S

SE

ER

RV

VI

IC

CE

E

F

FO

OR

RM

MS

S

© 2006 GM Holden LTD. A.B.N. 84 006 893 232

Service Department

A “HOLDEN” Product.

BRISBANE SYDNEY MELBOURNE ADELAIDE PERTH

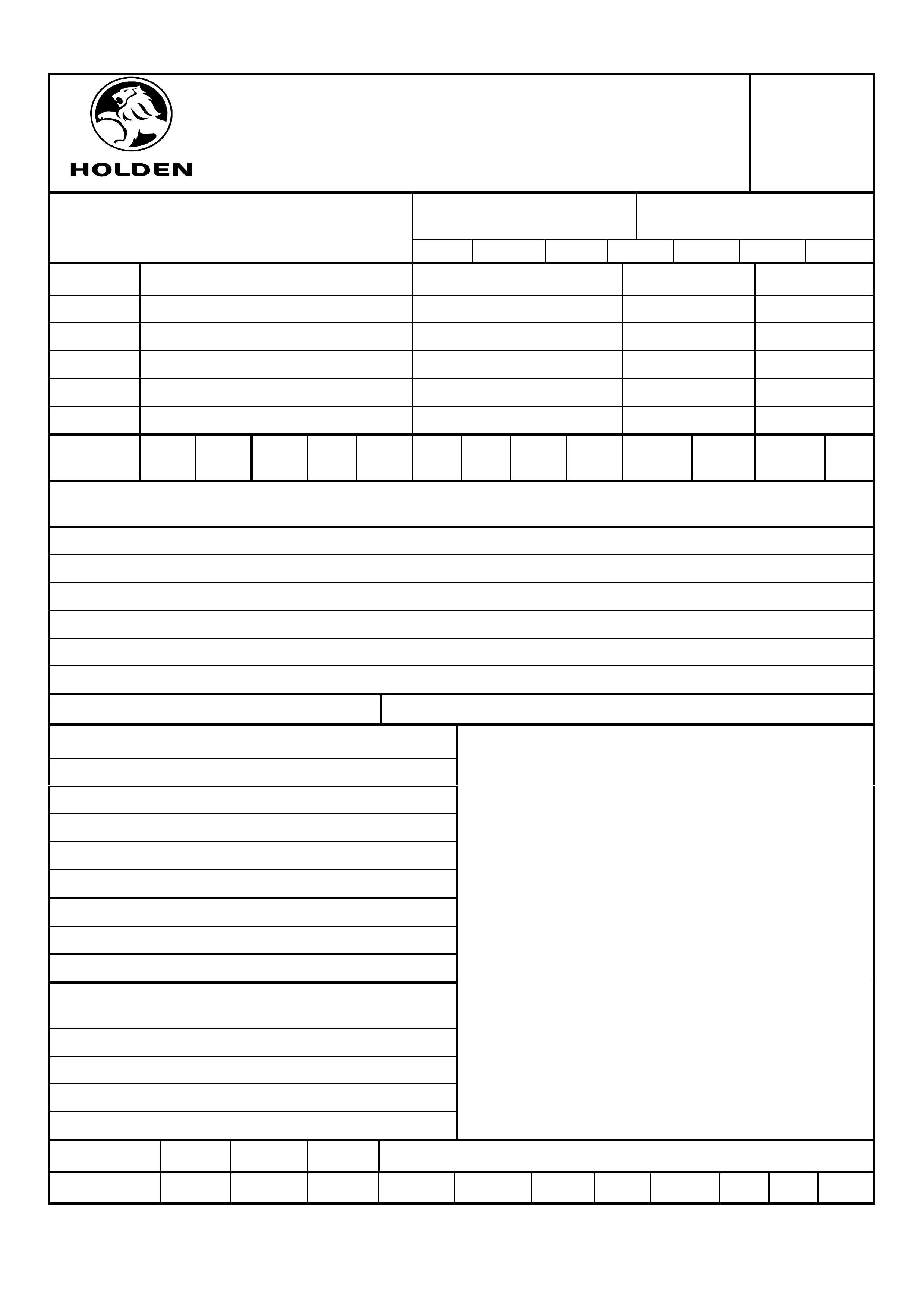

PRODUCT INFORMATION REPORT

HOLDEN LIMITED A.B.N. 84 006 893 232

USE THIS FORM TO REPORT ANY PRODUCT RELATED CONCERN AFFECTING ANY

HOLDEN PASSENGER OR LIGHT COMMERCIAL VEHICLE OR HSPO PART/ACCESSORY

Form No. GMH767 (REV 4/02) Re-Order Pad: SD 28331

SERIES

ie VX,JS,XC etc.

RETAILER NAME RETAILER CODE

DATE

ZONE: QLD NSW VIC S.A W.A HNZ

# AFFECTED ISO VIN(s)

(17 characters MANDATORY) ENGINE NUMBER

(Only if engine related)

BUILD DATE

(Day/Month/Year)

ODOMETER

(KM)

1

2

3

4

5

RELEVANT

OPTIONS

(Please tick)

MAN AUTO A/C

STD A/C

ECC ABS SRS IRS FE2 LPG “S”

PACK “SS”

PACK 9C1

POLICE HSV

DESCRIPTION OF COMPLAINT / FAILURE / DEFECT

AFFECTED PART No. PART DESCRIPTION

SUSPECTED CAUSE: ILLUS TRATE AS REQUIRED (Alternatively mark-up Service Manual

illustration and include as an attachment)

OPERATING CONDITIONS : (If related to condition)

CORR ECTIVE ACTION TAKEN:

WAS IT

SUCCESSFUL? YES NO NOT

KNOWN PLEASE PRINT

YOUR NAME

DISTRIBUTION

(Office use only)

LOADED VAP ENG SQA SERV HSPO HEC ZONE IGM HBD HSV

FAX THIS P.I.R TO EDAG FUTURE - FAX No. (03) 9552 8104

STIP006

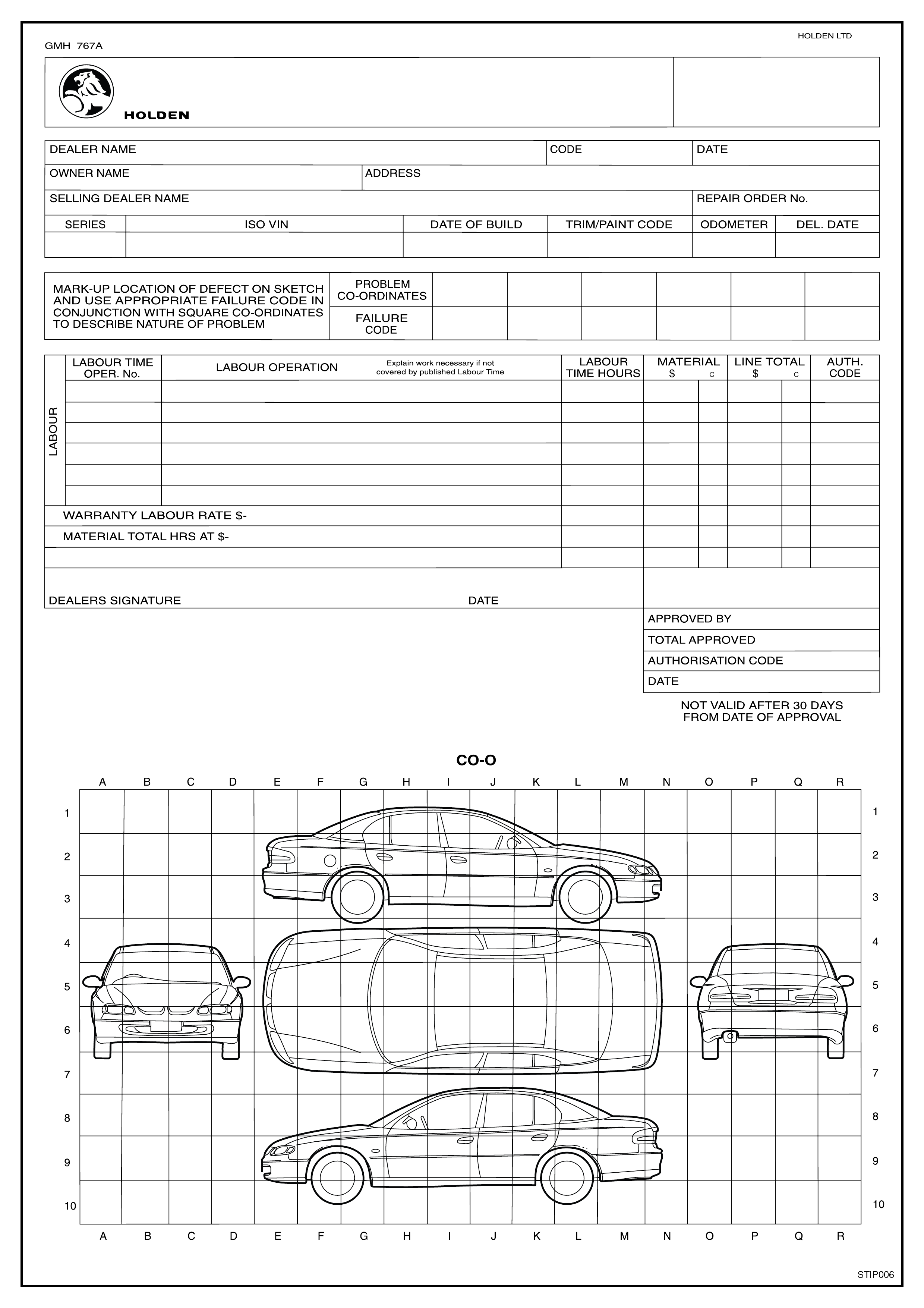

GMH 767A

REPORTRINFORMATIONIPRODUCTP

BODY PAINT AND TRIM

GMHAL USE ONLY

ABN 84 006 893 232

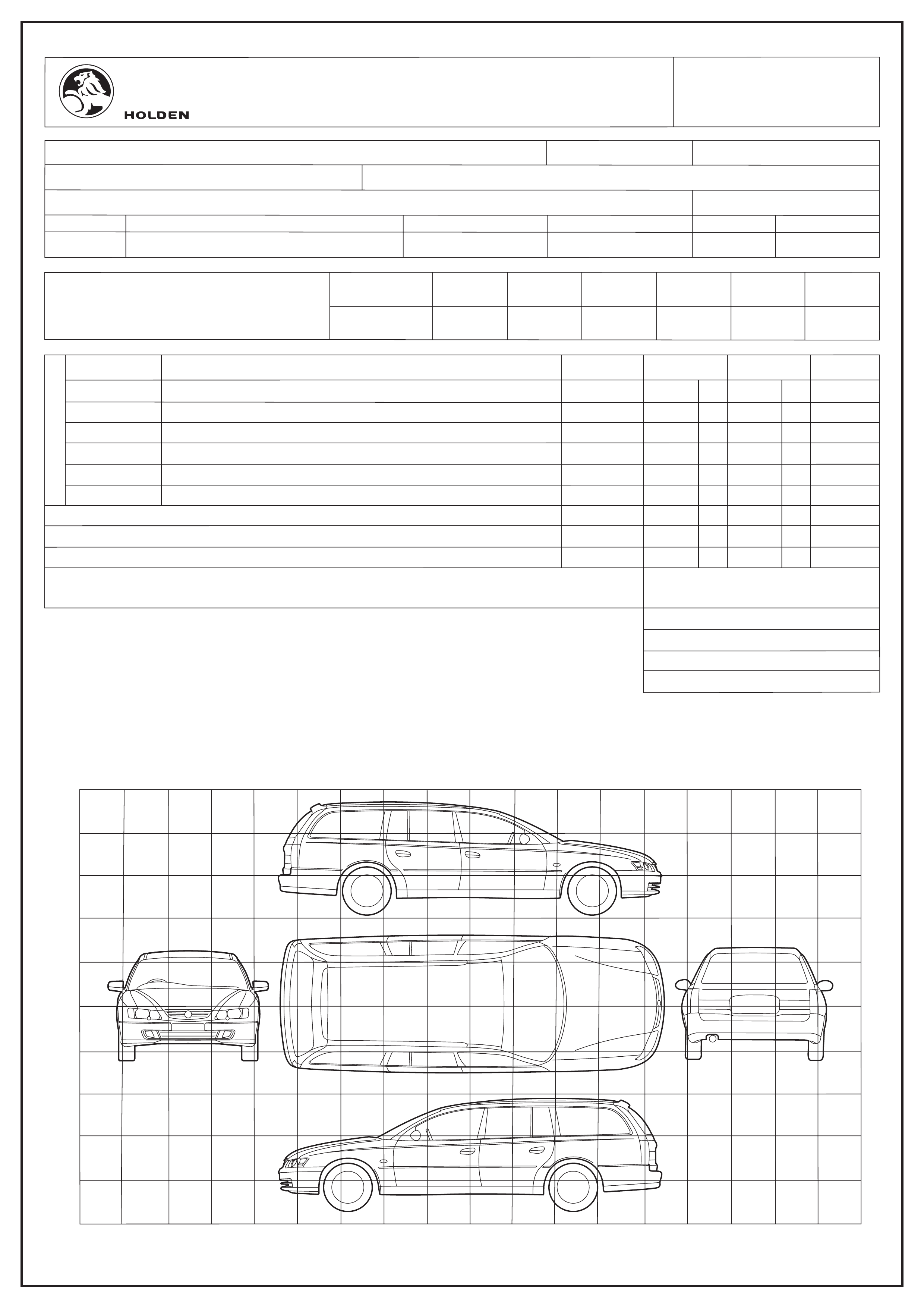

This combination P.I.R. can be used for paint, rust, water leaks, dust entry and sheet metal. The

form is to be used as follows: Defective points to be marked with cross in square. Failure code to

be entered in conjunction with square co- ordinates in square on P.I.R. form code. Failure codes

should be prefixed with applicable alpha followed by failure code number obtained from labour

time guide.

Paint

Rust

Alpha "P" Alpha "S" Alpha "D"

Alpha "R" Alpha "W"

Alpha "T"

Sheet Metal

Water Leaks

Dust Entry

Trim

(

(

$$

CC

PROBLEM CO-ORDINATES

S

E

T

A

N

I

D

R

O

O

-

C

M

E

L

B

O

R

P

MAIL TWO COPIES TO ZONE OFFICE (Retain one copy for your file)

G428-01

PROBLEM

CO-ORDINATES

FAILURE

CODE

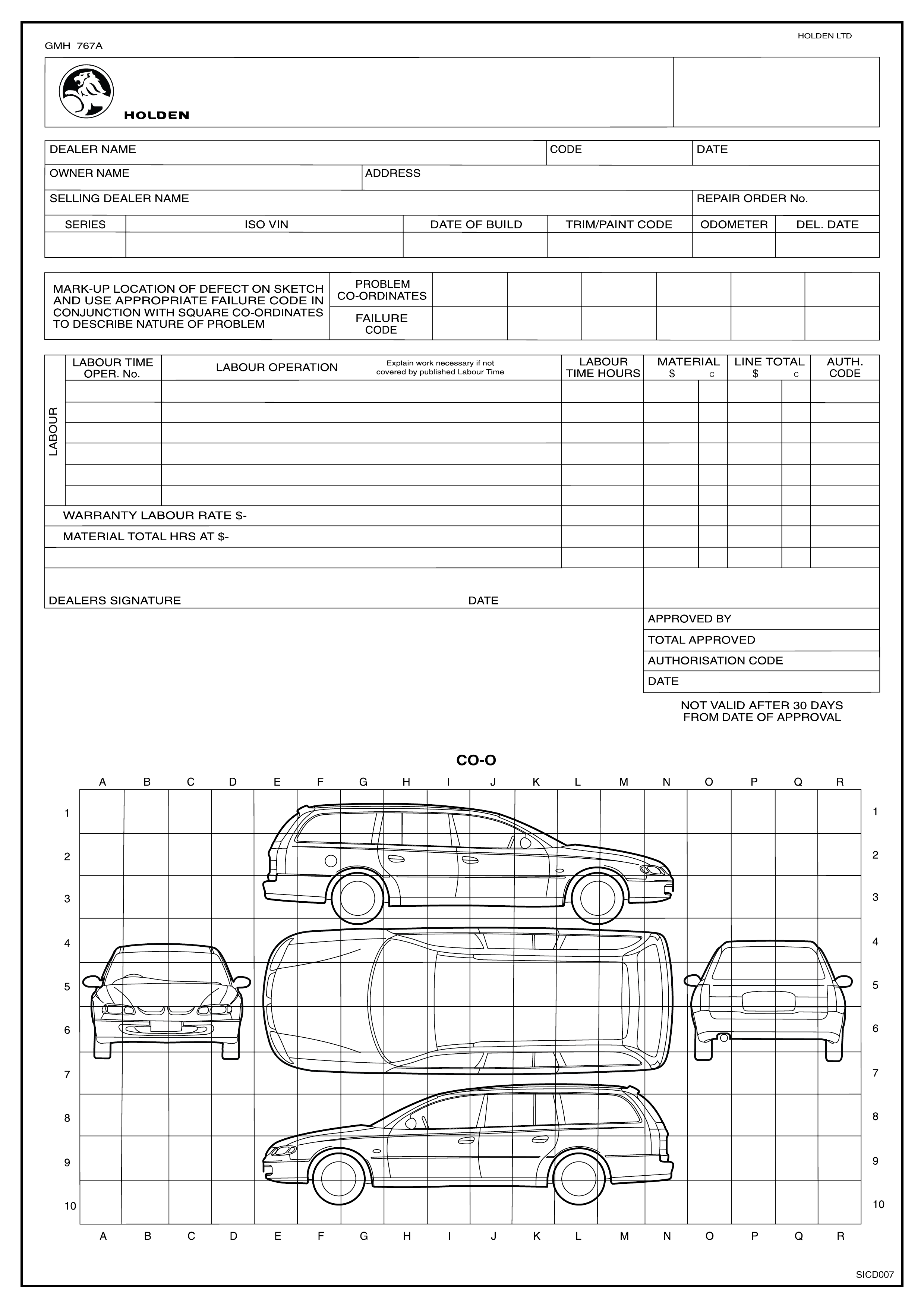

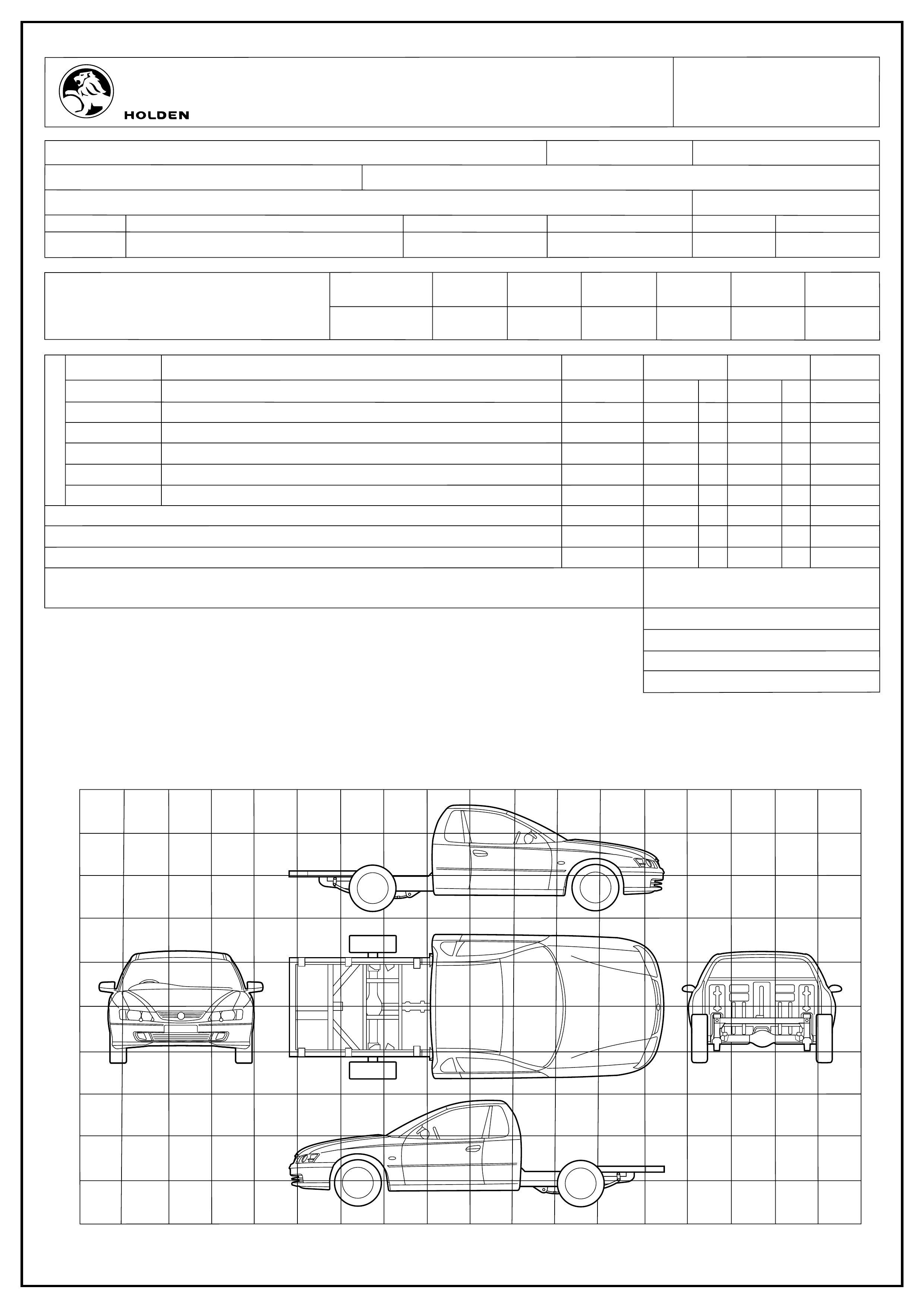

MARK-UP LOCATION OF DEFECT ON SKETCH

TO DESCRIBE NATURE OF PROBLEM

CONJUNCTION WITH SQUARE CO-ORDINATES

AND USE APPROPRIATE FAILURE CODE IN

GMH 767A

REPORTRINFORMATIONIPRODUCTP

BODY PAINT AND TRIM

GMHAL USE ONLY

HOLDEN LTD

ABN 84 006 839 232

OWNER NAME

DEALER NAME

SELLING DEALER NAME

SERIES

ISO VIN

ADDRESS

DATE OF BUILD

CODE

TRIM/PAINT CODE

DATE

REPAIR ORDER No.

ODOMETER

DEL. DATE

This combination P.I.R. can be used for paint, rust, water leaks, dust entry and sheet metal. The

form is to be used as follows: Defective points to be marked with cross in square. Failure code to

be entered in conjunction with square co- ordinates in square on P.I.R. form code. Failure codes

should be prefixed with applicable alpha followed by failure code number obtained from labour

time guide.

Paint

Rust

Alpha "P" Alpha "S" Alpha "D"

Alpha "R" Alpha "W"

Alpha "T"

Sheet Metal

Water Leaks

Dust Entry

Trim

DATE

APPROVED BY

TOTAL APPROVED

AUTHORISATION CODE

NOT VALID AFTER 30 DAYS

FROM DATE OF APPROVAL

DATE

DEALERS SIGNATURE

WARRANTY LABOUR RATE $-

MATERIAL TOTAL HRS AT $-

TIMELABOUR

LABOUR

OPER. No.

LABOUR OPERATION

Explain work necessary if not

covered by published Labour Time

(

(

TIME HOURS

LABOUR

MATERIAL

$$CC

LINE TOTAL

AUTH.

CODE

PROBLEM CO-ORDINATES

S

E

T

A

N

I

D

R

O

O

-

C

M

E

L

B

O

R

P

MAIL TWO COPIES TO ZONE OFFICE (Retain one copy for your file)

ABCDEFGHI JKL MNOPQR

ABCDEFGHI JKL MNOPQR

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

SICD007

GMH 767A

REPORTRINFORMATIONIPRODUCTP

BODY PAINT AND TRIM

GMHAL USE ONLY

ABN 84 006 893 232

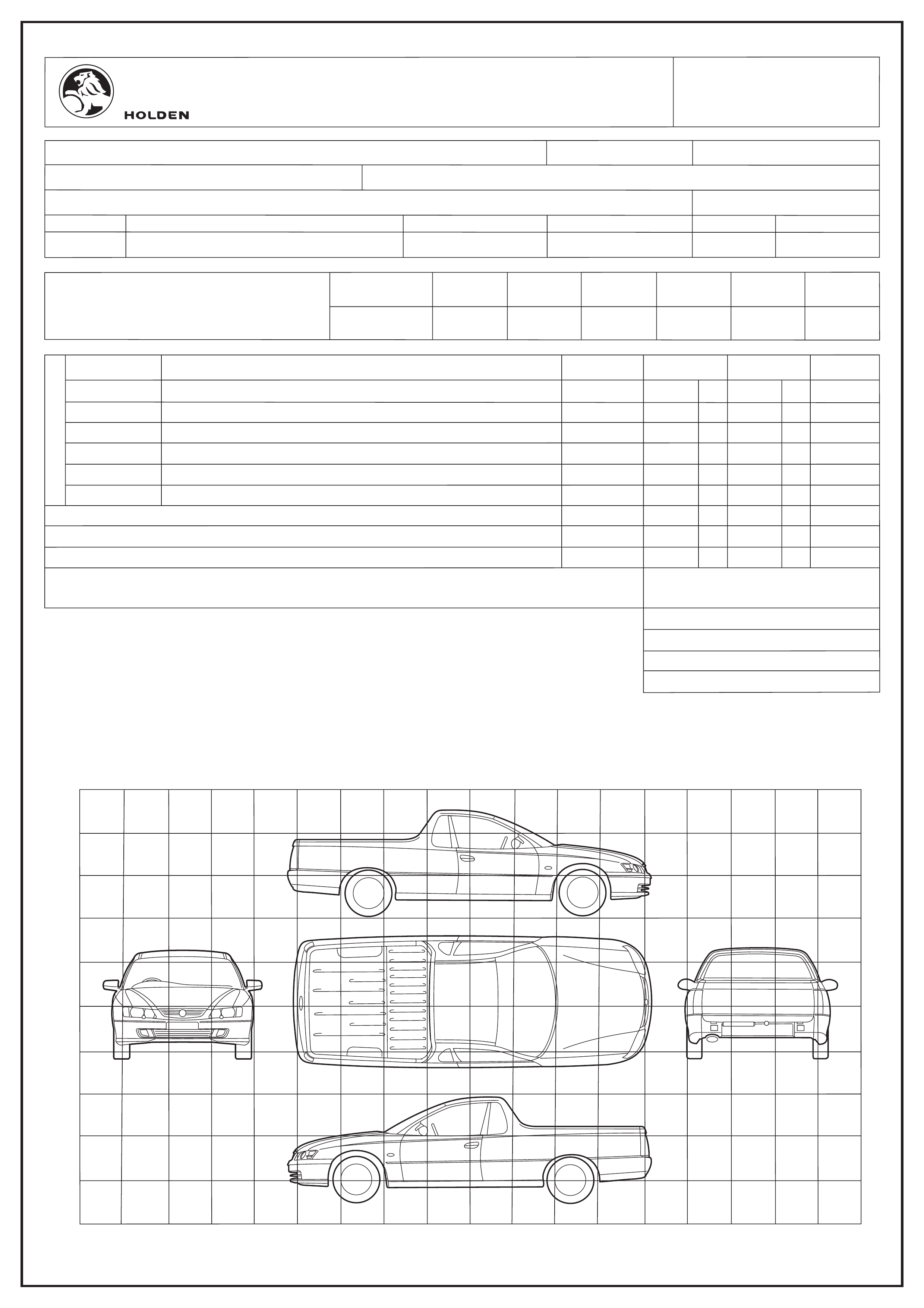

This combination P.I.R. can be used for paint, rust, water leaks, dust entry and sheet metal. The

form is to be used as follows: Defective points to be marked with cross in square. Failure code to

be entered in conjunction with square co- ordinates in square on P.I.R. form code. Failure codes

should be prefixed with applicable alpha followed by failure code number obtained from labour

time guide.

Paint

Rust

Alpha "P" Alpha "S" Alpha "D"

Alpha "R" Alpha "W"

Alpha "T"

Sheet Metal

Water Leaks

Dust Entry

Trim

(

(

$$

CC

PROBLEM CO-ORDINATES

S

E

T

A

N

I

D

R

O

O

-

C

M

E

L

B

O

R

P

MAIL TWO COPIES TO ZONE OFFICE (Retain one copy for your file)

SICD008

GMH 767A

REPORTRINFORMATIONIPRODUCTP

BODY PAINT AND TRIM

GMHAL USE ONLY

ABN 84 006 893 232

This combination P.I.R. can be used for paint, rust, water leaks, dust entry and sheet metal. The

form is to be used as follows: Defective points to be marked with cross in square. Failure code to

be entered in conjunction with square co- ordinates in square on P.I.R. form code. Failure codes

should be prefixed with applicable alpha followed by failure code number obtained from labour

time guide.

Paint

Rust

Alpha "P" Alpha "S" Alpha "D"

Alpha "R" Alpha "W"

Alpha "T"

Sheet Metal

Water Leaks

Dust Entry

Trim

(

(

$$

CC

PROBLEM CO-ORDINATES

S

E

T

A

N

I

D

R

O

O

-

C

M

E

L

B

O

R

P

MAIL TWO COPIES TO ZONE OFFICE (Retain one copy for your file)

DEALERSHIP NAME DEALER CODE DATE

ZONE QLD NSW VIC SA WA

SIP RELEASE DATE

SECTION AFFECTED TOPIC OR SUB-SECTION

NATURE OF PROBLEM

CONTACT NAME PHONE NUMBER

(please print)

FAX NUMBER

ACTION TAKEN

(Office Use Only)

DISTRIBUTION

Training and Technical Publications

Warranty

Service

Engineering

Datateck Publishing

Other

WHEN COMPLETE FAX TO: HOLDEN LIMITED - FAX NO. 03 9647 2525

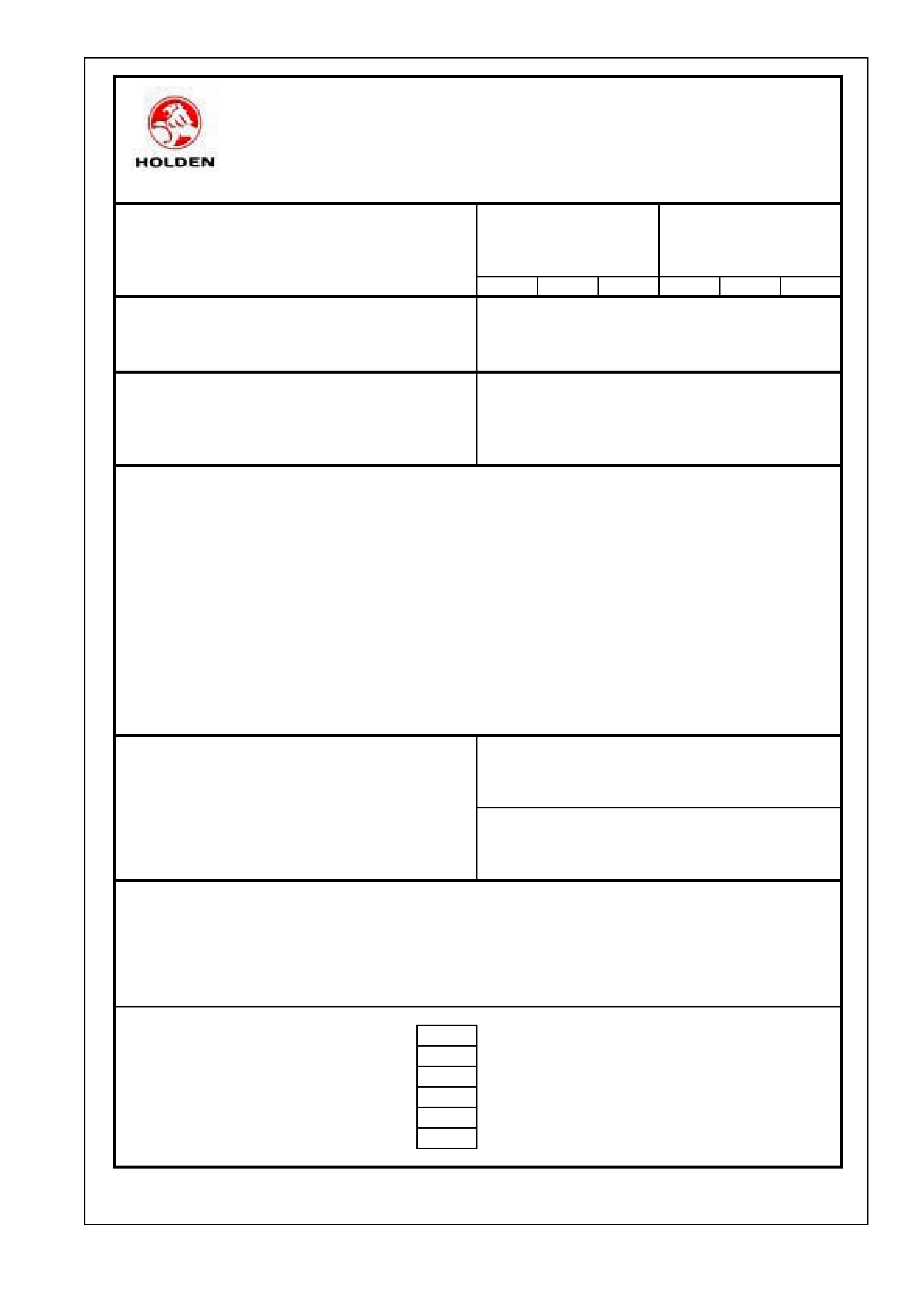

Use this form to report any product related concern affecting the Holden

Service Information Package (SIP).

PRODUCT INFORMATION REPORT

HOLDEN SERVICE INFORMATION PACKAGE

Holden Limited A.B.N. 84 006 893 232

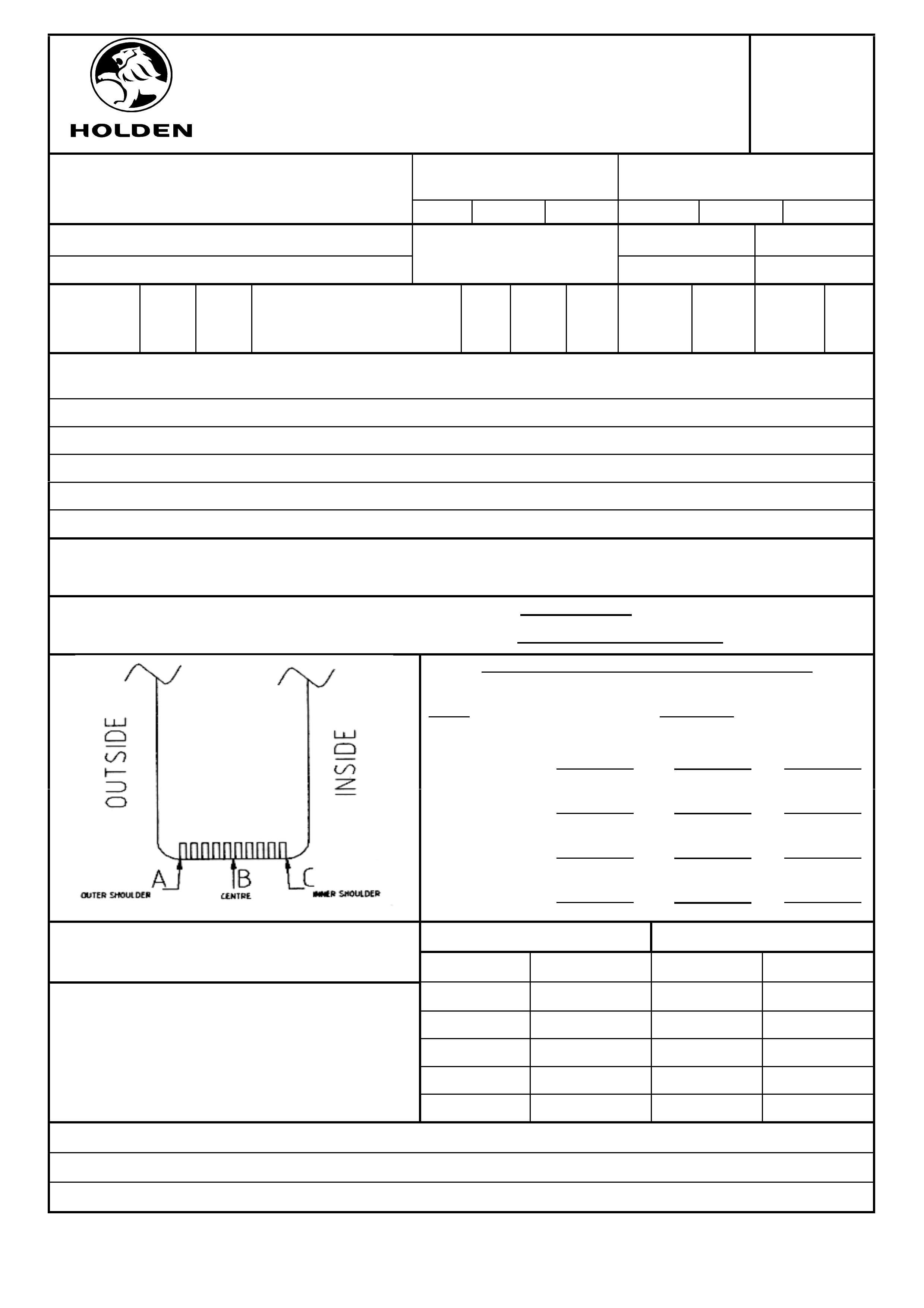

TYRE CONDITION REPORT

HOLDEN LIMITED A.B.N. 84 006 893 232

Holden Ltd FORM #GMH-TCR1

SERIES

DEALERSHIP NAME DEALER CODE

DATE

ZONE QLD NSW VIC S.A W.A

AFFECTED ISO V IN(s)

(17 characters MANDATORY) FLEET VEHICLE: YES NO BUILD DATE

(Day/Month/Year)

ODOMETER

(KM)

COMPANY:

RELEVANT

OPTIONS

(Please tick)

MAN AUTO TOWBAR: YES NO IRS FE2 LPG “S”

PA CK ”SS”

PACK 9C1

POLICE HSV

RATING: 1200 1590 2100

OPERATING CONDITIONS (include approximate towing and/or cargo loads, type of trailer & purpose):

TYRE BRAND/SIZE: ORIGINAL TYRES:

NO YES

IF NEW TYRES FITTED, ODOMETER READING WHEN FITTED: _____________KMS.

TYPE & SIZE: ________________________

TYRE TREAD DEPTH MEASUREMENTS (mm)

TYRE POSITION

LHF A _________ B _________ C _________

RHF A _________ B _________ C _________

LHR A _________ B _________ C _________

RHR A _________

B _________ C _________

FRONT REAR

SUSPENSION MEASUREMENTS

LEFT RIGHT LEFT RIGHT

TOE SETTINGS:

CAMBER SETTINGS:

TRIM HEIGHTS (at kerb weight):

SUSPENSION HEIGHTS (at kerb weight):

TYRE PRESSURES:

ACTION TAKEN:

FAX THIS FORM TO HOLDEN TAS WHEN COMPLETE

TICK ALL BOXES THAT ARE RELEVANT TO YOUR CONDITION!

DEALER

Date: Dealer Name: Dlr Code:

VEHICLE DATA

ISOVIN: Odometer:

Vehicle Model: VT VX VU WH Build Date:

ENGINE

Engine: V6 V6 S/C V8

DRIVETRAIN

Transmission: Manual Automatic

Rear Axl e: Standard LSD

Wheels/Tyres:

Standard wheels and OE tyres

Standard wheels and replacement ty r es

Tyre brand, type, size:

Non-Standard wheel s and tyres

Rim size, tyr e br and, type, s ize:

COMPLAINT

What did your customer complai n about (in their words)?

Can you reproduce the customer complaint? Yes No

How would you describe the complaint?

Is the complaint evident at ALL road s peeds or specific road speeds?

All S pecific (please list all road speeds if more than one):

a) km/h b) km/h c) km/h

Is the complaint evident at ALL engine speeds or specific engine speeds?

All S pecific (please list all engine speeds if more than one):

a) rpm b) rpm c) rpm

Driveline Noise, Vibration

and Refinement Report

Is the complaint evident in ALL gears or specific gears?

All S pecific (please list all gears if more than one):

a) gear b) gear c) gear

Engine Load:

No load Light Load Medium Load Heavy Load Any Load

When does it occur ?

Stationary Accelerating from stationary

Light Accelerati on Heavy Acceleration

Cruising at constant speed Coasting

Light Decelerati on Heavy Deceleration

Braking After Braking

Forward travel Reversing

Steering wheel straight ahead Steering wheel off centre

Steering wheel at full l ock

Transmission Upshif t Transmission Downshift

VIBRATION

Can the condit ion be felt (v ibration)? If yes, what word do you feel describes it?

Shake Roughness

Buzz Tingling

Where can you feel it?

Body Floor

Seats Brake Pedal

Accelerator Clutch Pedal

Gear Lever Steering Wheel

NOISE

Can the condition be heard (noise)? If yes, what word do you feel describes it?

Boom Moan or Drone

Howl Whine

Squeal or squeak Thump

Beat Shudder

Chatter Clunk

From which dir ection does the noise appear to come fr om?

Front Left Front Centre Front Right

Centre Left Centre Centre Right

Rear Left Rear Centre Rear Right

Can’t determine

REPAIRS

Were you able t o address the complaint?

Not at all Reduced the severity Fixed to customer’s satisfaction

What action di d you take while investigating the pr oblem?

Please fax dir ect l y to EDAG FUTURE on (03) 9552 8104. Thankyou for the r eport!

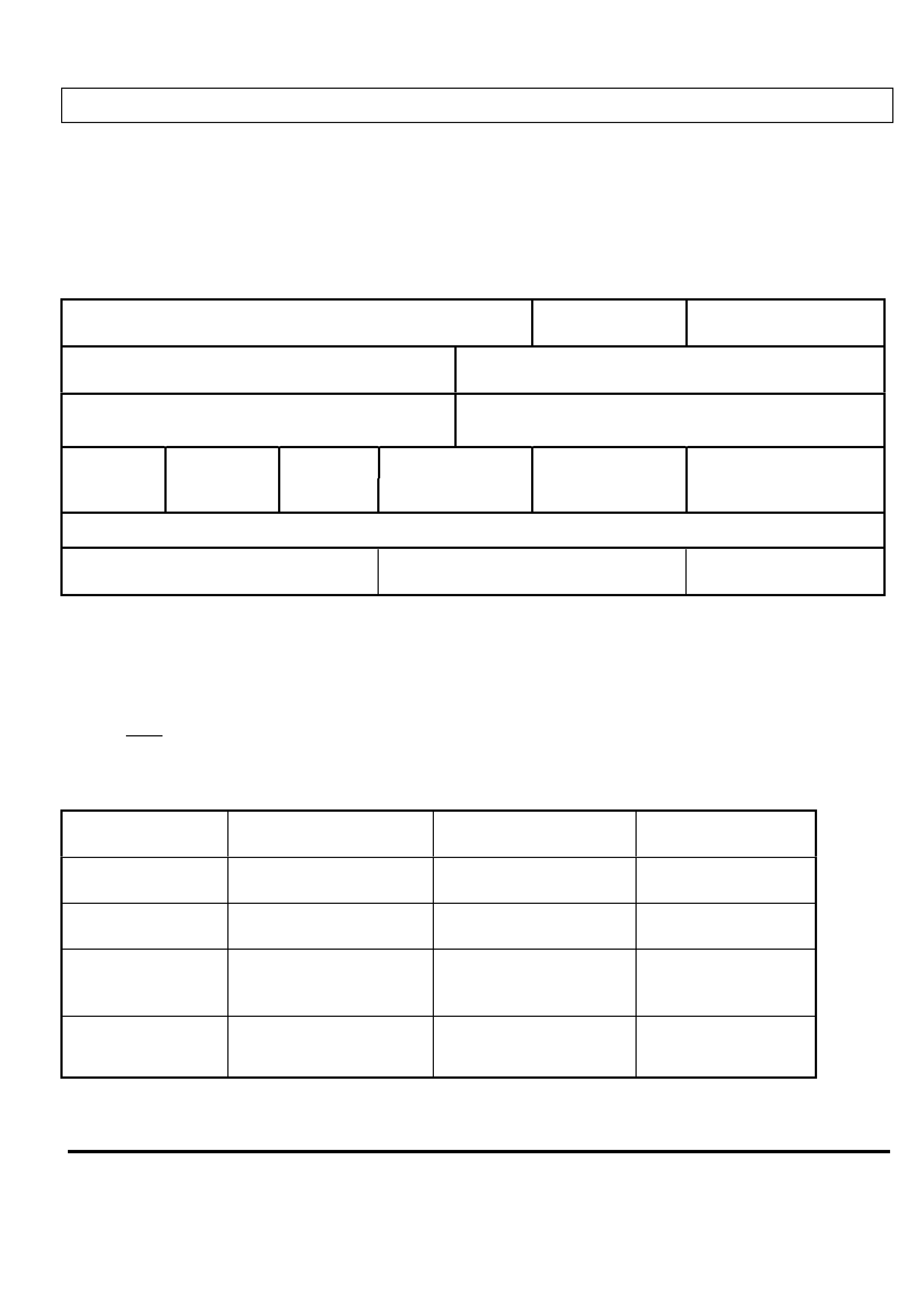

ENGINE OIL CONSUMPTION TEST REPORT

INTRODUCTION:Please complete this report when a customer complaint of oil consumption is received. It is

important that the actual consumption rate is first established before any work or disassembly is performed on the

vehicle. It is also extremely important that all variables are eliminated when checking the engine oil level at the start

and again at the finish of an oil consumption test. Please refer to the accompanying Engine Oil Level Measurement

Procedure.

Oil consum ption is best meas ured by determ ining the distance travelled for the oil level to move fr om the “FULL” m ark

to the “ADD” m ark on the dipstick . This m ethod is m or e reliable and acc urate than m easur ing the am ount of oil added

over a period of time or set kilometre frequency.

(tick boxes as required)

DEALERSHIP NAME DEALER CODE DATE

CUSTOMER

NAME CUSTOMER TYPE

(tick)O PRIVATE O FLEET O TAXI

ISOVIN

(17 digits) VEHICLE

USAGE

(tick)

O CITY O COUNTRY/HIGHWAY

O CITY/SUBURBAN O COMMERCIAL TRAVELLER

TRANS. FUEL SYSTEM ENGINE

TYPE ENGINE No. CURRENT ODOMETER LAST SERVICE ODOMETER

AUTO

OMAN

OPETROL

OLPG

OL4

OV6

OV8

Okm km

HOW DID CUSTOMER FIRST

NOTICE HIGH OIL USAGE (tick) O SMOKY

EXHAUST O OIL LEVEL BET WEEN

“FULL” AND “ADD” O OIL LEVE L

BELOW “ADD” O OIL LIGHT

“ON”

IF OIL CHANGED AT START OF OIL

CONSUMPTION TEST (or if known otherwise),

PLEASE STATE BRAND AND VISCOSITY

OIL BRAND VISCOS ITY

OIL CONSUMPTION TEST PROCEDURE

1. Check oil level as per Engine Oil Level Measurement Procedure

2. Top-up to “FULL” mark on dipstick (or as close as possible).

3. Measure actual oil level on dipstick with a ruler (1 mm increments) and record in the “start of test” column on

chart below.

Note: Record oil level if just above “FULL” mark as “+” mm.

Record oil level if just below “FULL” mark as “ - ” mm.

4. Run oil consumption test until oil level on dipstick reaches the “ADD” mark or below.

5. Measure actual level on dipstick (refer Engine Oil Level Measurement Procedure) and record in the “finish of

test” column on the chart below

DATA “START” OF TEST “F INISH” OF TEST RESULT

DATE / / / / DAYS

ODOMETER (km) KM KM KM

LEVEL ON DIPSTICK

“ + ” = above FULL

“ - ” = below FULL

+or mm

-- mm mm

TOP-UP AMO U NT

(millilitres) ml ml ml

WHERE FURTHER ACTION IS CONSIDERED NECESSARY AFTER THE DEALERSHIP HAS COMPLETED AN

ENGINE OIL CONSUMPTION TEST, CONTACT TAS DIRECTLY BY PHONE AND FURTHER FAX THE

COMPLETED TEST REPORT TO TAS FOR REVIEW AND FURTHER INSTRUCTIONS.

GENERAL MOTORS-HOLDEN’S AUTOMOTIVE LIMITED ABN 84 006 893 232

G733-01

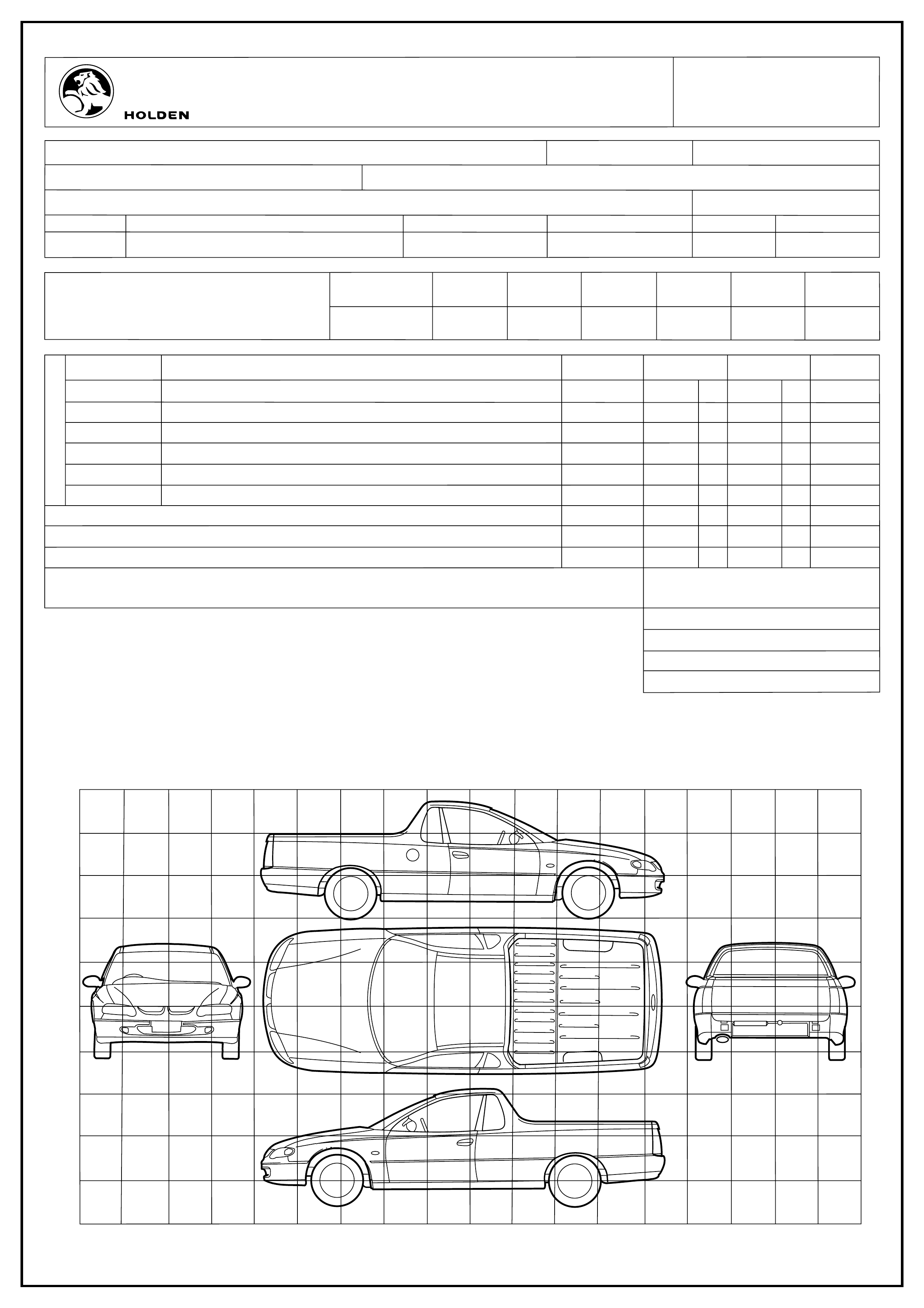

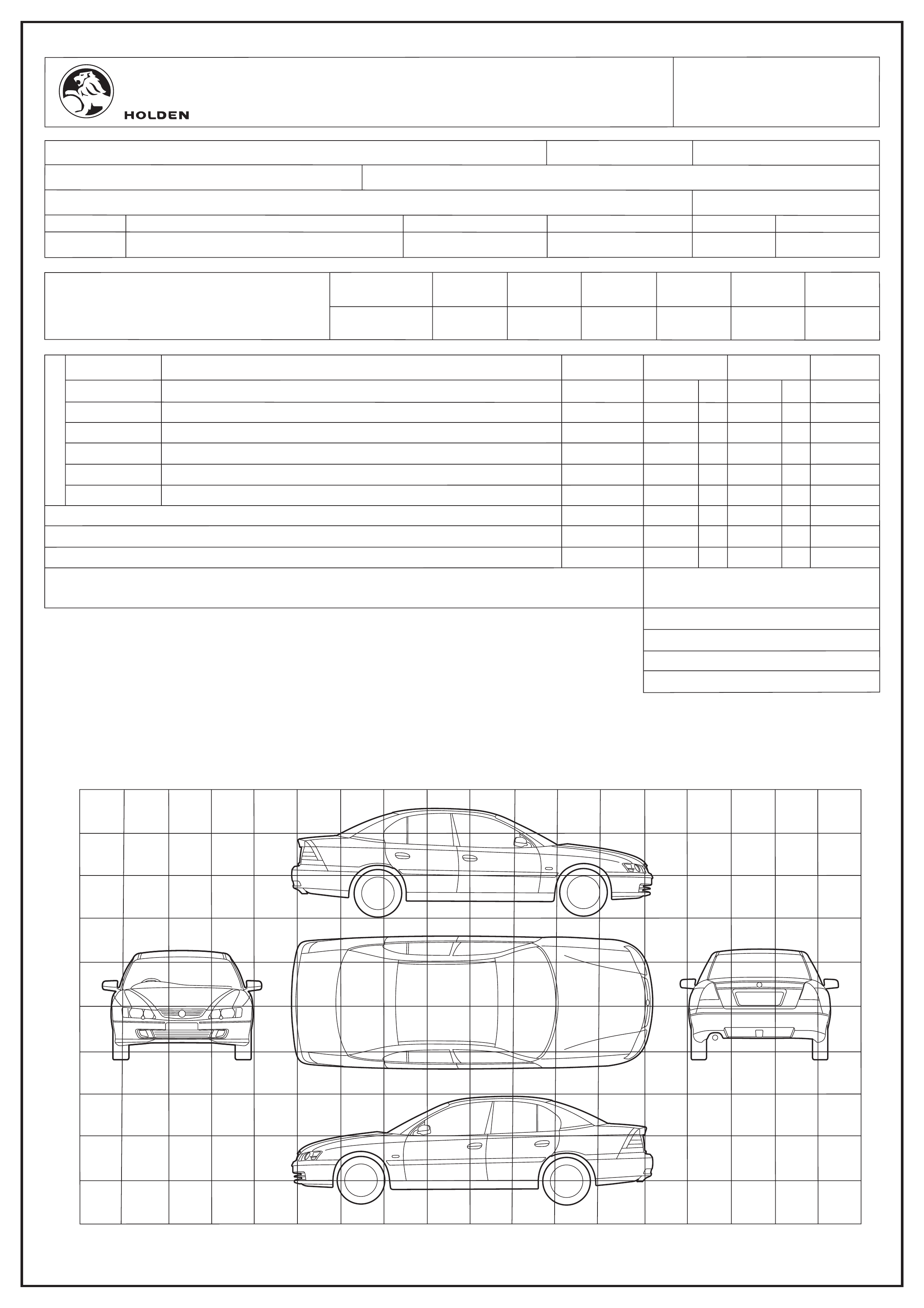

PROBLEM

CO-ORDINATES

FAILURE

CODE

MARK-UP LOCATION OF DEFECT ON SKETCH

TO DESCRIBE NATURE OF PROBLEM

CONJUNCTION WITH SQUARE CO-ORDINATES

AND USE APPROPRIATE FAILURE CODE IN

REPORTRINFORMATIONIPRODUCTP

BODY PAINT AND TRIM

GMHAL USE ONLY

HOLDEN LTD

ACN 006 839 232

OWNER NAME

RETAILER NAME

SELLING RETAILER NAME

SERIES

ISO VIN

ADDRESS

DATE OF BUILD

CODE

TRIM/PAINT CODE

DATE

REPAIR ORDER No.

ODOMETER

DEL. DATE

This combination P.I.R. can be used for paint, rust, water leaks, dust entry and sheet metal. The

form is to be used as follows: Defective points to be marked with cross in square. Failure code to

be entered in conjunction with square co- ordinates in square on P.I.R. form code. Failure codes

should be prefixed with applicable alpha followed by failure code number obtained from labour

time guide.

Paint

Rust

Alpha "P" Alpha "S" Alpha "D"

Alpha "R" Alpha "W"

Alpha "T"

Sheet Metal

Water Leaks

Dust Entry

Trim

DATE

APPROVED BY

TOTAL APPROVED

AUTHORISATION CODE

NOT VALID AFTER 30 DAYS

FROM DATE OF APPROVAL

DATE

RETAILERS SIGNATURE

WARRANTY LABOUR RATE $-

MATERIAL TOTAL HRS AT $-

TIMELABOUR

LABOUR

OPER. No.

LABOUR OPERATION

Explain work necessary if not

covered by published Labour Time

(

(

TIME HOURS

LABOUR

MATERIAL

$$CC

LINE TOTAL

AUTH.

CODE

PROBLEM CO-ORDINATES

S

E

T

A

N

I

D

R

O

O

-

C

M

E

L

B

O

R

P

MAIL TWO COPIES TO ZONE OFFICE (Retain one copy for your file)

ABCDEFGHI JKL MNOPQR

ABCDEFGHI JKL MNOPQR

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

G733-03

PROBLEM

CO-ORDINATES

FAILURE

CODE

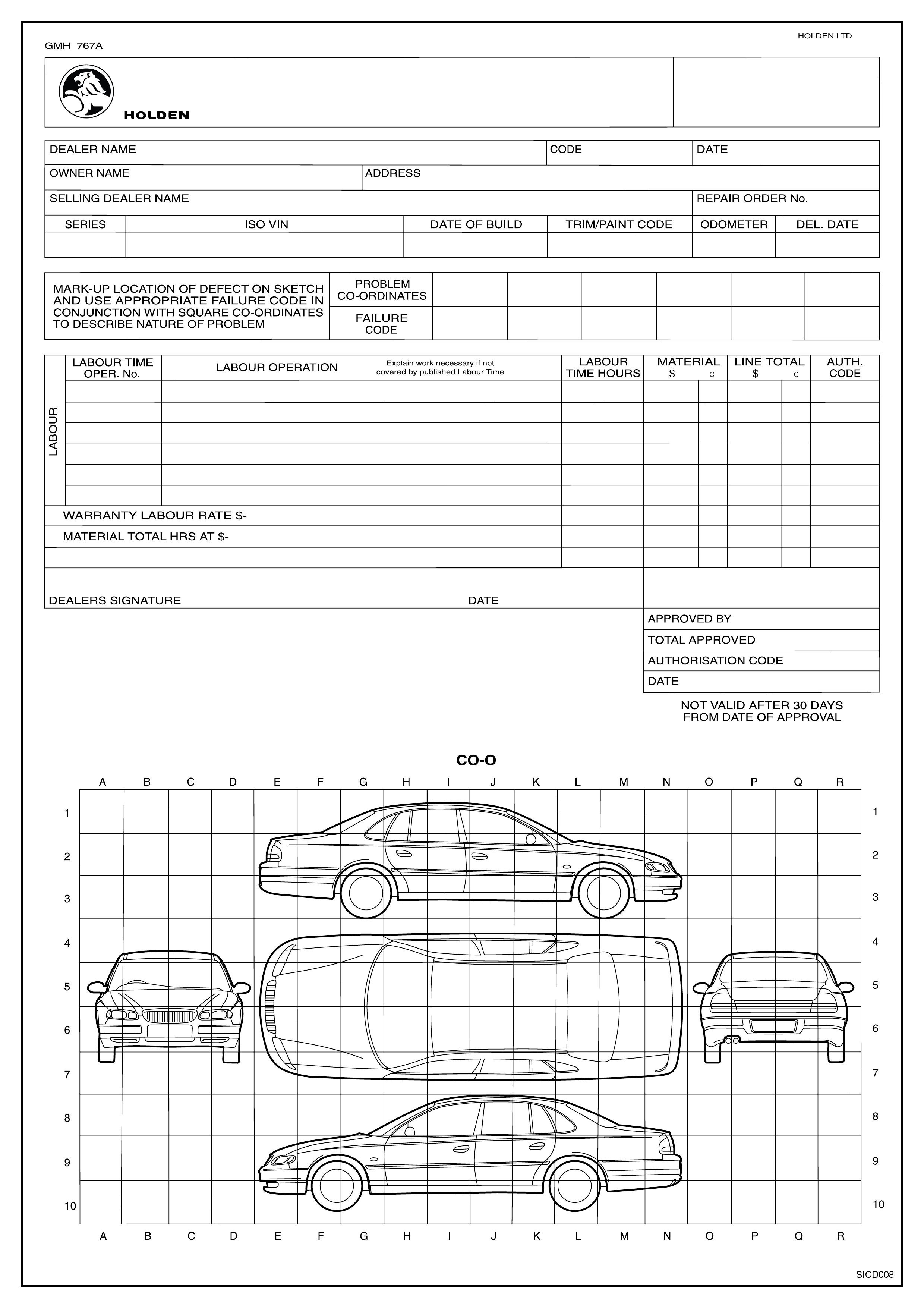

MARK-UP LOCATION OF DEFECT ON SKETCH

TO DESCRIBE NATURE OF PROBLEM

CONJUNCTION WITH SQUARE CO-ORDINATES

AND USE APPROPRIATE FAILURE CODE IN

REPORTRINFORMATIONIPRODUCTP

BODY PAINT AND TRIM

GMHAL USE ONLY

HOLDEN LTD

ACN 006 839 232

OWNER NAME

RETAILER NAME

SELLING RETAILER NAME

SERIES

ISO VIN

ADDRESS

DATE OF BUILD

CODE

TRIM/PAINT CODE

DATE

REPAIR ORDER No.

ODOMETER

DEL. DATE

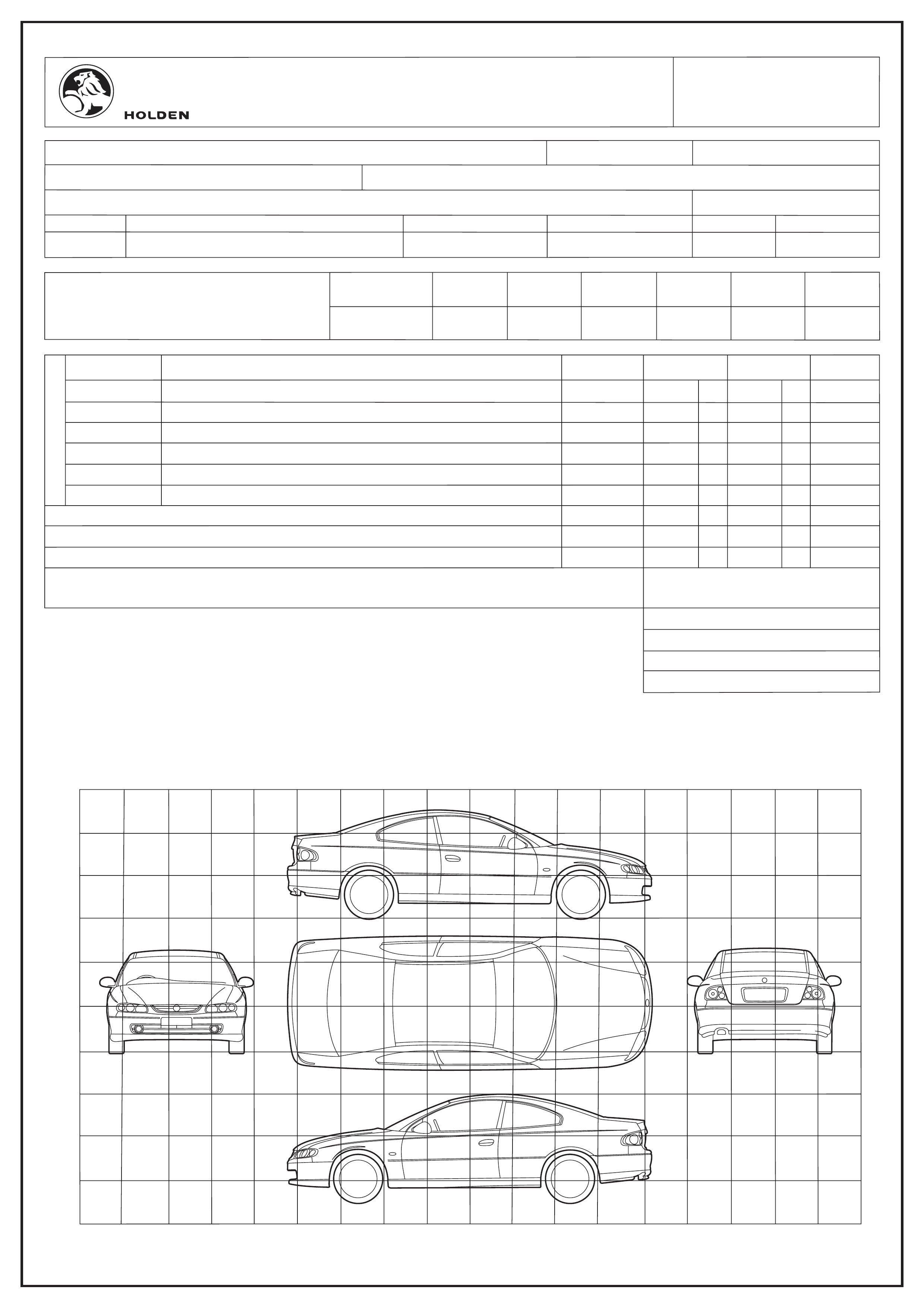

This combination P.I.R. can be used for paint, rust, water leaks, dust entry and sheet metal. The

form is to be used as follows: Defective points to be marked with cross in square. Failure code to

be entered in conjunction with square co- ordinates in square on P.I.R. form code. Failure codes

should be prefixed with applicable alpha followed by failure code number obtained from labour

time guide.

Paint

Rust

Alpha "P" Alpha "S" Alpha "D"

Alpha "R" Alpha "W"

Alpha "T"

Sheet Metal

Water Leaks

Dust Entry

Trim

DATE

APPROVED BY

TOTAL APPROVED

AUTHORISATION CODE

NOT VALID AFTER 30 DAYS

FROM DATE OF APPROVAL

DATE

RETAILERS SIGNATURE

WARRANTY LABOUR RATE $-

MATERIAL TOTAL HRS AT $-

TIMELABOUR

LABOUR

OPER. No.

LABOUR OPERATION

Explain work necessary if not

covered by published Labour Time

(

(

TIME HOURS

LABOUR

MATERIAL

$$CC

LINE TOTAL

AUTH.

CODE

PROBLEM CO-ORDINATES

S

E

T

A

N

I

D

R

O

O

-

C

M

E

L

B

O

R

P

MAIL TWO COPIES TO ZONE OFFICE (Retain one copy for your file)

ABCDEFGHI JKL MNOPQR

ABCDEFGHI JKL MNOPQR

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

G733-02

PROBLEM

CO-ORDINATES

FAILURE

CODE

MARK-UP LOCATION OF DEFECT ON SKETCH

TO DESCRIBE NATURE OF PROBLEM

CONJUNCTION WITH SQUARE CO-ORDINATES

AND USE APPROPRIATE FAILURE CODE IN

REPORTRINFORMATIONIPRODUCTP

BODY PAINT AND TRIM

GMHAL USE ONLY

HOLDEN LTD

ACN 006 839 232

OWNER NAME

RETAILER NAME

SELLING RETAILER NAME

SERIES

ISO VIN

ADDRESS

DATE OF BUILD

CODE

TRIM/PAINT CODE

DATE

REPAIR ORDER No.

ODOMETER

DEL. DATE

This combination P.I.R. can be used for paint, rust, water leaks, dust entry and sheet metal. The

form is to be used as follows: Defective points to be marked with cross in square. Failure code to

be entered in conjunction with square co- ordinates in square on P.I.R. form code. Failure codes

should be prefixed with applicable alpha followed by failure code number obtained from labour

time guide.

Paint

Rust

Alpha "P" Alpha "S" Alpha "D"

Alpha "R" Alpha "W"

Alpha "T"

Sheet Metal

Water Leaks

Dust Entry

Trim

DATE

APPROVED BY

TOTAL APPROVED

AUTHORISATION CODE

NOT VALID AFTER 30 DAYS

FROM DATE OF APPROVAL

DATE

RETAILERS SIGNATURE

WARRANTY LABOUR RATE $-

MATERIAL TOTAL HRS AT $-

TIMELABOUR

LABOUR

OPER. No.

LABOUR OPERATION

Explain work necessary if not

covered by published Labour Time

(

(

TIME HOURS

LABOUR

MATERIAL

$$CC

LINE TOTAL

AUTH.

CODE

PROBLEM CO-ORDINATES

S

E

T

A

N

I

D

R

O

O

-

C

M

E

L

B

O

R

P

MAIL TWO COPIES TO ZONE OFFICE (Retain one copy for your file)

ABCDEFGHI JKL MNOPQR

ABCDEFGHI JKL MNOPQR

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

G730-1

PROBLEM

CO-ORDINATES

FAILURE

CODE

MARK-UP LOCATION OF DEFECT ON SKETCH

TO DESCRIBE NATURE OF PROBLEM

CONJUNCTION WITH SQUARE CO-ORDINATES

AND USE APPROPRIATE FAILURE CODE IN

REPORTRINFORMATIONIPRODUCTP

BODY PAINT AND TRIM

GMHAL USE ONLY

HOLDEN LTD

ACN 006 839 232

OWNER NAME

RETAILER NAME

SELLING RETAILER NAME

SERIES

ISO VIN

ADDRESS

DATE OF BUILD

CODE

TRIM/PAINT CODE

DATE

REPAIR ORDER No.

ODOMETER

DEL. DATE

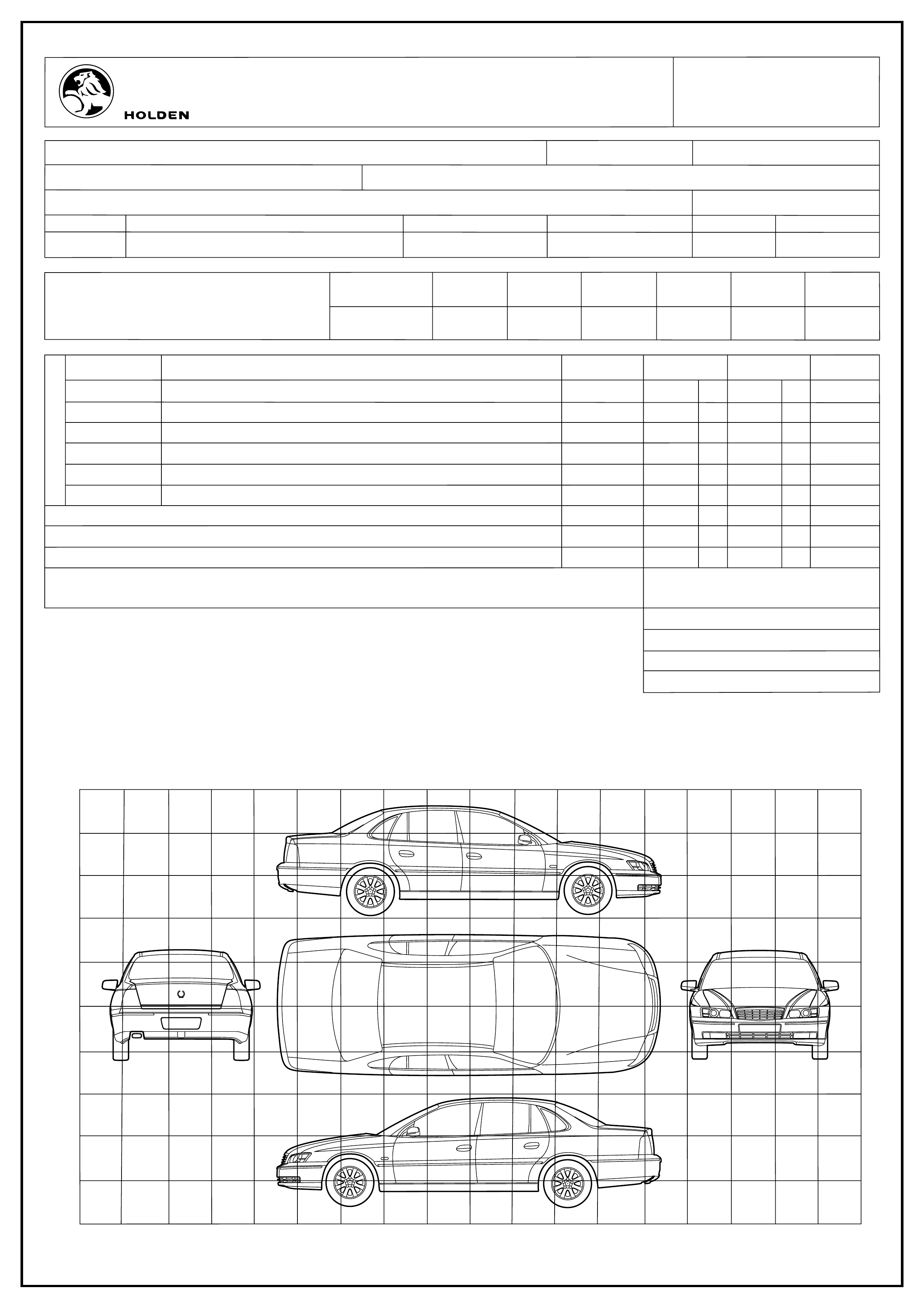

This combination P.I.R. can be used for paint, rust, water leaks, dust entry and sheet metal. The

form is to be used as follows: Defective points to be marked with cross in square. Failure code to

be entered in conjunction with square co- ordinates in square on P.I.R. form code. Failure codes

should be prefixed with applicable alpha followed by failure code number obtained from labour

time guide.

Paint

Rust

Alpha "P" Alpha "S" Alpha "D"

Alpha "R" Alpha "W"

Alpha "T"

Sheet Metal

Water Leaks

Dust Entry

Trim

DATE

APPROVED BY

TOTAL APPROVED

AUTHORISATION CODE

NOT VALID AFTER 30 DAYS

FROM DATE OF APPROVAL

DATE

RETAILERS SIGNATURE

WARRANTY LABOUR RATE $-

MATERIAL TOTAL HRS AT $-

TIMELABOUR

LABOUR

OPER. No.

LABOUR OPERATION

Explain work necessary if not

covered by published Labour Time

(

(

TIME HOURS

LABOUR

MATERIAL

$$CC

LINE TOTAL

AUTH.

CODE

PROBLEM CO-ORDINATES

S

E

T

A

N

I

D

R

O

O

-

C

M

E

L

B

O

R

P

MAIL TWO COPIES TO ZONE OFFICE (Retain one copy for your file)

ABCDEFGHI JKL MNOPQR

ABCDEFGHI JKL MNOPQR

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

G815-01

PROBLEM

CO-ORDINATES

FAILURE

CODE

MARK-UP LOCATION OF DEFECT ON SKETCH

TO DESCRIBE NATURE OF PROBLEM

CONJUNCTION WITH SQUARE CO-ORDINATES

AND USE APPROPRIATE FAILURE CODE IN

REPORTRINFORMATIONIPRODUCTP

BODY PAINT AND TRIM

GMHAL USE ONLY

HOLDEN LTD

ACN 006 839 232

OWNER NAME

RETAILER NAME

SELLING RETAILER NAME

SERIES

ISO VIN

ADDRESS

DATE OF BUILD

CODE

TRIM/PAINT CODE

DATE

REPAIR ORDER No.

ODOMETER

DEL. DATE

This combination P.I.R. can be used for paint, rust, water leaks, dust entry and sheet metal. The

form is to be used as follows: Defective points to be marked with cross in square. Failure code to

be entered in conjunction with square co- ordinates in square on P.I.R. form code. Failure codes

should be prefixed with applicable alpha followed by failure code number obtained from labour

time guide.

Paint

Rust

Alpha "P" Alpha "S" Alpha "D"

Alpha "R" Alpha "W"

Alpha "T"

Sheet Metal

Water Leaks

Dust Entry

Trim

DATE

APPROVED BY

TOTAL APPROVED

AUTHORISATION CODE

NOT VALID AFTER 30 DAYS

FROM DATE OF APPROVAL

DATE

RETAILERS SIGNATURE

WARRANTY LABOUR RATE $-

MATERIAL TOTAL HRS AT $-

TIMELABOUR

LABOUR

OPER. No.

LABOUR OPERATION

Explain work necessary if not

covered by published Labour Time

(

(

TIME HOURS

LABOUR

MATERIAL

$$CC

LINE TOTAL

AUTH.

CODE

PROBLEM CO-ORDINATES

S

E

T

A

N

I

D

R

O

O

-

C

M

E

L

B

O

R

P

MAIL TWO COPIES TO ZONE OFFICE (Retain one copy for your file)

ABCDEFGHI JKLMNOPQR

ABCDEFGHI JKLMNOPQR

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

G815-02

PROBLEM

CO-ORDINATES

FAILURE

CODE

MARK-UP LOCATION OF DEFECT ON SKETCH

TO DESCRIBE NATURE OF PROBLEM

CONJUNCTION WITH SQUARE CO-ORDINATES

AND USE APPROPRIATE FAILURE CODE IN

REPORTRINFORMATIONIPRODUCTP

BODY PAINT AND TRIM

GMHAL USE ONLY

HOLDEN LTD

ACN 006 839 232

OWNER NAME

RETAILER NAME

SELLING RETAILER NAME

SERIES

ISO VIN

ADDRESS

DATE OF BUILD

CODE

TRIM/PAINT CODE

DATE

REPAIR ORDER No.

ODOMETER

DEL. DATE

This combination P.I.R. can be used for paint, rust, water leaks, dust entry and sheet metal. The

form is to be used as follows: Defective points to be marked with cross in square. Failure code to

be entered in conjunction with square co- ordinates in square on P.I.R. form code. Failure codes

should be prefixed with applicable alpha followed by failure code number obtained from labour

time guide.

Paint

Rust

Alpha "P" Alpha "S" Alpha "D"

Alpha "R" Alpha "W"

Alpha "T"

Sheet Metal

Water Leaks

Dust Entry

Trim

DATE

APPROVED BY

TOTAL APPROVED

AUTHORISATION CODE

NOT VALID AFTER 30 DAYS

FROM DATE OF APPROVAL

DATE

RETAILERS SIGNATURE

WARRANTY LABOUR RATE $-

MATERIAL TOTAL HRS AT $-

TIMELABOUR

LABOUR

OPER. No.

LABOUR OPERATION

Explain work necessary if not

covered by published Labour Time

(

(

TIME HOURS

LABOUR

MATERIAL

$$CC

LINE TOTAL

AUTH.

CODE

PROBLEM CO-ORDINATES

S

E

T

A

N

I

D

R

O

O

-

C

M

E

L

B

O

R

P

MAIL TWO COPIES TO ZONE OFFICE (Retain one copy for your file)

ABCDEFGHI JKLMNOPQR

ABCDEFGHI JKLMNOPQR

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10