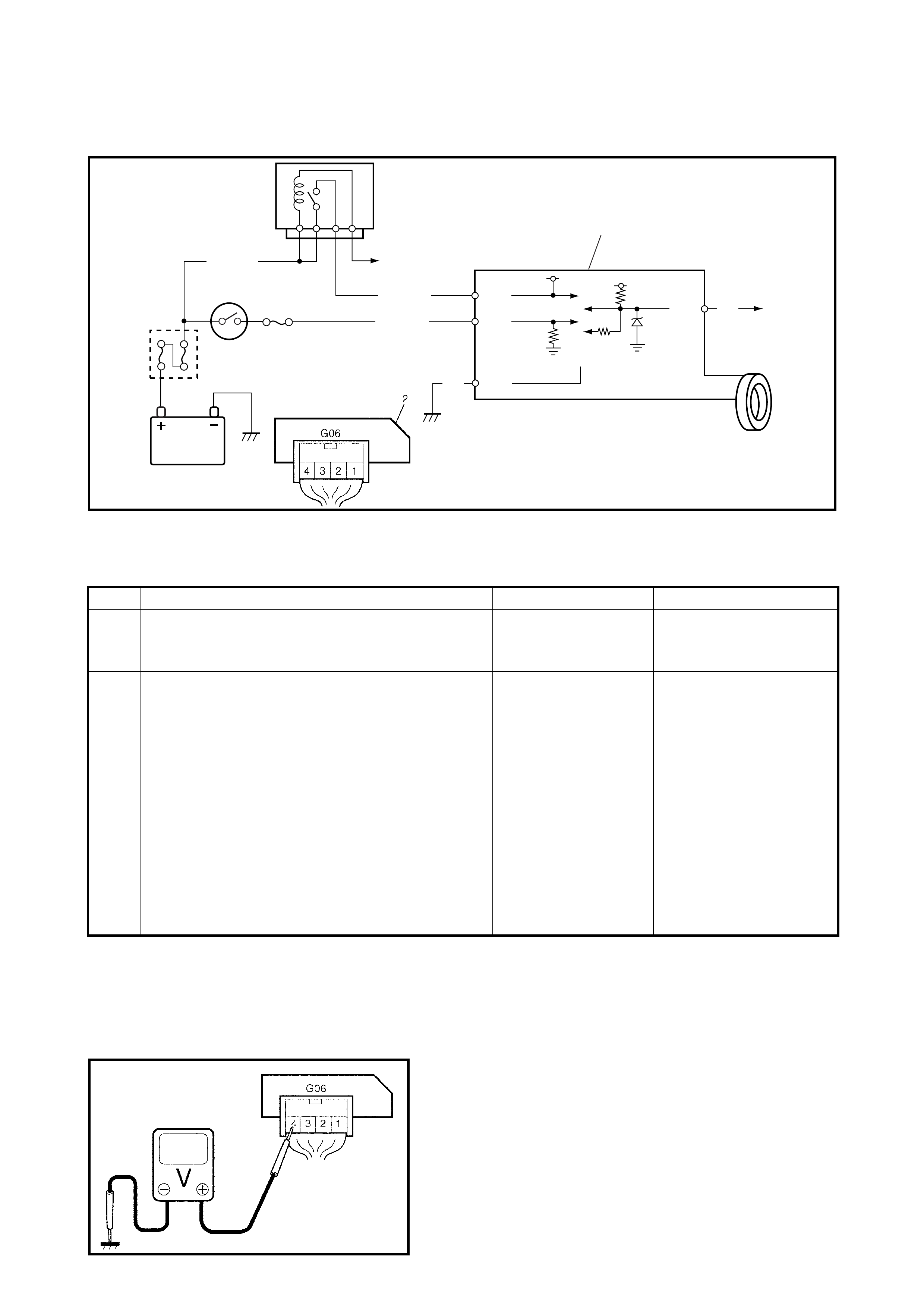

2.6 TABLE A - DTC IS NOT OUTPUT FROM IMMOBILISER CONTROL MODULE

WIRING DIAGRAM

Legend

INSPECTION

NOTE:

After replacing with a known good Immobiliser control module, register the ECM / immobiliser

control module code in ECM and Transponder code and ECM / immobiliser control module code in

immobiliser control module by performing the procedure described in 6. PROCE DURE AFTER

IMMOBILISER CONTROL MODULE REPLACEMENT in this Section.

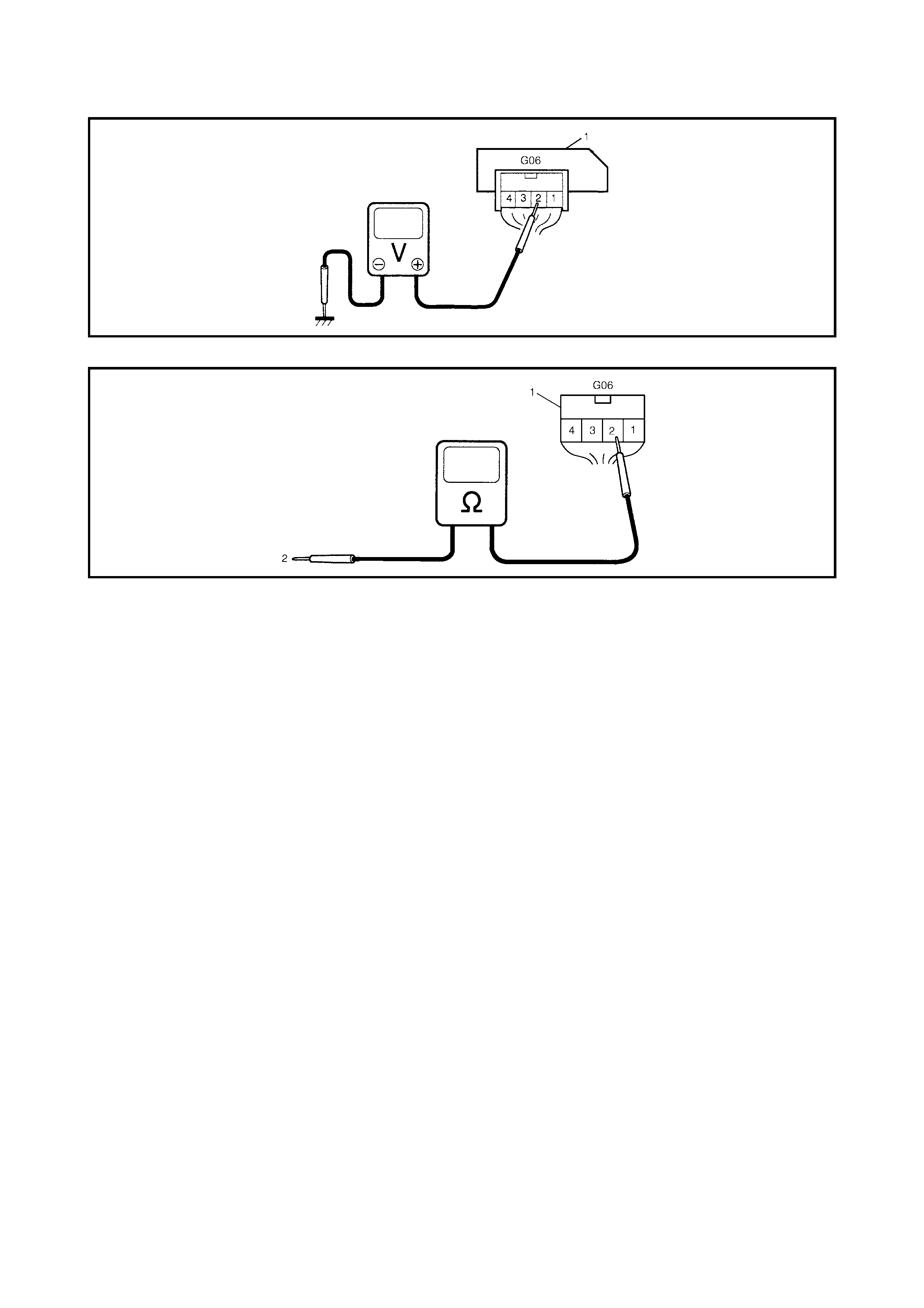

Fig. 1 for Step 1

BLK/RED

BLK/WHT

BLK/WHT

BLK

2

1

3

YEL

BLK/YEL

G06-4

G06-3

G06-1

G06-2

1. To ECM 2. Immobiliser control module 3. To #9-pin in DLC

Step Action Yes No

1 Check voltage between G06-4 terminal and body

ground with ignition switch turned ON. See Fig 1.

Is it 10 – 14 V?

Go to Step 2. BLK/RED wire open or

short to ground.

2 1. Disconnect connector (1) at immobiliser

control module.

Is there conti nuity between co nnecto r ter minal

G06-1 and body ground? See Fig 2.

• Poor G06-4 or

G06-1 connection

• Poor #9-pin con-

nection in DLC

• Serial data line

YEL open or short

to ground

If connections and

line are OK, subs ti-

tute a known good

Immobiliser Control

Module and recheck.

See NOTE below.

BLK wire open .

Fig. 2 for Step 2

2.7 DTC11/32 TRANSPO NDER CODE NOT MATCHE D

DESCRIPTION

The immobiliser control module checks if the transponder code transmitted from the ignition key and the code

registered in the immobiliser control module match when the ignition switch is ON. If they do not, DTC 11 and/

or 32 are set.

INSPECTION

Register the ignition key with built-in transponder using Tech 2 and performing following steps.

1. Register the transponder code in the immobiliser control module, refer to 5. HOW TO REGISTER

IGNITION KEY in this Section.

2. Turn the ignition switch OFF, then turn it ON and check that DTC11 and/or 32 are not set.

2.8 DTC31 TRANSPONDER CODE NOT REGISTERED

DESCRIPTION

The immobiliser control module checks if the transponder code transmitted from the ignition key and the code

registered in immobiliser control module match when ignition switch is ON. If there is no transponder code

registered in immobiliser control module, this DTC is set.

INSPECTION

Register the ignition key with built-in transponder using Tech 2 and performing following steps.

1. Register the transponder code in the immobiliser control module, refer to 5. HOW TO REGISTER

IGNITION KEY in this Section.

2. Turn the ignition switch OFF, then turn it ON and check that DTC31 is not set.

2.9 DTC12 FAULT IN IMMOBILISER CONTROL MODULE

DESCRIPTION

This DTC is set when an internal fault is detected in the immobiliser control module.

INSPECTION

NOTE:

After replacing with a known good Immobiliser control module, register the ECM / immobiliser

control module code in ECM and Transponder code and ECM / immobiliser control module code in

immobiliser control module by performing the procedure described in 6. PROCE DURE AFTER

IMMOBILISER CONTROL MODULE REPLACEMENT in this Section.

Step Action Yes No

1 1. Ignition switch OFF.

2. Disconnect the immobiliser control module

connectors.

3. Check for proper connection to immobiliser

control module at all terminals.

Are they in good condition?

Substitute a known

good immobiliser

control module and

recheck.

See NOTE below.

Repair or replace.

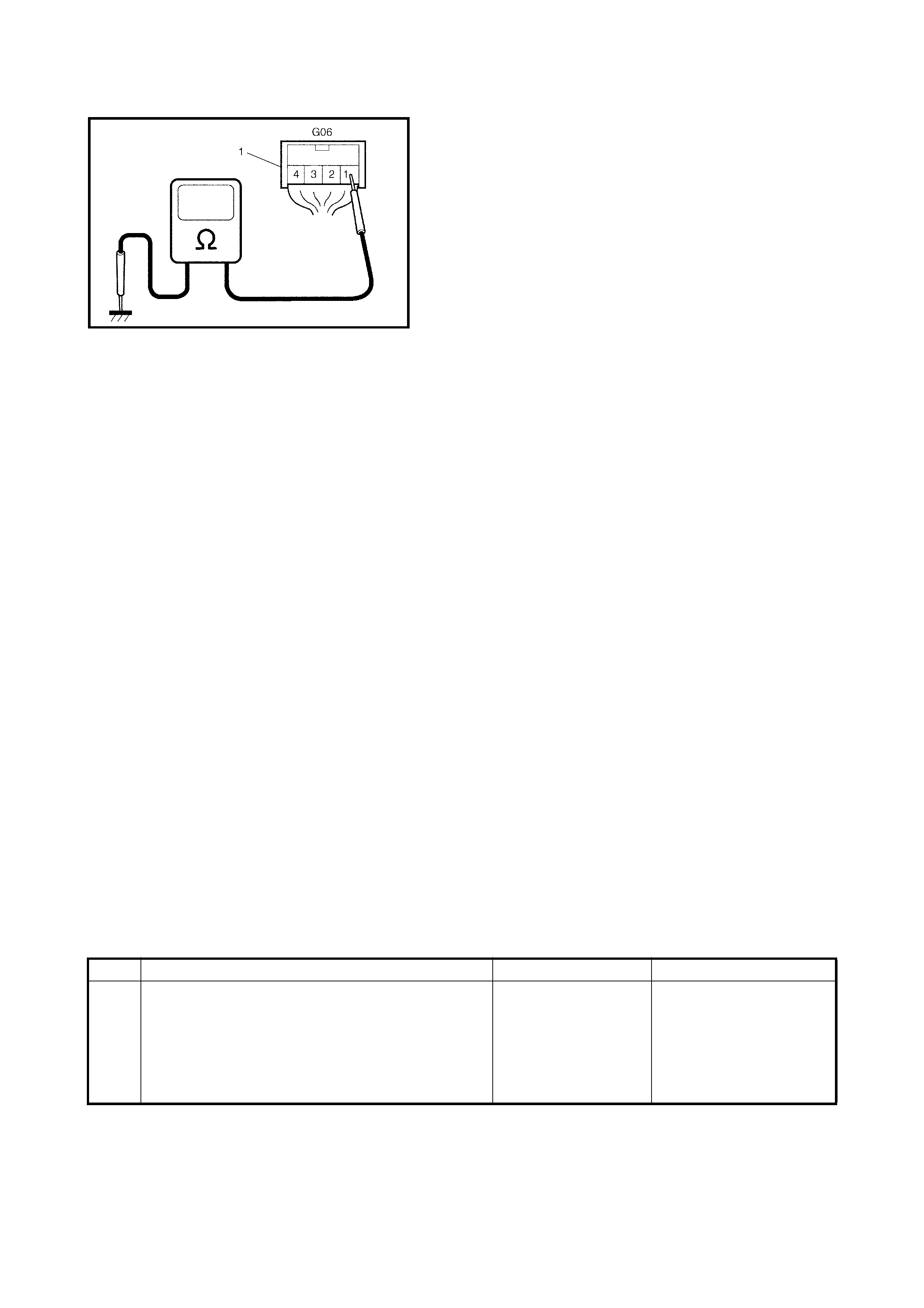

2.10 DTC13 NO TRANSPONDE R CODE TRANSMITTED OR COIL

ANTENNA OPENED / SHORTED

WIRING DIAGRAM

Legend

DESCRIPTION

The immobiliser control module energises the coil antenna when the ignition switch is ON and reads the tran-

sponde r code from the ignition ke y. Whe n the immobil iser control mo dule cannot rea d the transponde r code

from the ignition key, even when the coil antenna is energised, this DTC is set.

INSPECTION

NOTE:

After replacing with a known good Immobiliser control module, register the ECM / immobiliser

control module code in ECM and Transponder code and ECM / immobiliser control module code in

immobiliser control module by performing the procedure described in 6. PROCE DURE AFTER

IMMOBILISER CONTROL MODULE REPLACEMENT in this Section.

BLK/RED

BLK/YEL

G06-4

2

3

4

5

1. Main fuse 2. Main relay 3. Immobiliser control module 4. Coil antenna 5. To ECM

Step Action Yes No

1 Check that the ignition key a transponder key? Substitute a known

good immobiliser

control module and

recheck.

See NOTE below.

Replace ignition key with

correct one and follow

Diagnostic Flow Table

again.

2.11 DTC21 ECM / IMMOBILISER CONTROL MODULE CODE NOT MATCHED

(IMMOBILISER CONTROL MODULE SIDE)

2.12 DTC81 P1623 ECM / IMMOBILISER CONTROL MODULE CODE NOT MATCHED

(ECM SIDE)

2.13 DTC84 P1620 ECM / IMMOBILISER CONTROL MODULE CODE NOT

REGISTERED

DESCRIPTION

•DTC21

The immobiliser control module checks if the ECM / immobiliser control module code transmitted from the

ECM a nd the code regi stered in immob iliser control module ma tch whe n the ig nition switc h is ON. I f they

do not, this DTC is set.

•DTC81 P1623

The ECM checks if the ECM / immobiliser control module code transmitted from the immobiliser control

module a nd the code r egister ed in the EC M matc h when ign ition sw itch i s ON. If th ey do not, thi s DTC is

set.

•DTC84 P1620

The E CM checks if the co de transmitted from immobi liser contr ol module and the code r egistered i n the

ECM match when ignition switch is ON. If there is no ECM / immobiliser control module code registered in

ECM, this DTC is set.

INSPECTION

Perform procedure described in 6. PROCEDURE AFTER ECM REPLACEMENT in this Section.

2.14 DTC P1622 FAULT IN ECM

DESCRIPTION

This DTC is set when an internal fault is detected in the ECM.

INSPECTION

NOTE:

After replacing with a known good ECM, register the ECM / immobiliser control module code in

the ECM, refer 6 . PROCEDURE AFTER ECM REPLACEMENT in this Section.

Step Action Yes No

1 1. Ignition switch OFF.

2. Disconnect the ECM connectors.

3. Check for proper connection to the ECM at all

terminals.

Are they in good condition?

Substitute a known

good ECM and

recheck.

See NOTE below.

Repair or replace.

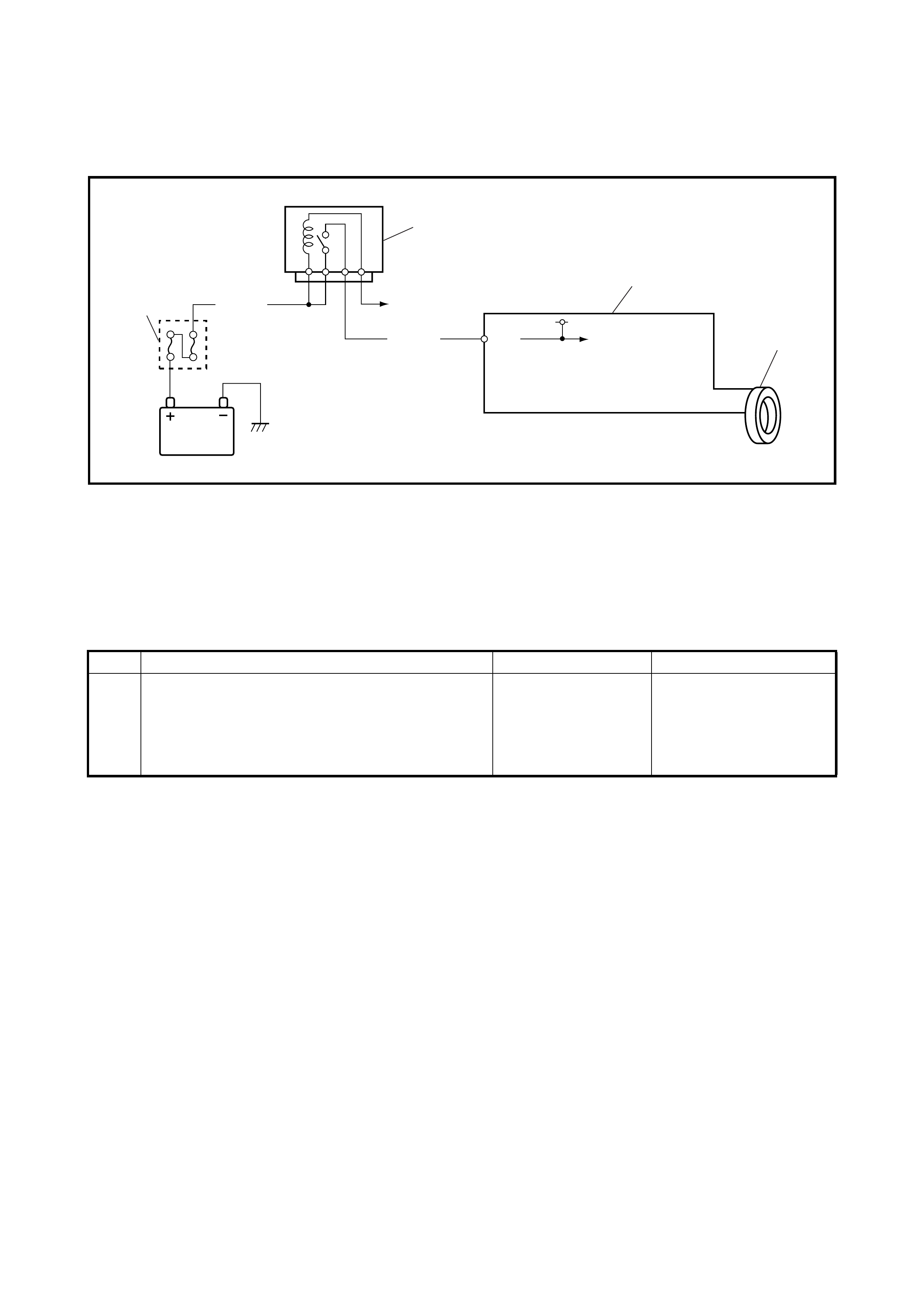

2.15 DTC22 IGNITION SWITCH CIRCUIT OPEN/SHORT

WIRING DIAGRAM

Legend

DESCRIPTION

The immobiliser control module monitors the ignition signal when the ignition switch is ON. This DTC is set

when no ignition signal input is detected by the immobiliser control module.

INSPECTION

NOTE:

After replacing with a known good Immobiliser control module, register the ECM / immobiliser

control module code in ECM and Transponder code and ECM / immobiliser control module code in

immobiliser control module by performing the procedure described in 6. PROCE DURE AFTER

IMMOBILISER CONTROL MODULE REPLACEMENT in this Section.

Fig. 1 for Step 1

BLK/WHT

BLK/WHT G06-3

12

3

1. Main fuse 2. Ignition switch 3. Immobiliser control module

Step Action Yes No

1 Check voltage between immobiliser control mod-

ule (1) connector terminal G06-3 and body ground

with ignition switch turned ON. (See Fig. 1)

Is it 10 – 14V?

Poor G06- 3 term in al

connection.

If connection is OK,

substitute a known

good immobiliser

control module and

recheck.

See NOTE below.

BLK/WHT wire open or

short.

2.16 DTC23 NO ECM / IMMOBILISER CONT ROL MODULE CODE TRANSMITTED

FROM ECM OR DLC CIRCUIT OPENED / SHORTED

2.17 DTC83 (P1621) NO ECM / IMMOBILISE R CONTROL MODULE CODE

TRANSMITTED FROM IMMOBILISER CONTROL MODULE OR DLC CIRCUIT OPENED

/ SHORTED

WIRING DIAGRAM

Legend

DESCRIPTION

When the ignition switch is ON, the immobiliser control module requests the ECM and the ECM requests

immobiliser control module to transmit the EC M / immobiliser control module code. If the ECM / immobiliser

control module code is not transmitted from the ECM or immobiliser control module, the immobiliser control

module sets DTC23 and ECM sets DTC83 (P1621).

INSPECTION

NOTE:

• After rep lacing with a known g ood ECM, r egister t he ECM / immo biliser c ontrol module c ode in the ECM

and by performing the procedure described in 6. PROCEDURE AFTER ECM REPLACEMENT in this

Section.

• After replacing with a known good Immobiliser control module, register the ECM / immobiliser control

module code in ECM and Transponder code and ECM / immobiliser control module code in immobiliser

control module by performing the procedure described in 6. PROCEDURE AFTER IMMOBILISER

CONTROL MODULE REPLACEMENT in this Section.

YEL

G06-2 G02-7

YEL

YEL

1

3

2

1. Immobiliser control module 2. ECM 3. To #9-pin in DLC

Step Action Yes No

1 Check voltage between immobiliser control mod-

ule (1) connector terminal G06-2 and body ground

with ignition switch turned ON.

Is it 4 – 5V?

Go to Step 2. YEL wire short.

2 1. Disconnect the ECM connector with ignition

switch turned OFF.

2. Is there continuity between the immobiliser

control module connector (1) terminal G06-2

and serial data link terminal (G02-7) of the

ECM connector?

(For positions of Data link connector terminal

of ECM connector, refer to 1.1 WIRING

CIRCUIT in this Section.)

Poor G06- 2 term in al

connection (immobil-

iser control module)

or poor Data link con-

nector terminal con-

nection (ECM).

If connections are

OK, substitute a

known good ECM or

immobiliser control

module and recheck.

See NOTE below.

YEL wire between immo-

biliser control module and

ECM open.

Fig. 1 for Step 1

Fig. 2 for Step 2

Legend

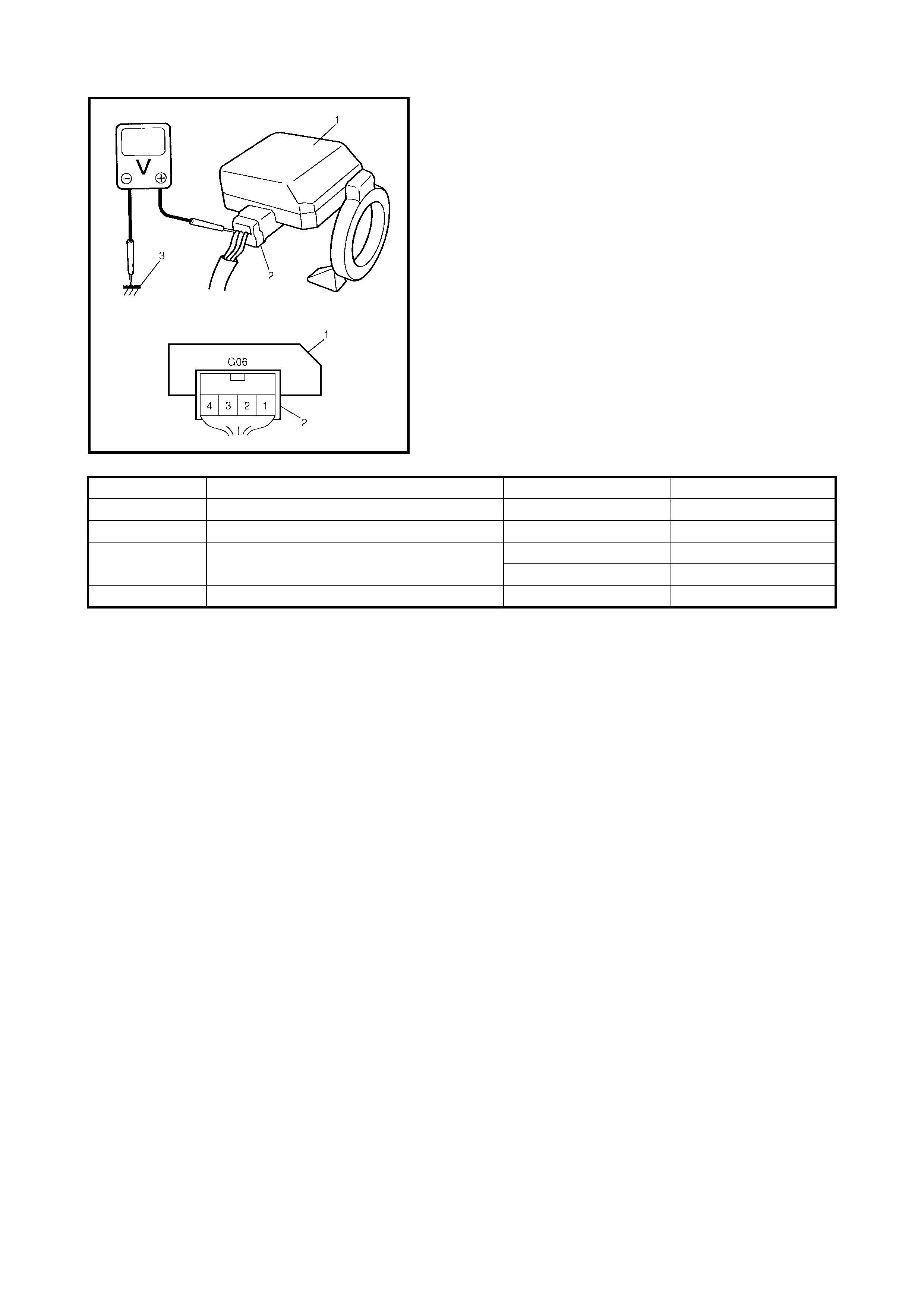

2.18 INSPECTION OF ECM, IMMOBILISER CONTROL MODULE AND ITS CIRCUIT

The ECM, immobil is er con tr ol mo dul e and i ts cir cuit ca n be

checked at the ECM wiring connectors and immobiliser

contro l m odule wiring con nector by measuring the vo ltag e.

Described here is only inspection of the immobiliser control

module. For inspection of the ECM, refer to the Engine &

Emission Control Input/output Table in 1.3 ELECTRONIC

CONTROL SYSTEM in Section 6E1.

CAUTION: The i

mmobiliser control module cannot be

checked by itself. It is strictly prohibited to connect

a voltmeter or ohmmeter to the immobiliser control

module with the connector disconnected.

VO LTAGE CHECK

1. Remove the immobiliser control module from the

steering lock assembly with ignition switch OFF, refer

to 3.3 IMMOBILISER CONTROL MODULE in this

Section.

2. Connect the immobiliser control module connector to

the immobiliser control module.

1. Immobiliser control module connector

2. Connect to serial data link terminal (G02-7) of ECM connector while disconnected

3. Check voltage at each terminal of the immobiliser

control module (1) connector (2) while connected to

ground (3).

NOTE:

As each terminal voltage is affected by the bat-

tery v oltage, con firm th at it is 11V or more w hen ign ition

switch is ON.

TERMINAL CIRCUIT NOMINAL VOLTAGE CONDITION

G06-1 Ground – –

G06-2 Data link connector (Serial data terminal) 4 – 5V Ignition switch ON

G06-3 Ignition signal 10 – 14V Ignition switch ON

0 – 0.8V Ignition switch OFF

G06-4 Power source 10 – 14V Ignition switch ON

3. ON-VEHICLE SERVICE

3.1 PRECAUTIONS IN HAND LIN G IMMOBILISER CONTROL SYSTEM

• Don’t turn the ignit ion switch ON while another igni tion

key for the immobiliser control system is placed close

by. The system may dete ct an ab normal con dition and

prevent the engine fr om starting.

• Do not turn the ignition switch ON using an ignition key

that has any type of metal wound around its grip or is in

contact with it. The system may detect an abnormal

condition and prevent the engine from starting.

• Do not leave the ignition key where high temperature is

anticipated. High temperature will cause the transpon-

der in ignition key to malfunction or be damaged.

• Do not turn ignition switch ON with a radio antenna

placed near the immobiliser control module. The sys-

tem may dete ct a n abn or mal co nditio n and prevent th e

engine from starting.

3.2 IMMOBILISER CONTROL MODULE

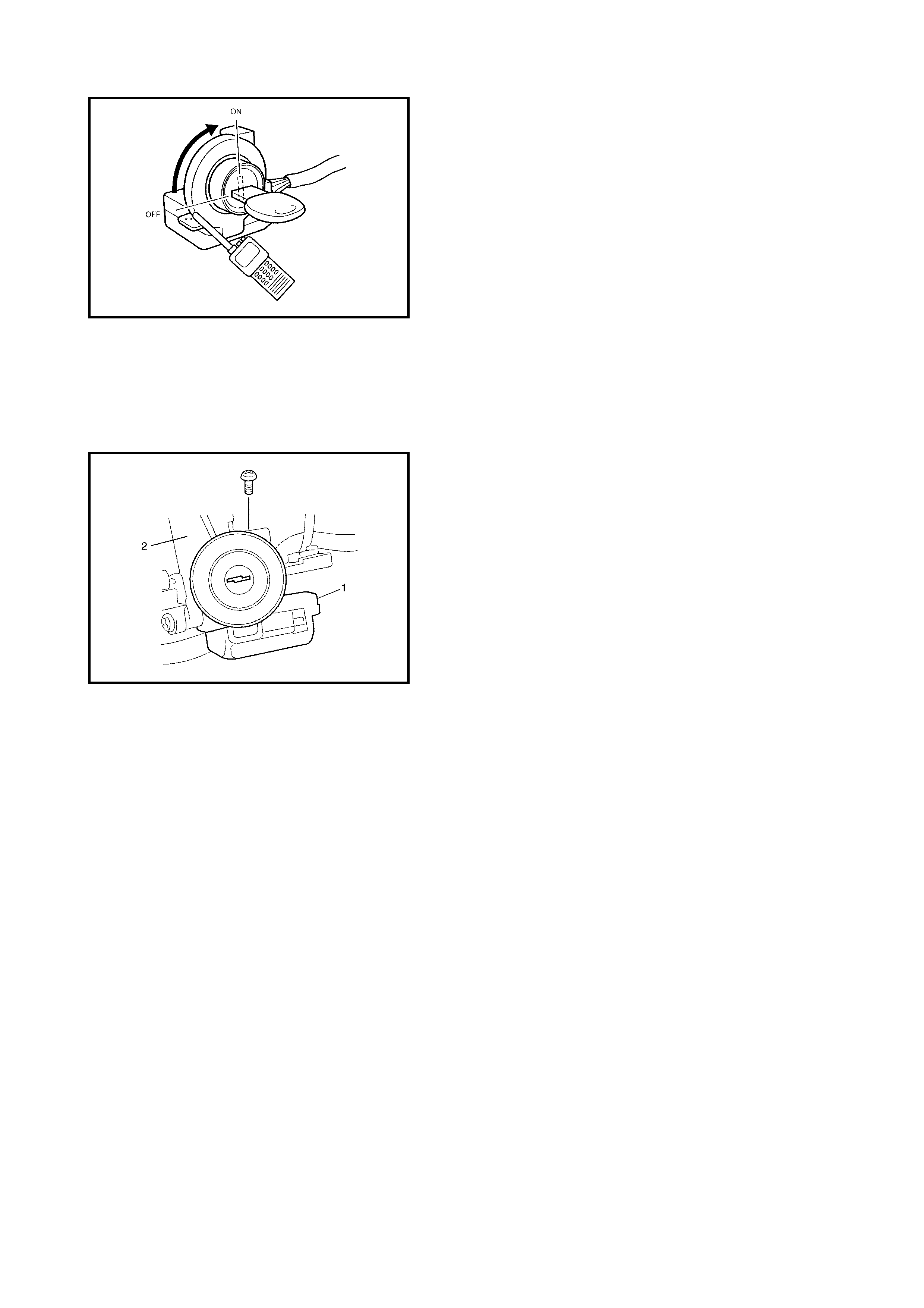

REMOVAL

1. Disconnect negative (–) cable at the battery.

2. Remove the steering column upper and lower covers.

3. Disconnect the immobiliser control module connector.

4. Remove the immobiliser control module (1) from the

steering lock assembly (2) after tilting the steering

column fully down.

INSTALLATION

Reverse removal procedure for installation.

NOTE:

After replacing the immobiliser control module,

register the transponder code and ECM / immobiliser

control module code in the immobiliser control module

and the ECM / immobiliser control module code in the

ECM, refer to 6. PROCEDURE AFTER IMMOBILISER

CONTROL MODULE REPLACEMENT in this Section.

4. IMMOBILISER FUNCTIONS

F0: DIAGNOSTIC TROUBLE CODES

In this test mode, DTC(s) stored by the Immobiliser Control Module can be displayed . Only one option is pro-

vided:

F0:Read DTC Information As Stored By ECU

As DTCs are stored in the ECM’s volatile memory, a Clear DTC option is not required.

F1: DATA DISPLAY

This mode TECH 2 displays the following data parameter:

Date of ECU Programming

Number of Transponder Keys Programmed.

F2: SNAPSHOT

In th is test mode, the TECH 2 scan tool c aptures data befo re an d after a snapshot trigger ing con ditio n whic h

may or may not set a DTC. The Snapshot mode will help identify problems that may cause intermittent opera-

tion of the Immobiliser system.

F3: ADDITIONAL FUNCTIONS

In this test mode, one additional operation may be carried out on the Immobiliser system.

The following operation can be performed:

F0: Erase Transponder Keys

F4: PROGRAMMING

This mode allows the programming of replacement or additional components to the Immobiliser system.

F0: Program Immobiliser

F1: Program Transponder Key

NOTE:

• Up to four transponder key codes can be registered.

• It is not possib le to register a trans ponder co de for an ignition ke y that is already reg istered in the imm obil-

iser control module.

5. HOW TO REGISTER IGNITION KEY

Register the ignition key with built-in transponder in the immobiliser control module by using the following pro-

cedure. 1. With the i gnitio n swit ch OF F, con nect Te ch 2 (A ) to the

data link connector (DLC) (1) located on underside of

instrument panel at driver’s seat side.

•NOTE: Refer to Section 0C for complete information

on connecting TECH 2 to the vehicle and navigation

through the initial screens.

I

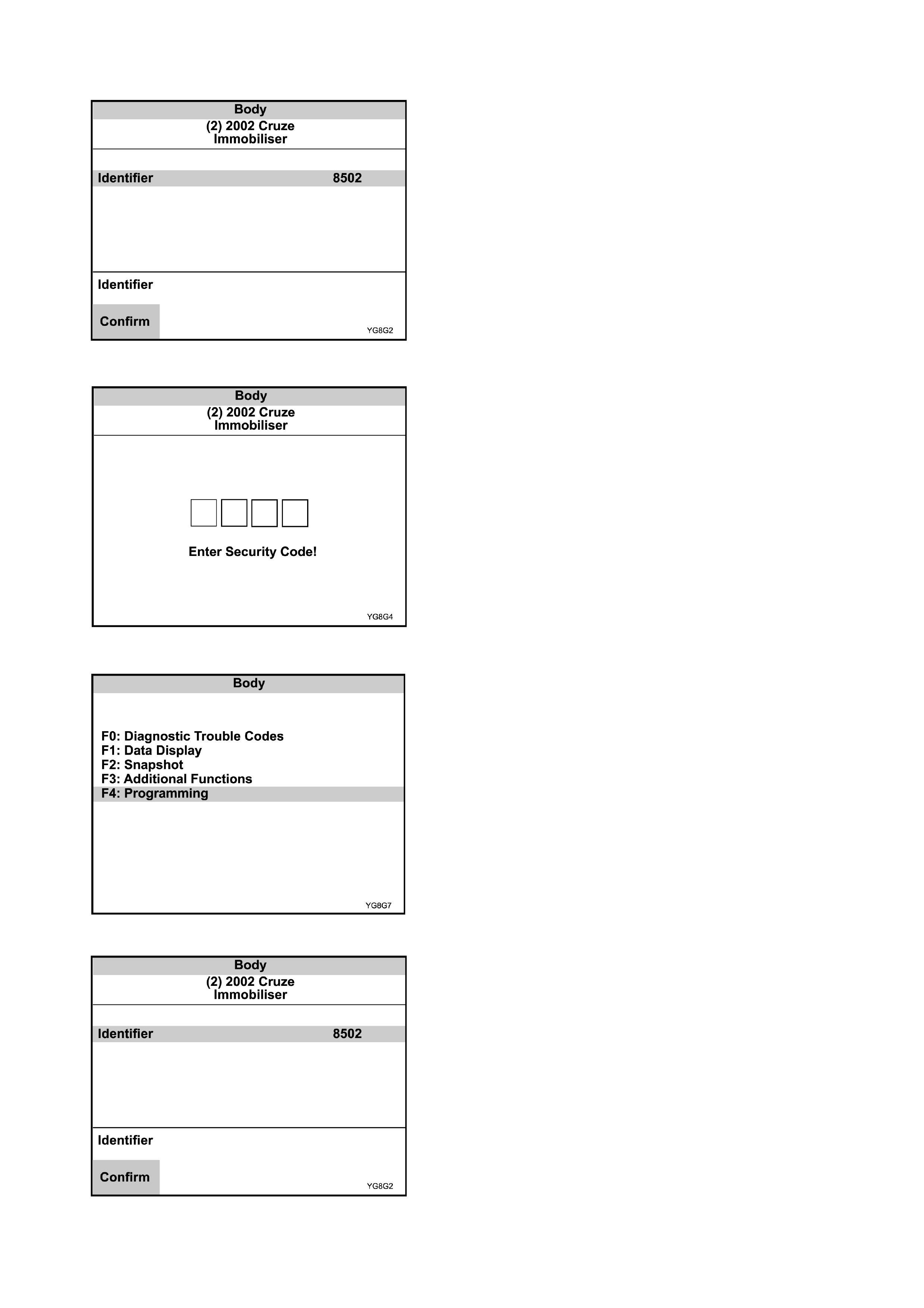

1. Select the correct body system from the Vehicle

Identification menu with the arrow keys, then press

ENTER and follow the instructions on the screen.

2. Turn on the ignition and press the Confirm soft key.

Techline

1. The System identification screen will then display the

control module Part number and System type.

Press the Confirm soft key.

2. The Security Screen will then be displayed. Enter the

4 digit securi ty num ber 089 5 usi ng the TECH 2 keypa d

Note: 0895 is used for ALL YG Cruze vehicles.

Confirm the security number when prompted, then follow

the On-screen instructions.

3. Select F4:Programming / F1:Program Immobiliser,

then follow the On-screen instructions.

4. The System identification screen will then display the

control module Part number and System type.

Press the Confirm soft key.

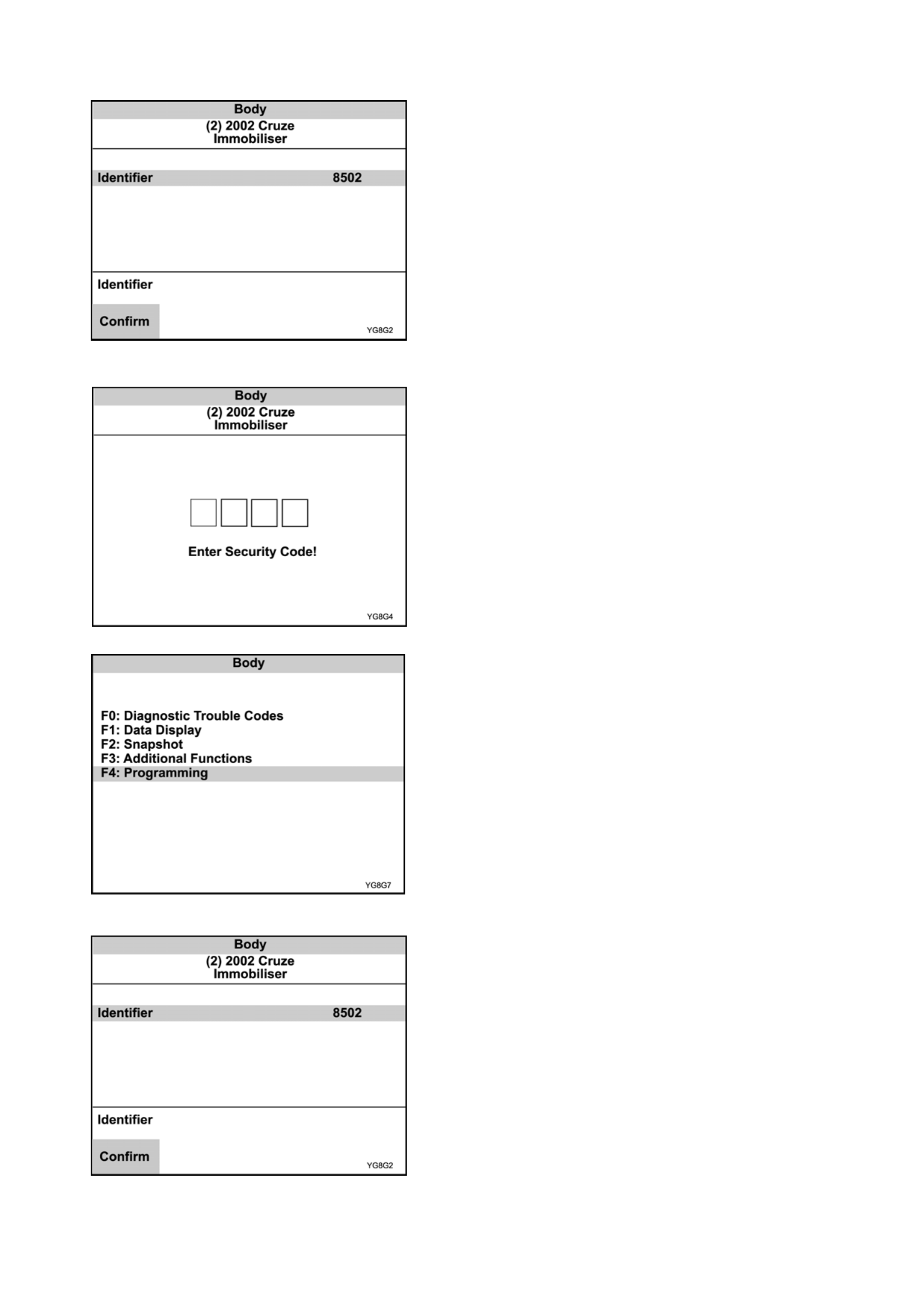

6. PROCEDURE AFTER IMMOBILISER CONTROL MODULE &/OR

ENGINE CONTROL UNIT REPLACEMENT

When an i mmobili ser control mod ule is re placed, in cluding rep lacement due to recheck ing by using a known

good immobiliser control module during trouble diagnosis, register the transponder code and the ECM /

immobiliser control module code in the immobiliser control module by performing the following procedure.

NOTE: The transponder Keys MUST be programmed to the ICM prior to carrying out the ICM registra-

tion procedure.

1. With the i gnitio n swit ch OF F, con nect Te ch 2 (A ) to the

data link connector (DLC) (1) located on underside of

instrument panel at driver’s seat side.

•NOTE: Refer to Section 0C for complete information

on connecting TECH 2 to the vehicle and navigation

through the initial screens.

I

1. Select the correct body system from the Vehicle

Identification menu with the arrow keys, then press

ENTER and follow the instructions on the screen.

2. Turn on the ignition and press the Confirm soft key.

3. The System identification screen will then display the

control module Part number and System type.

Press the Confirm soft key.

4. The Security Screen will then be displayed. Enter the

4 digit securi ty num ber 089 5 usi ng the TECH 2 keypad

Note: 0895 is used for ALL MY2002 YG Cruze

vehicles.

Confirm the security number when prompted, then follow

the On-screen instructions.

5. Select F4:Programming / F1:Program Immobiliser,

then follow the On-screen instructions.

6. The System identification screen will then display the

control module Part number and System type.

Press the Confirm soft key.

7. SPECIAL TOOLS

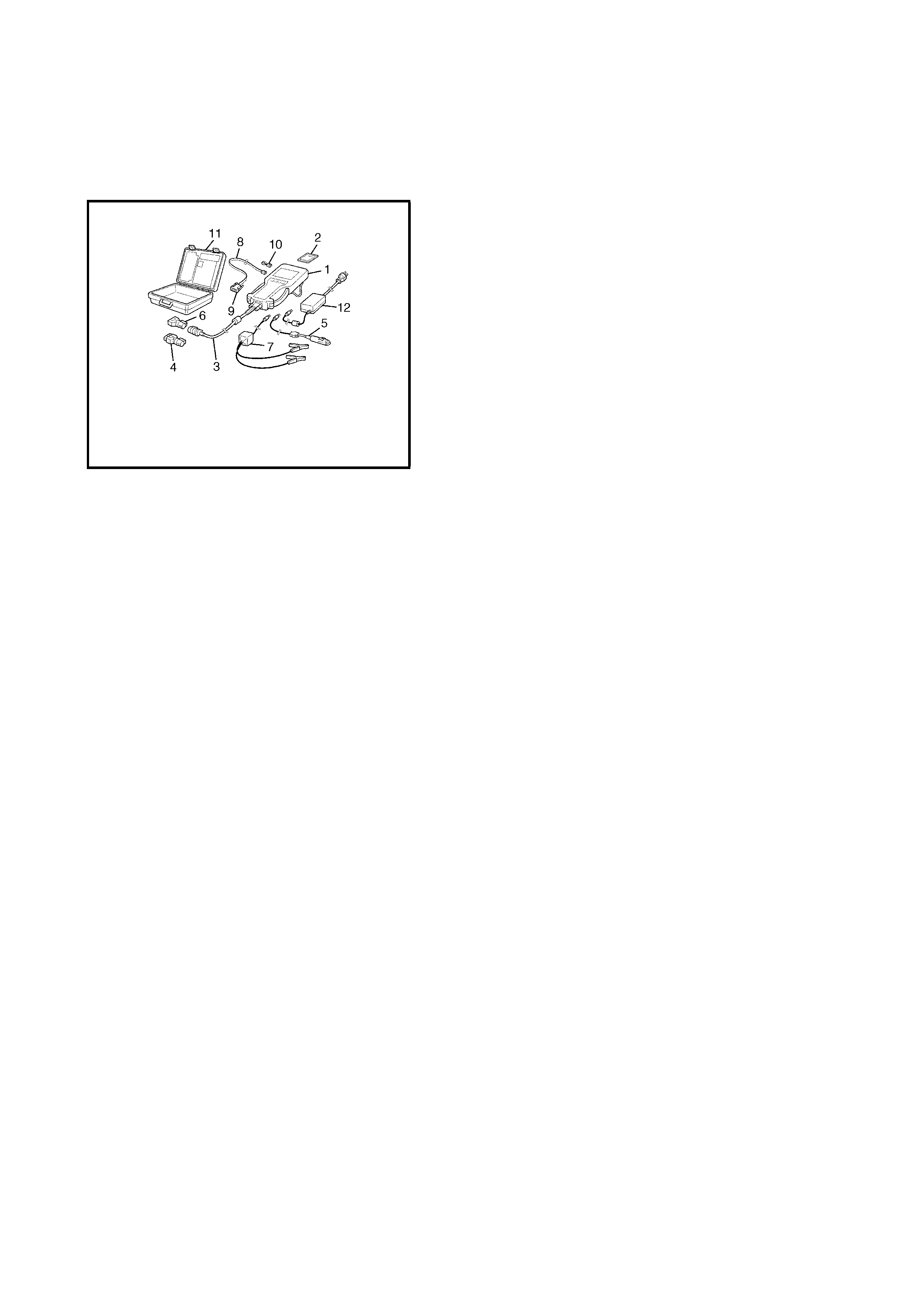

NOTE: Refer to Section 0A GENERAL INFORMATION – 7. CONSOLIDATED TOOLS for a detailed list of

special tools and the local equivalent if one is available.

NOTE: This kit includes the following items:

1.Tech 2,

2.PCM C IA ca rd ,

3.DLC cable,

4.SAE 16 /19 adapter,

5.Ciga rette cab le ,

6.DLC loopback adapter,

7.Battery power cable,

8.RS232 cable,

9.RS232 adapter,

10.RS232 loopback connector,

11.Storage case,

12.Power supply.

Tech 2 kit.

See NOTE.