SECTION 9 - BODY SERVICE

1. GLASS, WINDOWS AND MIRRORS

1.1 FRONT DOOR GLASS

Removal

Installation

1.2 FRONT DOOR WINDOW REGULATOR

Removal

Inspection

Installation

1.3 DOOR MIRROR

Removal

Installation

1.4 REAR DOOR GLASS

Removal

Installation

1.5 REAR DOOR WINDOW REGULATOR

Removal

Inspection

Installation

1.6 WINDSHIELD

Removal

Installation

1.7 QUARTER WINDOW

Removal and Installation

1.8 BACK DOOR GLASS

Removal and Installation

2. BODY STRUCTURE

2.1 FRONT DOOR ASSEMBLY

Removal

Installation

2.2 REAR DOOR ASSEMBLY

Removal and Installation

2.3 BACK DOOR ASSEMBLY

Removal

Installation

2.4 HOOD

Removal

Installation

Adjustment

Inspection

2.5 FRONT BUMPER SIDE EXTENSION

Removal

Installation

2.6 FRONT BUMPER CENTRE EXTENSION

Removal

Installation

WARNING:

For vehicles equipped with Supplemental Restraint (Airbag) System:

• Service on and around the airbag system components or wiring must be performed only by an

authorised HOLDEN retailer. Refer to AIRBAG SYSTEM COMPONENTS and WIRING LOCATION

VIEW under GENERAL DESCRIPTION in Section 10B AIRBAG SYSTEM in order to confirm

whether you are performing service on or near the airbag system components or wiring. Please

observe all WARNINGS and SERVICE PRECAUTIONS under ON-VEHICLE SERVICE in Section 10B

AIRBAG SYSTEM before performing service on or around the airbag system components or wir-

ing. Failure to follow WARNINGS could result in unintentional activation of the system or could

render the system inoperative. Either of these two conditions may result in severe injury.

• Technical service work must be started at least 90 seconds after the ignition switch is turned to

the “LOCK” position and the negative cable is disconnected from the battery. Otherwise, the sys-

tem may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

• When body servicing, if shock may be applied to airbag system component parts, remove those

parts beforehand. (Refer to Section 10B AIRBAG SYSTEM.)

NOTE:

Fasteners are important attaching parts in that they could affect the performance of vital compo-

nents and systems, and / or could result in major repair expense. They must be replaced with one of

the same part number of with an equivalent part if replacement becomes necessary.

Do not use a replacement part of lesser quality or substitute a design. Torque values must be used

as specified during reassembly to assure proper retention of these parts.

Techline

2.7 SILL PANEL EXTENSION

Removal

Installation

2.8 FRONT FENDER EXTENSION

Removal

Installation

2.9 REAR FENDER EXTENSION

Removal

Installation

2.10 REAR BUMPER CENTRE EXTENSION

Removal

Installation

2.11 REAR BUMPER SIDE EXTENSION

Removal

Installation

2.12 FRONT BUMPER

Removal

Disassemble

Installation

2.13 REAR BUMPER

Removal

Disassemble

Installation

2.14 FRONT FENDER

Removal

Installation

2.15 ROOF RAILS

Removal

Installation

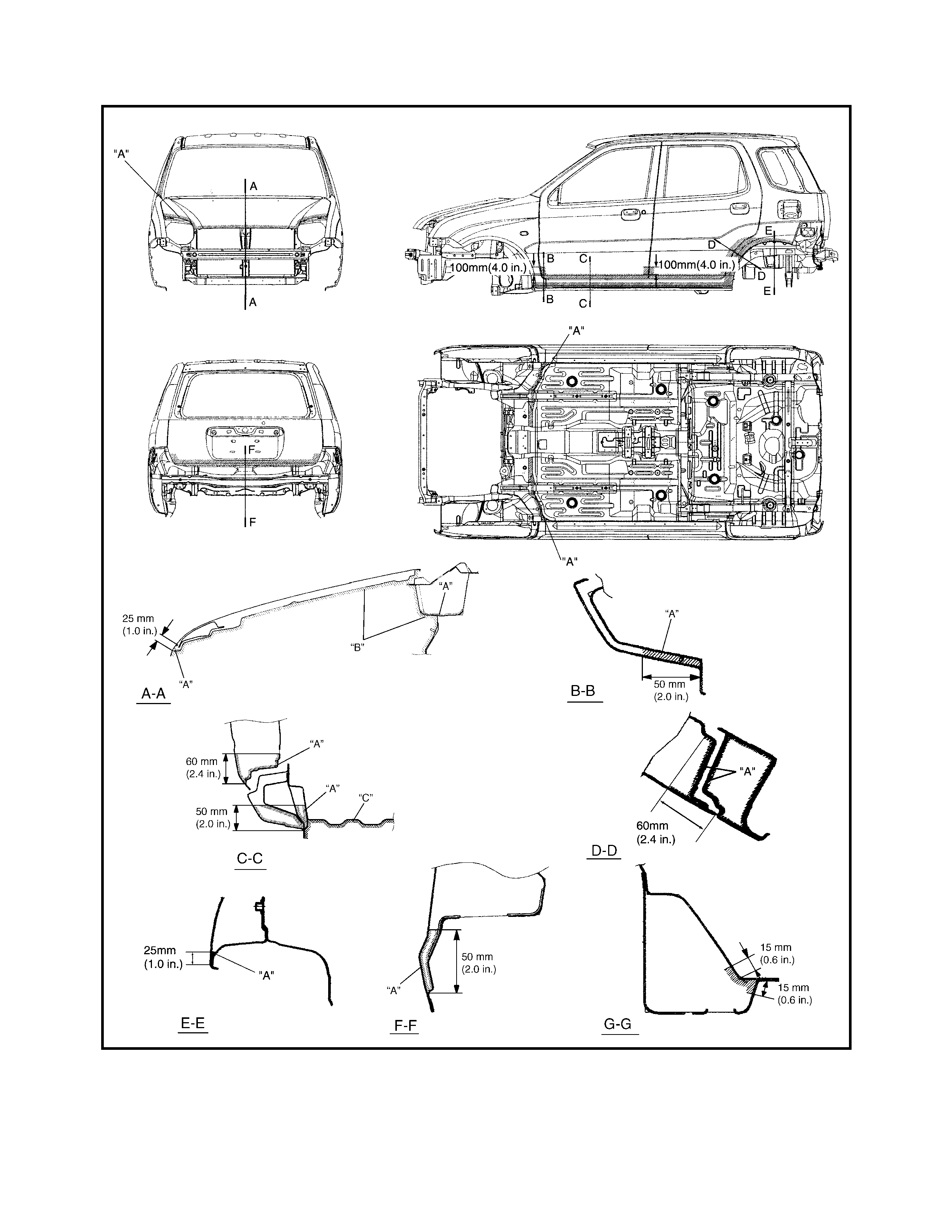

2.16 BODY DIMENSIONS

Engine Room

Back Door

Side Body

Under Body

2.17 PANEL CLEARANCE

3. INSTRUMENTATION AND DRIVER

INFORMATION

3.1 INSTRUMENT PANEL

Removal

Installation

4. SEATS

4.1 FRONT SEAT

Removal

Installation

4.2 REAR SEAT

Removal

Installation

5. SECURITY AND LOCKS

5.1 FRONT DOOR LOCK ASSEMBLY

Removal

Installation

Inspection

5.2 REAR DOOR LOCK ASSEMBLY

Removal

Installation

5.3 BACK DOOR LOCK ASSEMBLY

Removal

Installation

Inspection

5.4 KEY CODING

Key Usage and Identification

Ignition Switch Cylinder Lock

Removal and Install atio n

Electrical Diagnosis

6. EXTERIOR AND INTERIOR TRIM

6.1 FLOOR CARPET

Removal

Installation

6.2 HEADLINING

Removal

Installation

7. PAINT AND COATINGS

7.1 ANTI-CORROSION TREATMENT

7.2 SEALANT APPLICATION AREAS

7.3 UNDER COATING APPLICATION AREAS

7.4 ANTI-CORROSION COMPOUND

APPLICATION AREA

Plastic Par t s Finishing

Painting

Reference

8. REQUIRED SERVICE MATERIAL

1. GLASS, WINDOWS AND MIRRORS

1.1 FRONT DOOR GLASS

Legend 1. Door glass 5. Door sealing cover 10. Glass bottom channel

2. Window regulator assembly

: Apply Lithium grease

to sliding part

6. Door sash 11. Glass bottom rubber

7. Front door grip 12. Front door outer

weather-strip

8. Bottom channel attaching

screw

3. Glass weather-strip channel

4. Door trim 9. Door opening weather-strip

Techline

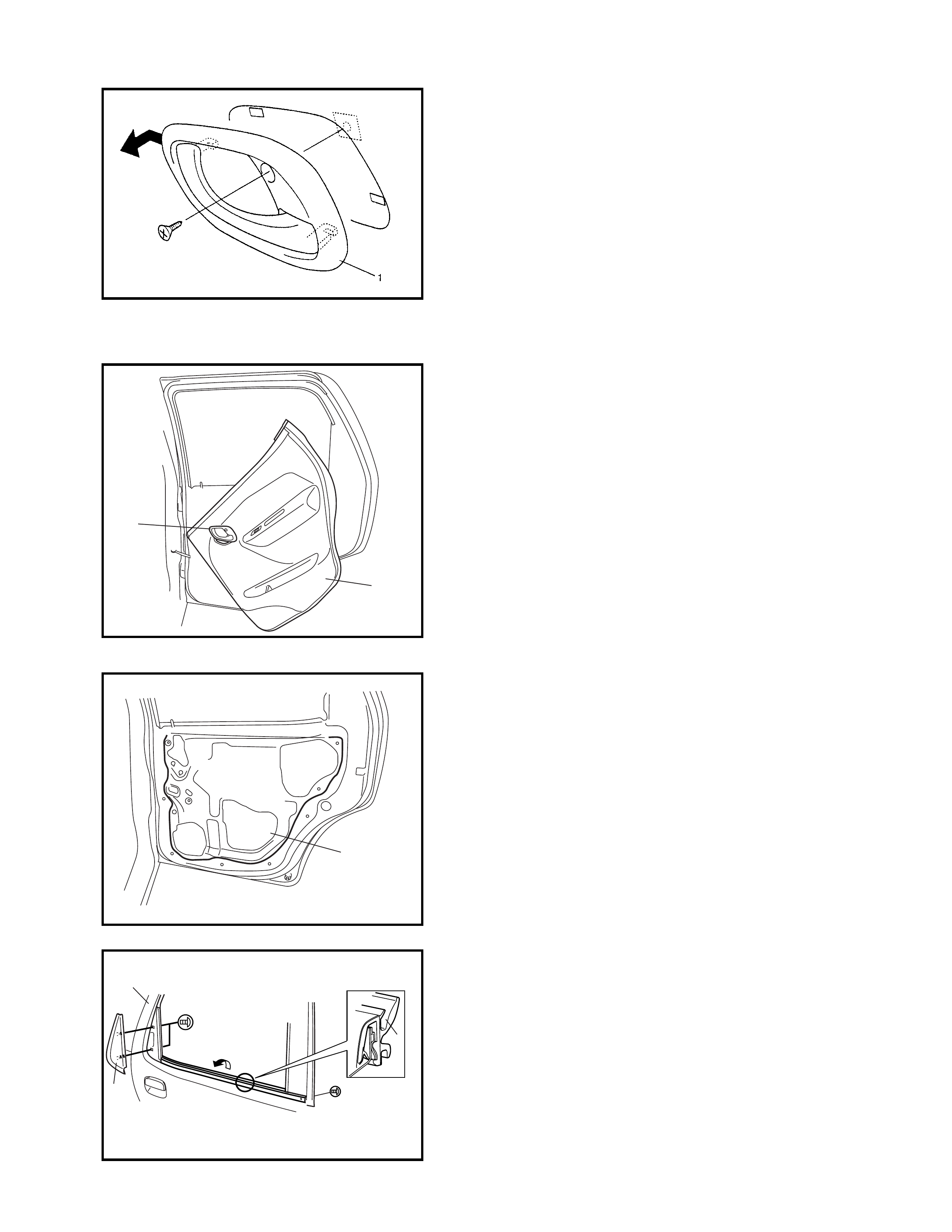

REMOVAL

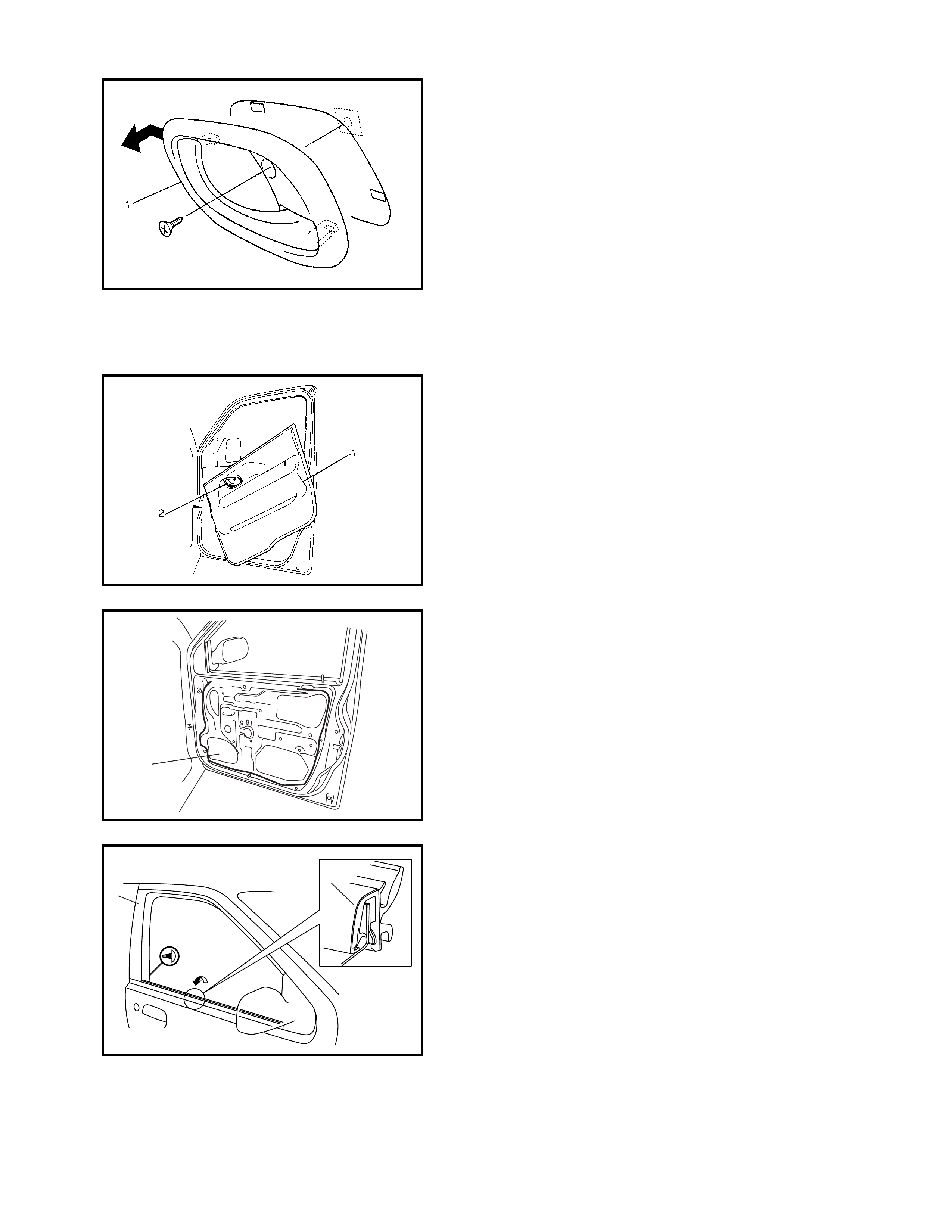

1. Remove the inside handle bezel (1).

2. Remove the inside door grip.

3. Remove the mirror inner garnish.

Refer to 1.3 DOOR MIRROR in this Section.

4. Remove the door trim (1).

• Remove retainer (2) and unclip from trim from door

panel.

• With the inside handle bezel (2) tilted as shown, turn

the door trim (1) 90° counterclockwise to remove it.

Disconne ct the power window s witch lead wire at c on-

nector.

5. Remove the door sealing cover (1).

6. Remove the door mirror.

Refer to 1.3 DOOR MIRROR in this Section.

7. Remove the outer weather-strip (1).

8. Lower the window all the way down.

9. Use a tape-protected putty-knife to pry off the outer

weather-strip (1).

NOTE: Take care not to deform the outer weather-strip (1)

when removing from door panel (2).

1

1

2

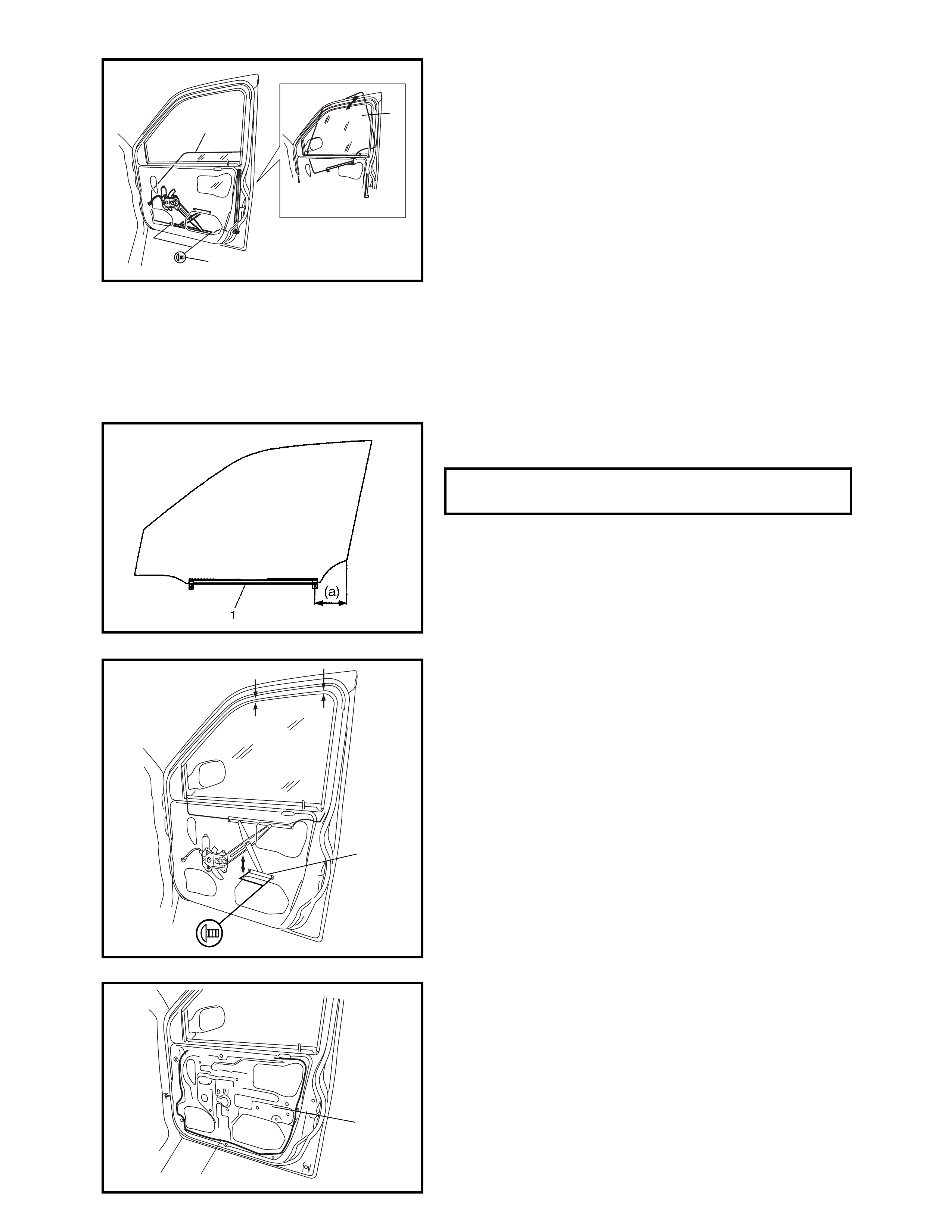

10. Remove bottom channel attaching screws (1).

11. Turn door glass (2) 90° counterclockwise to remove.

INSTALLATION

Reverse r emoval pr ocedure to i nstall door glass noting the

following instructions.

• If glass weather-strip channel is deformed, replace it.

• Tighten the bottom channel attaching screws, the rear

screw first followed by the front screw.

• Fit door glass into bottom channel (1) in the correct

position as shown in figure.

• Adjust window regulator equaliser (1) so that measure-

ment (a) and (b) are equal.

• Secure door sealing cover (1) with adhesive (2).

2

2

1

DOOR GLASS POSITION IN BOTTOM

CHANNEL (a) 90.6 - 93.8 mm

1

(a) (b)

1

2

1.2 FRONT DOOR WINDOW REGULATOR

REMOVAL

1. Remove the door glass, refer to 1.1, FRONT DOOR

GLASS in this Section.

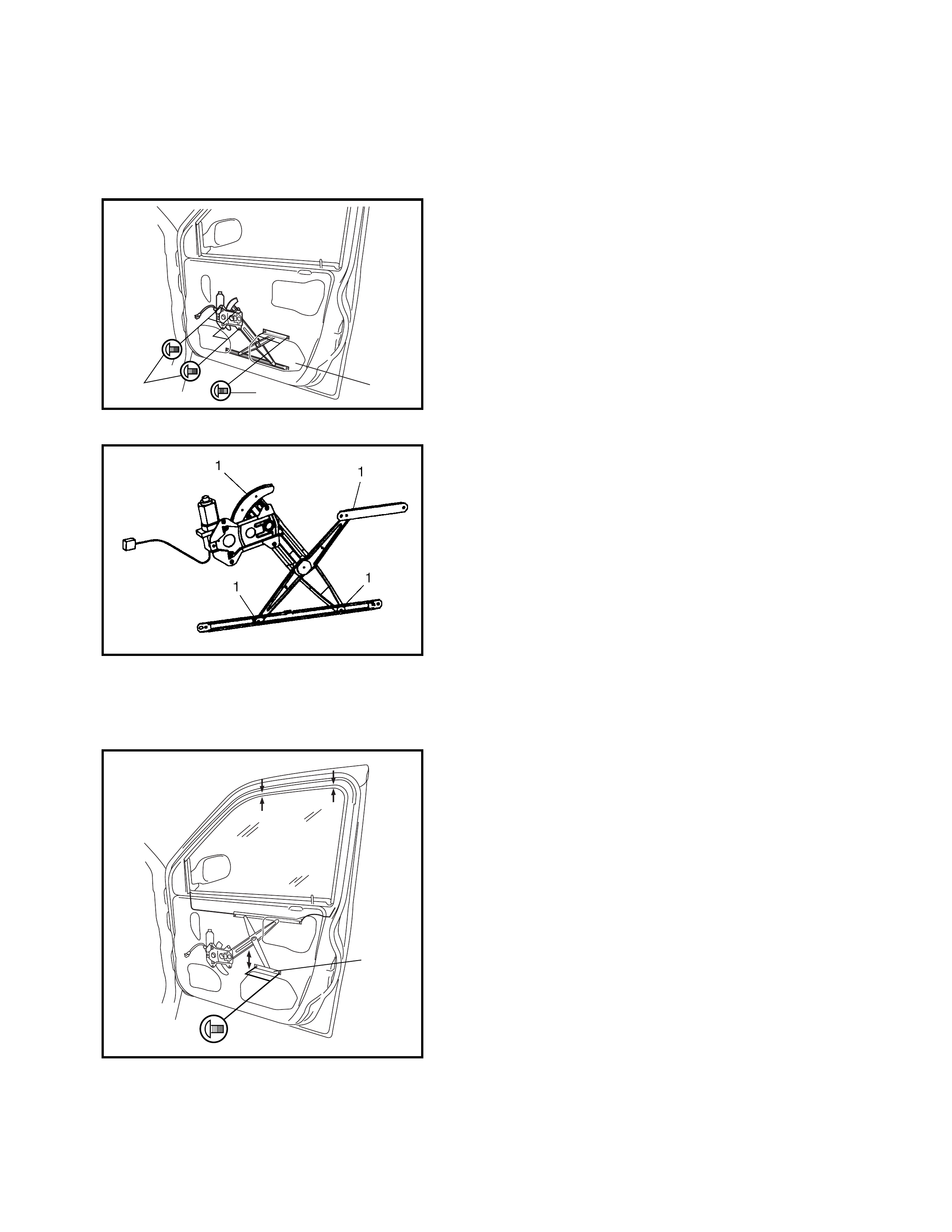

2. Disconnect the power window motor lead wire at the

connector and loosen clamp.

3. Loosen the regulator m ounting screws (1) and remove

the regulator through the hole (2) as shown in figure.

INSPECTION

Check the following parts :

• Check regulator sliding and rotating parts for

grease (1).

• Check rollers for wear and damage.

Replace if excessively worn.

INSTALLATION

Reverse r emoval pro cedure to install the win dow regulator

noting the following:

• When installing the door glass, check that the top of

the glass contacts the glass weather-strip channel

evenly and that the glass moves up and down

smoothly.

If the door glass is angled when refitted, adjust the win-

dow regulator equaliser (1) so that measurements (a)

and (b) are equal.

112

1

(a) (b)

1.3 DOOR MIRROR

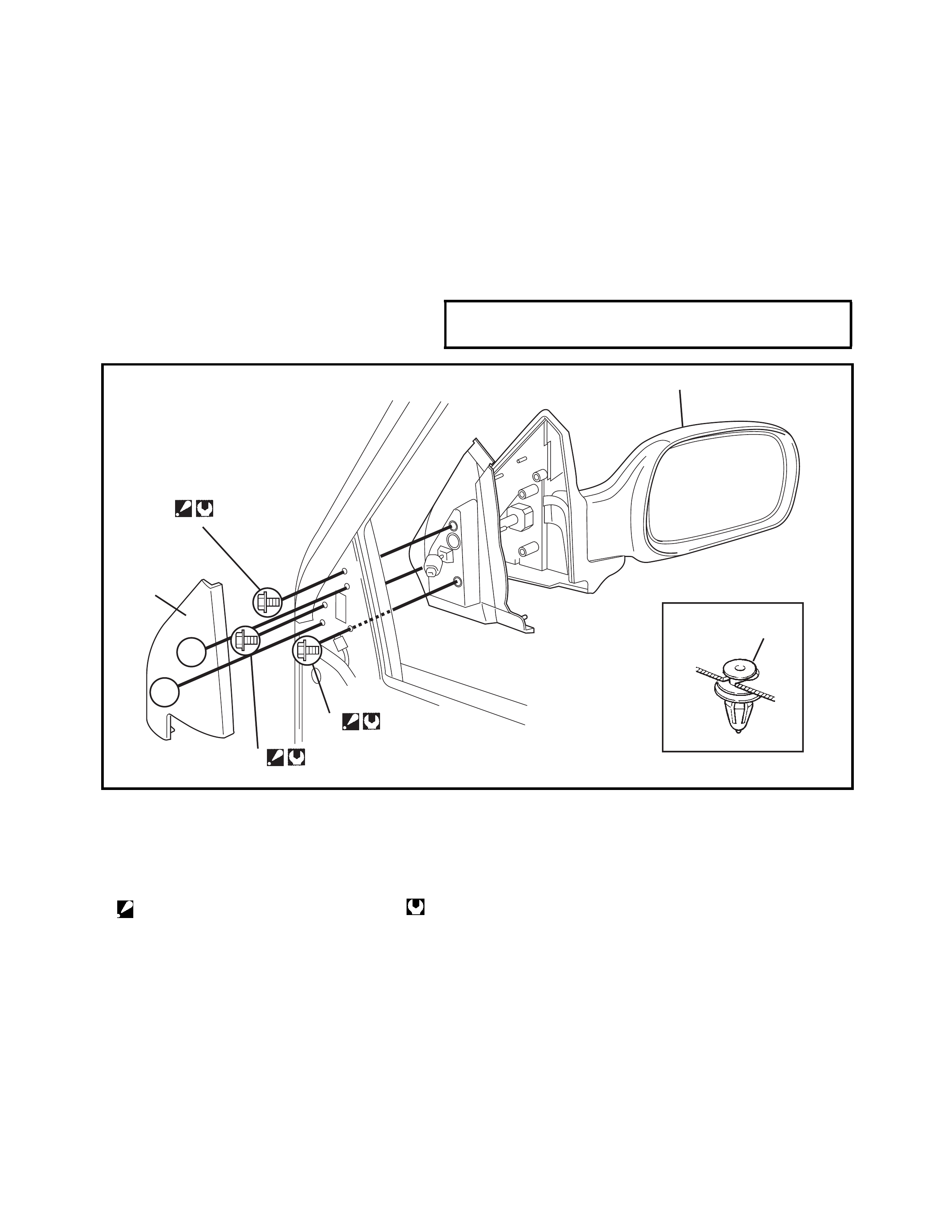

REMOVAL

1. Lower the window and ensure the ignition switch is in

the OFF position.

2. Carefully unclip (3) the inner mirror garnish (2) and

unplug electrical connector.

3. Support the door mirror, remove screws (a,b,c) and

carefully lift the door mirror away from the door.

INSTALLATION

Reverse removal procedure to install the door mirror noting

the tightening sequence of screws (a,b,c).

Legend

DOOR MIRROR MOUNTING SCREWS

TORQUE SPECIFICATION 4.5 Nm

a4.5 Nm

c4.5 Nm

4.5 Nm

b

2

2

3

[A]

[A]

[A]

1. Door mirror a. Mirror mount screw .

2. Inner garnish b. Mirror mount screw

3. Clip c. Mirror mount screw

Tighteni ng order : a → b → c Tightening torque

1.4 REAR DOOR GLASS

Legend

1. Door glass 5. Door sealing cover 9. Rear door inner garnish

2. Window regulator assembly

: Apply Lithium grease

to moving section.

6. Door sash 10. Rear door outer garnish

7. Rear door outer 11. Glass bottom channel

weath er-s tr ip 12. Glass bott om rub ber

3. Glass weather-strip channel 8. Rear door inside pull 13. Door inside pull

4. Door trim handle bracket handle case

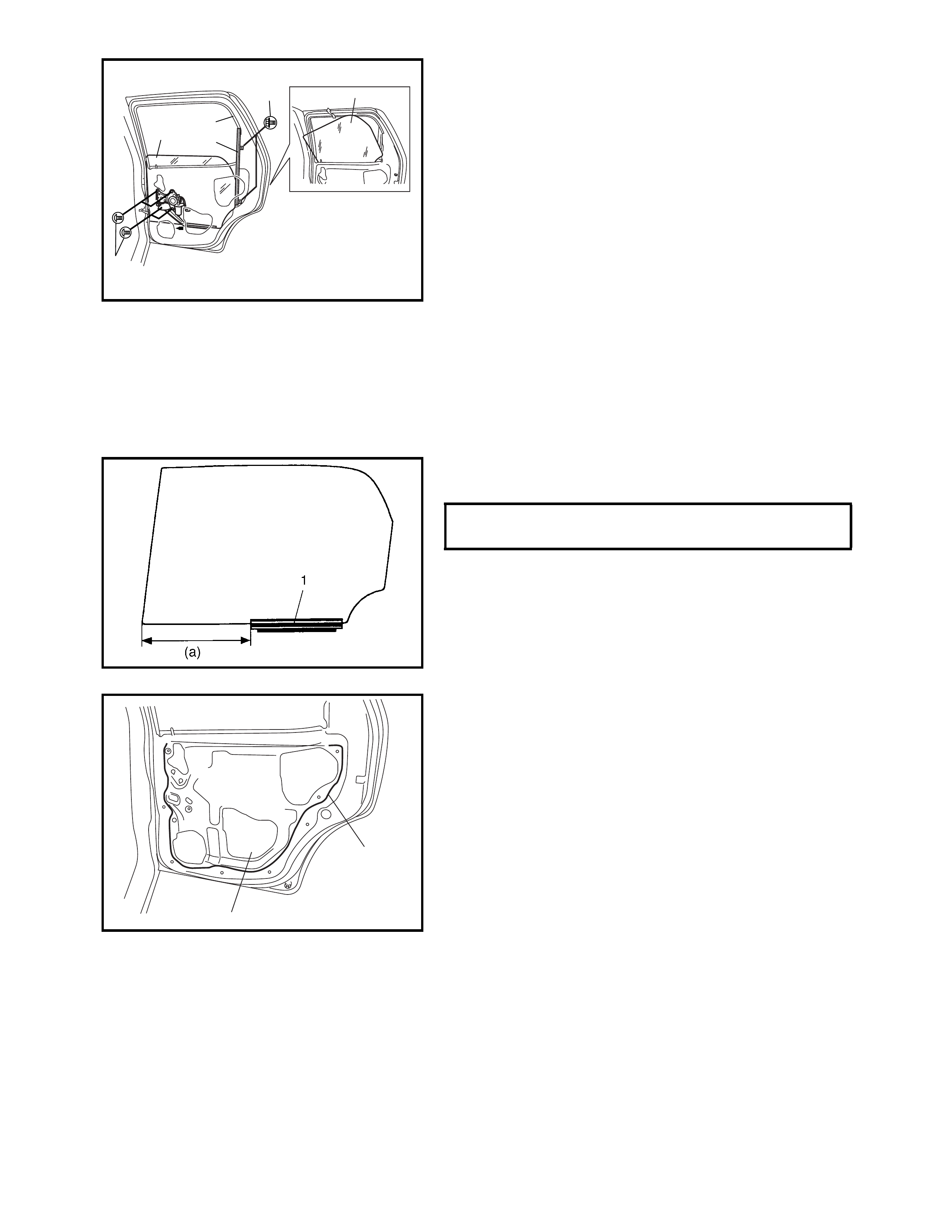

REMOVAL

1. Remove the inside handle bezel (1).

2. Remove the door inside pull handle case fitting screw.

3. Remove the rear door inner garnish.

4. Remove the door trim (1).

With the inside handle bezel (2) tilted as shown, turn

the door trim 90° counterclockwise to remove it.

Disconnect the power window switch lead wire at the

connector.

5. Remove the door inside pull handle bracket.

6. Remove the door sealing cover (1).

7. Remove the rear door outer garnish (1).

8. Remove the outer weather-strip (2).

9. Lower the window all the way down.

10. Use a tape-protected putty knife (or screwdriver) to pry

off the outer weather-strip.

NOTE: Take care not to deform the outer weather-strip (2)

when removing from door panel (3).

2

1

1

2

3

1

11. Detach rear part o f the gla ss weather -strip chan nel (1)

from the sash (2). Remove the sash retaining screws

(3) and remove the sash (2).

12. Loosen the window regulator mounting screws (5).

13. Turn the door glass (4) 90° counterclockwise to

remove.

INSTALLATION

Reverse the removal procedure to install door gl ass notin g

the following:

• If the gla ss weathe r-strip cha nnel is deforme d, replace

it.

• Tighten the bottom channel attaching screws, the rear

screw first followed by the front screw.

• Fit the door glass into the bottom channel (1) in the

correct position as shown in figure.

• Secure the door sealing cover (1) with adhesive (2).

4

1

2

3

5

4

FITTING POSITION OF GLASS IN

BOTTOM CHANNEL (a) 201.9 - 204.9 mm

1

2

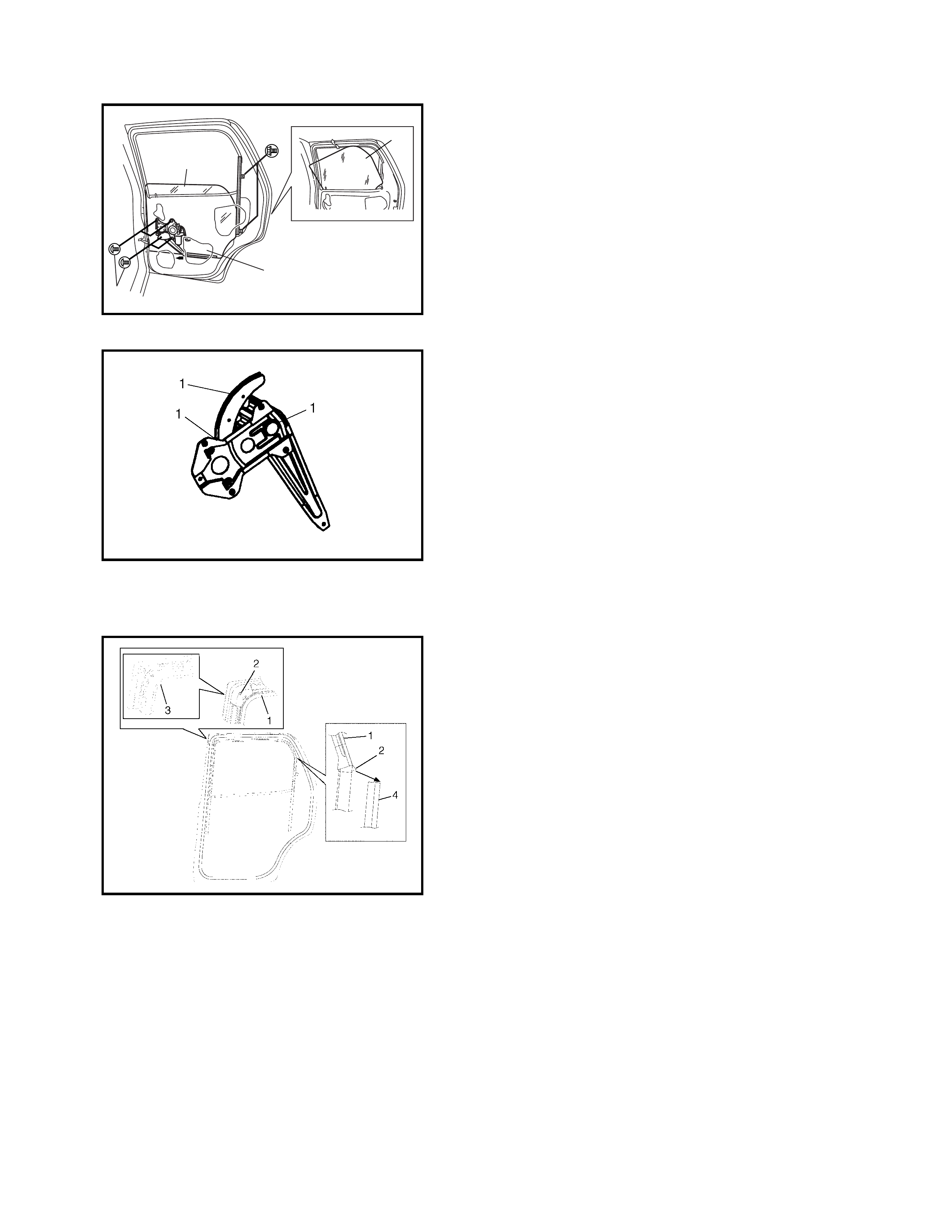

1.5 REAR DOOR WINDOW REGULATOR

REMOVAL

1. Remove the rear door glass (3), refer to 1.4 REAR

DOOR GLASS in this Section.

2. Loosen the regulator mounting screws (1) and take out

the regulator through the hole (2) as shown.

INSPECTION

Check the following points:

• Check the regulator sliding and rotating parts for

grease (1).

• Check the rollers for wear and damage

Replace if excessively worn.

INSTALLATION

Reverse r emoval pro cedure to install the win dow regulator

noting the following:

• When the glass weather-strip channel (1) is installed,

fit the glass weather-strip channel convex part (2) to

the door panel cut part (3) and door sash (4).

3

3

2

1

1.6 WINDSHIELD

The front windshield is installed using one component urethane adhesive and primer. When replacing the

windshield it is important to follow the correct procedures and use an approved adhesive which provides suffi-

cient adhe si on strength.

Legend

Caution:

• This section describes the glass replacement using 3 types of primers and 1 type of adhesive.

When using primer and adhesive, be sure to refer to handling instructions supplied by the adhe-

sive manufacturer. Negligence in following the correct procedure or misuse of the adhesive in any

way hinders its inherent adhesive property. Therefore, before beginning work, be sure to carefully

read the instructions and descriptions given by the manufacturer of the adhesive to be used and

to follow the procedure and observe all precautions.

• Should a coated surface be scratched or otherwise damaged, repair the damaged section to avoid

the onset of corrosion.

Use an adhesive of above mentioned type which has the following property.

Glass adhesive shearing strength

: 40 kg / cm2 or more.

Adhesive materials and tools required for removal and installation.

• One component urethane adhesive and primers used in combination (For each windshield replacement).

- Adhesive (470 g)

- Primer for glass (30 g)

- Primer for body (30 g)

- Primer for moulding (30 g)

• Piano string

• Needle punch

• Win ds hie ld kn ife

• Brush for primer application (x 2)

•Knife

• Suction cups

• Sealant gun (for filling adhesive)

• Putty spatula (for correcting adhered parts)

1. Winds hie ld gla ss 3. Stopp er 5. Side spacer

2. Windshield moulding 4. Centre spacer Do not reuse.

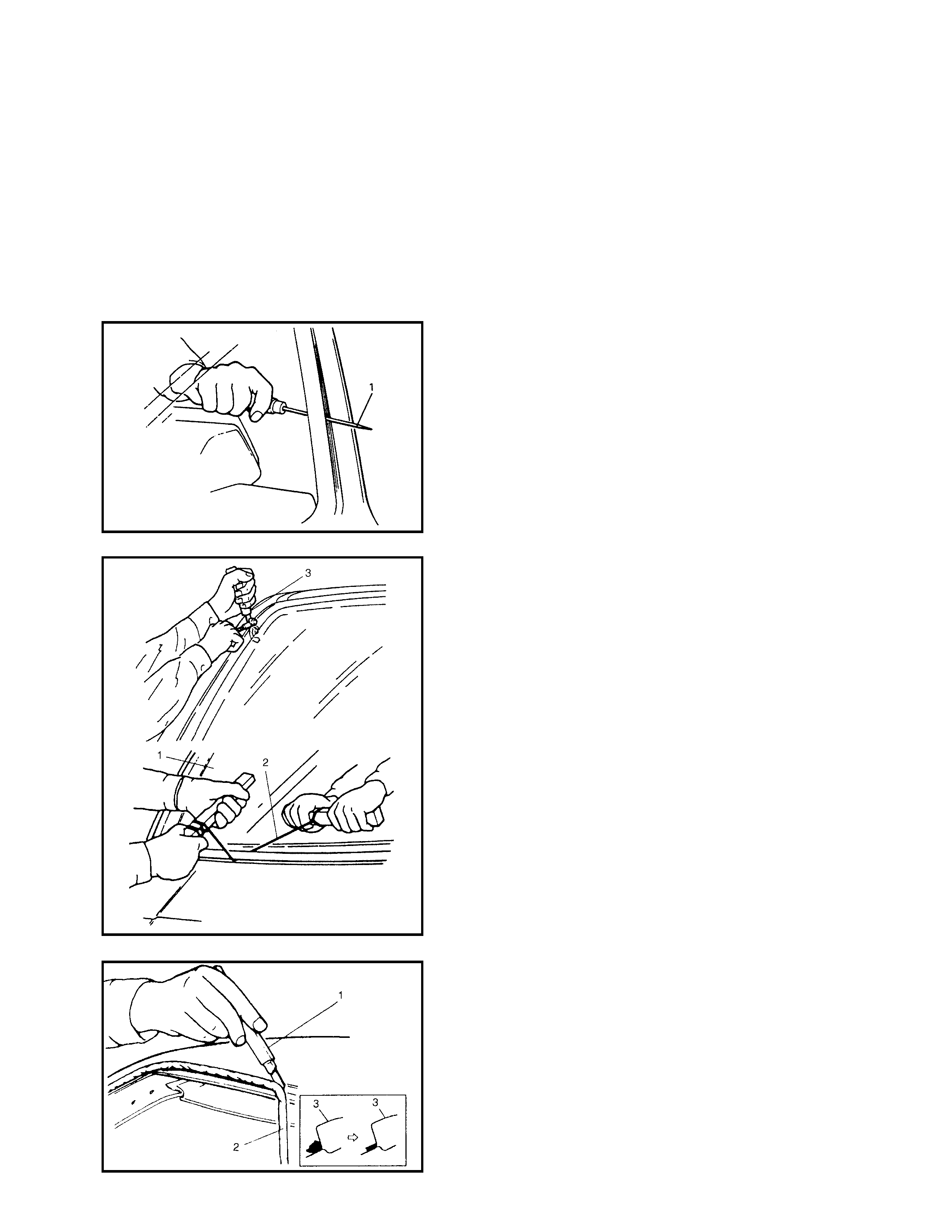

REMOVAL

1. Clean both inside and outside of the glass and sur-

rounds.

2. Remove the wiper arms and garnish.

3. Using tape, cover the body surface around the glass to

prevent any damage.

4. Remove the rear view mirror, sunvisor, and front pillar

trims (right & left).

5. If necessary, remove the instrument panel. Refer to

3.1 INSTRUMENT PANEL in this Section.

6. If necessary, remove the headlining. Refer to

6.2 HEADLINING in this Section.

7. Remove (or cut) the windshield moulding.

8. Carefully make a hole through the adhesive with a

needle punch (1) and pass piano string through it.

9. Cut adhesive all around the windshield (1) with piano

wire (2). When using a windshield knife (3) to cut

adhesive, take care not to damage windshield. Use

piano wire to cut adhesive along lower part of wind-

shield.

NOTE: Use the piano wire (2) as close to glass as possible

to prevent damage to the body and instrument panel.

10. Using a knife (1), tidy excess adhesive (2) remaining

on body side (3) so that it is 1 to 2 mm thick around

windsh ie ld open in g.

NOTE: Before us ing knife (1), cl ean it with alcoho l or simi-

lar to remove oil.

11. When reusing windshield, remove the remaining

adhesive (1), taking care not to damage the primer

coated surface (2).

INSTALLATION

1. Clean the windshield edge where windshield glass is to

adhere with cleaning solvent. (Allow to dry for at least

10 minutes.)

2. Install new glass stoppers (1) (2 pieces) to the lower

side of windshield.

3. To determine the correct installation position of the

glass (1) to the b ody (2) , posi tion the gl ass against th e

body so that the clearance between the upper end of

glass (1) and body (2) is approximately 5 mm and

clearances between each side (right & left) of the glass

(1) and body (2) are even. Make mating marks on the

glass (1 ) and body (2) as shown . Upper cl earance can

be adjusted by moving the position of glass stoppers.

4. Clean old adhesive (4), paint or bare metal thoroughly

from contact surfaces.

If paint lifts off the metal, apply primer (2) to the body

(3) taking care not to apply the primer (2) to the

adhesive (1) remaining on the body.

NOTE:

• Be sure to refer to the primer manufacturer’s instruc-

tion for proper handling and drying time.

• Do not touch the body and existing adhesive surfaces

where the glass is to be adhered.

1

WINDSHIELD CLEARANCE (a) 5 mm

5. Install a new moulding (1) to the glass (2).

6. Clean the glass surface to be adhered to the body with

a clean cloth. If cleaning solvent is used, let it dry for

more than 10 minutes.

7. Install new spacer (1) to the glass (2).

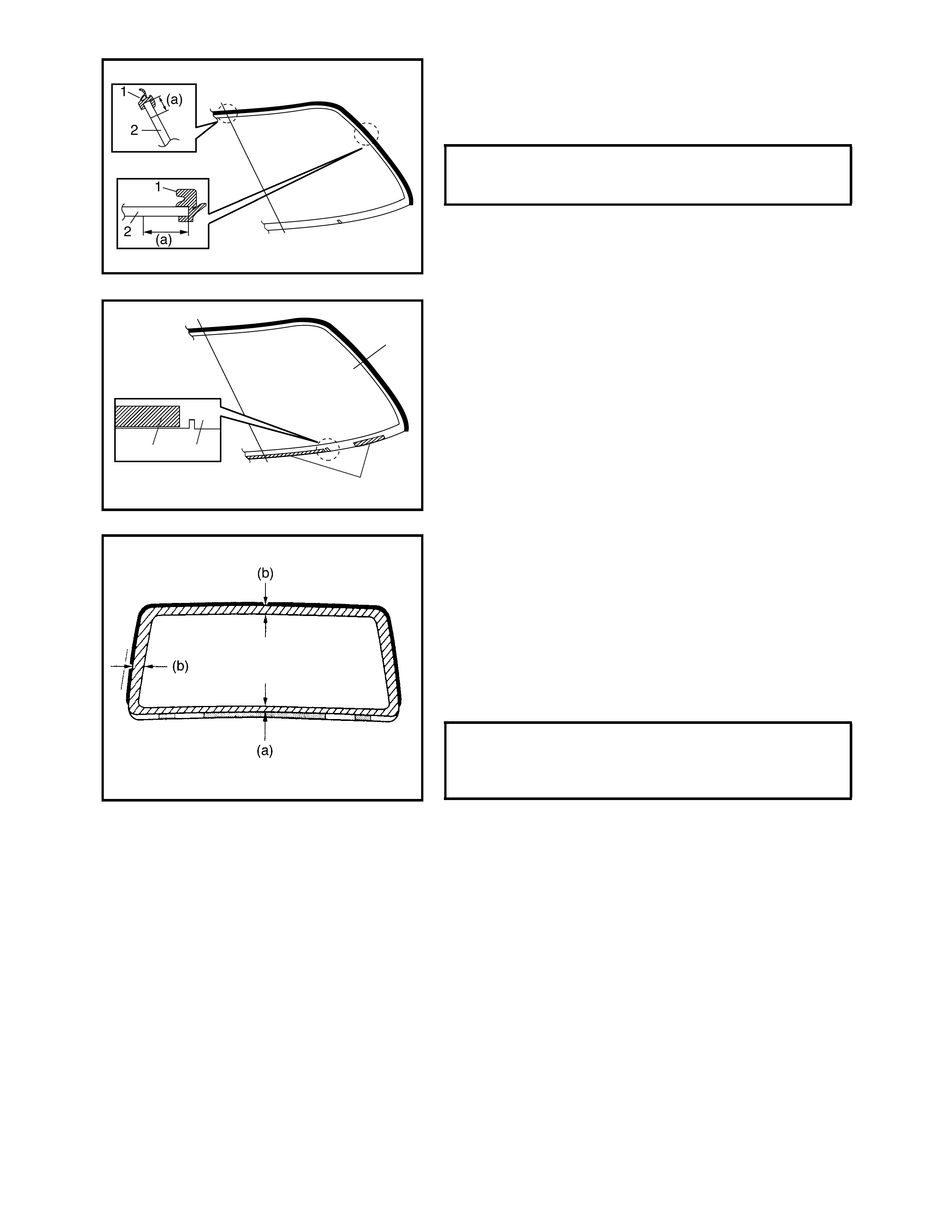

8. Using a new br ush, appl y the c orrect amou nt of pri mer

to the glass surface where it adheres to the body as

shown.

NOTE:

• Be sure to refer to manufacturer’s instruction for proper

handling and dryi ng tim e.

• Do not apply primer on the outside of ceramic coated

surface.

• Do not touch primer coated surface.

CLEANING AREA FOR WINDSHIELD

(DISTANCE FROM EDGE OF GLASS

OR MOULDING) (a) 30 - 50 mm

2

1

12

WIDTHS TO APPLY PRIMER TO

WINDSHIELD (a)

(b) 22 mm

15 mm

9. Apply primer to the moulding (3) along the moulding

surface.

10. Apply adhesive (1) referring to figure.

NOTE:

• Quickly press the glass (2) against the fitting surface of

the body panel after adhesive (1) is applied.

• Use of suction cups is helpful to hold and carry the

glass after the adhesive (1) is applied.

• Perfo rm Steps 8 to 9 withi n 10 m inutes t o en sure s uffi-

cient adhes ion .

• Be su re to ref er to the a dhe sive make r ’s i nstr uct ion for

proper handling and drying time.

• Start from the bottom side of the glass (2).

• Be careful not to damage the primer.

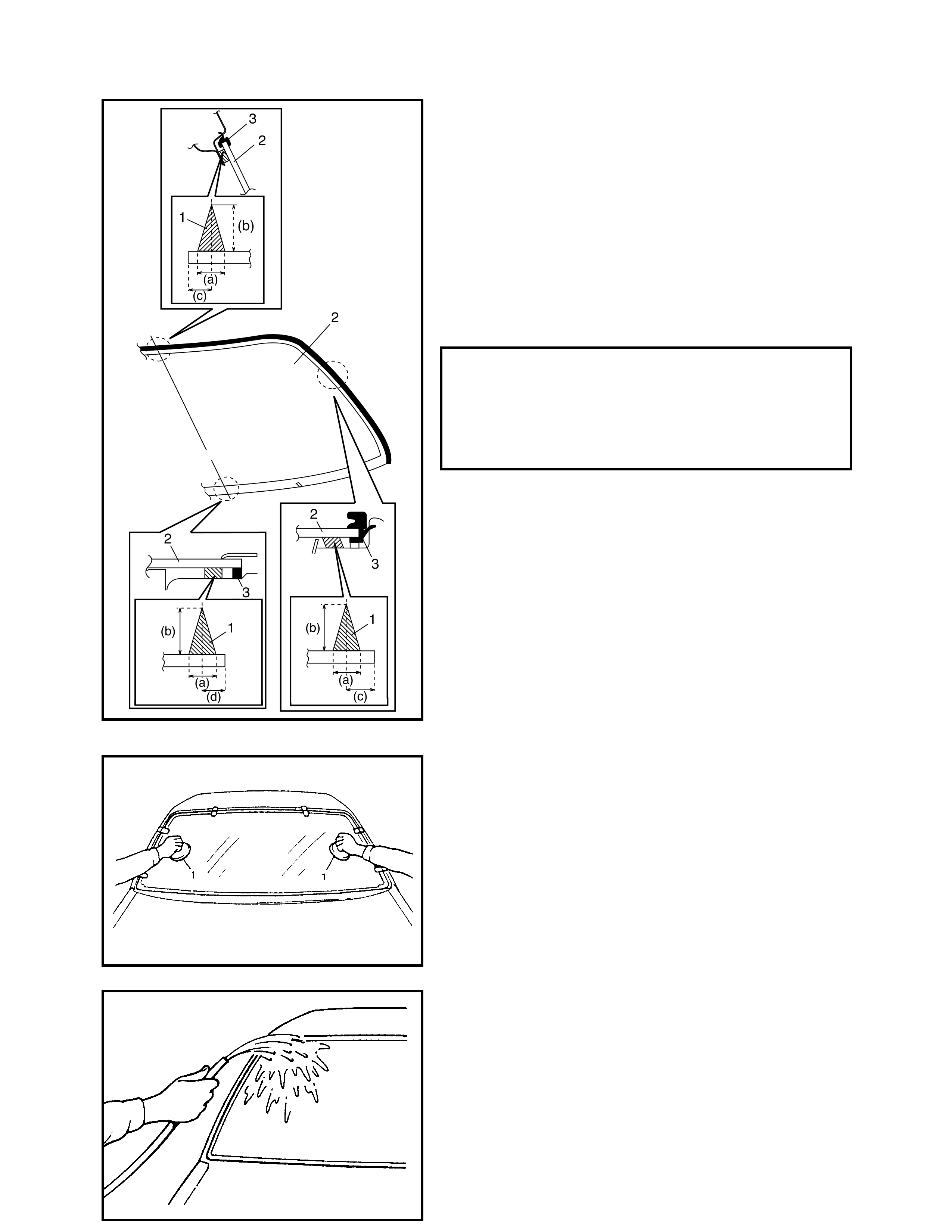

11. Holding the suction cups (1), place the glass onto the

body by aligning mating marks made in Step 3, then

press into position.

12. Check for water leakage by pouring water over wind-

shield with a hose. If leakage is found, dry windshield

and fill leak point with adhesive. If water still leaks,

remove the glass and repeat the installation procedure.

NOTE:

• Do not use high pressure water.

• Do not blow compressed air directly in areas where

adhesive is still drying.

• Do not use an infrared lamp or similar for drying.

ADHESIVE SPECIFICATIONS AND

POSITIONS FOR WINDSCREEN

(APPROX) WIDTH (a)

HEIGHT (b)

POSITION (c)

POSITION (d)

7 mm

15 mm

10 mm

17 mm

CAUTION:

Upon completion of installation, note the following.

• Sudden closing of the door(s) before adhesive is

completely set may cause the glass to become

loose or to come free. If the door(s) are opened or

closed before adhesive is completely set, ensure

that door windows are open and care is taken.

•If the moulding is not securely in place, hold it

down with tape until adhesive is completely set.

• Each adhesive has its own setting time.

• Be sure to refer to its manufacturer’s instruction,

check setting time of adhesive to be used and

observe precautions to be taken before adhesive is

set.

• Refrain from driving until adhesive is completely

set to ensure proper and sufficient adhesion.

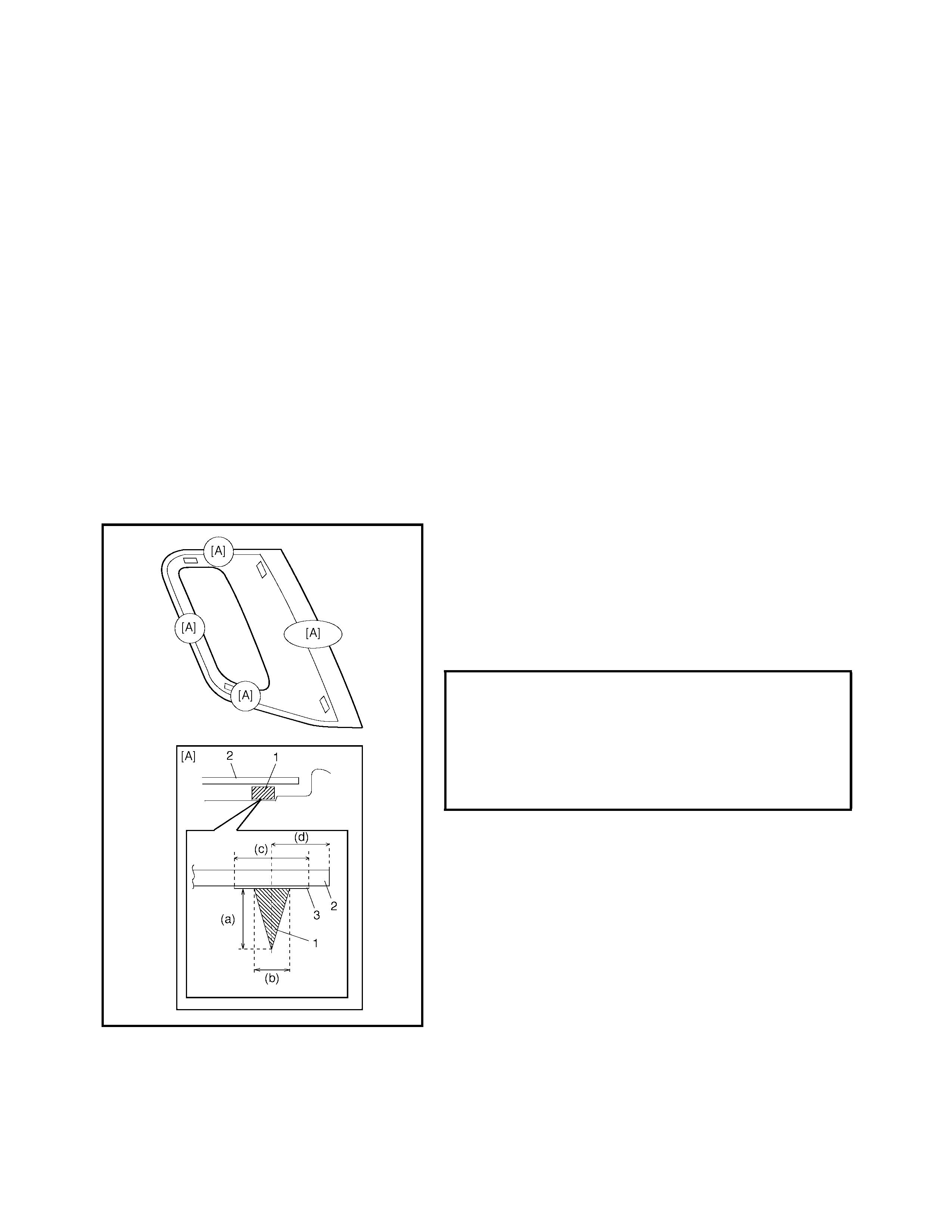

1.7 QUARTER WINDOW

REMOVAL AND INSTALLATION

Refer to 1.6 WINDSHIELD in this Section as removal and

installation procedures are basically the same. However,

note the following:

• Observe the following precautions when applying

adhesive (1) along the glass (2) edge.

• Adhesive (1) should be applied evenly, especially in

height.

• Be careful not to damage the primer (3).

• Press the glass against the body quickly after adhesive

(1) is applied.

.

ADHESIVE SPECIFICATION AND POSI-

TION FOR QUARTER WINDOW

HEIGHT (a)

WIDTH (b)

WIDTH (c)

GLASS FRONT & BOTTOM SECT. (d)

GLASS UPPER SECT. (d)

GLASS REAR SECT. (d)

13 mm

6 mm

14 mm

12 mm

11 mm

45 mm

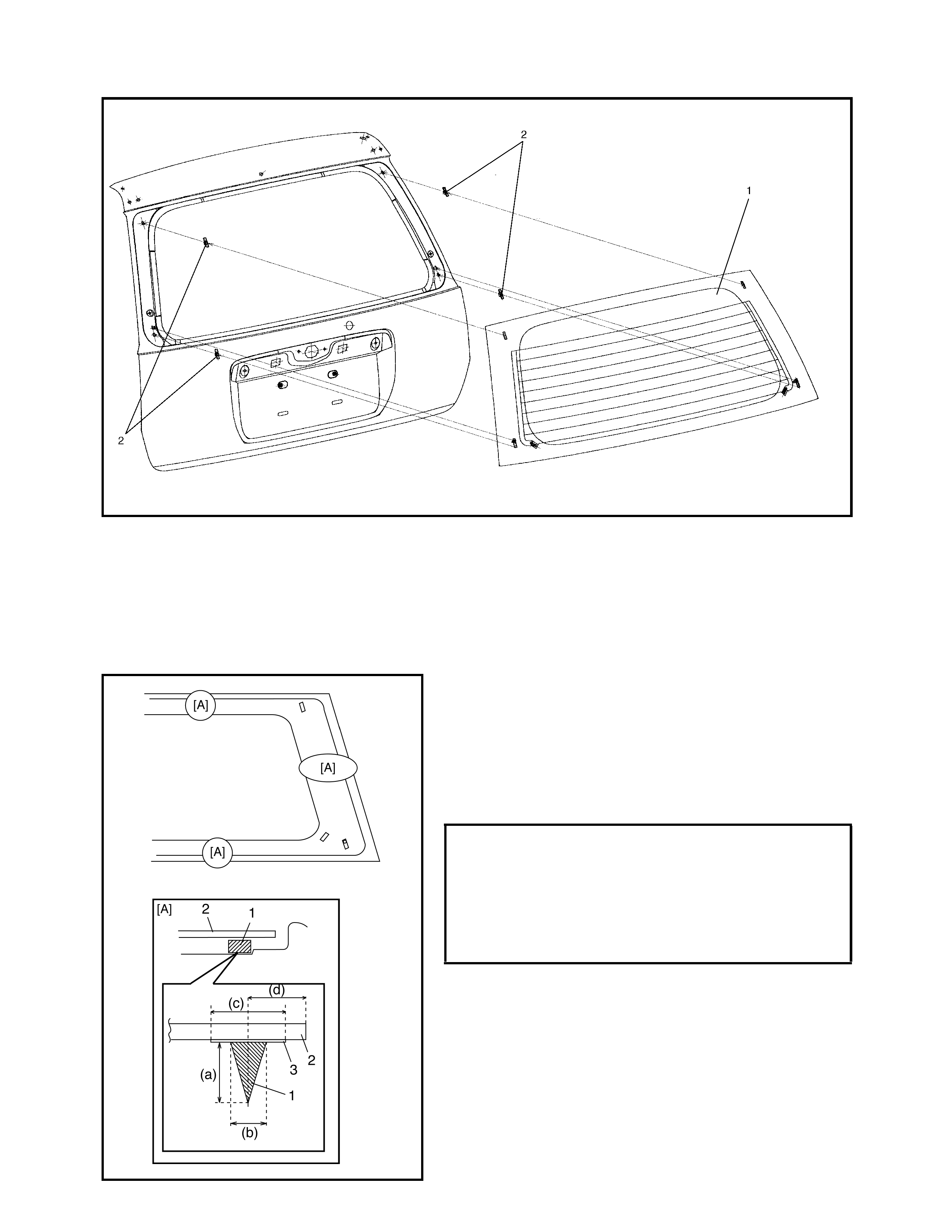

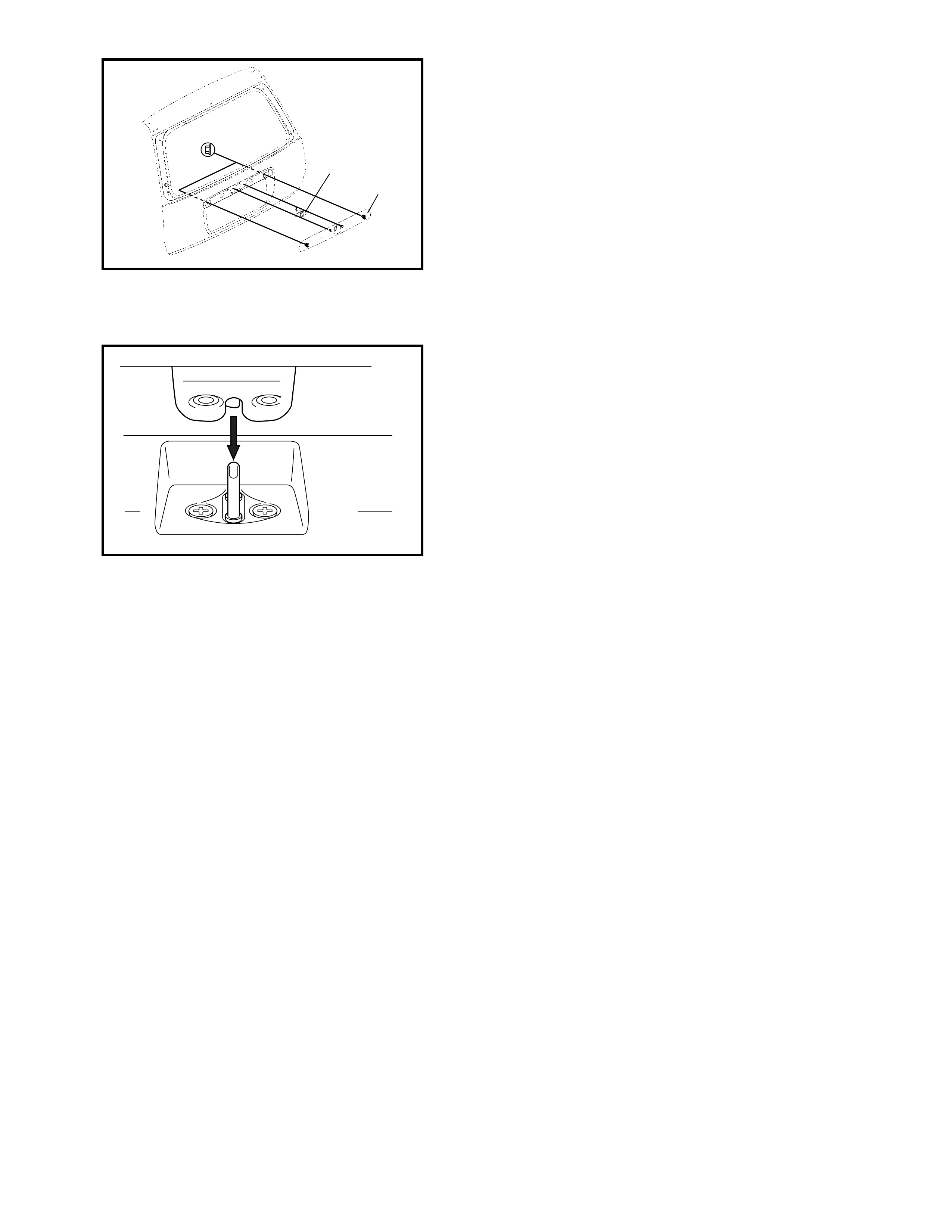

1.8 BACK DOOR GLASS

Legend

REMOVAL AND INSTALLATION

Refer to 1.6 WINDSHIELD in this Section as removal and

installation procedures are basically the same. However,

note the following:

• Observe the following precautions when applying

adhesive (1) along the glass (2) edge.

• Adhesive (1) should be applied evenly, especially in

height.

• Be careful not to damage the primer (3).

• Press the glass against the body quickly after adhesive

(1) is applied.

1. Back door glass 2. Fastener

ADHESIVE SPECIFICATION AND POSI-

TION FOR BACK DOOR GLASS

HEIGHT (a)

WIDTH (b)

WIDTH (c)

GLASS FRONT & BOTTOM SECT. (d)

GLASS UPPER SECT. (d)

GLASS REAR SECT. (d)

13 mm

6 mm

14 mm

14.5 mm

16 mm

45 mm

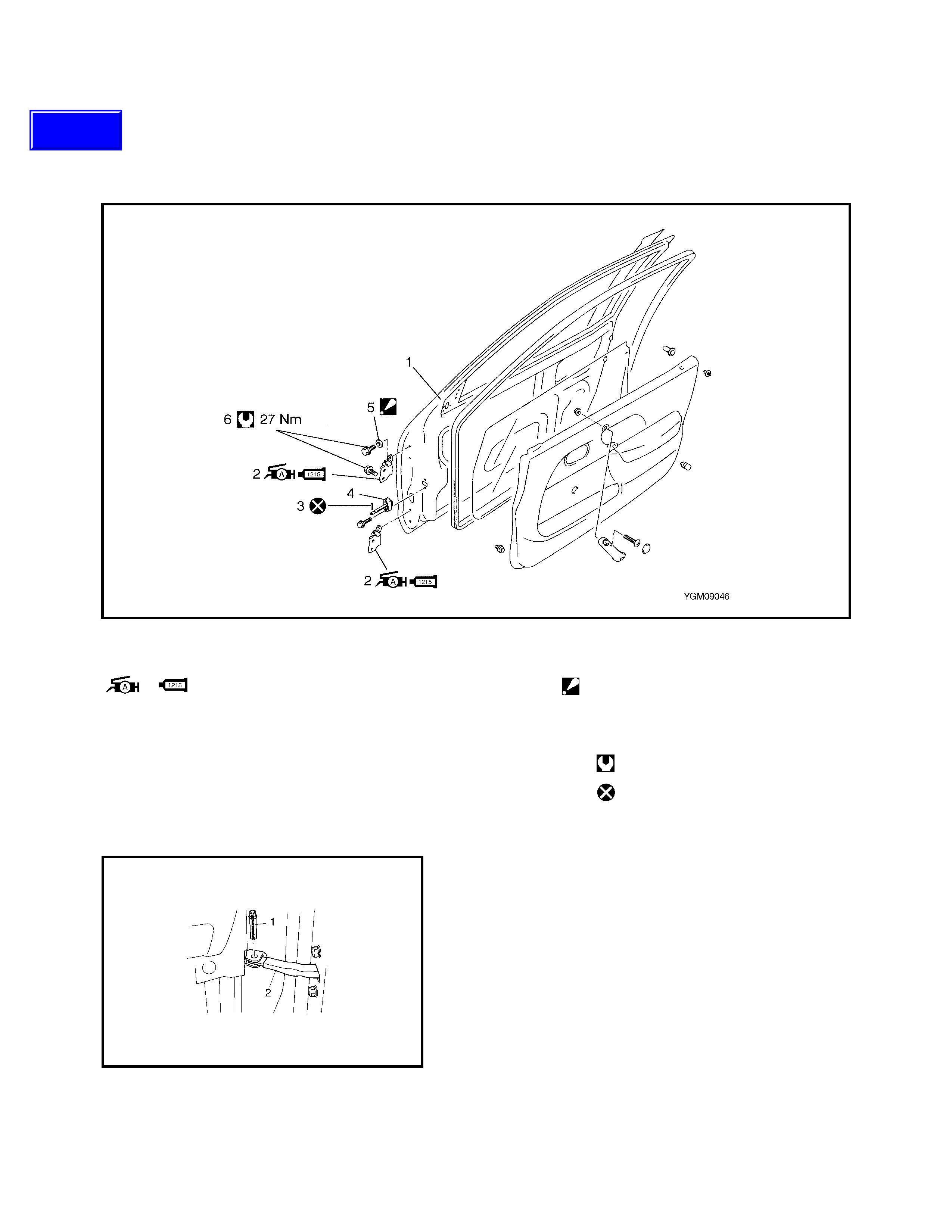

2. BODY STRUCTURE

2.1 FRONT DOOR ASSEMBLY

Legend

REMOVAL

1. Remove the front fender, refer to 2.14, FRONT

FENDER in this Section.

2. Disconnect the door harness lead wires at each con-

nector, if equipped.

3. Remove stopper pin (1) from the door open stopper

(2).

1. Door panel 4. Door open stopper

2. Door hinge

: Apply Lithium grease to rotating part

: Apply sealant Three Bond No. 1215 to

contact face

5. Door hinge washer

: Not necessary to install

6. Front door hinge bolt

Tightening torque

3. Door stopper pin Do not reuse

Techline

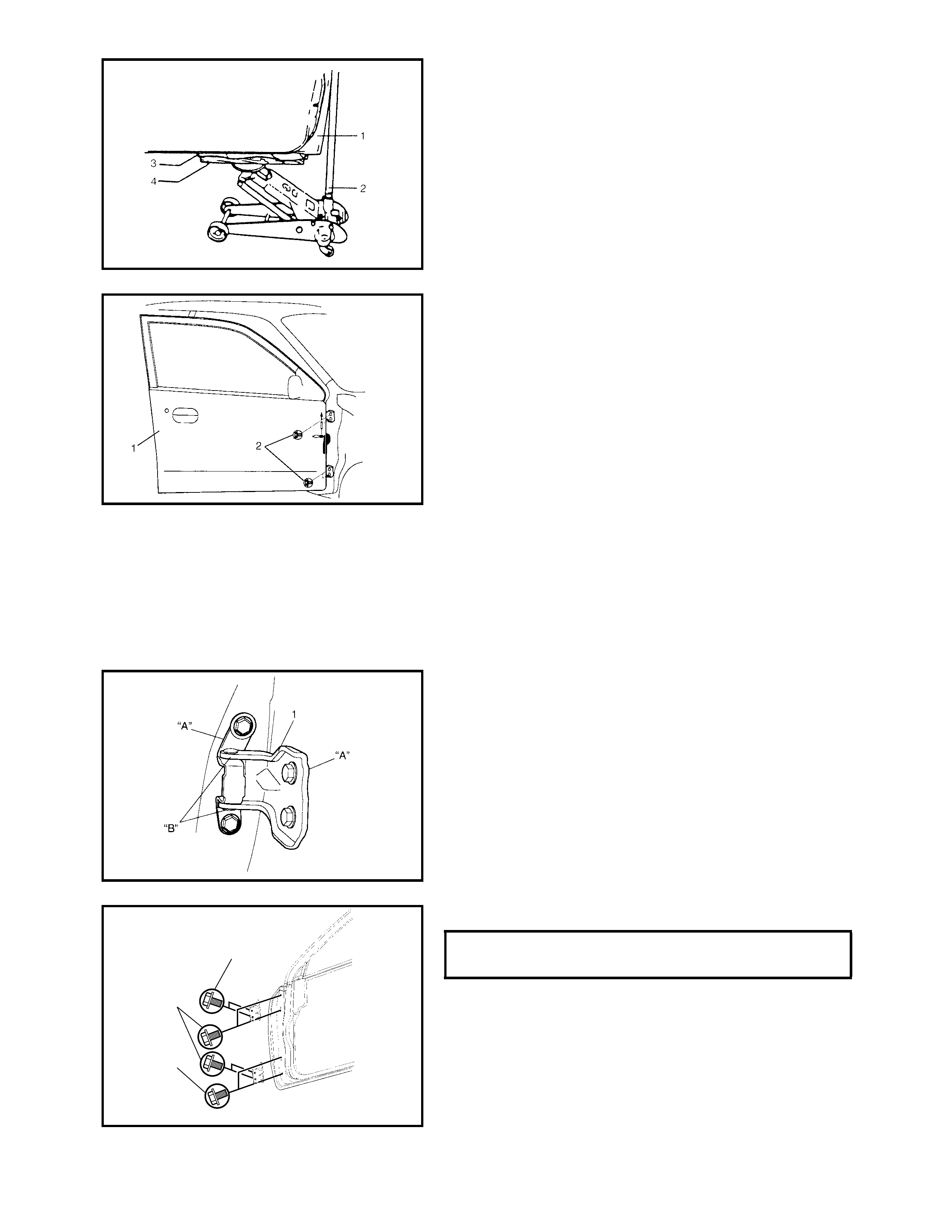

4. Support the door panel (1) using a jack (2) with a piece

of wood (4) covered with a cloth (3) placed between

jack (2) and panel (1) as shown.

5. Remove the door assembly (1) by removing hinge

mounting bolts (2).

INSTALLATION

Reverse removal procedure to install the door assembly

noting the following:

• When replacing the door, coat the inside of the

replacement door with anti-corrosion treatment wax.

Refer to 7.4 ANTI-CORROSION COMPOUND

APPLICATION AREA in this Section.

• Apply sealant to the contact face “A” of the hinge (1)

and apply grease to the rotating part “B” of the hinge

(1).

“A”: Sealant - Three Bond No. 1215

“B”: Lithium grease

• Tighten the hinge bolt (1) to specified torque.

DOOR HINGE MOUNTING BOLT (a)

TORQUE SPECIFICATION 27 Nm

1, (a)

1, (a)

1, (a)

• Ensure the door open stopper (1) is installed in the cor-

rect direction as shown.

• Adjust the door latch striker position, refer to

5.1 FRONT DOOR LOCK ASSEMBLY in this Section.

• Adjust the front door cushion so that the door closes

flush with the side body.

• After installation, open and close the door to check cor-

rect o pera t io n .

Replace the door open stopper pin if there is any

looseness.

• Replace the door weather-strip if it has become hard-

ened to prevent possible water leaks.

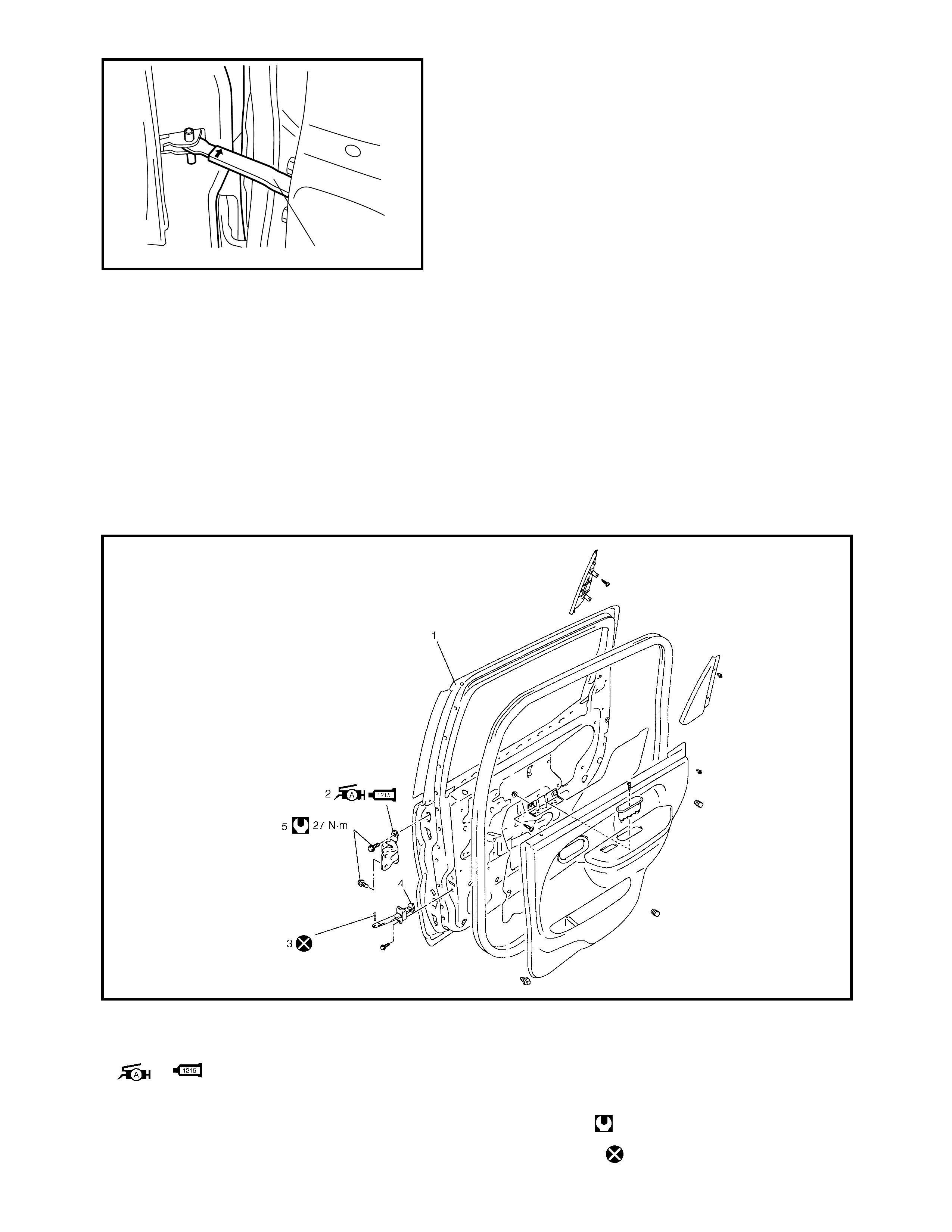

2.2 REAR DOOR ASSEMBLY

Legend

1

1. Door panel 3. Door stopper pin

2. Door hinge

: Apply Lithium grease to rotating part

: Apply sealant Three Bond No. 1215 to

contact face

4. Door stopper

5. Rear door hinge bolt

Tightening torque

Do not reuse.

REMOVAL AND INSTALLATION

Refer to 2.1 FRONT DOOR ASSEMBLY in this Section not-

ing the following instructions.

• Refer to the figure above for tightening torque, grease

and sealant locations.

• When the door open stopper is installed, be sure to

install in the correct orientation, see below.

Door stopper installation direction

Right side door: RR punch mark faces upward.

Left side door: RL punch mark faces upward.

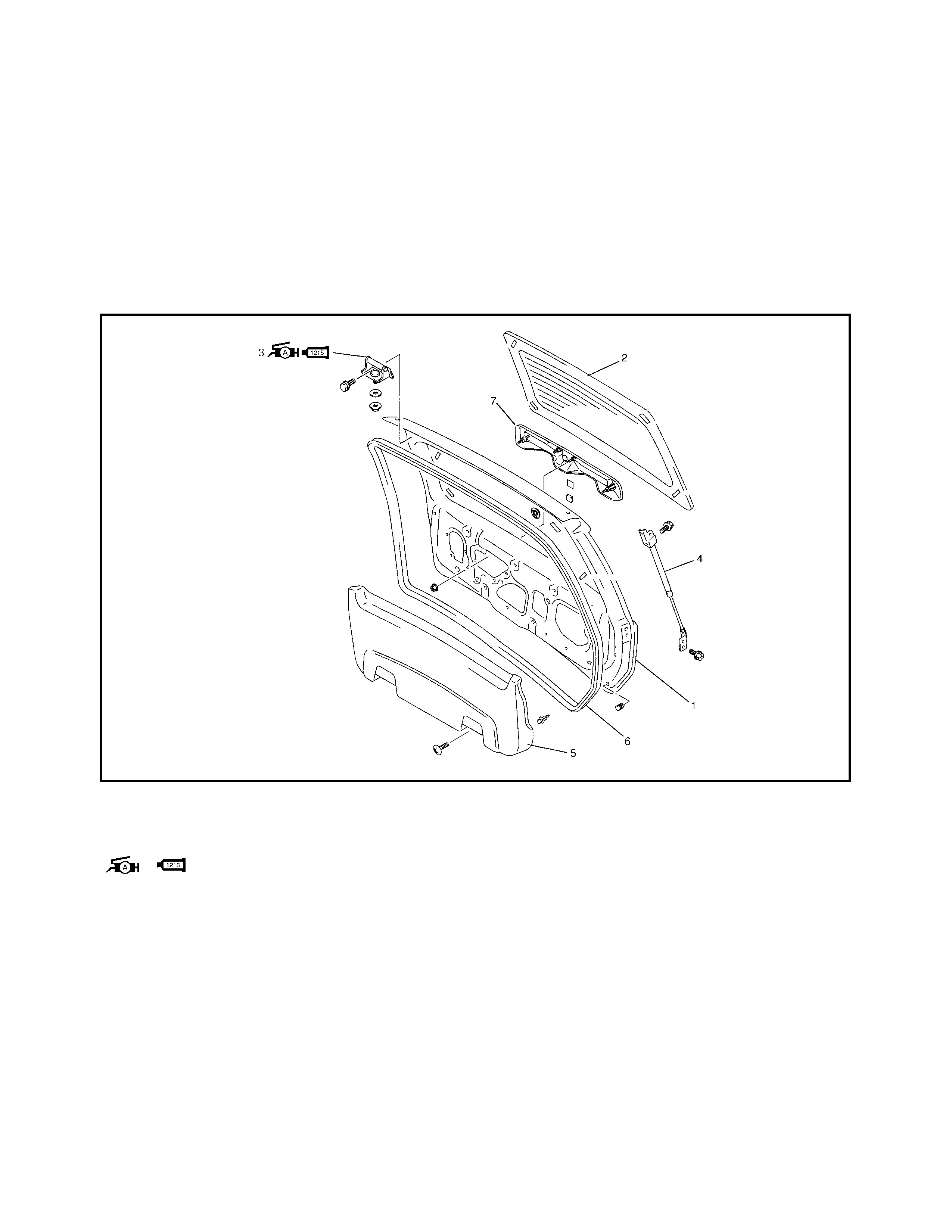

2.3 BACK DOOR ASSEMBLY

Legend 1. Back door panel assembly 4. Back door support strut

2. Back door window glass 5. Back door trim

3. Back door hinge

: Apply Lithium grease to door hinge

: Apply sealant Three Bond No. 1215 to contact

face

6. Weather strip

7. Licence garnish

REMOVAL

1. Remove the back door trim (1).

2. Remove the related section of headlining and quarter

trim, refer to 6.2 HEADLINING in this Section.

3. Disconnect the back door harness connectors (2) and

washer hose (3).

4. Remove the wire harness connectors inside the back

door.

5. Remove the back door support strut (4) (unbolt door

side first then unbolt body side).

6. Remove the door hinge nuts (5) and remove the back

door assembly (6).

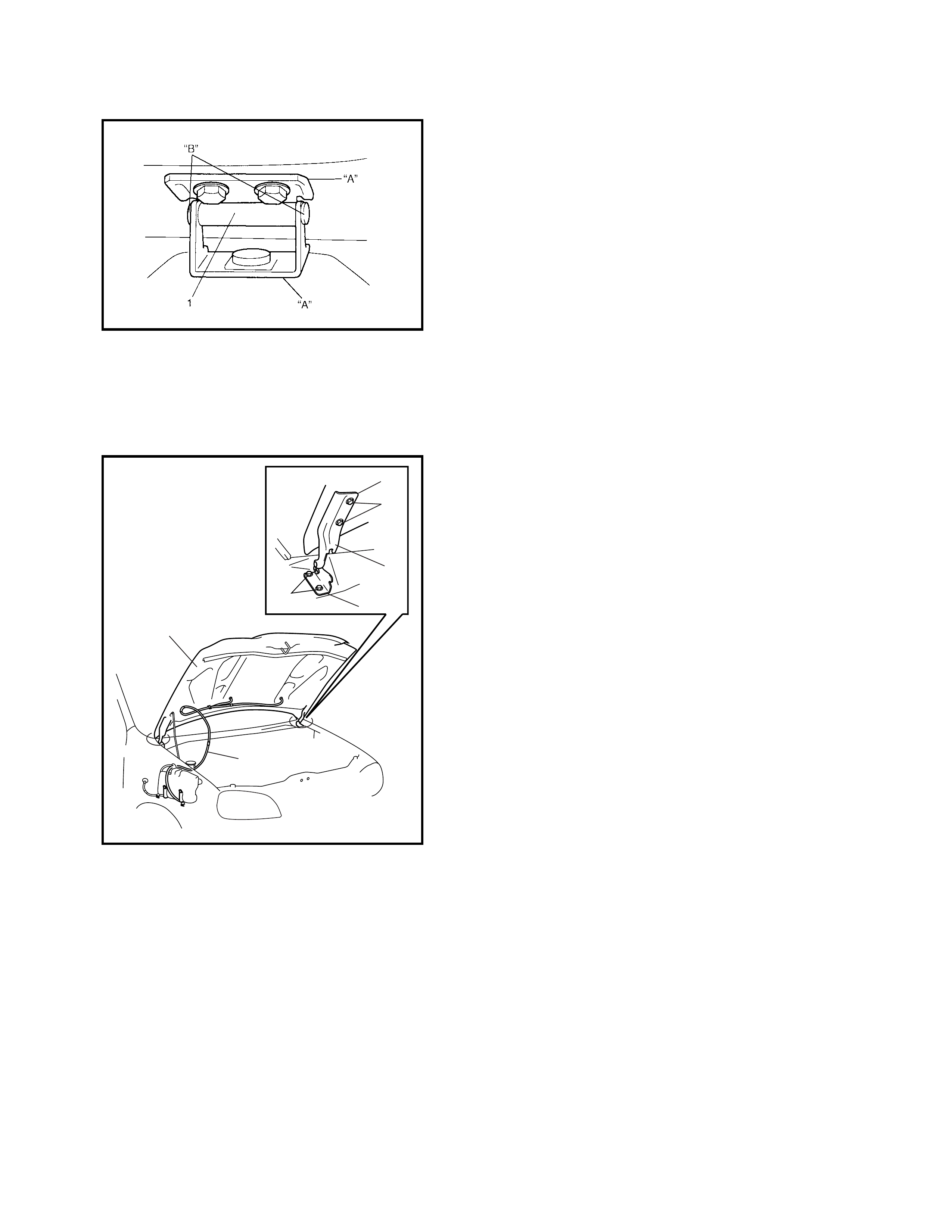

WARNING:

Handling of Back Door Support Strut

• Do not disassemble the support strut (1) as its cyl-

inder is filled with gas.

• Handle the support strut carefully. Do not scar or

scratch exposed surface of its piston rod, and

never allow any paint or oil to adhere to its surface.

• Do not turn piston rod with support strut fully

extended.

• When discarding the removed back door support

strut, use a 2–3 mm drill bit (2) to make a hole as

shown.

• When drilling (2) wear safety goggles. Although the

gas is harmless it may escape rapidly along with

metal filings creating a safety risk.

INSTALLATION

Reverse removal procedure to install back door noting the

following:

• Secure the wiring harness.

• Adjust the door latch striker position, refer to 5.3 BACK

DOOR LOCK ASSEMBLY in this Section.

• Adjust the door cushion so that the door contacts the

body when closed.

• Adjust the door clearance by loosening the door hinge

mounting bolts and nuts, refer to 2.17 PANEL

CLEARANCE in this Section.

• Apply sealant to the contact face “A” of door hinge (1)

and apply grease to the rotating part “B” of the hinge

(1).

“A”: Sealant - Three Bond 1216

“B”: Lithium grease

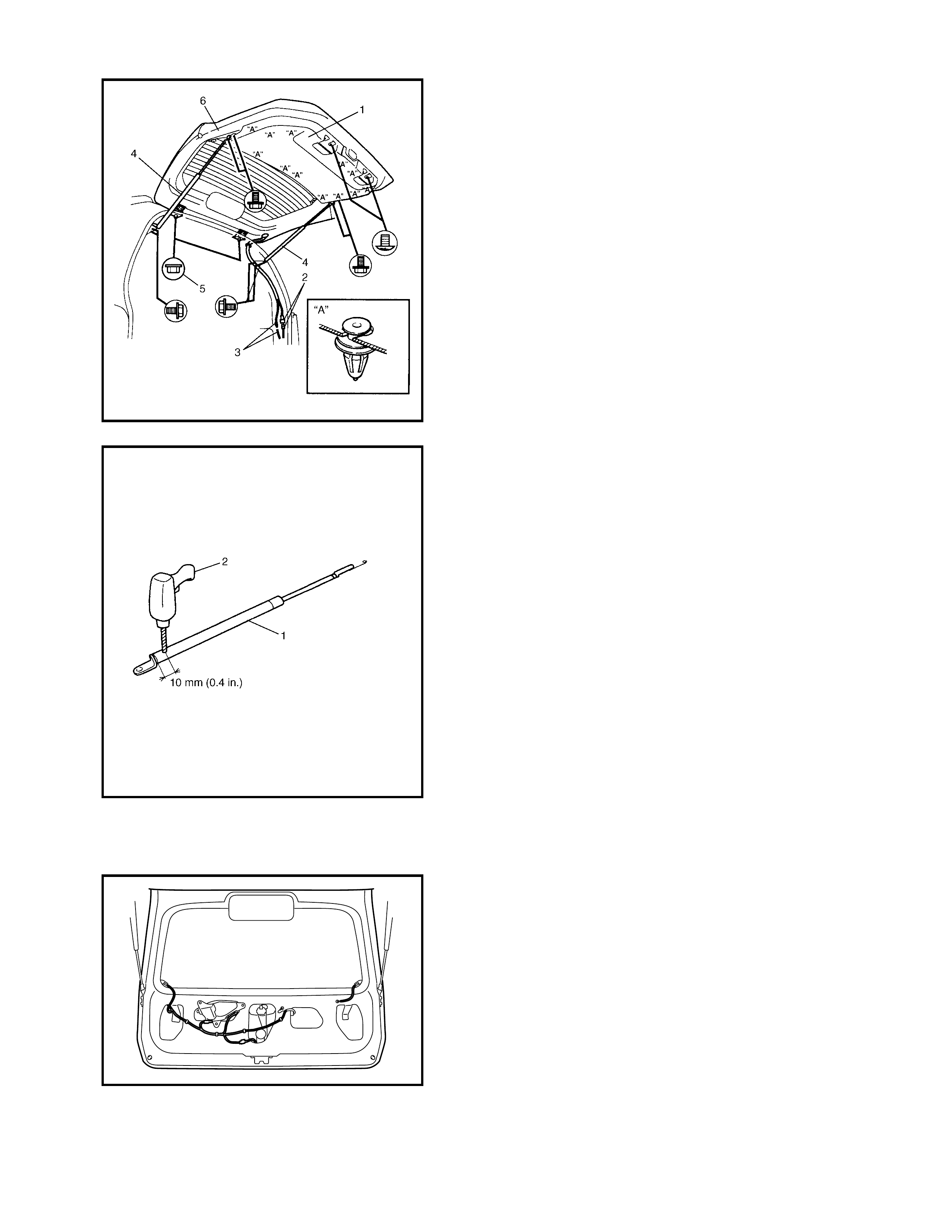

2.4 HOOD

REMOVAL

CAUTION: Place a fender cover on the fender “A” as

shown to prevent damage.

1. Remove the window washer hose (1) from the

hood (2).

2. Remove the four mounting bolts (3) to detach the

hood (2).

INSTALLATION

Reverse removal procedure to install the hood noting the

following:

• Apply sealant to the contact face “B” of the hood

hinge (4).

“B”: Sealant - Three Bond 1216

ADJUSTMENT

To adjust the hood alignment refer to the following:

• Hood position adjustment.

Fore-and-aft and right-and-left adjustment.

Adjust the hood clearance by loosening the hood

mounting bolts, making adjustments then re-tighte ning

the mounting bolts, refer to 2.17 PANEL CLEARANCE

in this Sectio n.

3

3

4

“B”

“B”

1

2

“A”

“A”

• Vertical adjustment

If only one side (right or left) of the hood is not level

with the front fender, adjust by tightening or loosening

the hood cushion (1).

• Hood lock position adjustment

When installing the hood lock (1), set the lock to the

highest position then move it in a vertical direction for

correct adjustment with the hood striker.

INSPECTION

Check that the hood opens and closes smoothly and cor-

rectly. Lubricate if necessary. Also check that the second-

ary latch operates correctly (check that the secondary latch

keeps the hood from opening all the way) and the hood

locks securely when closed.

Adjust the hood lock position if necessary.

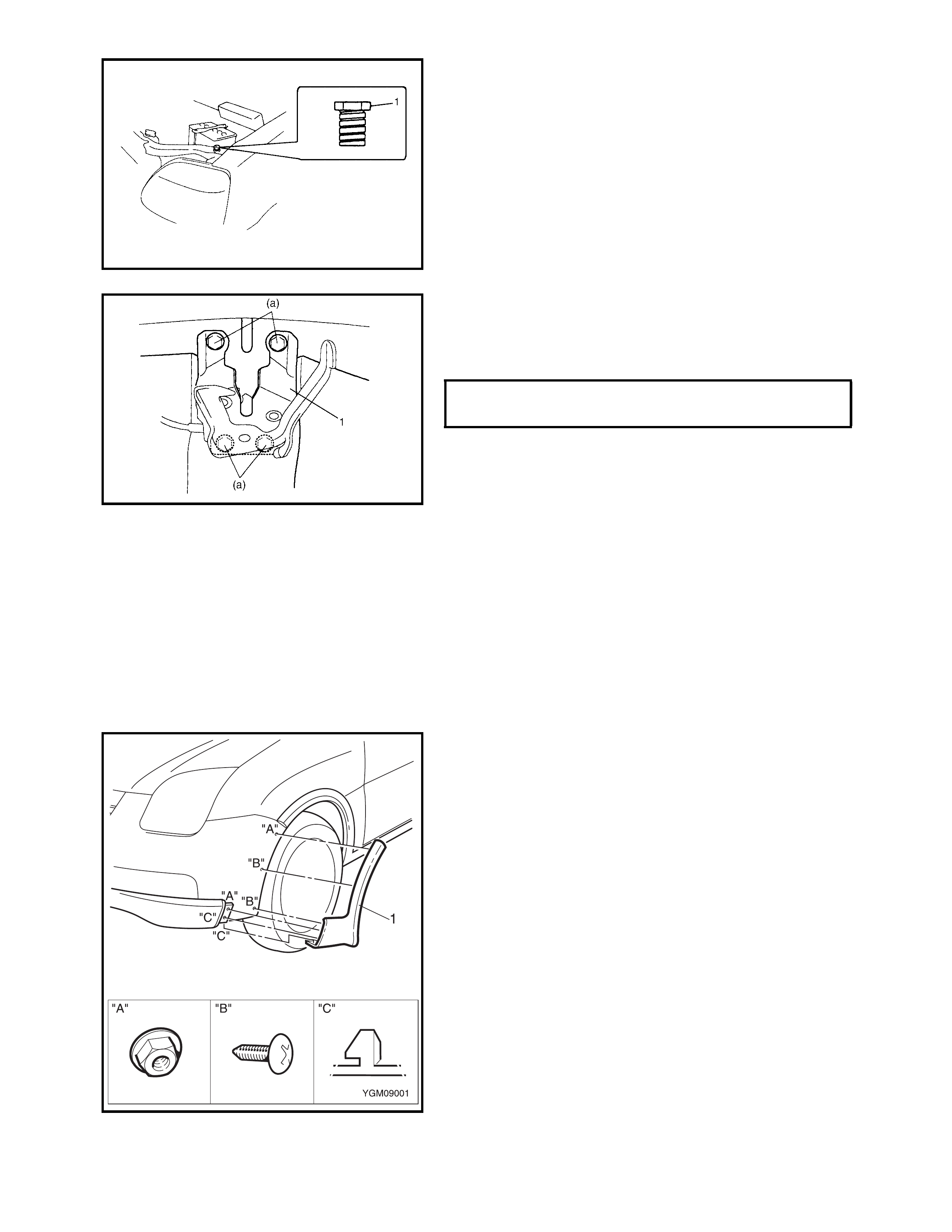

2.5 FRONT BUMPER SIDE EXTENSION

REMOVAL

1. Partially remove the front fender liner, refer

2.14 FRONT FENDER.

2. Remove the nuts “A” two places.

3. Remove the screws “B” two places.

4. Remove the front bumper side extension (1), detaching

the clips “C” two places.

INSTALLATION

Reverse removal procedure for installation.

HOOD LATCH BOLTS (a)

TORQUE SPECIFICATIONS 10 Nm

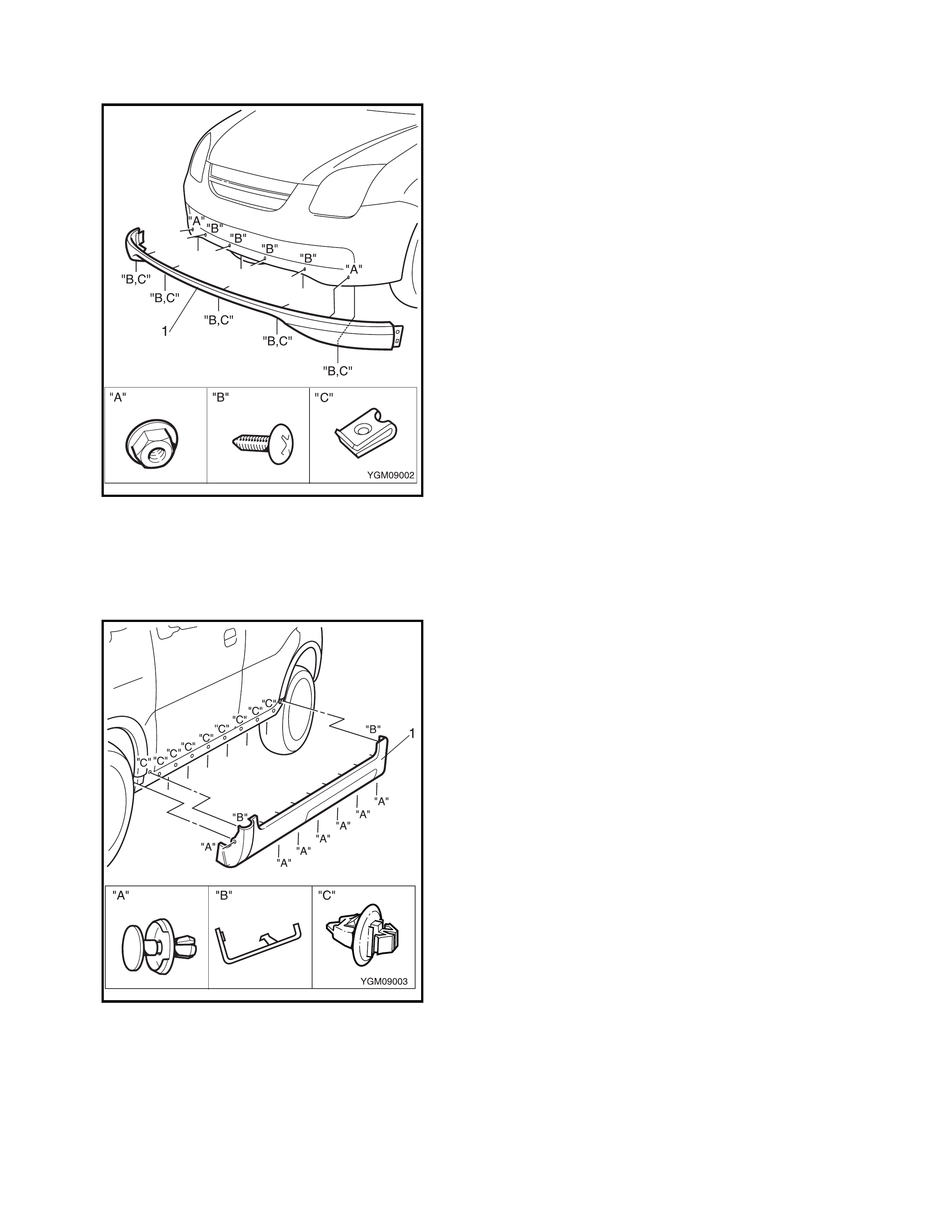

2.6 FRONT BUMPER CENTRE EXTENSION

REMOVAL

1. Remove the front bumper, refer 2.12, FRONT

BUMPER.

2. If required, d etach th e front s ecti on of the fr on t bum per

side extension from the centre extension (1).

3. Remove the nuts “A” two places.

4. Remove the screws “B” four places.

5. Remove the screws “B” and nuts “C” five places.

6. Remove the front bumper centre extension.

INSTALLATION

Reverse removal procedure for installation.

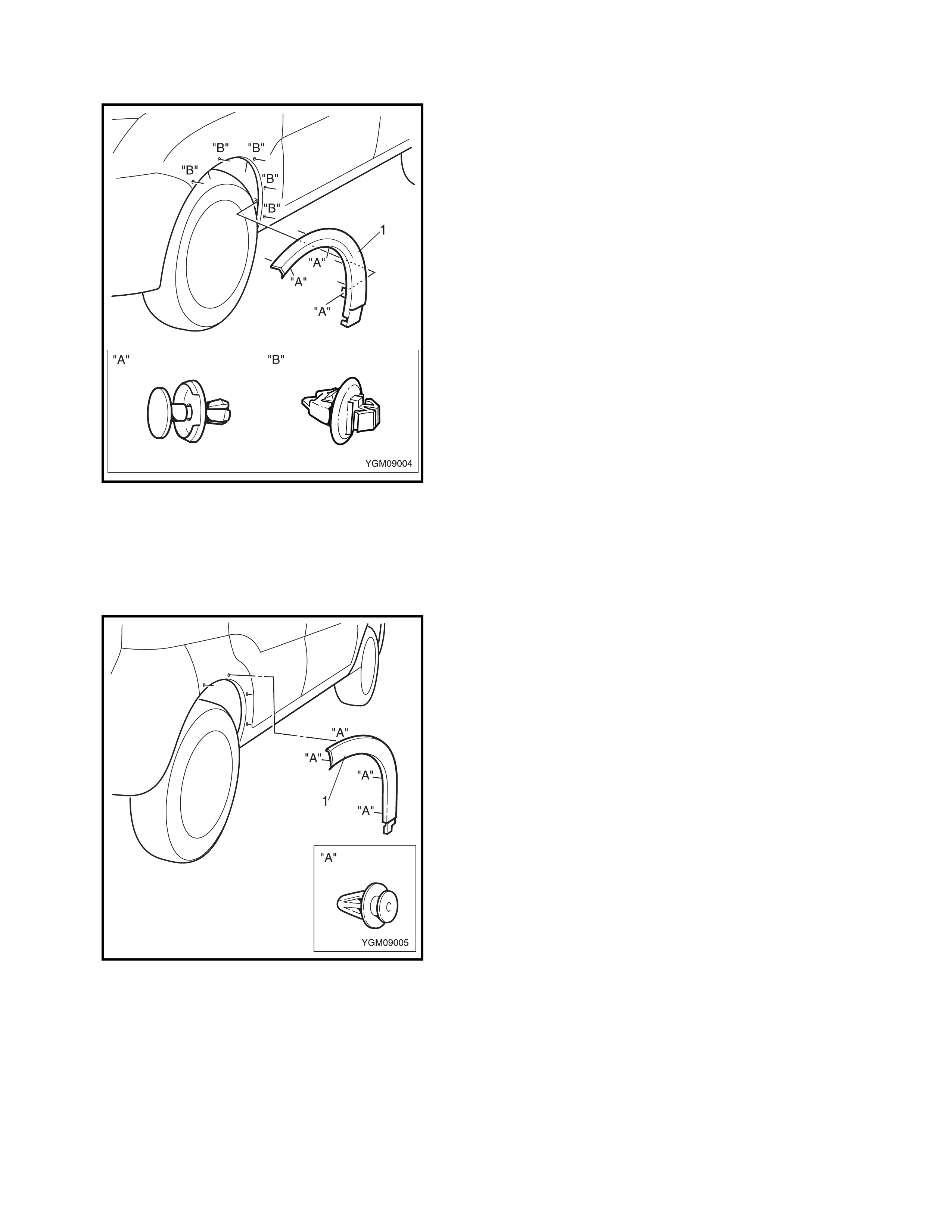

2.7 SILL PANEL EXTENSION

REMOVAL

1. Remove the clip “A” seven places.

2. Protect the paintwork with a shop rag and using a

screwdriver, carefully prise the sill panel extension (1)

from the front and rear fender extensions two places

“B”.

3. Protect the paintwork with a shop rag and using a

screwdriver , carefully prise the sill panel extension from

the vehicle nine places “C” and remove the extension.

INSTALLATION

Reverse removal procedure for installation.

2.8 FRONT FENDER EXTENSION

REMOVAL

1. If required, detach the front section of the sill panel

extension from the front fender extension (1).

2. Remove the clip “A” three places.

3. Protect the paintwork with a shop rag and using a

screwdriver, carefully prise the fender extension from

the front fender five places “B”.

INSTALLATION

Reverse removal procedure for installation.

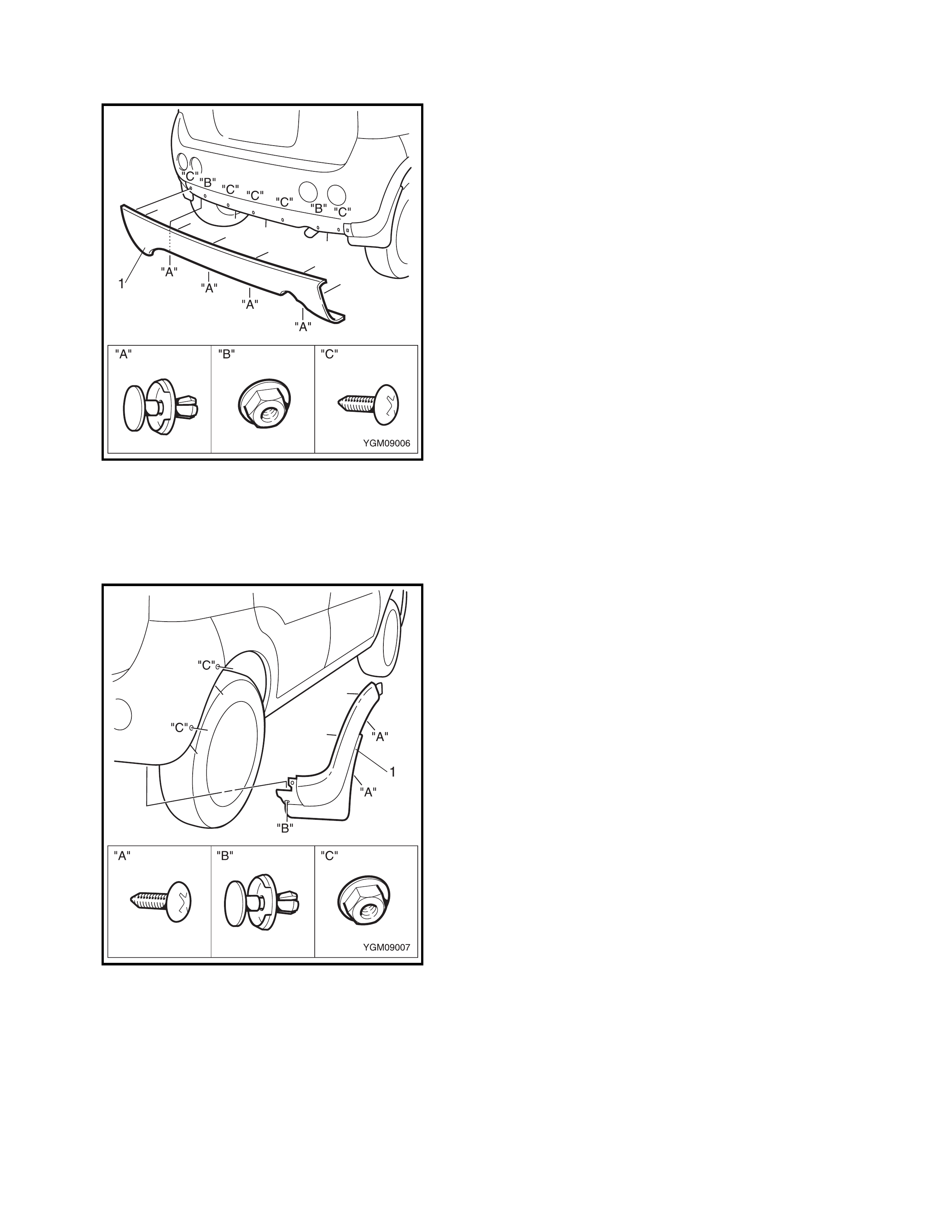

2.9 REAR FENDER EXTENSION

REMOVAL

1. If required, detach the rear section of the sill panel

extension from the rear fender extension (1).

2. Protect the paintwork with a shop rag and using a

screwdriver, carefully prise the fender extension from

the rear fender five places “A”.

INSTALLATION

Reverse removal procedure for installation.

2.10 REAR BUMPER CENTRE EXTENSION

REMOVAL

1. Remove the rear bumper, refer 2.13 REAR BUMPER.

2. Remove the clips “A” four places.

3. Remove the nuts “B” two places

4. Remove the screws “C” five places.

5. Remove the rear bumper centre extension (1).

INSTALLATION

Reverse removal procedure for installation.

2.11 REAR BUMPER SIDE EXTE NS ION

REMOVAL

1. Remove the screws “A” two places

2. Partially remove the rear fender liner.

3. If required, detach the end of the rear bumper centre

extension from the rear bumper side extension (1).

4. Remove the clip “B” one place.

5. Remove the nuts “C” two places.

6. Remove the side extension.

INSTALLATION

Reverse removal procedure for installation.

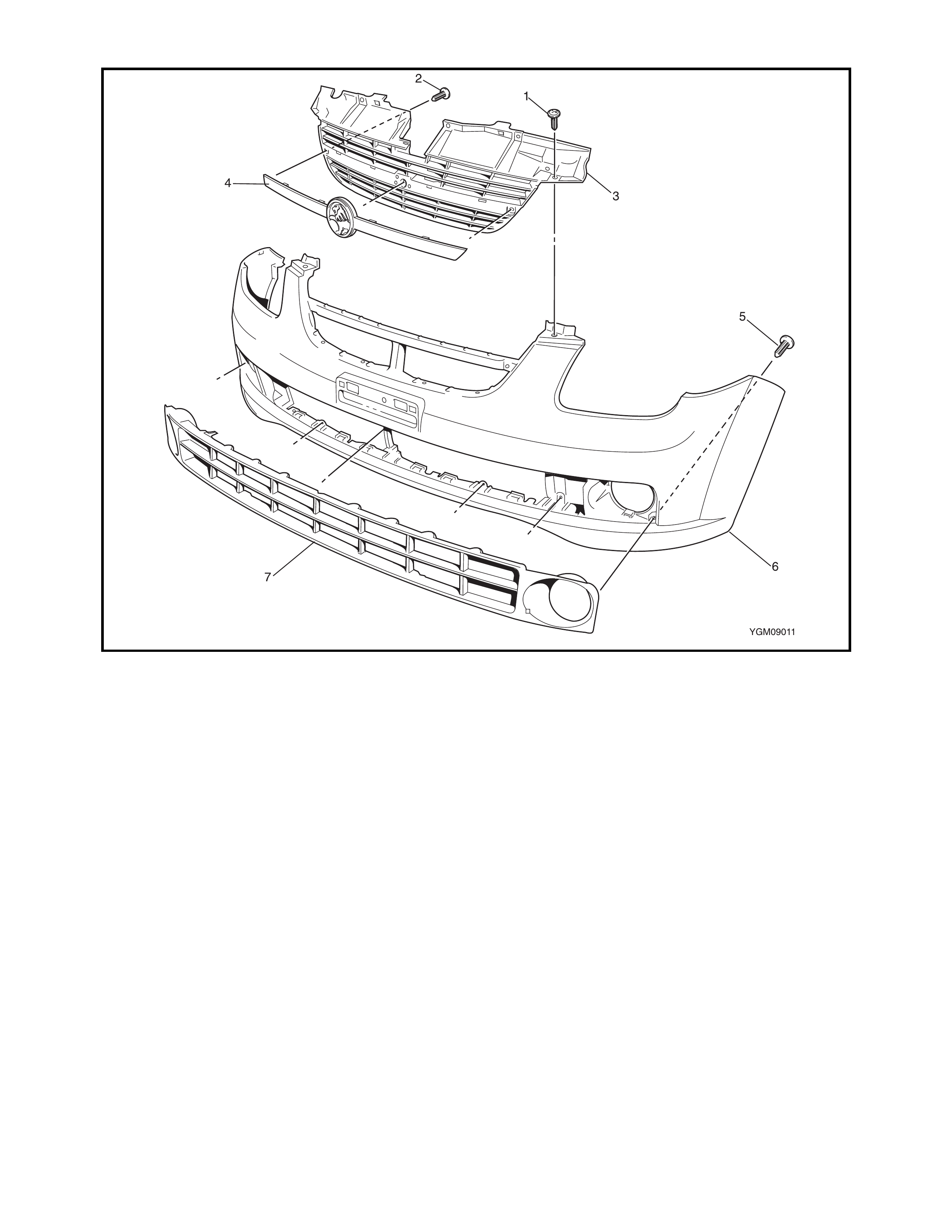

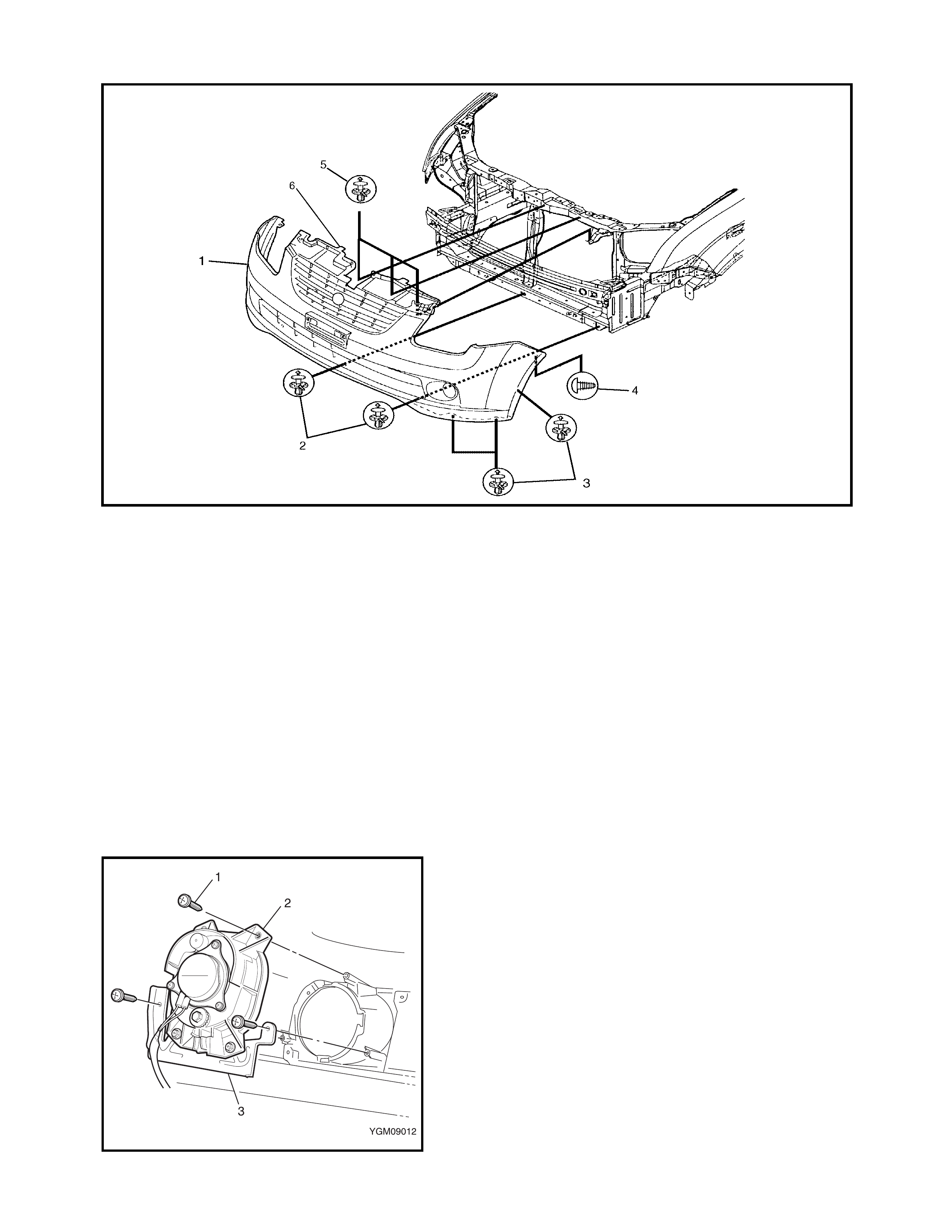

2.12 FRONT BUMPER

Legend

REMOVAL

1. Disconnect the fog lamp connectors.

2. Remove the clips (2) attaching the bumper to the

vehicle, three places.

3. Remove the clips (3) attaching the bumper (and front

bumper side extension) to the fender liner each side.

4. Remove the screw (4) attaching the bumper to the

fender each side.

5. Remove the clips (5) attaching the bumper to the

vehicle.

6. Prise the two retainers securing the bumper to the

radiator support panel and remove the bumper.

DISASSEMBLE

1. Remove the front bumper side and centre extensions,

refer 2.5 FRONT BUMPER SIDE EXTENSION and

2.6 FRONT BUMPER CENTRE EXTENSION in

this Section.

2. Remove the screws (1) three places attaching the fog

lamp and bracket to the bumper.

3. Remove the fog lamp and repeat for the other side.

4. Remove the screws and unclip the radiator grille,

garnish and lower grille as required, refer following

illustration.

NOTE: Use care the retaining clips can be easily broken.

1. Front bumper 3. Clips 5. Clips

2. Clips 4. Screw 6. Retainer

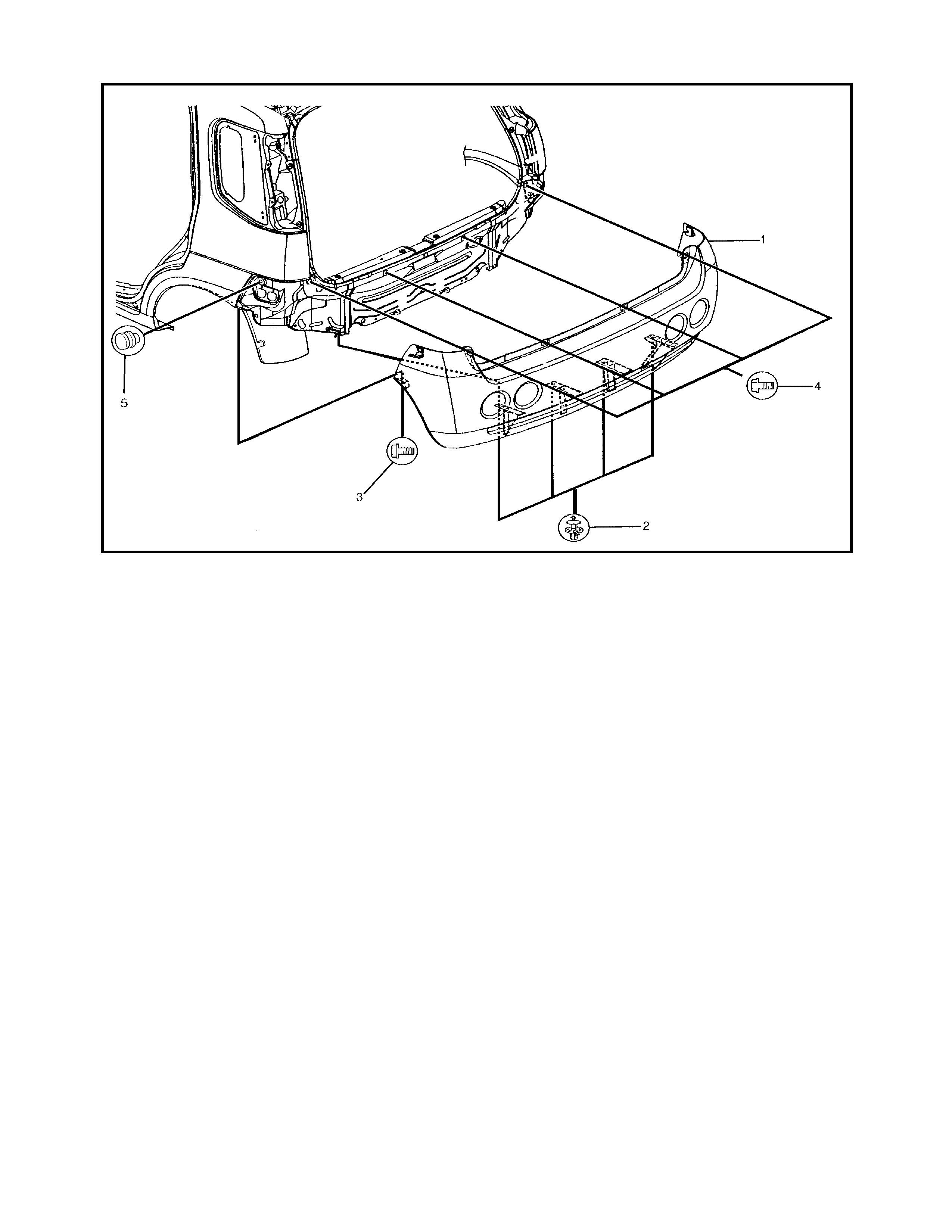

2.13 REAR BUMPER

Legend

REMOVAL

1. Partially remove the rear bumper side extension, refer

2.11 REAR BUMPER SIDE EXTENSION, and the rear

fender liner where it attaches the rear bumper.

2. Remove the clips (2) attaching the bumper to the

vehicle, four places.

3. Remove the bolt (3) attaching the bumper to the

vehicle each side.

4. Remove the bolt (4) attaching the bumper to the

vehicle four places.

5. Remove the bumper from the vehicle, disengaging it

from the damper (5) each side.

6. Disconnect the brake lamp wiring connector.

1. Rear bumper 3. Bolt 5. Damper

2. Clip 4. Bolt

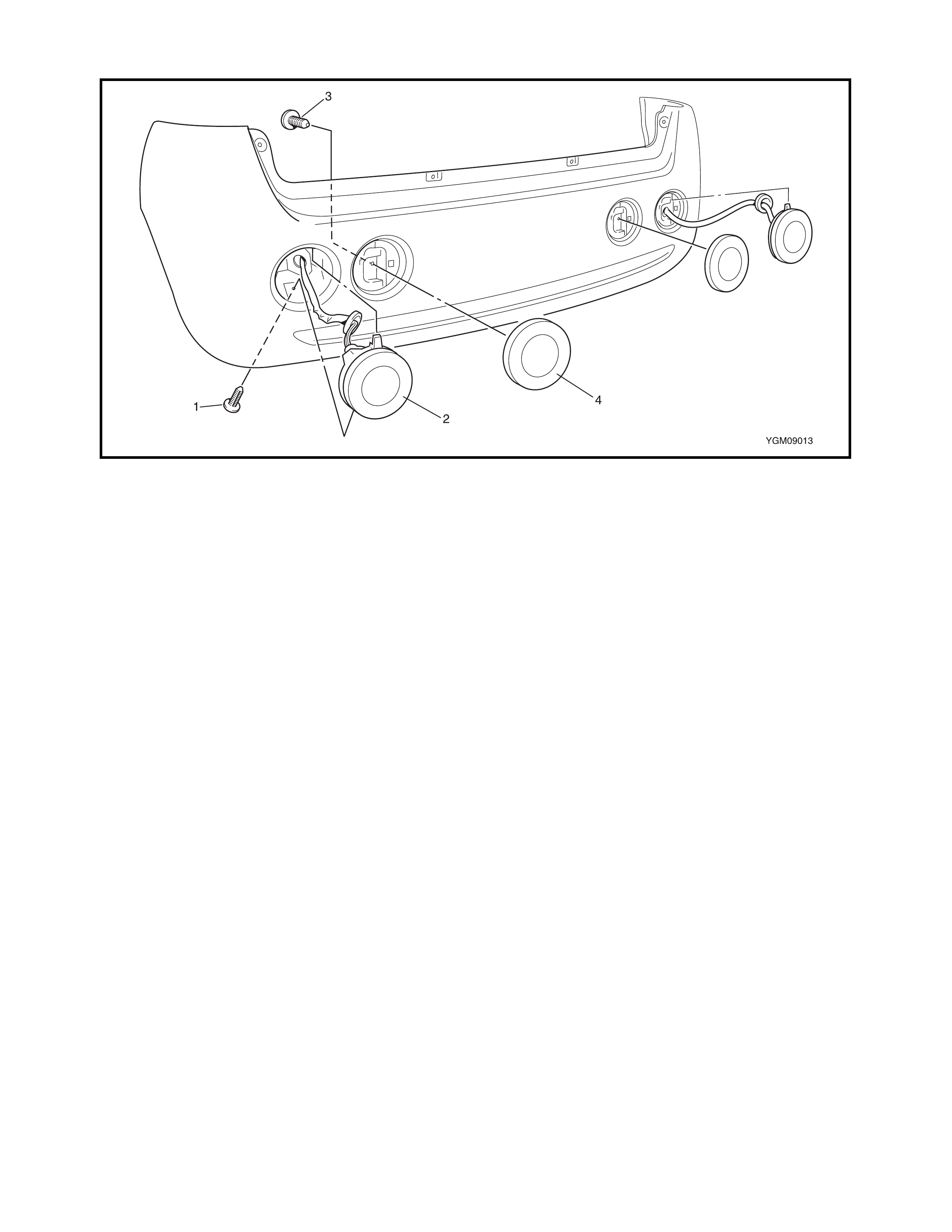

DISASSEMBLE

Legend

1. Remove the rear bumper side and centre extensions,

refer 2.10, REAR BUMPER CENTRE EXTENSION

and 2.11, FRONT BUMPER SIDE EXTENSION in this

Section.

2. Remove the screw attaching the brake & tail light and

remove the light unattaching the upper lug from the

bumper.

3. Remove the screw attaching the reflector and unclip

the reflector from the rear of the bumper.

4. Repeat for the opposite side.

INSTALLATION

Reverse removal procedure to install the front bumper.

Adjust panel clearance, refer to 2.17 PANEL CLEARANCE

in this Section.

1. Screw 3. Screw

2. Brake & tail light 4. Reflector

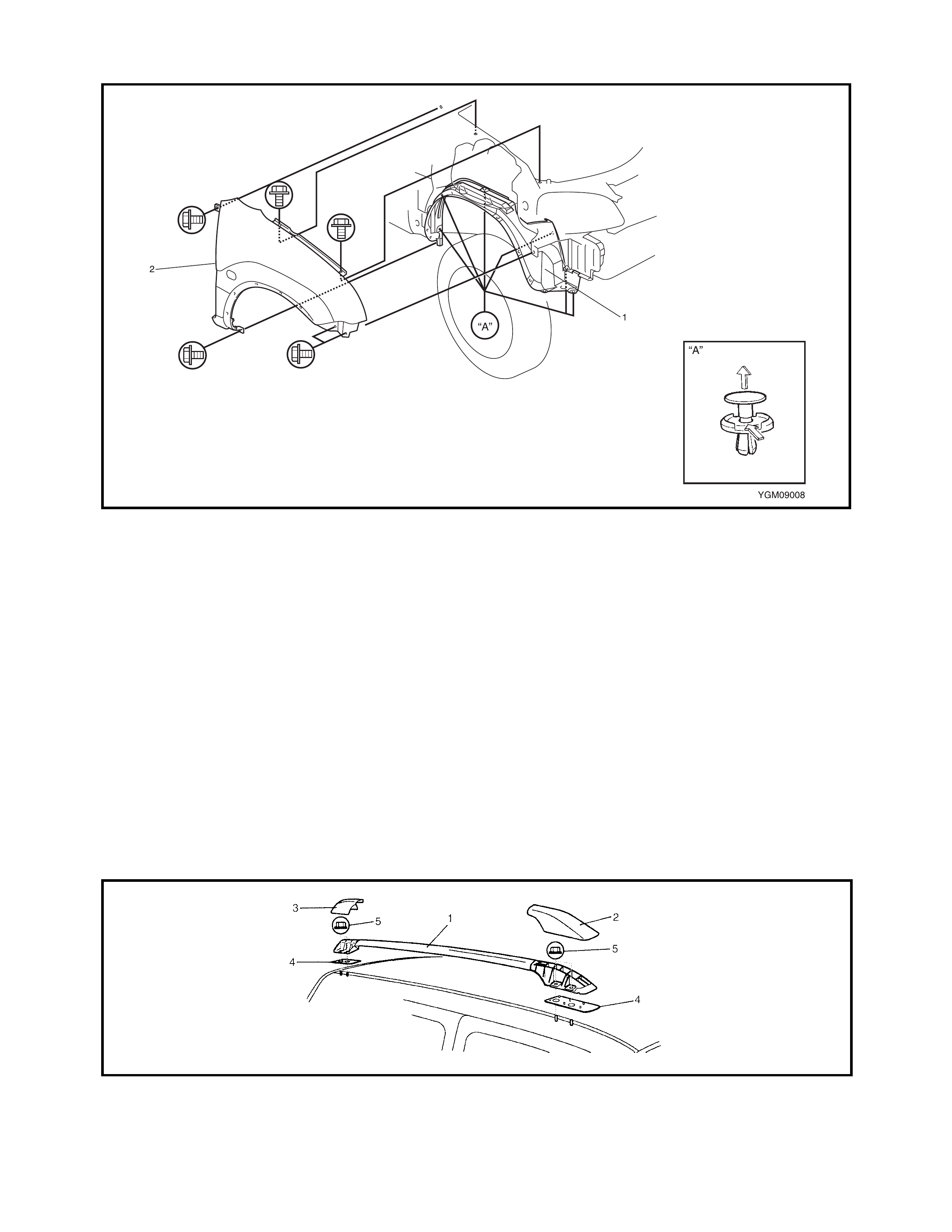

2.14 FRONT FENDER

Legend

REMOVAL

1. Remove the front bumper, refer to 2.12 FRONT

BUMPER in this Section.

2. Disconnect the side turn signal lamp connector.

3. Remove the front fender lining (1).

4. Remove the front fender (2).

INSTALLATION

Reverse removal procedure to install the front fender not-

ing the following:

• Repair any paint damage on the fender bolts.

• Adjust the panel clearance, refer to 2.17 PANEL

CLEARANCE in this Section.

2.15 ROOF RAILS

Legend

1. Front fender lining 2. Front fender 3. Front fender side moulding

1. Roof rail assembly 4. Base seal

2. Front cap 5. Nut

3. Rear cap

REMOVAL

1. Remove the roof rail front and rear caps as shown.

2. Remove the nuts.

3. Remove the roof rail assembly.

INSTALLATION

Reverse removal procedure for installation.

Confirm that each roof rail fixing nut is tightened securely.

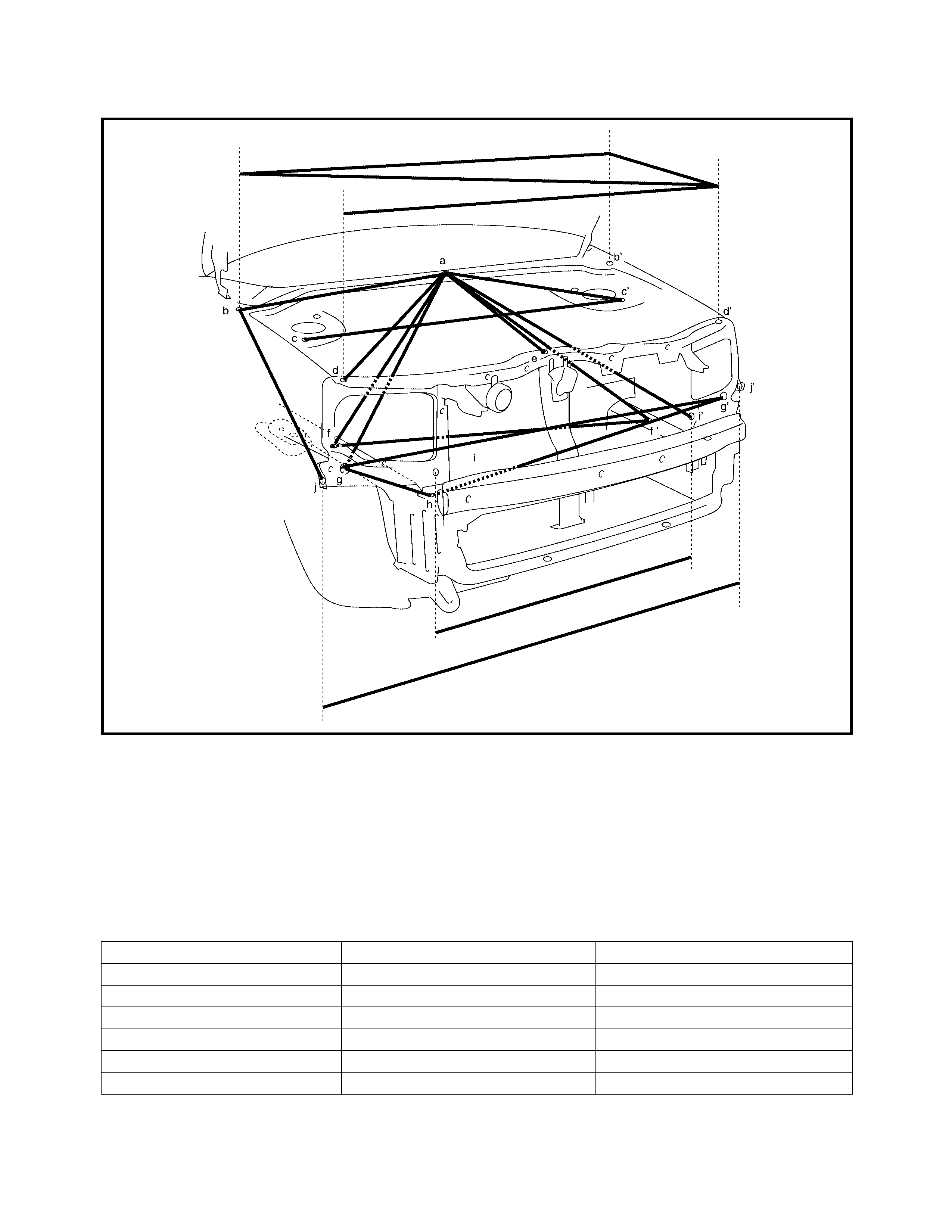

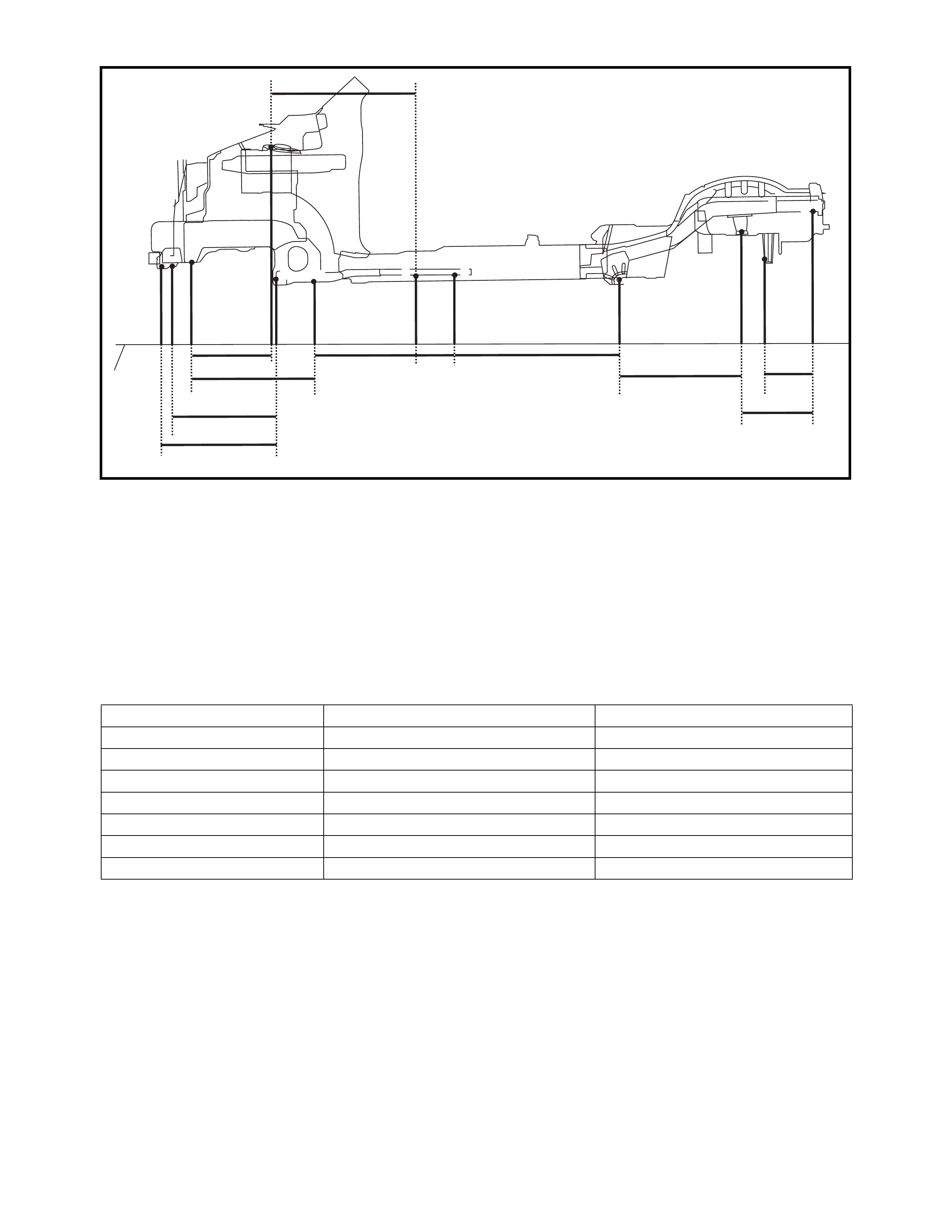

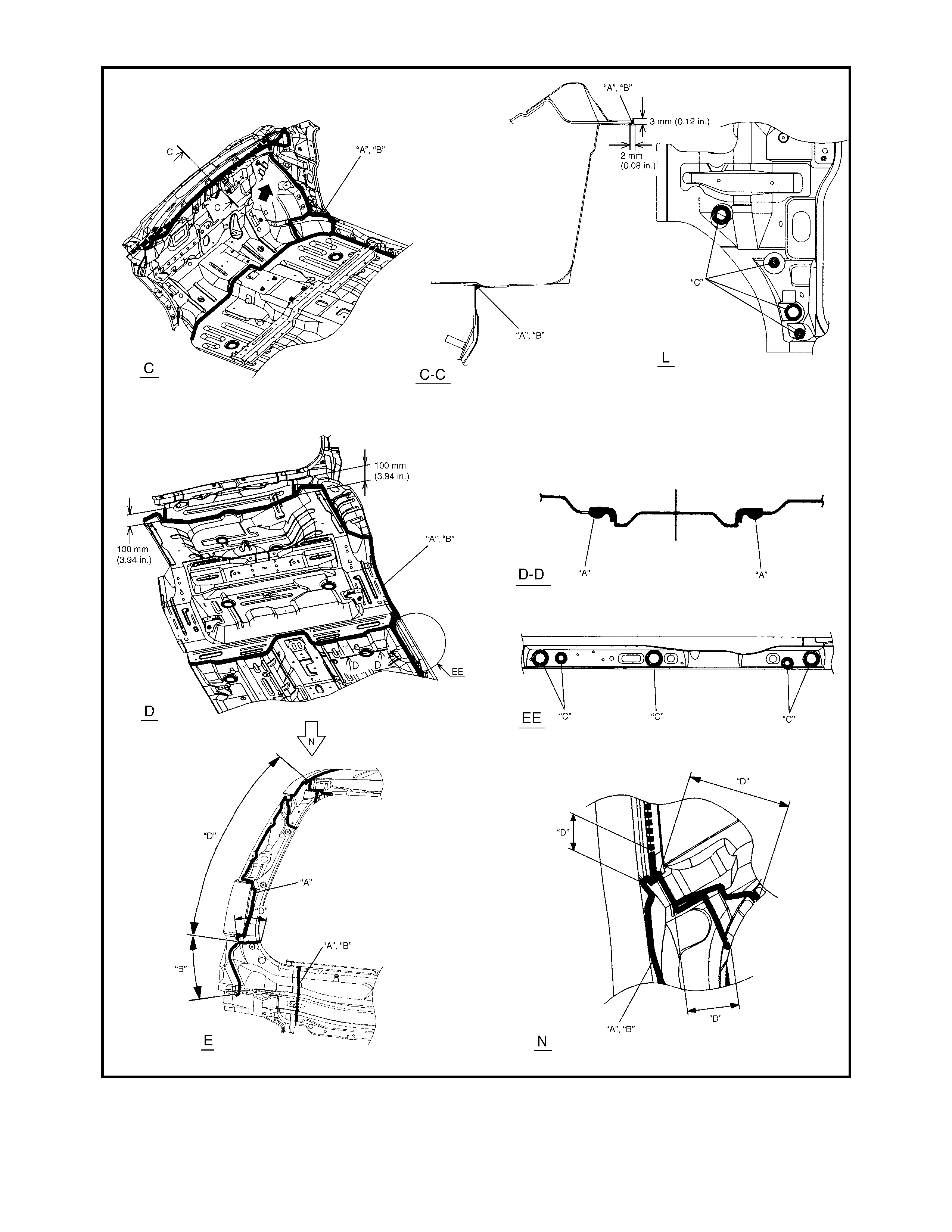

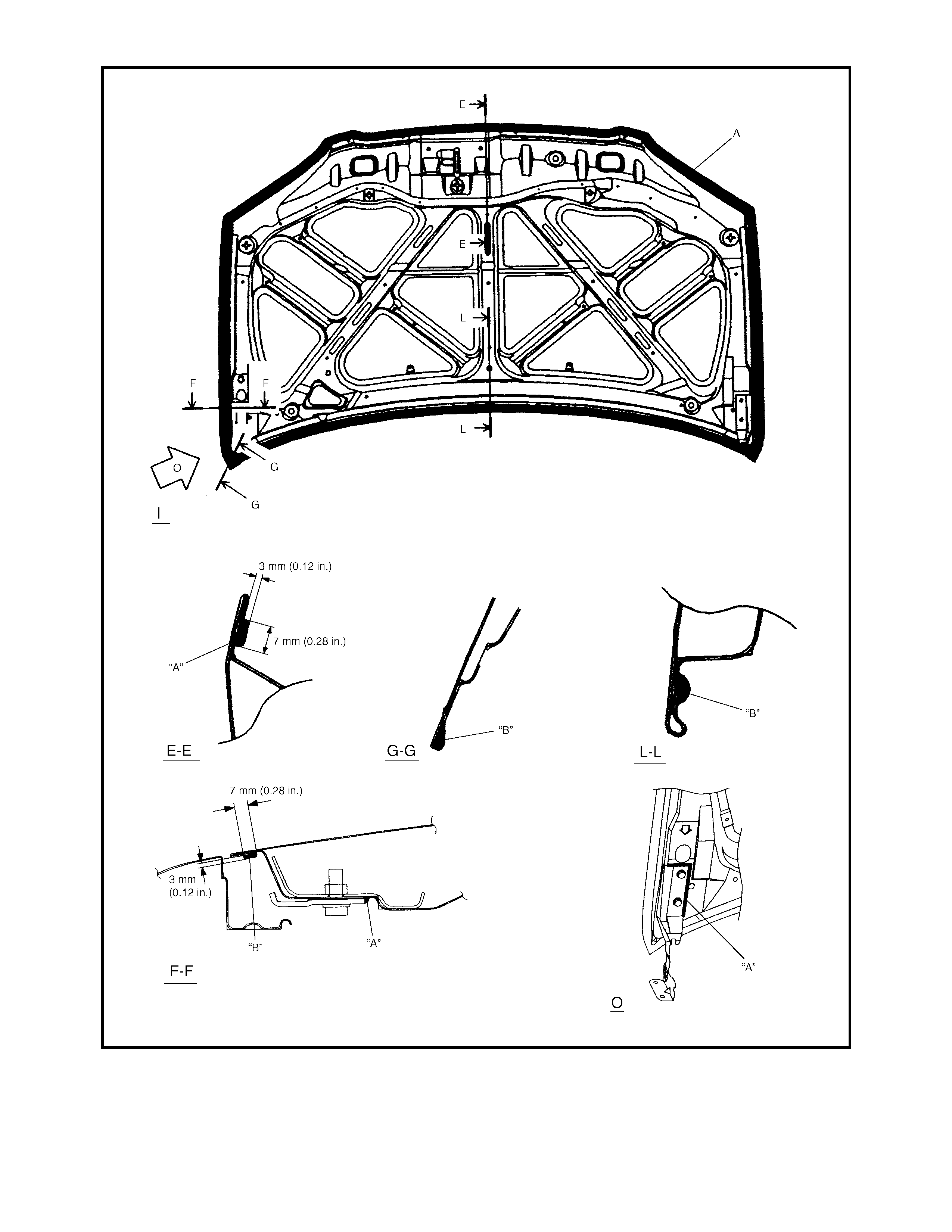

2.16 BODY DIMENSIONS

ENGINE ROOM

Legend

Hole to hole distance

a. Garnish installation

centre hole (φ5) d (d’). Front fender

installation hole g (g’). Jig hole (φ15 mm)

h. Bumper member upper side

installation hole

b (b’). Front fender

installation hole e. Hood cushion installation hole

f (f’). Engine mounting installation

front hole i (i’). Head light installation hole

c (c’). Strut installation front

hole j (j’). Front fender installation hole

a-b: 673 mm a-i’: 798 mm f-f’: 954 mm

a-c’: 584 mm b-b’: 1340 mm g-g’: 1315 mm

a-d: 760 mm b-d’: 1393 mm g-h: 231 mm

a-e: 599 mm b-j: 606 mm g’-h: 1139 mm

a-f: 774 mm b’-d’: 401 mm i-i’: 922 mm

a-f’: 836 mm c-c’: 1098 mm j-j’: 1417 mm

a-g: 889 mm d-d’: 1328 mm

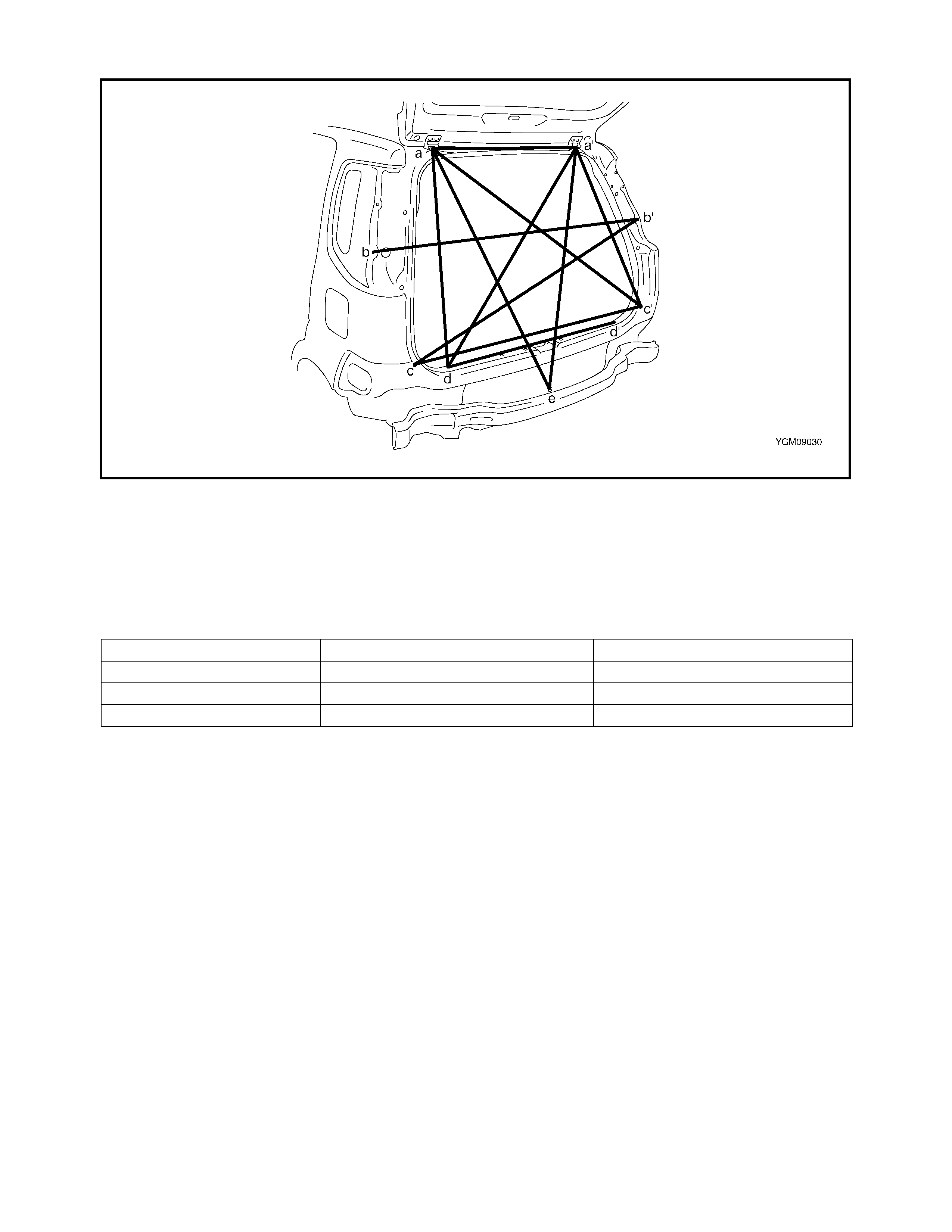

BACK DOOR

Legend

Hole to hole distance

a (a’). Back door hinge installation

hole c (c’). Rear bumper installation

hole e. Centre jig hole (φ7 mm)

b (b’). Rear combination lamp

installation hole d (d’). Tail end member trim

installation hole

a-a’: 725 mm a’-c’: 794 mm b’-c: 1340mm

a-c’: 1229 mm a’-d: 1128 mm c-c’: 1215 mm

a-d: 799 mm a’-e: 1096 mm d-d’: 875 mm

a-e: 1096 mm b-b’: 1340 mm

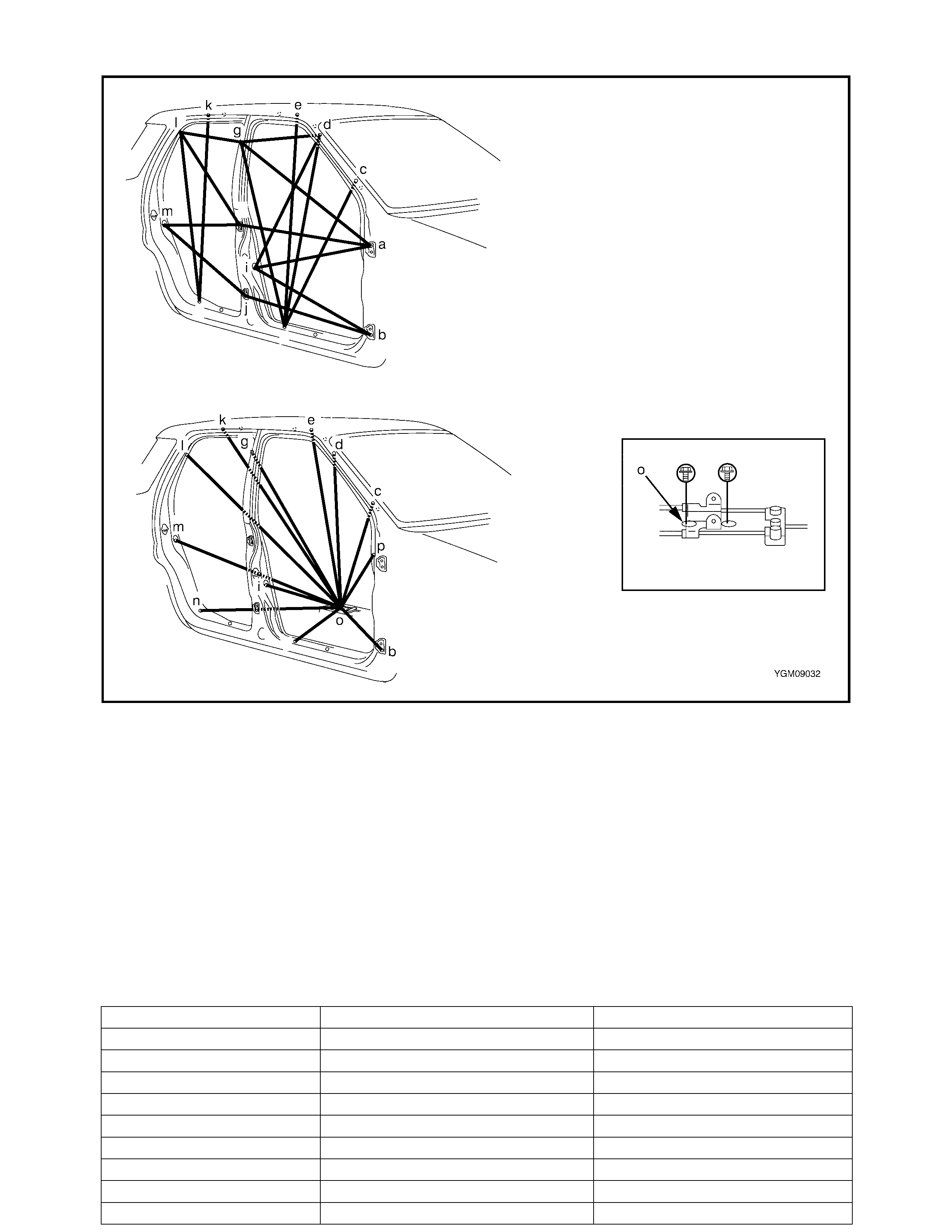

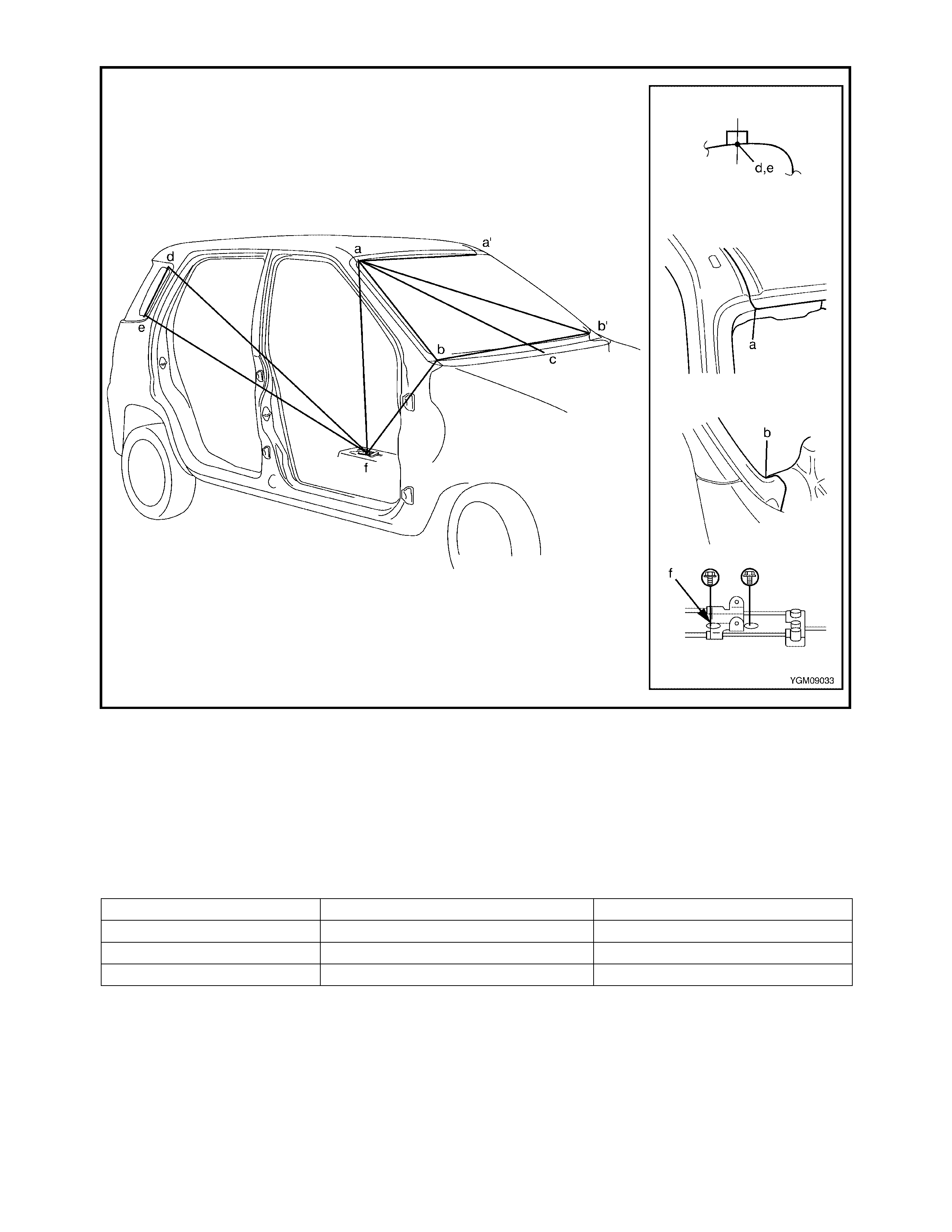

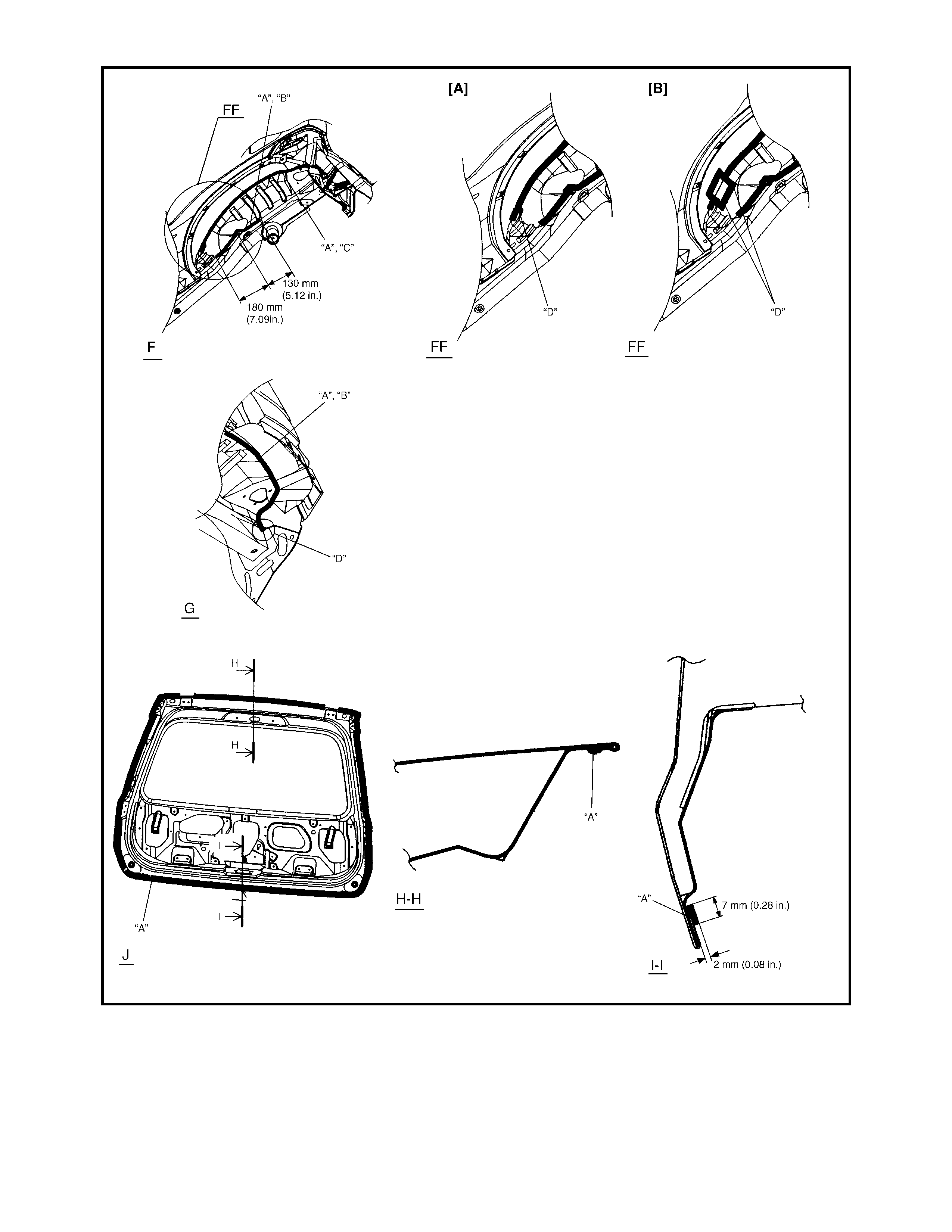

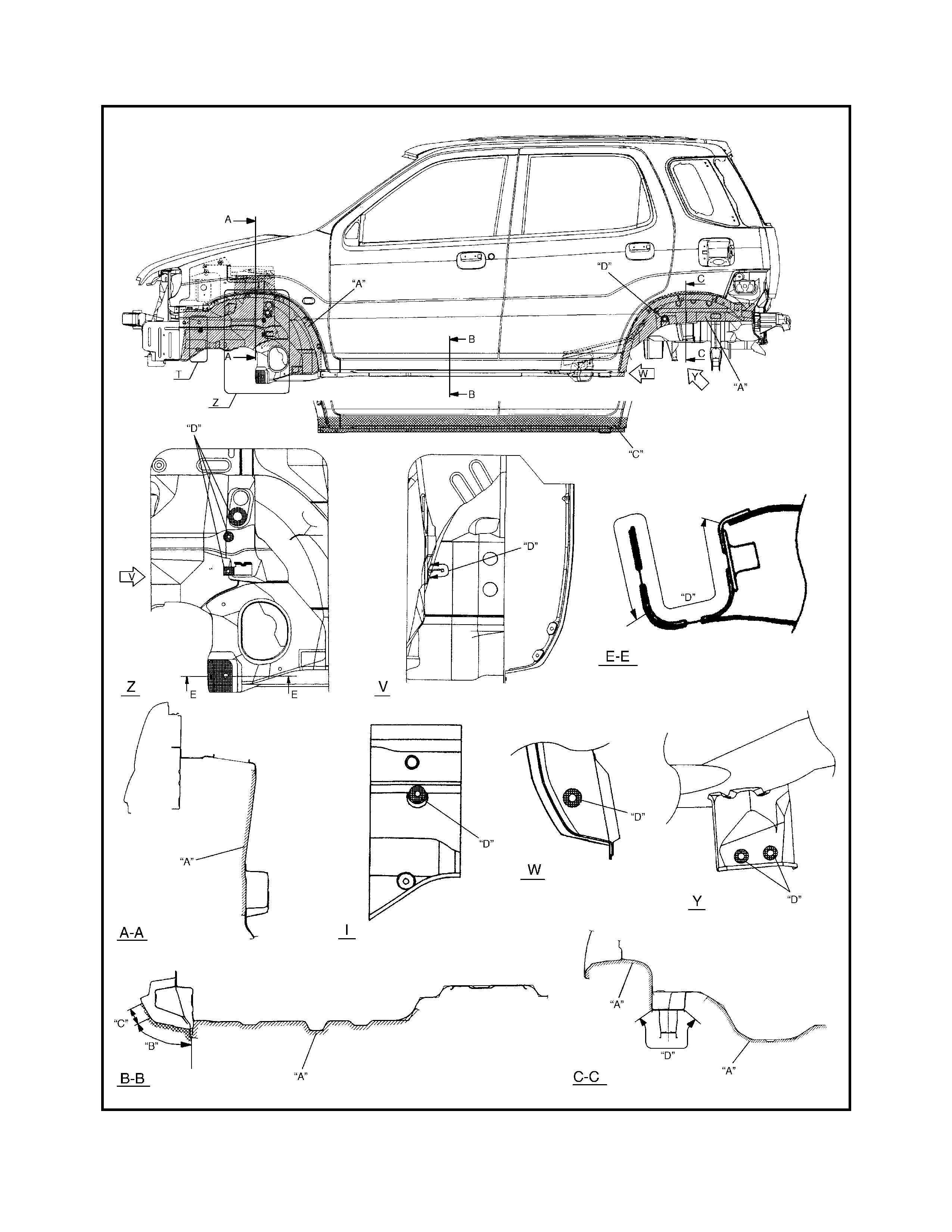

SIDE BODY

Legend

Hole to hole distance

a. Front door upper hinge

installation hol e g. Front shoulder adjuster instal-

lation upper hole l. Rear door rear notch

b. Front door lower hinge

installation hol e h. Rear door upper hinge instal-

lation hole m. Rear door switch installation

hole

c. Front pillar inner trim instal-

lation lower hole i. Front door switch installation

hole n. Side sill scuff installation rear

hole

d. Front pillar inner trim instal-

lation upper hole j. Rear door lower hinge instal-

lation hole o. Parking brake cable bracket

installation rear hole

e. Assistant grip installation

front hole k. Assistant grip installation

hole p. Steering support member

installation upper hole

f. Side sill scuff installation

rear hole

a-g: 1166 mm d-i: 820 mm i-o: 742 mm

a-h: 942 mm d-o: 1252 mm j-m: 895 mm

a-i: 901 mm e- f: 1077 mm k-n: 1089 mm

b-i: 891 mm e-o: 1244 mm k-o: 1321 mm

b-j: 902 mm f-g: 1048 mm l-n: 948 mm

b-o: 1222 mm f-o: 785 mm l-o: 1323 mm

c-f: 884 mm g-l: 621 mm m-o: 1111 mm

c-o: 1282 mm g-o: 1147 mm n-o: 813 mm

d-f: 993 mm h-l: 846 mm o-p: 1229 mm

d-g: 580 mm h-m: 813 mm

Legend

Hole to hole distance

a

(a’). Front end of front windshield upper installation

section d. Quarter window upper side notch

b (b). Front end of front windshield lower installation

section e. Quarter window lower side notch

c. Garnish installation centre hole (φ5 mm) k. Parking brake cable bracket installation rear

hole

a-a’: 1047 mm a-f: 1282 mm d-f: 1499 mm

a-b: 688 mm b-b’: 1305 mm e-f: 1443 mm

a-b’: 1356 mm b-f: 1411 mm

a-c: 1032 mm d-e: 289 mm

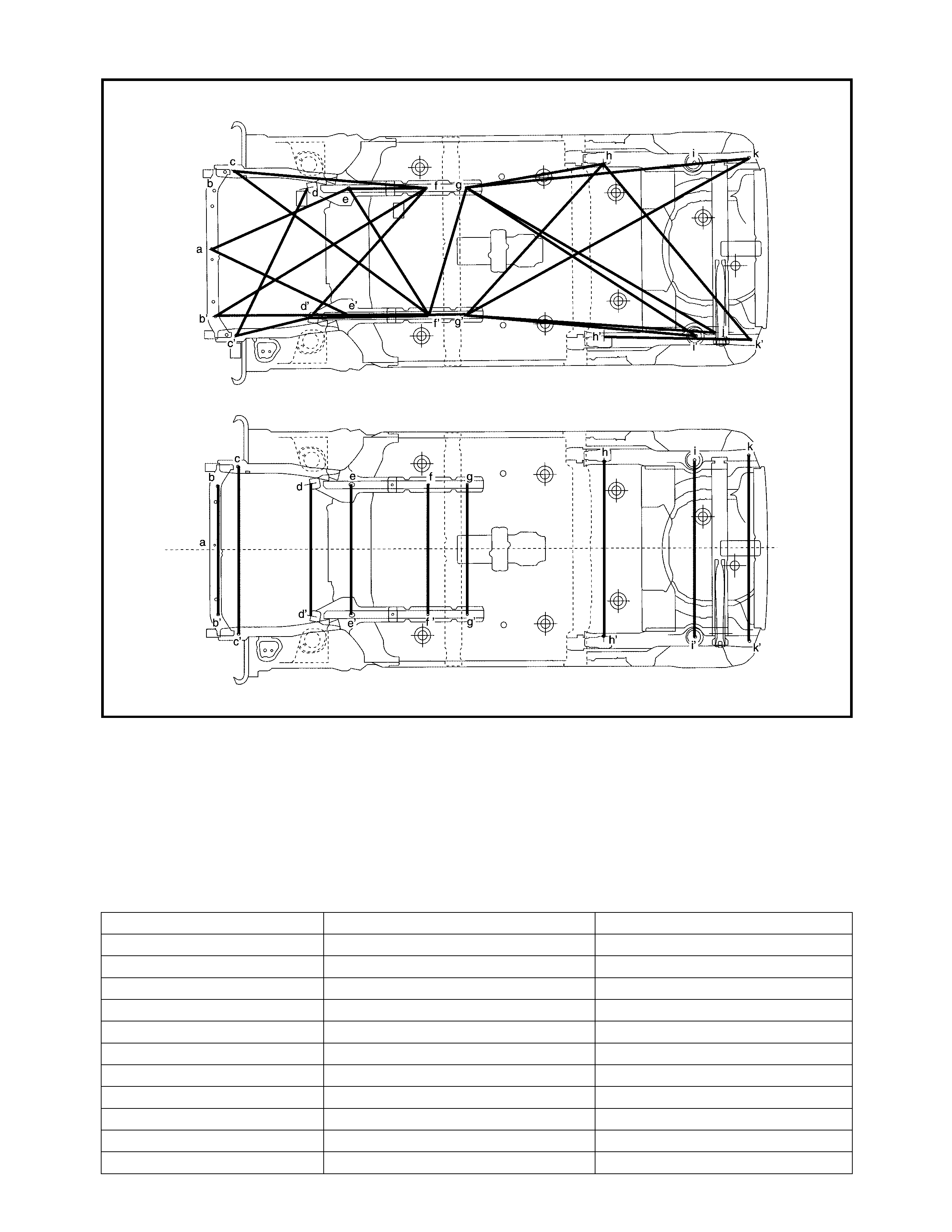

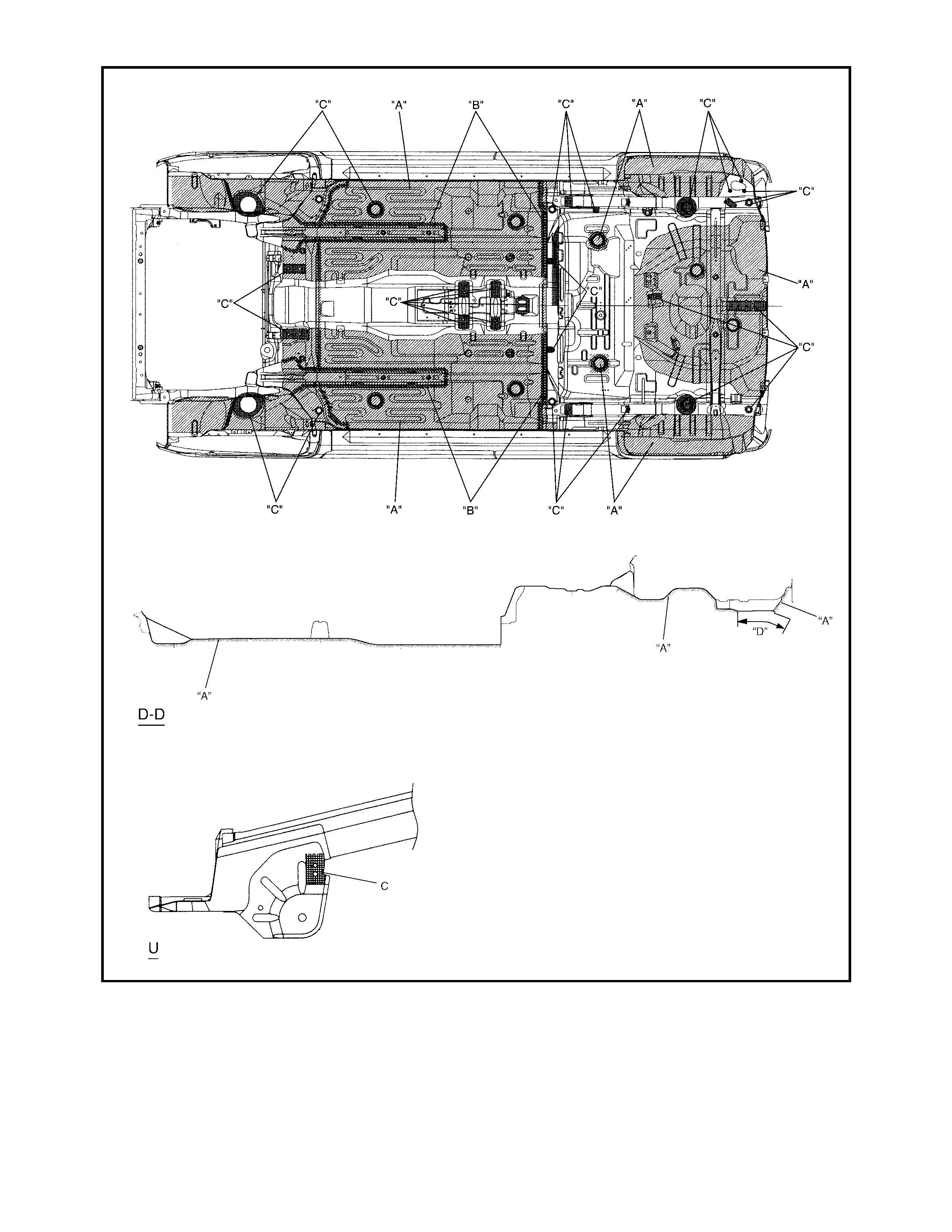

UNDER BODY

Legend

Hole to hole distance

a. Jack bracket installation hole g (g’). Jig hole (φ10 mm)

b (b’). Front stabiliser bracket front installation hole h (h’). Jig hole (φ10 mm)

c (c’). Front stabiliser bracket rear installation hole i (i’). Trailing arm installation hole

d (d’). Suspension control arm installation front hole j (j’). Bump stopper installation hole

e. Rear engine mounting front installation hole k. Lateral rod installation hole

f (f’). Jig hole (φ15 mm) l (l’). Jig hole (φ16 mm)

a-f: 909 mm d’-g’: 708 mm h-k: 1724 mm

a-f’: 862 mm e-g: 702 mm h-l: 1718 mm

b-b’: 740 mm e-g’: 647 mm h’-i: 1204 mm

b’-g: 1464 mm f-f’: 754 mm h’-j’: 1384 mm

b’-g’: 1259 mm f-g: 471 mm h’-k: 1497 mm

c-c: 968 mm f-g’: 889 mm h’-l: 1940 mm

c-g: 1148 mm g-g’: 754 mm i-i’: 1017 mm

c-g’: 1431 mm g’-h: 791 mm i-l’: 1392 mm

c’-d: 970 mm g’-h’: 240 mm i’-l’: 918 mm

c’-d’: 452 mm h-h’: 754 mm j-j’: 1028 mm

d-d’: 761 mm h-i: 826 mm l-l’: 1076 mm

d’-g: 1037 mm h-j’: 1640 mm

Legend

Point to point distance

d

abcefgh

h’j’

jk

k’l’

l

i’

i

g’f’

e’d’c’b’a’

1

1. Virtual baseline g. Jig hole (φ10 mm)

a. Jack bracket installation hole h. Jig hole (φ10 mm)

b. Front stabiliser bracket front installation hole i. Trailing arm installation hole

c. Front stabiliser bracket rear installation hole j. Bump stopper installation hole

d. Strut installation front hole k. Lateral rod installation hole

e. Suspension control arm installation front hole l. Jig hole (φ16 mm)

f. Jig hole (φ15 mm)

a-a’: 133 mm d’-g’: 749 mm h’-i’: 815 mm

a-e’: 558 mm e-e’: 77 mm i-i’: 85 mm

b-b’: 133 mm e’-f’: 238 mm i’-j’: 546 mm

b’-e’: 550 mm f-f’: 55 mm j-j’: 292 mm

c-c’: 162 mm f’-g’: 470 mm j’-l’: 324 mm

c’-d’: 391 mm g-g’: 80 mm k-k’: 139 mm

c’-e’: 432 mm g’-h’: 240 mm k’-l’: 193 mm

d-d’: 648 mm h-h’: 80 mm l-l’: 375 mm

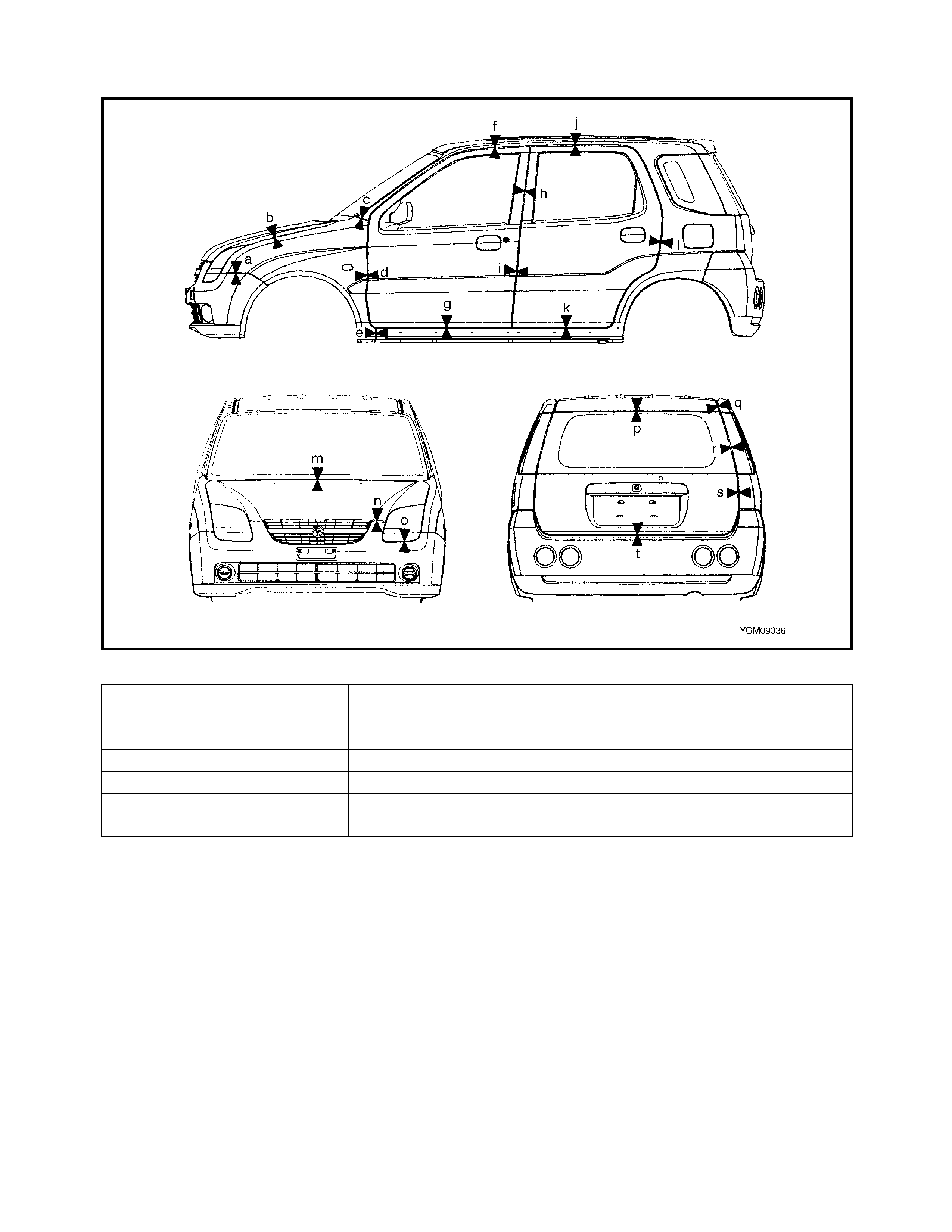

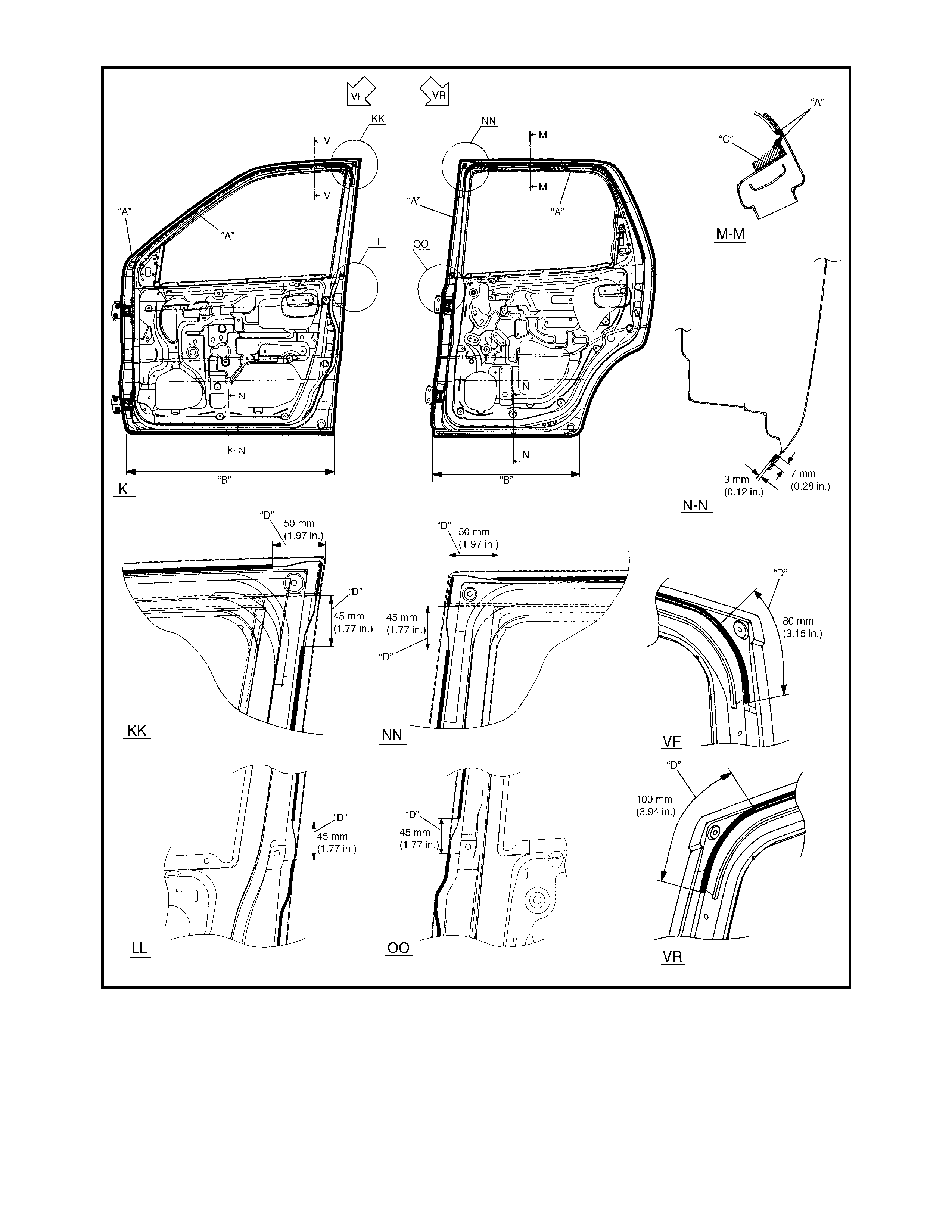

2.17 PANEL CL EARANCE

Panel to panel distanc e

a: 1.5-2.5 mm h: 3.6-5.6 mm o: 3.5-5.5 mm

b: 2.5-3.5 mm i: 4.2-6.2 mm p: 2.6-4.6 mm

c: 1.6-3.6 mm j: 5.0-7.0 mm q: 3.6-5.6 mm

d: 4.1-6.1 mm k: 4.7-6.7 mm r: 4.8-6.8 mm

e: 1.6-3.6 mm l: 3.6-5.6 mm s: 3.7-5.7 mm

f: 5.0-7.0 mm m: 4.8-6.8 mm t: 5.3-7.3 mm

g: 4.7-6.7 mm n: 7.8-9.8 mm

3. INSTRUMENTATION AND DRIVER INF ORM ATION

3.1 INSTRUMENT PANEL

WARNING: See WARNING at the beginning of this sec-

tion.

REMOVAL

1. Disconnect the negative cable at the battery.

2. Disable the airbag system, refer to Section 10B,

3.1 SERVICE PRECA U TIO NS .

3. Remove the steering column hole cover (1).

4. Remove the glove box (1) and hood latch release

lever (2).

5. Disconnect the instrument panel harness connectors,

antenna and heater control cables.

6. Remove the instrument panel ground wire.

7. Remove the steering column assembly, refer to

Section 3C, 3.6 STEERING COLUMN ASSEMBLY.

8. Remove the front pillar trims (1) and dash side

trims (2).

9. Remove the speaker covers (3).

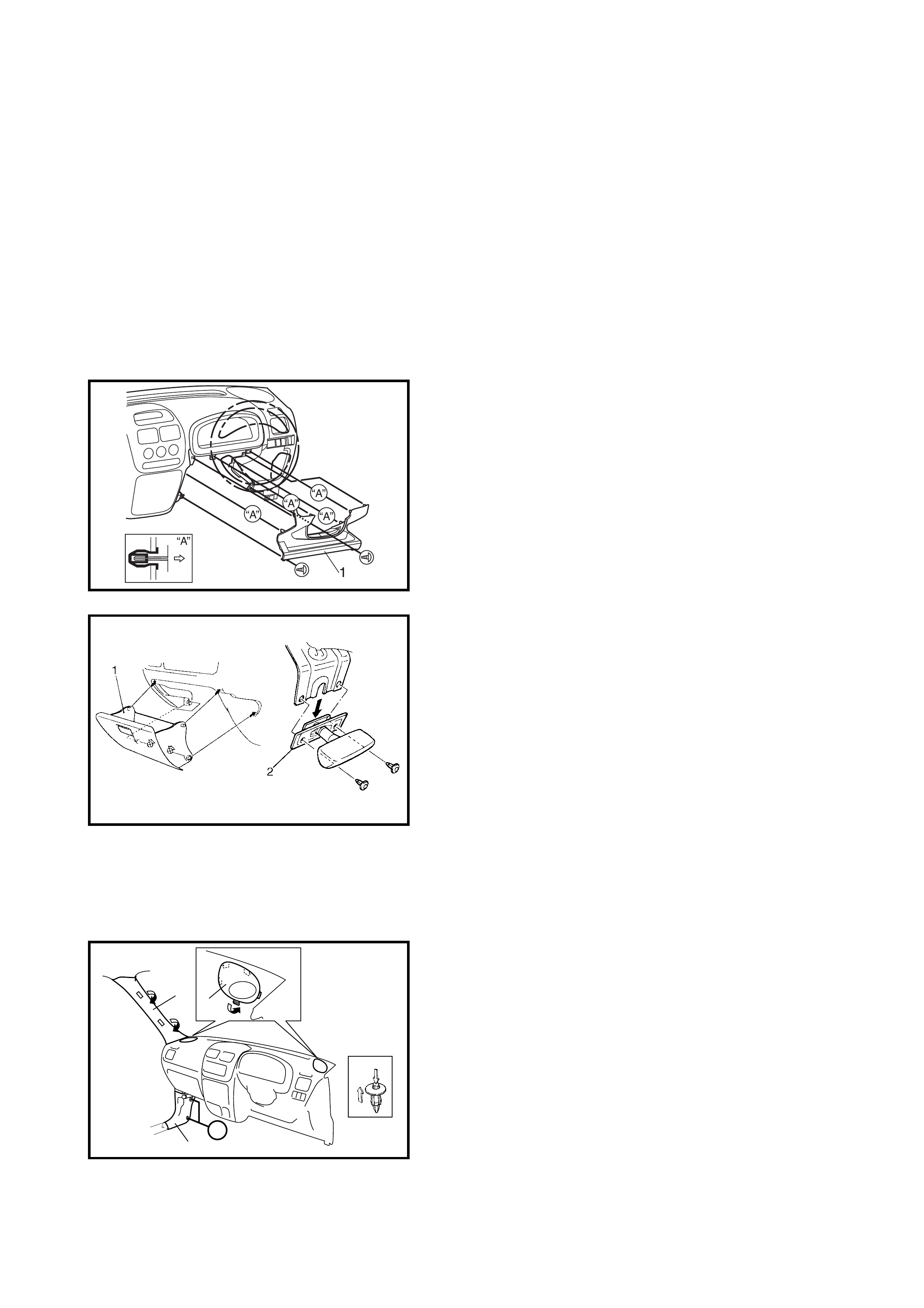

2“A”

13

“A”

10. Remove the instrument panel mounting bolts (2).

11. Remove the instrument panel (1) with the steering

support member and instrument panel harness.

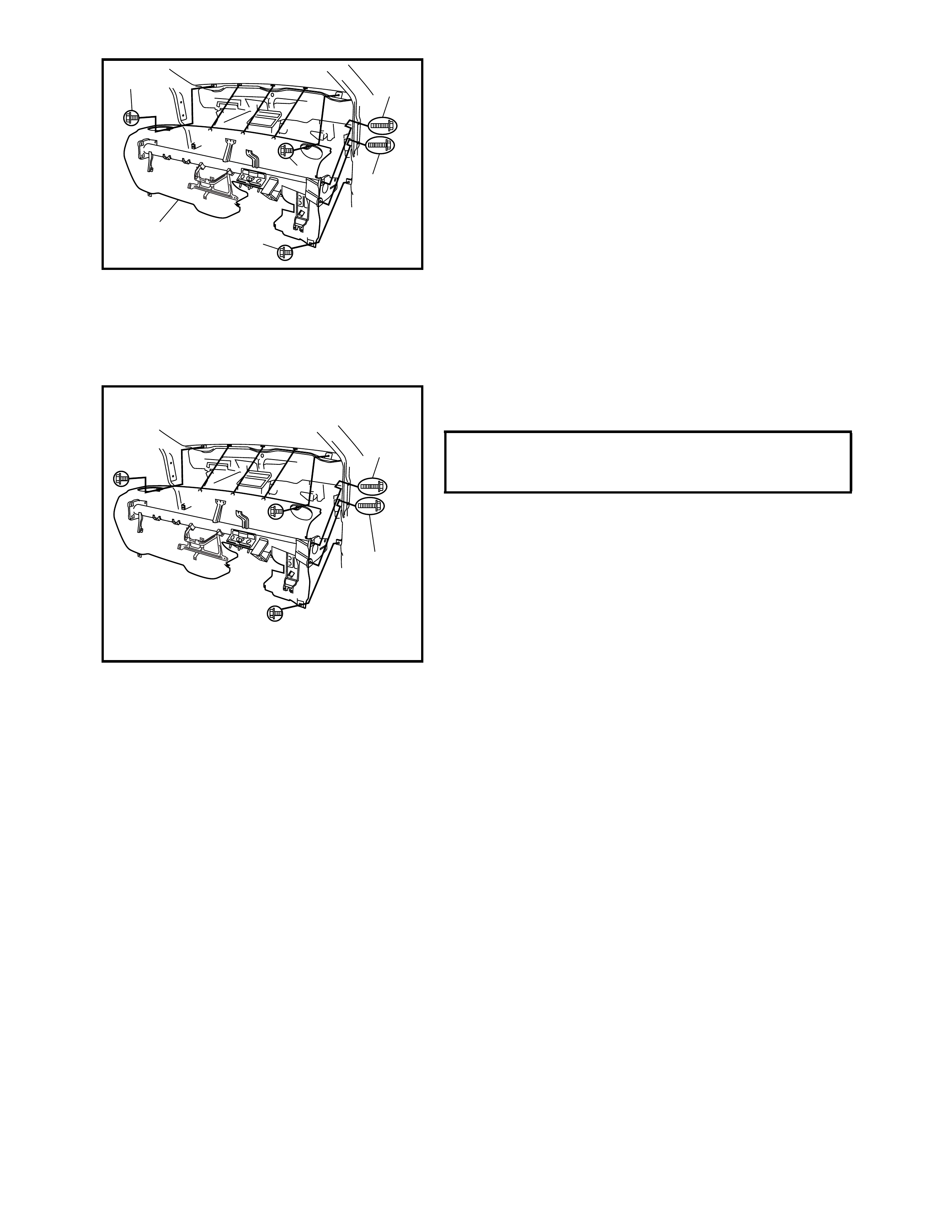

INSTALLATION

Reverse removal procedure to install the instrument panel

noting the following:

• When installing each part, be careful not to catch any

cable or wiring harness.

• Tighten the instrument panel mounting bolts (1) to the

specified torque.

• When installing the steering column assembly, refer to

3.6 STEERING COLUMN ASSEMBLY in Section 3C.

• Adjust the heater control cables. Refer to Section 1A,

3.4 HEATER CONTROL ASSEMBLY.

• Enable the airbag system if equipped, refer to Section 10B,

3.1 SERVICE PRECAUTIONS.

2

2

2

2

2

1

INSTRUMENT PANEL MOUNTING

BOLTS (a)

TORQUE SPECIFICATION 23 Nm

1, (a)

1, (a)

4. SEATS

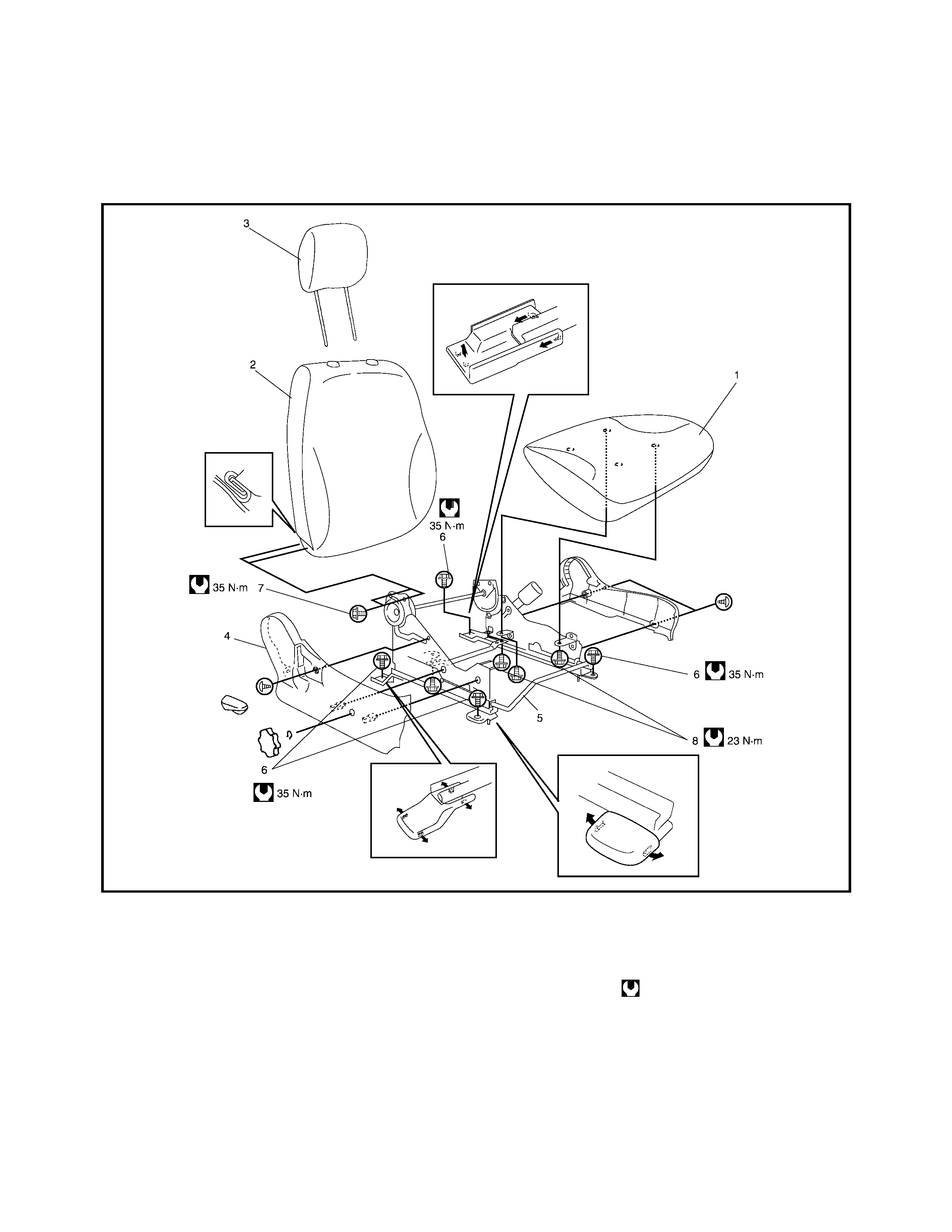

4.1 FRONT SEAT

Legend

REMOVAL

1. Remove the console box.

2. Remove the four mounting bolts to remove the seat

assembly.

3. Disassemble and repair the seat as necessary.

INSTALLATION

Reverse removal procedure to install the front seat.

Torque to specifications as shown.

1. Seat cushion 4. Side cover 7. Reclining bolt

2. Seat back 5. Seat adjuster (fore and aft) 8. Seat cushion bolt

3. Head rest 6. Seat adjuster bolt Tightening torque

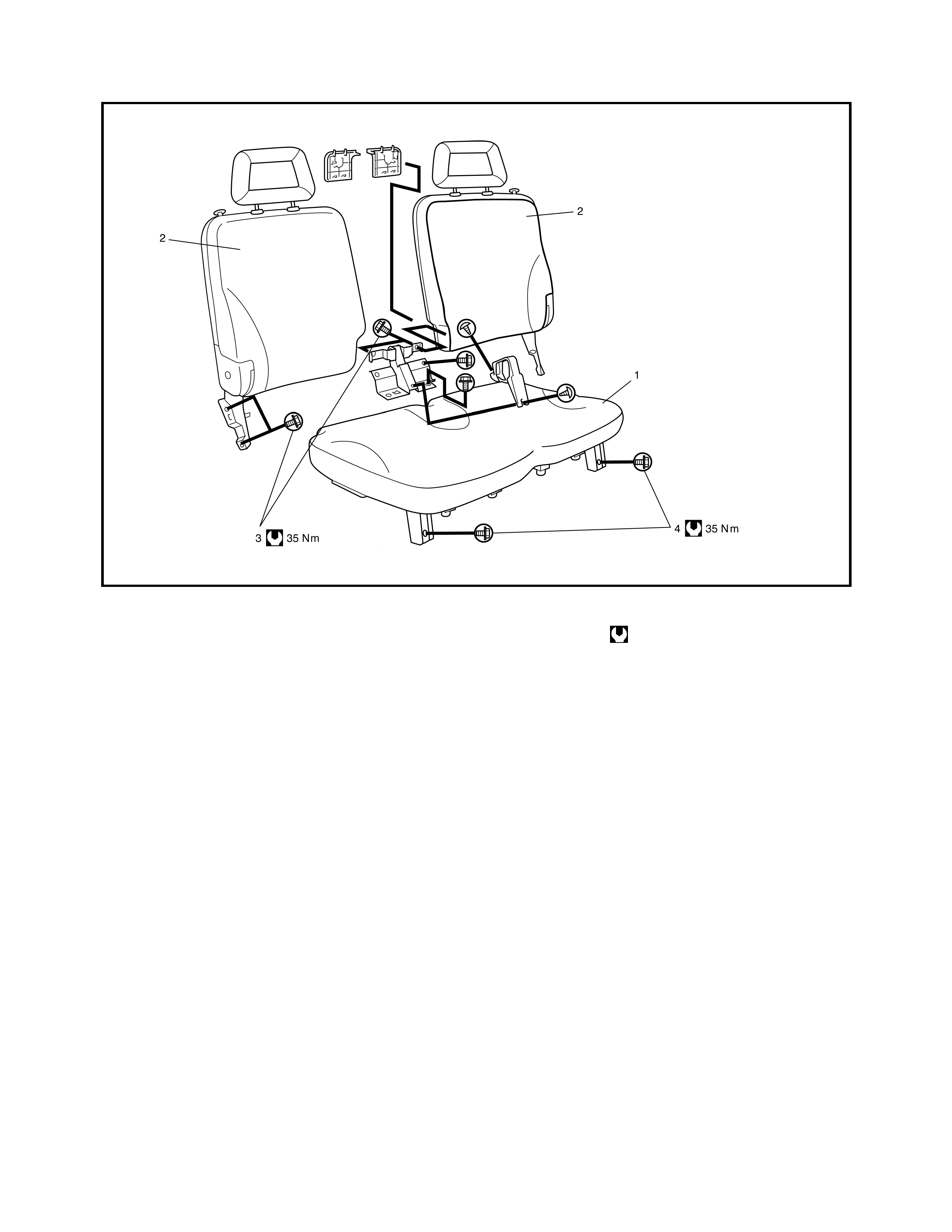

4.2 REAR SE AT

Legend

REMOVAL

1. Remove the two seat cushion bolts (4) to remove the

seat cushion.

2. Remove the three seat back bolts (3) to remove the

seat back.

3. Disassemble and repair the seat as necessary.

INSTALLATION

Reverse removal procedure to install the rear seat.

Torque to specifications as shown.

1. Seat cushion 3. Seat back bolt Tightening torque

2. Seat back 4. Seat cushion bolt

5. SECURITY AND LOCKS

5.1 FRONT DOOR LOCK ASSEMBLY

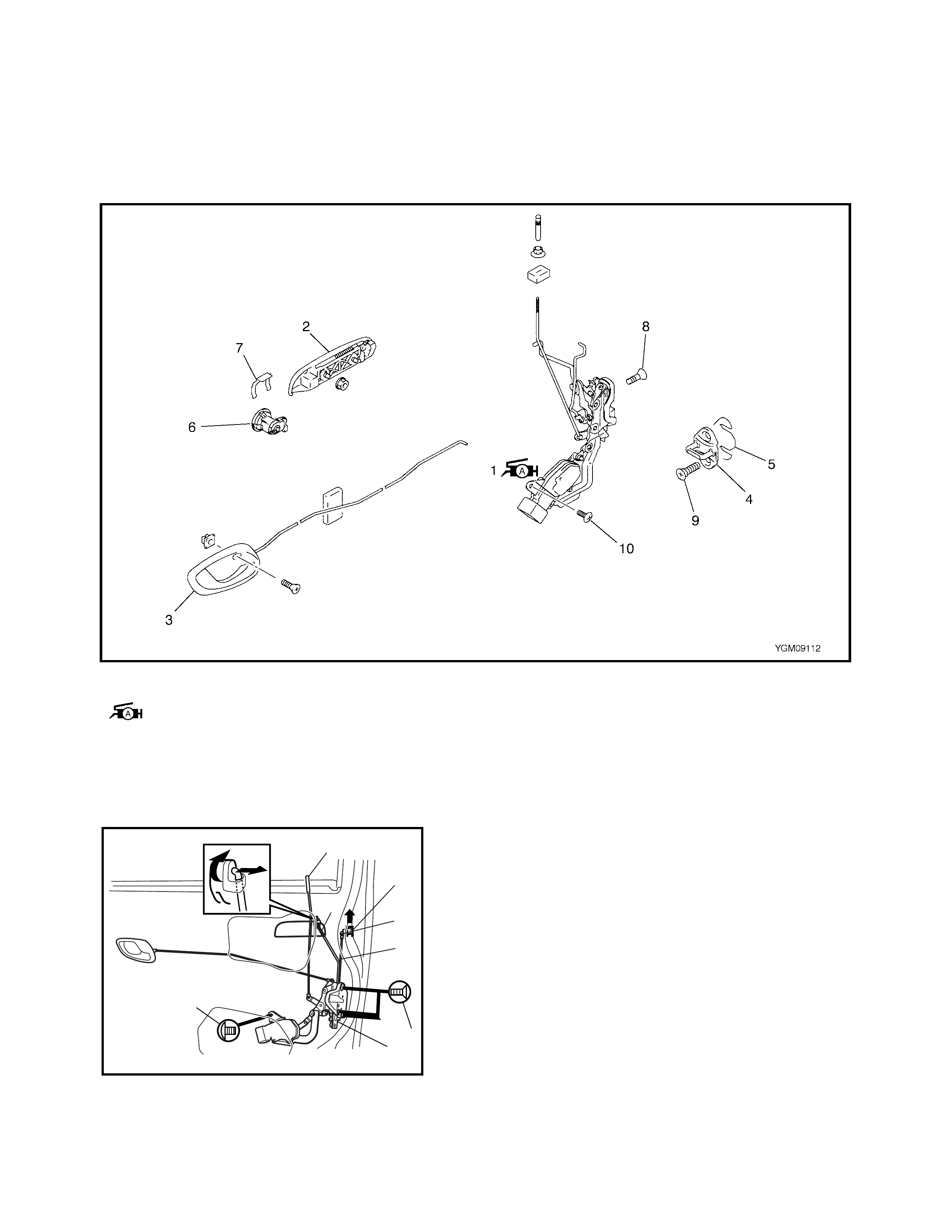

Legend

REMOVAL

1. Remove the door trim and door sealing cover, refer to

1.1 FRONT DOOR GLASS, REMOVAL in this Section.

2. Raise the window all the way up.

3. Remove the door sash.

4. Disconnect the door opening control rod (1) from the

outside handle.

5. Disconne ct the door latch con tr ol ro d (2).

6. Disconnect the door lock motor lead wire.

7. Remove the door lock knob (3).

8. Loosen the door latch screw (4), door latch actuator

screw (5) and remove the door lock assembly (6).

9. Remove the key cylinder retainer (7).

10. Remove the key cylinder (8).

1. Front door latch assembly

: Apply Lithium grease

to sliding part

3. Inside handle bezel 7. Key cylinder retainer

4. Latch striker 8 . D oo r latch sc r ew

5. Shim 9. Door latch st ri ker scr ew

2. Outside handle 6. Key cylinder 10. Door latch actuator screw

3

1

7

8

2

4

6

5

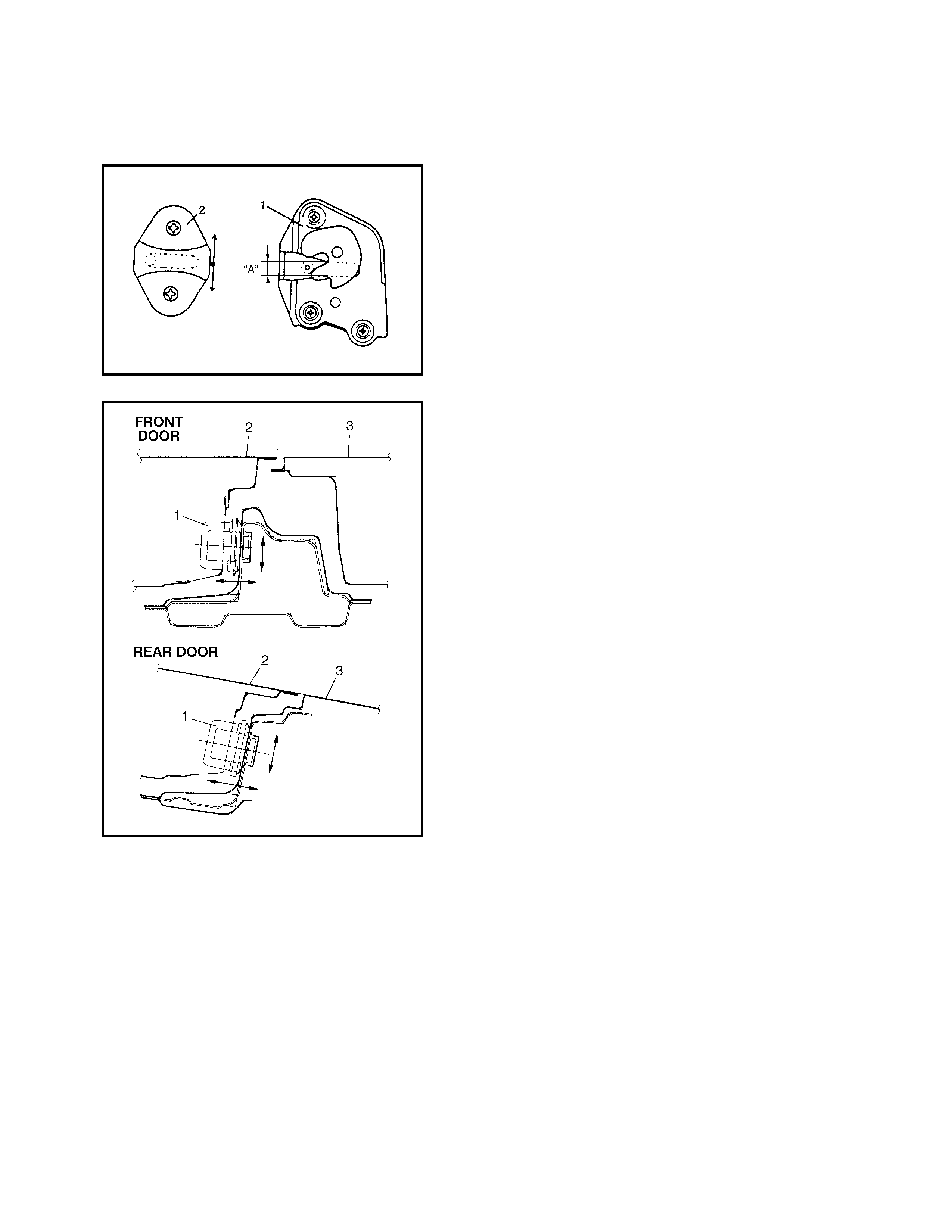

INSTALLATION

Reverse removal procedure to install the front door lock

assembly noting the following:

• Apply grease to the sliding parts of door latch

assembly.

• Move the doo r l atc h st rike r ( 2) up o r do wn s o its ce ntr e

aligns with the centre of groove “A” on the door lock

assembly (1) as shown.

Striker should be moved vertically and placed level. Do

not adjust the door lock.

• Move the door latch striker (1) sideways to adjust the

door outer panel surface (2) to be flush with the rear

door outer panel or body outer panel surface (3) as

shown.

Increase or decrease the number of shims between the

body and latch striker (1) until the door lock operates

correctly.

INSPECTION

Check that the door opens and closes correctly and

smoothly.

Also check that the door latch half lock operates correctly

(check that door latch half lock keeps door from opening all

the way) and that the door latch full lock, locks securely

when closed.

Adjust door latch striker position if necessary.

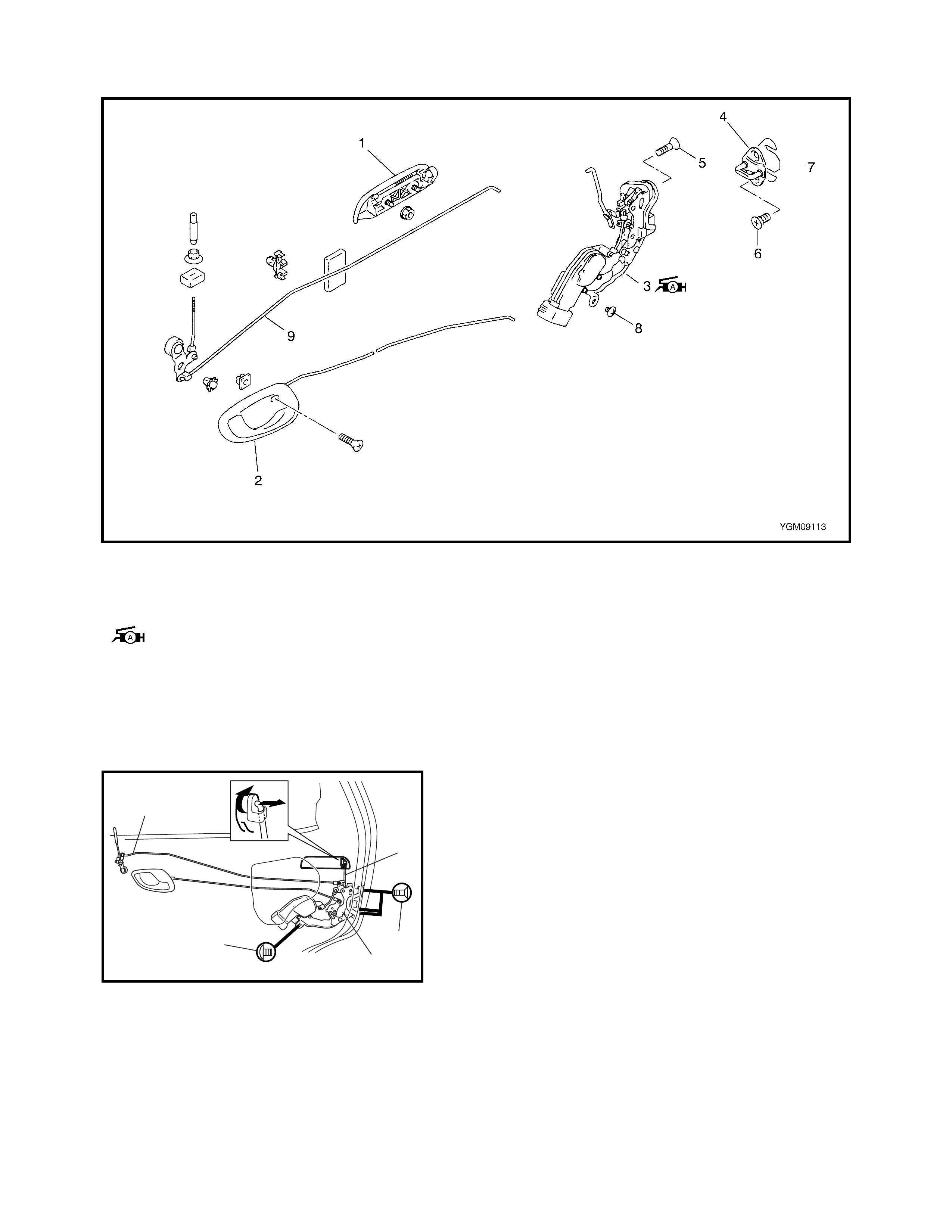

5.2 REAR DOOR LOCK ASSEMBLY

Legend

REMOVAL

1. Remove the door trim and door sealing cover, refer to

1.4 REAR DOOR GLASS, REMOVAL in this Section.

2. Disconnect the door opening control rod (1) and door

latch control rod (2).

3. Loosen the door latch mounting screw (3), door latch

actuator screw (5) and remove the door lock assembly

(4).

INSTALLATION

Reverse removal procedure to install the rear door lock

assembly referring to 5.1, FRONT DOOR LOCK ASSEMBLY

in this Section.

1. Outside handle 4. Latch striker 7. Shim

2. Inside handle bezel 5. Door latch screw 8. Door latch actuator screw

3. Rear door latch assembly

: Apply Lithium gr ease to

sliding part

6. Door latch striker screw 9. Door lock control rod

2

1

3

4

5

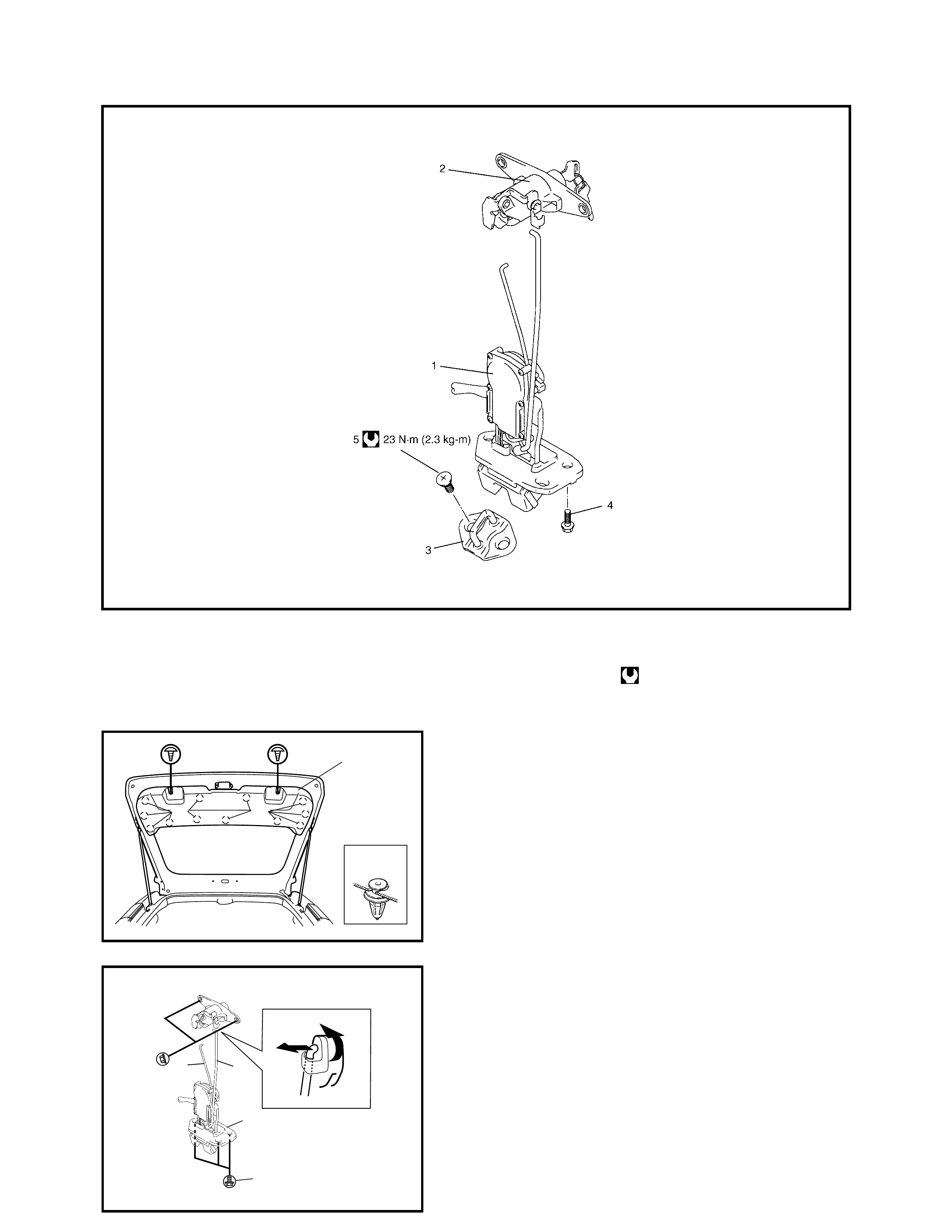

5.3 BACK DOOR LOCK ASS EMBLY

Legend

REMOVAL

1. Remove the door trim (1).

2. Disconnect the door lock control rod (1).

Disconnect the control rod (2).

3. Disconnect the door lock motor lead wire.

4. Loosen the door latch screw (3) and remove the door

latch asse mbl y (4 ).

1. Back door latch assembly 3. Latch striker 5. Latch striker screw

2. Back door lock cylinder 4. Door latch screw Tightening torque

“A”

“A”“A”

1

21

4

3

5. Remove the back door licence garnish (1).

6. Remove the back door lock cylinder (2).

INSTALLATION

Reverse removal procedure to install the back door lock

assembly noting the following:

• Adjust the door latch striker so that its centre aligns

with the centre of the groove in the door latch base.

INSPECTION

Check that the door open and closes correctly and

smoothly.

Also check that the door latch half lock operates properly

(Check that door latch half lock keeps door from opening all

the way) and the door latch full lock, locks securely when

closed.

Adjust the door latch striker position if necessary.

5.4 KEY CODING

KEY USAGE AND IDENTIFICATION

The Key is used for the ignition and the door lock cylinders.

Keys are cut on both edges to make them reversible.

Key identification is obtained from the five character key

code stamped on the key code tag. Using this key code,

the key code cutting combination can be determined from a

code list (available to owners of key cutting equipment).

If the key codes are not available from records or tags, the

key code can be obtained from the right hand door lock cyl-

inder (if lock has not been replaced). Lock cylinders sup-

plied as service parts are unmarked.

If the original key is available, key code cutting combination

can be determined by copying key.

IGNITION SWITCH CYLINDER LOCK

REMOVAL AND INSTALLATION

Refer to 3.7 STEERING LOCK ASSEMBLY (IGNITION

SWITCH) in Section 3C.

ELECTRICAL DIAGNOSIS

For ignition switch electrical troubleshooting refer to

Section 8, 2.9 IGNITION SWITCH.

2

1

6. EXTERIOR AND INTERIOR TRIM

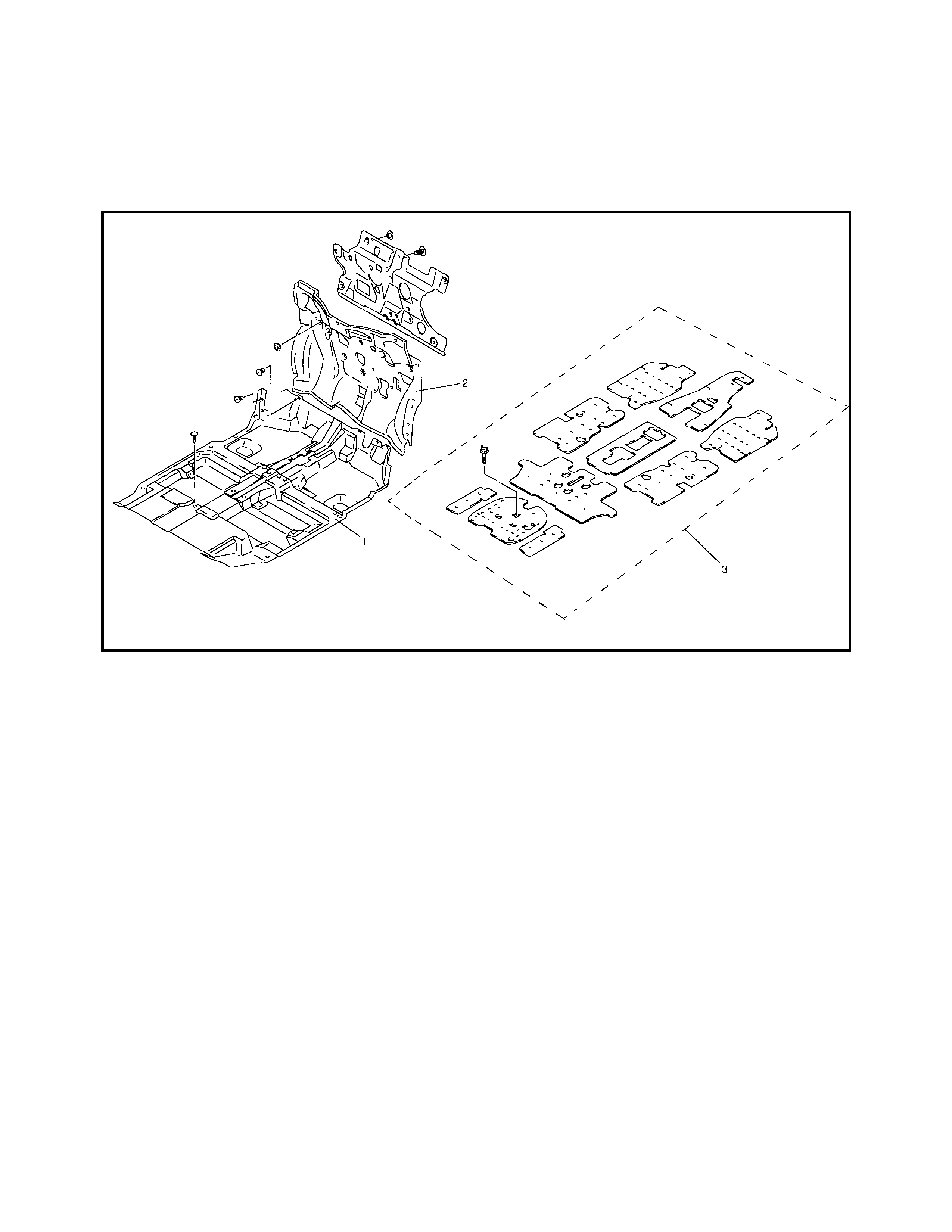

6.1 FLOOR CARPET

Legend

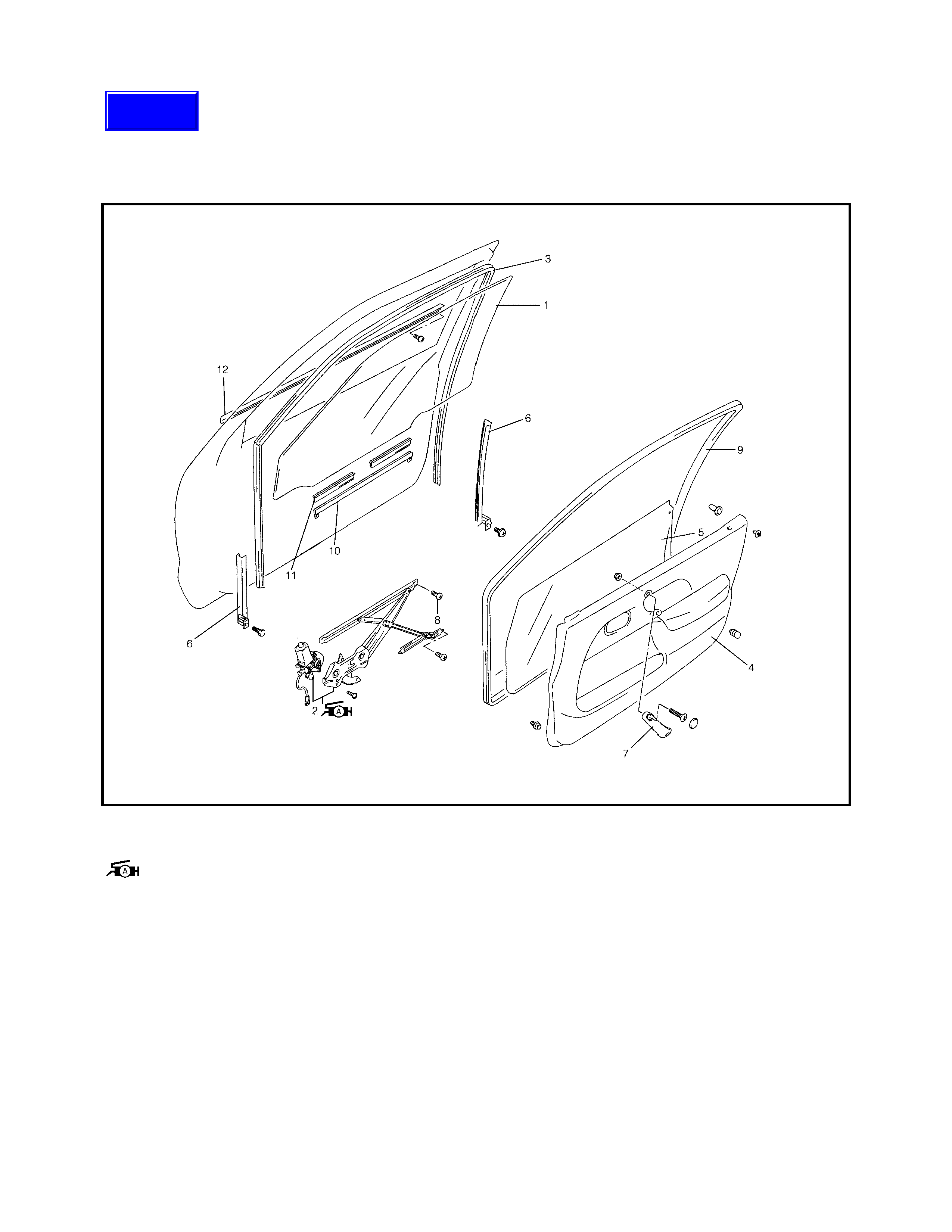

REMOVAL

1. Remove the front seats and rear seat cushion, refer to 4.1., FRONT SEAT and 4.2, REAR SEAT in this

Section.

2. Remove the seat belt lower anchor bolt, refer to Section 10, 3.2 FRONT SEAT BELT ASSEMBLY.

3. Remove the dash side trims, front side sill scuffs, centre pillar inner lower trims, quarter inner trims and

rear side sill scuffs.

4. Remove the parking brake lever cover and console box.

5. Remove the floor carpet.

INSTALLATION

Reverse removal sequence to install the front floor carpet, noting the following instruction.

• For tightening torque of seat belt anchor bolt, refer to Section 10, 3.2 FRONT SEAT BELT ASSEMBLY.

1. Floor carpet 2. Dash panel silencer 3. Silencer seat

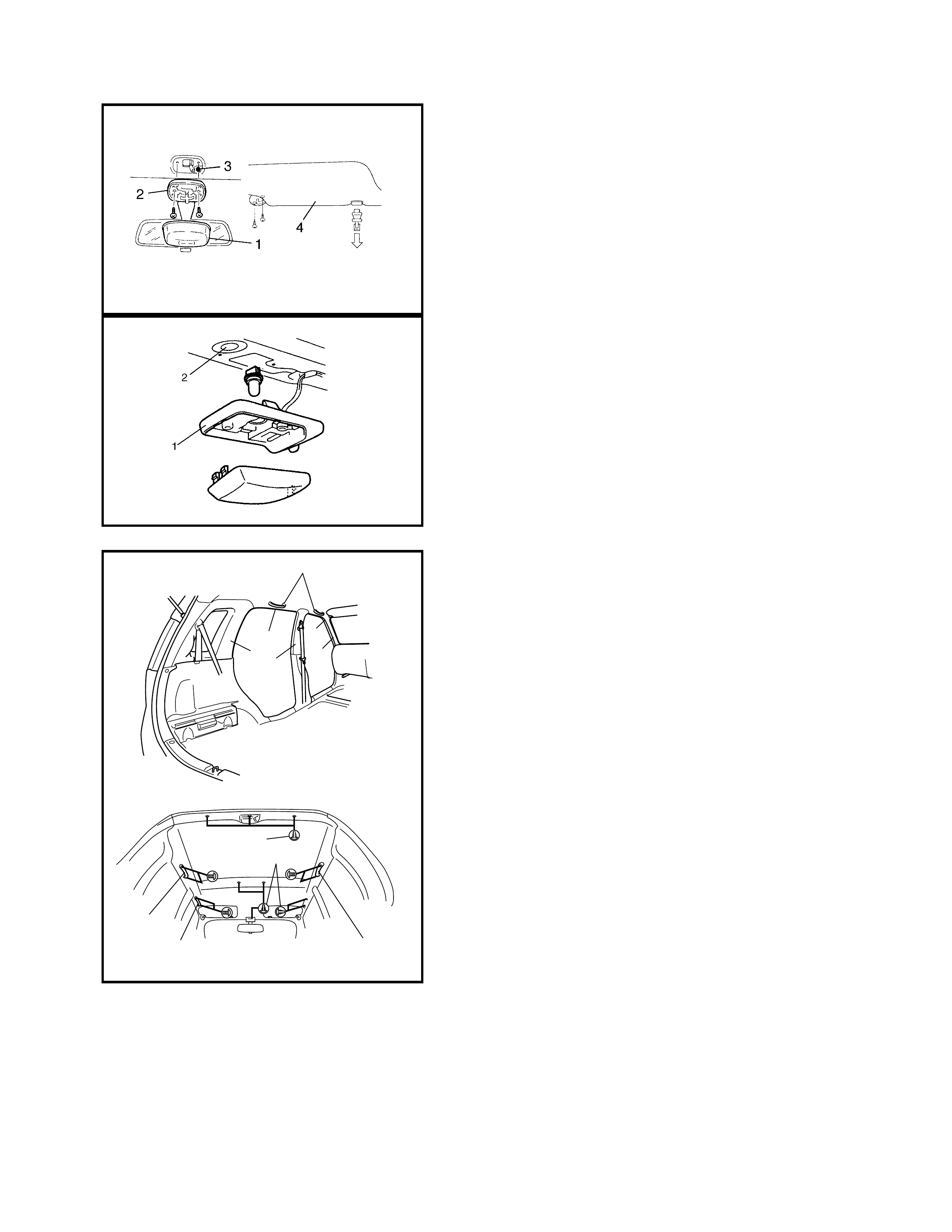

6.2 HEADLINING

REMOVAL

1. Unclip interior light cover (1).

2. Remove the interior light (2) 2 screws.

3. Remove the headlining clip (3).

4. Remove the sun visor (4).

5. Unclip the luggage room light (1).

6. Remove the headlining clip (2).

7. Remove the assistant grip (1).

8. Remove the door opening trim (2) and unclip the upper

section of the inside trims covering the headlining (3).

9. Remove the headlining clips (4) and remove the head

lining.

NOTE: Adhesive is used to attach headlining.

Clean the adhesive from the headlining and the roof after

removing the headlining.

1

11

44

1

223

3

3

YGM09097

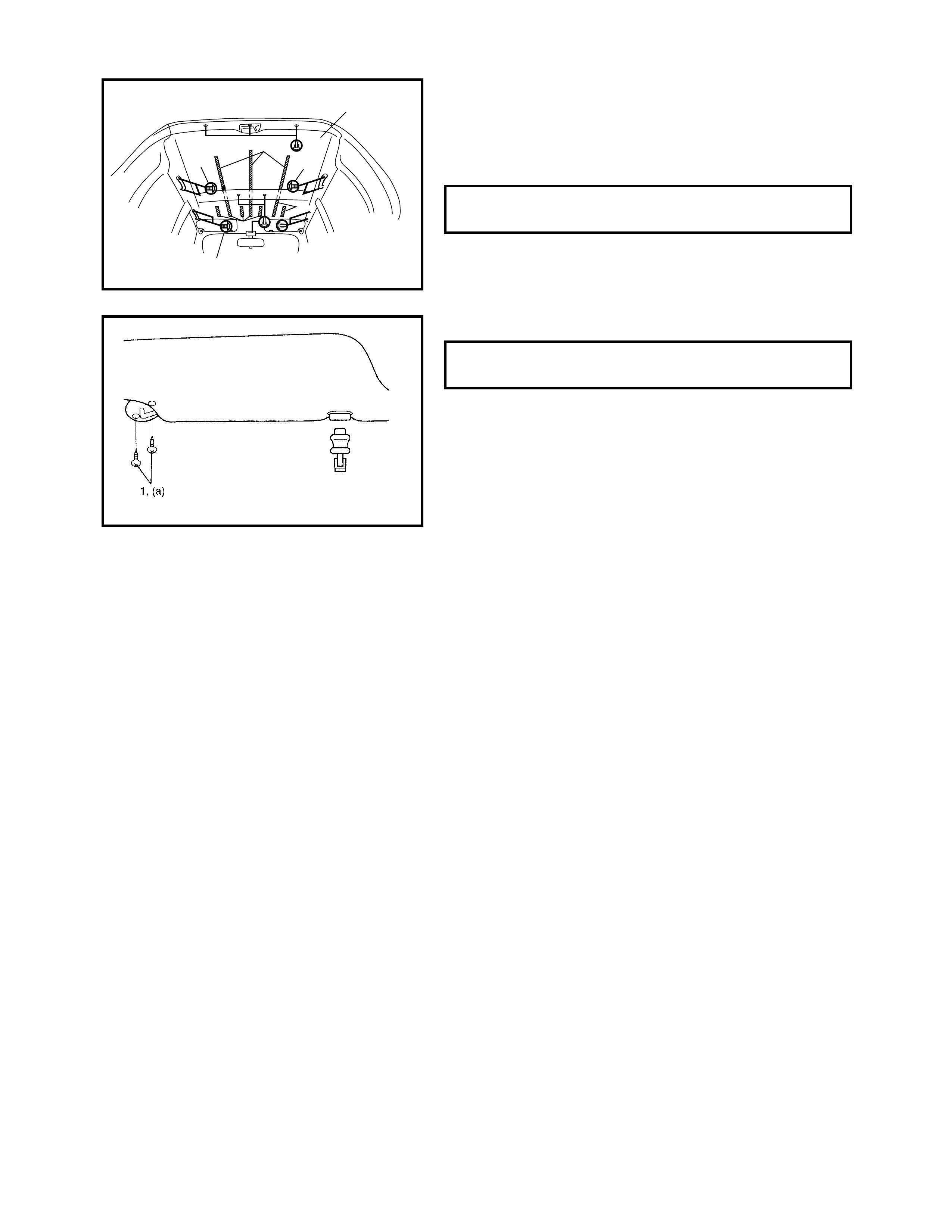

INSTALLATION

Reverse r emoval proced ure to install the headlining notin g

the following:

• Apply double-sided tape (1) to the headlining (2) as

shown in figure then install the headlining (2).

• Tighten the assistant grip screw (3) to specified torque.

• Tighten the sun visor screw (1) to specified torque.

ASSISTANT GRIP SCREW

TORQUE SPECIFICATION 4 Nm

1

1

1

3

33

2

SUN VISOR SCREW (a)

TORQUE SPECIFICATION 4 Nm

7. PAINT AND COATINGS

7.1 ANTI-CORROSION TREATMENT

WARNING: Standard shop practices, particularly eye protection, should be followed during the per-

forming the operations below to avoid personal injury.

To improv e th e c or rosi on res is tance of the body st ru ctu re, one or tw o side d gal v ani se d st eel she et i s used . In

addition, the following anti-corrosion measures are used:

• Steel sheets are treated with cathodic electroprimer which has excellent corrosion resistance.

• Rust proof wax coatings are applied to the inside of doors and side sills where moisture is likely to remain.

• Vinyl coating is applied to the underside of the body and to the inside of the wheel housing.

• Sealant is applied to door hems and panel joints to prevent water penetration and resulting rust.

When panels are replaced or there is collision damage repair, leaving the relevant area unt reated will leave

the area s usceptib le to cor rosion . There fore, it i s an es senti al func tion o f a ny repair operat ion to cor rectly re-

coat the relevant surfaces.

All metal panels are coated with metal conditioners and primer coating during vehicle production. Following

repair and/or replacement part installation, every accessible bare metal surface should be cleaned and coated

with rust proof primer. Perform this operation prior to the application of sealant and rust proof wax coating.

Sealan t is a ppl ied to t he s pec i fic joints of a v eh ic le durin g pr od uc tio n. T he se al ant is int ended to pr ev ent dus t

from ente ring the veh icle and also serves as an anti- corrosion bar rier. The seala nt is applied to the do or and

hood hem areas and between panels and must be correctly resealed if damaged. Reseal the joints of new

replacement panels and reseal the hem area of a replacement door or hood skins.

Use a quality sealant to seal flanged joints, overlapping joints and seams. The sealant must have flexible

characteristics and be able to be painted after it is applied to repaired areas.

Use caulking material to seal op en joints. Select the correct sealant for the situation and the purpose for its

use. Observe the manufacturer’s instructions when using the sealant.

In m any instances, wh ere repaired sectio ns requir e painting, fo llow the n ormal tech niques fo r finish prepara-

tion, colour painting and undercoating build-up.

Rust proof wax, a penetrative compound, is applied to metal-to-metal surfaces (inside doors and side sills)

where i t is di fficult t o use no rm al u nde rc oa tin g met hod s. S el ec t the cor r ect, pe netr at iv e rus t pr oof w ax f or this

application.

When undercoating (vinyl coating) underbody areas, care should be taken to keep engine related parts, shock

absor ber mo unts and mov ab le parts free fro m se al ant. Fo ll owin g un der -co ati ng, e ns ure tha t body dr ai n ho les

remain open.

The correct sequence for the application of anti-corrosion materials is as follows:

1. Clean and prepare the metal surface.

2. Apply primer.

3. Apply sealant (all joints original ly sealed).

4. Apply colour in areas where colour is required such as hem flanges, exposed joints and under body

components.

5. Apply anti-corrosion compound (penetrative wax).

6. Apply undercoating (rust proof material).

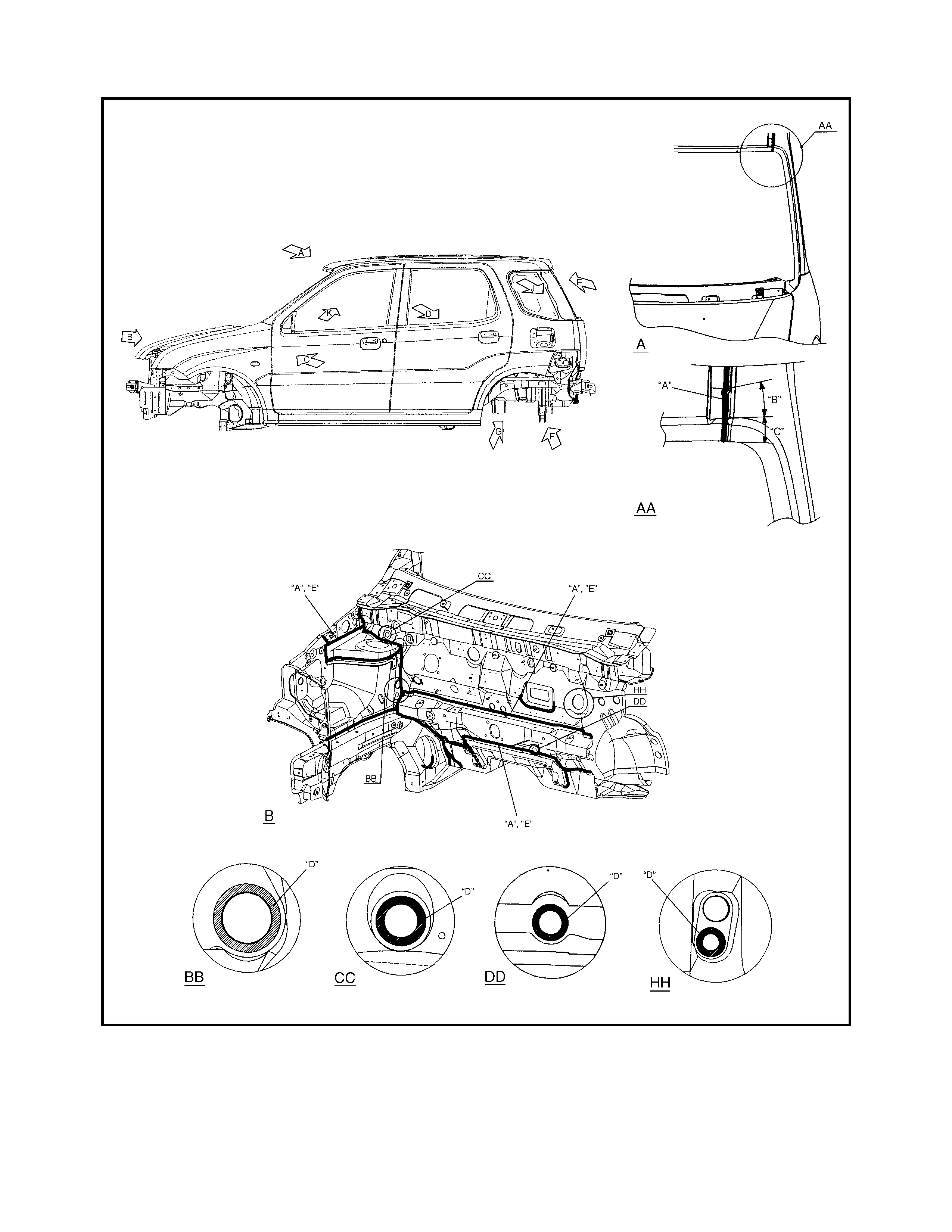

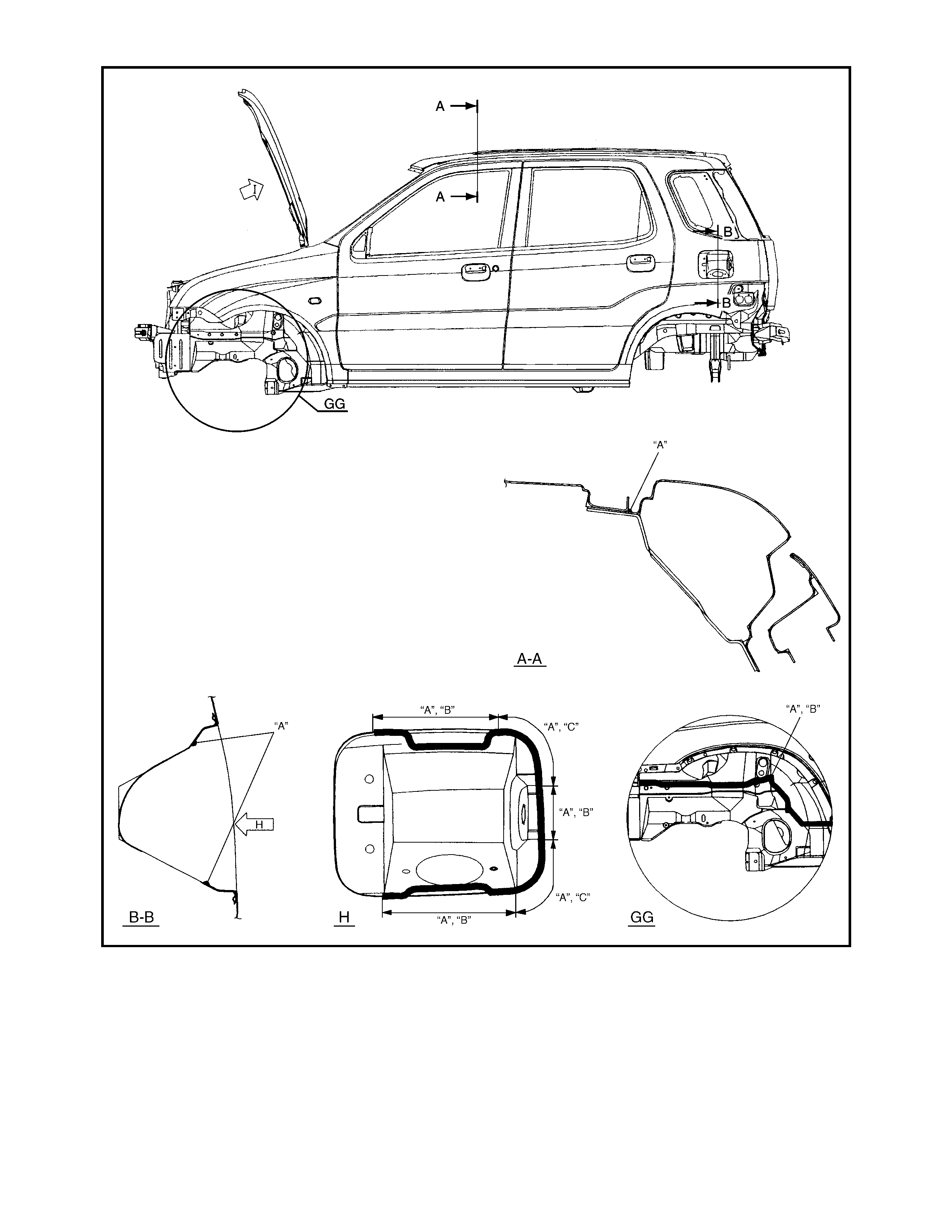

7.2 SEALANT AP PLICATION AREAS

Legend

“A” : Apply sealant “C” : Wipe off excess sealant after

application “E” : Smooth out sealant with a

brush

“B” : Apply sealant without heeling “D” : Do not apply sealant

Legend

“A” : Apply sealant “C” : Do not apply sealant “D” : Wipe off excess sealant after

application

“B” : Smooth out sealant with

a brush

Legend

“A” : Apply sealant “B” : Wipe off excess sealant

after application “C” : S mooth out sealant with a brush

“D” : Fill gap/hole with sealant

Legend

“A” : Apply sealant “C” : Keep hatched area free from

sealant “D” : Wipe off excess sealant

after application

“B” : Never fill up drain holes with

seala nt

Legend

“A” : Apply sealant “B” : Smooth out sealant with a

brush “C” : Wipe off excess sealan t

after application

Legend

“A” : Apply sealant “B” : Apply sealant so that top of

flange is covered

7.3 UNDER COAT ING APPLICATION AREAS

Legend

“A” : Apply undercoating (PCV,

400 µm or more) “B” : Apply anti-chip coat (100 µm

or more) “C” : Apply anti-chip coat (300

µm or more)

“D” : Do not apply undercoating

Legend

“A” : Apply undercoating (PCV,

400 µm or more) “B” : Apply undercoating (PCV,

600 µm or more) “C” : Do not apply undercoating

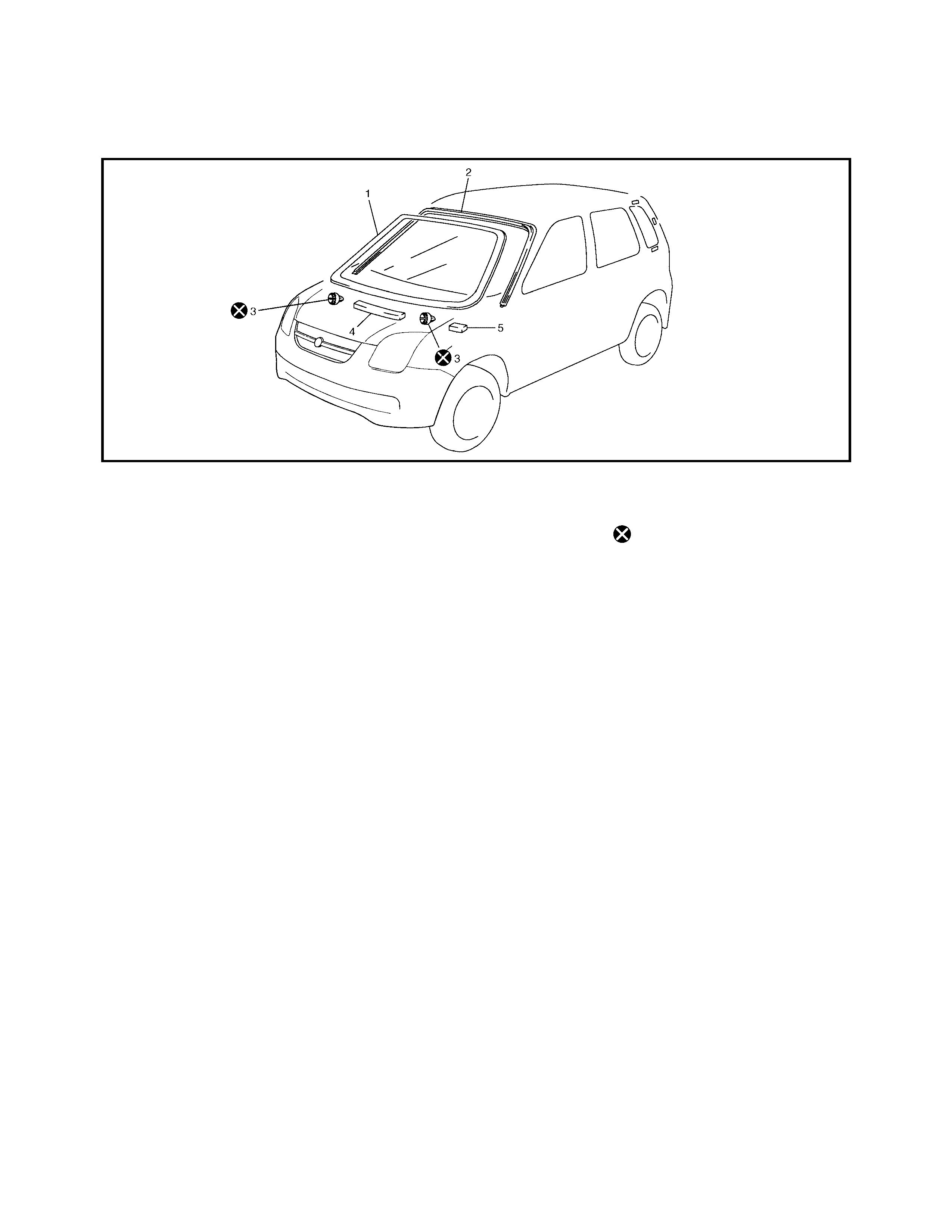

7.4 ANTI-CORR OSION COMPOUND APPLICATION AREA

Legend

“A” : Apply rust proof wax (hot

wax 50 µm or more) “B” : Apply rust proof wax (low

viscosity wax 10 µm or

more)

“C” : Apply rust proof wax (high

viscosi ty w ax 50 µm o r m ore )

PLASTIC PARTS FINISHING

Paintable plastic parts are made from ABS or PP plastic.

PAINTING

Plastic parts may require priming with specific plastic primer. Refer to your paint manufacturer for further infor-

mation.

1. Parts that require painting should be washed with cleaning solvent.

1. Apply plastic primer to the part in accordance with the paint manufacturer’s directions

2. Apply colour lacquer to the part in accordance with the paint manufacturer’s directions.

3. Follow directions for required drying times. REFERENCE

Plastic parts are identified in an inconspicuous area.

8. REQUIRED SERVICE MATERIAL

Material Recommended product Use

Lithium grease Lithium grease • Window regulator

• Door hing e

Sealant Three Bond No. 1215 • Hood hing e

• Door hing e