Wipers, Washers and Horn Page 12N–1

Page 12N–1

Section 12N

Wipers, Washers and Horn

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information ...............................................................................................................................7

1.1 Front Wiper Assemblies........................................................................................................................................ 7

Wiper Assemblies.................................................................................................................................................. 7

Wiper Motor............................................................................................................................................................ 7

1.2 Rear Wiper Assembly, Wagon.............................................................................................................................. 8

Wiper Assembly..................................................................................................................................................... 8

Wiper Motor............................................................................................................................................................ 8

1.3 Rear Wiper Assembly, AWD Wagon..................................................................................................................... 9

Rear Wiper Assembly............................................................................................................................................ 9

Rear Wiper Control Module................................................................................................................................. 10

Rear Wiper Motor Assembly............................................................................................................................... 11

Rear Wiper Ramp................................................................................................................................................. 11

Functional Operation........................................................................................................................................... 11

Intermittent Wipe Cycle Operation.................................................................................................................... 11

Continuous Wipe Mode.................................................................................................................................... 12

1.4 Washer Assemblies............................................................................................................................................. 13

Washer Assemblies, Except Wagon and AWD Wagon..................................................................................... 13

Washer Assemblies, Wagon and AWD Wagon ................................................................................................. 13

Washer Control, Wagon................................................................................................................................... 13

Washer Control, AWD Wagon.......................................................................................................................... 13

Front Washer Operation................................................................................................................................... 13

Rear Washer Operation ................................................................................................................................... 13

1.5 Horn Assemblies.................................................................................................................................................. 14

Horn Assembly..................................................................................................................................................... 14

Description ....................................................................................................................................................... 14

Horn Relay....................................................................................................................................................... 14

Steering Wheel Horn Contact........................................................................................................................... 14

Theft-deterrent Horn Assembly.......................................................................................................................... 14

Description ....................................................................................................................................................... 14

Theft-deterrent Horn Relay............................................................................................................................... 14

2 Preliminary Test – Front Wipers and Washers..................................................................................15

2.1 Test Front Wipers and Washers Assemblies .................................................................................................... 15

Introduction.......................................................................................................................................................... 15

Test Description................................................................................................................................................... 15

Diagnostic Table Notes ....................................................................................................................................... 15

Diagnostic Table.................................................................................................................................................. 16

3 Diagnostics – Front Wipers and Washers.........................................................................................17

3.1 Prerequisites........................................................................................................................................................ 17

Safety Requirements ........................................................................................................................................... 17

Equipment ............................................................................................................................................................ 17

Testing Procedures ............................................................................................................................................. 17

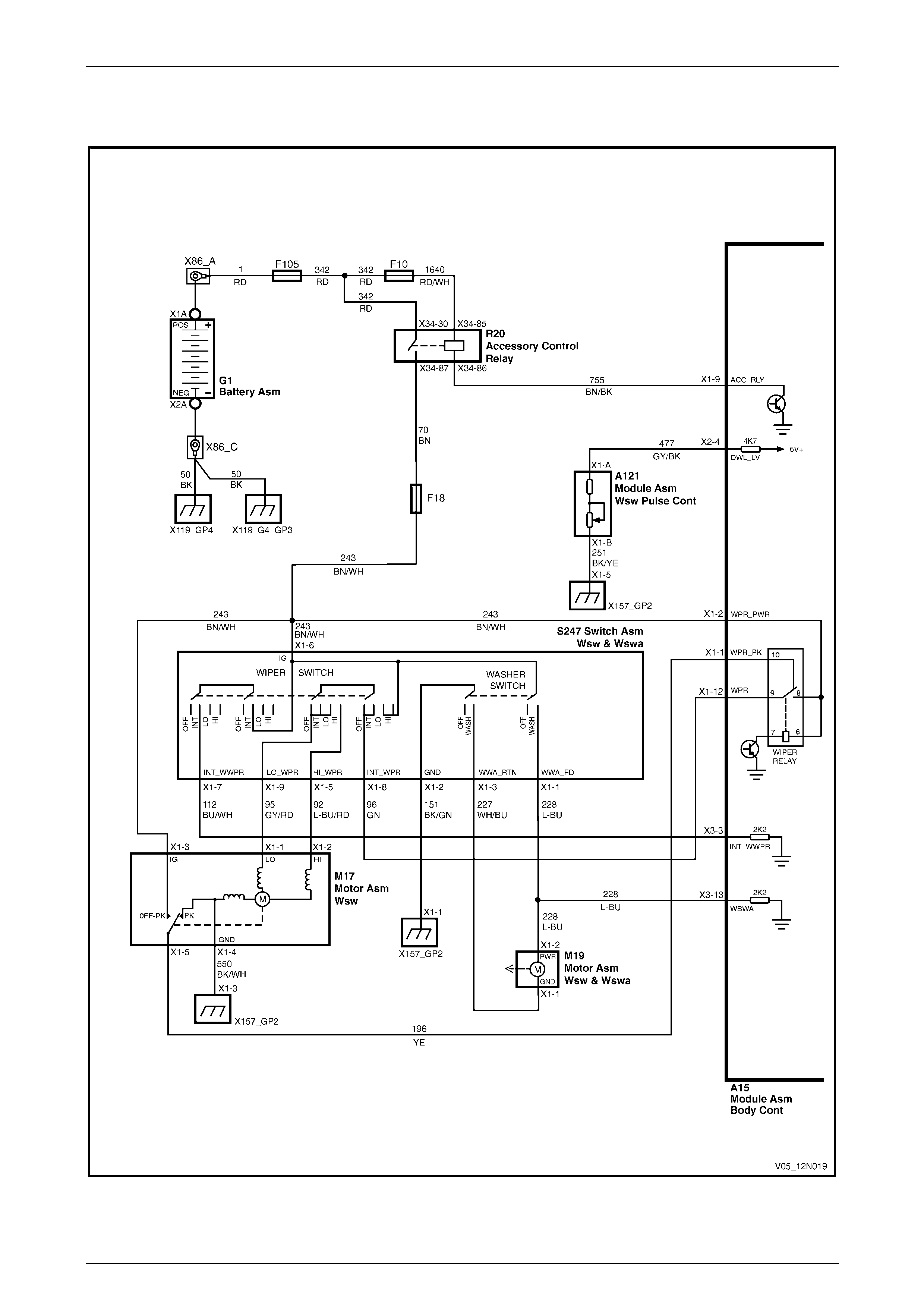

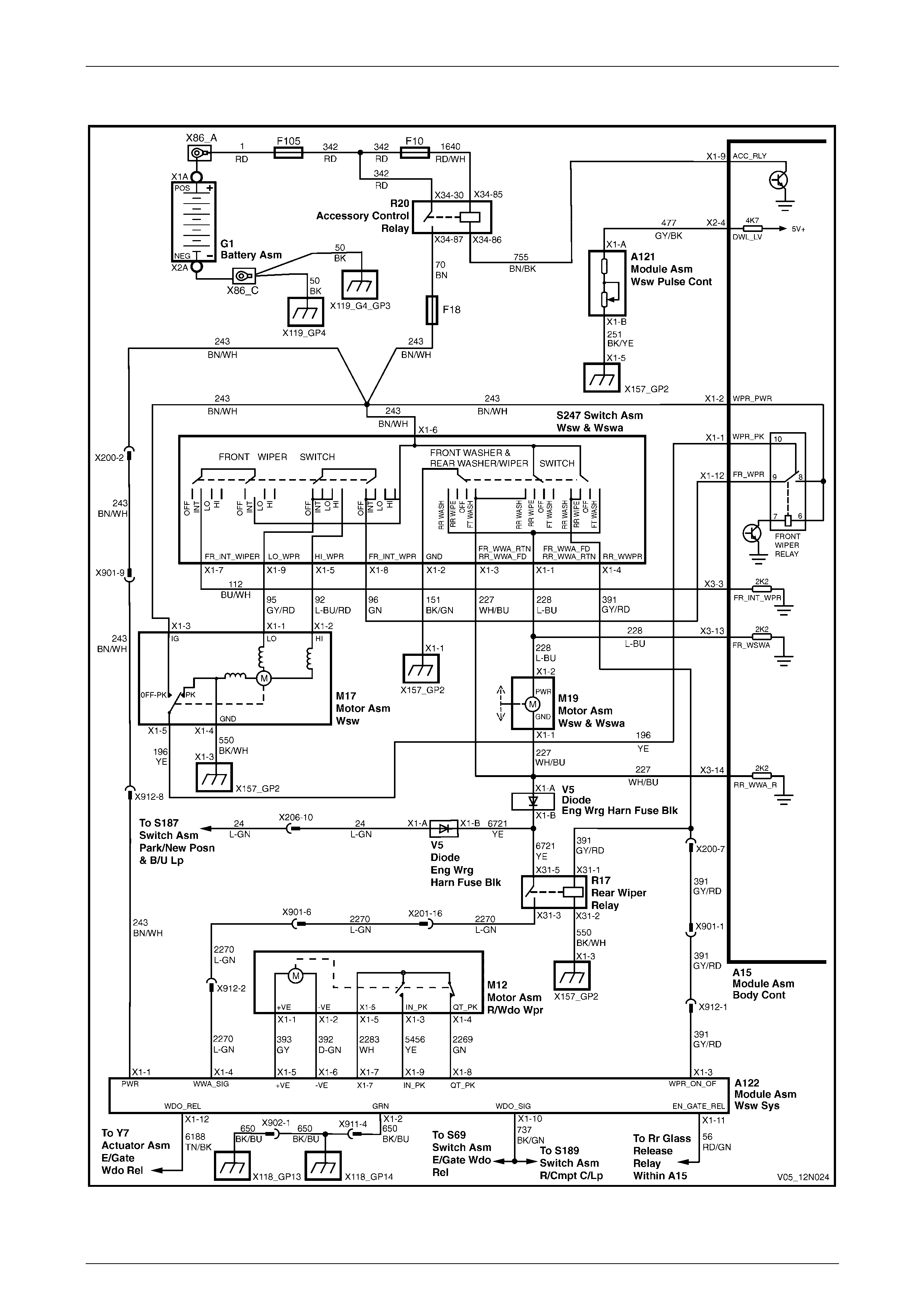

3.2 Wiring Diagram – Front Wiper/Washer, Except Wagon and AWD Wagon...................................................... 18

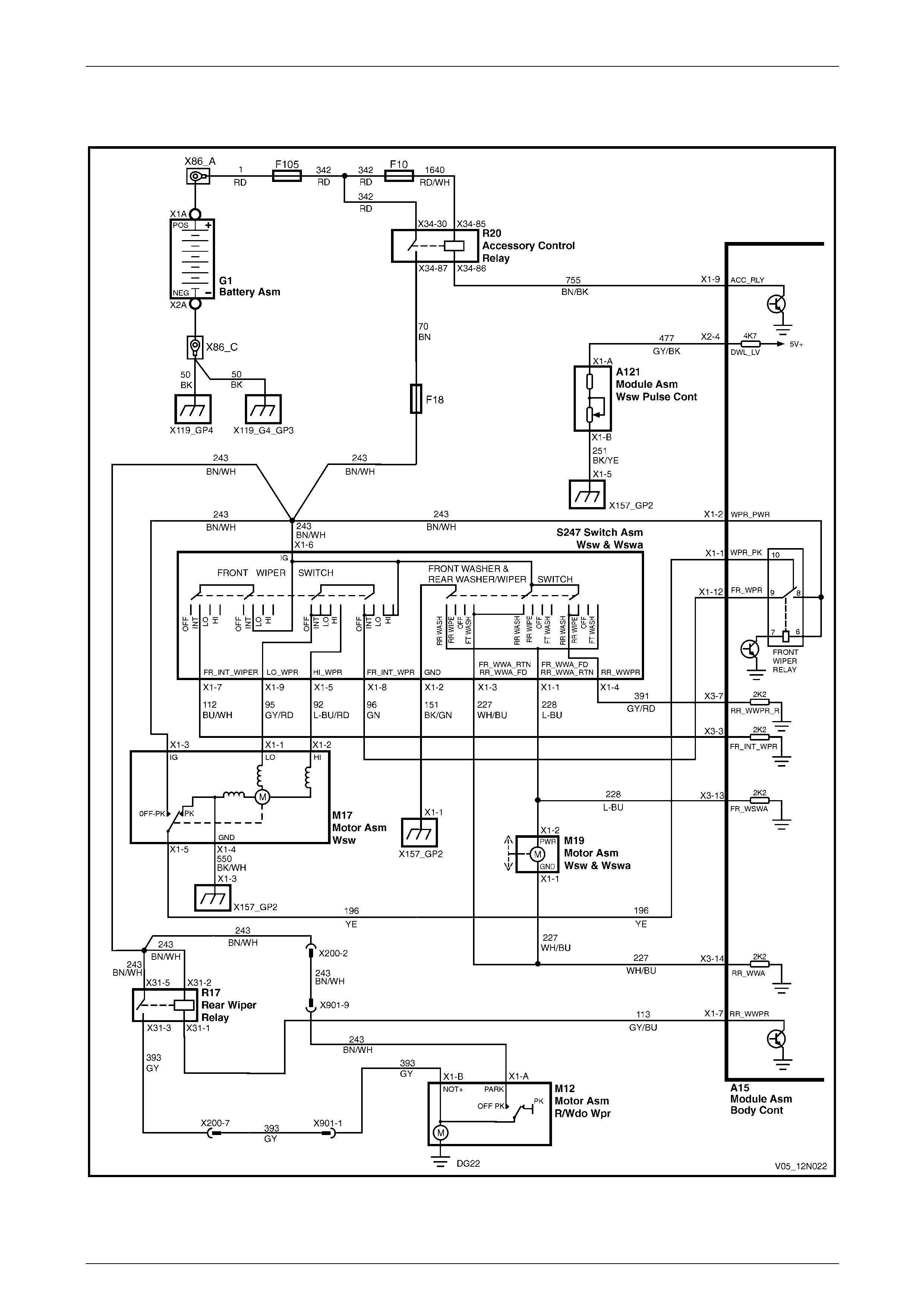

3.3 Wiring Diagram – Front Wiper/Washer, Wagon................................................................................................. 19

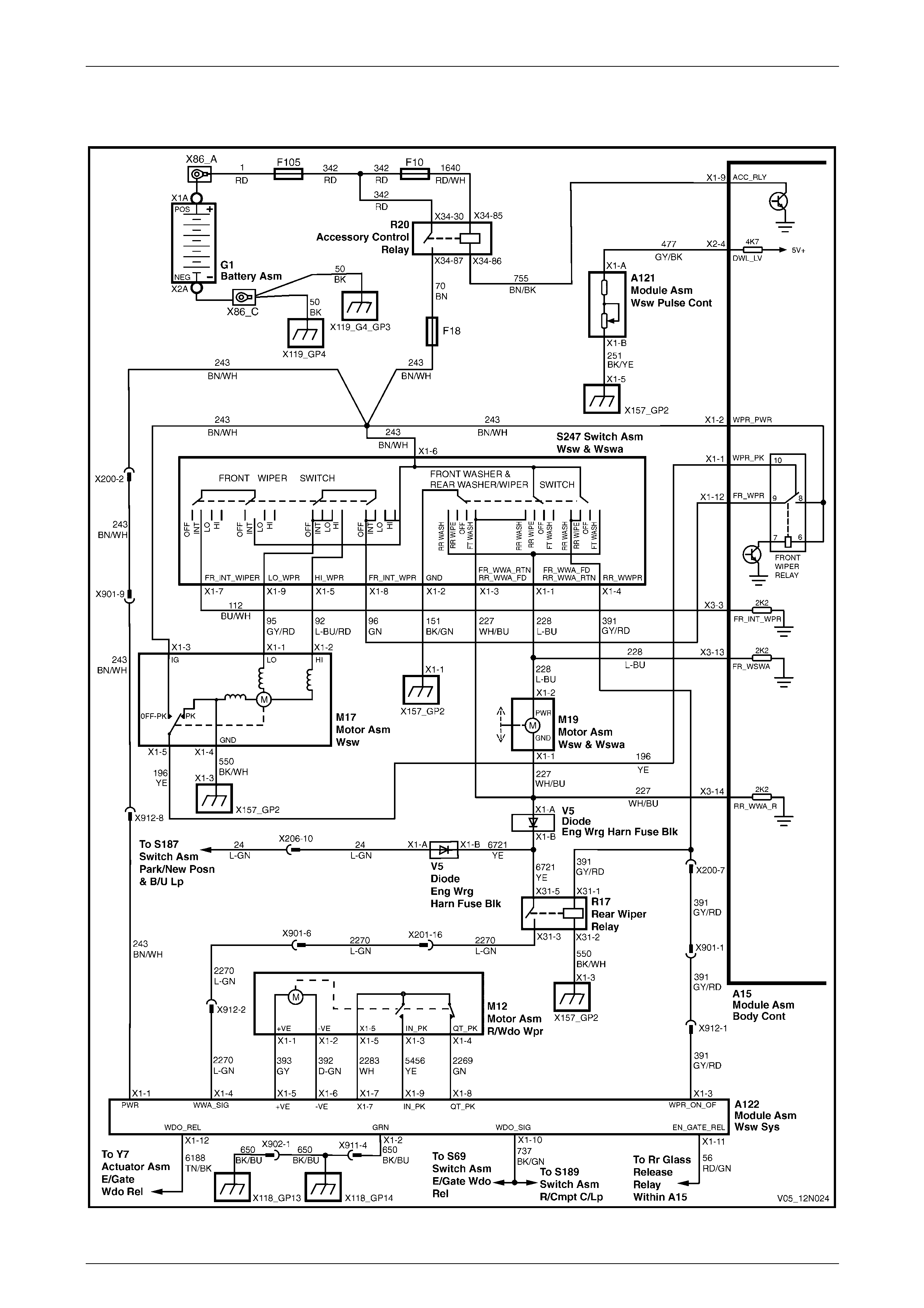

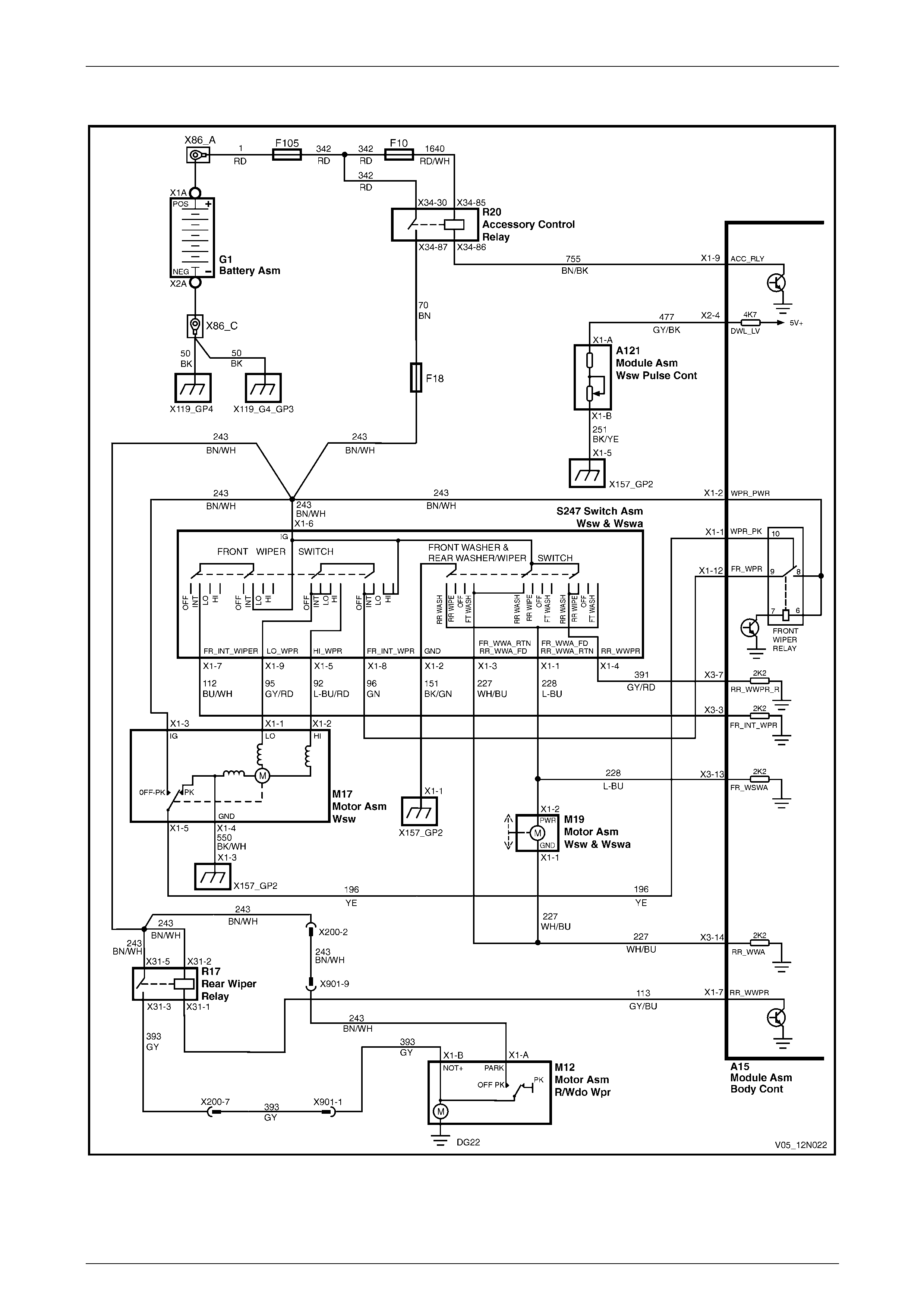

3.4 Wiring Diagram – Front Wiper/Washer, AWD Wagon....................................................................................... 20

Wipers, Washers and Horn Page 12N–2

Page 12N–2

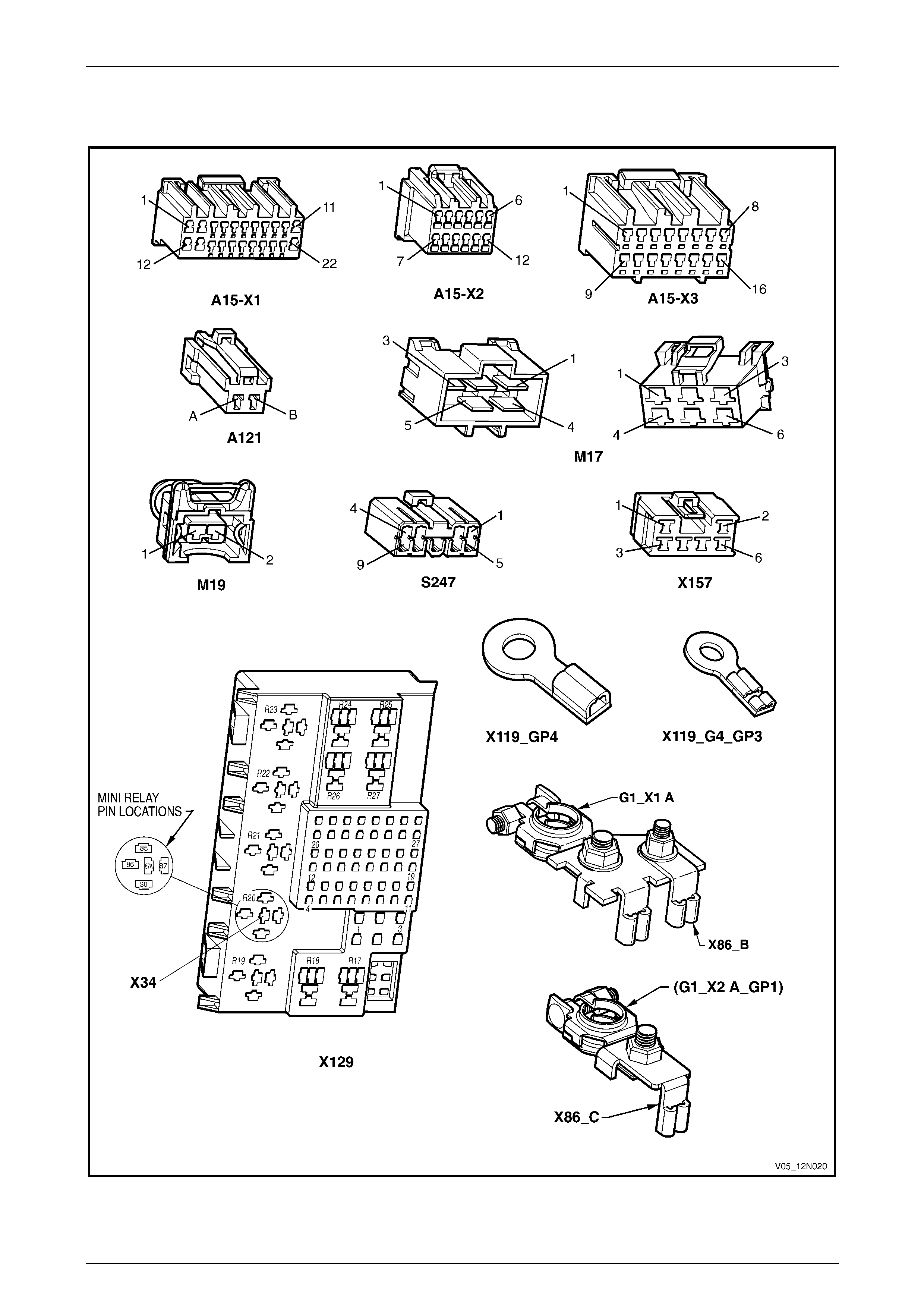

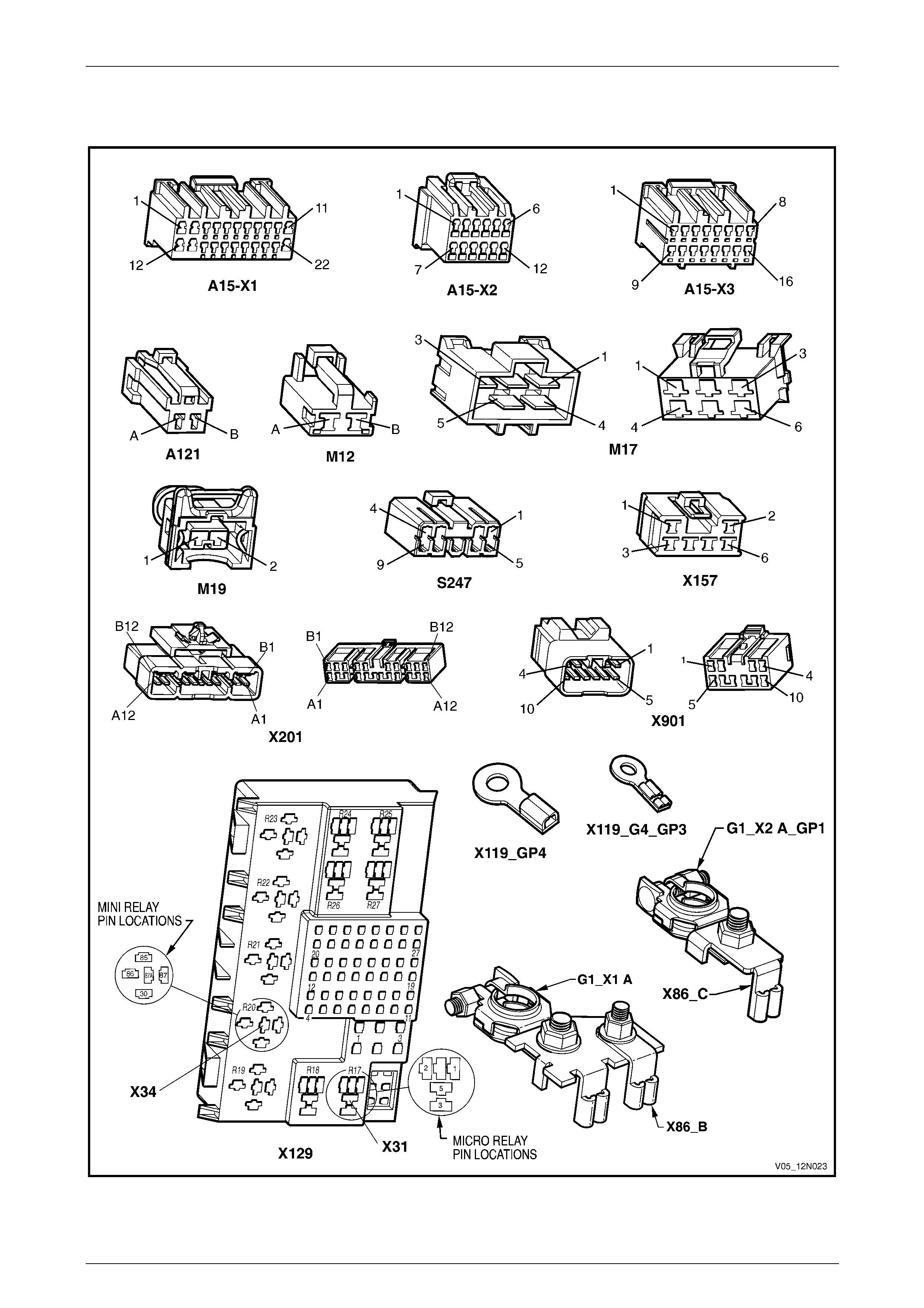

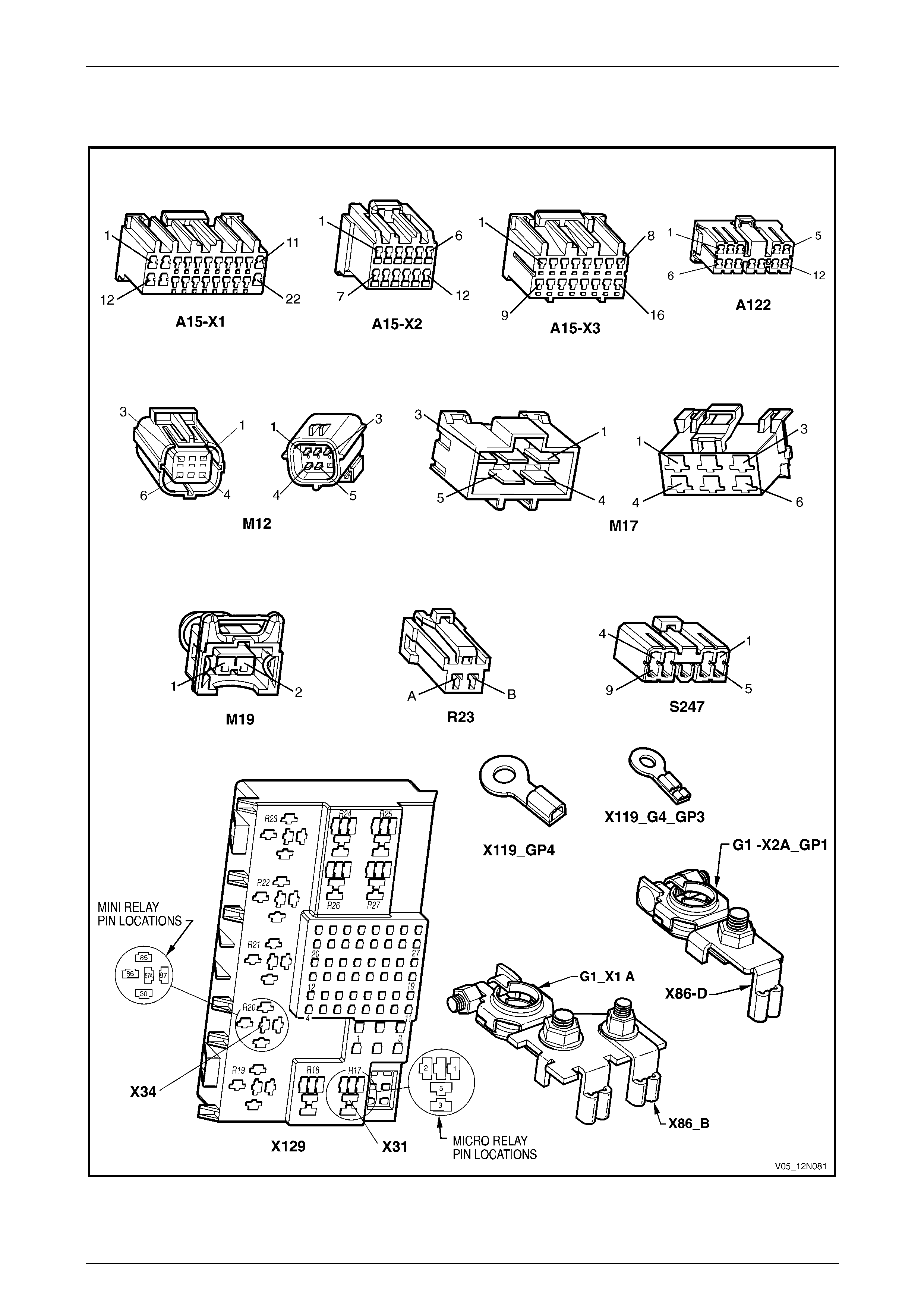

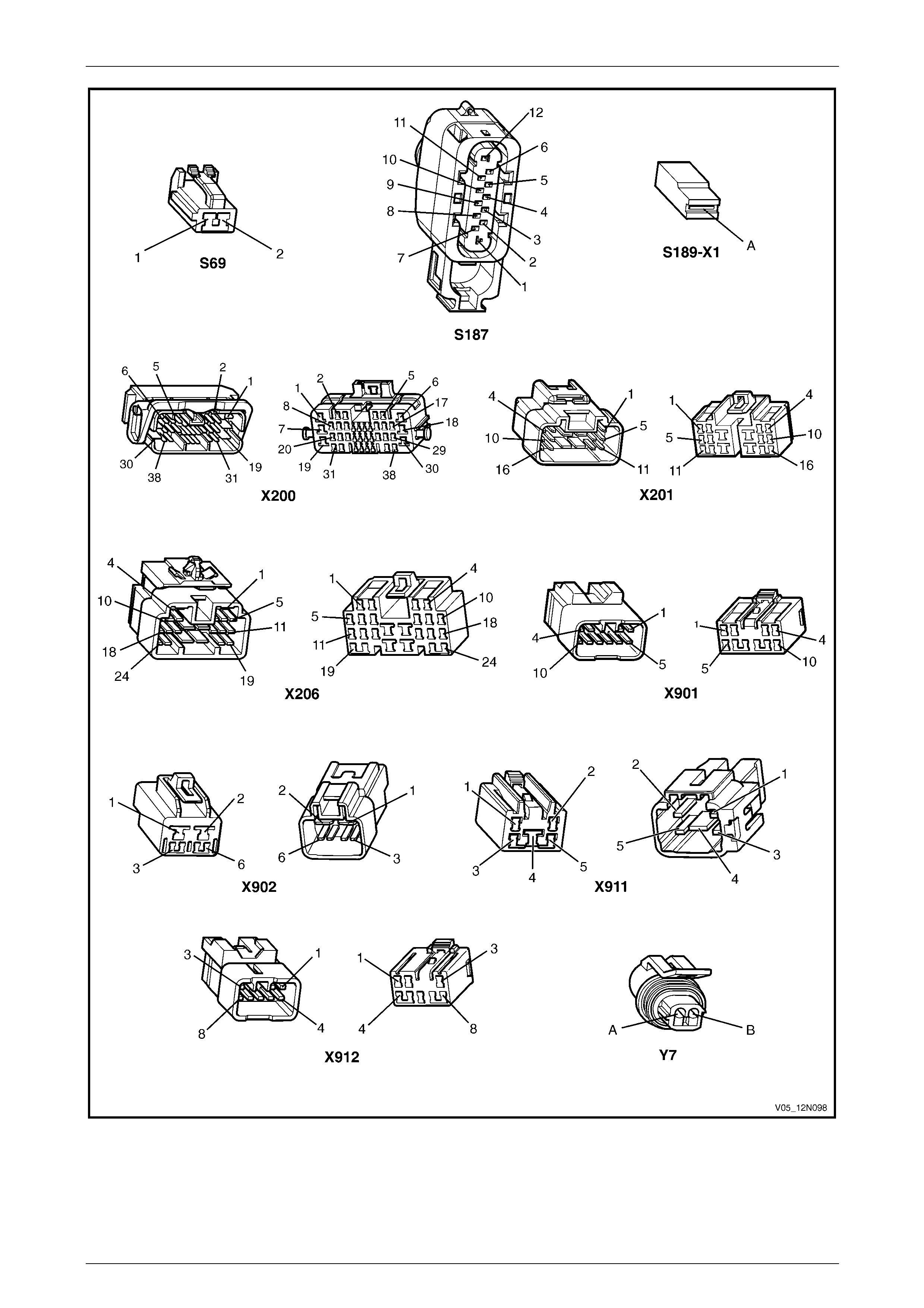

3.5 Connector Diagrams – Front Wiper/Washer...................................................................................................... 21

3.6 Diagnose Front Wiper Motor Wiring System Malfunction................................................................................ 22

Introduction.......................................................................................................................................................... 22

Electrical Test Description.................................................................................................................................. 22

Diagnostic Table Notes ....................................................................................................................................... 23

Diagnostic Table.................................................................................................................................................. 23

3.7 Diagnose Front Wiper Motor Assembly Operation........................................................................................... 25

Introduction.......................................................................................................................................................... 25

Electrical Test Description.................................................................................................................................. 25

Diagnostic Table Notes ....................................................................................................................................... 25

Diagnostic Table.................................................................................................................................................. 26

3.8 Diagnose Front Washer Pump and Wiring System Malfunction...................................................................... 27

Introduction.......................................................................................................................................................... 27

Electrical Test Description.................................................................................................................................. 27

Diagnostic Table Notes ....................................................................................................................................... 27

Diagnostic Table.................................................................................................................................................. 28

4 Preliminary Test – Rear Wipers and Washers, Wagon and AWD Wagon ......................................29

4.1 Test Rear Wiper and Washer Assembly ............................................................................................................ 29

Introduction.......................................................................................................................................................... 29

Test Description................................................................................................................................................... 29

Diagnostic Table Notes ....................................................................................................................................... 29

Diagnostic Table.................................................................................................................................................. 30

5 Diagnostics – Rear Wiper and Washer, Wagon ................................................................................31

5.1 Prerequisites........................................................................................................................................................ 31

Safety Requirements ........................................................................................................................................... 31

Equipment ............................................................................................................................................................ 31

Testing Procedures ............................................................................................................................................. 31

5.2 Wiring Diagram – Rear Wiper/Washer................................................................................................................ 32

5.3 Connector Diagrams – Rear Wiper/Washer....................................................................................................... 33

5.4 Diagnose Rear Wiper Motor Wiring System Malfunction................................................................................. 34

Introduction.......................................................................................................................................................... 34

Electrical Test Description.................................................................................................................................. 34

Diagnostic Table Notes ....................................................................................................................................... 34

Diagnostic Table.................................................................................................................................................. 35

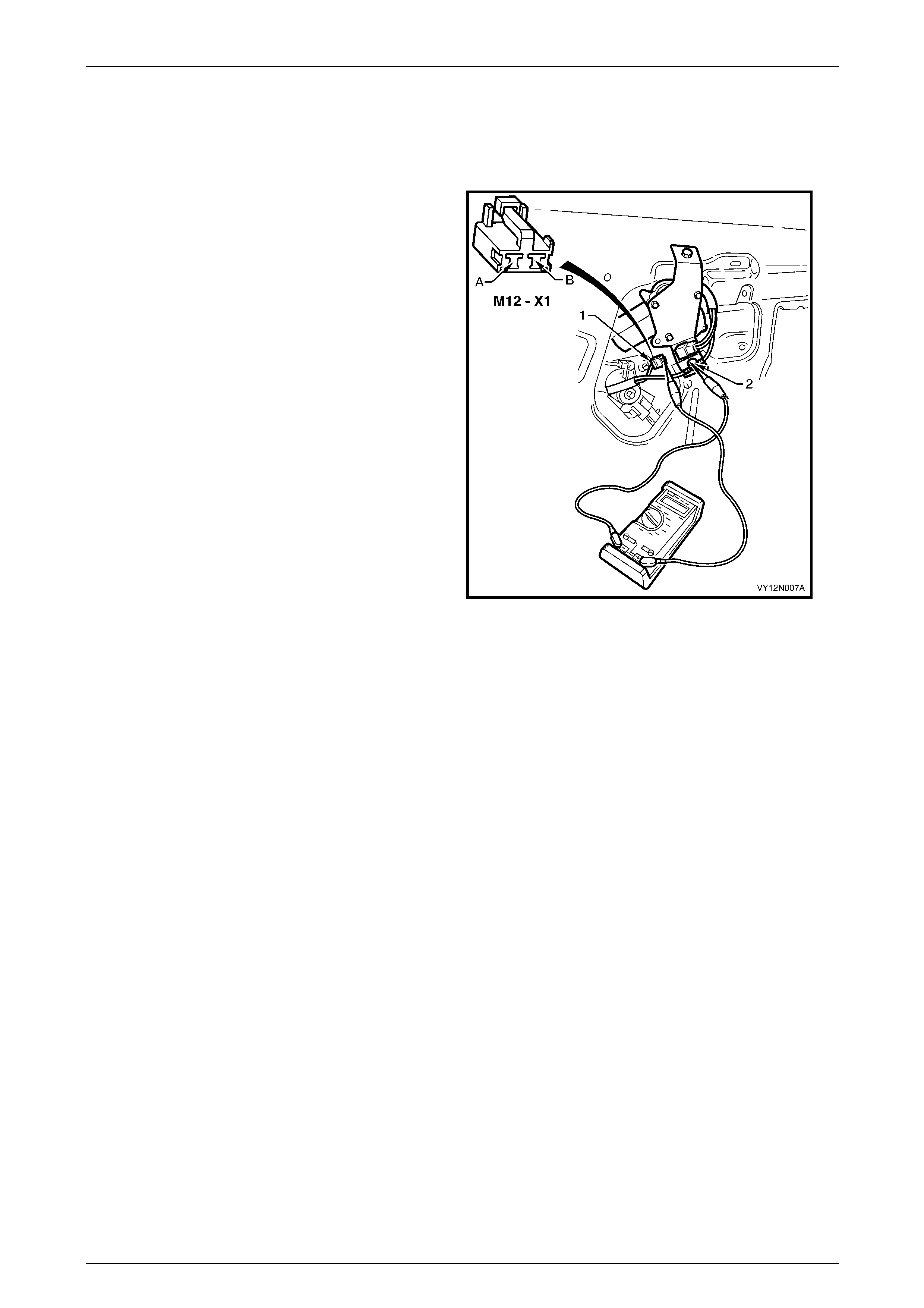

5.5 Diagnose Rear Wiper Motor Assembly Operation............................................................................................ 36

Introduction.......................................................................................................................................................... 36

Electrical Test Description.................................................................................................................................. 36

Diagnostic Table Notes ....................................................................................................................................... 36

Diagnostic Table.................................................................................................................................................. 37

5.6 Diagnose Washer Pump and Rear Washer Wiring System Malfunction......................................................... 38

Introduction.......................................................................................................................................................... 38

Electrical Test Description.................................................................................................................................. 38

Diagnostic Table Notes ....................................................................................................................................... 38

Diagnostic Table.................................................................................................................................................. 38

6 Diagnostics – Rear Wiper and Washer, AWD Wagon.......................................................................39

6.1 Prerequisites........................................................................................................................................................ 39

Safety Requirements ........................................................................................................................................... 39

Equipment ............................................................................................................................................................ 39

Testing Procedures ............................................................................................................................................. 39

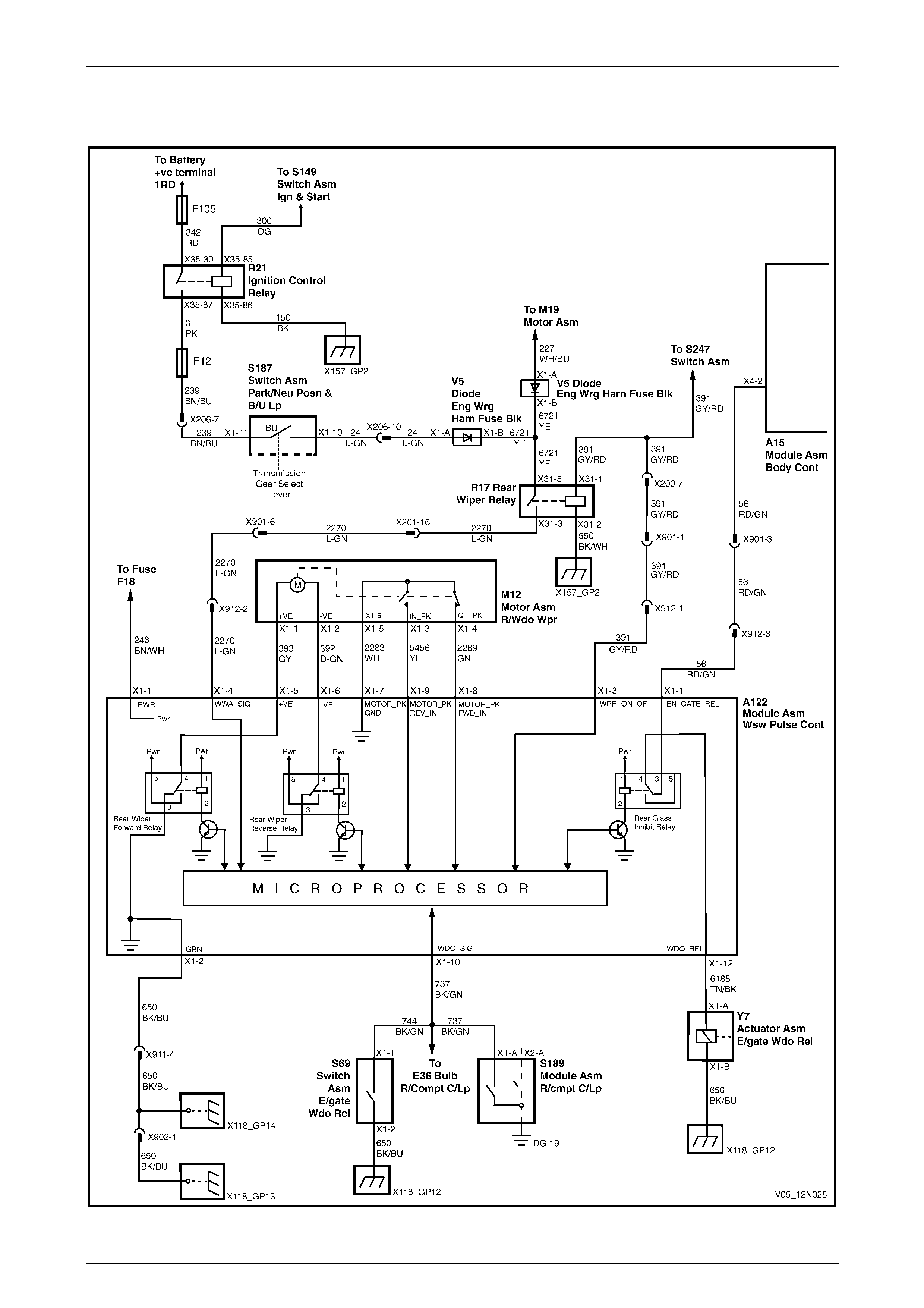

6.2 Wiring Diagram – Rear Wiper/Washer................................................................................................................ 40

6.3 Wiring Diagram – Rear Wiper Control Module .................................................................................................. 41

6.4 Connector Diagrams – Rear Wiper/Washer....................................................................................................... 42

Wipers, Washers and Horn Page 12N–3

Page 12N–3

6.5 Diagnose Rear Wiper Motor Wiring System Malfunction................................................................................. 44

Introduction.......................................................................................................................................................... 44

Electrical Test Description.................................................................................................................................. 44

Diagnostic Table Notes ....................................................................................................................................... 45

Diagnostic Table.................................................................................................................................................. 45

6.6 Diagnose Rear Wiper Motor Assembly Operation............................................................................................ 47

Introduction.......................................................................................................................................................... 47

Electrical Test Description.................................................................................................................................. 47

Diagnostic Table Notes ....................................................................................................................................... 47

Diagnostic Table.................................................................................................................................................. 48

Wiper Motor Limit Switches Malfunction Table................................................................................................. 49

6.7 Diagnose Rear Wiper and Liftgate Interface Operation.................................................................................... 50

Introduction.......................................................................................................................................................... 50

Electrical Test Description.................................................................................................................................. 50

Diagnostic Table Notes ....................................................................................................................................... 50

Diagnostic Table.................................................................................................................................................. 51

6.8 Diagnose Washer Pump and Rear Washer Wiring System Malfunction......................................................... 52

Introduction.......................................................................................................................................................... 52

Test Description................................................................................................................................................... 52

Diagnostic Table Notes ....................................................................................................................................... 52

Diagnostic Table.................................................................................................................................................. 52

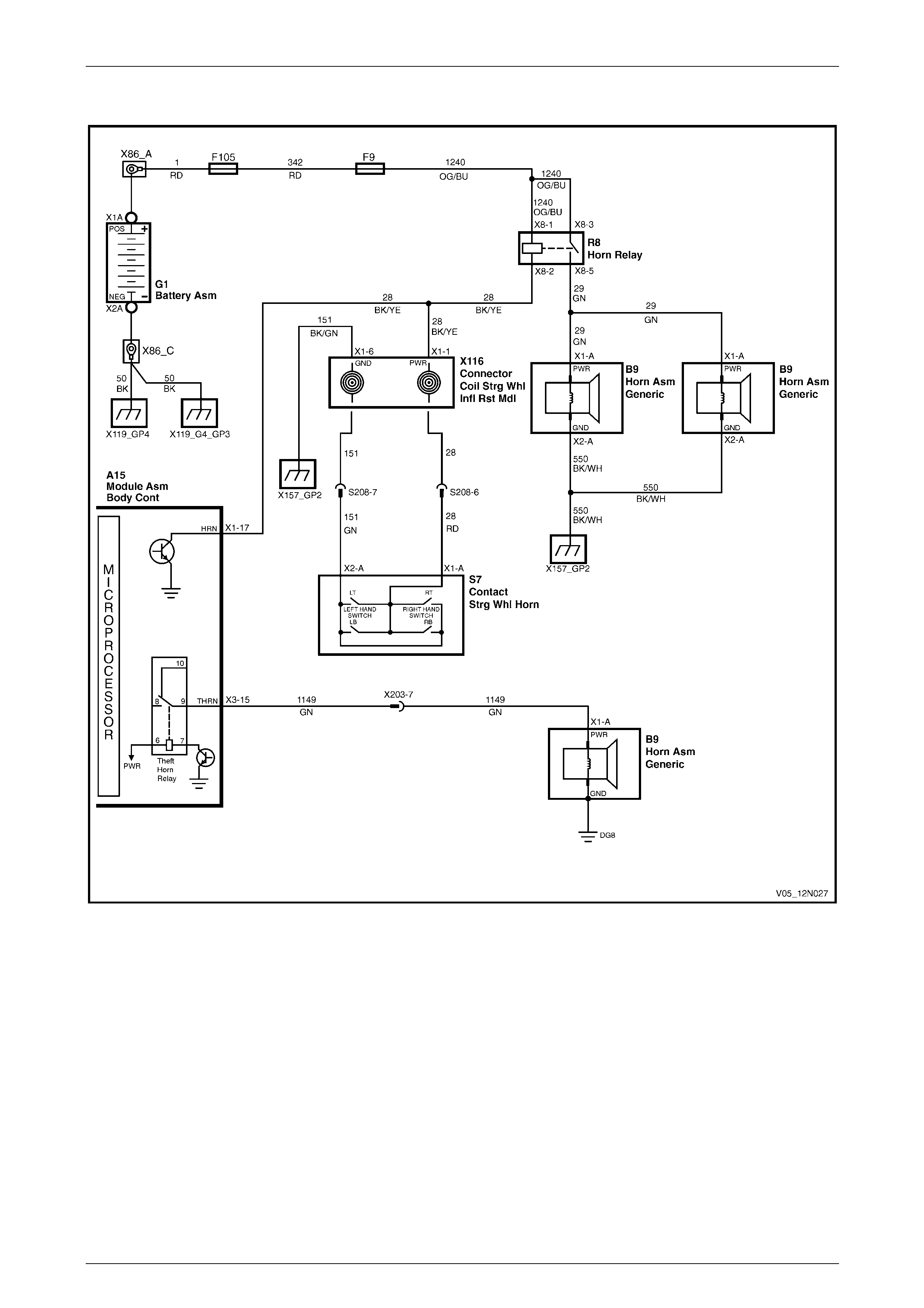

7 Diagnostics – Horn...............................................................................................................................53

7.1 Prerequisites........................................................................................................................................................ 53

Equipment ............................................................................................................................................................ 53

Testing Procedures ............................................................................................................................................. 53

7.2 Wiring Diagram – Horn Assembly...................................................................................................................... 54

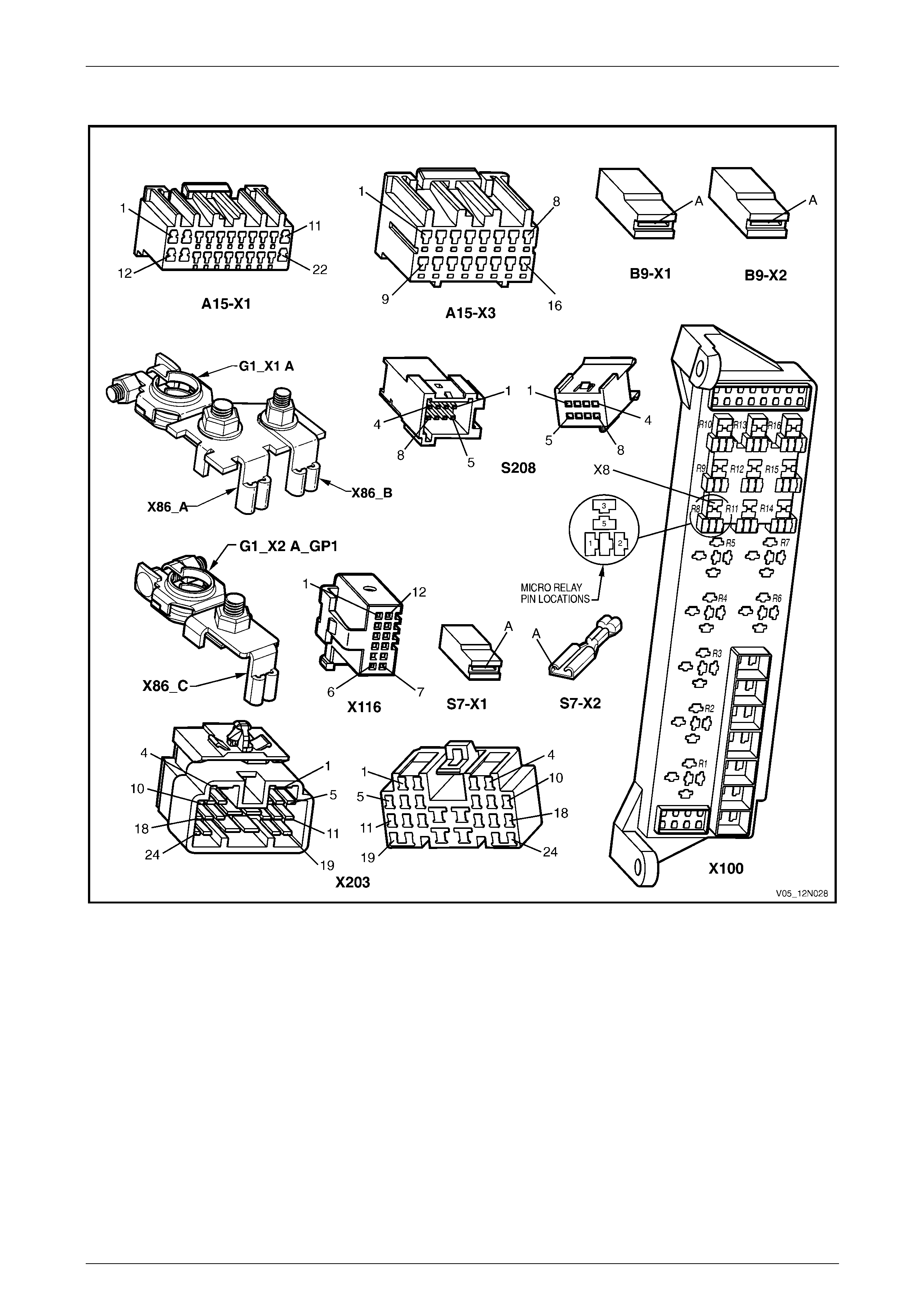

7.3 Connector Diagrams – Horn Assembly ............................................................................................................. 55

7.4 Diagnose Horn and Wiring System Malfunction............................................................................................... 56

Introduction.......................................................................................................................................................... 56

Electrical Test Description.................................................................................................................................. 56

Diagnostic Table Notes ....................................................................................................................................... 57

Diagnostic Table.................................................................................................................................................. 57

8 Service Operations – Front Wiper Assemblies, Except Coupe.......................................................59

8.1 Front Wiper Blade Insert ..................................................................................................................................... 59

Replace................................................................................................................................................................. 59

8.2 Front Wiper Blade Assembly.............................................................................................................................. 60

Remove................................................................................................................................................................. 60

Reinstall................................................................................................................................................................ 60

8.3 Fro nt Wiper Arm Assembly ................................................................................................................................. 61

Remove................................................................................................................................................................. 61

Reinstall................................................................................................................................................................ 62

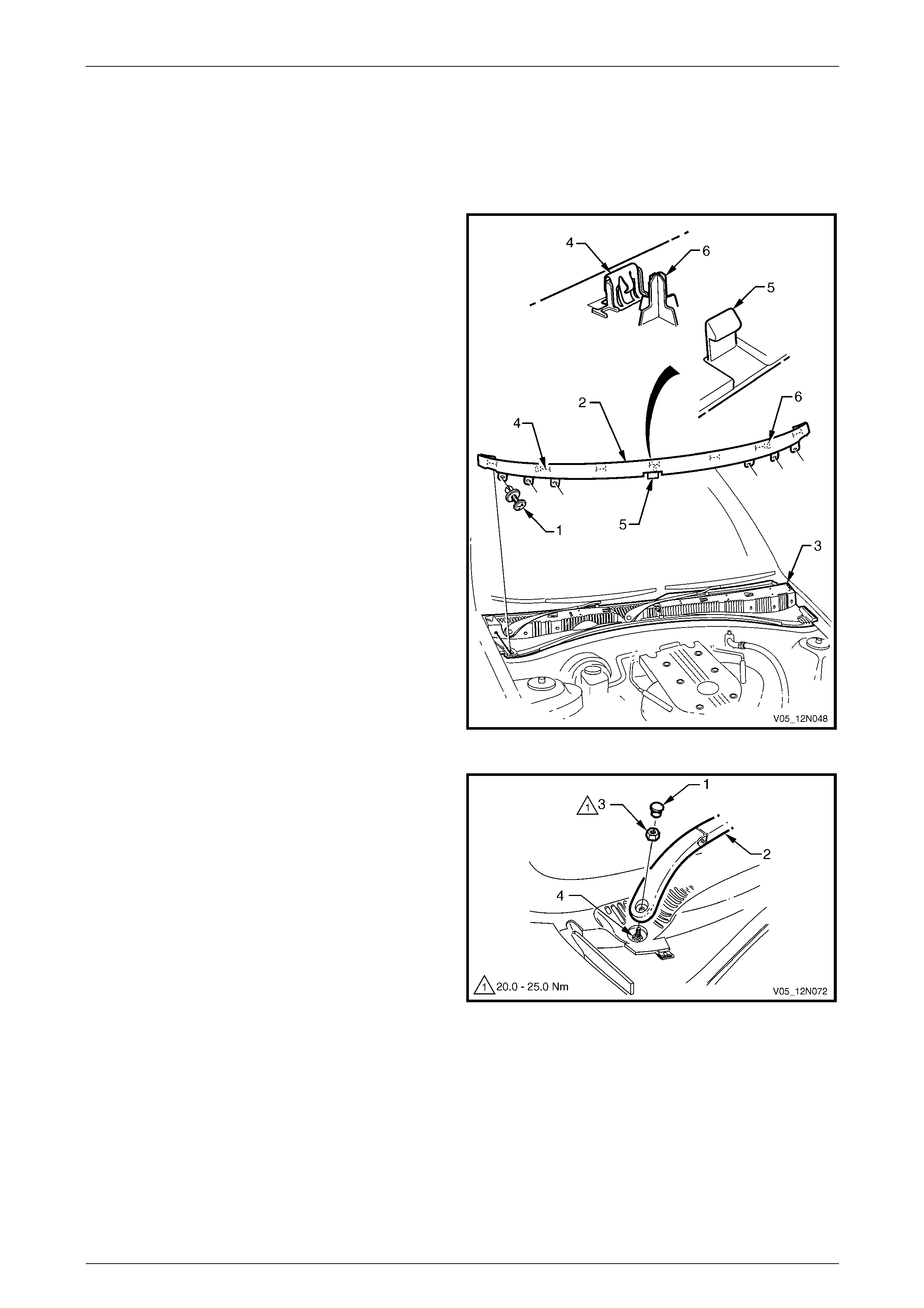

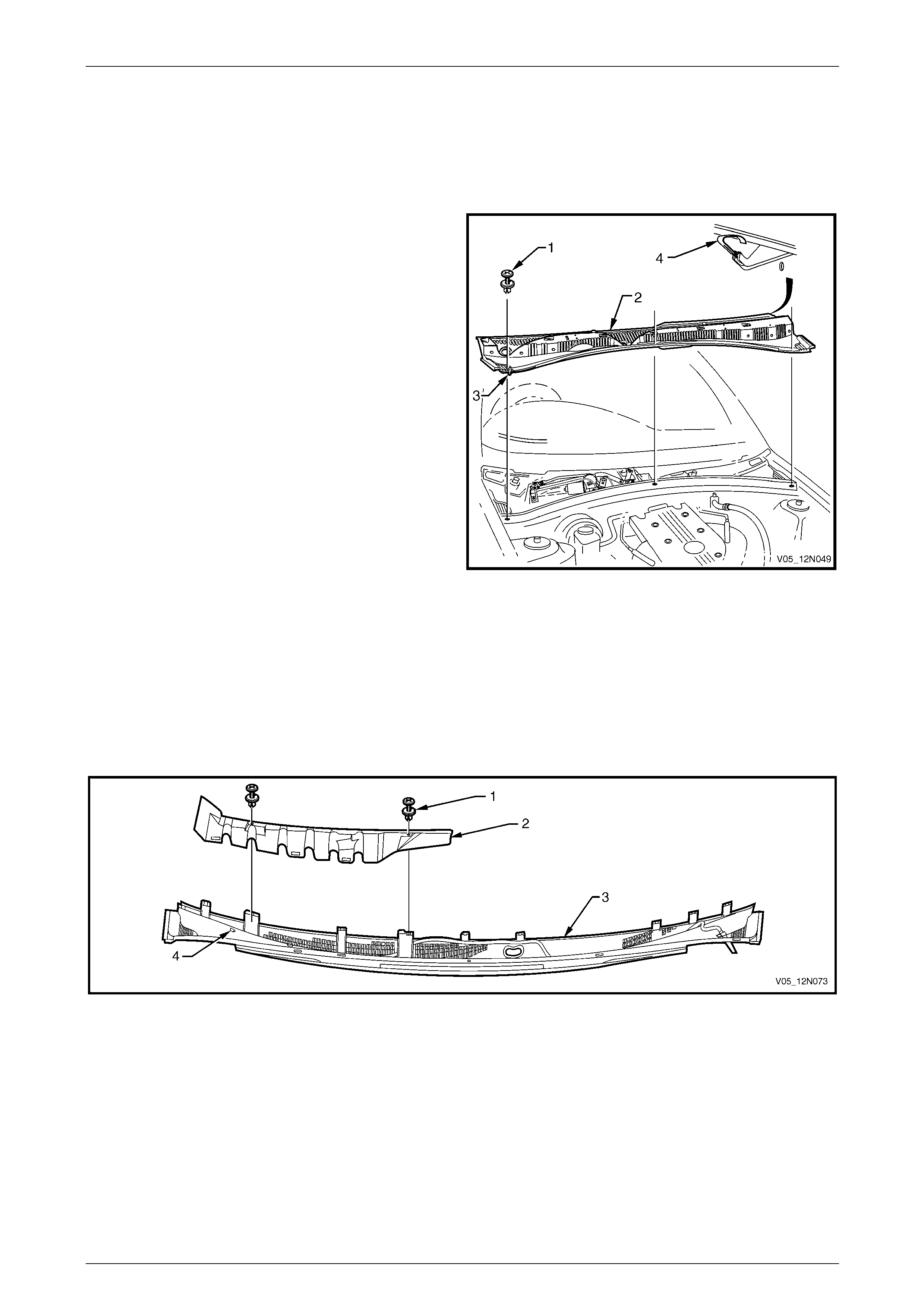

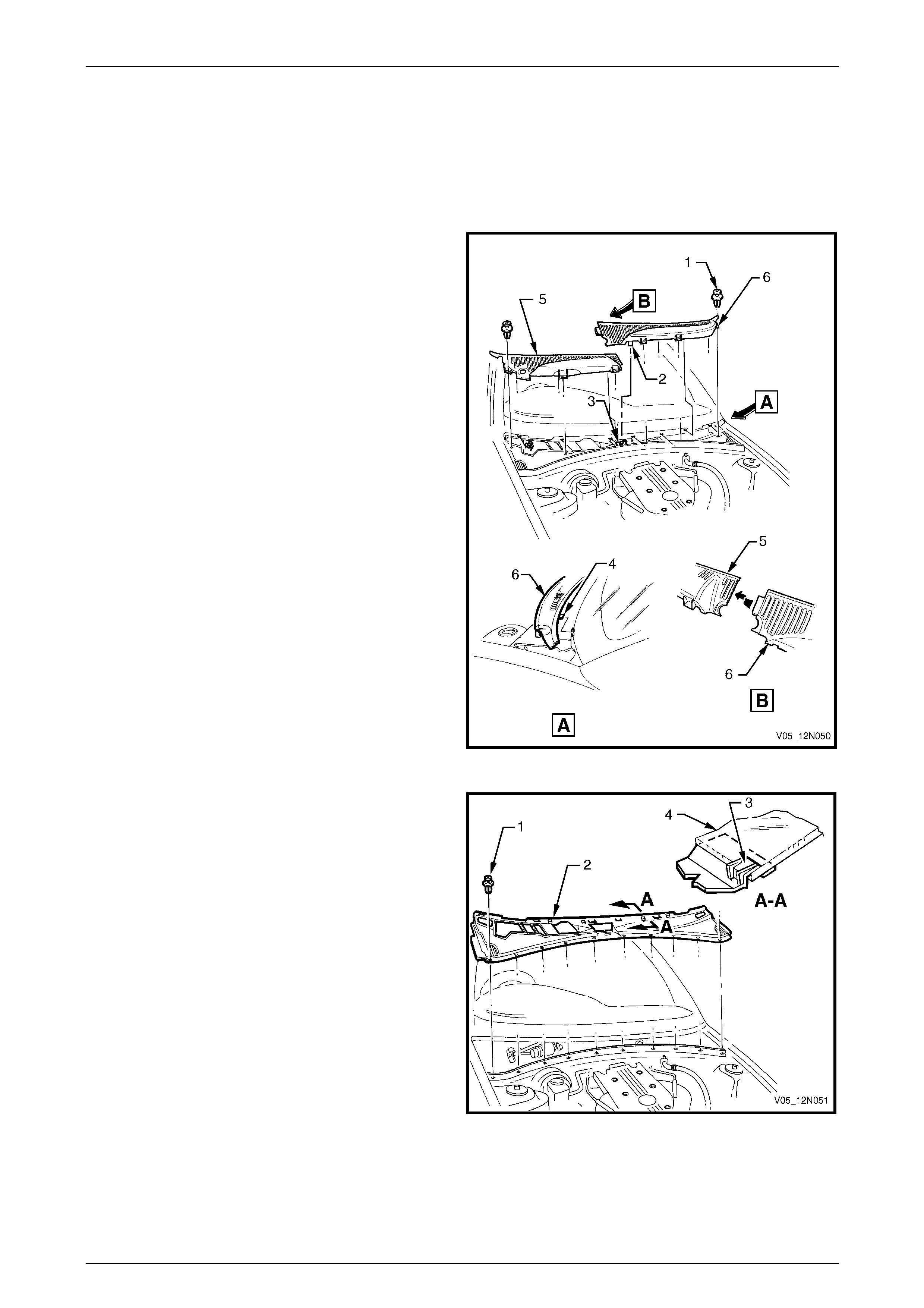

8.4 Plenum Cover Assembly..................................................................................................................................... 63

Remove................................................................................................................................................................. 63

Disassemble......................................................................................................................................................... 63

Reassemble.......................................................................................................................................................... 64

Reinstall................................................................................................................................................................ 64

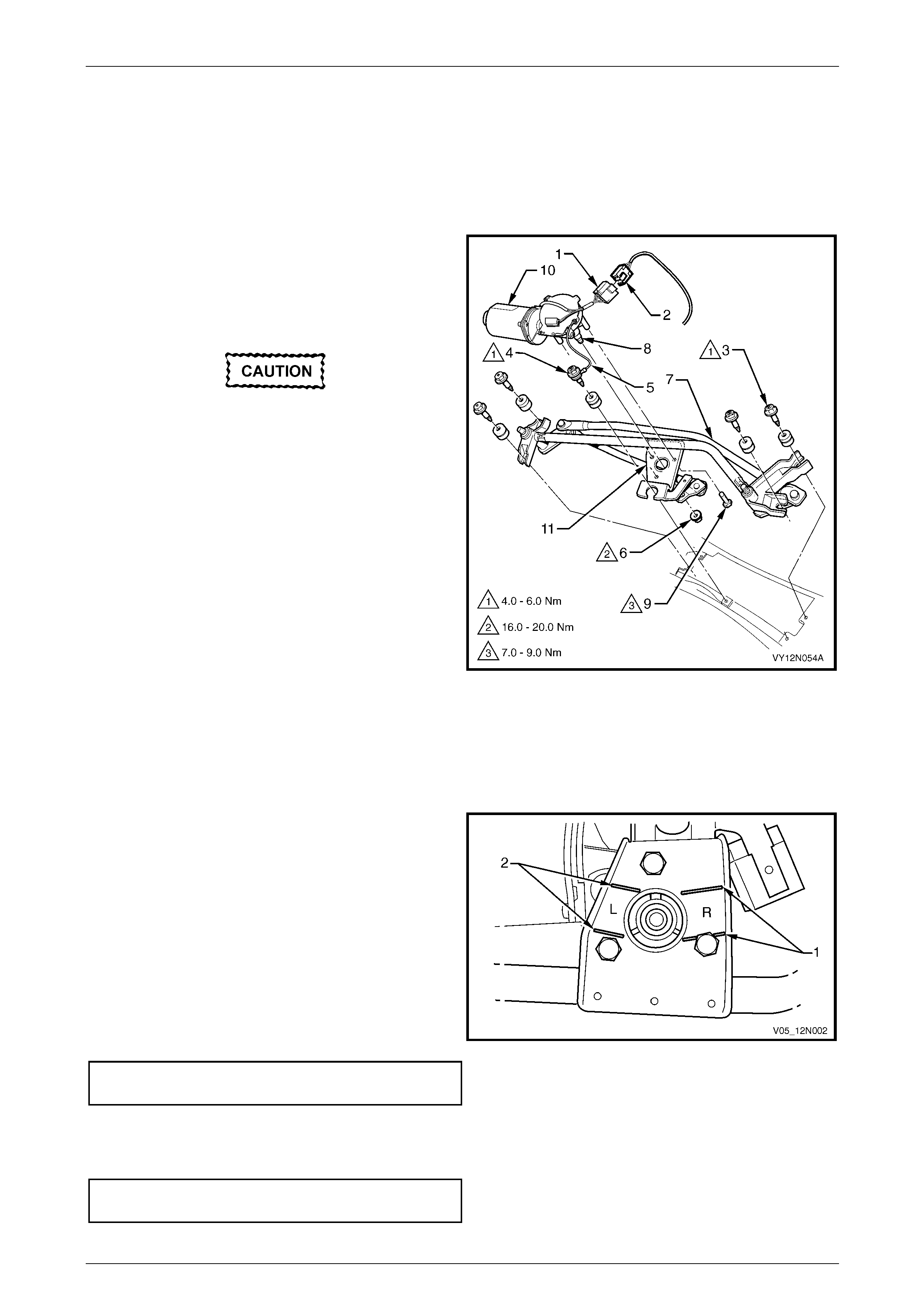

8.5 Front Wiper Motor Assembly and Linkages...................................................................................................... 65

Remove................................................................................................................................................................. 65

Reinstall................................................................................................................................................................ 65

Wipers, Washers and Horn Page 12N–4

Page 12N–4

9 Service Operations – Front Wiper Assemblies, Coupe....................................................................67

9.1 Front Wiper Blade Insert ..................................................................................................................................... 67

Replace................................................................................................................................................................. 67

9.2 Front Wiper Blade Assembly.............................................................................................................................. 68

Remove................................................................................................................................................................. 68

Reinstall................................................................................................................................................................ 68

9.3 Fro nt Wiper Arm Assembly ................................................................................................................................. 69

Remove................................................................................................................................................................. 69

Reinstall................................................................................................................................................................ 69

9.4 Plenum Cover Assembly..................................................................................................................................... 70

Remove................................................................................................................................................................. 70

Reinstall................................................................................................................................................................ 71

9.5 Front Wiper Motor Assembly and Linkages...................................................................................................... 72

Remove................................................................................................................................................................. 72

Reinstall................................................................................................................................................................ 73

10 Service Operations – Rear Wiper Assembly, Wagon .......................................................................74

10.1 Rear Wiper Blade Insert ...................................................................................................................................... 74

Replace................................................................................................................................................................. 74

10.2 Rear Wiper Blade Assembly ............................................................................................................................... 75

Remove and Reinstall.......................................................................................................................................... 75

10.3 Rear Wiper Arm Assembly.................................................................................................................................. 76

Remove................................................................................................................................................................. 76

Reinstall................................................................................................................................................................ 76

10.4 Rear Wiper Motor Assembly............................................................................................................................... 77

Remove................................................................................................................................................................. 77

Reinstall................................................................................................................................................................ 78

11 Service Operations – Rear Wiper Assembly, AWD Wagon..............................................................79

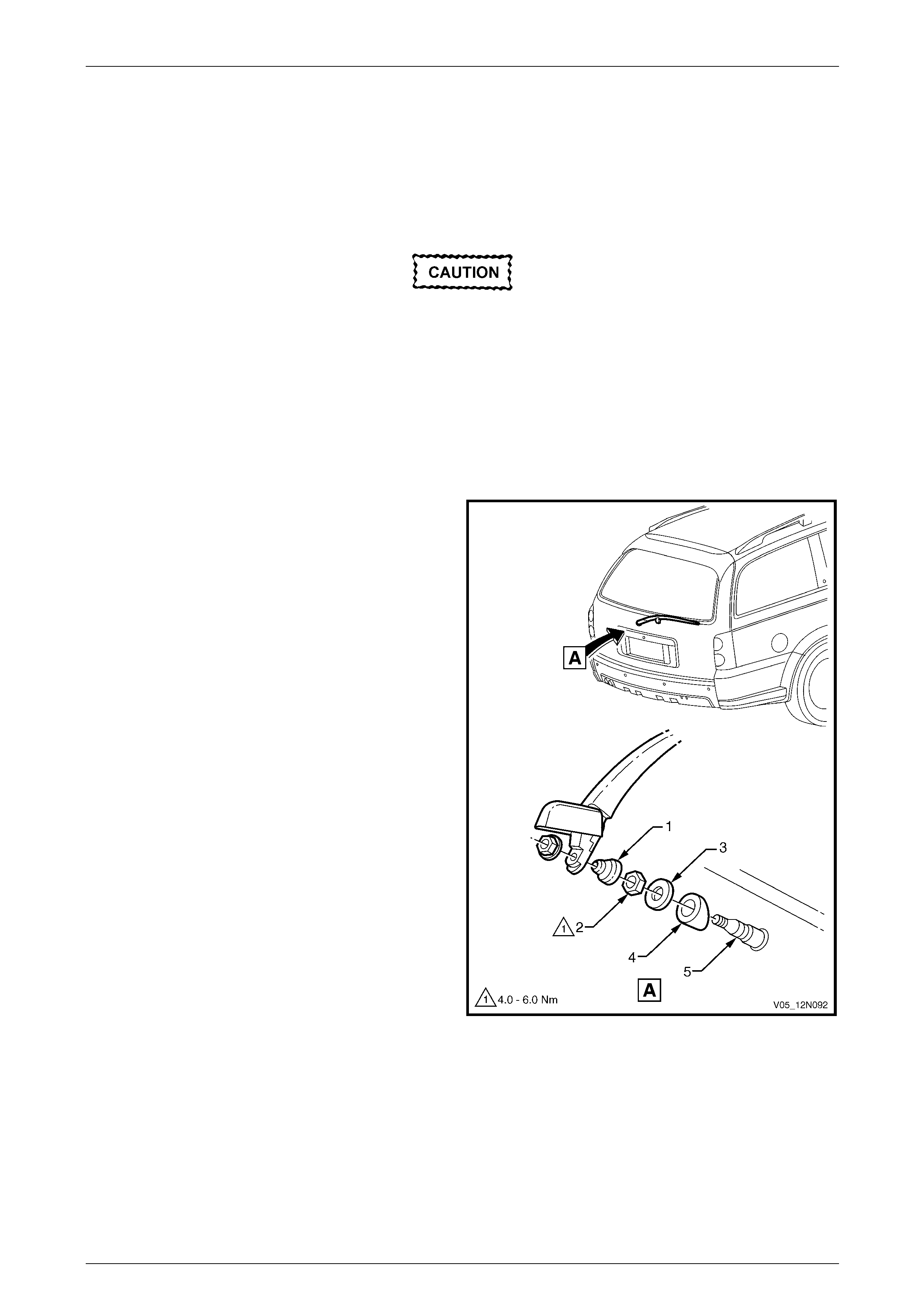

11.1 Rear Wiper Blade Insert ...................................................................................................................................... 79

Replace................................................................................................................................................................. 79

11.2 Rear Wiper Blade Assembly ............................................................................................................................... 80

Remove................................................................................................................................................................. 80

Reinstall................................................................................................................................................................ 80

11.3 Rear Wiper Arm Assembly.................................................................................................................................. 81

Remove................................................................................................................................................................. 81

Reinstall................................................................................................................................................................ 81

11.4 Rear Wiper Ramp................................................................................................................................................. 82

Remove................................................................................................................................................................. 82

Reinstall................................................................................................................................................................ 82

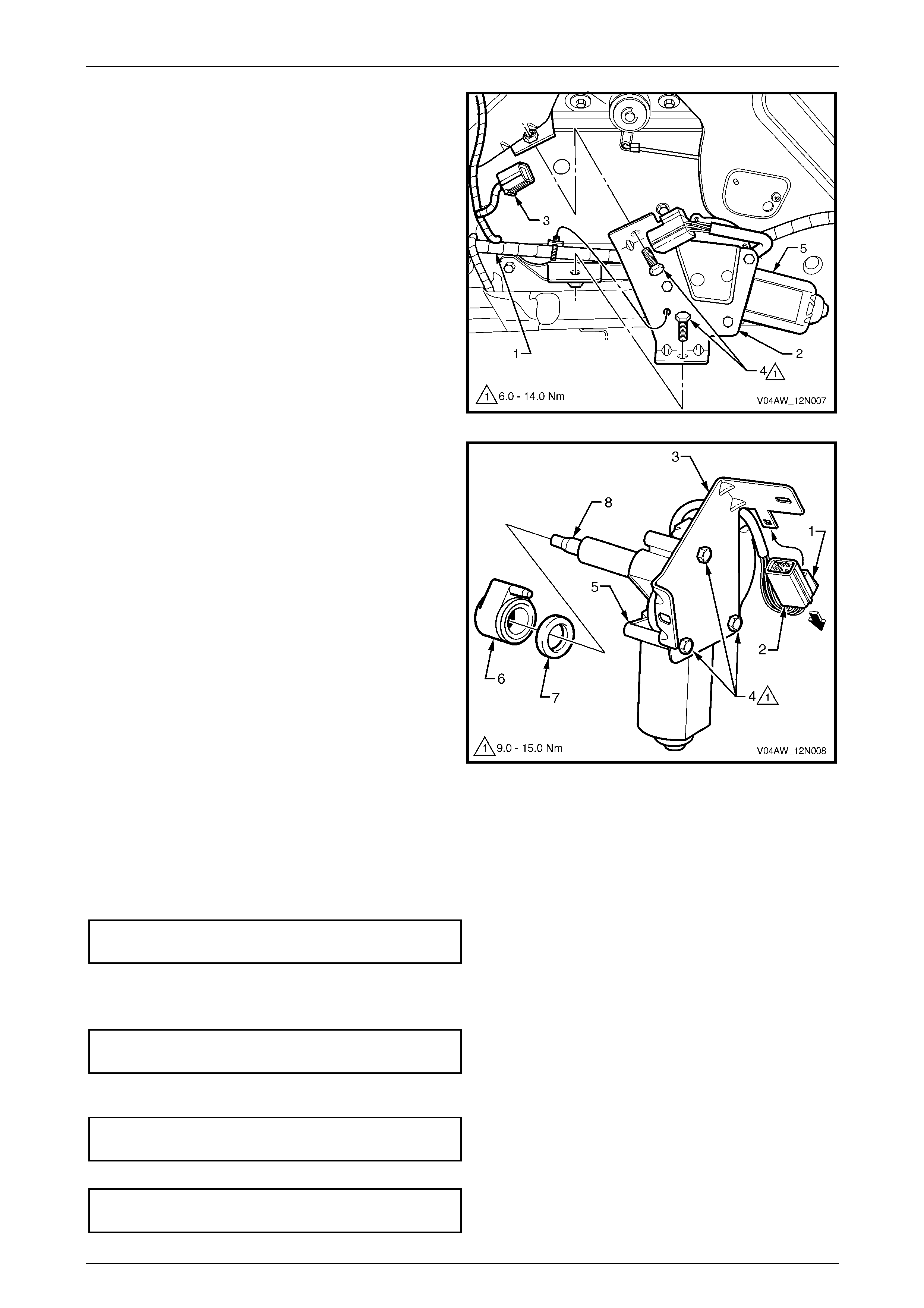

11.5 Rear Wiper Control Module................................................................................................................................. 83

Remove................................................................................................................................................................. 83

Reinstall................................................................................................................................................................ 83

11.6 Rear Wiper Motor Assembly............................................................................................................................... 84

Remove................................................................................................................................................................. 84

Reinstall................................................................................................................................................................ 85

12 Service Operations – Washer Assemblies, Sedan and Utility.........................................................86

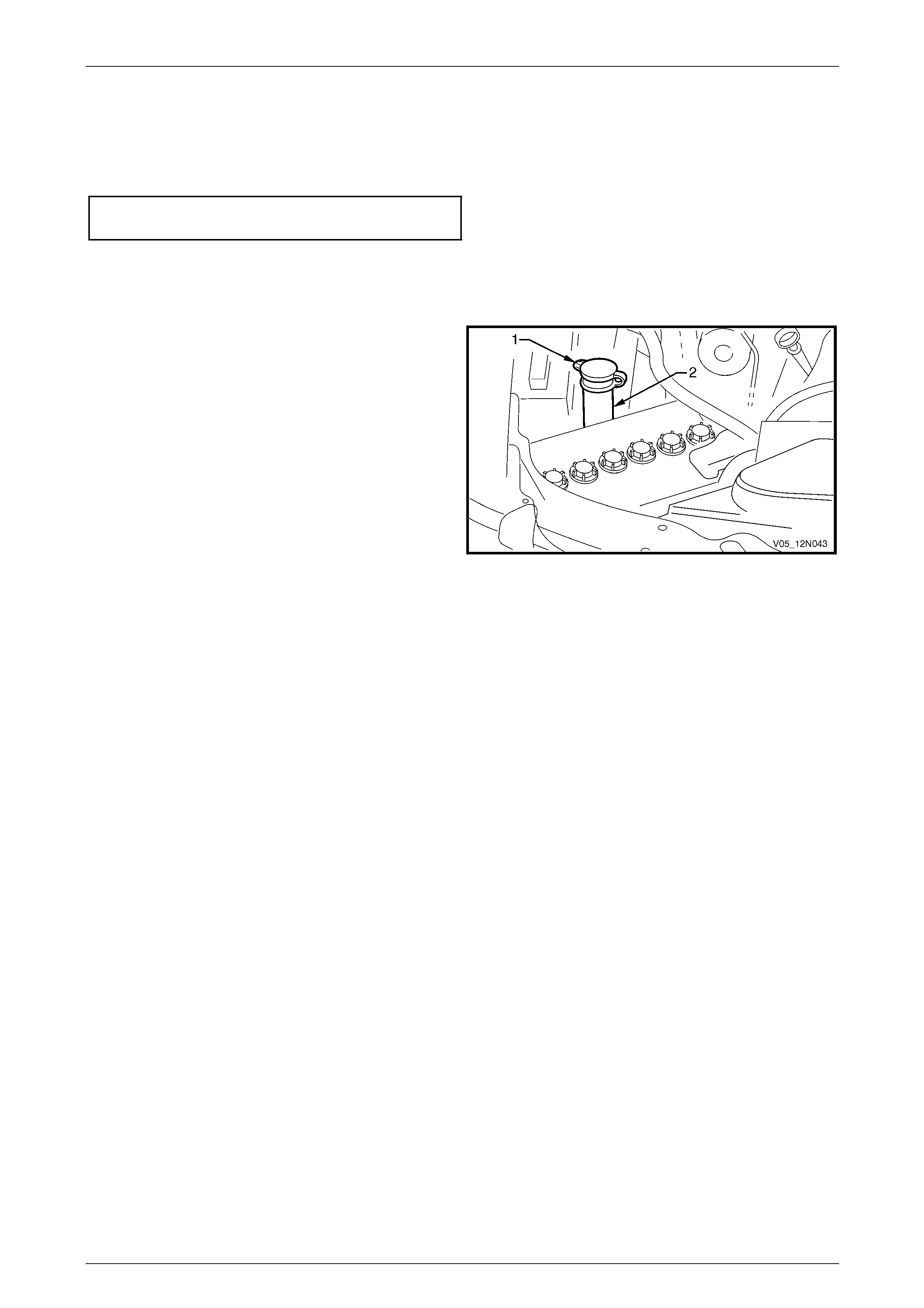

12.1 Washer Reservoir Assembly............................................................................................................................... 86

Remove................................................................................................................................................................. 86

Reinstall................................................................................................................................................................ 87

Filling the Washer Reservoir Assembly............................................................................................................. 87

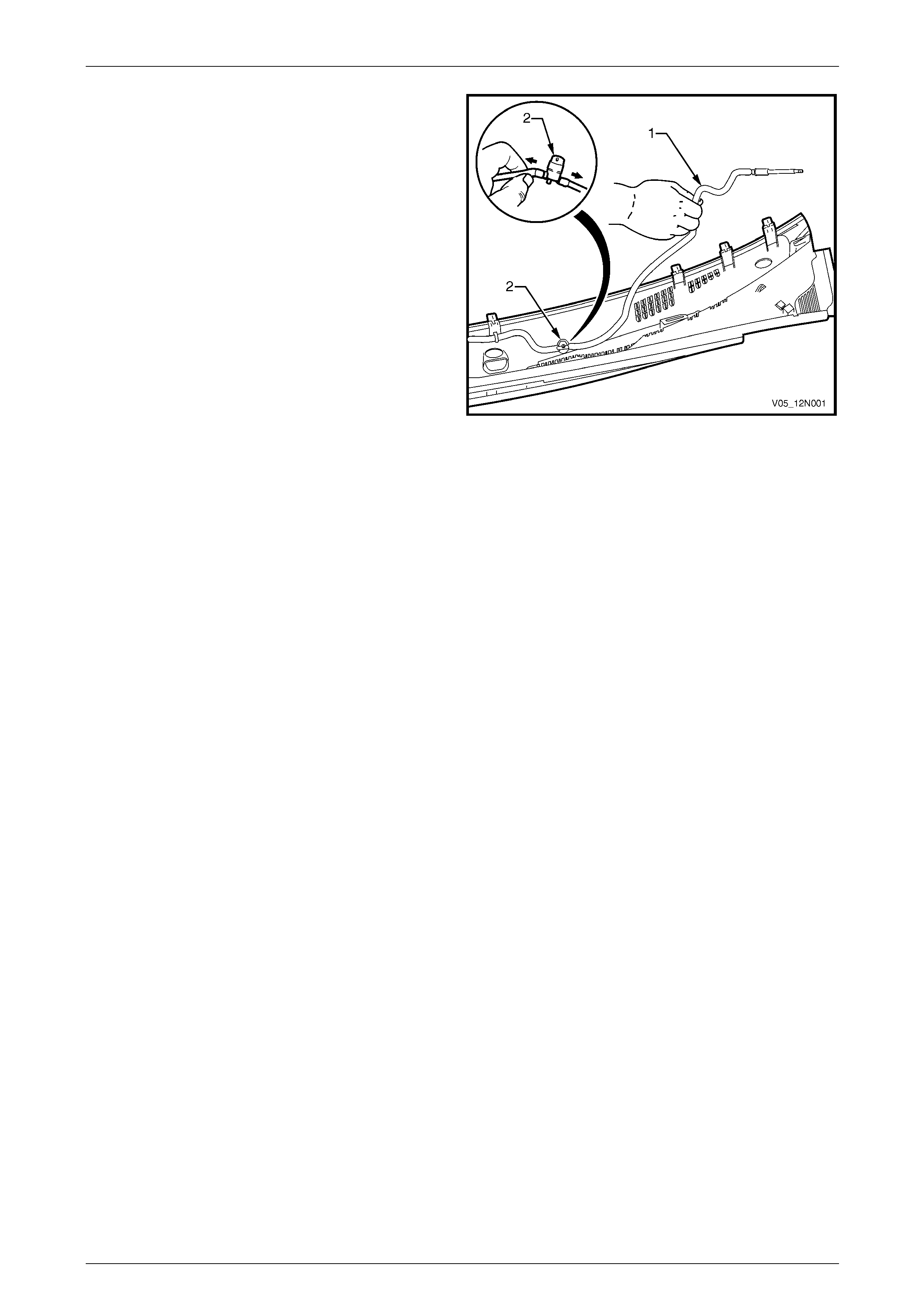

12.2 Front Washer Hose and Nozzle Assemblies...................................................................................................... 88

Remove................................................................................................................................................................. 88

Reinstall................................................................................................................................................................ 89

Spray Pattern Check............................................................................................................................................ 89

Wipers, Washers and Horn Page 12N–5

Page 12N–5

13 Service Operations – Washer Assemblies, Wago n ..........................................................................90

13.1 Washer Reservoir Assembly............................................................................................................................... 90

Remove................................................................................................................................................................. 90

Reinstall................................................................................................................................................................ 91

Filling the Washer Reservoir Assembly............................................................................................................. 91

13.2 Front Washer Hose and Nozzle Assemblies...................................................................................................... 92

Remove................................................................................................................................................................. 92

Reinstall................................................................................................................................................................ 93

Spray Pattern Check............................................................................................................................................ 93

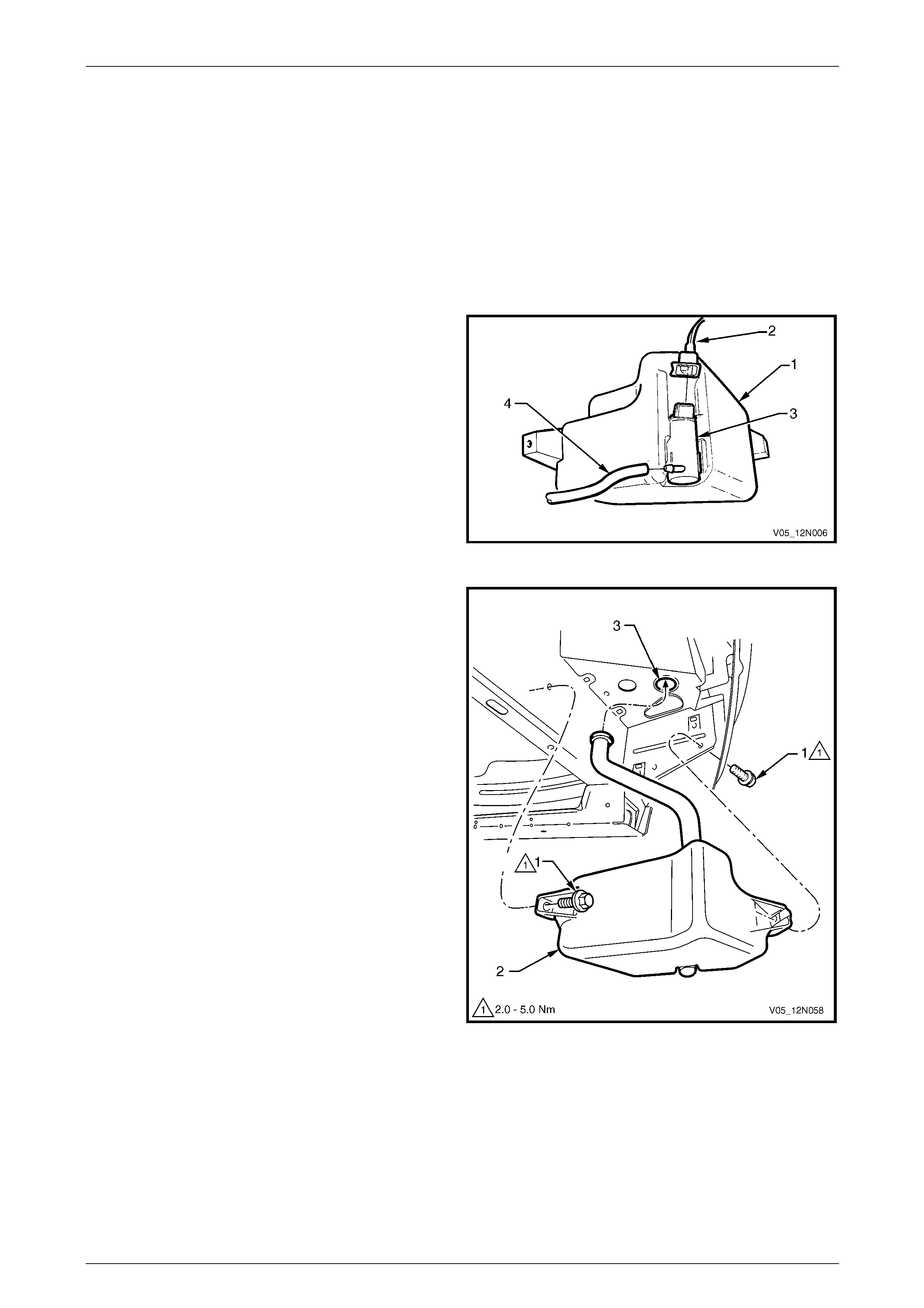

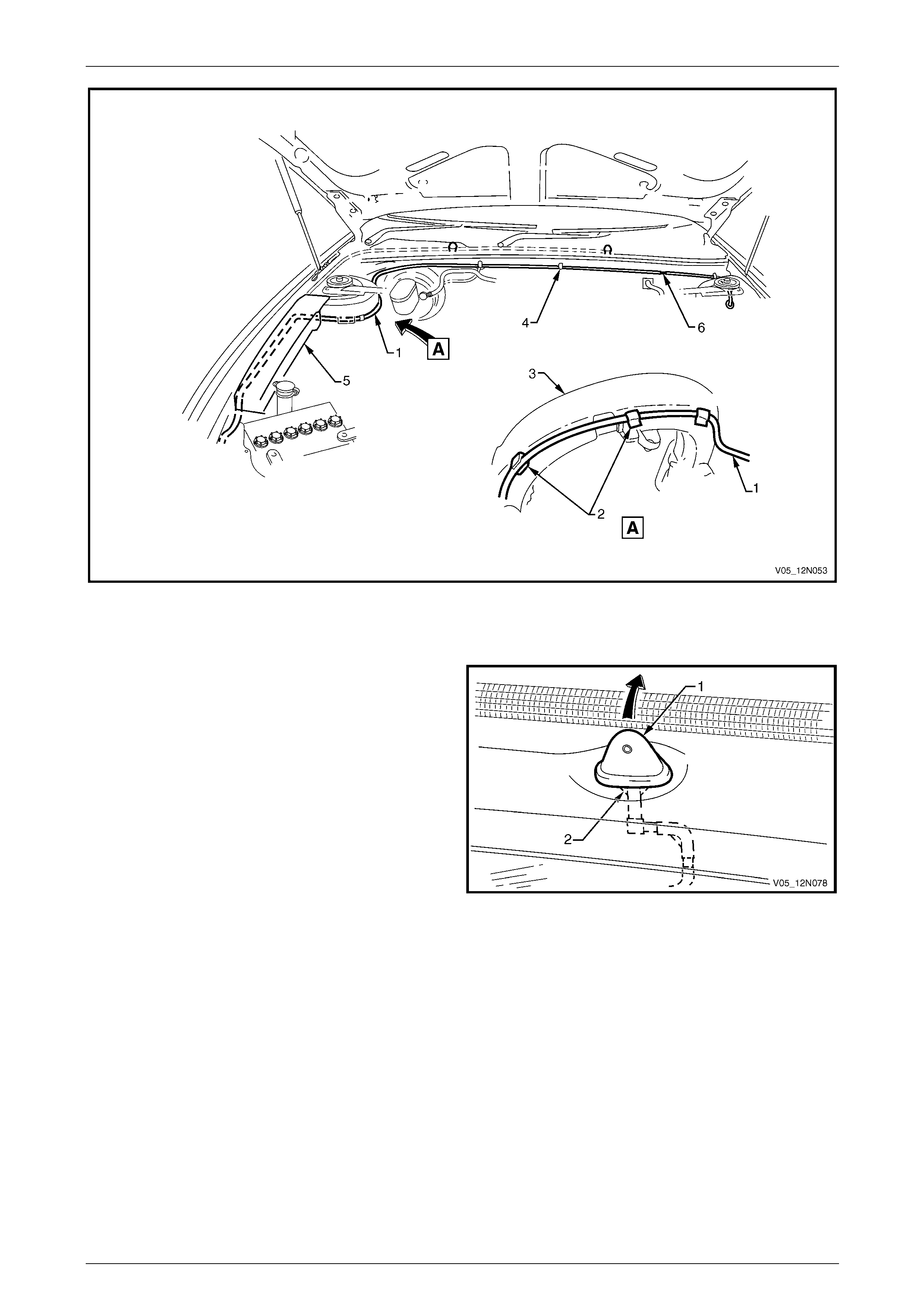

13.3 Rear Washer Hose and Nozzle Assembly.......................................................................................................... 94

Introduction.......................................................................................................................................................... 94

Remove................................................................................................................................................................. 94

Front Section.................................................................................................................................................... 94

Rear Section .................................................................................................................................................... 95

Reinstall................................................................................................................................................................ 97

Front Section.................................................................................................................................................... 97

Rear Section .................................................................................................................................................... 97

Spray Pattern Check............................................................................................................................................ 97

14 Service Operations – Washer Assemblies, AWD Wagon.................................................................98

14.1 Washer Reservoir Assembly............................................................................................................................... 98

Remove and Reinstall.......................................................................................................................................... 98

14.2 Front Washer Hose and Nozzle Assemblies...................................................................................................... 99

Remove and Reinstall.......................................................................................................................................... 99

14.3 Rear Washer Hose and Nozzle Assembly........................................................................................................ 100

Introduction........................................................................................................................................................ 100

Remove............................................................................................................................................................... 100

Front Section.................................................................................................................................................. 100

Rear Section .................................................................................................................................................. 101

Reinstall.............................................................................................................................................................. 103

Front Section.................................................................................................................................................. 103

Rear Section .................................................................................................................................................. 103

Spray Pattern Check.......................................................................................................................................... 104

15 Service Operations – Washer Assemblies, Coupe.........................................................................105

15.1 Washer Reservoir Assembly............................................................................................................................. 105

Remove............................................................................................................................................................... 105

Reinstall.............................................................................................................................................................. 106

Filling the Washer Reservoir Assembly........................................................................................................... 106

15.2 Front Washer Hose and Nozzle Assemblies.................................................................................................... 107

Remove............................................................................................................................................................... 107

Reinstall.............................................................................................................................................................. 108

Spray Pattern Check.......................................................................................................................................... 108

16 Service Operations – Wipers and Washers Control Switch ..........................................................109

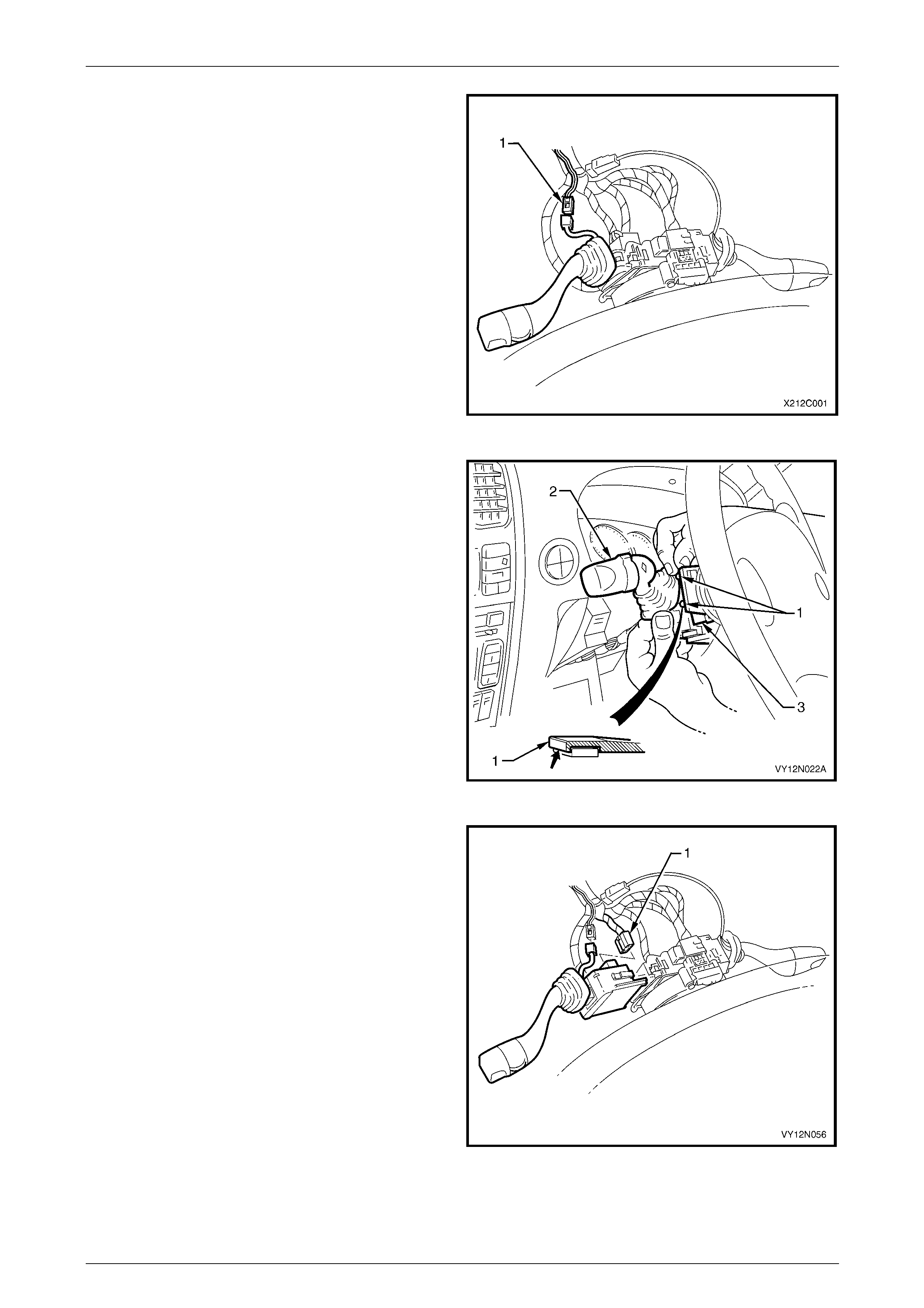

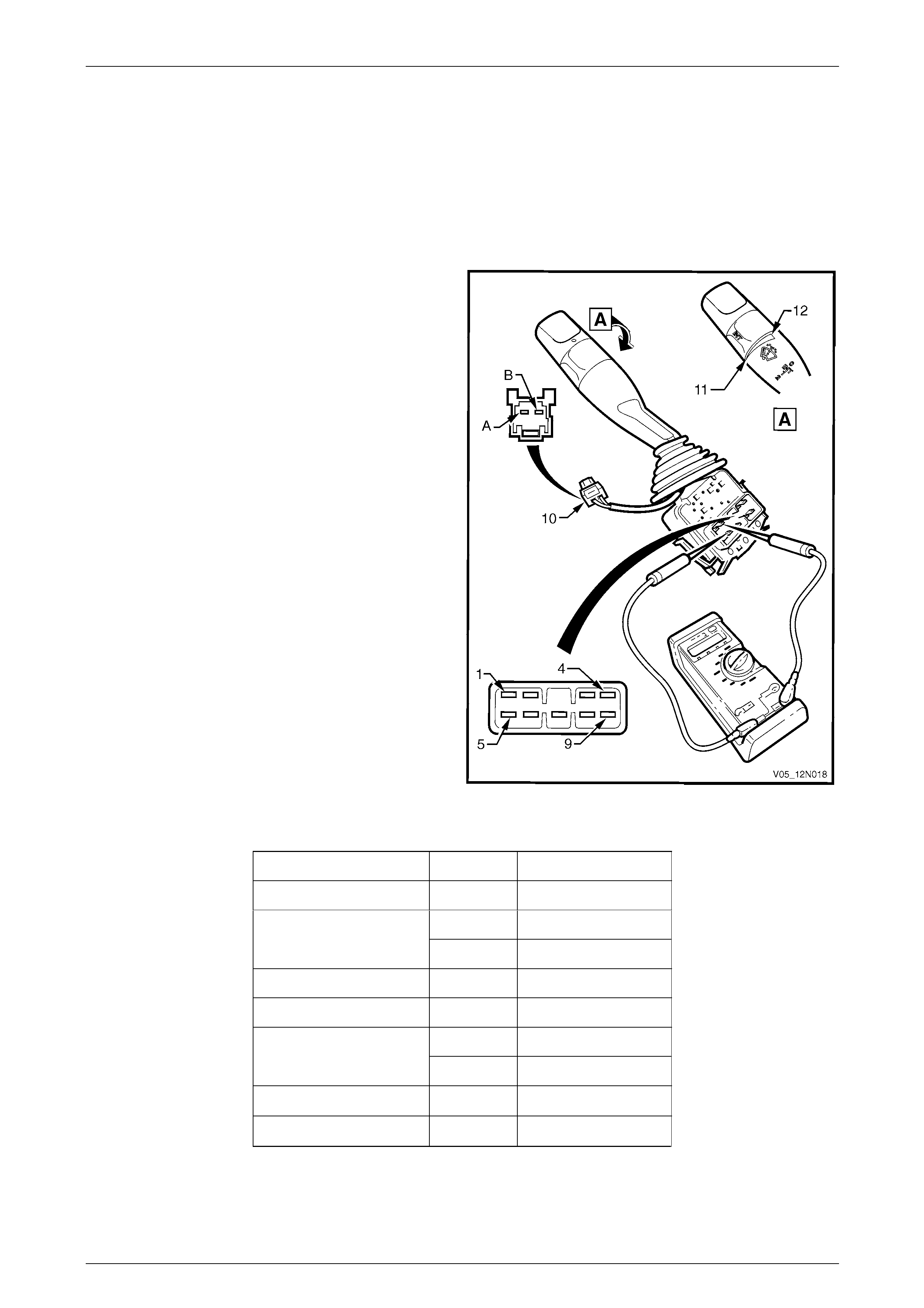

16.1 Wipers and Washers Control Switch, Except Wagon and AWD Wagon....................................................... 109

Remove............................................................................................................................................................... 109

Reinstall.............................................................................................................................................................. 111

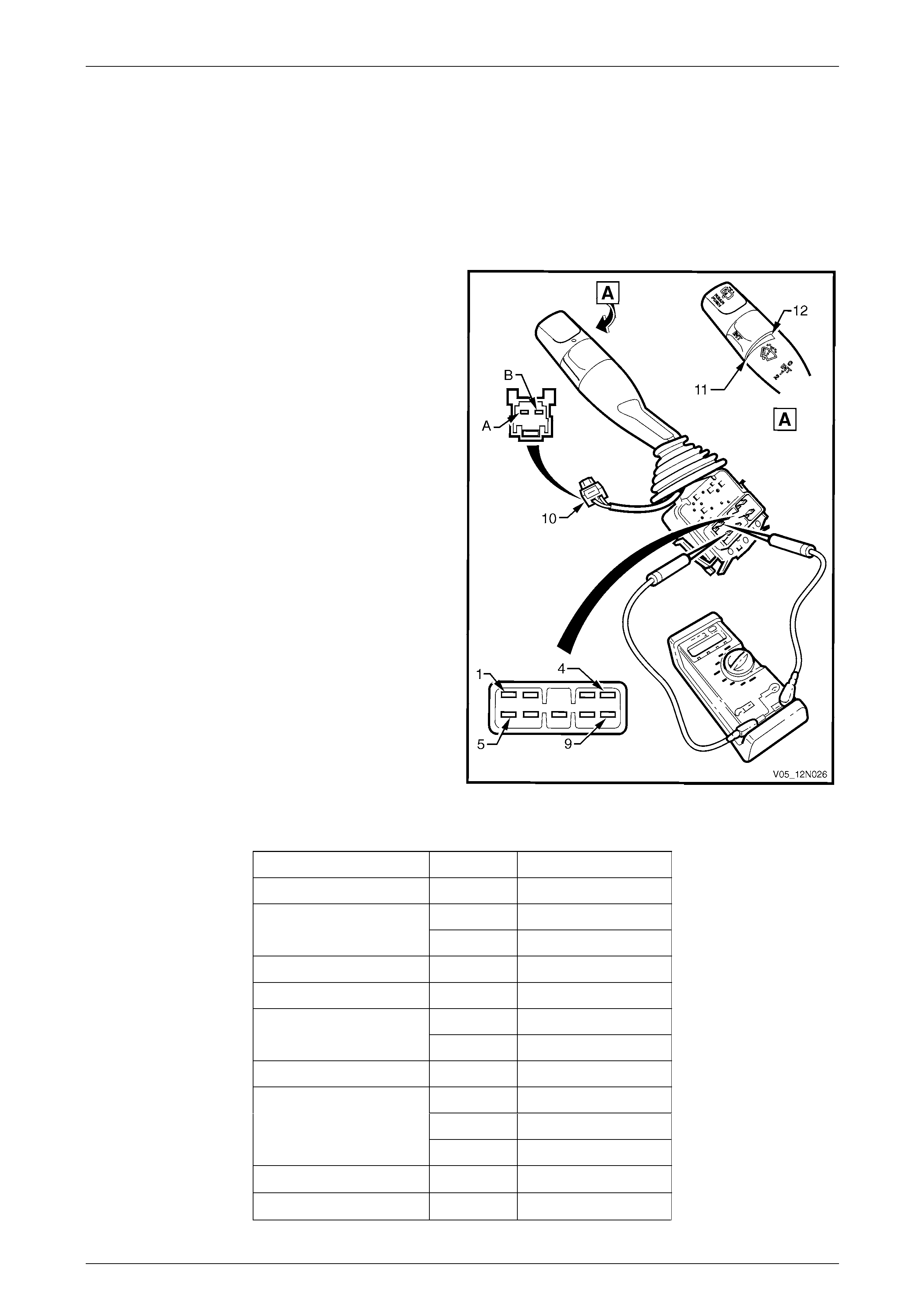

16.2 Wipers and Washers Control Switch Testing, Except Wagon and AWD Wagon ......................................... 112

Test Procedure................................................................................................................................................... 112

16.3 Wipers and Washers Control Switch, Wagon and AWD Wagon.................................................................... 113

Remove and Reinstall........................................................................................................................................ 113

16.4 Wipers and Washers Control Switch Testing, Wagon and AWD Wagon...................................................... 114

Test Procedure................................................................................................................................................... 114

Wipers, Washers and Horn Page 12N–6

Page 12N–6

17 Service Operations – Horn................................................................................................................115

17.1 Horn Assembly................................................................................................................................................... 115

Remove............................................................................................................................................................... 115

Reinstall.............................................................................................................................................................. 115

17.2 Theft-deterrent Horn Assembly........................................................................................................................ 116

Remove............................................................................................................................................................... 116

Reinstall.............................................................................................................................................................. 116

Test ..................................................................................................................................................................... 116

18 Torque Wrench Specifications..........................................................................................................117

18.1 Torque Wrench Specifications, Except Wagon and AWD Wagon................................................................. 117

18.2 Torque Wrench Specifications, Wagon ........................................................................................................... 118

18.3 Torque Wrench Specifications, AWD Wagon.................................................................................................. 119

19 Special Tools ......................................................................................................................................120

Wipers, Washers and Horn Page 12N–7

Page 12N–7

1 General Information

This Section describes the service, testing procedures and diagnosis for the wipers and washer systems as well as the

horns fitted to MY 2005 VZ Series vehicles.

1.1 Front Wiper Assemblies

Wiper Assemblies

The two front wiper assemblies consist each of a wiper blade secured to a wiper arm which is attached to a drive spindle

part of linkages attached to the plenum cham ber an d driven by the front wiper motor assembly.

A one piece plenum cover is fitted to Seda n, W agon and Utility vehicles. The front washer nozzle assemblies and part of

the front washer hose are secured to the plenum cover. An air deflector and a water deflector are attached to the plenum

cover.

A two pieces plenum cover is fitted to Coupe vehicles and the washer nozzle assemblies a re mounted in the hood

assembly. A water deflector is attached to the plenum chamber.

The front wiper assemblies are operated via the wipers and washers control s witch assembl y fitted to the steering

column. The operation inclu ding the intermittent dwell function is controlled by the body control module (BCM), refer to

Section 12J Body Control Module.

The wipers and washers control switch in the variable intermittent position decreases or increases the frequency the

wiper motor is actuated, through the détente. The wipers and washers control s witch has seven increments, and the

dwell time is determined via a combination of vehicle road speed and the wiper control stalk.

Wiper Motor

The front wiper motor assembly operates in one direction to drive the front wiper arms for the wiping of the windshield.

The front wiper motor assembly has three modes of operati on:

• intermittent wipe cycle,

• continuous low speed wipe mode, and

• continuous high speed wipe mode.

With the ignition switch in the ACC or ON position, and the wipers and washers control switch is moved to the position 1

or 2, power is directly supplied to the front wiper motor for low or high speed wipe operation. When the wipers and

washers control switch is moved to the INT position, power is supplied to the front wiper motor via the bo dy control

module (BCM) for intermittent wipe operatio n.

When the wipers and washers control switch is moved to the OFF position, the park s witch included in the front wiper

motor assembly supplies power to the front wiper motor via the BCM until the front wiper arms reach the park position. At

this point the park switch opens and disconnects the power supply to the front wiper motor and the front wiper arms

remain stationary at the park position.

For a complete wiring diagram of the front wiper system, refer to:

• 3.2 Wiring Diagram – Front Wiper/Washer, Except Wagon, or

• 3.3 Wiring Diagram – Front Wiper/Washer, Wagon, or

• 3.4 Wiring Diagram – Front Wiper/Washer, AWD Wagon.

Wipers, Washers and Horn Page 12N–8

Page 12N–8

1.2 Rear Wiper Assembly, Wagon

Wiper Assembly

The rear wiper assembly consists of a wiper blade secured to a wiper arm which is attached directly to the rear wiper

motor driveshaft.

The rear wiper motor assembly is attached to the liftgate ass embl y and drives the rear wiper arm assembly directly

through the motor driveshaft.

The rear wiper assembly is operated via the wipers and washers control switch assembly fitted to the steering column,

the operation is controlled by the BCM, refer to Section 12J Body Control Module.

With the ignition switch in the ON or ACC position the functions of the rear wiper are as follows:

• When the rear wiper switch is ON and the ne utral or drive gear is selected, the rear wiper activates intermittently at

8 second intervals.

• When the rear wiper switch is ON and the reverse gear is selected, the intermittent operation of the rear wiper goes

into continuous wipe mode until t he reverse gear is deselected.

• When the rear washer is selected, the rear wiper action is continuous wipe mode until the rear washer switch is

released.

Wiper Motor

The rear wiper motor is install ed in the liftgate and is directly linked to the rear wiper arm via a driveshaft.

With the ignition switch in the ACC or ON position and the wipers and washers control switch is moved to the rear wiper

ON position, power is supplied to the rear wiper motor via the body control module (BCM) and the rear wiper relay.

When the wipers and washers control switch is moved from the ON to OFF position, the park switch inclu ded in the rear

wiper motor assembly supplies power to the rear wiper motor until the rear wiper arm reaches the park position. At this

point the park switch contacts open and disconnects the power supply to the rear wiper motor and the rear wiper arm

remains stationary at the park position.

For a complete wiring diagram of the rear wiper system, refer to 5.2 Wiring Diagram – Rea r W iper/Washer.

Wipers, Washers and Horn Page 12N–9

Page 12N–9

1.3 Rear Wiper Assembly, AWD Wagon

Rear Wiper Assembly

The rear wiper assembl y cons ists of a wiper blade secured to the rear wiper arm which is attached to the rear wiper

motor shaft.

The rear wiper motor assembly is attached to the liftgate ass embl y and drives the rear wiper arm assembly directly

through the motor driveshaft.

A rear wiper ramp is located below the liftgate window to provide support for the wiper arm in the park position.

Protective clear PVC tape is applied to the liftgate where the wiper blade is resting.

The rear wiper assembly operation is not controlled by the BCM as in other Wagon ve hicles. The control functions have

been transferred to a rear wiper control module (A122).

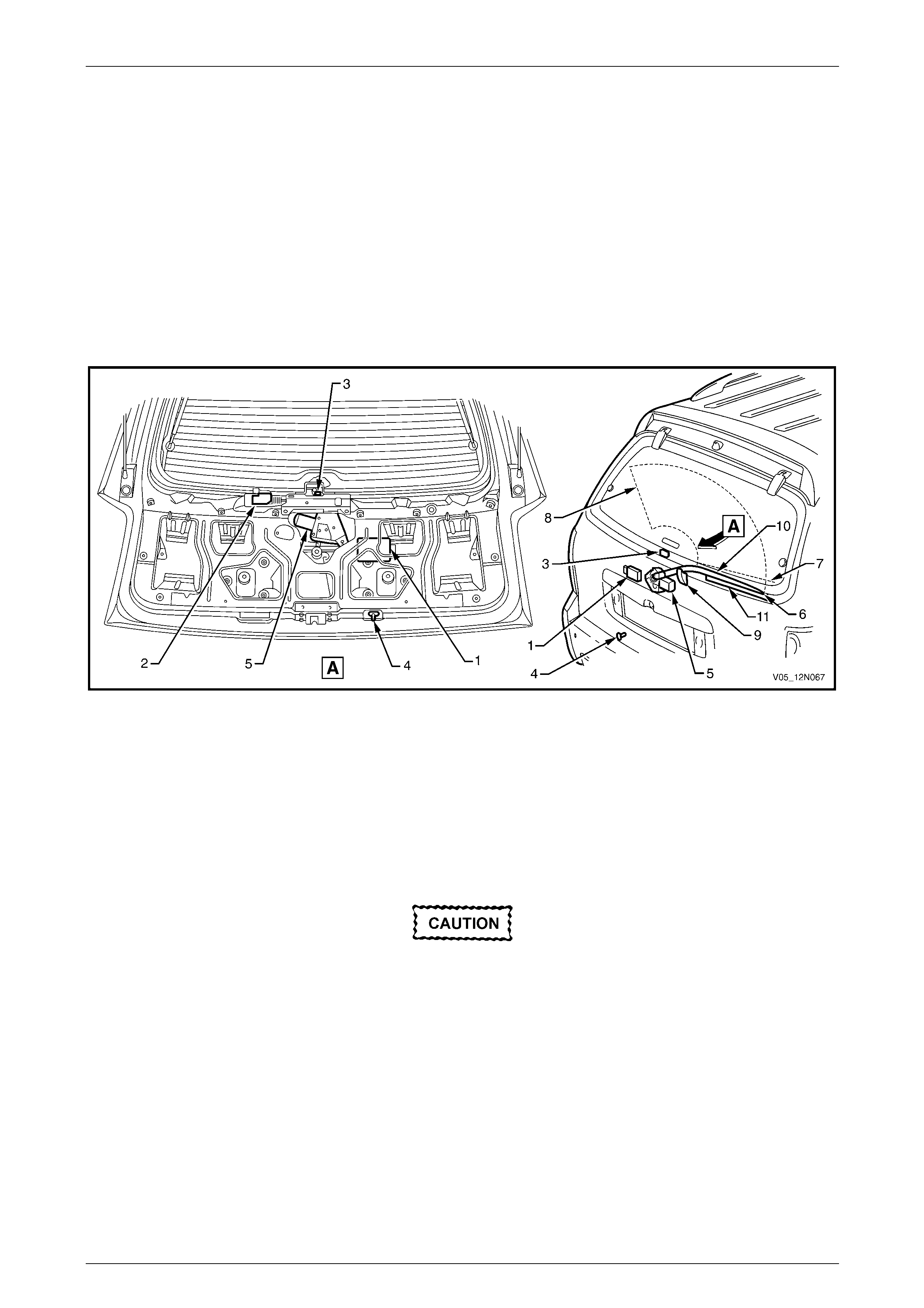

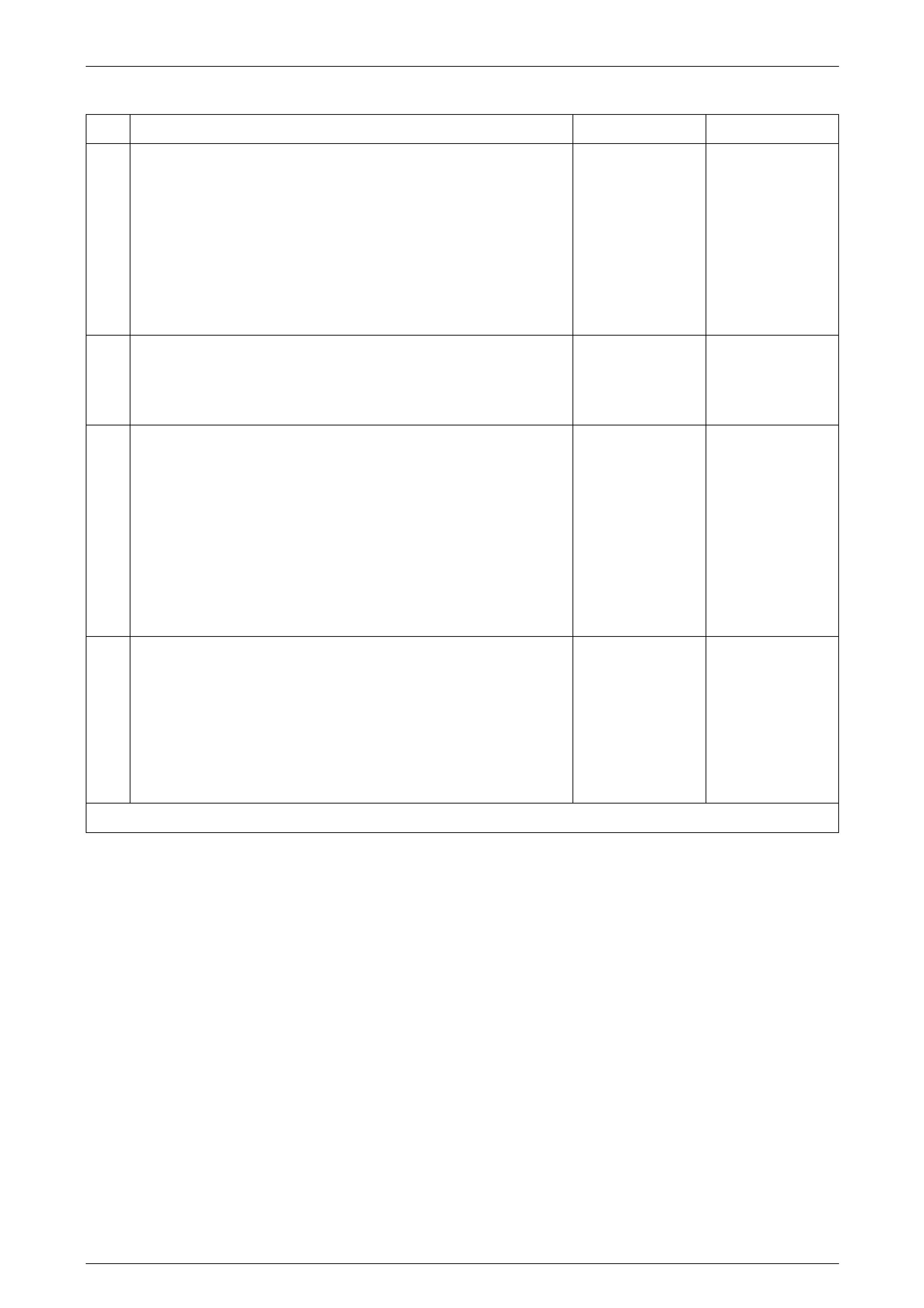

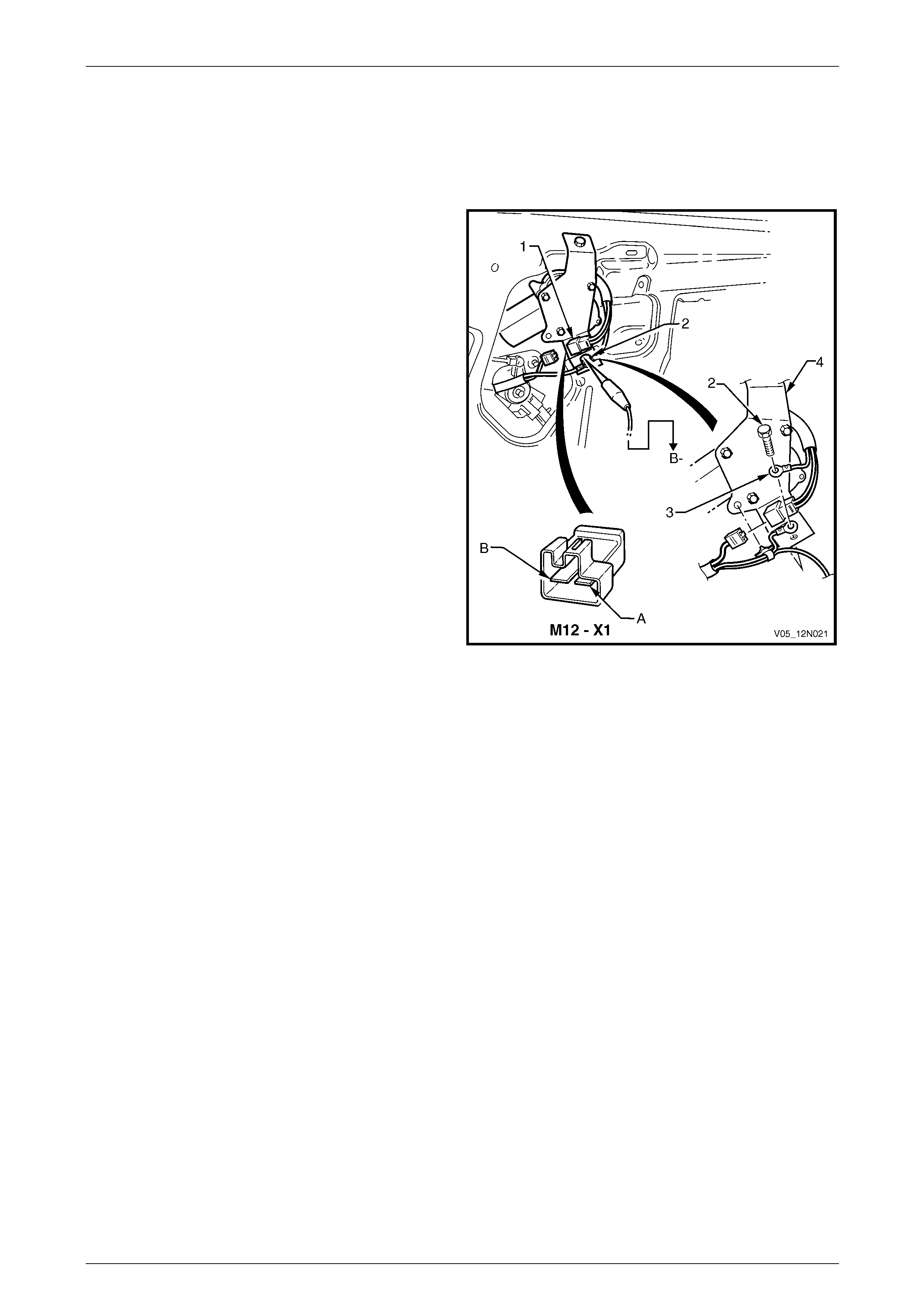

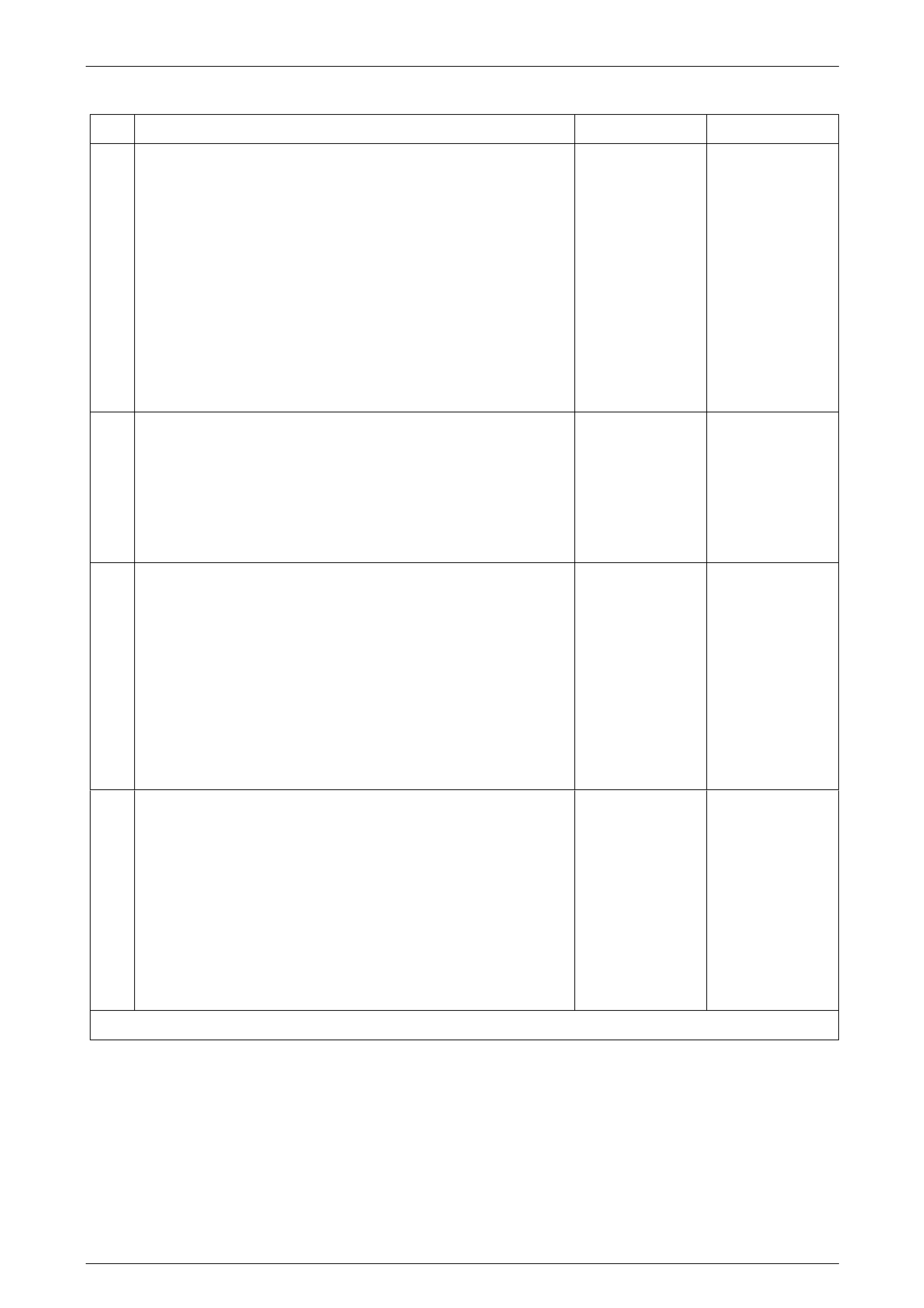

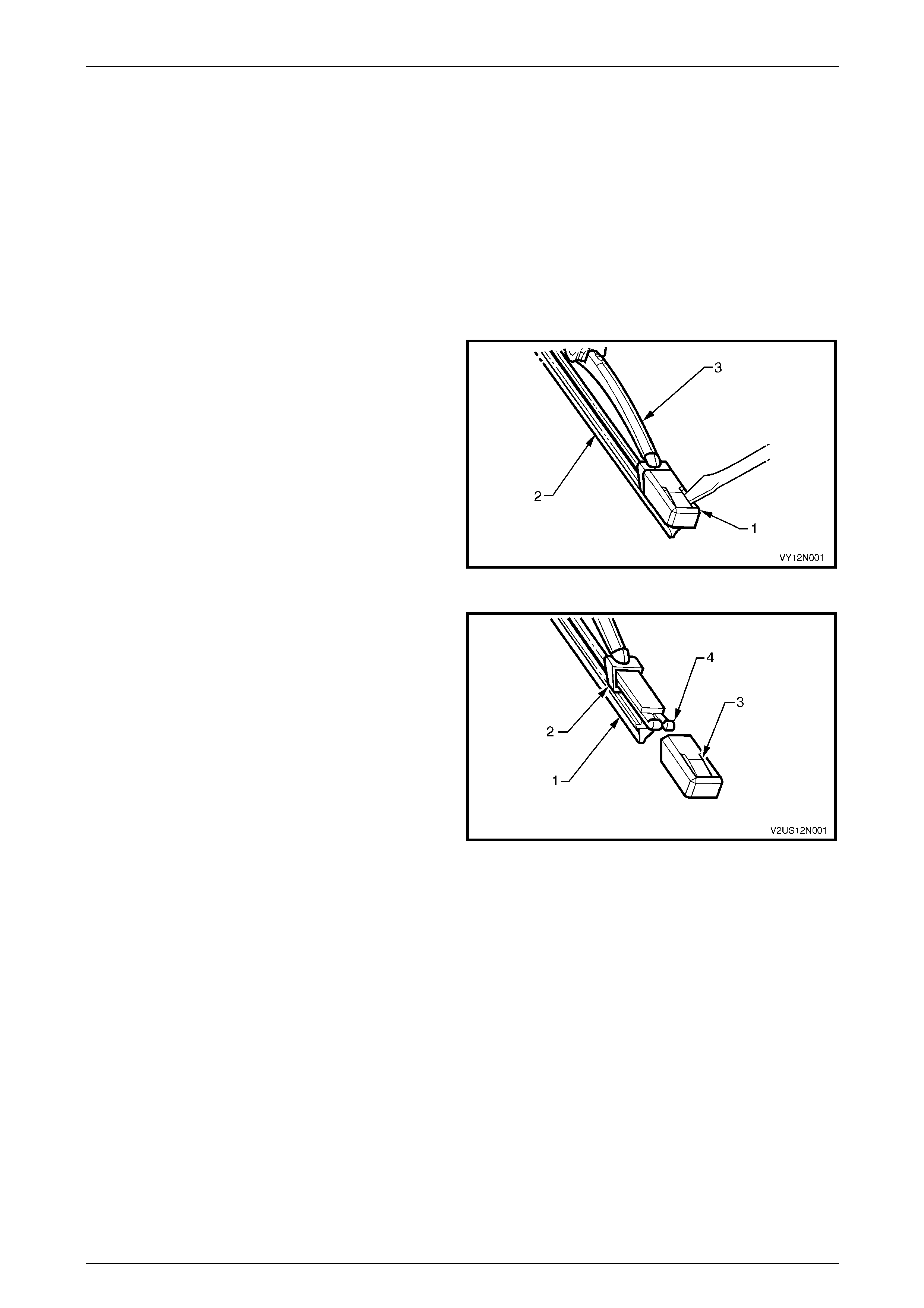

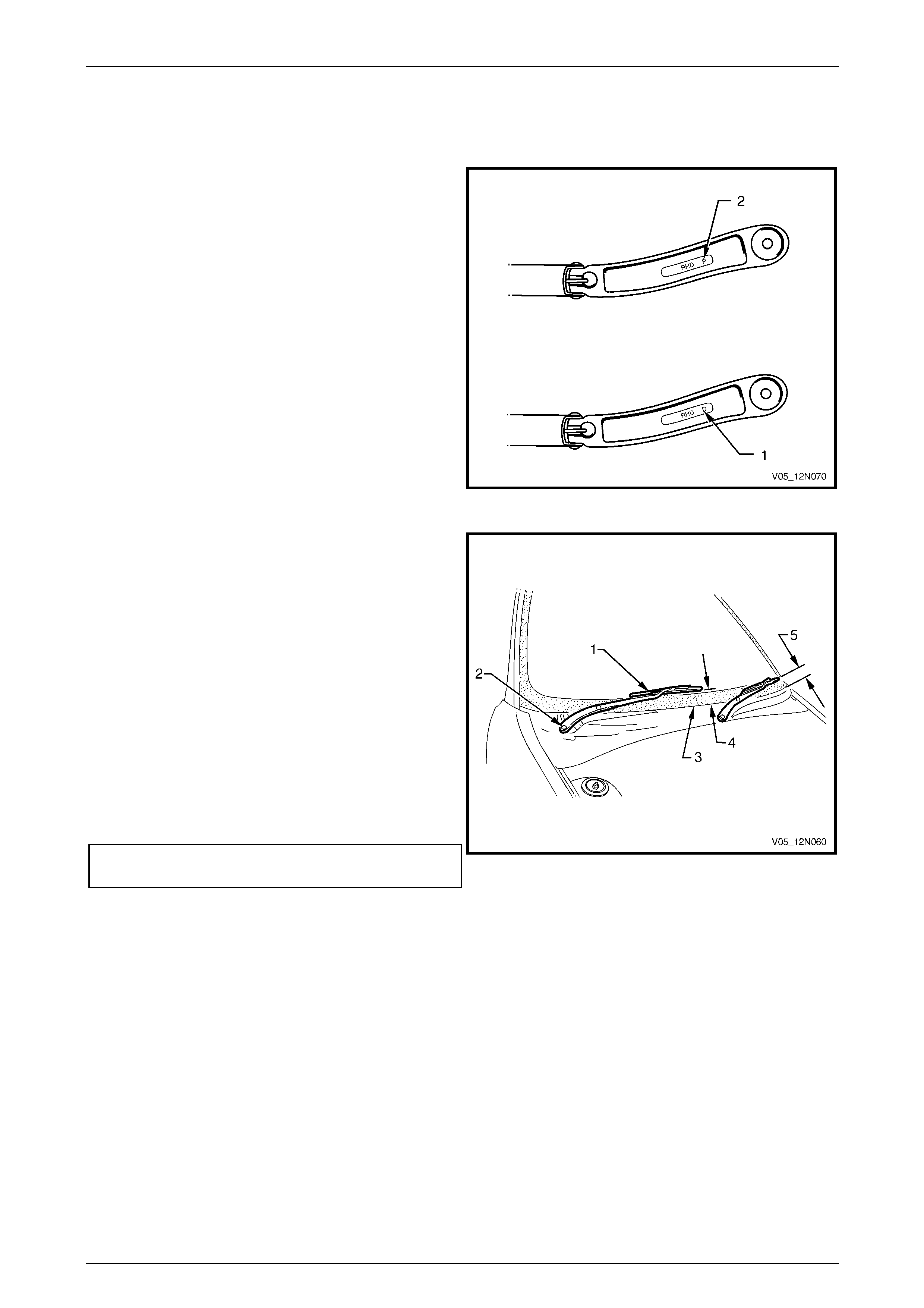

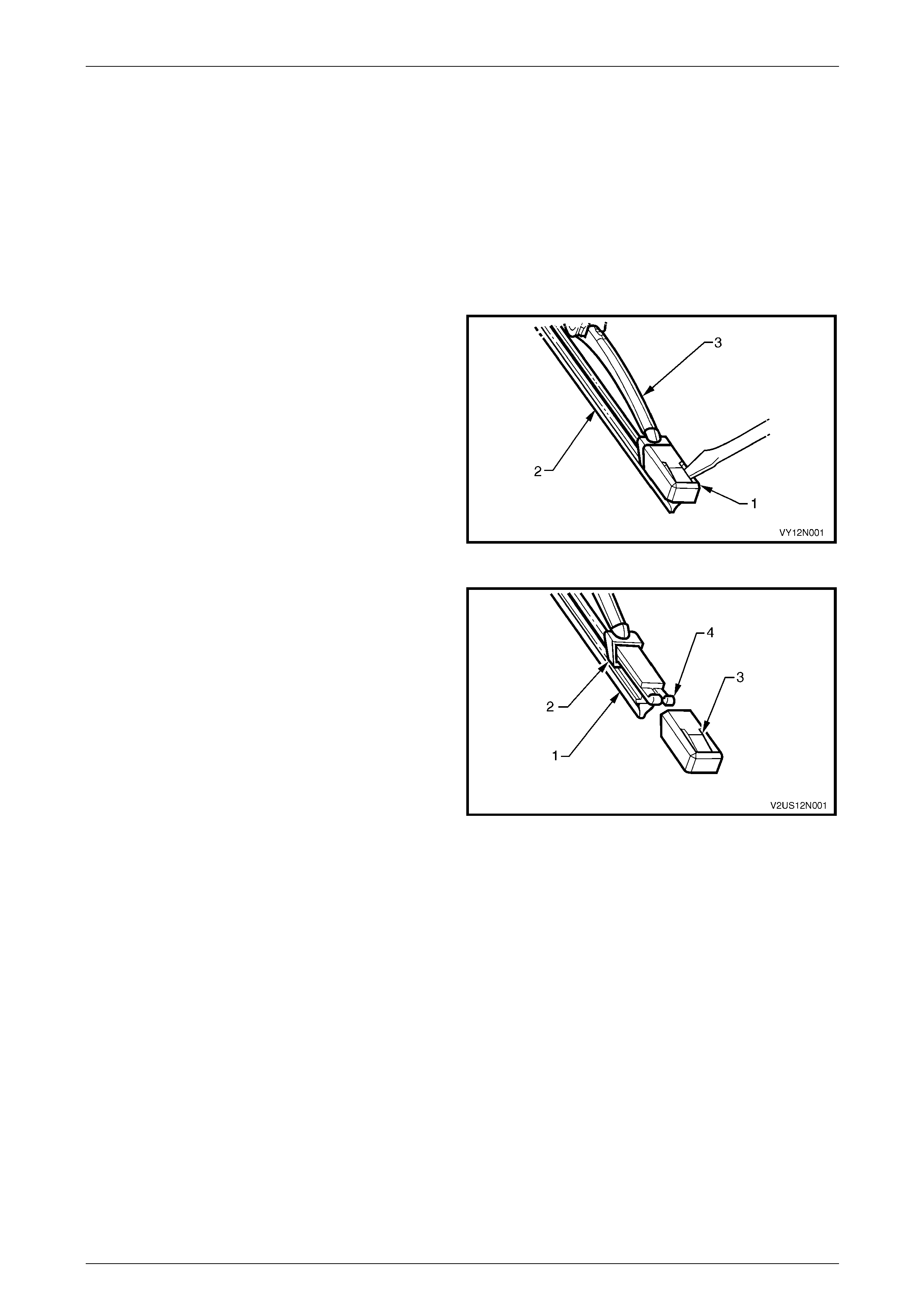

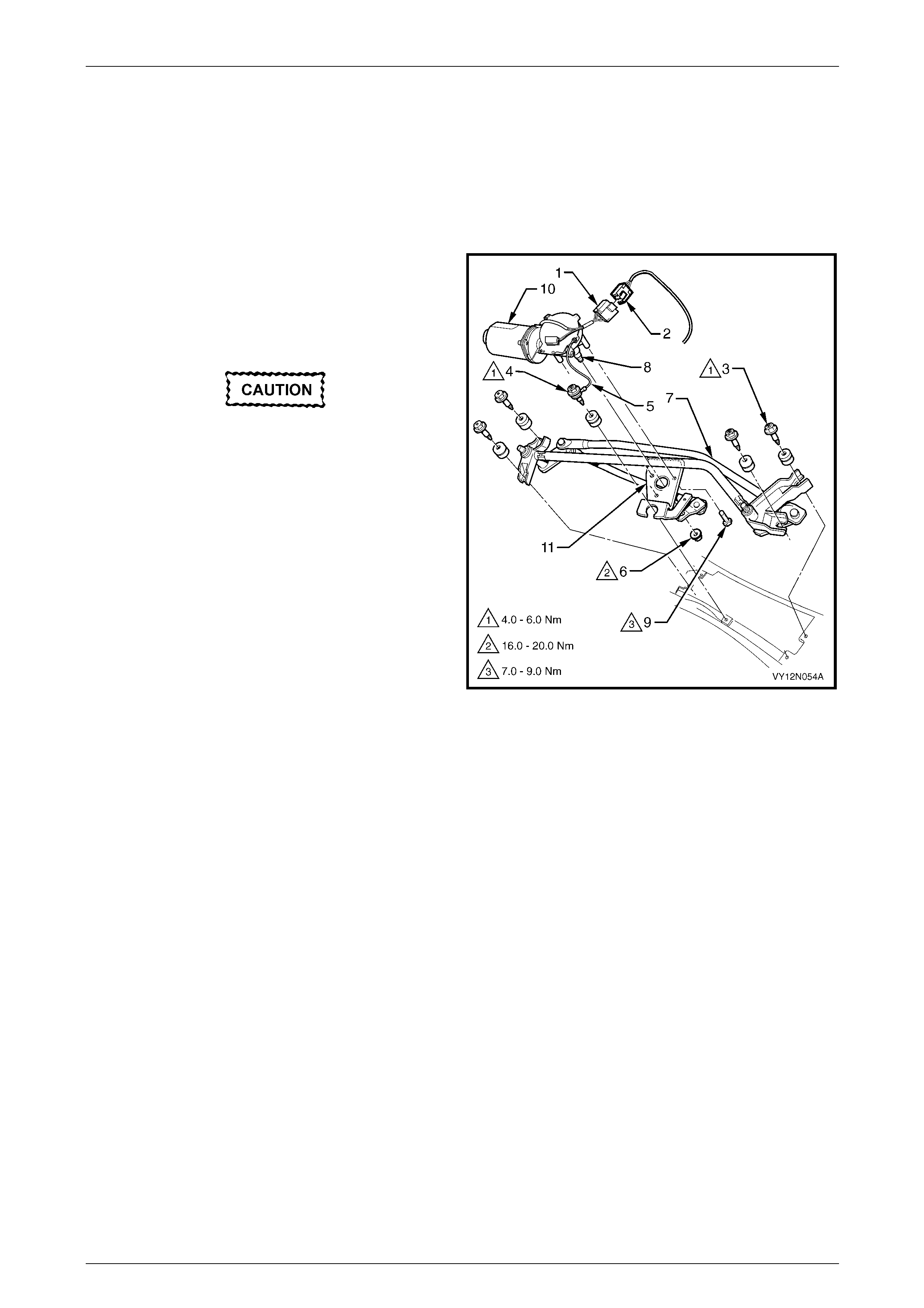

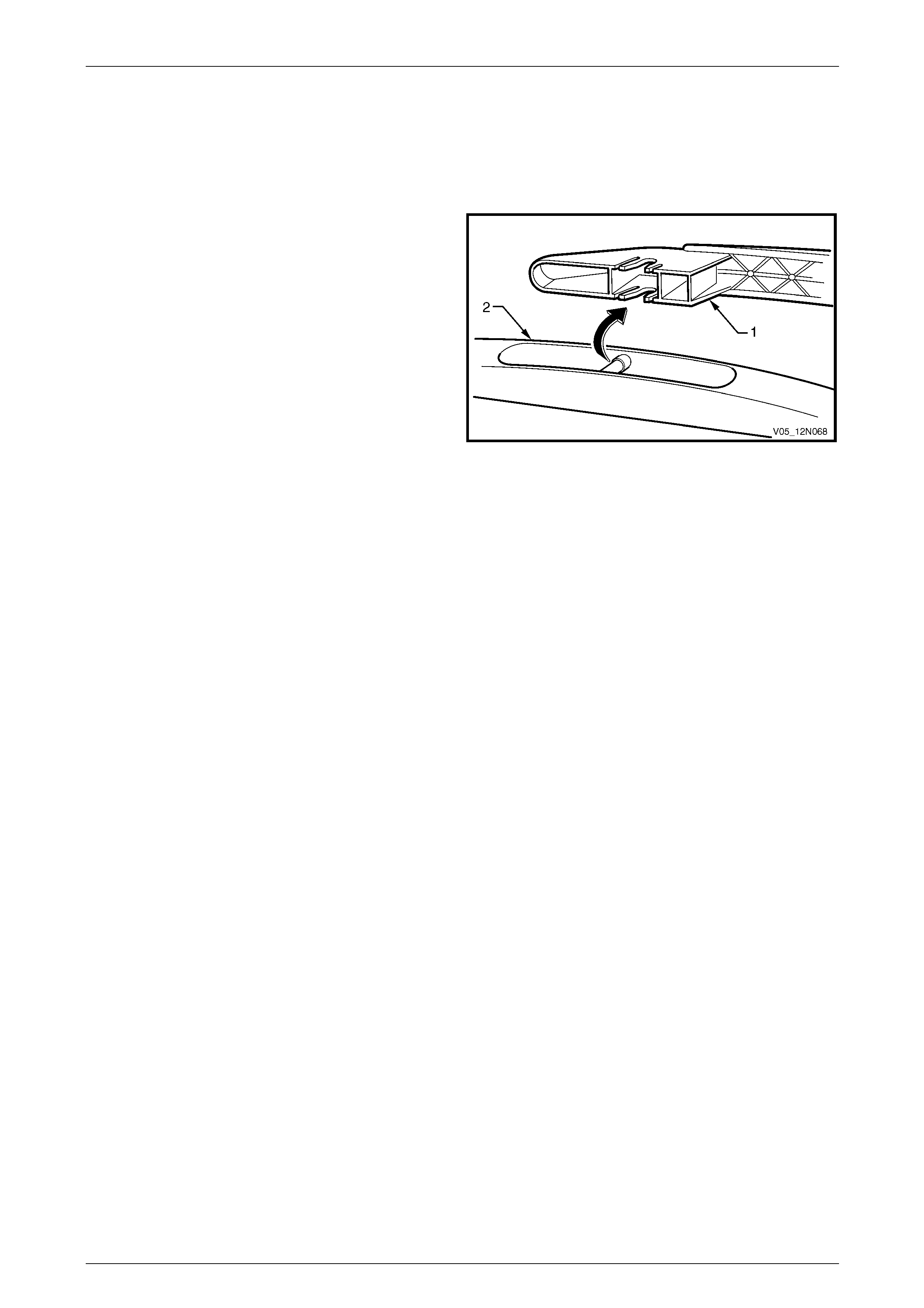

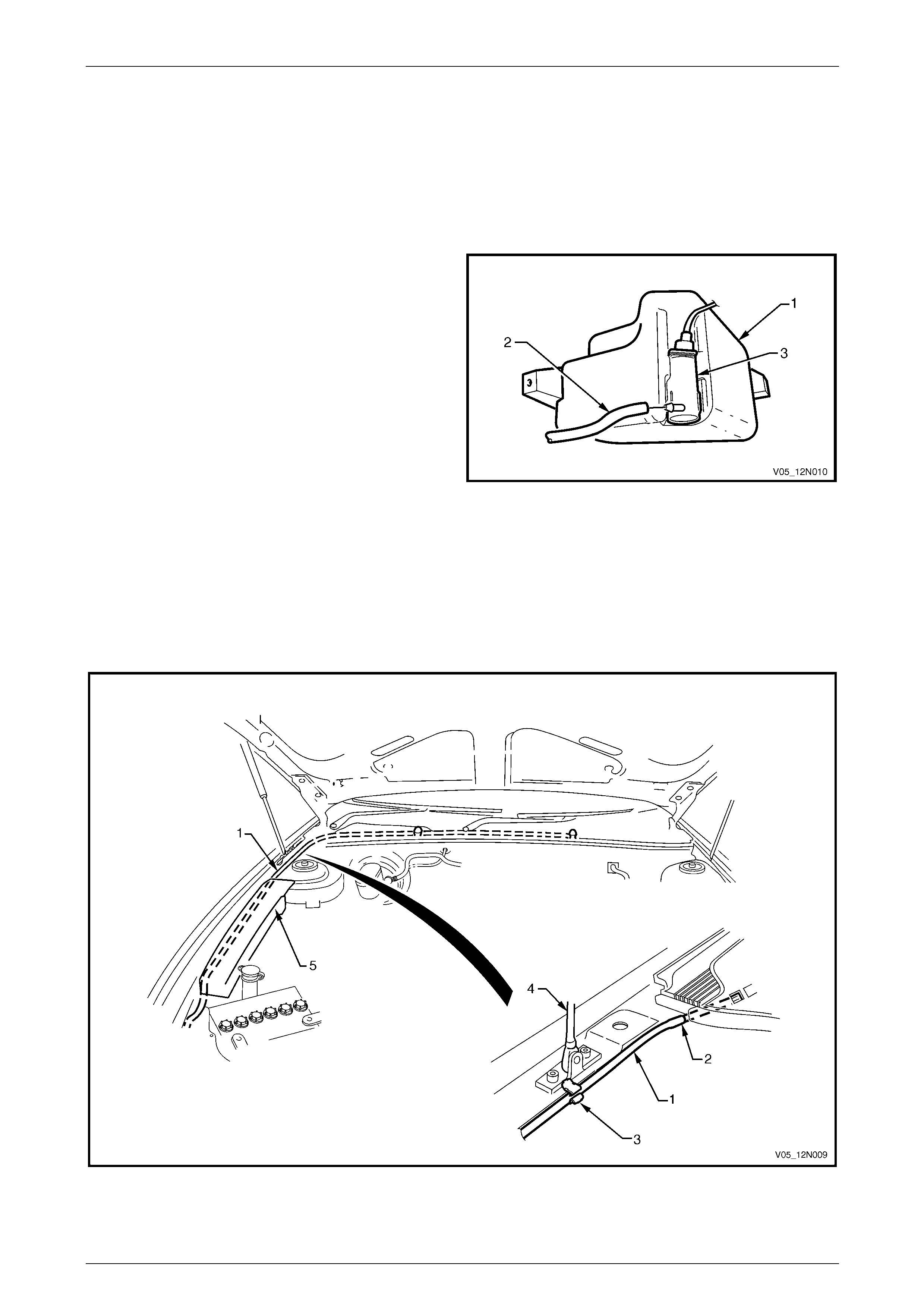

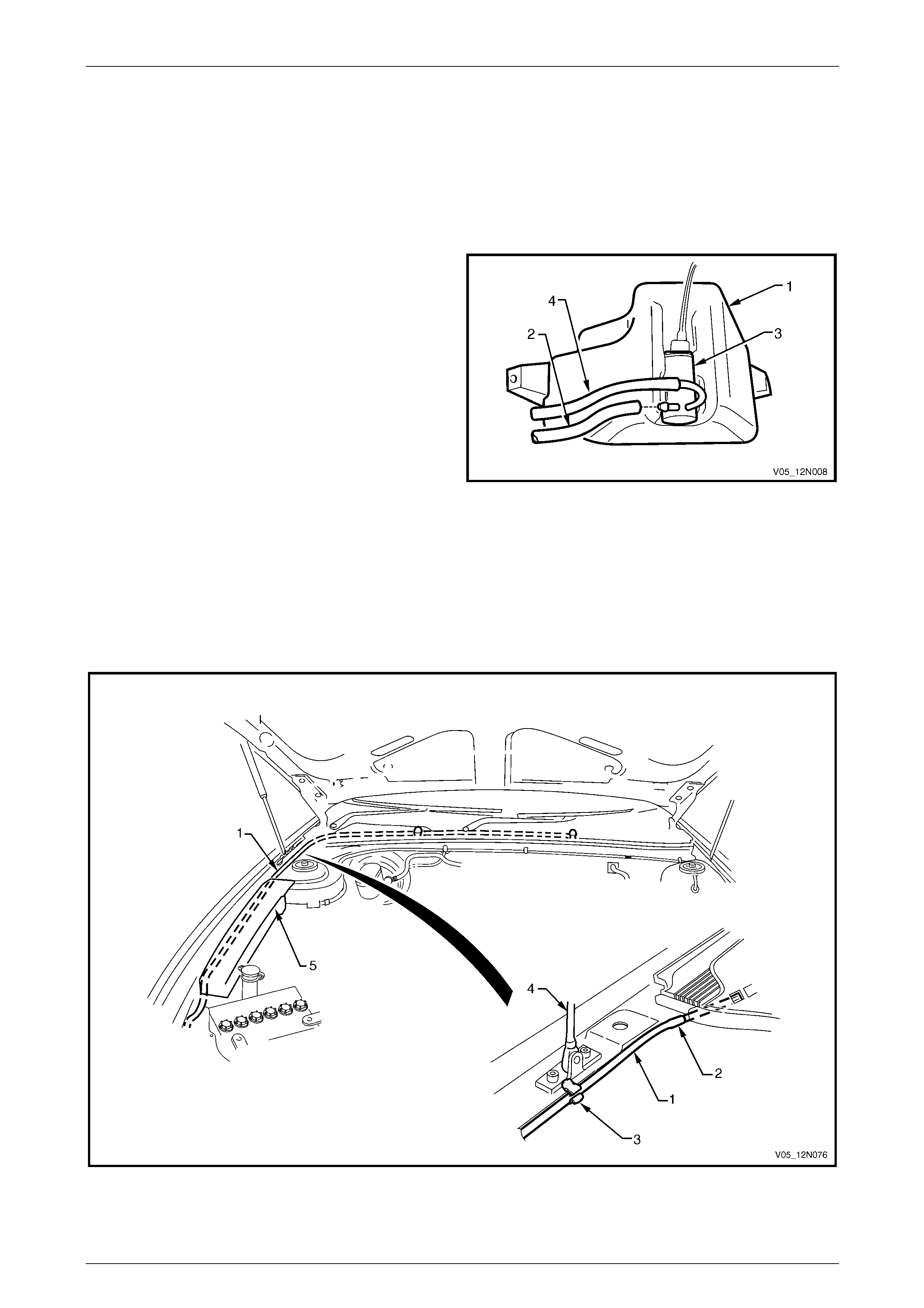

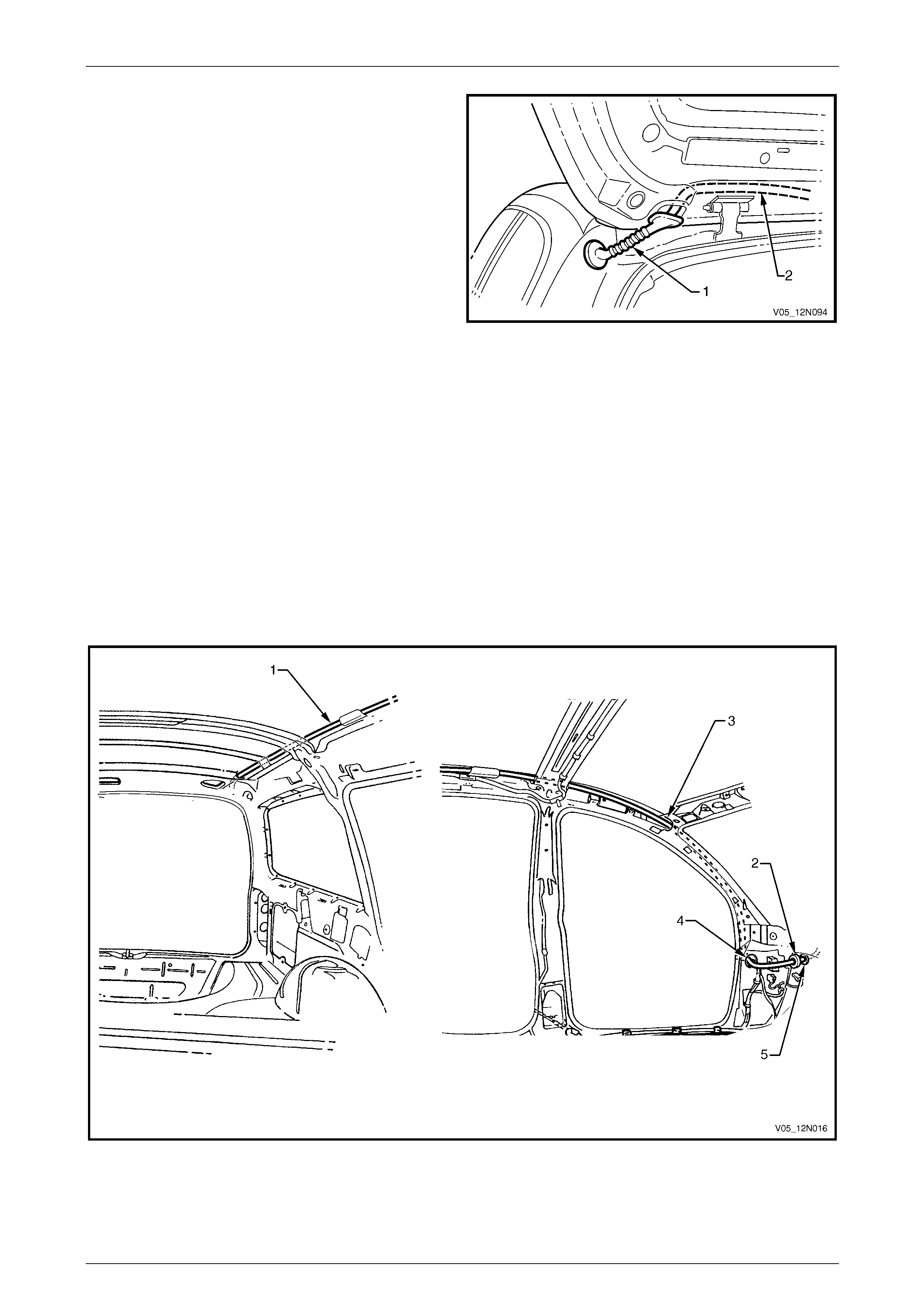

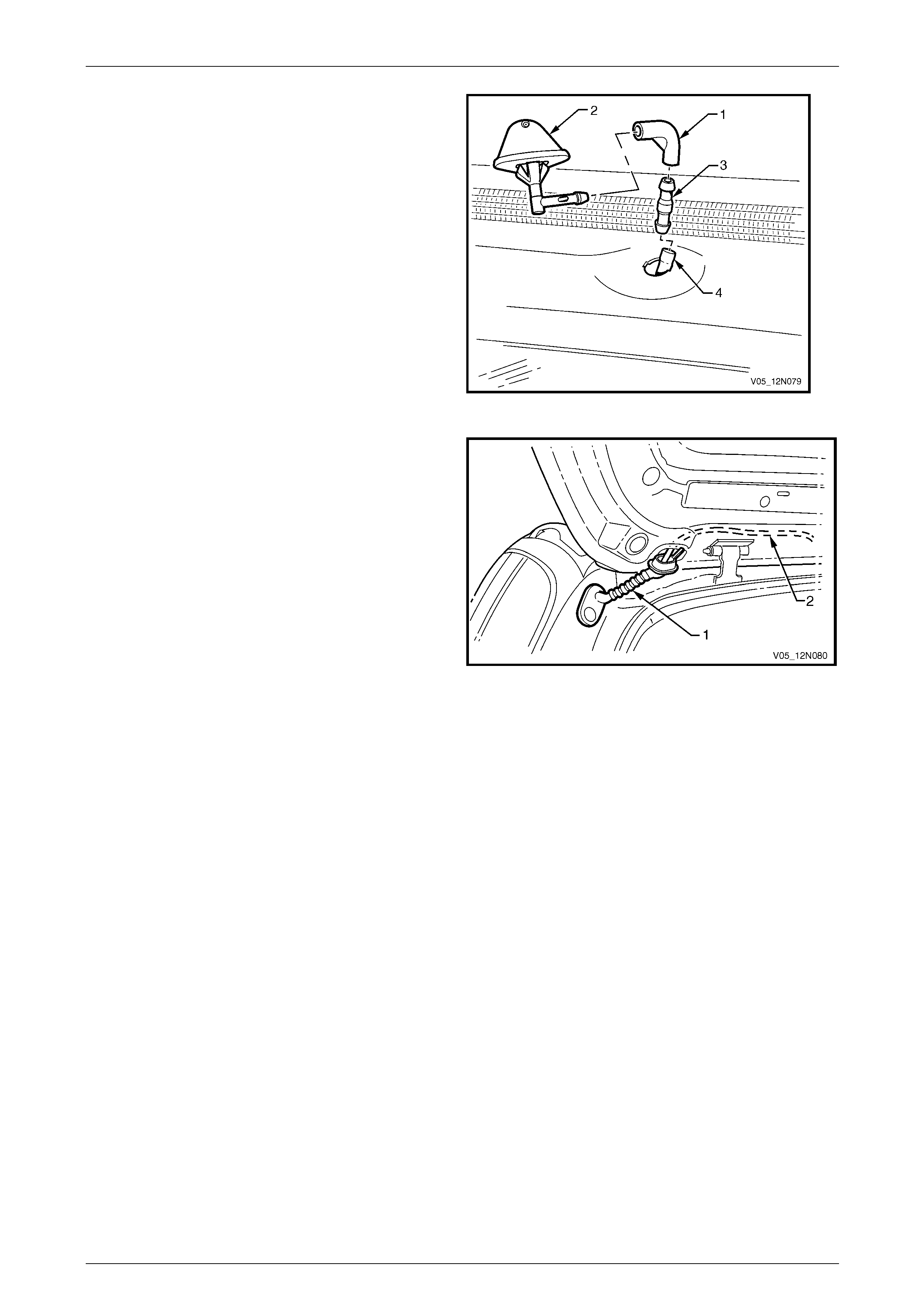

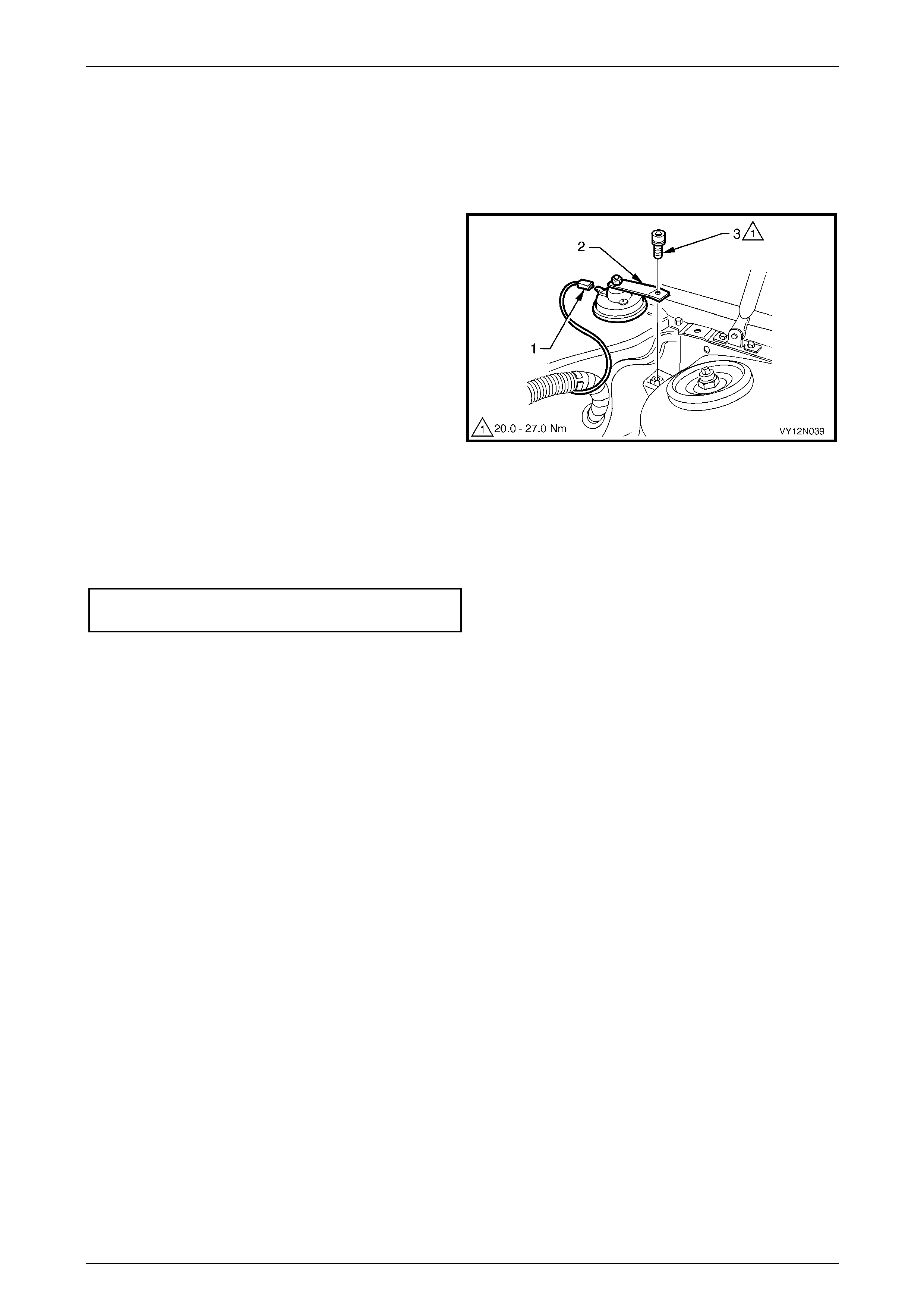

Figure 12N – 1

Legend

1 Rear Wiper Control Module A122

2 Liftgate Window Release Actuator Y7

3 Liftgate Window Microswitch S69

4 Liftgate Switch S189

5 Rear Wiper Motor Assembly M12

6 Rear Wiper Arm Offscreen Park

Position

7 Wipe Sweep Start (Rear Wiper Arm

Onscreen Park Position)

8 Full Wipe Sweep (Rear Wiper Arm

Furthest Onscreen Park Position)

9 Rear Wiper Ramp

10 Rear Wiper Arm

11 Protective Tape

When the rear wiper has been operating,

before turning off the ignition switch ensure

the rear wiper arm is in the offscreen park

position. If failing to do so, the situation could

arise where the liftgate window could be

opened with the rear wiper stopped on the

glass panel and vehicle damage co uld occur.

When the rear wiper is not in operation it parks below the liftgate window, the arm (10) resting on th e rear wiper ramp (9),

refer to Figure 12N – 1. This parking position enables the hinged liftgate window to be opened o utward with the rear

wiper positioned clear of the glass panel.

With the ignition switch in the ON or ACC position and the li ftgate is open, when the wipers and washers control switch is

moved to the rear wiper ON position, the rear wiper will not operate. For the rear wiper to be operational again, close the

liftgate, then move the wipers and washers control switch in the OFF position and back to the rear wiper ON position.

The same condition applies if the liftgate window is open when the wipers and washers control switch is moved to the

rear wiper ON position.

Wipers, Washers and Horn Page 12N–10

Page 12N–10

If the rear wiper is operating, the liftgate windo w can not be ope ned.

If the liftgate window is closed and the liftgate only is opened while the rear wiper is operating, the wipe mode will not

stop. Move the wipers and washers control switch in the OFF position to stop the operation of the rear wiper; the

operation can not be restarte d before the liftgate is closed.

With the ignition switch in the ON or ACC position the functions of the rear wiper are as follows:

• When the wipers and washers control switch is moved to the rear wiper ON position, the rear wiper activates

intermittently at 9 second intervals.

• When the wipers and washers control switch is moved to the rear wiper ON position and the reverse g ear is

selected, the intermittent operation of the rear wiper goes into continuous wipe mode until the reverse gear is

deselected.

• When the rear washer is selected, the rear wiper action is continuous wipe mode until the rear washer switch is

released.

• When the rear wiper is operating and the rear washer is selected, the intermittent operation of the rear wiper goes

into continuous wipe mode until the rear washer switch is released.

• When the wipers and washers control switch is moved from the rear wiper ON to OFF position, the rear wiper

suspends for one second in the furthest on-screen park position then returns to the off-screen park position.

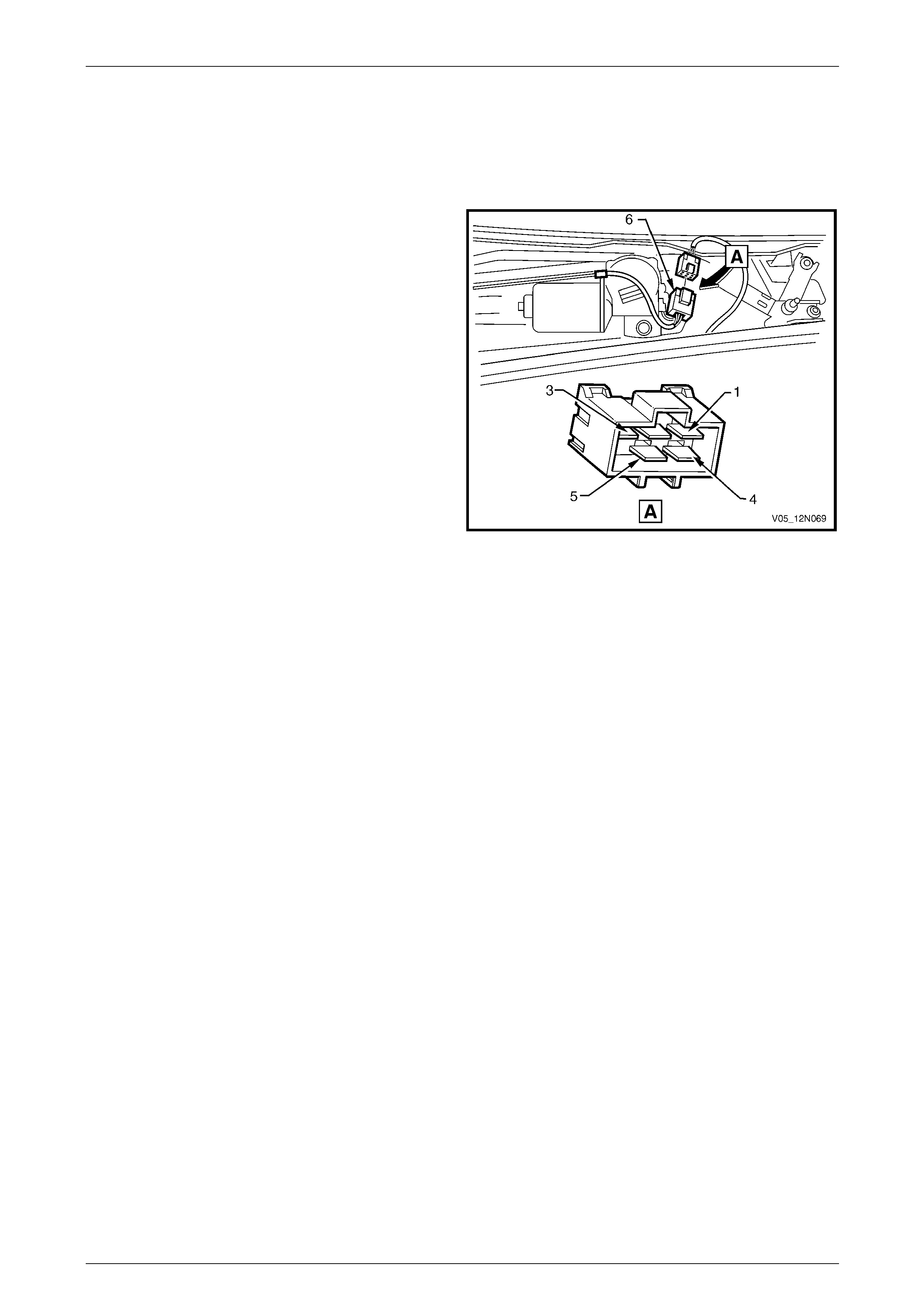

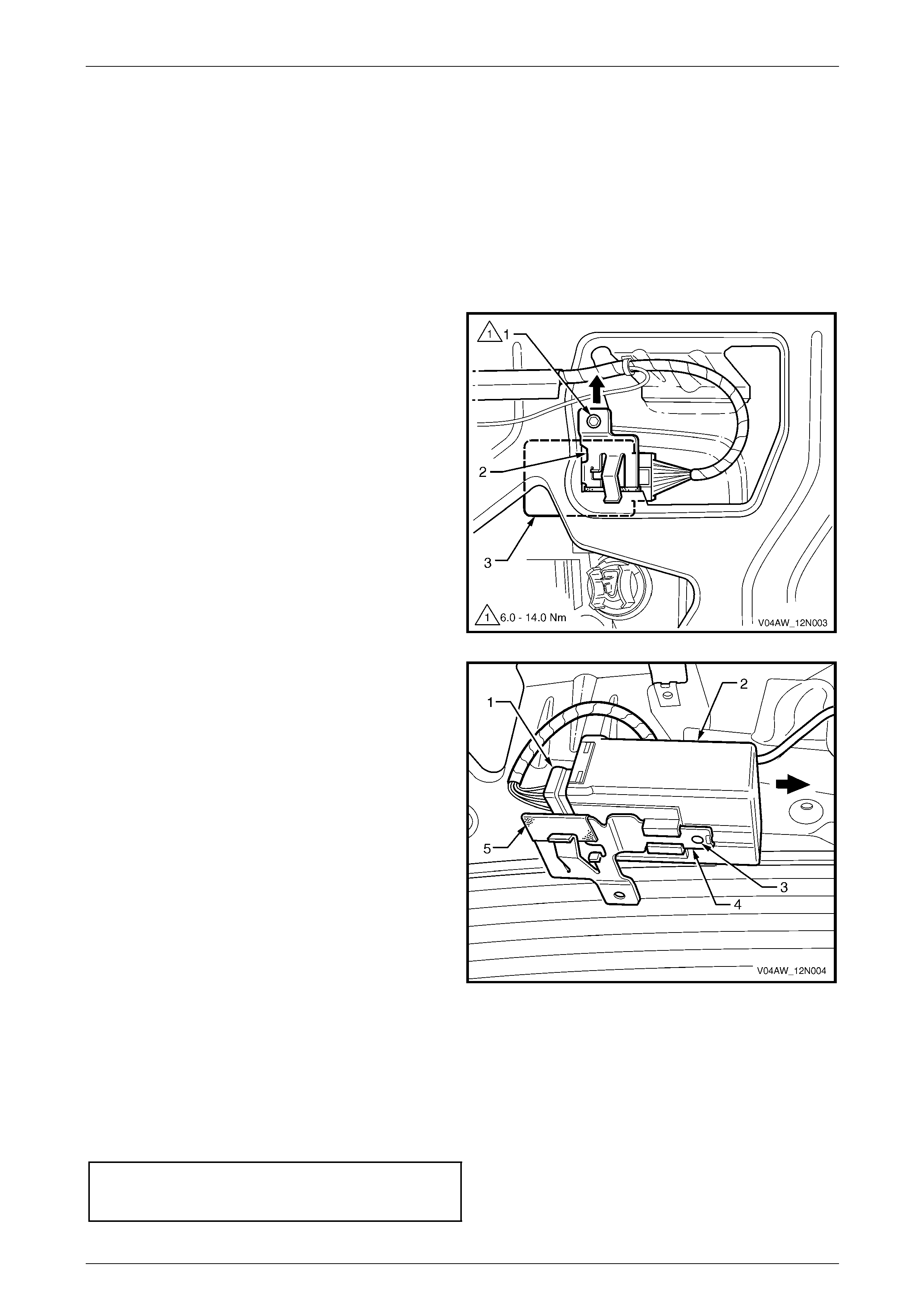

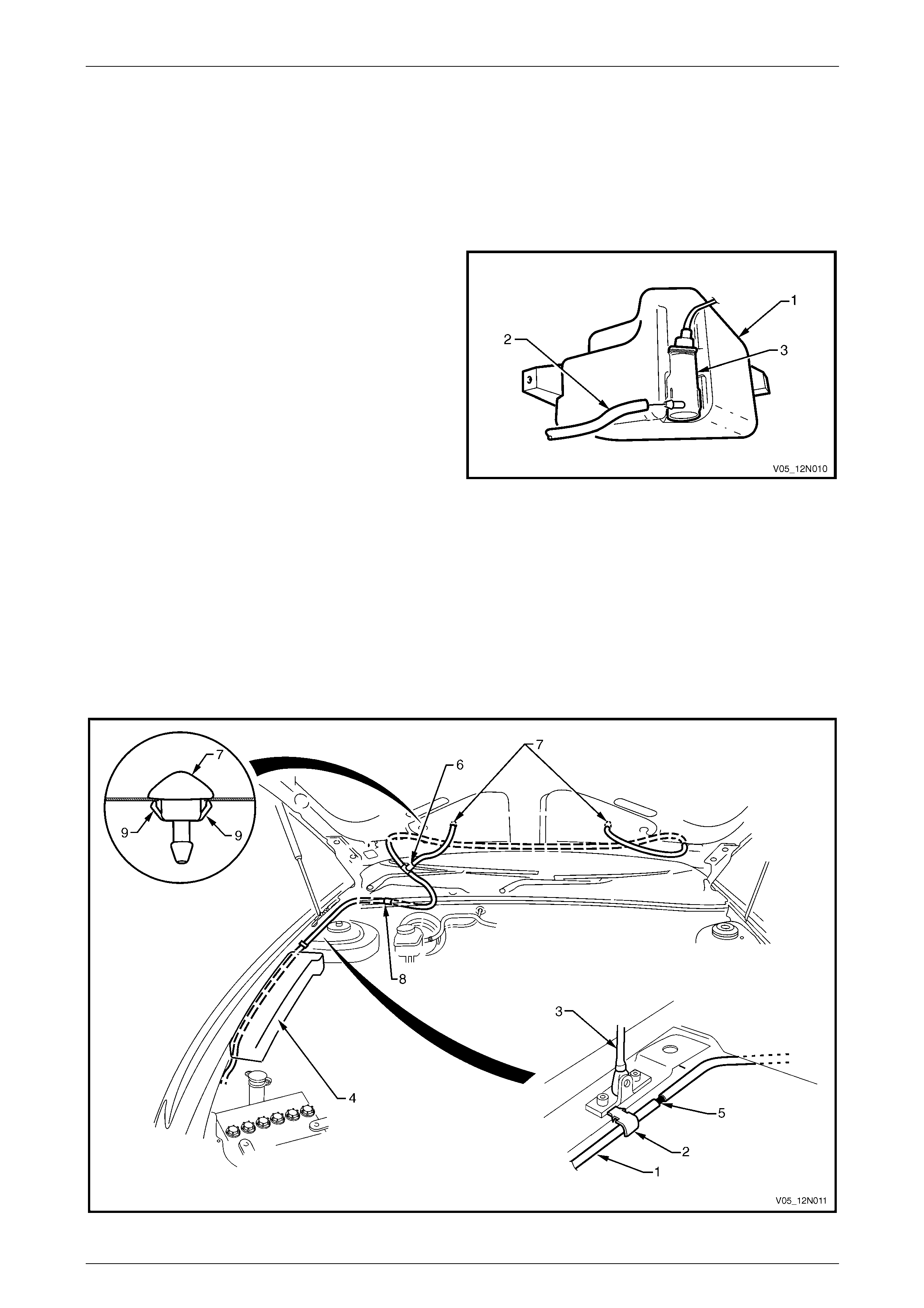

Rear Wiper Control Module

The rear wiper control module (1) is installed in the liftgate. It controls the various functions of the rear wiper / washer.

The rear wiper control modul e also provides a link with the liftgate window release actuator (2), the liftgate window

microswitch (3) (within the latch) and the liftgate switch (4) refer to Figure 12N – 1.

For a description and functions of the liftgate window release actuator, liftgate window microswitch and liftgate switch

refer to Section 1A4 Hood, Rear Compartment Lid, Liftgate and Endgate.

The rear wiper module will inhibit the rear wiper operation if the liftgate and/or the liftgate window are open.

The rear wiper module triggers the liftgate window release. The liftgate window release actuator solenoid is inhibited if

the rear wiper switch or the rear washer switch is ON.

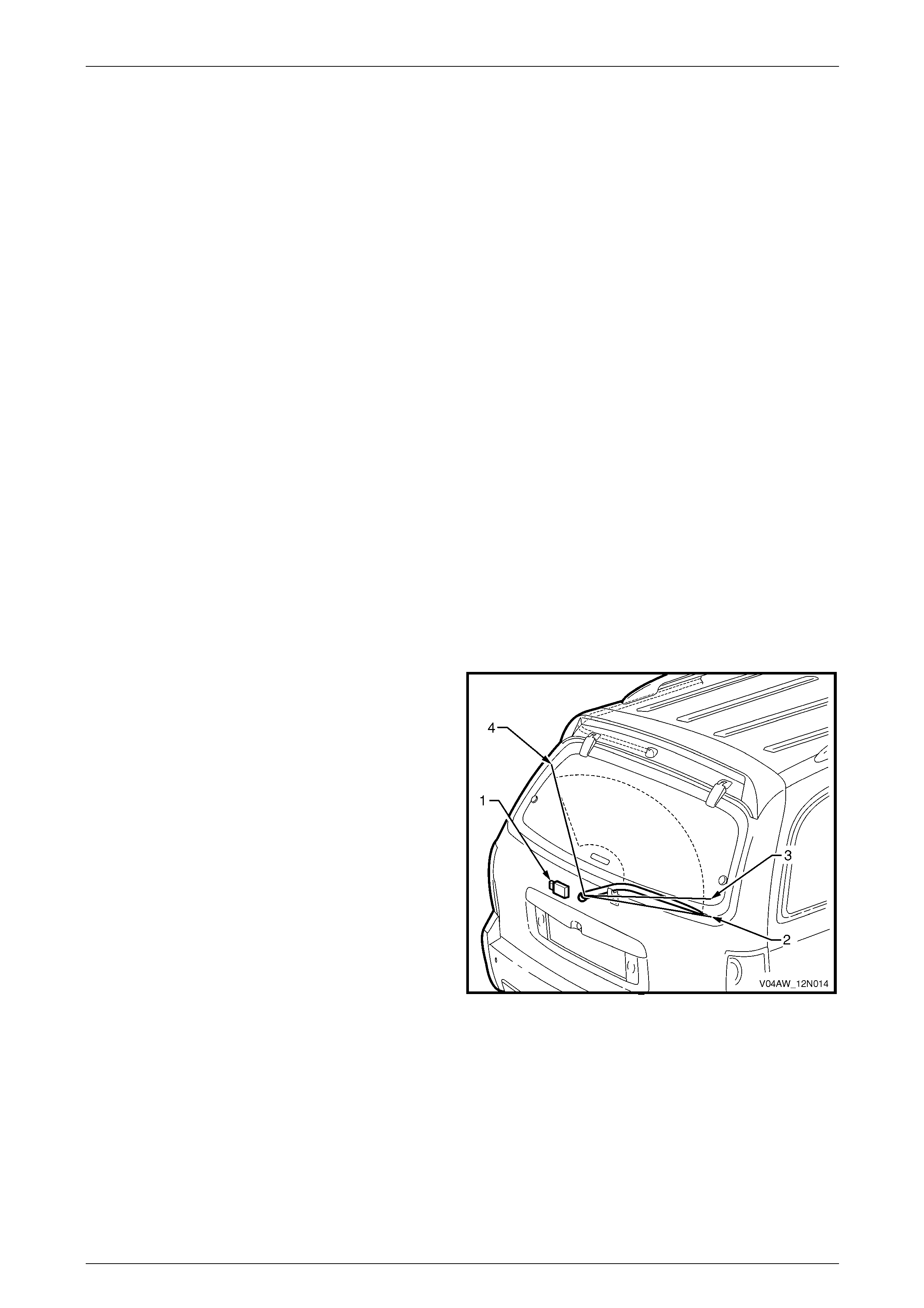

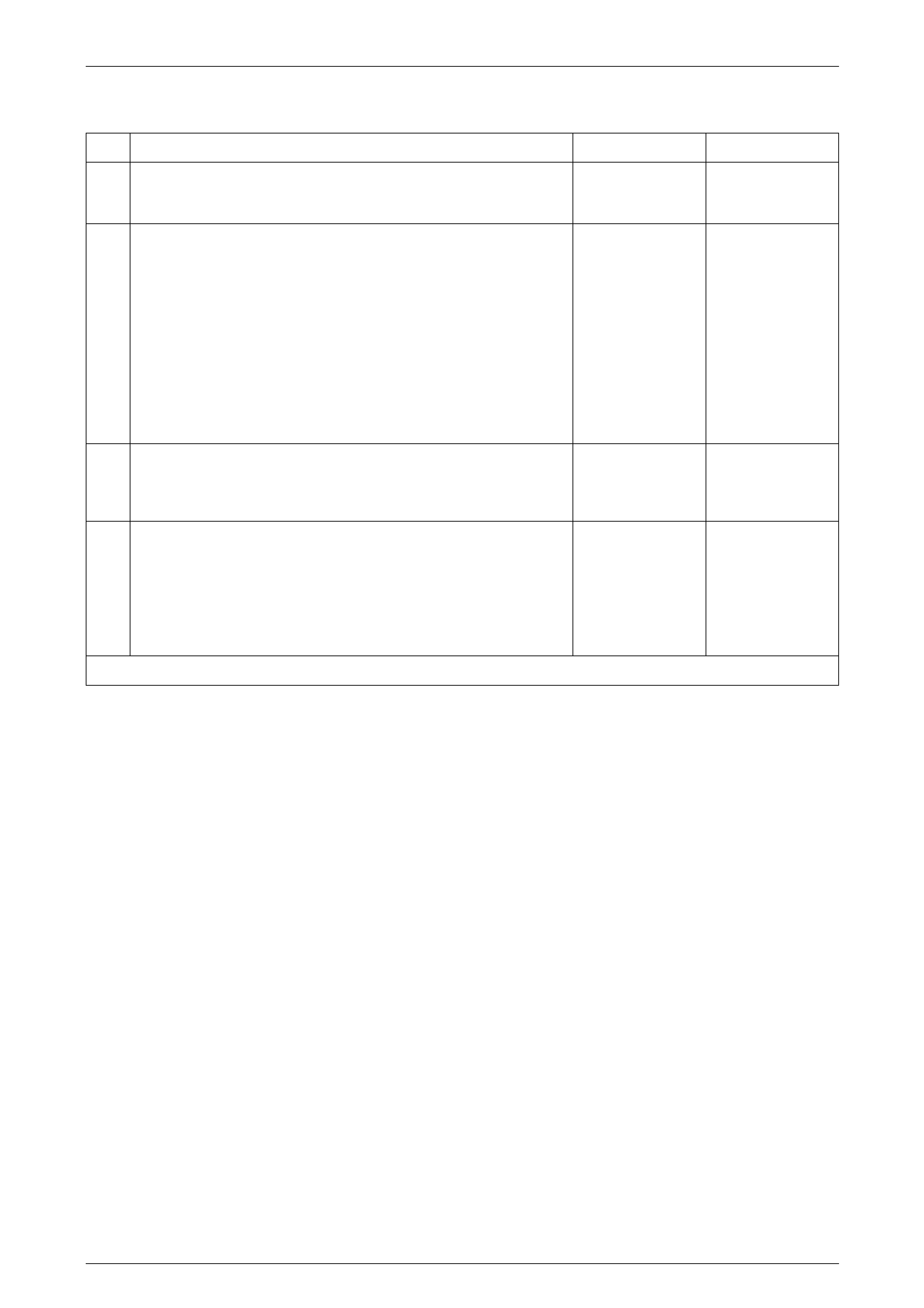

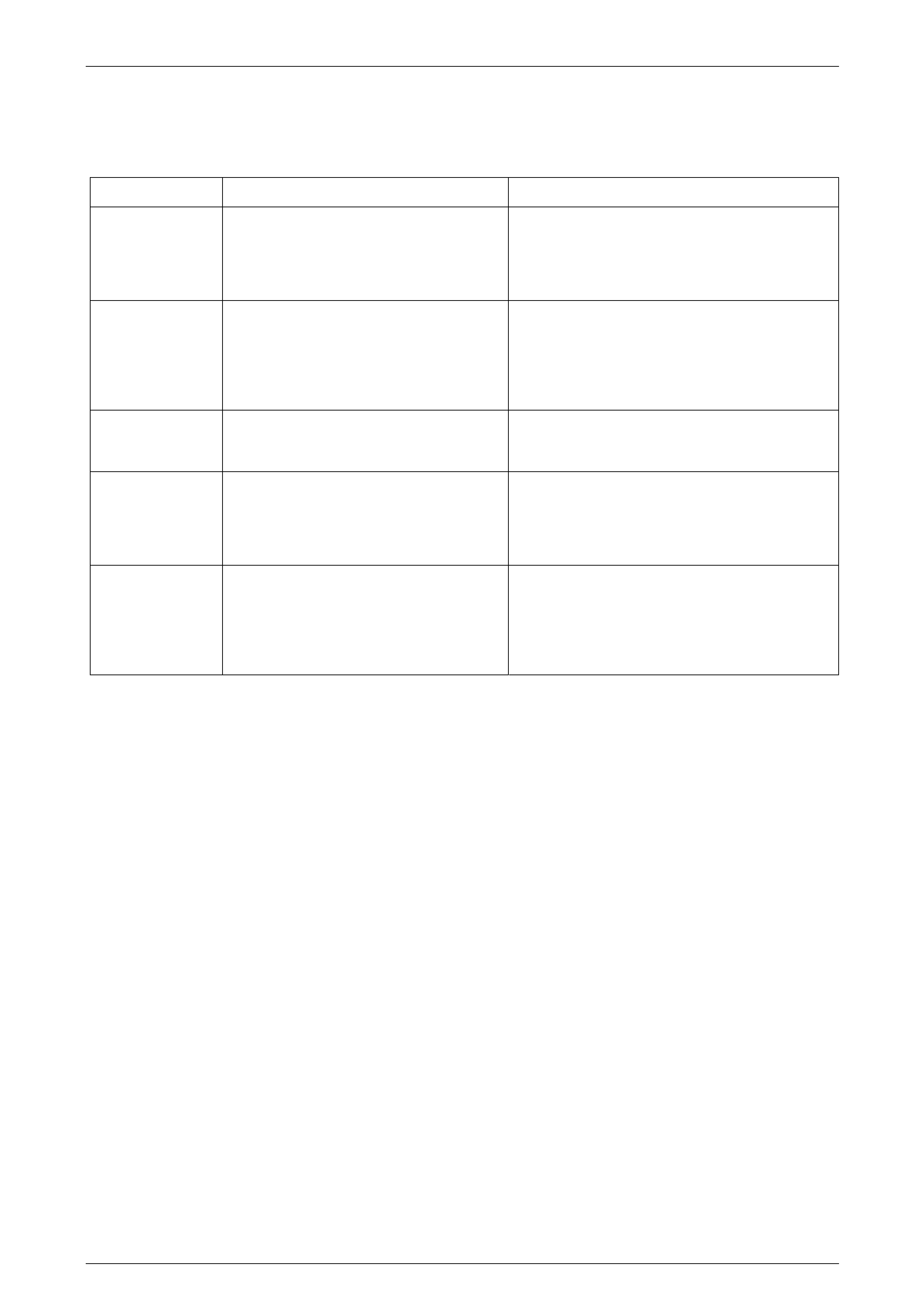

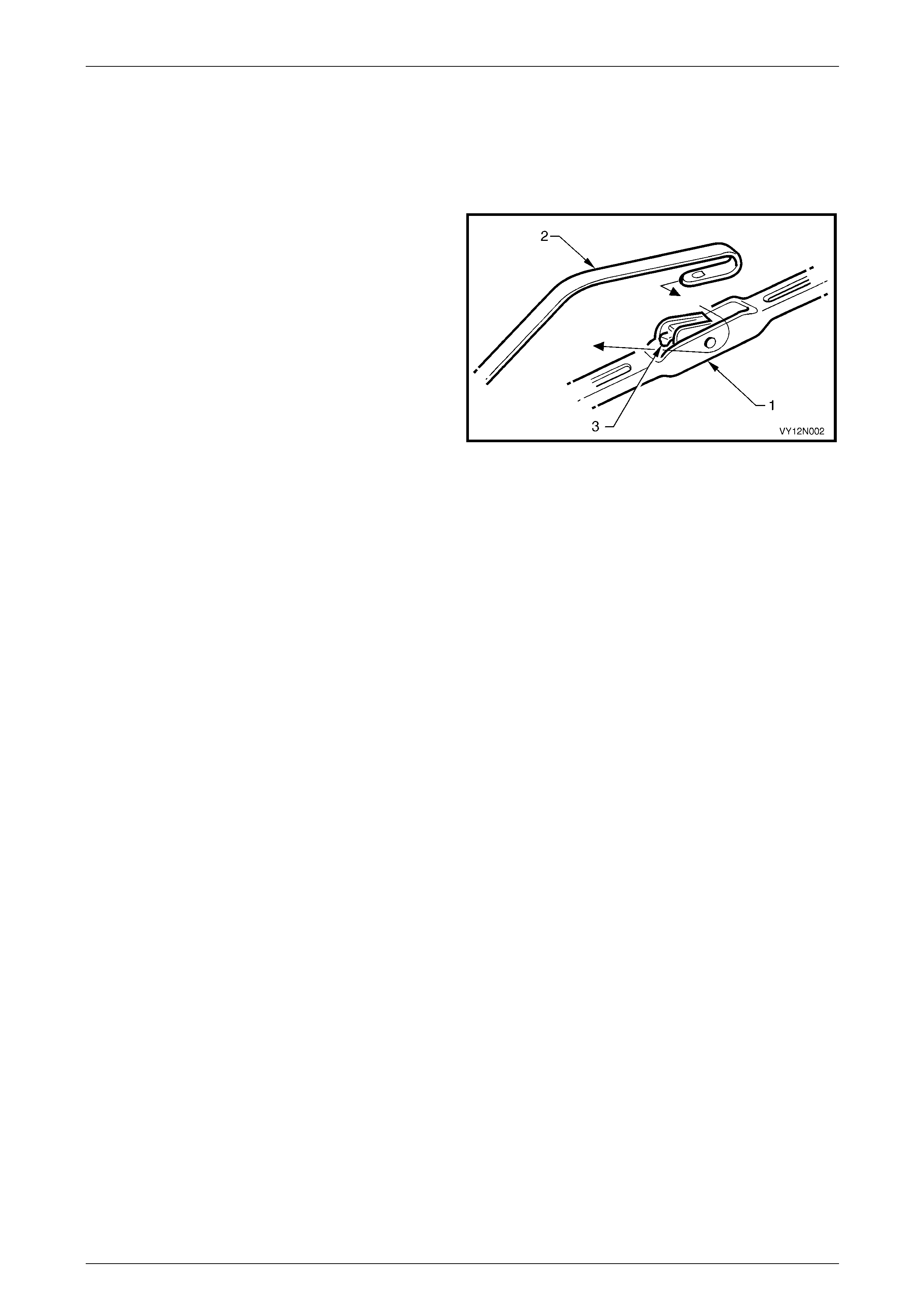

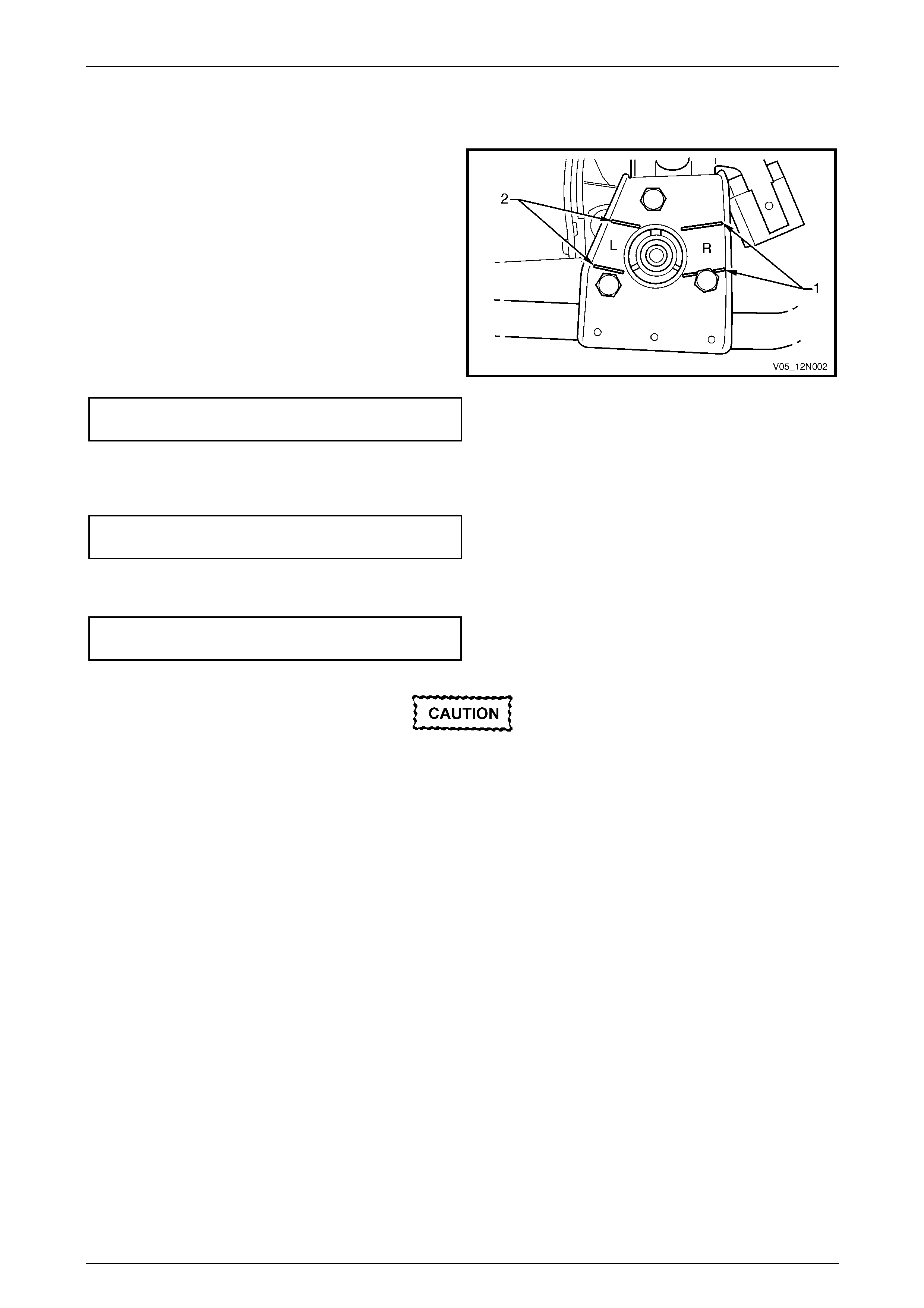

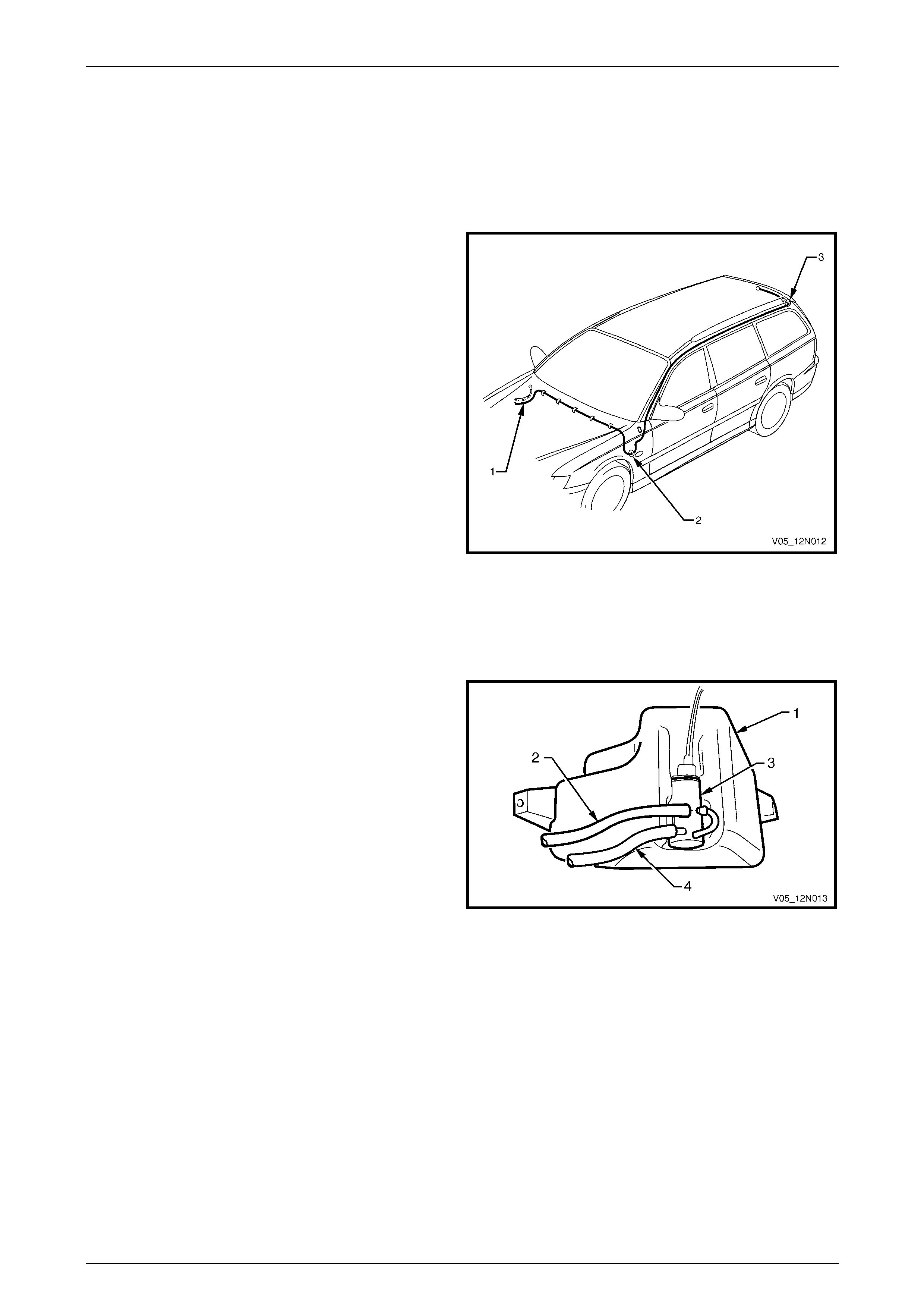

Before permitting the wiper motor to operate, the rear wiper

control module (1) monitors the positions of both the liftgate

and the liftgate window latch.

The rear wiper control module also monitors the rear wiper

three park positions:

• rear wiper offscreen park position (2),

• rear wiper onscreen park position (3), and

• rear wiper furthest onscreen park position (4).

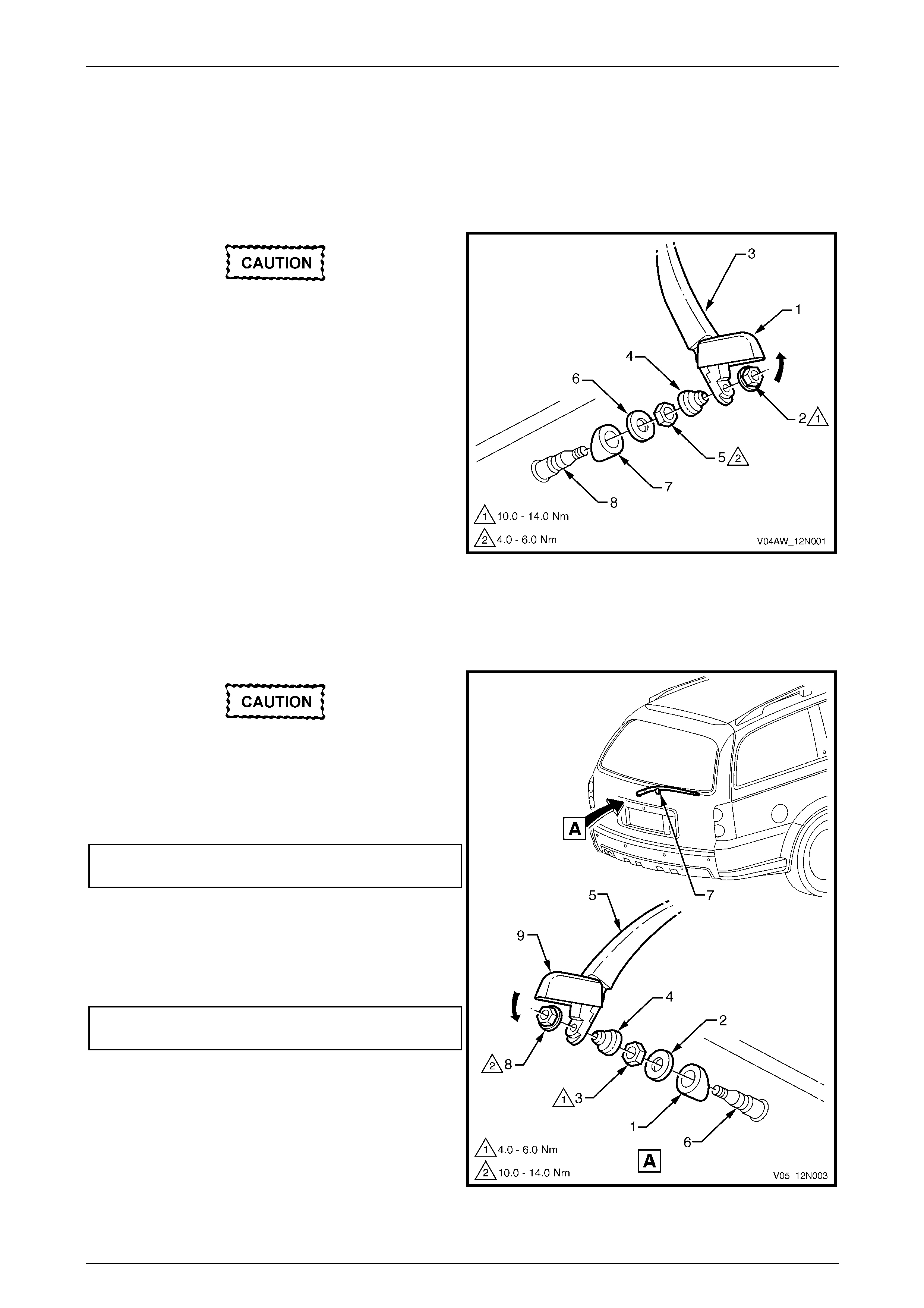

Figure 12N – 2

Wipers, Washers and Horn Page 12N–11

Page 12N–11

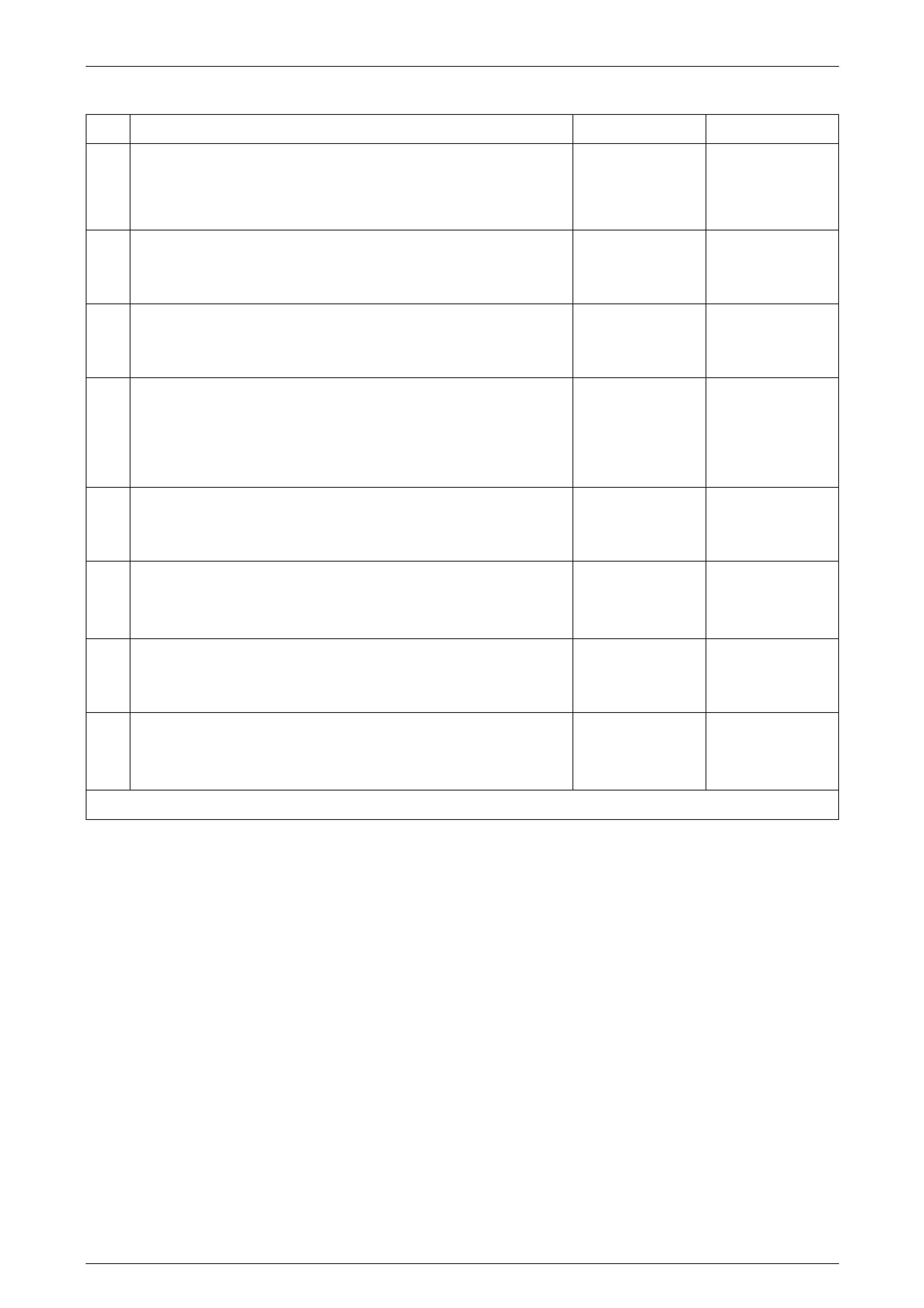

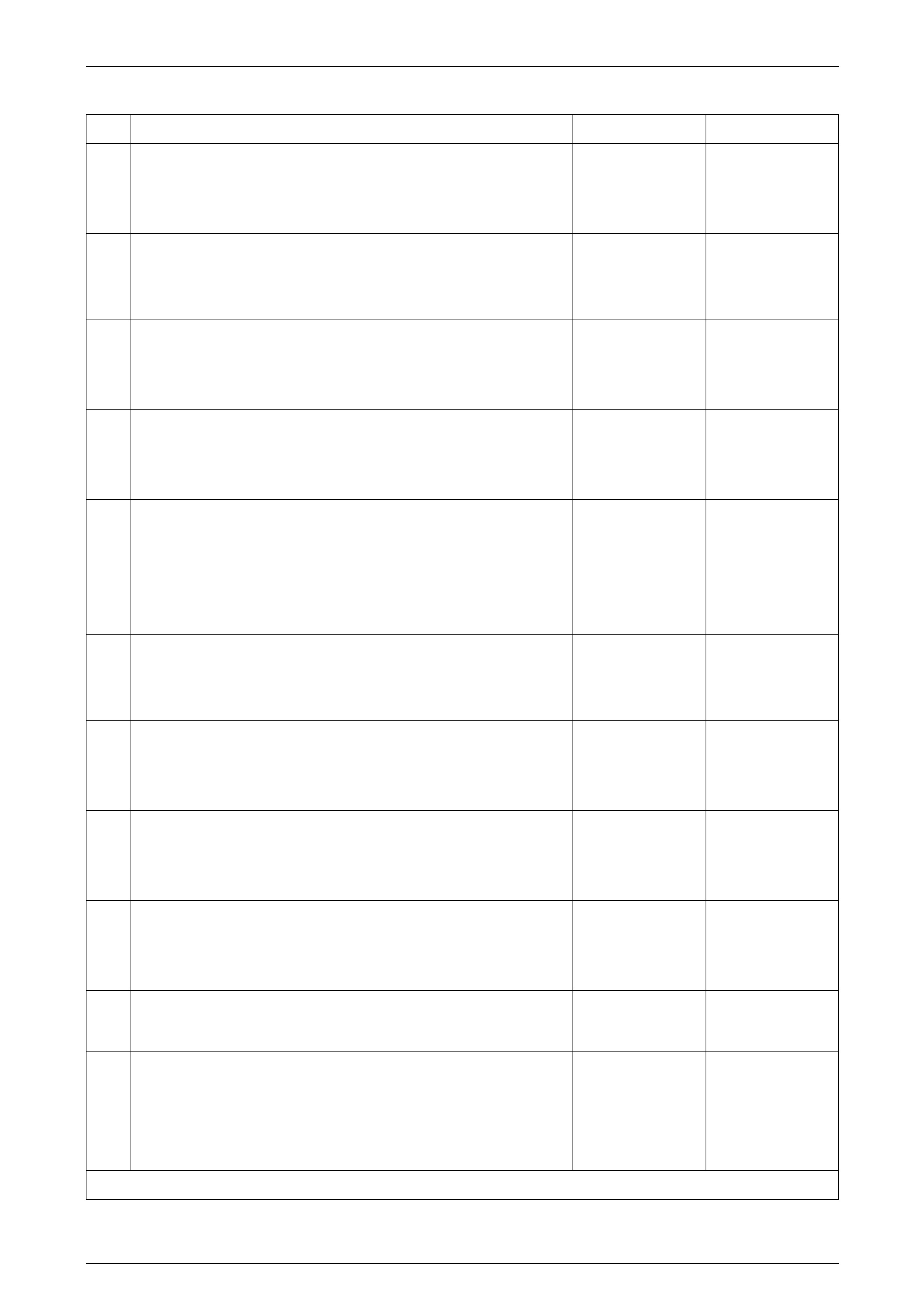

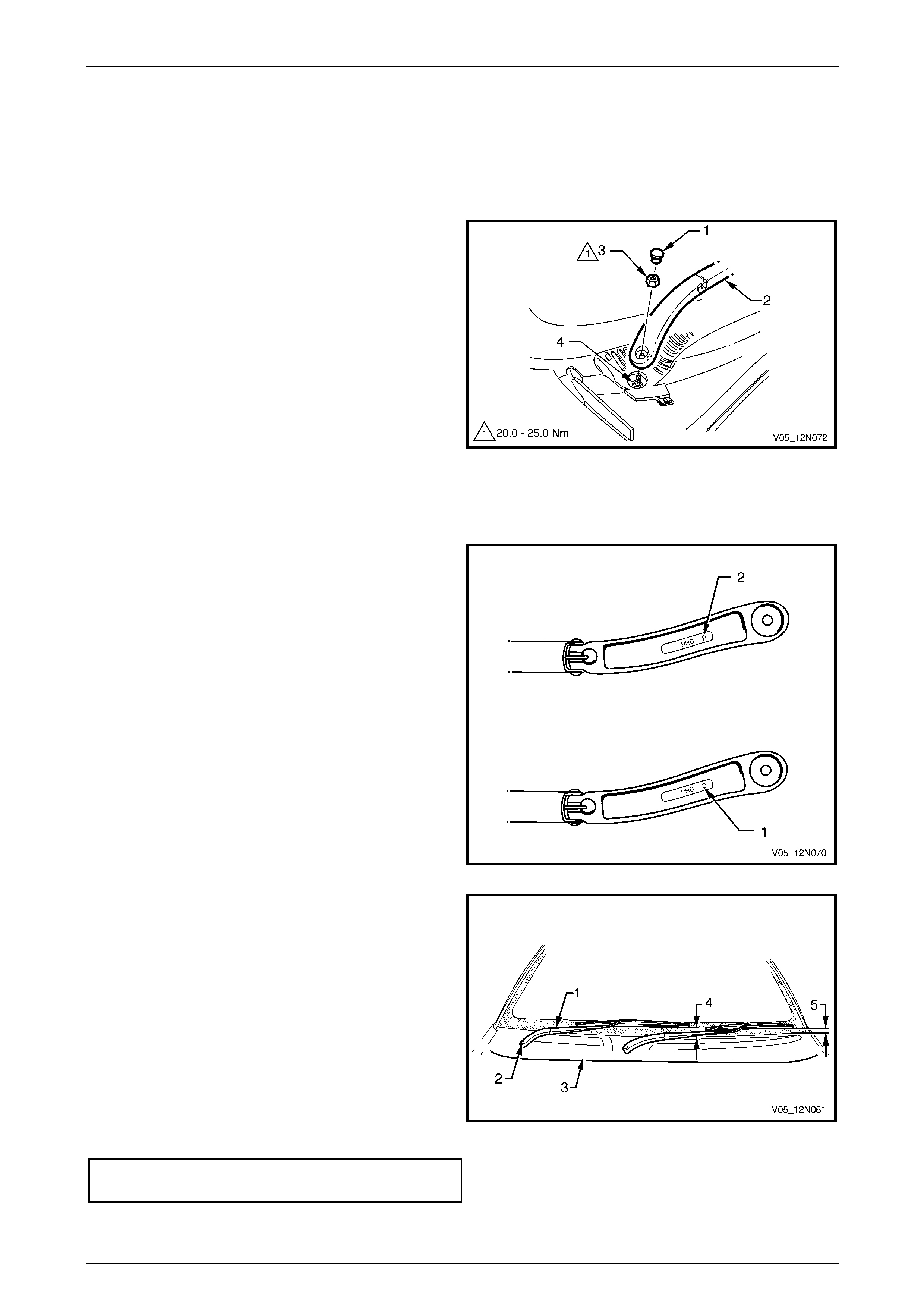

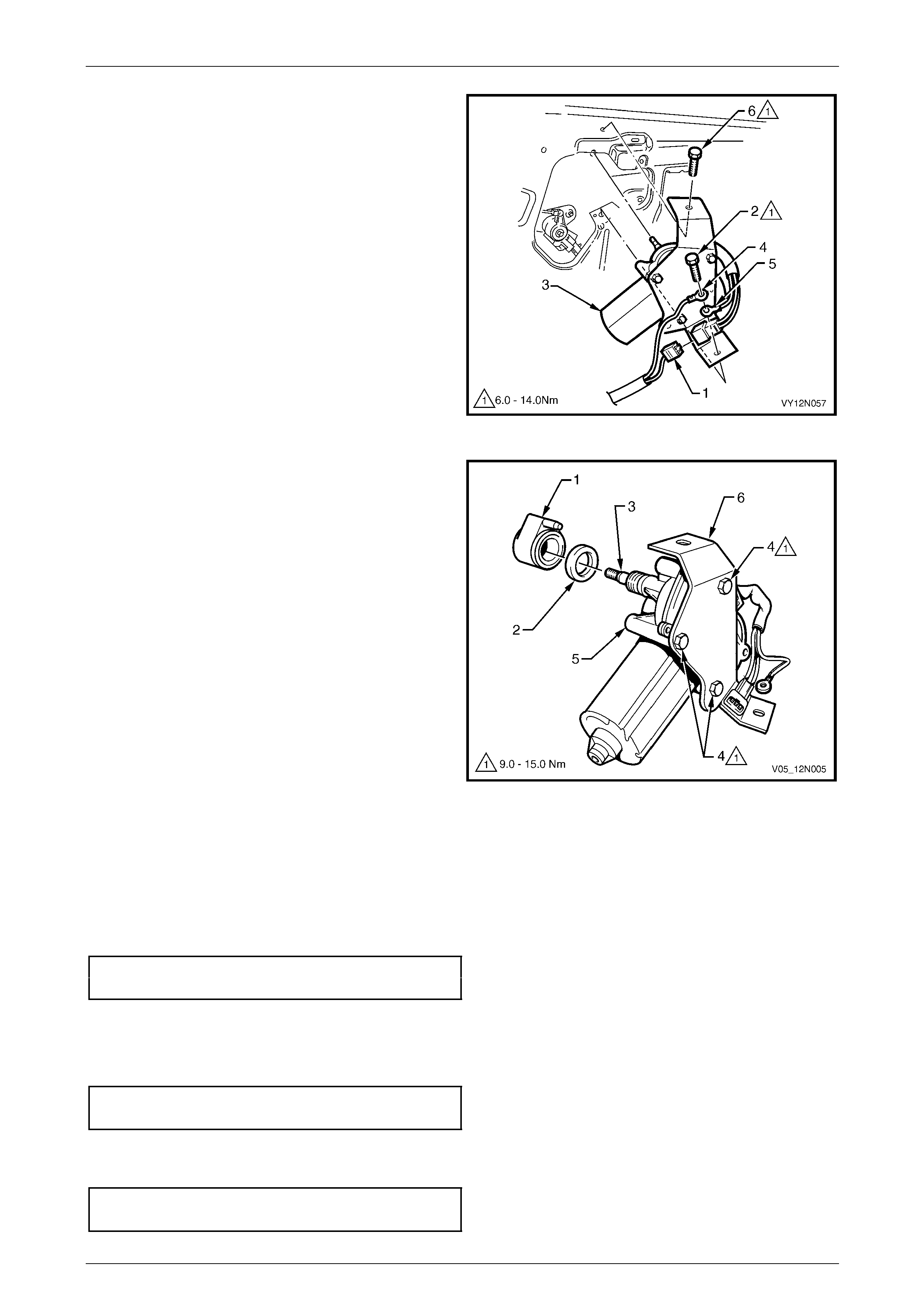

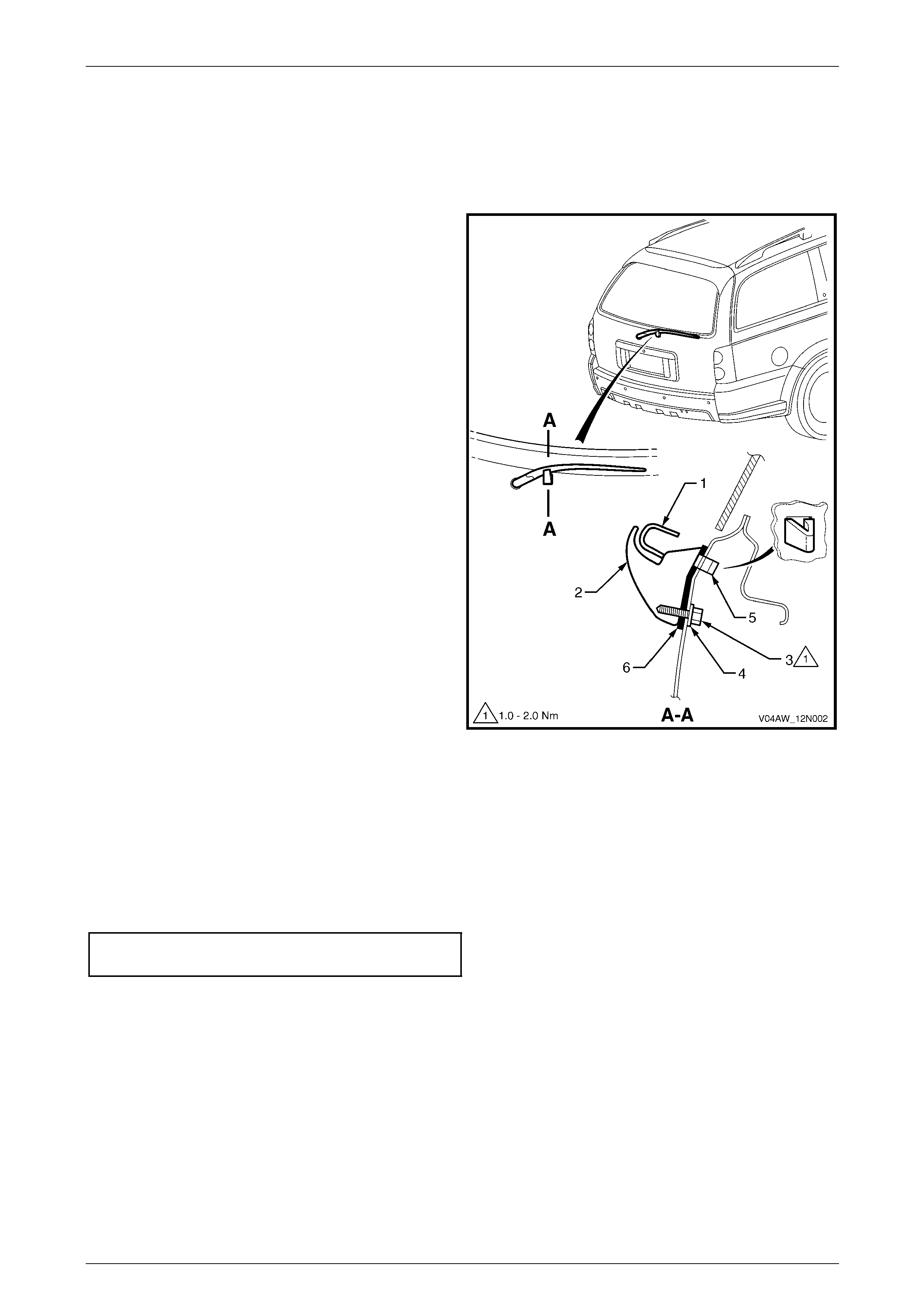

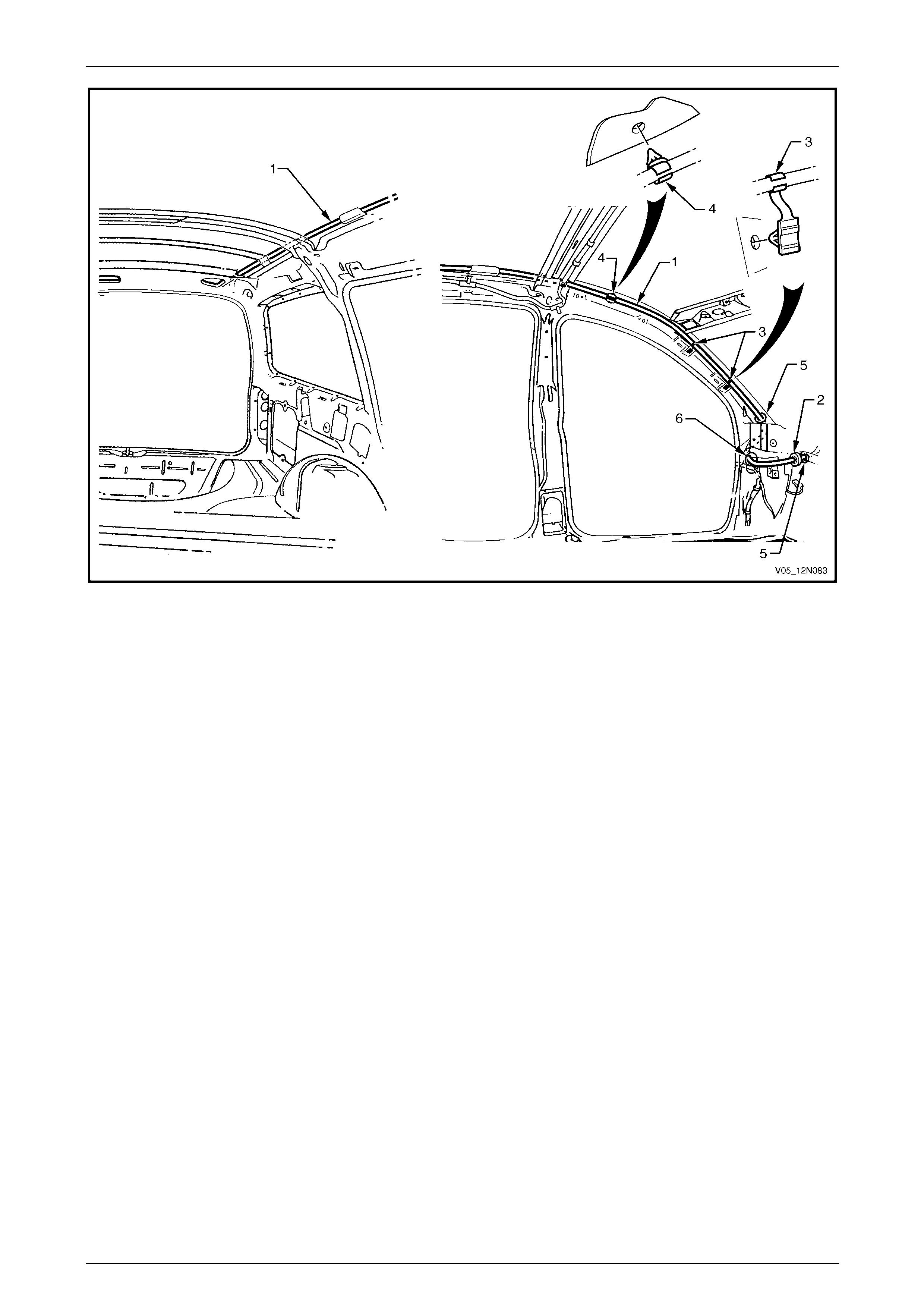

Rear Wiper Motor Assembly

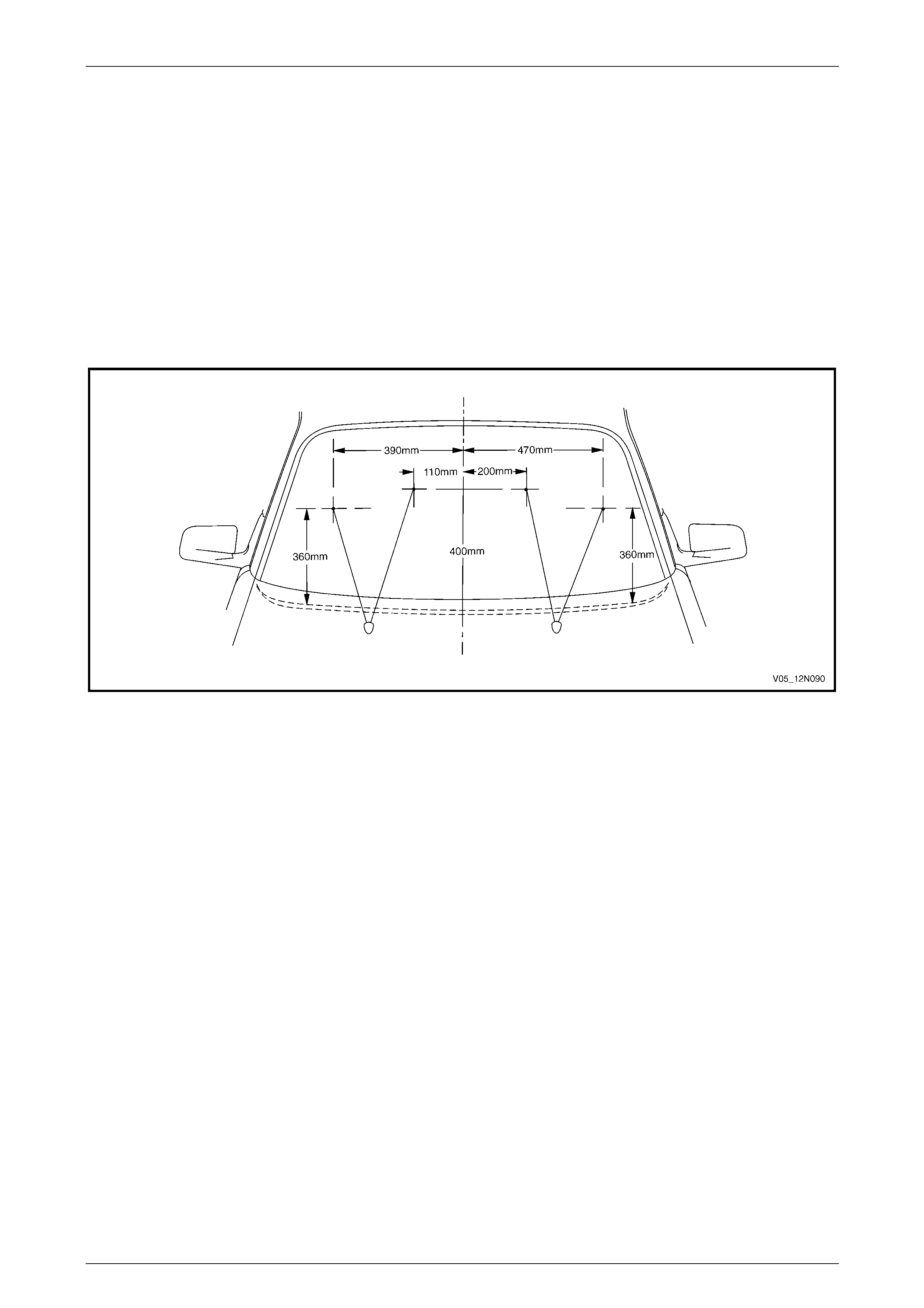

The rear wiper motor assembly (5) is introduced to suit the opening liftgate window and offscreen parking (6) of the rear

wiper arm, refer to Figure 12N – 1.

The rear wiper motor assembly has forward park and reverse park limit switches mec ha nically linked to the wiper arm

driveshaft. The forward park limit switch determines when the wiper arm is at the start of the wipe sweep (7) (onscreen

park position), while the revers e park limit switch determines when the wiper arm has reached the full wipe sweep (8)

(furthest onscreen park position).

The rear wiper motor assembly operates e ith er in the forward direction to drive the rear wiper arm for the wiping of the

liftgate window, or in the reverse direction to drive the re ar wiper arm to the offscreen park position, refer to

Figure 12N – 3.

Rear Wiper Ramp

The rear wiper ramp (9) is attached to the liftgate bel ow the liftgate window for the offscreen parking of the rear wiper

arm (10), refer to Figure 12N – 1.

Functional Operation

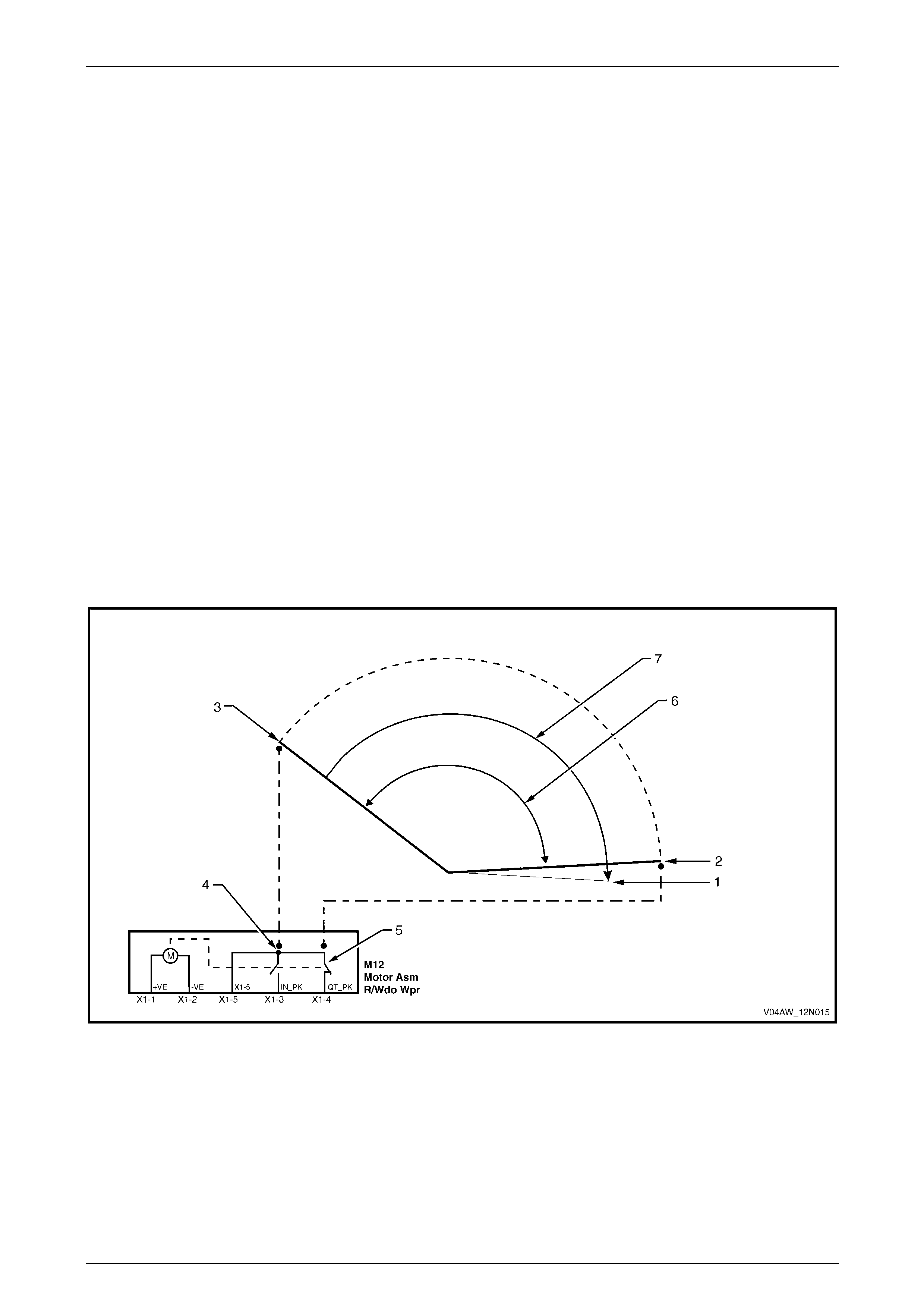

For the rear wiper assembly functional oper ation description, refer to Figure 12N – 3.

For a complete wiring diagram of the rear wiper system, refer to 6.2 Wiring Diagram – Rea r W iper/Washer and

6.3 Wiring Diagram – Rear Wiper Control Module.

Intermittent Wipe Cycle Operation

A wipe cycle consists of the rear wiper arm movement from the onscreen park position (2) to the furthest onscreen park

position (3) and back to the onscreen park position (2).

With the ignition switch in the ACC or ON position and the wipers and washers control switch is moved to the rear wiper

ON position, the rear wiper motor operates in the forward direction (6) for one wipe cycle and then waits for 9 seconds

before resuming the next wipe cycle. This procedure is repeated until the wipers and washers control switch is moved to

the OFF position.

During this cycle, the rear wiper control module suppl ies power to the rear wiper motor. The forward park limit switch (5)

in the rear wiper motor opens when the rear wiper arm leaves the onscreen park position (2) and moves in the forward

direction (6) towards the furthest onscreen park position (3). The reverse park limit switch (4) in the motor closes when

the rear wiper arm reaches the furthest onscreen p ark position (3), then it opens when the rear wiper arm leaves this

position (3) and returns towards the onscreen park pos ition (2). The forward park limit s witch (5) in the rear wiper motor

closes when the rear wiper arm reaches the onscreen park position (2). At this point the rear wiper control module

disconnects the power to the rear wiper motor and the rear wiper arm remains stationary at the onscreen park

position (2) for 9 seconds until the next wipe cycle occurs.

When the wipers and washers control switch is moved from the rear wiper ON position to the OF F position the following

occurs.

• If the rear wiper arm is in the onscreen park position (2), the rear wiper control module supplies power to the rear

wiper motor. The rear wiper arm moves in the forward direc t ion (6) towards the furthest onscreen park position (3)

where it stops. The reverse park limit switch (4) in the motor closes when the rear wiper arm reaches the furthest

onscreen park position (3) and the rear wiper arm remains stationary for 1 second. T hen the rear wiper control

module reverses polarit y to the rear wiper motor which turns in the reverse direction (7). The reverse park limit

switch (4) opens when the rear wiper arm leaves the furthest onscreen park position (3) and moves all the way to

the offscreen park position (1).

• If the rear wiper arm is moving towards the furthest onscreen park position (3), it continues to move to this position

where it stops. The reverse park limit switch (4) in the motor closes when the rear wiper arm reaches the furthest

onscreen park position (3) and the rear wiper arm remains stationary for 1 second. T hen the rear wiper control

module reverses polarit y to the rear wiper motor which turns in the reverse direction (7). The reverse park limit

switch (4) opens when the rear wiper arm leaves the furthest onscreen park position (3) and moves all the way to

the offscreen park position (1).

• If the rear wiper arm is moving towards the onscreen park position (2), the rear wiper control mod ule supplies

power to the rear wiper motor until the rear wiper arm reaches the furthest onscreen park position (3) where it

stops. The reverse park limit switch (4) in the motor closes when the rear wiper arm reaches the furthest onscreen

park position (3) and the rear wiper arm remains stationary for 1 second. T hen the rear wiper control module

reverses polarity to the rear wiper motor which turns in the reverse direction (7). The reverse park limit switch (4)

opens when the rear wiper arm leaves the furthest onscreen park position (3) and moves all the way to the

offscreen park position (1).

Wipers, Washers and Horn Page 12N–12

Page 12N–12

Continuous Wipe Mode

With the ignition switch in the ON position, the rear wiper operates in continuous wipe mode when:

• the wipers and washers control switch is pushed and held forward, or

• the wipers and washers control switch is in the rear wiper ON position and the reverse gear is selected.

During this wipe mode, the rear wiper motor operates in the forward directi on (6). The rear wiper arm moves continuously

between the furthest onscreen park position (3) and the onscreen park pos ition (2). The reverse park limit switch (4) and

the forward park limit switch (5) in the rear wiper motor close and re-op en alternatively as the rear wiper arm reaches the

two park positions (2 and 3). The rear wiper control module supplies constant power to the rear wiper motor.

When the wipers and washers control switch is released from the forward position the following occurs.

• If the rear wiper/washer switch is in the OFF position, the rear wiper motor continues to operate in the f orward

direction (6) until the rear wiper arm reaches the furthest onscreen park position (3) where it stops. The reverse

park limit switch (4) in the motor closes when the rear wiper arm reaches the furthest onscreen park position (3)

and the rear wiper arm remains stationar y for 1 second. Then the rear wiper control modul e reverses polarity to the

rear wiper motor which turns in the reverse direction (7). The reverse park limit switch (4) opens when the rear

wiper arm leaves the furthest onscreen park position (3) and moves al l the way to the offscreen park position (1).

• If the rear wiper/washer switch is in the ON position, the rear wiper motor continues to operate in the forward

direction (6) until the rear wiper arm reaches the onscreen park position (2). The forward park limit switch (5) in the

motor closes when the rear wiper arm reache s the onscreen park position (2). At this point the rear wiper control

module disconnects the power to the rear wiper motor and the rear wiper arm remains stationary at the o nscreen

park position (2) for 9 seconds until the next intermittent wipe cycle occurs.

When the reverse gear is deselected, the rear wiper motor continues to operate in the forward direction (6) until the rea r

wiper arm reaches the onscreen park position (2). The forward park limit switch (5) in the motor closes when the rear

wiper arm reaches the onscreen park positio n (2). At this point the rear wiper control module disconnects the power to

the rear wiper motor and the rear wiper arm remains stationary at the onscreen park position (2) for 9 seconds until the

next intermittent wipe cycle occurs.

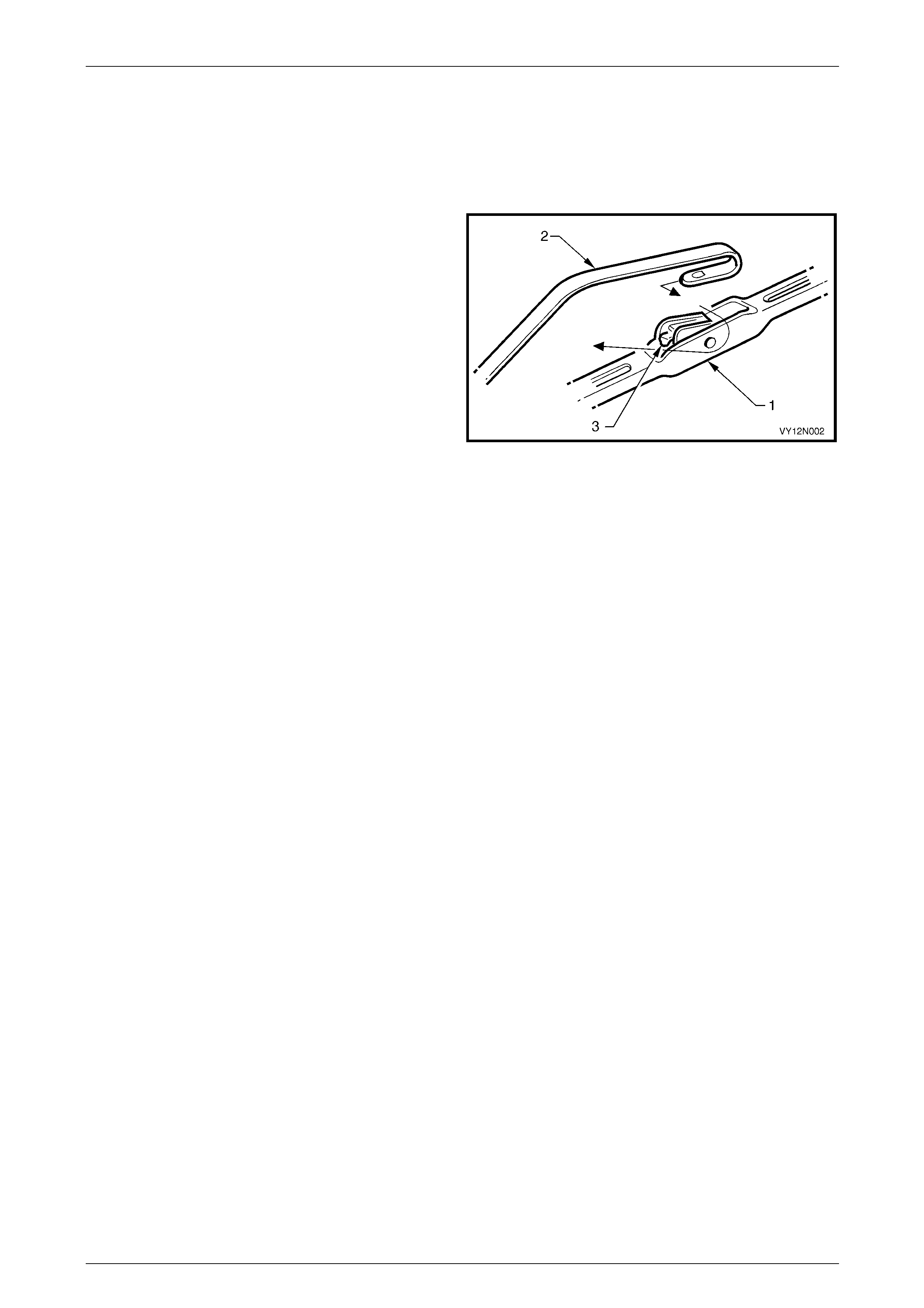

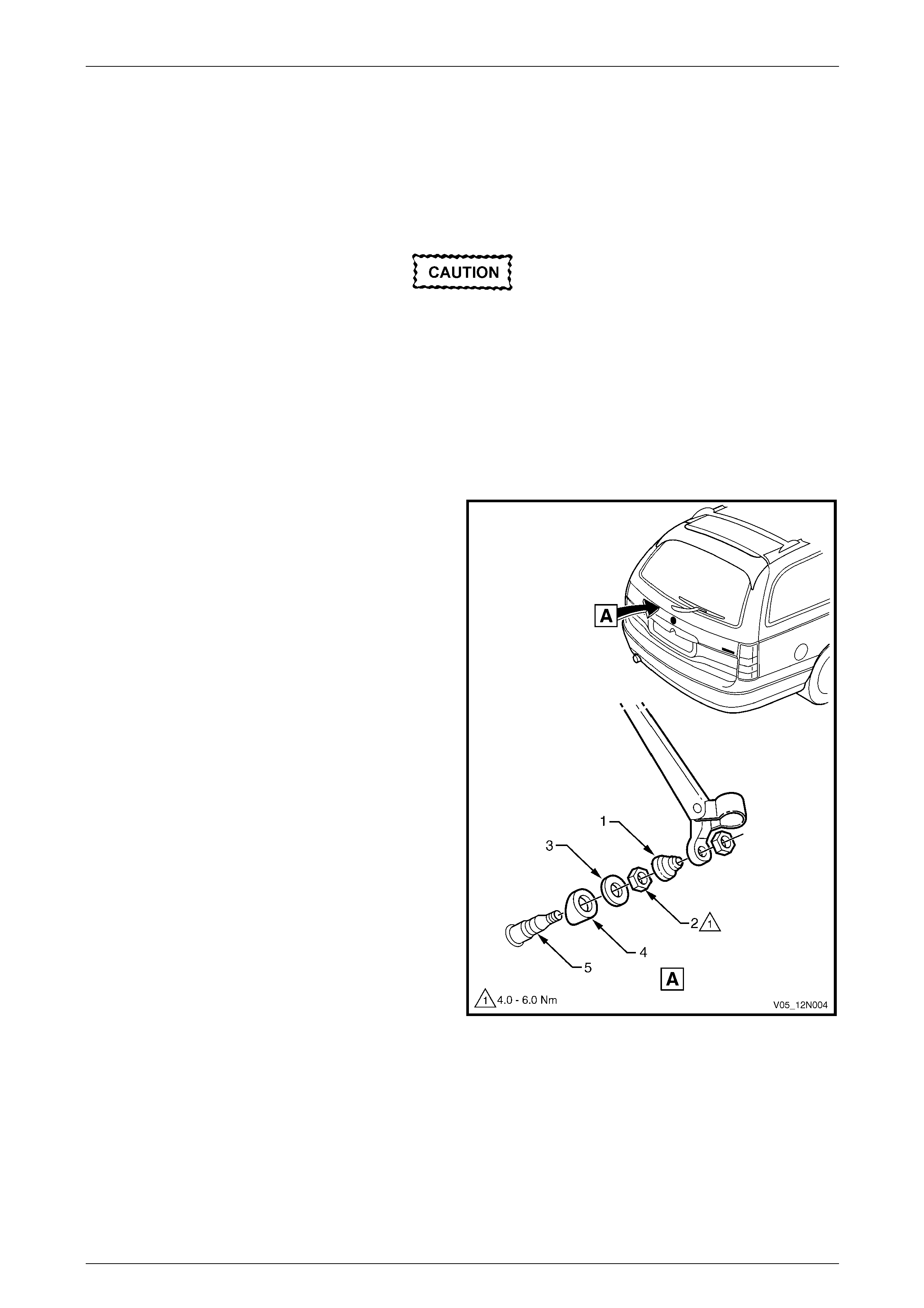

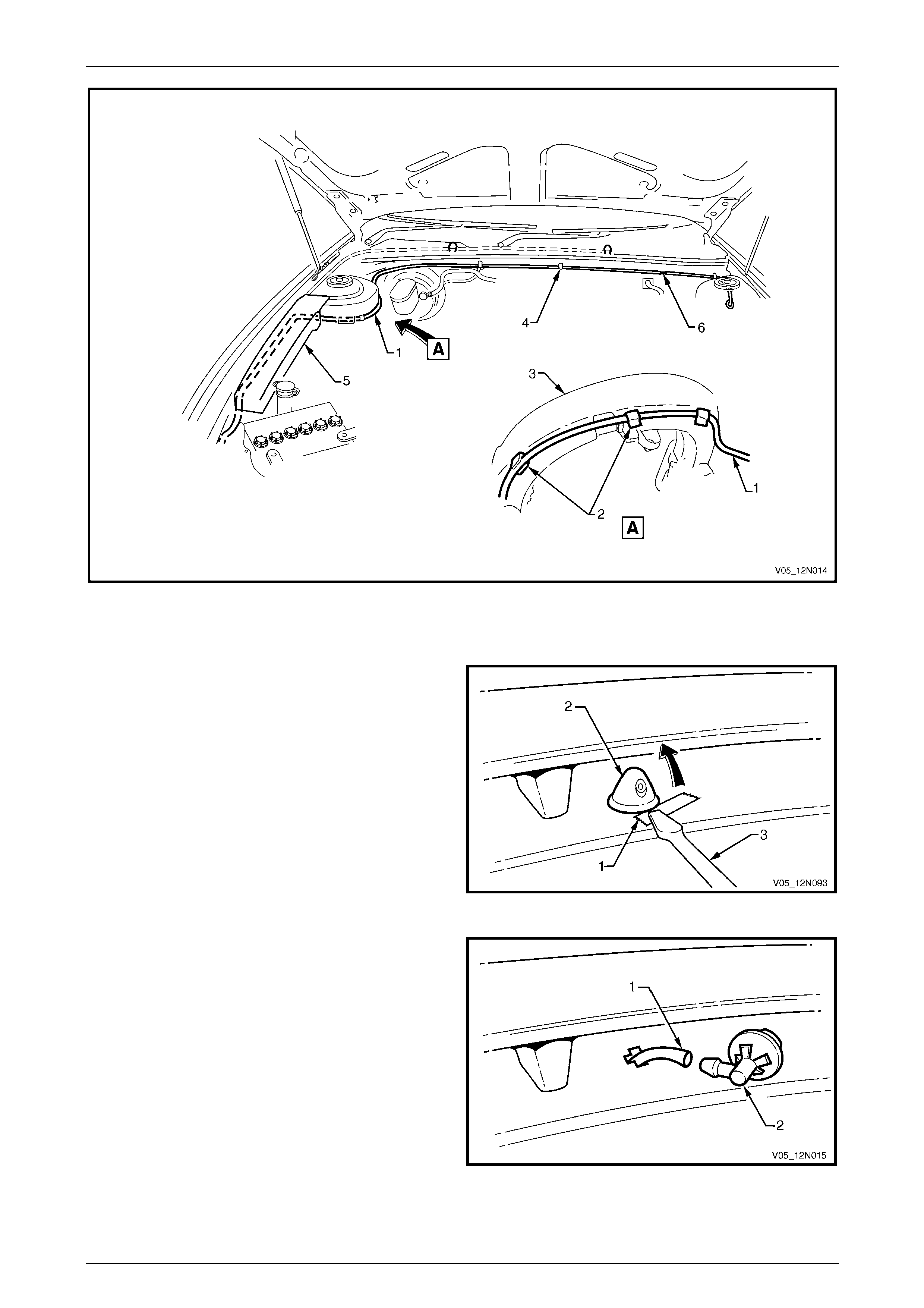

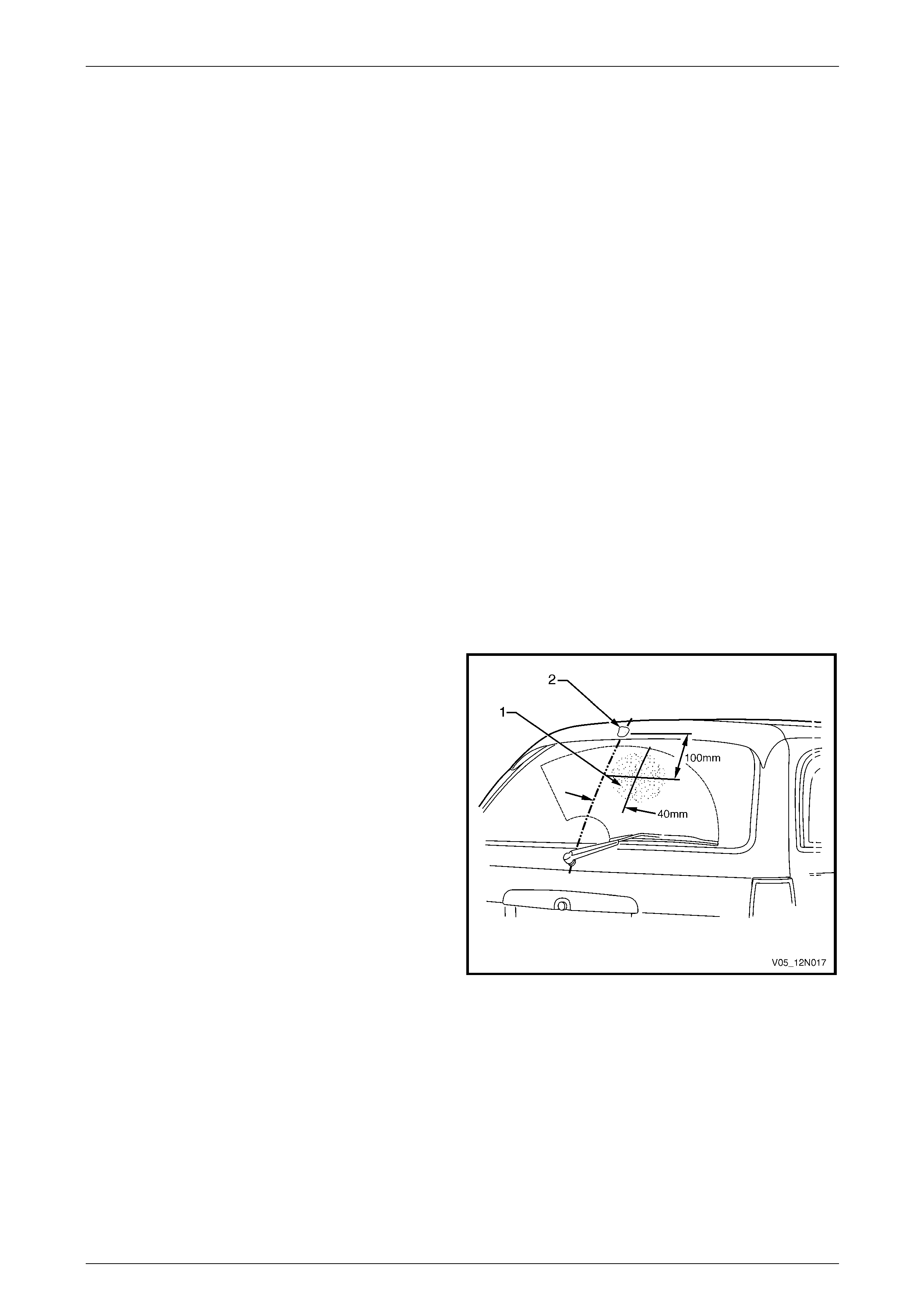

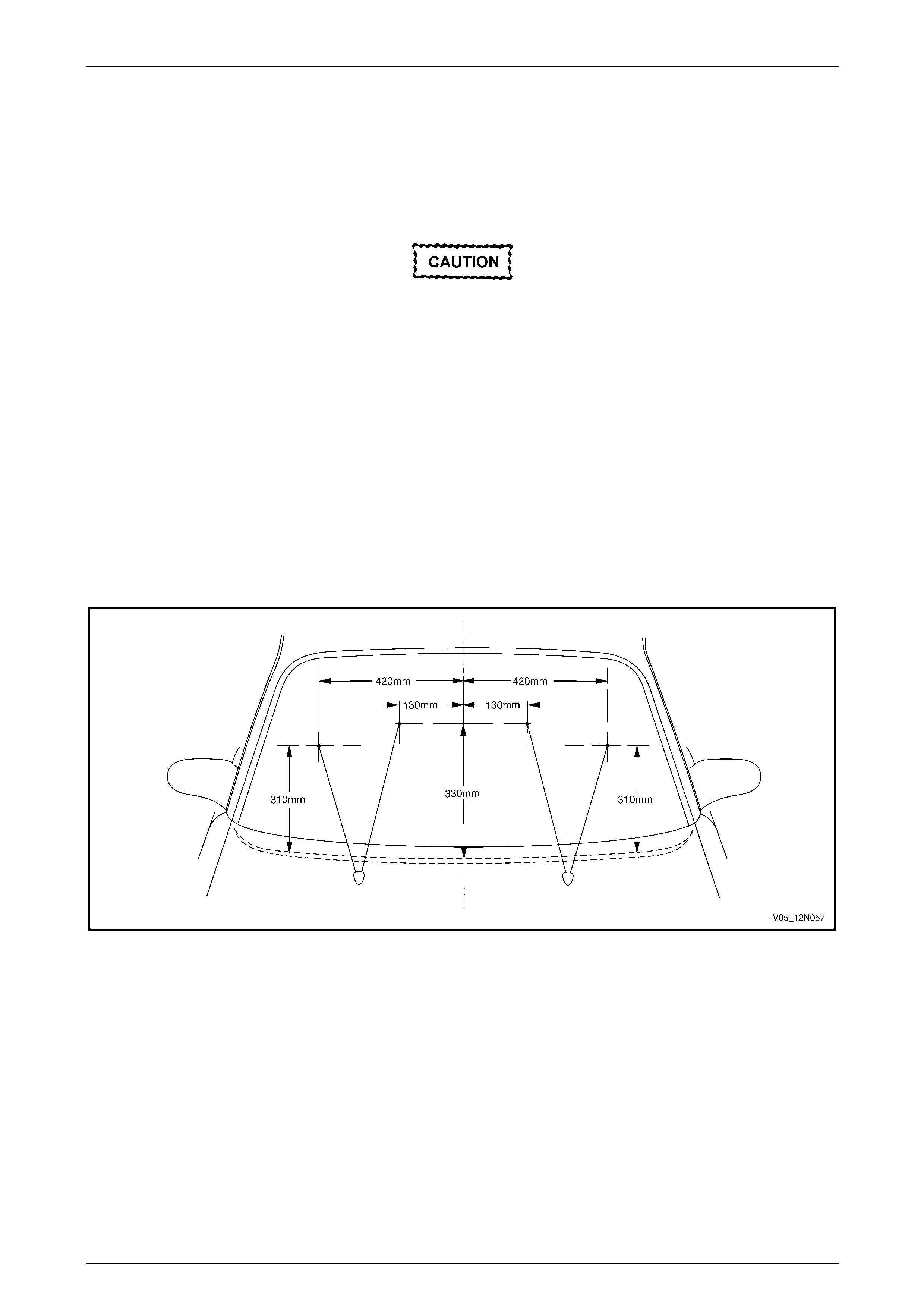

Figure 12N – 3

Legend

1 Rear Wiper Arm Offscreen Park

Position

2 Rear Wiper Arm Onscreen Park

Position

3 Rear Wiper Arm Furthest Onscreen

Park Position

4 Rear Wiper Motor Reverse Park Limit

Switch

5 Rear Wiper Motor Forward Park Limit

Switch

6 Rear Wiper Motor Forward Direction

7 Rear Wiper Motor Reverse Direction

Wipers, Washers and Horn Page 12N–13

Page 12N–13

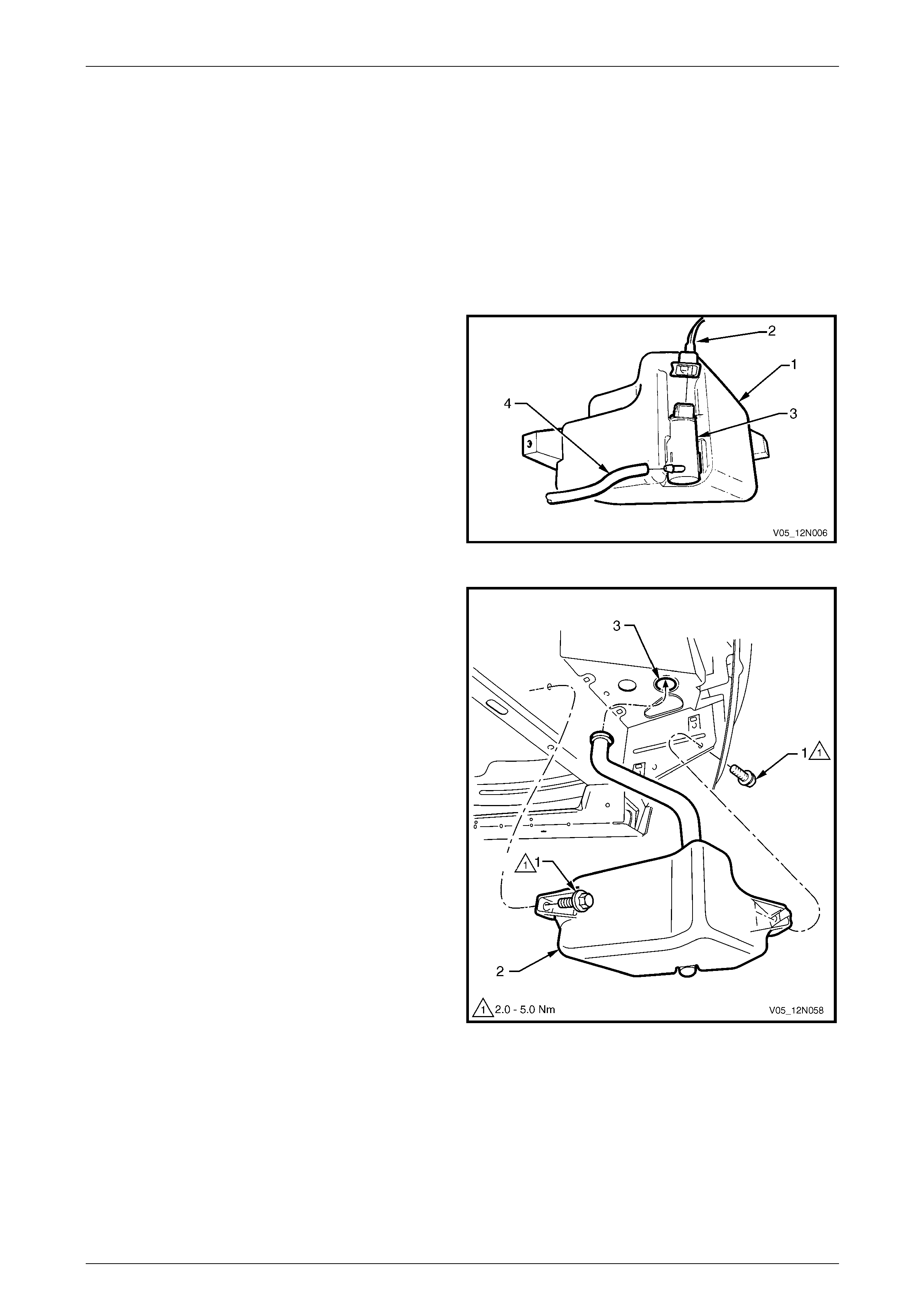

1.4 Washer Assemblies

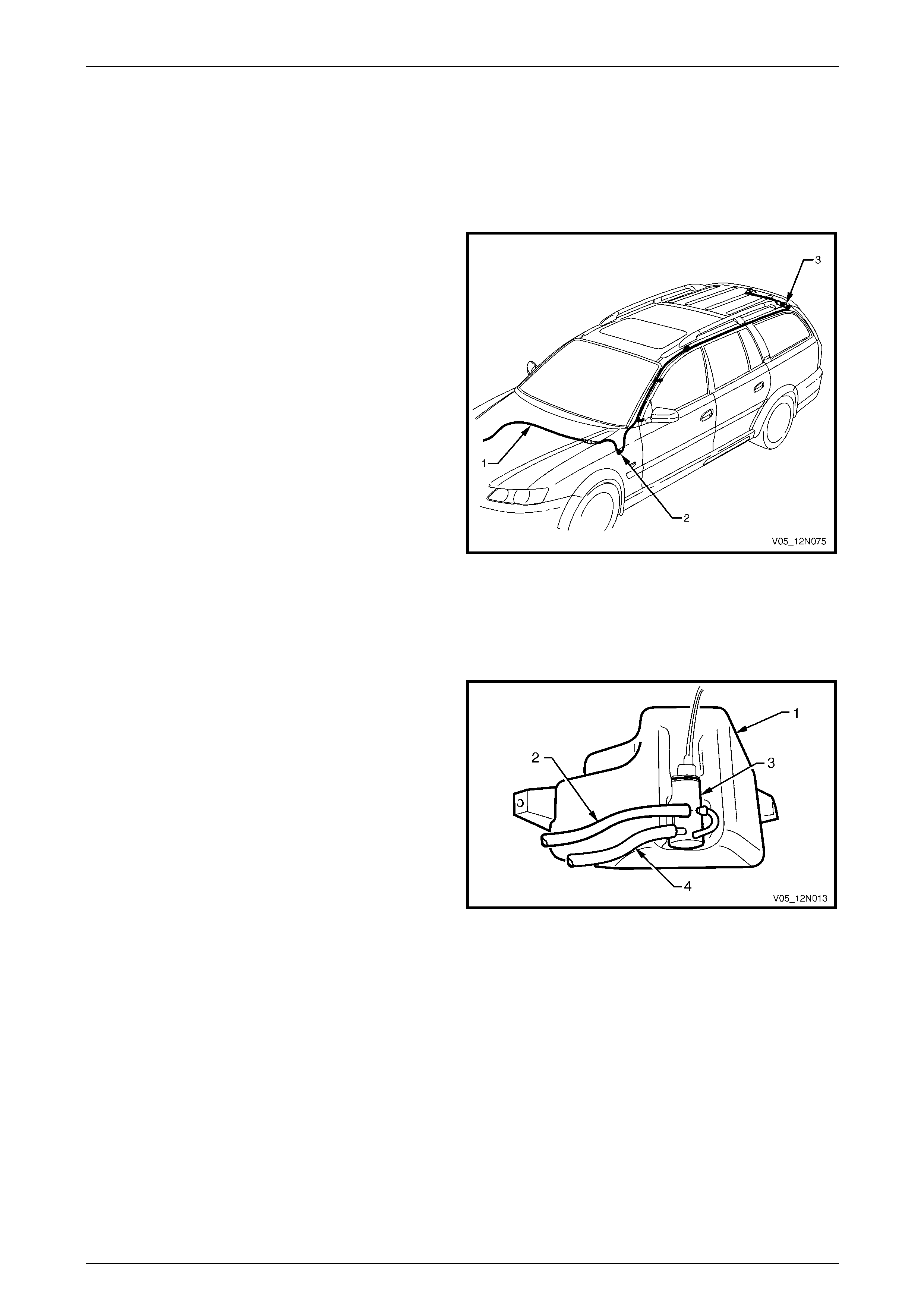

Washer Assemblies, Except Wagon and AWD Wagon

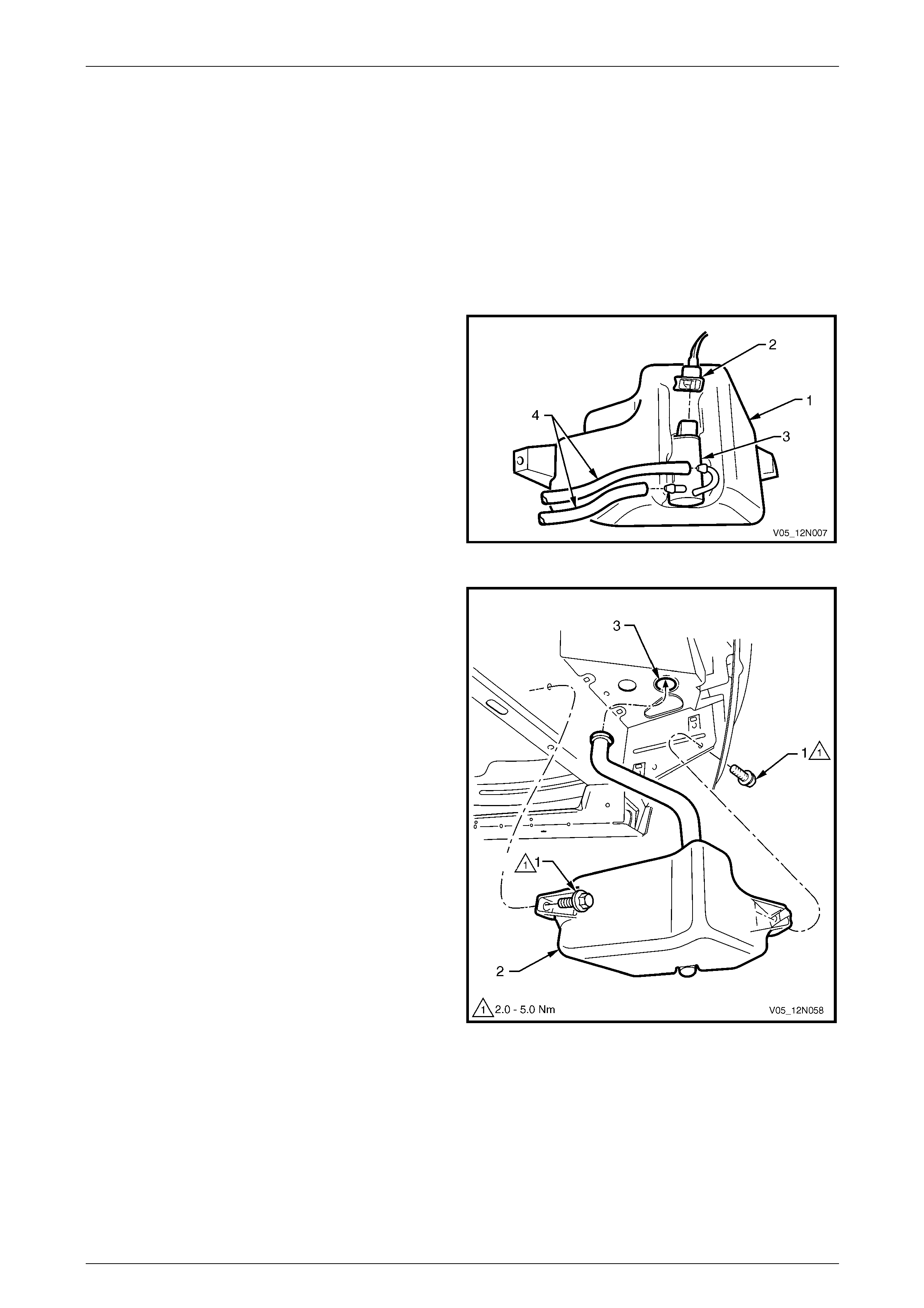

The washer reservoir assembl y has the washer pump attached to it and is located belo w the right-hand front wheelhouse

panel assembly.

The washer nozzles are a dual outlet t ype and are mounted to the plenum cover assembly. For Cou pe vehicles the

washer nozzles are mounted to the hoo d assembly.

The washer pump assembly is operate d via the wipers and washers control switch fitted to the steering column; the

operation is controlled by the (BCM), refer to Section 12J Body Control Module.

With the ignition switch in the ACC or ON position, the accessor y control relay within the passenger compartment fuse

and relay panel assembly, is activated. When the wipers and washers control switch is pulled and held back, power is

supplied to the washer motor until the wipers and washers control switch is released.

For a complete wiring diagram of the washer system, refer to 3.2 Wiring Diagram – Front Wiper/Washer, Except Wagon.

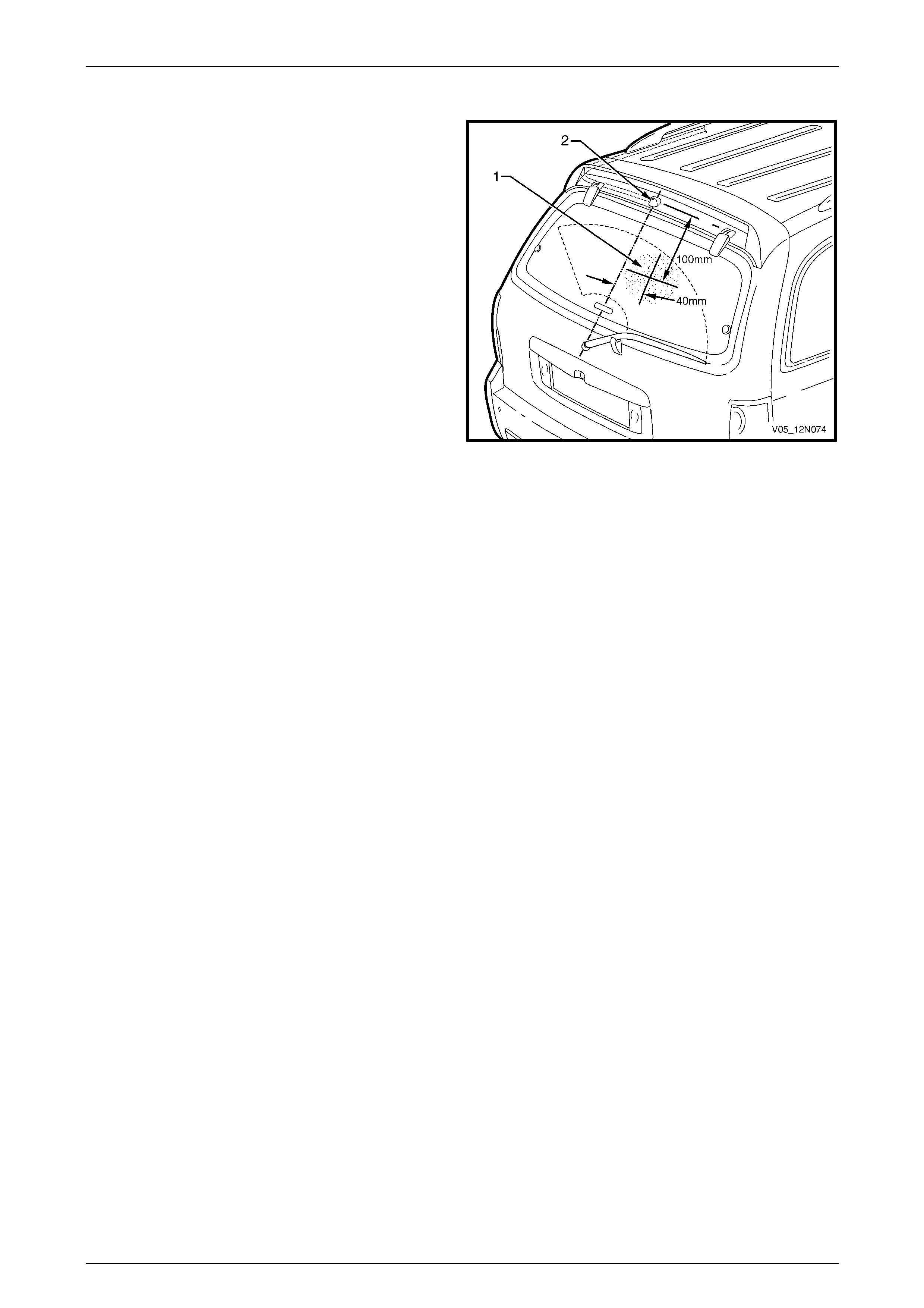

Washer Assemblies, Wagon and AWD Wagon

Wagon vehicles have a rear wash er for the liftgate window as well as the windshield fro nt washers.

Wagon vehicles have a single washer reservoir and a comm on washer pump with dual outlet used for the front washers

and the rear washer.

The washer reservoir assembl y has the washer pump attached to it and is located belo w the right-hand front wheelhouse

panel assembly.

The front washer nozzles are a dual outlet type and are mounted to the plenum cov er assembly. The single outlet type

rear washer nozzle is mounted to the liftgate above the rear window.

Washer Control, Wagon

The washer pump assembly is operated via the wipers and washers control switch assembly fitted to the steering

column, the operation is controlled by the BCM, refer to Section 12J Body Control Module.

For a complete wiring diagram of the washer system, refer to 5.2 Wiring Diagram – Rear Wiper/Washer

Washer Control, AWD Wagon

The washer pump assembly is operated via the wipers and washers control switch assembly fitted to the steering

column; a one way valve is fitted just prior to the rear washer nozzle. The rear washer operation is controlle d by the rear

wiper control module.

For a complete wiring diagram of the washer system, refer to 6.2 Wiring Diagram – Rear Wiper/Washer.

Front Washer Operation

With the ignition switch in the ACC or ON position, the accessor y control relay within the passenger compartment fuse

and relay panel assembly, is activated. When the wipers and washers control switch is pulled and held back on front

wash position, power is supplied to the washer motor until the switch is released.

The washer pump motor forces the fluid to the outlet leading to the front washer nozzles.

Rear Washer Operation

With the ignition switch in the ACC or ON position, the accessor y control relay within the passenger compartment fuse

and relay panel assembly, is activated. When the wipers and washers control switch is pushed and held forward on rear

wash position, power is supplied to the washer motor until the switch is released.

To feed the fluid to the rear washer nozzle, the polarity is reversed to the washer pump motor, making it spin in the

reverse direction and forcing fluid to the outlet leading to the rear washer nozzle.

Wipers, Washers and Horn Page 12N–14

Page 12N–14

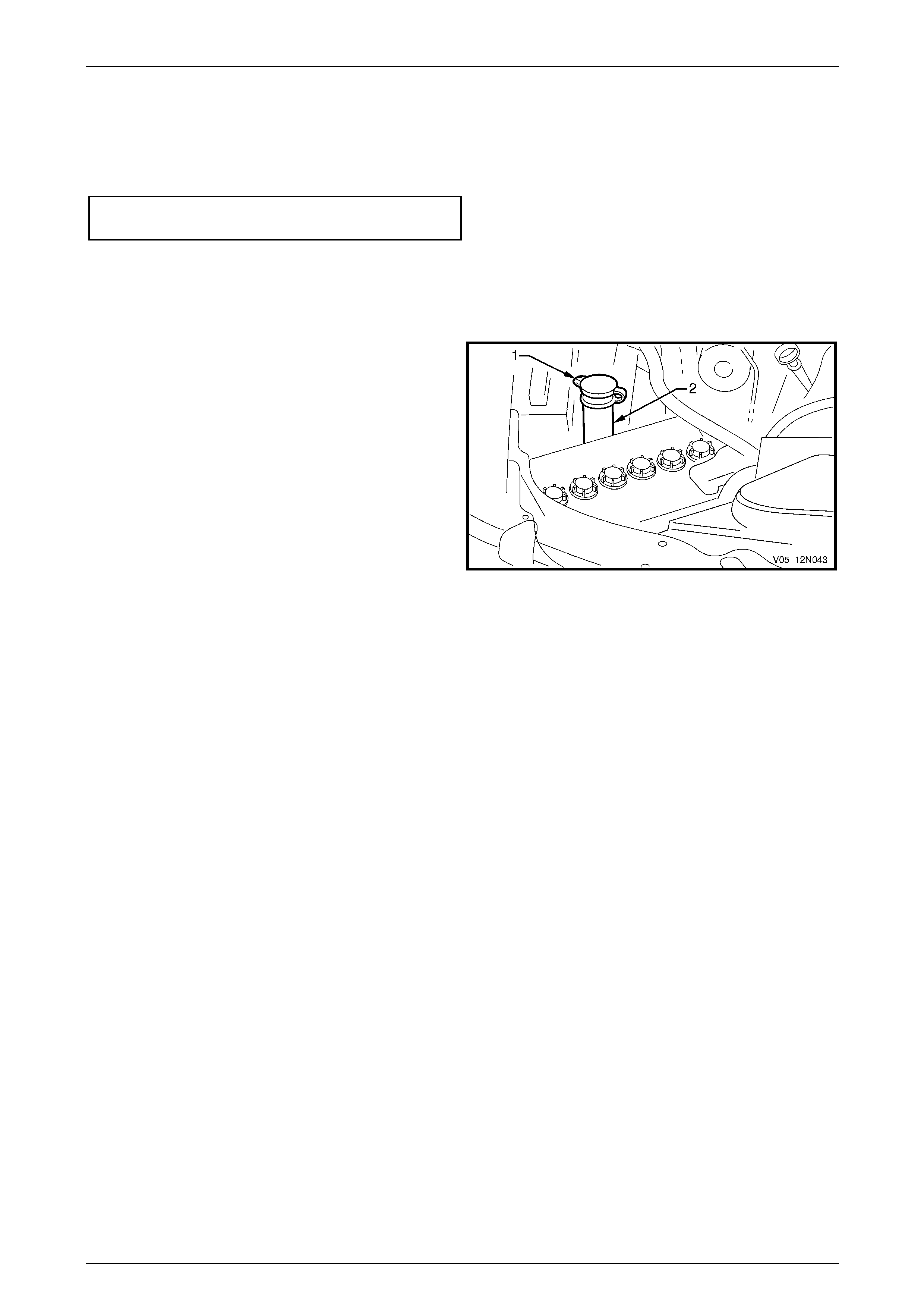

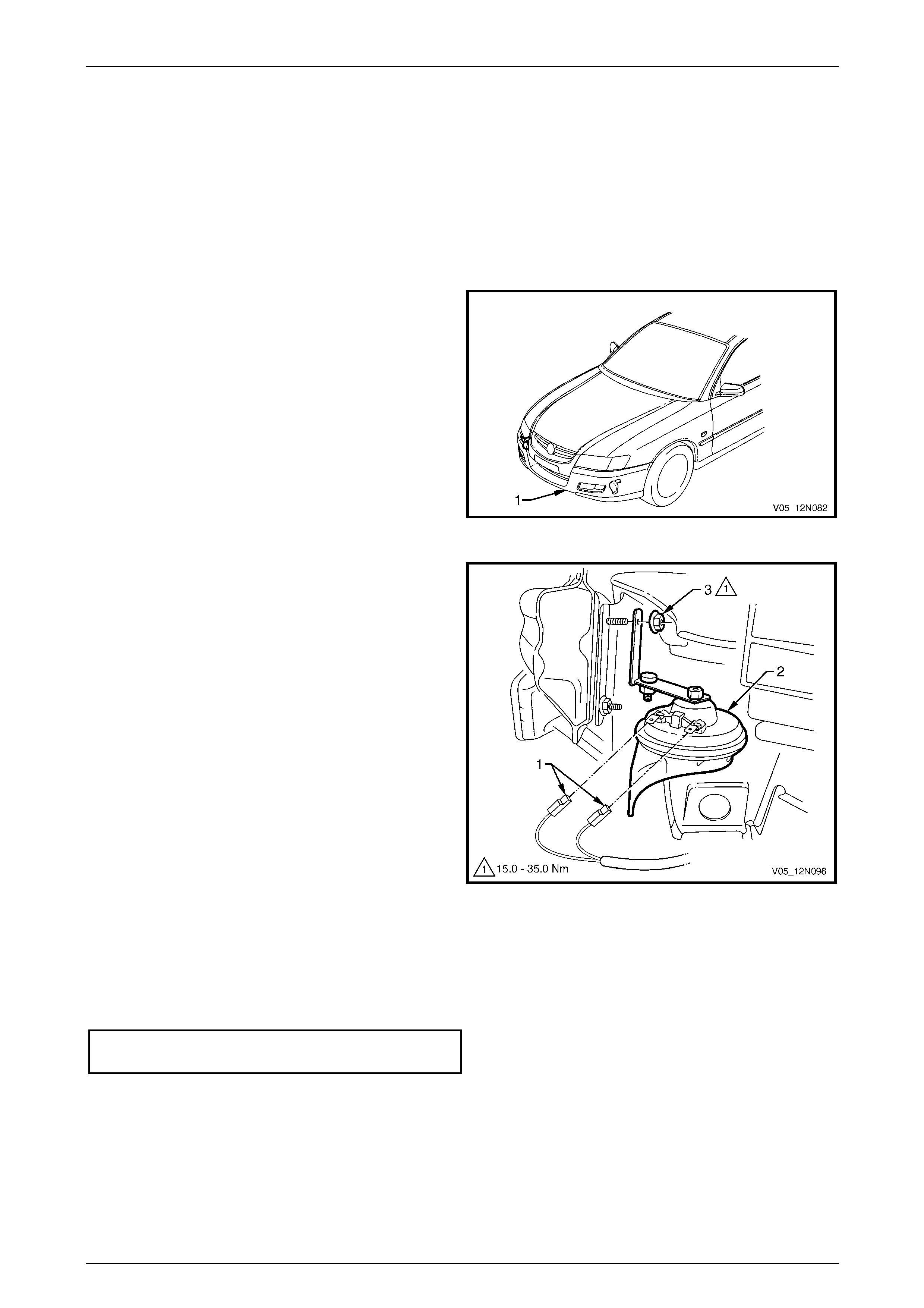

1.5 Horn Assemblies

Horn Assembly

Description

Two trumpet type horns are fitted to the vehicle.

The trumpet type dual horns are fitted behind the front bumper fascia with the high-note horn on the right-hand side and

the low-note horn on the left-hand side.

The horn assembly is operated via the steering wheel horn contact, the operation is controlled by the BCM, refer to

Section 12J Body Control Module.

Power is supplied to the horn assembly when the horn relay located within the pass enger compartment fuse and relay

panel assembly is activated. The horn relay is activated by a circuit which is closed when the steering wheel horn contact

switch is pushed in.

For a complete wiring diagram of the horn system, refer to 7.2 Wiring Diagram – Horn Assembly.

Horn Relay

The horn relay is locate d in the engine compartment fuse and rela y panel assembly,

refer to Section 12O Fuses, Relays and Wiring Harnesses.

Steering Wheel Horn Contact

The horn contact is incorporated into th e steering wheel inflatable restraint module in the centre of the steering wheel.

The horn contact is not serviced separatel y; for all servic e operations, refer to Section 12M Occupant Protection System.

Theft-deterrent Horn Assembly

Description

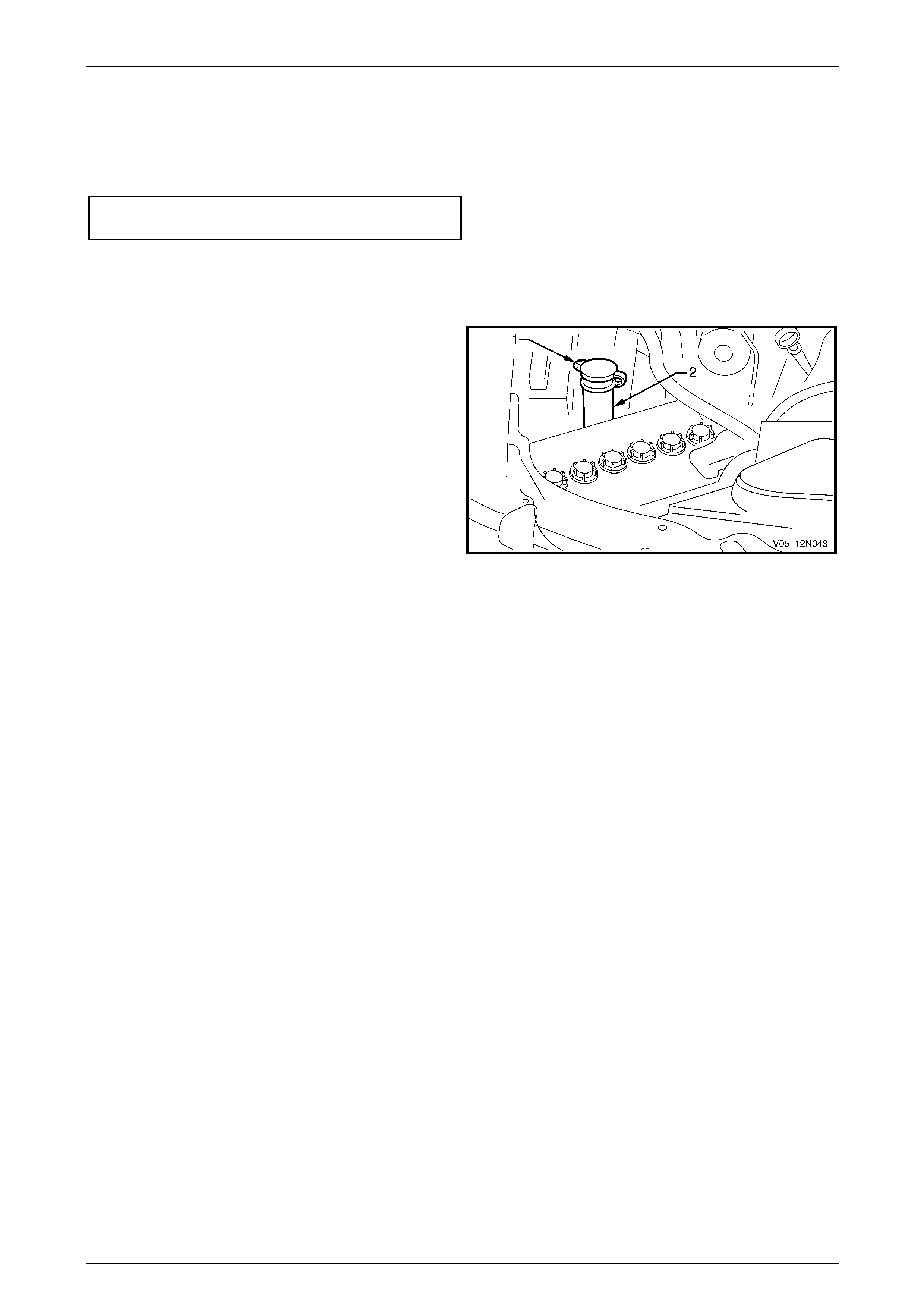

The theft-deterrent horn is a disc type horn located at the rear of the engine bay and is attached to the front left-hand

wheelhouse panel ass embly.

Power is supplied to the theft-deterrent horn assembly when the theft-deterrent horn relay located within the BCM is

activated. The operation of the theft-deterrent horn is controlled by the BCM, refer to Section 12J Body Contro l Module.

For a complete wiring diagram of the theft-deterrent horn system, refer to 7.2 Wiring Diagram – Horn Assembl y.

Theft-deterrent Horn Relay

The theft-deterrent horn relay is located in the BCM; for details refer to Section 12J Body Control Module.

Wipers, Washers and Horn Page 12N–15

Page 12N–15

2 Preliminary Test – Front Wipers

and Washers

2.1 Test Front Wipers and Washers

Assemblies

Introduction

The preliminary test is used to aid in localising the malfunction in the front wipers and washers wiring system and

confirms the serviceability of the wipers and washers control switch.

For a complete wiring diagram of the front wipers and washers wiring circuits, refer to:

• 3.2 Wiring Diagram – Front Wiper/Washer, Except Wagon and AWD Wagon, or

• 3.3 Wiring Diagram – Front Wiper/Washer, Wagon, or

• 3.4 Wiring Diagram – Front Wiper/Washer, AWD Wagon.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

1 Checks if the accessories operate. Isolates if the accessory control relay and/or associated circuits is at fault.

2 Checks if the wipers operate with the wipers and washers control s witch in position 1 and position 2.

3 Checks if the washers operate with the wipers functioning.

4 Checks if the wipers and washers control switch is serviceable. Isolates whether the wipers and washers control

switch or the washers wiring system is at fault.

5 Checks if the washers operate with the wipers not functioning.

6 Checks if the wipers and washers control switch is serviceable. Isolates whether the wipers and washers control

switch or the wipers wiring system is at fault.

7 Checks if the fuse F18 within the passenger compartment fuse and relay panel assembly is serviceable.

8 Checks if battery voltage is delivered to switch connector S247 – X1 pin 6, with the ignition switch in the ACC or

ON position. Isolates whether the battery power supply circuits 243 or 70 are at fault.

9 Checks if the wipers and washers control switch is serviceable. Isolates whether the wipers and washers control

switch or the wipers and washers wiring systems are at fault.

Diagnostic Table Notes

1 To diagnose the accessory control rel ay and associated wiring circuits, refer to Section 12J Body Control Module.

2 To test and/or replace the wipers and washers control switch,

refer to 16 Service Operations – Wipers and Washers Cont rol Switch.

3 To diagnose the front washers wiring system ,

refer to 3.8 Diagnose Front Washer Pump and Wiring System Malfunction.

4 To diagnose the front wipers wiring s ystem, refer to 3.6 Diagnose F r ont Wiper Motor Wiring System Malfunction.

5 Refer to Section 12O Fuses, Relays and Wiring Harnesses for harness routeing.

6 For wiring harness repairs, refer to Section 12P Wiring Diag rams.

Wipers, Washers and Horn Page 12N–16

Page 12N–16

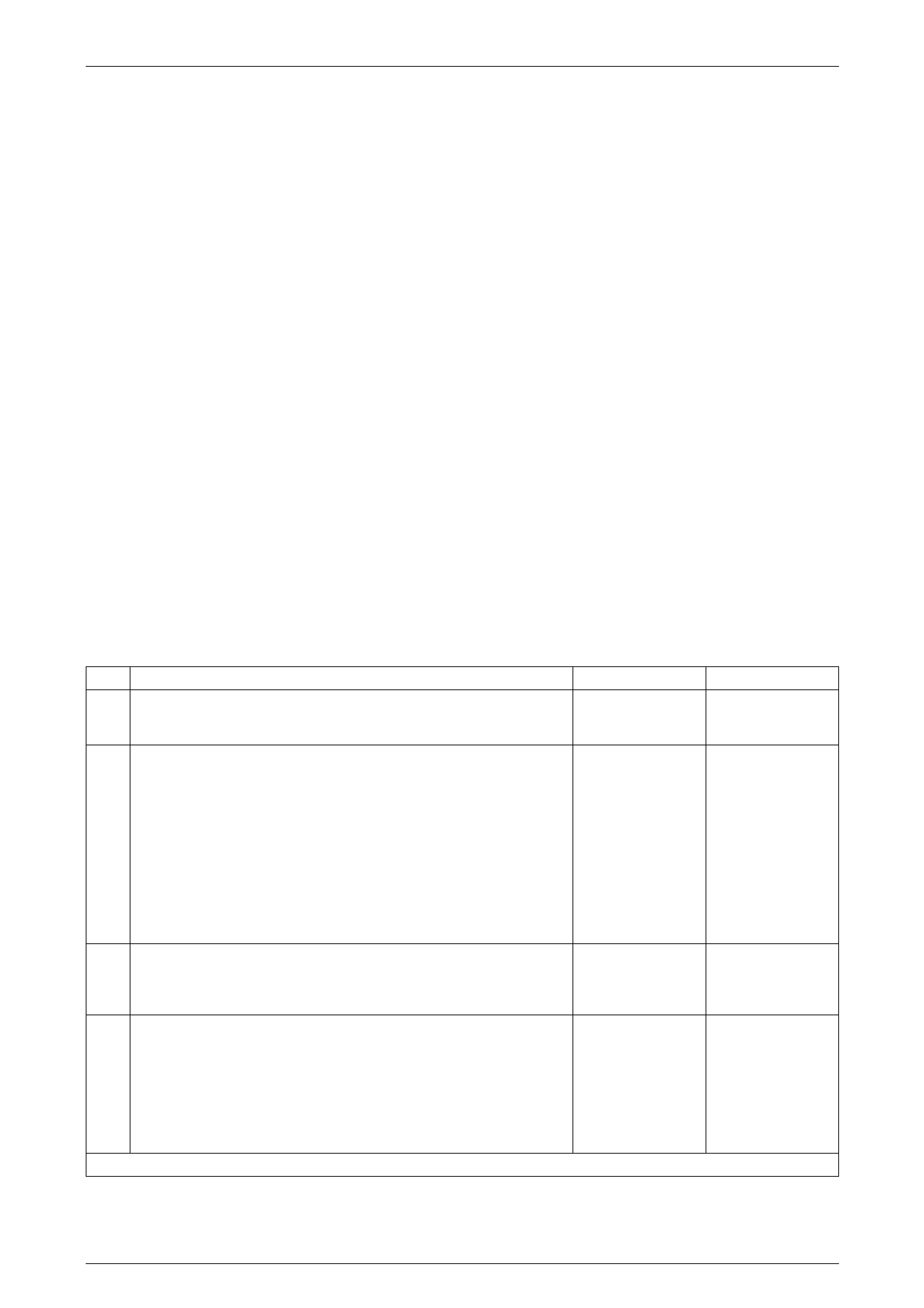

Diagnostic Table

Step Action Yes No

1 1 Switch the ignition to the ACC or ON position.

2 Check if the accessories operate (eg. radi o).

Do the accessories operate? Go to Step 2

Diagnose the

accessory control

relay and associated

circuits

(refer to Note 1)

2 With the ignition switch in the ACC or ON position, switch the wipers

and washers control switch in the position 1 then position 2.

Do the wipers operate, with the switch in both positions? Go to Step 3 Go to Step 5

3 With the ignition switch in the ACC or ON position, pull back and hold

the wipers and washers control switch.

Do the washers operate? System serviceable Go to Step 4

4 Test the wipers and washers control switch S247, (refer to Note 2).

Is the wipers and washers control s witch serviceable?

Diagnose the

washers wiring

system

(refer to Note 3)

Replace the wipers

and washers control

switch

(refer to Note 2)

5 With the ignition switch in the ACC or ON position, pull back and hold

the wipers and washers control switch.

Do the washers operate? Go to Step 6 Go to Step 7

6 Test the wipers and washers control switch S247, (refer to Note 2).

Is the wipers and washers control s witch serviceable? Diagnose the wipers

wiring system

(refer to Note 4)

Replace the wipers

and washers control

switch

(refer to Note 2)

7 Check the wipers and washers fuse F18 within the passenger

compartment fuse and relay panel assembly, (refer to Note 5).

Is the fuse serviceable?

Go to Step 8

Replace the fuse,

if the fuse blows

again check for a

short to ground in

circuit 243

(refer to Note 5)

8 1 Remove the wipers and washers control switch S247, (refer to

Note 2).

2 With the ignition switch in the ACC or ON position, backprobe

connector S247-X1 pin 6 with a test lamp.

Does the test lamp illuminate? Go to Step 9

Repair or replace

circuits 243 or 70

(refer to Note 6)

9 Test the wipers and washers control switch S247, (refer to Note 2).

Is the wipers and washers control s witch serviceable?

Diagnose the wipers

and the washers

wiring systems

(refer to Note 4 and

Note 3)

Replace the wipers

and washers control

switch

(refer to Note 2)

When all diagno sis an d repairs are completed, check the system for correct operati on.

Wipers, Washers and Horn Page 12N–17

Page 12N–17

3 Diagnostics – Front Wipers and

Washers

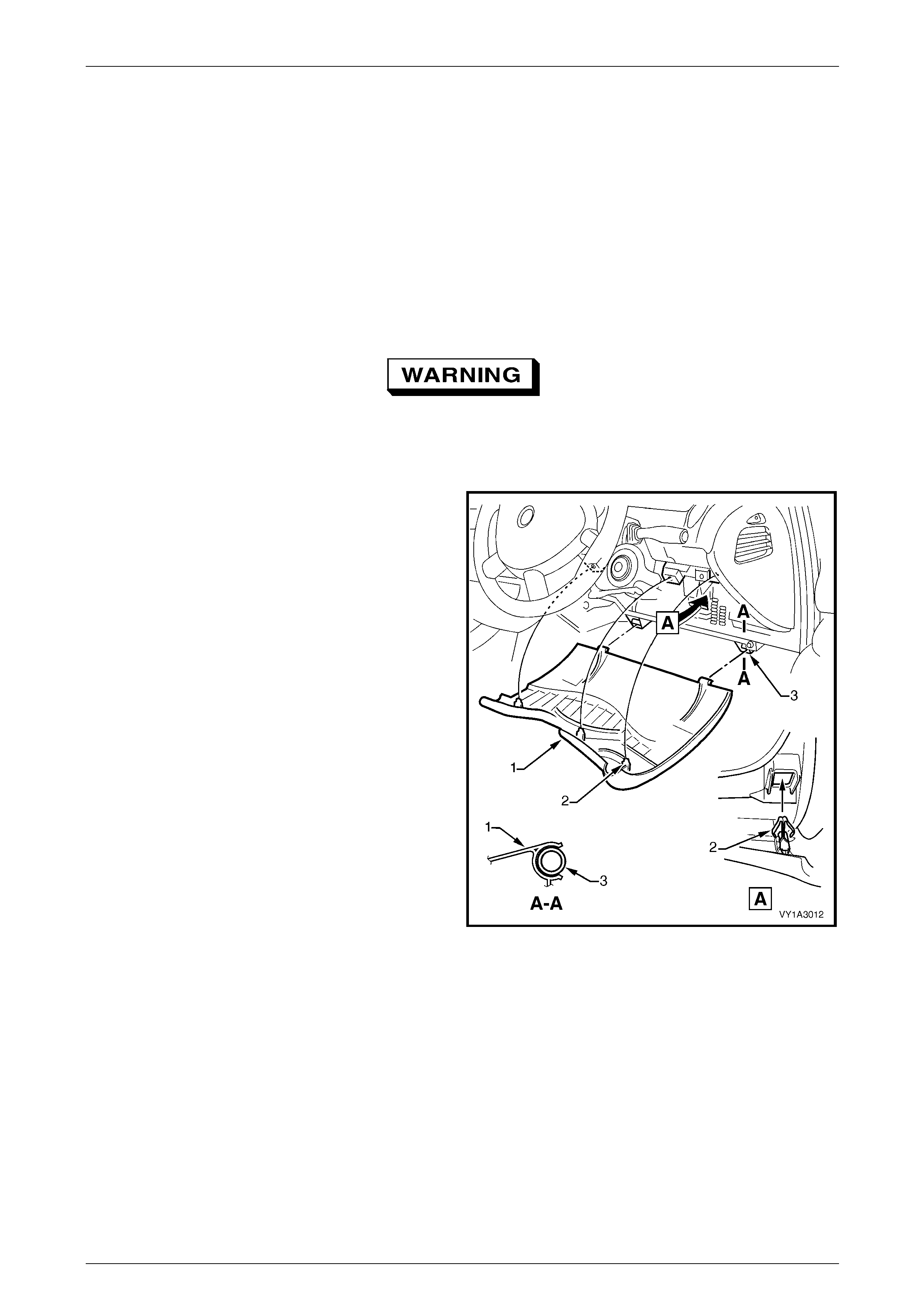

3.1 Prerequisites

Safety Requirements

When operating the front wipers and washers

as part of any steps in the diagnostic tables,

ensure that fingers and limbs are clear of

moving parts.

Equipment

The following equipment is required to diagnose the front wipers and washers:

• an unpowered test lamp with a current draw of less than 3 A, and

• a digital multimeter with a minimum impe dance of 10 MΩ.

Testing Procedures

Adhere to the following points when

performing diagnostic testing on

components:

• Take care when using testing equipment

to diagnose wiring harness connectors.

Backprobe the connector to avoid terminal

damage.

• When tests are required on connector

terminals, use the adapters in the

connector adapter kit KM–609 to prevent

damage to the terminals.

• Unless the multimeter being used has an

auto-ranging function, ensure the correct

range is selected.

• When backpro bing connectors, ensure the

test lamp ground lead is connected to an

appropriate ground point on the vehicle.

Ensure this ground point is not part of the

circuit being tested.

NOTE

Perform the front wipers and washers pr eliminary

test before diagnosing the wiring systems, refer

to 2.1 Test Front Wipers and Washers

Assemblies.

When following the steps in the di agnostic tables,

perform them in the order cited. If the required

nominal value or result is not achi eved, rectif y t he

problem before proceeding.

Wipers, Washers and Horn Page 12N–18

Page 12N–18

3.2 Wiring Diagram – Front Wiper/Washer,

Except Wagon and AWD Wagon

Figure 12N – 4

Wipers, Washers and Horn Page 12N–19

Page 12N–19

3.3 Wiring Diagram – Front Wiper/Washer,

Wagon

Figure 12N – 5

Wipers, Washers and Horn Page 12N–20

Page 12N–20

3.4 Wiring Diagram – Front Wiper/Washer,

AWD Wagon

Figure 12N – 6

Wipers, Washers and Horn Page 12N–21

Page 12N–21

3.5 Connector Diagrams – Front

Wiper/Washer

Figure 12N – 7

Wipers, Washers and Horn Page 12N–22

Page 12N–22

3.6 Diagnose Front Wiper Motor Wiring

System Malfunction

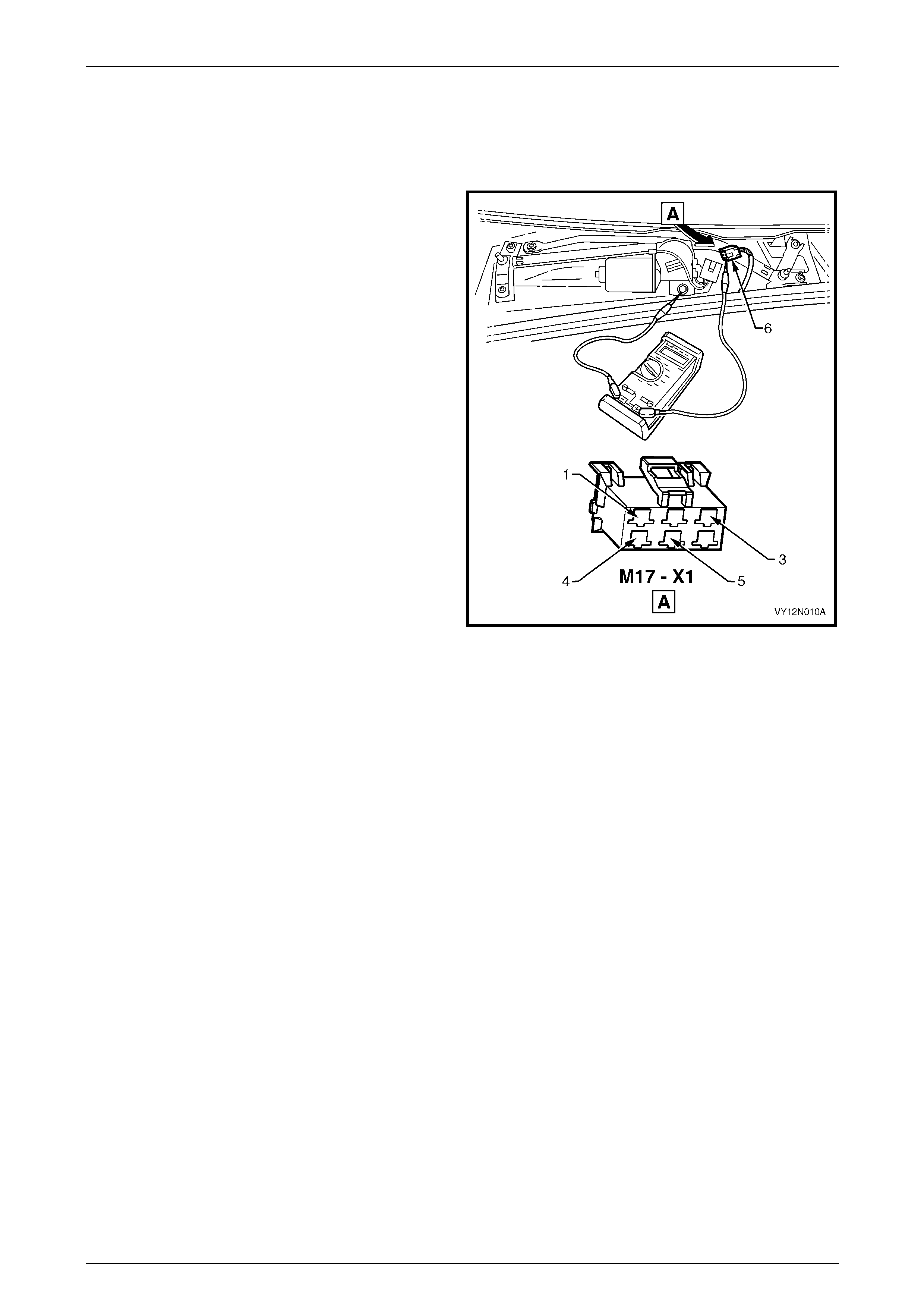

Introduction

The following operation checks the front wiper motor

assembly wiring at the front wiper motor connector

M17 – X1 (6), as an aid to diagnosing a fault in the front

wiper motor assembly system. This test confirms the

serviceability of the front wiper motor assembly wiring

system.

For a complete wiring diagram of the front wiper motor

assembly circuits, refer to:

• 3.2 Wiring Diagram – Front Wiper/Washer, Except

Wagon and AWD Wagon, or

• 3.3 Wiring Diagram – Front Wiper/Washer, Wagon, or

• 3.4 Wiring Diagram – Front Wiper/Washer, AWD

Wagon.

For connector pin location,

refer to: 3.5 Connector Diagrams – Front Wiper/W asher.

NOTE

The operation of the front wiper intermittent dwell

is controlled by the body co ntrol module A 15 and

can be checked with a Tech 2, refer to

Section 12J Body Control Module.

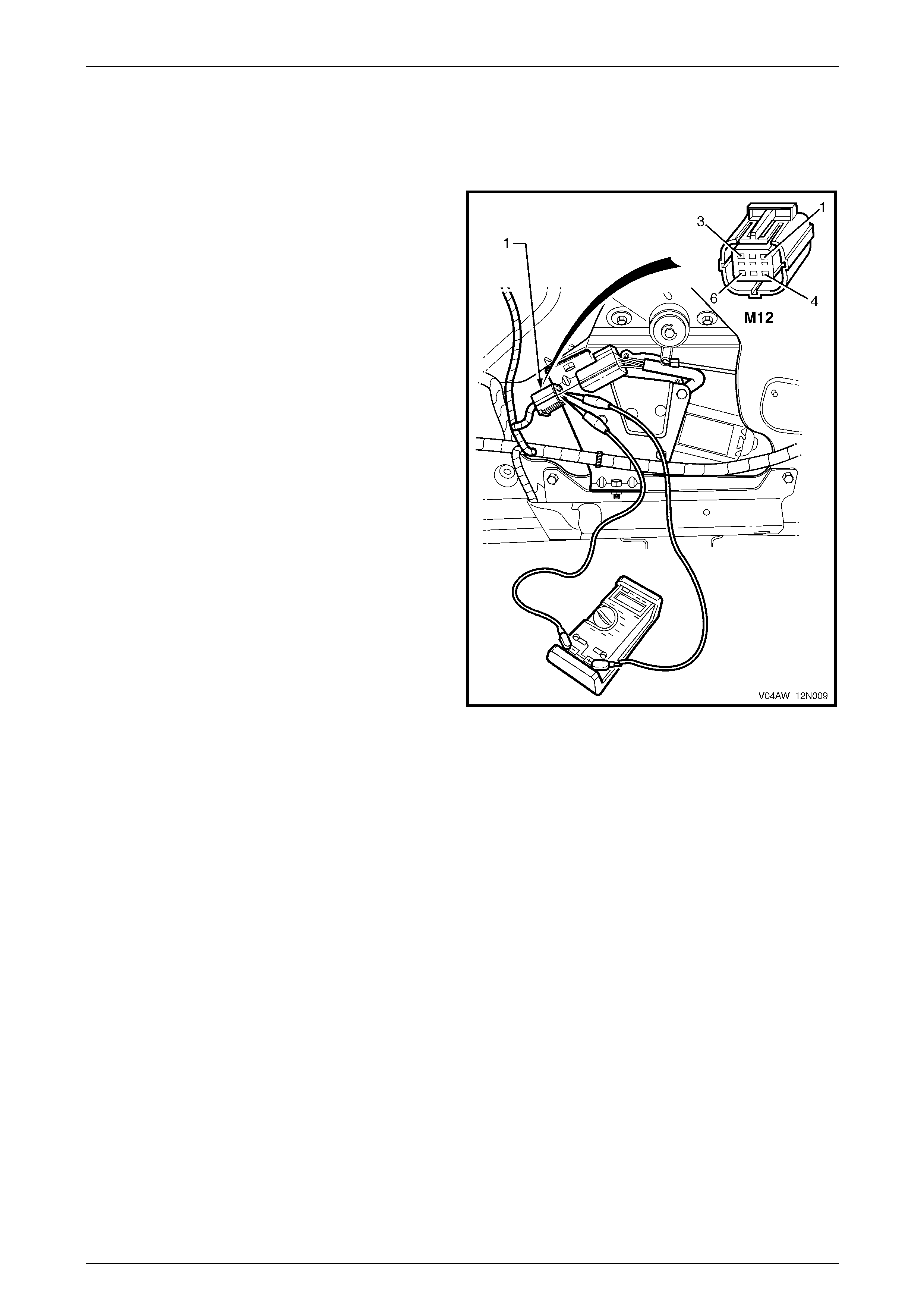

Figure 12N – 8

Electrical Test Description

The following numbers refer to the step numbers in the diagnostic table:

1 Checks if the front wipers and washers preliminary test has been performed.

2 Checks if battery voltage is delivered to connector M17 – X1 pin 3, with the ignition switch in the ACC or ON

position. Isolates if the battery po wer supply circuit 243 is at fault.

3 Checks if battery voltage is delivered to connector M17 – X1 pin 1, with the ignition switch in the ACC or ON

position and the wipers and washers control switch in position 1 (low speed).

4 Checks if the front wiper motor assembly ground circuit is serviceable. Isolates if the front wiper motor assembly

ground circuit 550 is at fault.

5 Checks if the front wiper motor assembly M17 is serviceable.

6 Checks if battery voltage is delivered to connector M17 – X1 pin 1, with the ignition switch in the ACC or ON

position and the wipers and washers control switch in position 1 (low speed). Isolates if the battery power supply

circuit 95 is at fault.

7 Checks if battery voltage is delivered to connector M17 – X1 pin 2, with the ignition switch in the ACC or ON

position and the wipers and washers control switch in position 2 (high speed). Isolates if the battery power supply

circuit 92 is at fault.

8 Checks if battery voltage is delivered to connector M17 – X1 pin 1, with the ignition switch in the ACC or ON

position and the wipers and washers control switch in INT position. Isolates whether the battery power supply

circuit 96 or 112 is at fault.

9 Checks if the front wiper motor assembly circuit 196 is serviceable. Isolates if the front wiper motor assembly

circuit 196 is at fault.

Wipers, Washers and Horn Page 12N–23

Page 12N–23

Diagnostic Table Notes

1 To perform the front wipers and washers preliminary test, refer to 2.1 Test Front Wipers and Washers Assemblies.

2 For removal of the front wiper arm assemblies, plenum cove r assembly and replacement of the front wiper motor

assembly, refer to:

• 8 Service Operations – Front Wiper Assemblies, Except Coupe, or

• 9 Service Operations – Front Wiper Assemblies, Coupe.

3 For all wiring harness fault diagnosis, refer to Section 12P Wiring Diagrams.