SECTION 7C – BODY SIDE – UTILITY

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to

Section 00 CAUTIONS AND NOTES and Section 2 PRECAUTIONS in this Supplement for correct

workshop practices with regard to safety and/or property damage.

CAUTION

The Structure of the M Y 2003 VY & V2 Series II body shell has been developed using complex design

and development techniques. In addition to meeting all required standards, the v ehicle body is also a

critical part of the overall safety systems. It is therefore imperative the repair procedures described

here are adhered to during all vehicle body repairs.

1. GENERAL DESCRIPTION

1.1 BODY SIDE COMPONENTS

2. SERVICE OPERATIONS

2.1 REAR QUARTER PANEL – REPLACE

REMOVE

REPLACE

2.2 QUARTER PANEL EXTENSION –

REPLACE

REMOVE

REPLACE

2.3 QUARTER INNER LOWER REAR

EXTENSION – REPLACE

REMOVE

REPLACE

2.4 QUARTER OUTER LOWER REAR PANEL –

REPLACE

REMOVE

REPLACE

2.5 QUARTER LOWER REAR PANEL –

REPLACE

REMOVE

REPLACE

2.6 DOOR OPENING FRAME ASSEMBLY –

REPLACE

REMOVE

REPLACE

2.7 DOOR OPENING FRAME ASSEMBLY –

PARTIAL REPLACE, HINGE PILLAR

REMOVE

REPLACE

2.8 DOOR OPENING FRAME ASSEMBLY –

PARTIAL REPLACE, CENTRE PILLAR

REMOVE

REPLACE

2.9 DOOR OPENING FRAME ASSEMBLY –

PARTIAL REPLACE, ROCKER PANEL

REMOVE

REPLACE

2.10 FENDER LOWER REAR BRACKET –

REPLACE

2.11 HINGE PILLAR INNER PANEL ASSEMBLY –

REPLACE

REMOVE

REPLACE

2.12 QUARTER INNER & REAR WHEELHOUSE

BRACE – REPLACE

REMOVE

REPLACE

2.13 QUARTER PANEL INNER ASSEMBLY –

REPLACE

REMOVE

REPLACE

2.14 SIDE INNER UPPER PANEL – REPLACE

REMOVE

REPLACE

2.15 SIDE INNER UPPER PANEL – PARTIAL

REPLACE

REMOVE

REPLACE

2.16 SIDE INNER UPPER FRONT PANEL –

REPLACE

REMOVE

REPLACE

2.17 LOAD FLOOR PANEL OUTER EXTENSION

& LOAD FLOOR PANEL OUTER

REINFORCEMENT – REPLACE

REMOVE

REPLACE

2.18 REAR WHEELHOUSE INNER PANEL –

REPLACE

REMOVE

REPLACE

1. GENERAL DESCRI PTI O N

This Section des cribes the replacem ent proc edures for the body side com ponents of the MY 2003 VY Series Utility

body structure. Removal of bolt-on panels and mechanical components is not covered.

When repairing the body side of the vehicle, care must be taken to ensure the structure is returned to its original

production configuration. This is especially important to maintain side impact standards.

This Section includes door opening f ram e ass em bly partial replacem ent procedur es f or the hinge pillar, c entre pillar

and rocker panel. These procedures must be followed carefully, as they can involve hidden reinforcement panels.

The cutting locations specified are the only places allowable.

NOTE: It is imperative that the correct body adhesives, sealers, deadeners and cavity waxes are used when

repairing the body structure of MY 2003 VY Series Utility vehicles. Refer to 5. BODY SEALING, ADHESIVES &

DEADENERS and 6. CAVITY WAX in Section 3C for details of the correct materials and their commercially

available equivalents.

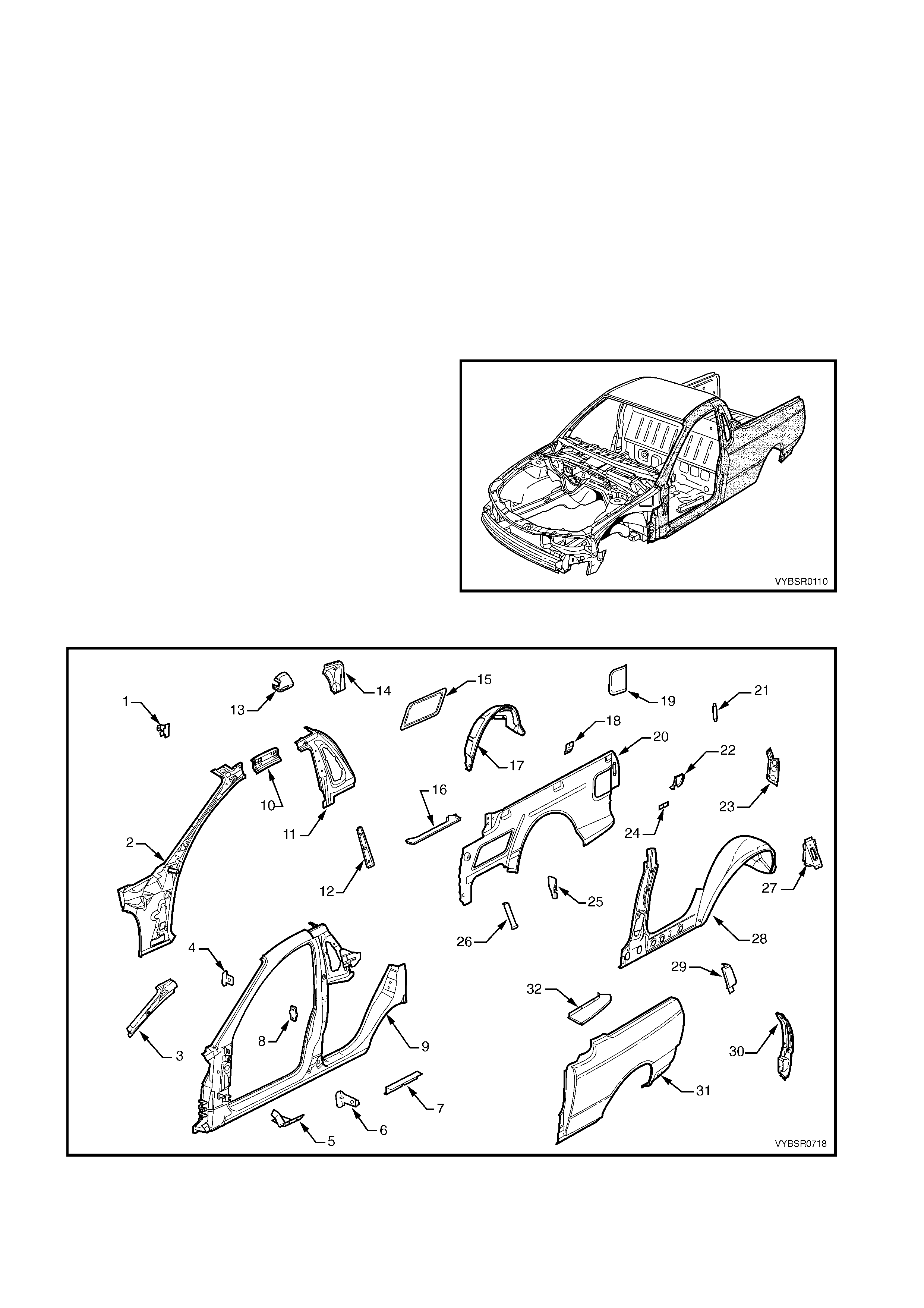

1.1 BODY SIDE COMPONENTS

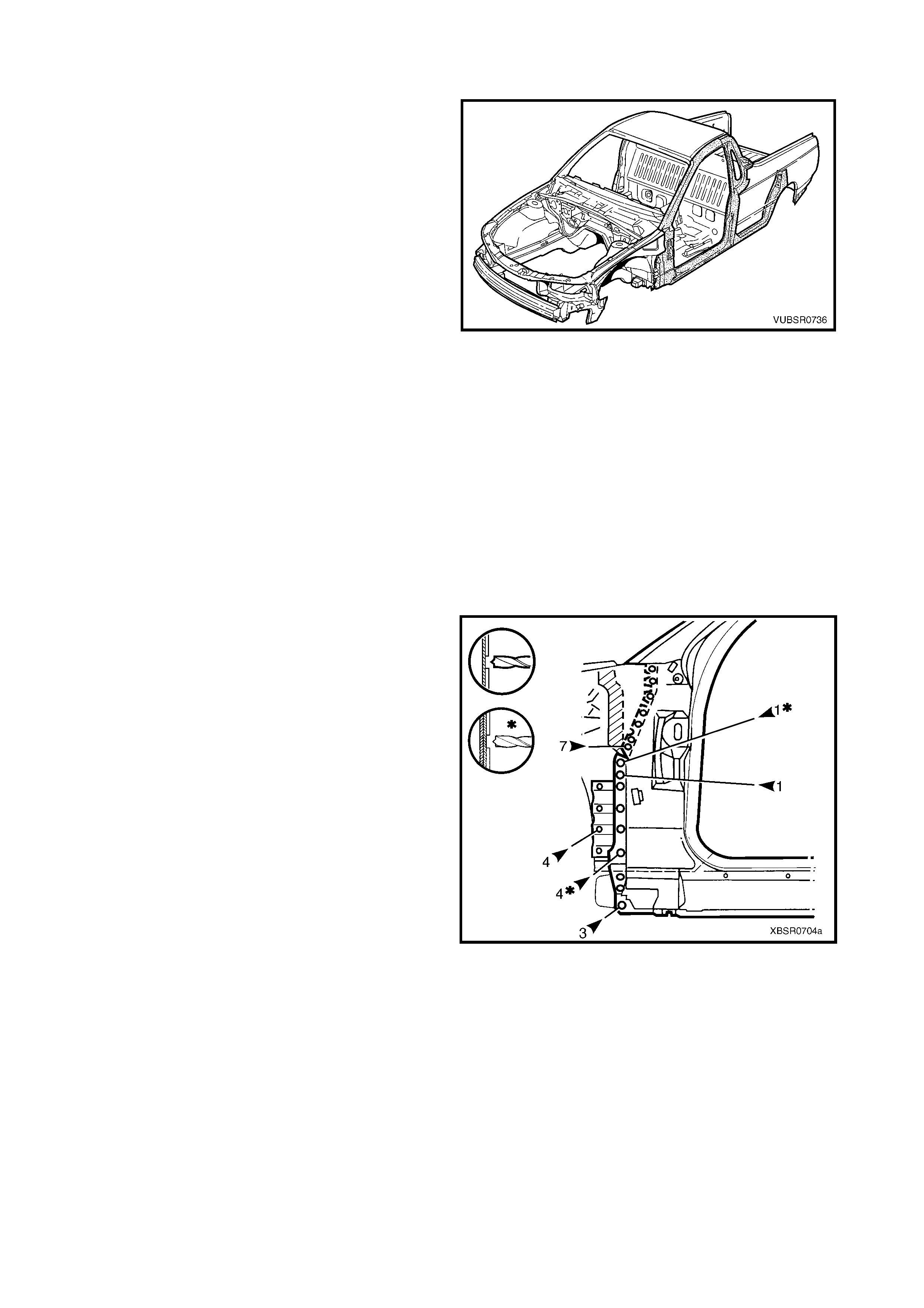

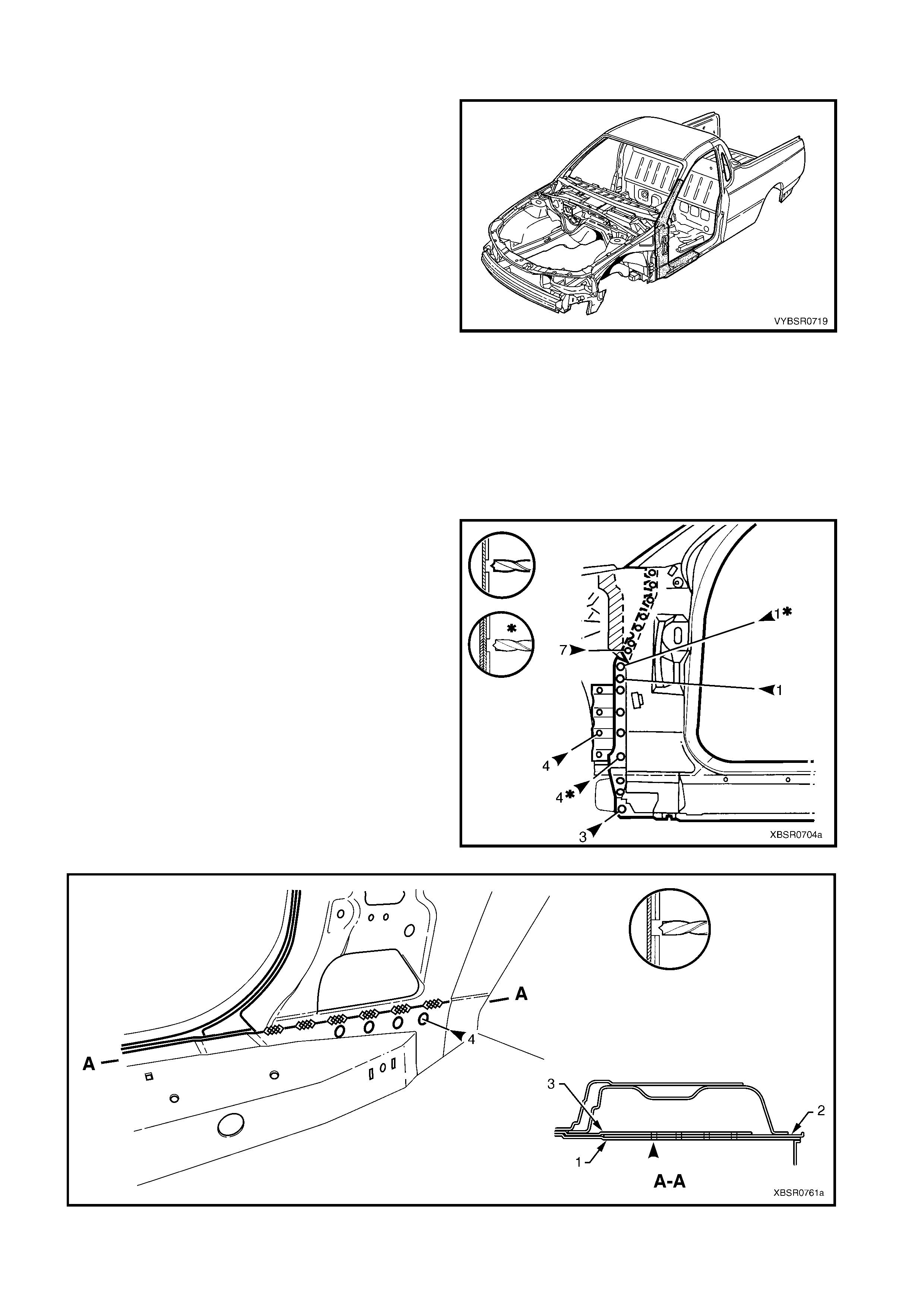

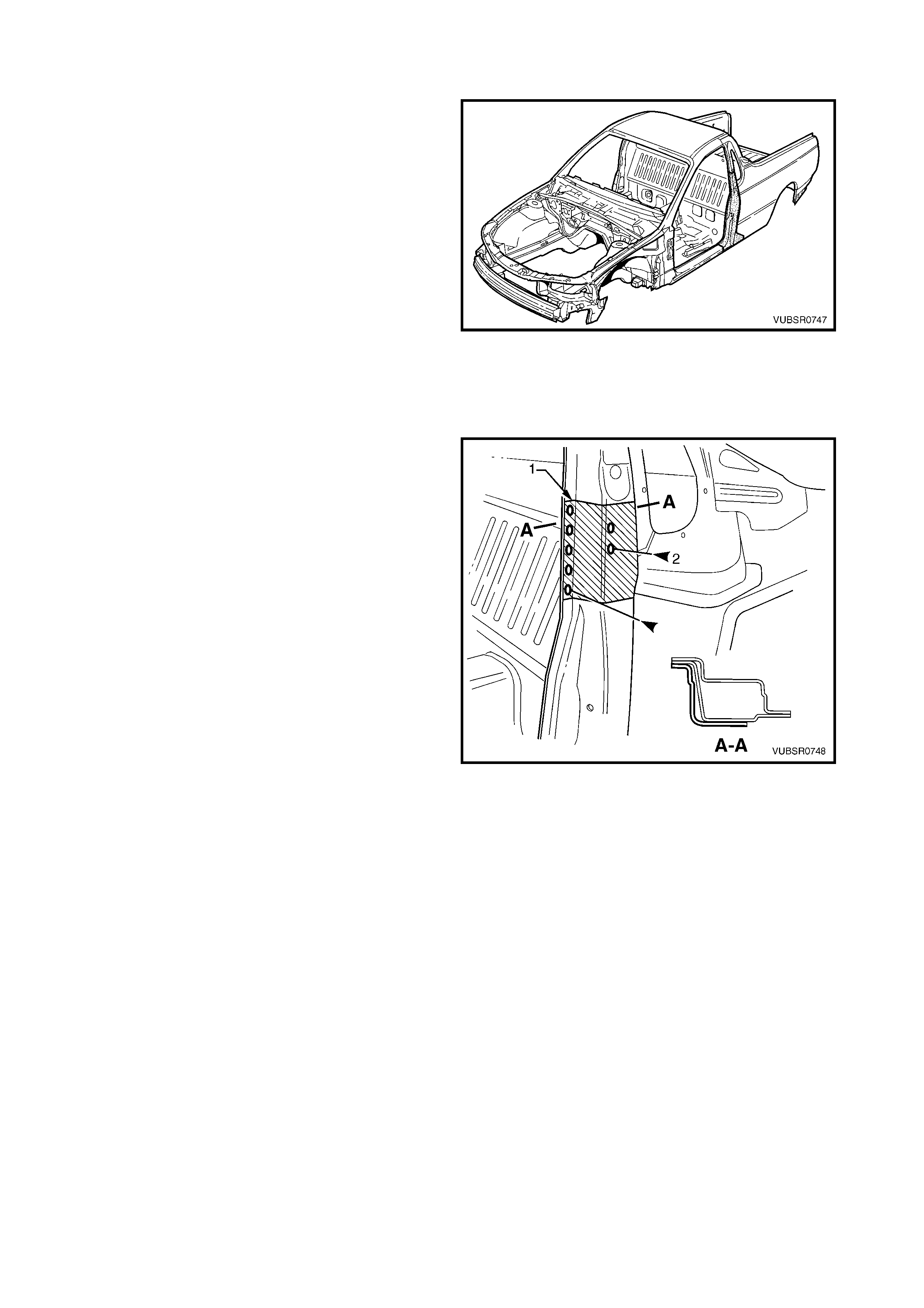

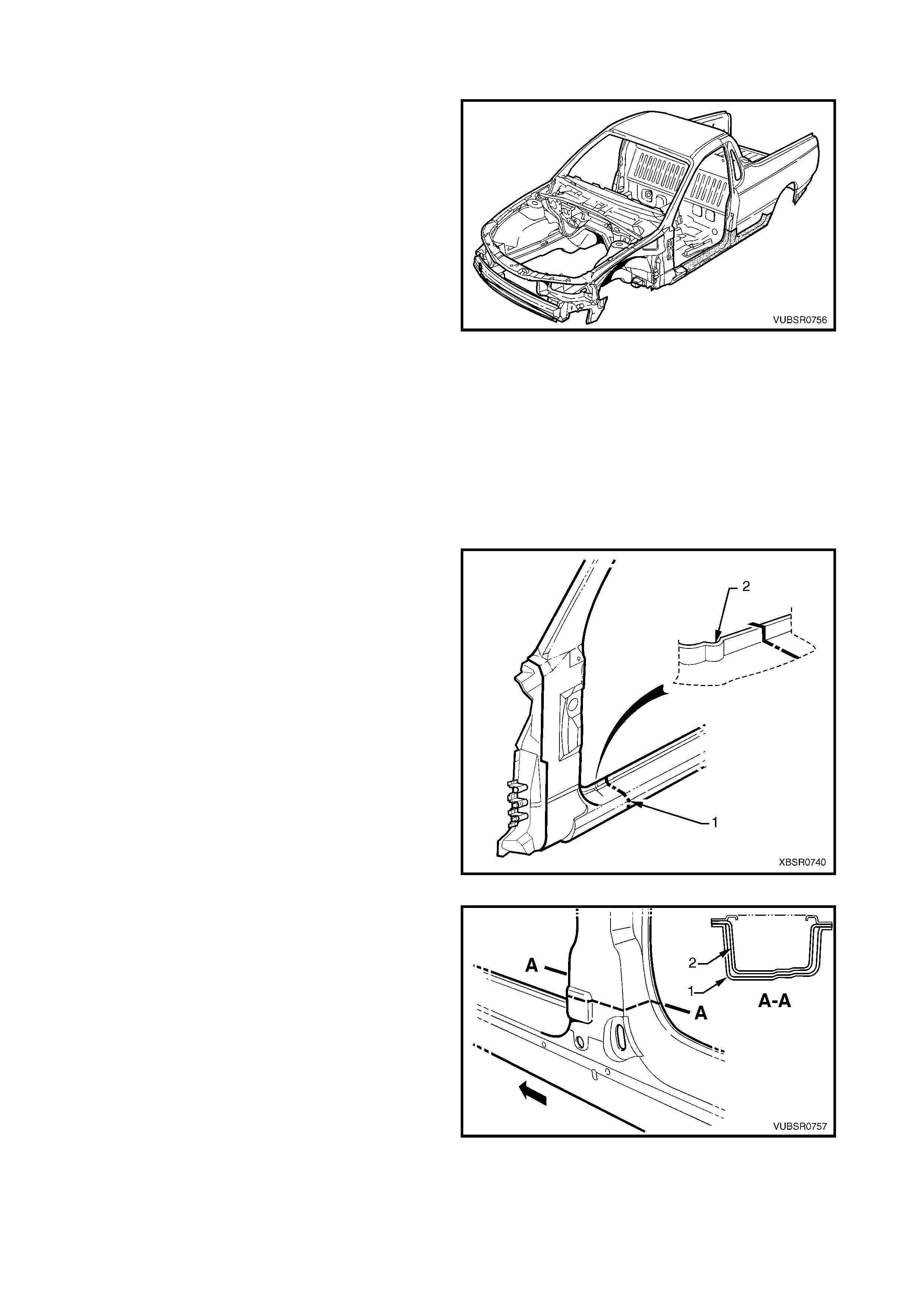

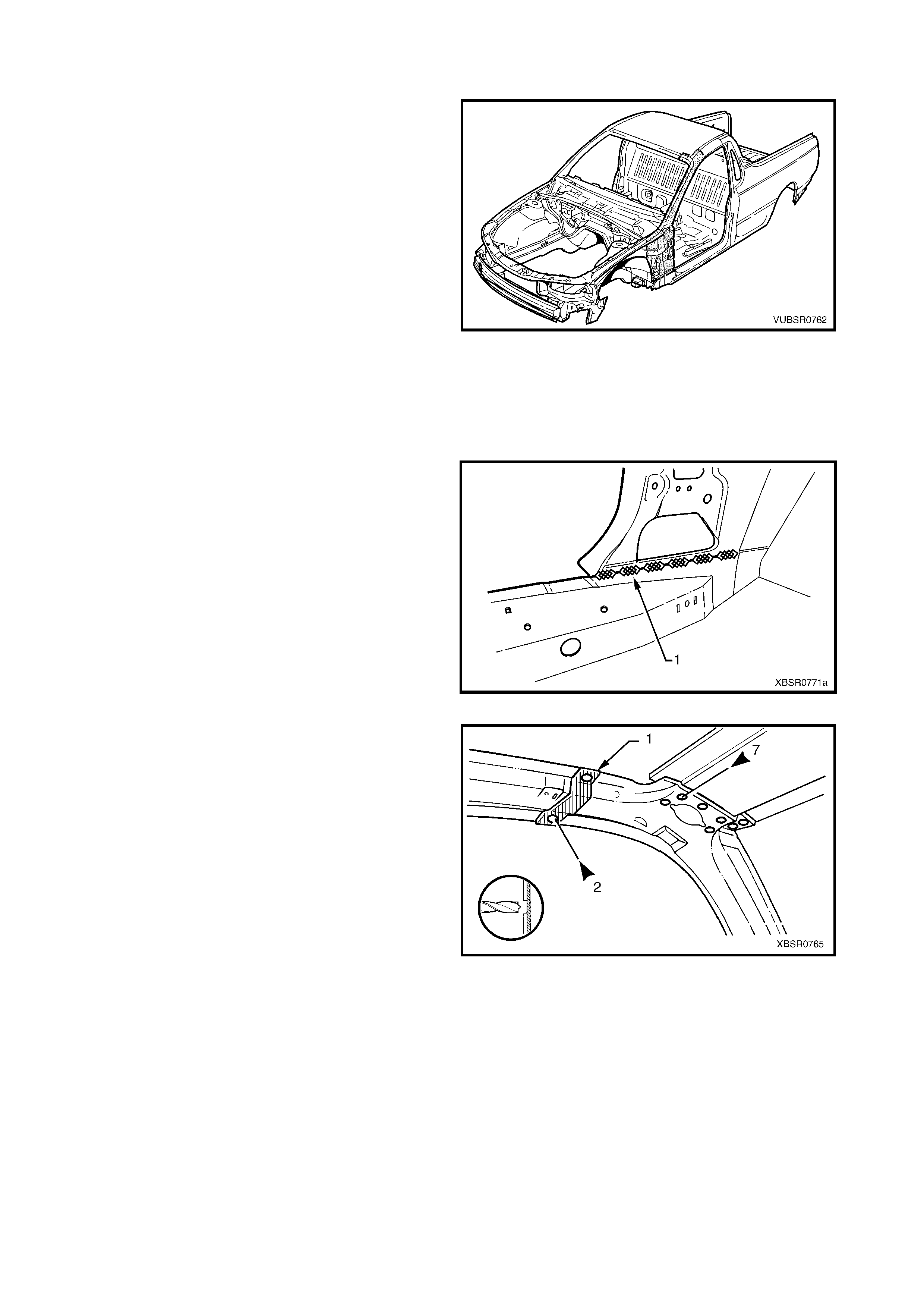

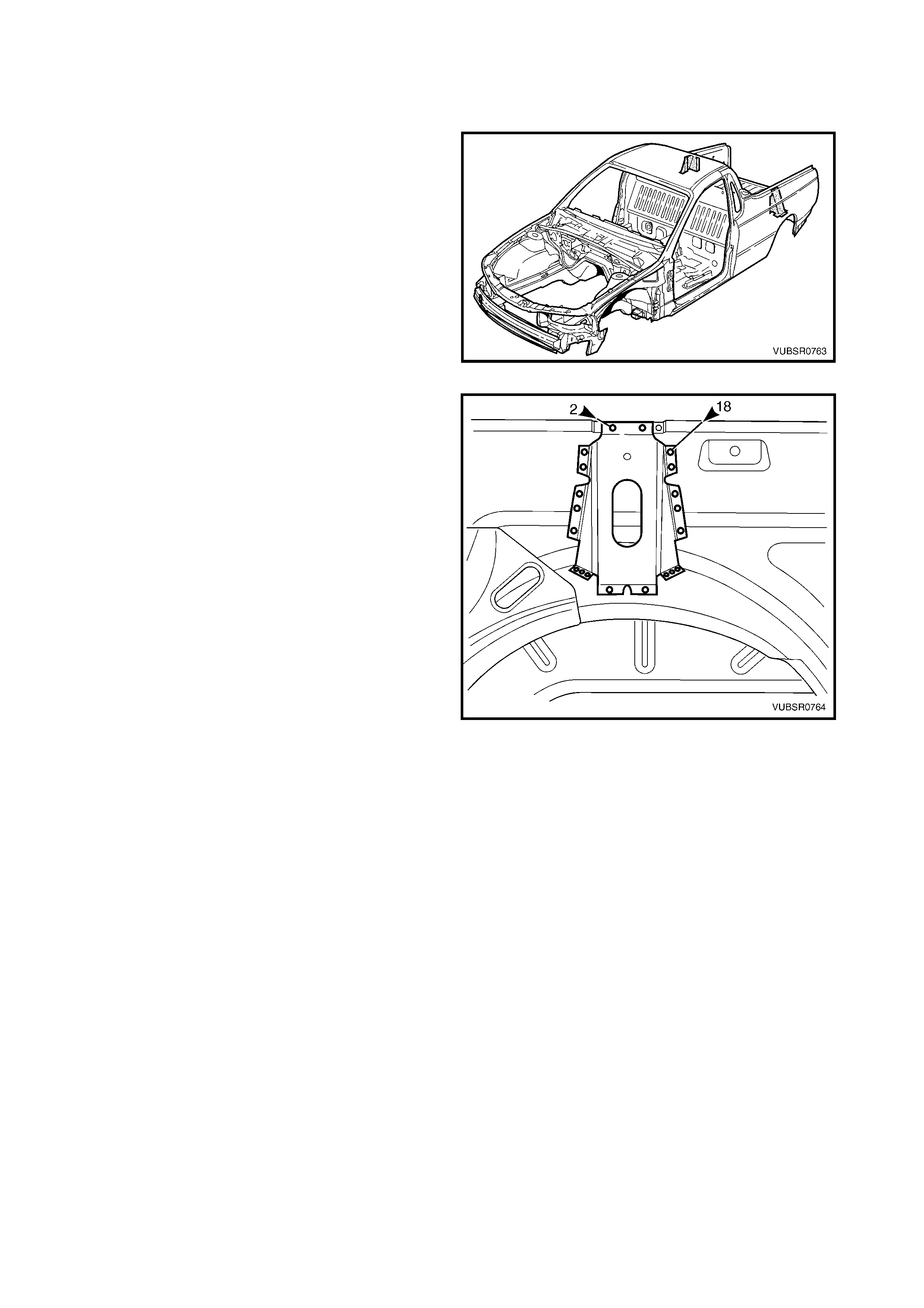

The shaded components in Figure 7C-1 are those

dealt with in this Section.

The components and assemblies shown in Figure 7C-

2 are the parts serviced for MY 2003 VY Series Utility

vehicles which form the basis of the repair procedures

in this Section. For a detailed view of the body

components, refer to Section 3C BODY

CONSTRUCTION - UTILITY.

NOTE: Always refer to your Authorised Retailer for

spare parts availability configurations.

IMPORTANT: Cavity foam may be used within

the hinge, and centre pillars. Care needs to be taken

when repairing the vehicle in these areas, refer to

Section 2, 10. CAVITY FOAM prior to beginning any

work for further information. Figure 7C-1

Figure 7C-2

Legend

1. Hinge Pillar Trim Panel Bracket

2. Hinge Pillar Inner Panel Assembly

3. Hinge Pillar Upper Reinforcement

4. Fender Upper Rear Bracket

5. Fender Lower Rear Bracket

6. Fender Rear Bracket

7. Underbody Jacking Locator

8. Front Door Striker Anchor Plate

9. Door Opening Frame Assembly

10. Quarter Panel Inner Extension

11. Side Inner Upper Front Panel

12. Seatbelt Guide Anchor Plate Assembly

13. Fuel Filler Pipe Housing

14. Rear Wheelhouse Outer Extension

15. Front Inner Side Panel Cover

16. Load Floor Panel Outer Extension

17. Rear Wheelhouse Inner Panel

18. Cargo Tie-down Bracket

19. Rear Inner Side Panel Cover

20. Side Inner Upper Panel

21. Endgate Striker Anchor Plate Retainer

22. Quarter Lower Rear Panel

23. Quarter Inner Lower Rear Extension

24. Cargo Tie-down Bracket Anchor Plate Assembly

25. Rear Wheelhouse Bracket

26. Load Floor Panel Outer Reinforcement

27. Quarter Inner & Rear Wheelhouse Brace

28. Quarter Panel Inner Assembly

29. Quarter Panel Upper Extension

30. Quarter Panel Extension

31. Rear Quarter Panel

32. Quarter Outer Lower Rear Panel

NOTE: The door opening frame assembly includes parts 3, 4, 5, 6, 7 and 8.

2. SERVICE OPERATIONS

2.1 REAR QUARTER P ANEL – REPLACE

NOTE: The rear body wiring harness is routed behind

the right-hand quarter panel; take care not to damage

or burn the harness.

CAUTION: The fuel tank is located under the rear

floor - front. To av oid the possibility of fire, remove

the fuel tank and plug all lines when grinding,

cutting or welding.

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Remove the rear and quarter windows, refer to

Section 1A6 STATIONARY WINDOWS in the

MY 2003 VY & V2 Series II Service Information.

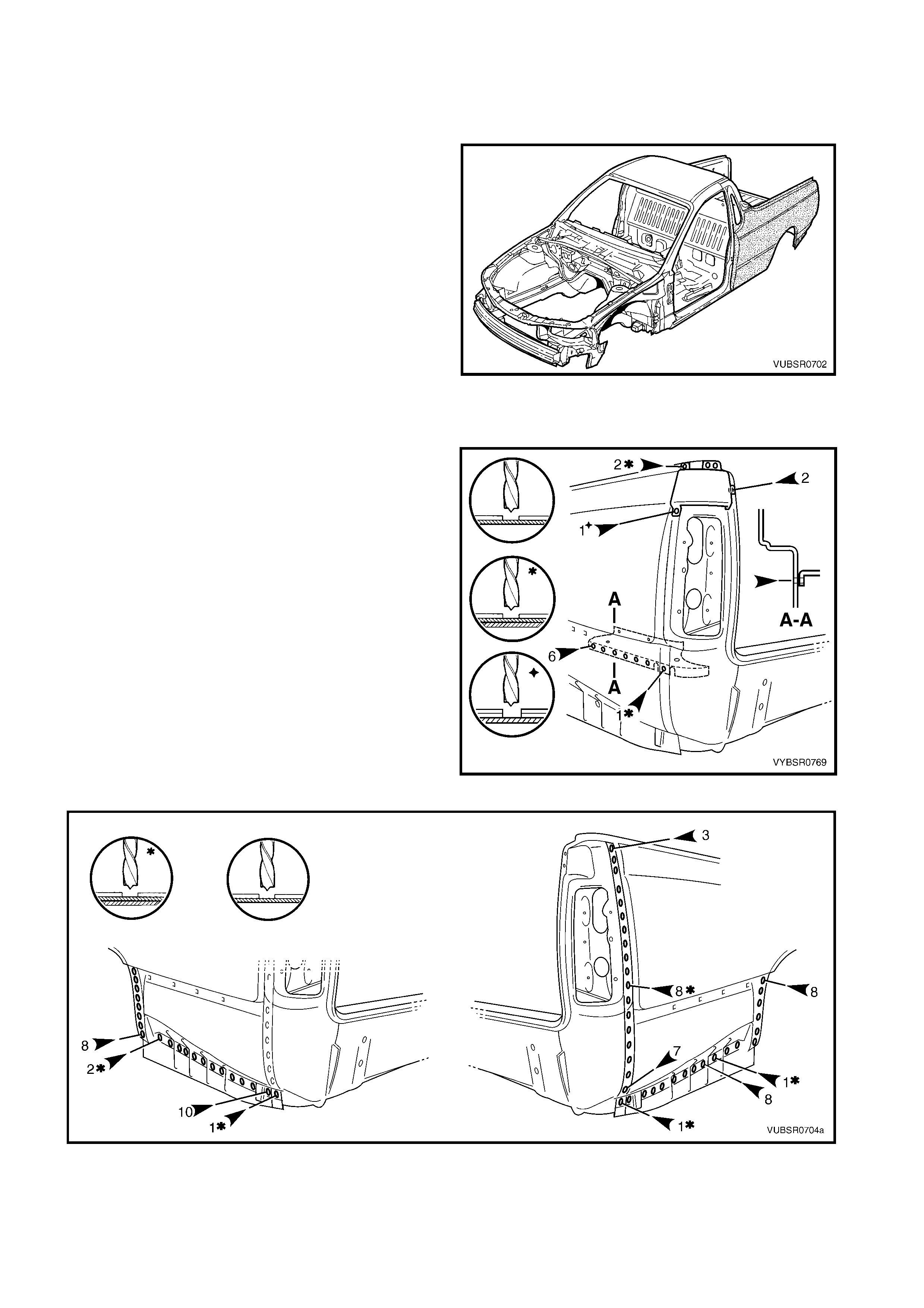

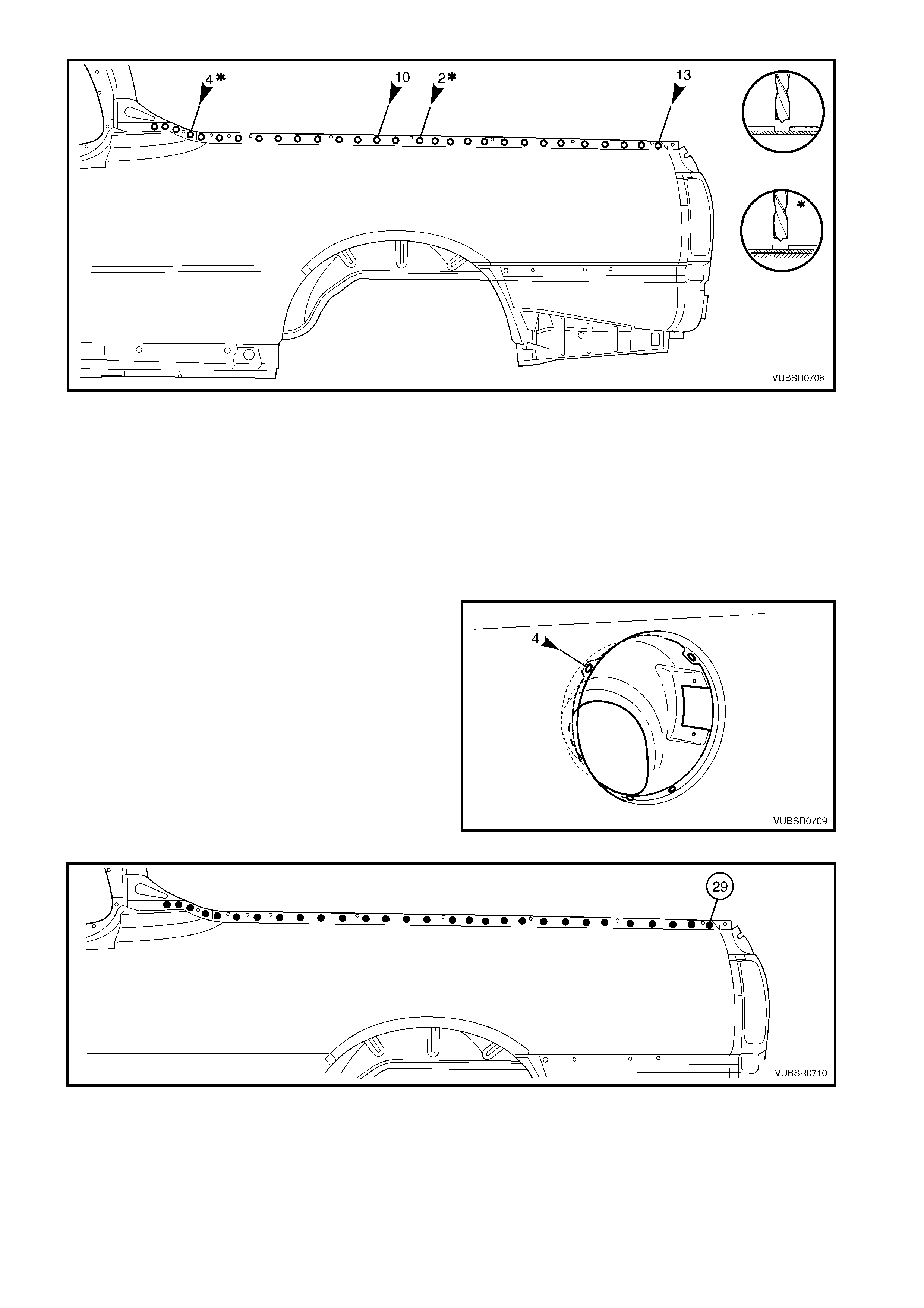

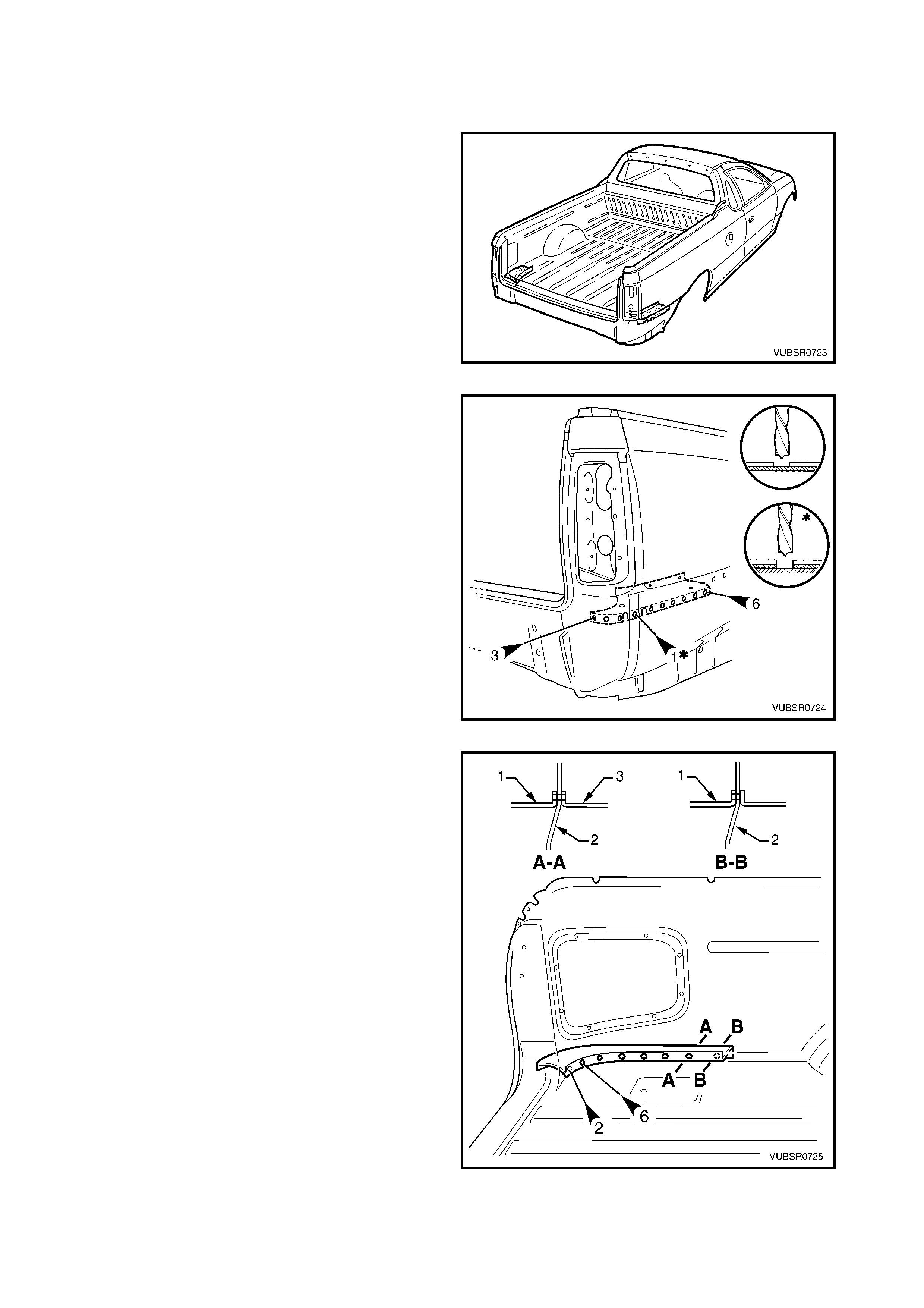

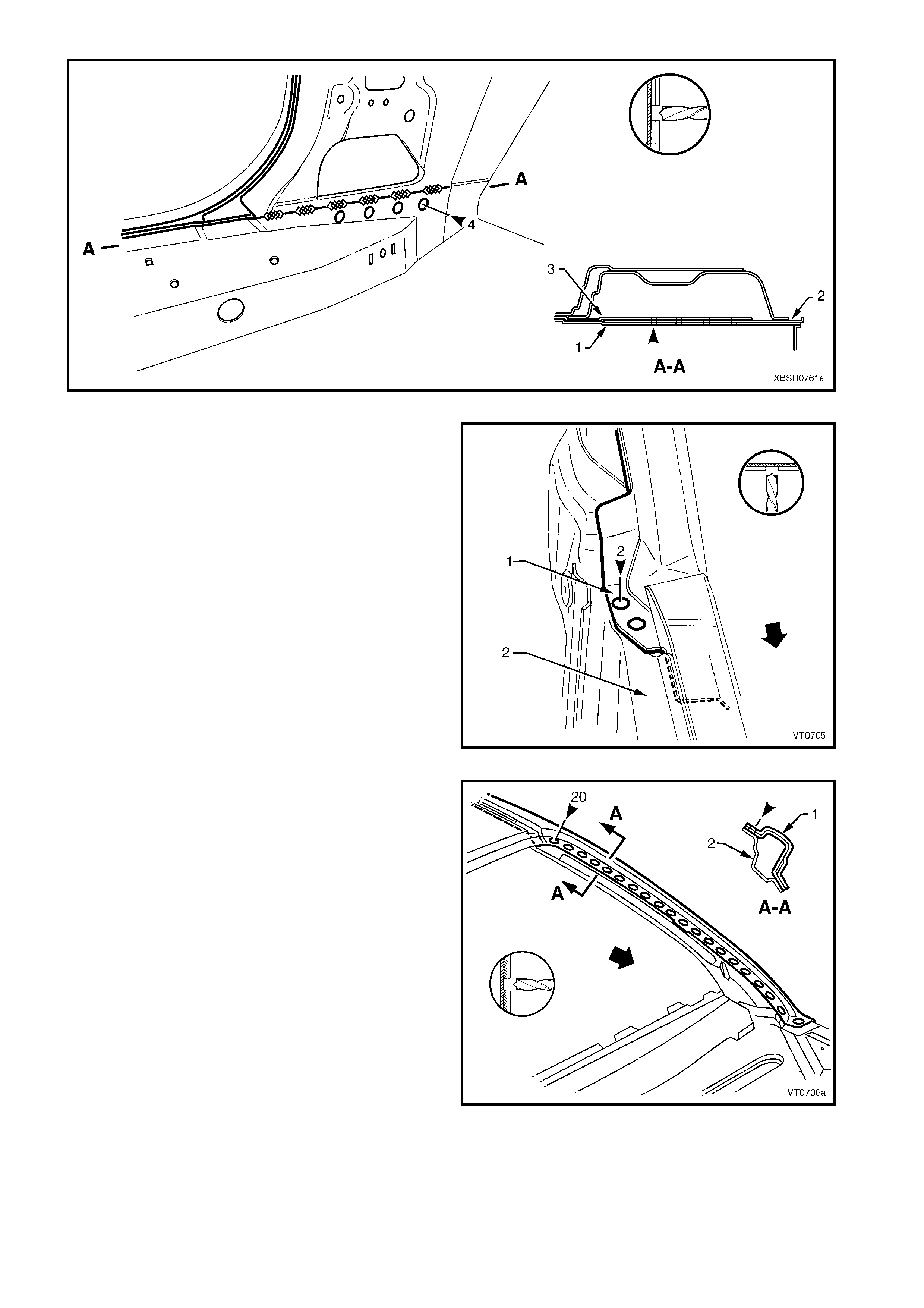

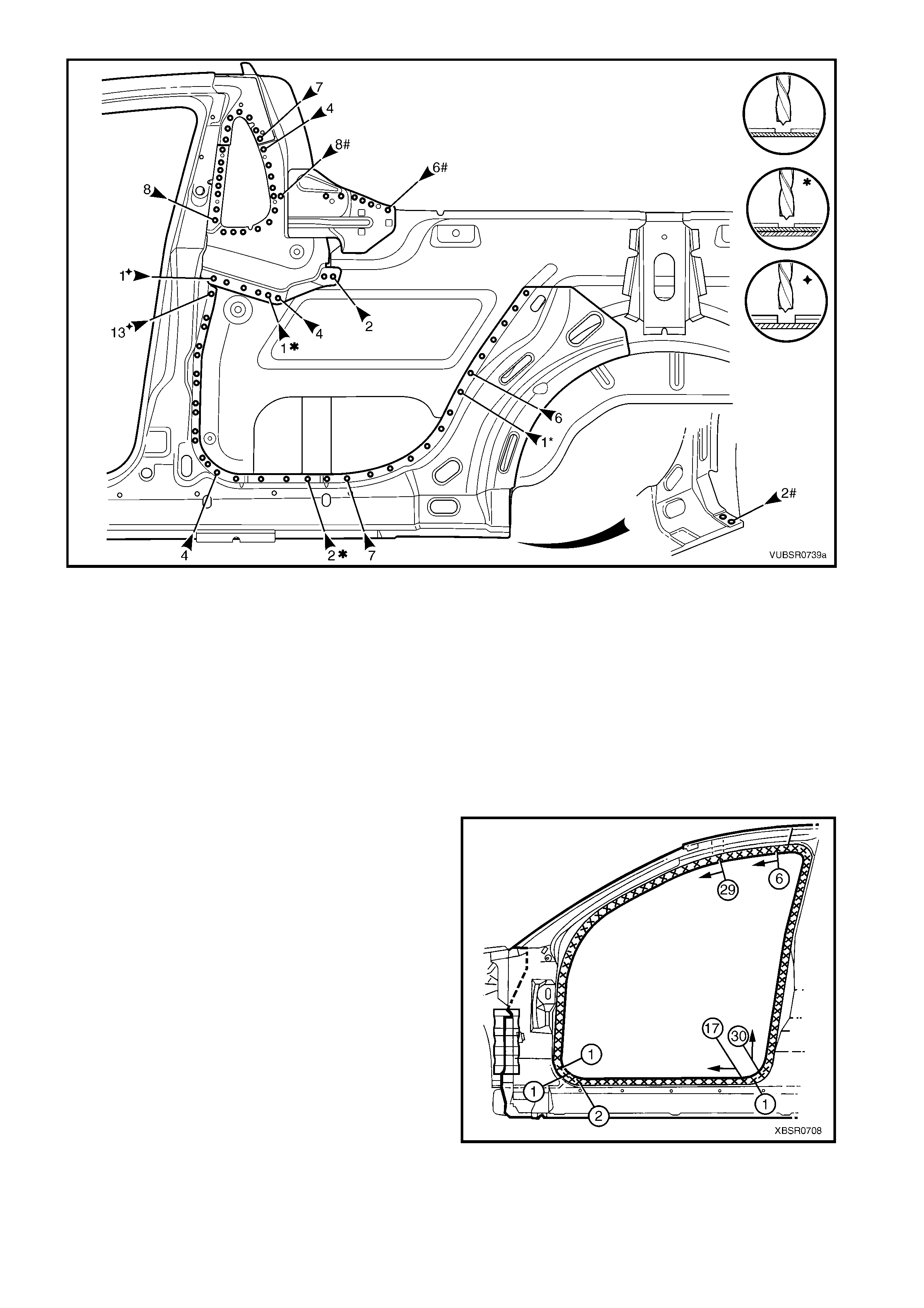

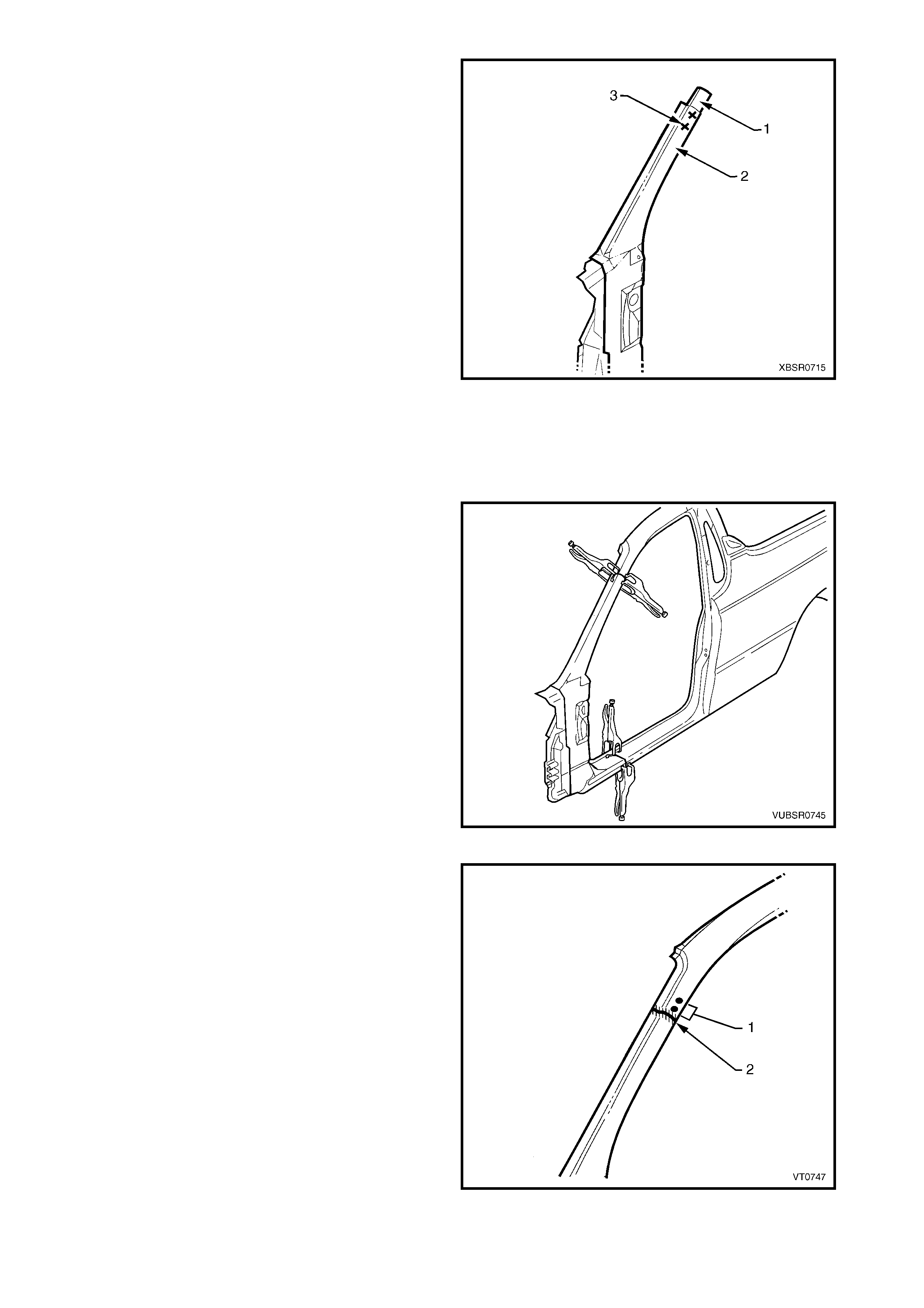

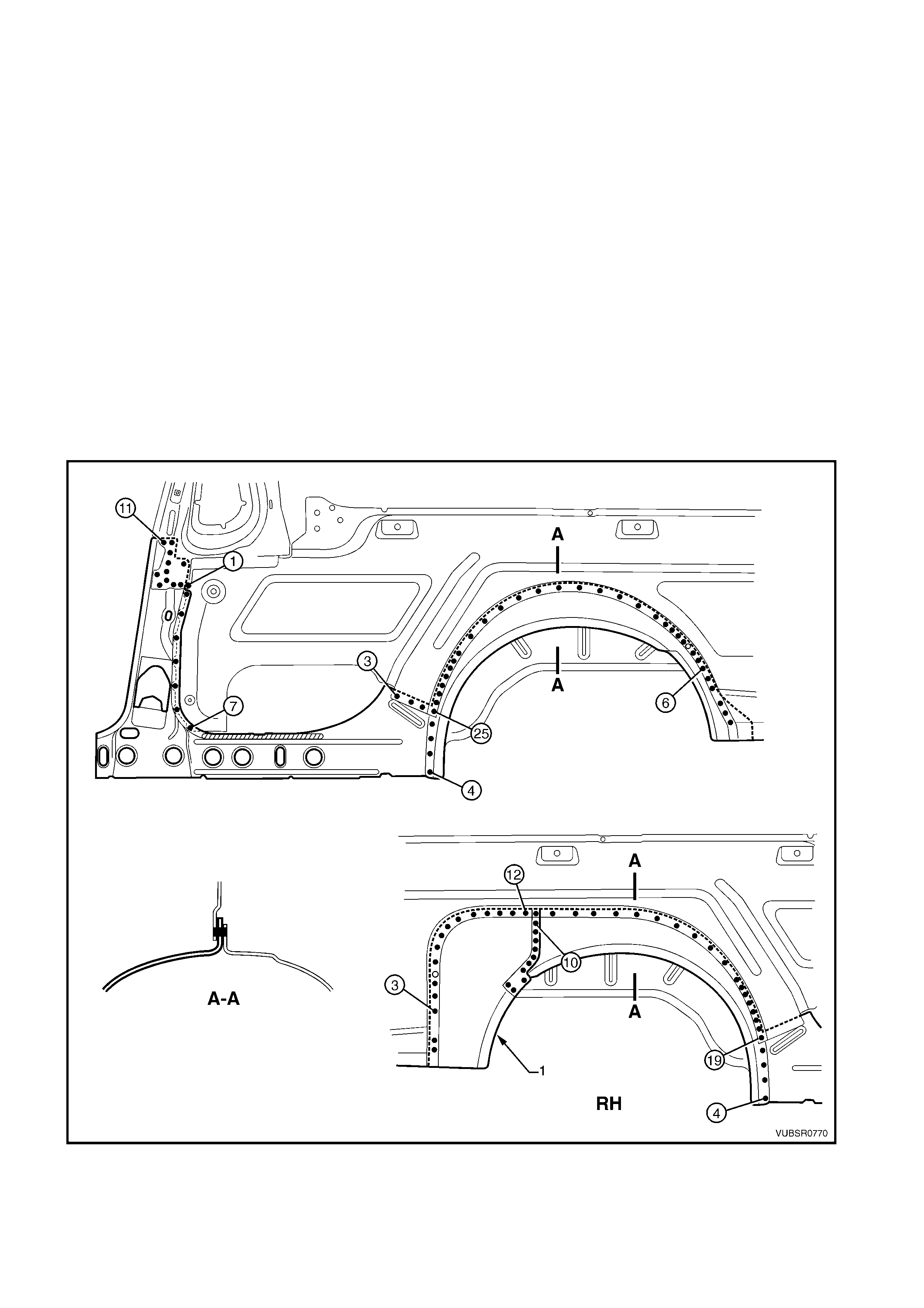

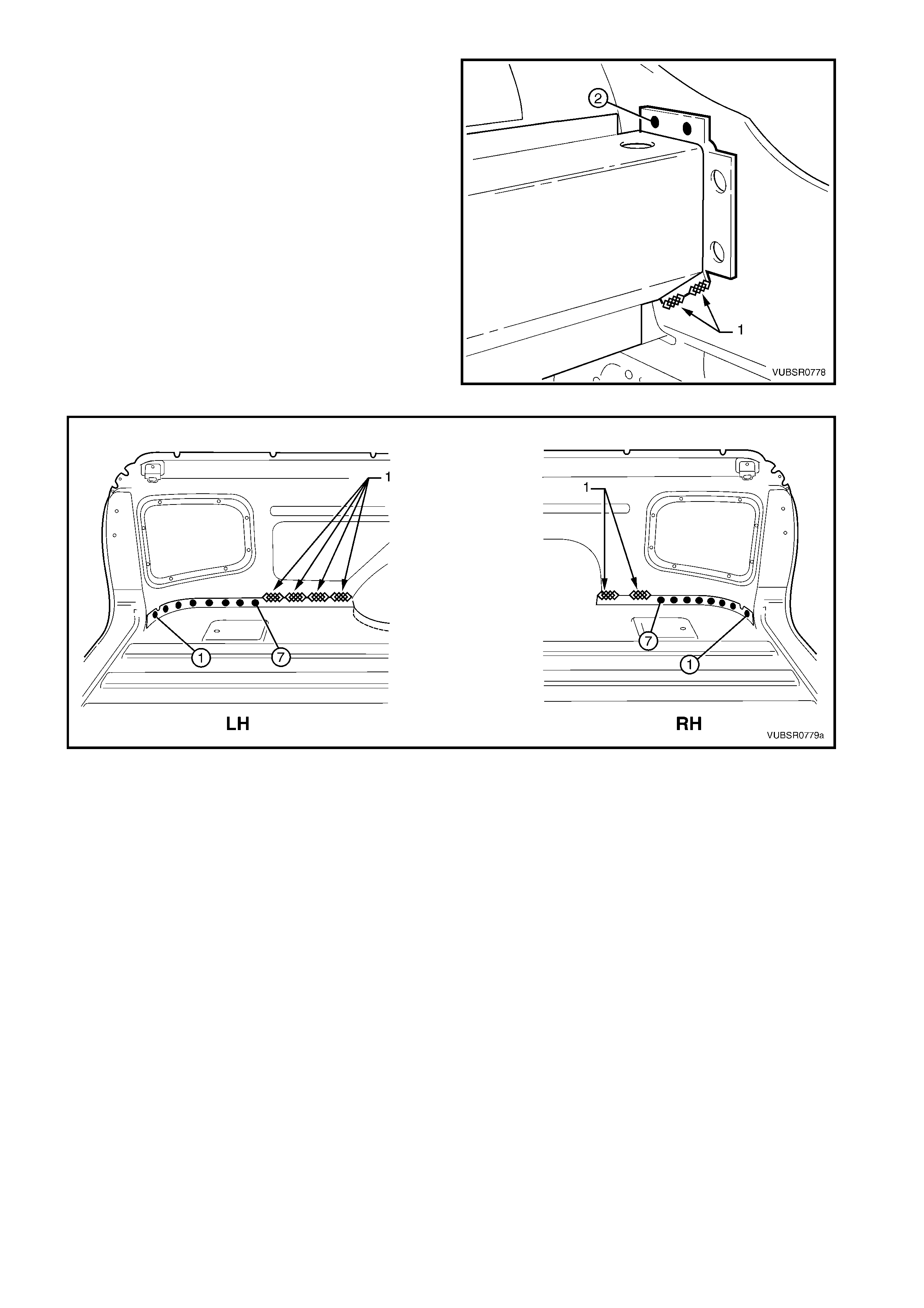

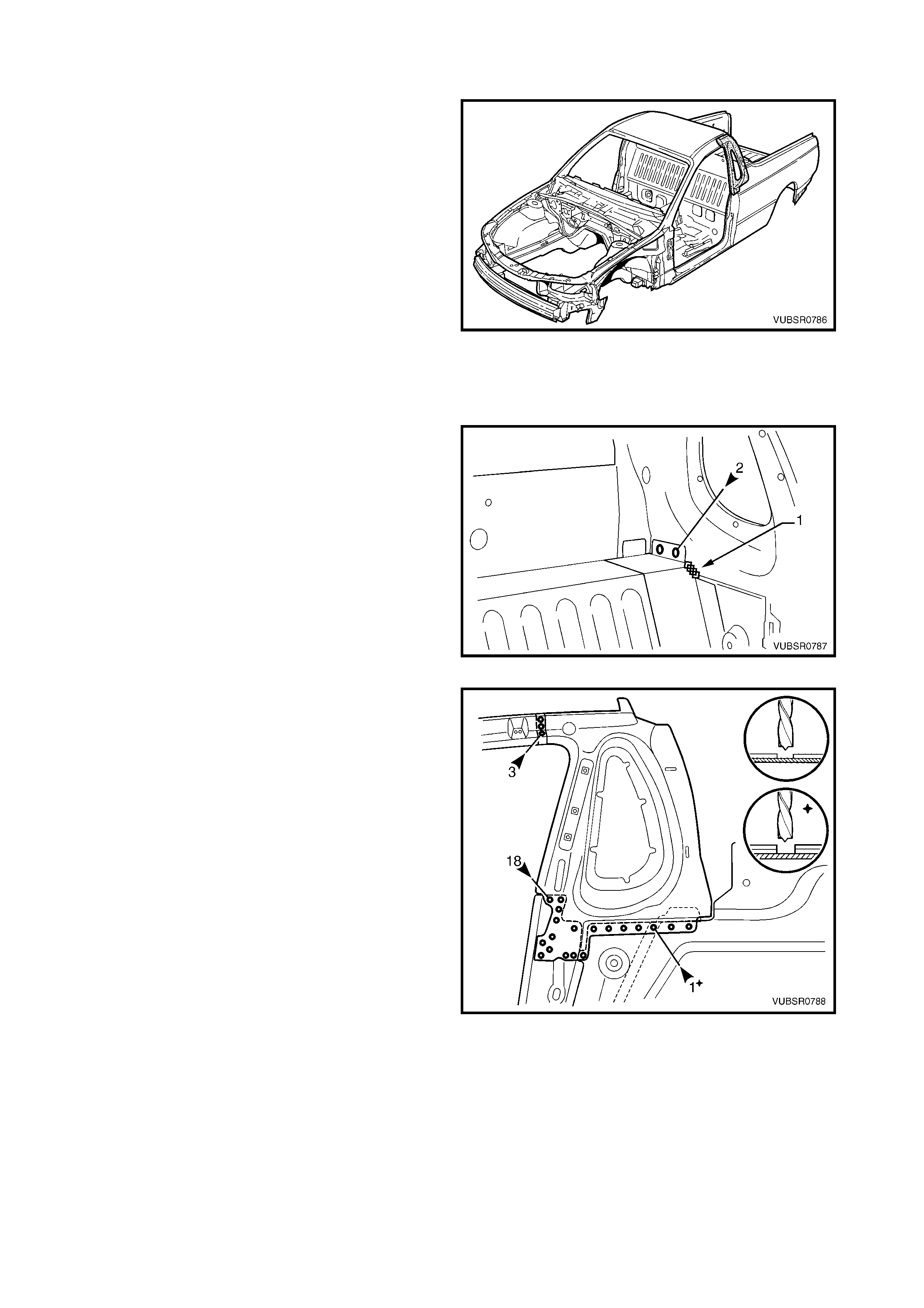

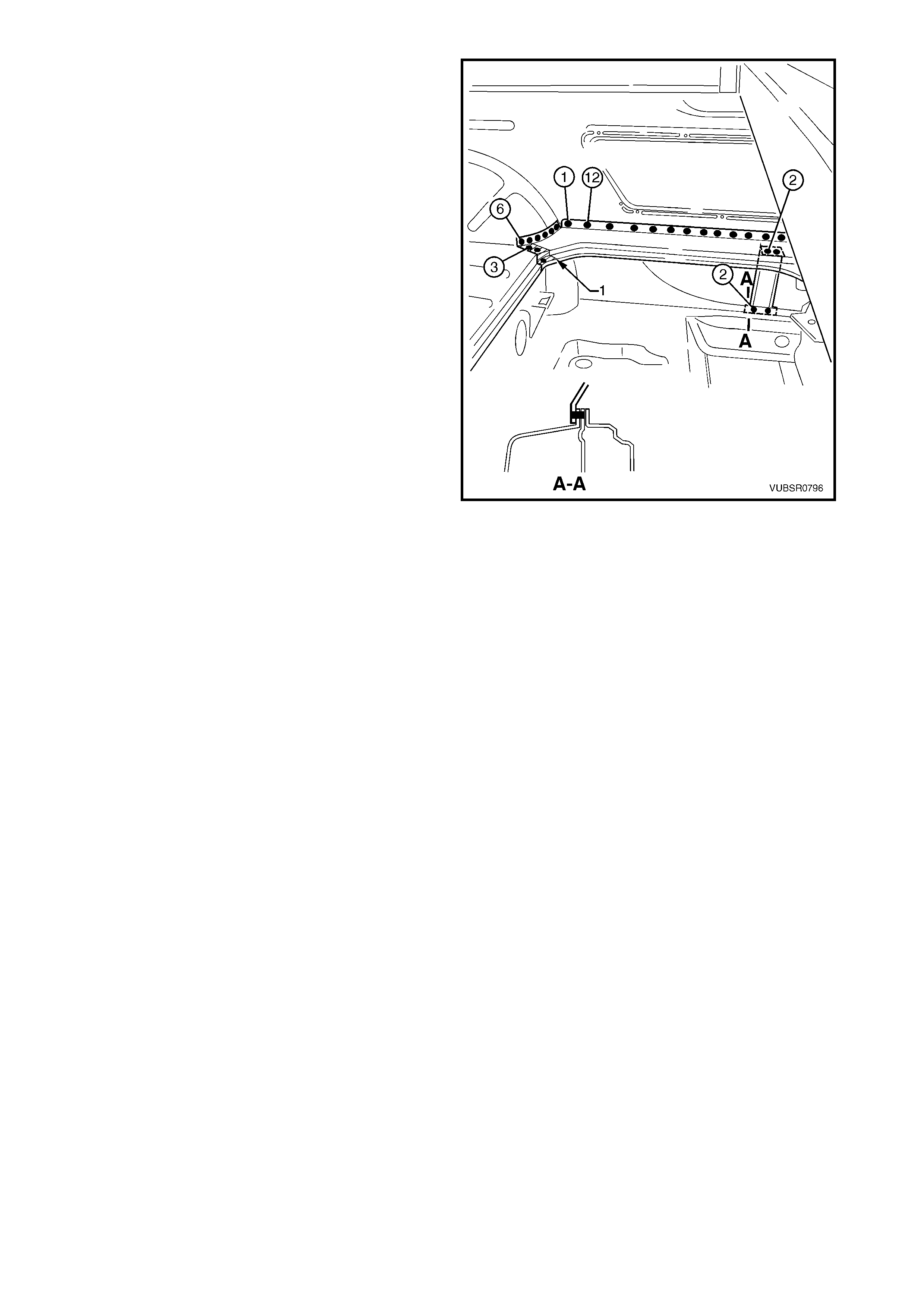

Figure 7C-3

3. To access the spot welds underneath, the quarter

panel upper extension will require removal. Spot

cut:

- two welds attaching it to the quarter panel

extension,

- two welds attaching it to the quarter panel

extension and side inner upper panel,

- one weld attaching it and the rear quarter panel

to the quarter panel extension.

4. Spot cut the six welds attaching the rear quarter

panel to the quarter outer lower rear panel.

5. Spot cut the weld attaching the rear quarter panel

and quarter panel extension to the quarter outer

lower rear panel.

6. Spot cut the welds attaching the rear quarter panel

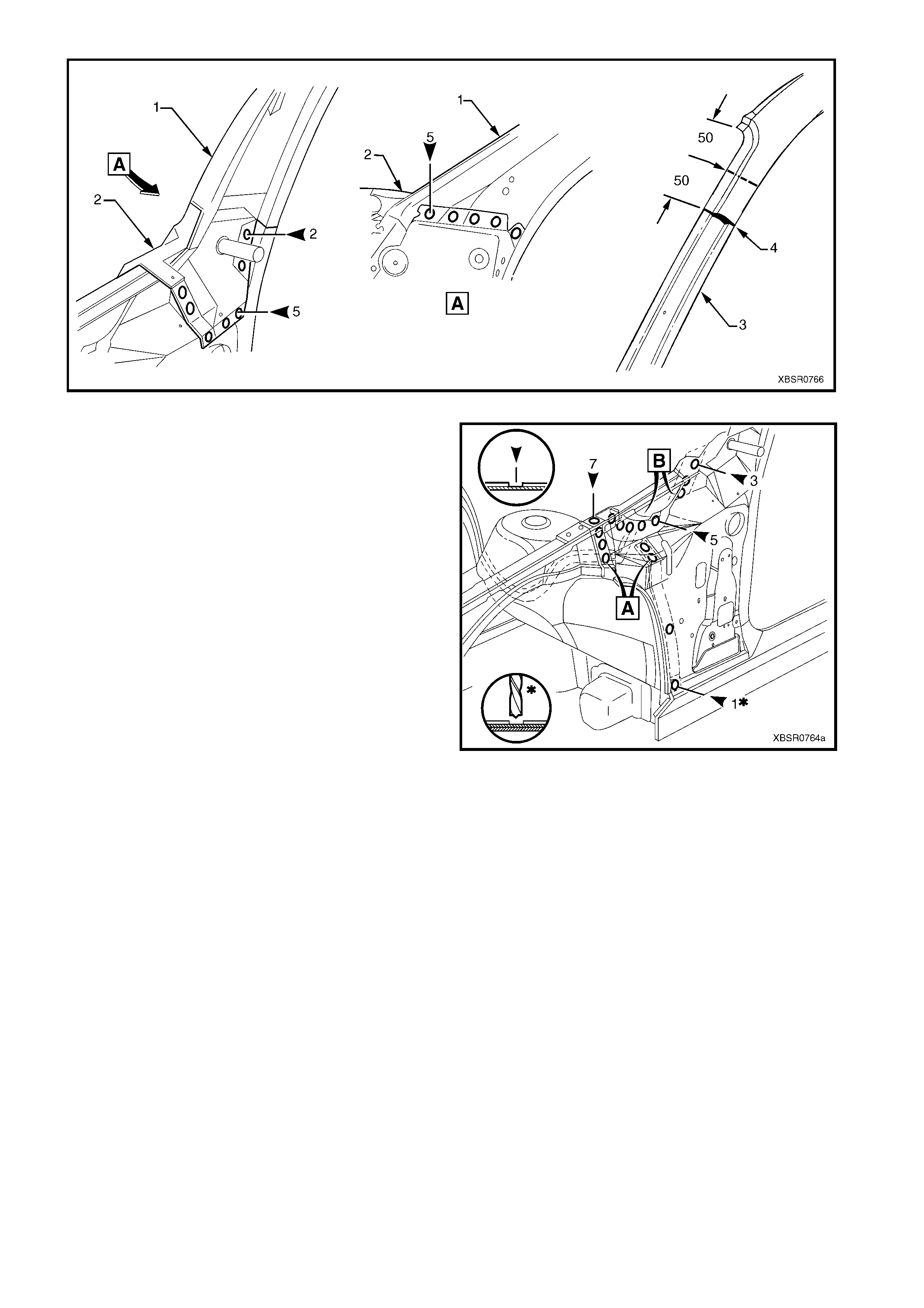

as shown in Figure 7C-5. Note differences

between left-hand and right-hand sides.

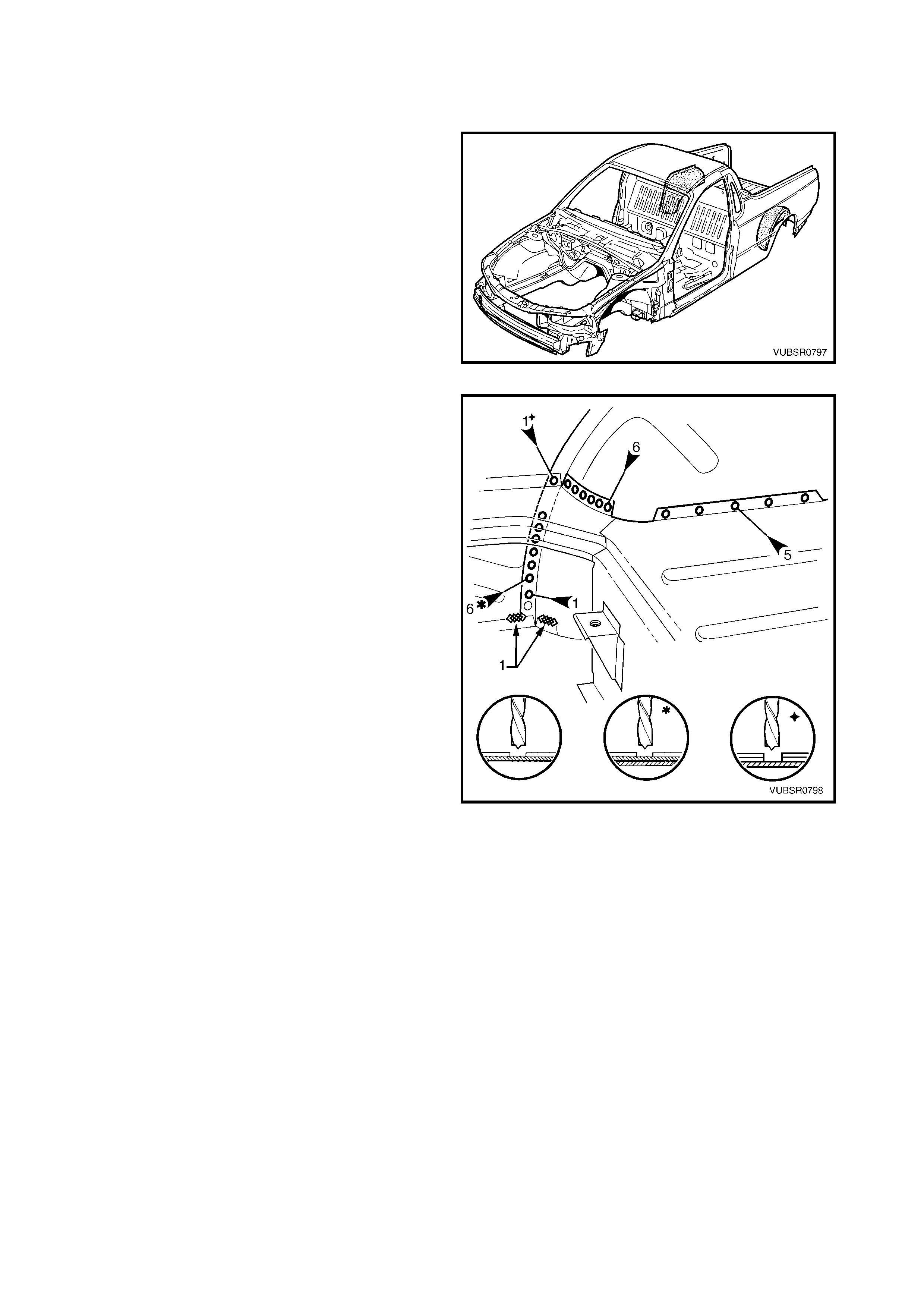

Figure 7C-4

Figure 7C-5

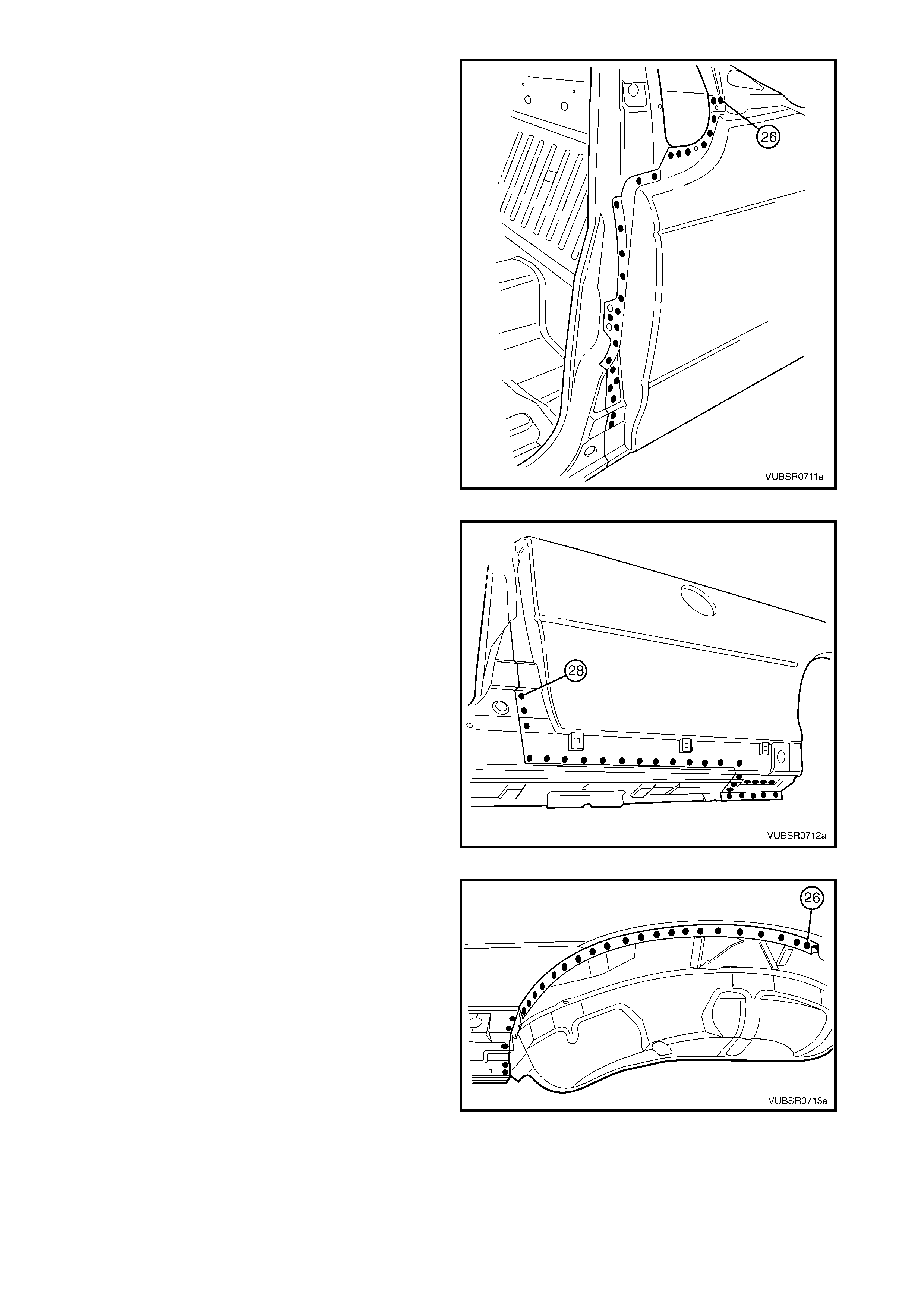

7. Spot cut the welds around the wheel arch opening

attaching the rear quarter panel to the door

opening frame assembly and quarter panel inner

assembly.

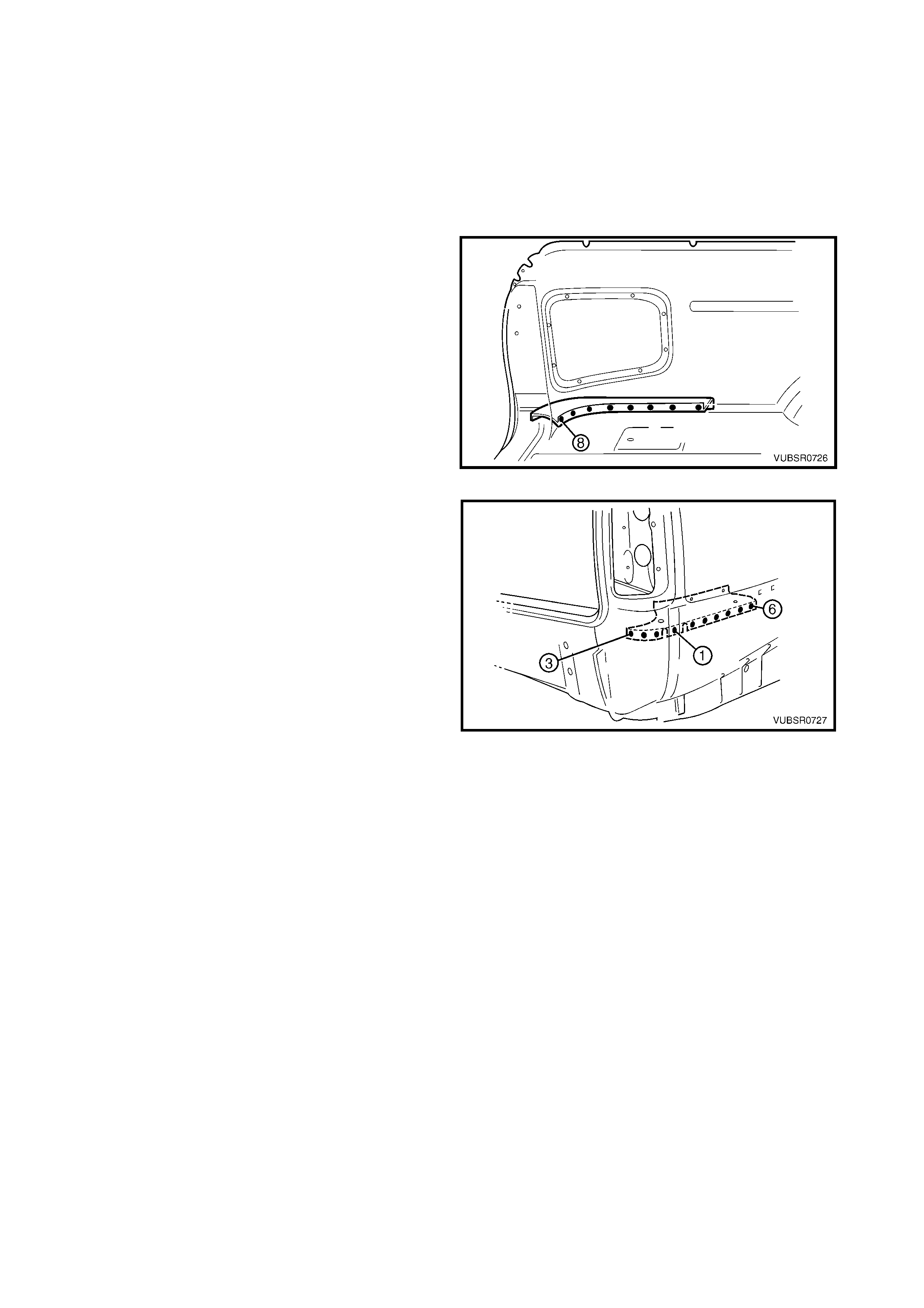

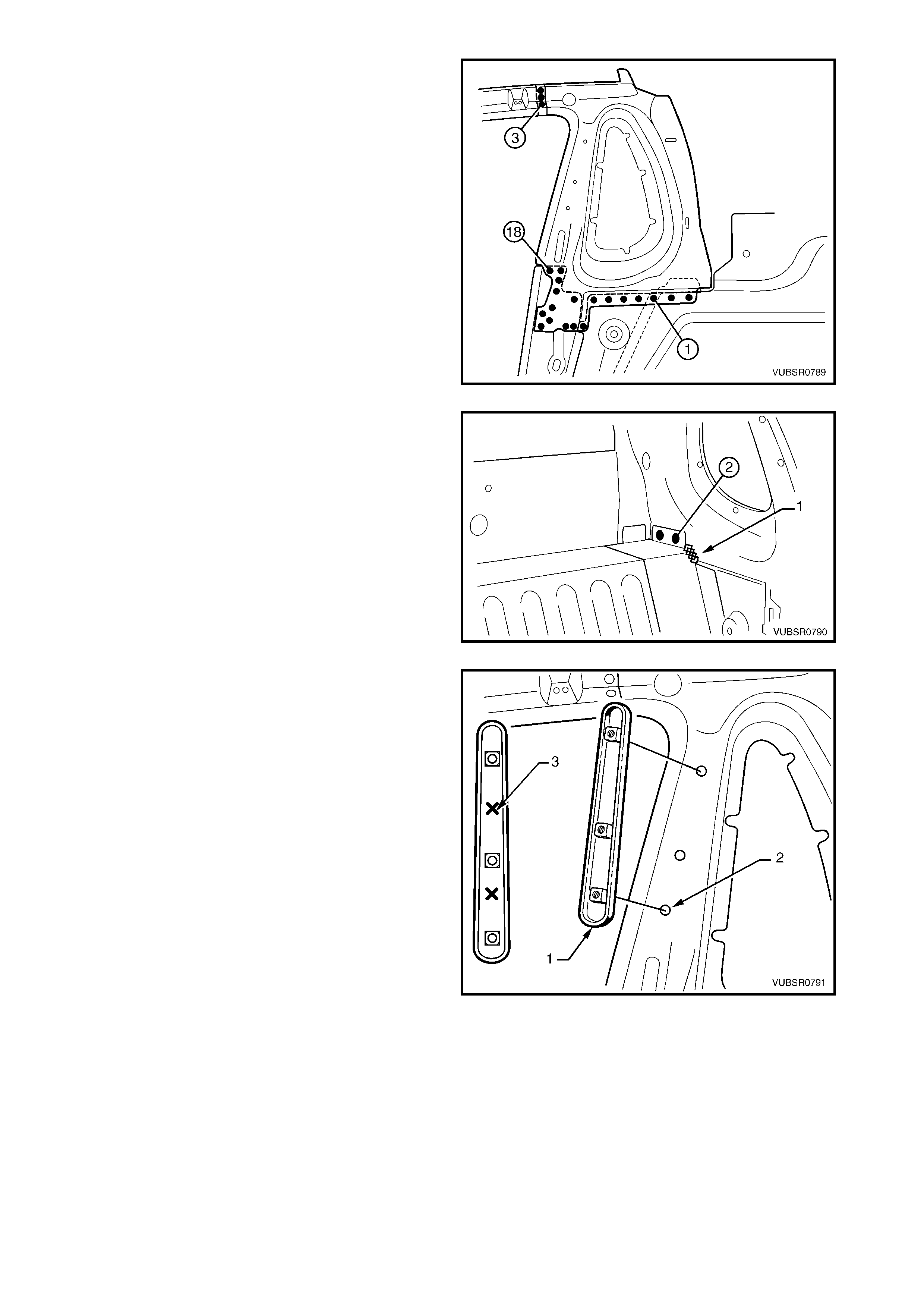

Figure 7C-6

8. Spot cut the welds attaching the rear quarter panel

to the door opening frame assembly.

Figure 7C-7

9. Spot cut the welds attaching the rear quarter panel

to the door opening frame assembly.

10. Spot cut the welds attaching the rear quarter panel

to the side inner upper panel assembly and lock

pillar outer panel brace, refer to Figure 7C-9.

11. Remove the rear quarter panel and repair any

damage to adjacent parts as required.

NOTE: Acrylic spot weld sealer is used in many of the

joints which may require prising apart.

12. Check and rectify the alignment of the body as

required, refer to 3. BODY DIMENSIONS in

Section 3C.

Figure 7C-8

Figure 7C-9

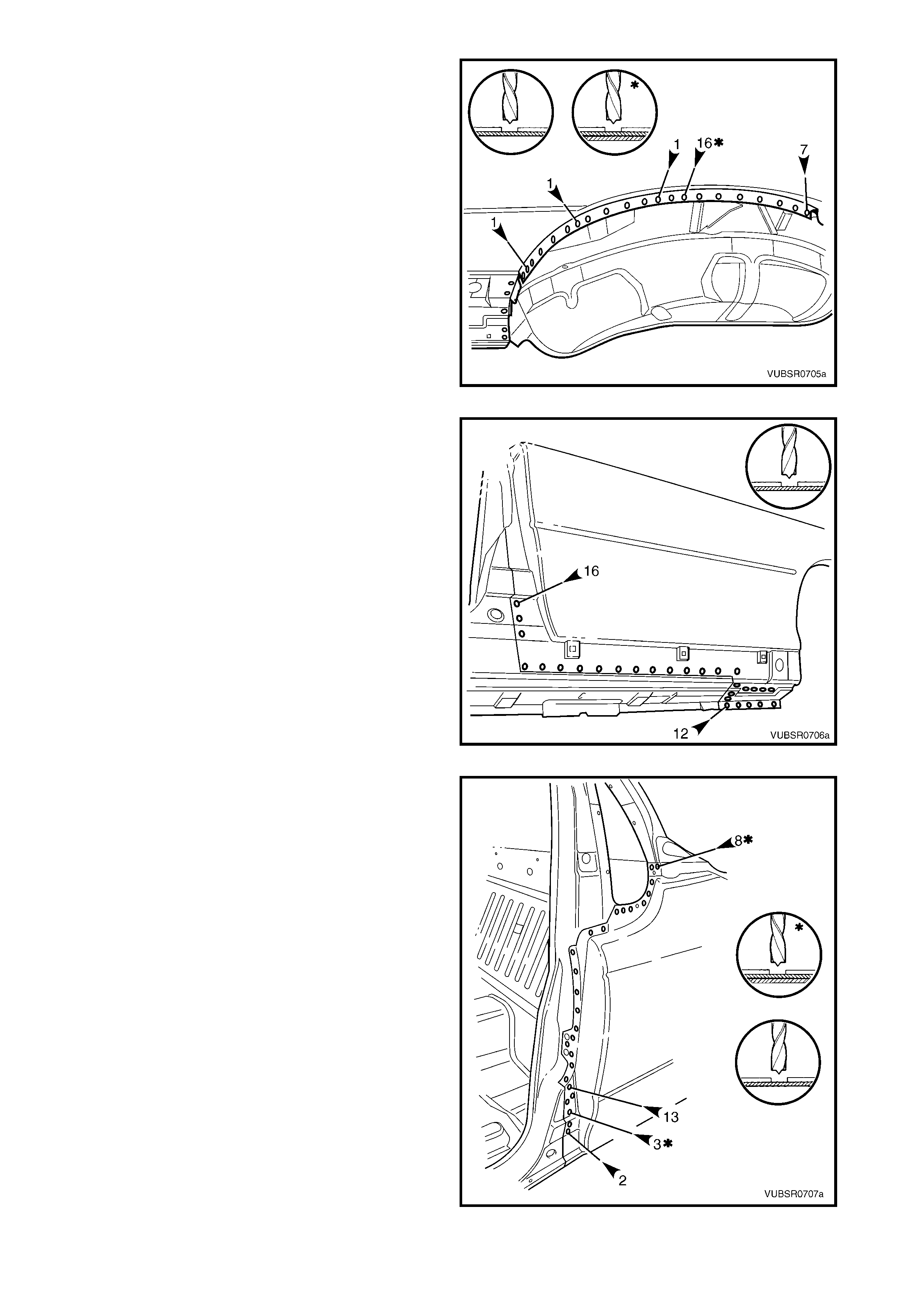

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The same number and position of s pot welds ( or plug welds) s hould be used when replacing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

3. For the right-hand side, if required spot or plug

weld the fuel filler pipe housing to the rear quarter

panel in four places.

4. Apply Acrylic Spot Weld Sealer (Item 2), refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

5. Clamp the panel into position ensuring correct

alignment with the door and the body structure.

6. Spot or plug weld the rear quar ter panel to the s ide

inner upper panel and lock pillar outer panel brac e,

refer to Figure 7C-11.

Figure 7C-10

Figure 7C-11

7. Spot or plug weld the rear quarter panel to the

door opening frame assembly .

Figure 7C-12

8. Spot or plug weld the rear quarter panel to the

door opening frame assembly .

Figure 7C-13

9. Spot or plug weld the rear quarter panel to the

door opening frame assembly and quarter panel

inner assembly around the wheel arch opening.

10. Spot or plug weld the rear quarter panel as shown

in Figure 7C- 15. Note diff erences between the left-

hand and right-hand sides.

Figure 7C-14

Figure 7C-15

11. Spot or plug weld the rear quarter panel to the

quarter outer lower rear panel, seven places.

12. Install and spot or plug weld the quarter panel

upper extension:

- to the quarter panel extension, two places,

- to the quarter panel extension and side inner

upper panel, two places,

- to the rear quarter panel and quarter panel

extension, one place.

13. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

14. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

15. Apply Cavity Wax (Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3C.

16. Apply Spray-on Deadener (Item 7) where

applicable, refer to 5. BODY SEALING,

ADHESIVES & DEADENERS in Section 3C.

17. Replace the rear and quarter windows, refer to

Section 1A6 STATIONARY WINDOWS in the

MY 2003 VY & V2 Series II Service Information.

18. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

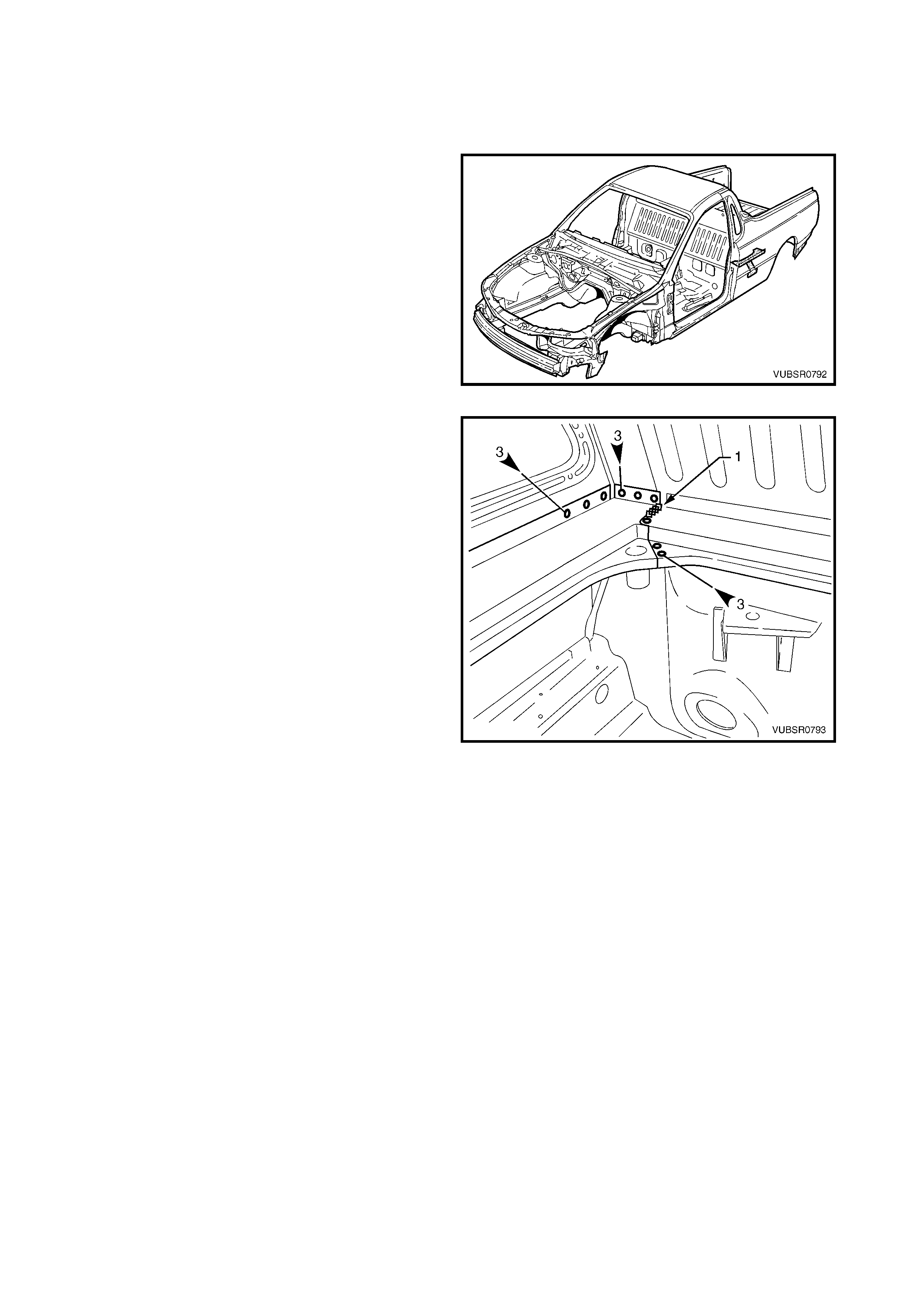

Figure 7C-16

2.2 QUARTER PANEL EXTENSION – REPLACE

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

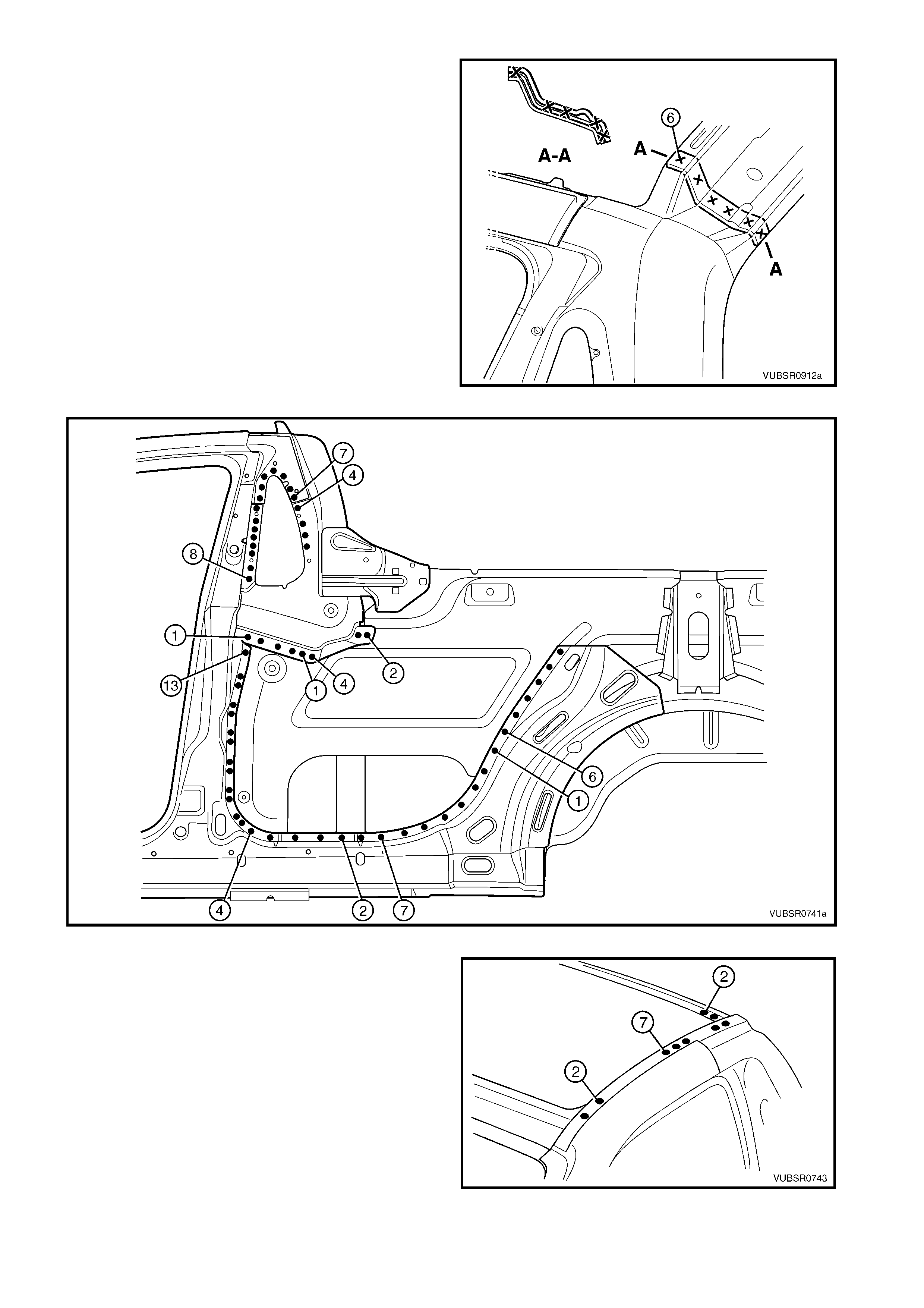

Figure 7C-17

2. To access the spot welds underneath, the quarter

panel upper extension piece will require removal.

Spot cut:

- two welds attaching it and the quarter panel

extension to the side inner upper panel,

- one weld attaching it and the rear quarter panel

to the quarter panel extension,

- two welds attaching it to the quarter panel

extension.

3. Spot cut the three welds attaching the quarter

panel extension to the quarter outer lower rear

panel.

4. Spot cut the weld attaching the rear quarter panel

and quarter panel extension to the quarter outer

lower rear panel.

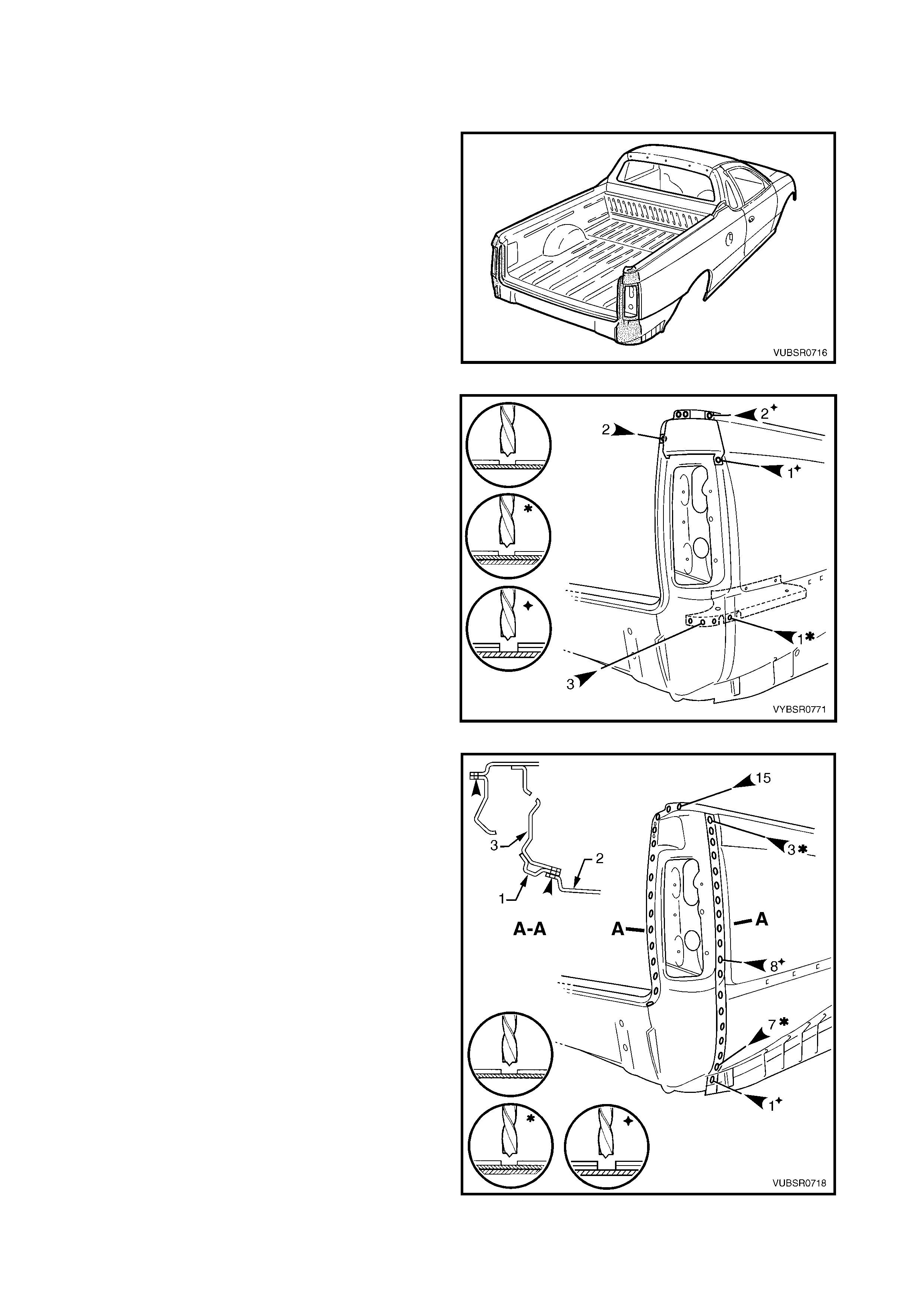

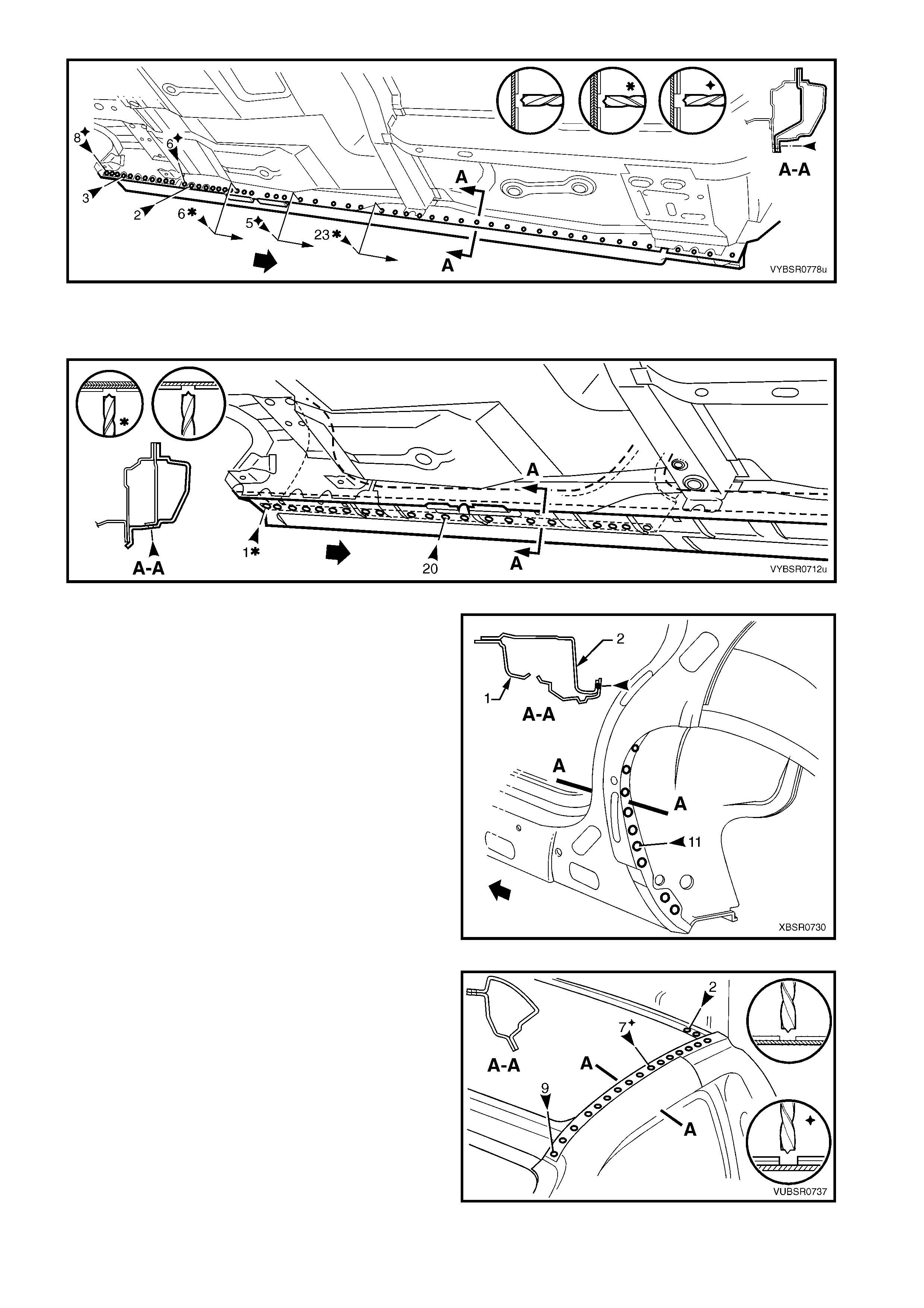

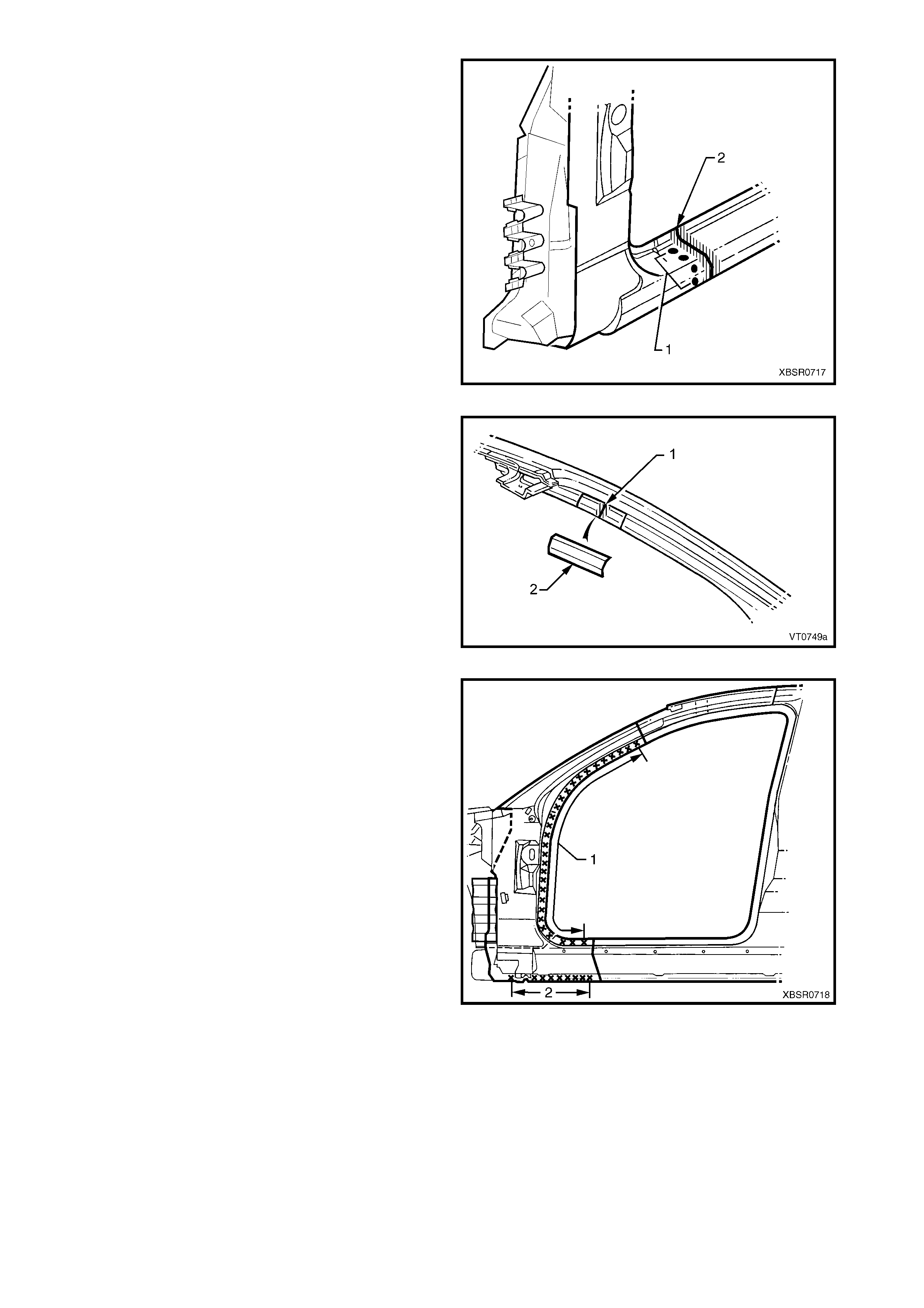

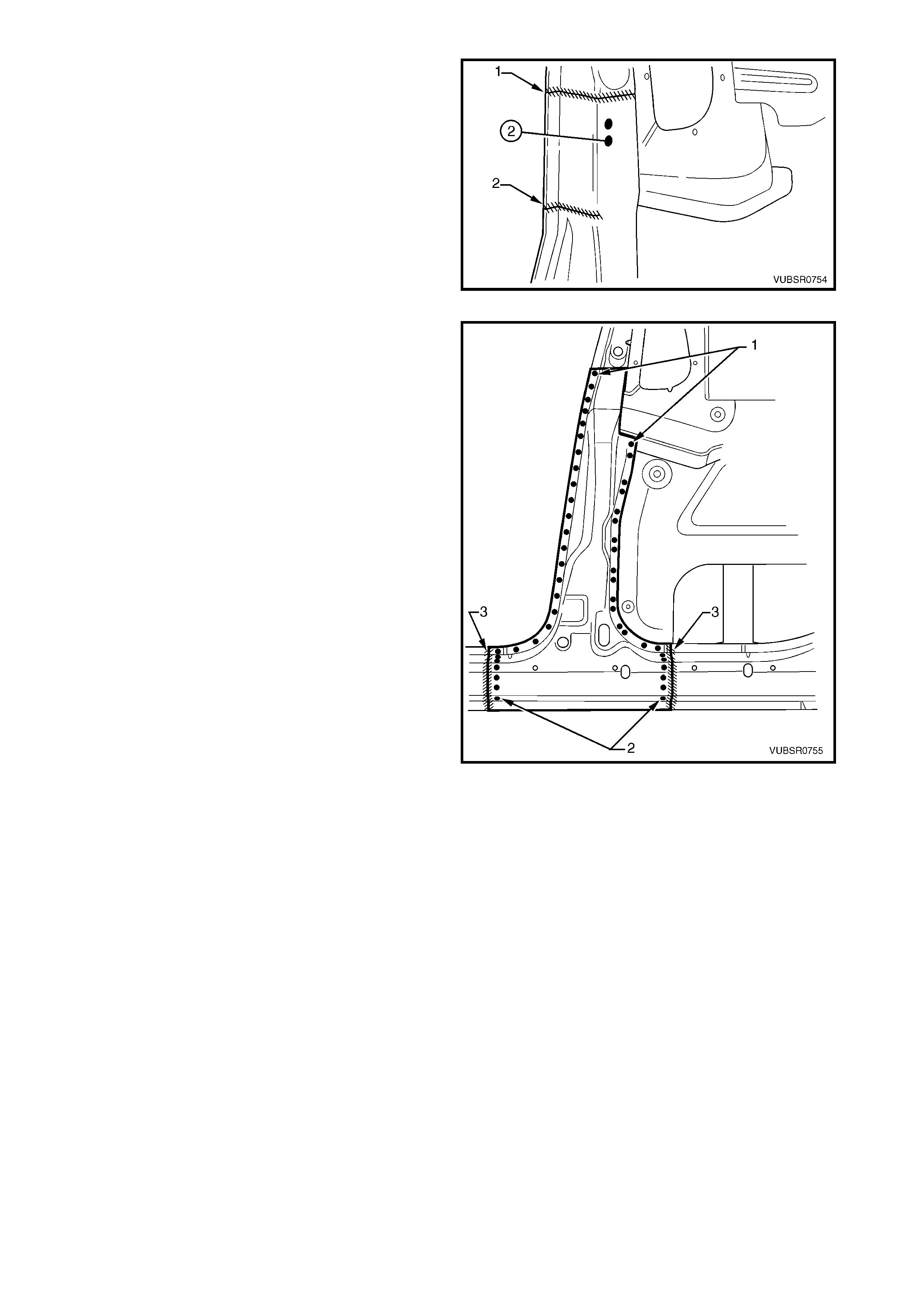

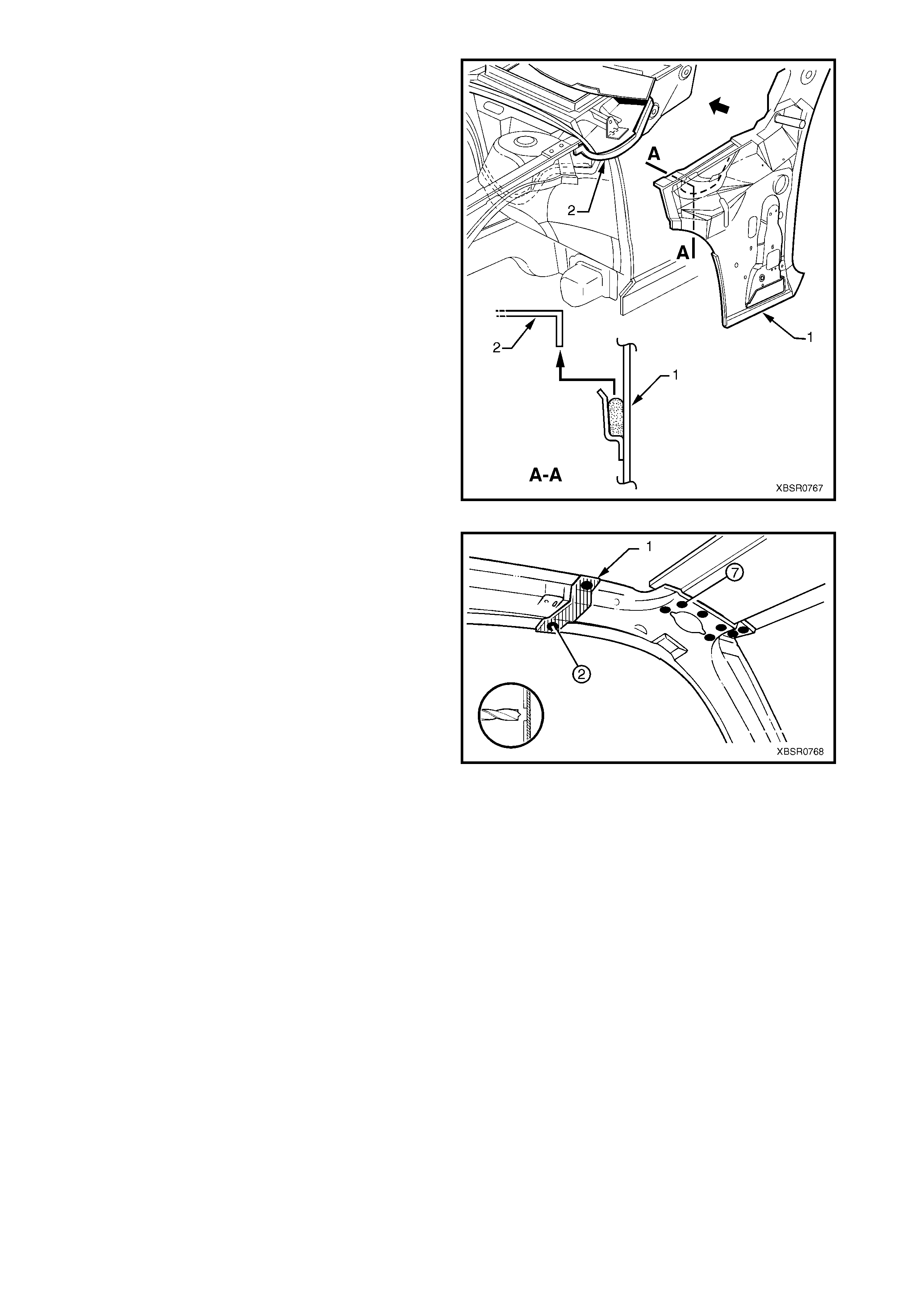

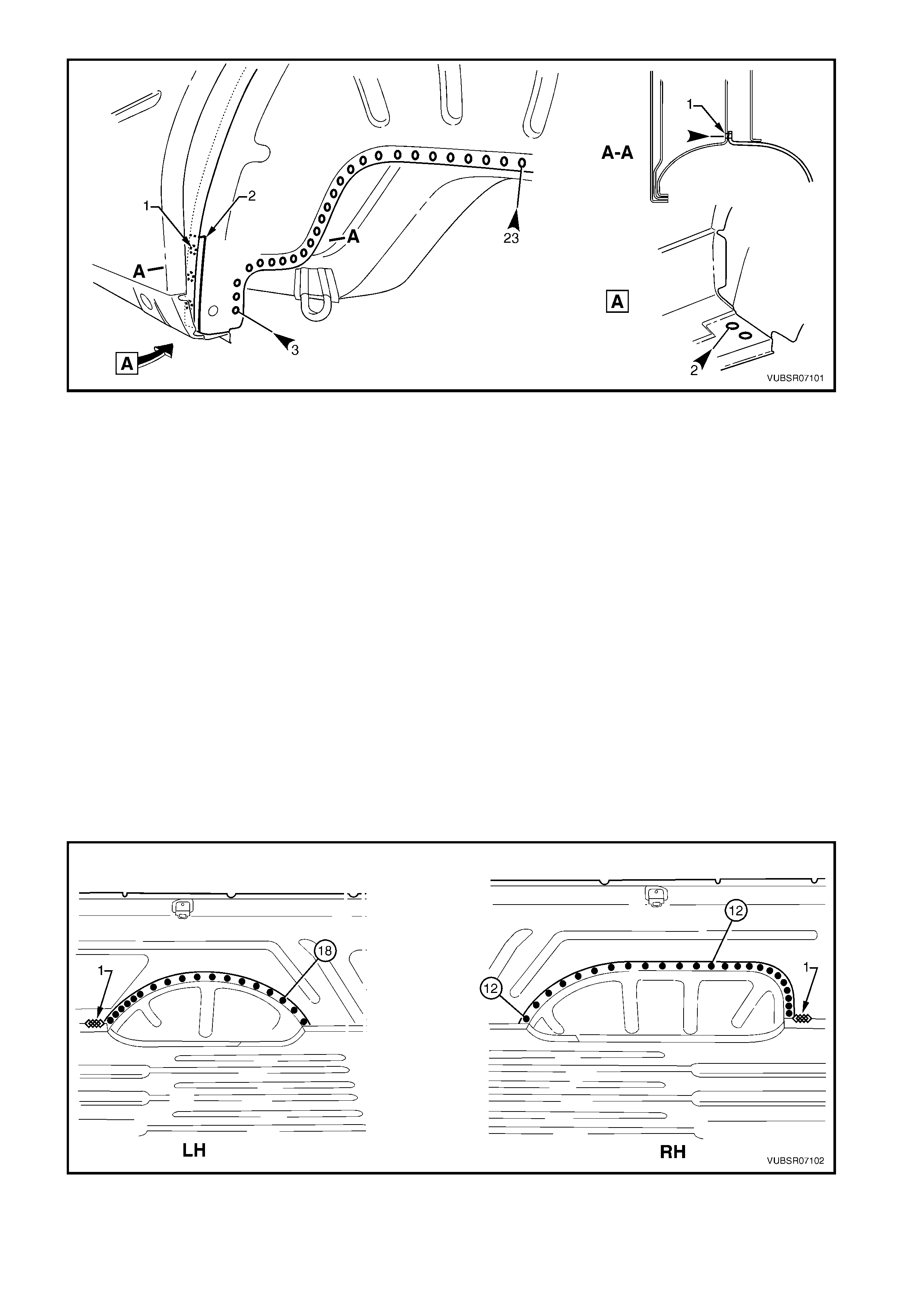

Figure 7C-18

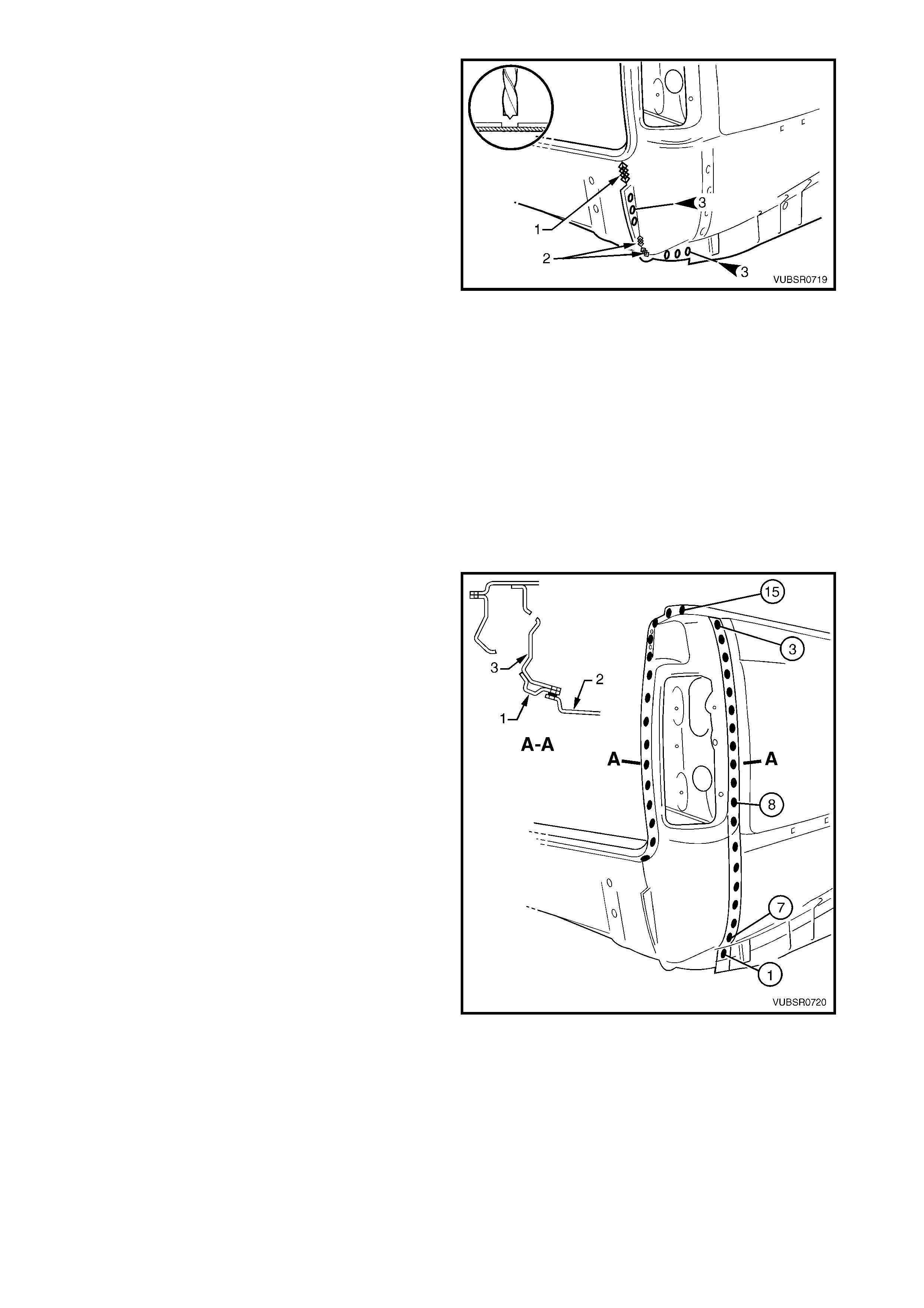

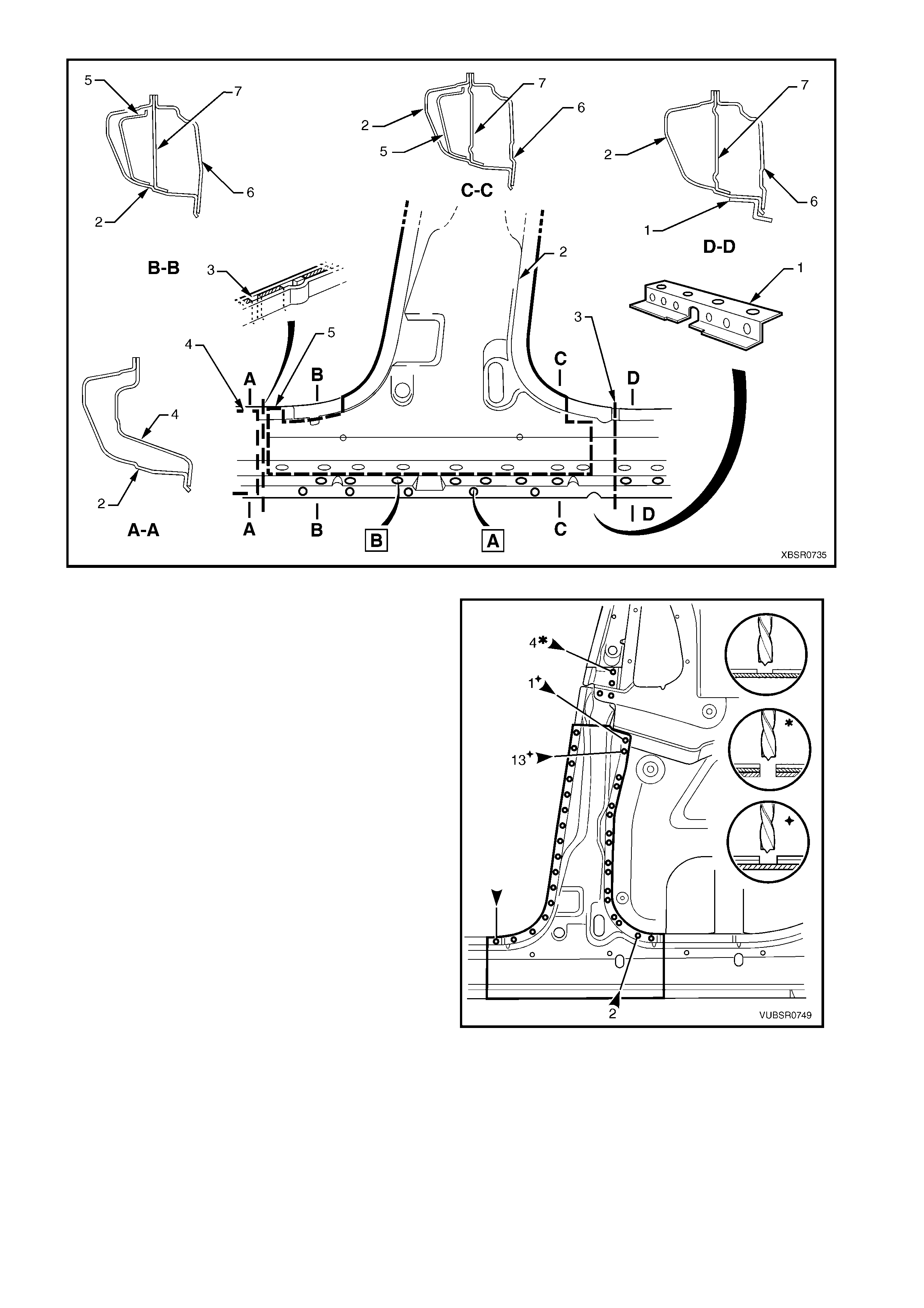

5. Spot cut the 8 welds attaching the quarter panel

extension (1) between the rear quarter panel (2)

and quarter inner lower rear extension (3), refer to

Section A-A.

6. Spot cut the 10 welds attaching the quarter panel

extension to the rear quarter panel.

7. Spot cut the weld attaching the rear quarter panel

and quarter panel extension to the side inner upper

panel.

8. Spot cut the 15 welds attaching the quarter panel

extension to the side inner upper panel.

Figure 7C-19

9. Spot cut the 3 welds attaching the quarter panel

extension to the side inner upper panel.

10. Spot cut the 3 welds attaching the quarter panel

extension to the rear end lower panel.

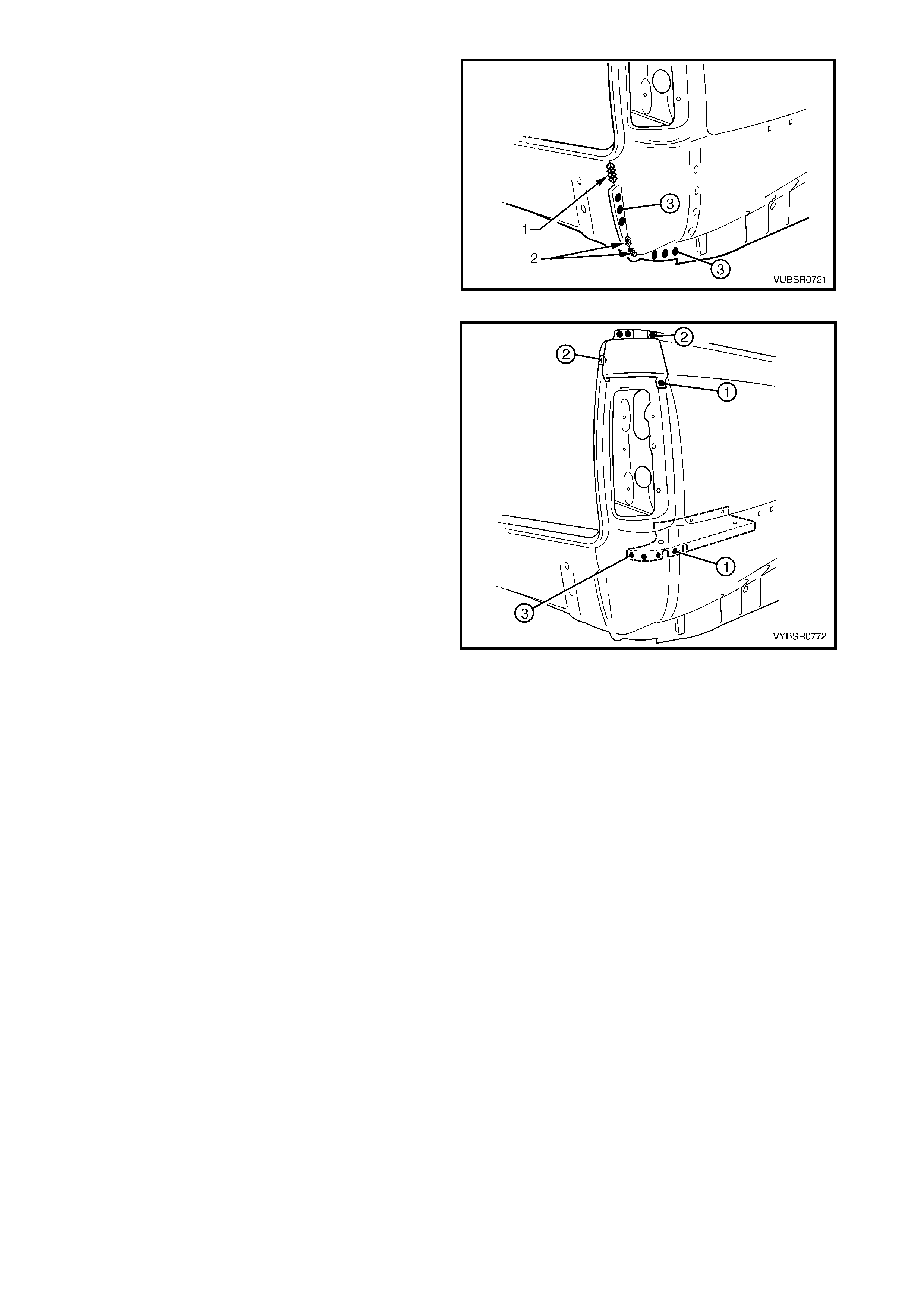

11. Grind off the MIG weld (1) and two MIG welds (2)

attaching the quarter panel extension to the rear

end lower panel.

12. Remove the quarter panel extension and repair

any damage to adjacent parts as required.

NOTE: Acrylic spot weld sealer is used between the

rear quarter panel and quarter panel extension which

may require prising apart.

13. Check and rectify the alignment of the body as

required, refer to 3. BODY DIMENSIONS in

Section 3C.

Figure 7C-20

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The same number and position of s pot welds ( or plug welds) s hould be used when replacing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

3. Apply Acrylic Spot Weld Sealer (Item 2), refer to 5. BODY SEALING, ADHESIVES & DEADENERS in

Section 3C.

4. Clamp the panel into position, fitting the quarter

panel extension flange (1) between the rear

quarter panel (2) and quarter inner lower rear

extension (3), refer to Section A-A.

5. Test fit the tail lamp and check for correct

alignment with the endgate and the body structure.

6. Spot or plug weld 8 places, the quarter panel

extension (1), rear quarter panel (2) and quarter

inner lower rear extension (3), refer to Section A-A.

NOTE: T ake care when welding the rear quarter panel

to avoid heat distortion.

7. Spot or plug weld 10 places, the rear quarter panel

to the quarter panel extension.

8. Spot or plug weld 1 place, the rear quarter panel

and quarter panel extension to the side inner

upper panel.

9. Spot or plug weld the quarter panel extension to

the side inner upper panel, 15 places.

Figure 7C-21

10. Spot or plug weld 3 places, the quarter panel

extension to the side inner upper panel.

11. Spot or plug weld 3 places, the quarter panel

extension to the rear end lower panel.

12. MIG weld one place 55 mm (1) and two places 30

mm (2), the quarter panel extension to the rear

end lower panel.

Figure 7C-22

13. Spot or plug weld three places, the quarter panel

extension to the quarter outer lower rear panel.

14. Spot or plug weld 1 place, the rear quarter panel

and quarter panel extension to the quarter outer

lower rear panel.

15. Install and spot or plug weld the quarter panel

upper extension:

- and the quar ter panel extens ion to the s ide inner

upper panel two places,

- and the rear quarter panel to the quarter panel

extension one place,

- to the quarter panel extension two places.

16. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

17. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

18. Apply Cavity Wax (Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3C.

19. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 7C-23

2.3 QUARTE R INNE R LOWER REAR EX TENSION – REPLACE

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Rem ove the quarter panel extension as previously

described.

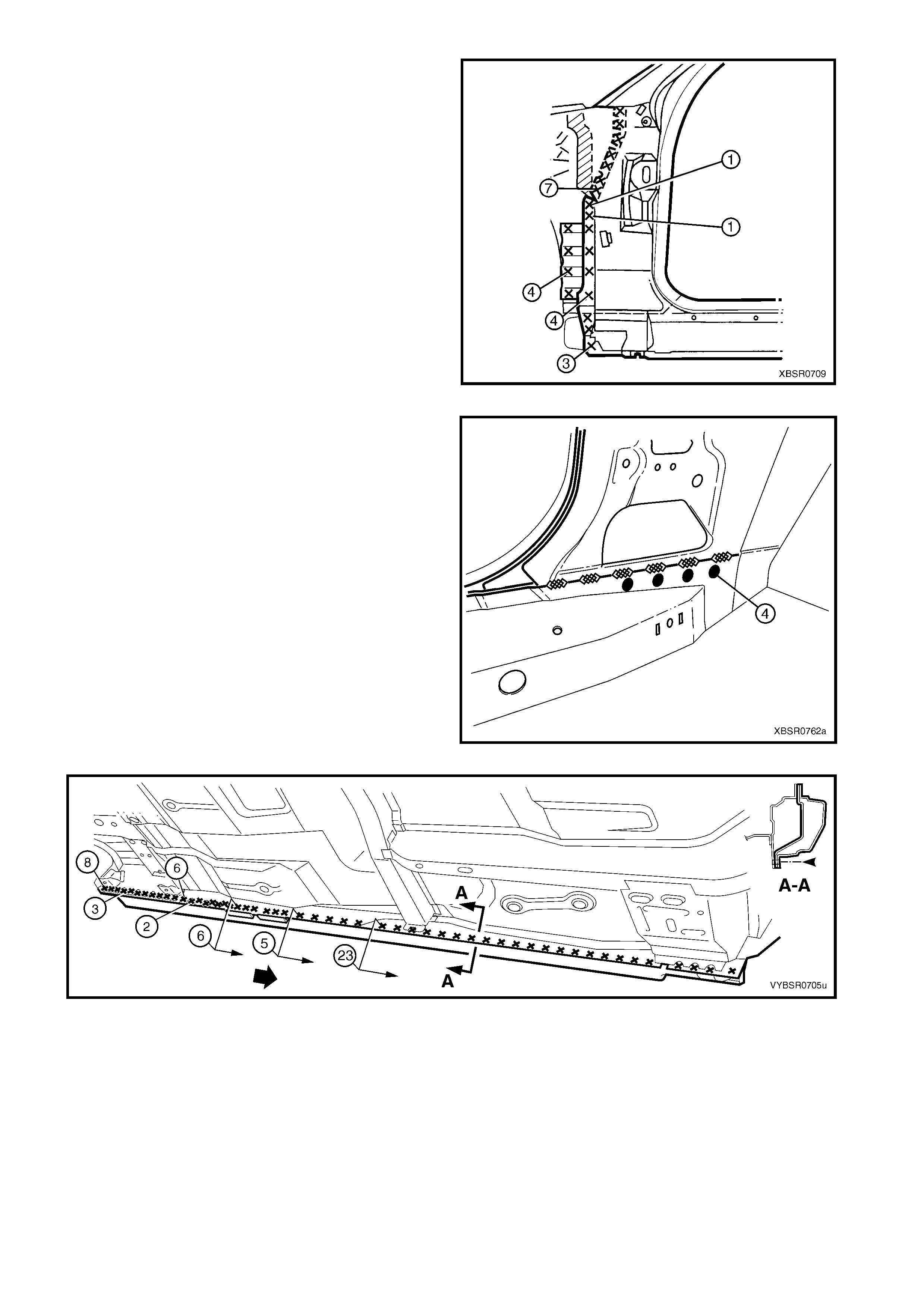

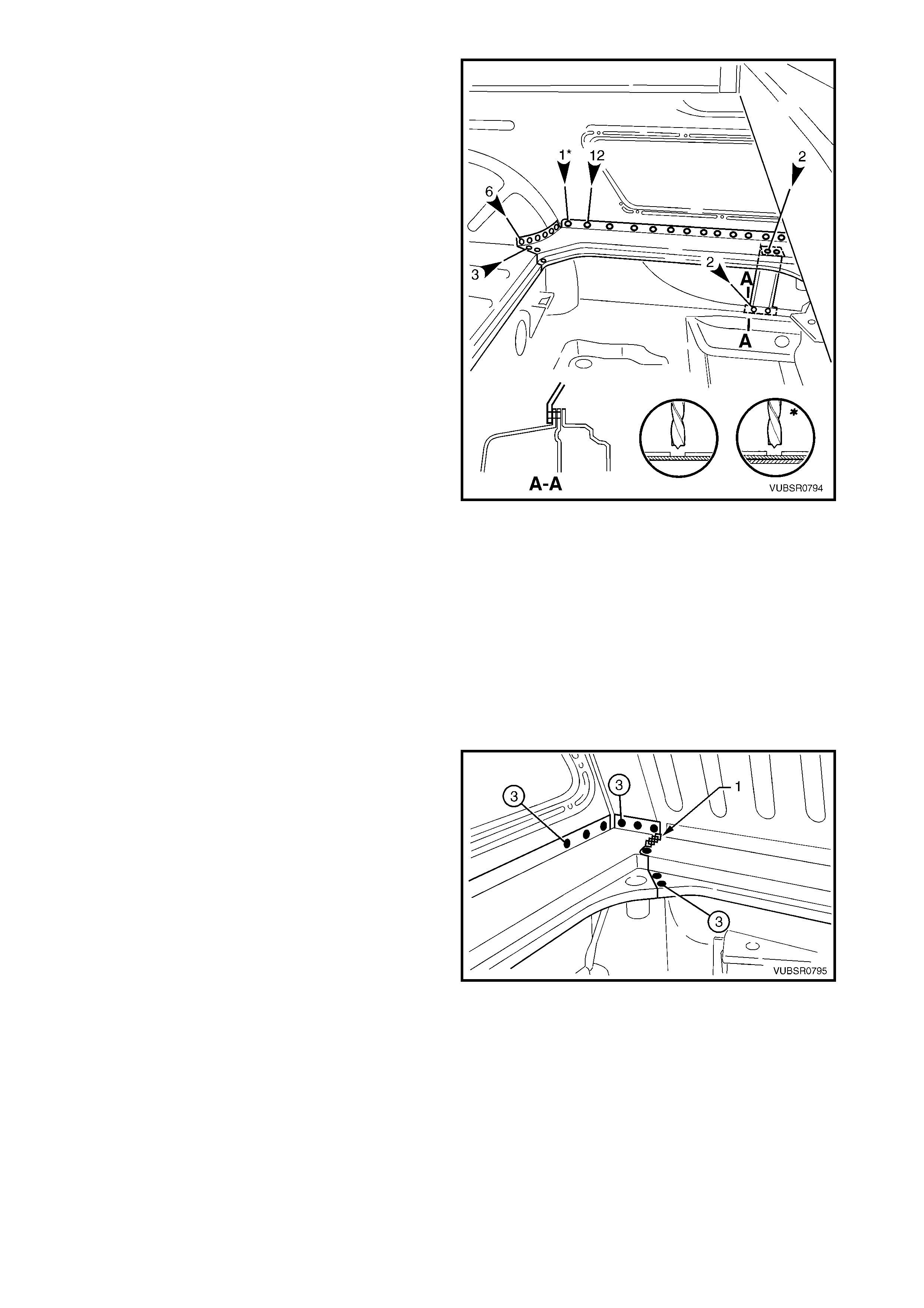

Figure 7C-24

3. Spot cut the welds attaching the quarter inner

lower rear extension to the side inner upper panel.

4. Remove the quarter inner lower rear extension and

repair any damage to adjacent parts as required.

Figure 7C-25

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The s ame number and pos ition of spot welds ( or plug welds) s hould be used when replac ing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

3. Clamp in position and spot or plug weld the quarter

inner lower rear extension to the side inner upper

panel.

4. Replace the quarter panel extension as previously

described.

5. Replace any other removed panels as required.

6. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

7. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

8. Apply Cavity Wax (Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3C.

9. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 7C-26

2.4 QUARTER OUTER LOWER REAR PANEL – REPLACE

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Remove the adjacent panels as required, refer to

the appropriate procedure in this Section.

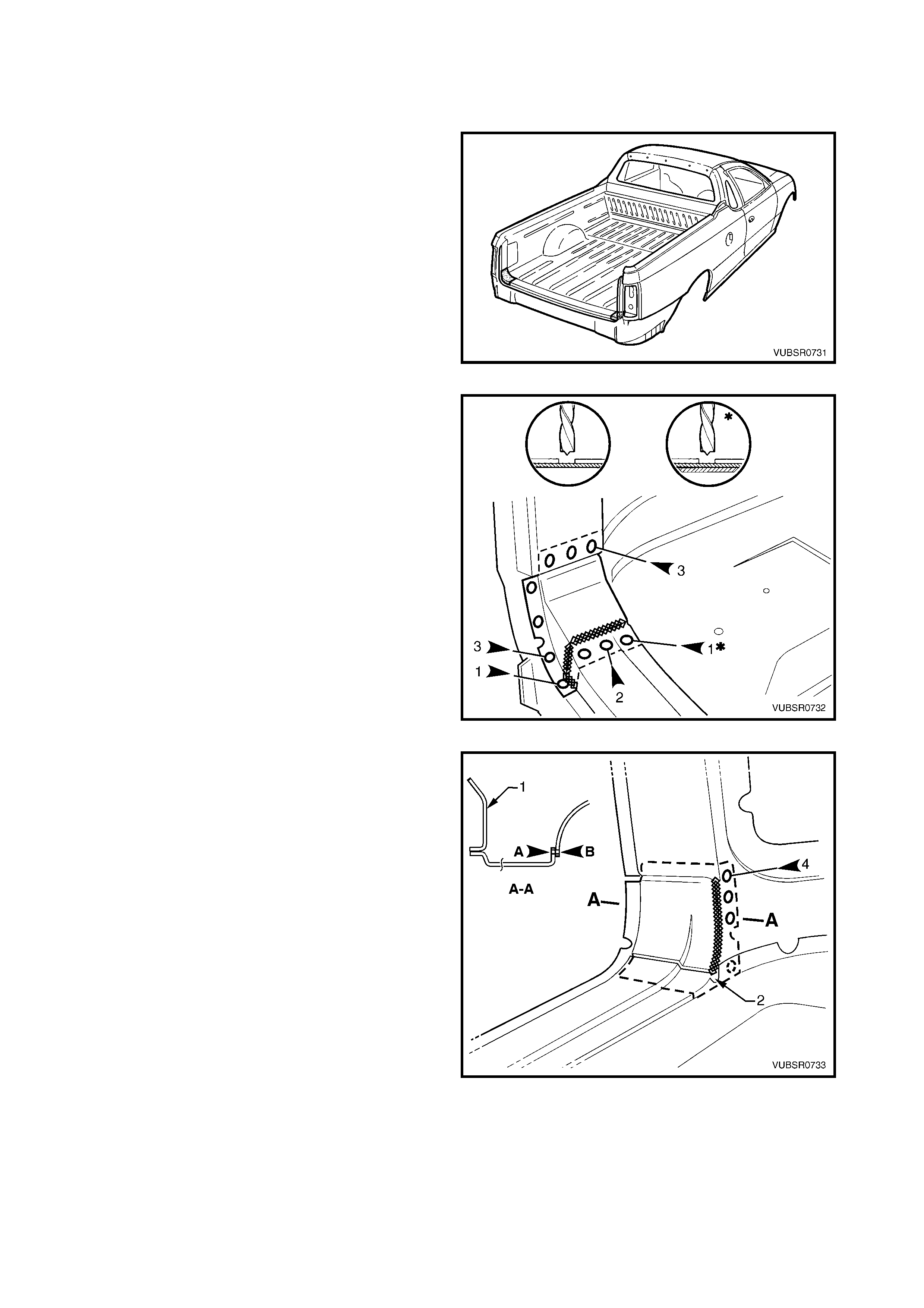

Figure 7C-27

3. Spot cut the welds attaching the rear quarter panel

and quarter panel extension to the quarter outer

lower rear panel.

Figure 7C-28

4. Spot cut the welds attaching the quarter outer

lower rear panel (1) to the side inner upper panel

(2) and load floor panel (3), refer to View A-A.

NOTE: If the rear quarter panel was removed, cut

these welds from the outer side.

5. Spot cut the two welds attaching the quarter outer

lower rear panel (1) to the side inner upper panel

(2), refer to View B-B.

NOTE: These two welds are hidden behind the load

floor flange. If the rear quarter panel has been

removed cut them from the outer side. If it wasn’t

removed, locate the spots through the inner panel

opening and drill through the flange and side inner

upper panel.

6. Remove the quarter outer lower rear panel from

the vehicle, then repair any damage to adjacent

parts as required.

Figure 7C-29

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The s ame number and pos ition of spot welds ( or plug welds) s hould be used when replac ing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

3. Spot or plug weld the quarter outer lower rear

panel to the side inner upper panel and load floor

flange.

Figure 7C-30

4. Spot or plug weld the quarter outer lower rear

panel to the rear quarter panel and quarter panel

extension.

5. Replace any other removed panels as required.

6. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

7. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

8. Apply Cavity Wax (Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3C.

9. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

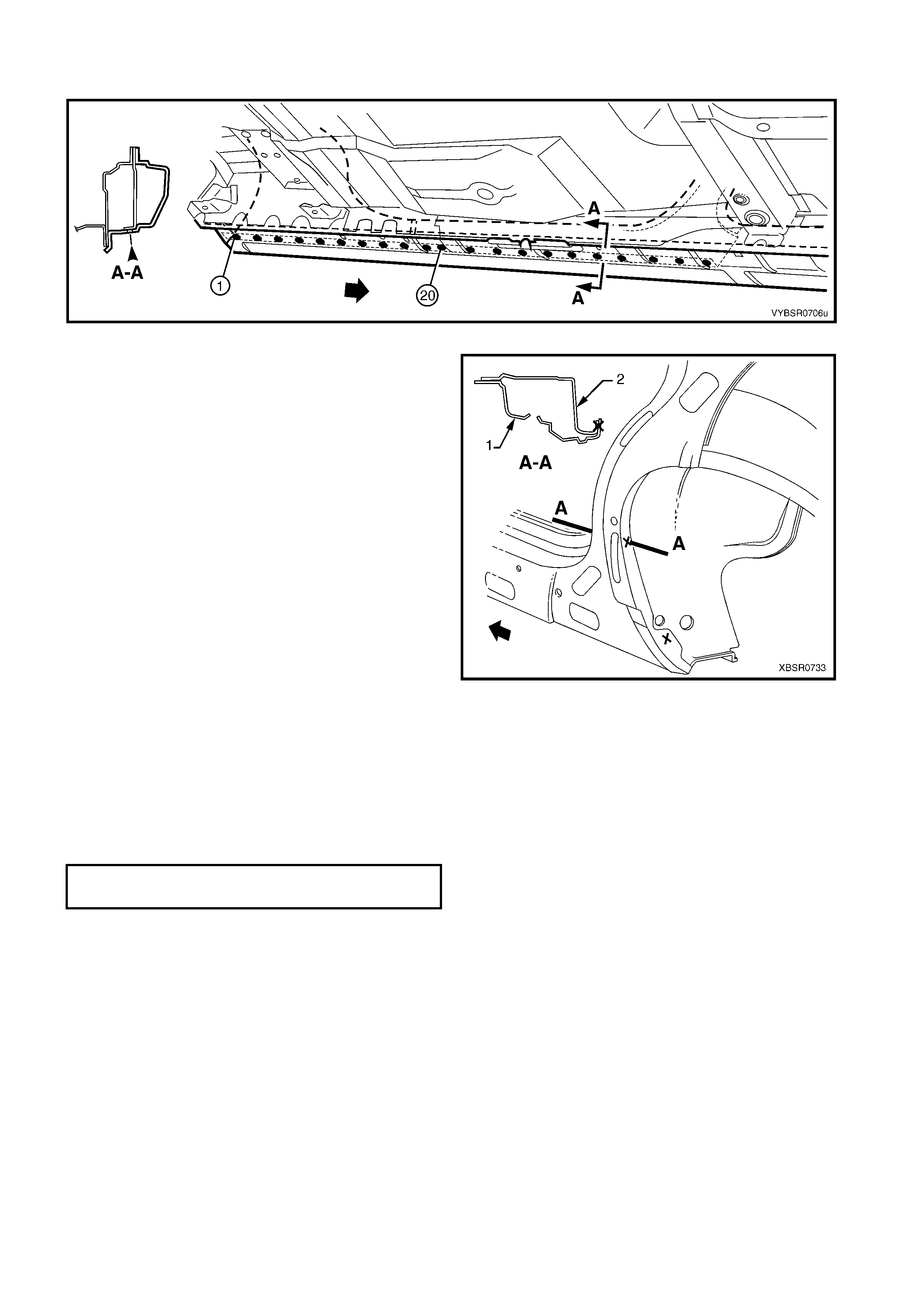

Figure 7C-31

2.5 QUARTER LOWER REAR PANEL – REPLACE

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Remove the adjacent panels as required, refer to

the appropriate procedure in this Section.

Figure 7C-32

3. Spot cut the welds attaching the quarter lower rear

panel to the:

- side inner upper panel, three places,

- quarter panel extension, three places,

- rear end lower panel, one place,

- rear end panel, three places.

4. Carefully grind the MIG weld along the quarter

lower rear panel and rear end lower panel join.

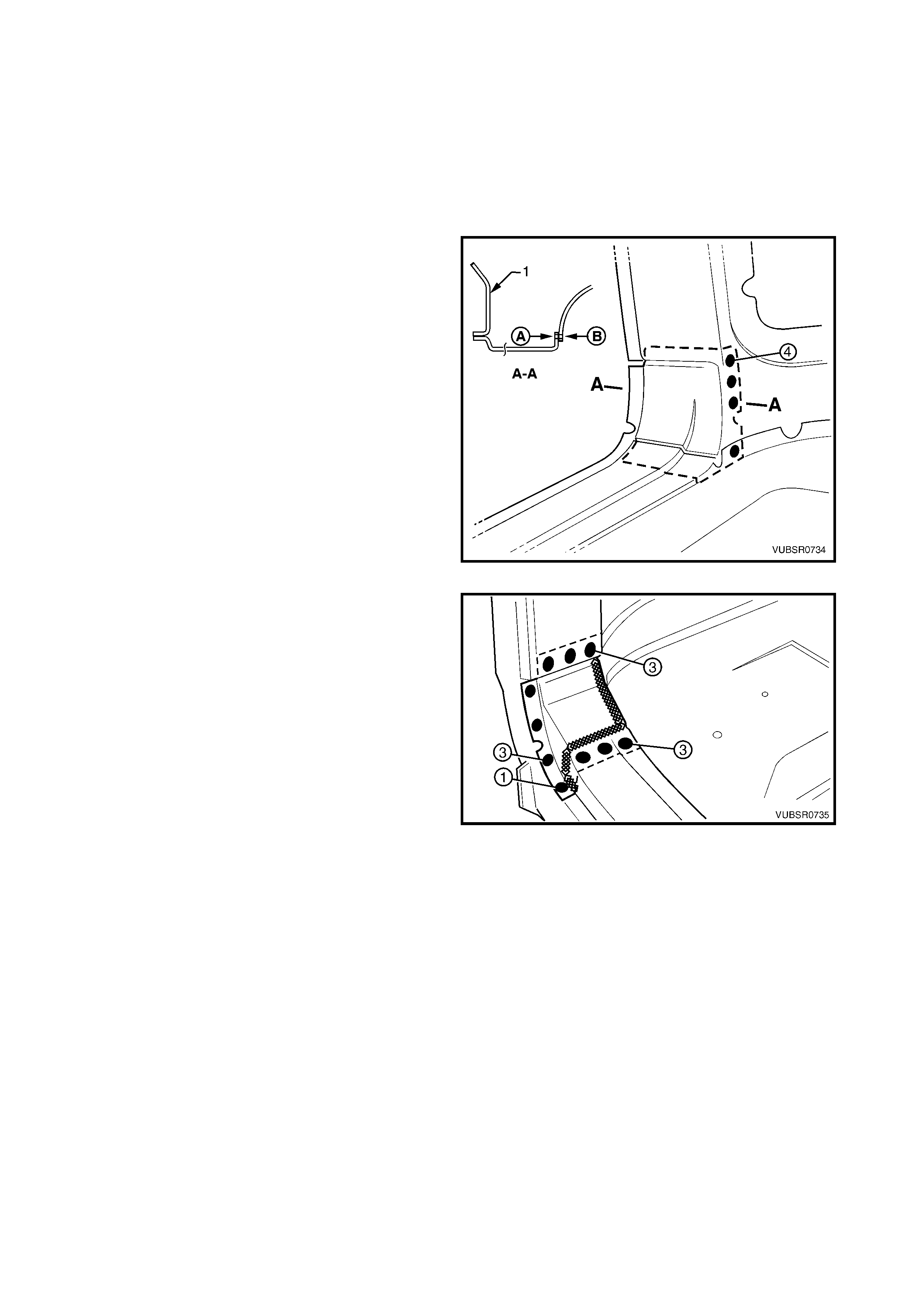

Figure 7C-33

5. If the quarter panel extension (1) was removed,

spot cut the four welds attaching the quarter lower

rear panel to the side inner upper panel (A).

NOTE: If the quarter panel extension was not

removed, spot cut through the side inner upper panel

and load floor panel, the four welds attaching the

quarter lower rear panel to the side inner upper panel

(B).

6. Carefully grind the MIG weld (2) along the quarter

lower rear panel and side inner upper panel join.

7. Remove the panel from the vehicle, then repair

any damage to adjacent parts as required.

Figure 7C-34

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The s ame number and pos ition of spot welds ( or plug welds) s hould be used when replac ing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

3. If the quarter panel extension (1) was removed,

spot or plug weld 4 places, the quarter lower rear

panel to the side inner upper panel (A).

NOTE: If the quarter panel extension was not

removed, spot or plug weld the quarter lower rear

panel through the s ide inner upper panel and load f loor

panel, four places (B).

Figure 7C-35

4. Spot or plug weld the quarter lower rear panel to

the:

- side inner upper panel, 3 places,

- quarter panel extension, 3 places,

- rear end lower panel, 1 place,

- rear end panel, 3 places.

5. MIG weld along the quarter lower rear panel, side

inner upper panel and rear end panel join.

6. Replace any other removed panels as required.

7. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

8. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

9. Apply Cavity Wax (Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3C.

10. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 7C-36

2.6 DOOR OPENING FRAME ASSEMBLY – REPLACE

NOTE 1: This procedure requires the removal

of the roof panel. As an alternative, the door opening

frame assembly can be separated at the upper pillar

sections by following the procedures in

DOOR OPENING FRAME ASSEMBLY – PARTIAL

REPLACE, HINGE PILLAR and CENTRE PILLAR in

this Section.

NOTE 2: Cavity Foam is used within the hinge &

centre pillar cavities. Care is required when repairing

the vehicle in these areas, refer to Section 2, 10.

CAVITY FOAM prior to beginning any work for further

information.

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Remove the windshield, quarter window and rear

window, refer to Section 1A6, STATIONARY

WINDOWS in the MY 2003 VY & V2 Series II

Service Information.

3. Remove the dash panel retaining bolt from the

hinge pillar.

4. Remove the roof panel, refer to Section 9, ROOF.

5. Rem ove the rear quarter panel, refer to 2.1 REAR

QUARTER PANEL – REPLACE.

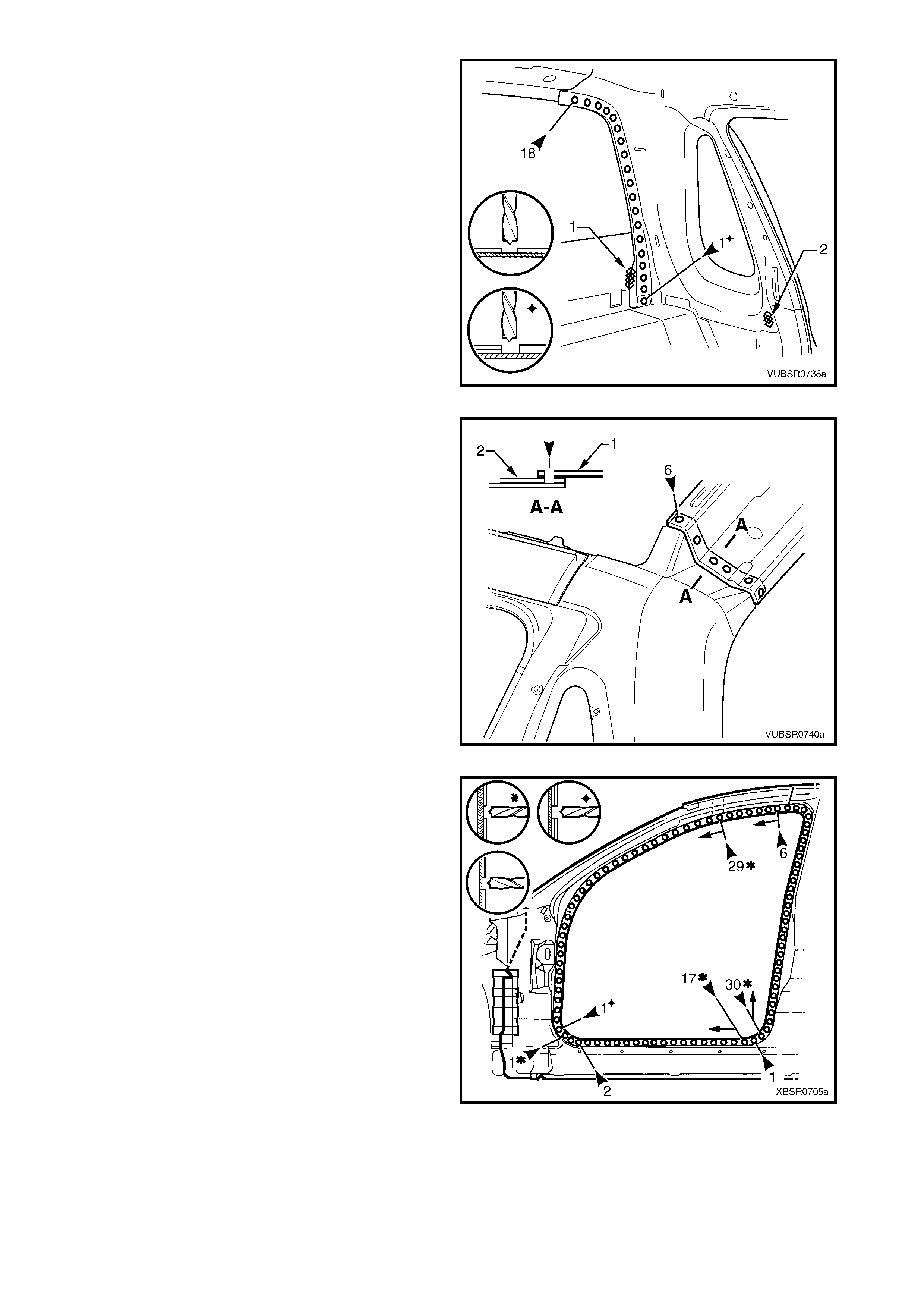

Figure 7C-37

6. Remove the front wheelhouse panel upper side

rail, refer to Section 4, 2.5 FRONT

WHEELHOUSE PANEL UPPER SIDE RAIL.

7. Spot cut the welds attaching the door opening

frame assembly to the inner rocker panel and to

the hinge pillar inner panel assembly.

NOTE: In order to spot cut the uppermost of these

welds it may be necessary to cut and peel back the

section of hinge reinforcement panel covering the

welds, to gain the required access.

8. If required, spot cut the welds attaching the inner

rocker panel (1) and hinge pillar inner panel

assembly (2) to the rock er panel reinforcement (3) .

Refer to Figure 7C-39.

NOTE 1: Not all vehicles have these welds.

NOTE 2: The MIG welds should not have to be

removed.

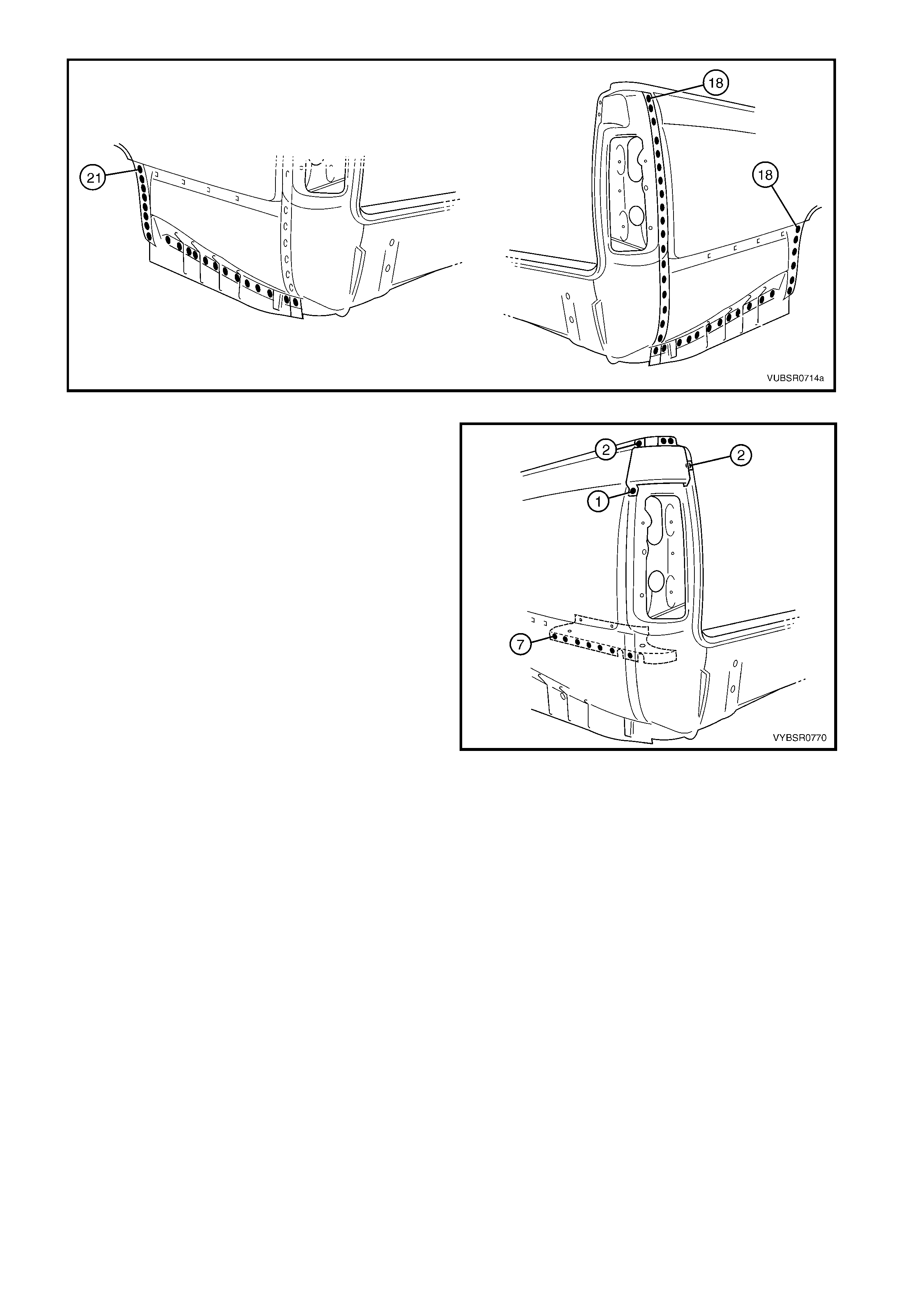

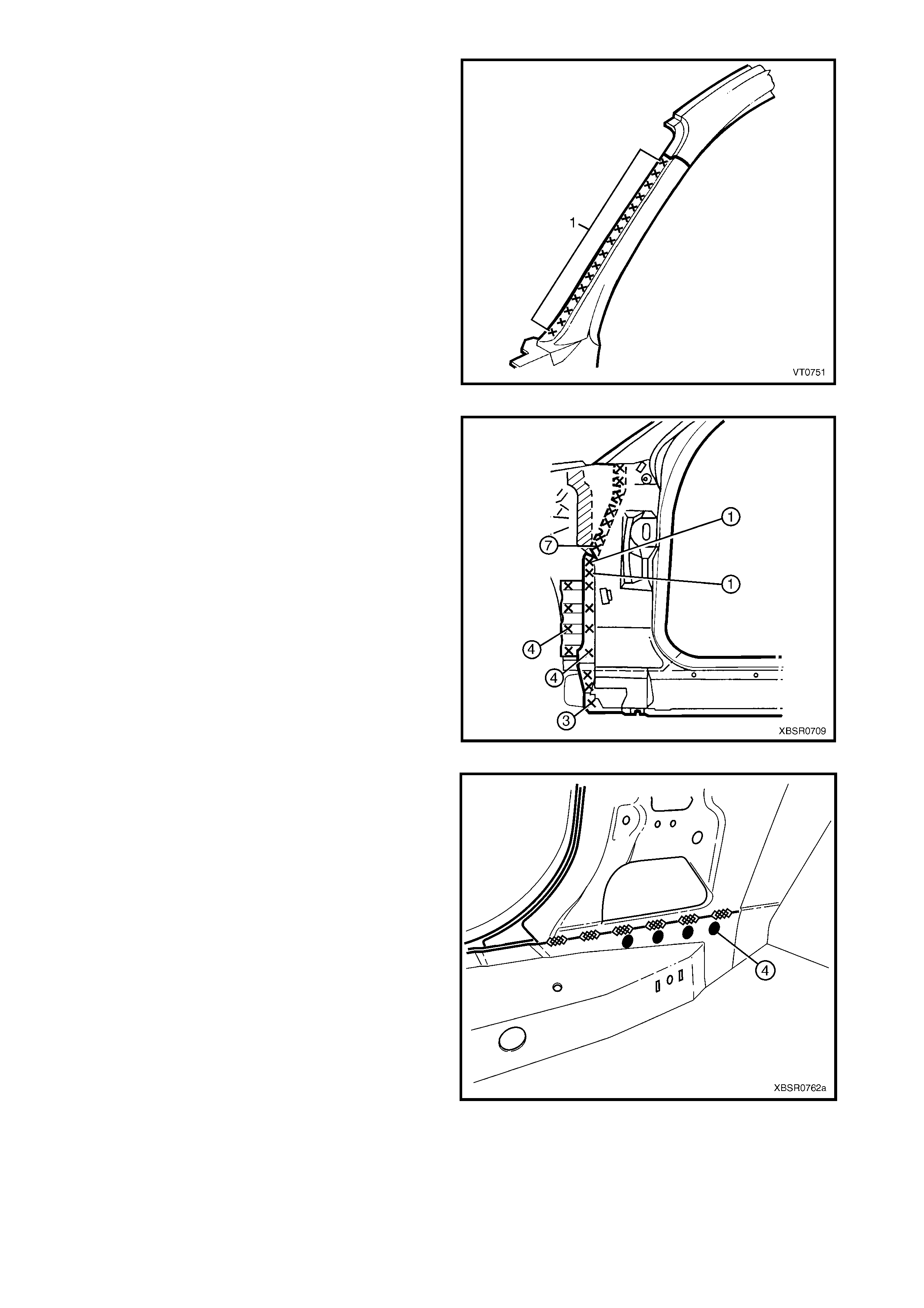

Figure 7C-38

Figure 7C-39

9. Spot cut the two welds at the base of the hinge

pillar, attaching the door opening frame assembly

(1) to the hinge pillar inner panel assembly (2).

Figure 7C-40

10. Spot cut the welds on the windshield side flange,

attaching the door opening frame assembly (1) to

the hinge pillar inner panel assembly (2).

11. Spot cut along the vertical flange below the rocker

panel to separate the door opening frame

assembly from the inner rocker panel, refer to

Figure 7C-42.

Figure 7C-41

Figure 7C-42

12. Spot cut from below, up into the rocker panel, the welds attaching the door opening frame assembly to the

quarter panel inner assembly, refer to Figure 7C-43.

Figure 7C-43

13. Spot cut the welds around the rear wheel arch,

joining the door opening fram e assem bly (1) to the

quarter panel inner assembly (2).

NOTE: Som e of thes e welds may have been removed

with the rear quarter panel.

Figure 7C-44

14. Spot cut the welds along the roof flange.

NOTE: Many of these welds may have been removed

with the roof panel.

Figure 7C-45

15. Spot cut the welds attaching the door opening

frame assembly to the side inner upper front panel.

16. Grind off the MIG weld (1) attaching the door

opening frame assembly to the front seatback

panel.

17. Grind off the MIG weld (2) attaching the door

opening frame assembly to the side inner upper

front panel.

Figure 7C-46

18. Spot cut the welds attaching the door opening

frame assembly to the roof rear panel.

Figure 7C-47

19. Spot cut the welds on the flange surrounding the

front door opening, attaching the door opening

fram e ass embly to the hinge pillar inner as sembly,

inner rocker panel and quarter panel inner

assembly.

20. Spot cut the welds attaching the door opening

frame assembly to the side inner upper front panel,

side inner upper panel and quarter panel inner

assembly, refer to Figure 7C-49.

NOTE: W elds mark ed # may have been rem oved with

the rear quarter panel.

21. Remove the door opening frame assembly and

repair any damage to adjacent parts as required.

22. Check and rectify the alignment of the body as

required, refer to 3. BODY DIMENSIONS in

Section 3C.

Figure 7C-48

Figure 7C-49

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The same number and position of s pot welds ( or plug welds) s hould be used when replacing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. As required, mark the new panel with drilling locations in preparation for plug welding. Drill holes as required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

3. Apply Acrylic Spot Weld Sealer (Item 2), refer to 5. BODY SEALING, ADHESIVES & DEADENERS in

Section 3C.

4. Securely clamp the door opening frame assembly

in position on the vehicle body.

5. Begin attaching the door opening frame assembly

by spot welding around the front door opening

flange.

Figure 7C-50

6. Spot weld the door opening fr ame as semb ly to the

roof rear panel.

7. Spot or plug weld the door opening frame

assembly to the side inner upper front panel, side

inner upper panel and quarter panel inner

assembly, refer to Figure 7C-52.

Figure 7C-51

Figure 7C-52

8. Spot or plug weld the door opening frame

assembly along the roof flange.

NOTE: The remaining welds are made when the roof

panel is installed.

Figure 7C-53

9. Spot or plug weld the door opening frame

assembly to the side inner upper front panel.

10. MIG weld 50 mm (1) the door opening frame

assembly to the front seatback panel.

11. MIG weld 20mm (2) the side inner upper front

panel to the door opening frame assembly.

Figure 7C-54

12. Spot weld along the windshield flange, attaching

the door opening frame assembly to the hinge

pillar inner panel assembly.

Figure 7C-55

13. Spot weld in two places at the base of the hinge

pillar, attaching the door opening frame assembly

(1) to the hinge pillar inner panel assembly (2).

Figure 7C-56

14. Spot or plug weld the door opening frame

assembly to the inner rocker panel and to the

hinge pillar inner panel assembly.

NOTE: If the s heet metal was modified to allow acces s

to these welds, it should be repaired to its original

configuration.

Figure 7C-57

15. If removed, plug weld the inner rocker panel and

hinge pillar inner panel assembly to the rocker

panel reinforcement.

16. Spot weld the door opening fram e assem bly along

the vertical flange below the rocker panel, refer to

Figure 7C-59.

Figure 7C-58

Figure 7C-59

17. Plug weld up through the roc ker panel to attac h the door opening f ram e assembly to the quarter panel inner

assembly, refer to Figure 7C-60.

Figure 7C-60

18. Spot or plug weld in two places around the rear

wheel arch, attaching the door opening frame

assembly to the quarter panel inner assembly.

NOTE: These welds will be completed when the rear

quarter panel is replaced.

19. Replace front wheelhouse panel upper side rail,

refer to Section 4, 2.5 FRONT WHEELHOUSE

PANEL UPPER SIDE RAIL.

20. Replace the roof panel, refer to Section 9, ROOF.

21. Replace the rear quarter panel, refer to 2.1 REAR

QUARTER PANEL – REPLACE.

22. Install the door hinges, refer to 2.3 DOOR HINGE

(BODY SIDE) – REPLACE in Section 8.

23. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

24. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

25. Apply Cavity Wax (Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3C.

Figure 7C-61

26. Apply Spray-on Deadener (Item 7) where applicable, refer to 5. BODY SEALING, ADHESIVES &

DEADENERS in Section 3C.

27. Install the dash panel retaining bolt through the hinge pillar and tighten to the specified torque.

28. Replace the windshield, quarter glass and rear window, refer to Section 1A6 STATIONARY GLASS the

MY 2003 VY & V2 Series II Service Information.

29. Insert Cavity Foam into the hinge & centre pillars as required, refer to Section 2, 10. CAVITY FOAM.

30. Install the rem aining com ponents as described in the appr opriate Section of the MY 2003 VY & V2 Series II

Service Information.

DASH PANEL RETAINING BOLT

TORQUE SPECIFICATION 35.0 – 45.0 Nm

2.7 DOOR OPENING FRAME ASSEMBLY – PARTIAL REPLACE, HINGE PILLAR

NOTE: Cavity Foam is used within the hinge & centre

pillar cavities. Care is required when repairing the

vehicle in these areas, refer to Section 2, 10.

CAVITY FOAM prior to beginning work for further

information.

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Secure an appropriate tool between the front door

opening flanges to maintain correct body

alignment.

3. Remove the windshield refer to Section 1A6,

STATIONARY WINDOWS in the MY 2003 VY &

V2 Series II Service Information.

4. Remove the dash panel retaining bolt from the

hinge pillar.

5. Remove the front wheelhouse panel upper side

rail, refer to Section 4, 2.5 FRONT

WHEELHOUSE PANEL UPPER SIDE RAIL.

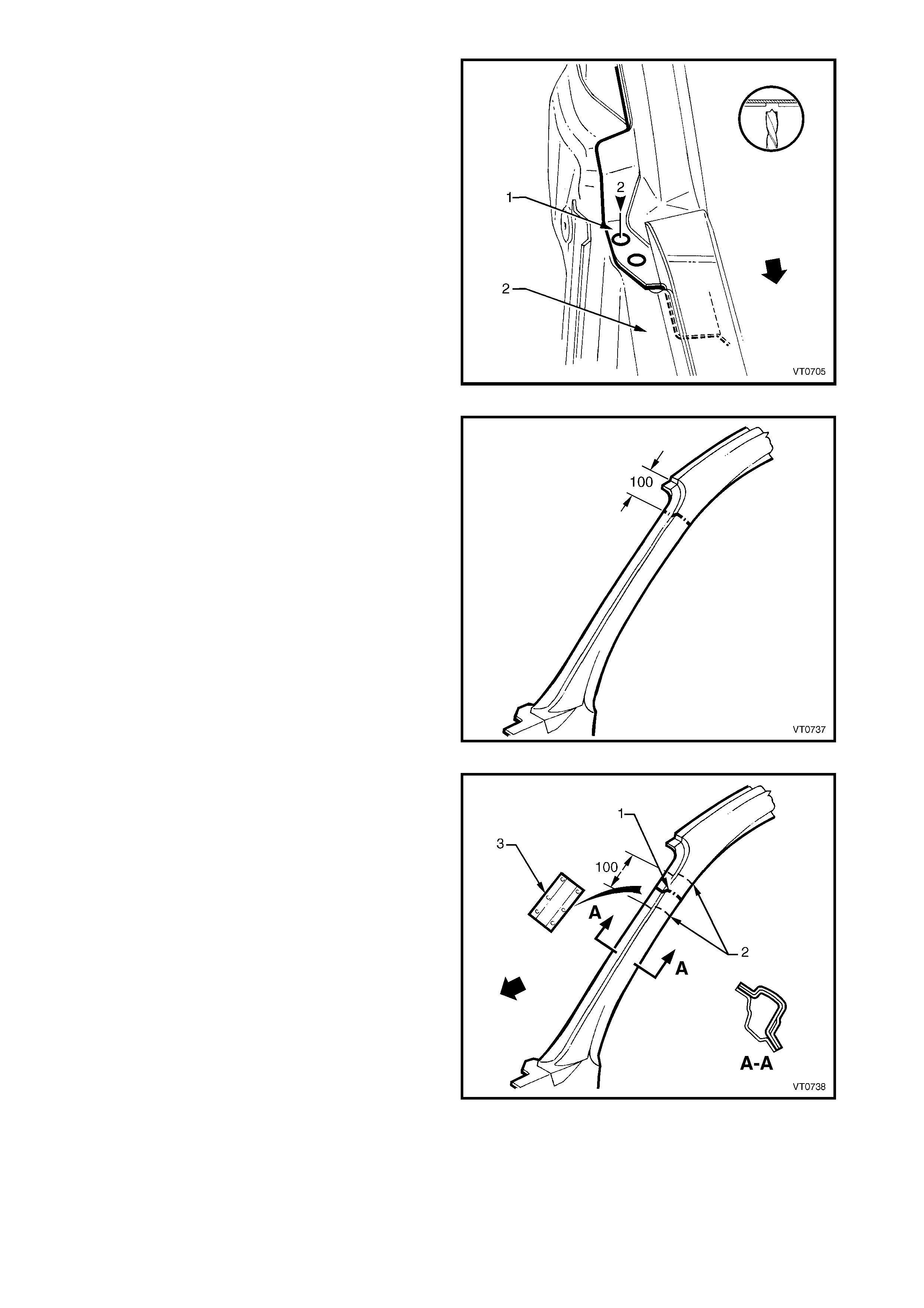

Figure 7C-62

6. Spot cut the welds attaching the door opening

frame assembly to the inner rocker panel and to

the hinge pillar inner panel assembly.

NOTE: In order to spot cut the uppermost of these

welds it may be necessary to cut and peel back the

section of hinge reinforcement panel covering the

welds, to gain the required access.

7. If required, spot cut the welds attaching the inner

rocker panel (1) and hinge pillar inner panel

assembly (2) to the rock er panel reinforcement (3) ,

refer to Figure 7C-64.

NOTE 1: Not all vehicles have these welds.

NOTE 2: The MIG welds should not have to be

removed.

Figure 7C-63

Figure 7C-64

8. Spot cut the two welds at the base of the hinge

pillar, attaching the door opening frame assembly

(1) to the hinge pillar inner panel assembly (2).

Figure 7C-65

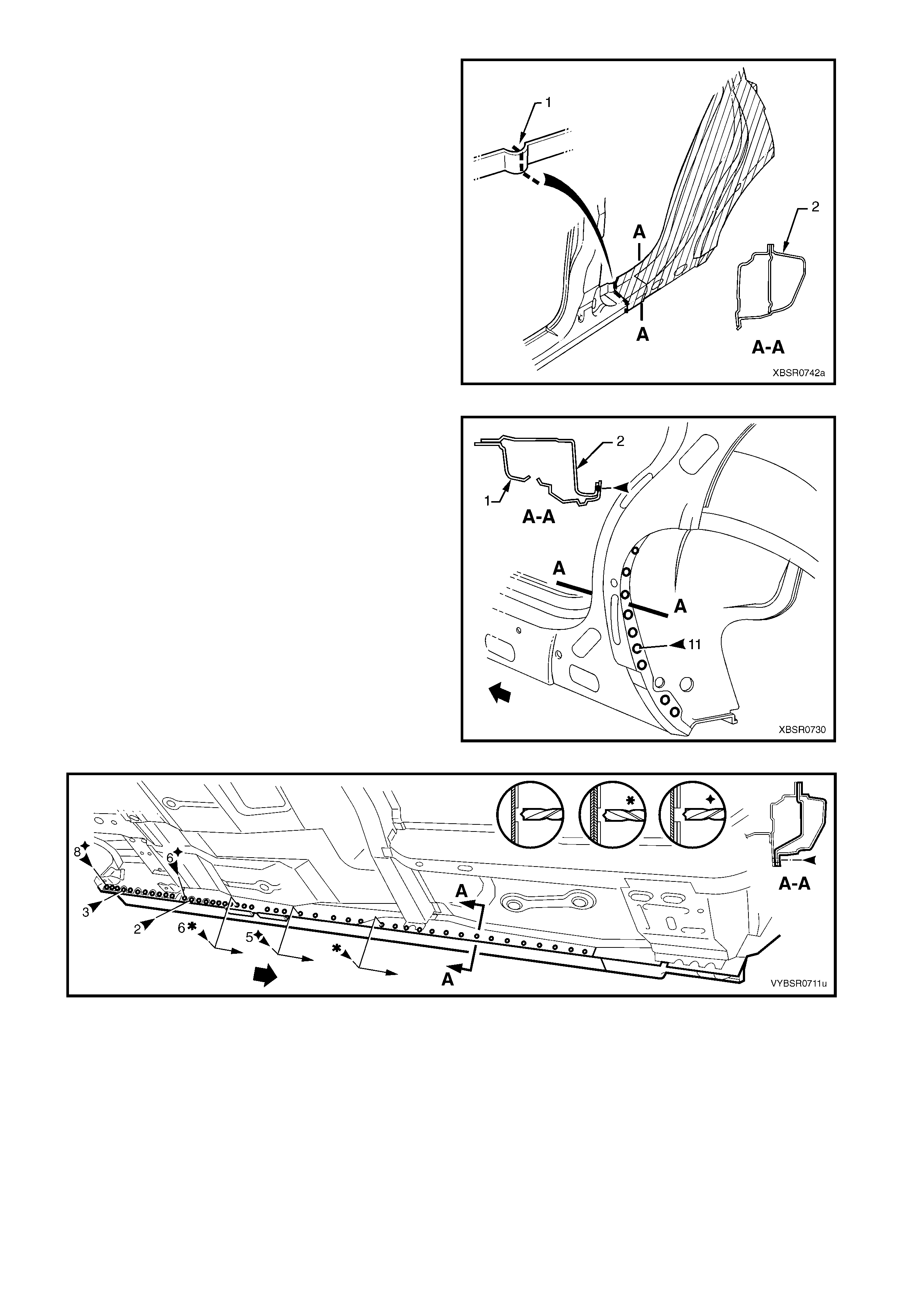

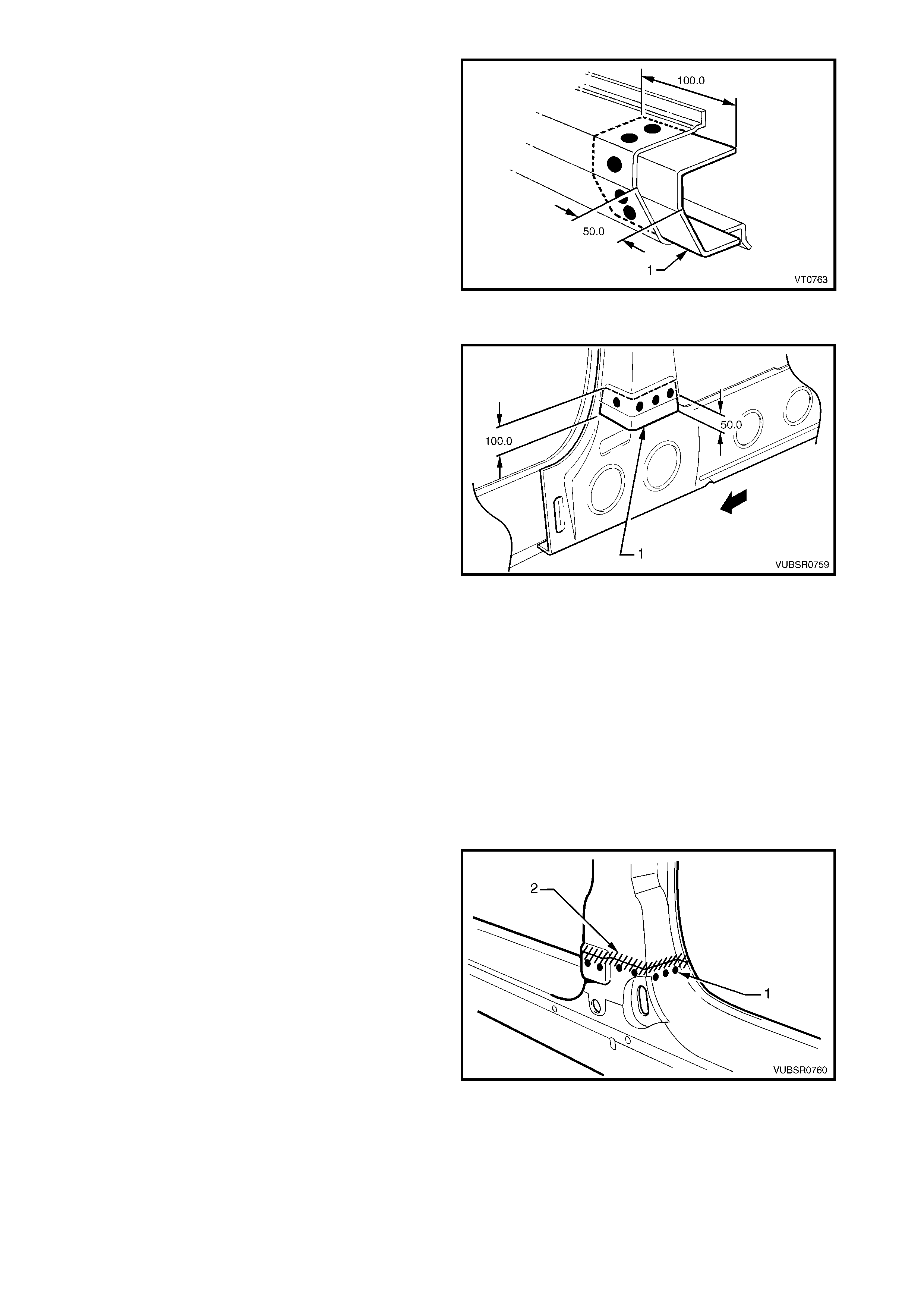

9. Select a cutting point on the hinge pillar. This cut

point should be within the region specified.

Figure 7C-66

10. At the selected point (1), cut through the outer and

reinforcement panels, leaving the inner panel

intact.

11. Mark the inner panel at points 50 mm either side of

the cut line on the outer panel and cut the inner

panel at these two points (2). Spot cut the welds

and remove the 100 mm section of inner panel (3).

Figure 7C-67

12. Spot cut the welds on the windshield side flange,

up to the point of the cut.

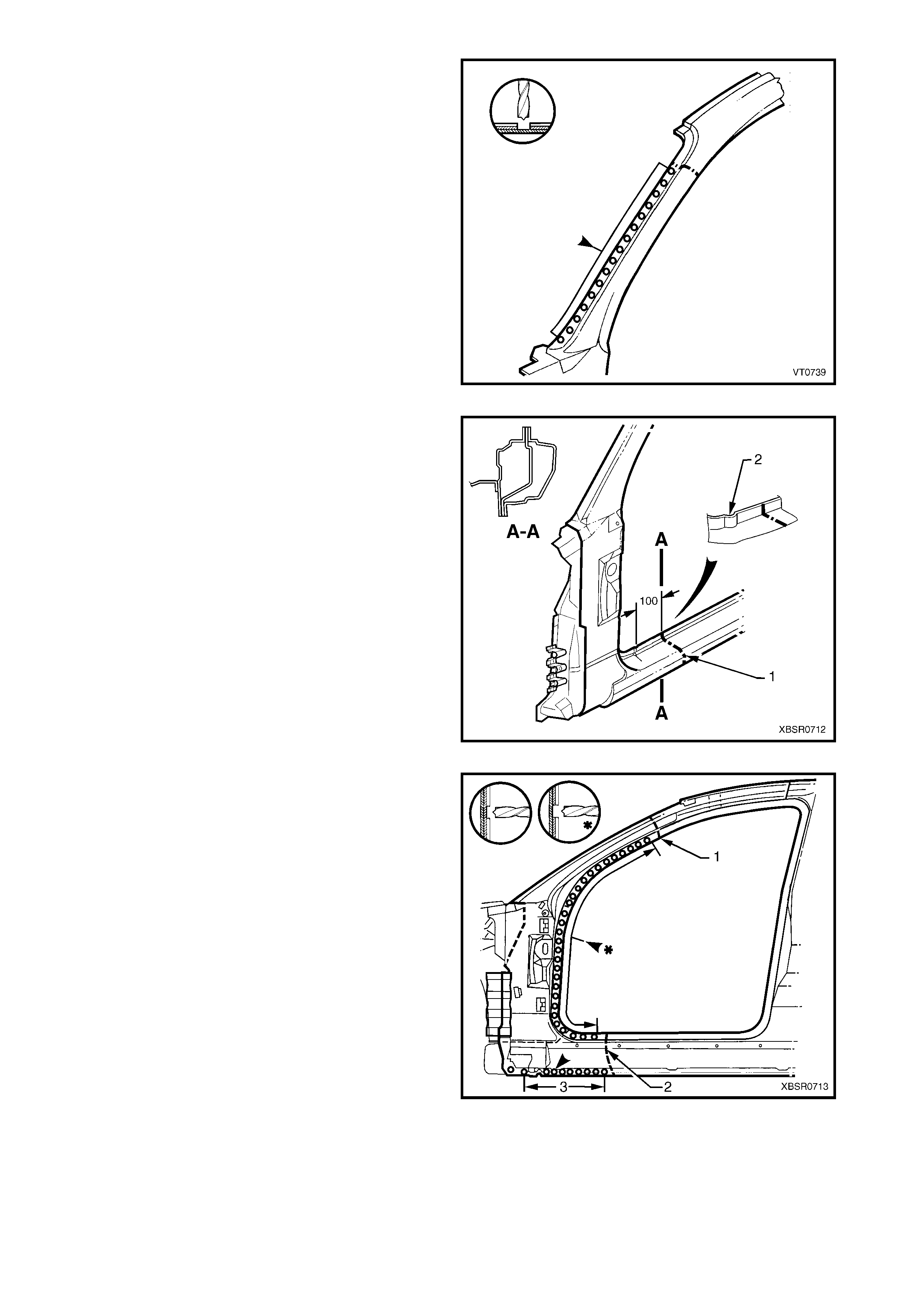

Figure 7C-68

13. Cut through the rocker panel section of the frame

door opening assembly. The cut point (1) should

be approximately 100 mm from the dimple (2) on

the flange. Cut through both the outer panel and

the reinforcement panel.

Figure 7C-69

14. Spot cut the welds on the flange along the front

door opening, from the cut near the top of the

hinge pillar (1) to the cut in the rocker panel (2).

15. Spot cut the welds along the flange (3) below the

rocker panel (to the point of the cut), separating

the door opening frame assembly from the inner

rocker panel.

16. Remove the partial hinge pillar from the vehicle,

then repair any damage to adjacent parts.

17. Check and rectify the alignment of the body as

required, refer to 3. BODY DIMENSIONS in

Section 3C.

Figure 7C-70

REPLACE

NOTE 1: Spot welding is the preferred method for

attaching of panels and should be used whenever

possible. Where the spot welding equipment will not

access the required weld position, a plug weld should

be performed.

NOTE 2: T he sam e num ber and position of spot welds

(or plug welds) should be used when replacing the

panel, as was used during manufacture, in order to

maintain the original structural strength of the vehicle.

1. Cut a replacement panel section (1), accurately

measuring the position of cuts to match the section

removed.

Figure 7C-71

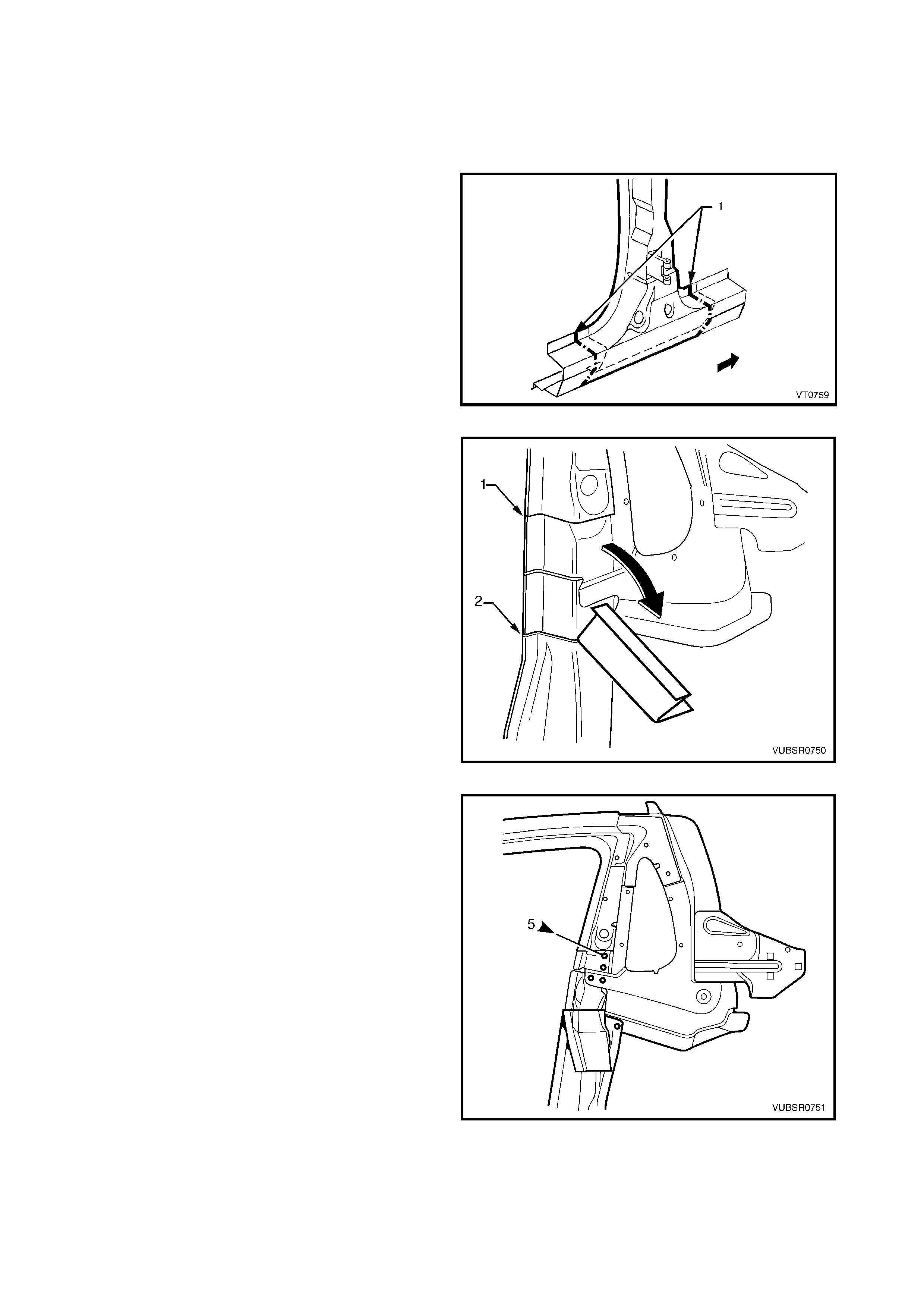

2. Remove a section of inner rocker panel (1), cut

50 mm each side of the cut in the roc ker panel (2).

This allows access for welding the rocker panel

reinforcement.

Figure 7C-72

3. Either manufacture a new section or cut an

existing length of surplus rocker panel section, to

form a reinforcement (1), approximately 100 mm in

length.

4. Prepare the mating surfaces and treat with Weld

Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

5. Clamp this reinforcement firmly behind the cut

section of rocker panel on the vehicle and spot or

plug weld in place. Position welds at a maximum

spacing of 35 mm apart.

Figure 7C-73

6. Using a similar technique, manufacture or cut a

section of reinforcement panel (1) (approximately

60 m m long) to fit on the inside of the replacem ent

hinge pillar outer panel (2) at the point of the cut.

NOTE: Remove the flanges from this reinforcement

panel.

7. Prepare the mating surfaces and treat with Weld

Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

8. Clamp the reinforcement panel firmly behind the

cut section of the hinge pillar outer and spot

weld (3) in place.

9. Mark the new hinge pillar panel with drilling

locations in preparation for plug welding where

required. Drill holes as marked.

10. Prepare the mating surfaces and treat with Weld

Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

11. Apply Acrylic Spot Weld Sealer (Item 2), refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

Figure 7C-74

12. Clamp the replacement panel in position on the

vehicle and check the door opening dimensions,

refer to 3. BODY DIMENSIONS in Section 3C.

Adjust position as required.

Figure 7C-75

13. Plug weld (1) the top of the pillar to the

manufactured reinforcement, then MIG butt

weld (2) the two sections together.

Figure 7C-76

14. Plug weld (1) the new panel in the rocker panel

region, then MIG butt weld (2) the two sections

together.

Figure 7C-77

15. Gaining access through the removed section of

inner panel, MIG butt weld (1) the reinforcement

panel together.

16. Butt weld the removed access panel (2) in

position. Replace the spot welds with the same

number that was removed.

Figure 7C-78

17. Spot weld (1) the pillar along the door opening

flange.

18. Spot weld (2) the flange beneath the rocker panel,

attaching the new panel to the inner rocker panel.

Figure 7C-79

19. Spot weld (1) the pillar along the windshield

opening flange.

Figure 7C-80

20. Spot or plug weld the door opening frame

assembly to the inner rocker panel and to the

hinge pillar inner panel assembly.

NOTE: If the s heet metal was modified to allow acc es s

to these welds, it should be repaired to its original

configuration.

Figure 7C-81

21. If removed, plug weld the inner rocker panel and

hinge pillar inner panel assembly to the rocker

panel reinforcement.

Figure 7C-82

22. Gaining access through the section of removed

inner rocker panel, MIG butt weld (1) the new

section of rocker panel reinforcement to the

existing section.

23. Replace the removed section of inner rocker

panel (2) by MIG butt welding it in place and spot

welding it along the door opening flange. Replace

the spot welds with the same number of as were

removed.

24. Install the door hinges, refer to, 2.3 DOOR HINGE

(BODY SIDE) – REPLACE in Section 8.

25. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

26. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

Figure 7C-83

27. Apply Cavity W ax (Item 8) as required to the ins ide of any box s ections or areas inacces sible to paint, refer

to 6. CAVITY WAX in Section 3C.

28. Install the dash panel retaining bolt through the hinge pillar.

29. Replace the windshield, ref er to Sect ion 1A6 STATIONARY GLASS the MY 2003 VY & V2 Series II Service

Information.

30. Insert Cavity Foam into the hinge pillar as required, refer to Section 2, 10. CAVITY FOAM.

31. Install the rem aining com ponents as described in the appr opriate Section of the MY 2003 VY & V2 Series II

Service Information.

DASH PANEL RETAINING BOLT

TORQUE SPECIFICATION 35.0 – 45.0 Nm

2.8 DOOR OPENING FRAME ASSEMBLY – PARTIAL REPLACE, CENTRE PILLAR

NOTE: Cavity Foam is used within the hinge & centre

pillar cavities. Care is required when repairing the

vehicle in these areas, refer to Section 2,

10. CAVITY FOAM prior to beginning work for further

information.

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Secure the vehicle on a suitable fixture. As a

minimum, support the appropriate structural

sections of the vehicle on safety stands. Secure a

suitable tool between the front door opening

flanges to maintain alignment.

3. Rem ove the rear quarter panel, refer to 2.1 REAR

QUARTER PANEL – REPLACE.

Figure 7C-84

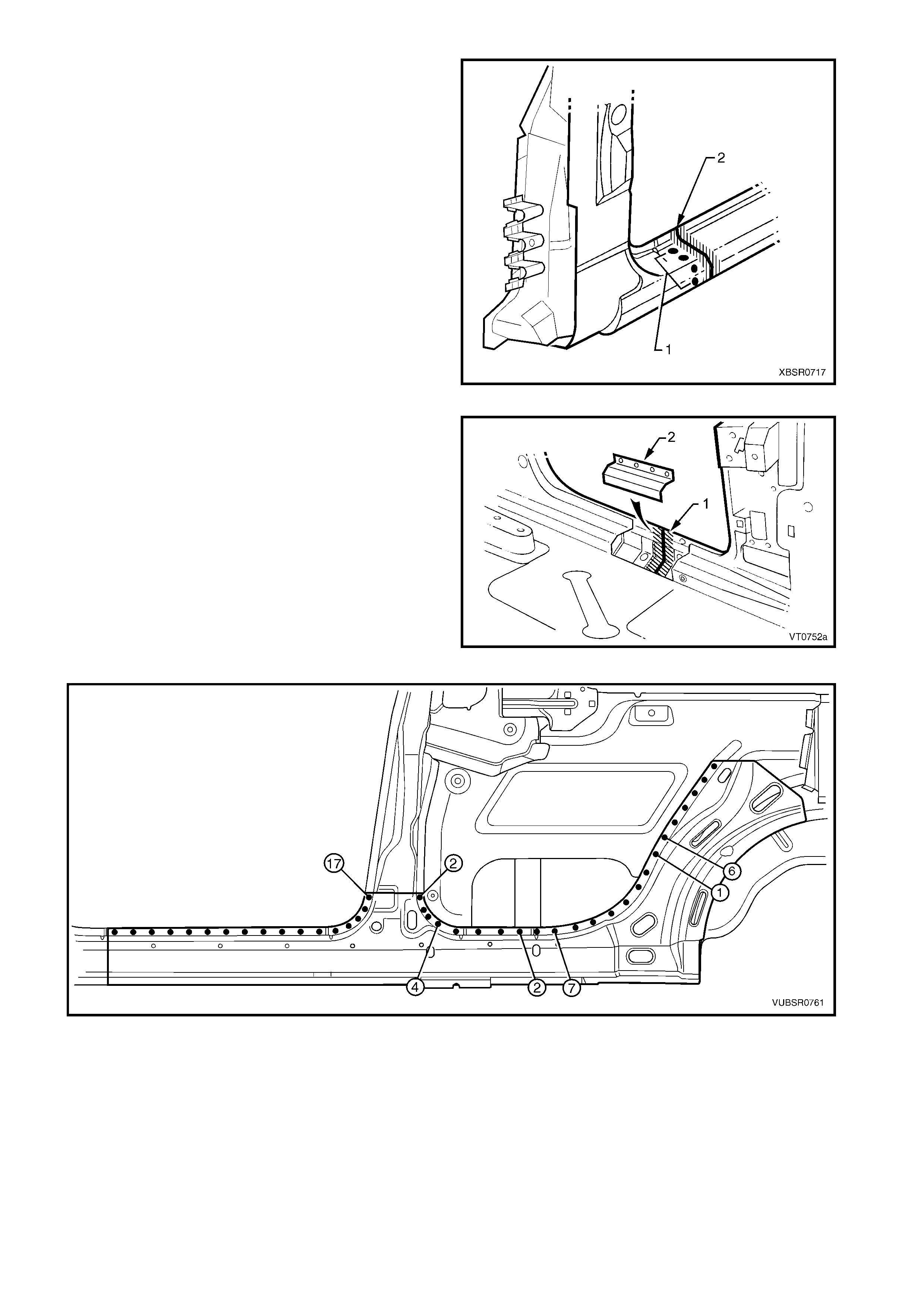

4. Cut the door opening frame assembly (1) as

shown.

NOTE: The upper cut is just below the recess and the

lower cut is approximately level with the centre pillar

upper reinforcement.

5. Spot cut the two welds attaching door opening

frame assembly to the centre pillar reinforcement.

6. Spot cut the welds attaching the door opening

frame assembly to the quarter panel inner

assembly.

7. Referring to Figure 7C-86, spot cut the welds

attaching the underbody jacking locator (1) and

remove.

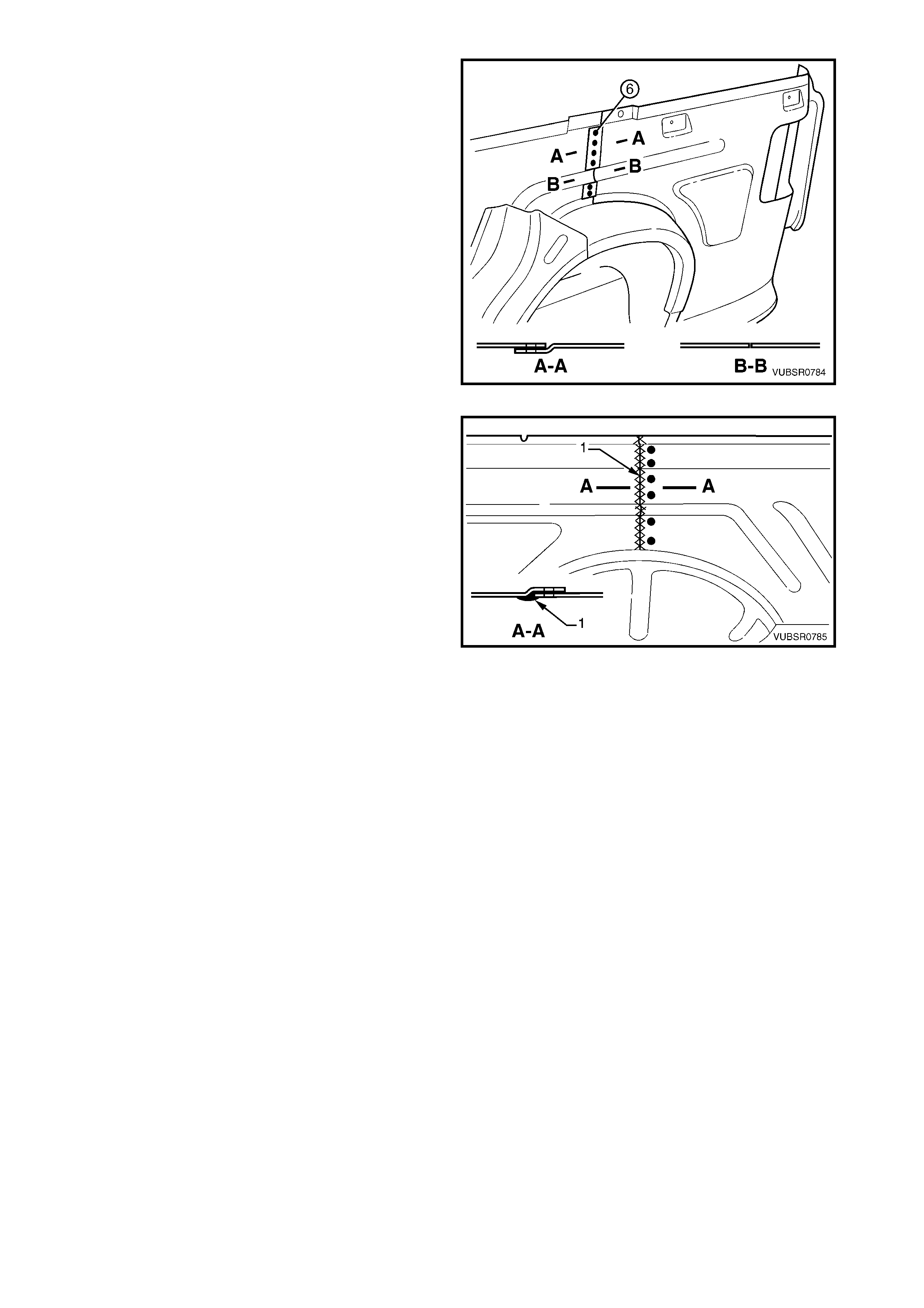

8. Referring to Figure 7C-86, cut through the door

opening frame assembly (2) in two places shown

(3):

- At the join of the rocker panel reinforcement (4)

and centre pillar lower reinforcement (5) for the

front cut, and

- At the dimple in the flange for the rear cut.

NOTE: Mak e the f ront cut c aref ully as the rock er panel

reinforcement (4) must not be cut. The centre pillar

lower reinforcement (5) is removed with the centre

pillar section.

Figure 7C-85

9. Spot cut the welds on the flange attaching the centre pillar section to the inner rocker panel (6). Refer to

weld group A.

10. Spot cut the welds on the underside of the rocker panel attaching the centre pillar section to the quarter

panel inner assembly (7). Refer to weld group B.

Figure 7C-86

11. Spot cut the welds attaching the front and rear

sides of the door opening frame assembly to the

quarter panel inner assembly.

NOTE: The number of welds will vary depending on

the cut locations.

12. Spot cut the four welds attaching the centre pillar

upper reinforcement to the centre pillar

reinforcement.

13. Remove the centre pillar section from the vehicle.

14. Repair any damage to adjacent parts as required.

Figure 7C-87

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The same number and position of s pot welds ( or plug welds) s hould be used when replacing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. Cut the r eplac ement door opening f r ame asse mbly

through rocker section as shown. Accurately

meas ur e the position of cuts to m atc h the rem oved

panel section.

Figure 7C-88

2. Cut the r eplac ement door opening f r ame assembly

below the recess to match the removed section

from the vehicle (1).

NOTE: Cut through the outer panel only.

3. Make a second cut approximately level with the

centre pillar upper reinforcement (2).

NOTE: Cut through the flange and front side ONLY.

4. Cut the required spot welds and carefully bend the

outer panel down to expose the spot welds

attaching the centre pillar upper reinforcement to

the centre pillar reinforcement.

Figure 7C-89

5. On the replacement panel, spot cut the five welds

attaching the centre pillar lower section to the

centre pillar upper reinforcement and remove the

section.

Figure 7C-90

6. Cut two sections from s urplus roc k er panel pieces ,

or manufacture new sections (1), each

approximately 100 mm in length.

7. Prepare the mating surfaces and treat with Weld

Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

8. Clamp these sections firmly behind both the cut

faces of rocker panel on the vehicle and spot or

plug weld in place. Perform the welds at a

maximum spacing of 35 mm.

9. Mark the new panel with drilling locations in

preparation for plug welding where required. Drill

holes as marked.

10. Prepare the mating surfaces and treat with Weld

Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

Figure 7C-91

11. Install the replacement panel in position, sliding the

centre pillar reinf orcement (1) and the centre pillar

lower reinforcement (2) behind the centre pillar

upper reinf orcement (3), until the front edge of the

lower reinf orcem ent butts against the f ront edge of

the upper reinforcement.

12. Manipulate the rocker panel section in position,

inserting the f ront firs t, then the r ear and c lamp the

assembly in place.

Figure 7C-92

13. Plug weld the centre pillar upper reinforcement to

the centre pillar lower reinforcement, two places

and the centre pillar reinforcement two places.

Figure 7C-93

14. Bend the outer panel bac k in pos ition and MIG butt

weld the sections together as shown (1 & 2).

15. Plug weld the outer panel, centre pillar upper

reinforcement and centre pillar reinforcement two

places.

Figure 7C-94

16. Plug weld (1) the front and rear sides of the door

opening fram e ass embly to the quarter panel inner

assembly.

NOTE: The number of welds will vary depending on

the cut locations.

17. Plug weld (2) the front and rear sides of the door

opening frame assembly to the rocker panel

reinforcements.

18. MIG butt weld (3) each join across the rocker

panel.

Figure 7C-95

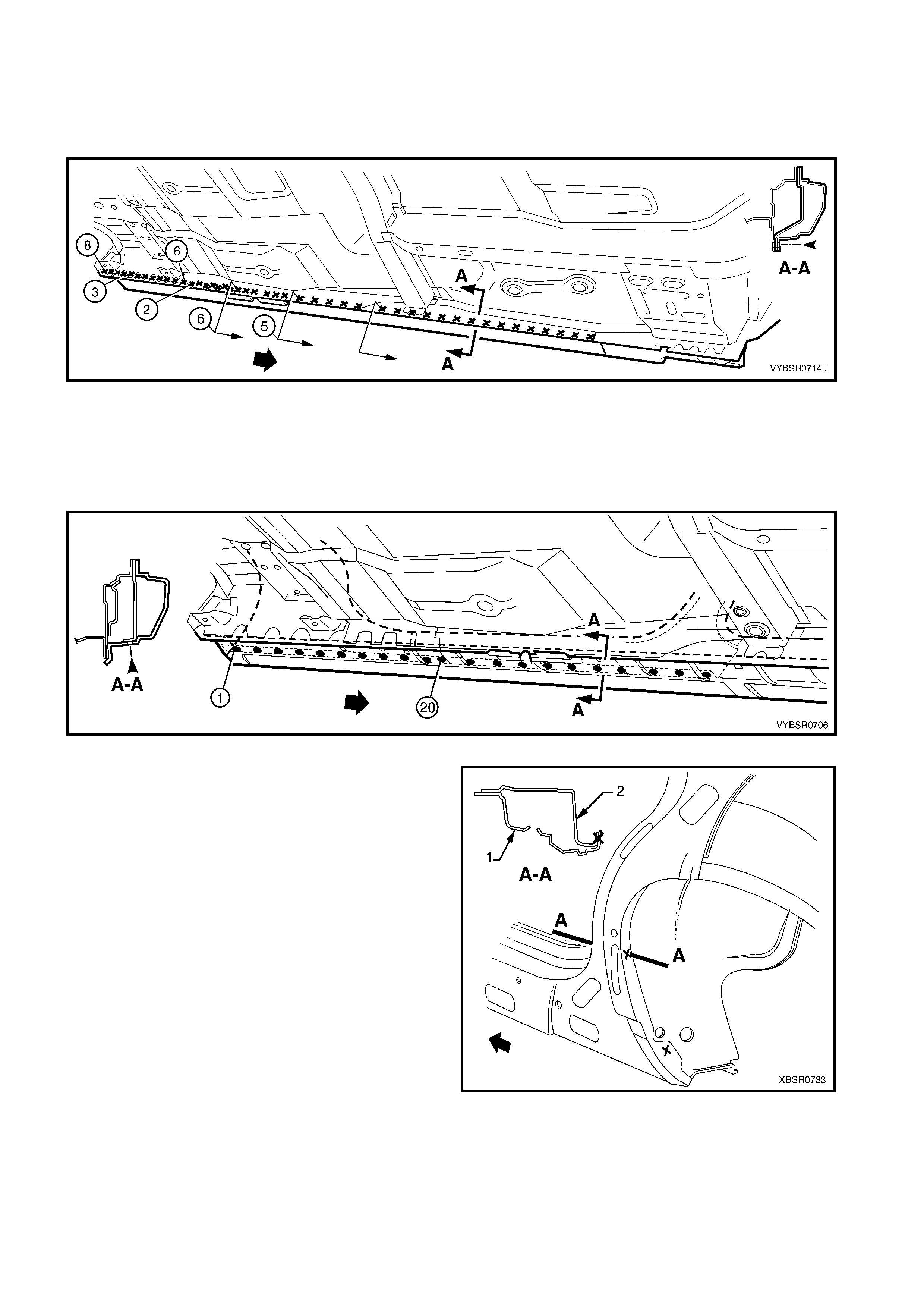

19. Plug weld the flange attaching the centre pillar

section (1) to the inner rocker panel (2). Refer to

weld group A.

20. Plug weld on the underside of the rocker panel, the

centre pillar section to the quarter panel inner

assembly (3). Refer to weld group B.

21. Plug weld the underbody jacking locator (4) in

place.

22. Dress the welds by grinding or sanding, ensuring

sufficient material remains to guarantee the

strength of the weld. Finish the area using an

appropriate technique.

23. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

24. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

25. Apply Cavity Wax (Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3C.

26. Insert Cavity Foam into the centre pillar as

required, refer to Section 2, 10. CAVITY FOAM.

27. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 7C-96

2.9 DOOR OPENING FRAME ASSEMBLY – PARTIAL REPLACE, ROCKER PANEL

This procedure details the replacement of the rocker

panel section of the door opening frame assembly.

IMPORTANT: As there are several critical

reinforcements in the lower hinge area, the rocker

panel m us t not be c ut f or ward of the area s hown. If the

rocker panel is damaged forward of this area, replace

the rock er panel and par tial hinge pillar as one section.

Modify this procedure accordingly, also referring to

2.7 DOOR OPENING FRAME ASSEMBLY –

PARTIAL REPLACE, HINGE PILLAR.

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Secure the vehicle on a suitable fixture. As a

minimum, support the appropriate structural

sections of the vehicle on safety stands. Install

suitable bracing in the vehicle to ensure that the

correct body alignment is maintained when the

rocker panel section is removed.

3. Rem ove the rear quarter panel, refer to 2.1 REAR

QUARTER PANEL – REPLACE.

Figure 7C-97

4. Cut through the door opening frame assembly (1)

and the rocker panel reinforcement, no further

forward than the dimple in the flange (2).

Figure 7C-98

5. Using a s uitable cutting tool, c ut thr ough the centr e

pillar. Cut through both the door opening fram e (1)

and centre pillar lower reinforcement (2).

Figure 7C-99

6. If required, select a cutting point through the rocker

panel, anywhere rearward of the dimple (1) in the

flange. Cut through the door opening frame

assembly (2) only.

NOTE: If required, it may be preferable to remove the

complete rear section.

Figure 7C-100

7. Depending on the cut location, spot cut any welds

remaining around the wheelhouse as required

(most would be removed with the rear quarter

panel), attac hing the door opening frame ass embly

(1) to the quarter panel inner assembly (2).

8. Spot cut along the flange below the rocker panel

as required, to separate the rocker panel section

(including the underbody jacking locator) from the

inner rocker panel and quarter panel inner

assembly, refer to Figure 7C-102.

NOTE: Some of these welds may have been

previously removed with the rear quarter panel.

Figure 7C-101

Figure 7C-102

9. Spot cut the welds attaching the rock er panel section to the quarter panel inner as sembly as required, ref er

to Figure 7C-103.

NOTE: Depending on the cut line position, some of these welds would have been previously removed with the

rear quarter panel.

Figure 7C-103

10. As required, spot cut the welds along the edge of the door opening frame assembly, refer to Figure 7C-104.

11. Remove the panel from the vehicle, then repair any damage to adjacent parts.

12. Check and rectify the alignment of the body as required, refer to 3. BODY DIMENSIONS in Section 3C.

Figure 7C-104

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The same number and position of s pot welds ( or plug welds) s hould be used when replacing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. Cut a new replacement rocker panel section. Accurately measure the position of the cuts on the removed

section.

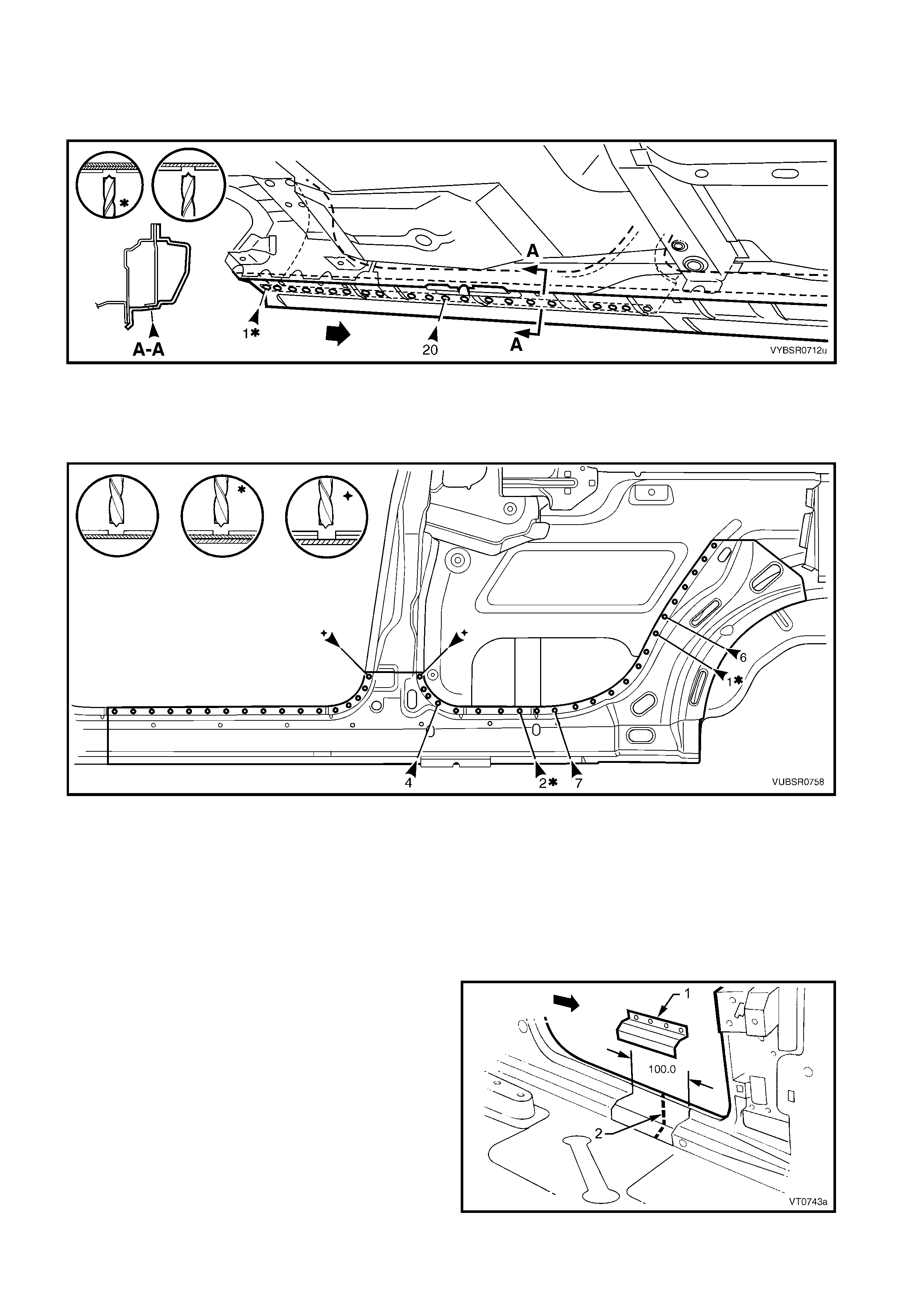

2. Remove a section of inner rocker panel (1), cut

50 mm each side of the existing cut in the rocker

panel (2). This allows access for welding the

rocker panel reinforcement.

Figure 7C-105

3. Manufacture or cut a reinforcement (1),

approximately 100 mm long, to fit on the INSIDE

ONLY of the existing rocker panel at the point of

the front cut.

4. Prepare the mating surfaces and treat with Weld

Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

5. Clamp the manufactured reinforcement firmly to

the inside of the rocker panel section of the door

opening frame assembly on the vehicle and plug

weld in position. Position welds at a maximum

spacing of 35 mm.

6. If the rear section has been cut, repeat the above

steps for the rear join.

Figure 7C-106

7. Manufacture or cut a reinforcement (1),

approximately 100 mm long, to fit inside of the

existing centre pillar section at the point of the cut.

8. Prepare the mating surfaces and treat with Weld

Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

9. Clamp the manufactured reinforcement panel

firmly to the inside of the outer panel of the door

opening frame assembly on the vehicle and plug

weld in position. Position welds at a maximum

spacing of 35 mm.

10. Mark the replacement rocker panel section with

drilling positions in preparation for plug welding as

required.

NOTE: The outer panel will be plug welded from the

outer side of the vehicle, while the rocker panel and

centre pillar reinforcements will be butt welded from

the inner side of the vehicle.

Figure 7C-107

11. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

12. Apply Acrylic Spot Weld Sealer (Item 2), refer to 5. BODY SEALING, ADHESIVES & DEADENERS in

Section 3C.

13. Install the replacement section onto the vehicle by sliding the front and centre pillar sections onto the

reinforcements, while lifting the rear into position.

14. Clamp the panel in position.

15. Weld the new centre pillar section in position by

plug welding (1).

16. MIG butt weld the reinforcement panel from inside

the centre pillar, through the seat belt retractor

opening in the inner panel immediately behind the

weld.

17. Finish the centre pillar attachment by MIG

welding (2) along the join of the outer panel.

Figure 7C-108

18. Plug weld (1) the replacement section at the front

join, then MIG butt weld (2) the two sections

together.

19. Repeat for the rear join if required.

Figure 7C-109

20. Gaining access through the section of removed

inner rocker panel, MIG butt weld (1) the new

section of rocker panel reinforcement to the

existing section.

21. Replace the removed section of inner rocker

panel (2) by MIG butt welding it in place and spot

welding it along the door opening flange. Replace

the spot welds with the same number of as were

cut.

22. Spot or plug weld the flanges of the door opening

frame assembly as required, refer to Figure 7C-

111.

NOTE: Us e the same number and pos ition of welds as

removed during removal.

Figure 7C-110

Figure 7C-111

23. Spot or plug weld the door opening frame along the flange below the rocker panel as required, refer to

Figure 7C-112.

NOTE: Place several welds only where the rear quarter panel will overlap the flange to hold the replacement

section in pos ition. Fully spot weld this f lange when the rear quarter panel is being attached, welding through all

panels.

Figure 7C-112

24. Plug weld up through the rocker panel to attach the replacement section to the quarter panel inner assembly.

Refer to Figure 7C-113.

NOTE: Place several welds only where the rear quarter panel will overlap the flange to hold the replacement

section in pos ition. Fully spot weld this f lange when the rear quarter panel is being attached, welding through all

panels.

Figure 7C-113

25. If required, spot weld the replacement section to

the quarter panel inner assembly around the rear

wheel arch at several places to retain new section

in position.

NOTE: Fully spot weld this flange when the rear

quarter panel is being attached, welding through all

three panels.

26. Clean up the welds made where the rear quarter

panel is located and prime all bare metal.

27. Replace the rear quarter panel, refer to 2.1 REAR

QUARTER PANEL – REPLACE.

28. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

29. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

30. Apply Cavity Wax (Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3C.

31. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 7C-114

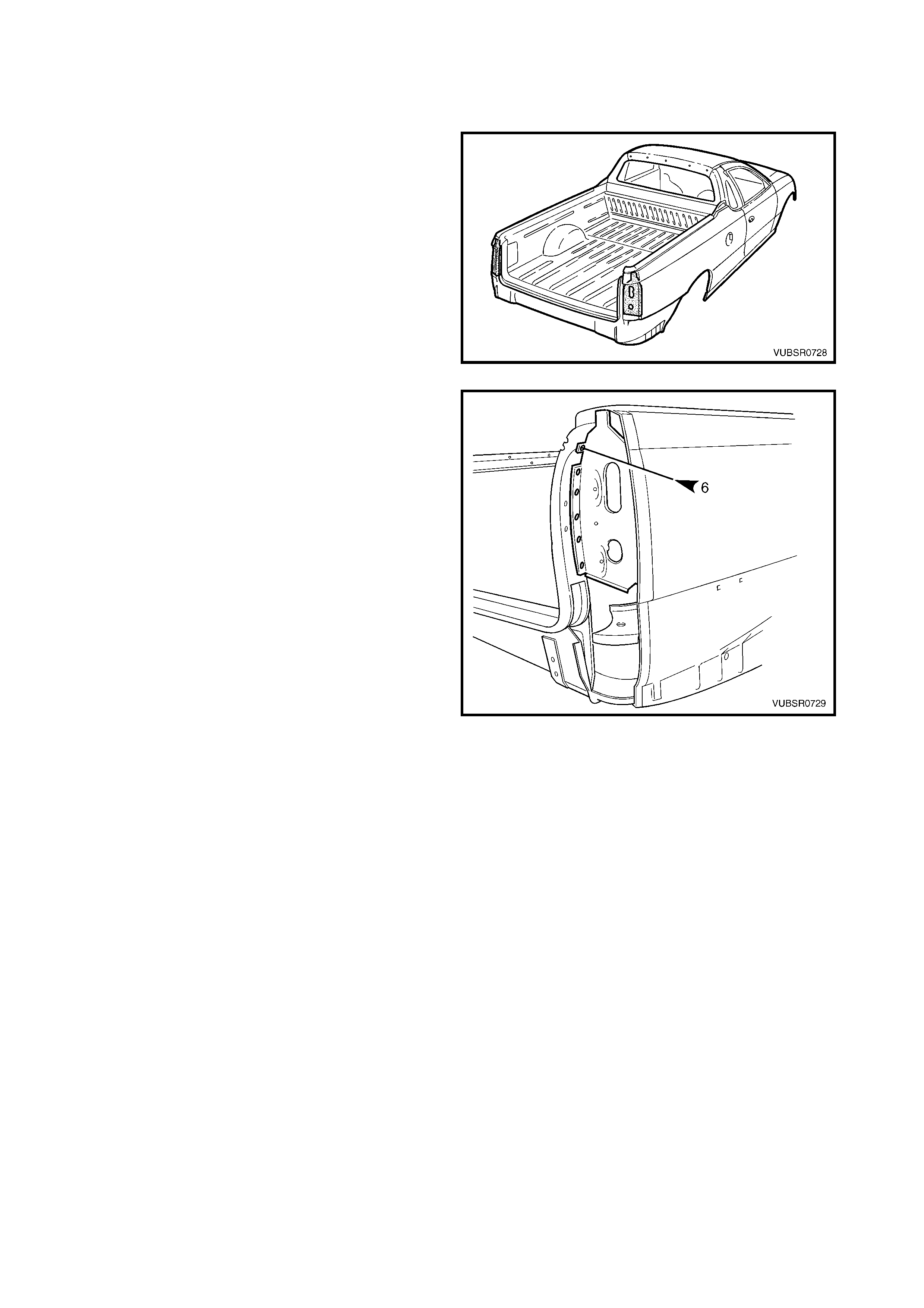

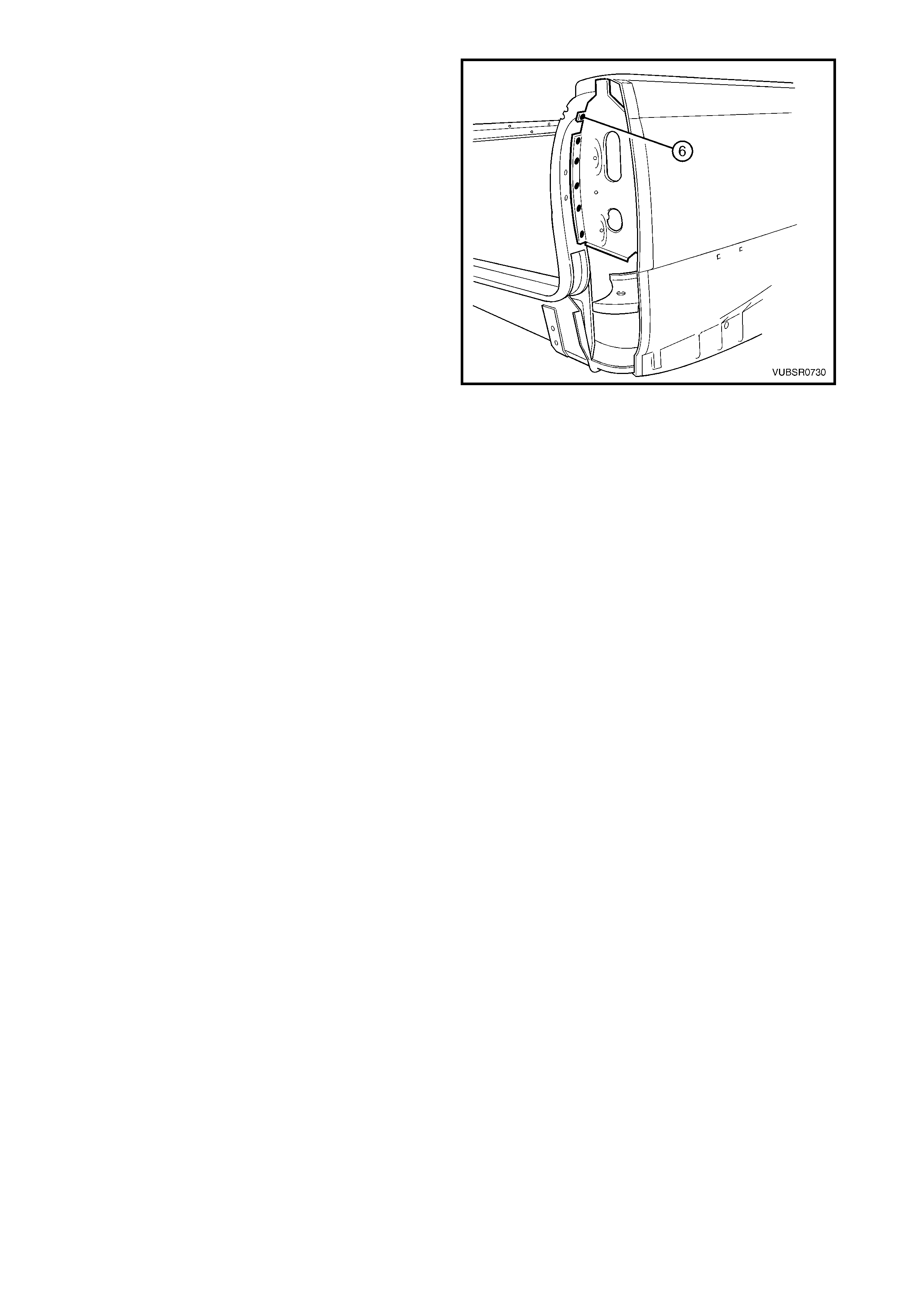

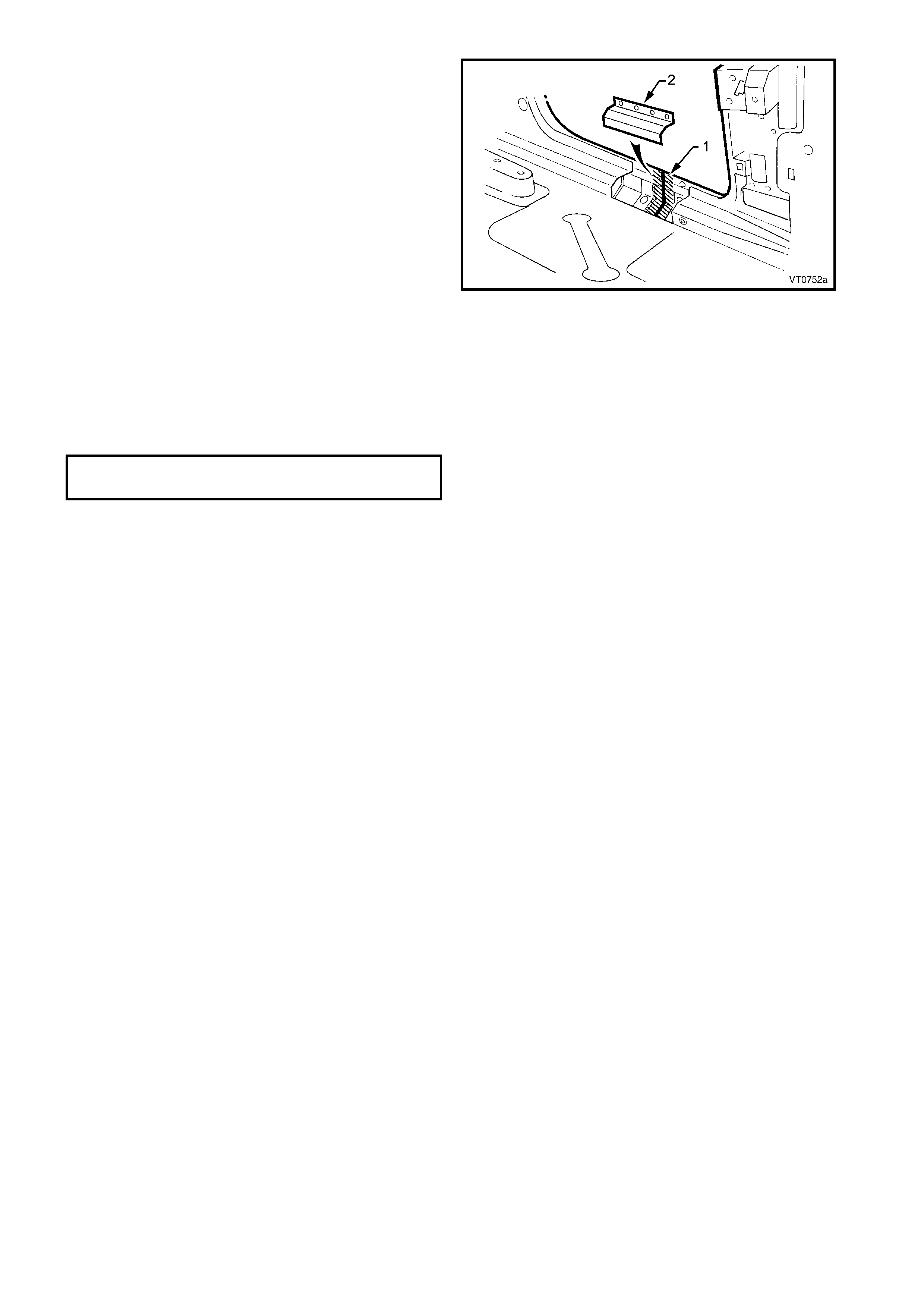

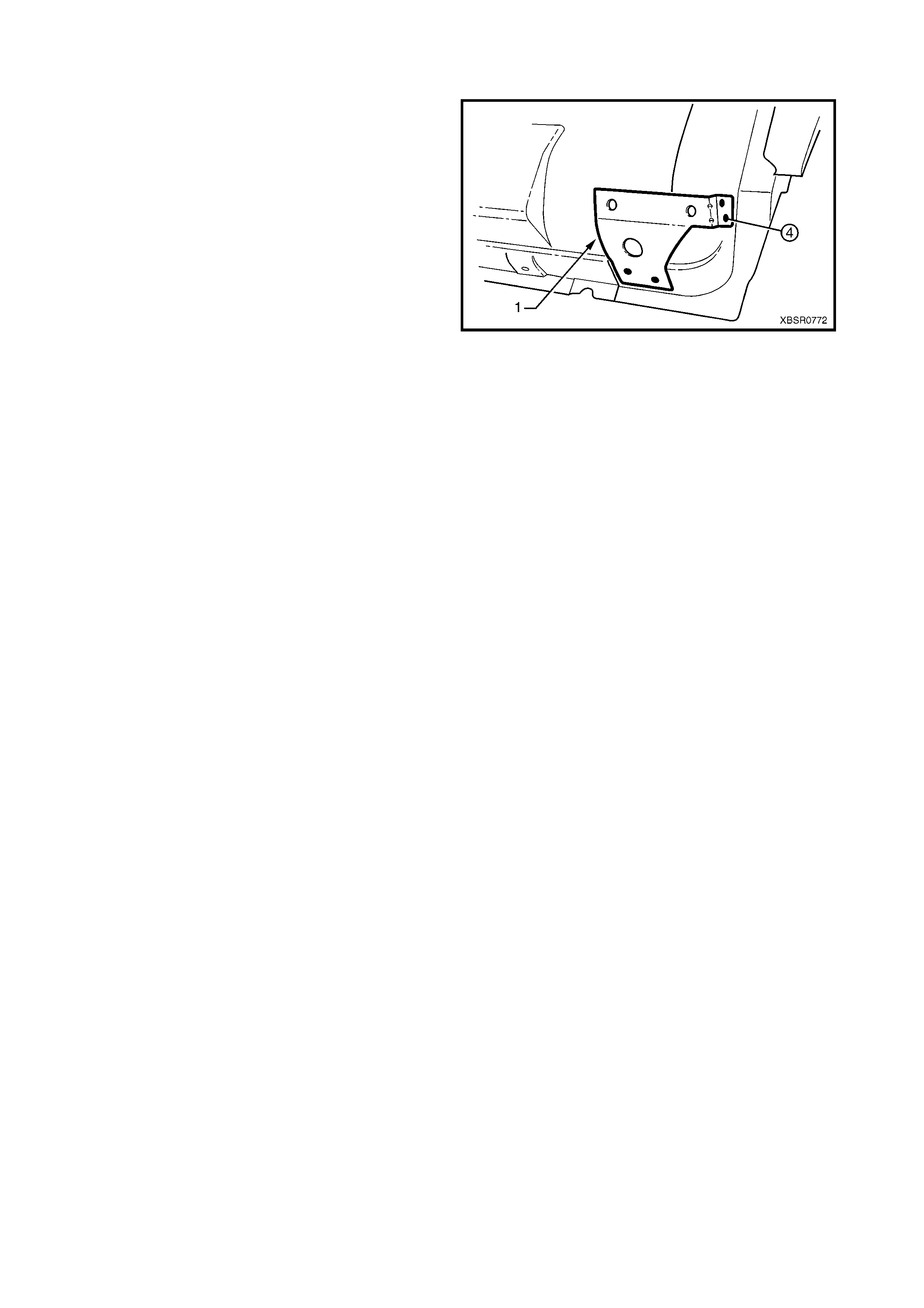

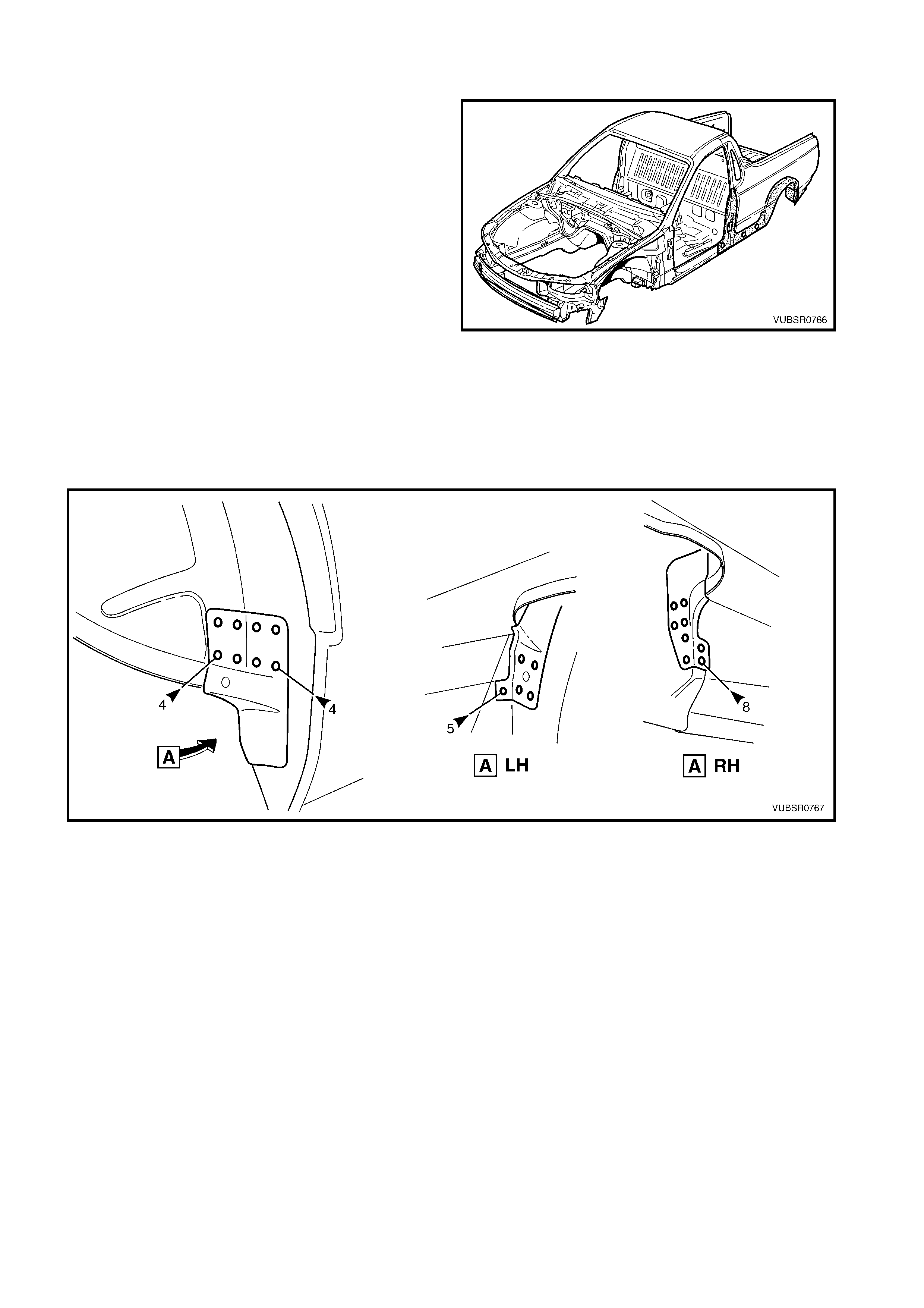

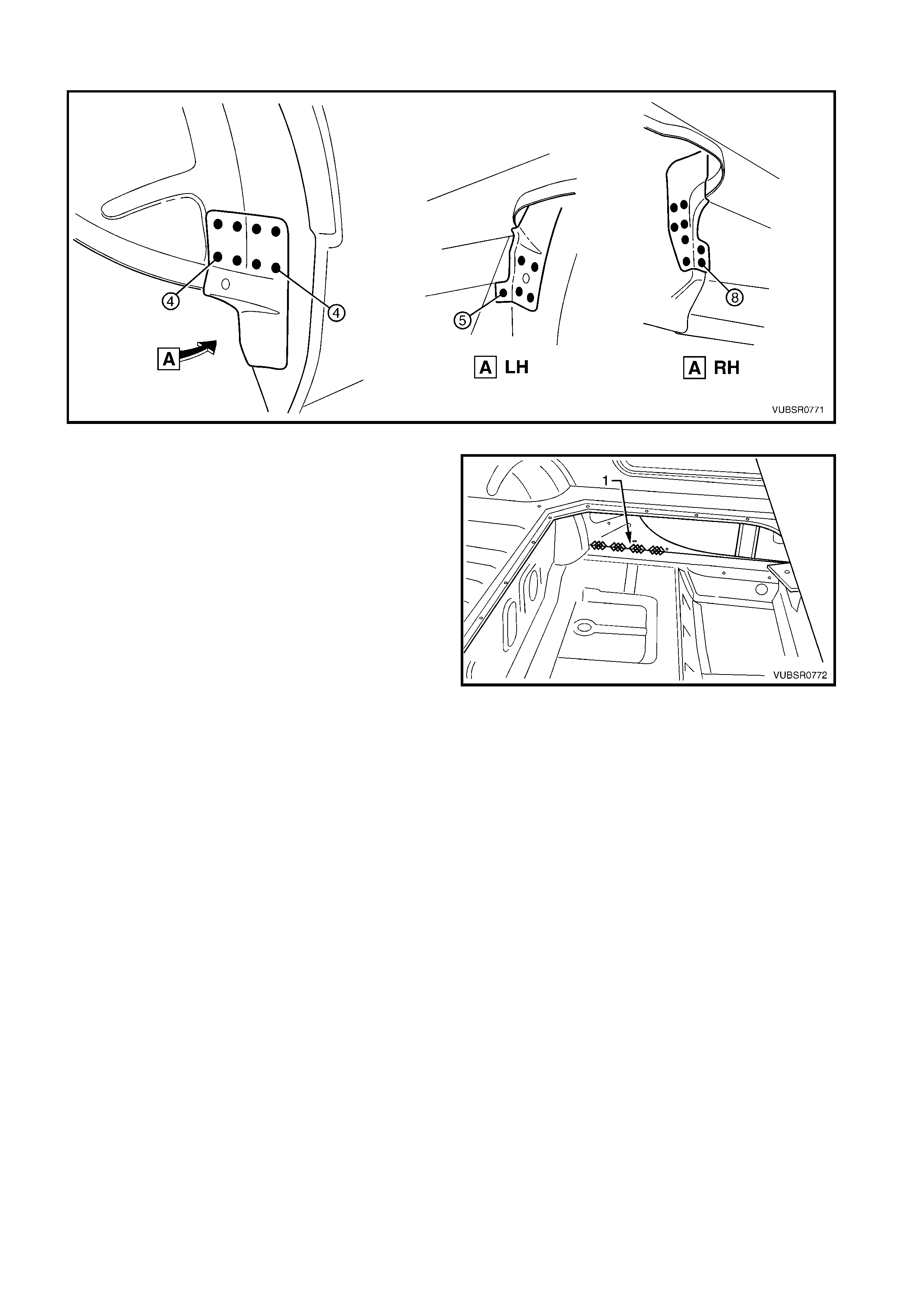

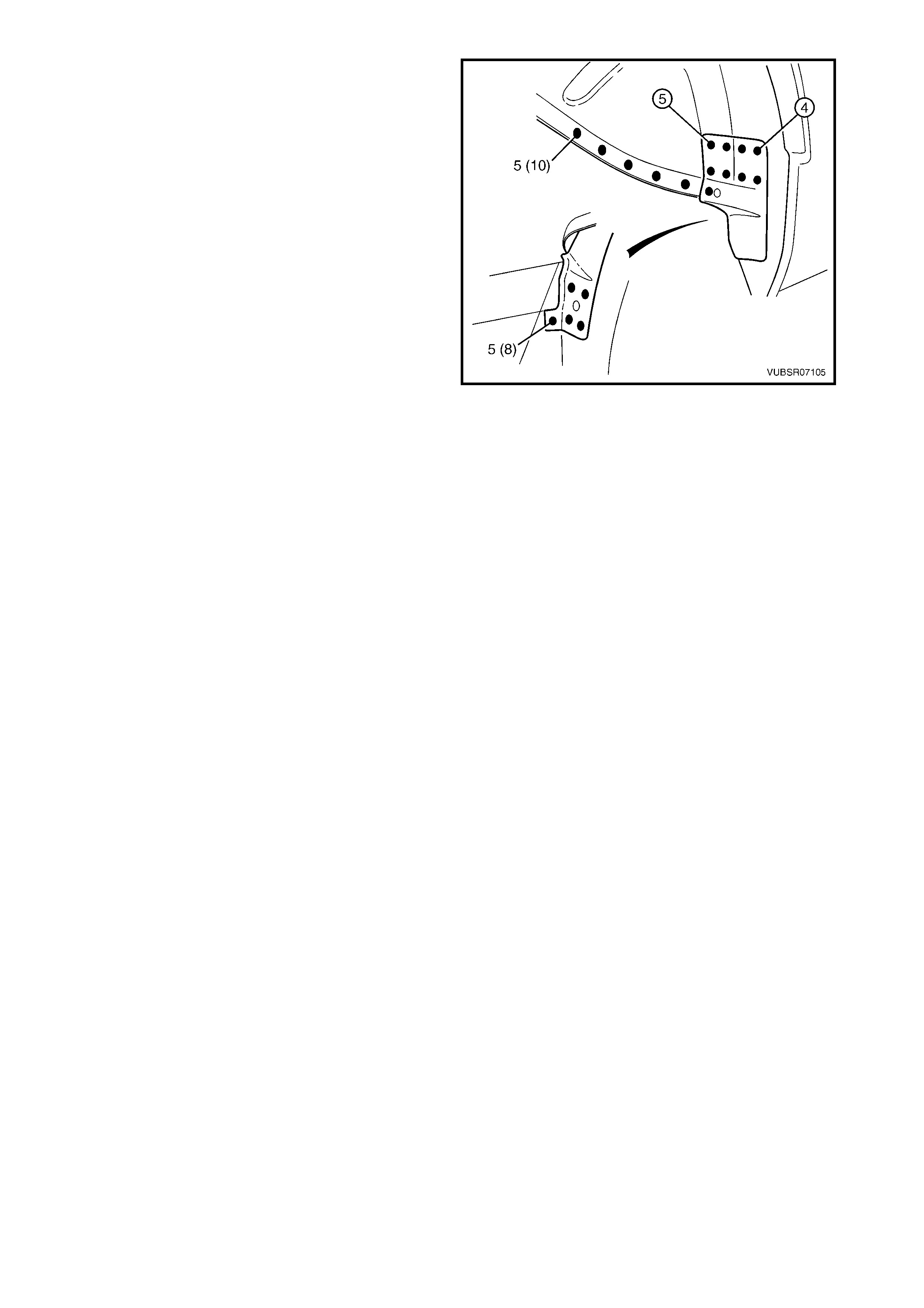

2.10 FENDER LOWER REAR BRACKET – REPLACE

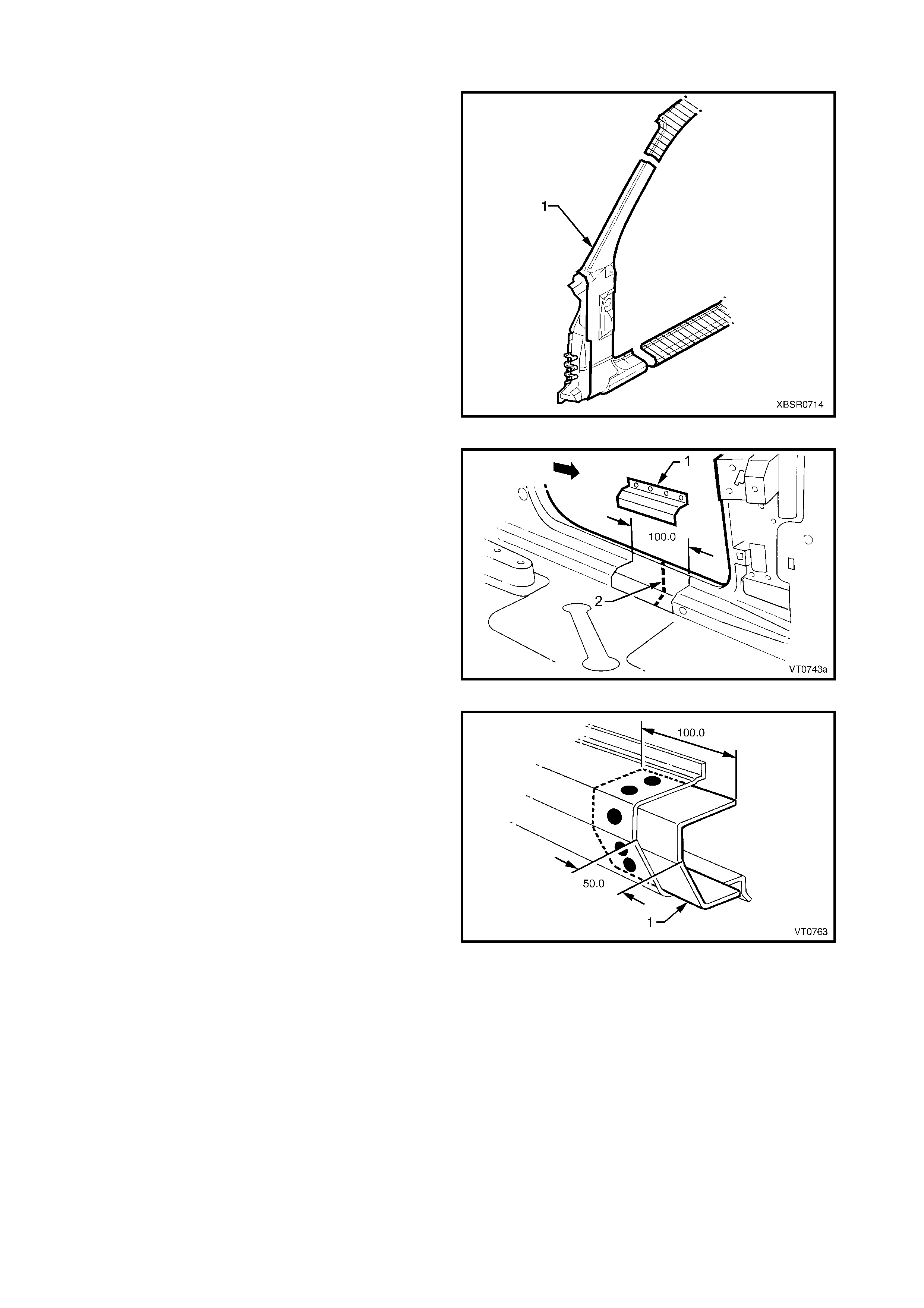

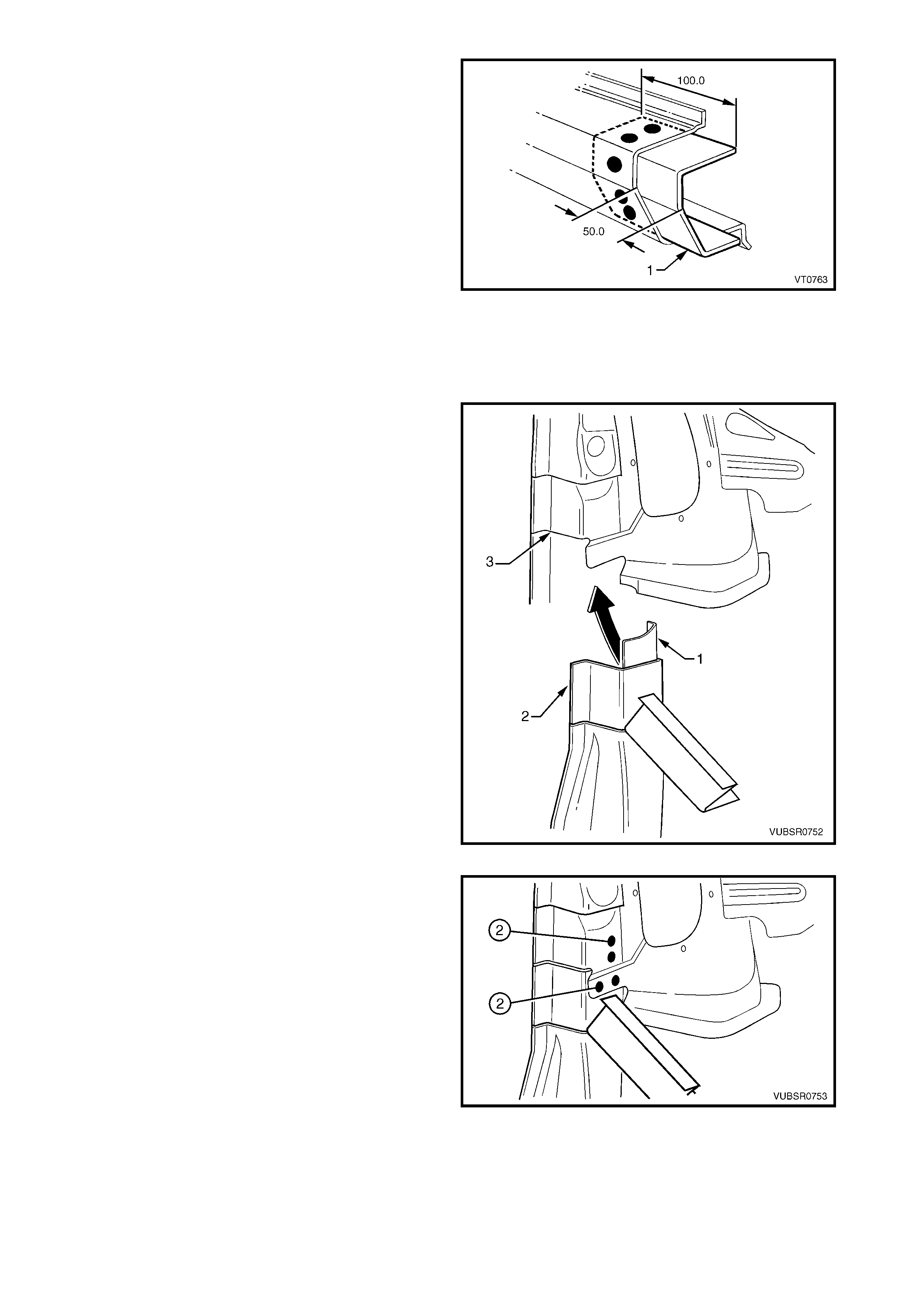

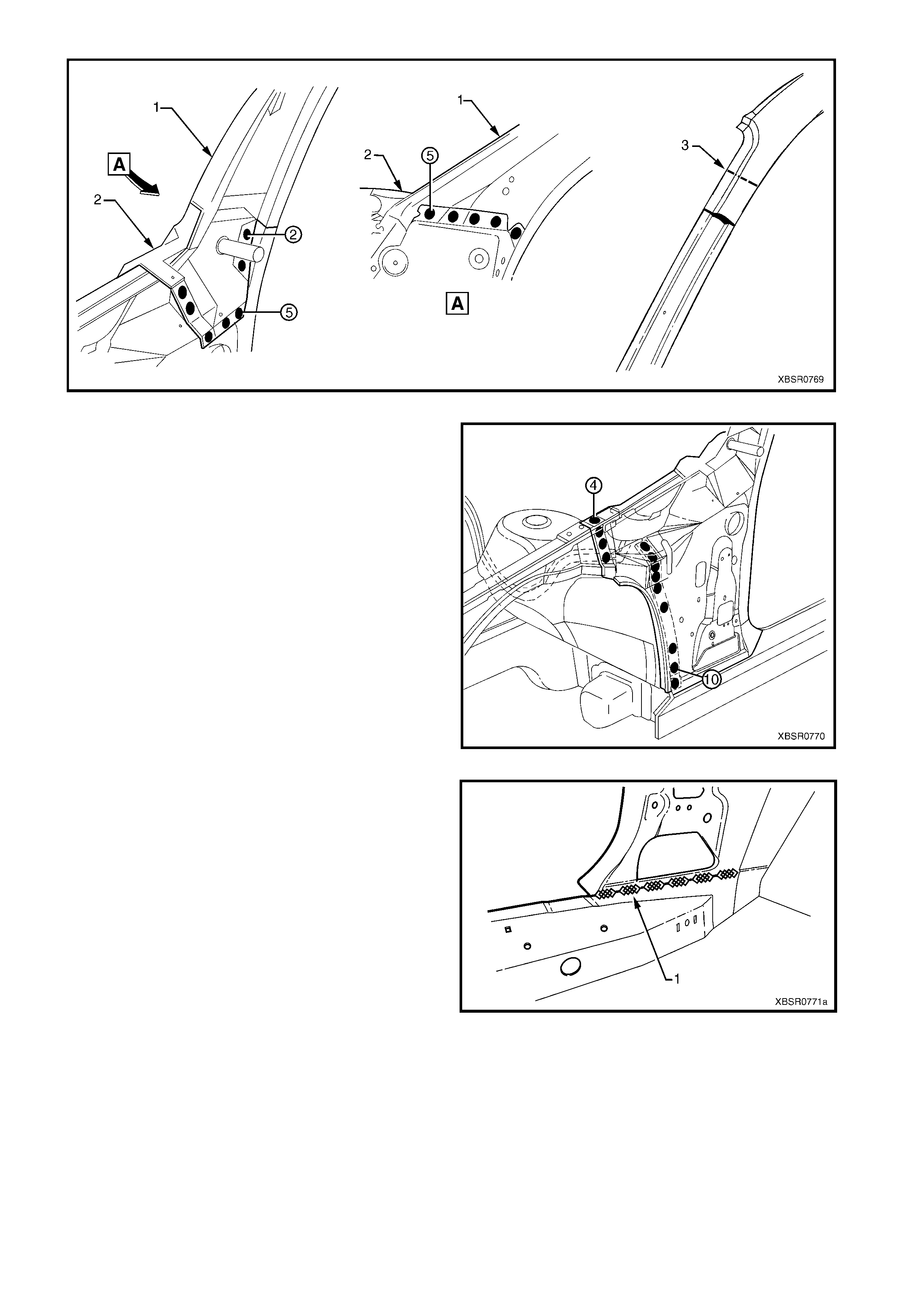

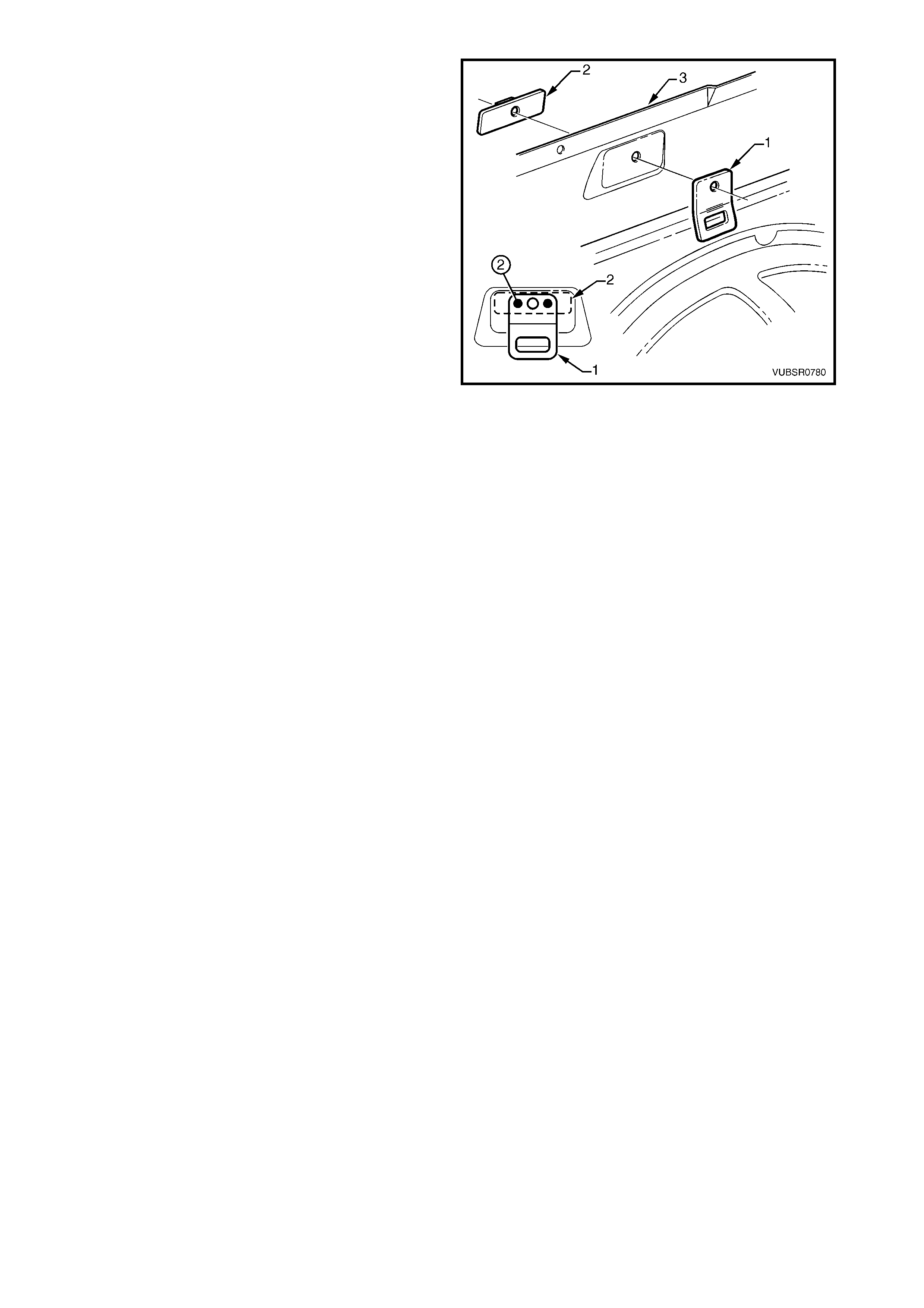

The Fender lower rear bracket (1) is spot welded four

places, to the door opening frame assembly and is

used to attach the fender lower mounts.

Clamp the f ender support in position as shown prior to

plug welding and check the alignment of the fender to

the body and front door.

Refinish and paint panels and other components as

required. Refer to Section 3, 1.3 PAINT

REFINISHING.

Apply Cavity W ax (Item 8) as required to the inside of

any box sections or areas inaccessible to paint, refer to

6. CAVITY WAX in Section 3C.

Figure 7C-115

2.11 HINGE PILLAR INNER PANEL ASSEMBLY – REPLACE

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Remove the door opening frame assembly, refer

to 2.6 DOOR OPENING FRAME ASSEMBLY –

REPLACE, or remove the hinge pillar section of

the door opening frame assembly, refer to

2.7 DOOR OPENING FRAME ASSEMBLY –

PARTIAL REPLACE, HINGE PILLAR.

3. If required, rem ove the dash panel assem bly, ref er

to Section 5 COCKPIT MODULE in this

Supplement.

NOTE: If the dash panel assem bly is not damaged an

alternative is provided in this procedure.

4. Add bracing as required to maintain the alignment

of the vehicle structure.

Figure 7C-116

5. Grind the MIG welds (1) attaching the hinge pillar

inner panel assembly to the inner rocker panel.

Figure 7C-117

6. Spot cut the welds attaching the hinge pillar inner

panel assembly to the roof front header and

quarter panel inner extension.

NOTE: Structural adhesive is applied to join (1). If the

roof panel has not been r emoved, it will be very diff ic ult

to remove the panel. As an alternative:

- If only the lower section is damaged, detach the

hinge pillar inner upper panel (1) from the hinge

pillar inner lower panel (2) and replace the lower

panel, or

- Cut the hinge pillar inner panel assembly (3)

approximately 50 mm from the top of the

windscreen aperture. If a partial replacement of

the door opening frame assembly is being

performed, this point is 50 mm above the cut in

the outer panels (4). Refer to Figure 7C-119.

Figure 7C-118

Figure 7C-119

7. Spot cut the welds attaching the hinge pillar inner

panel assem bly to the f ront wheelhouse panel and

front floor panel extension, refer to weld group A.

8. If the dash panel assem bly was not removed, spot

cut the eight welds attaching the adhesive

channels to the hinge pillar inner panel assembly,

refer weld group B.

9. If required, remove any remaining spot welds

where the wheelhouse panel upper side rail

attached the front wheelhouse panel and hinge

pillar inner panel assembly.

10. Cut the adhesive between the dash panel

assembly and hinge pillar inner panel assembly.

11. Remove the hinge pillar inner panel as s embly f r om

the vehicle and as required, clean off any

remaining adhesive and ensure the adhesive

channels are removed.

12. Repair any damage to adjacent parts as required. Figure 7C-120

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The same number and position of s pot welds ( or plug welds) s hould be used when replacing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. If an alternate removal method was used, referring to Figure 7C-119 either:

- Cut the replacement section to match the cut at the top of the hinge pillar, or

- Spot cut the welds attaching the hinge pillar inner upper panel to the hinge pillar inner lower panel.

2. Mark the new panel and drill holes in preparation for plug welding where required.

3. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

4. If the dash panel assembly was removed, it will be installed later, proceed to Step 7.

5. If the dash panel assembly was NOT removed, prepare the adhesive channels on the replacement section

and the dash panel assembly, refer to Section 5 COCKPIT MODULE.

6. Mix the dash panel silicone adhesive refer to Section 5 COCKPIT MODULE. Apply the adhesive to fill the

adhesive channels on the replacement section.

IMPORTANT: Only the correct material described in Section 5 COCKPIT MODULE is to be used.

7. If the f ull hinge pillar inner panel as s embly is being replaced, apply structural adhes ive (Item 6) to the mating

surfaces of the hinge pillar inner panel assembly and quarter panel inner extension, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

8. Install and clamp the new panel in position on the

vehicle.

NOTE: If the dash panel assembly was not removed,

place the hinge pillar inner panel assembly (1) slightly

lower and slide it upwards ensuring the dash panel

flange (2) seats into the adhesive channel.

9. Temporarily install the dash panel attaching bolts

through the hinge pillar inner panel assembly and

within the plenum chamber.

10. Finish the application of the dash panel adhesive,

refer to Section 5 COCKPIT MODULE.

Figure 7C-121

11. If the full hinge pillar inner panel assembly was

removed, spot or plug weld the hinge pillar inner

panel assembly to the roof front header and

quarter panel inner extension.

NOTE: Ensure the structural adhesive Item 6, is

applied to the join (1) refer to 5. BODY SEALING,

ADHESIVES & DEADENERS in Section 3C.

12. If only the lower section was removed, spot or plug

weld the hinge pillar inner upper panel (1) to the

hinge pillar inner lower panel (2), refer to Figure

7C-123.

13. If the pillar was cut near the top of the windscreen

aperture, either MIG butt weld the join (3) if the full

door opening frame assembly was removed, or

make two tack welds to secure it until the door

opening frame assembly hinge pillar section is

installed, refer to Figure 7C-123.

NOTE: This join forms the top access cut point

for joining of the reinforcement as described in

2.7 DOOR OPENING FRAME ASSEMBLY –

PARTIAL REPLACE, HINGE PILLAR.

Figure 7C-122

Figure 7C-123

14. Spot or plug weld the hinge pillar inner panel

assembly to the front wheelhouse panel and front

floor extension.

Figure 7C-124

15. MIG weld two places (1) across the inner rocker

panel and hinge pillar inner panel assembly.

16. Replace the door opening f rame assembly, refer to

2.6 DOOR OPENING FRAME ASSEMBLY –

REPLACE or the hinge pillar section of the

door opening frame assembly, refer to

2.7 DOOR OPENING FRAME ASSEMBLY –

PARTIAL REPLACE, HINGE PILLAR.

17. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

18. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

19. Apply Cavity Wax (Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3C.

20. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 7C-125

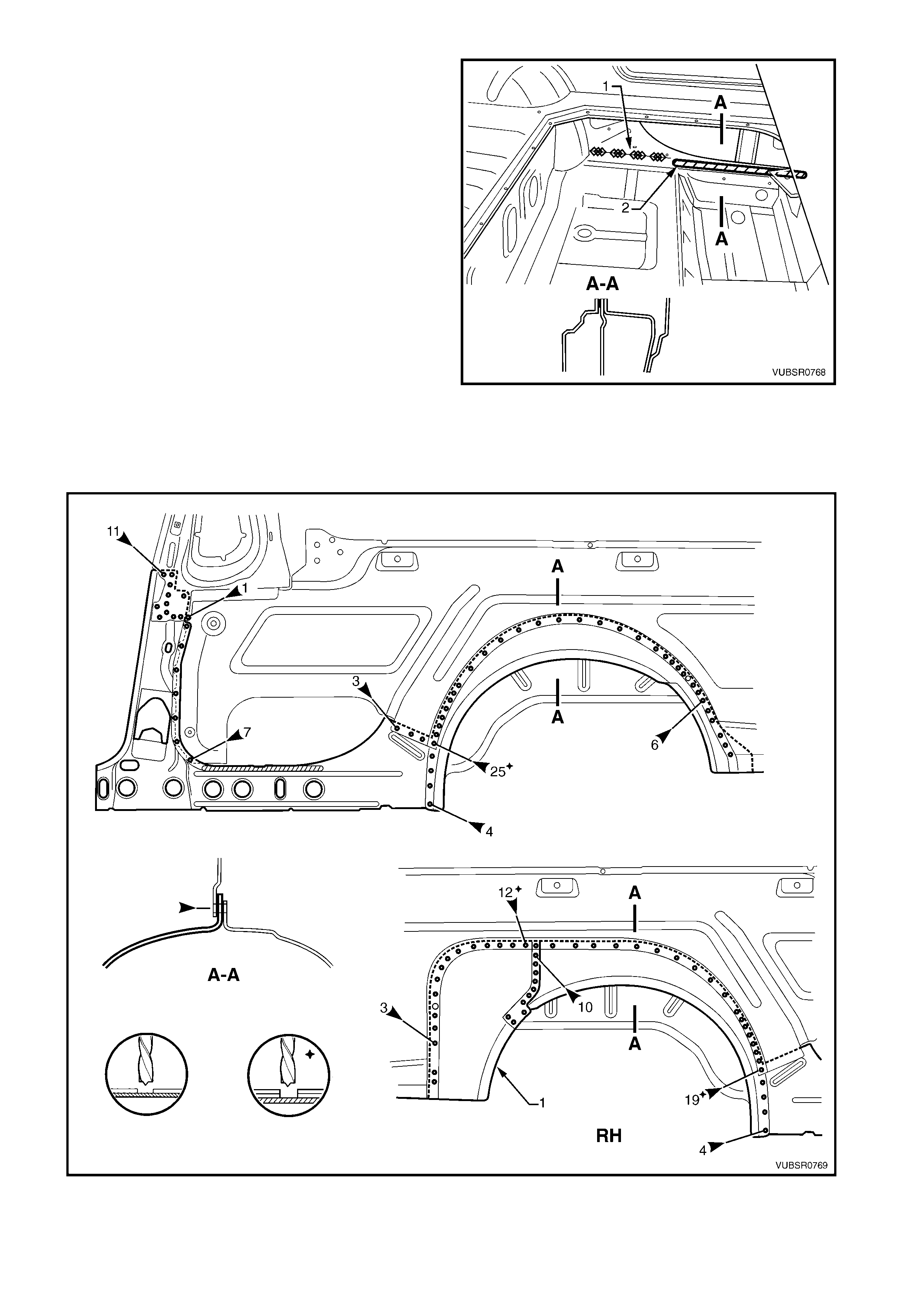

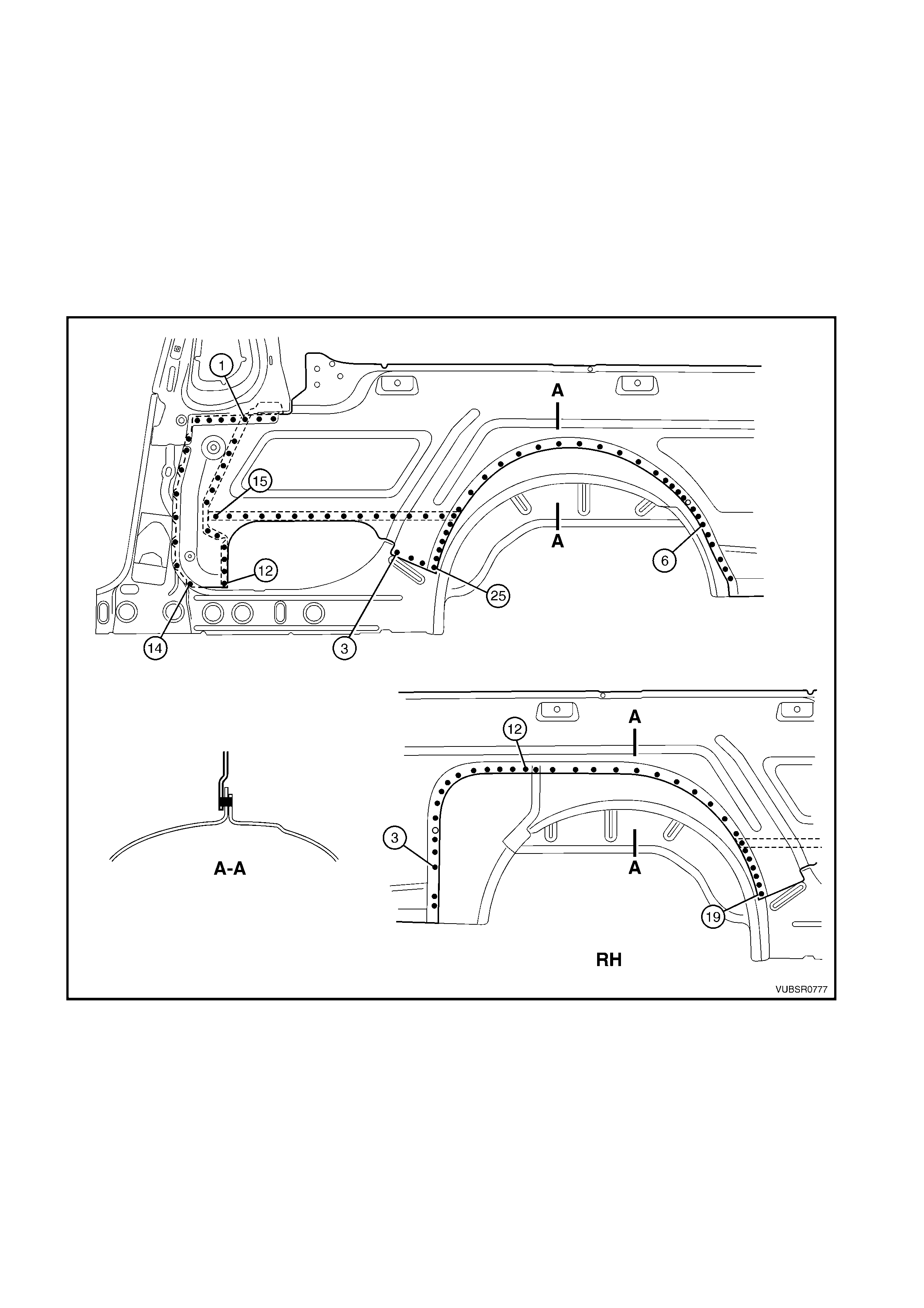

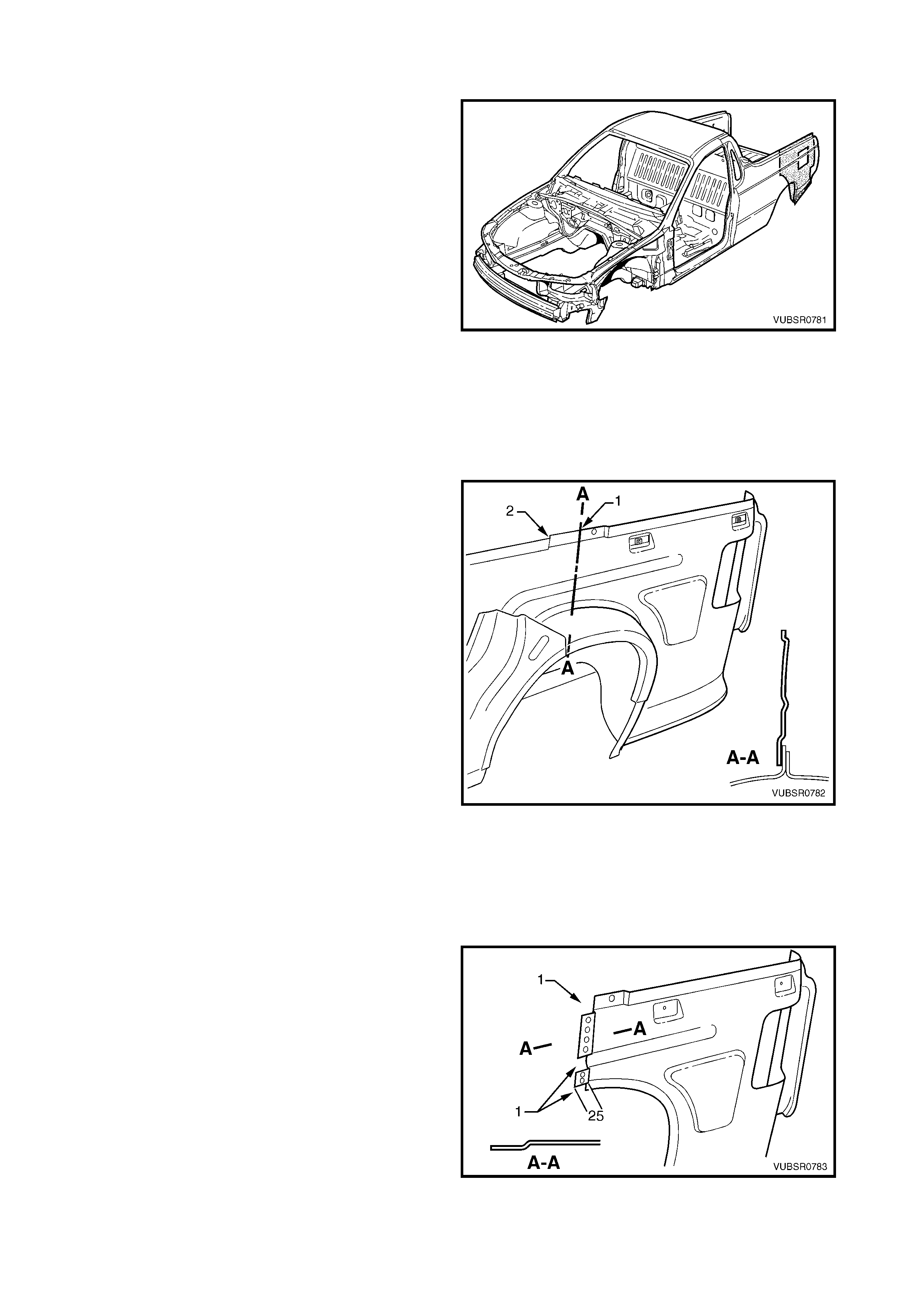

2.12 QUARTER INNER & REAR WHEE LHOUSE BRACE – REPLACE

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Remove the rear quarter panel, refer to

2.1 REAR QUARTER PANEL – REPLACE.

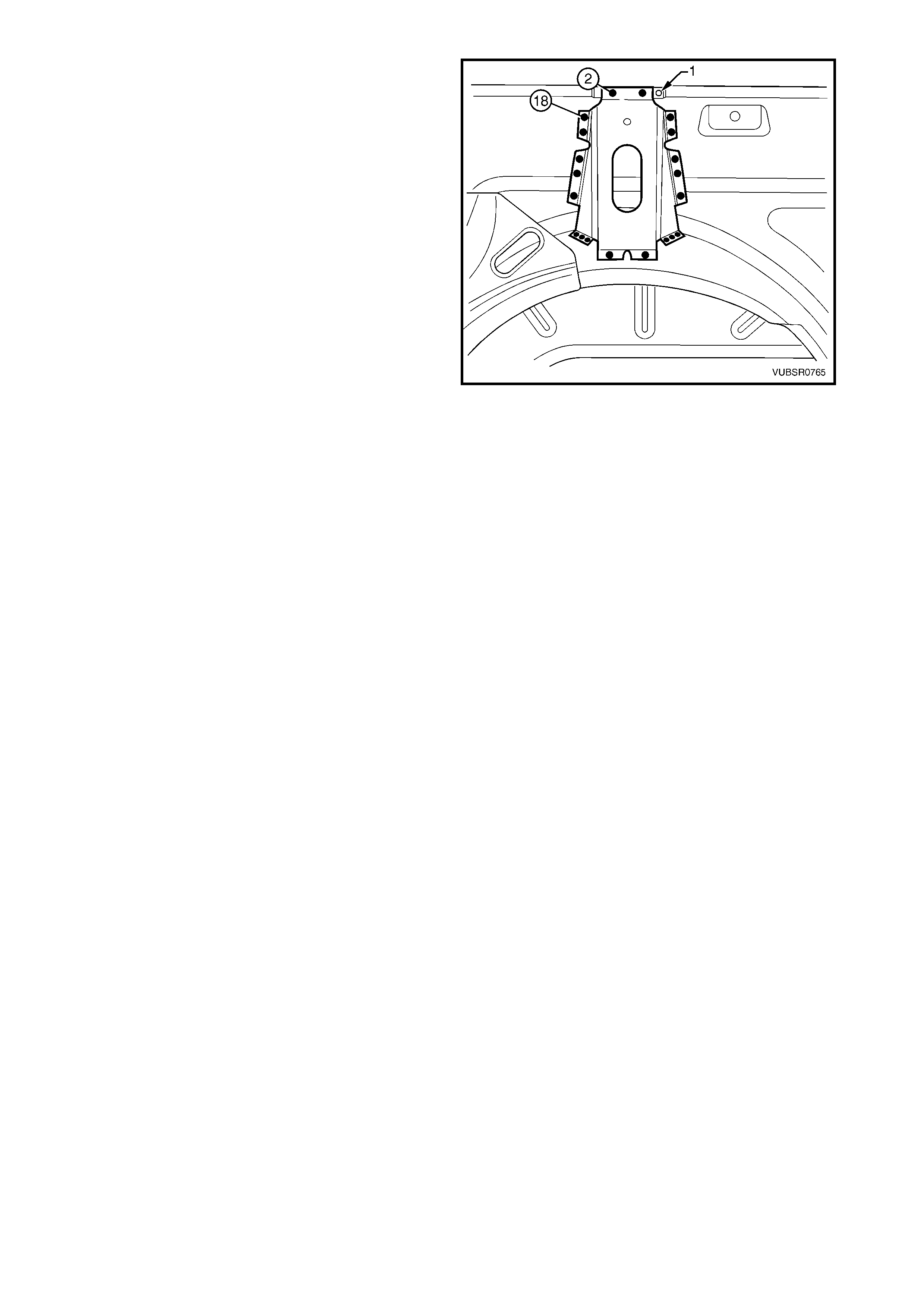

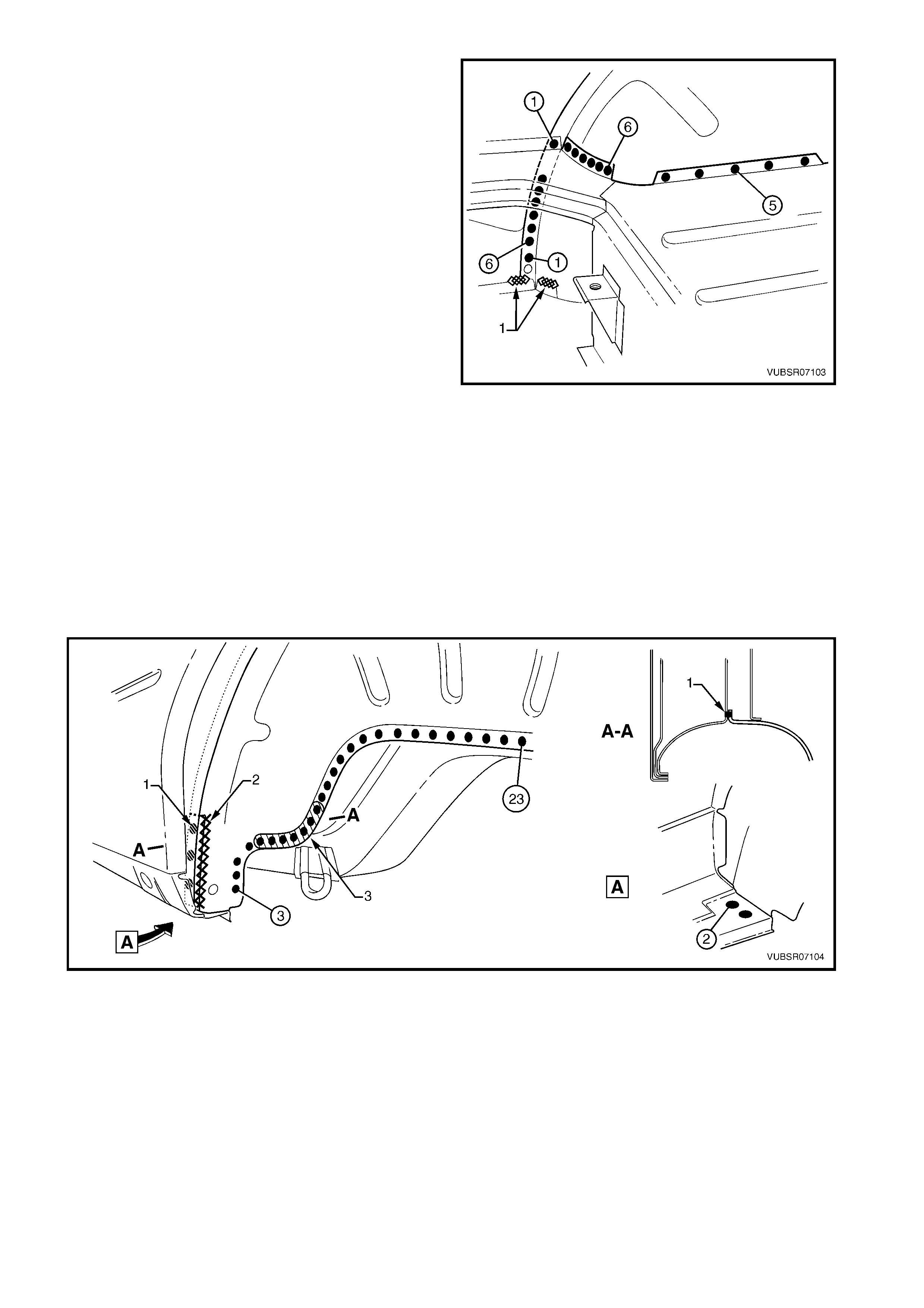

Figure 7C-126

3. Spot cut the welds attaching the quarter inner &

rear wheelhouse brace to the quarter panel inner

assembly and side inner upper panel, 18 places.

4. If not previously done, spot cut the welds attaching

the quarter inner & rear wheelhouse brace to the

side inner upper panel, 2 places.

5. Remove the brace and repair any adjacent

damage as required.

Figure 7C-127

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The same number and position of s pot welds ( or plug welds) s hould be used when replacing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. Mark the new panel and drill holes in preparation for plug welding where required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

3. Install and clamp the brace in position ensuring it

is located forward of the side inner upper panel

hole (1).

4. Spot or plug weld the brace to the side inner upper

panel and quarter , 18 places.

5. Clean up the welds and apply a coat of primer.

6. Install the rear quarter panel, refer to 2.1 REAR

QUARTER PANEL – REPLACE.

7. Refinish and paint panels and other components

as required. Refer to Section 3, 1.3 PAINT

REFINISHING.

8. Apply Joint Sealer (Item 3) as required. Refer to

5. BODY SEALING, ADHESIVES & DEADENERS

in Section 3C.

9. Apply Cavity Wax (Item 8) as requir ed to the inside

of any box sections or areas inaccessible to paint,

refer to 6. CAVITY WAX in Section 3C.

10. Apply Spray-on Deadener (Item 7) where

applicable, refer to 5. BODY SEALING,

ADHESIVES & DEADENERS in Section 3C.

11. Install the remaining components as described in

the appropriate Section of the MY 2003 VY & V2

Series II Service Information.

Figure 7C-128

2.13 QUARTER PANEL INNER ASSEMBLY – REPLACE

NOTE 1: This procedure also includes the rear

wheelhouse bracket and rear wheelhouse outer

extension (right-hand side only).

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Rem ove the rear quarter panel, refer to 2.1 REAR

QUARTER PANEL – REPLACE.

3. Remove the door opening frame assembly, refer

to 2.6 DOOR OPENING FRAME ASSEMBLY –

REPLACE.

Figure 7C-129

NOTE: If the damage is to the lower portion of the body, the partial door opening frame assembly, hinge pillar

and rocker panel sections can be removed.

4. Remove the welds attac hing the quarter inner & rear wheelhouse brace to the quarter panel inner ass em bly,

refer to 2.12 QUARTER INNER & REAR WHEELHOUSE BRACE – REPLACE.

5. Spot cut the welds attaching the rear wheelhouse bracket to the quarter panel inner assembly as required,

refer to Figure 7C-130.

Figure 7C-130

6. Grind the four MIG welds (1) from the inside of the

quarter panel inner assembly, joining the inner

rocker panel.

7. Structural adhesive (2) is applied along the flange

between the quarter panel inner assembly and

inner rocker panel. Either cut the flange or cut

around the adhesive and grind off the flange once

the panel is removed.

8. Spot cut the welds attaching the quarter panel

inner assembly to the side inner upper panel and

side inner upper front panel, refer to Figure 7C-

132.

NOTE 1: If the partial door opening frame assembly

hinge pillar section was removed, remove the welds

attaching the hinge pillar upper reinforcement to the

quarter panel inner assembly. Refer to 2.6 DOOR

OPENING FRAME ASSEMBLY – REPLACE and cut

the welds attaching the quarter panel inner assembly

to the side inner upper front panel from inside the

vehicle.

NOTE 2: For the right-hand side, either remove the

rear wheelhouse outer extension or spot cut the 10

welds attaching it to the quarter panel inner assembly.

Figure 7C-131

Figure 7C-132

9. As required, spot cut any remaining welds from where the door opening frame assembly and rear quarter

panel attached.

10. Remove the quarter panel inner assembly from the vehicle and repair any damage to adjacent parts as

required.

REPLACE

NOTE 1: Spot welding is the preferred method for attaching of panels and should be used whenever possible.

Where the spot welding equipment will not access the required weld position, a plug weld should be performed.

NOTE 2: The same number and position of s pot welds ( or plug welds) s hould be used when replacing the panel,

as was used during manufacture, in order to maintain the original structural strength of the vehicle.

1. Mark the new panel and drill holes in preparation for plug welding where required.

2. Prepare all mating surfaces and treat with Weld Through Primer (Item 1) as required, refer to

5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

3. Apply structural adhesive (Item 6) to the mating surfaces of the quarter panel inner assembly and inner

rocker panel, refer to 5. BODY SEALING, ADHESIVES & DEADENERS in Section 3C.

4. Clamp the new panel in position on the vehicle.

5. Spot or plug weld the quarter panel inner assem bly, to the side inner upper panel and side inner upper front

panel, refer to Figure 7C-133.

NOTE: For the right-hand side, ins tall the wheelhouse outer extension ( 1) if rem oved, and weld to the side inner

upper panel.

Figure 7C-133

6. Spot or plug weld the rear wheelhouse bracket to quarter panel inner assembly, refer to Figure 7C-134.

Figure 7C-134

7. MIG weld four places 25 – 50mm each, the quarter

panel inner assembly to the inner rocker panel (1).

8. Spot or plug the quarter inner & rear wheelhouse

brace to the quarter panel inner ass embly, refer to

2.12 QUARTER INNER & REAR WHEELHOUSE

BRACE – REPLACE.

9. If the centre pillar upper reinforcement was not

removed, spot or plug weld it to the quarter panel

inner assembly, refer to 2.6 DOOR OPENING

FRAME ASSEMBLY – REPLACE.

10. Clean up welds and prime any bare metal.

11. Replace the door opening f rame assembly, refer to

2.6 DOOR OPENING FRAME ASSEMBLY –

REPLACE.

12. Replace rear quarter panel, refer to 2.1 REAR

QUARTER PANEL – REPLACE.

Figure 7C-135

13. Refinish and paint panels and other components as required. Refer to Section 3, 1.3 PAINT REFINISHING.

14. Apply Joint Sealer (Item 3) as required. Refer to 5. BODY SEALING, ADHESIVES & DEADENERS in

Section 3C.

15. Apply Cavity W ax (Item 8) as required to the ins ide of any box s ections or areas inacces sible to paint, refer

to 6. CAVITY WAX in Section 3C.

16. Apply Spray-on Deadener (Item 7) to the wheel side of the rear wheelhouse, refer to 5. BODY SEALING,

ADHESIVES & DEADENERS in Section 3C.

17. Install the rem aining com ponents as described in the appr opriate Section of the MY 2003 VY & V2 Series II

Service Information.

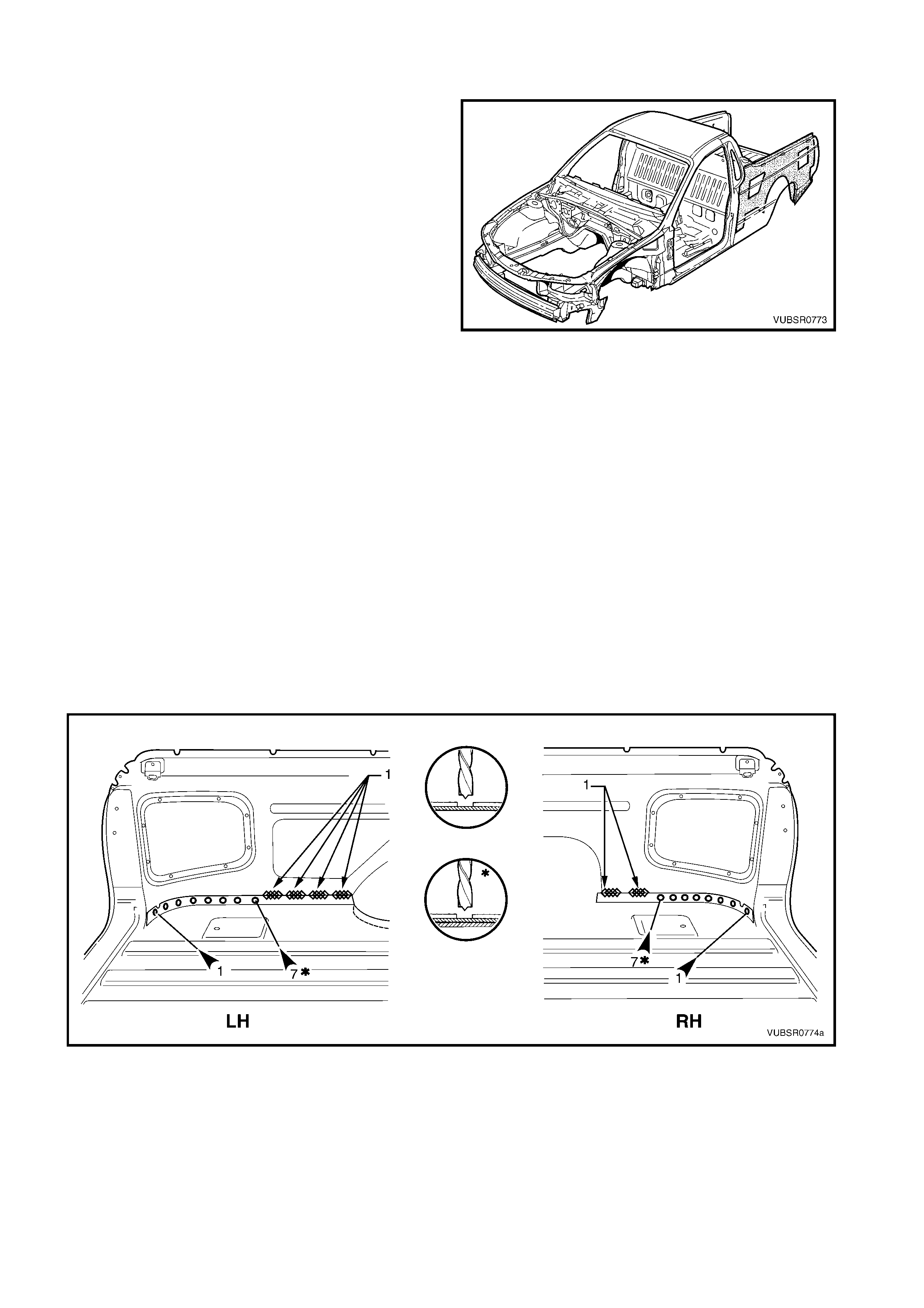

2.14 SIDE INNER UPPER PANEL – REPLACE

NOTE: This procedure also includes the cargo tie-

down brackets.

REMOVE

1. Remove the adjacent bolt-on panels and

components as described in the appropriate

Section of the MY 2003 VY & V2 Series II Service

Information.

2. Mount the vehicle on a suitable jig to maintain

correct body alignment when the side inner upper

panel is removed.

3. Rem ove the rear quarter panel, refer to 2.1 REAR

QUARTER PANEL – REPLACE.

4. Remove the quarter outer lower rear panel, refer to

2.4 QUARTER OUTER LOWER REAR PANEL –

REPLACE.

Figure 7C-136

5. Remove the quar ter inner lower rear extension, r efer to 2.3 QUARTER INNER LOWER REAR EXT ENSION

– REPLACE.

6. Remove the door opening frame assembly, refer to 2.6 DOOR OPENING FRAME ASSEMBLY –

REPLACE.

NOTE: If required, the partial door opening frame assembly centre pillar and rocker panel sections can be

removed. Spot cut the welds attaching the remaining door opening frame assembly to the side inner upper

panel, refer to 2.6 DOOR OPENING FRAME ASSEMBLY – REPLACE.

7. Remove the quarter inner & rear wheelhouse brace, refer to 2.12 QUARTER INNER & REAR

WHEELHOUSE BRACE – REPLACE.

8. Remove the welds attaching the side inner upper panel to the quarter lower rear panel, refer to

2.5 QUARTER LOWER REAR PANEL – REPLACE.

9. Remove the welds attaching the side inner upper panel to the rear end panel, refer to, 2.3 REAR END

PANEL – REPLACE in Section 10C.

10. Spot cut the welds and grind off the MIG welds attaching the side inner upper panel to the load floor panel,

refer to Figure 7C-137.

Figure 7C-137

11. Spot cut the welds (if not already removed) and

grind off the MIG welds (1) attaching the inner

upper side panel to the load compartment

extension panel.

12. Spot cut the welds attaching the side inner upper

panel to the quarter panel inner assembly, side

inner upper front panel, rear wheelhouse inner

panel, load floor panel outer extension and front

seatback panel outer, refer to Figure 7C-139.