GM POWERTRAIN

VR, VS, VT, VX & VU SERVICE REPLACEMENT TRANSMISSION ASSEMBLY (SRTA) PROGRAM

DL 22/96

March 26, 1996

As a cus tomer satisfac tion initiative, GM-Powertrain in conj unction with Holden has developed a VR/VS/VT Service

Replacement Transmission Assembly (SRTA) Program. This program replaces the existing VR & VS Holden

Warranty Transmission Changeover Program, refer to DL 39/95. Distribution of SRTA units will be through the

existing changeover program distributors. A list of these distributors is provided with this letter.

This program commenced on April 1, 1996.

SRTA transmissions are remanufactured at a single point site in a production environment under strict quality

control conditions.

SRTA distributors are committed to the next business day dispatch for all SRTA models on an FOC (Free of

Charge) basis.

Note:

Transmission orders received early in the day will be dispatched on the same day to Dealers within the

metropolitan area.

GENERAL GUIDELINES

The SRT A Program will operate on a sim ilar basis to the pr evious program in that transm issions will be supplied to

Dealers on an FOC basis.

This SRTA Program is restricted to warranty related transmission failures. Under no circumstances are STRA

transmissions to be used for vehicles outside the new vehicle powertrain warranty period of 100,000 k m or thr ee ( 3)

years.

In the event that the transmission fails and requires replacements on a vehicle with less t han 5,000 km , the Dealer

is to order a new replacement transmission from the local SRTA Distributor.

Dealers should order a SRTA replacem ent transmiss ion for all warranty repairs between 5,000 and 100,000 k m that

cannot be corrected by replacement of parts listed in the on-vehicle service components list. Holden strongly

recommends the use of the SRTA Program for all transmission warranty repairs that fall into the above criteria.

In summary, the on-vehicle service components consist of:

Components that are accessible external to the transmission.

Seals and gaskets for external oil leak repairs excluding torque converter and oil pump seal.

SRTA - ORDERING PROCEDURE

The transmission complaint must be confirmed using the correct diagnosis as detailed in the Diagnosis section of

this letter.

If the repair cannot be carr ied out by replacement of on-vehicle ser vice com ponents, the Dealer will order an SRT A

transmission from the local SRTA Distributor.

All SRTA orders should be faxed to your local Distributor using a completed copy of the SRTA

Order Form (Form F). Transmissions will not be supplied unless the Distributor receives a fully completed SRTA

Order Form.

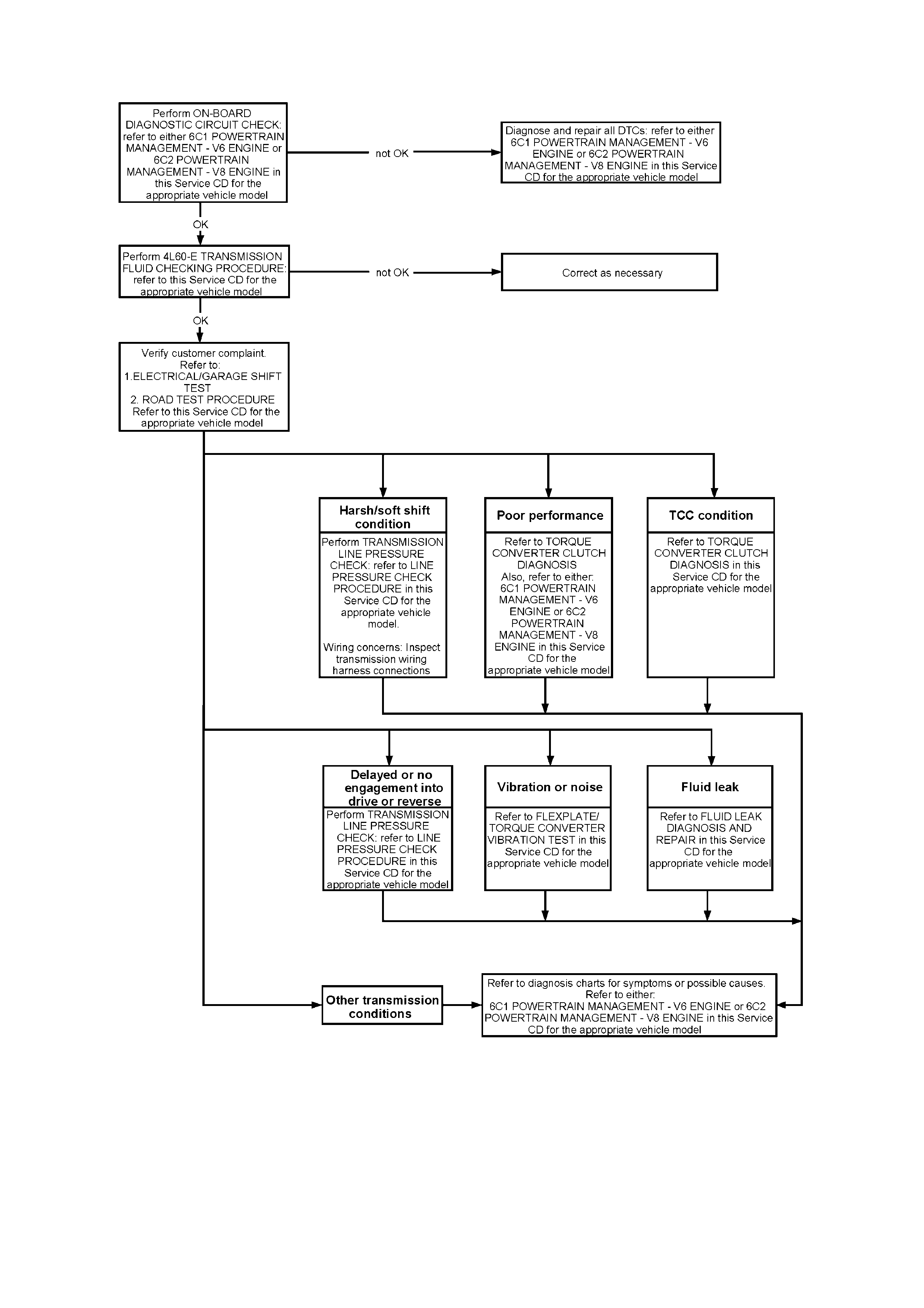

DIAGNOSIS

W hen diagnos ing transm ission com plaints, Dealers mus t first c arry out a transm ission f unctional tes t as detailed in

the appropriate section of the Service Information CD. This test procedure is reproduced at the rear of this

document, refer Transmission Function Check.

Technicians must carry out transmission line pressure checks where indicated in the transmission functional test

procedure. The line pressure checking procedure is reproduced at the rear of this document, refer

Line Pressure Check.

Transmission problems can often be attributed to poor electrical connections at the transmission electrical

connector. Guidelines for checking and servicing this connector are provided at the rear of this document, refer

Transmission Electrical Connector.

PlDL 40/00

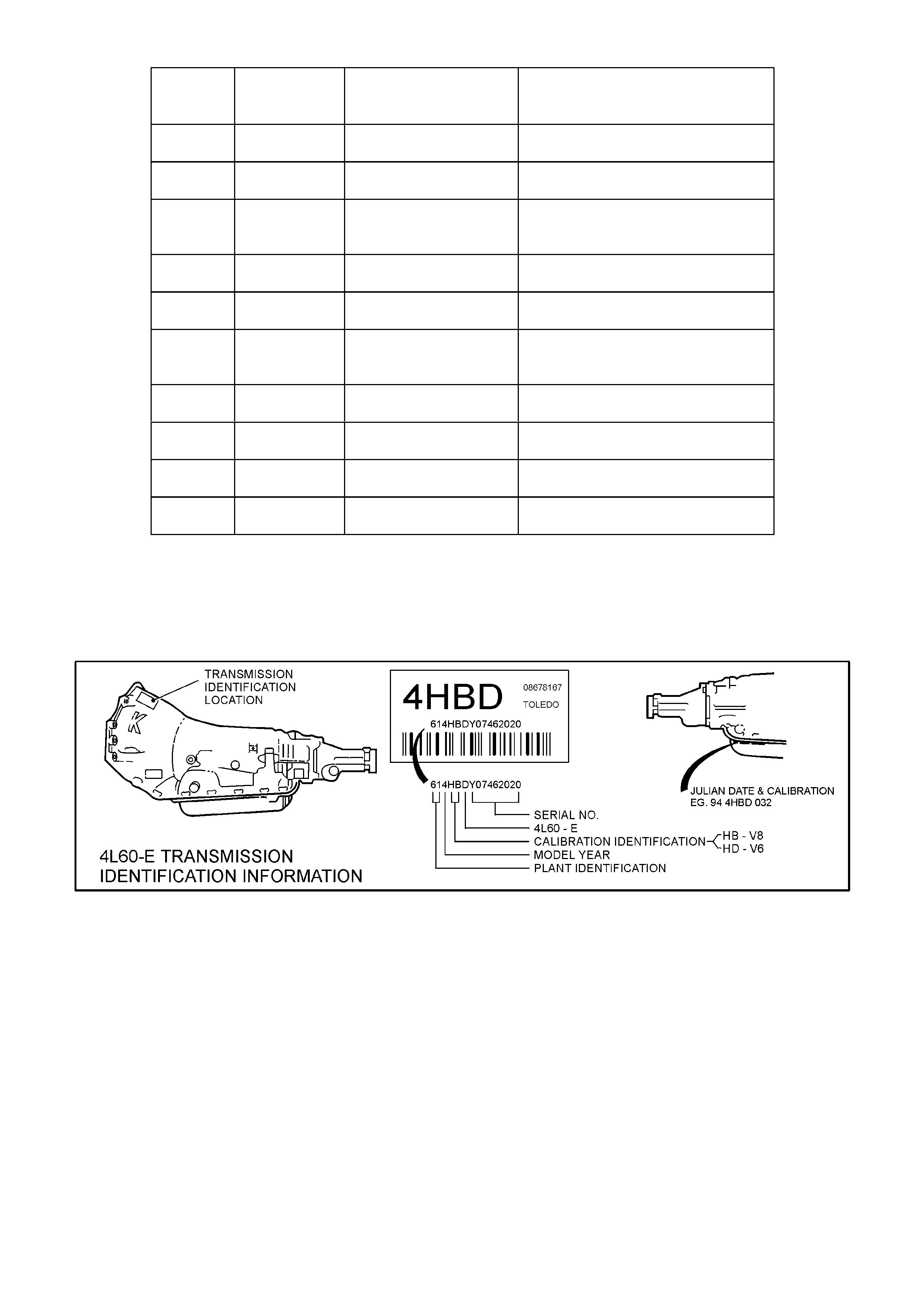

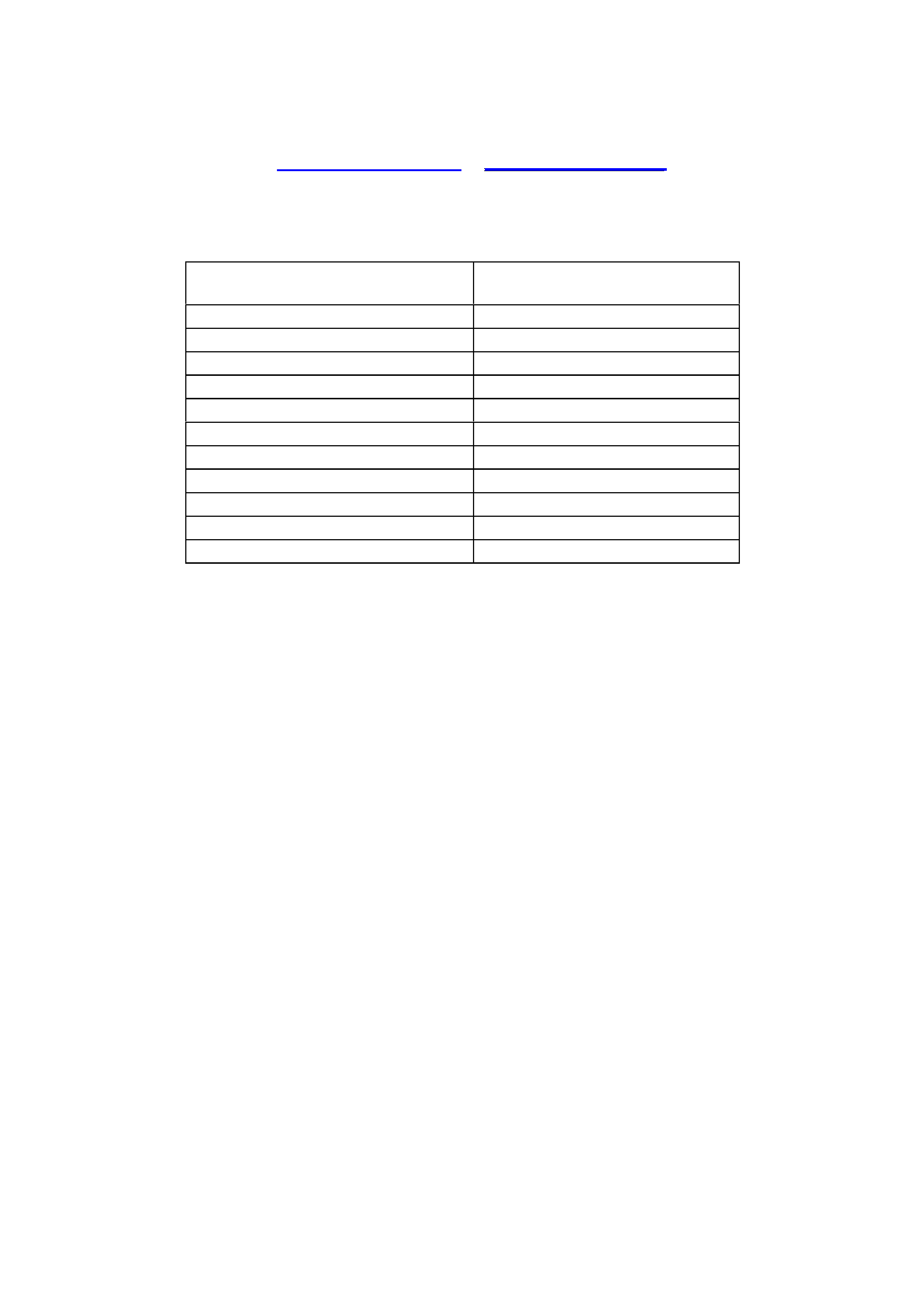

SRTA - MODEL INFORMATION

Model

Type SRTA Part

Number Description Vehicle Range

4HBD 8688982 VR 5.0L floor shift VR SOP to L778496 (22/11/94)

4HDD 8688983 VR 3.8L floor shift VR SOP to L772125 (2/11/94)

5HBD 24202441 VR/VS 5.0L floor shift L778497 (22/11/94) to

L871025 (17/10/95)

5HCD 24202442 VR 3.8L column shift L772868 (4/11/94) to VS SOP

5HDD 24202443 VR 3.8L floor shift L772126 (2/11/94) to VS SOP

5HSD 24203290 VR/VS 5.7L HSV From L756483 (12/9/94) to

L826471 (6/10/95)

6HDD 24203402 VS 3.8L floor shift From VS SOP

6HCD 24203403 VS 3.8L column shift From VS SOP

6HBD 24203404 VS 5.0L floor shift From L871026 (17/10/95)

6HSD 24203405 VS 5.7L HSV From L826472 (6/10/95)

NOTE:

As vehicles can be built out of sequence, the vehicle Production Serial Number breakpoints in the above table

should be used as a guide only. Transmission model type should be confirmed from the transmission ID number,

refer to Figure 1, prior to ordering an SRTA transmission.

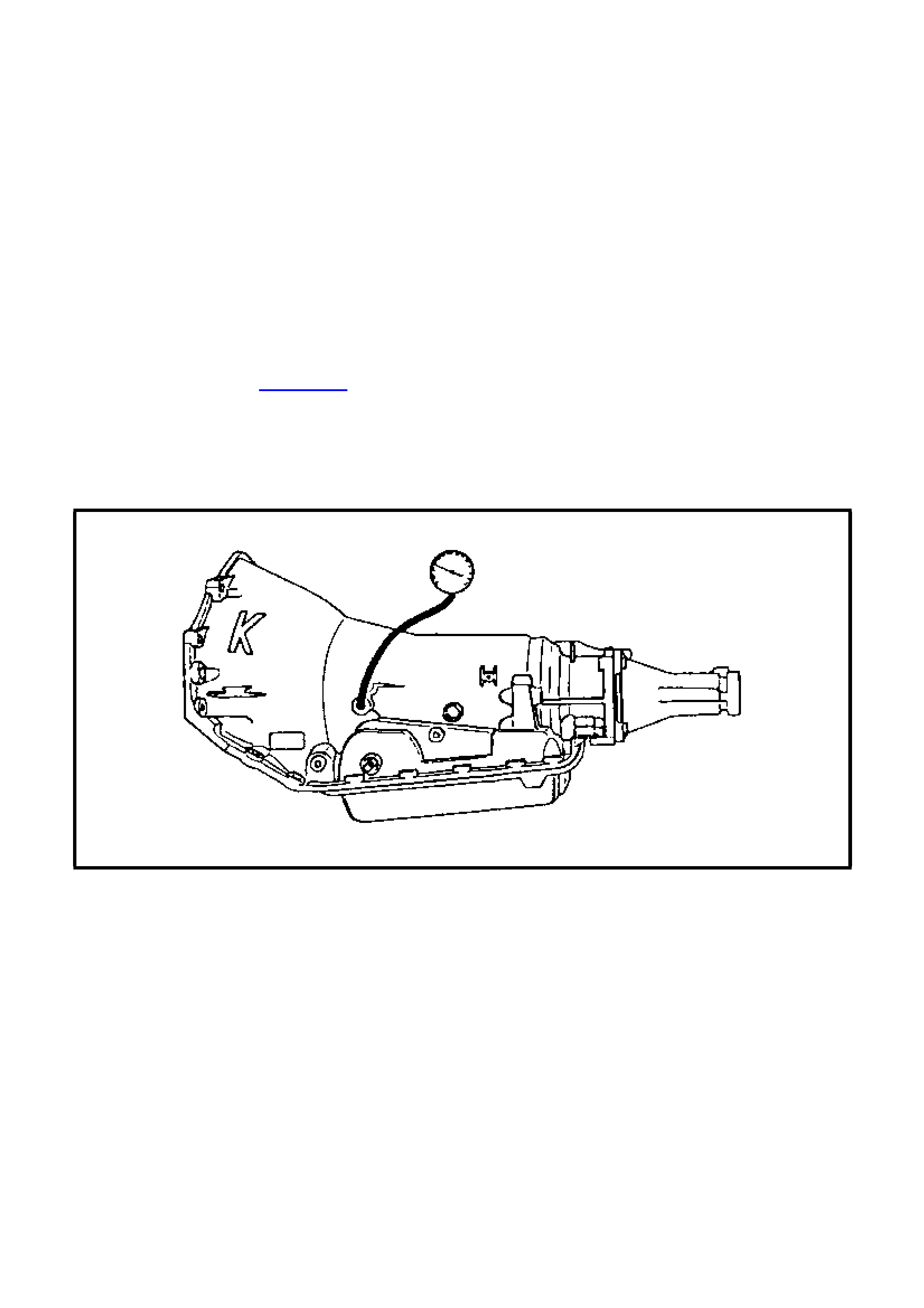

Figure 1 - Hydra-Matic 4L60-E Transmission Identification Information

DISTRIBUTION

SRTA Model transmissions can be ordered from your local SRTA Distributor listed below:

STATE DISTRIBUTOR ADDRESS CONTACT

Qld EAGERS RETAIL PTY LTD 95 Breakfast Creek Road,

Newstead, QLD 4006 Bill McElroy

PH: 07 3364 1124

FAX:07 3364 1044

Vic GM TRANSMISSION

REMANUFACTURING 70 Raglan St., Preston,

Vic. 3072 Mario Males

PH.: 03 9480 0988

FAX : 03 9480 2688

TAS MOTORS HOBART Collins St.

Hobart, TAS 7000 Tony Reardon or Barry Adcock

PH: 03 6220 1255

FAX: 03 6234 4732

SA MOTOR TRADERS 64 Grand Junction Rd

Kilburn, SA 5084 Ian Laughton or Lou Zauch

PH: 08 8349 4141

FAX: 08 8260 2447

NSW BOYDED INDUSTRIES 60 Hampstead Rd

Auburn, NSW 2144 Robert Mizzi

PH: 02 9648 3300

FAX: 02 9648 4534

NSW SUTTONS PARTS 22 Carter St

Lidcombe, NSW 2141 John Sherar

PH: 02 9648 3688

FAX: 02 9647 1483

WA COVENTRY’S 253 Walter Rd

Morley, WA 6062 Charlie Pintabona

PH: 08 9276 0111

FAX: 08 9276 1877

NT KERRY HOLDEN 21-25 Stuart Highway

Darwin, NT 0820 Dale Middleton

PH: 08 8980 8059

FAX: 08 8980 8051

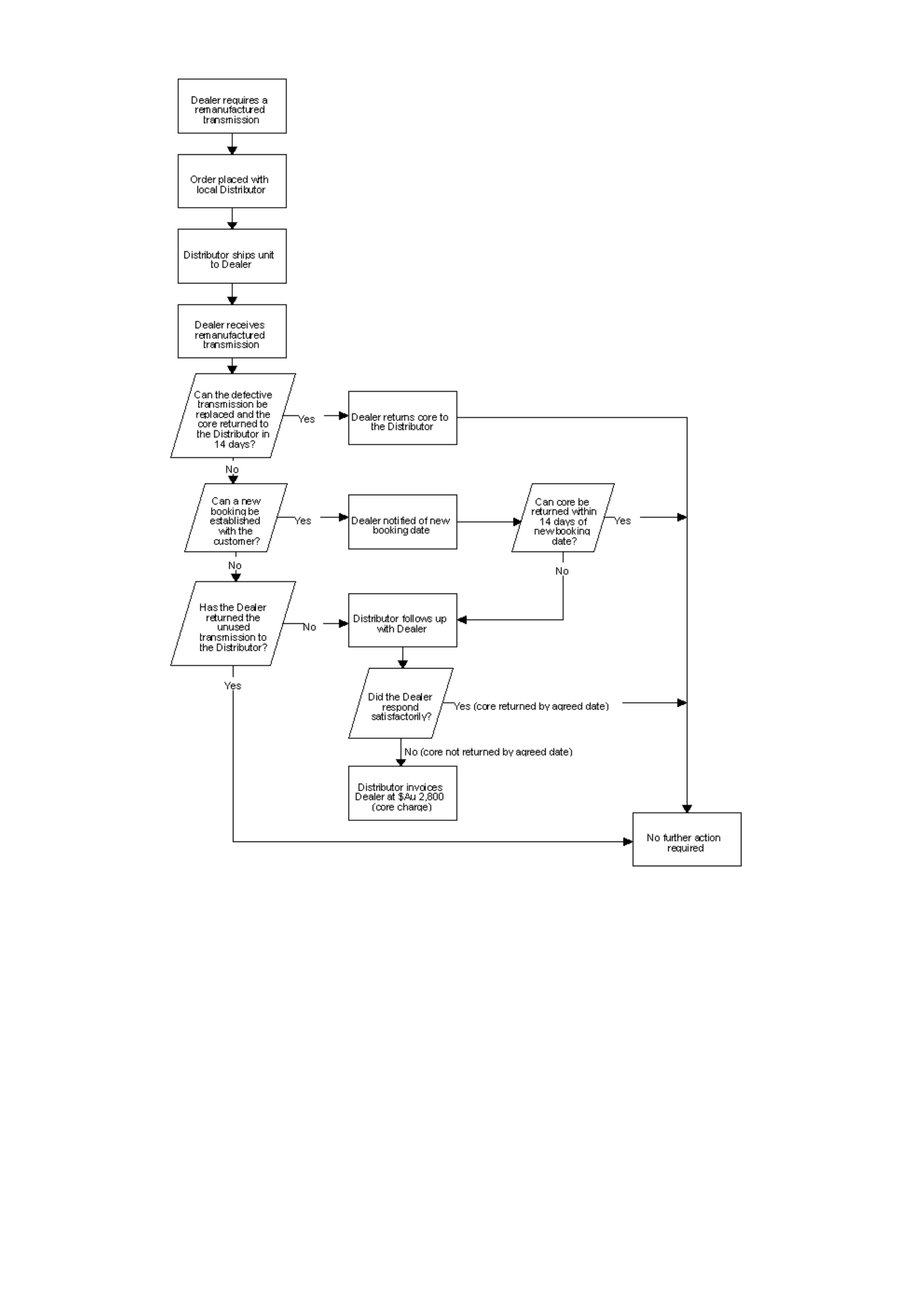

RETURN OF FAILED TRANSMISSION (CORE) ASSEMBLY

Refer to the Core Exchange Return Procedure for the instructions that must be followed when returning the

failed transmission (core) to the Distributor.

The Dealer must complete the Transmission Report Form and the SRTA Transmission Product Feedback

Form supplied with the SRTA transmission.

Metropolitan Dealers: Your local SRTA Distributor will supply a pickup and delivery service to deliver SRTA

transm iss ion to your Dealer ship and pic k up the failed trans m ission f or retur n. The Dealer m ust notif y the Distributor

when a core unit is ready for pickup.

Country Dealers: SRTA transmissions will be shipped to country Dealers via IPEC overnight road express. An

IPEC consignment note preprinted with the address of the Distributor will be supplied with the SRTA transmission

for return of the core to the Distributor as soon as possible.

Note:

The failed transmission (core) must be returned to your local Distributor within 14 days to avoid being charged

$2,800 replacem ent cost. If for any reason the SRTA trans miss ion cannot be used or the failed transmiss ion (core)

cannot be returned within 14 days, the Distributor must be notified to avoid being billed for the transmission core.

Refer to the Transmission Core Return Process.

DOCUMENTATION

The following three pages are copies of the documentation that will be supplied with each SRTA transmission

supplied. The Automatic Transmission SRTA Product Feedback Form and the Transmission Report Form

must be filled out completely to assist in root cause analysis. Preprinted IPEC consignment notes, used for the

return of the failed transmission, will be provided with each SRTA transmission shipped to country Dealers.

A defective material tag (GMH-906) is not required for SRTA transmission replacements.

OIL COOLER FLUSHING

W hen fitting an SRT A transm ission, it is mandator y to carry out a cooler flush and f low chec k as detailed in Gr oup

7B of the November 1995 Service Techline. The cooler flush and flow check procedure in Section 7C4 of the VR

Service Manual was revised in line with this Service T ec hline. Pleas e ensur e that all c opies of your Service Manuals

have been updated accordingly, with “Revised, November 1995” printed at the bottom of page 7C4-24.

Failure to perf orm this cooler flush and f low check procedure m ay result in a repeat of transmis sion failure. Please

ensure your Dealership performs this mandatory procedure.

WARRANTY CLAIM DATA

The cost of removing and replacing the SRTA transmission must be claimed using the following special labour

operation number. The time allowed for this labour operation has been increased buy 0.4 hour to allow for

mandatory cooler flush and flow check procedure.

Description: Remove transmission and fit SRTA unit.

Labour Operation Number: K000225

Standard Time: 3.0 hours

Vendor Handling Allowance: 0.5 hour

SRTA - TRANSMISSION FREIGHT CHARGES

There have been is olated reports of Dealers being char ged freight cos ts for s hipping SRTA cor e units bac k to their

SRTA dist ributor, refer to DL 22/96. The following inf ormation is provided to ensure that all f reight cos ts as sociated

with the program are charged correctly.

Metropolitan Dealers: The SRTA Distributors provide a pickup and delivery service to all metropolitan dealers.

Holden will not accept freight charges for the pickup or delivery of SRTA transmission within the metropolitan area.

Country Dealers: Distributors will be supplied preprinted IPEC consignment notes with the charges payable by

third party section completed. These consignment notes have been delayed due to printing errors. In the interim,

when returning the core transm is sion to your distributor, include the f ollowing details in the charges payable by third

party section of the consignment note.

(Charges payable by third party)

Holden

Accounts Payable

Box 4375 GPO

Melbourne, 3001

Account Number 1501-7341

VT SERVICE REPLACEMENT TRANSMISSION ASSEMBLY (SRTA) PROGRAM UPDATE

DL 66/97

November 11, 1997

Effective immediately, new transmissions for warranty replacement on vehicles with less than 5000 km travelled

and covered by new car warranty, must be procured from SRTA Distributors.

Previously, these transmissions were procured from HSPO (and non-SRTA Distributors).

These transmissions are supplied on an FOC (Free Of Change) basis, and old units must be returned to SRTA

Distributors under the sam e procedur e as all other SRT A transm issions. For details of existing pr ocedures, ref er to

dealer letters DL 22/96, DL 45/96 and DL 5/97.

New transmissions for warranty repairs must not be procured from HSPO (or a non-SRTA Distributor). However,

for any vehicle not covered by new car warranty which requires a tr ansmission, a tr ansmiss ion m ust be purchased

from HSPO.

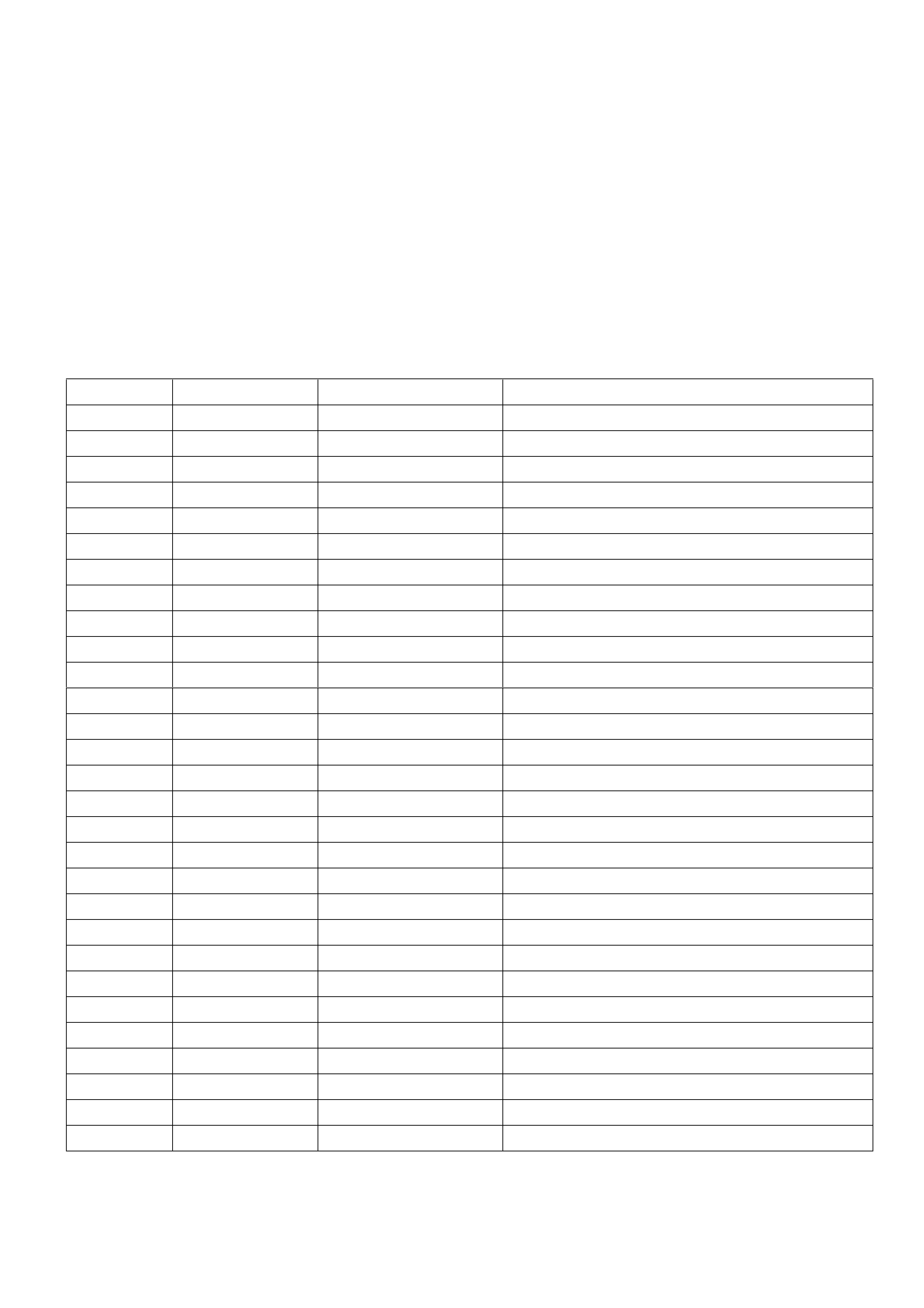

SRTA - MODEL INFORMATION

The following table lists the new transmissions now stocked by SRTA Distributors:

Year Model ID SRTA Part No. Description & Usage

1997 7HBD 24207572 VS 5.0L floor shift

7HCD 24207574 VS 3.8L column shift

7HDD 24207571 VS 3.8L floor shift

7HLD 24207575 VS 3.8L S/C floor shift

7HSD 24207573 VS 5.7L floor shift

1998 8HBD 24210662 VS & VT 5.0L floor shift

8HCD 24210663 VS 3.8L column shift

8HDD 24210664 VS 3.8L floor shift

8HFD 24210665 VT 3.8L floor shift

8HJD 24210667 VT 5.0L (195Kw, HSV) floor shift

8HLD 24210668 VS 3.8L S/C floor shift

8HND 24210669 VT 3.8L S/C floor shift

8HSD 24210670 VT 5.7L floor shift

1999 9HBD 24212817 VS & VT 5.0L floor shift

9HCD 24212812 VS 3.8L column shift

9HDD 24212813 VS 3.8L floor shift

9HFD 24212814 WH & VT 3.8L floor shift

9HJD 24212818 VS 5.0L (195Kw, HSV) floor shift

9HLD 24212815 VS 3.8L S/C floor shift

9HND 24212816 WH & VT 3.8L S/C floor shift

9HPD 24212821 WH & VT 5.7L (LS1) floor shift

9HSD 24212819 WH & VT 5.7L (L98) floor shift

2000 0HBD 24216091 VS & VT 5.0L floor shift

0HCD 24216092 VS 3.8L column shift

0HDD 24216093 VS 3.8L floor shift

0HFD 24216094 WH & VT 3.8L floor shift

0HJD 24216095 VS 5.0L (195Kw, HSV) floor shift

0HND 24216096 WH & VT 3.8L S/C floor shift

0HPD 24216097 WH & VT 5.7L (LS1) floor shift

DISTRIBUTION

The transmissions noted in the table above can be ordered from your local SRTA Distributor. An updated listing of

distributors is provided in the table below:

STATE DISTRIBUTOR ADDRESS CONTACT

Qld EAGERS RETAIL PTY LTD 95 Breakfast Creek Road,

Newstead, QLD 4006 Bill McElroy

PH: 07 3364 1124

FAX:07 3364 1044

Vic GM TRANSMISSION

REMANUFACTURING 70 Raglan St., Preston,

Vic. 3072 Mario Males

PH.: 03 9480 0988

FAX : 03 9480 2688

TAS MOTORS HOBART Collins St.

Hobart, TAS 7000 Tony Reardon or Barry Adcock

PH: 03 6220 1255

FAX: 03 6234 4732

SA MOTOR TRADERS 64 Grand Junction Rd

Kilburn, SA 5084 Ian Laughton or Lou Zauch

PH: 08 8349 4141

FAX: 08 8260 2447

NSW BOYDED INDUSTRIES 60 Hampstead Rd

Auburn, NSW 2144 Robert Mizzi

PH: 02 9648 3300

FAX: 02 9648 4534

NSW SUTTONS PARTS 22 Carter St

Lidcombe, NSW 2141 John Sherar

PH: 02 9648 3688

FAX: 02 9647 1483

WA COVENTRY’S 253 Walter Rd

Morley, WA 6062 Charlie Pintabona

PH: 08 9276 0111

FAX: 08 9276 1877

NT KERRY HOLDEN 21-25 Stuart Highway

Darwin, NT 0820 Dale Middleton

PH: 08 8980 8059

FAX: 08 8980 8051

Important:

Transmissions purchased from HSPO (or a non-SRT A Distributor) prior to the issue of this letter must be r eturned

when requested via the REPAC Report.

W hen transm issions are supplied on this FOC basis, old units must be returned to SRTA Distributors as per usual

SRTA procedures.

Dealers must assume responsibility for the completion of thorough and accurate diagnosis of fluid leaks prior to

commencing any rectification work or removing the transmission.

As in the past, dealerships are required to f lush and flow check the vehicles automatic transm ission cooling circuit

when changing a transmission. For details of this procedure for VT vehicles, refer to Section 7C4,

2.4 TRANSMISSION COOLER REVERSE FLUSH AND FLOW RATE CHECK, in the VT Series Service

Information CD.

SRTA - CORE RETURN PROCEDURE AND PROCESS CHART

AUTOMATIC TRANSMISSION - 24208340RW

CORE RETURN PROCEDURE

NOTE:

Instructions must be followed by your dealership when returning the core to the distributor.

1. Use care not to damage case.

2. Drain as much oil from the core as possible.

3. Remove all plastic shipping plugs from SRTA and install in core.

4. Install SRTA following the correct service procedures, refer Section 7C4, TRANSMISSION ASSEMBLY -

REINSTALL.

IMPORTANT:

Before installing Automatic Transmission (SRTA), oil cooler(s) and lines must be thoroughly flushed and clean.

5. Contact Holden Technical Assistance if you need diagnostic assistance.

6. Packet (plastic envelope) received with SRTA contains the following for:

VEHICLE OWNER:

Automatic Transmission/Transaxle Assembly (SRTA) Limited Warranty.

TECHNICIAN:

Product Feedback Form (Two-copy)

Must fill out Product Feedback Form completely.

Attach white copy of Product Feedback Form and a copy of the Repair Order inside the plastic envelope

supplied with the SRTA unit.

Place in plastic envelope received with SRTA.

Attach plastic envelope to bellhousing of Core Return.

Attach yellow copy of Product Feedback Form to original Repair Order and return to Service Manager.

SERVICE MANAGER:

Retain for your records yellow copy of Product Feedback Form and original Repair Order.

7. Carefully repack core in shipping container.

IMPORTANT:

Return core as soon as possible to your local distributor.

Core must be returned within 14 days.

If core cannot be returned within 14 days, contact you distributor immediately.

TRANSMISSION CORE RETURN PROCESS

SRTA - TRANSMISSION ORDER FORM (FORM F)

SRTA TRANSMISSION ORDER FORM

Use only black pen

DISTRIBUTOR:

DATE OF ORDER:

PART NUMBER REQUIRED:

(7 or 8 digit SRTA part number)

MODEL TYPE:

(4 digit Model eg. 6HDD)

VEHICLE ISO VIN NO:

(17 CHARACTERS)

ODOMETER READING:

VEHICLE WARRANTY START DATE:

SHIP TO:

DEALER NAME:

DEALER CODE:

CONTACT NAME:

TELEPHONE NUMBER:

ADDRESS:

Distribution Use Only:

Date shipped:

FORM ( F): ALL DETAILS TO BE FULLY CO MPLETED ON FORM.

SRTA - TRANSMISSION REPORT FORM (24208394RW)

SRTA - PRODUCT FEEDBACK FORM (24208339RW)

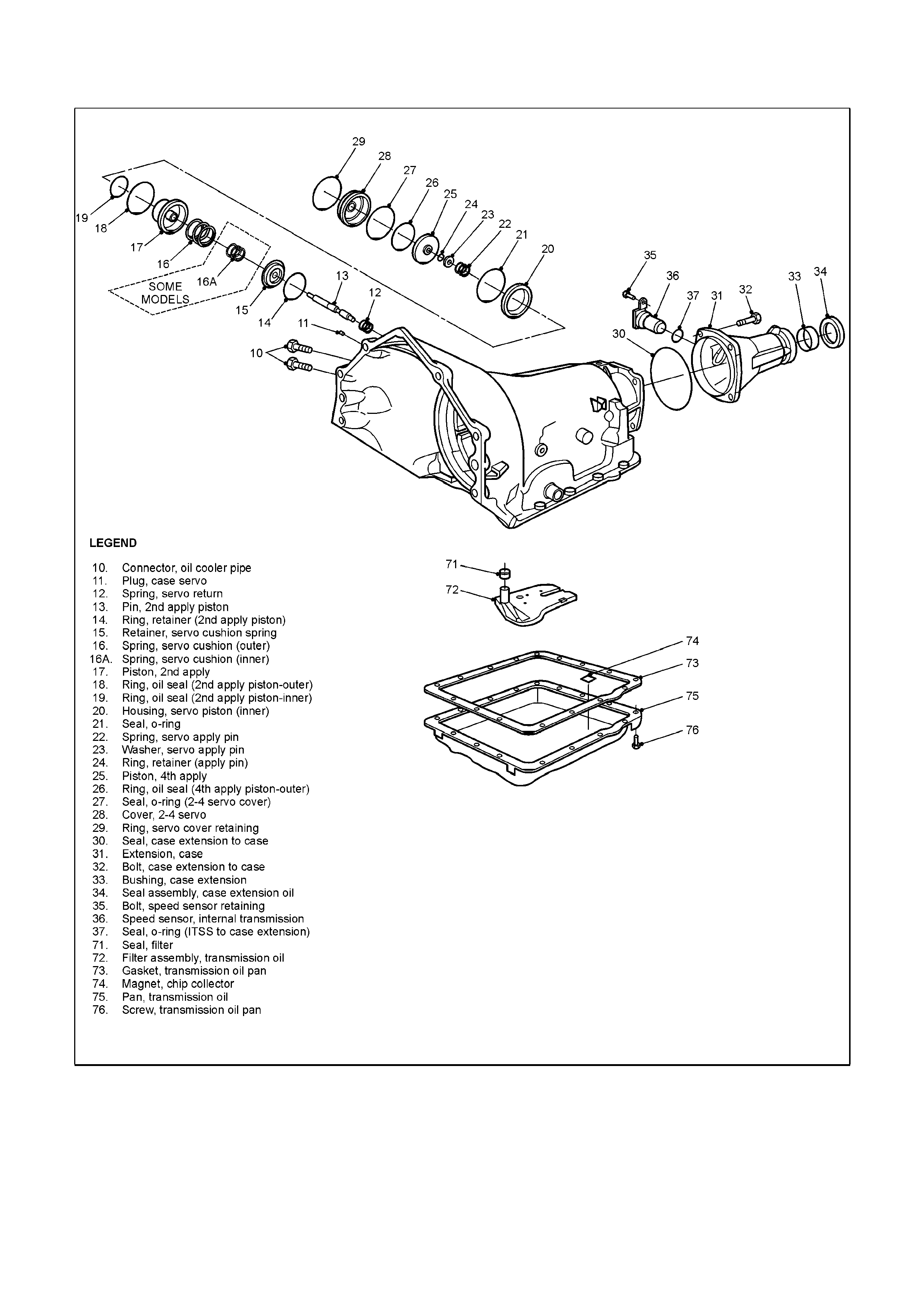

TRANSMIS S ION PARTS DIAGRAM AND TEST PROCEDURES

TRANSMISSION PARTS DIAGRAM

LINE PRESSURE CHECK PROCEDURE

Line pressures are calibrated for two sets of gear ranges, Drive-Park-Neutral and Reverse. This allows the

transmission line pressure to be appropriate for different pressure needs in different gear ranges:

Gear Range Line Pressure Range

Drive, Park or Neutral 55-189 psi

Reverse 64-324 psi

Before performing a line pressure check, verify that the pressure control solenoid is receiving the correct electrical

signal from the PCM:

1. Install the appropriate scan tool for the vehicle model.

2. Start the engine and set parking brake.

3. Check for a stored pressure control solenoid diagnostic trouble code, and other diagnostic trouble codes.

4. Repair vehicle if necessary :

Inspect

Fluid level (refer to Section 7C4 of this Service Information CD.)

Manual linkage

Install or connect

Appropriate scan tool for the vehicle model

Oil pressure gauge at line pressure tap

Oil Pressure Gauge Line Pressure Tap

5. Put gear selector in Park and check that the parking brake is still set.

6. Start engine and allow it to warn up at idle.

7. Access the ‘PCS Control’ test on the scan tool.

8. Increase DESIRED PCS in 0.1 Amp increments and read the corresponding line pressure on the pressure

gauge. Allow pressure to stabilise for 5 seconds after each current change.

9. Compare data to the Drive-Park-Neutral line pressure chart below.

NOTICE:

Total test running time should not exceed 2 minutes, or transmission damage could occur.

CAUTION:

Brakes must be applied at all times to prevent unexpected vehicle motion.

If pressure readings differ greatly from the line pressure chart, refer to the Diagnosis Charts contained in this

Service Information CD, refer Section 6C1 - V6 ENGINE or Section 6C2 - V8 ENGINE.

The s can tool is only available to control the press ure c ontrol solenoid in Par k and Neutr al with the vehicle stopped.

This protects the clutches from extremely high or low pressures in Drive or Reverse ranges.

DRIVE-PARK-NEUTRAL LINE PRESSURE CHART

Pressure Control Solenoid

Current (Amp) Line Pressure (psi)

0.02 170 – 190

0.10 165 – 185

0.20 160 – 180

0.30 155 – 175

0.40 148 – 168

0.50 140 – 160

0.60 130 – 145

0.70 110 – 130

0.80 90 – 115

0.90 65 – 90

0.98 55 – 65

Pressures at 1500 rpm and 66°C (150°F). Line pressure drops as temperature increases.

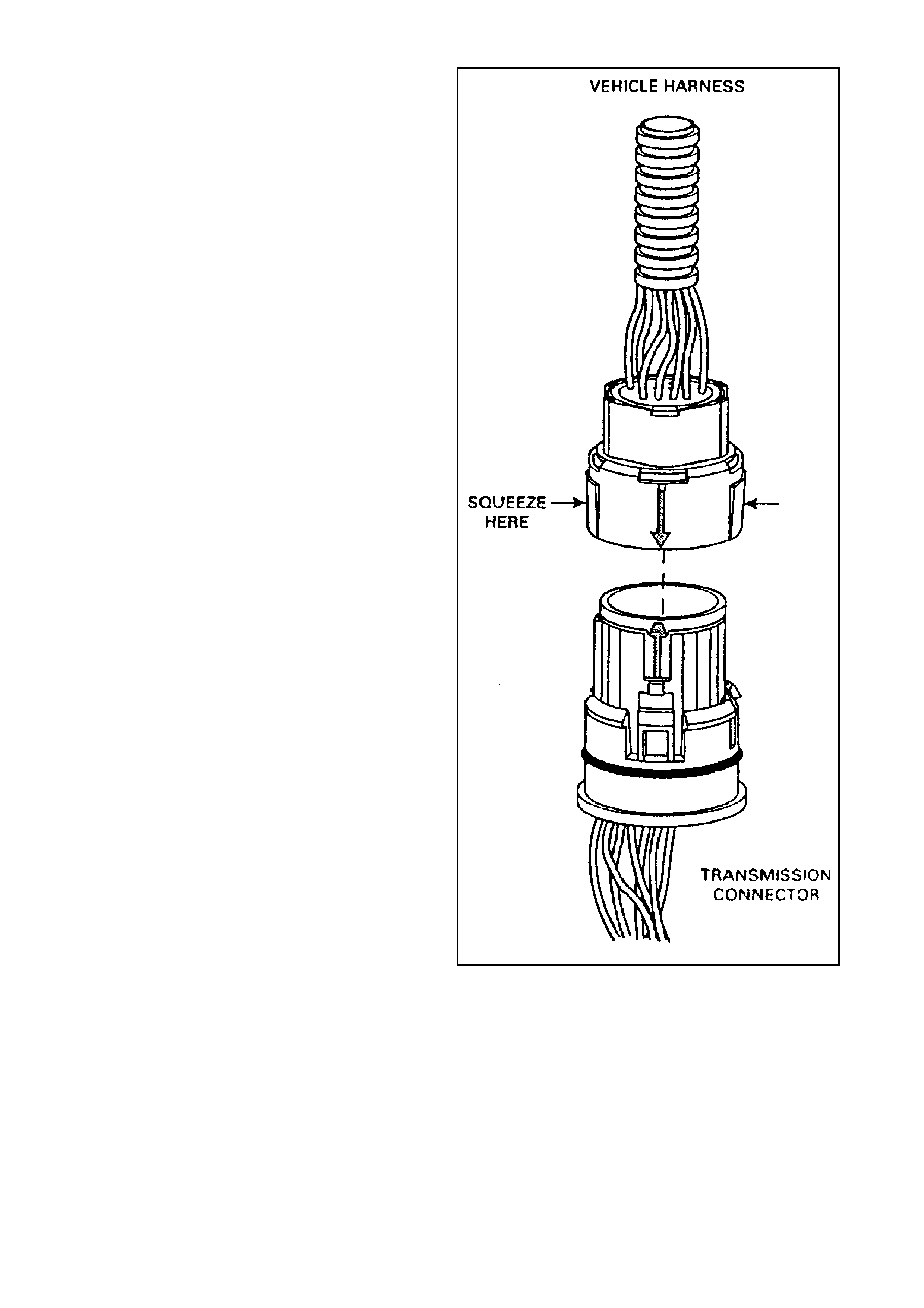

TRANSMISSION ELECTRICAL CONNECTOR CHECK PROCEDURE

The transmission electrical connector is a very

important part of the transmission operating

system. Any interference with the electrical

connection can cause the transmission to set

Diagnostic Trouble Codes (DTCs) and/or affect

proper operation.

The following items can affect the electrical

connection:

Bent pins in the connector f r om rough handling

during connection and disconnection.

Wires backing away from the pins or coming

uncrimped (in either internal or external wiring

harness).

Dirt contamination entering the connector

when disconnected.

Pins in the internal wiring connector backing

out of the connector or pushed out during

reconnection.

Excessive transmission fluid leaking into the

connector, wicking up into the external wiring

harness and degrading the wire insulation.

Water/moisture intrusion in the connector.

Low pin retention in the external connector

from excessive connection and disconnection

of the wiring connector assembly.

Pin corrosion from contamination.

Broken/cracked connector assembly.

Points to remember when working with the

transmission wiring connector assembly:

To remove the connector, squeeze the two

tabs towards each other and pull straight up

(refer to the illustration).

Carefully limit twisting or wiggling the

connector during removal. Bent pins can

occur.

DO NOT pry the connector off with a

screwdriver or other tool.

To install the external wiring connector, first

orient the pins by lining up the arrows on each

half of the connector. Push the connector

straight down into the transmission without

twisting or angling the mating parts.

The connector should click into place with a

positive feel and/or noise.

Whenever the transmission external wiring

connector is disconnected from the internal

harness and the engine is operating DT Cs will

set. Clear these DTCs after reconnecting the

external connector.

Transmission Electrical Connector

HYDRA-MATIC 4L60-E TRANSMISSION FUNCTION TEST