SECTION 1 - GENERAL INFORMATION

IMPORTANT:

Before performing any Service Operation or other procedure described in this Section, refer to

Section 00 CAUTIONS AND NOTES and Section 2 PRECAUTIONS in this Supplement for correct

workshop practices with regard to safety and/or property damage.

CAUTION:

The Structure of the VY & V2 Series II Ser ies body shell has be en developed using complex design and

development techniques. In addition to meeting all required standards, the vehicle body is also a

critical part of the overall safety systems. It is therefore imperative the repair procedures described

here are adhered to during all vehicle body repairs.

CONTENTS

1. INTRODUCTION

2. GENERAL INDEX

3. REPAIR PROCEDURES

3.1 FRAME STRAIGHTENING

3.2 ROUGH CUTTING

3.3 CUTTING MIG WELDS

3.4 SPOT WELD CUTTING

3.5 LAP JOINTING

3.6 REPAIRING THE BODY ALIGNMENT

4. WELD REPAIR METHODS

4.1 GENERAL INFORMATION

4.2 SPOT WELDING

SPOT WELDER

PANEL CONDITION

NUMBER OF WELDS

WELD TESTING

4.3 PLUG WELDING

4.4 FUSION WELDING

BUTT WELDED JOINTS

LAP WELDED JOINTS

BRONZE WELDS

WARP PREVENTION ON LONG WELDS

4.5 WELDING LEGEND

1. INTRODUCTI O N

The MY 2003 VY & V2 Series vehicles are designed to meet or exceed all frontal, offset frontal and side impact

standards. It is imperative therefore, that any repairs to a MY 2003 VY & V2 Series vehicle does not compromise:

• the vehicle’s compliance with relevant statutory regulations,

• the performance of the body structure, or

• the vehicle’s safety systems – including the occupant protection system.

Any repairs are to be performed in accordance with this Supplement, which provides replacement procedures for

MY 2003 VY & V2 Series body panels and structural members.

Hang-on panels suc h as the engine hood, deck lid and f ront f ender s are not covered and refer ence should be made

to the appropriate Section in the MY 2003 VY & V2 Series Service Information.

Replacement procedures for the door assemblies and outer panels, along with instructions for disassembling and

removing the glued-in dash panel assembly, are the only instructions in this Supplement that do not involve

components welded to the vehicle structure.

This Supplement has been prepared for trades persons suitably qualified in the Automotive Body Repair Industry.

As such, welding technique, panel beating or surface finishing instruction, etc. is not included. The purpose of this

Supplement is to ass ist the repairer to use his/her expertis e in m ak ing the correct judgem ents to restore the vehicle

to original condition and specification.

Prior to beginning repair work on a vehicle, the repairer should becom e fam iliar with Section 1 through Section 3 in

this Supplem ent, Section 00 in the MY 2003 VY & V2 Series II Service Inf orm ation and any appropriate regulations

covering repairs, welding and joining motor vehicles and accepted industry practices.

As collision damage differs in each case, this Supplement can only be a guide for the repairer. The best repair

procedure for each vehicle will need to be determined according to the judgements of a qualified trade’s person.

The Supplement describes the replacement procedures of service parts available for MY 2003 VY & V2 Series

vehicles. If several adjoining parts are replaced at the one time, modify the replacement procedures accordingly.

The nam ing of body sections and parts in this Supplement fo llows Global Part Descr iption System (GPDS) nam ing

conventions.

The information contained in this Supplement is correct at the time it was approved for printing. However, as the

motor vehicle industry is constantly updating and improving vehicle construction techniques, the repairer must use

his/her acquired skill in determining the appropriate procedure for replacing panels.

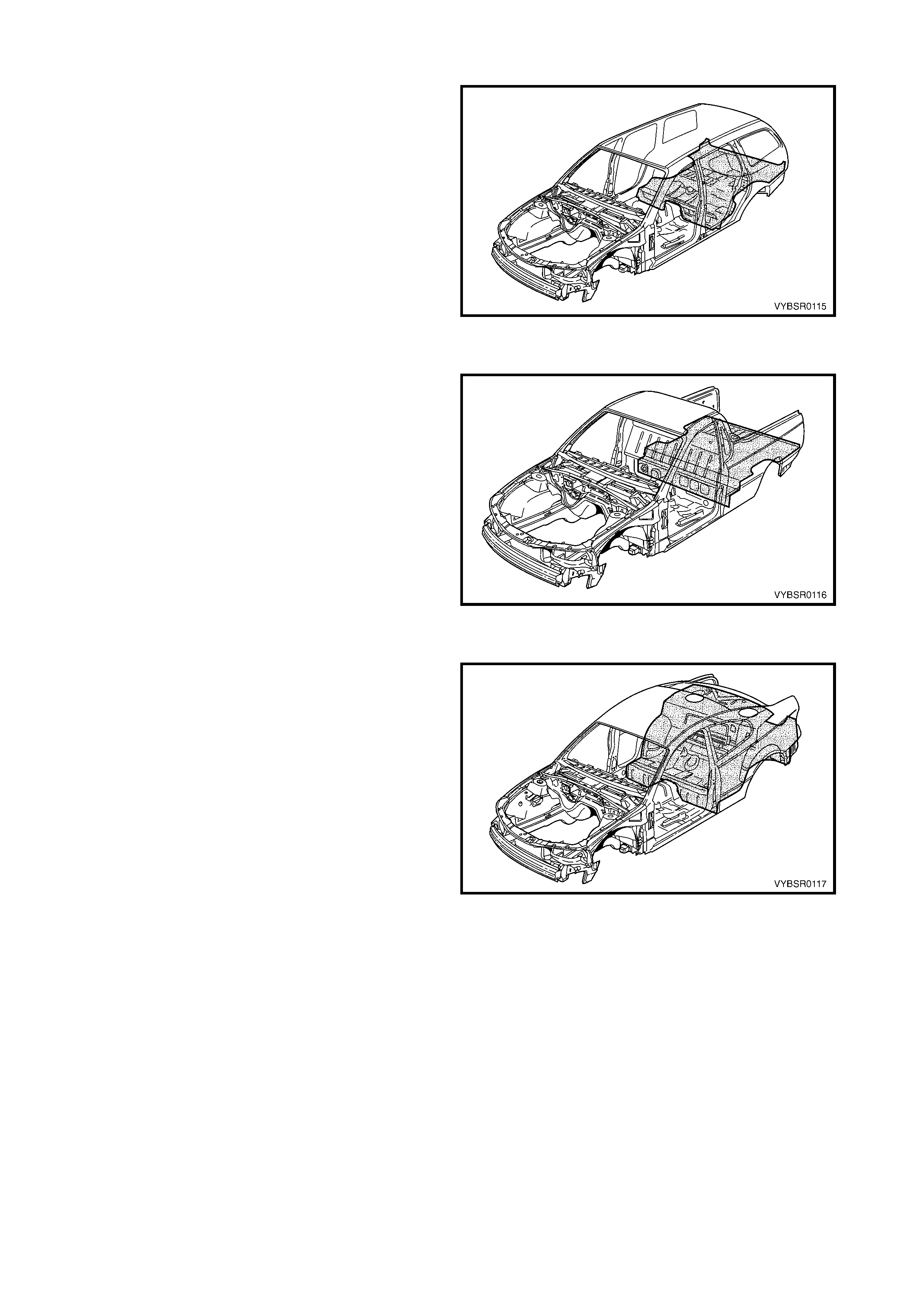

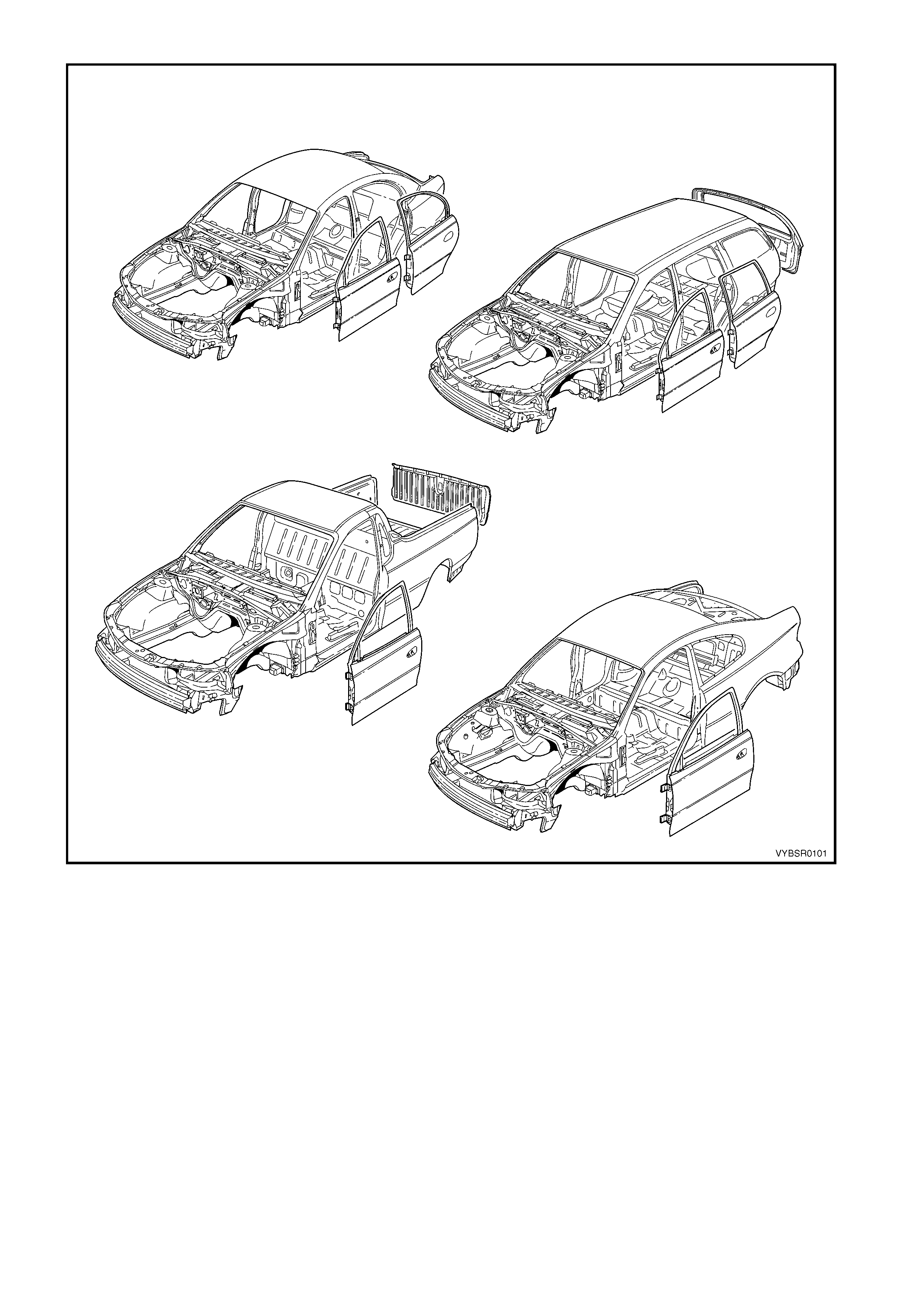

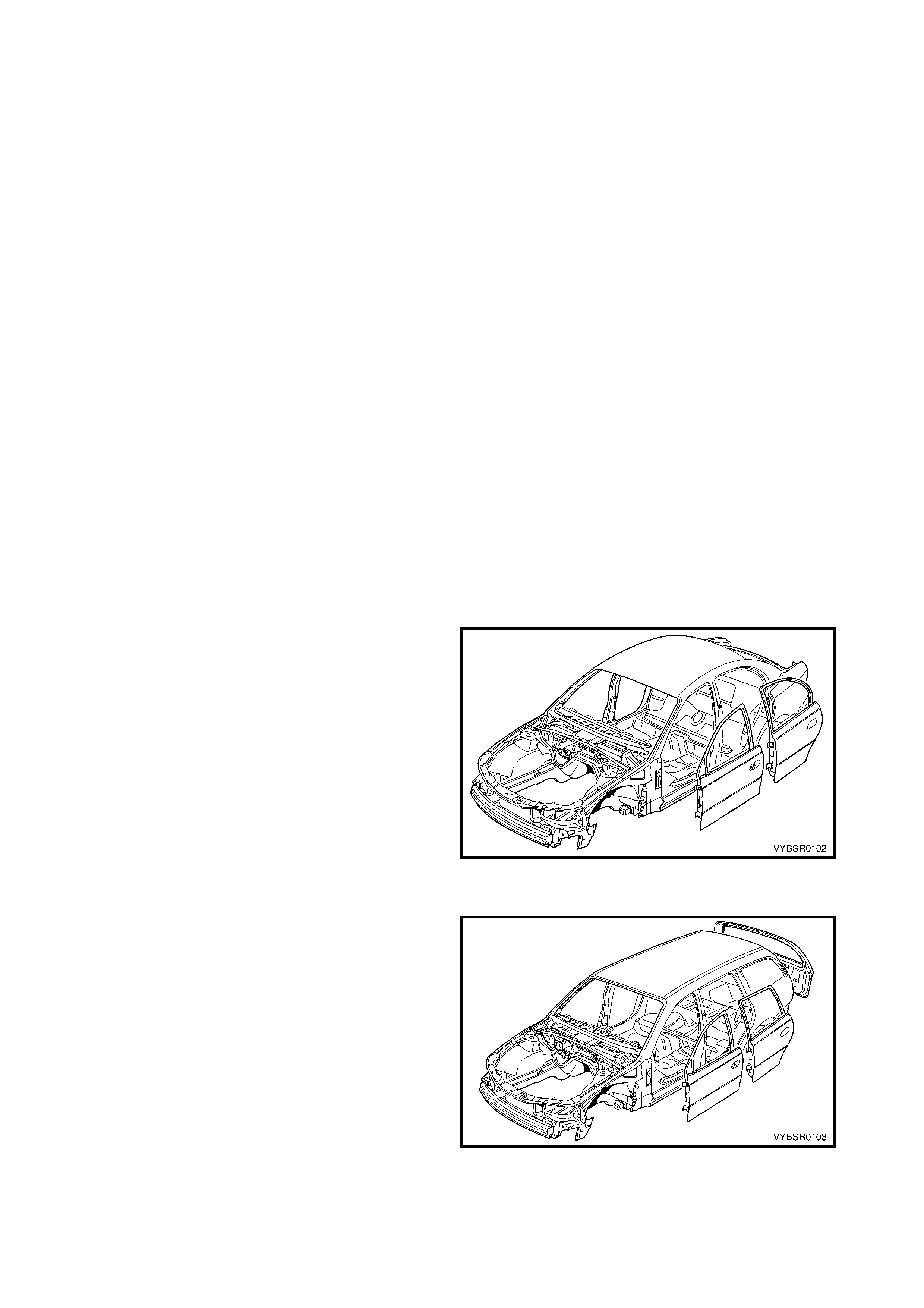

Figure 1-1 shows the MY 2003 VY & V2 Series II body structure as covered by this Supplement.

NOTE: The Vehicle Data information previously included in this Section is now located in Section OA GENERAL

INFORMATION of the MY 2003 VY & V2 Series Service Information.

Figure 1-1

2. GENERAL INDEX

SECTION 1 GENERAL INFORMATION

Description

1. Introduction

2. General Index

3. Repair Procedures

4. Weld Repair Methods

SECTION 2 PRECAUTIONS

Description

1. General Description

2. Personal Safety Precautions

3. General Precautions

4. Occupant Protection System Precautions

5. Electrical Precautions

6. Jacking Precautions

7. Towing Precautions

8. Plastic Components

9. Special Steel Precautions

10. Cavity Foam

11. LPG Precautions

SECTION 3 BODY CONSTRUCTION

Description

1. General Description

2. Bumper Impact Bar Assemblies

3. Special Tools

SECTION 3A BODY CONSTRUCTION – SEDAN

Description

1. General Description

2. Body Structure Panels

3. Body Dimensions

4. Body Margins

5. Body Sealing, Adhesives and Deadeners

6. Cavity Wax

Figure 1-2

SECTION 3B BODY CONSTRUCTION – WAGON

Description

1. General Description

2. Body Structure Panels

3. Body Dimensions

4. Body Margins

5. Body Sealing, Adhesives and Deadeners

6. Cavity Wax

7 Roof Joint Moulding

Figure 1-3

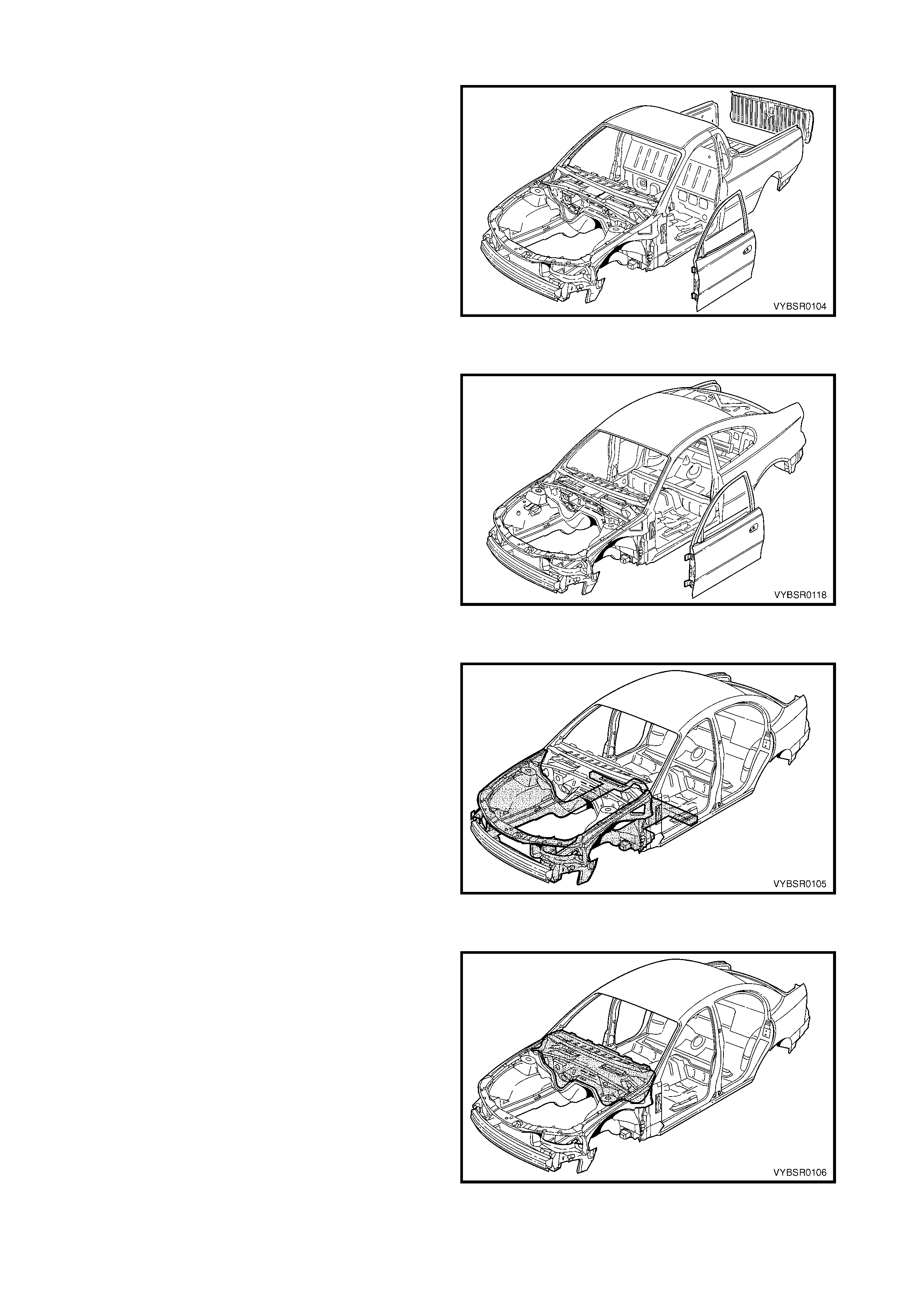

SECTION 3C BODY CONSTRUCTION – UTILITY

Description

1. General Description

2. Body Structure Panels

3. Body Dimensions

4. Body Margins

5. Body Sealing, Adhesives and Deadeners

6. Cavity Wax

Figure 1-4

SECTION 3D BODY CONSTRUCTION – COUPE

Description

1. General Description

2. Body Structure Panels

3. Body Dimensions

4. Body Margins

5. Body Sealing, Adhesives and Deadeners

6. Cavity Wax

7 Rear Seat Back Panel Centre Extension

Figure 1-5

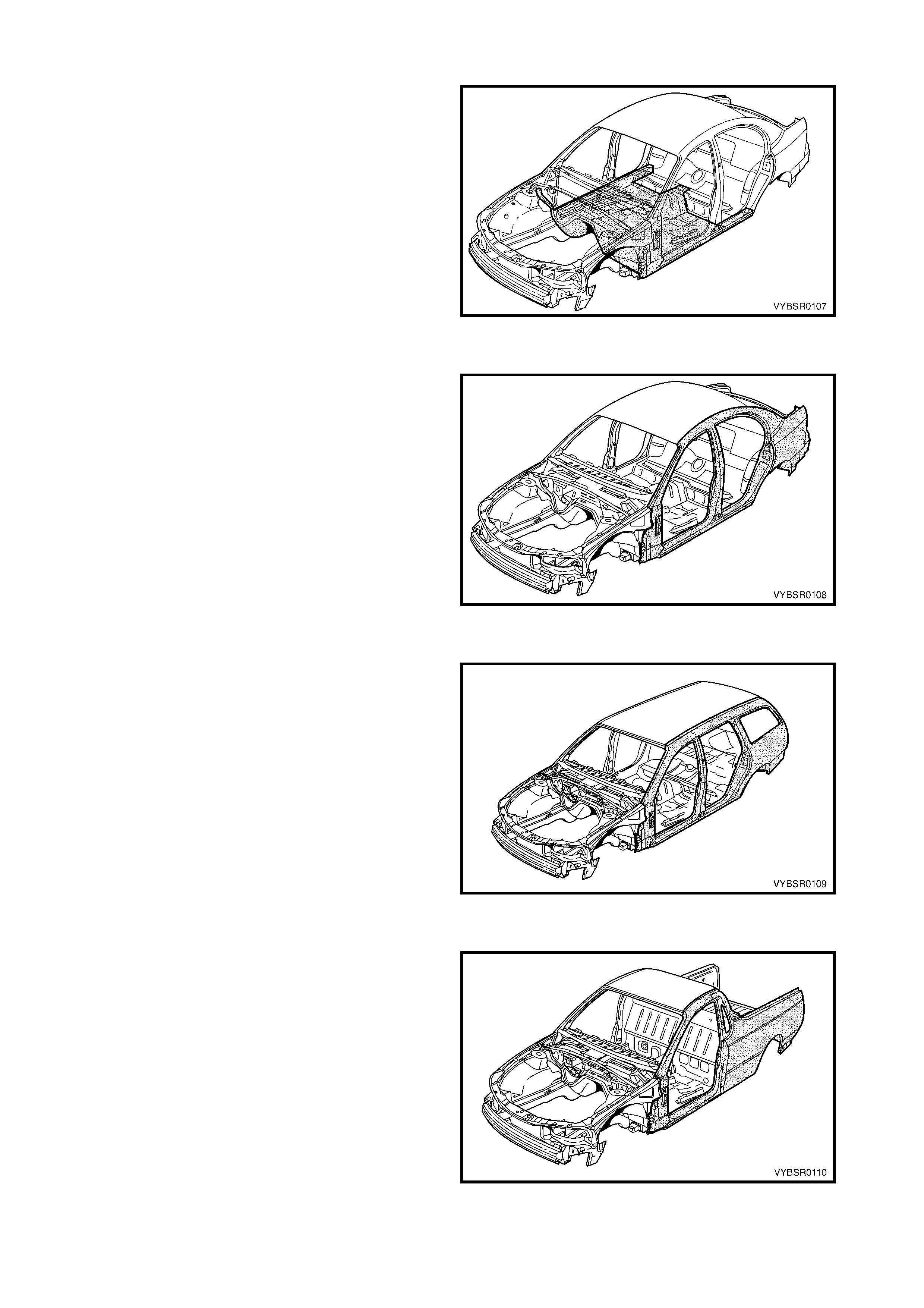

SECTION 4 FRONT END

Description

1. General Description

2. Service Operations

Figure 1-6

SECTION 5 COCKPIT MODULE

Description

1. General Description

Figure 1-7

SECTION 6 CABIN FLOOR & UTILITY SEATBACK ASSEMBLY

Description

1. General Description

2. Service Operations – Cabin Floor

3. Service Operations – Utility Seat Back

Assembly

Figure 1-8

SECTION 7A BODY SIDE – SEDAN

Description

1. General Description

2. Service Operations

Figure 1-9

SECTION 7B BODY SIDE – WAGON

Description

1. General Description

2. Service Operations

Figure 1-10

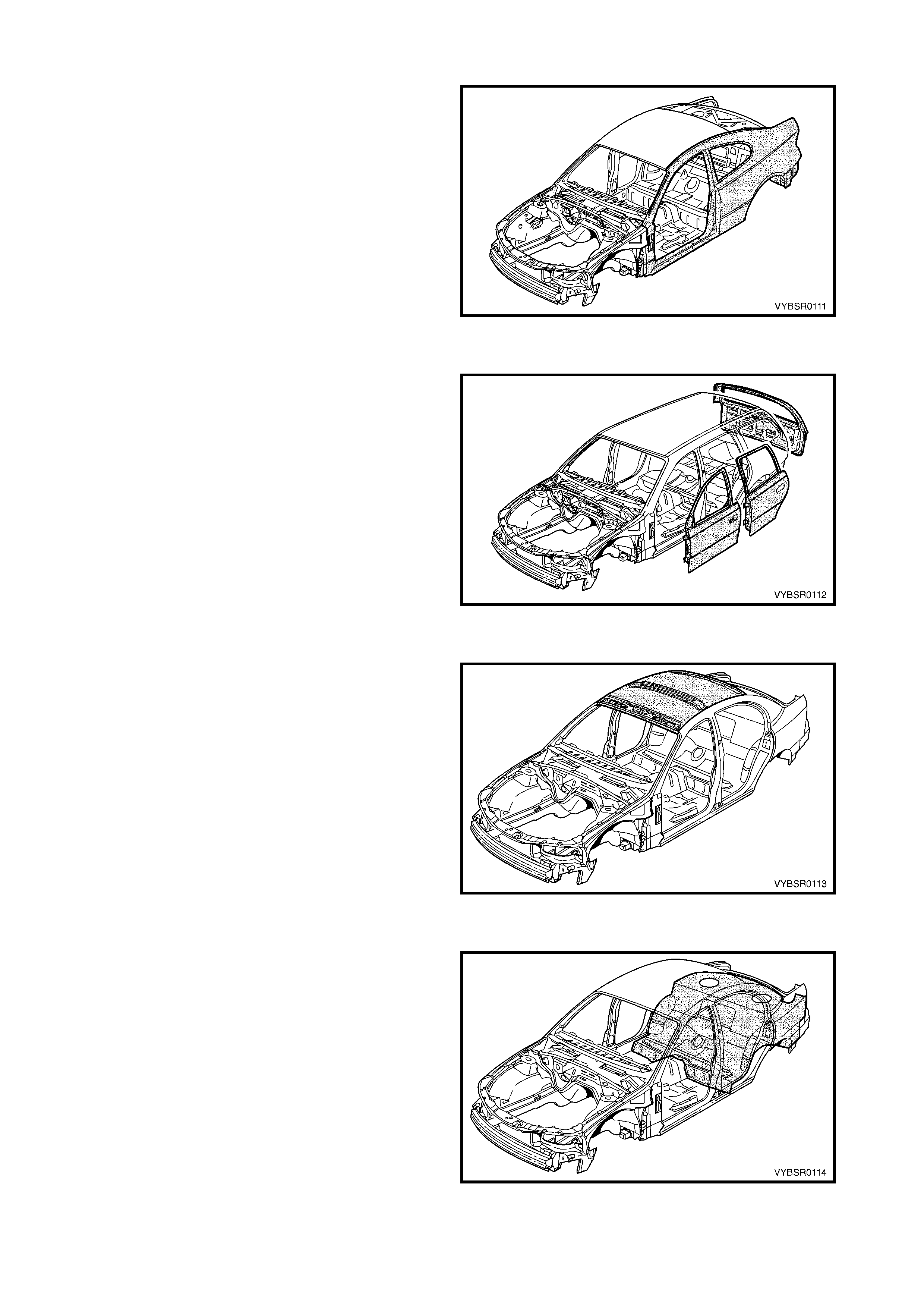

SECTION 7C BODY SIDE – UTILITY

Description

1. General Description

2. Service Operations

Figure 1-11

SECTION 7D BODY SIDE – COUPE

Description

1. General Description

2. Service Operations

Figure 1-12

SECTION 8 DOORS, LIFTGATE & ENDGATE

Description

1. General Description

2. Service Operations

3. Special Tools

Figure 1-13

SECTION 9 ROOF

Description

1. General Description

2. Service Operations

Figure 1-14

SECTION 10A BODY REAR – SEDAN

Description

1. General Description

2. Service Operations

Figure 1-15

3. REPAIR PROCEDURES

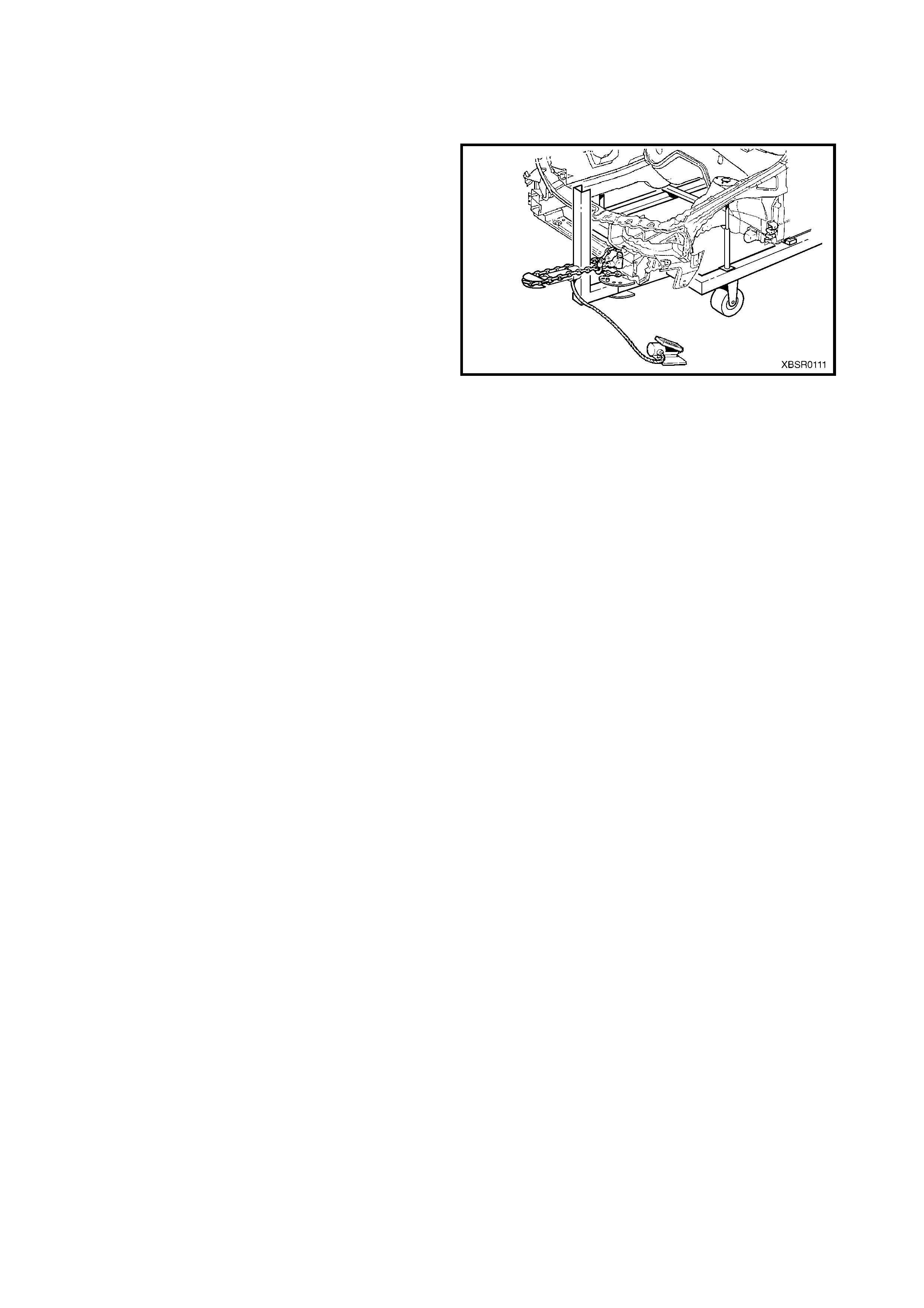

3.1 FRAME S TRAIGHTENING

Fram e st raightening equipm ent should be used initially

to return the vehicle to its approximate shape before

detailed repairs begin. The Equipment should be set

up in such a way as to reverse the direction of impact

that caused the damage. The use of an alignment

bench with either a jigging or measuring system is

prefer red for the r ealignment of VY Series & V2 Series

II vehicles.

CAUTION: Do not allow personnel to stand in the

direction of the pull. Make use of safety chains or

cables to minimise accidents.

Figure 1-19

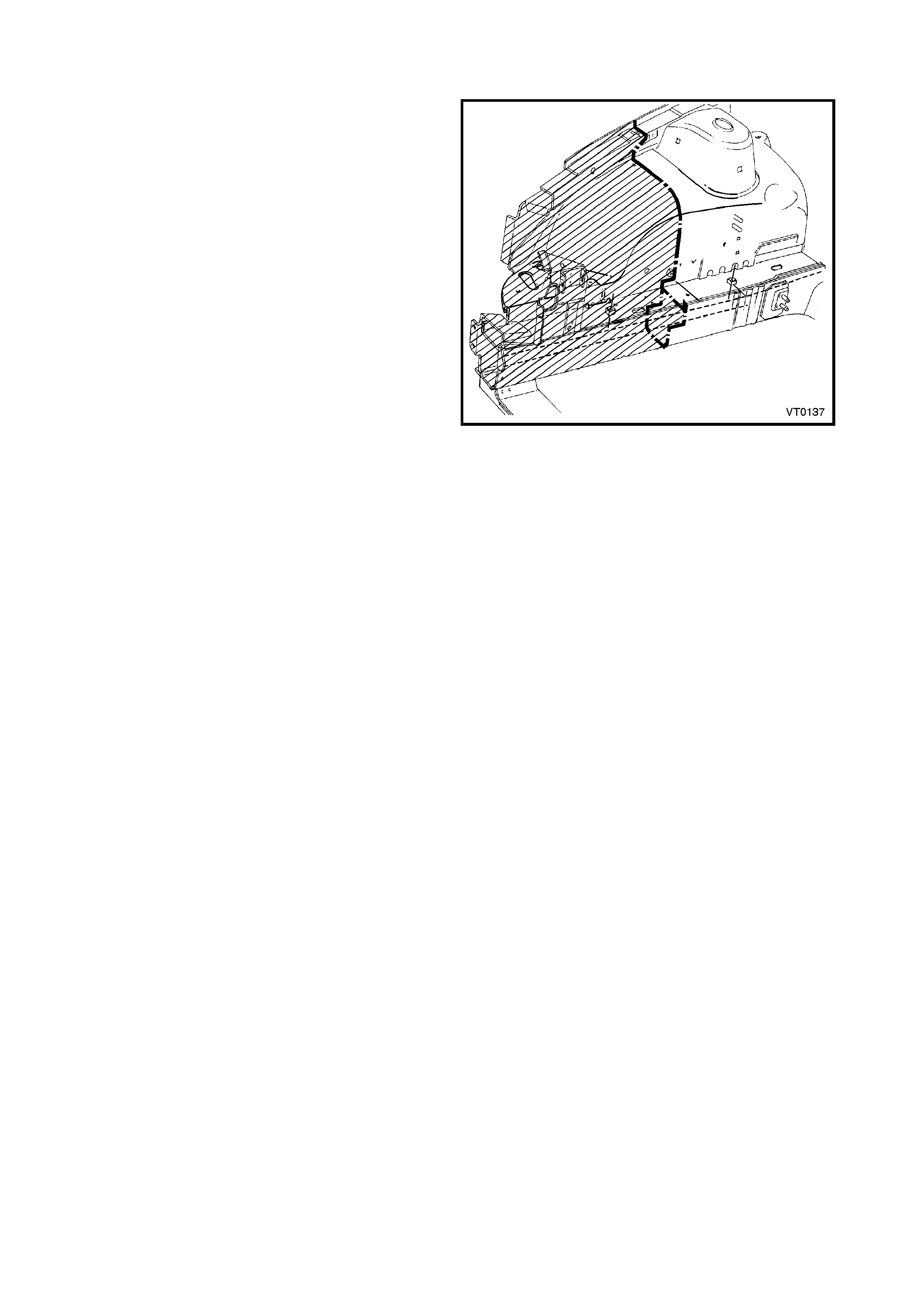

3.2 ROUGH CUTTING

Damaged panels should be rough cut f rom the vehicle

to make it easier to access and remove spot welds.

NOTE 1: Ensure that r einforcem ent panels are not cut

when the outer panels are being rough cut.

NOTE 2: Check for wiring harnesses, hoses, etc.

behind or inside the panels before performing any

cutting operations.

Figure 1-20

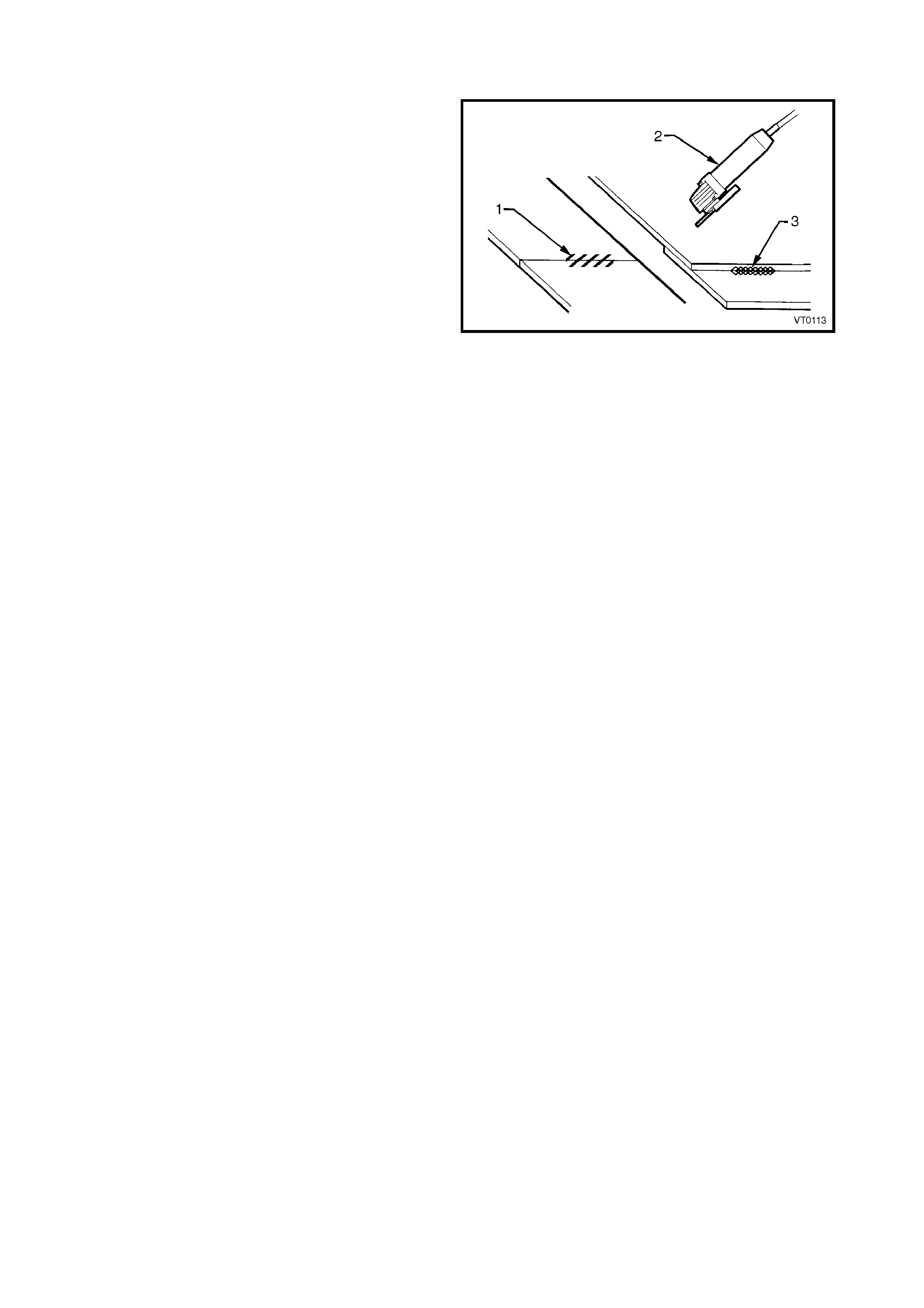

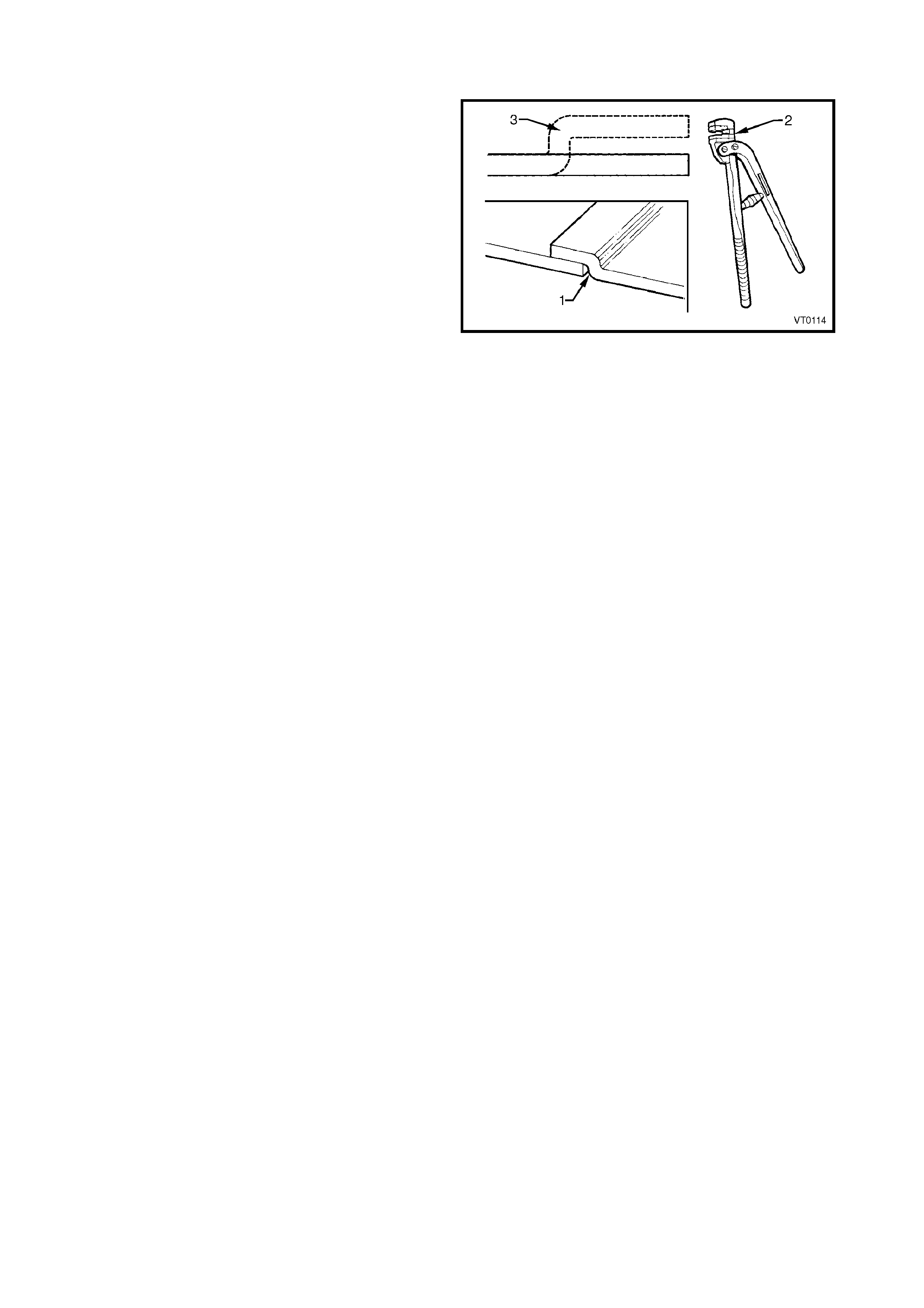

3.3 CUTTING MIG WELDS

MIG welding is used in various places on the body

structure for additional reinforcement and strength.

MIG welds (1) should be cut with a grinder (2) or power

saw. Where practical, a cross sectional view of areas

that may be MIG welded over a tw o panel thickness (3)

is shown.

NOTE 1: Chis elling MIG welds is not recom mended at

any time, as the weld is harder than the surrounding

material, which will tear before the weld is cut.

NOTE 2: Always take care when grinding or cutting,

not to damage either panels adjoining or panels below

the part being removed.

Figure 1-21

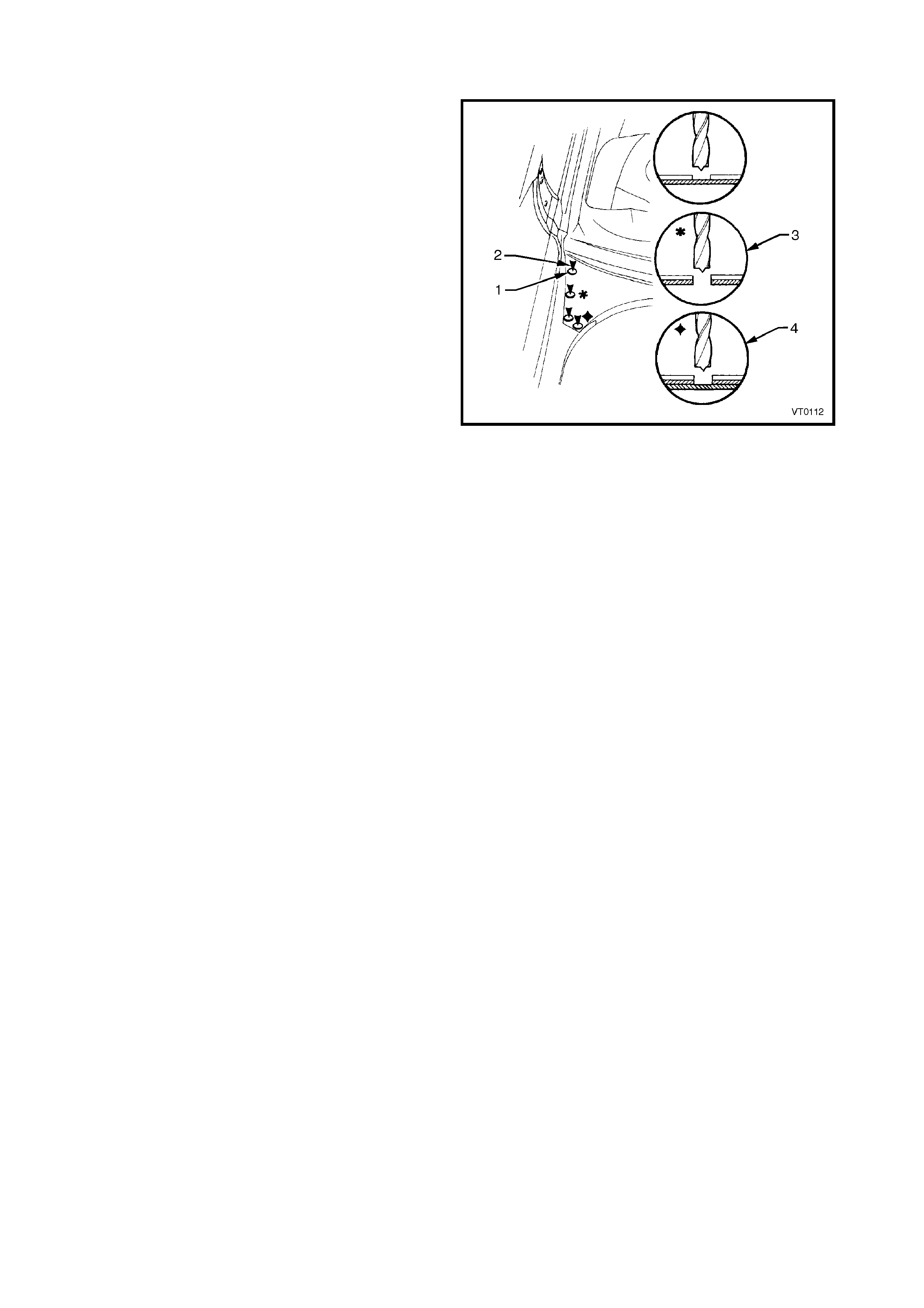

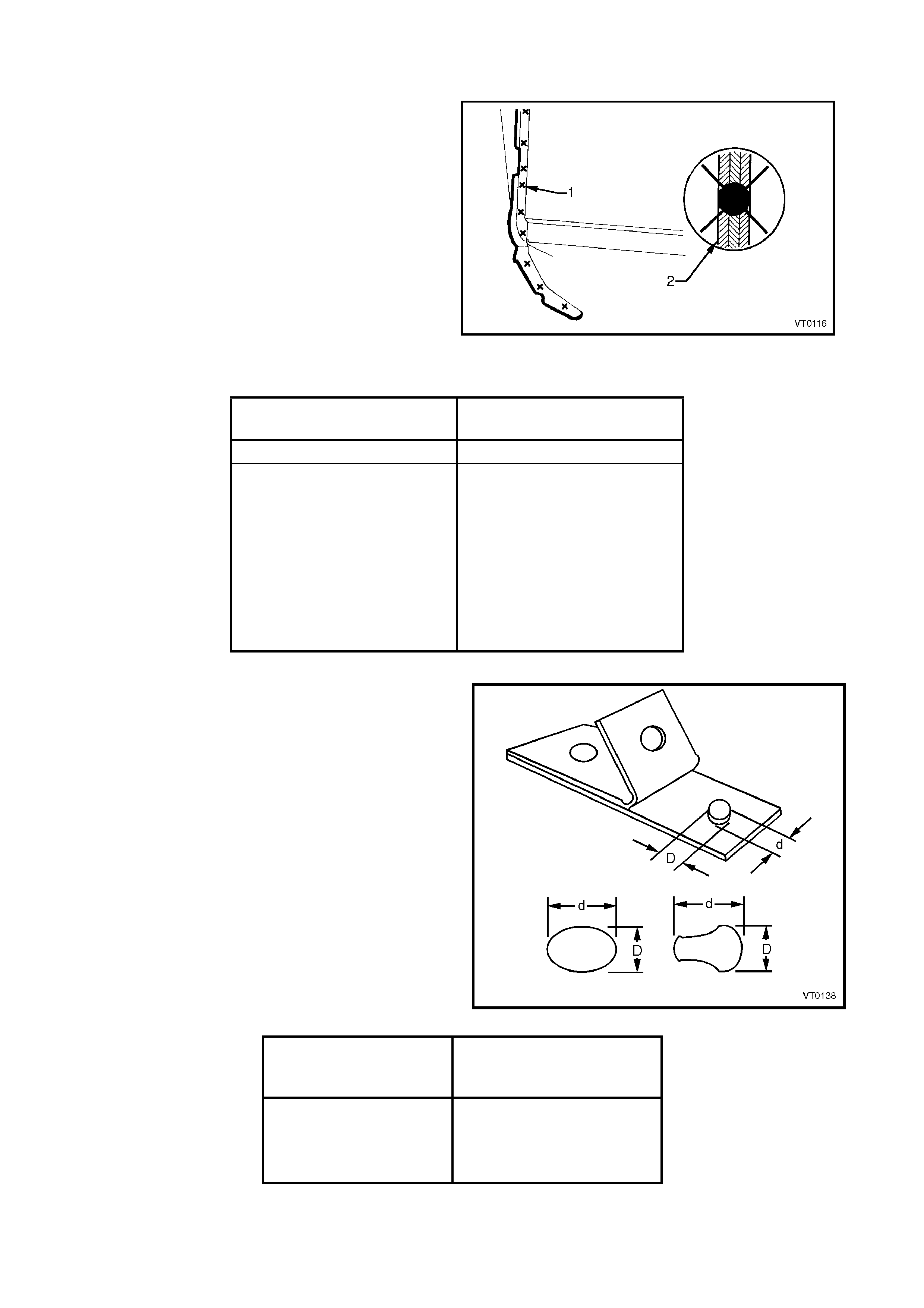

3.4 SPOT WELD CUTTING

Spot welding is the most predominate method of

welding used on the body s tructure. Spot welds should

be cut using a suitable spot cutting tool and a low

speed drill, preferably pneumatic.

Before spot cutting, deeply indent the centre of the

spot weld nuggets using a centre punch and hammer.

It is important to accurately indent the centre of the

spot weld nugget to completely remove the weld.

Referring to Figure 1-22, the symbol for spot cutting is

a circle (1). The arrows in the illustrations (2)

accom panying each oper ation procedure indicate fr om

which side the spot weld should be cut. Do not spot cut

through both panels unless specified to do so (3).

Repair any holes using a MIG welder.

W here it is necessary to spot cut three or m ore joined

panels, an encircled area within the accompanying

illustration will indicate the extent of the spot cut (4).

There will be some incidents where it is necessary to

chisel through spot welds rather than spot cut them.

Use care when ch iselling to avoid distor tion or damage

to the adjacent sheet metal.

Figure 1-22

3.5 LAP JOINTING

A lap j oint ( 1) is the m ethod of forming an over -lapping

seam between two panel sections. This should always

be done with an appropriate tool (2), and care should

be taken to maintain any original curvature of the

panel. It may be necessary the make som e incisions at

the corners to form the joint smoothly.

The joggle (3) is the part of the lap joint being formed

to over lap or under lap the adj acent panel. T he joggle

should always be orientated as specified or illustrated.

NOTE: Lap joints should be used wherever possible

when partially replacing panels because of the

additional strength this method provides.

Figure 1-23

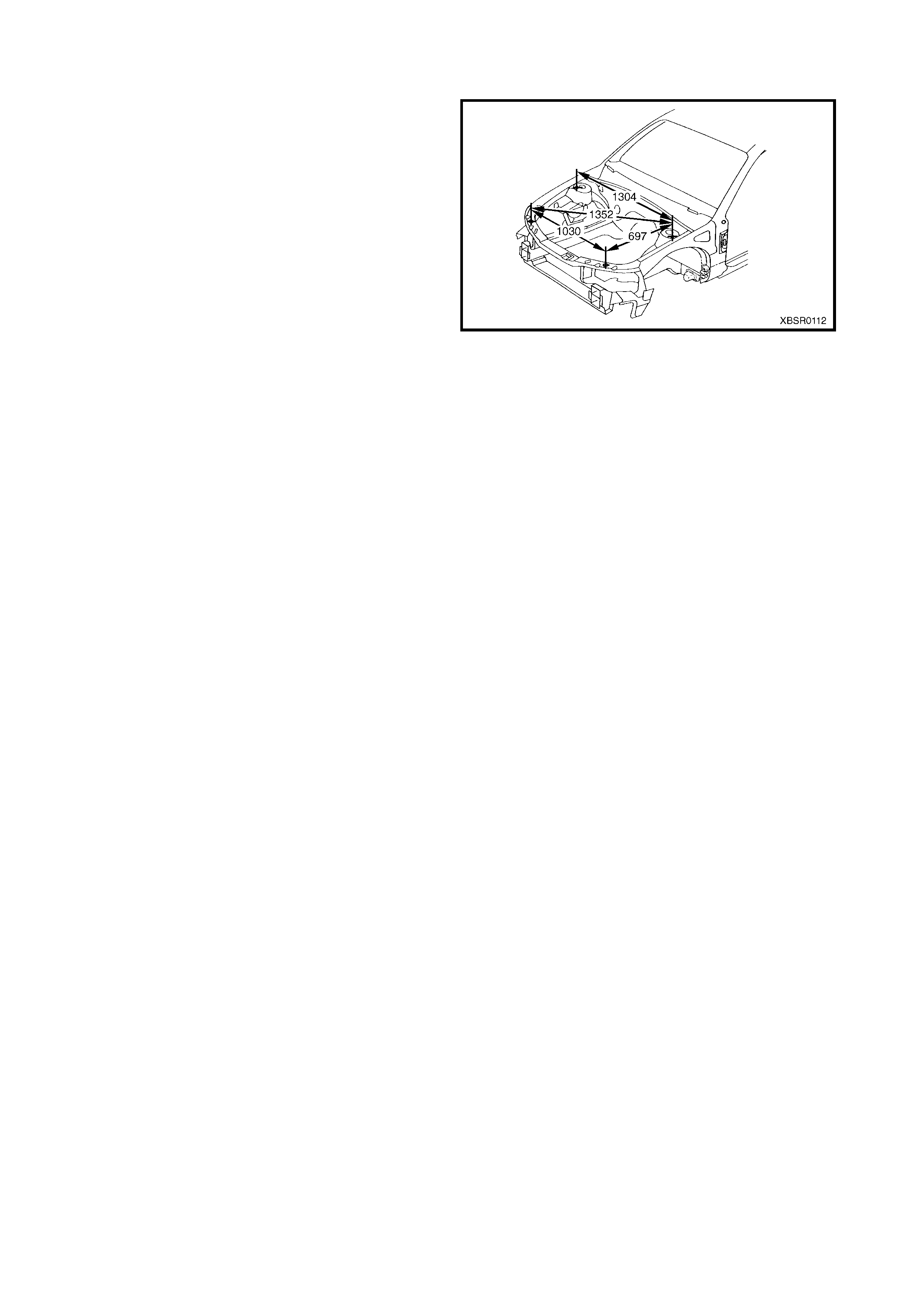

3.6 REPAIRING THE BODY ALIGNMENT

At all times when repairing the vehicle, use a suitable

jigging or measuring system and utilise any tooling

which is either specified or deemed necessary to

maintain the body alignment.

Check the alignment of the body using the charts in

BODY CONSTRUCTION in the following Sections,

3A – Sedan, 3B – Wagon, 3C – Utility or

3D – Coupe. The upperbody dimensions shown are

point to point in a direct line.

The underbody dimensions are projected; the

measuring points are transposed onto a two

dimensional (flat) surface and the measurements are

taken along the one plane.

All dimensions are in millimetres unless otherwise

specified.

NOTE: Always check the body alignment before

welding panels in position.

Figure 1-24

4. WELD REPAIR METHODS

4.1 GENERAL INFORMATION

Spot welding is the preferred method for attaching of panels and should be used whenever possible.

This Supplement indicates where spot welding is practical in repair conditions using portable spot welding

equipment. One repair weld shall be added for each spot weld being repaired, by using either a spot weld or a

plug weld.

Spot welding is not only faster and more efficient than other welding processes, but also causes less rust

formation, reduces the amount of refinishing and causes little distortion to the panel due to heat.

W here the spot welding equipment is not available, or it will not access the required weld position, a plug weld

should be performed. MIG welding should be used for plug welding and also for fusion welding when required.

Gas welding (oxy / acetylene welding) should be avoided as a m ethod of repair. The heat generated in mak ing

the fused joint causes both a decline in the strength of the areas surrounding the welded parts, and also

introduces a high possibility of warping.

CAUTION 1: Always take care when welding. Look behind the parts being welded to avoid additional

damage or poss ible fire.

CAUTION 2: Flammable materials are used in the vehicle, always take care to avoid fire when welding.

Also re fer to 4.5 WELDING LEGEND in this Section.

4.2 SPOT WELDING

Spot W elding (or electric resistance spot welding) is a

method of fusing metal parts together over a small

area.

Two or m ore metal s heets are positioned between two

electrodes (weld tips) where pressure and a large

current are applied. Due to the electrical resistance of

the me tals, a large amount of heat is locally generated

causing the metals to fuse together.

As a guide for weld tip selection and for the

recommended minimum spot weld diameter, the

repairer should refer to Table 1 below. The

recommended minimum spacing between spot welds

is provided in Table 2.

The symbol for spot welding is an " X " (1). Where

multi-ply panels are involved, they will be identified as

shown (2).

Figure 1-25

Governing Metal

Thickness (GMT) Minimum Average Diameter

of Button at Fay ing Plane

mm mm

0.40 – 0.59 3.0

0.60 – 0.79 3.5

0.80 – 1.39 4.0

1.40 – 1.99 4.5

2.00 – 2.49 5.0

2.50 – 2.99 5.5

3.00 – 3.49 6.0

3.50 – 3.99 6.5

4.00 – 4.50 7.0

Table 1

NOTE 1: To determine the minimum weld size for a

two metal st ack, us e the metal thic kness of the thinner

of the two sheets, called the Governing Metal

Thickness (GMT), when referring to Table 1. When

three or more sheets are being welded, the second

thinnest metal thickness in the total stack up will

determine the minimum weld size for each pair of

contacting sheets where fusion is required.

NOTE 2: Nominal sheet thickness is used to

determine GMT.

NOTE 3: Average button (nugget) diameter = (D+d)/2.

NOTE 4: Faying Plane. The mating surface of a sheet

which is in contac t with or in close proxim ity to another

sheet to which it is to be joined.

Figure 1-26

Governing Metal

Thickness

(mm)

Minimum Spot Weld

Spacing Centre to Centre

(mm)

0.7 – 0.9 12.0

1.0 – 1.4 22.0

1.6 25.0

1.8 28.0

Table 2

The efficiency of the spot welding operations during the repair will control the strength and durability of the

finished vehic le. It is recom m ended that the following points be adhered to in or der that a high quality of welding

is achieved.

SPOT WELDER

1. The spot welding machine should be adjusted for

the minimum length of arm appropriate to the

particular weld, so that maximum clamping

pressure is available.

2. The electrode tips should be aligned to be parallel

and on the same axis to maintain maximum

pressure and weld alignment.

3. The correct welding tips should be employed as

per Table 1 on the previous page.

Figure 1-27

PANEL CONDITION

1. The panel surface must be free of paint film, rust, dirt and other contaminates so that current flow will be

sufficient for proper fusion.

2. The m ating surfac es should be prepared suc h that there are no gaps between the surfaces . Current flow is

reduced considerably by poor contact.

3. All mating surfaces must be treated with a weld through primer to prevent corrosion in this inaccessible area.

The correct primer has high conductivity to facilitate the weld. Refer to 5 BODY SEALING, ADHESIVES &

DEADENERS in the following Sections, 3A – Sedan, 3B – Wagon, 3C – Utility or 3D – Coupe.

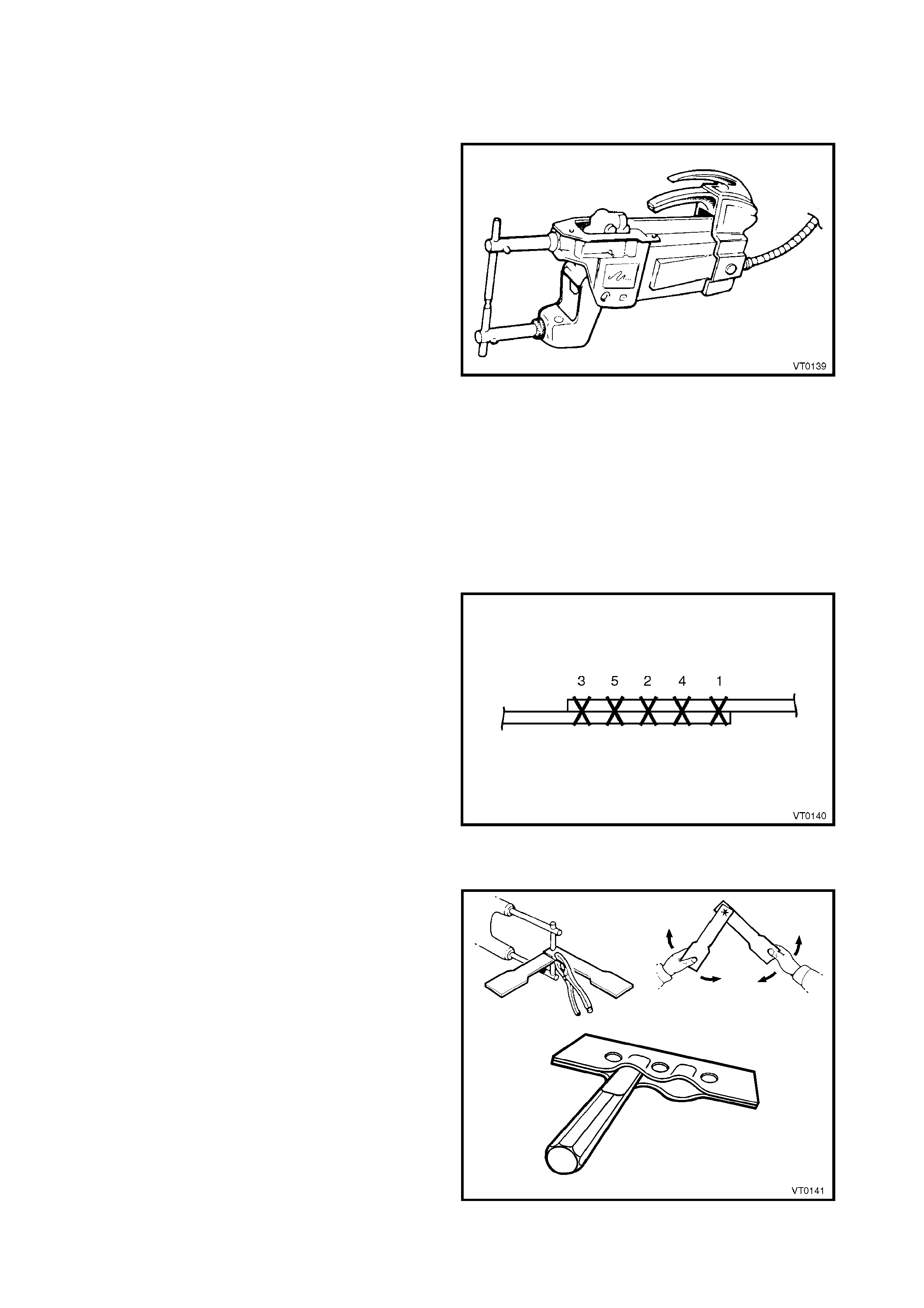

NUMBER OF WELDS

1. The same number and similar position of spot

welds should be used when replacing the panel, as

was used during manufacture. It is important to

maintain the original structural strength of

the vehicle, par ticular ly because of the implications

in deployment of the SRS system. Refer to

Section 2, PRECAUTIONS in this Supplement for

further information on the SRS.

2. The required spot weld diameter is specified in

Table 1, earlier in this Section.

3. Spot welding too closely spaced weakens the

welds due to the shunt effect of the current. Apply

a non-sequential welding procedure.

Figure 1-28

WELD TESTING

1. Prior to welding, two (or more) pieces of same

thickness panel should be test welded, using the

intended weld settings. The weld should then be

destroyed by twisting the pieces. If the settings are

correct, there should be a weld button (nugget)

pulled out of one test piece with the dimensions

recommended. If not, the weld settings must be

adjusted, and the test repeated.

2. Completed weld sections may be tested using a

hammer and chisel (or flat bladed screwdriver).

The testing should cease once the size of the

nuggets can be determined, and the welds should

still be intact.

NOTE: The test section must be returned to the

correct shape after testing.

Figure 1-29

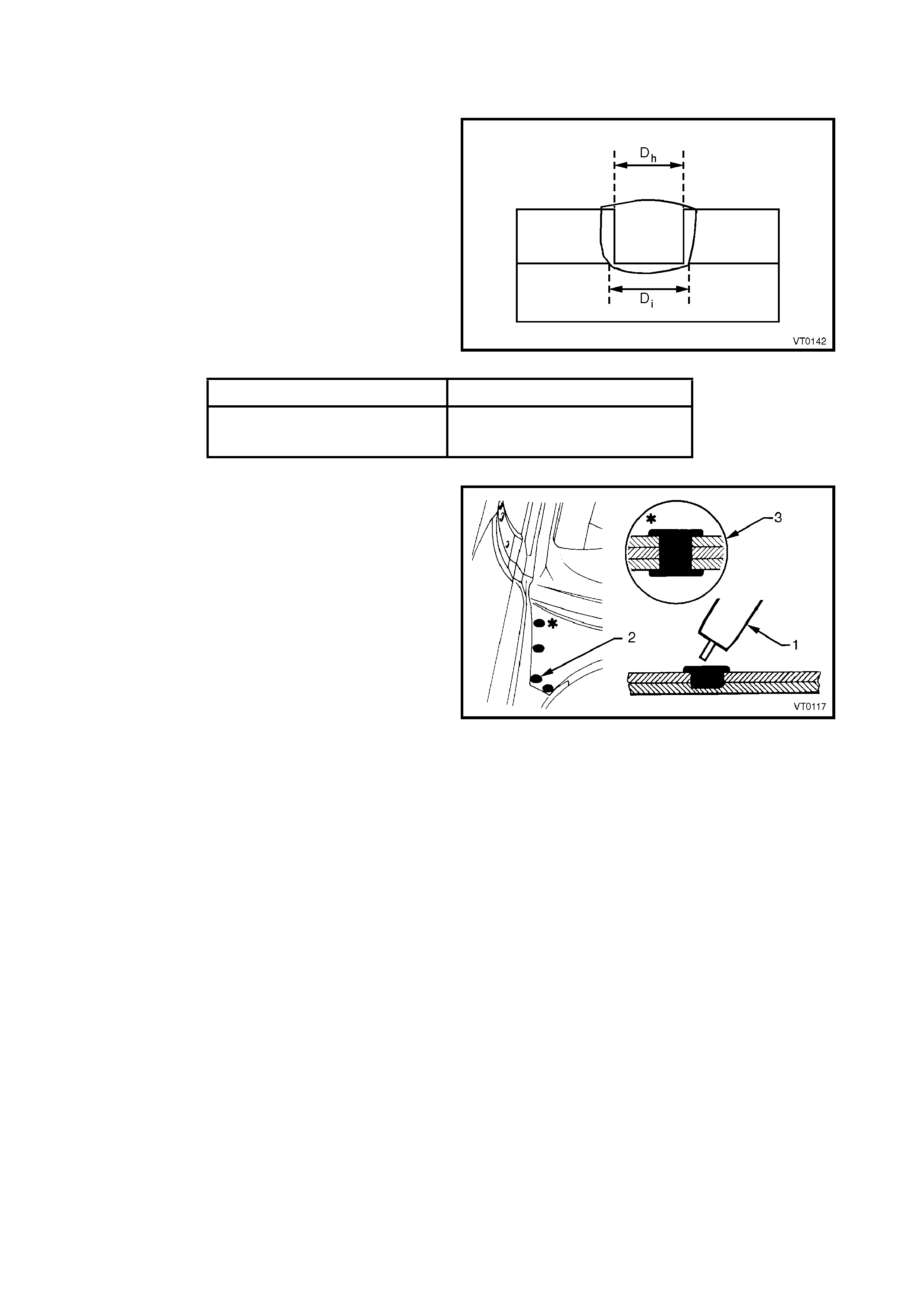

4.3 PLUG WELDING

In this Supplement, plug welding describes a weld

made inside a pre-drilled hole in one panel of a lap

joint, fusing that panel to the other in the joint.

Plug welding should be perf ormed us ing a MIG welder

of suitable capacity. The hole is filled with a puddle of

MIG weld, ensuring penetration into the panel below.

The weld interface diameter, Di must be at least equal

to the hole diameter, Dh. The nominal hole diameters

are given in Table 3.

Figure 1-30

Top Sheet Thickness (mm) Nominal Hole Diameter (mm)

0.40 – 1.0 6.0

1.0 – 2.0 8.0

Table 3

For plug welds with a top sheet thickness less than

2 mm, the welds shall be at leas t filled to the surface at

the hole circumference. For a thickness greater than

2 mm , all plug welds shall be filled to at least 2 m m or

90% of the top sheet thick ness ( whichever is larger) at

the hole circumference, unless otherwise specified.

Plug welding is best performed with a MIG welder (1)

of sufficient capacity. The required holes, as

recom m ended in Table 3, ar e drilled in the appropriate

panel which is secured in position using clamps.

The weld setting and wire gauge are at the discretion

of the operator, and theref ore only qualif ied individuals

should perform welding tasks during repairs.

The symbol for plug welding is a solid black dot (2) and

the plug welding of m ulti-ply panels will be identified as

shown (3).

Figure 1-31

4.4 FUSION WELDING

Fusion welding is a welding method in which the

metals to be joined are raised to a molten state and

fused together. Molten filler metal may also be

deposited at the point of welding to fuse with the base

metal/s.

Fusion welding repairs should be performed using a

MIG welder. Both butt and lap joint methods are

utilised, as specified in the repair procedures.

CAUTION: Always take care when welding. Look

behind the parts being welded to avoid additional

damage or possible fire. Use an assistant for this

purpose if required.

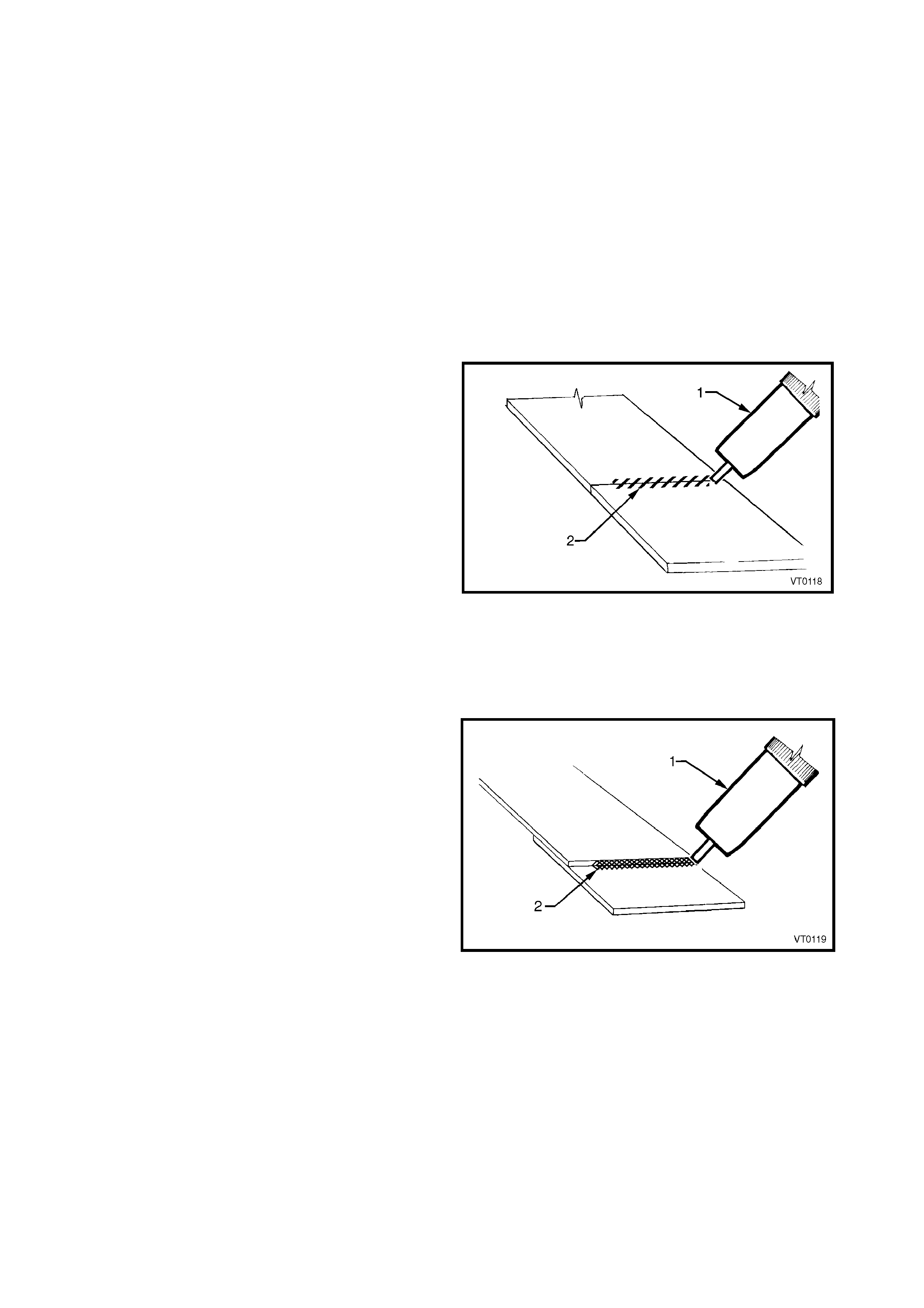

BUTT WELDED JOINTS

Joining two panels together on the same plane is butt

welding. There should be no gaps between the

adjoining edges, so that a strong weld is obtained.

A MIG welder (1) should be used for butt welding, as it

provides localis ed heat in c omparis on to other f orms of

welding (especially in com paris on to gas welding). T h is

localisation of heat significantly reduces panel

deformation.

An industrial MIG welder of suffic ient capacity m ust be

used in order to obtain the correct weld penetration

and maintain the strength and integrity of the structure.

The weld settings and the wire gauge are at the

discretion of the operator and therefore only qualified

individuals should perform the welding tasks on

repairs.

The s ymbol used in this Supplem ent f or butt welding is

shown (2).

Figure 1-32

LAP WELDED JOINTS

Where panels overlap or are placed together with flat

surfaces mating, fillet welding should be used to form

this lap joint. It is important that the gap between the

surfaces is minimal, to ensure a satisfactory result.

For the same reasons as outlined previously, a MIG

welder (1) of suitable capacity should be used for lap

welded joints.

The symbol for fillet welding is shown (2).

Figure 1-33

BRONZE WELDS

Bronze welding is used to complete the lock pillar

join of the rear quarter panel to the door opening

frame assembly on Coupe vehicles, refer to

Section 7D BODY SIDE – COUPE.

Other than for the aforementioned, bronze welding

should not be us ed in vehicle repair procedures as it is

not considered strong enough for the welding of body

sections or panels.

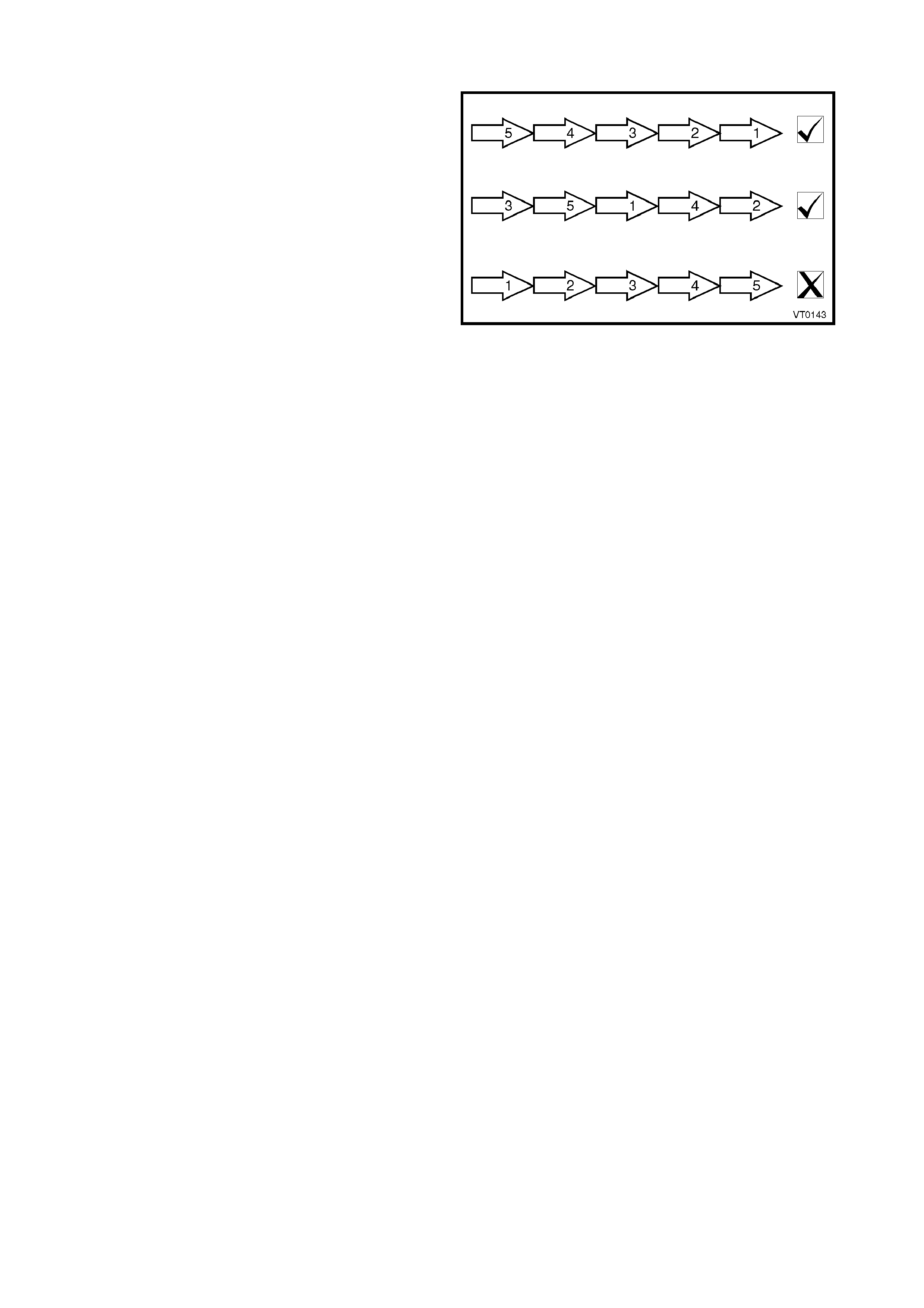

WARP PREVENTION ON LONG WELDS

A long continuous weld is likely to cause warping and

residual stresses. Various weld sequences can be

utilised to minimise this effect when long sections of

weld are required.

Figure 1-34

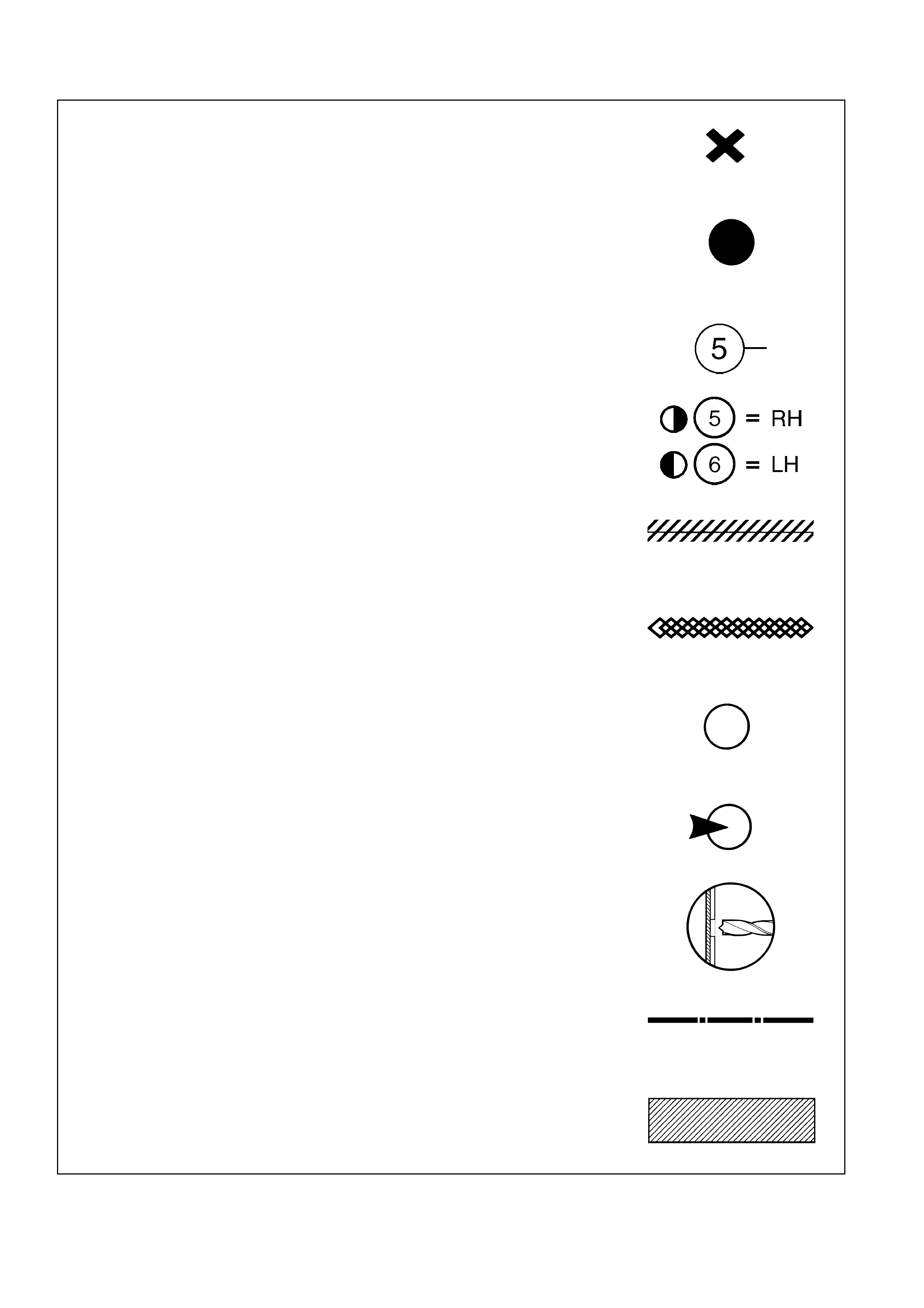

4.5 WELDING LEGEND

SPOT WELDING...............................................................................................

PLUG WELDING ..............................................................................................

NUMBER OF WELDS ......................................................................................

NUMBER OF WELDS (OR DRILLS) ON EACH SIDE OF VEHICLE..............

BUTT WELDING...............................................................................................

FILLET WELDING............................................................................................

SPOT WELD TO BE CUT ................................................................................

SPOT CUT FROM THIS SIDE..........................................................................

SPOT CUT TO THE DEPTH INDICATED........................................................

CUT THE PANEL ALONG THE LINE SHOWN ...............................................

DISCARD THIS PORTION ...............................................................................