CV6 & CV8 COUPE

Holden Limited A.B.N. 84 006 893 232

Warranty Department

A "Holden" Publication

WIRING AND CONNECTOR

WARRANTY CLAIM SUBMISSION

INFORMATION

FOR VEHICLE ELECTRICAL SYSTEM WIRING AND CONNECTION DEFECTS

IDENTIFIED ON :

V2 SERIES

1

INTRODUCTION

This manual has been prepared with the following objectives:

(1) To assist HOLDEN Dealership Technicians in the identification and diagnosis of electrical wiring

defects in V2 Coupe.

(2) To enable reporting of defects in a manner which will identify cause of failure, thereby assisting in

quality improvement and achievement of objectives for CUSTOMER SATISFACTION.

This manual is an essential element in the Warranty Claim Submission process therefore must be made

available to Technicians performing warranty related electrical wiring repairs and to those personnel

involved in Warranty Claim Submission.

The Technician simply identifies the affected harness or connector by referring to this manual and

recording the affected part on the Repair Order in addition to the usual work description. This number is

then used to create a Labour Operation Number by the Warranty Clerk, which can then be used by

HOLDEN to clearly identify the cause of electrical failure.

Step-by-step instructions for using the wiring harness illustrations are included in this manual, along with

Warranty Claim Submission procedures.

INDEX

PAGE

WIRING PROBLEM REPORTING FOR WARRANTY CLAIMS 3

TECHNICIAN RESPONSIBILITY 3

A. FOR TERMINAL PROBLEMS (INCLUDING EXAMPLE) 3

B. FOR CONNECTOR PROBLEMS (INCLUDING EXAMPLE) 3

C. FOR HARNESS/WIRING DEFECTS/DAMAGE (INCLUDING EXAMPLE) 3

WARRANTY CLERK RESPONSIBILITY 4

FAILURE CODES 5

WIRING COLOUR CODES 5

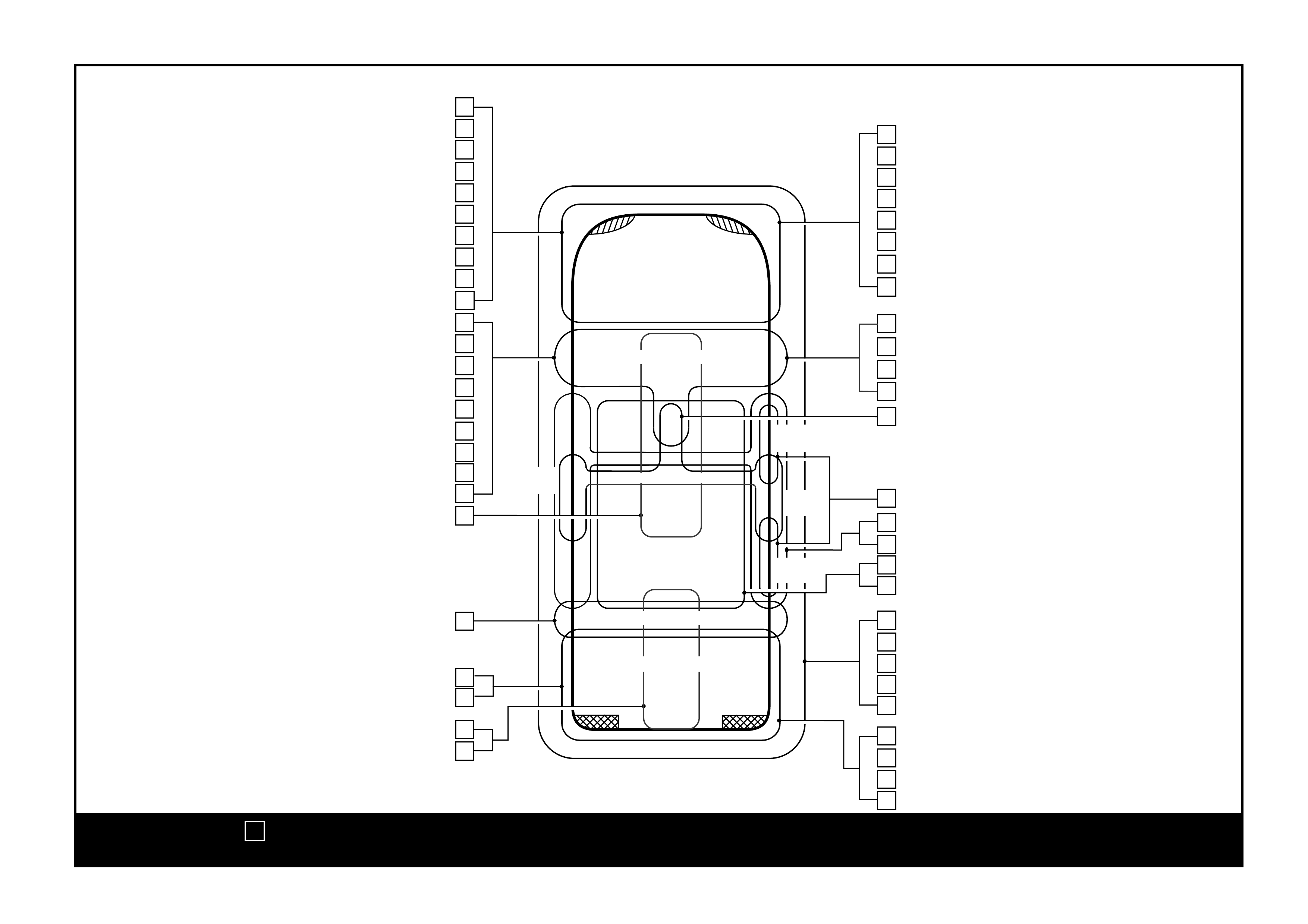

WIRING HARNESS LOCATION DIAGRAM 6

WIRING HARNESS ILLUSTRATIONS REFER FlG.1 TO FIG. 52 7 - 58

HOLDEN LIMITED A.B.N. 84 006 893 232

WARRANTY DEPARTMENT

COPYRIGHT - HOLDEN LIMITED

Reproduction in whole or in part prohibited without written approval

2

WIRING PROBLEM REPORTING

FOR WARRANTY CLAIMS

THE TECHNICIAN RESPONSIBILITY

Terminal Problems, Connector Body

Problems and Wire and/or Harness Problems.

A For Terminal problems

·

·

·

B For Connector Problems

·

·

·

C For Wire / Harness Problem

·

·

·

TERMINAL OR CONNECTOR PROBLEM

·

·

·

WIRE OR HARNESS DAMAGE / DEFECT

·

·

·

·

All Technicians are requested to carefully identify the problem area of wiring that needs rectification. Three

categories have been listed to cover all situations, these are

Technicians are required to record on the Repair Order, one of the following:

Figure Number

Affected Terminal Number (as circled on each Figure Number)

Failure Code Number (as per selection on Page Number 5)

Figure Number

Affected Connector Number

Failure Code Number (as per selection on Page Number 5)

Figure Number

Affected Zone numbers (being the vertical strip or zone of where damage is on Harness

Failure Code Number (as per selection on Page Number 5)

After troubleshooting an intermittent problem on a V2 Coupe, the largest of the

connectors at the PCM is found to have a terminal which has backed out, and is not

making contact with a pin on the PCM.

The engine bay diagram on Page 6 tells us that the location of the problem

harness is on Figure 12. We turn to Figure 12 and find the connector labelled as

8.

From Page 5 we select Failure Code 28 for 'terminal not retained in connector

body.

Hence write on the Repair Order:

Fig. 12

Conn. 8

F.C. 28

A V2 Coupe is found to continually blow indicator lamp fuses. It is found that the indicator

wire is bare and earthing out on the metal seat-back mounting panel above the RH rear

wheel arch. Because it is a wire and not a connector which is damaged, the two digit

Number which identifies the specific area where the damage has occurred on the wiring,

is to be used in lieu of connector number. Use the wire failure code for 'bare wire' - 94.

Reference to Page 6 tells us to refer to Figure 25. In fact this Figure shows the

exact section of damaged harness, so record Fig. 25 on the Repair Order.

Because the Failed Component is a harness and damaged within the vertical

Zone 90, the actual Zone Number is recorded on the Repair Order.

The failure code to use for bared wires is shown on Page 5 as '94'.

Hence write on the Repair Order:

Fig. 25

Zone. 90

F.C. 94

EXAMPLE:

EXAMPLE:

3

WARRANTY CLERK RESPONSIBILITY

To submit a V2 Coupe Warranty Claim under this system, the required Labour Operation Number to be

claimed is simply constructed by putting together the information recorded on the Repair Order by the

Technician. That is, the and (terminal or connector problems) or

(harness damage) plus the .

The Labour Operation Number is to be made up of the prefix followed by the two digit

on which the wiring is shown, and then the two digit or

(for Wiring and/or Harness damage) shown on that Figure.

Take care to ensure the number has been constructed properly, and consists of followed by a further

four digits.

The appropriate Failure Code should have been selected and recorded on the Repair Order by the Service

Technician. The earlier used Code 50 (Electrical Failure) is no longer acceptable for recording

Wiring Warranty faults.

If the repair involves replacement of a HarnessAssembly:

Please discuss further with your Service Manager or Holden's Service representative if you require further

assistance with submission of Electrical Wiring related Warranty Claims.

Please use the Wiring Warranty manual for photocopying and then attaching with a PIR when submitting a

wiring related PIR.

Figure Number Connector Number

Zone Number Failure Code

N98 Figure Number

Connector Number, Terminal Number Zone

Number

N980408

PREFIX FIGURE NO. CONNECTOR, OR

TERMINAL

OR ZONE NO.

N98

Note:

A Remember to claim the Labour Operation Number for the component that caused

the failure.

B Use appropriate Failure Code (From Page Number 5)

C If the Wiring Harness is replaced by a new part, then record the replaced Harness

Assembly Part Number in 'Failed Part Number" column of the Warranty Claim.

EXAMPLE:

4

FAILURE CODES

WIRING COLOUR CODES

The correct Failure Code must be provided if your claim is to assist Holden's in defining Electrical Faults in

V2 Coupe. Please use the appropriate code.

The following is a list of failure codes which are to be used when claiming for work done to Wiring

Harnesses.

20 Corroded/Heated/Melted

27 Terminal poorly crimped on wire

28 Terminal not retained in connector body

37 Loose in mating terminal

54 Wrong part fitted

58 Terminal in wrong position in connector body

78 Poor earth connection to body

80 Terminal damaged, preventing engagement

99 Dry solder connection

57 Not connected

89 Will not lock into mating connector

01 Pinched/cut wire

71 Harness/wire too short

86 Spliced connection open circuit

92 Incorrectly routed

94 Bare wires/short circuit

99 Dry solder connection

These abbreviations are used throughout FlG.01 to 52 illustrations to identify and

that are visibly identical in appearance. This will assist in the reporting process by selecting

the correct terminal or connector.

(W) WHITE (B/Y) BLACK/YELLOW (0/B) ORANGE/BLACK

(B) BLACK (B/R) BLACK/RED (O/R) ORANGE/RED

(BLU) BLUE (B/G) BLUE/GREEN (O/W) ORANGE/WHITE

(0) ORANGE (B/W) BLACK/WHITE (W/B) WHITE/BLACK

(BR) BROWN (BR/W) BROWN/WHITE (v/W) VIOLET/WHITE

(G) GREEN (P/B) PINK/BLACK (P/V) PINK/VIOLET

(R) RED (GY) GREY (V/W) VIOLET/WHITE

(Y) YELLOW (TA) TAN (LT/G) GREEN

TERMINAL PROBLEMS (Within Connector Bodies or Ring Type Terminals)

CODE DESCRIPTION

CONNECTOR BODY PROBLEM

CODE DESCRIPTION

WIRE / HARNESS PROBLEMS

CODE DESCRIPTION

CONNECTORS

TERMINALS

5

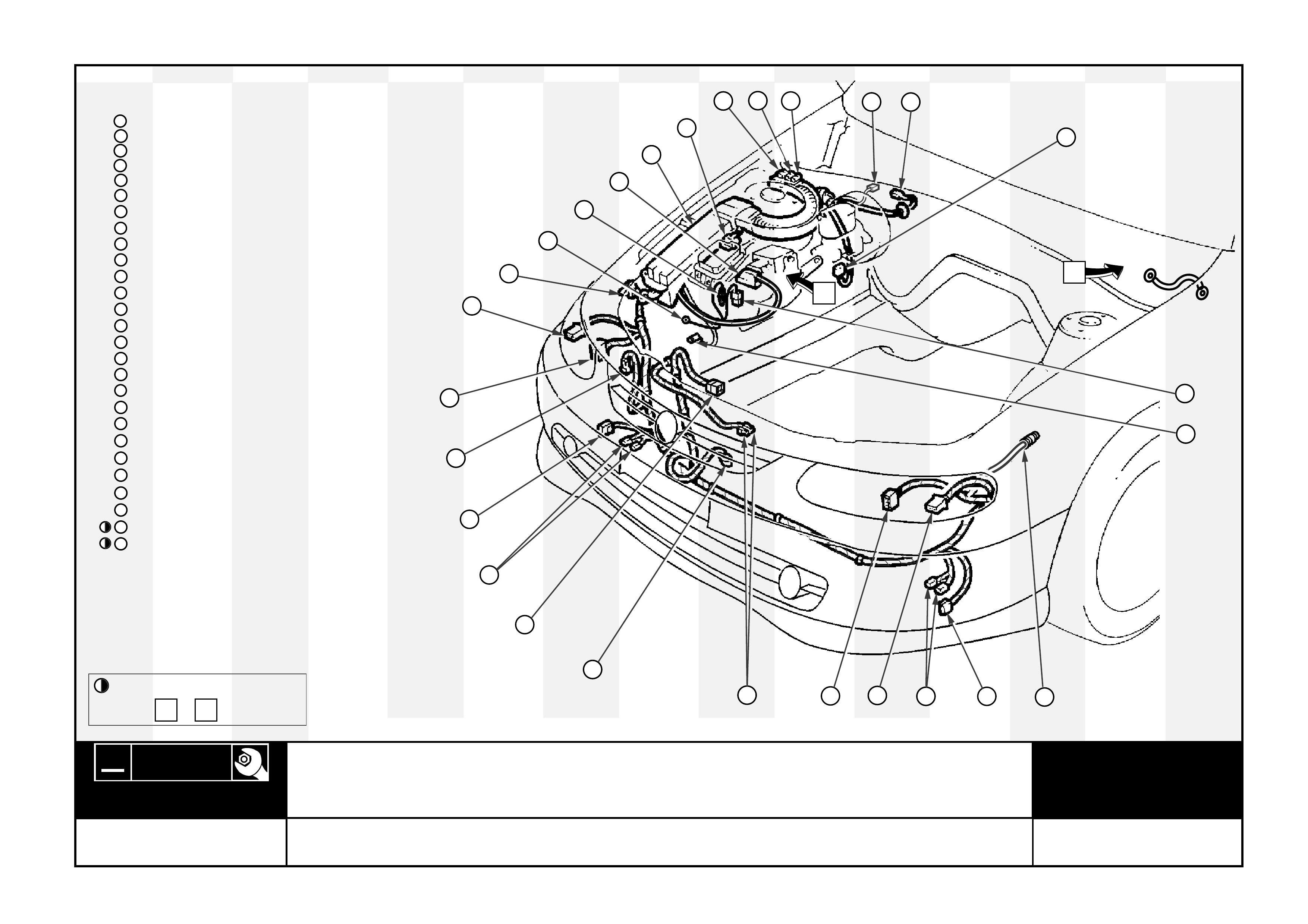

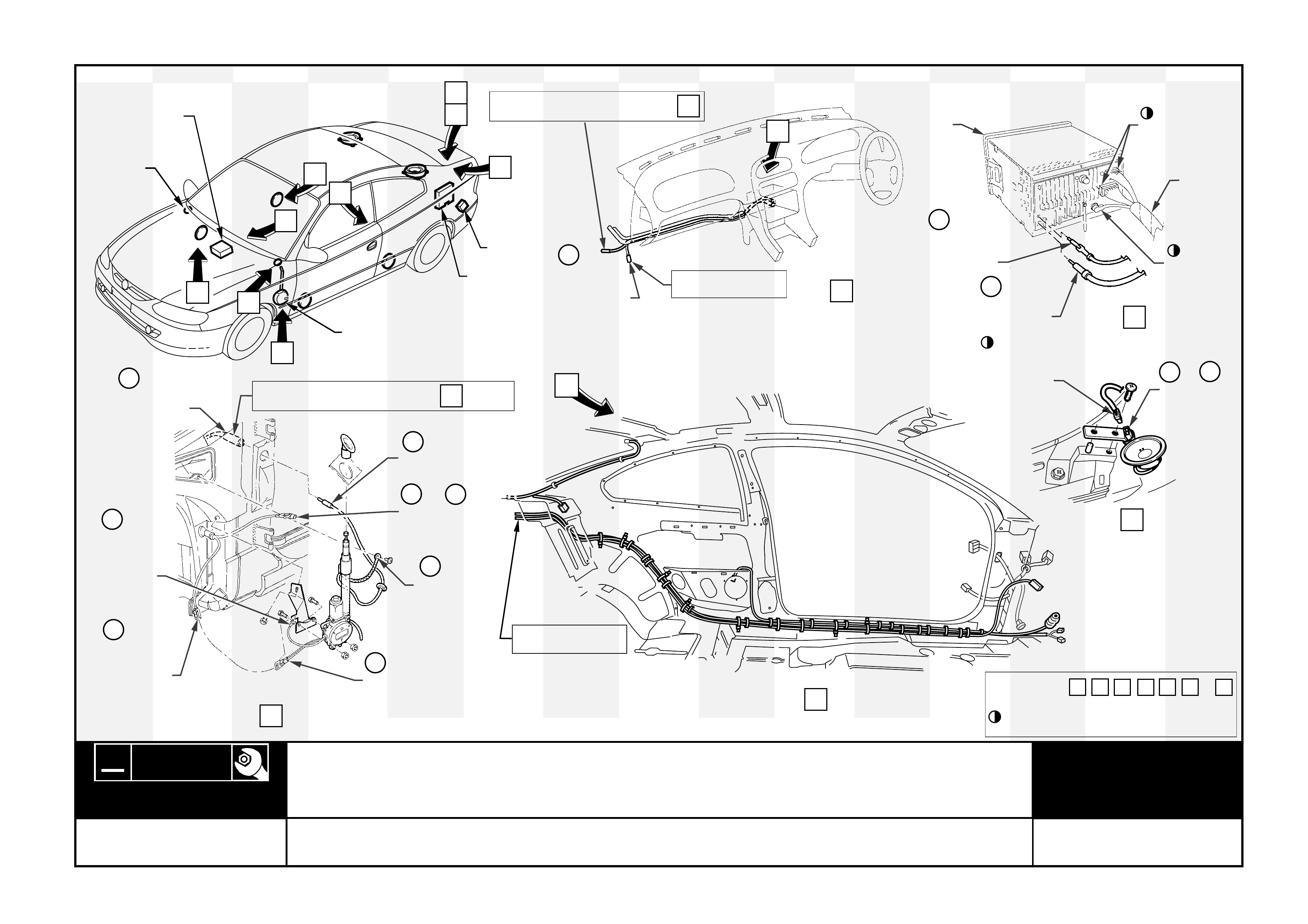

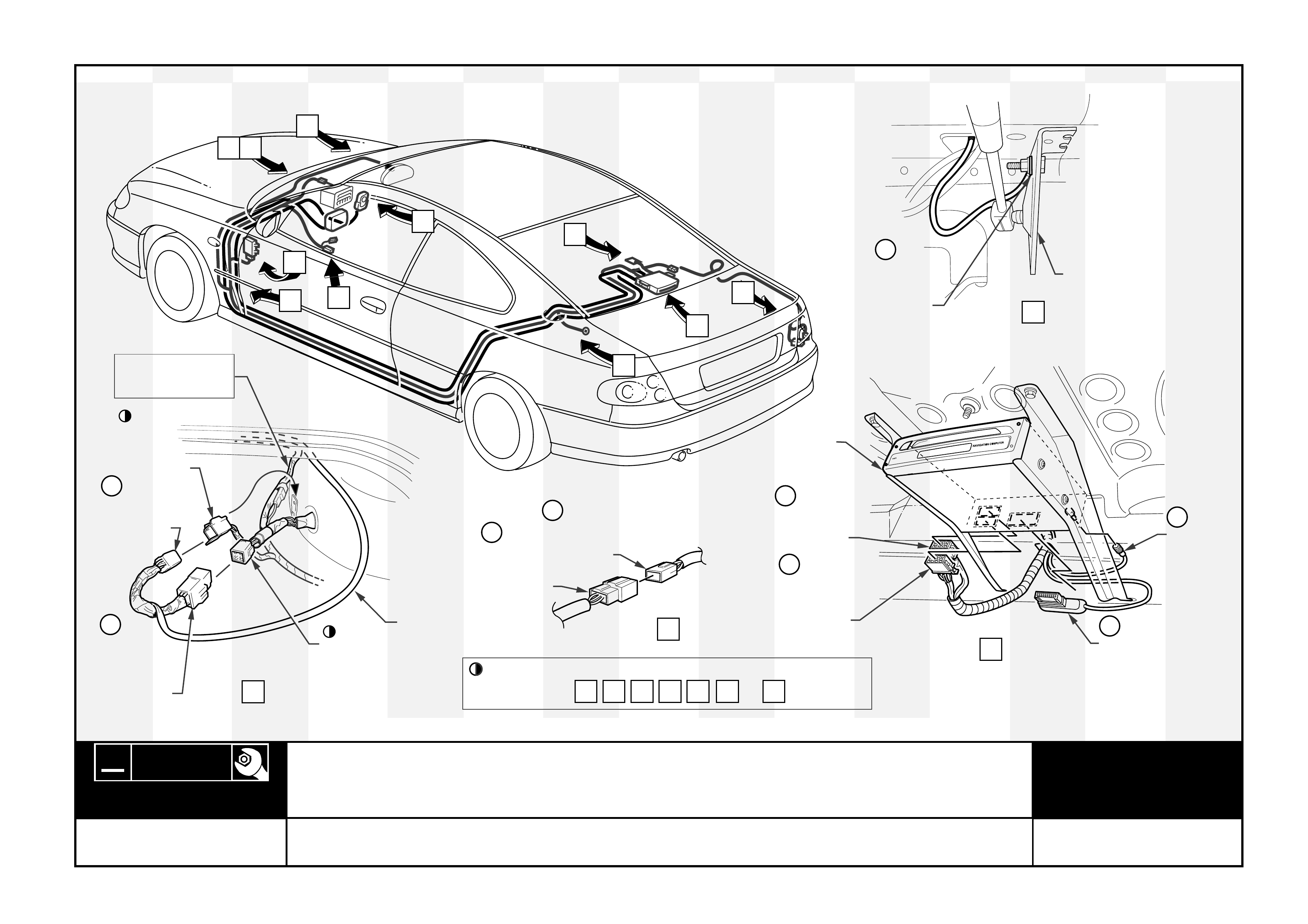

WIRING HARNESS LOCATION DIAGRAM

V2 COUPE SERIES

High Mounted Stop Lamp & Licence Plate Lamps

ITEM NO. (eg. FOR DOOR WIRING HARNESS) INDICATES FIG. NO.

OF WIRING ILLUSTRATION RECTIFICATION AREA IN VEHICLE

FIG.'S 01 TO 43 FEATURE HOLDEN INSTALLATIONS

FIG.'S 44 TO 52 FEATURE HSV INSTALLATIONS

6

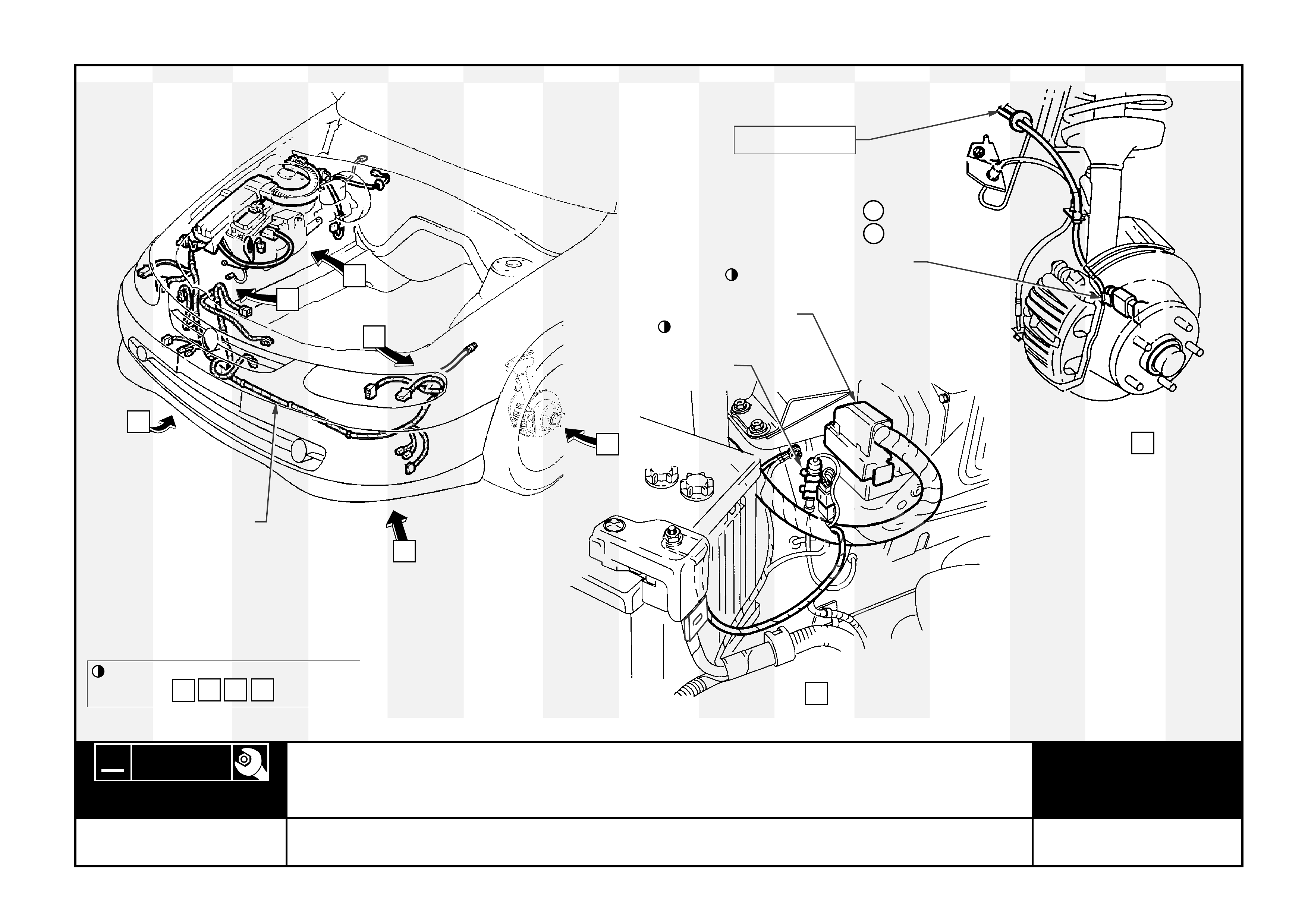

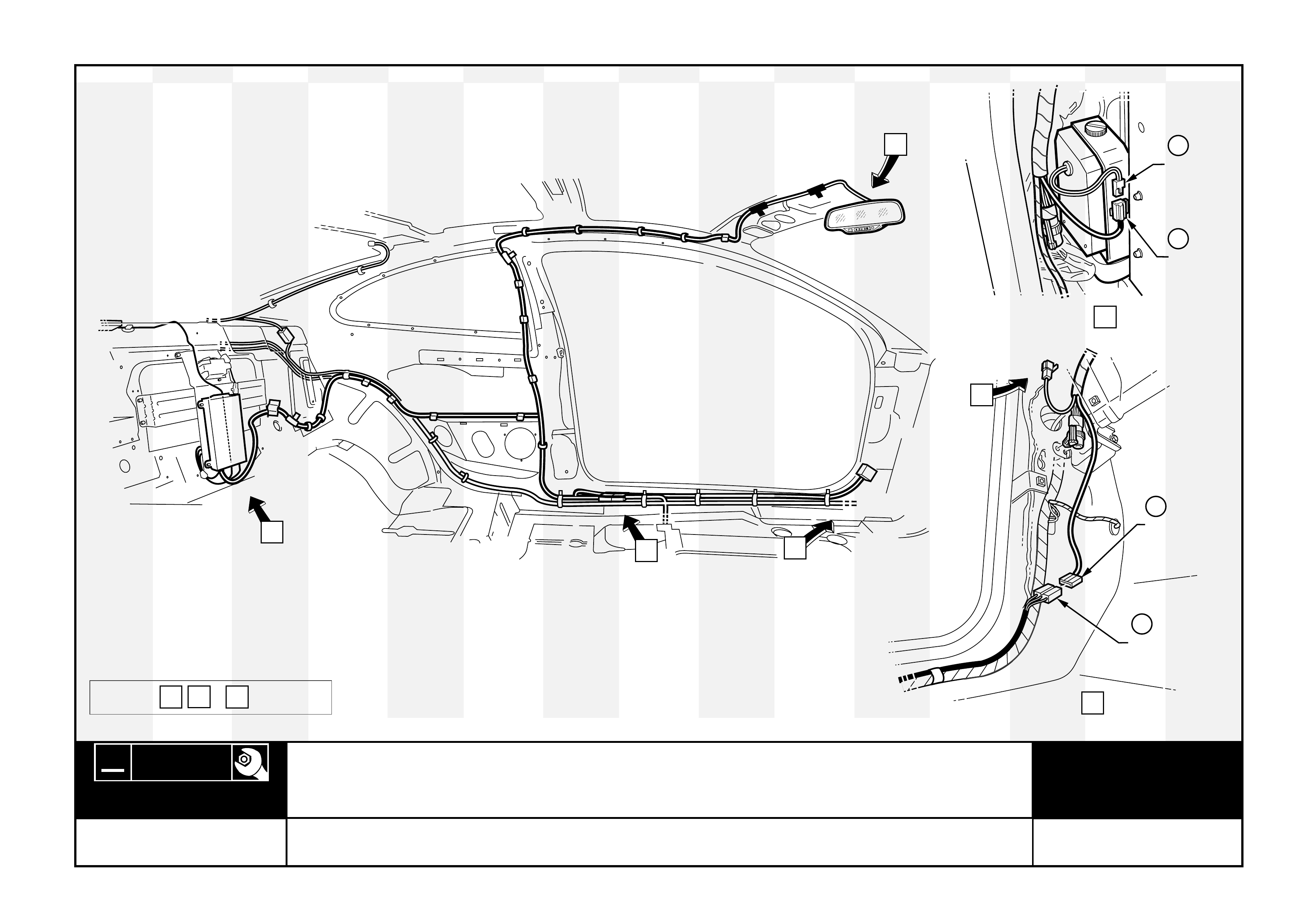

ENGINE COMPARTMENT

PASSENGER

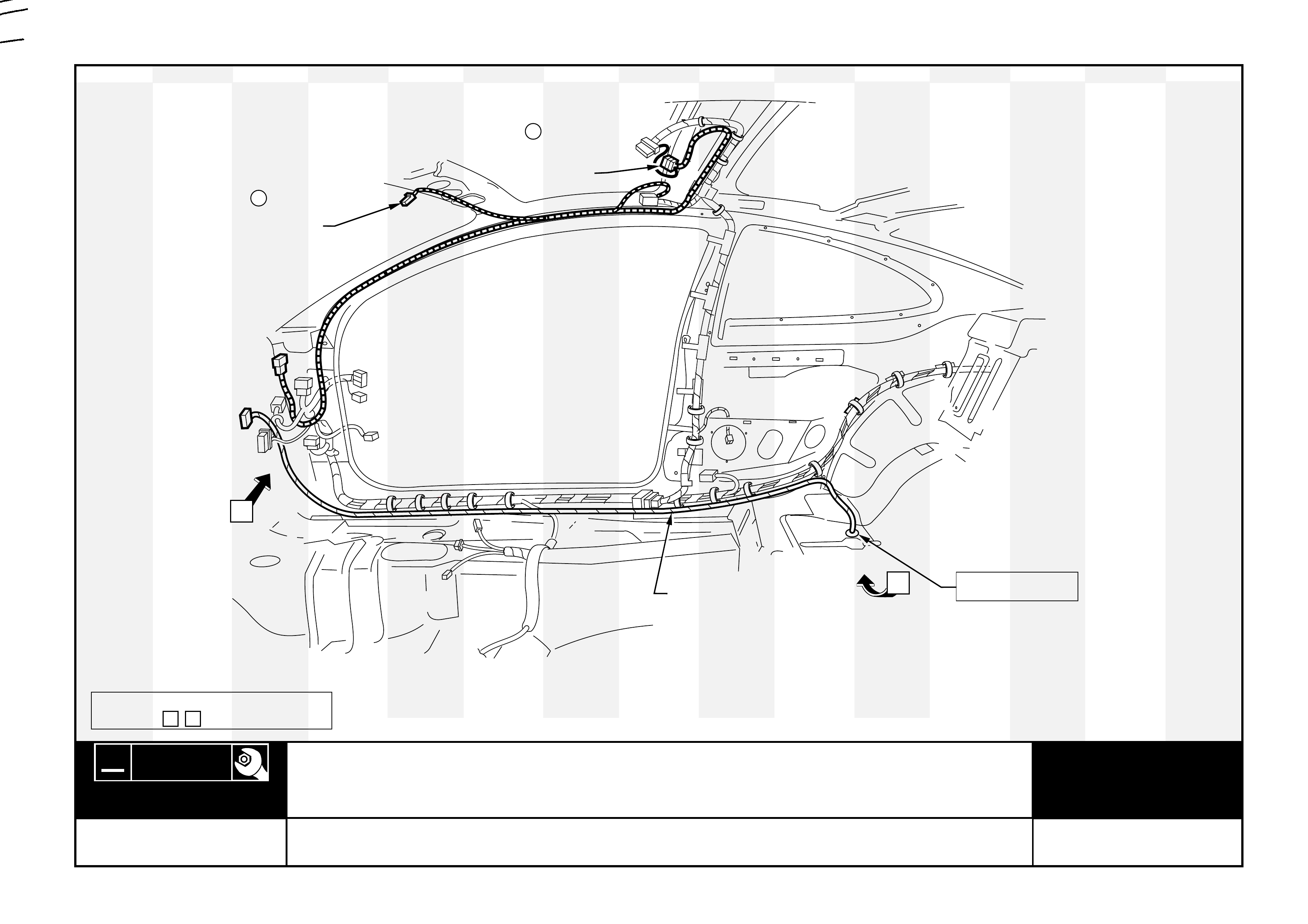

COMPARTMENT

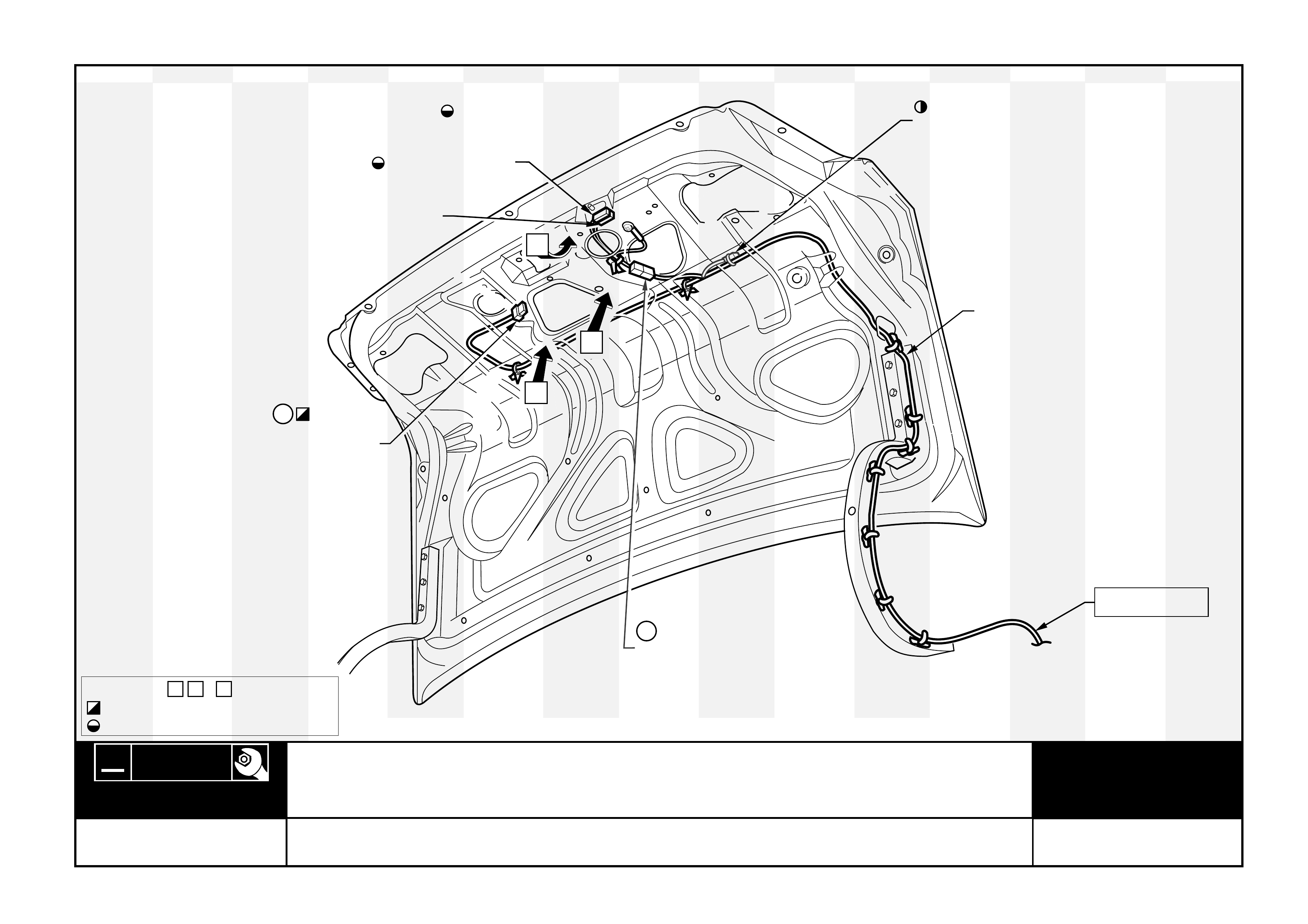

ROOF

BODY

SIDE

OVERALL SYSTEM

BODY

SIDE

FRONT

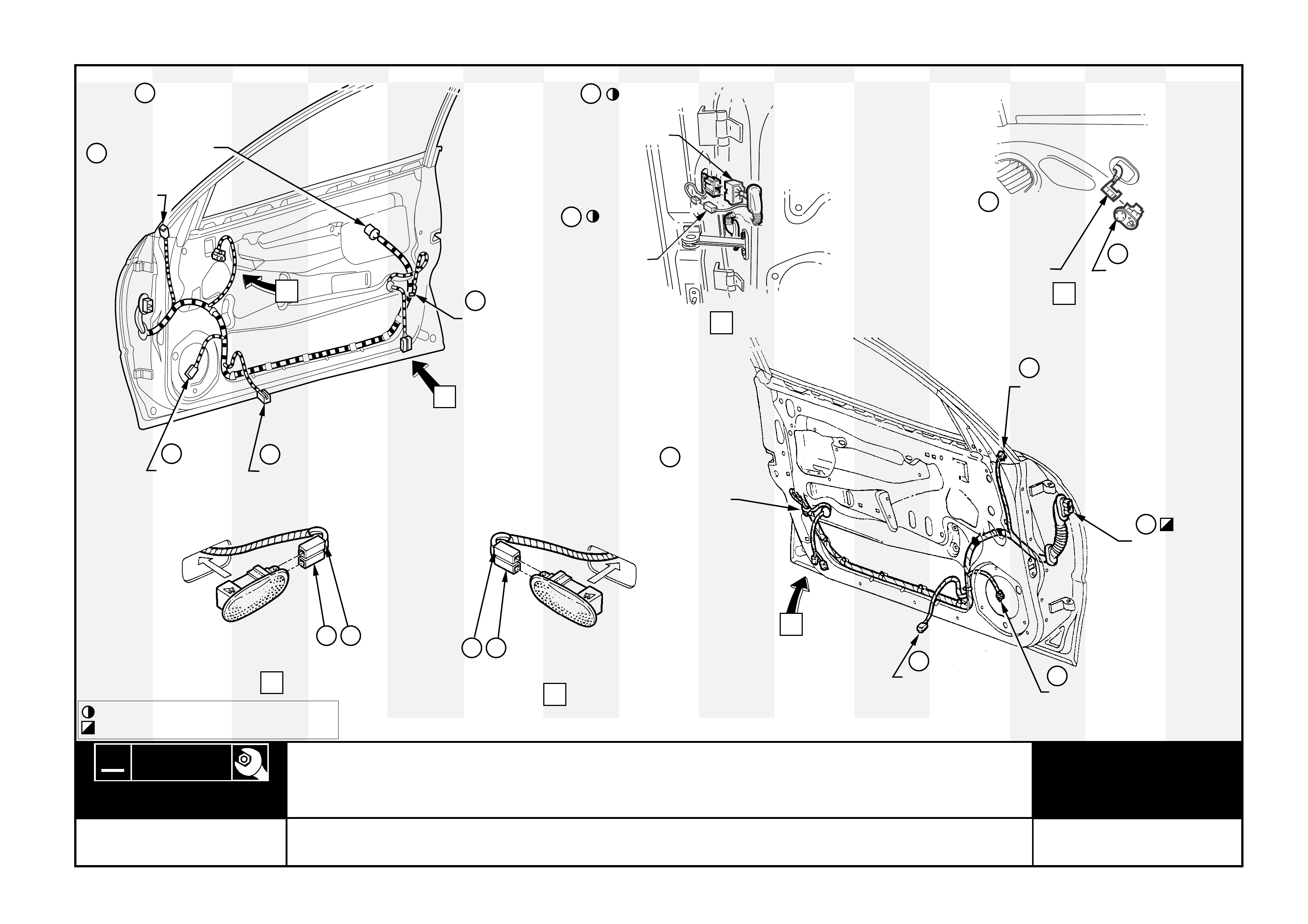

DOORS

REAR

DOORS

22

24

23

1

9

5

31

3

25

34

7

16

44

2

6

4

8

17

18

20

21

19

26

30

33

52

32

27

38

10

12

11

14

13

39

40

41

37

28

29

45

46

36

50

51

35

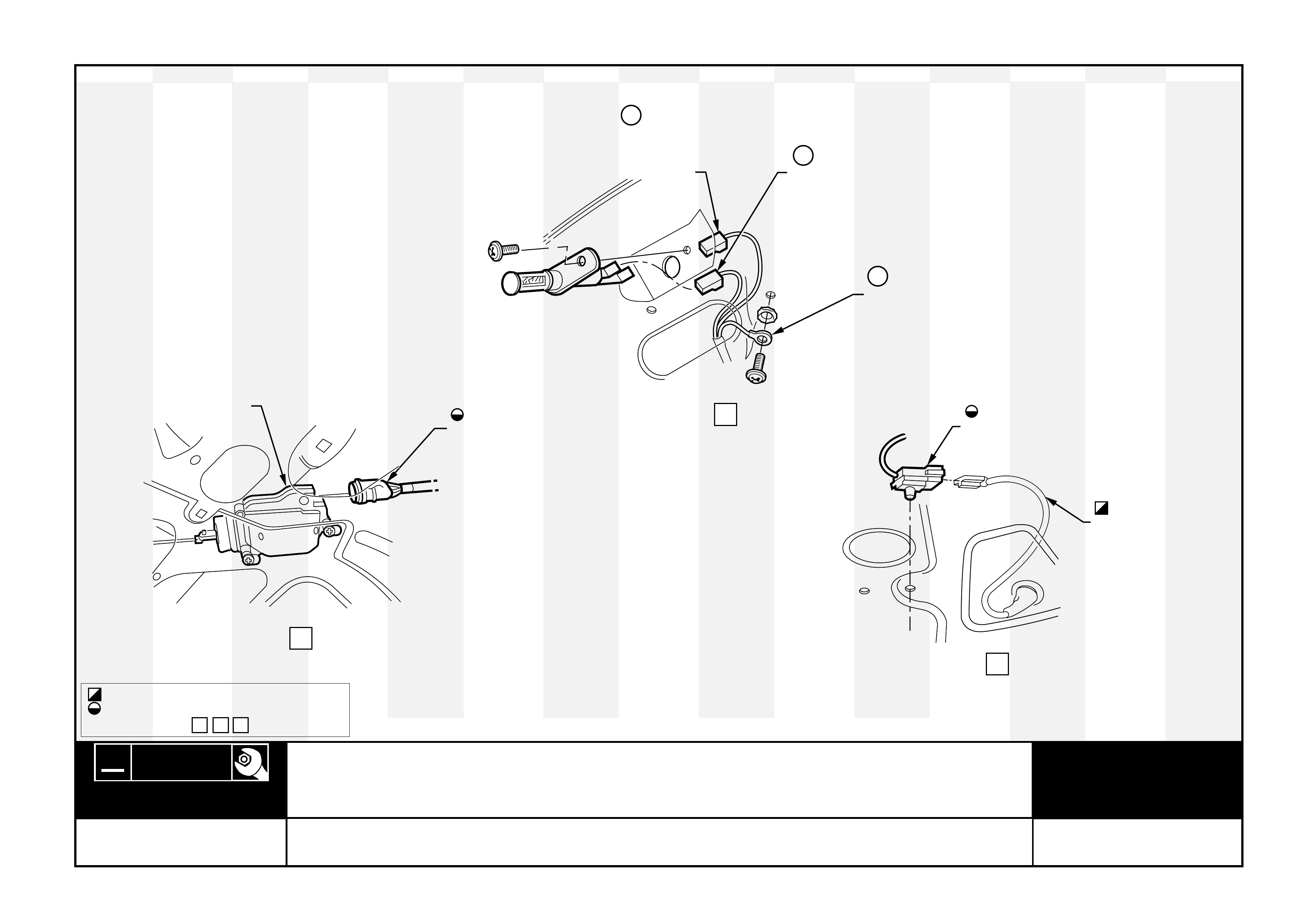

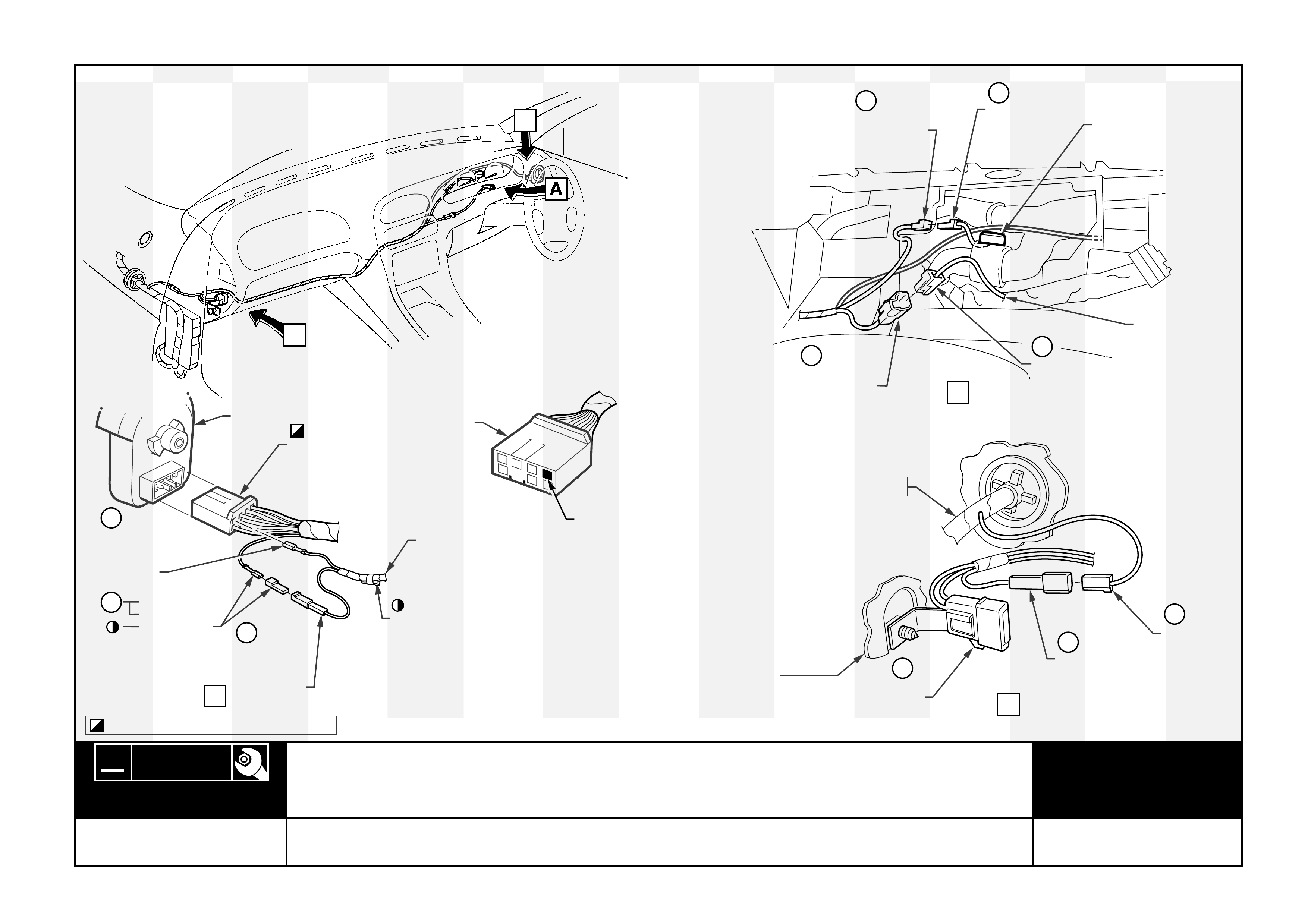

PCM /Interface & Cruise Control Clutch Switch

Door Wiring Harness

Body Wiring Harness

Body Wiring/Roof Lamps Harnesses & Dome Lamp

Body Audio System

Body Audio System

A.B.S. Wiring

MWH - Front Lamps, Fog Lamps & Horns

Upshift Indicator Harness - GTS

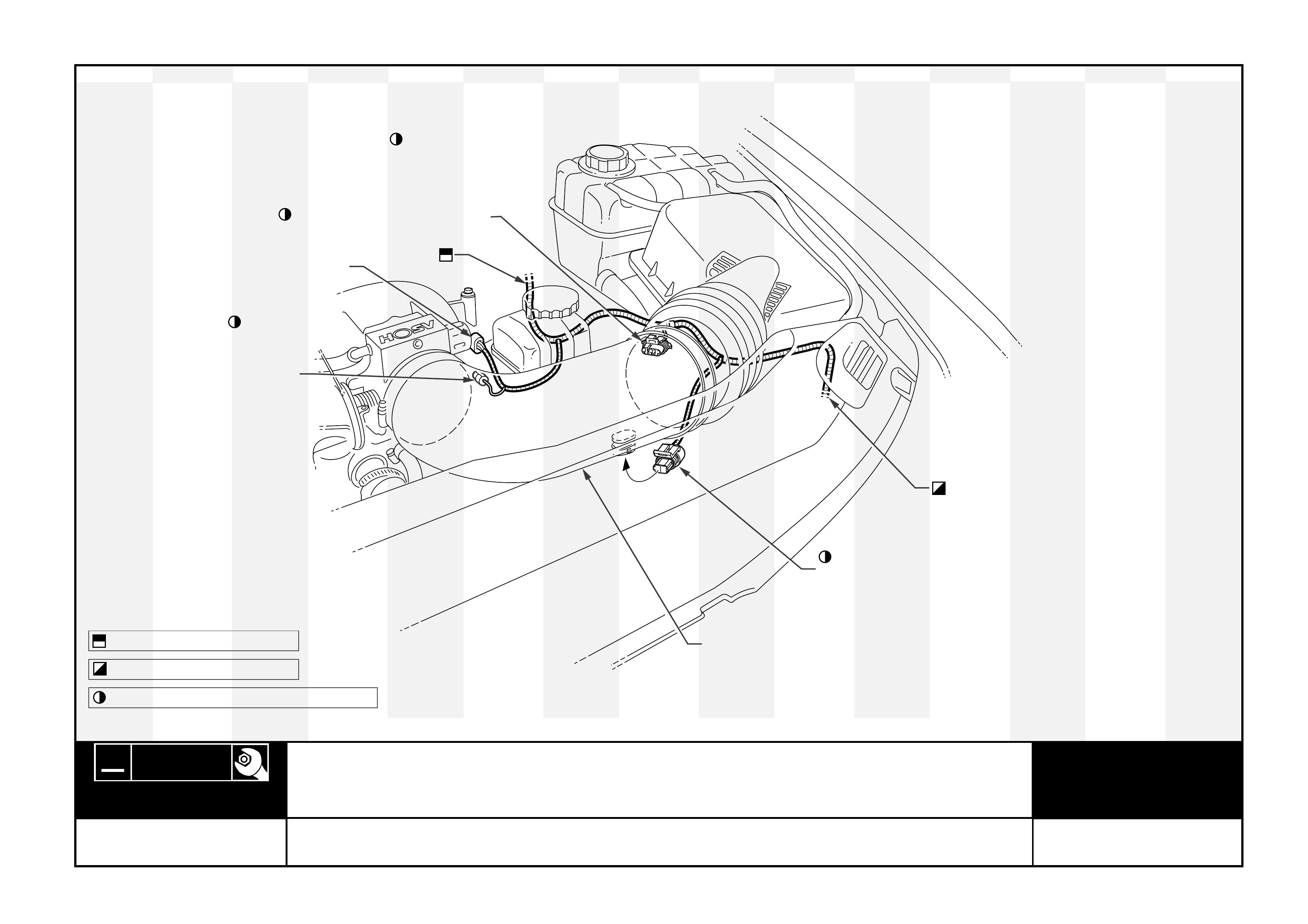

Powertrain & Engine Harnesses GEN III

MWH - Engine Compartment V6 S/C & GEN III

MWH - Engine Compartment V6 S/C & GEN III

Powertrain Harness GEN III

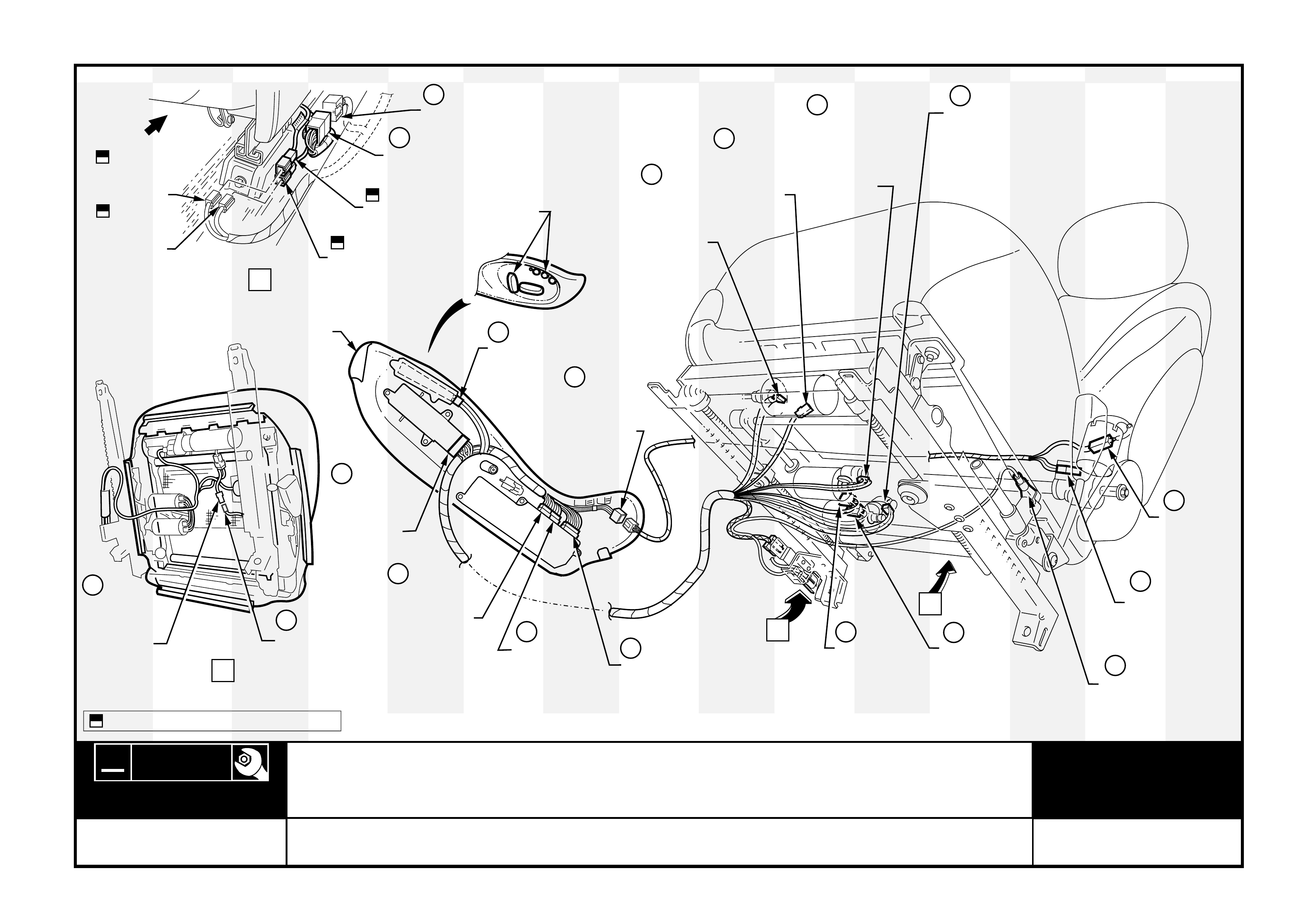

Power Seats - CV6 & CV8

Power Seats - CV8 (Driver)

S.R.S. Wiring

S.R.S. Wiring

Body Wiring Harness - Trunk Lid

Body Wiring Harness - Trunk Lid

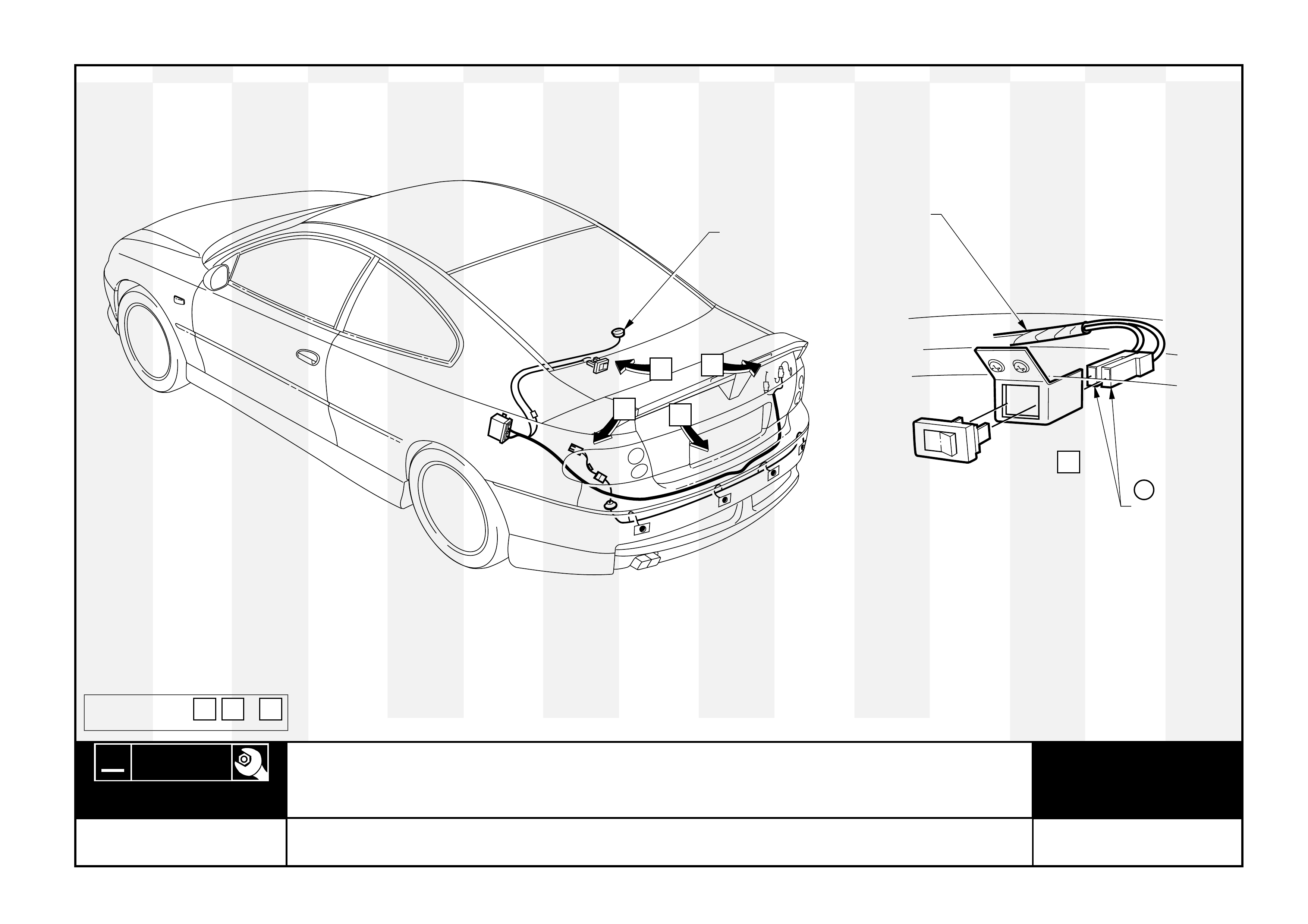

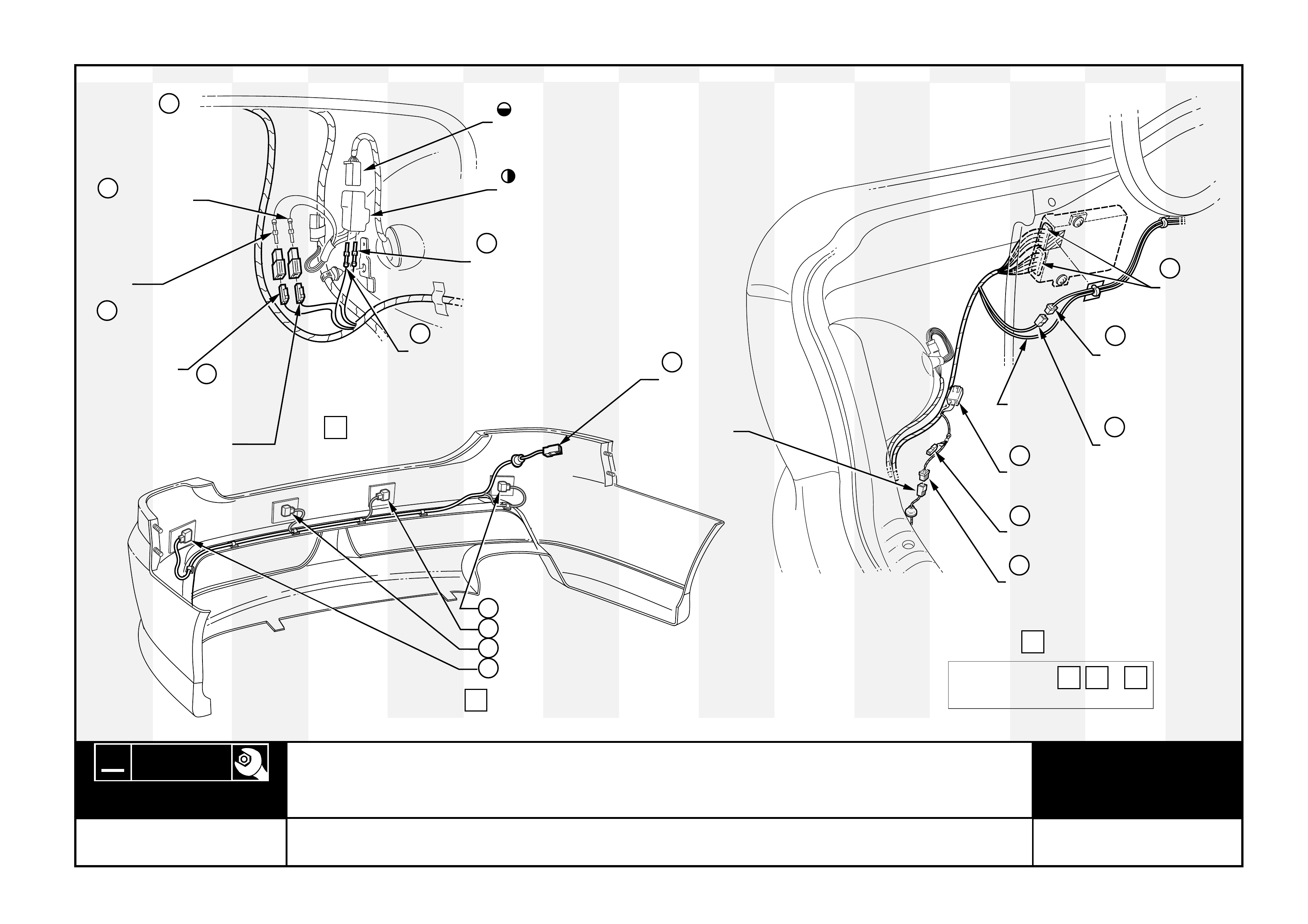

Reverse Parking Aid System - GTS

Reverse Parking Aid System - GTS

47

48

49

Level Ride

43

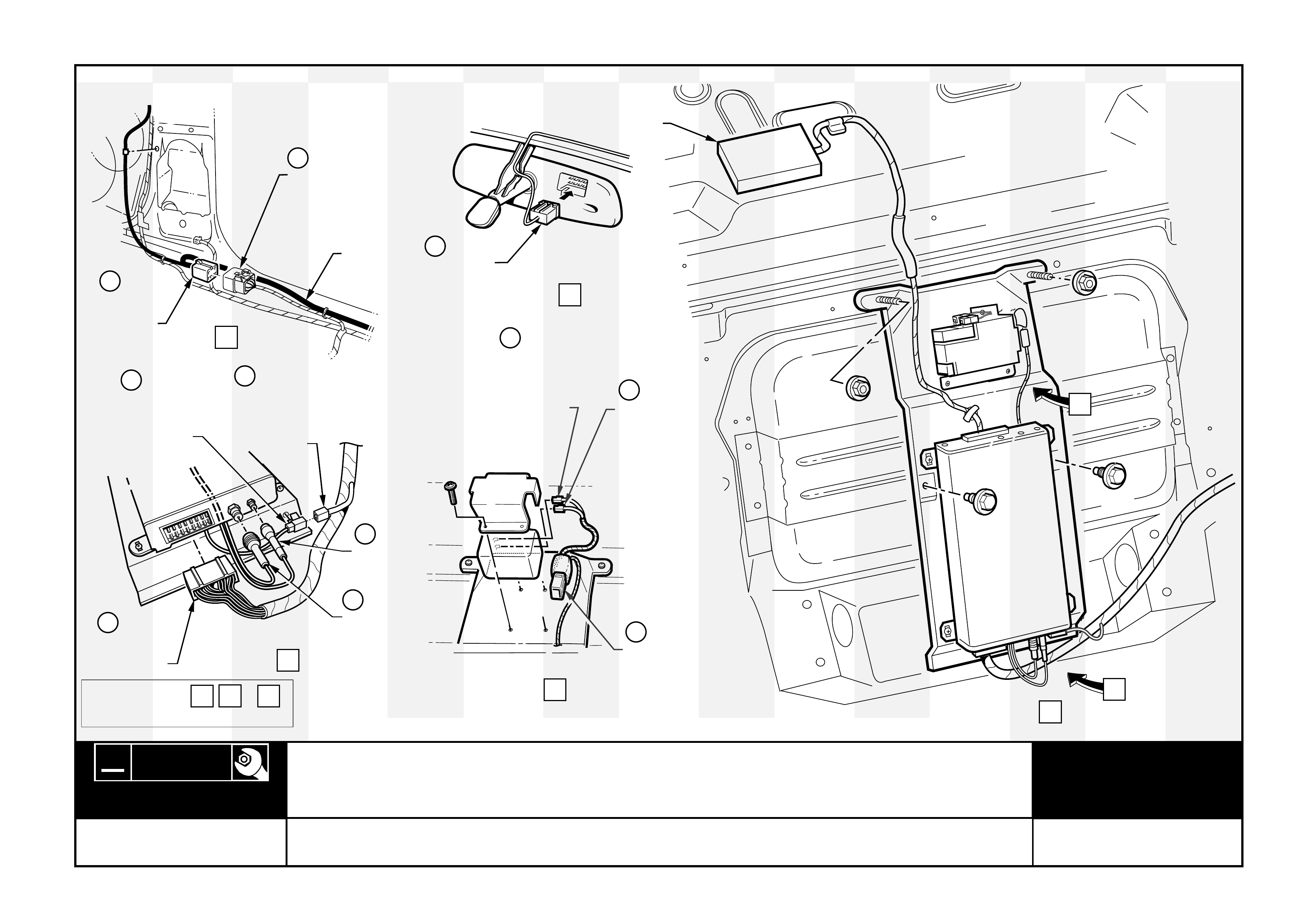

42 Telematics System

Telematics System

Satellite Navigation System

Satellite Navigation System

REAR AXLE

REAR COMPARTMENT

REAR

LAMPS

Battery Harness GEN III

Battery Harness V6

Battery Harness V6/GEN III

Powertrain Harness GEN III

Mass Sensor Deletion - GTS GEN III

Powertrain Harness V6

Powertrain Harness V6

Powertrain Harness GEN III

Powertrain Harness V6

Powertrain Harness V6

Main Wiring Harness - GTS

Main Wiring Harness - GTS

Main Wiring Harness - GTS

Main Wiring Harness - GTS

Main Wiring Harness

MWH to BCM & Body Harness

Main Wiring Harness

Main Wiring Harness

Main Wiring Harness

Body Wiring Harness

Body Wiring Harness - Fuel Sender Unit

High Mounted Stop Lamp & Licence Lamps

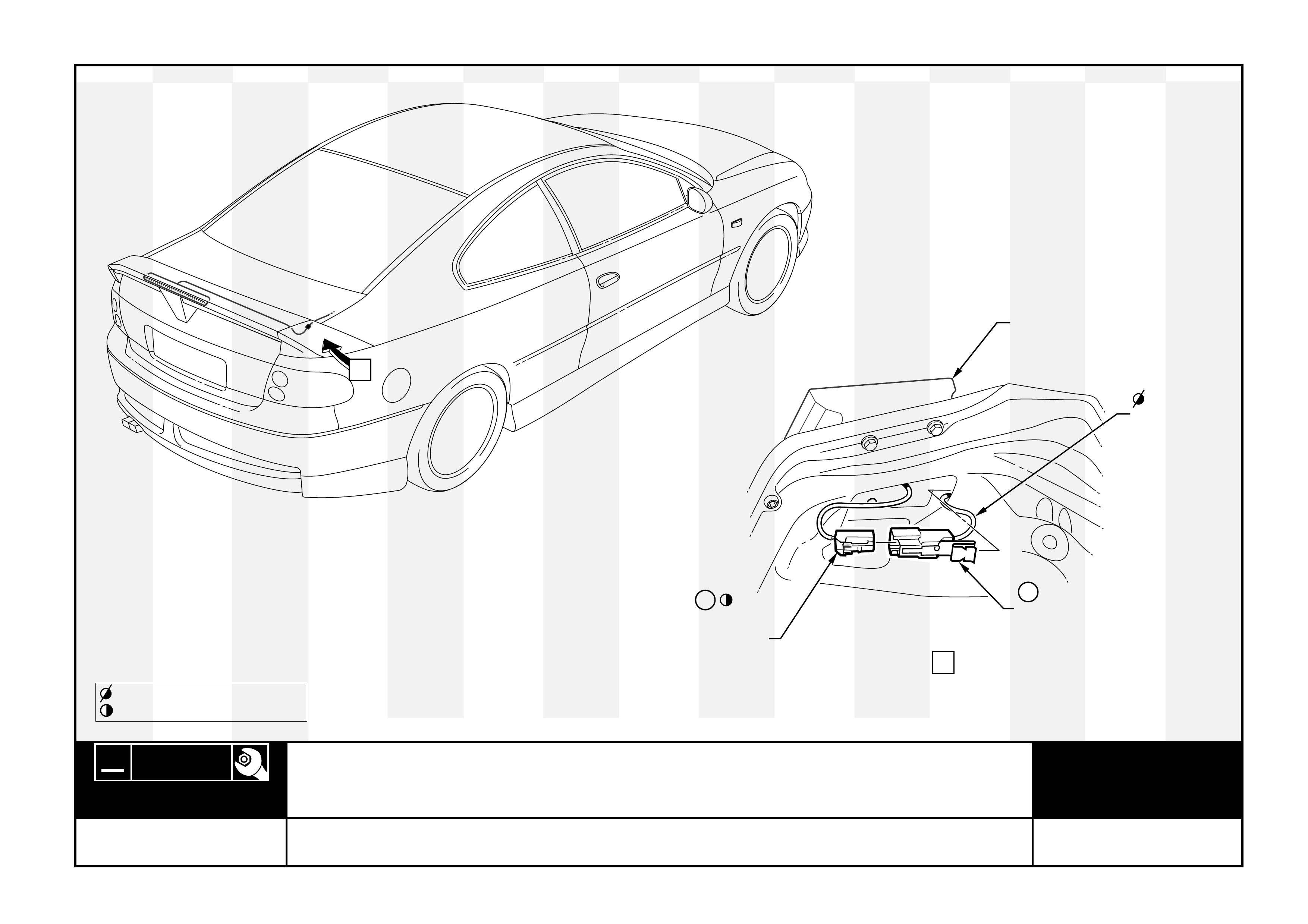

Spoiler Stop Lamp Harness

A.B.S. & Fuel Tank Wiring

Electro Chromatic Mirror - Except with Telematics

34

15 Engine Cooling Harness V6 S/C & GEN lII

COCKPIT MODULE

SIDE AIRBAGS

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

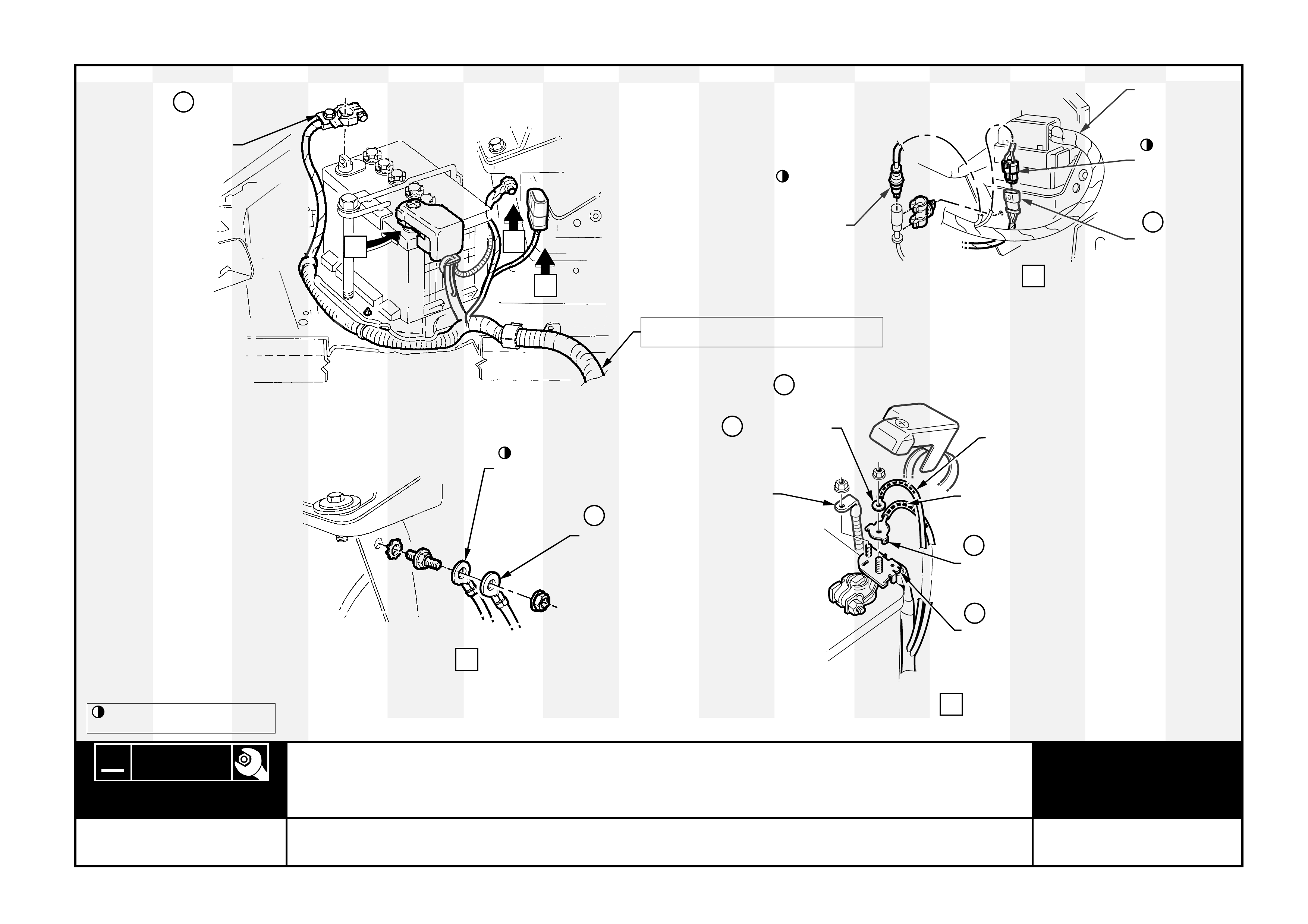

FIG. 01

7

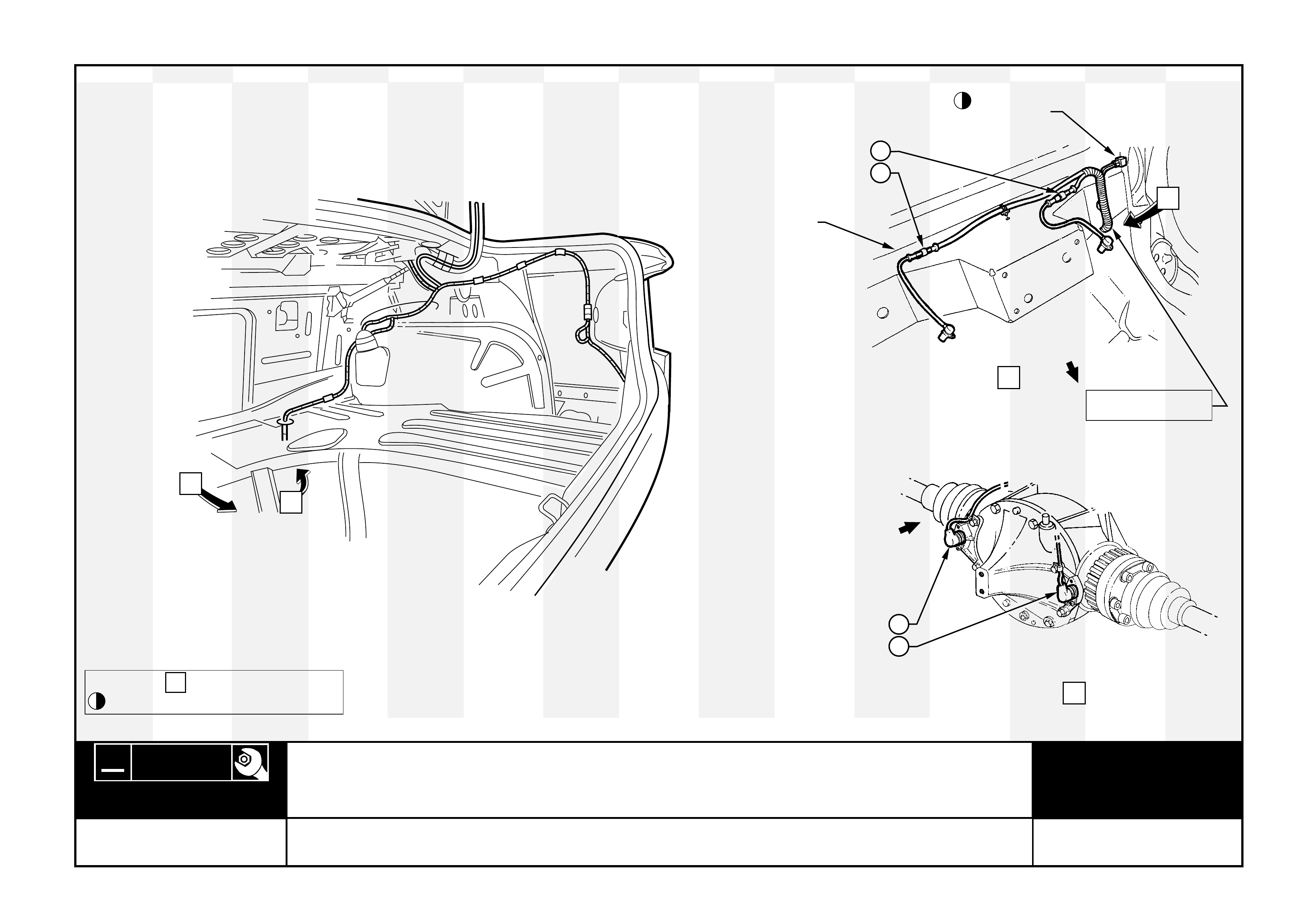

MODEL V2 COUPE BATTERY HARNESS V6 S/C & GEN lll

1

BATTERY

NEGATIVE

TERMINAL

A

C

B

FOR TERMINAL & CONNECTOR

NUMBERS REFER FIG. 13

2

VIEW

A

BODY

EARTH

TERMINAL

MAIN WIRING

HARNESS

BODY EARTH

TERMINAL

FOR CONTINUATION REFER FIG. 02 - V6 S/C

FOR CONTINUATION REFER FIG. 03 - GEN III

5

6

VIEW

B

MAIN

WIRING

HARNESS

FUSE PANEL

SUPPLY

BATTERY

POSITIVE

TERMINAL

COOLING

FANS

TERMINAL

4

3

VOLTAGE

SENSE

TERMINAL BROWN

FUSIBLE

LINK WIRE

BLUE

FUSIBLE

LINK WIRE

VIEW

C

RHF ABS

WHEEL

SENSOR

CONNECTOR 7

MAIN

WIRING

HARNESS

CONNECTOR

BATTERY

HARNESS

CONNECTOR

MAIN

WIRING

HARNESS

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

FIG. 02

8

MODEL V2 COUPE BATTERY HARNESS V6 S/C

A

B

C

G

BODY

EARTH

TERMINAL

MAIN WIRING

HARNESS

CONNECTOR

BATTERY

NEGATIVE

TERMINAL

BATTERY

POSITIVE

TERMINAL

VIEW

G

STARTER

SOLENOID

CONNECTOR

STARTER

MOTOR

TERMINAL

VIEW

D

POWER

STEERING

PIPE

ASSEMBLY

VIEW

F

OIL

COOLER

PIPES

VIEW

E

FOR CONNECTOR NUMBERS REFER FIG. 01

ALTERNATOR

CONNECTOR

VIEW

A

ALTERNATOR

TERMINAL

3

24

5

VIEW

B

POWERTRAIN

HARNESS

D

VIEW

C

ENGINE

EARTH

TERMINAL

ENGINE

MOUNT

RH.SIDE

1

E

F

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

FIG. 03

9

MODEL V2 COUPE BATTERY HARNESS GEN III

A

C

D

B

MAIN WIRING

HARNESS

CONNECTOR

BODY

EARTH

TERMINAL

BATTERY

POSITIVE

TERMINAL

BATTERY

NEGATIVE

TERMINAL

FOR CONNECTOR NUMBERS REFER FIG. 01

VIEW

E

ALTERNATOR

TERMINAL

3

VIEW

A

ENGINE

EARTH

TERMINAL

1

VIEW

B

STARTER

MOTOR

TERMINAL

4

VIEW

D

E

STARTER

SOLENOID

CONNECTOR

5

VIEW

C

ALTERNATOR

CONNECTOR

2

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

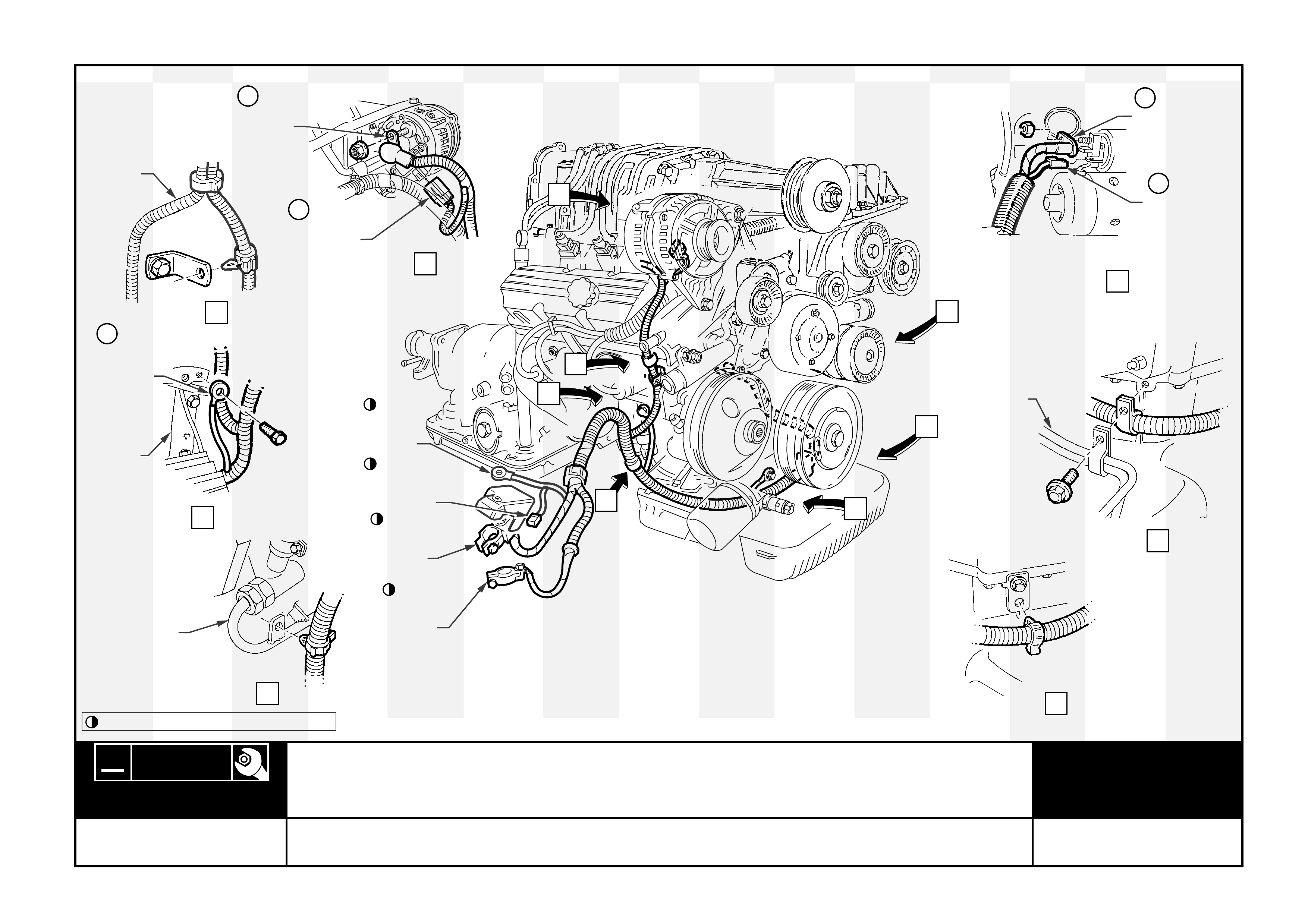

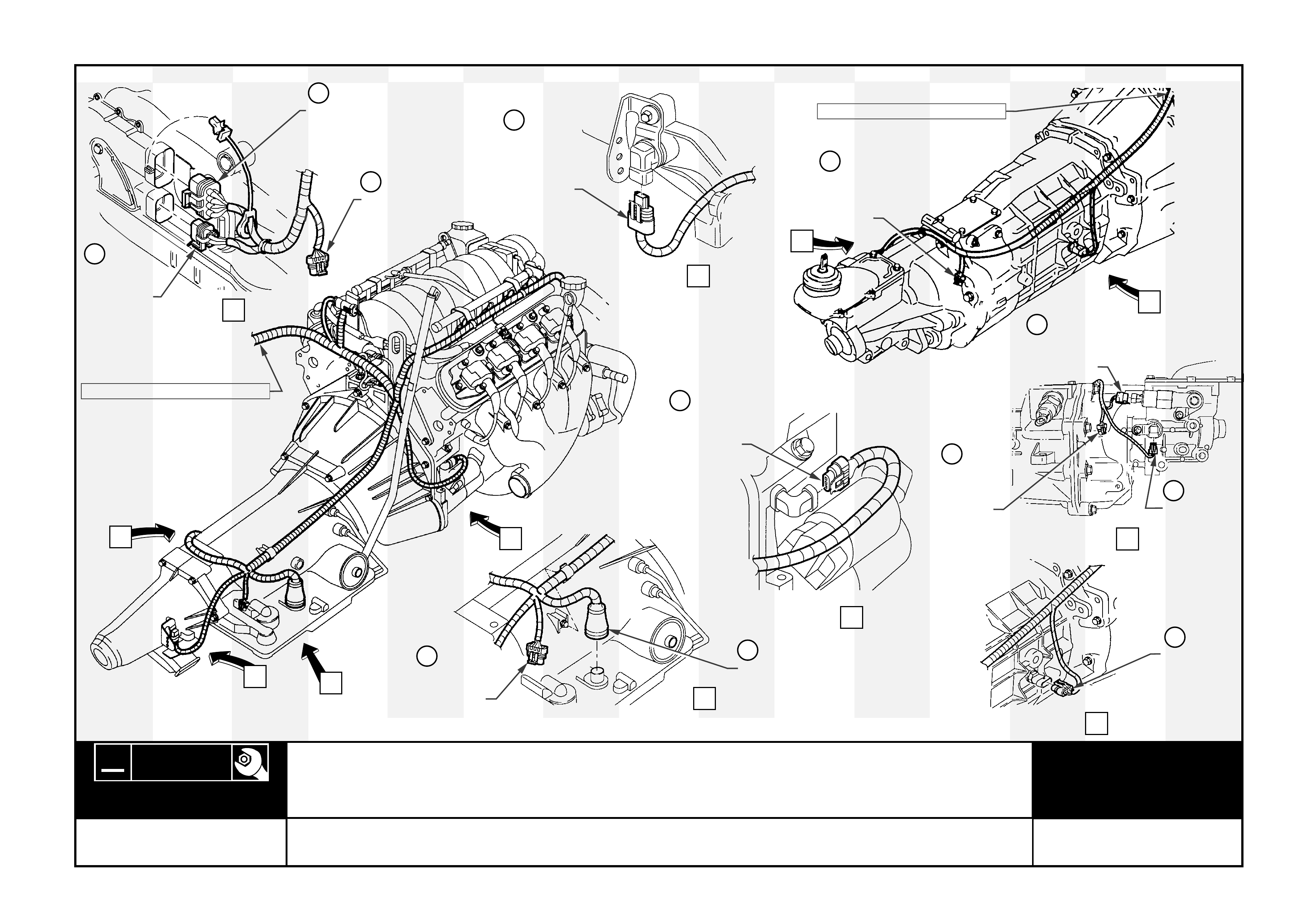

FIG. 04

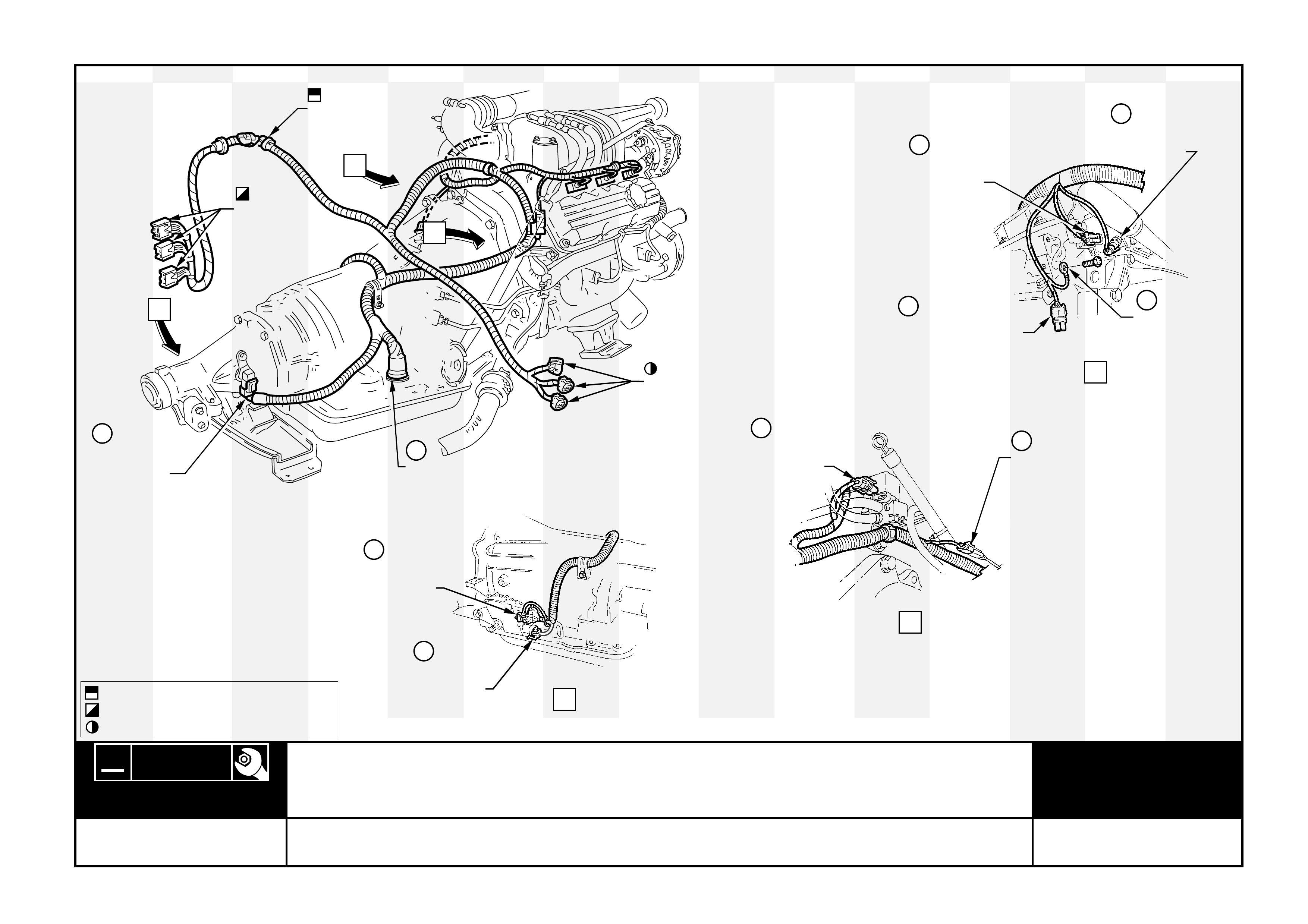

10

MODEL V2 COUPE POWERTRAIN HARNESS V6 S/C

11

VIEW

B

VIEW

C

A/C COMPRESSOR

CONNECTOR

2

VIEW

A

KNOCK SENSOR

CONNECTOR (L.H)

BATTERY

HARNESS

DIRECT

FIRE

MODULE

CONNECTOR

10

12

8

7

9

6

No.1 INJECTOR

No.3 INJECTOR

No.5 INJECTOR

IDLE AIR

CONTROL

MOTOR

CONNECTOR

THROTTLE

POSITION

SENSOR

CONNECTOR

AIR

TEMPERATURE

SENSOR

CONNECTOR

4

3

A

B

1

CRANKSHAFT

SENSOR

CONNECTOR

A/C PRESSURE

TRANSDUCER

CONNECTOR

M.A.F.

SENSOR

CONNECTOR

5

C

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

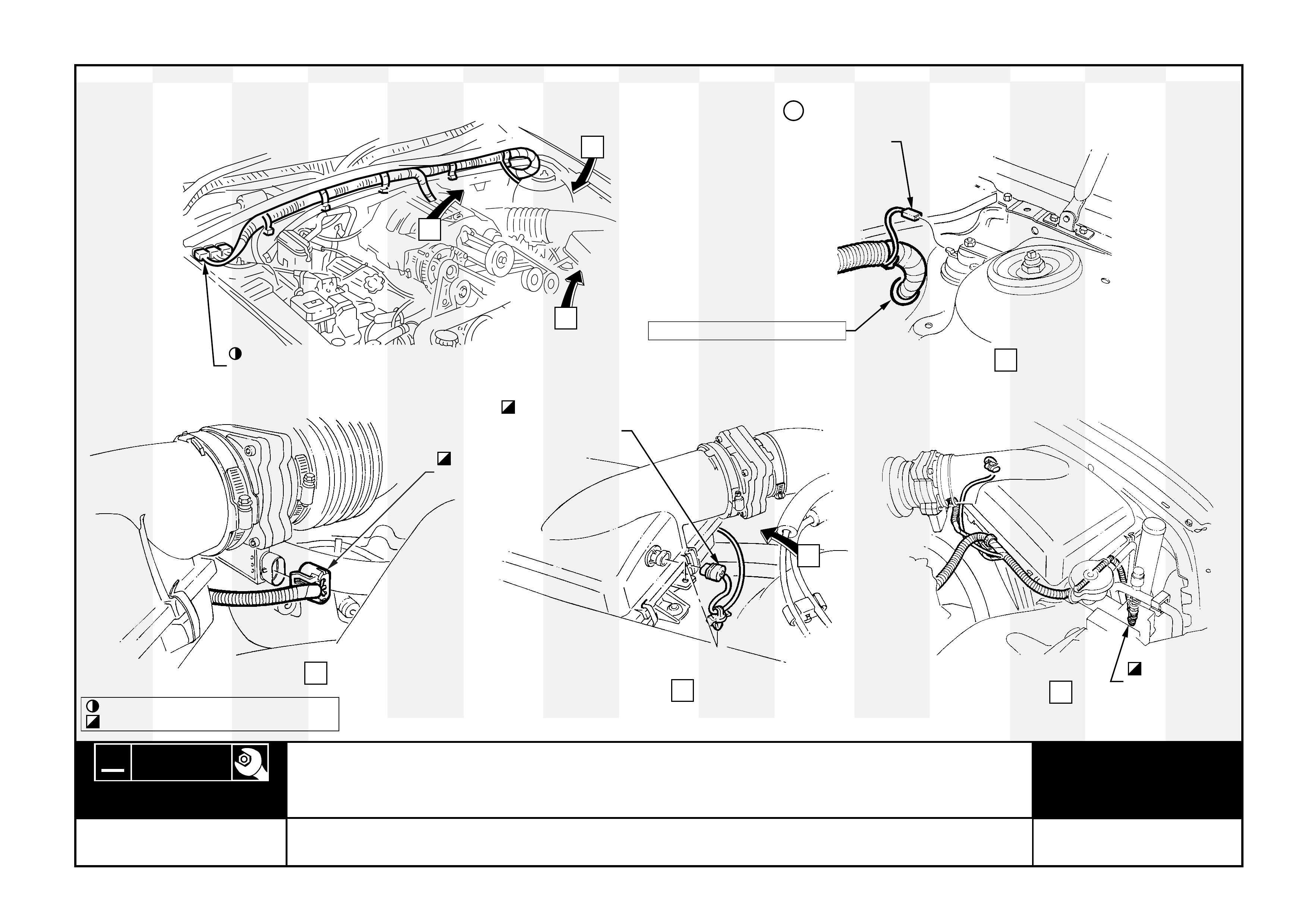

FIG. 05

11

MODEL V2 COUPE POWERTRAIN HARNESS V6 S/C

ENGINE

EARTH

TERMINAL

VIEW

A

5

KNOCK

SENSOR

CONNECTOR

(R.H)

VIEW

B

7

FOR CONNECTOR NUMBERS REFER FIG.01 & 02

OIL PRESSURE

SWITCH CONNECTOR

6

4

VIEW

C

CAM SENSOR

CONNECTOR

6

VIEW

D

NO.2 INJECTOR

NO.4 INJECTOR

NO.6 INJECTOR

1

2

3

C

D

B

B

BATTERY

HARNESS

A

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

FIG. 06

12

MODEL V2 COUPE POWERTRAIN HARNESS V6 S/C

FOR CONNECTOR NUMBERS REFER FIG 13

FOR CONNECTOR NUMBERS REFER FIG 12

FOR CONNECTOR NUMBERS REFER FIG 07 VIEW

A

NSBU

SWITCH

CONNECTOR

PRNDL

SWITCH

CONNECTOR

2

3

RH EXHAUST

GAS SENSOR

CONNECTOR

CANISTER

PURGE

CONNECTOR

VIEW

B

5

8

MAIN WIRING

HARNESS

CONNECTORS

ANTI-THEFT HORN

CONNECTOR

PCM

CONNECTORS

A

C

AUTOMATIC TRANSMISSION

TRANSMISSION

SPEED SENDER

CONNECTOR TRANSMISSION

CONNECTOR

1

4

EARTH

TERMINAL

VIEW

C

LH EXHAUST GAS

SENSOR CONNECTOR

7

ANTI-BOOST

SOLENOID

CONNECTOR

COOLANT

TEMP SENSOR

CONNECTOR

6

9

10

B

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

FIG. 07

13

POWERTRAIN HARNESS V6 S/C

ANTI - THEFT

HORN CONNECTOR

VIEW

A

VIEW

D

M.A.F. SENSOR

CONNECTOR

AIR TEMPERATURE

SENSOR CONNECTOR

VIEW

B

D

1

FOR CONNECTOR NUMBERS REFER FIG 13

FOR CONNECTOR NUMBERS REFER FIG 04

VIEW

C

A/C PRESSURE

TRANSDUCER

CONNECTOR

MAIN WIRING

HARNESS CONNECTORS

FOR CONTINUATION REFER FIG. 12

MODEL V2 COUPE

B

A

C

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

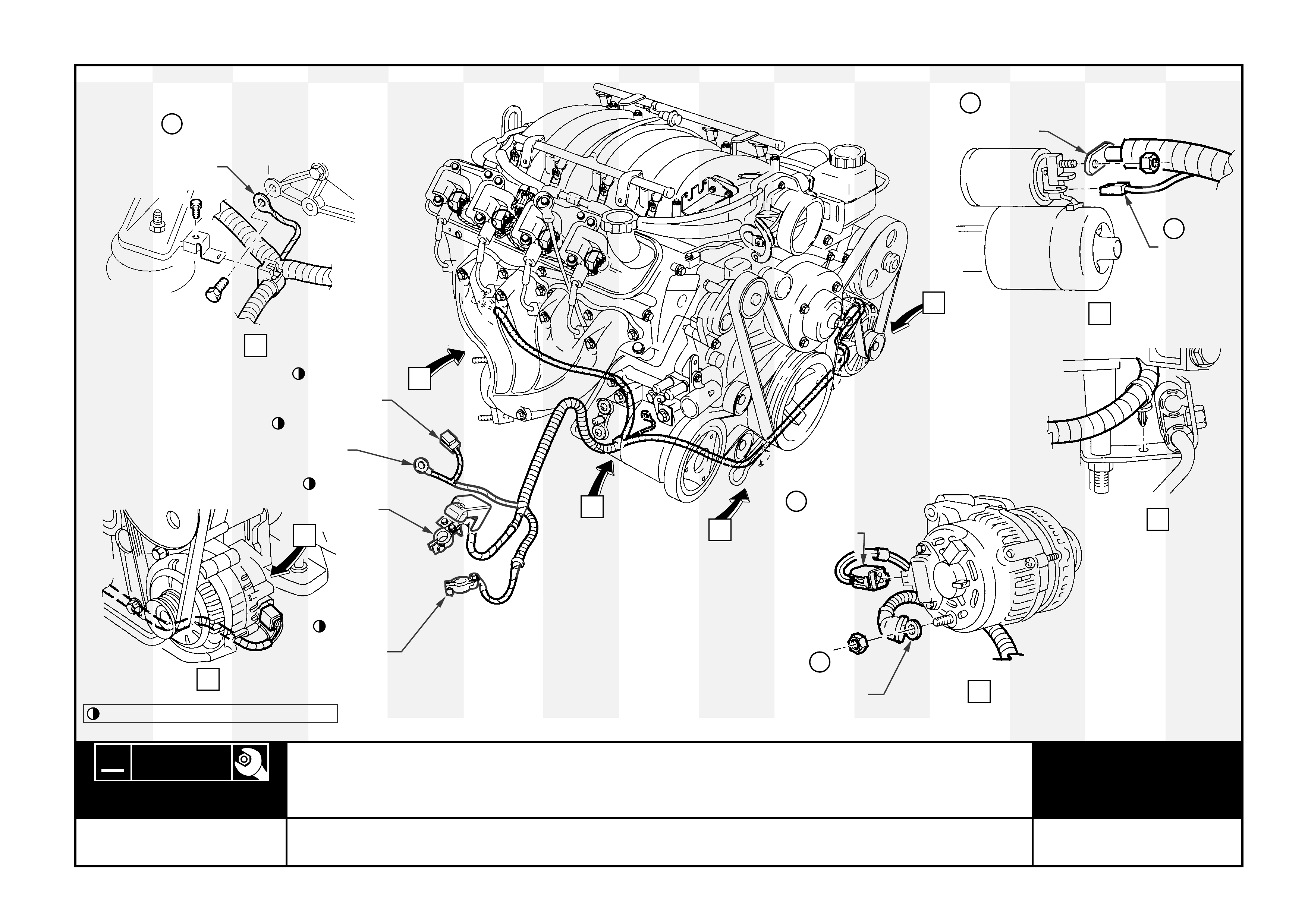

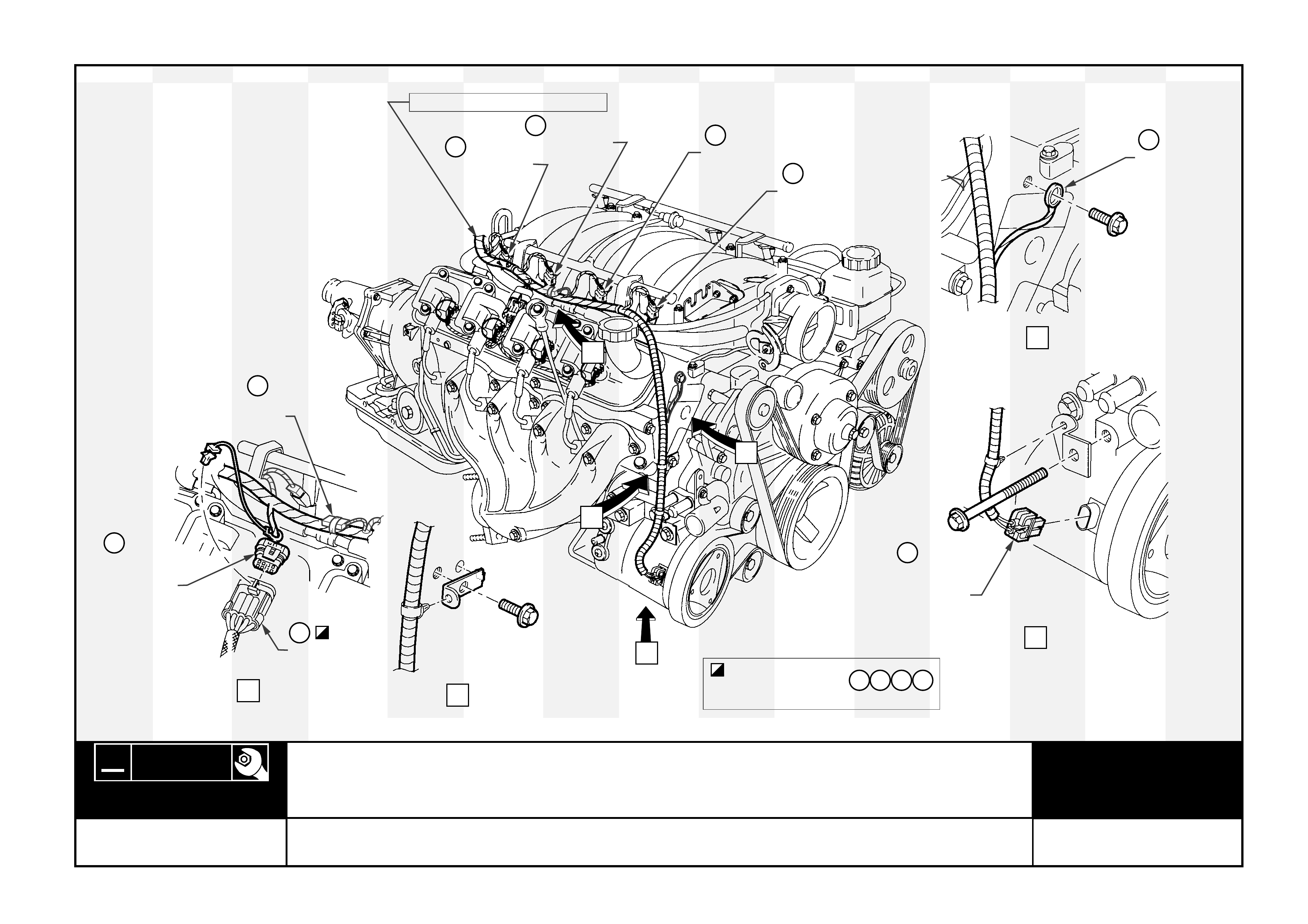

FIG. 08

14

POWERTRAIN HARNESS GEN III

VIEW

A

VIEW

B

VIEW

C

VIEW

D

No. 6 INJECTOR

No. 8 INJECTOR

No. 4 INJECTOR

No. 2 INJECTOR

A/C

DIODE

RH IGNITION

MODULE

CONNECTOR

RH COIL

PACK

HARNESS

CONNECTOR

A/C

COMPRESSOR

CONNECTOR

ENGINE

EARTH

TERMINAL

A

C

B

9

8

2

1

3

5

4

6

7

FOR CONTINUATION REFER FIG. 10

D

10 11 12 13

NOT ILLUSTRATED:

COIL PACK CONNECTORS 2, 4, 6 & 8

MODEL V2 COUPE

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

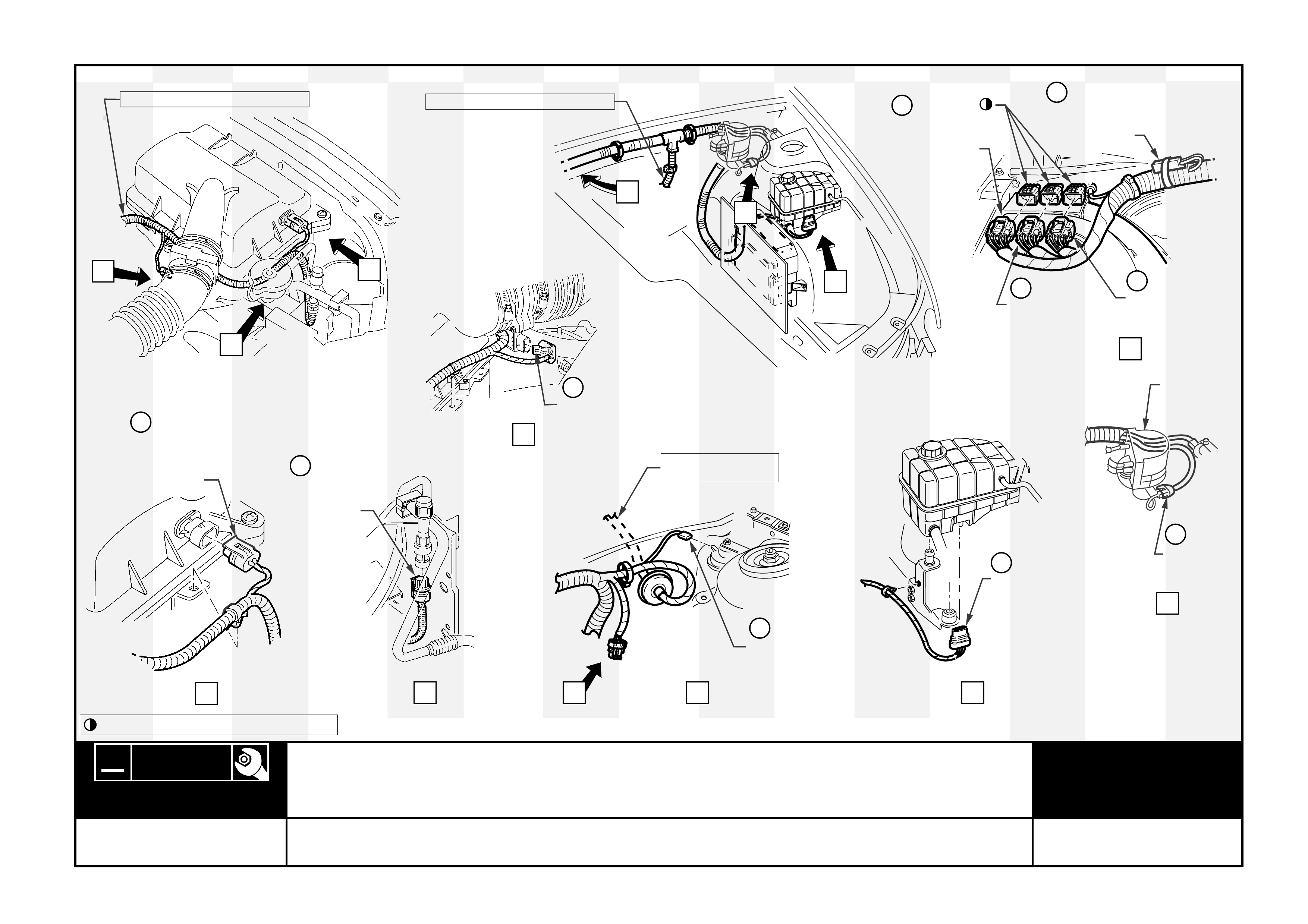

FIG. 09

15

POWERTRAIN HARNESS GEN III

COOLANT

TEMPERATURE

SENSOR

CONNECTOR

5

VIEW

C

VIEW

B

CANISTER

PURGE

CONNECTOR

LH IGNITION

MODULE

CONNECTOR

2

3

RH COIL PACK

HARNESS

CONNECTOR

NOT ILLUSTRATED:

COIL PACK CONNECTORS 1, 3, 5 & 7

A

B

C

D

IDLE AIR

CONTROL

MOTOR

CONNECTOR

THROTTLE

POSITION

SENSOR

CONNECTOR

No 3 INJECTOR

No 1 INJECTOR

1

4

7

8No 5 INJECTOR

9

No 7 INJECTOR

10

FOR CONTINUATION

REFER FIG. 11

VIEW

A

DEF

16 17 18

VIEW

F

VIEW

E

M.A.P.

SENSOR

CONNECTOR

OIL

PRESSURE

SENSOR

CONNECTOR

CAM

SENSOR

CONNECTOR

12

15

VIEW

D

ENGINE

EARTH

TERMINAL

11

FRONT & REAR

KNOCK

SENSOR

CONNECTOR

19

14

13

6

MODEL V2 COUPE

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

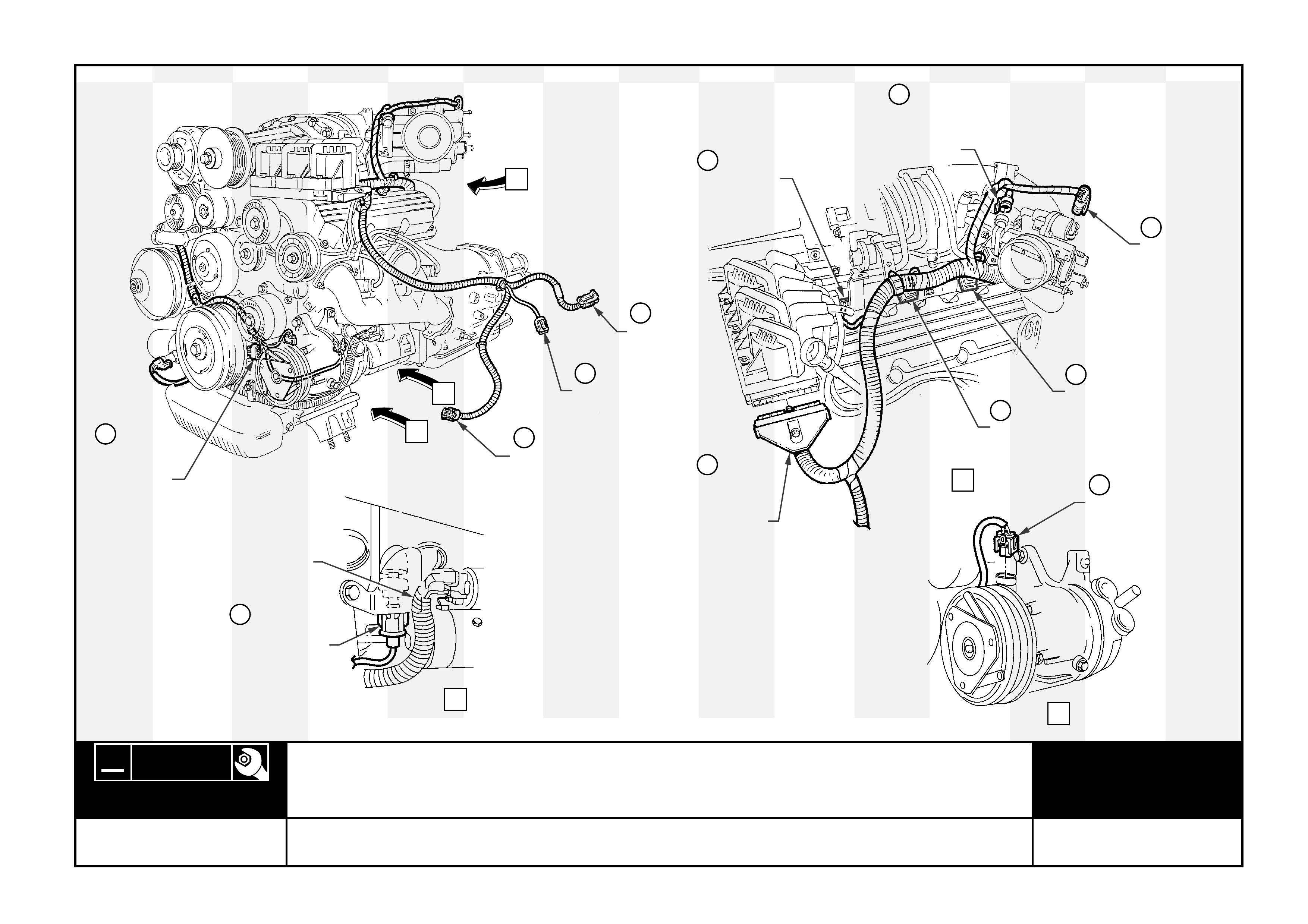

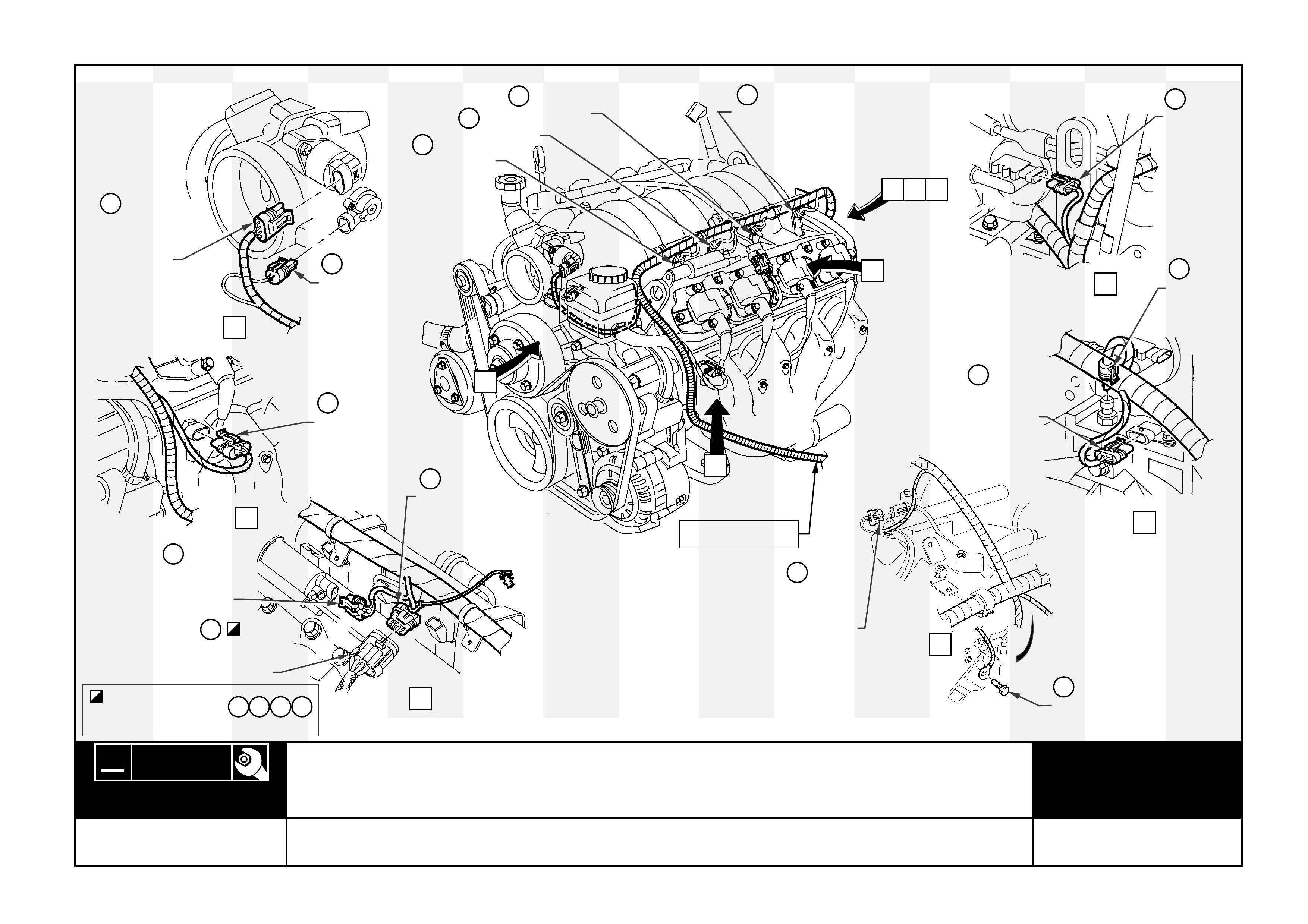

C

A

FIG. 10

16

POWERTRAIN & ENGINE HARNESSES GEN III

VIEW

D

VIEW

E

6

9

12

CRANK

SENSOR

CONNECTOR

SPEED

SENSOR

CONNECTOR

OXYGEN

SENSOR

CONNECTOR

(LH SIDE)

REVERSING

LAMP

SWITCH

CONNECTOR

VIEW

B

AUTOMATIC

TRANSMISSION

SPEED

SENDER

CONNECTOR

5

FOR CONTINUATION REFER FIG.11

3

LH OXYGEN

SENSOR

CONNECTOR

NEUTRAL

START &

BACK-UP

SWITCH

CONNECTOR

2

PRNDL

SWITCH

CONNECTOR

1

VIEW

A

VIEW

F

AUTOMATIC

TRANSMISSION

MANUAL

TRANSMISSION

AUTOMATIC

TRANSMISSION

CONNECTOR

REVERSE

LOCK OUT

CONNECTOR

VIEW

C

RH OXYGEN

SENSOR

CONNECTOR

8

OXYGEN

SENSOR

CONNECTOR

(RH SIDE)

D

F

E

FOR CONTINUATION REFER FIG.11

B

47

10

11

MODEL V2 COUPE

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

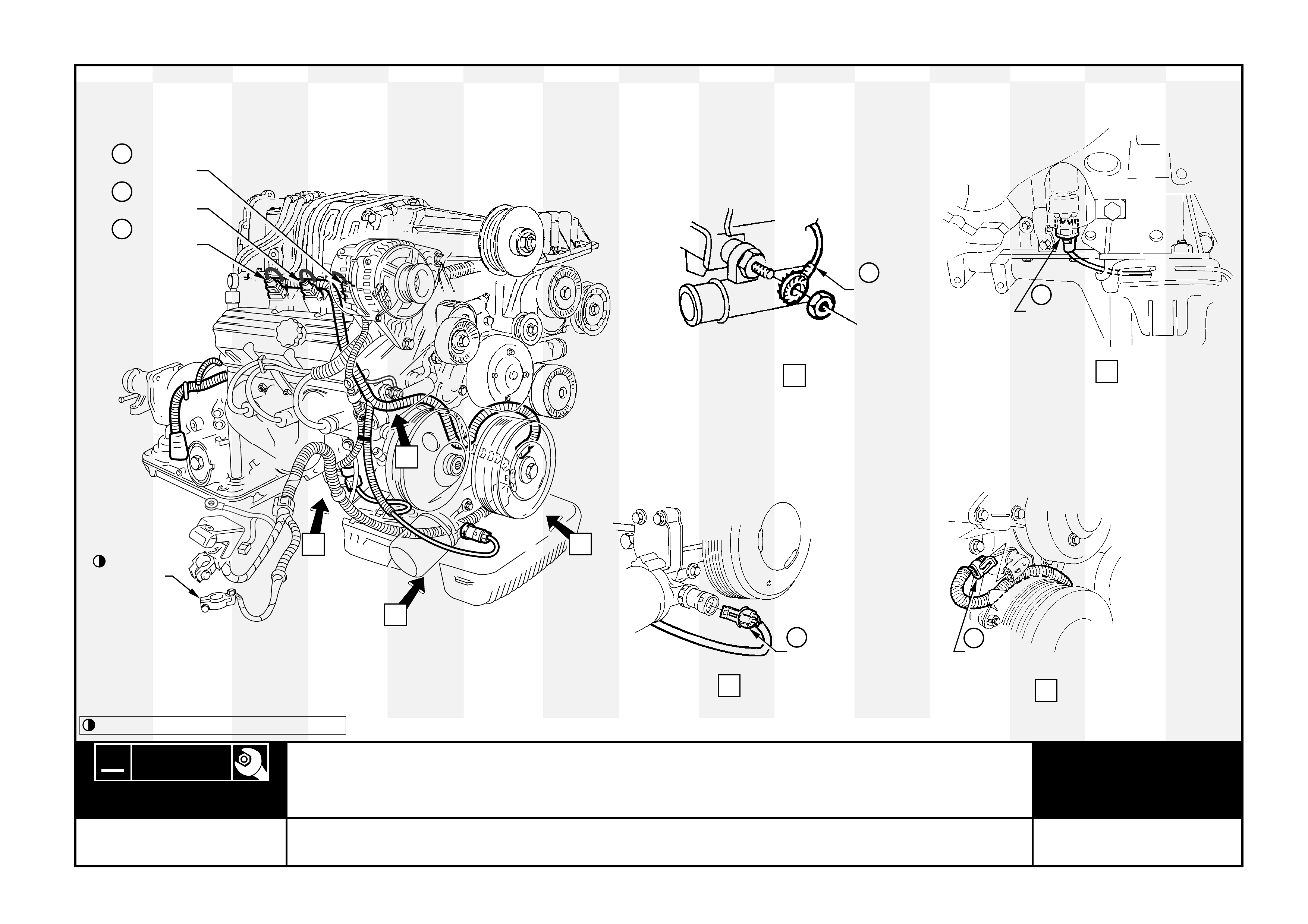

FIG. 11

17

POWERTRAIN HARNESS GEN III

VIEW

VIEW

F

G

THROTTLE

RELAXER

CONNECTOR

THROTTLE

RELAXER

C

B

A

FOR CONTINUATION REFER FIG.10

E

VIEW

A

M.A.F.

SENSOR

CONNECTOR

3

10

VIEW

E

COOLANT

LEVEL

SENSOR

CONNECTOR

6

FOR CONTINUATION REFER FIG. 9

D

VIEW

D

FOR CONTINUATION

REFER FIG.12

F

THEFT

DETERRENT

HORN

CONNECTOR

4

5

8

79

VIEW

C

A/C PRESSURE

TRANSDUCER

CONNECTOR

2

G

VIEW

B

AIR

TEMPERATURE

SENSOR

CONNECTOR

1

MAIN WIRING

HARNESS

CONNECTOR (1)

MAIN WIRING

HARNESS

CONNECTOR (2)

MAIN WIRING

HARNESS

CONNECTOR (3)

MAIN WIRING

HARNESS

CONNECTOR (4)

FOR CONNECTOR NUMBERS REFER FIG. 13

MODEL V2 COUPE

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

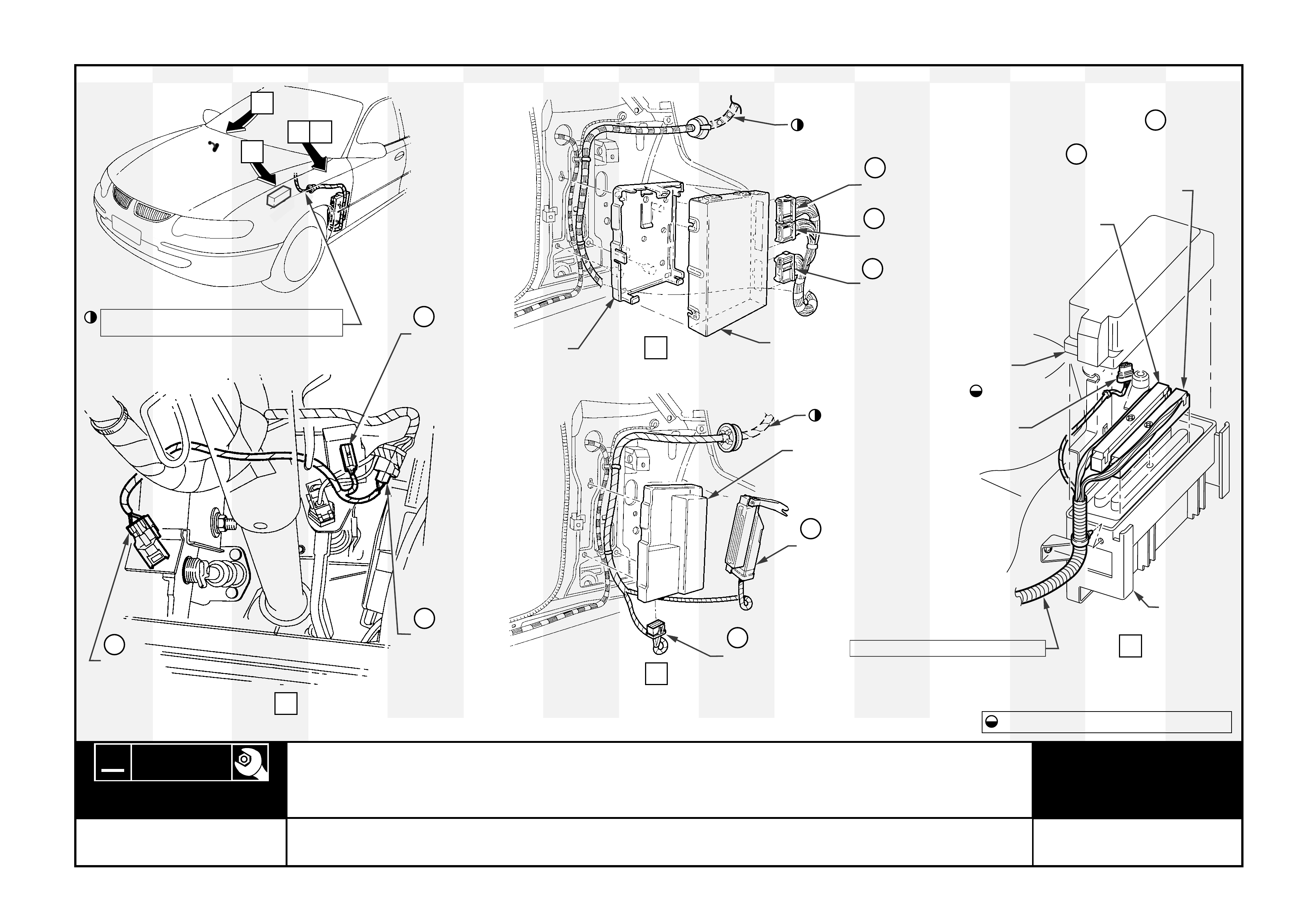

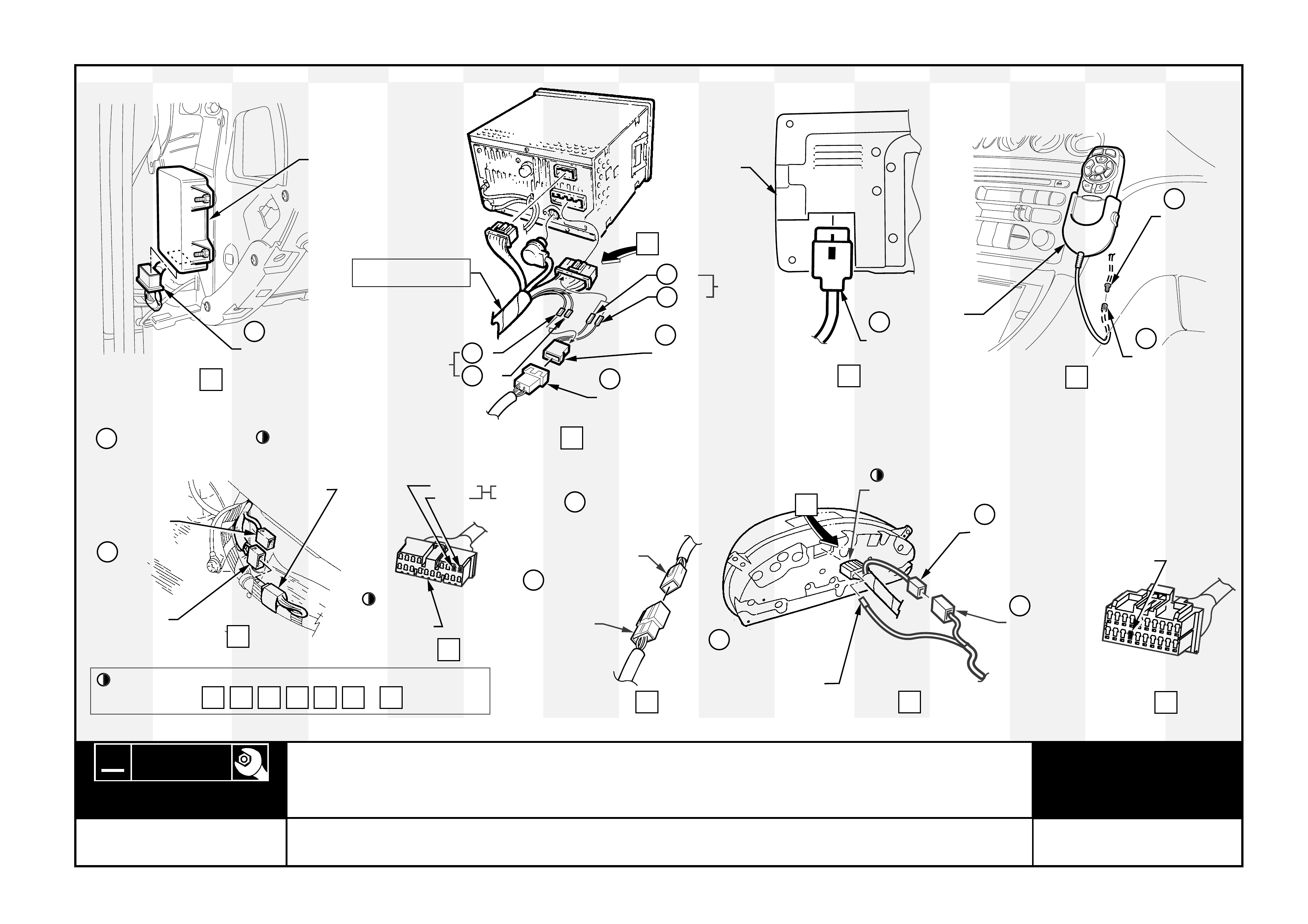

FIG. 12

18

POWERTRAIN CONTROL MODULE/INTERFACE & CRUISE CONTROL CLUTCH SWITCH

5

VIEW

C

GEN III

POWERTRAIN

INTERFACE

MODULE

CONNECTOR

AUTOMATIC

THROTTLE

RELAXER

MODULE

CONNECTOR

POWERTRAIN

INTERFACE

MODULE

2

1

VIEW

A

MAIN

WIRING

HARNESS

CONNECTOR

CLUTCH

CRUISE

CANCEL

SWITCH

CONNECTOR

BRAKE

CRUISE

CANCEL

SWITCH

CONNECTOR

FOR CONNECTOR NUMBER REFER FIG. 11

POWERTRAIN

CONTROL

MODULE

FOR CONTINUATION REFER FIG. 11

9

10

VIEW

D

POWERTRAIN

CONTROL

MODULE

CONNECTOR

(BLUE)

POWERTRAIN

CONTROL

MODULE

CONNECTOR

(RED)

GEN III

COVER

COOLANT

LEVEL

SENSOR

VIEW

B

POWERTRAIN

CONTROL

MODULE

SUPPORT

BRACKET

B

D

C

FOR CONTINUATION REFER FIG.07 - V6 S/C

FOR CONTINUATION REFER FIG.11 - GEN III

A

NO.1 PCM

CONNECTOR

NO.2 PCM

CONNECTOR

NO.3 PCM

CONNECTOR

6

7

8

V6 S/C

3

4

MODEL V2 COUPE

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

FIG. 13

19

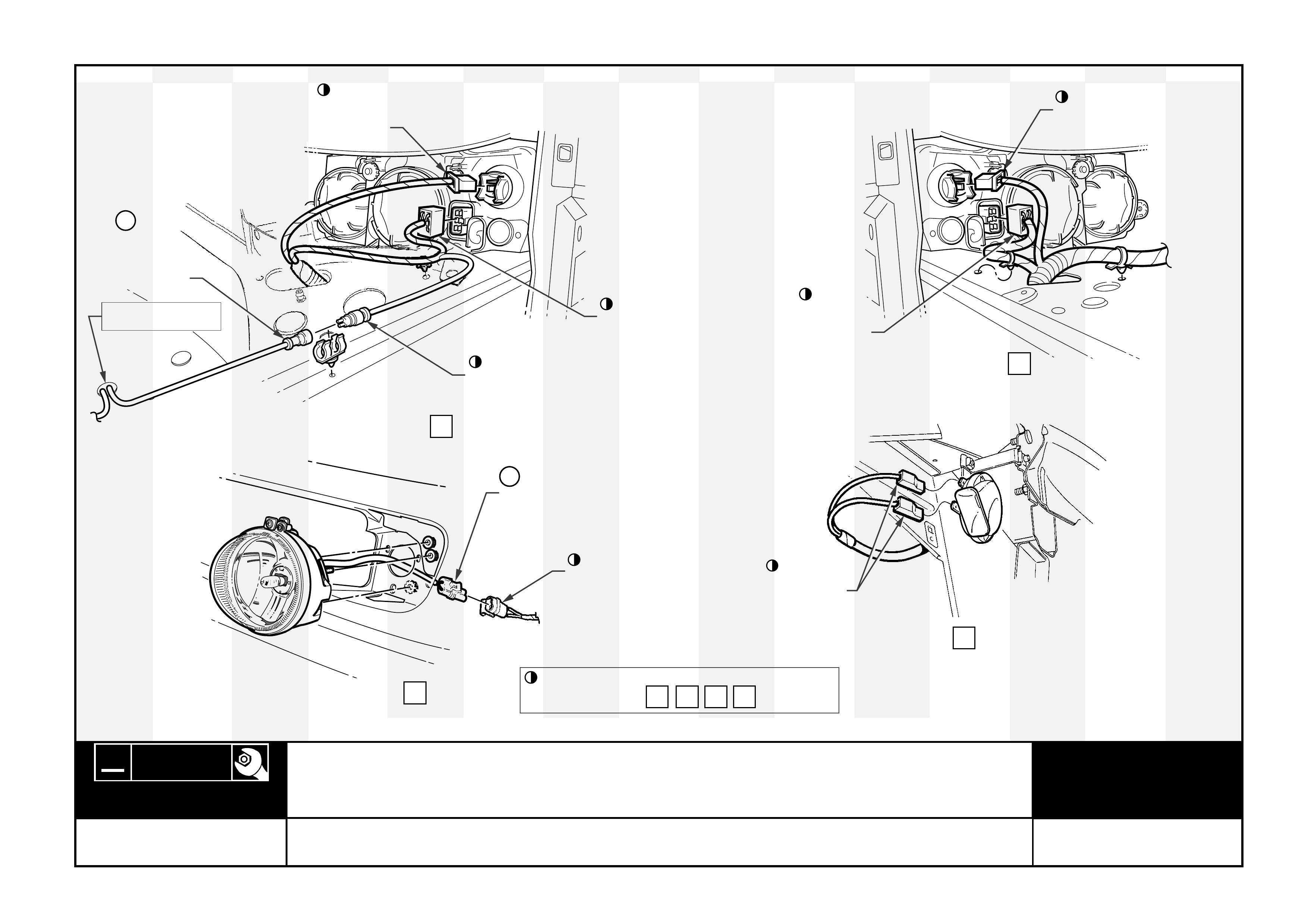

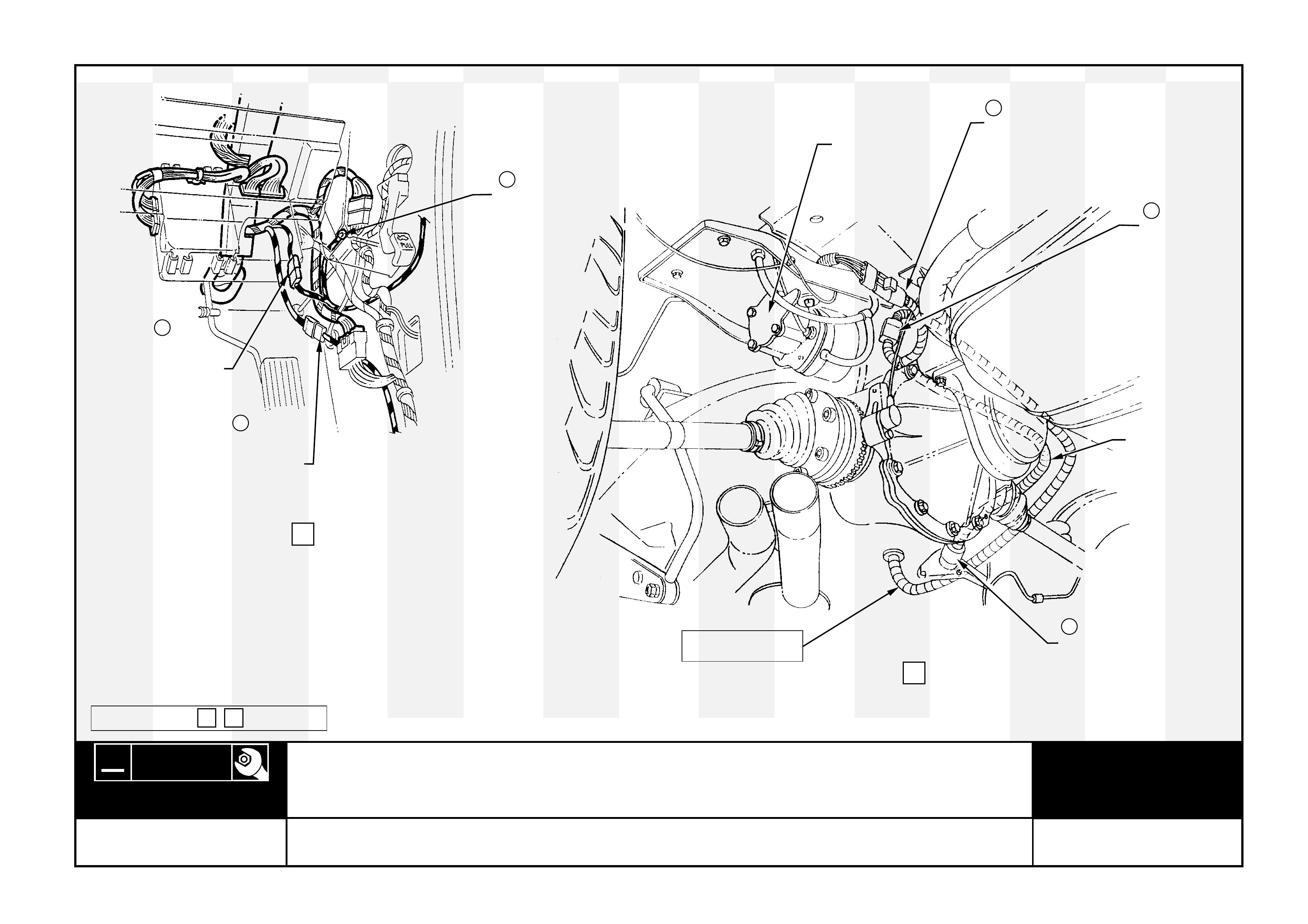

MODEL V2 COUPE MWH - ENGINE COMPARTMENT V6 S/C & GEN III

A

M.W.H. TO BATTERY POSITIVE TERMINAL

M.W.H. TO BATTERY HARNESS CONNECTOR

25

ENGINE/CONDENSER FAN MOTOR

27

26

LH. HORN (2 CONN,S)

LH. FRONT HEADLAMP

RH.HORN(2CONN,S)

RH & FOG LAMP

WASHER PUMP

BRAKE FAILURE WARNING SWITCH

LH. FOGLAMP

LH.F. ABS WHEEL SENSOR

LH. FRONT TURN SIGNAL LAMP

ANTI-THEFT HOOD SWITCH (2 CONN,S)

AMBIENT SENSOR (GEN III)

20

24

23

22

21

18

19

17

16

RH. FRONT HEADLAMP

15

14

RH. FRONT TURN SIGNAL LAMP

BODY EARTH

BODY EARTH

ENGINE HARNESS (2)

ENGINE HARNESS (4) (GEN III)

WIPER MOTOR

6ENGINE HARNESS (3)

RH.F. ABS WHEEL SENSOR

ABS HYD.INTEGRATED ECU

RELAY BOX

CRUISE CONTROL ACTUATOR

13

12

11

10

9

8

7

ENGINE HARNESS (1)

5

4

3

2

1

REFER FIG. 01 FOR CLARIFICATION

FOR VIEW & REFER FIG. 14

B

A

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

B

3

11

15

14

18

17

7

2

1

654

8

12

13

16

24

9

10

25

23

22

21

20

19

27

26

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

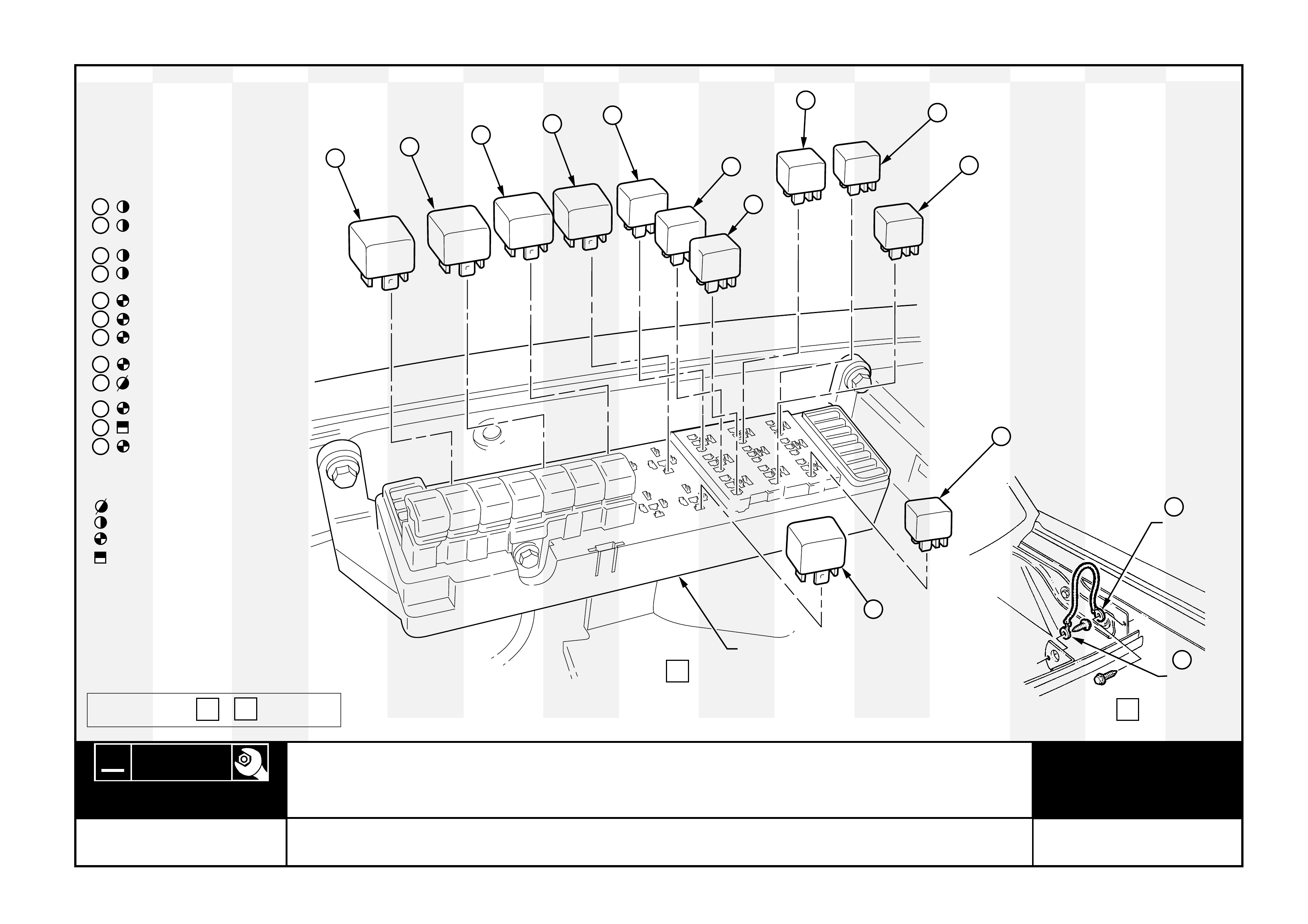

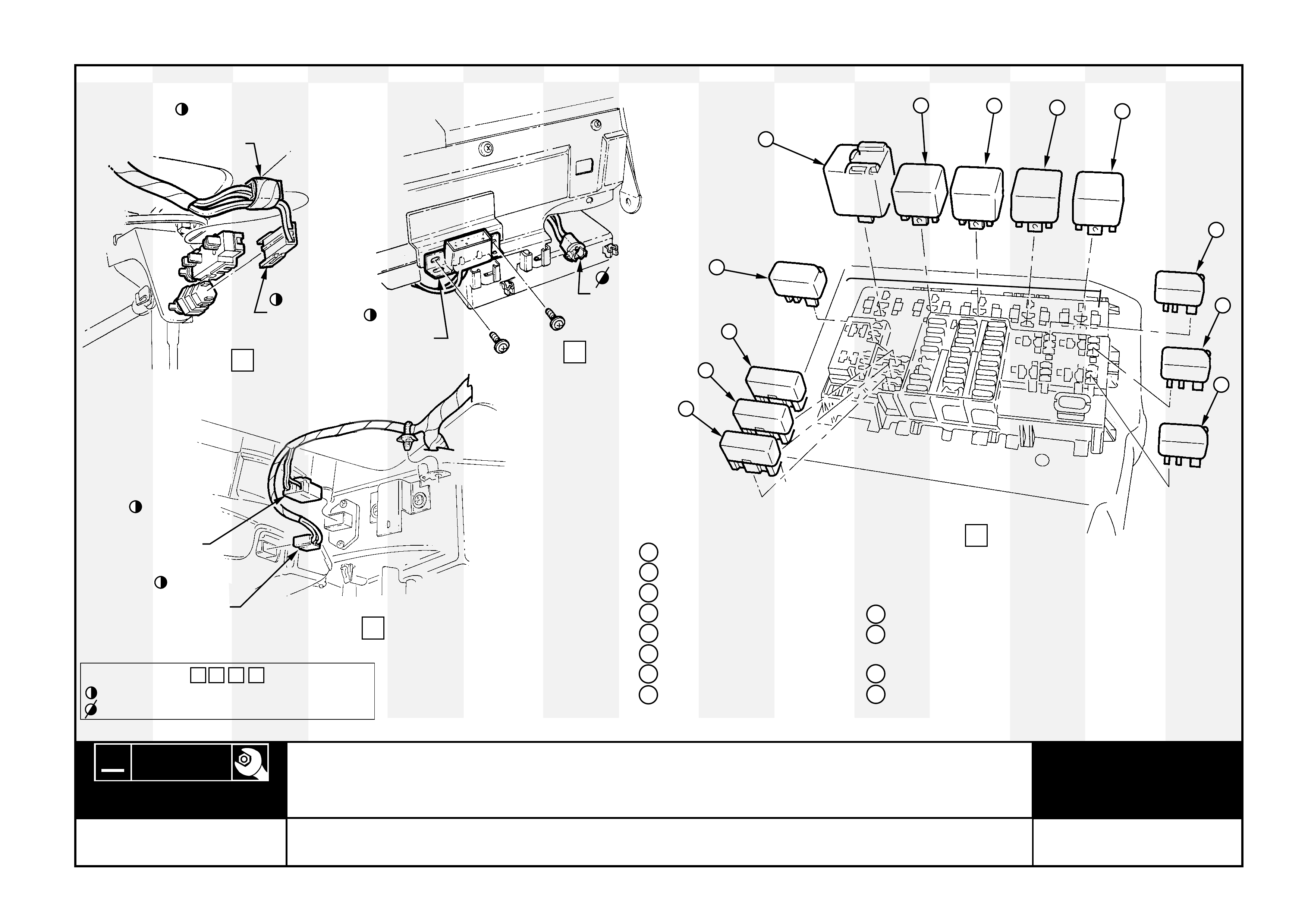

FIG. 14

20

MWH - ENGINE COMPARTMENT V6 S/C & GEN III

4 TERMINAL MINI RELAY

4 TERMINAL MINI RELAY

5 TERMINAL MICRO RELAY

5 TERMINAL MINI RELAY

START RELAY

FRONT WIPER RELAY

11

1

ENGINE COOLING FAN RELAY

(HIGH SPEED)

4

HEADLAMP RELAY

(HIGH BEAM)

2

ENGINE CONTROL RELAY

3

AB

TO LOCATE VIEWS & REFER FIG. 13

9ENGINE COOLING FAN RELAY

(LOW SPEED)

5HORN RELAY

6A/C RELAY

8ANTI-THEFT HORN RELAY

7HEADLAMP RELAY

(LOW BEAM)

10 FOG LAMP RELAY

12 FUEL PUMP RELAY

RELAY TYPE

VIEW

A

RELAY BOX

3

10

7

2

16

5

4

9

8

12

BODY TO

COCKPIT

TERMINAL

COCKPIT

TO BODY

TERMINAL

VIEW

B

13

14

11

NOTE :

FOR TERMINAL PROBLEM

IDENTIFY RELAY CONCERNED

MODEL V2 COUPE

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

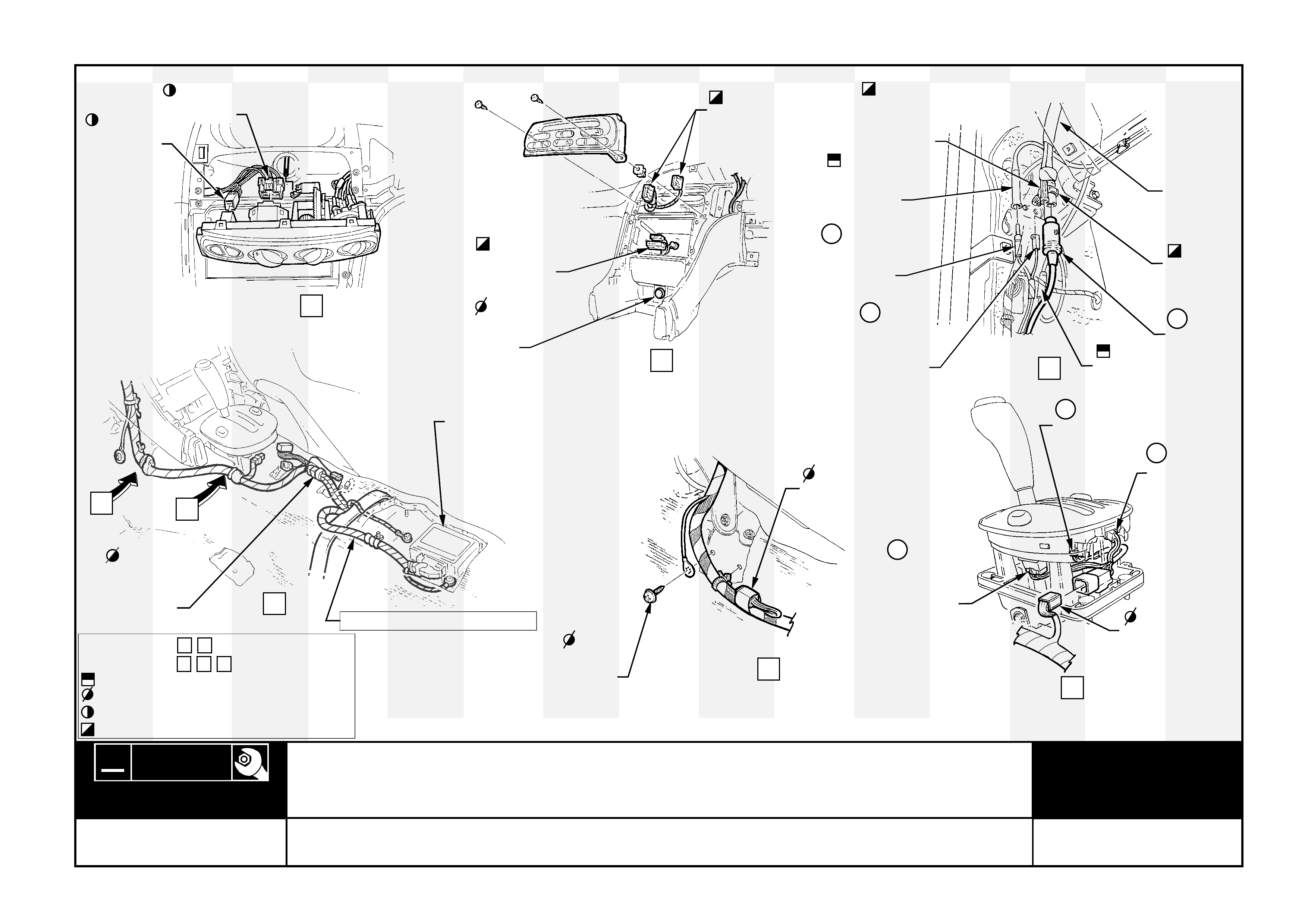

FIG. 15

21

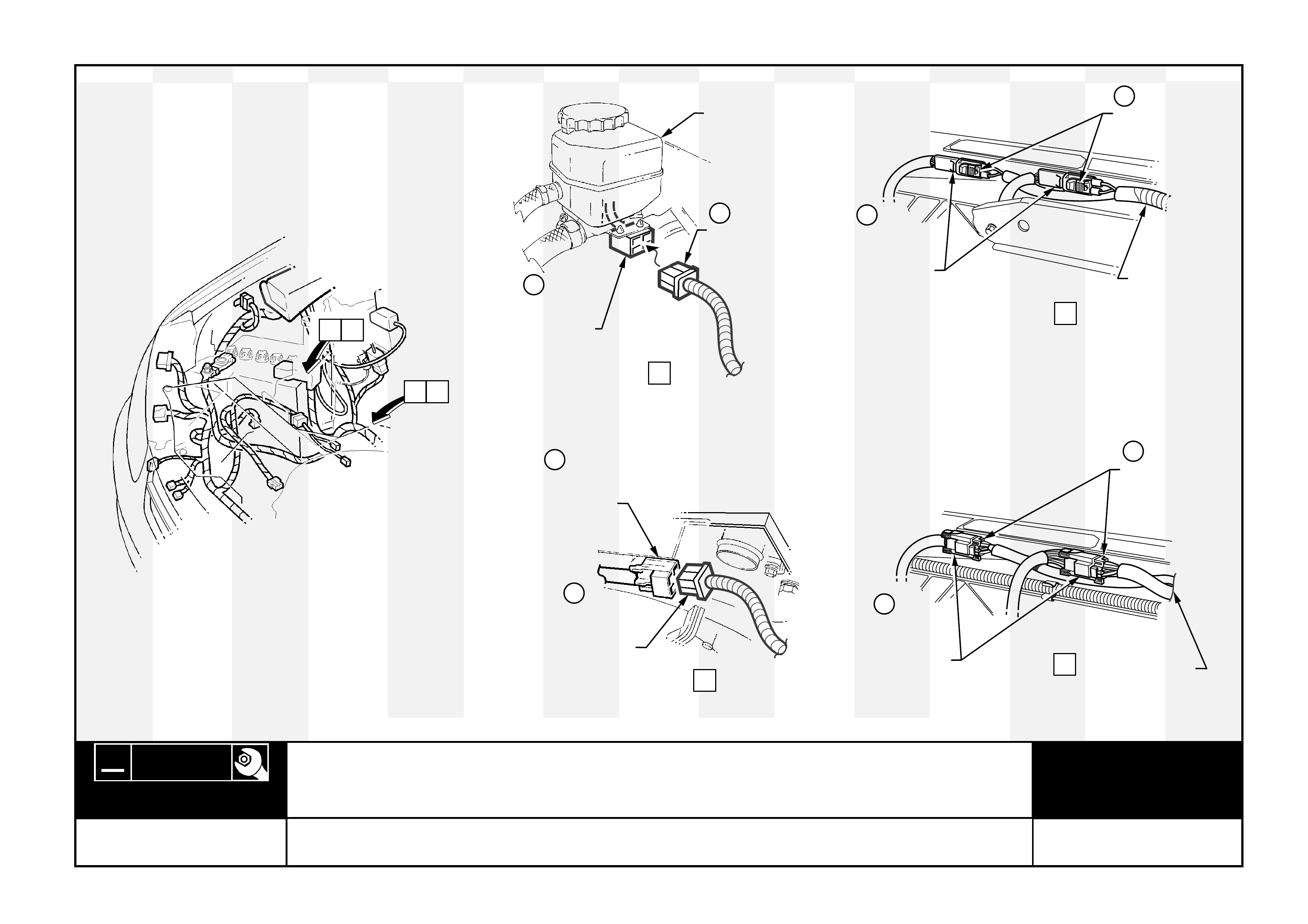

ENGINE COOLING HARNESS V6 S/C & GENlll

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

VIEW

D

ENGINE

COOLING FAN

CONNECTORS

VIEW

VIEW

C

A

ENGINE

COOLING FAN

HARNESS

CONNECTOR

6

8

3

"V6 S/C"

"V6 S/C"

"GENlll" "GENlll"

ENGINE

COOLING FAN

HARNESS

CONNECTOR

4

ENGINE

COOLING FAN

HARNESS

CONNECTORS

VIEW

B

ENGINE COOLING

FAN CONNECTORS

ENGINE

COOLING

FAN HARNESS

ENGINE COOLING

FAN HARNESS

5

7

ENGINE

COOLING FAN

HARNESS

CONNECTORS

POWER STEERING

PUMP RESERVOIR

BD

MAIN WIRING

HARNESS

CONNECTOR

2

MAIN WIRING

HARNESS

CONNECTOR

1

MODEL V2 COUPE

AC

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

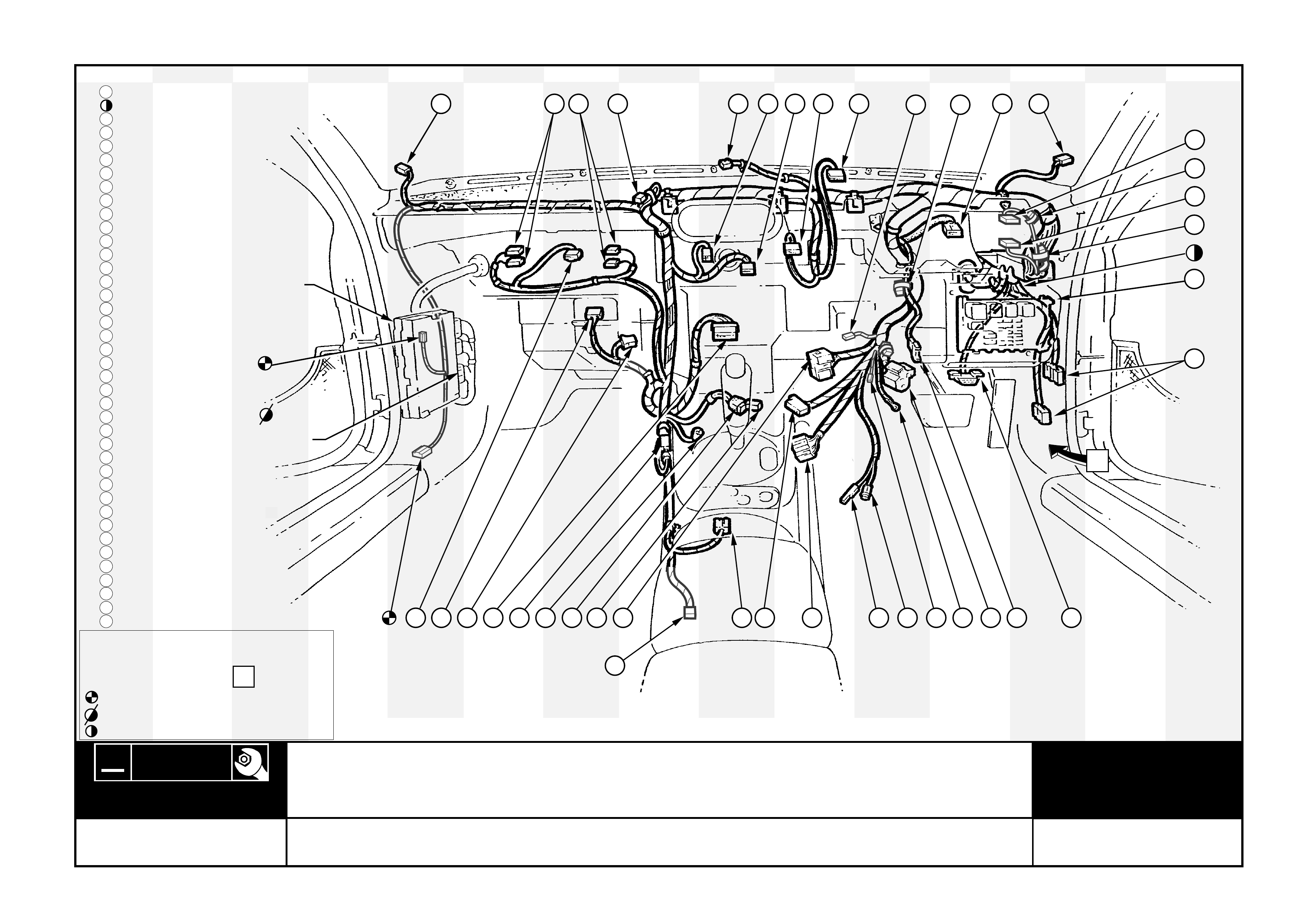

FIG. 16

22

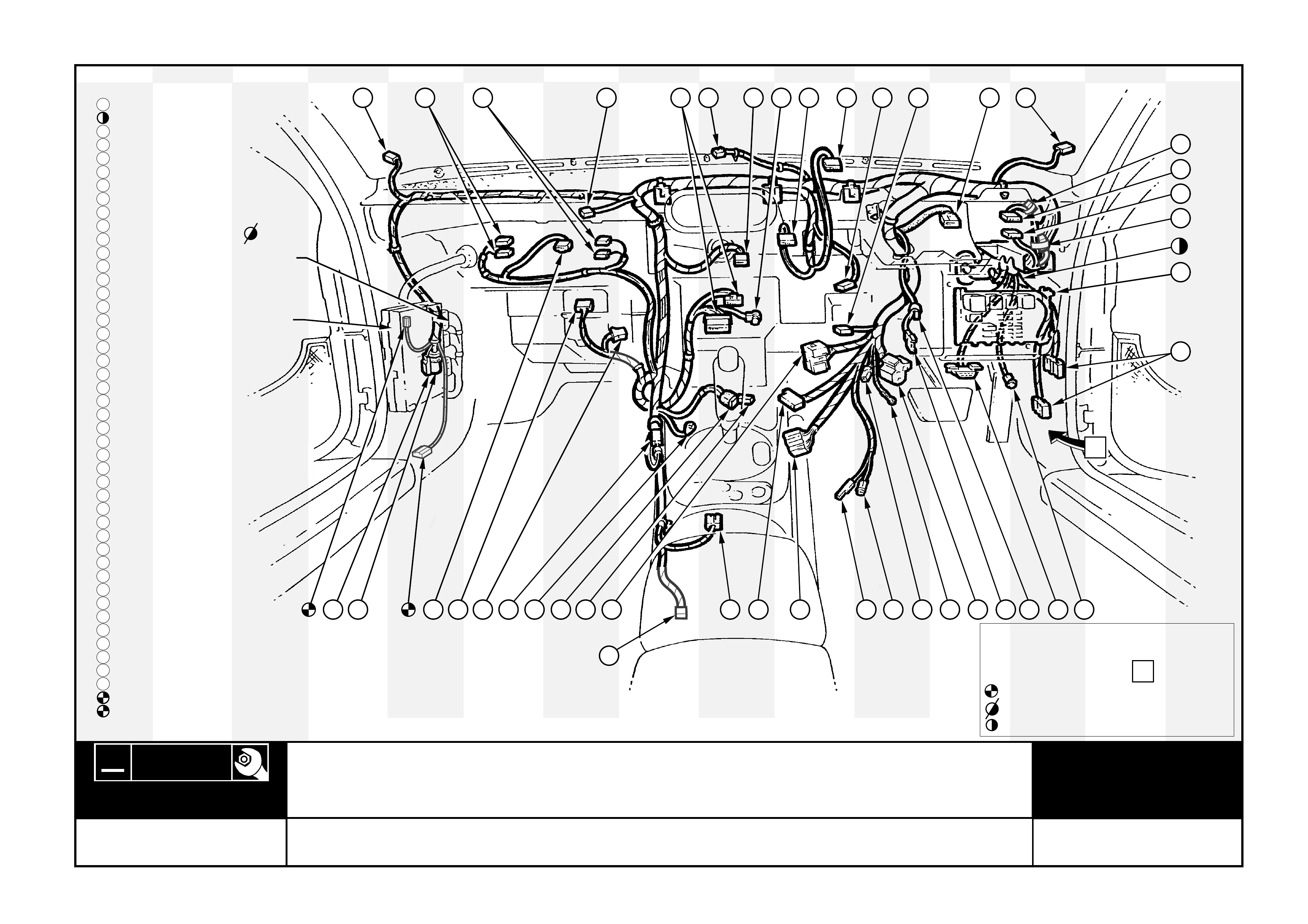

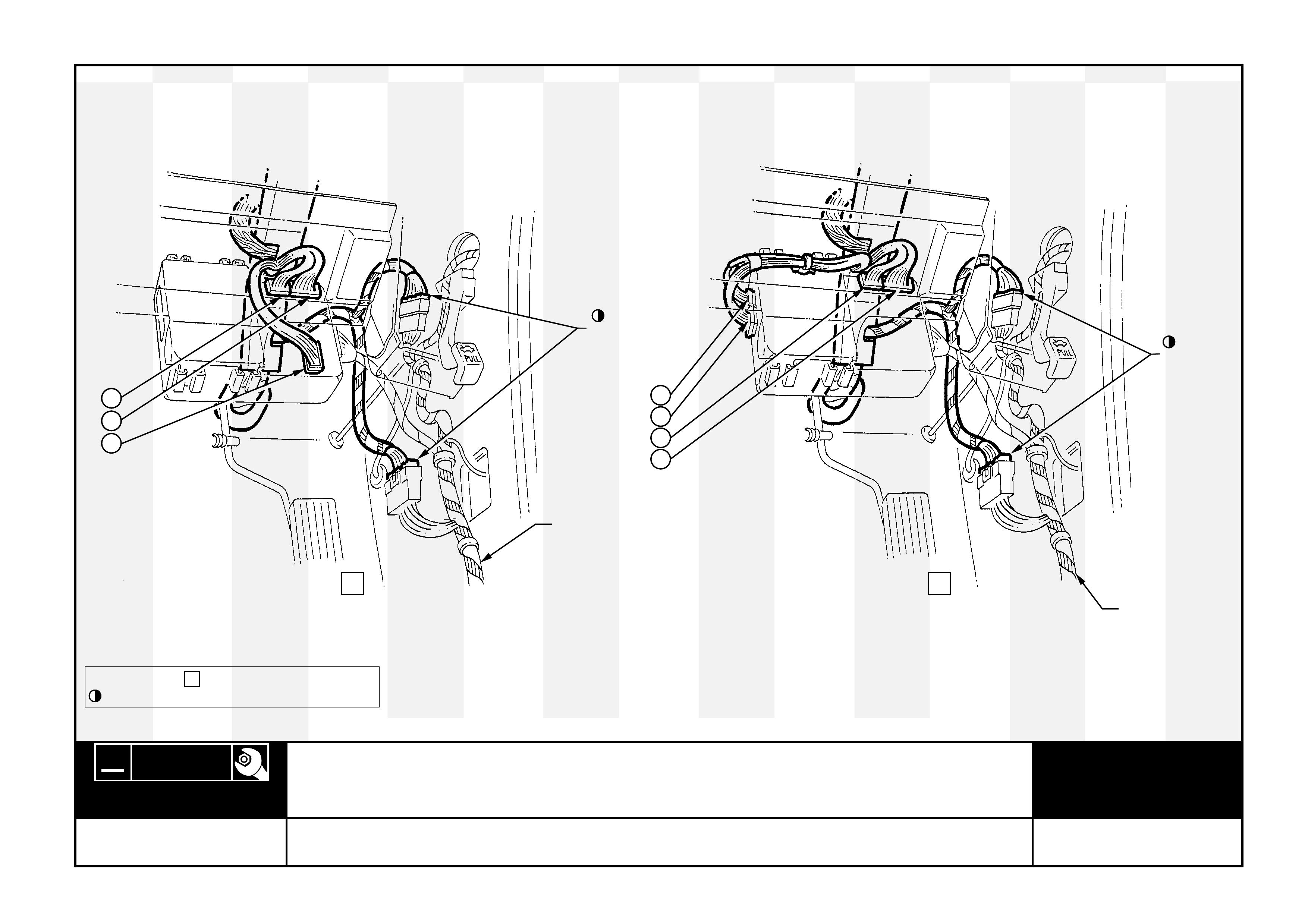

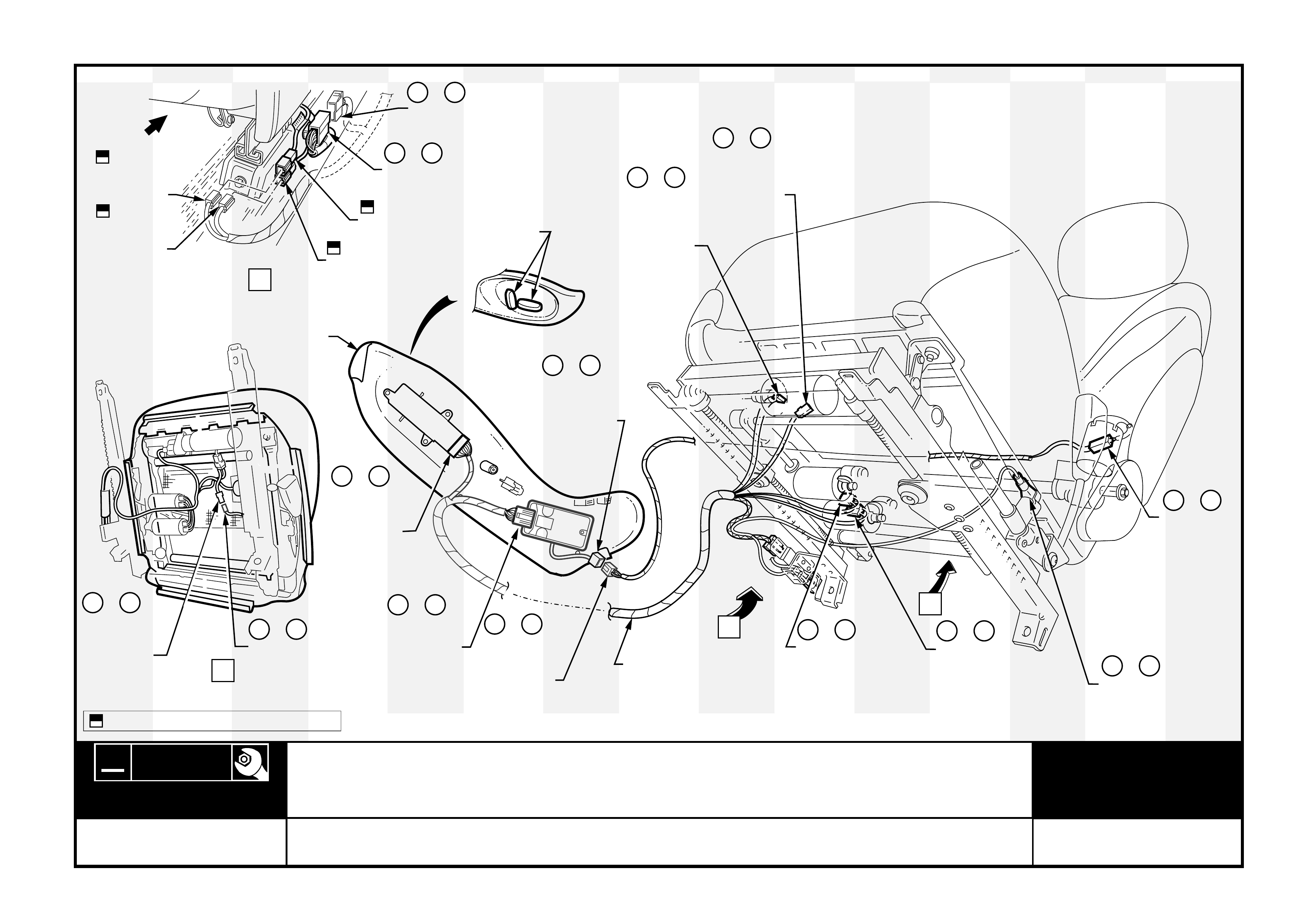

MODEL V2 COUPE

MAIN WIRING HARNESS - CV6

STEERING COLUMN NOT SHOWN FOR CLARITY

FOR STEERING COLUMN M.W.H. CONNECTOR

LOCATIONS REFER FIG 23

33

3539

13

17 16 12

4

5

7

6

8

3

2

23 22

27

12

14

11

15

13

22

32

30

19

26

16

24

34

37

28

17

21

31

29

18

25

35

38

36

39

23

33

20

27

10

6

4

8

1

9

5

3

2

7

1

18

21 9

19 1415

38

36 2425 1011

2029

34

26 28 30 31

3237

FOR LOCATION OF VIEW REFER FIG 22

A

BODY CONTROL MODULE (3 CONN'S)

BLOWER MOTOR

IGNITION LOCK ILLUMINATION

AIR BAG INTERFACE

GLOVE BOX SWITCH (2 CONN'S)

IGNITION KEY EARTH

DWELL CONTROL

BLOWER SWITCH

RHF DASH SPEAKER

HEADLAMP PATCH

AUXILIARY POWER OUTLET

WIPER/WASHER SWITCH

LHF DASH SPEAKER

BODY HARNESS (2 CONN'S)

FAN SPEED CONTROL

IGNITION KEY READER

IGNITION SWITCH

AUTO TRANS. SELECTOR

REMOTE RECEIVER MODULE

HEADLAMP SWITCH

FOG LAMP

TRACTION CONTROL SWITCH

RADIO BODY EARTH

CLOCK SPRING

PASSENGER SIDE AIRBAG INFLATOR

DIAGNOSTICS

TURN SIGNAL/HI-BEAM DIP SWITCH

GLOVE BOX LAMP (2 CONN'S)

FUSE PANEL

RADIO

TRUNK LOCK SWITCH

A/C CONTROLS

INSTRUMENTS

CRUISE CANCEL SWITCH

CRUISE CONTROL SWITCH

HAZARD SWITCH

STOP LAMP SWITCH

CELLULAR PHONE/AUXILIARY

TRIP COMPUTER

AUXILIARY POWER OUTLET ILLUM.

FOR CONNECTOR NUMBERS REFER FIG 12

FOR CONNECTOR NUMBERS REFER FIG 42

FOR CONNECTOR NUMBERS REFER FIG 22

A

POWERTRAIN

CONTROL

MODULE

POWERTRAIN

HARNESS

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

FIG. 17

23

MODEL V2 COUPE

MAIN WIRING HARNESS - CV6

C

AB

H

D

E

REFER FIG 21

REFER FIG 20

EH

ABCD

FOR VIEWS

FOR VIEWS

FOR CONNECTOR NUMBERS REFER FIG 16

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

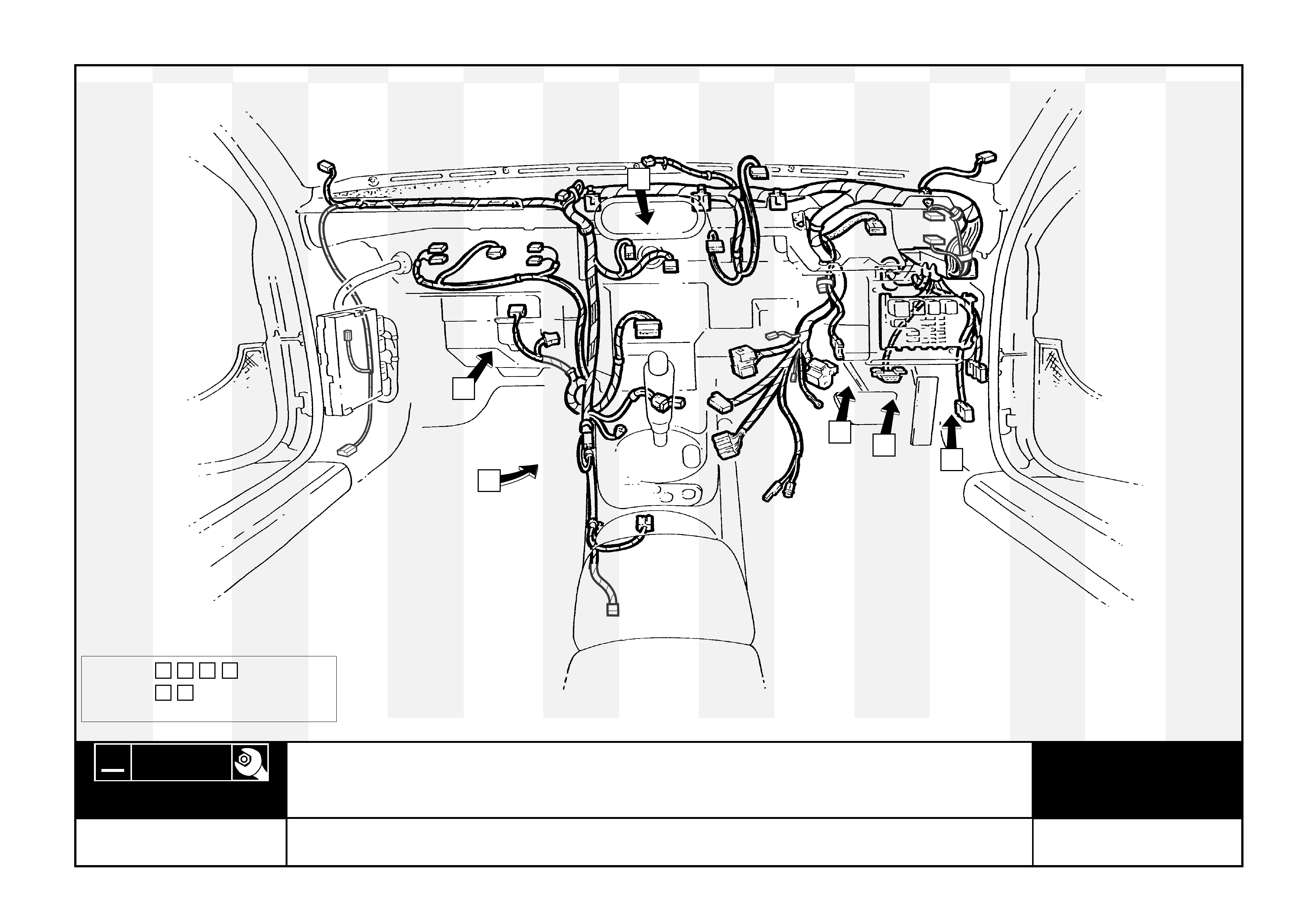

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

FIG. 18

24

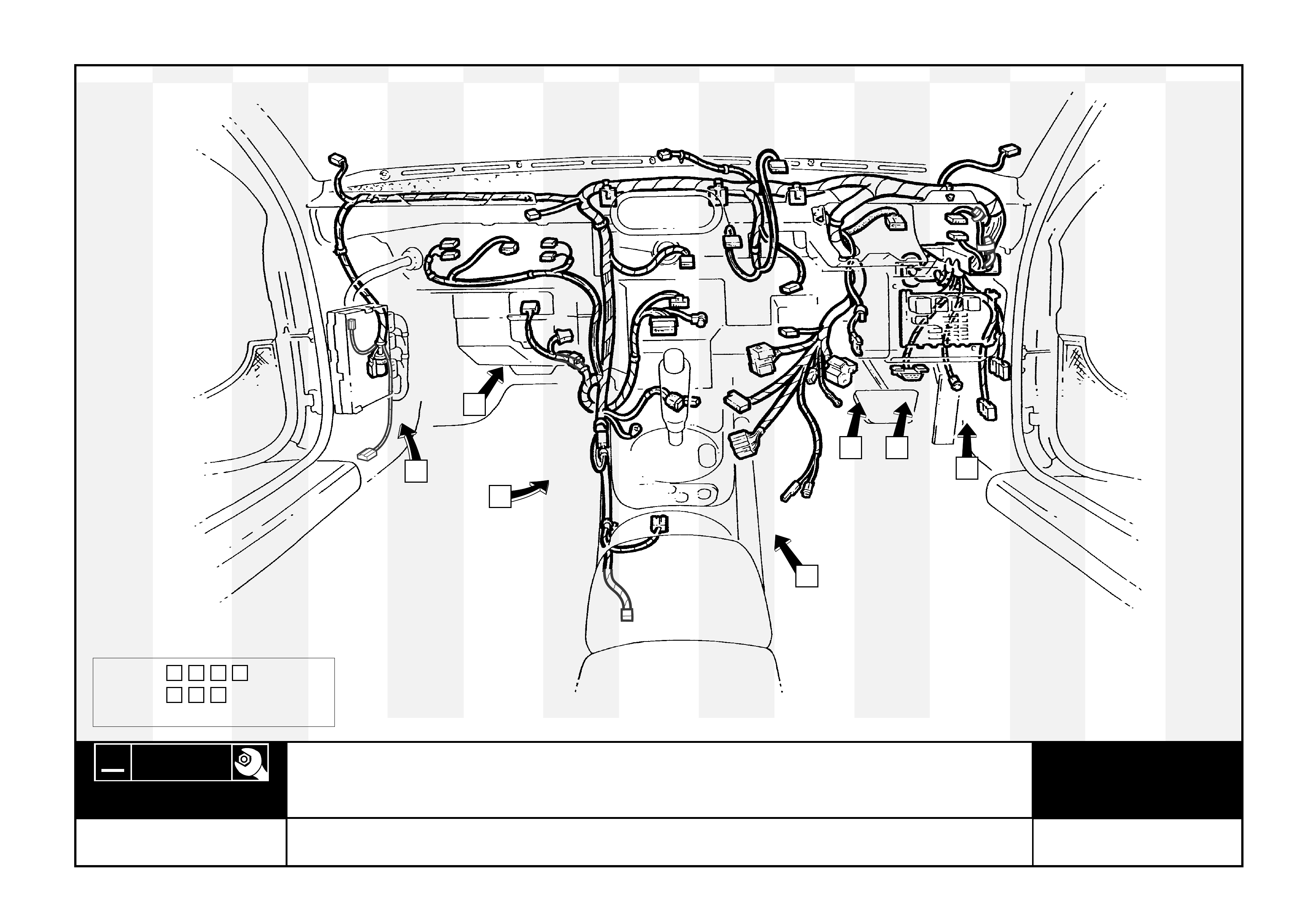

MODEL V2 COUPE

A

41

39

40

43

42

BODY CONTROL MODULE (4 CONN'S)

IN-CAR SENSOR (EXC. 8VK)

CRUISE CONTROL SWITCH

AUXILIARY POWER OUTLET

STOP LAMP SWITCH

RADIO - CD PLAYER

CLOCK SPRING

TRUNK LOCK SWITCH

LHF DASH SPEAKER

HEADLAMP PATCH

CD PLAYER

TELEMATICS PATCH

HEADLAMP SWITCH

FAN SPEED CONTROL

IGNITION KEY READER

BODY HARNESS (2 CONN'S)

SOLAR SENSOR

CRUISE CANCEL SWITCH

RADIO BODY EARTH

INSTRUMENTS

RADIO (2 CONN'S)

GLOVE BOX LAMP (2 CONN'S)

FOG LAMP SWITCH

IGNITION KEY EARTH

AUTO TRANS. SELECTOR

AIRBAG INTERFACE

RHF FOOTWELL LAMP

HAZARD SWITCH

DWELL CONTROL

AUXILIARY POWER OUTLET ILLUM.

DIAGNOSTICS

TRACTION CONTROL SWITCH

TRIP COMPUTER SWITCH

IGNITION SWITCH

CELLULAR PHONE/AUXILIARY

WIPER/WASHER SWITCH

PASSENGER SIDE AIRBAG INFLATOR

DIVERSITY ANTENNA POWER

TELEMATICS SPEAKER

FUSE PANEL

BLOWER MOTOR

IGNITION LOCK ILLUMINATION

RHF DASH SPEAKER

TURN SIGNAL/HI-BEAM DIP SWITCH

GLOVE BOX SWITCH (2 CONN'S)

20

5

6

43

21 12

7

22 8

18

23 9

19

24

16 1117 13 214 3

15 10

4

30

35

26

39

3127 32

36

33

37 28

34384142

40 2925

POWERTRAIN

HARNESS

POWERTRAIN

CONTROL

MODULE

STEERING COLUMN NOT SHOWN FOR CLARITY

FOR STEERING COLUMN M.W.H. CONNECTOR

LOCATIONS REFER FIG 23

FOR LOCATION OF VIEW REFER FIG 22

A

FOR CONNECTOR NUMBERS REFER FIG 42

MAIN WIRING HARNESS - CV8

33

37

35

32

36

34

38

31

27

25

29

30

26

28

23

20

22

19

24

21

16

14

18

15

17

12

11

13

10

6

8

9

7

2

4

5

3

1

ELECTRONIC CLIMATE CONTROL

1

FOR CONNECTOR NUMBERS REFER FIG 12

FOR CONNECTOR NUMBERS REFER FIG 22

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

FIG. 19

25

MODEL V2 COUPE

H

D

G

C

AB

F

MAIN WIRING HARNESS - CV8

REFER FIG 21

REFER FIG 20

FGH

ABCD

FOR VIEWS

FOR VIEWS

FOR CONNECTOR NUMBERS REFER FIG 18

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

FIG. 20

26

MAIN WIRING HARNESS

12

11

7

8

10

5

4

3

2

POWER WINDOWS RELAY

HEATED REAR WINDOW RELAY

BLOWER FAN RELAY

FLASHER UNIT

PARK LAMPS RELAY

POWER WINDOW CIRCUIT BREAKER

POWER SEATS CIRCUIT BREAKER

POWER SEATS CIRCUIT BREAKER

HAZARD/TURN SIGNAL RELAY

INTERIOR ILLUMINATION RELAY

ALARM STATUS RELAY (CV8)

OR DRIVERS WINDOW (CV6)

BLOWER INHIBIT RELAY

6

9

1

DIAGNOSTIC

CONNECTOR

VIEW

B

R.H.F FOOTWELL

LAMP

CONNECTOR

VIEW

C

CRUISE CANCEL

SWITCH

CONNECTOR

STOP LAMP

SWITCH

CONNECTOR

VIEW

A

FAN SPEED

CONTROL

CONNECTOR

VIEW

D

BLOWER MOTOR

CONNECTOR

FOR CONNECTOR NUMBERS REFER FIG. 16 & 18

FOR CONNECTOR NUMBER REFER FIG. 18

REFER FIG. 17 & 19

A B C D

TO LOCATE VIEWS

NOTE :

FOR TERMINAL PROBLEM

IDENTIFY RELAY CONCERNED

4

5

6789

10

11

12

MODEL V2 COUPE

1

3

2

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

FIG. 21

27

MAIN WIRING HARNESS

REFER FIG'S 19

REFER FIG'S 17

F

E

G

H

H

TO LOCATE VIEWS

TO LOCATE VIEWS

FOR CONNECTOR NUMBERS REFER FIG 18

FOR CONNECTOR NUMBERS REFER FIG 16

FOR CONNECTOR NUMBERS REFER FIG 16 &18

FOR CONNECTOR NUMBERS REFER FIG 30

BLOWER SWITCH

CONNECTOR

A/C CONTROLS

CONNECTOR

MANUAL CLIMATE CONTROL

VIEW

E

VIEW

J

3

4

1

26

5

T.C.S.

CONTROL

SWITCH

CONNECTOR

POWER &

ECONOMY

SHIFT SWITCH

CONNECTOR

AUTOMATIC

TRANSMISSION

SELECTOR

HARNESS

CONNECTOR

AUTOMATIC

TRANSMISSION

INDICATOR

ILLUMINATOR

CONNECTOR

F

RADIO / CD PLAYER

CONNECTORS

AUXILIARY

POWER

OUTLET

ELECTRONIC CLIMATE CONTROL

VIEW

ELECTRONIC

CLIMATE

CONTROL

(2 CONNS)

CD PLAYER

CONNECTOR

CD PLAYER

CONNECTOR

MAIN WIRING

HARNESS

DIVERSITY

ANTENNA

POWER

CONNECTOR

ANTENNA

CONNECTOR

VIEW

G

DIVERSITY

ANTENNA

CONNECTOR

DIVERSITY

ANTENNA

CONNECTOR

DIVERSITY

ANTENNA

POWER

CONNECTOR

IJ

AIRBAG

MODULE

BODY

AIRBAG

INTERFACE

CONNECTOR VIEW

H

FOR CONTINUATION REFER FIG. 25

VIEW

I

RADIO BODY

EARTH

TERMINAL

CELLULAR PHONE/

AUXILIARY

CONNECTOR

MODEL V2 COUPE

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

FIG. 22

28

MAIN WIRING HARNESS TO BCM & BODY HARNESS

VIEW

A

CV6 CV8

BODY HARNESS

VIEW

A

BODY HARNESS

BODY

CONTROL

MODULE

CONNECTORS

BODY

CONTROL

MODULE

CONNECTORS

BODY

HARNESS

CONNECTORS BODY

HARNESS

CONNECTORS

REFER FIG'S 16 & 18

A

TO LOCATE VIEW

FOR CONNECTOR NUMBERS REFER FIG'S 16 & 18

7

3

2

14

5

6

2

1

MODEL V2 COUPE

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

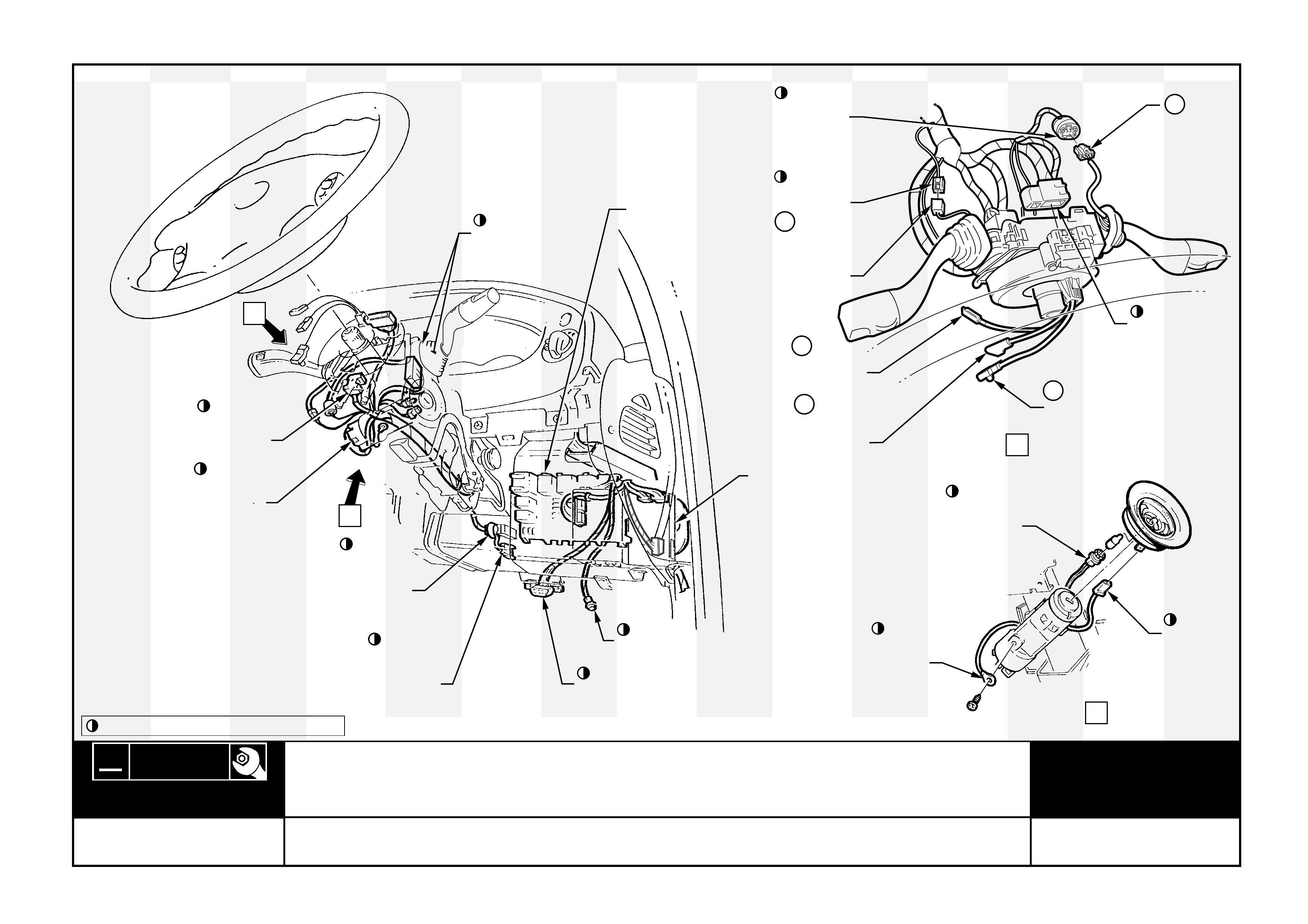

FIG. 23

29

MODEL V2 COUPE MAIN WIRING HARNESS

A

B

IGNITION

SWITCH

CONNECTOR

WIPER / WASHER

SWITCH

CONNECTOR

STOP

LAMPS

SWITCH

CONNECTOR

R.H.F. FOOTWELL LAMP

CONNECTOR

DIAGNOSTICS

CONNECTOR

TURN SIGNAL/

HI-BEAM DIP

SWITCH

CONNECTOR

BODY

CONTROL

MODULE

VIEW

A

CLOCK SPRING

CONNECTOR

DRIVER AIRBAG

INFLATOR

CONNECTOR

HORN

CONNECTOR

VIEW

B

IGNITION LOCK

ILLUMINATION

CONNECTOR

IGNITION

KEY READER

CONNECTOR

IGNITION

KEY EARTH

TERMINAL

CRUISE

CANCEL

SWITCH

CONNECTOR

REMOTE

RADIO

CONNECTOR

3

4

5

2

1

FOR CONNECTOR NUMBERS REFER FIG. 16 & 18

CRUISE CONTROL

CONNECTOR

DWELL CONTROL

CONNECTOR

FUSE PANEL

MAIN

WIRING

HARNESS

CONNECTOR

MAIN

WIRING

HARNESS

CONNECTOR

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

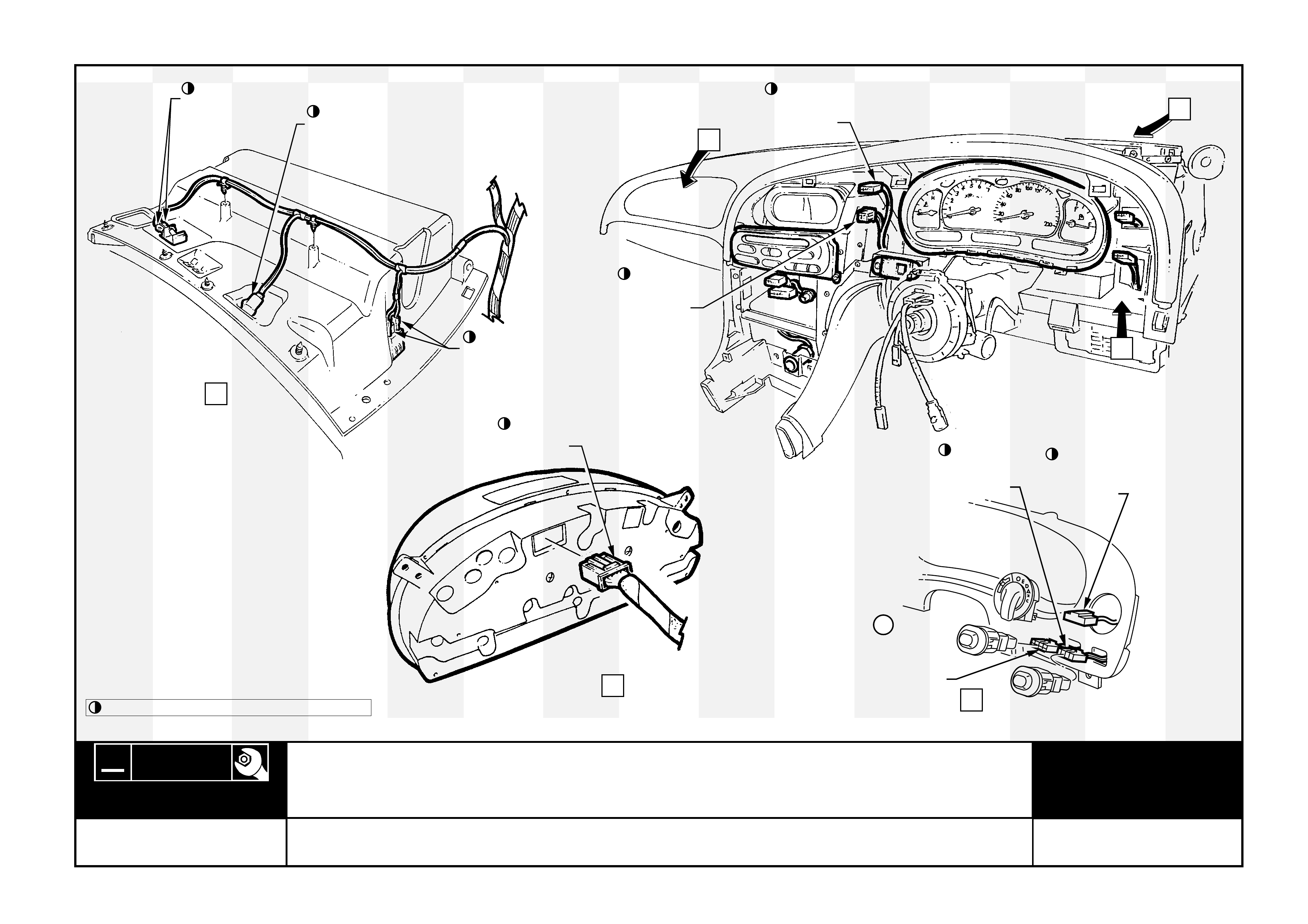

FIG. 24

30

MODEL V2 COUPE MAIN WIRING HARNESS

VIEW

T.C.S.

SWITCH

ILLUMINATION

CONNECTOR

C

CTRL

TRAC

VIEW

A

INSTRUMENTS

CONNECTOR

VIEW

B

FOR CONNECTOR NUMBERS REFER FIG'S 16 &18

GLOVE BOX

LAMP

CONNECTORS TRUNK LOCK

SWITCH

CONNECTOR

GLOVE BOX

SWITCH

CONNECTORS

HAZARD

SWITCH

CONNECTOR

TRIP COMPUTER

SWITCH

CONNECTOR

B

A

FOG LAMPS

SWITCH

CONNECTOR

LIGHT

SWITCH

CONNECTOR

11

C

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

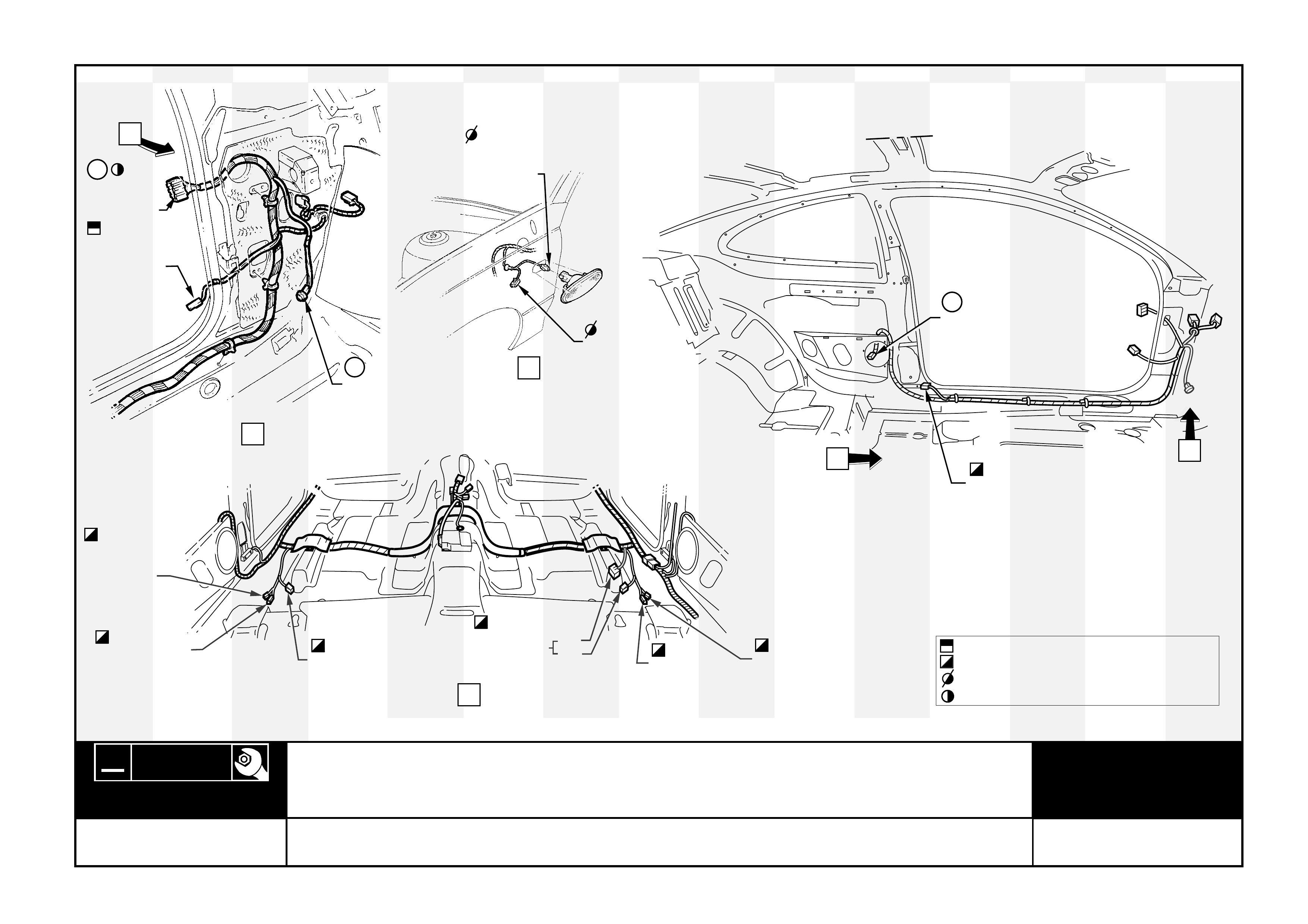

FIG. 25BODY WIRING / ROOF LAMPS HARNESSES & DOME LAMP

ROOF LAMPS

HARNESS

CONNECTOR

VISOR LAMPS

HARNESS

CONNECTOR

FOR CONNECTOR NUMBERS REFER FIG'S 16 & 18

FOR CONNECTOR NUMBERS REFER FIG'S 29

FOR CONTINUATION REFER FIG 34

VIEW

B

15

3

12

17

18

POWER

WINDOW

SWITCH

ASSEMBLY

POWER

WINDOW

SWITCH

CONNECTOR

MAIN

WIRING

HARNESS

AIRBAG

INTERFACE

CONNECTOR

CONSOLE

HARNESS

CONNECTOR PARK BRAKE

SWITCH

CONNECTOR

BODY

EARTH

TERMINAL

AIR BAG

MODULE

AIR BAG

MODULE

CONNECTOR

AIR BAG

MODULE

EARTH

TERMINAL

11

MODEL V2 COUPE

VIEW

A

SINGLE

CONTACT

SWITCH FRT DR RHS G/W

FRT DR LHS W

4

5

DOME

LAMP

CONNECTOR

VIEW

D

31

16

SUN VISOR

ILLUMINATION

CONNECTOR

SUN VISOR

FRONT

OF

CAR

910

RH LH

VIEW

C

14

13

FRONT RH DOOR

CONNECTOR (1)

FRONT RH DOOR

CONNECTOR (2)

MAIN WIRING

HARNESS

(2 CONN'S)

BA

C

ROOF LAMPS

HARNESS

CONNECTOR

BODY

HARNESS

CONNECTOR

RH REAR

SPEAKER

CONNECTOR

2

3

6

7

8

BODY

CONTROL

MODULE

CONNECTOR

1

RH PERIPHERAL

ACCELERATOR

SENSOR

CONNECTOR

FOR CONTINUATION

REFER FIG. 27

B

D

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

FOR CONTINUATION REFER FIG 34

FOR CONNECTOR NUMBERS REFER FIG 30

FOR CONNECTOR NUMBERS REFER FIG 29

FOR CONNECTOR NUMBERS REFER FIG 25

ANTENNA

CONNECTOR

VIEW

B

SIDE

REPEATER

CONNECTOR

FRONT LH DOOR

JAMB SWITCH

CONNECTORS

LHF FOOTWELL

LAMP CONNECTOR

FRONT LH

DOOR

CONNECTOR

B

1

1

2

1

3

FIG. 26

32

BODY WIRING HARNESS

VIEW

C

DRIVER SIDE

PRE-TENSIONER

CONNECTOR

DRIVER SIDE

POWER SEAT

CONNECTOR

CV8

DRIVER SIDE

AIRBAG

CONNECTOR

PASSENGER SIDE

AIRBAG

CONNECTOR

VIEW

A

MODEL V2 COUPE

PASSENGER SIDE

POWER SEAT

CONNECTOR

C

A

LH PERIPHERAL

ACCELERATOR

SENSOR

CONNECTOR

LH REAR

SPEAKER

CONNECTOR

PASSENGER SIDE

PRE-TENSIONER

CONNECTOR

CV6

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

FIG. 27

33

BODY WIRING HARNESS

FOR CONTINUATION

REFER FIG 35

FOR CONTINUATION

REFER FIG 31

FOR CONTINUATION

REFER FIG 25

A

VIEW

B

(Or/B)

(B/G)

3

2

REAR COMPARTMENT

LAMP CONNECTORS

LH TURN

TRAILER

CONNECTOR

(TIE BACK) 2

1

4

1

RH TAIL

LAMP

CONNECTOR

VIEW

C

(R. SIDE SHOWN)

VIEW

D

(R. SIDE SHOWN)

BACK UP

LAMP

CONNECTOR

BODY

HARNESS

CONNECTOR STOP LAMP

CONNECTOR

REAR TURN

SIGNAL LAMP

CONNECTOR

11 LH

LH

RH

RH

RH

RH

VIEW

E

BODY

EARTH

TERMINAL

14

13

12

MODEL V2 COUPE

VIEW

A

LH TAIL LAMP

CONNECTOR

5

C

E

D

B

FOR CONTINUATION

REFER FIG 32

7

9

8

6

LH

LH

10

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

FIG. 28

34

MODEL V2 COUPE S.R.S. WIRING

DRIVER AIRBAG

INFLATOR

CONNECTOR

HORN

CONNECTOR

REMOTE RADIO

CONNECTOR

(IF FITTED)

VIEW

A

PASSENGER

SIDE AIRBAG

PASSENGER SIDE

AIRBAG INFLATOR

CONNECTOR

REFER FIG 29

C

FOR VIEW

FOR CONNECTOR NUMBERS REFER FIG'S 16 & 18

VIEW

B

A

B

C

FOR CONNECTOR NUMBERS REFER FIG'S 23

STEERING WHEEL

REMOVED FOR CLARITY

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

FIG. 29

35

MODEL V2 COUPE S.R.S. WIRING

POWER SEAT

HARNESS

CONNECTORS

SIDE AIRBAG

HARNESS

CONNECTOR

LH RH

FOR CONTINUATION

REFER FIG. 25 & 26

FRONT

OF

CAR

PRE-TENSIONER

HARNESS

CONNECTOR

LH RH

7

5

8

6

11

9

12

10

RH SIDE SHOWN

PERIPHERAL

ACCELERATOR

SENSOR

CONNECTOR

FOR CONTINUATION

REFER FIGS. 25 & 26

LH RH

4

3

VIEW

VIEW

2

AIRBAG

MODULE

EARTH

TERMINAL

AIRBAG

MODULE

CONNECTOR

1

AIRBAG

MODULE

FOR CONTINUATION REFER FIG. 25

A

C

RH SIDE SHOWN

PRETENSIONER

HARNESS

CONNECTOR

SIDE AIRBAG

HARNESS

CONNECTOR

LH

LH

RH

RH

SIDE AIRBAG

ASSEMBLY

A

FOR CONNECTOR NUMBERS REFER FIG. 40

FOR CONNECTOR NUMBERS REFER FIG. 25

C

TO LOCATE VIEW REFER FIG. 28

FRONT

ROOF LAMPS

HARNESS

CONNECTOR

BODY

HARNESS

CONNECTOR

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

FOR VIEWS &

REFER FIG. 31

FOR CONNECTOR NUMBERS

REFER FIG. 16 & 18

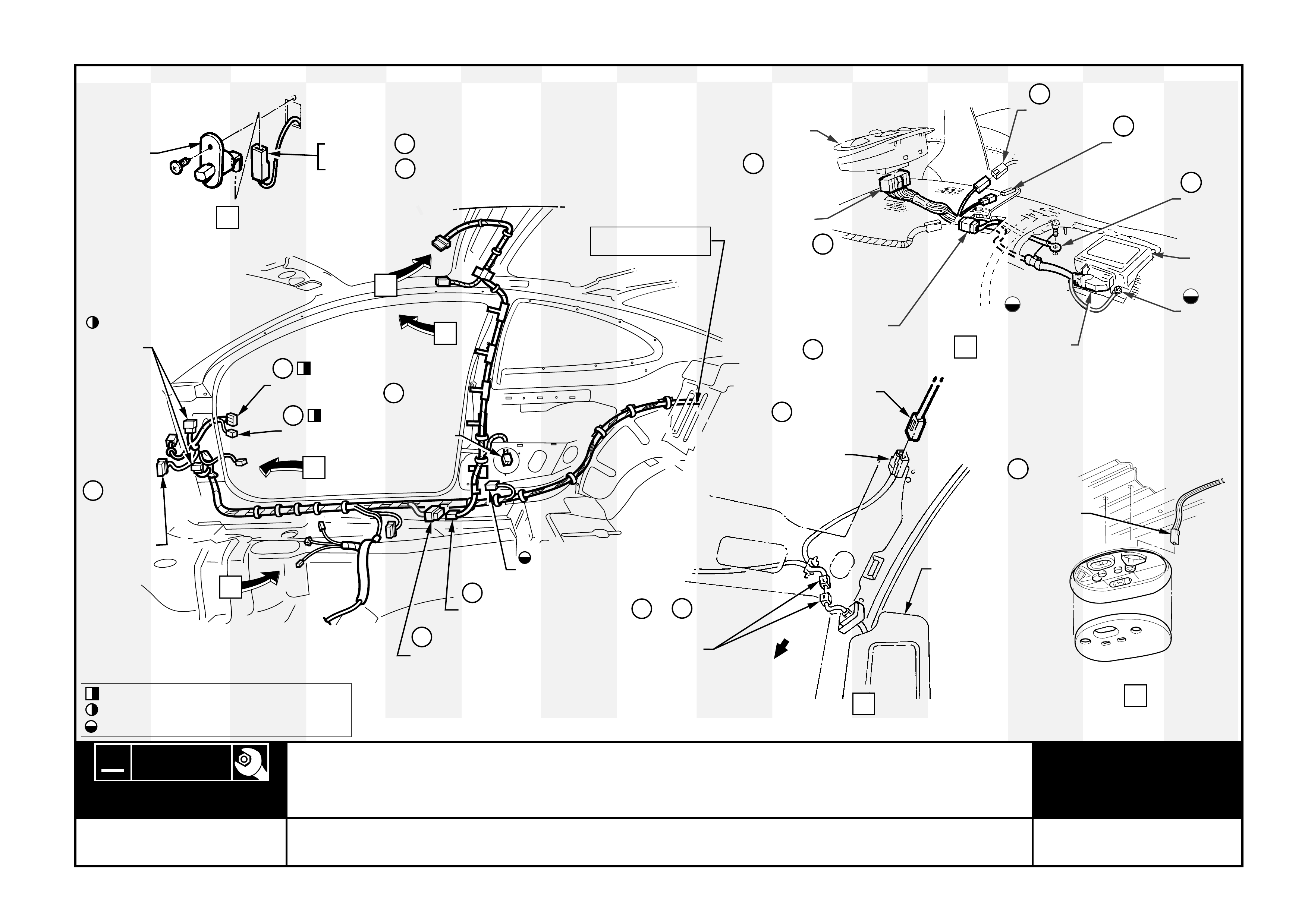

FIG. 30

36

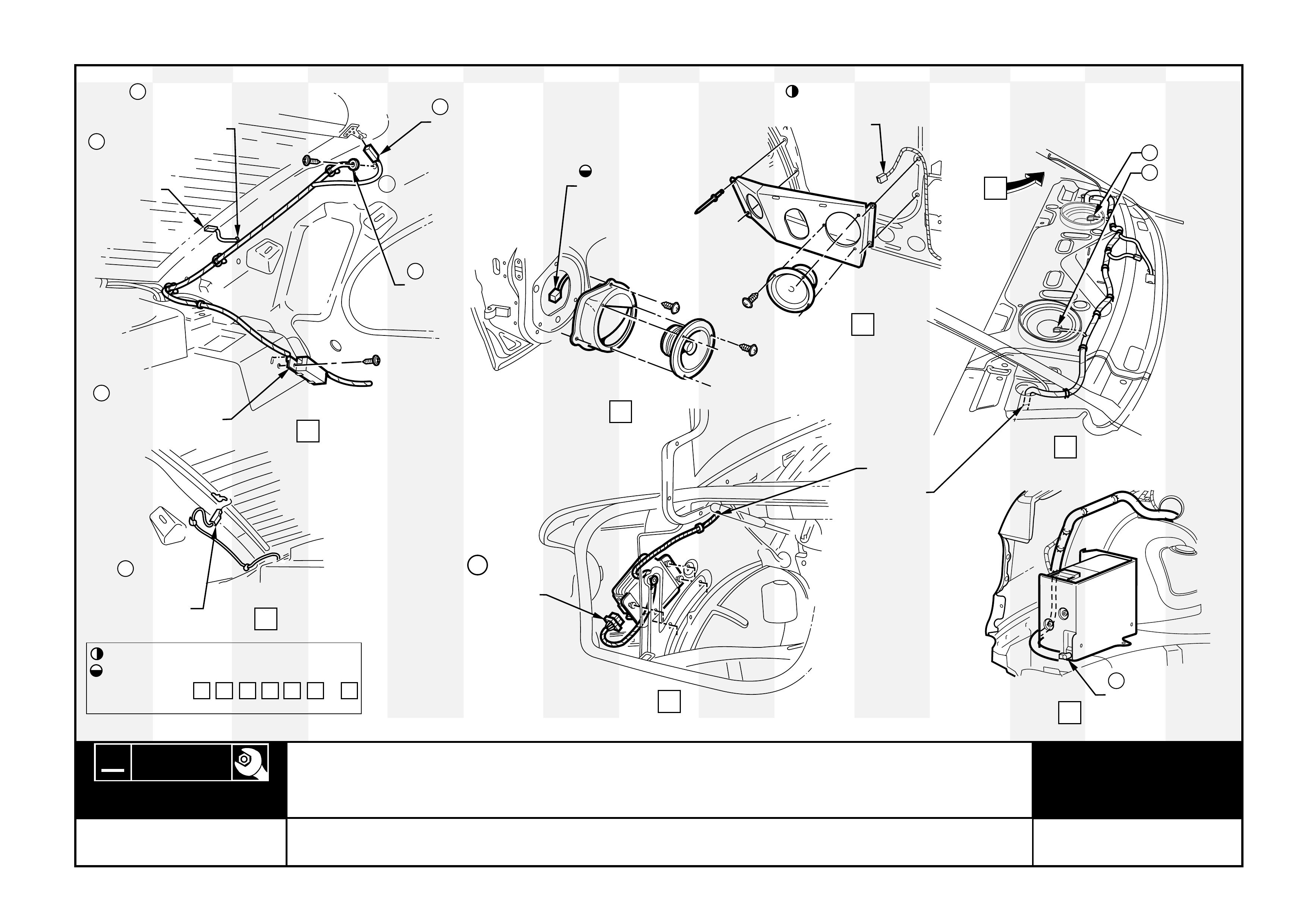

BODY AUDIO SYSTEM

RADIO

FRONT

SPEAKERS

POWER ANTENNA

AMPLIFIER

CD CHANGER

B

A

C

FOR CONTINUATION

REFER FIG. 21

ANTENNA

CONNECTOR

ANTENNA

CONNECTOR

SIDE

REPEATER

CONNECTOR

ANTENNA

EARTH

TERMINAL

8

67

5

3

POWER

ANTENNA

CONNECTOR

2

4

LH RH

1

9

ANTENNA

MOTOR

EARTH

TERMINAL

10

11

VIEW

C

RADIO

MAIN

WIRING

HARNESS

RADIO

(2 CONNS)

RADIO-

CD PLAYER

CONNECTOR

DIVERSITY

ANTENNA

CONNECTOR

ANTENNA

CONNECTOR

VIEW

VIEW

AE

VIEW

D

12 13

LHF DASH

SPEAKER

CONNECTOR LH RH

DIVERSITY

ANTENNA

CONNECTOR VIEW

B

BODY

HARNESS

CONNECTOR

F

FOR CONTINUATION

REFER FIG 32

FJGK

HLI

FOR CONTINUATION REFER VIEW & FIG 21

FOR CONTINUATION REFER VIEW

MAIN

WIRING

HARNESS

CONNECTOR

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

MODEL V2 COUPE

G

E

HI

K

L

B

A

D

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

FIG. 31

37

BODY AUDIO SYSTEM

VIEW

F

HEATED REAR

WINDOW

EARTH

CONNECTOR

EARTH

TERMINAL

2

6

1

DIVERSITY

ANTENNA

CONNECTOR

DIVERSITY ANTENNA

AMPLIFIER & LEAD ASM.

3

HEATED REAR

WINDOW

EARTH TERMINAL

MODEL V2 COUPE

VIEW

L

CD HARNESS

CONNECTOR

10

VIEW

J

HEATED REAR

WINDOW

CONNECTOR

4

RH

LH

SUBWOOFER

CONNECTORS

(CV8)

8

9

VIEW

I

J

VIEW

K

AMPLIFIER

CONNECTOR

BODY

WIRING

HARNESS

7

VIEW

RH & LH REAR

DOOR

SPEAKER

CONNECTOR

H

FH KGJIL

TO LOCATE VIEWSTO LOCATE VIEWS

REFER FIG 30

&

FOR CONNECTOR NUMBERS REFER FIG'S 25 & 26

FOR CONNECTOR NUMBERS REFER FIG 34

VIEW

RH & LH FRONT

DOOR

SPEAKER

CONNECTOR

G

5

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

FIG. 32

38

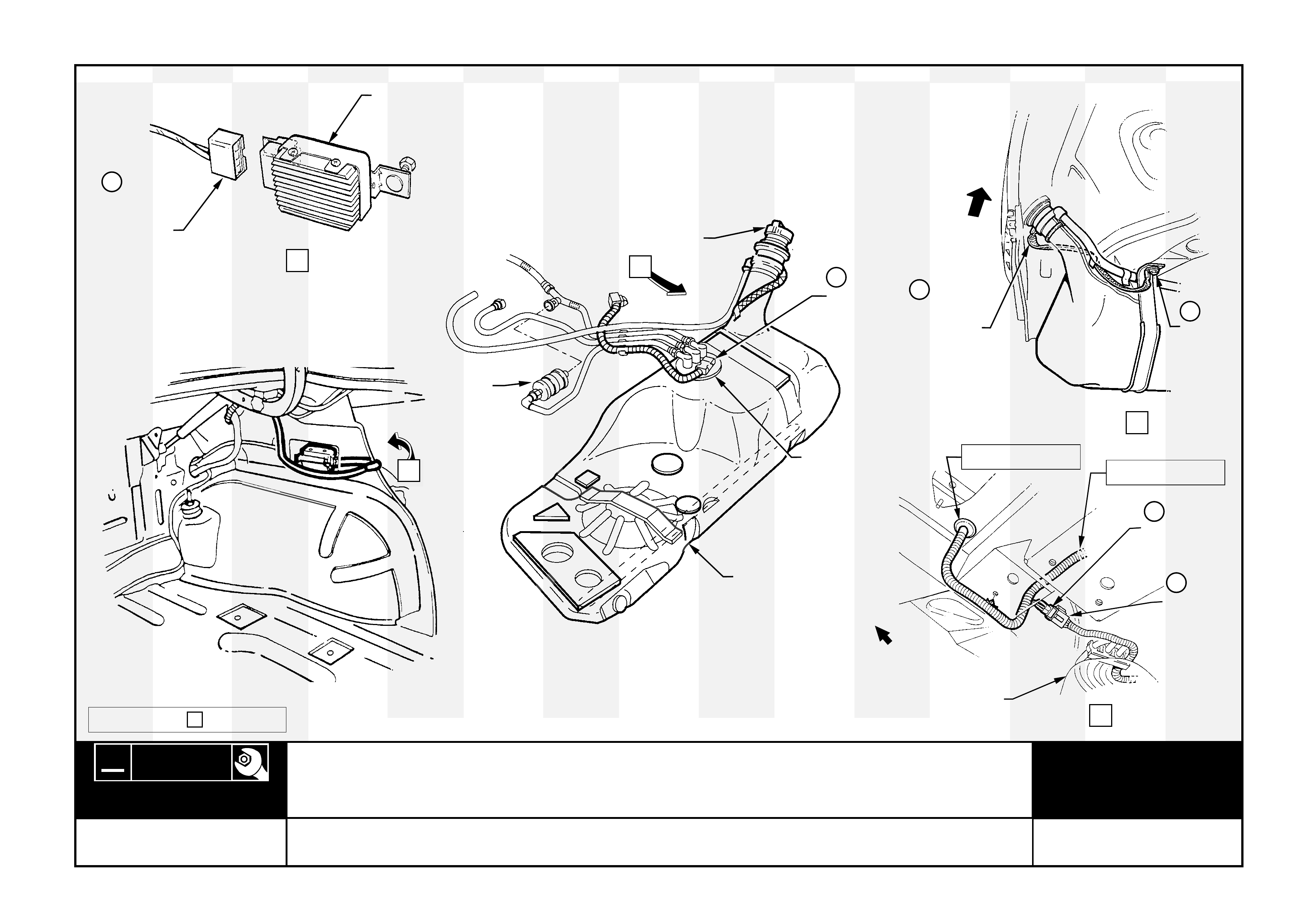

MODEL V2 COUPE BODY WIRING HARNESS - FUEL SENDER UNIT

VIEW

B

FRONT

OF

VEHICLE

EARTH

STRAP

TERMINAL

FUEL FILLER

EARTH STRAP

CONNECTOR

6

2

3

VIEW

A

FUEL PUMP

SPEED

CONTROLLER

CONNECTOR

FUEL PUMP

SPEED

CONTROLLER

ASM.

11

REFER FIG 38

C

TO LOCATE VIEW

B

FUEL

TANK

ASM.

FUEL

PUMP

FUEL

FILTER

FUEL TANK

CONNECTOR

FUEL

FILLER

CAP

2

FRONT

OF

VEHICLE FUEL

TANK

ASM.

BODY

WIRING

HARNESS

CONNECTOR

VIEW

C

FOR CONTINUATION

REFER FIG 38

FOR CONTINUATION

REFER FIG 27

CV6 ONLY

A

FUEL TANK

HARNESS

CONNECTOR

5

4

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector

Pinched cut

Too short

Splice open circuit

Not connected

Will not lock

Wrong position

Poor earth

Terminal damaged

Dry solder connector

Corroded

Poorly crimped

Not retained

Loose terminal

Wrong part

DO NOT USE FAILURE CODE 50

USE ZONE NUMBER FOR THE LOCATION OF WIRING DAMAGE

WARRANTY

PROCESSING

WARRANTY

PROCESSING

ONLY

GMH

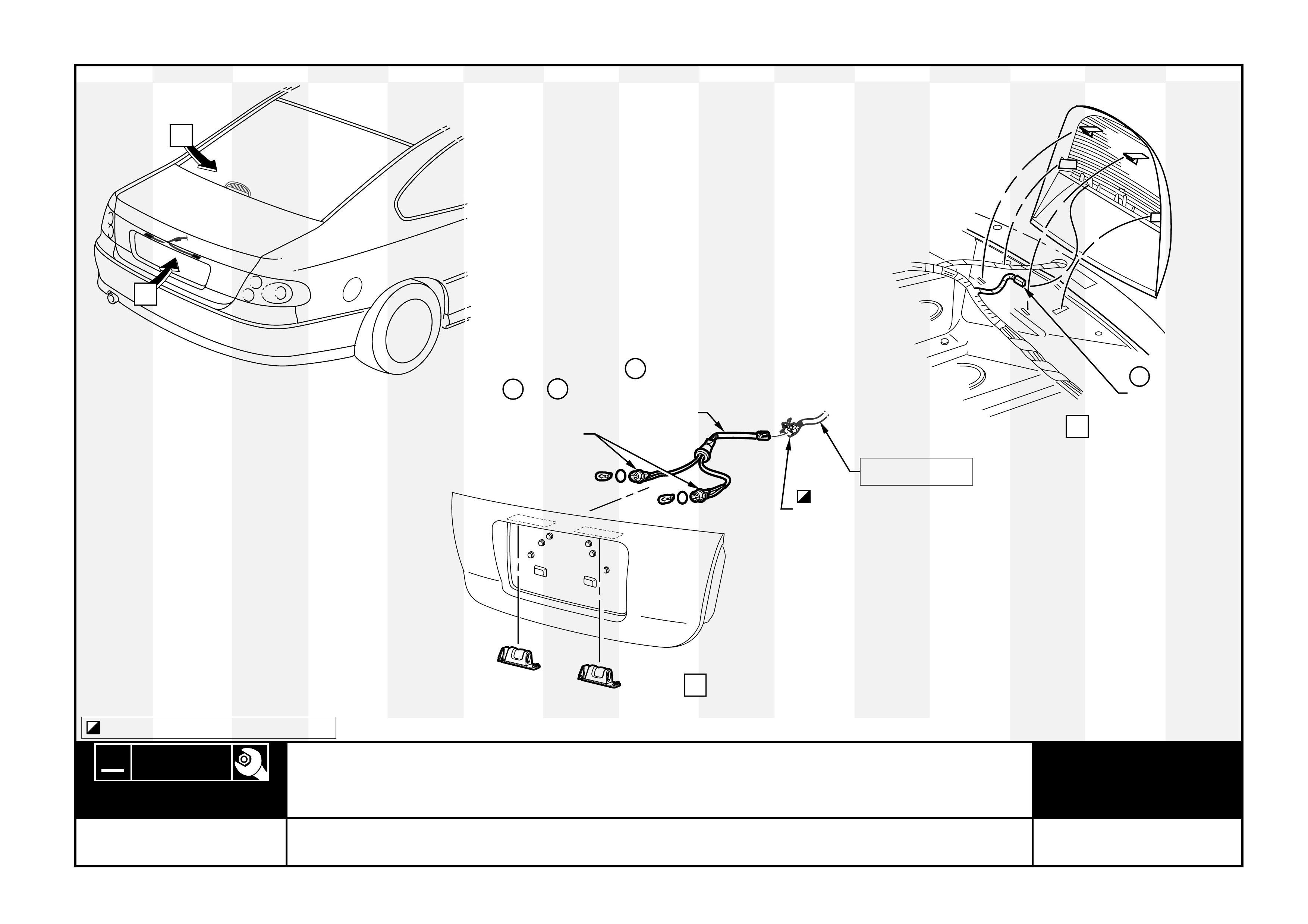

FIG. 33HIGH MOUNTED STOP LAMP & LICENCE LAMPS

B

12

3

LICENCE

LAMPS

CONNECTORS

BODY

HARNESS

CONNECTOR

LICENCE

LAMPS

HARNESS

CONNECTOR

FOR CONTINUATION

REFER FIG. 35

LH RH

FOR CONNECTOR NUMBER REFER FIG. 38

39

REFER TO THE

APPROPRIATE SERVICE

INFORMATION MANUAL

MODEL V2 COUPE

VIEW

VIEW

A

HIGH MOUNTED

STOP LAMP

CONNECTOR

4

B

A

85 86 87 88 89 90 91

ZONES

92 93 94 95 96 97 9884

TERMINAL PROBLEMS WIRE/HARNESS PROBLEMS

CONNECTOR BODY PROBLEMS

Code Description Code Description Code Description Code Description Code Description

20

27

28

37

54

58

78

80

99

57

89

01

71

86

92

94

99

Wrong routed

Short circuit

Dry solder connector