2

20

00

03

3

S

SE

ER

RV

VI

IC

CE

E

T

TE

EC

CH

HL

LI

IN

NE

ES

S

©

2006 GM Holden Ltd. A.B.N. 84 006 893 232

Service Department

A “HOLDEN” Product.

BRISBANE SYDNEY MELBOURNE ADELAIDE PERTH

HOLDEN SERVICE TECHLINE_____________________________________________________ __________JANUARY, 2003

5

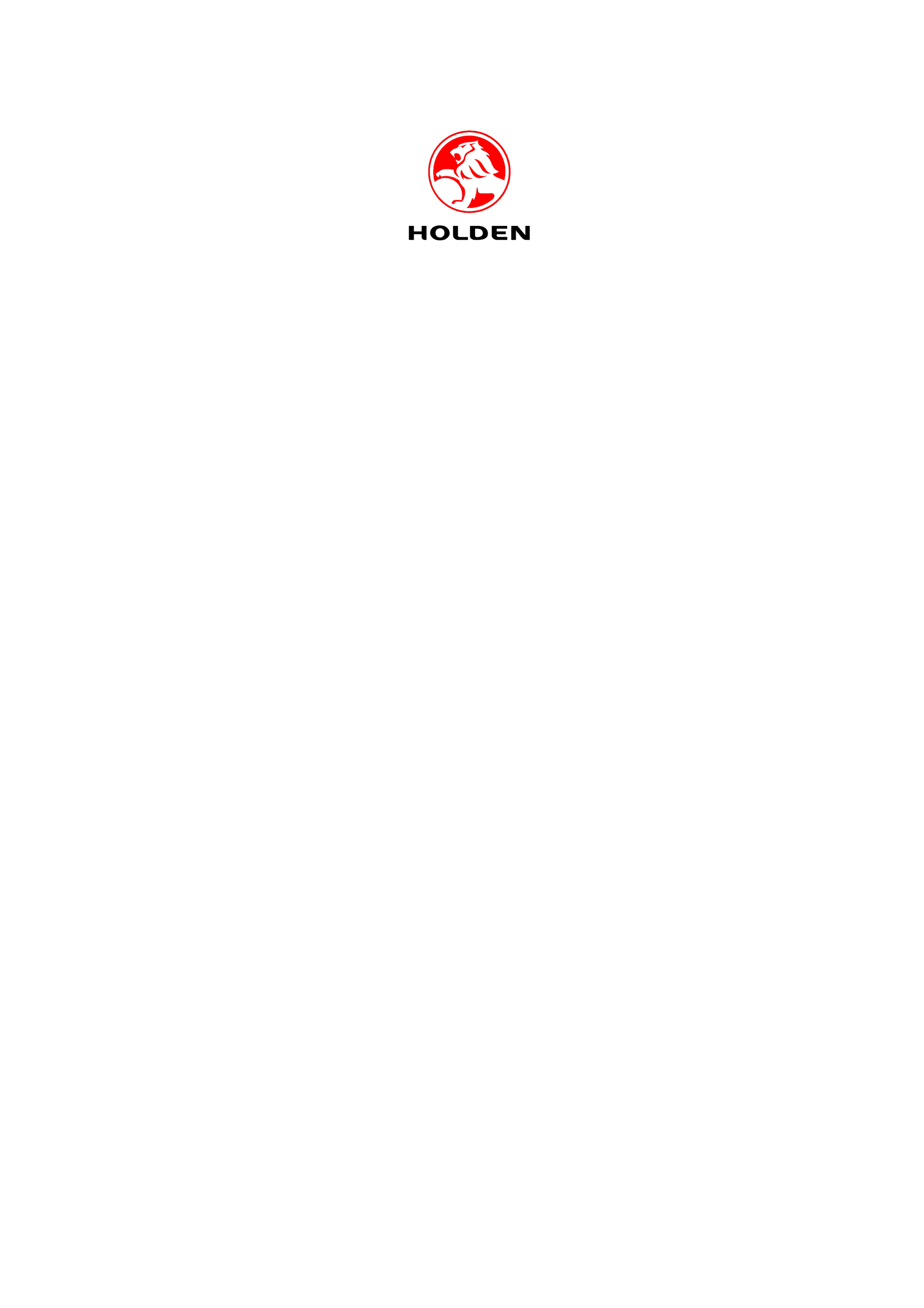

Spare Wheel –Soft Cover Staining

UBS Jackaroo & UES Frontera

(GROUP 10) TL410-0301

PROBLEM DESCRIPTION

Some customers may complain of stains appearing

on the outside of the soft spare wheel cover.

Investigations show staining can be caused by the

migration of anti oxidants from the tyre onto the PVC

cover.

Figure 1. Staining of spare wheel cover

SERVICE RECTIFICATION

On vehicles with above complaint, install plastic liner

part number 91151997 to the tyre prior to fitting a

new soft spare wheel cover.

PARTS INFORMATION

Part No.: Description: Qty:

91151997 sleeve - spare wheel 1

WARRANTY CLAIM INFORMATION

Description Spare wheel sleeve -

install

Labour Op. No. R000109

Time 0.2hr

Failure Code 78 discoloured

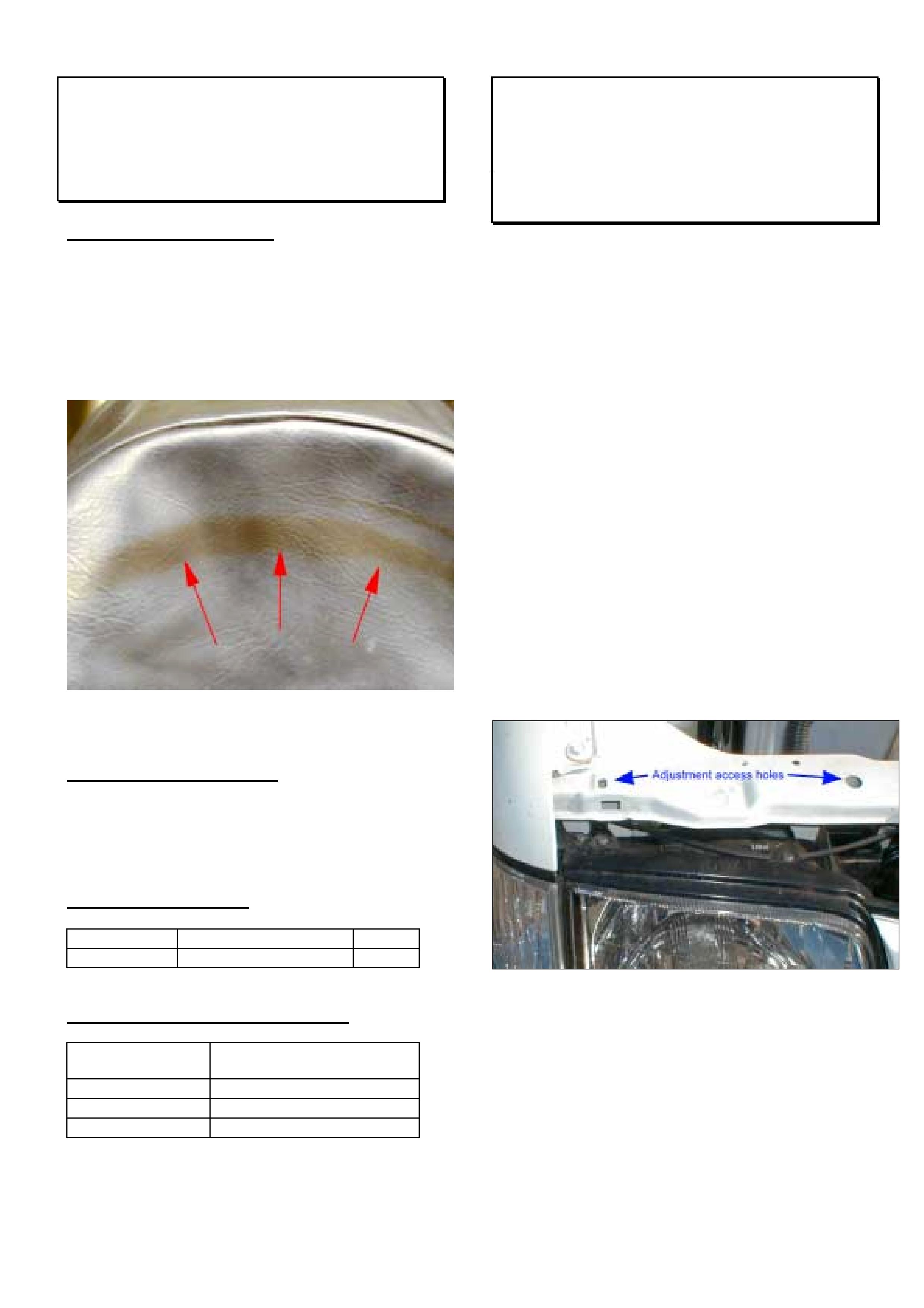

Headlamp Adjustment Procedure

TF Rodeo - LT, LT Sport and all Model

Year 2002

(GROUP 12) TL412-0301

This techline provides instructions for adjusting the

headlamp aim on the flush style lamps as there are

currently no instructions contained in the LCRV SIP

CD. These instructions will be included in a future

LCRV SIP update.

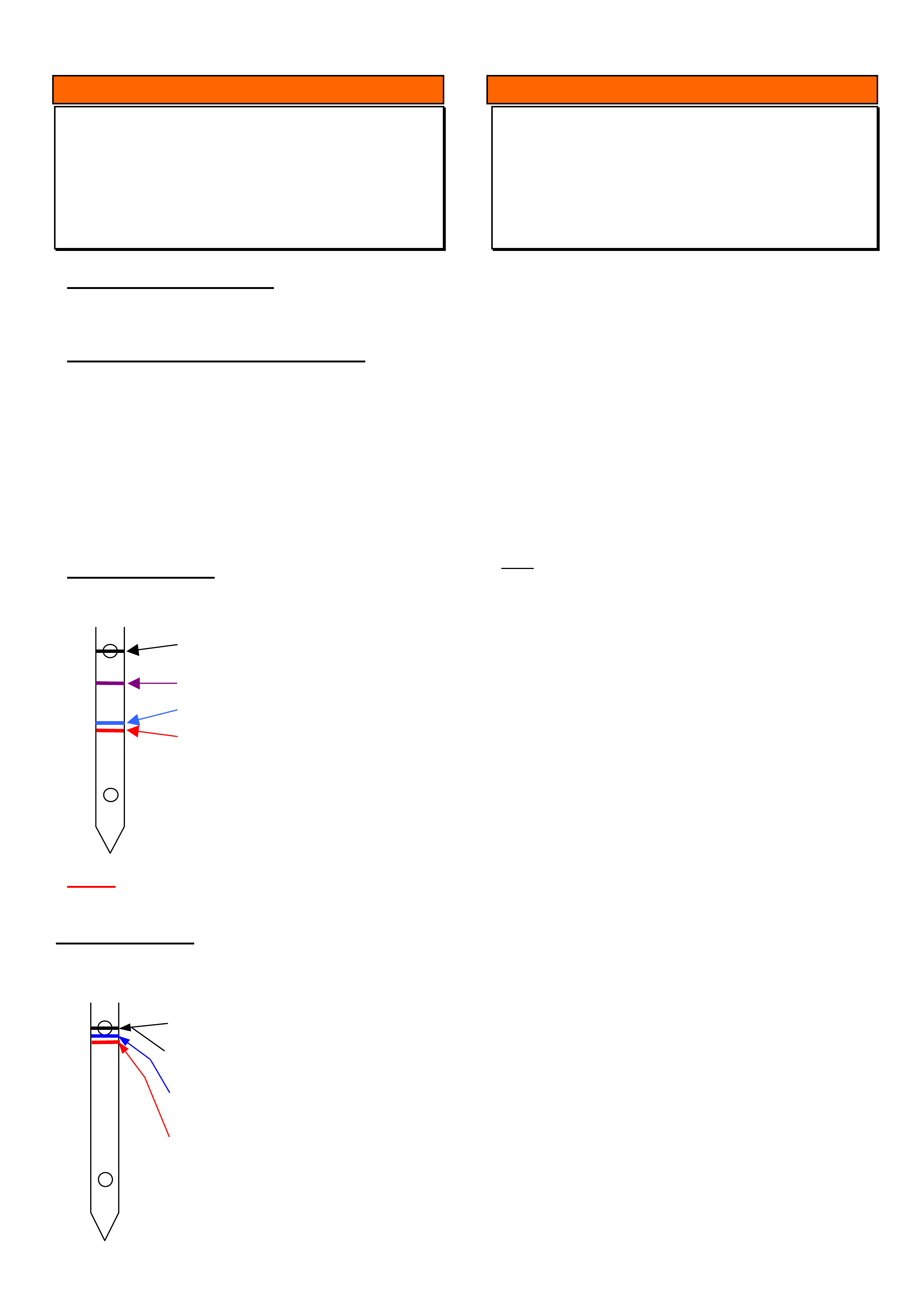

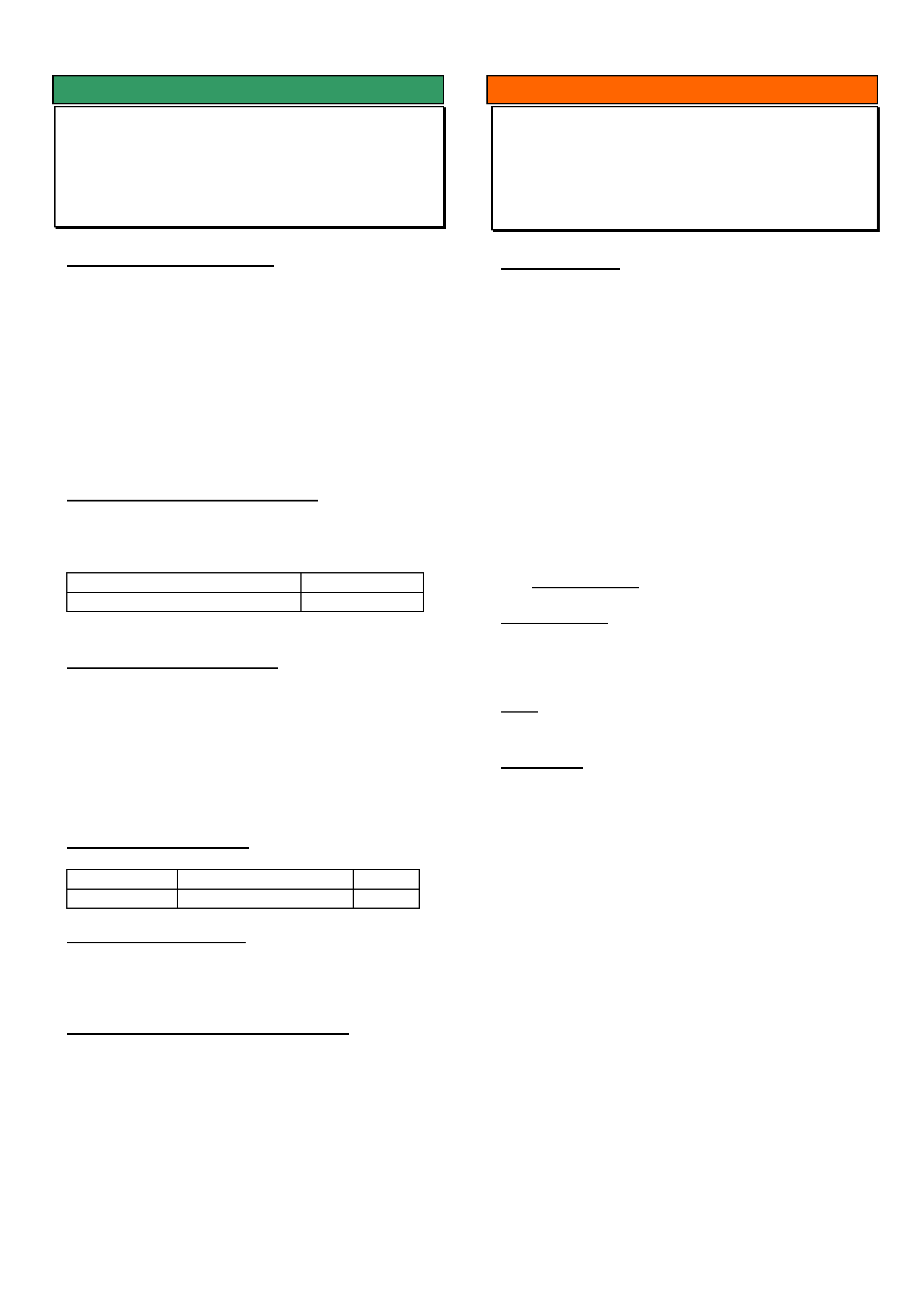

Adjustment Procedure.

To adjust headlamp aim, a Phillips No.2 screwdriver

with a minimum shaft length of 150mm and shaft

diameter no greater than 6.3 mm is required.

The adjusting mechanisms are accessed through the

holes shown in figures 1 and 2.

To adjust vertical aim use the outer hole as shown in

figure 3, insert the screwdriver so that it meshes with

the white gears of the adjustment mechanism and

turn the screwdriver to achieve the appropriate

movement.

For horizontal adjustment, use the inner hole as

shown in figure 4. Insert the screwdriver so that it

meshes with the adjuster gears and turn in the

required direction.

Figure 1. RHS adjustment access holes

HOLDEN SERVICE TECHLINE_____________________________________________________ __________JANUARY, 2003

6

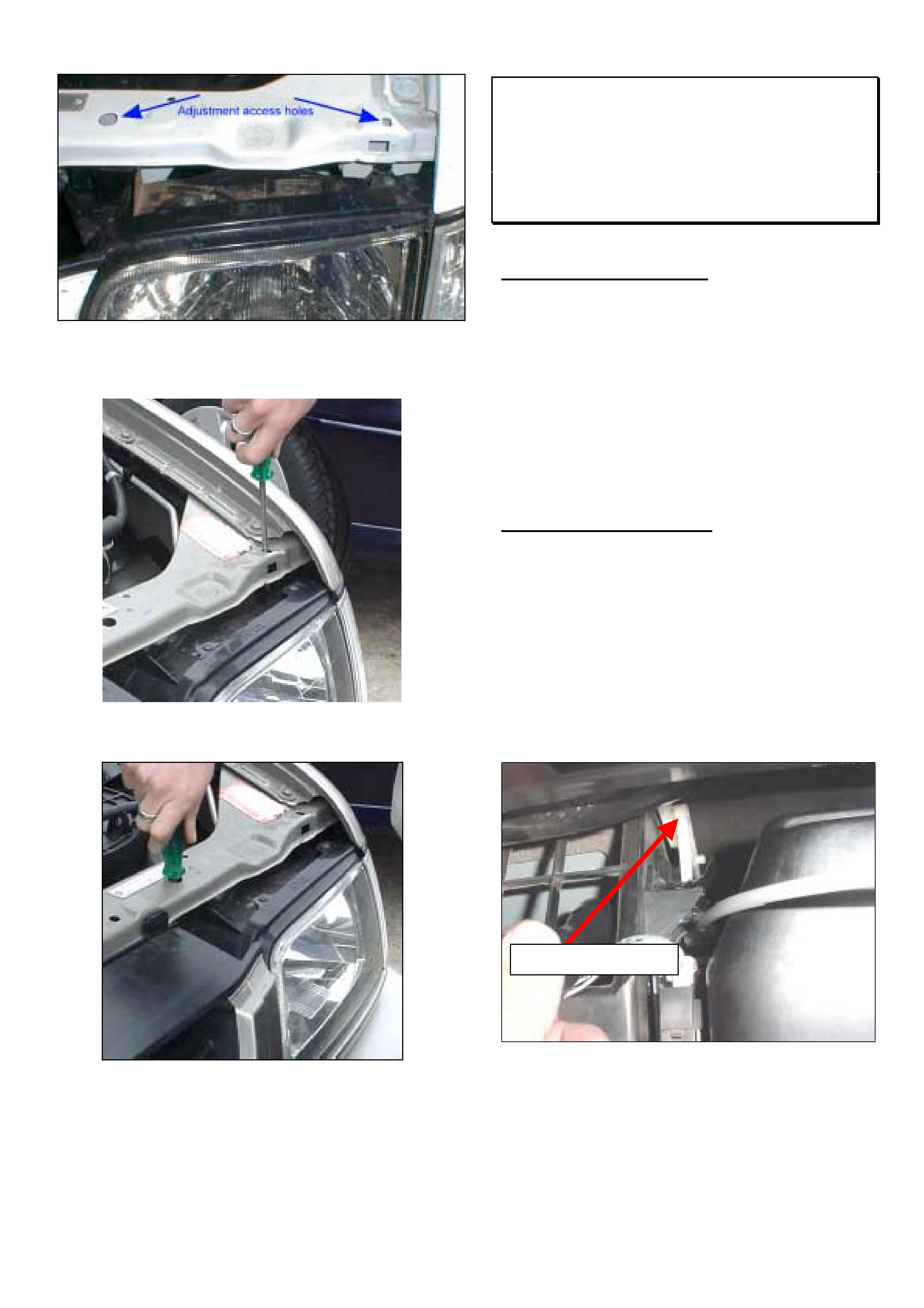

Figure 2. LHS adjustment access holes

Figure 3. Vertical adjustment

Figure 4. Horizontal adjustment

HVAC Air Source Lever Moves While

Driving At Speed

TF Rodeo – Pre 03 MY

(GROUP 2) TL391-0301

PROBLEM DESCRIPTION

Customers may report that the HVAC air source lever

moves from the re-circulate position to the centre

position while driving. This is most likely to occur

when driving at 80km/hr or above, passing on-coming

trucks or driving with the window down.

Investigation of affected vehicles has found that the

air source cable has been incorrectly adjusted in

production. This does not allow the lever to detent at

the HVAC unit.

SERVICE RECTIFICATION

Complete the adjustment procedure below to obtain

full detent operation.

1. Remove the glove box hinge screws and glove

box.

2. Disconnect the air source flap cable at the

retaining spring.

3. Move the air source control lever (on the dash)

fully to the re-circulate position.

4. Push the air source flap linkage (behind the glove

box) as indicated in figure 1.

Figure. 1

Note: Pushing directly on the air source flap does not

locate the vent correctly.

Apply Pressure Here

HOLDEN SERVICE TECHLINE_____________________________________________________ __________JANUARY, 2003

7

5. Pull gently on the control cable while installing

into the retaining spring, this will ensure good

adjustment is achieved.

Note: The air source control lever and linkage must

remain in the correct position while installing the control

cable.

6. Check that the air source system has full

movement.

7. Reinstall the glove box.

WARRANTY CLAIM INFORMATION

Description Cable Adjustment – Air

Source Lever

Labour Op. No. D000342

Time 0.3 hr

Failure Code 26 Misadjusted

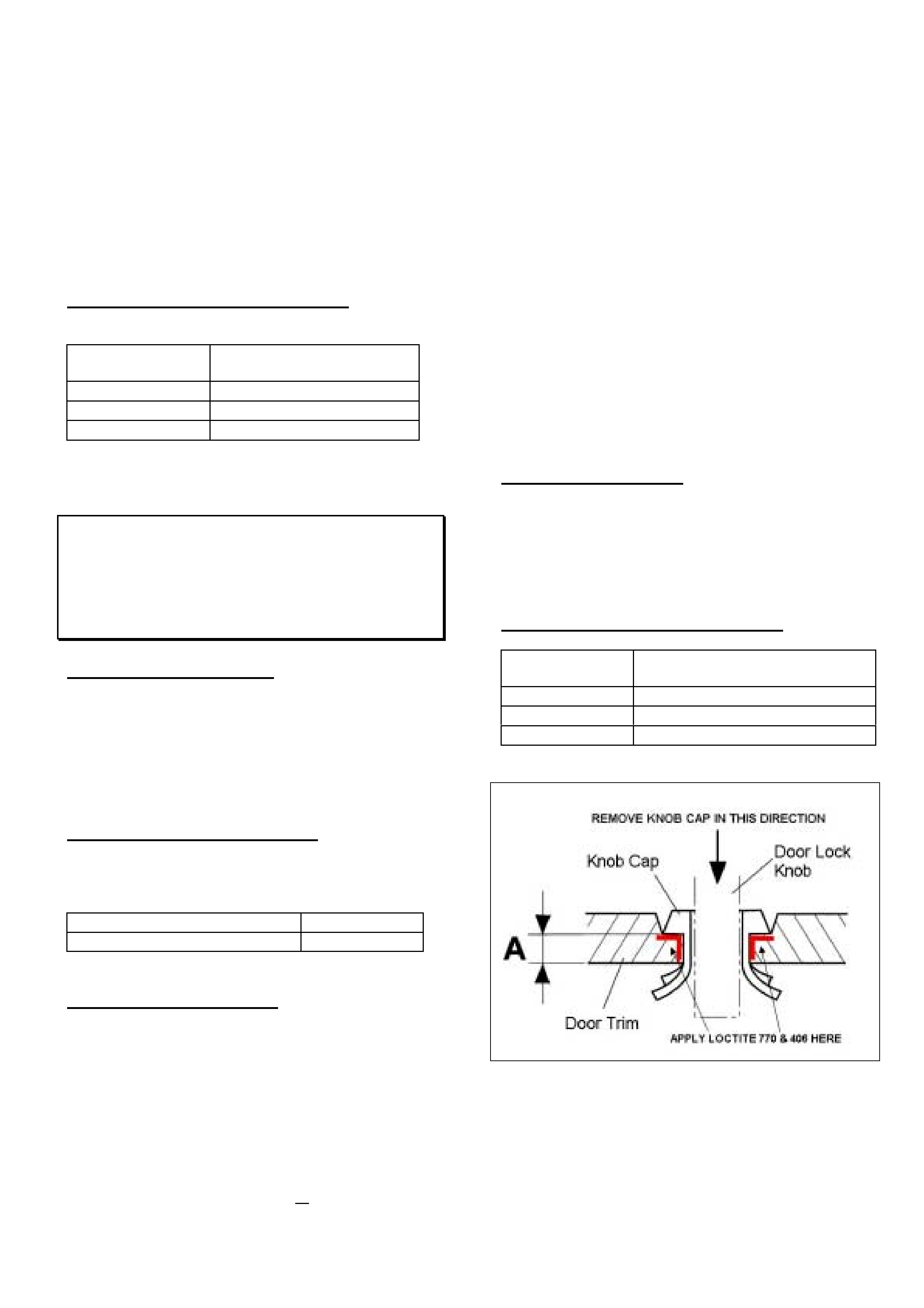

Door Lock Knobs Rattle

YG Cruze

(GROUP 1) TL414-0301

PROBLEM DESCRIPTION

Some customers may complain of a rattle noise from

door trims in the door lock knob area.

Investigations show this condition is caused by

insufficient retention of the door lock knob cap in the

door trim which results in a rattle.

PRODUCTION RECTIFICATION

Door trims with improved retention of knob cap

(dimension A increased) have been fitted to vehicles

from:

ISOVIN: Build Date:

JSAGHY81S00110001 3/09/2002

SERVICE RECTIFICATION

Summary: On all 4 doors, glue door knob cap to

door trim as per following procedure.

1. Remove door trim from each door by referring to

instructions in LCRV SIP. Select: Section 9 –

Body Service / 2 – Body Structure / 2.1 – Front

door asm. OR 2.2 – Rear door asm.

2. Note which way the knob cap is oriented in the

door and then remove it from the door trim by

pushing down hard on cap or carefully levering

with a screw driver from the flared side of the

cap.

3. Apply LOCTITE 770 Primer (or equivalent) to

both knob cap and door trim where these parts

touch – Refer Figure 1. NOTE: Take care NOT

to apply primer to areas of knob cap or door trim

which are visible by customer. Allow to dry

according to manufacturers instructions.

4. Apply a very small amount of LOCTITE 406 (or

equivalent) instant adhesive to those areas on

the knob cap and door trim where primer has

already been applied. Applying with toothpick-

sized object prevents excessive adhesive being

used.

5. Immediately insert knob cap back into door trim

using correct orientation of knob cap.

6. Allow to cure for 30 seconds.

7. Reinstall door trim into vehicle.

PARTS INFORMATION

LOCTITE 770 (Activator - Polyolefin Primer) and

LOCTITE 406 (Instant Adhesive - Prism) are both

available from most Industrial suppliers such as BSC,

CBC, Blackwoods, etc.

WARRANTY CLAIM INFORMATION

Description Remove door trim and glue

door lock knob cap – All doors

Labour Op. No. C000479

Time 0.9 hr

Failure Code 28 rattle

Figure 1.

HOLDEN SERVICE TECHLINE____________________________________________________________FEBRUARY, 2003

12

Radio Lock Up

UBS Jackaroo / TF Rodeo / UES Frontera

with Eurovox Radios

(GROUP 12) TL406-0302

PROBLEM DESCRIPTION

Customers may advise that they have experienced a

“lock up” condition of their radio. In this condition, the

radio will not operate and the screen is blank when

presented to the Retail Outlet.

NOTE: These radios will normally go into lock up

mode as a protection from a high voltage condition.

SERVICE RECTIFICATION

When investigating a complaint of radio lock up

condition it is recommended that you disconnect the

radio from battery power for at least one hour then re-

enter the radio pin number and re-evaluate the

operation of the radio. This can be done by either

disconnecting the vehicle battery or removing the

radio from the dash.

If the radio still fails to operate then proceed with

normal repair/replacement procedures.

HOLDEN SERVICE TECHLINE__________________________________________________________________MARCH, 2003

6

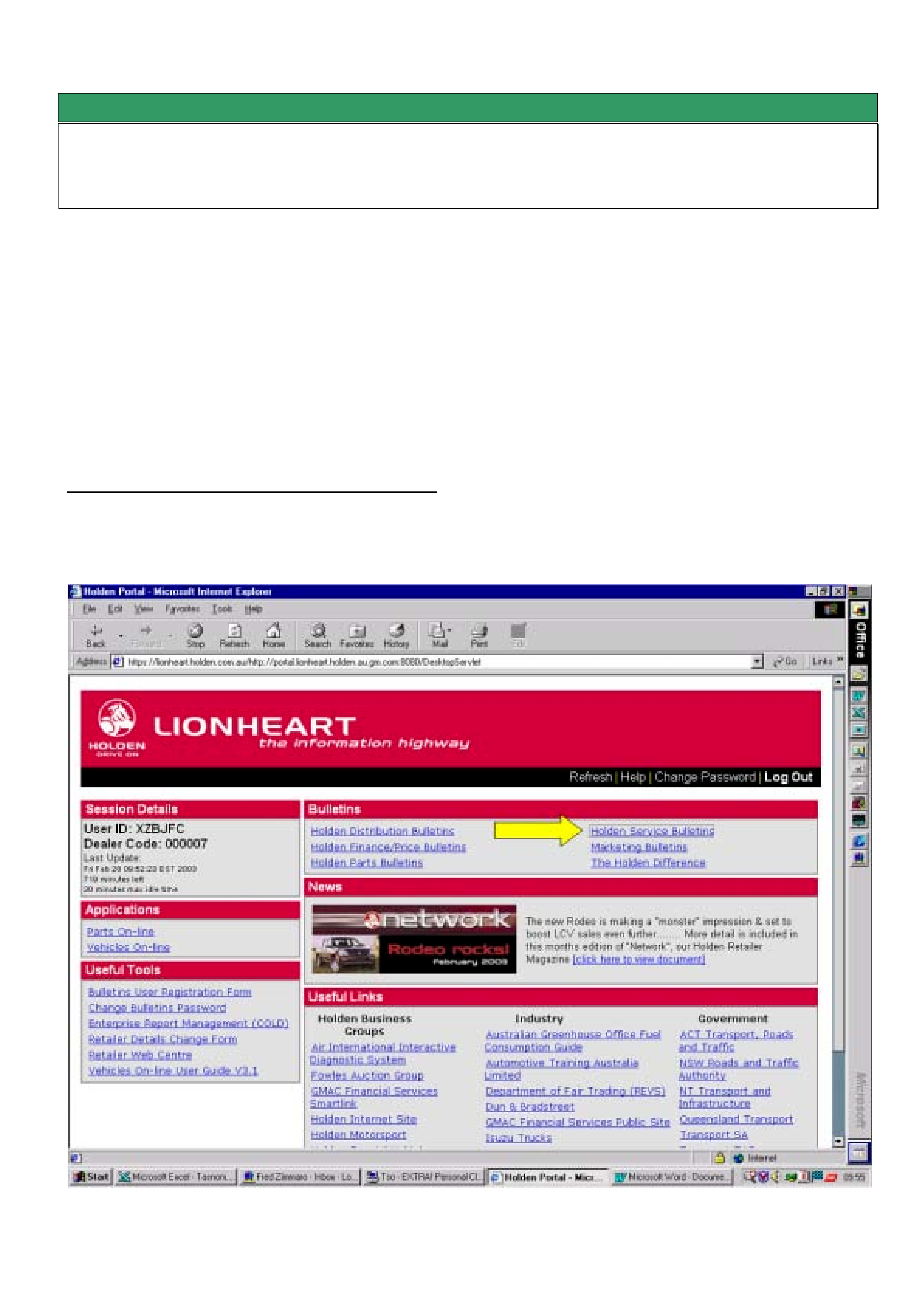

INFORMATION

SERVICE TECHLINES “ON-LINE”

(GROUP 0B) TL458-0303

Service Techlines are available “on-line” at Retailers through the “Holden Lionheart Portal”. The latest Techlines can

be viewed “on-line” immediately they have been approved for publication which means that you can have the latest

Techline information about 2 weeks earlier than you currently receive it. Note; two weeks is about the minimum

period of time it takes to print and distribute Techlines to Retailers via the Technicians Guild program or by direct mail

to Service Managers.

As Techlines are currently prepared on a monthly cycle it is suggested that you check for new bulletins at the

commencement of each month.

The Holden Lionheart Portal should be available on your Sales/Stock Controllers computer and should soon be on

most warranty clerks computers to allow them to access the new On Line warranty system due mid 2003. In order to

have the Holden Lionheart Portal installed on your Service Departments computer you will need to get the necessary

approval from your Retailer’s IT systems administrator.

Procedure For Viewing Service Techlines On Line.

Step 1. When the Holden Portal is accessed via Microsoft Internet Explorer the first screen to appear is as follows.

From the section titled “Bulletins” select Holden Service Bulletins.

HOLDEN SERVICE TECHLINE__________________________________________________________________MARCH, 2003

7

Step 2. The next screen to appear is as follows. Select “1. Service Techline”. As you can see from this screen you

can also access other Service information such as Product Campaign Bulletins, All Retailer Letters etc.

Step 3. The next screen to appear is as follows. Select Group OB – General and look for the latest Issue number.

You can then open the file provided you have Acrobat Reader software installed. As Service Techlines are currently

prepared on a monthly cycle it is suggested that you check for new bulletins at the commencement of each month.

HOLDEN SERVICE TECHLINE__________________________________________________________________MARCH, 2003

8

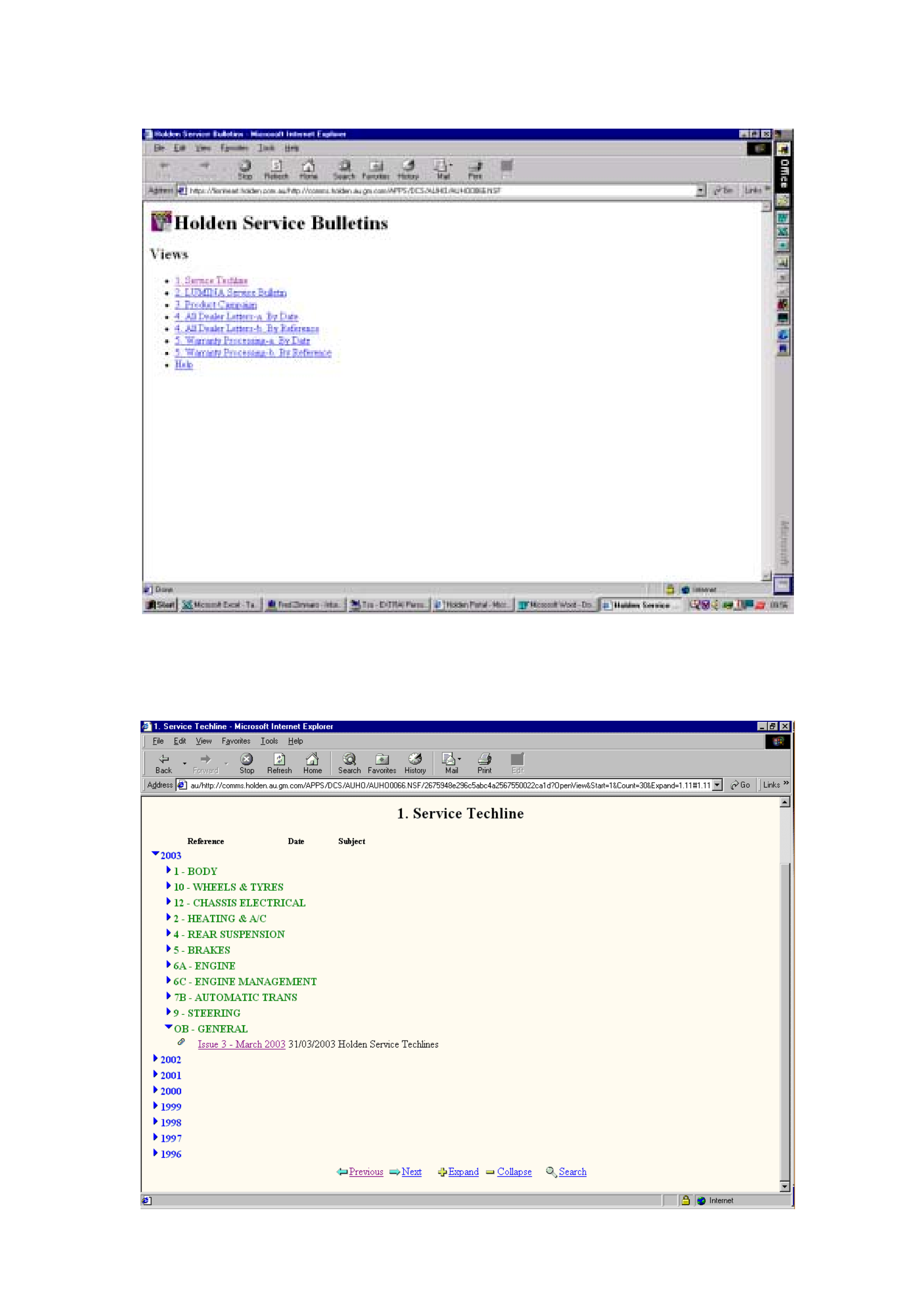

SERVICE PROCEDURE

Head Restraint Removal Procedure

RA Rodeo

(GROUP 1) TL455-0303

Retailers have reported difficulties when removing

the head restraint.

Head restraint adjustment is achieved by simply

moving the head rest up or down as required.

However, to remove the head restraint it must be

disengaged whilst in the highest position.

The locking mechanism that prevents the head

restraint being removed is located at the rear of the

white guide immediately under the seat trim. Refer

Figure. 1.

Figure 1.

Note: The release latch must be pressed directly as

there is a solid block below the latch.

Depress both release latches simultaneously while

moving the headrestraint upwards to remove as

shown in Figure 2.

Figure 2.

Press Release Latch

Front

Rear

HOLDEN SERVICE TECHLINE_________________________________________________________________ APRIL, 2003

INFORMATION

Seat Belts Replaced For Complaint Of

Not Extending

UES Frontera, YG Cruze, RA Rodeo

(GROUP 1) TL253A-0304

This Techline supercedes the previous one in Issue

4, May, 2002. It is revised by adding YG & RA

models.

PROBLEM DESCRIPTION

Numerous seat belts returned through the warranty

system cannot be faulted. The reason for

replacement of these belts is given as "seat belt will

not extend" or "seat belt jamming".

It appears that customers and Retailer staff may be

unaware of the Auto Locking Ratchet (ALR) system.

Refer to following for explanation of ALR.

Automatic Locking Ratchet (ALR) Mechanism.

The rear outer seat belts (all rears on RA Rodeo) and

left hand front seat belt have an Automatic Locking

Ratchet (ALR) mechanism. When this mechanism is

activated it will only allow the belt to retract. When

the mechanism is de-activated the belt can be

extended or retracted as normal.

To activate the ALR mechanism, extend the seat

belt to its maximum length.

To de-activate the ALR mechanism, allow the seat

belt to retract fully.

The ALR function may be useful as an additional

means of locating a child seat, when used in

conjunction with the approved child restraint anchor

points.

Note: It is always better to install a child restraint in

the rear seat.

SERVICE RECOMMENDATION

To avoid mis-diagnosis of seat belts, Holden Retailer

frontline staff should familiarise themselves with the

operation of the ALR system . They will then be able

to explain this feature to any customers who

complain that their seat belts “will not extend” or are

“jamming”.

NOTE: Seat belts replaced unnecessarily for

complaint of “not extending” will not be accepted as

warranty.

SERVICE FIX

LSD Shudder/Chatter Noise

Jackaroo, TF & RA Rodeo, Frontera

(GROUP 4) TL442-0304

PROBLEM DESCRIPTION

There have been some reports to TAS and in PIRs of

rear Limited Slip Differential (LSD) chatter on the

Light Commercial Vehicle (LCV) range.

These vehicles all use similar types of LSD and share

the same factory fill of API GL5 LSD Oil, which

contains additives to reduce the amount of chatter

from the differential arising from normal operation.

NOTE: Normal operation of these LSD's will produce

some noise. They are designed so that the amount

of differential movement between the two axle halves

is limited by the use of pre-loaded multiplate clutches.

This means that until the torque difference limit of the

clutches is reached, any differential movement

between the wheels will be taken up by slippage of

the tyres, resulting in noise. When the torque

difference reaches the limit, the clutches may

experience a stick/slip condition resulting in noise.

This will be particularly noticeable on cornering under

power during takeoff etc.

SERVICE RECTIFICATION

Summary: On complaint vehicles add Friction

Modifier Additive to rear axle.

If an owner complains of differential noises that are

caused by LSD operation and the differential oil is of

the correct specification and has not been

contaminated it is recommended to add LSD friction

modifier additive (P/N 1052358) to reduce the noise.

On vehicles that have done 10,000km or less

since last rear axle oil change- the additive can be

poured directly into the differential housing. It may

first be necessary to ensure enough capacity in the

housing by draining approximately 120ml of oil from

the rear axle.

On vehicles that have done more than 10,000km

since last rear axle oil change - drain the

differential when warm. Then pour in the additive and

fill the differential with the specified lubricant.

Friction Modifier Run-in. The friction modifier

requires a run-in to work the additive into the clutch

plates. This can be done either by normal driving

(may take up to 1000 kms), or alternatively, the

Retailer or customer may perform up to 10 minutes of

figure 8 driving on a hard flat surface.

Update

HOLDEN SERVICE TECHLINE_________________________________________________________________ APRIL, 2003

PARTS INFORMATION

Part No.: Description: Qty:

1052358 Additive-friction

modifier for LSD oil

120 ml.

1

WARRANTY CLAIM INFORMATION

Use the following information if submitting a warranty

claim.

Description Add friction modifier to LSD

Labour Op. No. F000188

Time 0.3 hr

Failure Code 40

INFORMATION

White Marks On Interior Trim

All Models

(GROUP 1) TL468-0304

PROBLEM DESCRIPTION

There have been some dash trims returned to

REPAC that were replaced for exhibiting white stains.

Investigation has found that these stains are in areas

where customer hands are likely to contact the trim.

In all cases the stains were able to be removed using

dish washing liquid diluted with water.

HOLDEN SERVICE TECHLINE_________________________________________________________________ APRIL, 2003

SERVICE PROCEDURE

Quick Connect Fittings

All

(GROUP OB) TL466-0304

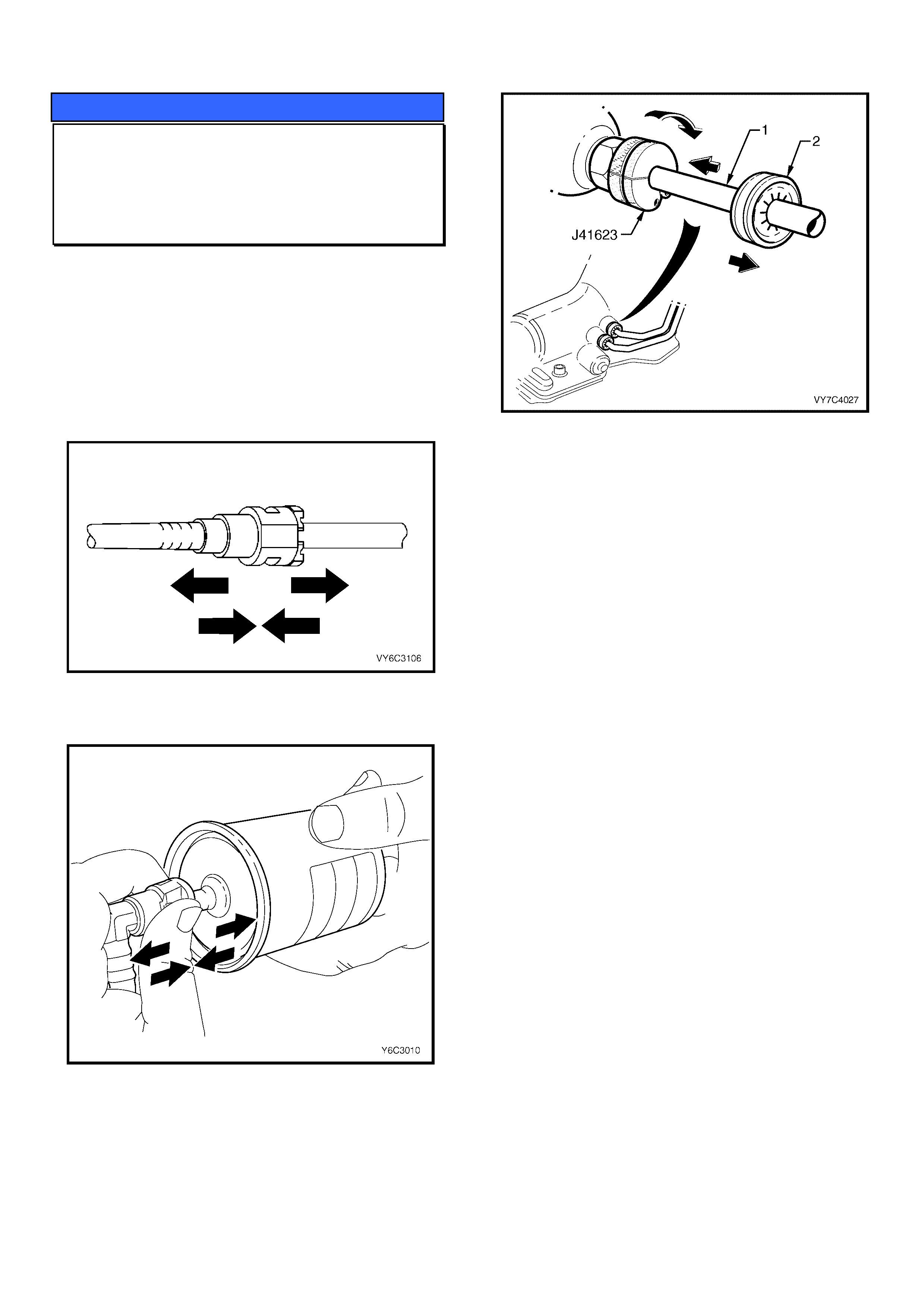

The purpose of this techline is to remind technicians

of the importance of always checking quick connect

fittings after reconnection. This is normally done by

pushing/pulling on both sides of the fitting.

Refer to the following drawings from PV SIP which

shows the checking method for some of the different

types of quick connect fittings.

Figure 1. Fuel line fitting (Plastic collar type)

Figure 2. Fuel filter fitting.

Figure 3. 4L60E Auto Trans Cooler lines.

To check A/T cooler pipe quick connect fittings after

reconnection, attempt to pull the pipe free. A 2nd

check is to slide each verifier disc (#2) up to the

fitting. If it engages with the fitting then the pipe has

been correctly installed. NOTE the verifier disc

should be left in this position.

(NOTE; figure 3 shows the quick connect removal

tool J41623 in position)

HOLDEN SERVICE TECHLINE_________________________________________________________________ APRIL, 2003

SERVICE FIX

TURBO (SHAFT) FAILURE

UBS JACKAROO with 4JX1 DIESEL

ENGINE

(GROUP 6A) TL430-0304

This Service Techline supersedes the previous

Techline on this topic (Issue 7, 2001 page 12). The

previous Techline should be destroyed.

PROBLEM DESCRIPTION

The engine loses power and emits an abnormal

amount of smoke.

PRODUCTION RECTIFICATION

A revised turbocharger assembly has been

developed with an increase in impeller diameter

which allows the turbo to do the same work at a lower

speed.

PRODUCTION BREAK POINT

The revised turbo was introduced with the Euro 3

compliant engine at the B/P below.

ISOVIN: Build Date:

JACUBS73G27106468 09/01/03

SERVICE RECTIFICATION

Fit a new turbo assembly to any vehicle presented to

your dealership that has a failed turbo assembly.

When fitting a new turbo you must:

1. To prevent further bearing failures, confirm that

the injector sleeve replacement has been carried

out on the vehicle if required (refer All Retailer

Letter RL 72/02).

2. Never run the vehicle before priming the

turbo bearings with oil and, never run the

vehicle with the oil supply to the turbo

disconnected.

3. Check the oil supply to and from the turbo before

fitting the new turbo assembly. Disable the

vehicle by disconnecting the cam sensor and

check oil supply at cranking speed. Oil flow tests

are easier to complete with the failed turbo

removed.

The following are approximate values to use as a

guide only. Oil viscosity, temperature, battery

condition, etc, will cause results to vary between

vehicles.

• Oil should flow from the turbo feed pipe

within approx. 7 seconds of cranking;

• Approximately 25ml of oil should flow from

the turbo lubrication feed pipe for every 1

second of cranking (once the oil flow has

commenced);

• Check the oil return from the turbo to the

crank case. When oil is poured into the return

hose it should flow freely into the crank case.

4. Prime the turbo by adding 100ml of oil to the

turbo oil lubrication inlet. Rotate the turbo shaft

slowly by hand, this will ensure the turbo bearings

are lubricated at initial start up.

Detailed fitting instructions for removal and

installation of the turbo unit are in LCV SIP. Once in

SIP follow the path:

! UBS Jackaroo

! Engine – 4JX1

! Section 6A – Engine Mechanical

! Engine Assembly

! Turbocharger

PARTS INFORMATION

Part No.: Description: Qty:

8973125140 Turbo Assembly 1

WARRANTY CLAIM INFORMATION

Use existing warranty information in LCV SIP as

below.

Description Turbo Asm - Replace

Labour Op. No. J586300

Time 2.2 hr

Failure Code 85

HOLDEN SERVICE TECHLINE___________________________________________________________________ MAY, 2003

6

INFORMATION

Air Conditioning Kit Fitment Concerns

RA Rodeo

(GROUP 2) TL492-0305

It has come to Holdens attention that on some

vehicles the air conditioning kits have not been fitted

in accordance with the manufacturers fitting

instructions.

The short cuts which are being taken, together with

poor fitting practices will have a detrimental effect on

A/C performance and ultimately lead to customer

dissatisfaction.

Some of the deficiencies observed on recent

installations are as follows.

1. Condensor lower seal not fitted.

2. Suction line retaining bracket not fited

3. Evaporator drain hose not fitted.

4. Styrene liner not fitted to inside of evaporator

lower case.

5. Thermister wire routed incorrectly.

6. Condensor fan bolts loose. (Removing fan is not

part of fitting procedure)

7. Incorrect refrigerant charge. (Believed to be

caused by use of smaller than required aerosol

charging can)

IMPORTANT: Warranty on the A/C kit may be voided

if failures can be attributed to kits not being fitted in

accordance with the manufacturers instructions.

Please ensure that if you are fitting A/C kits in your

Retailership that you follow the Manufacturers fitting

instructions.

Fitting instructions for RA Rodeo A/C kits were

mailed to all Retailers in March 2003.

If you require additional copies they can be

purchased from HSPO using the following part

numbers.

Part No. Description

61388910 A/C Fitting Instructions for engine

6VE1

61388898 A/C Fitting Instructions for engine

4JH1

61388906 A/C Fitting Instructions for engine

C24SE

Fitting instructions are also available on the latest

Light Commercial & Recreational Vehicle SIP CD.

DIAGNOSIS HINT

Hard To Start or Lack of Engine

Response (Intake Throttle Valve Sticking)

Jackaroo Diesel 4JX1

(GROUP 6C) TL489-0305

This Techline is repeated from Jan 2001 in response

to a query raised at the April 2003 Queensland SMA

Foremans meeting.

PROBLEM DESCRIPTION

Some 4JX1 engines may with time, develop condition

of “Hard to Start” and/or “Lack of Engine Response

Under Acceleration.”

DTC 1486 (Intake throttle position sensor high

voltage) will usually be set. The check engine light

may also be illuminated.

The problem may disappear once the engine has

warmed up to normal operating temperature.

Possible Cause.

The above conditions can be caused by the Intake

Throttle Valve sticking due to an excessive build up

of carbon.

NOTE: It is normal for the 4JX1 engine to experience

some acceleration lag when cold due to oil viscosity.

SERVICE RECTIFICATION

Summary: Confirm complaint. Perform diagnosis as

per SIP. Clean Throttle Valve.

Procedure.

After confirming the complaint condition, conduct a

thorough diagnosis as per procedures found in Light

Commercial SIP CD via following path:

4JX1 Engine / Section 6D3 - 3.0L Engine Driveability

& Emissions / Symptom Diagnosis / Hard Start,

Lacks Power etc.

If this diagnosis fails to rectify the condition, remove

the Throttle Valve Assembly and thoroughly clean

any carbon buildup which may be causing the intake

throttle valve to stick.

IMPORTANT: Do not remove or immerse the Throttle

Valve Sensors into any form of cleaning agent.

HOLDEN SERVICE TECHLINE___________________________________________________________________ MAY, 2003

7

INFORMATION

Oil Level Checking At PD

TF and RA Rodeo With 4JH1-TC Diesel

Engines

(GROUP 6A) TL498-0305

PROBLEM DESCRIPTION

Engine oil level is reported as low when checked

during the PD inspection.

OIL LEVEL CHECKING PROCEDURE

When checking the engine oil level it is crucial that

the engine oil is at running temperature (hot to

touch). The vehicle must be on level ground and the

engine oil allowed to settle for a few minutes.

The diagrams below give an indication of how the oil

level will settle after being left for a specified length of

time when the oil is hot and cold.

Note: Oil level was full at the start of each test

Cold Oil Checking – Not Recommended

Vehicle driven for 5 minutes from cold then engine oil

left to settle.

NOTE: The oil level did not completely recover to

the full mark, even after 24hrs.

Hot Oil Checking - RECOMMENDED

Engine run until the oil is at operating temperature then

allowed to settle.

INFORMATION

Remote Central Door Locking Operating

Logic

RA Rodeo

(GROUP12) TL493-0305

The operating logic of the central door locking system

in RA Rodeo is different to other Holden vehicles as

is evident in the following explanation.

If the central locking is activated from inside the

vehicle using the switch on the dash or on the driver's

door (where fitted) to lock all the doors and a door is

then unlocked using the snib on the door, the remote

key will not lock the vehicle until the Remote unlock

button is first pressed to unlock all doors.

The Remote lock button will then activate the central

locking.

The RA Rodeo Owners Handbook will be revised at

the next reprint in line with the above.

Note: Other Holden vehicles will activate the central

locking regardless of the snib position on each

individual door.

Oil level before

Oil settled for 10 min

Oil settled for 3 min

Oil settled for 5 min

Oil level before startin

g

Oil Level Before startin

g

Start

Oil settled for 1 hour

Oil settled for 3 min

Oil settled for 5 min

HOLDEN SERVICE TECHLINE___________________________________________________________________ MAY, 2003

8

INFORMATION

Electronic Odometer Programming

UBS / UES / RA

(GROUP 12) TL481-0305

PROBLEM DESCRIPTION

When a replacement instrument cluster is installed

into a UBS Jackaroo MY98 onwards, a UES Frontera

MY01 onwards or RA Rodeo, it is necessary to

program the odometer to the value of the one

removed.

SERVICE RECTIFICATION

If your Service Department does not know of any

instrument repairers who are capable of performing

this operation below are some contacts of instrument

repairers presently being used by other Retailers.

Victoria

Automotive Instrument Repairs

59 C Glenvale Crescent,

Mulgrave, Victoria 3170

Phone (03) 9561 2366

Fax (03) 9562 2513

NSW

Macarthur Instruments

Unit 2/16 Cawdor Road

Camden, NSW 2570

Phone (02) 4655 3335

Mobile (0416) 241 903

Web site www.macarthurinstruments.com.au

QLD

Future Auto Instruments

P.O. Box 959

Paradise Point QLD 4216

Phone (07) 5529 5325

Fax (07) 5529 5065

Mobile (0414) 518 766

New Zealand

Robinson Instruments

19 Fale Street

Freeman's Bay

Auckland

Phone (09) 3771565

Fax (09) 3580573

Update

HOLDEN SERVICE TECHLINE________________________________________________________________ JUNE, 2003

6

SERVICE FIX

Manual Transmission 2nd Gear

Synchromesh Repairs

YG Cruze

(GROUP 7A) TL505-0306

PROBLEM DESCRIPTION

Transmissions are being replaced under warranty for

synchromesh failure on second gear.

Investigations have traced the cause of these

failures to be the gear shift interlock plate 92124142

incorrectly installed (upside down) in production. This

results in abnormal wear of 2nd synchroniser ring

during reverse drive. (The 2nd synchroniser ring is

also used for synchronising reverse shift).

PRODUCTION RECTIFICATION

Transmissions with the interlock plate installed the

correct way up have been fitted to vehicles from:

ISOVIN: Build Date:

JSAGHY81S00112283 12/02/2003

SERVICE RECTIFICATION

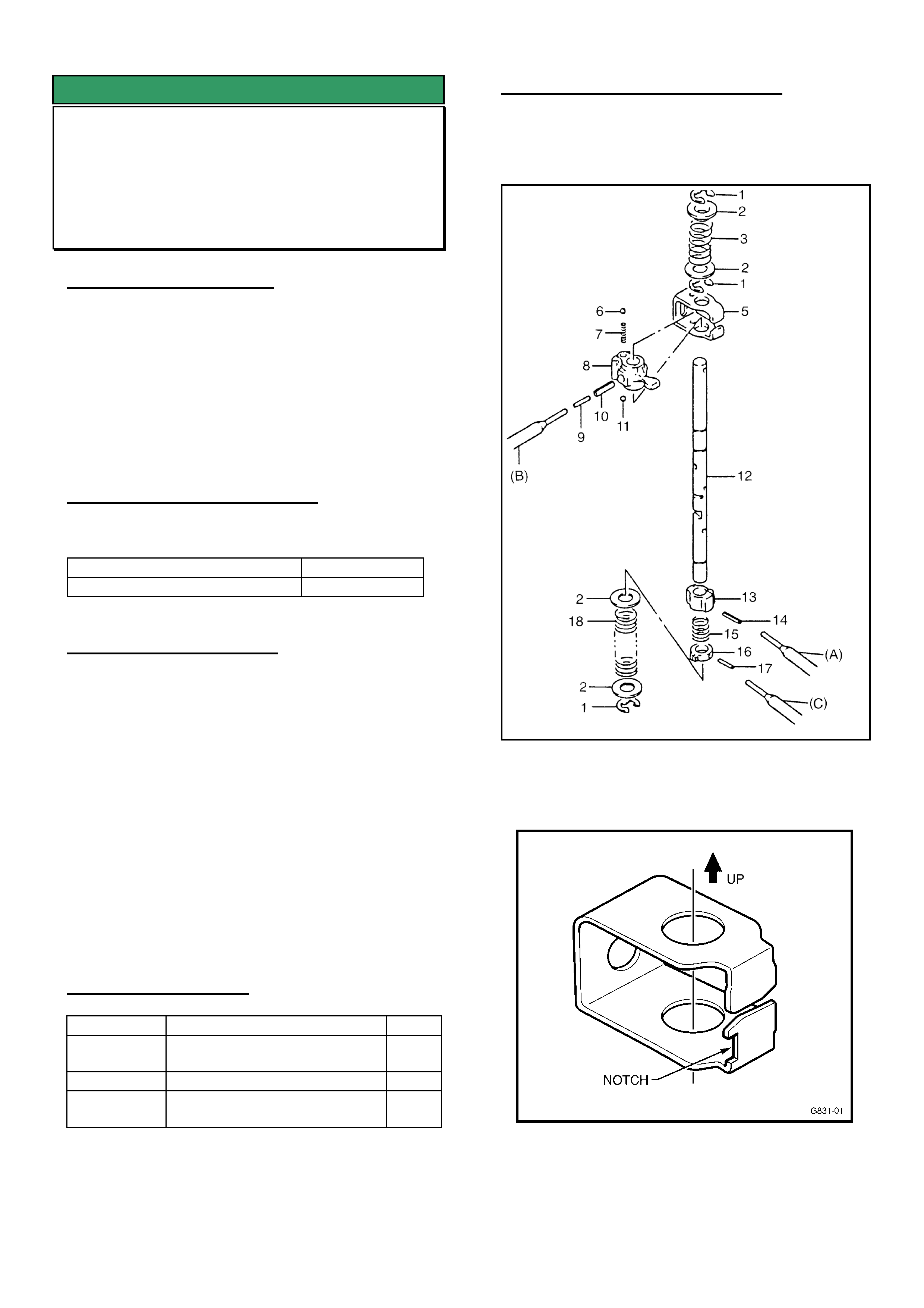

Retailers are requested to repair transmissions for

this problem rather than replace them.

Repair procedure.

Refer to the procedure in LCRV SIP CD to replace

the following parts.

! Hub Asm. low speed synchroniser

! Gear Counter shaft 2nd

! Ring synchroniser, 2nd/3rd counter gear

IMPORTANT. During the repair, the gear shift

interlock plate must be installed the right way up as

shown in Figure 2.

PARTS INFORMATION

Part No.: Description: Qty

92124061 Hub Asm. low speed

synchroniser

1

92124055 Gear Counter shaft 2nd 1

92124065 Ring synchroniser, 2nd/3rd

counter gear

1

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty

Information section of current PV SIP CD

Figure 1. Drawing from LCRV SIP showing location

of interlock plate (5) in gearshift assembly.

Figure 2. Shows Correct Orientation Of Gearshift

Interlock Plate.

HOLDEN SERVICE TECHLINE________________________________________________________________ JUNE, 2003

7

SERVICE FIX

Front Hub Noises When Turning

YG Cruze

(GROUP 3) TL511-0306

PROBLEM DESCRIPTION

A clicking/knocking type noise from the front wheels

when turning.

Investigations have shown the major cause for

noises in this area is wheel bearings which are

outside manufacturing tolerances.

Retailers who have been replacing driveshafts for this

condition are now requested to cease this practice

and replace wheel bearings as described below.

PRODUCTION RECTIFICATION

Revised front wheel bearings have been fitted to

vehicles from:

ISOVIN: Build Date:

JSAGHY81S00111647 23/01/2003

SERVICE RECTIFICATION

On vehicles with above complaint condition, fit new

wheel bearing as listed in Parts Information to both

sides.

DO NOT replace driveshafts for this condition unless

the noise is still evident after fitting new wheel

bearings.

PARTS INFORMATION

Part No.: Description: Qty:

92125536 Bearing front wheel 2

Attention Parts Managers:

Any of the previous bearings p/n 92124547 should be

returned to HSPO for credit via the CRRM system.

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty

Information section of current PV SIP CD

INFORMATION

4WD Selection & Diagnosis

RA 4WD

(GROUP 4) TL499-0306

4WD Selection

Concerns have been raised regarding 4WD shifting

to 4L from 2H.

During this shift, the transfer case ratio is changed,

followed by the front drive being engaged. The front

drive splines must align for front drive engagement to

occur. If spline misalignment occurs, the shift will not

occur and the “4L” indicator lamp in the instrument

cluster will flash more rapidly, indicating an

incomplete shift.

Understanding this will explain the concerns some

customers may have with “4L” engagement from

“2H”.

If the front drive splines do not align exactly and the

warning lamp flashes more rapidly - move the vehicle

slightly to align the front drive splines exactly.

IE.: in A/T vehicles, Select R or D with light brake

application to move the vehicle, then N;

in M/T vehicles select 2nd, move the vehicle slightly,

then select N.

The members will then engage, the “4L” indicator

lamp will stop flashing, and 4L drive is fully engaged.

Note: Use of the handbrake does not affect the

selection of 4L.

Diagnosis

The following five pages of revised “RA Rodeo –

T150 Transfer Case” diagnosis will be provided in the

next LCV SIP CD issue 4.3.

Copy and use of these pages is recommended until

the LCV SIP CD 4.3 becomes available.

For any 4WD shift concerns refer to these pages for

explanations and diagnosis – which will also be

reproduced in future RA Owner Handbooks.

HOLDEN SERVICE TECHLINE________________________________________________________________ JUNE, 2003

8

RA RODEO – T150 TRANSFER CASE

DIAGNOSIS

Neither the Transfer Case Control System or Shift On The Fly (SOF) System can be accessed with the TECH 2 scan

tool. Incorrect diagnosis can be both time-consuming and expensive. Refer to LCRV SIP – MY2003 RA Rodeo –

Section 7 – Transfer Case Control System for correct the diagnostic procedures and symptom charts.

ROAD TESTING

Before attempting diagnosis, the vehicle should be road-tested to determine if a mechanical/electrical fault actually

exists. Many reports of incorrect transfer case or S.O.F. system operation can be attributed to the driving conditions

at the time of “failure”.

Noting the operation of the 4WD, 4 Low, Neutral indicator lamps and the CHECK 4WD warning lamp will provide

valuable information when testing the performance of the four wheel drive system. Observe the operating sequence

of the indicator/warning lamps when operating the transfer case controls, then use the information below to

determine whether or not further diagnosis is required.

SHIFTING FROM 2H TO 4H

1. 4WD Indicator Lamp: Flash rate increases from 2Hz to 4Hz.

Probable Cause: High vehicle speed or extremely low operating temperatures.

Corrective Action: Reduce speed or stop the vehicle and perform the required shift.

At high road speed the relative speed difference between the internal components of the transfer case is too high

for the shift to occur. The TCCM will make four attempts to shift from 2H to 4H. If the shift is not achieved on the

fourth attempt, the 4WD indicator lamp frequency will increase to 4Hz for 10 seconds and then go out. The

transfer case will then remain in 2H.

Similarly, extremely low operating temperature (high transfer case oil viscosity) will give rise to excessive

component speed difference.

2. 4WD Indicator Lamp: Flash rate of 2Hz continues for more than 11.5 seconds.

Probable Cause: Speed or phase difference between LH front wheel and front axle.

Corrective Action: If moving, accelerate and decelerate the vehicle in a straight line.

If stationary, move the vehicle backwards and forwards a few metres.

If there is difference of speed and/or phase between the LH front wheel and axle, the S.O.F. system cannot

operate correctly.

Until the both the transfer case and S.O.F. actions are completed, the 4WD Indicator Lamp flashes at a frequency

of 2Hz. The indicator continues flashing at a frequency of 2Hz until the S.O.F. internal switch indicates front axle

engagement.

By correcting the difference in relative speeds or axle phase, the S.O.F. action can be completed.

SHIFTING FROM 4H TO 2H

1. 4WD Indicator Lamp: Flash rate of 2Hz continues for more than 11.5 seconds.

Probable Cause: High torque loading on drivetrain components – possible ‘wind-up’ condition.

Corrective Action: If moving, accelerate and decelerate the vehicle in a straight line.

If stationary, move the vehicle backwards and forwards a few metres.

High torque loading of the drivetrain will usually occur if the vehicle is driven in 4WD on hard ground, particularly if

performing turning manoeuvres. The high torque load will prevent the ‘separation’ of the front axle and transfer

case components and the vehicle will remain in 4WD.

Moving the vehicle with the road wheels in the straight ahead position will usually reduce the torque loading

sufficiently to allow the shift from 4H to 2H to complete.

NOTE: In cases of extreme drivetrain ‘wind-up’, it will be necessary to lift the front wheels of the vehicle from the

ground to remove the torque loading. This operation should be performed with extreme caution due to the rapid

wheel movement that occurs when the torque load is released.

HOLDEN SERVICE TECHLINE________________________________________________________________ JUNE, 2003

9

SHIFTING FROM 4H TO 4L

1. 4L Indicator Lamp: Flash rate of 2Hz continues for more than 11.5 seconds.

Probable Cause: Spline phase difference between transfer case components.

Corrective Action: A/T – Select [D] range and then [N] range.

M/T – Select 2nd gear and partially engage the clutch, depress the clutch and

select neutral.

Failure to shift due to spline phase difference may occur if the drivetrain is under load. Selecting [D] or [N] (A/T) or

selecting 2nd gear with a gentle application of the clutch (M/T) will generally allow sufficient component movement

for the transfer case shift to complete.

2. 4L Indicator Lamp: Flash rate of 2Hz for 10 seconds, then remains ‘ON’ continuously (A/T only)

Probable Cause: High torque loading on drivetrain components.

Corrective Action: Apply the footbrake and then Select [N] range.

The transfer case H-L Shift Assembly stand-by mechanism cannot overcome the load applied to the H-L shift

components. This condition will usually occur when a high torque loading has been generated between the

drivetrain and the road surface.

Applying the footbrake and then selecting [N] range will allow the components to dissipate the torque loading.

3. 4L Indicator Lamp:` Flash rate of 4Hz

Probable Cause: High engine speed.

Transmission not in [N] or [P] – (A/T)

Transmission not in Neutral – (M/T)

Corrective Action: Reduce engine speed to below 2000rpm.

Select correct transmission range.

Push the 4L Transfer Shift switch.

The TCCM will not allow the transfer case to shift from 4H to 4L or from 4L to 4H if the engine speed is above

2000rpm, the transmission is not in neutral (M/T & A/T) or ‘Park ‘ (A/T). Any of these conditions will cause the

TCCM to enter “Restricted Operation” mode.

NOTE:

‘Restricted Operation’ Mode

The 4H, neutral and 4L shifting mechanism has no synchronisation components. Consequently, attempting to shift

with a high relative component speed difference may lead to component failure. To avoid this incidence, the TCCM

will restrict transfer case and S.O.F. operation if any or all of the following conditions are detected:

• Vehicle is moving.

• Engine Speed above 2000rpm.

• Transmission not in neutral (M/T & A/T) or ‘Park ‘ (A/T).

The programming of the TCCM logic circuit includes a Wait-Time function. When certain conditions are detected

via the input signals to the TCCM, a delay (wait time) will be encountered before the transfer case or S.O.F. system

will operate in response to a driver command.

• A/T: If the vehicle has been idling in any drive range for up to three minutes, the wait-time will be between one

and five seconds.

• M/T: If the vehicle has been idling, with the transmission in any gear and the clutch disengaged, for up to three

minutes, the wait-time will be between one and five seconds.

Should either of the above conditions be continued for longer than three minutes, the wait-time will increase to a

maximum of three minutes.

Wait-time can be reduced to zero by turning the ignition OFF, then ON or driving the vehicle for 5 metres.

HOLDEN SERVICE TECHLINE________________________________________________________________ JUNE, 2003

10

SHIFTING FROM 4L TO 4H

1. 4L Indicator Lamp: Flash rate of 2Hz continues for more than 11.5 seconds.

Probable Cause: Spline phase difference between transfer case components.

Corrective Action: A/T – Select [D] range and then [N] range.

M/T – Select 2nd gear and partially engage the clutch, depress the clutch and

select neutral.

Failure to shift due to spline phase difference may occur if the drivetrain is under load. Selecting [D] or [N] (A/T) or

selecting 2nd gear with a gentle application of the clutch (M/T) will generally allow sufficient component movement

for the transfer case shift to complete.

2. 4L Indicator Lamp: Flash rate of 2Hz for 10 seconds, then remains ‘ON’ continuously (A/T only)

Probable Cause: High torque loading on drivetrain components.

Corrective Action: Apply the footbrake and then Select [N] range.

The transfer case H-L Shift Assembly stand-by mechanism cannot overcome the load applied to the H-L shift

components. This condition will usually occur when a high torque loading has been generated between the

drivetrain and the road surface.

Applying the footbrake and then selecting [N] range will allow the components to dissipate the torque loading.

3. 4L Indicator Lamp: Flash rate of 4Hz

Probable Cause: High engine speed.

Transmission not in [N] or [P] – (A/T)

Transmission not in Neutral – (M/T)

Corrective Action: Reduce engine speed to below 2000rpm.

Select correct transmission range.

Push the 4H Transfer Shift switch.

The TCCM will not allow the transfer case to shift from 4H to 4L or from 4L to 4H if the engine speed is above

2000rpm, the transmission is not in neutral (M/T & A/T) or ‘Park ‘ (A/T). Any of these conditions will cause the

TCCM to enter “Restricted Operation” mode.

SHIFTING FROM 4L OR 4H TO NEUTRAL

1. Neutral Indicator Lamp: Flash rate of 2Hz continues for more than 11.5 seconds.

Probable Cause: Spline phase difference between transfer case components.

Corrective Action: A/T – Select [D] range and then [N] range.

M/T – Select 2nd gear and partially engage the clutch, depress the

clutch and select neutral.

Failure to shift due to spline phase difference may occur if the drivetrain is under load. Selecting [D] or [N] (A/T) or

selecting 2nd gear with a gentle application of the clutch (M/T) will generally allow sufficient component movement

for the transfer case shift to complete.

2. Neutral Indicator Lamp: Flash rate of 4Hz

Probable Cause: High engine speed.

Transmission not in [N] or [P] – (A/T)

Transmission not in Neutral – (M/T)

Corrective Action: Reduce engine speed to below 2000rpm.

Select correct transmission range.

Push and hold the 2H and 4L Transfer Shift switches for 10 seconds.

The TCCM will not allow the transfer case to shift from 2H, 4H or 4L Neutral if the engine speed is above

2000rpm, the transmission is not in neutral (M/T & A/T) or ‘Park ‘ (A/T). Any of these conditions will cause the

TCCM to enter “Restricted Operation” mode.

HOLDEN SERVICE TECHLINE________________________________________________________________ JUNE, 2003

11

SHIFTING FROM NEUTRAL TO 2H, 4H OR 4L

1. 4L or 4WD Indicator Lamp: Flash rate of 2Hz continues for more than 11.5 seconds.

Probable Cause: Spline phase difference between transfer case components.

Corrective Action: A/T – Select [D] range and then [N] range.

M/T – Select 2nd gear and partially engage the clutch, depress the

clutch and select neutral.

Failure to shift due to spline phase difference may occur if the drivetrain is under load. Selecting [D] or [N] (A/T) or

selecting 2nd gear with a gentle application of the clutch (M/T) will generally allow sufficient component movement

for the transfer case shift to complete.

4WD INDICATOR LAMP FLASHES WHEN IGNITION IS TURNED ON

1. 4WD Indicator Lamp: Flash rate of 2Hz.

Probable Cause: Ignition turned OFF with 4H or 4L selected.

Corrective Action: A/T – Select [D] range and then [N] range.

M/T – Select 2nd gear and partially engage the clutch, depress the

clutch and select neutral.

When the ignition is first turned ON, the TCCM initialises and commands the Shift Actuator motor to the 2WD

position. At the completion of initialisation, the TCCM will the command the Shift Actuator motor to the last

selected position. Failure to shift to that position may be due to spline phase difference if the drivetrain is under

load. Selecting [D] or [N] (A/T) or selecting 2nd gear with a gentle application of the clutch (M/T) will generally allow

sufficient component movement for the transfer case shift to complete.

‘CHECK 4WD’ INDICATOR LAMP ON WHEN IGNITION IS ON

1. ‘CHECK 4WD’ Indicator Lamp: ON when ignition is turned ON

Probable Cause: Failure of Shift Actuator motor or harness

Corrective Action: Conduct the test procedure outlined below, replace failed

components.

1. The initial test is best performed at the TCCM. Refer to the TCCM Pin Out illustration and the chart below for

the test conditions and harness pin location.

2. Should the test fail at Step 1, remove the harness connector with the transfer case in each drive range, and

conduct the test on the respective Limit Switch pin.

3. If the test fails at step 1, but passes at step 2, then a harness/connector fault is the most probable cause of

the CHECK 4WD lamp illuminating.

NOTE:

• The ignition switch must be in the OFF position whenever removing or replacing the TCCM or Limit Switch

harness connectors.

• Under no circumstances should the Transfer Case Actuator harness connector be back-probed. This will

damage the weather-pak seal, leading to possible failure of the system due to contamination of the harness

connector and actuator pins.

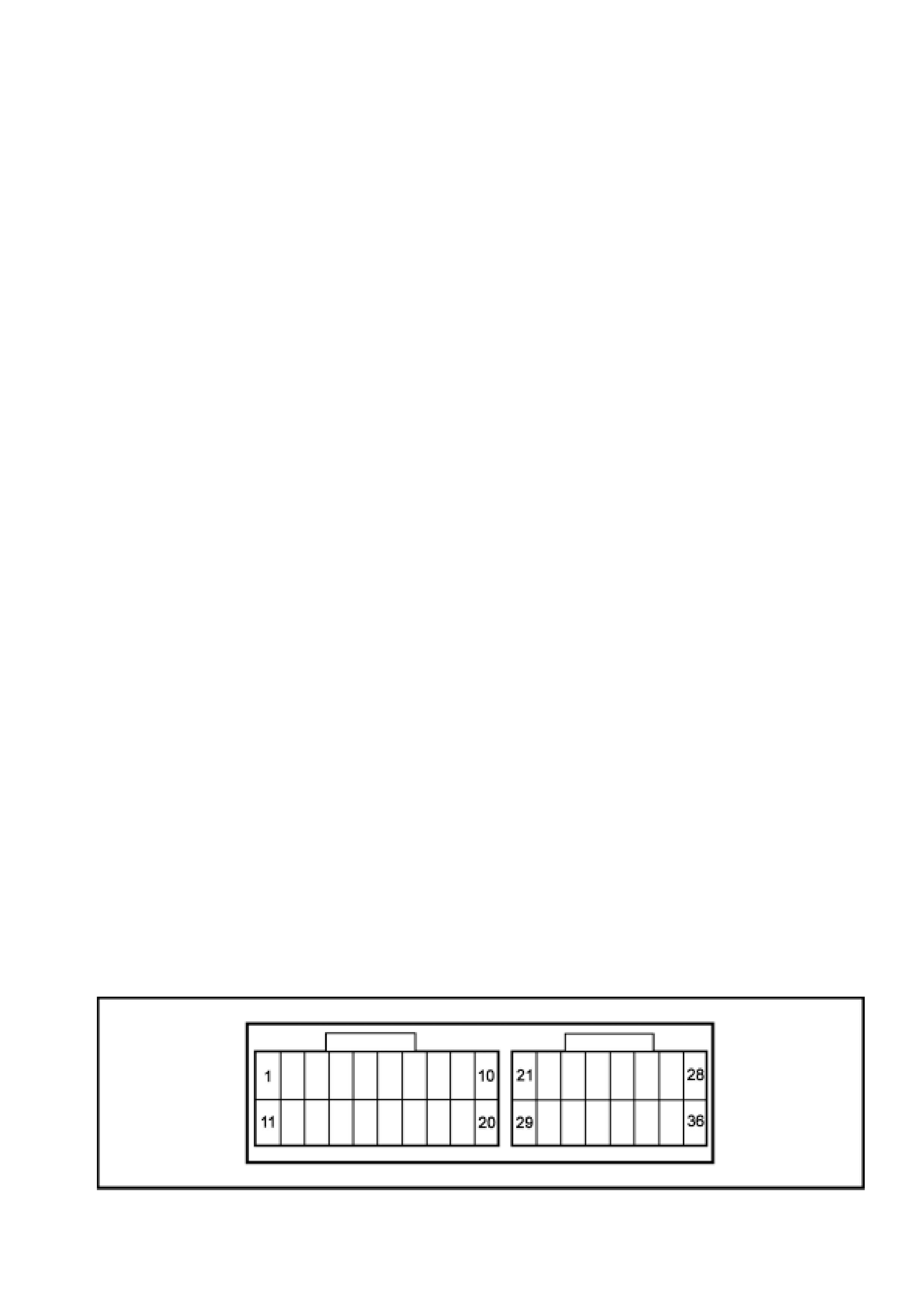

TCCM Pin Assignment

HOLDEN SERVICE TECHLINE________________________________________________________________ JUNE, 2003

12

TCCM Pin Shift Actuator Pin 2H 4H N 4L

14 LS1 Closed Open Open Closed

5 LS2 Open Open Closed Closed

16 LS3 Closed Closed Open Open

17 LS4 Open Closed Open Closed

NOTE:

“Closed” indicates continuity between the respective pin and GND pin. (Continuity should also exist between the

“Closed” pins.)

TCCM MEMORY ERASE PROCEDURE

1. Bare both ends of two pieces (about 200mm long) of wire,

2. Ensure the ignition is OFF.

3. Remove the driver seat assembly.

4. Locate the TCCM by opening the cut-out in the floor mat.

5. Keeping the TCCM connected, bridge the terminals from the back of the connector as illustrated.

6. Turn ON the ignition, wait for 2 seconds, and turn OFF the ignition after confirming the relay sound.

7. Remove the two pieces of wire, turn ON the ignition again, and confirm the “Check 4WD” lamp in the meter

panel is OFF.

TCCM Memory Clear Pin Assignment

HOLDEN SERVICE TECHLINE___________________________________________________________JULY, 2003

2

DIAGNOSIS HINT

4WD Transfer Controller Memory Erasing

(Resetting) Procedure

RA Rodeo with 4WD

(GROUP 4) TL534-0307

PROBLEM DESCRIPTION

Some Transfer Controller Modules returned to

Holden REPAC have defective material tags with the

following description:

"Check 4WD warning lamp illuminated. Carried out

SIP reset procedure. Unable to reset".

All of these modules have subsequently been reset

using the procedure as detailed in Light Commercial

SIP CD version 4.3 although there was some

difficulty encountered in performing the procedure. It

was found to be difficult to make good contact to pins

29 and 30 on the module which are accessed

through cavity numbers 15 and 16 on the connector.

(The number 15 and 16 pin positions in the connector

do not contain any wiring)

SERVICE RECOMMENDATION

Whenever resetting the Transfer Controller Module

as per SIP procedure, carefully move the wire

probes that are placed in pin positions 15 and 16 to

ensure good electrical contact is made.

In addition, the SIP procedure advises to listen for a

"relay sound". There are in fact two relay sounds; the

first when the ignition is turned on, the second when

the electrical contact necessary for the reset

procedure is made.

HOLDEN SERVICE TECHLINE___________________________________________________________JULY, 2003

3

DIAGNOSIS HINT

Poor A/C Performance In Ambients Above 30 ºC

TF Rodeo Model Year 2002 Petrol and Diesel

(GROUP 2) TL533-0307

The information in this Techline is provided by Air International, supplier of the A/C kits for the above model.

PROBLEM DESCRIPTION

Information received from Holden Retailers has shown that some 2002 Holden Rodeo’s fitted with A/C kit

part numbers 92145593, 92145594 and 92145595 could suffer from “poor A/C performance” in Ambient

temperatures above 30 Degrees.

SERVICE RECTIFICATION

Outlined below is a list of recommended adjustments / procedures / inspections that should help to improve

the A/C system performance on a complaint vehicle:

1. Ensure that the Heater blend door cable is correctly adjusted so that the door is fully closed in the “Max

Cold” position. The following test can be carried out to verify if the Heater blend door is still slightly

opened in the Max Cold position.

! Remove the Glovebox (2 screws)

! Insert the probe of an Electronic Thermometer (approx 100mm) through the hole in the Evaporator

case used for the Thermistor wire.

! Operate the A/C system on Blower Fan speed 2, Recirculation mode, windows closed, Face vent

mode and Max Cold for approx 5 Minutes. Take a reading from your Thermometer, this is the actual

“air off temperature” from the Evaporator coil.

! Remove the Thermometer probe from the Evaporator case and now insert your Thermometer probe

into the Face vent, and take a reading.

! The difference between the “air off” temperature and the Face vent temperature should be no more

than 3 – 5 Degrees C.

! If the Difference is higher the Heater air mix door is still opened – ADJUST and recheck.

2. Check the A/C Drive belt Tension to ensure that no “slippage’ is occurring, the average tension

specification is 50 KG, measured at the longest section of the belt between pulleys. Adjust as required.

3. Remove the Glovebox (2 x screws) Check and Adjust if necessary the Fresh / Recirculation door

activating cable.

4. Recover the A/C system Refrigerant. Remove the Evaporator assembly (3 nuts). Dismantle the

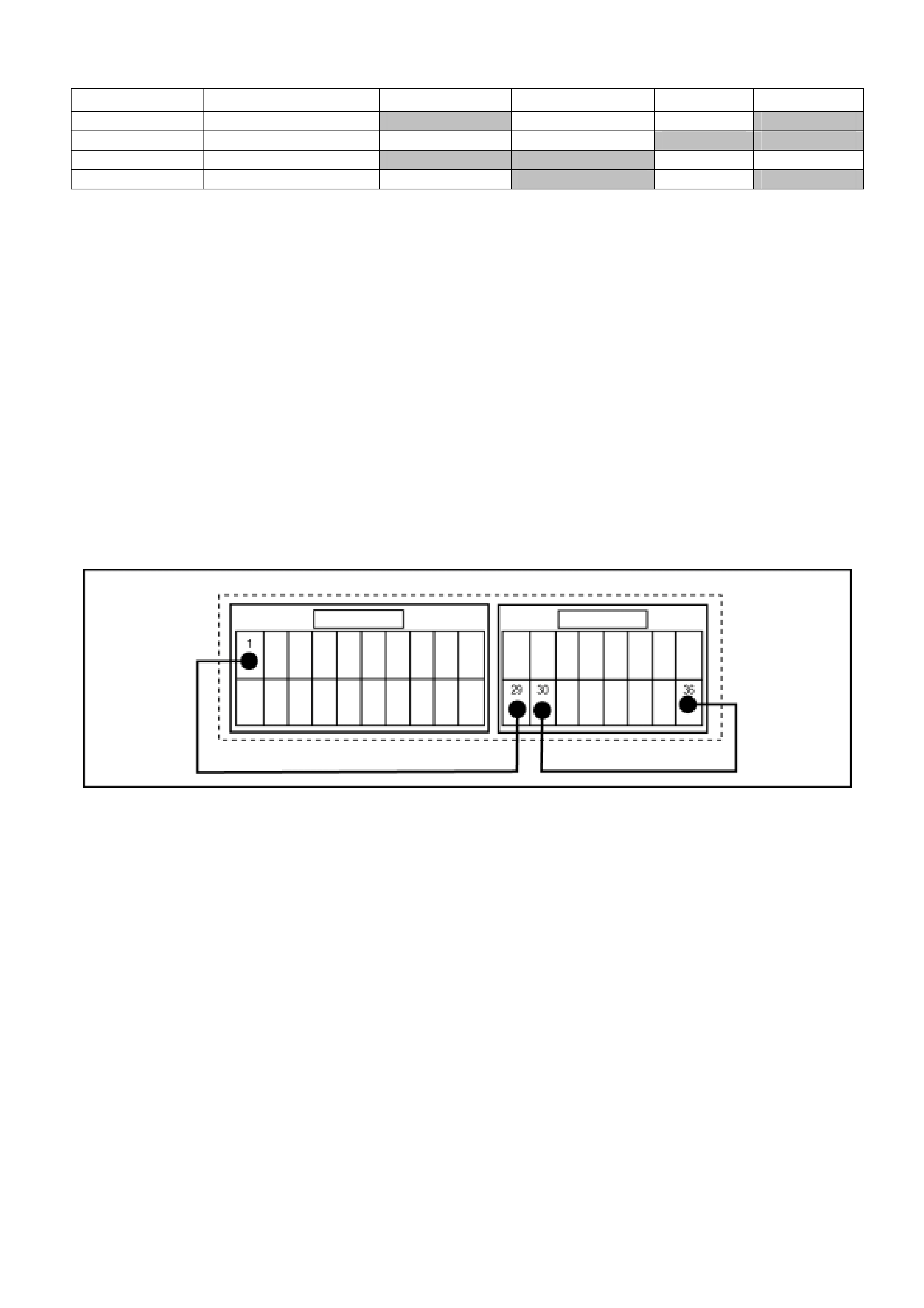

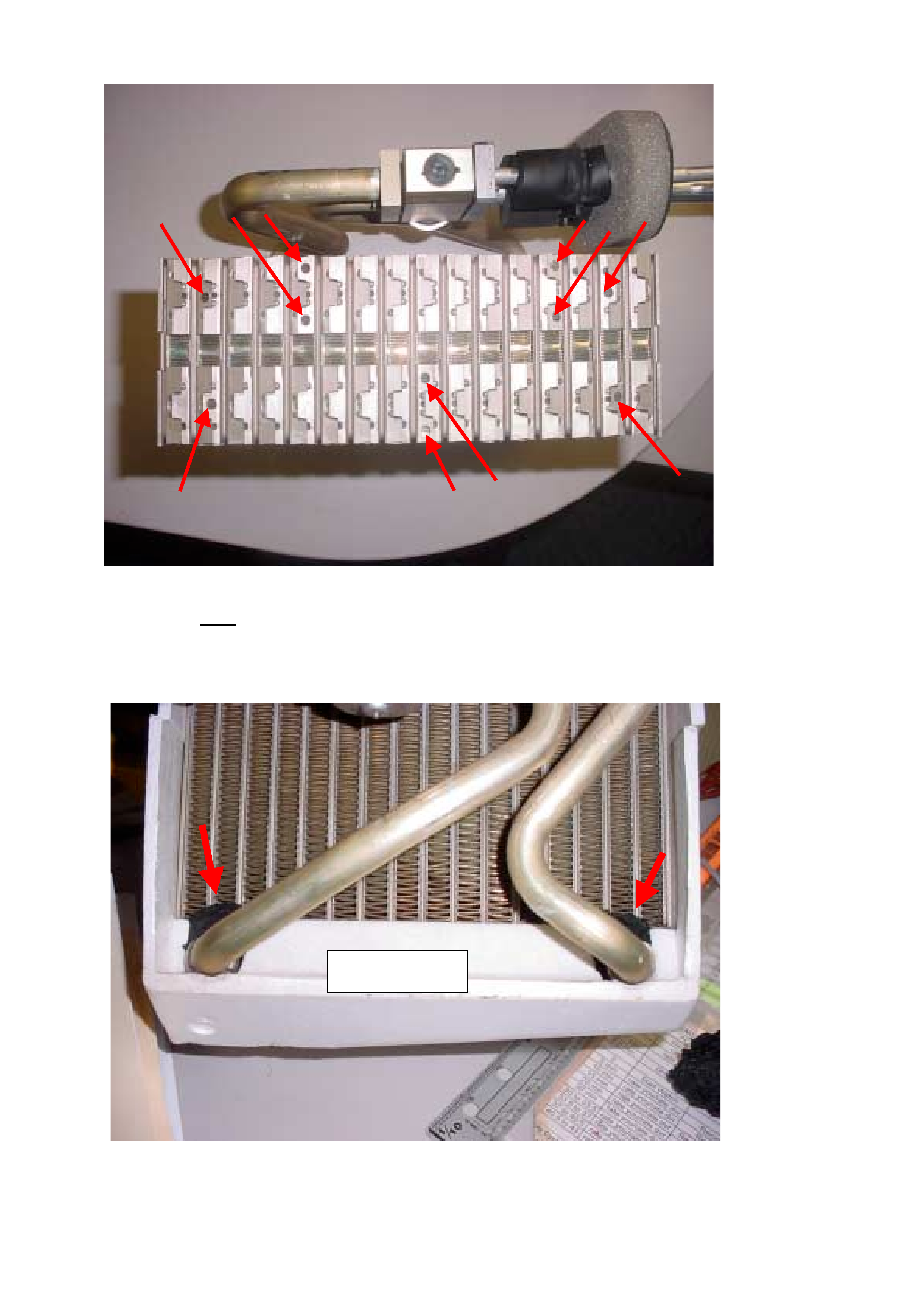

Evaporator assembly. Carefully remove the Evaporator coil. Referring to Figure A, inspect the

underside of the Evaporator coil to see if the “holes” (paths) outlined on the diagram are in the same

position as the removed Evaporator coil. If your Evaporator has the “holes” in the same location as

Figure A the Evaporator coil is OKAY. Proceed to Step 5. If NOT, replace the Evaporator coil as the

Refrigerant flow paths are incorrect and will affect A/C performance. Refer to Dec 2002 Techline on

“Poor Performance” for details of replacement evaporator.

5. From the Inlet air-side of the Evaporator coil, add “black A/C lagging tape” around the fin area where

the inlet / outlet tubes join the Evaporator tank. See Figure B for the area to be sealed. The reason for

doing this task is to eliminate any possibility of warm / hot inlet air bypassing the Evaporator coil and

mixing with the refrigerated cold air which will then effect the Face vent temperature.

6. If all of the above has been checked and adjusted finally replace the TX valve with part number VS

20558.

7. If all of the above fails to improve the A/C performance to a satisfactory level, contact Air International

Service Department on 1800 673 716.

HOLDEN SERVICE TECHLINE___________________________________________________________JULY, 2003

4

Figure A. Underside Of Evaporator Coil.

Note: Block valve and TX valve Evaporators (Tripac -Gold coloured) must have

the same “hole” positions as shown by arrows.

Figure B. Add black bitumen tape to plug gaps where shown. Apply tape with evaporator coil

in place. DO NOT dismantle.

AIR “ON” SIDE

HOLDEN SERVICE TECHLINE___________________________________________________________JULY, 2003

5

INFORMATION

5000km Service Coupon Error

RA Rodeo

(GROUP OB) TL532-

0307

PROBLEM DESCRIPTION

The first RA Rodeos delivered had yellow

coloured owners handbooks The 5000km

Service Coupons in these books incorrectly

stated that the Manual Transmission and Front

and Rear Differential oil should be changed.

This was corrected in the next reprint of the

owners handbook which was green in colour.

NOTE 1. The first standard oil change for the

M/T and Differentials is at 40,000km or 2 years.

NOTE 2. Owner Handbooks should not be

replaced for this concern.

OWNER HANDBOOK INFORMATION

Part No.: Description: Qty:

92157473 RA Owners Handbook –

yellow printed Nov 2002

1

92162965 RA Owners Handbook –

green printed Feb 2003

1

SERVICE PROCEDURE

Clock Spring Coil Damaged When

Replacing Power Steering Rack

YG Cruze

(GROUP 9) TL526-0307

PROBLEM DESCRIPTION

Investigation of broken clock spring coils

returned to REPAC shows that in every case,

the clockspring damage occurred at the same

time as the steering rack was replaced.

This highlights that technicians are removing the

Rack and Pinion Assembly without observing the

CAUTION notice in the LCV SIP CD Service

Instructions.

The caution notice reads as follows.

CAUTION: Be sure to set front wheels in

straight direction and remove ignition key

from ignition before these steps, otherwise

contact coil of airbag system may be

damaged.

The above caution notice in Light Commercial

SIP CD is found as follows.

Refer Section 3B Manual Rack and Pinion / 3.3

Manual Rack & Pinion Assembly (Steering Gear

Case) - Removal

HOLDEN SERVICE TECHLINE______________________________________________________________NOVEMBER, 2003

6

SERVICE FIX

Intermittent No Crank or No Start

RA

(GROUP 12) TL0541-0311

PROBLEM DESCRIPTION

Customers may advise that intermittently their vehicle

will not crank or will crank and not start.

This problem has been isolated to an intolerance

within the immobiliser control unit software, which can

be highlighted by electrical noise generated from the

accessory socket relay and any accessories powered

from the accessory socket circuit.

PRODUCTION RECTIFICATION

There will be two stages of rectification for this

problem. The first is a revised accessory socket relay

which will be fitted to every vehicle at Port of Entry

starting in early December 2003.

The second will be a revision of the immobiliser

software, which is scheduled for introduction into

production in February 2004.

SERVICE RECTIFICATION

The revised accessory socket relay is now available

from HSPO and should be fitted to any vehicle when

the customer advises of this problem.

Fit the revised relay as per the following steps,

Step 1. Due to the increase in length of the revised

accessory socket relay, fitment may

necessitate the removal of the Instrument

Panel Drivers Side Lower Cover Assembly.

For this procedure refer to:-

LCRV / Service Information / RA Rodeo / Body

/ Section 2C – Cab & Interior Trim / Instrument

Panel.

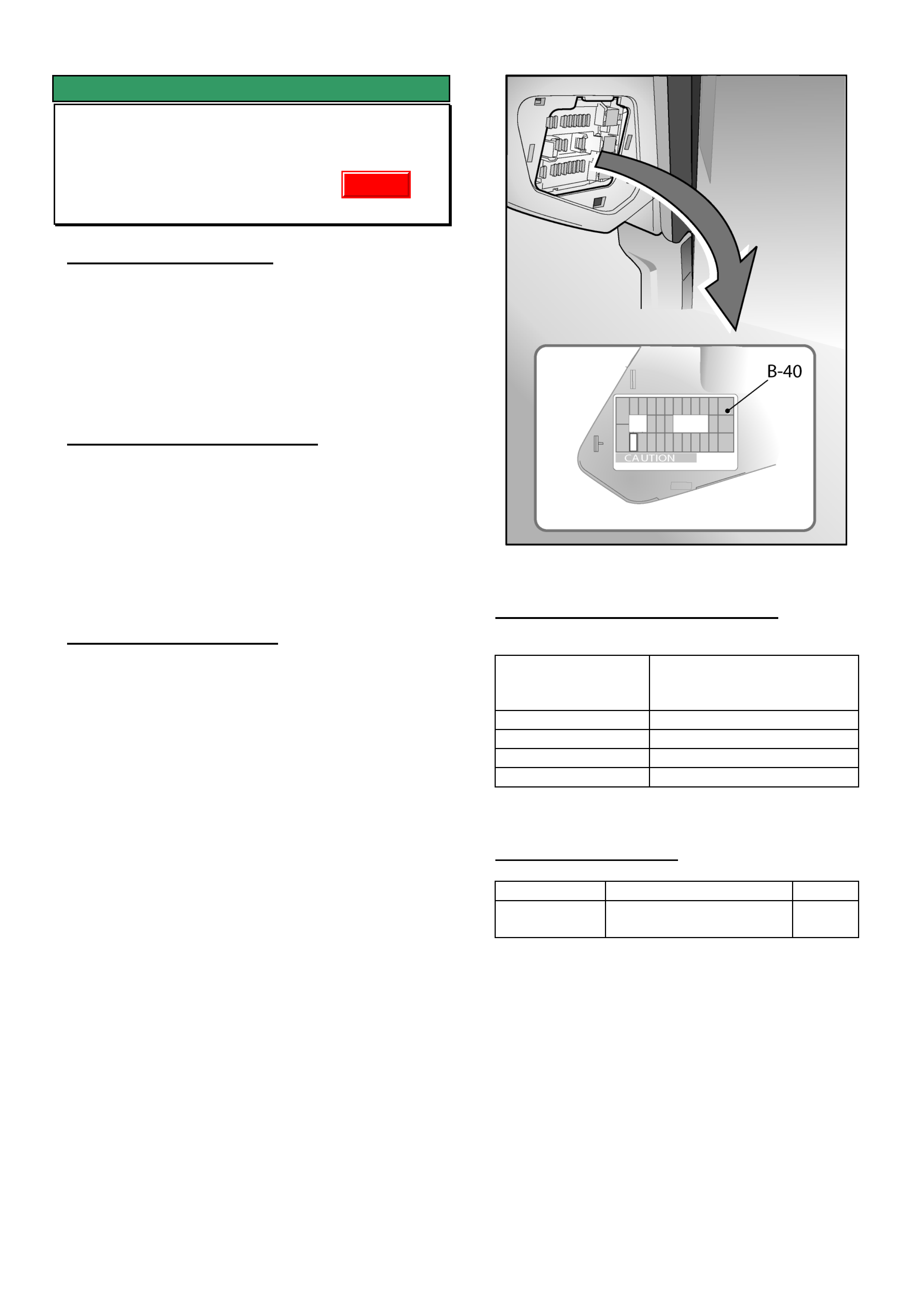

Step 2. Replace the accessory socket relay B-40 with

the revised relay supplied. B-40 is located in

the fuse box at the right hand end of the

instrument panel as per diagram below.

Step 3. If removed, replace the Instrument Panel

Drivers Lower Cover Assembly following LCRV

SIP procedure.

WARRANTY CLAIM INFORMATION

Description Hard Start Service Fix

Accessory Relay

Replacement

Labour Op. No. N000435

Time 0.3 hr

Failure Code 84 Hard Starting

Failure Code NOW N0084 Hard Starting

PARTS INFORMATION

Part No.: Description: Qty:

92147876 Service Fix Accessory

Socket Relay

1

Update

HOLDEN SERVICE TECHLINE______________________________________________________________NOVEMBER, 2003

11

INFORMATION

Built Date Explained

All Imported Vehicles – XC, TS, TT, JS,

ZC, UES, UBS, RA, YG

(GROUP OB) TL0606-0311

Holden Breakpoint Information in Service Techlines,

SMA handout material, Partfinder, etc. usually refers

to a BUILT DATE.

The BUILT DATE is the date the vehicle was

assembled in the factory.

Whenever quoting vehicle details in PIRs, talking to

TAS, etc., always quote the vehicle BUILT DATE.

The BUILT DATE is located in various locations on

imported vehicles.

On TS it is shown on a small label on the radiator

panel. On ZC it is shown on a small label on the strut

tower.

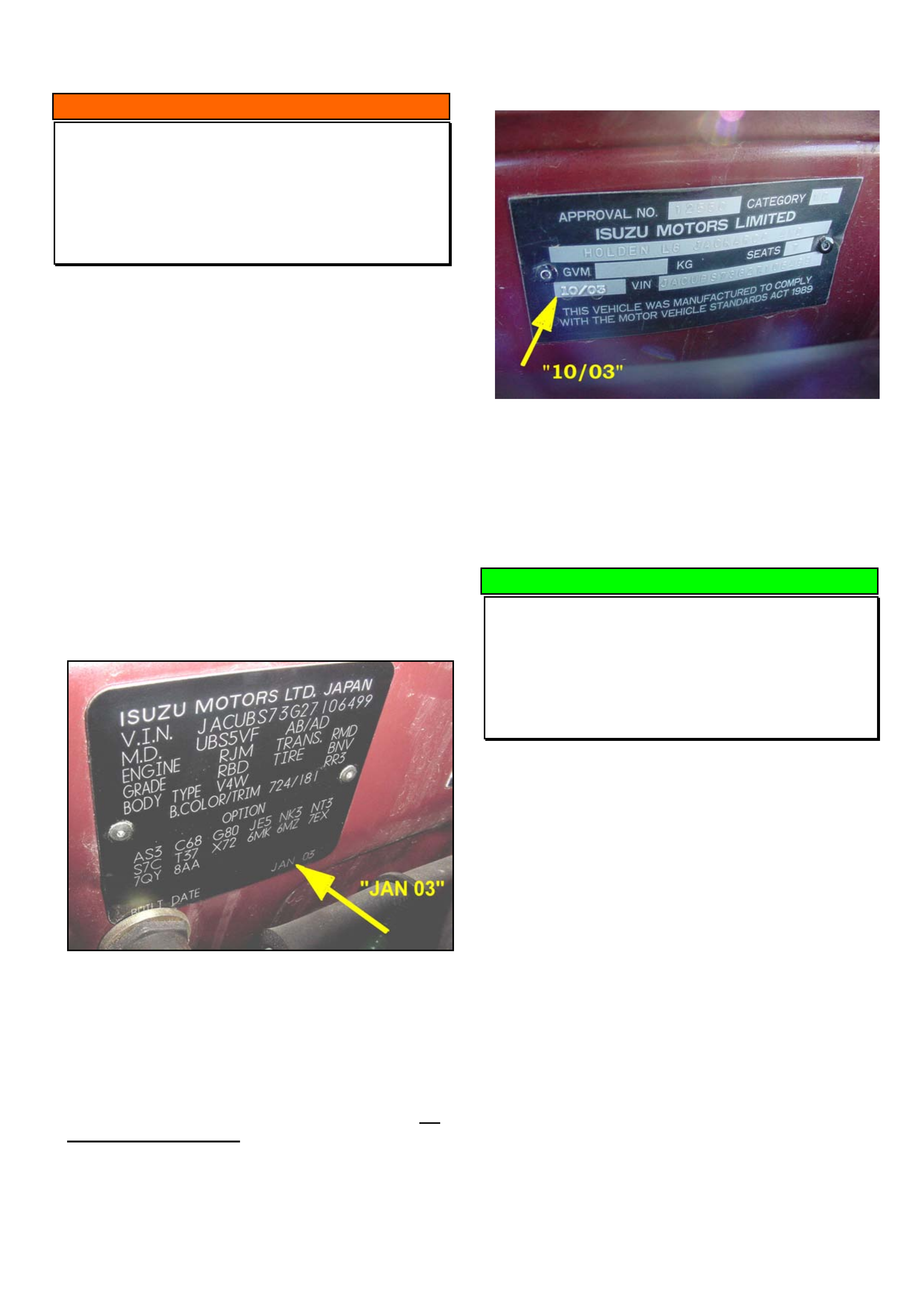

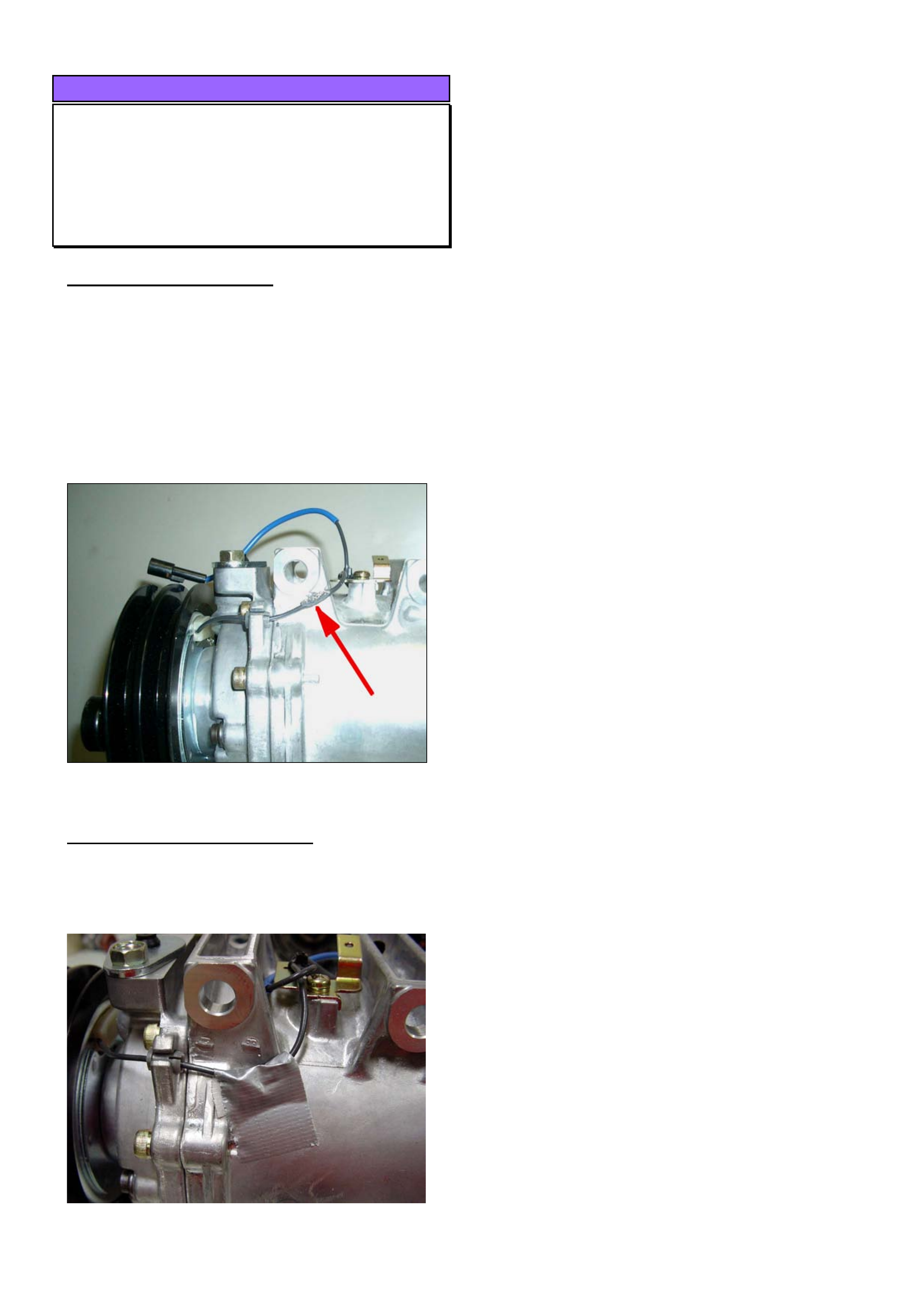

On UBS Jackaroo the BUILT DATE is shown on the

Body/Option plate on the dash panel as shown in

Figure 1.

Figure 1. Body/Option plate - Jackaroo

IMPORTANT. The BUILT DATE described above

must not be confused with the date stamped on the

Safety Compliance Plate rivetted to the dash panel.

Refer Figure 2.

The date shown on the Safety Compliance Plate, for

imported vehicles only, is the date when the plate

was attached to the vehicle at the Port Of Entry (POE)

into Australia. This date can be from 2 to several

months after the vehicle BUILT DATE because of the

time taken for shipping the vehicle to Australia plus

storage at POE.

Figure 2. Safety & Compliance plate - Jackaroo

SERVICE HINT

Transferring Information from Old to New

Modules

All

(GROUP 12) TL0589-0311

When installing a new module the following

information is generally required for inputting into the

new module.

• Vehicle options

• Vehicle configuration

• Code Index

Prior to removing any module, it is recommended to:

1. Connect Tech 2.

2. Record on paper the Vehicle options, Vehicle

configuration, and Code Index.

3. Confirm all the values recorded in step 2 using

TIS 2000 or SIP.

4. Once these values are confirmed they can then

be entered into the new module when called for

by Tech 2 during the installation process.

HOLDEN SERVICE TECHLINE______________________________________________________________NOVEMBER, 2003

13

ACCESSORY INFORMATION

A/C Compressor Clutch Wire Damaged

During Installation

RA Rodeo & 4JH1 Diesel Engine

(GROUP 2) TL0586-0311

PROBLEM DESCRIPTION

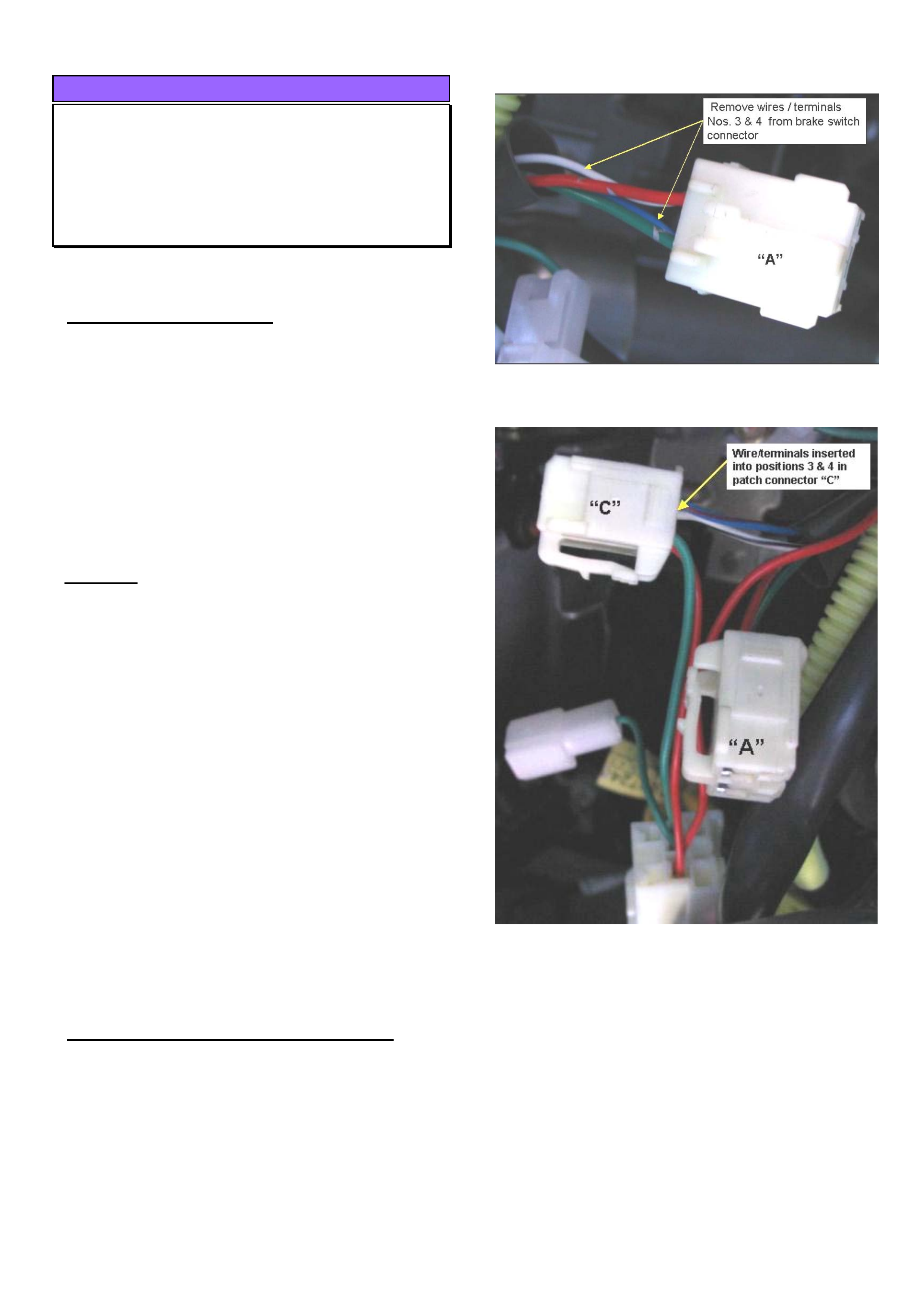

It has been found that during installation of the air

conditioning compressor p/n 61366371 for the 4JH1

engine, it is possible to trap the lead wire for the

clutch between the compressor and the mounting

bracket. When the fasteners are tensioned, the wire is

damaged, causing either an open circuit, or short

circuit to ground. This may cause a failure of electrical

components within the compressor (which are not

serviceable), requiring the replacement of the entire

compressor. Figure 1 shows damaged wiring

Figure 1. Shows damaged wire

SERVICE RECOMMENDATION

Prior to installing the compressor, tape the lead wire

against the body of the compressor to ensure it

cannot be trapped when the fasteners are tensioned.

Figure 2 shows recommended taping of wiring.

Figure 2. Shows taping of wire prior to installation

HOLDEN SERVICE TECHLINE______________________________________________________________NOVEMBER, 2003

14

ACCESSORY INFORMATION

HVAC Temperature Control Not Working

– Air Mix Cable Incorrectly Installed

RA

(GROUP 2) TL0587-0311

PROBLEM DESCRIPTION

There have been reports of the HVAC temperature

control (air mix dial) not working.

Investigation of complaint vehicles shows this

problem is due to the air mix cable not being held in

the retaining clip. This results in the outer cable

moving, which in turn causes the inner cable to

dislodge from the air mix door control lever.

In most cases, the cause of the above problem is the

cables have not been placed correctly into the

retaining clips when air conditioning has been

originally fitted to the vehicle.

SERVICE RECOMMENDATION

When installing air conditioning (or re-installing the

cable for any reason) it is important to pay special

attention to the correct installation of the air mix cable.

After installing the cable in the retaining clip, ensure

the full range of hot/cold adjustment can be achieved

with the control dial.

Figure 1. Shows Temperature control cable correctly retained in clip on side of HVAC case.

Update

HOLDEN SERVICE TECHLINE______________________________________________________________NOVEMBER, 2003

15

ACCESSORY INFORMATION

Check Engine Light Comes On After

Fitting Cruise Control

RA (LT with 4JH1 Engine Only)

(GROUP 12) TL0601-0311

The following information must be read in conjunction

with the Cruise Control Fitting instructions.

PROBLEM DESCRIPTION

After fitting cruise control, the check engine light

comes on and DTC P0703 (brake switch incorrect

signal) is logged.

The RA Rodeo (LT, 4JH1 diesel) brake switch has 4

contacts. A recent change in vehicle self diagnostics

now requires all four brake switch contacts to be

checked. Consequently, after fitting cruise control,

DTC P0703 will be logged as existing cruise control

patch harnesses do not make contact with all of the

terminals in the brake switch.

REMEDY

On vehicles where the CEL comes on after fitting

cruise control, perform the following rework. This

rework should also be performed on any accessory

cruise control kit made prior to batch code “0025303”.

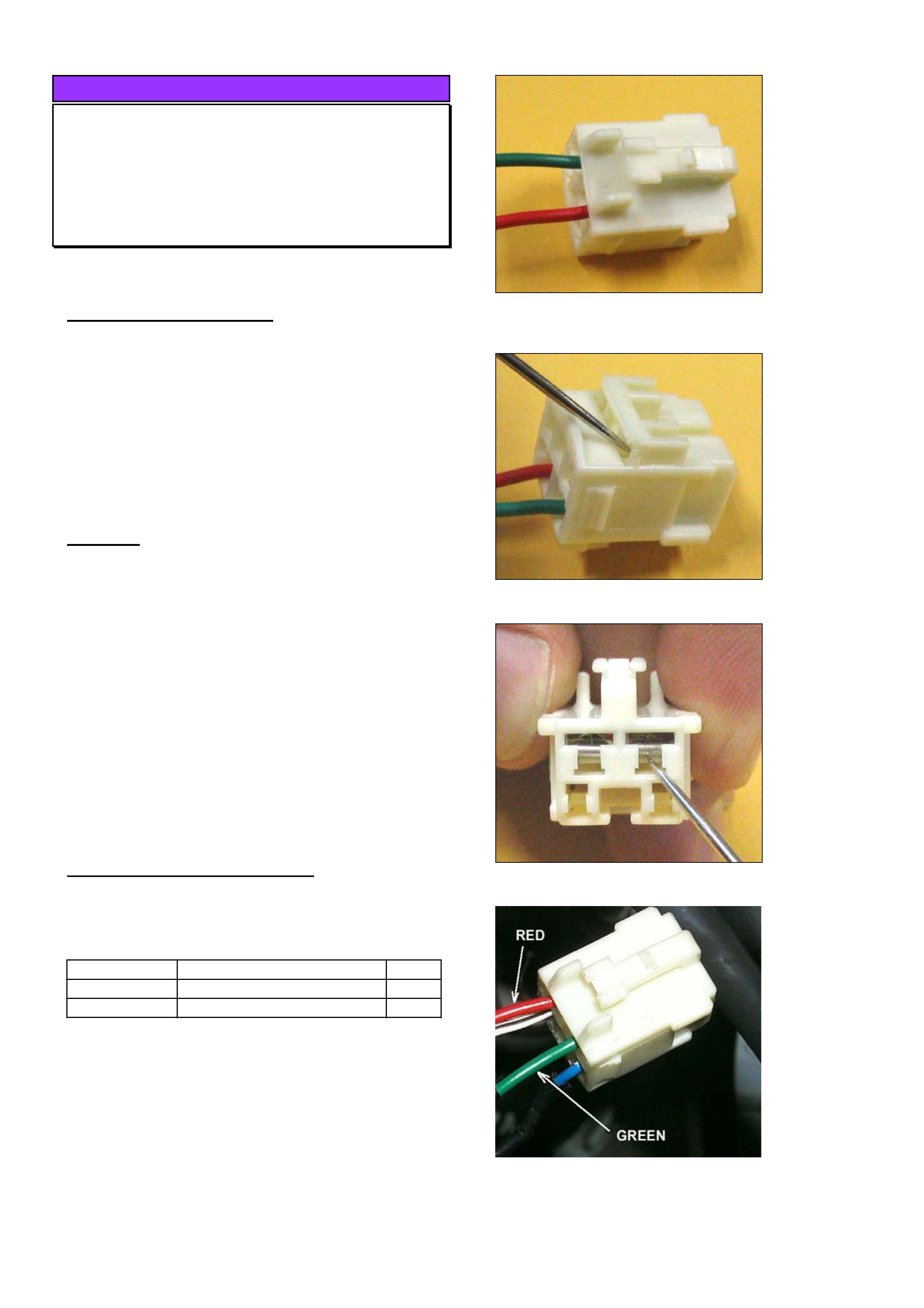

1. Disconnect the cruise control brake patch

harness.

2. Remove the anti back-out combs from both the

vehicle brake switch connector “A” and the cruise

control patch harness female connector “C”.

3. Release the retaining tangs and back out the

terminals 3 & 4 from the brake switch connector

“A”. Refer Figure 1.

4. Now insert these into terminal positions 3 & 4 in

the cruise control connector “C” as shown in

Figure 2.

5. Replace the anti-back out combs and re-connect

the patch harness to the vehicle.

CRUISE CONTROL KIT RECTIFICATION

Cruise control kits P/N 92145334 made from batch

code 0025303 onwards have had their patch

harnesses revised to overcome the above condition.

NOTE: The batch code which is located on the label

on the box refers to the day of the year the kit was

produced. In this case 0025303 refers to the 253rd

day of the year 2003.

Figure 1. Brake Switch Connector A

Figure 2

HOLDEN SERVICE TECHLINE______________________________________________________________NOVEMBER, 2003

16

ACCESSORY INFORMATION

Cruise Control Does Not Engage When

Activated

RA

(GROUP 12) TL0593-0311

The following information is to read in conjunction with

the Cruise Control Fitting instructions.

PROBLEM DESCRIPTION

When checking operation after fitting cruise control

accessory kit, it is observed the "cruise control" LED

illuminates but the system does not engage.

The cause for this condition may be due to incorrect

wiring on the cruise control harness brake switch

connector. Investigations show the the red and green

wires in the connector have been installed the wrong

way around in some kits manufactured in September

2003. Refer Figure 1.

REMEDY

Check if the cruise control patch harness wires at the

brake switch connector match the colours of the

corresponding wires in the vehicle harness; i.e. Red

to Red, Green to Green. If they don’t match, proceed

to swap the wires around as follows.

1. Remove the anti-backout comb from the cruise

control patch harness. Refer Figure 2.

2. Release the terminals for the Green and Red

wires. Refer Figure 3.

3. Swap the wires over in the connector housing.

The green goes into pin 1 and the red into pin 2

as shown in Figure 4. Refit the anti-backout

comb.

ACCESSORY KITS AFFECTED

The kits affected are those with Batch numbers

between 00025003 and 00025303. The batch

number is stamped on the edge of the part no. label.

Part No.: Description: Qty

92145334 Cruise control kit – 4JH1 1

92145971 Cruise control kit – 6VE1 1

Before installing any kit built between the above batch

numbers check and correct the brake switch

connector wiring as described above.

Figure 1. Shows red and green wires installed wrong way

round in cruise control brake switch connector

Figure 2 Releasing backout comb.

Figure 3 Releasing wire terminals

Figure 4. Shows red and green wires installed correctly

HOLDEN SERVICE TECHLINE______________________________________________________________NOVEMBER, 2003

17

ACCESSORY INFORMATION

Change To Accessory Cruise Control

Fitting Instructions

RA (LT with 4JH1 Engine Only)

(GROUP 12) TL0592-0311

The following information is to be read in conjunction

with the Cruise Control Fitting instructions.

PROBLEM DESCRIPTION

The current fitting instructions for the LT 4JH1 engine

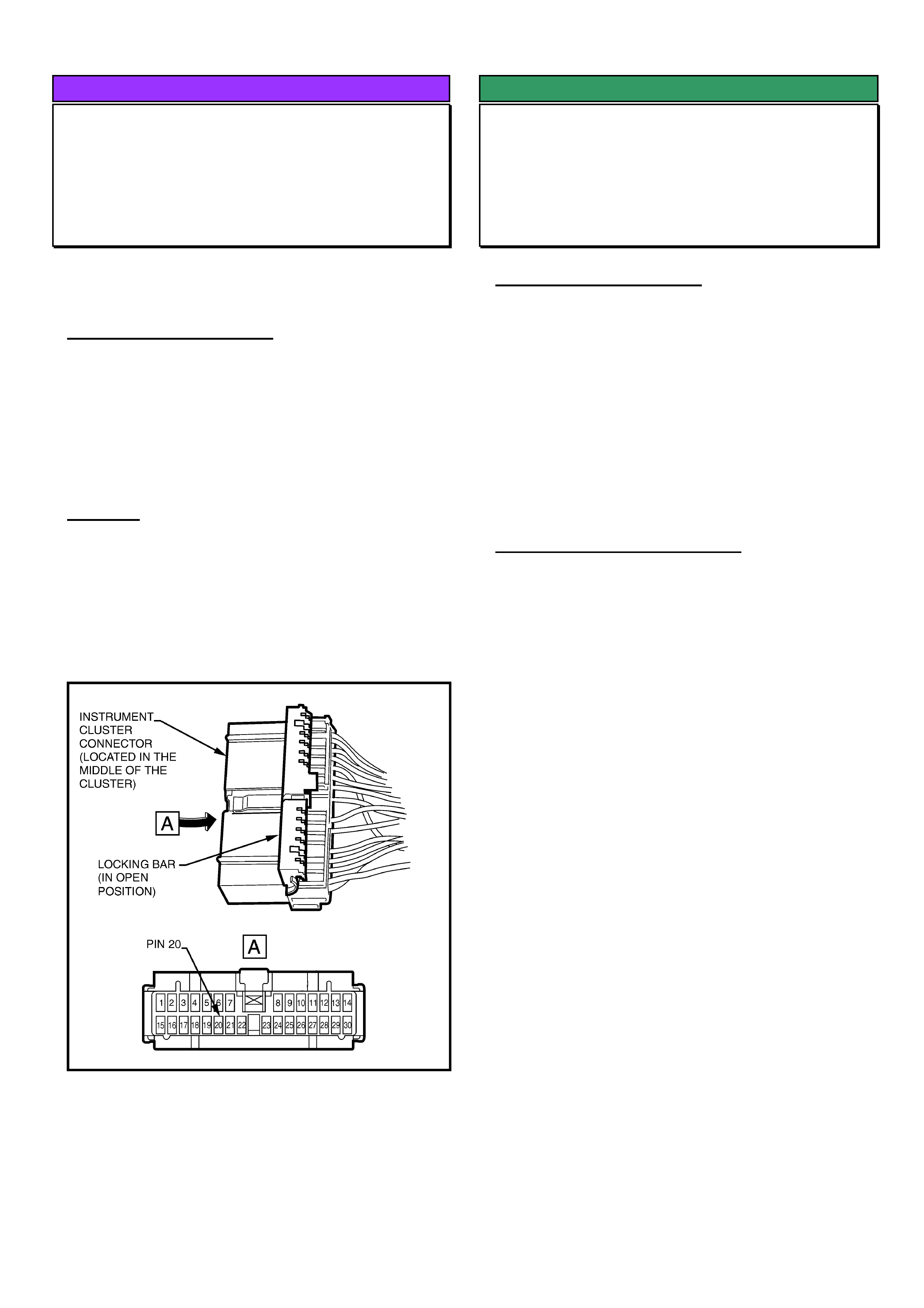

cruise control kit P/N 92145334 indicate that

receptacle 20 in the instrument cluster connector is

vacant, and to place the orange wire/terminal from the

kit into this position. This is no longer correct as

receptacle 20 is now occupied.

REMEDY

As per the current fitting instructions, remove the

terminal retaining clip from the connector. Then

release the terminal in position 20 (Green/Yellow

wire) and tape back against the vehicle harness.

Place the orange wire/terminal from the cruise control

kit into position 20.

NOTE: Fitting Instructions “FD1146 DEC03” have

been modified to reflect above changes.

SERVICE FIX

Air Conditioning Noise Caused By Low

Refrigerant Charge

RA

(GROUP 2) TL0596-0311

PROBLEM DESCRIPTION

Some customers may report a hissing/gurgling noise

coming from the dash area when the A/C is operating.

Investigations show that this noise, which occurs as

refrigerant flows through the TX valve, is louder in

vehicles which have low refrigerant levels.

Low refrigerant level can also cause compressor rattle

(affecting compressor life) therefore, refrigerant level

should be checked before commencing with

compressor noise diagnosis.

SERVICE RECOMMENDATION

For owner complaints of noisy A/C, ensure that the

system has the correct charge of refrigerant. The

only way of ensuring this is to remove the existing

charge and recharge with the specified amounts as

follows:

Refrigerant R134A Diesel 700 ± 25 grams

Petrol 750 ± 25 grams

Retailerships must use A/C charging equipment

capable of accurately measuring out the refrigerant

charge specified. When cans of refrigerant are used

for recharging it is generally not possible to achieve

the same level of accuracy as a proper charging

station. Cans are therefore not recommended for

charging.

The A/C fitting instructions detail the correct

evacuation and charging procedure. Following this

procedure will ensure that the system is correctly

evacuated and that the complete charge is transferred

into the vehicle.

Cooling Performance.

Another essential reason for having the correct

amount of refrigerant in the system is for achieving

best cooling performance. This cannot be achieved

with an undercharged or overcharged system.

Noises from Refrigerant Pipes & Hoses

Refrigerant pipes and hoses can generate noise if

they touch other components. Check all routing and

adjust or isolate all lines from body and engine

components as required.

HOLDEN SERVICE TECHLINE______________________________________________________________NOVEMBER, 2003

18

ACCESSORY INFORMATION

Accessory Pre-Cleaner For Air Cleaner

Element

TF and RA with 4JH1 Diesel

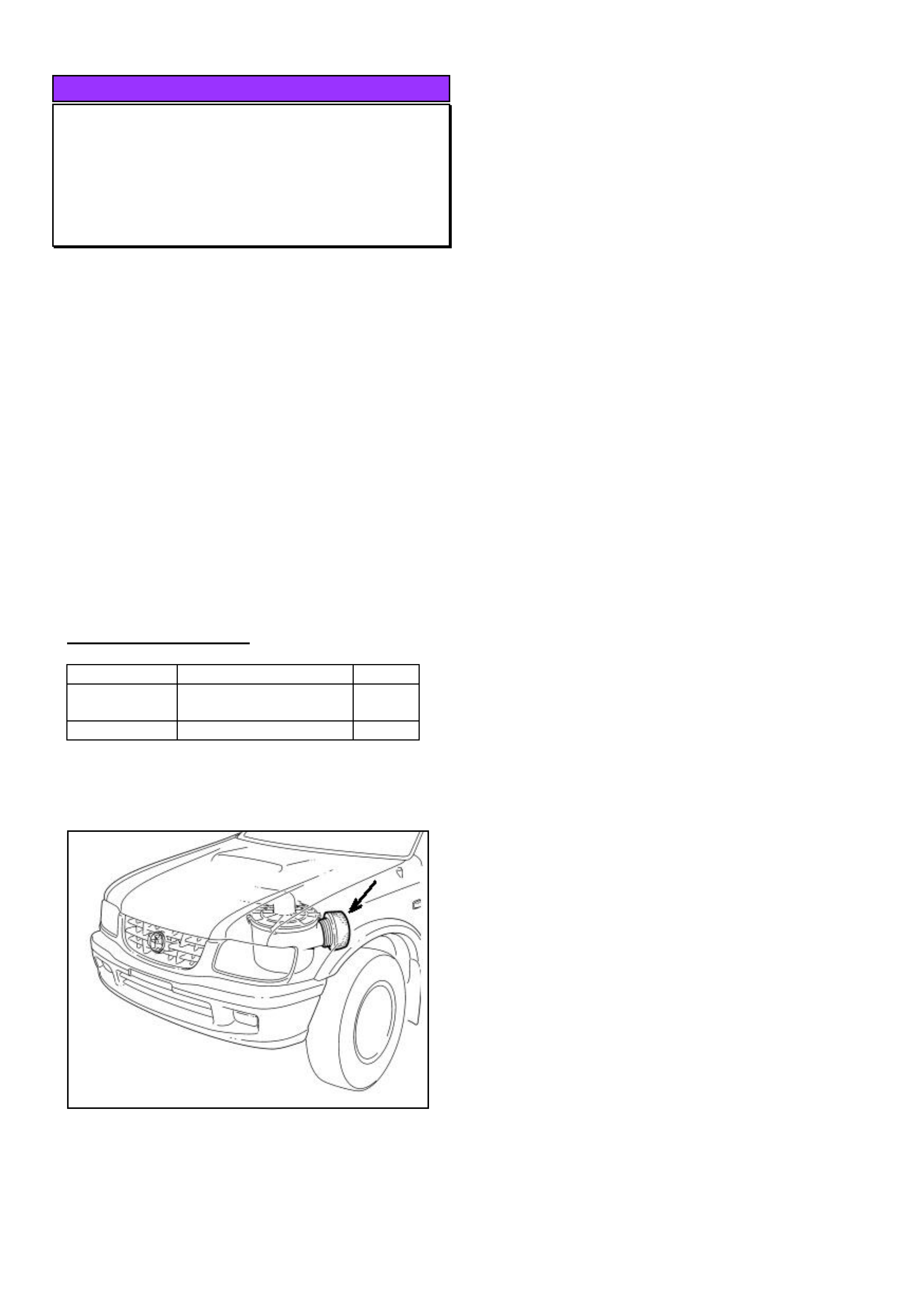

(GROUP 6A) TL0572-0310

A filter which pre-cleans air prior to it entering the

standard air cleaner element is now available from

HSPO as an accessory fitment.

For vehicles which operate in “extreme”¿ dusty

conditions, this filter is available as an accessory for

prolonging the life of the standard air cleaner element.

¿ ( For a definition of “extreme” conditions refer to the

Servicing section of the Owners Handbook.)

The pre-cleaner is an oil-foam type filter and comes in

a quantity of 2 per package. The package also

contains fitting instructions and an Owner Servicing

Instruction Sheet.

NOTE: The pre-cleaner is to be fitted at customer

expense.

PARTS INFORMATION

Part No.: Description: Qty:

92148001 Air cleaner – prefilter

element.

1

92147879 Filter oil 1

Figure 1. Shows prefilter