2

20

00

04

4

S

SE

ER

RV

VI

IC

CE

E

T

TE

EC

CH

HL

LI

IN

NE

ES

S

© 2006 GM Holden Ltd. A.B.N. 84 006 893 232

Service Department

A “HOLDEN” Product.

BRISBANE SYDNEY MELBOURNE ADELAIDE PERTH

For the latest and/or any missing Techline bulletins,

please refer to Holden Lionheart

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

15

SERVICE PROCEDURE

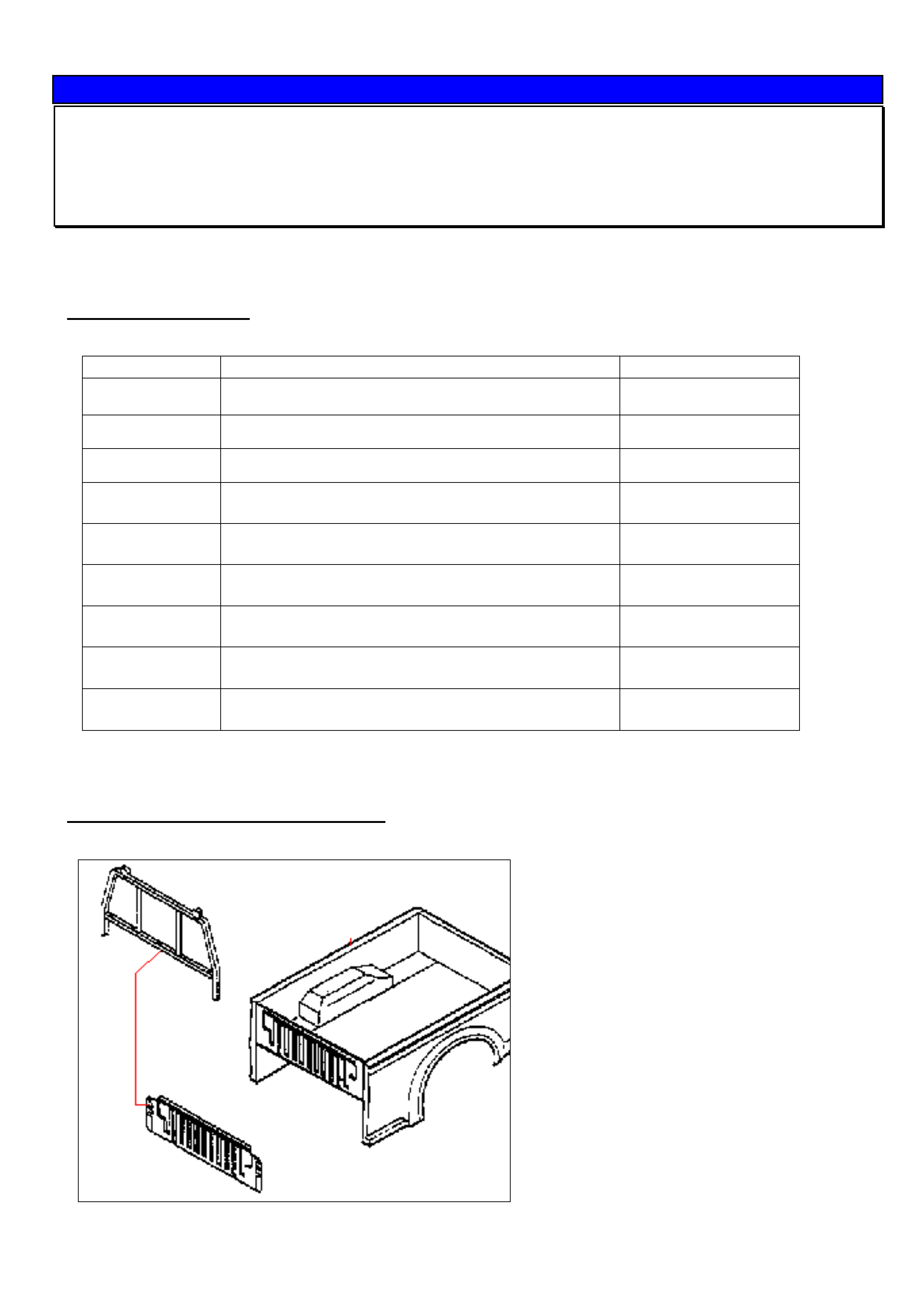

Fitting Instructions For Cargo Bar

RA Rodeo Space & Crew Pickup Models

(GROUP 01) TL0610-0401

The following instructions are provided in the event a customer requires a Cargo Bar Guard fitted to the rear body of

one of the above models.

PARTS INFORMATION

For vehicles that require a cargo bar fitted the following parts will be required.

P/N DESCRIPTION QUANTITY (PER CAR)

8973100752 FRAME - GUARD, REAR BODYSPACE/CREW CAB 1

8973526240 STOPPER - GUARD FRAME, REAR BODY

2

9091606060 WASHER - GUARD FRAME STOPPER

2

8944810220 BOLT - GUARD FRAME STOPPER, REAR BODY

- M6x45

2

8944814280 NUT - GUARD FRAME

- M6 FLANGE

2

0280806120 BOLT - GUARD FRAME

- M6x12 FLANGE

7

09440004 NUT - GUARD FRAME

- M6

5

8973106112 BOLT - REAR BODY MOUNT

- M12X50

- 4 (CrewCab)

- 6 (SpaceCab)

8973542010 BOLT - REAR BODY MOUNT

- M12X50

- 2 (CrewCab)

Also, PPG Multi Surface Epoxy Primer 410-39790 will be required. This is a 2-pack air-dry black paint available from

PPG Distribution centres in 1 and 4 litre containers. NOTE. An equivalent paint may be used.

Cargo Bar (Frame – Guard, Rear Body)

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

16

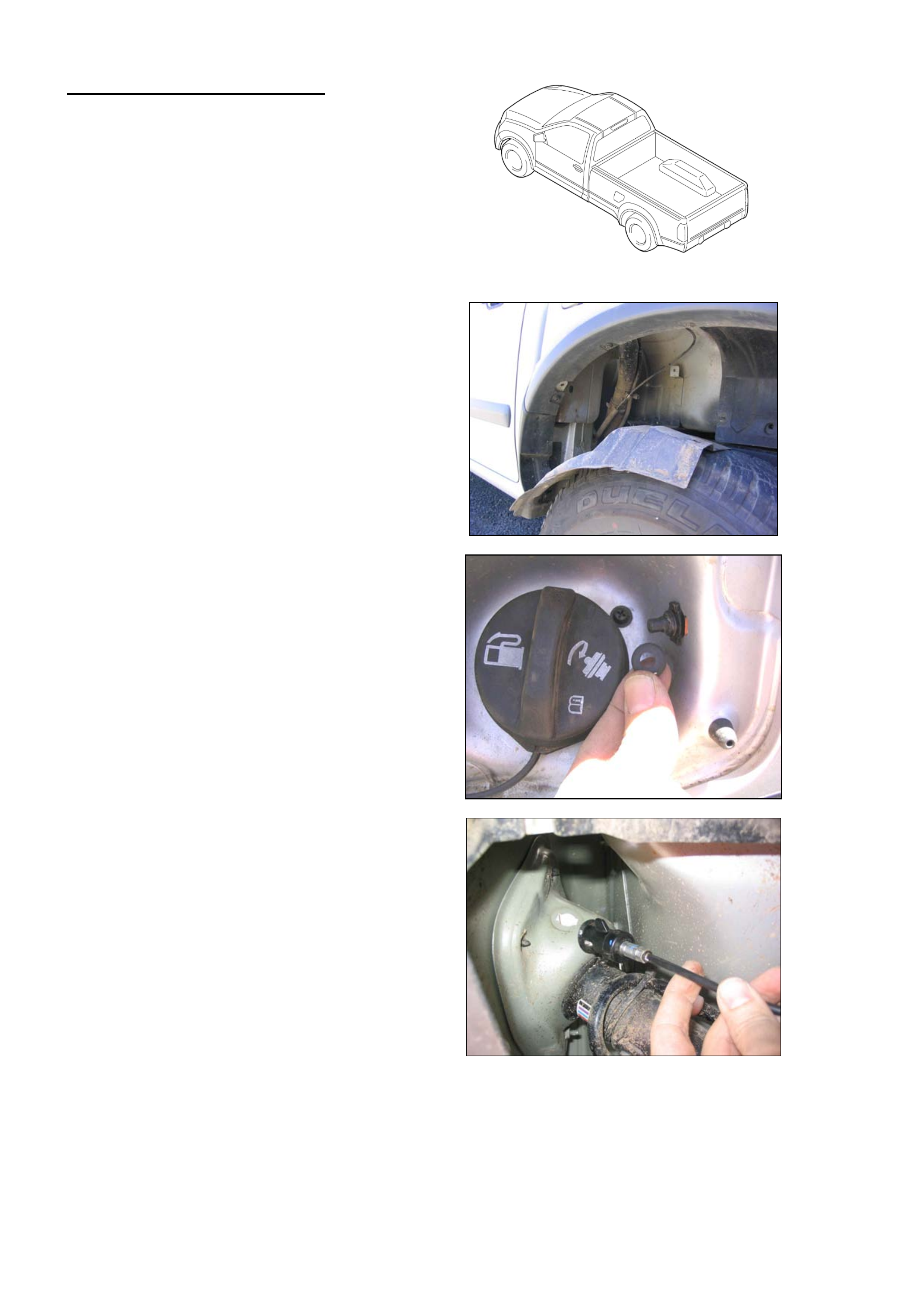

Rear Body Removal (Steps 1-6)

1. Disconnect negative battery terminal.

2. Disconnect rear combination lamp &

license lamp harness connector.

3. Remove rear wheelhouse extension

panels (LH & RH)

4. Disconnect fuel filler door release cable

assembly.

- Remove seal

- Twist and pull cable to remove

5. Disconnect fuel filler pipe and evaporator hose. Cover filler pipe with a rag to prevent

contamination of the fuel tank

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

17

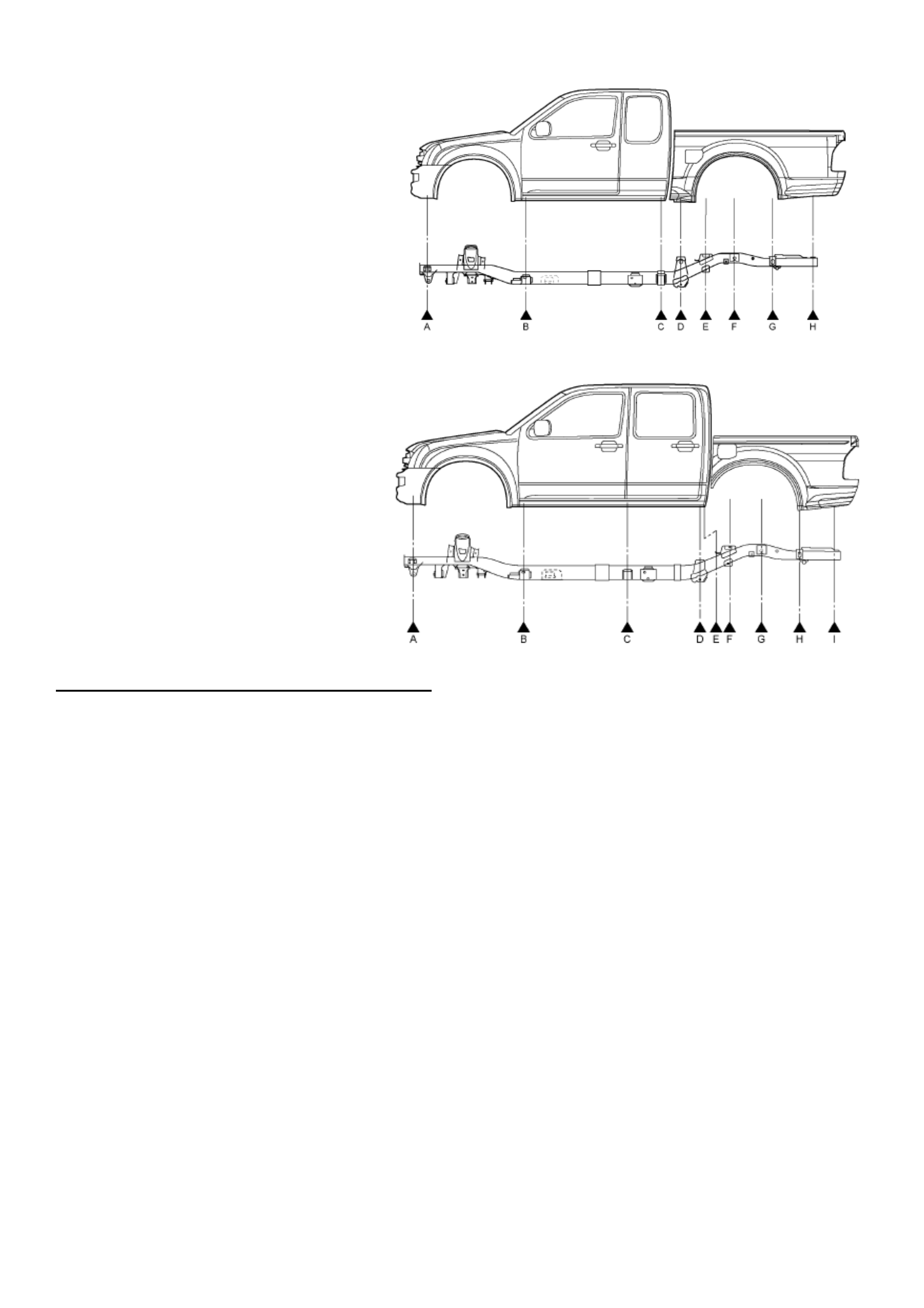

6. Unbolt rear body from frame

– Space Cab

- Undo bolts at points ‘D’, ‘G’ &

‘H’

- Lift rear body off the frame

and move

back from the cab to gain

access.

6. Unbolt rear body from frame

– Crew Cab

- Undo bolts at points ‘F’, ‘H’ &

‘I’

- Lift rear body off the frame

and move

back from the cab to gain

access.

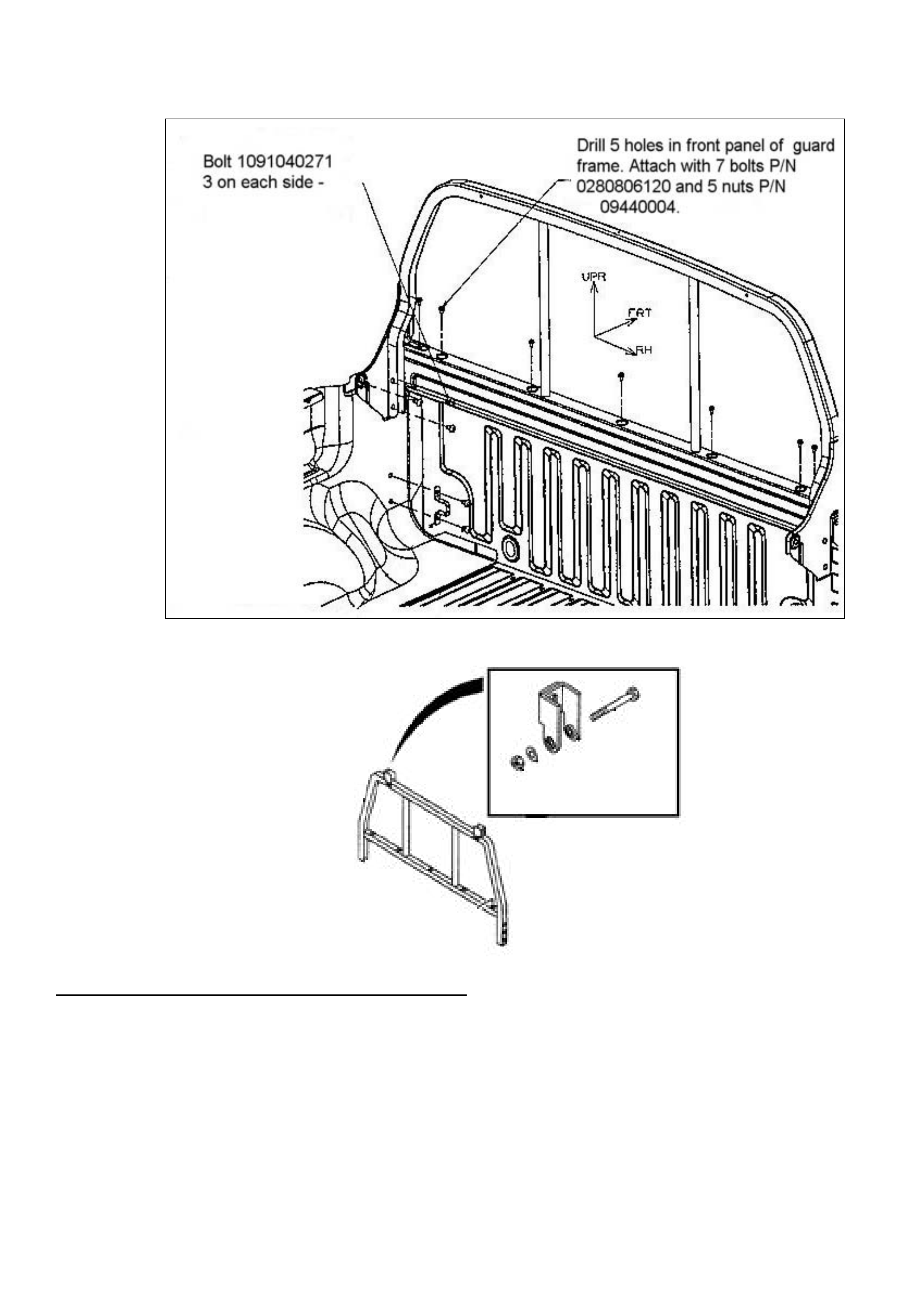

Guard Frame Installation – Refer Figures 1 & 2

1. Paint the following parts to match rear body colour:

• 1 x guard frame P/N 8973100752

• 2 x stopper – guard frame P/N 8973526240

Hint: The next steps show how to use the guard frame as a template for drilling the 5 holes in the front panel of the rear body.

2. Remove the 6 bolts P/N 1091040271 (3 on each side) that are already attached to the rear body.

3. Fit the guard frame P/N 8973100752 to the side walls of the rear body and fasten the 6 bolts with torque: 13.0 +/-

5.0 Nm.

4. Ensure that the Guard Frame is aligned correctly. Drill 5 holes with 7mm diameter drill in the centre of the 5 guard

frame bar holes.

5. Remove the Guard Frame from the rear body.

6. Apply PPG Multi Surface Epoxy Primer 410-39790 (or equivalent) to 5 holes just drilled. Ensure that surrounding

rear body area is protected from overspray.

7. Repeat step 3 to refit the Guard Frame.

8. Fit 2 bolts P/N 0280806120 to the outer holes on Guard Frame bar. Fit 5 bolts P/N 0280806120, and 5 nuts P/N

09440004. Torque all 7 bolts to 6.0 +/- 2.0 Nm

9. Fit the following parts to the top of the Guard Frame to construct the two guard frame stoppers. (Figure 2)

STOPPER - GUARD FRAME P/N 8973526240

WASHER - GUARD FRAME STOPPER P/N 9091606060

BOLT - GUARD FRAME STOPPER P/N 8944810220

NUT - GUARD FRAME P/N 8944814280

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

18

Figure 1.

Figure 2

Rear Body Installation Steps (Reverse of Removal)

1. Bolt rear body to frame.

NOTE: Discard used mounting bolts and replace with new ones.

Torque for all mounting bolts is 54 Nm(40 ft-lb)

2. Attach Fuel filler pipe and evaporator hose.

3. Connect fuel filler door release cable assembly

4. Attach rear wheel house extension panels

5. Connect the rear combination lamp & license Lamp connector.

6. Connect negative battery terminal

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

19

SERVICE INFORMATION

Laden Vehicle Trim Height Specification

RA Rodeo

(GROUP 4) TL0624-0401

The following information is provided to assist

Retailers when a customer complains of excessive

spring deflection when vehicle is loaded.

SERVICE RECOMMENDATION

To check spring deflection against specification

proceed as follows.

Step 1. Have the customer present the vehicle

to the retailership in the complaint condition (i.e.

loaded). Check all spring shackles/bushes for

condition. Rectify/replace as required.

Step 2. The vehicle must then be loaded to

achieve the Gross Vehicle Weight (GVW) Axle

Loadings as shown in following table. This will need

to be done on a vehicle weighing platform. It is

recommended to use sand bags to achieve the GVW

axle loadings.

Gross Vehicle Weight - Axle Loadings (kgs)

4x2 vehicle 4x4 vehicle

Front axle 1120 kg 1220 kg

Rear axle 1680 kg 1680 kg

Step 2 After achieving the above front and

rear axle loads, the dimensions as shown in the

following figures 1, 2, 3, & 4 can now be measured.

Step 3. Compare measurements taken in step

2 to those in Figure 5. Remember to take into

account the tolerances (+/-) on the specifications.

Also, the bump stop clearances are given for

reference only. If the measured vehicle trim heights

are below the specifications given, the spring

deflection is greater than production specification.

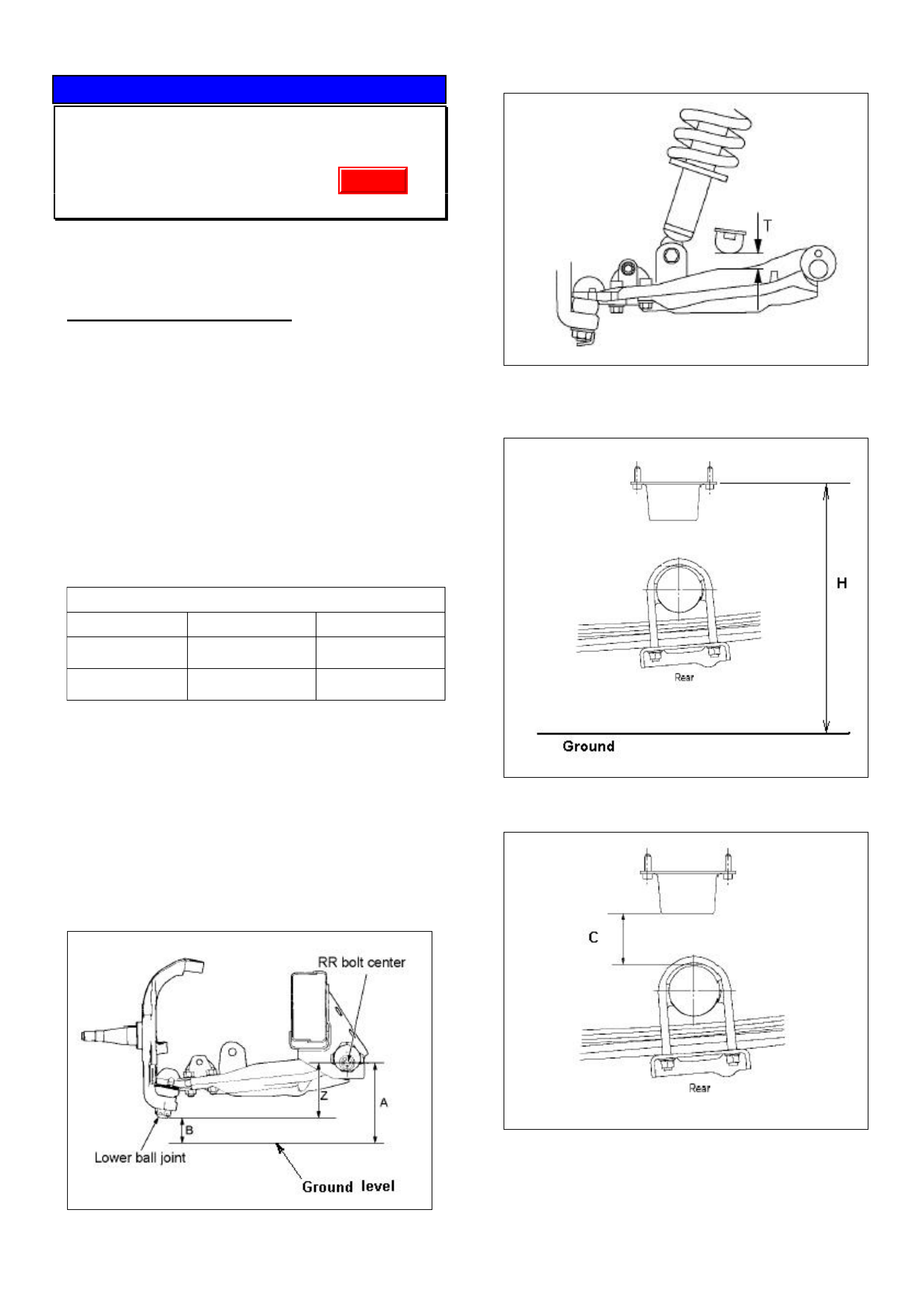

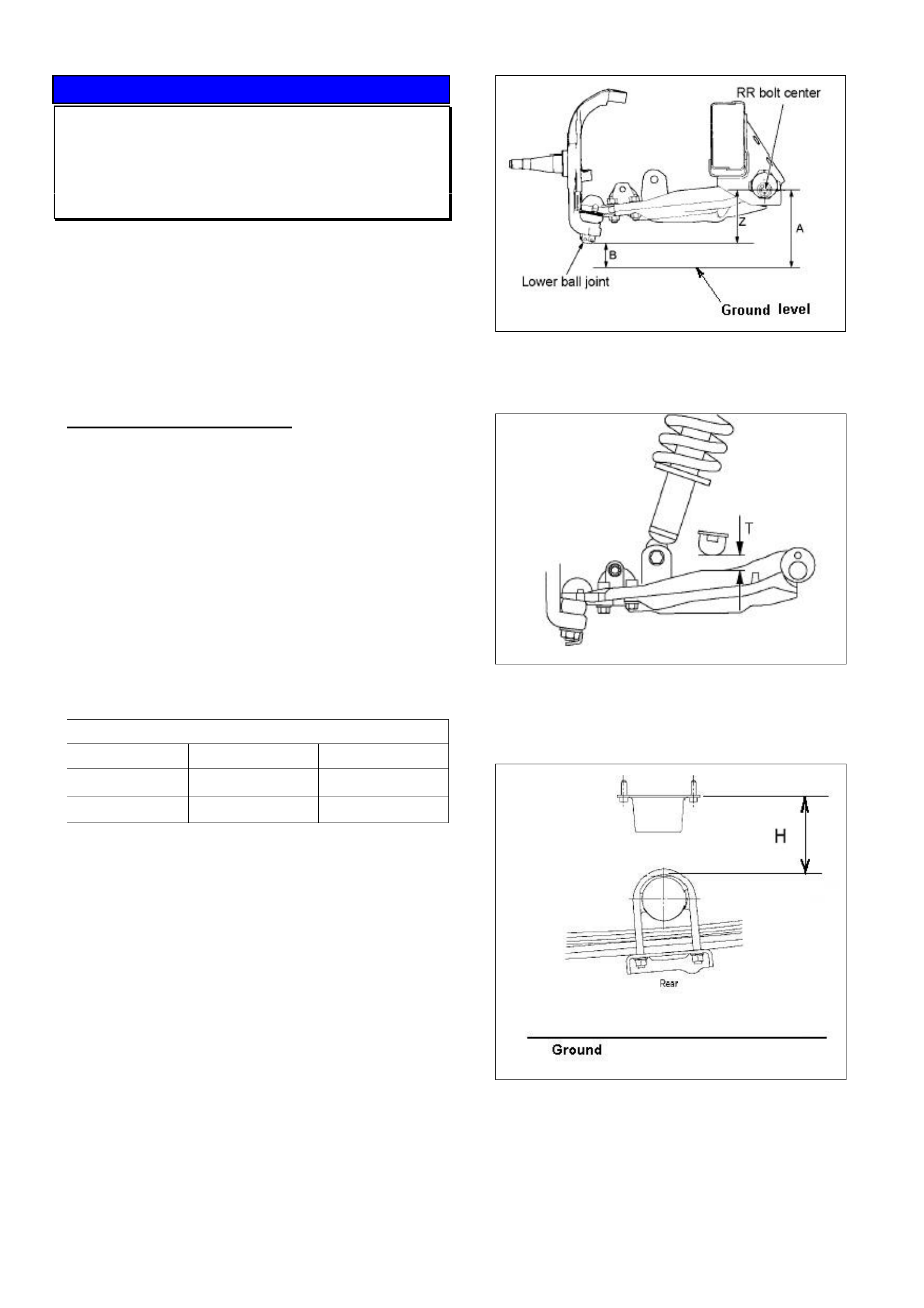

Figure 1. Front Trim height “Z” = A - B

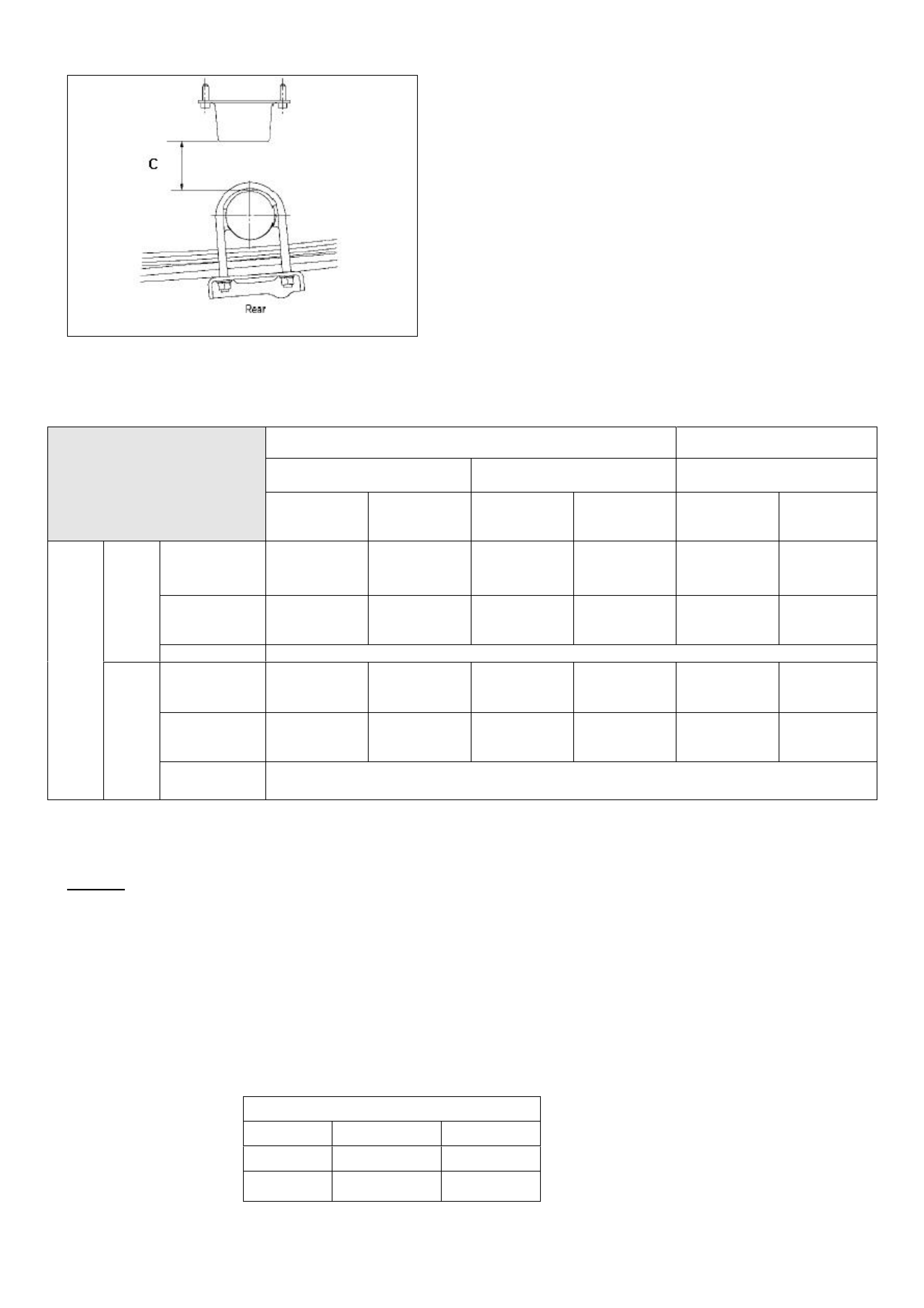

Figure 2. Front bump stop clearance T (for

reference only)

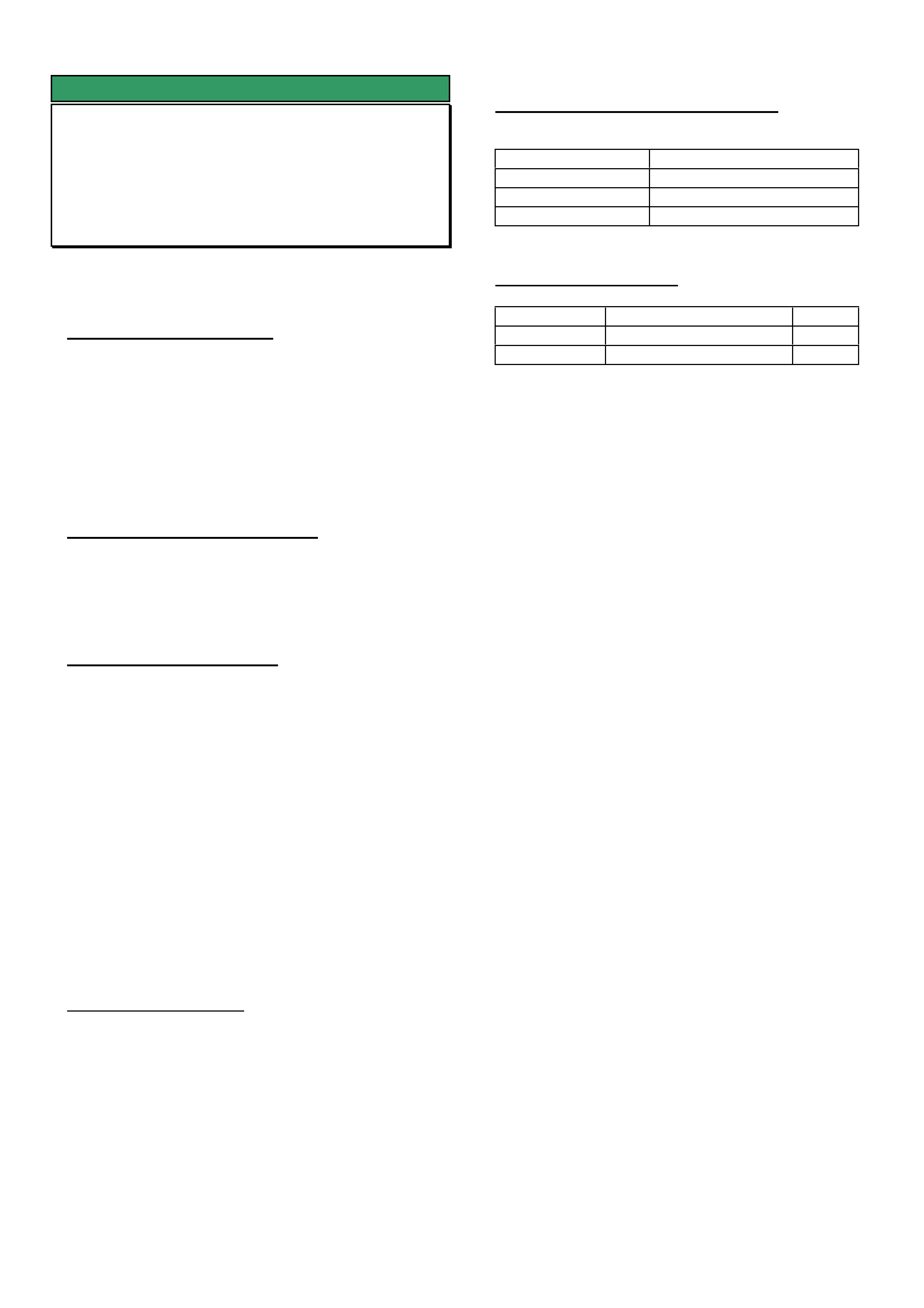

Figure 3. Rear bump stop mount height “H”

Figure 4. Rear bump stop clearance “C” (for

reference only)

Update

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

20

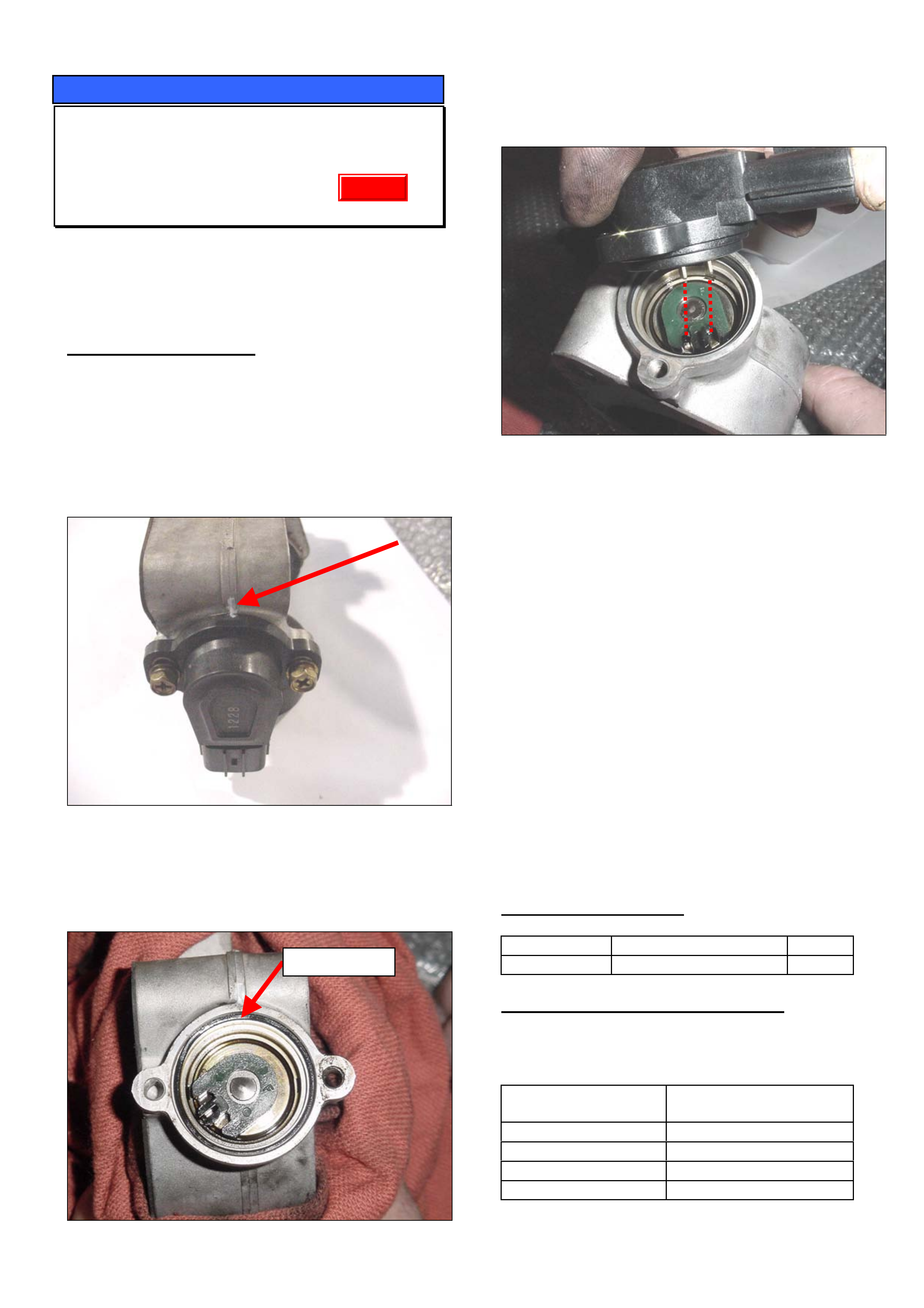

4 x 2 4 x 4

4JH1 & 6VE1 C24SE 4JH1 & 6VE1

RA Rodeo

Vehicle Trim Height

Specifications @ GVW Standard

Rear springs

(5 leaves)

HD

Rear springs

(7 leaves)

Standard

Rear springs

(5 leaves)

HD

Rear springs

(7 leaves)

Standard

Rear springs

(5 leaves)

HD

Rear springs

(7 leaves)

Trim Height

Z 83.2 83.2 60.8 60.8 108.0 108.0

Bump stop

clearance

T (Ref only)

17.8 17.8 9.4 9.4 17.0 17.0

Front

Tolerance mm +/- 7

Bump stop

mount height

H

446.8 433.7 446.8 433.7 490.5 478.4

Bump stop

clearance

C (Ref only)

22.5 9.4 22.5 9.4 21.6 9.5

GVW

Rear

Tolerance

(mm) +/- 6

Figure 5. RA Rodeo -Trim Height Specifications at Gross Vehicle Weight. (All dimensions are in mm).

NOTES.

• Front Trim Height “Z” and Rear Bump stop mount height “H” are the critical dimensions to be looked at

when assessing the condition of the vehicle springs.

• Front ( “T” ) & Rear ( “C” ) bump stop clearance should be used as reference data only.

• All measurements should be taken with the vehicle on a flat surface

• Vehicle weight distribution must comply with the front and rear axle weights for GVW loading as per

following table.

Gross Vehicle Weight - Axle Loadings (kgs)

4x2 vehicle 4x4 vehicle

Front axle 1120 kg 1220 kg

Rear axle 1680 kg 1680 kg

• The above information will be available in the next update to LCRV SIP (i.e. version 4.6)

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

21

SERVICE PROCEDURE

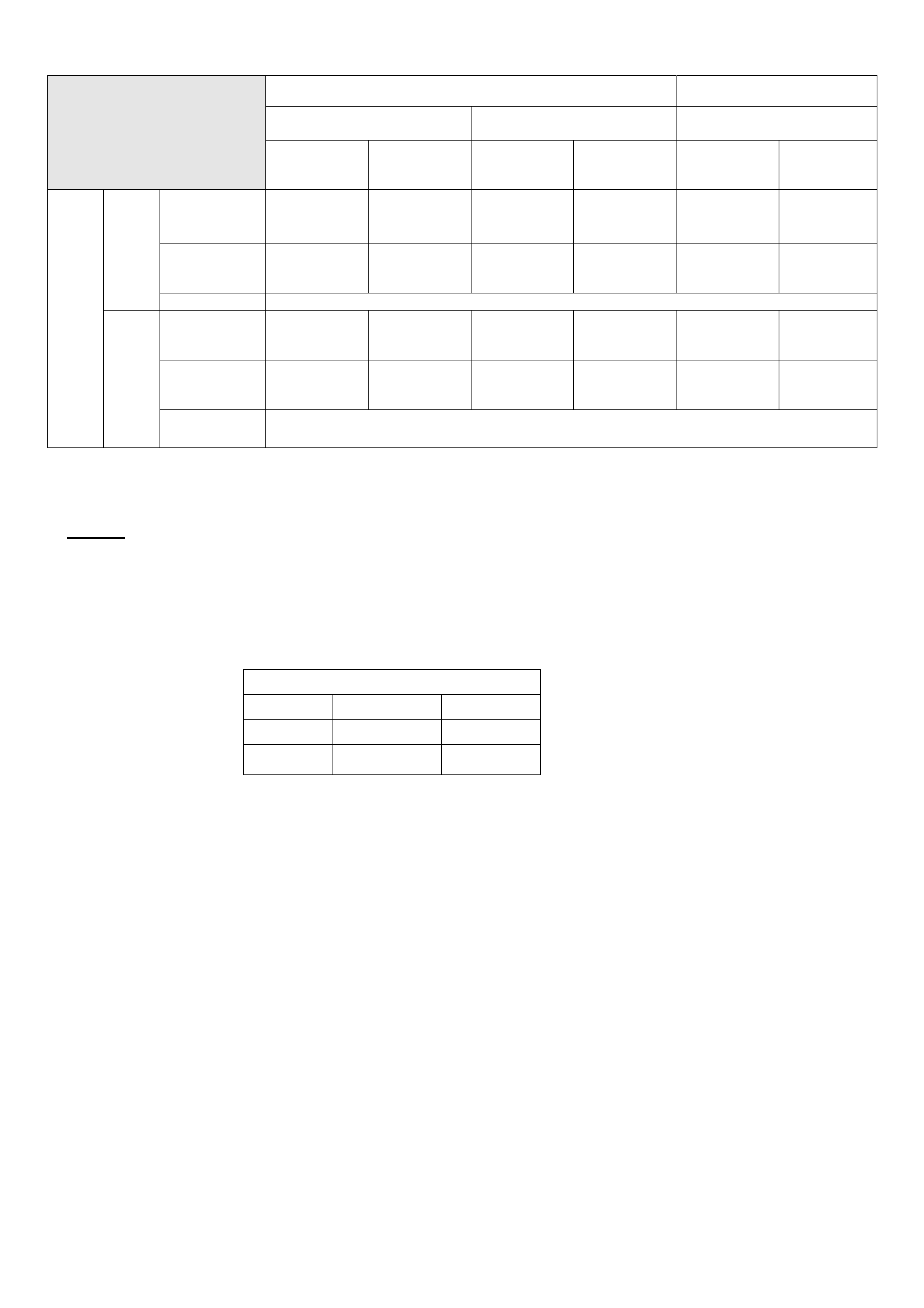

Throttle Position Sensor Replacement

UBS – Jackaroo Diesel (4JX1)

(GROUP 6C) TL0585-0401

Previously, the TPS was not available as a separate

component. This required the complete throttle body

assembly to be replaced if the TPS required

replacing.

SERVICE PROCEDURE

1. Remove intake throttle body from intake manifold

2. Clean the throttle body of any carbon sludge.

3. Mark the throttle body, with a marker pen, in a

position that can act as a reference on both the

new and old sensor e.g. casting mark (Fig. 1).

Figure 1.

4. Remove the TPS From the Throttle Boby.

5. Clean inside the TPS mount and replace the o-ring

seal.

Figure 2

6. Fit a new TPS to the throttle body and torque

screws to 3.0 Nm. Ensuring that TPS teeth are

engaged correctly as shown in figure 3.

Figure 3.

7. Reinstall the throttle body to the vehicle.

8. Connect Tech-2 and enter the correct vehicle and

engine information:

• Select F3: Miscellaneous Tests function.

• Select F3: Throttle position Motor Control function.

• Scroll down until Throttle Position Sensor

Voltage and Throttle Position Steps are displayed.

9. Verify the Throttle Position Sensor Voltage at each

valve step is within the threshold values shown in

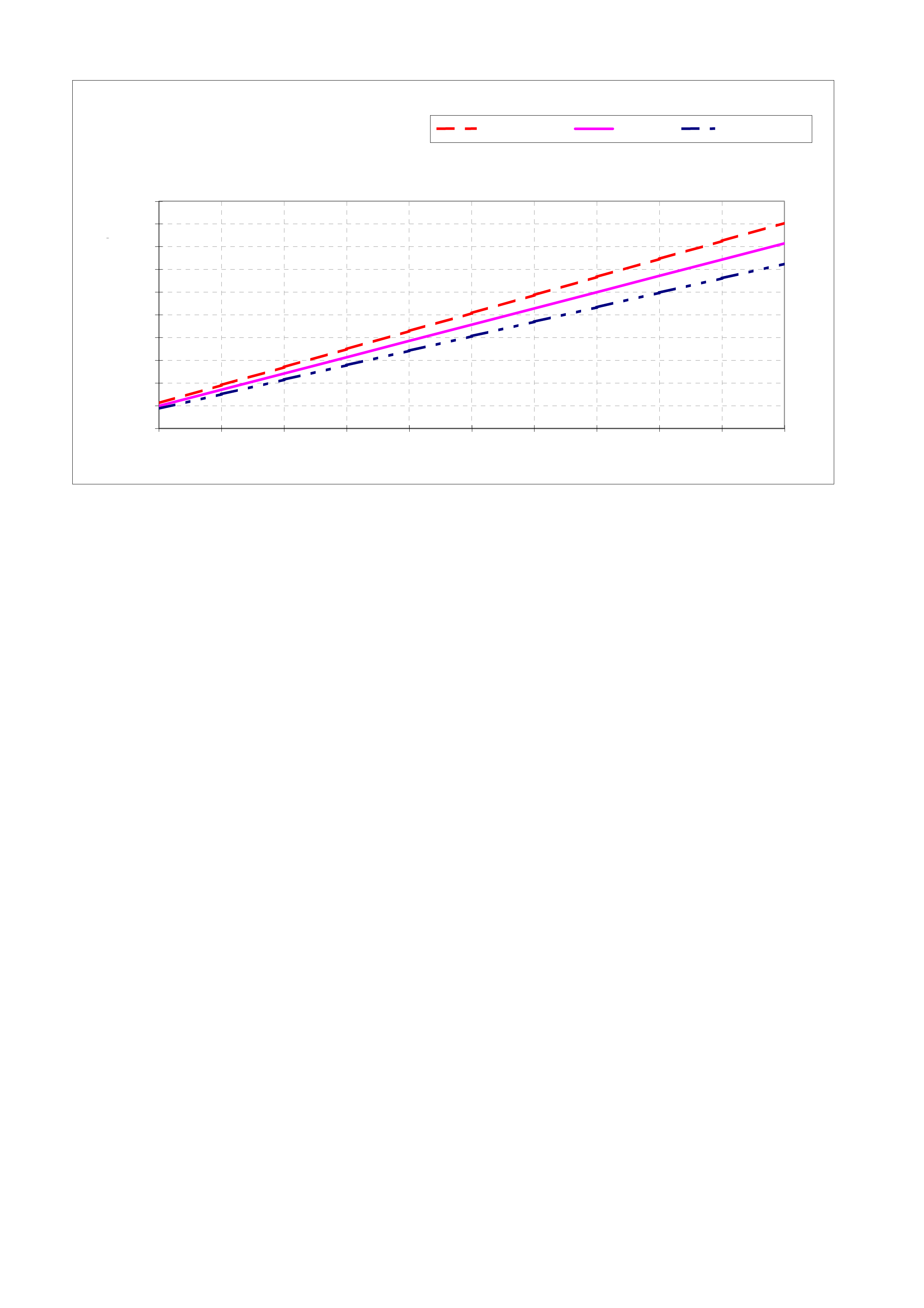

graph 1 below.

10. If the values are outside the threshold range,

adjust the TPS so that they fall within the

threshhold range.

11. Reassemble the vehicle and check the complaint

has been rectified.

PARTS INFORMATION

Part No.: Description: Qty:

8973728510 Sensor, TPS 1

WARRANTY CLAIM INFORMATION

If the vehicle is still covered by new vehicle warranty

use the information below:

Description Sensor, Throttle

Position - Replace

Labour Op. No. J637400

Time 0.5 hr

Failure Code 50

Failure Code NOW J0050

O-rin

g

Seal

Update

HOLDEN SERVICE TECHLINE _____________________________________________________________FEBRUARY, 2004

22

Threshold Value at Each Step of Throttle Valve

0.95

1.35

1.75

2.14

2.54

2.94

3.33

3.73

4.13

4.52

0.75

1.07

1.39

1.71

2.03

2.35

2.67

2.99

3.31

3.62

0.56

0.44

0.00

0.50

1.00

1.50

2.00

2.50

3.00

3.50

4.00

4.50

5.00

012345678910

T hro ttle Valve Step

TPS Output Signal Voltag

e

Upper Limit Median Lower Limit

HOLDEN SERVICE TECHLINE __________________________________________________________________MARCH, 2004

5

INFORMATION

Security Code

YG

(GROUP 0B) TL0662-0402

The vehicle security code for all YG Cruze is the

same.

Technicians often request the security number

through the Security Information request procedure

only to be advised by Security Department that the

number is available on LCV SIP.

The number is located in System Electrical, Section

8G / 5 / page 24.

INFORMATION

SPS Programming and Linking

All Models

(GROUP 0B) TL0664-0402

TAS receive many calls from retailer technicians who

run into problems when trying to perform the

"Program Immobiliser Function" or PCM to BCM link.

Please be aware that if you are installing a new

PCM/ECU you must do SPS programming before

carrying out the above.

This is only required for new PCMs/ECUs.

HOLDEN SERVICE TECHLINE __________________________________________________________________MARCH, 2004

6

DIAGNOSIS HINT

Erratic Tachometer Operation, and/or

4WD Not Operating (if fitted)

RA Petrol or Diesel

(GROUP 12) TL0649-0402

CONDITION

Erratic tacho or speedo operation and/or no 4WD

operation (if 4wd equipped).

CAUSE

This condition may be caused by a blown or missing

fuse located at Position 2 in the interior fuse box.

CORRECTION

Verify that the ABS fuse at position 2 in interior fuse

box isn’t blown / missing.

NOTE: Vehicles without ABS require this fuse to be in

place for correct instrument cluster and 4WD

operation.

SERVICE PROCEDURE

Throttle Position Sensor Replacement

UBS – Jackaroo Diesel (4JX1)

(GROUP 6C) TL0585-0401

There has been an update to this Techline which was

previously published in Issue 1, 2004.

It has been updated by highlighting the fact that when

a new sensor is ordered, it also comes with a new O-

ring and sensor attaching screws. These parts do not

need to be ordered separately .

NOTE. The updated techline is now available on the

Holden Lionheart Portal which is accessed via your

Retailer’s PC.

The updated techline number is TL0585A-0402

Update

HOLDEN SERVICE TECHLINE __________________________________________________________________MARCH, 2004

10

SERVICE FIX

4WD Transfer Case Control Module

(TCCM) “Lock- up”

RA 4WD

(GROUP 4) TL0623-0402

CONDITION

Complaints have been received of Transfer Case

Control Module (TCCM) “lock-up” – e.g. the CHECK

4WD lamp on the instrument panel stays on to

indicate a 4WD selection malfunction. The condition

appears to occur at random.

CAUSE

The above condition is due to the TCCM

engagement signal “recognition” timing being too

short – these are the vehicle’s electrical system

feedback or monitoring signals that define correct

operation of the 4WD selection components.

CORRECTION in PRODUCTION

Revised TCCM’s with increased recognition timing

were introduced into production from:

ISOVIN: Built Date:

MPATFS77H4H510581 August, 2003

CORRECTION in SERVICE

Summary: Check electrical circuit integrity, correct

any problems. Fit a new TCCM if required.

Step 1.

Vehicles that suffer from “cannot select 4WD”, or

“module lock-up” when 4WD Hi or Low is being

selected; may have loss of continuity of one or more

of the limit switch circuits to the transfer case

actuator, or to the module’s return control. These

vehicles should have continuity checks of the

connections to TCCM, Trans. Case Actuator circuits

LS1, LS2, LS3, LS4 as described in Techline

published in June, 2003 titled “4WD Selection &

Diagnosis” . These checks are also in current LCV

SIP.

IMPORTANT. Any electrical faults must be

corrected, as only resetting or replacing the TCCM

will allow the customer complaint to re-occur, as the

root cause has not been addressed.

Step 2.

If all connections/circuits prove to be OK and the

condition is still present, replace the TCCM with later

TCCM, 8973684490. This module features a greater

internal time delay, allowing the module to better

monitor the return signals from the 4WD selection

components.

PARTS INFORMATION

Part No.: Description: Qty:

8973684490 TCCM Asm. 1

WARRANTY CLAIM INFORMATION

Warranty Administrators please note – the following

standard Labour Operation number has been

released for this module.

Failure Code 37 is recommended for use when

replacing as per this Techline instruction.

Description Transfer Case Control

Module Asm – R & R,

Replace or Reset

Labour Op. No. K651800

Time 0.4 hr

Failure Code 37 – Poor Engagement

Failure Code NOW K0037

Understanding 4WD Selection Criteria

To help technicians understand the 4WD selection

criteria, a Service Techline was released in June,

2003, Issue 6, page 11. Information in that Techline

has also been reproduced in Owner Handbooks and

the LCV SIP.

Customers who complain they have difficulty in

selecting 4WD, or may have “lock-up” occur may not

fully understand the 4WD selection criteria. It may

be helpful to show them this information.

HOLDEN SERVICE TECHLINE __________________________________________________________________MARCH, 2004

11

INFORMATION

Isuzu Tech 2 Software Downloading from

TIS 2000

RA

(GROUP 0B) TL0663-0402

With the introduction of RA Rodeo, LCV Tech 2

software is downloaded from TIS 2000 to the 10

megabite PCMCIA card.

When downloading the LCV software, Technicians

need to have the 10 Meg card in the slot closest to

the screen and select "Isuzu - General Export"

from the menu in the software download screen as

shown below.

Select Dealer Software Type:

Holden

Isuzu–General Export, North America (Isuzu Based Veh), Domestic

Isuzu NA (GM Based Veh.) – North America

Isuzu NA (Isuzu Based Veh.) – North America

Opel/Vauxhall

HOLDEN SERVICE TECHLINE __________________________________________________________________APRIL, 2004

5

DIAGNOSIS HINT

Engine Poor Performance After Driving

Through Water Or Washing Engine

RA with 3.0L 4JH1 Diesel Engine

(GROUP 6C) TL0677-0403

PROBLEM DESCRIPTION

Complaint of poor engine performance or lack of

power on RA Rodeo fitted with 3.0L 4JH1 diesel

engine after driving through water or washing the

engine.

This can be caused by dust in the Electrical Vacuum

Regulating Valve (EVRV) getting wet and blocking

the filter in the valve.

The EVRV valve is located in the engine

compartment on the RHS guard area and is used to

control the operation of the EGR valve.

SERVICE RECTIFICATION

Verify correct operation of the EGR valve. If the

EGR valve is not operating correctly, remove the

EVRV, and visually inspect for dust or water entry to

the valve. If the valve is found to be contaminated it

must be replaced.

TIP

For testing purposes, the vacuum line to the EGR

valve can be removed and plugged for duration of

test drive to confirm if it is the EGR system that is

causing the low performance.

THIS HOSE MUST BE RECONNECTED AFTER

THE TEST.

DIAGNOSIS HINT

Engine Poor Performance Due to

“Oil type” Air Filters

RA / TF with 3.0L 4JH1 Diesel Engine

(GROUP 6C) TL0678-0403

PROBLEM DESCRIPTION

Complaint of poor engine performance or lack of

power on RA/TF Rodeo fitted with 3.0L 4JH1 diesel

engine.

This condition can be caused by the use of non

approved foam oil-type air filters being used in place

of the specified paper element type air filter. The oil

can be drawn from the foam air filter and

contaminate the Mass Air Flow (MAF) sensor.

DTC’s may or may not be set.

SERVICE RECTIFICATION

Retailers are reminded that Holden does not

recommend the fitting and use of non specified foam

oil type air filters in the above models.

If fitted, these filters should be removed and replaced

with the recommended paper element type filter.

Remove the MAF from the vehicle, clean with a

cleaning solution such as throttle body cleaner and

refit to the vehicle.

If engine performance is still poor, a new MAF will

need to be fitted after confirming that the MAF is

damaged.

NOTE 1: The above non approved foam oil type air

filter must not be confused with the approved foam

pre-cleaner that can be fitted as described in Service

Techline issue 11, 2003, page 18.

NOTE 2: The above rectification work is not covered

by new vehicle warranty.

Update

HOLDEN SERVICE TECHLINE __________________________________________________________________APRIL, 2004

6

INFORMATION

Holden Contacts and Procedures

(GROUP OB) TL0679-0403

This techline summarises some of the Holden

contact procedures and gives a quick reference

guide for contact numbers.

Security information.

To obtain security information a completed security

information request form must be faxed through to

the security information department, as security

information cannot be given out by phone. TAS does

not process security information requests. Please

ensure you have the latest security information

request form, which is available on SIP. Contact

details are listed below. There can be up to a 4-hour

turn around on requests however if the information

needs to be obtained from overseas, it may take up

to 24 hrs. Do not phone the security information

department unless you have not received a response

in the normal turn around time. For further

information please refer to ADL 63/99.

Parts inquiries and information

If any information or assistance is required in regards

to part numbers or Partfinder, please refer to the

Holden Help section in Partfinder.

Warranty Authorisation and enquiries

Warranty can only be authorised by your Aftersales

District Manager. Labour times information is

available on SIP or from the warranty department.

For any other warranty inquiries please contact

Warranty Administration.

TAS

Technical Assistance Service (TAS) is a service

provided by Holden to assist Holden Dealers in

problem resolution.

TAS operating hours are:

Monday to Thursday 8.30am – 8.00pm and Friday

9.30am – 5.00pm Melbourne time. Contact to TAS

must be made by a Nominated Contact as outlined in

Section 5 of the TAS procedures manual. All

techlines, dealer letters and service information must

be checked prior to contacting TAS. The Nominated

Contact must not contact TAS until he/she has been

fully involved with the faulting vehicle and all Dealer

expertise has been exhausted. Problems should be

escalated through the Dealership to the senior

technician/foreman before contacting TAS.

TAS cases must be updated or closed within 30 days

unless a Dealer is waiting on a service fix to be

provided. It is the Dealers responsibility to update

cases. All cases should be recorded in the TAS

procedures manual, which should be referred to prior

to contacting TAS. Please note that an electronic

copy of the TAS procedures manual is also available

on passenger SIP.

Under no circumstances are TAS or other Holden

contact details to be supplied to customers or

independent repairers. TAS is a service restricted to

assisting Holden Dealer service departments.

Quick reference contact numbers

Air International Ph 1800 673 716

Australian Arrow Ph 03 9785 0792

Blaupunkt/Bosch Ph 1300 307 036

Clarion Ph 03 8558 1115

Fax 03 9551 0377

Customer Assistance Ph 1800 033 349

Dana Ph 02 9892 9237

Fax 02 9892 9310

www.spiceraxle.com.au

Delphi Ph 1800 335 777

Eurovox Ph 03 9237 0800

Fujitsu Ten Ph 03 9646 6008

Holden Assist Ph 1300 880 088

HSV Ph 03 9265 9500

Infomedia Ph 1800 810 103

Panasonic Ph 02 9986 7635

Petro-Ject Ph 02 9890 5701

Ph 02 9890 5244

Philips/Siemens-VDO Ph 1800 335 282

Salmat Ph 03 9358 2900

Security Ph 03 9647 2001

SPX Australia Ph 03 9544 6222

TAS Ph 1800 033 417

Fax 03 9647 2495

Warranty Ph 03 9647 1972

Ph 03 9647 2401

Ph 03 9647 1970

Update

HOLDEN SERVICE TECHLINE __________________________________________________________________APRIL, 2004

11

SERVICE FIX

Low Clutch Engagement Point

YG Cruze with M/T

(GROUP 7A) TL0653-0403

CONDITION

Customer complains clutch engagement point is

lower than normal.

Technicians should confirm condition by checking

clutch pedal freeplay adjustment as per LCV SIP

Section 7C-Clutch/Section 3.1-Clutch Cable

CAUSE

Clutch cable adjusting nut loosens.

CORRECTION - Production

Lock nut added to clutch cable from:

ISOVIN: Built Date:

JSAGHY81S00112181 Mar 2003

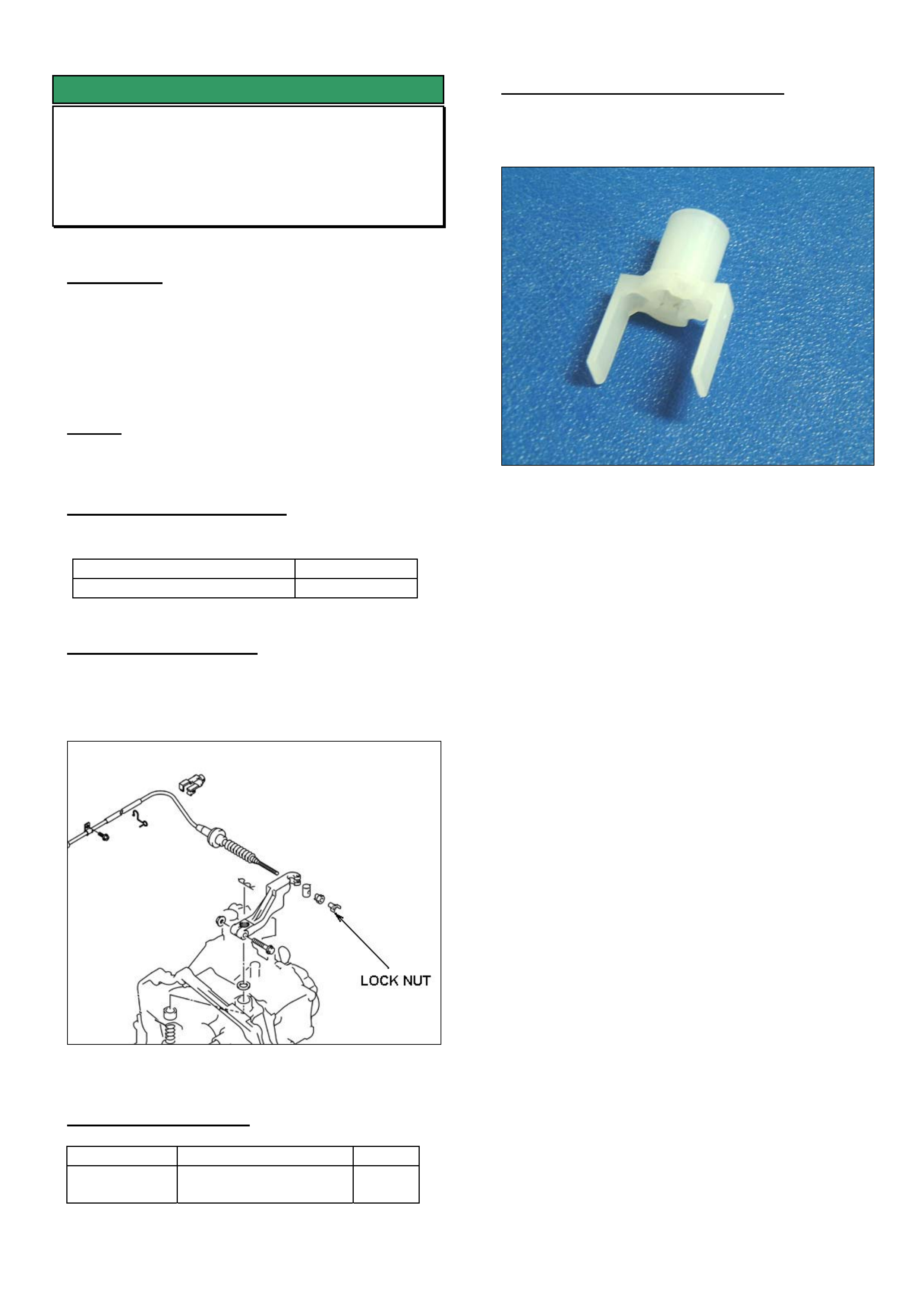

CORRECTION - Service

1. Add locknut 92125625 to end of clutch cable.

Refer Figure 1.

2. Adjust clutch cable as per procedure in LCV SIP

Figure 1

PARTS INFORMATION

Part No.: Description: Qty:

92125625 Nut Lock Cable

adjusting

1

WARRANTY CLAIM INFORMATION

Use Labour Times information in Warranty

Information section of current PV SIP CD

Figure 2. Closeup of Locknut

HOLDEN SERVICE TECHLINE __________________________________________________________________APRIL, 2004

14

SERVICE INFORMATION

Laden Vehicle Trim Height Specification

RA Rodeo

(GROUP 4) REVISED TL0624A-0403

This techline supersedes the previous one (TL0624-

0401) published in Issue 1, 2004.

IMPORTANT: All copies of the previous techline

should be destroyed or marked as being superseded.

----------------------------------------------------------------------

The following information is provided to assist Dealers

when a customer complains of excessive spring

deflection when the vehicle is loaded.

SERVICE RECOMMENDATION

Use the following procedure to check spring deflection

against factory specification.

Step 1. Have the customer present the vehicle

to the retailership in the complaint condition (i.e.

loaded).

Check all spring shackles/bushes for condition and

rectify as required.

Step 2. The vehicle must then be loaded to

achieve the Gross Vehicle Weight (GVW) Axle

Loadings as shown in following table. This will need

to be done on a vehicle weighing platform. It is

recommended to use sand bags to achieve the GVW

axle loadings.

Gross Vehicle Weight - Axle Loadings (kgs)

4x2 vehicle 4x4 vehicle

Front axle 1120 kg 1220 kg

Rear axle 1680 kg 1680 kg

Step 2 After achieving the above front and

rear axle loads, the dimensions as shown in the

following figures 1, 2, 3, & 4 can now be measured.

Step 3. Compare measurements taken in step

2 to those in Figure 5. Remember to take into

account the tolerances (+/-) on the specifications.

Also, the bump stop clearances are given for

reference only. If the measured vehicle trim heights

are below the specifications given, the spring

deflection is greater than production specification.

Figure 1. Front Trim height “Z” = A - B

Figure 2. Front bump stop clearance T (For

reference only)

Figure 3. Rear suspension height “H”

HOLDEN SERVICE TECHLINE __________________________________________________________________APRIL, 2004

15

Figure 4. Rear bump stop clearance “C”

(for reference only)

4 x 2 4 x 4

4JH1 & 6VE1 C24SE 4JH1 & 6VE1

RA Rodeo

Vehicle Trim Height

Specifications @ GVW Standard

Rear springs

(5 leaves)

HD

Rear springs

(7 leaves)

Standard

Rear springs

(5 leaves)

HD

Rear springs

(7 leaves)

Standard

Rear springs

(5 leaves)

HD

Rear springs

(7 leaves)

Trim Height

Z 83.2 83.2 60.8 60.8 108.0 108.0

Bump stop

clearance

T (Ref only)

17.8 17.8 9.4 9.4 17.0 17.0

Front

Tolerance mm +/- 7

Suspension

height

H

75.2 88.3 75.2 88.3 91.9 104.0

Bump stop

clearance

C (Ref only)

9.4 22.5 9.4 22.5 9.5 21.6

GVW

Rear

Tolerance

(mm) +/- 6

Figure 5. RA Rodeo -Trim Height Specifications at Gross Vehicle Weight. (All dimensions are in mm).

NOTES.

• Front Trim Height “Z” and Rear Suspension height “H” are the critical dimensions to be looked at when

assessing the condition of the vehicle springs.

• Front ( “T” ) & Rear ( “C” ) bump stop clearance should be used as reference data only.

• All measurements should be taken with the vehicle on a flat surface

• All measurements should be taken at the specified tyre pressure

• Vehicle weight distribution must comply with the front and rear axle weights for GVW loading as per

following table.

•

Gross Vehicle Weight - Axle Loadings (kgs)

4x2 vehicle 4x4 vehicle

Front axle 1120 kg 1220 kg

Rear axle 1680 kg 1680 kg

HOLDEN SERVICE TECHLINE __________________________________________________________________ MAY, 2004

5

SERVICE FIX

Intermittent No Crank or No Start

- Immobiliser Related

RA Rodeo

(GROUP 12) TL0541A-0404

This Techline supersedes and cancels the previous

one (TL0541-0311) published in Issue 11 Nov, 2003.

PROBLEM DESCRIPTION

Customers may advise that intermittently their vehicle

will not crank or will crank and not start.

This problem has often been isolated to an

intolerance within the immobiliser control unit

software, which can be highlighted by electrical noise

generated from the accessory socket relay and any

accessories powered from the accessory socket

circuit.

PRODUCTION RECTIFICATION

Revised immobiliser software was introduced into

vehicle production in May 2004. The specific

breakpoint will be published in the breakpoint

summary when available.

SERVICE RECTIFICATION

A revised immobiliser is now available from HSPO

and should be fitted to any vehicle when the customer

advises of this problem.

Install the revised immobiliser as per the LCV SIP

procedures:

• RA Rodeo/Section 11 – Immobiliser

System/Tech 2 Scan Tool/Reset Immobiliser.

• RA Rodeo/Section 11 – Immobiliser

System/Tech 2 Scan Tool/Programming ICU.

• RA Rodeo/Section 11 – Immobiliser

System/Tech 2 Scan Tool/Transponder

Program.

Please note the following;

Ensure that the vehicle is presented with both the

original ignition keys so they can be programmed to

the new immobiliser.

Use the original vehicle security code when

programming the new immobiliser.

WARRANTY CLAIM INFORMATION

Description Immobiliser Replacement

Labour Op. No. R123000

Time 0.4 hr

Failure Code R0084

PARTS INFORMATION

Part No.: Description: Qty:

8973773240 Diesel Immobiliser 1

8973773230 Petrol Immobiliser 1

HOLDEN SERVICE TECHLINE __________________________________________________________________ MAY, 2004

6

Central locking module

SERVICE FIX

Central Locking System Poor Remote

Range

RA Rodeo

(GROUP 12) TL0669-0404

CONDITION

Some customers may advise that intermittently their

central locking remotes do not operate.

CAUSE

High levels of environmental electrical interference

caused by mobile telephone transmitter towers or

high voltage power lines may interfere with the

operation of the central locking remote.

CORRECTION – Production

The central locking module has been repositioned

and revised central locking remotes with improved

range have been fitted in production from the

following breakpoint.

ISOVIN: Built Date:

MPATFS77J4H533835 01/04/04

CORRECTION – Service

When presented with a vehicle where the customer

advises the central locking remotes intermittently do

not operate, the following steps should be performed.

Step 1. Ensure the vehicle has been presented

with both original remotes and the

vehicle security code.

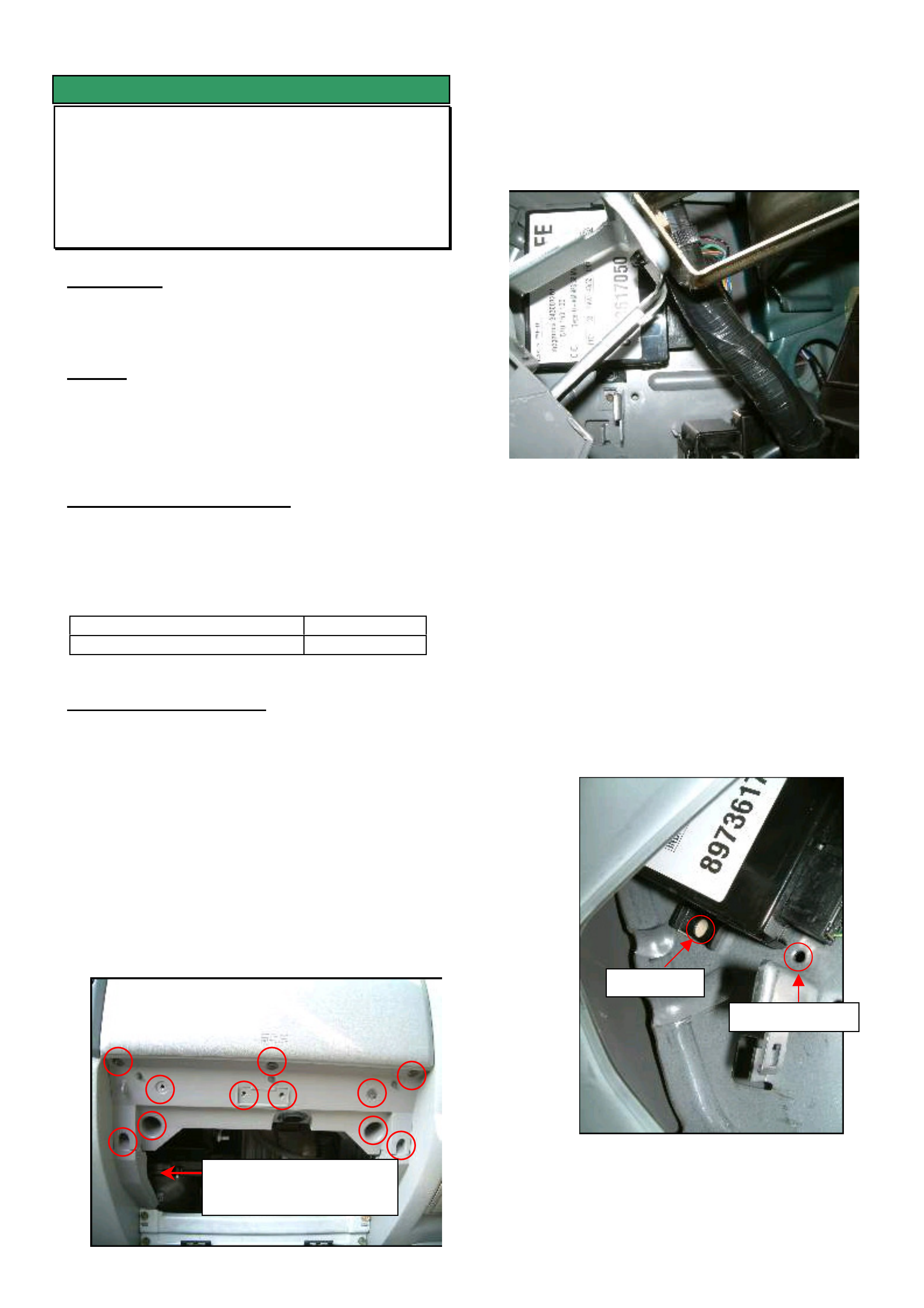

Step 2. Remove the glove box (two screws on the

lower edge) and the glove box cover (9

screws and two bolts as per the picture

below).

Step 3. Remove the central locking module located

to the left hand side of the glove box

opening (as per the photo below) by

removing the two attaching screws.

Step 4. Clean any grease or oil from the back of

the central locking module and the panel it

mounts to (to allow the double sided tape

to stick).

Step 5. Attach one side of the double-sided tape

(92148253) to the lower attaching lug of the

central locking module, refit the module in

position with the top attaching screw only

(do not tighten yet).

Step 6. Rotate the module clockwise approximately

300 (or as far as possible) around the top

mounting screw (as per the picture below).

Step 7. Tighten the top mounting screw and

confirm the module is securely located.

Ori

g

inal

New

HOLDEN SERVICE TECHLINE __________________________________________________________________ MAY, 2004

7

Step 8. Using Tech 2 program the two new remote

keys as per LCV SIP.

RA Rodeo / System Electrical / Section 8A Electrical –

Body and Chassis / Keyless Entry

Step 9. Ensure that both remotes operate after

programming.

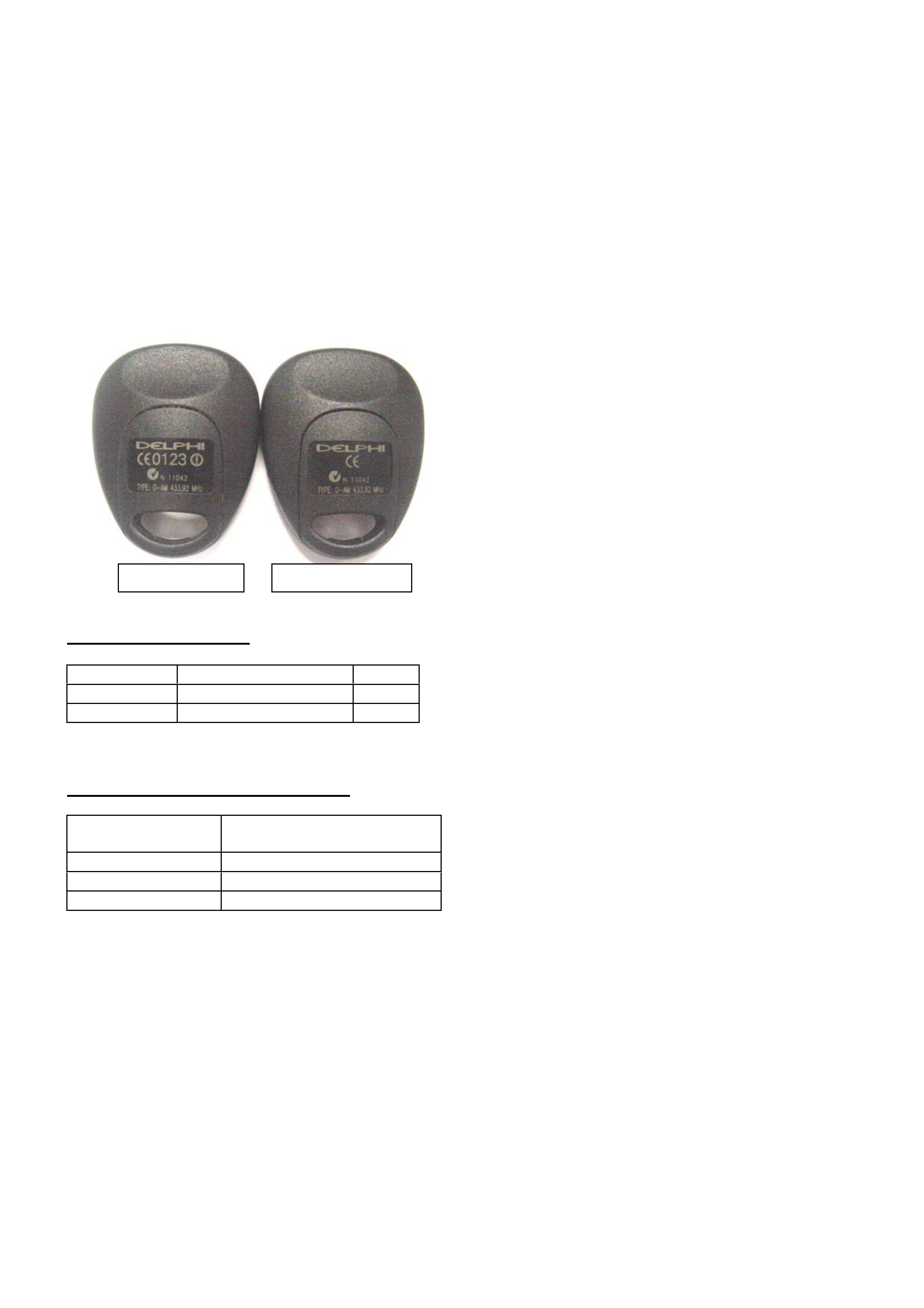

The new remotes can be identified by a change to the

numbering on the back as per the photo below.

PARTS INFORMATION

Part No.: Description: Qty:

8973784420 Remote Transmitter 2

92148253 Double sided tape 1

WARRANTY CLAIM INFORMATION

Description Central Locking Remote

Improved Range

Labour Op. No. N000463

Time 0.5 hr

Failure Code N0057

Old t

yp

e remote

N

ew t

yp

e remote

HOLDEN SERVICE TECHLINE __________________________________________________________________ MAY, 2004

8

INFORMATION

Immobiliser VIN Number Programming

RA Rodeo

(Group 12) TL0693-0404

PROBLEM DESCRIPTION

When programming the VIN number into the

immobiliser on an RA Rodeo, only 8 digits can be

programmed

PRODUCTION RECTIFICATION

When installing a new immobiliser into an RA Rodeo

you are requested via Tech 2 to program the VIN

Number into the new immobiliser. Tech 2 only allows

you to program 8 of the numbers. The 8 numbers

required are the last 8. Even if the old immobiliser

had something other than the last 8 you are still

required to program the last 8 .

E.g. Full VIN number is: MPATFS77J3T100177

Number to be programmed is: 3T100177

To program letters use the up/down arrow keys and

scroll through the alphabet, numbers can be

programmed in the same way or by using the

numbers on the keypad.

Please note the following;

Ensure that the vehicle is presented with both the

original ignition keys so they can be programmed to

the new immobiliser.

Use the original vehicle security code when

programming the new immobiliser.

HOLDEN SERVICE TECHLINE __________________________________________________________________ MAY, 2004

10

INFORMATION

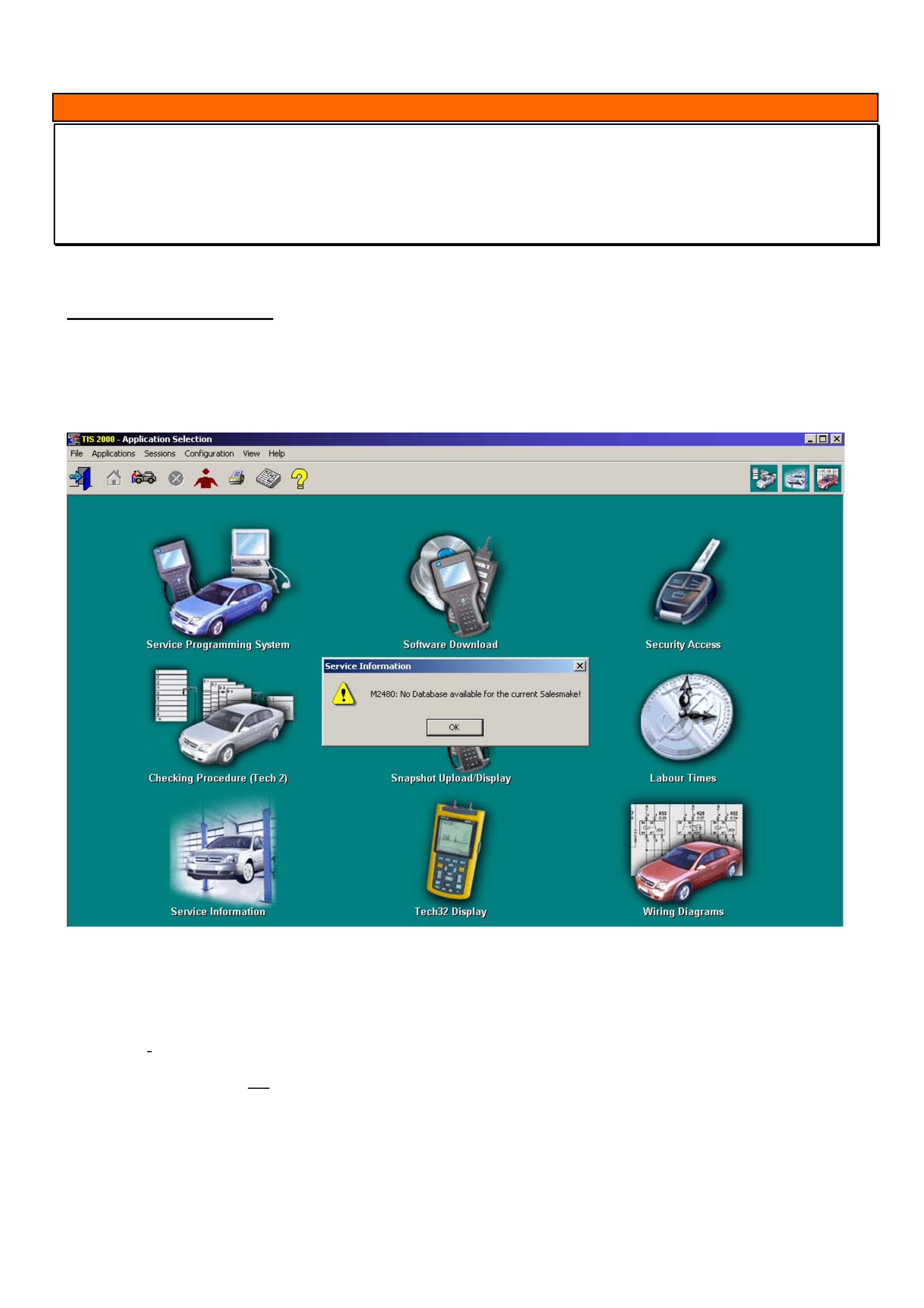

TIS 2000 error message when accessing Service Information or Security Access

TIS 2000

(GROUP OB) TL0690-0404

This techline is to be used in conjunction with Technicians guild article number 8 of 2003

PROBLEM DESCRIPTION

TIS 2000 displays error codes when user attempts to access some functions. Prior to seeking help from

TAS, it is recommended you perform the following checks.

When accessing Service Information the following screen may appear.

To overcome this problem, click the “ok” button in the message box. Click on the word “configuration” at the top of

the screen, select “options”. Starting from the left tab make sure the following selections are made.

Language: English (united states)

Country: Australia or New Zealand as applicable

Salesmake: Opel (unless doing Isuzu product then select Isuzu, do not select Holden for any product)

Dealership: Holden

WWW: Do not tick the enable java box

Click “ok”

After the settings have changed, a message box will appear advising that the salesmake settings have changed and

TIS must be restarted, click YES to this. Another message about closing open sessions will appear. If there are no

other open sessions click “YES”. Restart TIS and retry service information. If you continue to have problems with

service information a TAS nominated contact should contact TAS.

HOLDEN SERVICE TECHLINE __________________________________________________________________ MAY, 2004

11

When accessing Security Access the following message may appear.

(Make sure your hardware key is installed prior to attempting to obtain Security Access).

.

Click the “ok” button in the message box and then click on the word “configuration” at the top of the screen.

Select “I/O management” and make sure “Dongle” is highlighted (unless you have the new super pro USB hardware

key in which case “super pro” will need to be highlighted). Press the “test” button on the right hand side. The

following message may appear.

Click “ok” in the message box and then press the “properties” button on the right hand side. A box displaying the

current com port that is selected will appear. Click on the black arrow on the right of the message box; this will

display the other com ports available. Select a different com port than the one displayed (not LPT1) and click ok.

Press the test button again. If more than 2 com ports available then this may have to be done again on all com ports

until it passes. When message appears saying “Driver test successful” click “ok” and close I/O management box.

Retry Security access.

If problems still occur a TAS nominated contact should contact TAS.

HOLDEN SERVICE TECHLINE __________________________________________________________________ MAY, 2004

12

INFORMATION

TIS 2000 Update And Uninstall Procedure

(GROUP 0B) TL0691-0404

TAS receive many calls where a TIS 2000 Update or

a new TIS 2000 Installation has failed. This techline

is to clarify the following procedures:

• Update TIS 2000

• Uninstall TIS 2000

• TIS 2000 Configuration Options

If your Dealership has a PC specialist, it would be an

advantage to utilise his/her expertise.

Update TIS 2000

To update TIS 2000 proceed as follows:

• Place TIS CD1 in your disc drive, wait a few

seconds and then click on the icon, which

opens TIS 2000. This will then see the disc as

an update and continue to upload. On

completion of the first, it will request that you

load the second disc. When the second disc

is inserted, click OK in the dialog box to begin

the upload.

• Both LCV TIS and Wiring Diagrams CD’s

should be treated as an Update.

Uninstall TIS 2000

To uninstall TIS 2000 proceed as follows:

• Remove any cd’s from all drives.

• Shut down and Restart your computer (PC).

• Click on the Start button (lwr left of screen).

• Move up to programs then across to TIS 2000

and again across to TIS 2000 Uninstall.

Select Uninstall from this menu.

• When the Uninstall is fully complete it should

advise if it was successful. If not, you will

need to run through the following procedures.

• Click on the Start button again and choose

Search or Find, moving over to Files or

Folders.

• Type cosids in the search field, and then

choose local hardrives in the look-in field.

Now select Search/Find now. This will

generate a search for the TIS 2000 main files.

(If any files are found it will be displayed in the

large box to the right, if not continue to next

step)

• Delete all files that have been found, by

selecting with your mouse and hitting the

delete button on your keyboard.

• Now click on the Start button again and scroll

up to Settings, then move across to Control

Panel. In this menu, double click on

Add/Remove Programs and look for the

following items:

JAVA 2 RUNTIME ENVIRONMENT STD EDITION

and

JAVA SERVLET DEVELOPMENT KIT.

• If they are available, select one at a time then

hit the Change/Remove button for each.

Close this window.

• It is now very important to restart your

computer.

TIS 2000 CONFIGURATION OPTIONS

When attempting a complete TIS 2000 install, place

CD1 in the drive and this should now begin the

installation. It will request the second CD when

required.

Follow all prompts until the installation is complete.

NOTE: it is very important that you select the following

configuration when prompted:

• Language – English

• Country – Australia/New Zealand (whichever

is applicable)

• Salesmake – OPEL

• Dealership – HOLDEN

• WWW – not checked (ticked)

You will also need to select which COM port you

would like your TECH 2 and Hardware Key to

communicate with. You must ensure these are both

the same. E.g.; COM1 or COM2.

HOLDEN SERVICE TECHLINE __________________________________________________________________ MAY, 2004

16

SERVICE FIX

Fuel Gauge Reads Empty With 25 Litres

Left In The Tank

RA Diesel

(GROUP 12) TL0576-0404

CONDITION

Customers may advise that when the fuel gauge

reads empty they can still have approximately 25

litres left in the tank.

CAUSE

The fuel sender card calibration results in “Empty”

being displayed too early.

CORRECTION – Production

A revised fuel sender card has been fitted in

production from the following breakpoint.

ISOVIN: Built Date:

MPATFR77H4H514631 (2 X 4) 10/11/03

MPATFS77H4H515657 (4 X 4) 19/11/03

CORRECTION – Service

The revised fuel sender card assembly is available

from HSPO and should be fitted to the original

Modular Reservoir Assembly (MRA).

Step 1. Remove the MRA as per the LCV SIP

instructions.

RA Rodeo / Engine 4JH1 / Section 6C-Engine Fuel / Fuel

Gauge Unit

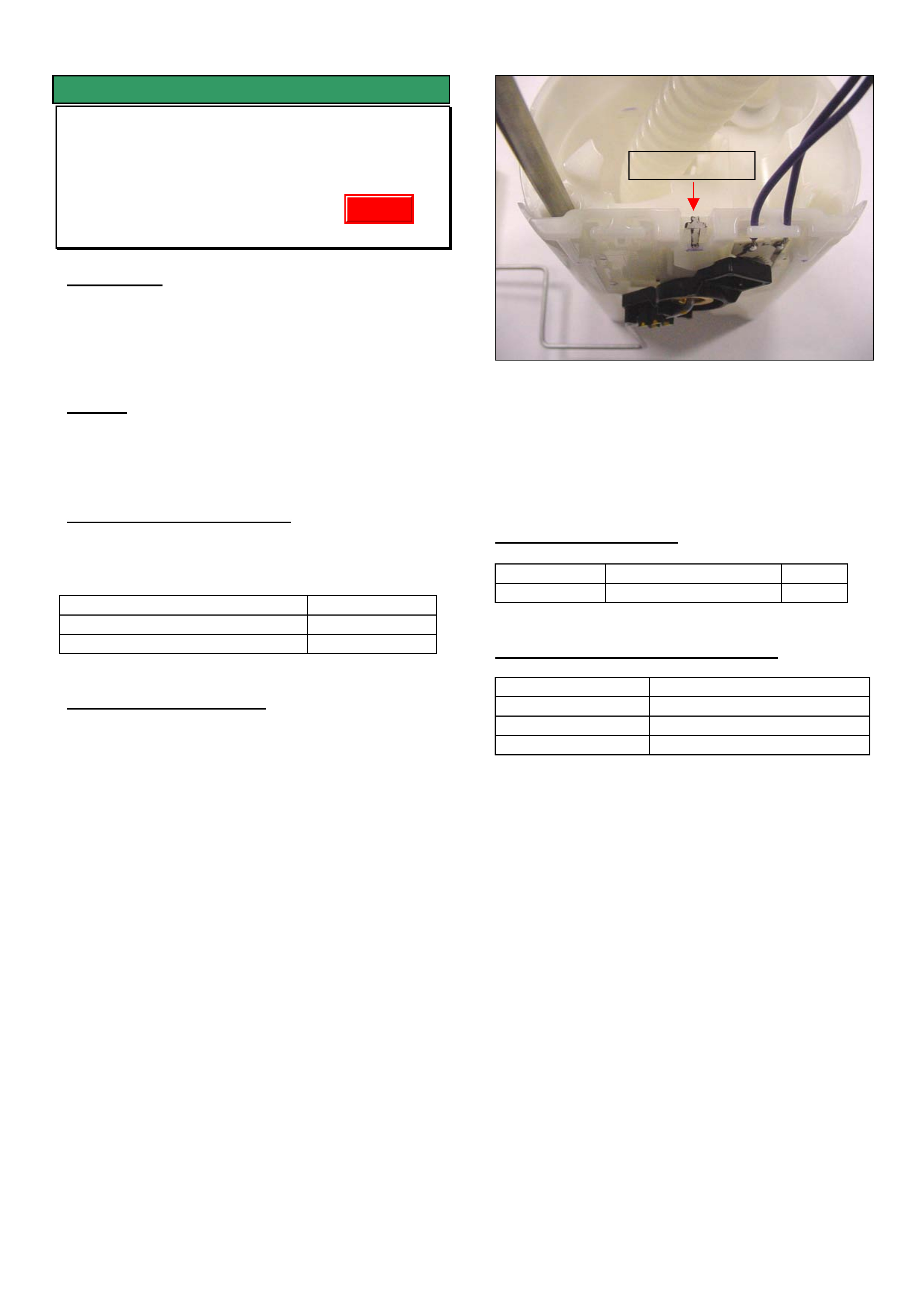

Step 2. Once the MRA is removed disconnect the

sender card wiring under the top cover.

Step 3. The fuel sender card assembly can now be

removed from the MRA body by

disengaging the double-sided clip at the

top. (refer picture)

NOTE: Care should be taken not to damage the MRA

when removing the sender card assembly.

Step 4. Refit the new sender card assembly and

reconnect the wiring.

Step 5. Refit the fuel tank as per the LCV SIP

procedure and check the operation of the

fuel gauge.

PARTS INFORMATION

Part No.: Description: Qty:

8979431780 Fuel Sender Card 1

WARRANTY CLAIM INFORMATION

Description R& R Fuel Sender Card

Labour Op. No. L000239

Time 1.1 hr

Failure Code NOW N0057

Double sided

Update

HOLDEN SERVICE TECHLINE __________________________________________________________________ MAY, 2004

20

SERVICE FIX

Air Outlet Vents Difficult To Adjust

RA Rodeo

(GROUP 2) TL0668-0404

CONDITION

Customer complains the interior air vent(s) are difficult

to adjust.

Closer inspection reveals the vent is fractured.

CAUSE

Incorrect chemical composition of vent material which

results in embrittlement of the material with age.

CORRECTION – Production

Revised material vents have been fitted to vehicles

from:

ISOVIN: Built Date:

MPATFS77H4H501806 01/07/2003

CORRECTION – Service

On any vehicle built prior to the above Breakpoint

which has a fractured air vent grille, it is

recommended to replace all four vents in the dash

pad with latest revised parts.

PARTS INFORMATION

To obtain a kit of revised vents (kit contains 1 x LH

outer, 1 x RH outer and 2 centre) fax an order form to

Salmat on 9358 2999. The order form is to be a

copy of this page.

NOTE: When the sets of revised vents can no longer

be obtained from Salmat (supplies are limited) the

following parts will need to be obtained from HSPO.

Refer to the latest Partfinder for part numbers of these

components.

Part No.: Description: Qty

refer latest

Partfinder

Cluster – Instrument centre

(contains 2 centre vents)

1

refer latest

Partfinder

Grille – side, air outlet LH 1

refer latest

Partfinder

Grille – side, air outlet RH 1

WARRANTY CLAIM INFORMATION

Description Replace all 4 air outlet

vents in dash.

Labour Op. No. D000348

Time 0.6 hr

Failure Code D0005 Cracked

REQUEST for - RA Air Vent Car Set

Fax this form to Salmat on 03 9358 2999

Date of request :

Dealer Name :

Dealer Code :

Dealer Address for parts

delivery :

17 digit ISOVIN of vehicle

parts are required for :

Name of person

requesting parts :

Contact Numbers : Phone: Facsimile:

For Salmat Use Only:

Date Parts Despatched