2

20

00

04

4

S

SE

ER

RV

VI

IC

CE

E

T

TE

EC

CH

HL

LI

IN

NE

ES

S

© 2006 GM Holden LTD. A.B.N. 84 006 893 232

Service Department

A “HOLDEN” Product.

BRISBANE SYDNEY MELBOURNE ADELAIDE PERTH

For the latest and/or any missing Techline bulletins,

please refer to Holden Lionheart

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

5

SERVICE FIX

LSD Additive Available For Oil “Top-Up”

VS/VT/VX/VU/WH with IRS LSD

(GROUP 04) Re-Issue TL279A-0401

This Techline supercedes the previous one in Issue 4,

May, 2002. It is revised by correcting the kit contents

and clarifying that usage is only for “top-up”, NOT for

an axle “chatter” fix.

BACKGROUND

Many vehicles have previously had LSD additive and

a revised pinion seal installed for a “chatter” condition

(Refer to Dealer Letter DL 30/02).

The additive is now available separately, for any of

the above vehicles whose differentials require oil

replenishment or top-up following a repair.

This additive is NOT for use in correcting LSD

“chatter” complaints until a chatter kit has

been fitted.

LSD “chatter” complaints must still be corrected in

vehicles covered by warranty by the use of an LSD

“Chatter” Kit – Refer to Dealer Letter DL 30/02 which

advises the method of obtaining LSD Chatter Kits

Free of Charge and the Dana provision of automatic

kit replenishment at Retailers.

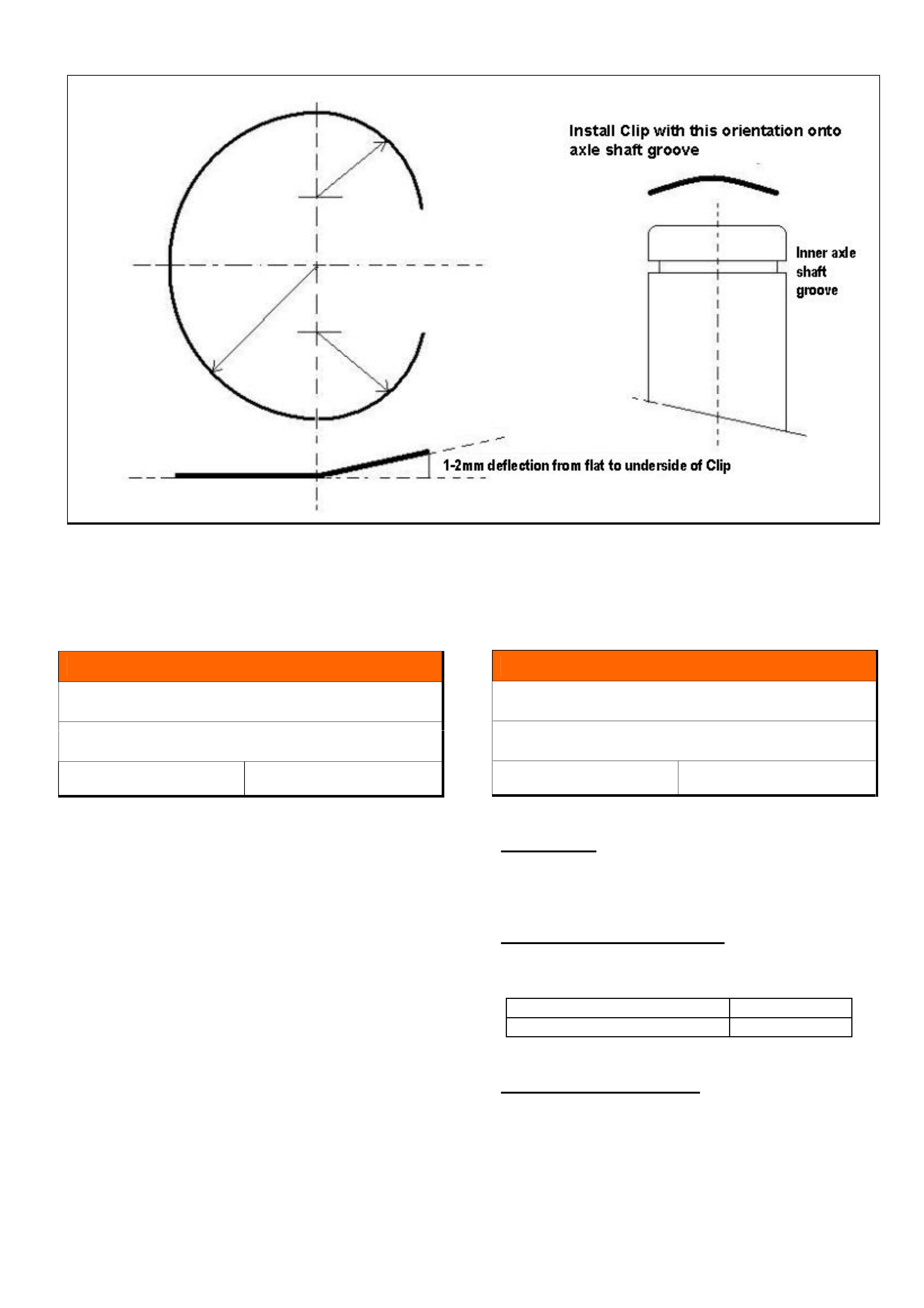

PRODUCTION RECTIFICATION

Final drives with the additive and revised seal

included have been fitted to vehicles from:

ISOVIN: Build Date:

6H8VXK69F1L762226 20/08/01

SERVICE RECOMMENDATION

This additive is ONLY for replenishment of oil to final

drive units that:

(a). are fitted to any vehicle built after breakpoint

L762226;

OR

(b). are built before breakpoint L762226 and have

had the additive and the seal installed as per DL

54/01 or RL 30/02. These vehicles are identified by a

metal ID tag fitted to the rear of the differential,

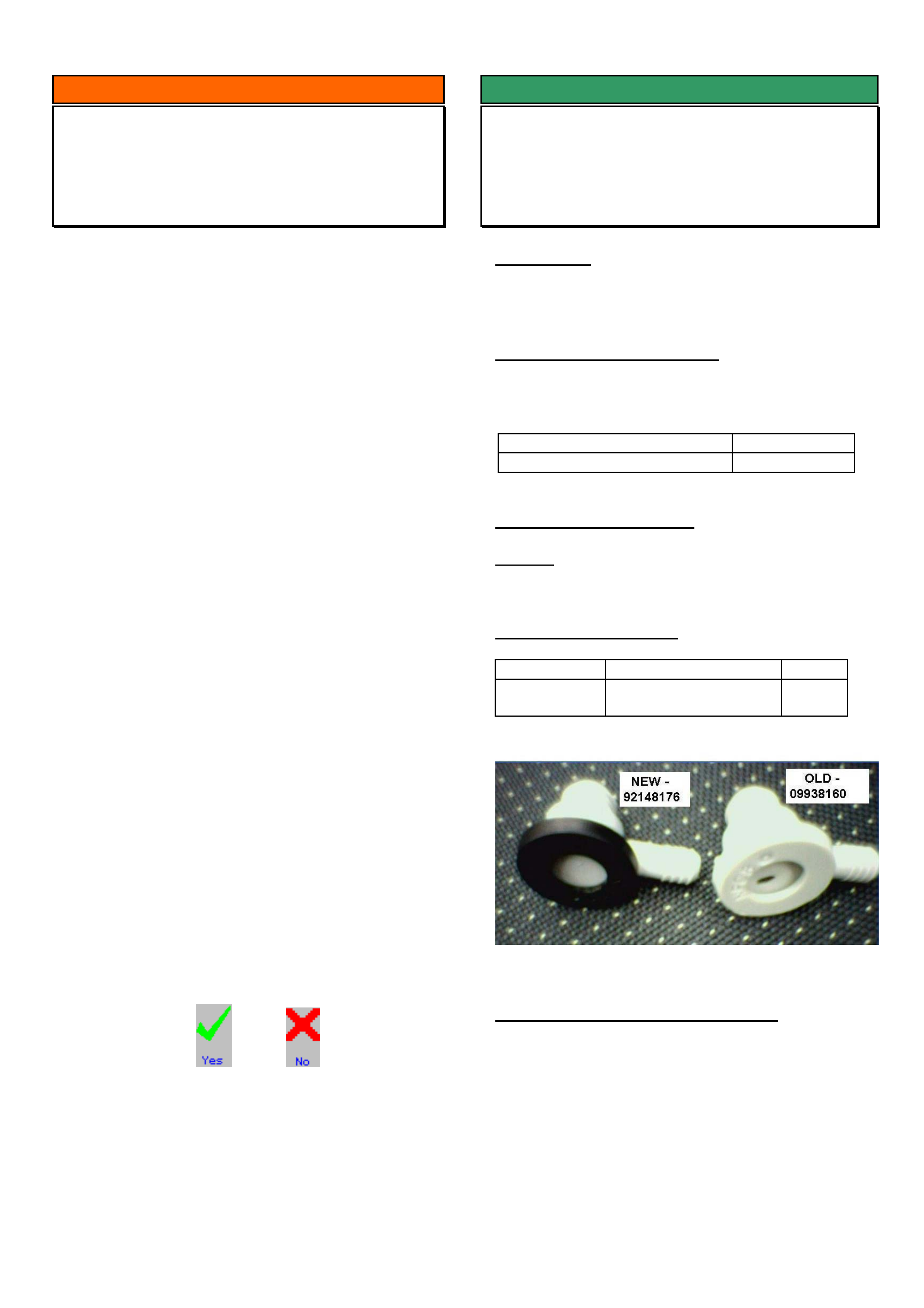

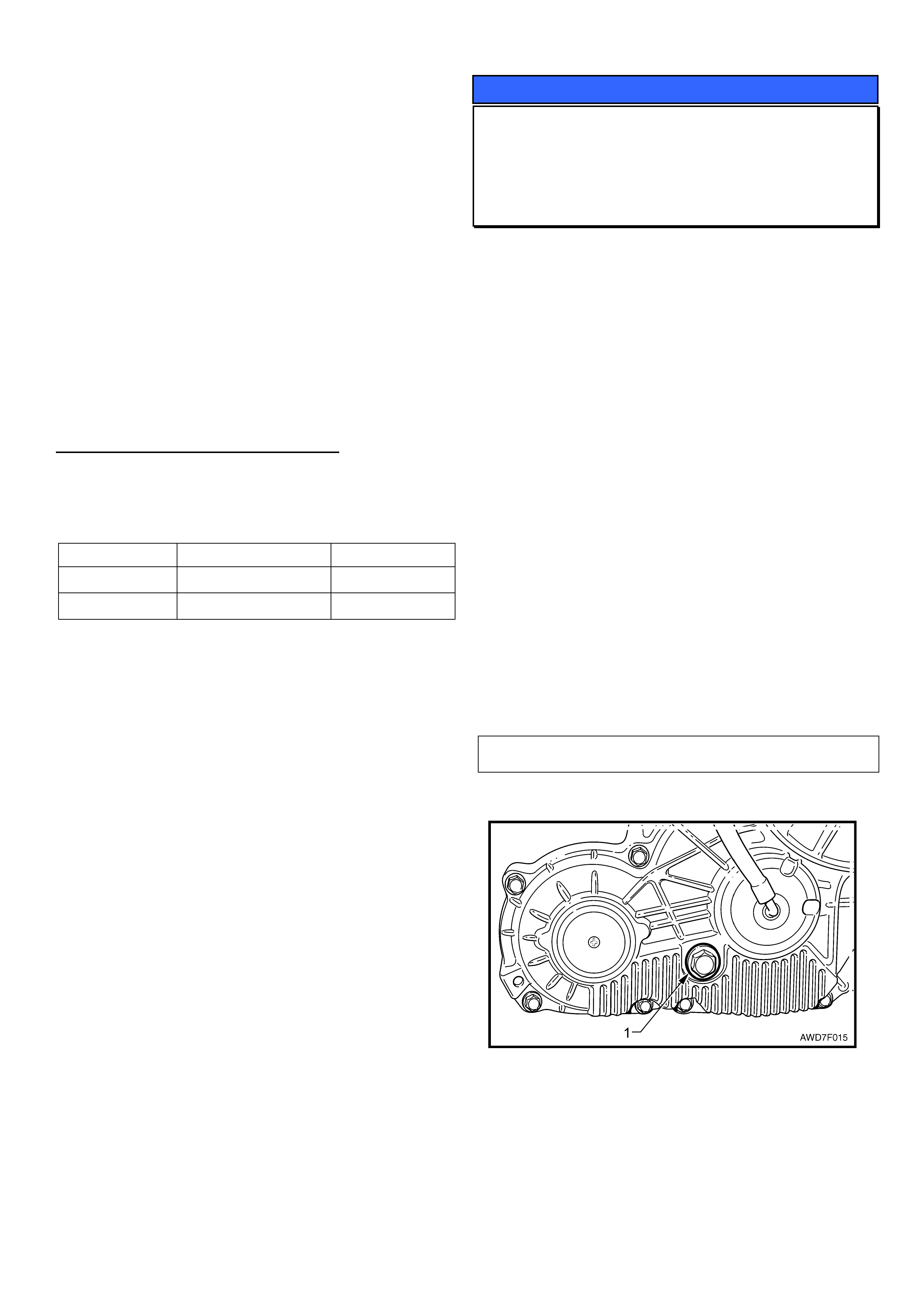

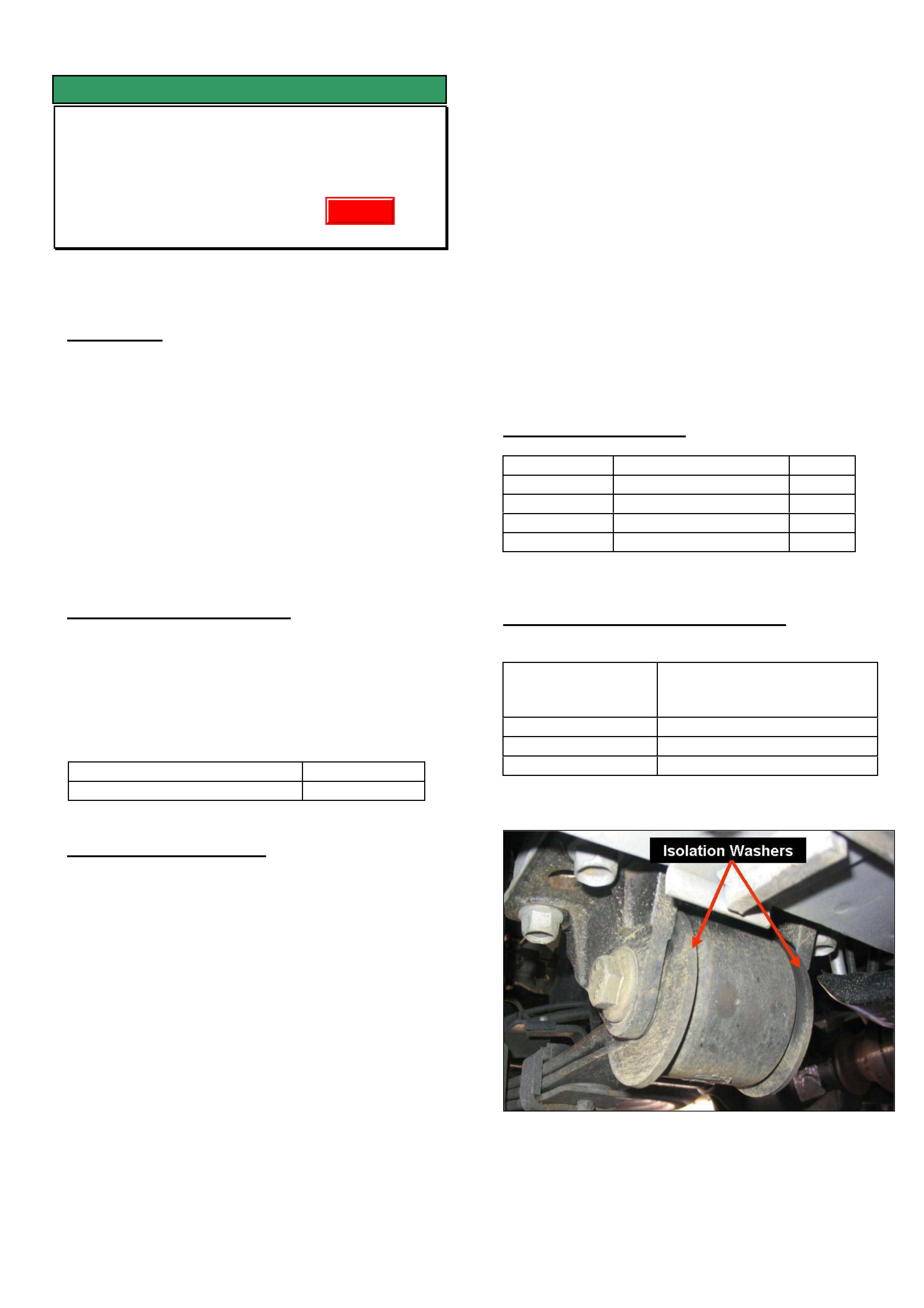

carrying the words “Field Fix”, as shown here:

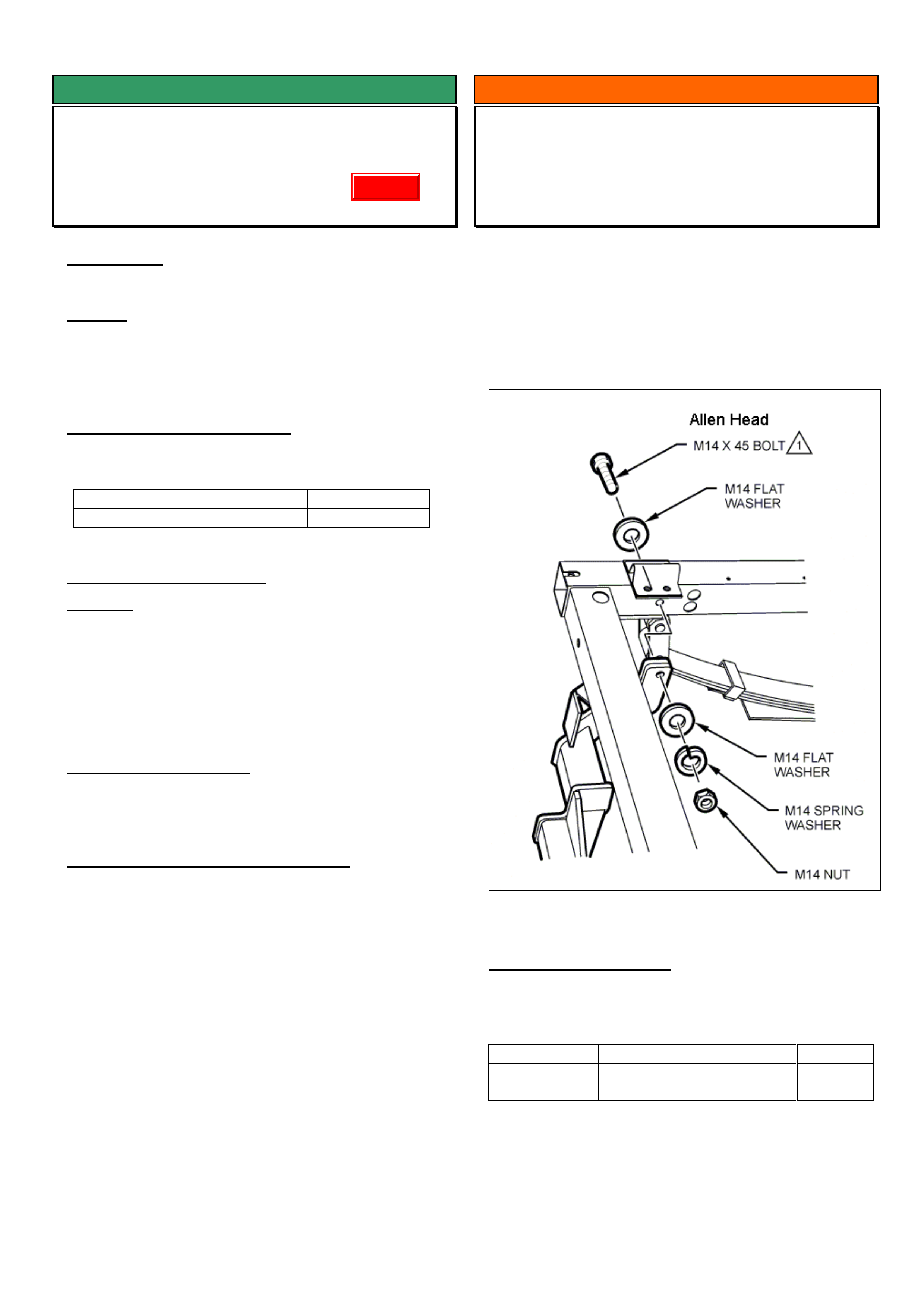

PARTS INFORMATION

Part No.: Description: Qty:

92145121 Additive Kit 1

This kit consists of: - 1 bottle, 100ml LSD Additive,

IMPORTANT: This additive is NOT suitable

for use in differentials that are not fitted with

the revised seal and additive – as seal

degradation and failure will result.

DIAGNOSIS HINT

Rear Axle Pinion Seal - Oil Leak

Diagnosis

V & W

(GROUP 4) TL0613-0401

PROBLEM DESCRIPTION

Technicians have reported “oil leaks” from the axle

pinion seal on the assumption that the seal is leaking.

Vehicles with such “leaks” have been investigated

and seals returned for checking. No faults could be

found and the oil leakage is only “assembly oil”.

Pinion oil seals are assembled to axles using oil to

assist installation. At times, excessive oil is used, and

after some use and temperature cycling of the axle,

this excessive oil can run out of the pinion nose –

appearing like an oil “leak” from a faulty or damaged

seal.

PRODUCTION RECTIFICATION

Holdens axle supplier will be changing from

installation oil to grease, used in lesser quantity, that

will not migrate out of the pinion seal.

Breakpoint information for this change will be advised

in a future Breakpoint Summary page entry in

Techlines.

SERVICE RECTIFICATION

Summary: Clean off excess oil.

Should any vehicle be presented with an apparent oil

“leak” at low kms or age – do not immediately replace

the seal - wipe off the excess oil and road test for any

continuing immediate leak. If none occurs, monitor the

vehicle at next service.

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

6

SERVICE FIX

Gear Shift Lever Rattle/Buzz - Caused by

Shifter Linkage Rattle

VTII, VX, VU, VY, V2, with Gen III & M/T

(GROUP 7A) REVISED TL608A-0401

This techline replaces the previous one TL608-0311

in issue 11,2003. It is revised by changing the

lubricants to ones that are currently available (shown

in red) and updating Production breakpoint

information.

PROBLEM DESCRIPTION

Complaints may be received of gear shifter “rattle” at

various engine speeds/road speeds. Most common

complaints are from 3rd or 4th gears.

The condition is a “metallic rattle” which can be heard

by removing the gear knob/lever assembly, then

revving the engine in neutral with medium to heavy

throttle, above 2500rpm – as a quick diagnosis. The

shifter linkage rattle occurs mainly during heavy

acceleration in 3rd or 4th gear above 3000rpm. The

rattle is more prominent if you touch the back of the

gear knob with your finger in 3rd gear, or if you touch

the front of the gear knob with your finger in 4th gear.

It is recommended that this test be done with a known

non-rattling gear knob, so no confusion exists.

NOTE: the following procedure must not be carried

out until diagnosis and any necessary repair, as

described in Issue 11, November, 2003 Service

Techline for “Knob Rattle/Buzz” has been carried out.

EG: Where the Gear Lever & Knob Assembly has

been assessed and changed if necessary, and the

source of “gear lever rattle” has been defined as

coming from the shifter mechanism – NOT the lever

and knob assembly.

PRODUCTION RECTIFICATION

Revised shifter assemblies with anti-rattle feature, as

described in this bulletin, introduced in production

from

ISOVIN: Built Date:

6G1YK42F14L213500 08/12/2003

SERVICE RECTIFICATION

Summary: Fit a Shifter Upgrade Kit as described

below.

NOTE: Upgraded “exchange” Shifters have been

supplied via TAS and HSPO since mid 2003 – These

parts do NOT need upgrading as described below,

and must not be upgraded or claimed for as warranty.

These exchange assemblies are identified by the

presence of either four red fibre washers between the

bridging piece and levers, or the black plastic “linked”

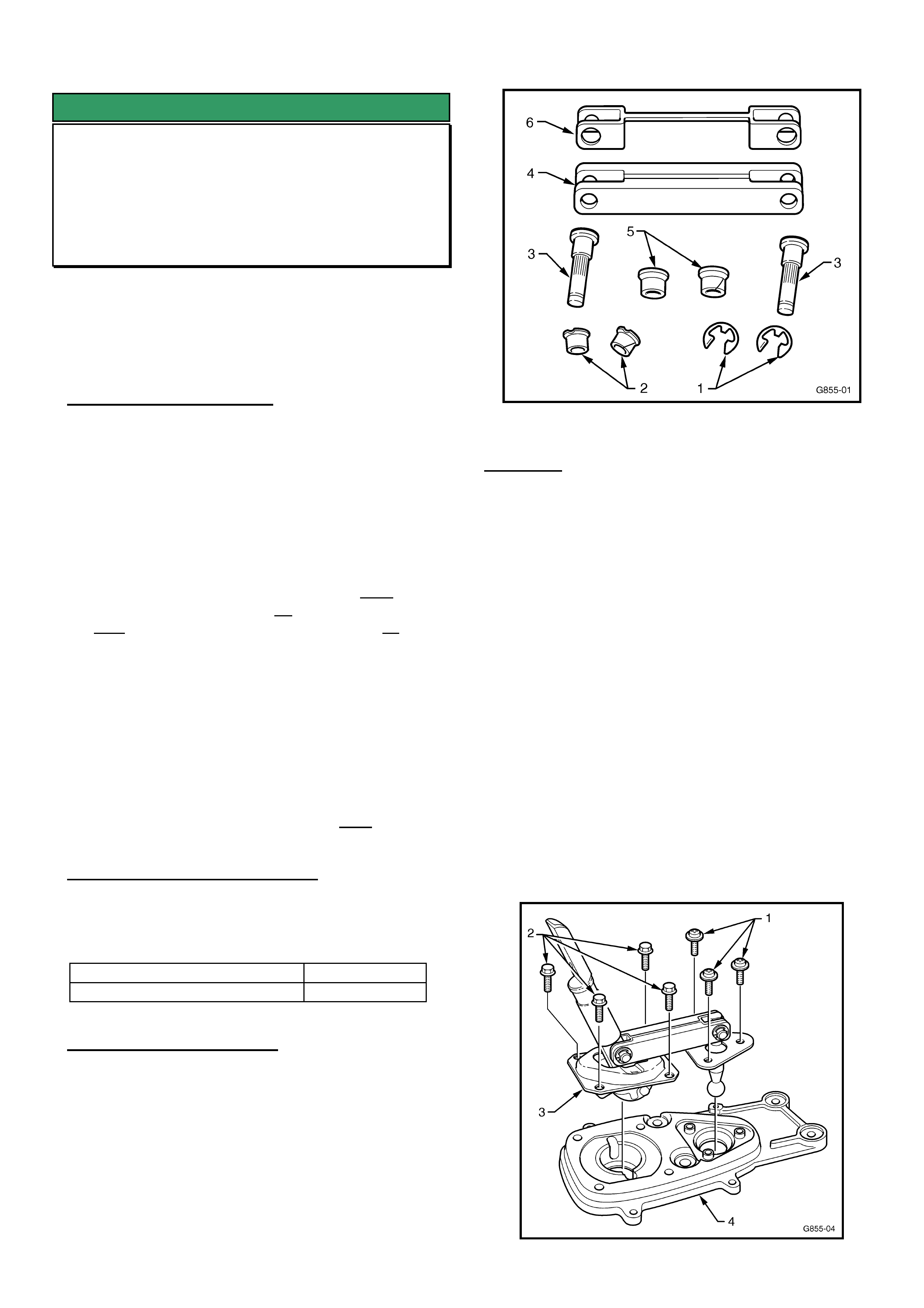

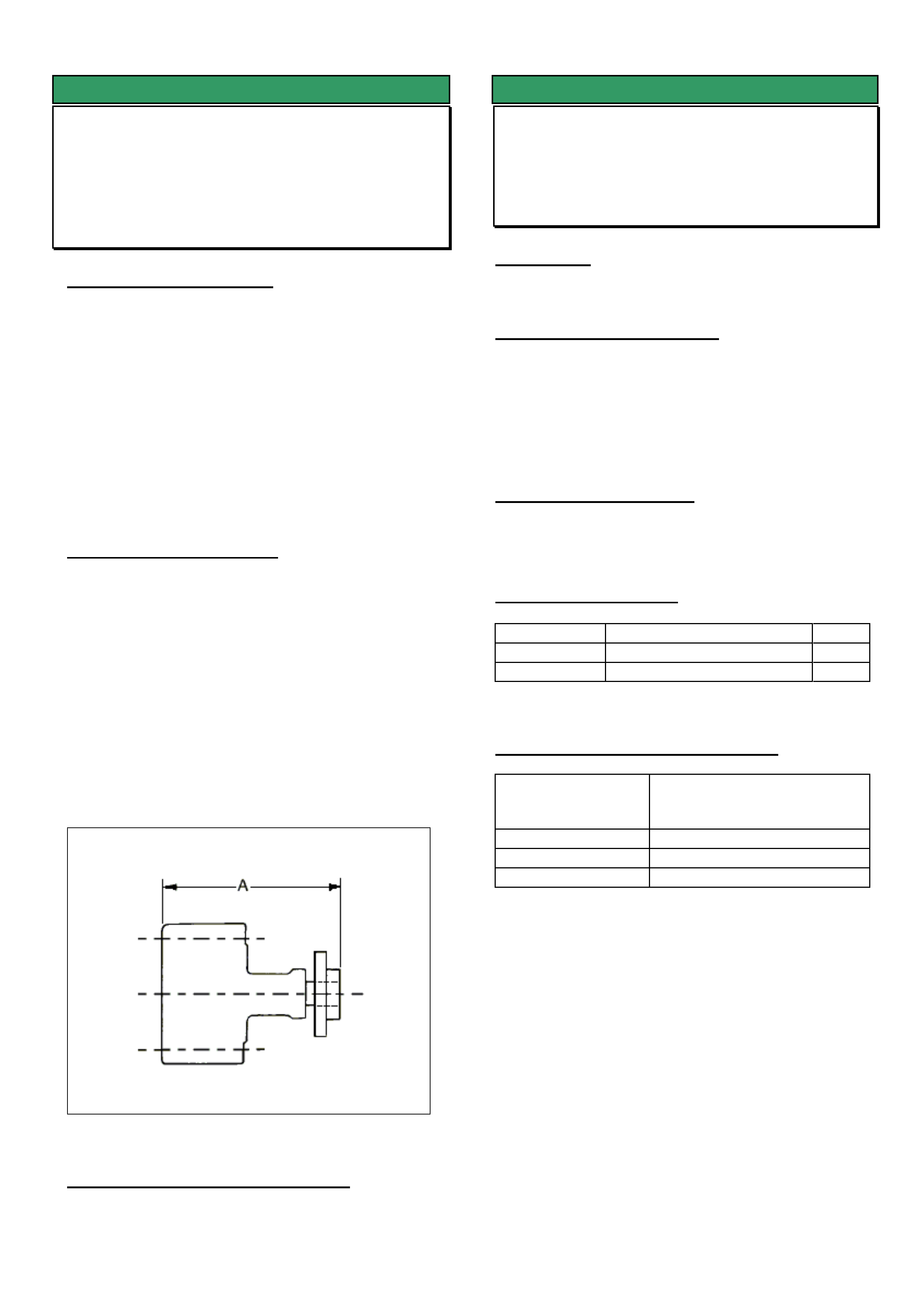

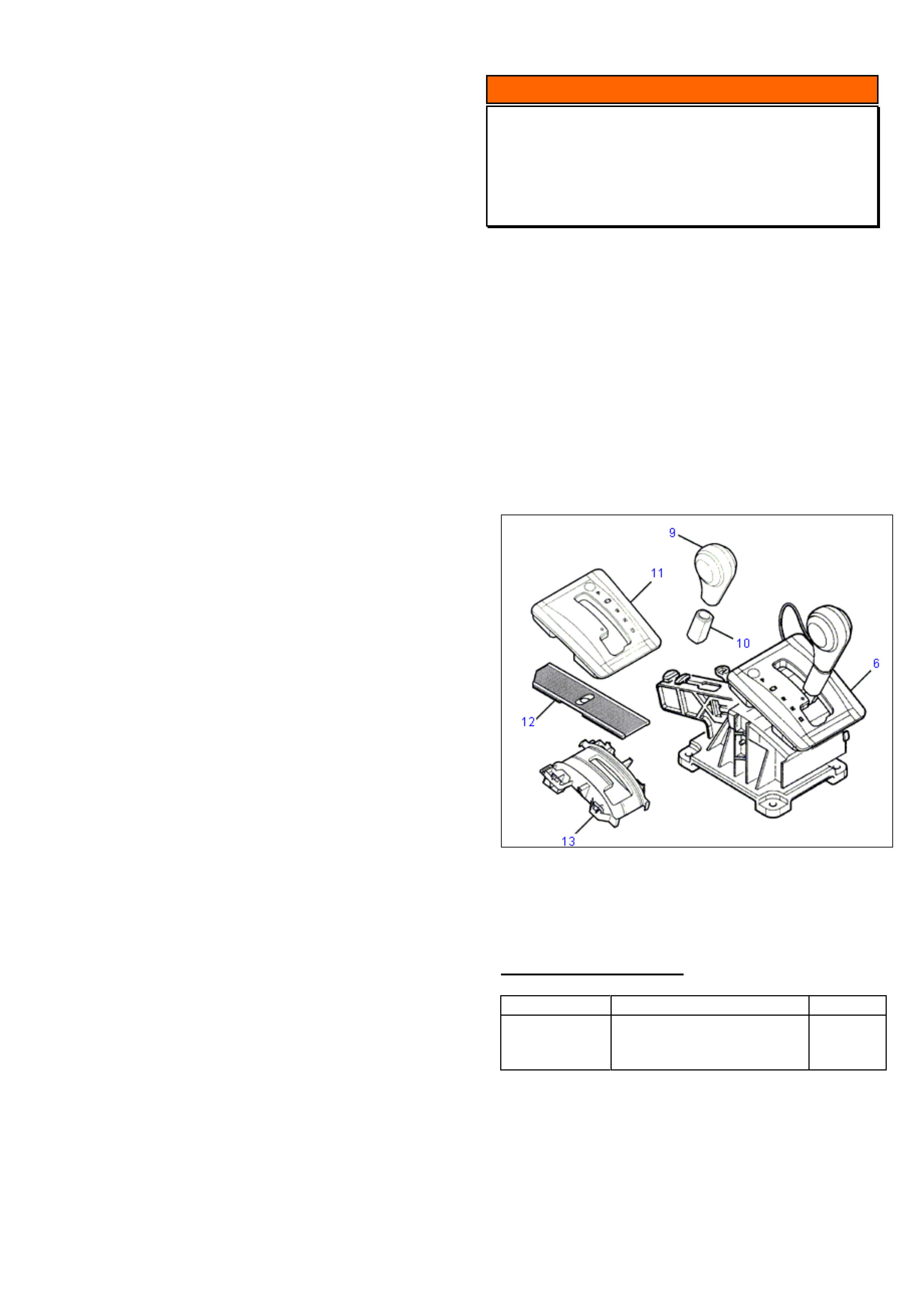

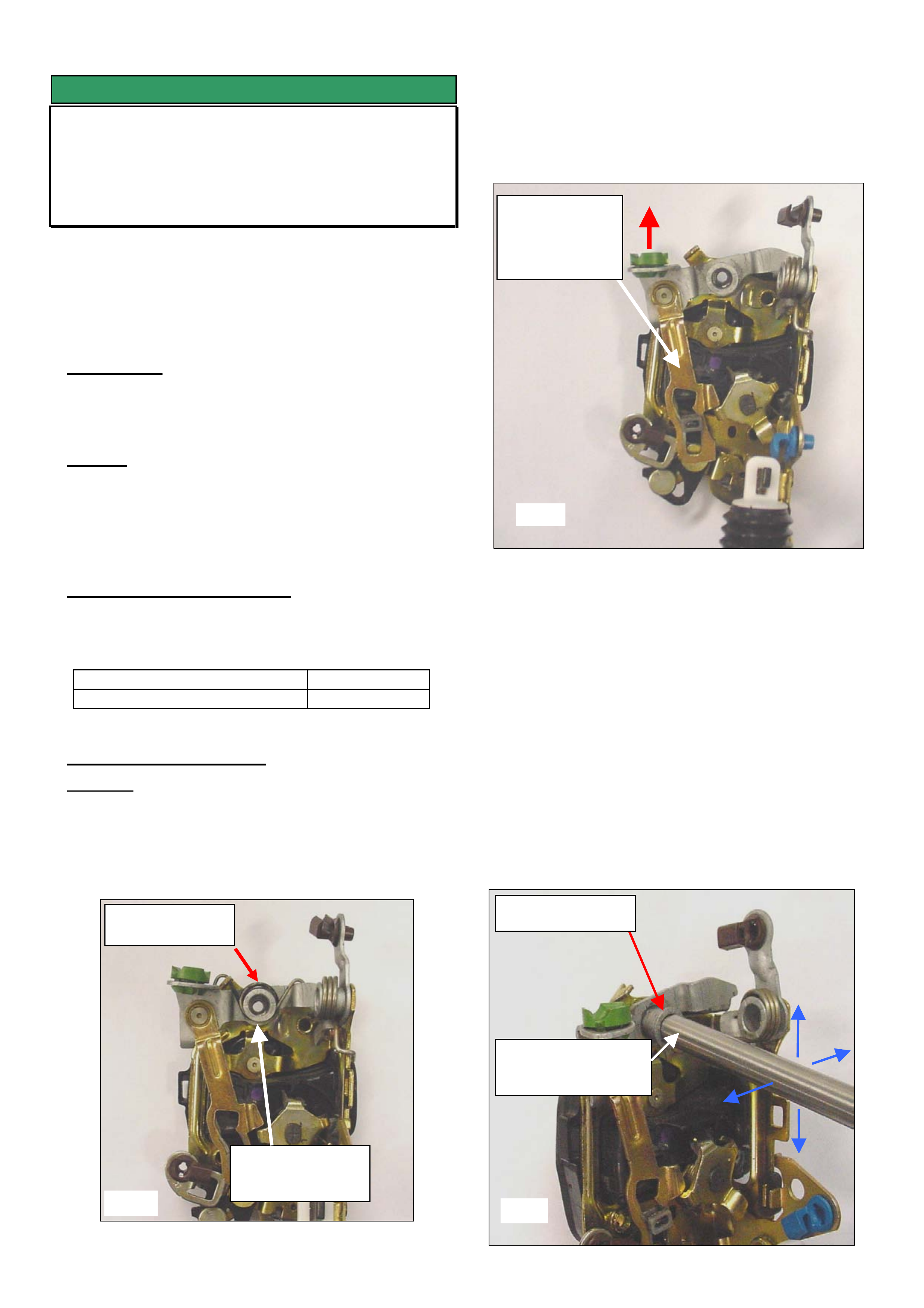

washers (6) shown below.

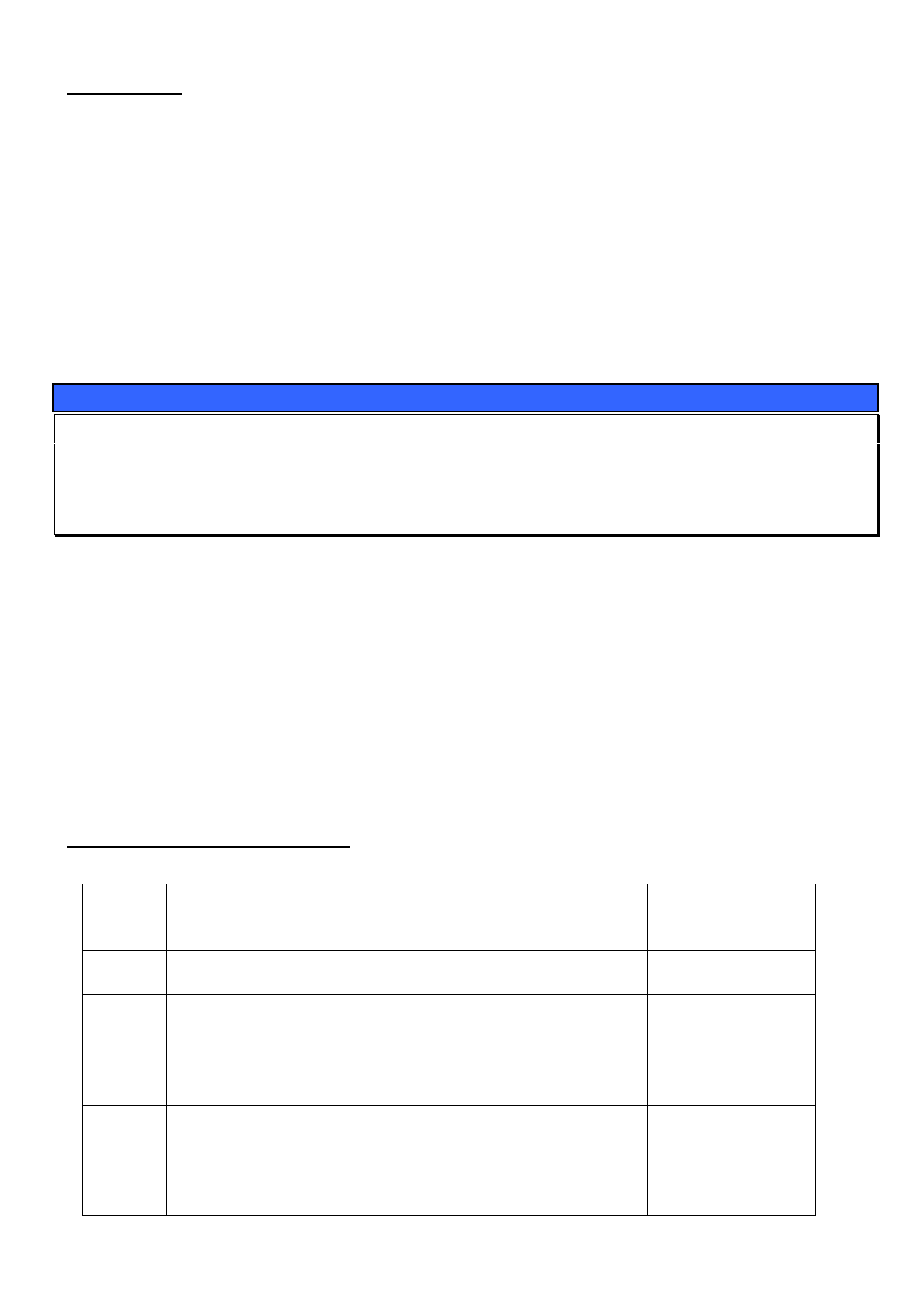

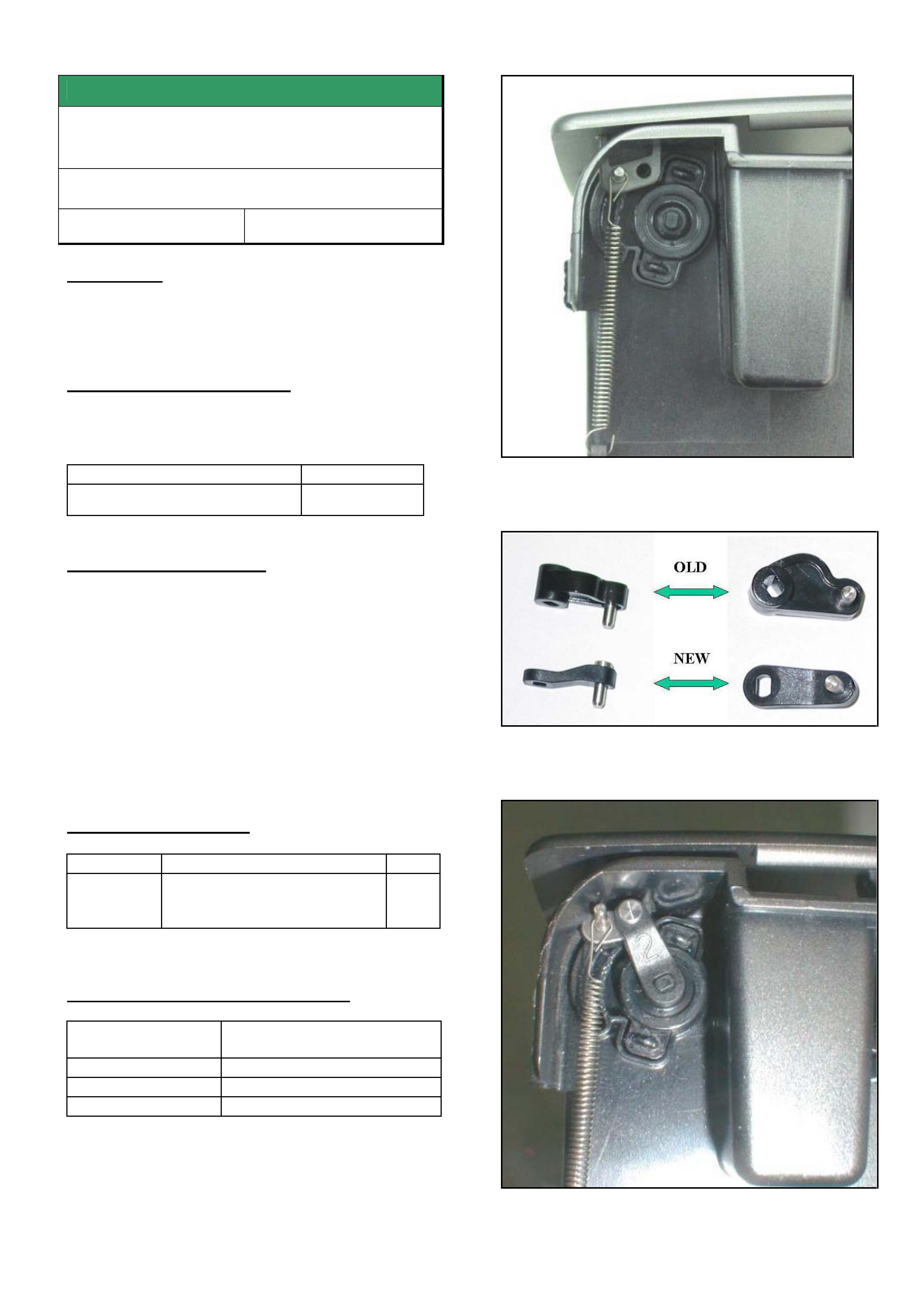

Bridging piece and related retaining parts (latest

types shown).

REMOVAL

1. Disconnect the battery earth lead.

3. Place gear lever in neutral.

4. Remove Gear shift knob/boot/lever assembly, and

centre console including the console cap - as per

the relevant procedures in Passenger SIP

Sections 7B3 and 1A3 for the model vehicle being

rectified.

5. Remove shifter cover and boot assembly by

removing the three Philips head screws.

6. Remove shift lever boot retaining plate:

Early build vehicles – remove the four bolts

securing the shift lever boot retaining plate, from

inside the vehicle, and lift off the plate;

Late build vehicles – remove the four nuts

securing the shift lever boot retaining plate to the

floor pan after raising the vehicle on a hoist. Front

LH nut access is limited, remove using an open

end spanner.

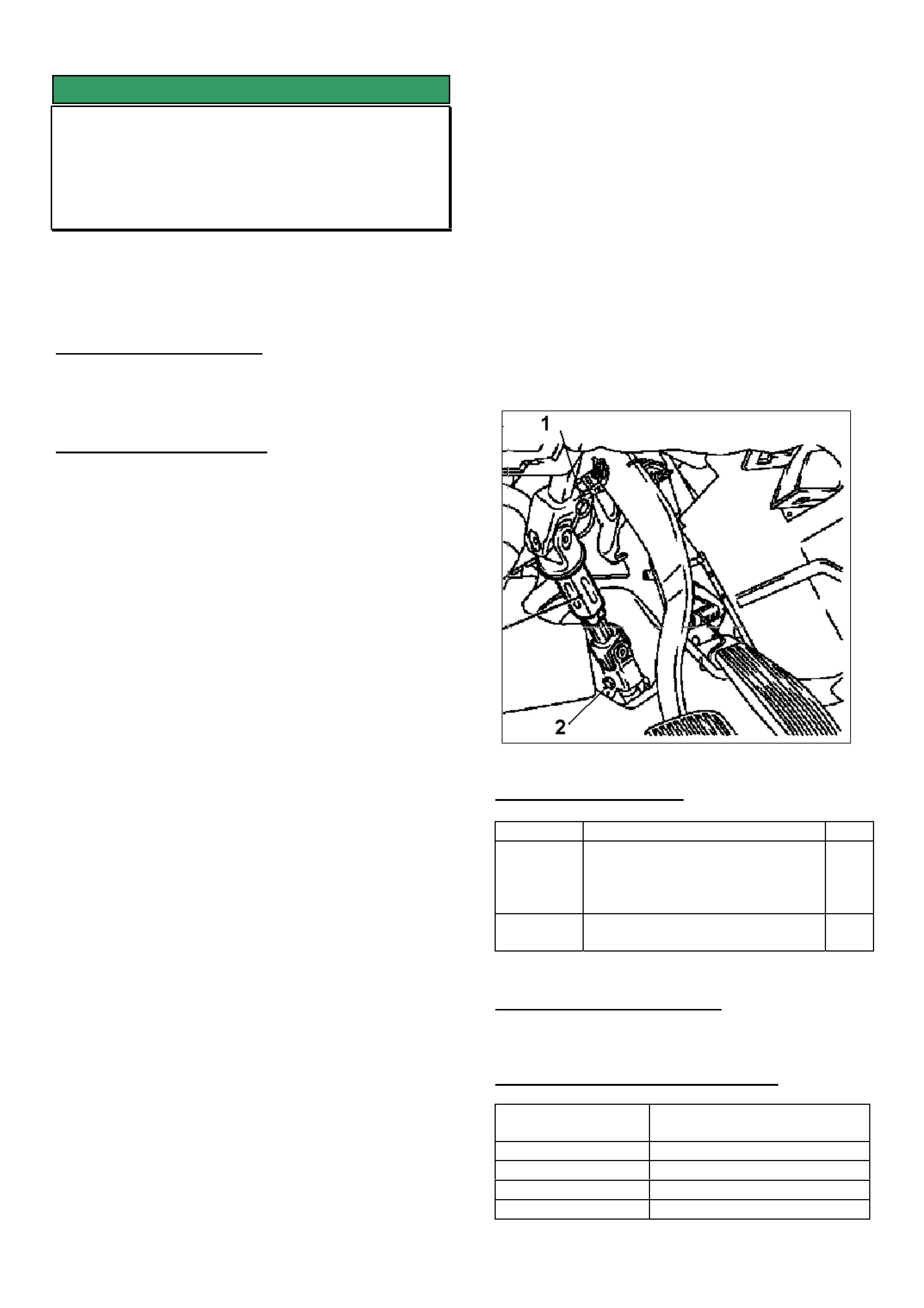

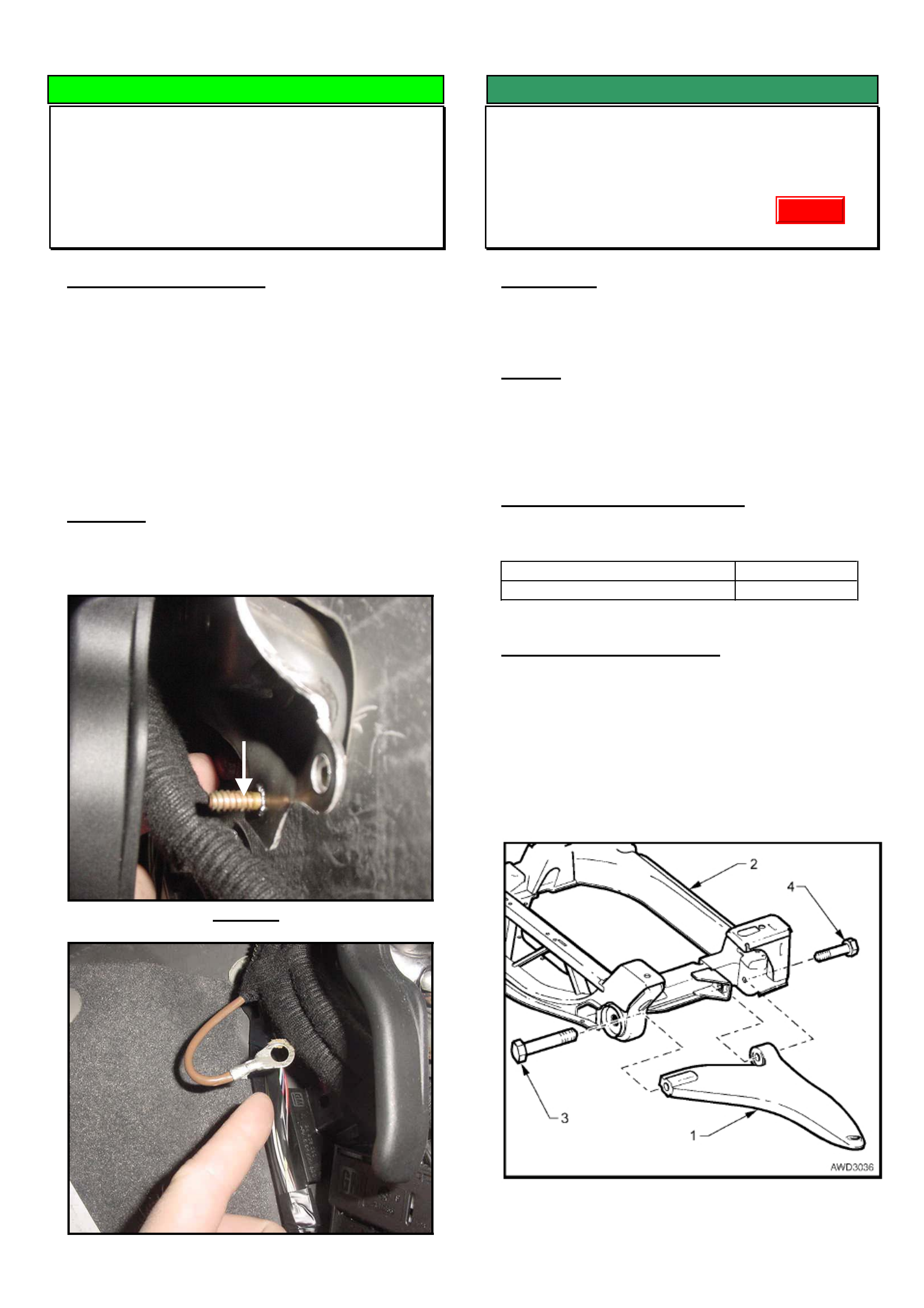

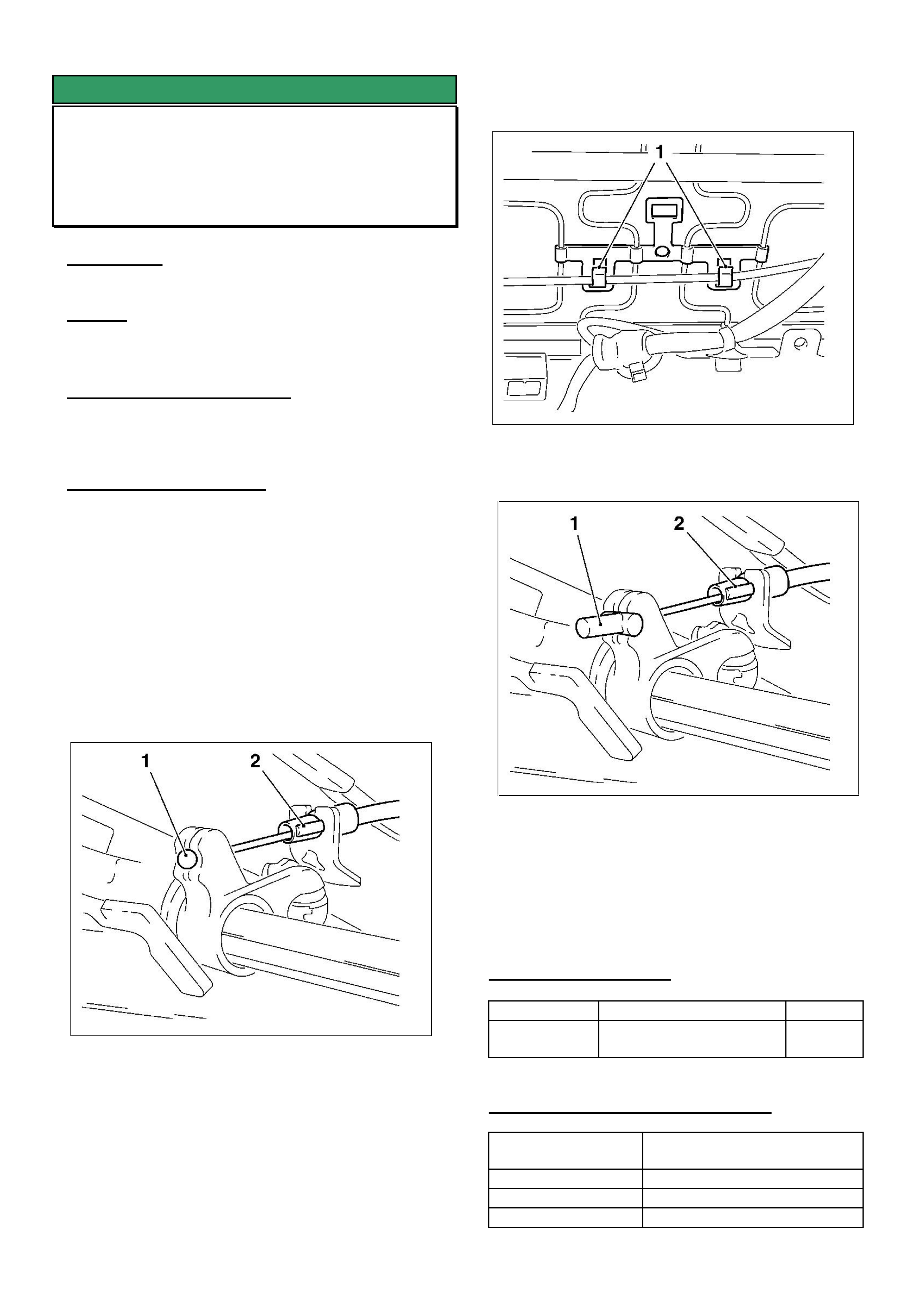

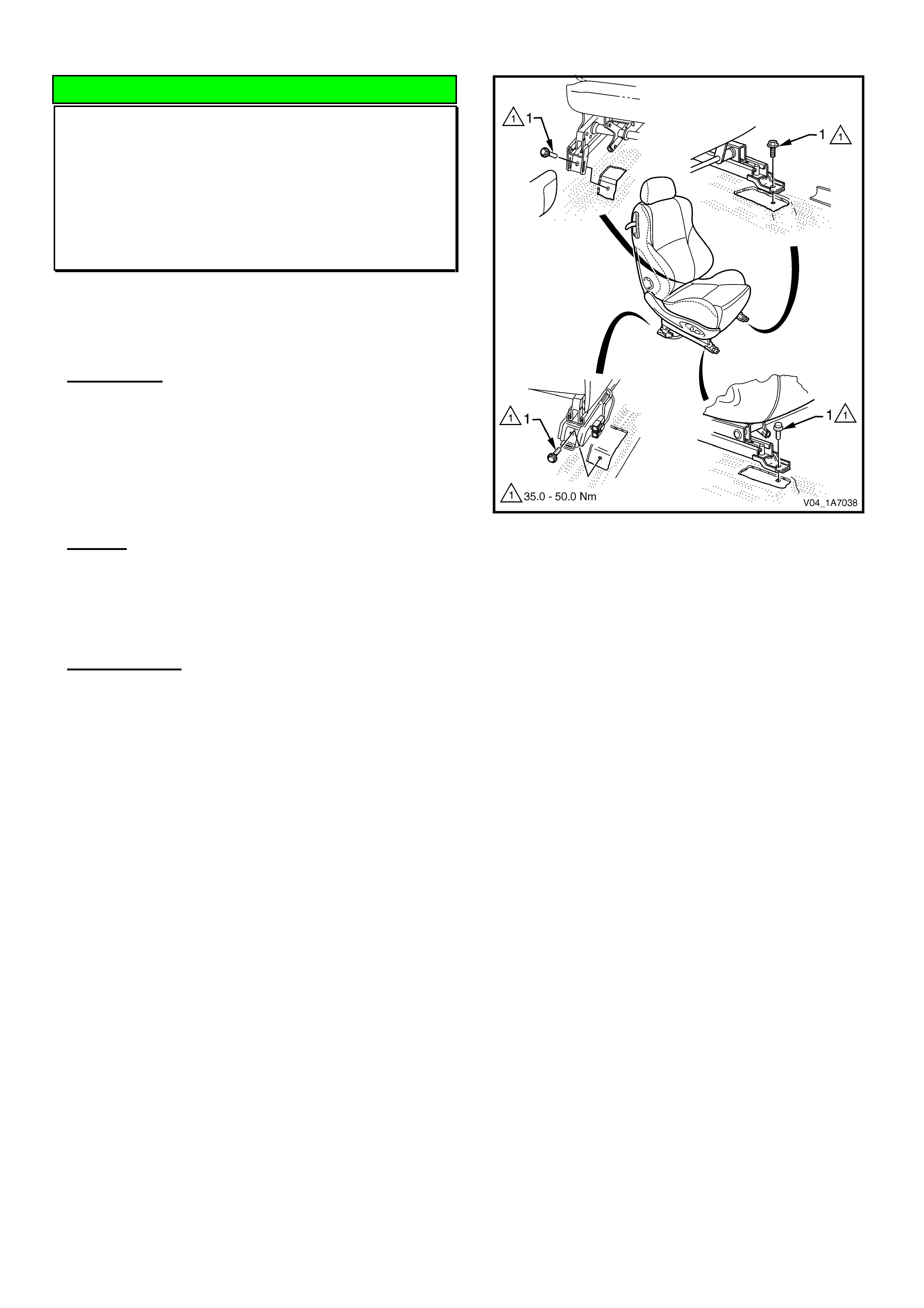

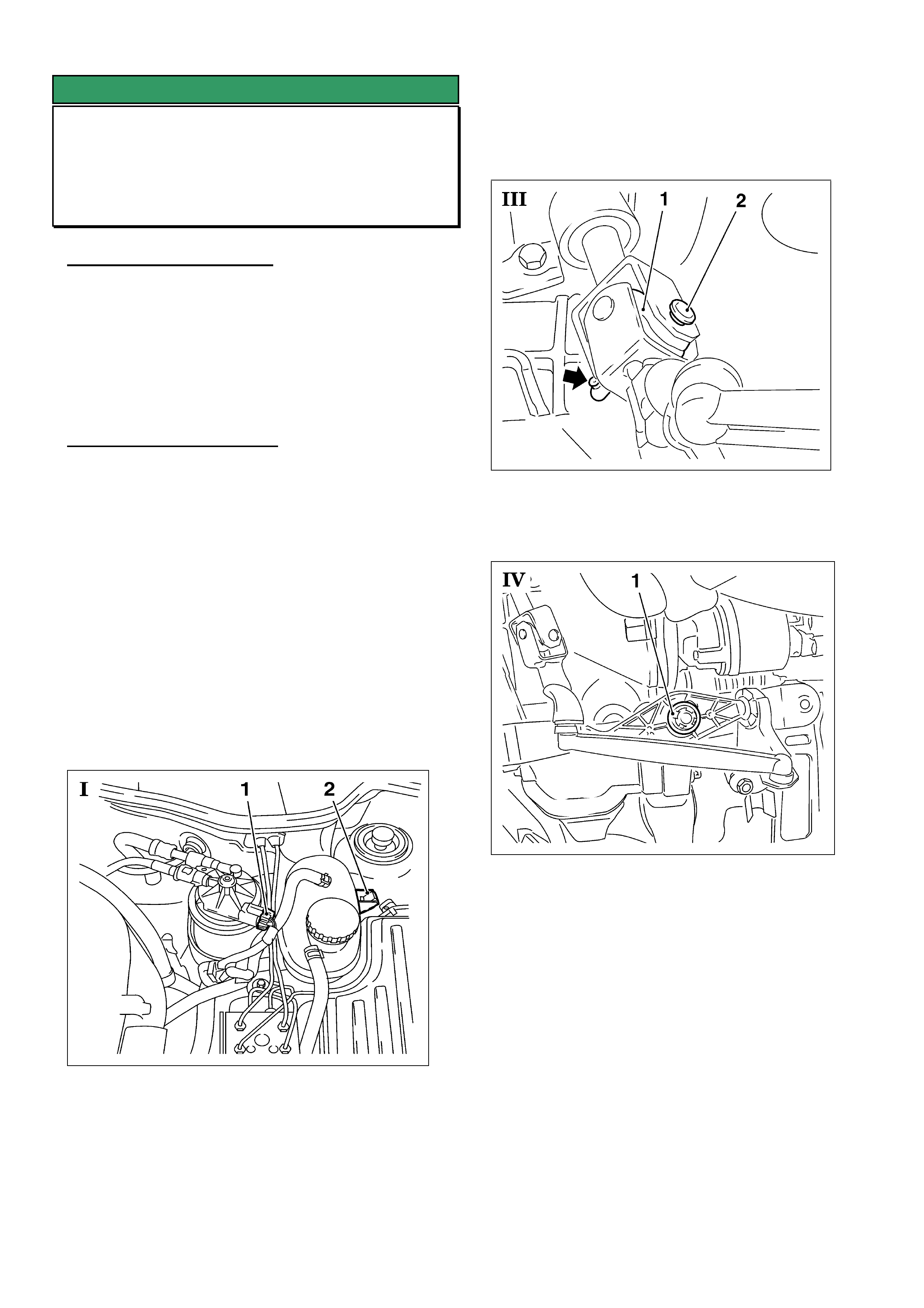

7. Remove the three self tapping screws (1)

retaining the front selector lever pivot assembly,

using a Phillips screwdriver – see Figure 1.

8. Remove the four hex head screws (2) holding the

rear selector lever pivot retaining plate (3), from

the baseplate (4) – see Figure 1.

Figure 1.

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

7

9. Lift the front and rear selector levers and bridging

piece assembly up and out of the shifter base

plate (4) on the transmission, as shown in Figure

1. Ensure the ball seat (7) and seat support ring

(8) remain in the base plate (2) (these parts

shown in Figure 3).

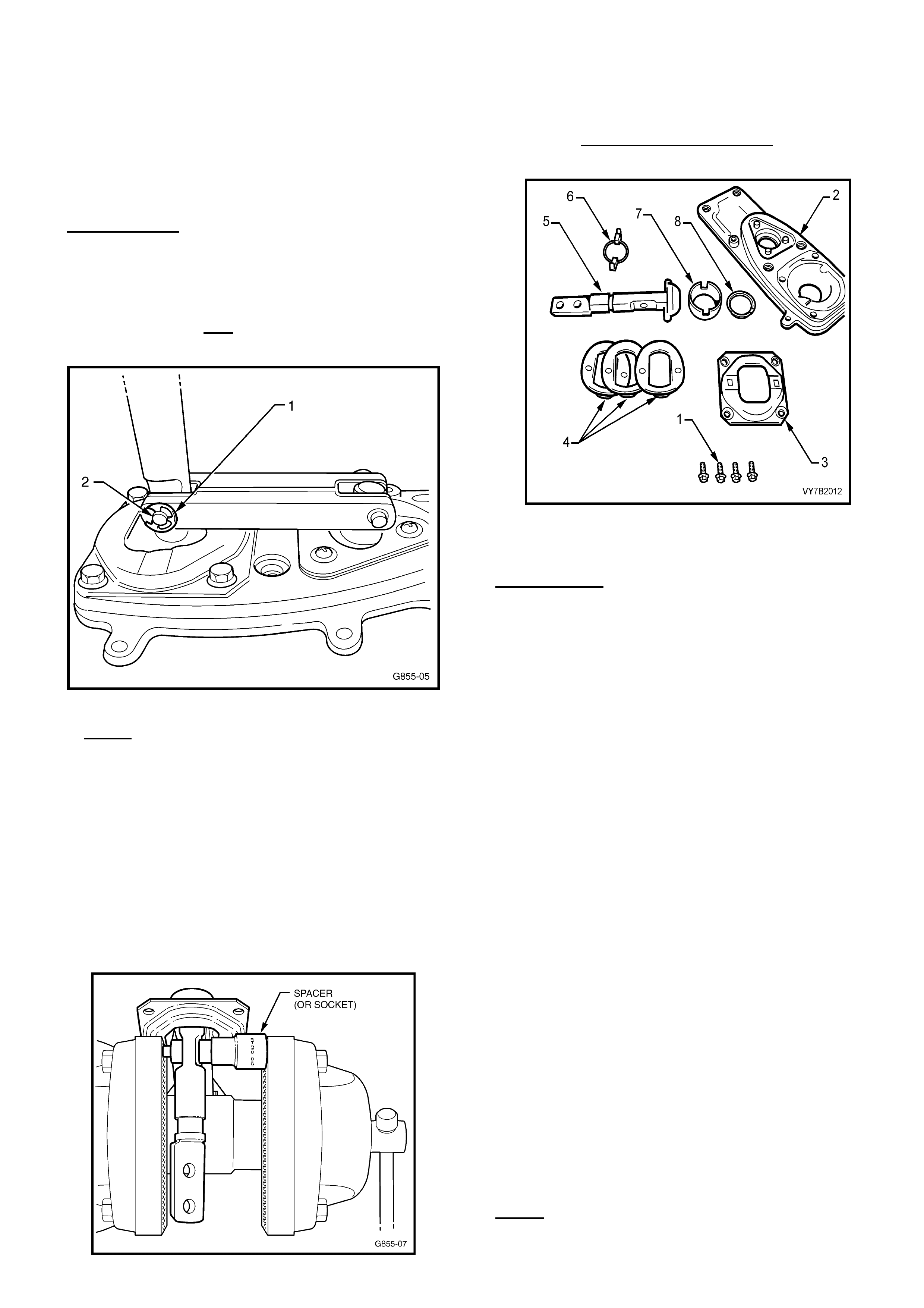

DISASSEMBLE

CAUTION: During the disassembly process - wear

safety glasses to avoid possible eye injury.

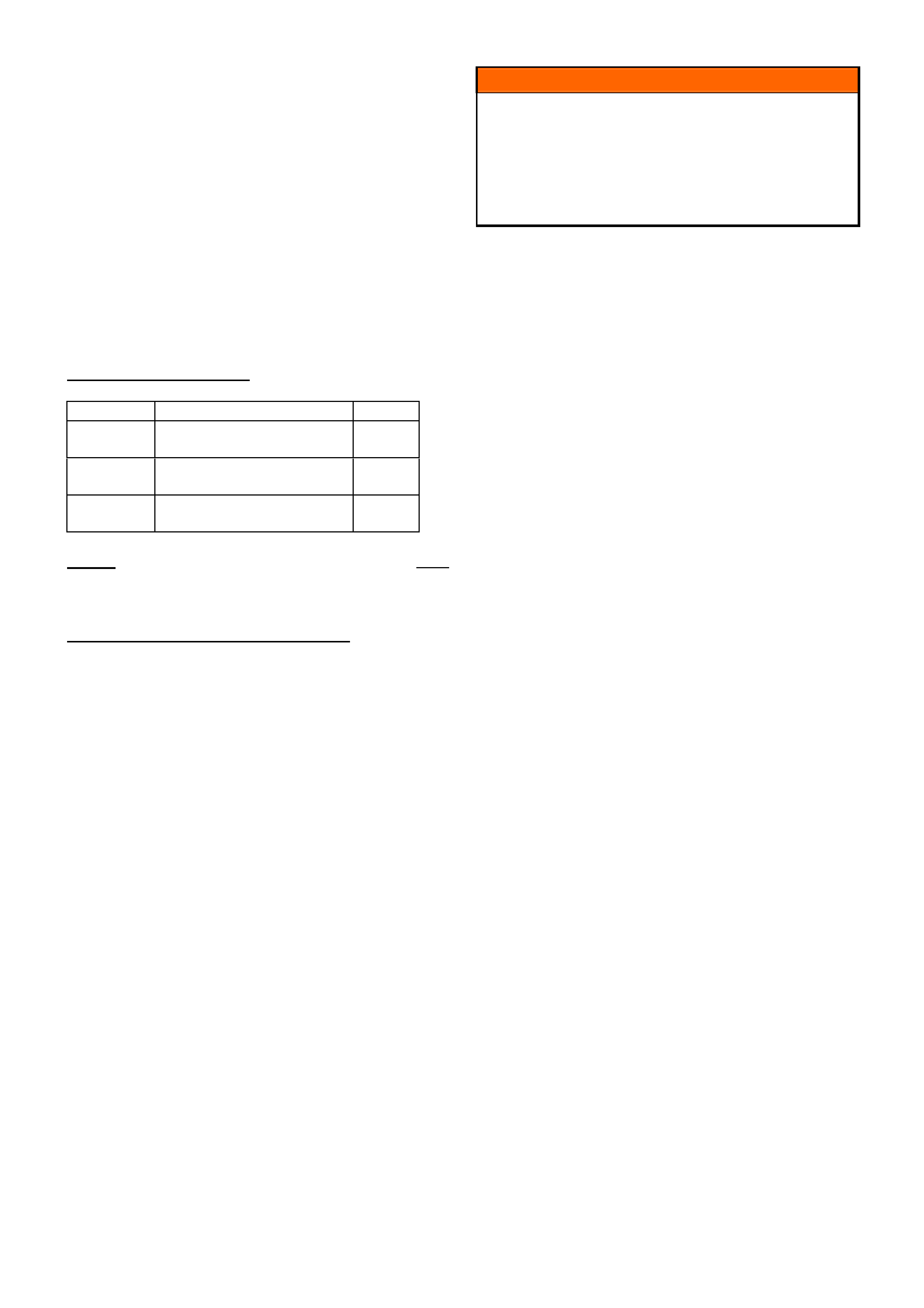

1. Using a small flat bladed screwdriver, remove

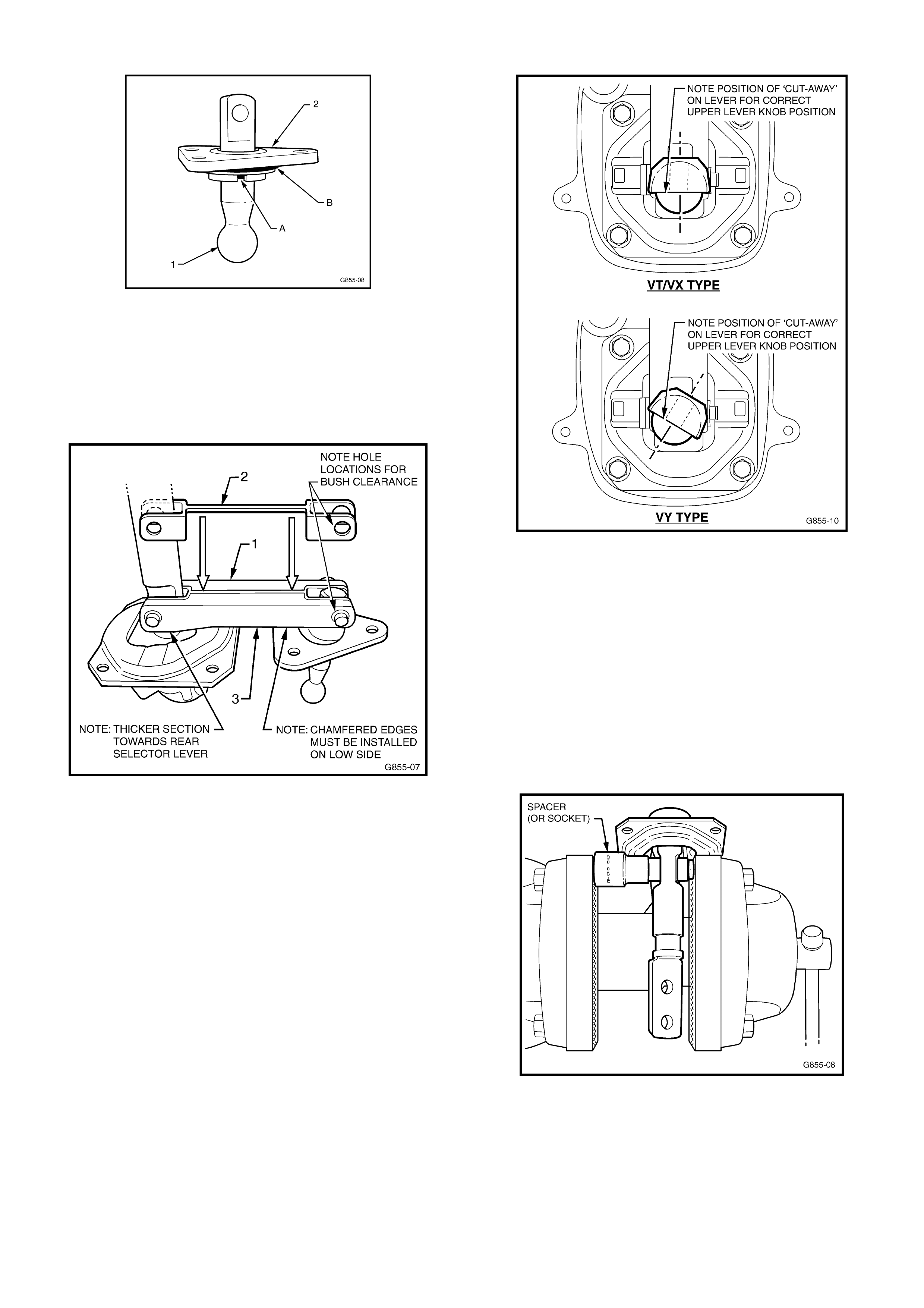

circlip (1) from the rear lever/bridging piece retaining

pin (2) – see Figure 2.

Figure 2.

2. NOTE: BEFORE STARTING THIS STEP note

carefully the position and direction of the shifter upper

lever bolt holes and the shaft ‘cutaway’ for

reassembly! This determines the final position of the

gear lever, and gear knob direction! Refer Figure 5.

Tap or press the retaining pin – see Figure 2A - out of

the rear selector lever and bridging piece. This pin is

an interference fit into the selector lever, and may

need to be pressed out of the assembly. This can be

done by clamping the rear lever/pin in a vice, using a

spacer to fit over the pin head (if a suitable spacer is

not available, a suitable sized socket may be used).

Figure 2A. Rear Selector Lever Pin Removal.

3. After pin removal, retain the rear retaining plate (3),

the wave springs (4), and guide (6) shown in Figure 3

for re-use. Note the order of removal of the wave

springs and guide for re-assembly.

Figure 3 – showing rear selector shaft and rear

pivot components.

REASSEMBLE

Reassembly uses parts 1, 3, 4, 6, 7, 8 (in Figure 3)

and the following new parts in the Shifter Upgrade Kit,

• Front Selector Lever

• Front Selector Lever Retainer (triangular plastic)

• Front Selector Lever Retainer O-Rings (2)

• Rear Selector Lever

• Bridging Piece

• Anti-rattle “bridged” washers (black plastic)

• Pins

• small Bushes (blue plastic)

• Large Bushes (blue plastic)

• Circlips

CAUTION: During the reassembly process - wear

safety glasses to avoid possible eye injury.

1. Place the guide (6), wave springs (4) and rear

retaining plate (3) onto the new rear selector lever

(5) - shown in Figure 3 - in reverse order to their

removal.

NOTE: Apply NLGI No.2 lithium soap based EP

grease with molybdenum disulphide, such as Shell

Retinax HDX2 grease, BP Energrease LMS-EP 23 or

equivalent, to all moving parts in the rear selector

lever assembly.

2. Apply NLGI No. 3 Lithium based EP grease,

such as Shell Retinax LX 3 grease or equivalent, to

the new retainer (triangular ball socket) of the new

front selector shaft, then assemble by hand, pushing

the front selector lever (1) into the plastic retainer (2)

– see Figure 6.

NOTE: ensure the plastic ball retainer is located with

O-ring section toward the ball end of the lever as

shown in Figure 4 below.

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

8

Figure 4 – front selector lever and pivot.

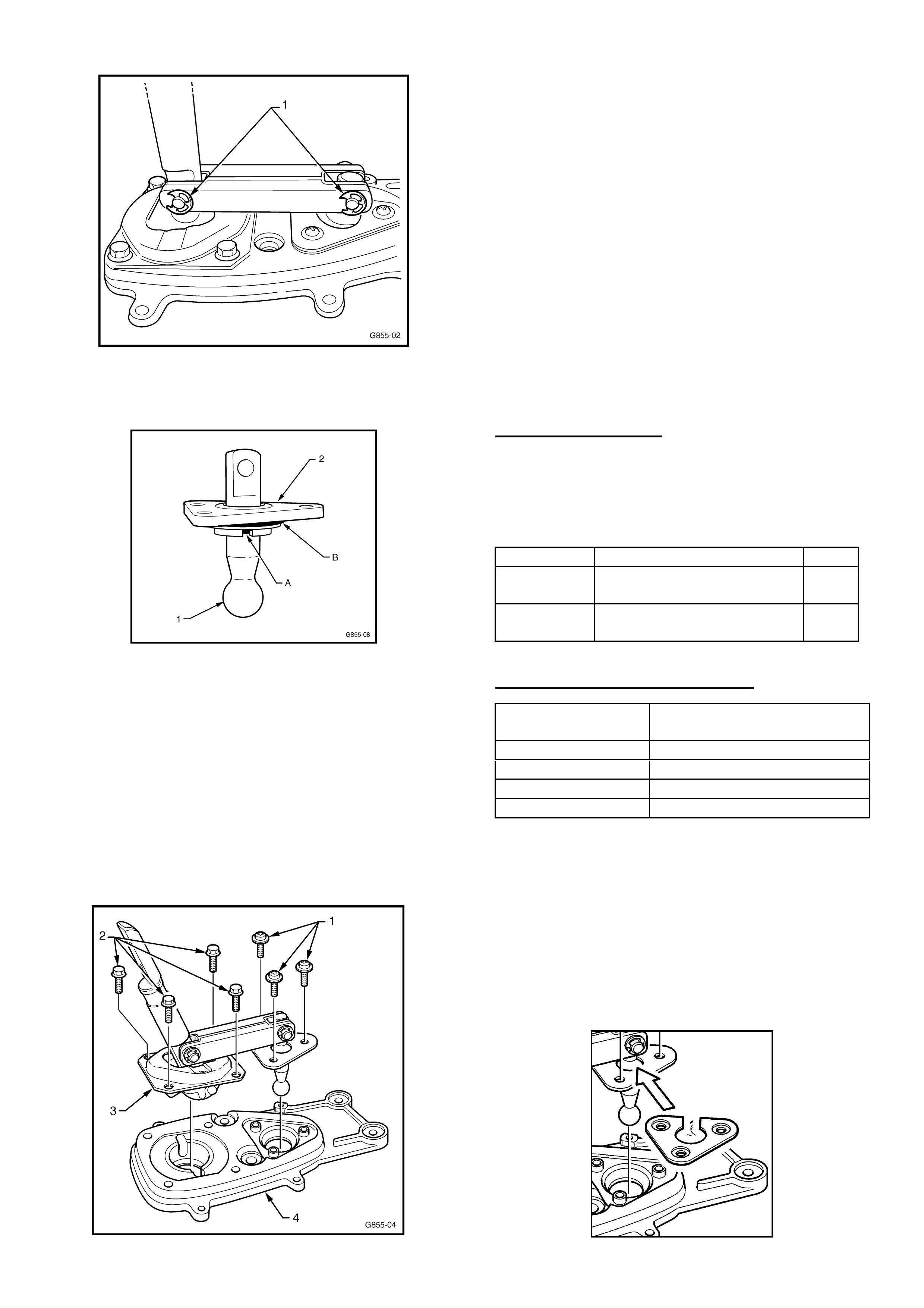

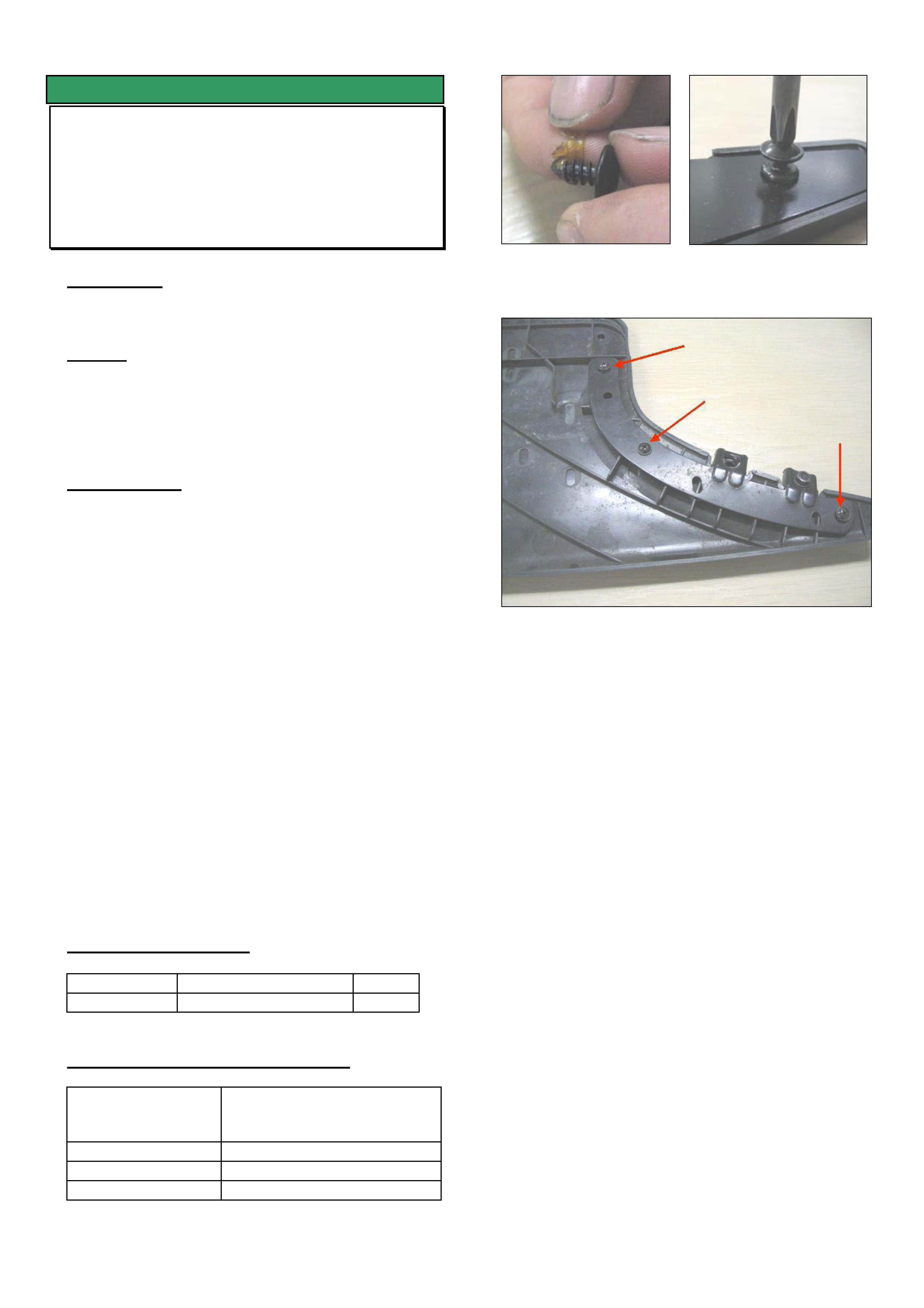

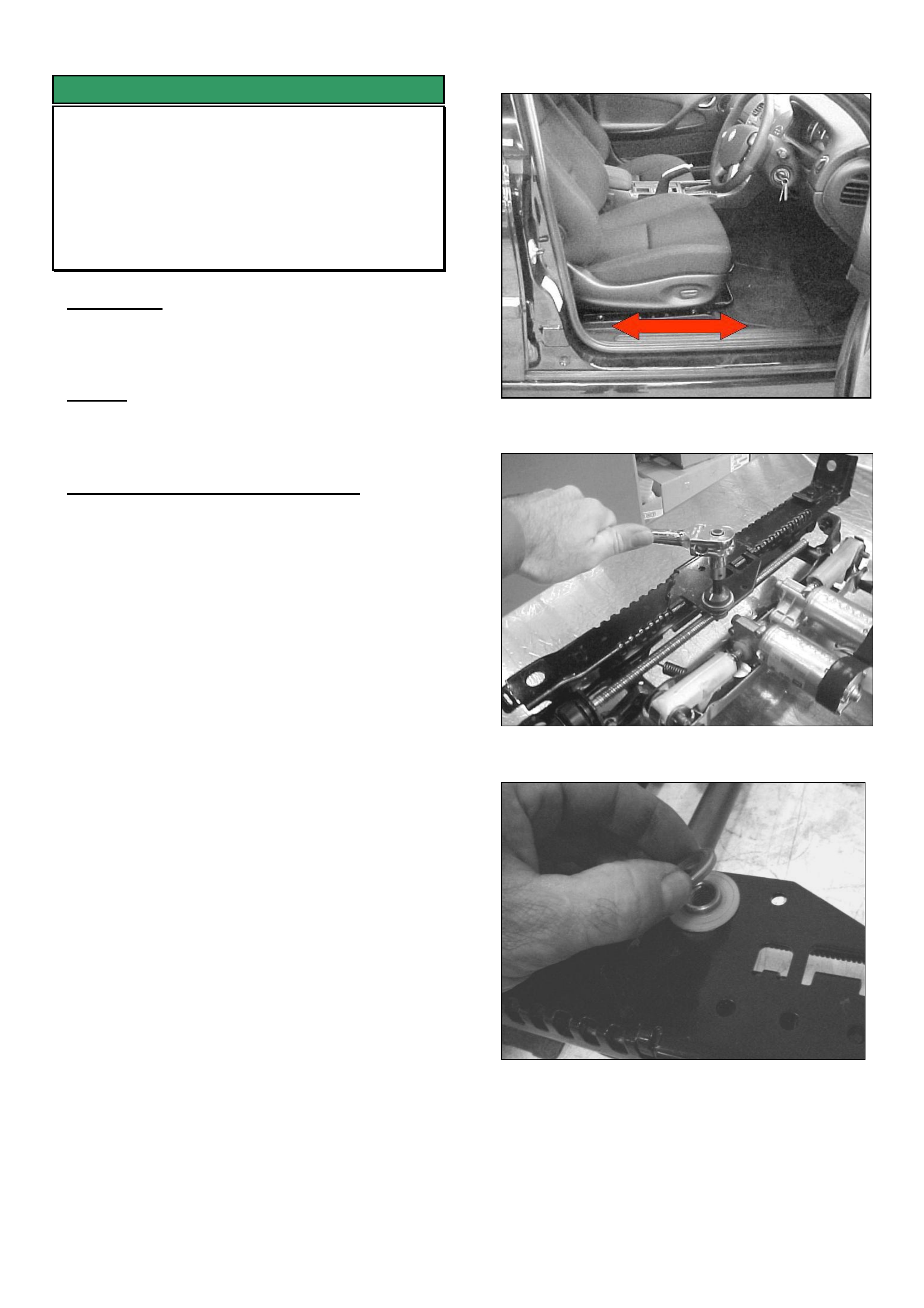

1. Install the new “linked” anti-rattle washers (2) to the

new bridging piece (1) – refer Figure 5 below.

Ensure correct diameter holes match the holes in

the bridging piece.

Figure 5 – showing anti-rattle ‘linked’ washer

location.

4. Install the new (blue) bushes to the bridging piece

(outer) holes after lubricating with a NLGI No. 3

Lithium based EP grease, such as Shell Retinax LX

3 grease, or equivalent. . Ensure the bushes are in

the correct size holes in the bridging piece/anti-rattle

washers.

5. Install the new bridging piece assembly (3) to the

two new front and rear selector lever assemblies –

refer Figure 4 above. NOTE: Ensure that the rear

selector lever top retaining screw ‘cut-away’ and

holes are positioned the same way as when

removed from the shifter, and the chamfer on the

bridging piece is to the bottom, as shown in Figure 5

above. Figure 6 shows the correct location of rear

selector lever for both types of shifter:

Figure 6. Shows correct ‘cut-away’ and hole

locations.

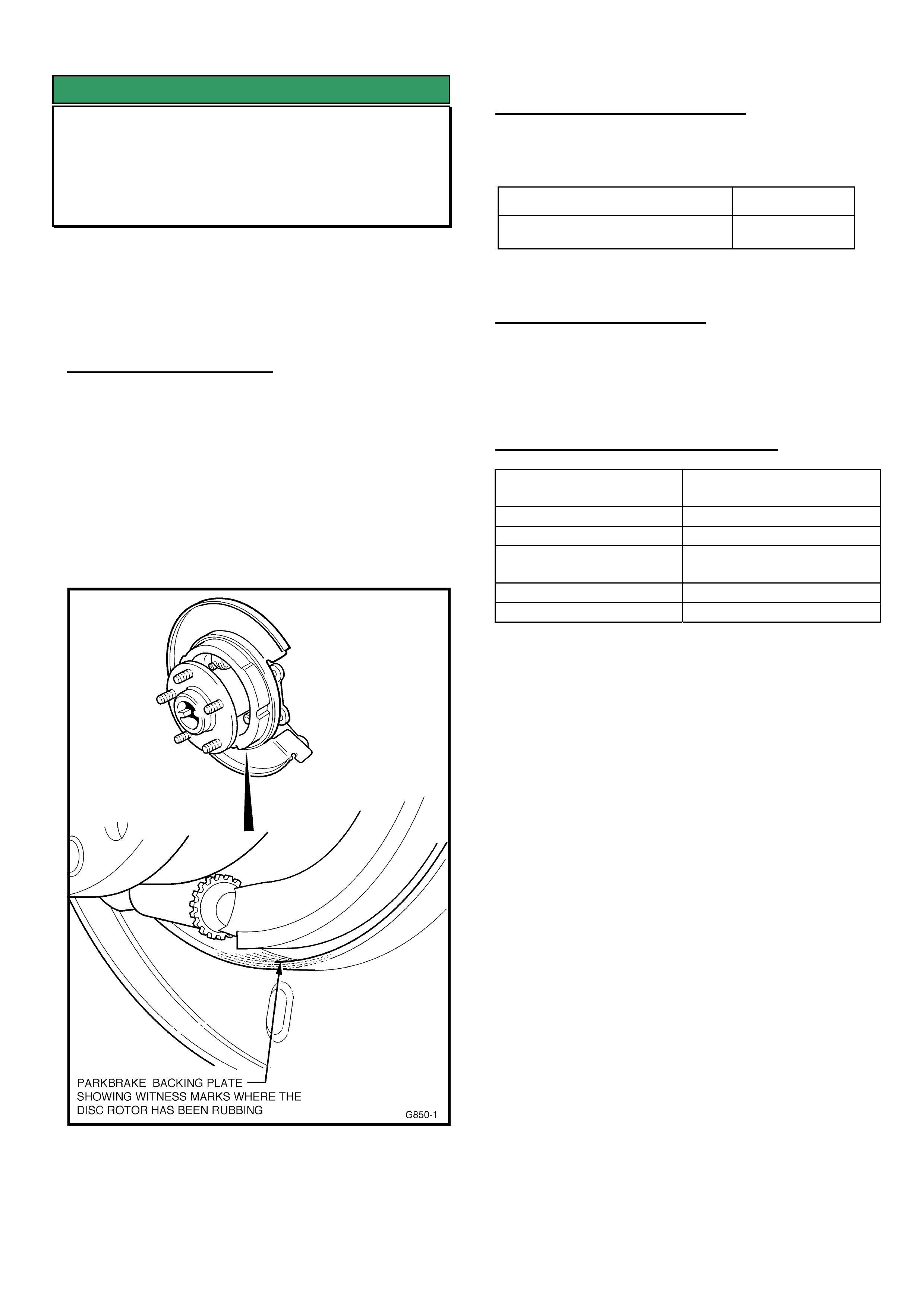

6. Install new pivot pins to bridging piece/selector

levers and press home by clamping in a vice - use a

spacer to fit over the pin circlip grooved pin end and

blue bush (if a suitable spacer is not available, a

suitable sized socket may be used). Refer Figure 7.

NOTE: the pins fit easily into the bushes and

bridging piece holes, but are an interference fit into

the lever holes – after initial pressure to start the

pins into the lever holes – STOP - inspect the pin

installation for straightness - then complete the

pressing operation.

Figure 7. Selector Lever Pin Installation.

7. When the pin head butts up against the blue bush,

stop the pressing operation so that the bushes and

bridged washers are not damaged, then fit new

circlips (1) to secure each pin – refer Figure 8.

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

9

Figure 8. – Circlips in final installed position.

8. Install new O-ring seals ‘A’ & ‘B’ to front selector

lever ball socket (2) – see Figure 9.

Figure 9 – front selector lever and pivot.

9. Reinstall the assembled bridging piece/selector

levers (3) into the base plate (4) on the

transmission and reinstall the four rear retaining

plate bolts (2) – see Figure 9 - tightening to the

correct torque specification: 10 –12 Nm.

10. Reinstall the front selector pivot assembly retaining

screws (1) to the baseplate (4) on the transmission

– see Figure 10 - tightening to the correct torque

specification: 5-8 Nm. Note: If a triangular metal

reinforcing plate was fitted to the shifter – refer to

Additional Information at the end of this Techline.

Figure 10.

11. Reinstall dust cover and boot assembly (4 screws)

to the remote shifter assembly on the

transmission.

12 Reinstall the gearshift remote lever boot and plate

and secure to the floor pan as follows:

Early build vehicles – install the four bolts, from

inside the vehicle, tightening to the correct torque

specification: 6-14 Nm.

Later build vehicles - install the four nuts, with

vehicle raised on a hoist, tightening to the correct

torque specification: 15 Nm.

13 Reinstall the gear shift knob/boot/lever assembly

and console/console cap as per procedures in

Passenger SIP Sections 7B3 and 1A3 for the

relevant model.

14 Reinstall the battery ground lead.

PARTS INFORMATION

Use Figure 6 (above) for identification of the shifter

type fitted to the vehicle. To do this, remove the

console boot to determine the angle of the gear lever

retaining bolts and cut-away. Select the correct part

number kit as follows:

Part No.: Description: Qty

92147248 VT/VX type Shifter

Upgrade Kit

1

92147246 VY type Shifter Upgrade

Kit

1

WARRANTY CLAIM INFORMATION

Description Shifter Asm – Rattle

Upgrade

Labour Op. No K000294

Time 1.0 hr

Failure Code 28 rattle

Failure Code NOW K0028

Additional Information:

If a shifter assembly removed from a vehicle is fitted with

the triangular metal reinforcing plate shown below, the

triangular plate and retaining screws (which are longer

than standard screws) should be refitted to the shifter

assembly before reassembly Step 10 above. This action

is only as a precaution, as the new front lever pivot

(white plastic) is a stronger material than the original

part which makes fitting of triangular reinforcing plates

no longer necessary.

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

10

SERVICE FIX

Intermediate Steering Shaft Knock

JR, JS

(GROUP 9) REVISED TL362A-0209

This Service Techline supersedes the previous techline

on this topic TL362-0209 (Issue 9/2002). It is revised

by adding information on greasing the Intermediate

shaft.

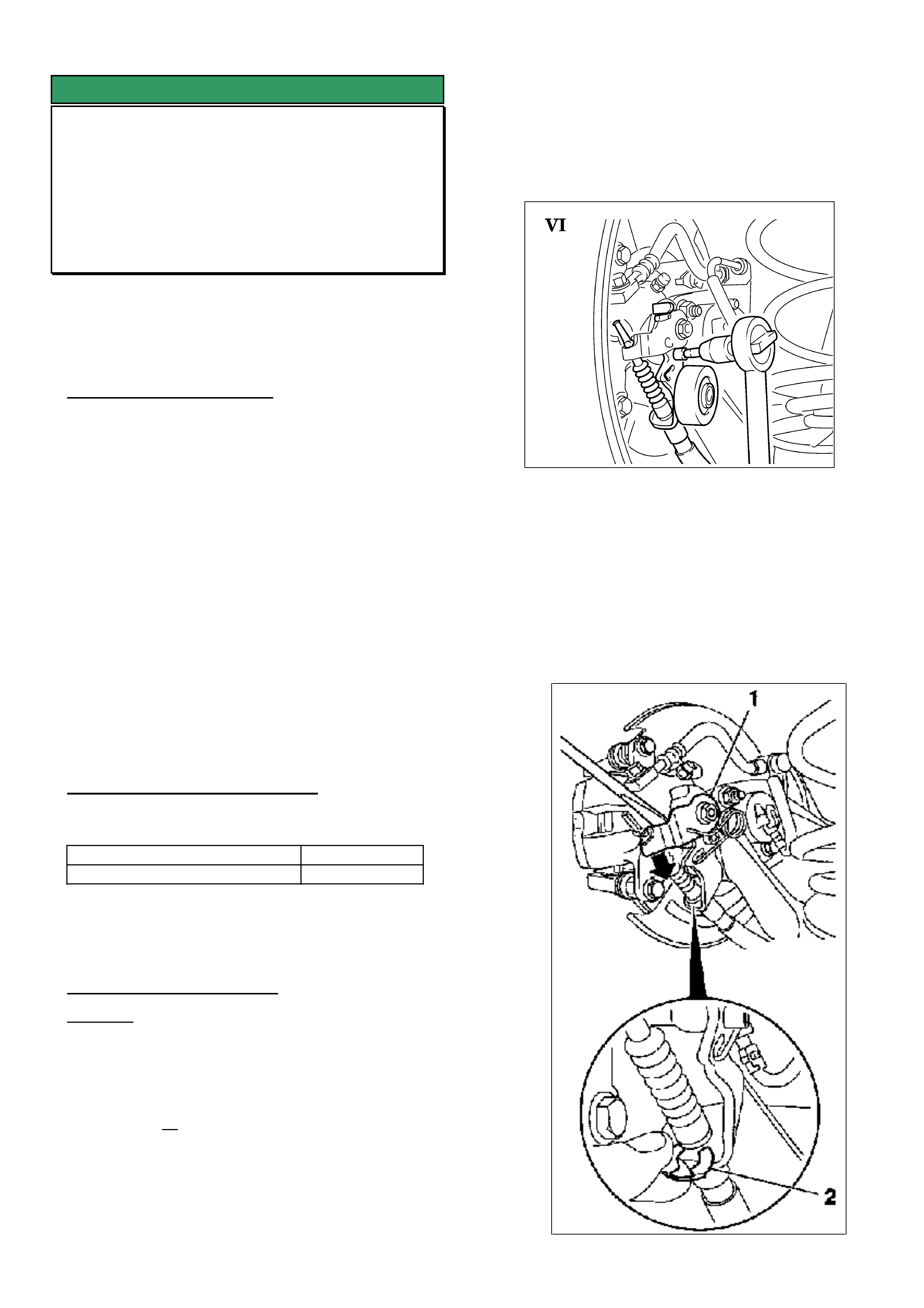

PROBLEM DESCRIPTION

A knocking noise on turns caused by clearances within

the steering intermediate shaft components.

SERVICE RECTIFICATION

Summary: On complaint vehicles, replace the

intermediate steering shaft with a new shaft as per

following procedure. If the vehicle has previously been

fitted with a new shaft and still knocks, simply remove

the shaft and add grease as per following procedure

1. IMPORTANT: Disconnect the battery and wait at

least 1 minute for the capacitor in the control unit to

discharge. (Airbag safety precautions as outlined in

service manual Volume 1 must be observed).

2. Centre the steering wheel.

3. Remove foot well panels and air ducting.

4. Loosen the pinch bolts of the steering

intermediate shaft (Nos.1 and 2) and engage the

steering lock, see Figure 1.

5. Compress the steering intermediate shaft and

remove.

6. Unless already installed, fit a new steering

intermediate shaft kit 09119322.

IMPORTANT. Prior to installation, disassemble the

intermediate shaft and grease the sliding area with

grease p/n 90512280. Reassemble the shaft and

slide a few times to spread grease.

7. Release the ignition steering lock, then secure the

shaft using new pinch bolts (Torx screws) and an

appropriate thread locking sealant.

8. Torque the upper and lower pinch bolts to:

22 Nm/16 lbf.ft + 45° + 15°.

Failure to tighten these bolts correctly could result

in not eliminating the knock condition.

9. Refit air ducting and foot well panels.

10. Mark the steering wheel position and remove the

steering wheel using special tool Puller KM 210-A.

11. Offset the steering wheel 2 teeth to the right.

12. If necessary, with a screwdriver, depress the

clock spring locking tab and move the clockspring

until the driving lugs on the steering wheel locate

correctly into the clockspring.

13. Refit the steering wheel and secure the fastening

nut with the locking plate supplied.

Torque to 25 Nm/18 Ibf.ft.

14. Refit the air ducts and foot well panels.

15. Reconnect the battery.

16. Test drive the vehicle and ensure that the steering

is centered.

Figure 1.

PARTS INFORMATION:

Part No. Description Qty.

09119322 Repair Kit - Steering Coupling

Joint (consists of revised shaft,

2 Torx screws, 1 locking

washer)

1

90512280 Grease (High adhesion type)

100 gram

1

SPECIAL TOOL REQUIRED:

KM-210-A Puller

WARRANTY CLAIM INFORMATION

Description Repair Kit - Steering

Coupling Joint - Replace

Labour Op. No. E000302

Time 0.8 hr

Failure Code 28 rattle

Failure Code NOW E0028

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

11

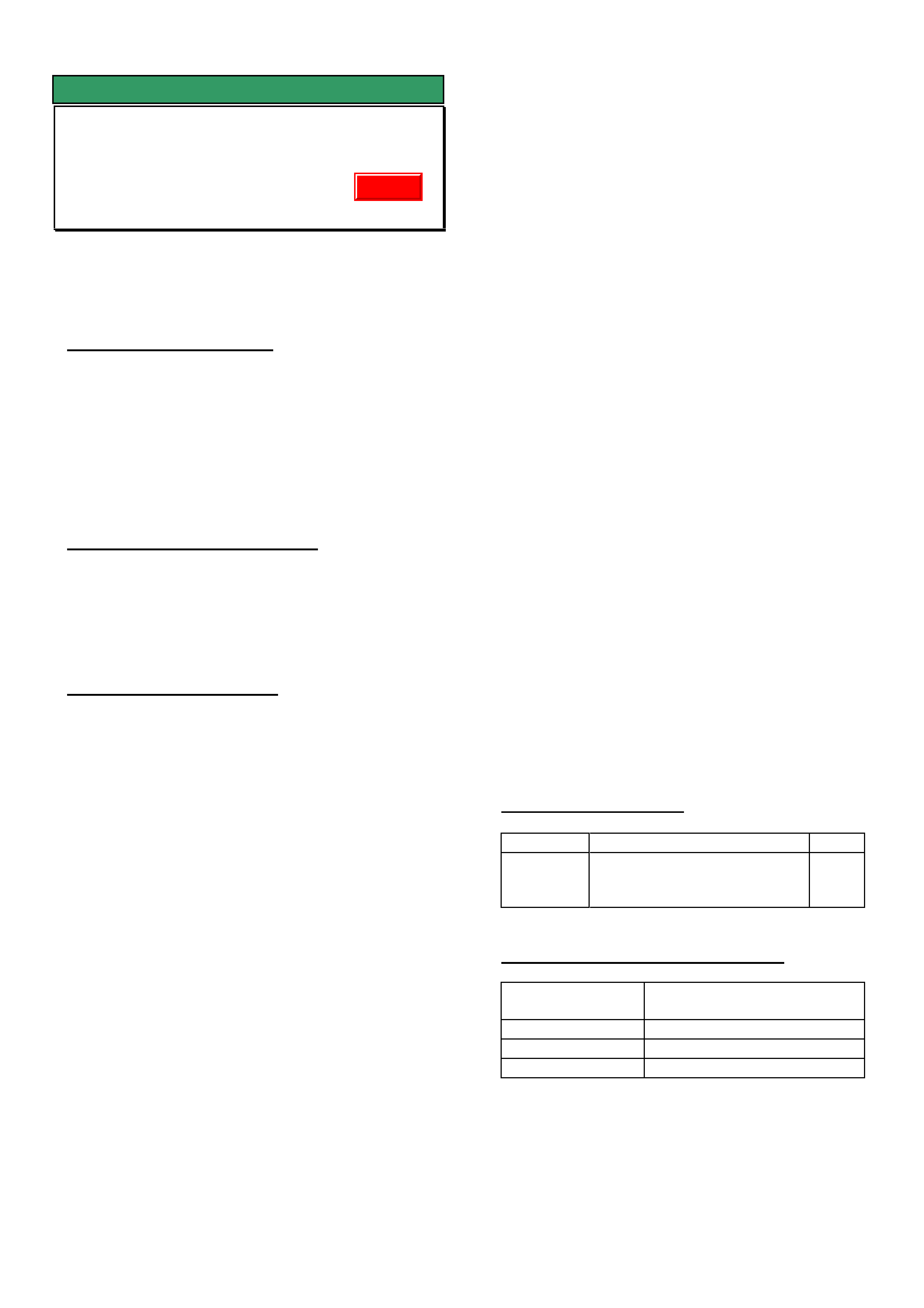

SERVICE FIX

Rear Disc Brake Scraping Noise

VY Regular Cab & Crewman

(GROUP 5) REVISED TL0555B-0401

This Techline supercedes TL0555A-0310 in issue 10,

2003. It is revised by changing Service Rectification

from replacing rear axle asm. to machining the rear

disc brake rotors. This information was also released

in DL 6403 dated 16 Dec 03.

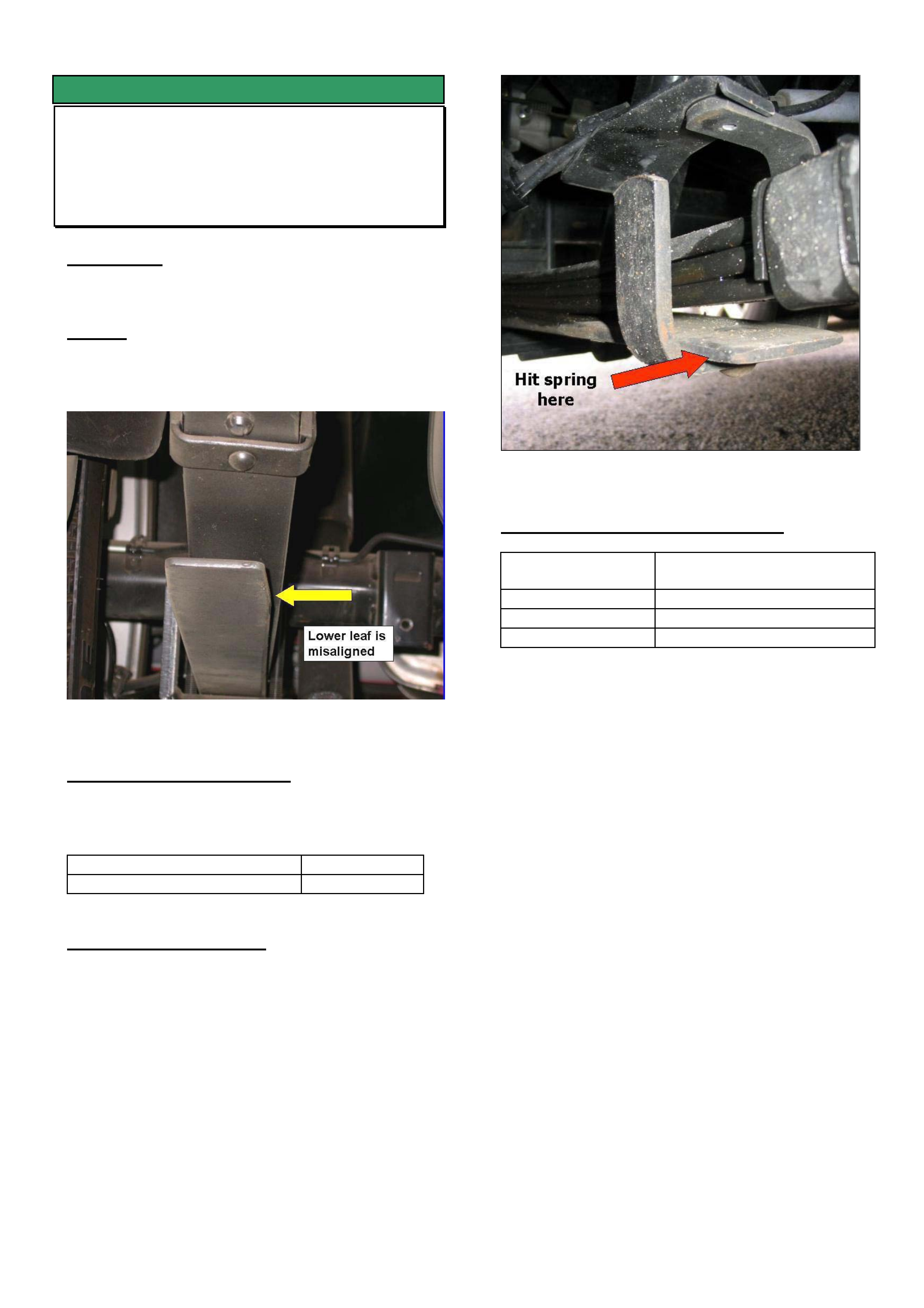

PROBLEM DESCRIPTION

Some vehicles may experience a scraping noise from

the rear brakes when loaded, cornering or travelling

over bumps at low speed.

Investigations show this noise is caused by the disc

brake rotor scraping on the backing plate sealing

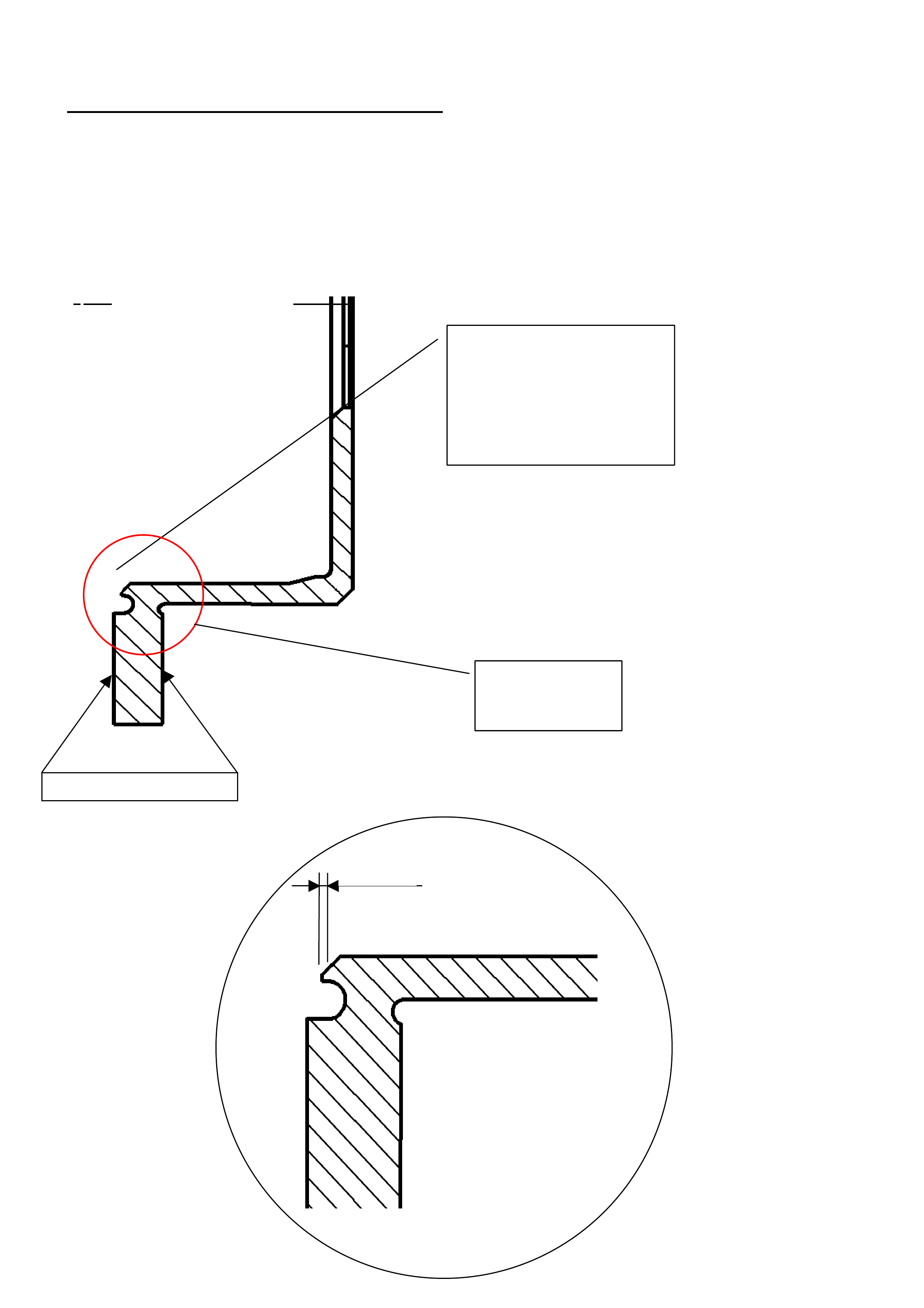

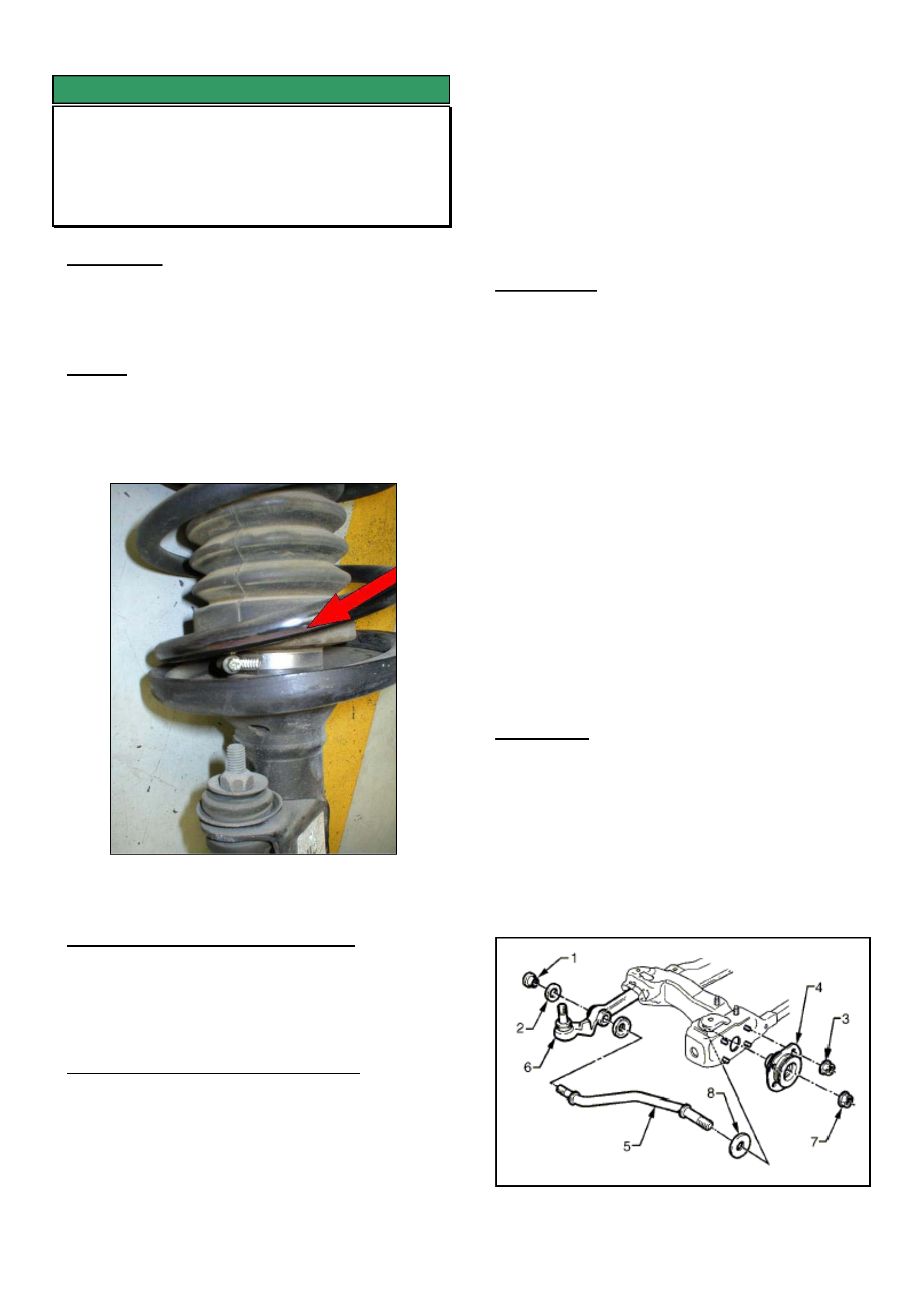

flange, because of insufficient clearance. Figure 1

below shows typical rear backing plate “scrape”

marks on the sealing flange - with disc brake rotor

removed

Figure 1.

PRODUCTION RECTIFICATION

Revised rear brake discs to provide clearance to the

backing plate were fitted from:

ISOVIN No.: Build Date:

6G1YK03F64L225326 23/01/2004

SERVICE RECTIFICATION

Summary: Machine the rear disc brake rotors as per

procedure on next page.

WARRANTY CLAIM INFORMATION

Description Remove, Machine & Re-

install Rear Brake Discs

Labour Op. No. H000257

Standard Time 0.4 hr

Add time for

Machining

0.4 hr

Failure Code 31

Failure Code NOW H0031 Poor Machining

NOTE: If machining is sublet, claim expense in “net

items” column. Please note that add times cannot be

claimed when work is sublet

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

12

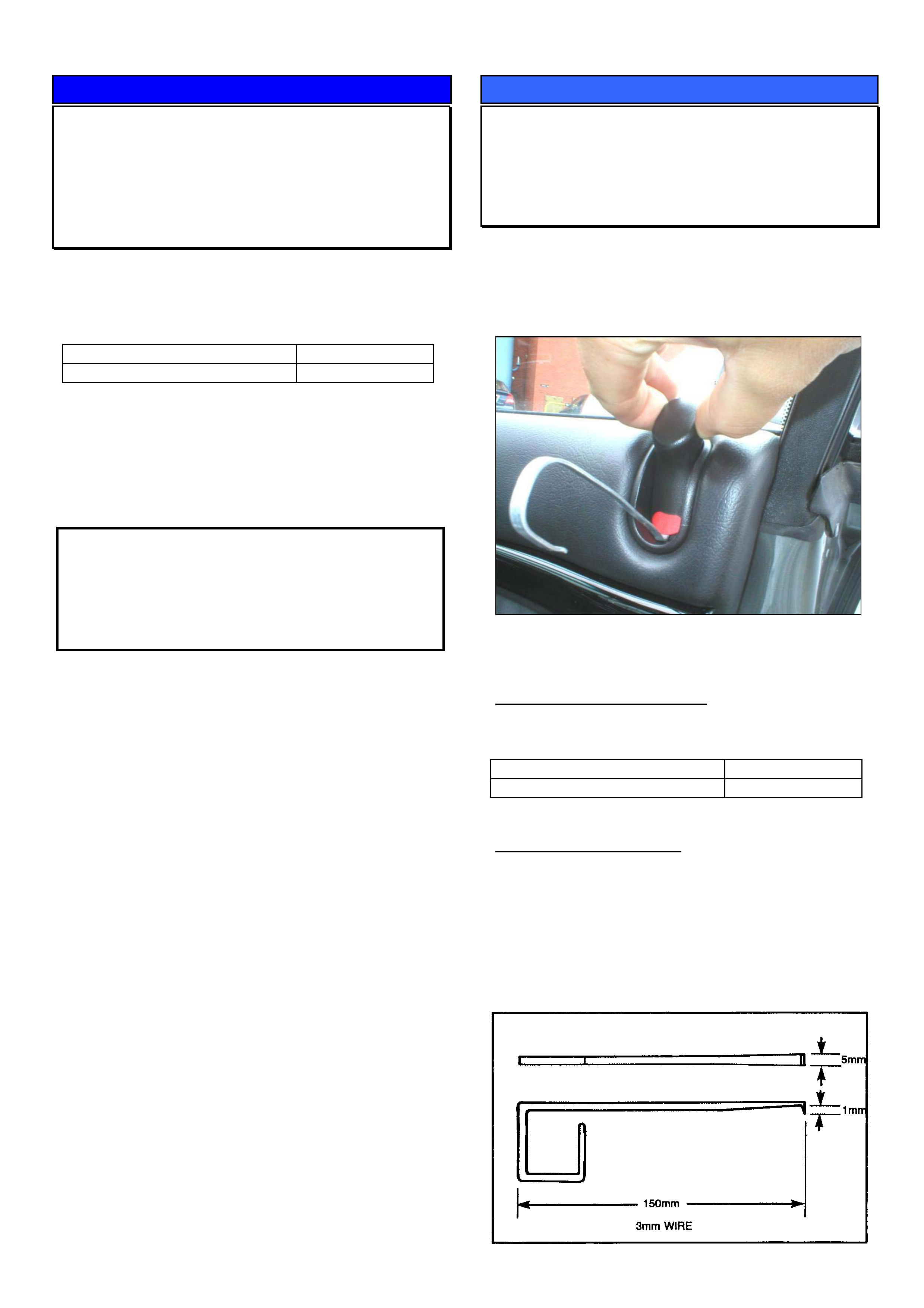

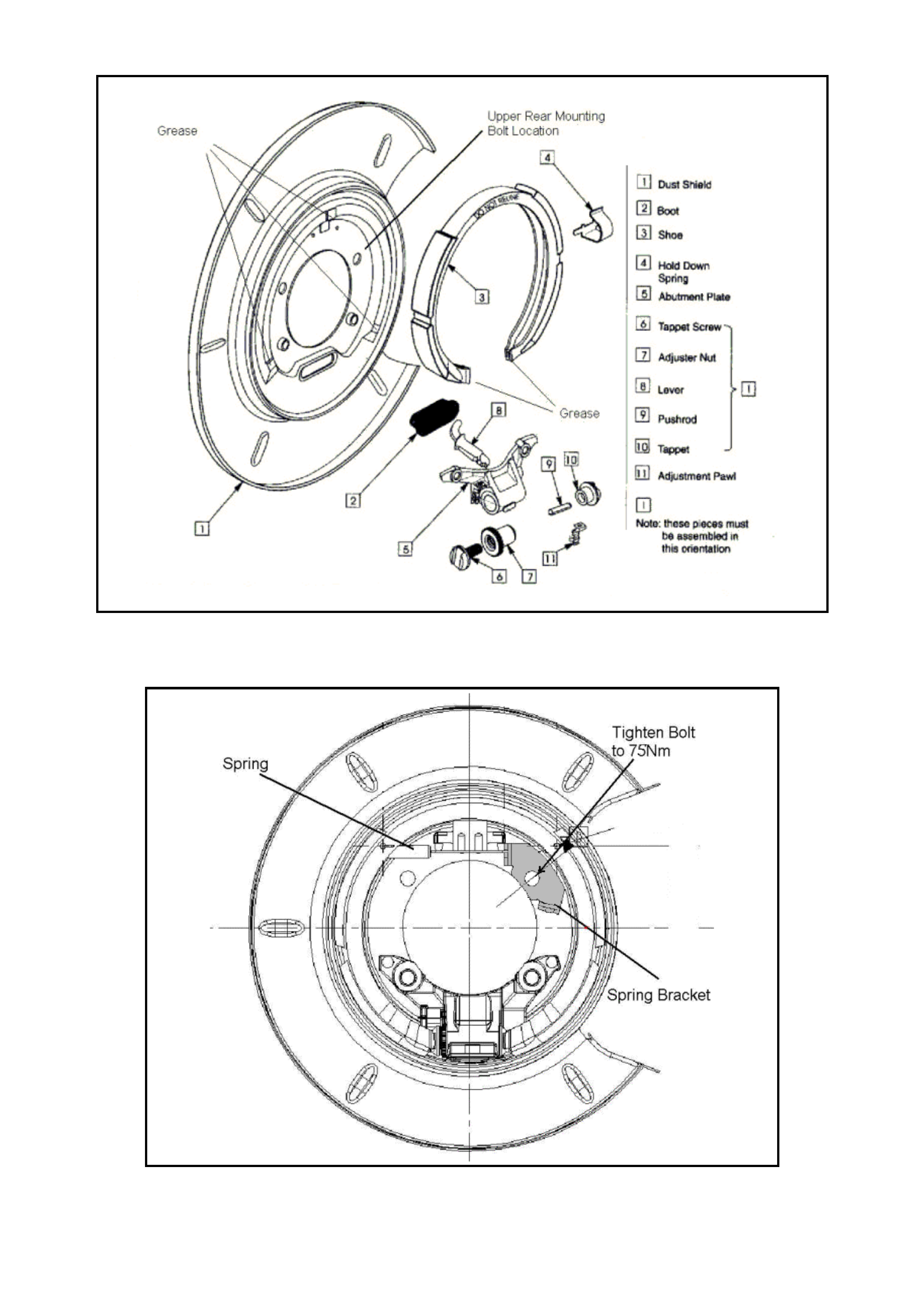

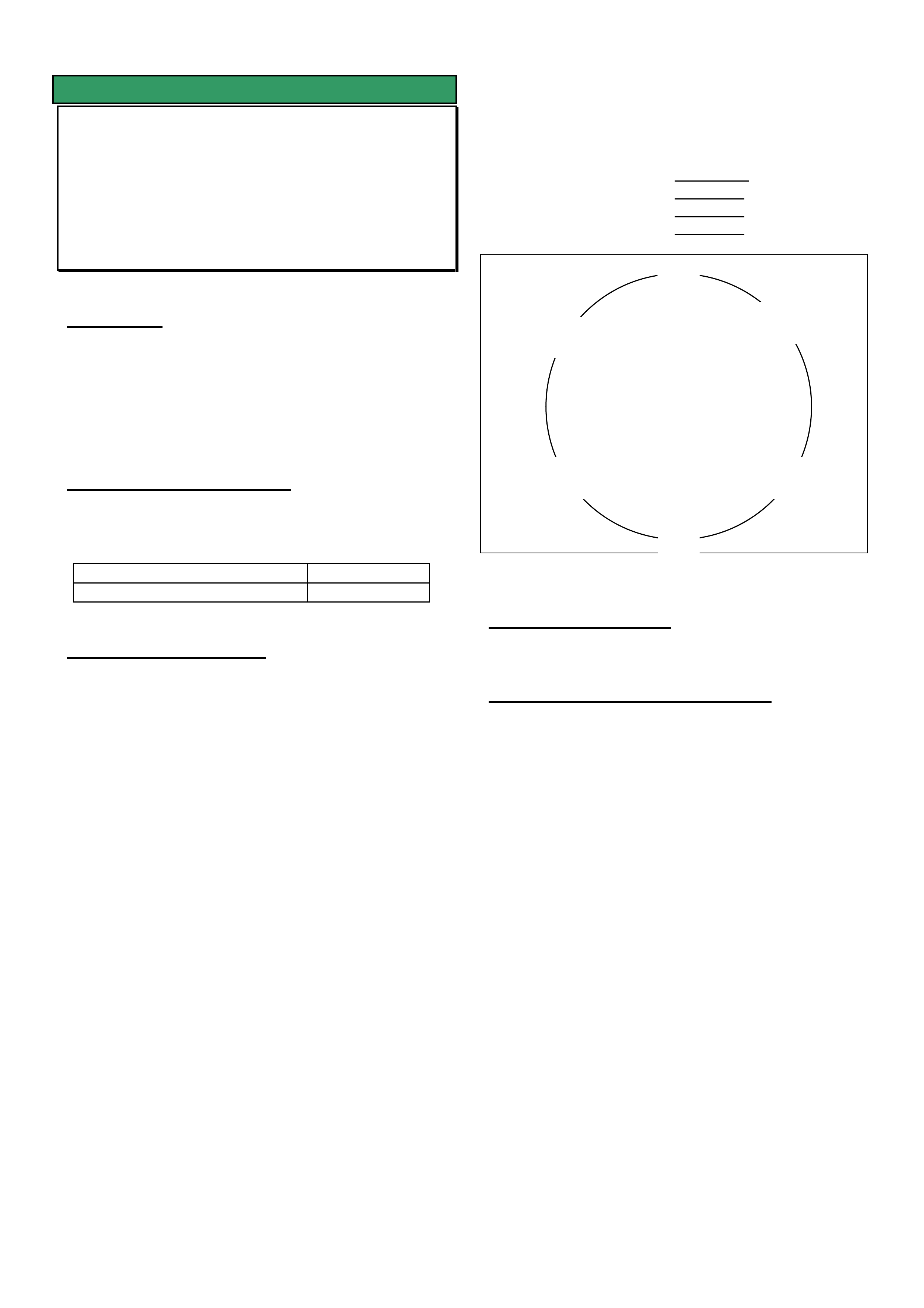

REAR BRAKE DISC MACHINING PROCEDURE

1. Prior to removing brake discs ensure they are marked with side of vehicle and stud position, so that on re-

installation they are put back in the same position. This is to ensure that the least possible installed runout is

achieved.

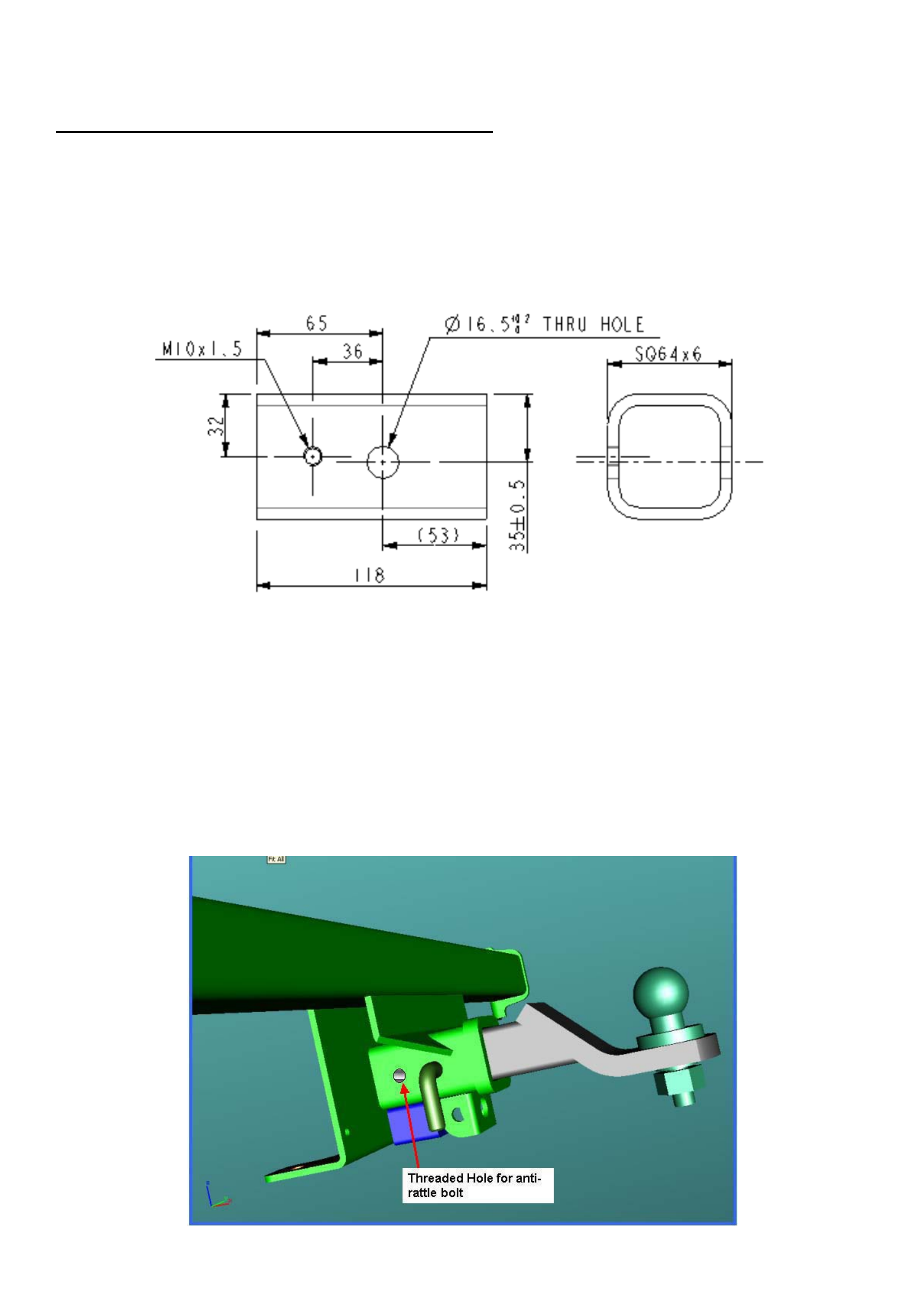

2. Machine inner lip of the disc as per the drawings below.

3. Re-install brake discs.

1mm

±

Remove 1 mm of material

parallel to the disc friction

surface. See enlarged figure

below for detail. This is to

increase clearance between the

rotor and dust shield to

eliminate scra

p

e

Brake disc section

where machining is

required

Centre line of disc

Friction surfaces of disc

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

13

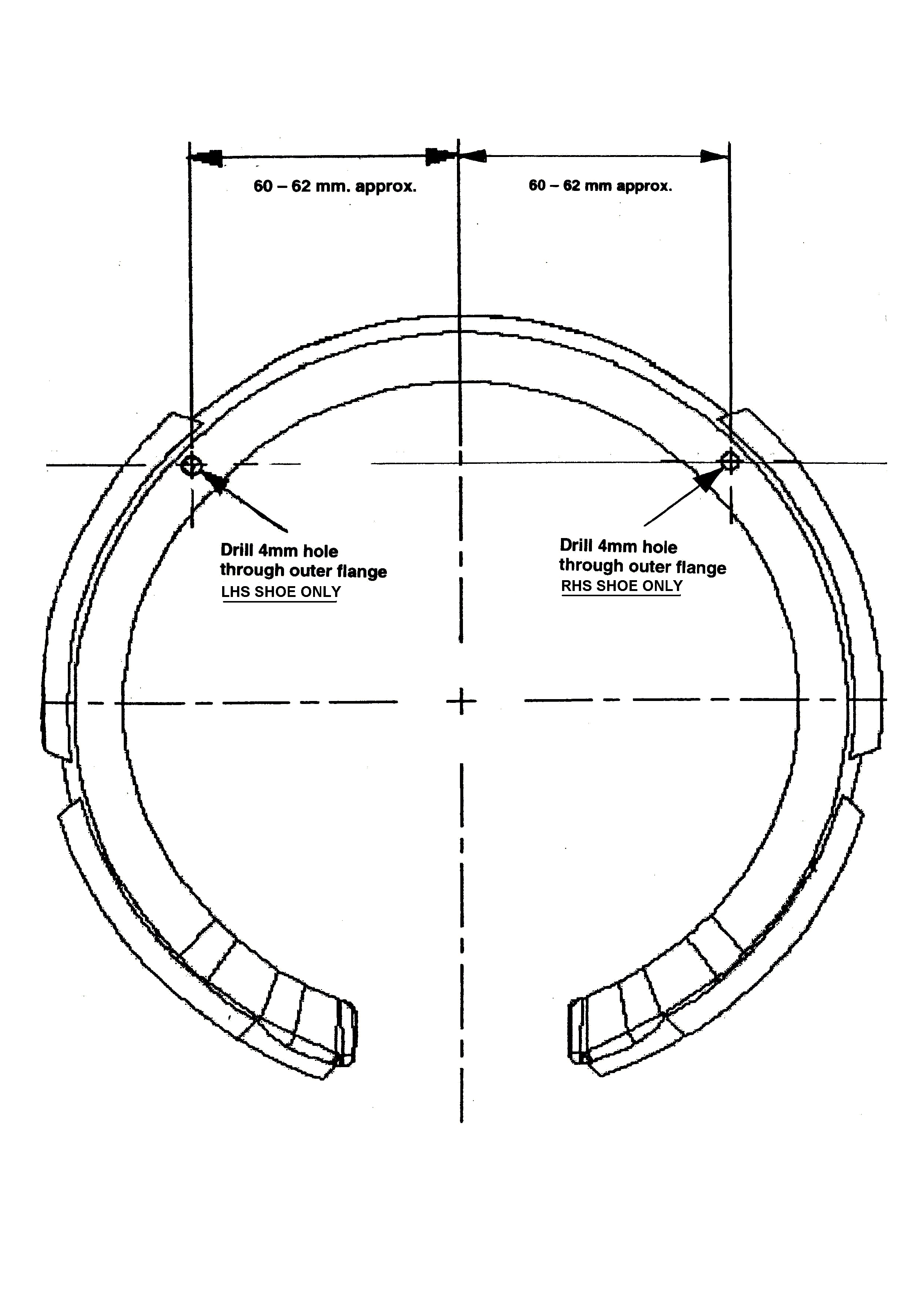

SERVICE FIX

Ignition Module Failure

XC & Z14XE

(GROUP 6Y) TL0611-0401

PROBLEM DESCRIPTION

On some vehicles the ignition coil module may fail

causing the engine to misfire and/or the vehicle not to

start. Diagnostic Troubles Codes P0300, P0301,

P0302, P0303, P0304 may be logged.

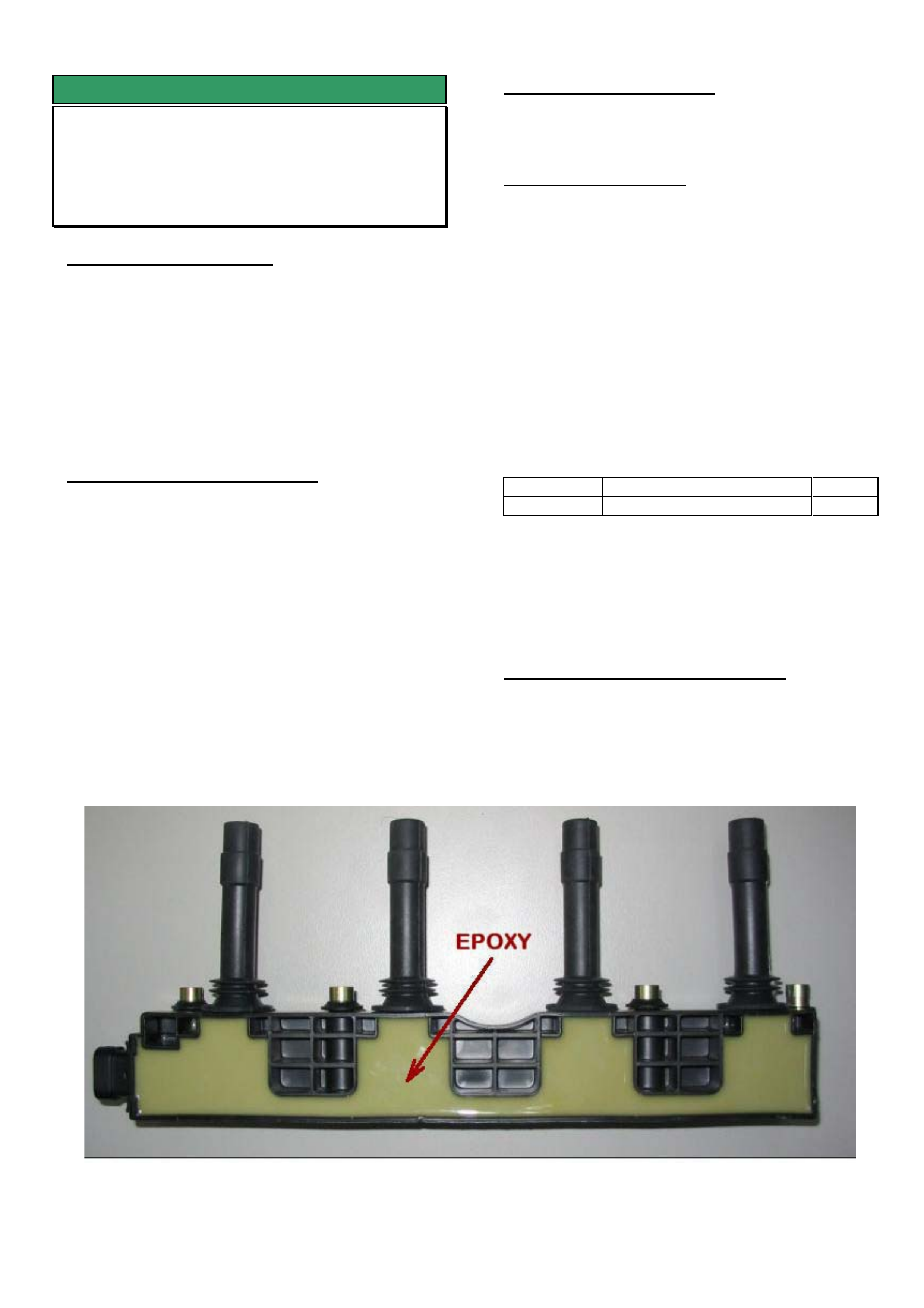

This problem is caused by the epoxy in the ignition

module becoming brittle and cracking, resulting in

internal arcing.

PRODUCTION RECTIFICATION

The corrective action for this problem has been to

replace the epoxy in the ignition module with a new

type of epoxy.

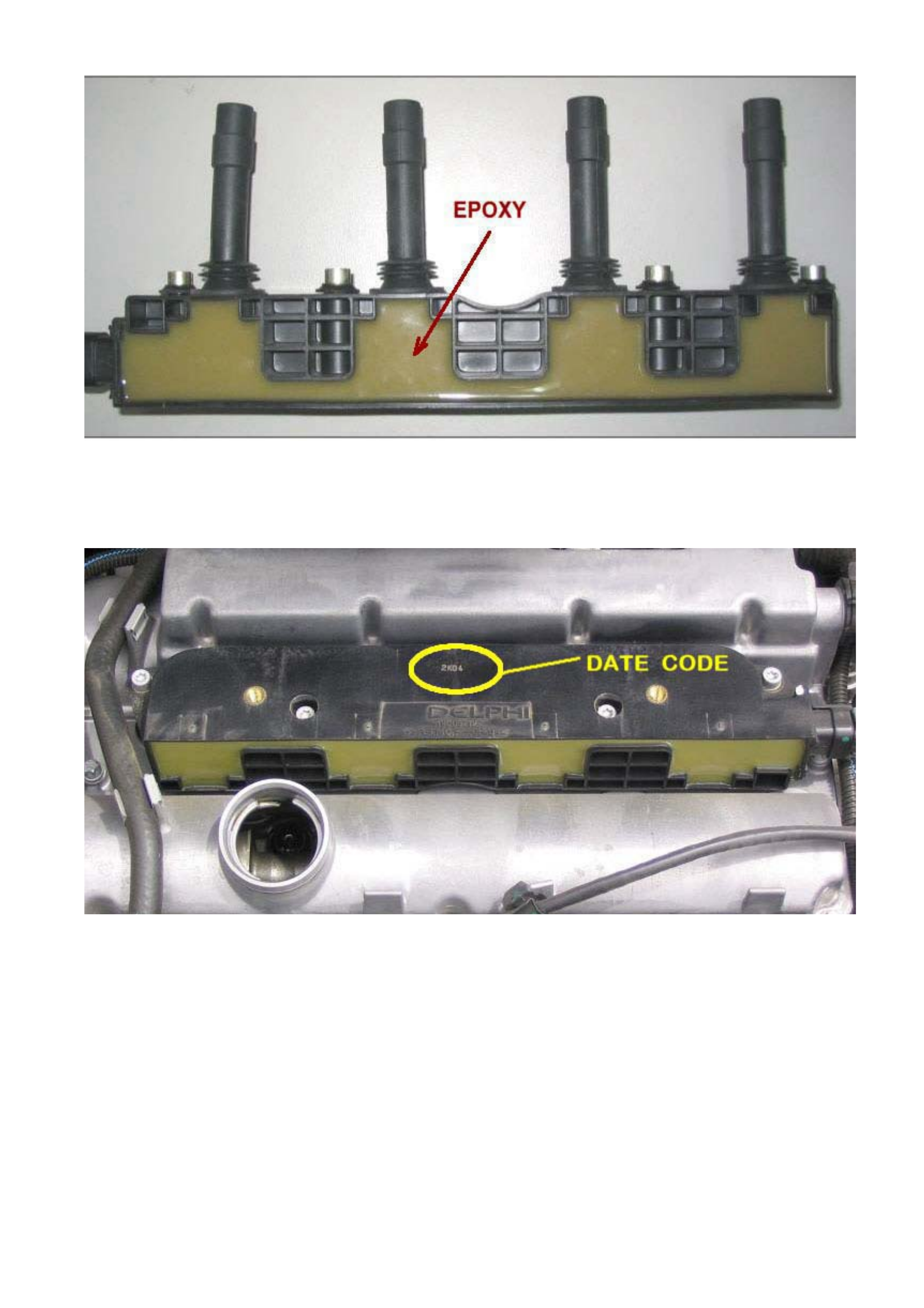

Revised ignition modules with the new epoxy have

been fitted to engines from engine Breakpoint

Z14XE20CB4883. (approx vehicle build date 10th

Oct 2003)

SERVICE RECTIFICATION

On vehicles where the ignition module has failed, fit a

new module from HSPO.

PARTS INFORMATION

NOTE: The new ignition module part number remains

the same.

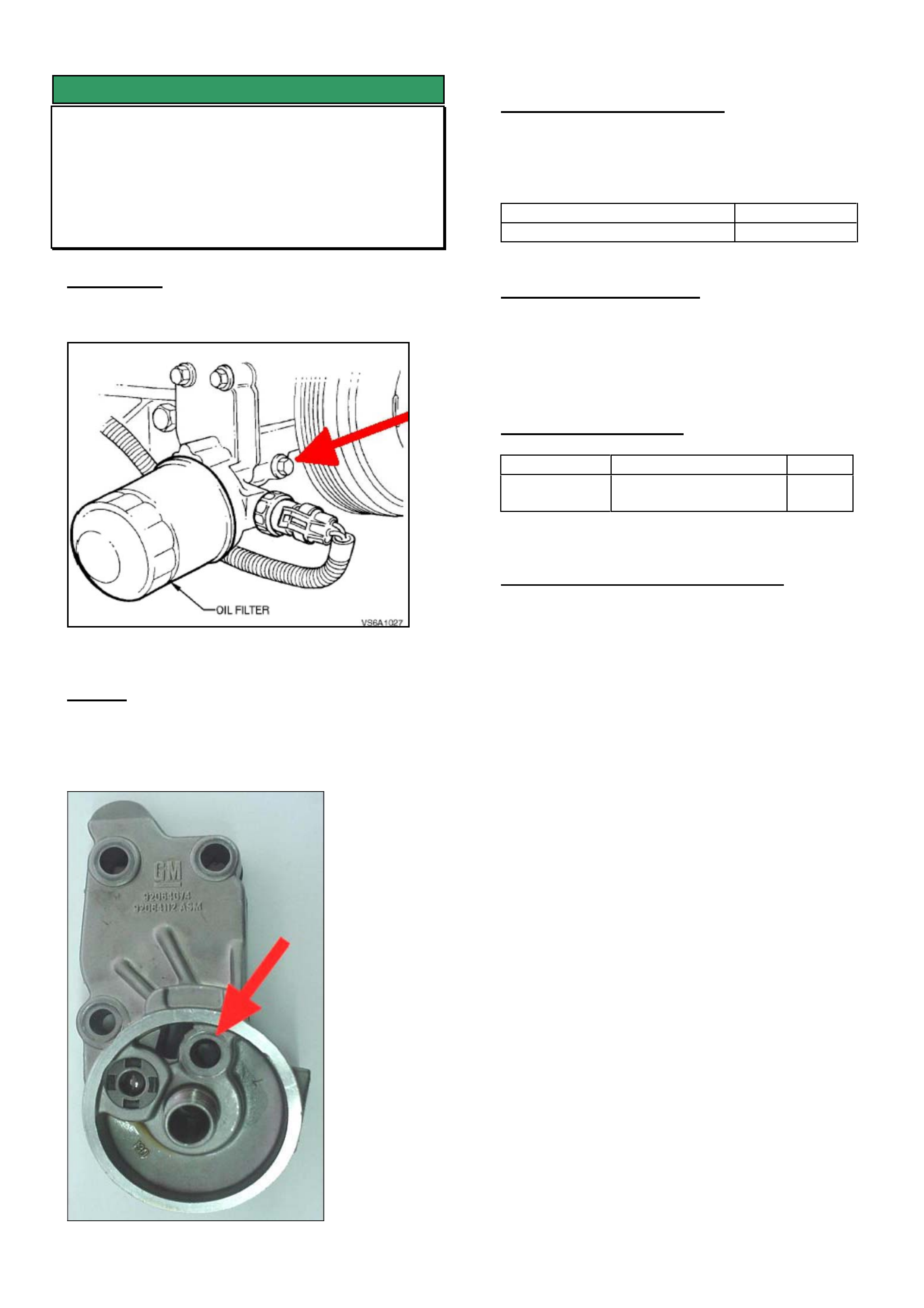

The new ignition module can be identified by the

epoxy colour which is darker, and the date code

stamp. Refer Figure 2.

The date code is stamped on the top of the ignition

module (as seen in Figure 3).

The new module can be identified by a date code that

is post (after) 3J22.

where: 3 = 2003, J = September, 22 = Day

Part No.: Description: Qty:

19005212 Module – direct ignition 1

Attention Parts Managers:

Any ignition coils prior to breakpoint should be

returned to HSPO for credit via the CRRM system.

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty

Information section of current PV SIP CD

Figure 1. Old module has light coloured epoxy

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

14

Figure 2. New module has dark coloured epoxy

Figure 3. Location of date code

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

22

DIAGNOSIS HINT

Dash Panel Creak – Glue Track Region

VY Utility & V2

(GROUP 1) TL625-0401

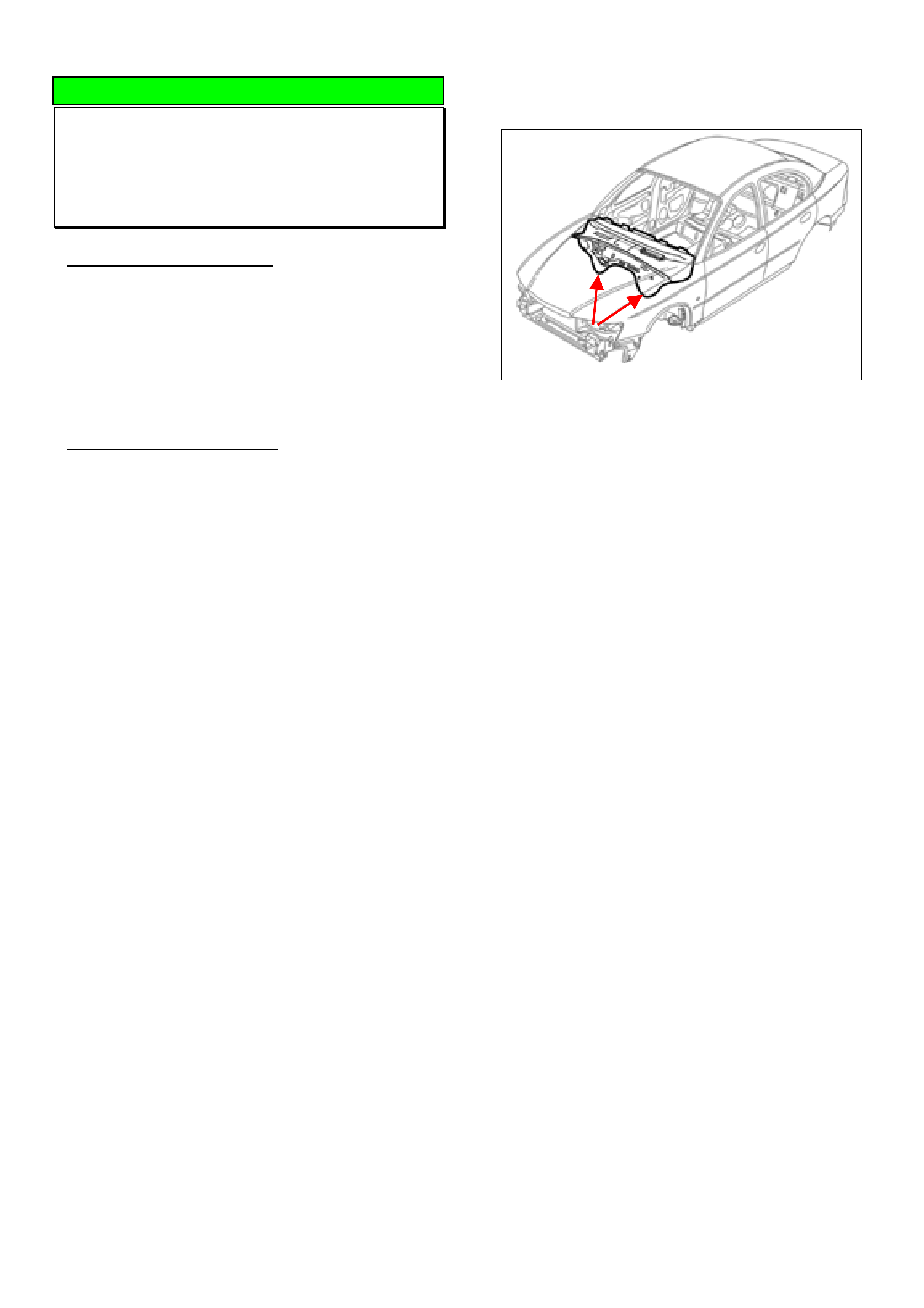

PROBLEM DESCRIPTION

While driving through uneven driveways or on

acceleration and braking a creak may be heard from

the lower dash area.

This creak noise may be due to dash panel sheet

metal contact within the “glue track” in the

transmission tunnel area.

SERVICE RECTIFICATION

To rectify vehicles with the above condition:

1. Attempt to reproduce the noise by jacking the

vehicle from one side at the recommended jacking

points.

2. Confirm that the noise is loudest on the glue track

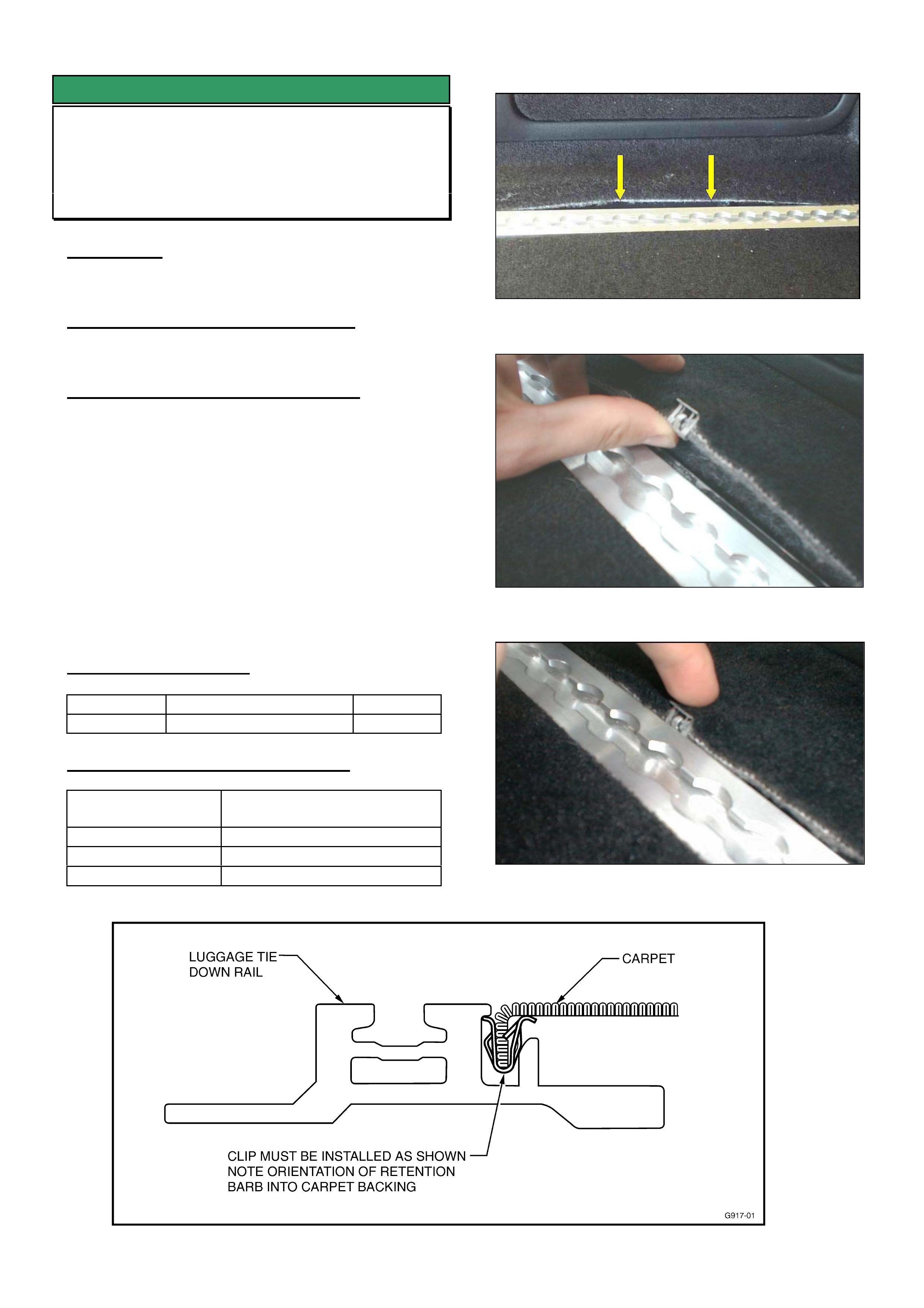

in the transmission tunnel area (between the arrows

in Figure 1) using either chassis ears or a

stethoscope.

Note: Reproducing the creak while stationary may

not be possible in every case. The sensitivity of the

listening device will also affect the ability to

reproduce the creak.

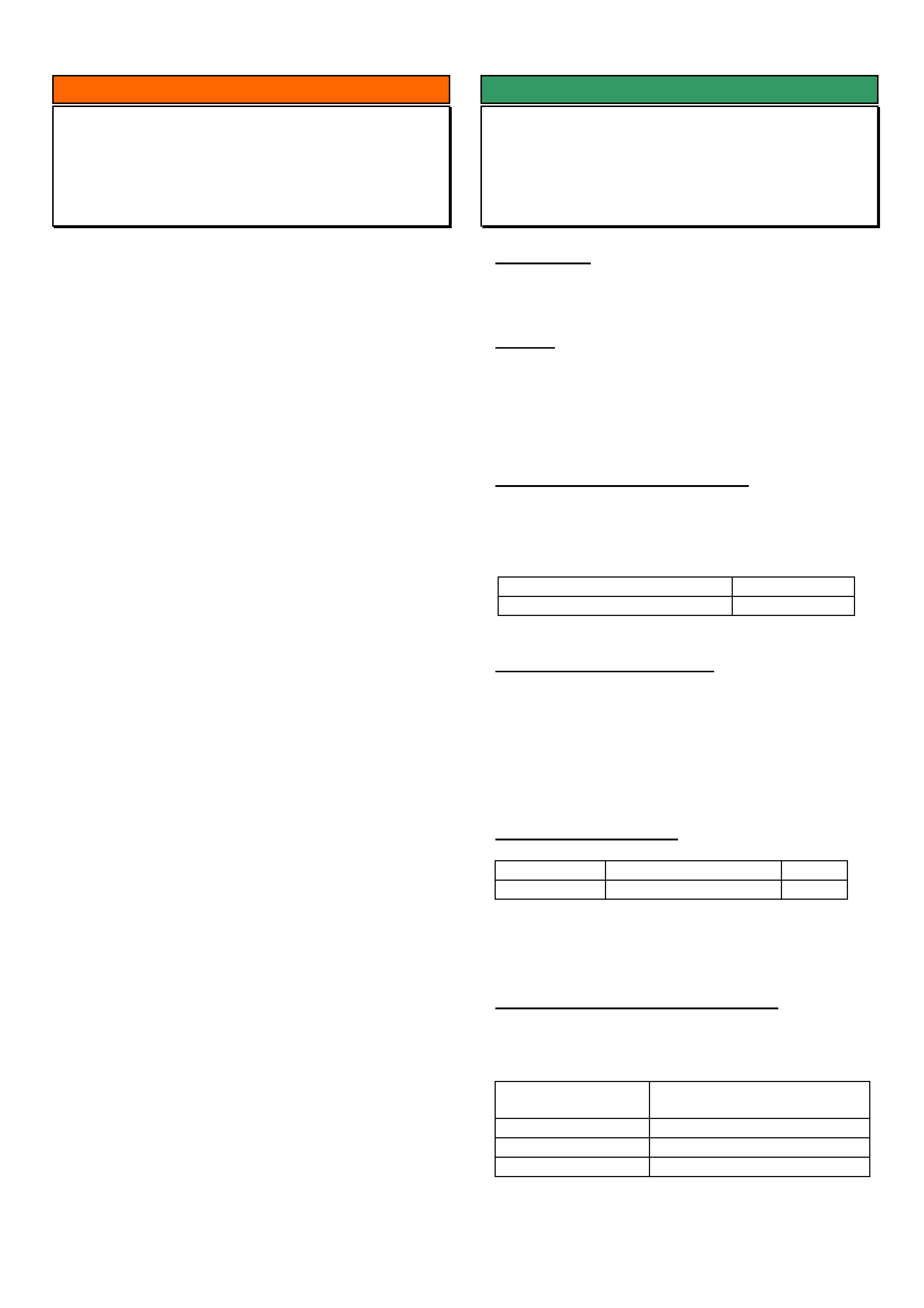

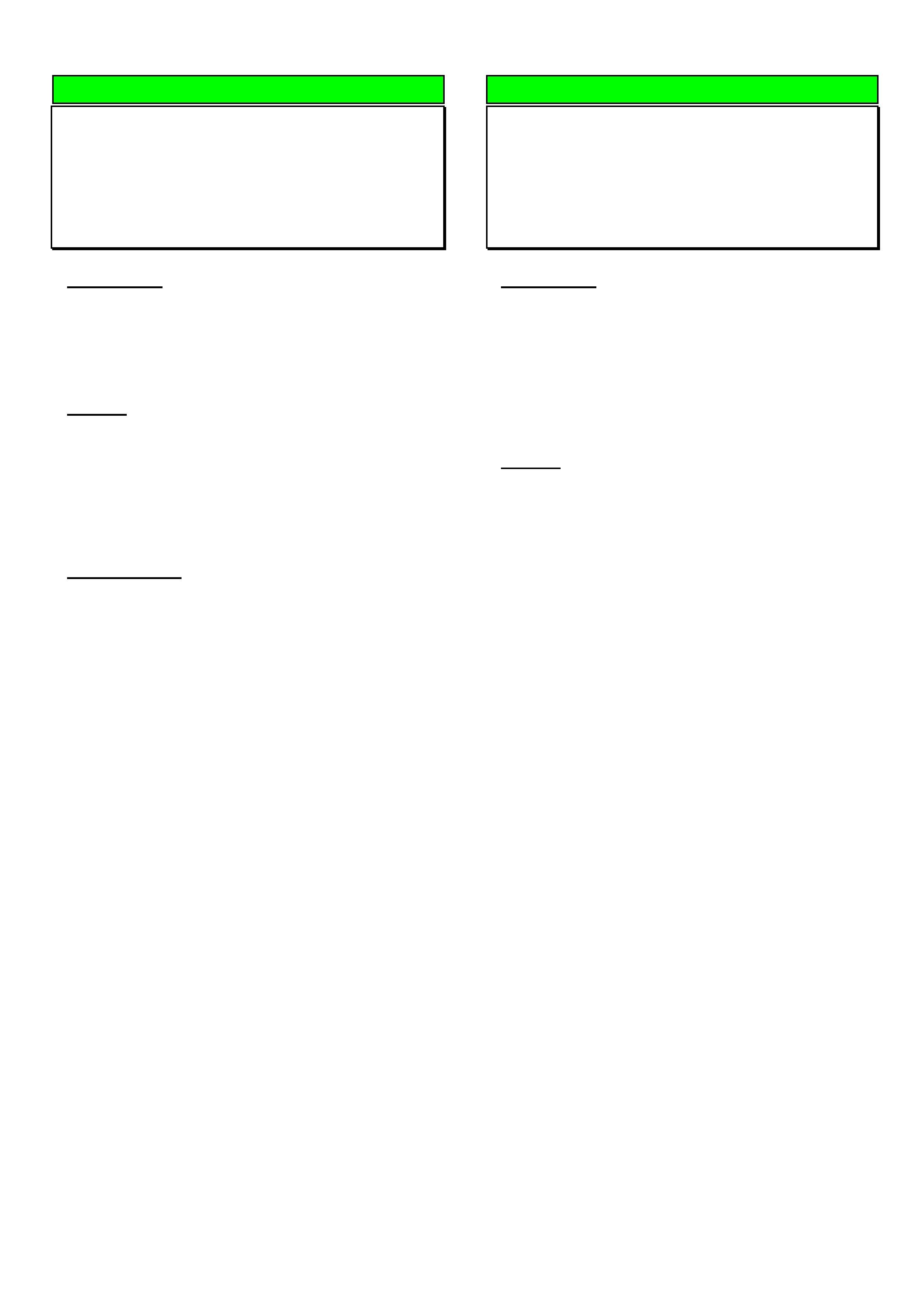

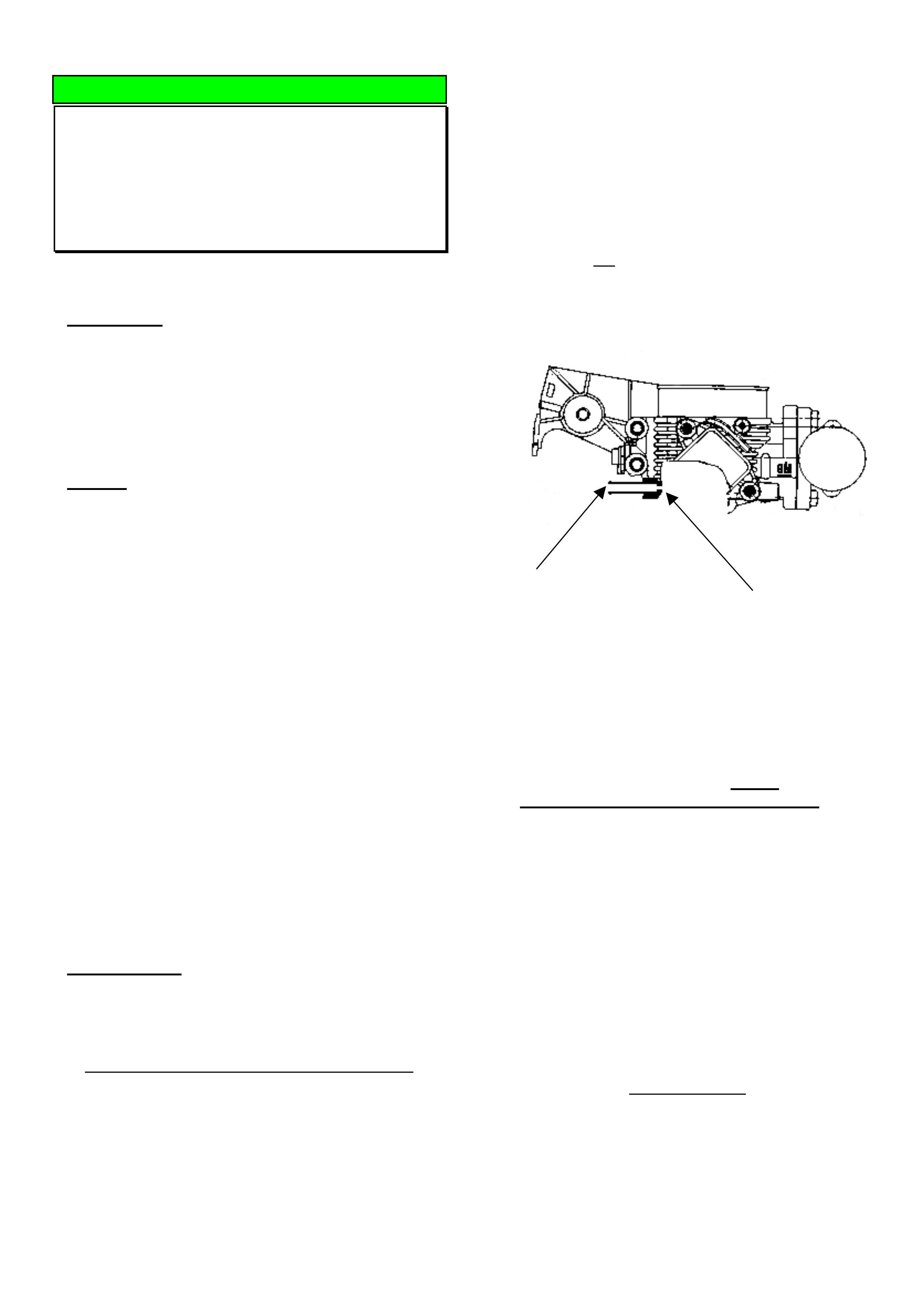

Figure 1.

3. After confirming the creak is coming from the

transmission tunnel area (between the arrows in

figure 1), use a pry bar from inside the vehicle to

widen the glue track sufficient to separate the two

panels, starting at the area where the creak was

identified.

4. Confirm that the creak has been eliminated by

repeating step 1.

5. Fill the “widened” glue track with RTV 732

silicone sealer to prevent the creak from returning

and to ensure the join is sealed.

NOTE: Sufficient access to the transmission tunnel

may require removal of the HVAC unit.

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

23

SERVICE FIX

Front Exhaust On-Pipe Heat Shields

Vibrate

WK, VYII, V2 with Gen III

(GROUP 8) REVISED TL514B-0401

This Techline supercedes the previous techlines

TL514-0306 & TL514A-0308. It includes revised

service fix and parts information.

PROBLEM DESCRIPTION

A buzz/vibration from front exhaust pipe heat shields

(long type) which occurs on takeoff under light loads

such as driving uphill.

The insulator pads adhered to the inside of the heat

shields may have become detached.

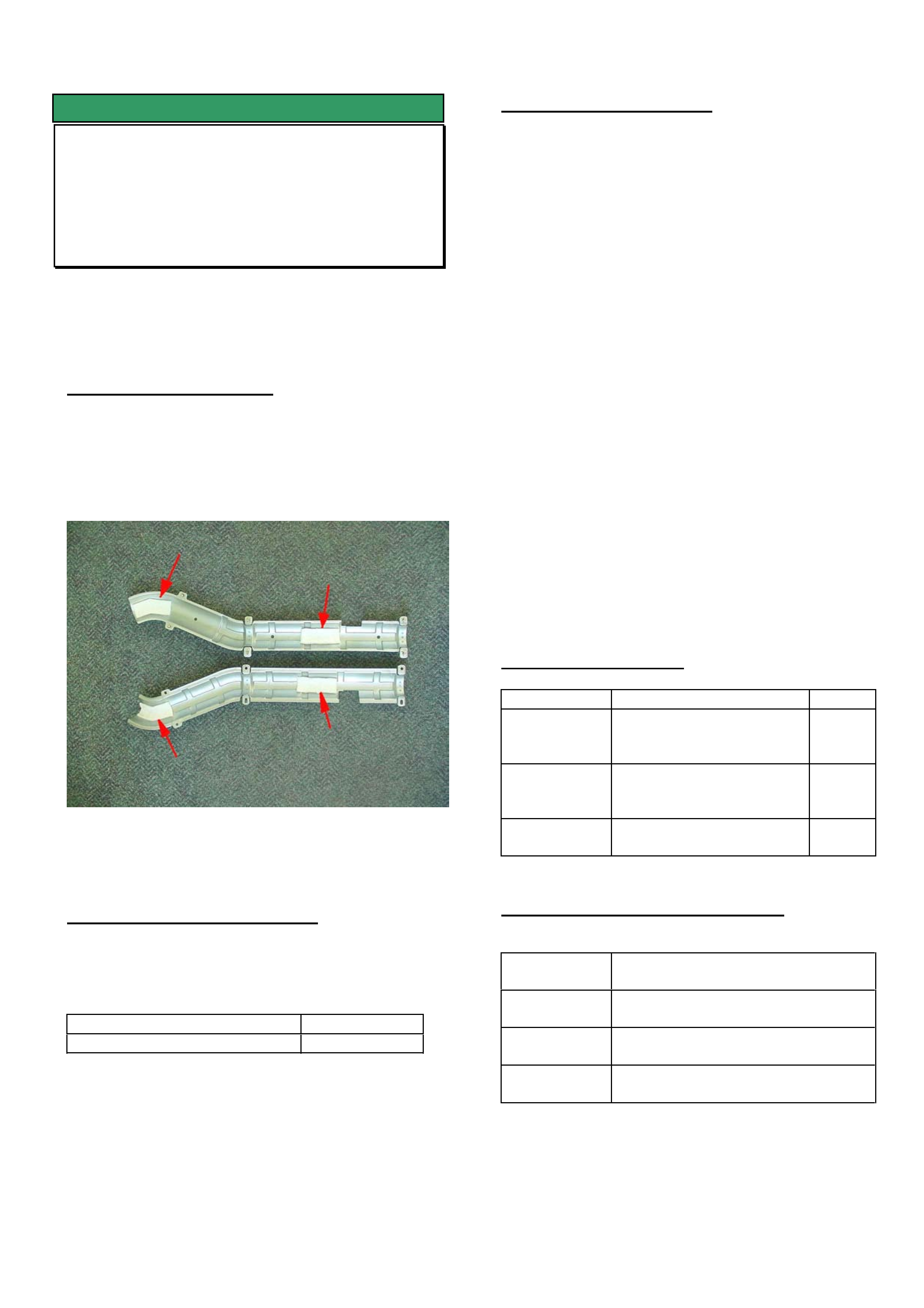

Figure 1. Shows insulation pads adhered to inside of

long-type heat shields.

PRODUCTION RECTIFICATION

The long type heat shields were replaced with

shorter heat shields and underfloor reflective foil

insulators from:

ISOVIN: Build Date:

L172001 12/9/2003

NOTE:

On-pipe heat shields and underfloor stick-on

reflective foil insulators have been removed from all

vehicles with Gen III engines built from 9/1/04. All

vehicles built from this date are fitted with floor

mounted “bolt on” type heat shield.

SERVICE RECTIFICATION

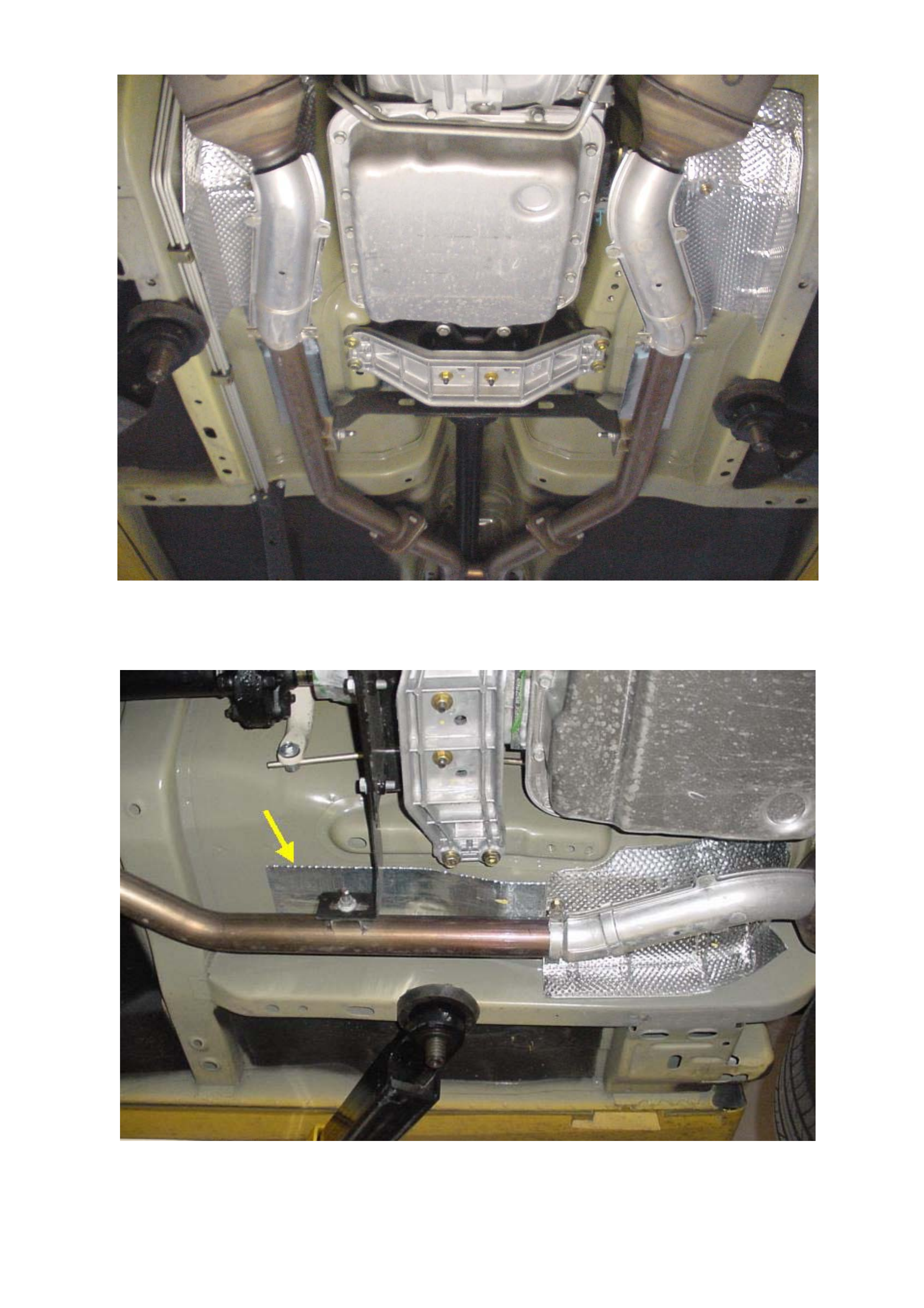

Summary: On complaint vehicles featuring the long

type on-pipe heat shields install new shorter on-pipe

heat shields as per following procedure.

1. Remove existing long-type exhaust heat shields.

2. Check if there are underfloor stick-on reflective

foil insulators located as shown in Figure 2. If

not, order new part 92056511 and install as

follows

.

(a) Clean underfloor area using a solvent

soaked rag to remove any dirt, sealer or paint

overspray.

(b) Soften the new reflective foil insulator by

heating with a heat gun to approximately 40 deg C.

(c) Wearing heat resistant protective gloves,

peel the adhesive paper from the reflective foil

and apply to the underfloor area in-line with the

exhaust pipe as shown in Figure 2. Smooth out

any bubbles.

3. Install new short-type heat shield kits 92210214

and 92210217 as shown in Figures 1 & 2.

PARTS INFORMATION

Part No.: Description: Qty:

92210214 Exhaust heat shield kit –

RHS (2 halves plus 4

nuts)

1

92210217 Exhaust heat shield kit –

LHS (2 halves plus 4

nuts)

1

92056511 Heat shield - self

adhesive

1

WARRANTY CLAIM INFORMATION

Description Replace heat shields both sides

and install underfloor reflective foil

Labour Op.

No.

L000223

Time

0.5hr

Failure

Code

36 vibration

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

24

Figure 1. Shows installation of new shorter “on-pipe” heat shields

Figure 2 Close up view of LHS underfloor stick-on heat shield

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

25

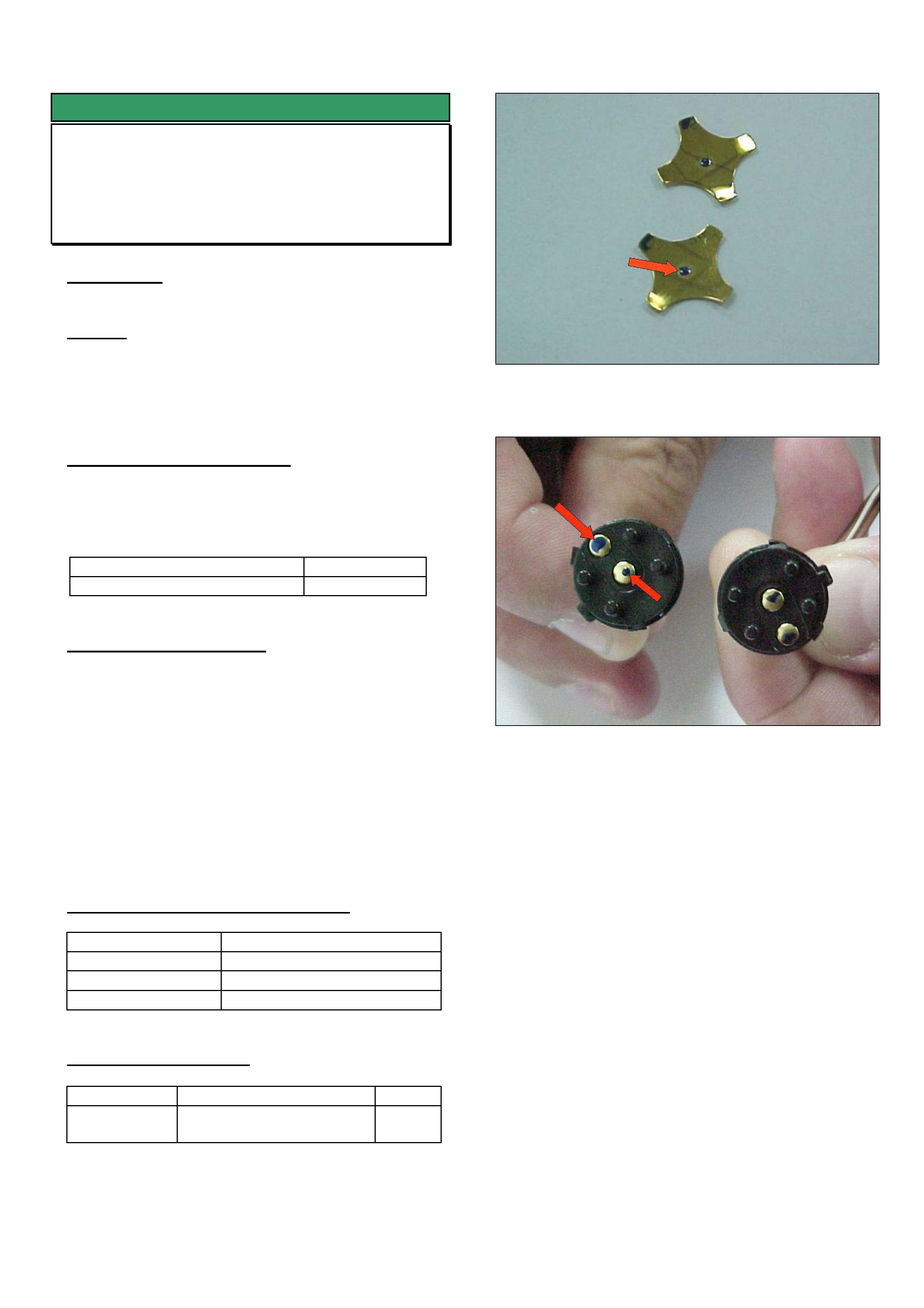

SERVICE FIX

Rear Brake Groan/Graunch - Repeat

Failure After Dampers Have Been Fitted

TS & TT MODEL YEAR 2002 Fitted with

Lucas Calipers

(GROUP 5) TL0441-0401

The procedure below should only be followed after

the previously issued information in Service Techline

July 2002, Issue 6 for Rear Brake Graunch has been

carried out (i.e. fitting dampers).

PROBLEM DESCRIPTION

Some vehicles are reported as having the low

frequency graunch still evident even after the

dampers have been fitted as per Service Techline

July 2002, Issue 6.

This noise must not be confused with brake squeal,

drag or scraping. Therefore, to avoid misdiagnosis,

the complaint noise needs to be

demonstrated/reproduced to a Technician/Service

Manager to confirm it is the low frequency graunch.

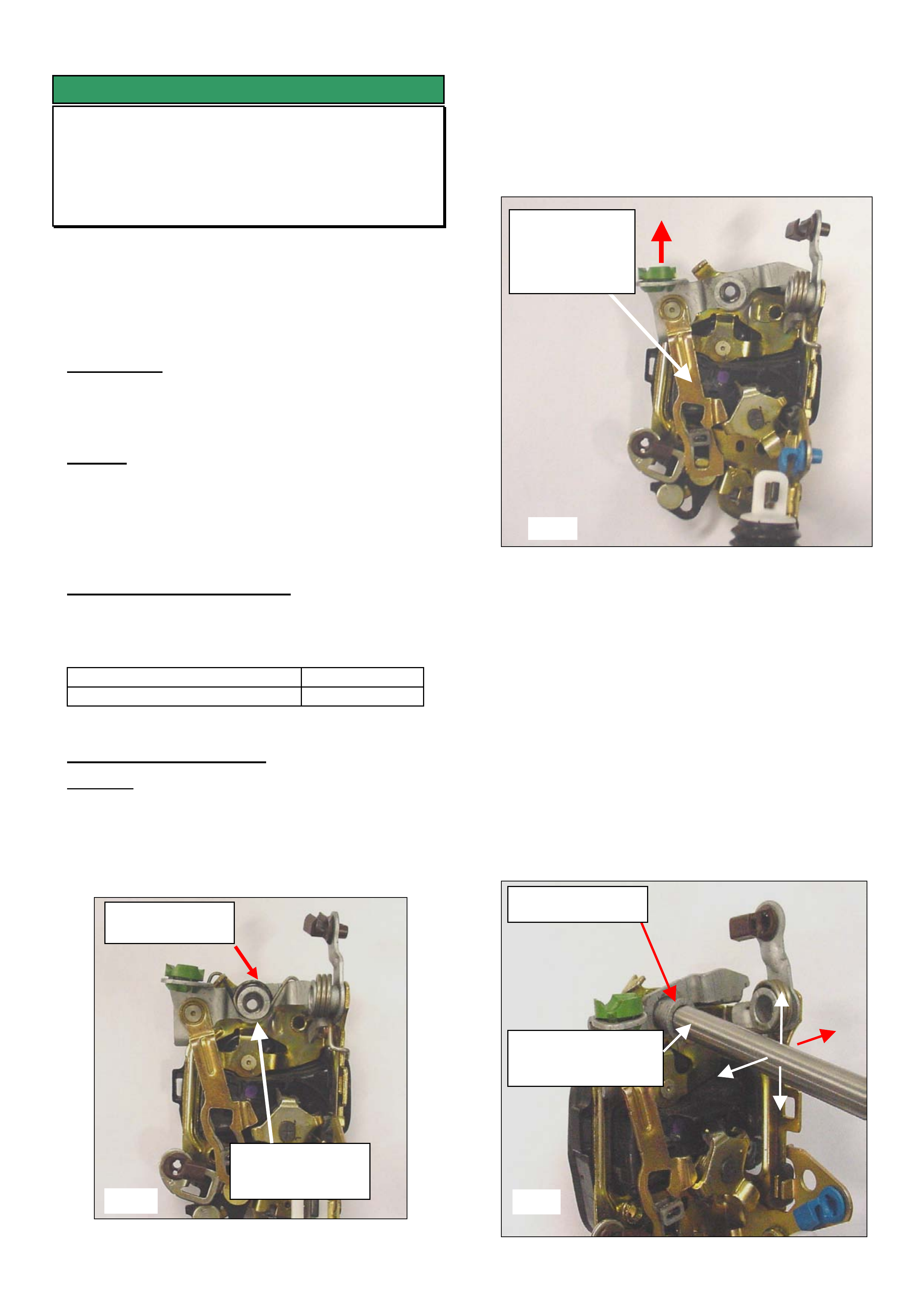

Cause

The dampers are tuned to damp out a specific

frequency. Testing has revealed that on vehicles

where the graunch is still evident with the dampers

fitted, the components are vibrating at a frequency

that is slightly different to that which the damper is

tuned for.

PRODUCTION RECTIFICATION

Dampers fitted in production from :

ISOVIN: Build Date:

W0L0TGF3535043736 27/09/02

Solid slide pins fitted in production from:

Calendar Week 36 (Sept) 2002.

SERVICE RECTIFICATION

Summary: Confirm complaint noise, confirm vehicle

has Lucas calipers, check damper installation, then

install solid slide pin kit.

IMPORTANT: Although the solid pin kit has been

successful in rectifying repeat graunch vehicles it will

not eliminate all brake noises. It is therefore vital to

confirm that the vehicle has the low frequency brake

graunch noise before proceeding to fit a solid pin kit.

Procedure:

1. Check that the damper to caliper attaching screw

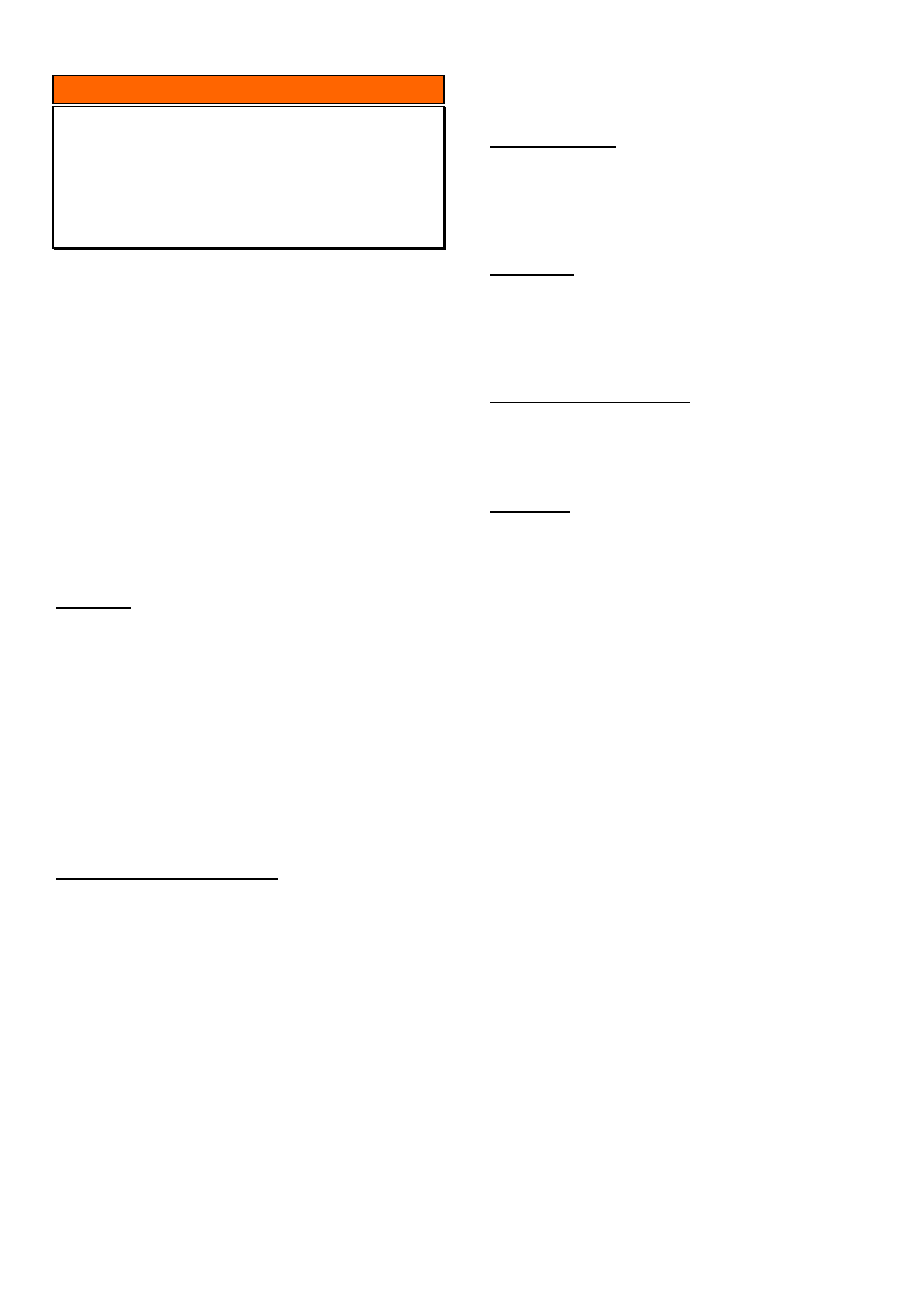

has been set to the correct torque of 9-11Nm.

NOTE. Failure to check this torque may result

in the graunch noise remaining. Refer Figure 1.

Figure 1

2. Release/disengage the park brake. Remove park

brake handle cover and release tension on the park

brake cable by unscrewing the adjustment nut.

3. Remove rear wheels.

4. Push brake caliper actuation lever (1) with a

screwdriver downwards in direction of arrow and

detach parking brake cable. Remove the retention

clip (2) and withdraw parking brake cable from

bracket. Refer Figure 2.

Figure 2

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

26

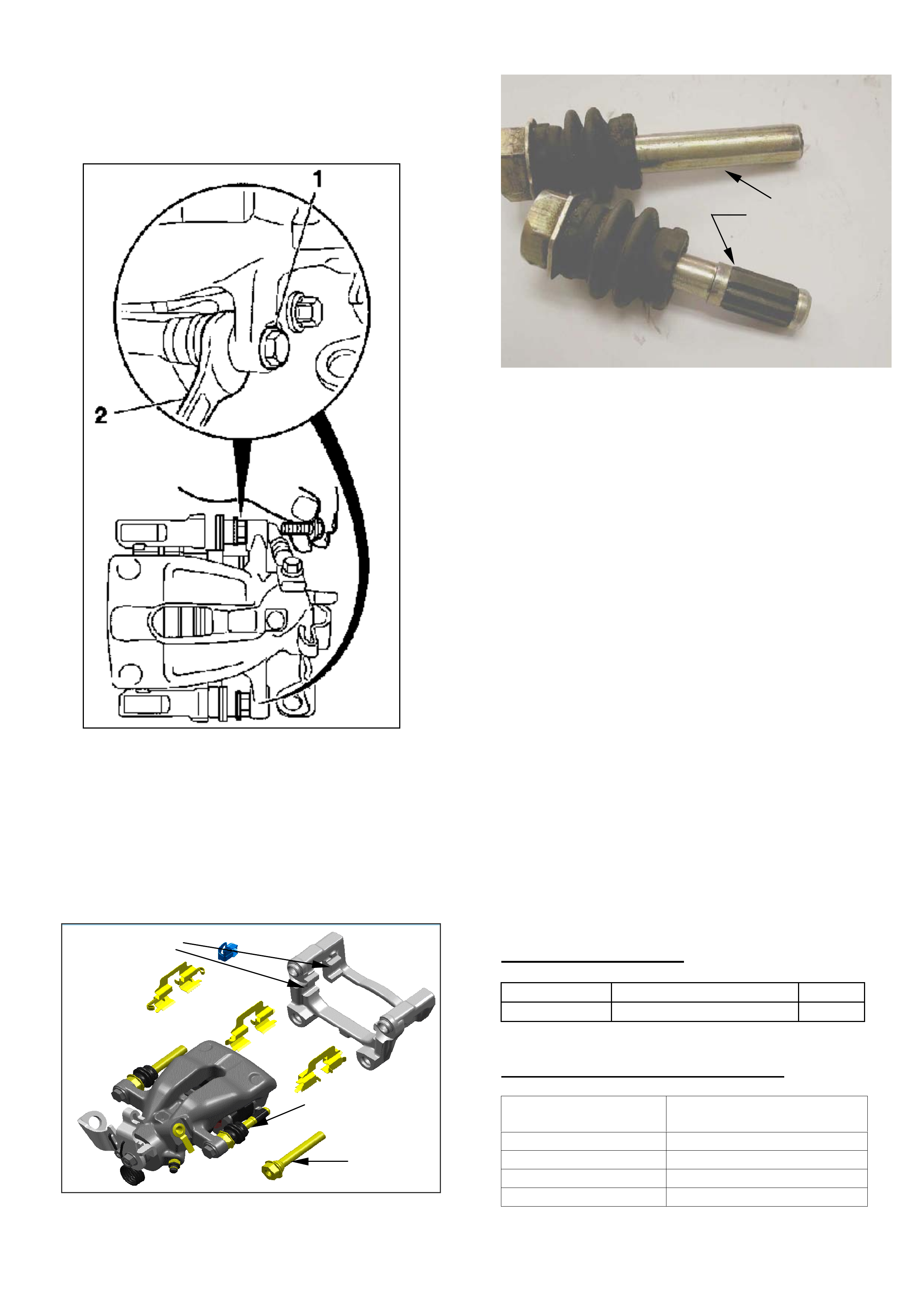

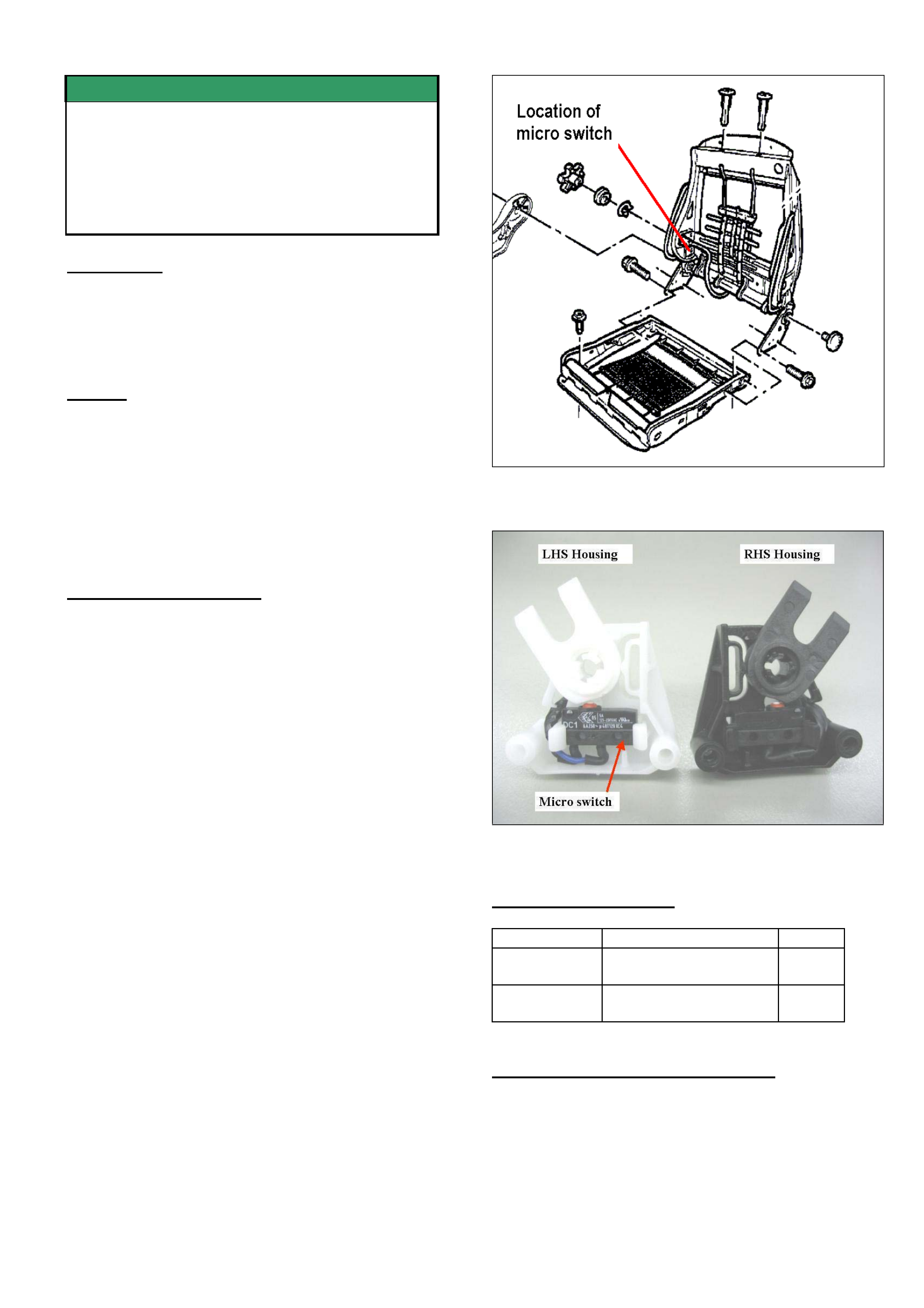

Solid Pin

Rubber Sleeved

Pin

Shim Grease

5. Remove fastening bolts (1) from brake calliper –

counterhold with open-ended wrench (2). Refer

Figure 3

Figure 3

6. Remove the rear brake caliper from brake carrier

and secure to the rear spring with cable ties or

suitable wire.

7. Remove carrier from vehicle.

8. Remove the caliper slide pins from the brake

carrier. See Figure 4.

9. Swap the rubber sleeved pin for a plain pin as

supplied in the kit. Refer Figure 5.

Figure 4.

Figure 5 Shows difference between pins

10. Coat slide pins with silicon type grease (Dow

Corning No. 44 or equivalent)

11. Install the slide pins into the brake carrier

12. Install carrier shims as supplied into carrier with

installation grease (p/n 32960041), making sure

the carrier is cleaned with a wire brush to remove

old grease prior to installation of the new shims.

Note: Grease is to go between the shim and the

carrier. It is not the same grease as the slide pin

grease.

13. Install the new pads ,as supplied, into the carrier-

do not remove the self adhesive backing paper

from the pad.

14. Install the brake carrier to the vehicle. Use thread

locking compound – tightening torque 100 Nm/74

lbf.ft.

15. Clean the caliper piston and fingers where the

pads contact the caliper.

16. If necessary retract caliper piston to allow for new

pads.

17. Remove backing paper from pads self adhesive

section and slide the caliper into position over the

pads.

18. Install new mounting bolts (as supplied) for brake

caliper to brake carrier – tightening torque 25 Nm /

18 lbf. ft.

19. Repeat for the other side of the vehicle

20. Adjust handbrake cable.

21. Confirm that graunch noise has been eliminated.

PARTS INFORMATION

Part No.: Description: Qty:

93176419 Solid Slide Pin Kit 1

WARRANTY CLAIM INFORMATION

Description Solid Slide Pin Kit

Installation – Both sides

Labour Op. No. H000243

Time 1.0 hr

Failure Code 40 Noisy

NOW Failure Code H0040 Noisy

Plain pin

Rubber sleeve pin

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

27

SERVICE PROCEDURE

LPG Mixer Removal and Reinstallation

Precaution

HBD fitted LPG

(GROUP 6C) TL0607-0401

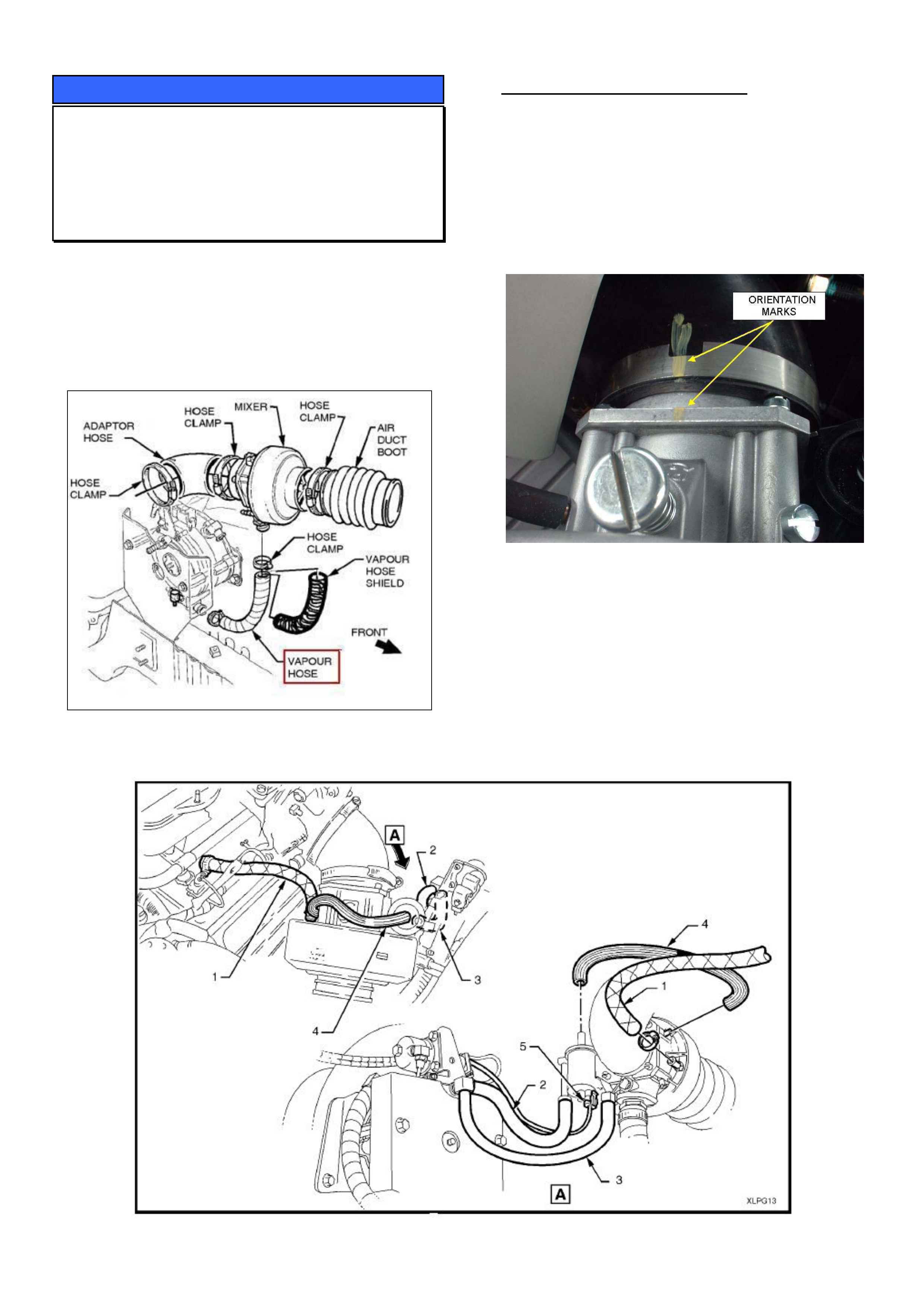

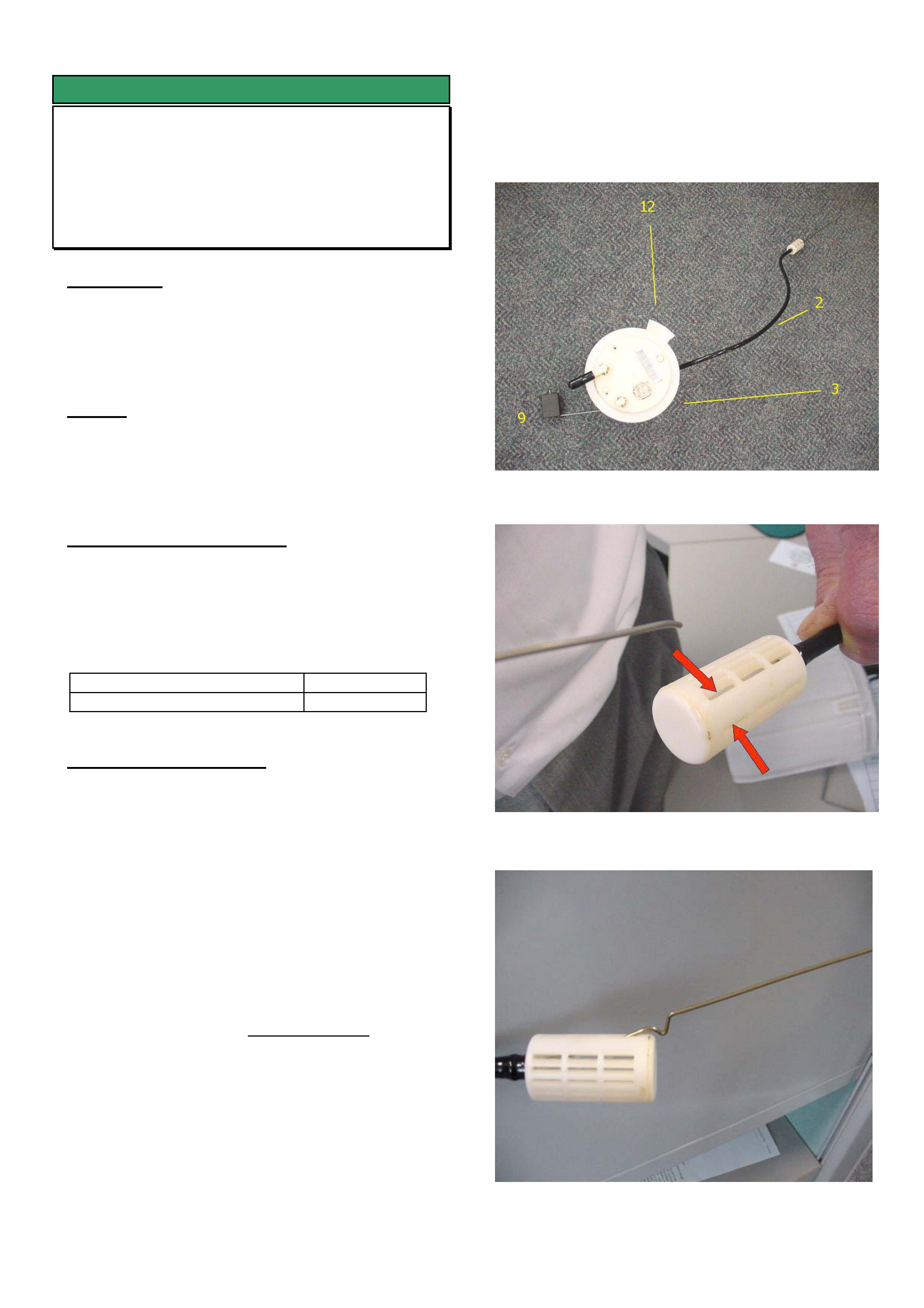

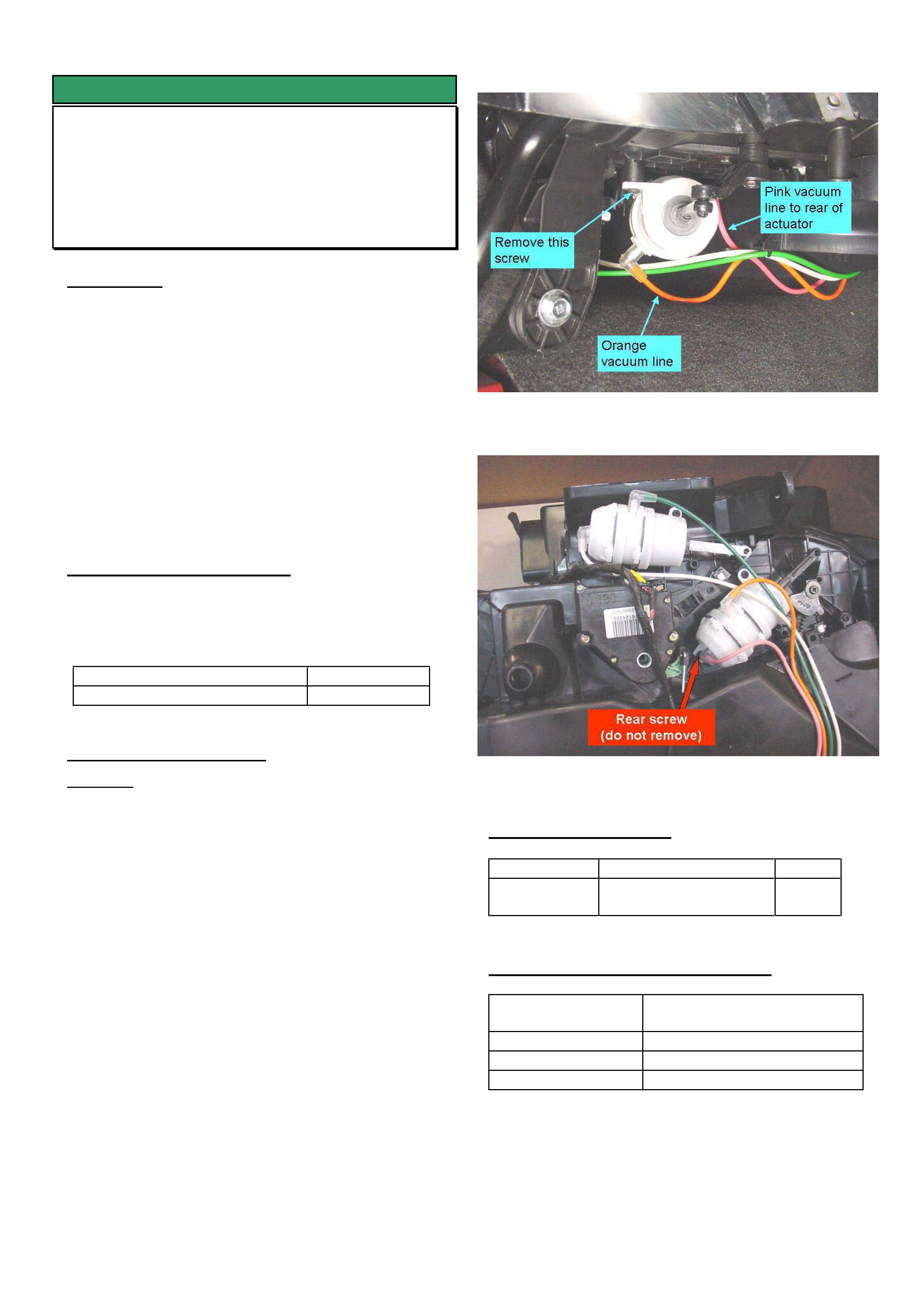

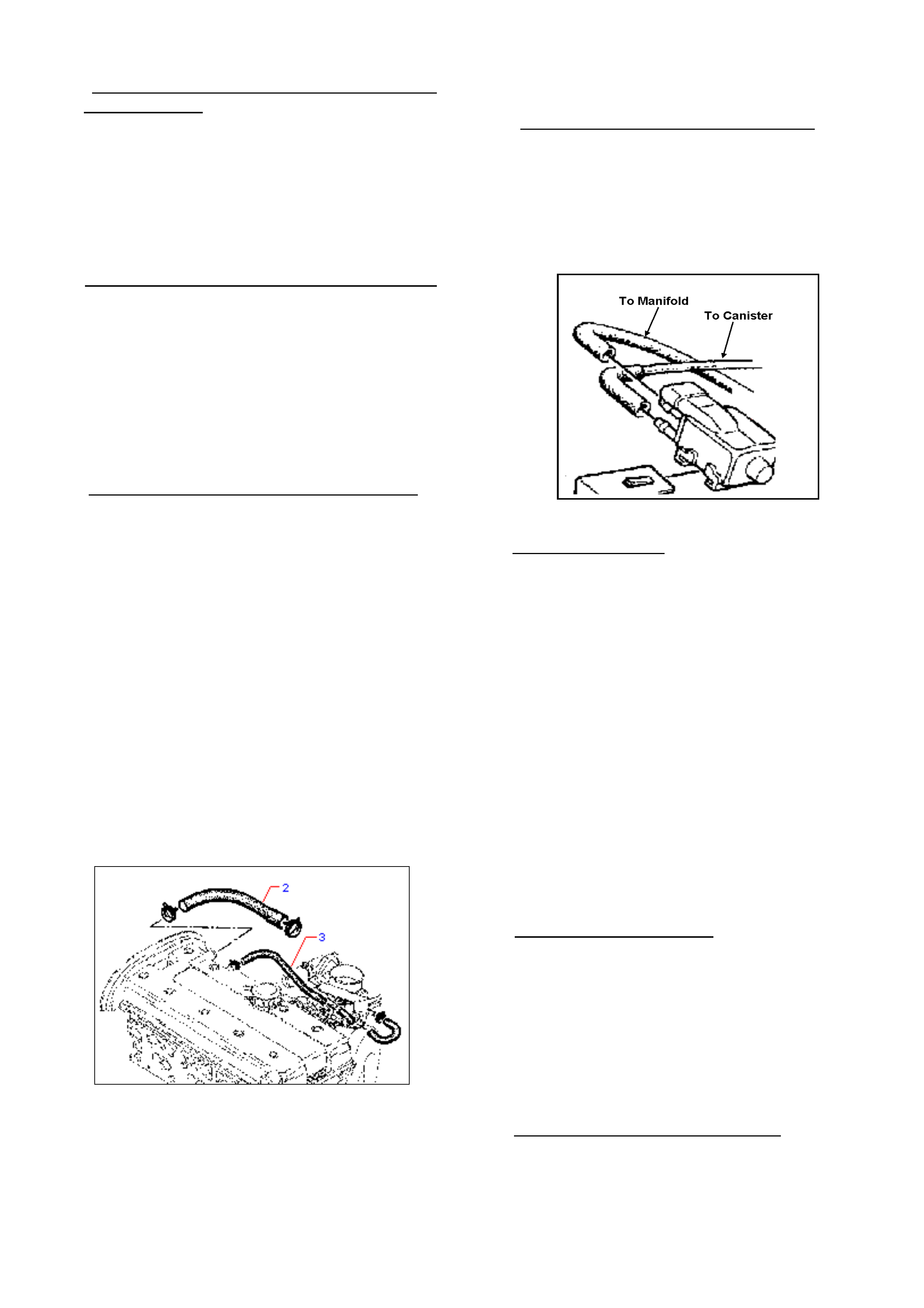

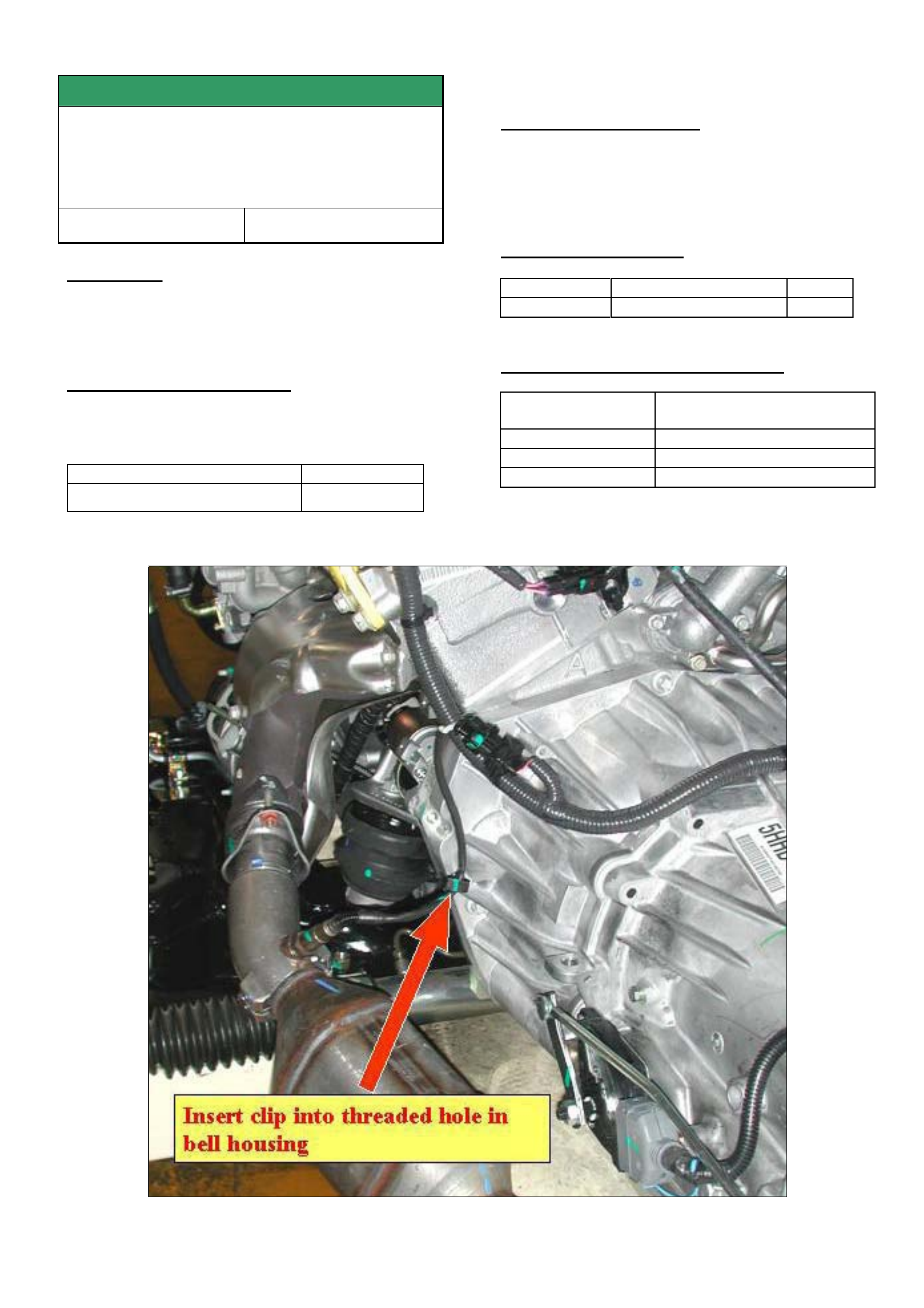

Whenever the LPG mixer is removed to service

spark plugs etc. it must be reinstalled in exactly the

same orientation it was in prior to removal. If the

mixer is twisted slightly from its original position, this

may result in the vapour hose fouling on the spark

plug leads. Figure 1 shows the parts in question.

Figure 1

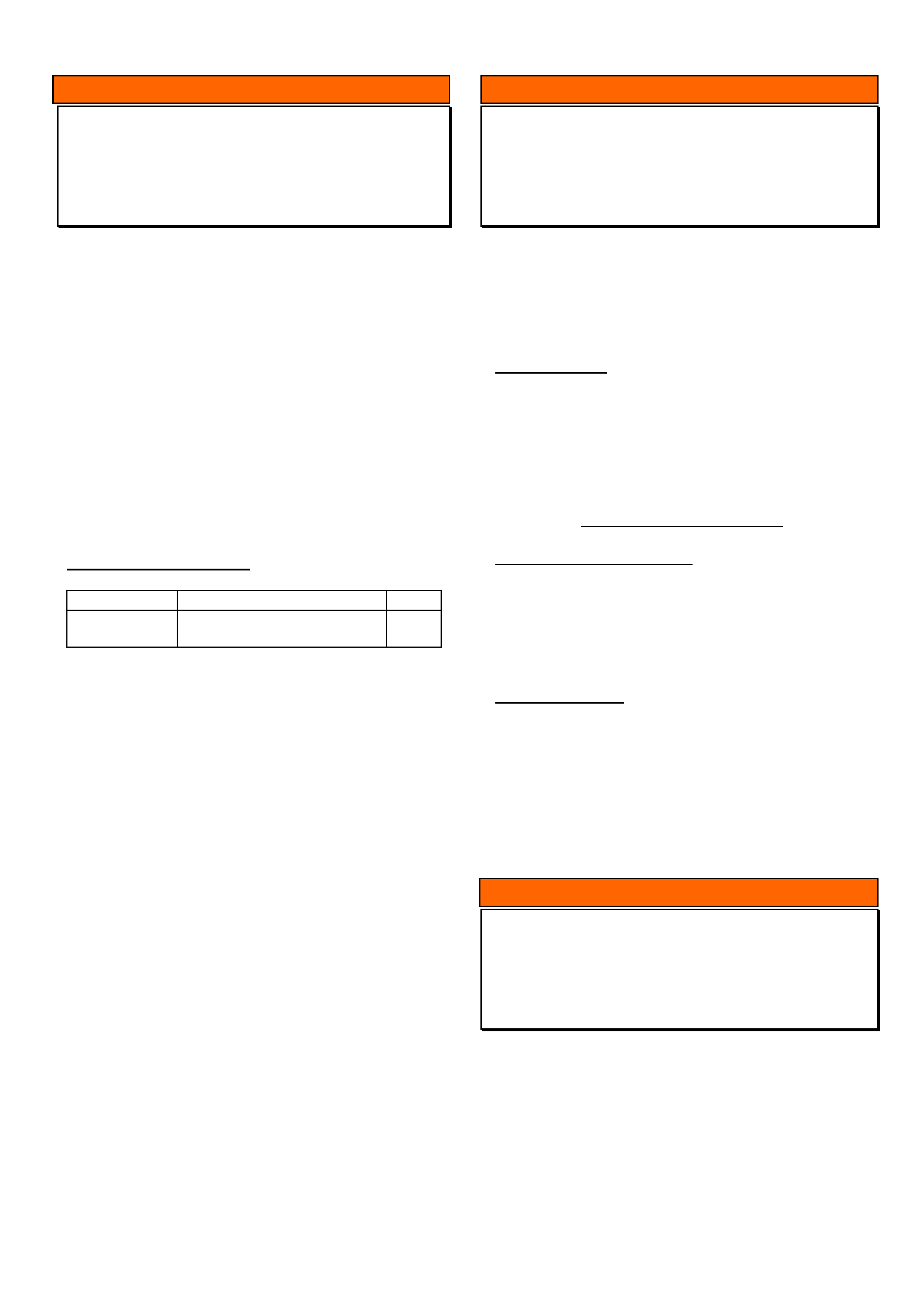

SERVICE RECOMMENDATION

If the mixer is removed for any reason it should be

reinstalled in exactly the same orientation it was in

prior to removal. To ensure this happens, place

alignment marks on the mixer and elbow as shown in

Figure 2 prior to unclamping the mixer.

NOTE: Holden By Design (HBD) have been adding

alignment marks on the mixer and elbow as shown in

Figure 2 from July 2002.

Figure 2.

NOTE. Holden TAS report that they have had some

cases where the following DTCs have been set due

vacuum hoses (numbers 2 & 3 in Figure 3) being

swapped around when reinstalling the mixer.

P0132 - RH oxygen sensor signal voltage high

P0152 - LH oxygen sensor signal voltage high

Please ensure that these vacuum hoses are

reinstalled correctly if they are taken off when

removing the mixer.

Figure 3.

HOLDEN SERVICE TECHLINE __________________________________________________________________MARCH, 2004

5

INFORMATION

Gen III Oil Pan Drain Plug Sealing Washer

VY II

(GROUP 6A) TL0635-0402

At introduction of VY Series II, the engine oil pan drain

plug and sealing washer were revised as follows.

A. The plug changed from 13mm to 15mm hex.

B. The sealing washer was no longer available

as a serviceable part.

Therefore, when servicing vehicles do not remove

and discard the existing sealing washer from the plug.

Wipe the sealing washer to remove excess engine oil

and reinstall drain plug and washer assembly.

In the event the sealing washer is damaged, a

complete drain plug and washer assembly will need to

be fitted.

PARTS INFORMATION

Part No.: Description: Qty

11519408 Plug and seal assembly

oil pan drain A9W

1

NOTE: A9W is the production option code for

introduction of VY series II.

INFORMATION

Dana Contacts for Exchange Axles

V & W cars

(GROUP 4) TL0640-0402

Dana Automotive Systems Group is Holdens supplier

of V & W car rear and front drive axle units for vehicle

production, and exchange axle units for warranty

replacement. Dana has recently changed address

and contact details are as follows:

Dana Website

Dana should be contacted on their Website for all

warranty axle exchange requests and LSD “chatter”

kits.

For use of the Dana Website refer to Dealer Letters

DL 54/01 and DL 83/02.

Dana Website address is:

http://www.spiceraxle.com.au

Axle Warranty Enquiries

For any issues relating to supply of exchange axle

units not addressed by the Website – contact:

Robert Linton : (02) 9892 9237, Fax: (02) 9892 9310

Michael Morgan: (02) 9892 9343, Fax: (02) 9892

9442

Address Details

Dana Automotive Systems Group

205 - 231 Fairfield Road (Cnr. Foray Street)

Yennora, NSW 2161

These details will be updated in the next issue of

Passenger SIP.

INFORMATION

SPS Programming and Linking

All Models

(GROUP 0B) TL0664-0402

TAS receive many calls from retailer technicians who

run into problems when trying to perform the

"Program Immobiliser Function" or PCM to BCM link.

Please be aware that if you are installing a new

PCM/ECU you must do SPS programming before

carrying out the above.

This is only required for new PCMs/ECUs.

HOLDEN SERVICE TECHLINE __________________________________________________________________MARCH, 2004

6

DIAGNOSIS HINT

Interior Light Fuse Blows or Interior

Lights Staying On

VY / V2 / WK

(GROUP 12) TL0639-0402

CONDITION

Interior light fuse (number 6) blows or interior lights

stay on.

DIAGNOSIS HINT

If presented with a vehicle having either of above

conditions, it is recommended that the following areas

be inspected (in the order shown) for possible wiring

damage prior to performing the standard diagnosis.

1. The driver’s and passenger’s sun visor pivot area.

2. Rear map lamps (above the passengers doors).

3. Passenger door light switch circuit trapped behind

the PCM / PIM mounting bracket.

4. The wiring around the key reader slip ring.

5. Door sill screws holding the sill trim panels on.

6. Upper B pillar, B pillar trim clips or seat belt

bracket.

DIAGNOSIS HINT

Centre Rear Seat Belt Cannot Be

Withdrawn

ZC

(GROUP 1) TL0656-0402

A Retailer call to TAS has highlighted the following

issue relating to the operation of the centre rear seat

belt.

If the seat back is not correctly latched in the

vertical position, the centre rear seat belt “locks-

up” and cannot be withdrawn from the seat back.

Therefore, if a customer complains that the centre

rear seat belt has locked-up and cannot be

withdrawn, the first thing to check is if the seat back

is correctly latched in the upright position.

Please ensure that all your Service Advisors are

aware of this item.

HOLDEN SERVICE TECHLINE __________________________________________________________________MARCH, 2004

7

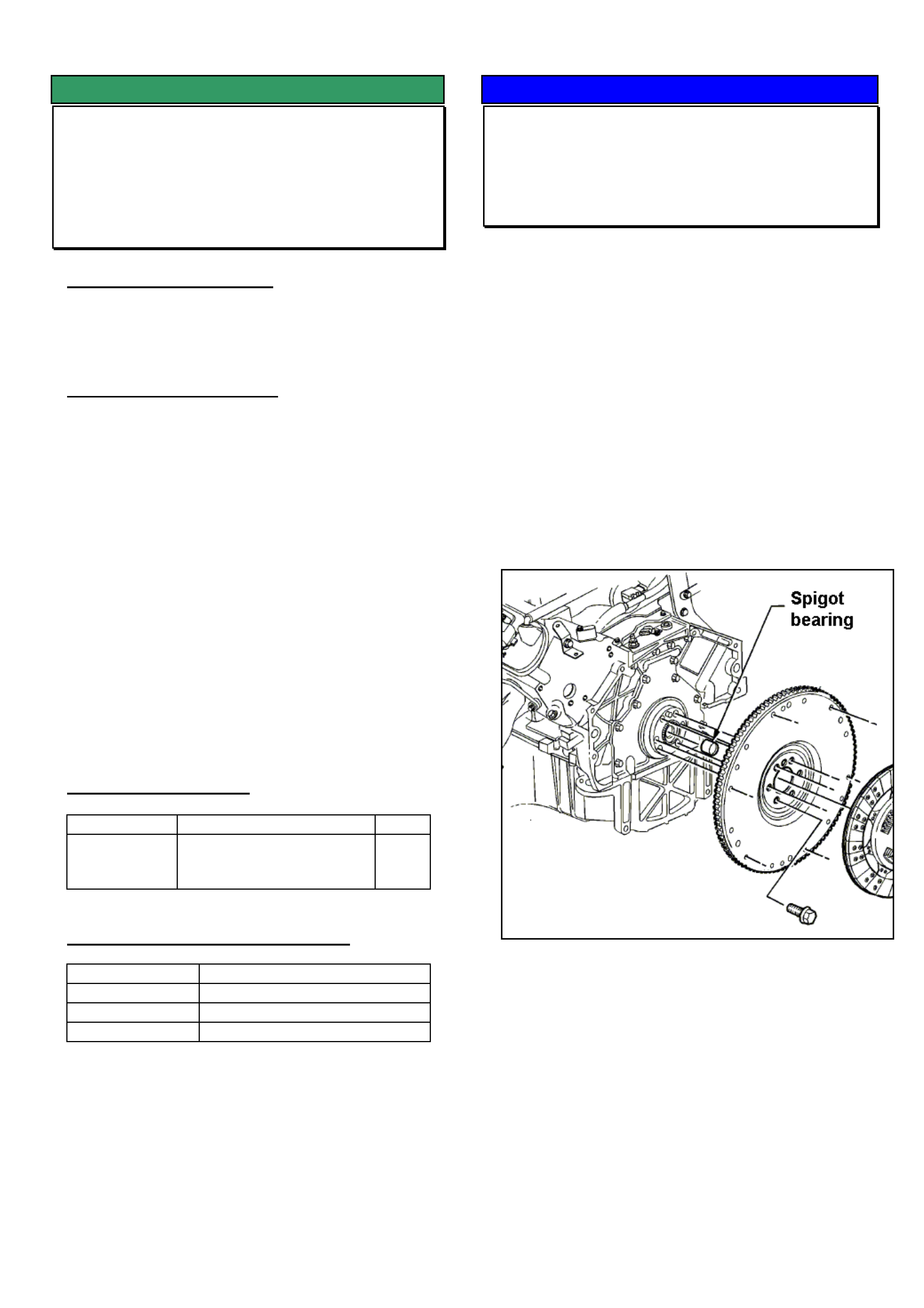

SERVICE PROCEDURE

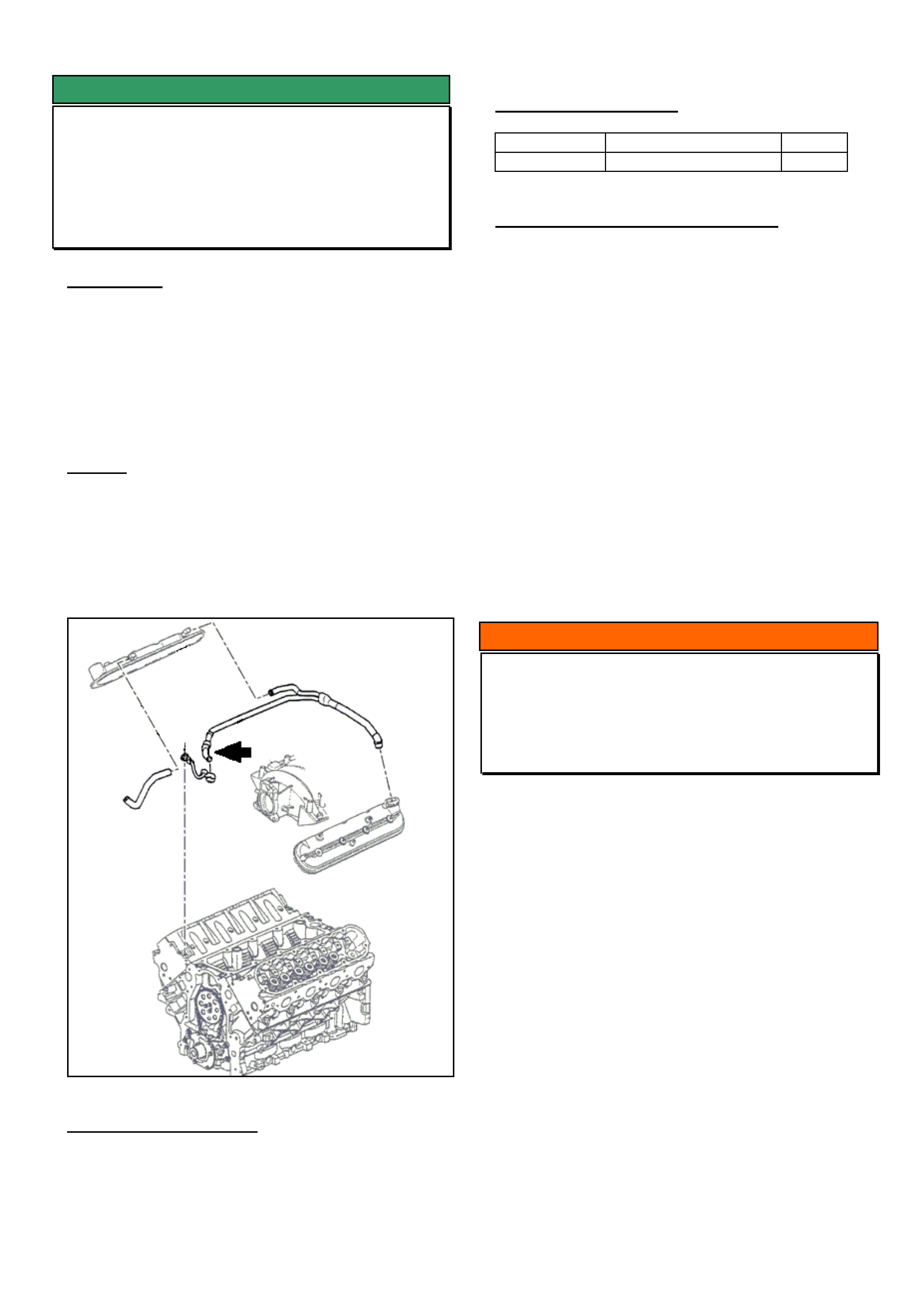

Clutch Pressure Plate Bolt Torque

Revised

All with Gen III 6-Speed M/T

(GROUP 7A) TL0634-0402

The pressure plate bolt torque specification has been

revised in production to 70 +/- 7 Nm from:

ISOVIN: Built Date:

6G1VX12F04L234149 12/2/2004

NOTE: Whenever performing repairs to the clutch

assembly, ensure that the 6 pressure plate retaining

bolts are tightened in sequence as shown in PV SIP

and evenly over 4 stages until the correct torque is

reached.

CLUTCH PRESSURE PLATE

BOLT TORQUE SPECIFICATION.

Stage 1 15 Nm

Stage 2 35 Nm

Stage 3 55 Nm

Stage 4 70 Nm

Holden PV SIP will be updated at the earliest

opportunity to show this new specification.

SERVICE PROCEDURE

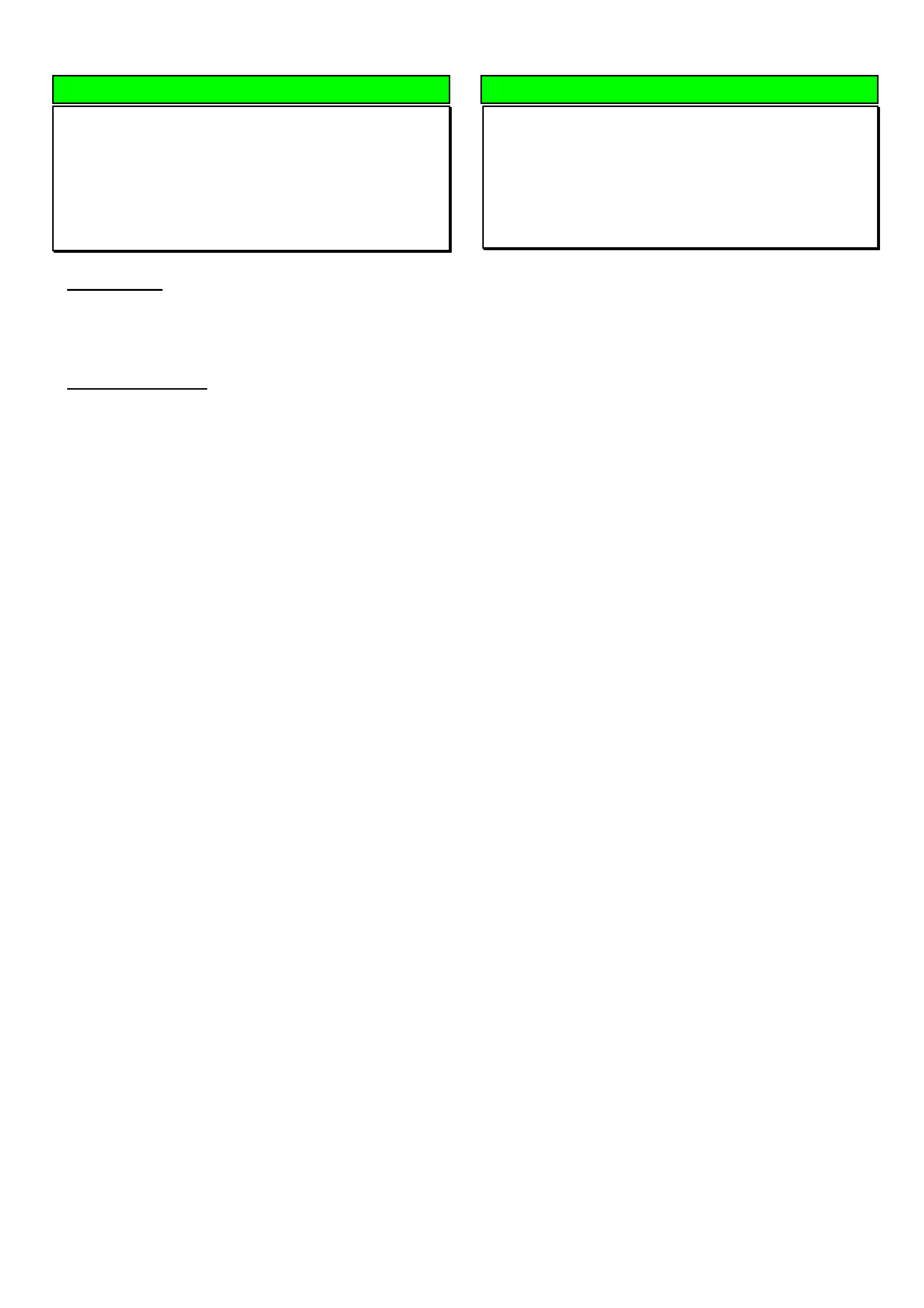

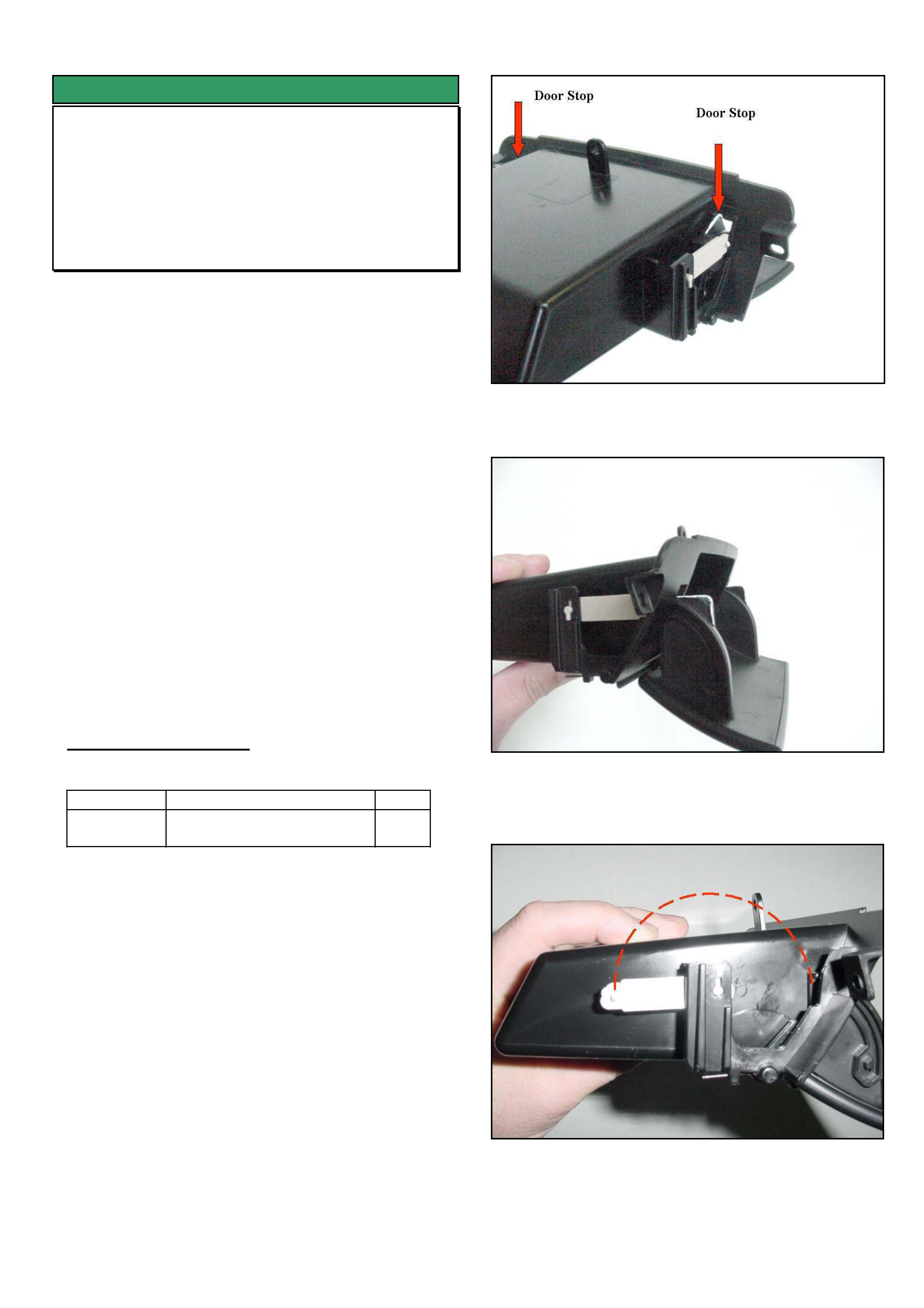

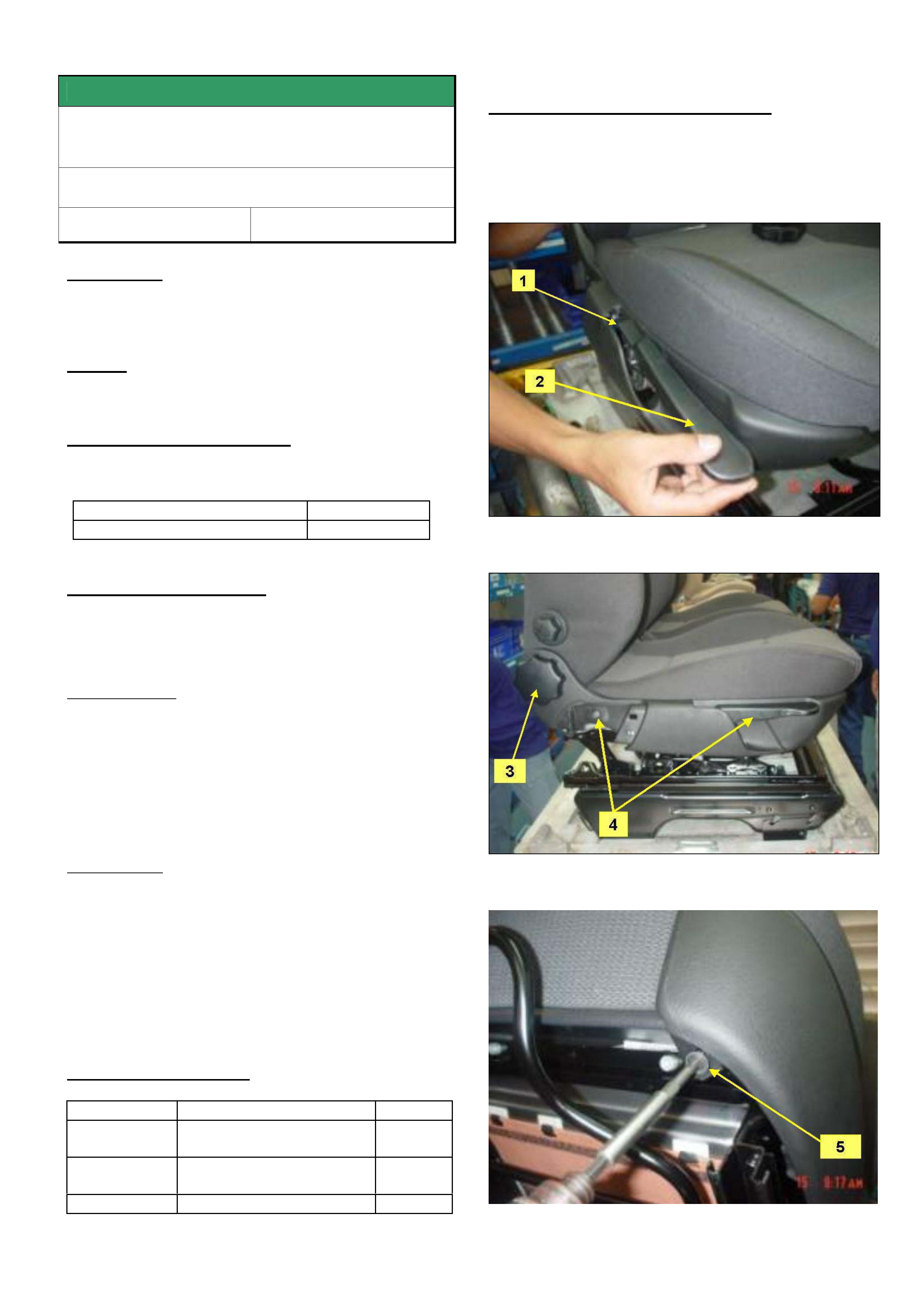

Revised Door Lock Knob Assembly

VYII, V2, WK

(GROUP 1) TL0636-0402

A revised door lock knob assembly has been

introduced which has a tool access slot added below

the red locking insert. This slot allows the red locking

insert to be released without damage. Refer Figure 1.

Figure 1. Shows a removal tool inserted into slot

below red locking insert.

PRODUCTION BREAKPOINT

Revised door lock knob assemblies with added

access slot have been fitted to vehicles from:

ISOVIN: Built Date:

L238377 18/2/2004

REMOVAL PROCEDURE.

1. Pull door lock knob up to reveal slot below red

locking insert.

2. Insert removal tool into slot.

3. Pull red locking insert outwards to allow door lock

knob to be withdrawn.

A removal tool can be manufactured from steel to the

following dimensions. (previously used for VN)

HOLDEN SERVICE TECHLINE __________________________________________________________________MARCH, 2004

8

INFORMATION

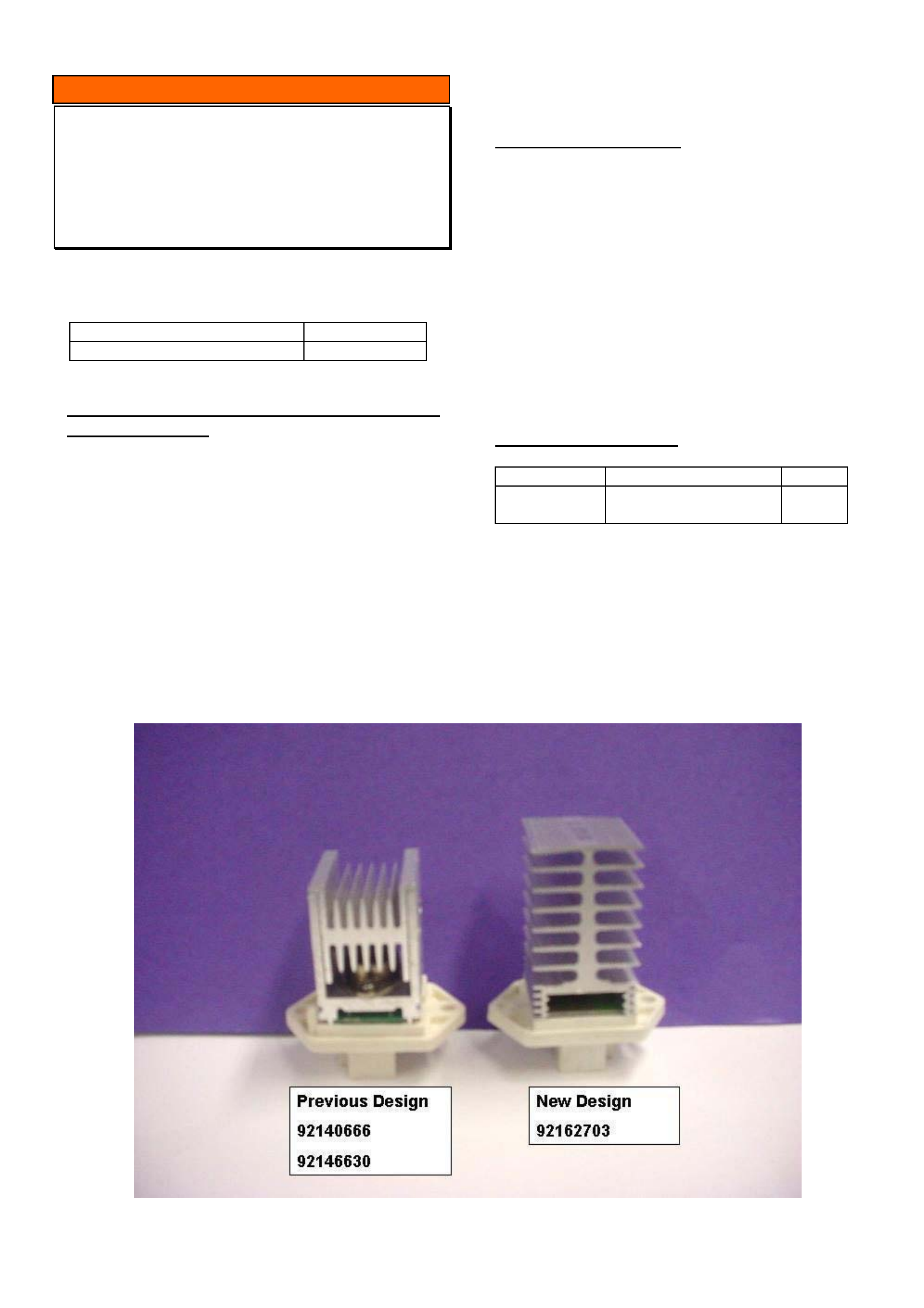

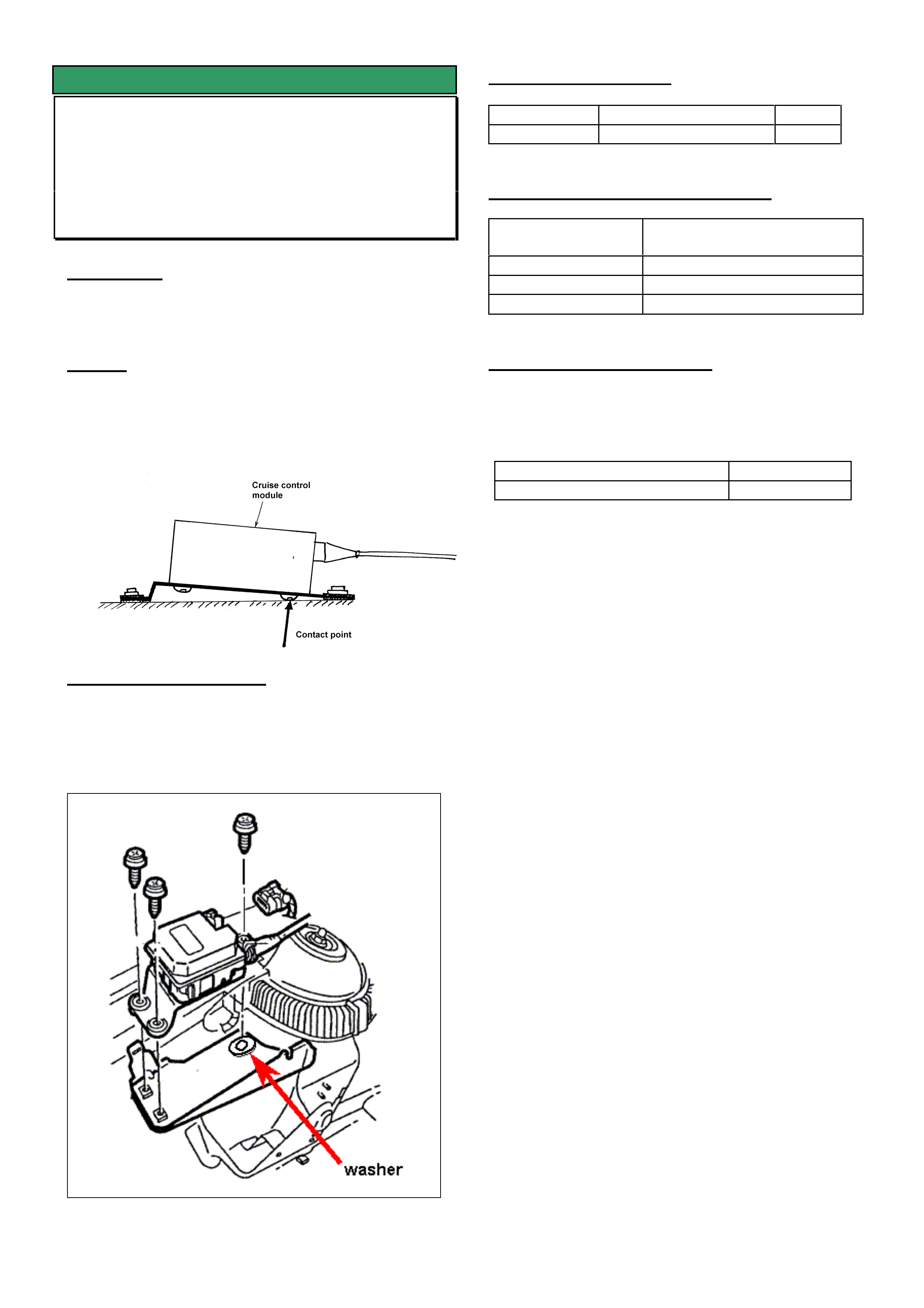

New design Blower Speed Controller for

ECC Vehicles

VYII, WK, V2

(GROUP 2) TL0642-0402

A new design HVAC blower speed controller has

been introduced into vehicles from:

ISOVIN: Built Date:

6G1YX54F44L236466 10/02/2004

Operating Characteristics Of New Blower

Speed Controller.

The main feature of the new blower speed controller

is an internal resettable circuit breaker. This circuit

breaker is to prevent damage to the blower motor

electrical circuit in the case of electrical current

surges, blower motor lock up on slower speeds or

extreme temperature build up.

If any of the above situations occur in the blower

motor circuit, the circuit breaker will open circuit and

render the blower motor inoperative.

The circuit breaker will reset after the ignition is cycled

from OFF to ON.

PROBLEM DIAGNOSIS

If a customer reports that “the blower motor switched

off while driving and resumed after the ignition was

cycled from OFF to ON do not replace the blower

speed controller as it has performed the function it

was designed for. Check the following:

- Blower motor and circuit for excessive current draw.

- Blower motor for foreign material caught in plastic

impeller.

In cases where the blower speed controller switches

the blower motor OFF regularly, and the above

checks do not reveal any abnormalities, replace the

blower motor as this could be the cause of excessive

current.

PARTS INFORMATION

Part No.: Description: Qty:

92162703 Blower Speed

controller ECC

1

The blower speed controller 92162703 can be used

as a replacement for previous controllers 92146630

and 92140666, from VT to VY.

Note that the new controller has 3 terminals whereas

the previous controllers had 4 terminals.

HOLDEN SERVICE TECHLINE __________________________________________________________________MARCH, 2004

9

SERVICE FIX

Blaupunkt Radio Speed Dependent

Volume Malfunction

TS / XC / ZC

(GROUP 12) TL0660-0402

This is advance service fix information. An updated

techline will be issued when Production Correction

information is available.

CONDITION

Customers may advise that the speed dependent

volume control feature does not function even when

the highest level of speed dependent volume control

is selected on the audio head unit.

CAUSE

The above condition is related to a change in the

software in Blaupuntkt audio head units from the

middle of 2003. The revised software can be

identified by adjusting the volume control; if the word

VOLUME is displayed, the head unit has the affected

software level.

CORRECTION in PRODUCTION

To be advised in a future techline

CORRECTION in SERVICE

To rectify customer complaints of this condition,

perform the following operation. Ensure that only the

PULSE setting is changed.

1. Turn radio off.

2. Push and hold number 5 and 6 buttons then

press ON.

3. Keep all three buttons pressed until the word

"Service" appears on the screen.

4. Release buttons.

5. Push "SEEK" button unit the word "PULSE 2"

appears on screen.

6. Push the "TUNE/TRACK" button left to reduce

setting to "PULSE 1".

7. Turn radio off then back on or leave for 10

seconds (Radio automatically exits service

mode)

NOTE: For reference, the configuration of

each parameter shown within the “Service” selection

should be as follows;

ZC Vectra equipped with a 2620 audio head unit

Range2

GID

MAXVOL40

P01 007

Pulse 1

ZC Vectra equipped with a 2020 audio head unit

Range2

10T CHAR

MAXVOL40

P01 007

Pulse 1

TS Astra equipped with a 520 audio head unit

Range2

MAXVOL40

P01 006

Pulse 1

XC Barina equipped with a 2020 audio head unit

Range2

MAXVOL40

P01 007

Pulse 1

HOLDEN SERVICE TECHLINE __________________________________________________________________MARCH, 2004

11

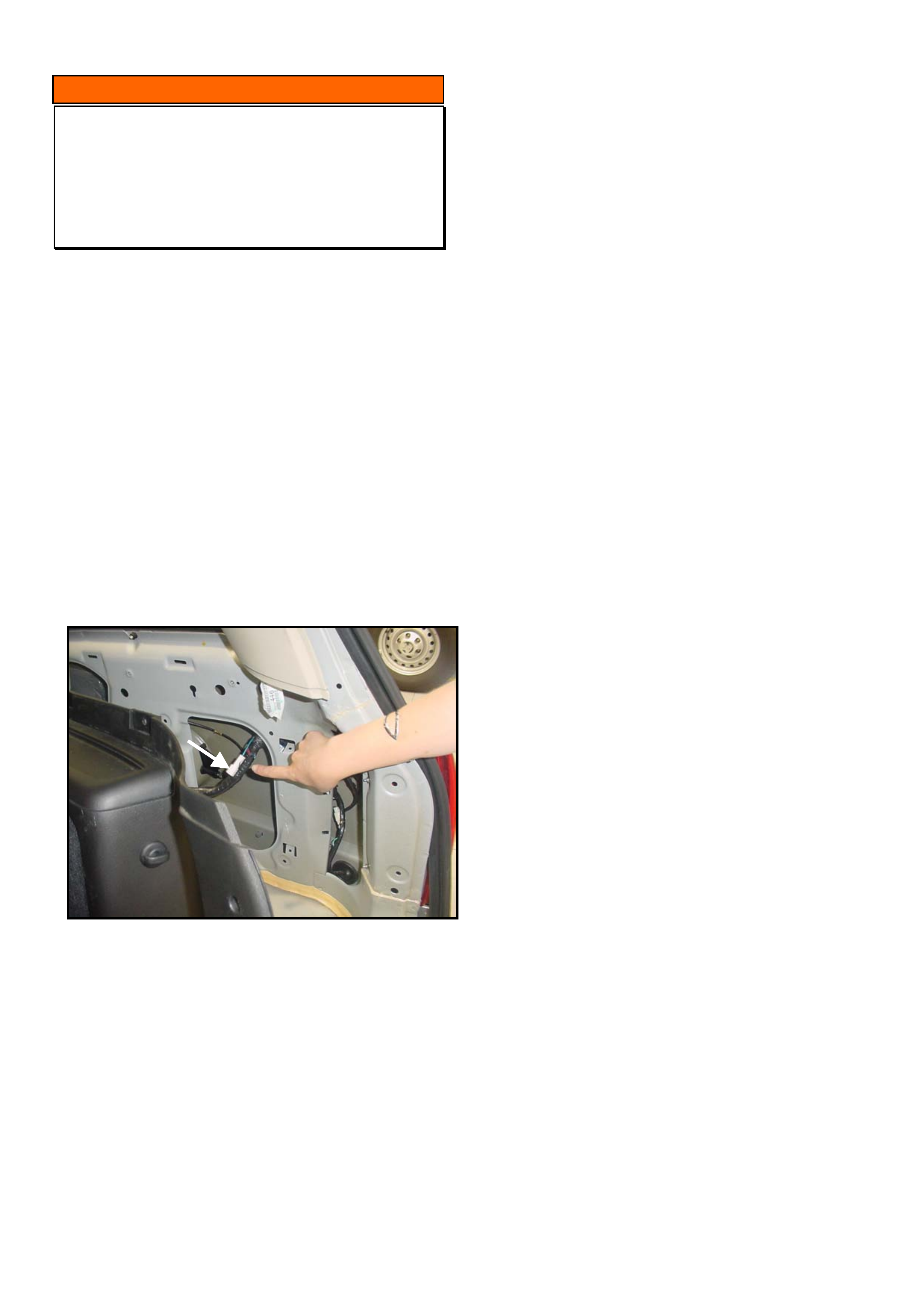

INFORMATION

Trailer Harness – Location of Electric

Brake Connection

AWD Adventra Wagon

(GROUP 0B) TL0647-0402

Trailer harnesses are fitted as standard equipment to

Adventra.

The trailer harness is connected to the vehicle wiring

harness behind the right hand tail light assembly.

The blue wire within the trailer harness used for

connecting electric brakes, has previously been tied

near the end of the harness connector. On Adventra,

this blue wire continues through the connector to the

vehicle harness and terminates approximately 10 -15

cm along the vehicle wiring harness behind the inner

rear panel / trim.

The wire and connector is taped to the vehicle

harness which is hidden behind the panel. Refer to

Figure 1 below.

Figure 1. Shows harness pulled down to reveal

electric brake connection.

HOLDEN SERVICE TECHLINE __________________________________________________________________MARCH, 2004

12

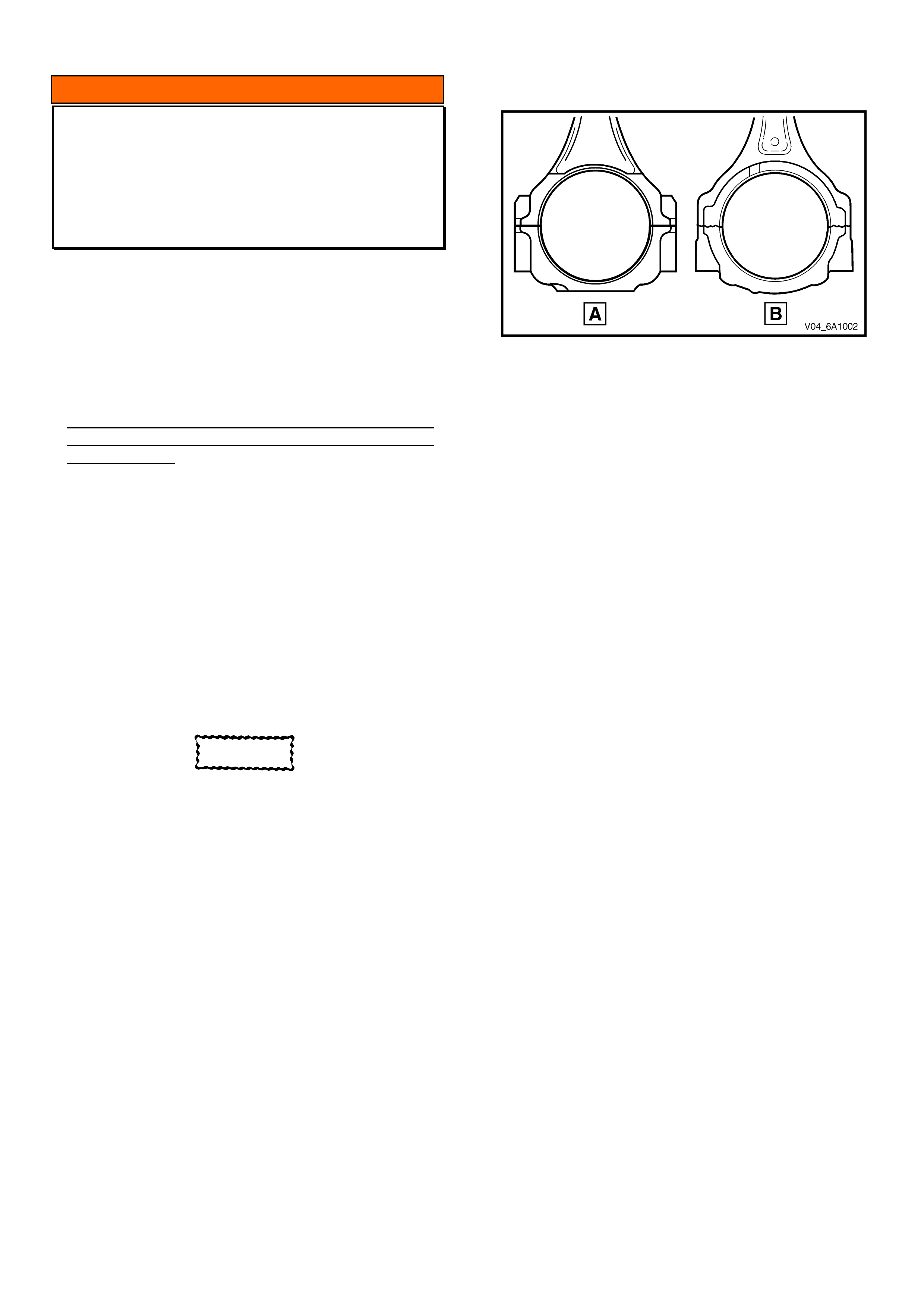

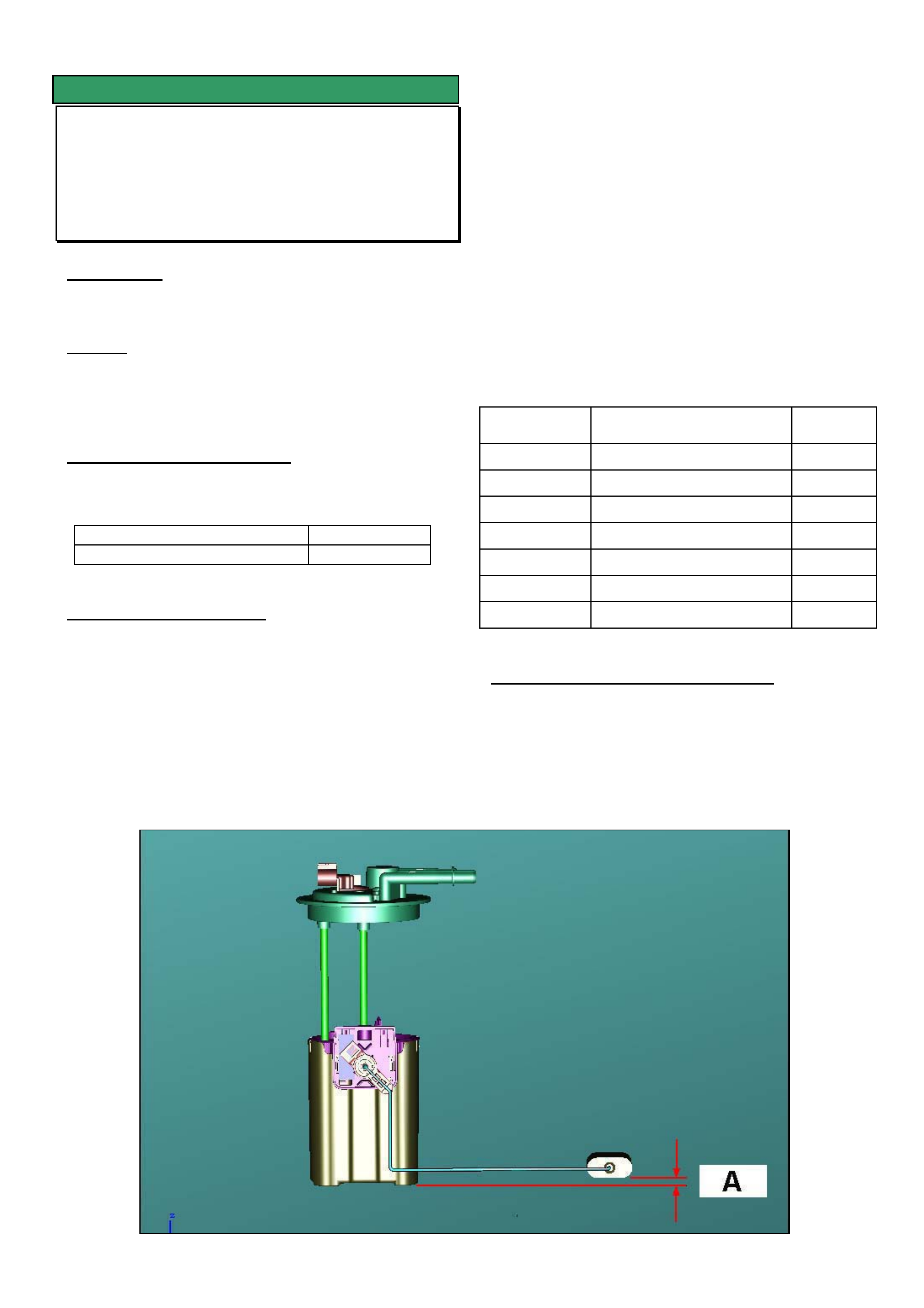

INFORMATION

Revision to Con Rod Big End

Manufacturing Process

All V6 3.8L Engines

(GROUP 6A) TL0650-0402

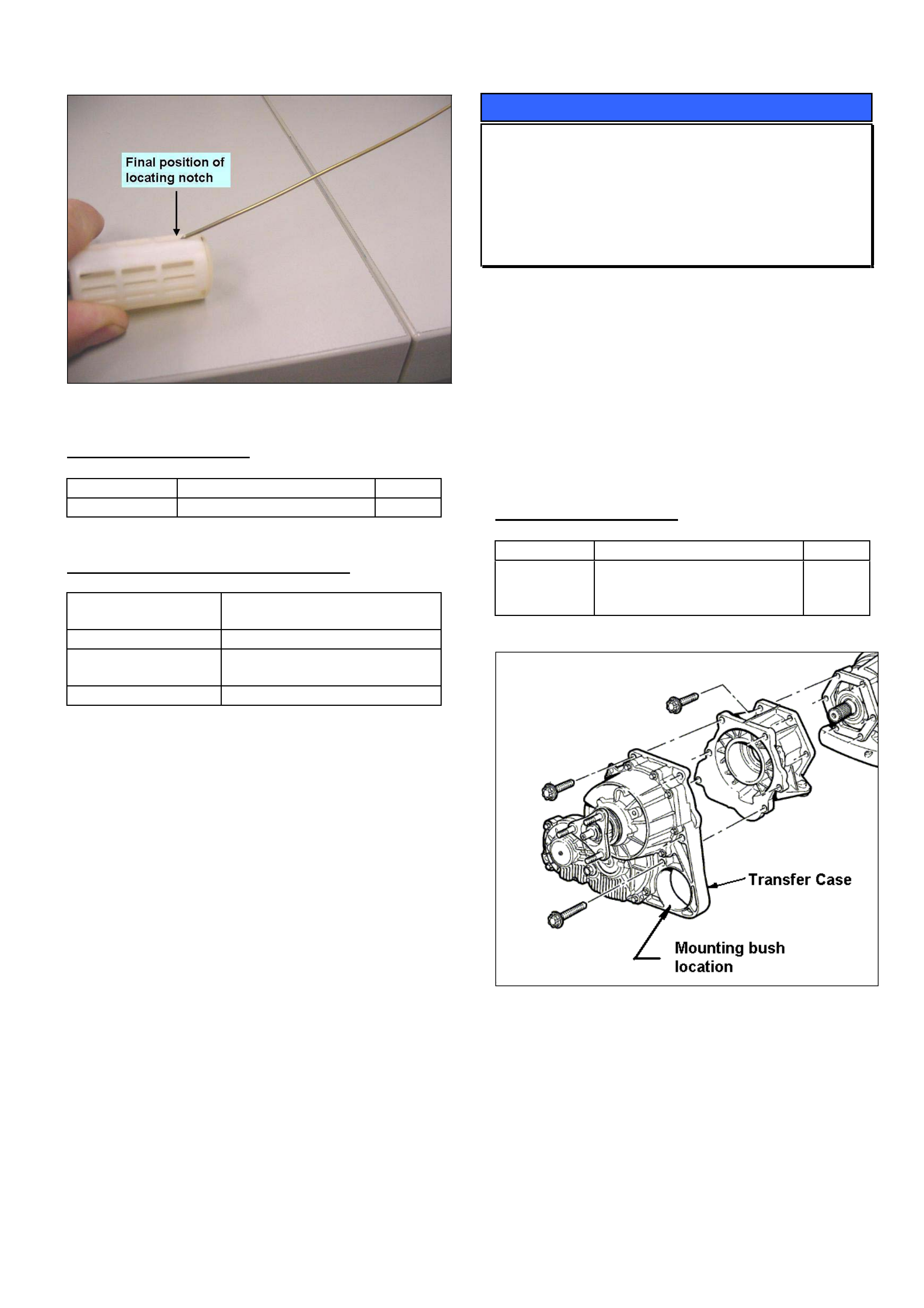

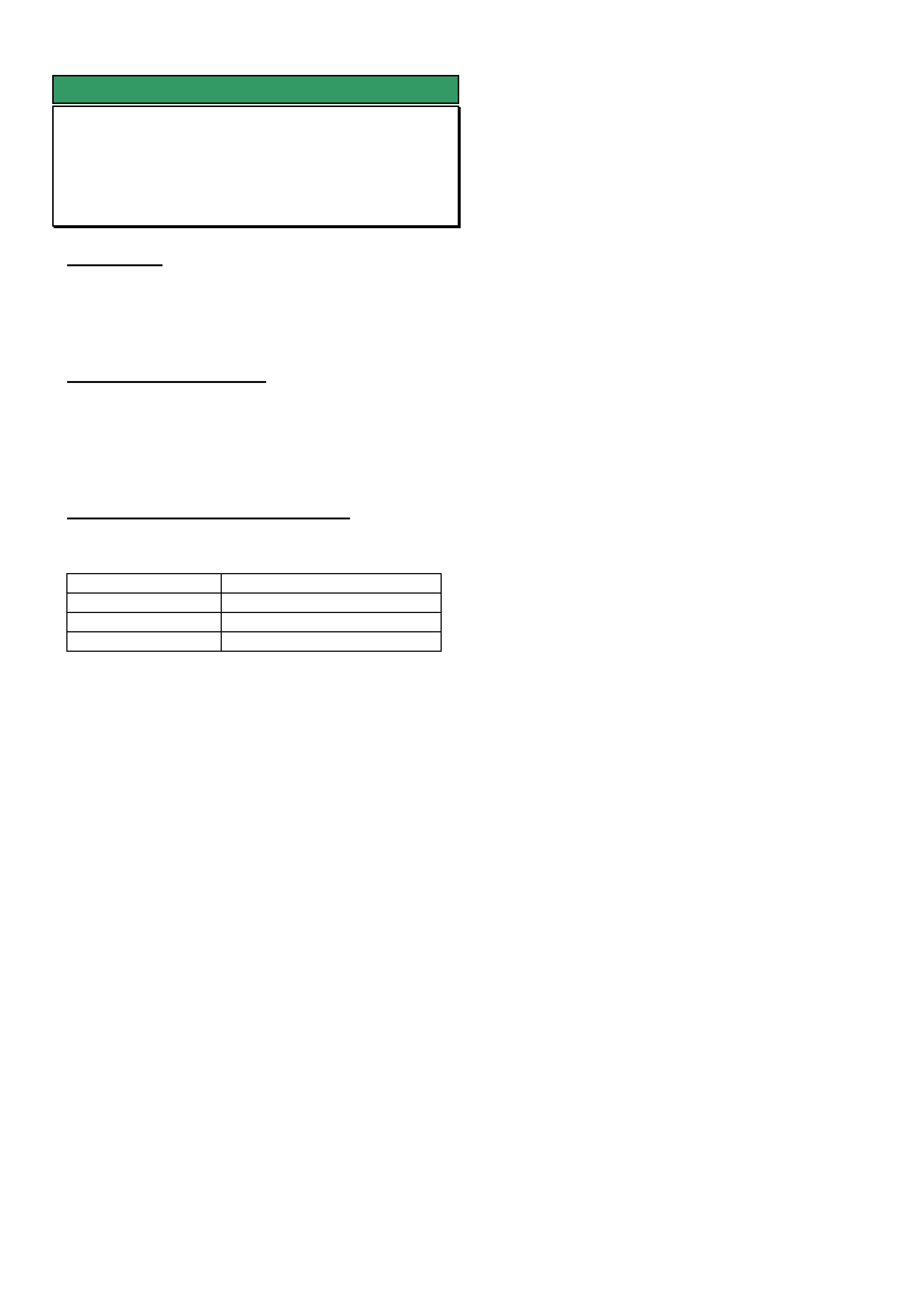

Commencing from Engine No. VA375970, fitted to

vehicle tag No. L179991, all 3.8L V6 engines are

fitted with connecting rods manufactured using the

latest powder forged metal technology and the “big

ends” are cracked apart in lieu of conventional

machining – refer illustration 6A2-1

The following information is provided for use by

technicians until the information is available in

Passenger SIP:

Powder forged cracked type connecting rods were

introduced into production as a running change

during September 2003. Illustration 6A2-1 shows the

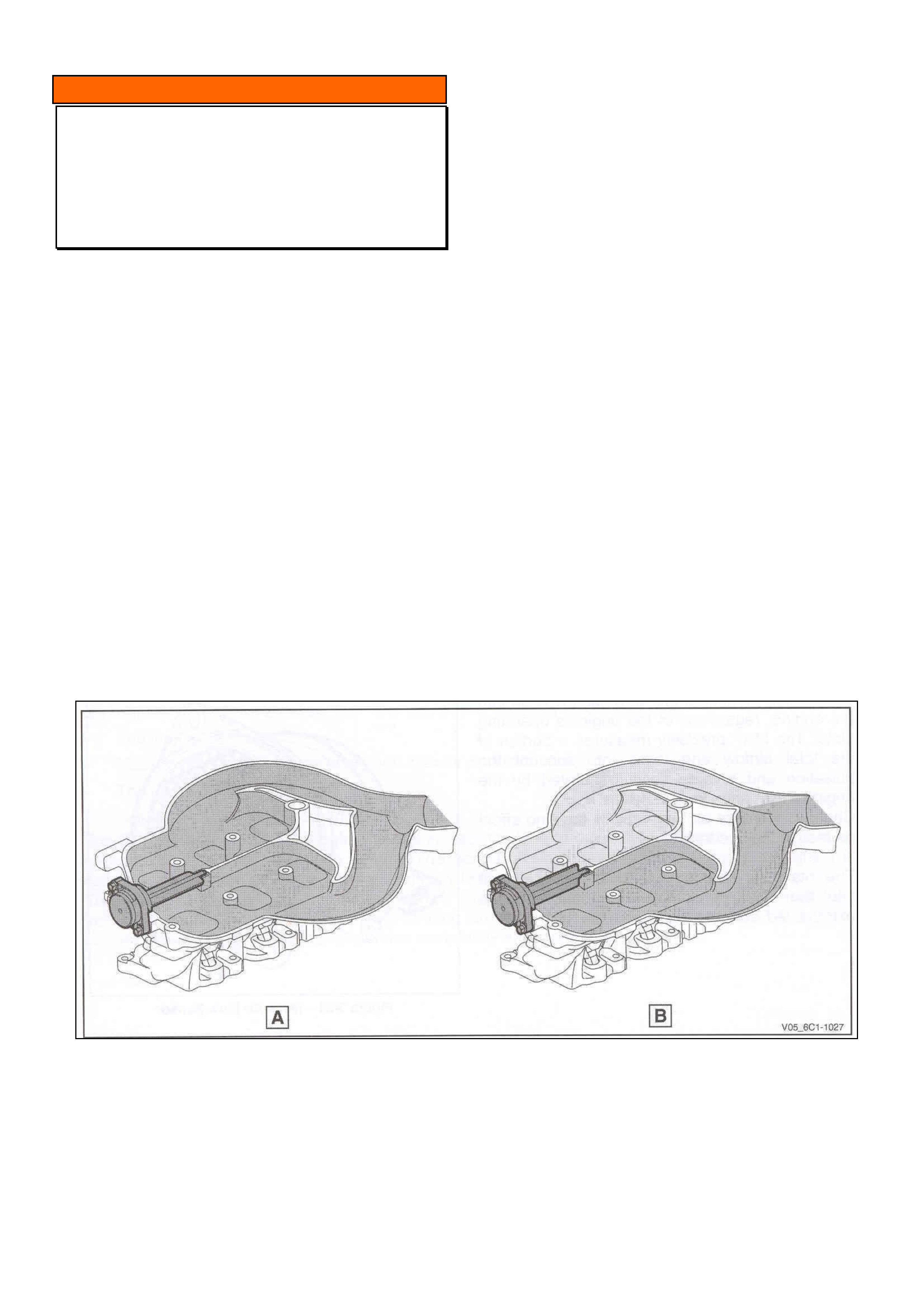

difference in the early cast and machined type (A)

and later powder forged and cracked type (B)

connecting rods.

NOTE

Other than the revised manufacturing process and a

revised connecting rod cap bolt torque specification,

all other specifications and servicing procedures

relating to the connecting rods remain unchanged.

CAUTION

The early type connecting rods can be replaced

by the late type connecting rods.

However, to avoid confusion with having different bolt

torque values, when replacing early type connecting

rods with the late type, it is recommended that the

connecting rods be replaced as an engine set.

Illustration 6A2-1

Connecting Rods:

Early Type: Malleable Cast Iron 'I' Section

Late Type: Powder Forged ‘I’ Section

Length: (centre to centre)

Std V6 : 143.20 – 143.30 mm

S/C V6: 145.90 – 145.80 mm

Alignment: Bend 0.020/25.4 mm;

Twist 0.038/25.4 mm

Torque Wrench Specifications:

Early Type Connecting Rod (machined big

ends) Cap Bolts:

27 ±3 Nm plus 50 ±3° turn angle

Late Type Connecting Rod (cracked big ends)

Cap Bolts:

20 ±3 Nm plus 75 ±3 ° turn angle

HOLDEN SERVICE TECHLINE __________________________________________________________________APRIL, 2004

6

INFORMATION

Holden Contacts and Procedures

(GROUP OB) TL0679-0403

This techline summarises some of the Holden

contact procedures and gives a quick reference

guide for contact numbers.

Security information.

To obtain security information a completed security

information request form must be faxed through to

the security information department, as security

information cannot be given out by phone. TAS does

not process security information requests. Please

ensure you have the latest security information

request form, which is available on SIP. Contact

details are listed below. There can be up to a 4-hour

turn around on requests however if the information

needs to be obtained from overseas, it may take up

to 24 hrs. Do not phone the security information

department unless you have not received a response

in the normal turn around time. For further

information please refer to ADL 63/99.

Parts inquiries and information

If any information or assistance is required in regards

to part numbers or Partfinder, please refer to the

Holden Help section in Partfinder.

Warranty Authorisation and enquiries

Warranty can only be authorised by your Aftersales

District Manager. Labour times information is

available on SIP or from the warranty department.

For any other warranty inquiries please contact

Warranty Administration.

TAS

Technical Assistance Service (TAS) is a service

provided by Holden to assist Holden Dealers in

problem resolution.

TAS operating hours are:

Monday to Thursday 8.30am – 8.00pm and Friday

9.30am – 5.00pm Melbourne time. Contact to TAS

must be made by a Nominated Contact as outlined in

Section 5 of the TAS procedures manual. All

techlines, dealer letters and service information must

be checked prior to contacting TAS. The Nominated

Contact must not contact TAS until he/she has been

fully involved with the faulting vehicle and all Dealer

expertise has been exhausted. Problems should be

escalated through the Dealership to the senior

technician/foreman before contacting TAS.

TAS cases must be updated or closed within 30 days

unless a Dealer is waiting on a service fix to be

provided. It is the Dealers responsibility to update

cases. All cases should be recorded in the TAS

procedures manual, which should be referred to prior

to contacting TAS. Please note that an electronic

copy of the TAS procedures manual is also available

on passenger SIP.

Under no circumstances are TAS or other Holden

contact details to be supplied to customers or

independent repairers. TAS is a service restricted to

assisting Holden Dealer service departments.

Quick reference contact numbers

Air International Ph 1800 673 716

Australian Arrow Ph 03 9785 0792

Blaupunkt/Bosch Ph 1300 307 036

Clarion Ph 03 8558 1115

Fax 03 9551 0377

Customer Assistance Ph 1800 033 349

Dana Ph 02 9892 9237

Fax 02 9892 9310

www.spiceraxle.com.au

Delphi Ph 1800 335 777

Eurovox Ph 03 9237 0800

Fujitsu Ten Ph 03 9646 6008

Holden Assist Ph 1300 880 088

HSV Ph 03 9265 9500

Infomedia Ph 1800 810 103

Panasonic Ph 02 9986 7635

Petro-Ject Ph 02 9890 5701

Ph 02 9890 5244

Philips/Siemens-VDO Ph 1800 335 282

Salmat Ph 03 9358 2900

Security Ph 03 9647 2001

SPX Australia Ph 03 9544 6222

TAS Ph 1800 033 417

Fax 03 9647 2495

Warranty Ph 03 9647 1972

Ph 03 9647 2401

Ph 03 9647 1970

HOLDEN SERVICE TECHLINE __________________________________________________________________APRIL, 2004

7

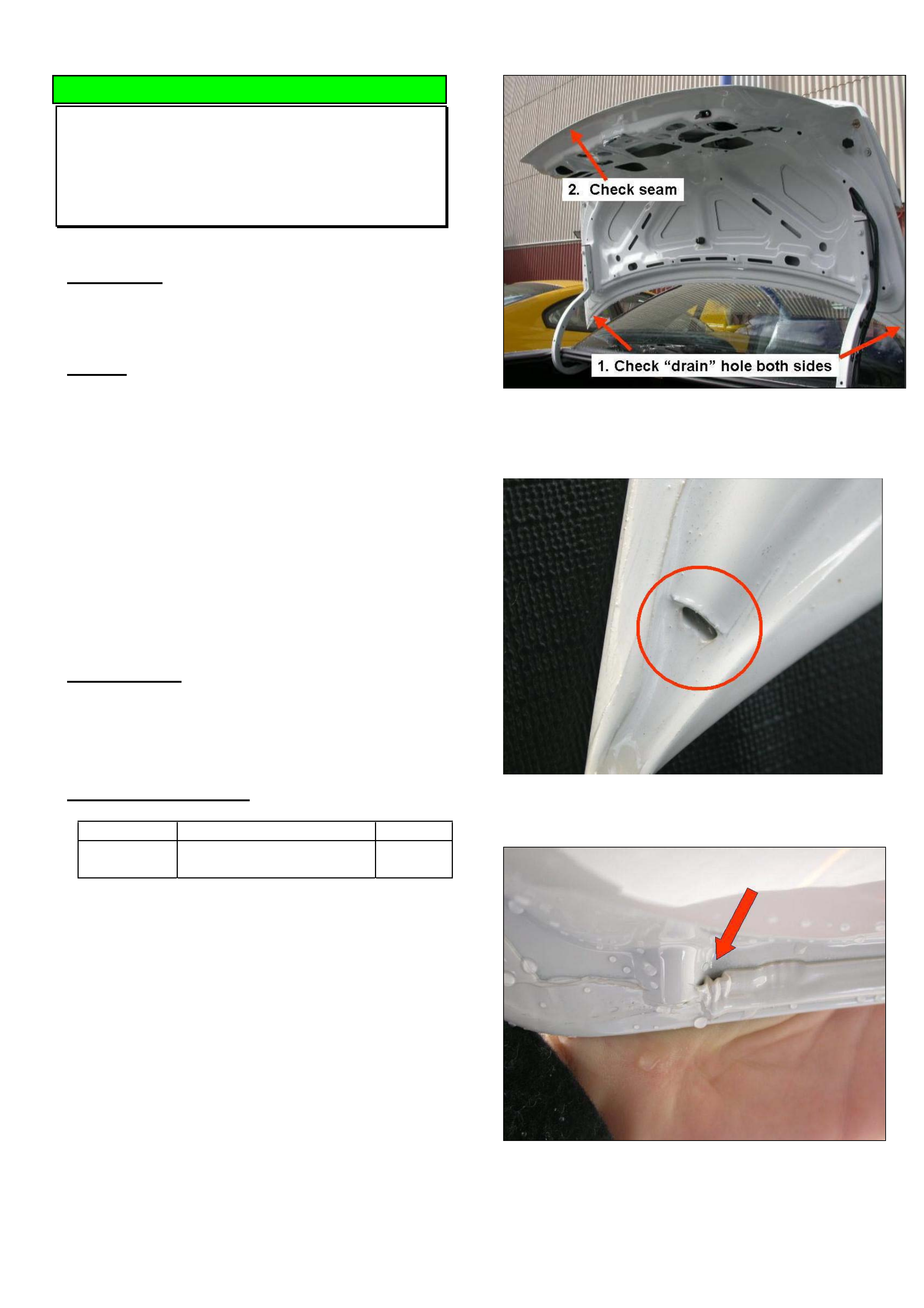

DIAGNOSIS HINT

Electric Power Steering (EPS) Problems

Due To Poor Ground Point

XC Barina

(GROUP 9) TL0680-0403

Background Information

TAS has received calls from retailers regarding no

Tech 2 communication with the Electric Power

Steering (EPS), EPS light on in instrument cluster,

and/or repeat failure of the EPS module.

Investigation has found the EPS module high current

earth to ground point 4 at the drivers side A pillar, to

be loose, stripped or disconnected.

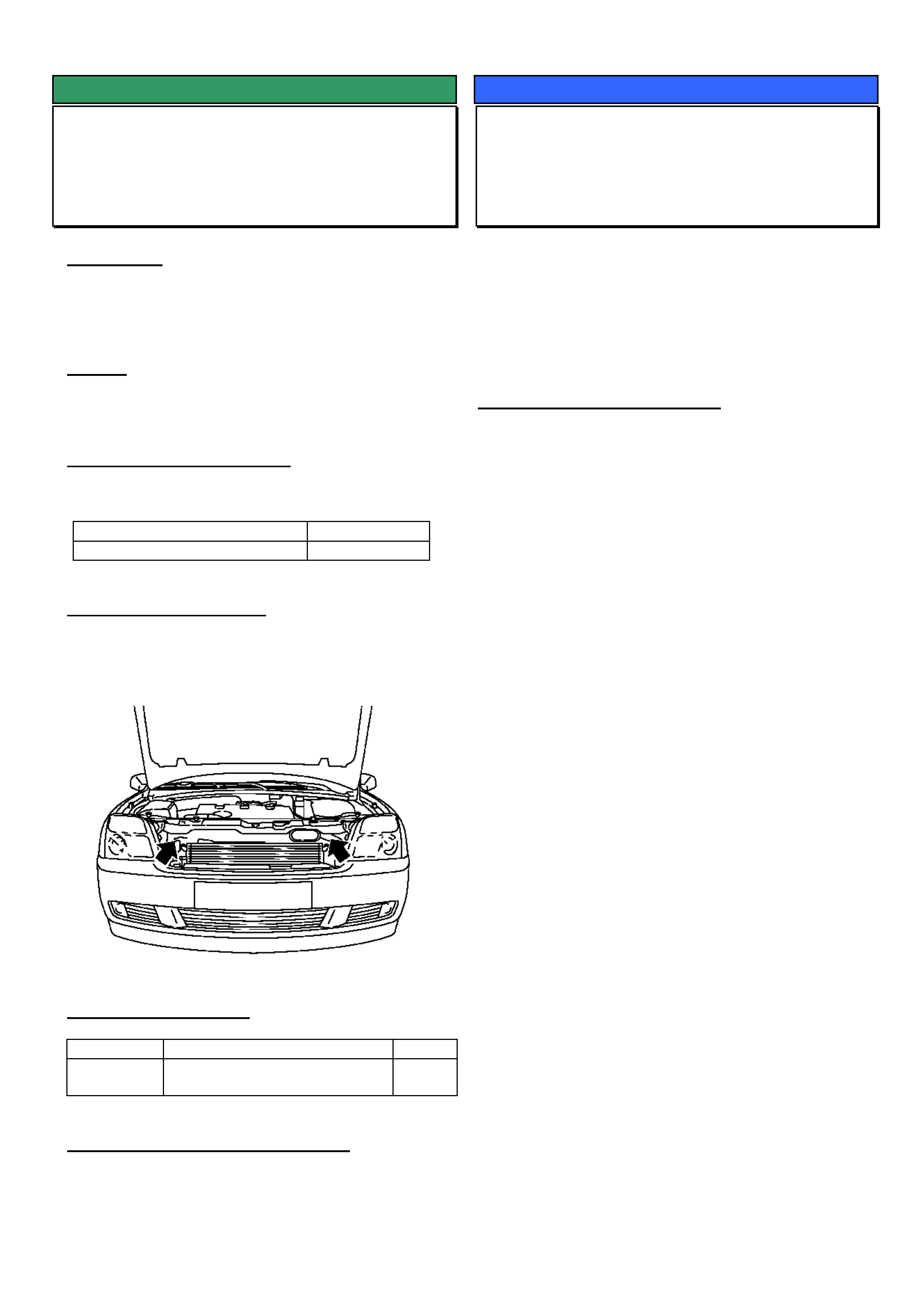

This ground point is located on a metal bracket to the

righthand side of the bonnet release lever as shown

in figure 1.

Important

When diagnosing any EPS related fault, check

ground point 4 retaining nut is fitted and tightened.

Figure 1

Figure 2.

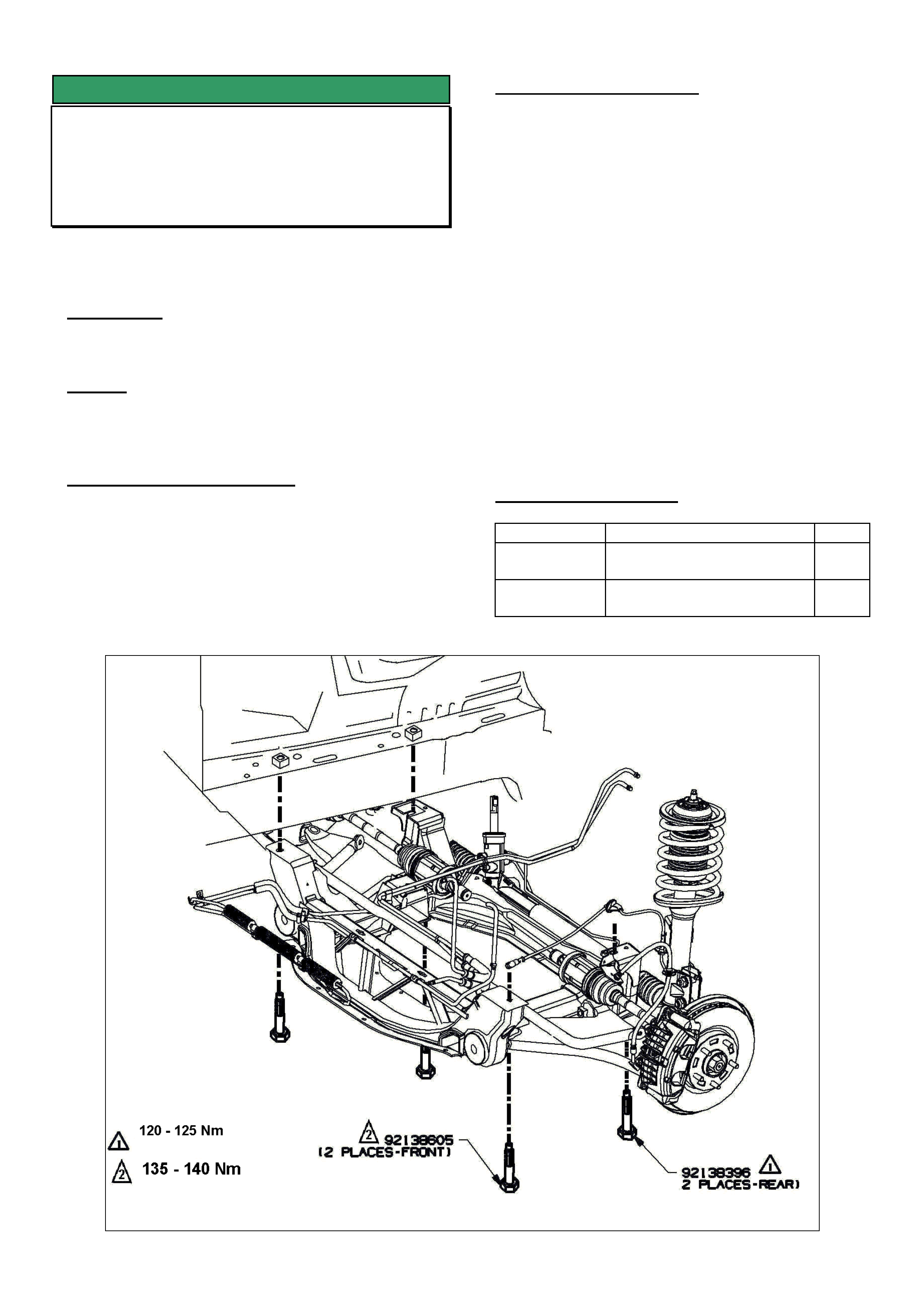

SERVICE FIX

Front Suspension Clunk (Lower Control

Arm Rear Bush Movement)

VY Adventra

(GROUP 3) TL0638-0403

CONDITION

Clunk from front suspension usually heard when

wheel impacts deep pot hole.

CAUSE

One potential cause of front suspension clunk which

has been identified is movement of the control arm

bush in the cross member due to insufficient clamp

load.

CORRECTION – in Production

Front lower control arm bush rear bolt torque revised

on vehicles from:

ISOVIN: Built Date:

**********L237289 23/02/2004

CORRECTION – in Service

After verifying that vehicle has symptoms as

described above, increase torque on the front lower

control arm rear bush bolt to 175 – 185 Nm. Refer

bolt No. 4 in Figure 1.

Note. The bolt does not need to be replaced prior to

applying revised torque.

Figure 1.

B

O

N

N

E

T

L

E

V

E

R

Ground Point

4

Update

HOLDEN SERVICE TECHLINE __________________________________________________________________APRIL, 2004

8

SERVICE FIX

Front and Rear Accessory Mudflaps

Dislodge

TS

(GROUP 1) TL0675-0403

CONDITION

Accessory mudflaps become dislodged.

CAUSE

The mudflaps are attached to a metal mounting

bracket with plastic “heat stakes”. These joints may

be damaged in service which allows the plastic

mudflap to detach from its mounting.

CORRECTION

On any vehicle where the mudflaps become

dislodged as a result of damage to the “heat stakes”,

perform the following procedure.

Use fasteners P/N 92138352, to re-attach the

mudflap to the metal mounting bracket by simply

screwing the fasteners into the original heat stake

positions. Refer Figure 2

NOTE: The fastener tip is covered in a sealant

material which needs to be removed prior to

screwing into the plastic. (Refer Figure 1)

Add fasteners to each heatstake position regardless

of whether they are broken or not. This will ensure

the mudflap does not fail in the same manner again.

Front – 2 screws per mudflap

Rear – 3 screws per mudflap

NOTE: Fasteners, as described in this techline, will

be applied to all new Holden accessory mudflaps.

PARTS INFORMATION

Part No.: Description: Qty:

92138352 Screw 10

WARRANTY CLAIM INFORMATION

Description Attach mudflap to mounting

bracket with screws (4

mudflaps)

Labour Op. No. C000517

Time 0.4 hr

Failure Code 71 / C0071 Pulled loose

Figure 1. Remove

sealer from screw.

Figure 2. Screwing into

heatstake

Figure 3. Add a screw to each heatstake position.

HOLDEN SERVICE TECHLINE __________________________________________________________________APRIL, 2004

9

SERVICE FIX

Fuel Odour and Dust Entry

VU, VY Ute

(GROUP 8) TL0603-0403

ThisTechline should be read in conjunction with

Techline TL509-0308 (issue 8, Aug. 2003) which

provides sealing procedures for preventing dust/fuel

odour entering cabin.

PROBLEM DESCRIPTION

Customer complains of fuel smell in cabin usually

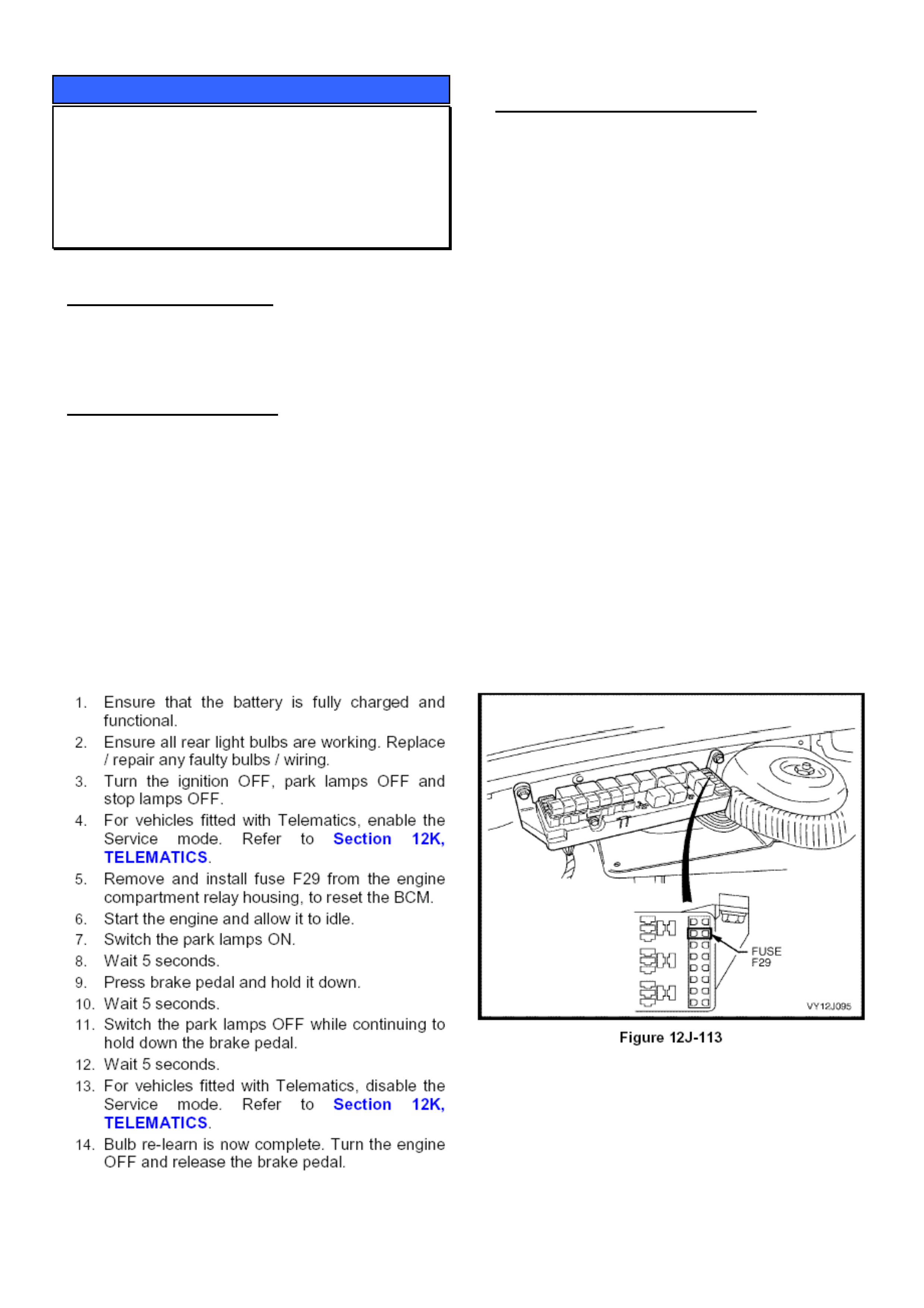

after the vehicle has been parked for some time.

Investigations show that small amounts of fuel

vapour may permeate the fuel filler hose and result in

a fuel odour.

PRODUCTION RECTIFICATION

An improved fuel filler hose with lower permeability

was installed into vehicles from

ISOVIN: Built Date:

**********L209199 4/12/2004

In addition to the above, expanding foam has been

added into the rocker panels (to prevent dust/fuel

odours entering the cabin) on vehicles from:

ISOVIN: Built Date:

**********L238316 17/2/2004

SERVICE RECTIFICATION

Summary: On complaint vehicles, replace the fuel

filler hose and seal the dust/fuel odour pathways in

body as per following procedure .

1. Replace fuel filler hose with new hose shown in

Parts Information.

2. On vehicles built before tag L238316,

(A) Seal all dust/fuel odour pathways as

described in Techline No. TL509-0308 (Issue 8,

Aug. 2003).

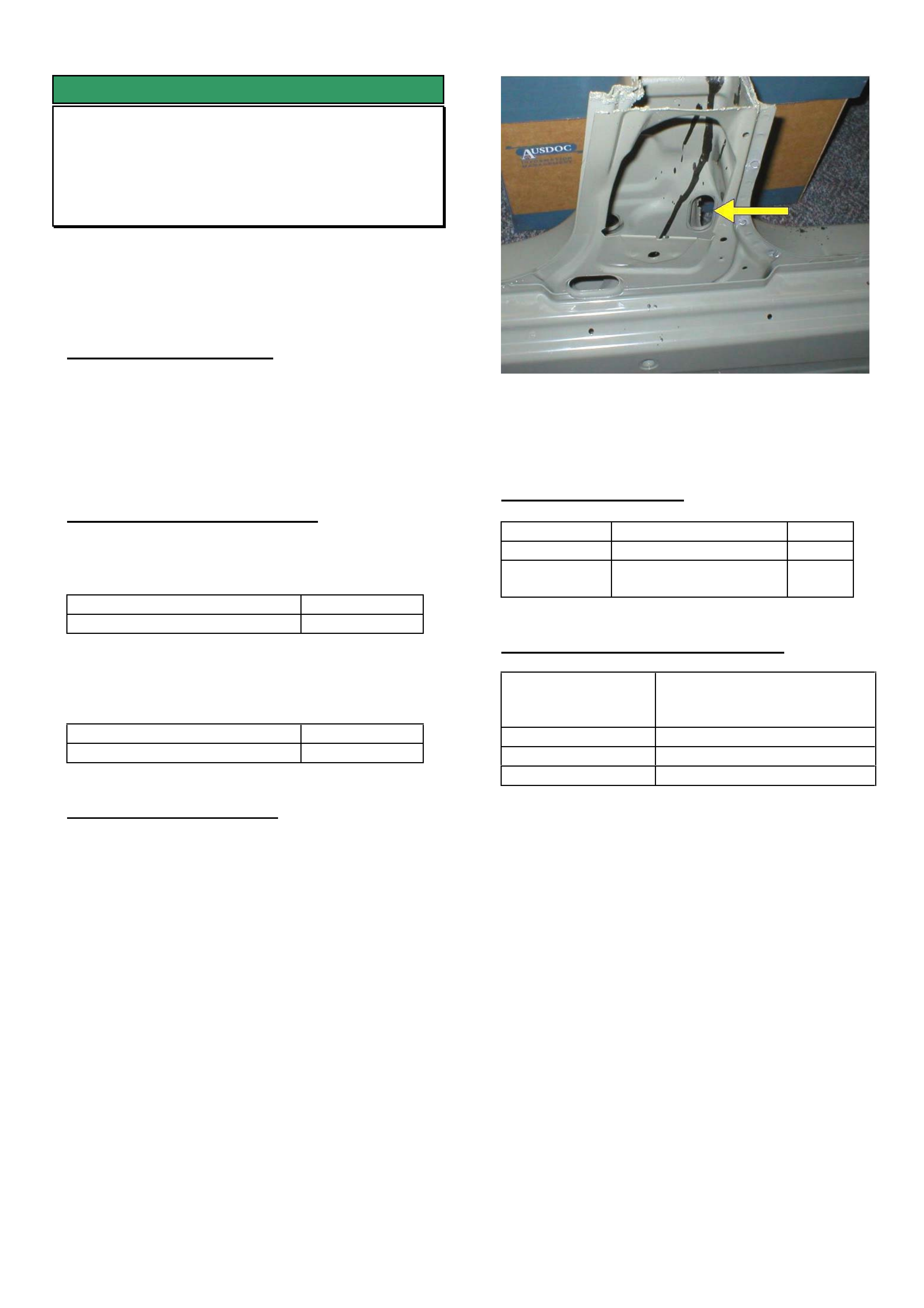

(B) Seal the hole in the sheetmetal at the base of

the drivers side B-pillar behind the seatbelt

retractor as shown in Figure 1. Seal the hole with

butyl patches cut from part No. 92156600.

NOTE: Vehicles built after tag L238316 do not

require above sealing procedures as they have

expanding foam inside the rocker panels to restrict

dust/fuel odours.

Figure 1. Section of lower RHS B-pillar showing oval

shaped hole (behind seat belt retractor) that requires

covering with a butyl patch.

PARTS INFORMATION

Part No.: Description: Qty:

92211421 Hose fuel filler 1

92156600 Deadener (butyl

patch)

1

WARRANTY CLAIM INFORMATION

Description Replace fuel filler hose and

add butyl patch to oval hole

in base of RHS B Pillar

Labour Op. No. L000226

Time 0.9

Failure Code 74/ L0074

HOLDEN SERVICE TECHLINE __________________________________________________________________APRIL, 2004

10

SERVICE FIX

Low Speed Engine Cooling Fan Relay

Sticking On

VYI, WK, V2 II With Gen III

(GROUP 12) TL0673-0403

CONDITION

Engine cooling fan remains on continuously after

ignition is switched off. In some instances the

vehicle battery may be fully discharged.

CAUSE

Contaminant on internal relay contacts due to a

quality control issue at the relay manufacturer.

Relays from the suspect batch were fitted to all

vehicles built between Jan 03 and Jul 03.

CORRECTION - Production

Known good relays were fitted to vehicles from:

ISOVIN: Built Date:

**********L145369 11/07/2003

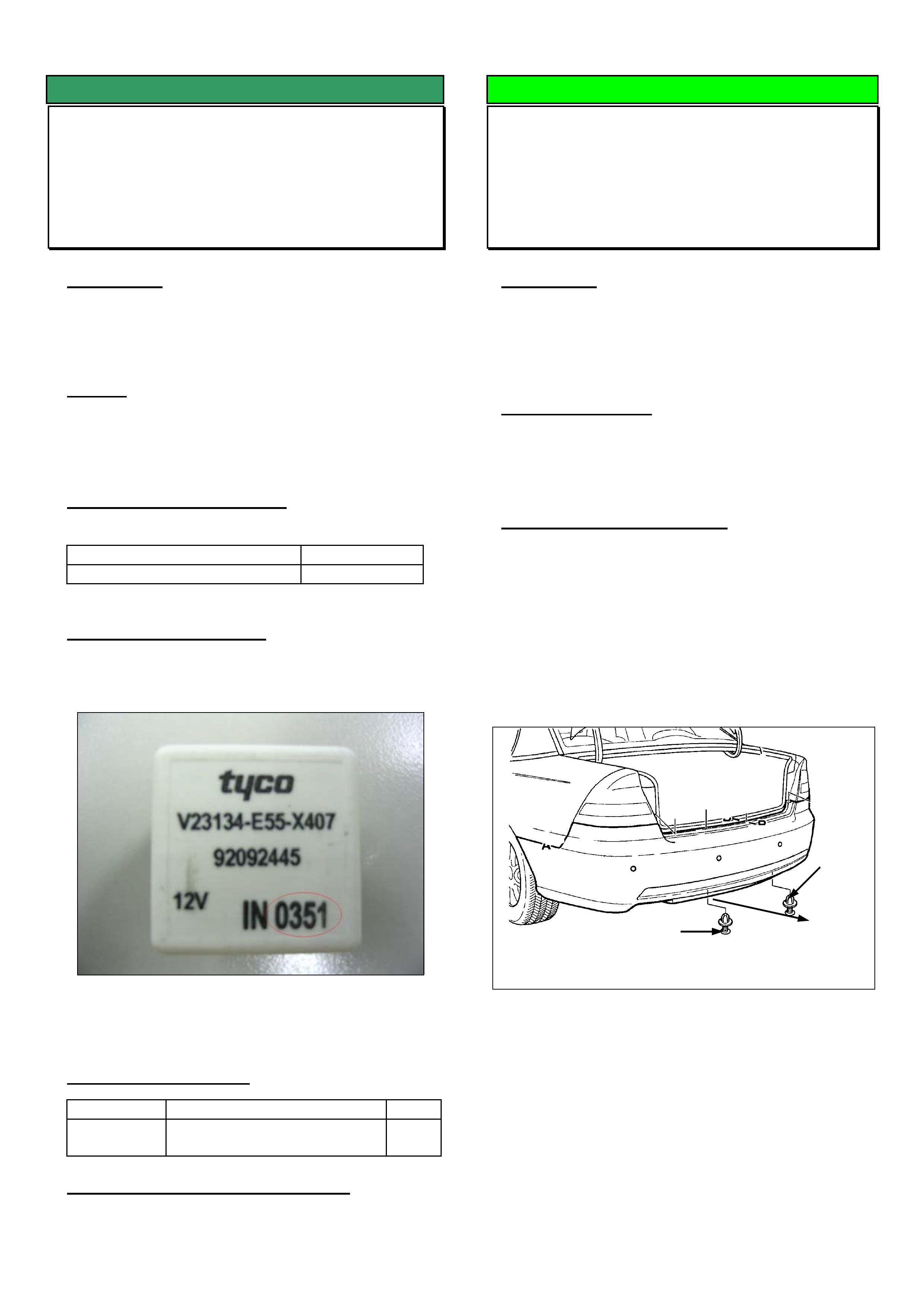

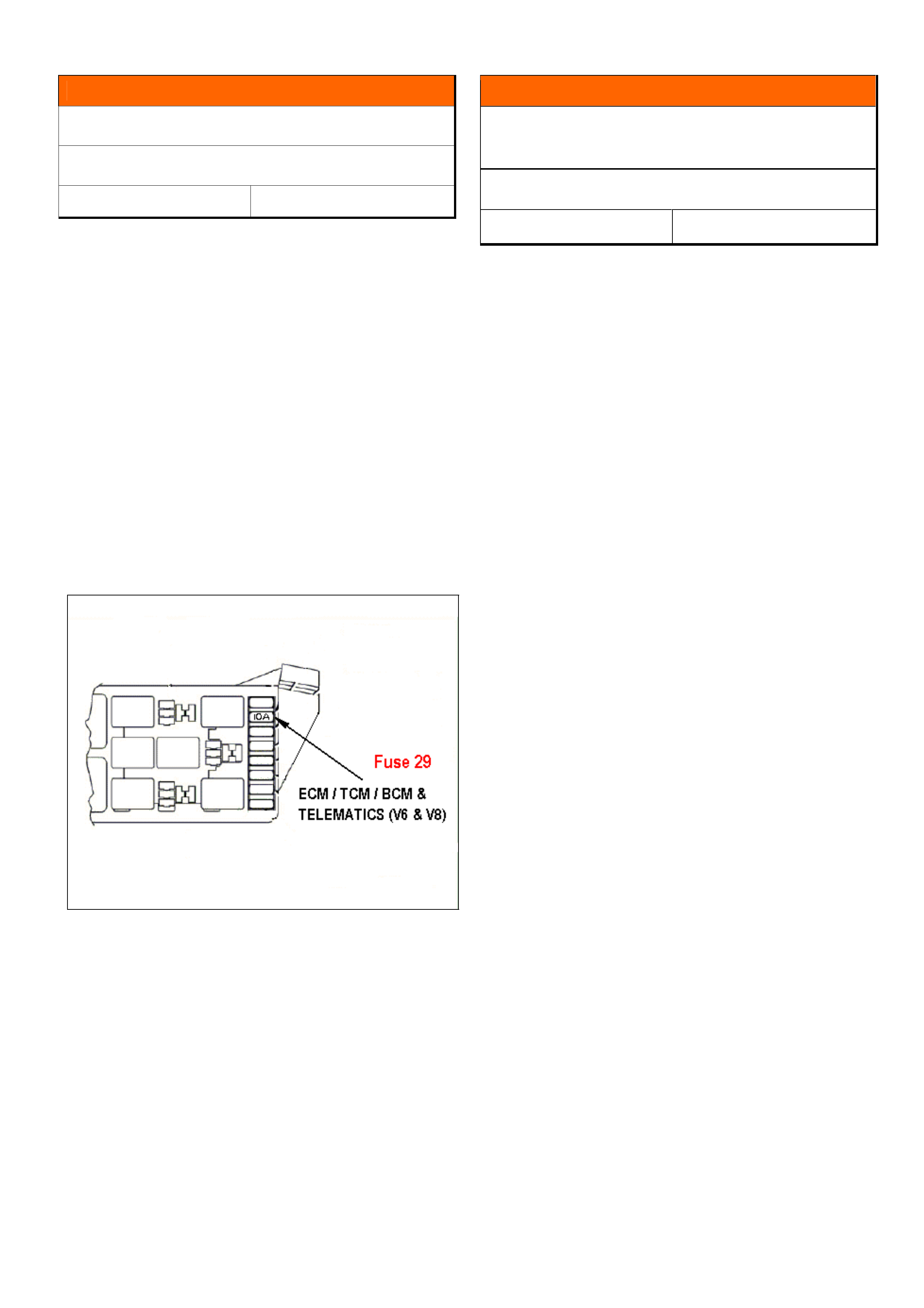

CORRECTION – Service

On vehicles affected by this condition, replace the

relay with one where the date code, as shown in

Figure 1, reads “IN 0314” or higher.

All relays manufactured prior to date code IN 0314

have been removed from HSPO stock.

PARTS INFORMATION

Part No.: Description: Qty

92092445 Low Speed Cooling Fan

Relay

1

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty

Information section of current PV SIP CD

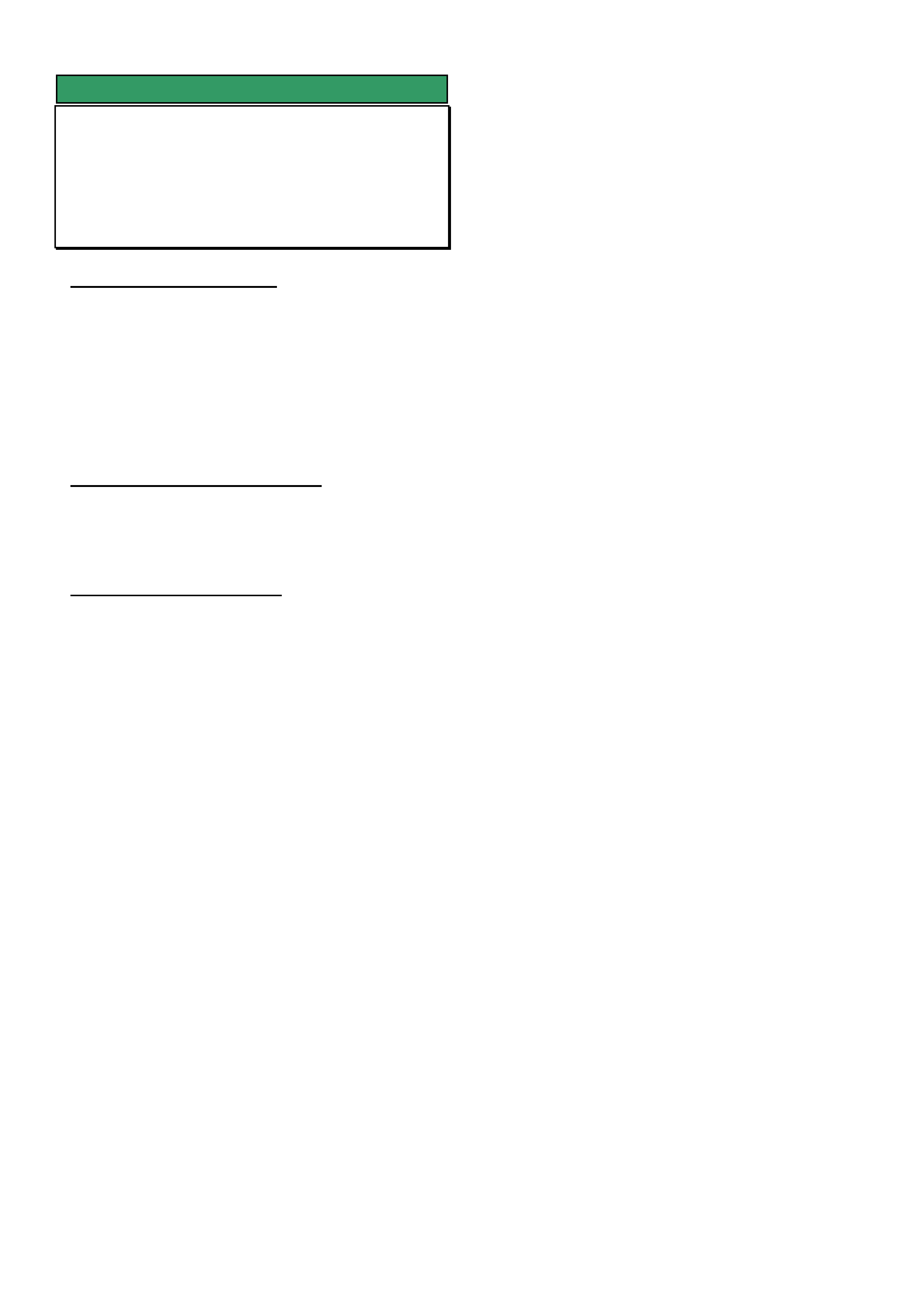

DIAGNOSIS HINT

False Triggering Of Reverse Park Aid By

Tow Ball

VY, WK, V2

(GROUP 12) TL0654-0403

CONDITION

Reverse Park Aid is triggered for no “apparent

reason, i.e. there are no objects within range behind

the vehicle

POSSIBLE CAUSE

The reverse parking aid sensors may be detecting

the tow ball.

SUGGESTED CORRECTION

1. For vehicles with the above condition it is

recommended to adjust the bottom of the rear

bumper fascia rearwards by 10mm. This action is

intended to alter the angle of the sensors.

NOTE: Relocating the bottom of the fascia rearwards

by 10mm will require drilling new holes in the lower

attaching metal bracket for the 2 retainers.

2. Check the Rear Parking Aid system operation

again. If the system no longer detects and triggers off

the tow ball then adjustment is complete.

3. If the system continues to be triggered off the

tow ball, interchange the two inner sensors with the

two outer sensors and re evaluate system operation.

4. If the system continues to be triggered off the

tow ball perform the rear park aid diagnosis

procedure as shown in Passenger SIP.

Retainer

Retainer

PULL

HOLDEN SERVICE TECHLINE __________________________________________________________________APRIL, 2004

11

SERVICE FIX

DTC’s P0171 & P0174 Fuel system lean,

Banks 1 & 2

VY II, V2 III, with GEN III V8 and M/T

(GROUP 6C) TL0682-0403

PROBLEM DESCRIPTION

DTC’S P0171 and P0174 setting (banks 1 & 2 lean

indication). After conducting extensive diagnosis

including checking for low fuel pressure, fuel quality

and vacuum leaks, no fault can be found.

The cause of codes P0171 & P0174 setting when no

evidence of running lean can be found, is

oversensitive PCM software calibration.

PRODUCTION RECTIFICATION

Breakpoint information for the introduction of revised

PCM software calibration into vehicle production will

be advised in a future Techline.

SERVICE RECTIFICATION

Revised PCM software to rectify P0171 and P0174

setting unnecessarily was released on TIS 2000 CD

50.

HOLDEN SERVICE TECHLINE __________________________________________________________________APRIL, 2004

12

SERVICE FIX

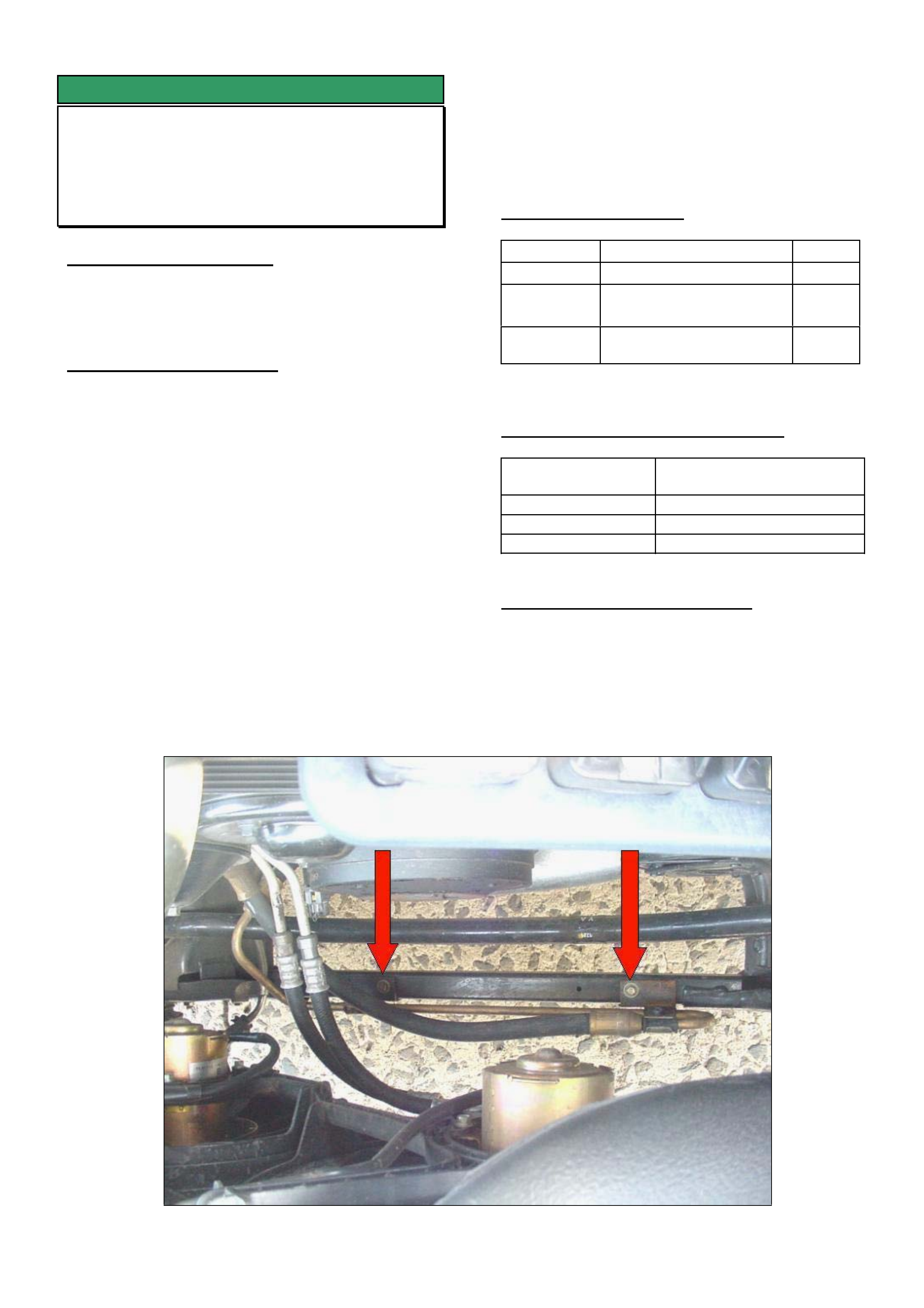

Low Speed Steering Shudder

VY with V6 engine (non S/C)

(GROUP 9) TL0615-0403

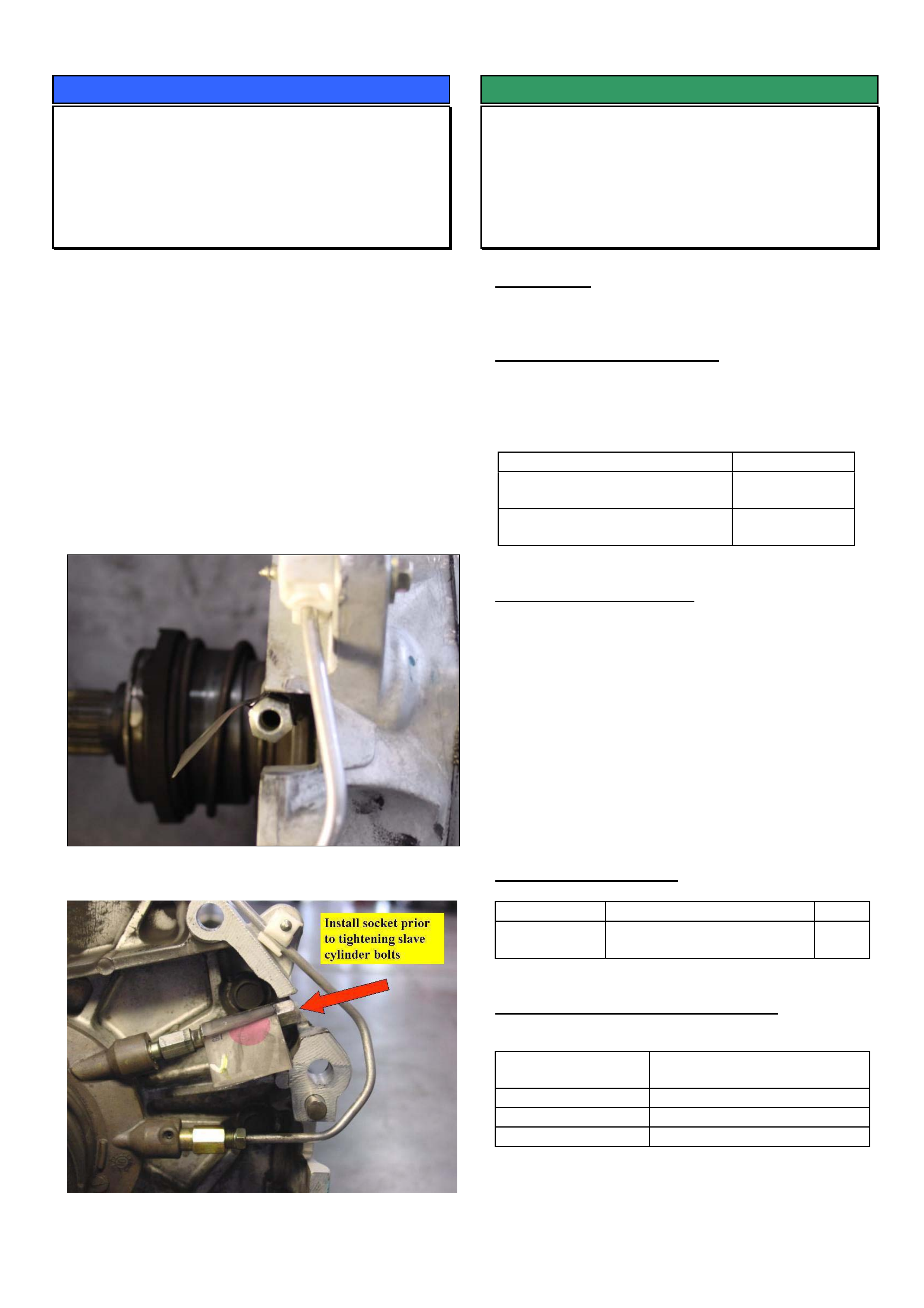

PROBLEM DESCRIPTION

Some vehicles may experience a shudder felt

through the steering wheel, when very low speed or

stationary steering operation is performed.

SERVICE RECTIFICATION

Summary: Fit revised high pressure power steering

hose between pump and steering gear.

Procedure:

1. Remove power steering high pressure hose

between pump and steering gear.

2. Fit revised high pressure power steering hose

(p/n 92174786) between the pump and steering

gear. Use new seals at the pump and the

steering gear (p/n 08526398).

3. The new hose has extra length which is to be

routed across the front of the engine. Refer figure

1.

4. The two brackets that are integral to the new

hose are to be fixed to the front cross member

brace using screws (p/n 11069615) inserted into

existing holes as shown in figure 1 by arrows.

5. Top up power steering system and bleed as per

SIP procedure.

PARTS INFORMATION

Part No.: Description: Qty:

92174786 High Pressure Hose 1

11069615 Screw -Pressure power

steering hose

2

08526398 Seal – Pressure Pipe to

pump and steering gear

2

WARRANTY CLAIM INFORMATION

Description Power Steering Hose Kit

Installation

Labour Op. No. M000205

Time 0.5 hr

Failure Code 36/ M0036 vibrates

PRODUCTION RECTIFICATION

At the time of printing, the breakpoint for fitting

revised high pressure hoses to vehicles has not

been established. When it is established, this

techline will be updated on Holden Lionheart.

HOLDEN SERVICE TECHLINE __________________________________________________________________APRIL, 2004

13

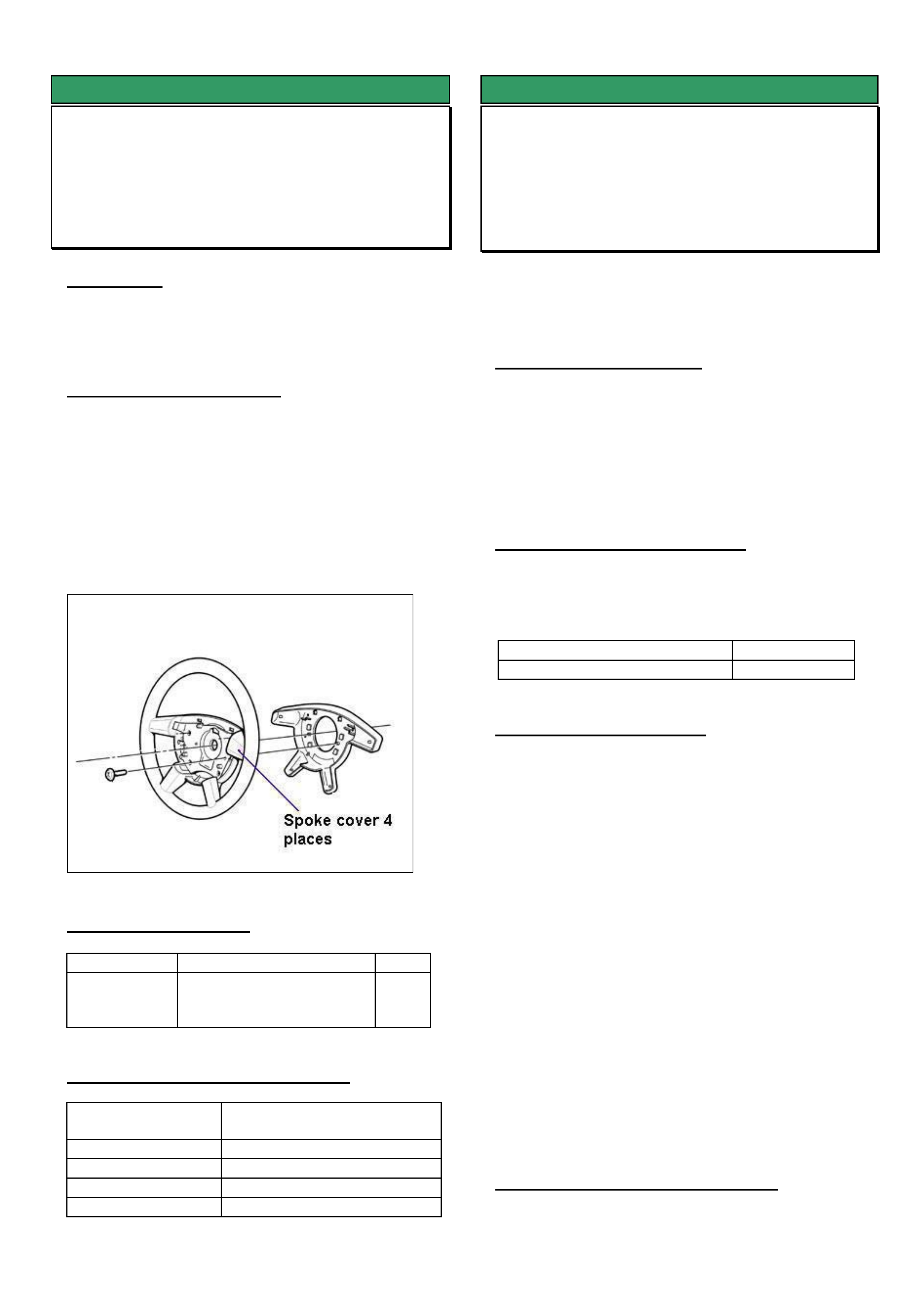

SERVICE FIX

Steering Wheel Spokes - Satin Chrome

Finish Comes Off

V2, WK, VY

(GROUP 9) TL0655-0403

CONDITION

On some vehicles the satin chrome finish may come

away from the steering wheel spoke substrate

material.

CORRECTION in SERVICE

Summary: On complaint vehicles, replace faulty

spoke covers as per following procedure.

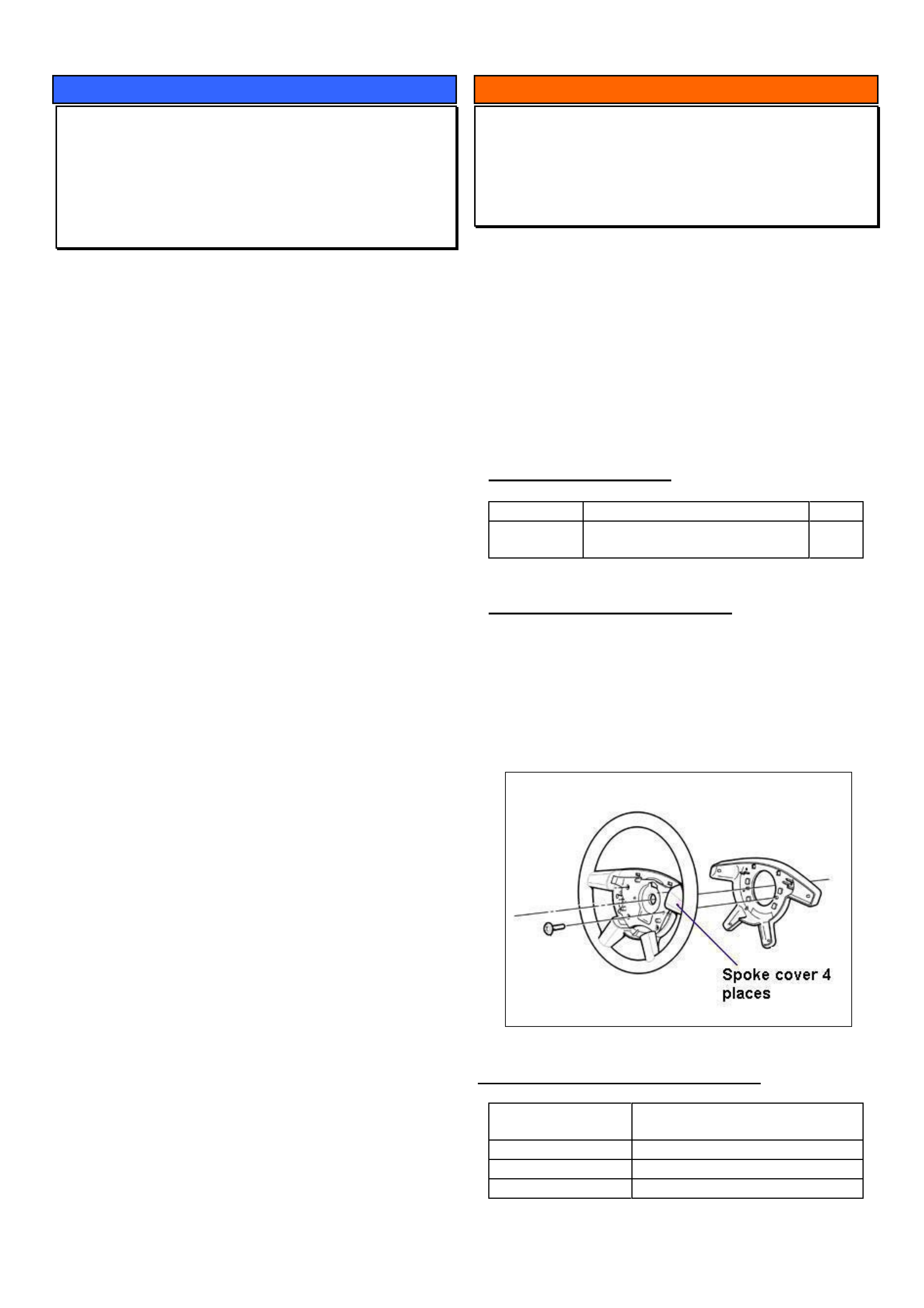

1. Remove steering wheel as per procedure in PV

SIP.

2. Detach rear cover from steering wheel.

3. Remove four spoke covers by undoing attaching

screws from rear.

4. Install new spoke covers.

5. Reinstall all parts.

PARTS INFORMATION

Part No.: Description: Qty

92147964 Cover package steering

wheel spokes (contains

4 covers)

1

WARRANTY CLAIM INFORMATION

Description Replace steering wheel

spoke covers

Labour Op. No. C000514

Time 0.5 hr

Failure Code 23 - Finish comes off

Failure Code NOW C0023 – Finish comes off

SERVICE FIX

Blaupunkt Radio Losing Time or CD Will

Not Eject

VY / V2 II

(GROUP 12) REVISED TL0580A-0403

This techline supersedes the previous one

TL580-0311) in Issue 11, Nov. 2003. It is revised

by removing WK from the models affected.

Please correct all previous copies of TL0580-0311.

PROBLEM DESCRIPTION

Customers may complain of the clock in their

Blaupunkt radio losing time or that the CD will not

eject.

After investigation into the root cause, Blaupunkt has

made a software revision to rectify this condition.

PRODUCTION RECTIFICATION

Blaupunkt has implemented a software revision for all

radios introduced into production as of the following

break point.

ISOVIN: Build Date:

6G1YX54AX4L170039 8/09/03

SERVICE RECTIFICATION

If a customer presents a vehicle with the above

condition, request a replacement radio using the

standard change over request procedure which is

found in SIP “SPECIAL WARRANTY COMPONENT

REPLACEMENT REQUIREMENTS” section .

IMPORTANT: The Main Software Version number

must also be included on the request form.

Below is an example of the Identification Data screen

displayed on Tech 2 where this information can be

found.

Identifier 404

Part number 92118704

Production Date 60103

Main Software Version ????

Panel Software Version 1A22

Serial Number 804697

VIN Digit 1-10 6G1YK54A74

VIN Digit 11-17 L169008

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty

Information section of current PV SIP CD

HOLDEN SERVICE TECHLINE __________________________________________________________________ MAY, 2004

DIAGNOSIS HINT

Tech 2 Communications with

ABS/ TC/ ESP

TS Convertible & SRi Turbo

(GROUP 5) TL0689-0404

TAS receive many calls where technicians are

experiencing difficulty when trying to communicate

with ABS on the vehicles listed above.

Technicians are selecting ABS/TC from the Chassis

menu on Tech 2 as they are unaware that ESP is

fitted standard to these vehicles. Tech 2 will continue

to display “waiting for data” until “abort” is chosen.

ESP should be selected from the Chassis menu. This

will allow Tech 2 communications for the

ABS/TC/ESP system including all data lists,

miscellaneous tests and diagnostic trouble codes.

HOLDEN SERVICE TECHLINE __________________________________________________________________ MAY, 2004

SERVICE FIX

ABS Light Comes On, DTC 71 Set

VY, V2, WK

(GROUP 5) TL0685-0404

CONDITION

Customer reports the ABS Instrument panel light

comes on.

Dealer diagnosis reveals DTC 71 “Control Module

Internal Fault” is being logged. Diagnostic checks as

per SIP lead to module replacement.

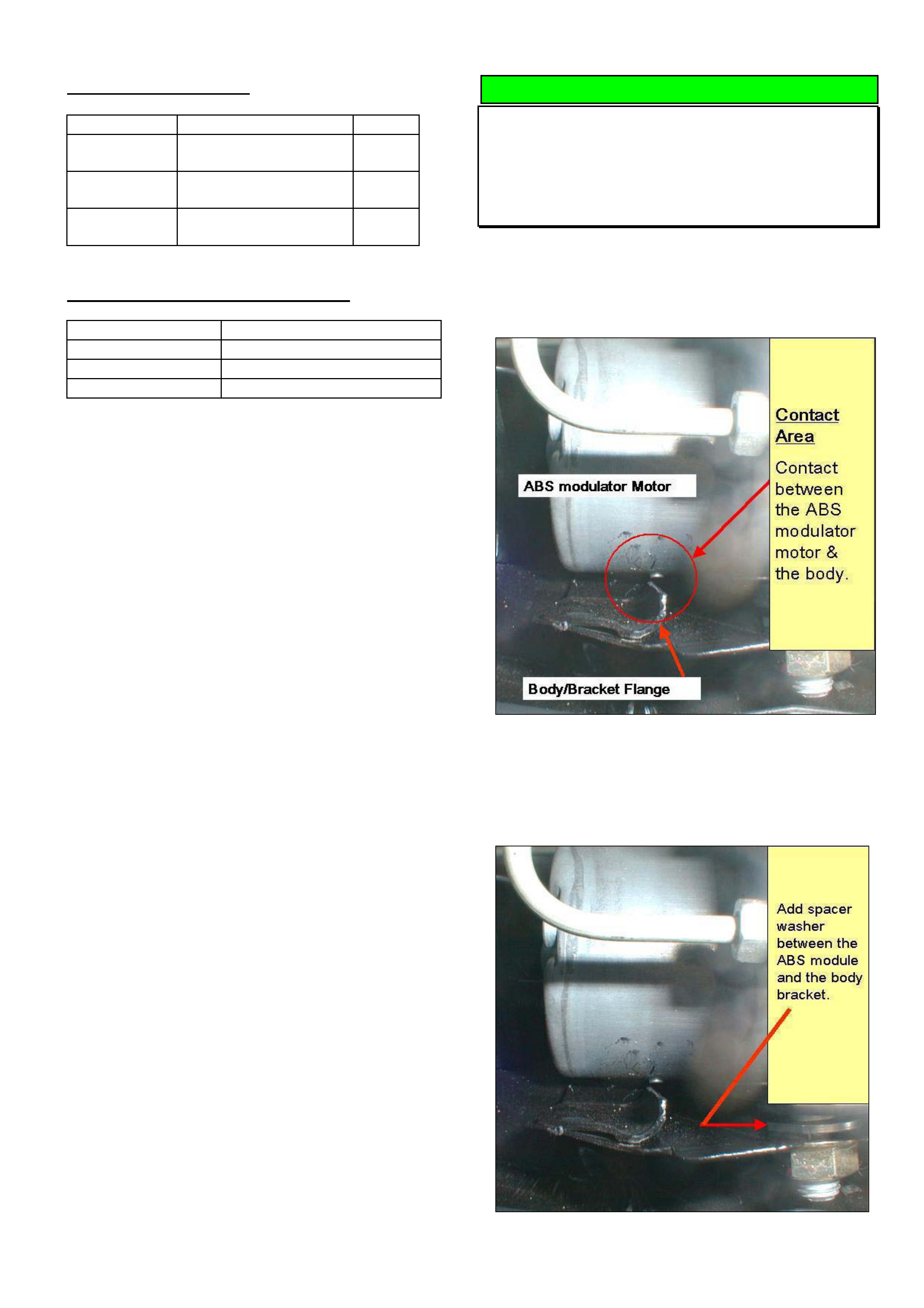

CAUSE

An abnormality with the electronics in the ABS control

module which only occurs at vehicle start up.

CORRECTION – Production

Revised ABS control modules have been fitted to

vehicles from:

ISOVIN: Built Date:

**********L239319 20/2/2004

NOTE: Revised modules fitted in production and

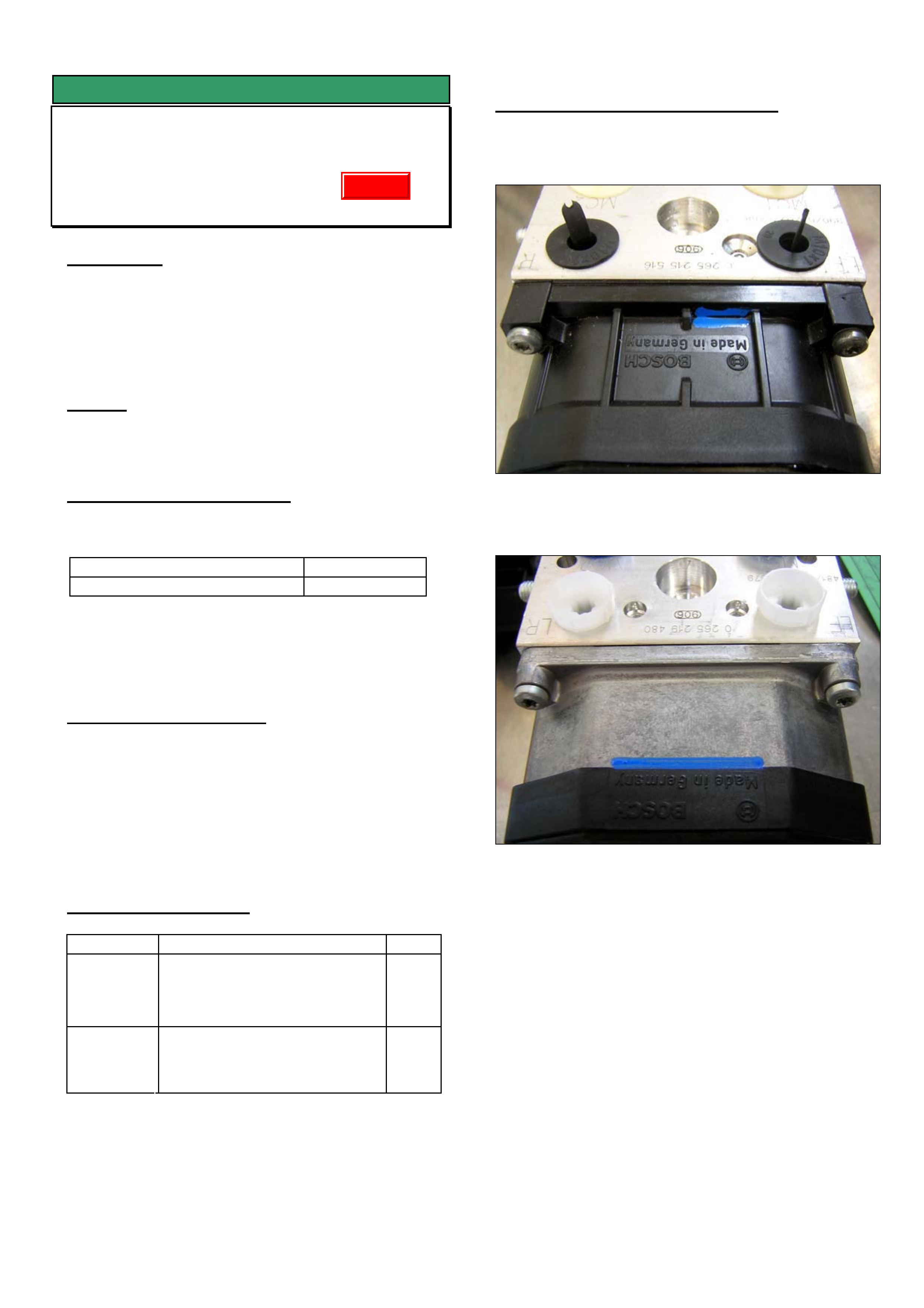

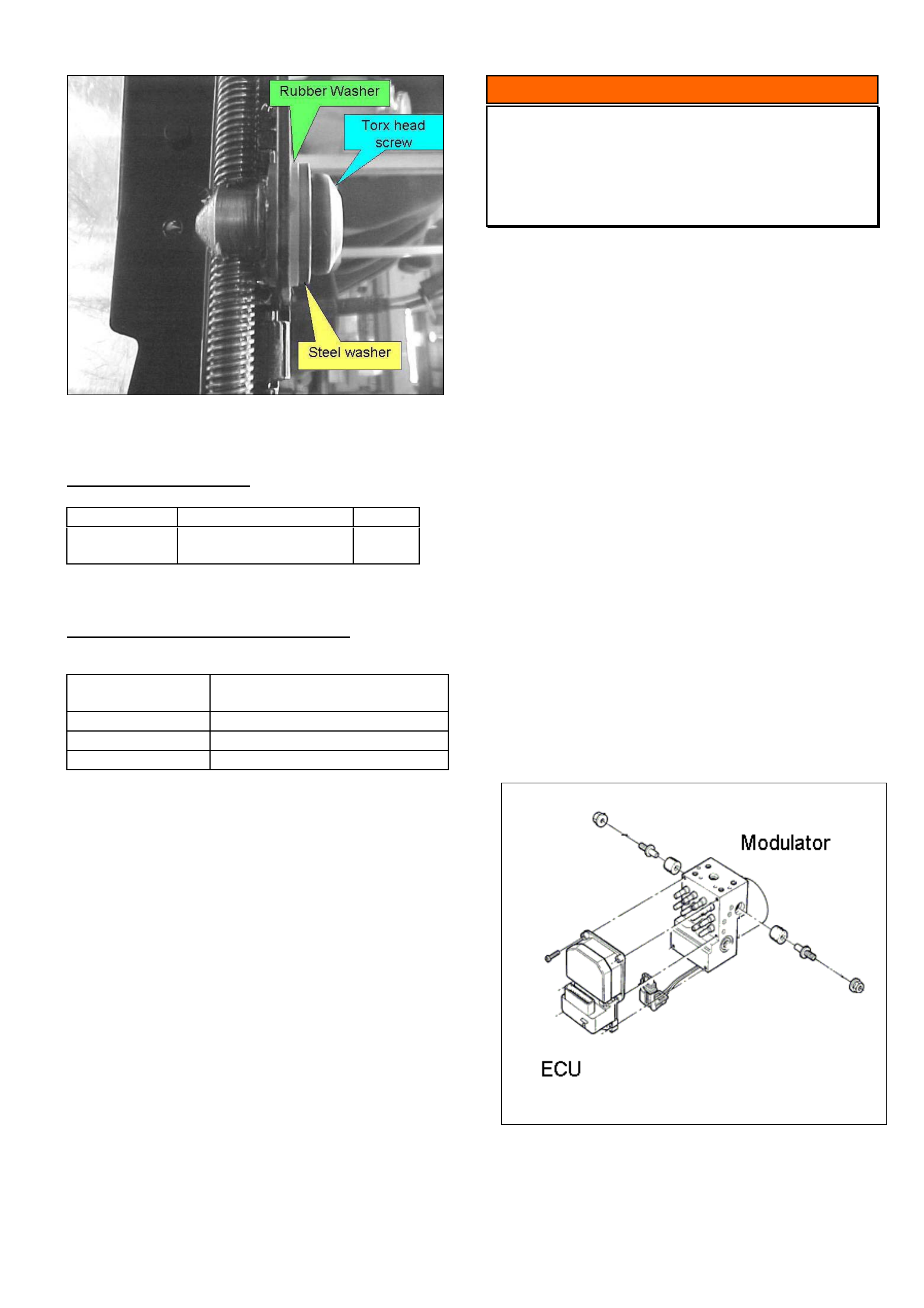

supplied from HSPO are identified with blue paint as

shown in the attached photographs.

CORRECTION – Service

After verifying that vehicle has symptoms as

described above, fit a new ABS control module and

hydraulic modulator assembly.

This can only be obtained from HSPO after receiving

approval from BOSCH via the Prior Approval

program.

PARTS INFORMATION

Part No.: Description: Qty

92093868ABS control module &

hydraulic modulator assembly

(V6 & V8 without traction

control)

1

92093870ABS control module &

hydraulic modulator assembly

(V6 with traction control)

1

Attention Parts Managers!!

Any ABS control module & hydraulic modulator

assemblies prior to breakpoint (i.e units without blue

paint mark) should be returned to HSPO for credit via

the CRRM system.

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty

Information section of current PV SIP CD

Figure 1. 92093868

Figure 2. 92093870

Update

HOLDEN SERVICE TECHLINE __________________________________________________________________ MAY, 2004

INFORMATION

TIS 2000 error message when accessing Service Information or Security Access

TIS 2000

(GROUP OB) TL0690-0404

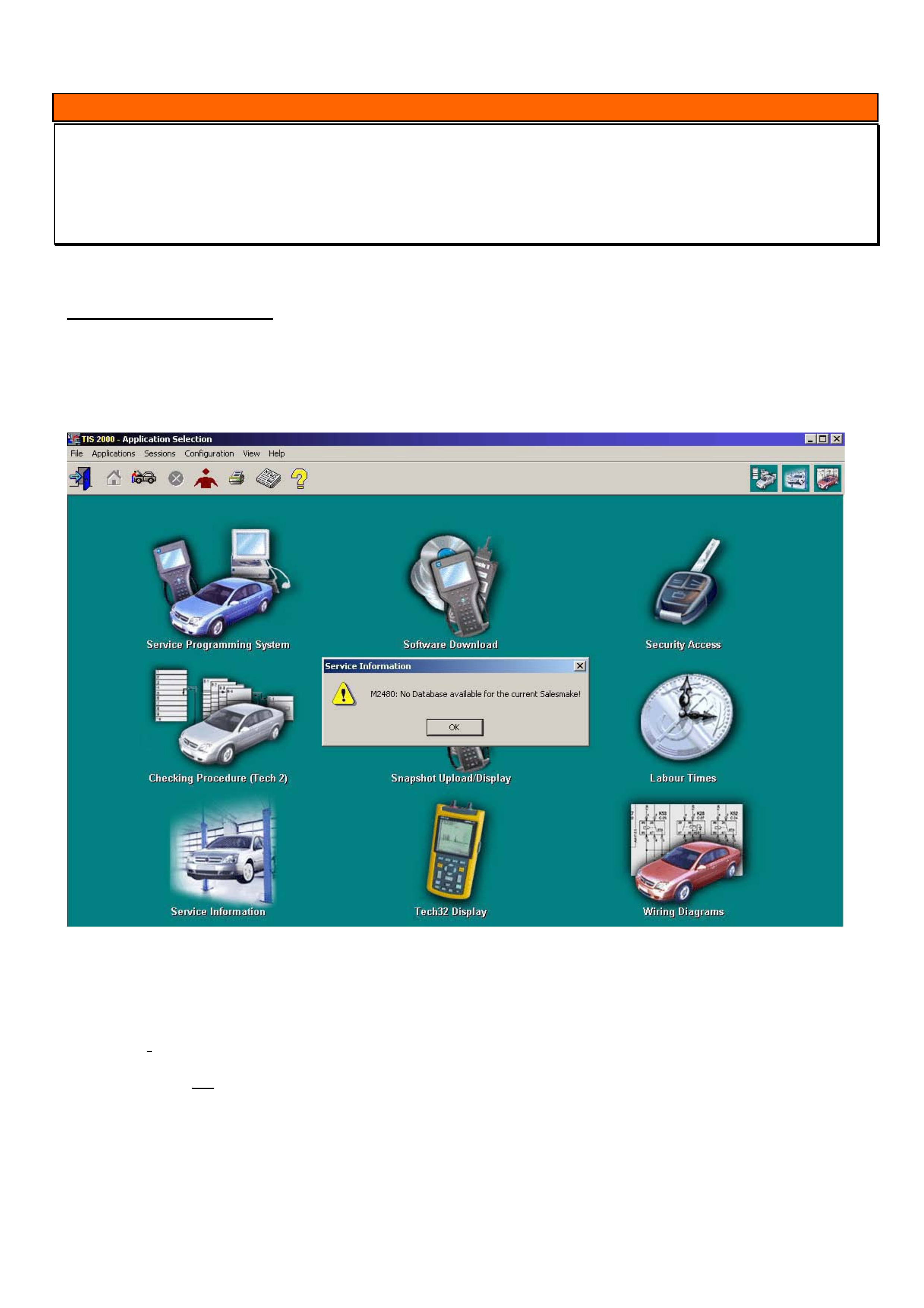

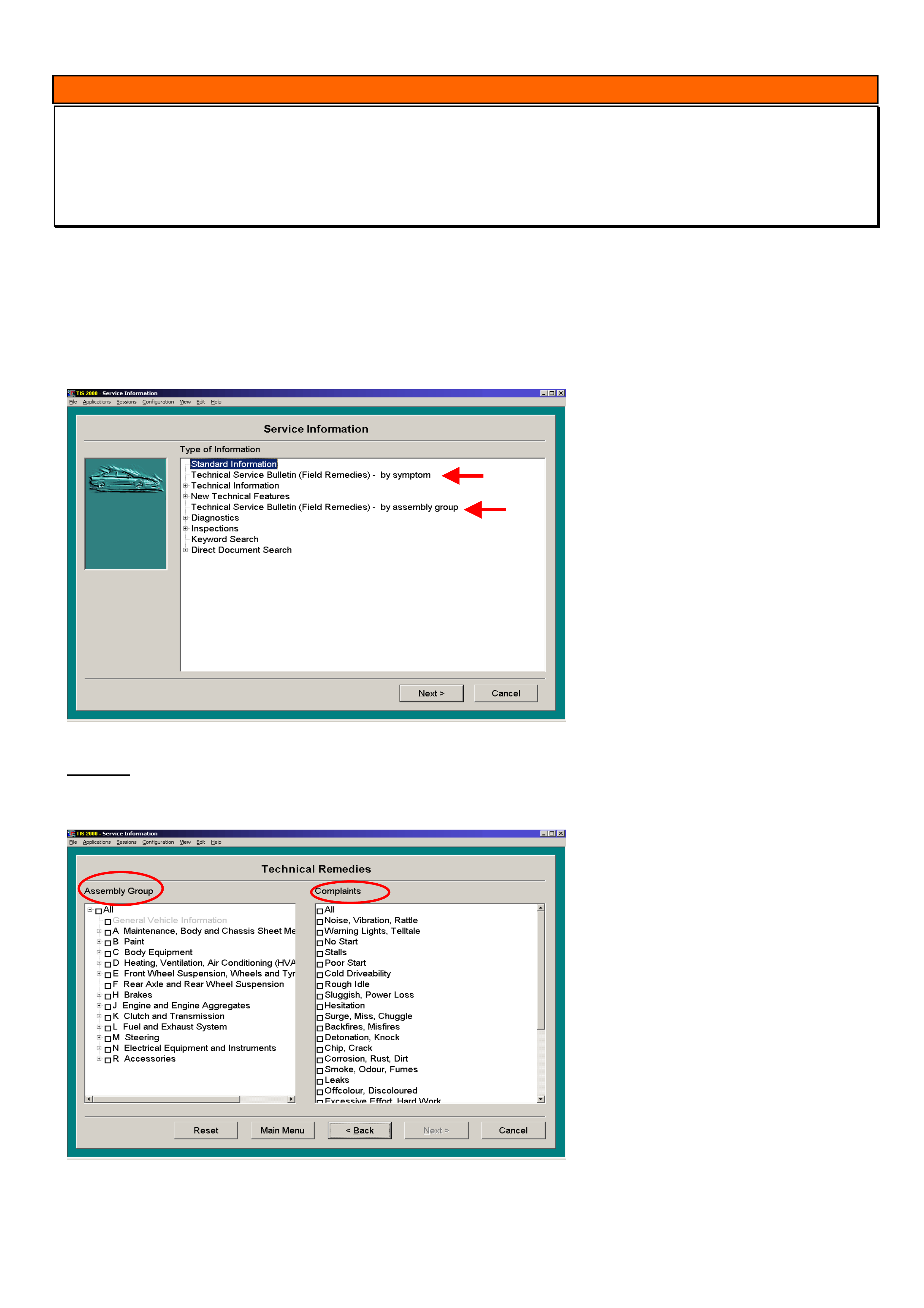

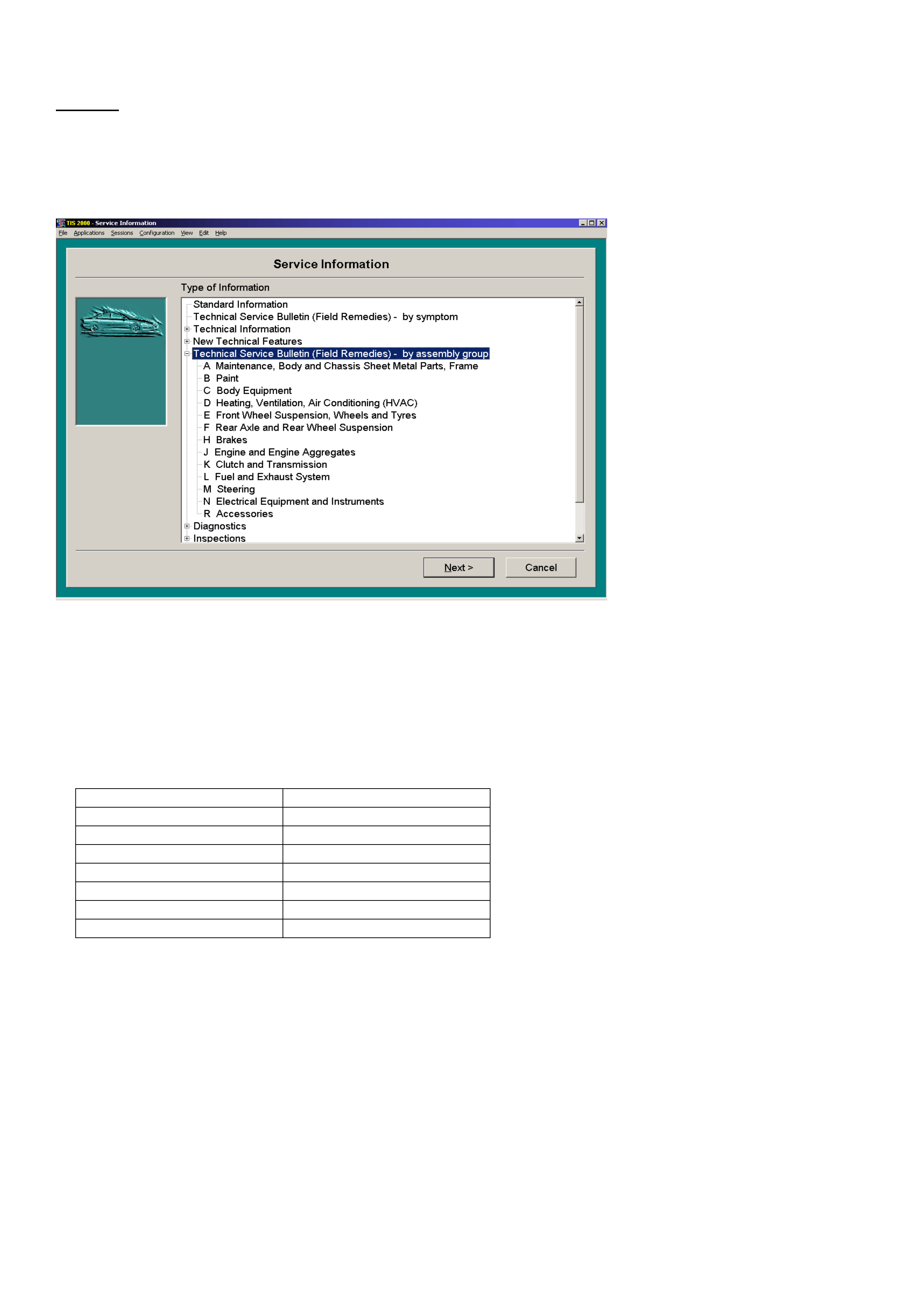

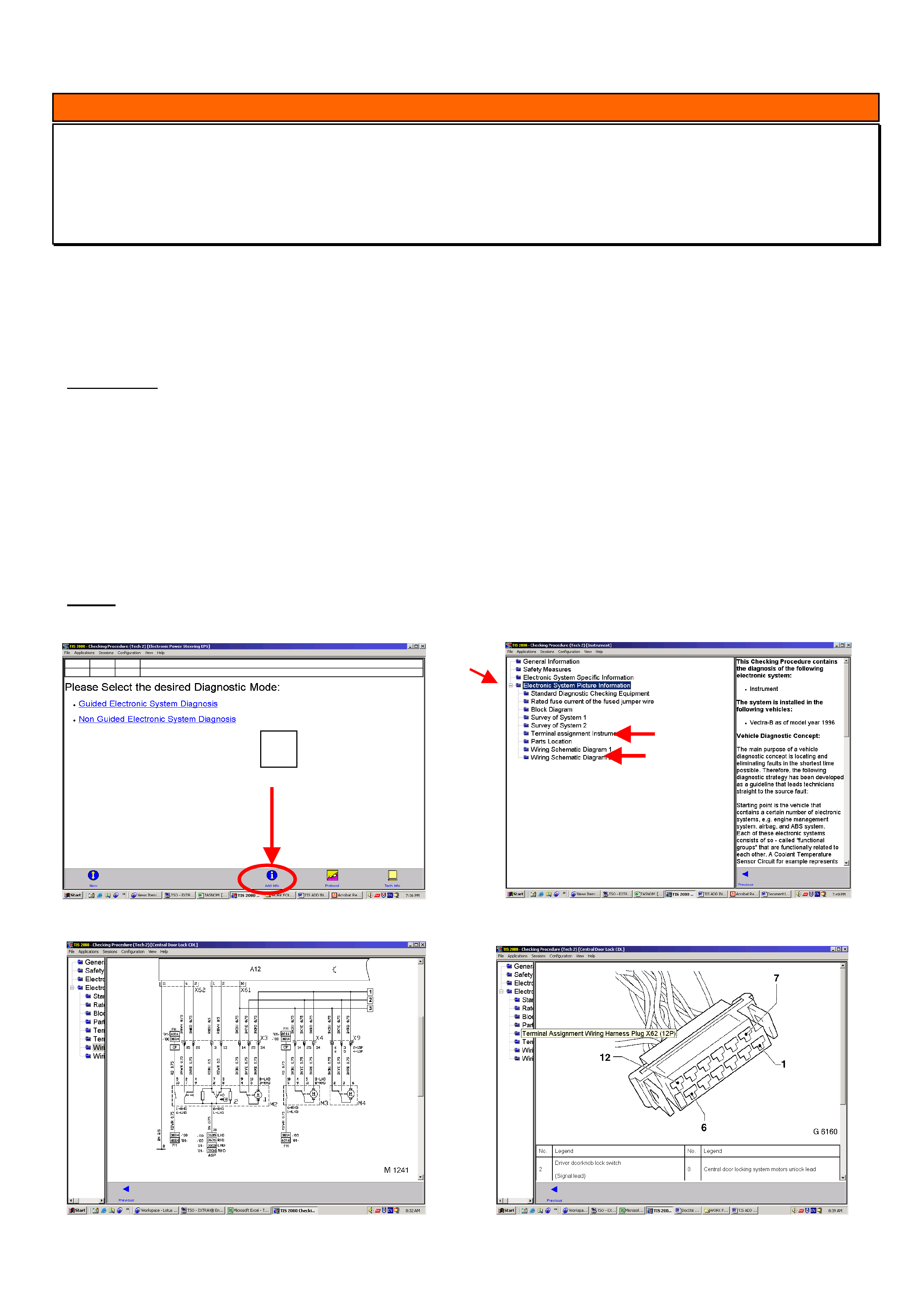

This techline is to be used in conjunction with Technicians guild article number 8 of 2003

PROBLEM DESCRIPTION

TIS 2000 displays error codes when user attempts to access some functions. Prior to seeking help from

TAS, it is recommended you perform the following checks.

When accessing Service Information the following screen may appear.

To overcome this problem, click the “ok” button in the message box. Click on the word “configuration” at the top of

the screen, select “options”. Starting from the left tab make sure the following selections are made.

Language: English (united states)

Country: Australia or New Zealand as applicable

Salesmake: Opel (unless doing Isuzu product then select Isuzu, do not select Holden for any product)

Dealership: Holden

WWW: Do not tick the enable java box

Click “ok”

After the settings have changed, a message box will appear advising that the salesmake settings have changed and

TIS must be restarted, click YES to this. Another message about closing open sessions will appear. If there are no

other open sessions click “YES”. Restart TIS and retry service information. If you continue to have problems with

service information a TAS nominated contact should contact TAS.

HOLDEN SERVICE TECHLINE __________________________________________________________________ MAY, 2004

When accessing Security Access the following message may appear.

(Make sure your hardware key is installed prior to attempting to obtain Security Access).

.

Click the “ok” button in the message box and then click on the word “configuration” at the top of the screen.

Select “I/O management” and make sure “Dongle” is highlighted (unless you have the new super pro USB hardware

key in which case “super pro” will need to be highlighted). Press the “test” button on the right hand side. The

following message may appear.

Click “ok” in the message box and then press the “properties” button on the right hand side. A box displaying the

current com port that is selected will appear. Click on the black arrow on the right of the message box; this will

display the other com ports available. Select a different com port than the one displayed (not LPT1) and click ok.

Press the test button again. If more than 2 com ports available then this may have to be done again on all com ports

until it passes. When message appears saying “Driver test successful” click “ok” and close I/O management box.

Retry Security access.

If problems still occur a TAS nominated contact should contact TAS.

HOLDEN SERVICE TECHLINE __________________________________________________________________ MAY, 2004

INFORMATION

TIS 2000 Update And Uninstall Procedure

(GROUP 0B) TL0691-0404

TAS receive many calls where a TIS 2000 Update or

a new TIS 2000 Installation has failed. This techline

is to clarify the following procedures:

• Update TIS 2000

• Uninstall TIS 2000

• TIS 2000 Configuration Options

If your Dealership has a PC specialist, it would be an

advantage to utilise his/her expertise.

Update TIS 2000

To update TIS 2000 proceed as follows:

• Place TIS CD1 in your disc drive, wait a few

seconds and then click on the icon, which

opens TIS 2000. This will then see the disc as

an update and continue to upload. On

completion of the first, it will request that you

load the second disc. When the second disc

is inserted, click OK in the dialog box to begin

the upload.

• Both LCV TIS and Wiring Diagrams CD’s

should be treated as an Update.

Uninstall TIS 2000

To uninstall TIS 2000 proceed as follows:

• Remove any cd’s from all drives.

• Shut down and Restart your computer (PC).

• Click on the Start button (lwr left of screen).

• Move up to programs then across to TIS 2000

and again across to TIS 2000 Uninstall.

Select Uninstall from this menu.

• When the Uninstall is fully complete it should

advise if it was successful. If not, you will

need to run through the following procedures.

• Click on the Start button again and choose

Search or Find, moving over to Files or

Folders.

• Type cosids in the search field, and then

choose local hardrives in the look-in field.

Now select Search/Find now. This will

generate a search for the TIS 2000 main files.

(If any files are found it will be displayed in the

large box to the right, if not continue to next

step)

• Delete all files that have been found, by

selecting with your mouse and hitting the

delete button on your keyboard.

• Now click on the Start button again and scroll

up to Settings, then move across to Control

Panel. In this menu, double click on

Add/Remove Programs and look for the

following items:

JAVA 2 RUNTIME ENVIRONMENT STD EDITION

and

JAVA SERVLET DEVELOPMENT KIT.

• If they are available, select one at a time then

hit the Change/Remove button for each.

Close this window.

• It is now very important to restart your

computer.

TIS 2000 CONFIGURATION OPTIONS

When attempting a complete TIS 2000 install, place

CD1 in the drive and this should now begin the

installation. It will request the second CD when

required.

Follow all prompts until the installation is complete.

NOTE: it is very important that you select the following

configuration when prompted:

• Language – English

• Country – Australia/New Zealand (whichever

is applicable)

• Salesmake – OPEL

• Dealership – HOLDEN

• WWW – not checked (ticked)

You will also need to select which COM port you

would like your TECH 2 and Hardware Key to

communicate with. You must ensure these are both

the same. E.g.; COM1 or COM2.

HOLDEN SERVICE TECHLINE __________________________________________________________________ MAY, 2004

INFORMATION

Sat Nav Computer Upgrade

All with HBD SATNAV

(GROUP 12) TL0658-0404

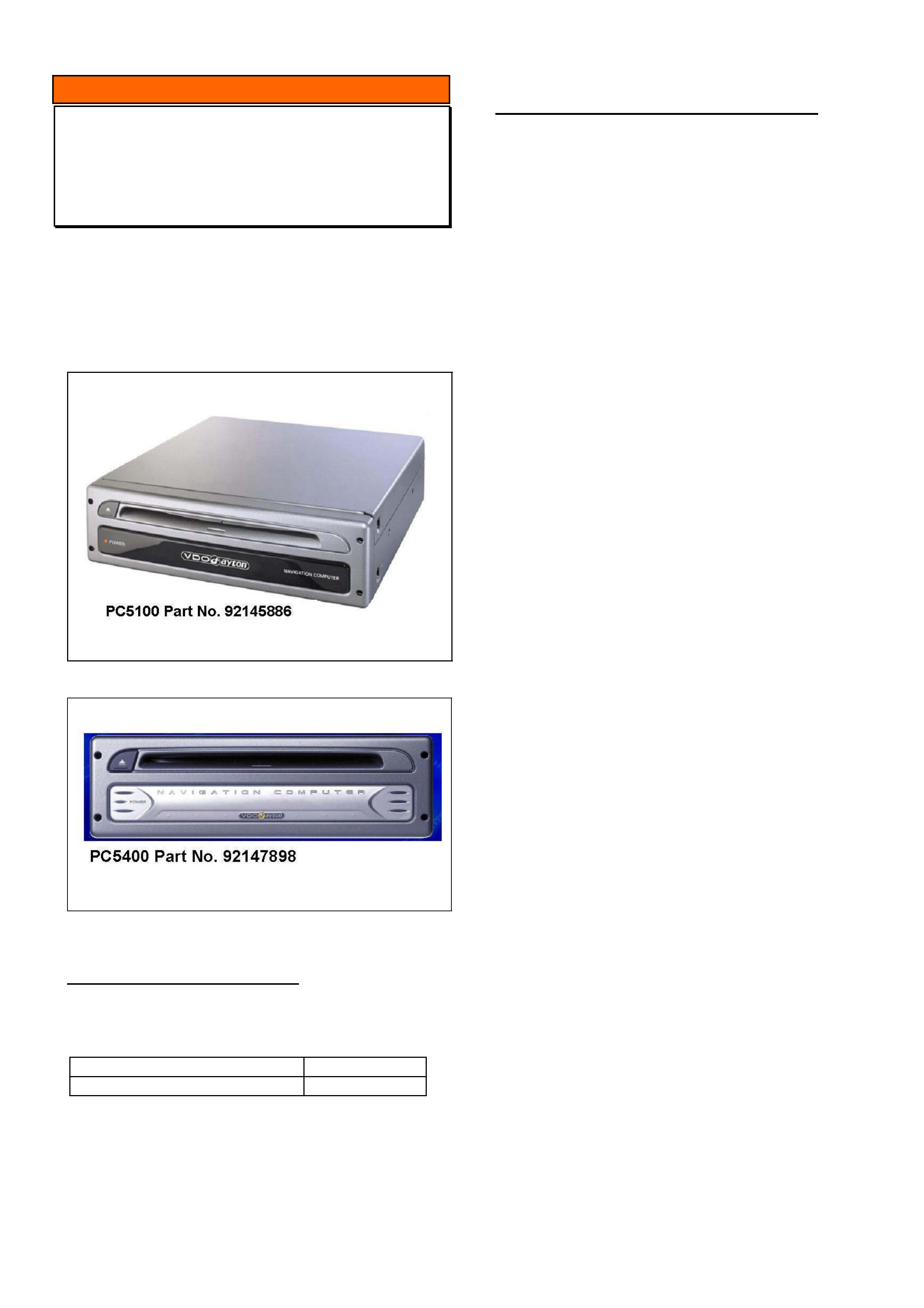

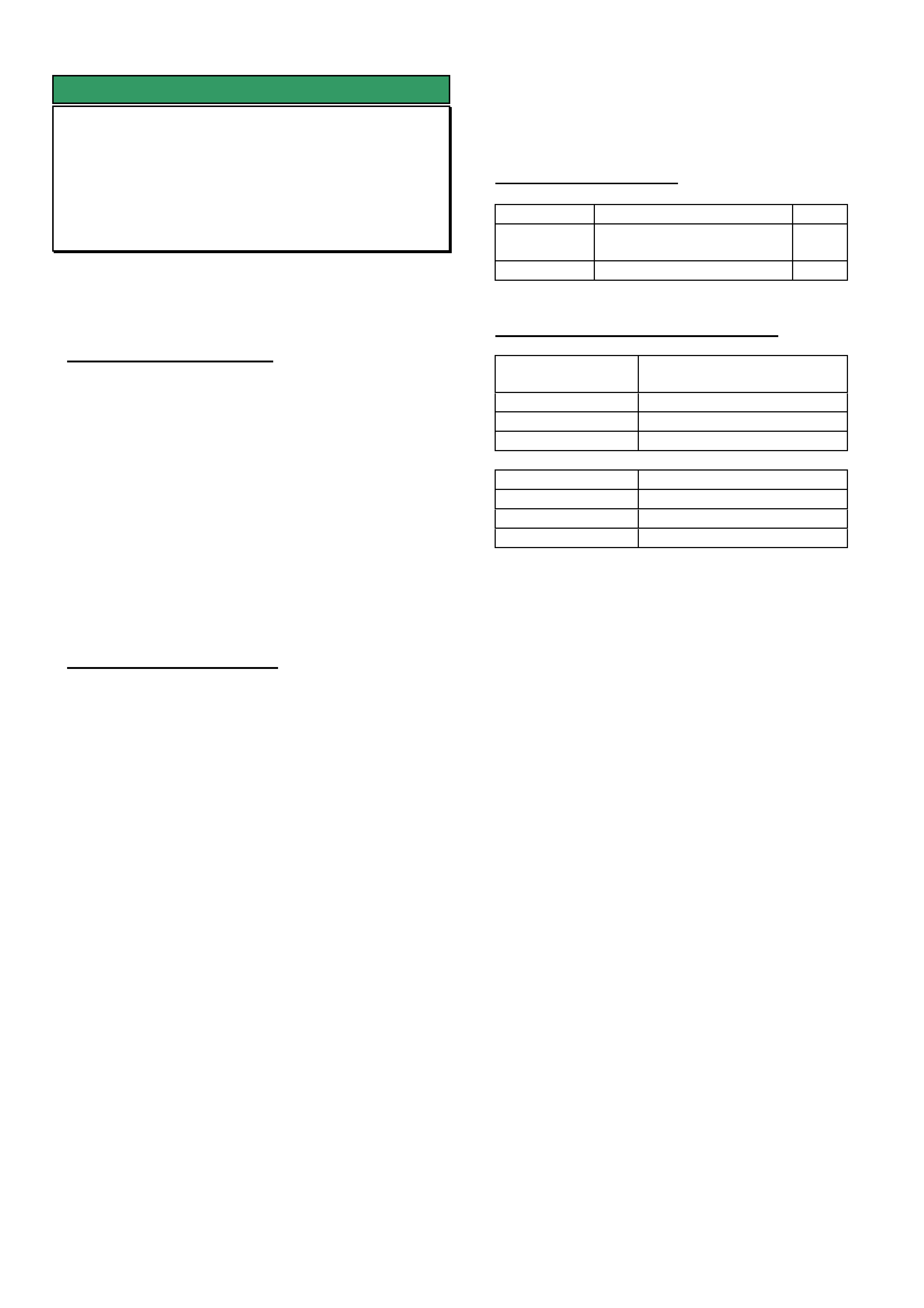

The PC5100 Navigation Computer Part No. 92145886

has been superseded by an upgraded PC5400

Navigation Computer Part No. 92147898.

The PC5100 Navigation Computer Part No. 92145886

is no longer available.

PRODUCTION BREAKPOINT

The improved PC5400 Navigation Computer

92147898 has been fitted to vehicles from:

ISOVIN: Built Date:

6G1YK52A84L226898 23/1/2004

SERVICE REPLACEMENT PROCEDURE

If a vehicle with a PC5100 Navigation Computer

(92145886) ever requires replacement with a PC5400

Navigation Computer (92147898) the following

additional parts are required for correct operation:

• Patch harness Part No. 92147901 (includes zero

ohm link).

• Disc - Navigation Data (Map) Part No. 92211882.

The patch harness is installed in line between the

Navigation Computer and the vehicle wiring harness.

Installation procedure:

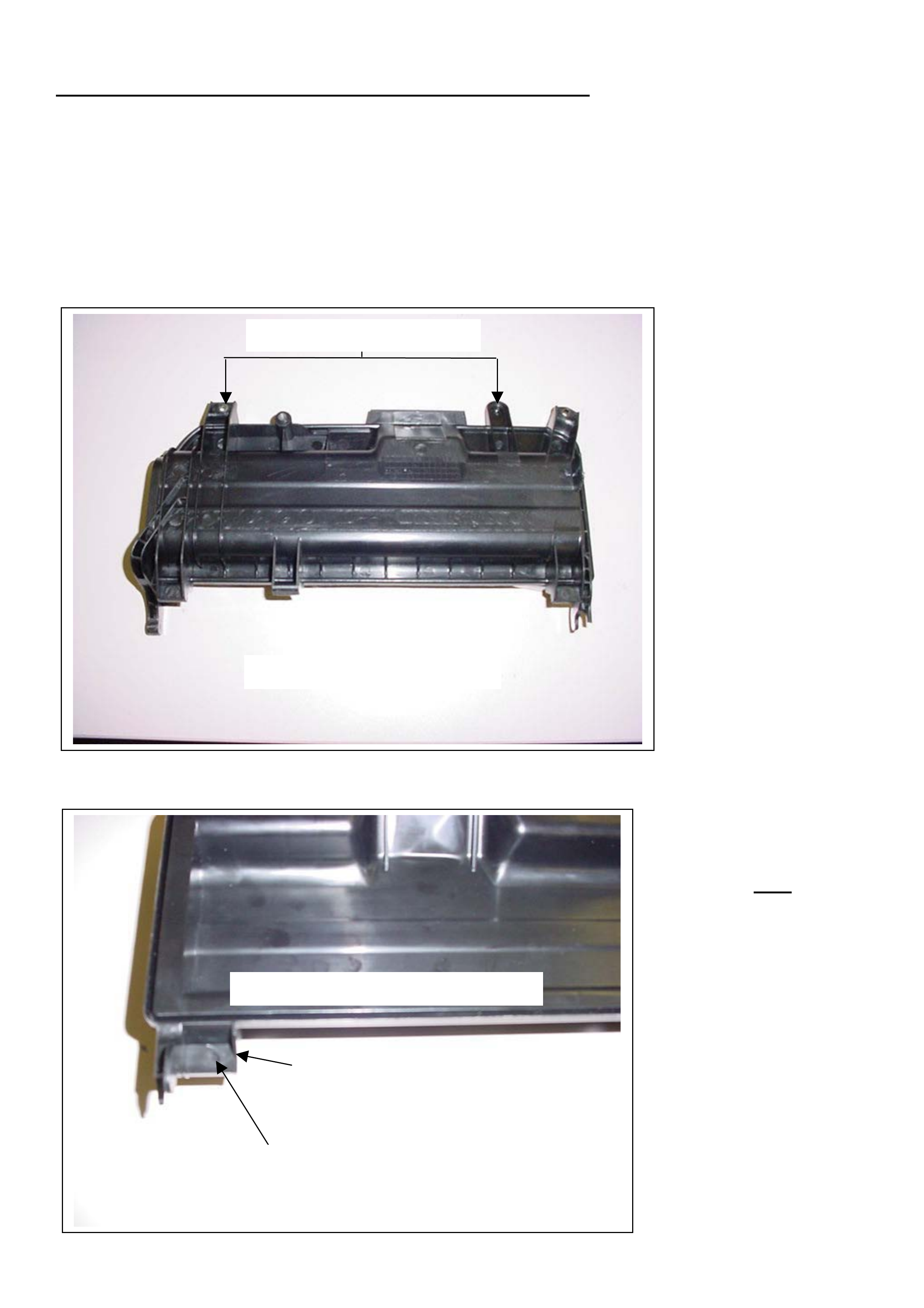

1. Disconnect vehicle battery.

2. Remove the vehicle wiring harness connector

from the back of the Navigation Computer located

in the boot.

3. Replace the plug-in resistor in the vehicle wiring

harness with the zero ohm links.

4. Remove the Navigation Computer from the cradle

using the removal tools.

5. Plug the patch harness 92147901 into the vehicle

wiring harness.

6. Insert the patch harness connectors into the back

of the newly installed Navigation Computer.

7. Install the PC5400 Navigation Computer Part No.

92147898 into the Cradle.

8. Reconnect vehicle battery.

9. Follow installation instructions as supplied with

the Disc - Navigation Data (Map) Part No.

92211882.

10. NOTE: When inserting a C-IQ Map disc (this is