HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-1

Page 2A-1

Section 2A

HVAC Climate Control (Manual A/C) –

Description and Operation

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and / or property damage.

1 General Information ...............................................................................................................................4

1.1 Caution Label......................................................................................................................................................... 4

2 General Description ...............................................................................................................................5

2.1 Air Flow................................................................................................................................................................... 5

Sedan...................................................................................................................................................................... 5

Wagon..................................................................................................................................................................... 6

Coupe...................................................................................................................................................................... 7

Utility....................................................................................................................................................................... 8

Regular Cab............................................................................................................................................................ 9

Crew Cab .............................................................................................................................................................. 10

2.2 HVAC Inlet and Outlet Ducts............................................................................................................................... 11

Inlet ....................................................................................................................................................................... 11

Air Distribution Ducts.......................................................................................................................................... 12

Sedan, Wagon, Coupe and Crew Cab............................................................................................................. 12

Utility and Regular Cab .................................................................................................................................... 13

Cabin Ventilation Outlets .................................................................................................................................... 14

Sedan, Wagon, Coupe and Crew Cab............................................................................................................. 14

Utility and Regular Cab .................................................................................................................................... 15

Body Ventilation Outlets..................................................................................................................................... 16

Sedan............................................................................................................................................................... 16

Wagon.............................................................................................................................................................. 16

Coupe............................................................................................................................................................... 17

Utility ................................................................................................................................................................ 17

Regular Cab and Crew Cab ............................................................................................................................. 18

Outlet Assembly............................................................................................................................................... 19

2.3 HVAC Controller – Manual A/C........................................................................................................................... 20

Configuration ....................................................................................................................................................... 20

Functions.............................................................................................................................................................. 21

A/C Switch........................................................................................................................................................ 21

Heated Rear Window Switch............................................................................................................................ 21

Blower Fan Switch............................................................................................................................................ 22

Temperature Control........................................................................................................................................ 22

Manual Mode Control Symbols........................................................................................................................... 22

Components and Construction .......................................................................................................................... 23

Exploded View.................................................................................................................................................. 24

Electrical Connections ........................................................................................................................................ 25

Connector X1................................................................................................................................................... 25

Connector X2................................................................................................................................................... 25

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-2

Page 2A-2

2.4 Heater.................................................................................................................................................................... 26

Temperature Control Switch – Manual A/C........................................................................................................ 26

Air Mix Door Control Mechanism – Manual A/C................................................................................................ 26

Water Valve Assembly – V6 ................................................................................................................................ 27

Water Valve Assembly – GEN III V8.................................................................................................................... 27

Heater Operation – Manual A/C – V6.................................................................................................................. 28

Full Cold........................................................................................................................................................... 28

Warm................................................................................................................................................................ 29

Full Hot............................................................................................................................................................. 30

Heater Operation – Auto A/C – V6...................................................................................................................... 31

Full Cold........................................................................................................................................................... 31

Warm................................................................................................................................................................ 32

Full Hot............................................................................................................................................................. 33

Heater Operation – Manual A/C – GEN III V8 ..................................................................................................... 34

Full Cold........................................................................................................................................................... 34

Warm................................................................................................................................................................ 35

Full Hot............................................................................................................................................................. 36

Heater Operation – Auto A/C – GEN III V8 ......................................................................................................... 37

Full Cold........................................................................................................................................................... 37

Warm................................................................................................................................................................ 38

Full Hot............................................................................................................................................................. 39

Under-hood Heater Components – V6............................................................................................................... 40

Under-hood Heater Components – GEN III V8................................................................................................... 41

2.5 Air-conditioning Refrigerant Circuit................................................................................................................... 42

2.6 Vacuum Circuit..................................................................................................................................................... 43

Vacuum Mode Switch and Vacuum Lines – Manual A/C.................................................................................. 43

Solenoid Pack and Vacuum Lines – Auto A/C................................................................................................... 44

Vacuum Circuit Schematic – Manual A/C.......................................................................................................... 45

Vacuum Circuit Schematic – Auto A/C .............................................................................................................. 46

2.7 HVAC Unit Airflow Modes – Manual A/C............................................................................................................ 47

HVAC Flow Diagrams .......................................................................................................................................... 47

Recirculation Mode............................................................................................................. ................................. 48

Full Cold........................................................................................................................................................... 48

Full Heat........................................................................................................................................................... 48

Face Mode ............................................................................................................................................................ 49

Full Cold........................................................................................................................................................... 49

Full Heat........................................................................................................................................................... 49

Bi-level Mode........................................................................................................................................................ 50

Full Cold........................................................................................................................................................... 50

Full Heat........................................................................................................................................................... 50

Floor Mode............................................................................................................................................................ 51

Full Cold........................................................................................................................................................... 51

Full Heat........................................................................................................................................................... 51

Blend Mode........................................................................................................................................................... 52

Full Cold........................................................................................................................................................... 52

Full Heat........................................................................................................................................................... 52

Demist Mode......................................................................................................................................................... 53

Full Heat and A/C Activated ............................................................................................................................. 53

Default Mode ........................................................................................................................................................ 54

Loss of Vacuum Supply to HVAC Unit ............................................................................................................. 54

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-3

Page 2A-3

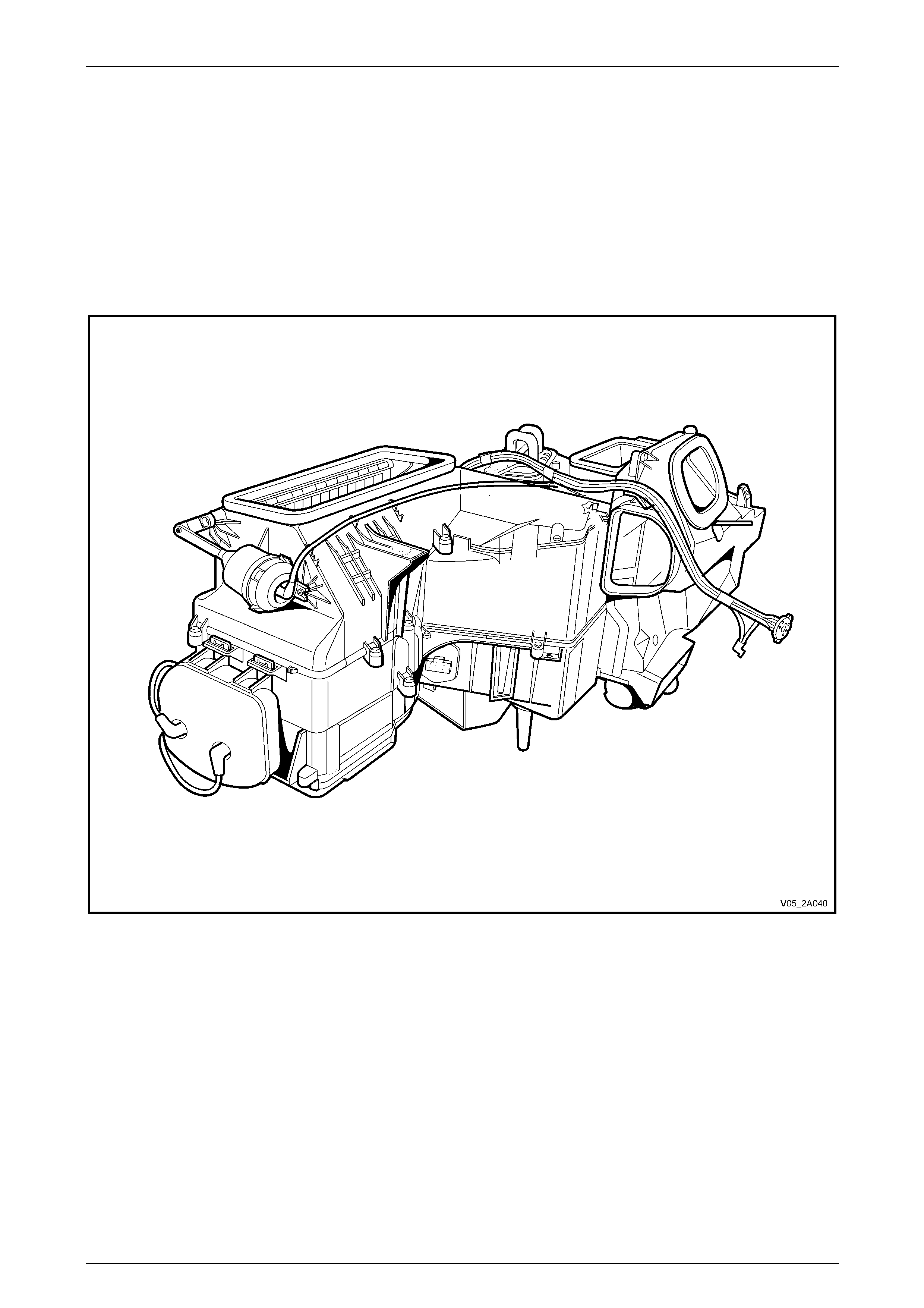

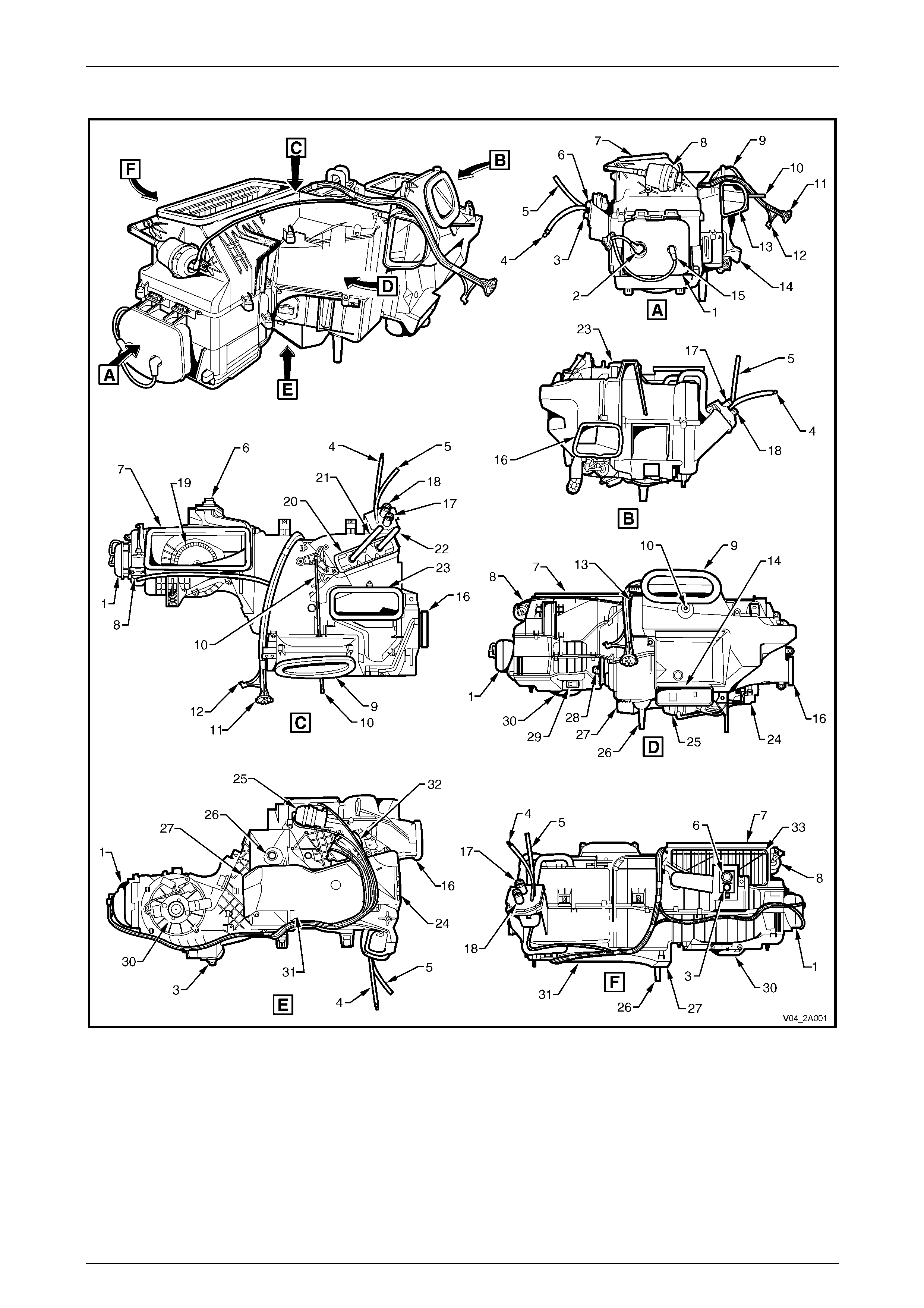

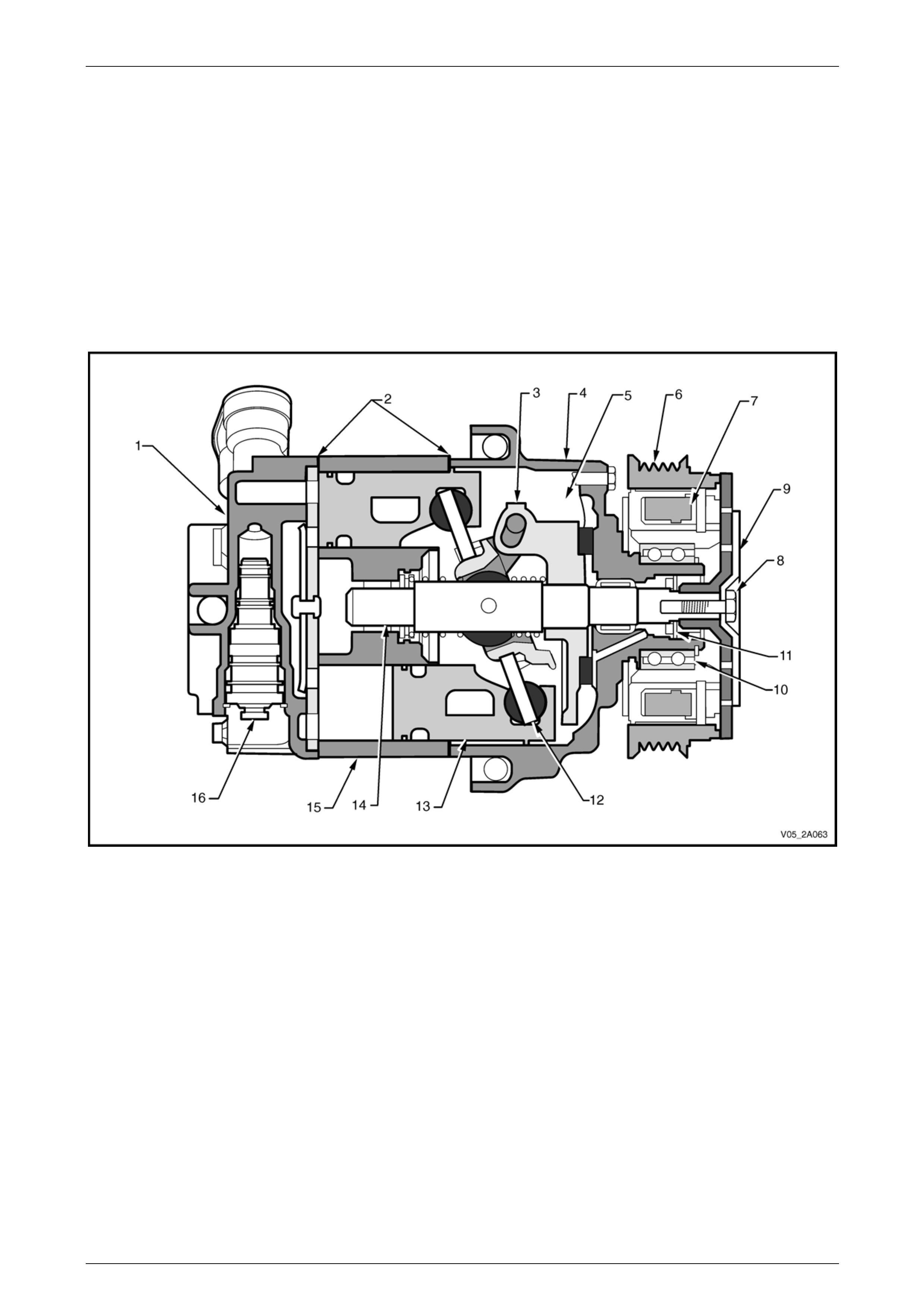

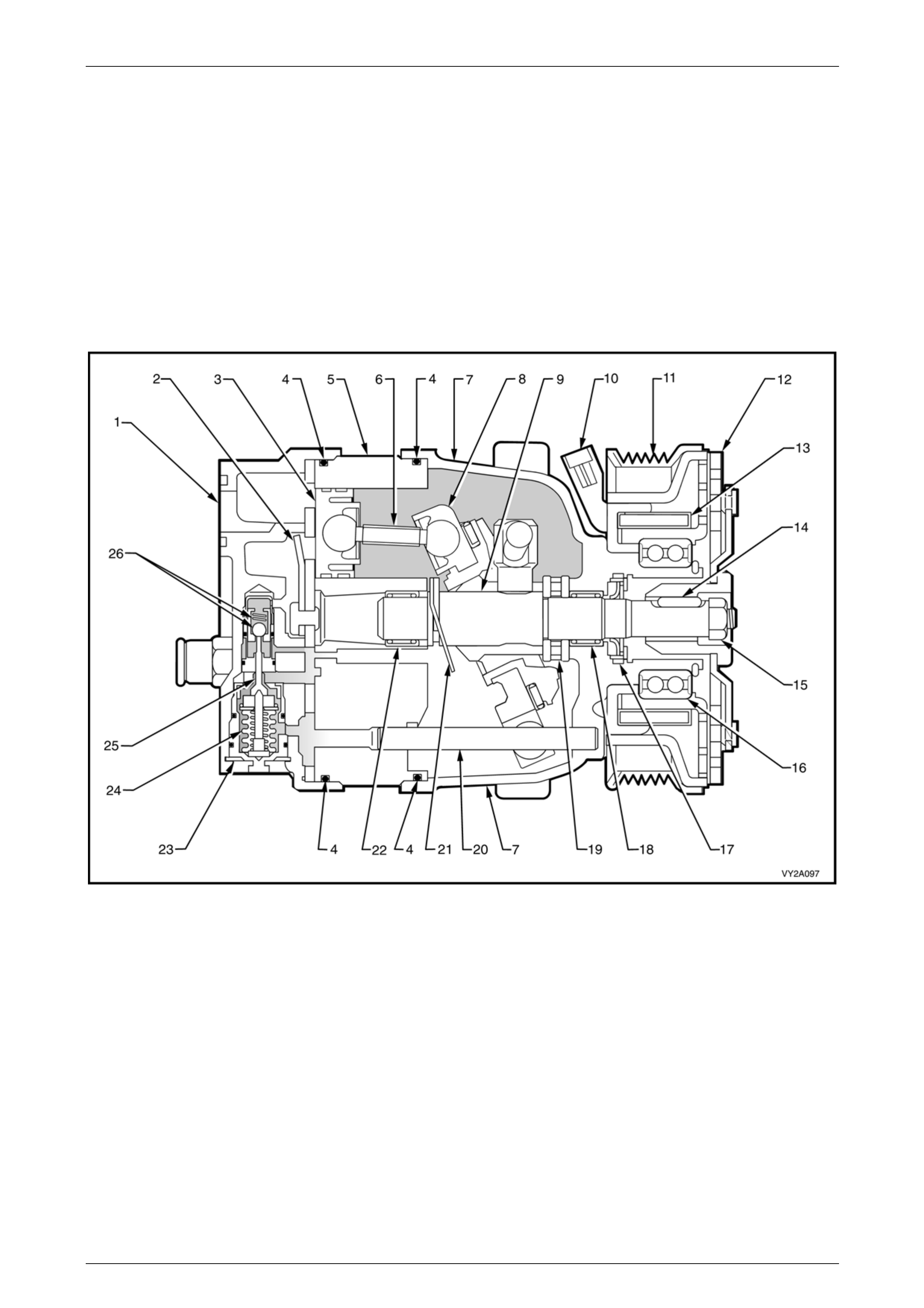

2.8 Heating, Ventilation and Air-conditioning (HVAC) Unit.................................................................................... 55

General Description – Manual A/C ..................................................................................................................... 55

Assembled Views – Manual A/C...................................................................................................................... 56

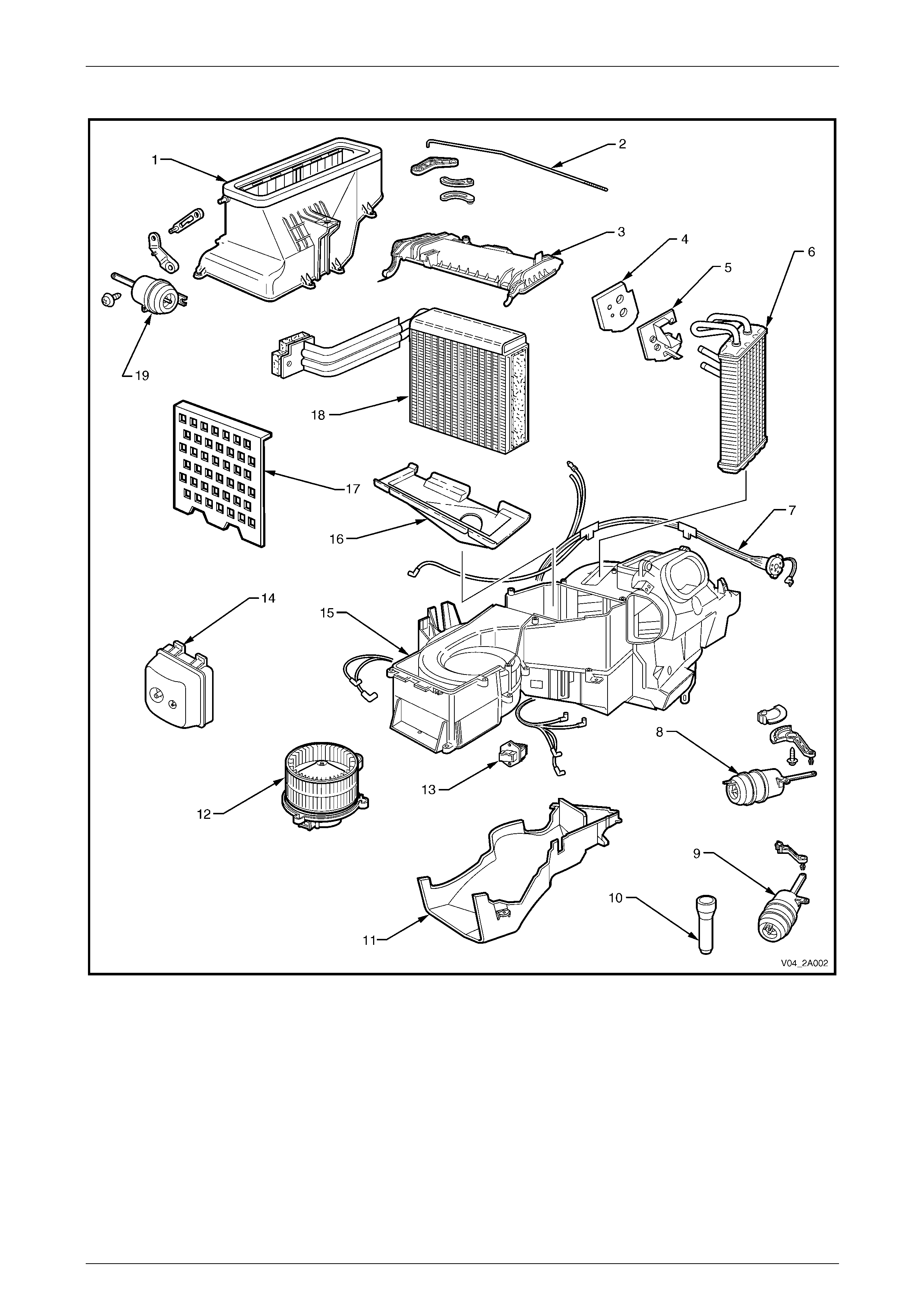

Exploded View – Manual A/C........................................................................................................................... 58

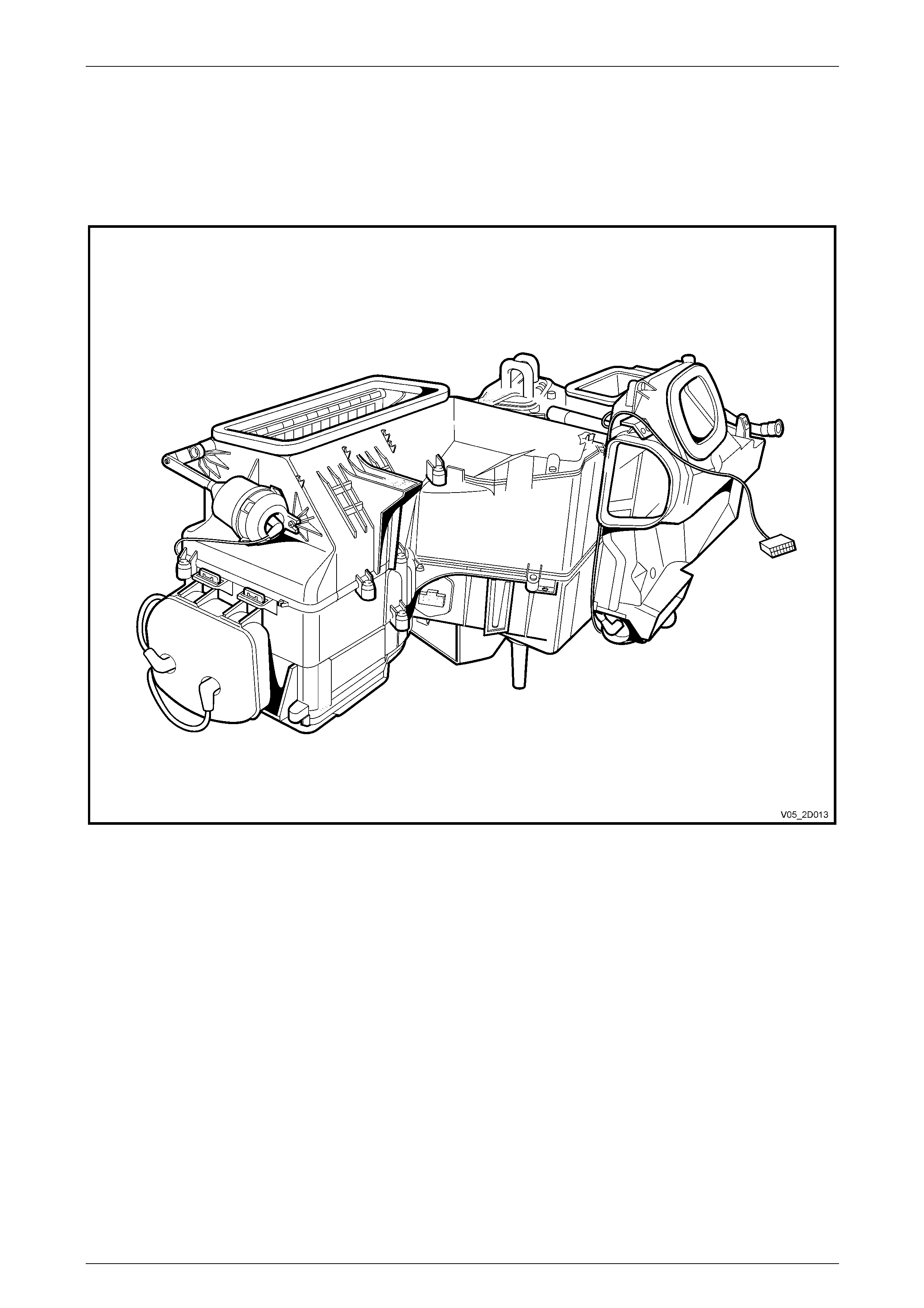

General Description – Auto A/C.......................................................................................................................... 59

Assembled Views – Auto A/C........................................................................................................................... 60

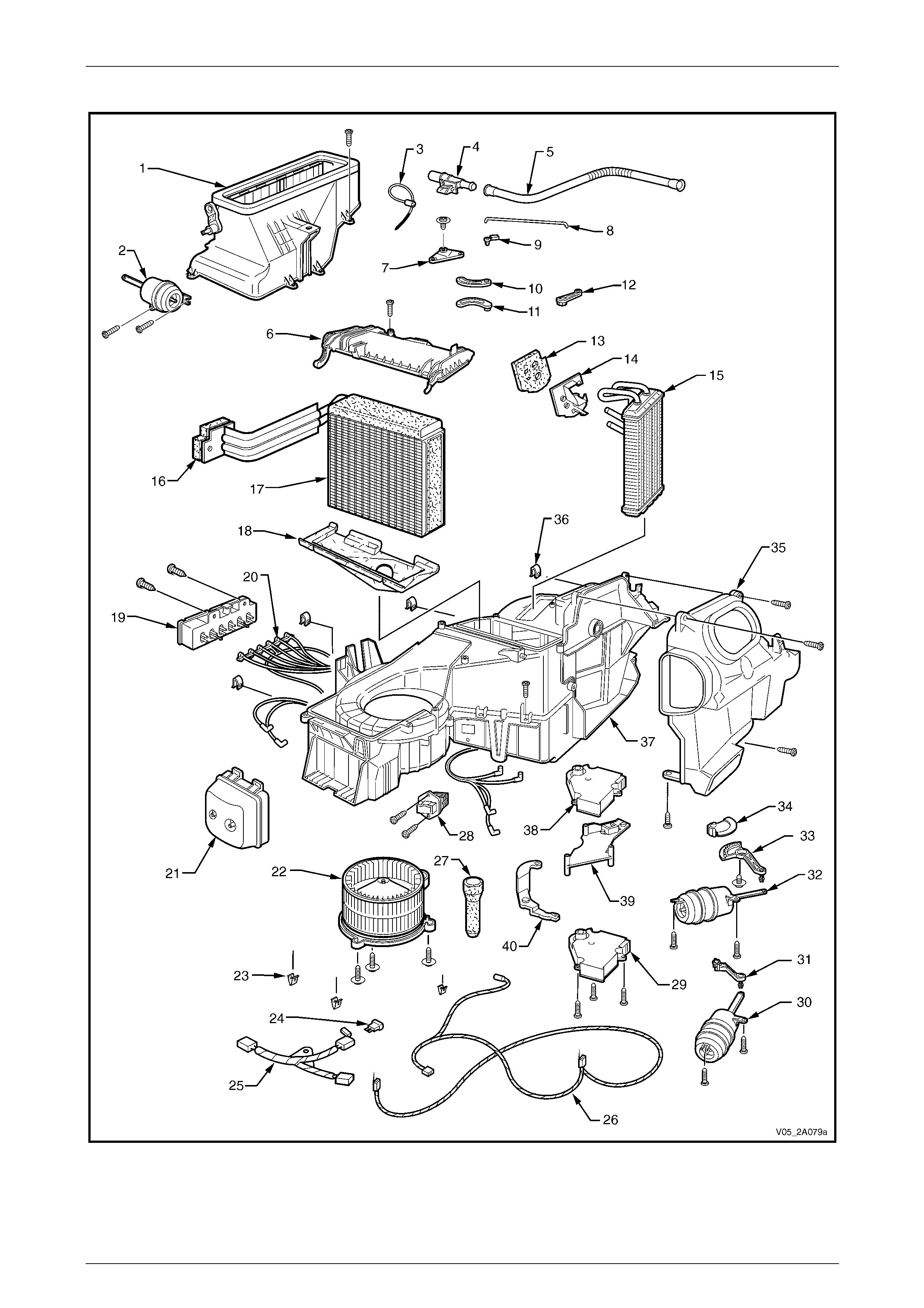

Exploded View – Auto A/C............................................................................................................................... 62

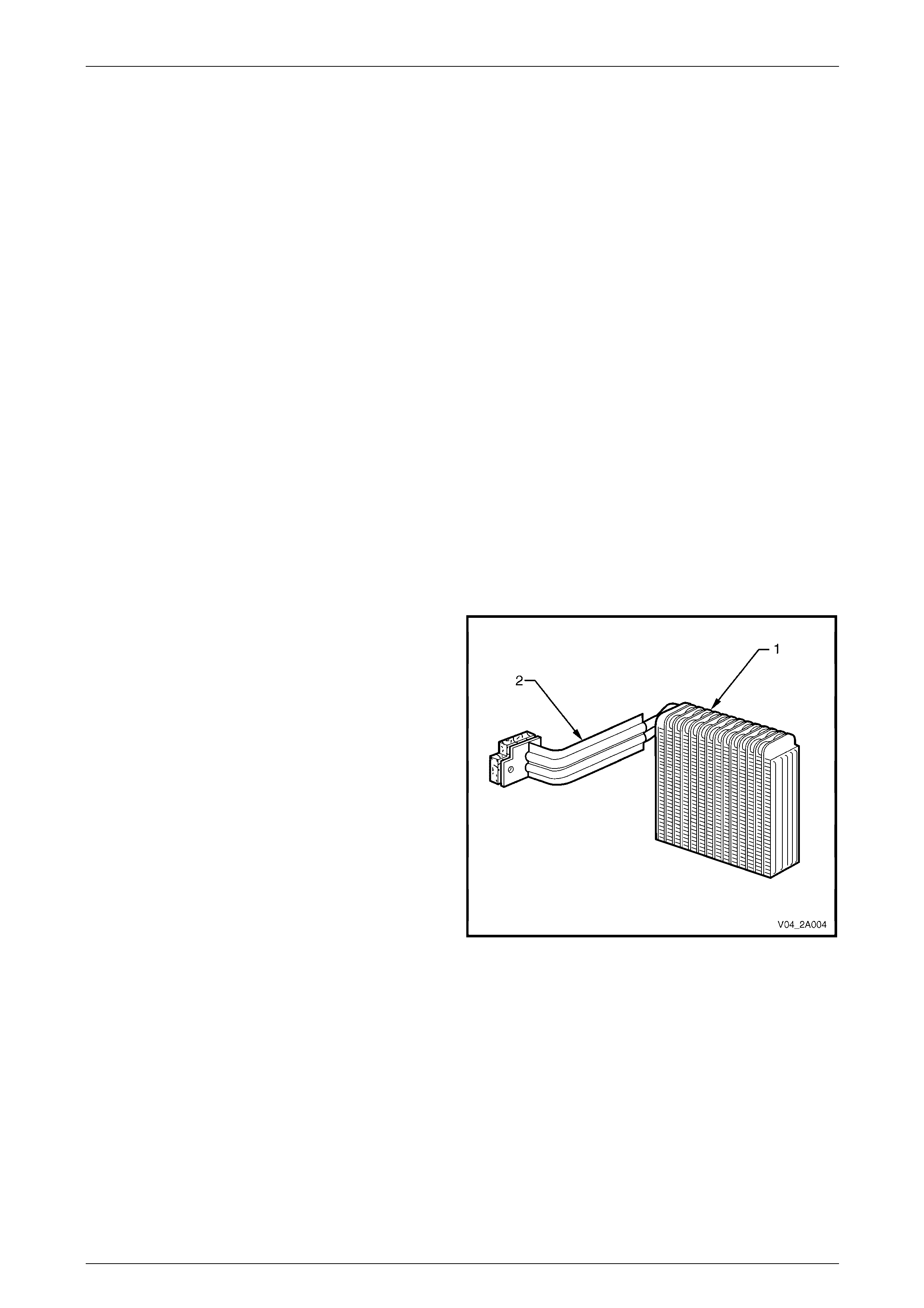

Evaporator............................................................................................................................................................ 63

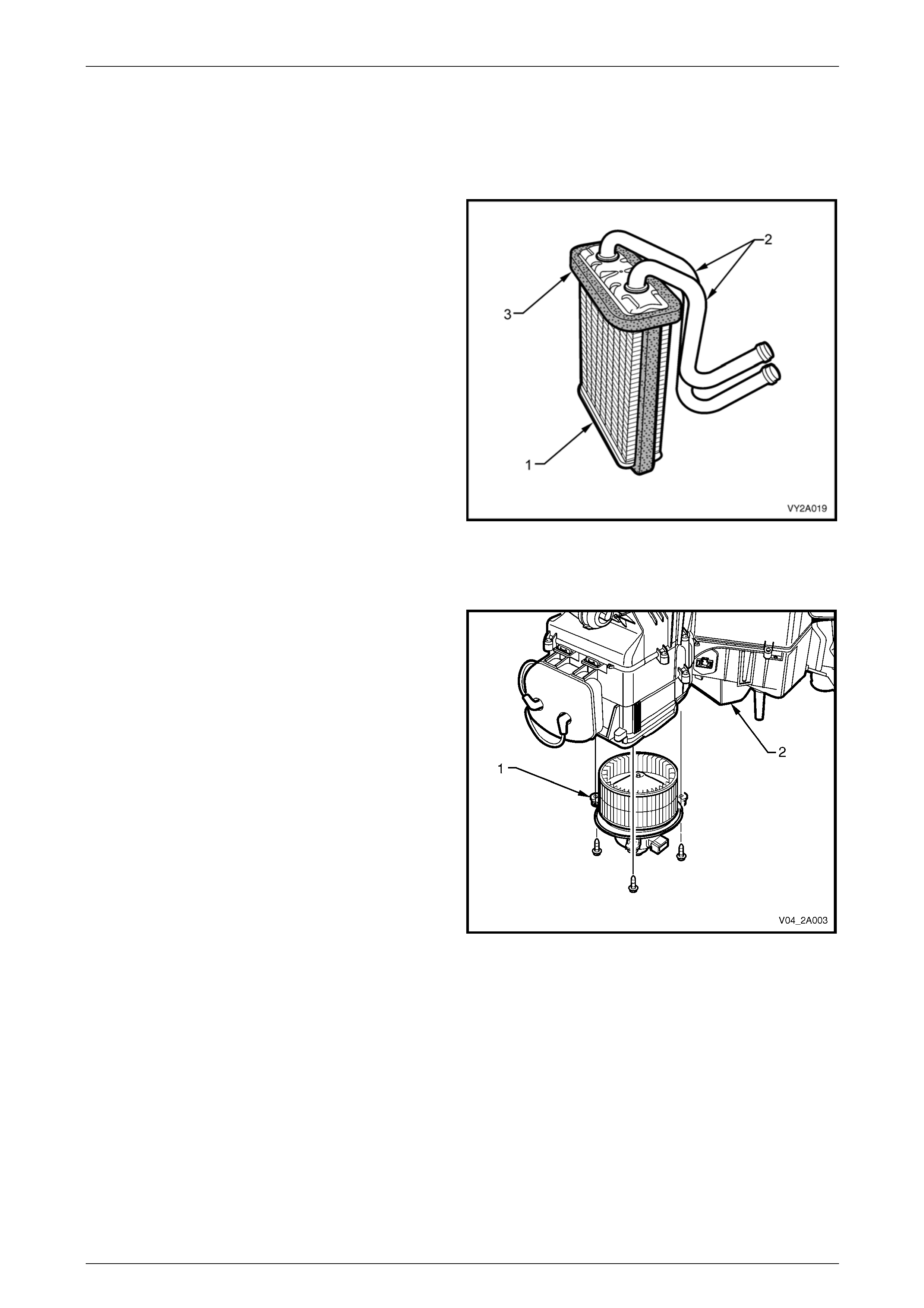

Heater Core........................................................................................................................................................... 64

Blower Motor and Fan Assembly ....................................................................................................................... 64

Blower Motor Resistor Assembly – Manual A/C ............................................................................................... 65

Electronic Blower Motor Controller – Auto A/C ................................................................................................ 65

Air Mix Doors – Manual A/C................................................................................................................................ 66

Air Mix Doors and Motor – Auto A/C.................................................................................................................. 68

Air Mix Doors.................................................................................................................................................... 68

Air Mix Door Motor ........................................................................................................................................... 68

Motor and Door Configurations ........................................................................................................................ 68

Air Mix Door Motor/Door Calibration................................................................................................................. 69

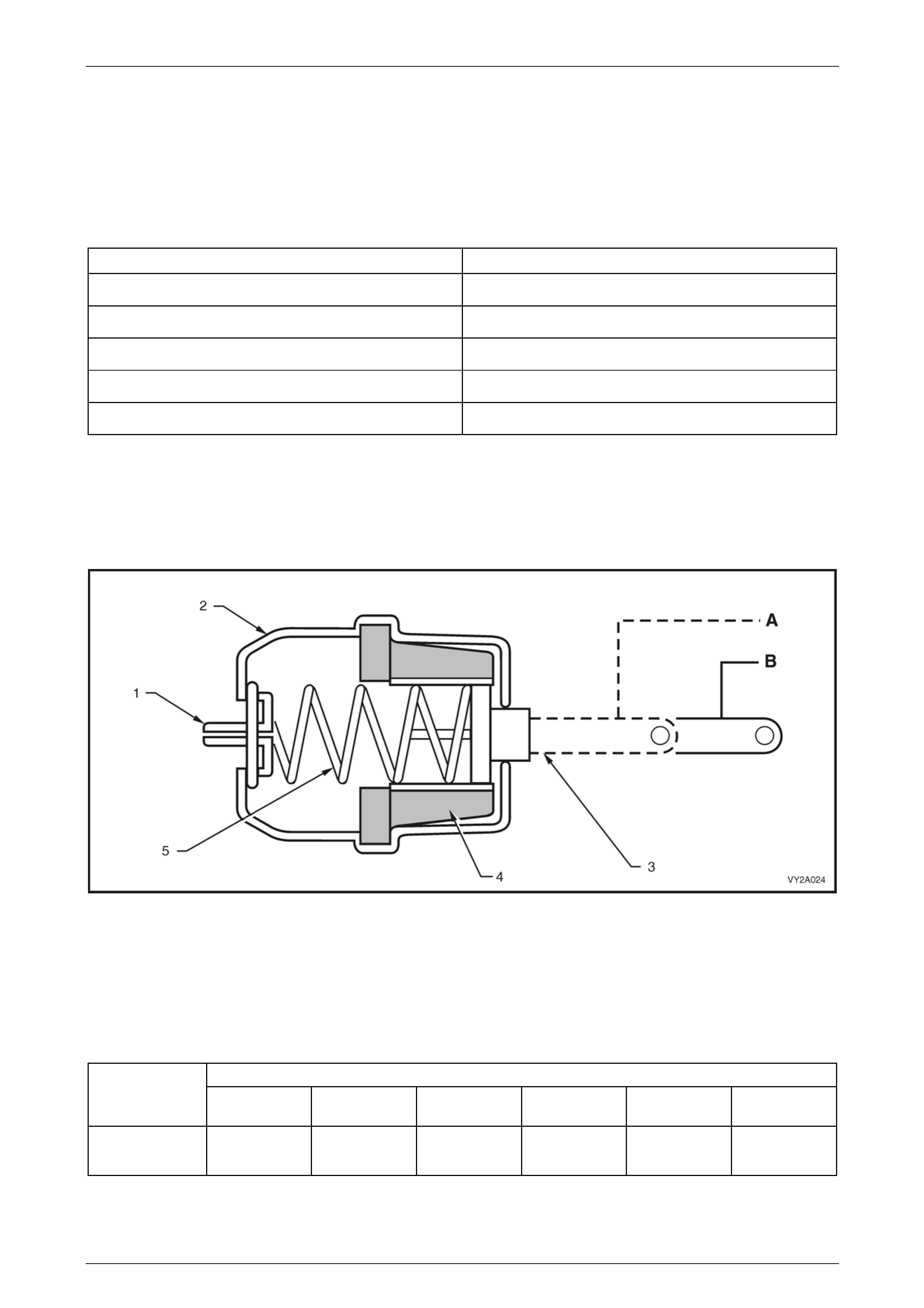

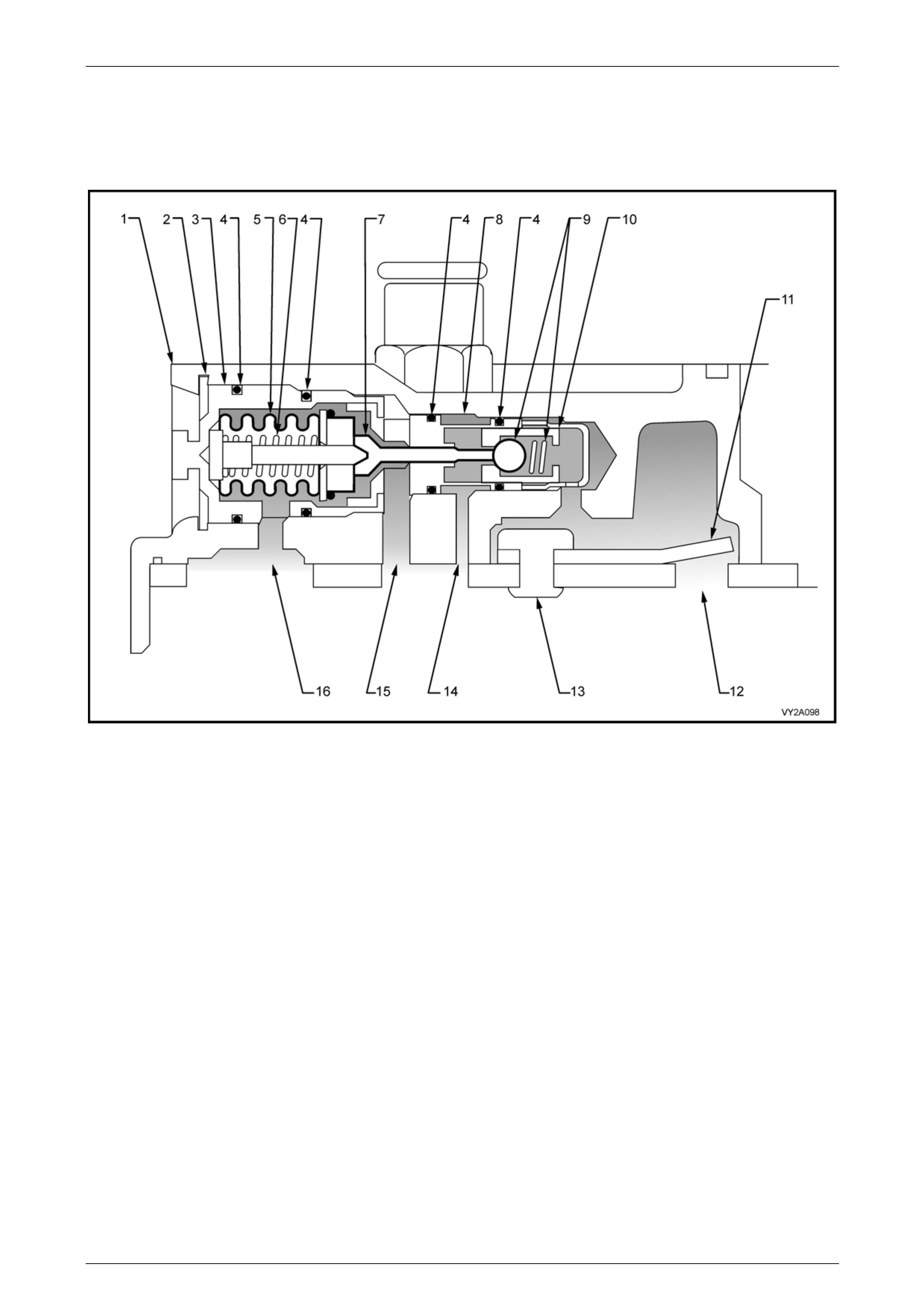

Vacuum Actuators............................................................................................................................................... 70

Single-stage Actuator....................................................................................................................................... 70

Two-stage Actuators ........................................................................................................................................ 71

Vacuum Solenoid Pack – Auto A/C.................................................................................................................... 72

Vacuum Tank – Manual A/C................................................................................................................................ 72

Vacuum Tank – Auto A/C .................................................................................................................................... 73

Vacuum Tank Check Valve ................................................................................................................................. 73

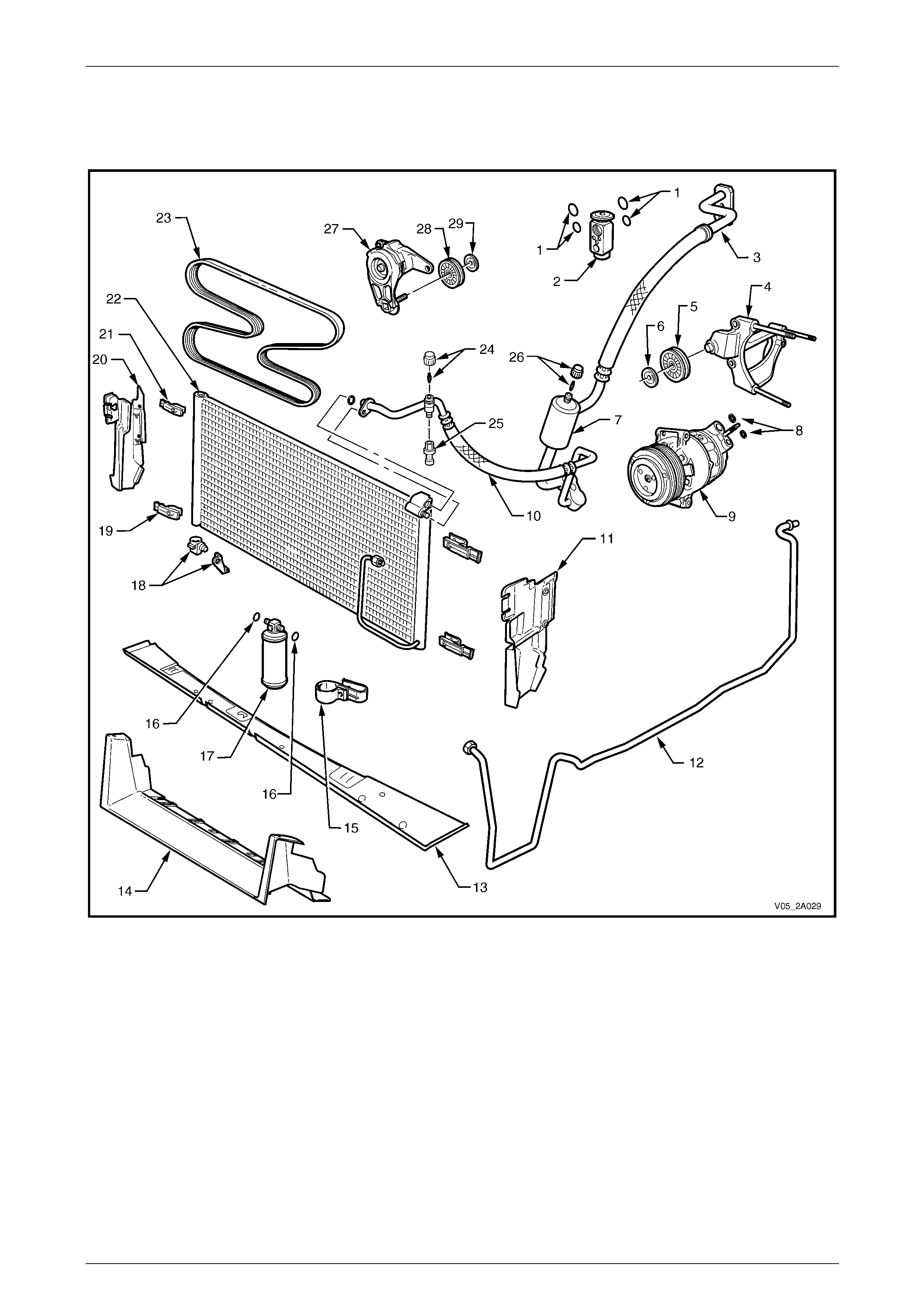

2.9 Under-hood Components.................................................................................................................................... 74

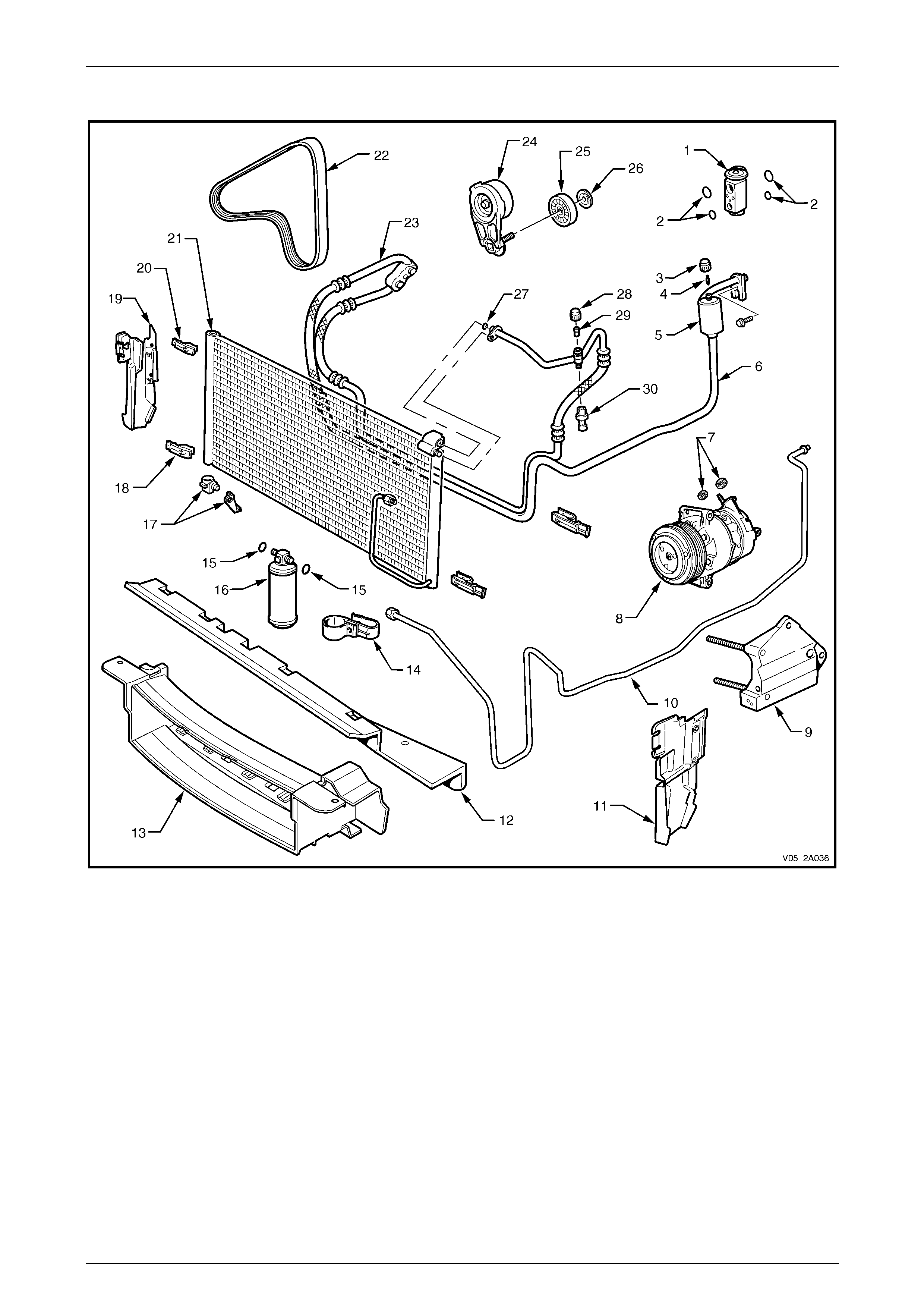

Under-hood Air-conditioning Components – V6............................................................................................... 74

Under-hood Air-conditioning Components – V6 – AWD .................................................................................. 75

Under-hood Air-conditioning Components – GEN III V8.................................................................................. 76

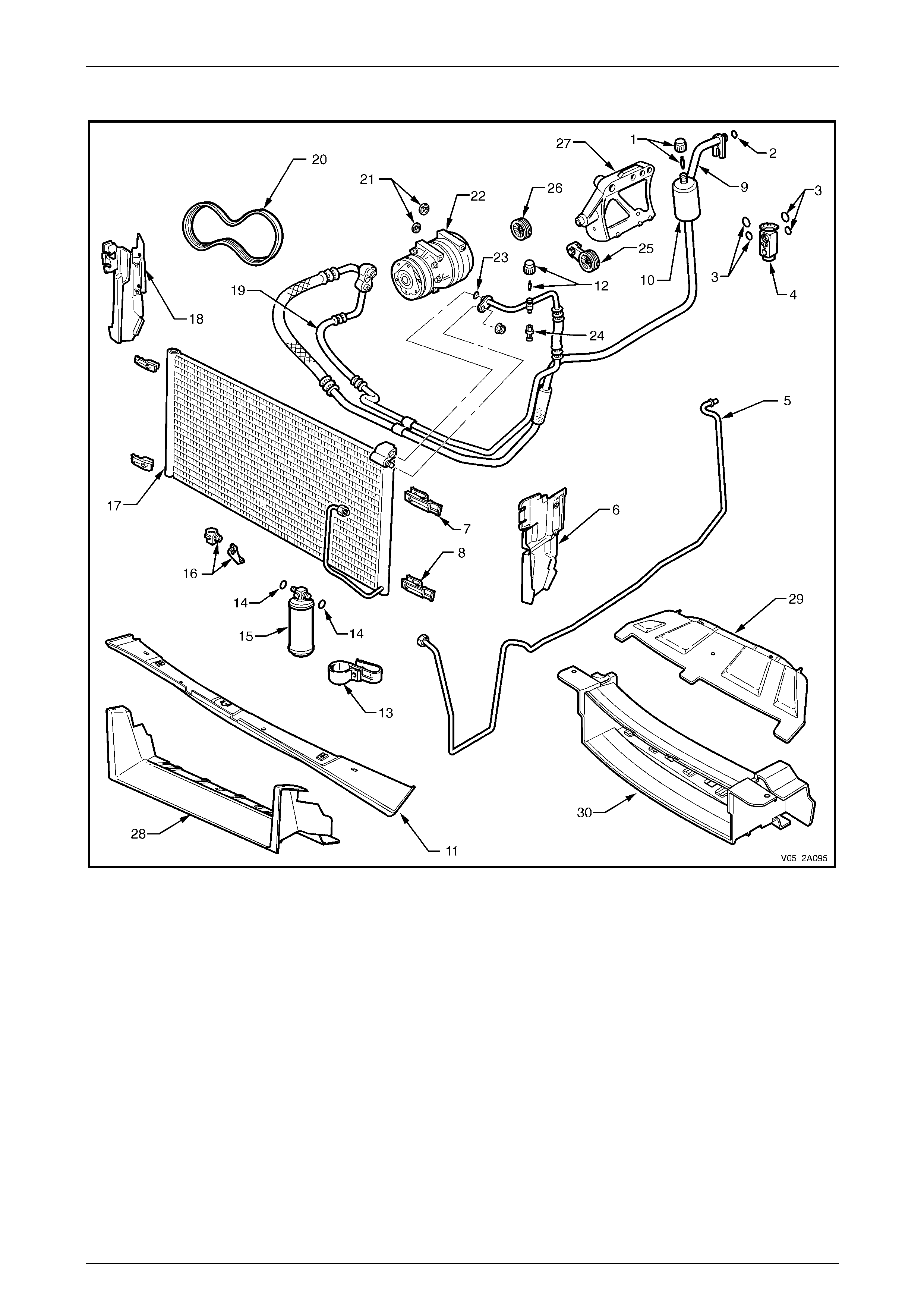

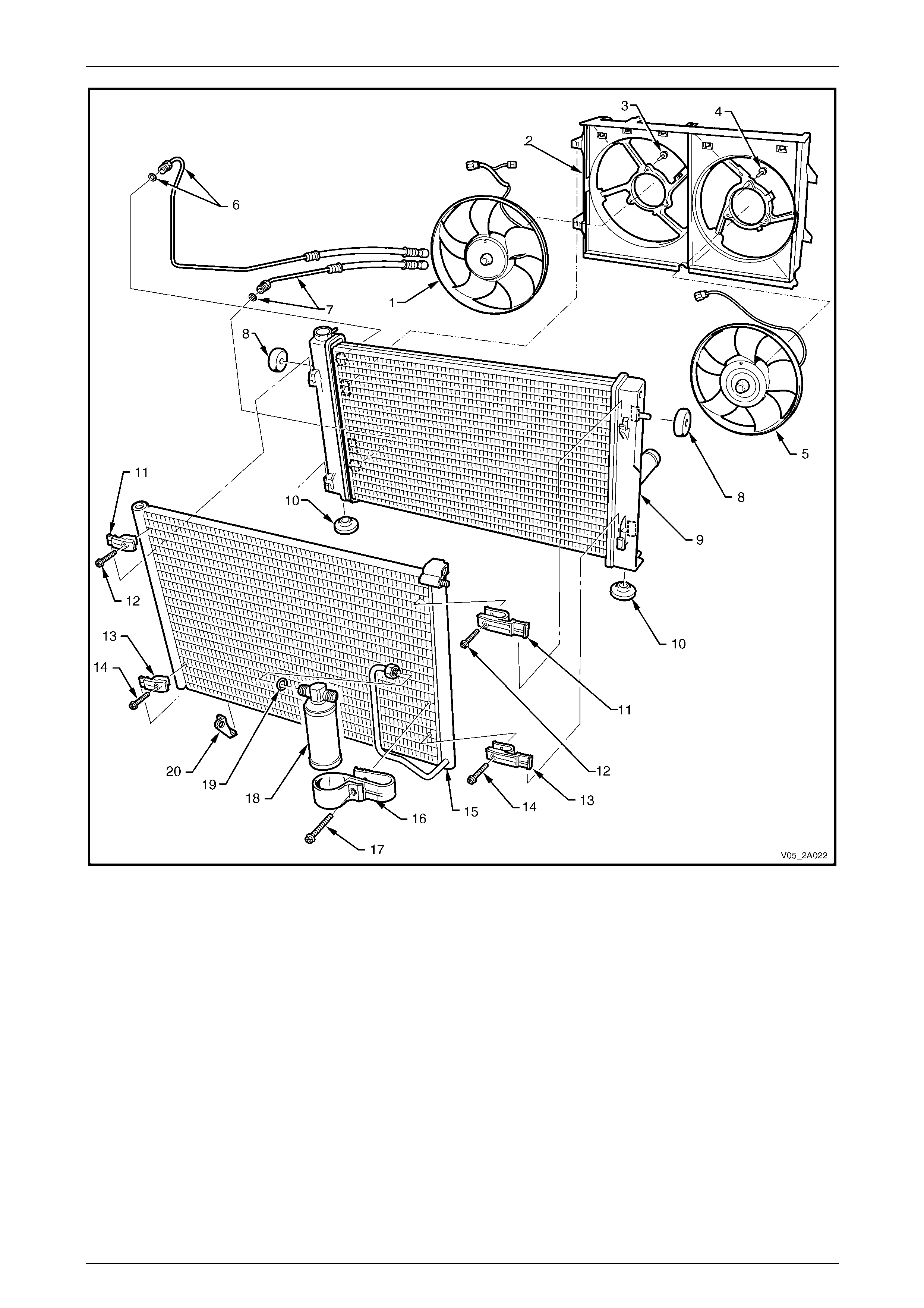

Condenser, Radiator and Fan Module ............................................................................................................... 77

Condenser........................................................................................................................................................ 79

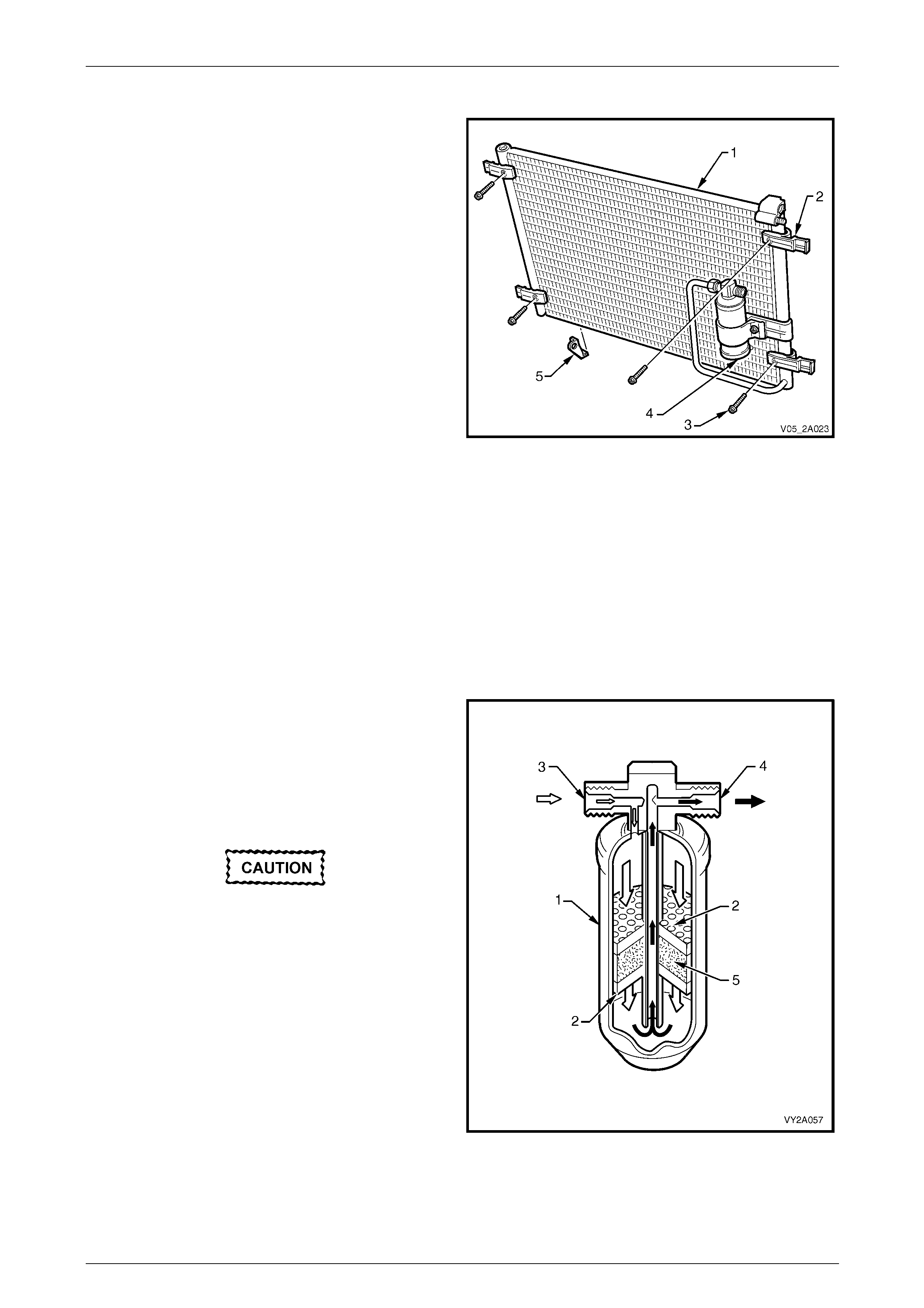

Filter Drier Receiver ......................................................................................................................................... 79

A/C Pressure Transducer.................................................................................................................................... 80

V6 Engine......................................................................................................................................................... 80

GEN III V8 Engine............................................................................................................................................ 81

Specification Table........................................................................................................................................... 81

Thermostatic Expansion Valve........................................................................................................................... 82

Opening............................................................................................................................................................ 82

Closing............................................................................................................................................................. 83

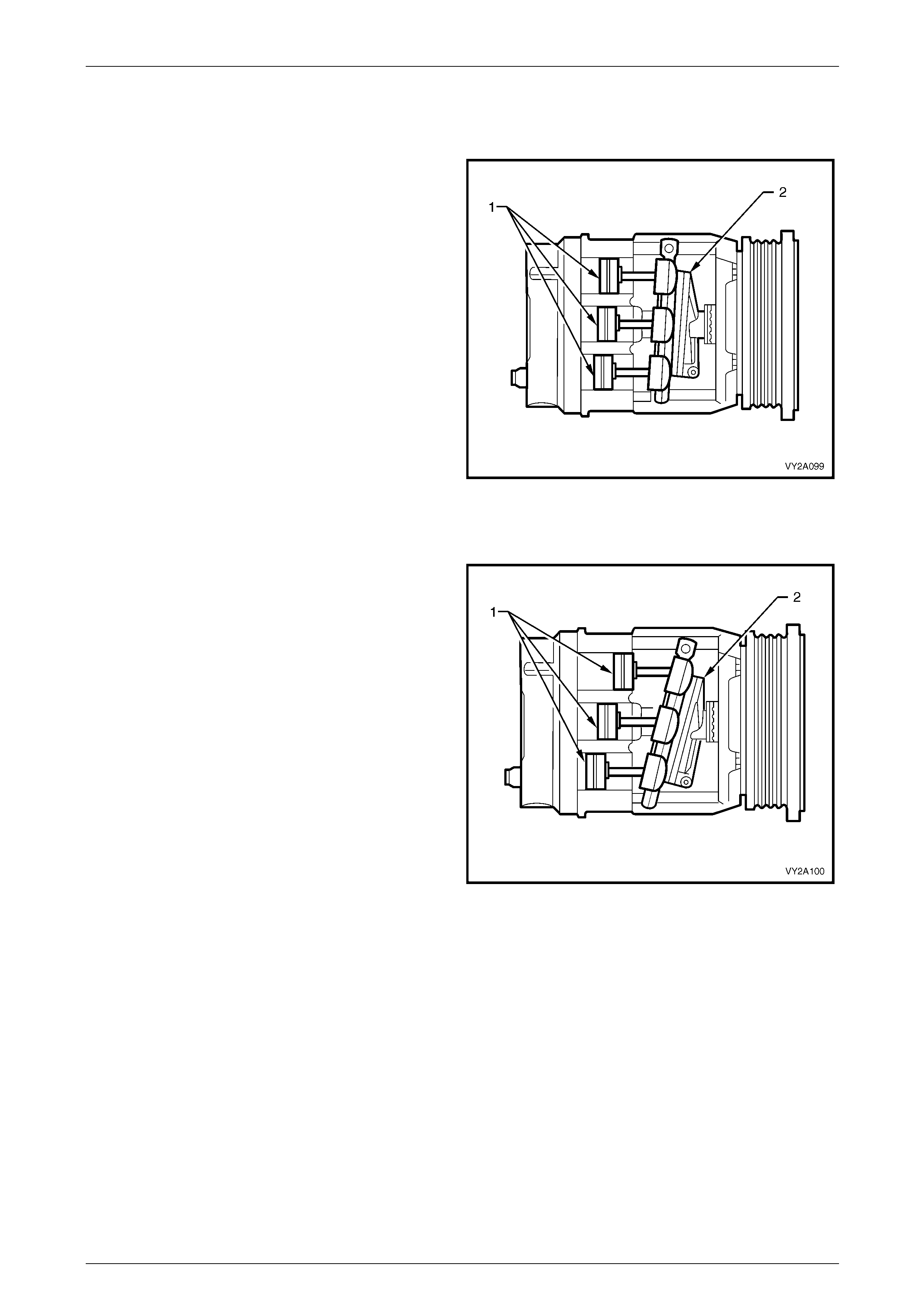

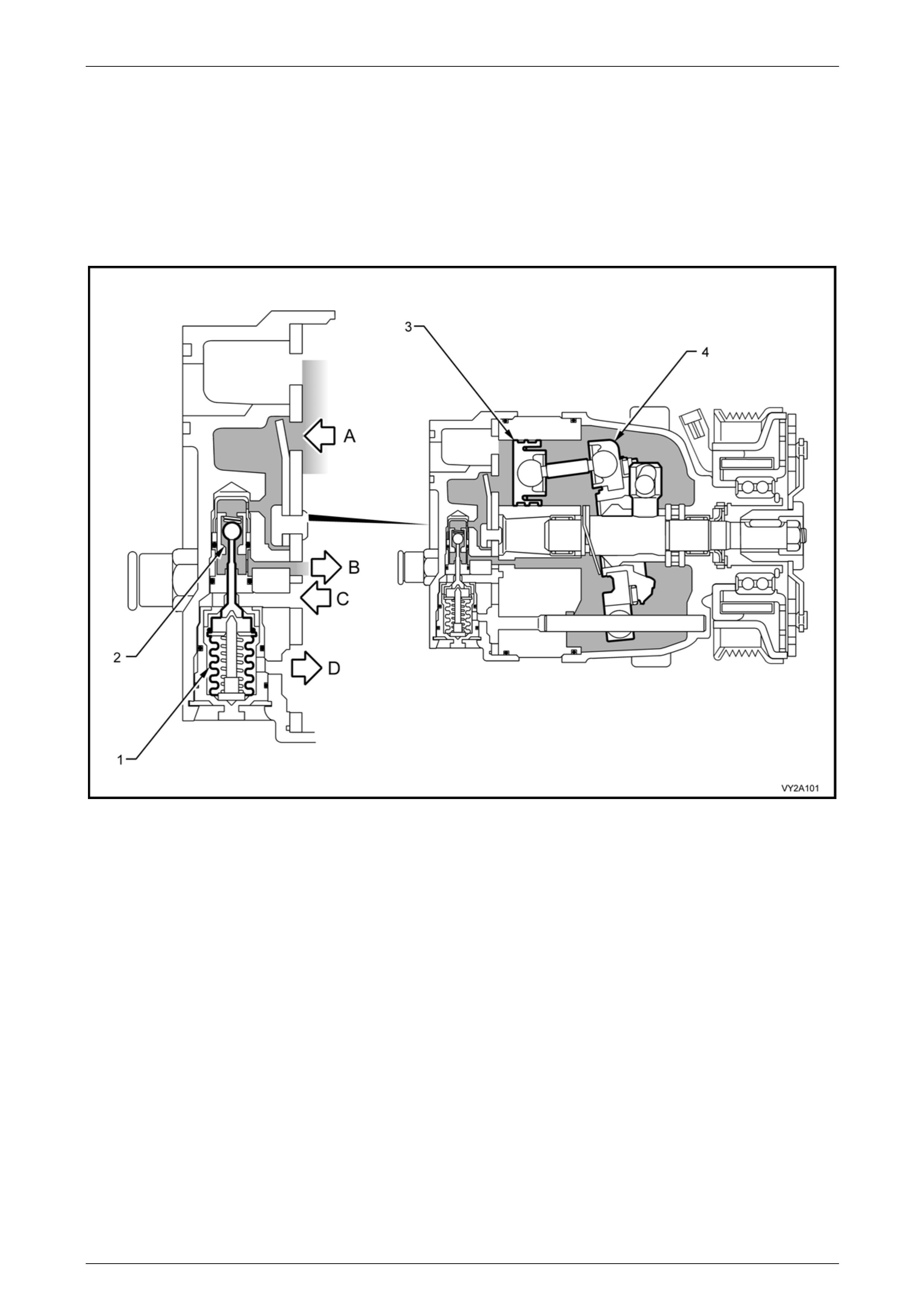

Air-conditioning Compressor Assembly – V6................................................................................................... 84

Compressor Control Valve............................................................................................................................... 85

Compressor Operation..................................................................................................................................... 86

Low A/C Demand............................................................................................................................................. 87

High A/C Demand ............................................................................................................................................ 88

Air-conditioning Compressor Assembly – GEN III V8...................................................................................... 89

Compressor Control Valve............................................................................................................................... 90

Compressor Operation..................................................................................................................................... 91

Low A/C Demand............................................................................................................................................. 92

High A/C Demand ............................................................................................................................................ 93

3 Specifications.......................................................................................................................................94

3.1 General ................................................................................................................................................................. 94

3.2 Water Valve........................................................................................................................................................... 95

3.3 HVAC Unit............................................................................................................................................................. 96

3.4 Compressor – V6 ................................................................................................................................................. 97

3.5 Compressor – GEN III V8..................................................................................................................................... 98

3.6 Refrigerant............................................................................................................................................................ 99

3.7 Condenser.......................................................................................................................................................... 100

3.8 Pressure Transducer......................................................................................................................................... 101

3.9 A/C System Lubricant........................................................................................................................................ 102

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-4

Page 2A-4

1 General Information

Two levels of air-conditioning can be fitted to the vehicles, the two heating, ventilation and air-conditio ning (HVAC)

systems are described as follows:

• HVAC climate control – manual air-cond ition ing (A/C) control, and

• HVAC occupant climate control – automatic air-conditioning (A/C) control.

The manual HVAC system uses a rotary dial type controller to select the desired operating modes and temperature. It

will be referred to as manual A/C in this Section.

The occupant climate control system features an electronic control module to control the desired operating mod es and

temperature. It is also referred to as auto A/C or OCC system.

The service information is divided into six sub-sections as follows:

Section 2A HVAC Climate Control (Manual A/C) – Description and Operation

• Provides a general description of the operation of the heater and air-conditioner s ystem, except the el ectronic

control system.

Section 2B HVAC Climate Control (Manual A/C) – Servicing and Diagnosis

• Provides the servicing procedures and diagnosis of the heater and air-conditioner system, except the elec tronic

control system.

Section 2C HVAC Climate Control (Man ual A/C) – Removal and Installation

• Provides the removal and installation procedures of the heater and air-conditioner system components, except the

electronic control system components.

Section 2D HVAC Occupant Climate Contro l (Auto A/C) – Description and Operation

• Provides a general description of the oper ation of the electronic control system.

Section 2E HVAC Occupant Climate Control (Auto A/C) – Diagnostics

• Provides the diagnostic proce dures of the electronic control system.

Section 2F HVAC Occupant Climate Control (Auto A/C) – Removal and Installation

• Provides the removal and installation procedures of the ele ctronic contro l system components.

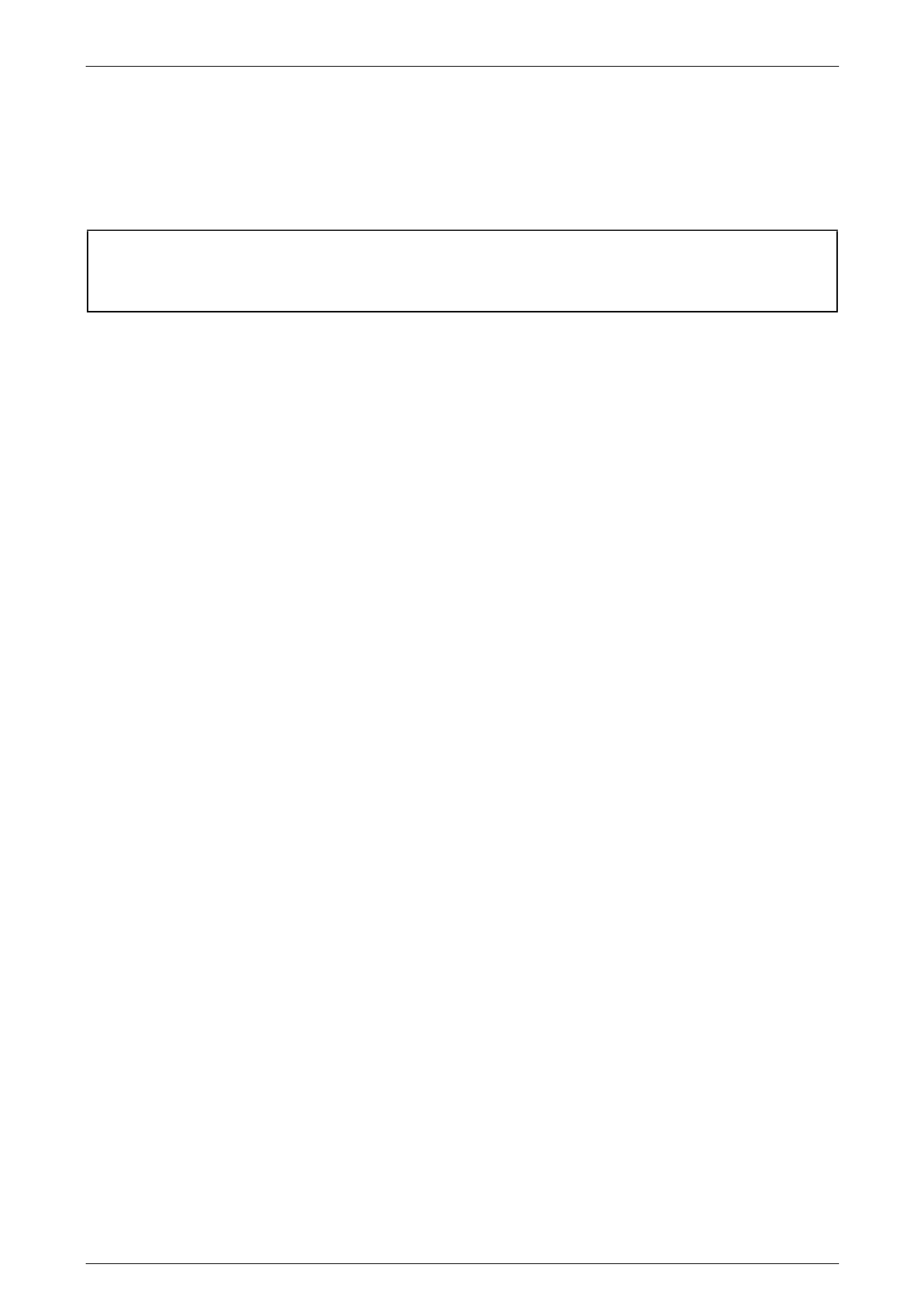

1.1 Caution Label

A fan operation caution and HVAC information label (1), is located on the right-hand side of the radiator shroud (2), refer

to Figure 2A – 1. This label provides information on the type and quantity of refrigerant required for the a ir-conditioning

system. It also specifies the type of lubricant required for the air-conditionin g compressor.

Figure 2A – 1

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-5

Page 2A-5

2 General Description

The integrated air-conditi oning system combines both the heating and cooling functions in a single unit. The vehicle’s

interior can be heated, cooled or vented (or a combination of these operations) depen ding on the modes and s witches

activated on the HVAC controller or the OCC control module. The controller or modu le is mounted in the instrument

panel centre fascia below centre ventilati on outlets.

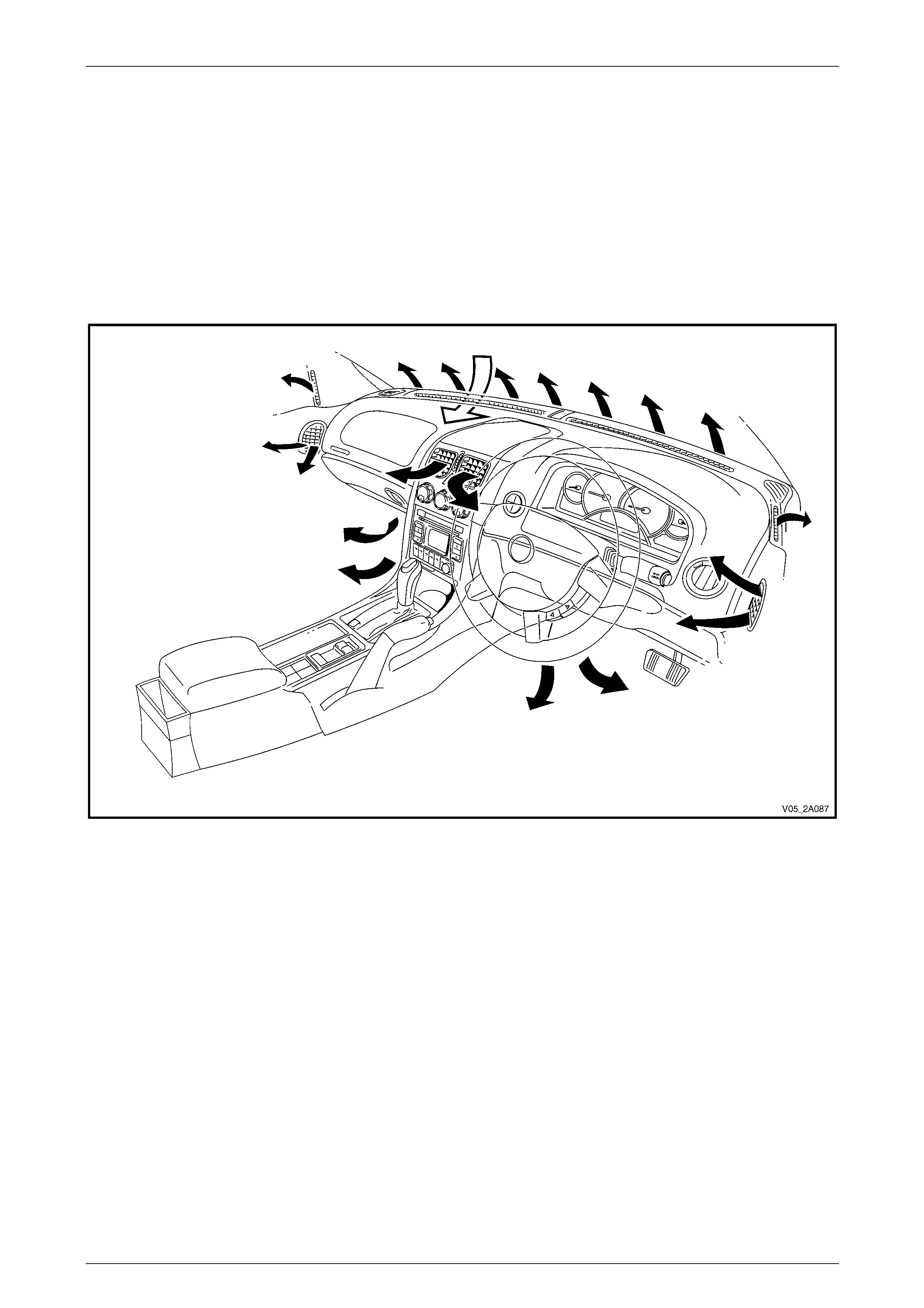

2.1 Air Flow

Air enters the HVAC system from beneath the ple num chamber cover and passes through the blo wer motor/fan,

evaporator and heater assemblies within the HVAC unit to be cooled or heated as required. The air leaves the HVAC unit

and enters the vehicle interior through the centre, side, rear (where fitted), floor or demist outlets depending on the mode

selected.

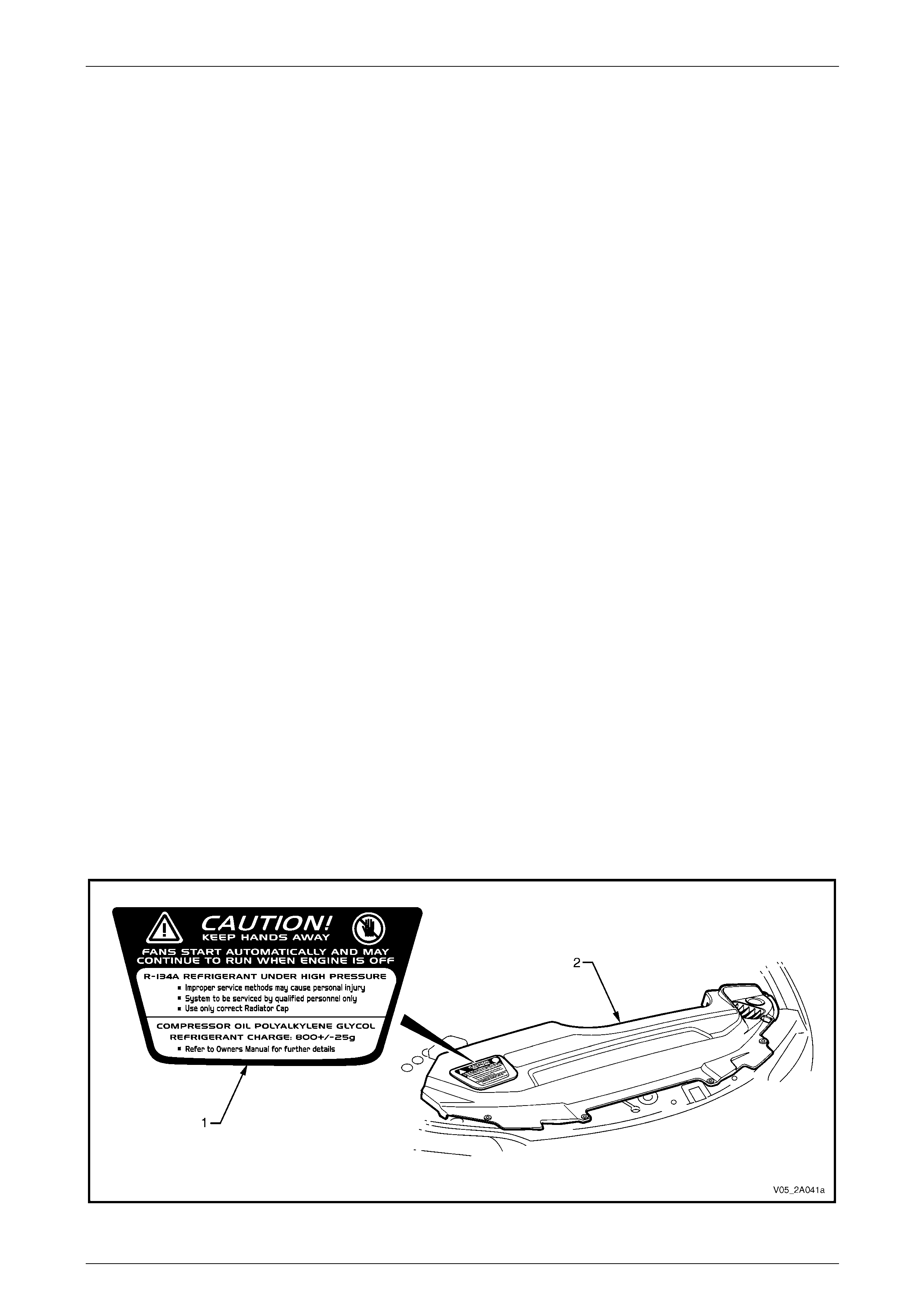

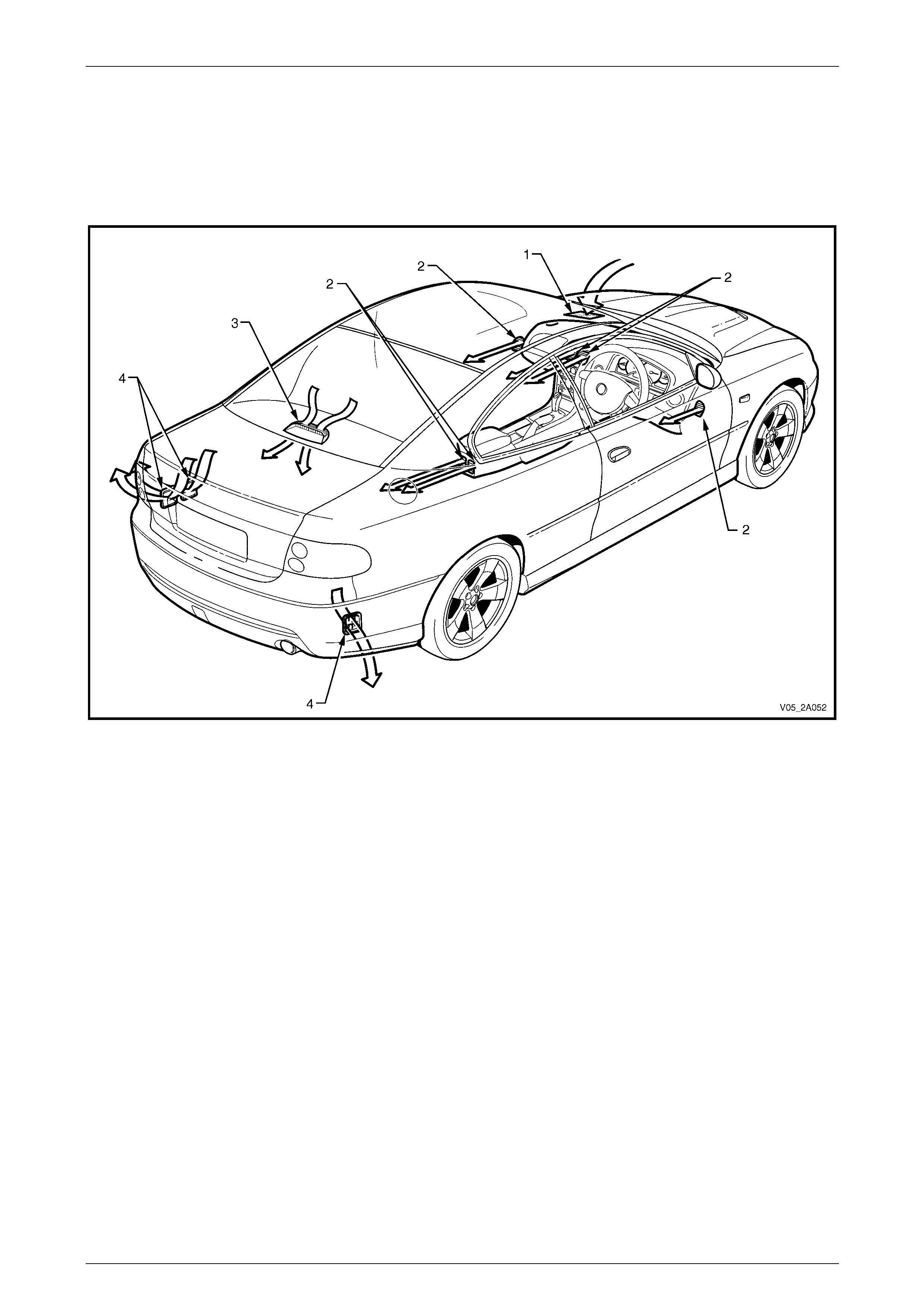

Sedan

When the doo rs and all movab le window s are cl osed , air passes through tw o grilles mounted in the rear window trim

panel (3) and exits the vehicle throu gh three body moun ted air outle ts (4) locate d behind the rea r bump er fascia , refer to

Figure 2A – 2.

The centre, side and rear ventilation outlets (2) can be turned on or off and are directionally adjustable. Turning off these

outlets will increase airflo w to the other open outlets.

Figure 2A – 2

Legend

1 Plenum Inlet

2 Cabin Air Outlets 3 Rear Window Trim Panel Grilles

4 Body Air Outlets

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-6

Page 2A-6

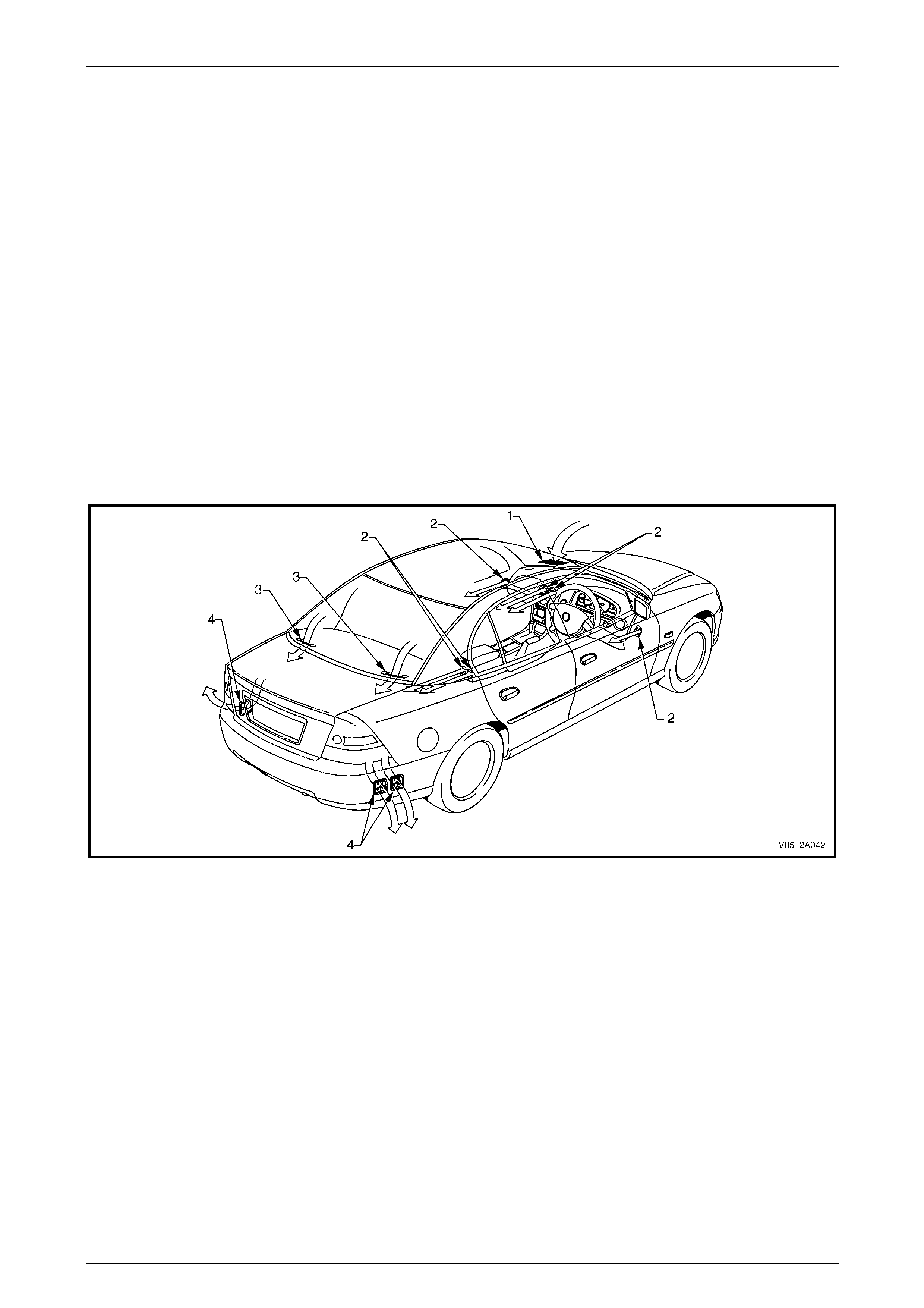

Wagon

When the doo rs and all movab le w indows are close d , air exits the vehicle through th ree body moun ted air outlets (3) loca ted

at the rear of the vehicle behind the rear bumper bar fascia, refer to Figure 2A – 3.

The centre, side and rear ventilation outlets (2) can be turned on or off and are directionally adjustable. Turning off these

outlets will increase airflo w to the other open outlets.

Figure 2A – 3

Legend

1 Plenum Inlet

2 Cabin Air Outlets 3 Body Air Outlets

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-7

Page 2A-7

Coupe

Whe n the doors an d a l l mo va b l e w i nd ows are clo se d, ai r pa s s es t h ro ug h th e parcel shelf grille in centre stop light

housing (3) and ex its th e vehi cle throug h thre e body mou nted air outle ts (4) loca ted be h i nd th e rear bu mp e r fascia, refer to

Figure 2A – 4.

The centre, side and rear ventilation outlets (2) can be turned on or off and are directionally adjustable. Turning off these

outlets will increase airflo w to the other open outlets.

Figure 2A – 4

Legend

1 Plenum Inlet

2 Cabin Air Outlets 3 Parcel Shelf Grille in Centre Stop Light Housing

4 Body Air Outlets

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-8

Page 2A-8

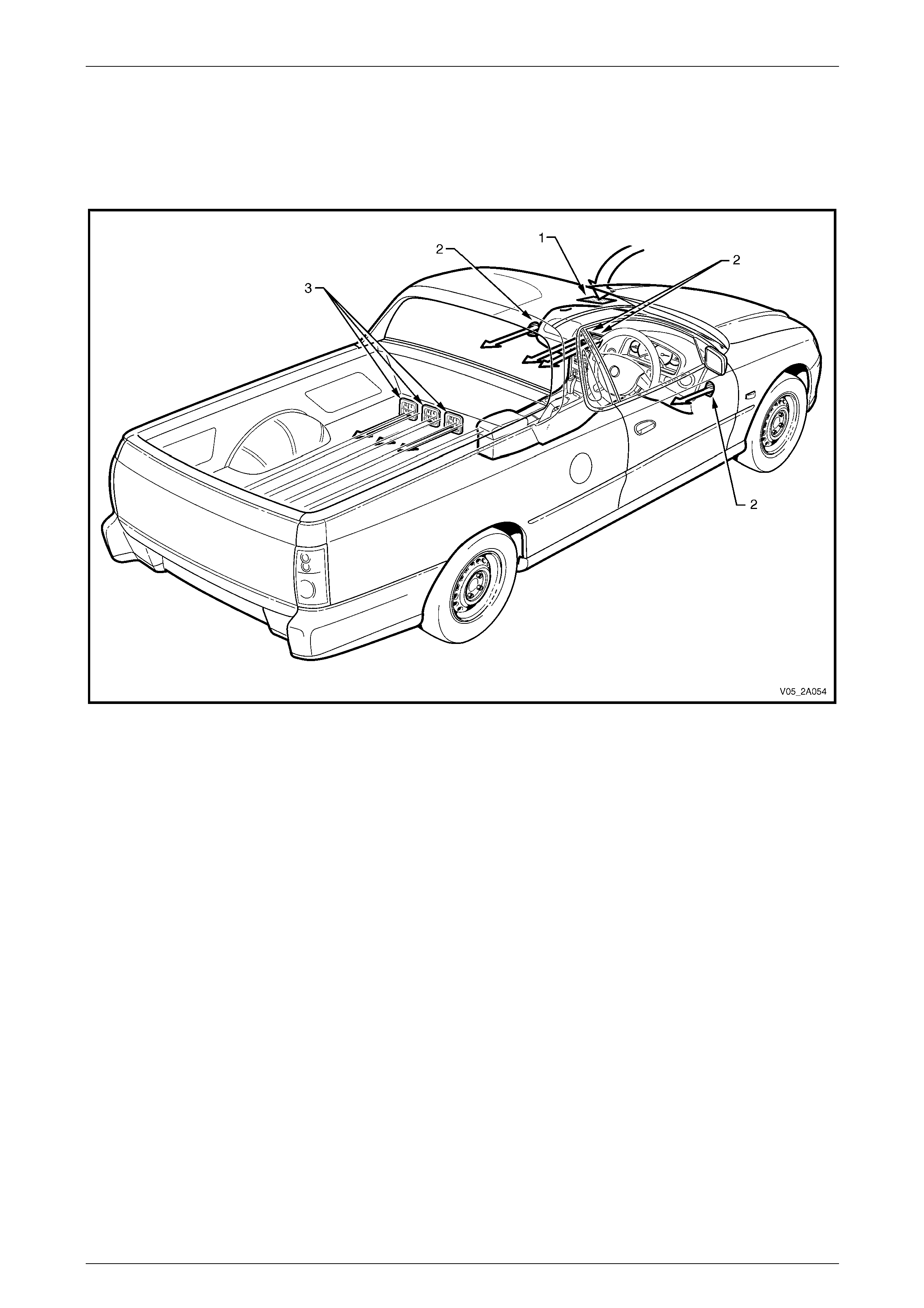

Utility

When the doo rs and all movab le w indows are close d , air exits the vehicle through th ree body moun ted air outlets (3) loca ted

at the rear of the cabin, r efer to Figure 2A – 5.

The centre and side ventilation outlets (2) can be turned on or off and are directionall y adjustable. Turning off these

outlets will increase airflo w to the other open outlets.

Figure 2A – 5

Legend

1 Plenum Inlet

2 Cabin Air Outlets 3 Body Air Outlets

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-9

Page 2A-9

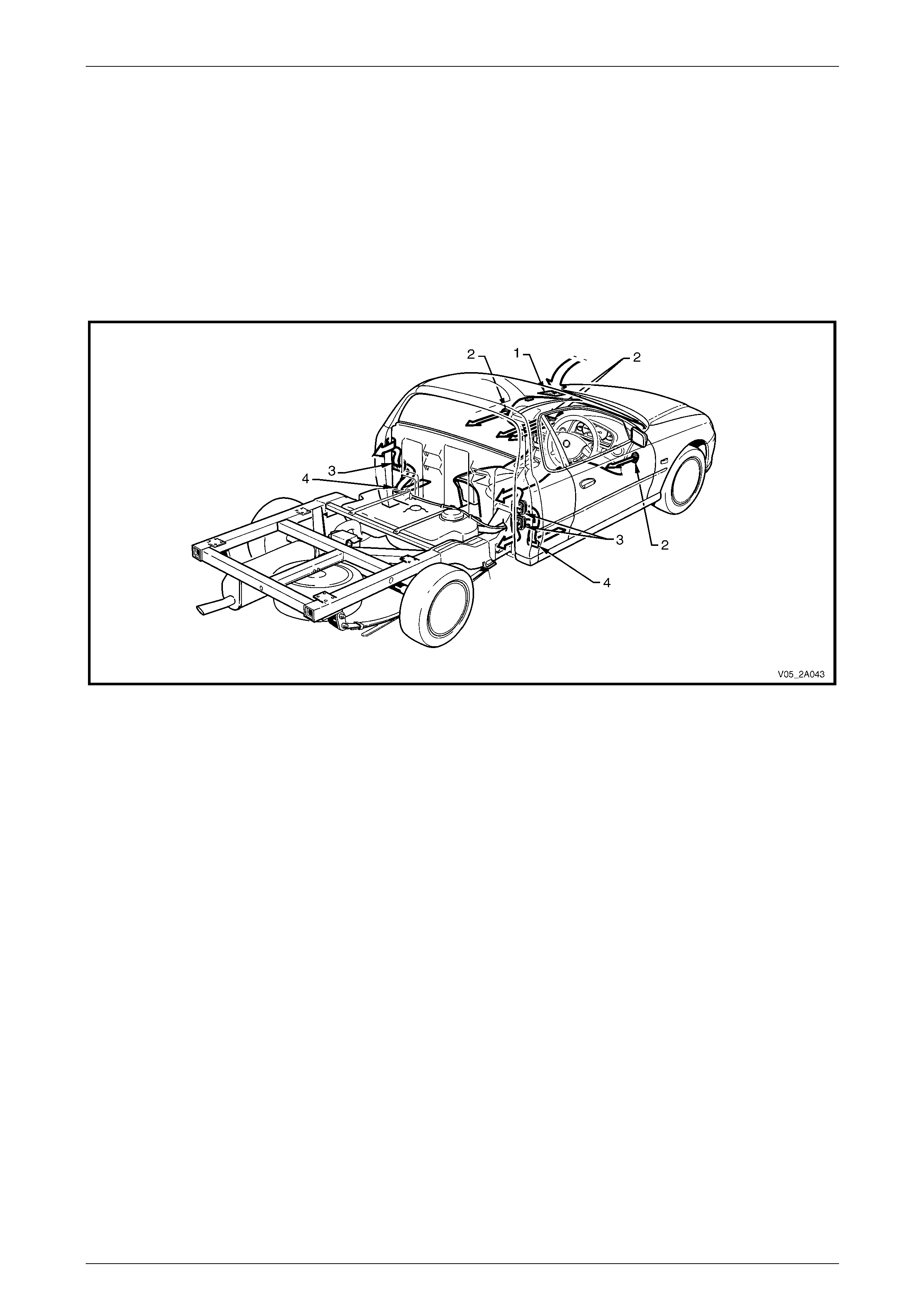

Regular Cab

When the doo rs and all movab le w indows are close d , air exits the vehicle through two rectangular apertures (4) located in

the seat back body panel trim assembly below the body ventilation outlets (3). These outlets are installed into the rear

inner panel. Two outlets are located on the right-hand side and one on the left-hand side of the cabin, refer to

Figure 2A – 6.

After passing through the body ventilation outlets, the air enters a cavity between the inner rear body panel and the rear

outer trim panel. It leaves the vehicle via a small air g ap located around the entire lower and side perimeters of the rear

outer trim panel.

The centre and side ventilation outlets (2) can be turned on or off and are directionall y adjustable. Turning off these

outlets will increase airflo w to the other open outlets.

Figure 2A – 6

Legend

1 Plenum Inlet

2 Cabin Air Outlets 3 Body Air Outlets

4 Airflow Apertures

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-10

Page 2A-10

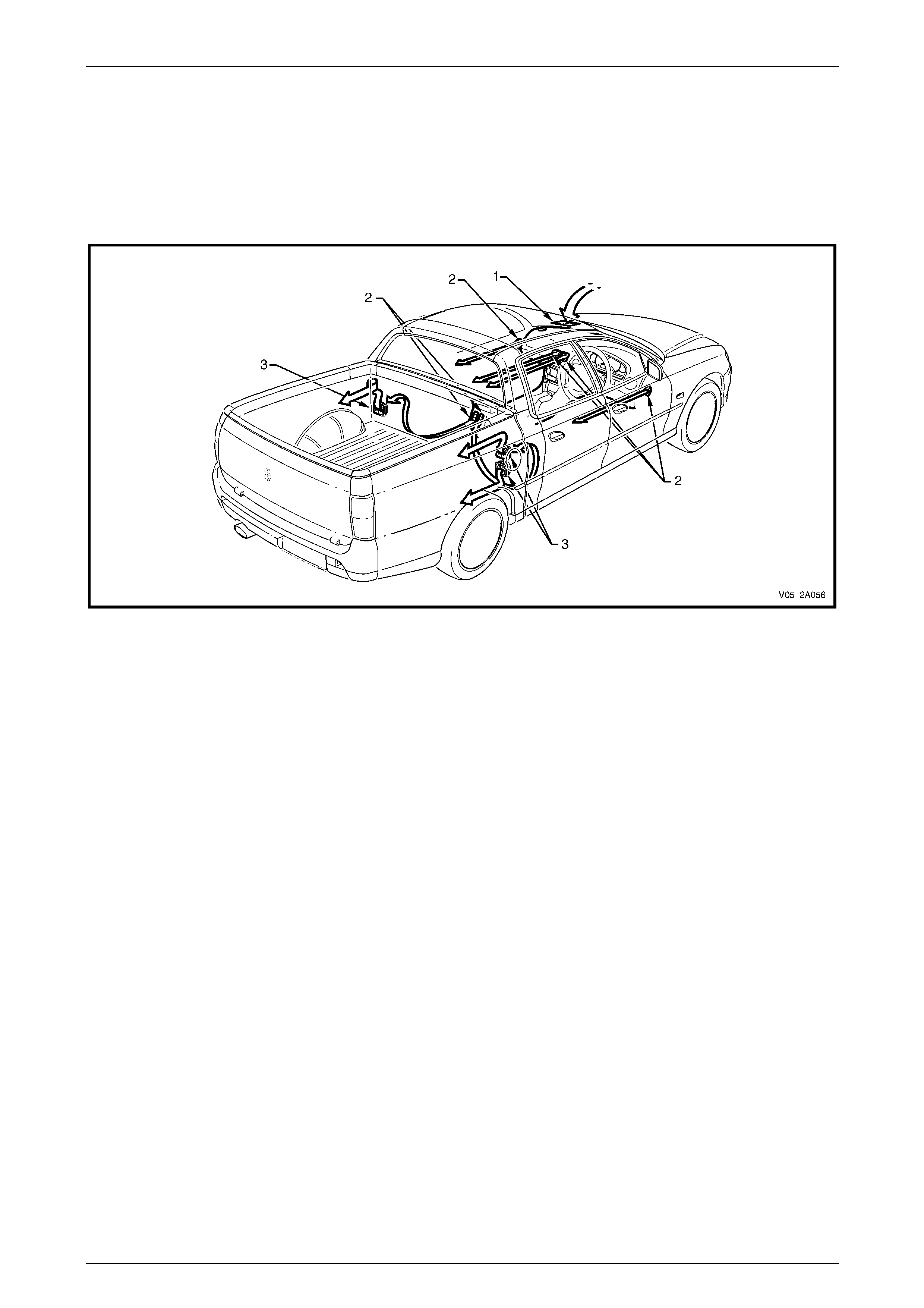

Crew Cab

When the doo rs and all movab le w indows are close d , air exits the vehicle via the underside of the rear seat cushion. Three

body ventilation outlets (3) are installed in the rear inner panel. Two outlets are located on the right-hand side and one on

the left-hand side of the cabin, refer to Figure 2A – 7.

The centre and side ventilation outlets (2) can be turned on or off and are directionall y adjustable. Turning off these

outlets will increase airflo w to the other open outlets.

Figure 2A – 7

Legend

1 Plenum Inlet

2 Cabin Air Outlets 3 Body Air Outlets

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-11

Page 2A-11

2.2 HVAC Inlet and Outlet Ducts

Inlet

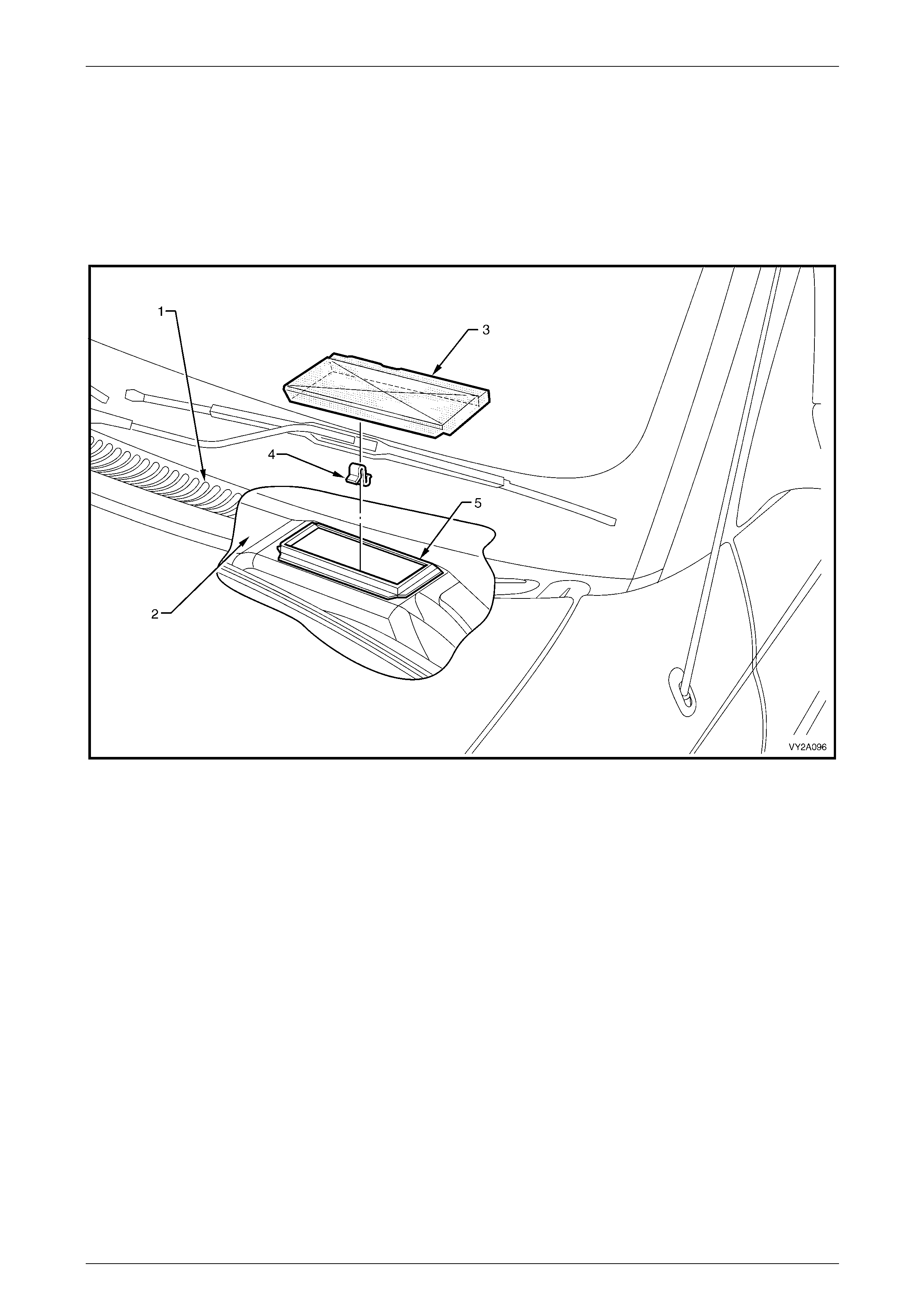

Air enters the rectangular air inlet located on a raised area within the plenum chamber, refer to Figure 2A – 8. To prevent

foreign matter such as leaves or t wigs entering the HVAC unit, a stainless steel mesh screen is installed over the inlet.

Although not a regular maintenance item, this mesh screen can be removed to clear away any foreign matter that may

have accumulated at the HVAC inlet.

Figure 2A – 8

Legend

1 Plenum Cover

2 Plenum Chamber

3 Mesh Screen

4 Mesh Screen Retaining Clip

5 HVAC Inlet

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-12

Page 2A-12

Air Distribution Ducts

Sedan, Wagon, Coupe and Crew Cab

Air that is directed to the sides and rear of the cabin is ch annelled throu gh plastic ducts attached to the HVAC case, refer

to Figure 2A – 9. Air leaving the side ducts is channelled through the left-hand and right-hand side instrument panel outer

covers and exits through air outlets installed into the door trims. A portion of this air is directed into sid e window

demisting outlets also installed as part of the door trims.

Air to the rear outlets is channelled through a two-piece rear duct installed under the floor conso le. Air leaving this duct is

divided into two paths by the rear ventilation outlet.

Air directed to the front floor is channelled thr ough foot ducts located on the underside of the HVAC un it.

Air for demisting the windscreen directly enters into a cavity formed by the dash panel assembly. This air is then directed

through eight openings located in the upper dash panel, and e xits through the demister grilles installed at the front of the

instrument panel pad.

Figure 2A – 9

Legend

1 HVAC Unit

2 Passenger Side Duct

3 Demister Cavity

4 Driver Side Outer Duct

5 Driver Side Inner Duct

6 Driver Foot Duct Outlet

7 Floor Console Front Duct

8 Floor Console Rear Duct

9 Passenger Foot Duct Outlet

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-13

Page 2A-13

Utility and Regular Cab

Air that is directed to the sides of the cabin is channelled through plastic ducts attached to the HVAC case, refer to

Figure 2A – 10. Air leaving the side ducts is channelled through the left-hand and right-h and side instrument panel outer

covers and exits through air outlets installed into the door trims. A portion of this air is dire cted into side window

demisting outlets also installed as part of the door trims.

Air directed to the front floor is channelled thr ough foot ducts located on the underside of the HVAC unit.

Air for demisting the windscreen directly enters into a cavity formed by the dash panel assembly. This air is then directed

through eight openings located in the upper dash panel, and e xits through the demister grilles installed at the front of the

instrument panel pad.

Figure 2A – 10

Legend

1 HVAC Unit

2 Passenger Side Duct

3 Demister Cavity

4 Driver Side Outer Duct

5 Driver Side Inner Duct

6 Driver Foot Duct Outlet

7 Passenger Foot Duct Outlet

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-14

Page 2A-14

Cabin Ventilation Outlets

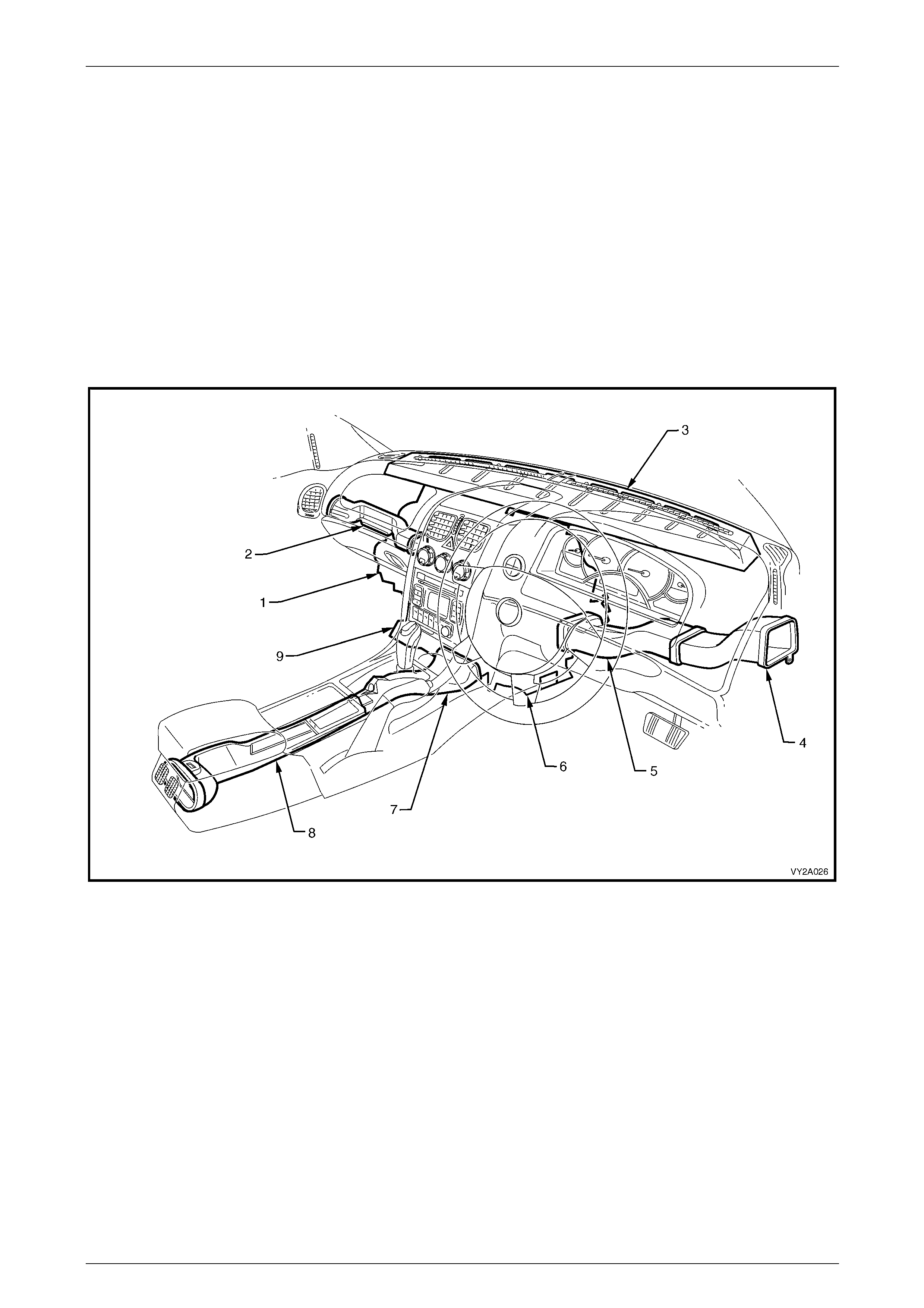

Sedan, Wagon, Coupe and Crew Cab

Air entering the HVAC unit through the plenum chamber enters the cabin through ventilation outl ets at the following

points, refer to Figure 2A – 11:

• windscreen (fixed, part of upper instrument panel assembly),

• driver and front passenger side foot outlet (fixed, part of HVAC unit underside),

• driver and front passenger side outlet (adjustable, installed into door trims),

• driver and front passenger side window demist outlet (fixed, installed into door trims),

• driver and front passenger face level outlet (adjustable), and

• rear outlets (adjustable, installed to rear of floor console).

Figure 2A – 11

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-15

Page 2A-15

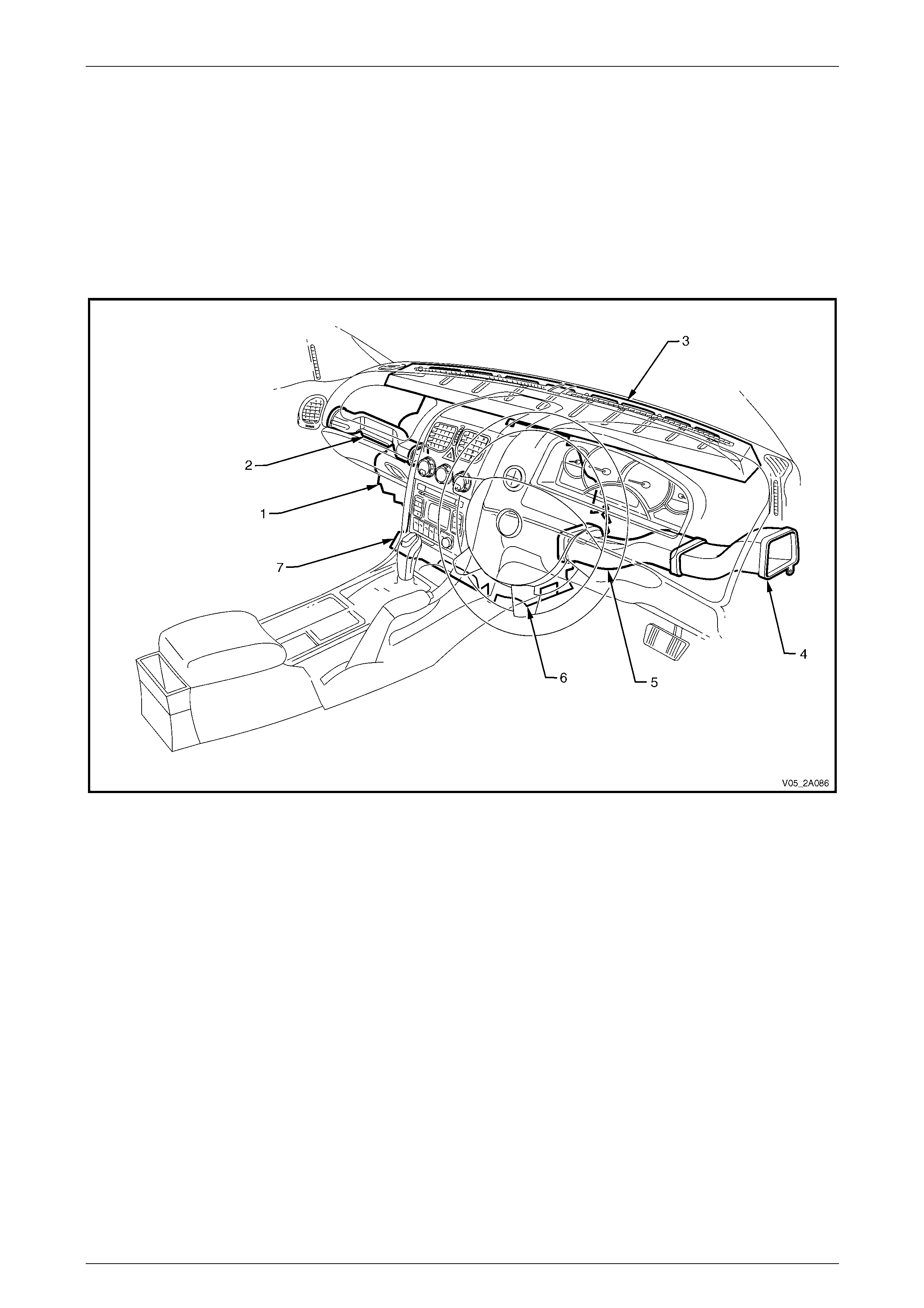

Utility and Regular Cab

Air entering the HVAC unit through the plenum chamber enters the cabin through ventilation outl ets at the following

points, refer to Figure 2A – 12:

• windscreen (fixed, part of upper instrument panel assembly),

• driver and front passenger side foot outlet (fixed, part of HVAC unit underside),

• driver and front passenger side outlet (adjustable, installed into door trims),

• driver and front passenger side window demist outlet (fixed, installed into door trims), and

• driver and front passenger face level outlet (adjustable).

Figure 2A – 12

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-16

Page 2A-16

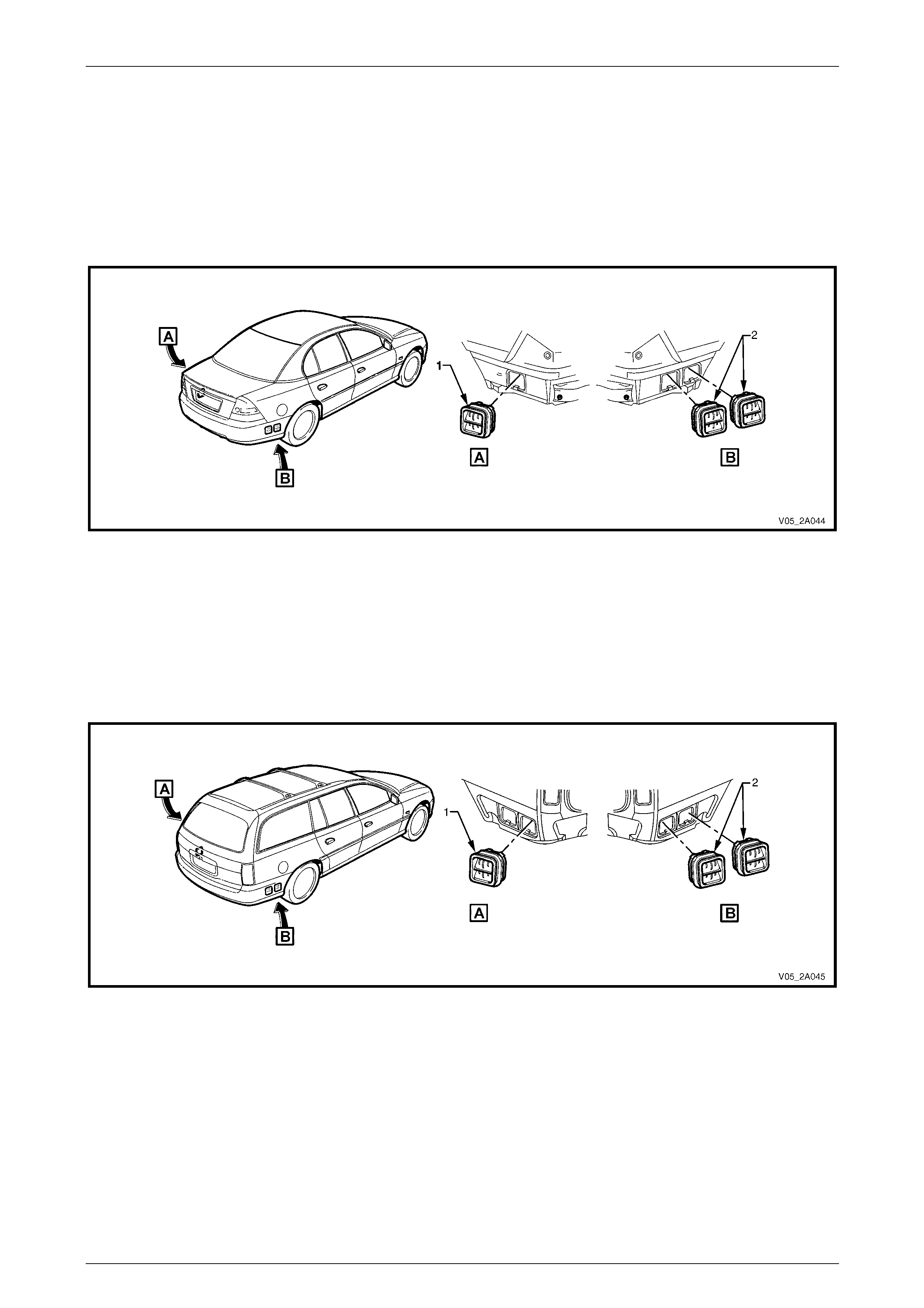

Body Ventilation Outlets

To allow the HVAC system to operate efficiently, air must be allowed to leave the vehicle even when all wind ows and

doors are closed. This is achieved b y the installation of body ventilation outlets at the rear of the vehicle.

Sedan

Sedan vehicles have one venti latio n outlet (1) on the left-hand side and two outlets (2) on the right-hand side, refer to

Figure 2A – 13.

Figure 2A – 13

Legend

1 Body Ventilation Outlet – Left-hand Side 2 Body Ventilation Outlets – Right-hand Side

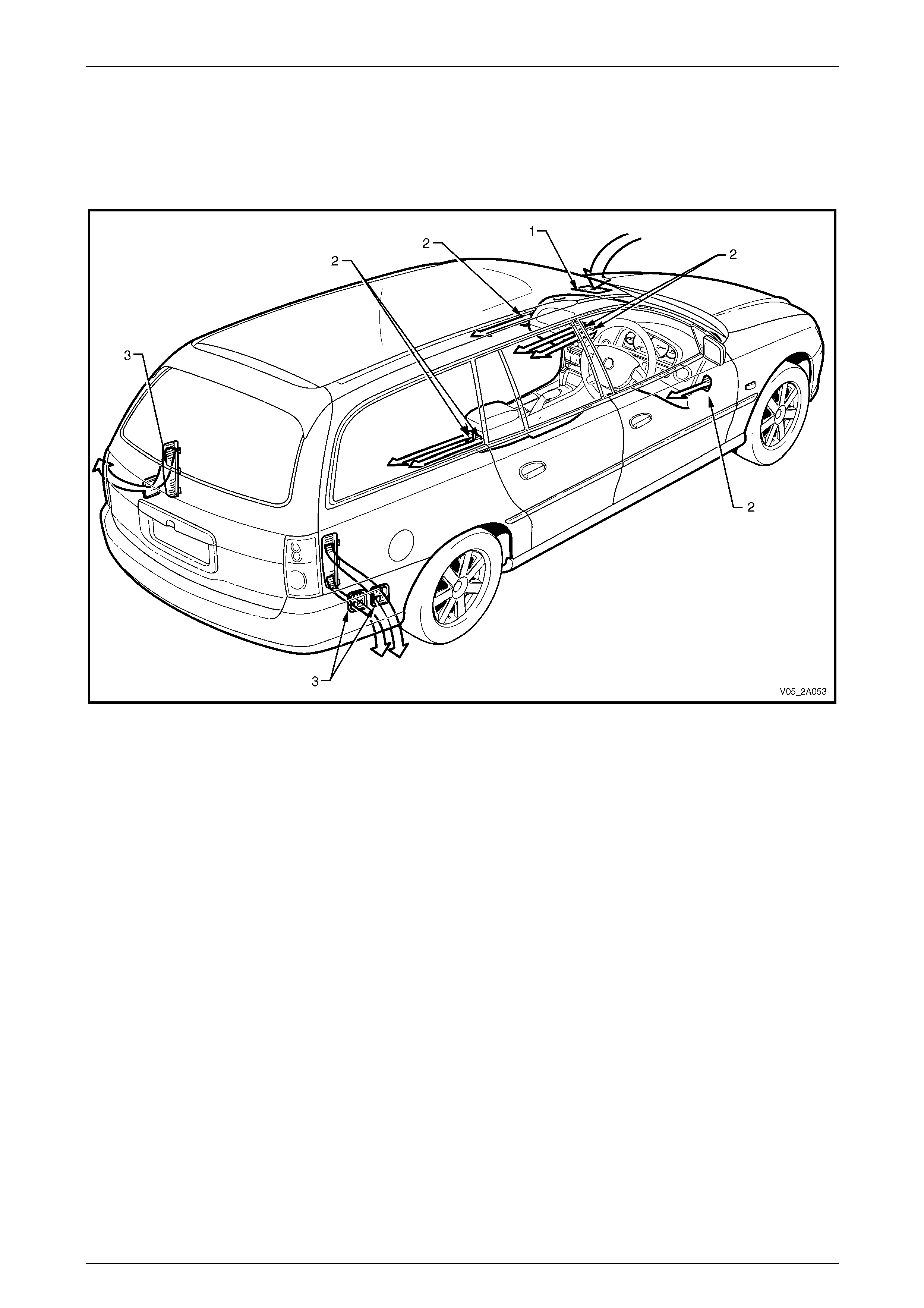

Wagon

Wagon vehicles have one ventilation outlet (1) on the left-hand side and two outlets (2) on the right-hand side, refer to

Figure 2A – 14.

Figure 2A – 14

Legend

1 Body Ventilation Outlet – Left-hand Side 2 Body Ventilation Outlets – Right-hand Side

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-17

Page 2A-17

Coupe

Coupe vehicles have two ventilation outlets (1) on the left-hand side and one outlet (2) on the right-hand side, refer to

Figure 2A – 15.

Figure 2A – 15

Legend

1 Body Ventilation Outlets – Left-hand Side 2 Body Ventilation Outlet – Right-hand Side

Utility

Utility vehicles have three ventilation outlets (1) on the floor panel extension located behind the seat on the left-hand

side, refer to Figure 2A – 16.

Figure 2A – 16

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-18

Page 2A-18

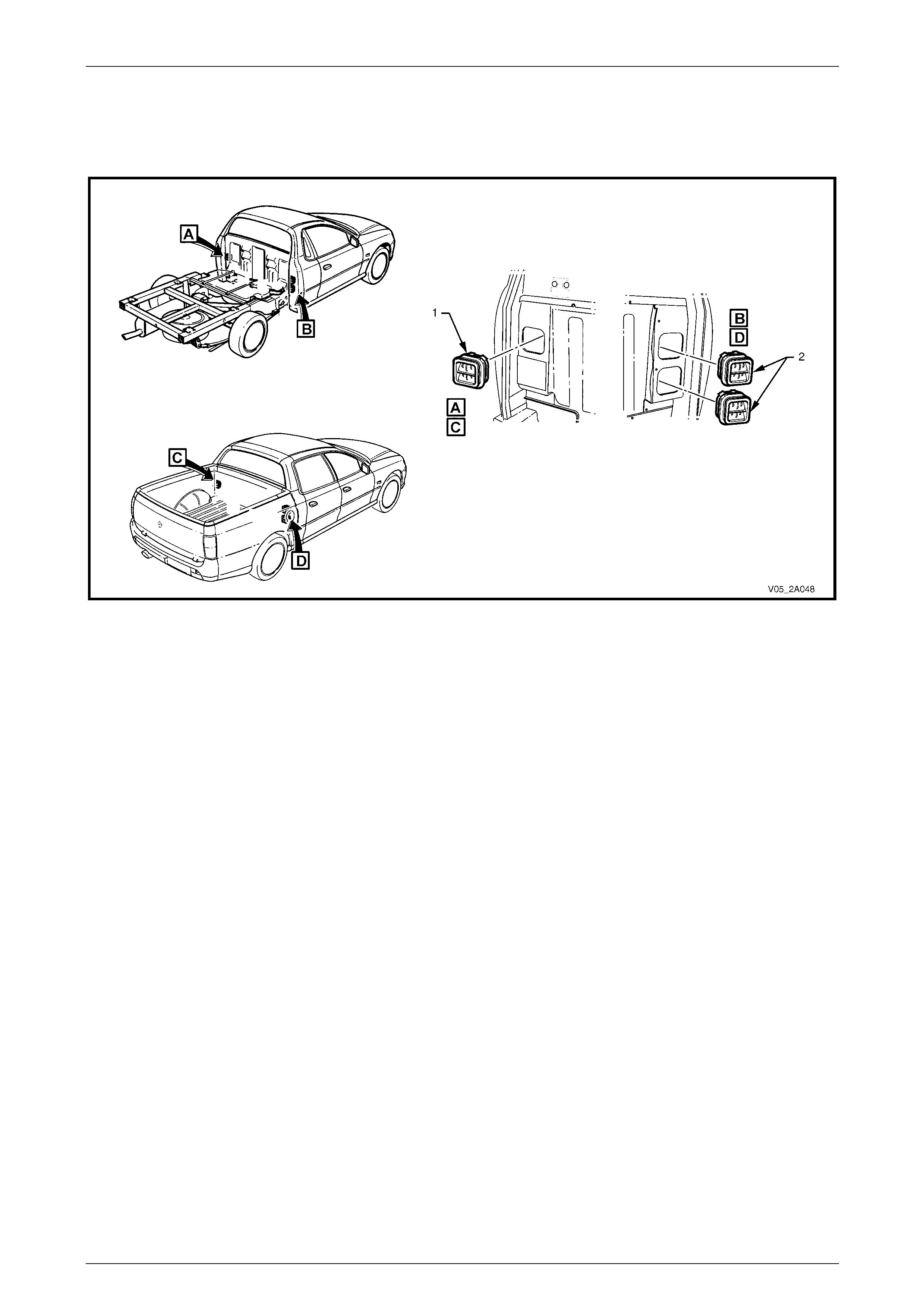

Regular Cab and Crew Cab

Regular Cab and Cre w Cab v ehicles have one ventilati on outlet (1) on the left-hand side and two outlets (2) on the

right-hand side of the cabin, refer to Figure 2A – 17.

Figure 2A – 17

Legend

1 Body Ventilation Outlet – Left-hand Side 2 Body Ventilation Outlets – Right-hand Side

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-19

Page 2A-19

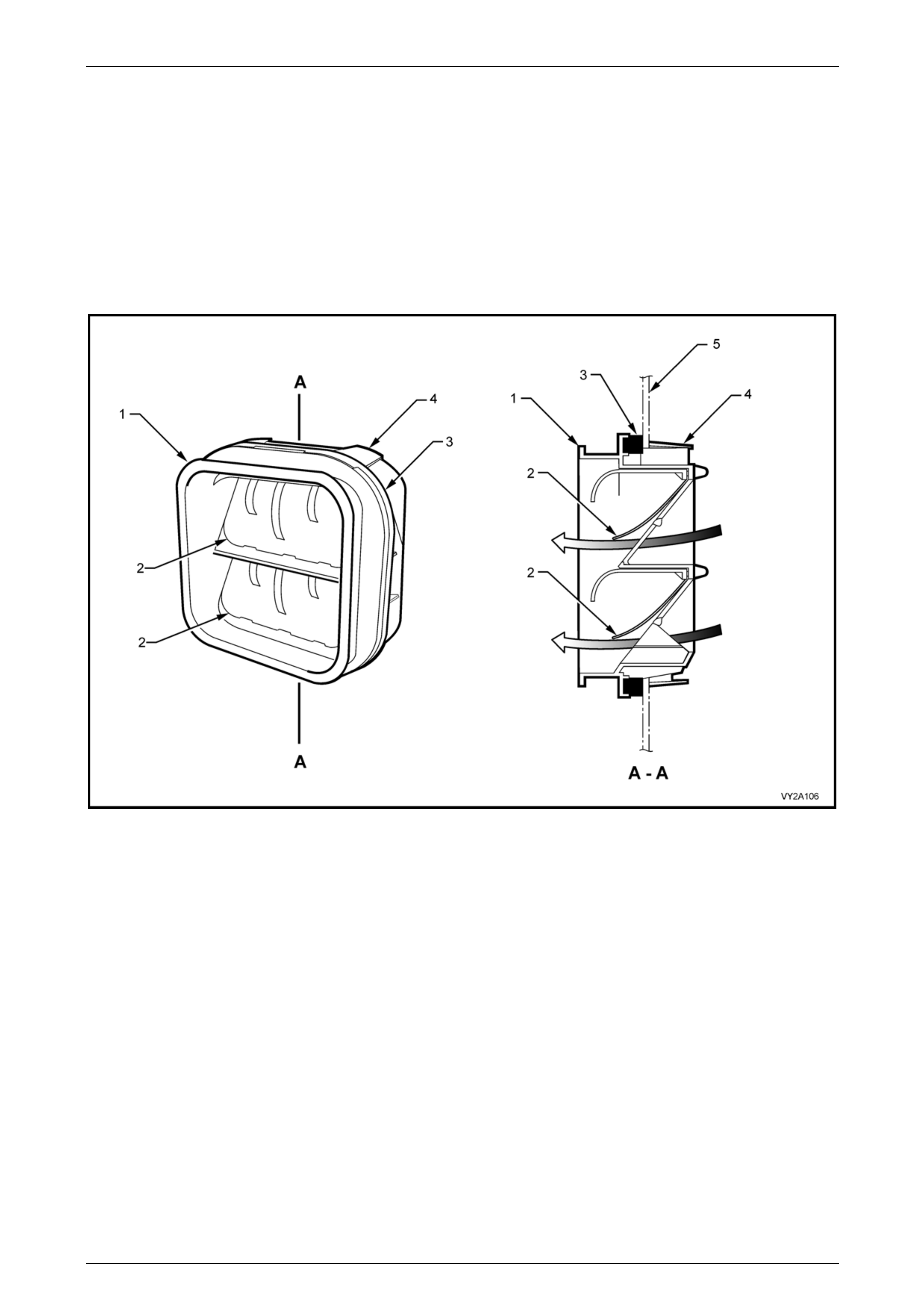

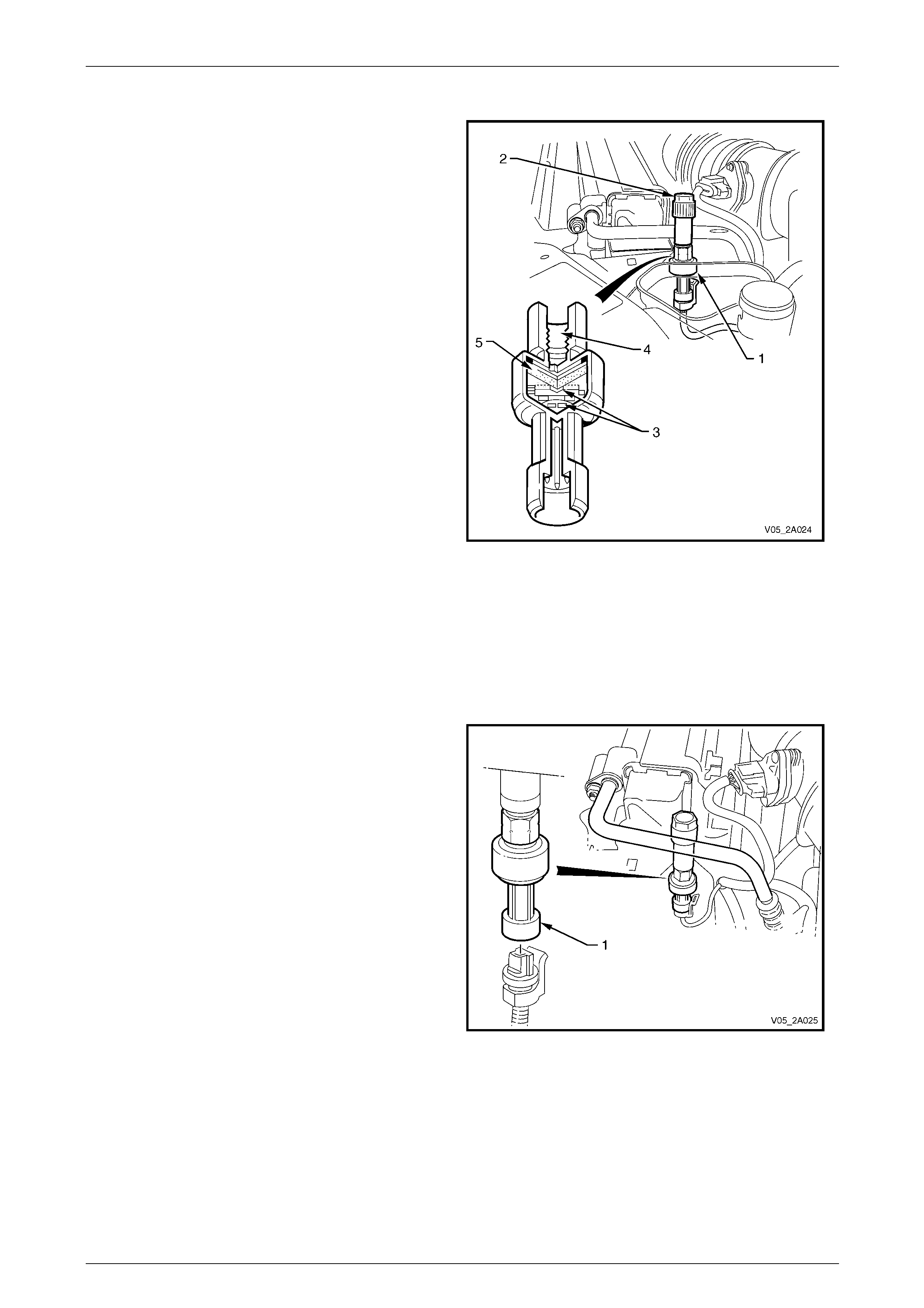

Outlet Assembly

Each ventilation outlet consist s of a fluted plastic housing (1) containing two flexible rubb er seals (2), refer to

Figure 2A – 18. When positiv e cabin air pressure acts upon the seals, they deflect outward to allow air to exit the vehicle.

Air may only exit and not enter the vehicle via the body ventilation outlets.

The ventilation outlet housing is retained to the body panel by a locking tab (4) located at each corner. Although not a

regular maintenance item, the bod y outlets can be removed to clear away any dust or foreign matter that may impede

them from operating efficiently. This is important for reasons of dust exclusion (outlets not sealing) or over-pressurisation

of the cabin (outlets obstructed) causing poor OCC system performance.

The body ventilation outlets fulf il an additional function in allowing the doors to be closed without exerting undue air

pressure upon the windows and dust seals of the vehicle.

Figure 2A – 18

Legend

1 Outlet Housing

2 Rubber Seal

3 Foam Seal

4 Locking Tab (four places)

5 Body Panel

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-20

Page 2A-20

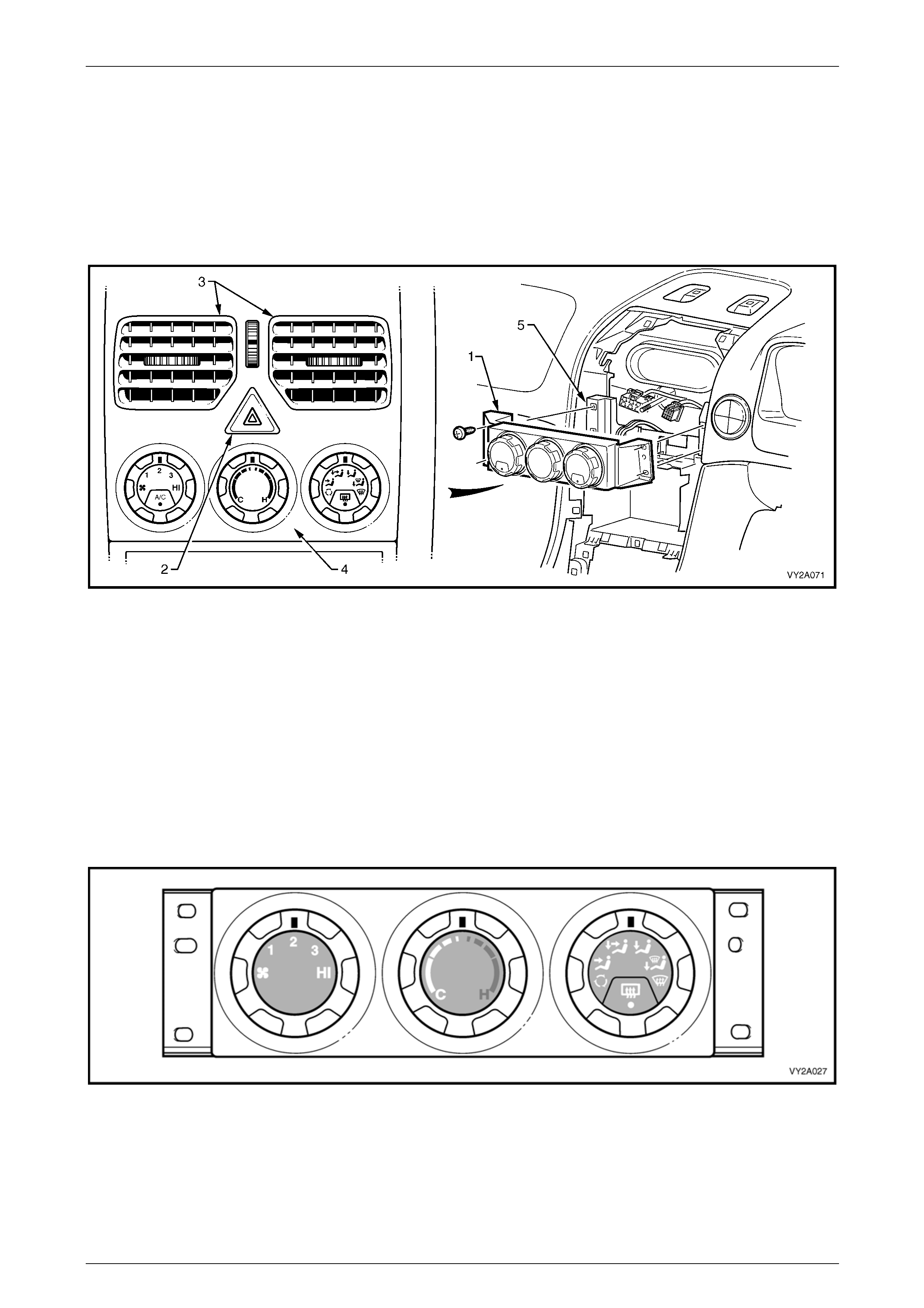

2.3 HVAC Controller – Manual A/C

The manual type HVAC controller (1) is located below the hazard switch (2) and face level centre vents (3), refer to

Figure 2A – 19. It is of modular construction and has contained within, or mounted to the rear of it, all switching hardware

required to control the HVAC system. Included in its functions are buttons for activating the air-conditioning and the

heated rear window.

The controller is installed b ehind the instrument panel centre fascia (4) and is attached to the instrument panel (5) at four

points.

Figure 2A – 19

Configuration

Three rotary switches are mounted on the front housing of the controller. They are, from left to right:

• blower fan switch (incorporating a push-button A/C switch where A/C is fitted),

• temperature control switch, and

• mode control switch (incorpor ating a push-button heated rear window switch).

There are two configurations of manual type HVAC controll ers:

1 Figure 2A – 20 shows the controller fitted to mode ls without air-conditioning. The air-conditioning switch is deleted

from the fan speed switch. The centre bezels of the switches are grey.

Figure 2A – 20

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-21

Page 2A-21

2 Figure 2A – 21 shows the controller fitted to all mo dels with air-conditioning. The air-conditioning switch is fitted to

the fan speed switch. The centre bezels of the switches are grey.

Figure 2A – 21

3 A design variation between equivalent co nfiguration controllers is a 3° facing angle, biase d towards the driver, of

the dials and front housing. The rear housing of the controller (1) is coloured bl ack. The letter R (2) (for RHD) is

moulded to the mounting flange of the rear housing for additional identification purposes, refer to Figure 2A – 22.

Figure 2A – 22

Functions

A/C Switch

The A/C switch is located at the bottom of the blower fan rotary switch, which is used to engage or disengage the

air-conditioner compressor. The in dicator lamp within the switch will illuminate when the A/C compressor is engaged.

Heated Rear Window Switch

The heated rear windo w switch is located at the bottom of the mode control switch, which is used to turn on or off the

heated rear window element. The indicator lamp within the switch will illuminate when the heated rear windo w elem ent is

on.

After switching the heated rear window on, it will automatically turn off after 15 minutes. To reactivate the heated rear

window, push the button again. This will turn on the heated rear window circuit for an ad ditional 15 minutes.

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-22

Page 2A-22

Blower Fan Switch

Four blower fan speeds are available – a fan speed has to be selected before the A/C system can be engaged. The fan

is in the off position when the position indicator is aligned with the fan symbol.

Temperature Control

On the temperature control switch, C is the full cold position and H is th e full hot position.

The controller is connected vi a a rod and levers to the air mix doors in the HVAC case. The air mix d oors control the

amount of incoming air flowing throug h the heater core, in accordance with the selected cabin temper ature. This

regulates the amount of heated air mixing with the unheated or air-conditioned air.

Refer to 2.8 Heating, Ventilation and Air-conditioning (HVAC) Unit for further information.

The heater water valve is held in the close d p ositio n by vacuum generated by the engine. When the third detent is

selected from the full cold position via the te mperature control, the water valve vacuum s witch located on the rear of the

HVAC controller is activated and the vacuu m line to the water valve is vented. This allows hot water flow into the heater

core and subsequent heatin g of the vehicle cabin. Refer to 2.4 Heater for further information.

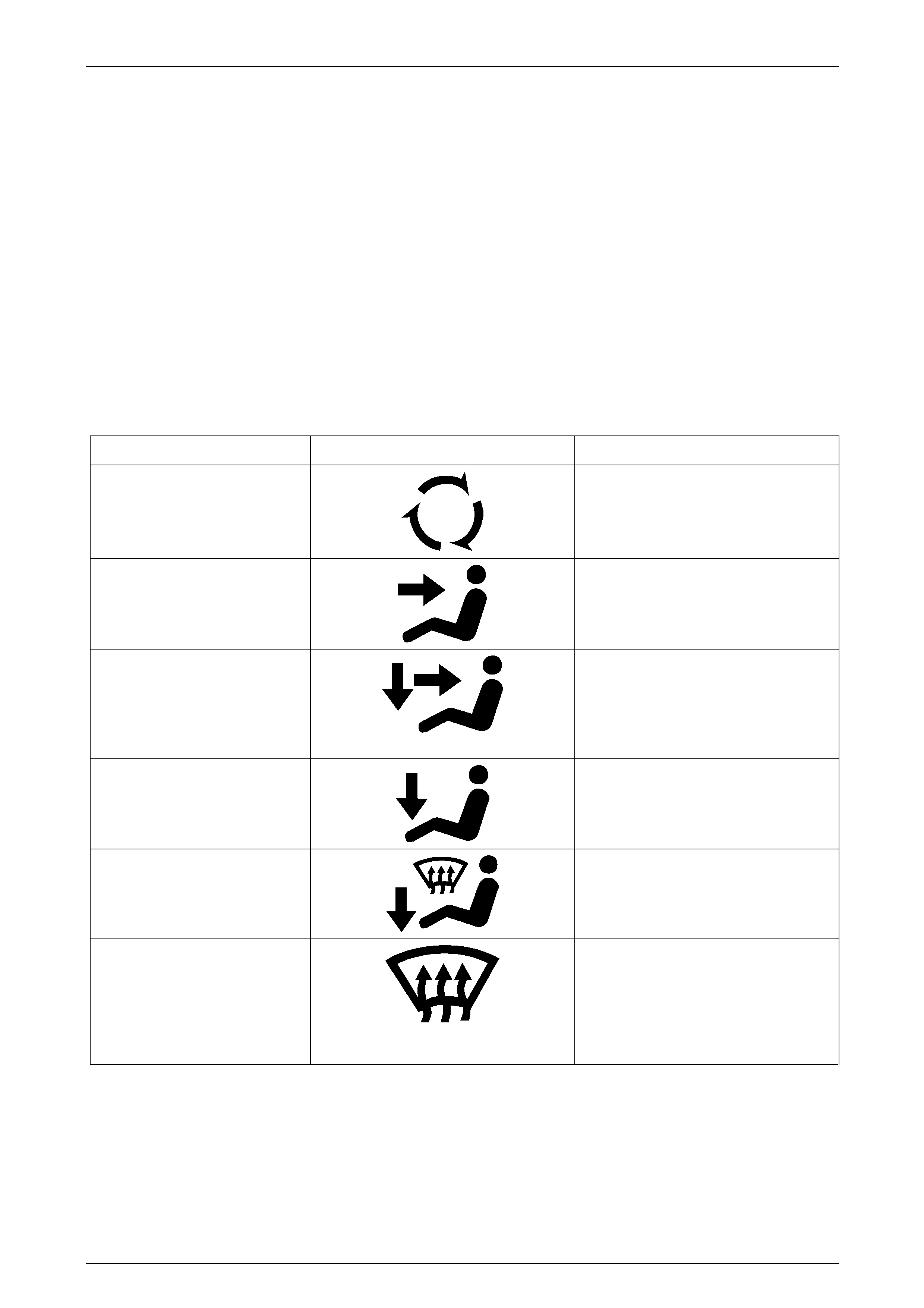

Manual Mode Control Symbols

Mode Symbol Description

100% Recirculated Air

With the manual mode control switched to

this position there is no fresh air entry into

the vehicle. Air is directed to the centre,

side and rear (where fitted) passenger

vents.

Face Mode

In this position air is directed to the

centre, side and rear (where fitted)

passenger vents.

Bi-Level

In this position the air is directed to the

floor, centre and side vents. When using

bi-level with the temperature control i n the

central position, warm air will be directed

to the feet and cooled air direct ed to the

face and side vents.

Floor

In this position the main airflow is directed

to the floor.

Blend

In this position air is directed to the floor

as well as to the demist ducts.

Demist

In this position air is directed to front

windscreen and front side windows only,

through the demist ducts. It is

recommended that the A/C button and

maximum heating be selected, as this will

provide accelerated dem isting

(dehumidification).

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-23

Page 2A-23

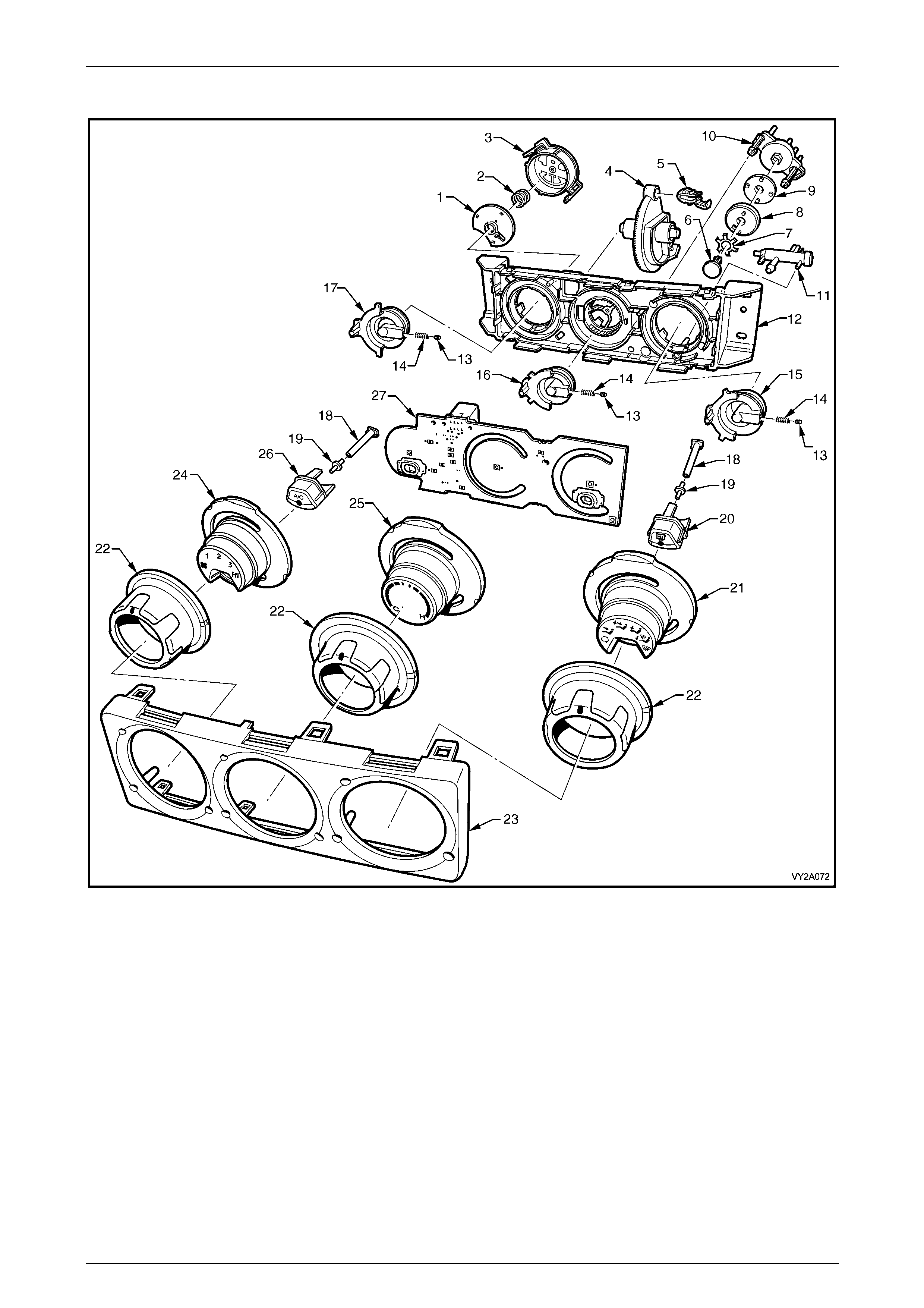

Components and Construction

The front and rear housings of the HVAC controller are cons tructed of plastic. The complete unit is assembled without

the use of fasteners; the front housing clips over the rear housi ng at six locations. Contained within this assemb ly is a

printed circuit board, which is retained within the rear housin g.

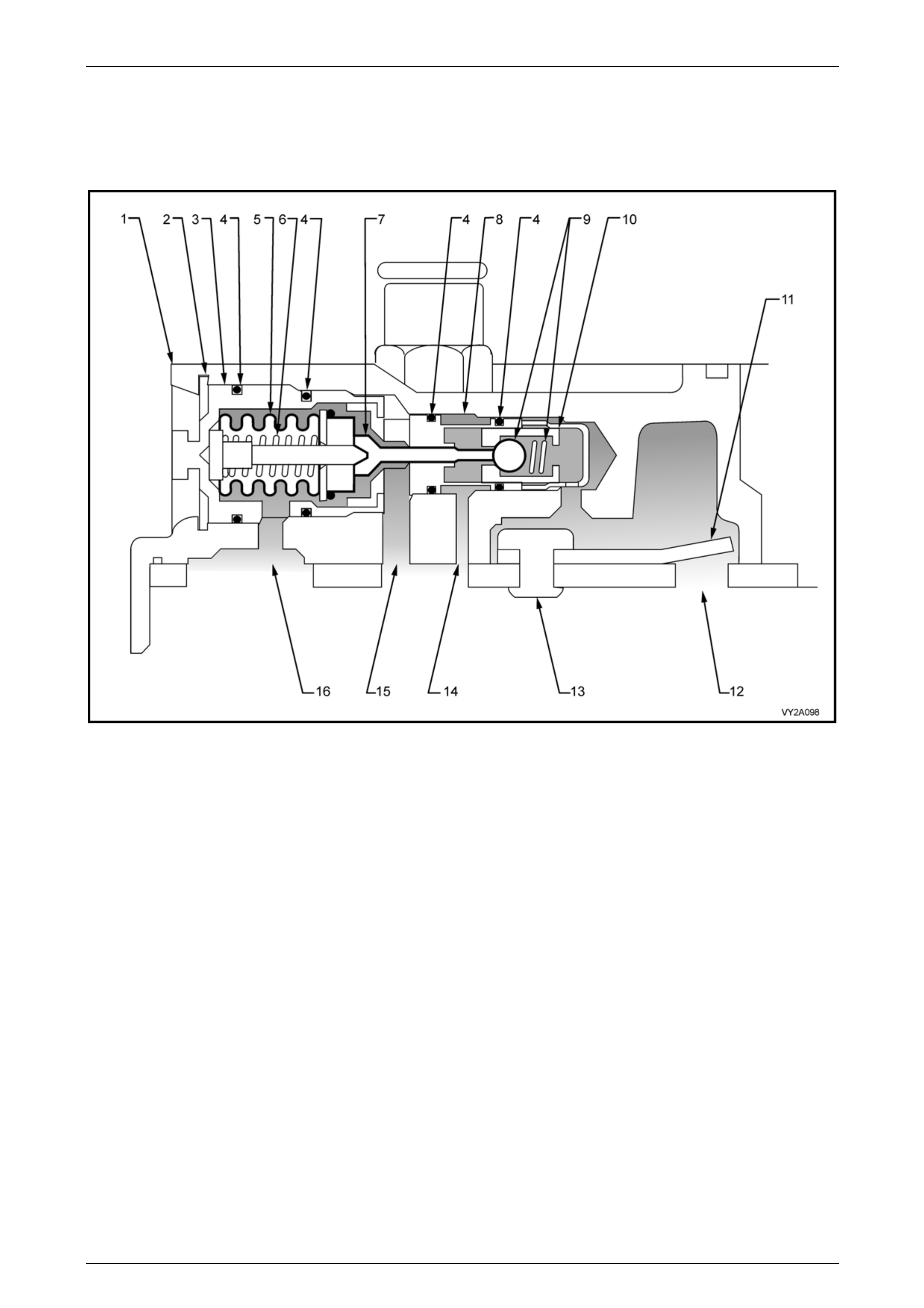

Attached to the back of the rear housing are the following components, refer to Figure 2A – 23:

• Water valve vacuum switch (14) – for water valve control (heater core flow).

• Mode switch vacuum valve (15) – for operation of the HVAC vacuum actuators.

• Pinion and crescent gear (11) – for mechanical actuation of the water valve vacuum switch and HVAC air mix

doors.

• Electrical switch / connector (9) – for blower fan operation.

• Electrical connector (10) – for illumination, A/C and heated rear window swit ching.

All these items are removable from the rear housing, except the illumination, A/C switch and heated rear window

electrical connector which is bonded to the printed circuit board.

There are no replaceabl e bulbs contained within the unit. Five LEDs provide the necessary illumination. If an LED fails to

function, the printed circuit board must be replaced.

Other components that may be individually serviced are the water valve vacuum switch, the mode switch vacuum valve

and the air mix door rod retainer (12). The three rotary switches and the front housing are service d as a u nit.

Figure 2A – 23

Legend

1 Blower Fan Switch

2 Blower Fan Speed Position Indicator

3 Temperature Control Switch

4 Temperature Control Position Indicator

5 Mode Position Switch

6 Mode Position Switch Position Indicator

7 Heated Rear Window Switch

8 Heated Rear Window Switch ON Indicator LED

9 Blower Fan Switch Connector

10 Illumination, A/C Switch and Heated Rear Window

Connector

11 Temperature Control Pinion

12 Air Mix Door Rod Retainer

13 Temperature Control Crescent Gear

14 Water Valve Vacuum Switch

15 Mode Switch Vacuum Valve

16 A/C Switch

17 A/C ON Indicator LED

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-24

Page 2A-24

Exploded View

Figure 2A – 24

Legend

1 Disc – Blower Fan Switch

2 Spring – Blower Fan Switch

3 Housing – Blower Fan Switch

4 Crescent Gear

5 Air Mix Door Rod Retainer

6 Retaining Pin – Vacuum Valve

Mode Switch

7 Preload Spring – Vacuum Valve

Mode Switch

8 Disc – Vacuum Valve Mode

Switch

9 Gasket – Vacuum Valve Mode Switch

10 Housing – Vacuum Valve Mode Switch

11 Water Valve Vacuum Switch

12 Rear Housing

13 Detent Ball (3 places)

14 Detent Spring (3 places)

15 Shaft – Mode Switch

16 Shaft – Temperature Switch

17 Shaft – Blower Fan Switch

18 Diode Illumination Tube (2 places)

19 Diode Illumination Lens (2 places)

20 Heated Rear Window Switch Button

21 Bezel – Mode Switch

22 Dial (3 places)

23 Front Housing

24 Bezel – Blower Fan Switch

25 Bezel – Temperature Switch

26 A/C Switch Button

27 Printed Circuit Board

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-25

Page 2A-25

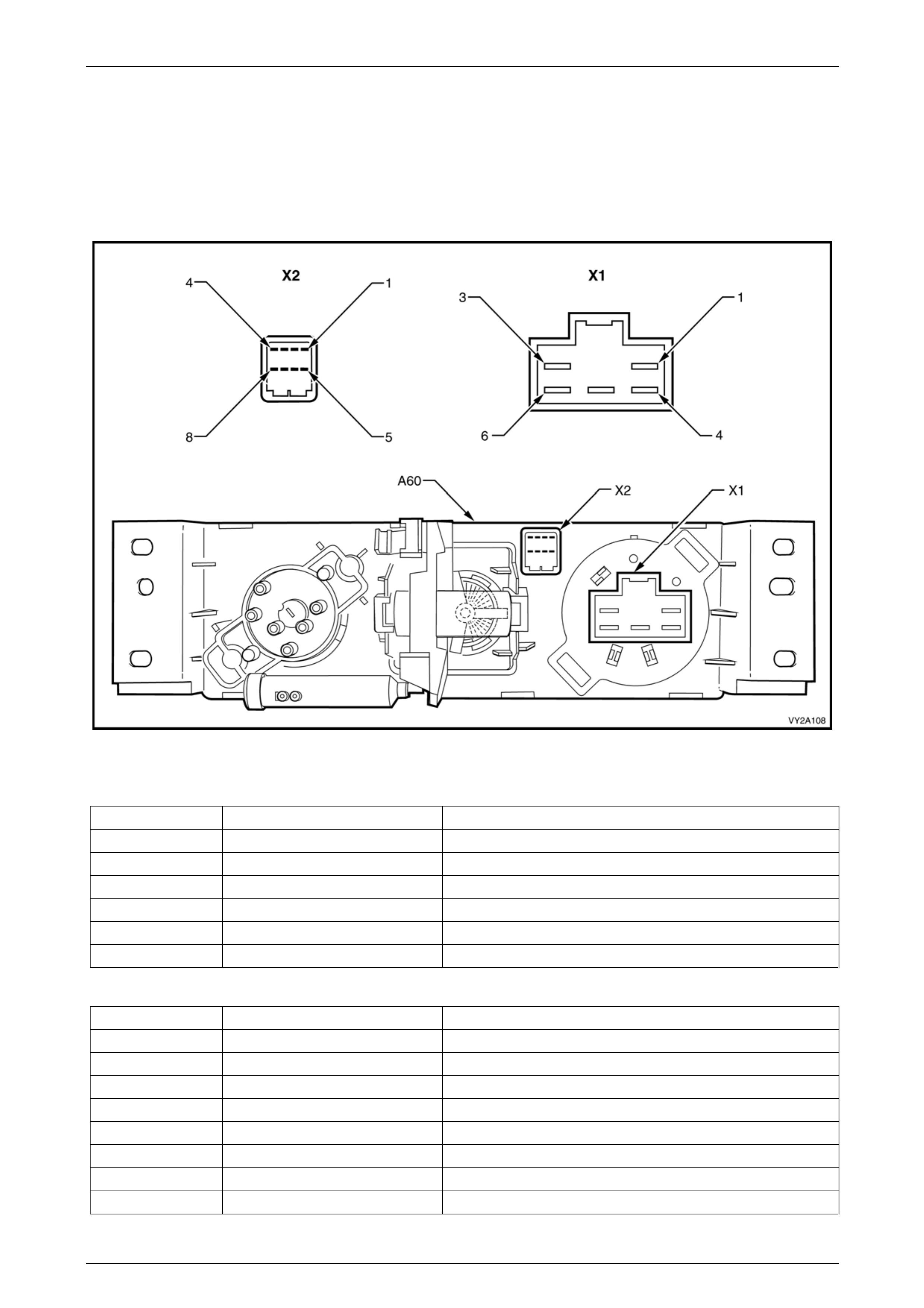

Electrical Connections

Two electrical connectors are located at the rear of the manual HVAC controller. In accordance with the Integrated

Vehicle Electrical Design (IV ED) standard, the controller is designated as A60 and the connectors ar e designated as X1

and X2.

Connector X1 is moulded to the rear of the b lower switch and connector X2 is bonded to the rear of the printed circuit

board. Figure 2A – 25 provides a view of the connector terminal assignments and the following tables provide information

on their function.

Figure 2A – 25

Connector X1

Pin Number Wire Colour Function

X1-1 Orange / Green Ground via Blower Inhibitor Relay

X1-2 – Not Connected

X1-3 Dark green / Yellow Fan Speed 1 – Blower Resistor Assembly

X1-4 Yellow / Black Fan Speed HI – Blower Relay

X1-5 Red / Yellow Fan Speed 3 – Blower Resistor Assembly

X1-6 Red / Green Fan Speed 2 – Blower Resistor Assembly

Connector X2

Pin Number Wire Colour Function

X2-1 Orange Rear Window Demister Select to BCM

X2-2 Red / White Air-conditioning Select to BCM

X2-3 Red / Black Air-conditioning ON LED Indication and Status to BCM

X2-4 Grey Instrument Dimming Control to BCM

X2-5 Pink / Blue Fuse F13 – Power for Switching and LED Indication

X2-6 – Not Connected

X2-7 Black / Red Demister ON LED Indication and Status to BCM

X2-8 Brown / White F use F 11 – Power for Instrument Illumination

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-26

Page 2A-26

2.4 Heater

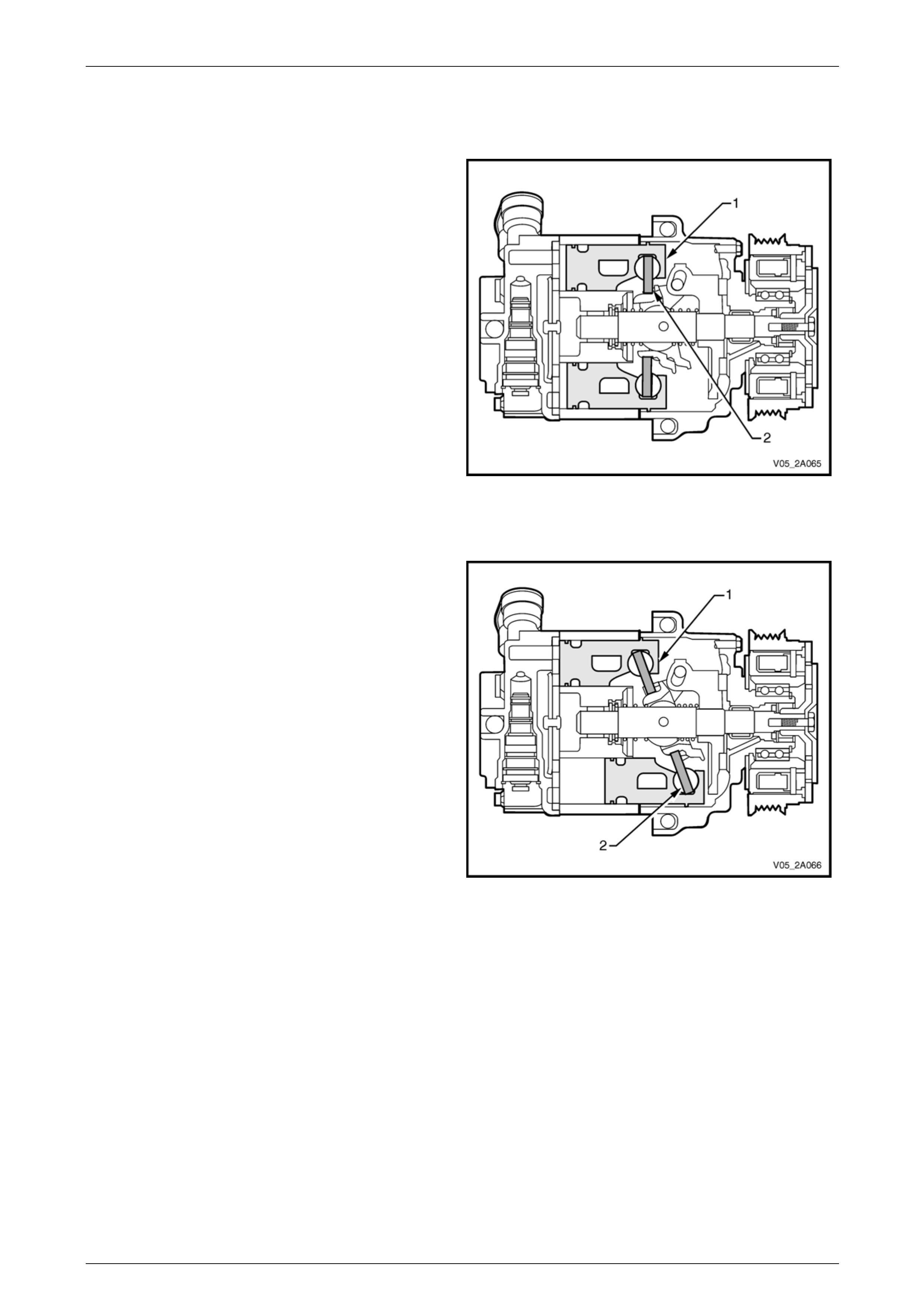

Temperature Control Switch – Manual A/C

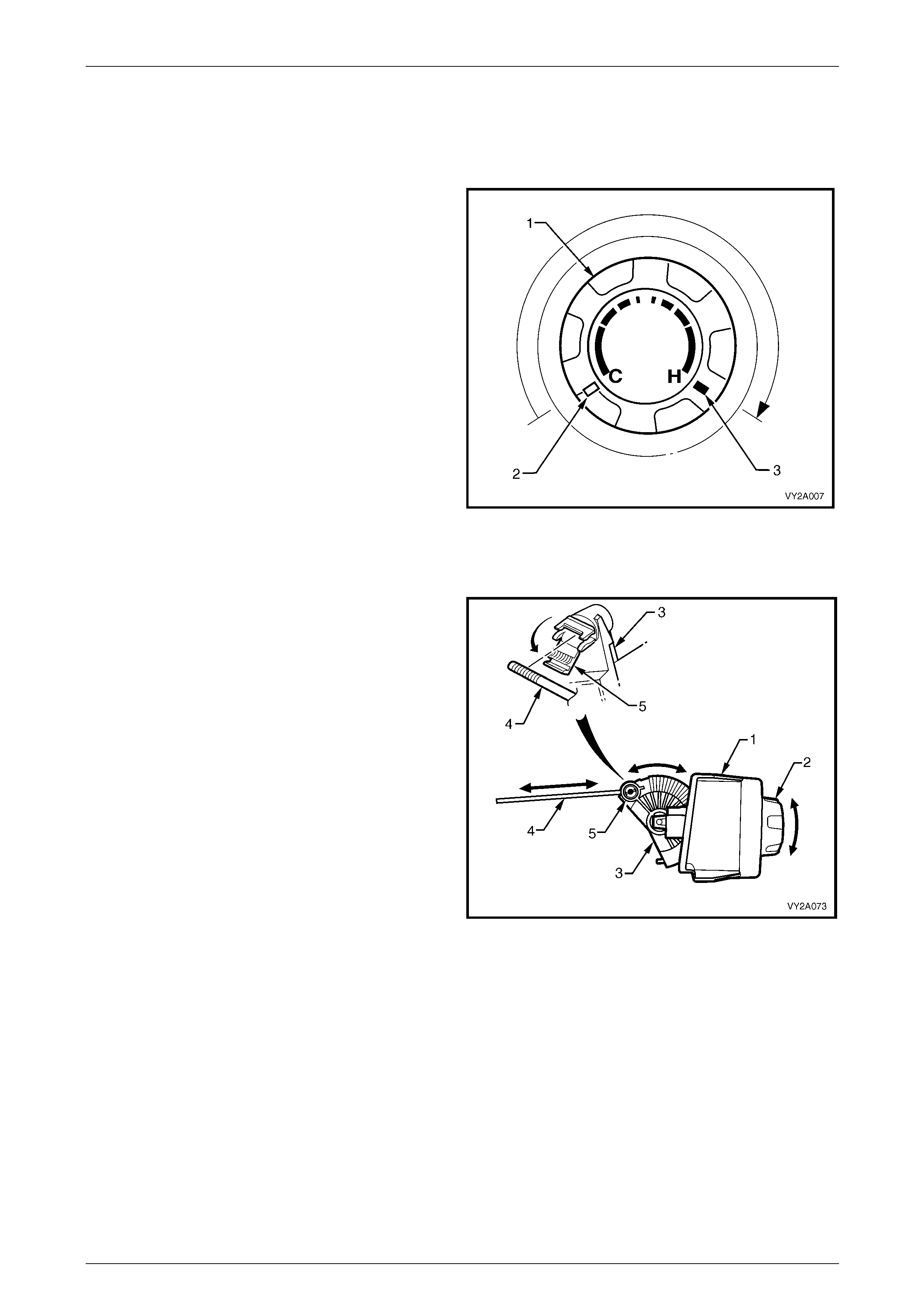

When the temperature switch (1) is turned clockwise from

the full cold position (2) to the full hot position (3), the pinion

and crescent gear mounted to the rear of the controller are

rotated. This action simultaneously opens HVAC airflow

through the heater core and vents vacuum from the water

valve allowing heated coolant to flow through the heater

core.

Figure 2A – 26

Air Mix Door Control Mechanism – Manual A/C

On all manual air-conditioni ng systems the air mix door

function is the only HVAC airflow control not to use a

vacuum actuator.

An actuating rod provides a mechanical connection between

the HVAC controller (1) and the HVAC unit. The rod is

installed between the tempera t ure switch mechanism and

the air mix door levers.

The amount of airflow through the heater cor e is determined

by the degree of opening at the air mix door. When the

temperature switch (2) is rotated, the air mix door is opened

or closed by the crescent gear (3) pushing or pulling the

actuating rod (4). The rod is attached to the crescent gear

by a pivoting rod retainer (5).

The assembled position of the retainer on the actuating rod

is adjustable. The retainer must clamp the actuating rod at a

specific location if the correct relative positions of the air mix

door and temperature switch are to be maintained.

For correct installation of the actuating rod, refer to

Section 2C HVAC Climate Control (Manual A/C) – Removal

and Installation. Figure 2A – 27

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-27

Page 2A-27

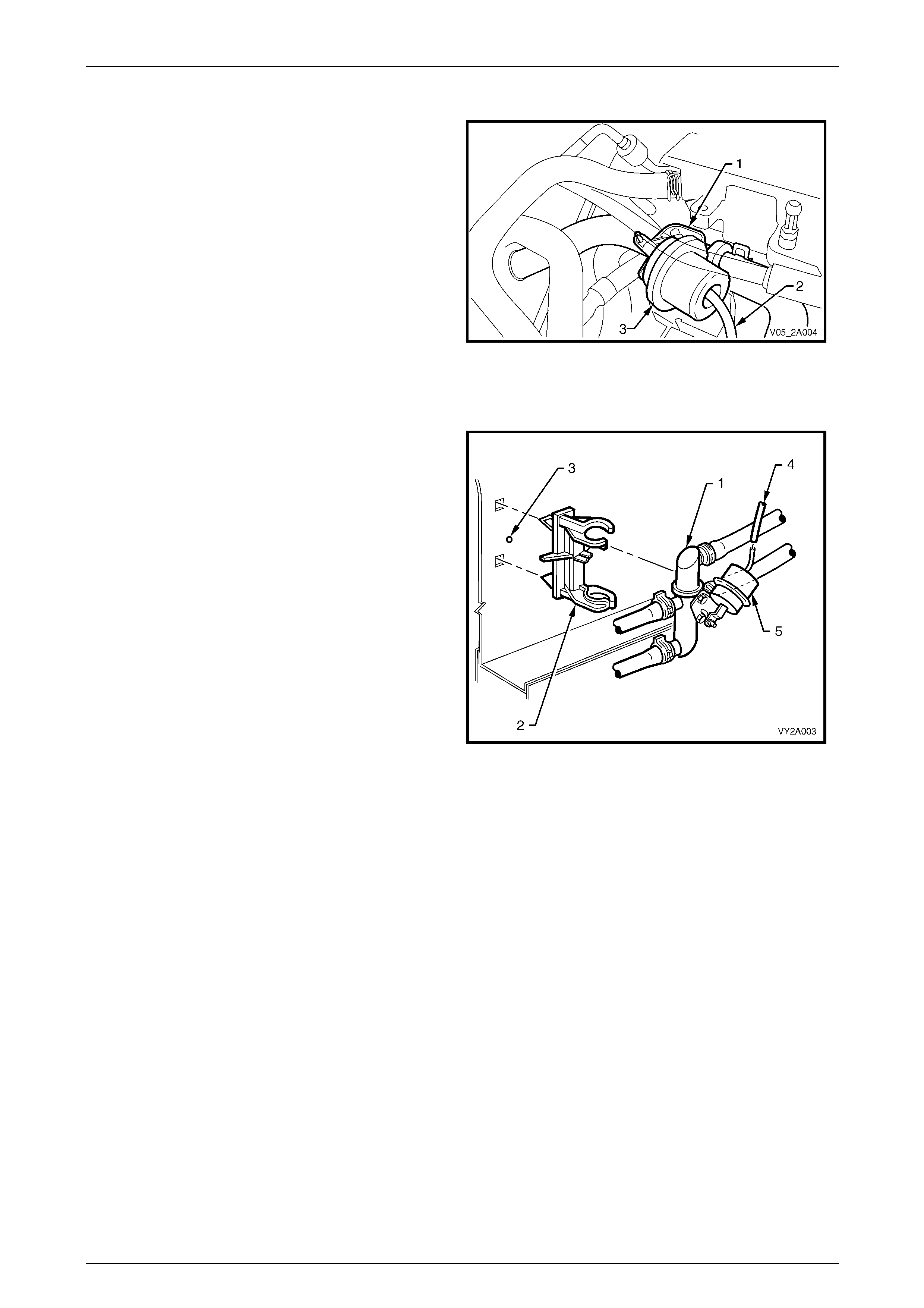

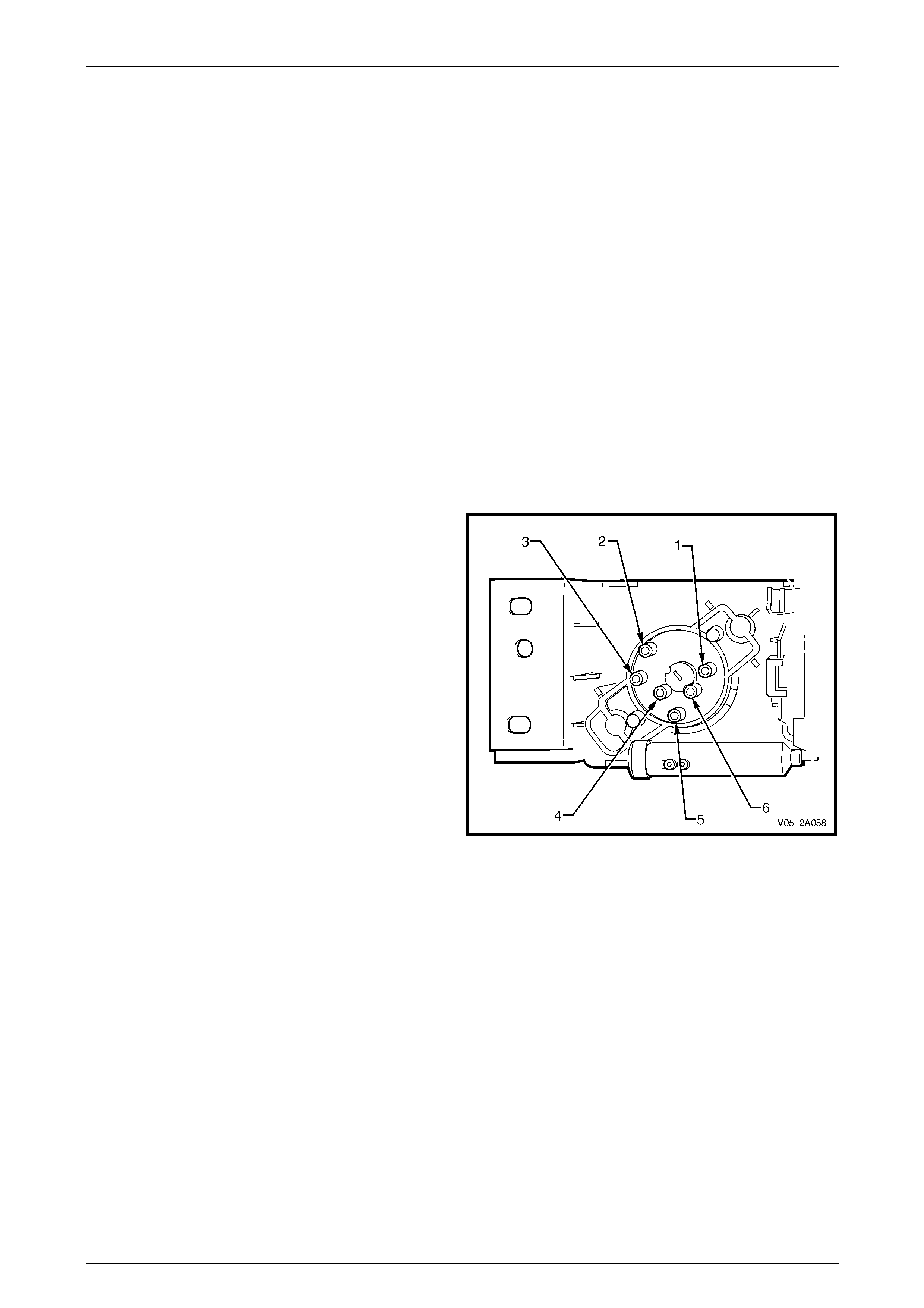

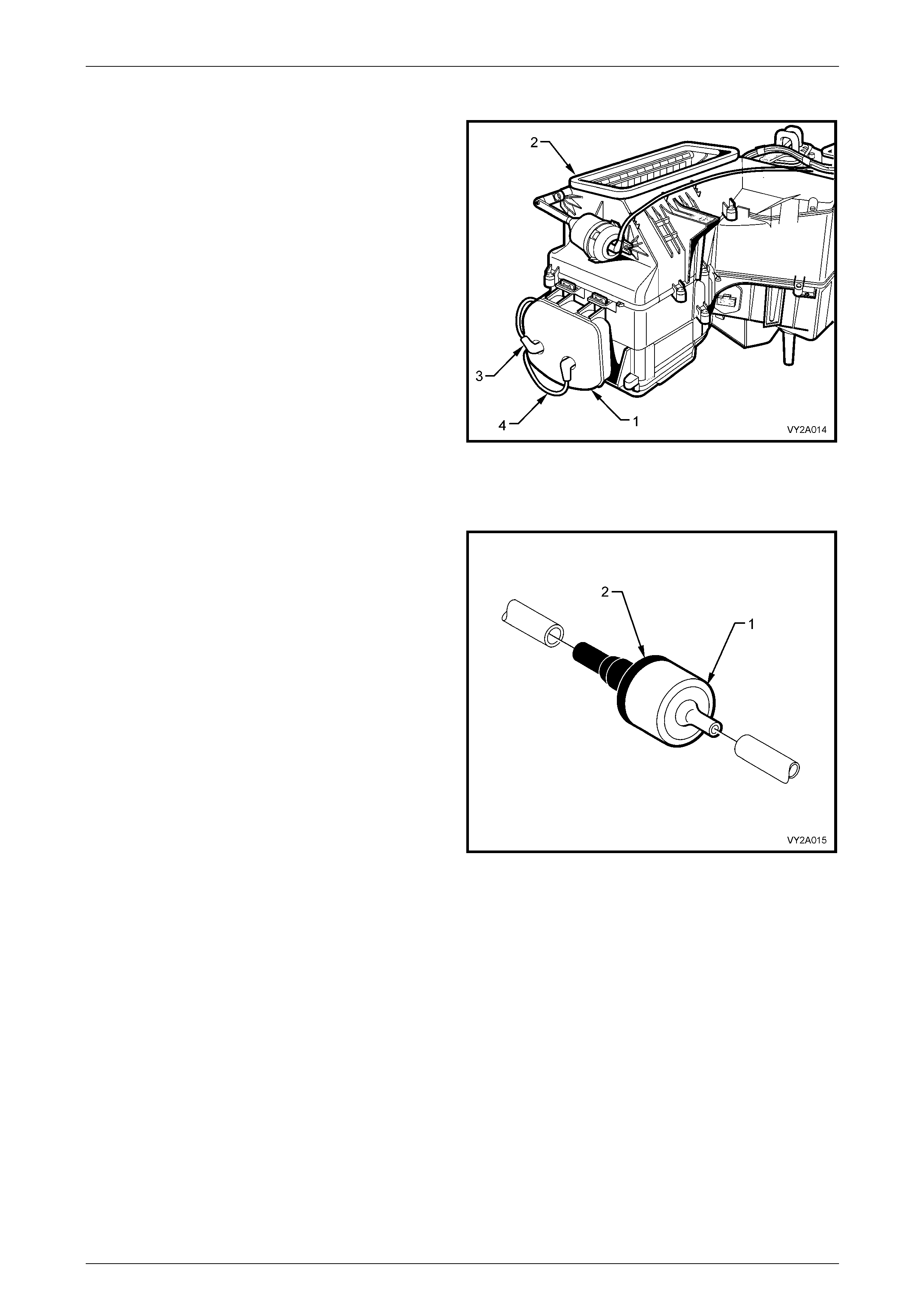

Water Valve Assembly – V6

The heater water valve is located in the engine bay and

rests above the right-hand side camshaft cover.

It is attached to a mounting bracket (1) and bolt on the

engine block.

The vacuum line (2) attached to the water valve vacuum

actuator (3) is connected to the water valve vacuum switch

mounted on the HVAC controller.

When full vacuum is applied to the water valve actuator, full

closure of the valve occurs and no coola nt will flow through

the heater core.

Figure 2A – 28

Water Valve Assembly – GEN III V8

The heater water valve assembly (1) is located in the engine

bay attached to a mounting clip (2), on the ri ght-hand side

wheelhouse panel (3).

The vacuum line (4) attached to the water valve vacuum

actuator (5) is connected to the water valve vacuum switch

mounted on the HVAC controller.

When full vacuum is applied to the water valve actuator, full

closure of the valve occurs and no coola nt will flow through

the heater core.

Figure 2A – 29

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-28

Page 2A-28

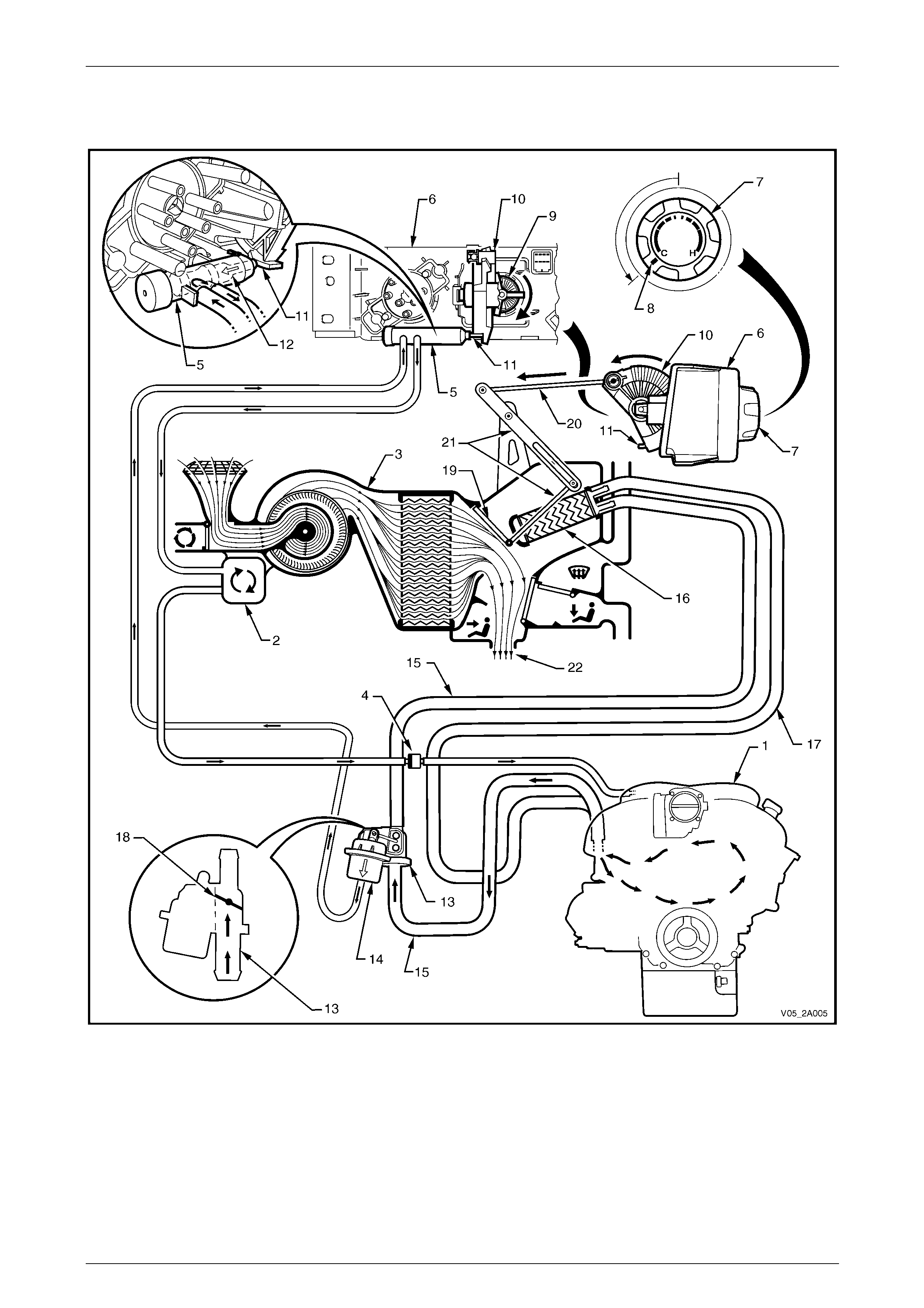

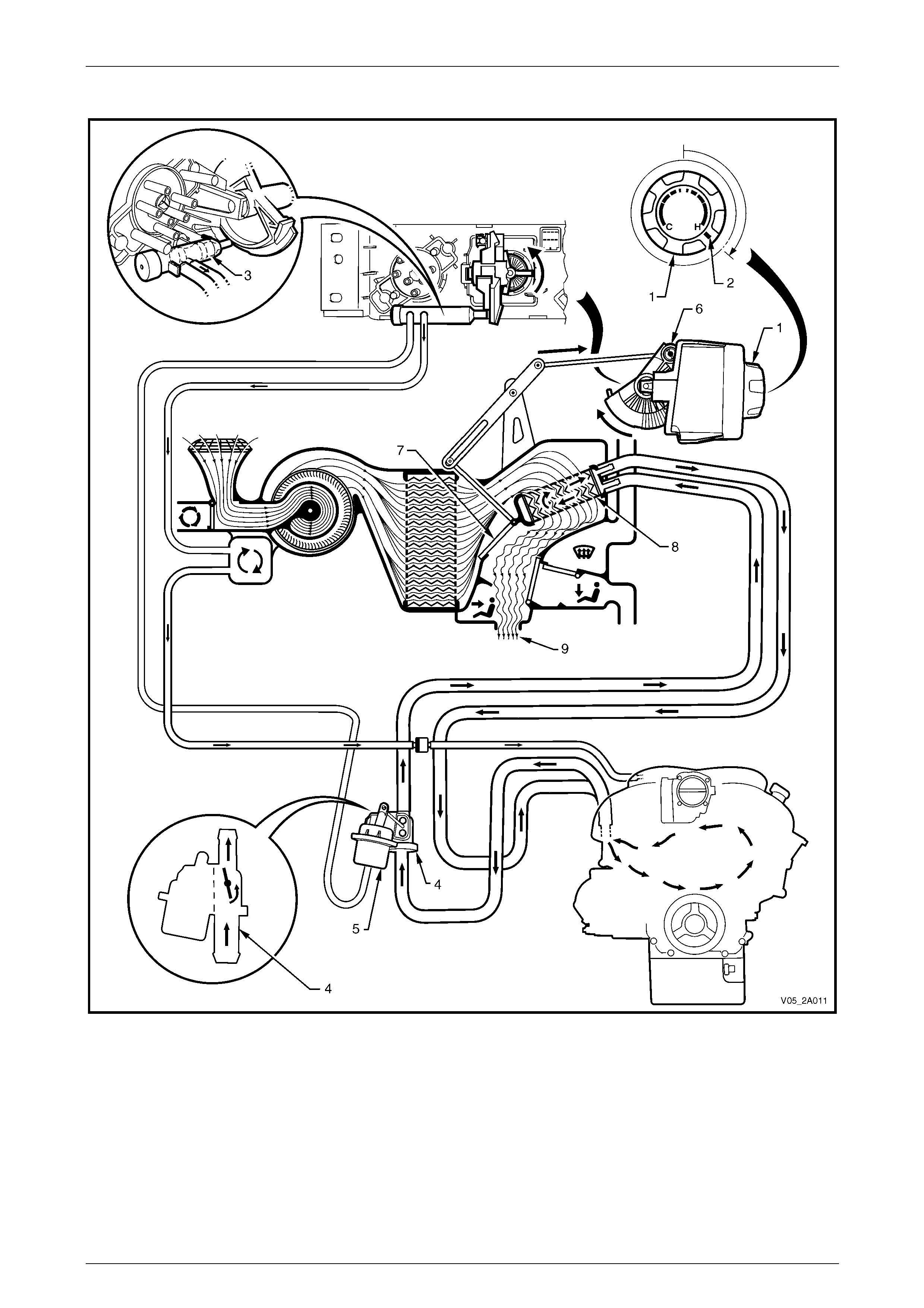

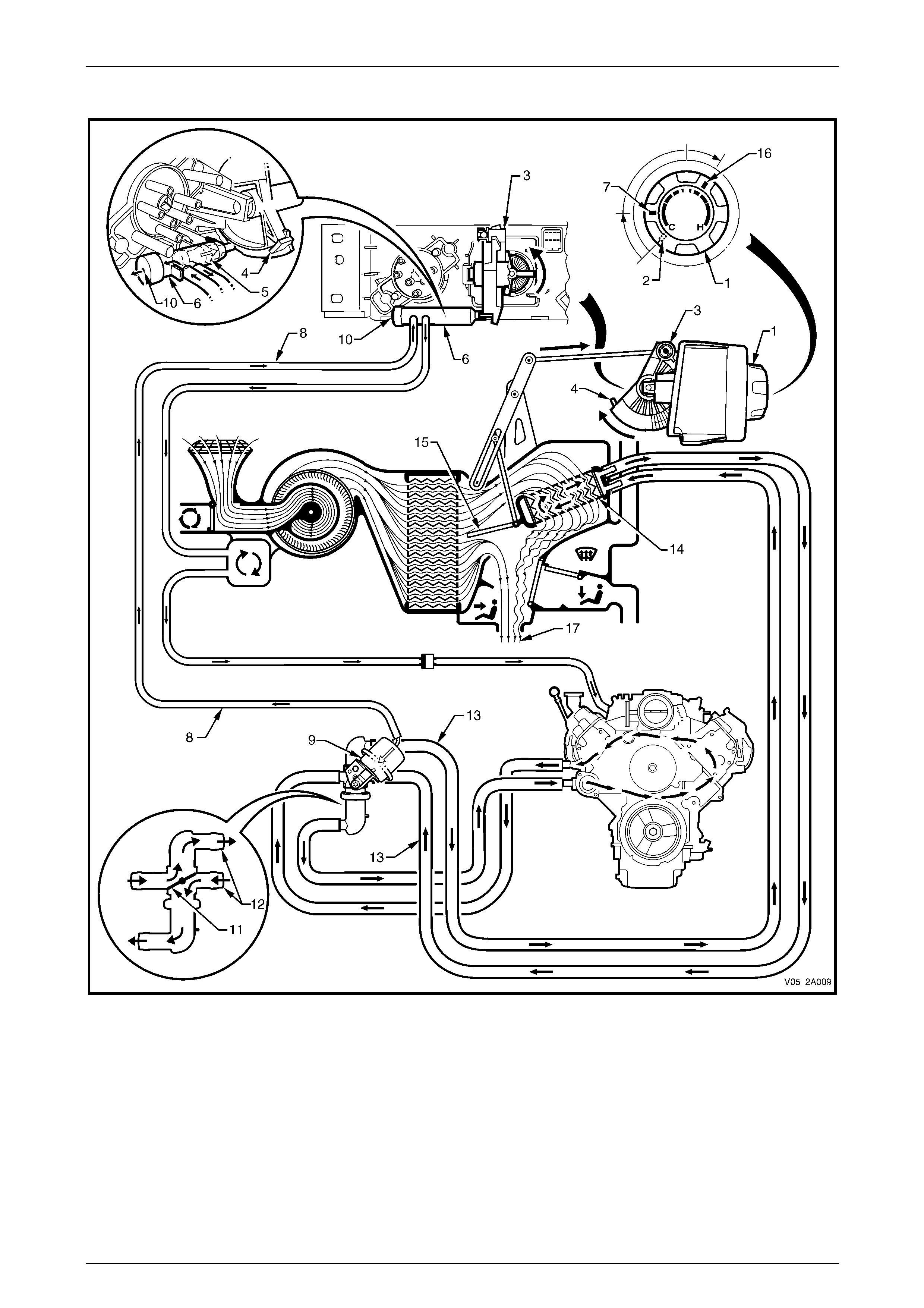

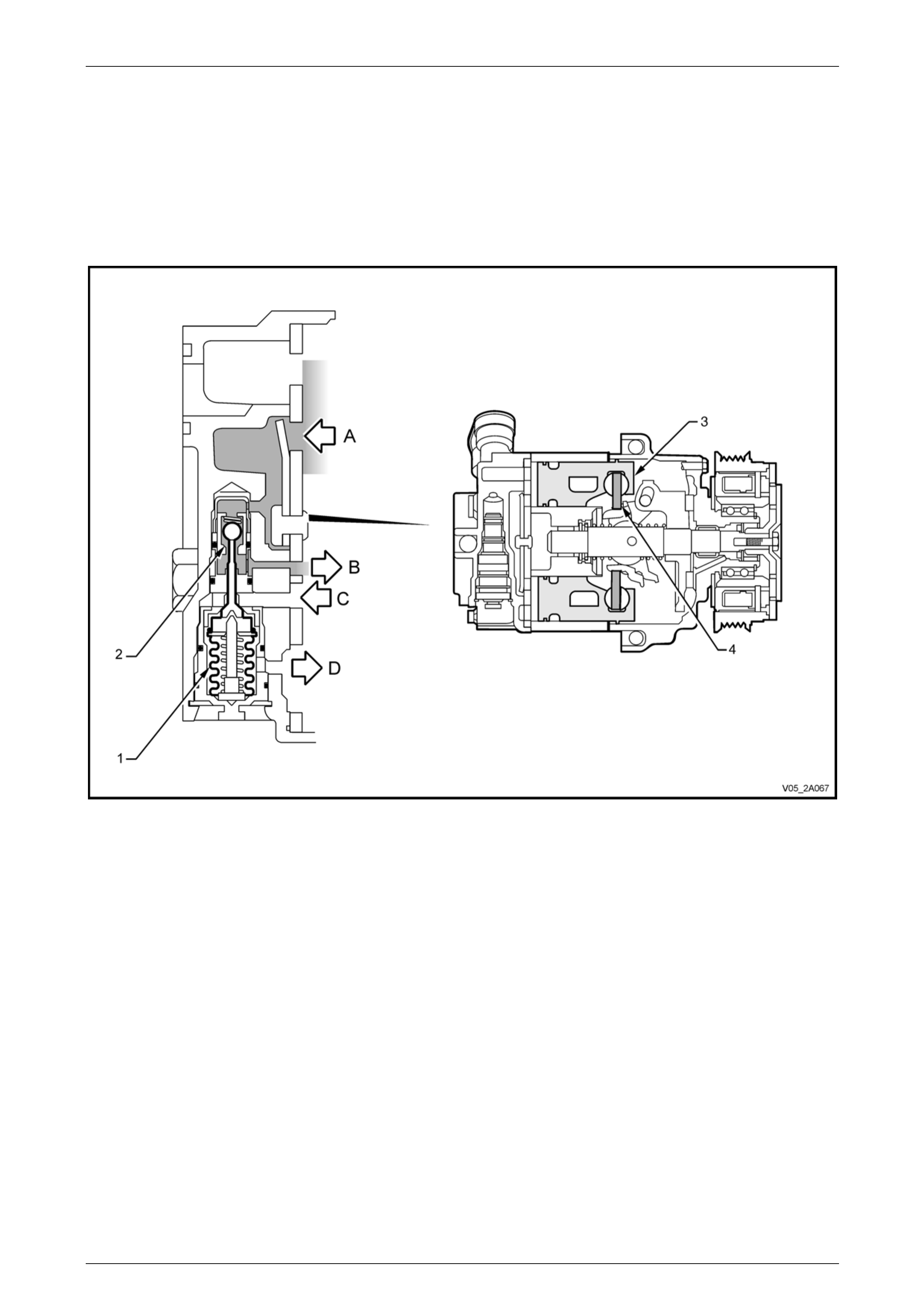

Heater Operation – Manual A/C – V6

Full Cold

Figure 2A – 30

Vacuum generated within the inle t manifold (1) o f the eng ine is stored within the vacu um tank (2) mo unted on the side the

HVAC unit (3), refer to Figure 2A – 30. Vacuum is retained within the HVAC system by the one way check valve (4) and is

directed to the water valve vacuum switch (5) mounted to the rear of the HVAC controller (6). When the temperature switch

(7) is turned to the full co ld positi on (8 ), the pinion gea r (9) rotate s the crescent ge ar (10) so the ramp (11) on th e cres cent

gear pushes the plun ger (12) insi de the w ater val ve va cuu m swit ch inward aga in st spring pre s sure . In th is posi tion , t he

water valve vacuum switch allows vacuum to be directed to the water valve (13). When vacuum is applied to the water valve

vacuum actuator (14), no coolant can flow through the inlet heater hose (15), the heater core (16) or the outlet heater hose

(17) because the disc (18) in the water valve is in the closed position.

The crescent gear is also mechan ically connected to the HVAC air mix door (19) via the actuating rod ( 20) and

levers (21). As well as operating the pl unger of the water valve vacuum switch, the crescent gear simulta neously locates

the air mix door in a position that does not allow any air to flow through the heater core i n the full cold mode. The result is

that all air (22) entering the vehicle cabin will be cold air.

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-29

Page 2A-29

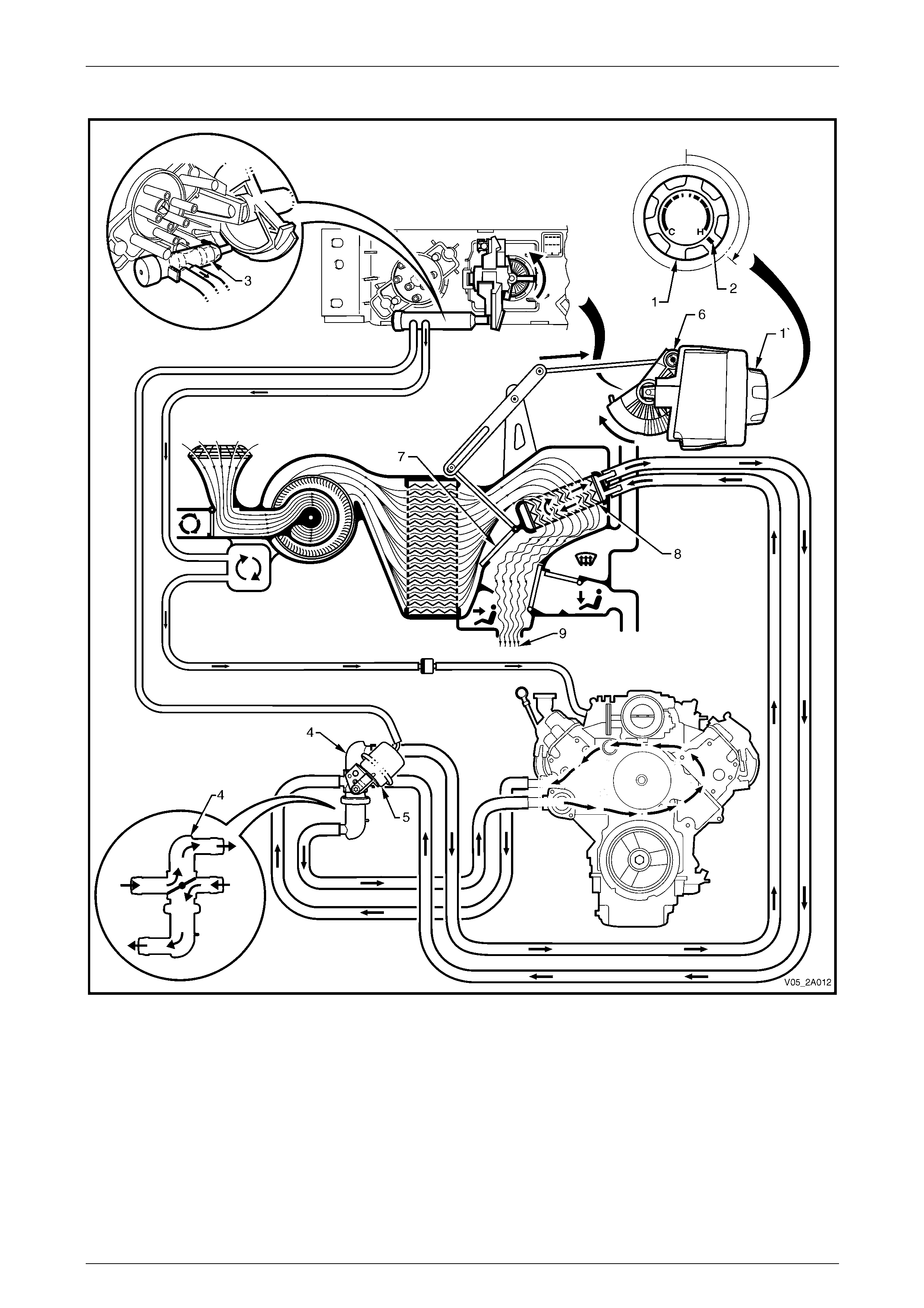

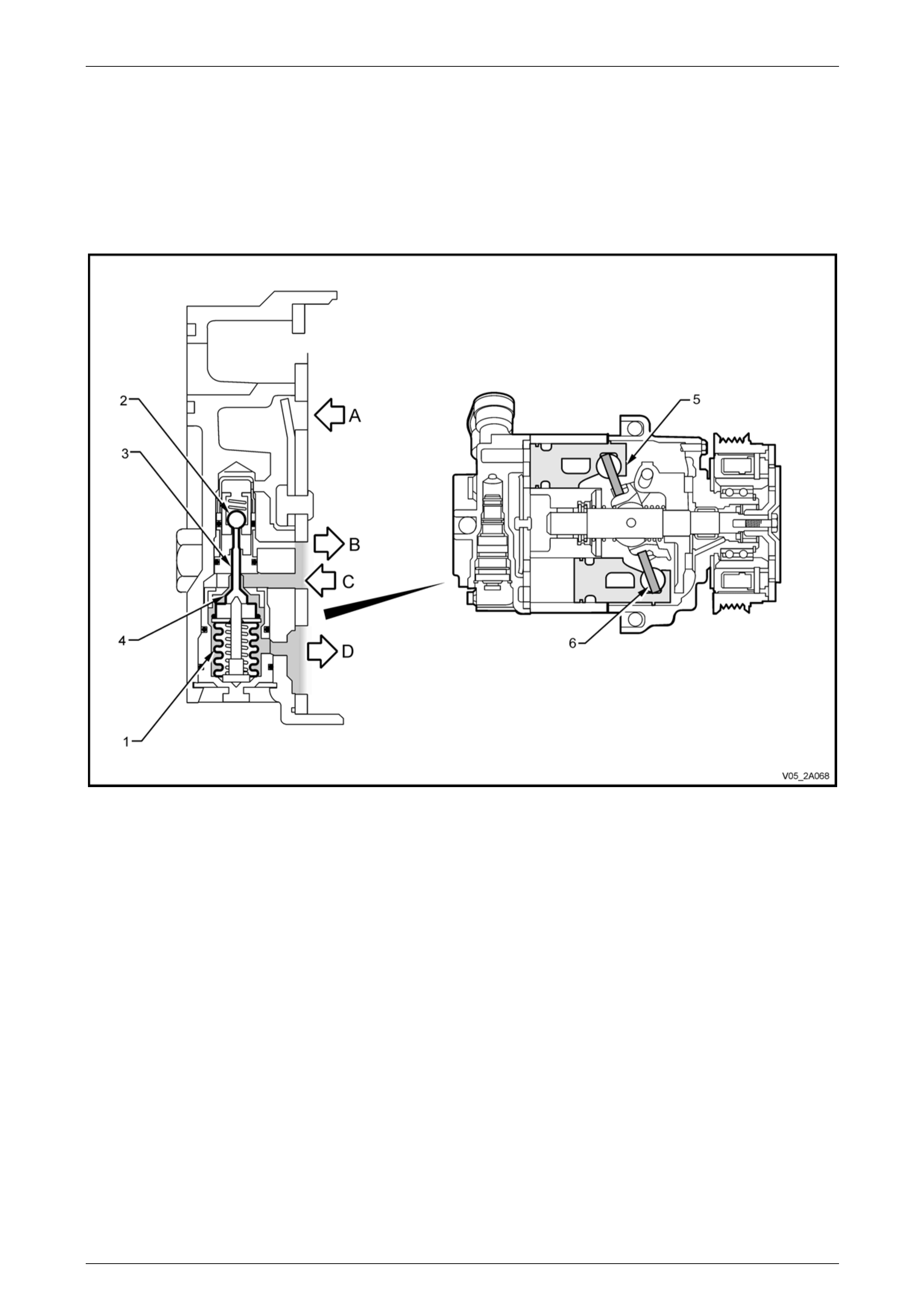

Warm

Figure 2A – 31

When the temperature switch (1) is turned from the full cold position (2), the crescent gear (3) rotates backwards moving

the ramp (4) away from the plunger (5) of the water valve vacuum switch (6), refer to Figure 2A – 31. Spring pressure

moves the plunger out ward and at the third detent positi on (7) of the temperature switch, the vacuum line (8) to the water

valve actuator (9) is vented through the exhaust port (10) of the water valve vacuum switch. When the actuator is

relieved of vacuum, the disc (11) in the water valve (12) will rotate and allow hot water to flow through inlet heater hose

(13) into the heater core (14) and through the outlet heater hose (15) back to the engine. As the crescent gear rotates

backward, it pulls the air mix door (16) ope n. W hen the temperature switch is turned to a warm position (17), the air mix

door will be partially open. This will cause some incoming air to pass through the heater core and some to air to bypass

the heater core. The mixture of heated and cool air (18) will result in warm air entering the vehicle cabin.

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-30

Page 2A-30

Full Hot

Figure 2A – 32

When the temperature switch (1) is turned to in the full hot positio n (2) the water valve vacuum switch plunger (3)

remains in the same position, refe r to Figure 2A – 32. Therefore, the water valve (4) remains in the fully o pen position

because the water valve actuator (5) is devoid of vacuum.

In the full hot position the crescent gear (6) will be rotated fully rearward. This action will move the air mix door (7) to a

position that directs all incoming air thro ugh the heater core (8). Therefore, all air (9) entering the vehicle cabin will be

heated air.

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-31

Page 2A-31

Heater Operation – Auto A/C – V6

Full Cold

Vacuum generated within the engine inlet manifold (1) is stored within the vacuum tank (2), which is mounted on the side

the HVAC unit (3), refer to Figure 2A – 33. Vacuum is retained within the system by the one-way check valve (4) and is

directed to the vacuum solenoid pack (5). When the temperature is set to a cold position, the solenoid pack allows vacuum

to be directed to the water valve vacuum actuator (6). No coolant can flow through the inlet heater hose (7), the heater

core (8) or the outlet heater hose (9) because the disc (10) in the water valve (11) is in the closed position.

An air mix door motor (12) is mechanically connected to the air mix door (13) via an actuating rod (14) a nd levers (15).

When the temperature is set to a cold position, the motor operates and mo ves the air mix door to a position that does not

allow any air to flow through the heater core. The result is that all air (16) entering the ve hicle cabin will be ambient

temperature or cooled if the air-conditioning is operating.

Figure 2A – 33

Legend

1 Inlet Manifold

2 Vacuum Tank

3 HVAC Unit

4 One-way Check Valve

5 Vacuum Solenoid Pack

6 Water Valve Vacuum Switching Valve

7 Water Valve Vacuum Actuator

8 Inlet Heater Hose

9 Heater Core

10 Outlet Heater Hose

11 Water Valve Disc

12 Water Valve

13 Air Mix Door Motor

14 Air Mix Doors

15 Actuating Rod

16 Actuating Levers

17 Cabin Air

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-32

Page 2A-32

Warm

When the temperatu re is set to a warm posi tion, th e vacuum sol enoid pack va lve (1) clo ses, and the vacuum a t the wate r

valve vacuum actuator (2) is vented, refer to Figure 2A – 34. Coolant can flow now flow through the inlet heater hose (3), the

heater core (4) and outlet heater hose (5) because the disc (6) in the water valve (7) is in the open position.

When the temperature is set to a warm position, the air mix door motor (8) also operates and moves the air mix door (9)

to a partially open position that allows some air to flow through the heater core. The position of the door is variable,

based on the temperature set. A position sensor within the motor provides feedback to the control module. The result is

that all air (10) entering the vehicle cabin will be warm.

Figure 2A – 34

Legend

1 Water Valve Vacuum Switching Valve

2 Water Valve Vacuum Actuator

3 Inlet Heater Hose

4 Heater Core

5 Outlet Heater Hose

6 Water Valve Disc

7 Water Valve

8 Air Mix Door Motor

9 Air Mix Doors

10 Cabin Air

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-33

Page 2A-33

Full Hot

When the temperature is set to the hot position, the air mix door motor (1) operates and moves the air mix door (2) to the

fully open position which directs all air through the heater core (3), refer to Figure 2A – 35. The result is that all air (4)

entering the vehicle cabin will be hot.

Figure 2A – 35

Legend

1 Air Mix Door Motor

2 Air Mix Doors 3 Heater Core

4 Cabin Air

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-34

Page 2A-34

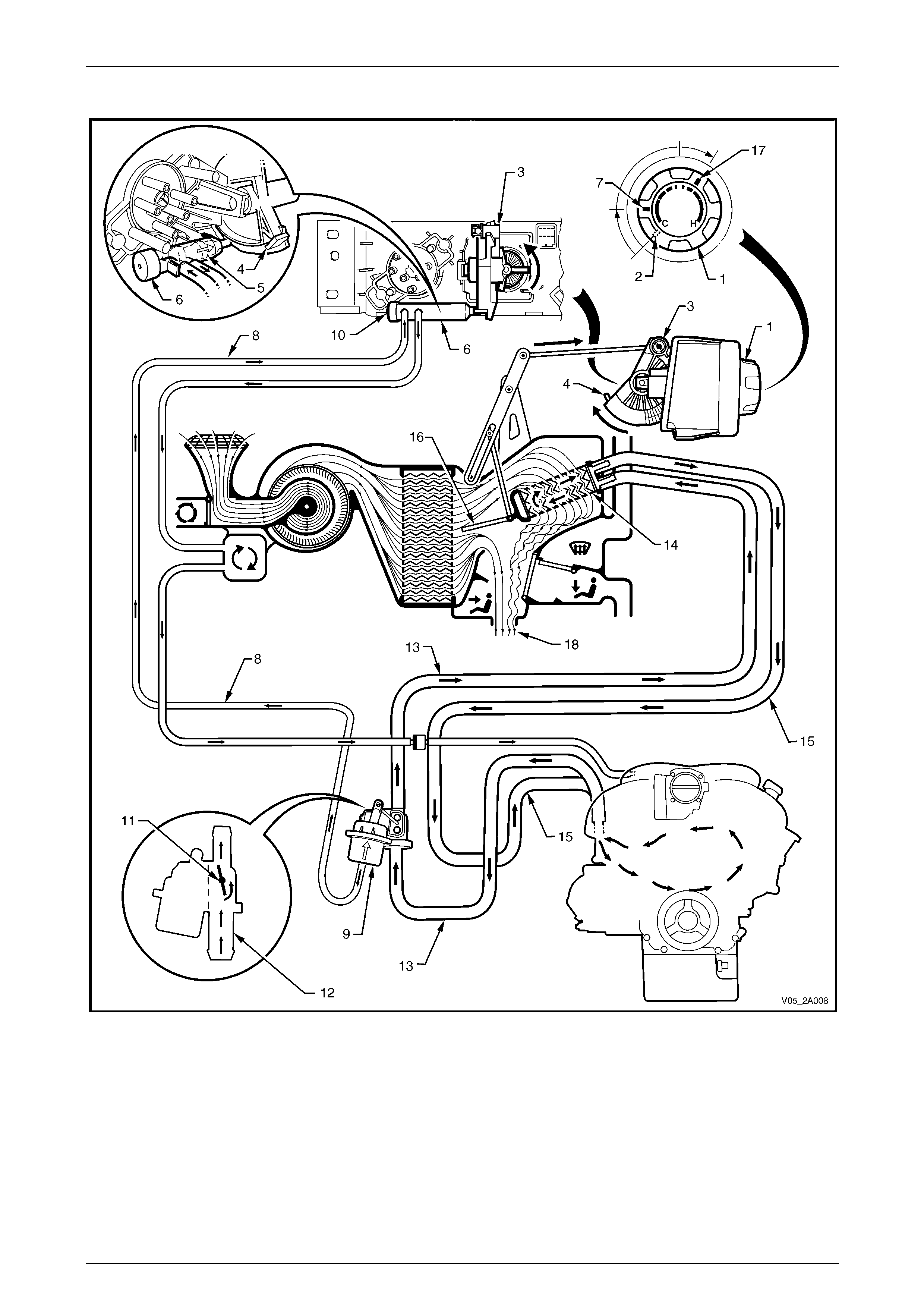

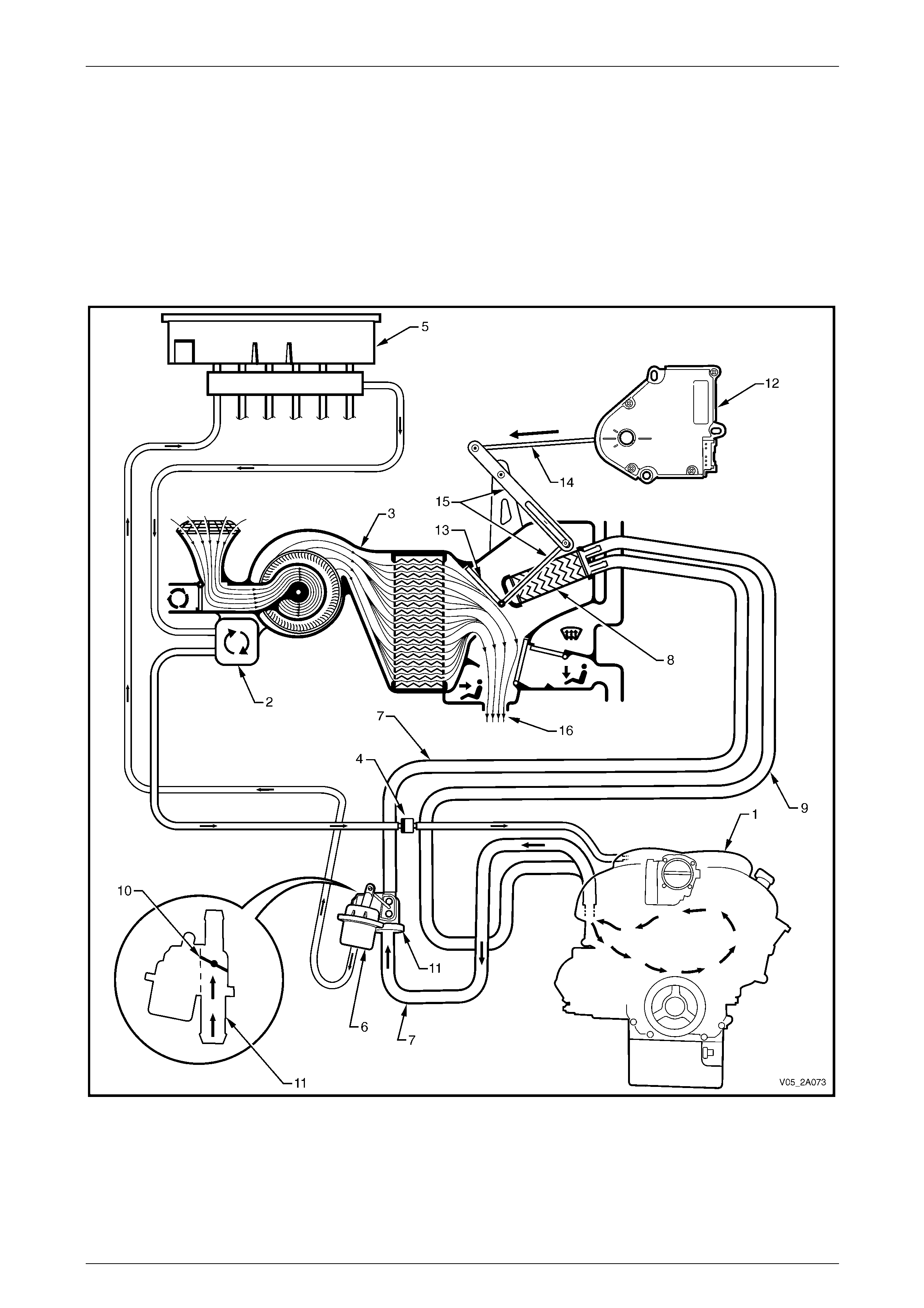

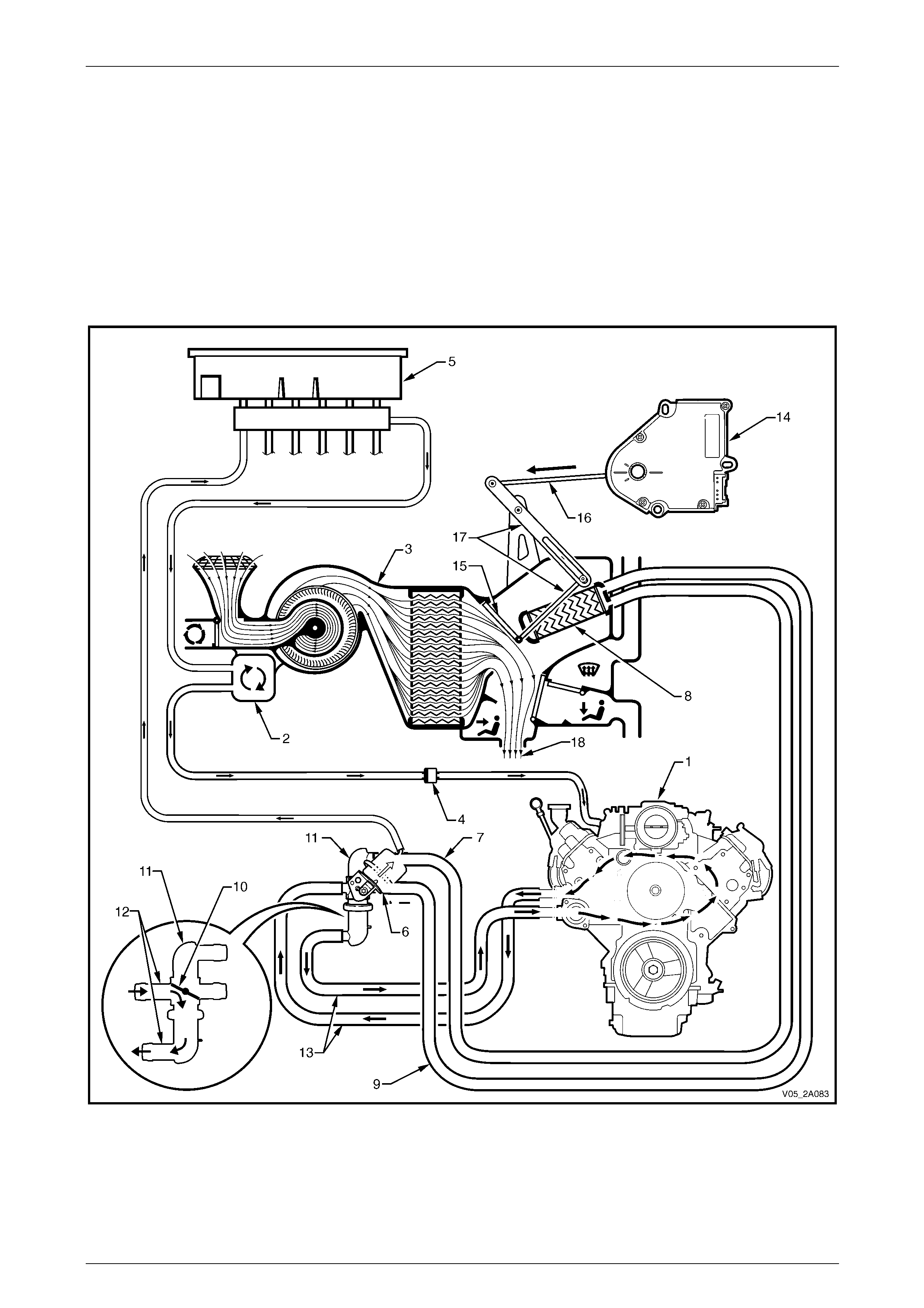

Heater Operation – Manual A/C – GEN III V8

Full Cold

Figure 2A – 36

Vacuum generated within the inlet manifold (1) of the engine is stored within the vacuum tank (2) mounted on the side

the HVAC unit (3), refer to Figure 2A – 36. Vacuum is retained within the HVAC system by the one way check valve (4)

and is directed to the water valve vacuum switch (5) mounted to the rear of the HVAC cont roller (6). W he n the

temperature switch (7) is turned to the full cold position (8), the pinion gear (9) rotates the crescent gear (10) so the ramp

(11) on the crescent gear pushes the plunger (12) inside the water valve vacuum switch inward against spring pressure.

In this position, the water valve vacuum switch allows vacuum to be directed to the water valve (13). When vacuum is

applied to the water valve vacuum actuator (14), no coolant can flow through the heater core (15). However, coolant is

still able to flow from the engine through the water valve via its engine side ports (16) and engine side heater hoses (17).

The crescent gear is also mechan ically connected to the HVAC air mix door (18) via the actuating rod (19) and

levers (20). As well as operating the pl unger of the water valve vacuum switch, the crescent gear simulta neously locates

the air mix door in a position that does not allow any air to flow through the heater core i n the full cold mode. The result is

that all air (21) entering the vehicle cabin will be cold air.

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-35

Page 2A-35

Warm

Figure 2A – 37

When the temperature switch (1) is turned from the full cold position (2), the crescent gear (3) rotates backwards moving

the ramp (4) away from the plunger (5) of the water valve vacuum switch (6), refer to Figure 2A – 37. Spring pressure

moves the plunger out ward and at the third detent positi on (7) of the temperature switch, the vacuum line (8) to the water

valve actuator (9) is vented through the exhaust port (10) of the water valve vacuum switch. When the actuator is

relieved of vacuum, the disc (11) in the water valve will rotate and allow hot water to flow through the cabin side water

valve ports (12) and the cabin side heater ho ses (13) into the heater core (14). As the crescent gear rotates backward, it

pulls the air mix door (15) open. When the temperature switch is turned to a warm positio n (16), the air mix door will be

partially open. This will cause some incoming air to pass through the heater core and some to air to b ypass the heater

core. The mixture of heated and cool air (17) will result in warm air entering the vehicle cabin.

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-36

Page 2A-36

Full Hot

Figure 2A – 38

When the temperature switch (1) is turned to in the full hot positio n (2) the water valve vacuum switch plunger (3)

remains in the same position, refe r to Figure 2A – 38. Therefore, the water valve (4) remains in the fully o pen position

because the water valve actuator (5) is devoid of vacuum.

In the full hot position the crescent gear (6) will be rotated fully rearward. This action will move the air mix door (7) to a

position that directs all incoming air thro ugh the heater core (8). Therefore, all air (9) entering the vehicle cabin will be

heated air.

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-37

Page 2A-37

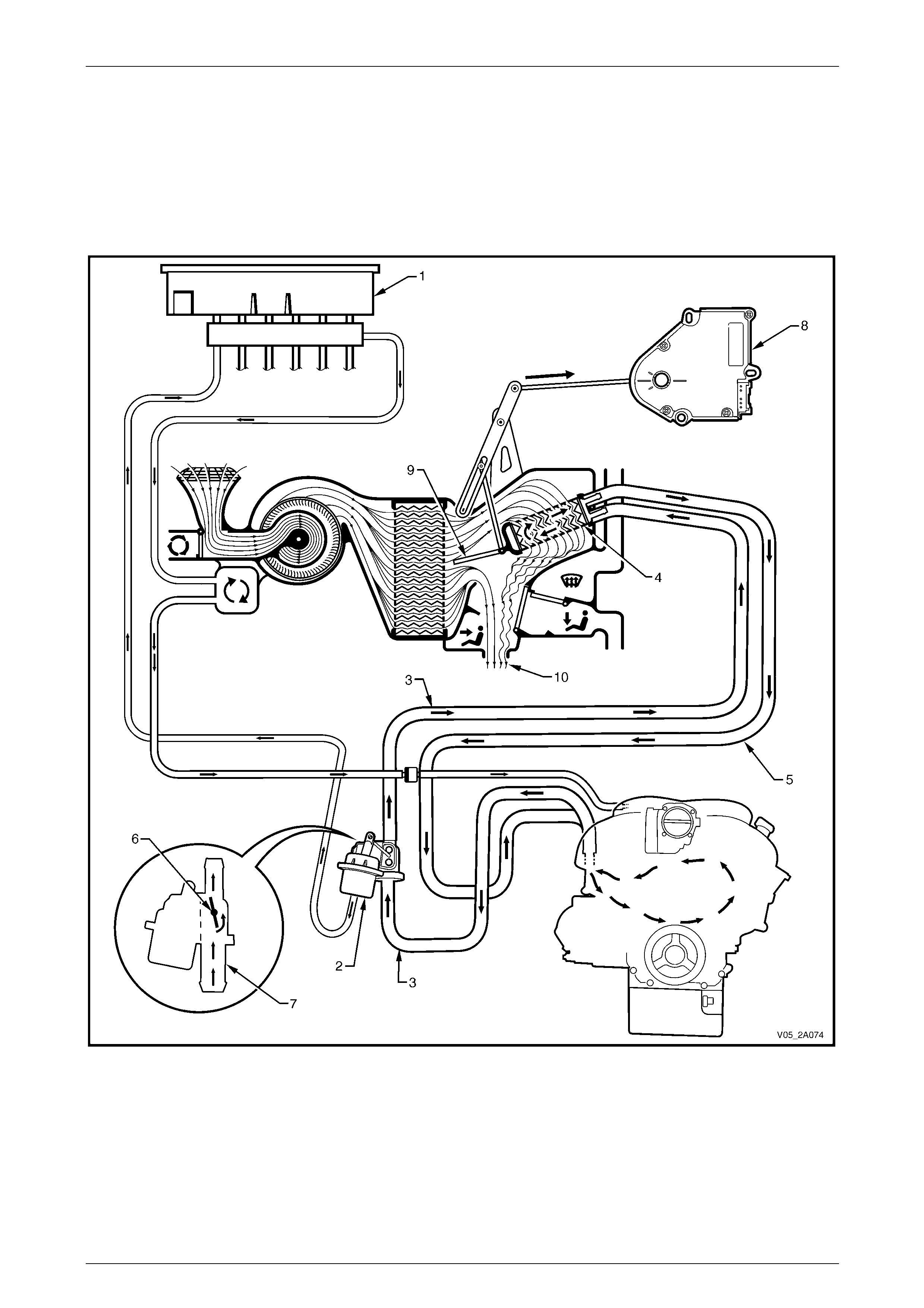

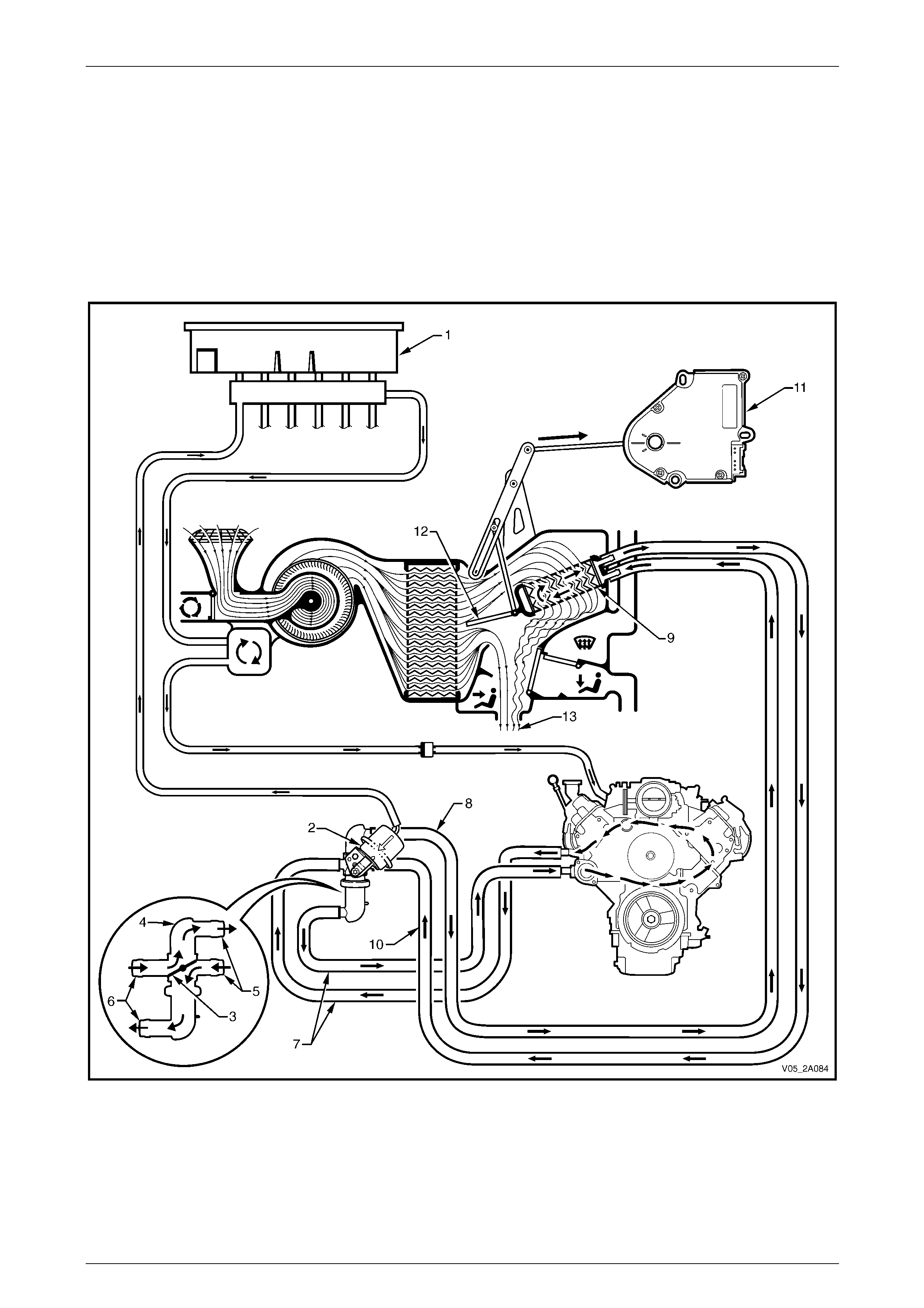

Heater Operation – Auto A/C – GEN III V8

Full Cold

Vacuum generated within the engine inlet manifold (1) is stored within the vacuum tank (2), which is mounted on the side

the HVAC unit (3), refer to Figure 2A – 39. Vacuum is retained within the system by the one-way check valve (4) and is

directed to the vacuum solenoid pack (5). When the temperature is set to a cold position, the solenoid pack allows vacuum

to be directed to the water valve vacuum actuator (6). No coolant can flow through the inlet heater hose (7), the heater

core (8) or the outlet heater hose (9) because the disc (10) in the water valve (11) is in the closed position. However,

coolant is still able to flow from the engine thr ough the water valve via its engine side ports (12) and e ngine side heater

hoses (13).

An air mix door motor (14) is mechanically connected to the air mix door (15) via an actuating rod (16) a nd levers (17).

When the temperature is set to a cold position, the motor operates and mo ves the air mix door to a position that does not

allow any air to flow through the heater core. The result is that all air (18) entering the ve hicle cabin will be ambient

temperature or cooled if the air-conditioning is operating.

Figure 2A – 39

Legend

1 Inlet Manifold

2 Vacuum Tank

3 HVAC Unit

4 One-way Check Valve

5 Vacuum Solenoid Pack

6 Water Valve Vacuum Actuator

7 Inlet Heater Hose

8 Heater Core

9 Outlet Heater Hose

10 Water Valve Disc

11 Water Valve

12 Water Valve Engine Side Ports

13 Engine Side Heater Hoses

14 Air Mix Door Motor

15 Air Mix Door

16 Actuating Rod

17 Actuating Levers

18 Cabin Air

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-38

Page 2A-38

Warm

When the temperatu re is set to a warm posi tion, th e vacuum sol enoid pack va lve (1) clo ses, and the vacuum a t the wate r

valve vacuum actuator (2) is vented, refer to Figure 2A – 40. With the actuator relieved of vacuum, the disc (3) in the water

valve (4) rotates and allows hot water to flow through the cabin side water valve ports (5). Coolant flows from the engine

through the water valve via its engine si de ports (6) and engine side heater hoses (7) and is also flowing through the inlet

heater hose (8), the heater core (9) and the outlet heater hose (10) because of the disc position in the water valve.

When the temperature is set to a warm position, the air mix door motor (11) also operates and moves the air mix

door (12) to a partially open position allowing some air to flow through the heater core. The position of the door is

variable, based on the temperature set. A po sition sensor within the motor provides feedback to the control module. The

result is that all air (13) entering the vehicle cabin will be warm.

Figure 2A – 40

Legend

1 Vacuum Solenoid Pack

2 Water Valve Vacuum Actuator

3 Water Valve Disc

4 Water Valve

5 Water Valve Cabin Side Ports

6 Water Valve Engine Side Ports

7 Engine Side Heater Hoses

8 Inlet Heater Hose

9 Heater Core

10 Outlet Heater Hose

11 Air Mix Door Motor

12 Air Mix Door

13 Cabin Air

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-39

Page 2A-39

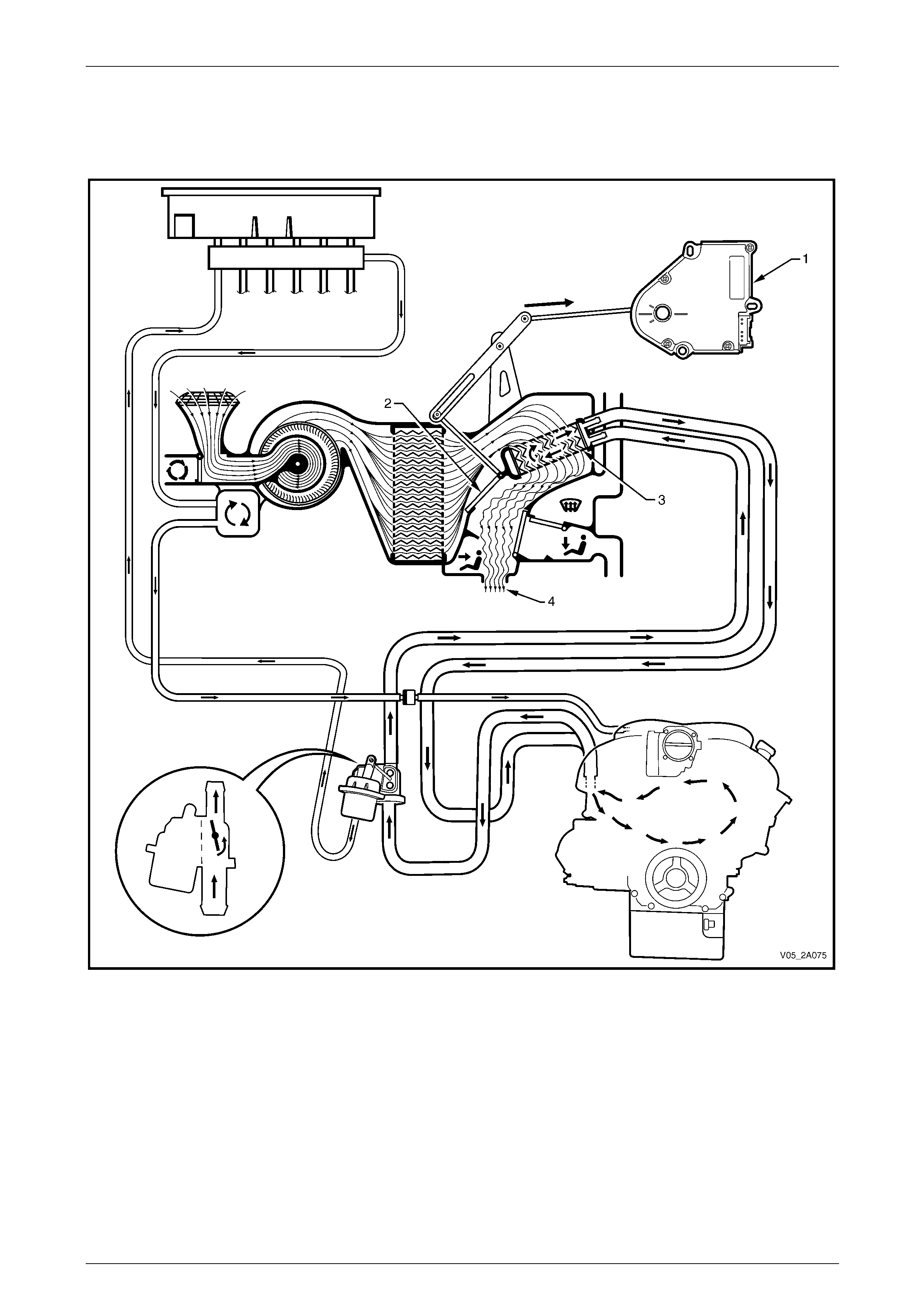

Full Hot

When the temperature is set to the hot position, the disc (1) in the water valve (2) allows hot water to flow through the

cabin side water valve ports (3), refer to Figure 2A – 41. The coolant flow pattern is the same as described for the warm

position.

The air mix door motor (4) operates and moves the air mix door (5) to the fully open position which direct s all air through

the heater core (6). The result is that all air (7) entering the vehicle cabin will be hot.

Figure 2A – 41

Legend

1 Water Valve Disc

2 Water Valve

3 Water Valve Cabin Side Ports

4 Air Mix Door Motor

5 Air Mix Door

6 Heater Core

7 Cabin Air

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-40

Page 2A-40

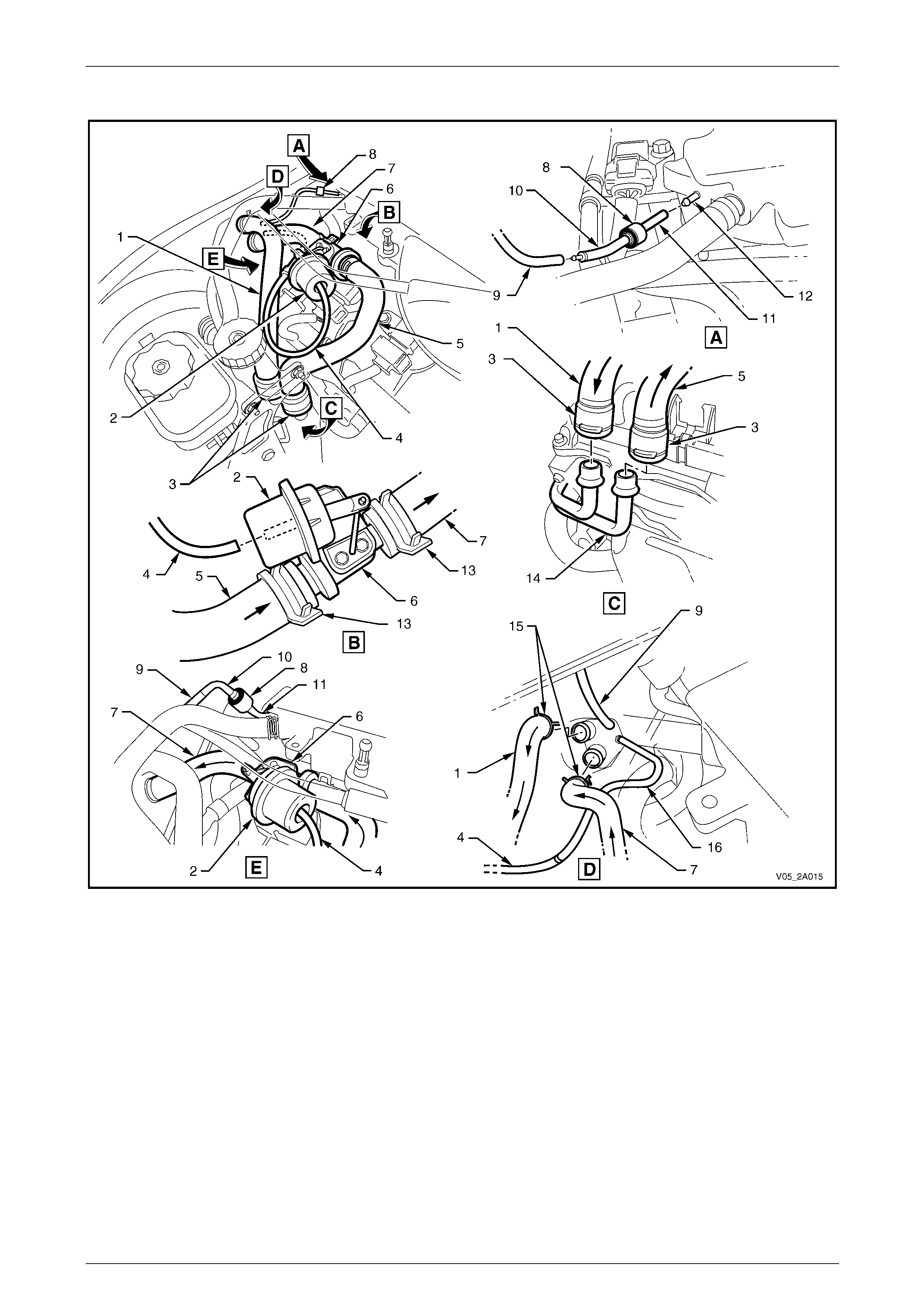

Under-hood Heater Components – V6

Figure 2A – 42

Legend

1 Heater Hose – from Cabin

2 Water Valve Actuator

3 Heater Hose Connectors (2 places)

4 Vacuum Hose – to Water Valve Actuator

5 Heater Hose – to Water Valve

6 Water Valve

7 Heater Hose – to Cabin

8 Vacuum Check Valve

9 Vacuum Hose – to HVAC Vacuum Tank

10 Vacuum Hose – to Check Valve

11 Vacuum Hose – to Inlet Manifold

12 Inlet Manifold Connection

13 Hose Clamps – Water Valve (2 places)

14 Heater Pipes

15 Hose Clamps – HVAC Unit (2 places)

16 Vacuum Hose – to Water Valve Vacuum Switch

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-41

Page 2A-41

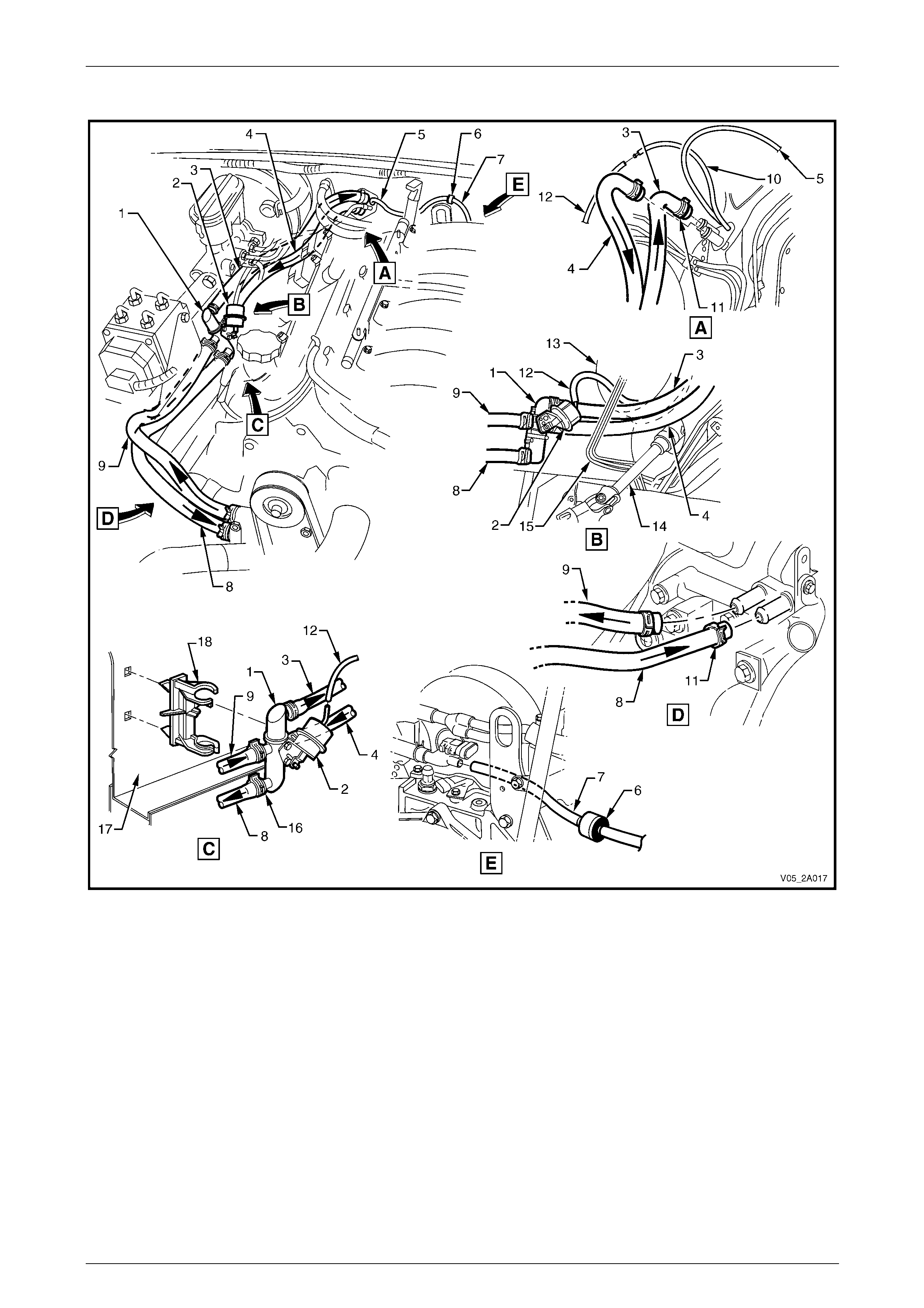

Under-hood Heater Components – GEN III V8

Figure 2A – 43

Legend

1 Water Valve

2 Water Valve Actuator

3 Heater Hose – to Cabin

4 Heater Hose – from Cabin

5 Vacuum Hose (2 piece) – HVAC Supply

6 Check Valve

7 Vacuum Hose – to Inlet Manifold

8 Heater Hose – to Engine

9 Heater Hose – from Engine

10 Vacuum Hose – to Water Valve Vacuum Switch

11 Hose Clamps – Engine (2 places)

12 Vacuum Hose – to Water Valve Actuator

13 Brake Booster

14 Steering Column

15 Brake Lines

16 Hose Clamps – Water Valve (4 places)

17 Wheel House – Right-hand Side

18 Mounting Clip – Water Valve

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-42

Page 2A-42

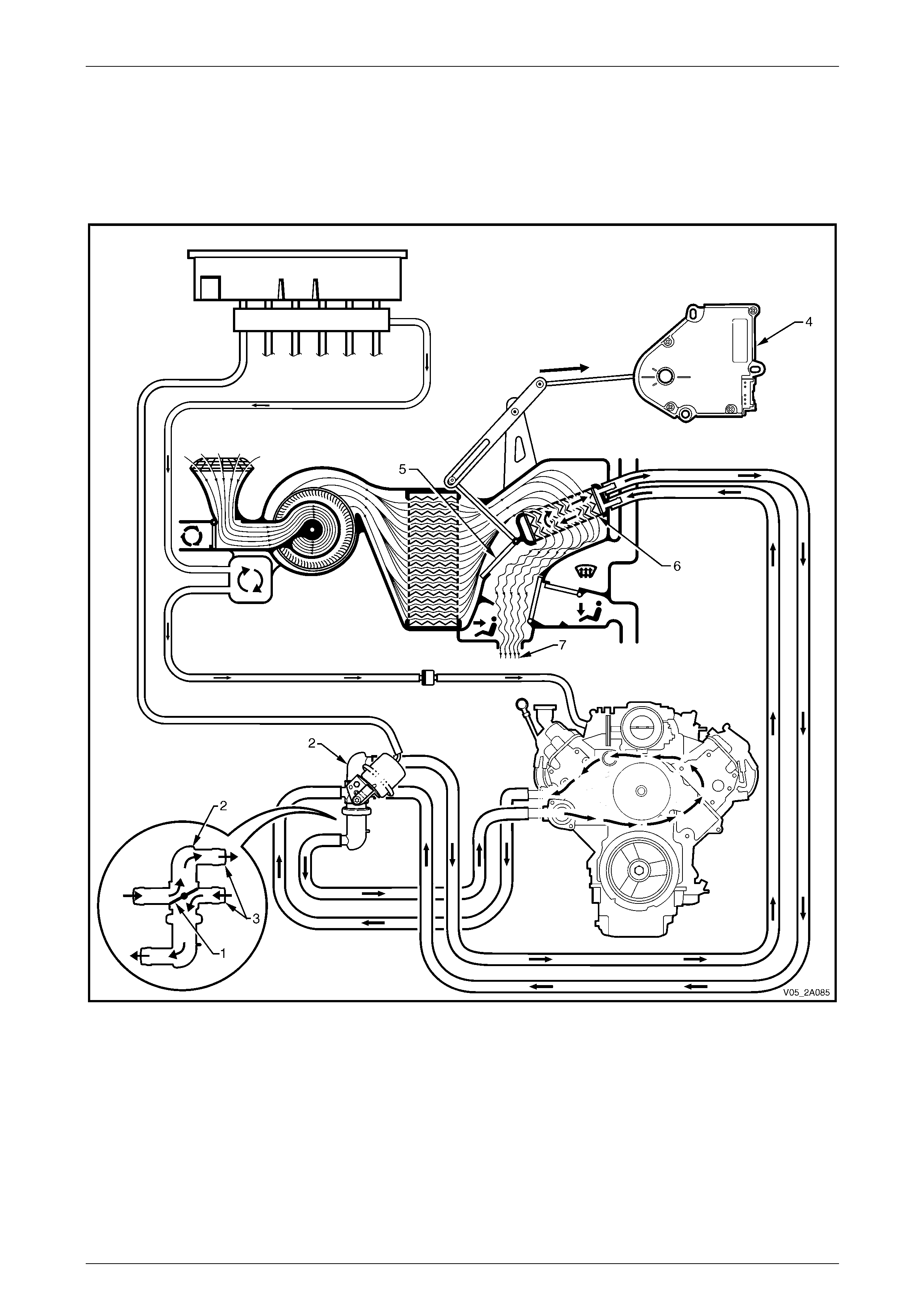

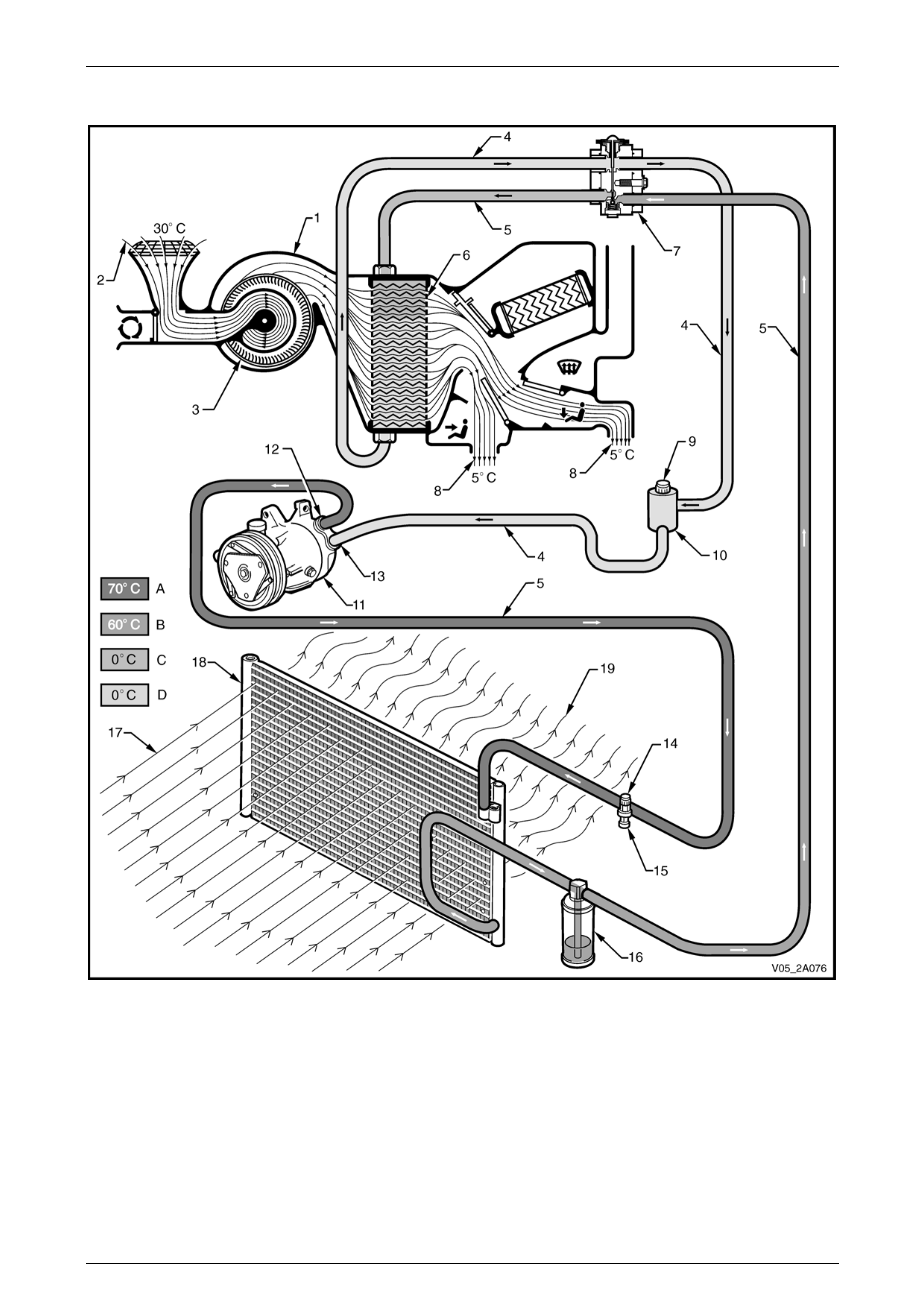

2.5 Air-conditioning Refrigerant Circuit

Figure 2A – 44

Legend

A High Pressure Vapour

D Low Pressure Vapour

B High Pressure Liquid

C Low Pressure Liquid

1 HVAC Unit

2 Inlet Air

3 Blower Fan

4 Low Pressure Line

5 High Pressure Line

6 Evaporator

7 Thermal Expansion Valve

8 Air-conditioned Air

9 Low Pressure Port

10 Muffler

11 Compressor

12 Compressor Pressure Port

13 Compressor Suction Port

14 High Pressure Port

15 Pressure Transducer

16 Filter Drier Receiver

17 Cool Ram (inlet) Air

18 Condenser

19 Warm (outlet) Air

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-43

Page 2A-43

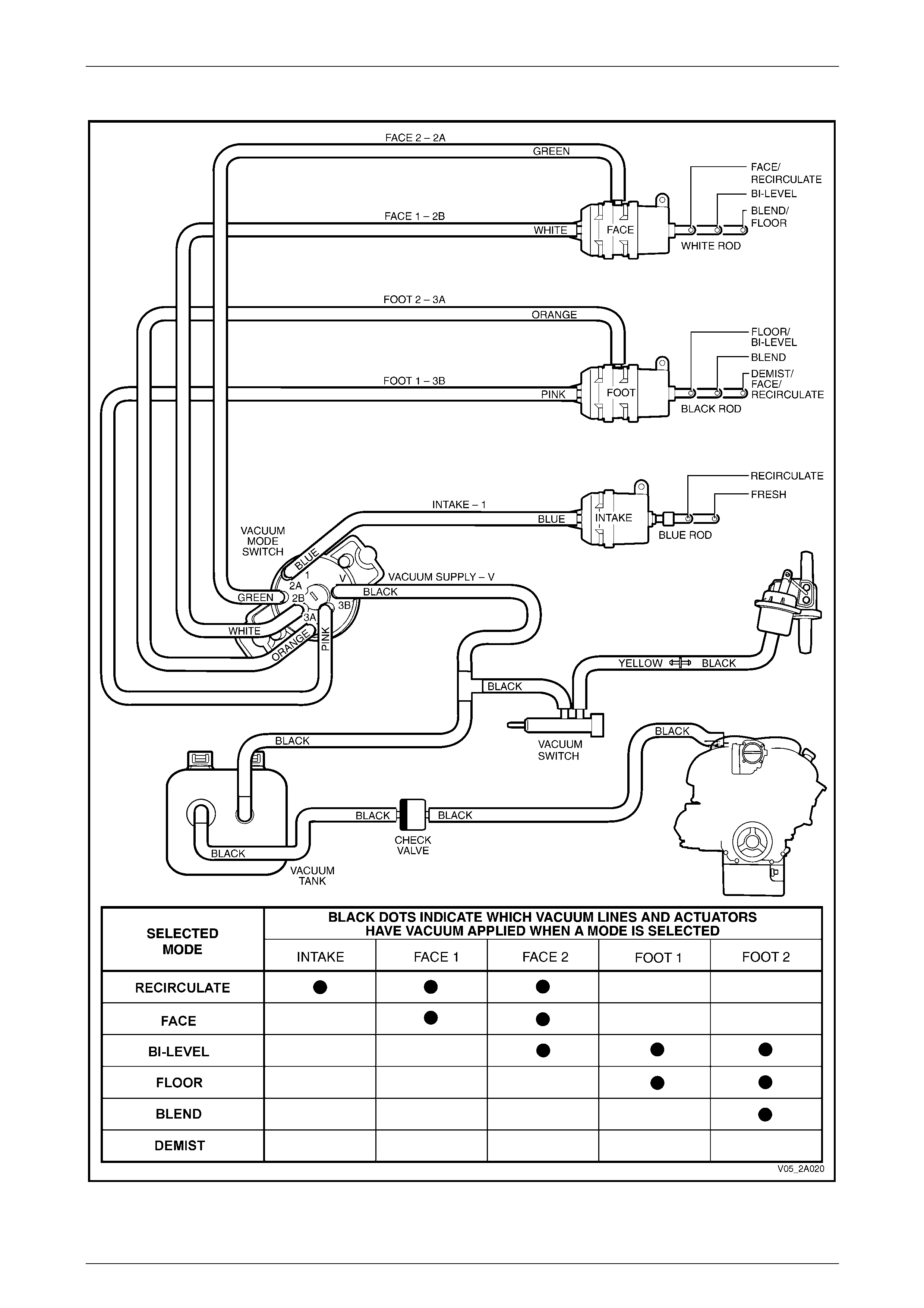

2.6 Vacuum Circuit

The vacuum gene rated w ithin the engine inle t manifold is used to ope ra te the vacuu m ac tuato rs and the wate r val ve.

For further information on the water valve operation, refer to 2.4 Heater.

A vacuum tank located on the side of the HVAC unit is use d to store vacuum for times when engine vacuum is low such

as at full engine throttle. A check valve is fitted on the supply line between the inlet manifold and the vacuum tank to

ensure that vacuum is maintained within the system at all times.

Vacuum Mode Switch and Vacuum Lines – Manual A/C

A black plastic vacuum supply line on the HVAC unit supplies vacuum to the vacuum tank. The check valve is used to

join the supply line to the hose connected to the inlet manifold.

Vacuum from the vacuum tank is then directed through a black supply hose to the vacuum mode switch, for HVAC door

operation, and from a tee joint to the water valve vacuum switch, for water valve operatio n.

From the water valve vacuum switch, vacuum moves into a yellow plastic tube a nd then connects to the black hose

(inside the cabin at the dash panel) which in turn is connected to the vacuum operated heater water valve. When vacuum

is applied to the water valve, the valve remains closed and water does not flow through the heater core.

As the vacuum mode switch is turned, vacuum is directed through the switch and onto th e desired vacuum actuators

through different coloured plas tic tubing. This vacuum will activate the actuator rod, which then moves a vent position

door.

Vacuum is vented from the vacuum actuator/plastic tube once the vacu um mode switch is turned to another position.

The six vacuum hoses between the vacuum mode switch

and the vacuum actuators are colour keyed. The function of

the switch connections and the colour of the attached

vacuum lines are listed belo w:

Legend

1 Vacuum supply (Black)

2 Fresh/Recirculation (Blue)

3 Face 2 (Green)

4 Face 1 (White)

5 Foot 2 (Orange)

6 Foot 1 (Pink)

Figure 2A – 45

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-44

Page 2A-44

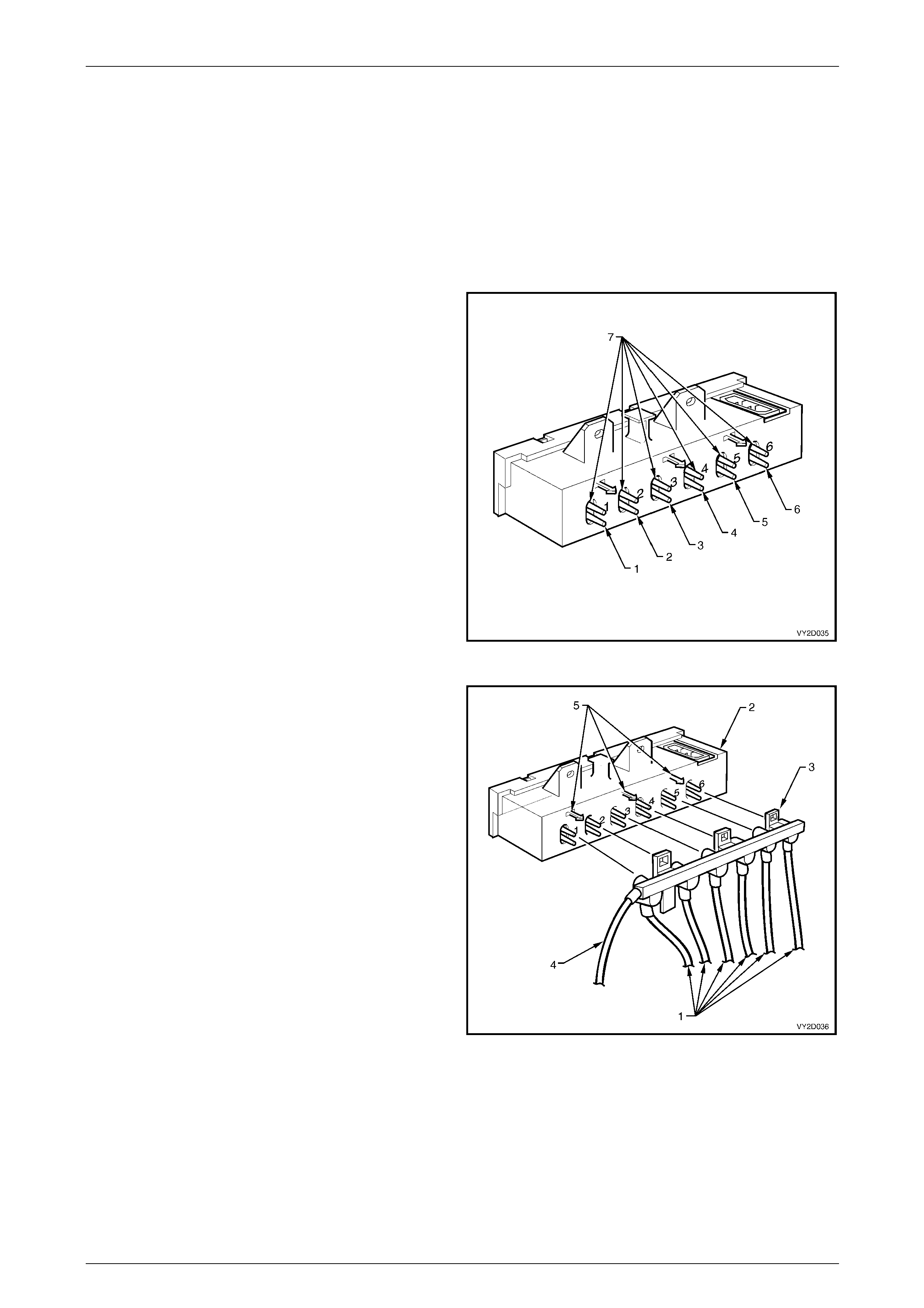

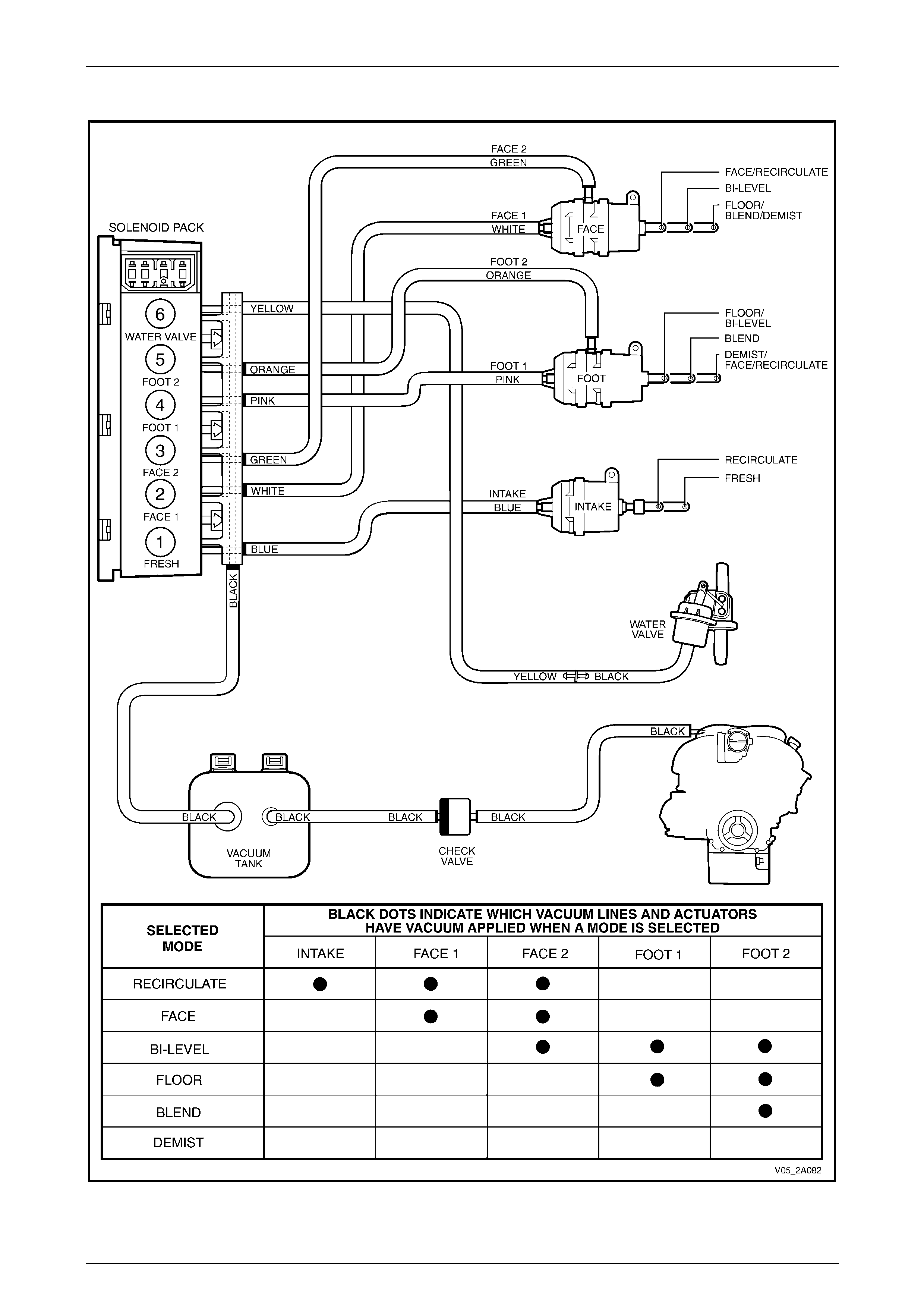

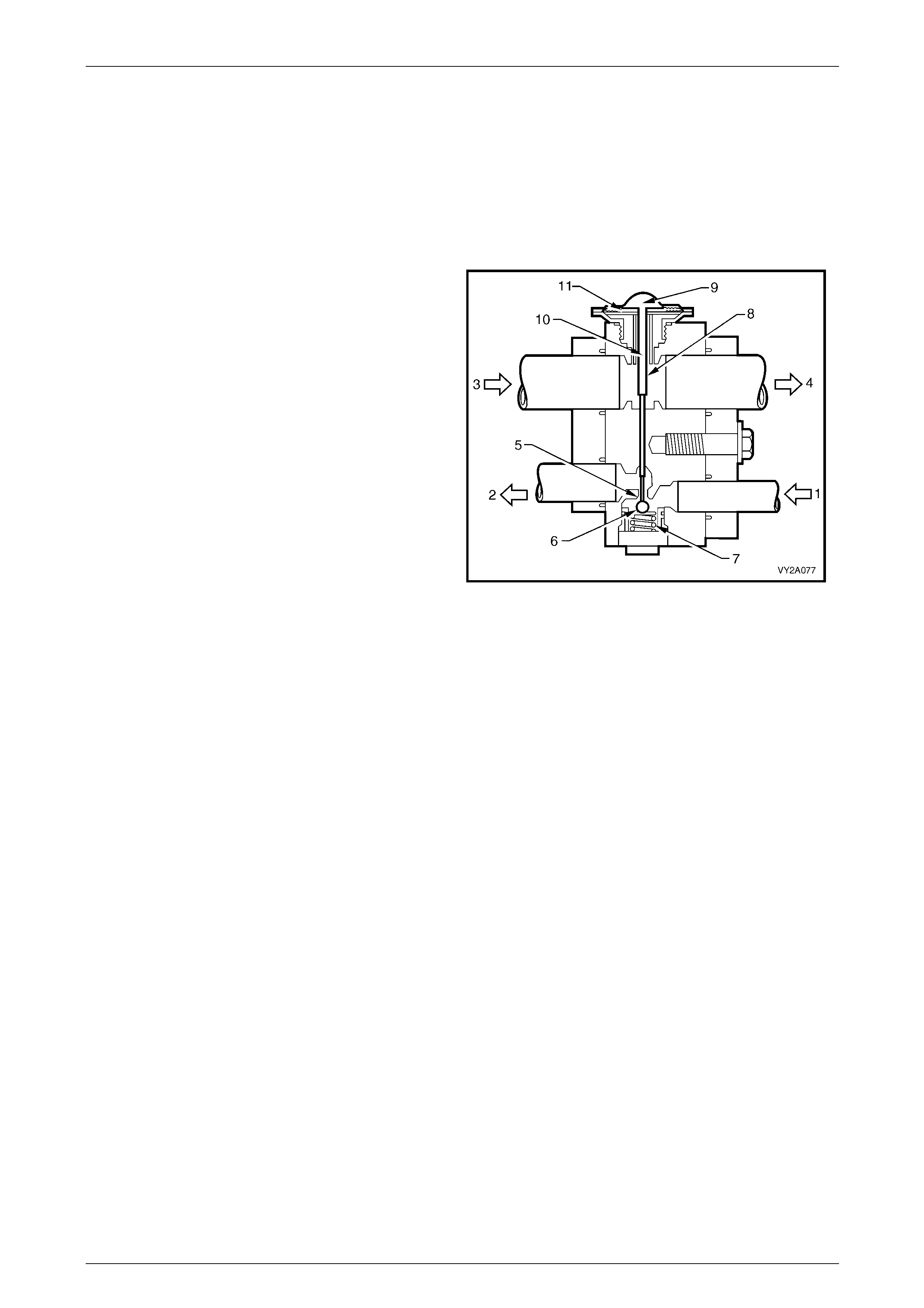

Solenoid Pack and Vacuum Lines – Auto A/C

A six solenoid vacuum solenoid pack is used to direct vacuum to the vacuum actuators an d the water valve The solenoid

pack is connected to the vacuum tank throug h a black p lastic vacuum hose. The OCC control module operates the

solenoids on and off to direct vacuum to the vacuum actuators and water valve when required. This alters the position of

the water valve and the various doors within the HVAC unit to bring about the desired heating, demisting or cooling

effect.

Vacuum is vented from the vacuum actuator / plastic hose once an OCC control module mode switch or temperature

switch is used to select a different setting. When vacuum is applied to the water valve, the valve rem ains closed and no

water will flow through the heater core.

The six vacuum hoses between the solenoid pack and the

vacuum actuators are colour keyed.

The function of the solenoid connections and the colour of

the attached vacuum lines are listed below:

Legend

1 Fresh/Recirculation (Blue)

2 Face 1 (White)

3 Face 2 (Green)

4 Foot 1 (Pink)

5 Foot 2 (Orange)

6 Water valve (Yellow)

7 Vacuum supply (Black)

Figure 2A – 46

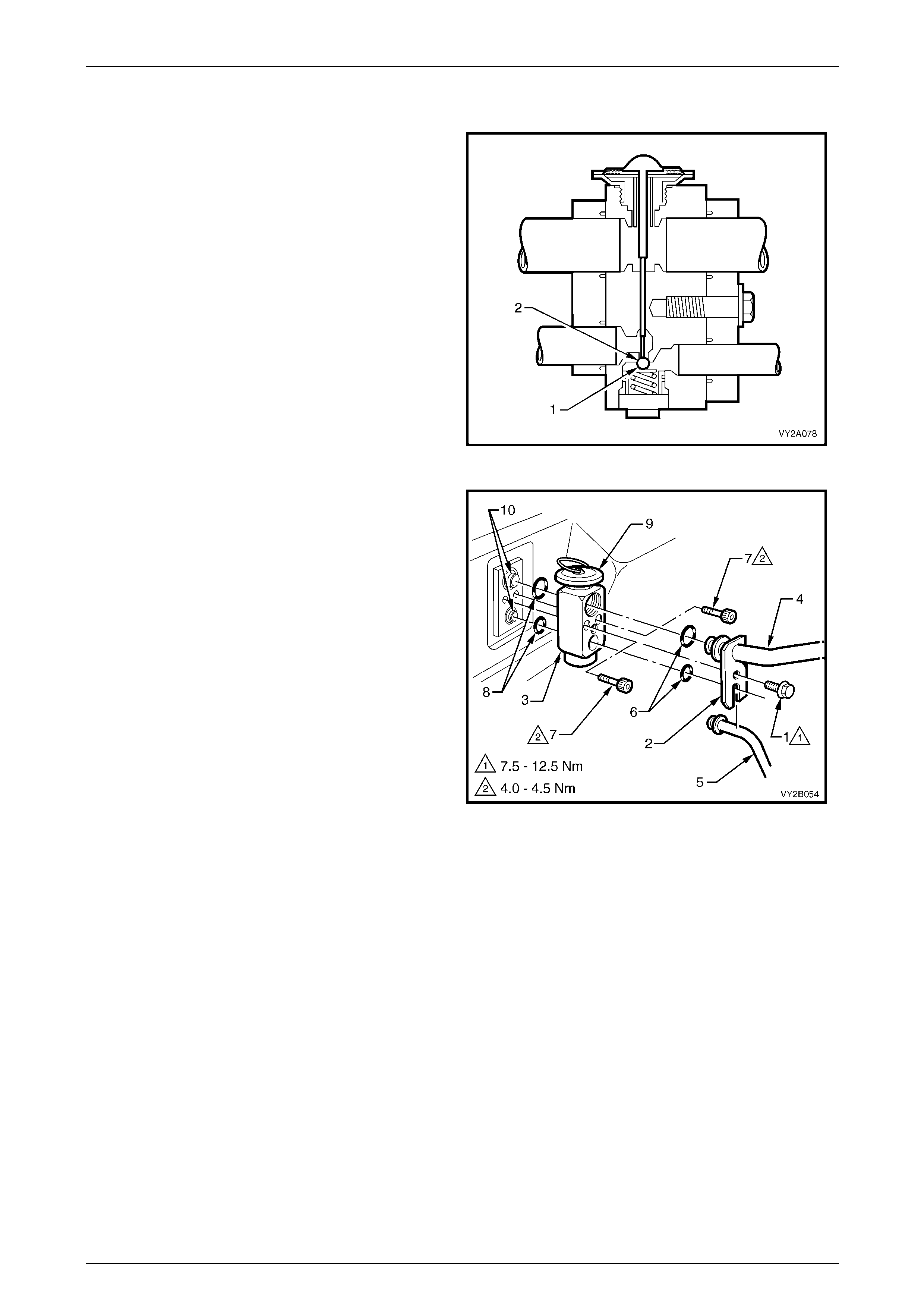

All actuator vacuum hoses (1) at the solenoid pack (2) are

permanently connected to a common, soft plastic

manifold (3), which is installed to the front of the solenoid

pack.

The black hose (4) at the left-hand side of the manifold is

the vacuum supply line from the vacuum tank and is also

permanently connected.

The manifold is locked into its install ed position by three

retaining tangs (5) protruding from the solenoid pack

housing.

Figure 2A – 47

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-45

Page 2A-45

Vacuum Circuit Schematic – Manual A/C

Figure 2A – 48

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-46

Page 2A-46

Vacuum Circuit Schematic – Auto A/C

Figure 2A – 49

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-47

Page 2A-47

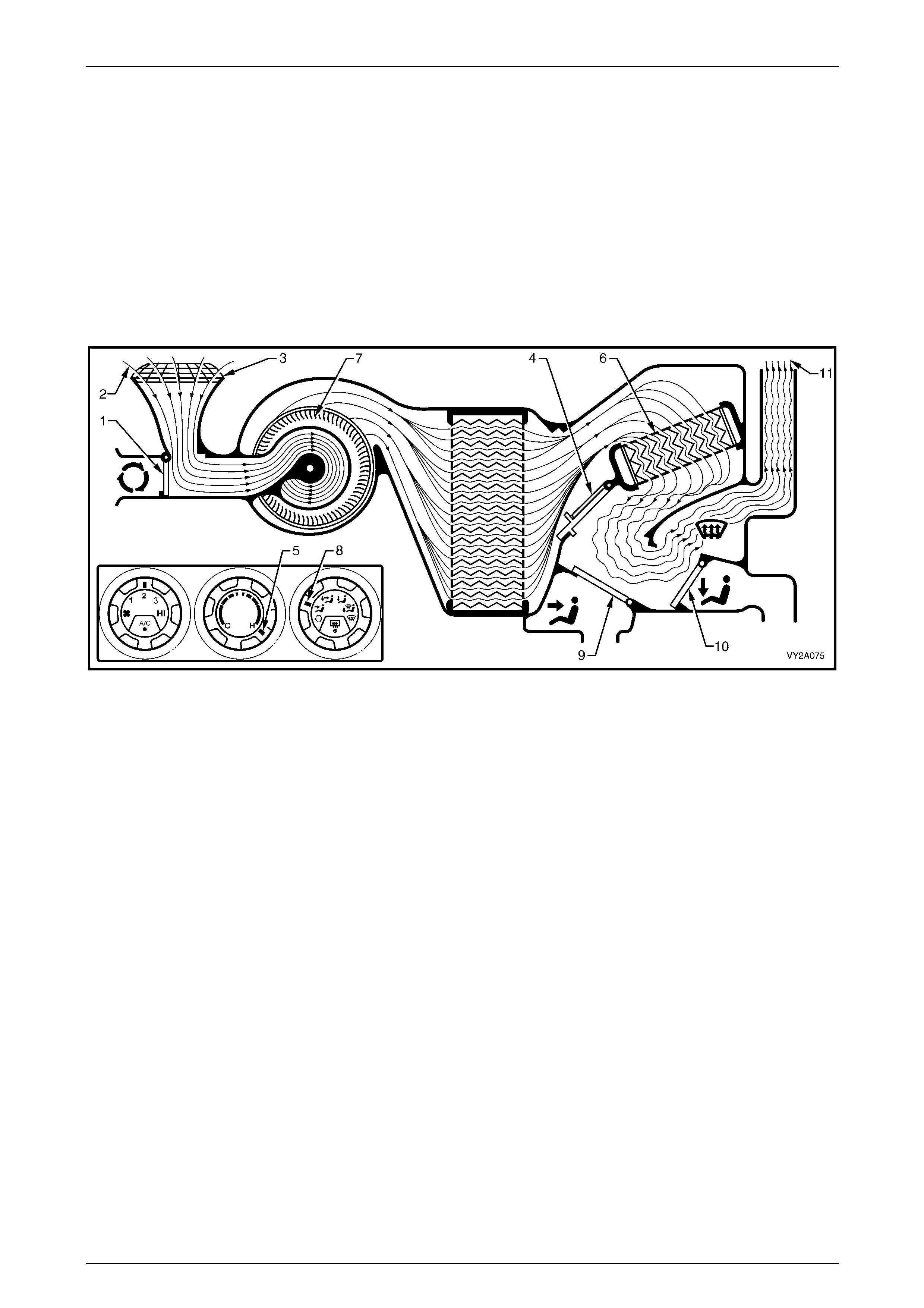

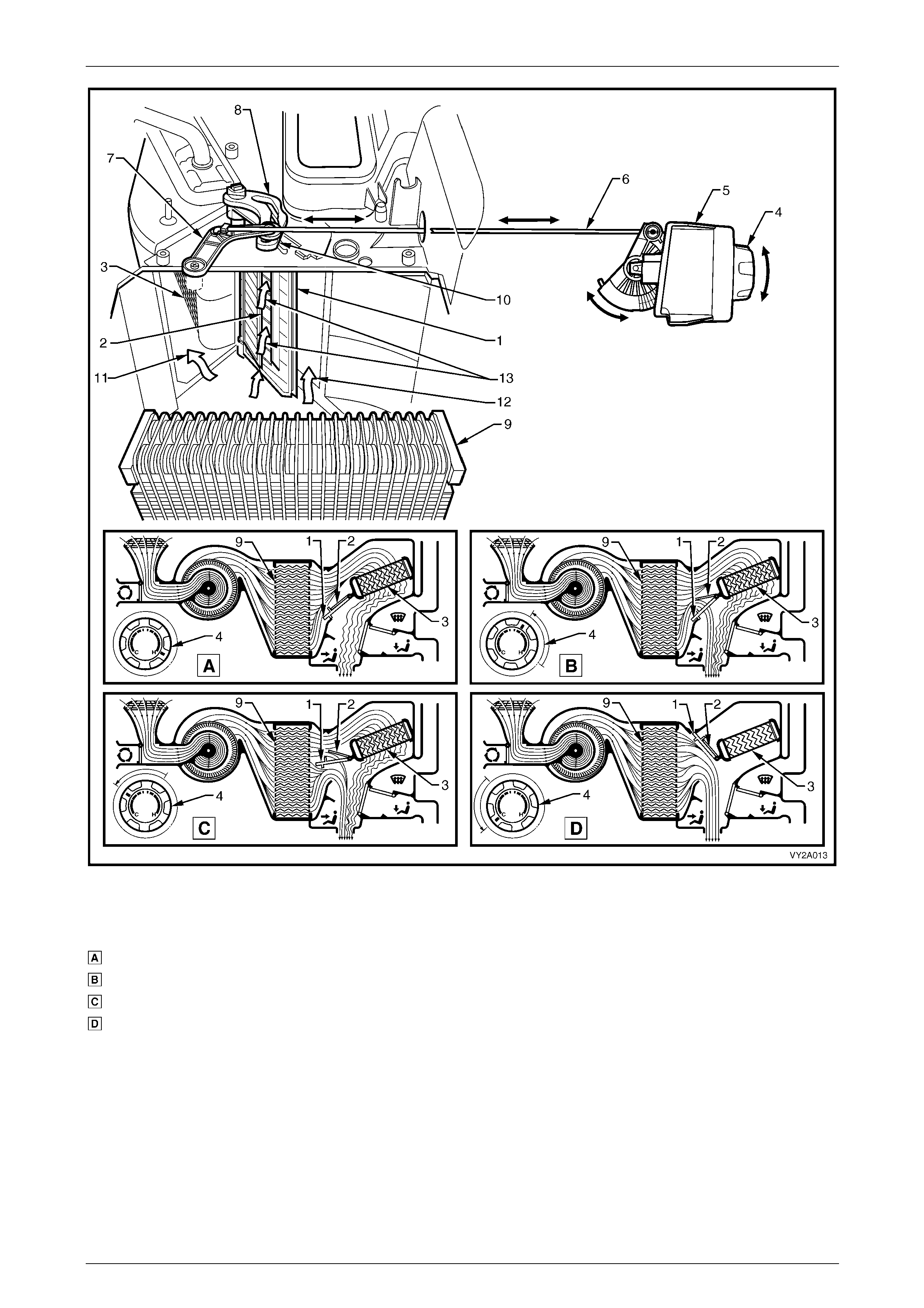

2.7 HVAC Unit Airflow Modes – Manual A/C

NOTE

For auto A/C airflow modes, refer to

Section 2D HVAC Occupant Climate Control

(Auto A/C) – Description and Operation

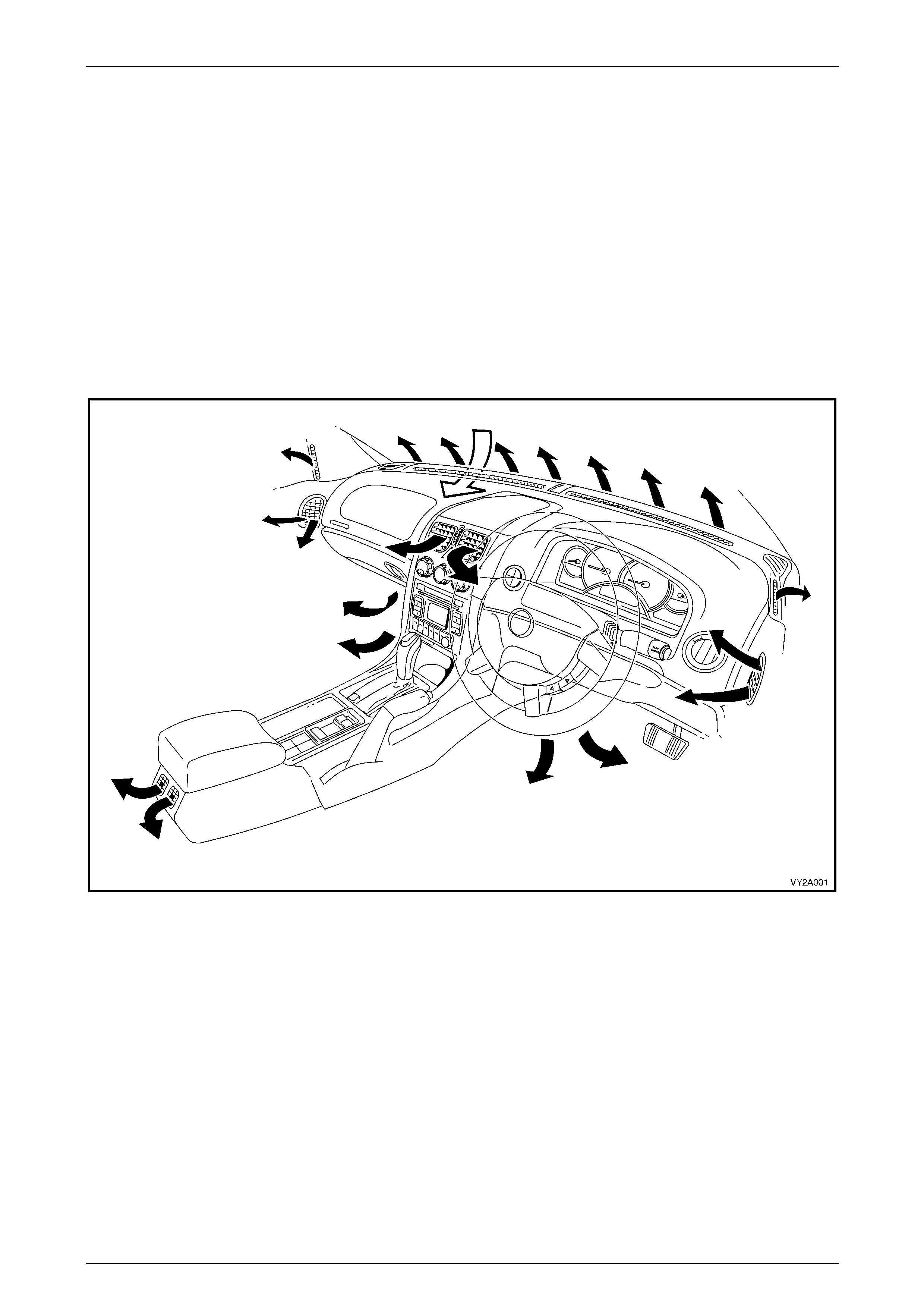

HVAC Flow Diagrams

The HVAC unit has seven different possible modes:

• recirculation

• face,

• bi-level,

• floor,

• blend,

• demist, and

• default.

The following airflow mode diagrams provide a schematic representation of how cold and heated air flows through the

HVAC unit during the seven different possible modes.

Each schematic has a graphic representation of the HVAC controller with switch settings matching the given mode.

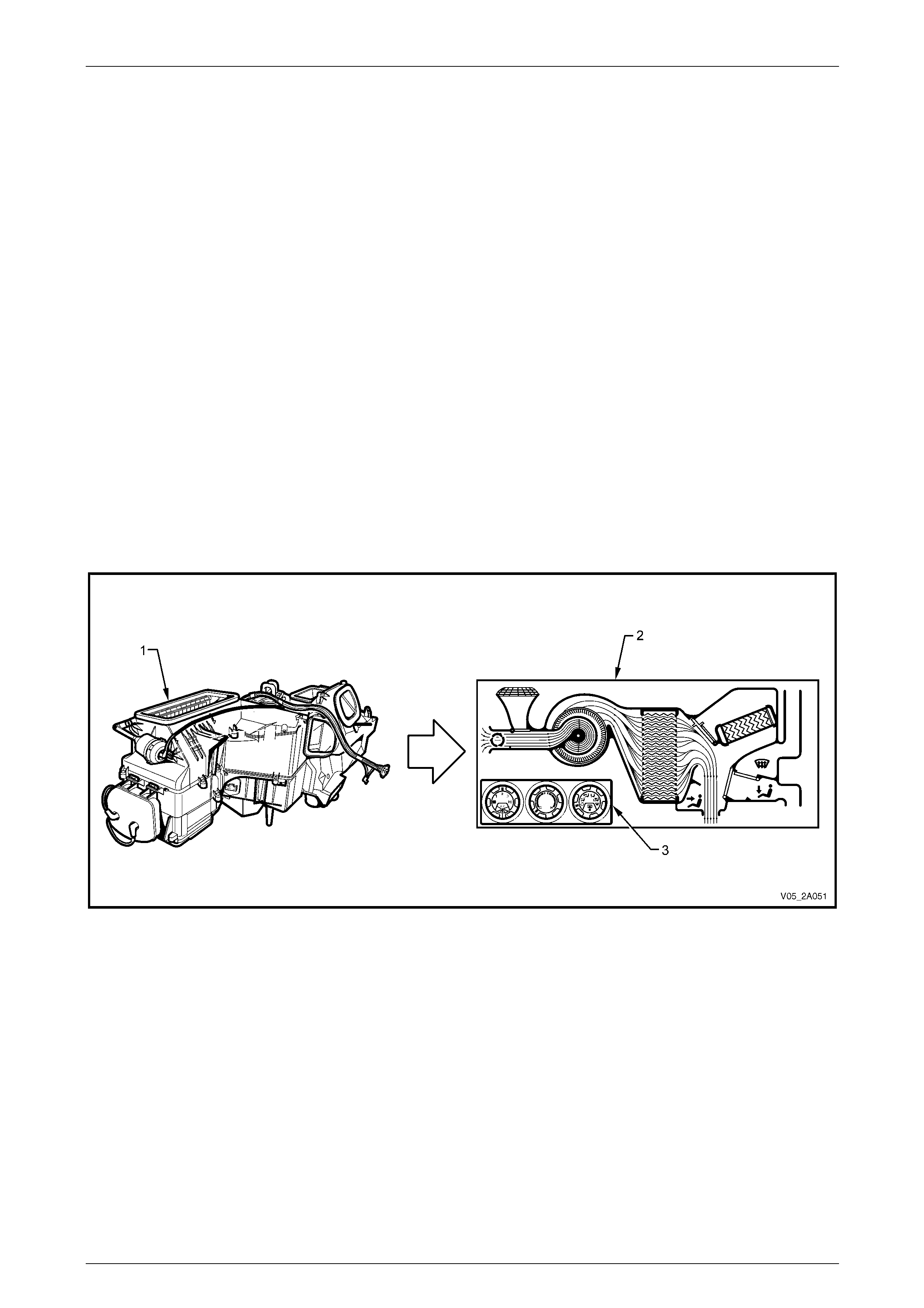

Figure 2A – 50

Legend

1 HVAC Unit

2 Airflow Schematic 3 HVAC Controller

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-48

Page 2A-48

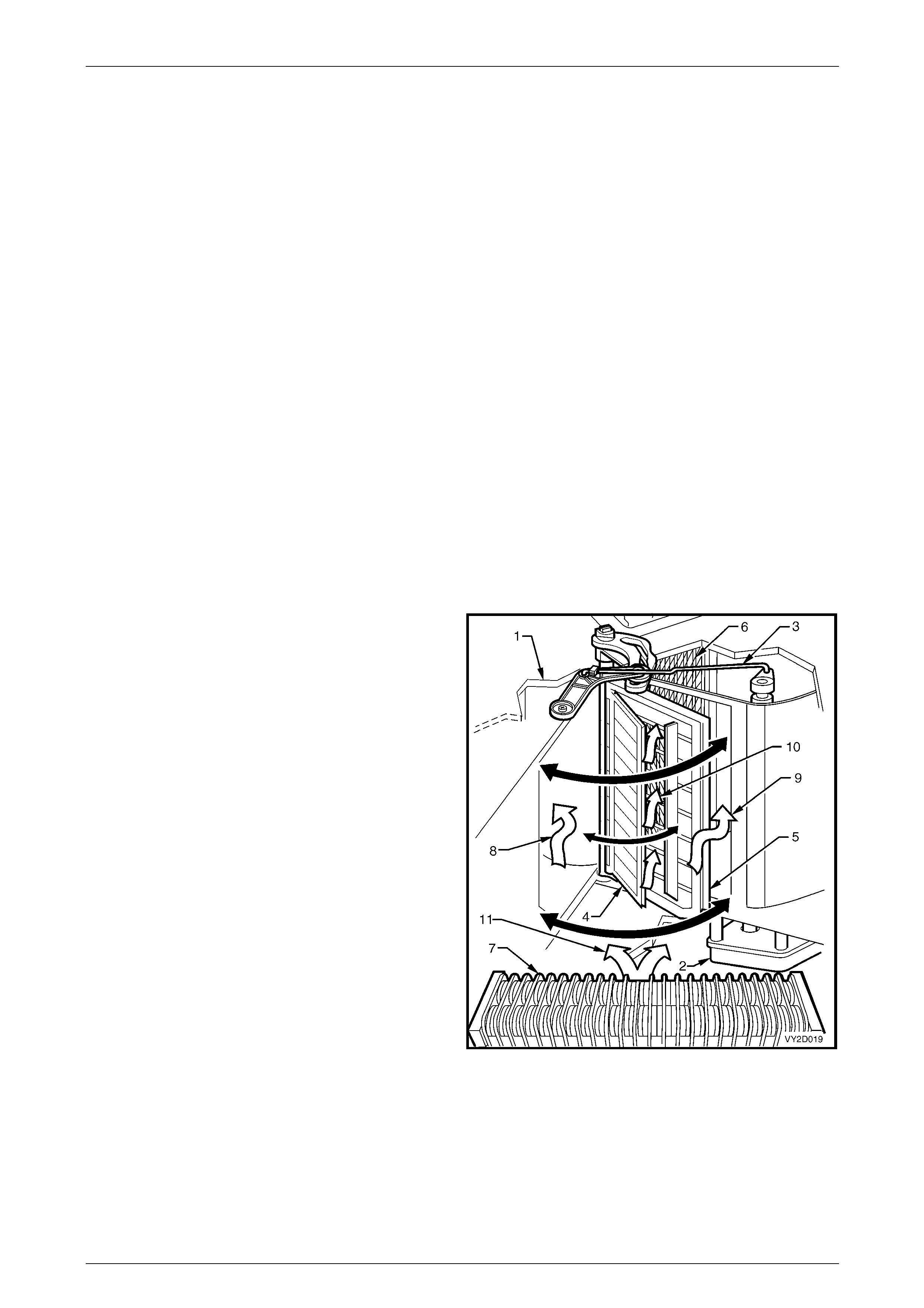

Recirculation Mode

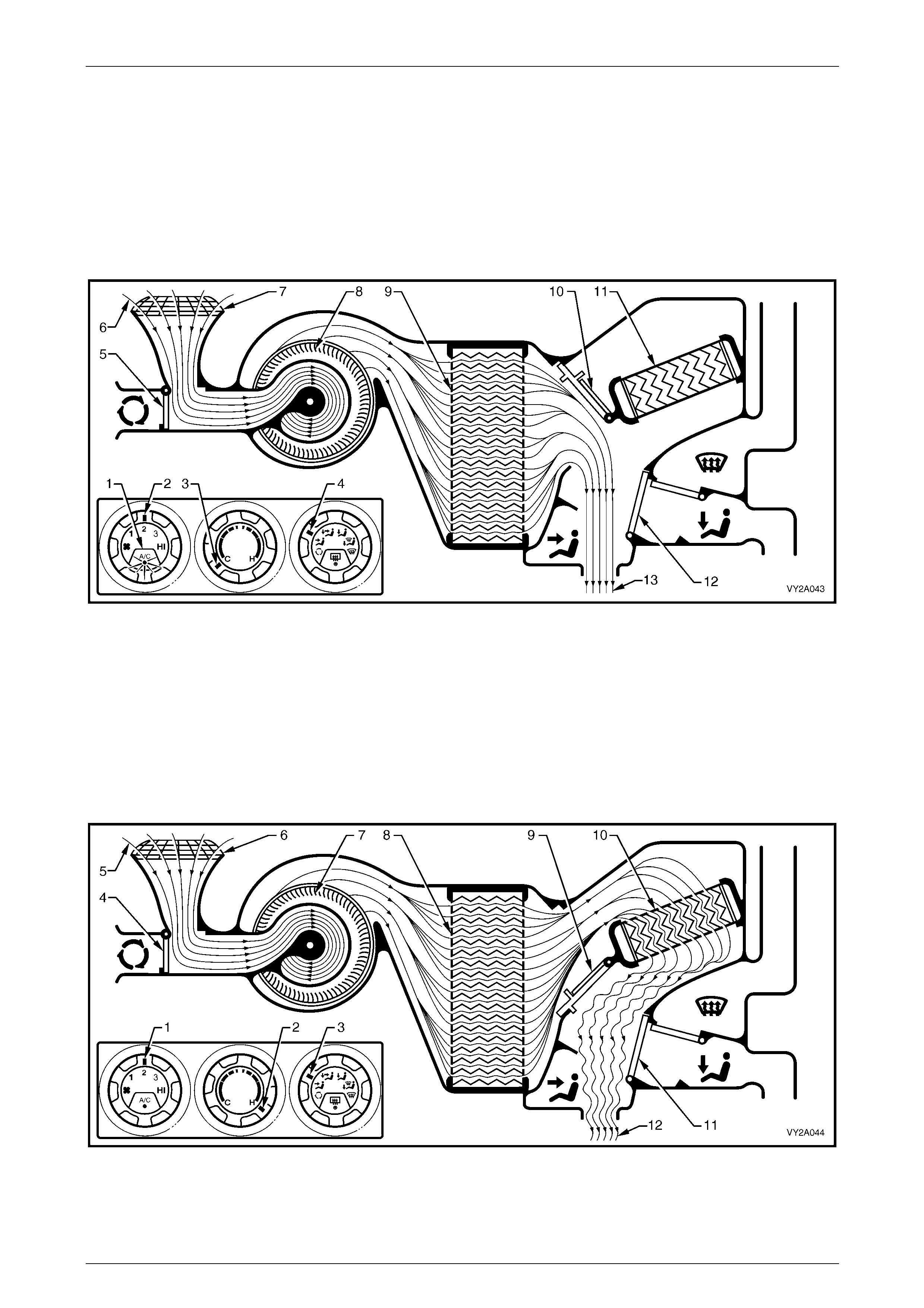

Full Cold

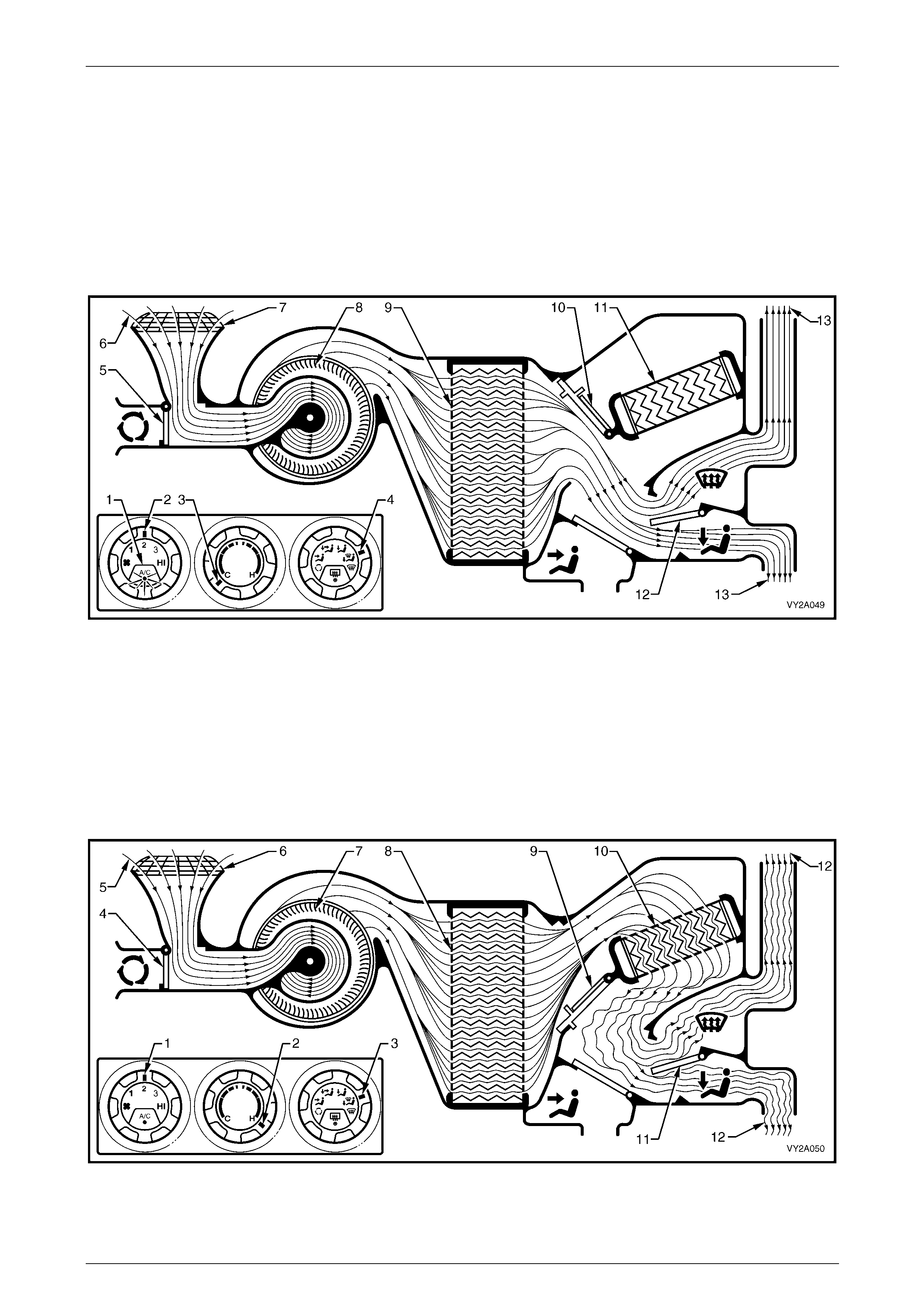

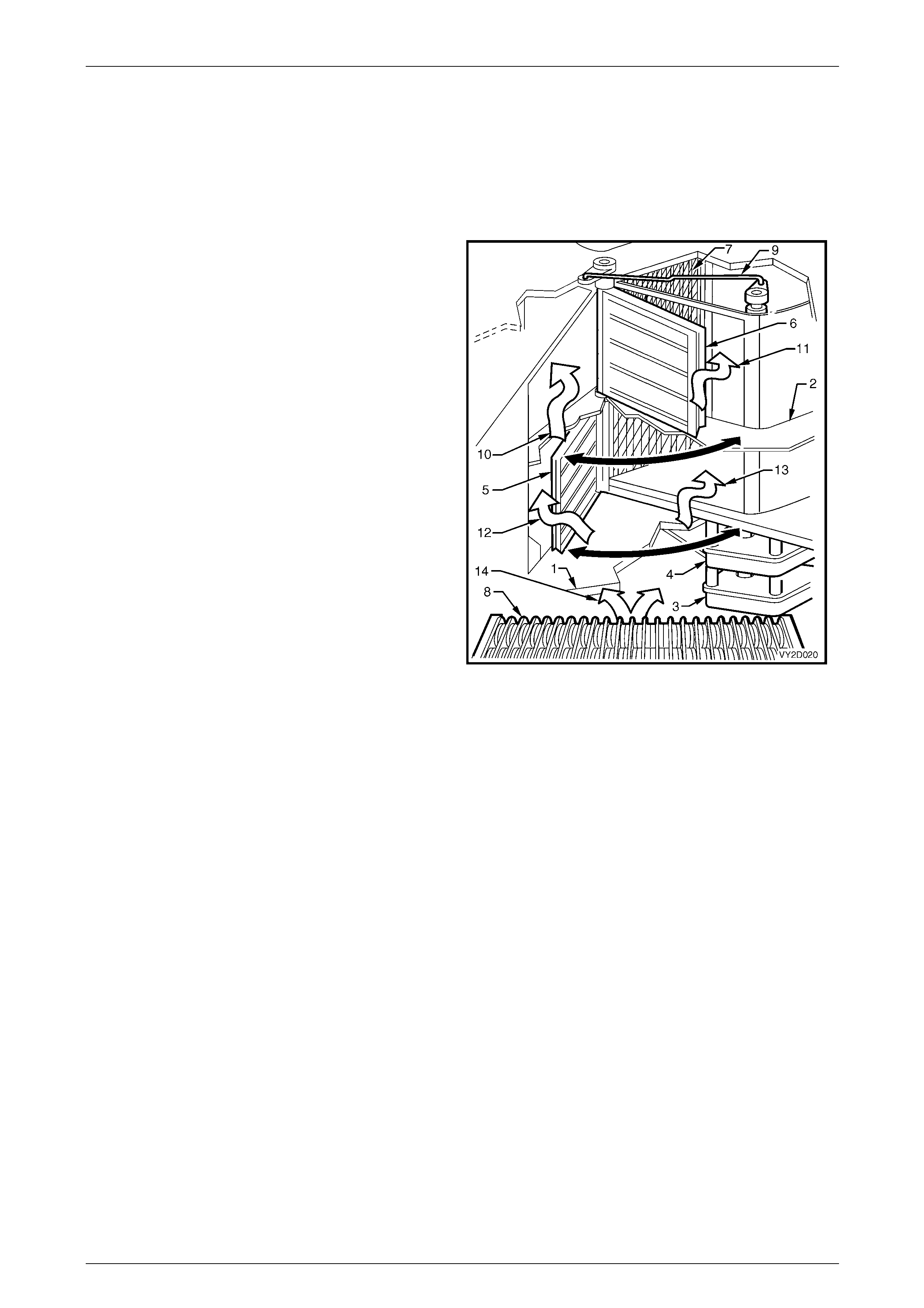

The A/C switch is on (1). The fan switch is set to an y one of four speeds (2), refer to Figure 2A – 51. The temperature

switch is set to the full cold position (3). The mode control switch is set to recirculation (4).

The plenum chamber (outside air) inlet (5) to the HVAC unit is closed off by the recirculation door (6). Interior air (7) is

drawn into the HVAC unit through the recircu lation inlet (8) by the blower motor fan (9), and is then forced through th e

cold evaporator fins (10). In full cold mode the air mix doors (11) are fully close d sealing off the passage through the

heater core (12). The air travels through the open face door (13). The cold air (14) is then d irected out through the centre

and side vents.

Figure 2A – 51

Full Heat

The fan switch is set to any one of four speeds (1), refer to Figure 2A – 52. The temperature switch is set to the full hot

position (2). The mode control switch is set to recirculation (3).

The plenum chamber (outside air) inlet (4) to the HVAC unit is closed off by the recirculation door (5). Interior air (6) is

drawn into the HVAC unit through the recircu lation inlet (7) by the blower motor fan (8), and is then forced through th e

evaporator fins (9). In full heat mode, the air mix doors (10) are fully o pen directing all incoming air through the heater

core (11). The air travels through the open face door (12). The heated air (13) is then directed out throu gh the centre and

side vents.

Figure 2A – 52

HVAC Climate Control (Manual A/C) – Description and Operation Page 2A-49

Page 2A-49

Face Mode

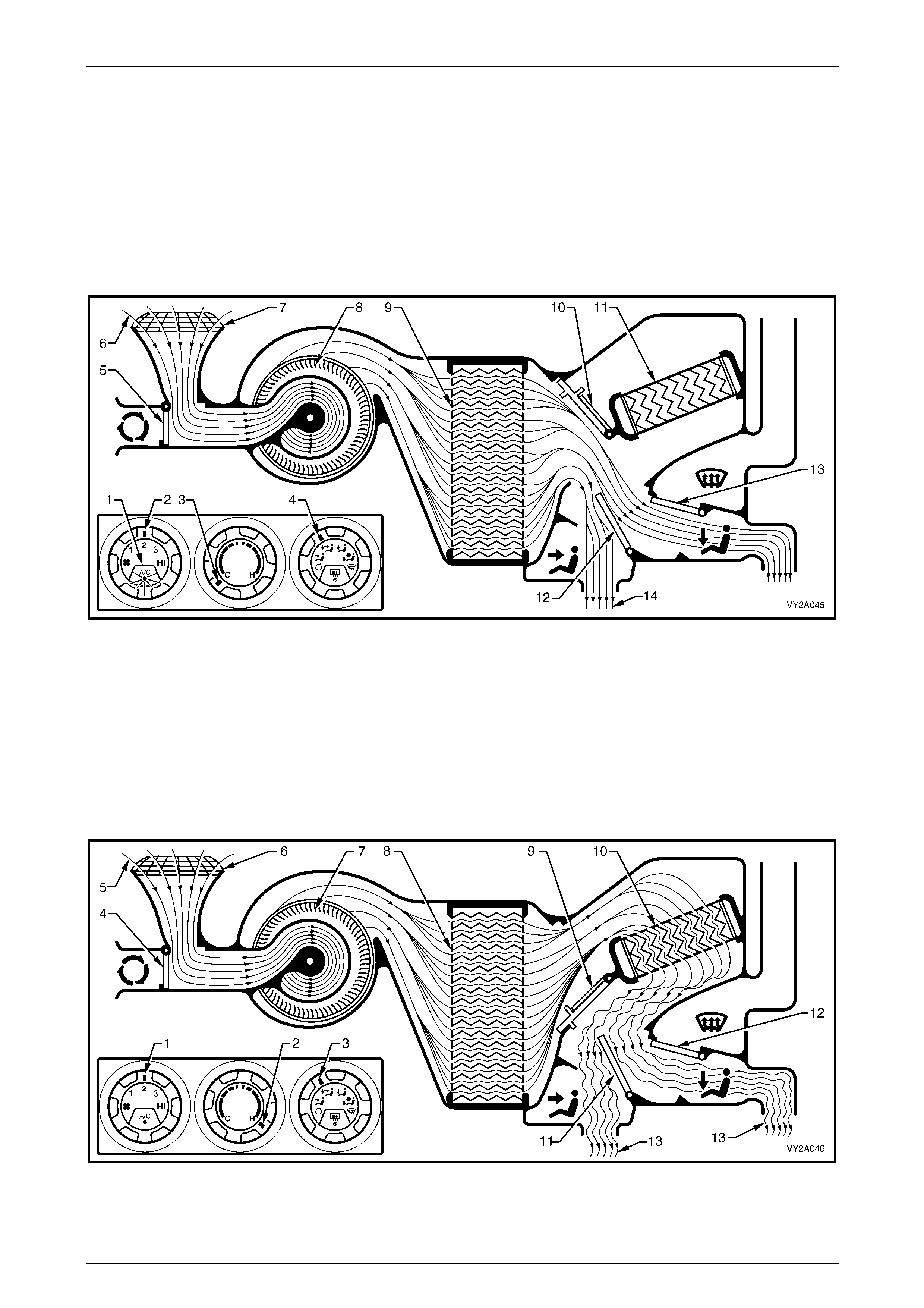

Full Cold

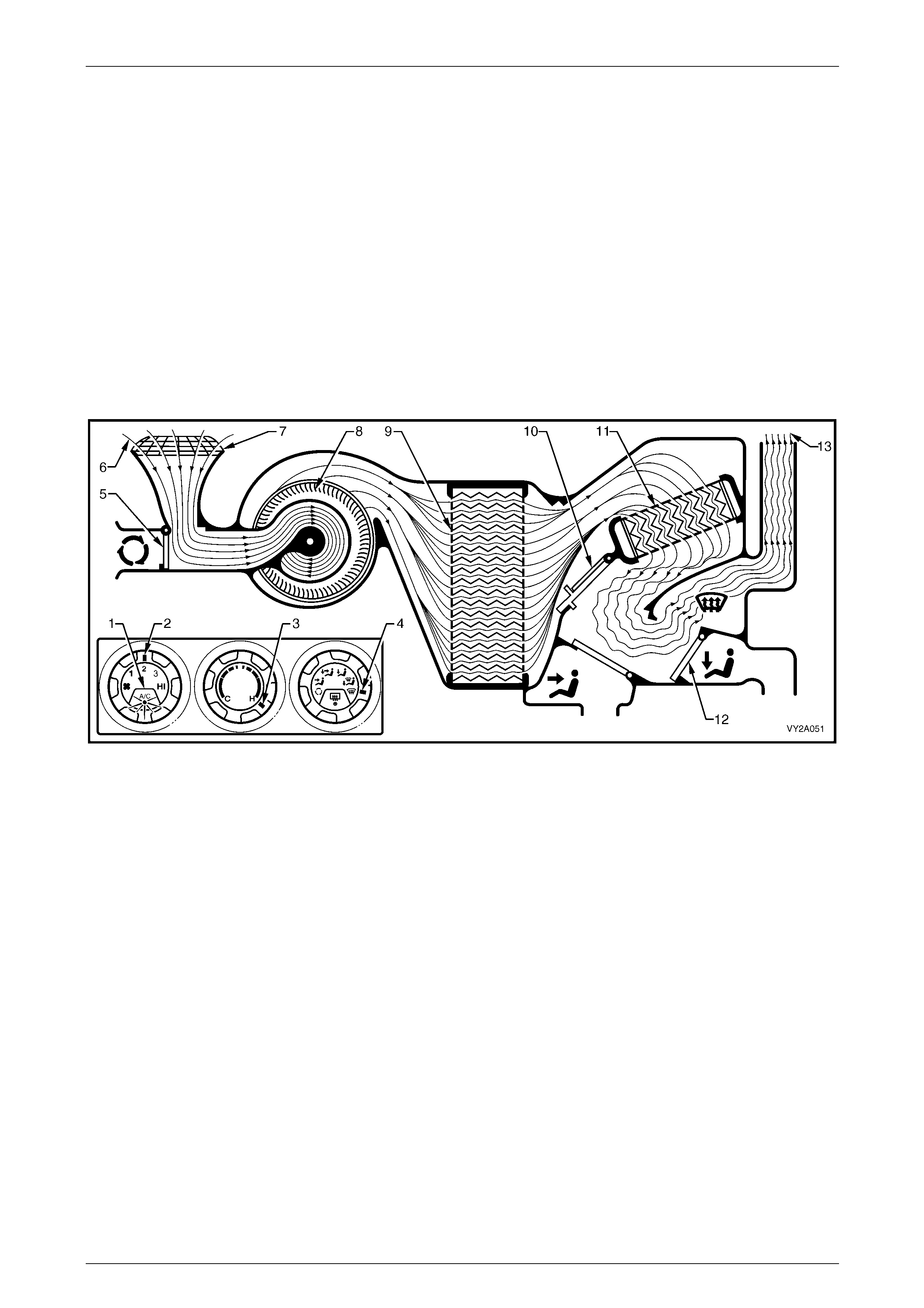

The A/C switch is on (1), refer to Figure 2A – 53. T he fan switch is set to any one of four speeds (2). The temperature

switch is set to the full cold position (3). The mode control switch is set to face mode (4).

The recirculation door (5) is closed allowing outside air (6) to enter and flow into the HVAC unit via the p lenum chamber

inlet (7). Air is drawn into the HVAC unit by the blower motor (8), and is then forced through the cold evaporator fins (9).

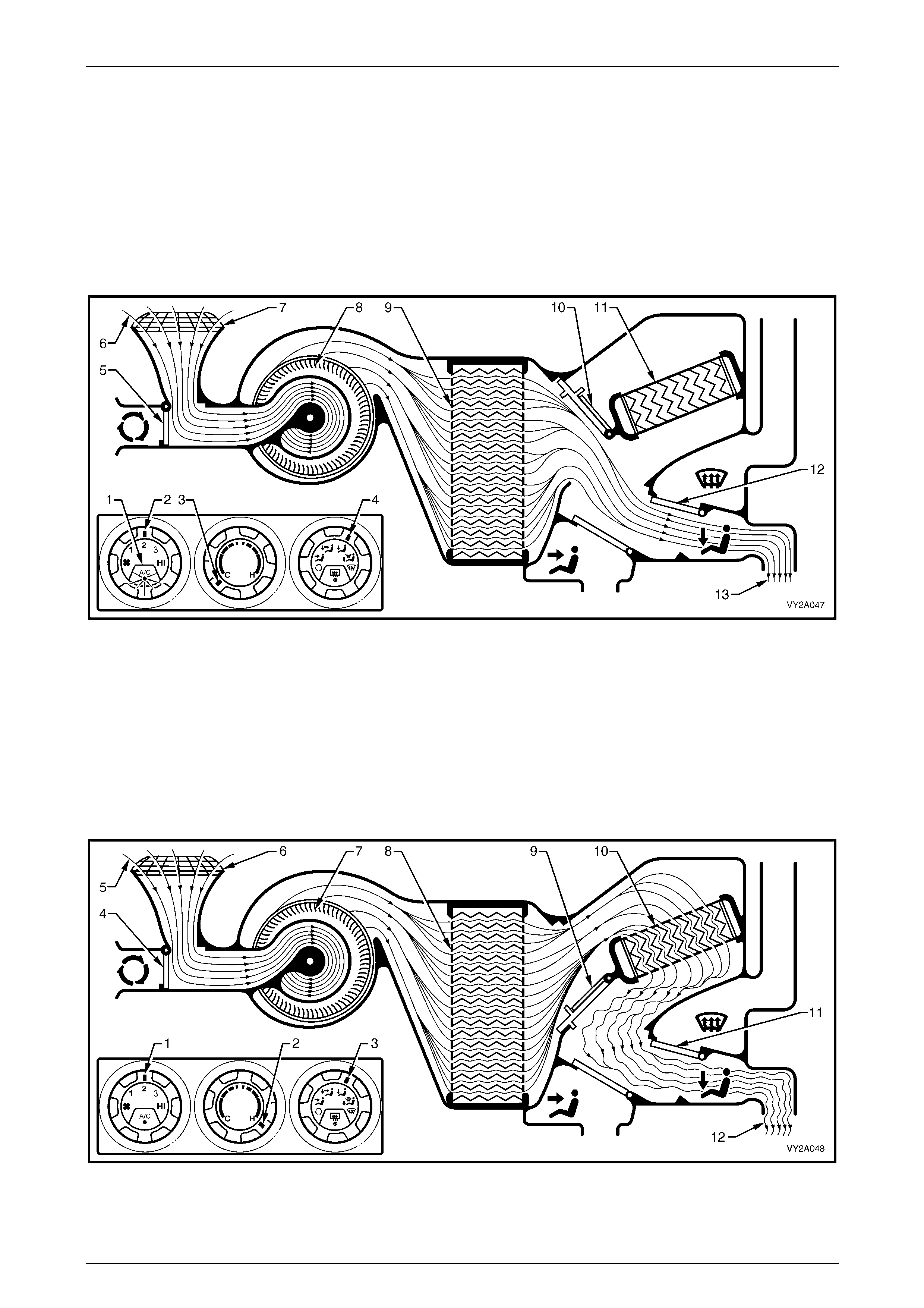

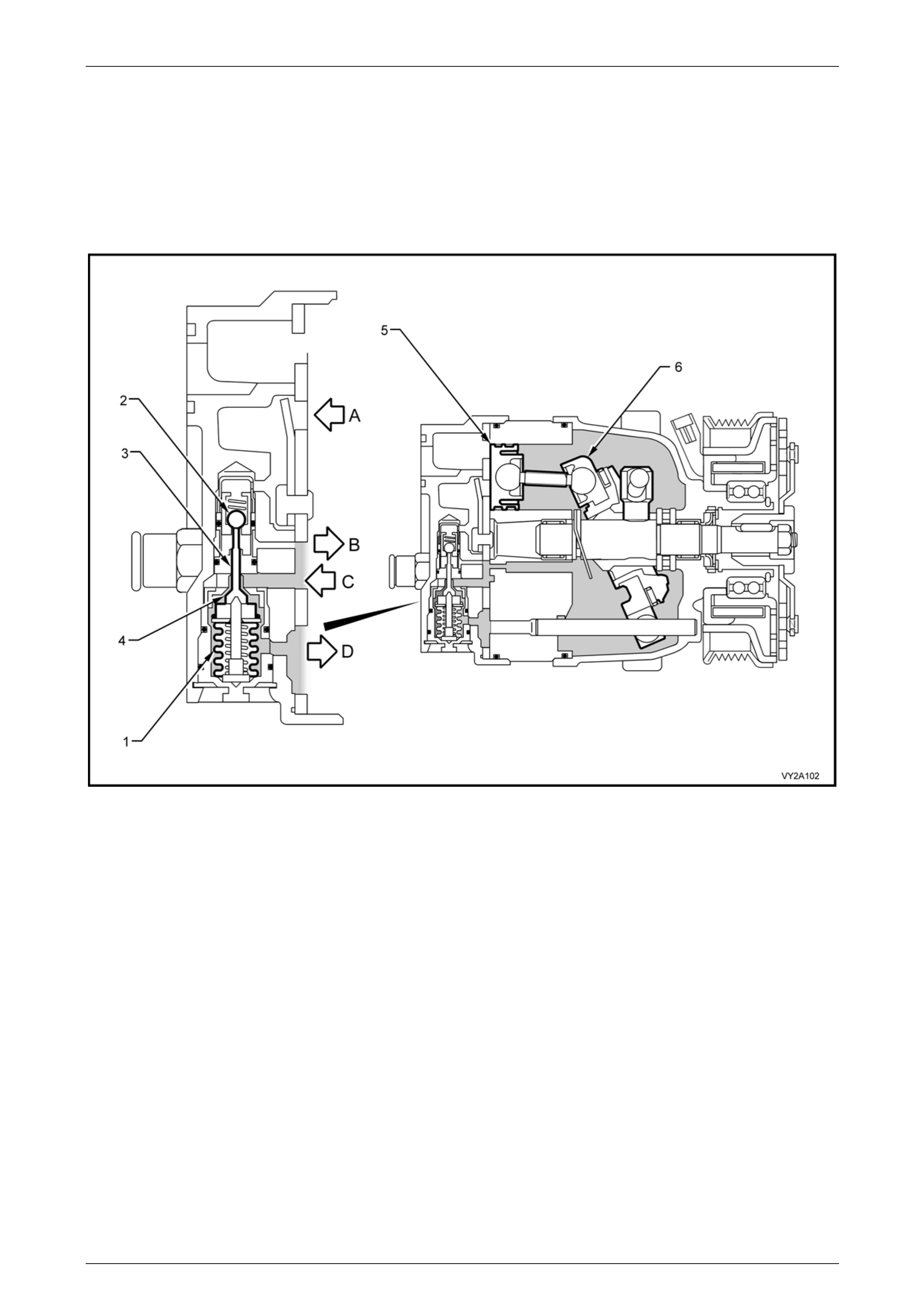

In full cold mode, the air mix doors (10) ar e fully closed sealing off the passage through the heater core (11). The air